Patents

Literature

4250results about How to "Small molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature-resistant salt-resistant efficient gel, and preparation and use thereof

InactiveCN101475667AImprove solubilityGood viscosity increasing effectDrilling compositionSulfite saltAging resistance

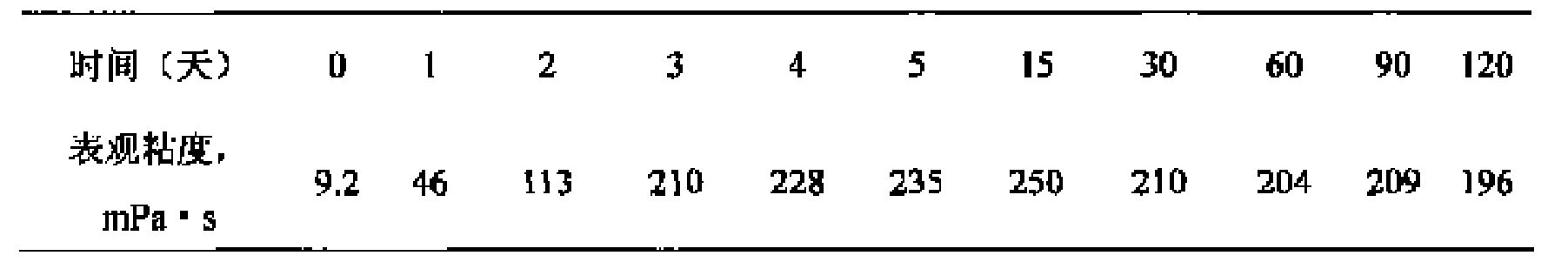

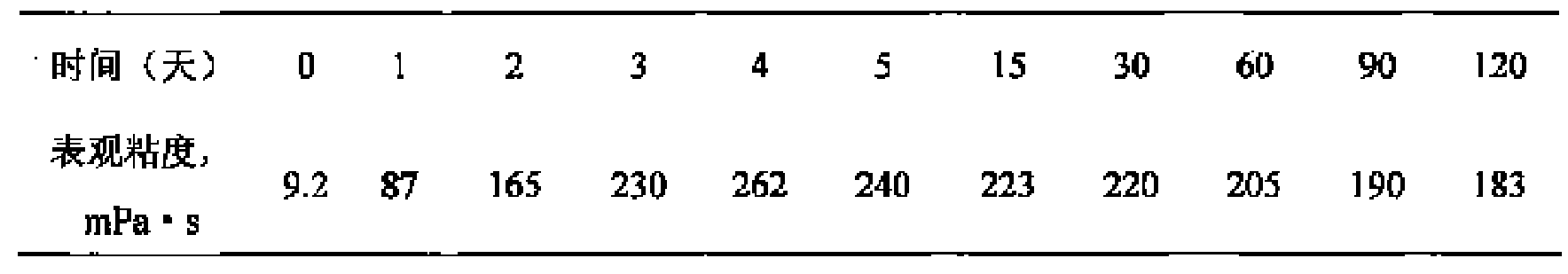

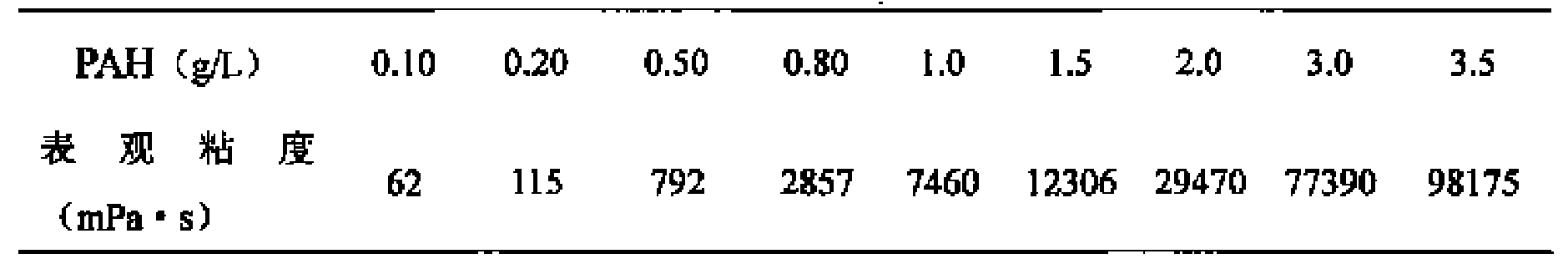

The invention discloses a temperature resistant salt tolerant high efficiency gel and a preparation method and application thereof. The preparation method is characterized in that the preparation method comprises the following steps: preparing a comb-shaped associated copolymer PAH containing macromonomers and functional hydrophobic monomers into an aqueous solution having the concentration of 0.1 to 4g / L, the crosslinking agent concentration of 0.01 to 1.0g / L, the surfactant concentration of 0.01 to 8mmol / L and the sodium sulfite thermal stabilizer concentration of 0.005 to 1.0g / L; adding the aqueous solution into a mixing container with a stirring device; stirring the aqueous solution evenly at the room temperature; regulating the pH value of the solution to be equal to between 4 and 11, and obtaining a temperature resistant salt tolerant high efficiency gel polymer solution system used for tertiary oil recovery and scavenge, displacement modification, profile modification or water shutoff. The polymer solution system has micro-crosslinking to form the gel during the flowage inside the oil reservoir. The gel has good elasticity, not easy dehydration, stable gelling performance, and excellent tackification, temperature resistance, salt tolerance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

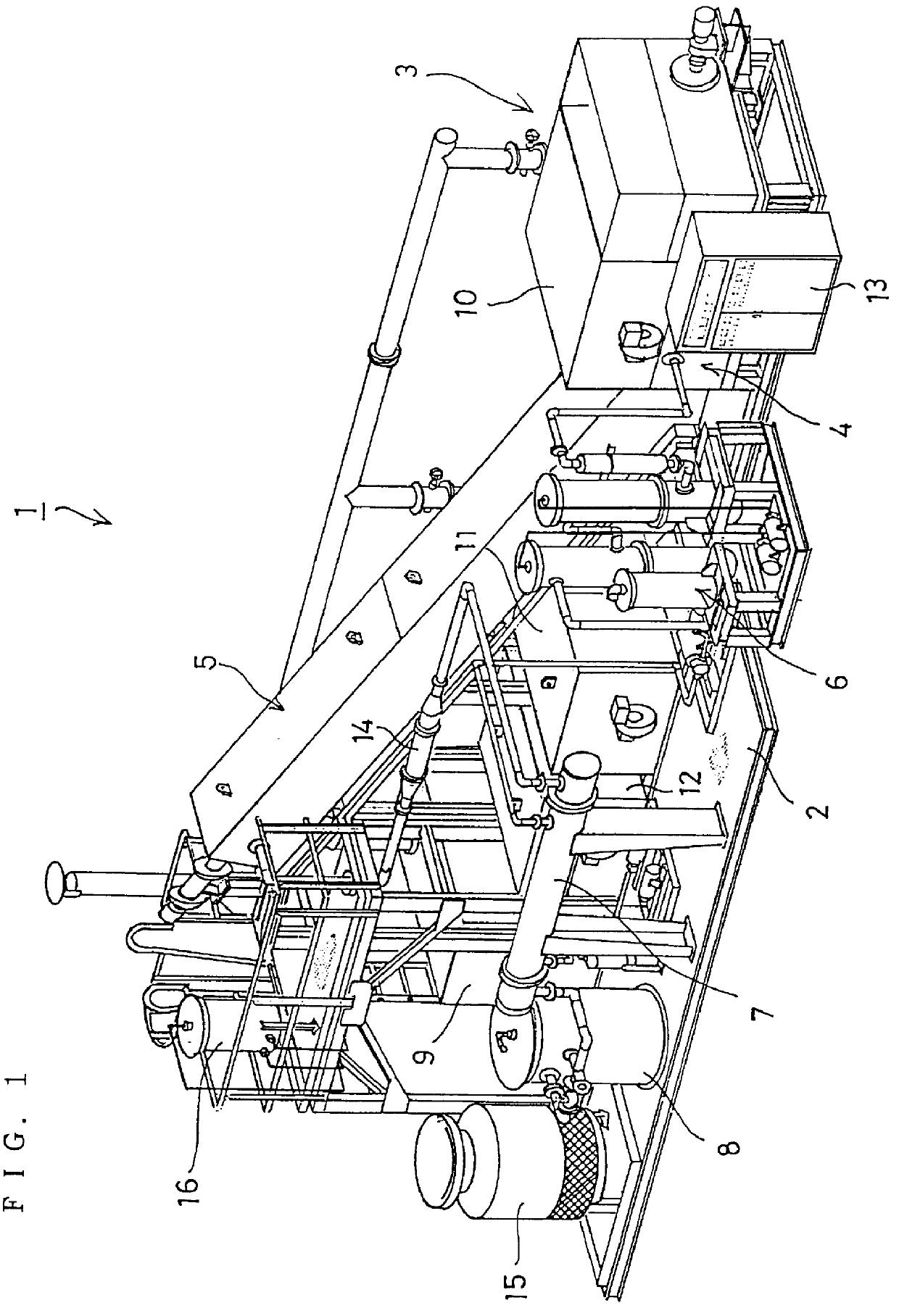

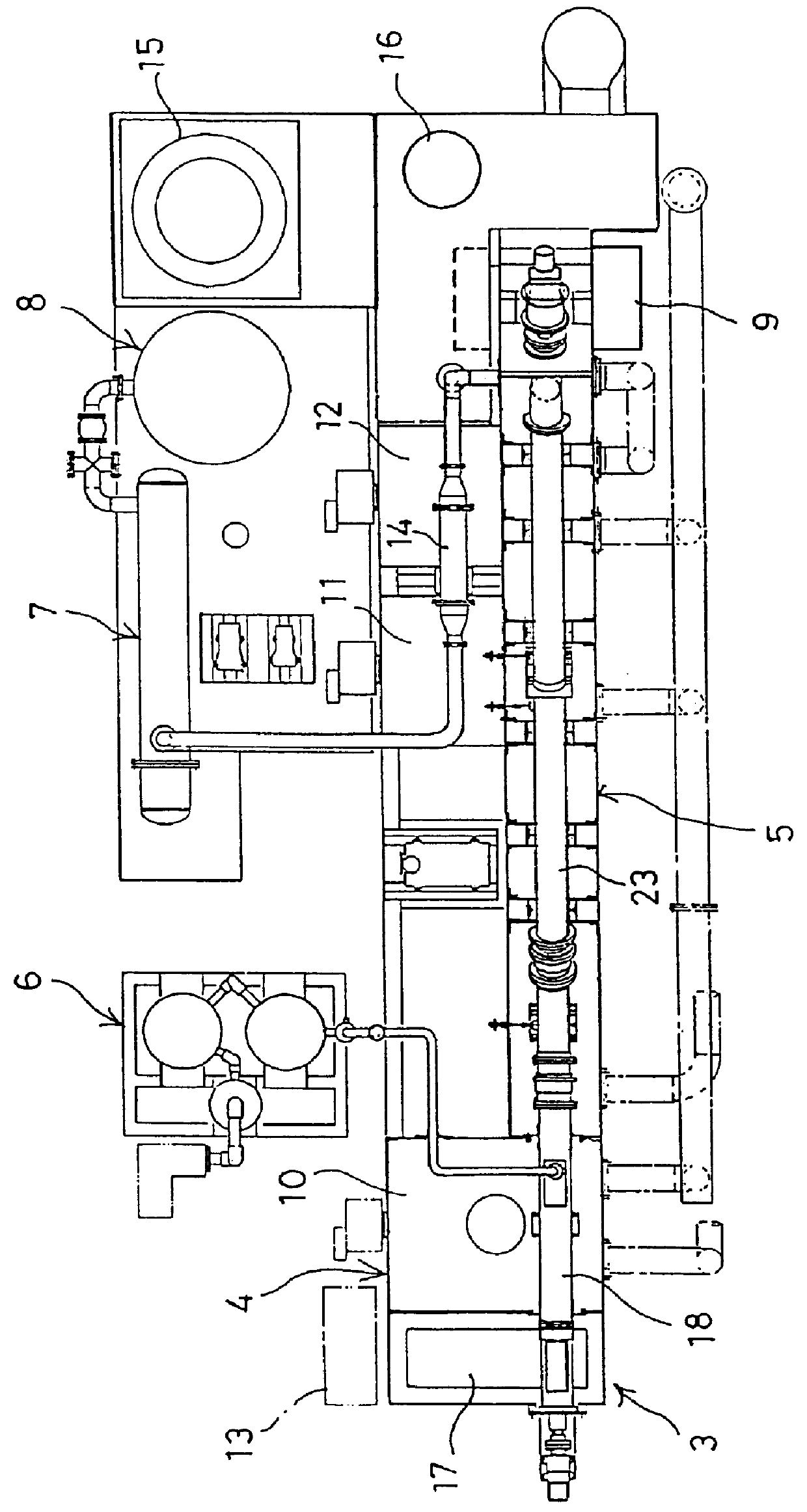

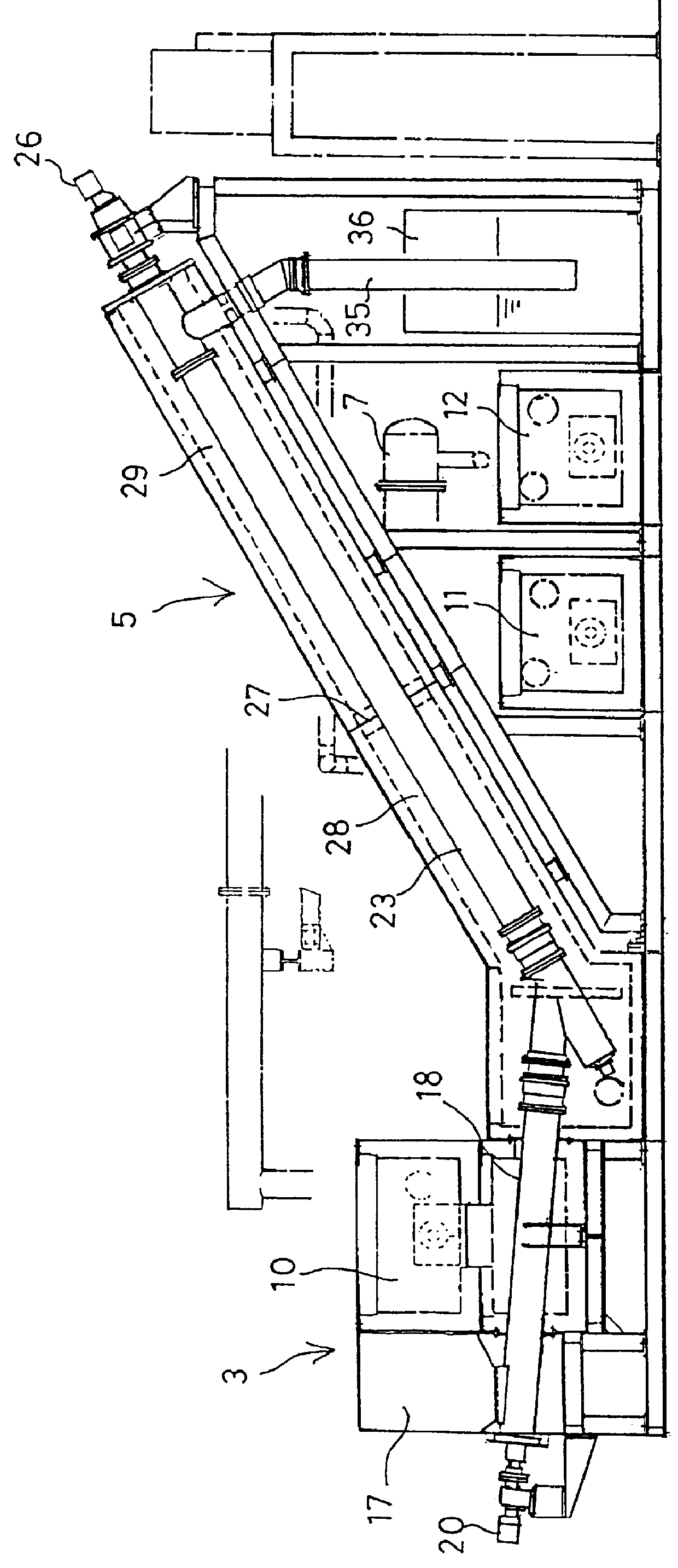

Thermal decomposition apparatus of reversed temperature gradient type for polymer waste

InactiveUS6126907ASimple structureSmall sizeSolid waste disposalDirect heating destructive distillationDecompositionSludge

A thermal decomposition apparatus for decomposing polymer waste is provided which is simple in structure, small in size and inexpensive, and also the operating cost thereof is low. A feed pipe 18 and an inclined pipe 23 are connected in the form of the letter V at a large angle therebetween, and a feed screw 19 and an feed-up screw 25 are arranged inside the respective pipes. Polymer waste introduced into a hopper 17 is melted in the interior of the feed pipe 18 by heat from a first hot air furnace 10 and accumulated in the V-shaped portion. The polymer melt is then conveyed upward by the feed-up screw 25. In the process of conveyance, the polymer melt undergoes primary decomposition by means of heat from a second hot air furnace 11 and the cracked gas thus generated undergoes secondary decomposition by the heat from a third hot air furnace 12, the resultant gas being guided to a condenser 7. Sludge drops down through a chute pipe 35 into a water tank 36.

