Patents

Literature

14208 results about "Mother liquor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mother liquor is the part of a solution that is left over after crystallization. It is encountered in chemical processes including sugar refining.It is the liquid obtained by filtering the crystals by filtration.

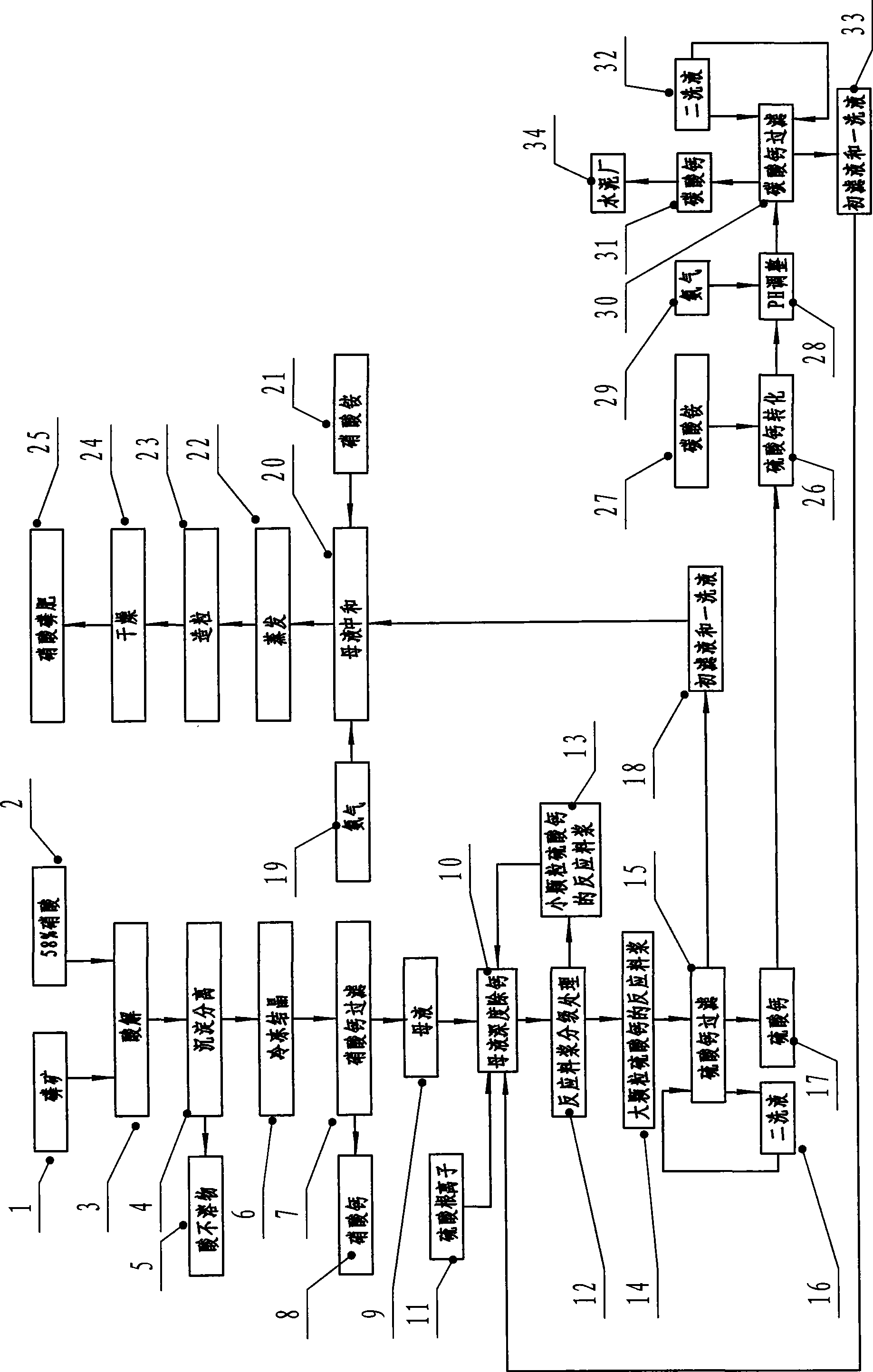

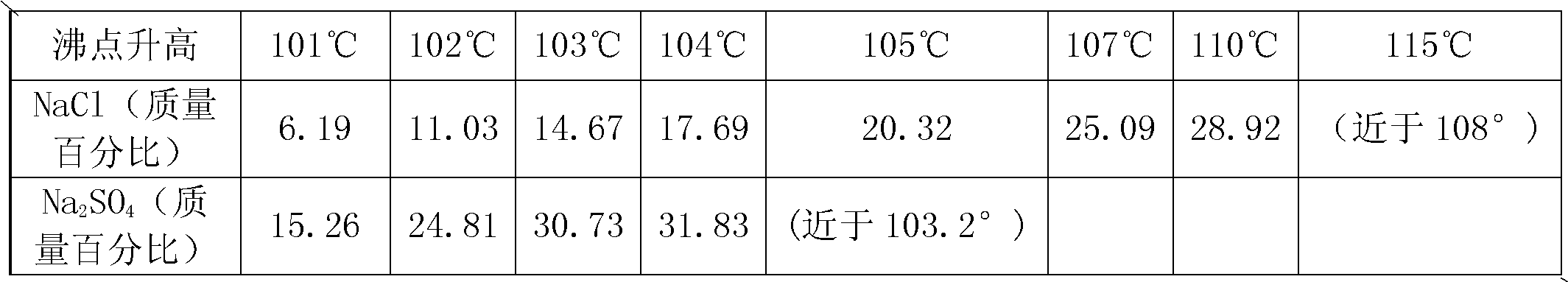

Process for producing sodium sulfate and sodium chloride in Na2SO4-NaCl-H2O system

InactiveCN1944256AIncrease profitReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal halide purificationInorganic saltsSeparation technology

The process of producing sodium sulfate and sodium chloride in a Na2SO4-NaCl-H2O system belongs to the field of mixed inorganic solution evaporating separation technology. Mixed solution of sodium sulfate and sodium chloride as material is first evaporated and then separated to obtain sodium sulfate, sodium chloride and evaporated mother liquor; the evaporated mother liquor is low temperature evaporated and separated to obtain sodium chloride and salt-making mother liquor; and the salt-making mother liquor is evaporated and separated to obtain sodium sulfate and saltpeter-making mother liquor. The present invention has the features of high main and side product quality, high material adaptability, low cost, low cost, no waste draining, etc.

