Patents

Literature

2674results about "Food freezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Probiotic microcapsules as well as preparation method and application thereof

ActiveCN105310080AImprove the situation of low freeze-drying survival rateImprove stabilityFood freezingFood shapingFreeze-dryingK carrageenan

The invention relates to probiotic microcapsules as well as a preparation method and application thereof. The probiotic microcapsules comprise a core material and a wall material, wherein the core material is probiotics; the outer layer of the wall material is coated with chitosan; the wall material is prepared from an aqueous solution containing a natural polymer material and a freeze-drying protection agent; the freeze-drying protection agent comprises one or more of glucose, fructose, sucrose, lactose, trehalose, soluble starch, glycerin, mannitol, Arabic gum, dextran 40 and skim milk; the natural polymer material comprises one or more of gellan gum, xanthan gum, k-carrageenan, sodium alginate, cellulose acetate phthalate or gelatin; in the aqueous solution, the volume fraction of the freeze-drying protection agent is 4.0%-20.0% and the volume fraction of the polymer material is 0.5%-5.0%. The probiotic microcapsules can keep excellent acid resistance and storage stability before and after being freeze-dried.

Owner:SUN YAT SEN UNIV

Aerated confection with interfacially stabilised air cells

InactiveUS20170318833A1Increasing heat shockReduce the overall heightFood ingredient as antioxidantFood freezingAir cellMedicine

Owner:NESTEC SA

Aerated frozen confectionary product

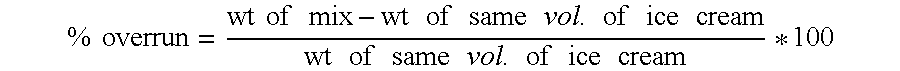

The present invention relates to an aerated frozen confection with an overrun of between 120% and 160%, which includes acacia gum as all or part of a natural emulsifier. A process for the preparation of this frozen confection is also disclosed.

Owner:SOC DES PROD NESTLE SA

Preparation method of freeze-dried Chinese wolfberry

ActiveCN103976304AFull sizeUnchanged flavorFood freezingFood thermal treatmentFreeze-dryingAdditive ingredient

The invention discloses a preparation method of freeze-dried Chinese wolfberry. The preparation method comprises the following operating steps: (1) preparing a compound dietary alkali solution, namely preparing a mixed solution by using sodium carbonate and potassium carbonate with the mass concentrations of respectively 50%, and then adjusting a pH value to 8-9; (2) soaking Chinese wolfberry in the compound dietary alkali solution, wherein the weight ratio of Chinese wolfberry to the compound dietary alkali solution is 1: (1-1.5), soaking for 30-50 minutes, fishing up, draining off water, cleaning by using drinking water till the pH value of the surfaces of Chinese wolfberry is 7, draining off water, weighing, and putting on plates; (3) freezing for 4-6 hours at the temperature of subzero 37-39 DEG C; and (4) carrying out vacuum freeze-drying treatment on the frozen Chinese wolfberry, and taking out from warehouses, thus obtaining the finished product. The preparation method has the beneficial effects that compound dietary alkali is used for removing paraffin, a heating gradient technology of performing sequential heating, cooling and vacuum-degree reduction is adopted during vacuum freeze drying, so that the freeze-dried Chinese wolfberry is complete in size, and unchanged in color, flavor and nutritional ingredients, and when being directly eaten, the freeze-drying Chinese wolfberry is crisp and palatable and is nourishing food suitable for eating by people of all ages and visiting friends and relatives.

Owner:安徽本纪控股有限公司

Health food containing Maca reactive powder and preparation method thereof

InactiveCN103750298AFast dissolutionImprove qi and lungFood freezingNatural extract food ingredientsActive componentBULK ACTIVE INGREDIENT

The invention provides a health food containing Maca reactive powder and a preparation method thereof. The health food comprises, by mass, 30 to 80% of Maca reactive powder, 10 to 50% of milkvetch root and 5 to 30% of American ginseng, with the balance being auxiliary materials. The preparation method comprises the following steps: respectively sieving Maca reactive powder, milkvetch root, American ginseng and the auxiliary materials with an 80-mesh sieve; respectively weighing the processed raw materials according to above-mentioned proportion; and putting the raw materials into a three dimensional mixer for uniform mixing so as to obtain the health food. The invention has the following beneficial effects: the health food may be a particle, a pulvis, a tablet or a capsule; Maca reactive powder prepared in the invention has rich nutrients, utmostly retains its active components, i.e., Macaenes, macamides, volatile oil and the like, and has a uniform and stable structure, a great surface area, good fluidity and a fast dissolving speed; the health food prepared in the invention is capable of improving human immunity, tonifying qi, benefiting the lung, resisting fatigue, enhancing sexual activity, etc.

Owner:FUYANG TINGHOE BIOLOGICAL TECH CO LTD

Ultrasonic thawing device and method and application in ice breaking and defrosting

PendingCN106721903AKeep it authenticEasy to break awayOverhead installationFood freezingProcess engineeringFreezing environment

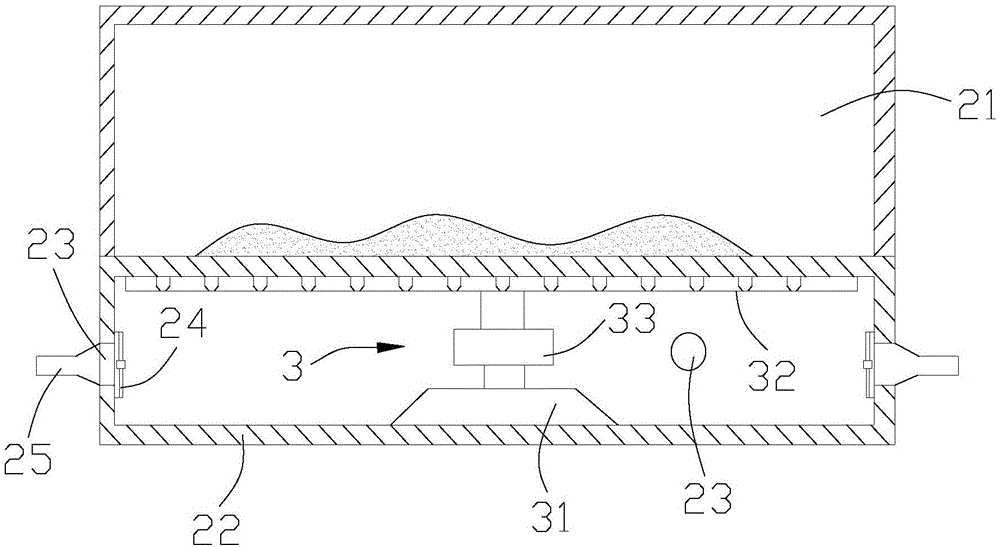

The invention relates to a thawing technology, in particular to an ultrasonic thawing device and method and application in ice breaking and defrosting. The ultrasonic thawing device comprises a machine body and a freezing area arranged on the machine body, wherein the freezing area comprises a thawing cabinet and a cold storage cabinet capable of freezing food, the thawing cabinet is provided with an ultrasonic thawing apparatus, the ultrasonic thawing apparatus breaks ice on the frozen food in the thawing cabinet under the freezing environment, so that nutritional substances of the food can be prevented from being lost along with the water, the original taste of the food is ensured, the taste is good, and the thawing efficiency is improved. The ultrasonic thawing method can be used for ice breaking of ocean, rivers, roads, railways, bridges, electric power and telecommunication circuits, can also be used for defrosting of fast-freezing tunnels, subzero storages, refrigerators, and air conditioner condensers, is not only short in ice breaking time and high in efficiency, but also low in energy consumption and convenient in operation.

Owner:HUNAN JIASHENG FRESH PRESERVATION TECH

Production method for high-quality instant lentinus edodes crisp chips

InactiveCN103652833AComplete shapeFlat surfaceFood freezingFood coatingAdditive ingredientAdditional values

The invention relates to a production method for high-quality instant lentinus edodes crisp chips and belongs to the technical field of deep processing of agricultural products. A main process for producing the instant lentinus edodes crisp chips comprises the following steps: harvesting fresh lentinus edodes with good quality; removing pedicles; washing; immersing; freezing; freezing and drying in vacuum; and seasoning and carrying out nitrogen-filled packing. The production method adopts a novel vacuum freezing and drying process to produce the lentinus edodes crisp chips. Compared with the prior art, the process adopts a low-temperature dehydration manner of freezing and drying in vacuum to keep the nutrition and the flavor components of the lentinus edodes to the greatest extent; the sensory quality of the product is improved and the defects of traditional oil fried crisp chips that the oil content is high, the color and luster are poor, the mouth feel is hard and the like are avoided. The product obtained by the process has the characteristics of rich flavor, crispy mouth feel, low oil content, high additional value, good sensory quality and the like; the invention provides a feasible new way for deeply processing the lentinus edodes.

