Graphene and preparation method thereof and lithium ion battery

A lithium-ion battery and graphene technology, applied in the field of electrochemistry, can solve the problem of low energy storage capacity, and achieve the effects of simple preparation process, easy mass production, and high energy storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

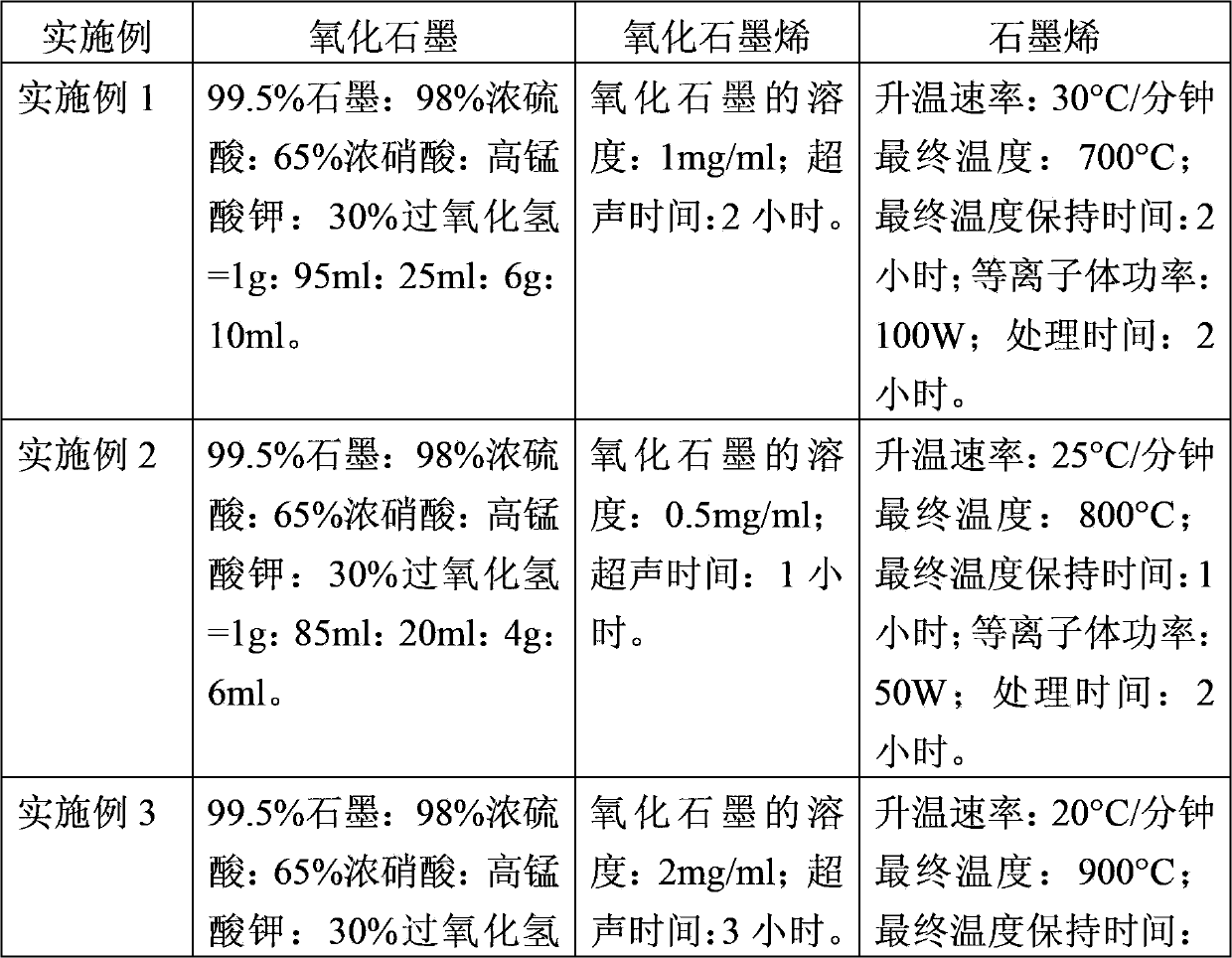

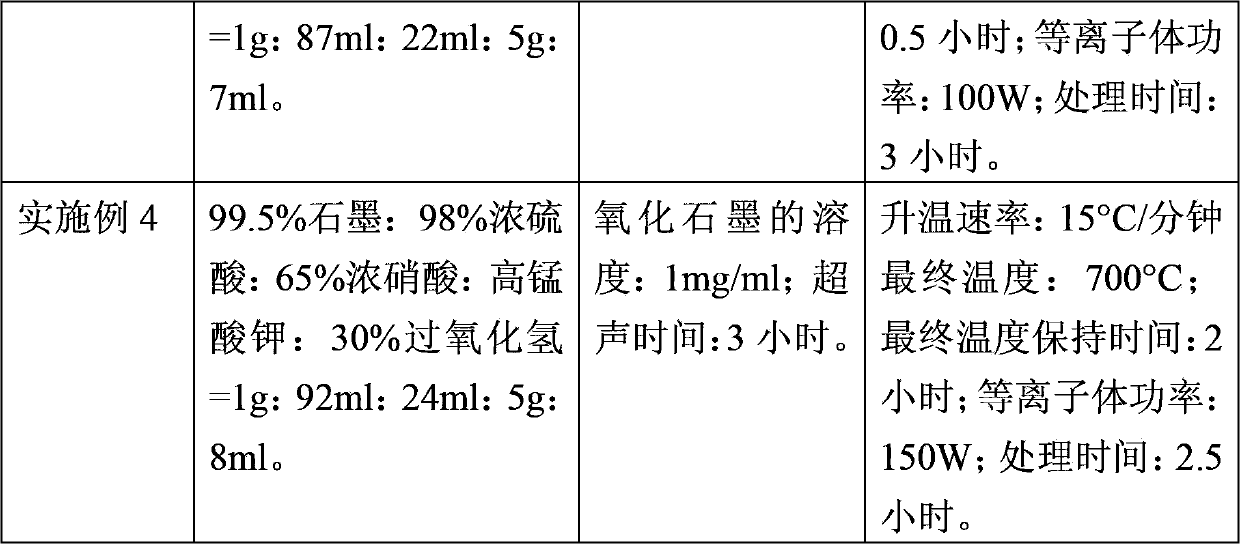

[0018] Preparation of graphene: the specific preparation process flow of graphene of the present invention is as follows: graphite→graphite oxide→graphene oxide→graphene.

[0019] In the present invention, the preparation process of graphene is roughly divided into the following steps.

[0020] (1) Preparation of graphite oxide: adding graphite with a purity of 99.5% to a mixed solution composed of concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 65%, adding permanganic acid to the mixed solution after stirring Potassium is heated and oxidized, and then 30% mass fraction of hydrogen peroxide solution is added to stir to remove potassium permanganate, then the mixed solution is suction-filtered, and then the suction-filtered product is washed and dried with dilute hydrochloric acid and deionized water in turn. Graphite oxide was obtained, and graphite oxide was dried in a vacuum oven at 60° C., and the drying time was 1...

Embodiment 1

[0031] Embodiment 1: The preparation method in Embodiment 1 of the present invention includes the following steps.

