Patents

Literature

112 results about "Defective graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

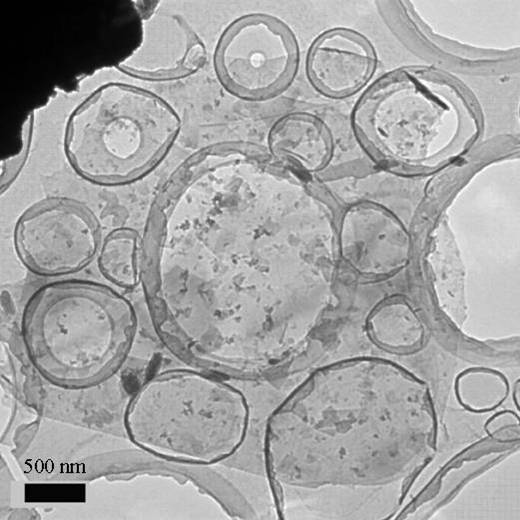

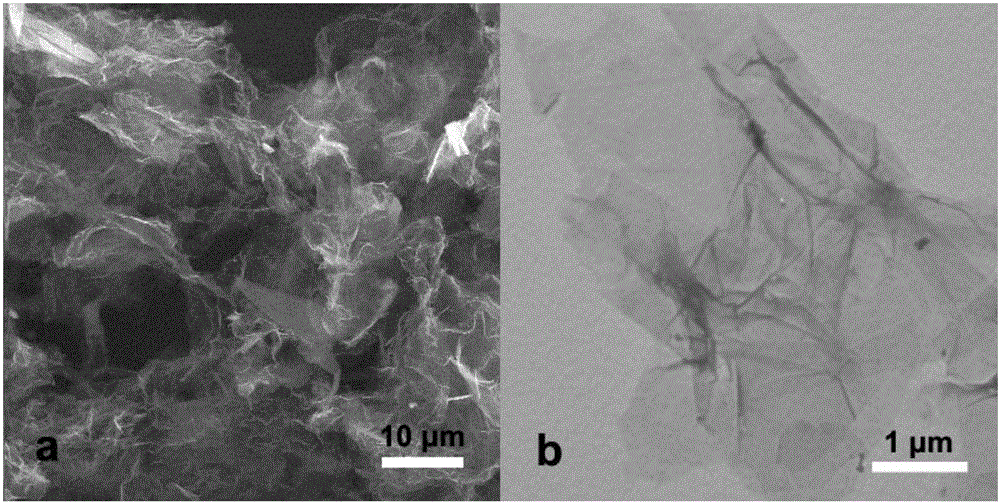

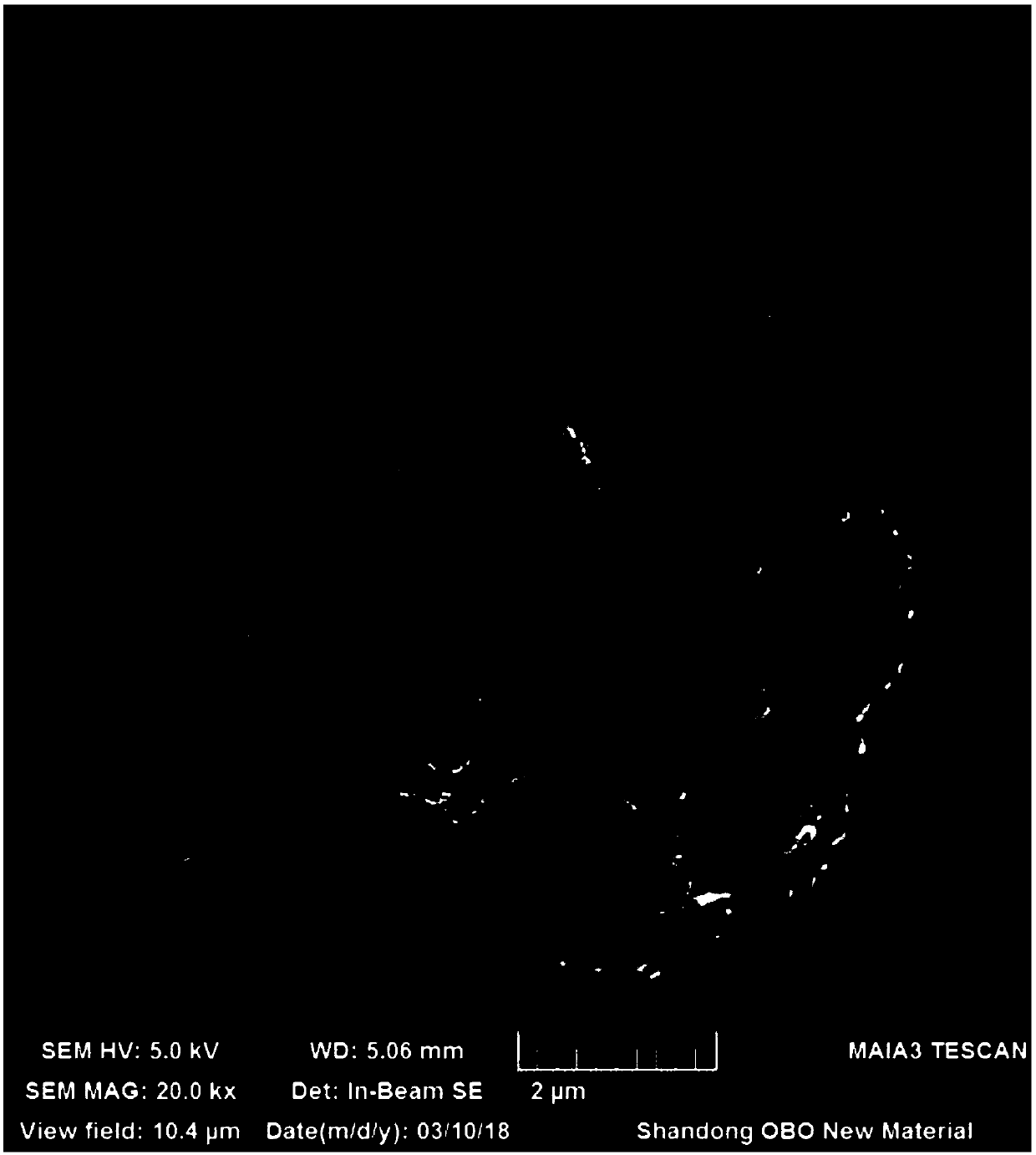

There are two kinds of defects in graphene. One is point defects, typically vacancies or interstitial atoms are zero-dimensional. The other is on one dimensional line of defects.

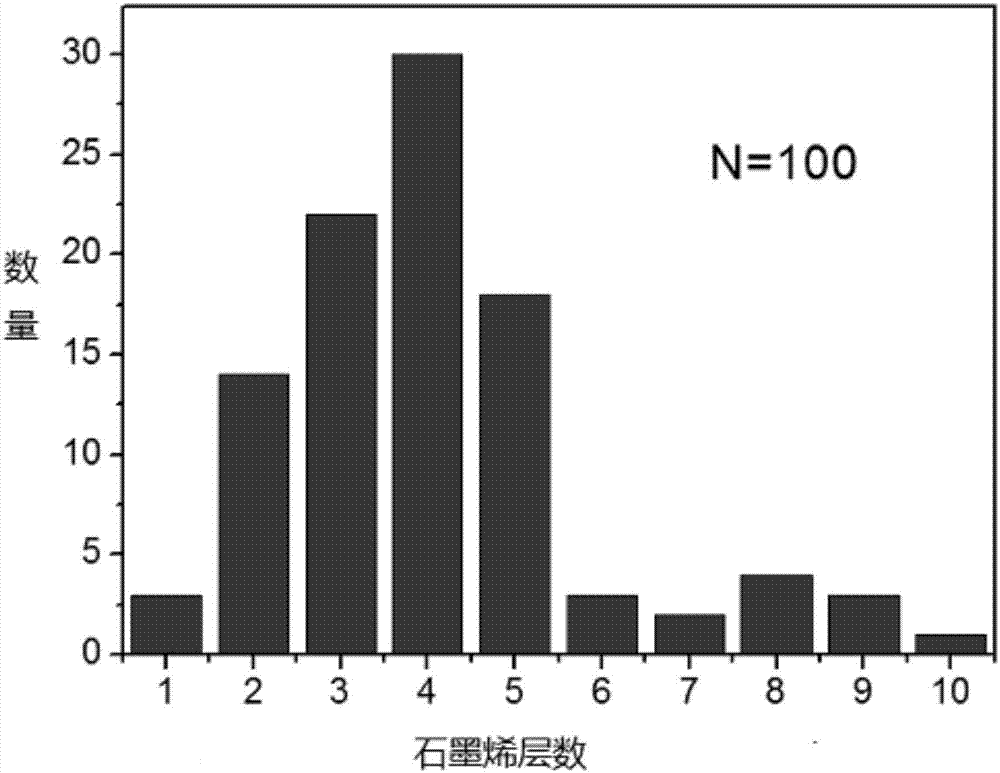

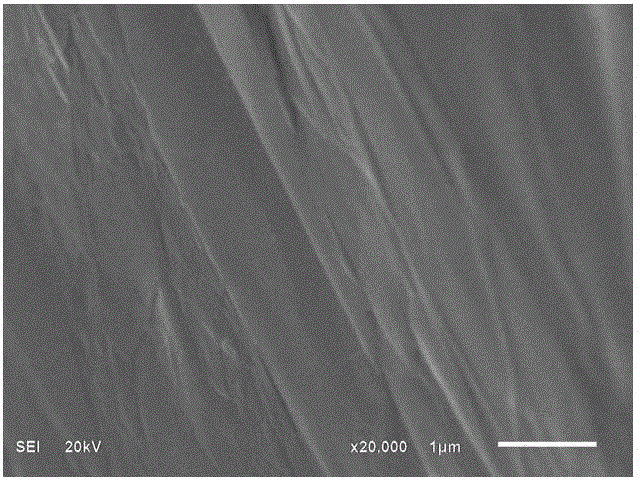

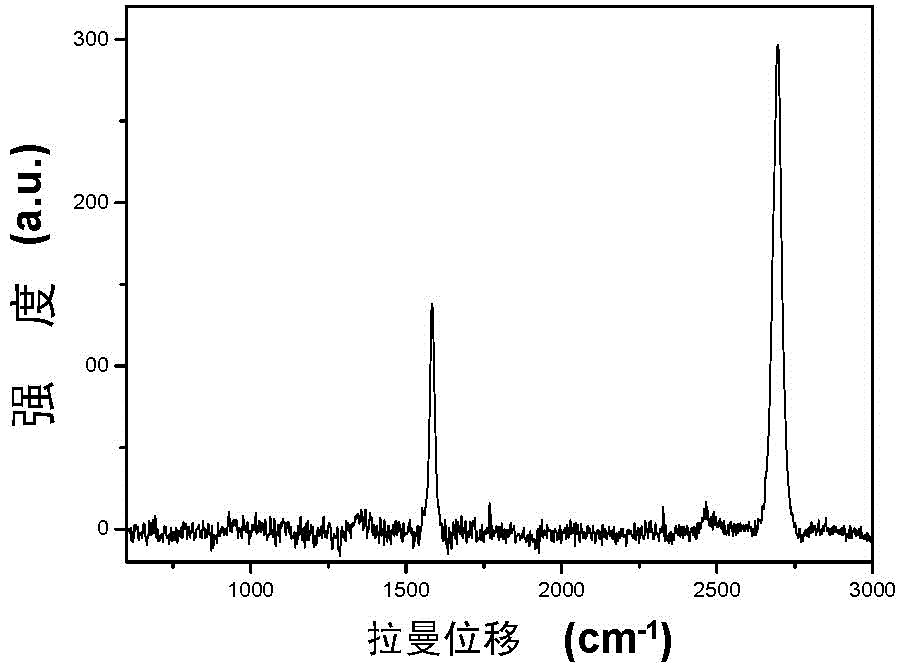

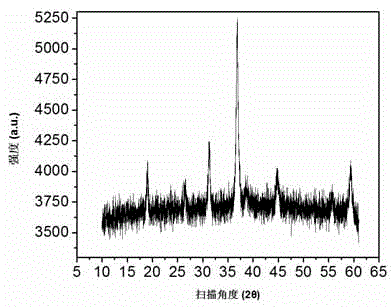

Method for preparing graphene

The invention relates to a method for preparing graphene, belonging to the field of the preparation of inorganic non-metallic material powder. The method comprises the following steps of: taking natural flake graphite powder with a certain grain size as a raw material; adding the natural flake graphite powder into an organic solvent dissolved with alkali metal compounds, and carrying out ultrasonic dispersion processing (the ultrasonic frequency is no less than 10 KHz); filtering or carrying out centrifugal separation; washing; and carrying out vacuum drying to obtain a mixed product formed by the graphene with n atomic layers, wherein n is no less than 1 and no more than 5. In order to increase the peeling ratio, the natural flake graphite powder with the certain grain size can be prepared into a lithium battery cathode material by serving as a raw material, after the lithium battery cathode material is charged by a lithium battery to activate, the lithium battery cathode material is peeled from a current collector and is collected, and then, the ultrasonic dispersion processing is carried out. Compared with the prior art, the method for preparing the graphene has the advantages of simple operating process, easiness in enlarged production, high peeling efficiency, little graphene defects and no generation of wastewater.

Owner:DALIAN LICHANG NEW MATERIAL CO LTD

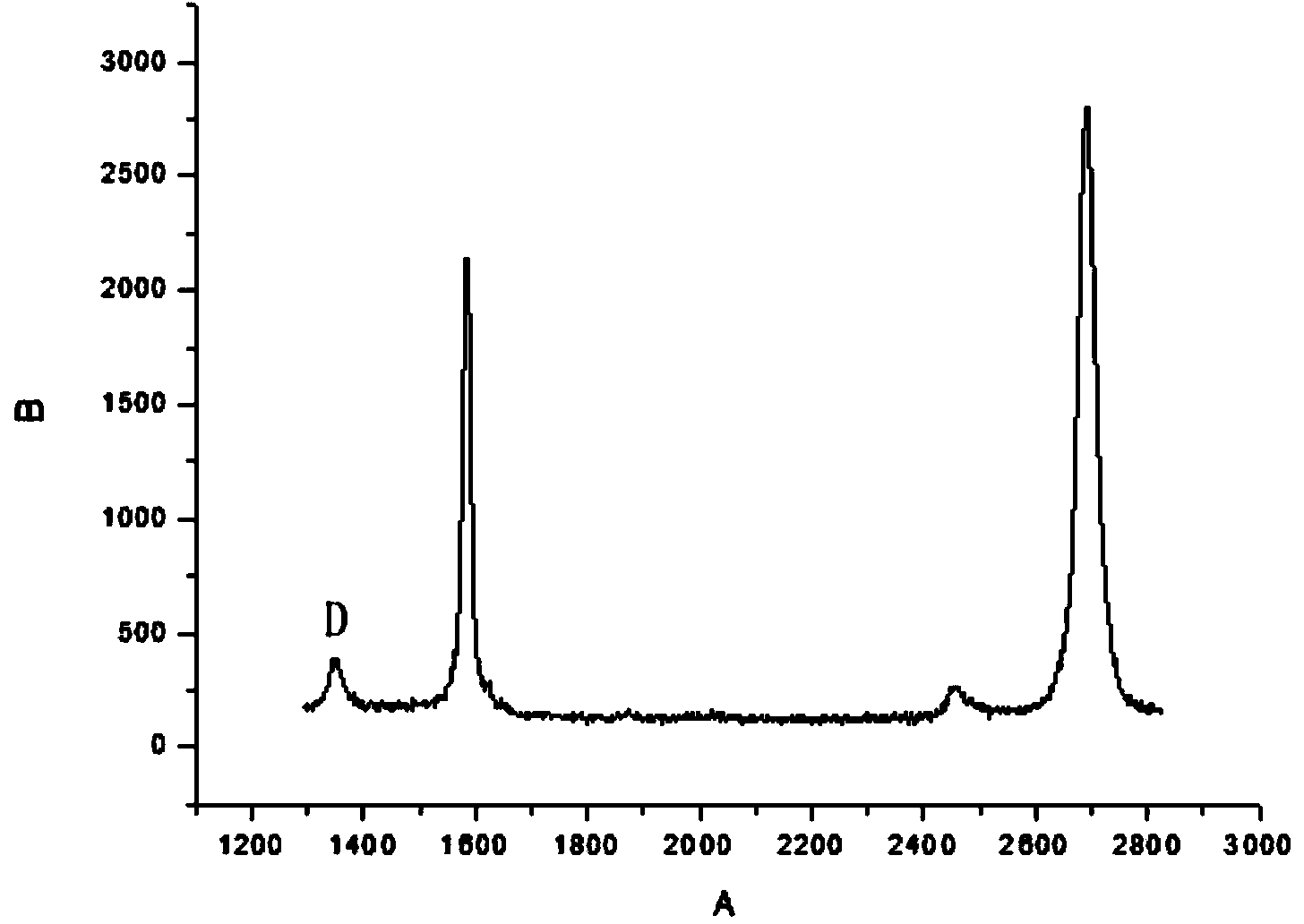

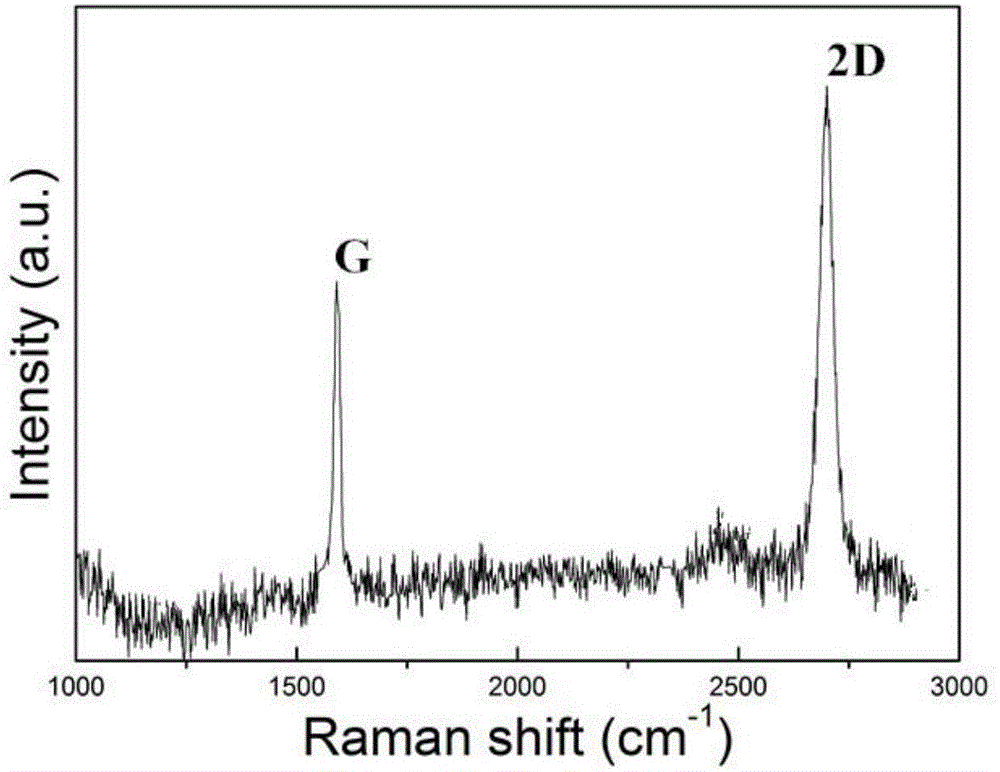

Low-temperature direct preparation method of graphene under double-temperature-zone control, and double-temperature-zone tube furnace

InactiveCN102849733APrecise control of growth temperatureSimple growth processGrapheneHydrogenDefective graphene