Owner:CHINA LIGHT IND INT ENG CO LTD +1

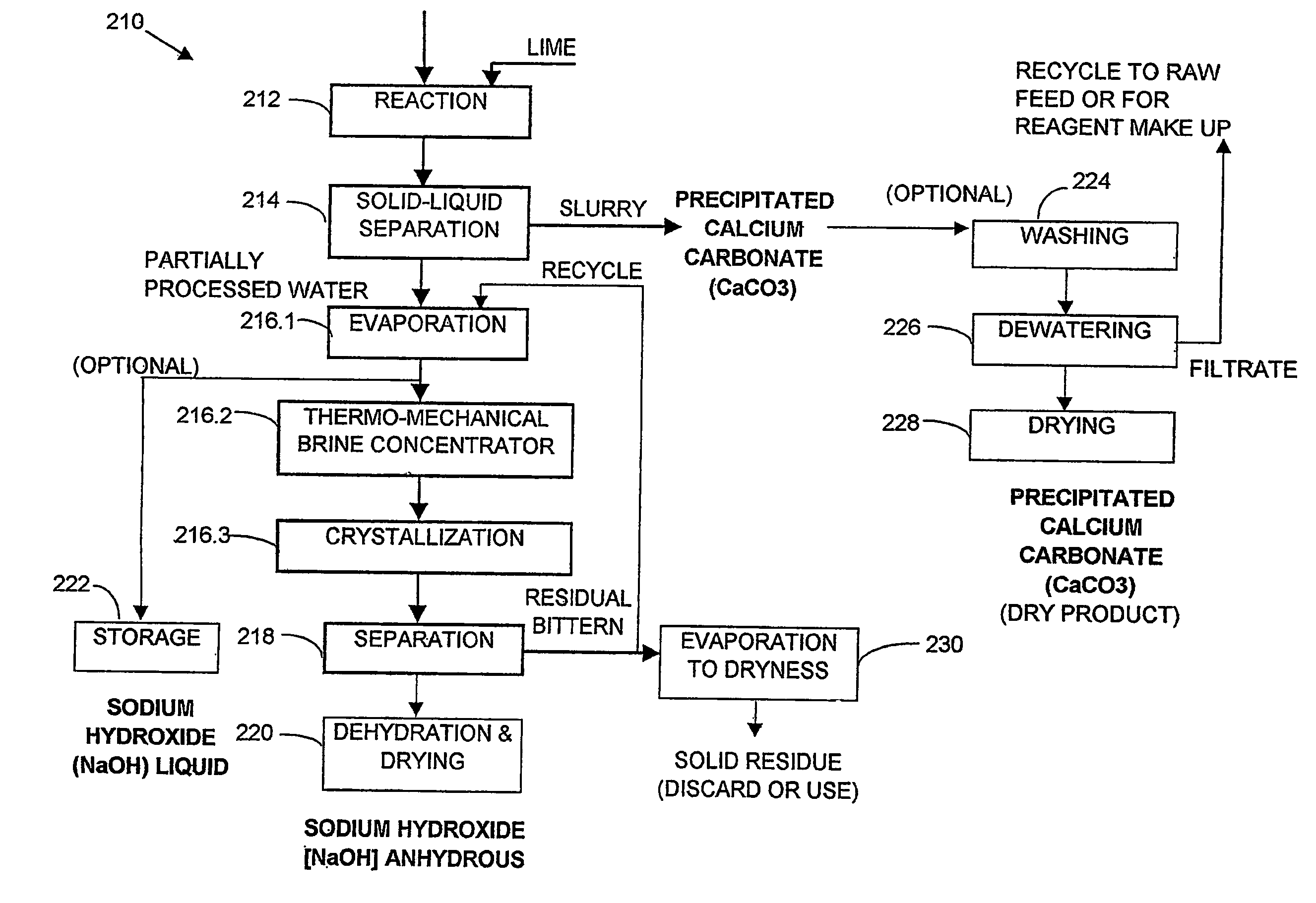

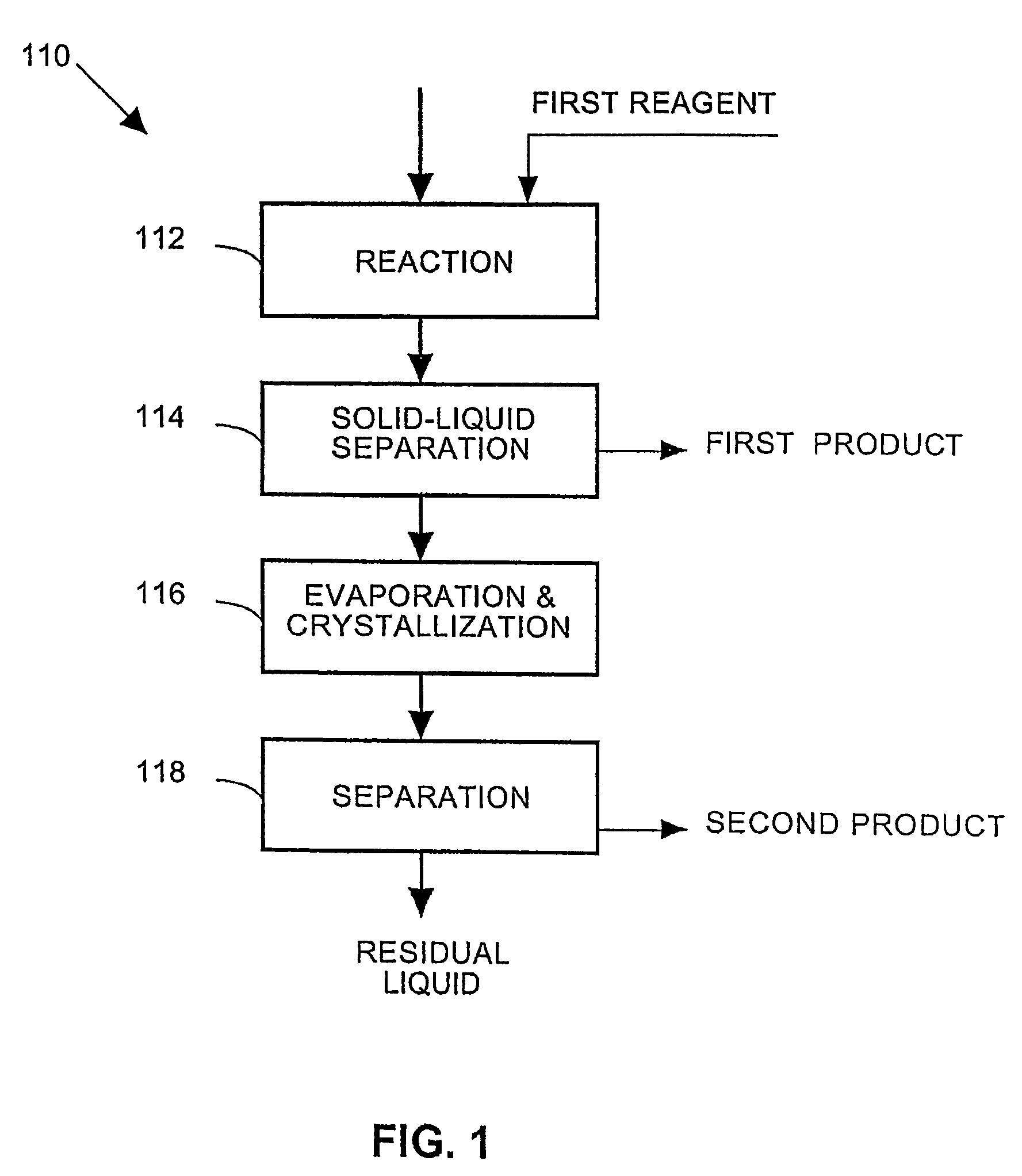

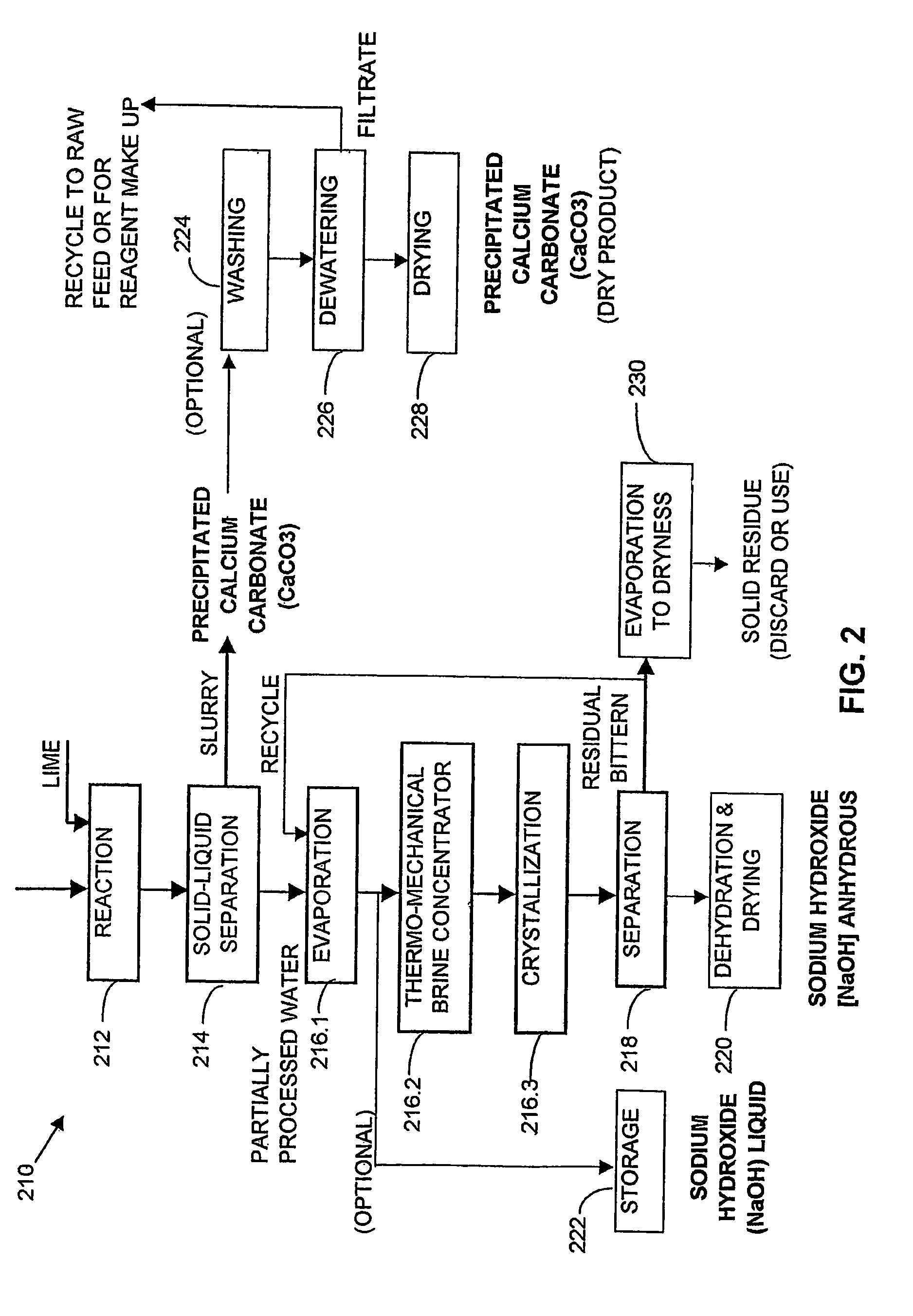

Process and apparatus for the treatment of saline water

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

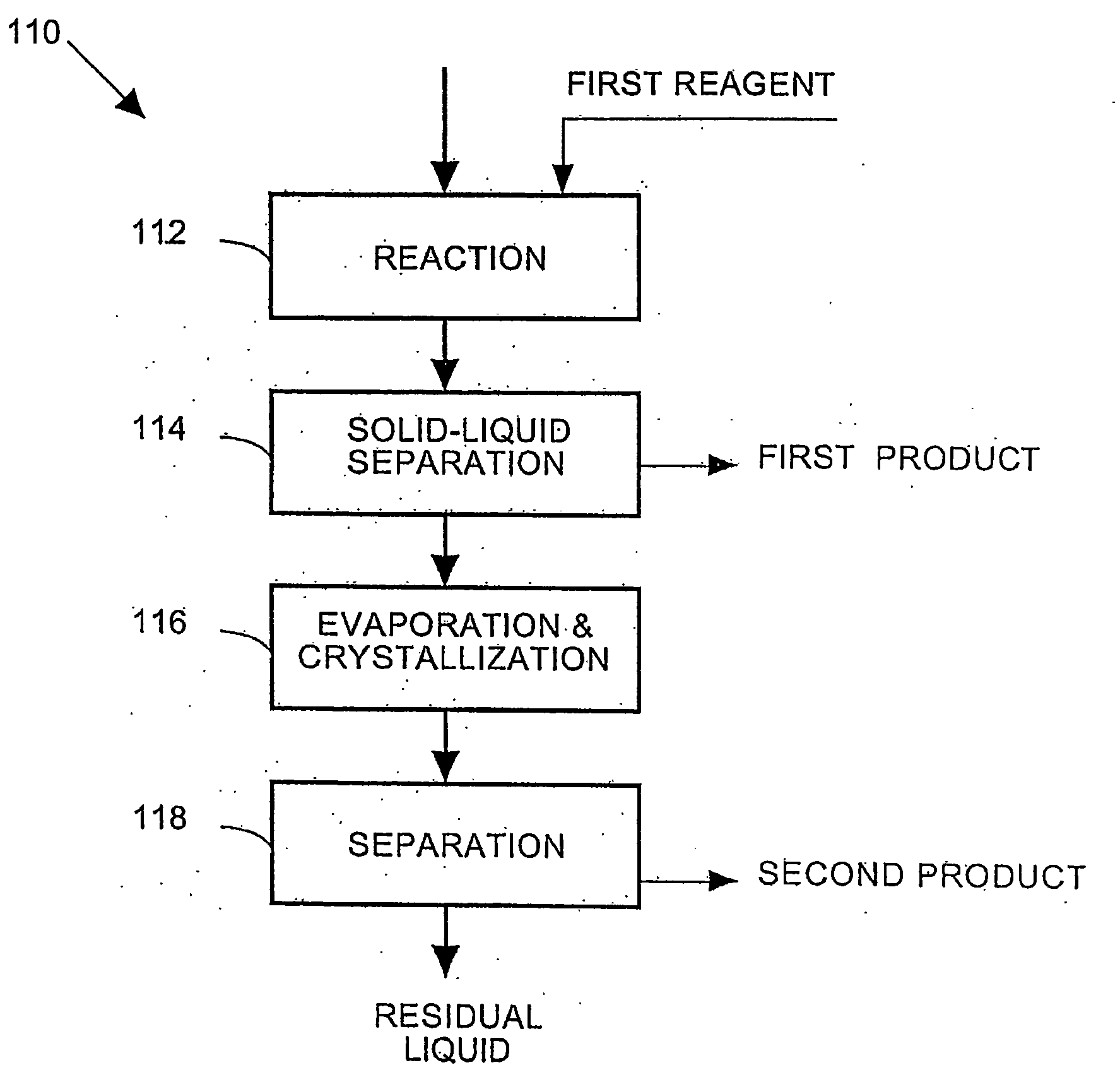

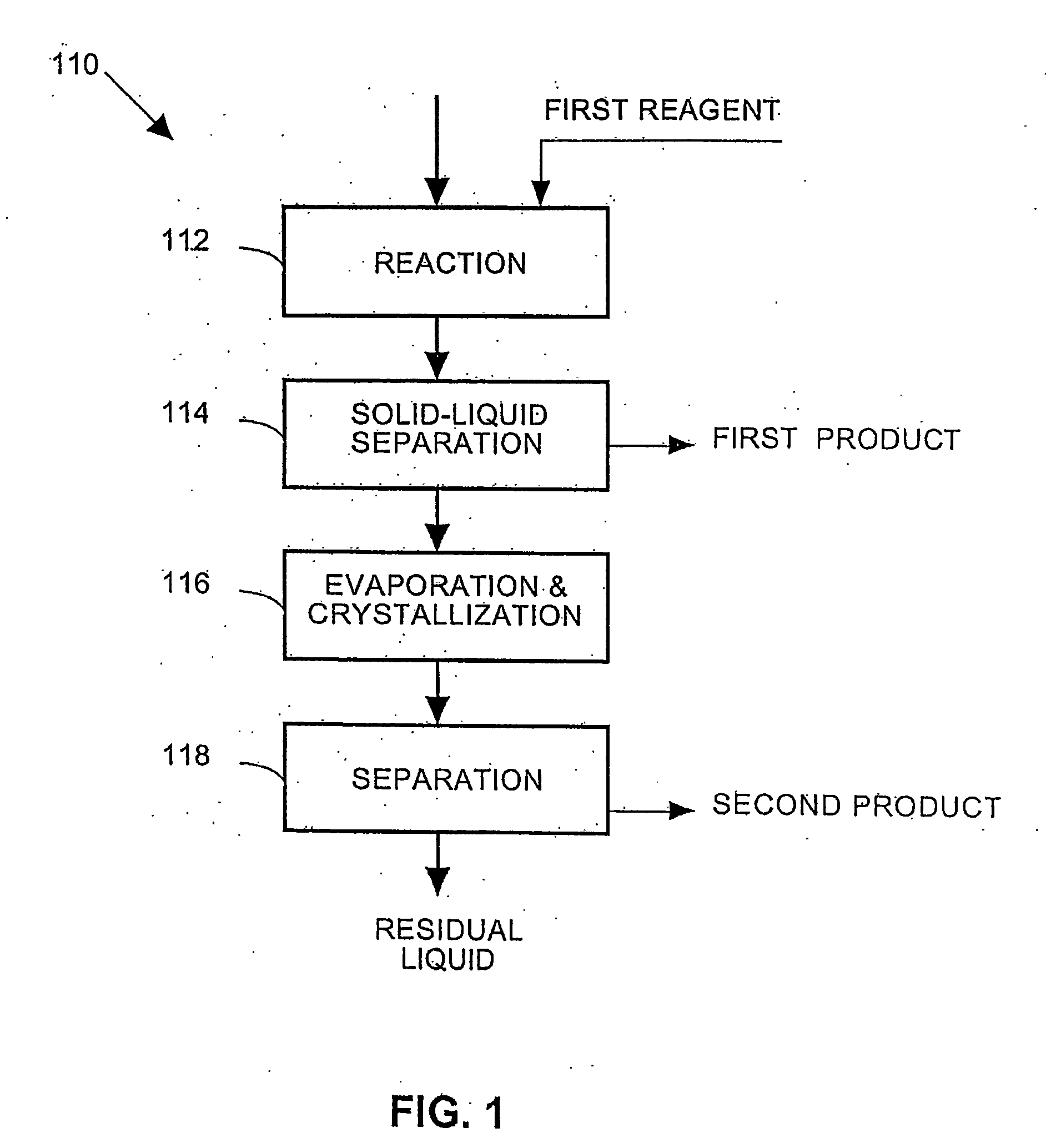

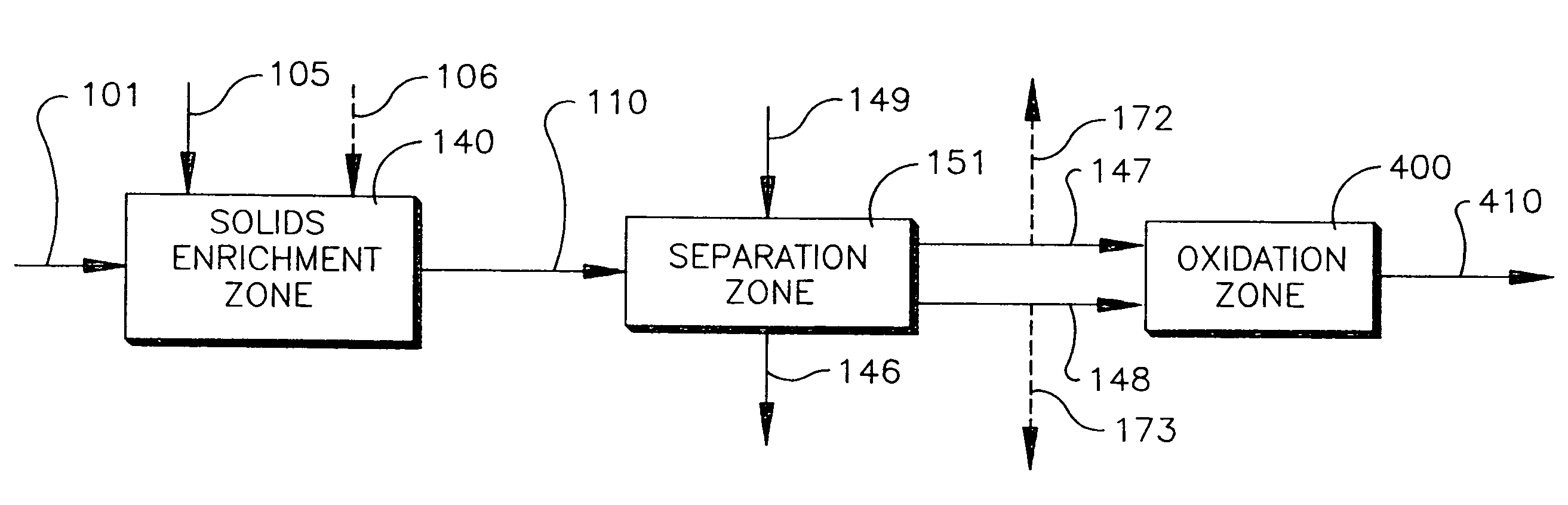

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

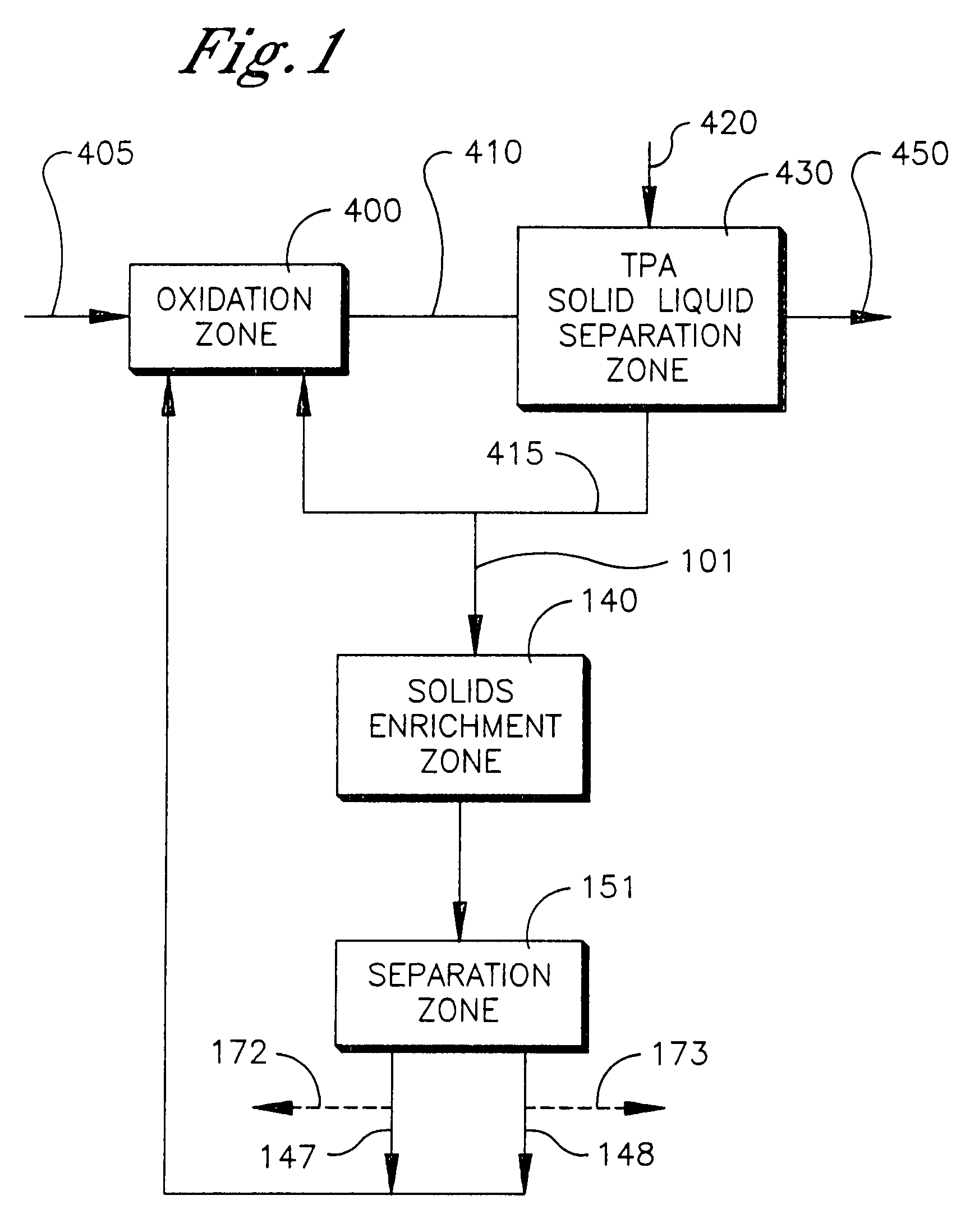

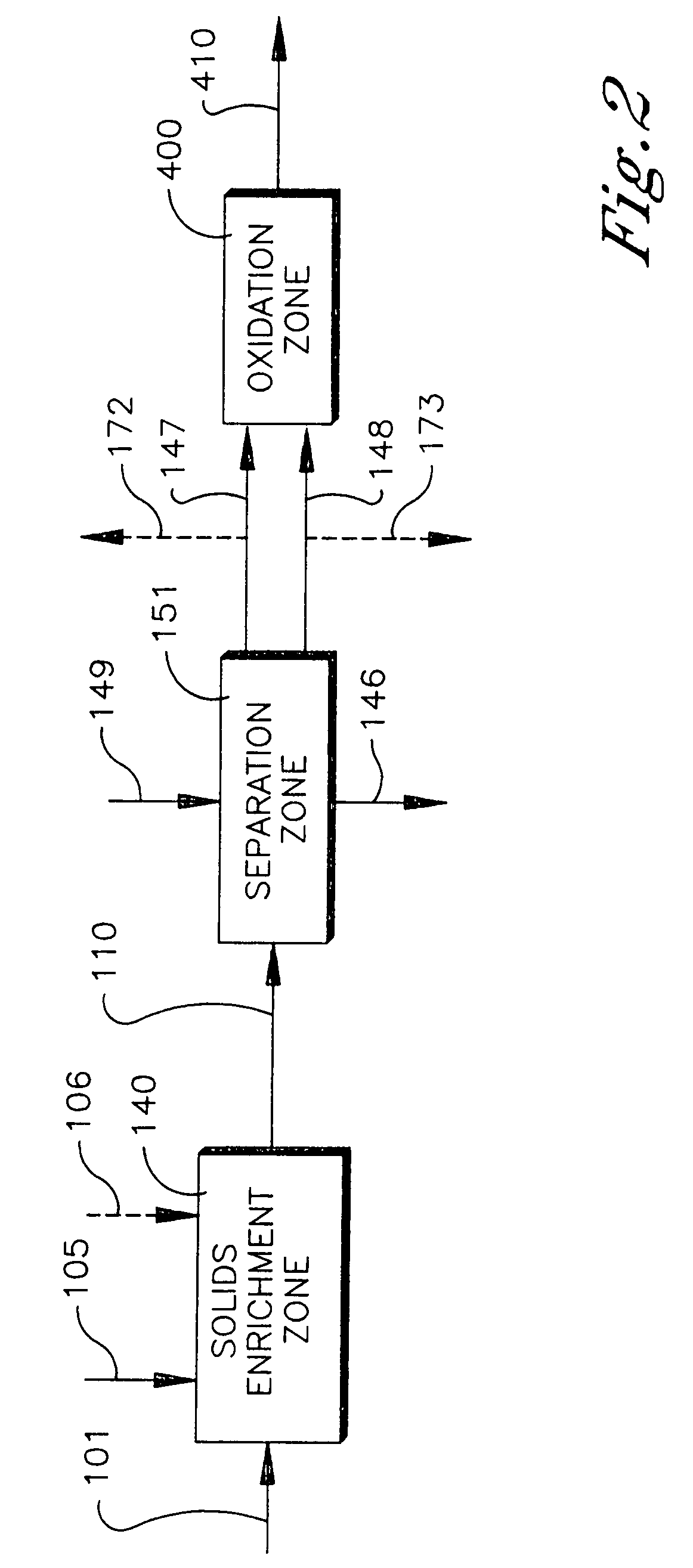

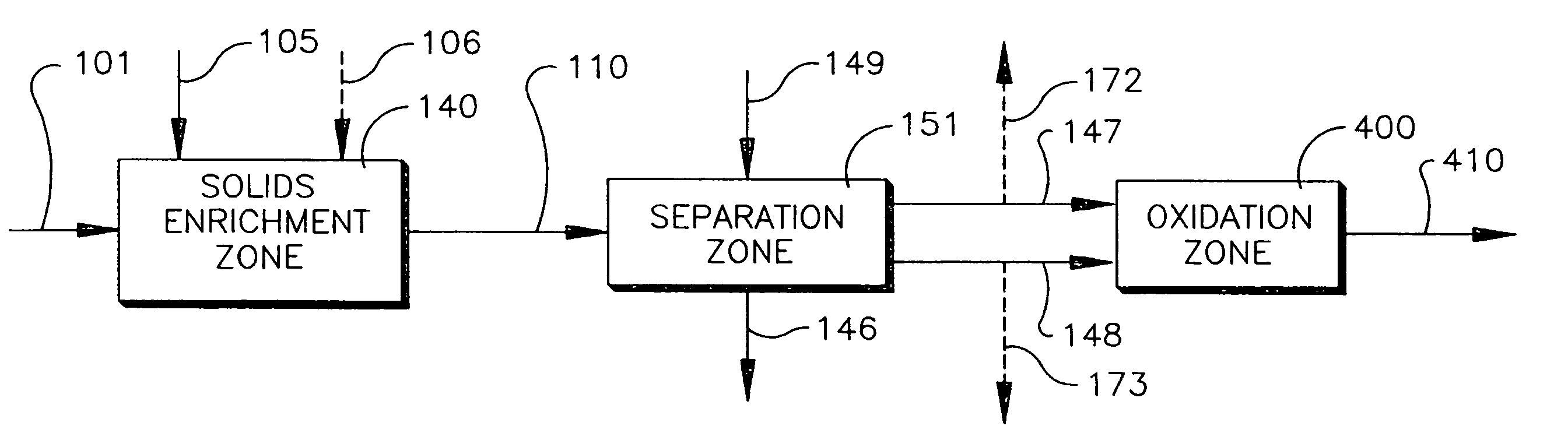

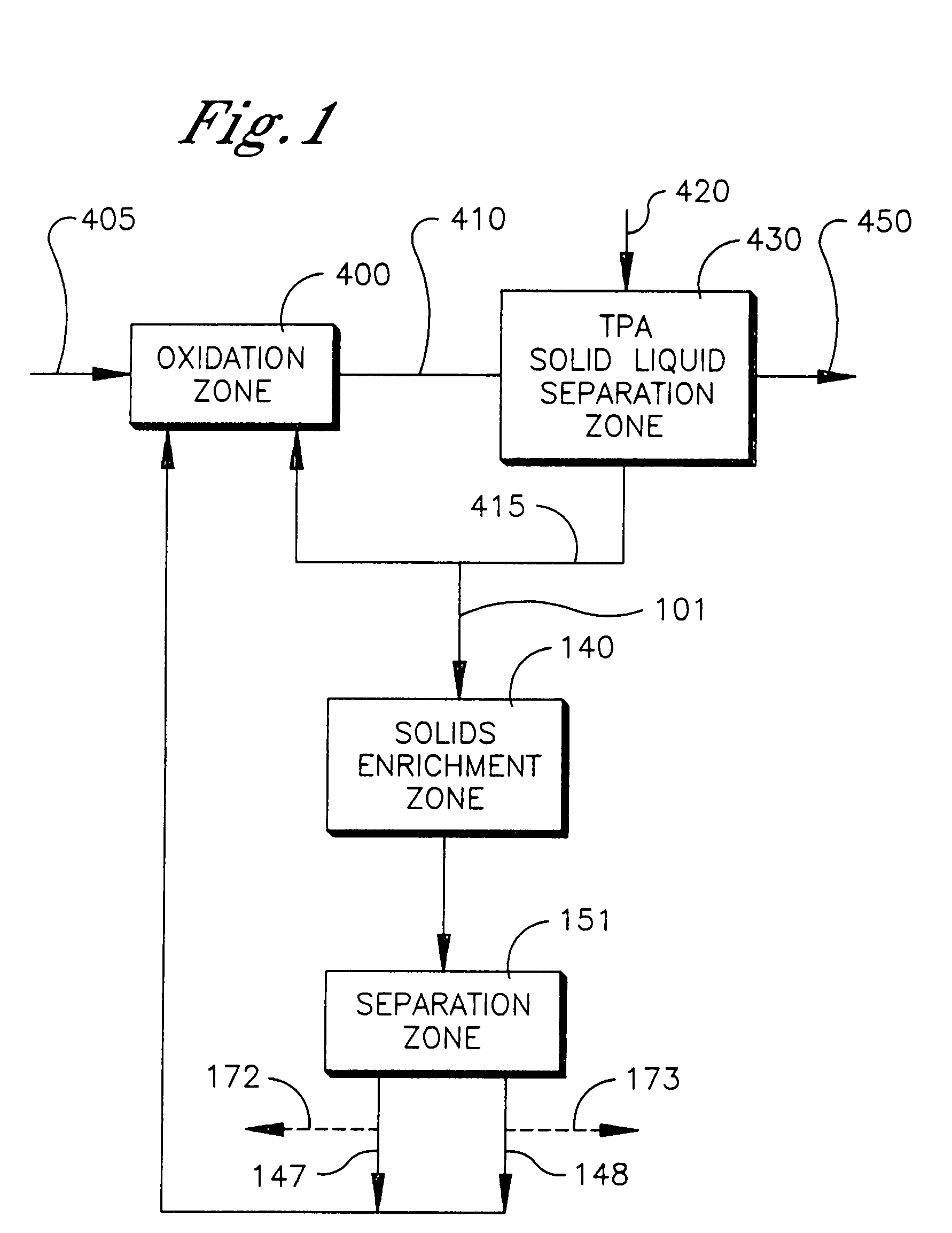

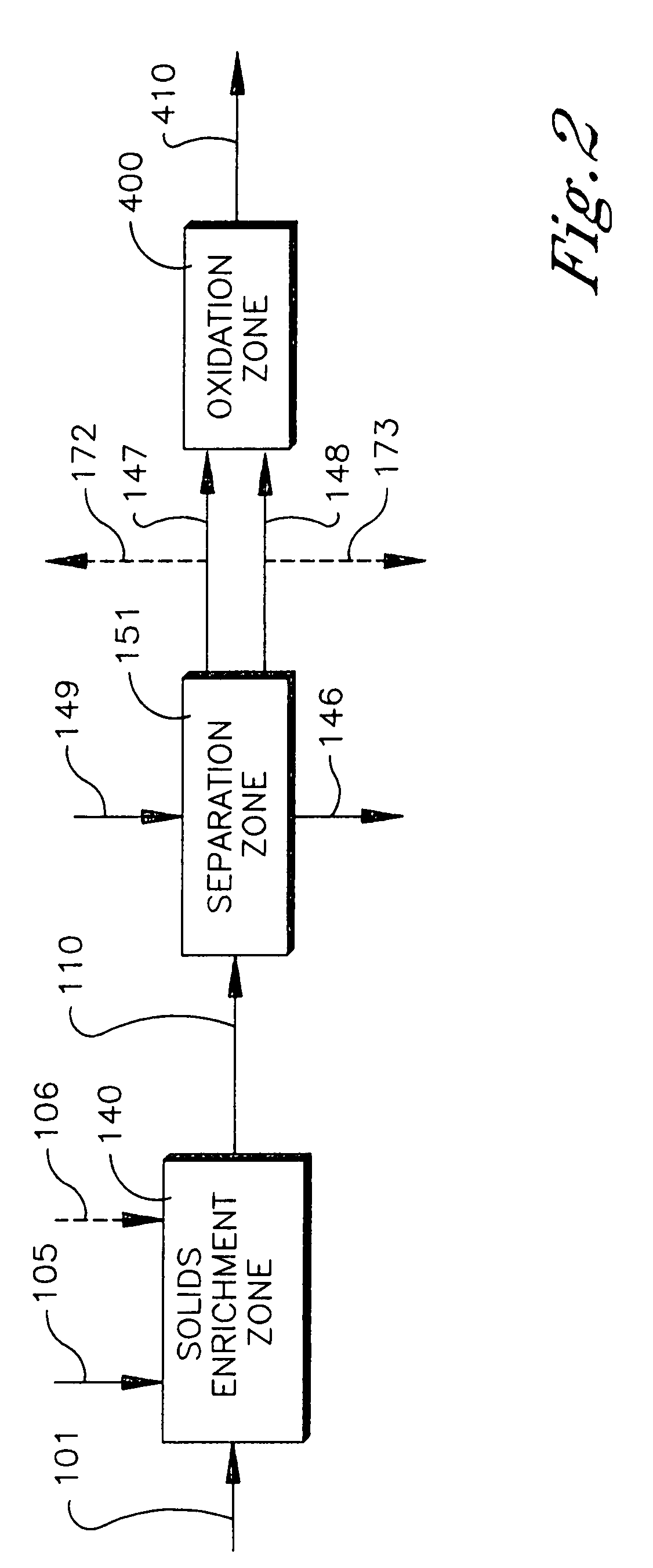

Process for removal of impurities from an oxidizer purge stream

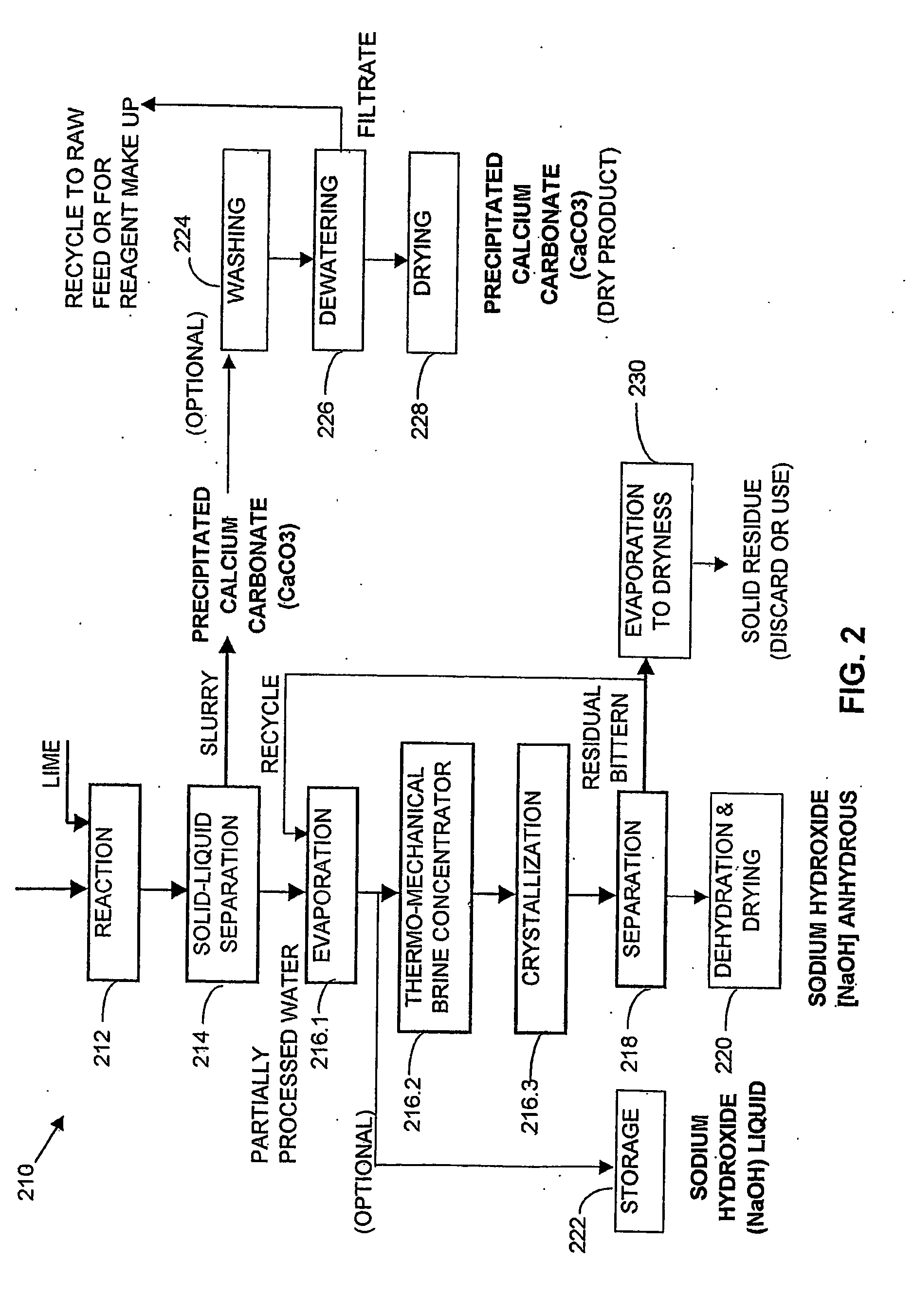

A process is disclosed that relates to the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic. More particularly, the process involves the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream and then routing the mother liquor and or wash filtrate to an oxidation zone.

