Patents

Literature

2013results about How to "Not easy to corrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engineering oil pipe surface paint spraying device

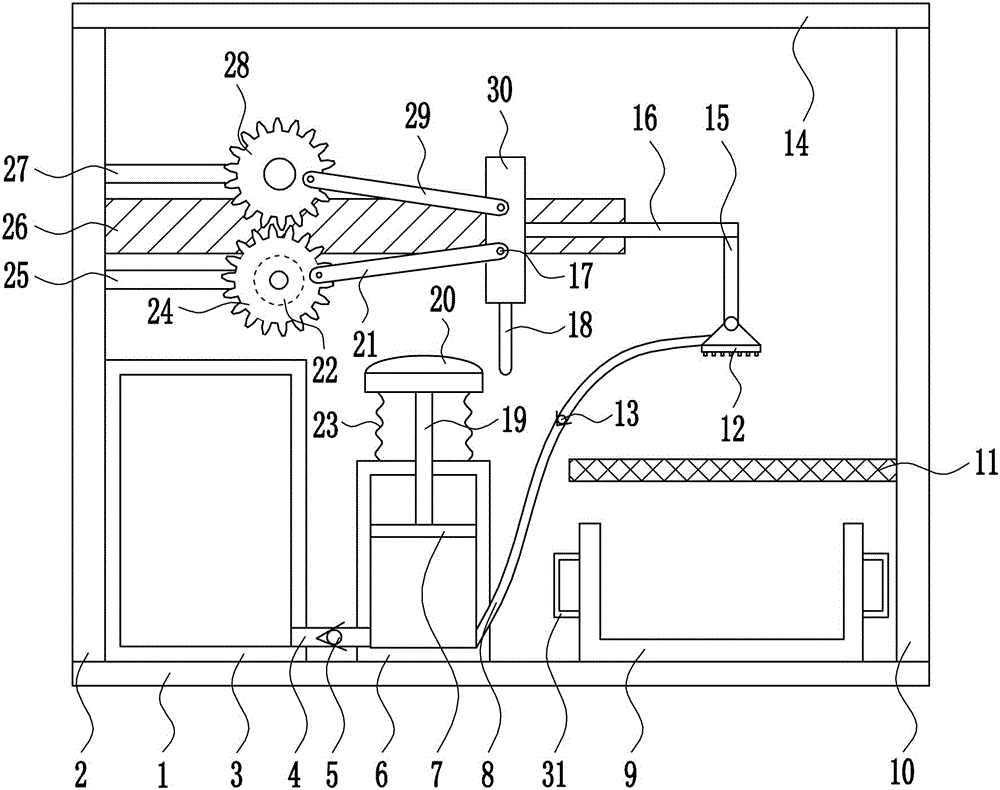

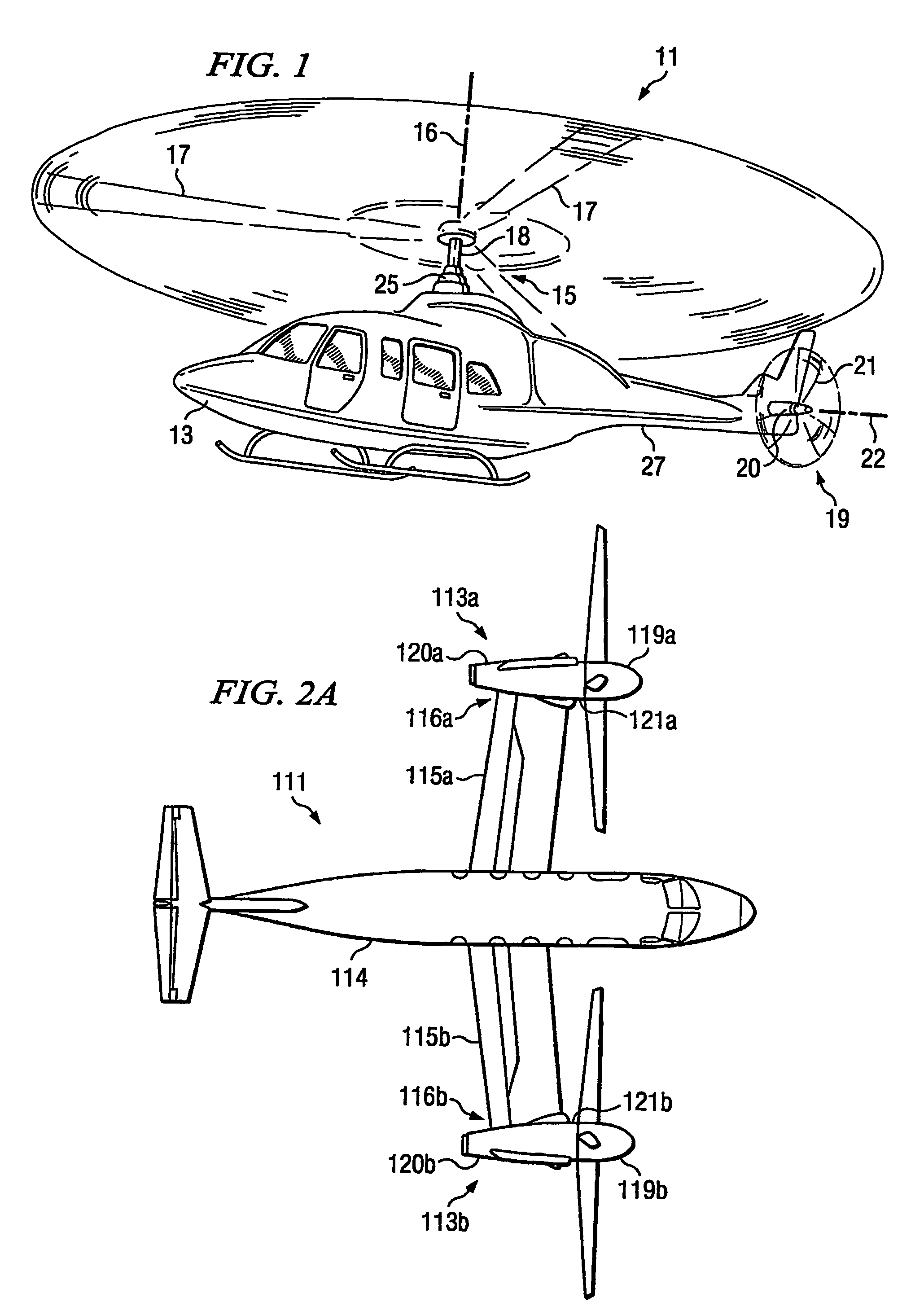

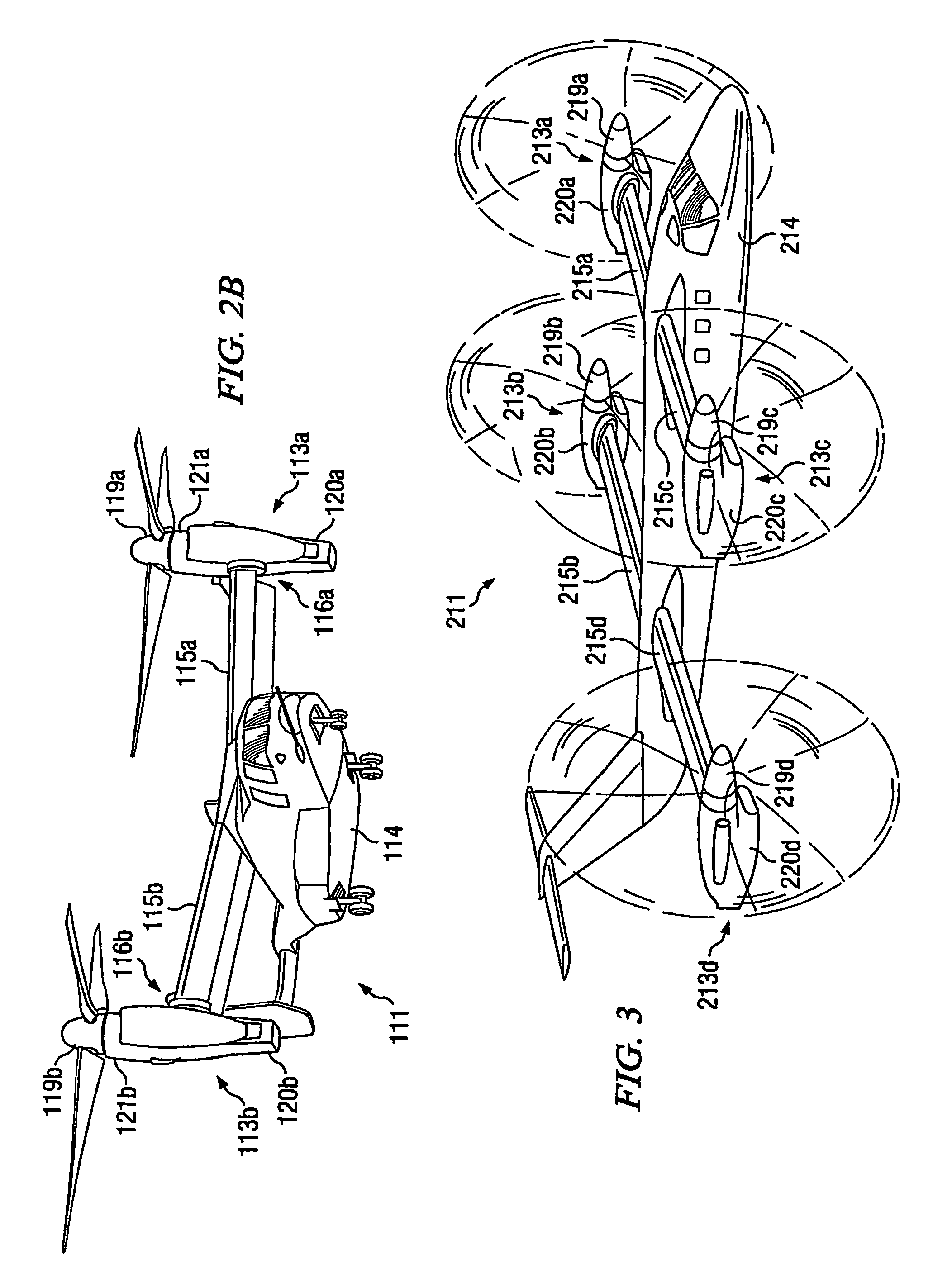

The invention relates to an engineering oil pipe paint spraying device, in particular to an engineering oil pipe surface paint spraying device. According to the technical problem to be solved, the engineering oil pipe surface paint spraying device does not need assistance of manual labor, and is good in automatic performance, high in maneuverability, high in working efficiency, convenient to operate and capable of uniformly spraying paint to the surface of an engineering oil pipe. To solve the technical problem, the engineering oil pipe surface paint spraying device comprises a left support, a right support, a material collecting frame, a top plate, a sliding block, a sliding rail, a hollow pipe, a spraying head, an air cylinder, a hairbrush, a first motor, a first rotating shaft, a first bevel gear and the like. The left support and the right support are vertically arranged in a bilateral symmetry manner. The material collecting frame is arranged below the position between the left support and the right support. According to the engineering oil pipe surface paint spraying device, in the process of spraying the paint to the surface of the engineering oil pipe, while the engineering oil pipe rotates, the spraying head sprays the paint.

Owner:平湖市穗丰五金有限公司

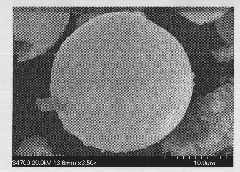

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

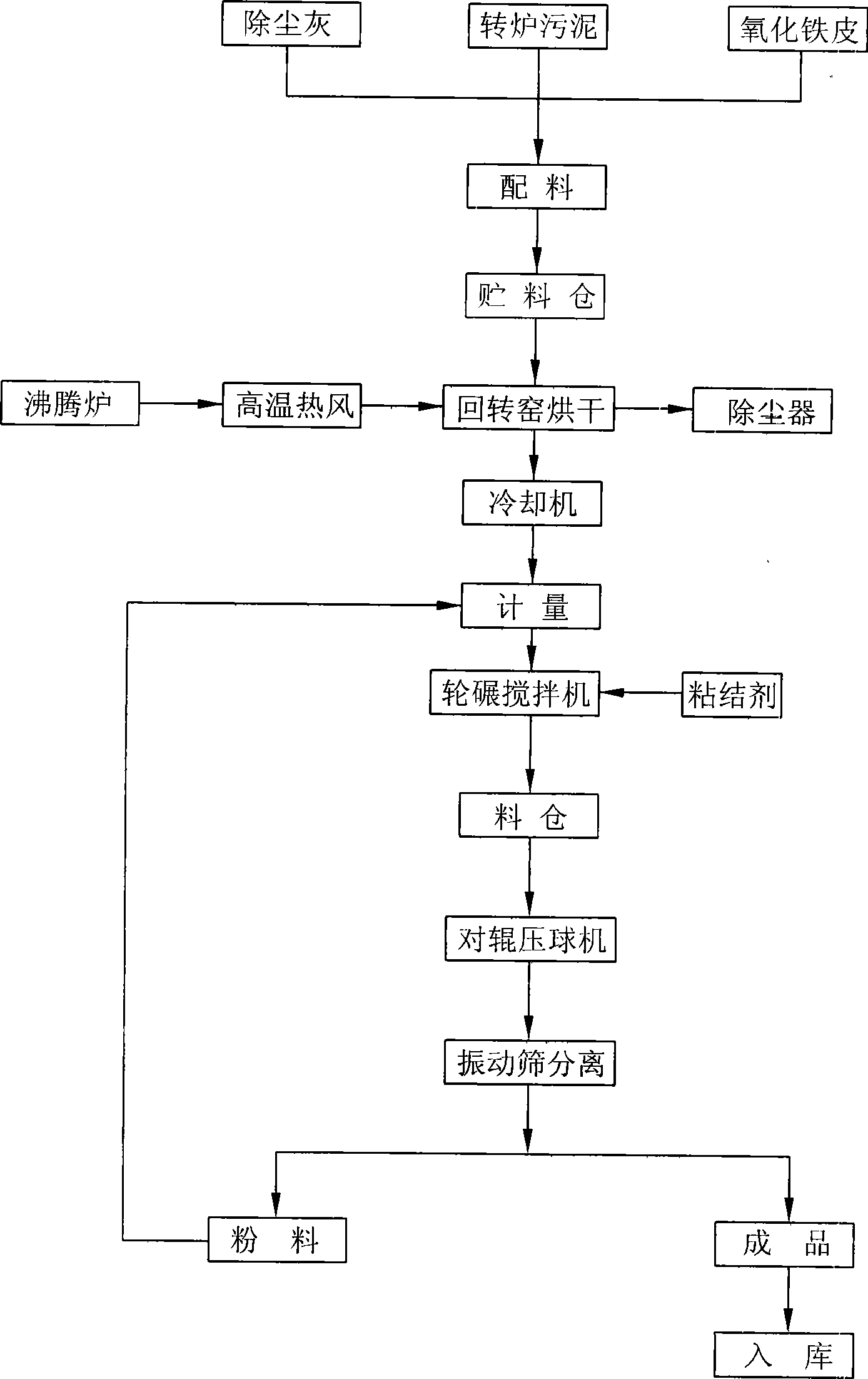

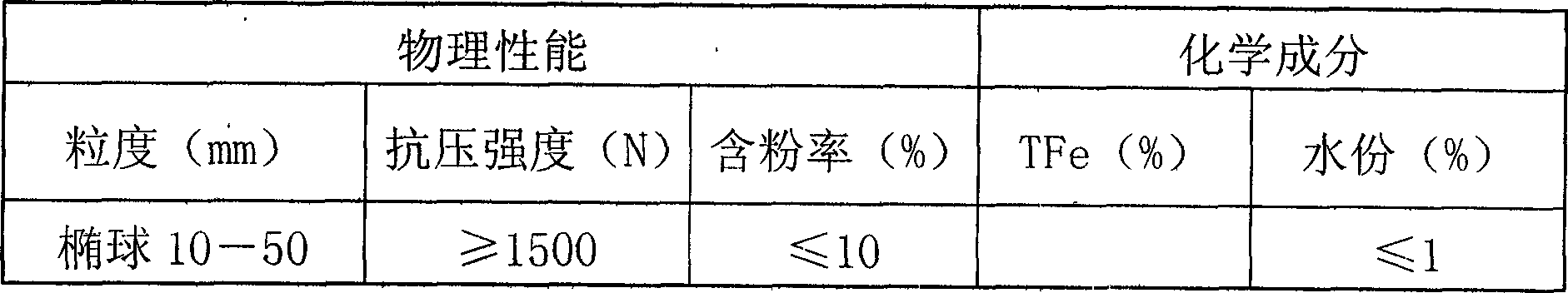

Method for utilizing iron containing metallurgical dust

The invention relates to a method for utilizing iron containing metallurgical dust, which comprises that: steel-making sludge, metallurgical dust-removing powder and iron scale are mixed; the mixed raw materials are sent into a rotary kiln and dried, and the drying temperature is determined according to moisture content of the raw materials and controlled to be between 300 and 500 DEG C; the dried materials are cooled by a cooler, the cooled materials are added with 5 to 10 percent of caking agent by weight, and the material and the caking agent are fully stirred evenly by a wheel-rolling mixer; and finally, the mixture is pressed into cooled agglomerated pellet products by a twin-roller machine, the pressure of the twin-roller machine is more than or equal to 500 Kg / cm<2>, and the cooled agglomerated pellet products are prepared into finished products after separation by a vibration sieve. The method has the advantages of low production energy consumption, high product strength, low moisture content and good quality, and can realize full effective utilization of resources; and the finished products of cooled agglomerated pellets can be directly used as a cooling agent and a slag former in steel making, can improve smelting effect and achieve functions of cooling and slag forming, and can be also used for blast furnace process.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

Semiconductor device

InactiveUS20110089549A1Not easy to corrodeProlong lifeSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceCopper wire

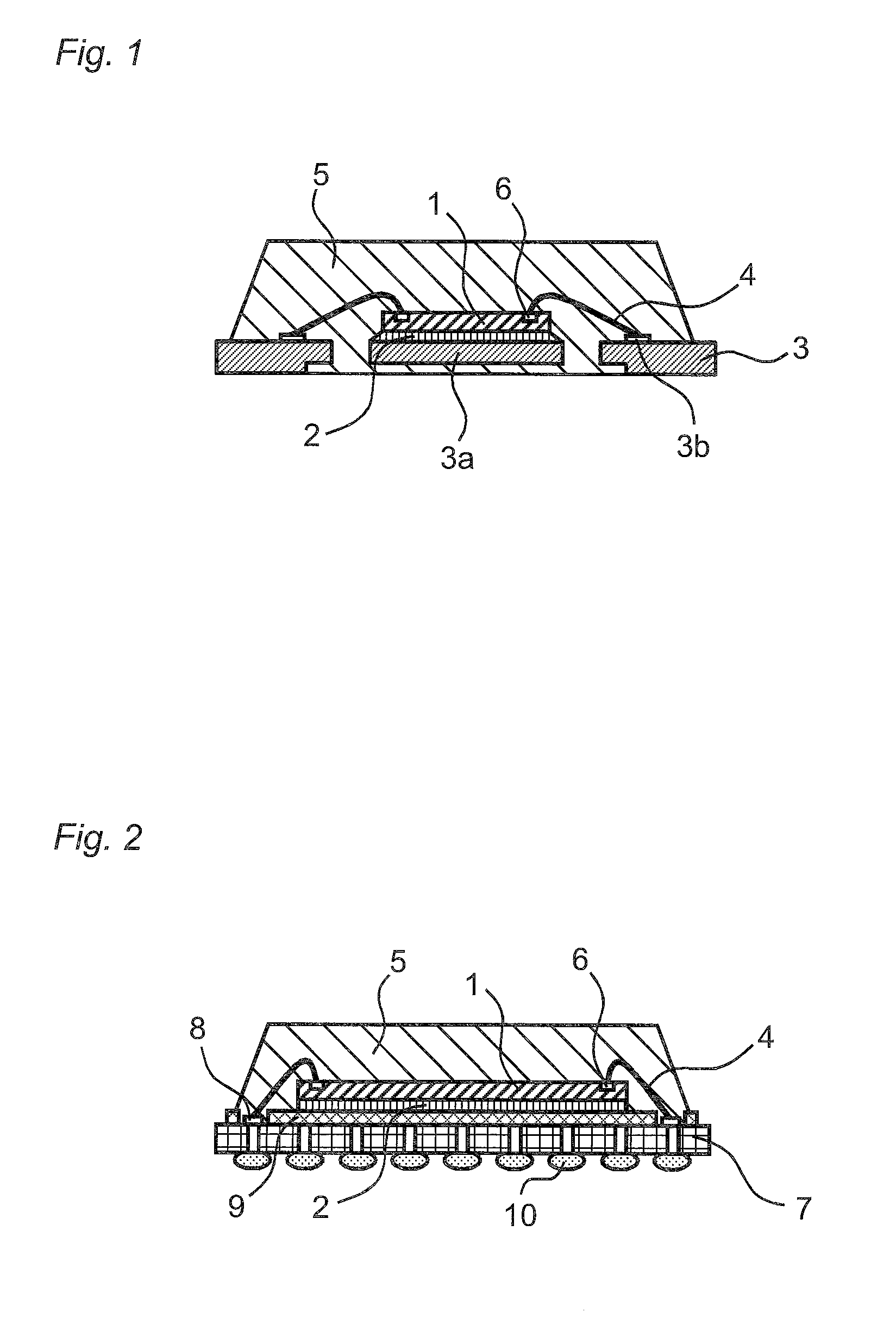

A semiconductor device comprises a lead frame having a die pad portion or a circuit board, one or more semiconductor elements mounted on the die pad portion of the lead frame or on the circuit board, a copper wire that electrically connects electrical joints provided on the lead frame or the circuit board to an electrode pad provided on the semiconductor element, and an encapsulating member which encapsulates the semiconductor element and the copper wire, wherein the electrode pad and / or the encapsulating member having predetermined properties are combined with the copper wire having predetermined properties.