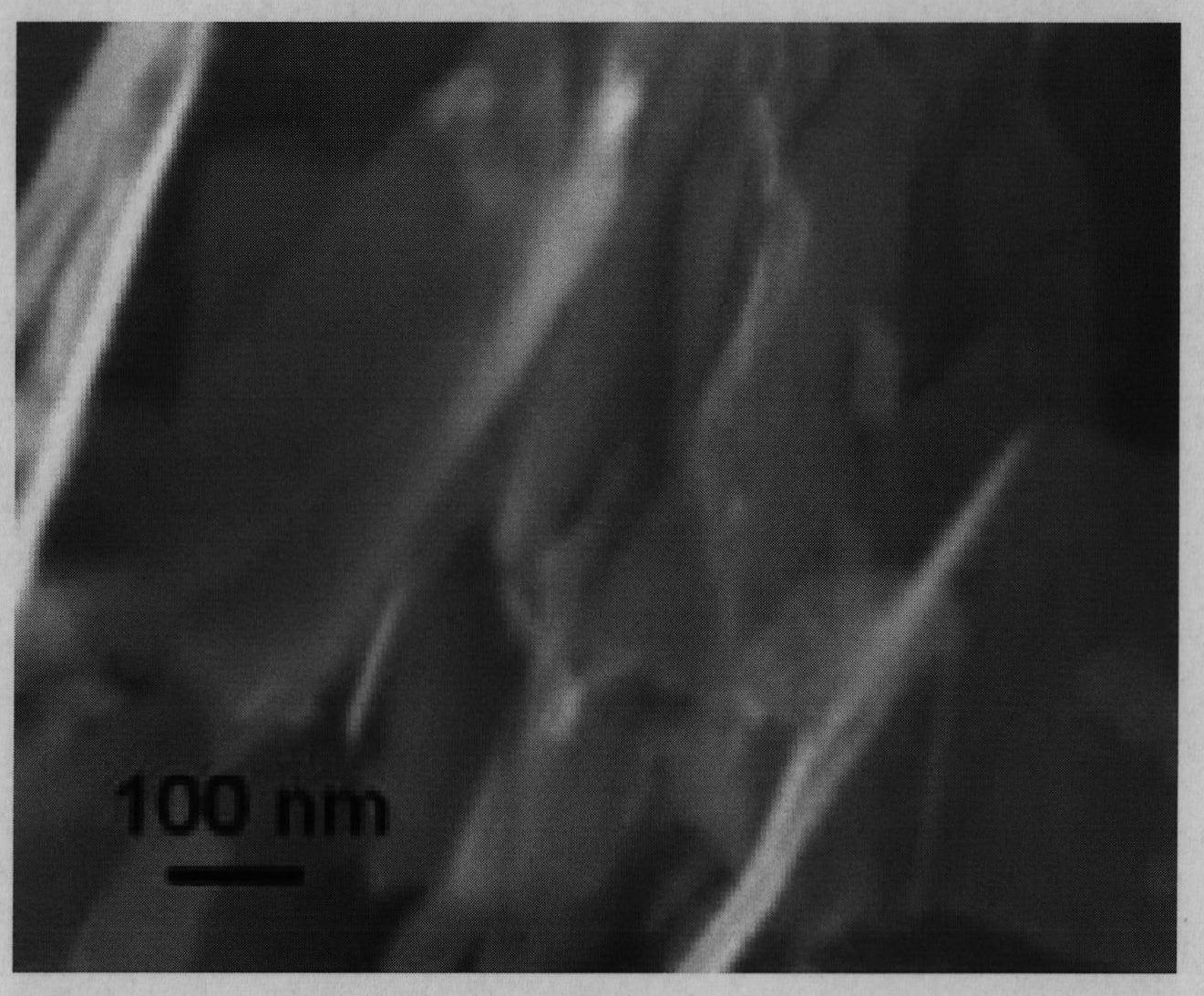

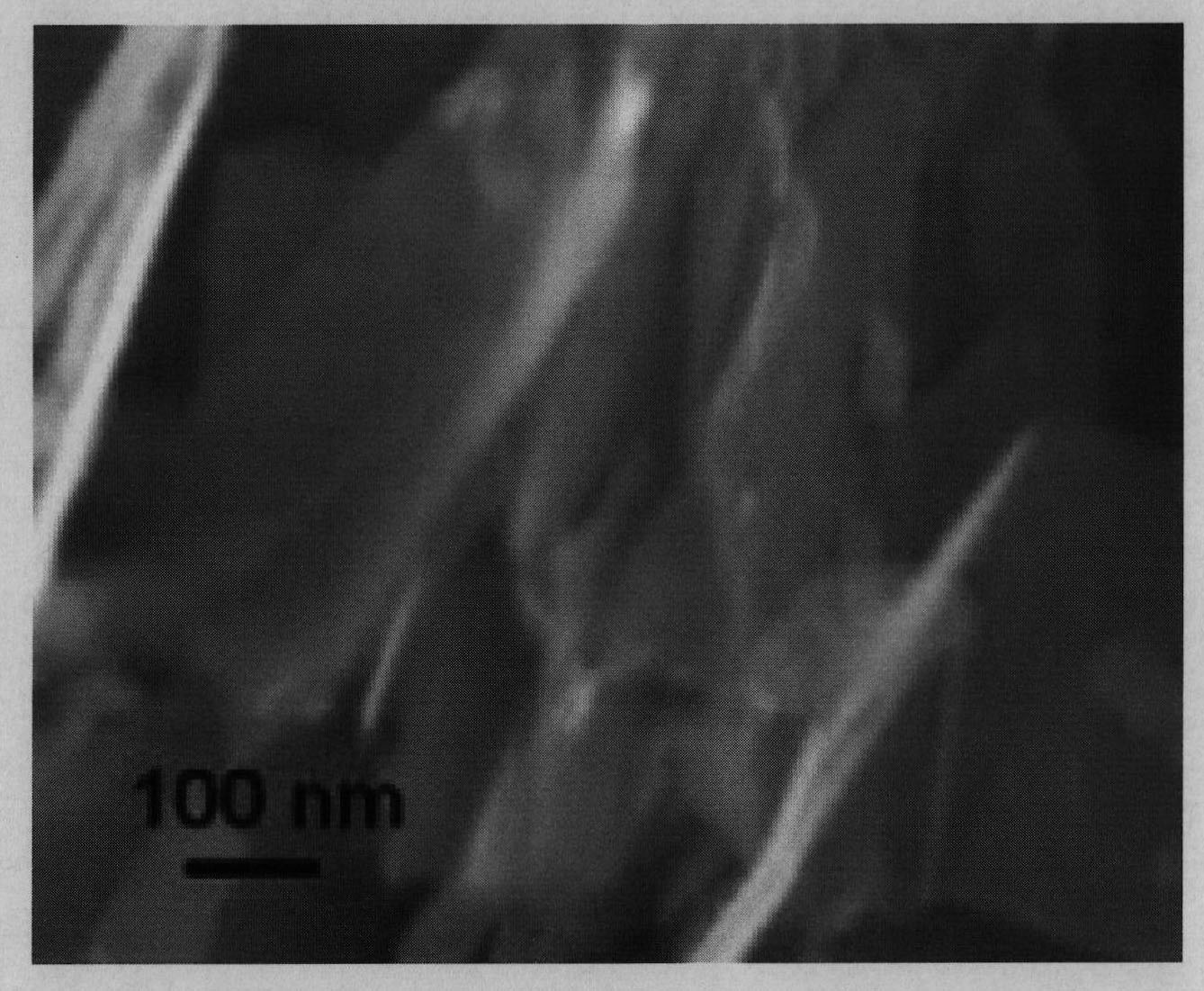

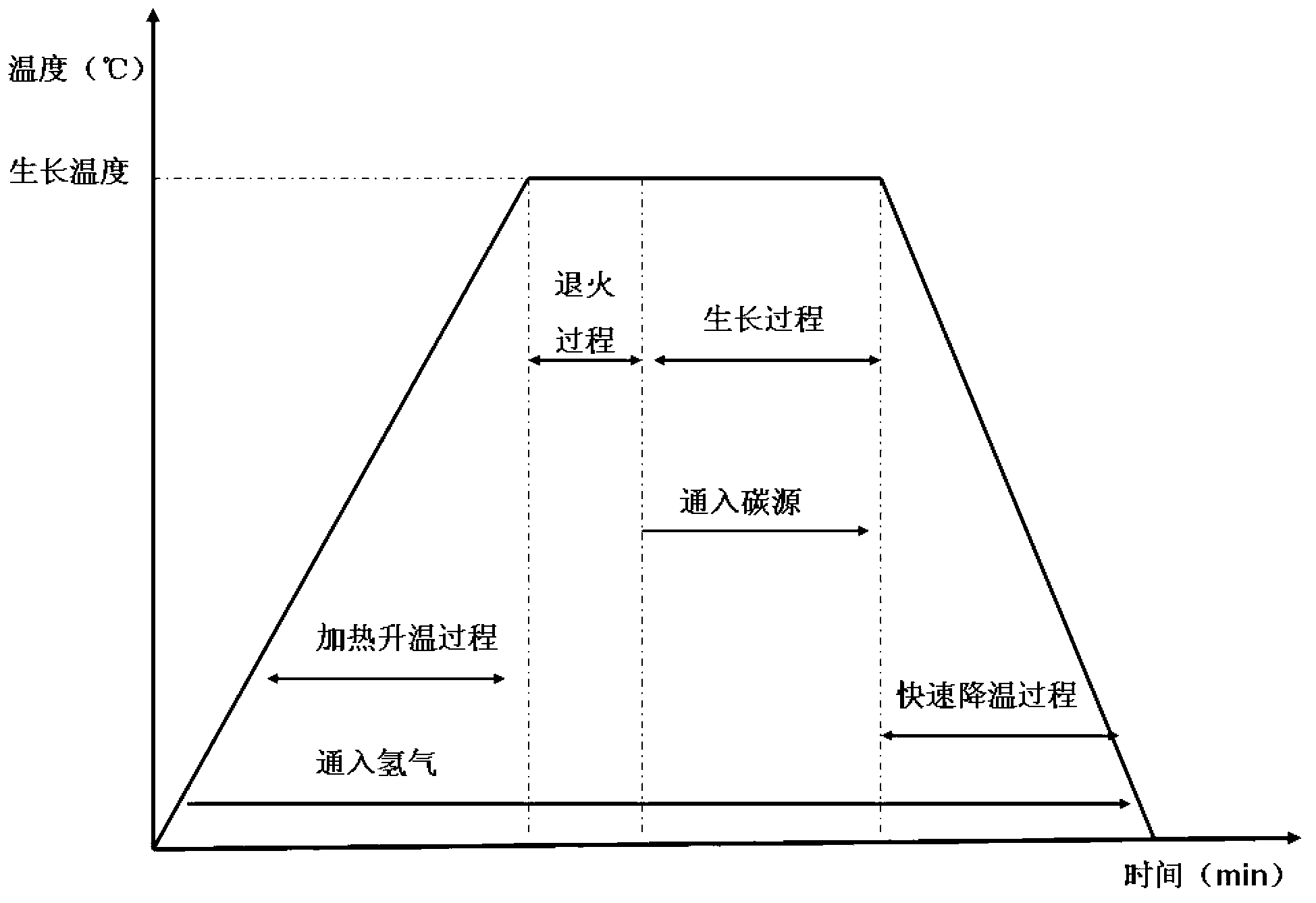

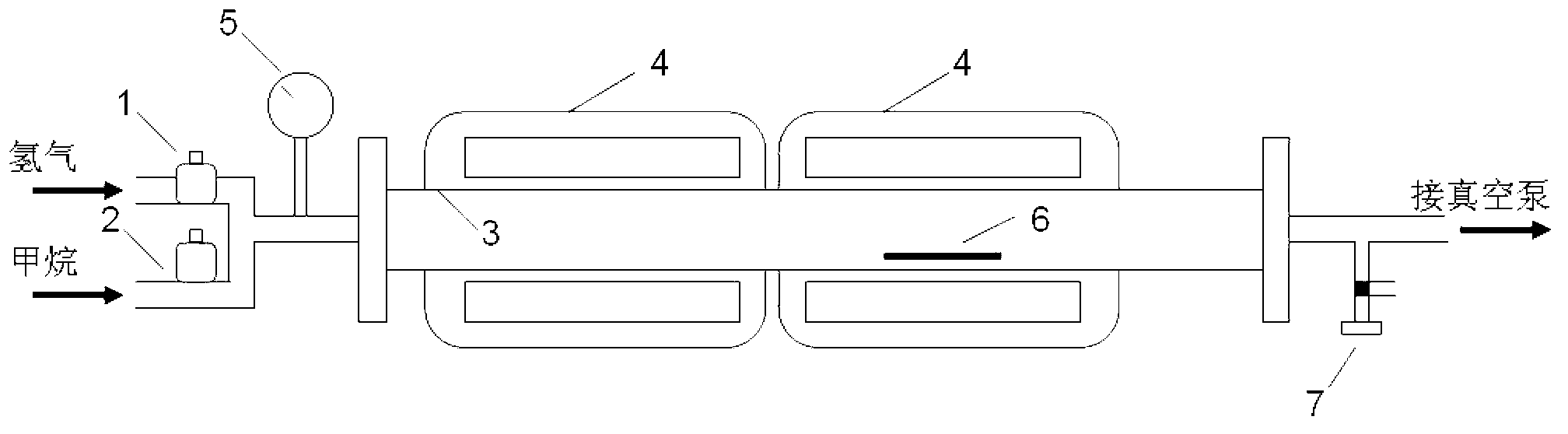

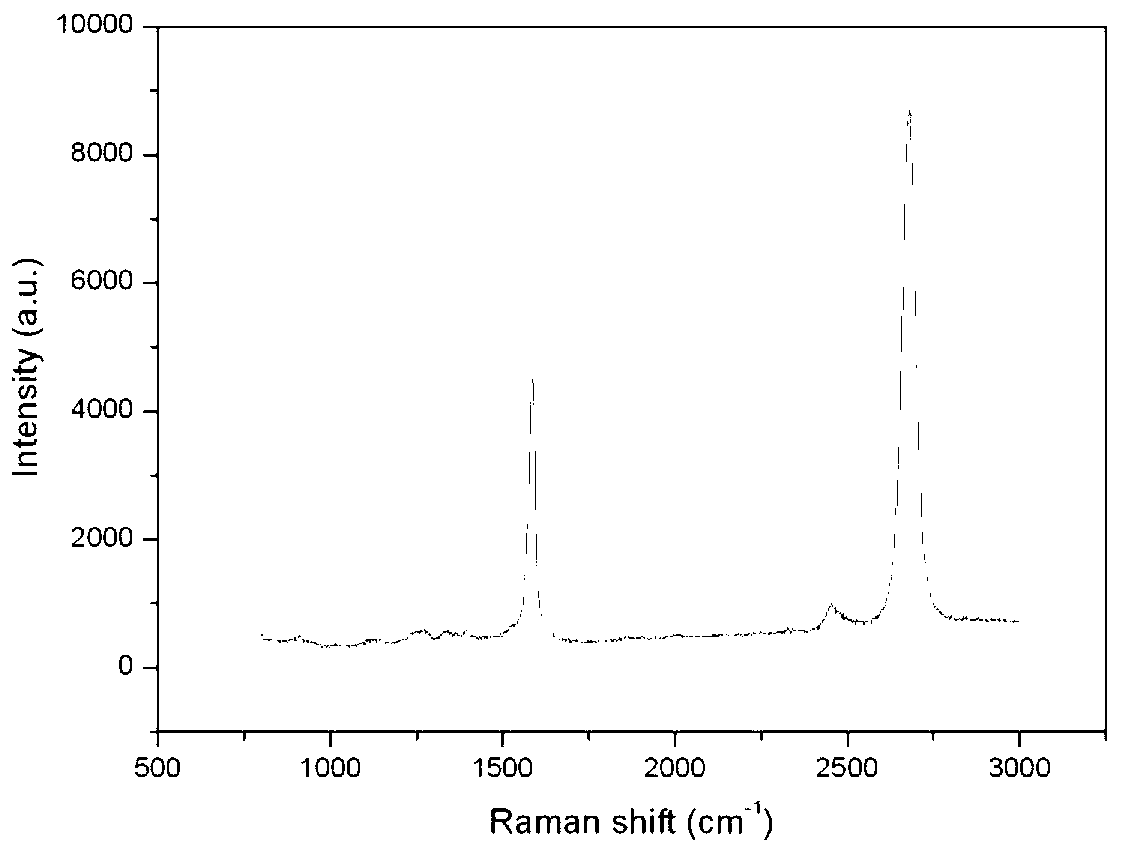

The invention discloses a low-temperature direct preparation method of graphene under double-temperature-zone control, and a double-temperature-zone tube furnace. The method comprises the steps of dividing a vacuum reaction furnace into a high-temperature zone and a low-temperature zone, putting transition metal into the high-temperature zone, directly putting substrate material into the low-temperature zone, vacuumizing, injecting hydrogen gas into the vacuum reaction furnace, heating the low-temperature zone to 100-1,000 DEG C, heating the high-temperature zone to 1,000-1,100 DEG C, introducing carbon source into the vacuum reaction furnace, cracking the carbon source in the high-temperature zone, and performing chemical vapor deposition (CVD) for 5-180 min in the low-temperature zone while keeping constant hydrogen gas flow, to obtain graphene directly deposited on the substrate. The preparation method has the advantages of simple growth process, no need of catalysis, low growth temperature of 100-1,000 DEG C, no restriction on substrate material, and large-area growth of graphene. The grown graphene has low defect peak, high crystal quality, excellent light transmittance and electrical conductivity.

Owner:SHANDONG NORMAL UNIV

Method for preparing graphene powder at large scale

The invention relates to a method for preparing high-quality graphene powder at low cost and large scale. The method comprises the following steps of: adding graphite to mixed solution containing an oxidizing agent and an intercalator, stirring evenly and then performing ultrasonic treatment, and simultaneously, continuously introducing He to form a graphite intercalation compound intercalated with the intercalator and He gas molecules; next, filtering, washing and drying, and performing thermal treatment in air to realize the first time of stripping of the graphite intercalation compound; later, dispersing the graphite intercalation compound in an organic solvent and performing ultrasonic treatment again under the condition of continuously introducing He; and then centrifuging and removing precipitate, and filtering, washing and drying the solution of the upper layer, thereby obtaining the graphene powder. The method provided by the invention is safe and environment-friendly, simple to operate and suitable for large-scale production; the prepared graphene has few defects and good electrical conductivity.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Preparation method of graphene

The invention belongs to the technical field of materials, in particular relates to a preparation method of graphene and particularly relates to a method of preparing graphene by virtue of assistance of ultrasonic waves. The preparation method is mainly used for preparing graphite with high quality, large yield and low cost and is characterized by comprising the following steps: treating a graphite raw material by virtue of an acid solution firstly, then adding the graphite raw material after acid treatment into an active matter solution, carrying out ultrasonic treatment on a mixture to obtain a graphene dispersion liquid, and then carrying out drying treatment on the graphene dispersion liquid to obtain a graphene powder. By adopting the preparation method, the graphene prepared by virtue of the method has an integral structure, little defects and larger size and is stable in the performance; in addition, the experimental process is simple and effective and can be used for large-scale industrial production; the self properties such as thermal property, the electric property and mechanical property of the graphene are better preserved; as the reaction condition is mild, high-temperature and high-pressure reaction is not related, the procedure is simple, and the production cost is low; the method has better potential in large-scale industrial application.