Owner:ALPEK POLYESTER SA DE CV

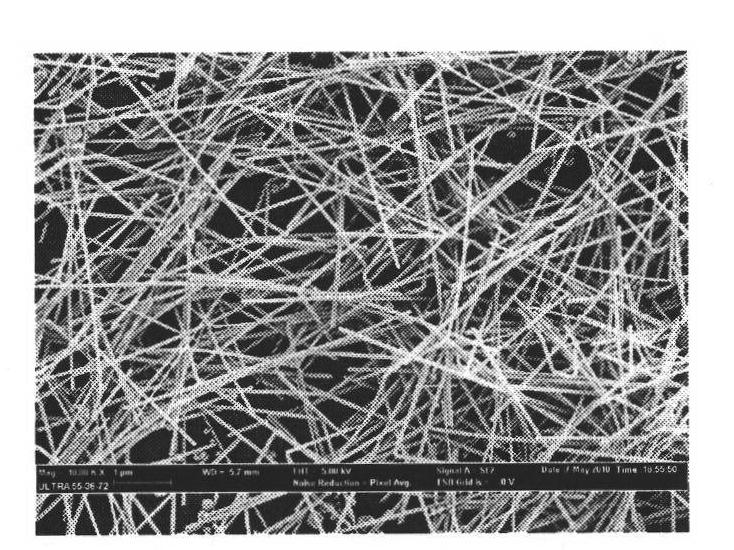

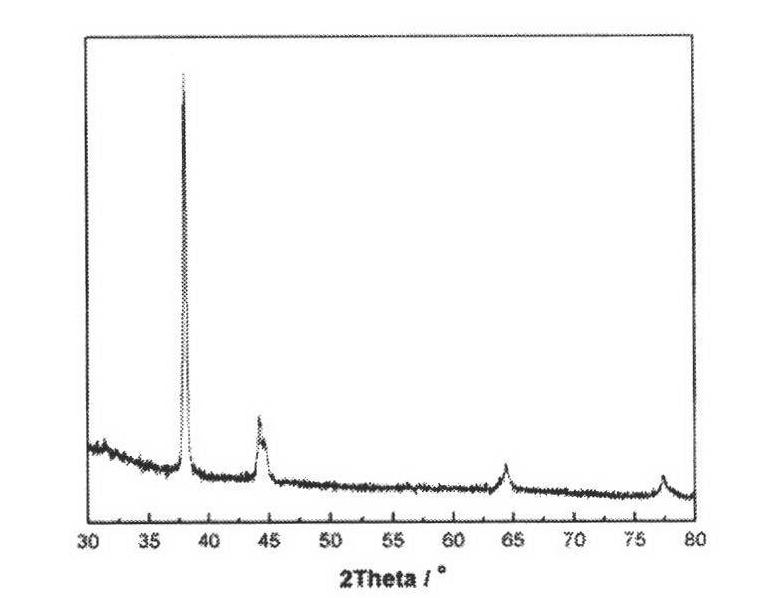

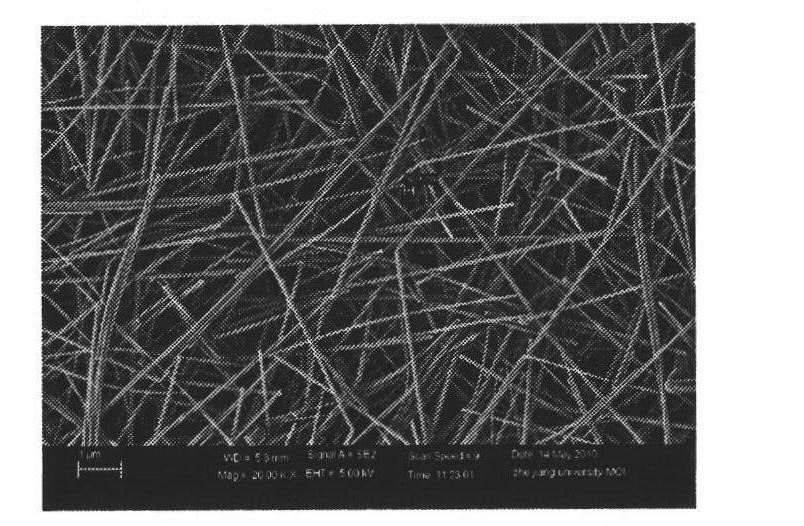

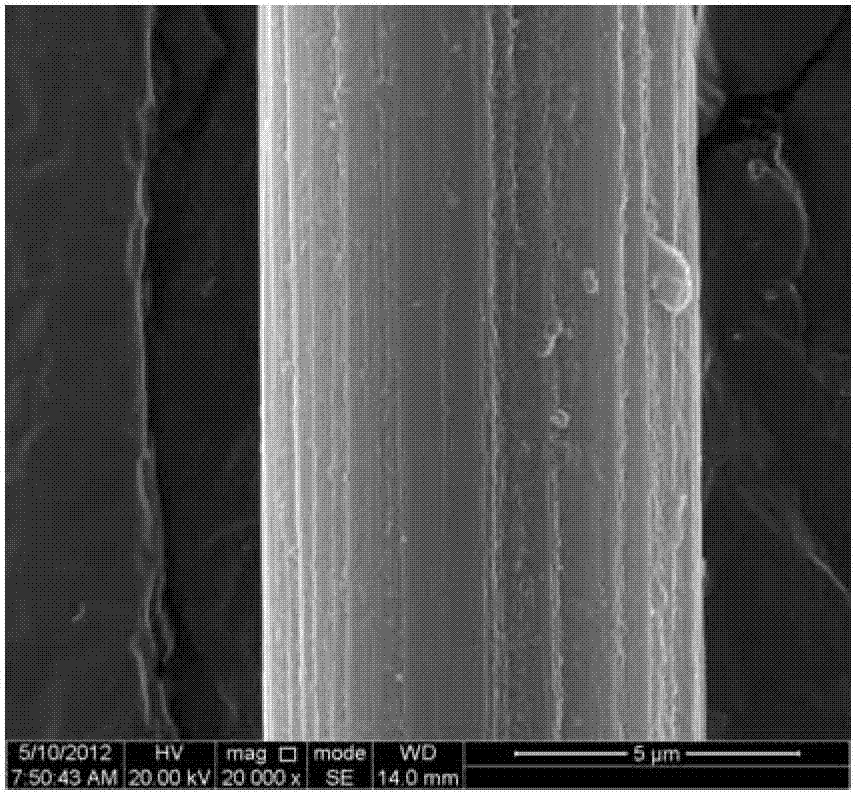

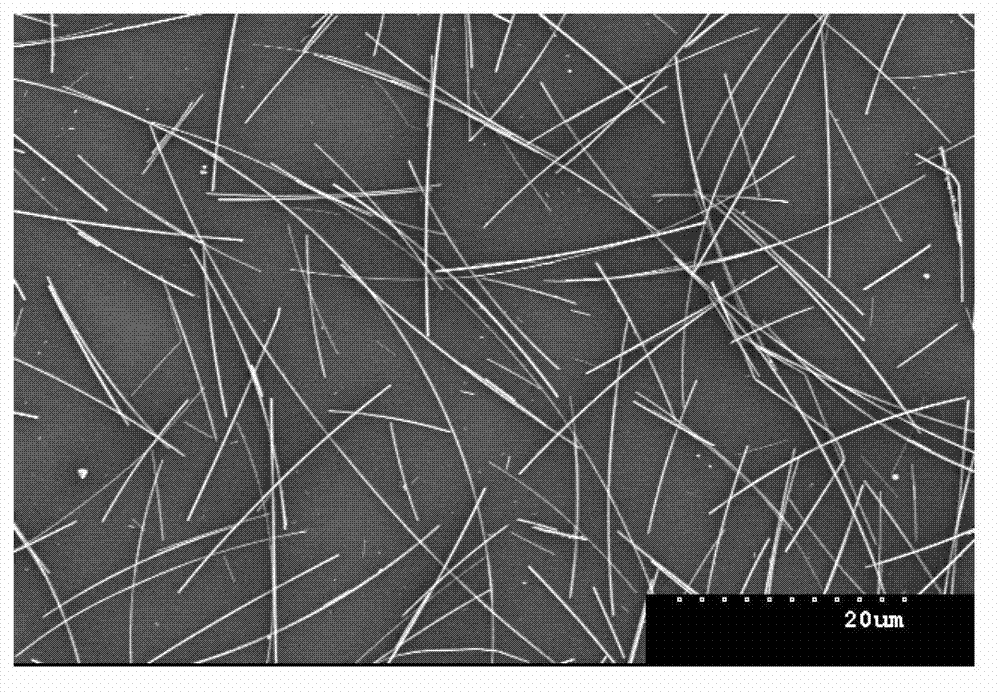

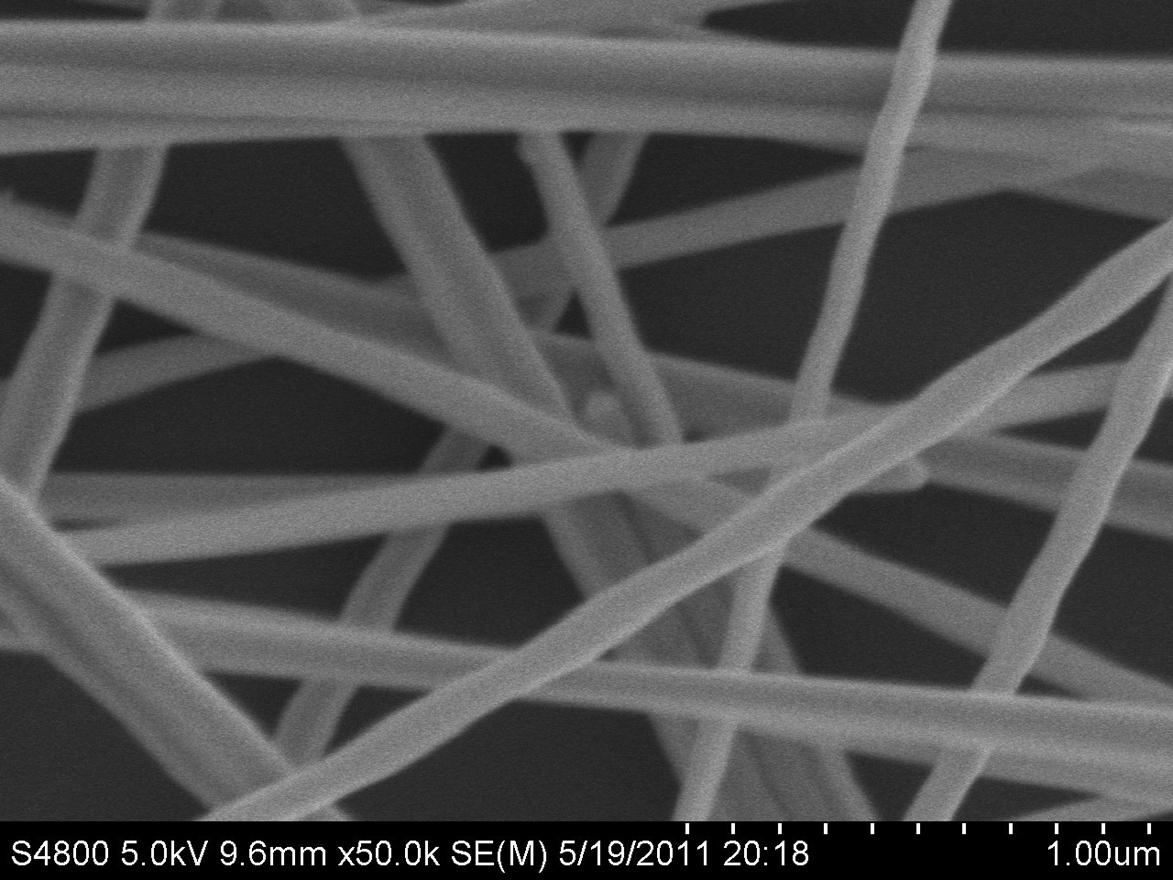

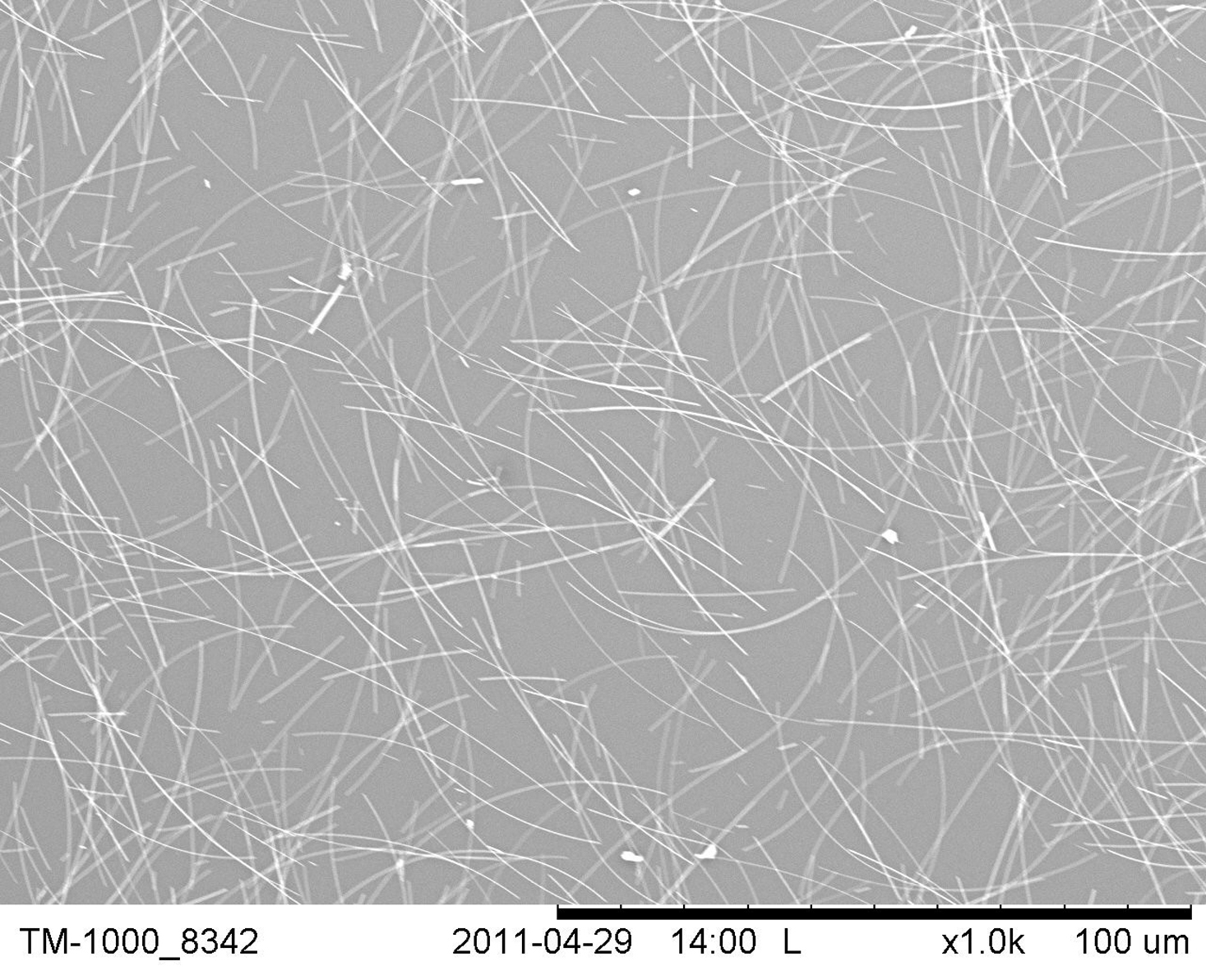

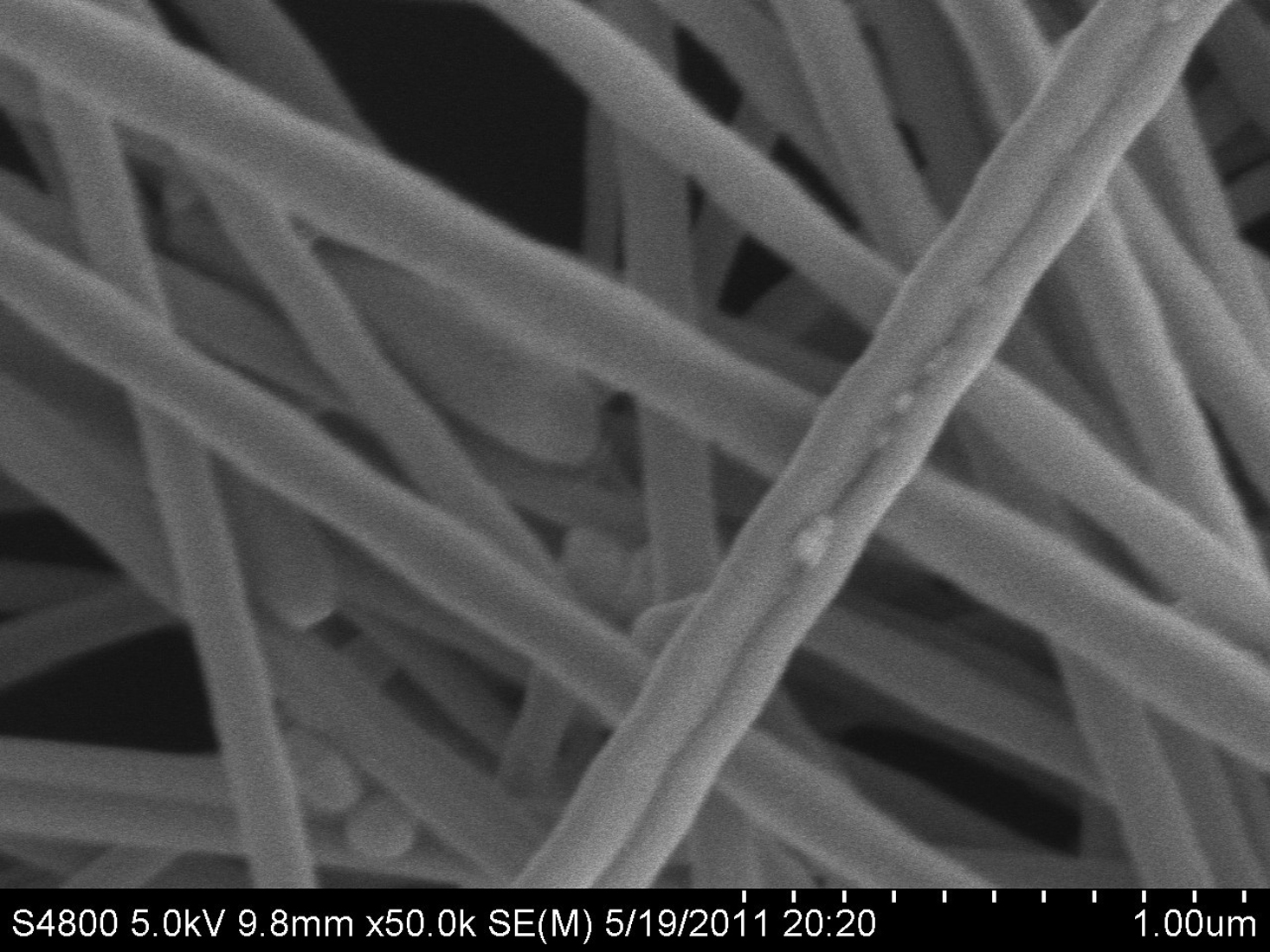

Quick and efficient synthesis method for silver nanowires

InactiveCN101934377AImprove production efficiencyReduce reaction preparation timeHigh concentrationSynthesis methods

The invention discloses a quick and efficient synthesis method for silver nanowires. The method comprises the following steps of: 1) introducing inert gas into a reactor, adding 2 volume parts of glycol into the reactor, and stirring, heating, condensing and refluxing the glycol; quickly adding 1 volume part of glycol solution of silver nitrate at molar concentration of between 0.1 and 0.5m into the reactor; slowly dropwise adding 1 to 2 volume parts of PVP at molar concentration of between 0.15 and 0.75m and 4 to 32 mu m of glycol solution of MnCl2 at the same time; and reacting and cooling the mixture to the room temperature to obtain reaction mother liquor of the silver nanowires; and 2) transferring the reaction mother liquor of the silver nanowires into a centrifugal tube; adding acetone into the centrifugal tube and performing centrifugal separation to remove supernatant and retain precipitate; adding de-ionized water or ethanol into the centrifugal tube and performing centrifugal separation to remove the supernatant and retain precipitate, and repeating the operation for 1 to 3 times; and extracting and dispersing the precipitate with ethanol to obtain the silver nanowires. The method shortens the reaction time and also has high selectivity for the synthesis of the silver nanowires under conditions of high concentration.

Owner:ZHEJIANG UNIV

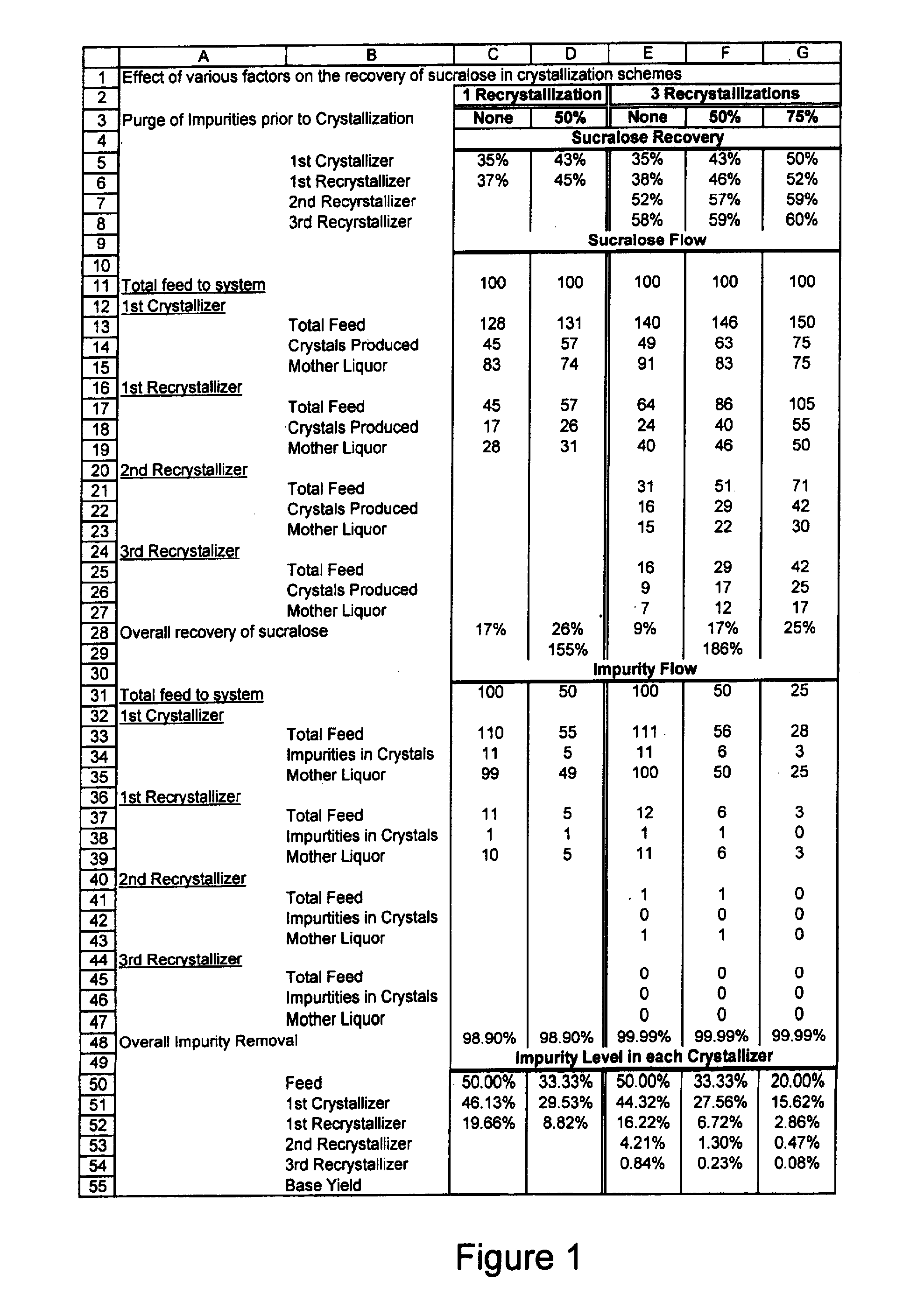

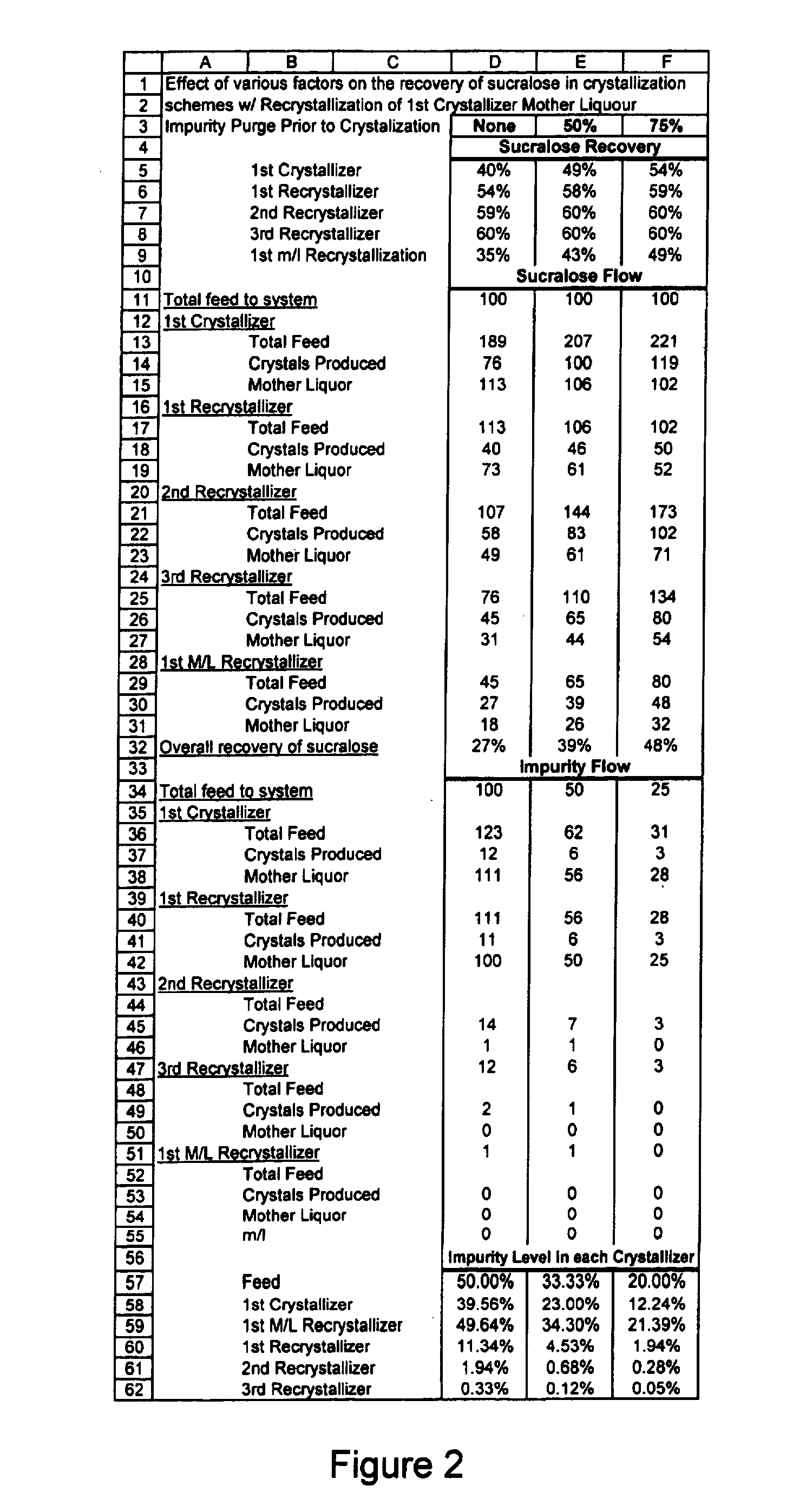

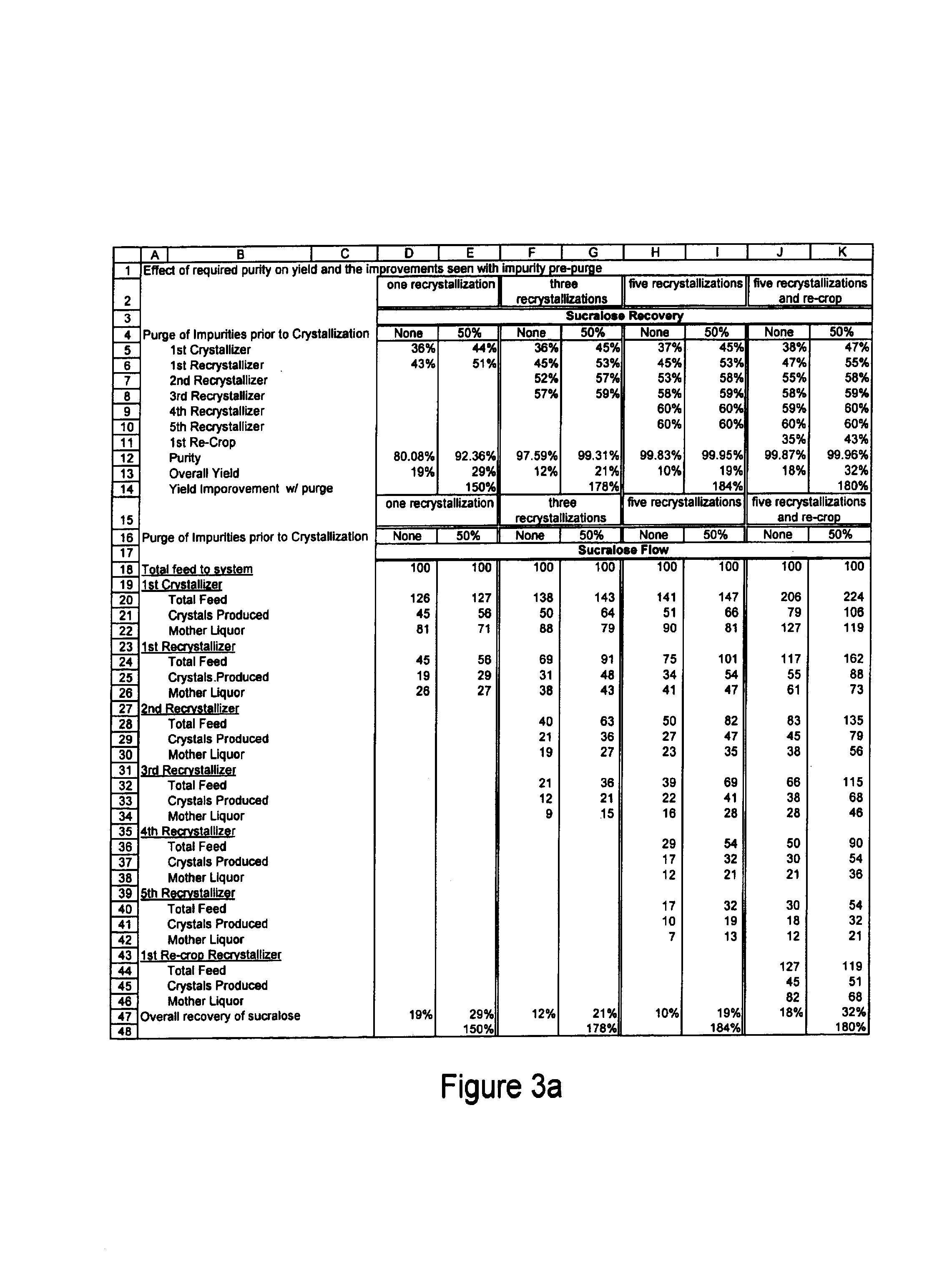

Process for improving sucralose purity and yield

InactiveUS6998480B2Improve efficiencyHigh purityEsterified saccharide compoundsSugar derivativesSucraloseCrystallization Purification

This invention relates to processes for purifying sucralose by the use of an initial non-crystallization purification procedure followed by three or more sequential crystallization steps and recycle of the mother liquor remaining from each crystallization step to the feed of another crystallization or purification step. This invention also relates to sucralose compositions as well as compositions comprising the sucralose compositions of the present invention. These compositions may be highly pure and have a superior taste profile.

Owner:TATE & LYLE TECH LTD

Method for extracting and refining rutin

ActiveCN102718820AReduce pollutionGuaranteed withdrawal rateSugar derivativesSugar derivatives preparationAlkaline waterOrganic solvent

A method for extracting and refining rutin comprises the following steps of (1) extraction: smashing raw materials, adding organic solvent into the smashed raw materials, performing extraction for 2-4 times, mixing extracting solution and concentrating the mixed extracting solution to thick extract with organic solvent content smaller than or equal to 5wt%; (2) alkali dissolution-acid sediment: adding alkaline water into the thick extract, then heating the mixture and stirring, filtering the heated mixture, regulating pH of alkaline filtrate to be 3-4, standing, filtering, drying to obtain a rutin pure product; and (3) mother liquor treatment: enabling obtained acid mother liquor to penetrate through a chromatographic column filled with resin, after the acid mother liquor penetrates through the chromatographic column, firstly using deionized water to wash a column bed until outflow liquid is neutral and colorless, introducing eluent into the chromatographic column and collecting eluate until outflow liquid is colorless, concentrating the eluate to the volume which is 5-10% of the original volume in a pressure reduction mode, cooling the concentrated eluate to achieve crystallization, filtering, using the deionized water to elute a filter cake, and drying the eluted filter cake to obtain a mother liquor rutin product. The prepared rutin is high in yield and purity, and the quality of the rutin reaches the international standard.

Owner:湖南莱崔尔生物科技有限公司

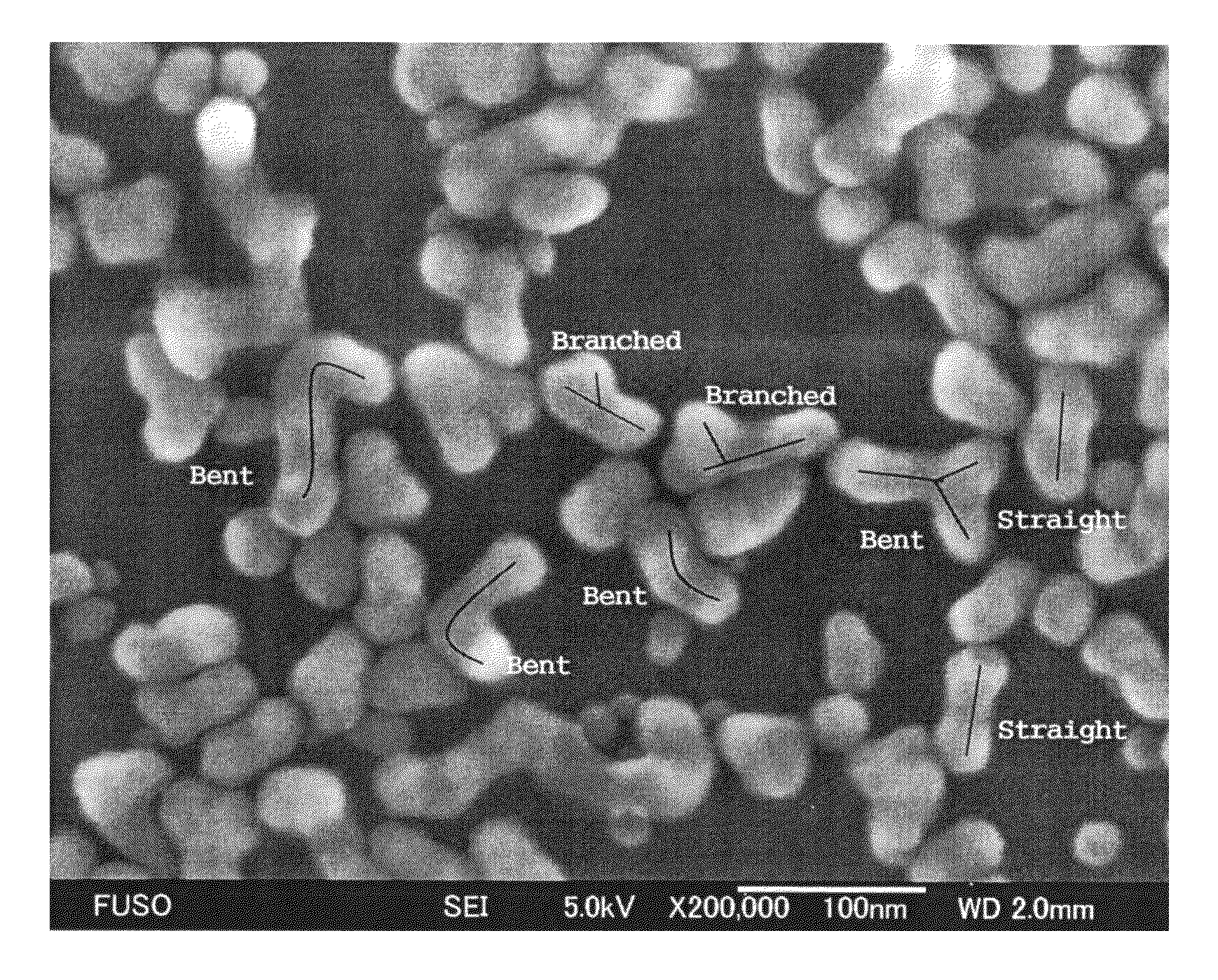

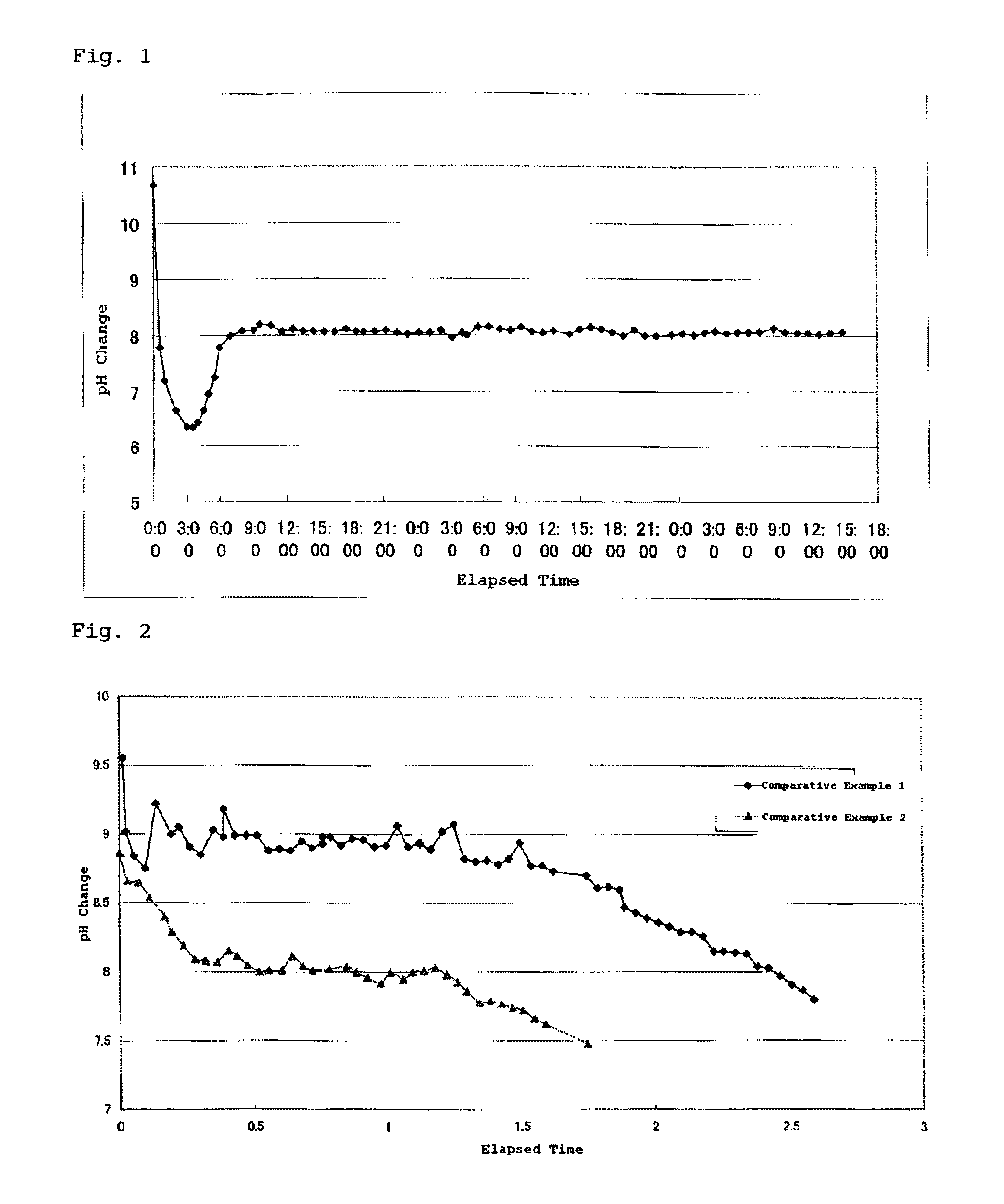

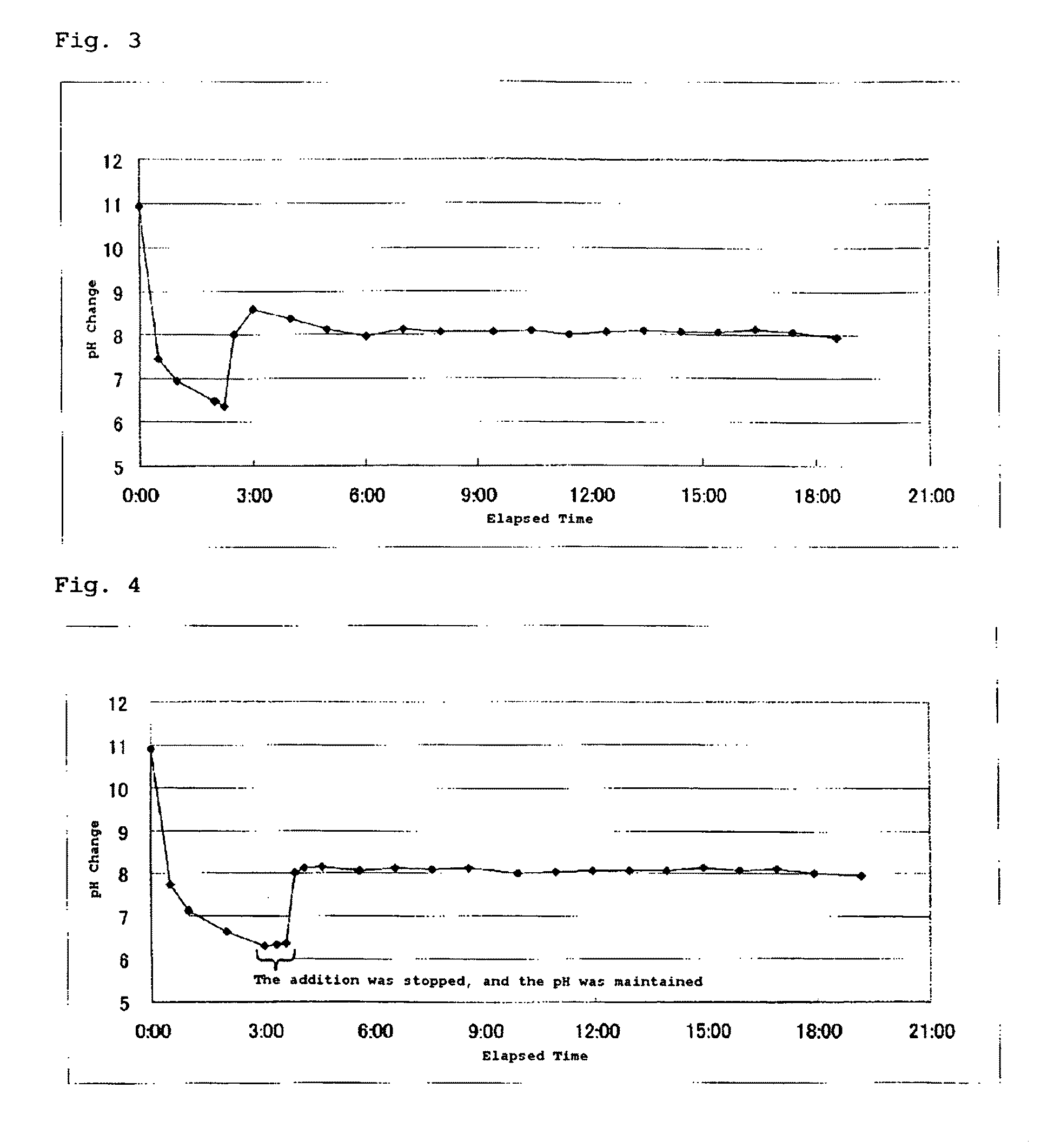

Colloidal silica containing silica secondary particles having bent structure and/or branched structure, and method for producing same

ActiveUS8529787B2Improve polishing rateLarge aspect ratioSilicaOther chemical processesColloidal silicaColloid

This invention provides a dense, high-purity colloidal silica containing silica secondary particles having a branched and / or bent structure, and a production method thereof. Specifically, this invention provides a method for producing a colloidal silica, comprising the steps of 1) preparing a mother liquid containing an alkali catalyst and water, and having a pH of 9 to 12; and 2) adding a hydrolysis liquid obtained by hydrolysis of an alkyl silicate to the mother liquid, wherein the step of adding the hydrolysis liquid to the mother liquid sequentially comprises A) step 1 of adding the hydrolysis liquid until the pH of the resulting liquid mixture becomes less than 7; B) step 2 of adding an aqueous alkali solution until the pH of the liquid mixture becomes 7 or more; and C) step 3 of adding the hydrolysis liquid while maintaining the pH of the liquid mixture at 7 or more, and a colloidal silica containing silica secondary particles having a branched and / or bent structure, obtained by this method.

