Dry garment leather base and preparation process thereof

A garment leather base and preparation process technology, applied in the field of dry-process garment leather base and its preparation process, can solve the problems of poor moisture permeability, unrecyclable solvents, environmental and human hazards, etc., and achieve soft hand feeling and easy continuous production The effect of high production and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of preparation technology of dry-process garment leather bass, comprises the following steps:

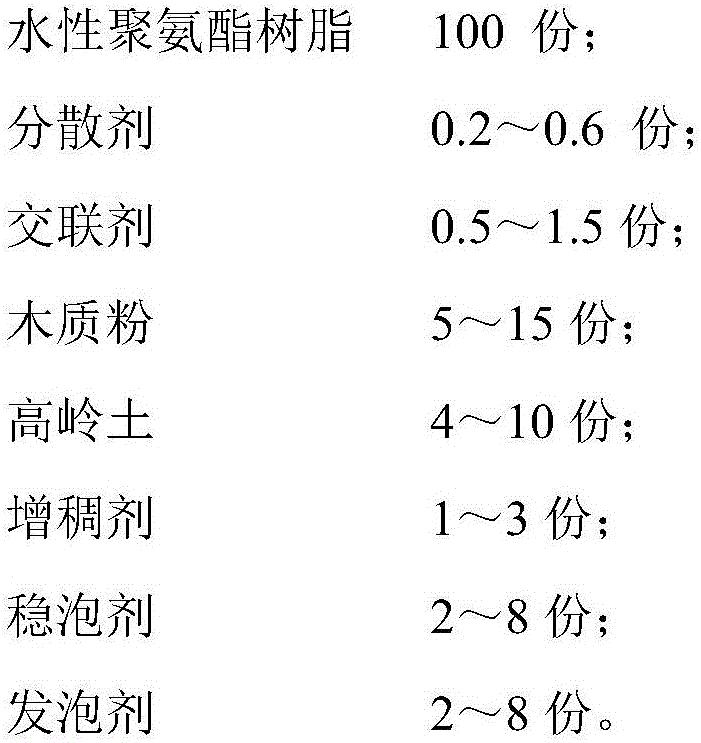

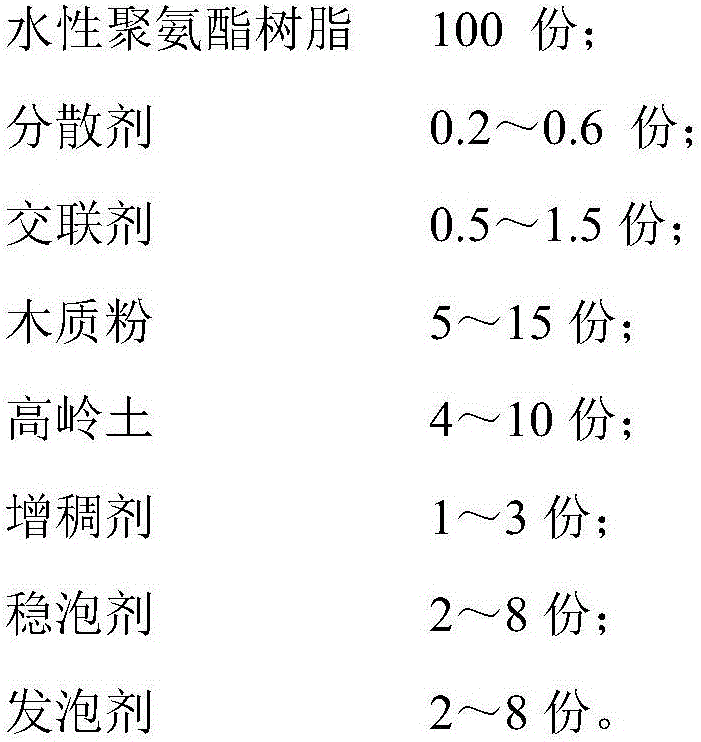

[0042] (1) Prepare water-based polyurethane synthetic leather foaming slurry:

[0043] Add 50kg water-based polyurethane KT702E (Hefei Ketian company) in the dispersing kettle, add 0.2kg dispersant, 0.5kg cross-linking agent, 5kg 500 order wood flour, 4kg 1250 order kaolin under the condition of 500 rev / min at stirring speed, 3kg of foam stabilizer and 1.5kg of lignocellulose thickener were dispersed for 30 minutes at a stirring speed of 1000 rpm after the feeding was completed, and the viscosity was adjusted to 15000-20000mPa.s to obtain a dry synthetic leather slurry.

[0044] Before coating, under the stirring condition of 500 rev / min, add 3kg of foaming agent to the dry synthetic leather slurry for foaming, and use compressed air to bubble the slurry with a bubbling rate of 0.5m 3 / h, while bubbling, the stirring speed was increased to 1500 rpm, and the foaming ra...

Embodiment 2

[0050] A kind of preparation technology of dry-process garment leather bass, comprises the following steps:

[0051] (1) Prepare water-based polyurethane synthetic leather foaming slurry:

[0052] Add 50kg water-based polyurethane KT631 (Hefei Ketian company) in the dispersing kettle, add 0.2kg dispersant, 0.5kg cross-linking agent, 5kg 500 order wood flour, 4kg 1250 order kaolin under the condition of 500 rev / min at stirring speed, 3kg of foam stabilizer and 1.5kg of lignocellulose thickener were dispersed for 30 minutes at a stirring speed of 1000 rpm after the feeding was completed, and the viscosity was adjusted to 15000-20000mPa.s to obtain a dry synthetic leather slurry.

[0053] Before coating, under the stirring condition of 500 rpm, add 3kg of foaming agent to the dry-process synthetic leather slurry for foaming, and use compressed air to bubble the slurry with a bubbling rate of 0.5m 3 / h, while bubbling, the stirring speed was increased to 1200 rpm, and the foaming...

Embodiment 3

[0059] A kind of preparation technology of dry-process garment leather bass, comprises the following steps:

[0060] (1) Prepare water-based polyurethane synthetic leather foaming slurry:

[0061] Add 40kg water-based polyurethane KT702E (Hefei Ketian company) and 10kg water-based polyurethane KT631 (Hefei Ketian company) in the dispersion kettle, add 0.3kg dispersant, 0.5kg cross-linking agent, 7kg 600-mesh wood flour, 5kg 1250-mesh kaolin, 3kg foam stabilizer, 1.8kg lignocellulose thickener, after feeding, disperse for 30min at a stirring speed of 1200 rpm, and adjust the viscosity to 22000-26000mPa.s , to prepare dry-process synthetic leather slurry;

[0062] Before coating, under the stirring condition of 500 rpm, add 3kg of foaming agent to the dry synthetic leather slurry for foaming, and use compressed air to bubble the slurry with a bubbling rate of 0.6m 3 / h, foaming under stirring conditions, while bubbling, the stirring speed was raised to 1500 rpm, and the foamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com