Owner:安徽百特新材料科技有限公司

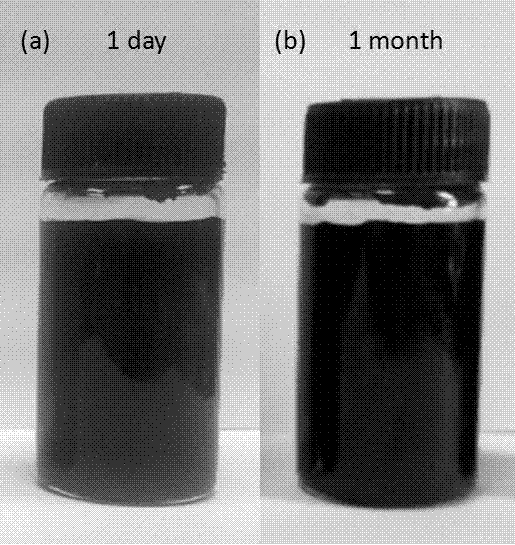

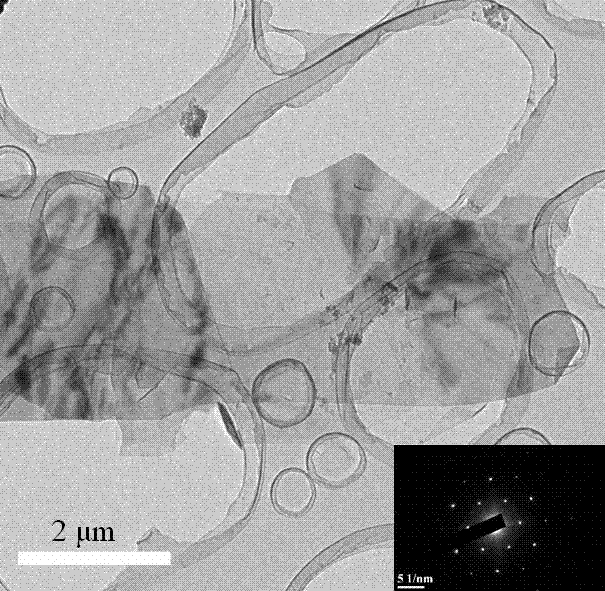

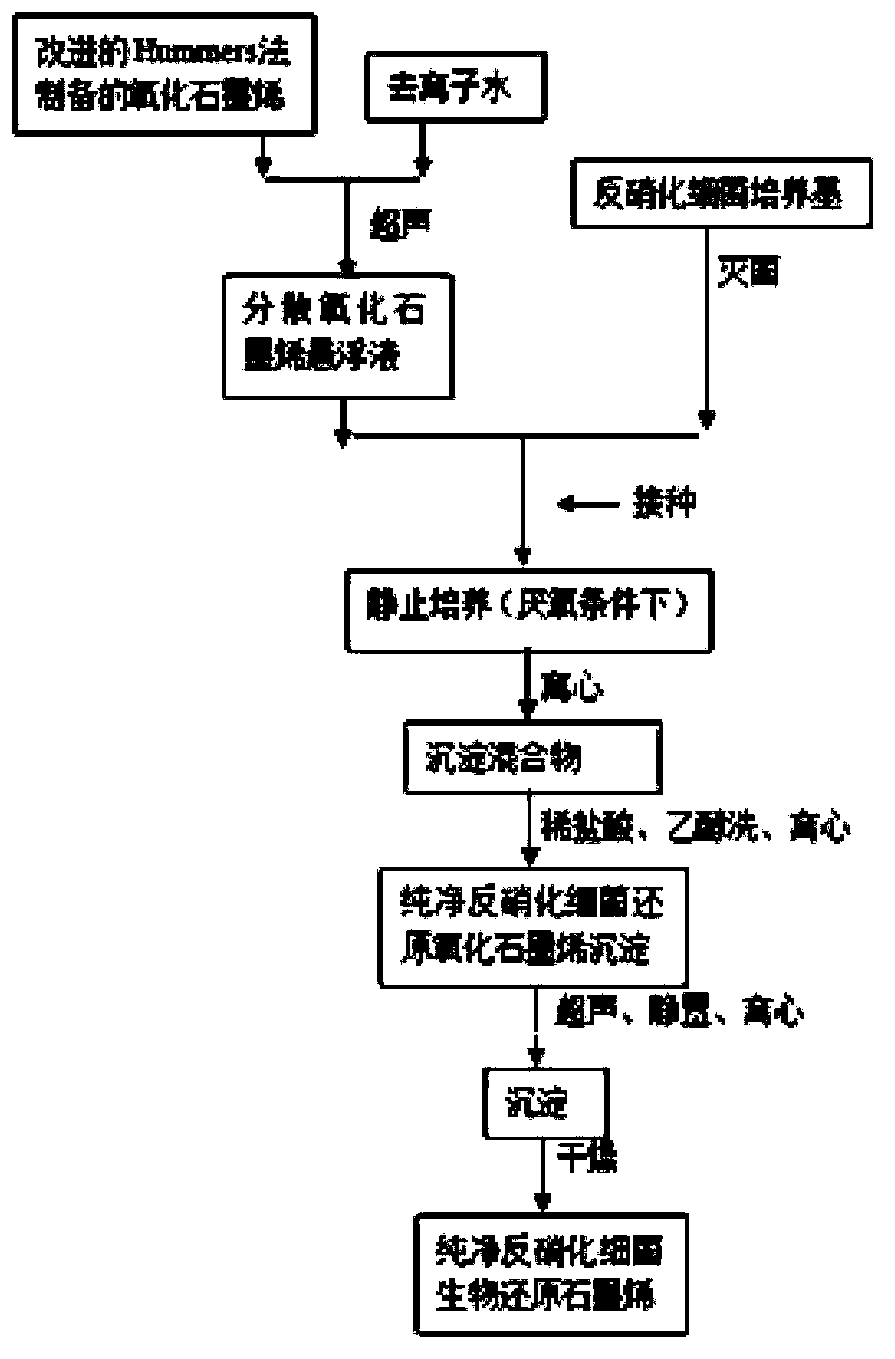

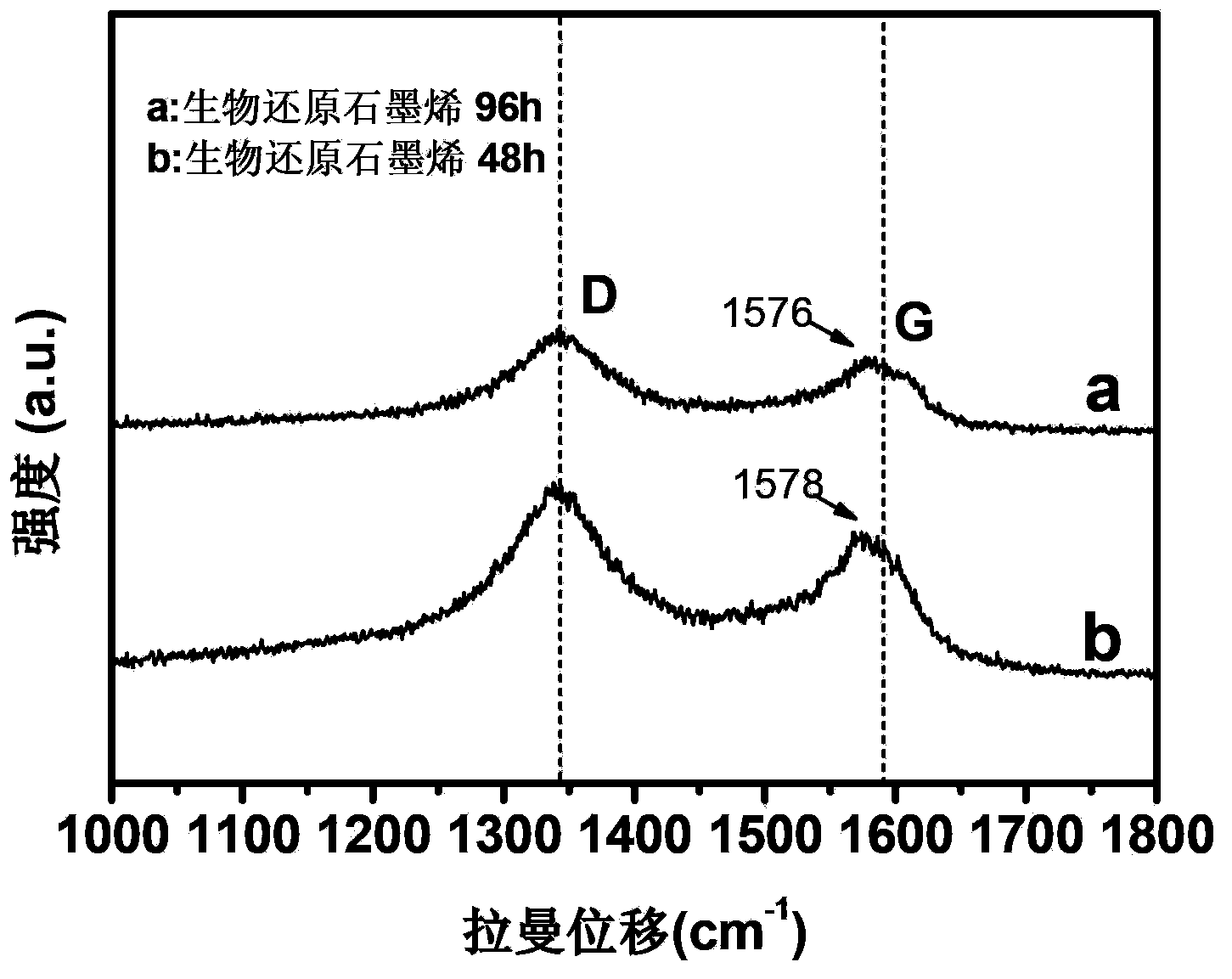

Microbial reduction of graphene oxide and preparation method for graphene

The invention discloses a microbial reduction of graphene oxide and a preparation method for graphene. The method comprises the following steps: dispersing graphene oxide in water to form a graphene oxide suspending solution with better dispersion; mixing denitrifying bacteria culture medium being subjected to sterilization and cooling with the graphene oxide suspending solution; inoculating a seed solution; culturing in still standing state in anaerobic condition for a few days, removing the oxygen-containing functional group of the dispersed graphene oxide with the effect of denitrifying bacteria to form graphene; after finishing the culturing, using hydrochloric acid, alcohol, and deionized water to remove bacterial cells, metabolite, and other ions produced in the reduction process, using water to cleaning until the water is neutral finally, and drying to obtain pure graphene. The method using microorganism denitrifying bacteria capable of reducing high valence state inorganic nitrogen and carbon as the microbial strain to conduct microbial reduction on graphene oxide; compared with similar reducing bacteria of Shewanella, the denitrifying bacteria has the advantages that the environmental safety is good, the reaction condition is mild and controllable, the medium component is simple, and the graphene obtained by preparation has less defects and layers.

Owner:NANJING UNIV OF SCI & TECH

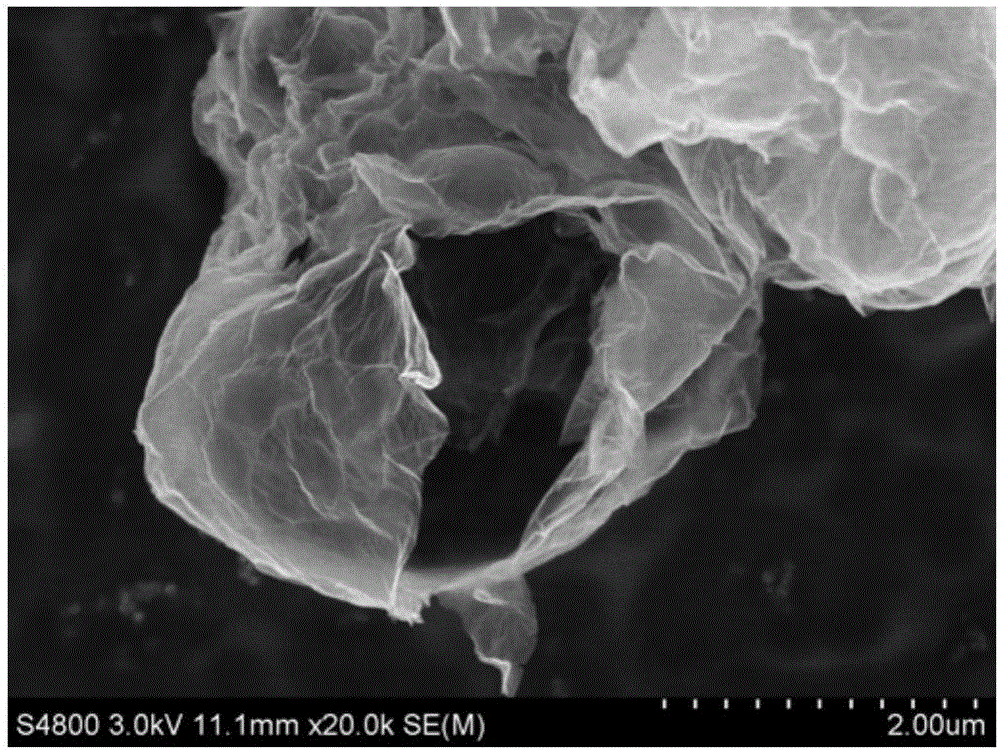

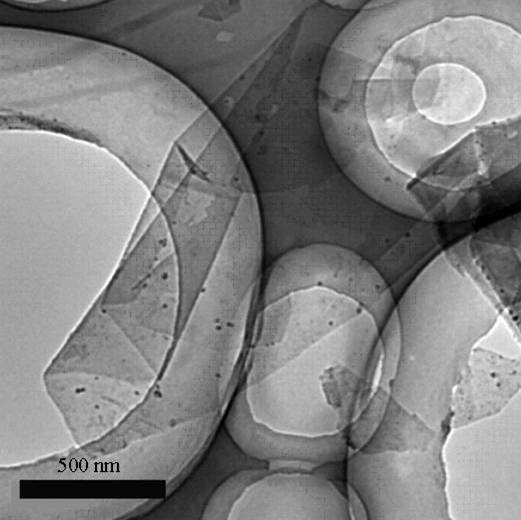

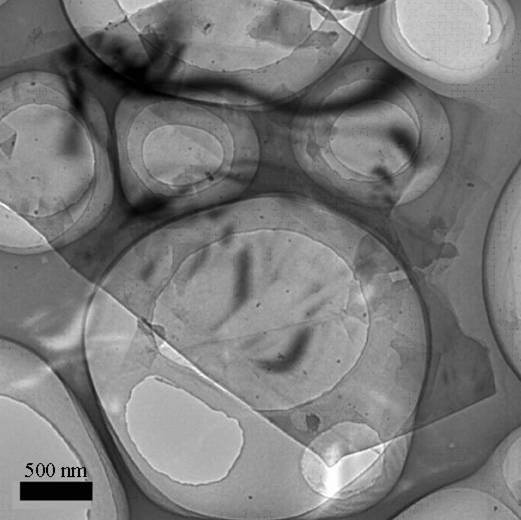

Pure graphene composite electromagnetic shielding film and method for preparing same

ActiveCN106185905AGood electromagnetic shieldingSimple processMagnetic/electric field screeningDefective grapheneElectromagnetic shielding

The invention discloses a pure graphene composite electromagnetic shielding film and a method for preparing the same. Graphene solid micro-spheres, hollow micro-spheres and lamellar graphene oxide are assembled to obtain the pure graphene composite electromagnetic shielding film. The pure graphene composite electromagnetic shielding film and the method have the advantages that defects of graphene are repaired by the aid of high-temperature annealing procedures, accordingly, perfect large conjugation structures can be formed, and the smoothness of conductive paths of the graphene can be guaranteed; functional groups on the graphene oxide can fall off to generate gas owing to the high-temperature annealing procedures, graphene lamellas can be peeled off under synergistic effects of the graphene micro-spheres, and multilevel porous structures can be formed; the multilevel porous structures are added to high-conductivity graphene substrates, and accordingly the pure graphene composite electromagnetic shielding film is extremely high in electromagnetic shielding performance.

Owner:杭州德烯科技集团有限公司

Method for preparing graphene

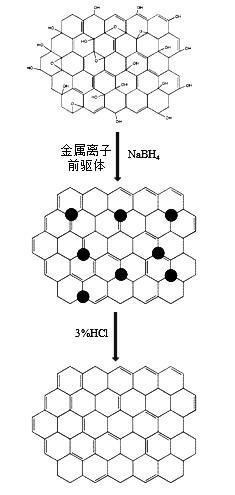

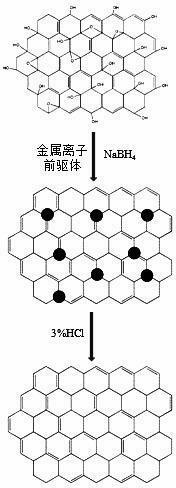

InactiveCN102530934AEnvironmentally friendlySafeGrapheneNanotechnologyDefective grapheneAcid washing

The invention provides a method for preparing a large amount of graphene by reducing graphene oxide by a chemical reduction method at room temperature. The method comprises the following steps of: firstly, adding a metal salt solution into a graphene oxide aqueous solution; secondly, adding NaBH4, and catalyzing NaBH4 to hydrolyze and release a large quantity of hydrogen atoms with high reducibility by using reduced metal particles at the room temperature; reducing the graphene oxide with the hydrogen atoms; and finally, removing metal particles through acid washing to obtain the graphene. By the method, the graphene is prepared without use of a chemical compound such as hydrazine hydrate and derivatives thereof and the like with strong toxicity and volatility as a reducing agent, so the method has the characteristics of environment friendliness, safety and the like, and the method can be implemented under a room temperature condition, and the reaction condition is mild, so that graphene defects in the reducing process are reduced.

Owner:SUZHOU UNIV

Method for preparing graphene solution based on supercritical carbon dioxide and pyrenyl polymers

InactiveCN102502607AEffective peelingImprove diffusion abilityGrapheneBulk chemical productionHigh concentrationDefective graphene

The invention belongs to the technical field of graphene preparation, and discloses a method for preparing graphene solution based on supercritical carbon dioxide and pyrenyl polymers. Graphites of 10 to 20 mg and the pyrenyl polymers of 15.4 to 30.8 mg are dispersed in dimethyl sulfoxide of 5 to 10 ml; then obtained suspending liquid containing the graphites and the pyrenyl polymers is put in a supercritical carbon dioxide reaction device, is stirred and reacts for 3 to 6 hours under the temperature ranging from 40 to 45 DEG C and the pressure ranging from 12 to 16 MPa, and then is processedthrough pressure relief; obtained liquid reactant is separated to remove supernatant; sediments are repeatedly washed through solvent so as to remove unreacted pyrenyl polymers, and then are dispersed in the same type of solvent renewedly; and finally, the graphites that are not exfoliated are removed, and then graphene solution is obtained. The method solves the problem that high-concentration uniform graphene solution is difficult to prepare at present, can achieve the high-yield and high-quality preparation and the functionalization of graphene in one step, can enable the output of non-defective graphene layers to be high to 51.8 wt percent, and is a simple and effective method for preparing graphene solution.

Owner:ZHENGZHOU UNIV

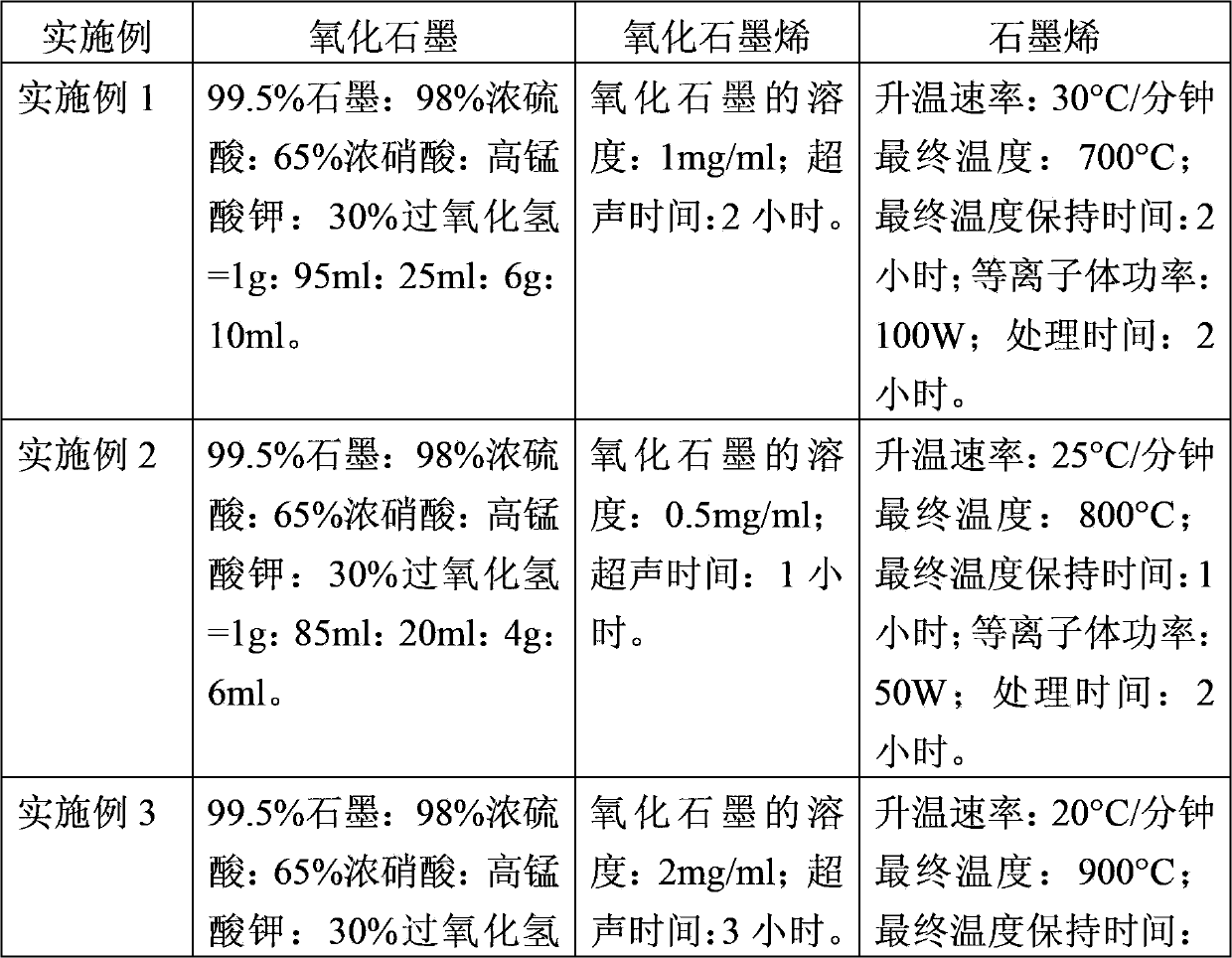

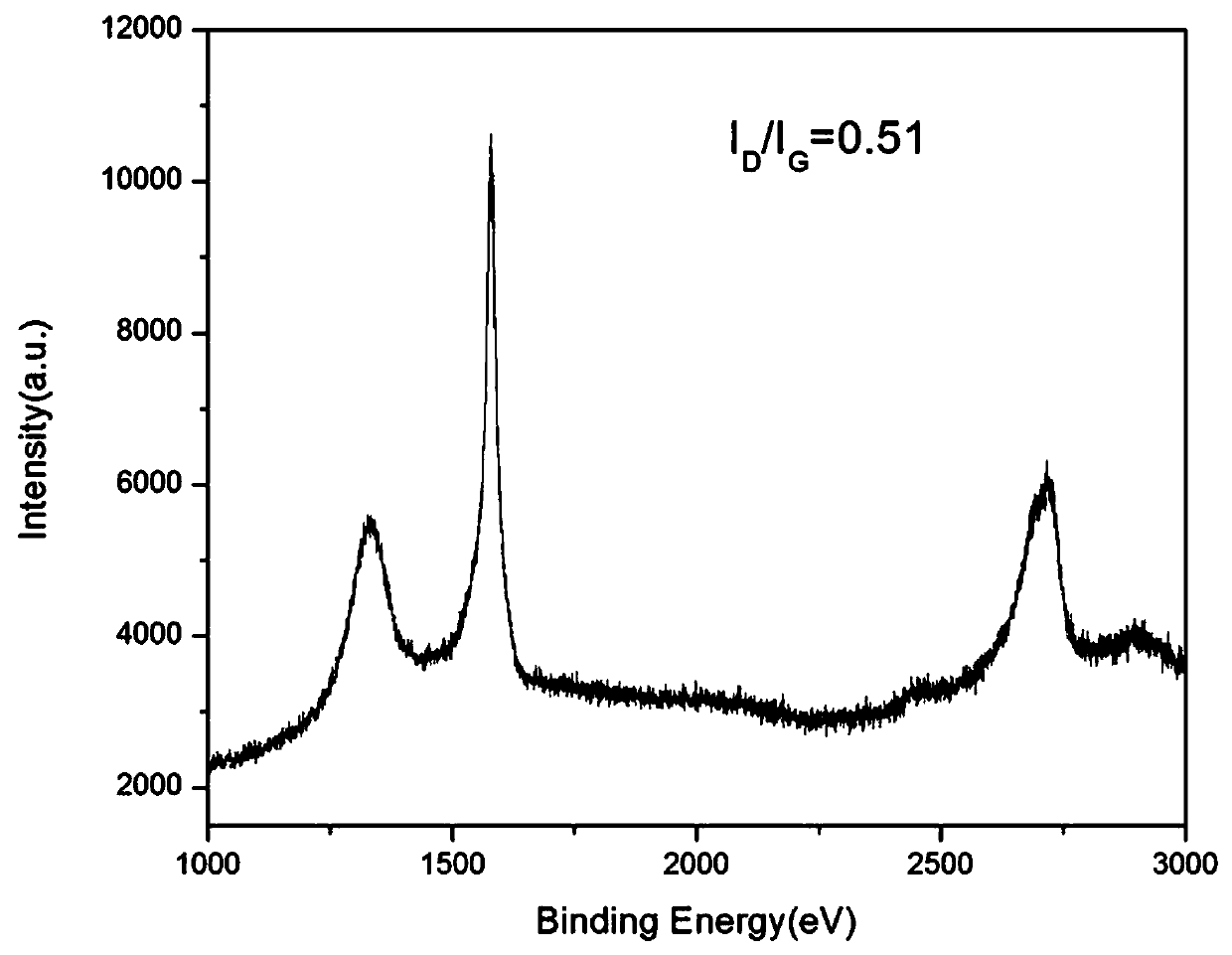

Graphene and preparation method thereof and lithium ion battery

InactiveCN103663432AImprove energy storage capacitySimple preparation processCarbon compoundsCell electrodesDefective grapheneHigh energy