Owner:FUSO CHEM

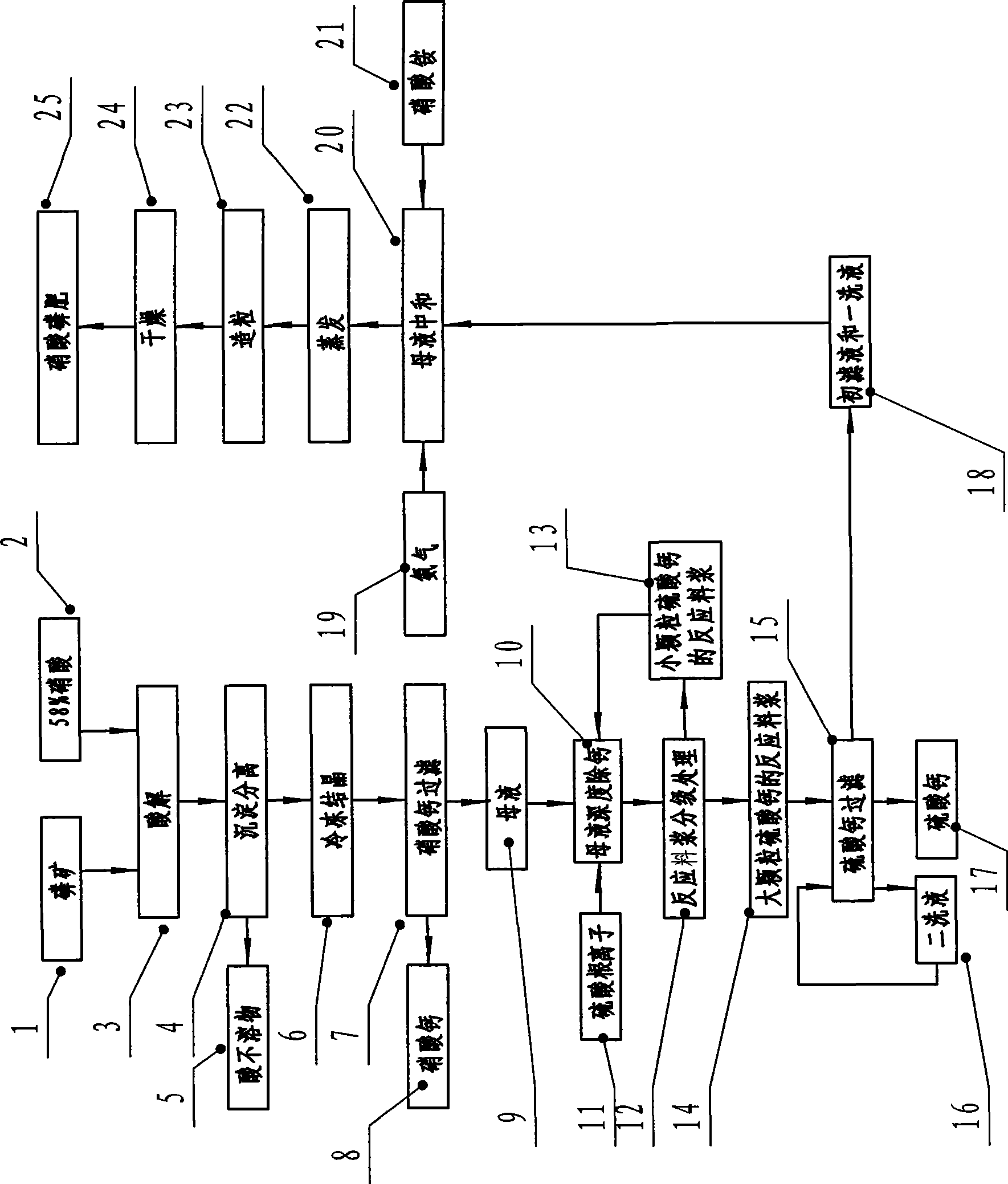

Technological process for producing high concentration nitric-phosphate fertilizer

The invention discloses a technique method for producing high-concentration nitric phosphate, which comprises the following steps of: adding nitric acid into phosphorus ore for acidolysis, depositing and separating acid non-soluble substance, freezing and crystallizing calcium nitrate, filtering the calcium nitrate, neutralizing the mother liquid, vaporization, pelleting and drying. The invention is characterized in that: a step of thoroughly removing the calcium of the mother liquid is arranged between the steps of filtering the calcium nitrate, and neutralizing the mother liquid. The steps comprise the following steps of: I) thoroughly removing the calcium of the mother liquid and adding sulfuric acid or ammonium sulfate; the calcium ions and the sulfate ions in the mother liquid generate dihydrate calcium sulfate crystal; II) the grading processing of reaction slurry: employing a grading device to carry out grading processing to the reaction slurry; returning the reaction slurry provided with small grain calcium sulfate to the mother liquid for thoroughly removing the calcium, and feeding the reaction slurry provided with large grain calcium sulfate to the calcium sulfate for filtering; and III) filtering and washing the filtering reaction slurry of calcium sulfate by a filter, feeding the primary filtrate and the primary lavage fluid into the working procedure of neutralizing, and returning the secondary lavage fluid to the filter. The invention has the advantage of using middle-low quality phosphorite to prepare the high-concentration nitric phosphate.

Owner:TIANJI COAL CHEM IND GROUP +1

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

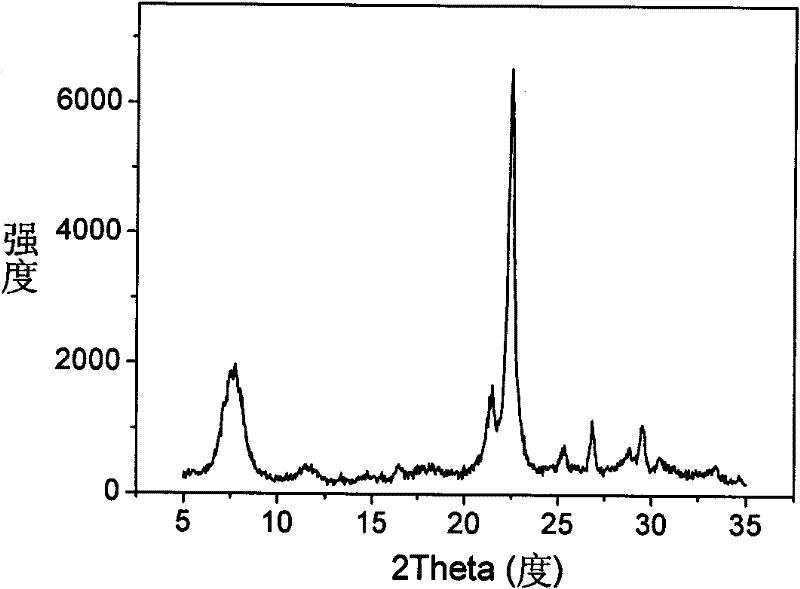

Method for recycling molecular sieve mother solution

InactiveCN102190312AReduce dosageConserve waterMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveSeed crystal

The invention discloses a method for recycling molecular sieve crystallization mother solution, which comprises the following steps of: (1) preparing a material for synthesizing a molecular sieve, gelatinizing, crystallizing, filtering, and collecting all molecular sieve crystallization mother solution; (2) using the obtained all molecular sieve crystallization mother solution for synthesis of the molecular sieve directly, mixing with a solid silicon source, an aluminum source and alkali, and adding or not adding molecular sieve seed crystals and a template agent to obtain a reaction mixture; and (3) crystallizing the obtained reaction mixture according to the conventional hydrothermal method, obtaining a filter cake, namely a molecular sieve product, and filtering and collecting all molecular sieve crystallization mother solution, wherein the obtained all molecular sieve crystallization mother solution can be circularly utilized according to the sequence of steps (2) and (3). In the synthesis of the molecular sieve, alkaline waste liquor is not discharged basically, the total silicon utilization rate is more than or equal to 90 percent, and the yield of the molecular sieve product is over 90 percent.

Owner:EAST CHINA NORMAL UNIV

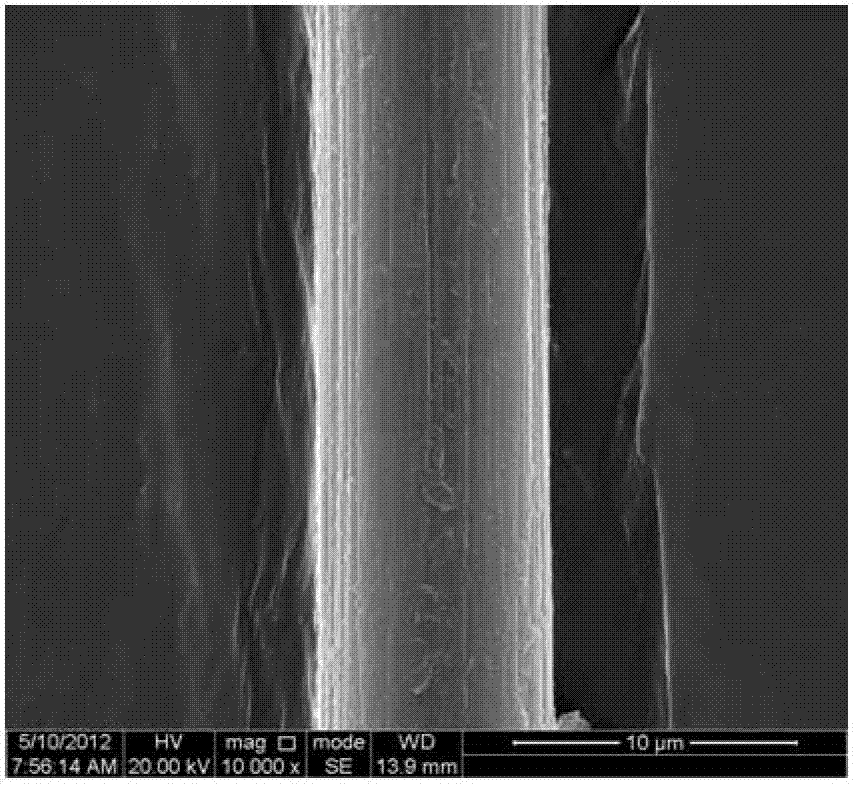

Method for preparing graphene oxide grafting surface modification carbon fiber

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

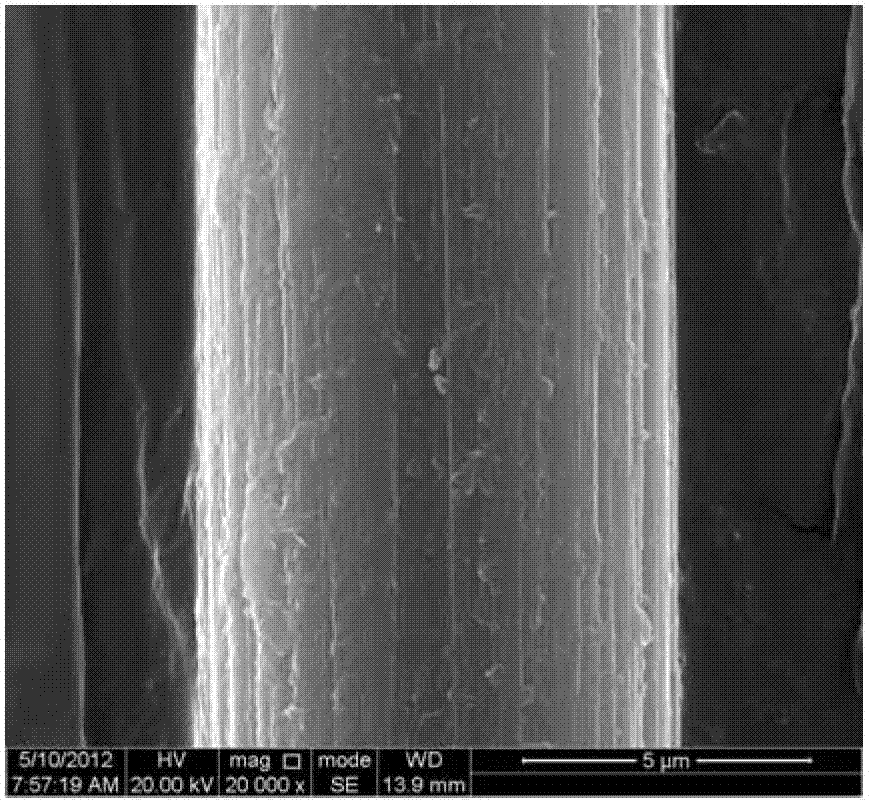

Method of preparing silver nanowire by utilization of hydrothermal method

InactiveCN103084584AImprove processing stabilityLow sensitivity to process parametersNanotechnologyMetal chlorideHigh volume manufacturing

The invention relates to a method of preparing silver nanowire by utilization of a hydrothermal method. The steps including: directly mixing ethylene glycol PVP solution which contains metal chloride with the concentration of 0.01M-2MPVP and the concentration of 1*10M-1*10-2M with ethylene glycol silver nitrate solution with the concentration of 0.01M-1M at normal temperature, stirring the mixed solution to be uniformed mixed, obtaining mixed reaction mother solution; the volume ratio of ethylene glycol silver nitrate solution to ethylene glycol PVP solution is 1:1-10:1; the molar ratio of silver nitrate to the PVP in the mixed reaction mother solution is 1:10-10:1, and the molar ration of silver nitrate to metal chloride is 10:1-104:1; putting the mixed reaction mother solution into an reaction kettle, warming the mixed reaction mother solution to 160 DEG C - 180 DEG C to carry out reduction reaction, the silver salt in the mother solution is restored, and silver nanowire is obtained. The method of preparing silver nanowire by utilization of the hydrothermal method has the advantage of being simple and high-efficient, no need of being preheated when the preliminary reaction is carried out at the normal temperature, easy to control of reaction conditions, and especially applicable to mass production.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

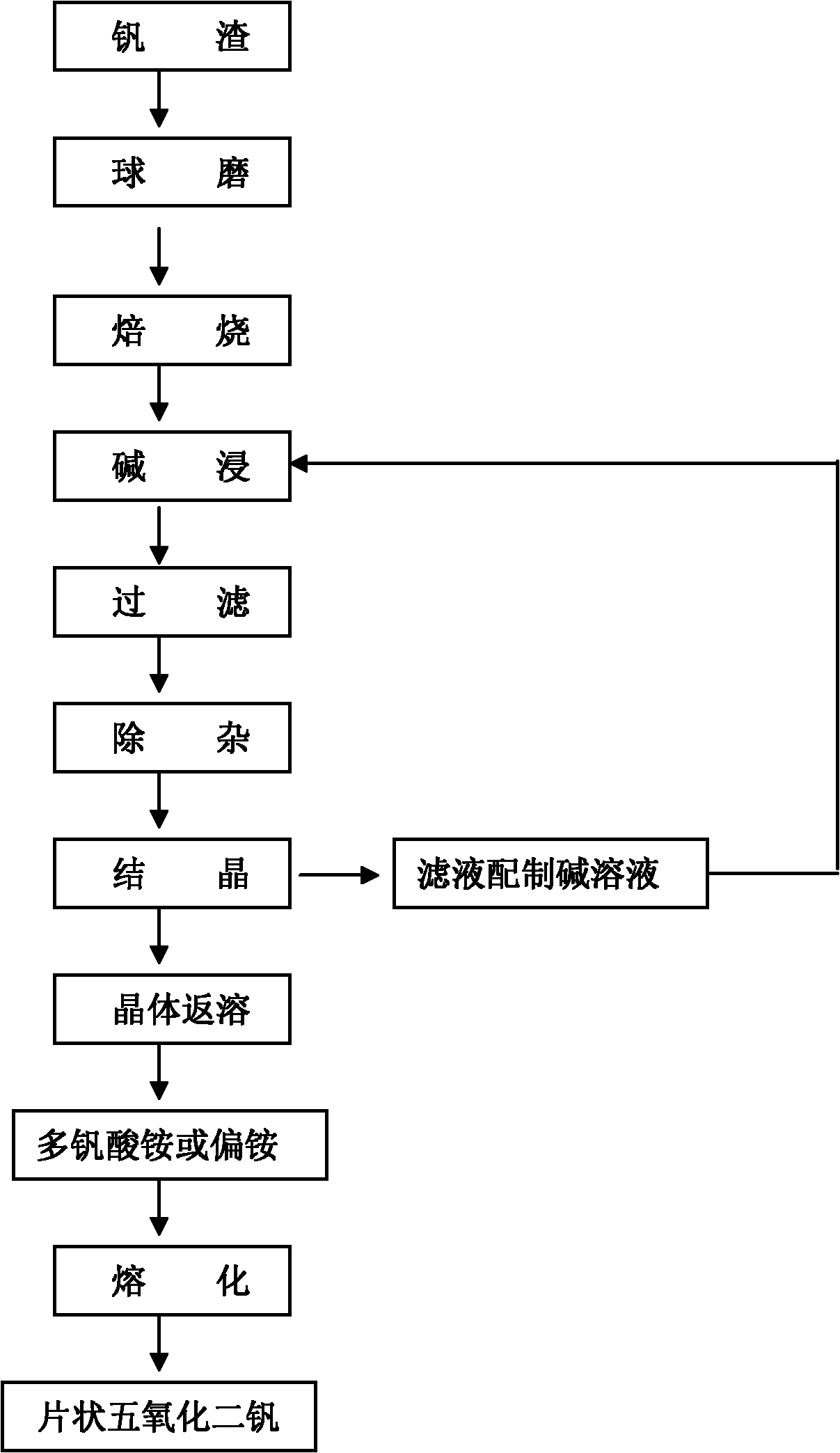

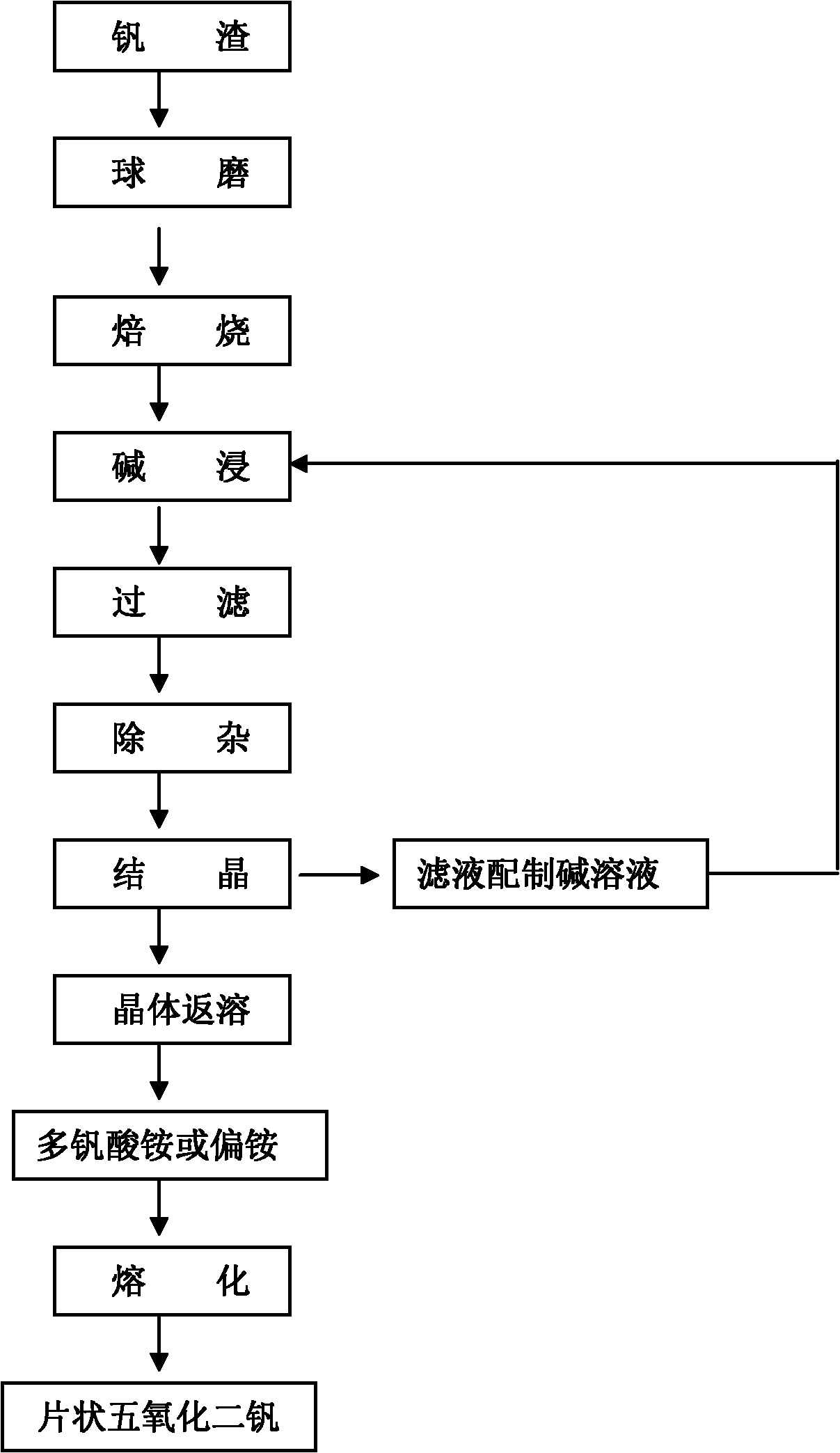

Method for extracting vanadium pentoxide from vanadium slag

InactiveCN101899582AReduce pollutionHigh extraction rateProcess efficiency improvementSlagAmmonium metavanadate

The invention relates to a method for extracting vanadium pentoxide from vanadium slag, belonging to the field of vanadium metallurgy. In order to solve the technical problem, the invention provides a method for extracting vanadium pentoxide from vanadium slag with less environment pollution. The method comprises the following steps of: a. smashing the vanadium slag, and removing metal iron to obtain the refined vanadium slag; b. baking the refined vanadium slag at 800-1000 DEG C to obtain grog; c. adding the grog into alkali liquor for leaching, and filtering with hot to obtain vanadium-containing solution and tailings; d. removing impurity in the vanadium-containing solution, reducing the temperature of the impurity-removed and vanadium-containing solution to be less than 35 DEG C, crystallizing and filtering to obtain Na3VO4.5-12H2O crystalloid and filtering mother liquor thereof; and e. dissolving the Na3VO4.5-12H2O crystalloid by adding water, treating with an acid ammonium salt precipitation method to obtain ammonium poly-vanadate or ammonium metavanadate, and dehydrating, deaminizing and melting the ammonium poly-vanadate or the ammonium metavanadate to obtain the vanadium pentoxide.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

Blueberry health care beverage and preparation method thereof

The invention relates to a blueberry health care beverage and a preparation method thereof. The beverage is prepared from blueberry and Chinese medicine components and contains pure biological active bacteria, the beverage is prepared from the following components in weight proportion: 20-80 parts of blueberry, 5-20 parts of semen cassiae, 2-10 parts of medlar, 2-10 parts of Chinese date, 1-8 parts of stevioside, 1-10 parts of composite mother liquor, 0.5-3 parts of crystal sugar and 0.5-5 parts of honey. In the invention, the blueberry and the traditional Chinese components are utilized to culture a bacterium solution, and fermentation is carried out multiple times to obtain the beverage, and the obtained beverage has the health care effects of delaying senility, inhibiting and resisting to cancer, improving the immunity of human bodies, protecting eyesight, reinforcing the memory, and the like.