Owner:NANJING AGRICULTURAL UNIVERSITY

Blueberry lozenge for relieving asthenopia and preparation method thereof

ActiveCN103494134AFull of nutritionIncrease health functionFood freezingSenses disorderBiotechnologyFreeze-drying

The invention relates to a blueberry lozenge for relieving asthenopia and a preparation method thereof. The preparation method comprises that blueberry residues obtained by blueberry juicing is used as a main raw material and based on a plurality of modern food processing novel technologies, by vacuum freeze drying and superfine grinding processes, the blueberry residues are processed into a blueberry residue base material; and through mixing, granulation, drying and tabletting, the blueberry residue base material, wolfberry powder, xanthophylls, xylitol, corn starch and dextrin as main raw materials are prepared into the blueberry lozenge having a sour-sweet taste and health-care functions of resisting oxidation and relieving asthenopia. The preparation method is safe and has the simple processes, a low cost and no pollution.

Owner:建昌县亿丰蓝莓饮料有限公司

Preparation method of dried mangoes

InactiveCN104082694AHigh nutritional valueIncrease productivityFood freezingClimate change adaptationNutritive valuesFreeze-drying

The invention discloses a preparation method of dried mangoes. The preparation method comprises the steps of removing rotten mangoes and impurities from mangoes, cleaning the mangoes with saline water, removing skins and kernels of the mangoes, slicing regularly, performing color protection on the sliced mangoes, pickling with sugar, putting in a tray in a microwave drying device for microwave drying to remove 55-60% of moisture in the sliced mangoes, quickly freezing with liquid nitrogen, lyophilizing in a tray of a vacuum freezing-drying device for reducing the moisture of the mangoes to be 5-6%, and performing vacuum drying to obtain the dried mangoes. The dried mangoes prepared by adopting the method have the high nutritive value and the good quality.

Owner:莆田市川佰投资有限公司

Method for enhancing the content of soybean seed gamma-aminobutyric acid

A method for enhancing the content of soybean seed gamma-aminobutyric acid through soaking, freezing and defreezing is dislosed, and a soybean seed richly containing gamma-aminobutyric acid prepared using the same is also provided. At the same time, the soybean seed richly containing GABA is processed to a functional food.