[0032] (1) Preparation of graphite oxide: 1 g of graphite with a purity of 99.5% is added to a mixed solution consisting of 95 ml of concentrated sulfuric acid (98% by mass fraction) and 25 ml of concentrated nitric acid (65% by mass fraction), and the mixture is placed on ice Under the water mixing bath environment, stir for 20 minutes, then slowly add 6g of potassium permanganate to the mixture, stir for 1 hour, then heat the mixture to 85°C and keep it for 30 minutes, then add 92ml of deionized water and continue to stir at 85°C Keep at ℃ for 30 minutes, finally add 10ml hydrogen peroxide solution (mass fraction 30%), stir for 10 minutes, filter the mixture with suction, then wash the solids with 100ml dilute hydrochloric acid and 150ml deionized water successively, and finally The solid matter was dried in a vacuum oven at 60°C for 12 hours to obtain graphit...

Embodiment 2

[0035] Embodiment 2: The preparation method in Embodiment 2 of the present invention includes the following steps.

[0036](1) Preparation of graphite oxide: 1 g of graphite with a purity of 99.5% is added to a mixed solution consisting of 85 ml of concentrated sulfuric acid (98% by mass fraction) and 20 ml of concentrated nitric acid (65% by mass fraction), and the mixture is placed on ice Under the water mixing bath environment, stir for 20 minutes, then slowly add 4g of potassium permanganate to the mixture, stir for 1 hour, then the mixture is heated to 85°C and kept for 30 minutes, then add 92ml of deionized water and continue at 85 Keep at ℃ for 30 minutes, finally add 6ml of hydrogen peroxide solution (mass fraction 30%), stir for 10 minutes, filter the mixture with suction, then wash the solids with 100ml of dilute hydrochloric acid and 150ml of deionized water successively, and finally The solid matter was dried in a vacuum oven at 60°C for 12 hours to obtain graphite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com