Owner:深圳市唤然生物科技开发有限公司

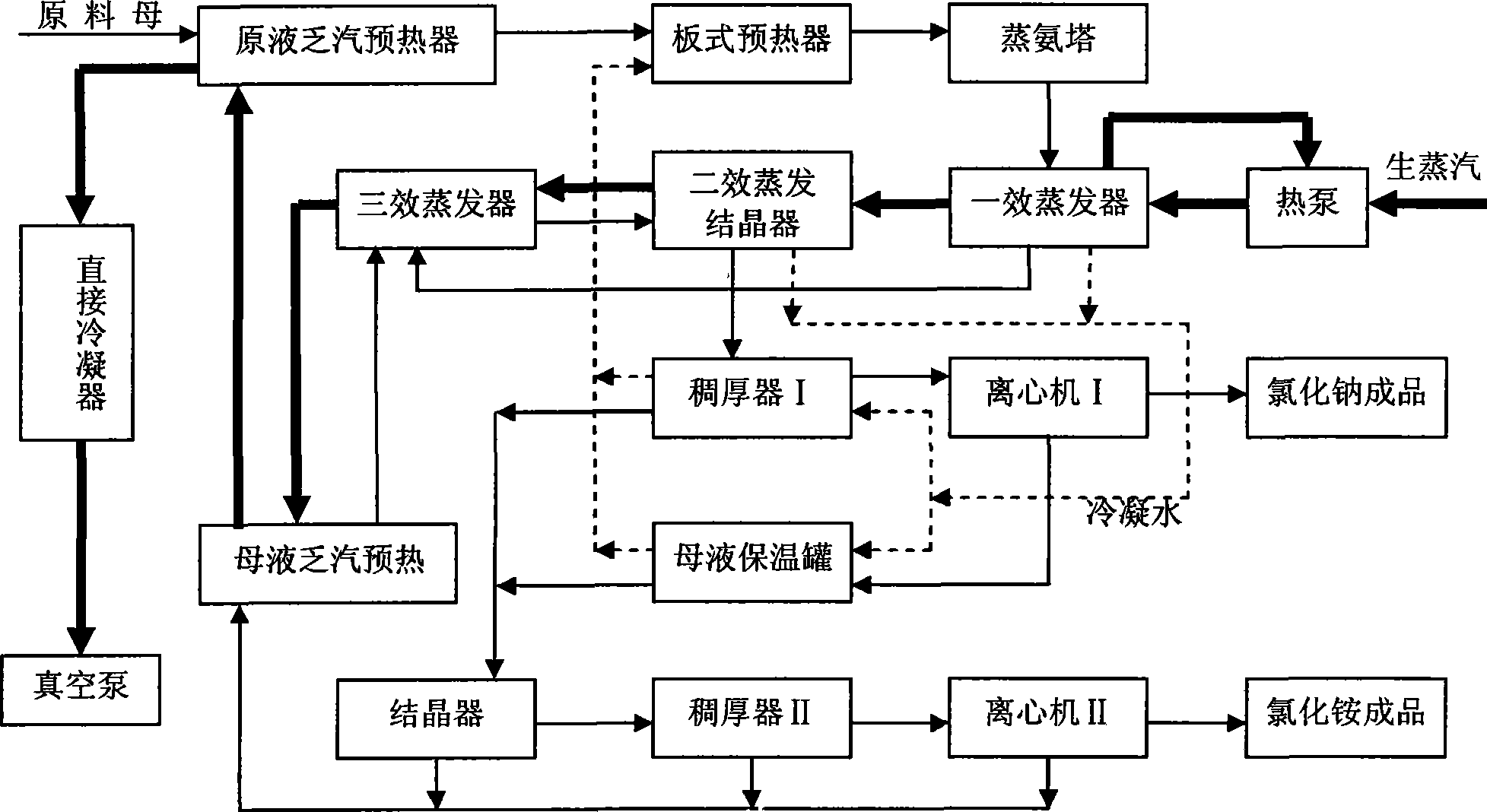

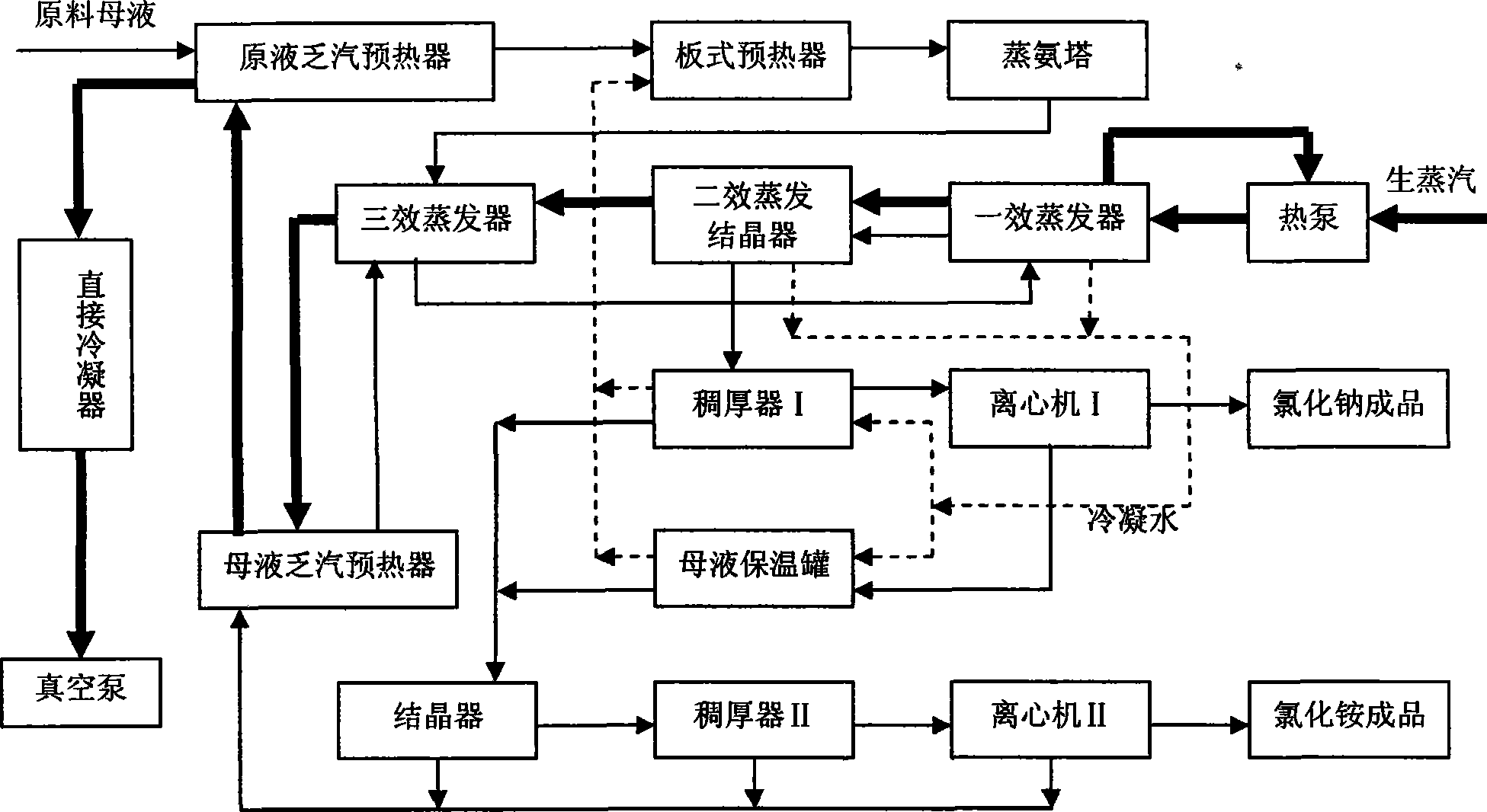

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

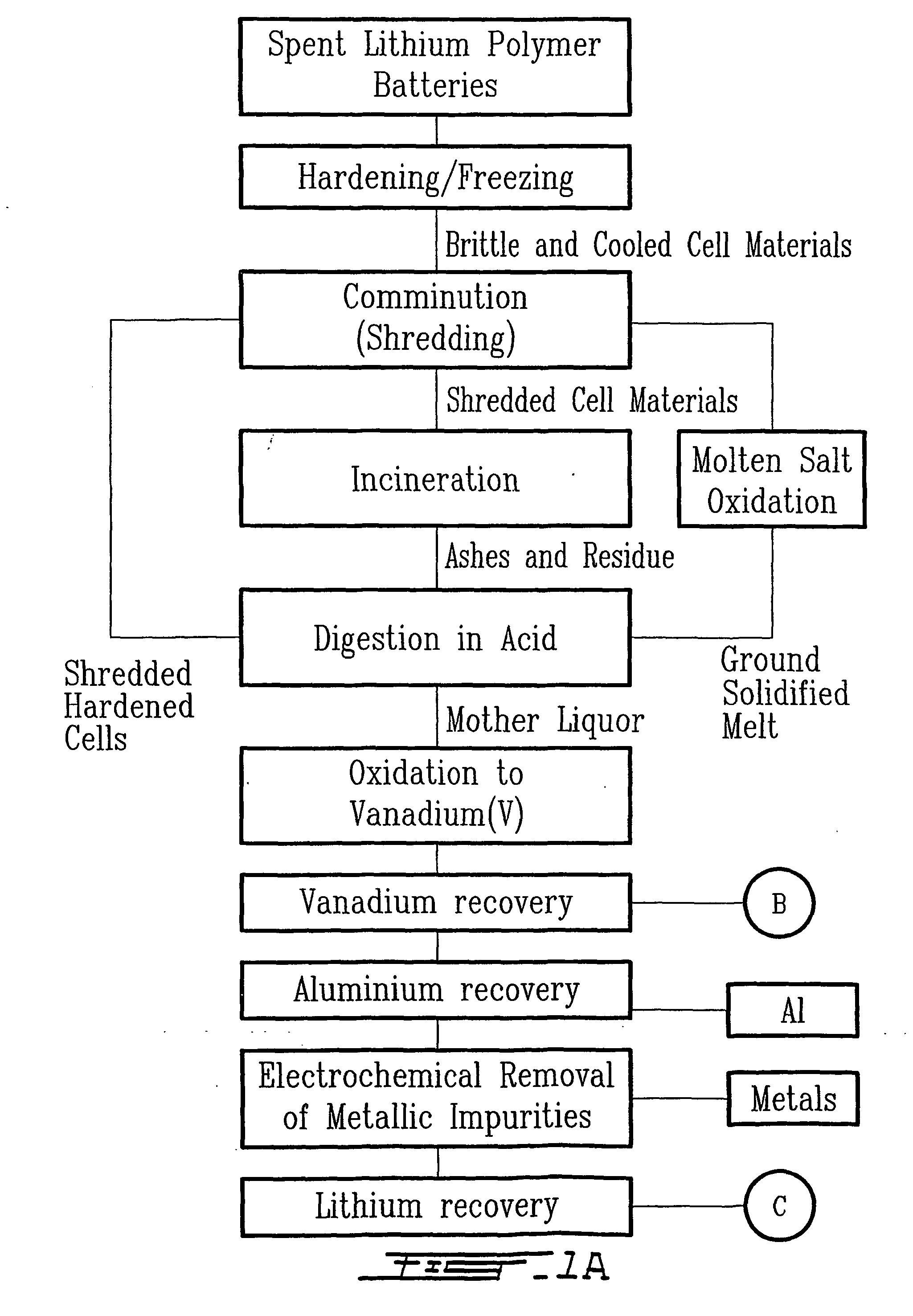

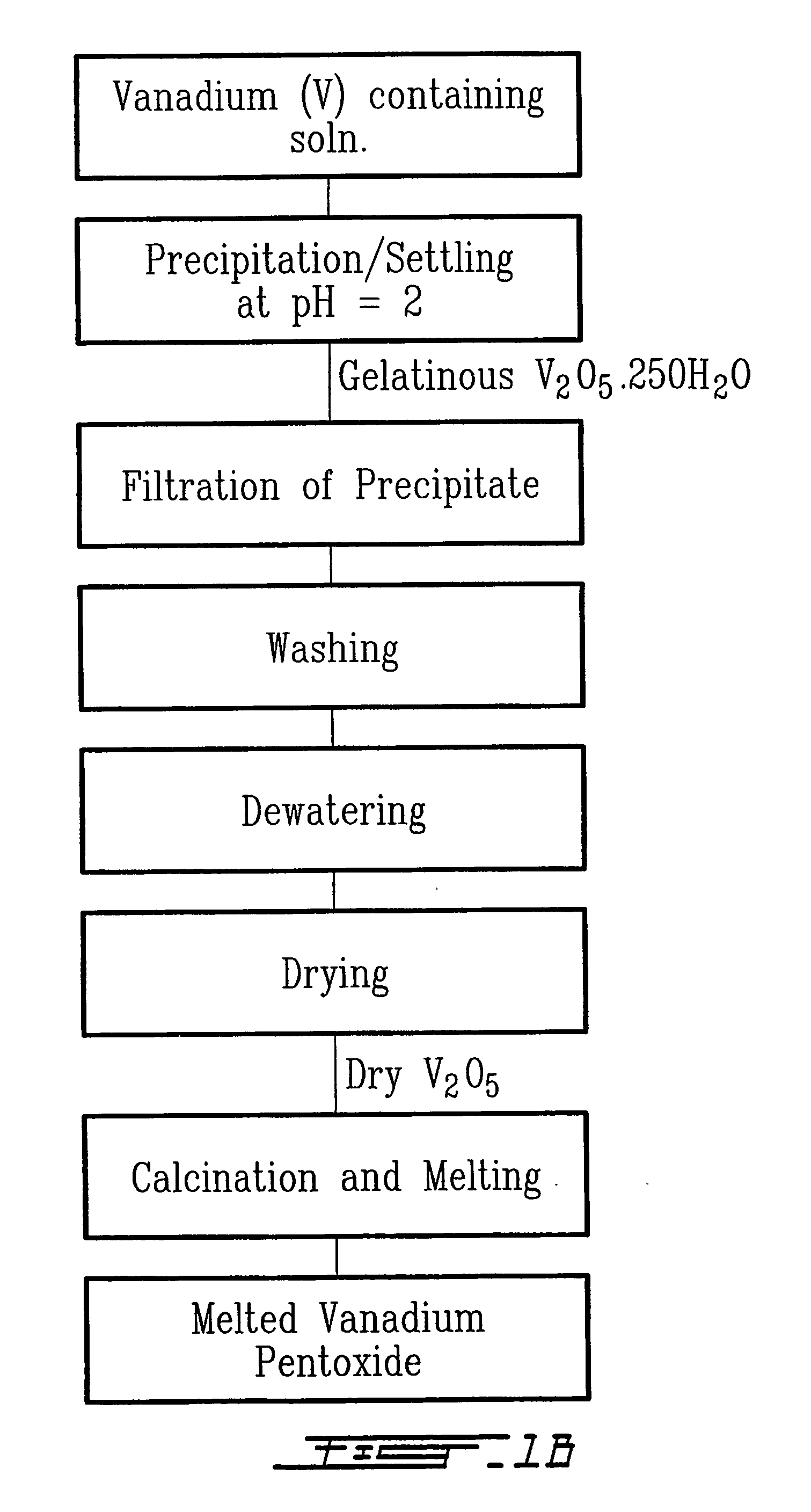

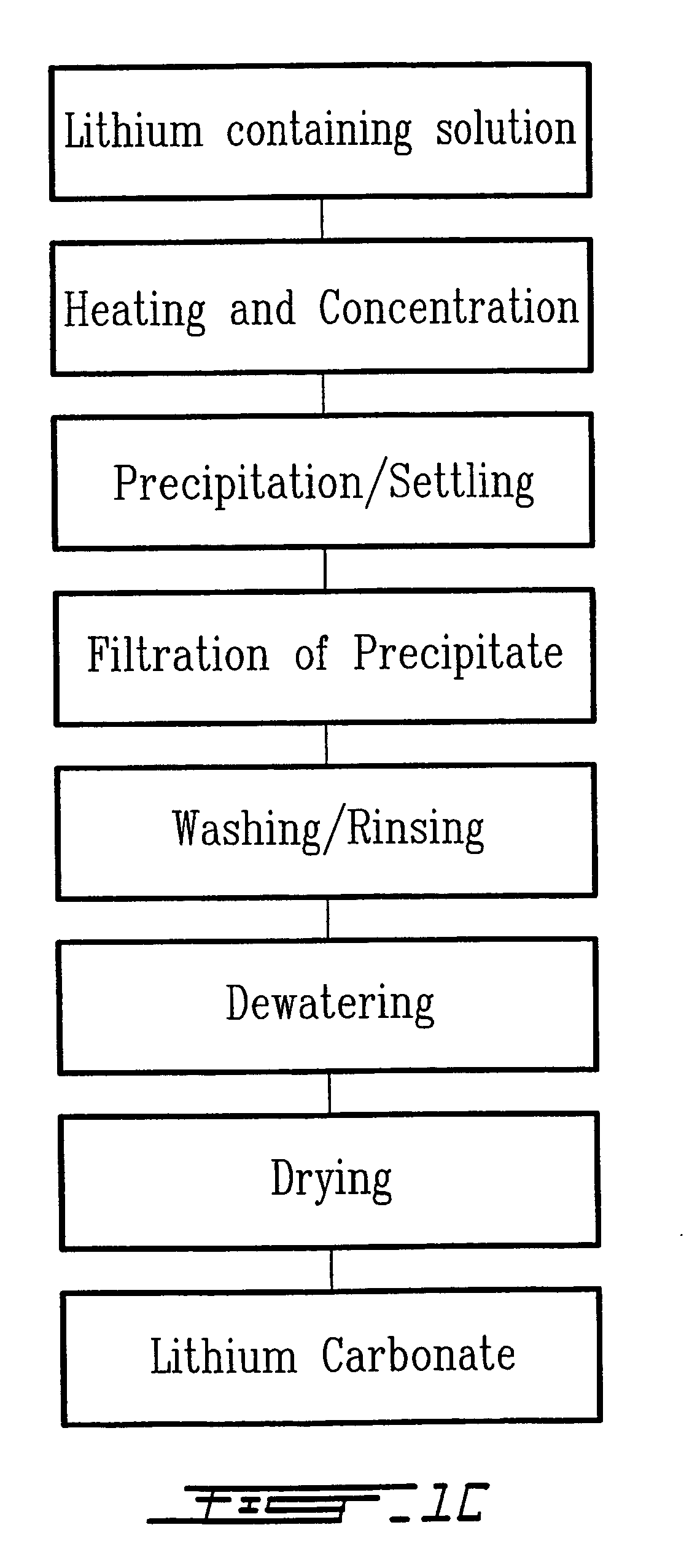

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

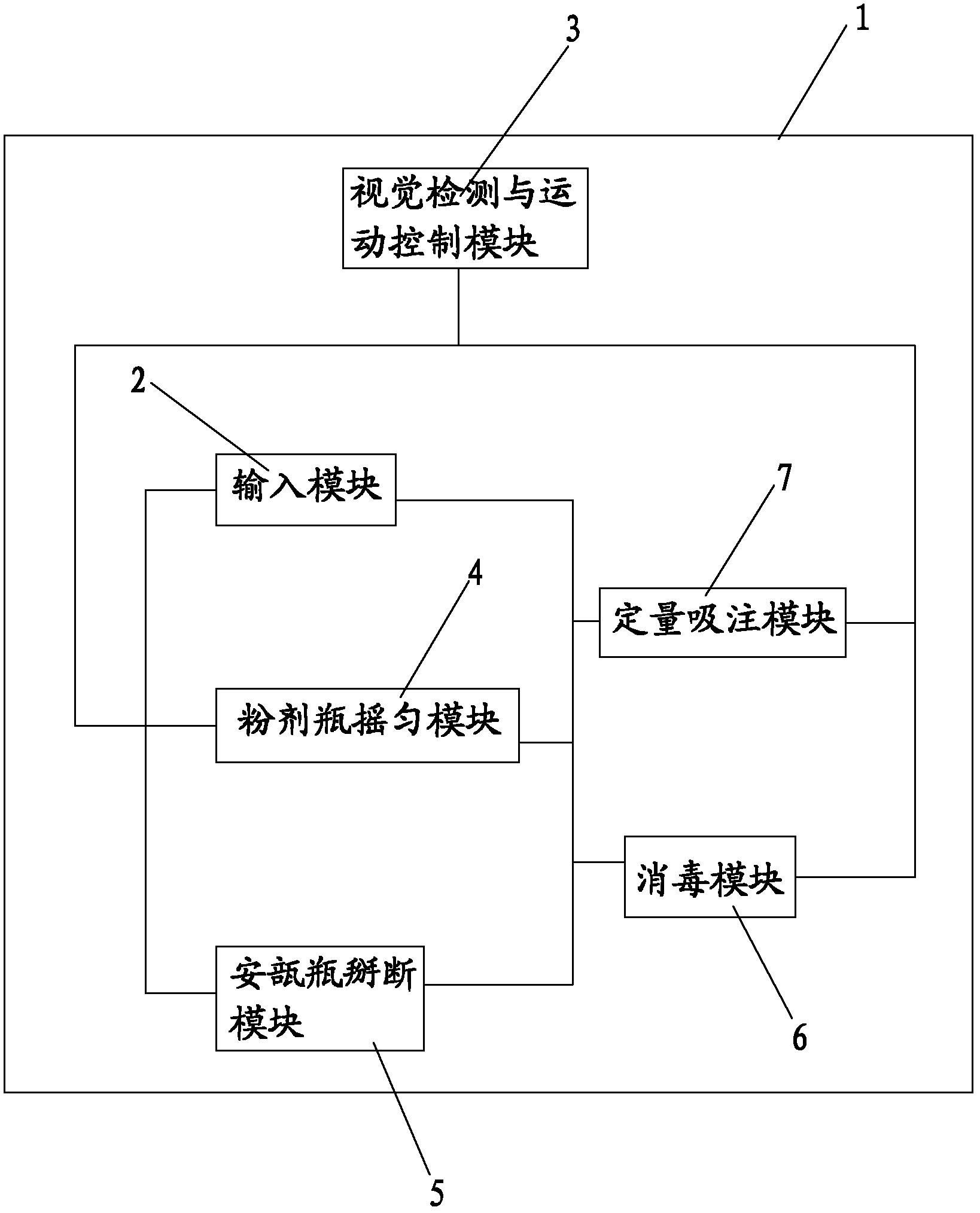

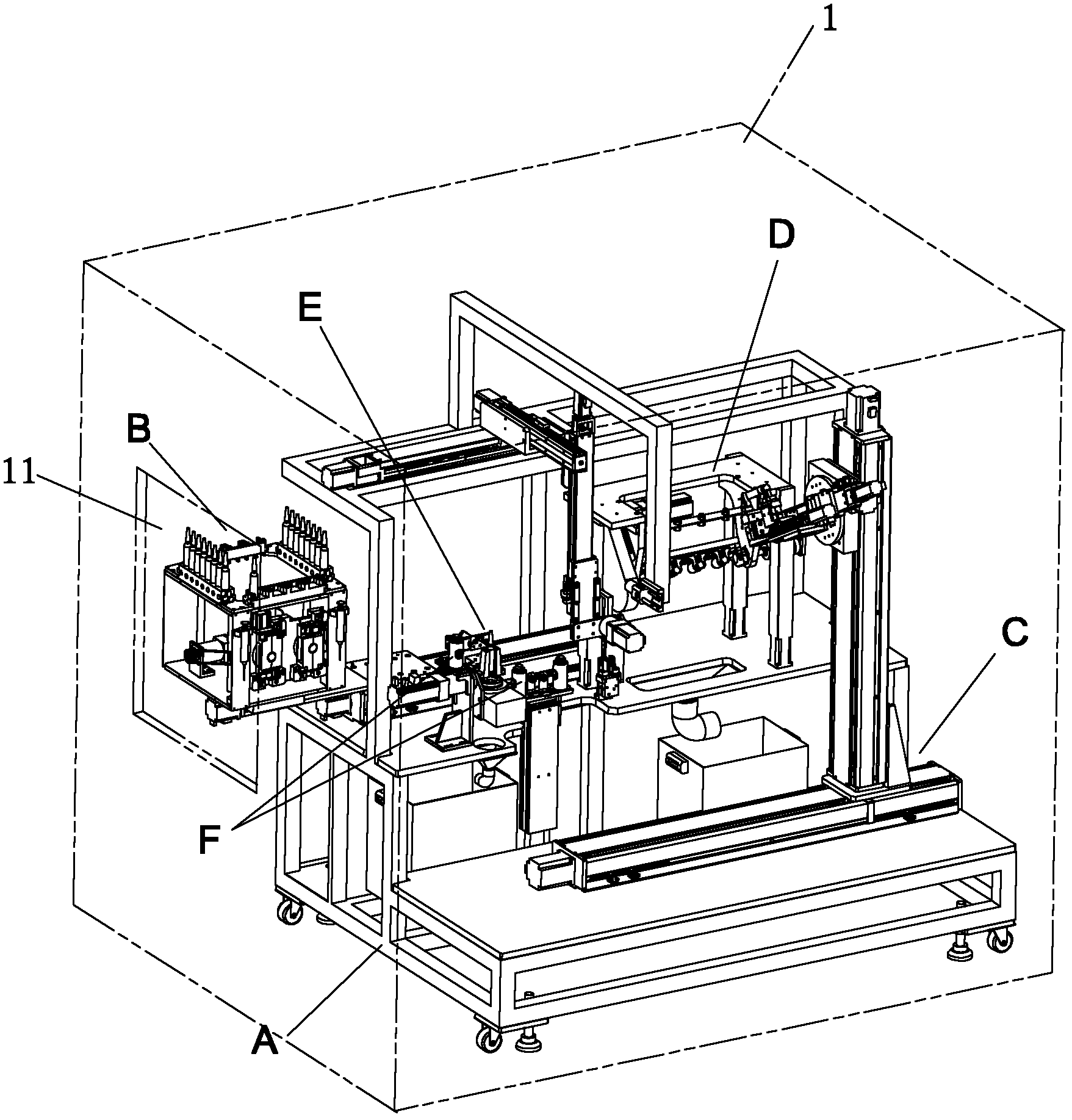

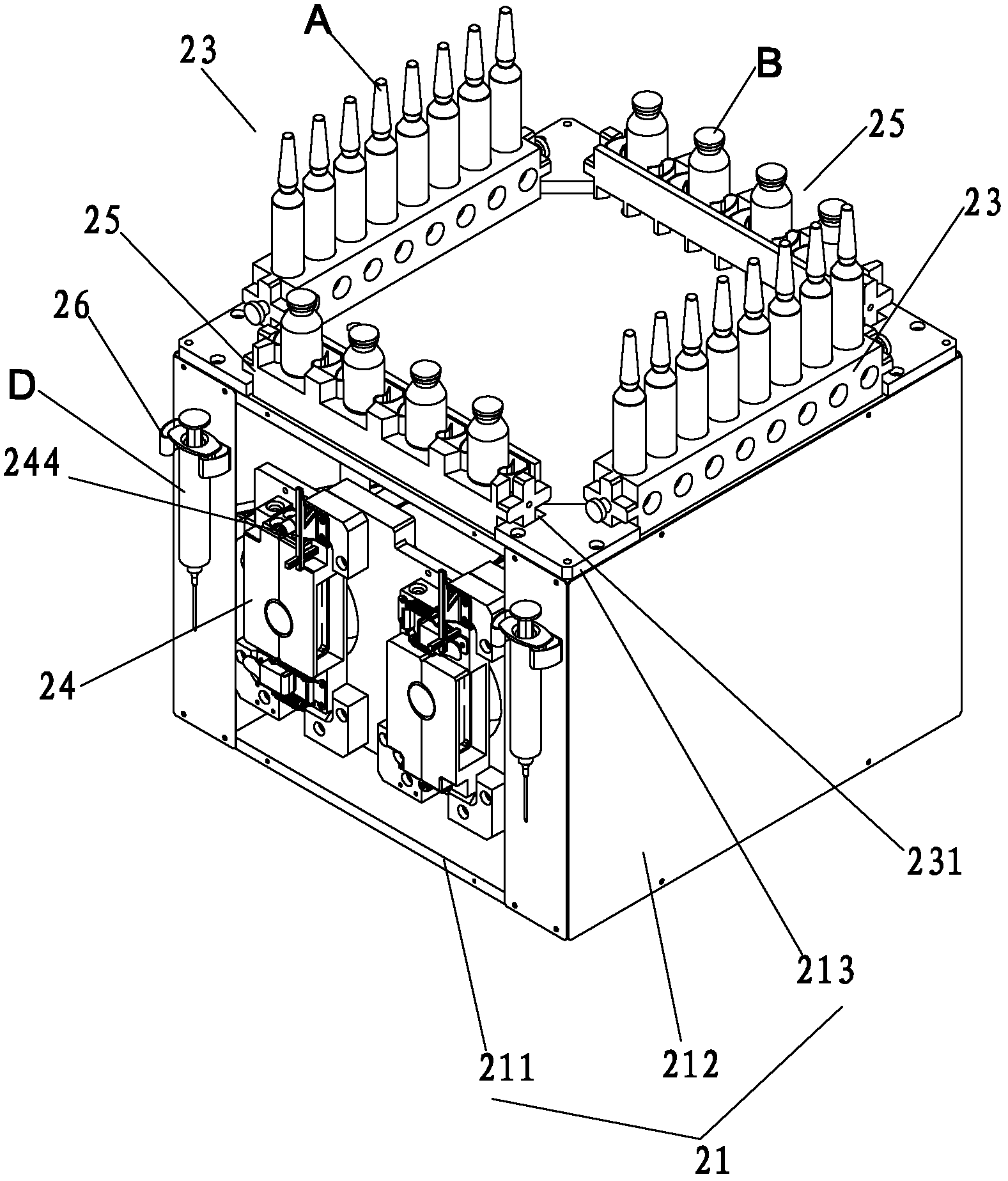

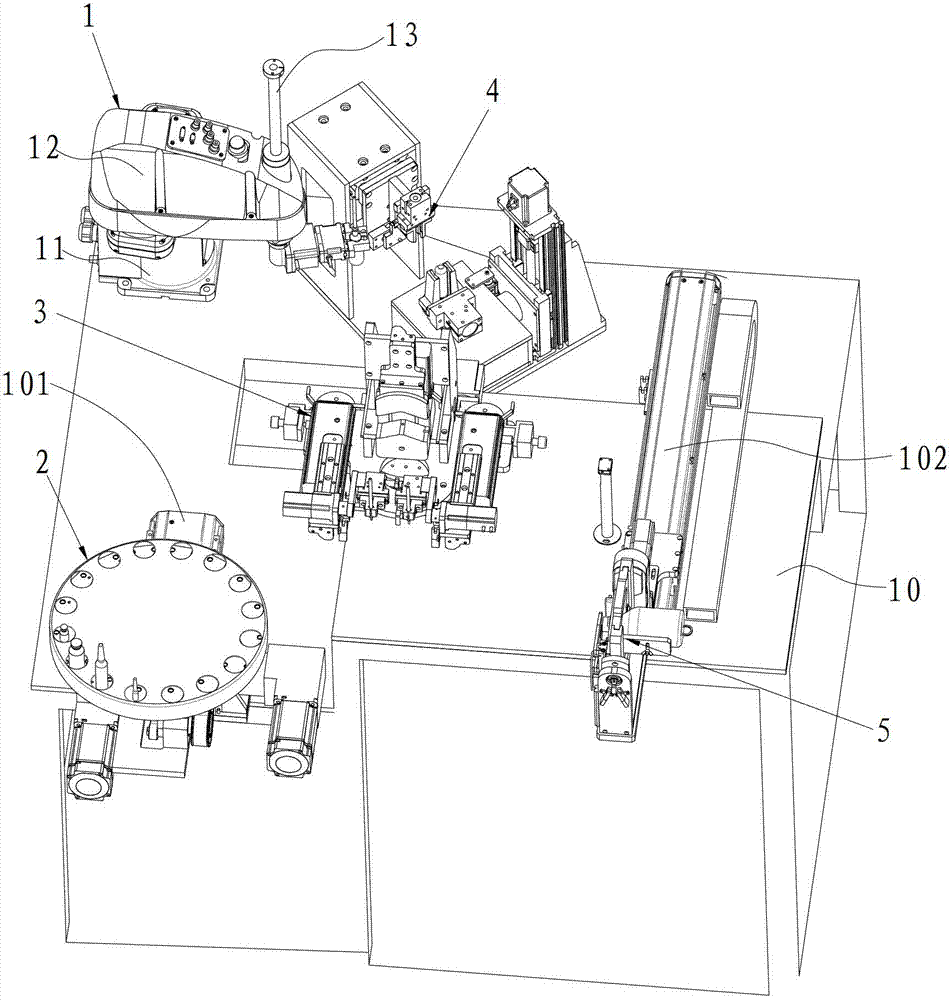

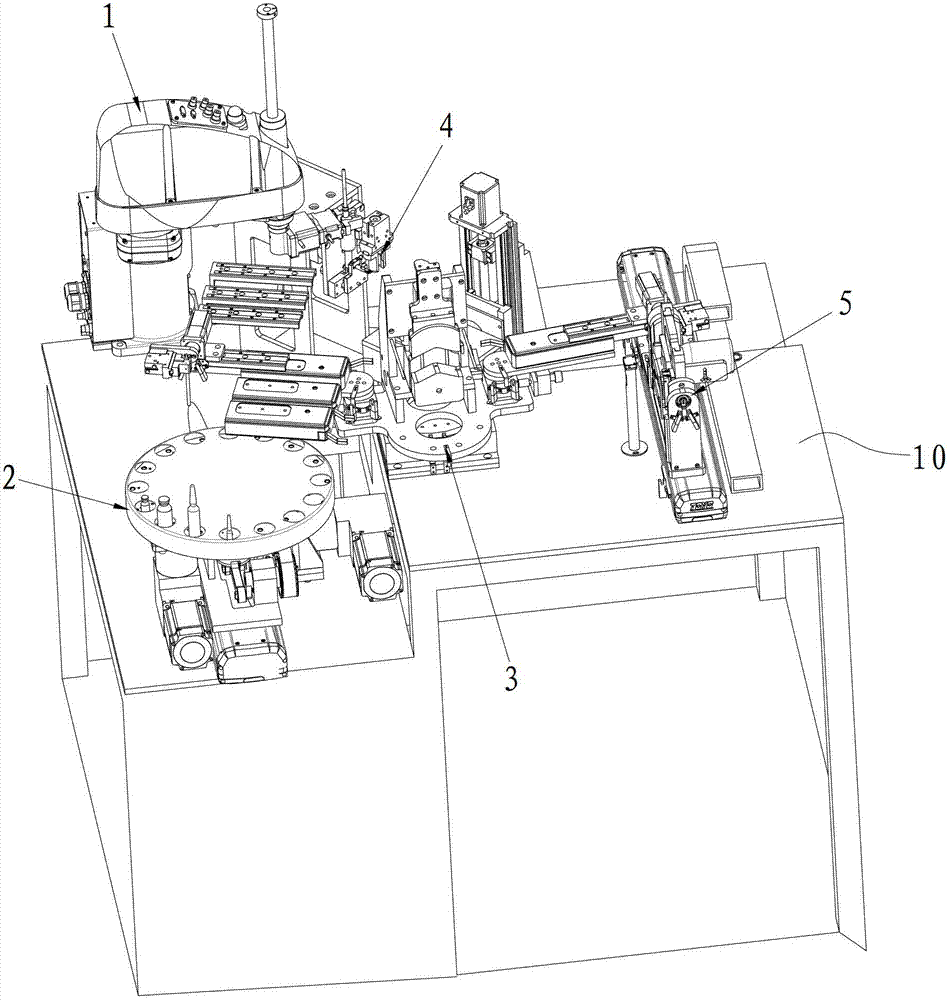

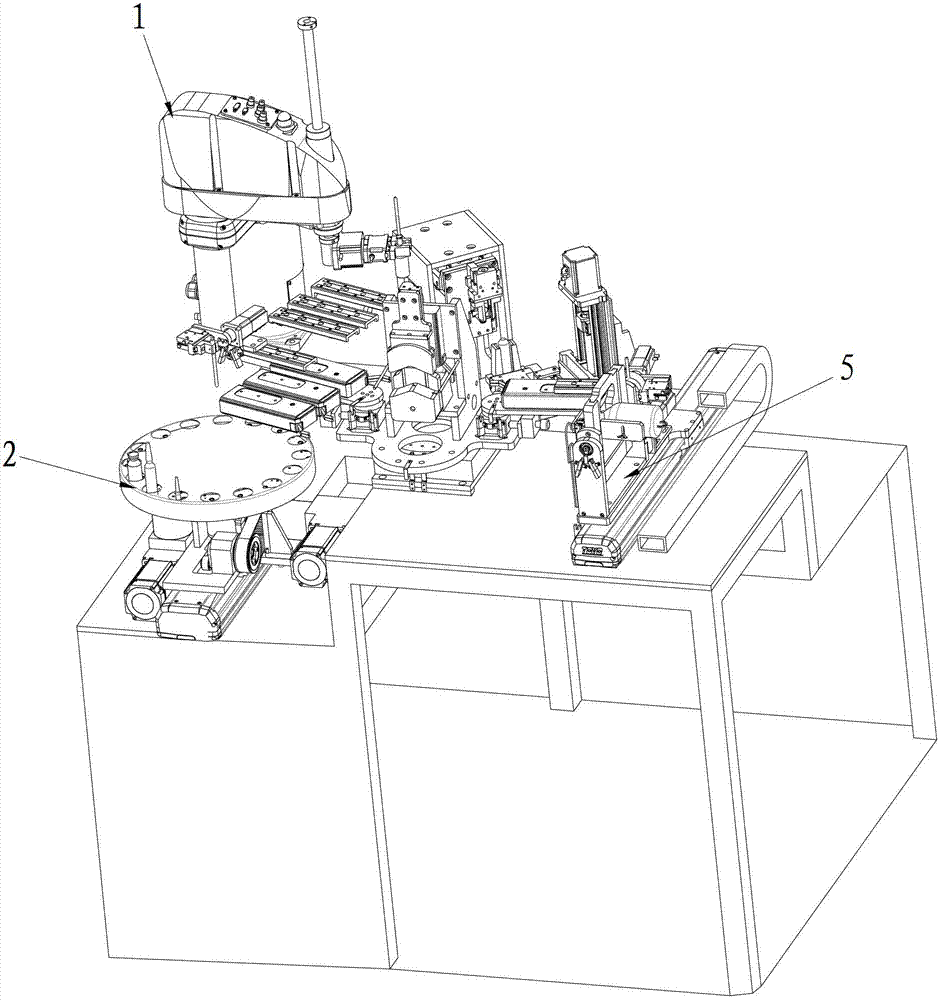

Automatic dispensing robot system and method

ActiveCN103006436AAvoid pollutionAvoid damageMixing methodsPharmaceutical containersHazardous substanceEngineering

The invention discloses an automatic dispensing robot system and an automatic dispensing method, which are used for preparing an intravenous infusion solution. The system comprises a closed cavity, wherein the closed cavity can be opened, and an input module, a powder bottle shaking module, an ampoule bottle breaking module, a disinfection module, a quantitative injection module and a visual detection and motion control module are arranged in the closed cavity. According to the automatic dispensing robot system, the breaking, disinfection and quantitative suction of an ampoule bottle, the disinfection and quantitative suction of a powder bottle and the mixing with a mother solution can be automatically realized, and the solution is prevented from being polluted; additionally, nursing personnel are prevented from being radiated and hurt by harmful substances; the probability of misoperation is reduced; the operating standard of intravenous infusion dispensing is standardized; and the dispensing efficiency is increased.

Owner:SHENZHEN CITY WEIBANG TECH

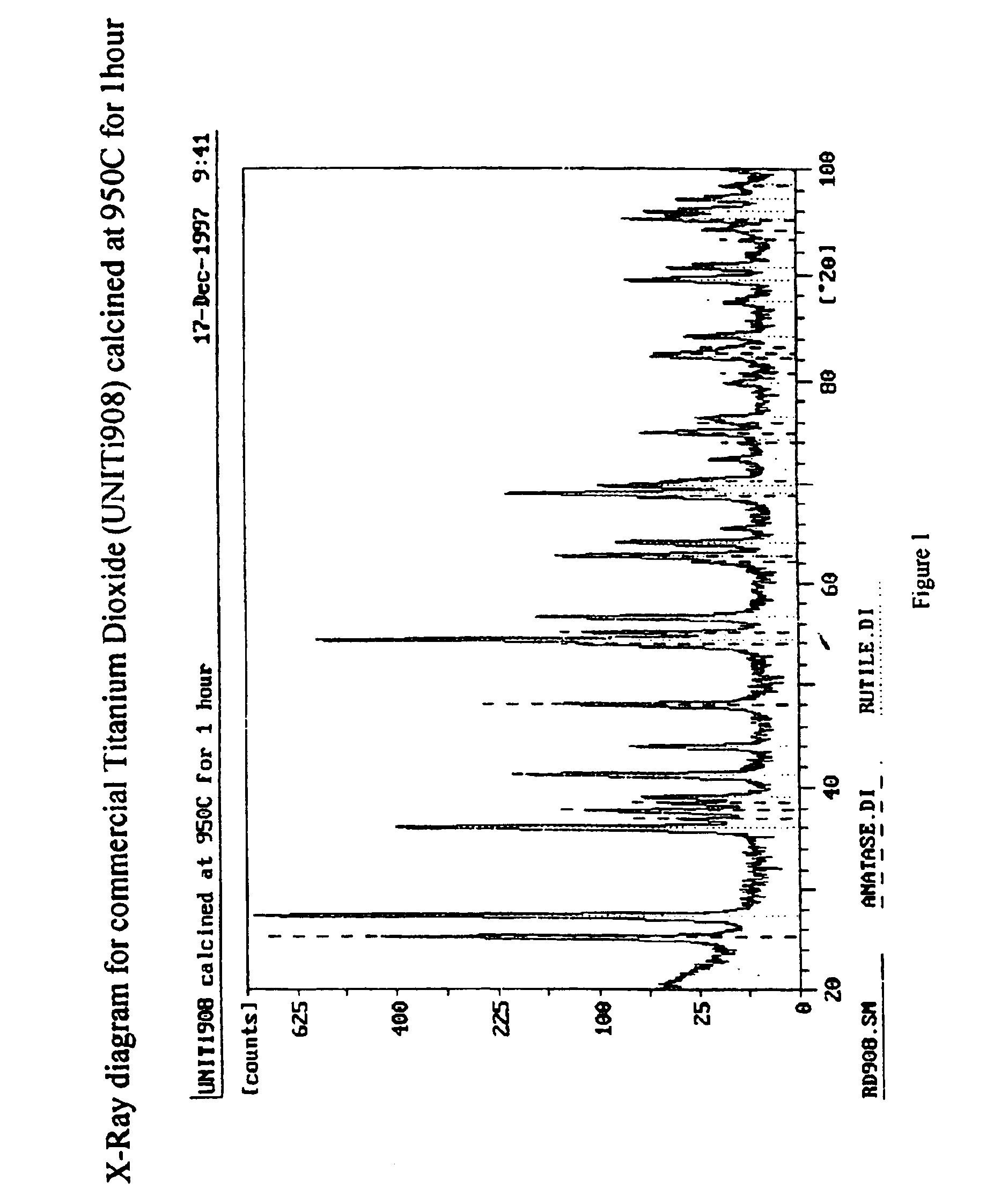

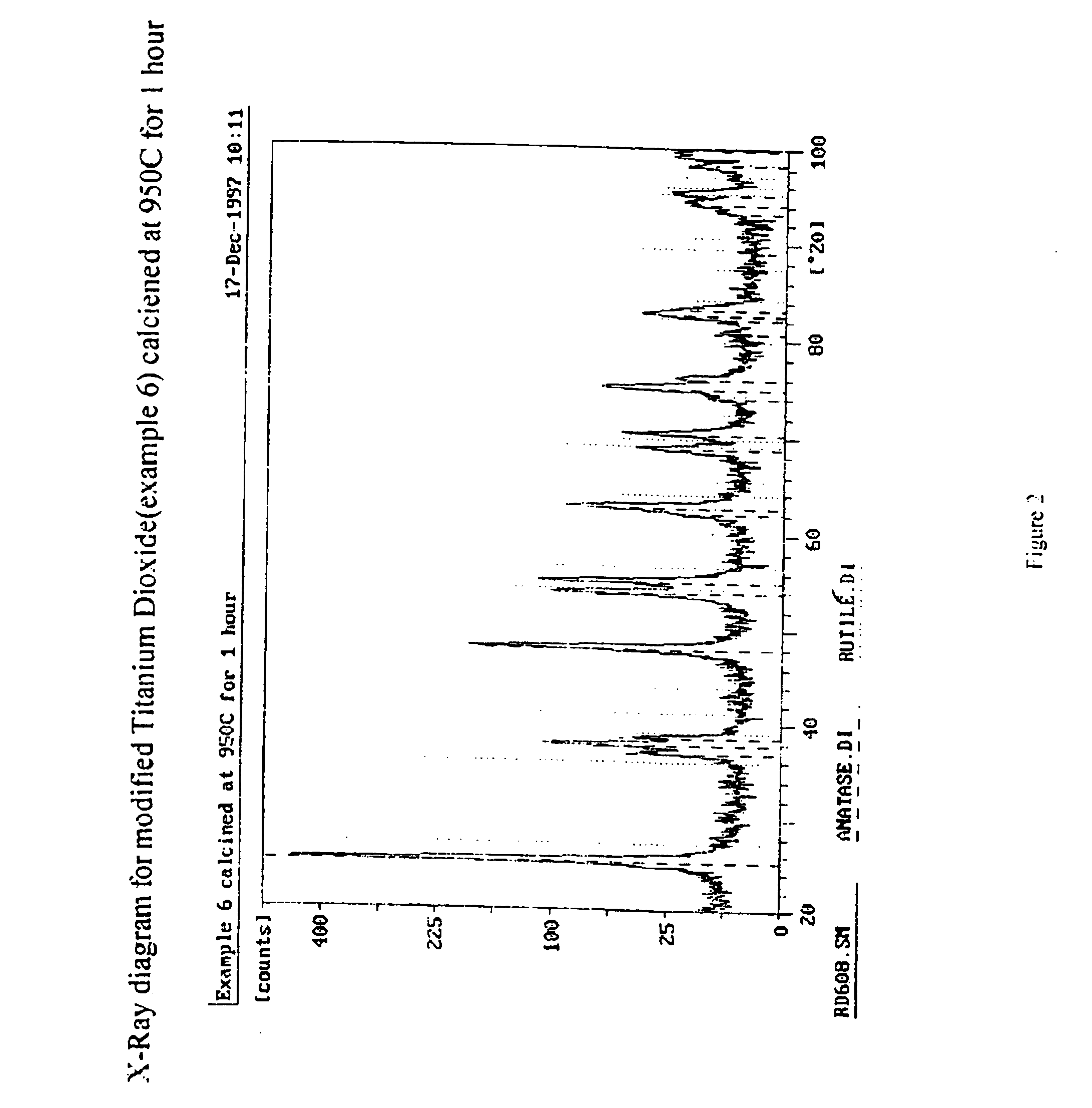

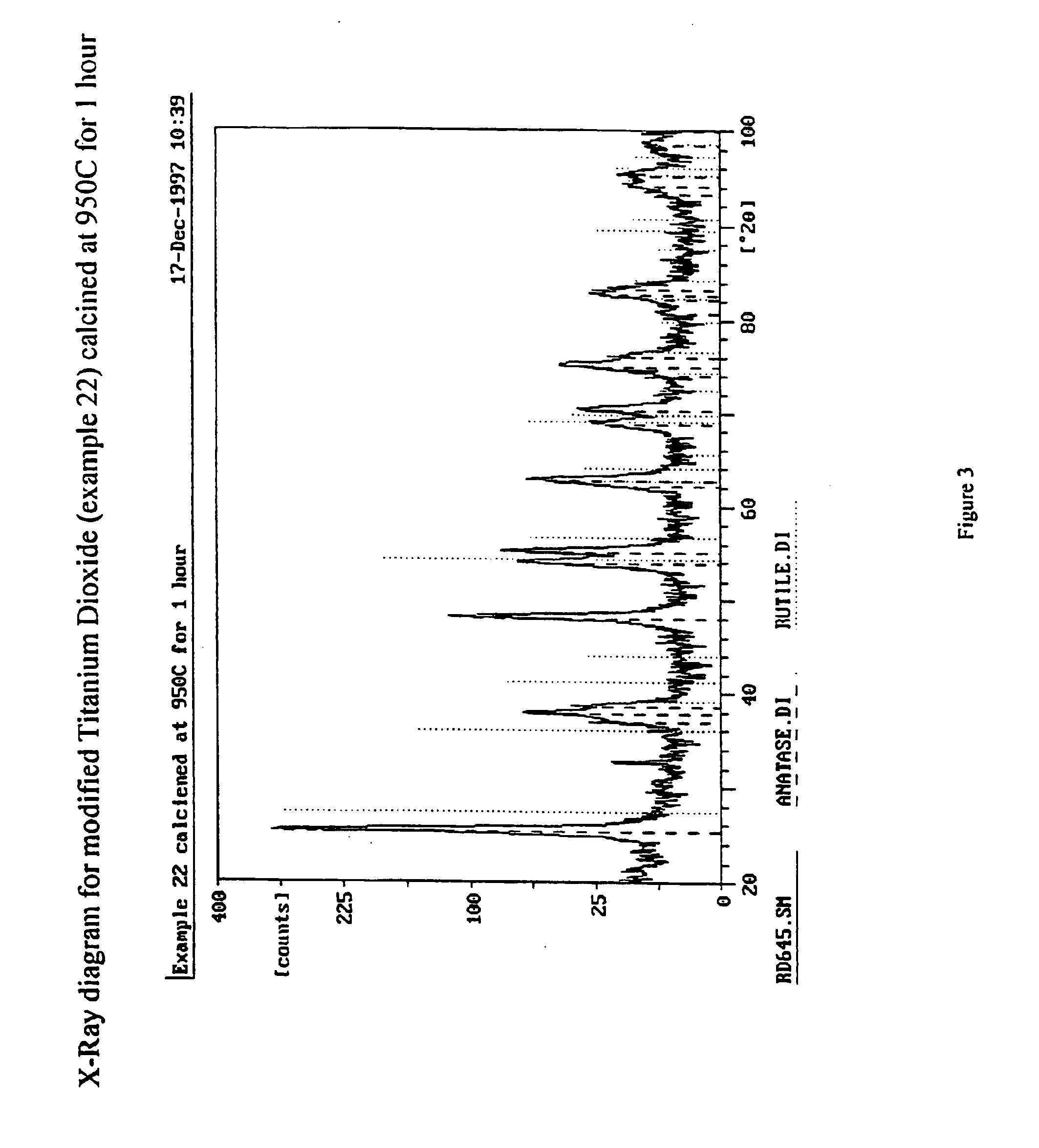

Modified titanium dioxide and a method for its preparation

The invention relates to a composite material comprising silicon and titanium dioxide characterized by an enhanced thermal and hydrothermal stability of the pore structure. The composite is obtainable by precipitating titanium hydroxide from an aqueous solution containing sulfate salts and urea, followed by an hydrothermal treatment in the mother liquor, and by reacting the precipitate with a basic silica sol. The composite has a specific surface area of up to 228 m2 / g for a material calcined at 800° C. for 3 hours, and is suitable for catalyzing a variety of reactions, including Claus reaction and degradation of organic impurities.

Owner:ROTEM AMFERT NEGEV

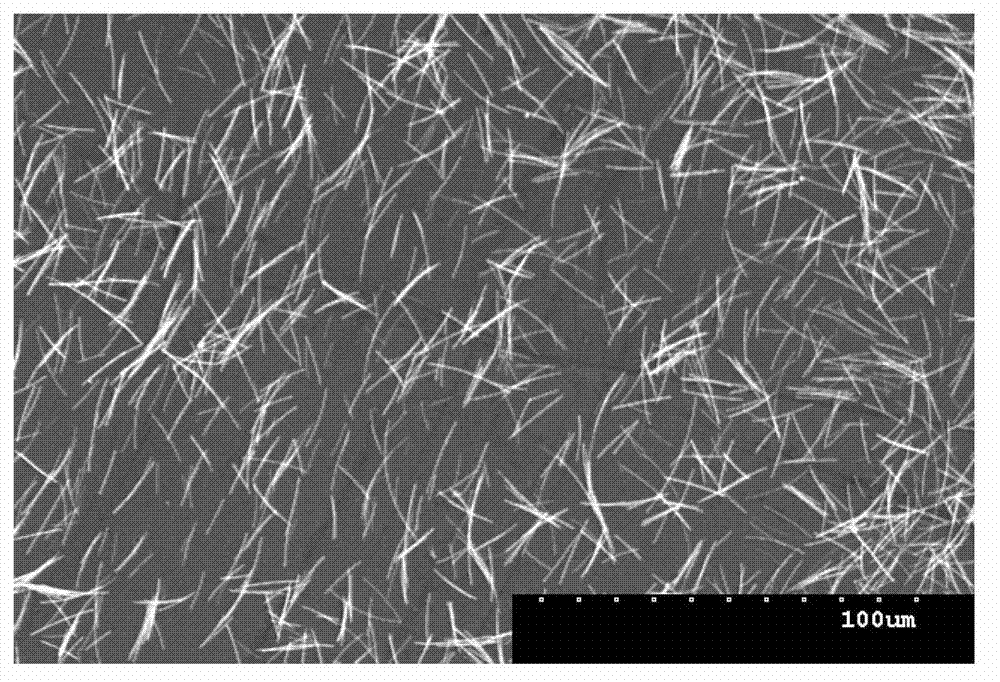

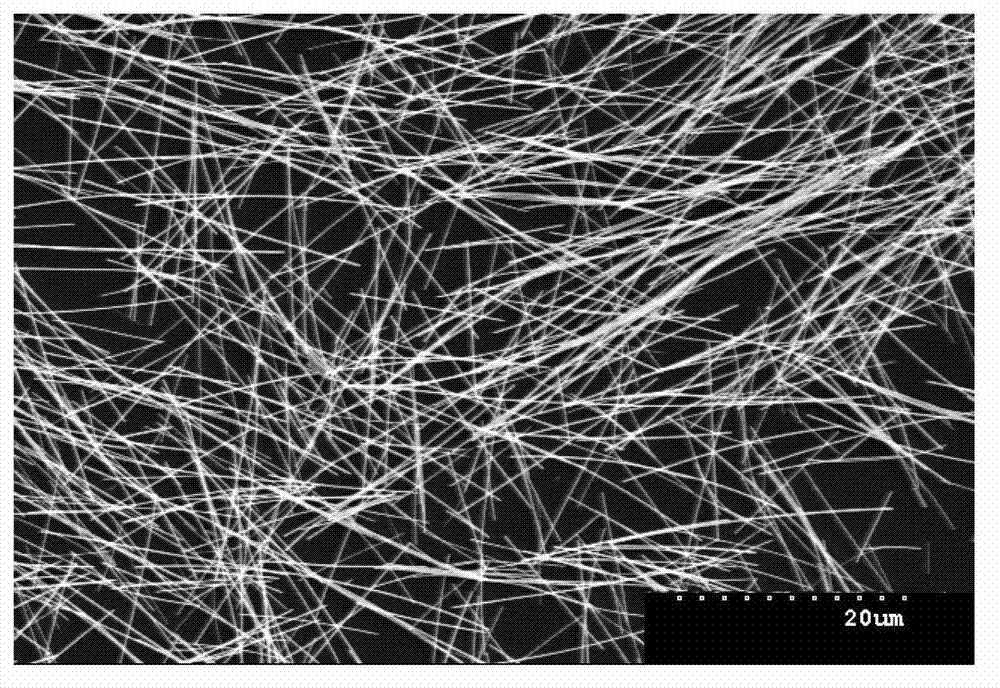

Method for preparing length-diameter-ratio nano-silver wire by pH-value regulation solvothermal method