Owner:WADA YOUICHI

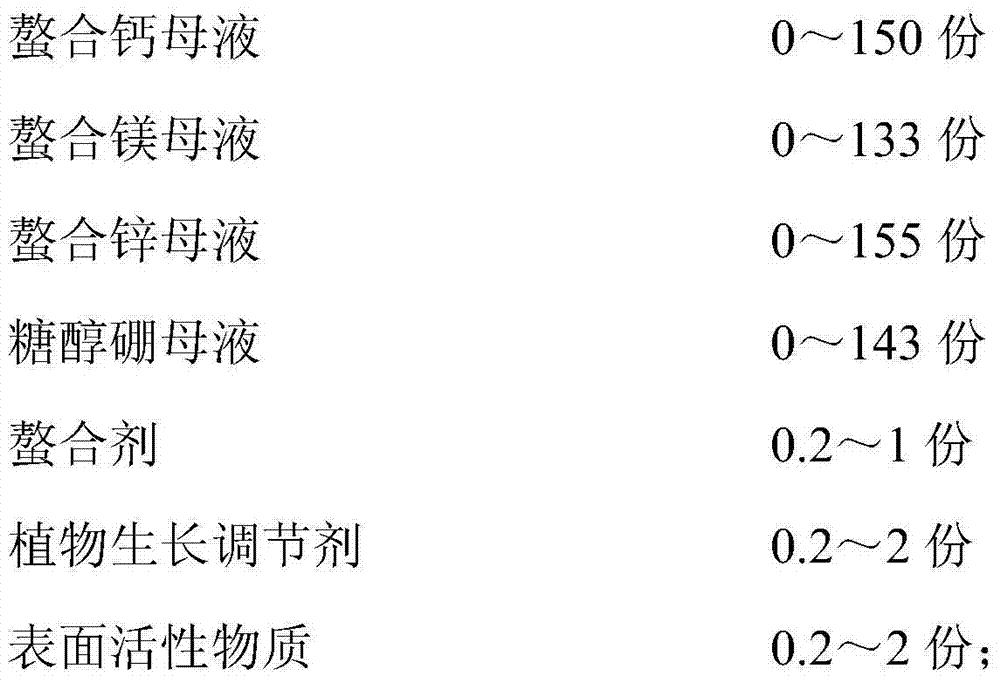

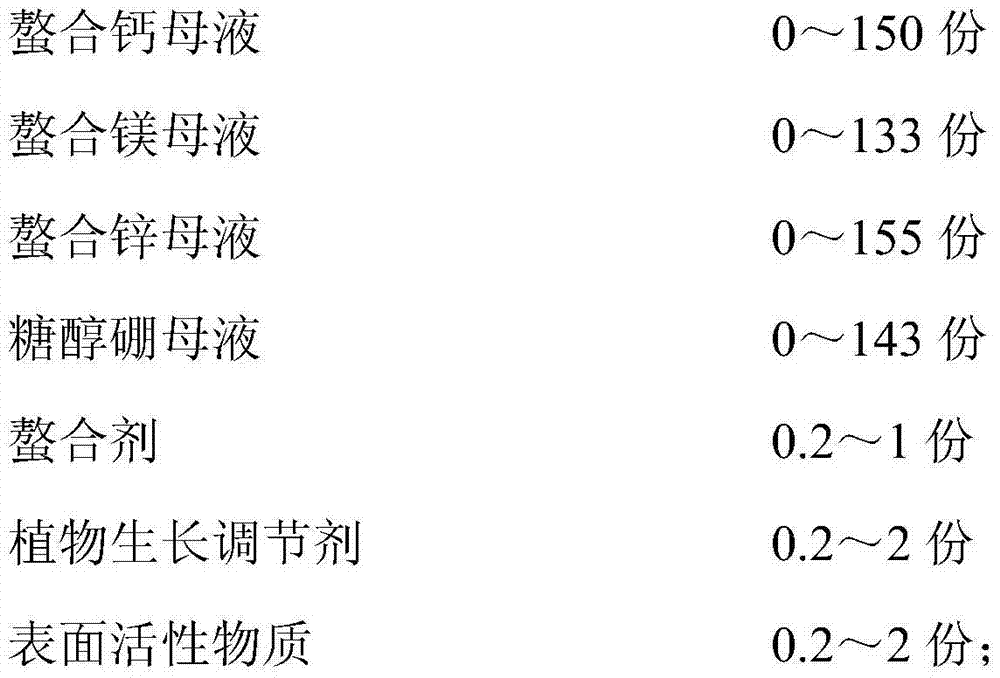

Sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and preparation method and applications thereof

ActiveCN103588564AAvoid reactionAchieve preparationFertilizer mixturesHigh concentrationMagnesium salt

The invention belongs to the field of agricultural production and discloses a sugar alcohol calcium magnesium zinc boron compound liquid fertilizer and a preparation method and application thereof. The liquid fertilizer is prepared from various mother solutions, a chelating agent, a plant growth regulator and surface active materials. The preparation method comprises the following steps: causing sugar alcohol to respectively react with calcium salt, magnesium salt, zinc salt and boric acid to prepare calcium, magnesium, zinc and boron mother solutions, then mixing the mother solutions according to a certain ratio, and adding the chelating agent to cause the mother solutions to carry out secondary chelating reaction; after a while, adding the plant growth regulator and the surface active materials into reaction liquid, uniformly mixing, and cooling to the room temperature to obtain the high-concentration, stable and good-effect compound liquid fertilizer. The prepared liquid fertilizer provides adequate calcium, magnesium, zinc and boron and other nutrients for plants and can also carry out mixing of different elements and proportions according to the needs of different plants and different growth stages of plants.

Owner:SOUTH CHINA AGRI UNIV +1

Active peptide feed additive and its preparation method and use

ActiveCN1579198APromote growthPromote growth and differentiationHydrolasesFood processingAnimal proteinDigestion

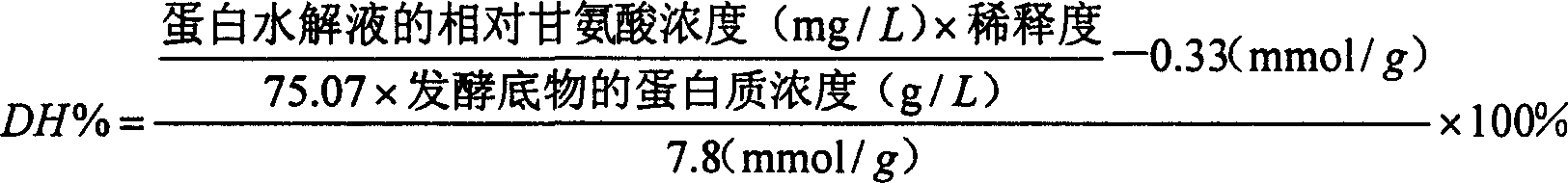

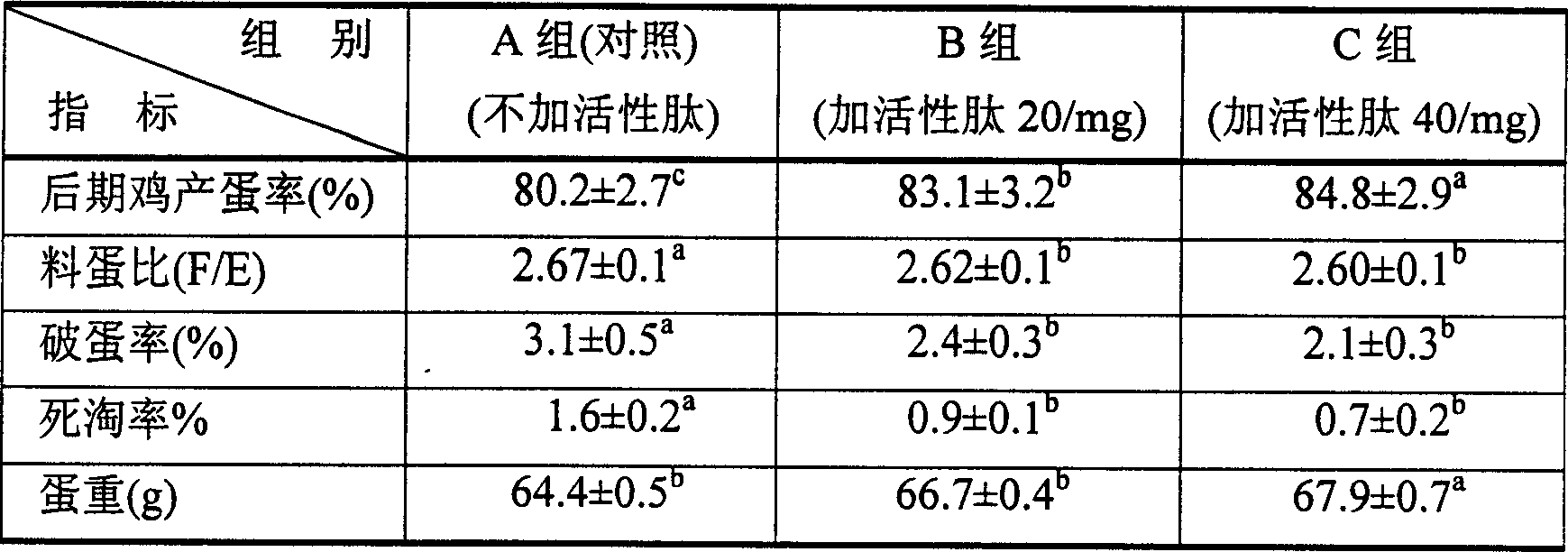

The present invention relates to an active peptide feed addictive, as a mixture of one or more plant protein and animal protein, which is the product of the following steps: fermenting and degrading the mixture through bacillus and the like, controlling the degree of hydrolysis at 20-35%, obtaining a fermentation supernatant after a separation post-processing process, concentrating drying the supernatant or directly adsorbing the supernatant onto the carrier, and then low temperature drying it. Said active peptide feed addictive is capable of obviously depressing development of bacillus coli and salmonella, and can prevention and cure diarrhea caused by bacilli or lienteric diarrhea; can exert its functions at a very low concentration, with a very intense effect; can regulate stomach and intestine bacterium group and promote animals digestion functions; can excite animal immune function, reinforce animal disease resistance against a plurality of epidemic diseases and greatly reduce the morbidity and death rate; can promote animal development and improve the growth velocity; can improve the feed use ratio and reduce production costs. Applications of the microorganism fermentation degradation method provided by the present invention have a low fabricating cost, and the obtained peptides have many kinds and high content, without environment pollutions.

Owner:CHINA AGRI UNIV

Method of preparing organization bracket performing selectivity laser sintering by using macromolecule microsphere

InactiveCN101138651AParticle size controllableHigh forming precisionBone implantSelective laser sinteringPolymer science

The present invention discloses a manufacture method of a tissue frame, which conducts the selective laser sintering by the polymer micro spheres. The method comprises the following steps. The polymer material dissolved in the solvent is dropped in the dispersant under stirring status at a uniform speed. The polymer micro spheres are obtained after cleaning, ultrasound dispersion and freezing preparation. The mixing powder is obtained after mixing the polymer micro spheres with a pore-foaming agent. A three-dimensional model of the frame is designed by the computer assistant software. The mixing powder is formed by the selective laser sintering according to the three-dimensional model; therefore the frame is produced. The polymer micro spheres produced by the method in the present invention have regular shapes and adjustable particle diameter. The method is simple and practical. The mechanical property of the frame after forming is excellent. The horizontal movement between the layers is small and the forming accuracy is high.

Owner:HUAZHONG UNIV OF SCI & TECH

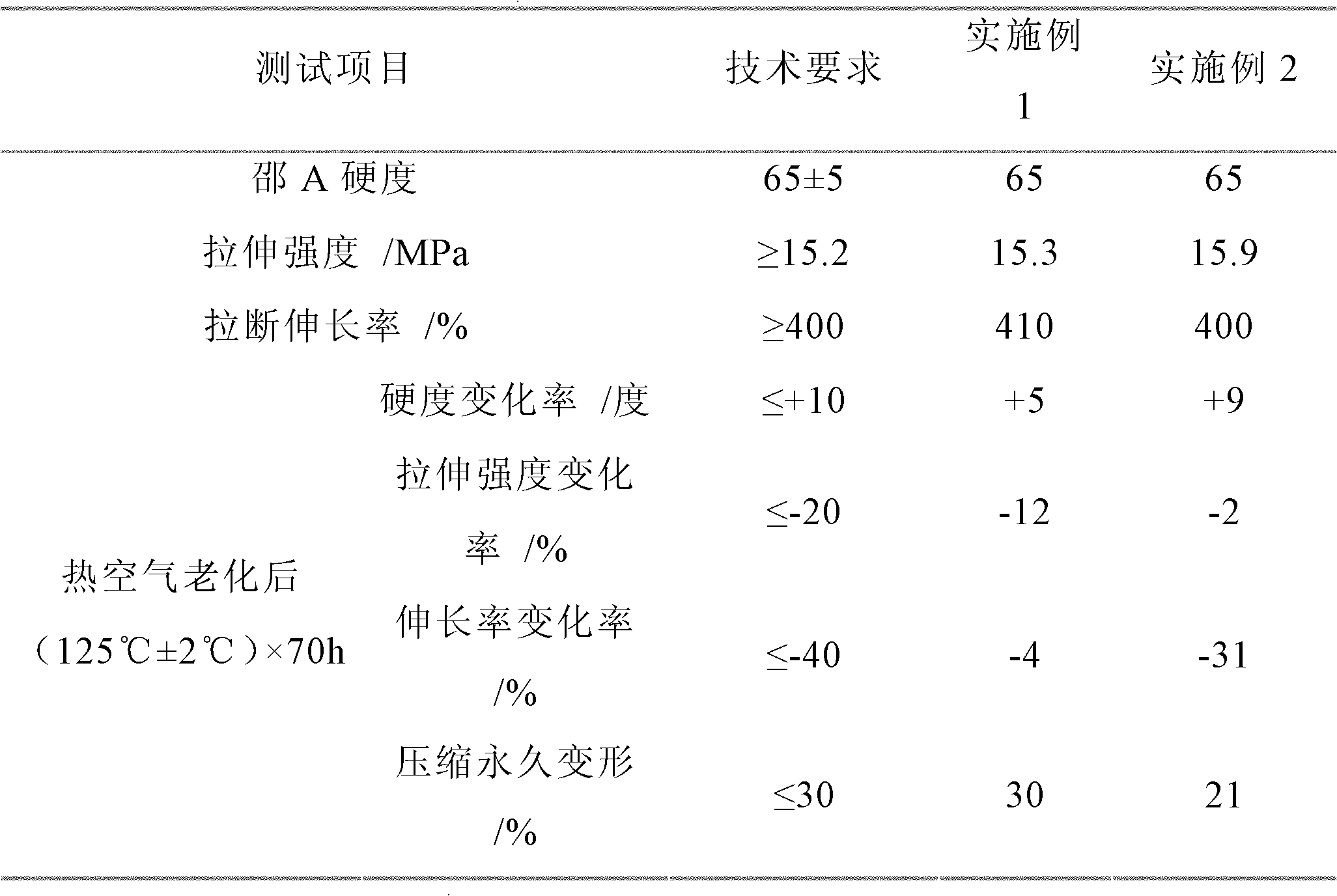

Ethylene propylene diene rubber composition and preparation method

The invention discloses an ethylene propylene diene rubber composition and a preparation method. The preparation method comprises the following steps of: firstly, performing after plastication on ethylene propylene diene rubber; then, adding zinc oxide, stearic acid, anti-aging agent, carbon black, plasticizers, accelerant, vulcanizer and the like in sequence; evenly mixing and then extruding a sheet; and preparing the sheet into the ethylene propylene diene rubber / carbon black nanometer composite material by adopting the after vulcanization process. Through adding various plasticizers and adopting special process treatment, the tensile strength of the ethylene propylene diene rubber composition disclosed by the invention is at least 15.2MPa, the elongation at break is at least 400 percent, and the compression set is lower than 30 percent under the condition of 125 DEG C*70h. The composite material can be used as a sealing article of rubber, especially a rubber sealing washer applied to a groove-type pipeline joint part of an automatic water spray fire extinguishing system, and thereby, a long-term sealing effect is ensured.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