Owner:SUMITOMO BAKELITE CO LTD

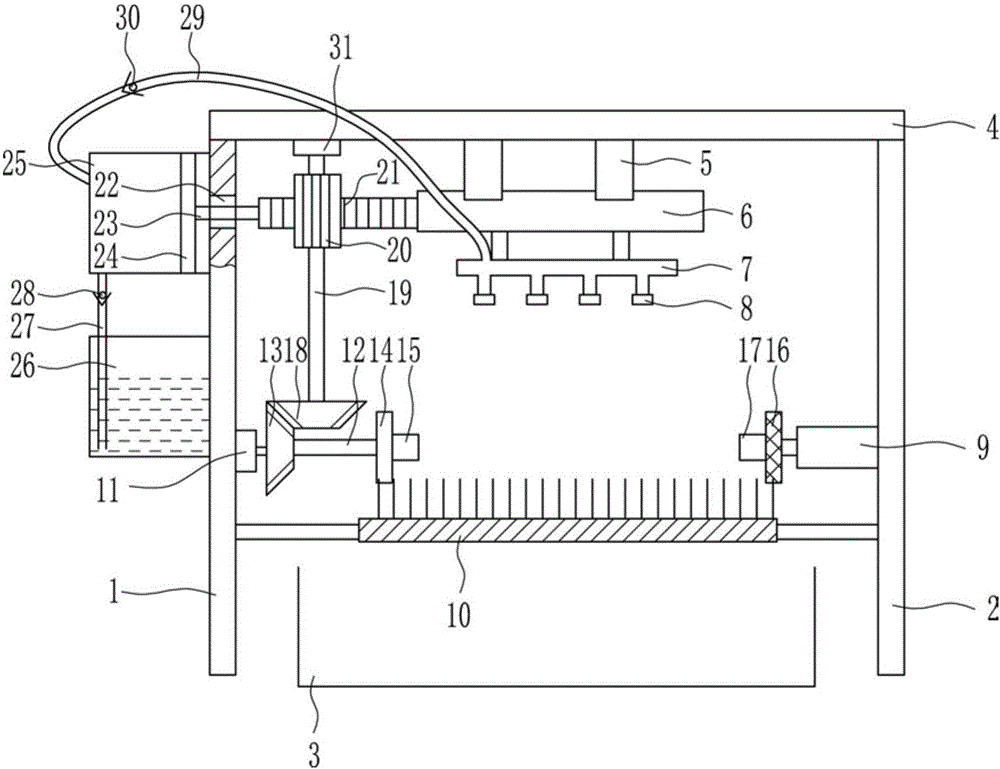

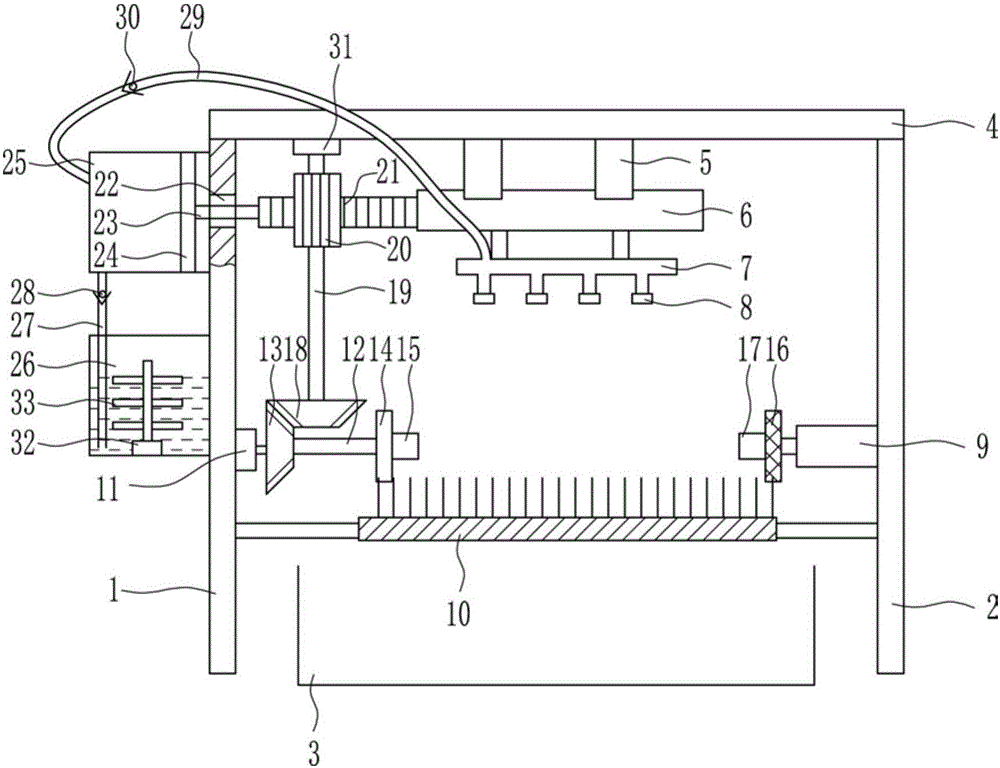

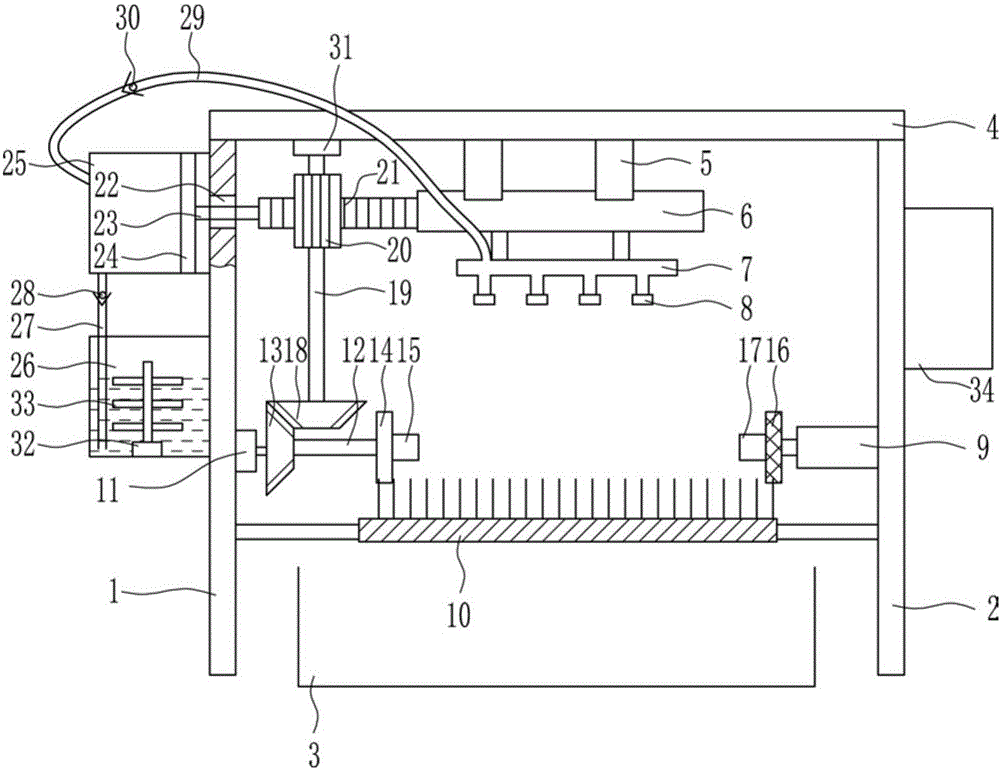

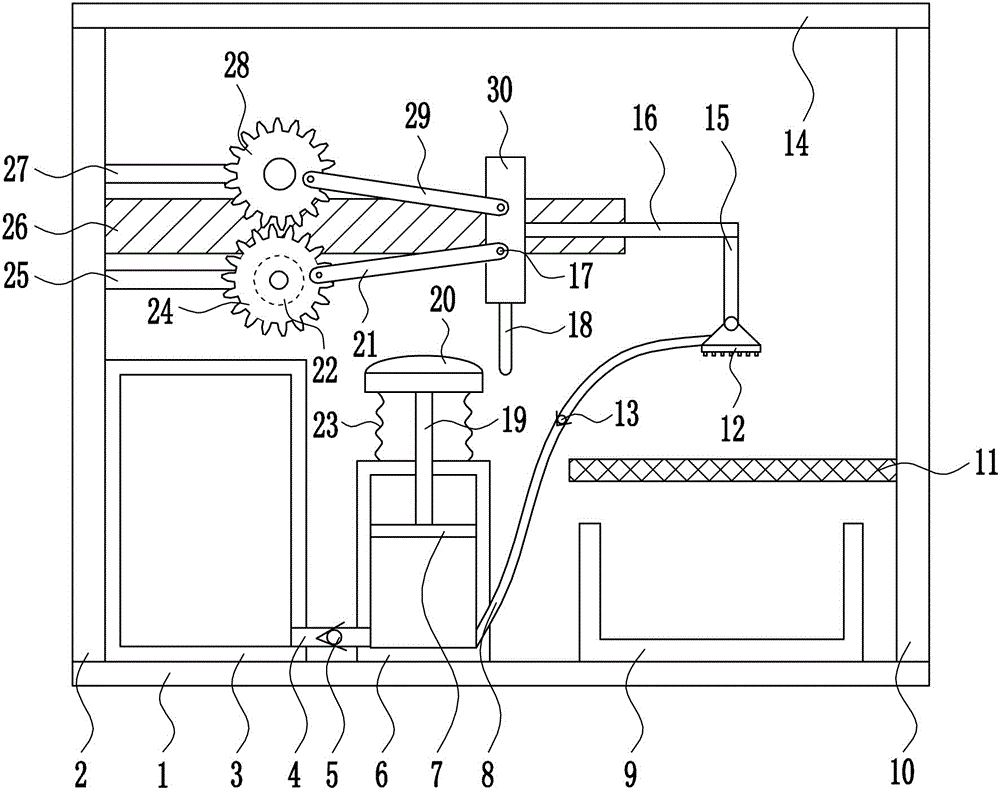

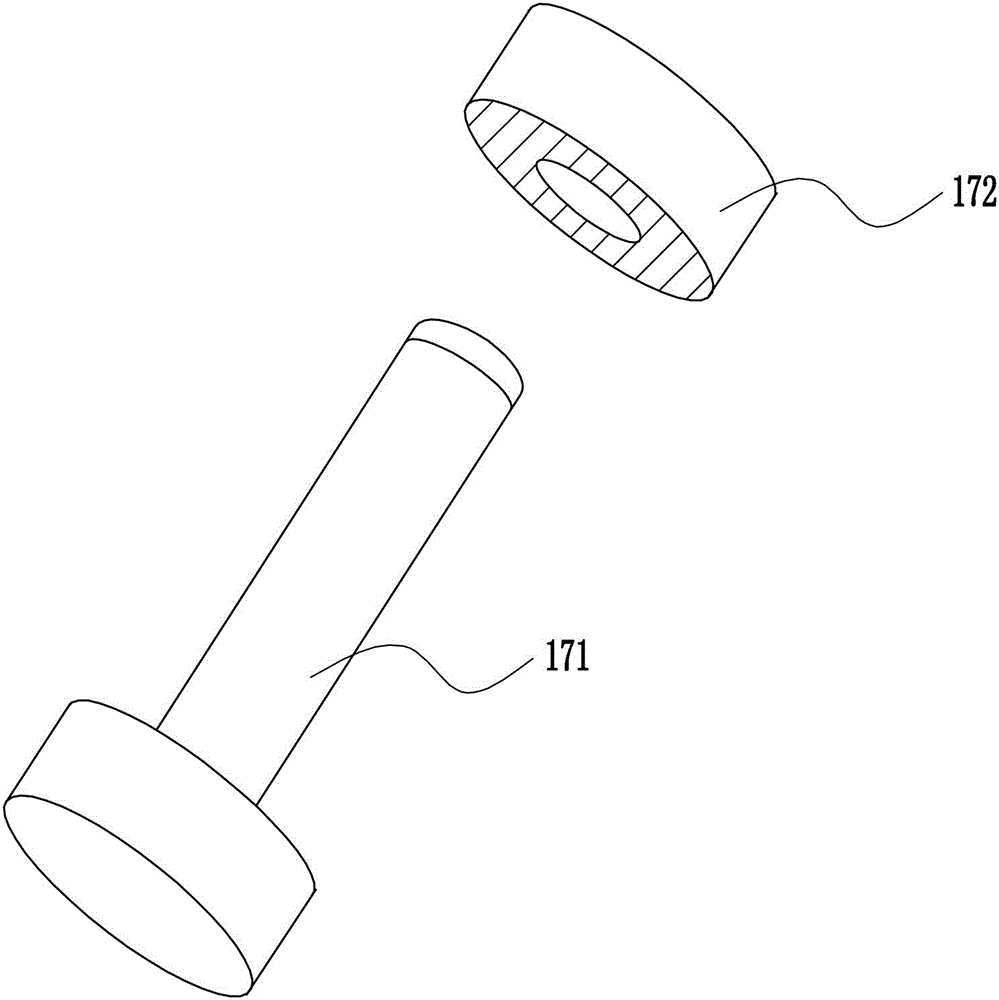

Rapid mechanical component antirust oil spraying device

InactiveCN106733345AFlexible swingExtended service lifeLiquid surface applicatorsLiquid spraying apparatusMechanical componentsSprayer

The invention relates to an antirust oil spraying device, and in particular relates to a rapid mechanical component antirust oil spraying device. The technical problem to be solved by the invention is to provide the rapid mechanical component antirust oil spraying device which is uniform in spraying, saving in material, and convenient to operate. In order to solve the technical problem, the invention provides the rapid mechanical component antirust oil spraying device comprising a base plate, a left rack, a box, a water pipe, a first check valve, a cylinder, a piston, a flexible pipe, a processing frame, a right rack, a screen plate, a sprayer, a second check valve and a top plate, wherein the left rack is welded with the left side of the top of the base plate, a first fixing rod is welded with the upper part of the right side of the left rack, and a motor is connected with the first fixing rod via a bolt. According to the device provided by the invention, the effects of being uniform in spraying, saving in material, and convenient to operate are achieved, and the device is low in manufacturing cost, reasonable in structure, prone to maintain and repair, convenient to use, reduced in investment of manpower and material resources and improved in work efficiency.

Owner:孝感市伊莱迦电子科技有限公司

Pressure type microwave reactor

InactiveCN1861249AReduce lossNot easy to corrodeEnergy based chemical/physical/physico-chemical processesPressure vessels for chemical processNuclear engineeringGas cylinder

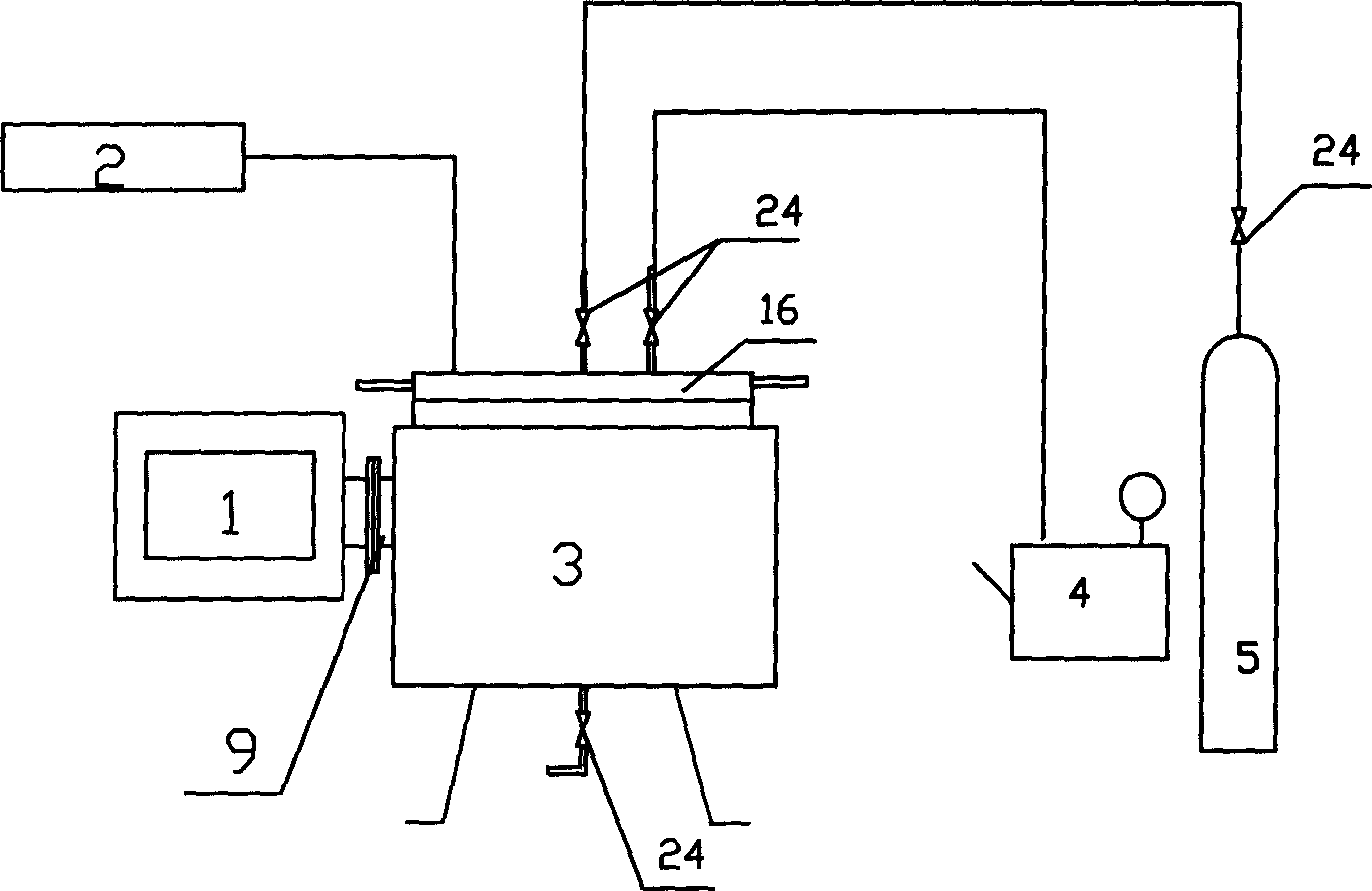

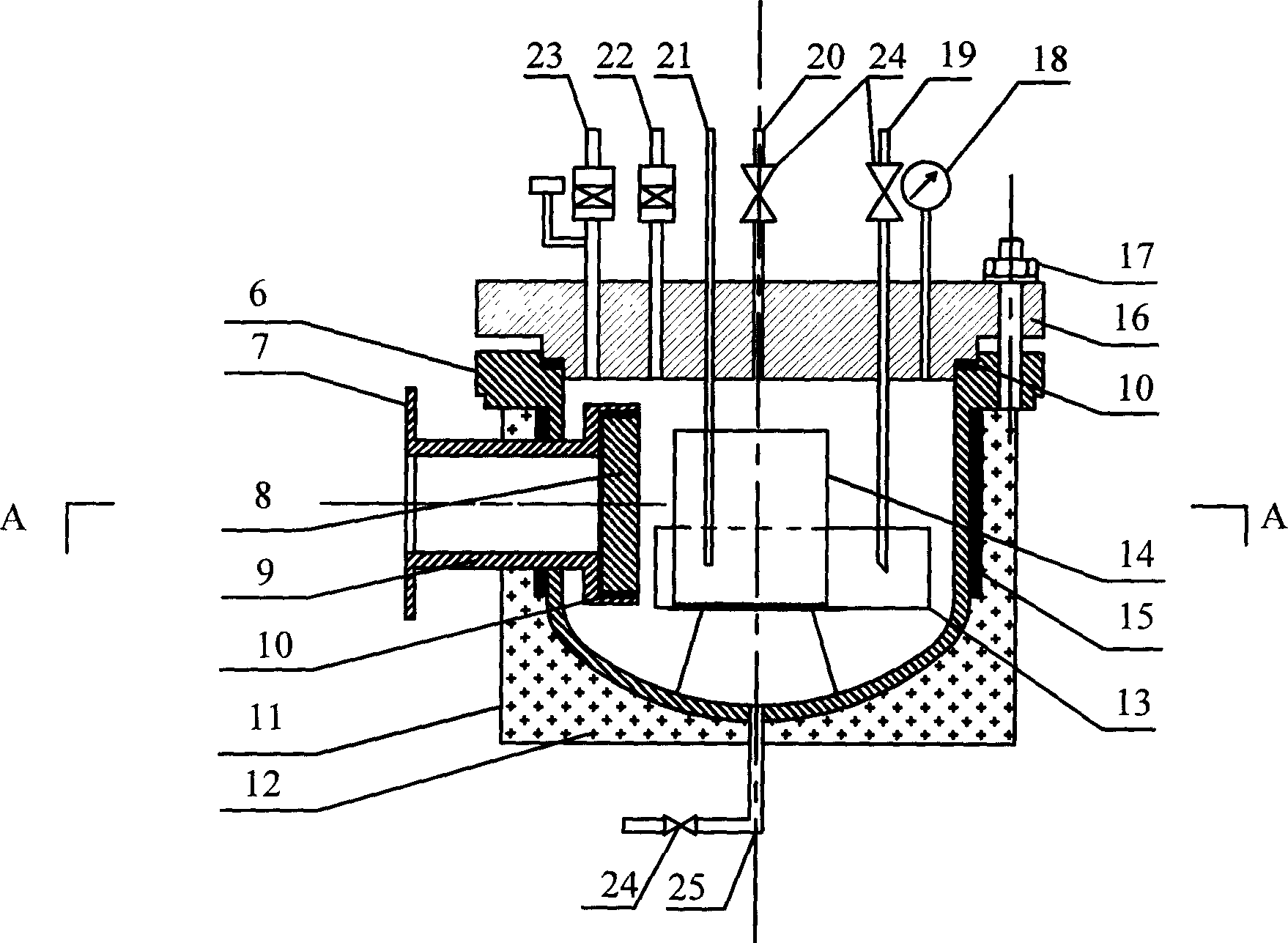

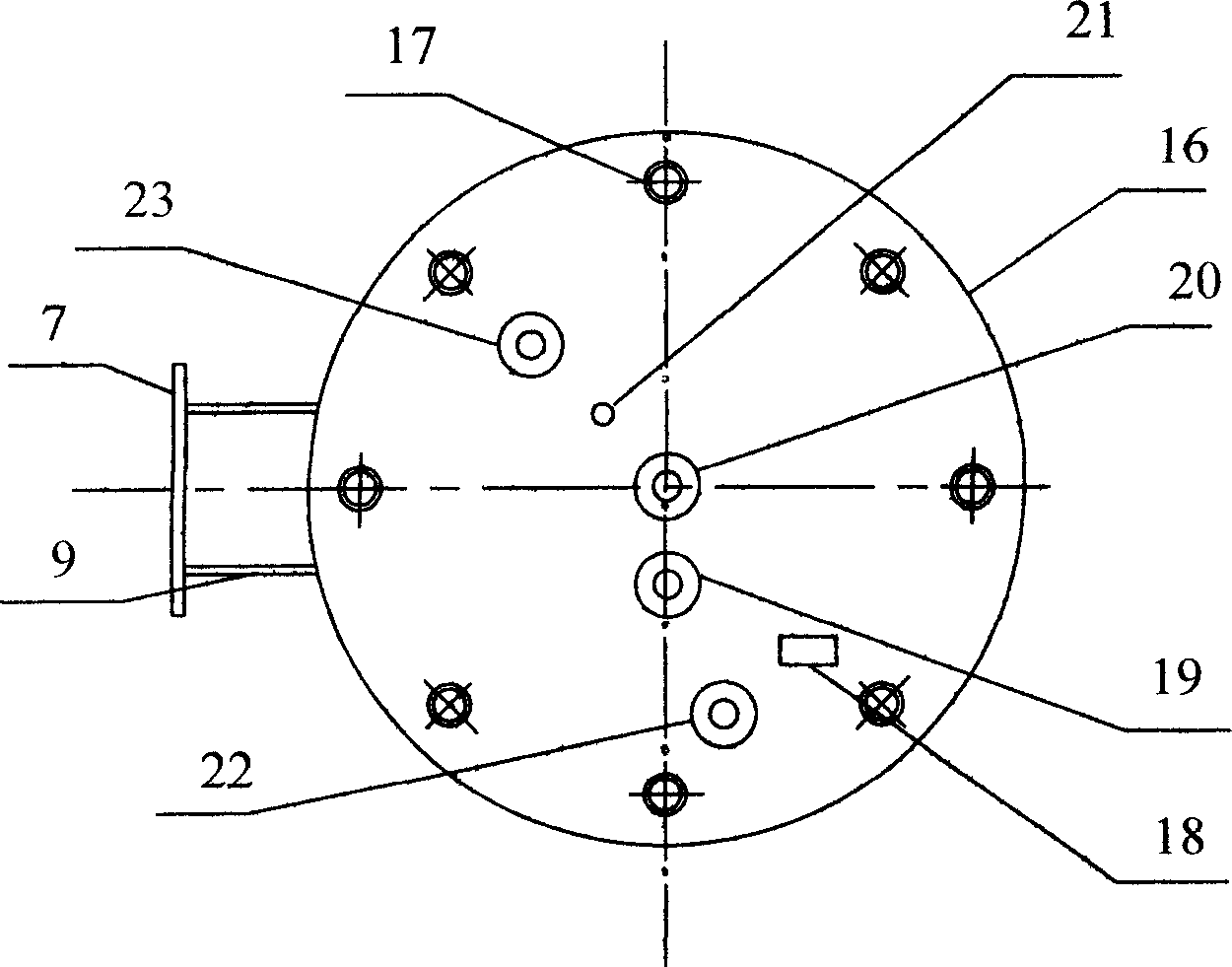

A pressure-type microwave reactor system is composed of a microwave generator, a waveguide tube with rectangular flange and quartz glass window, a cylindrical microwave reactor with external jacket made of stainless steel, enclosing head, internal high-pressure wall and insulating layer, controller for microwave reactor, hydraulic water pump and high-pressure gas cylinder.

