Sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and preparation method and applications thereof

A technology of compound liquid, calcium sugar alcohol, applied in application, fertilization device, fertilizer mixture, etc., can solve the problems of high production cost, high packaging cost, impact on absorption efficiency, high price, etc., to prolong the time of absorbing nutrients, improve The effect of absorbing utilization and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

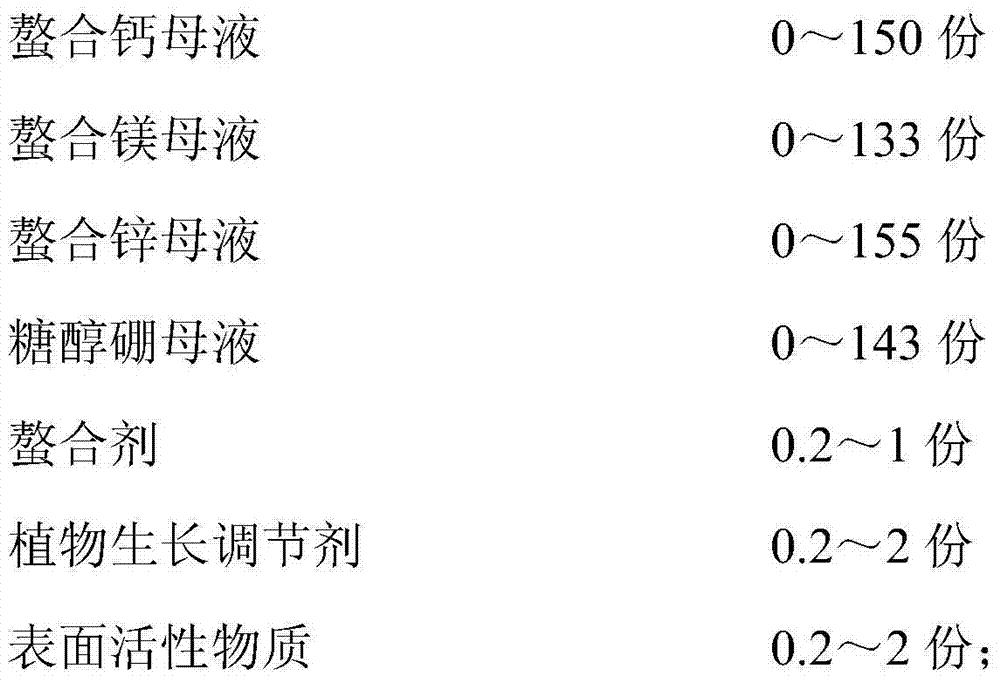

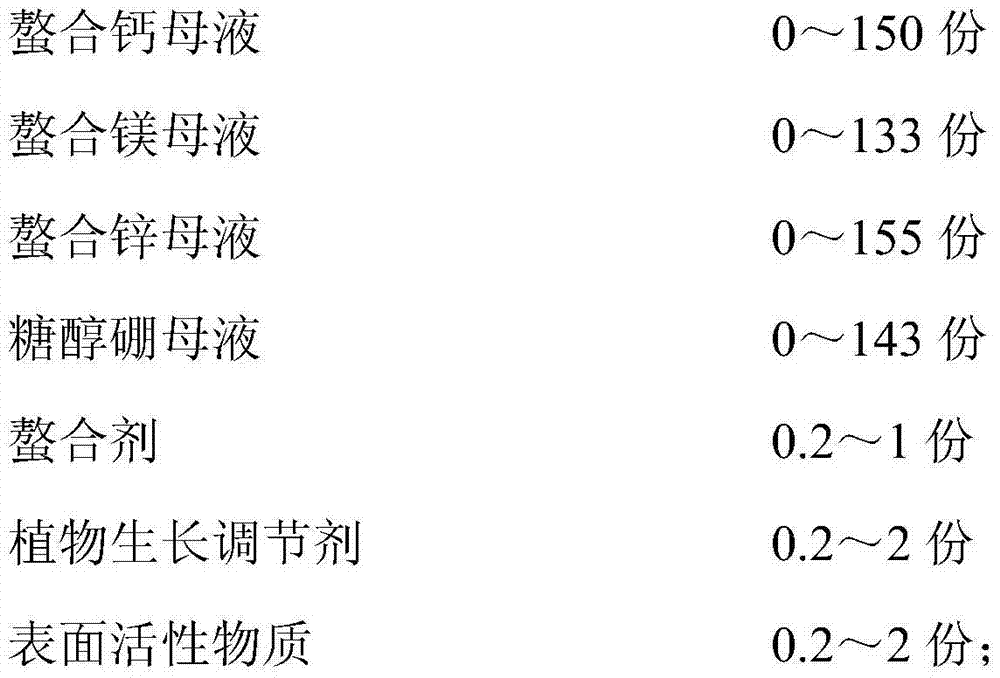

Method used

Image

Examples

Embodiment 1

[0057] (1) Preparation of chelated calcium mother liquor: Add 8 parts of sorbitol, 3 parts of mannitol, 3 parts of xylitol, 6 parts of glycerin and 0.5 parts of potassium hydroxide into 35 parts of water, heat at 70°C, and dissolve Finally, add 5 parts of calcium acetate, then add 83 parts of calcium ammonium nitrate, and continue to react for 30 minutes. After cooling, it will be the chelated calcium mother liquor, wherein the calcium concentration is 170g / L;

[0058] (2) Preparation of chelated zinc mother liquor: Add 5 parts of sorbitol, 5 parts of mannitol and 0.2 parts of sodium hydroxide to 40 parts of water, keep it warm at 70°C for 30 minutes, then add 18 parts of zinc acetate and 80 parts of zinc nitrate , continue to react for 30min, after cooling, it will be chelated calcium mother liquor, wherein the zinc is 230g / L;

[0059] (3) Preparation of sugar alcohol boron mother liquor: Add 4 parts of sorbitol, 4 parts of mannitol, and 5.5 parts of glycerin to 23 parts of w...

Embodiment 2

[0063] (1) Preparation of chelated calcium mother liquor: same as Example 1