The invention relates to a method for preparing a length-diameter-ratio nano-silver wire by a pH-value regulation solvothermal method. The method comprises the following steps of: preparing the following ethylene glycol solution, namely an ethylene glycol solution A of silver nitrate or silver acetate, an ethylene glycol solution B of polyvinyl pyrrolidone (PVP), an ethylene glycol solution C of water-soluble chloride and concentrated acid D; mixing the components according to a certain amount and fully stirring to form a final mixed solution; moving the final mixed solution into a reaction kettle; placing in an oven for reaction for a certain time; taking the reaction kettle out and cooling to room temperature to obtain mother liquid of the nano-silver wire; adding alcohol into the mother liquid for diluting, and removing supernatant liquor to obtain a precipitate; and repeatedly performing centrifugal separation, and thus obtaining nano-silver wire dispersion liquid uniformly dispersed in the alcohol. The method is simple, high in efficiency and low in cost, and can prepare high-quality nano-silver wires within a wider range of reaction condition; and prepared products are high in length-diameter ratio, good in length uniformity and low in impurity content.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

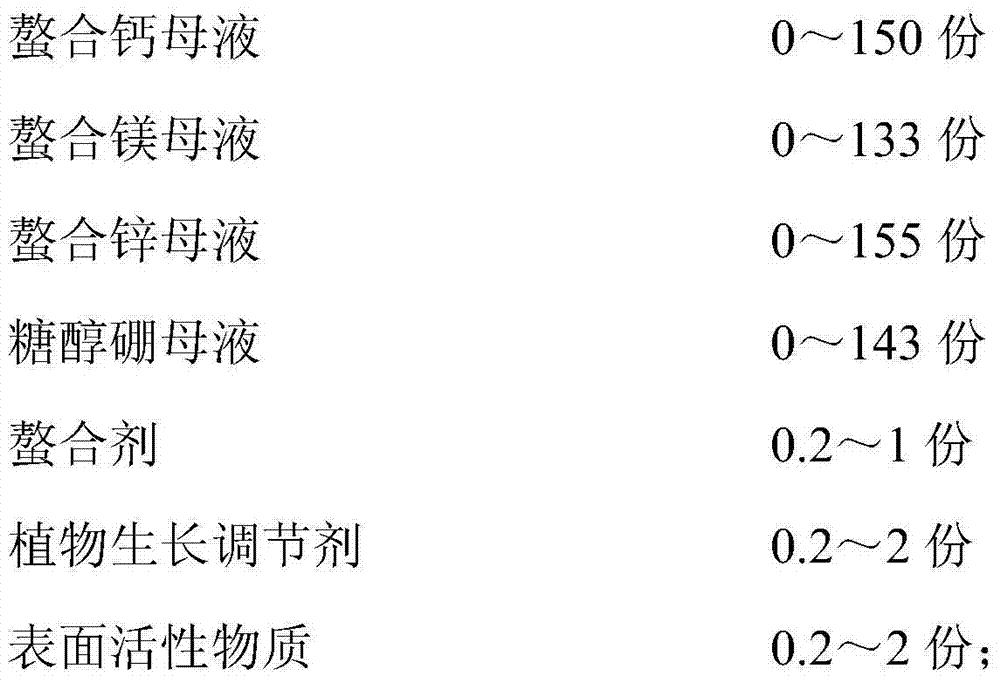

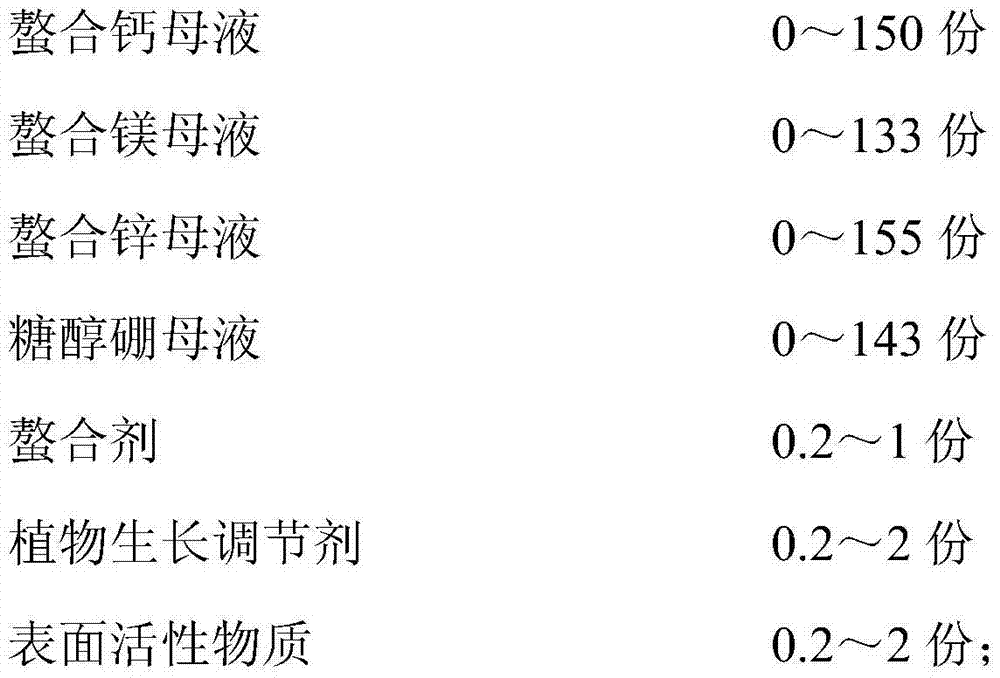

Sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and preparation method and applications thereof

ActiveCN103588564AAvoid reactionAchieve preparationFertilizer mixturesHigh concentrationMagnesium salt

The invention belongs to the field of agricultural production and discloses a sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and a preparation method and application thereof. The liquid fertilizer is prepared from various mother solutions, a chelating agent, a plant growth regulator and surface active materials. The preparation method comprises the following steps: causing sugar alcohol to respectively react with calcium salt, magnesium salt, zinc salt and boric acid to prepare calcium, magnesium, zinc and boron mother solutions, then mixing the mother solutions according to a certain ratio, and adding the chelating agent to cause the mother solutions to carry out secondary chelating reaction; after a while, adding the plant growth regulator and the surface active materials into reaction liquid, uniformly mixing, and cooling to the room temperature to obtain the high-concentration, stable and good-effect compound liquid fertilizer. The prepared liquid fertilizer provides adequate calcium, magnesium, zinc and boron and other nutrients for plants and can also carry out mixing of different elements and proportions according to the needs of different plants and different growth stages of plants.

Owner:SOUTH CHINA AGRI UNIV +1

Process for removal of impurities from an oxidizer purge stream

ActiveUS7273559B2Organic compound preparationSedimentation separationEnvironmental engineeringCarboxylic acid

A process is disclosed that relates to the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic. More particularly, the process involves the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream and then routing the mother liquor and or wash filtrate to an oxidation zone.

