Patents

Literature

37results about How to "Full size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

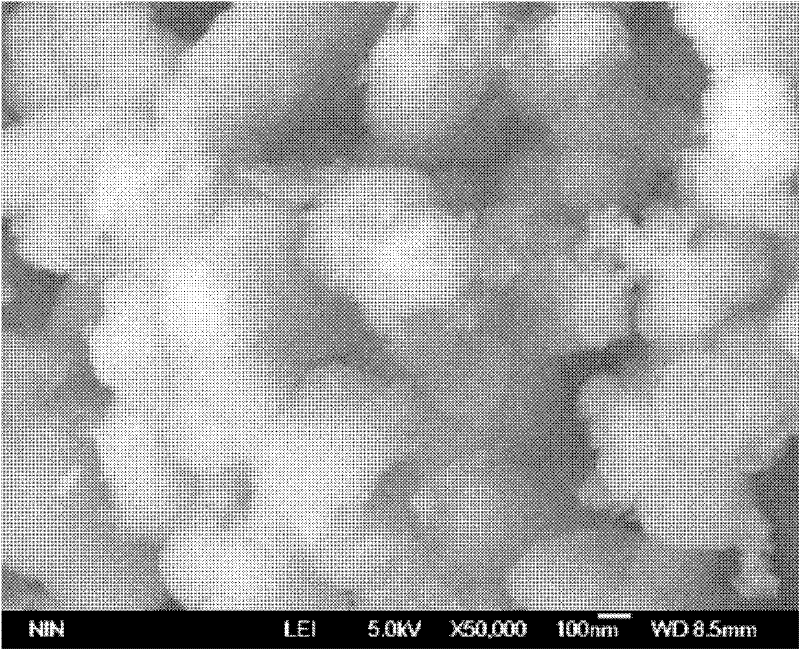

Preparation method of SiO2/TiO2 composite microspheres

InactiveCN101891206AHigh purityGood dispersionPhysical/chemical process catalystsSilicaWater bathsAlcohol

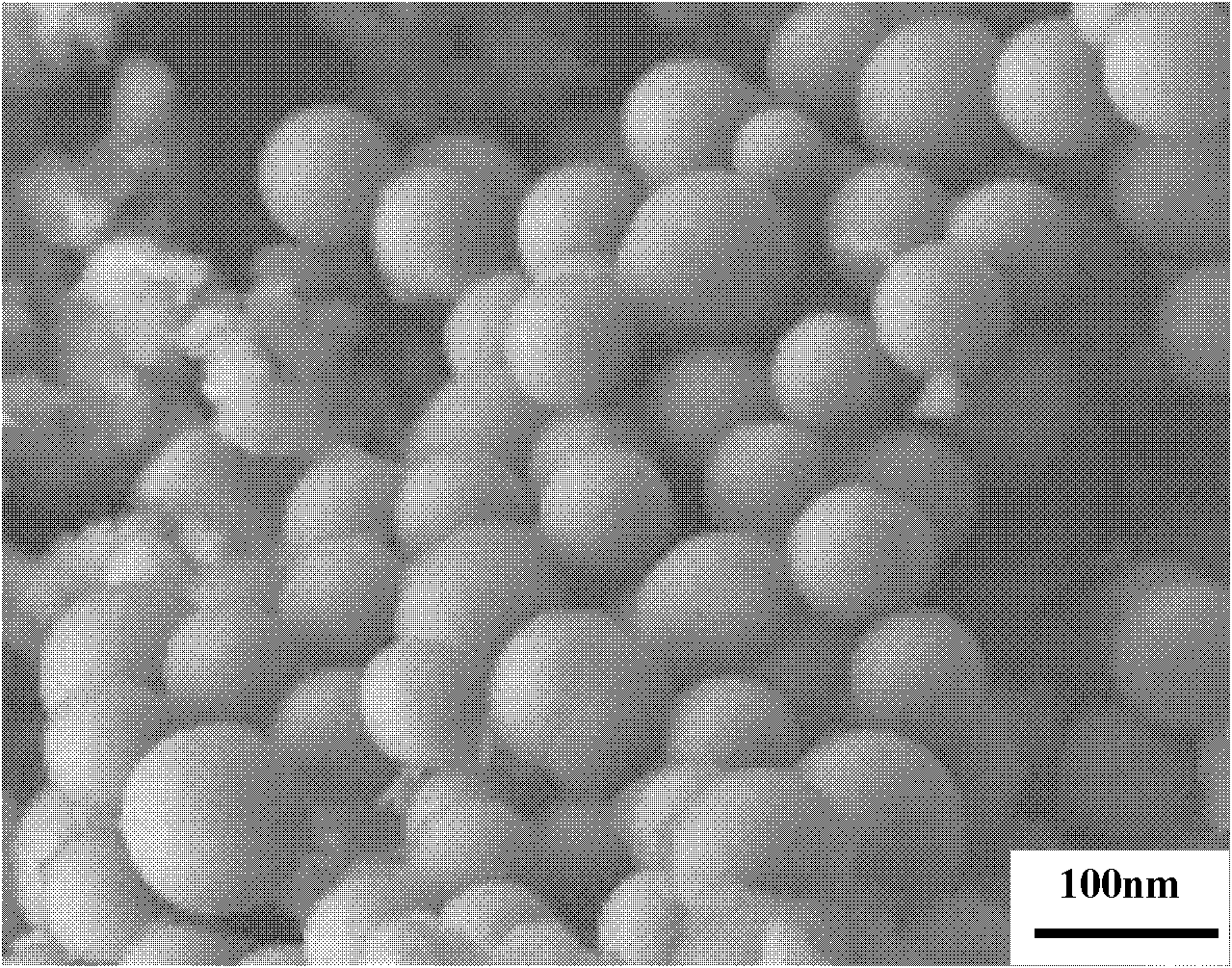

The invention discloses a preparation method of SiO2 / TiO2 composite microspheres, which comprises the following steps: taking butyl titanate and ethyl orthosilicate as raw materials, taking ammonia and anhydrous alcohol as solvents, taking citric acid as a complexing agent, taking polyoxyethylene as a dispersant, adding sol containing Ti into wet gel containing Si under continuous stirring, then evaporating by a water bath, drying and foaming for leading the two to compound, finally calcining and then preparing the SiO2 / TiO2 composite microspheres. The method has short preparation cycle, the prepared SiO2 / TiO2 composite microspheres are shaped like complete spheres with the size of 70-200nm, and the purity and the finished product rate are very high.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing multi-shape controllable nano nikel-cobalt spinel oxide

The invention relates to a method for preparing multi-shape controllable nano nikel-cobalt spinel oxide. The method includes the steps that nickel nitrate and cobalt nitrate are dissolved in anhydrous ethanol according to the cobalt-nickel atom ratio to form a solution A; oleylamine is dispersed in an ethanol solution to form a solution B, and the solution B and the solution A are mixed to obtain a mixed solution; the mixed solution is fully and evenly stirred and moved into a dynamic reaction kettle, H2 is replaced in a sealed mode, pressure intensity of H2 is adjusted to 6-15 bar after replacement, and a steel cylinder air outlet valve is closed; the stirring speed of the dynamic reaction kettle is adjusted to 400 r / min, temperature is set to be 150 DEG C, and reaction is carried out for 10 h; a product is cleaned through ethanol and other nonpolar solvents respectively, centrifugal separation is carried out, and a sediment precursor is obtained through drying at the temperature of 60 DEG C; the temperature of the obtained sediment precursor rises in an air atmosphere at the speed of 10 DEG C / min, and the sediment precursor is heated to 200-400 DEG C and kept warm. According to the method, procedures are few, materials are easy to get and low in price, the procedures are safe, nikel-cobalt spinel oxide of different shapes can be obtained by changing a small condition in the procedures, and accordingly preparing of the controllable nano nikel-cobalt spinel oxide is achieved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