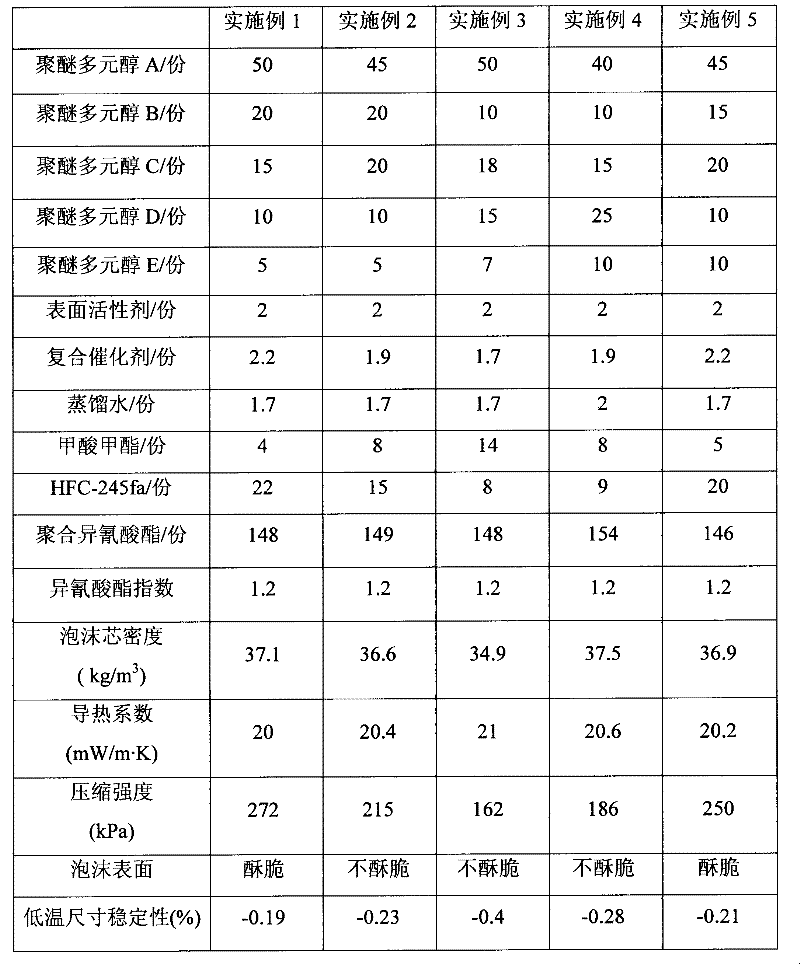

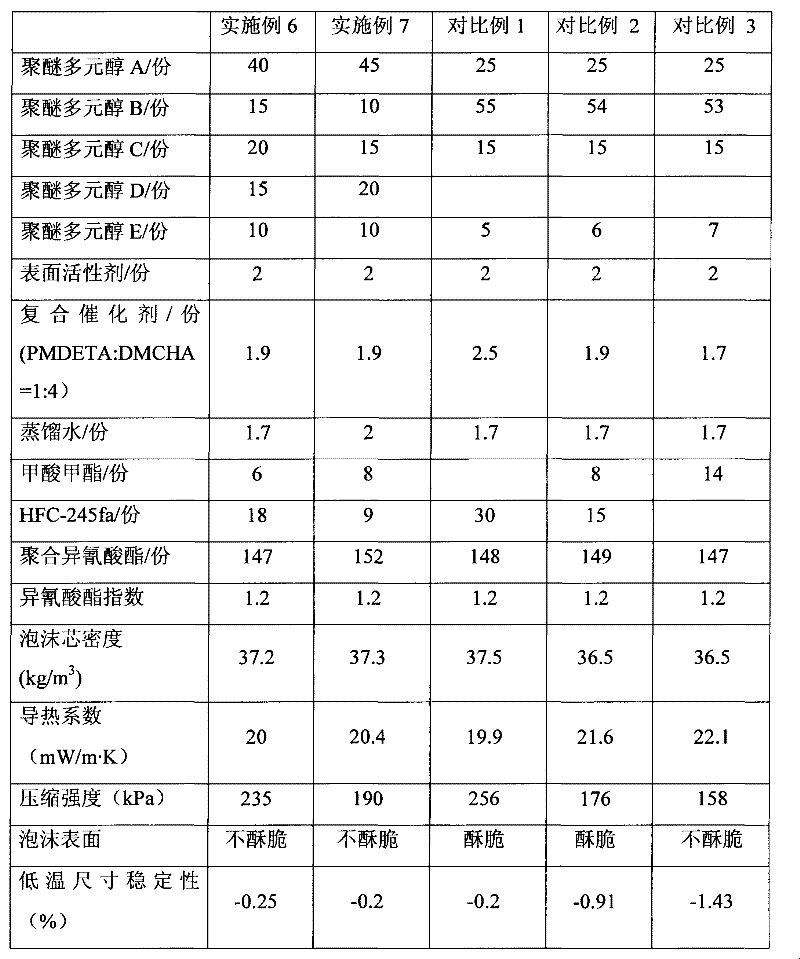

Polyurethane rigid foam and preparation method thereof

The invention discloses polyurethane rigid foam and a preparation method thereof, wherein foam plastic is prepared from the following raw materials by a high pressure foaming machine in parts by weight: 100 parts of combined polyether, 1.5-3 parts of surfactant, 1.5-3 parts of complex catalyst, 1-3 parts of water, 16-26 parts of mixed foaming agent and 140-170 parts of polymerized isocyanate, wherein the mixed foaming agent consists of methyl formate and 1,1,1,3,3-pentafluoropropane (HFC-245fa). The prepared polyurethane foam has low heat conductivity, good dimensional stability and proper cost.

Owner:万华化学(佛山)容威聚氨酯有限公司 +2

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Traditional Chinese medicine solid type mixed culture fermentation tech. and its application

The invention discloses a Chinese drugs multi-bacterium species mixture solid fermenting method and its application. It is made up from crushing the Chinese drugs, filtering, adjusting water content and pH value, adding bean pulp, bran, and inorganic salt, sterilization, cooling and adding bacterium species fermenting liquid to take ferment, and drying. The invention could be used to make drugs and feed additive that has antibiotic, antivirus and growth improvement functions. The invention has the features of simple process method, and improving the growth benefit bacterium.

Owner:NANJING SBEED BIOTECH +1

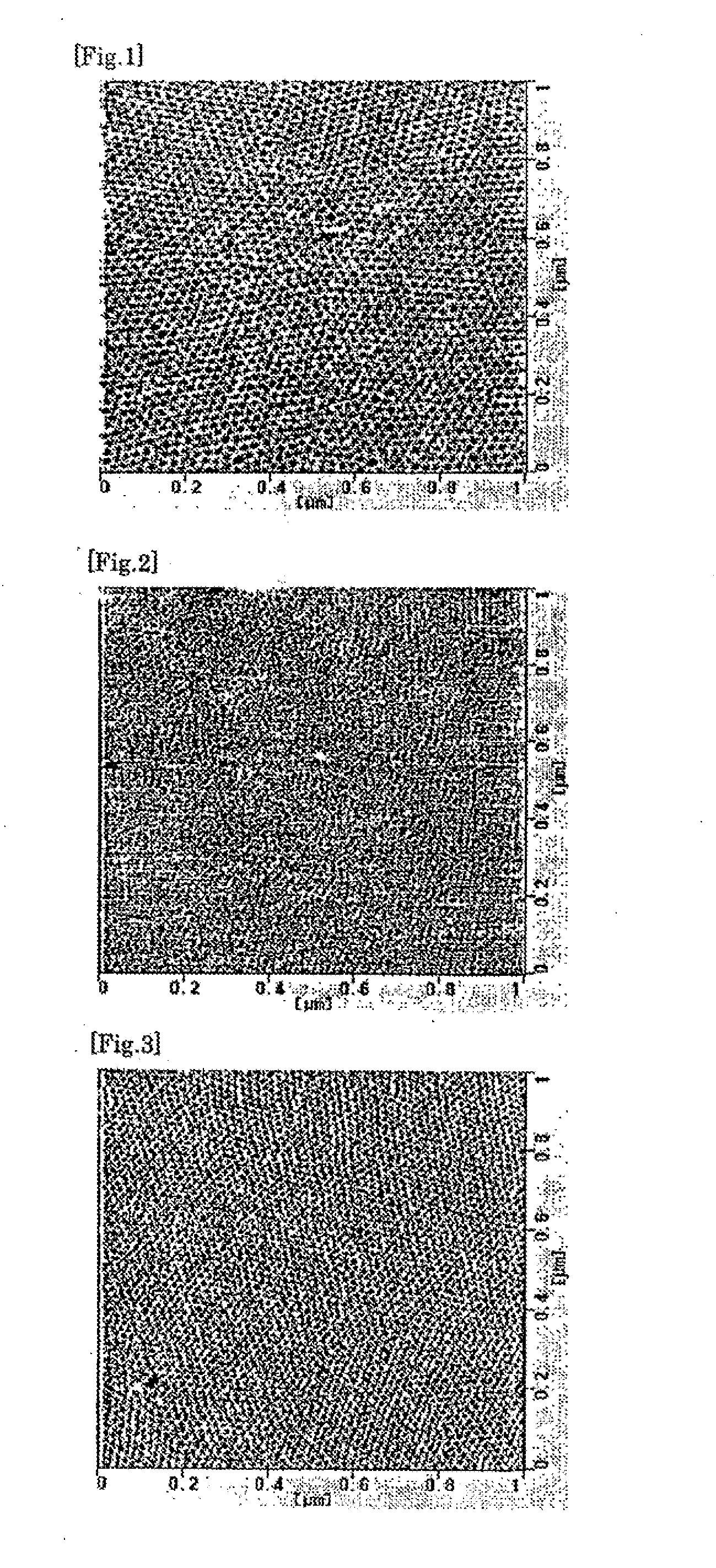

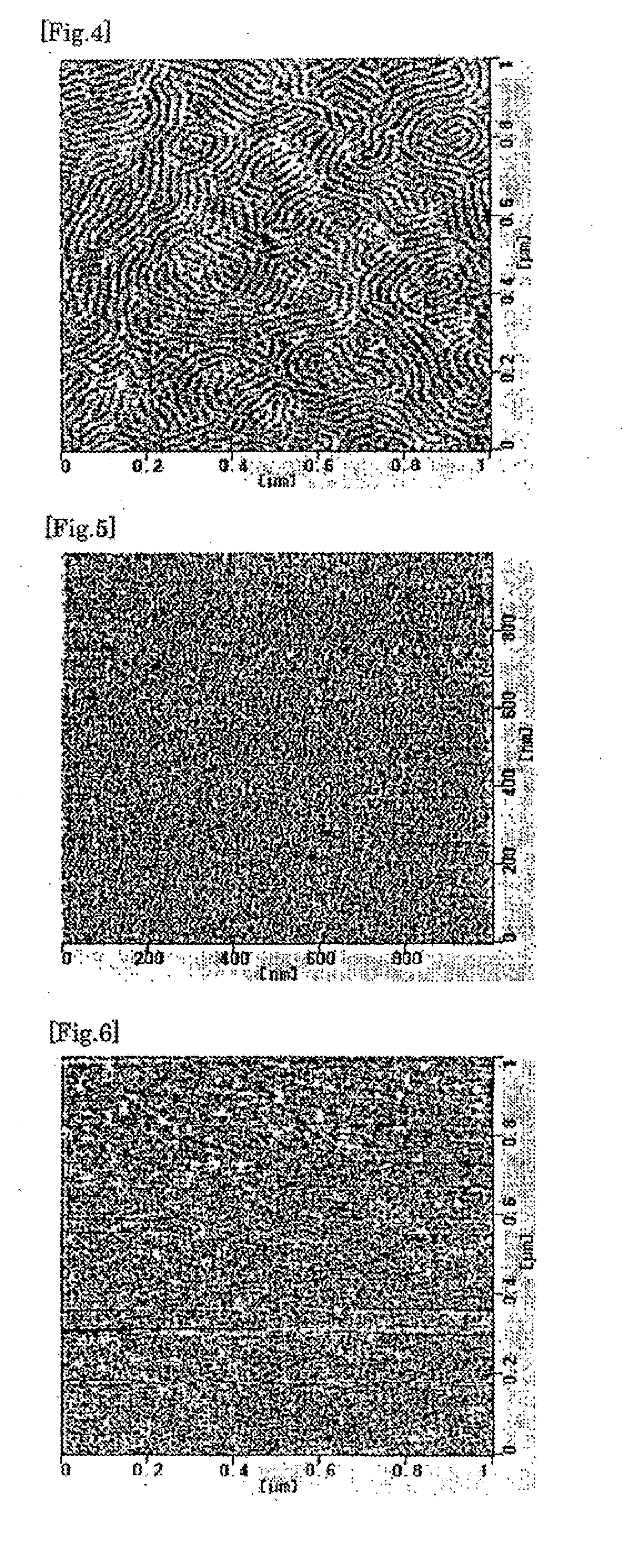

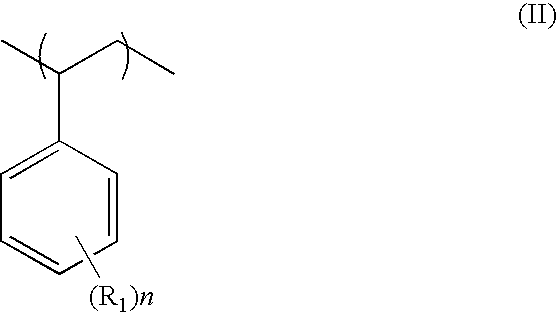

Block copolymers

It is to provide a block copolymer that can form a microphase separation structure even with a small molecular size, and that can form a microphase separation structure with a small domain size.It is a block copolymer represented by the formula A-C-B (wherein A represents a segment which is a homopolymer or random or block copolymer consisting of at least 1 kind or repeat units represented by formula (II);B represents a segment which is a homopolymer, or random or block copolymer consisting of at least 1 kind of repeat units represented by formula (III);C represents A, B or A-B; however, at least 1 segment of eachA has a water-repellent group, or at least 1 segment of each B has a polar group); which block copolymer has a mass average molecular weight of 50,000 or less, and that can form a microphase separation structure.

Owner:NIPPON SODA CO LTD

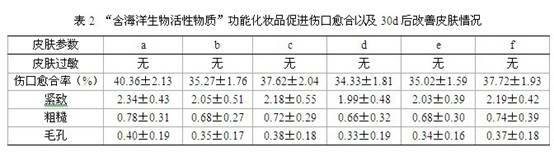

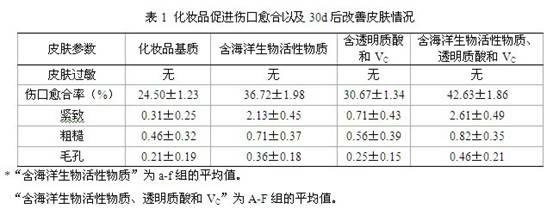

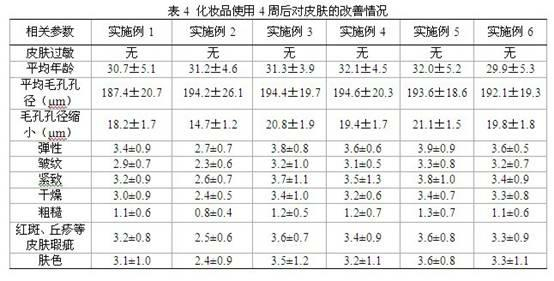

Marine biological function cosmetic for minimizing pores

ActiveCN102178636ANo side effectsSmall molecular weightCosmetic preparationsToilet preparationsEmulsionActive ingredient

The invention discloses marine biological function cosmetics for minimizing pores. The marine biological function cosmetics for minimizing the pores are prepared by mixing and homogenizing main active ingredients and a cosmetic substrate, wherein the main active ingredients comprise marine shellfish active peptide, marine collagen protein peptide, seaweed polysaccharide and fish oil. Hyaluronic acid and vitamin C (Vc) are added, so that the effect is more obvious. The marine biological function cosmetics for minimizing the pores solve the problems that the conventional cosmetics for minimizing the pores have high irritation and short action time, the marine shellfish active peptide is not applied to cosmetics, the marine biological active substances are not applied to the cosmetics for minimizing the pores and the like. The marine biological function cosmetics for minimizing the pores are safe, mild, high-efficiency and durable, can minimize the pores from inside to outside, recover fineness, softness and smoothness, and enable skin to give out natural, clean and transparent gloss. The marine biological function cosmetics for minimizing the pores have various types, such as cream, emulsion, water agent, gel, spray or masks, have obvious and durable pore-minimizing effect and can serve as the common skin-care products or the cosmetics with the function of minimizing the pores. After the marine biological function cosmetics are not used, the pore bulky symptom is not rebounded.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