The invention relates to graphene and a preparation method thereof. The preparation method comprises the following steps: (1) preparing oxidized graphene, and (b) preparing the graphene. The invention also relates to application of the graphene in a lithium ion battery. The graphene prepared by adopting the preparation method disclosed by the invention is processed by plasma. The graphene is more in defects, so that the graphene has high energy storage capacity when being coated on a current collector to use, and the preparation technology is simple. Therefore, large-scale production is easily achieved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Method for preparing graphene by peeling graphite in electrochemical manner by using molten salt

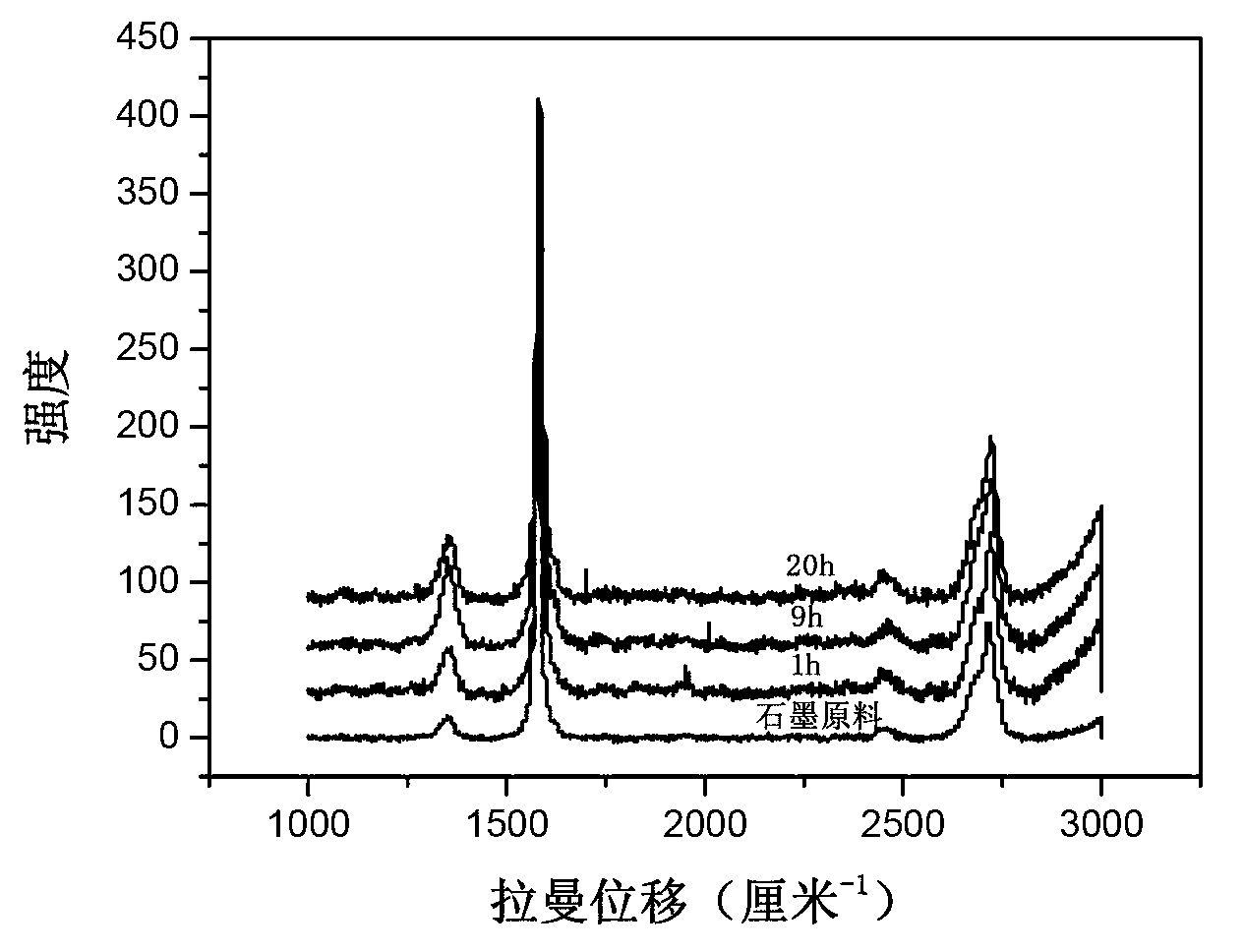

The invention discloses a method for preparing graphene by peeling graphite in an electrochemical manner by using molten salt. The method is characterized by combining an electrochemical method and a solvent method. According to the method, molten salt is used as a peeling medium, and the peeling power is provided by migration of charge particles in the molten salt. According to the technical scheme, the method comprises the following three steps: (1) preparing mixing salt of aluminum chloride, sodium chloride and potassium chloride of appreciate ratio, heating to be 150 DEG C, and keeping the temperature; (2) respectively introducing appreciate current into graphite and an aluminum electrode for electrochemical peeling; and (3) separating the graphene which is obtained by peeling by using the molten salt. The method has the advantages that the graphene defects are small, the equipment requirements are small, the graphene can be rapidly and massively prepared, the industrialization is easy to achieve, and the like.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

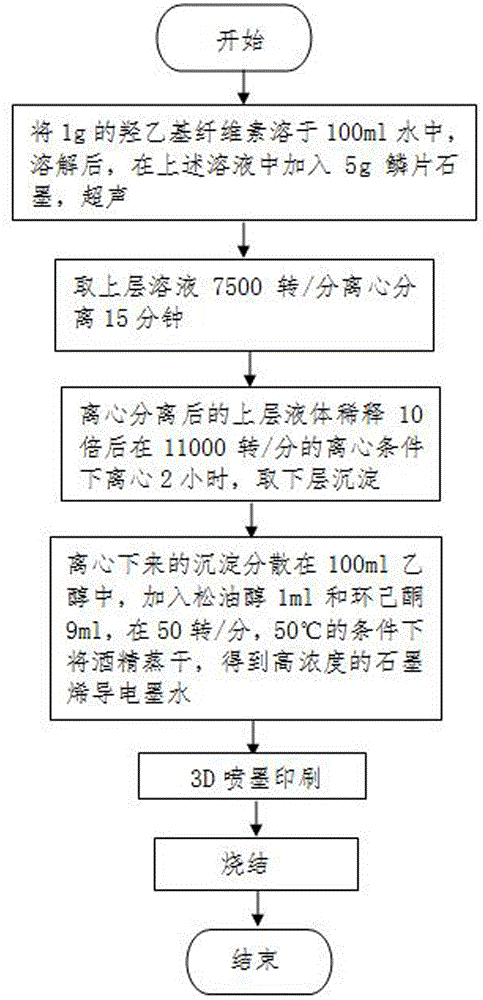

Graphene conductive ink as well as preparing method and application thereof

ActiveCN106519804AAvoid the influence of electrical conductivityImprove conductivityInksDefective grapheneGraphite

The invention discloses graphene conductive ink as well as a preparing method and an application thereof. The preparing method comprises the following steps: 1, ultrasonically dispersing a dispersant and a graphite flake in a first solution so as to obtain a mixture A; 2, carrying out first centrifuging on the mixture A, and carrying out secondary centrifuging on upper-layer dispersion liquid which is obtained after first centrifuging so as to obtain precipitates B; 3, dispersing the precipitates B in a second solvent so as to obtain dispersion liquid C; 4, adding solvents and additives for the conductive ink into the dispersion liquid C; and 5, removing the second solvent so as to obtain the graphene conductive ink. In the method, the graphene is obtained through in-situ preparation, so that the influence of graphene flaws on conductive performance is avoided. The graphene conductive ink which is high in concentration and high in conductivity can be obtained.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Method for preparing large-sized graphene by highly-efficiently exfoliating graphite powder

ActiveCN106976870AAchieve strippingPrevent overlapping againSingle layer grapheneDefective grapheneGraphite

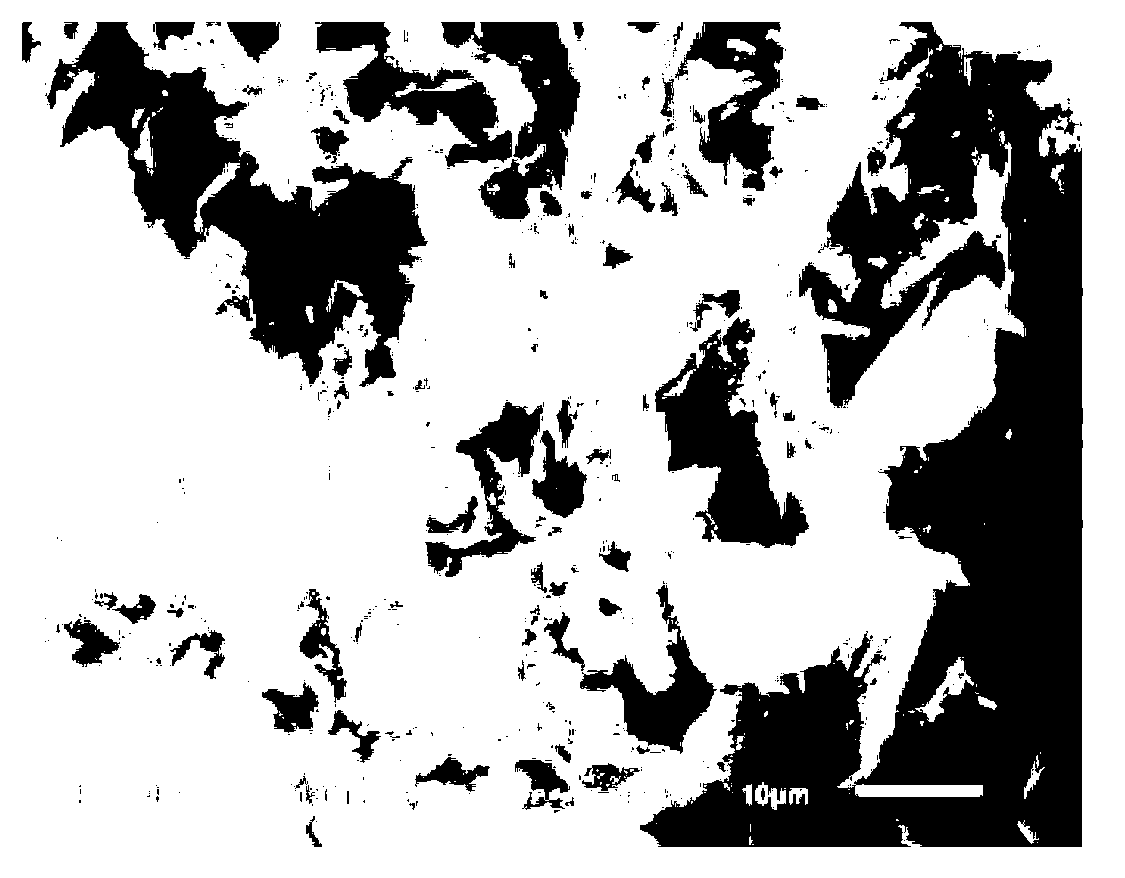

The invention discloses a method for preparing large-sized graphene by highly-efficiently exfoliating graphite powder. The method comprises the following steps: 1) dissolving an intercalating agent in deionized water to prepare an intercalating agent solution, wherein the intercalating agent is a water-soluble polymer; 2) adding graphite powder to the intercalating agent solution, and uniformly mixing the graphite powder and the intercalating agent solution to obtain a graphite powder suspension; 3) allowing the graphite powder suspension to go through a microfluidizer at a rate of 50-450 mL / min, and carrying out circulating treatment multiple times to obtain a suspension I; and 4) filtering the suspension I, repeatedly washing the filtered suspension I with deionized water, carrying out filtration drying to obtain a graphene filter cake, and using the graphene filter cake directly or carrying out spray drying and vacuum drying to remove water in order to obtain dry graphene powder. The method utilizes the microfluidizer to exfoliate the graphite powder, and the water-soluble intercalating agent is combined, so abuses which can not be avoided by ultrasonic separation are avoided, and the water-soluble intercalation agent is easy to remove; and the finally prepared graphene has few defects, and the size is 3-15 [mu]m.

Owner:TIANJIN POLYTECHNIC UNIV

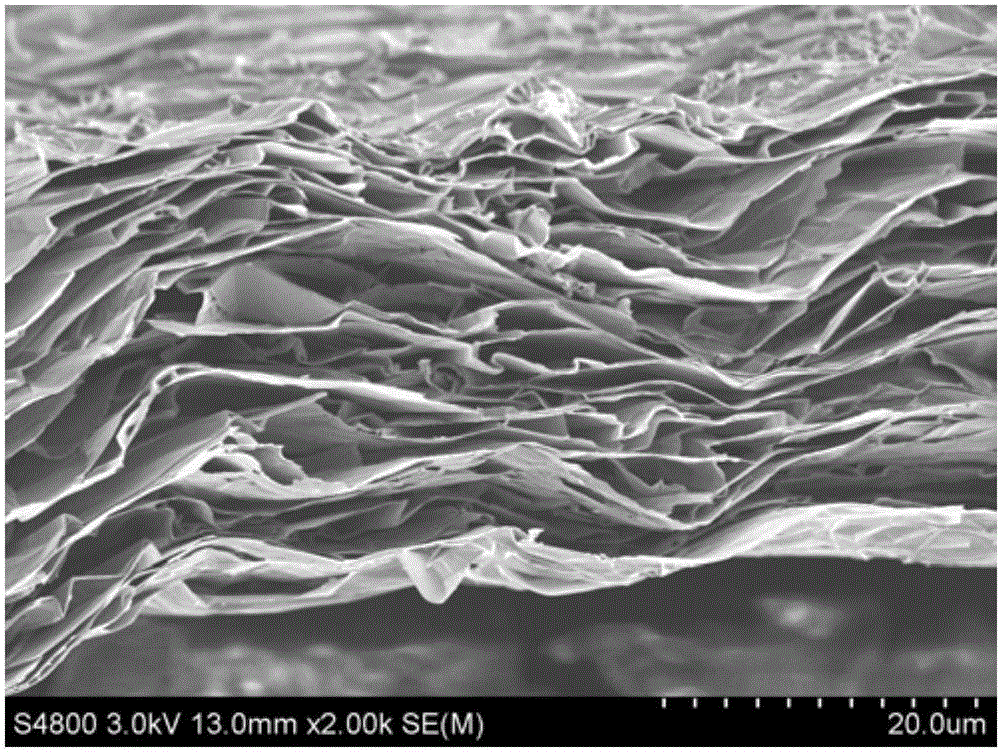

Novel liquid-phase oriented preparation method of high-electric-conductive and high-heat-conductive graphene film

ActiveCN104973592AImproved thermal managementImprove conductivityChemical vapor deposition coatingTemperature controlDefective graphene

The invention relates to a novel liquid-phase oriented preparation method of a high-electric-conductive and high-heat-conductive graphene film, wherein the method includes the steps of (1) performing vacuum temperature-controlled oriented deposition to graphene oxide and performing vacuum suction filtration to deposited graphene oxide to obtain an orientedly-deposited graphene oxide film, and (2) reducing the orientedly-deposited graphene oxide film through chemical vapor deposition, and repairing defects in graphene to obtain an orientedly-deposited graphene film; and (3) high-pressure moulding the orientedly-deposited graphene film to obtain the high-electric-conductive and high-heat-conductive graphene film.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

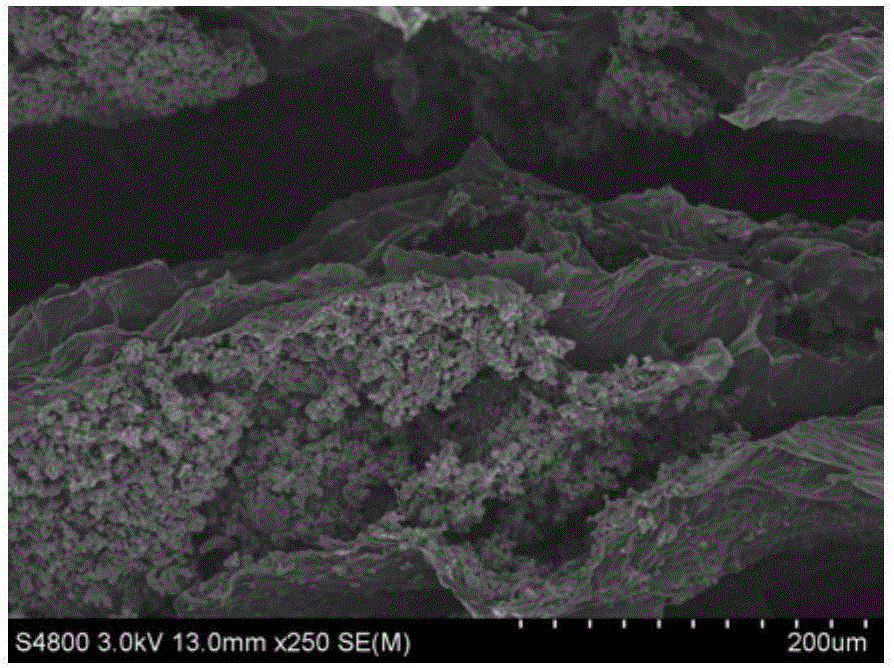

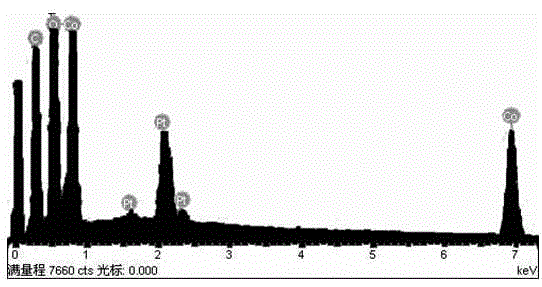

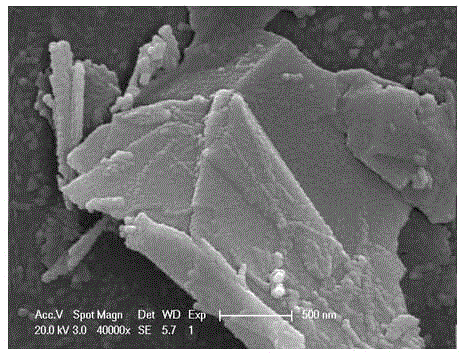

Preparation method of nanometer cobalt oxide/graphene composite material

ActiveCN104785266ASimple processMild conditionsEnergy based wastewater treatmentMetal/metal-oxides/metal-hydroxide catalystsDefective grapheneActive agent

The invention discloses a preparation method of a nanometer cobalt oxide / graphene composite material. A surface active agent is dissolved into water, graphite is added, after 10 to 50 hours of ultrasonography, the rotational speed is controlled to be 4000 to 5000 r / min and the centrifugation is performed for 10 to 30 min, cobalt salt is added into an obtained supernatant fluid, stirring is unceasingly performed for 20 to 30 min, and a solution A is obtained; a urea water solution with the concentration of 1-5 mol / L is dripped into a solution A, then the temperature is controlled to be 90 to 180 DEG C for reaction for 5 to 15 hours, an obtained reacting liquid is naturally cooled to be at the room temperature and then centrifugation is performed, after washing, precipitates are treated through vacuum drying, then under the protection of inert gas, and the temperature is risen at a speed of 1 DEG C / min and under the protection of inert gas to be 400 to 500 DEG C for calcination for 3 to 5 hours, that is, the nanometer cobalt oxide / graphene composite material is obtained. According to the preparation method provided by the invention, the reaction conditions are mild, oxidation of a strong oxidant is not used, the prepared graphene is less in defects, and the catalytic performance is improved greatly.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

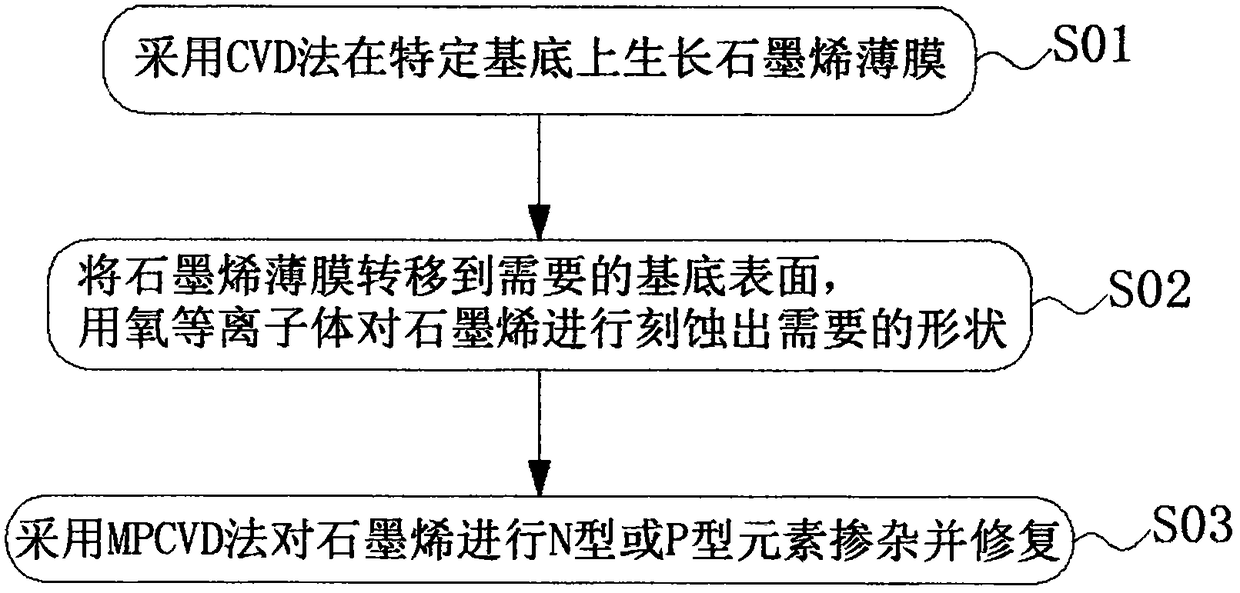

Doping preparation and repair method for graphene

The invention belongs to the field of semiconductor preparation and discloses a doping preparation and repair method for graphene. The method comprises the following steps: a graphene film grows on aspecific substrate with a CVD method; the graphene film is transferred to the surface of a required substrate, and graphene is etched in a required shape by oxygen plasma; N-type or P-type element doping is performed on graphene with an MPCVD method, and semiconductor graphene is repaired during doping. The prepared semiconductor graphene is applicable to wider substrates, concentration of dopingelements is controllable, part of graphene defects in a semiconductor can be overcome by repairing, a semiconductor graphene film with a certain area can be formed by flaky semiconductor graphene andhas lower impedance and shorter response time.