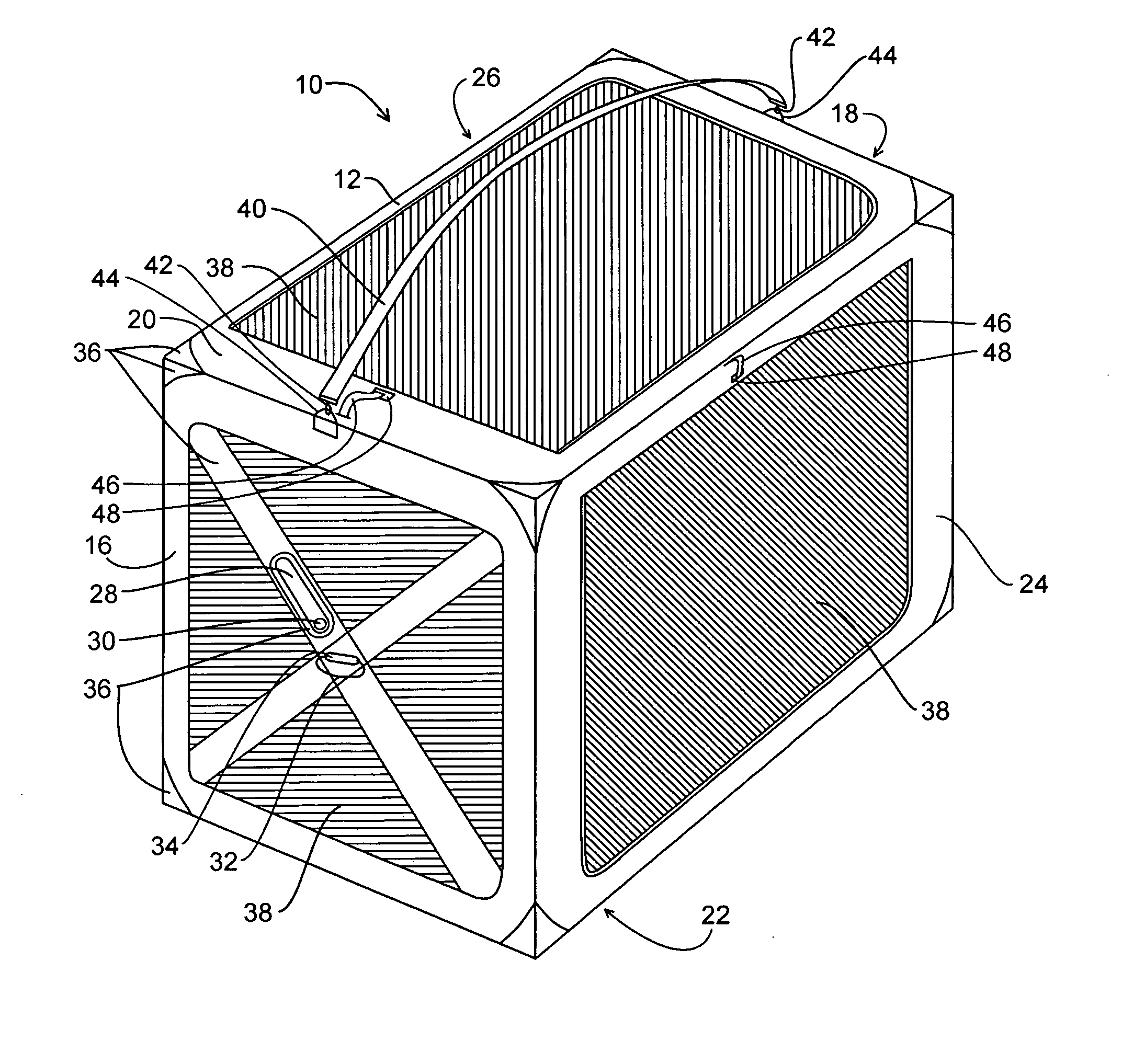

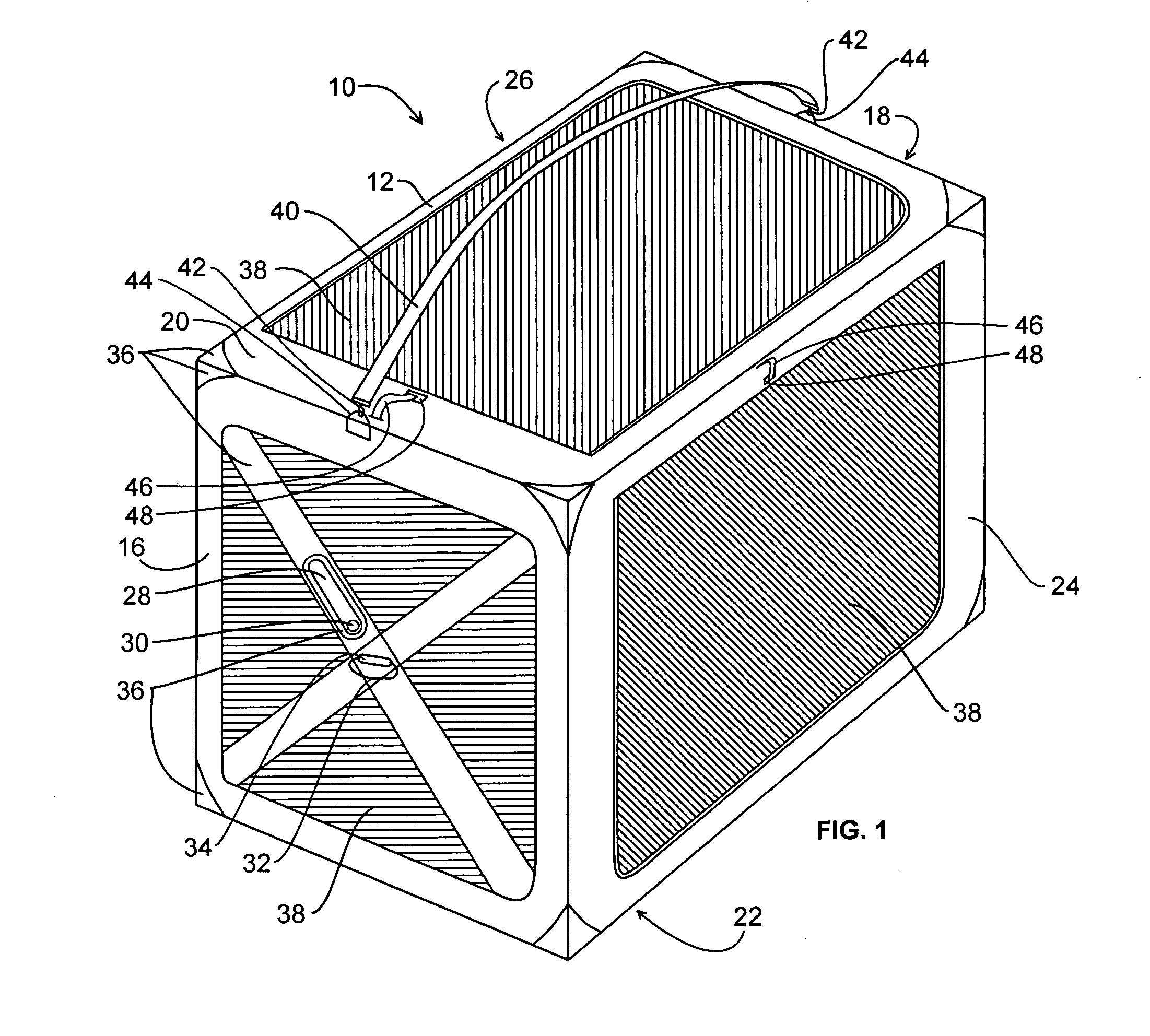

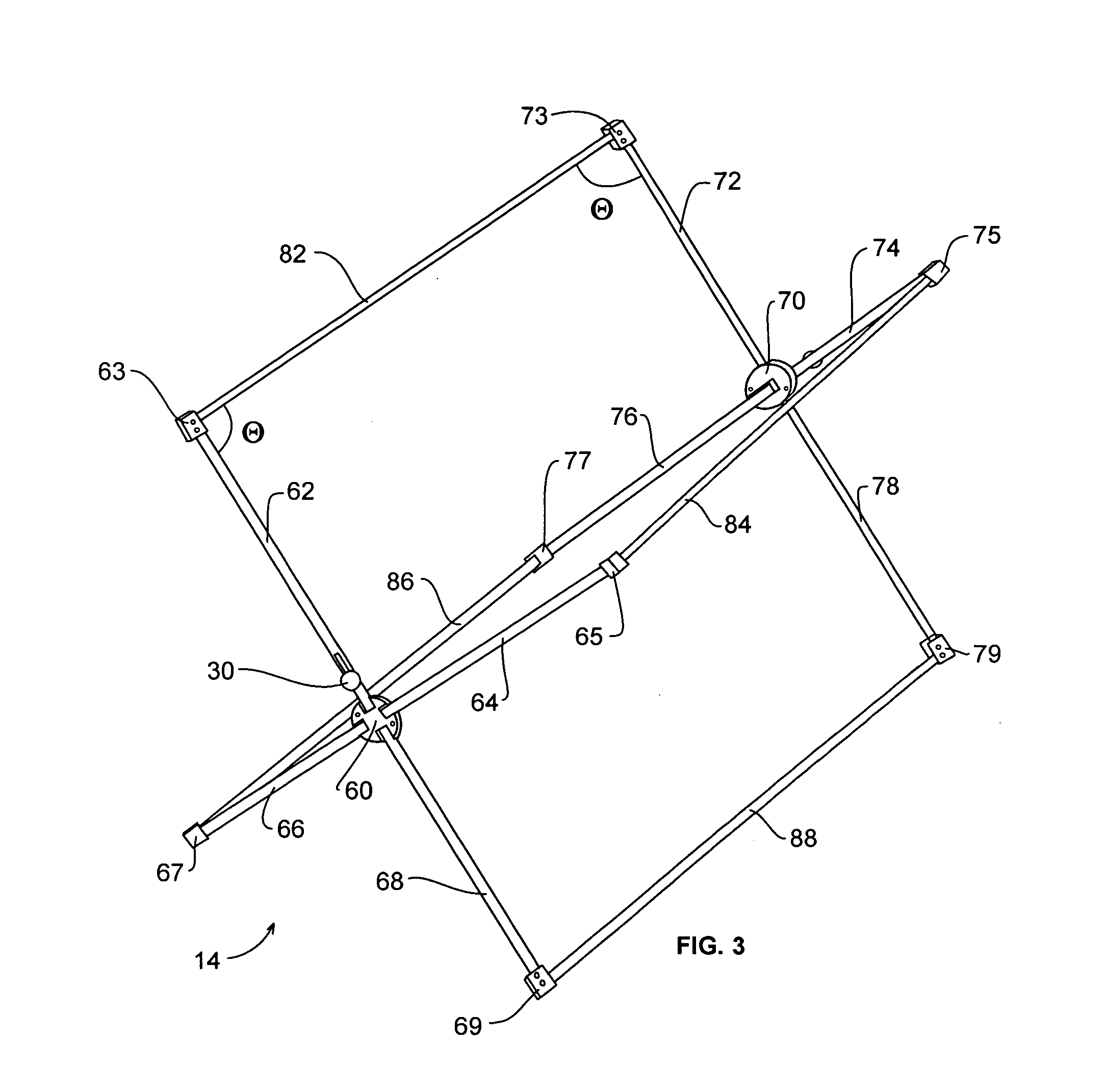

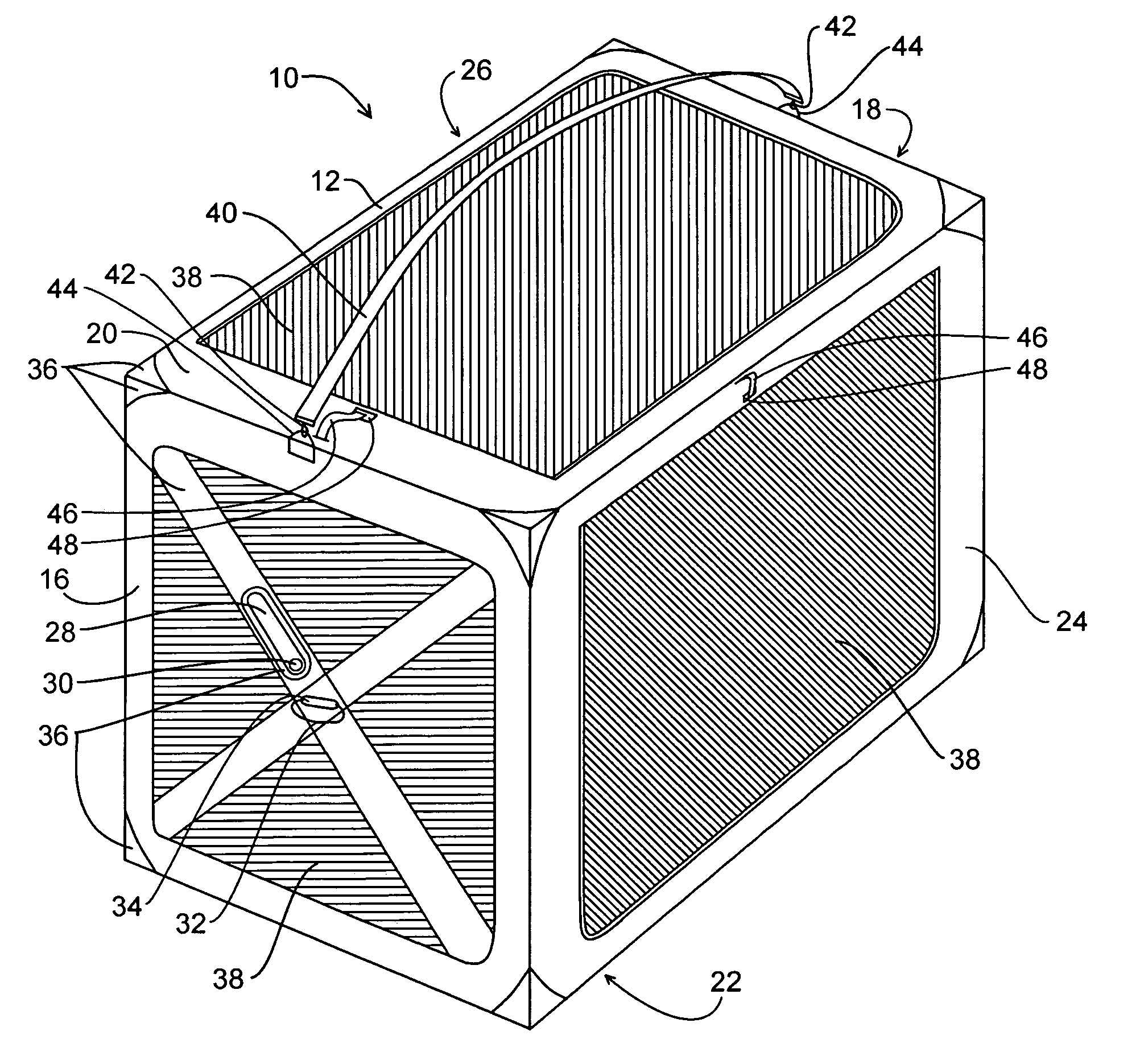

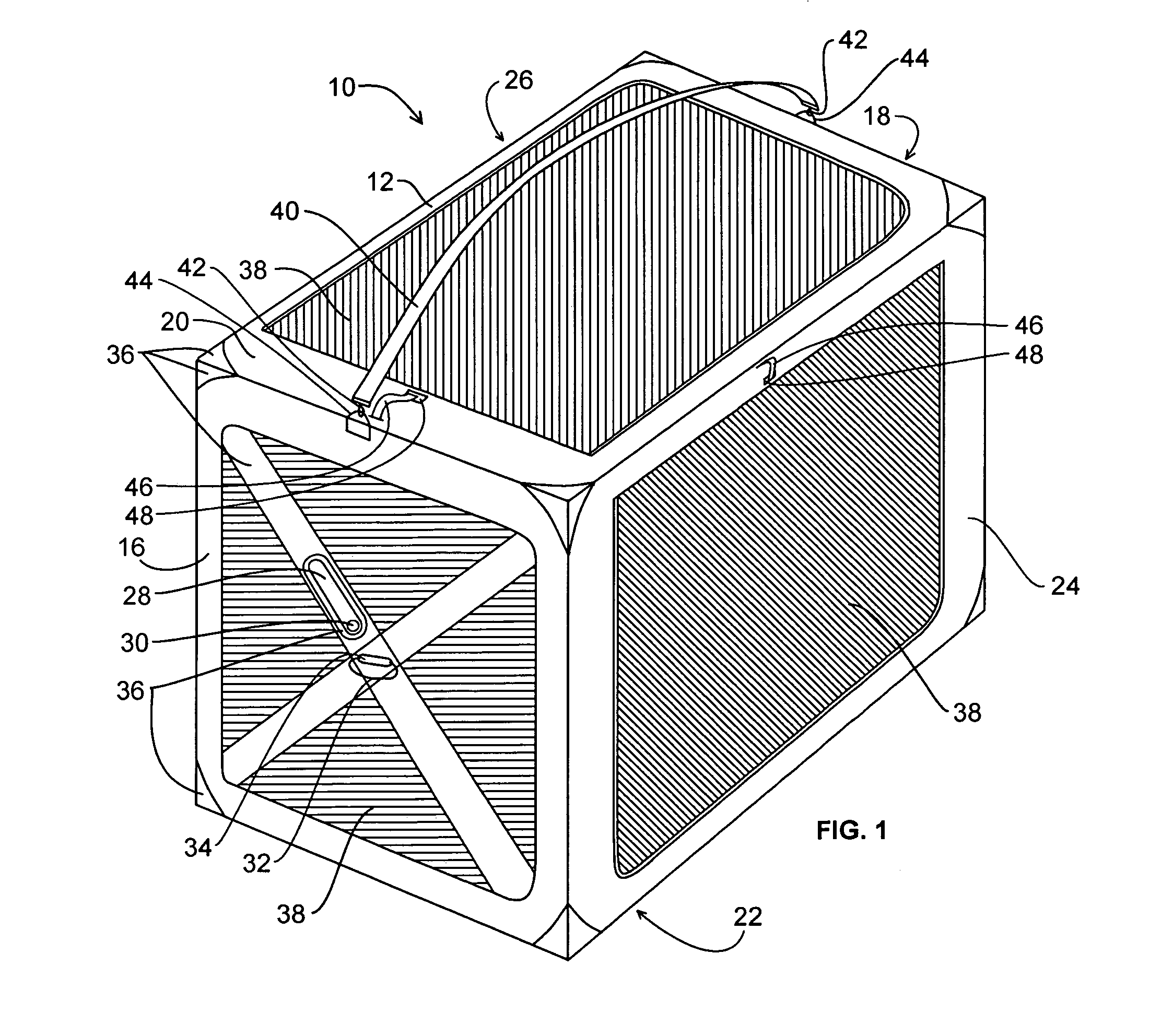

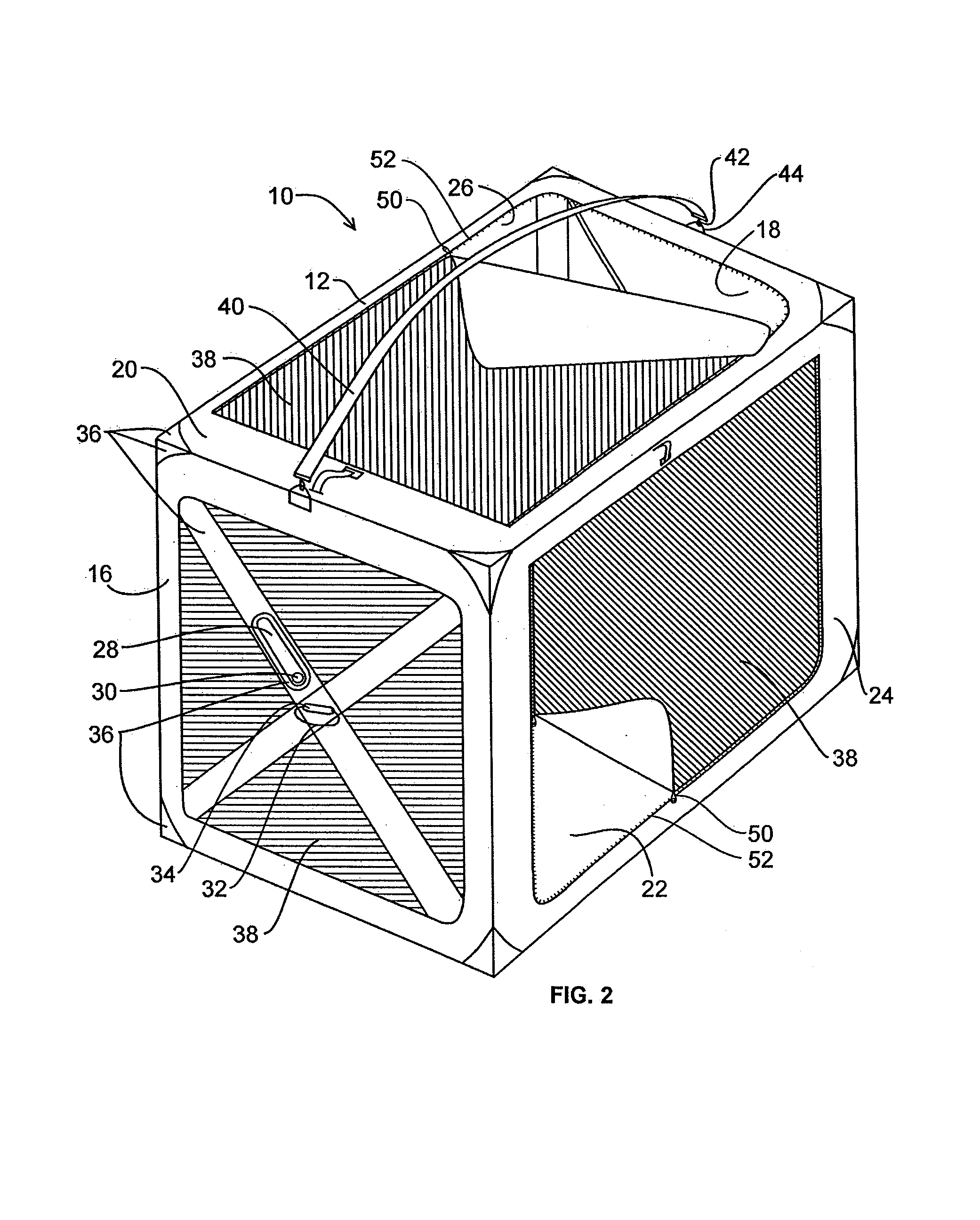

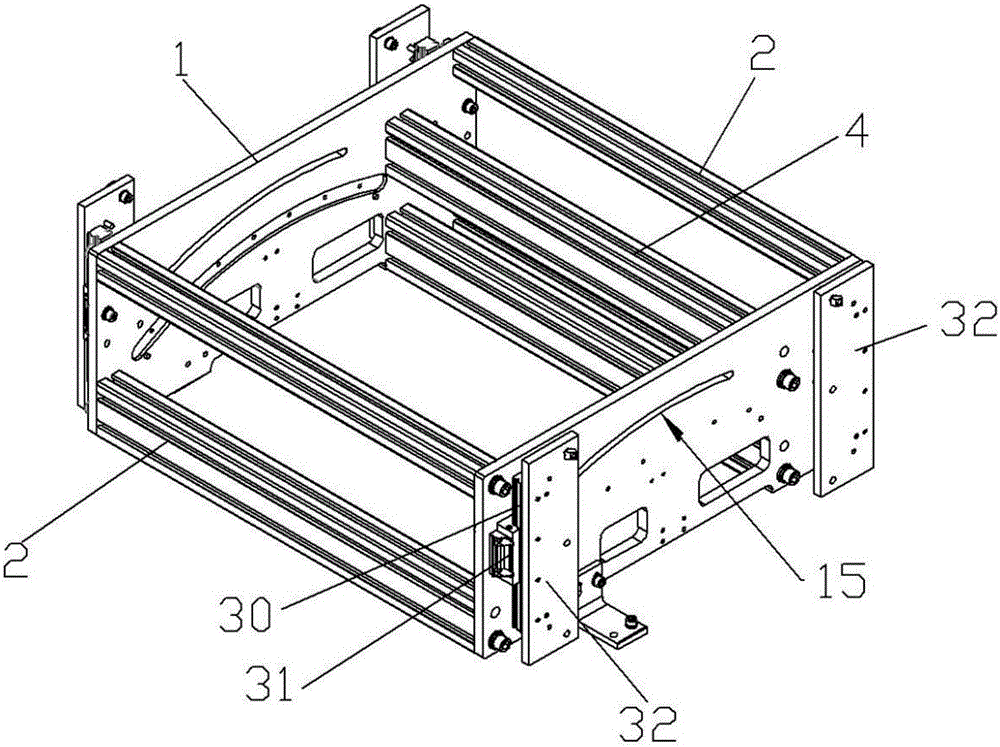

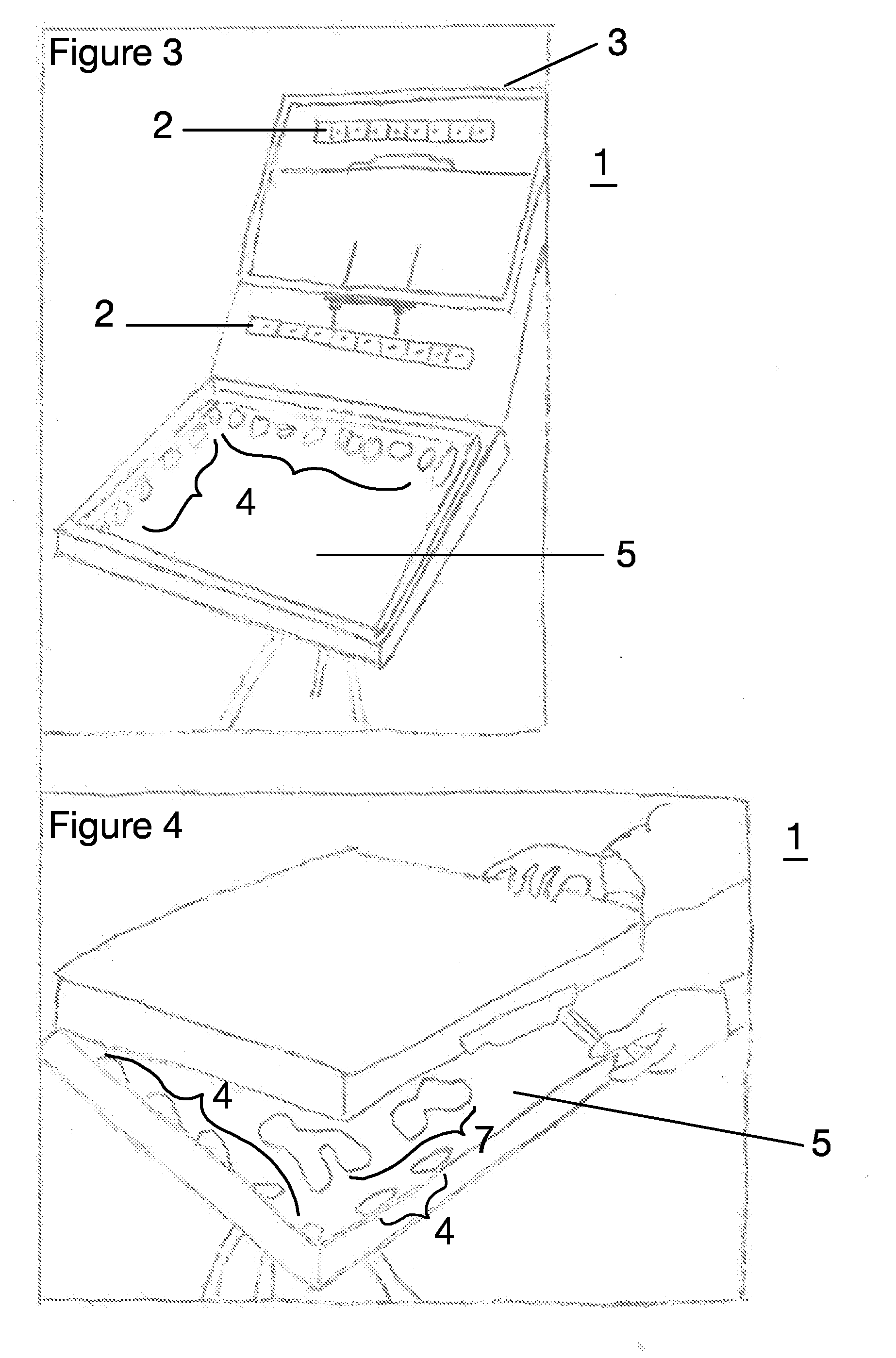

Collapsible pet crate

A collapsible cage / crate for pets having an inner framework within a soft-sided shell. The internal framework is integrated and manipulated by two locking hubs such that when the hubs are unlocked and urged towards each other, the crate collapses. In its deployed configuration, the crate provides an area for an animal to be confined whereas when the crate is collapsed the crate is compact and easy to transport. The outer shell of the crate is formed of fabric and includes one or more mesh panels in order to provide airflow into and out of the crate. Access is gained to the interior of the crate through one or more doors.

Owner:HYPER PET

Method for preparing SiO2/TiO2 composite powder

The invention discloses a method for preparing SiO2 / TiO2 composite powder, which comprises the following steps of: dissolving tetraethoxysilane and ammonia water in absolute ethyl alcohol respectively, mixing the tetraethoxysilane and the ammonia water at one time under the ultrasonic condition, continuously performing ultrasonic separation and precipitation to obtain SiO2 submicron spheres with uniform particles and complete appearance; adding the SiO2 submicron spheres into tetrabutyl titanate sol C taking the ammonia water as a solvent, citric acid as a complexing agent and polyethylene glycol as a dispersing agent, performing sufficient ultrasonic dispersion, and stirring and heating to obtain wet gel; and further drying and foaming to compound SiO2 and TiO2 constantly, and calcining to obtain the SiO2 / TiO2 composite powder. The method disclosed by the invention has short preparation period; and the prepared SiO2 / TiO2 composite powder is complete spheres of which the particle size is 200 to 600nm and has high purity and yield.

Owner:SHAANXI UNIV OF SCI & TECH

Collapsible pet crate

Owner:HYPER PET

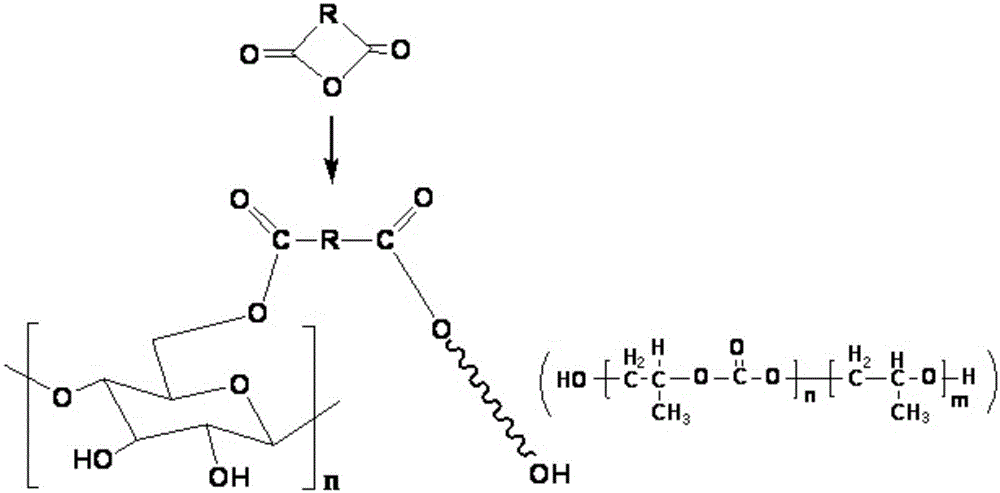

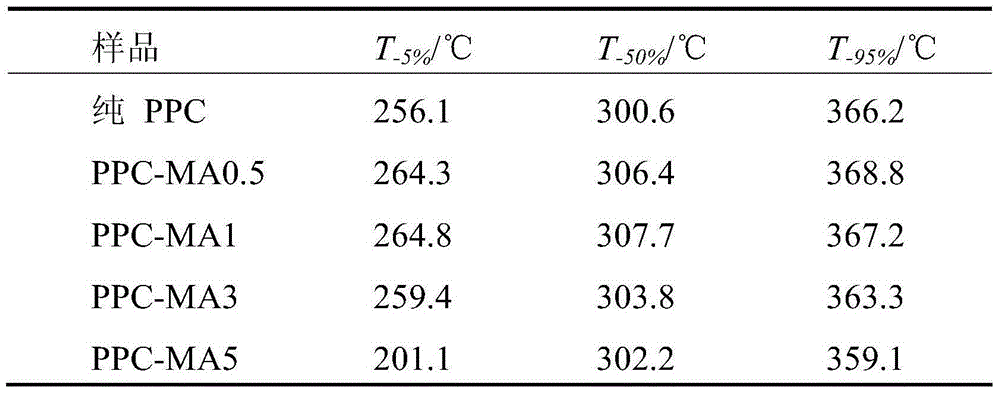

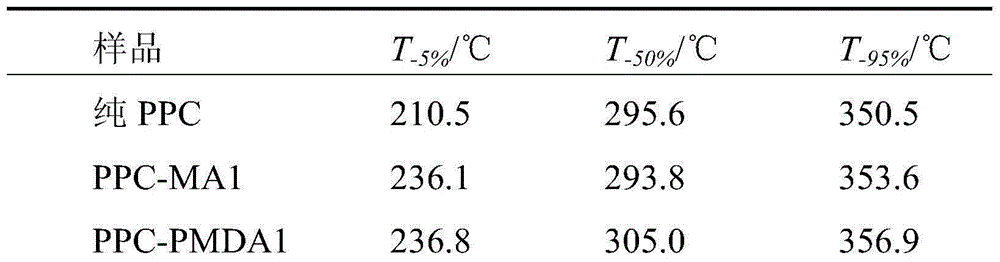

Method for preparing completely-degradable composite material through acid anhydride and microcrystalline cellulose synergetic modification on poly(propylene carbonate)

InactiveCN105061971ASmall sizeComplete crystalline structurePropylene carbonateMicrocrystalline cellulose

The present invention discloses a method for preparing a completely-degradable composite material through acid anhydride and microcrystalline cellulose synergetic modification on poly(propylene carbonate), wherein 50-95 parts by mass of degradable poly(propylene carbonate), 0.1-10 parts by mass of an acid anhydride and 5-50 parts by mass of microcrystalline cellulose are subjected to melt mixing to form a master batch of a completely-degradable composite material, and mold pressing molding is performed to obtain the sample. According to the present invention, the completely-degradable composite material prepared through the method has characteristics of good mechanical property and good thermal stability, and the processing stability and the mechanical property of the prepared product can be effectively improved.