Owner:CJ CHEILJEDANG CORP

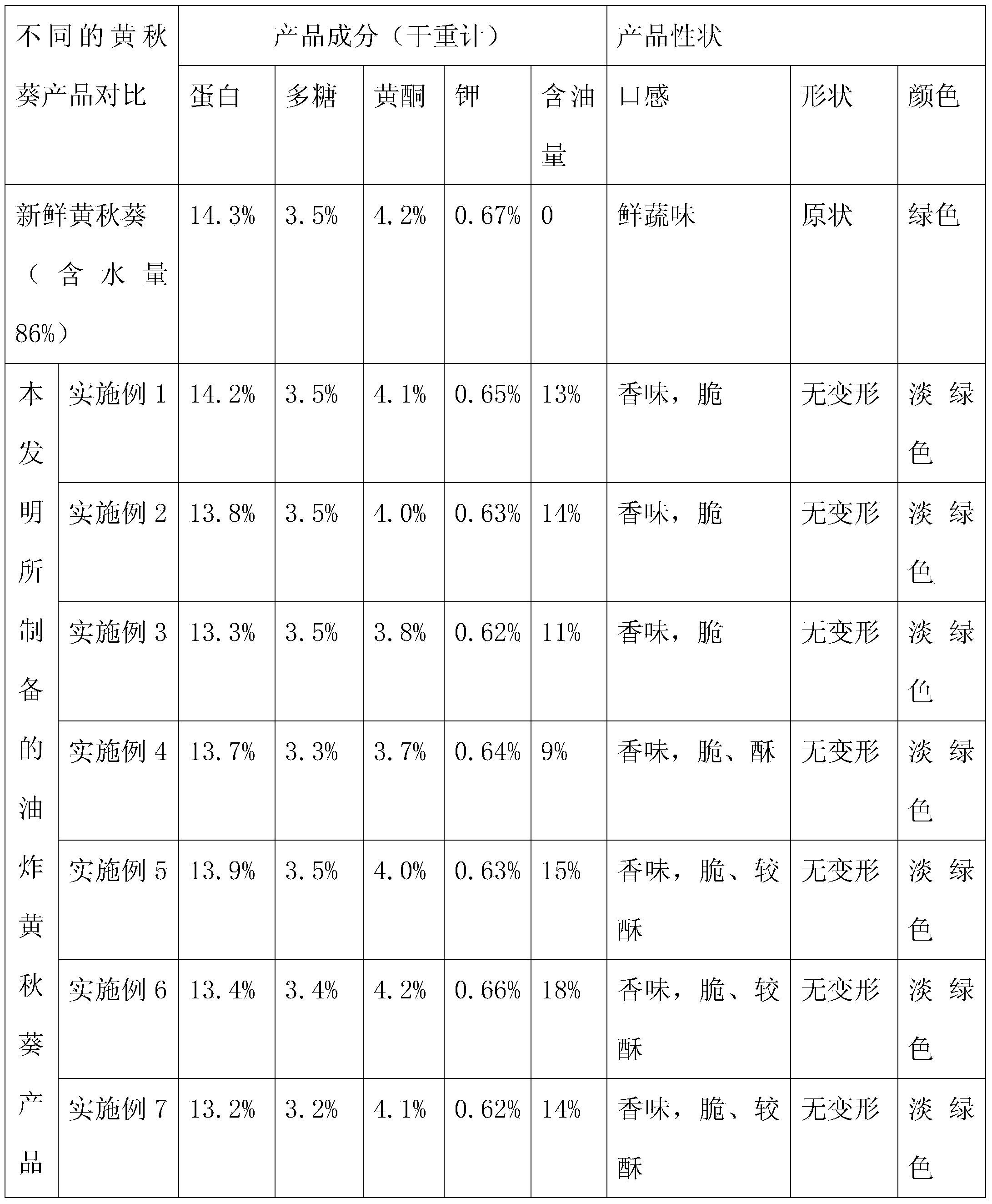

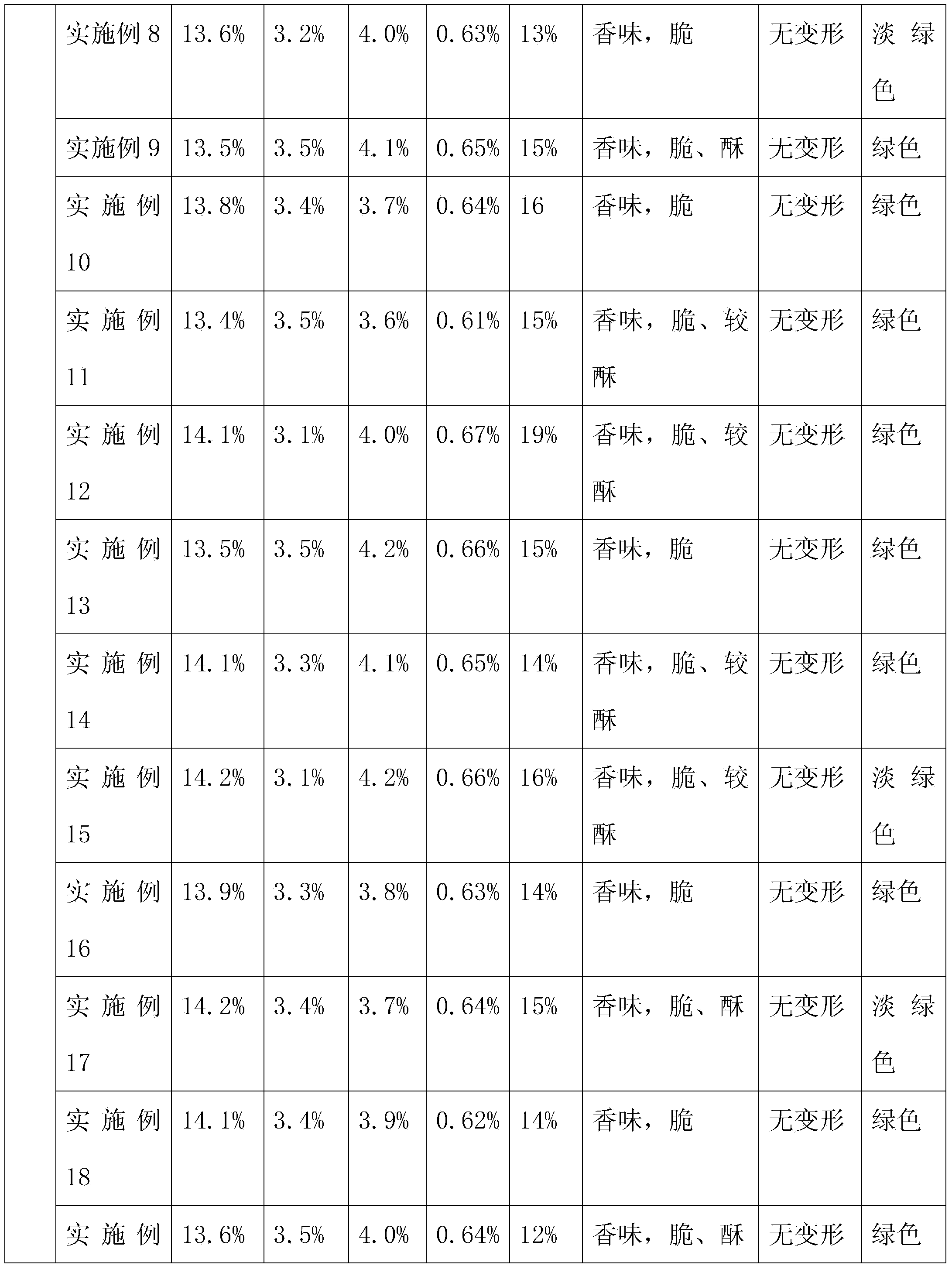

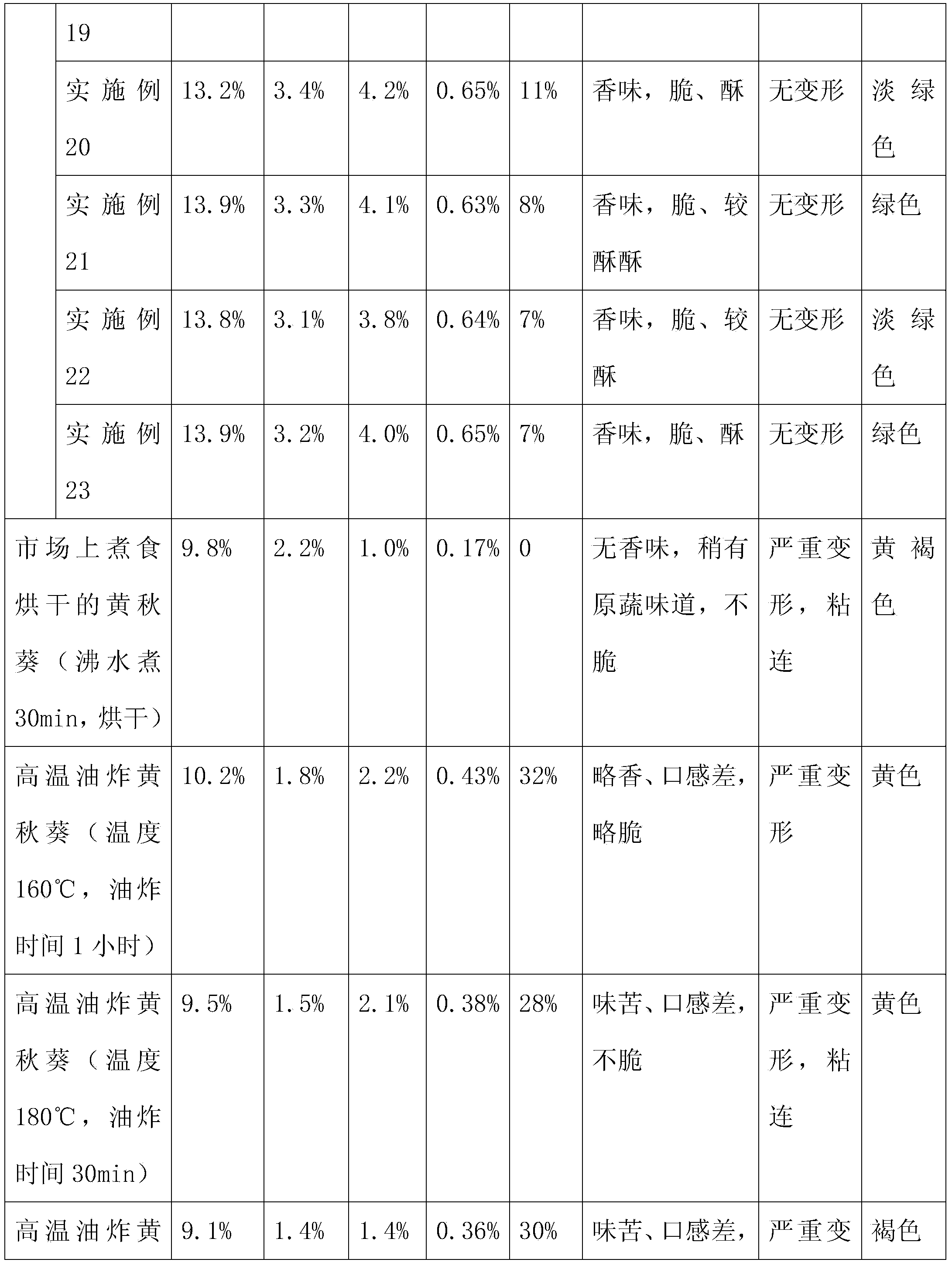

Production process for frying abelmoschus esculentus with different tastes at low temperature in vacuum

ActiveCN103919074ANotable featuresSignificant positive effectFood freezingFood thermal treatmentDiabetes mellitusAdditive ingredient

The invention discloses a production process for frying abelmoschus esculentus with different tastes at low temperature in vacuum. The production process comprises the following steps: blanching washed abelmoschus esculentus in hot water; cooling and putting the abelmoschus esculentus into an instant freezer to be instantly frozen; putting the frozen abelmoschus esculentus into a seasoning solution to be immersed in vacuum; leaching and putting the abelmoschus esculentus into the instant freezer to be instantly frozen; carrying out vacuum low-temperature frying on the frozen abelmoschus esculentus; centrifuging and removing oil to obtain a product. The instant abelmoschus esculentus food prepared by the invention keeps the color, aroma, taste and nutritional components of the abelmoschus esculentus; meanwhile, the fried abelmoschus esculentus with different tastes are prepared and are suitable for different crowds including children, youngsters, middle-aged and aged people, diabetes mellitus patients and the like.

Owner:LAIYANG HENGRUN FOODSTUFF

Instant okra snack food

ActiveCN103719867AMild process conditionsEasy to eatFood freezingFood thermal treatmentBiotechnologyAntioxidant

The invention provides an instant okra snack food which is prepared from okra bud as a main raw material together with corn starch, egg white, an antioxidant, salt, citric acid and wheat bran, and the preparation method comprises the following steps: collecting the bud, deactivating, soaking in vacuum, drying in vacuum, mixing size, hanging the size, wrapping powder, quickly freezing, frying in oil in vacuum, removing the oil and packaging. The product is gentle in machining process, the original appearance, nutrition and favor of okra are maintained, the prepared product is rich in nutrient elements such as dietary fiber, multivitamins and mineral substances, and active substances such as polysaccharide and flavone, and the snake food is nutrient, health care and convenient to eat.

Owner:HUNAN AMAZING GRACE BIOTECH

Flavored low-fat white mushroom crisp chip and preparation method thereof

InactiveCN103689552AImprove processing qualityGood colorFood freezingFood thermal treatmentMushroomFat content

The invention belongs to the technical field of food processing and specifically relates to a flavored low-fat white mushroom crisp chip and a preparation method thereof. The flavored low-fat white mushroom crisp chip comprises the following materials in parts by weight: 1000 parts of white mushrooms, 5-10 parts of konjac glucomannan, 10-80 parts of chitosan, 10-60 parts of salt, 60-200 parts of isolated soybean protein and 40-200 parts of a nutrition balancing agent. The preparation method comprises the following steps: pre-treating the white mushrooms, preparing impregnation liquid, carrying out vacuum soaking and ultrasonic coating, carrying out quick-freezing and slicing, carrying out vacuum frying and dehydrating, removing oil, and packaging. The prepared flavored low-fat white mushroom crisp chip has the advantages of being low in fat content, uniform in color, crisp in mouthfeel, full in nutrition, complete in product shape and almost free of fractures.

Owner:SHANDONG INST OF COMMERCE & TECH

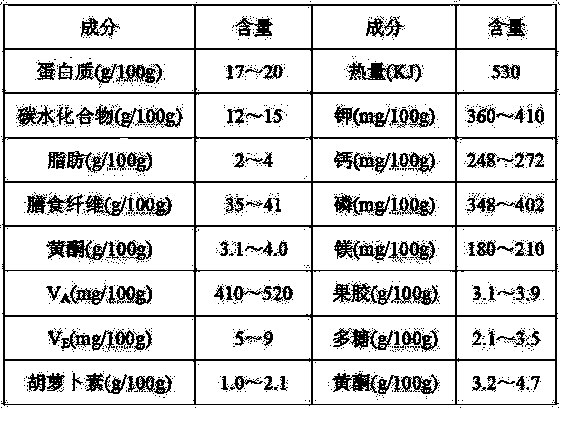

Production process of on-board euphausia superba mince

ActiveCN103549510AReduced fluorine and enzyme contentImprove qualityFood freezingFood ingredient as anti-freezing agentCarrageenanAdditive ingredient

The invention discloses a production process of on-board euphausia superba mince. The production process of on-board euphausia superba mince particularly comprises the following steps of rinsing euphausia superb twice after flesh extraction, dehydrating, adding an antifreeze agent, and storing frozen euphausia superb mince at minus 24 DEG C after quick-freezing; rinsing the euphausia superb mince by fresh water or seawater again which contains 0.1-0.3% of CaC12 for one time, and then rinsing the euphausia superb mince by fresh water or seawater for the second time, thus improving the jelly strength and the whiteness of the euphausia superba mince and reducing the loss of fluorine content and nutritional components; and adding 3-5% of saccharose, 3-5% of sorbitol, 0.2-0.3% of polyphosphates, 0.1-0.3% of sodium alginate tech grade as well as 0.2-0.4% of carrageenan, thus reducing the possibility of the protein denaturation of the euphausia superba mince during the freezing process, and improving the euphausia superba mince quality and yield.