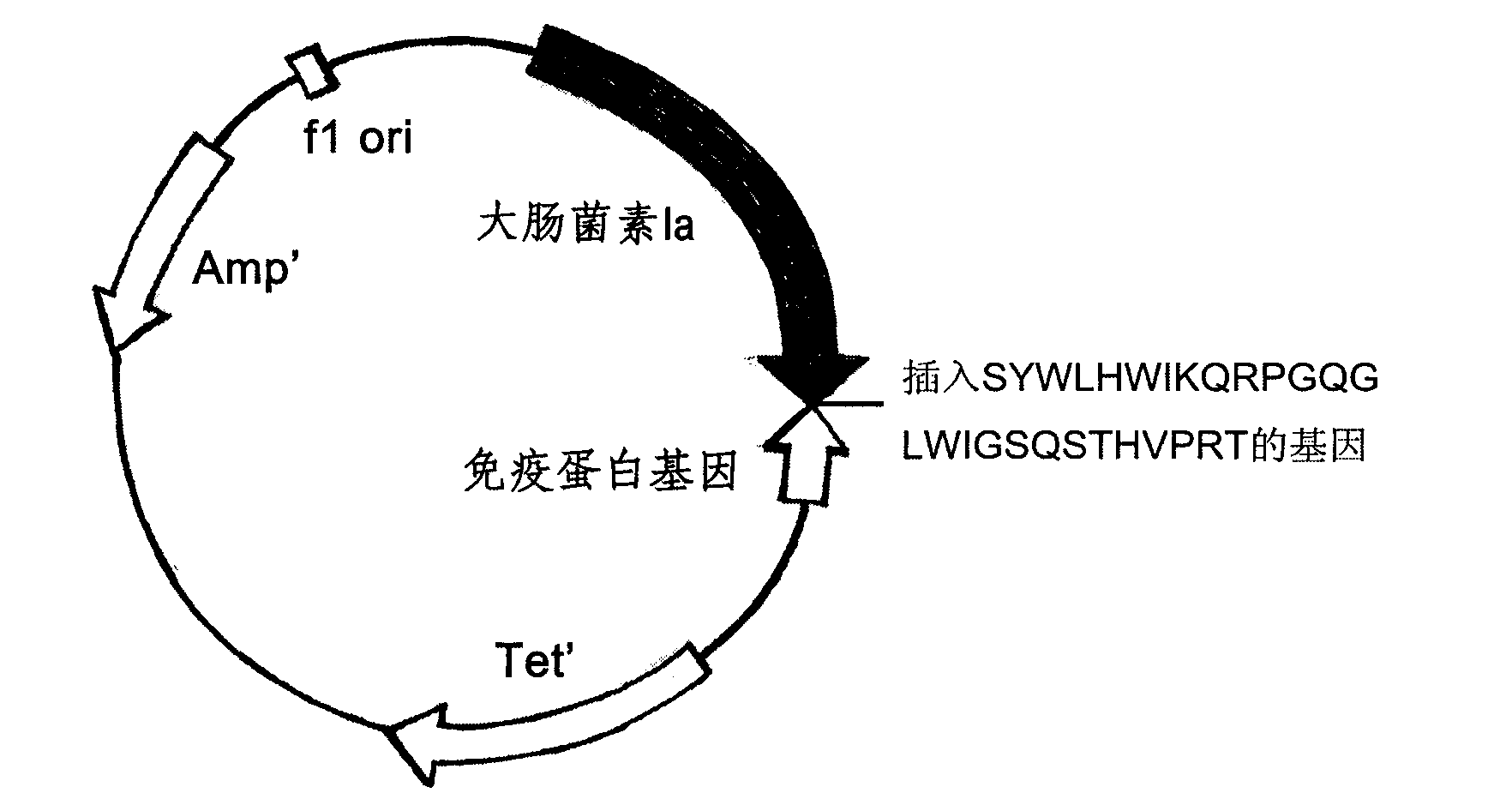

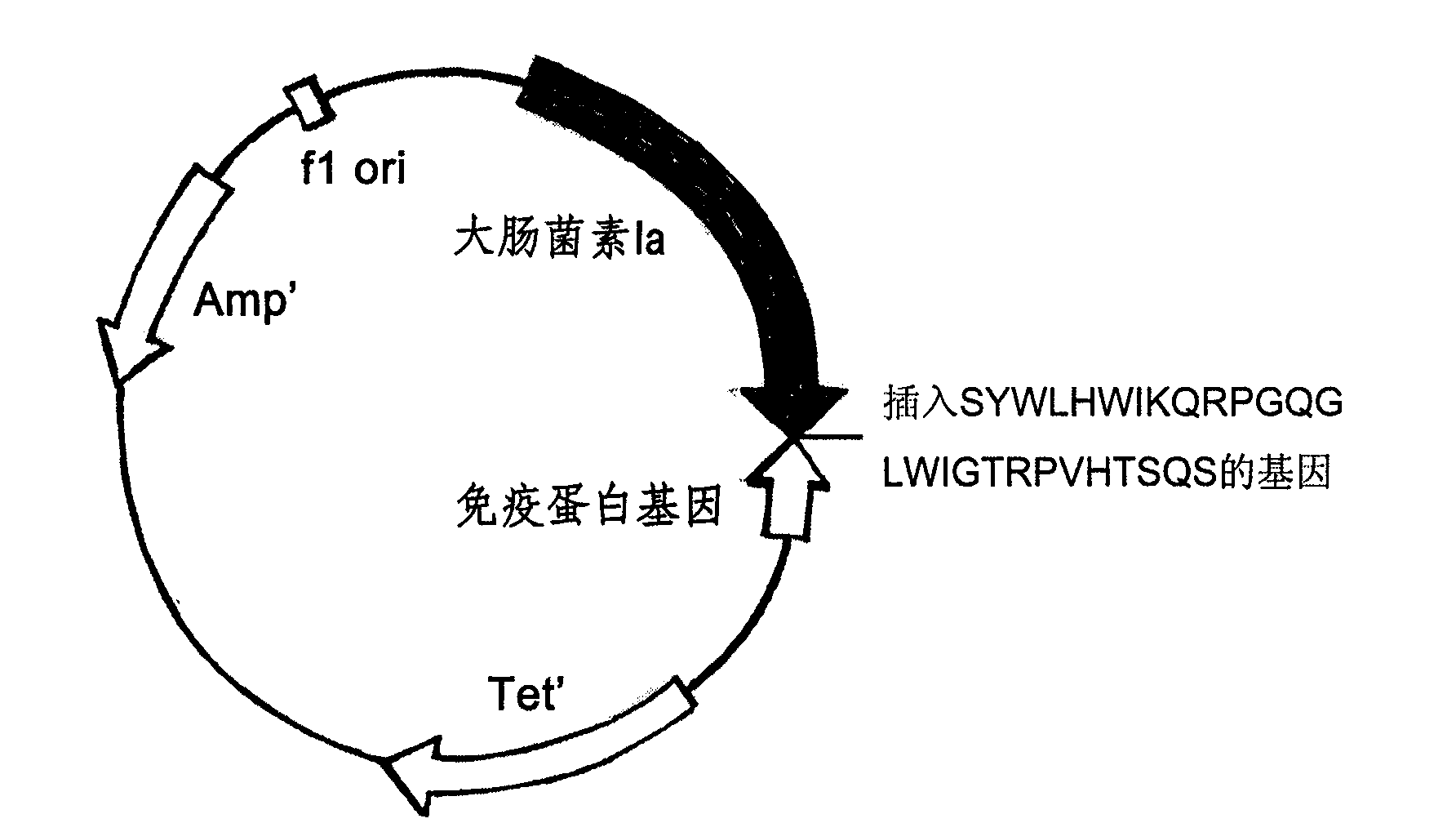

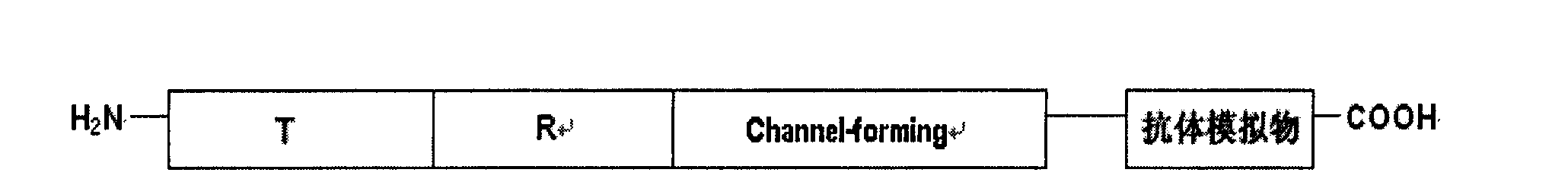

New type antibiotic containing an antibody analog, preparation method and application method thereof

ActiveCN101633699AImprove permeabilityLow immunogenicityAntibacterial agentsPeptide/protein ingredientsNormal cellAntibiotic Y

The invention relates to a new type antibiotic containing an antibody analog, a preparation method and an application method thereof, which belong to the field of biological medicaments. The new type antibiotic containing an antibody analog comprises colicin E1, Ia, Ib, A, B, N or a water pore canal domain thereof and an antibody analog, wherein the antibody analog is formed by connecting the carboxyl terminal of VHCDR1 of immunoglobulin with the amidogen terminal of VHFR2 and connecting the carboxyl terminal of VHFR2 with the amidogen terminal of VLCD; and porin is identified specifically by the immunoglobulin. The sterilization capability of the antibiotic is thousands of times of that of commonly used antibiotics. Because the action mechanism is special, pathogen is difficult to produce medicament resistant property; human normal cells are not harmed in the process of sterilization; and the new type antibiotic containing an antibody analog can be used for preparing medicaments of resisting meningococcus, vancocin enterococcus, methicillin staphylomycin or multi-medicament resistant cyanomycosis.

Owner:PHEROMONICIN BIOTECHNOLOGY LTD

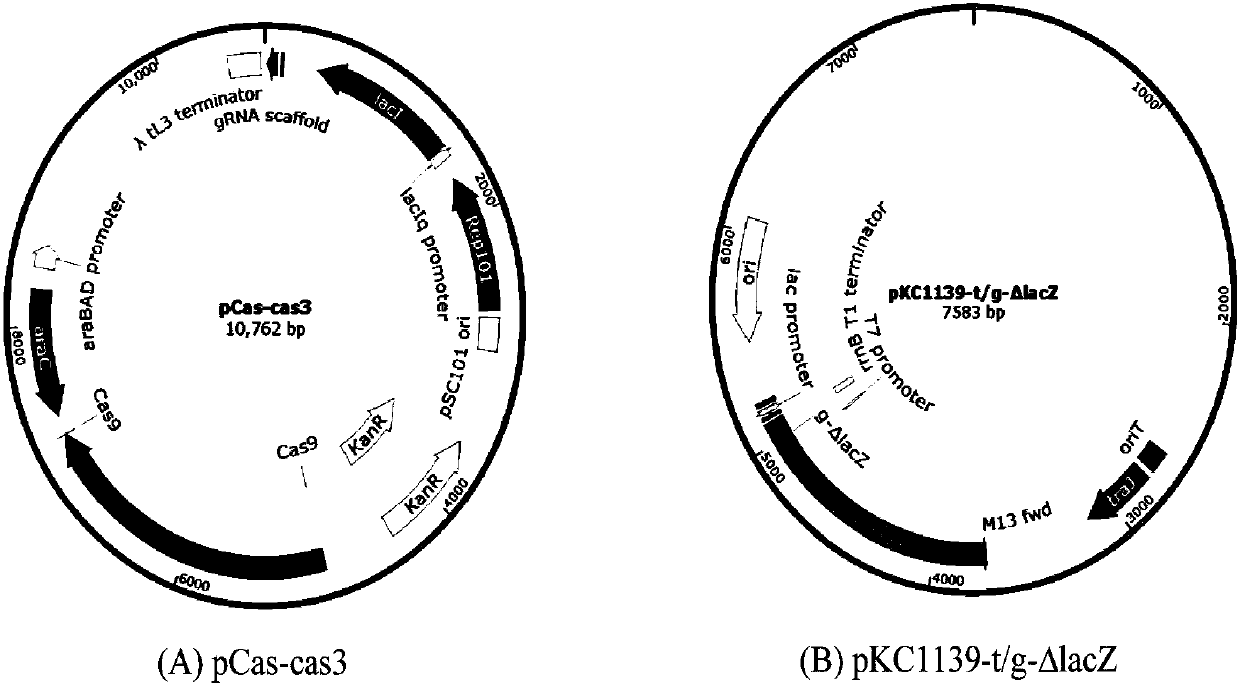

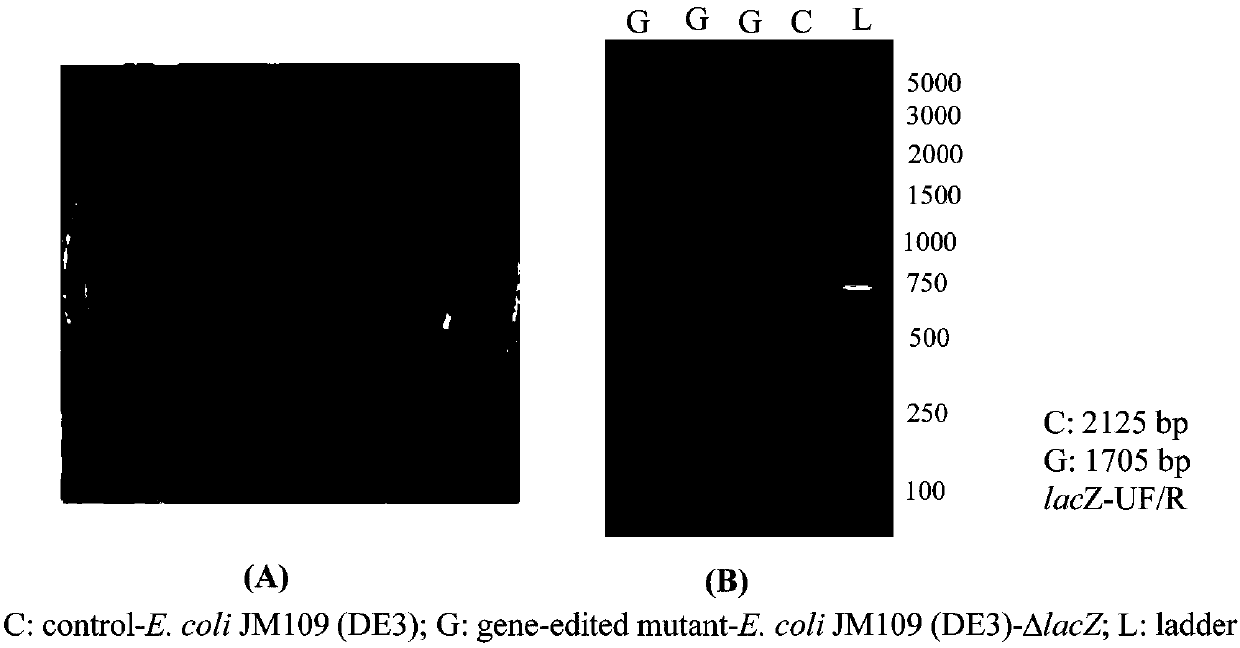

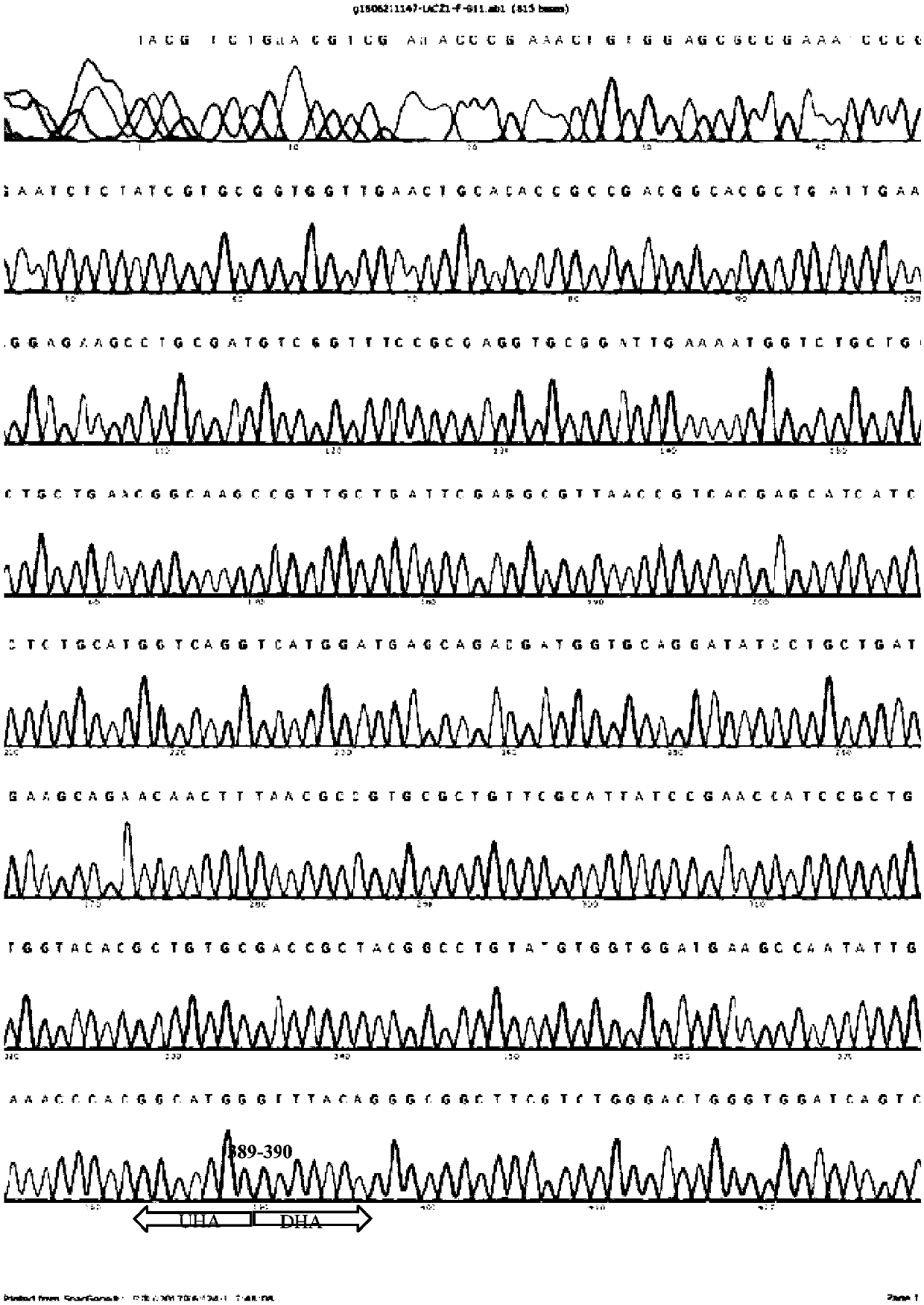

Gene editing method based on gene cas3 of I-B type CRISPR-Cas system

PendingCN107557373ASmall molecular weightGene editing is correctHydrolasesStable introduction of DNABiological cellEucoenogenes

The invention discloses a novel gene editing system which is established based on gene cas3 of an I-B type CRISPR-Cas system in a chromosome of Virginia streptomycete IBL14, the gene editing of an I type CRISPR-Cas system to a biological cell genome is realized for the first time, and new supplement and choice are provided for the gene editing system which is established by II type commercializedCas9. In the system, a target DNA can be specifically cut by the Cas3 through crRNA guide or t-DNA location. By adopting the system, error-free, simple and rapid gene editing can be performed on prokaryotic and eukaryotic genomes. The optimized gene editing system is expected to be superior to the commercialized gene editing system which is established based on Cas9 in multiple fields due to low molecular weight and ability to be guided by DNA.