Owner:SOUTH CHINA UNIV OF TECH

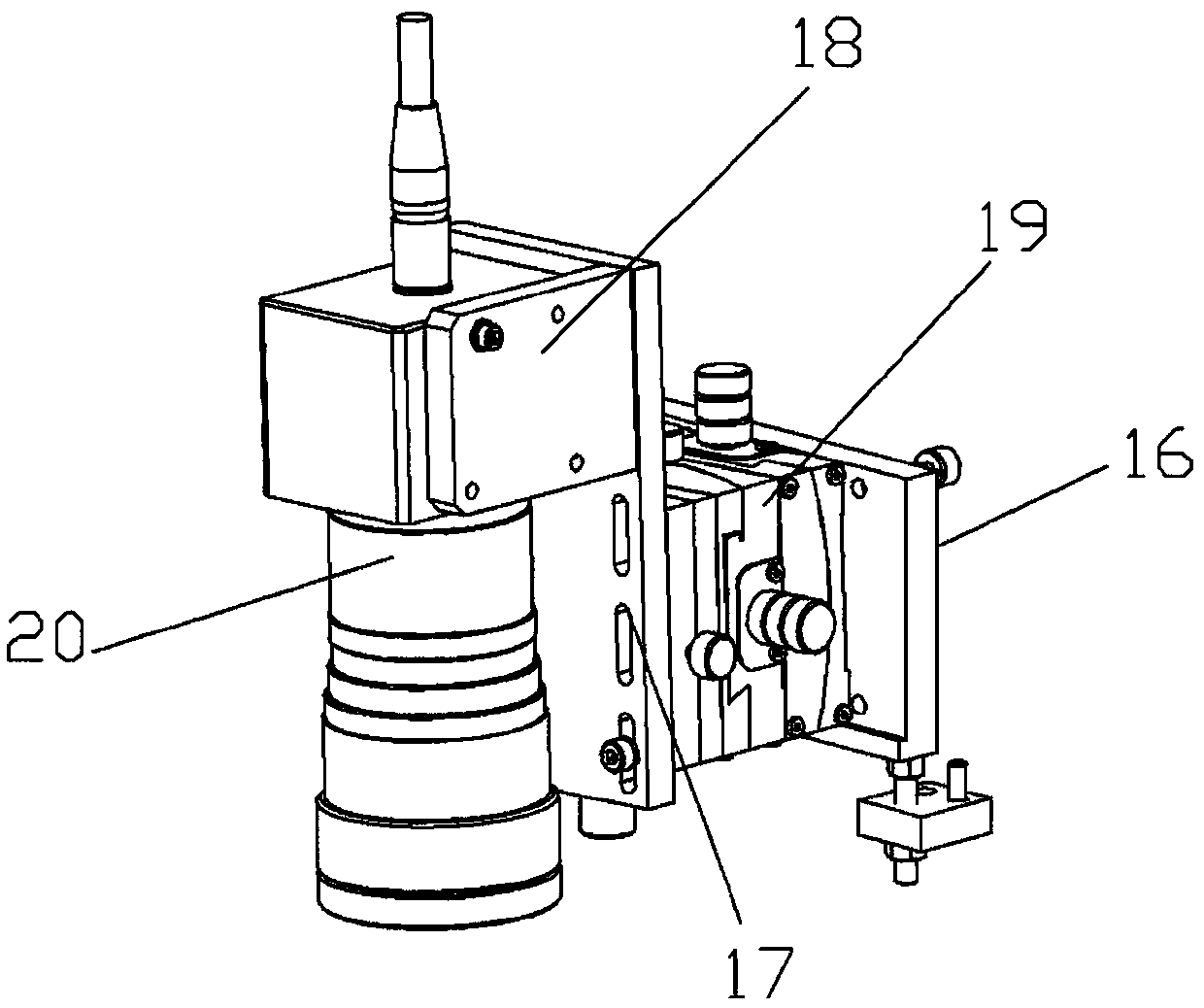

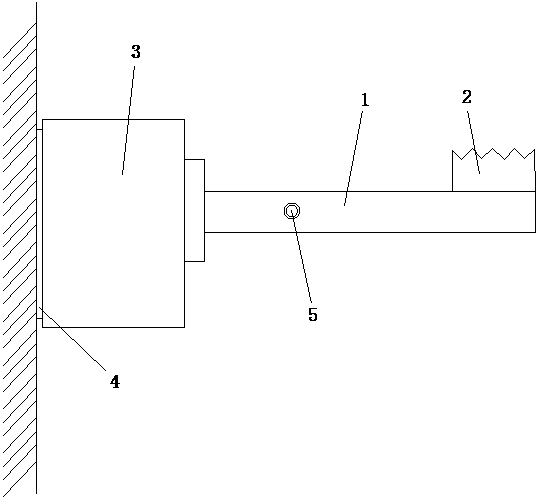

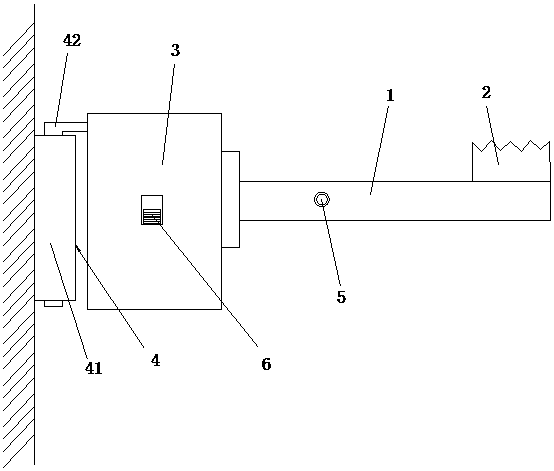

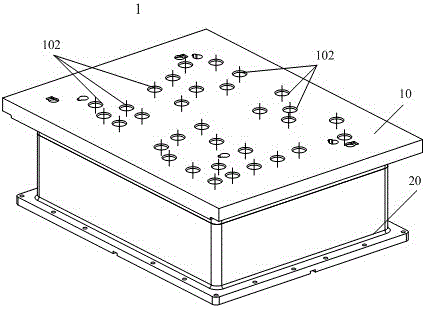

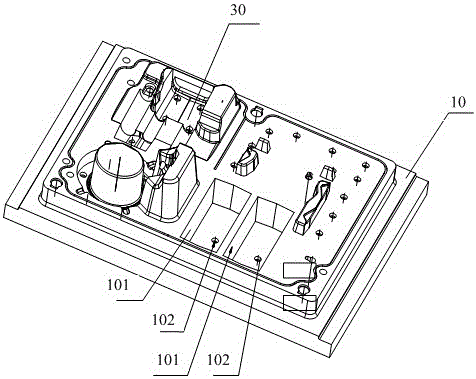

Intelligent camera shooting monitoring device and mounting and debugging method thereof

ActiveCN106657878AExpand the scope of monitoringHigh integrityTelevision system detailsColor television detailsEngineeringFixed Beam

Owner:上海智领网络科技有限责任公司

A method for artificially cultivate wild rhizoma Gastrodiae

InactiveCN108887124APromote growthThe growth rate is not short-term improvementCultivating equipmentsRoot crop cultivationEconomic benefitsArmillaria mellea

A method for artificially cultivate wild rhizoma Gastrodiae comprises prepare bacterial culture medium, inoculating, cultivating Armillaria mellea, preparing bacterial material, planting rhizoma Gastrodiae, cultivate rhizoma Gastrodiae protocorm, growing and managing rhizoma Gastrodiae, and harvesting. The germination rate of Gastrodia elata seeds is up to 99% and the growth rate of Gastrodia elata is constantly improved through the comprehensive adjustment and control of artificial cultivation method. The obtained Gastrodia elata seeds are uniform in size, plump and good in quality, and the yield of Gastrodia elata is increased and the economic benefit is increased through the way of laying fungus wood in multiple layers.

Owner:通化县兴隆中药材专业合作社

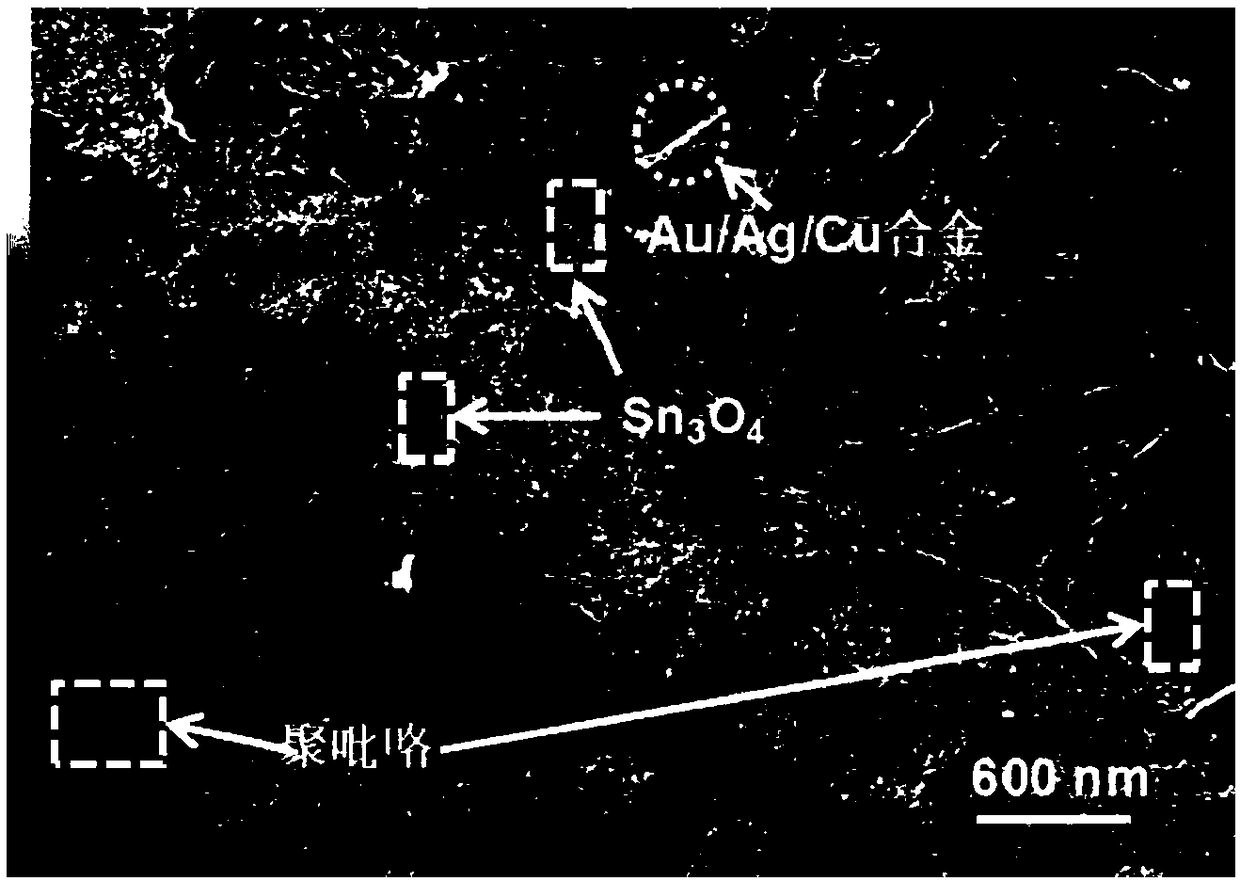

Preparation method of polypyrrole/metal-modified Sn3O4 nano composite photocatalytic material

InactiveCN109107614AEnhanced Broad Spectrum Light AbsorptionImprove photocatalytic performanceGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsHeterojunctionPhotocatalytic reaction

The invention discloses a preparation method of a polypyrrole / metal-modified Sn3O4 nano composite photocatalytic material. The nano composite material is a composite photocatalyst material obtained byloading and dispersing metal-modified Sn3O4 semiconductor heterojunction on polypyrrole in a chemical bond complexing form; and the metal-modified Sn3O4 is obtained by separately loading metal nano particles of a single-component metal or multi-component alloy of Pt, Au, Ag, Cu and the like having a plasma resonant effect onto Sn3O4. The photo-induced electron-hole separation rate in the photocatalytic reaction can be sufficiently improved by utilizing the visible light photocatalytic oxidation and reduction characteristics of Sn3O4, the plasma resonant effect of metal nano particles, photo conduction and conductivity of polypyrrole as well as the chemical bond heterojunction structure among different components, so that the performance for degrading pollutants in a photocatalytic oxidation and reduction manner and generating hydrogen by photocatalytic and decomposition of water can be improved. The easy-to-mold characteristic of polypyrrole can effectively avoid the recycling difficulty of the powder material.

Owner:PINGDINGSHAN UNIVERSITY

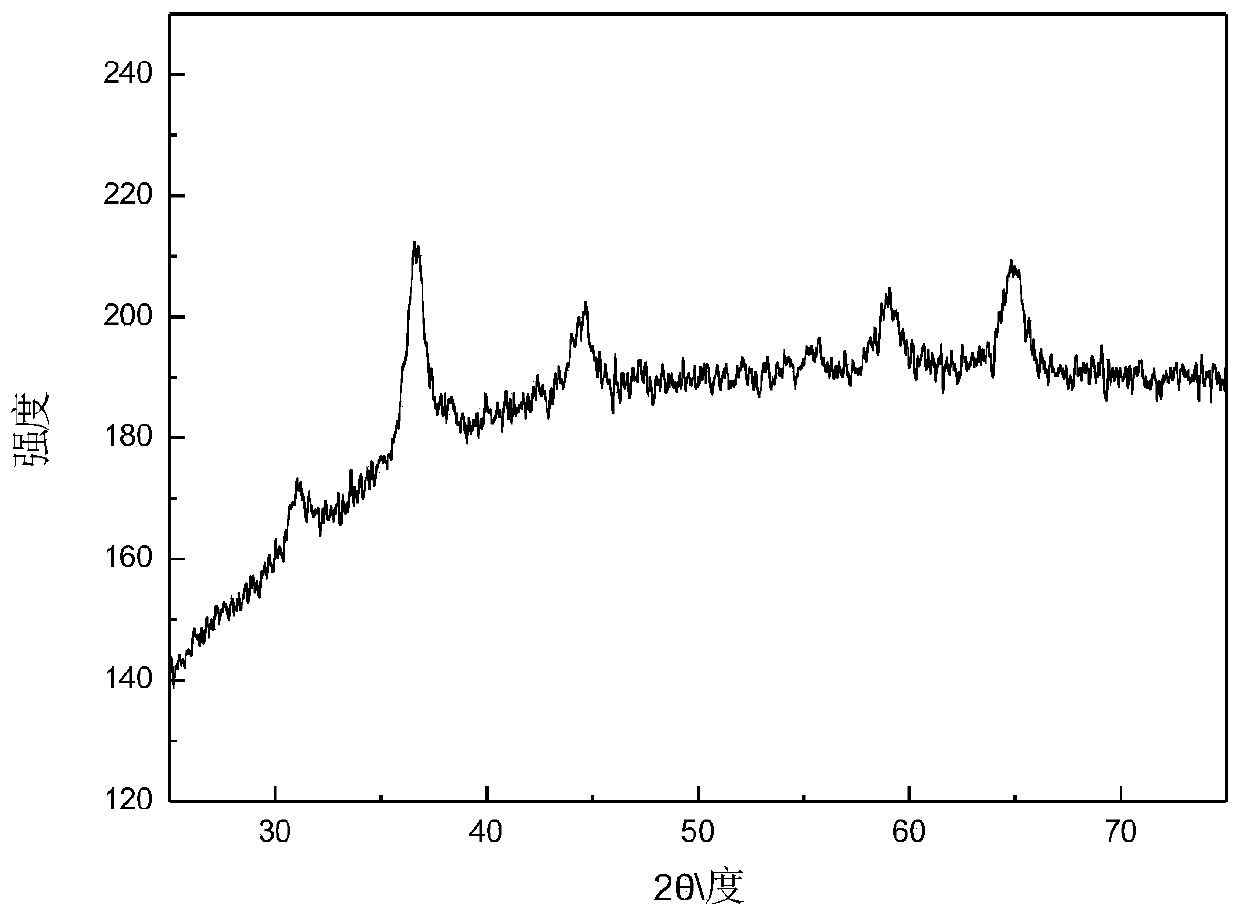

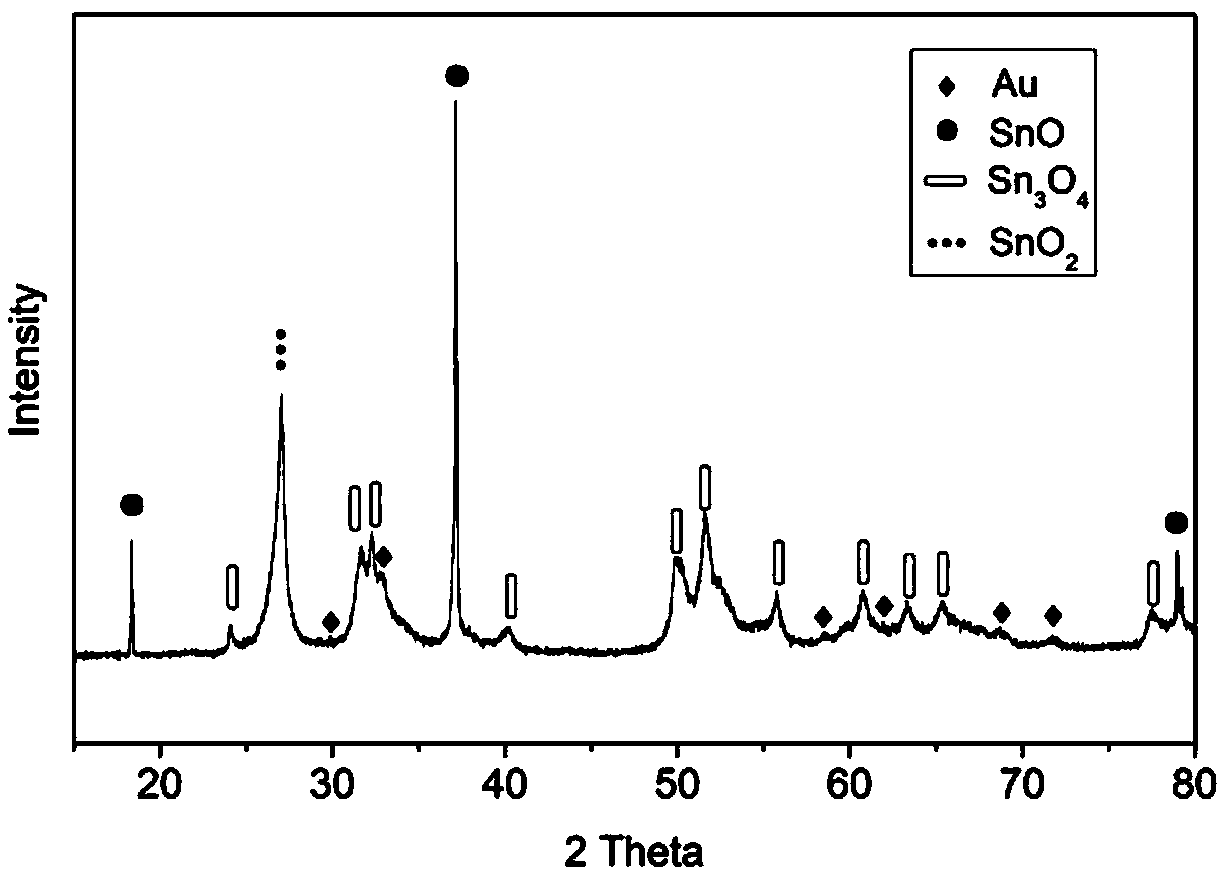

Preparation method of Au modified SnO/Sn3O4/SnO2 nano composite photocatalytic material

InactiveCN109092307AEnhanced light absorptionEasy to separateHydrogen productionHydrogen/synthetic gas productionHeterojunctionPhotocatalytic water splitting

The invention relates to a preparation method of an Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material. The nano composite material is obtained by placing chloroauric acid and a tin source into a solvent, a surfactant and a reducing agent and forming chemical bond complexing among composite ingredients of the materials according to an ice salt bath and solvent combined hot wet chemical in-situ synthesis method. The composite material prepared by the invention utilizes a plasma resonance effect of Au metal nanoparticles, an excellent energy level matching heterojunction structureamong composite components of a tin oxide material and excellent electron conduction of Au metal nanoparticles, and implements rapid electron-hole separation in the process of cooperating photocatalytic oxidation and reduction degradation of pollutants with photocatalytic water splitting hydrogen production, thereby improving efficiency of photocatalytic water splitting and photocatalytic rhodamine B degradation of the Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material.