Owner:DALIAN UNIV OF TECH

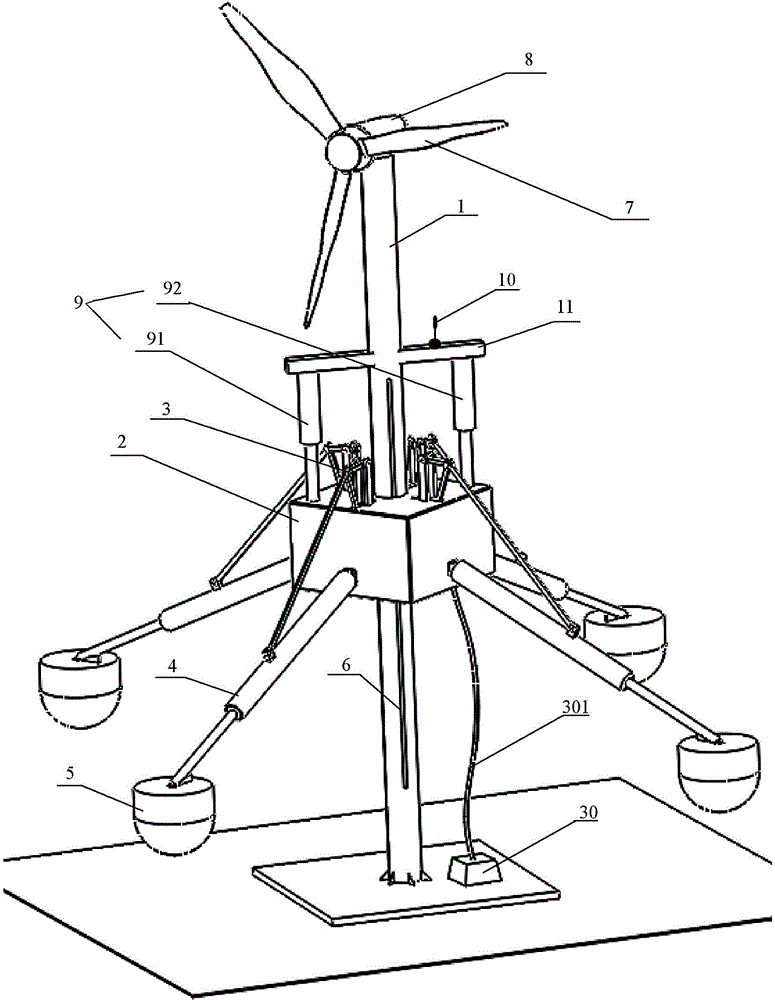

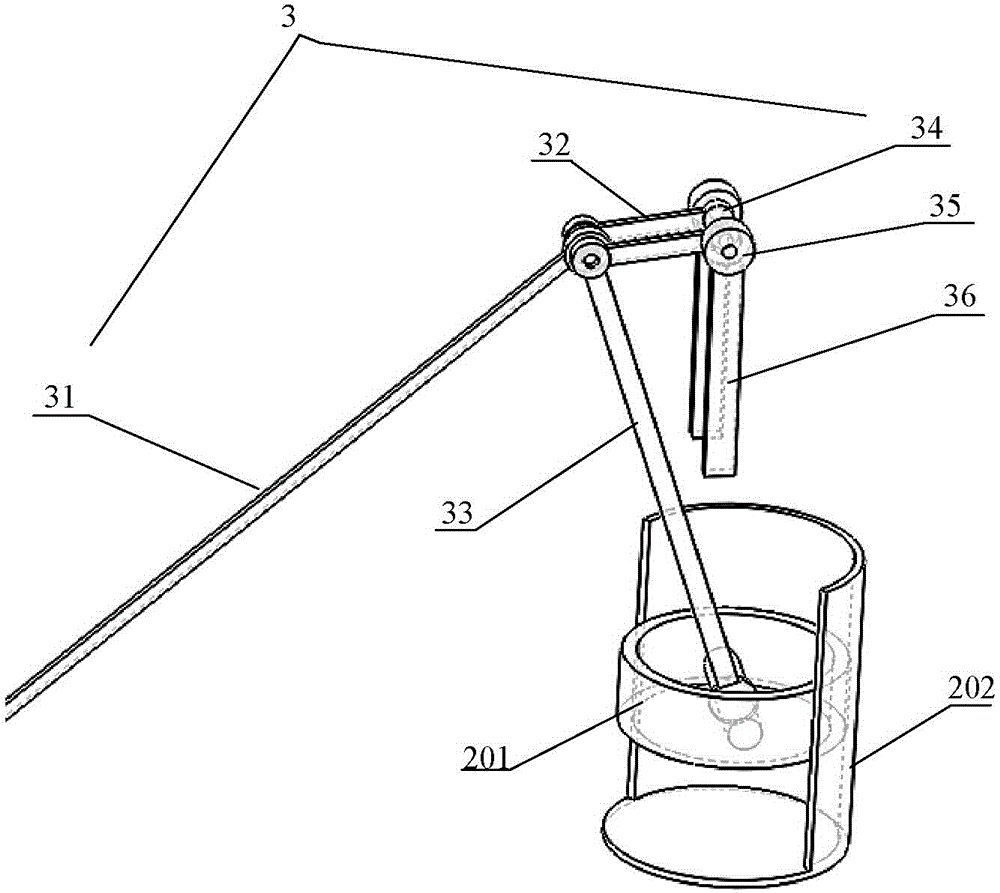

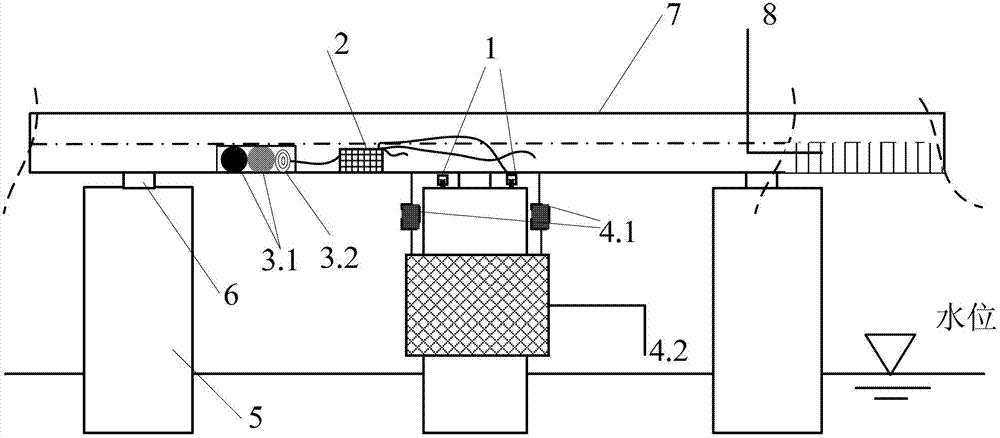

Variable torque wave energy hydraulic power generation device

InactiveCN103557112ALengthen or shortenInput stableMachines/enginesWind motor combinationsEngineeringWave height

The invention provides a variable torque wave energy hydraulic power generation device, which consists of a plurality of pieces of equipment such as a pile body, a wave energy power generator room, a plurality of groups of crank rocker devices, a plurality of groups of floater moment arms, a plurality of groups of oscillating floaters, a generator room pushrod, a wireless communication device and a wave instrument. The wave instrument can be used for measuring the real-time wave height and tide level data of waves, and driving the floater moment arms and the generator room pushrod to be elongated or shortened according to preset rules, thereby changing the lengths of the floater moment arms and the floating position of the wave energy power generator room and actively adjusting the magnitude of wave energy input torque. The device can be used for obtaining more stable wave energy, and a wave energy collection device and an offshore wind energy collection device are fused into a whole to collect both the wave energy of the oscillating floaters and offshore wind energy for power generation, so that the utilization efficiency of energy resources is favorably improved, and the power generation cost is lowered.

Owner:JIMEI UNIV

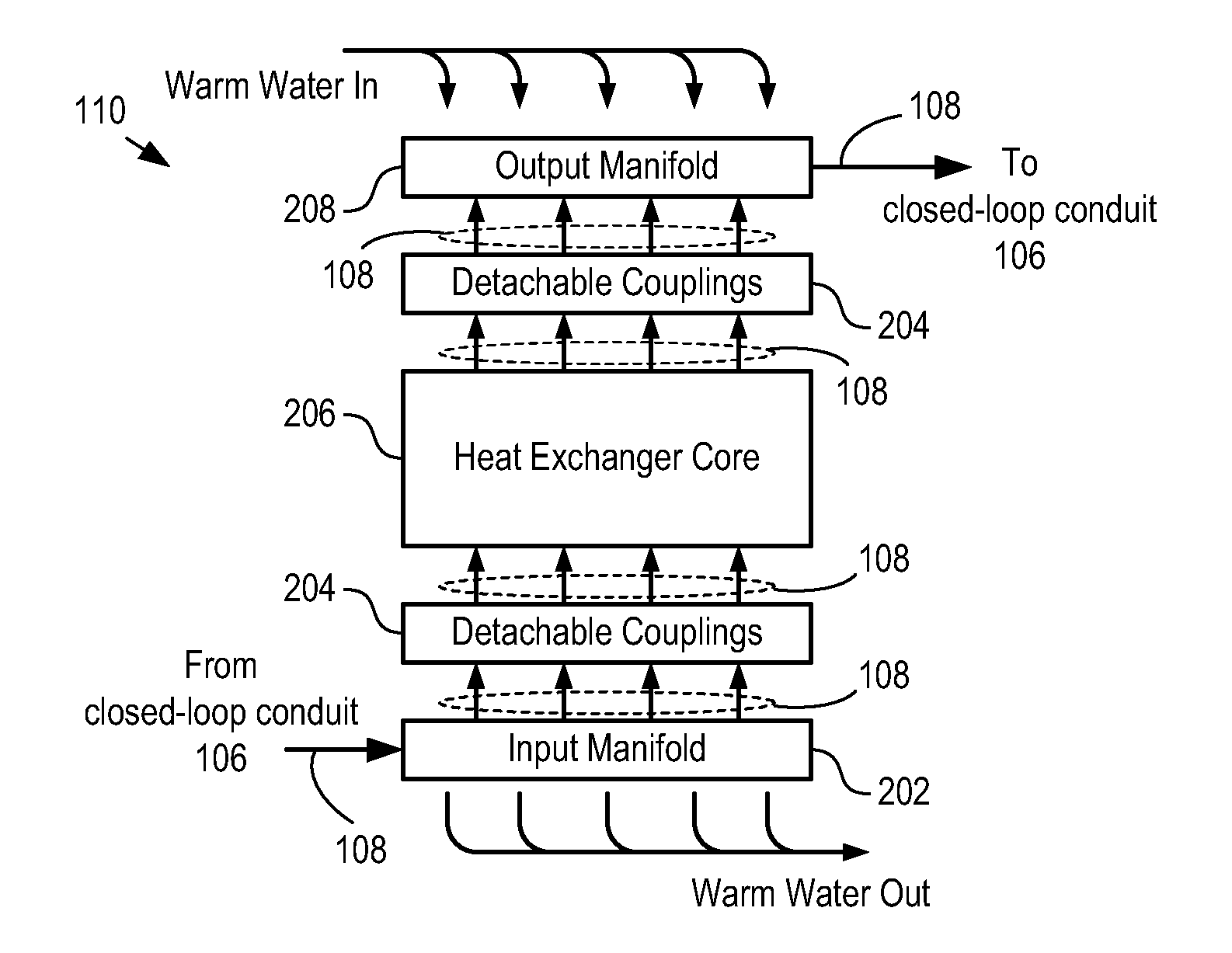

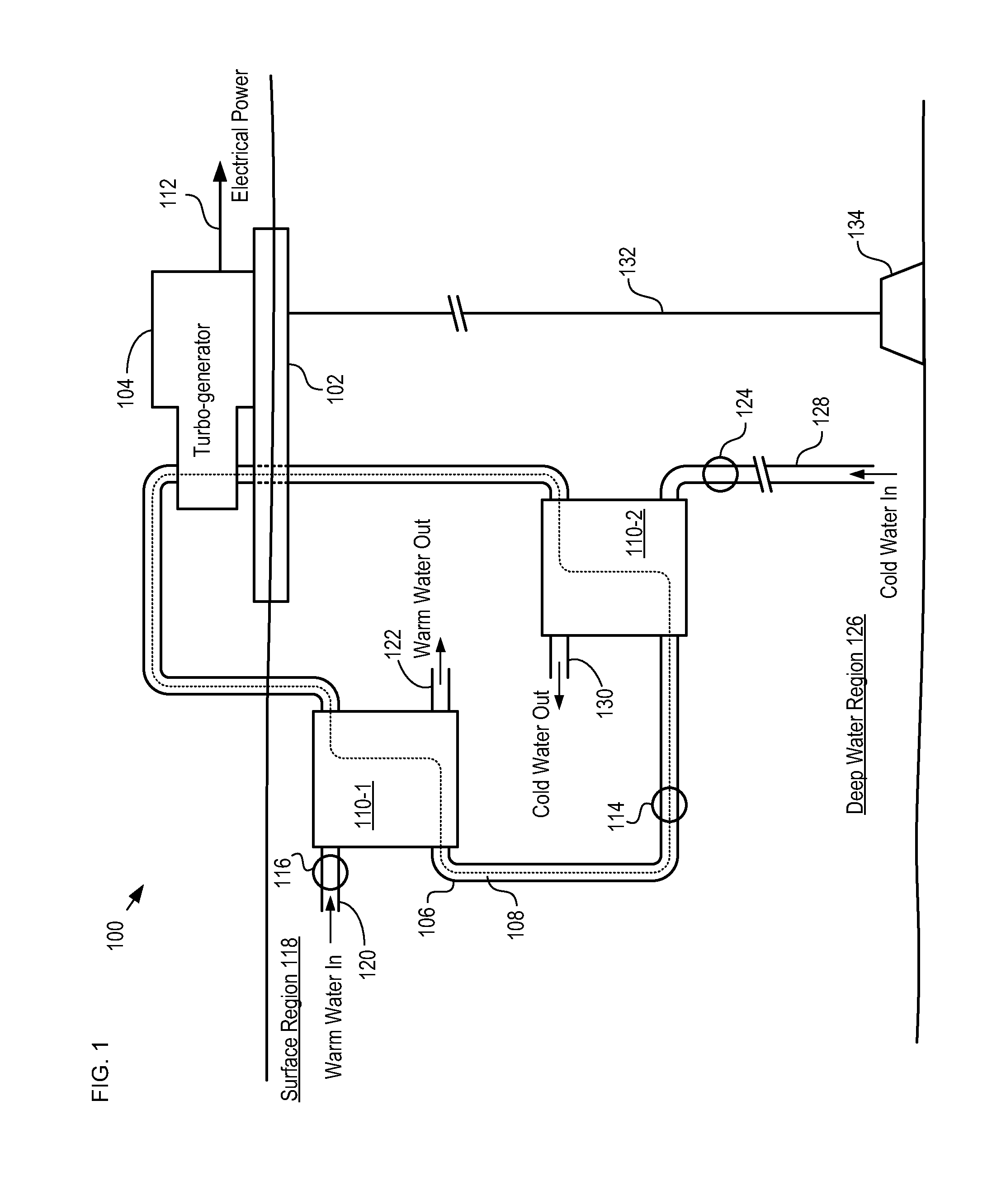

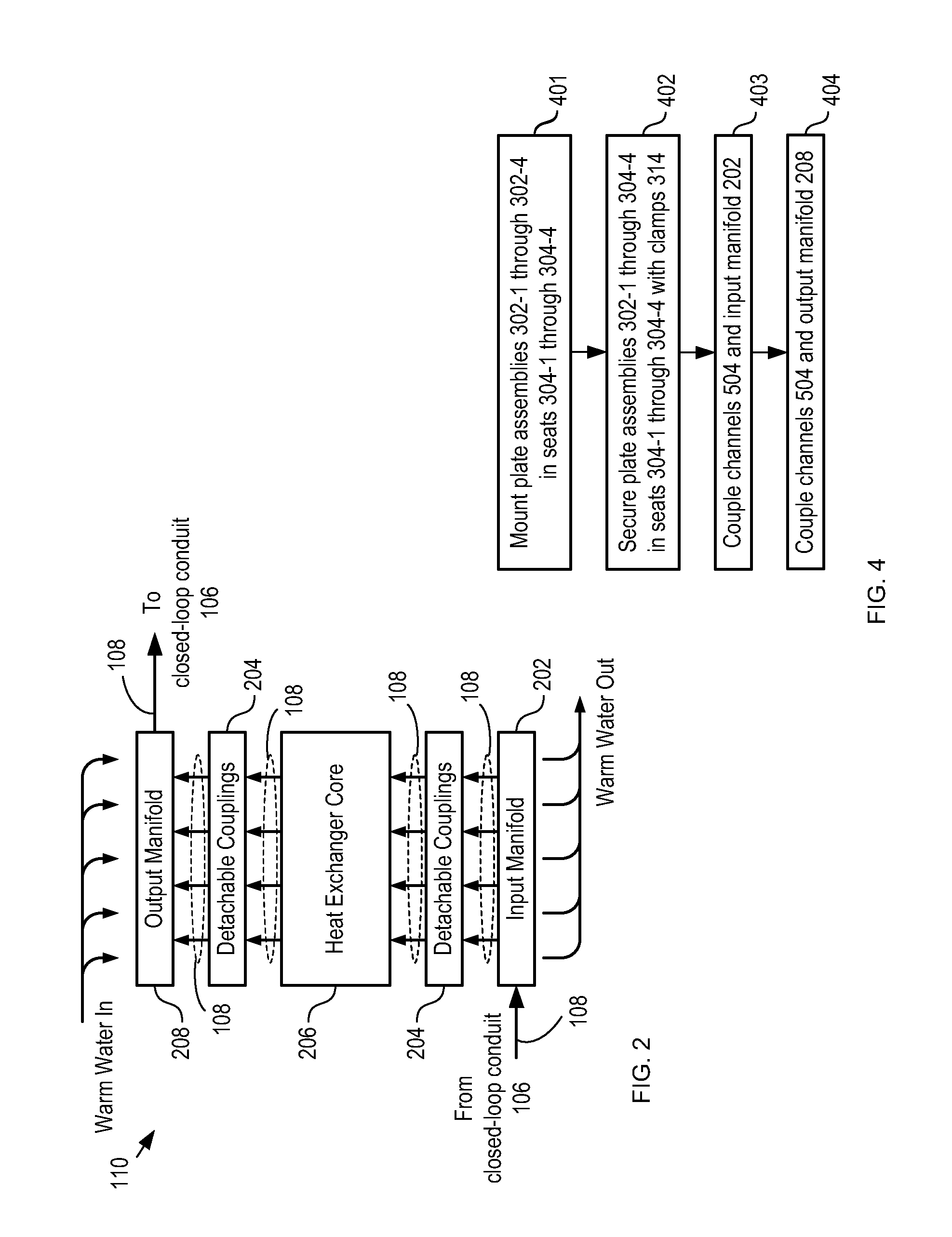

Modular Heat Exchanger

ActiveUS20110079375A1Easily repair or replaceMore serviceCorrosion preventionMachines/enginesEngineeringPlate fin heat exchanger

A heat exchanger comprising a plurality of plates that are demountably attached to a frame is disclosed. Each plate comprises a plurality of channels for conveying a primary fluid through the heat exchanger. The frames are arranged in the frame so that spaces between adjacent frame pairs define conduits for conveying a secondary fluid through the heat exchanger. The plates are mounted in the frame so that they can be individually removed from the frame. Further, each of the channels is fluidically connected to input and output ports for the primary fluid by detachable couplings. As a result, heat exchangers in accordance with the present invention are more easily repaired or refurbished than prior-art heat exchangers.

Owner:LOCKHEED MARTIN CORP

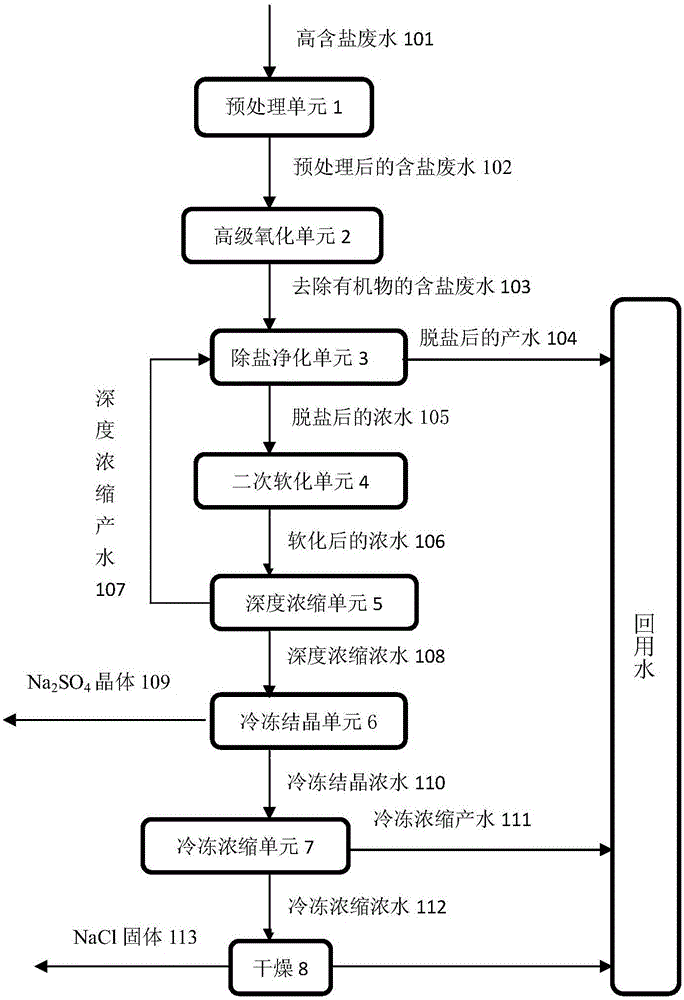

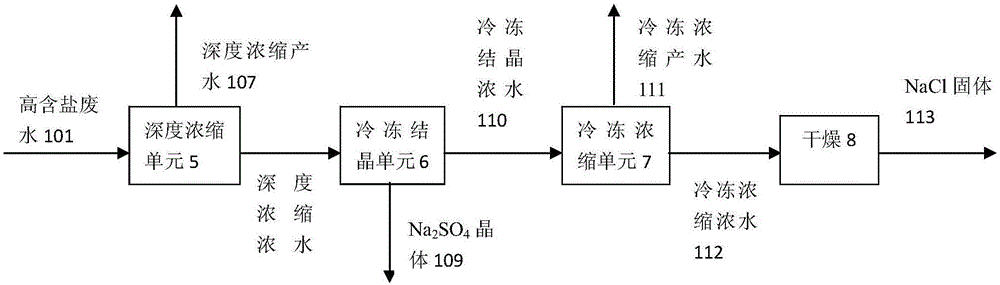

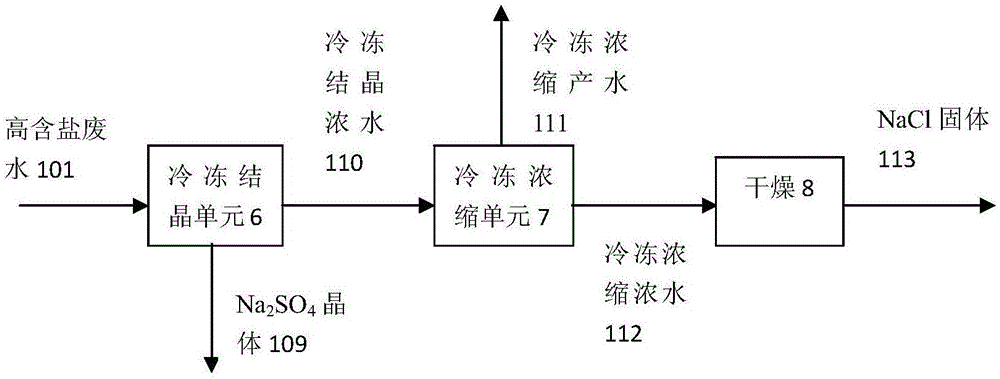

Salt separation and purification recovery method for salt-containing wastewater

ActiveCN106830465AAvoid easy cloggingRealize processingGeneral water supply conservationWater/sewage treatment by ion-exchangeRecovery methodCell separation

The invention discloses a salt separation and purification recovery method for salt-containing wastewater. The method comprises the following steps: performing advanced oxidation treatment on pretreated salt-containing wastewater so as to obtain salt-containing wastewater in which organic matters are removed; desalting and purifying the salt-containing wastewater in which organic matters are removed so as to obtain desalted produced water and desalted concentrated water, performing secondary softening treatment on the desalted concentrated water so as to obtain softened concentrated water; performing deep concentration on the softened concentrated water so as to obtain deeply concentrated produced water and deeply-concentrated concentrated water; performing freezing crystallization on the deeply-concentrated concentrated water so as to obtain sodium sulfate crystals and freezing crystallized concentrated water; performing freezing crystallization on the freezing crystallized concentrated water for at least one time so as to obtain freezing crystallized produced water and freezing crystallized concentrated water; and evaporating or drying the freezing crystallized concentrated water, thereby obtaining the sodium chloride crystal. The traditional evaporative crystallization process is replaced with the freezing crystallization, the process is implemented under low temperature and normal pressure, the equipment is difficultly corroded, the operation is safe and reliable, the energy consumption is effectively reduced, the pipeline is difficultly blocked, and the investment and operating cost can be reduced.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD +1