Owner:SHANGHAI OCEAN UNIV

Freeze-dried compound berry superfine powder and production method thereof

ActiveCN103750328ARich in compositionPromote absorptionFood freezingFood shapingFreeze-dryingGranularity

The invention discloses freeze-dried compound berry superfine powder and a production method thereof. The freeze-dried compound berry superfine powder is produced from the following berries in percent by weight: 40-45 percent of raspberry, 25-30 percent of blueberry, 6-8 percent of mulberry, 10-14 percent of sea-buckthorn, 4-6 percent of medlar and 5-7 percent of Lonicera caerulea. The method comprises the following specific steps: weighing and cleaning the berries, and draining for standby; mixing the drained berries under the condition of normal pressure and the temperature of 80 DEG C below zero, freezing for 1-3 hours, and rapidly freezing the fruits; keeping the frozen mixed berries in an environment with the pressure of 50-100Pa for 3-4 hours, controlling additional heating, and returning the temperature to 0 DEG C within 4-5 hours; raising the temperature from 0 DEG C to 45 DEG C within 6-8 hours, wherein the pressure is kept to be 20-50Pa; grinding the berries into the granularity of 5000-10000 meshes at the temperature of 0 DEG C by adopting nitrogen protection; preparing the ground superfine powder into tablets. The berries are reasonably proportioned, so that a health care effect is achieved, the functional ingredients in the product are enriched, the taste characteristics of the product are improved, the product is fresh to drink, contributes to human body absorption and is conveniently prepared into the tablets, and the active substances are well kept.

Owner:山东尚美健康产业技术发展有限公司

Method for deeply refrigerating, quickly freezing and preserving litopenaeus vannamei

InactiveCN103960745AIntegrity guaranteedClose in qualityFood freezingFood ingredientsFlavorIce crystals

The invention discloses a method for deeply refrigerating, quickly freezing and preserving litopenaeus vannamei. The complete process for deeply refrigerating, quickly freezing and preserving litopenaeus vannamei comprises the steps of cleaning, draining, positioning, quickly freezing, rinsing, draining to dryness, packaging and the like. Ice crystals formed by products processed by adopting the method are small, the cell completeness of the products is ensured, the original color, freshness and flavor of the products can be kept, the shelf life of the products is greatly prolonged, the preservation effect is good, the year-round supply requirement can be met, and the method has very good application values.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

Processing method of microwave-vacuum dried quick-cooking coarse grains and microwave-vacuum dried quick-cooking coarse grains processed by processing method

InactiveCN107969612ASolve the problems of pre-soaking, long cooking time and poor tasteRetain nutrientsFood freezingDrying solid materials with heatRoom temperatureMicrowave power

The invention relates to a processing method of microwave-vacuum dried quick-cooking coarse grains and the microwave-vacuum dried quick-cooking coarse grains processed by the processing method. The processing method of the microwave-vacuum dried quick-cooking coarse grains comprises the following steps: 1, pretreatment of raw materials; 2, freezing treatment: putting the predried raw materials ina freezing chamber and performing freezing treatment at low temperature; 3, microwave-vacuum treatment: thawing the frozen raw materials obtained in the step 2 to room temperature and performing microwave-vacuum drying treatment by using a microwave-vacuum drier, wherein the microwave power is 100-850W, the vacuum degree is -0.05 to -0.1Mpa, the temperature is 50-90 DEG C, the microwave-vacuum drying time is 5-30min and the thickness of a material layer is 1-3cm, thereby obtaining the microwave-vacuum dried coarse grains of which the moisture content is 8-13%; 4, cooling; and 5, screening andmixing to obtain the quick-cooking coarse grains. The quick-cooking coarse grains prepared by the processing method disclosed by the invention can serve as an auxiliary nutritional product of rice andalso can be cooked singly into congee for eating, and the quick-cooking coarse grains can be cooked with rice or cooked singly by performing cooking for 20min, so the quick-cooking coarse grains arequick and convenient.