Owner:PINGDINGSHAN UNIVERSITY

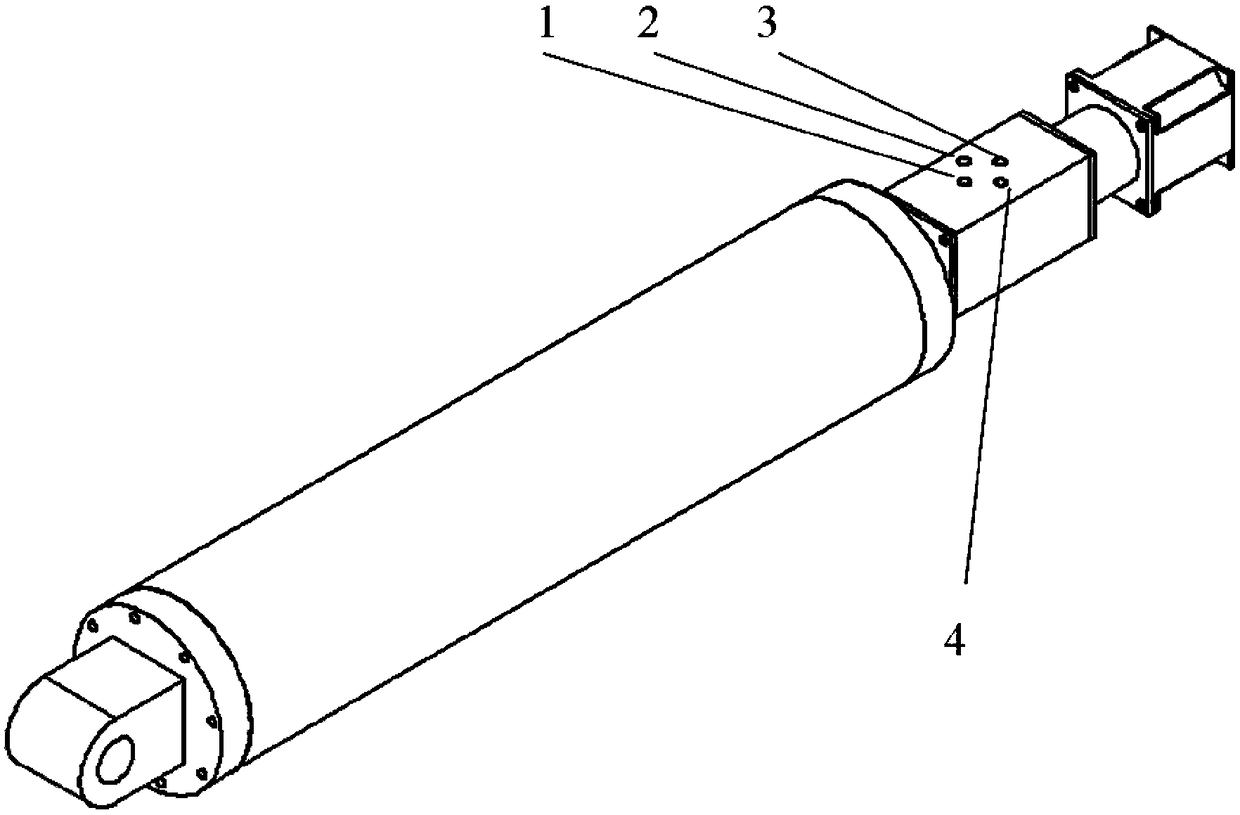

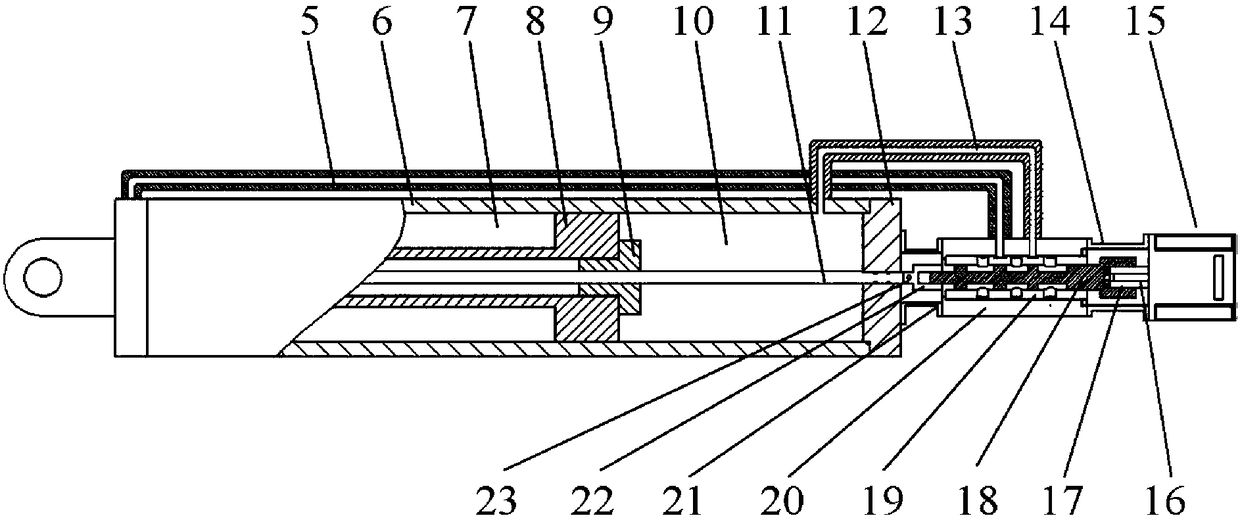

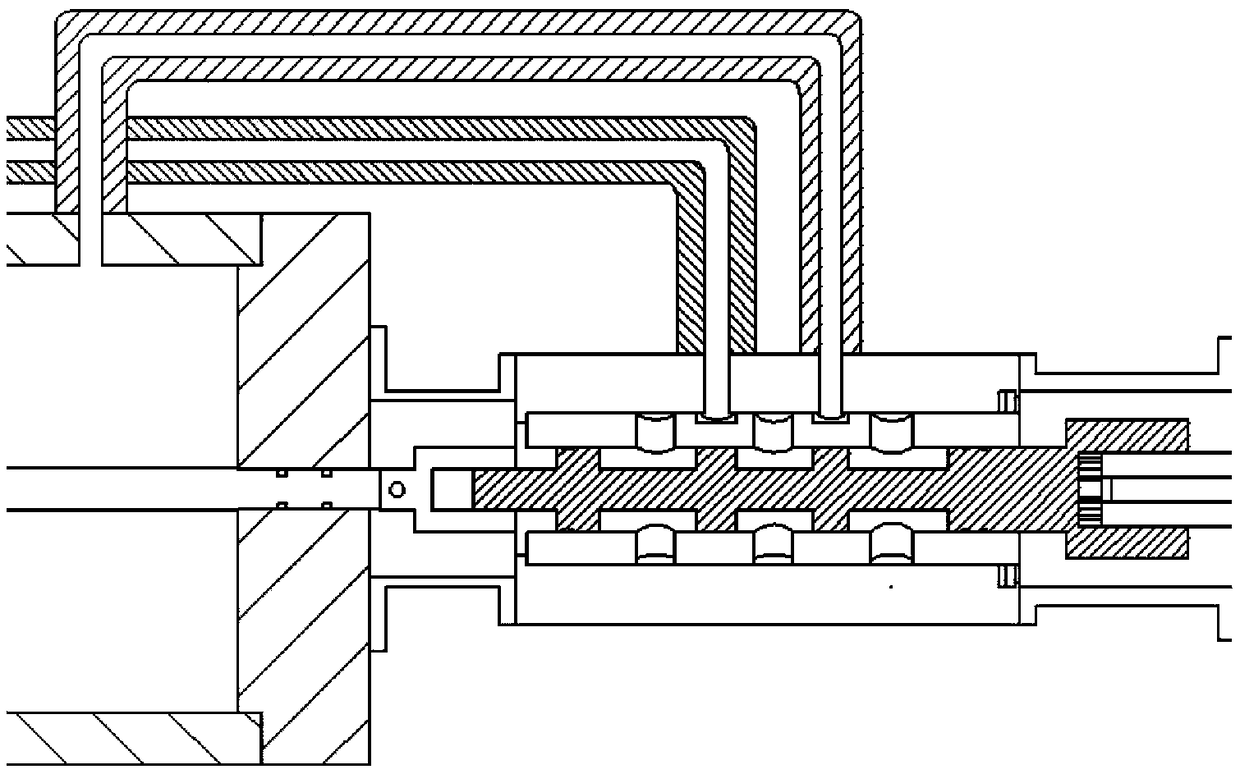

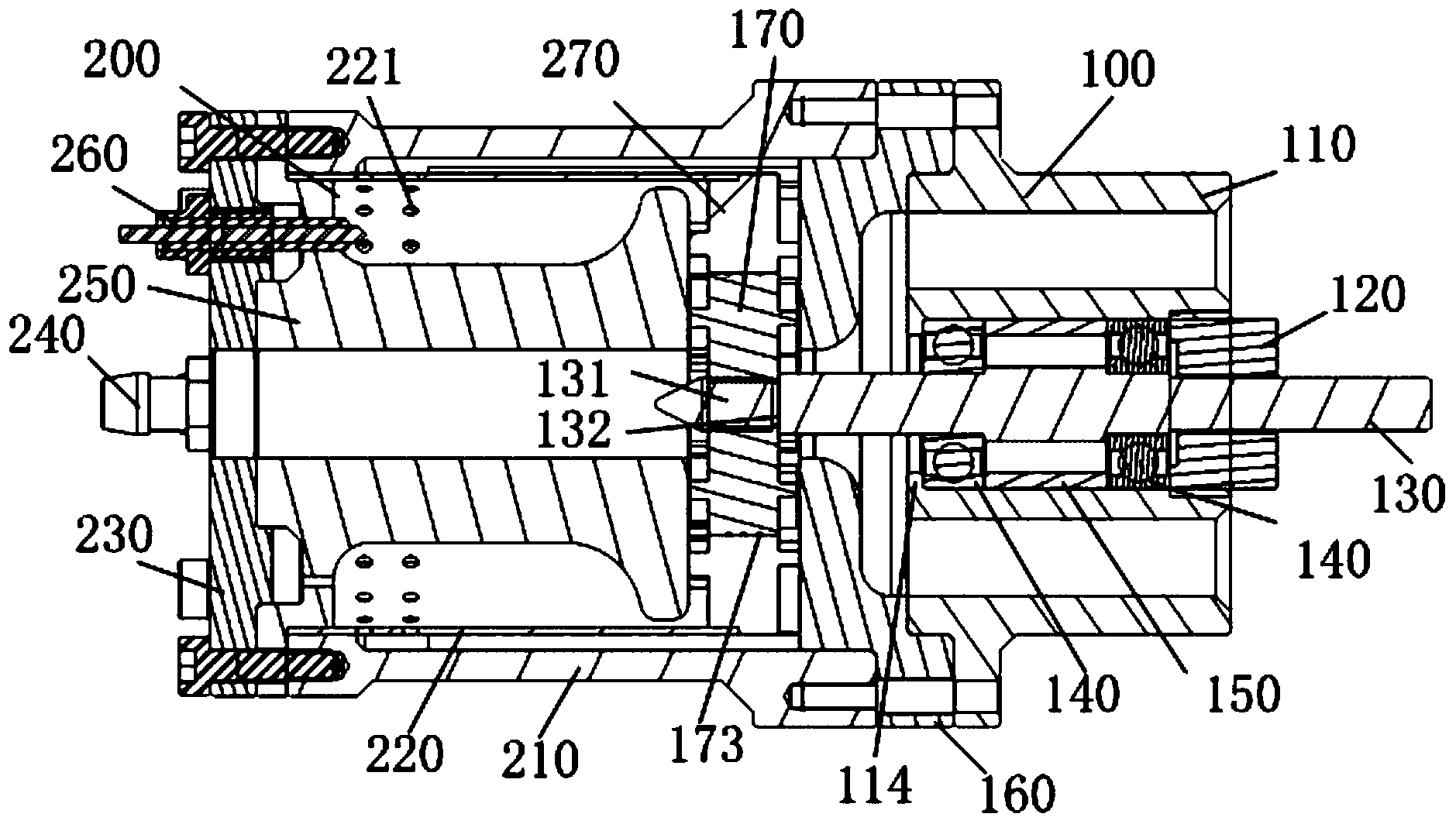

Internal-drive internal indirect feedback type digital hydraulic cylinder structure

The invention relates to an internal-drive internal indirect feedback type digital hydraulic cylinder structure. The internal-drive internal indirect feedback type digital hydraulic cylinder structurecomprises a cylinder body, a hollow piston rod, a large-lead spiral body, a valve element, a valve body and a stepping motor; the hollow piston rod is slidably mounted in the cylinder body, the valvebody is mounted on a cylinder body rear end cover and coaxially connected with the cylinder body, the valve element is arranged in the valve body, and one end of the valve element is coaxially and rotatably connected with the large-lead spiral body; the large-lead spiral body enters a hollow cavity of the hollow piston rod through the cylinder body rear end cover and a cylinder rear cavity; a nutis fixedly mounted at the position, at an inlet of the large-lead spiral body, of the end of the hollow piston rod, and the nut is engaged with the large-lead spiral body; and the other end of the valve element is fixedly connected with the output end of the stepping motor. The internal-drive internal indirect feedback type digital hydraulic cylinder structure has the advantages that the hydraulic cylinder stroke reaches 0.5-1.0 m or even more, the operating speed is higher, and the price is lower relatively; and through structural optimization and the layout design of the space position of oil holes, the valve structure becomes compact, and the overall structure size of a hydraulic cylinder is smaller under the situation that a certain stroke is met.

Owner:NORTHEASTERN UNIV

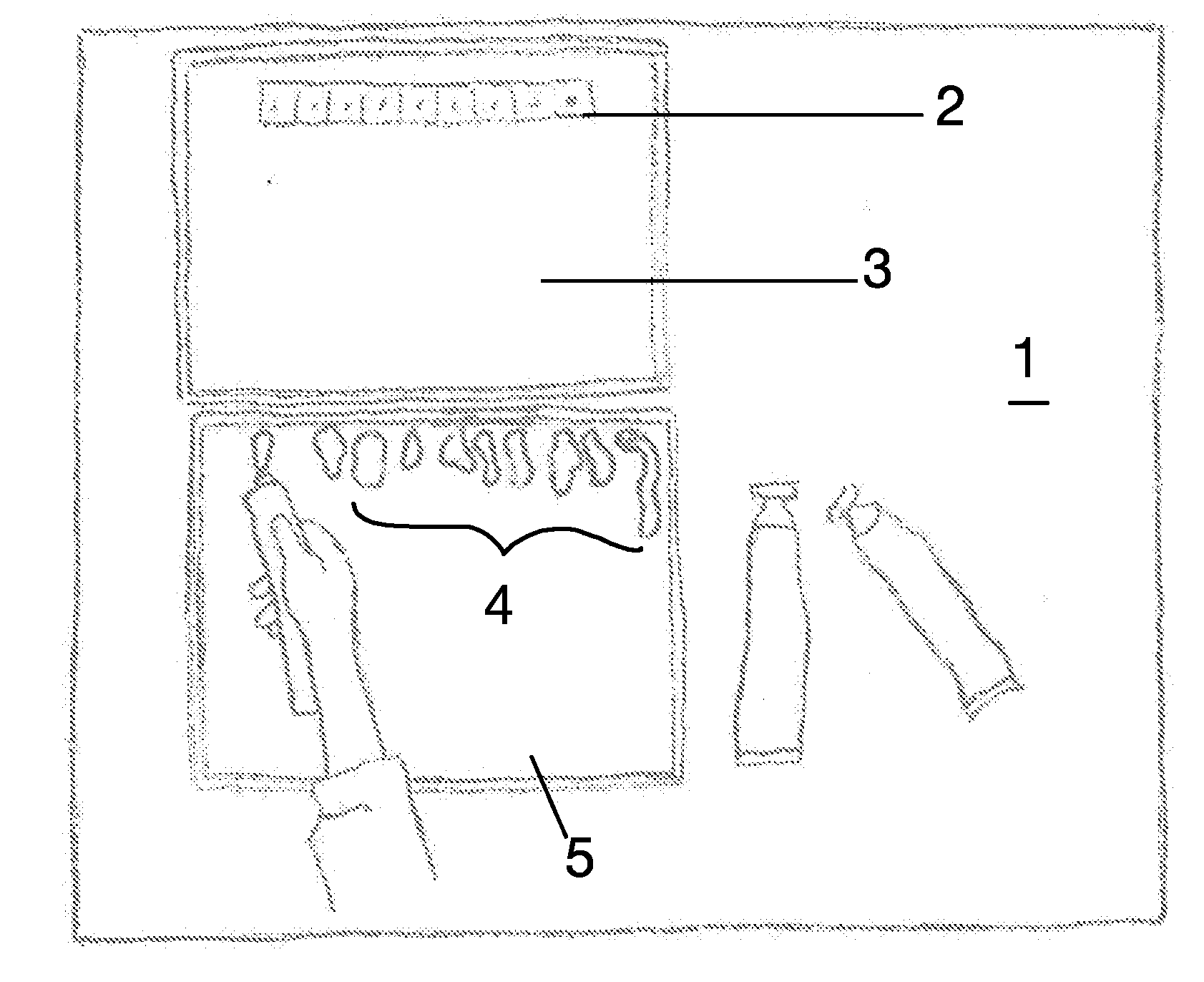

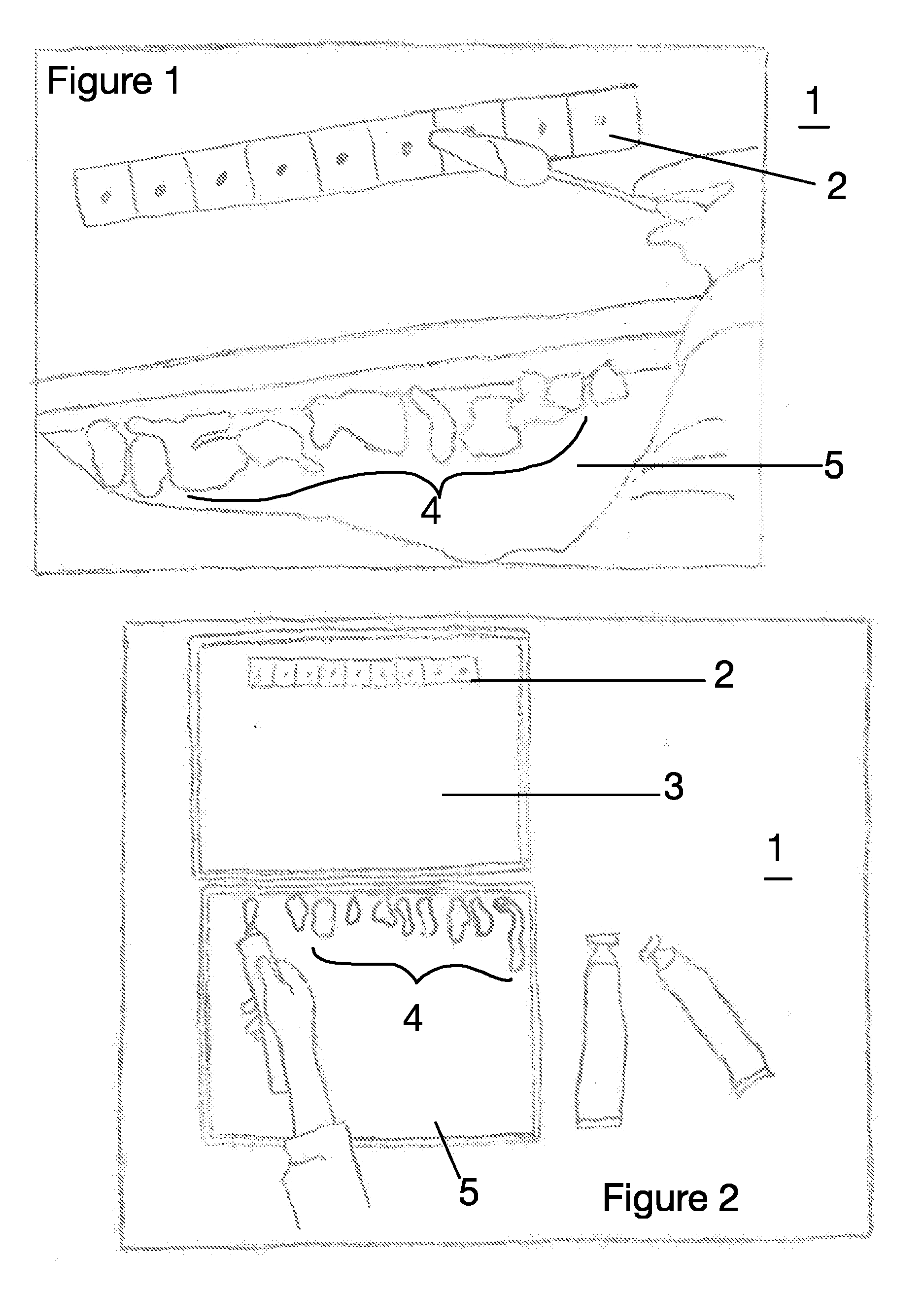

Artist Palette, Paint Storage, Preservation and Compositional System

InactiveUS20150321505A1Maximize useShorten the timeLiquid surface applicatorsContainer/bottle contructionVisibilitySubject matter

This invention, integrates and combines artists functions; is both a stand-alone and companion product in near custom fits for many, various sized pochade easels. It simultaneously functions as an all in one, optimally sized acrylic or similarly transparent; smooth, undivided palette tray in materials oil and outdoor painters need and as a paint storage / preservation device that withstands freezing temperatures; eliminates the transfer of unused paint; and as a tool to apply color mixes, evaluating them directly to artists subject, visible through the transparent cover that also affords instant visibility of palette's current pigment load. Its Value and Color Isolator, readily aids in assessments and comparisons of artist subject and finished paintings. Meaningful changes and improvements in materials and sizes along with the combination of additional functions makes artists work easier with almost effortless strategy for preserving unused paint, thus reducing paint waste, benefitting the environment and artists pocketbook.

