Temperature-resistant salt-resistant efficient gel, and preparation and use thereof

A temperature-resistant, salt-resistant, high-efficiency technology, applied in the fields of polymer materials and oilfield chemistry, can solve problems such as poor salt resistance, poor anti-aging stability, and high polymer dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

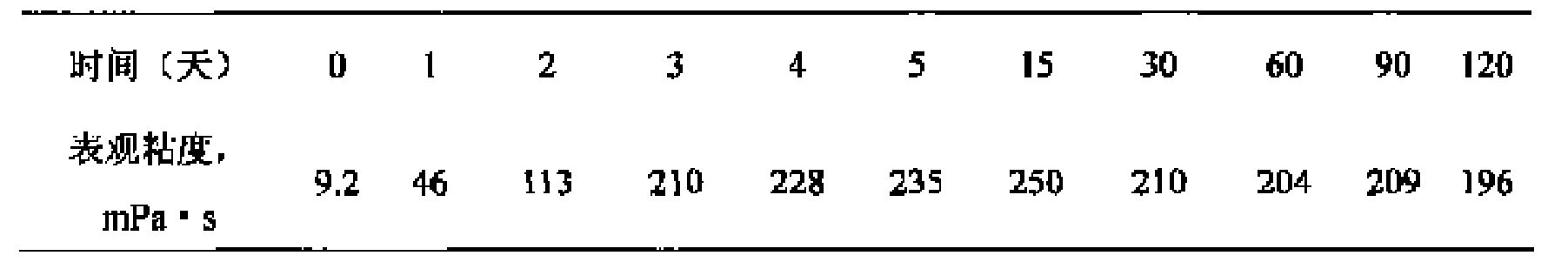

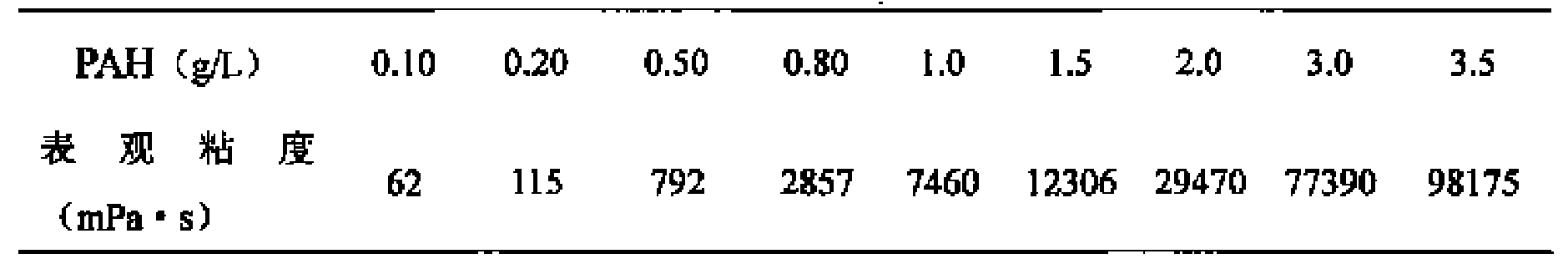

[0028] 20.000 grams of acrylamide, 10.530 grams of acrylic acid, 3.500 grams of 4-vinylbenzyloctylphenol polyoxyethylene ether (the adduct EO of polyoxyethylene ether is 20), 3,5-bis(trifluoromethyl) Dissolve 1.410 grams of styrene and 5.630 grams of sodium lauryl sulfate in 460 mL of distilled water, add them to a three-necked reaction flask, adjust the pH of the solution to 8 with NaOH, the reaction temperature is 65 ° C, and pass N 2 After 30 minutes, add 9.50 mL of 0.05 mol / L potassium persulfate initiator solution, react for 36 hours, and dilute the polymer with water to obtain a concentrated PAH solution. Take a certain amount of polymer PAH to prepare the oil displacement agent aqueous solution sample, the sample is colorless and transparent. The polymer concentration is 0.4g / L, the total concentration of phenol and glutaraldehyde is 0.10g / L, the concentration of sodium dodecylbenzenesulfonate is 0.2mmol / L, and the aqueous solution of sodium sulfite concentration is 0.0...