[0064] (2) Preparation of chelated magnesium mother liquor: add 6 parts of sorbitol, 3 parts of mannitol, 3 parts of xylitol and 0.5 parts of potassium hydroxide into 35 parts of water, heat at 90°C, dissolve and add 11 parts of acetic acid Magnesium, add 80 parts of magnesium nitrate afterwards, continue to react 30min, use after cooling to be chelated magnesium mother liquor, wherein calcium is 95g / L;

[0065] (3) Preparation of chelated zinc mother liquor: same as Example 1

[0066] (4) Preparation of sugar alcohol boron mother liquor: Add 3 parts of sorbitol, 3 parts of mannitol, and 8 parts of glycerin to 20 parts of water in sequence, stir evenly, then add 65 parts of boric acid and 20 parts of ethanolamine, and react at 70°C for 30 minutes. Be sugar alcohol boron mother liquor after cooling, wherein boron is 130g / L;

[0067] (5) Mixing: Mix 84 parts of chelated calcium mother liquor, 26.6 pa...

Embodiment 3

[0070] (1) Preparation of chelated calcium mother liquor: Add 6 parts of sorbitol, 4 parts of mannitol and 0.2 parts of sodium hydroxide to 45 parts of water, heat at 90°C, add 2 parts of calcium formate after dissolution, and then add 75 parts Calcium ammonium nitrate, continue to react for 30 minutes, use after cooling to be the mother liquor of chelated calcium, wherein the calcium is 150g / L;

[0071] (2) Preparation of chelated magnesium mother liquor: Add 6 parts of sorbitol, 2 parts of mannitol and 0.3 parts of sodium hydroxide to 28 parts of water, heat at 90°C, add 2.5 parts of magnesium formate after dissolution, and then add 90 parts Magnesium nitrate, continue to react 30min, use after cooling to be chelated magnesium mother liquor, wherein calcium is 87g / L;

[0072] (3) Preparation of chelated zinc mother liquor: Add 6 parts of sorbitol, 6 parts of mannitol and 0.3 parts of sodium hydroxide to 47 parts of water, keep it warm at 90°C for 30 minutes, then add 2 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com