Owner:CARTER AMY L

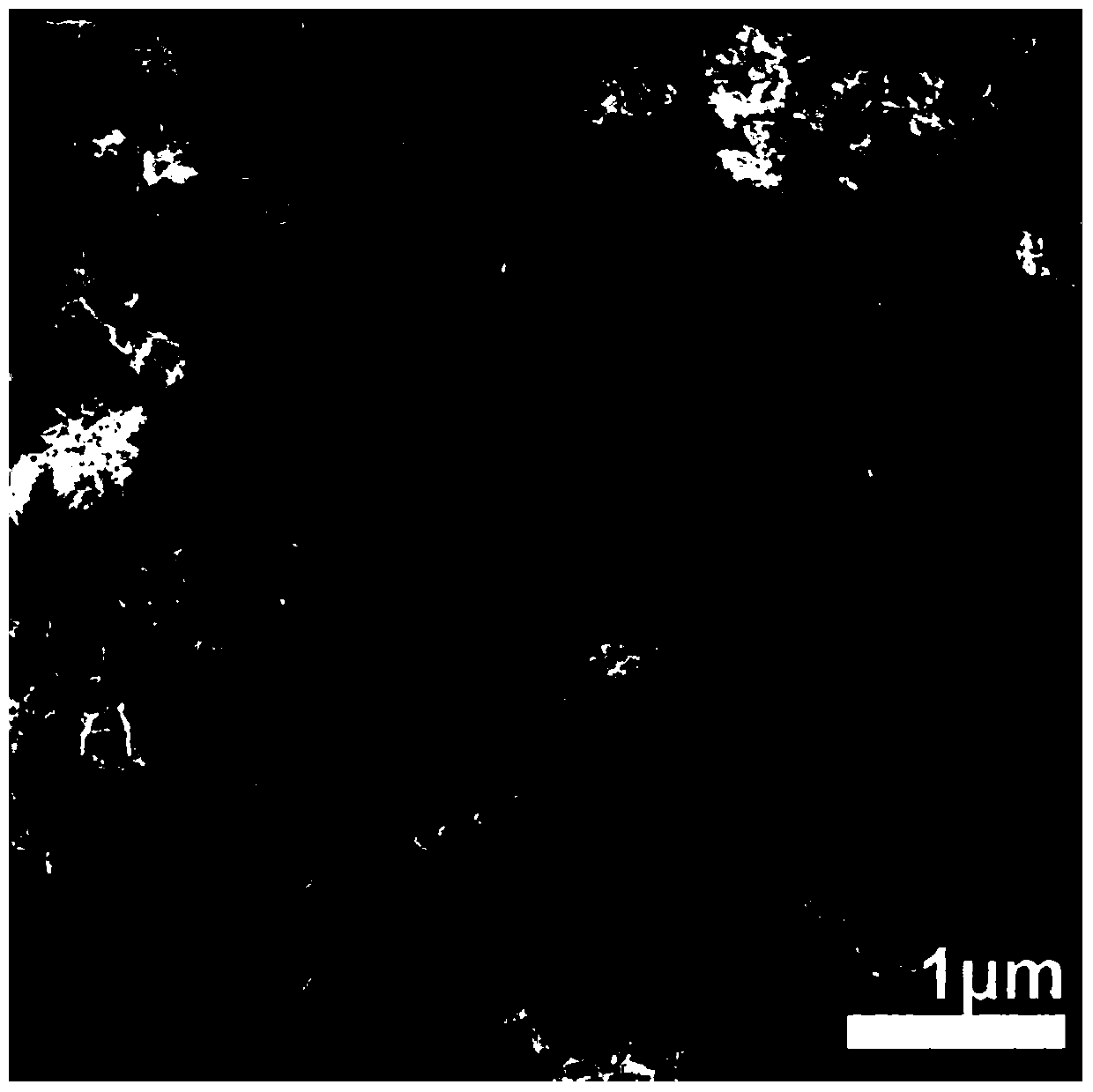

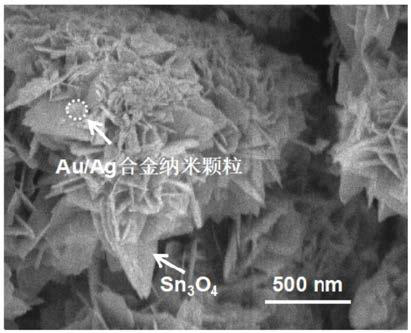

Preparation method of Au/Ag co-modified Sn3O4 nano composite photocatalytic material

InactiveCN109107573AFully developedImprove photocatalytic performanceHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsSource materialOxygen vacancy

The invention discloses a preparation method of an Au / Ag co-modified Sn3O4 nano composite photocatalytic material. The nano composite material is an Au / Ag co-modified Sn3O4 nano composite material which is obtained through forming chemical bonds among the composite ingredients of the nano composite material to complex by using a wet chemistry in-situ synthesis method, in which ice baths are combined with solvent heat, in the solvent, surface active agent and reducing agent of chloroauric acid, silver nitrate and a tin source material. The composite material prepared by the invention utilizes the plasma resonance effect of Au / Ag binary metal nanoparticles, the oxygen vacancy defect effect of a Sn3O4 material and the excellent electron conduction of Au / Ag metal nanoparticles to realize rapidelectron-hole separation in the process of reducing and degrading pollutants through photocatalytic oxidation to collaborate with photocatalytic decomposition of water to generate hydrogen, thereby improving the efficiency of the photocatalytic decomposition of the water and the photocatalytic decomposition of Rhodamine B.

Owner:PINGDINGSHAN UNIVERSITY

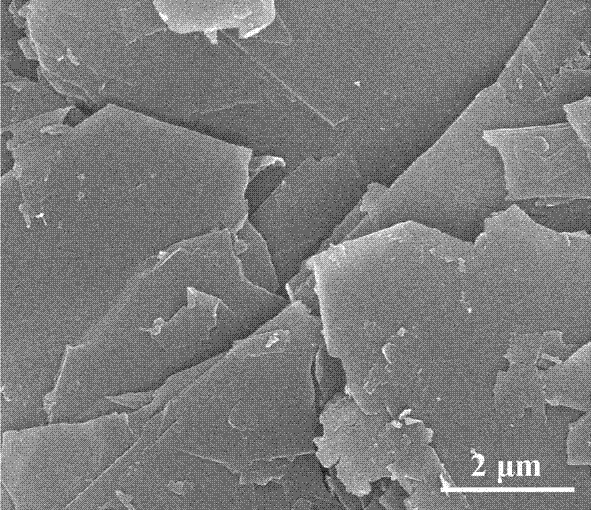

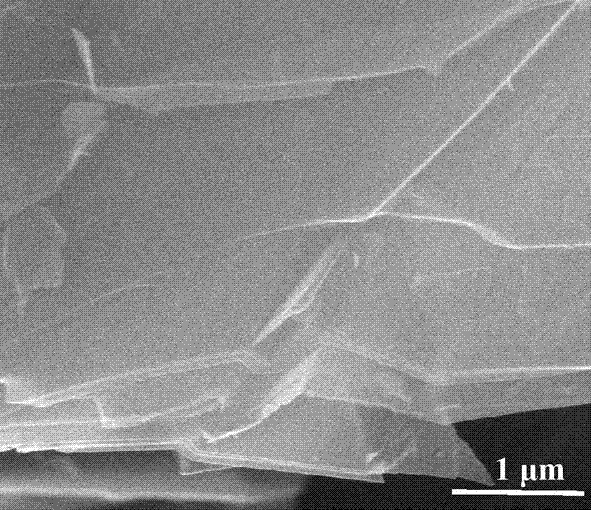

Novel route for preparing graphene using ethanol as liquid phase by planetary ball mill wet method

The invention provides a novel rout for preparing graphene using ethanol as liquid phase by a planetary ball mill wet method. The preparation method comprises the following steps: using expanded graphite after being calcinated at a high temperature as a raw material, using ethanol as an organic solution, and grinding and mechanically exfoliating the expanded graphite by the planetary ball mill wetmethod to obtain the graphene with a relatively complete sheet layer and relatively large crystal size. The method has the advantages of simple production process and low cost. The prepared graphenehas fewer defects, more complete sheet layers, and broader prospect for the future application of the graphene compared with dry graphene.

Owner:UNIV OF JINAN

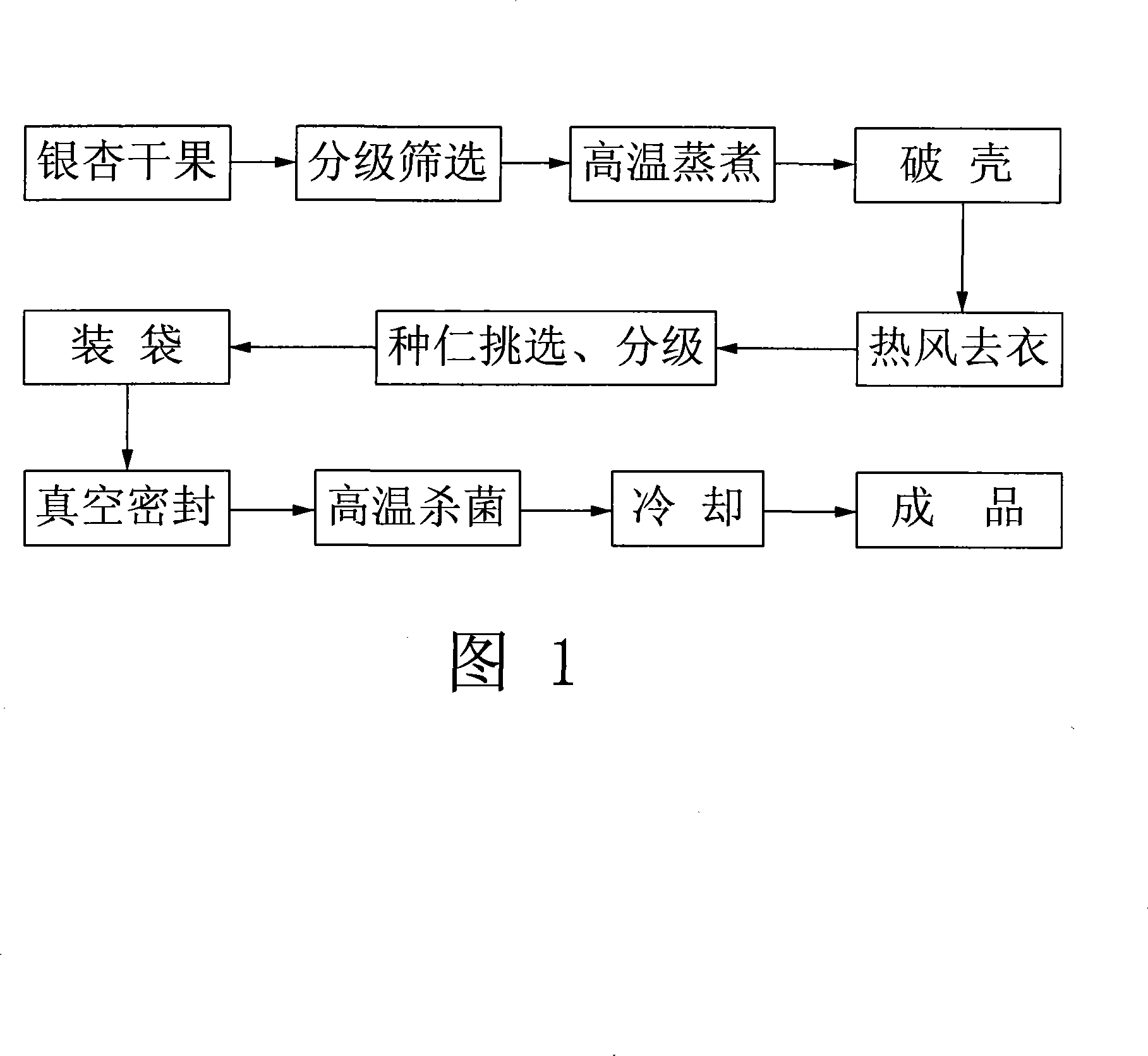

Vacuum flexible packing technique for ginkgo biloba

InactiveCN101214070AUniform sizeFull sizeFruits/vegetable preservation by heatingFood preparationFlavorAdditive ingredient

The invention relates to a ginkgo vacuum flexible packaging process. The process is that: implementing the screening classification on ginkgo nuts first; boiling the classified ginkgo nuts at high temperature, wherein, the central temperature during the high temperature boiling reaches to 90 DEG C and the time is 15-25min; then implementing cracking, hot air decorticating, kernel selecting, classifying packaging, vacuum sealing, high temperature sterilization and cooling, wherein, the cooling temperature is required to be decreased within 10-12min. At last, the finished product is obtained. The product made through the invention is light green and light yellow. The kernel is uniform and integrated. The original flavor and nutrition components of the ginkgo in Nanxiong are reserved.