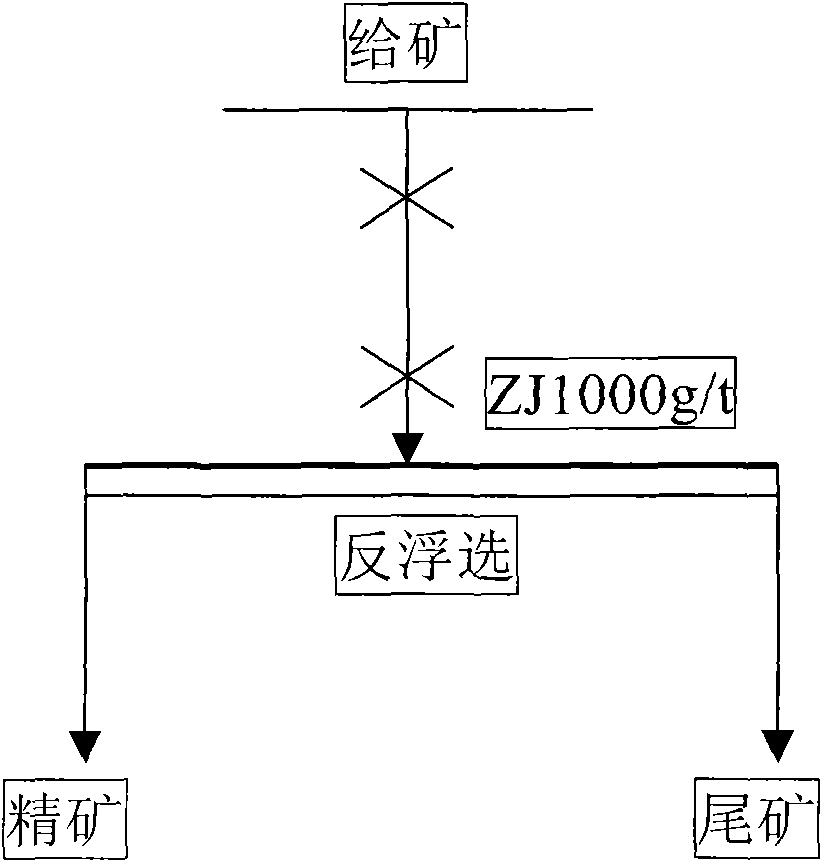

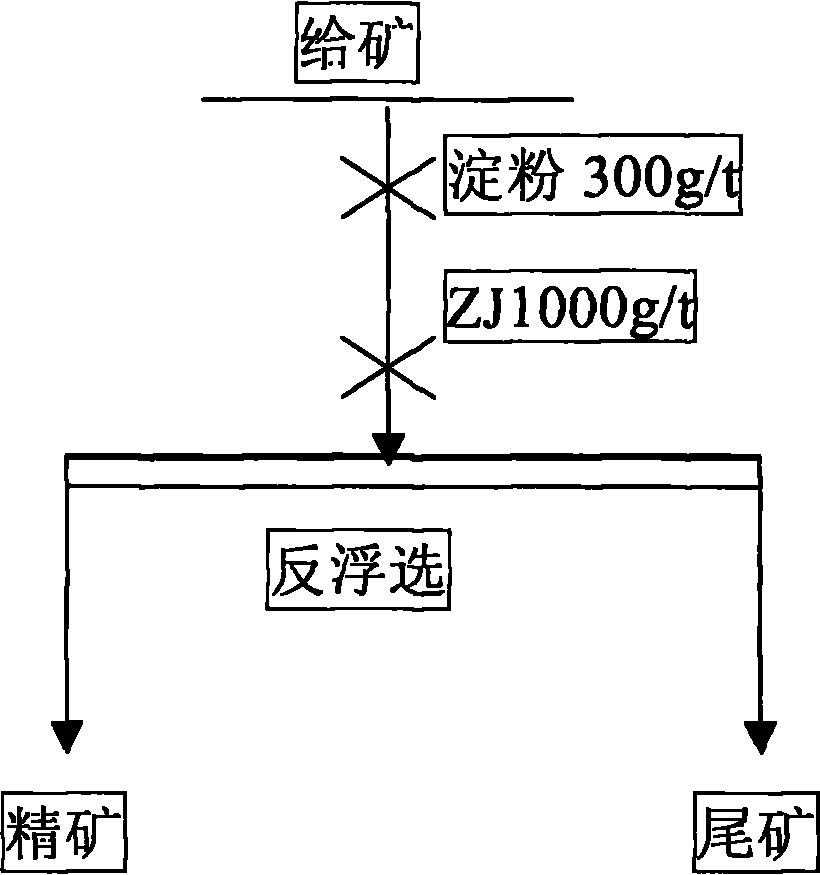

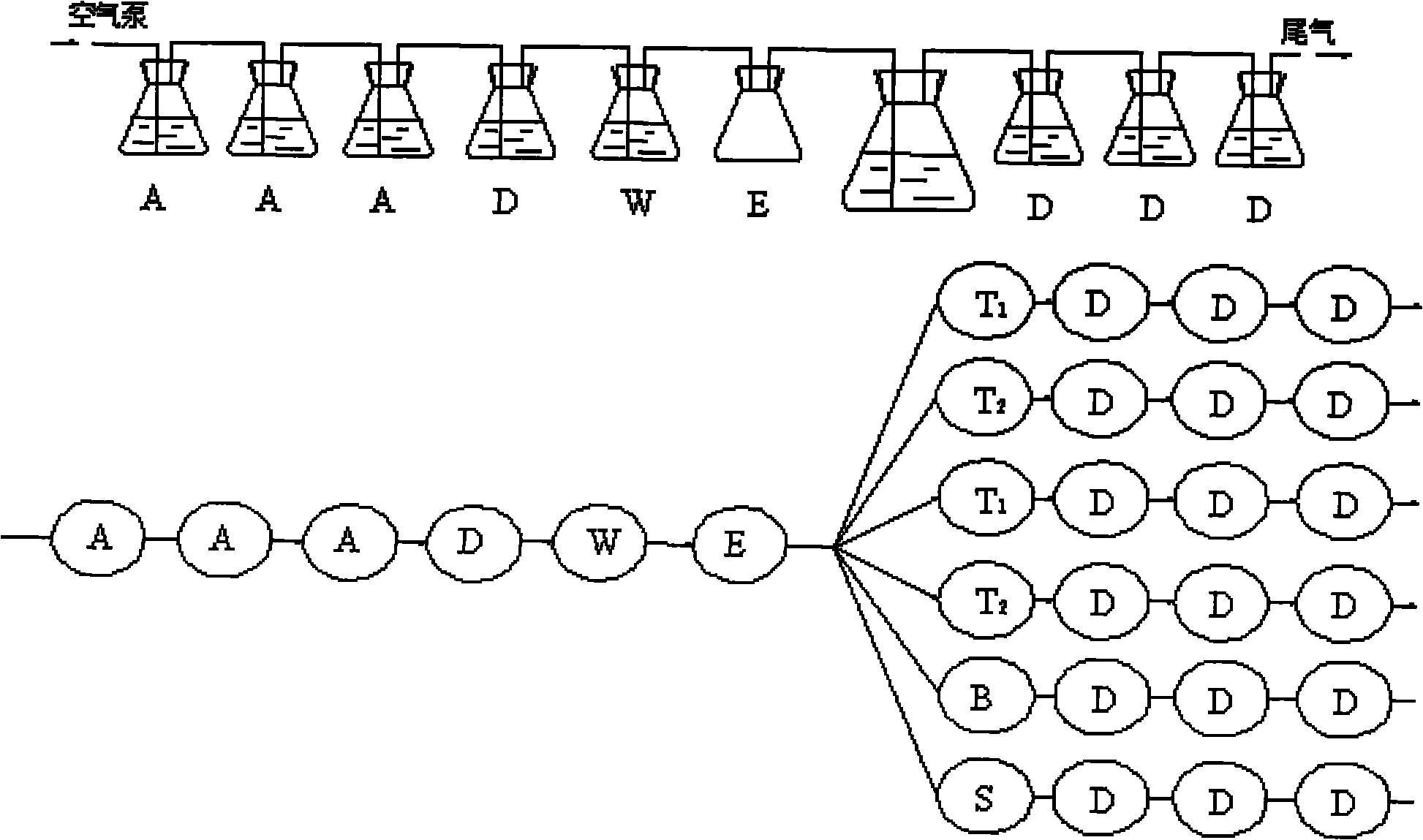

Environmentally-friendly amine cationic collector and using method thereof

InactiveCN101816981ASave on heating costsPracticalOrganic compound preparationFlotationSURFACTANT BLENDToxicity

The invention discloses an environmentally-friendly amine cationic collector and a using method thereof. The collector ZJ is ester group-containing quaternary ammonium salt cationic surfactant and has a plurality of alkyl groups, wherein an R alkyl group has 6 to 18 carbon atoms; an R1 alkyl group has 1 to 4 carbon atoms; the number of ester groups is 1 or two; and the number of the quaternary ammonium group is 1. The collector is obtained by esterification and quaternarization. As a hydrophobic chain has a carbonyl structure, the collector can hydrolyze easily into nonsurfactant fragments, and is a surfactant with high biodegradability, small toxicity and high performance. The collector is used in ore flotation for the first time and demonstrates high collecting capacity and selectivity.The collector forms fine and fragile foam that is low temperature resistant. The collector can be used under the condition that the pH value of ore pulp is 7 without corroding equipment. The preparation process of the collector is simple and easy in operation. And the collector is easy to biodegrade and is environmentally-friendly.

Owner:WUHAN UNIV OF TECH

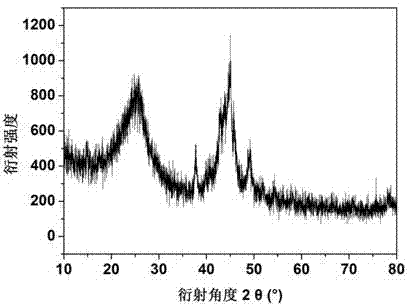

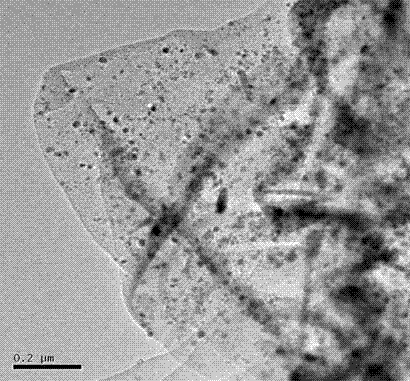

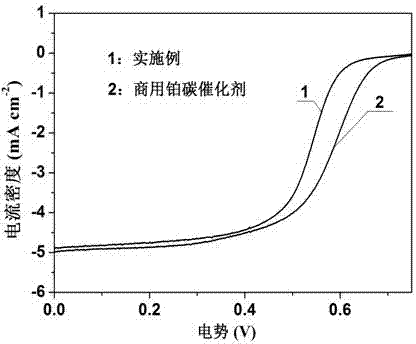

Preparation method and application of nitrogen-doped porous carbon nano sheet composite material

The invention discloses a preparation method of a nitrogen-doped porous carbon nano sheet composite material. The preparation method comprises the steps of performing high-temperature carbonization treatment on a mixture which consists of melamine and adjacent phenanthroline iron and serves as a precursor in a tubular furnace under an inert gas environment, and then removing dissolved iron compounds from an acidic solution to obtain a porous carbon nano sheet layer with carbon-coated iron carbide nano particles. The preparation method has the advantages that the technology is simple, the raw materials are cheap, and operation is easy to implement; in the prepared composite material, iron carbide is uniformly dispersed in the carbon nano sheet layer, so that the composite material is high in specific surface area and pore volume; iron carbide nano particles are completely coated by graphitized carbon, so that oxidization and corrosion are hardly caused; the composite material is stable in acidic electrolyte, and the battery activity can be effectively improved; when used as an electrocatalyst, the composite material is relatively high in electrocatalysis efficiency; the preparation method has an important value and significance in the field of preparation of doped carbon nano composite materials and electrocatalysis of proton membrane fuel batteries.

Owner:NANKAI UNIV

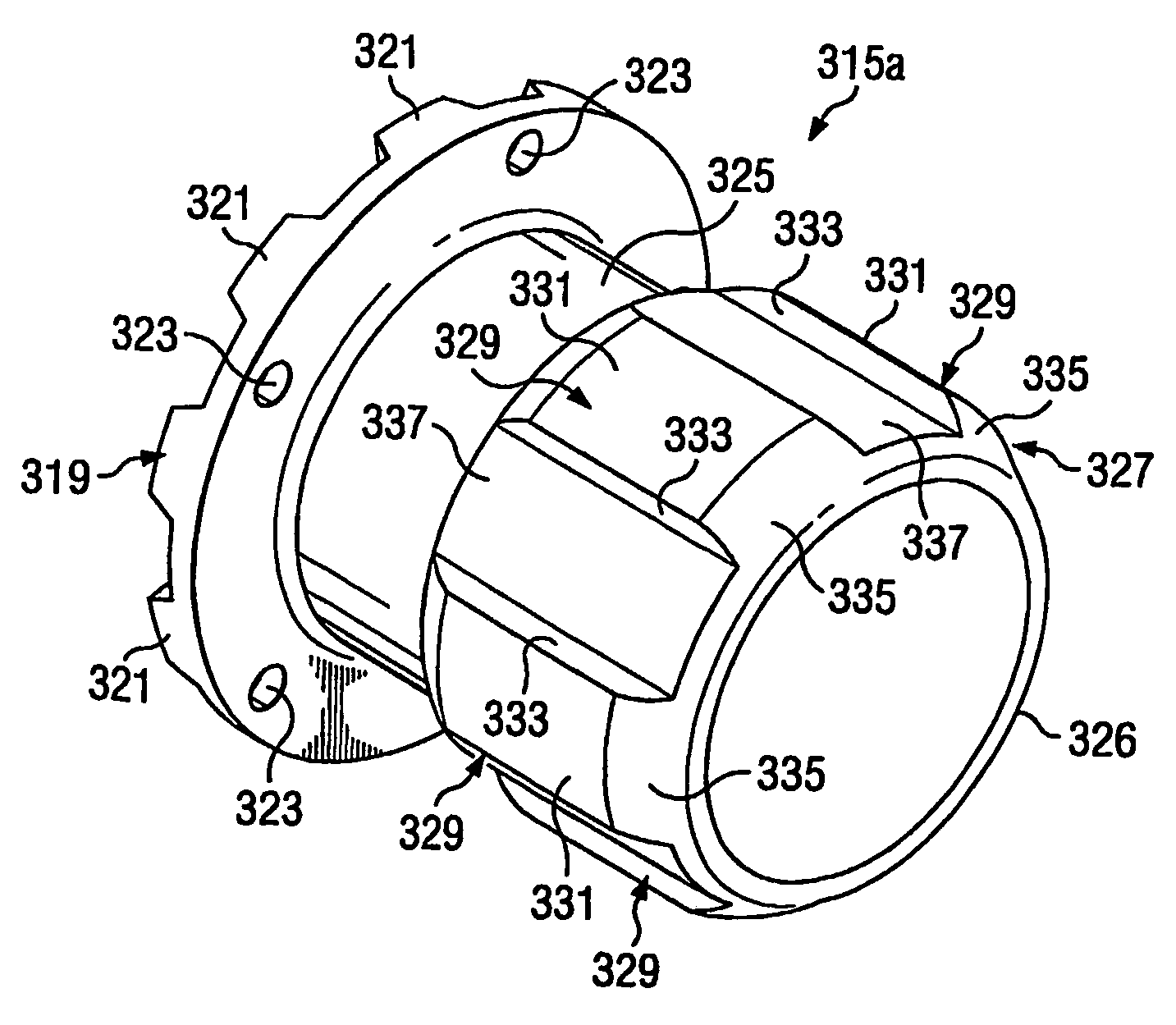

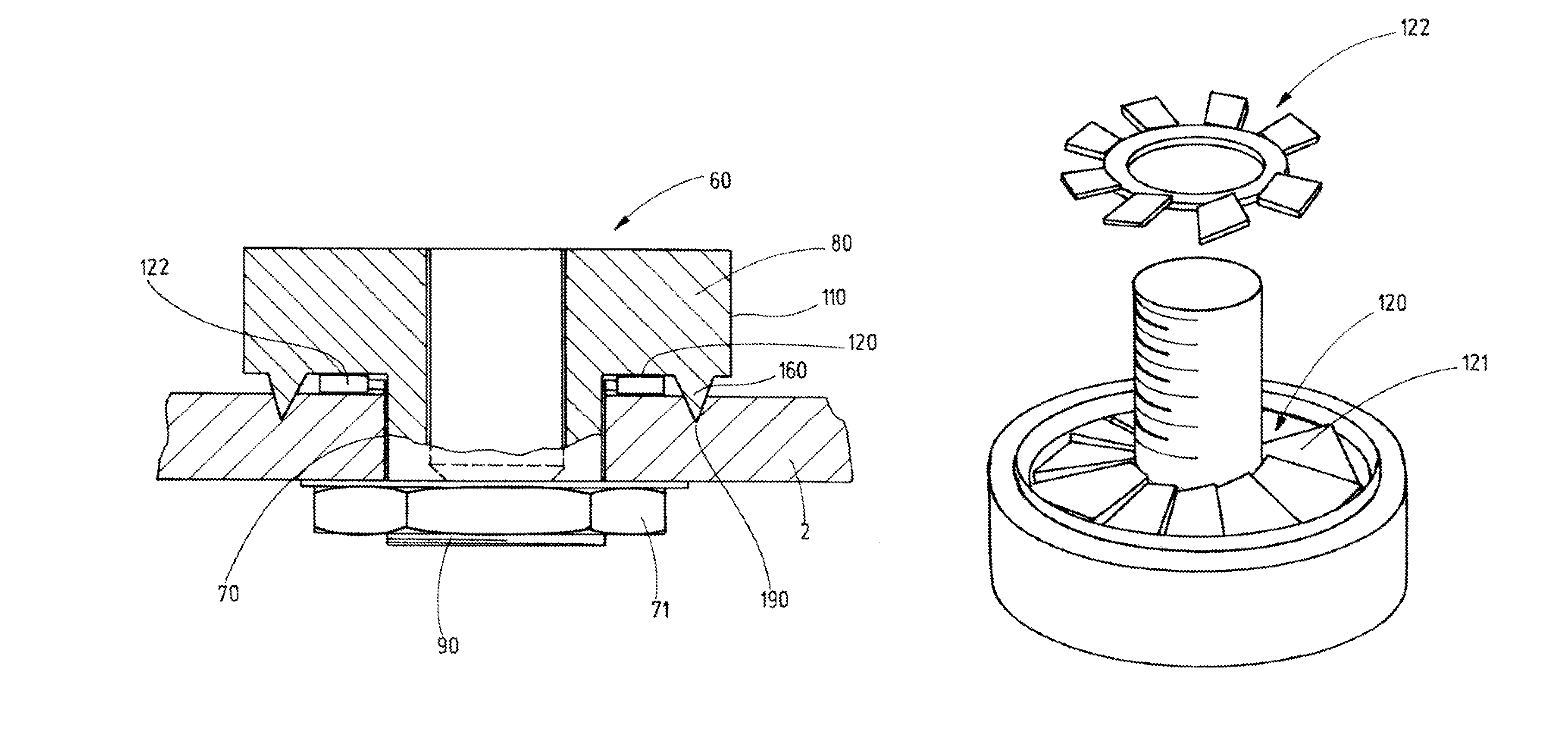

Composite drive shaft with captured end adapters

ActiveUS7335108B2Not easy to corrodeHigh strengthShaftsCouplings for rigid shaftsCarrying capacityDrive shaft

A composite drive shaft in which the end adapters are captured in the composite material portion during the process of manufacturing of the composite drive shaft assembly is disclosed. The end adapters include lugs that protrude outward longitudinally to transmit torque, tensile, and compressive forces, and bending moments to the composite material portion and vice versa. To increase the load carrying capacity for axial force and bending moment, the end adapters may have at least one recessed circumferential groove. Before the manufacturing process, one or more bonding agents may be applied onto the interface of the end adapter to enhance the performance of engagement between the end adapters and the composite material portion. The composite material portion and end adapters are co-cured to produce a final drive shaft that requires no additional work for assembly.

Owner:BELL HELICOPTER TEXTRON INC

Phosphogypsum water hard road base, road base material and preparation method thereof

The invention discloses a phosphogypsum water hard road base, a road base material and a preparation method thereof, relating to the field of road engineering construction. The preparation method of the road base material comprises the following steps: weighing 85-92 percent of phosphogypsum and 15-8 percent of ordinary portland cement, uniformly mixing and stirring, thereby obtaining a preliminary mixture; weighing 99.7-99.95 percent of preliminary mixture and 0.3-0.05 percent of a phosphogypsum water hard curing agent, uniformly mixing and stirring, thereby obtaining a premix; controlling the moisture content of the premix to be 14-18 percent, thereby obtaining a base material, wherein the phosphogypsum water hard curing agent is prepared by mixing the following components in percentage by mass: 40-60 percent of elastic styrene-acrylic emulsion, 30-20 percent of nanometer alumina sol and 30-20 percent of nanometer silica sol. The road base is prepared from the road base material according to a standard road base construction method. The road base material is produced by utilizing phosphogypsum, the environmental pollution is reduced, and wastes are changed into valuable materials; and moreover, the formed road base is high in crack resistance, difficult to corrode and long in service life.

Owner:黄菁华 +2

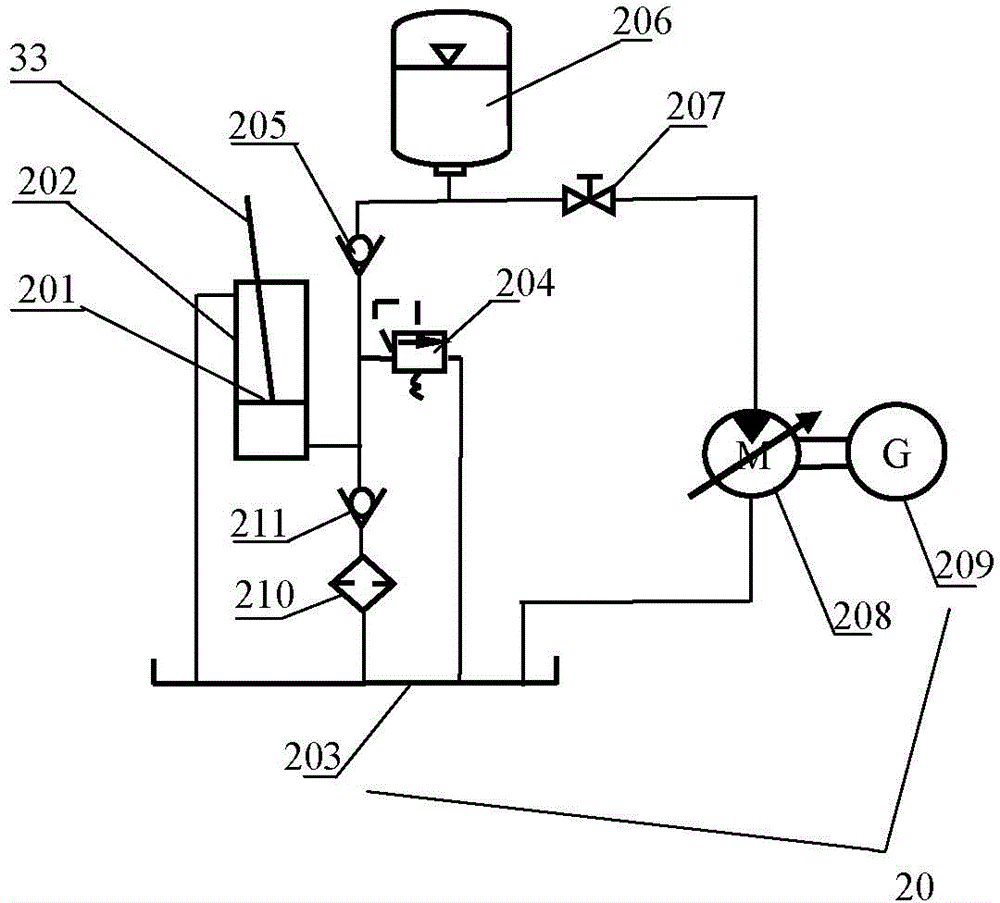

Hydraulic wave energy generator

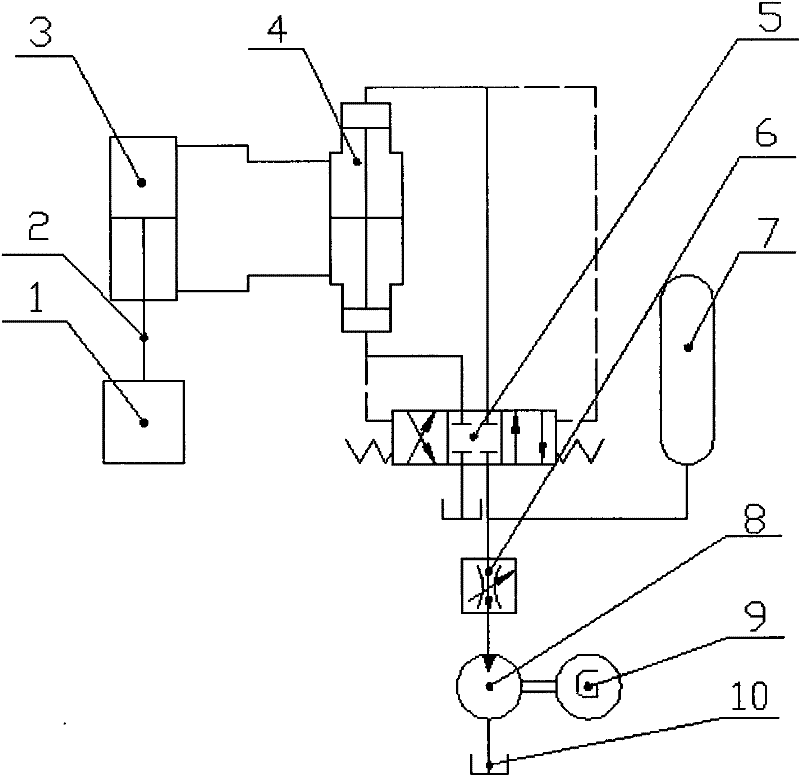

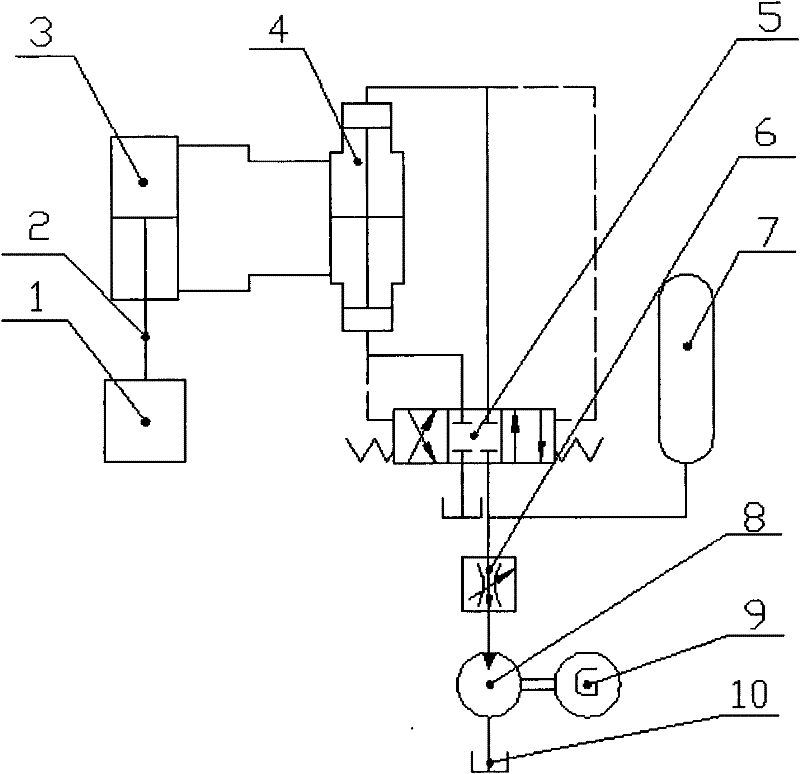

InactiveCN102287312AEfficient power generationNot easy to corrodeMachines/enginesEngine componentsMechanical energyEngineering

A hydraulic wave energy generating device includes an absorbing device, a converting device and a generating device. The absorption device is composed of a float and a connecting rod, and the float is immersed in seawater. The conversion device and the power generation device are arranged in the buoy body. The conversion device is composed of a hydraulic cylinder, a supercharger, a reversing valve, a speed regulating valve, an accumulator, and a hydraulic motor. The float moves up and down under the action of waves, and the hydraulic cylinder piston moves up and down through the connecting rod. The hydraulic oil drives the hydraulic motor to rotate through the supercharger, reversing valve, and speed control valve. The accumulator plays the role of energy storage and voltage stabilization. The power generation device is composed of a generator, and the hydraulic motor is connected with the generator with a coupling to drive the generator to generate electricity. The invention mainly uses the hydraulic system to transfer energy, and realizes the conversion from ocean wave energy to buoy mechanical energy, then to hydraulic energy, then to motor mechanical energy, and finally to electric energy. The hydraulic wave energy generating device has a simple structure and is easy to install, and can be well applied to small ocean buoys.