Owner:曹龙奎

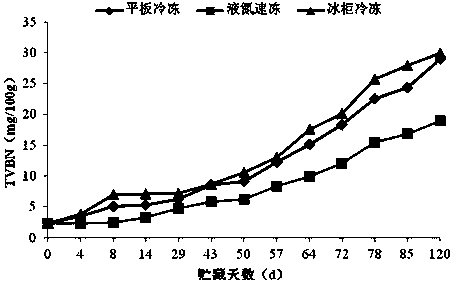

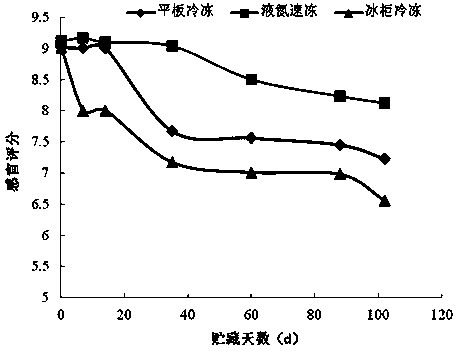

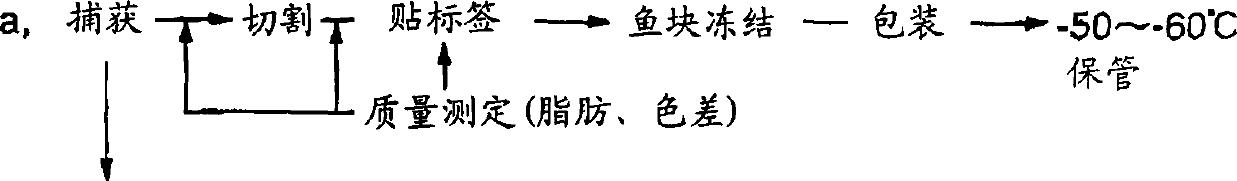

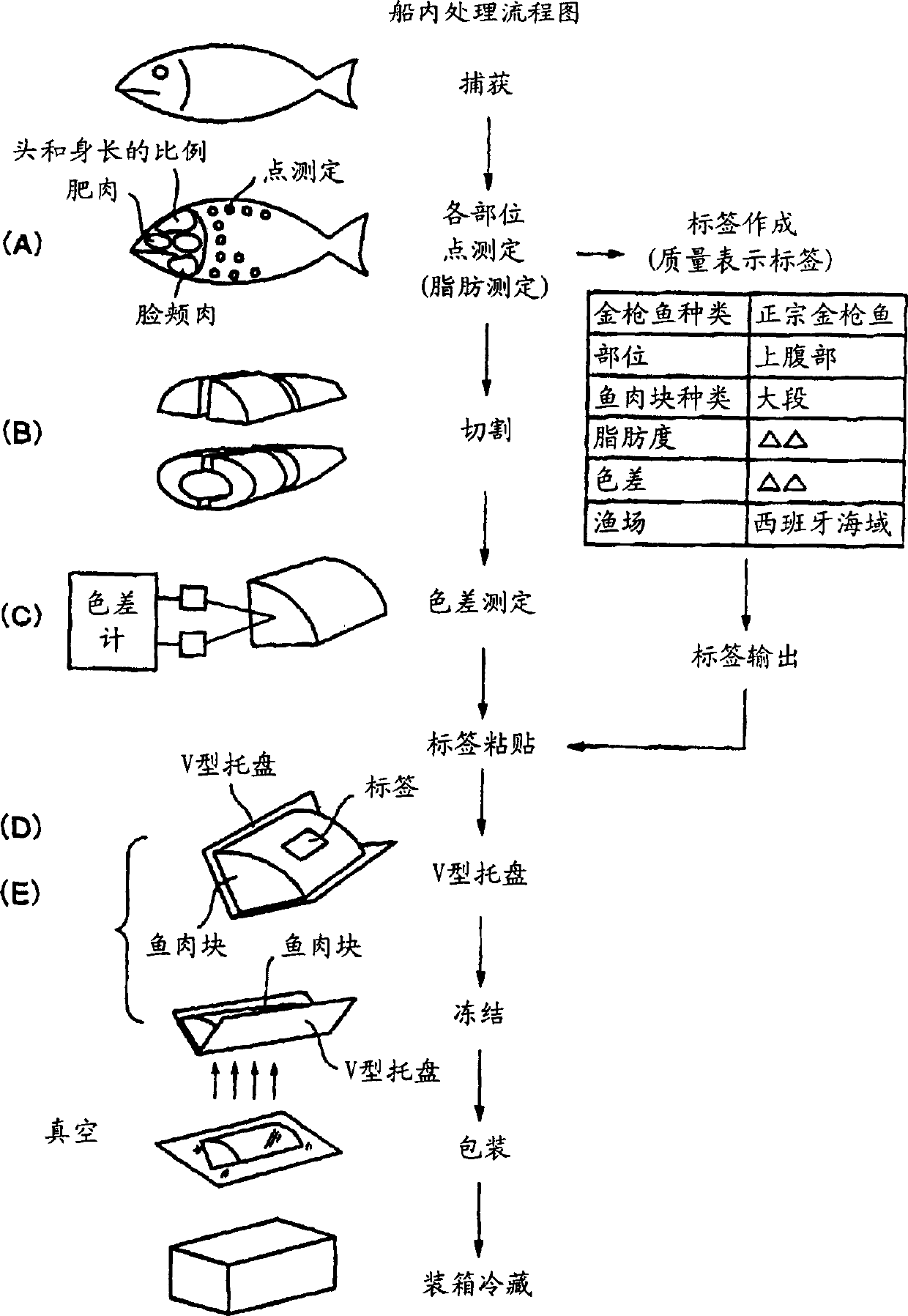

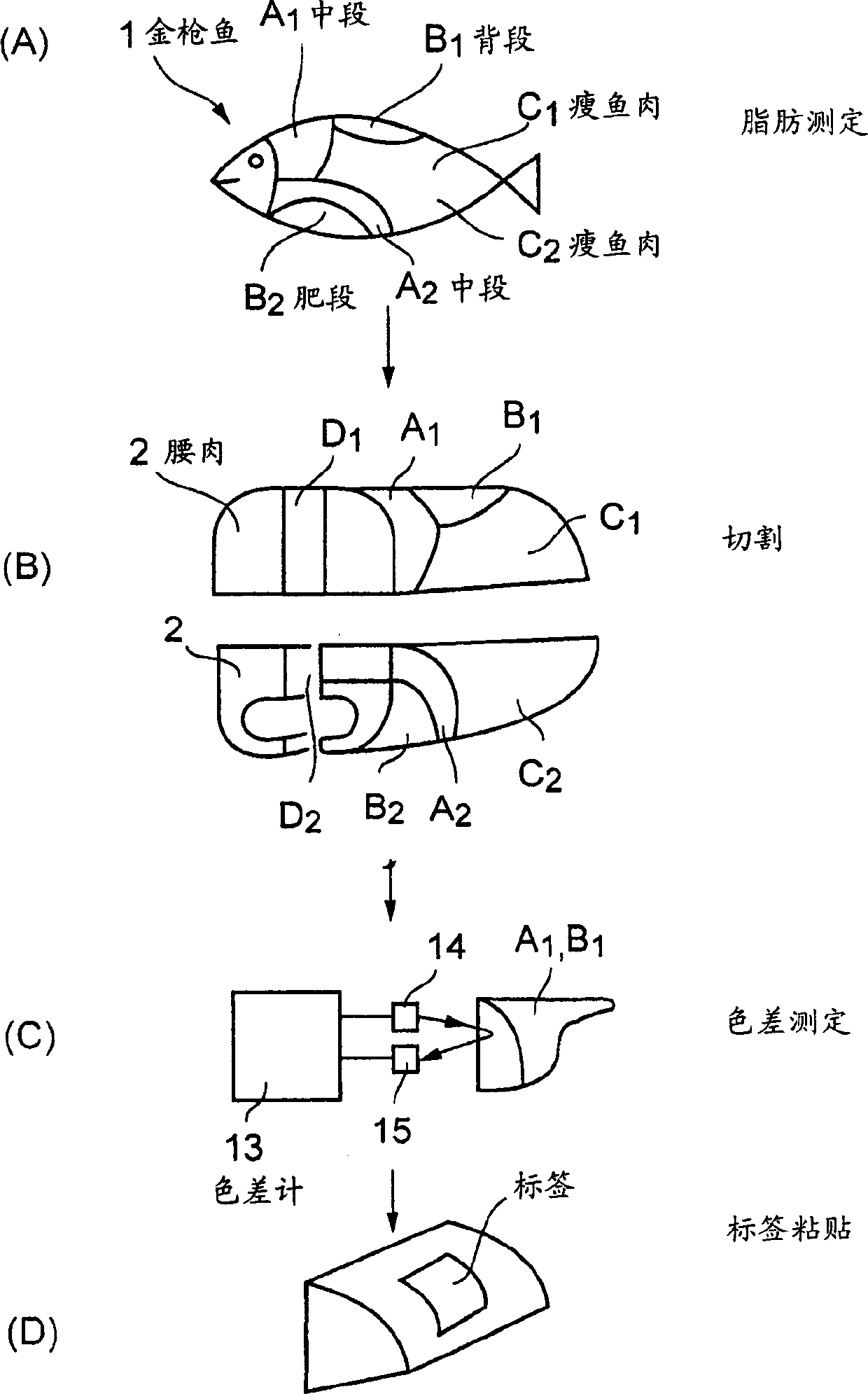

Freezing processing method and processing system for large-type fishes

InactiveCN1397175APrevent drynessReduce cooling effectFood freezingMeat/fish preservation by freezing/coolingLipid MeasurementEngineering

The present invention provide a freezing processing method for fish body blocks. The internal organs of large-sized fishes such as tuna fish-caught in a fishing site such as the interior of a fishing vessel having a freezing apparatus are removed and the fish bodies are cut into blocks in the fishing site before freezing and display labels for displaying the quantities in addition to type of fish, fish bodies and fished places are prepared and each quality-displaying label is preferably attached to the block before freezing and at least one quality measurement of lipid measurement and color difference is carried out in the fishing site after fishing and before freezing and the display labels for displaying the qualities in addition to type of fish, fish bodies and fished places are prepared and the quality-displaying labels are attached to the blocks before freezing and a cooling medium is made to collide with a heat transfer plate composed of a material having high heat conductivity in a state in which at least one face among cut faces of the block is brought into face contact with the heat transfer plate and the block is frozen, preferably rapidly frozen to -50 DEG C to carry out freezing. The invention is capable of carrying out freezing of large-sized fishes in good quality on a fishing vessel or in a fishery base in the neighborhood thereof without causing breaking of the fish body even when frozen in each block unit.

Owner:MAYEKAWA MFG CO LTD

Production method of black pepper chicken cutlet

ActiveCN104432187AFull of flavorVisible Chicken FiberFood freezingMulti-step food processesMinced chickenFlavor

The invention discloses a production method of black pepper chicken cutlets. The production method comprises the following steps: mixing minced drumstick meat with skins and minced chicken breast meat with skins in a weight ratio of 1 to 1, and mincing by using a 13mm mincing disc to obtain the minced chicken meat; putting the meat into a vacuum rolling machine, and adding a flavor immersing solution; rolling until a rolling solution is completely absorbed; putting the processed meat into a molding mold to form chicken cutlets; putting the molded chicken cutlets into a steaming pot and steaming for 3-6 minutes; then gradually coating the steamed chicken cutlets by powder one by one; then taking the chicken cutlets coated by the powder and gradually dipping paste on the chicken cutlets one by one; and frying the chicken cutlets with oil and quickly freezing until the central temperature of the product is lower than -18 DEG C. According to the production method, the minced chicken meat is prepared into the black pepper flavored chicken cutlets and the chicken cutlets have obvious chicken fibers and chicken quality; after being steamed, fiber textures still can be shrunk; the chicken cutlets molded by the minced meat have large area and are relatively thin, and have a relatively good taste when being eaten; and the minced chicken meat is rolled in a process of preparing the chicken cutlets so that the minced chicken meat is sufficiently tasty and the sufficient utilization of the chicken products is realized.