Owner:GUANGDONG NANXIONG NEW CENTRY GINKGO PLANTATION

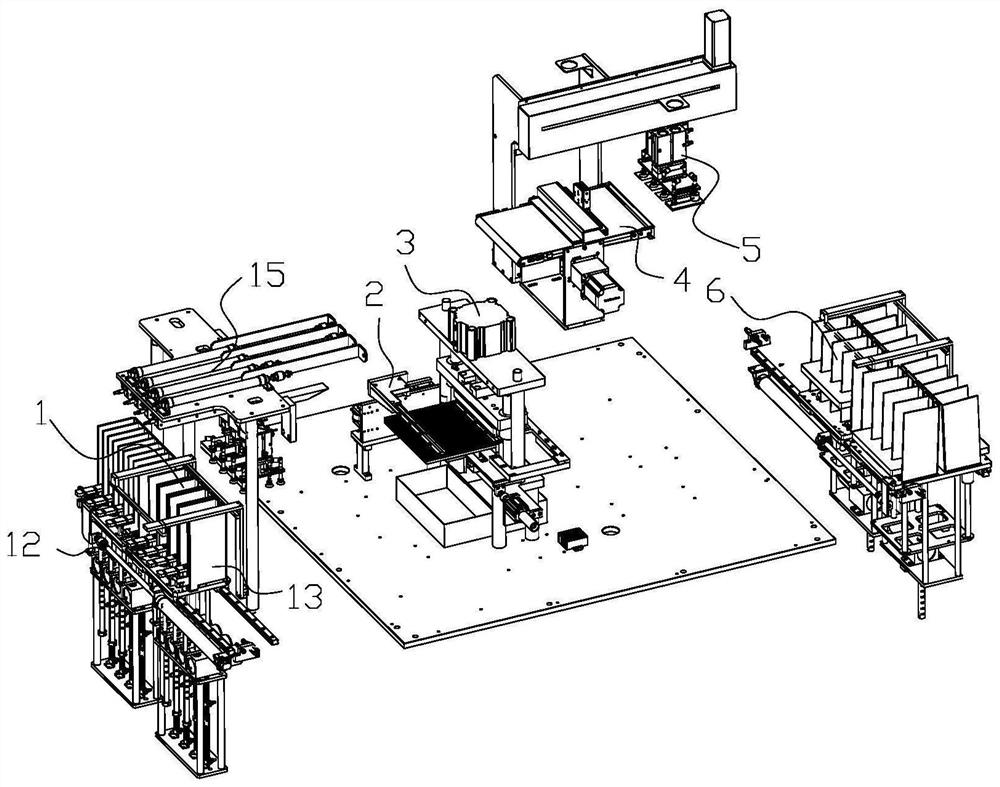

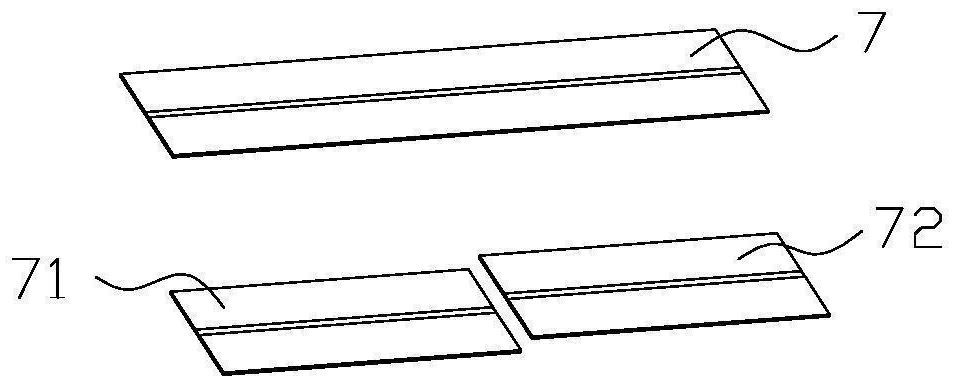

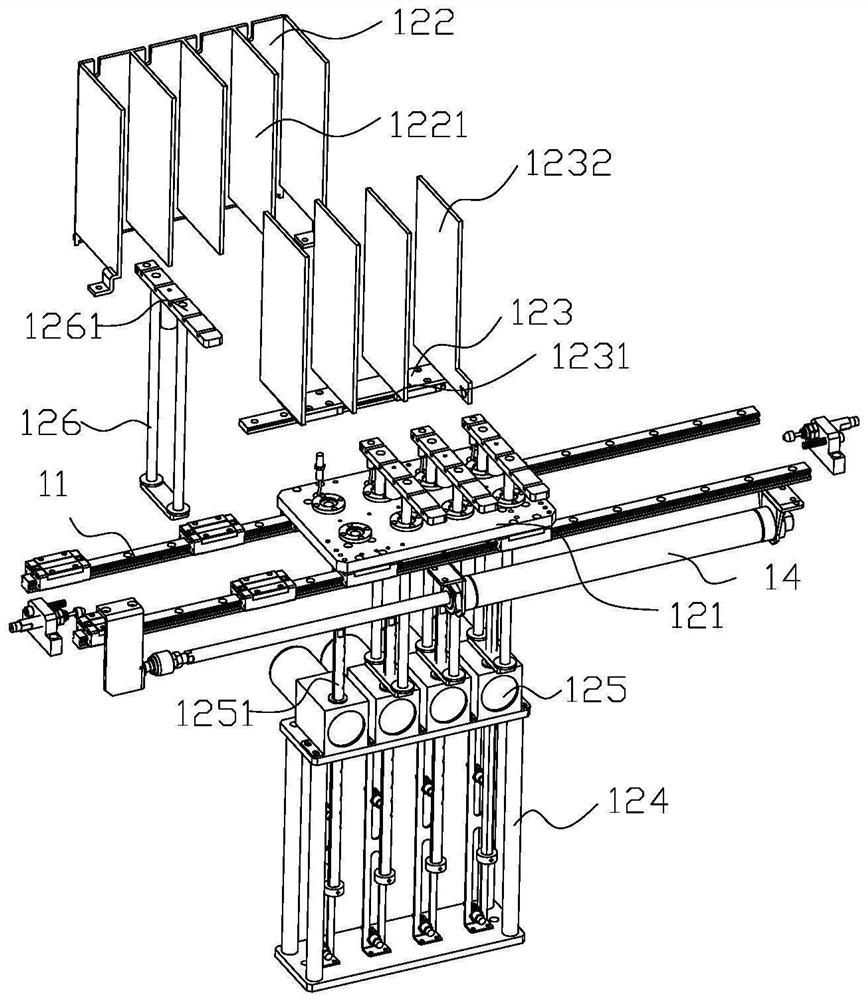

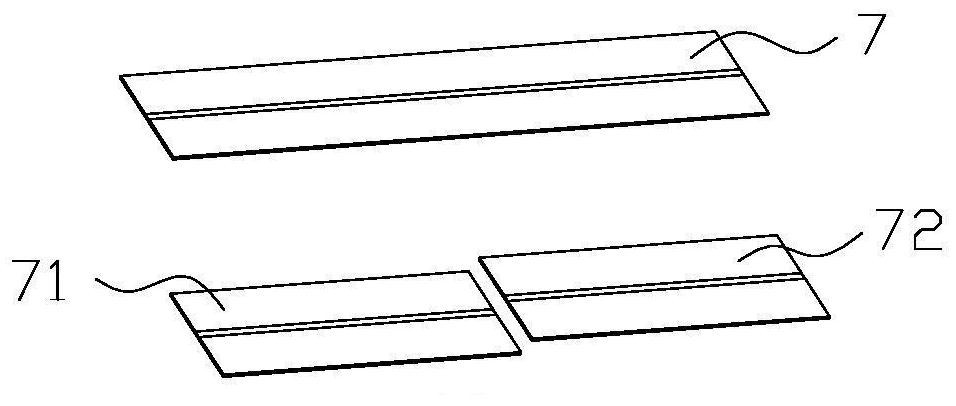

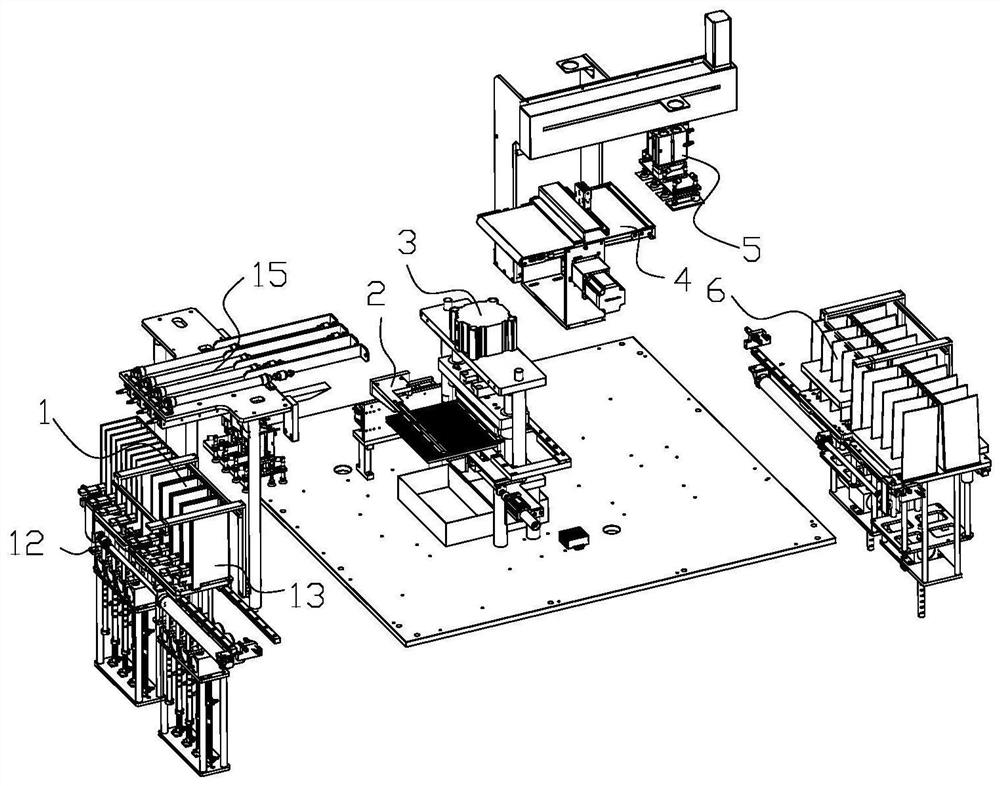

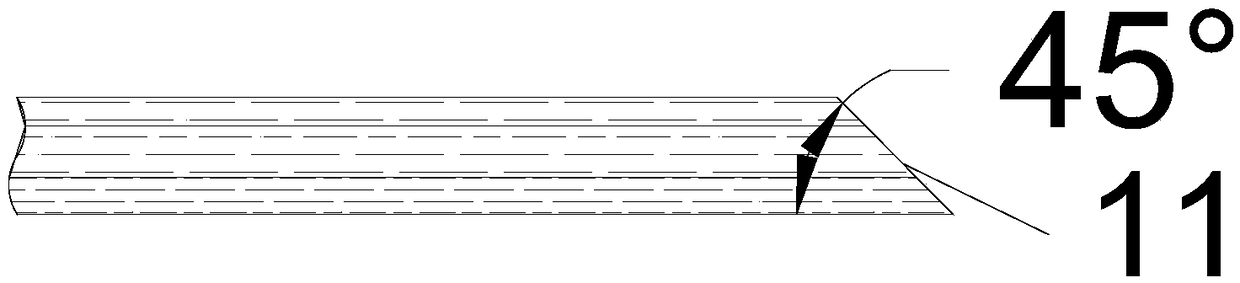

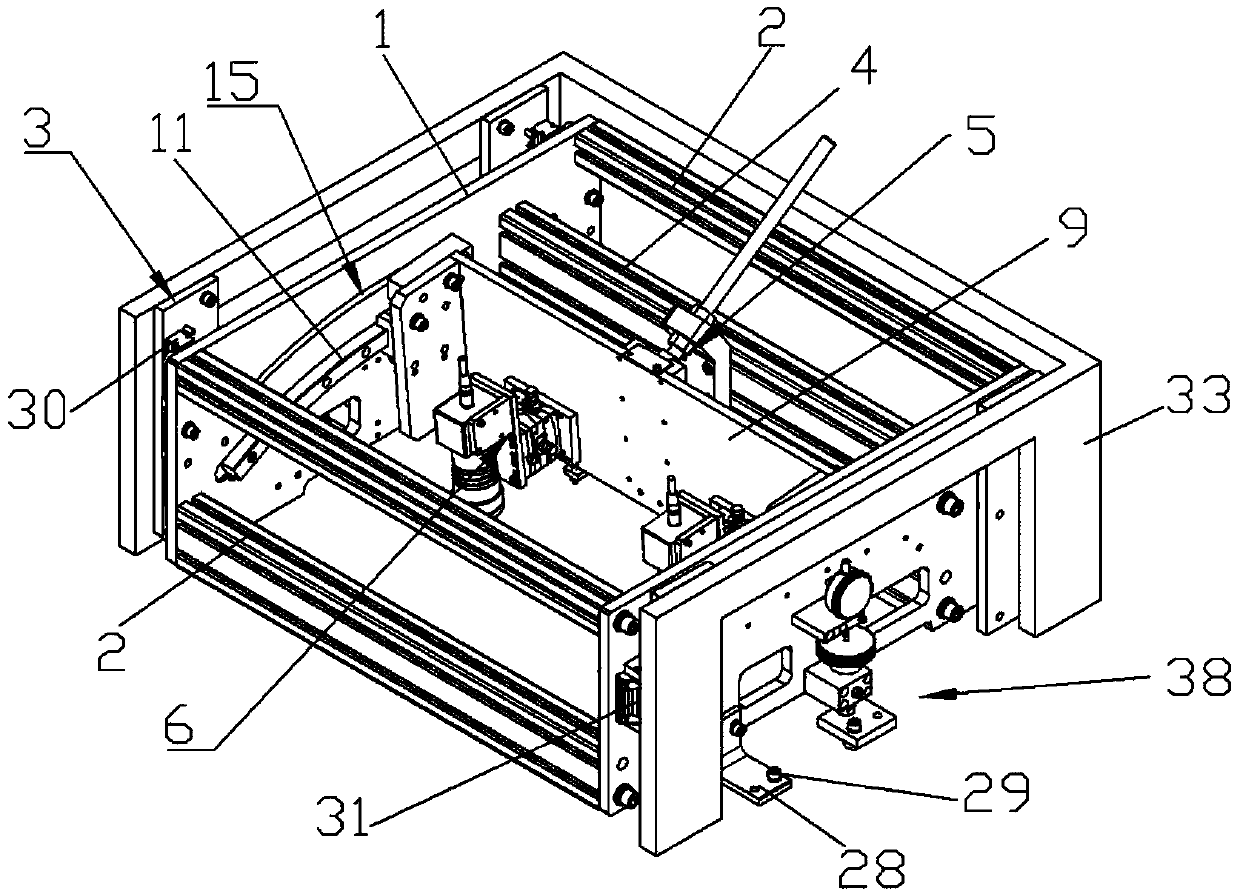

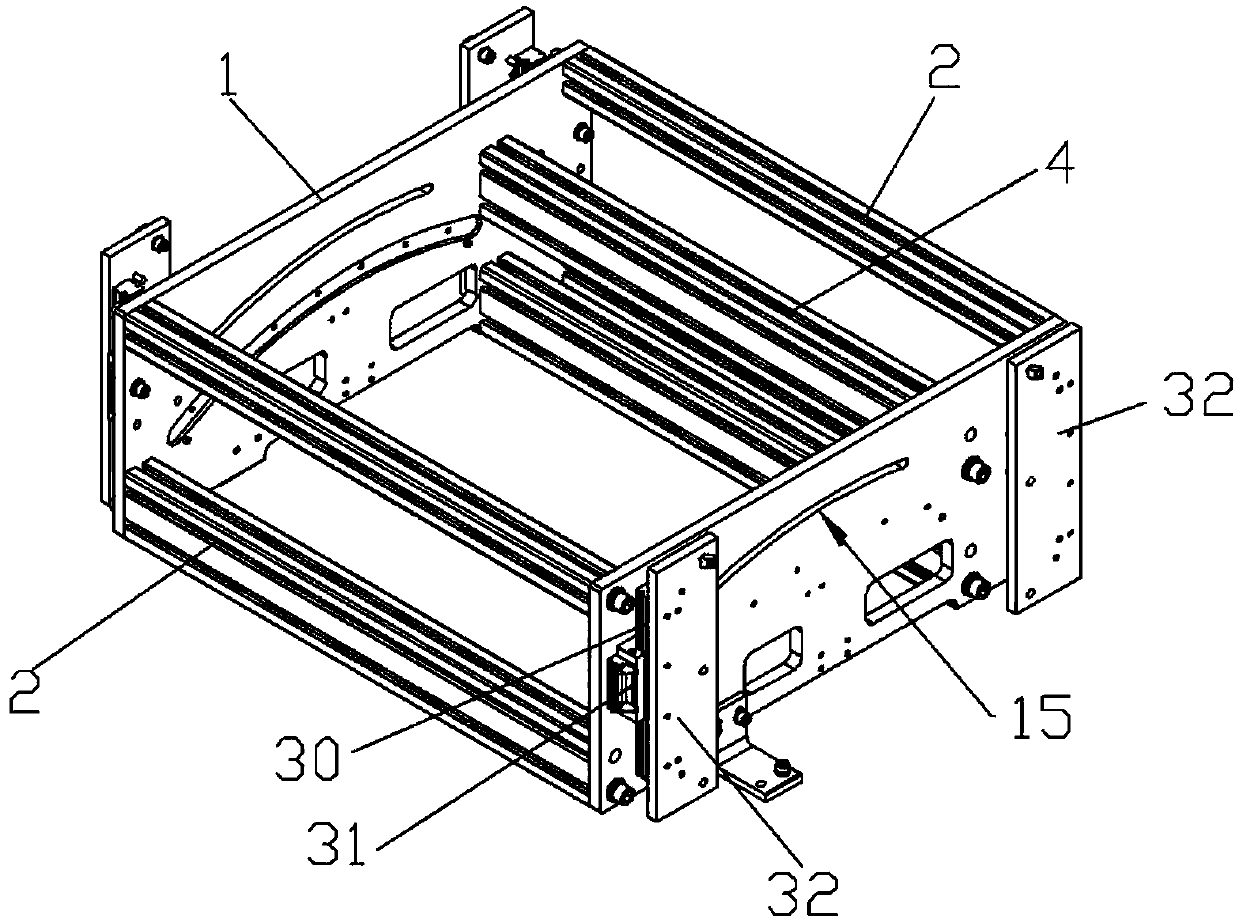

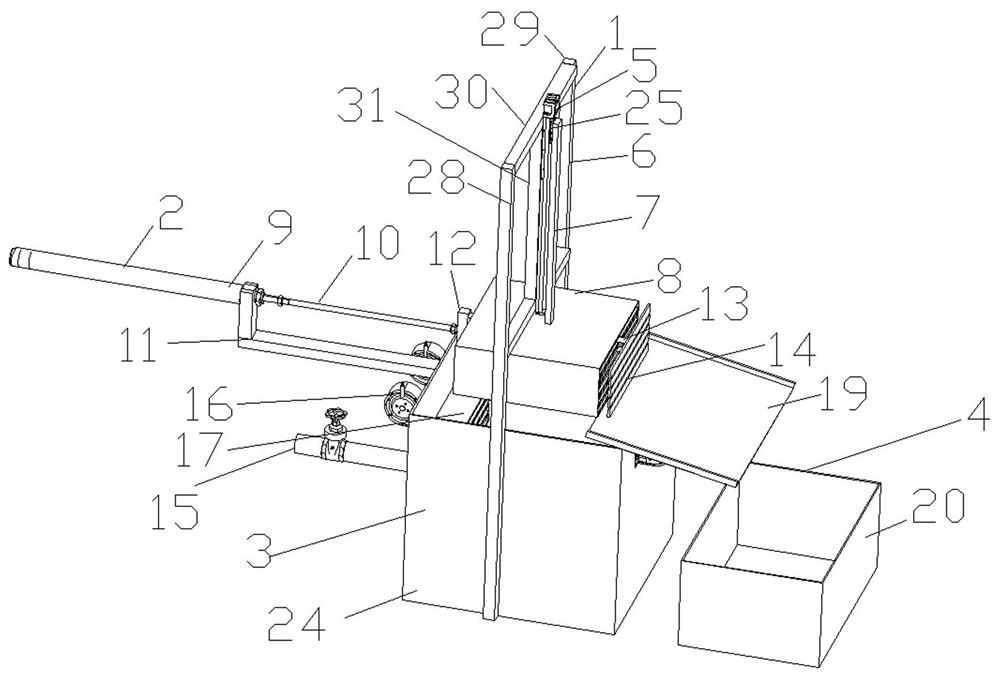

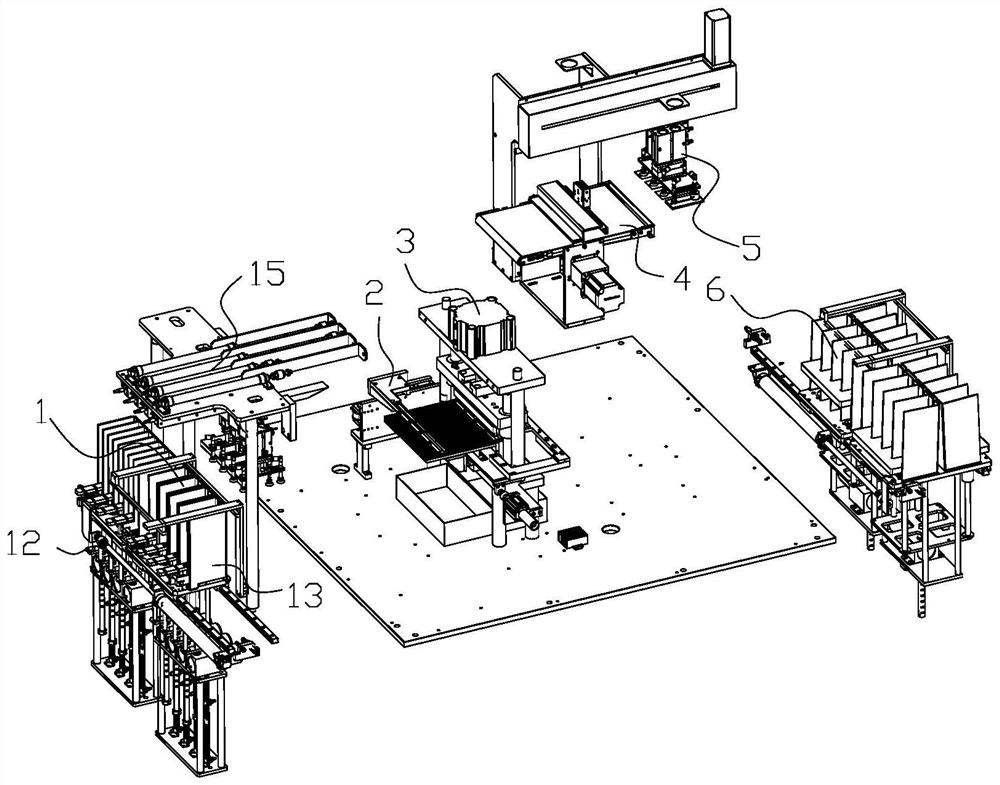

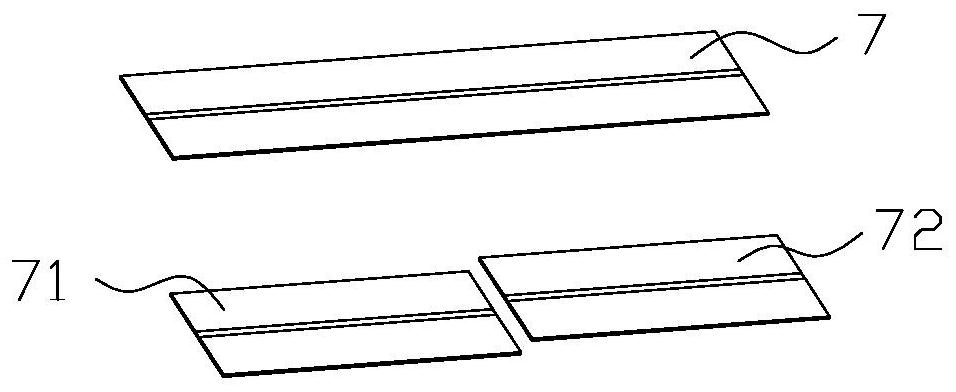

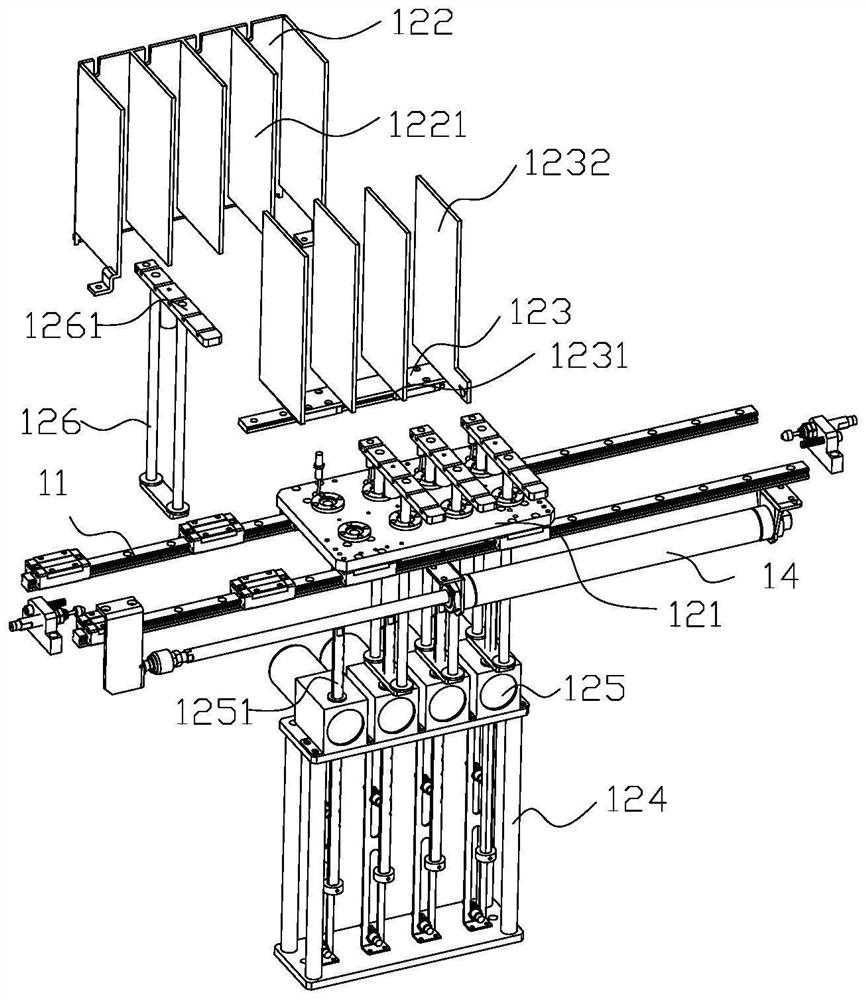

Rubber sealing strip cutting and feeding device and method

InactiveCN112192630AEasy to transport at the same timeEasy to placeMetal working apparatusConveyor partsFeed driveElectric machinery

The invention belongs to the technical field of rubber sealing strip cutting. A rubber sealing strip feeding device comprises two feeding sliding rails, a first feeding assembly, a second feeding assembly, a feeding moving air cylinder and a feeding transferring assembly; the two feeding sliding rails are arranged on a rack in the front-back direction; the first feeding assembly and the second feeding assembly are connected through a feeding connecting plate; the feeding moving air cylinder is arranged on the bottom face of the rack, and a moving portion of the feeding moving air cylinder is connected with the first feeding assembly; the first feeding assembly comprises a feeding moving bottom plate, a rubber sealing strip limiting frame, a rubber sealing strip limiting adjusting frame, amotor support, a plurality of feeding driving motors and a plurality of motor matching lifting frames; and the feeding transferring assembly is used for sucking and transferring rubber sealing stripsin a plurality of limiting neutral positions. The rubber sealing strip feeding device has the beneficial effects that the multiple rubber sealing strips can be conveniently conveyed at the same time,and the device can be suitable for the rubber sealing strips of different specifications.

Owner:王友猛

Rubber sealing strip cutting equipment and cutting method

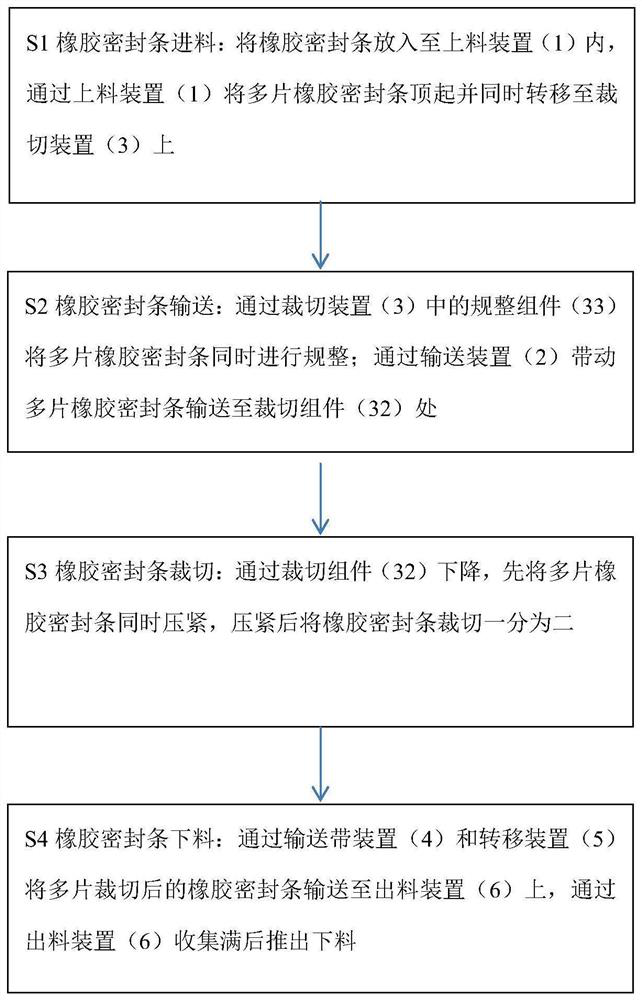

InactiveCN112207870AEasy to placeEasy to transportMetal working apparatusConveyor partsAssembly lineComposite material

The invention belongs to the technical field of rubber sealing strip cutting. Rubber sealing strip cutting equipment comprises a rack, and a feeding device, a conveying device, a cutting device, a conveying belt device, a transferring device and a discharging device arranged on the rack. The feeding device is used for conveying and feeding a plurality of rubber sealing strips to the cutting deviceat the same time; the cutting device is used for cutting the rubber sealing strips; the conveying belt device is used for horizontally conveying the cut rubber sealing strips; and the discharging device is used for conveying and discharging the cut rubber sealing strips. The rubber sealing strip cutting equipment and cutting method provided by the invention have the advantages that the rubber sealing strip conveying efficiency is improved, the cohesion between rubber sealing strip conveying and rubber sealing strip cutting is improved, and the overall assembly line machining fluency is improved.