Embodiment 2

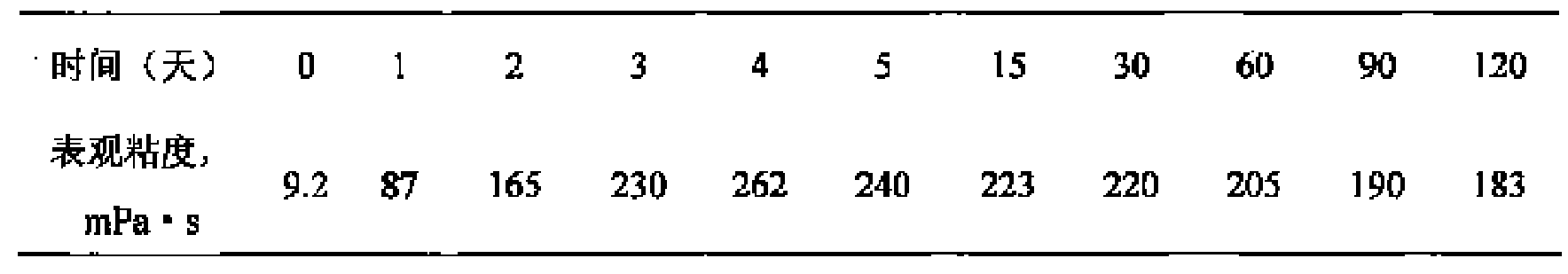

[0030] 20.000 grams of acrylamide, 12.500 grams of 2-acrylamide-2-methylpropanesulfonic acid, 9.500 grams of 4-vinylbenzyl hexadecyl polyoxyethylene ether (the adduct EO of polyoxyethylene ether is 60) , 2.102 grams of 4-butylstyrene and 7.350 grams of sodium lauryl sulfate were dissolved in 670 mL of distilled water, added to a three-necked reaction flask, and the pH of the solution was adjusted to 7 with NaOH, the reaction temperature was 70 ° C, and N 2 After 30 minutes, add 11.60 mL of 0.05 mol / L potassium persulfate initiator solution, react for 32 hours, and dilute the polymer with water to obtain a concentrated PAH solution. Take a certain amount of polymer PAH to prepare the oil displacement agent aqueous solution sample, the sample is colorless and transparent. The concentration of the polymer is 1.8g / L, the concentration of oligophenolic resin is 0.40g / L, the concentration of sodium dodecylbenzenesulfonate is 0.2mmol / L, and the concentration of sodium sulfite is 0.04...

Embodiment 3

[0032] 20.000 grams of acrylamide, 9.600 grams of 3-acrylimido-3-methylbutanoic acid, 13.000 grams of allyl nonylphenol polyoxyethylene ether (the adduct EO of polyoxyethylene ether is 18), Dissolve 4.720 grams of hexylphenylstyrene and 21.800 grams of sodium lauryl sulfate in 750 mL of distilled water, add them to a three-necked reaction flask, adjust the pH of the solution to 5 with NaOH, the reaction temperature is 60 ° C, and pass through N 2 After 30 minutes, add 15.0 mL of 0.05 mol / L potassium persulfate initiator solution, react for 24 hours, and dilute the polymer with water to obtain a concentrated PAH solution. Take a certain amount of polymer PAH to prepare an oil displacement agent aqueous solution sample, and the sample is colorless and transparent. The polymer concentration is 1.0g / L, the total concentration of phenol and glutaraldehyde is 0.15g / L, the concentration of sodium dodecylbenzenesulfonate is 0.15mmol / L, and the aqueous solution of sodium sulfite concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com