Owner:SHANGHAI OCEAN UNIV

Ester flame-proof hydraulic-oil containing nano abrasion-resistant additive and production method thereof

ActiveCN101113383AExtended service lifeReduce use costAdditivesBase-materialsOrganic chemistryRaw material

The invention relates to ester type flame retardant hydraulic oil containing nano antiwear additive. The mixture ratio by weight of the raw materials is that: 90-95 percent of synthetic ester compound base oil, 1.0-5.0 percent of synthetic multifunctional additive and 1.0-5.0 percent of nano antiwear additive. The production method is that: first, the synthetic ester compound base oil is heated up to 100-120 DEG C, antioxidant is added and stirred for 1-2 hours at 100-120 DEG C until the solid is completely dissolved, then antirust agent and demulsifying agent are added, finally the finished products are filtered to be used; second, the synthetic ester compound base oil is heated up to 60-80 DEG C, and the synthetic multifunctional additive, the nano antiwear additive and antifoamer are added and stirred for 1-3 hours at a constant temperature of 60-80 DEG C, then heating is stopped, and sample is selected for analysis and packaged into finished products after the analysis. The beneficial effects of the invention are that: high temperature using performance and long time lubricant performance of the products are greatly promoted, the service life of hydraulic systems and oil change period can be greatly prolonged.

Owner:杭州新港润滑科技有限公司

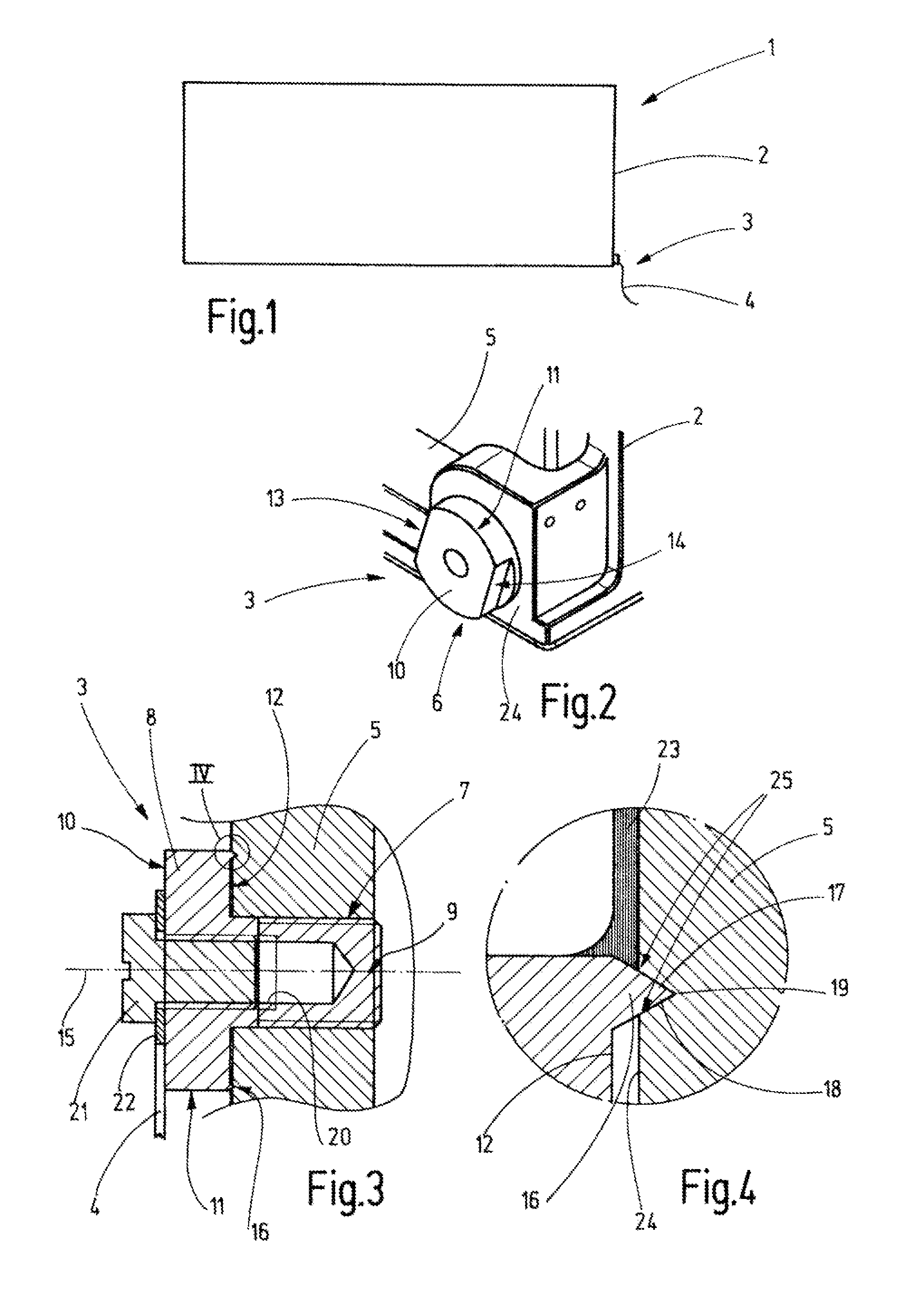

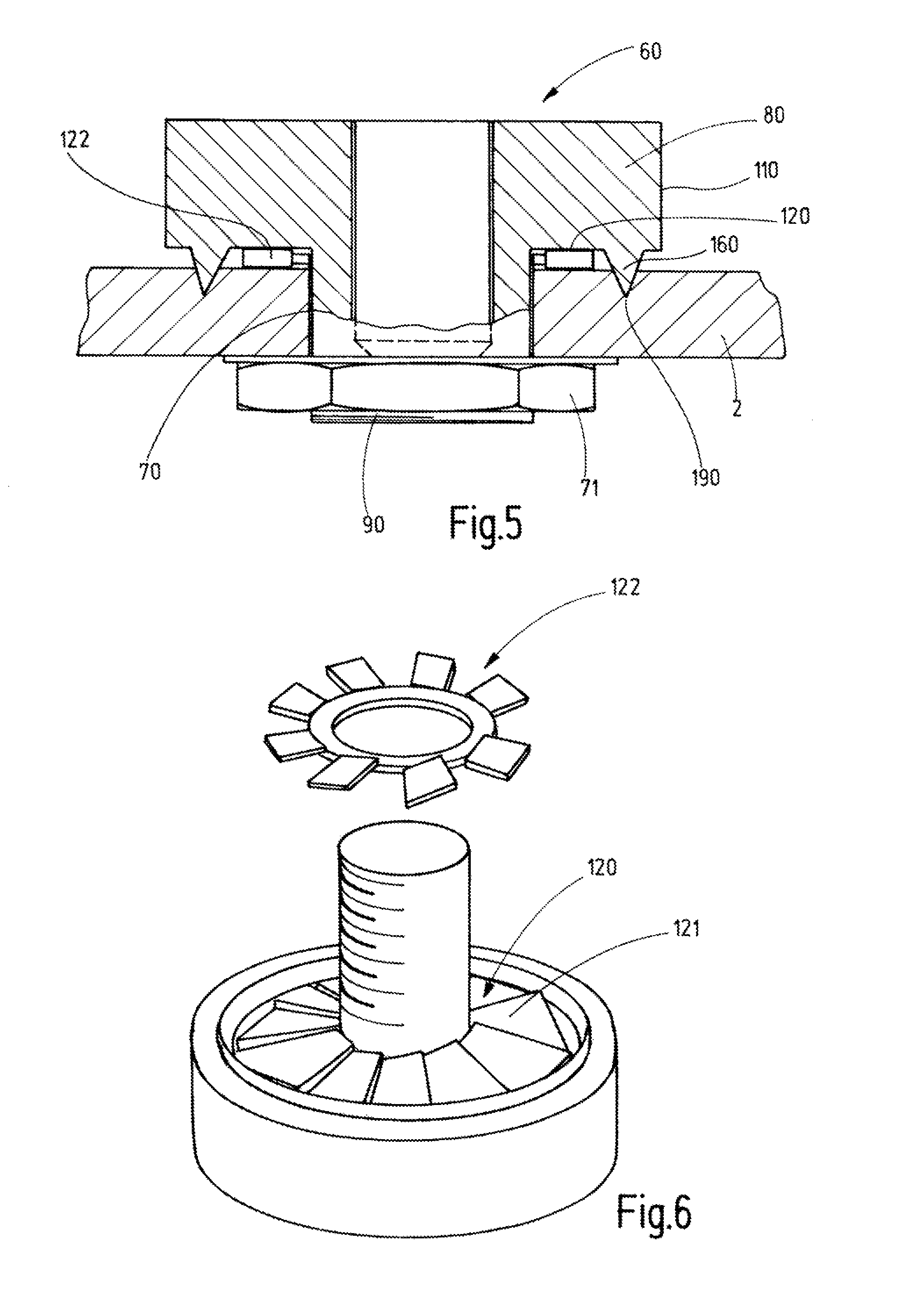

Electrical connector element

An aluminum enclosure of an electronic device is used in a corrosion environment. A long-term low impedance ground connection is needed because of security and EMC reasons. While common surface protection for aluminum in corrosion environments as for example polyurethane paint is not conductive, a stainless steel connector is provided which comprises a head portion and a bolt portion. The bolt portion is inserted into a bore of the enclosure or frame. An annular rib provided on the back side of the head portion defines a cutting edge which cuts into the surface of the aluminum enclosure and provides a gas-tight electrical contact. The front surface of the stainless steel head of the electrical connector element provides a metallic surface for connecting ground wires or other conductors.

Owner:ABACO SYST INC

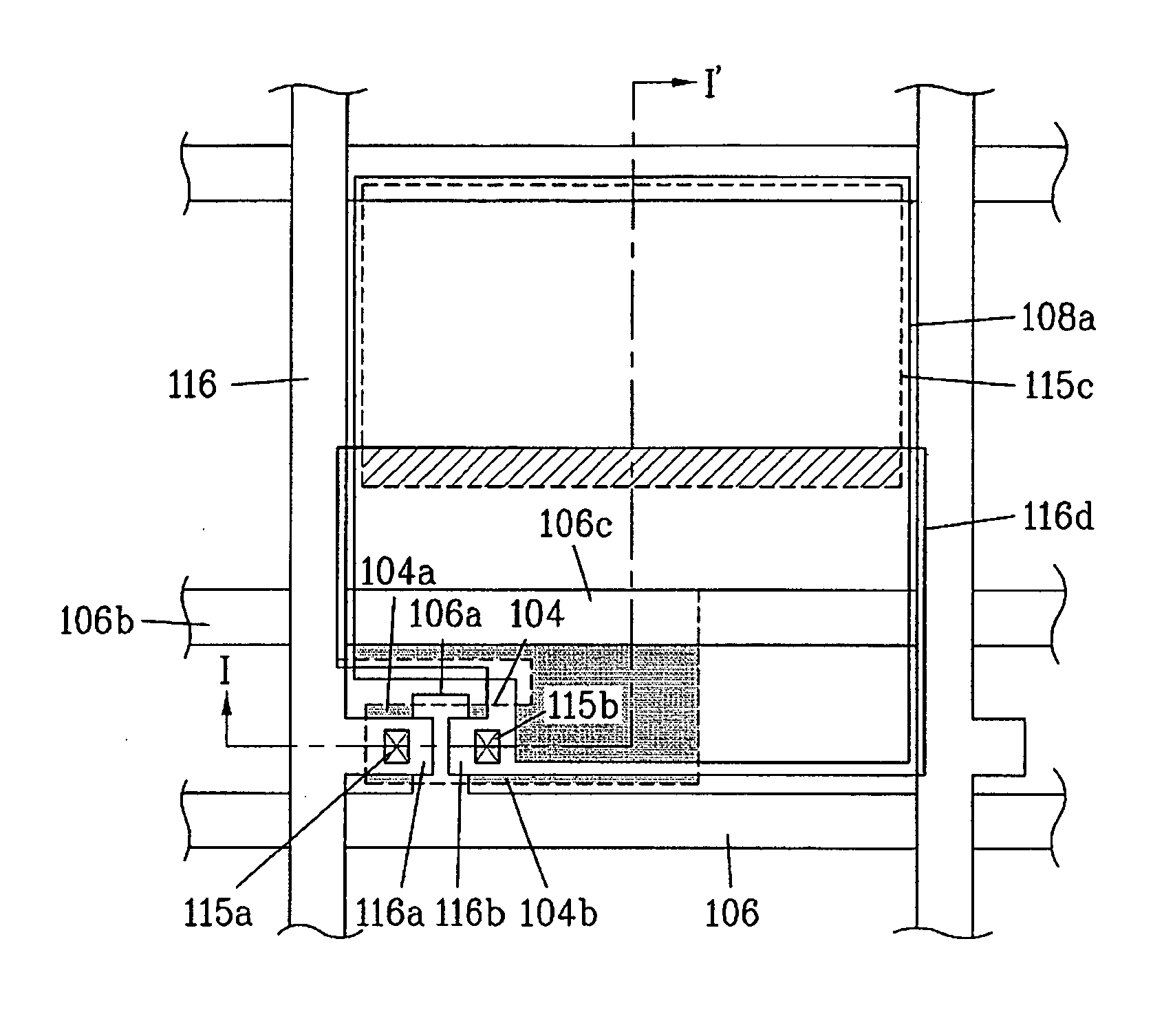

Trans-reflective type liquid crystal display device and method for fabricating the same

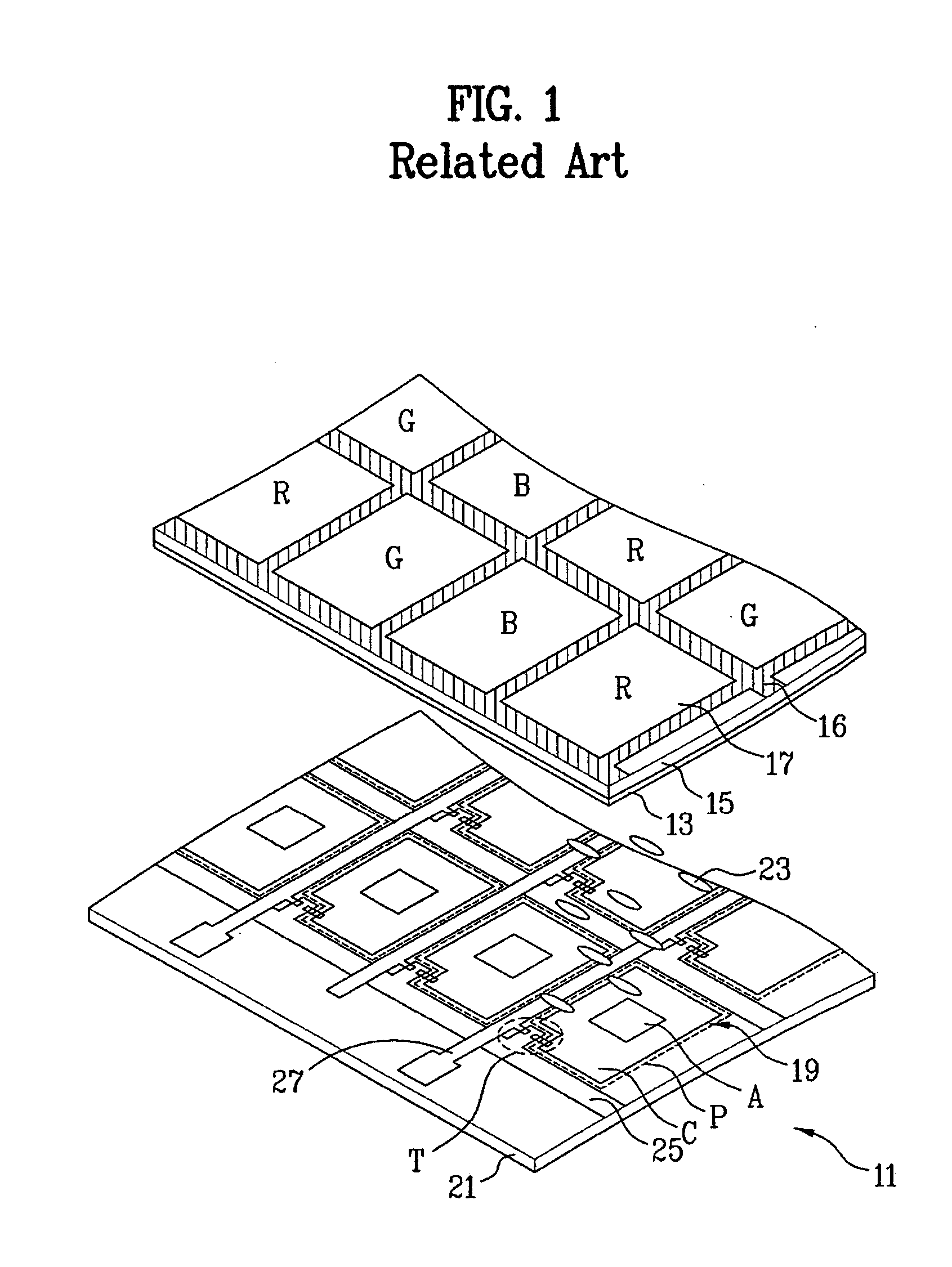

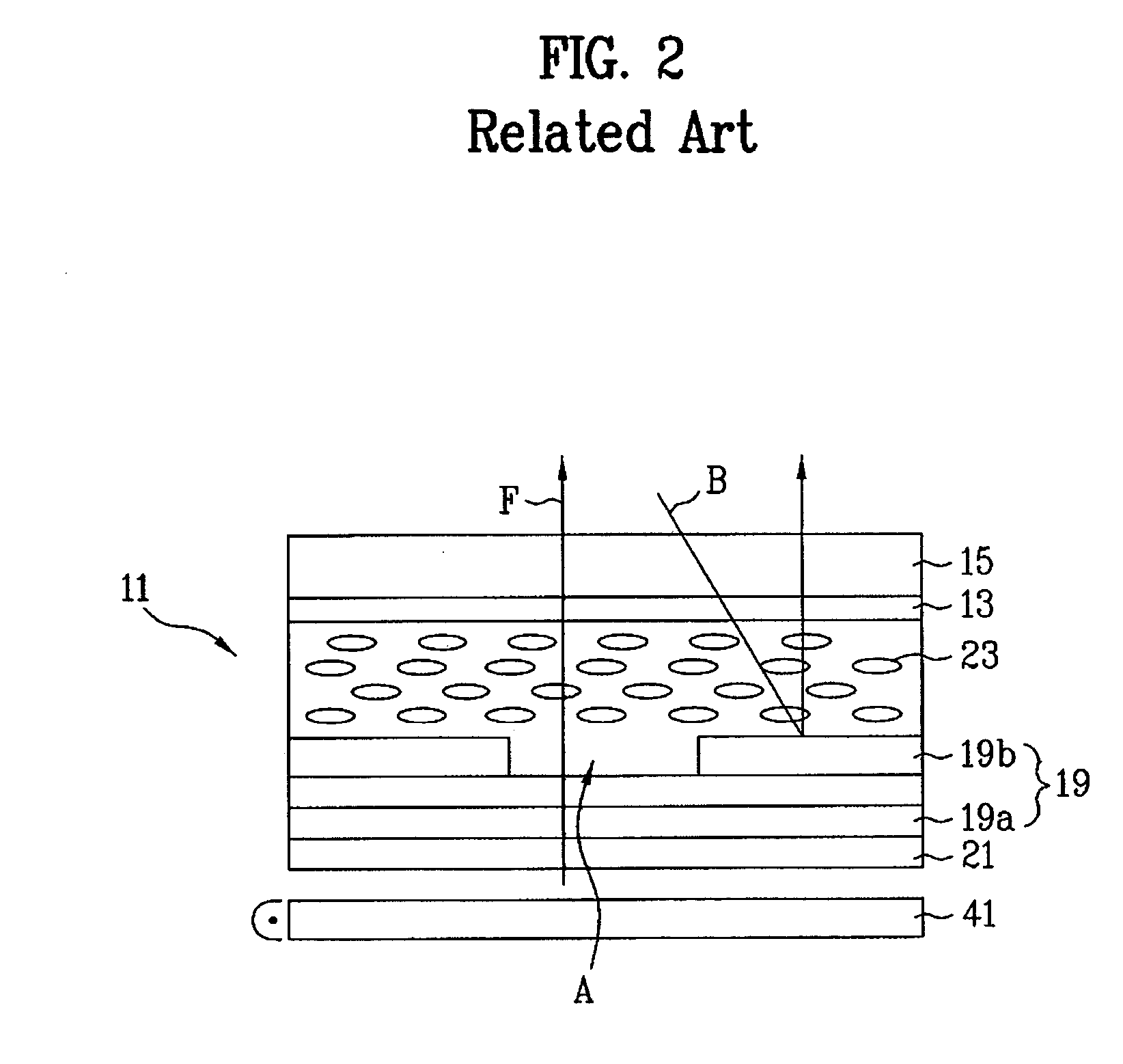

InactiveUS20050140877A1Reduce in quantityWide rangeTransistorStatic indicating devicesLiquid-crystal displayHeat treated

Disclosed is a trans-reflective type LCD device and a method for fabricating the same wherein the method reduces the required number of masks by using a half-tone mask and a diffraction exposure process. Further, by using a half-tone mask and diffraction exposure process, a desired uneven surface may be formed on the reflective part of the pixel region without resorting to thermal processes that may otherwise degrade an insulating layer under the reflective electrode. Accordingly, an organic insulating material may be used between the transmissive electrode and the reflective electrode.