Owner:王友猛

Novel method for preparing graphene with glycerol as liquid phase by using planetary muller through wet method

The invention provides a novel method for preparing graphene with glycerol as a liquid phase by using a planetary muller through a wet method. The preparation method comprises the following specific steps: by taking expanded graphite after high-temperature calcination as a raw material and glycerol as an organic solution, performing mechanical peeling on the expanded graphite by using the planetary muller through wet-type grinding, thereby obtaining graphene which is relatively complete in lamella and relatively large in crystal size. The novel method is simple in production process, low in cost, relatively small in defect when being compared with dry-type graphene, relatively complete in lamella, and relatively wide in application prospect.

Owner:UNIV OF JINAN

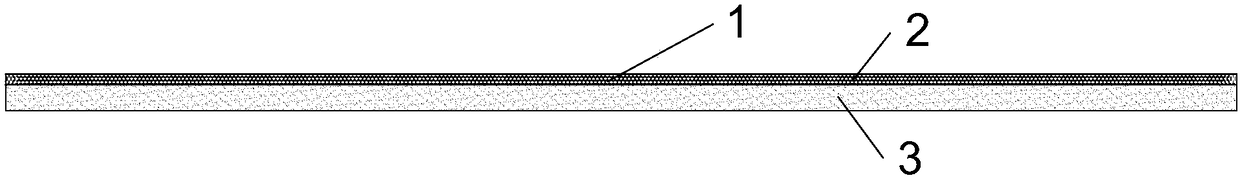

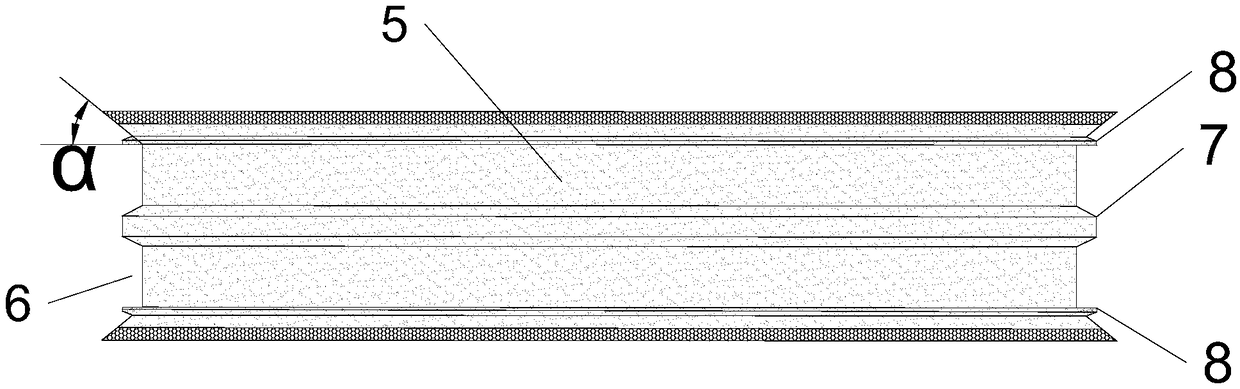

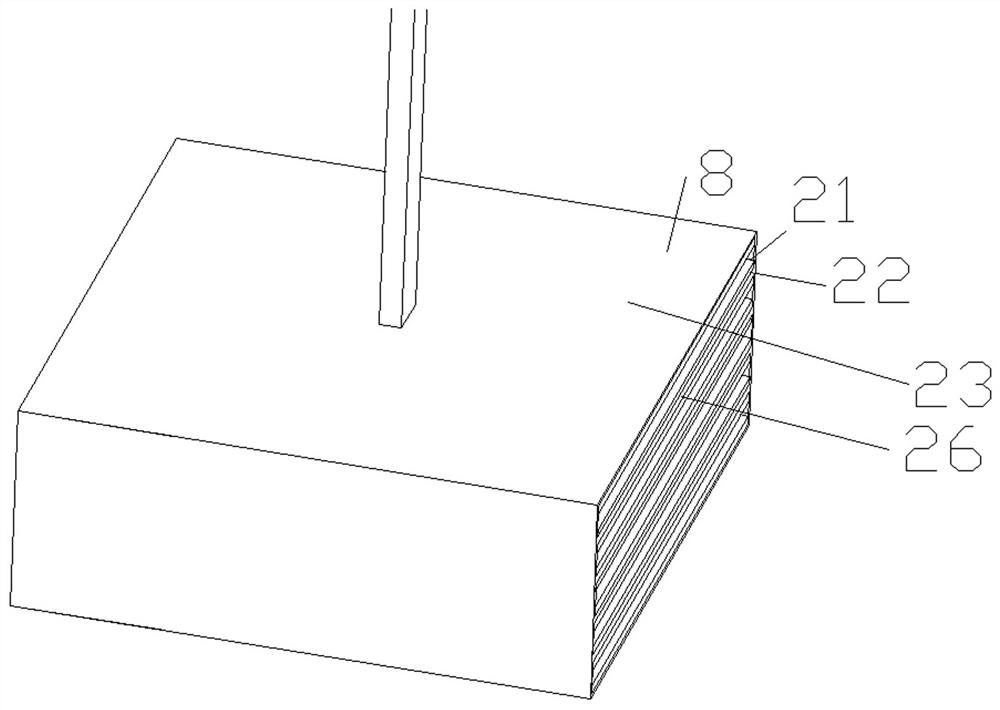

Edge sealing method of dipped veneer laminated board

ActiveCN109333749AImprove structural stabilityGood dimensional stabilityWood working apparatusDomestic articlesEngineeringEdge banding

The invention provides an edge sealing method of a dipped veneer laminated board; the method can quickly and efficiently finish oriented assembly of edge sealing strips and edge sealing grooves; and the obtained dipped veneer laminated board is excellent in structure and size stability. The method comprises the following steps: two edge sealing groove thrust positioning guide rail pairs are placedon the wide edges and the long edges of the dipped veneer laminated board on a table surface for thrust positioning; two edge sealing strips are positioned on the other pair of wide edges and long edges of the dipped veneer laminated board, and are longitudinally and transversely pushed to glue with the edge sealing grooves on the wide edges and the long edges of the dipped veneer laminated board; the edge sealing groove thrust positioning guide rails are taken down; the dipped veneer laminated board is rotated by 180 degrees; two plane thrust positioning guide rails are contacted with the side surfaces of two edge sealing strips glued on the dipped veneer laminated board; and the two edge sealing strips are positioned on the other pair of wide edges and long edges, not glued with the edge sealing strips, of the dipped veneer laminated board, and are longitudinally and transversely pushed to glue with the edge sealing grooves on the dipped veneer laminated board.

Owner:NANJING FORESTRY UNIV

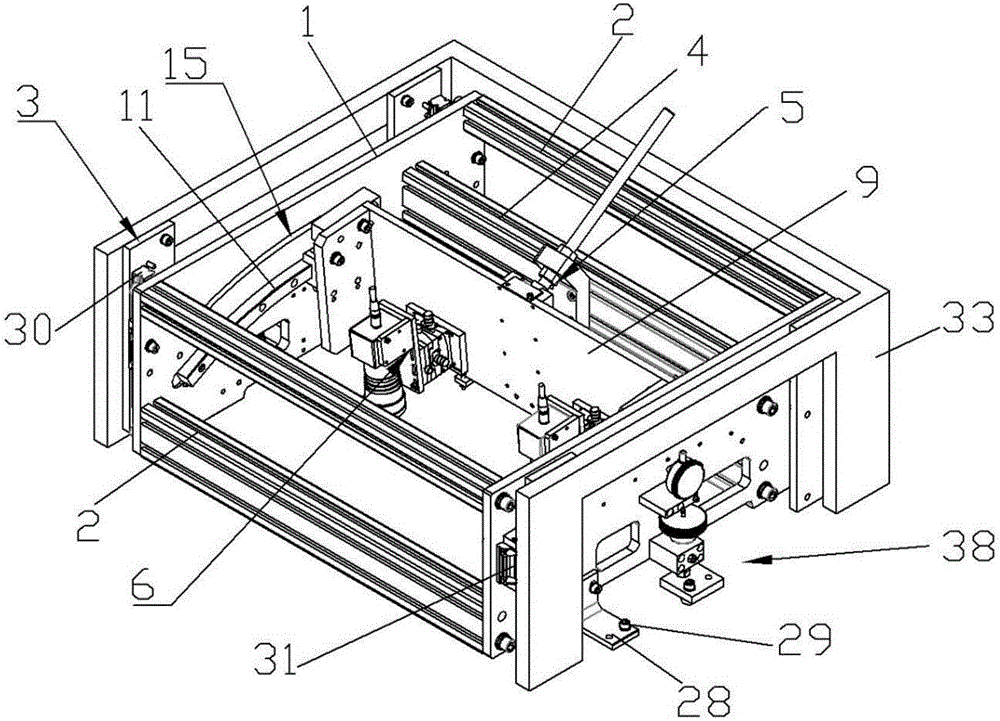

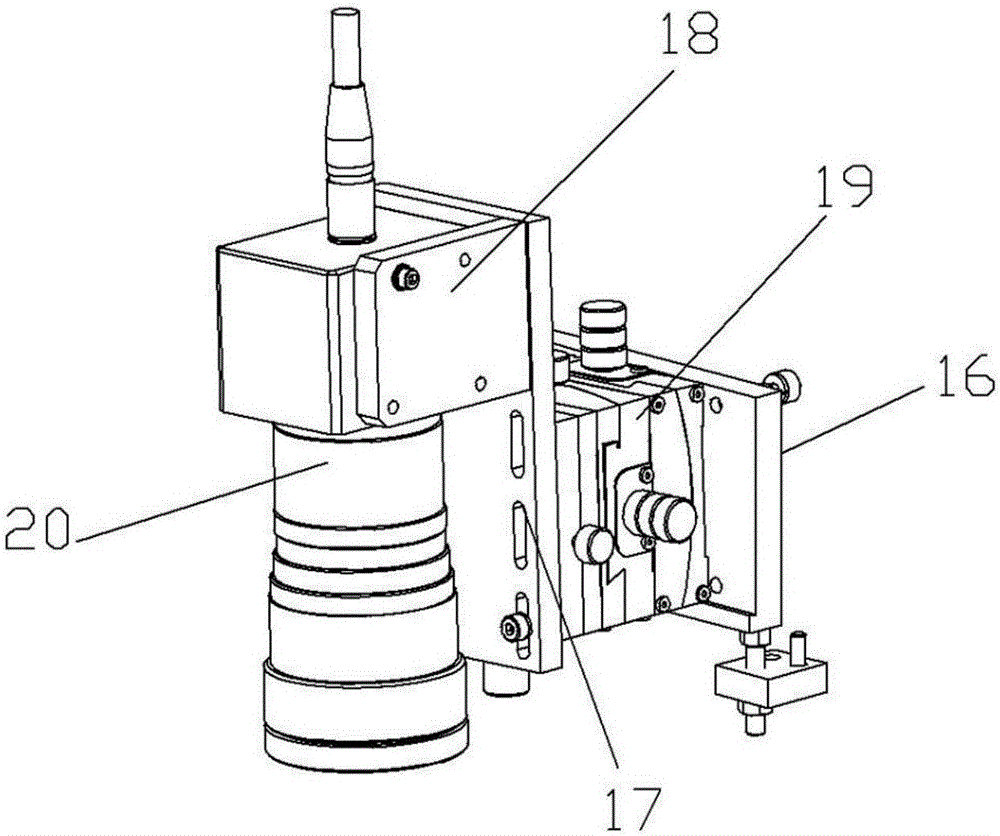

An intelligent camera monitoring device and its installation and debugging method

ActiveCN106657878BExpand the scope of monitoringHigh integrityTelevision system detailsColor television detailsEngineering

The invention discloses an intelligent camera monitoring device and its installation and debugging method. The device includes a mounting frame and a fixed beam. Lifting mechanisms are arranged on both sides of the mounting frame, and a camera device is arranged between the mounting frames. The camera device includes a mounting beam, The camera mechanism and the camera adjustment mechanism are provided with angle adjustment components on both sides of the installation frame, and the angle adjustment components are matched with the camera mechanism. The method includes (1) determining the installation location; (2) installing the lifting mechanism; (3) installing the main frame of the intelligent camera monitoring device; (4) installing the camera adjustment mechanism; (5) installing the camera mechanism; (6) installing the angle adjustment Components; (7) Layout of camera lines and auxiliary equipment; (8) Debugging of cameras. The device expands the monitoring range of the intelligent camera monitoring device by fine-tuning the height and inclination of the two cameras, ensuring that complete and clear monitoring points and the monitoring range specified by the design can be obtained on the display screen.

Owner:上海智领网络科技有限责任公司

Method for preparing SiO2/TiO2 composite powder

The invention discloses a method for preparing SiO2 / TiO2 composite powder, which comprises the following steps of: dissolving tetraethoxysilane and ammonia water in absolute ethyl alcohol respectively, mixing the tetraethoxysilane and the ammonia water at one time under the ultrasonic condition, continuously performing ultrasonic separation and precipitation to obtain SiO2 submicron spheres with uniform particles and complete appearance; adding the SiO2 submicron spheres into tetrabutyl titanate sol C taking the ammonia water as a solvent, citric acid as a complexing agent and polyethylene glycol as a dispersing agent, performing sufficient ultrasonic dispersion, and stirring and heating to obtain wet gel; and further drying and foaming to compound SiO2 and TiO2 constantly, and calcining to obtain the SiO2 / TiO2 composite powder. The method disclosed by the invention has short preparation period; and the prepared SiO2 / TiO2 composite powder is complete spheres of which the particle sizeis 200 to 600nm and has high purity and yield.

Owner:SHAANXI UNIV OF SCI & TECH

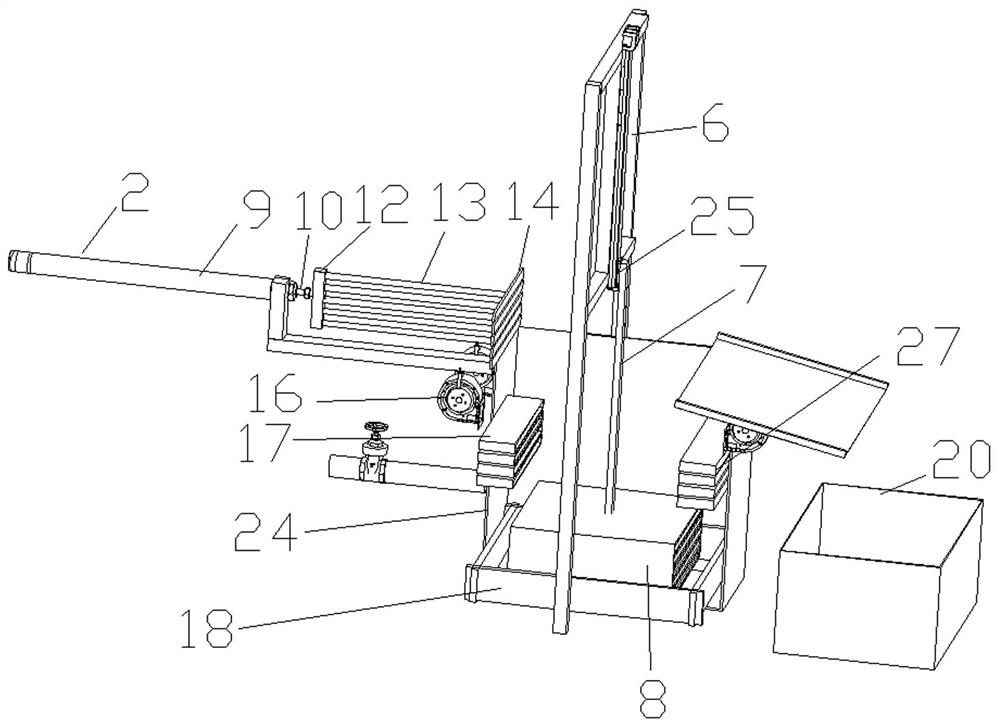

A kind of high-efficiency trehalose extraction equipment and its extraction method

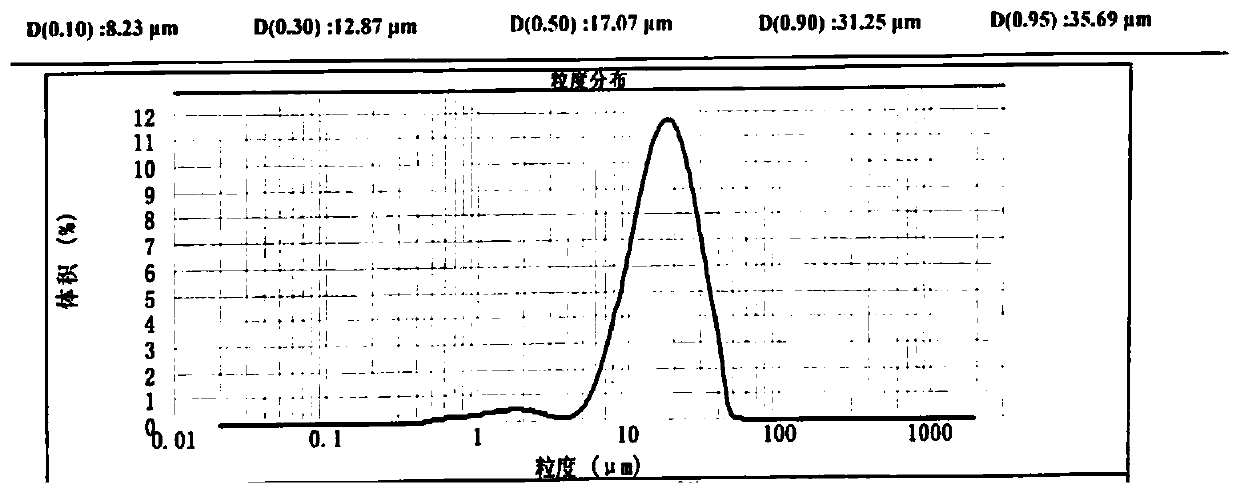

ActiveCN110251984BFull granularityParticle size fullSugar derivativesSolution crystallizationEngineeringMechanical engineering

The invention discloses a high-efficiency trehalose extraction device and an extraction method thereof, which include a lifting module, a push-out module, a main body module and a collection module. The main body module includes a material box with an open upper end. The left side wall is connected with the feed pipe, and the left and right sides of the inside of the material box are symmetrically fixed with left and right heating box components. The left and right outer walls of the material box are equipped with air ducts in the material box. It includes a uniaxial driver bracket installed with a vertical uniaxial driver, the ejection module includes cylinders arranged horizontally and horizontally, and the collection module includes a collection plate for collecting trehalose crystals scraped off from the absorbent cloth. The beneficial effects of the present invention are: Not only can trehalose crystals be extracted efficiently, but also the problem of crystallization blocking the outlet caused by long-term operation of traditional extraction equipment can be avoided.

Owner:河南卢师傅食品有限公司

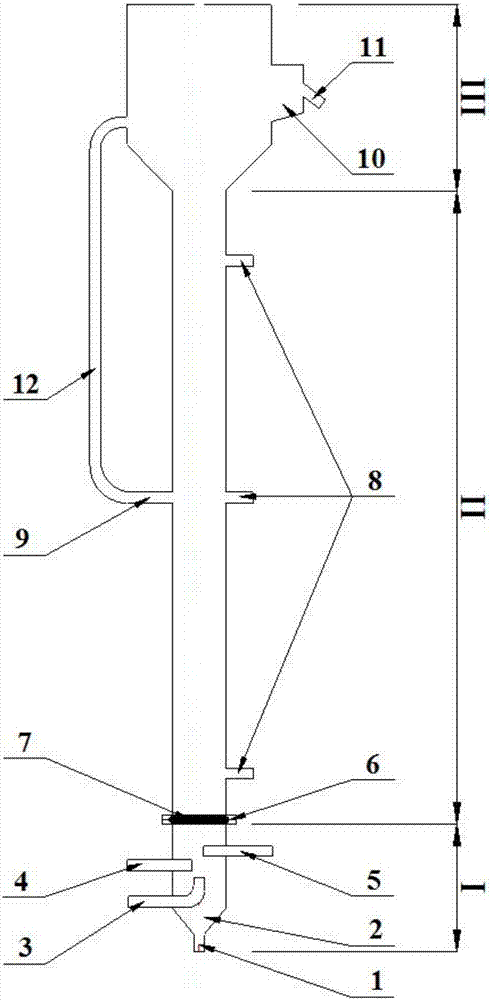

Current-limiting variable phosphate-removing reactor and method for removing phosphate in waste water

ActiveCN106915819AIncrease profitReduce sizeBiological treatment apparatusSustainable biological treatmentSlagSludge

The invention discloses a current-limiting variable phosphate-removing reactor and a method for removing phosphate in waste water. A reactor body comprises a water inlet zone, a variable reaction zone and a settling zone respectively from down to up, a slag removal opening and a sludge bucket are arranged at the lower part of the water inlet zone, an inlet pipe, an aeration pipe and a drug inlet pipe are arranged in the water inlet zone, a control flange, a support separation net, a sludge removal port, and a backflow port are arranged in the variable reaction zone; and an overflow port, an outlet pipe and a back flow pipe are arranged in the settling zone. The method combines flocculation, adsorption, filtering, crystallization for phosphate removing, and combines phosphate removing and phosphate storage; the functions of each unit is complementary, the structure is compact, the land occupation area is little; the reaction zone is adjustable, the operation is flexible; the biological sludge is taken as a medium, waste can be used for treating waste, and the method has large reutilization potential.

