Salt separation and purification recovery method for salt-containing wastewater

A technology for salt-containing wastewater and salt separation, applied in chemical instruments and methods, general water supply conservation, multi-stage water treatment, etc., can solve the problem of increasing the operating cost of evaporative crystallization technology, increasing unit steam consumption, and increasing equipment heat transfer resistance. and other problems, to achieve significant economic and social benefits, reduce energy consumption, and not easily corrode equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

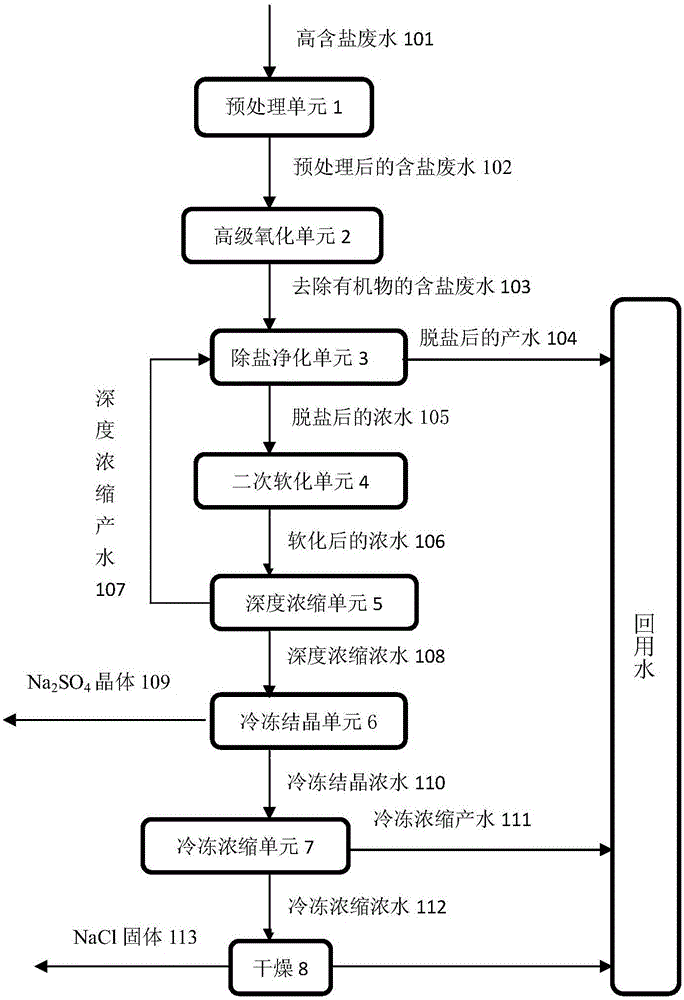

[0065] according to figure 1 In the process shown, the high-salt wastewater 101 from the upstream unit passes through the pretreatment unit 1 to obtain the pretreated saline wastewater 102, and after entering the advanced oxidation unit 2, the high-salt wastewater 103 from which organic matter is removed is obtained.

[0066] The saline waste water 103 from which organic matter has been removed enters the desalination purification unit 3 to obtain desalted product water 104 and concentrated water 105 ; the concentrated water 105 passes through the secondary softening unit 4 to obtain softened concentrated water 106 .

[0067] The softened concentrated water 106 enters the deep concentration unit 5 to obtain deep concentrated product water 107 and deep concentrated concentrated water 108; the deep concentrated product water 107 returns to the desalination purification unit 3 for further processing.

[0068] The deeply concentrated concentrated water passes through the freeze cr...

Embodiment 2

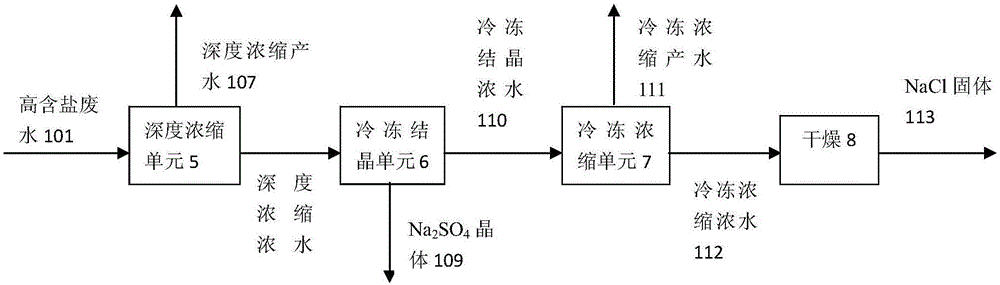

[0078] according to figure 2 In the process shown, the high-salt wastewater 106 from the upstream unit enters the deep concentration unit 5 and is concentrated by the ED membrane to obtain the deep concentrated product water 107 and the deep concentrated concentrated water 108; the deep concentrated product water 107 is desalted and purified again Reuse, deeply concentrated concentrated water 108 enters the freeze crystallization unit 6, and the temperature of the freeze crystallization unit 6 is -8°C to obtain Na 2 SO 4 Crystal 109 and frozen crystal concentrated water 110; Na 2 SO 4 Crystal 109 was dried to obtain Na 2 SO 4 Solid, frozen and crystallized concentrated water 110 passes through the freeze-concentration unit 7 to obtain freeze-concentrated product water 111 and freeze-concentrated concentrated water 112; the heat exchanger temperature of the freeze-concentration unit is -35°C, the temperature of the crystallizer is -22°C, and the pressure of the cleaning to...

Embodiment 3

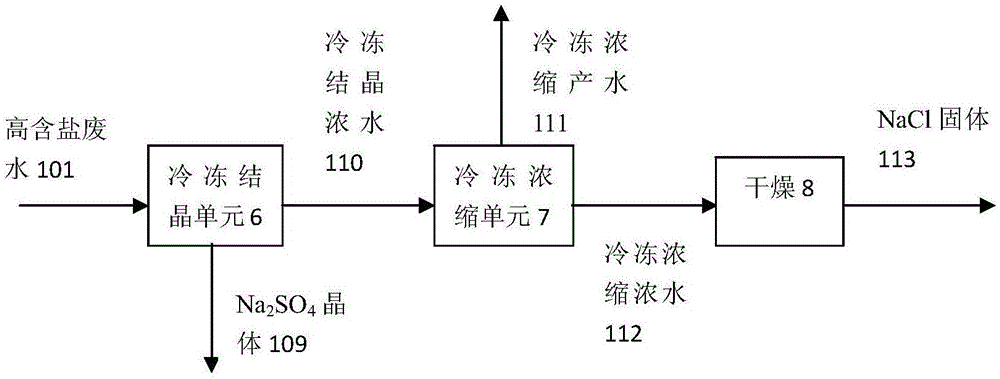

[0083] according to image 3 In the process shown, the high-salt wastewater 101 from the upstream unit enters the freezing crystallization unit 6, and the temperature of the freezing crystallization unit 6 is -8°C to obtain Na 2 SO 4 Crystal 109 and frozen crystal concentrated water 110; Na 2 SO 4 Crystal 109 Na after drying 2 SO 4 Solid, frozen and crystallized concentrated water 110 passes through the freeze-concentration unit 7 to obtain freeze-concentrated product water 111 and freeze-concentrated concentrated water 112; the heat exchanger temperature of the freeze-concentration unit is -35°C, the temperature of the crystallizer is -23°C, and the pressure of the cleaning tower is 6 bar; the freeze-concentrated product water is reused after desalination and purification, and the freeze-concentrated concentrated water 112 is further dried 8 to obtain NaCl solid 113.

[0084] Each logistics mass flow rate, water quality index and crystalline salt purity in table 4 embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com