Owner:恒力(厦门)石墨烯科技产业集团有限公司

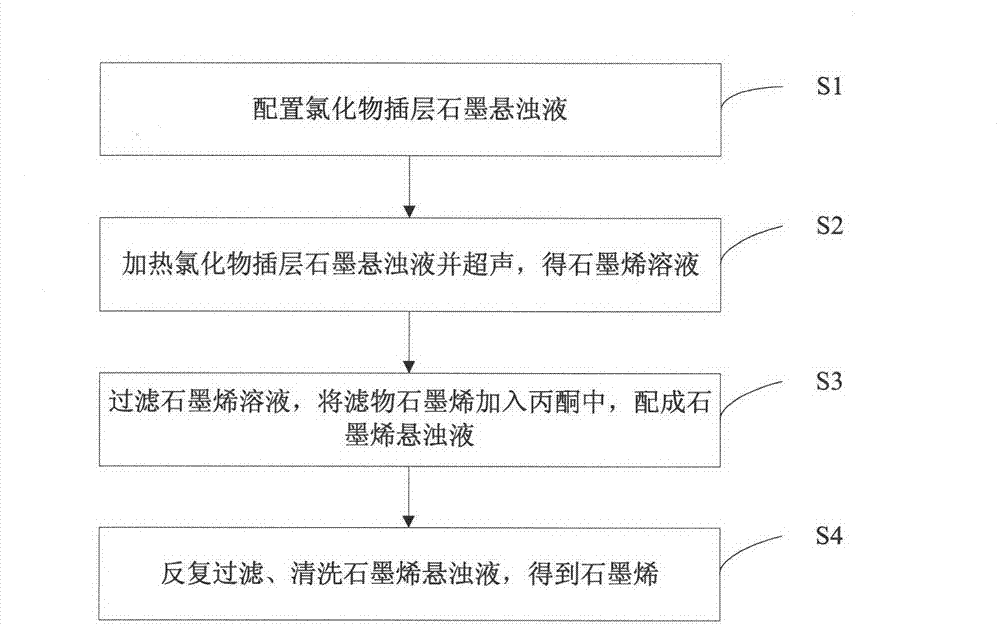

Preparation method of graphene

The invention belongs to the field of graphene, and discloses a preparation method of graphene, which comprises the following steps: preparing chloride intercalated graphite into a chloride intercalated graphite suspension; carrying out heating and ultrasonic treatment on the chloride intercalated graphite suspension to obtain a graphene; filtering the graphene solution, and preparing the filtered graphene and acetone into a graphene suspension; and carrying out ultrasonic and filtration treatment on the graphene suspension at room temperature, and removing chloride to obtain the graphene. By utilizing ultrasonic to strip the chloride intercalated graphite to prepare the graphene, the ultrasonic stripping method disclosed by the invention has the advantages of smaller number of layers of graphene, high yield, simple equipment, and simple and feasible operation, and can easily implement automatic and industrial production; and meanwhile, the graphene prepared by the ultrasonic stripping method has the advantages of fewer defects and complete crystal structure.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

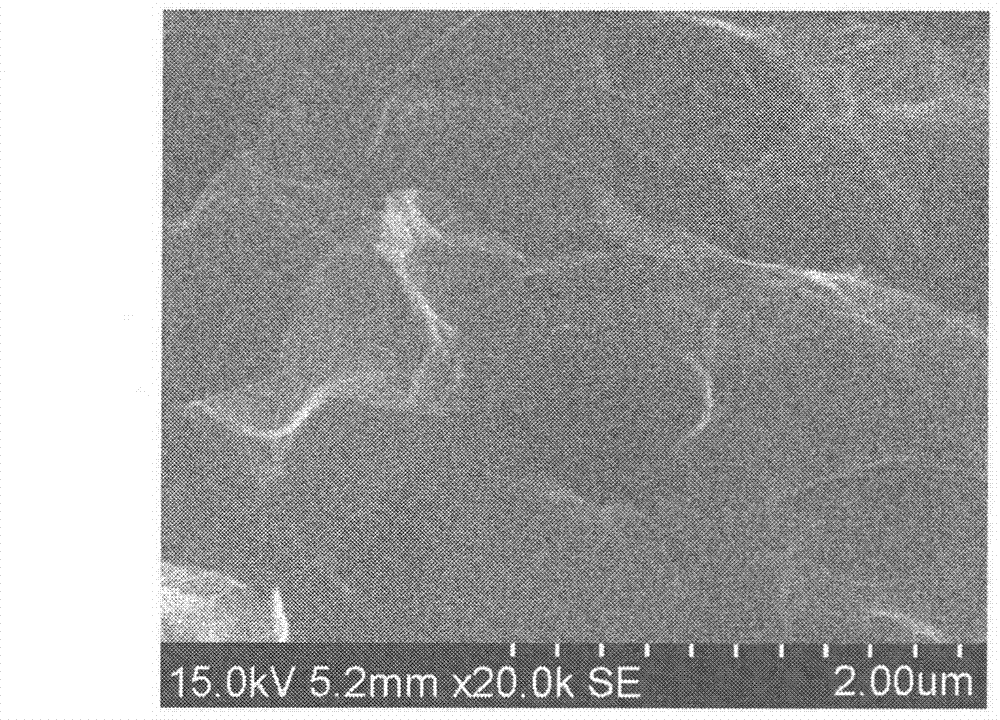

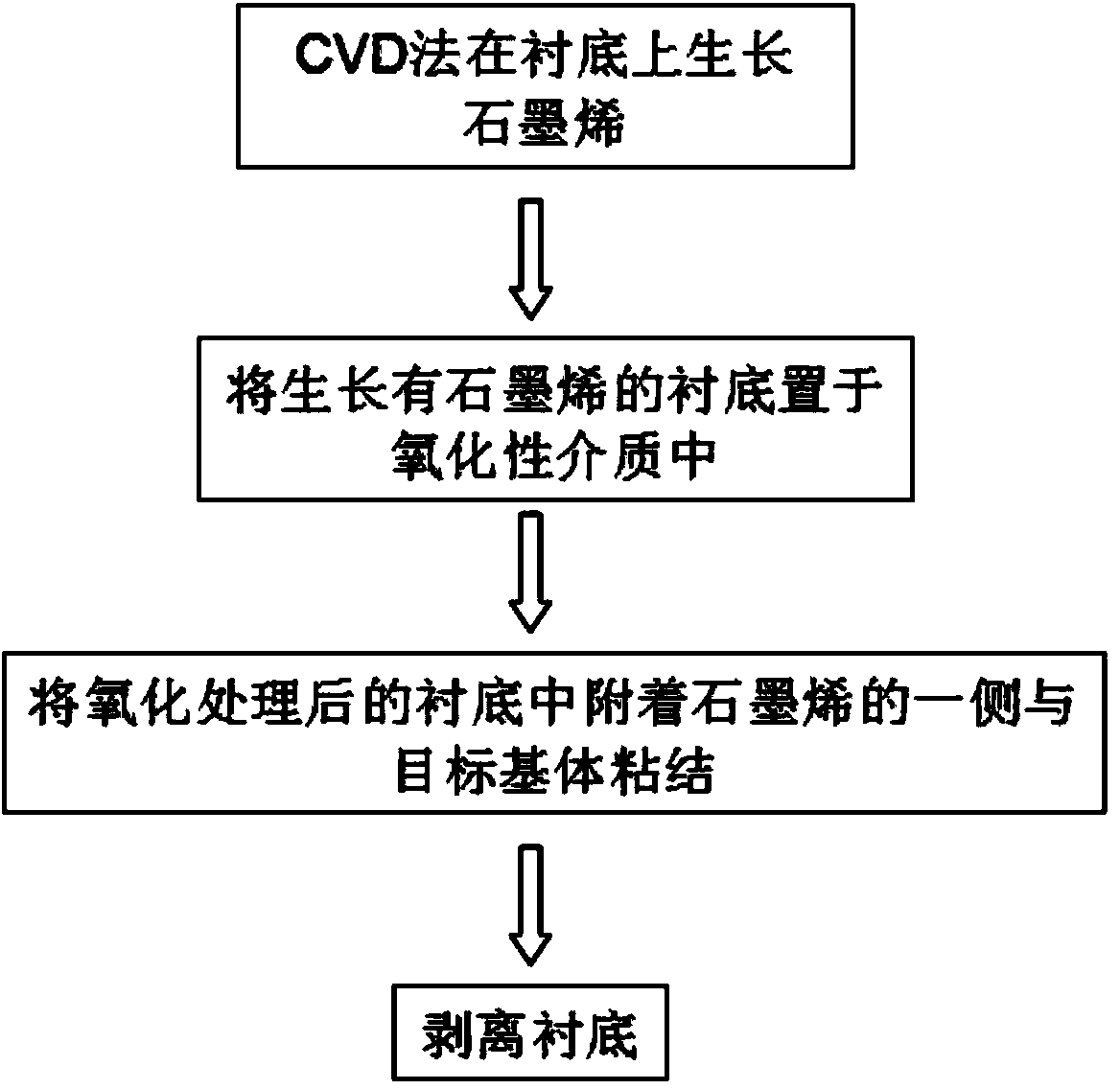

Graphene transfer method

The invention provides a graphene transfer method. The method comprises the following steps: 1, placing a substrate on which graphene is deposited in a medium containing oxidizing substances to be processed; 2, adhering one side, on which the graphene is deposited, of the substrate processed in the step 1 to a target matrix; 3, stripping off the substrate in a sample obtained in the step 2 so as to complete transfer of the graphene. According to the method provided by the invention, firstly, the substrate on which the graphene is deposited is placed in the oxidant to be processed, so that the interface bonding force between the graphene and the substrate is reduced, so that the graphene is easy to fall out of the surface of the substrate in the later period of stripping off the substrate, integrity of the graphene cannot be damaged, the graphene transferred to the target matrix is not damaged and the graphene has small defects.

Owner:宁波柔碳电子科技有限公司

Graphene and preparation method thereof

InactiveCN106365155AImprove conductivityReduce defectsGrapheneMaterials preparationDefective graphene

The present invention relates to the technical field of graphene material preparation, particularly to a graphene preparation method, which comprises: (1) mixing graphite and a liquid-phase medium, and mechanically stripping to obtain a mixture containing graphite and graphene; and (2) carrying out centrifugal separation on the mixture containing graphite and graphene, and collecting the graphene-containing supernatant. The present invention further discloses the graphene prepared through the method. According to the present invention, the prepared graphene has the good conductivity, wherein the highest conductivity can achieve 40000 S / m; with the method of the present invention, the structure of graphene cannot be destroyed, the integrity of the graphene lamina can be well maintained, and the Sp2 hybridization degree is high, ie., the defect of the prepared graphene is less; and the process is simple, the cost is reduced, and the preparation method is suitable for mass production.

Owner:北京中科云腾科技有限公司

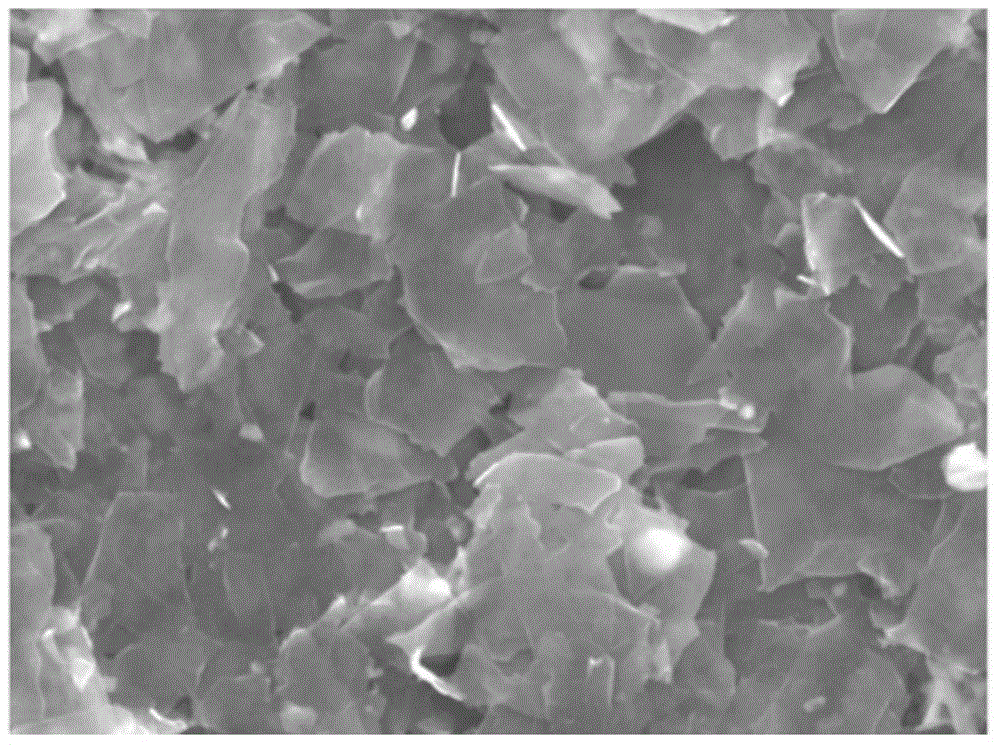

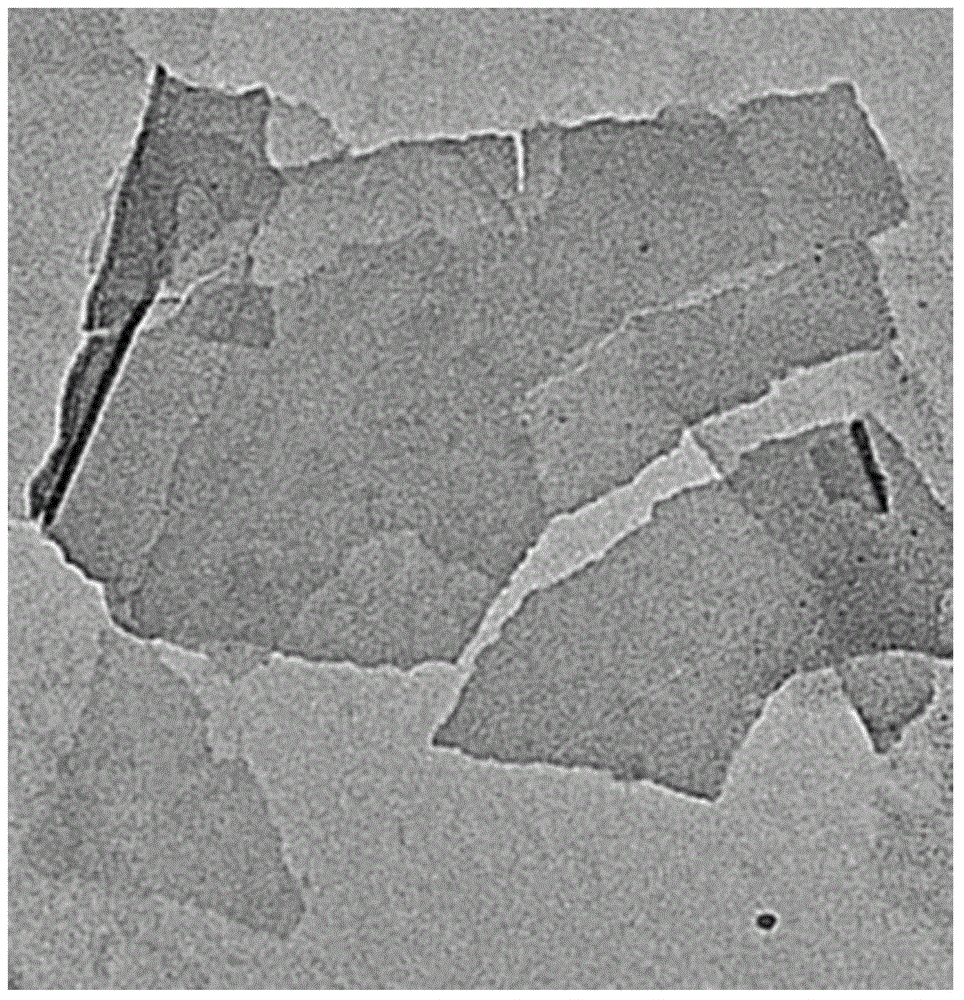

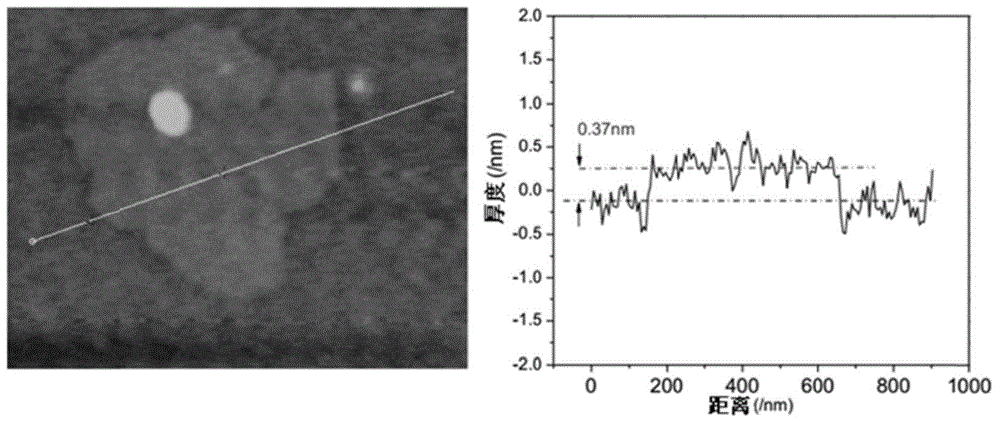

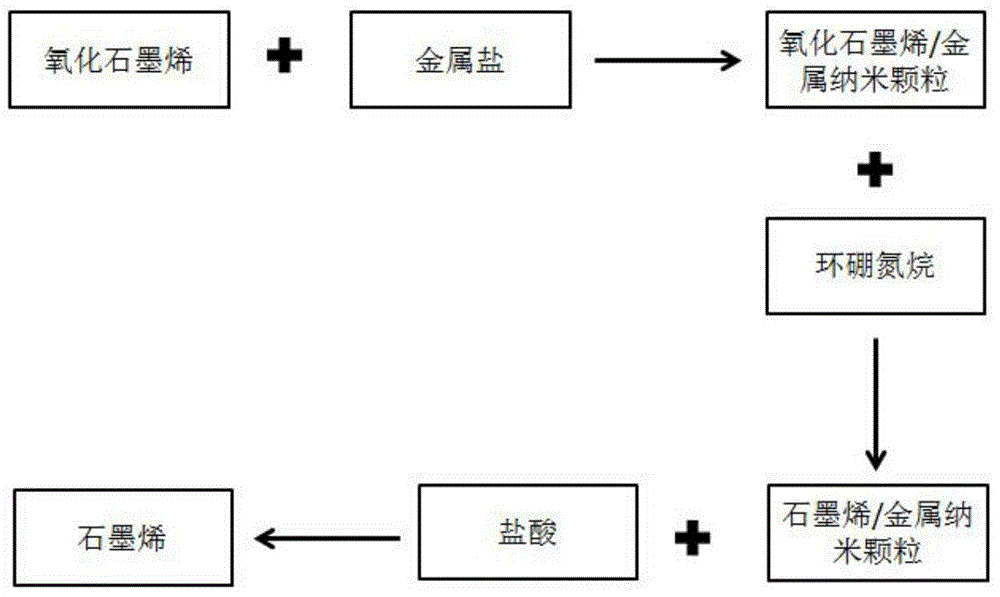

Method for catalytic reduction of graphene oxide

The invention provides a method for catalytic reduction of graphene oxide. The method comprises the following steps: firstly, adding a metal salt solution into a graphene oxide water solution based on a salting-out effect of the graphene oxide to form a cotton-like suspended substance; adding NH3BH3 and catalyzing hydrolysis of the NH3BH3 by utilizing reduced metal particles at room temperature so as to release nascent hydrogen atoms with high reducibility on the surface of the graphene oxide; reducing the graphene oxide by utilizing the hydrogen atoms; and finally removing the metal particles by means of acid washing to obtain graphene. The method disclosed by the invention is used for reducing the graphene oxide without using compounds such as hydrazine hydrate, derivatives of the hydrazine hydrate, hydrogen iodide and the like with high toxicity, high volatility and high corrosivity as a reducing agent and has the characteristics of being environment-friendly and safe; compared with a metal powder / hydrochloric acid reduction system, the method is relatively high in reduction efficiency; meanwhile, the method can be implemented at room temperature, the reaction condition is mild and generation of defects of the graphene during reduction is reduced.