Owner:河南永达清真食品有限公司

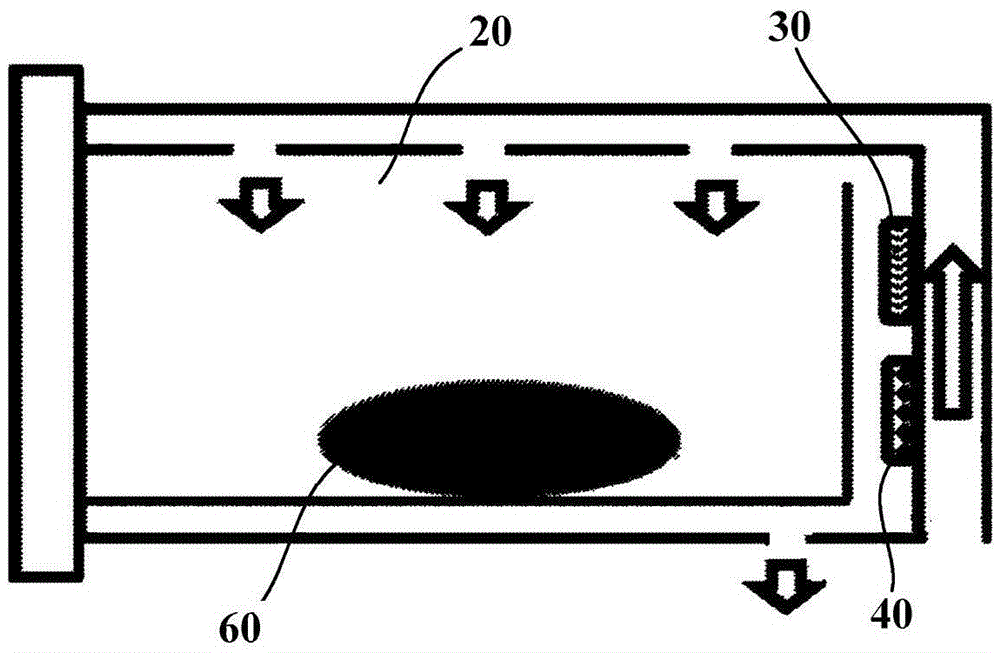

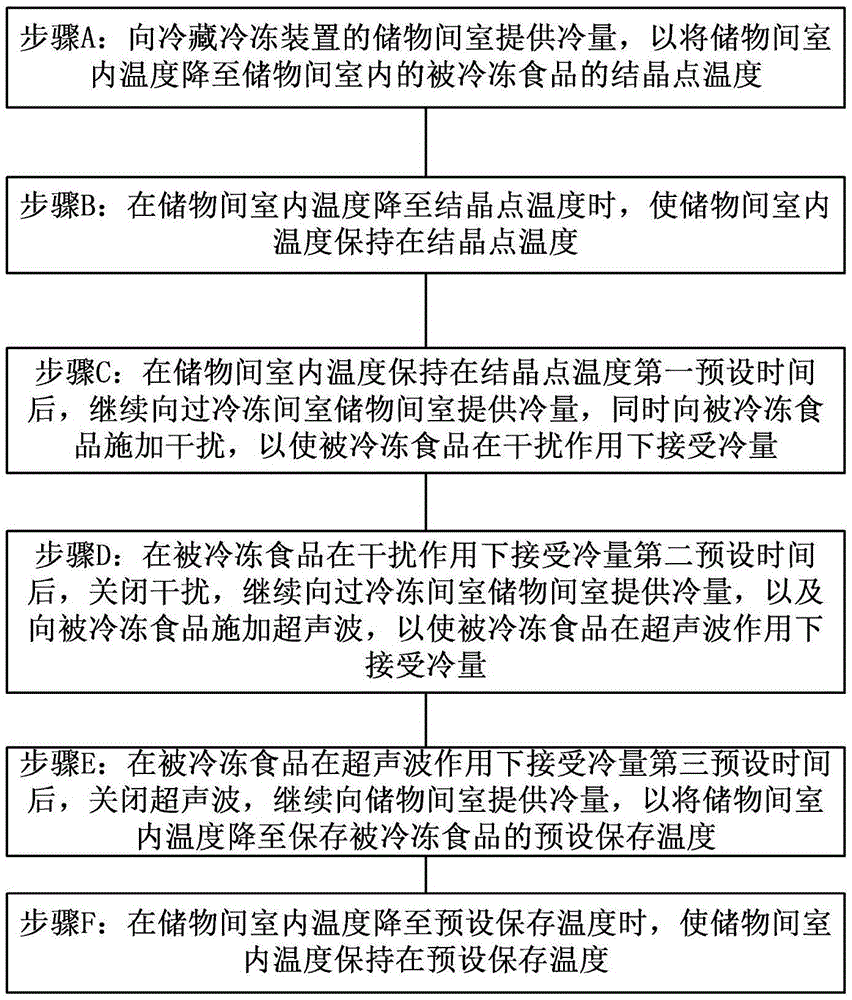

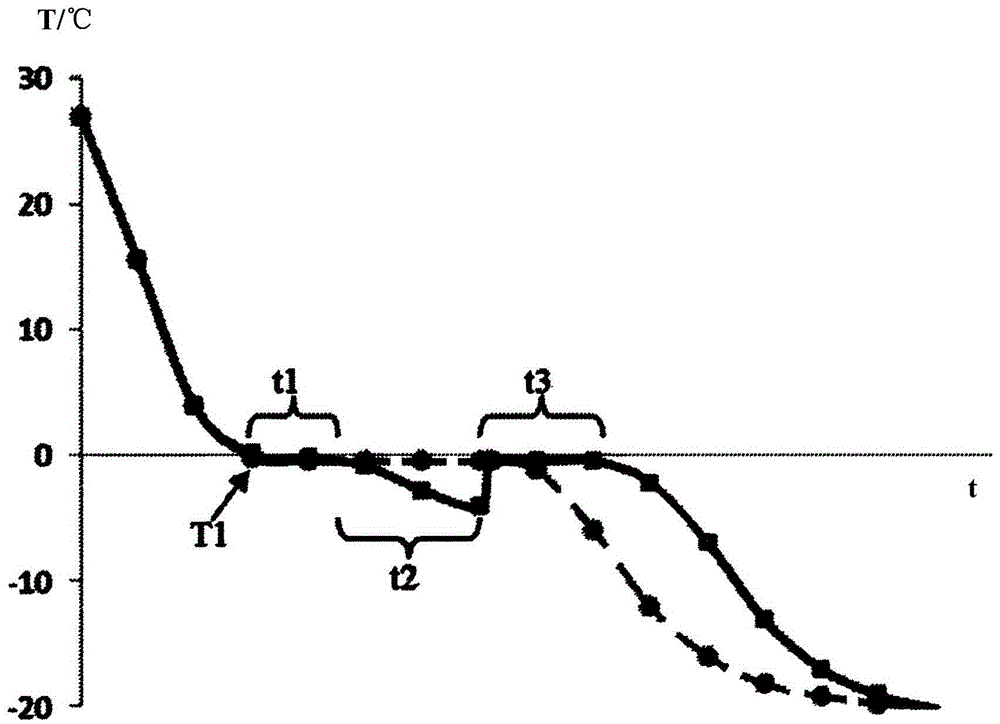

Refrigeration and freezing device and freezing method thereof

InactiveCN105546905AUniform crystallizationBright colorFood freezingLighting and heating apparatusStopped workCell integrity

The invention provides a refrigeration and freezing device and a freezing method thereof. The refrigeration and freezing device comprises a liner, a refrigeration system, an interference device and an ultrasonic generation device, wherein a storage chamber for storing frozen foods is limited in the liner; the refrigeration system is configured to be controlled to supply cooling capacity to the storage chamber, so that the temperature of the storage chamber is reduced to and kept at a crystallization point temperature first preset time of the frozen foods, and then, is reduced to and kept at a preset preservation temperature of the frozen foods; the interference device is configured to be started to interfere the frozen foods after the temperature in the storage chamber is reduced to the crystallization point temperature first preset time, and works for a second preset time; and the ultrasonic generation device is configured to be started to apply ultrasonic waves to the frozen foods when the interference device is stopped working, and works for a third preset time. The refrigeration and freezing device and the freezing method thereof excellently preserve the cell integrity of the foods in the freezing process, and perfectly guarantee the freezing quality of such foods as meat loafs.

Owner:HAIER SMART HOME CO LTD

Non deep-fried instant noodles and preparation method thereof

PendingCN107279724ASmooth tasteFast rehydrationFood freezingFood ingredient as thickening agentFreeze-dryingProcess engineering

The invention relates to non deep-fried instant noodles and a preparation method thereof. The non deep-fried instant noodles adopt a one-piece structure that an upper layer is a seasoning block and a lower layer is a cake. Cooked noodles and dishes processed in kitchens are integrated, and a vacuum freeze drying technique is used wholly, so that novel non deep-fried instant noodles are prepared. The non deep-fried instant noodles have the advantages that the non deep-fried instant noodles are low in fat, rapid in rehydration, good in soup sucking properties and pure and delicious in flavor, have the feel of conditioning in family kitchens, and can well reserve original nutrient components. Besides, the noodles and the dishes are integrated together to process a noodle product in a container, and the non deep-fried instant noodles can be eaten when being brewed with boiling water for 3min, so that the non deep-fried instant noodles are convenient and rapid, and tedious steps that when conventional instant noodles are brewed, material bags of seasoning powder bags, sauce bags, vegetable bags and the like need to be tore are omitted, and the non deep-fried instant noodles are time-saving, bag-material-saving, environmental-friendly and healthy.