Owner:ANHUI UNIVERSITY

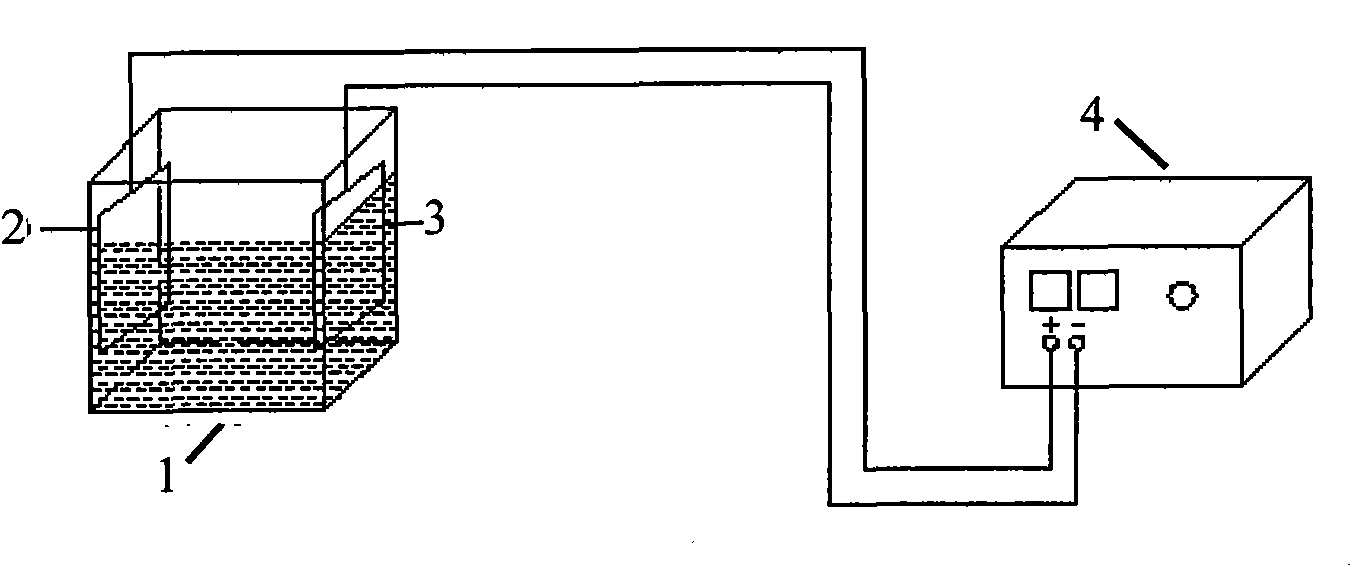

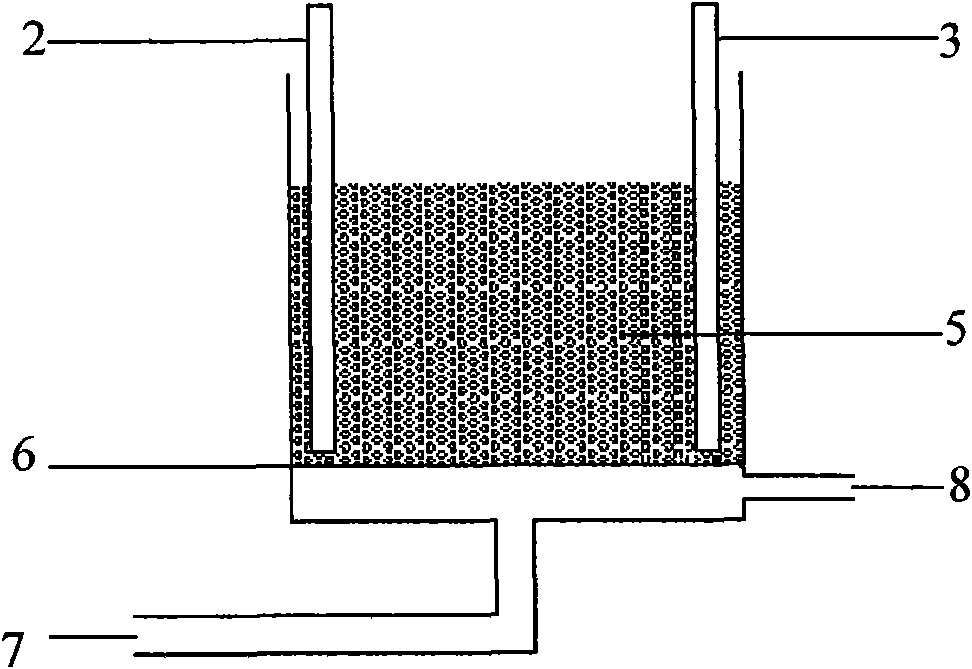

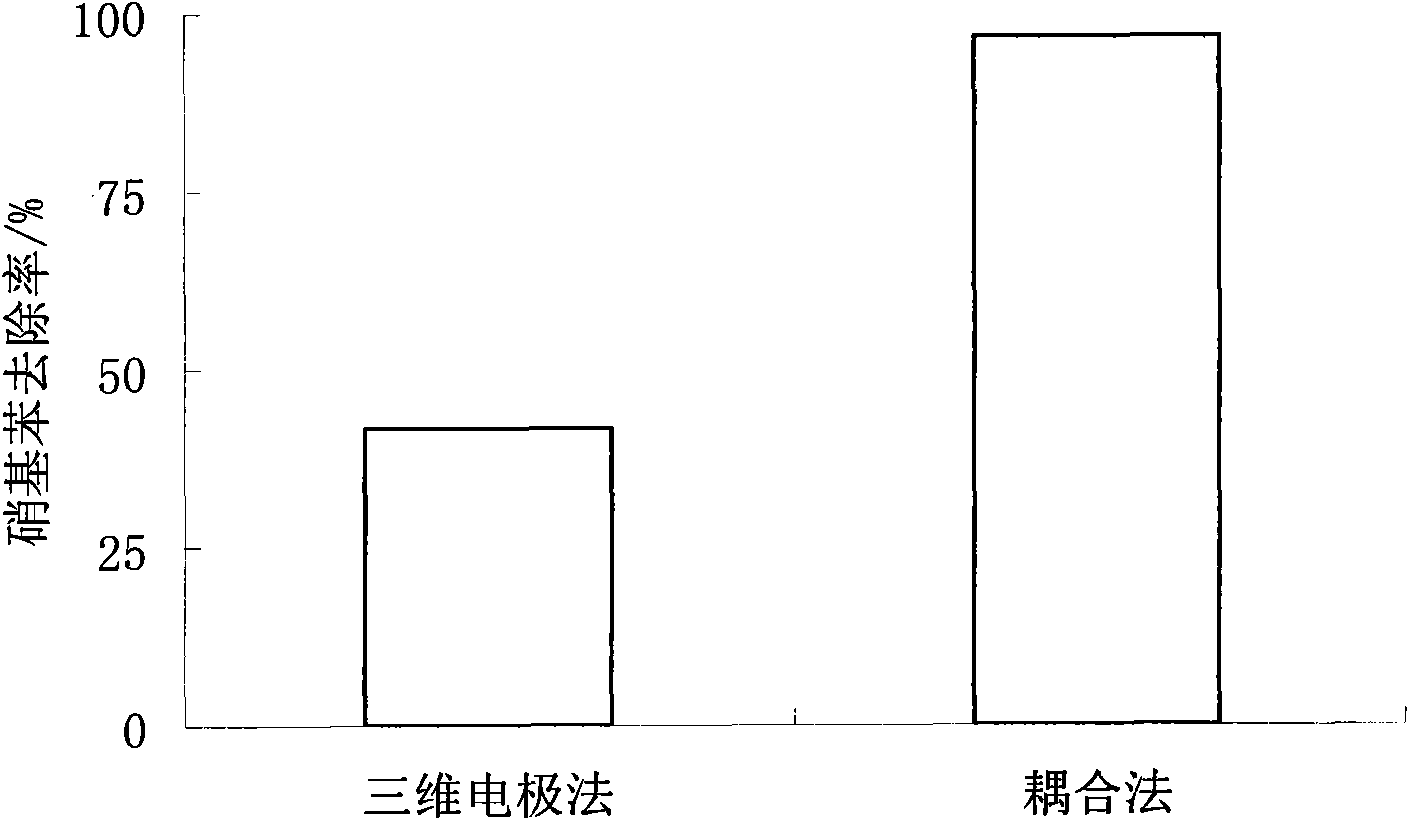

Method for degrading nitrobenzene waste water by polyphase electrocatalytic oxidation-Fenton coupling process and reactor thereof

ActiveCN101838074AGuaranteed emission standardsPromote generationMultistage water/sewage treatmentWater/sewage treatment by oxidationCarbon dioxideHigh concentration

The invention belongs to the technical field of treatment of high concentration organic waste water, and particularly relates to a method for degrading nitrobenzene waste water by a polyphase electrocatalytic oxidation process. The invention solves the problems of high cost and long time consumption in the traditional nitrobenzene waste water methods, low efficiency and high energy consumption in the electrolytic process, high oxidant consumption, high cost and the like in the Fenton process in the prior art for treating high concentration nitrobenzene water waste. The invention mainly adopts the catalytic oxidation action of transition metal catalysts in the electric field, and combines the Fenton process, thereby effectively degrading the high concentration nitrobenzene waste water. The method comprises the following steps that: (1) heterocatalytic reagents (solid catalysts) and particle electrodes, mainly including active carbon, and transition metal oxides and salts, are used for avoiding economic loss and secondary pollution to the environment, which are caused by catalyst loss in heterocatalytic oxidation; (2) under the condition of low pH value of the waste water in cooperation with Fe2+ with strong reducibility, a coupling reactor composed of an electrolysis field and oxidation reaction is used for generating chain reaction for generating an OH hydroxyl free radical, and the OH hydroxyl free radical can carrying out nonselective oxidization on organic substances, thereby finally oxidizing organic pollutants into carbon dioxide and water; (3) by using electric energy as an excitation energy and using cheap air as raw material, nitrobenzene substances in waste water are efficiently degraded under the coupling action of the polyphase electrocatalytic oxidation process and the Fenton process; (4) and the reactor is composed of a direct current regulated power supply, a feed electrode and an electrolytic bath.

Owner:广东华凯明信科技有限公司

High-strength high modulus polyimide fiber and preparation method thereof

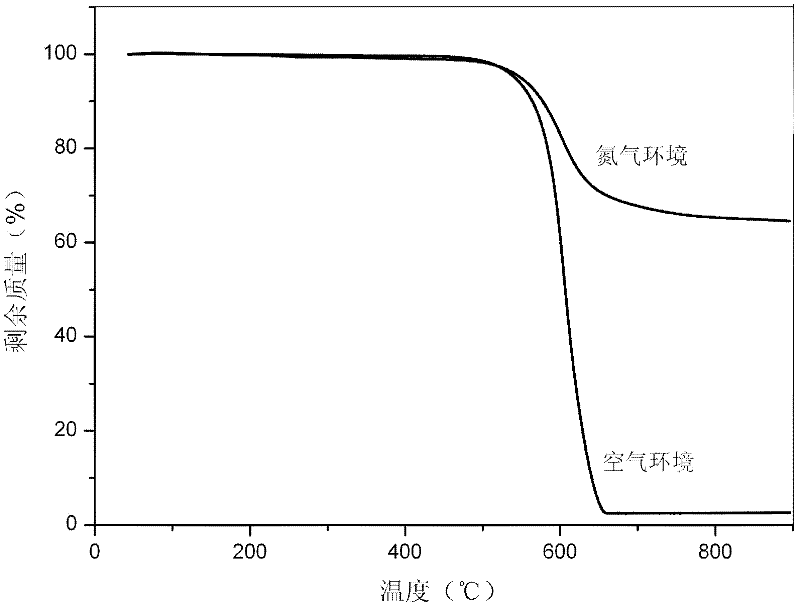

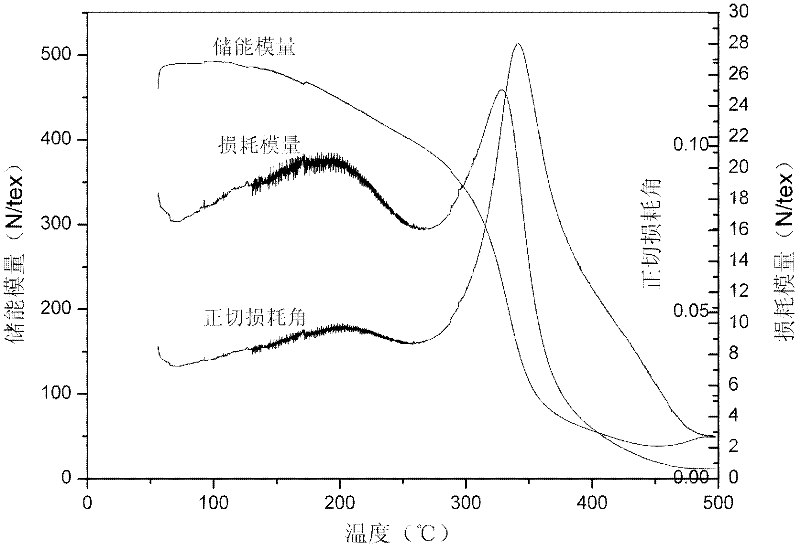

ActiveCN102345177AImprove performanceReasonable molecular structureArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to high-strength high modulus polyimide fiber and a preparation method thereof, which belongs to the high performance organic fiber technical field. The fiber comprises the polyimide fiber which is prepared by biphenyltetracarboxylic dianhydride (BPDA), para-phenylene diamine (pPDA) and 2-(4-aminophenyl)-5-aminobenzimidazoles (BIA), wherein the mol ratio of pPDA to BIA is 1:10-3:1, other di-amine and di-anhydride monomers are added in the synthesis process, a gradient temperature reaction method and a one step continuous preparation method are used in the preparation process, so that the difficulties for synthesizing and processing due to the content increase of 2-(4-aminophenyl)-5-aminobenzimidazoles are solved, the problems of poor homogeneity and stability of thefiber performance can be solved, and the high-strength high modulus polyimide fiber can be obtained, the strength can reach 4.5GPa, the modulus can reach 201GPa, and the raw material source is wide, the spinning process can be continuously performed, the method has low cost and high efficiency which is capable of realizing the industrial production.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