Owner:LG DISPLAY CO LTD

Dredged sediment based plant adaptability matrix and ecological restoration method of bare slope

InactiveCN102229485AImprove stabilityNot easy to corrodeExcavationsHorticultureVegetationRestoration method

According to the invention, by using dredged sediment from water body such as eutrophicated rivers and lakes as the aggregate, plant straws, plant ash, ordinary portland cement, an organic fertilizer, a release fertilizer, a water-retaining agent and the like are added into the dredged sediment with uniformly stirring to form the bare slope plant adaptability matrix with certain adhesive performance. By employing the wet-type guniting technology for two-layer matrix guniting, the plant adaptability matrix is used for the plant restoration of bare mountain slope and can form a new plant cover layer in a short period. The dredged sediment is used as the matrix to control the loss of water and soil, thus minimizing the dependence on the clay resource and the restoration cost in slope restoration and solving the issue of dredged sediment treatment by the resource mode; and furthermore, the restoration method provided by the invention has high environmental, ecological and economic benefits.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Polymer-type water glass curing agent and application in water glass chemical grouting materials

InactiveCN101885591AResolution timeSolve the strength problemOther chemical processesBuilding constructionsSolubility(Hydroxyethyl)methacrylate

The invention relates to a polymer-type water glass curing agent with easily-controlled curing time and high toughness. The curing agent is mainly formed by polymerizing and copolymerizing double bonds-containing acids such as crylic acid, methacrylic acid and the like and double bonds-containing esters such as butyl methacrylate, vinyl acetate, hydroxy-ethyl methacrylate and the like by latex. The polymer-type water glass curing agent of the invention is a novel water-soluble water glass curing agent, which can control the curing time of the water-soluble grouting materials by controlling the content of carboxyl and ester group in a polymer. By using the curing agent, a water glass consolidating body has vey high compressive strength and toughness, synthetically overcomes the shortages of too fast curing time, high corrosiveness, low consolidating body strength and the like of an acid curing agent which is commonly used in the water glass grouting materials and the shortages of poor water solubility, slow curing time and the like of an organic ester curing agent, and can be widely applied in the field of anti-seepage stoppage engineering.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

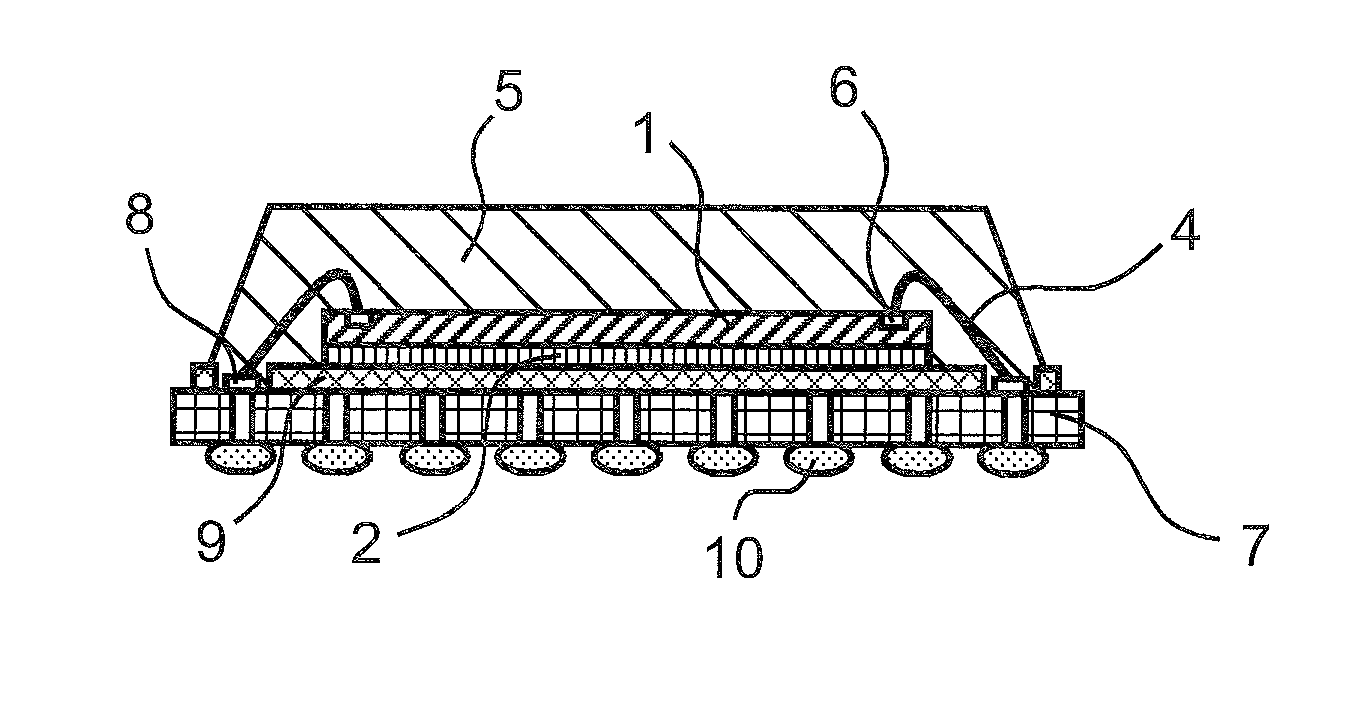

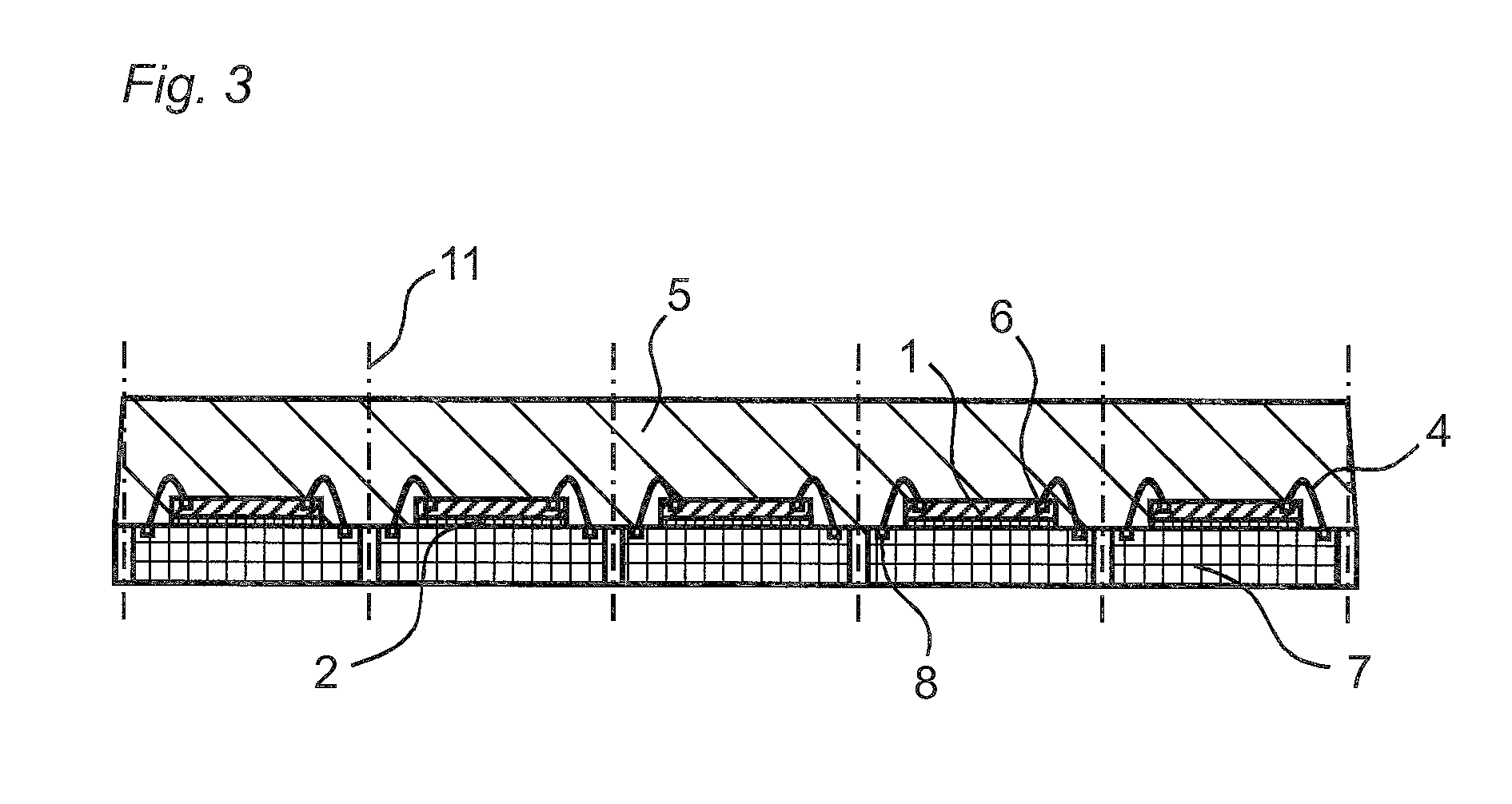

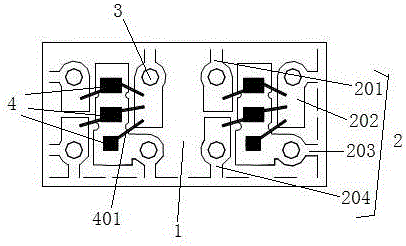

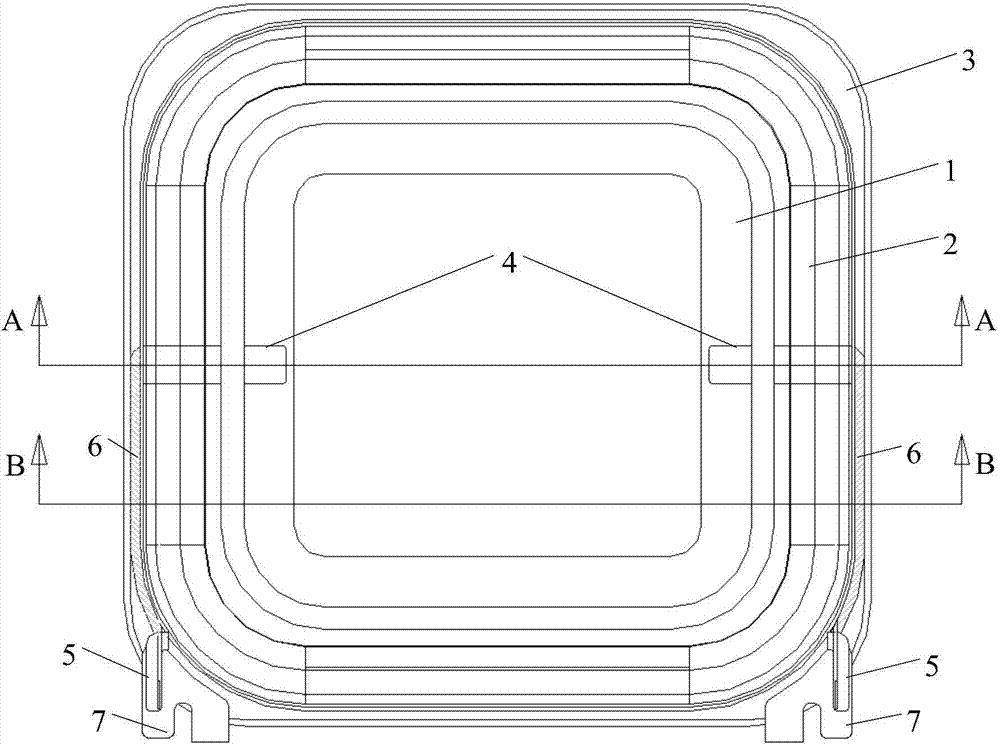

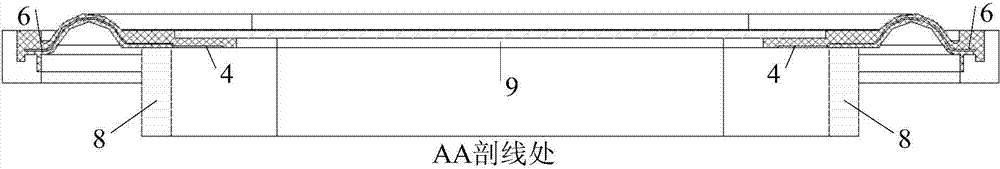

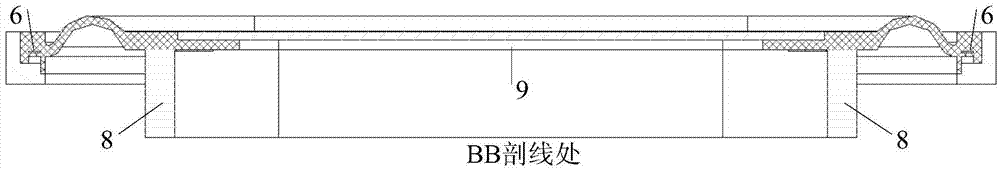

Encapsulation module for surface mounted RGB-LED (Red, Green, Blue-Light Emitting Diode) and manufacturing method thereof

ActiveCN106847801AIncrease productivityImprove the ability to resist external mechanical strengthSolid-state devicesIdentification meansSurface mountingEngineering

The invention provides an encapsulation module for a surface mounted RGB-LED (Red, Green, Blue-Light Emitting Diode) and a manufacturing method thereof. The encapsulation module comprises a substrate and light emitting units, wherein the light emitting units are arranged on the substrate; the light emitting units are provided with protective layers; the quantity of the light emitting units is at least two; each light emitting unit comprises four mutually independent upper bonding pads and one group of RGB LED chips; the RGB LED chips are arranged on any one upper bonding pad, and are connected with the other three upper bonding pads through keys and lines; the upper bonding pads are provided with metallic holes which pass through the substrate and are conductively communicated up and down; the positions, corresponding to the metallic holes, of the reverse surface of the substrate are provided with lower bonding pads; the lower bonding pads are mutually independent. By using the encapsulation module, multiple light emitting units are integrated in one encapsulation module; the production efficiency of an LED in subsequent application and production is greatly improved; the production cost is greatly decreased.

Owner:SHANDONG JIERUNHONG OPTOELECTRONICS CO LTD

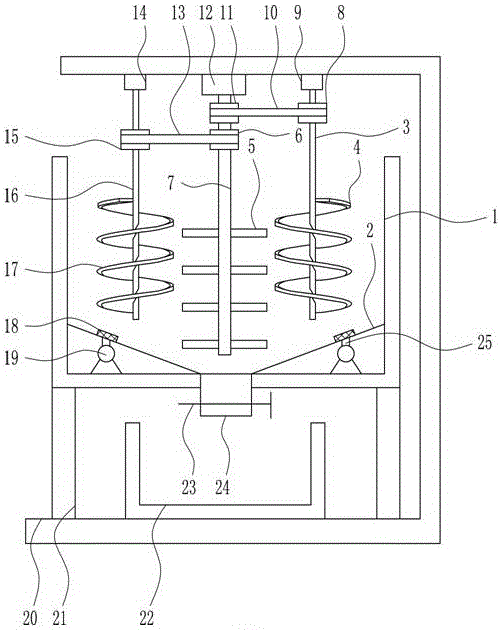

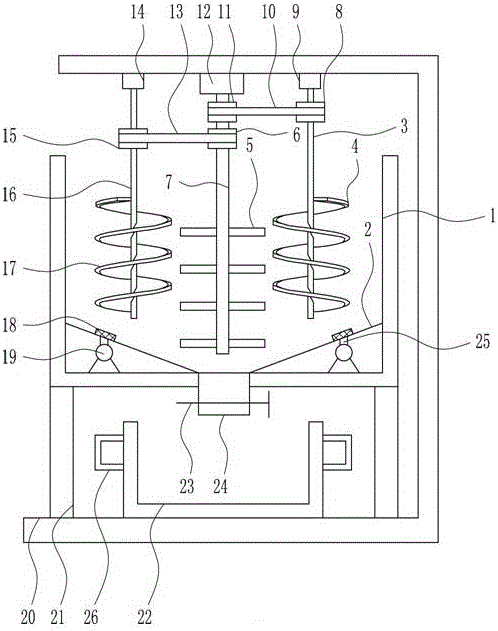

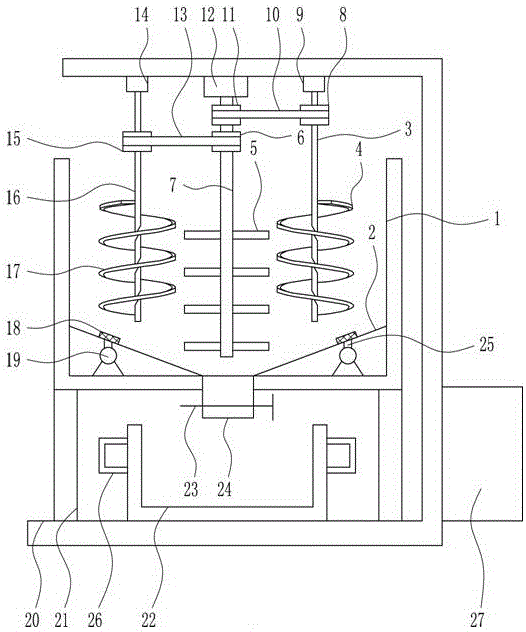

Polyurethane foaming plastic reaction molding device

InactiveCN106478907ANot easy to corrodeExtended service lifeRotary stirring mixersTransportation and packagingSpiral bladePolymer chemistry

The invention relates to a reaction molding device, and particularly relates to a polyurethane foaming plastic reaction molding device. The technical problem to be solved in the invention is to provide a polyurethane foaming plastic reaction molding device with ideal reaction molding and thorough reaction. In order to solve the technical problem, the invention provides the polyurethane foaming plastic reaction molding device. The polyurethane foaming plastic reaction molding device comprises a frame body, a clapboard, a first stirring shaft, a first spiral blade, a stirring blade, a third belt wheel, a second stirring shaft, a first belt wheel, a first bearing base and others; left and right sides of the bottom part in an installing frame are symmetrically welded with supporting rods, and top ends of the supporting rod are welded with the frame body; the center of the bottom part of the frame body is welded with a discharge pipe, and a valve is arranged on the discharge pipe. Through a motor, the stirring blade is driven to rotate, so as to mix raw materials in the frame; meanwhile, the first spiral blade and the second spiral blade are driven to rotate, and thus the raw materials are vertically conveyed.

Owner:WUXI TONGXIN PLASTIC PROD

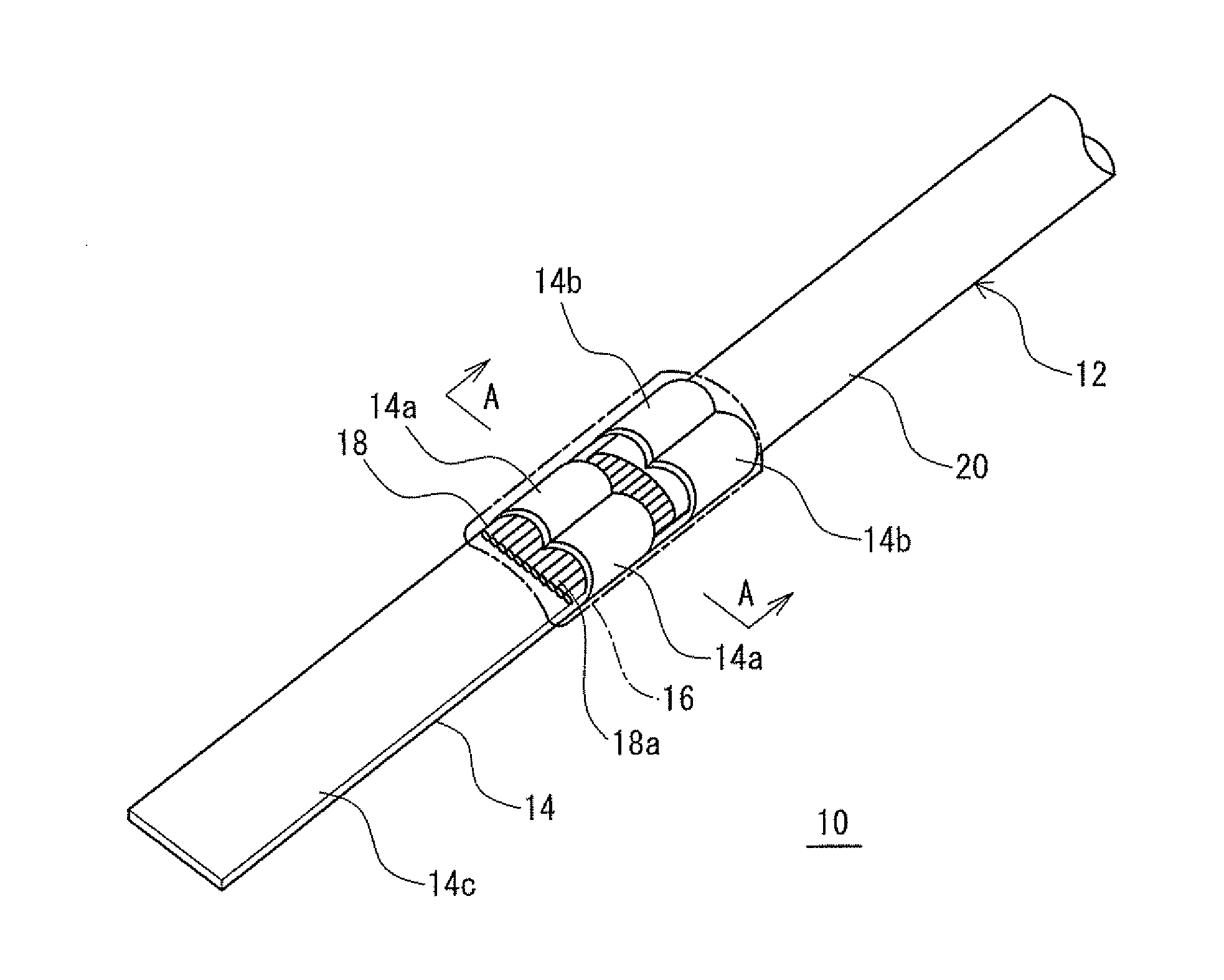

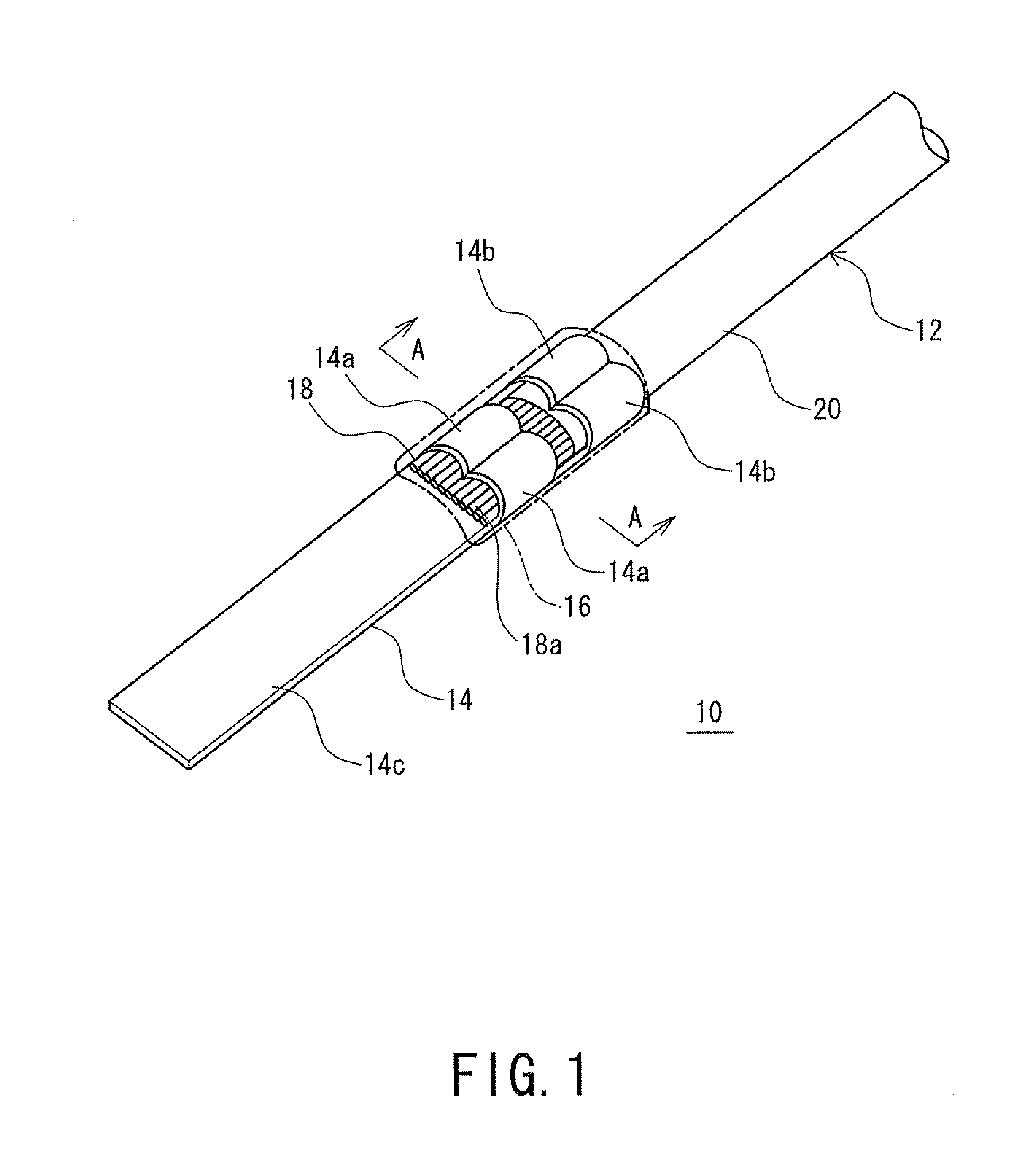

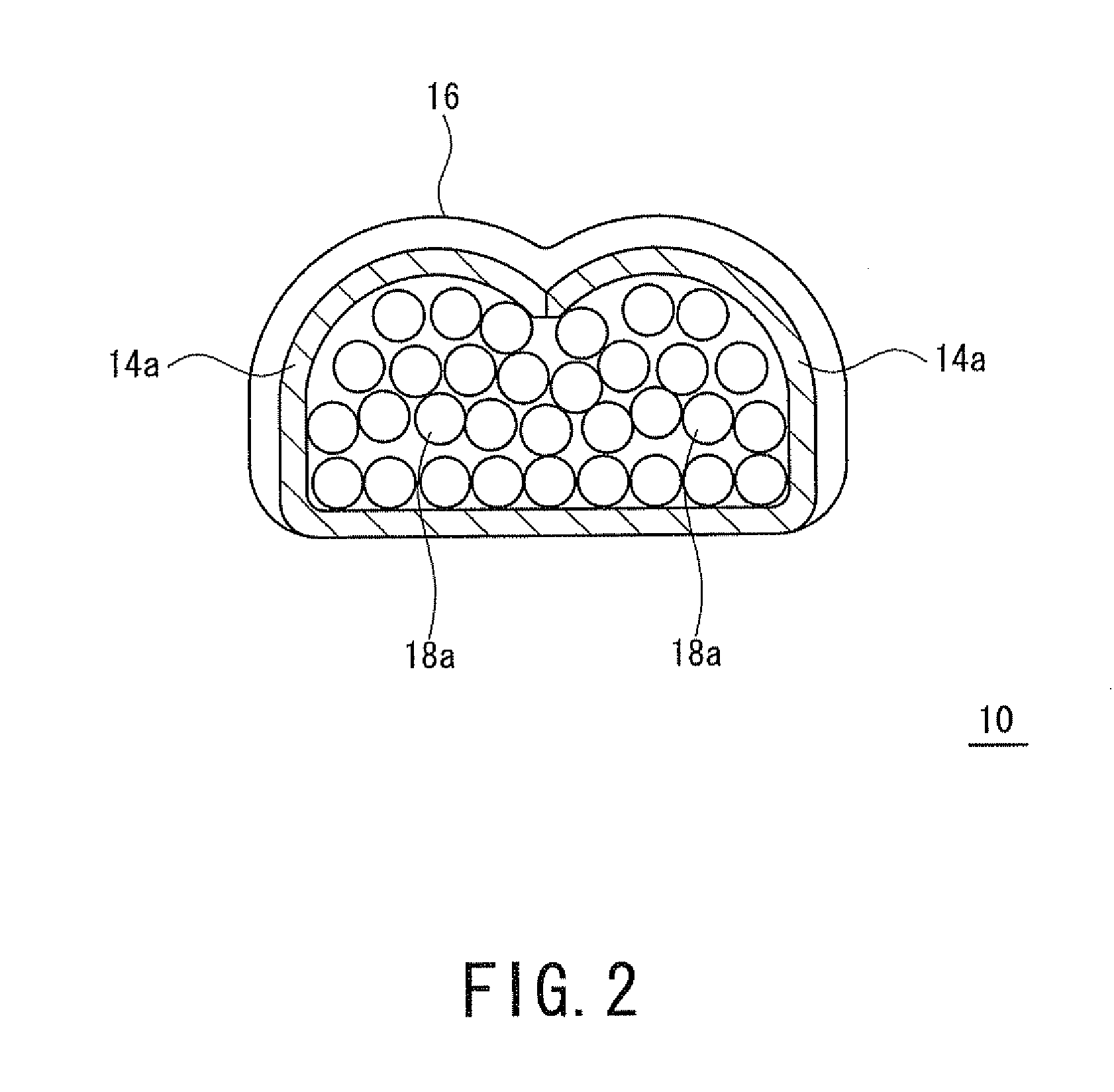

Anticorrosive, coated electric wire with terminal, and wiring harness

InactiveUS20120205151A1Easy to operateAvoid corrosionElectrically conductive connectionsPlastic/resin/waxes insulatorsElectrical conductorAlpha-olefin