Owner:ALPEK POLYESTER SA DE CV

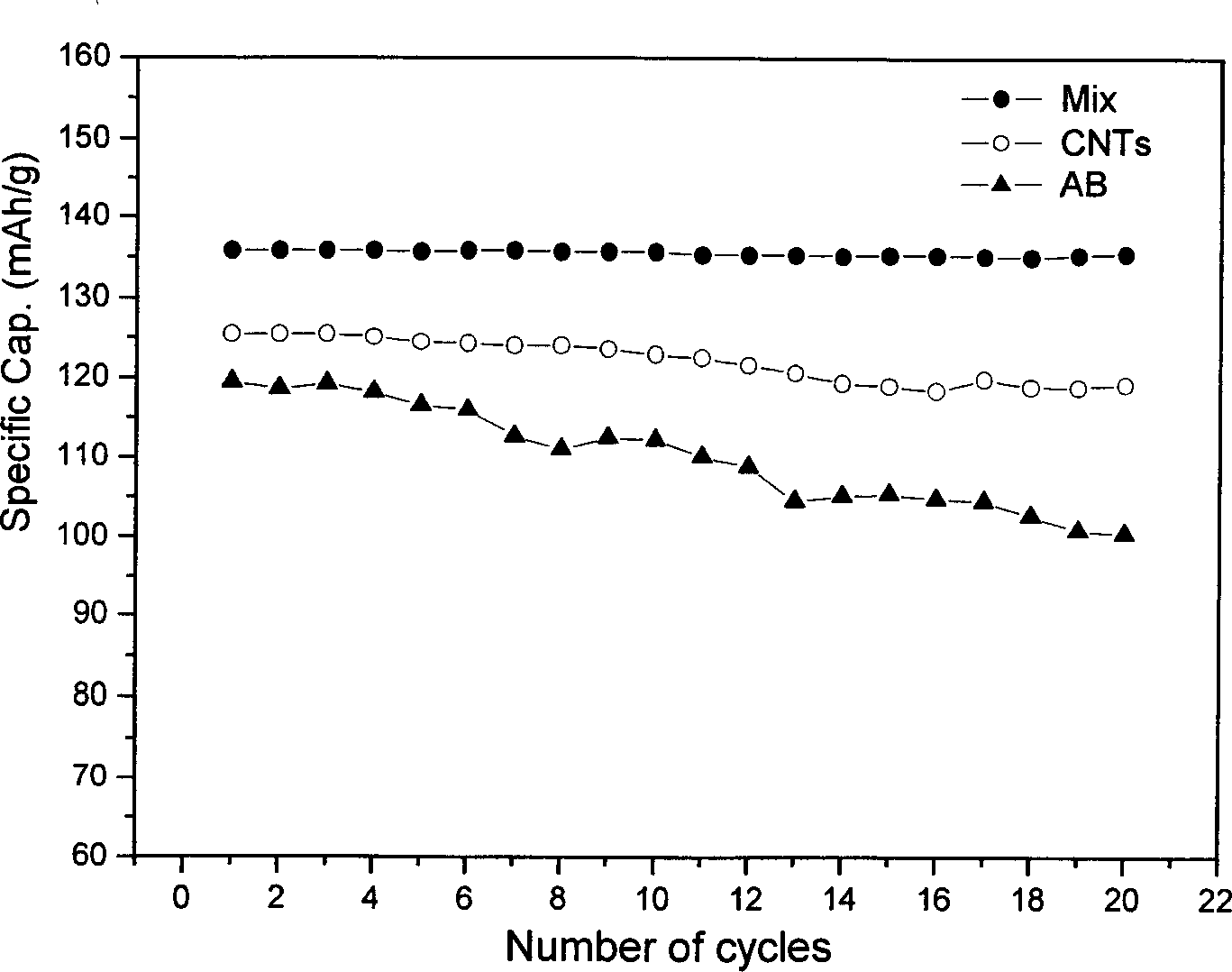

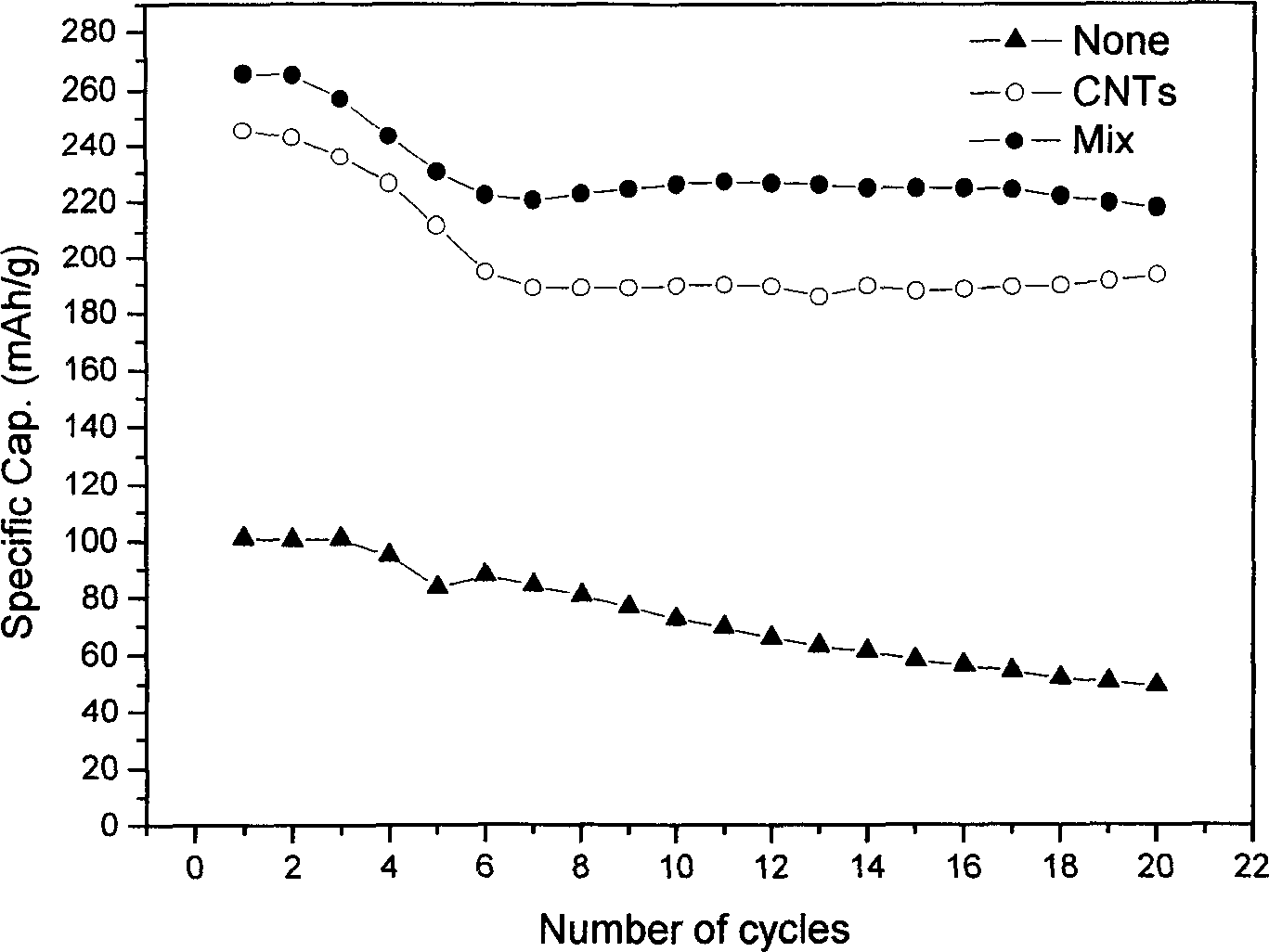

Anode, cathode material conductive agent for lithium-ion secondary battery and preparation method thereof

This invention discloses one second battery anode and negative conductive agent and its process method by use of carbon nanometer tube and acetylene black compound, wherein, the method comprises the following steps: Processing the mother liquid with concentration of 0.5 to 8 percent by adding the carbon nanometer tube and acetylene black compound into dispersion agent; or after adding the dispersion agent water or organic agent to dissipate the nanometer tube to process the low concentration mother liquid with 0.5 to 8 by adding acetylene black; The mother liquid passes filter or pressing to process compound conductive agent with dry weight of 6 to 60 percent. Comparing with conductive carbon or fiber, the nanometer tube has high capacity with high charging efficiency,

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

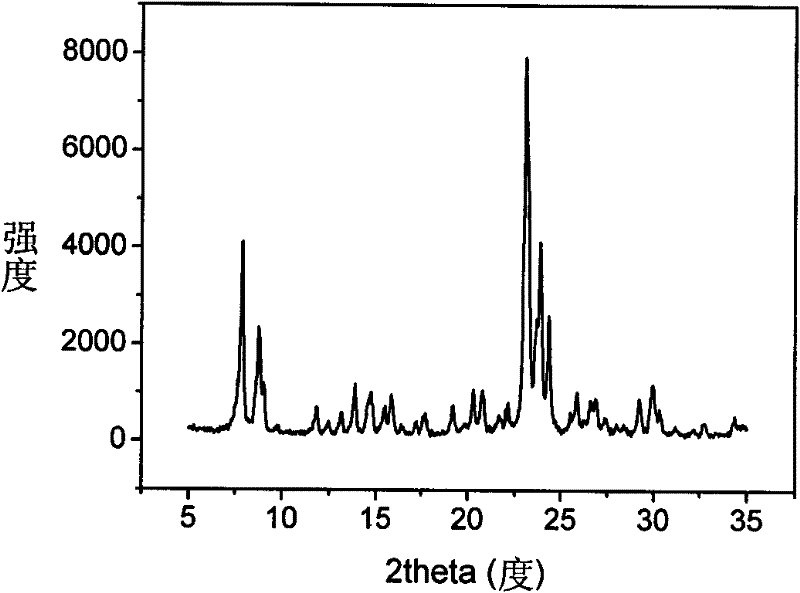

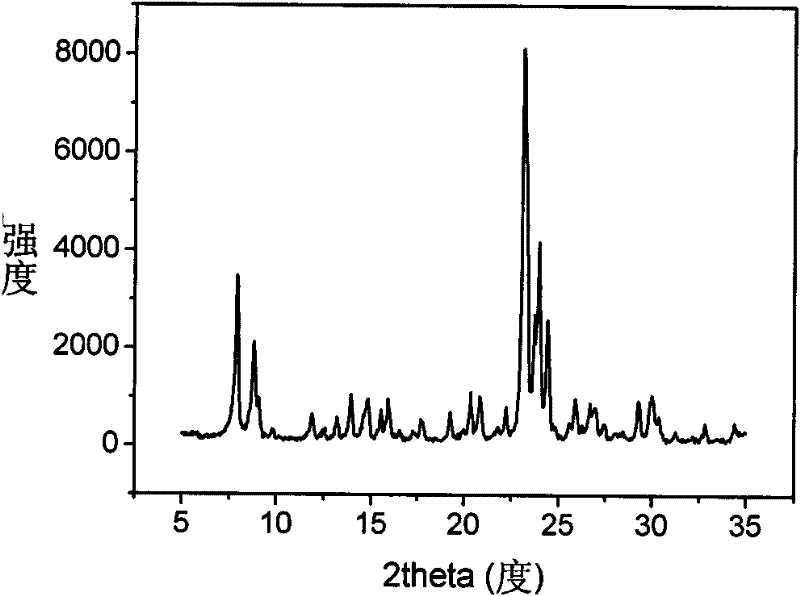

Method for quickly synthesizing small-crystallite titanium-silicon molecular sieve in cheap system

ActiveCN101913620ALower synthesis costFast crystallization rateCrystalline aluminosilicate zeolitesCyclohexanoneHigh activity

The invention provides a method for preparing a small-crystallite titanium-silicon molecular sieve in a cheap system by changing the adding mode of seed crystals and by a hydrothermal process. The titanium-silicon molecular sieve is prepared by using silicon sol as a silicon source, titanium tetrachloride or tetrabutyl titanate as a titanium source, tetrapropylammonium bromide ( TPABr) as a template agent, organic amine as an alkali source and unseparated nanoscale TS-1 mother liquor as seed crystals directly and by the hydrothermal process. The grain size of the titanium-silicon molecular sieve is less than 1 micrometer, and the titanium-silicon molecular sieve has high activity for selective oxidization reactions using hydrogen peroxide as an oxidant, such as epoxidation of olefins, hydroxylation of phenol, ammoxidation of cyclohexanone and the like. The method simplifies the synthesis process of small crystallite TS-1 in the cheap system and reduces synthesis time and cost.

Owner:DALIAN UNIV OF TECH

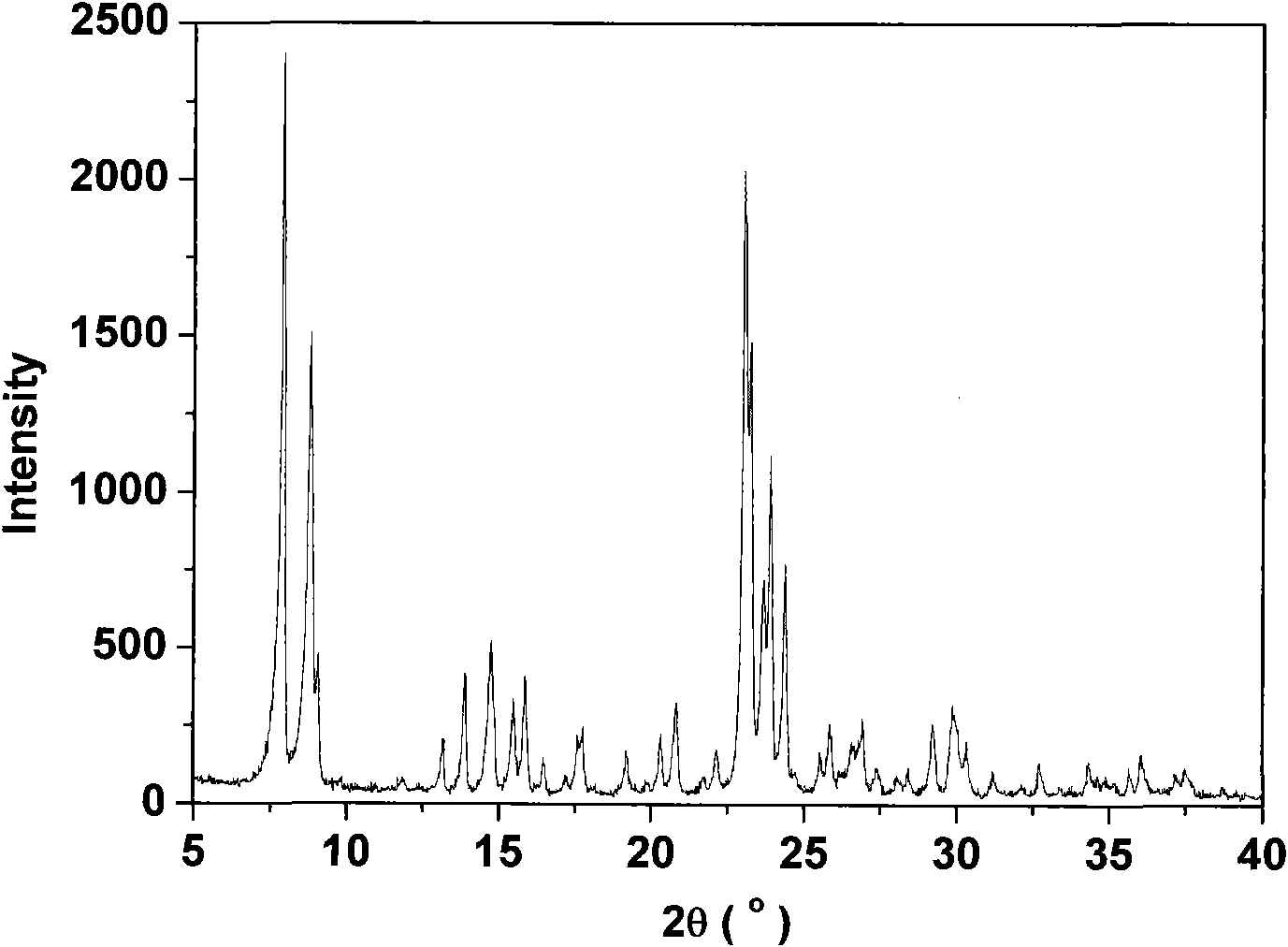

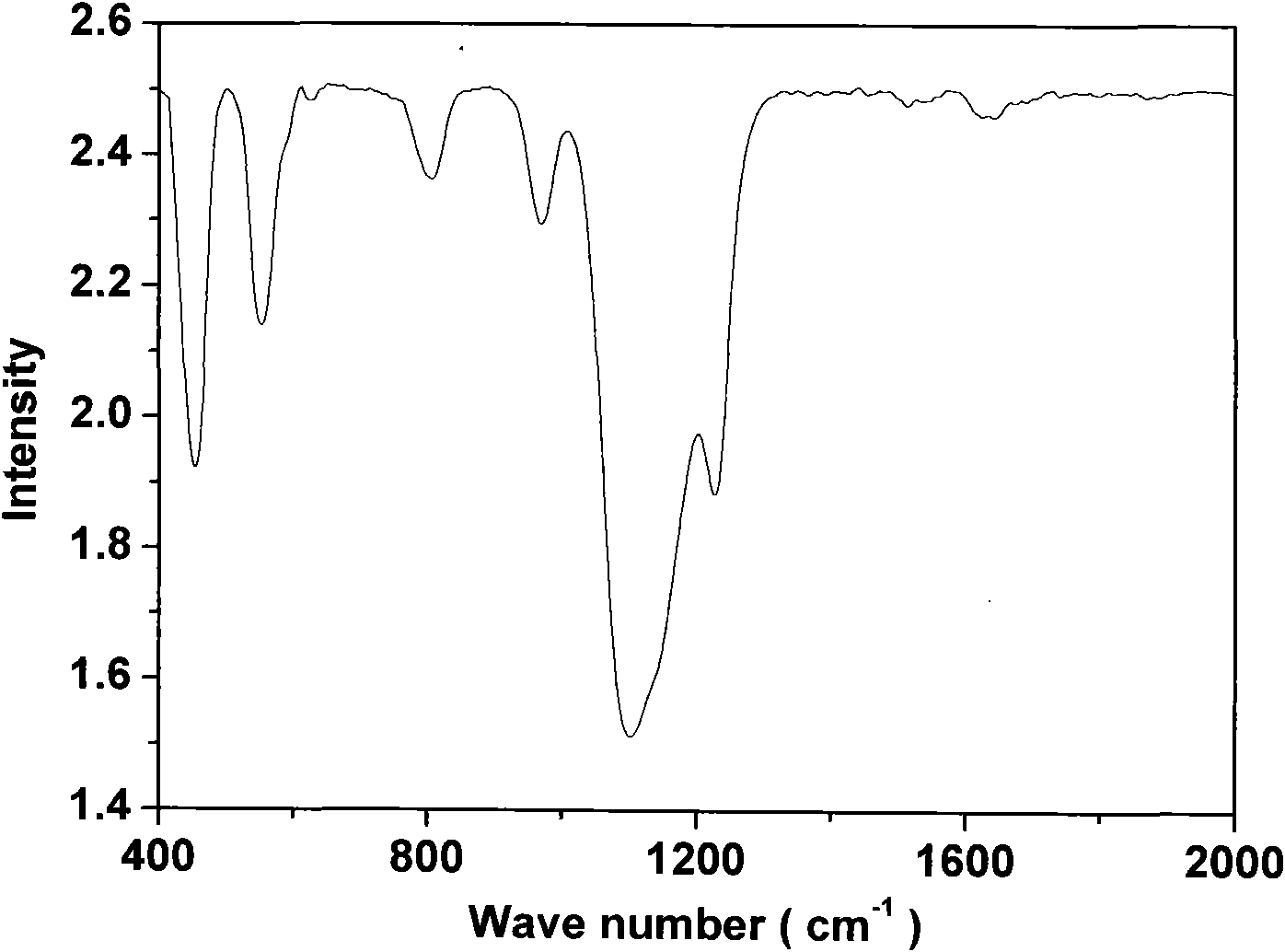

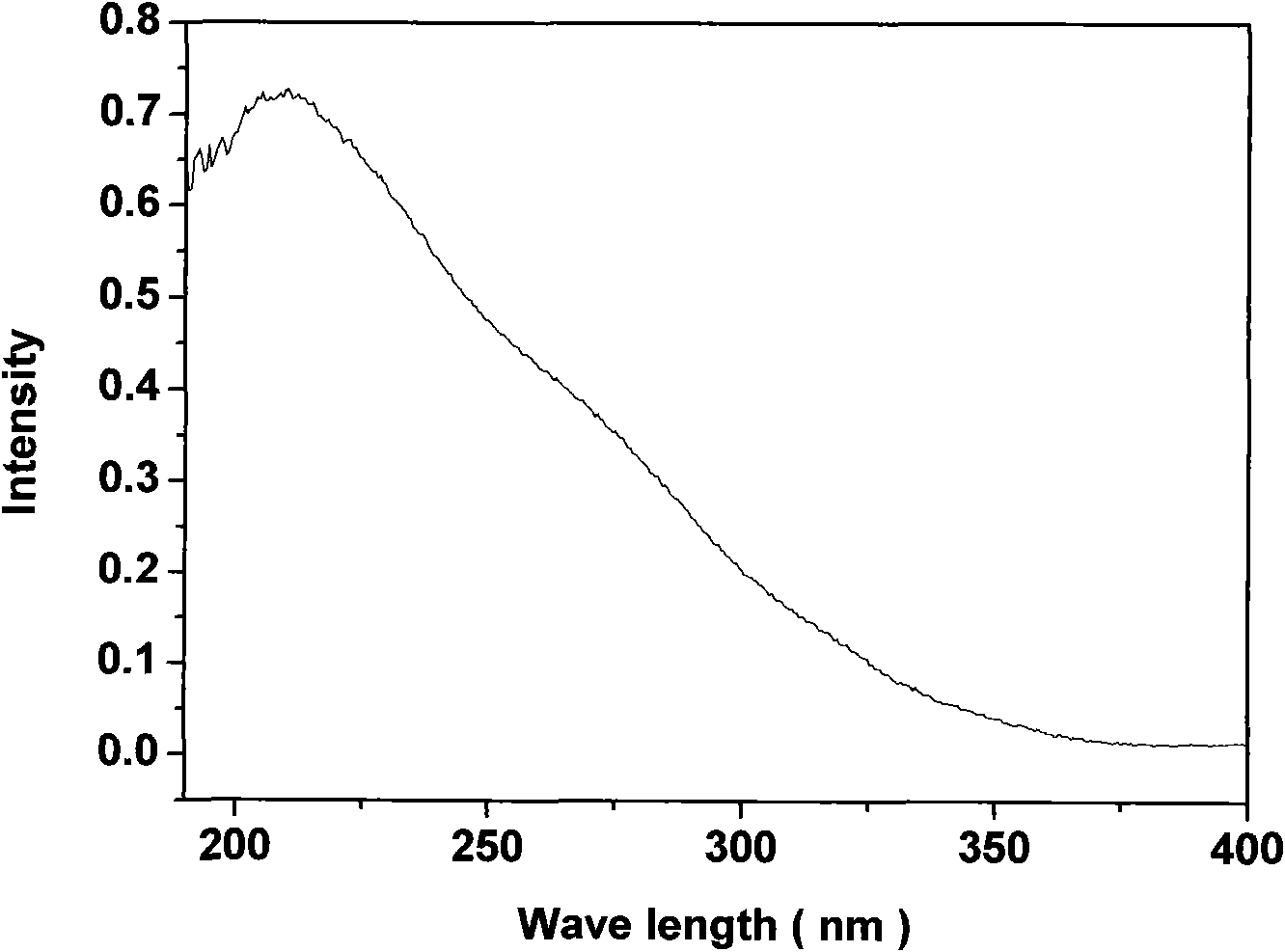

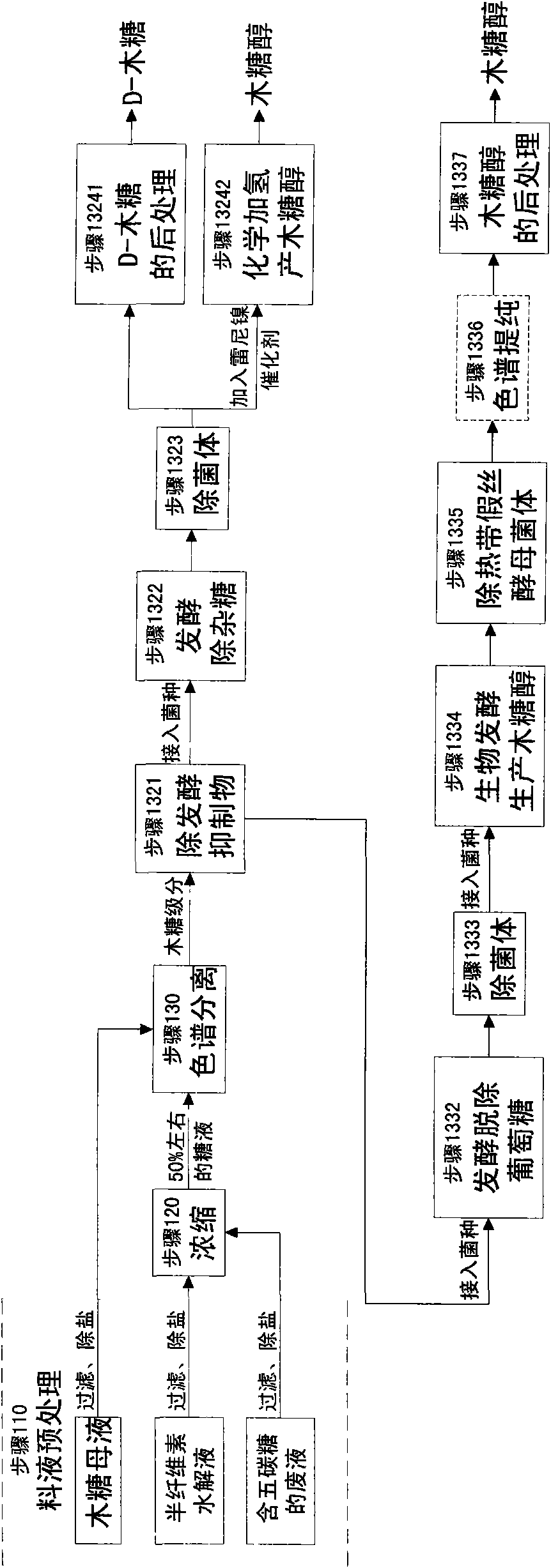

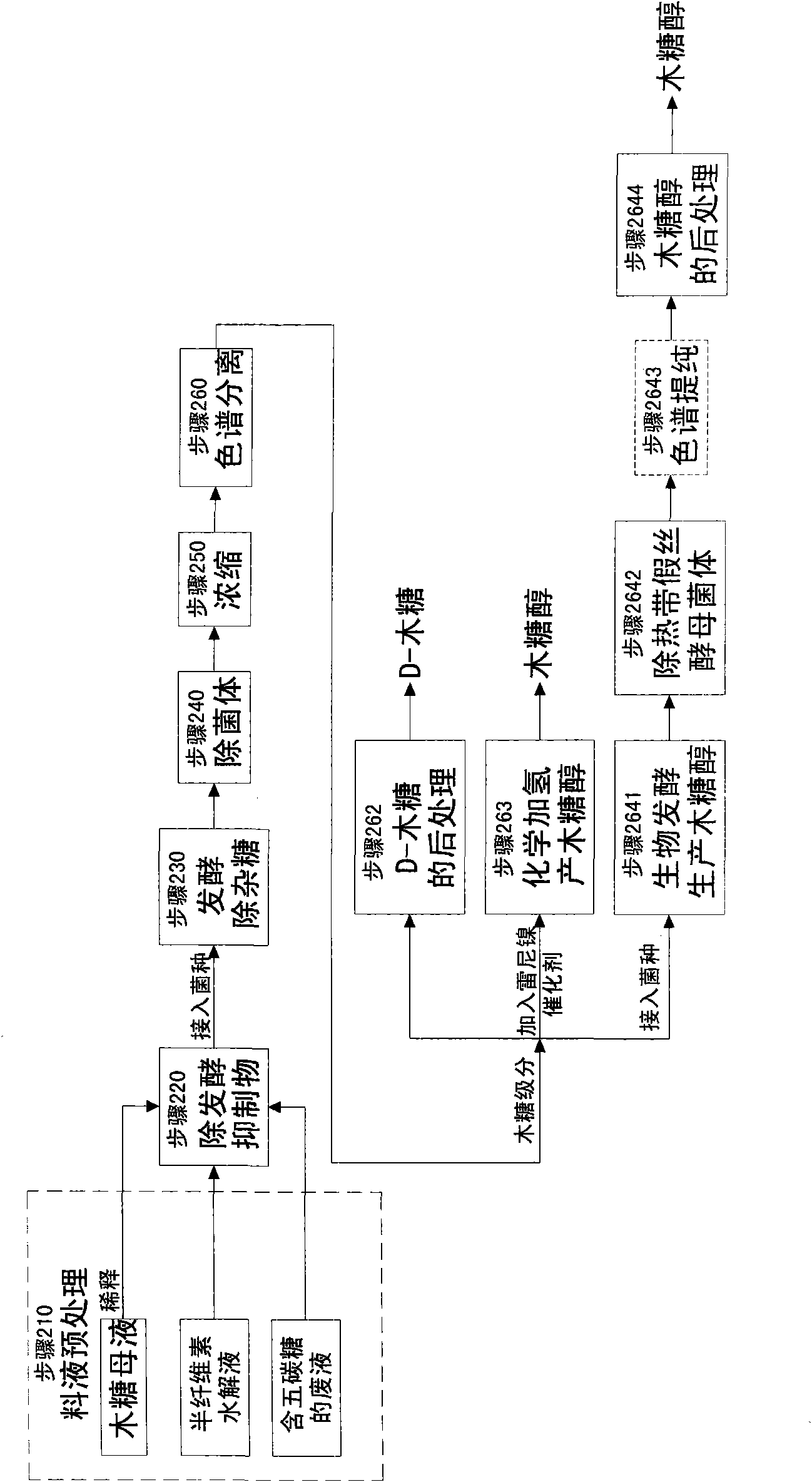

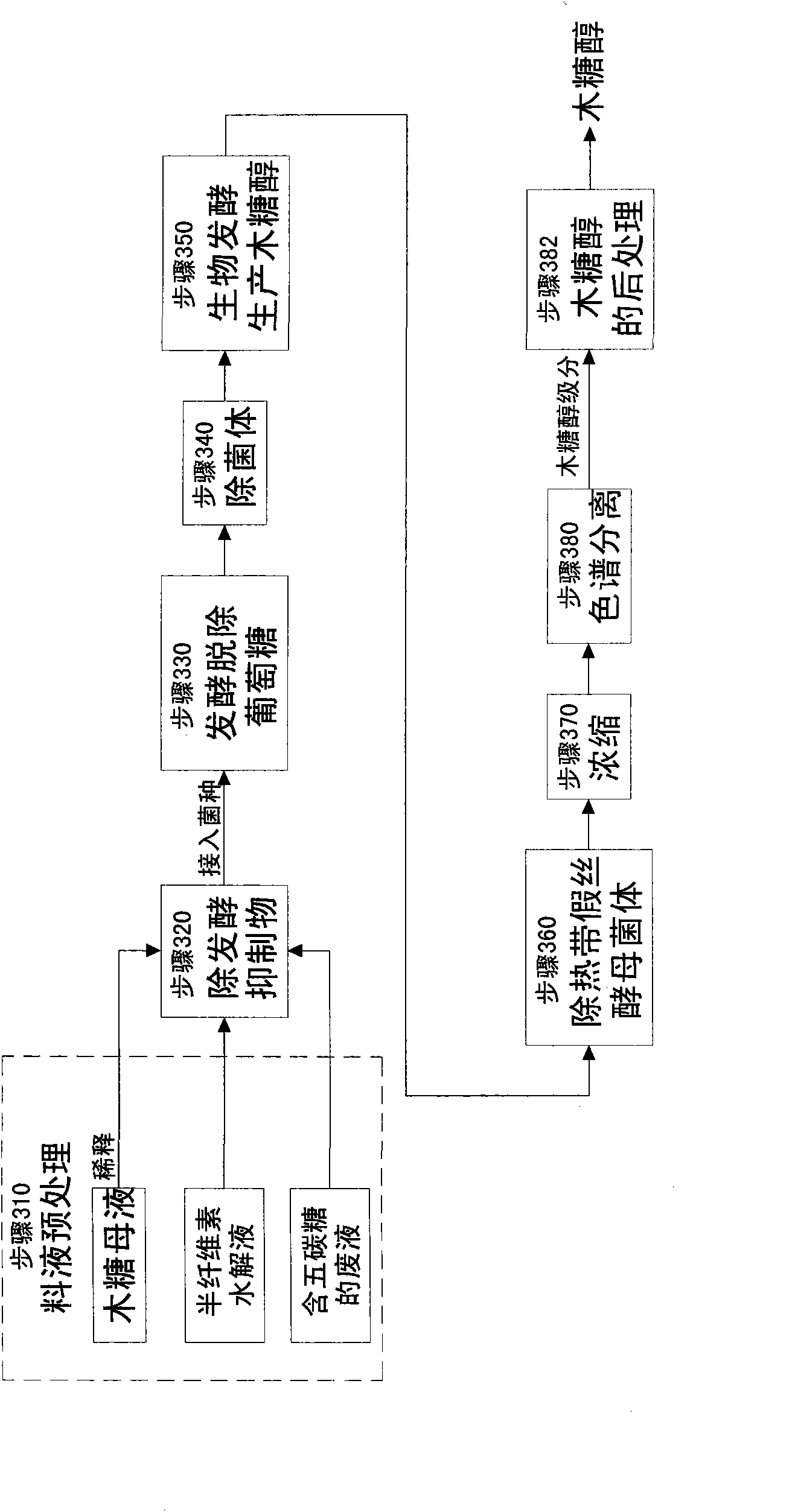

Method for producing wood sugar product

ActiveCN101659681AHigh purityFermentation went wellIon-exchange process apparatusSugar derivativesChromatographic separationHydrolysis

The invention relates to a method for producing a wood sugar product and a byproduct of ethanol or D-ribose or citric acid. The method takes hydrolysis liquid, wood sugar mother liquor and / or production waste liquid containing pentose of agricultural or forestry waste as the raw materials, comprising the following steps: (a) preprocessing feed liquid; (b) colour spectrum separation: separating thefeed liquid into arabinose fraction feed liquid and wood sugar fraction feed liquid; (c) removing mixed sugar at least containing glucose and galactolipin; and (d) carrying out aftertreatment on thewood sugar fraction feed liquid to obtain the wood sugar product. The wood sugar product comprises xylitol and D-wood sugar. The invention has low production cost and high efficiency and is suitable for large-scale industrial production.