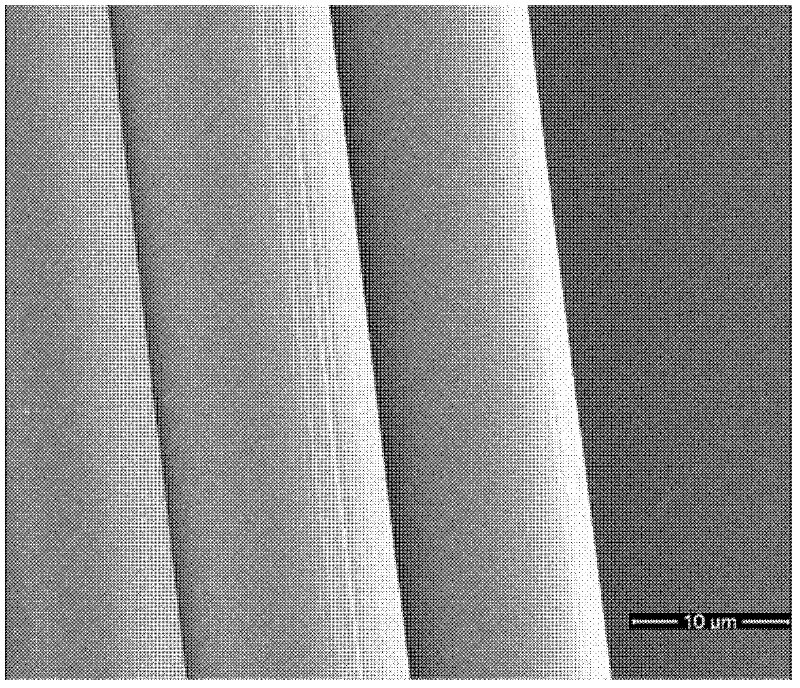

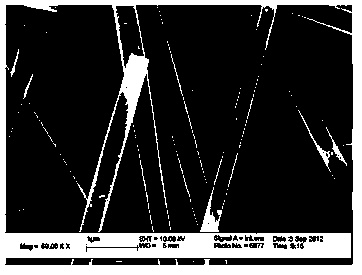

Strong-hydrophobic porous carbon nanofiber and preparation method thereof

ActiveCN103422194AEasy to prepare and effectiveLow surface oxygen contentMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberCarbon fibers

The invention relates to strong-hydrophobic porous carbon nanofiber and a preparation method thereof, and belongs to the technical field of porous carbon fiber. The preparation method comprises the following steps: adding thermosetting phenol resin and high molecular weight linear polymers into organic solvent with two proportions to be mixed until the thermosetting phenol resin and the high molecular weight linear polymers are fully dissolved, performing electrostatic spinning on the solution to form phenolic resin fiber, and carrying out curing and carbonizing to obtain the hydrophobic porous carbon nanofiber. The porous carbon nanofiber and the preparation method have the advantages as follows: the diameter, the pore structure and the hydrophobicity of the fiber can be adjusted and controlled through the change of the proportions of the solvent, the prepared carbon nanofiber has good flexibility, a developed pore structure and strong hydrophobicity, and is more conductive to practical application.

Owner:TSINGHUA UNIV

Method for comprehensive utilization of grass type stalk

ActiveCN101451315AHigh in Fulvic AcidSmall molecular weightPulp liquor regenerationDigestersCelluloseBlack liquor

The invention relates to a comprehensive utilization method for grass straws. Firstly, cellulose in the straws is utilized to pulp to serve as a raw material of paper pulp; during the pulping, lignin is dissolved in a stewing liquor to become a main constituent of a solid in a black liquor; the lignin is fully refined through the stewing and has easy degradation, and crops are easy to absorb, so the black liquor becomes a good organic fertilizer; at the same time, a fulvic acid with considerable quantity can be formed under conditions of high temperature and high pressure during the pulping, so the black liquor can be prepared into a high-quality fulvic acid fertilizer; the aim of comprehensive utilization of the grass straws is achieved through the steps, and the good economic benefit can be obtained thanks to the fact that the paper pulp and the fulvic acid fertilizer are expensive.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Maize oligopeptide and method for preparing same

ActiveCN101531700AIncrease contentImprove enzymatic hydrolysis efficiencyPeptide preparation methodsFermentationAlkaline waterEnzymatic hydrolysis

The invention relates to a maize oligopeptide and a method for preparing same, belonging to the field of biological technology. The method takes the byproduct, namely corn protein powder (also called maize yellow powder containing about 60% of protein) in corn starch production as a raw material, removes the impurities such as starch, grease and the like by the treatment of alkaline water and obtains high-purity corn protein slag; furthermore, the corn protein slag is taken as enzymatic hydrolysis substrate and treated by the following process of pre-treatment, enzymatic hydrolysis, multi-step separation and purification, concentrating, drying and the like so as to prepare the maize oligopeptide powders with edible value and various health-care functions. The method for preparing maize oligopeptide has the advantages of easily obtaining raw material, simple process and higher industrial feasibility. The prepared maize oligopeptide sample has high crude protein content and small molecular weight, has various physiological activities of prompting immunity adjustment, anti-fatigue and the like, and can be used as new functional nutritional compounding and widely applied to the development and production of products such as foods, health-care foods and the like.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +1

Hollow fiber type filtration membrane

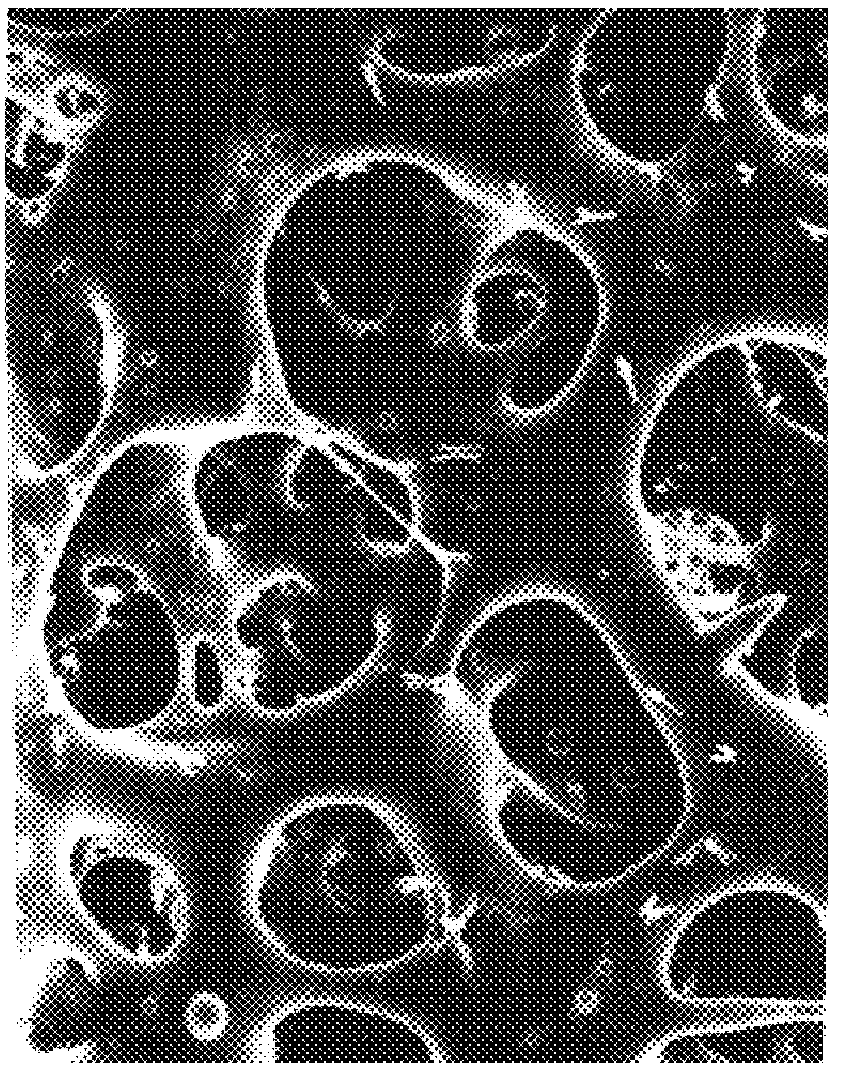

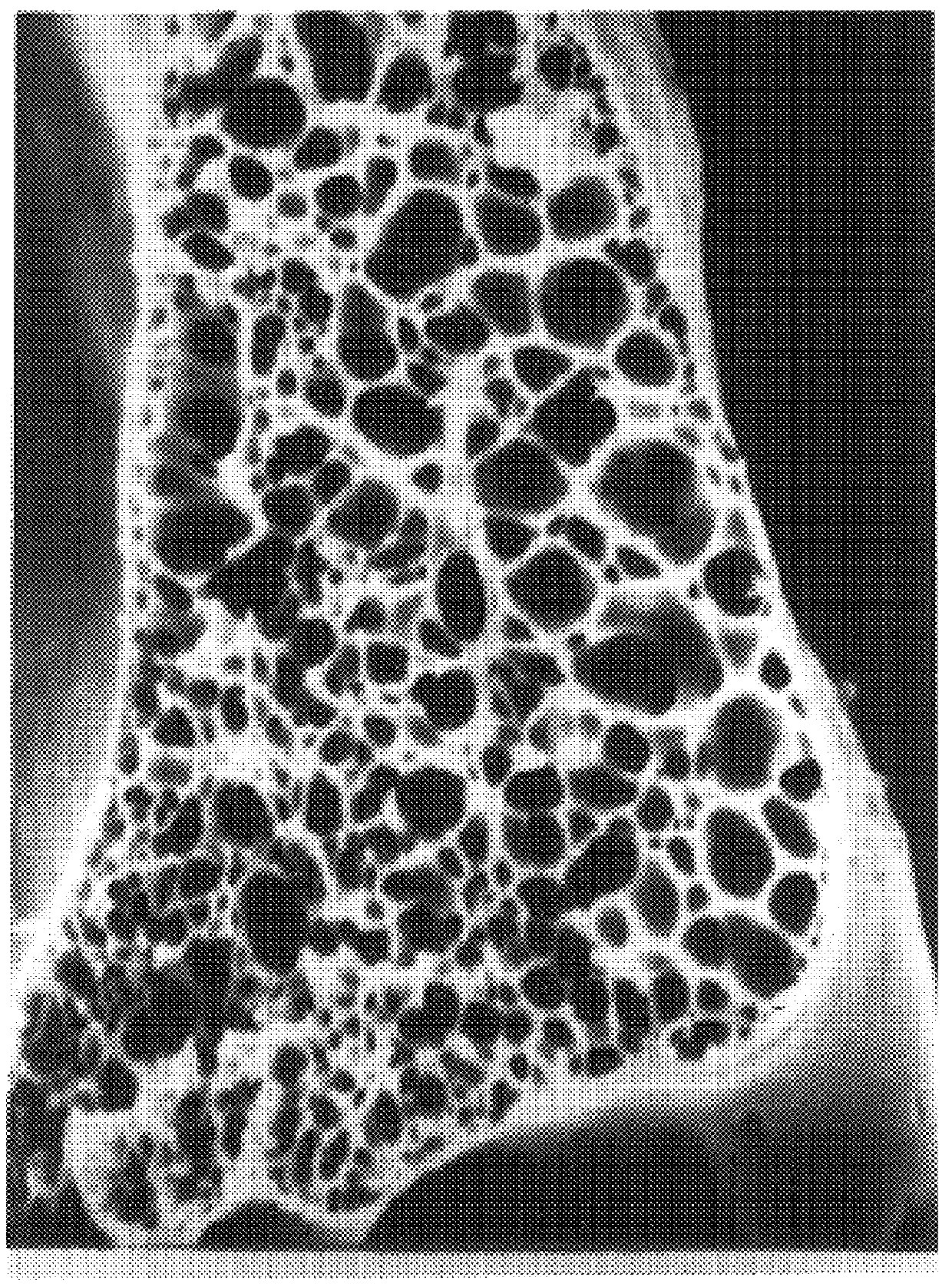

InactiveUS6165363AHigh enough strengthHigh strengthSemi-permeable membranesMoving filtering element filtersHollow fibreFiltration membrane

PCT No. PCT / JP96 / 03677 Sec. 371 Date Jun. 18, 1998 Sec. 102(e) Date Jun. 18, 1998 PCT Filed Dec. 17, 1996 PCT Pub. No. WO97 / 22405 PCT Pub. Date Jun. 26, 1997A hollow fiber filter membrane where the inner surface comprises a three-dimensional network structure having thick trunks of 10-30 mu m in maximum diameter and the average pore diameter of a minimum pore diameter layer of the membrane is 0.01 mu m or more and less than 1 mu m.

Owner:ASAHI KASEI KK

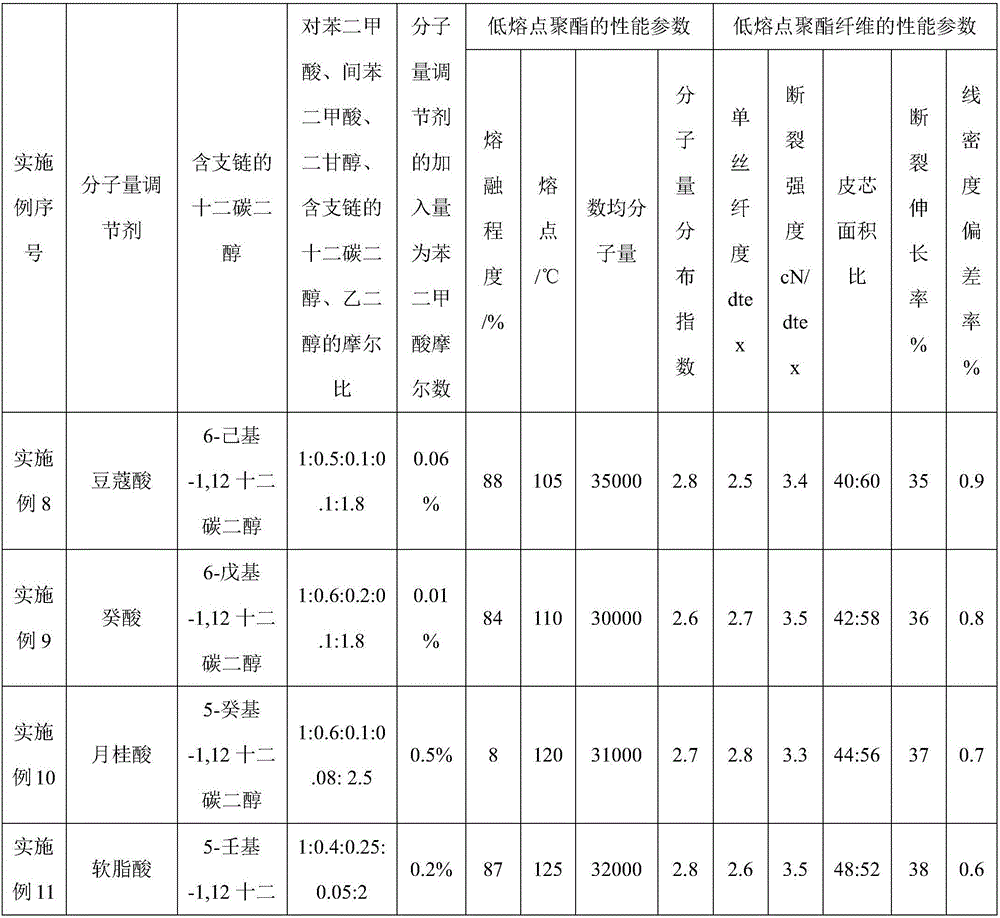

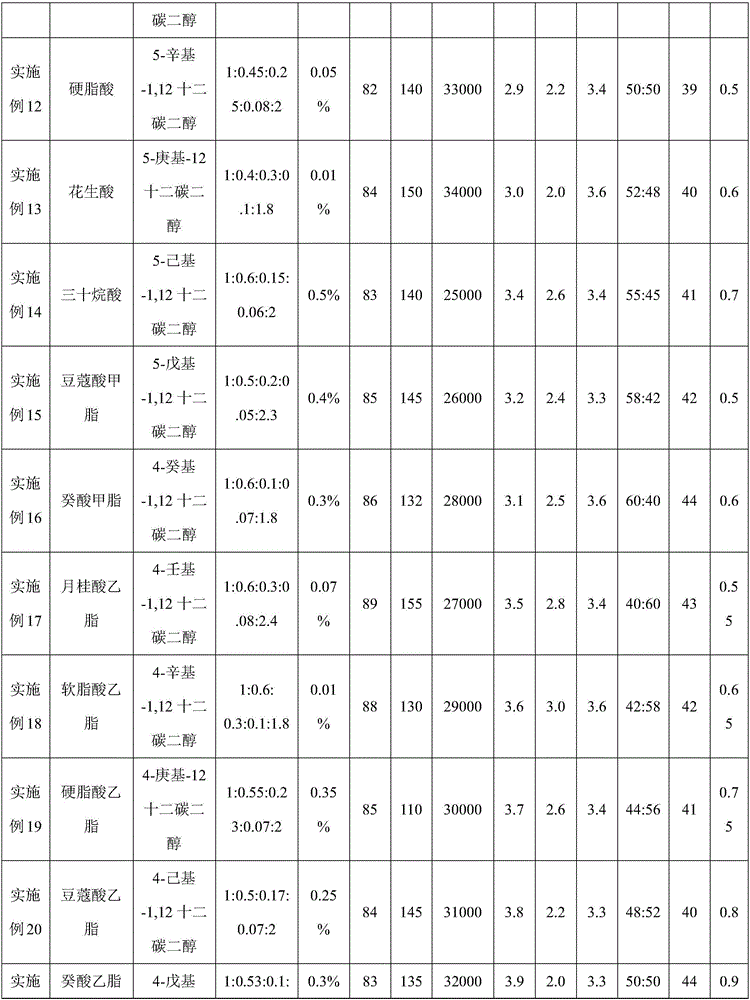

Filament low-melting-point polyester fiber and preparation method thereof

ActiveCN106757518AImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate

The invention relates to a filament low-melting-point polyester fiber and a preparation method thereof. The filament low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester; a core layer is made of PET (polyethylene terephthalate); the low-melting-point polyester consists of a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier chain segment and a 1, 12-Dodecanediol chain segment containing branched chains; a molecular weight modifier corresponding to the molecular weight modifier chain segment is specifically a monoacid series or a diacid series; the preparation method of the filament low-melting-point polyester fiber comprises the following steps: polymerization of the low-melting-point polyester and skin-core composite spinning, so as to obtain the filament low-melting-point polyester fiber. The prepared filament low-melting-point polyester fiber has the advantages that the initial melting point is reduced, the melting speed is increased, the polyester fiber is immediately melted at the corresponding temperature, and the melting effect is good.