Owner:ZHEJIANG UNIV

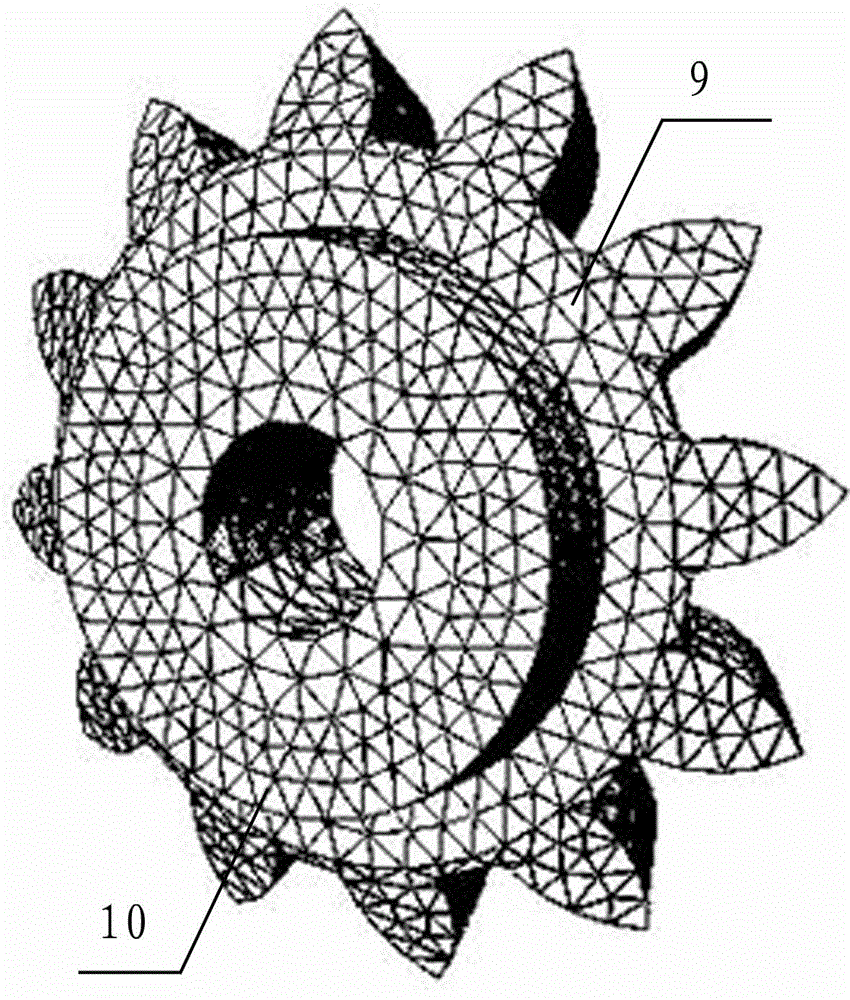

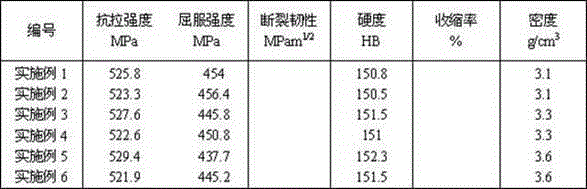

A kind of gear and its manufacturing method

InactiveCN102865350BImprove wear resistanceHigh strengthPortable liftingGearing elementsVolumetric Mass DensityHardness

The invention provides a gear and a method for manufacturing the same. The gear comprises an alloy base body and a reinforcing body which is embedded in the alloy base body and is a gear framework woven from transverse steel wires and longitudinal steel wires in a staggered manner. By the method for manufacturing the gear, a process of performing two forging steps in one heat and an ion sputtering and spraying method are adopted. Compared with the prior art, the gear and the method for manufacturing the same maintain characteristics of high strength, high hardness, high temperature resistance and high heat conduction coefficient of the conventional steel and iron materials, also have characteristics of good plasticity and low density of an aluminum alloy material. By the method for manufacturing the gear, the obtained gear is complete in shape and dimension and is light through plastic deformation such as precision forging, tooth profile deformation is low, the wear resistance of a tooth surface is increased, meshing noise is low, and the gear is long in service life and has excellent popularization and application value.

Owner:UNIV OF JINAN

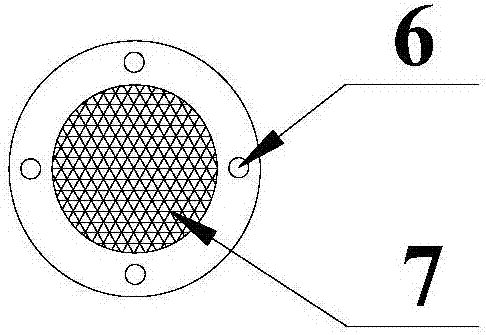

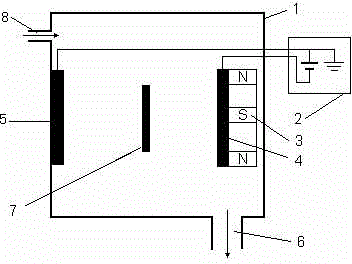

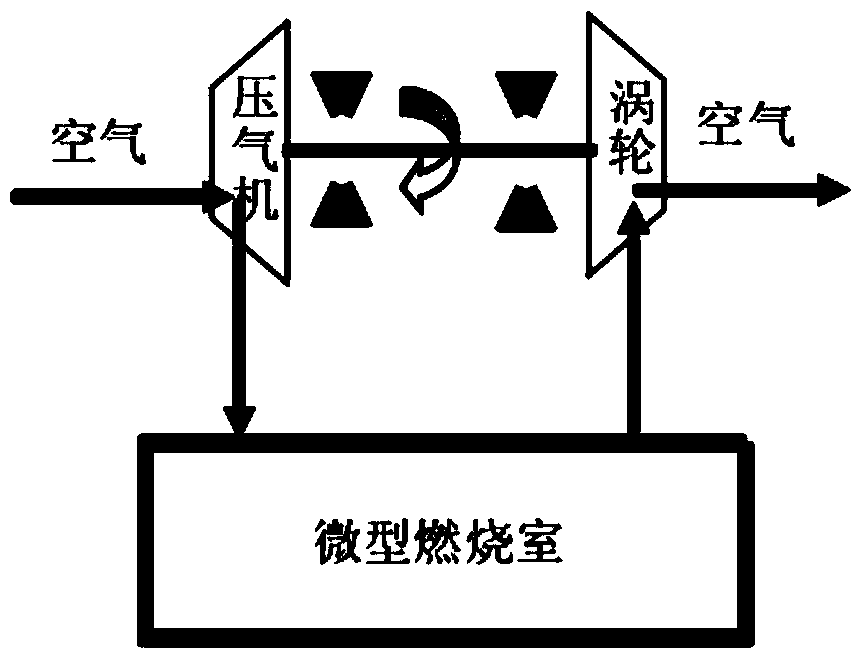

Small turbine jet engine

ActiveCN103758661AEasy processing and assemblyLower quality requirementsJet propulsion plantsCombustion chamberJet engine

The invention provides a small turbine jet engine which comprises a compressor component and a combustion chamber component. The compressor component and the combustion chamber component are respectively located an air inlet end and a jet end of the small turbine jet engine. The compressor component comprises a compressor and a turbine, and the compressor and the turbine are integrally designed. By the adoption of the integral design of compressed air turbine blades, difficulty in design is reduced, and machining and assembling of a small structure are benefited; by the adoption of a reversed-flow type combustion chamber, compactness of the overall layout is benefited, dimensions in design are well controlled, and sufficient space is reserved for improving combustion efficiency; besides, the temperature of a whole shafting is effectively lowered due to outside motion of a bearing, overall system reliability is improved, service life is prolonged, requirements on bearing quality is lowered, and overall cost can be beneficially reduced.

Owner:CHANGCHUN UNIV OF SCI & TECH

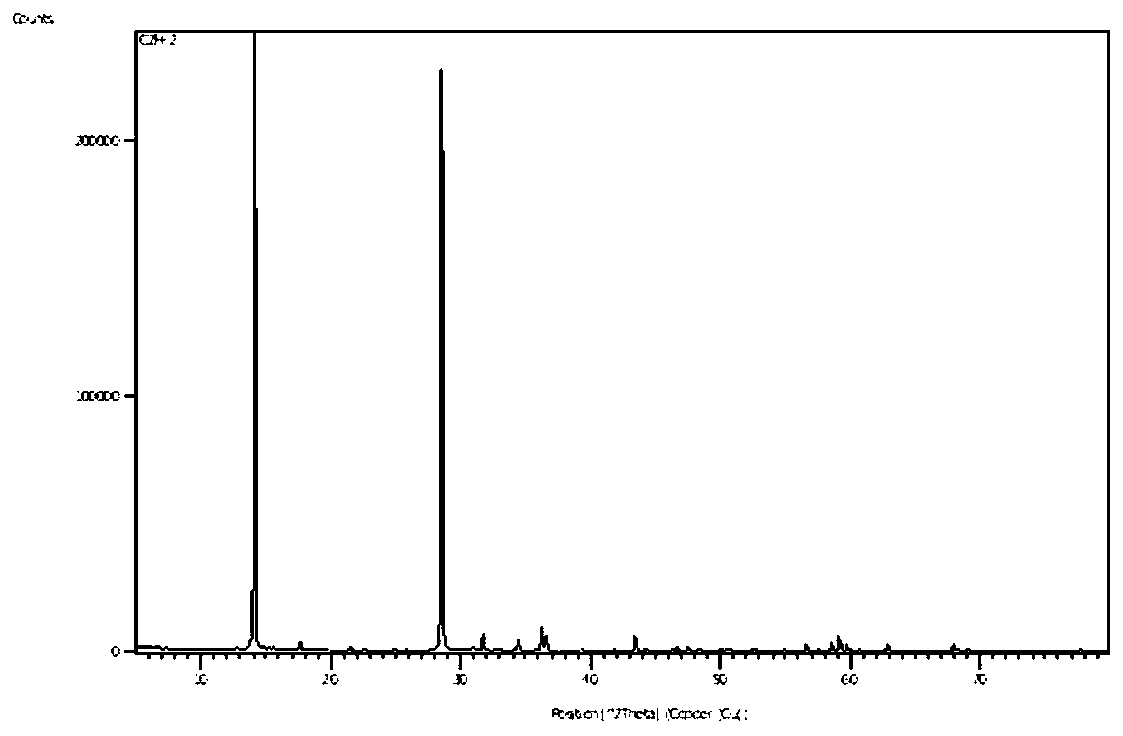

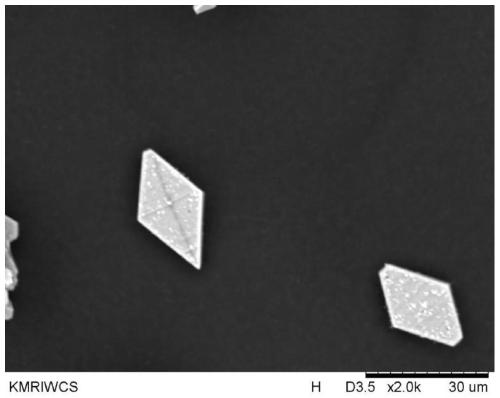

Preparation method for ultrafine calcium zincate crystal applied to zinc battery

InactiveCN110386619AImprove electrical performanceSmall particle sizeFinal product manufactureAlkaline accumulator electrodesCalcium silicateFiltration

Embodiments of the invention disclose a preparation method for an ultrafine calcium zincate crystal applied to a zinc battery. The preparation method comprises the following steps: (a) dissolving zincoxide in an alkaline solution to prepare an alkaline saturated zinc oxide solution; (b) adding a calcium silicate seed crystal having a particle size of 2000-8000 meshes into the alkaline saturated zinc oxide solution under stirring to obtain a mixed solution; (c) separately adding calcium hydroxide and zinc oxide in a molar ratio of 1: 2 into the mixed solution for a reaction under the conditionof continuous stirring; and (d) after the reaction is completed, performing suction filtration, washing and drying to obtain the ultrafine calcium zincate crystal. The calcium zincate crystal prepared by using the preparation method of the invention has a small and uniform particle size, a complete crystal form and a high purity, and can effectively inhibit battery deformation and zinc dendrite formation when added to a zinc-nickel battery as a negative electrode material of the battery. The preparation method is short in reaction time, does not require long-time aging, saves energy consumption, and has high labor productivity.

Owner:KUNMING METALLURGY INST

Cutting device for cutting rubber sealing strip

InactiveCN112297079AImprove delivery efficiencyImprove cohesionMetal working apparatusConveyor partsPolymer scienceEngineering

The invention belongs to the technical field of rubber sealing strip cutting and in particular relates to a cutting device for cutting a rubber sealing strip. The cutting device comprises a cutting bracket, a cutting assembly and a regularizing assembly. The cutting device has the advantages that the rubber sealing strip conveying efficiency is improved, the consistency between rubber sealing strip conveying and rubber sealing strip cutting is improved, the rubber sealing strip is regularized conveniently, and the rubber sealing strip cutting quality is improved.

Owner:王友猛

Electric toothbrush with music playing function

The invention discloses an electric toothbrush with a music playing function. The electric toothbrush has the advantages that a music playing box is separated from a toothbrush handle, the music playing box can be fixed to a wall of a place where a user frequently brushes teeth, and the electric toothbrush can be connected to the music playing box in an inserted manner; the toothbrush is indirectly fixedly connected to the wall in an inserted manner, use convenience is achieved, and additional storage is not needed; the toothbrush is separated from the music playing box, so that the music playing box can be prevented being wetted by saliva, foam and tooth brushing water, use safety is achieved, the music playing box cannot be easily damaged due to the fact that water enters the music playing box, and long service life is achieved; the music playing box is separated from the toothbrush handle, so that the music playing box is not limited by the space of the toothbrush handle any more, the size of the music playing box can be set at will, the music playing box can have comprehensive components inside, the sound quality and functions of the music playing box can be improved, and the user can enjoy better sound quality.

Owner:GUANGZHOU WANYUAN ELECTRONICS CO LTD

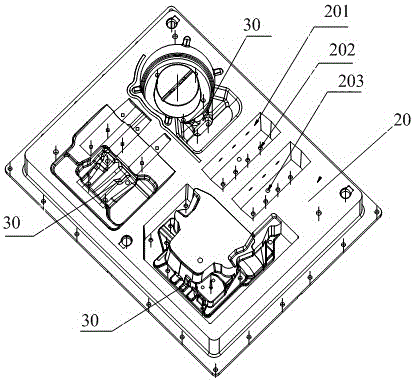

Core box for the production of rod-shaped sand cores

Owner:KOCEL EQUIP

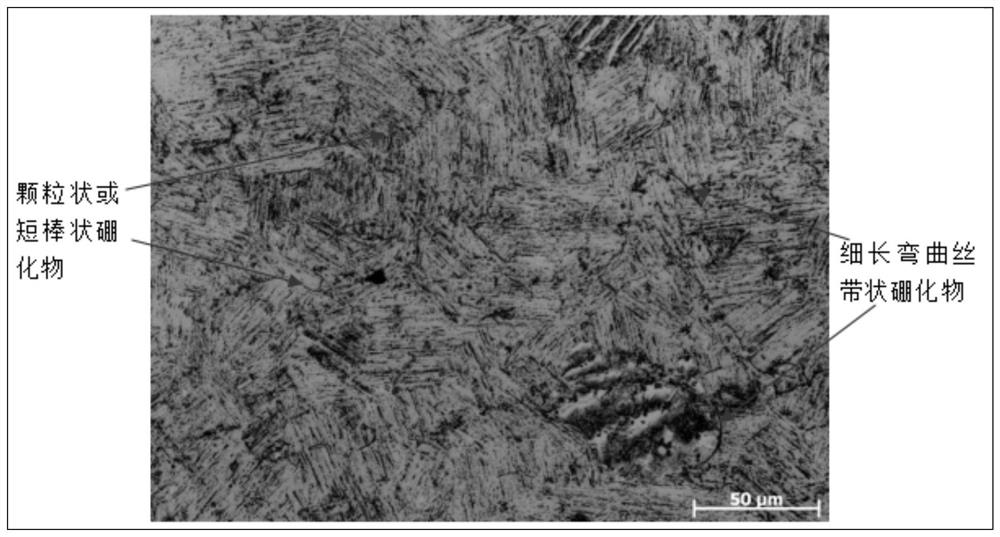

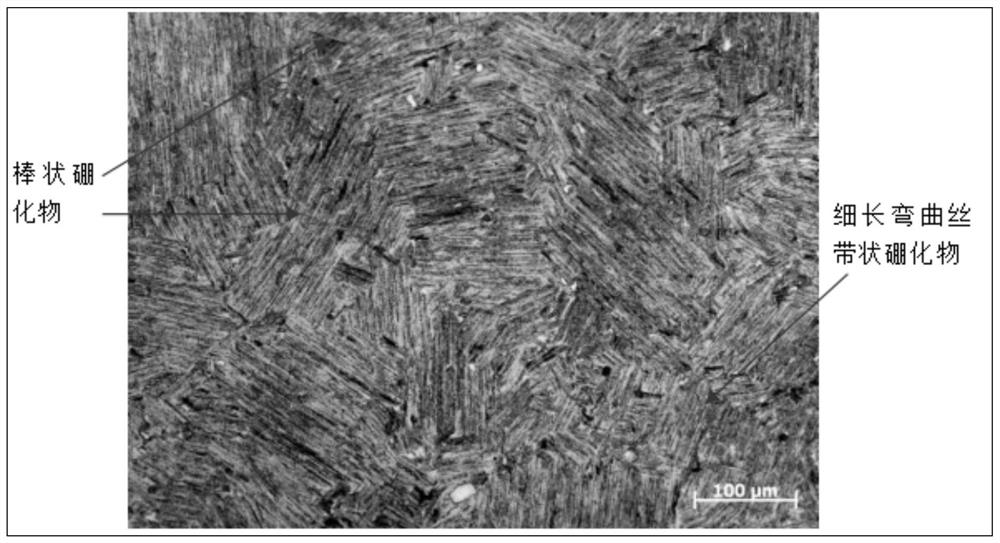

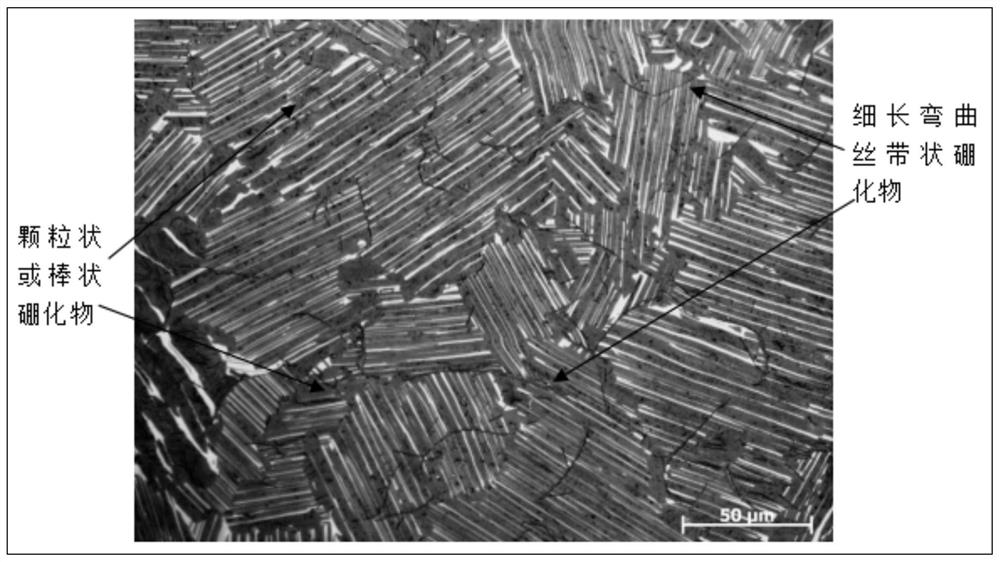

Method for displaying boride in gamma-TiAl-based alloy

InactiveCN112649259AEasy to distinguish and judge the sizeEasy to distinguish and judge the shapePreparing sample for investigationMaterial analysis by optical meansBorideElectrolysis

The invention relates to a method for displaying boride in gamma-TiAl-based alloy, and belongs to the technical field of observation of internal organizational structures of materials. A TiAl alloy sample containing an element B is sequentially subjected to rough grinding and fine grinding by using different numbers of waterproof abrasive paper, and is cleaned and blow-dried after being polished to a mirror surface. A metallographic sample to be observed is connected with an anode, a pure titanium sheet is connected with a cathode, the product is immersed into a metallographic electrolytic corrosive agent for electrolytic corrosion, wherein the temperature of the electrolytic corrosive agent is room temperature, the electrolytic corrosion voltage is 15-35 V, and the electrolytic corrosion time is 10-20 s; and then cleaning and blow-drying are conducted. A red boride metallographic microstructure obviously different from a light red gamma-phase matrix can be observed by adopting a bright field image of a conventional optical metallographic microscope. According to the method, the problems that fine boride in the metallographic structure of the gamma-TiAl-based alloy cannot be distinguished and the shape and size are difficult to count are solved, scientific researchers can easily regulate and control the shape and size of the boride, and research and production of the gamma TiAl-based alloy and components of the gamma TiAl-based alloy are promoted.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com