Owner:JIANGSU UNIV OF SCI & TECH

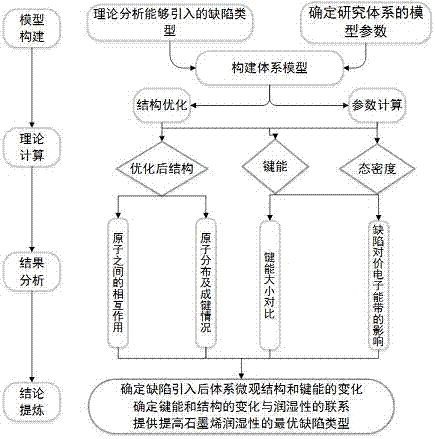

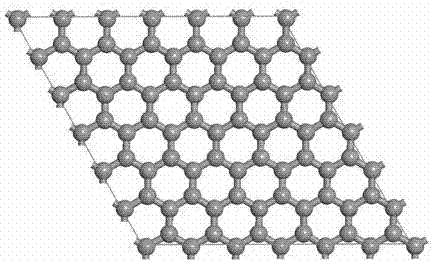

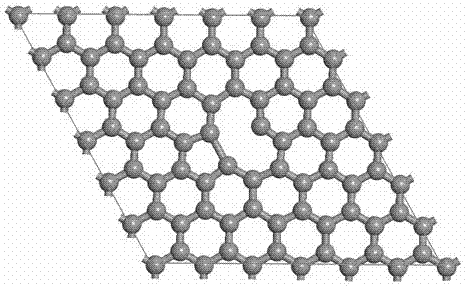

Method for predicting wettability between defect-introduced graphene and metal

ActiveCN107341301AReduce blindnessShorten the timeDesign optimisation/simulationSpecial data processing applicationsMetal clustersBond energy

The invention discloses a method for predicting wettability between defect-introduced graphene and metal. The method comprises the following step: based on a density functional theory of first principles, calculating the change of adsorption energy, bond energy and structures between graphene that is introduced with different types of defects and a metal cluster to predict the wettability between graphene and the metal cluster, wherein the defects introduced to graphene mainly include point defects, doped Ni defects and adsorption Ni defects. By separately calculating the change of the adsorption energy, the bond energy and the structure of graphene after being adsorbed with metal Cu13 clusters or Al13 clusters, the result shows that the introduction of graphene defects can improve the wettability between graphene and the metal, and particularly, the wettability between graphene doped with Ni atoms and the metal can be significantly improved. According to the method disclosed by the invention, the wettability between objects introduced with different defects and the metal can also be effectively predicted and analyzed according to the difference of the introduced defects or the difference of the objects introduced with the defects.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for preparing graphene through liquid phase chemical technology intercalation and graphite peeling

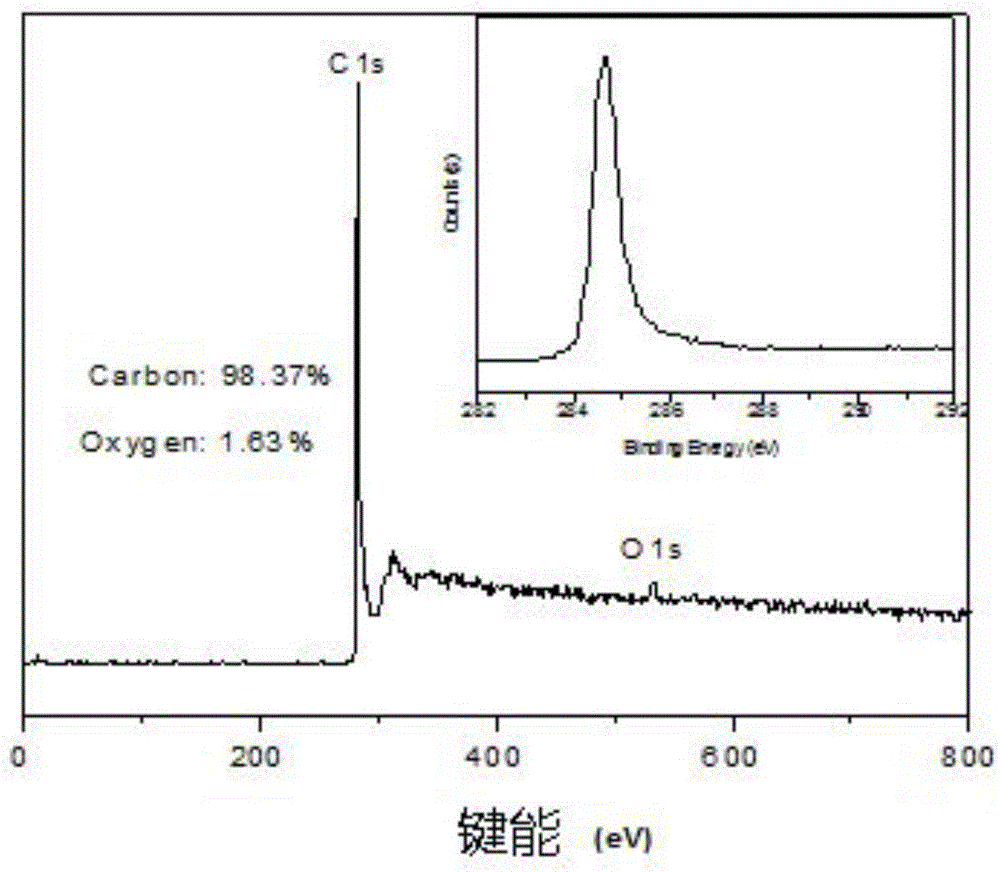

The invention provides a method for preparing graphene through liquid phase chemical technology intercalation and graphite peeling, and belongs to the technical field of graphene materials. The problems of complex technology, large energy consumption in the electrolysis process and high oxygen content of present graphene preparation methods are solved. The method comprises the following steps: immersing graphite in a mixed acid solution, adding an intercalator, stirring graphite, the mixed acid solution and the intercalator to obtain a mixed solution; and adding an organic reagent to the mixed solution, and reacting to obtain a water dispersion of graphene. A special reagent is used to carry out intercalation treatment, and a sharp chemical reaction is carried out to instantly gasify the reagent between graphite layers in order to peel graphite into graphene. The yield of graphene prepared through the method is extremely high, the weight of the obtained graphene is almost same to the weight of graphite, the graphene has extremely few defects, the oxygen content of the prepared graphene is 1.63% and is extremely low, and the conductivity of the graphene is high.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

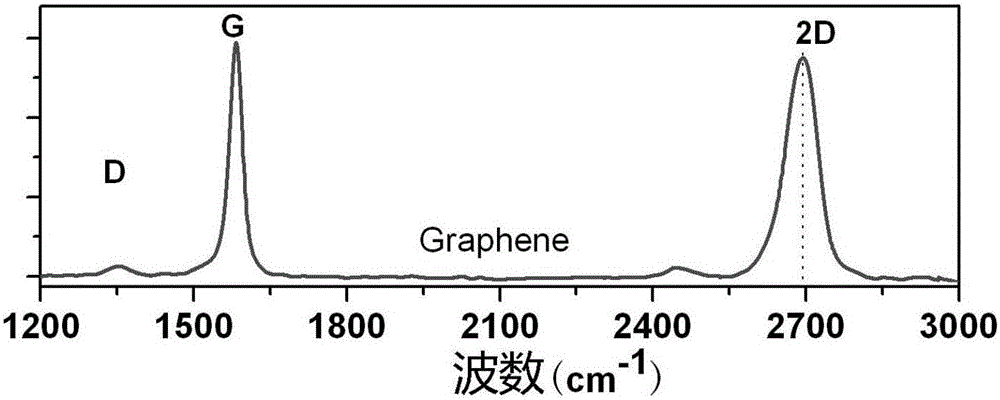

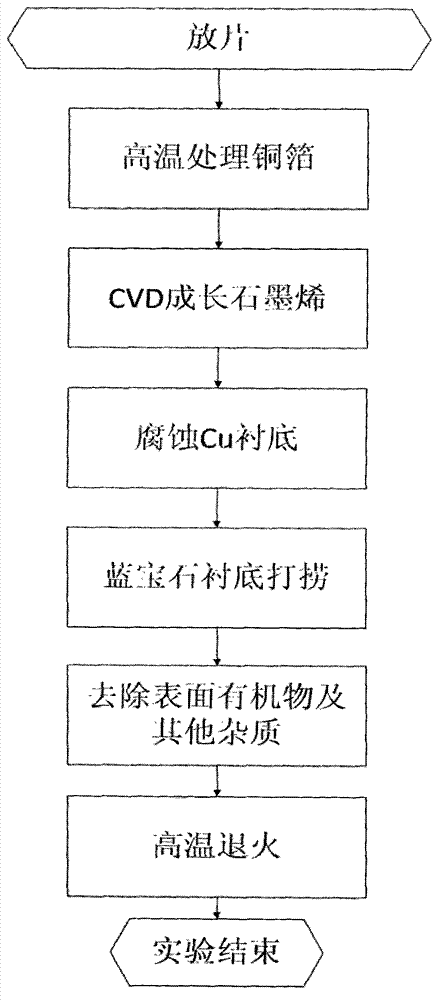

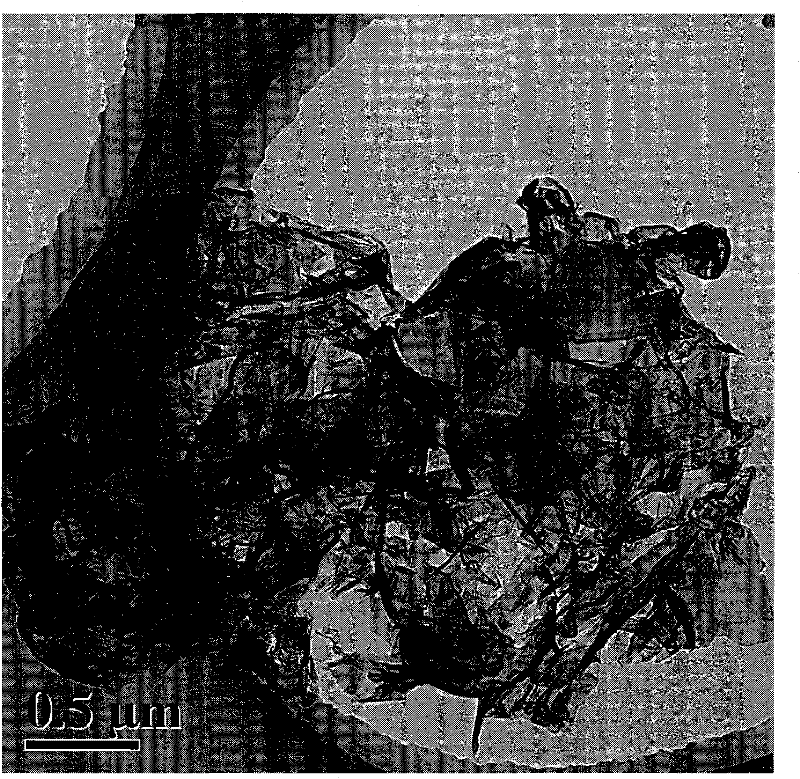

Annealing method of sapphire substrate transfer graphene

InactiveCN102931078AEliminate adverse effects of electrical propertiesEfficient removalSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDefective grapheneCvd graphene

The invention discloses an annealing method of sapphire substrate transfer graphene. By adopting a high-temperature annealing mode, graphene defect generated in a substrate transfer process is repaired, and impurities which can not be removed in a transfer process or are newly introduced are further removed. Meanwhile, the high-temperature annealing can ensure that the contact of the substrate and the graphene is improved, influence of a sapphire substrate to the graphene is effectively processed, electric properties of the graphene attached on the sapphire substrate are optimized, and finally, the surface of the transferred graphene is cleaner, the defects are less, and the flat graphene is in better contact with the SiC substrate.

Owner:XIDIAN UNIV

A kind of method for macroscopically preparing graphene

The invention discloses a method of macroscopic preparation of grapheme, characterized by that: product SiC polycrystalline powder is subject to thermal splitting to sublimate Si rapidly, and grapheme can be prepared through self-assembly of the obtained carbon species. The prepared grapheme has little defects and high oxidation resistance ability. By changing the particle size, type of crystals, heating rate, degree of vacuum of the system and the reaction atmosphere, the dimension, thickness, regularity, shape and types of function groups of the prepared grapheme can be regulated and controlled. The method has the advantages of simple and easiness in operation and control.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

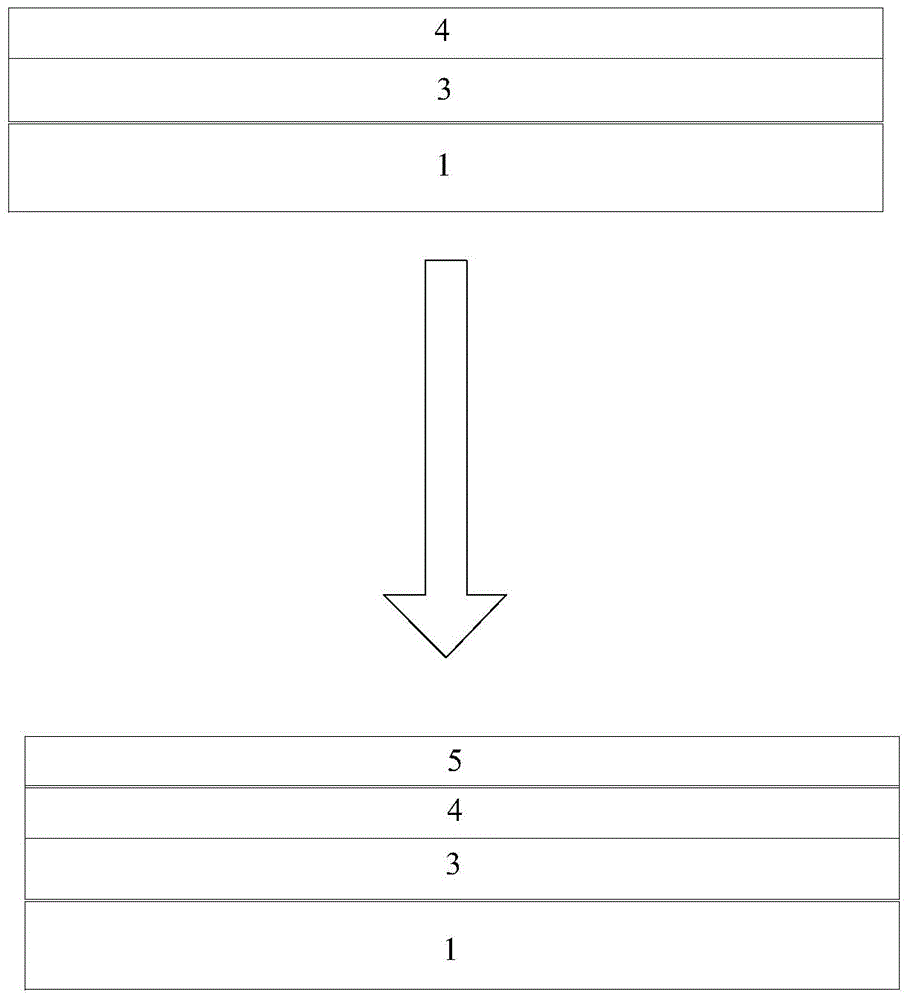

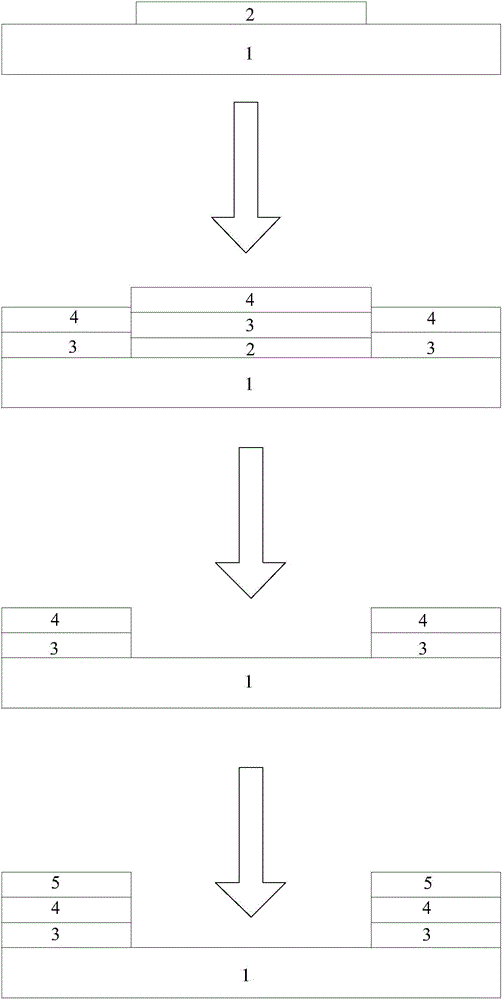

Silicon composite negative electrode material of lithium ion battery, preparation method thereof and lithium ion battery

InactiveCN110581260AImprove the first Coulombic efficiencyHigh capacity retentionMaterial nanotechnologyCell electrodesDefective grapheneLithium-ion battery