Owner:扬州富威尔复合材料有限公司

A method of producing a healthcare yang-invigorating preparation for males

InactiveCN106943586AImprove immunityPromote growthAnthropod material medical ingredientsPeptide/protein ingredientsOysterPine pollen

A method of producing a healthcare yang-invigorating preparation for males is provided. The method is characterized in that: male silkworm pupa-cordyceps militaris-oyster peptides prepared by subjecting raw materials including male silkworm pupae, cordyceps militaris (L.) Link and oyster to enzymolysis, a composite extract prepared from mulberry fruit, barbary wolfberry fruit, palmleaf raspberry fruit, solomonseal rhizome, common yam rhizome, gordon euryale seed, poria, jujube kernels, cortex cinnamomi, Chinese date and ginseng and broken pine pollen prepared from pine pollen are added and fully mixed, an excipient is added into the mixture and the mixture is prepared into granules, capsules, and a tablet candy preparation according to conventional preparing processes. Compatibility of components adopted is scientific. An adopted preparing process is unique and simple. According to the method and the preparation, a production process is simple, the preparation is simple to eat, has effects of tonifying the kidney and qi, tonifying the lung and kidney, promoting sperm production, boosting marrow, invigorating the spleen and the stomach, improving microcirculation of human bodies, eliminating moisture, removing paralysis, boosting immunity, preventing fatigue, resisting viruses, strengthening bodies, invigorating yang and treating impotence, has obvious curative effects, mild functions and no side or toxic effects, and is an ideal healthcare yang-invigorating preparation for males.

Owner:山东岐伯堂生物科技有限公司

Polyester paint of high solid for coiled material and lithographed sheet

InactiveCN1415682AIncreased irregularitySmall molecular weightLiquid surface applicatorsPolyester coatingsChemistryBoiling point

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

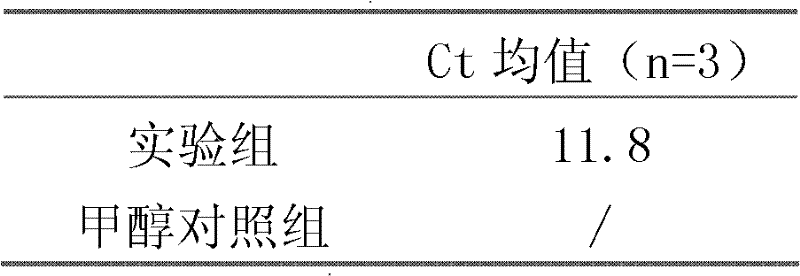

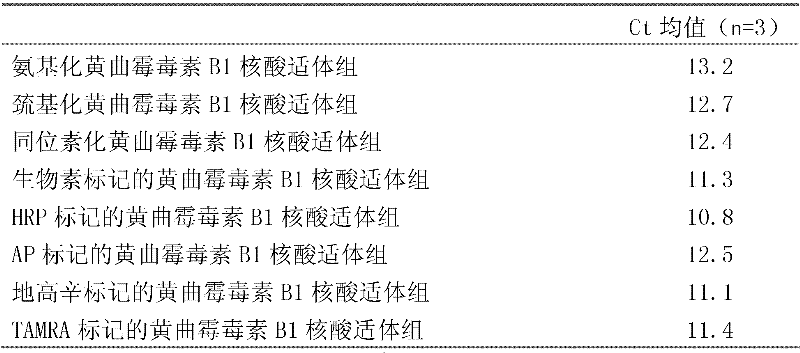

Nucleic acid aptamer of aflatoxin B1 and application thereof

InactiveCN102517289ALow costHigh affinity and specificityMicrobiological testing/measurementPreparing sample for investigationBiologyAflatoxin B

The invention relates to a nucleic acid aptamer which is in high-specificity and high-affinity combination with aflatoxin B1 and application thereof. The nucleic acid aptamer can be used for detection analysis and separating enrichment of aflatoxin B1, and has the advantages of being good in specificity, high in affinity, homogeneous in quality, good in stability, short in development cycle, low in production cost and convenient to use. The invention further relates to derivation sequences of a nucleic acid aptamer sequence and comprises sequences after modification.

Owner:CHINA NAT ACAD NANOTECH & ENG

Process for industrial production of oligochitose and chitooligose

InactiveCN1401652ASmall molecular weightHigh molecular weightOligosaccharidesFreeze-dryingVacuum drying

An industrial process for preparing oligochitose or chitoligose by degradating chitosan with complex enzyme includes specifically opening the beta (1,4) glycoside bond of chitosan with complex enzyme, separating out oligothitose in alkaline condition, freezing, centrifugal dewatering, vacuum drying, superfiltering for removing enzyme, nano-filtering for dewatering and freeze drying. Its advantages are high quality of product and low cost.