Owner:JIN MAILANG MIANPIN CO LTD

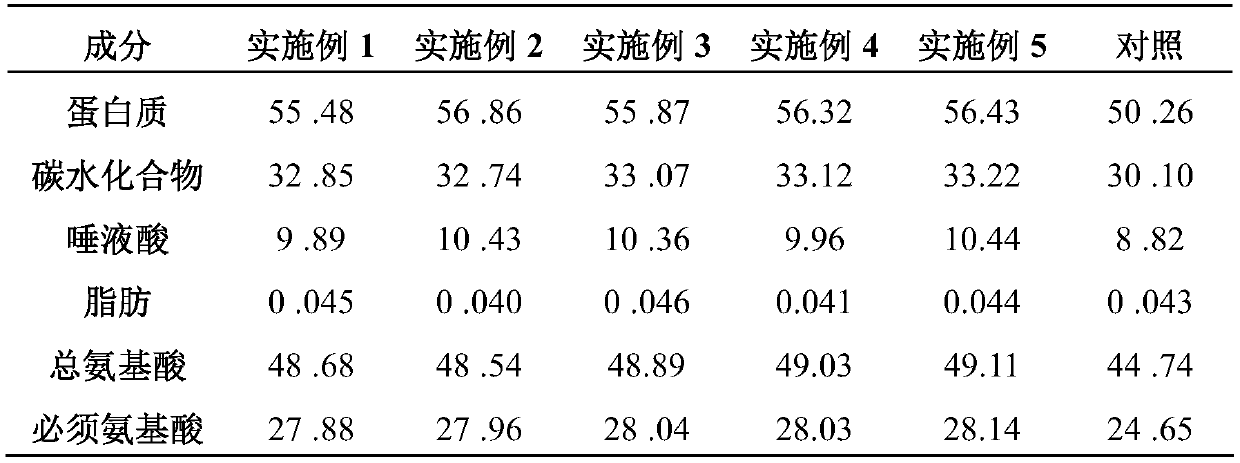

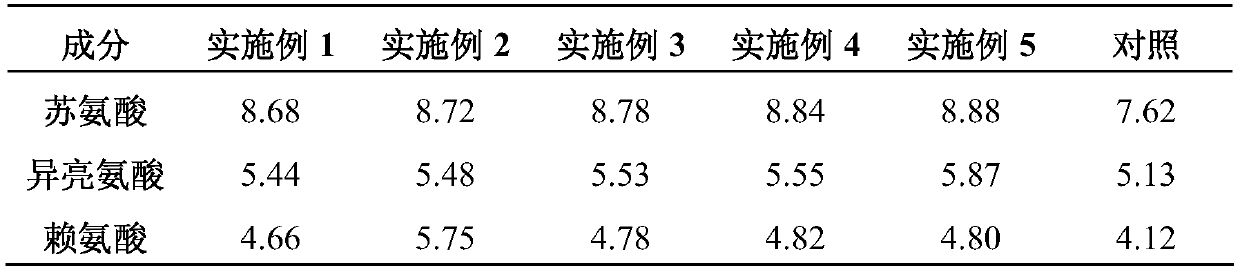

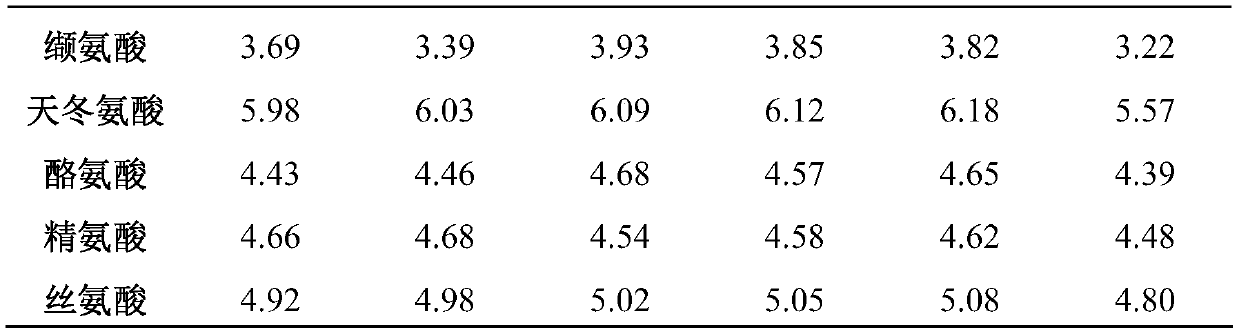

Instant freeze-dried bird's nest product and preparation method thereof

The invention provides an instant freeze-dried bird's nest product and a preparation method thereof. The preparation method comprises the following steps of: adding purified water into the bird's nest, soaking for 4-8 h at the temperature of 35-45 DEG C, and changing water once in the period; tearing along fibers after soaking to remove impurities, cleaning, adding auxiliary materials including crystal sugar and trehalose for blending, adding water for stewing, stewing on slow fire for 25-35 min, naturally cooling to the temperature of 50 DEG C or below, performing low-temperature dehydrationconcentration to 70-85% of water content for weighing; pre-freezing at the temperature of minus 35 DEG C to minus 40 DEG C, then freeze-drying in a freeze-dryer at the temperature of minus 60 DEG C tominus 65 DEG C for 44-52 hours, and packaging the freeze-dried bird's nest under vacuum to obtain the finished product. Under the condition that the taste of the freshly stewed bird's nest is not changed, the nutritional value of the bird's nest is kept, the quality is stable, the bird's nest is easy to absorb, the utilization rate is high, the storage time is long under the condition that no preservative is added, industrial production is facilitated, and the bird's nest is safe and convenient to eat.

Owner:福建品鉴食品有限公司

Method for processing persimmons

The present invention relates to a method for processing persimmons. after removing skin and stalk of a persimmon, the persimmon is dried in a cold-wind moisture-removed drying chamber. The drying process is characterized by the following steps: forming the skin by drying for 12-24 hours in humidity of 55-65% at a temperature of 23 to 28 DEG C; dyring and softening the persimmon for 24 hours in humidity of 50-60% at a temperature of 30 to 35 DEG C after skin-forming process; performing an adstringent step to the persimmon for 24 hours in humidity of 60-70% at a temperature of 1 to 5 DEG C after the drying and softening process; and drying the persimmon with the sweetness of 60-63% for 90 to 100 hours in humidity of 55-65% at a temperature of 23 to 28 DEG C after the adstringent process. According to the invention, the stalk is removed firstly and then dried, the moisture of the persimmon can be vaporized rapidly so as to dry the persimmon evenly to greatly shorten a drying period, simultaneously, the stalk has been removed, such that the persimmon can be eated.

Owner:DOJU FARMING ASSOC +1

Quick-freezing process for food

ActiveCN104799394AFast heat transferIncrease the number ofFood freezingFood processingSmall footprintContact type

The invention belongs to the technical field of quick-freezing processes for food, and particularly relates to a quick-freezing process for food. In the process, the food is immersed into liquid nitrogen for contact type freezing. The freezing implementation method of the quick-freezing process for food is simple, increases the efficiency of food freezing, reduces energy consumption in the process of food freezing, and increases the quality of frozen food. Equipment corresponding to the process is low in one-time investment, can be constructed in a short time, and occupies small floor area.

Owner:HENAN AGRICULTURAL UNIVERSITY

Treatment method of bird's nests

The invention discloses a treatment method of bird's nests. The treatment method mainly comprises the following steps of cleaning, sterilizing, soaking, dehydrating, quick-freezing and vacuum drying, the bird's nests are obtained through the treatment steps and are hygienic, safe, bacteria-free and free from additives, nutrient components in bird's nest raw materials are reserved, and users can eat favorable bird's nests in a short time through the manners of brewing and stewing. According to the treatment method disclosed by the invention, the problem that the bird's nests are difficult to process, preserve or transport is perfectly solved, and the bird's nests have high market values.

Owner:杨新远

Moringa oleifera leaf detoxifying method and application of moringa oleifera leaf product

InactiveCN103583930AReduced nutritional valueEasy to disengageFood freezingAcidic food ingredientsMORINGA OLEIFERA LEAFMoringa pterygosperma

The invention discloses a moringa oleifera leaf detoxifying method and application of a moringa oleifera leaf product. The method comprises the following steps: rinsing fresh moringa oleifera leaves by an ultrasonic principle and a water solution added with 1%-5% of edible citric acid or edible acetic acid to remove most of pungent taste and bitter taste, drying by infrared rays or a quick-freezing drying method, grinding into powder with 60-400 meshes, and preparing the powder into various foods, 100% of moringa oleifera powder tablets or capsules convenient for people to eat. According to the method, the pungent taste in the moringa oleifera leaves is dissolved, the toxins of the moringa oleifera leaves are separated, the pungent taste and a few alkaloids in the moringa oleifera leaves can be satisfactorily removed, the due nutritional ingredients of the moringa oleifera leaves are not destroyed, microorganisms can be killed, and the nutritional value of moringa oleifera is guaranteed not to be lowered.

Owner:唐国平

Instant freeze-dried fungus soup

InactiveCN103610158AConvenient nutrition mixFull of nutritionFood freezingFood shapingFreeze-dryingCordyceps militaris

The invention discloses instant freeze-dried fungus soup which takes pleurotus eryngii, lentinus edodes, pleurotus ostreatus, flammulina velutipes, cordyceps militaris and eggs as main materials, and is prepared by the following steps: washing the pleurotus eryngii, the lentinus edodes, the leurotus ostreatus, the flammulina velutipes and the cordyceps militaris, removing roots, and cutting into sections; preparing hot fungus soup; cooling the hot fungus soup in air and putting the cooled soup into a freezing plate; putting the freezing plate into a quick-freezing tunnel and freezing into a soup ice block; putting the soup ice block into a vacuum bin with the vacuum degree less than 100Pa, and performing dehydrating and drying; when the water content of an entity is less than 3%, obtaining a freeze-dried dehydrated soup ice block, namely the instant freeze-dried fungus soup. The instant freeze-dried fungus soup has the advantages of being rich in nutrition, delicious in taste, convenient and quick to eat and beneficial to health.