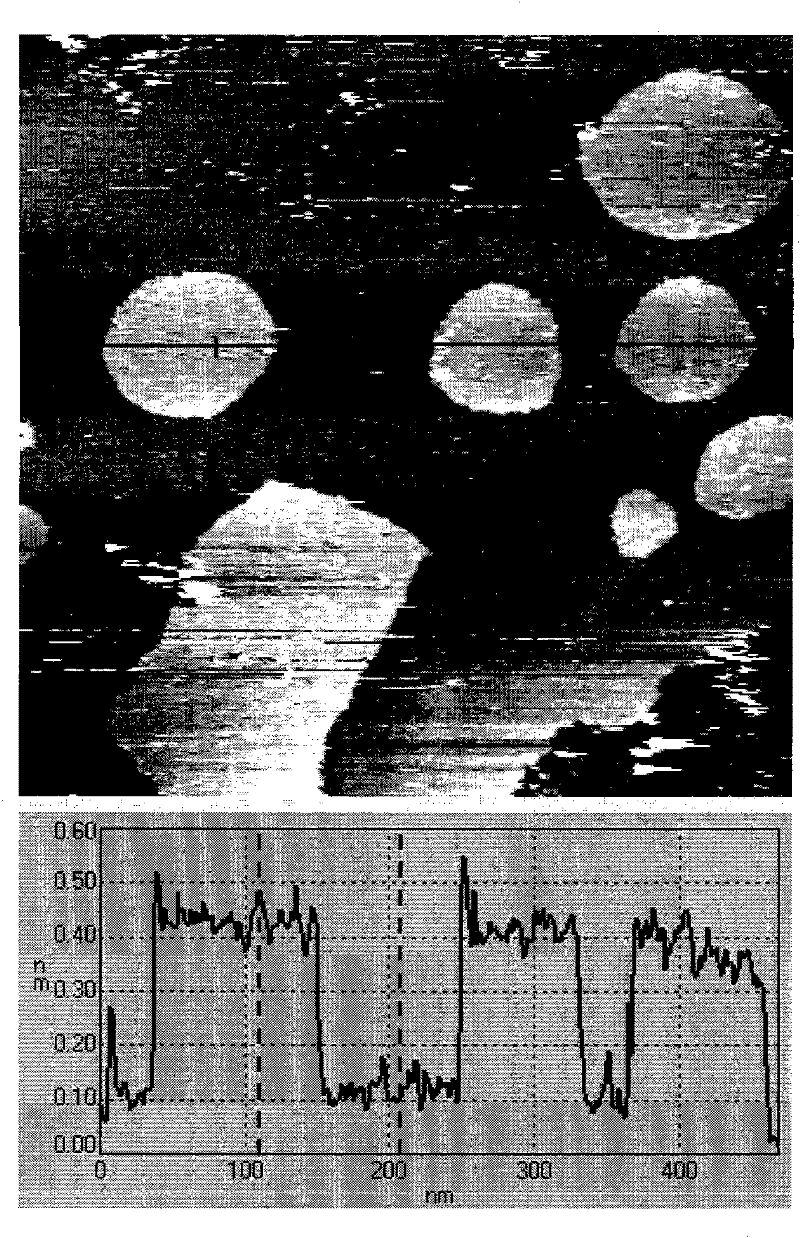

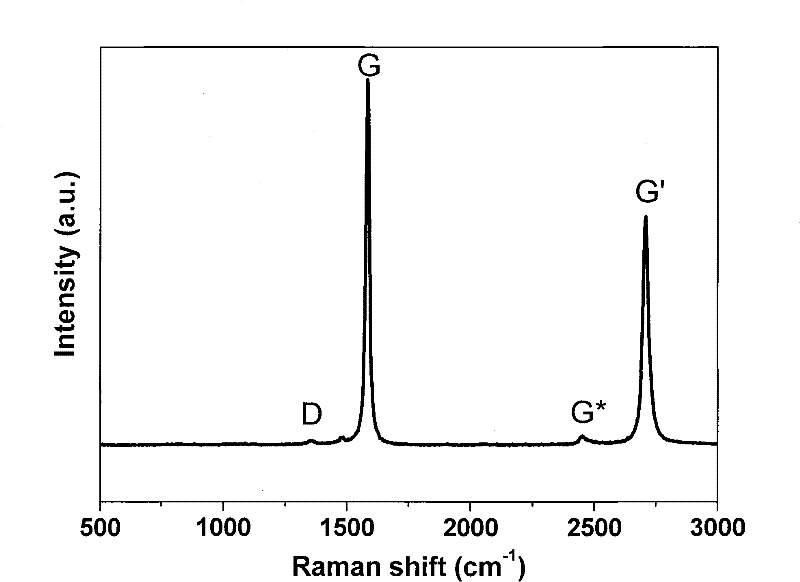

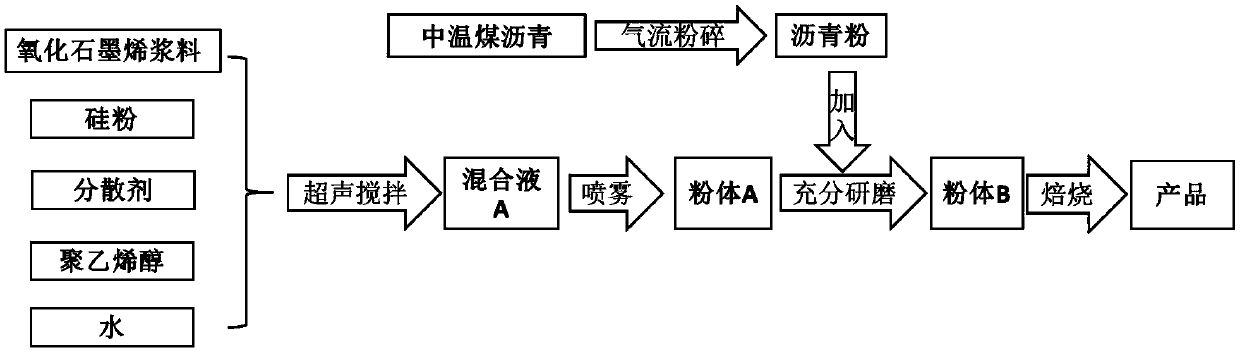

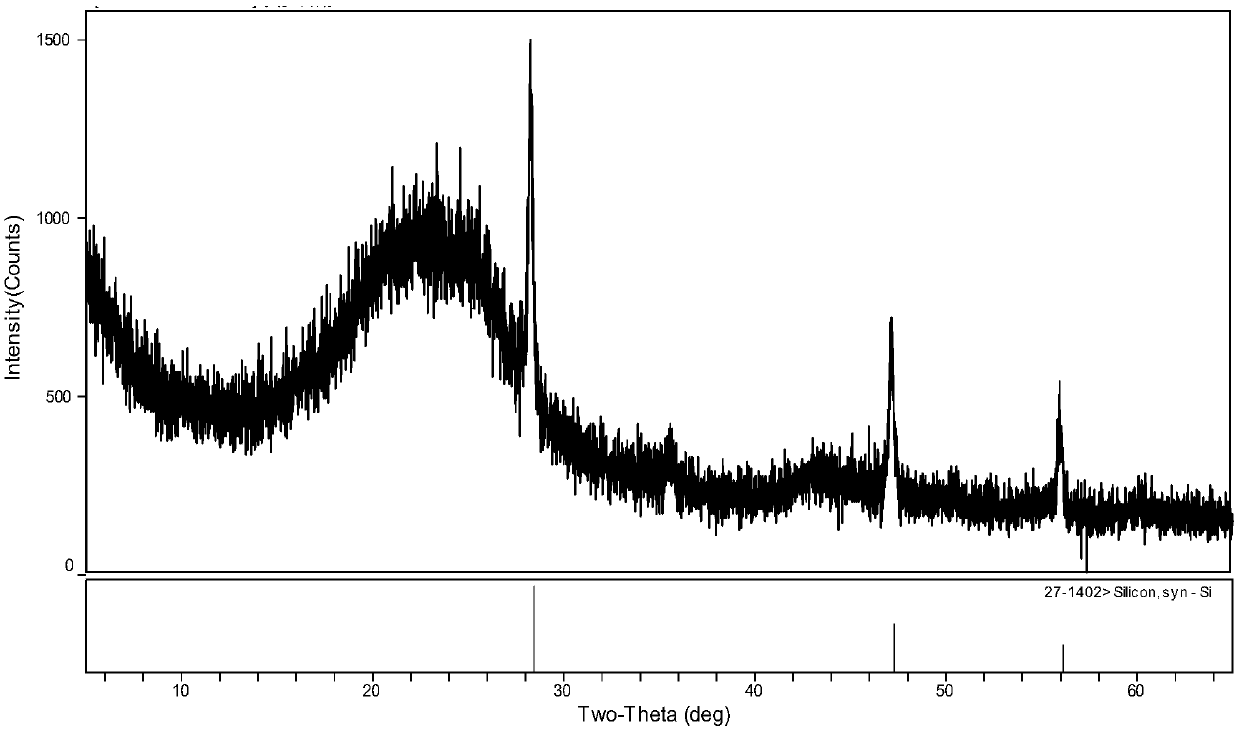

The invention provides a silicon composite negative electrode material, which comprises nanometer silicon secondary particles, a graphene layer and amorphous carbon, wherein the graphene and the nanometer silicon secondary particles have a core-shell structure, the graphene layer is a shell, and the nanometer silicon secondary particles are a core; gaps are formed between the graphene layer and the nanometer silicon secondary particles; and the amorphous carbon is filled in the vacancy of the graphene layer. According to the invention, the structure of the silicon composite negative electrodematerial is improved, and especially the gaps are reserved between the graphene layer and the nanometer silicon secondary particles, so that a space is reserved for expansion of the silicon material in the charging and discharging process. Meanwhile, amorphous carbon is obtained by roasting a specific carbon source, so that defects of the graphene are effectively compensated, the gaps can be effectively filled, and expansion failure in the later charging and discharging process is prevented. In addition, the preparation method of the silicon composite negative electrode material provided by the invention is simple and easy to implement, and has a prospect of large-scale application.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Graphene/Cu/Ni composite electrode and preparation method thereof

ActiveCN104681801AReduce the numberAvoid destructionCell electrodesComposite electrodeDefective graphene

The invention discloses a graphene / Cu / Ni composite electrode and a preparation method thereof. The composite electrode comprises a Cu / Ni alloy layer and a graphene film covering the Cu / Ni alloy layer, wherein the Cu / Ni alloy layer is formed by mutual diffusion of Ni atoms and Cu atoms of an Ni film and a Cu film covering the Ni film, and the thickness ratio of the Ni film to the Cu film is in a range of 1:(3-10). According to the graphene / Cu / Ni composite electrode and the preparation method thereof, damage caused by a graphene transfer process and a graphical process to the quality of graphene is avoided, the number of graphene defects is decreased, thicknesses of the Ni film and the Cu film are adjusted, a temperature-gradient CVD (chemical vapor deposition) technology is adopted, the high-quality graphene is obtained, the protection capability of the graphene to a Cu / Ni alloy is enhanced, and the obtained composite electrode has the excellent corrosion resistance.

Owner:HUAZHONG UNIV OF SCI & TECH

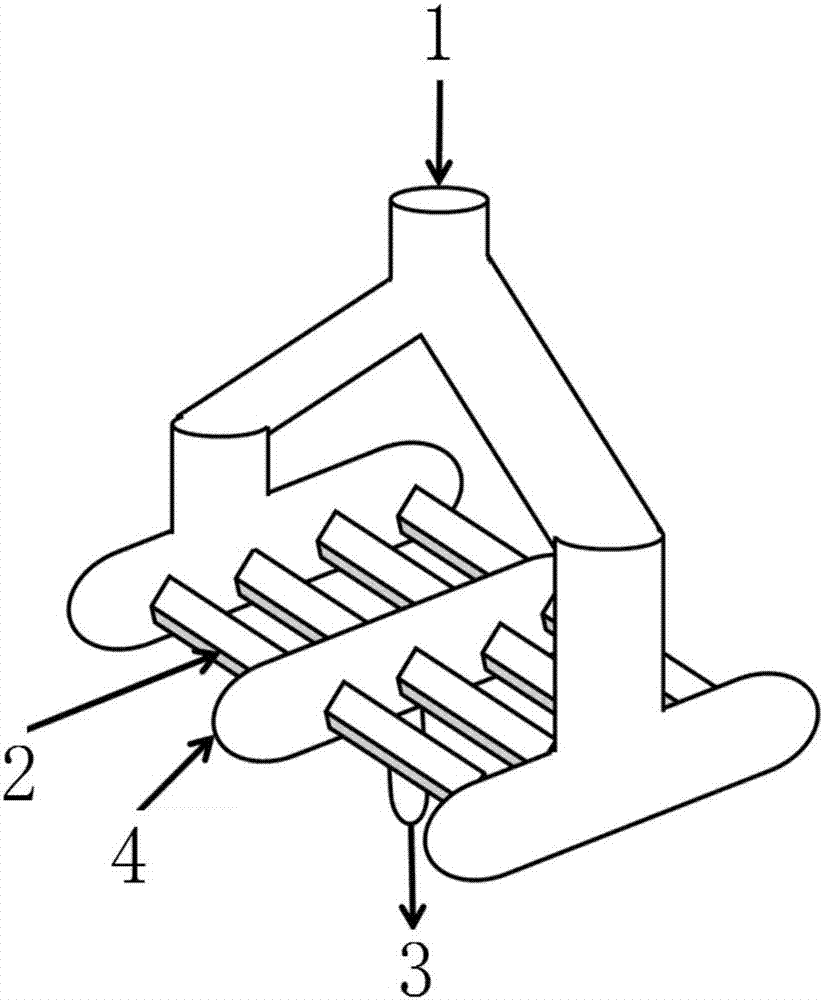

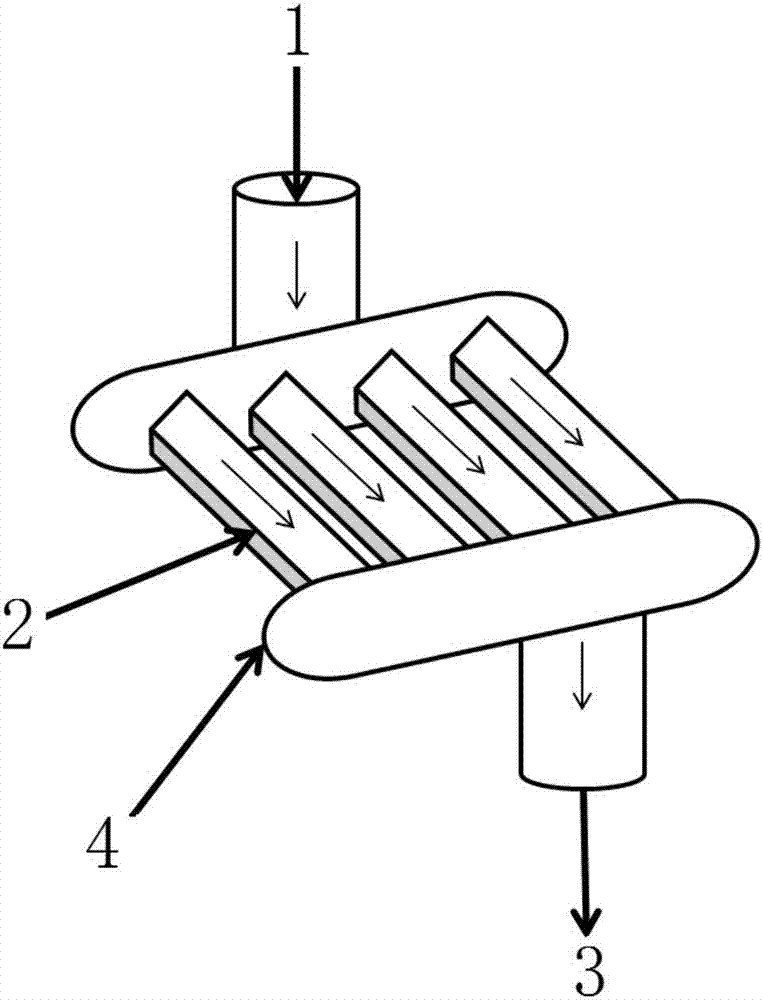

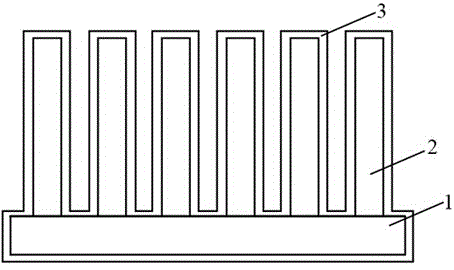

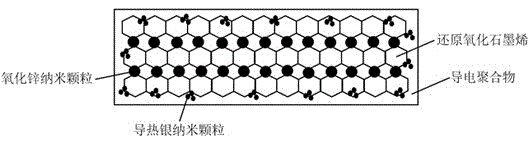

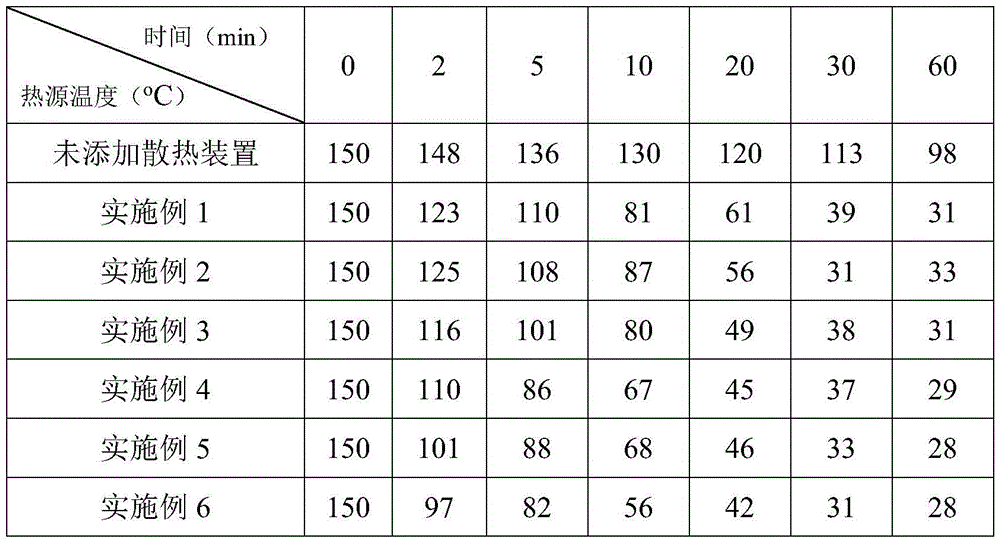

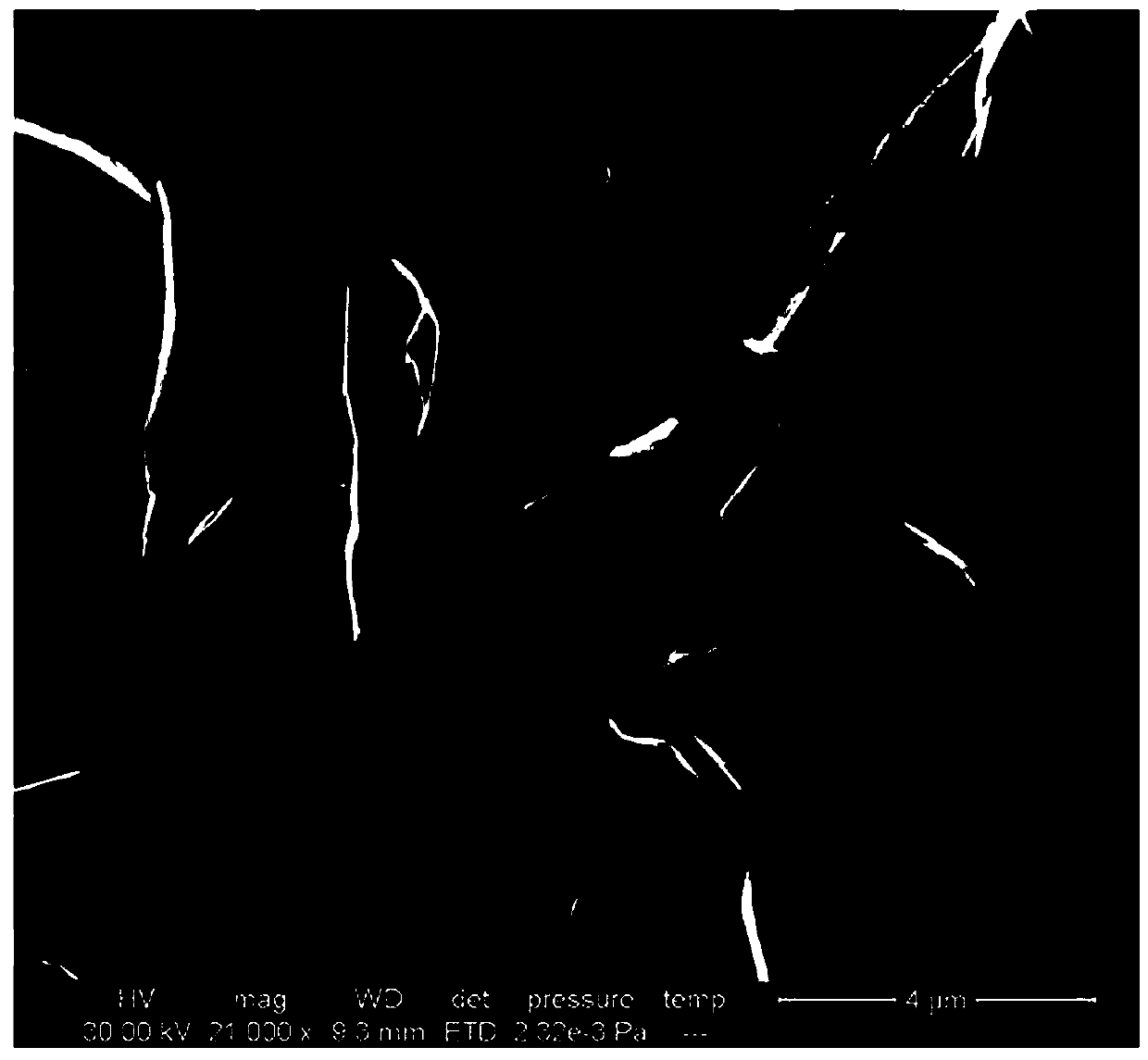

Radiator for laser display and preparation method of radiator

ActiveCN105679725ALarge specific surface areaSmall sizeSemiconductor/solid-state device detailsSolid-state devicesDefective grapheneHeat conducting

The invention discloses a radiator for laser display and a preparation method of the radiator. The radiator comprises a heat-conducting substrate (1), radiating fins (2) and an ultra-thin composite heat-conducting coating (3), wherein the ultra-thin composite heat-conducting coating is formed by combination of reduced graphene oxide, heat-conducting silver nanoparticles, zinc oxide nanoparticles and a conductive polymer at a certain ratio. The zinc oxide nanoparticles are doped into the reduced graphene oxide; a zinc oxide-graphene composite porous structure is formed through high-temperature reaction; the specific surface area of a film is increased; the radiator has super-high heat conductivity and radiating performance; meanwhile, graphene defects in the film are filled with the doped small-size heat-conducting silver nanoparticles; and the film has a uniform heat-conducting effect; the conductive polymer is doped, so that the viscosity of a heat-conducting film raw material solution is improved; the interface compatibility of the heat-conducting film and the heat-conducting substrate is improved; the film is relatively good in flatness after being prepared; and match with a heat source is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

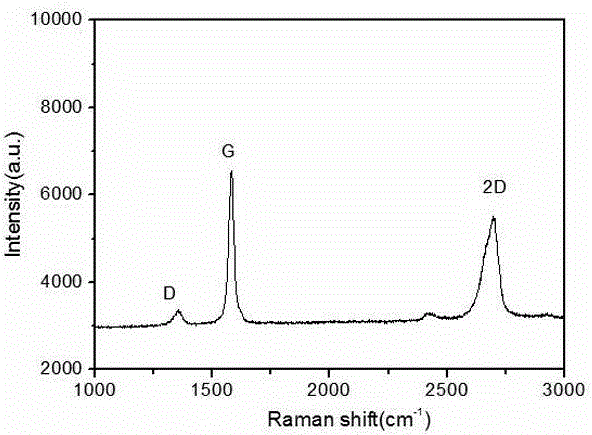

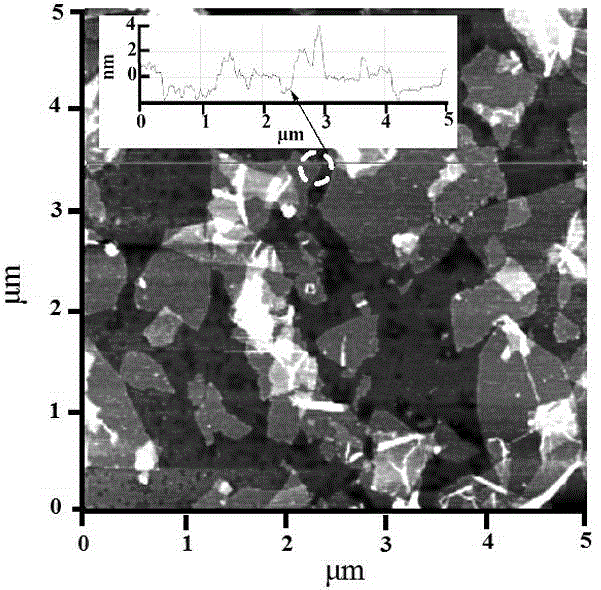

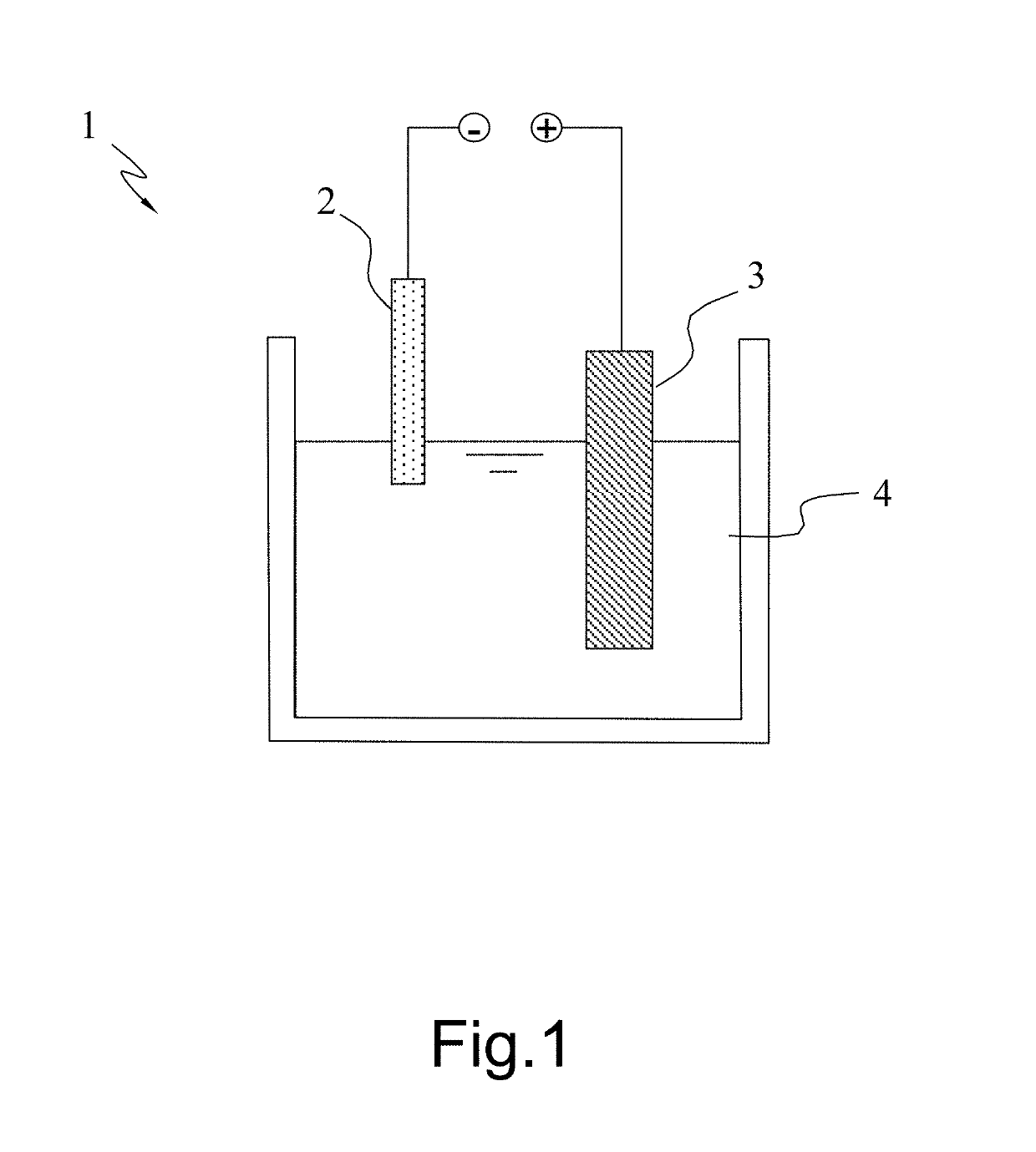

Method for preparing graphene from electrochemical cathode striped graphite foil with TTAB (Tetradecyl Trimethyl Ammonium Bromide) as electrolyte