Provided are an anticorrosive that is not sticky when a connected portion between a wire conductor and a terminal is subjected to anticorrosive treatment using the anticorrosive and accordingly has excellent handleability, and can coat the connected portion in a convincing way to prevent corrosion from building up at the connected portion, a coated electric wire with a terminal using the anticorrosive, and a wiring harness using the anticorrosive. The anticorrosive contains an ethylene-alpha-olefin copolymer that has a melt flow rate of 200 g / 10 min or more at 190 degrees C. at 21.18 N, which is measured in accordance with the JIS K6922-1, wherein the ratio of copolymerization of an alpha-olefin in the ethylene-alpha-olefin copolymer is 10% by mass or more. In a coated electric wire with a terminal, a connected portion between a wire conductor and a terminal is coated with the anticorrosive.

Owner:AUTONETWORKS TECH LTD +2

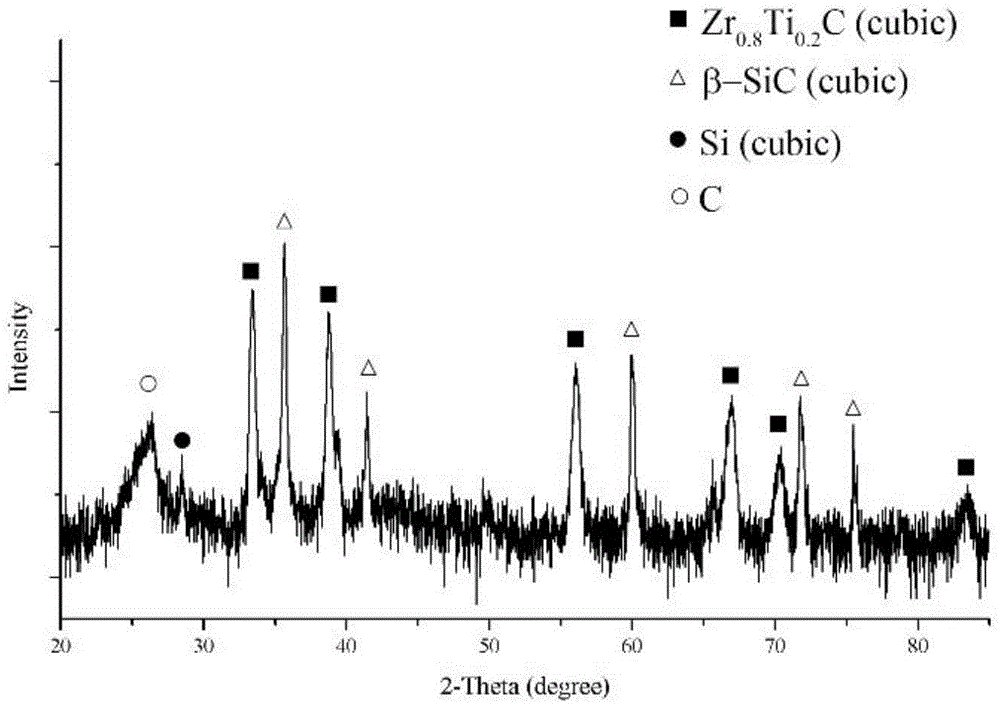

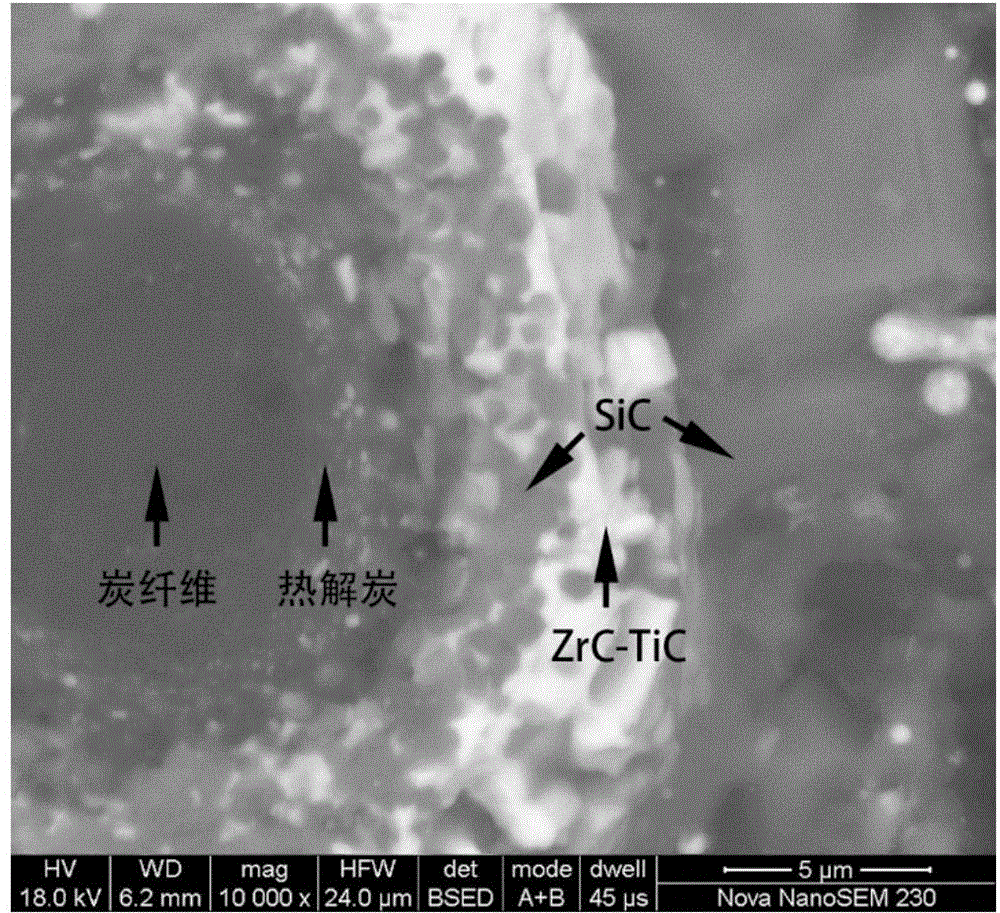

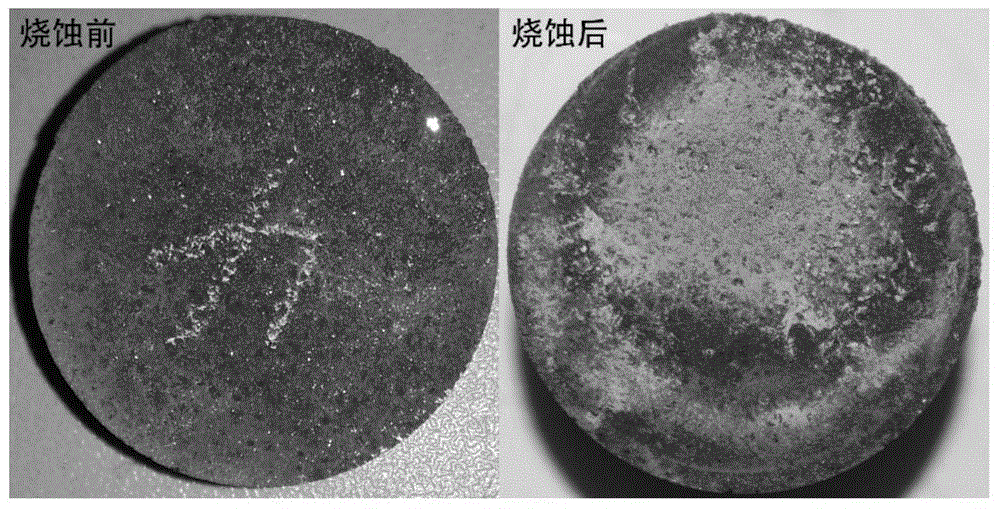

ZrC-TiC modified C/C-SiC composite material and preparation method thereof

The invention relates to a ZrC-TiC modified C / C-SiC composite material and a preparation method thereof, belonging to the technical field of preparation of composite materials. The composite material disclosed by the invention comprises carbon fibers, a pyrolytic carbon layer, SiC and ZrC-TiC, wherein the pyrolytic carbon layer coats the surface of the carbon fibers; SiC and ZrC-TiC coat the surface of the pyrolytic carbon layer; and ZrC-TiC is uniformly distributed in SiC. The preparation method comprises the following steps: preparing a low-density C / C composite material by adopting chemical vapor infiltration; melting Si, Zr and Ti powder, infiltrating the powder into the C / C composite material by virtue of a capillary action, and forming a ceramic phase in pores by virtue of a high-temperature in-situ reaction, thereby obtaining the ZrC-TiC modified C / C-SiC composite material. With the adoption of the process method which is low in cost, rapid and convenient, the service temperature of the C / C-SiC composite material is effectively improved, and the ultra-high temperature ablation resistance of the material is greatly enhanced.

Owner:深圳金羽先进材料有限公司

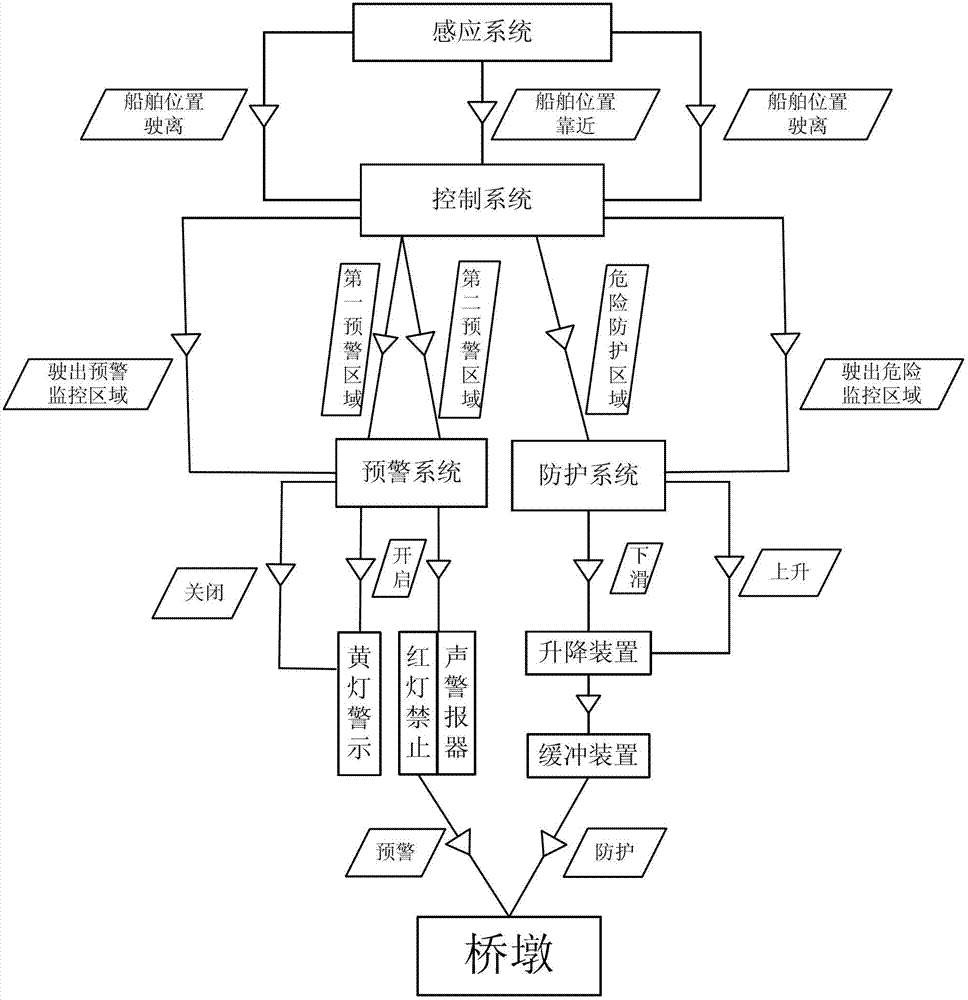

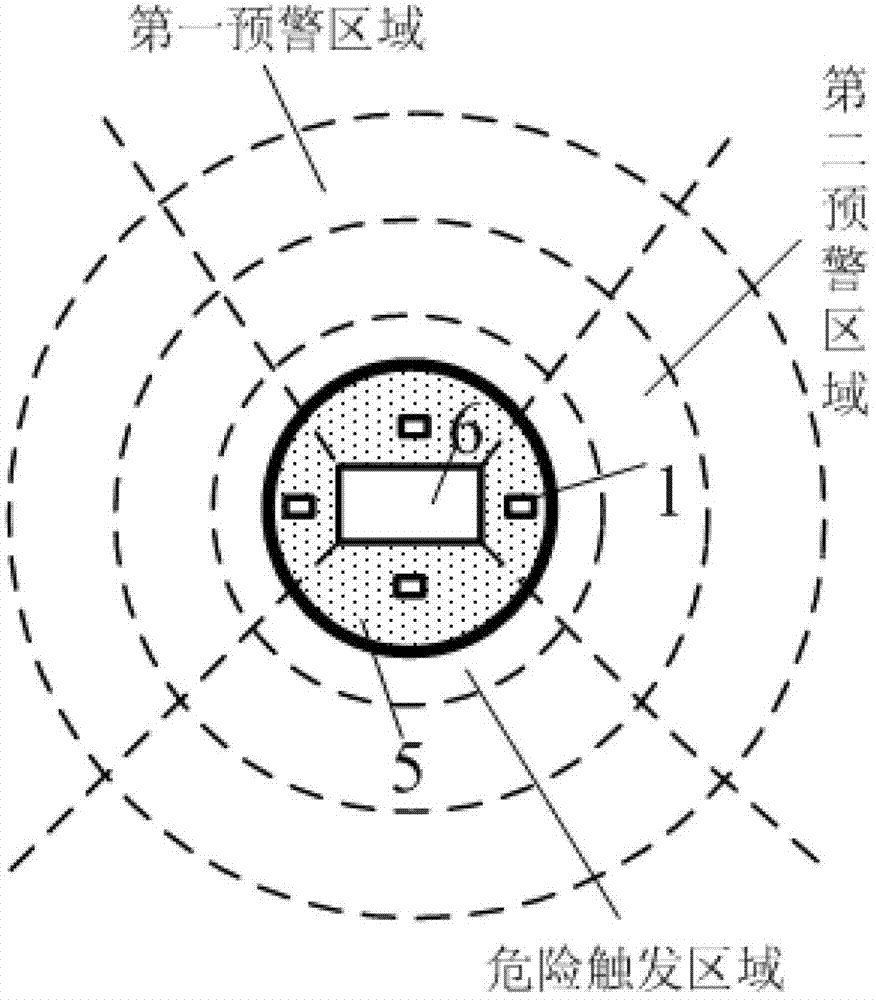

Early warning and protective method for collision resistance of bridge piers

ActiveCN103195023AAvoid Corrosion FailureExtend your lifeClimate change adaptationMarine craft traffic controlControl systemElectrical impulse

The invention provides an early warning and protective method for collision resistance of bridge piers. The method includes that step one, an electronic induction device detects ships within a certain sea area range and amplifies detected physical signals into electrical impulse signals, when the ships sail into a monitored and early warned area, a control system controls an alarm system to raise the alarm, and the ships can adjust sailing directions; step two, when the ships move on and sail into danger areas, the control system controls output of high-low levels to achieve early warning and / or protective functions according to the sizes of the electrical impulse signals; and step three, when the ships leave the monitored sea area after collision and the electronic induction device cannot detect signals, the control system controls reset of an early warning and protective system so as to achieve recycling. According to the early warning and protective method, early warning and protection are combined, ship-bridge collision accidents can be avoided effectively by the aid of intelligent early warning, and the protective system does not occupy navigation channels and not prone to corrosion by seawater and capable of being recycled under the normal state.