Owner:EAST CHINA UNIV OF SCI & TECH

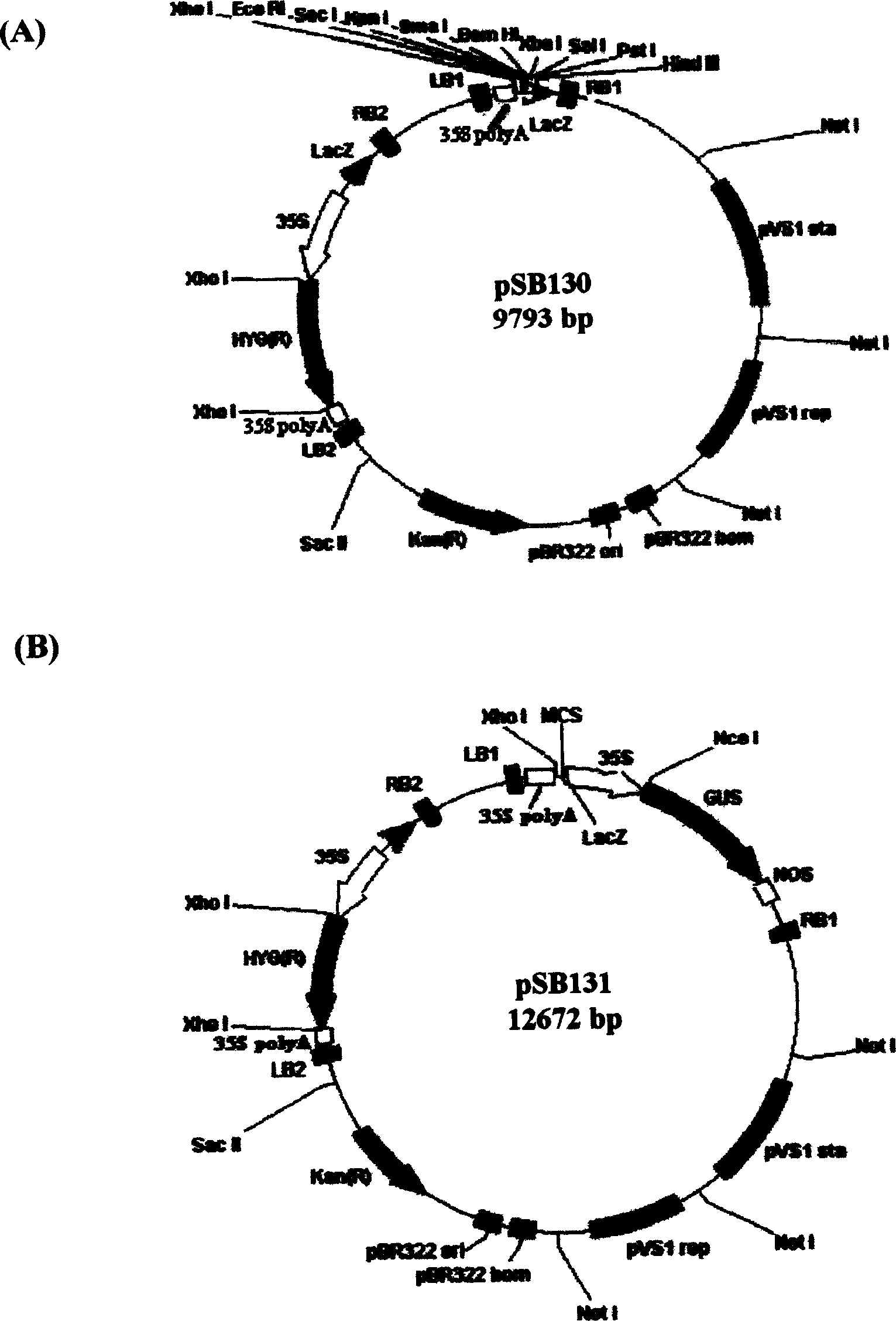

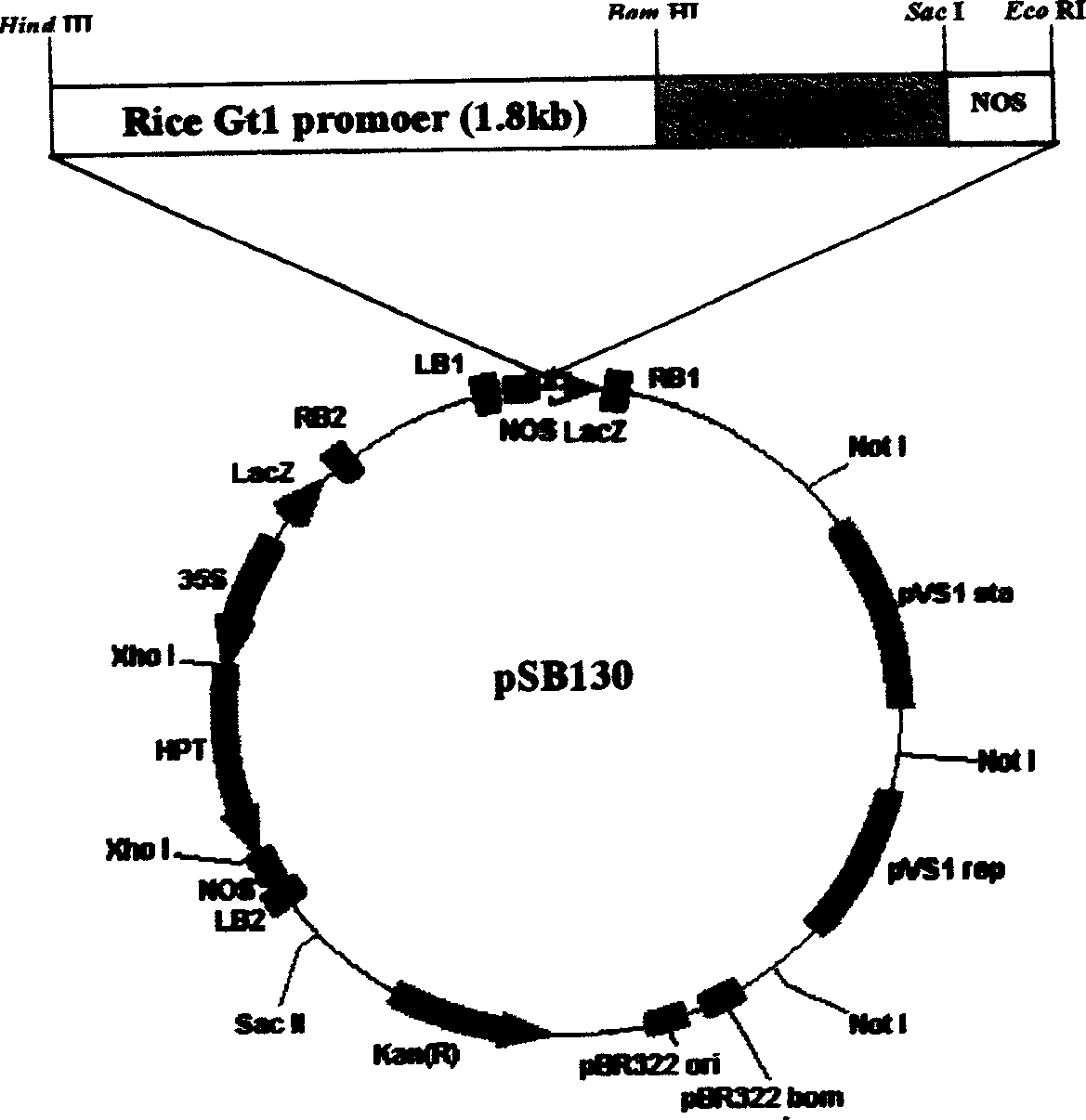

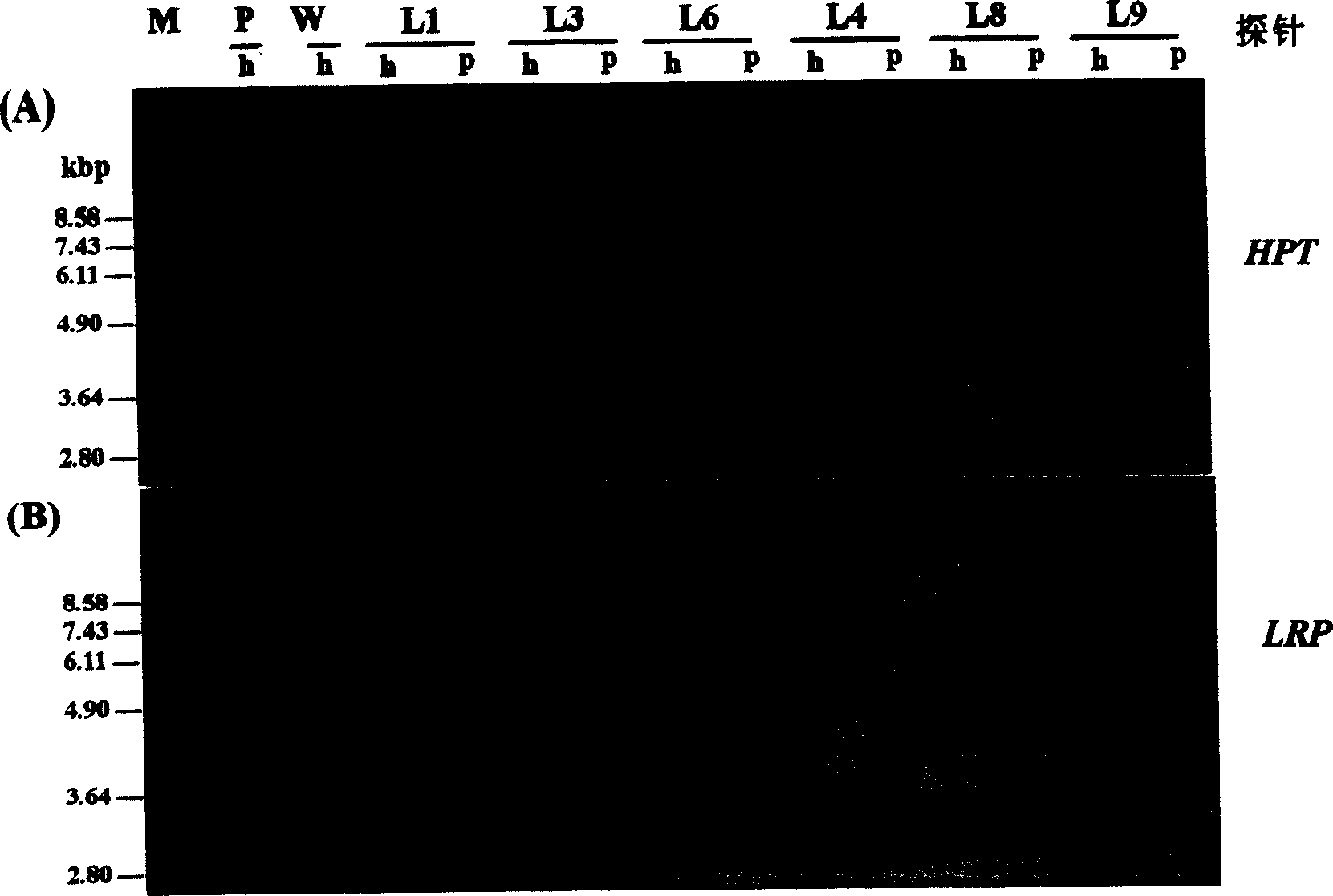

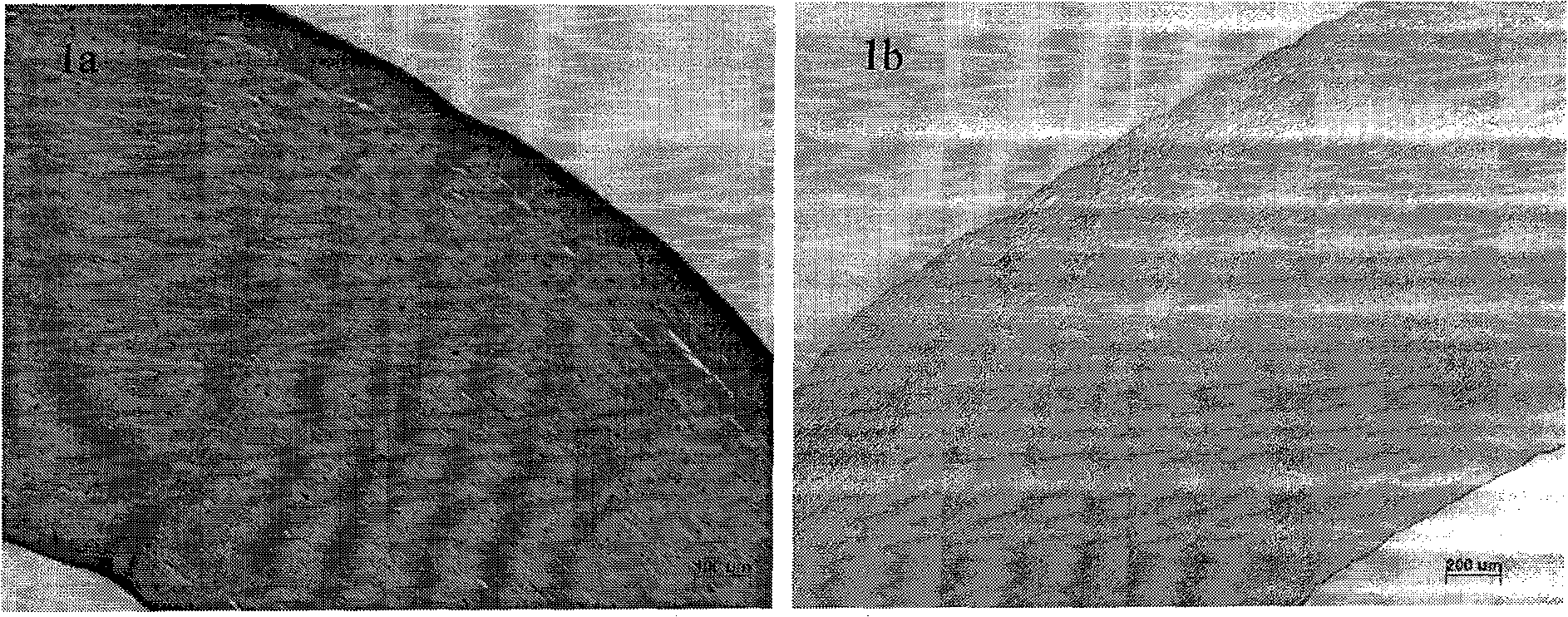

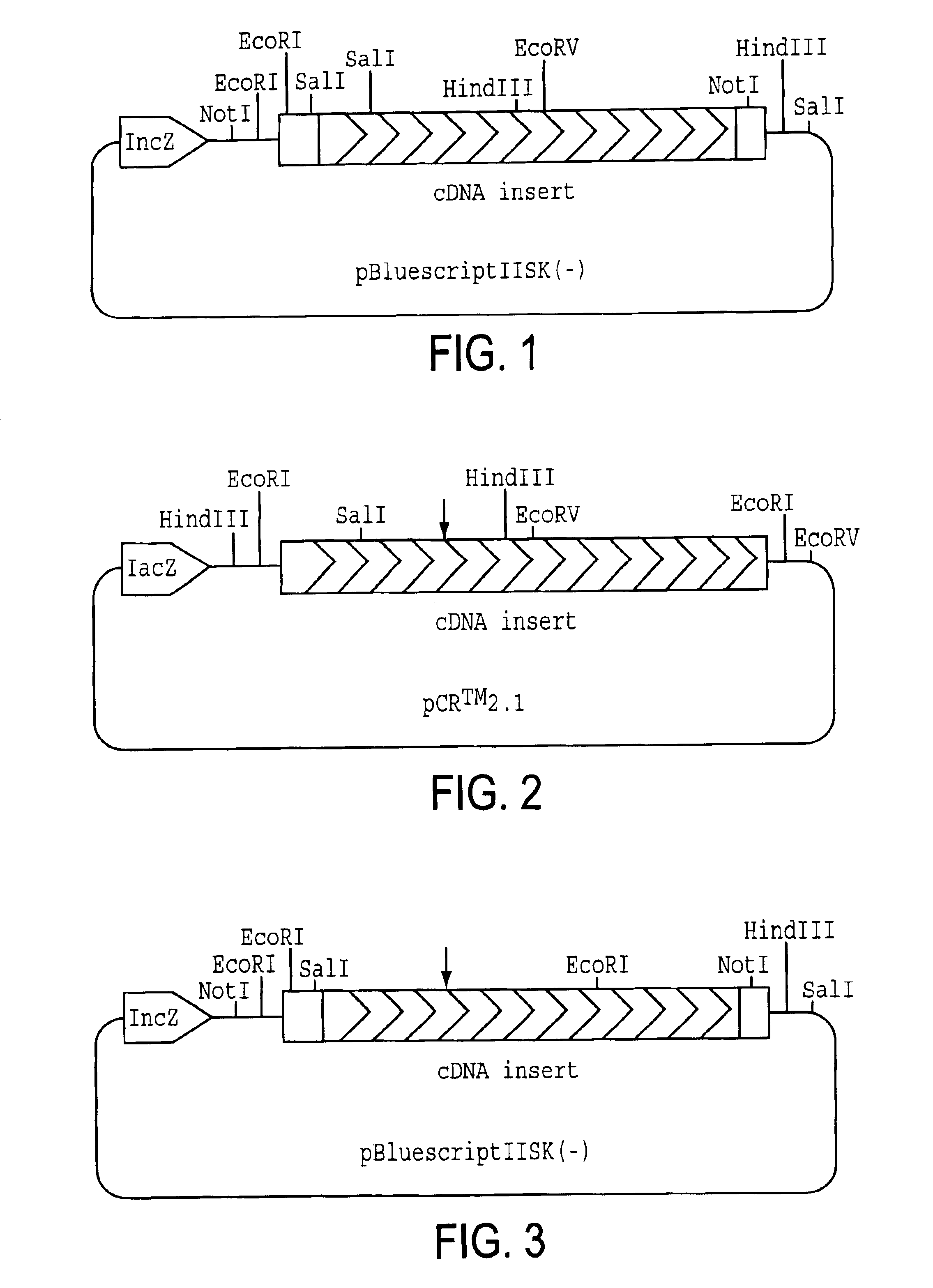

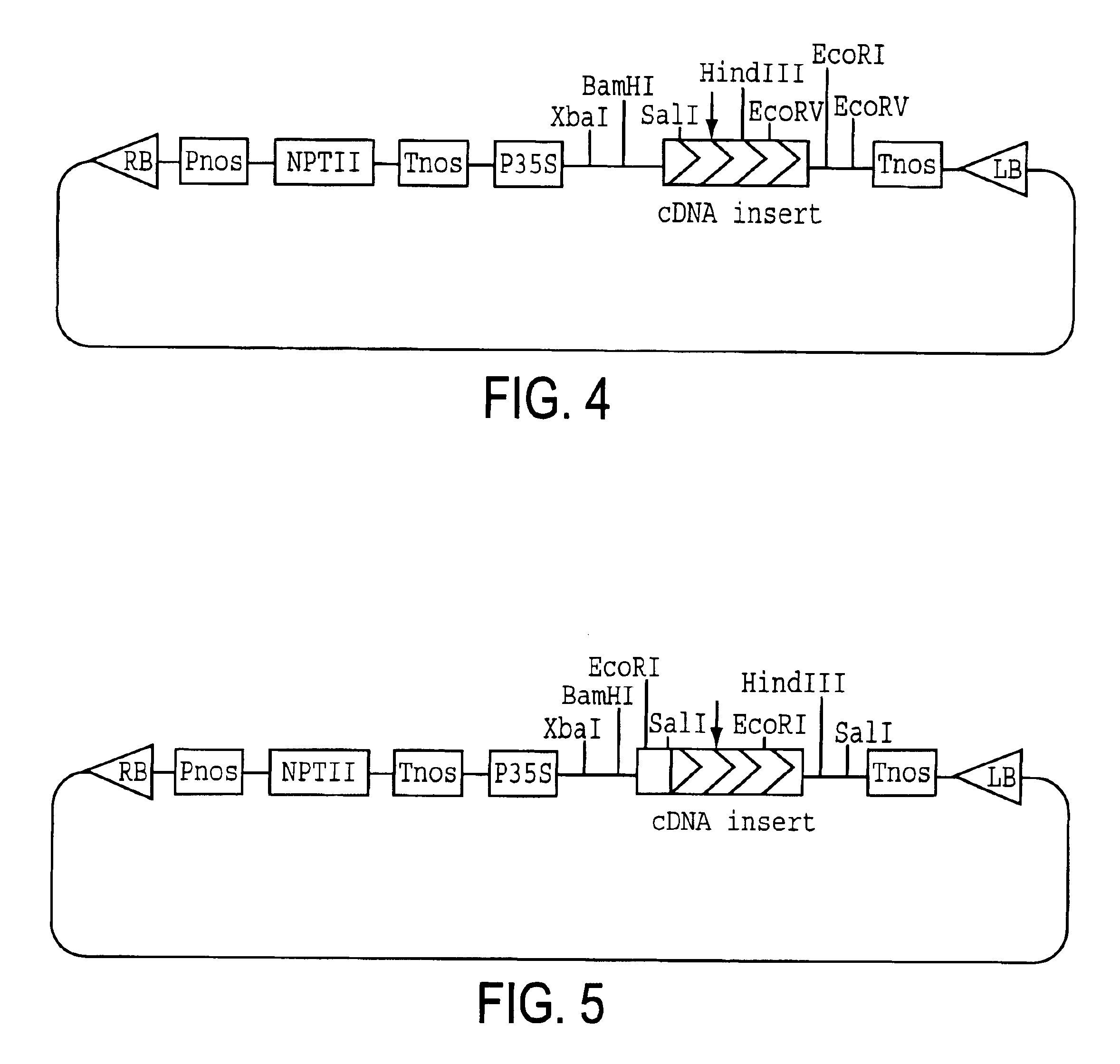

Double T-DNA carrier and its application in cultivating of non selecting sign transgene rice

InactiveCN1597969ASmall molecular weightHigh co-transformation efficiencyFermentationVector-based foreign material introductionGenetically modified ricePlant nodule

The invention provides a simple and convenient Agrobacterium Tumefacies dual carrier containing double T-DNA structural regions, and a method of using the carrier system to cultivate transgenic rice without resistance selection label. With the help of the principle of co-conversion mediated by root nodule Agrobacterium Tumefacies, the system contains two separate T-DNA structural sections, where the first T-DNA region contains antibiotic resistance selection label gene and the second one contains a universal polyclonal site able to be arbitrarily inserted with destination gene. The double-T-DNA carrier has small molecular weight, easy to clone and after the destination gene and necessary regulation and control series are cloned in the T-DNA region containing the polyclonal site, it realizes rice co-conversion; by selfing, it selects transgenic individual with destination gene but without selectin label gene from the self-bred progeny, thus eliminating the negative effect on transgenic plant commercialized production, etc, possibly caused by selection label gene.

Owner:YANGZHOU UNIV

Method for preparing water-soluble solid styrene/acrylic resin and application thereof

InactiveCN101575397AAvoid it happening againAvoid cloggingInksCoatingsAcrylic resinUnsaturated monomer

The invention discloses a method for preparing water-soluble solid styrene / acrylic resin and application thereof. The method prepares the required resin by simultaneously performing free radical polymerization reaction and esterification reaction on an aromatic vinyl unsaturated monomer, an aliphatic vinyl unsaturated monomer, an unsaturated carboxylic acid monomer, fat alkanol, an initiating agent and an alpha-methyl styrene dimer in a reactor. In the method, the alpha-methyl styrene dimer is added as a chain transfer agent to reduce the branching degree and avoid the generation of gel and the blockage of the reactor; and simultaneously, the added fat alkanol performs esterification reaction with acroleic acid to inhibit the esterification reaction between an alcohol ether solvent and the acroleic acid, thus the viscosity of the reaction mixture is controlled effectively, and the finally prepared resin has narrow molecular weight distribution (Mw / Mn is less than 2.0), low molecular weight (Mw is less than 10,000), few organic volatile matters, and good wetting dispersion of pigment, and can be applied to preparing water color ink, coating or oil polish.

Owner:SUN YAT SEN UNIV

Hydrofining catalyst and preparation method thereof

InactiveCN101590417AImprove physical and chemical propertiesImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsTitaniumBoron

The invention provides a hydrofining catalyst and a preparation method thereof. The catalyst comprises an aluminum oxide carrier which is modified by an assistant and VIII group and VIB group metal oxides which are loaded on the carrier, wherein, the assistant is at least one of boron, phosphorus, silicon and titanium compounds. The catalyst is prepared by an immersion method which is characterized in that an organic stabilizer is added into immersion fluid; the number of metal active centers of the catalyst is increased with the addition of the organic stabilizer; the physicochemical properties of the catalyst is improved by the way the aluminium oxide is modified by the assistant; therefore, the hydrofining catalyst prepared by the method in the invention has high desulfuration and denitrification activity, and is applicable to the hydrotreating process of various distillate oil, in particular to poor quality diesel oil.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Method for preparing acellular matrix

InactiveCN101274106AStrong decellularization specificityStrong specificityTissue regenerationProsthesisDiseasePhospholipase

The invention discloses a method of preparing acellular matrixes by using phospholipase. The method of the invention is characterized in that stand-by organ tissue is first pre-treated and then added into solution containing the phospholipase to prepare the acellular matrixes under a controlled condition; the prepared acellular matrixes are then washed. By adopting the preparation method of the invention, the obtained acellular matrix can have good physical property and biological function. Therefore, the preparation method in the invention is not only a great breakthrough in the tissue engineering, but also opens a new way for clinical treatment of diseases. The preparation method of the invention has the advantages of reliable theory, simple and flexible process technique, good product reproducibility and is very easy to be industrialized.

Owner:ZHONGSHAN OPHTHALMIC CENT SUN YAT SEN UNIV

Plant nutrient solution with high bioactivity

InactiveCN101723757ASmall molecular weightImprove biological activityFertilizer mixturesSolubilityRare earth

The invention discloses plant nutrient solution with high bioactivity, which is prepared by uniformly mixing, stirring and dissolving the following raw materials in percentage by weight: 8 to 12 percent of nitro-fulvic acid, 10 to 15 percent of chelating protein, 8 to 15 percent of nitrogen, phosphorus and potassium, 2 to 4 percent of microelement and rare earth, 0.8 to 1.0 percent of compound microbe and the balance of water. The nutrient solution has the advantages of having comprehensive nutrition, low molecular weight of oxides, high bioactivity, good water-solubility, strong anti-hard water capacity, high stability in natural environment, and difficult reduction when mixed with reductive substances, well promoting the growth of root system of the plant, helping the absorption of nutritive elements, stimulating the crop growth, improving the content of chlorophyll, promoting the crop photosynthesis, particularly properly controlling the opening degree of leaf stomas of crop, reducing moisture transpiration, increasing antivirus capacity of the crop, also strengthening drought resistance and resilience capacity of the crop, effectively improving the quality of farm products, and having remarkable output increasing effect.

Owner:唐荣敏

Herbicide-resistant protoporphyrinogen oxidase isolated from Nicotiana tabacum

A protoporphyrinogen oxidase tolerant to photobleaching herbicide and derivatives thereof, comprising a polypeptide having the amino acid sequence represented by SEQ ID No. 2 or mutated peptides derived therefrom by deletion, addition, substitution, etc. of one or more amino acids in the above amino acid sequence and having an activity substantially equivalent to that of the protoporphyrinogen oxidase. The acquisition of the novel protoporphyrinogen oxidase, which is highly tolerant to photobleaching herbicide and originates in plant, make it possible to construct plants highly tolerant to photobleaching herbicide via the expression of this enzyme in host plants.

Owner:NIHON NOHYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com