InactiveCN107902647AEasy to operateRaw materials are easy to obtainGrapheneDefective grapheneFreeze-drying

The invention discloses a method for preparing graphene from electrochemical cathode striped graphite foil with TTAB (Tetradecyl Trimethyl Ammonium Bromide) as electrolyte. The method is characterizedby comprising the following steps: 1) preparing materials; 2) preparing an electric striping solution; 3) assembling an electric stripping device; 4) performing electric stripping; 5) performing filtration and washing; 6) performing ultrasonic dispersion; and 7) performing freeze drying on the obtained graphene solution, thereby obtaining graphene powder. The method has the advantages of being simple and easy in preparation raw material obtaining, easy in operation, low in cost, simple in process, simple in step and short in production period, and the prepared graphene is low in defect degree, small in layer number and very applicable to industrial production.

Owner:GUANGXI NORMAL UNIV

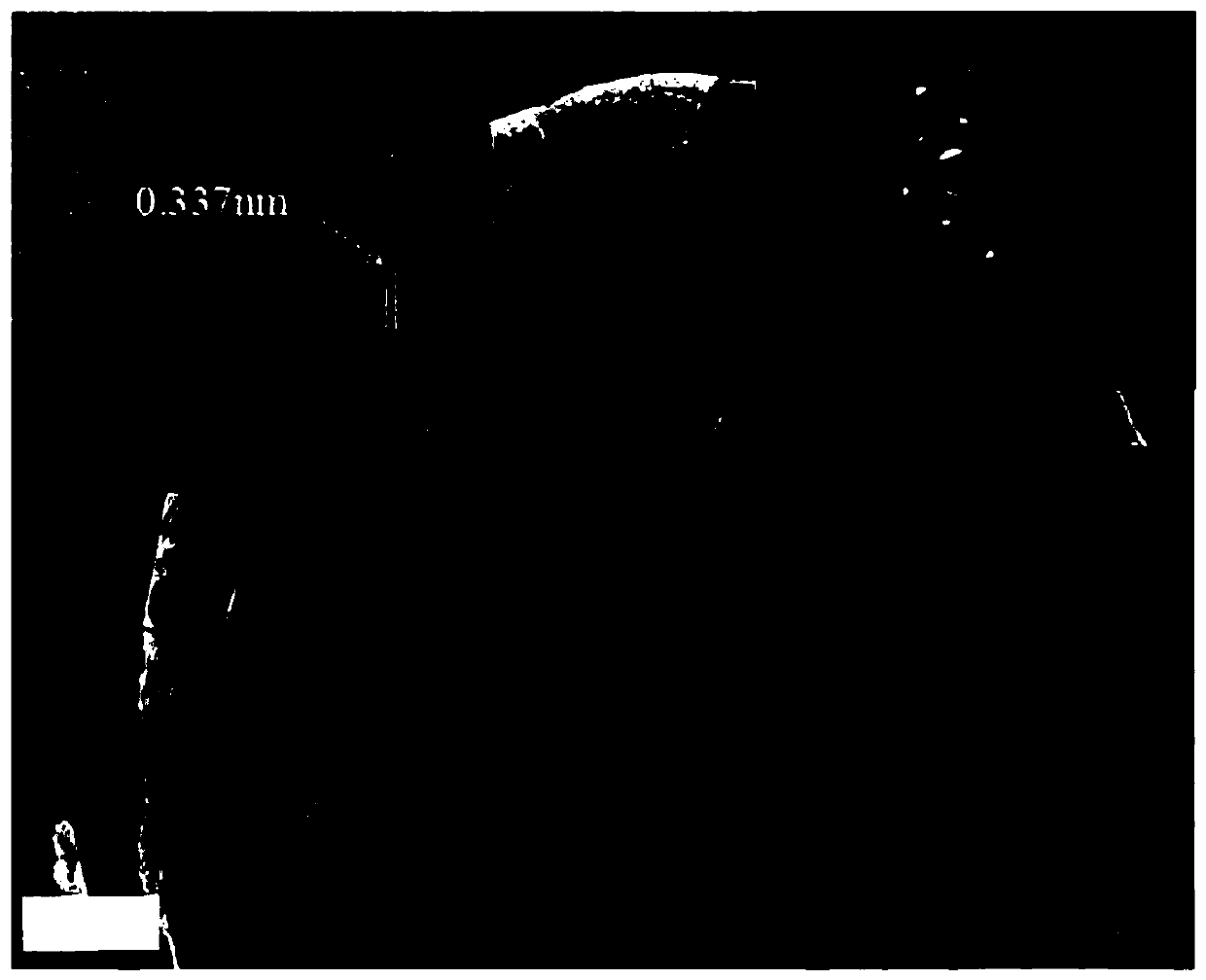

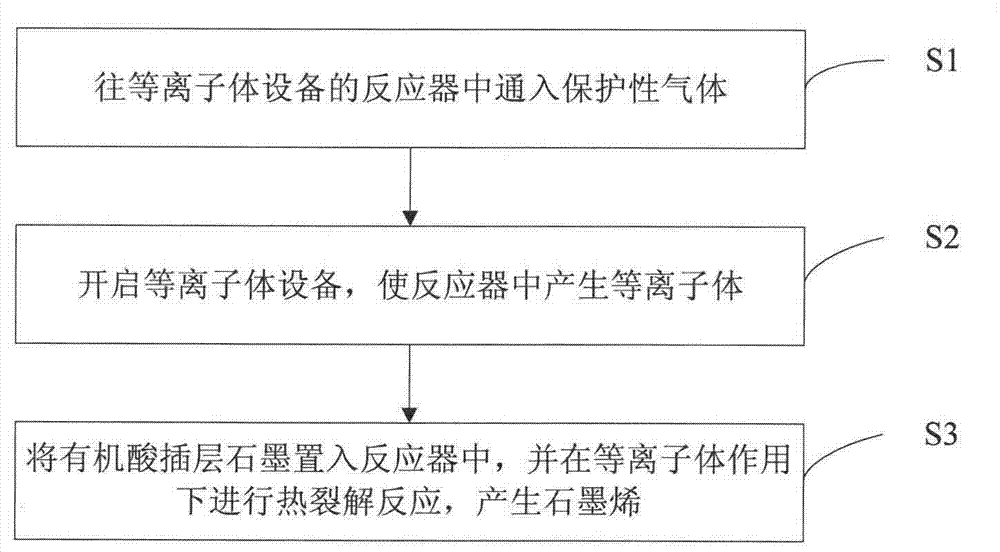

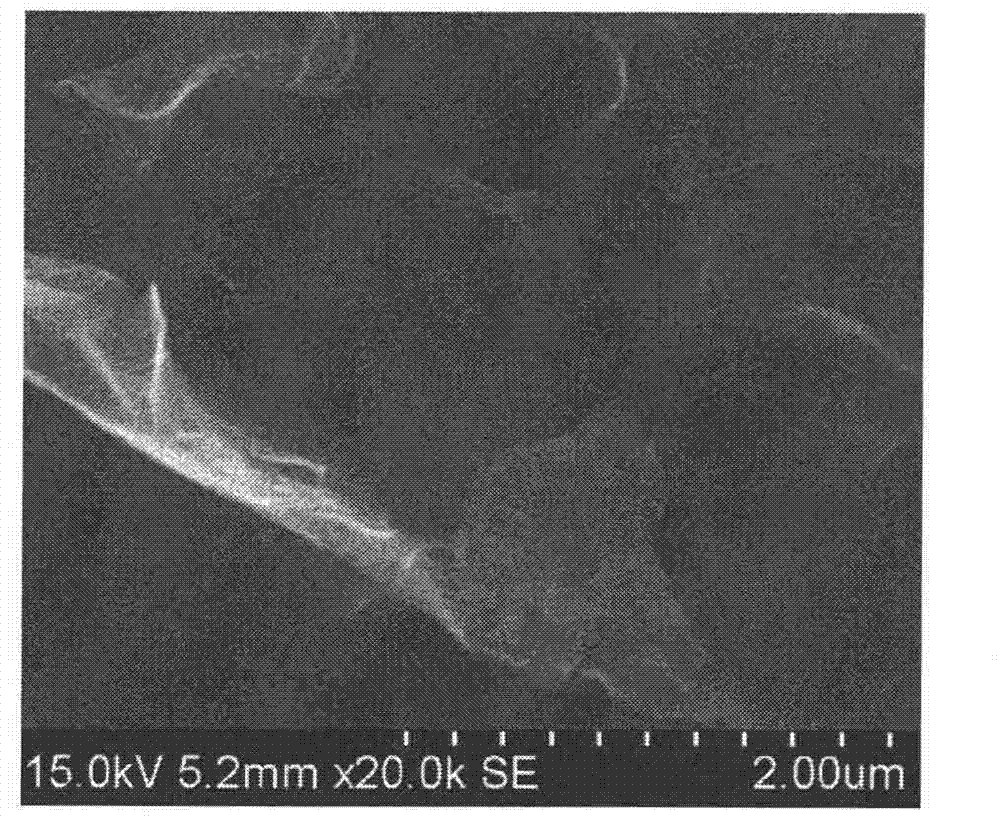

Preparation method of graphene

InactiveCN103359713AReduce defectsCrystal structure intactGrapheneDefective grapheneCrystal structure

The invention belongs to the field of graphene, and discloses a preparation method of graphene, which comprises the following steps: introducing protective gas into a reactor of plasma equipment; starting the plasma equipment to generate plasma in the reactor; and adding organic acid intercalated graphite into a reactor, and carrying out pyrolysis reaction under the action of plasma to obtain the graphene. By using the method for preparing the graphene by quickly pyrolyzing organic acid intercalated graphite, the prepared graphene has the advantages of fewer defects and complete crystal structure, and is free of sulfur, chlorine and other corrosive elements; and meanwhile, the invention has the advantages of favorable stripping effect, centralized number of layers, simple equipment, and simple and feasible operation, and can easily implement automatic and industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

High-conductivity graphene preparing method

The invention relates to a graphene preparing method, in particular to a high-conductivity graphene preparing method. The method is used for solving the problems that according to an existing preparing method, low-cost batched production can be difficultly achieved on the graphene with the stable performance and high conductivity, many steps exist, and factors influencing the product stability in the preparing process are multiple and complex. According to the scheme, the method includes the steps that firstly, expansible graphite is heated, and the expanded graphite is prepared; secondly, the expanded graphite is stripped off under the double action of organic matter with low surface tension and ultrasounds, impurities are removed through secondary centrifugation, secondary centrifugation sediment is dried, and high-conductivity graphene is obtained. The high-conductivity graphene preparing method has the advantages that the expanded graphite is stripped off under the double action of the organic solvent with the low surface tension and the ultrasounds, a redox reaction does not exist, impurities are not introduced, and compared with a traditional chemical preparing method, the generated graphene is few in defect, few in layer and higher in conductivity; a special device is not needed, the preparing method is simple and convenient, the stability of the performance of the prepared graphene is good, the performance is good, and industrial production is facilitated.

Owner:ZHONGBEI UNIV

Graphite composite conductive bar material and method for producing graphene using the same

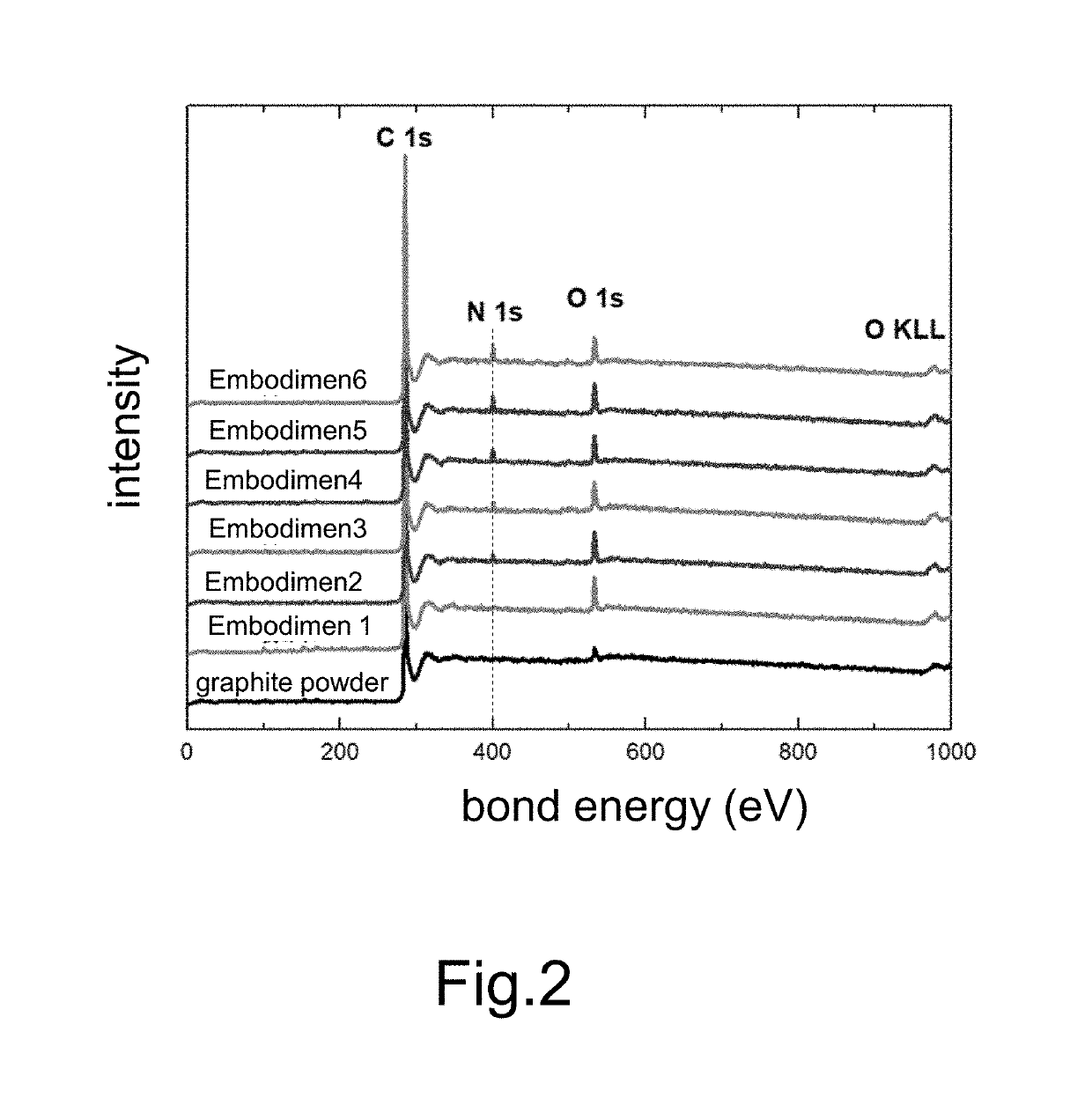

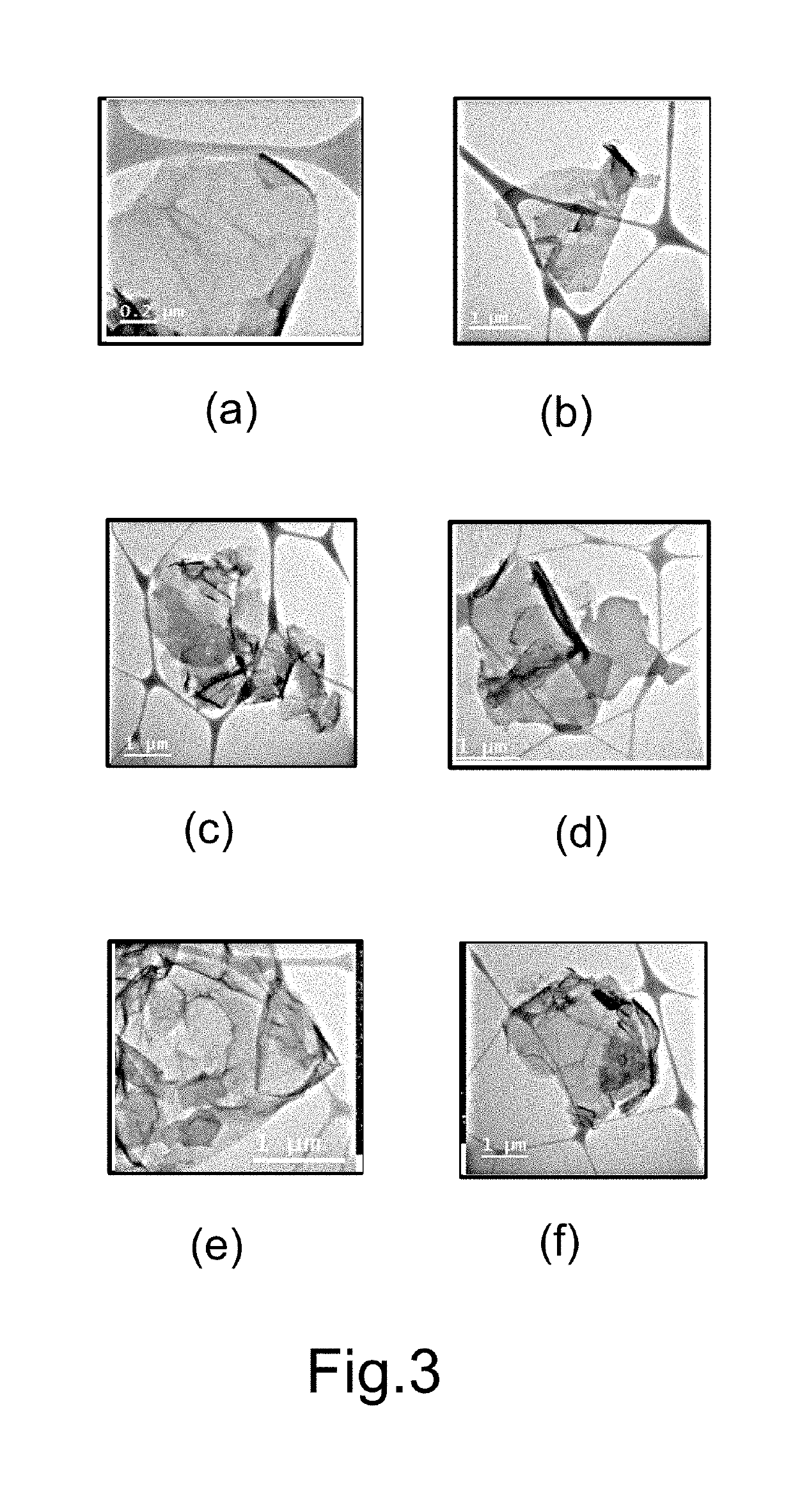

InactiveUS20190330065A1Less defectiveIncrease productionMaterial nanotechnologyGrapheneDefective grapheneNitrogen

A graphite composite conductive bar material and a method for producing graphene using the same are provided. The graphite composite conductive bar material is fabricated via mixing graphite powder more than 50% by weight with a polymeric material. The graphite composite conductive bar is used in a plasma electrochemical exfoliation process as a cathode and contacts with the surface of the electrolytic solution, whereby the bar material is exfoliated to obtain a less defective graphene. Therefore, the present invention can improve product yield and reduce production cost. In addition, a solid-state nitrogen-containing precursor may be added to the graphite composite conductive bar material for producing nitrogen-doped graphene. In the nitrogen-doped graphene produced by the present invention, the amount of doped nitrogen is increased and tunable compared to the former invention, and the level of oxidization is decreased.

Owner:NAT CHIAO TUNG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com