Owner:SHANGHAI JIAO TONG UNIV

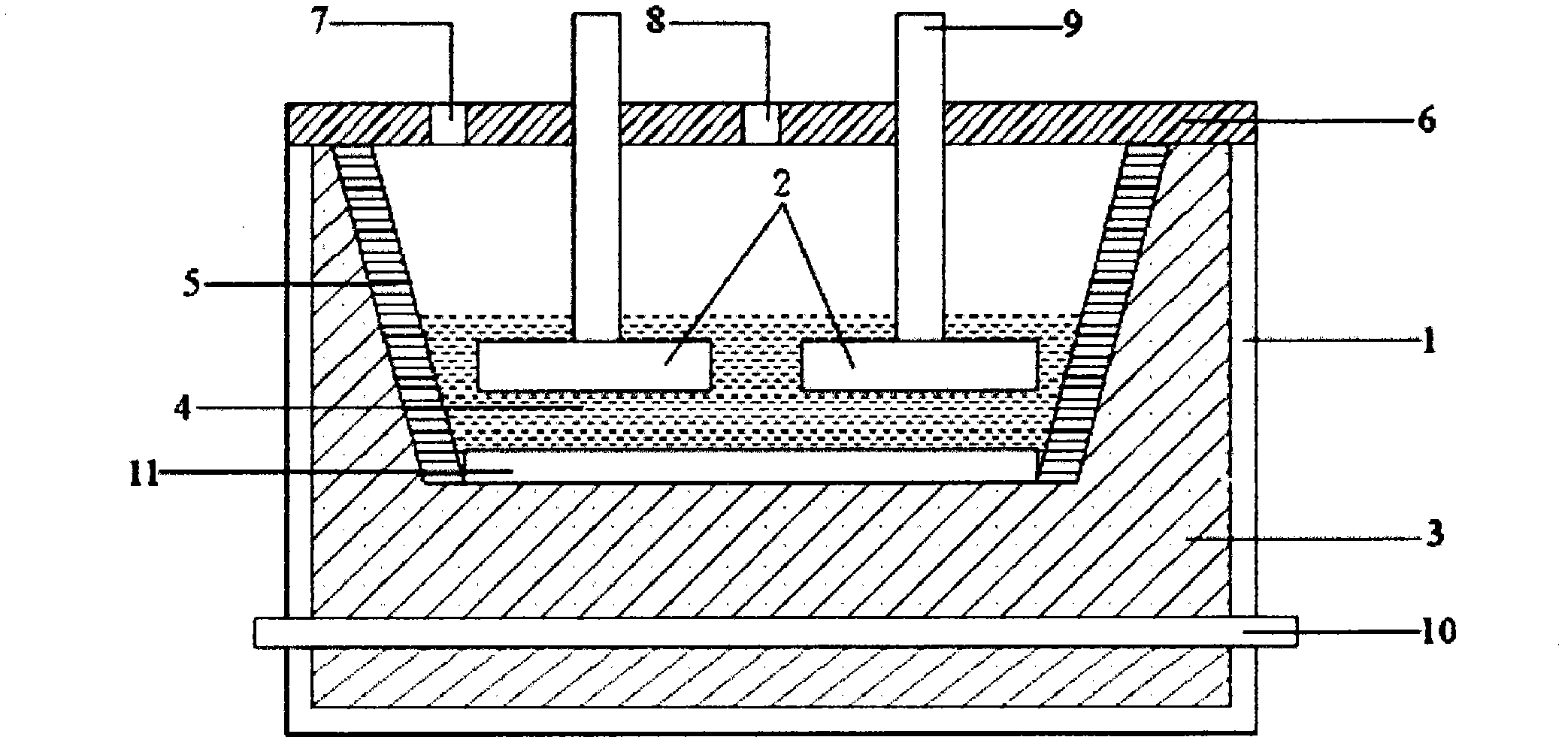

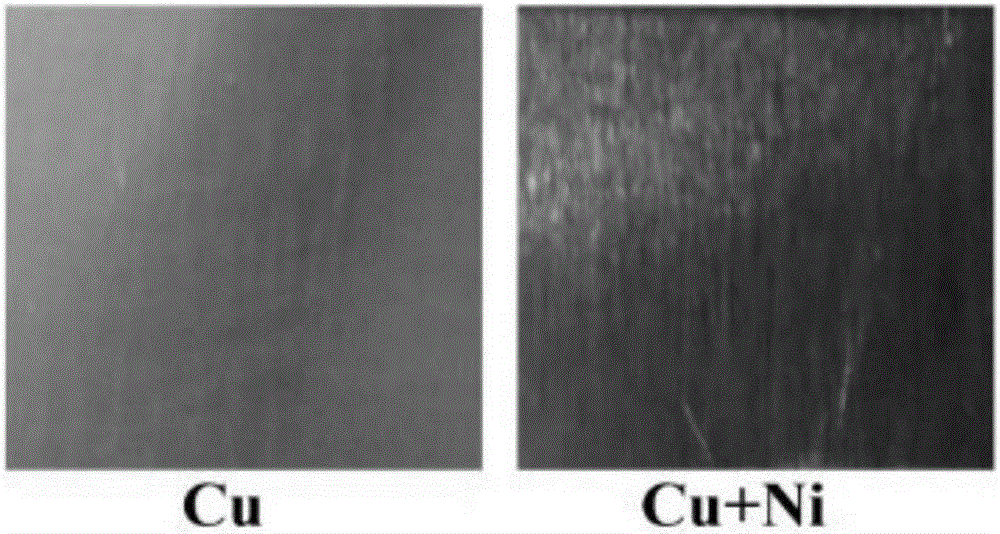

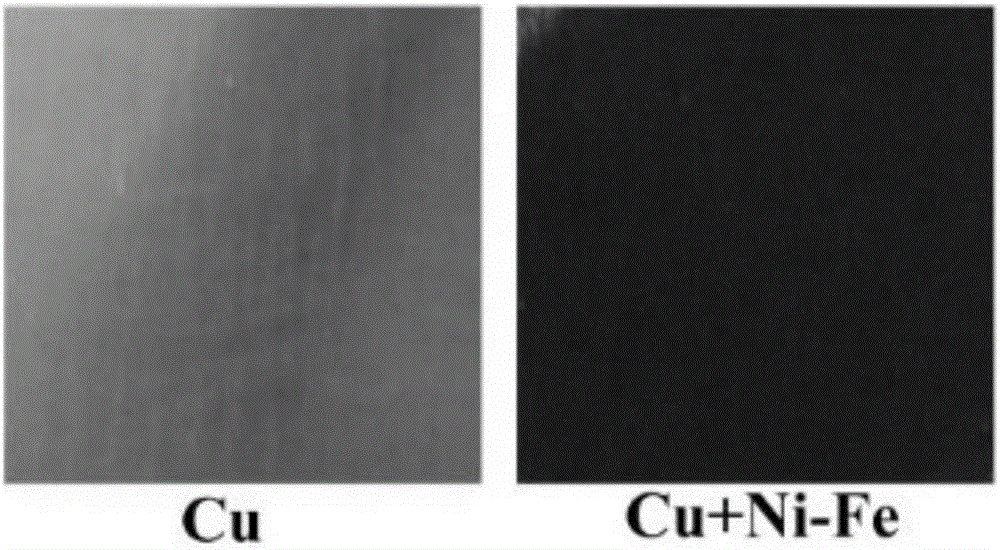

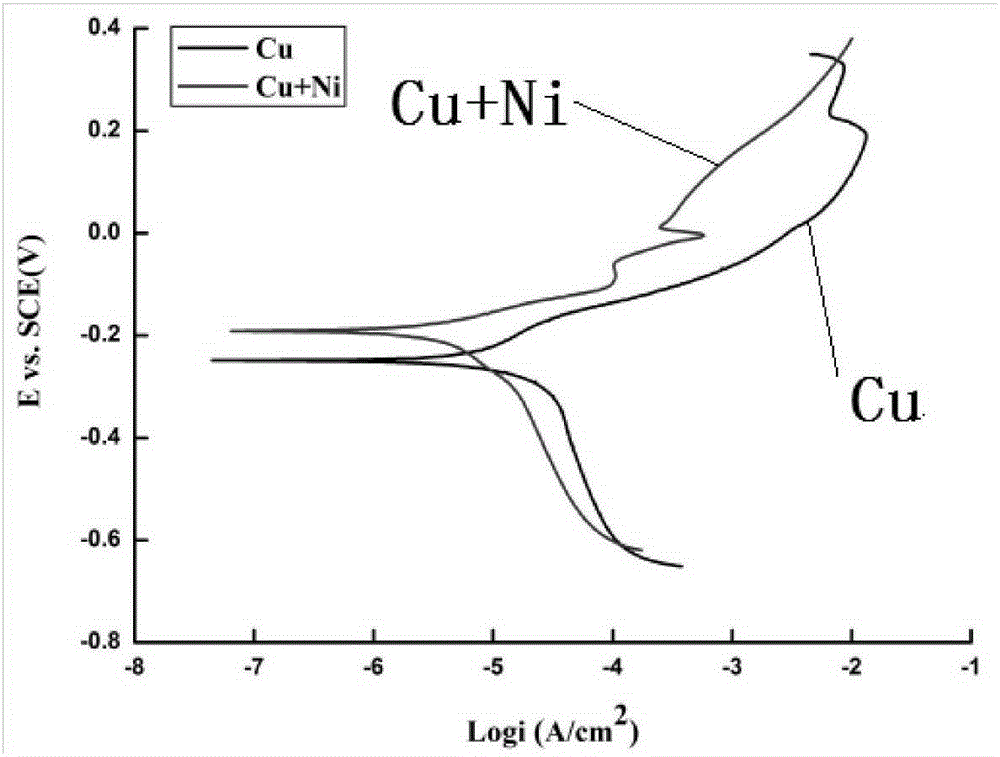

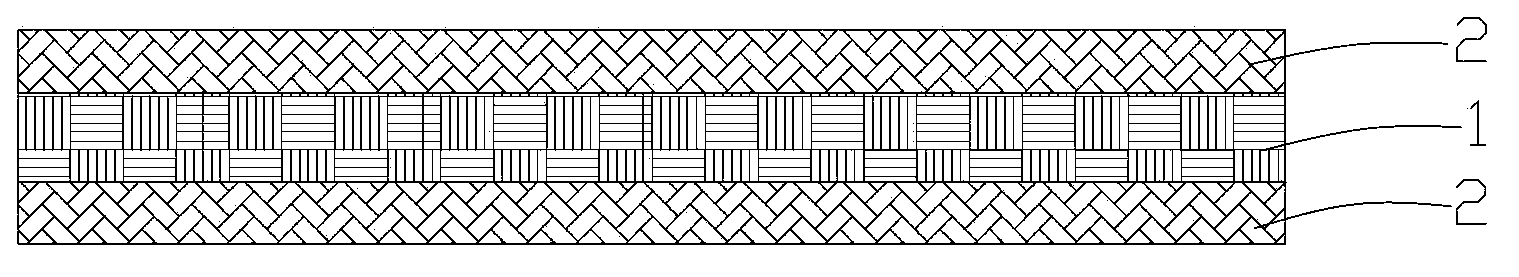

Electrolytic bath for aluminium electrolysis and electrolysis technology using same

An electrolysis tank used for aluminum electrolysis, comprising a tank body, an anode and a cathode arranged within the tank body, also an electrolyte accommodated within the tank body, where at least a part of the anode is submerged in the electrolyte. The anode is arranged above the tank body. The cathode is arranged at the tank bottom and is covered by a certain amount of liquid aluminum. The electrolyte is provided between the anode and the cathode. The electrolyte covers the liquid aluminum. The tank body has arranged on an inner sidewall thereof an insulation layer for use in separating oxygen or the electrolyte from a carbon block. The tank is characterized in that: the constituents of the anode comprise Fe, Cu, Ni, and Sn, where Fe and Cu are the main constituents; the electrolyte consists of 30 to 38 wt% of NaF, 49 to 60 wt% of AlF3, 1 to 5 wt% of LiF, 1 to 6 wt% of KF, and 3 to 6 wt% of Al2O3, where the molar ratio of NaF to AlF3 is between 1.0 and 1.52. The electrolysis tank is applicable in industrialized production of electrolyzed aluminum.

Owner:INNER MONGOLIA UNITED IND

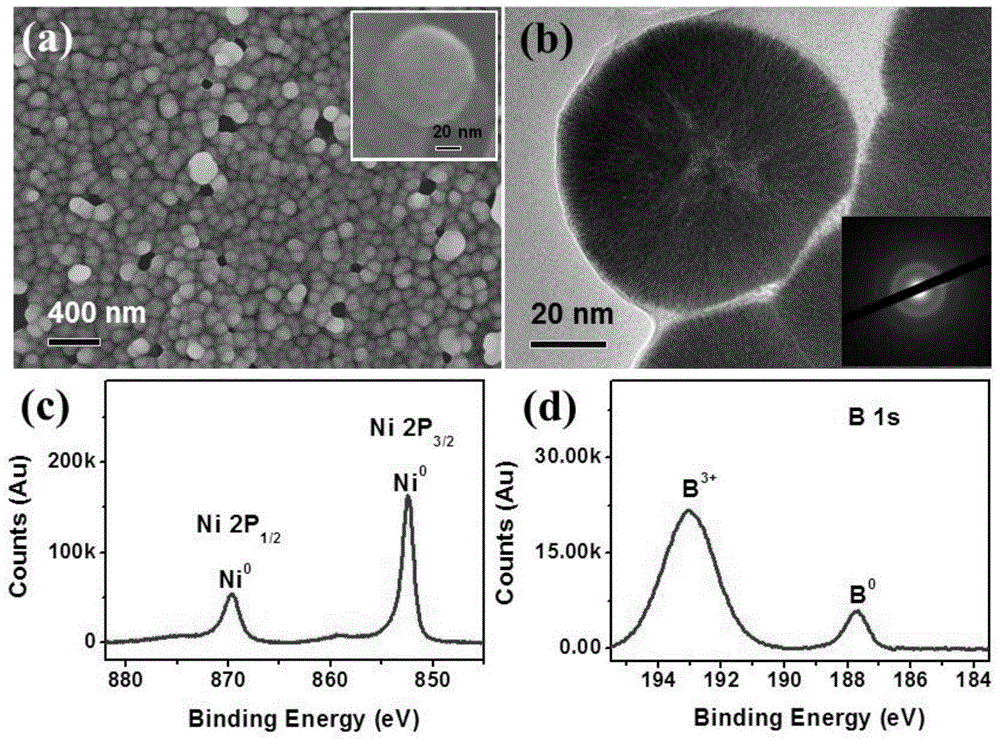

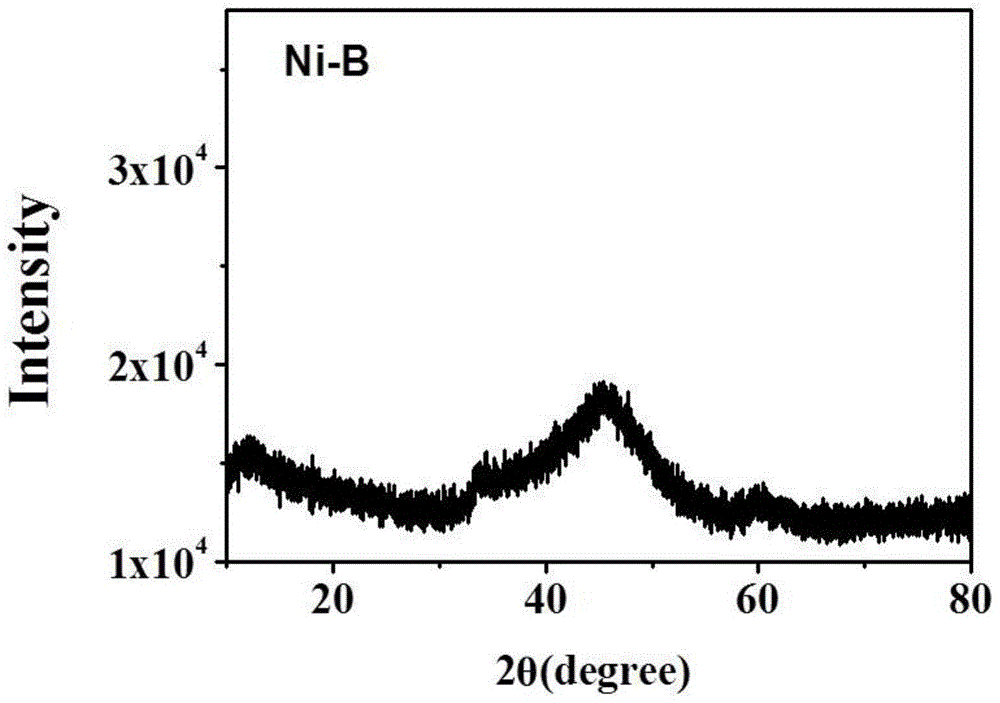

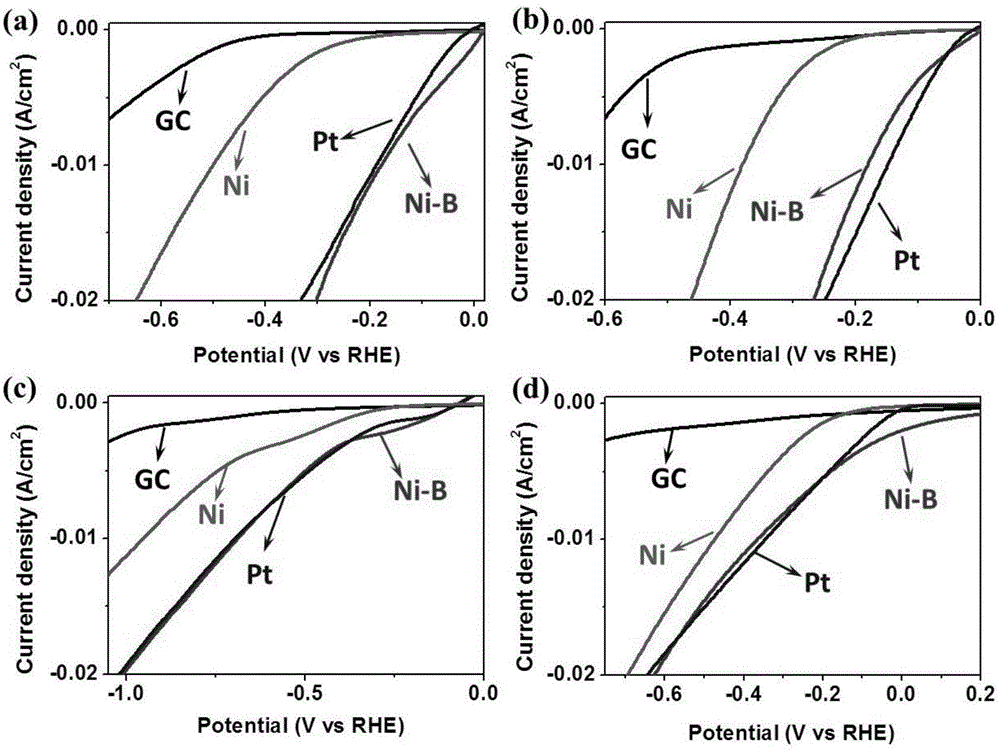

Catalyst used for preparation of hydrogen through water electrolysis, and preparation method thereof

ActiveCN103952719AReduce hydrogen evolution overpotentialHigh activityLiquid/solution decomposition chemical coatingMetal/metal-oxides/metal-hydroxide catalystsPlatinumElectrolysis

The invention provides a catalyst used for the preparation of hydrogen through water electrolysis. The catalyst is amorphous Ni-B, and an atom ratio of Ni to B is 1.0-5.0. The invention also provides a preparation method for the catalyst. The method is characterized in that Ni-B is loaded on the surface of a carrier through a chemical plating method, and the feeding atom ratio of B to Ni in a chemical plating liquid is 3.0-10.0. The amorphous Ni-B is successfully applied in the catalysis of a hydrogen evolution reaction through water decomposition, and the reaction activity of the amorphous Ni-B can be comparable with that of platinum. The amorphous Ni-B has the advantages of low hydrogen evolution over-potential, high catalytic efficiency, stable performances, low price and simple preparation, and becomes one of the most ideal catalysts for substituting the present noble metal Pt catalyst.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Silicone vibrating diaphragm, receiver module and method for processing silicone vibrating diaphragm

InactiveCN104853304AAchieve connectionTroubleshoot hearing problemsEarpiece/earphone attachmentsPlane diaphragmsSilica gelInjection moulding

The invention discloses a silicone vibrating diaphragm, a receiver module and a method for processing the silicone vibrating diaphragm. Two blocks of sheet metal are integrally formed on the silicone vibrating diaphragm through injection molding, the two blocks of sheet metal are embedded in the silicone vibrating diaphragm symmetrically, and both ends of each sheet metal are provided with a first welding part and a second welding part; each first welding part is embedded in a plane part, close to a folded ring part, of the silicone vibrating diaphragm, and is used for welding a coiling tap of a voice coil on the inner side of the voice coil; each second welding part extends out of or is embedded in a fixing part of the silicone vibrating diaphragm, and is used for welding a welding pad on an outer shell; and a connecting part connecting each first welding part and the corresponding second welding part is embedded in the silicone vibrating diaphragm to form a conductive path. By adopting the technical scheme of replacing lead wires of the voice coils with the two blocks of sheet metal of the silicone vibrating diaphragm, the problem of poor listening effect caused by collision of lead wires of the voice coils can be solved thoroughly, a wire-break risk of the lead wires of the voice coils can be avoided through the sheet metal embedded in the silicone vibrating diaphragm, and the product stability is improved.

Owner:GOERTEK INC

Nickel plating liquid and method for preparing nickel-based plating layer by using same

The invention discloses nickel plating liquid and a method for preparing a nickel-based plating layer by using the same. The nickel plating liquid comprises nickel salt, a complexing agent, a pH adjusting agent, a composite, a brightening agent and water. The method for preparing the nickel-based plating layer by using the nickel plating liquid comprises the following steps: (1) the oil removal and the cleaning are performed for a metal surface; (2) metal is contacted with pure aluminum or zinc; and the two are dipped in the nickel plating liquid for plating; and (3) after the plating is finished, the metal surface is flushed and blown. The nickel plating liquid contains no traditional reducing agent, stable in plating liquid and low in cost; the nickel-based plating layer preparation process is few in steps, short in time consumption, simple in operation and easy to be controlled; and the prepared nickel-based plating layer has such advantages as excellent bonding force and excellent corrosion preventing and wear reducing performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

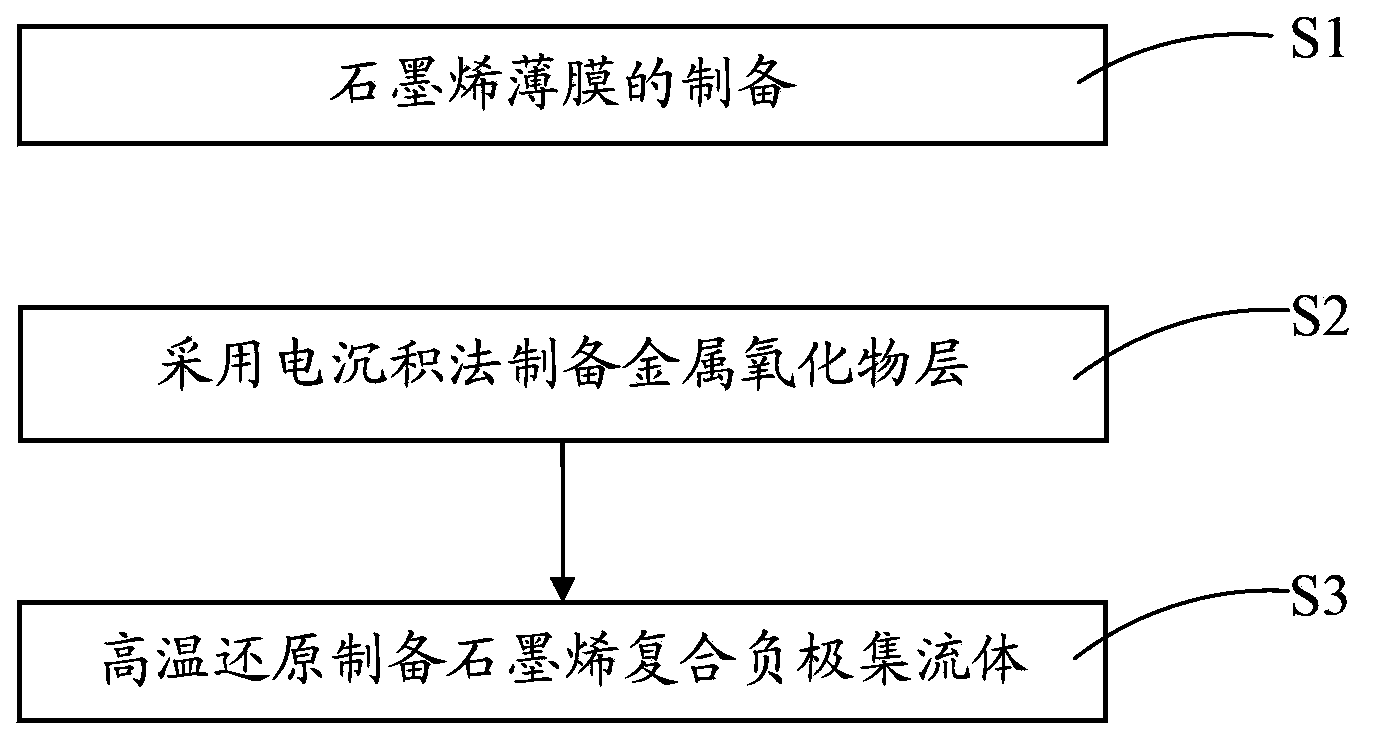

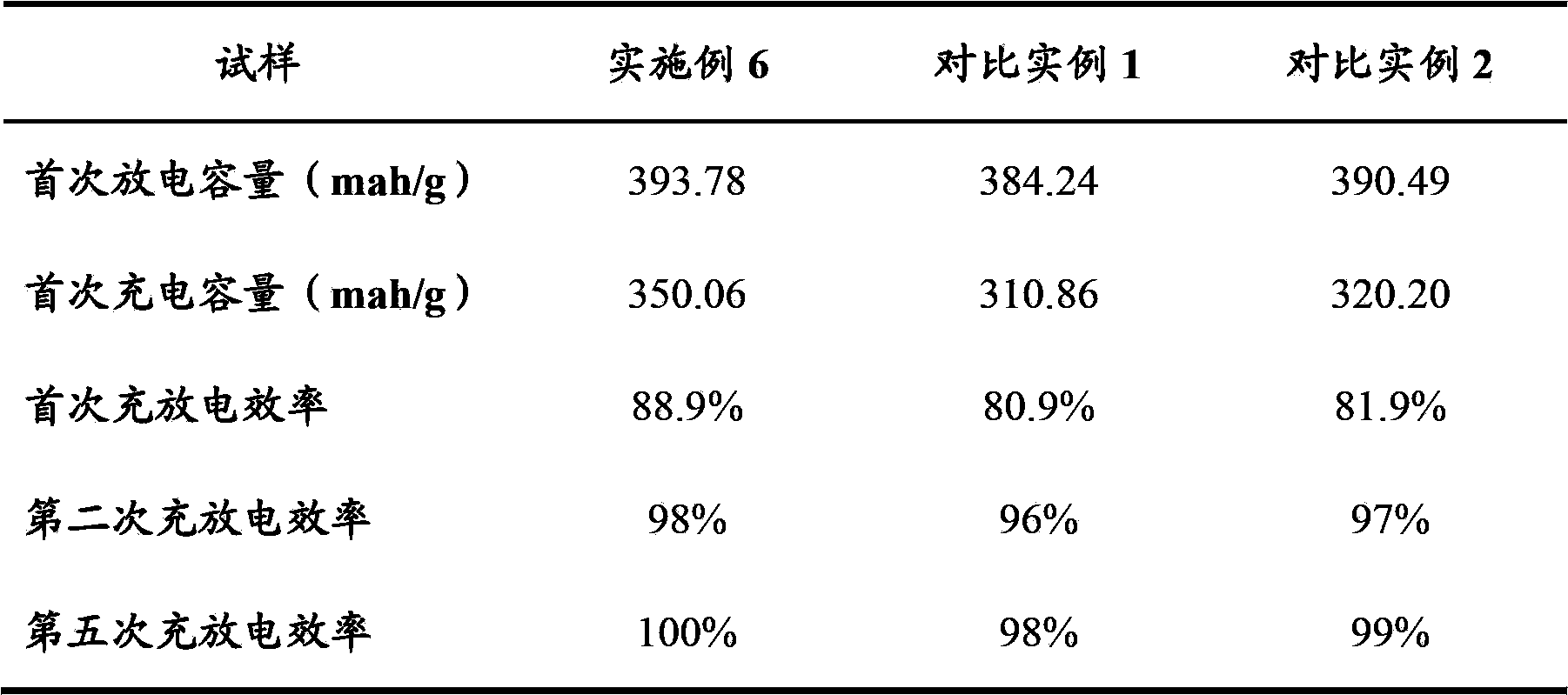

Graphene composite negative current collector, preparation method thereof and lithium ion battery

InactiveCN103579632AHigh mechanical strengthReduce weightElectrode carriers/collectorsSecondary cellsLithium-ion batteryCvd graphene

The invention discloses a graphene composite negative current collector, a preparation method thereof and a lithium ion battery. The graphene composite negative current collector comprises a graphene thin-film layer and a metal oxide layer combining with the surface of the graphene thin-film layer, and the metal oxide in the metal oxide layer is at least one of Cr2O3, MnO2, V2O5 and TiO2. The graphene composite negative current collector is high in mechanical strength and light in weight, and also is capable of effectively preventing lithium ions from being embedded in the graphene thin-film layer, avoiding generation of irreversible capacity and further improving the capacity. The preparation method is simple in technology, easily controllable in conditions and low in equipment requirements.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Red mud phosphogypsum hydraulic road base course, red mud phosphogypsum hydraulic road base course material and preparation method of red mud phosphogypsum hydraulic road base course material

The present invention discloses a red mud phosphogypsum hydraulic road base course, a red mud phosphogypsum hydraulic road base course material and a preparation method of the red mud phosphogypsum hydraulic road base course material, and relates to the field of road engineering construction. The preparation method comprises: weighing 10-50% of phosphogypsum and 90-50% of red mud, and uniformly mixing and strring to obtain a primary mixing material; weighing 85-92% of the primary mixing material and 15-8% of ordinary Portland cement, and uniformly mixing and strring to obtain a premix; and weighing 99.7-99.95% of the premix and 0.3-0.05% of a hydraulic curing agent, uniformly mixing and strring to obtain a mixture, and controlling the water content of the mixture to 14-18% to obtain the base course material, wherein the hydraulic curing agent is obtained by mixing the following components by mass: 40-80% of an elastic styrene-acrylic emulsion, and 60-20% of nanometer silicon sol. According to the present invention, the road base course is prepared by using the road base course material according to the standard road base course construction method; the red mud and the phosphogypsum are used to produce the road base course material, such that the pollution of the red mud and the phosphogypsum on the environment is reduced, and the waste is turned into treasure; and the formed road base course has characteristics of strong cracking resistance, corrosion resistance, and long service life.

Owner:湖北炼石环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com