Owner:SHENGQUAN HEALTANG

Method for recovering valuable metals from waste printed circuit board

ActiveCN101787547ASolve pollutionReduce energy consumptionPhotography auxillary processesProcess efficiency improvementElectrolysisFiltration

The invention discloses a method for recovering valuable metals from a waste printed circuit board. The method comprises the following steps: sorting and crushing the printed circuit board, evenly mixing powder containing multiple metal parts with a fluxing agent, and smelting at low temperature for 1-3.5h; adding hot water into smelting products for leaching; evaporating and concentrating filtrate after filtration, and then returning evaporation mother liquor to the water leaching process step; using solution after leaching for swirl electrodeposition of metal silver, and adding 5-25% of HNO3 into filter residue for leaching; filtering the solution after electrodeposition, and adding 1-5 times of the weight of aqua regia into the filter residue for leaching; using the solution after leaching by the aqua regia for the swirl electrodeposition of gold, adding saturated NH4Cl into the solution after the electrodeposition for reaction, then filtering, using ammonium chloroplatinate for refining the filter residue, obtaining sponge platinum, adding methanoic acid into the solution after precipitation, and carrying out reaction for obtaining crude palladium powder. The method can extract copper, nickel, silver, gold, platinum, palladium and other main products and other by-products, realize the maximization of reutilization of value metal resources in the waste printed circuit board and solve the environmental pollution problem; and the adoption of the swirl electrolysis technology can realize low energy consumption, low reagent consumption, short process flow and simple operation.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

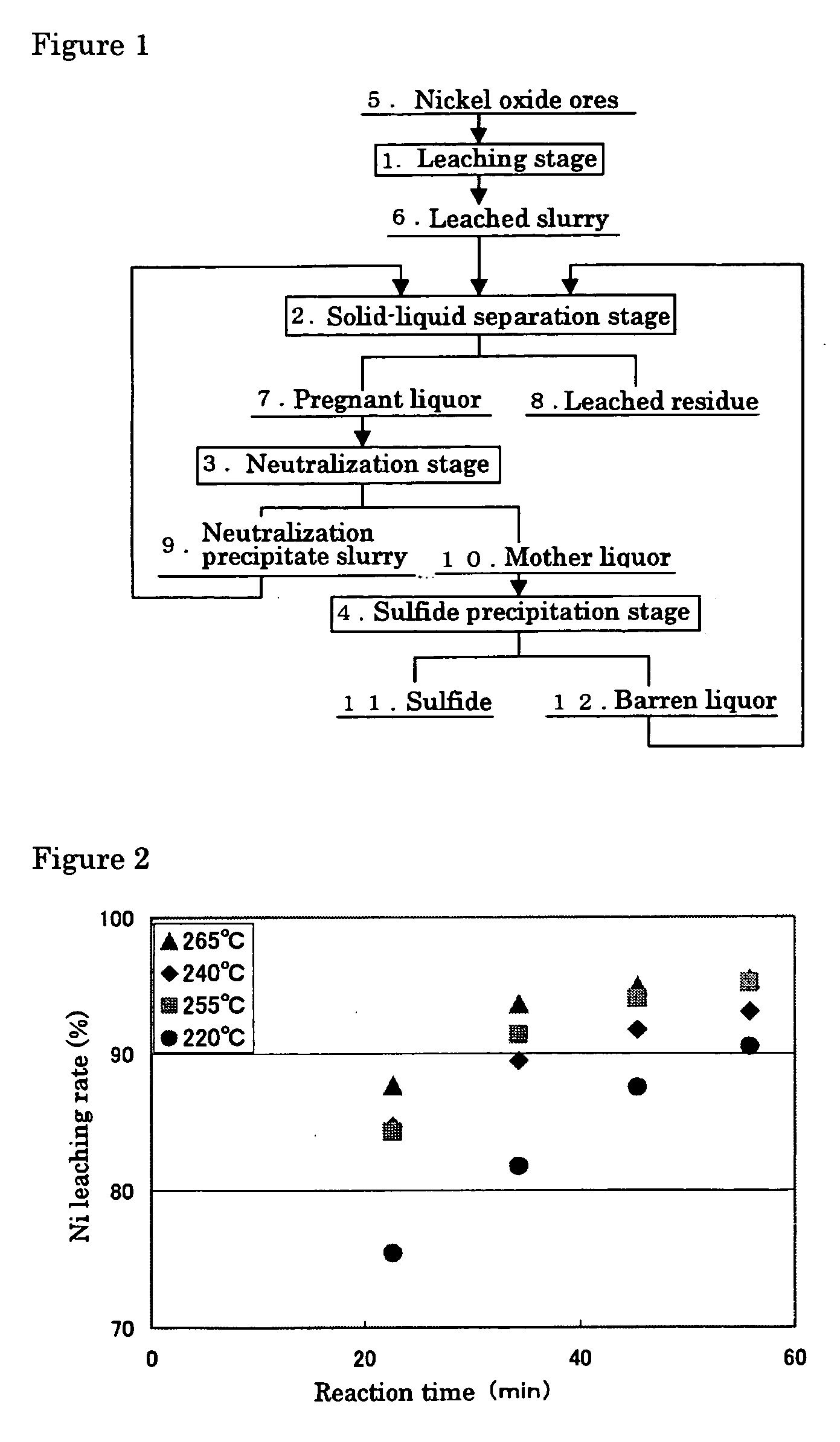

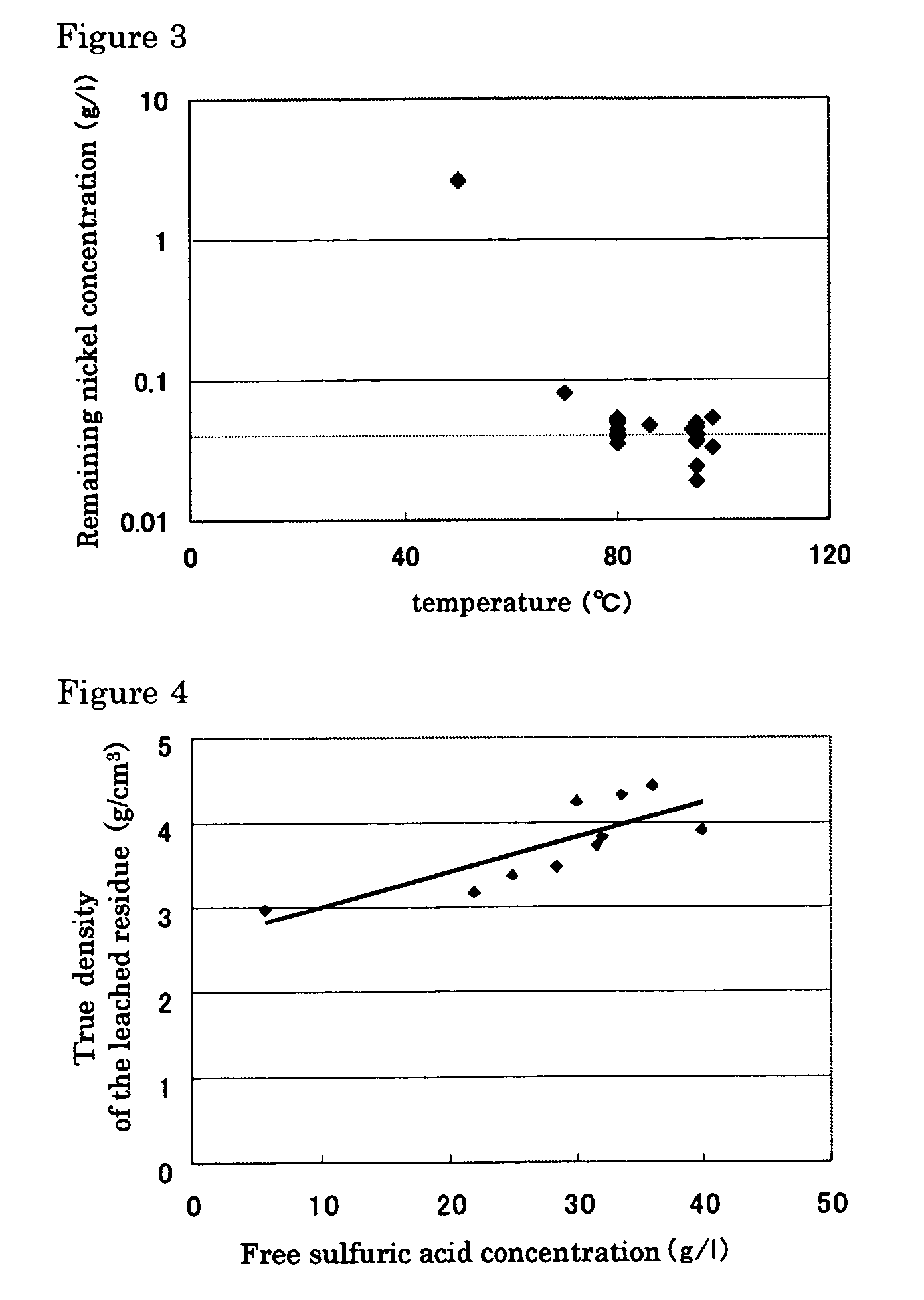

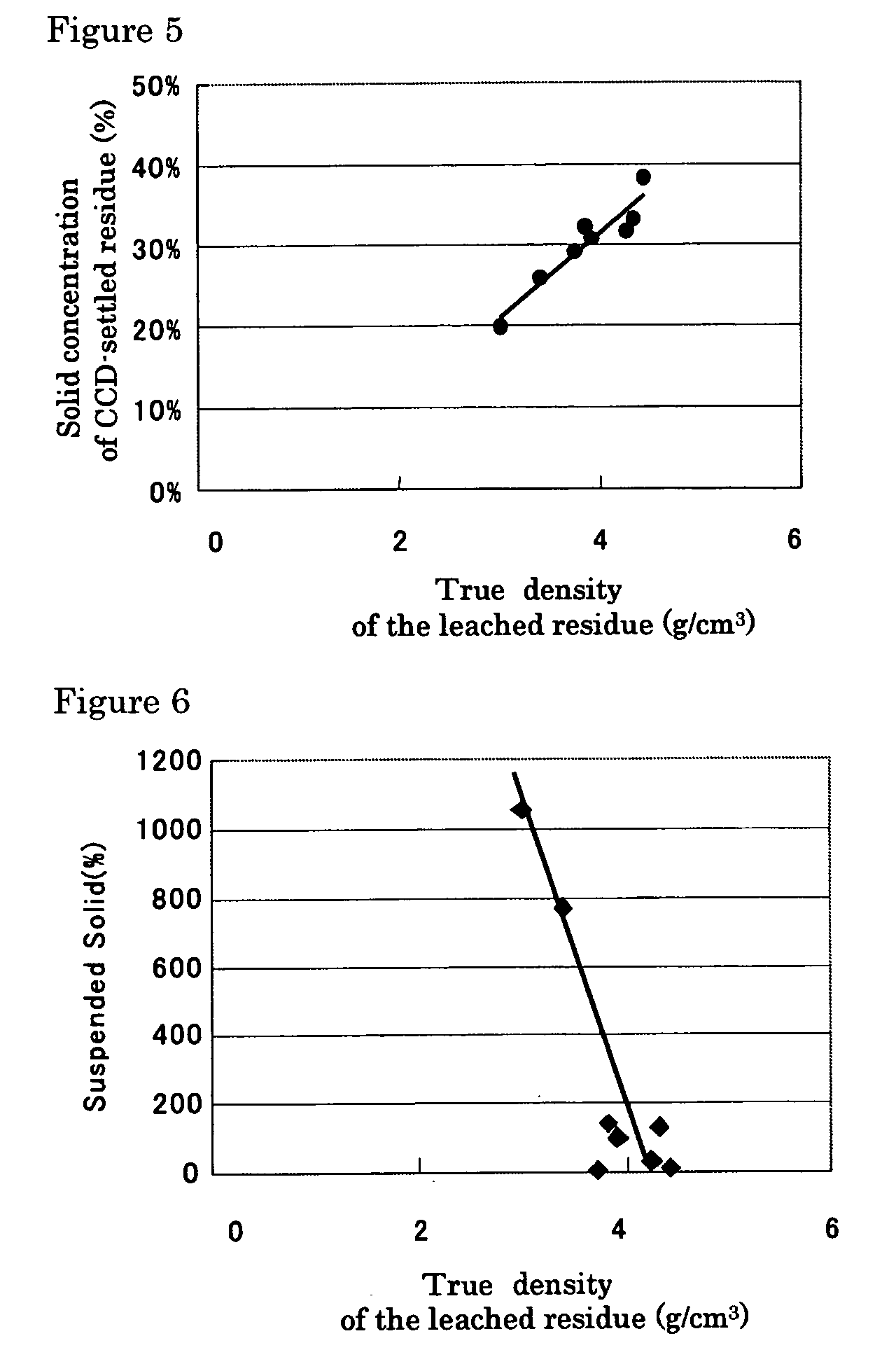

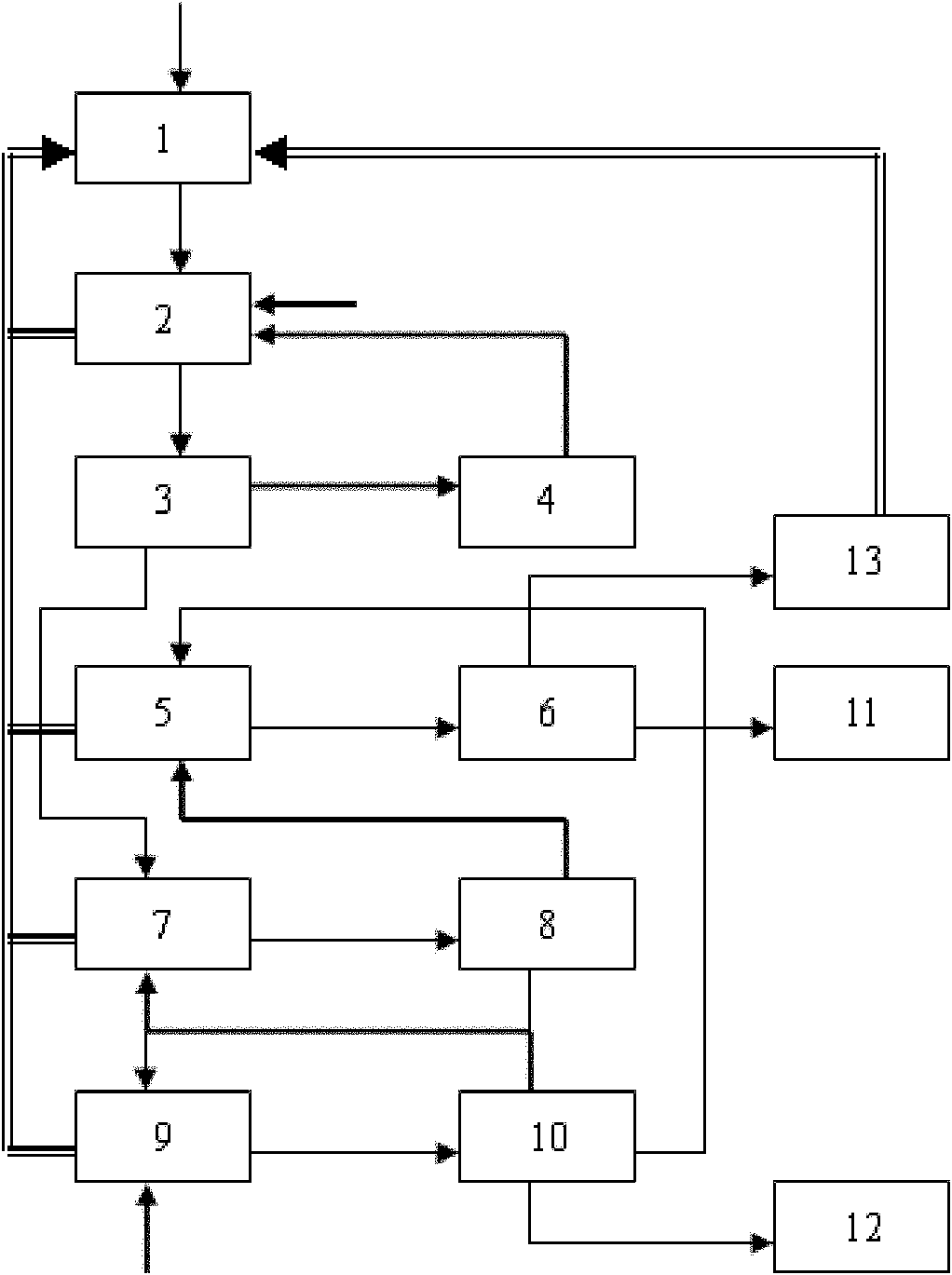

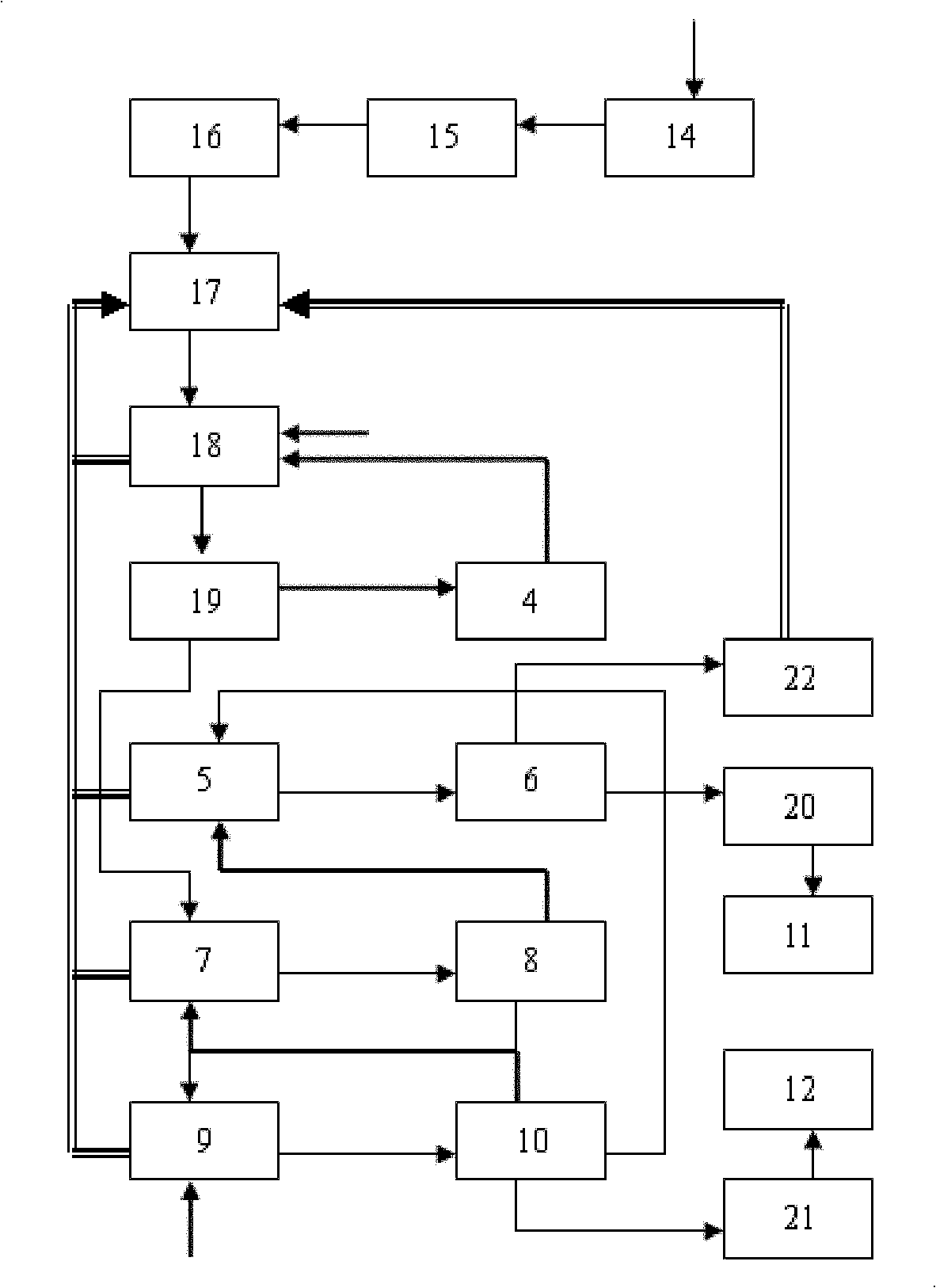

Hydrometallurgical process of nickel oxide ore

InactiveUS20050265910A1Simple and efficient processSimplified leaching stageSolvent extractionIron compoundsSlurryHydrometallurgy

A hydrometallurgical process based on pressure leaching at elevated temperature for recovering nickel from nickel oxide ores, characterized by a simplified and efficient process as a whole, realizing a simplified leaching stage, reduced neutralizer consumption and precipitate production in the neutralization stage, and efficient use of recycled water. The hydrometallurgical process of the present invention, comprising a leaching stage which stirs the slurried ore in the presence of sulfuric acid at 220 to 280° C. to produce the leached slurry; solid-liquid separation stage which washes the leached slurry in multi-stages to produce the pregnant liquor and leached residue, the former containing nickel and cobalt; neutralization stage which treats the pregnant liquor in the presence of calcium carbonate incorporated to keep the pH level at 4 or less, while suppressing oxidation of the liquor, to produce the neutralization precipitate slurry and mother liquor for nickel recovery, the former containing trivalent iron; and a sulfide precipitation stage which blows hydrogen sulfide gas into the mother liquor to produce the sulfide solution and barren liquor, the former containing nickel and cobalt.

Owner:SUMITOMO METAL MINING CO LTD

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

Method for totally extracting vanadium, gallium and scandium by using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium

InactiveCN102011010AReduce processing costsSave the cost of sulfuric acidProcess efficiency improvementSlagHydrolysis

The invention relates to a method for extracting, separating and recovering vanadium, gallium and scandium in pickle liquor by adopting a total extracting method and using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium, comprising the following steps of: mixing and stirring titanium dioxide hydrolysis waste acid and steel slag containing vanadium to obtain leaching pulp; performing solid-liquid separation for the leaching pulp, totally extracting vanadium, gallium and scandium in filtered liquor with five-category return flow, then back-extracting vanadium and gallium with five-category return flow, neutralizing with ammonium bicarbonate or ammonia water, warning up, precipitating vanadium to obtain ammonium polyvanadate, repeatedly back-extracting and precipitating vanadium for precipitating-vanadium mother liquor, and then recovering gallium; and when a back-extracting vanadium and gallium organic phase is repeatedly totally extracted and back-extracted till the content of scandium in the back-extracting vanadium and gallium organic phase is 50-1000mg, recovering scandium. The invention has the beneficial effects that waste is treated with waste, namely vanadium, gallium and scandium are recovered by using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium, and the sulfuric acid cost is saved; the method has great social and economic benefits and low production cost for producing gallium and scandium; without roasting, no waste gas is produced, and three wastes can be discharged with corresponding standards.

Owner:杨秋良 +1

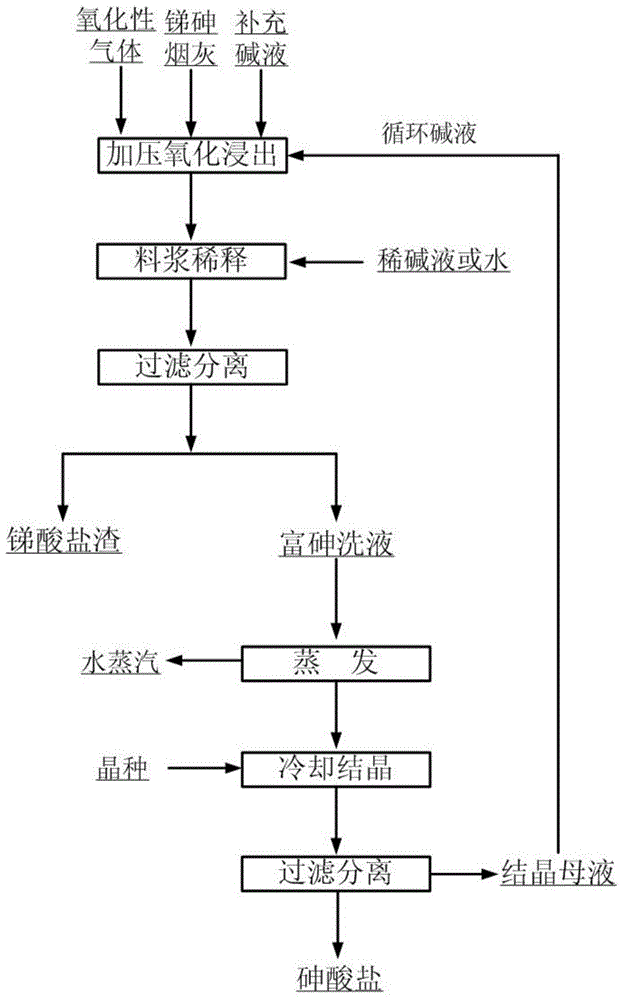

Method for separating antimony from arsenic in antimony-arsenic soot

The invention relates to a method for separating antimony from arsenic in antimony-arsenic soot through oxidation alkaline leaching. The method specifically includes the steps that the antimony-arsenic soot and an alkali solution of a certain concentration are mixed and placed in an alkali-resisting and pressure-resisting reaction still, a gas oxidizing agent of certain pressure is introduced, and a reaction is carried out at a certain temperature; after the reaction, the alkali concentration is adjusted to be below 150 g / L with water or dilute alkali, liquid and solid are separated, an arsenic-rich leaching solution and antimonate slags are obtained, and the antimonate slags can be used for preparation of antimonious oxide powder as antimony concentrate; the arsenic-rich leaching solution is evaporated and added with little seed crystals for cooling crystallization, arsenate crystal products are obtained, and crystallization mother liquor returns to the leaching process of the antimony-arsenic soot. The method is simple in process, capable of separating antimony and arsenic thoroughly and short in flow path; and the method can also avoid arsenic volatilization of the roasting process and harm caused by arsenic hydride gas of the acid leaching process, thereby being environmentally friendly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Drug dispensing method of automated drug dispensing system, and automated drug dispensing system

ActiveCN102847473AReduce labor intensityEnsure health and safetyRotating receptacle mixersShaking/oscillating/vibrating mixersDrug dispensingBottle

The present invention belongs to the technical field of automated drug dispensing methods and apparatuses, and discloses a drug dispensing method of an automated drug dispensing system, and the automated drug dispensing system. The drug dispensing method comprises the following steps that: a drug bottle is placed on a drug liquid input shaking apparatus; a multi-shaft robot moves the drug bottle to a bottle breaking device, and the drug bottle is broken through the bottle breaking device; the multi-shaft robot moves the drug bottle to the drug liquid input shaking apparatus; a hose filling transferring and drug liquid distribution device inserts needles on both ends of an infusion hose into the drug bottle or / and a mother liquor bottle, and pumps the drug liquid; and the drug liquid input shaking apparatus shakes the drug liquid on the drug liquid input shaking apparatus. With the drug dispensing method of the automated drug dispensing system, and the automated drug dispensing system in the present invention, dispensing of multiple groups of drug liquids can be rapidly completed so as to improve drug dispensing efficiency, greatly reduce labor intensity of health care workers, and easily ensure health and safety of health care workers.

Owner:上海市卫邦机器人有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com