Owner:NORTH GREEN FOOD

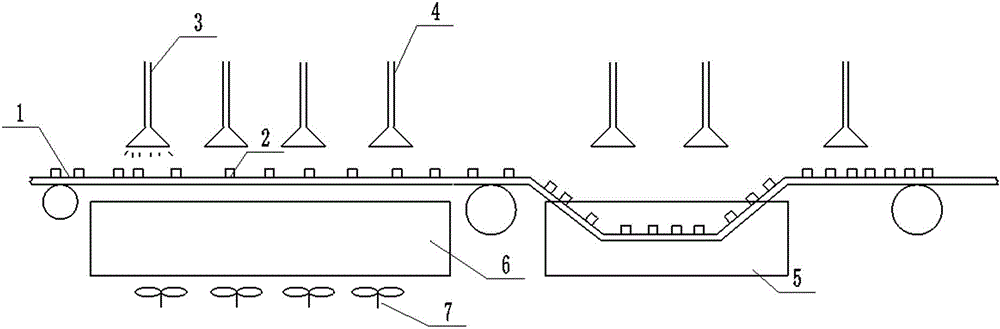

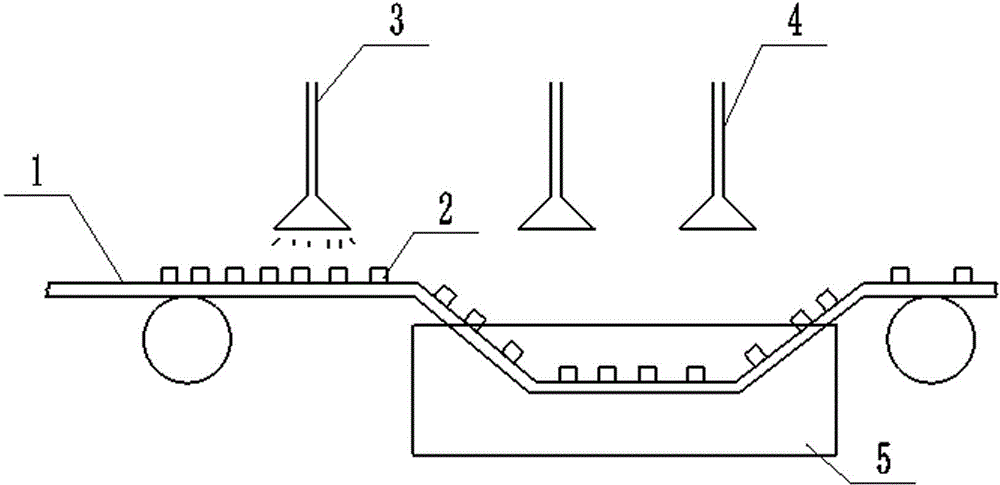

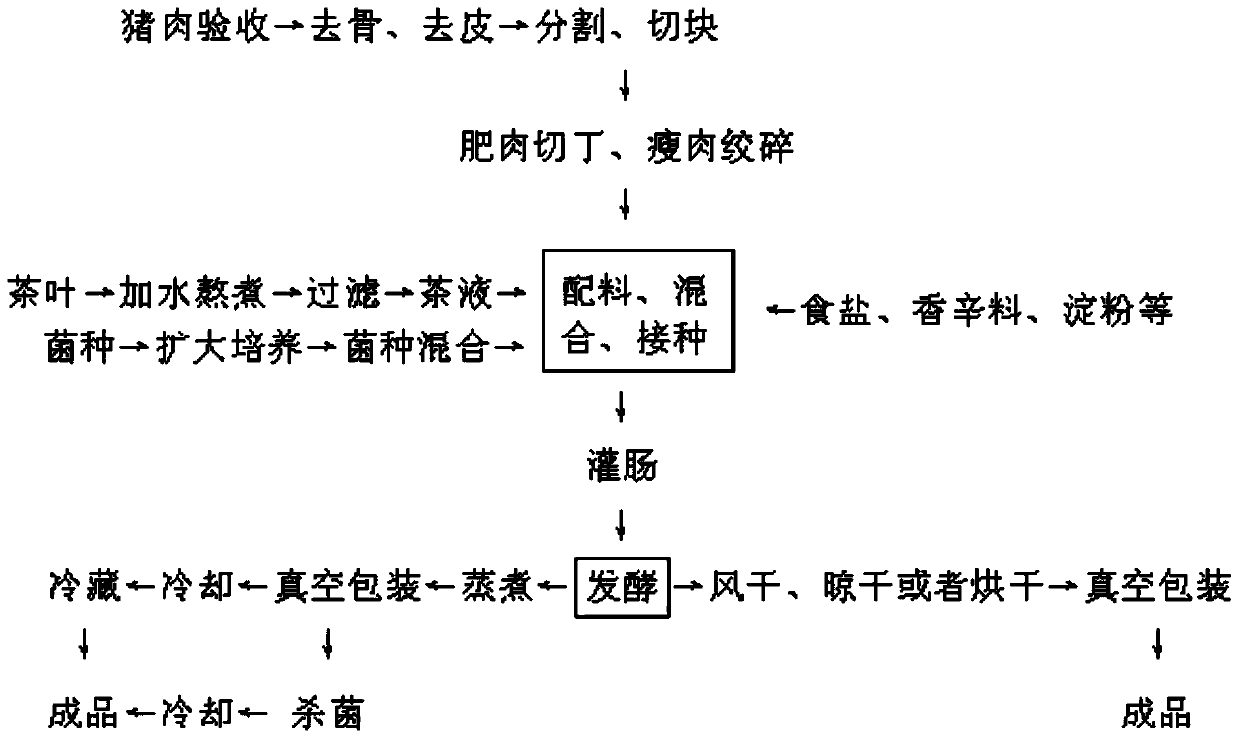

Fermented tea sausage and processing method thereof

ActiveCN103798831ADeliciousHigh nutritional valueFood freezingMeat/fish preservation by heatingNutritive valuesFood flavor

The invention discloses fermented tea sausage and processing methods thereof. The fermented tea sausage is produced by adopting tea liquid and pork as main raw materials to be fermented by a mixed strain consisting of lactobacillus, saccharomycetes and micrococcus. According to different product preservation methods, the invention provides the processing methods of three products such as dry-type fermented tea sausage, cold-stored cooked fermented tea sausage and normal-temperature-stored cooked fermented tea sausage. By adding the tea liquid and the mixed strain which is prepared from the purely-cultured lactobacillus, saccharomycetes and micrococcus into the processing flow of the sausage, the growth and propagation of inoculated microorganisms, such as the lactobacillus, which are beneficial to processing and cooking of the sausage can be effectively promoted, the production and accumulation of nitrite and biogenic amine in the sausage processing process can be suppressed by adequately utilizing tea polyphenol in the tea liquid; meanwhile, the sausage is unique in flavor, and the grease of the sausage can be reduced; the fermented tea sausage is delicious in taste, high in nutritional value, low inn nitrite and biogenic amine content, free from benzopyrene and high in food safety.

Owner:XIANGTAN UNIV

Nutrient rice flour and preparation method thereof

InactiveCN109511872AGreat tasteDelicate tasteFood freezingFood thermal treatmentAdditive ingredientPyrophosphate

The invention discloses a nutrient rice flour comprising the following raw materials in parts by weight: 50-80 parts of milled early long-grain non-glutinous rice, 10-20 parts of milled late long-grain non-glutinous rice, 30-50 parts of broken rice, 10-20 parts of potato whole powder, 1-5 parts of corn starch, 0.02-0.05 part of sodium pyrophosphate, 0.03-0.06 part of disodium hydrogen phosphate, 0.01-0.04 part of guar gum, 0.01-0.03 part of konjac gum, 1-5 parts of mung bean starch and 1-3 parts of gluten. The preparation method comprises the following steps: screening, cleaning, soaking, fermenting and grinding the milled early long-grain non-glutinous rice, the milled late long-grain non-glutinous rice and the broken rice, adding other residual ingredients, and carrying out paste mixing,flake steaming, extrusion molding, flour steaming, cooling, quick freezing, sterilizing and packaging to obtain a finished product of the rice flour. The nutrient rice flour disclosed by the invention contains abundant nutrient components and is not easy to break and good in toughness and taste.

Owner:湖南仕杰农业股份有限公司

Processing method of novel nutrition blended cedrela sinensis

ActiveCN103907845AStrong characteristic flavorLong-lasting characteristic flavor substancesFood freezingFood dryingNutritionEconomic benefits

The invention discloses a processing method of novel nutrition blended cedrela sinensis. The processing method comprises the following steps: selecting and cleaning a cedrela sinensis raw material; dewatering the cleaned cedrela sinensis raw material; freezing the dewatered cedrela sinensis raw material; blanching the frozen cedrela sinensis by combining boiling water and microwaves; preserving heat and coloring after blanching; cooling and rinsing; draining; cutting; adding seasoning oil for blending; vacuum-packaging; and performing ultra-high pressure sterilization to prepare a cedrela sinensis dish. According to the processing method, the problem of color of a product is effectively solved by using boiling water and microwave blanching and trace sodium copper chlorophyllin, and the flavor of the cedrela sinensis is maximally remained by adopting a fat embedding technology and ultra-high pressure instant sterilization. The cedrela sinensis dish is green in color, thick and durable in flavor substance, rich in nutrients, good in taste, suitable for most of people, wide in market and high in social and economic benefits.

Owner:HENAN ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com