Patents

Literature

8007results about How to "High molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable low molecular weight triblock poly (lactide-co-glycolide) polyethylene glycol copolymers having reverse thermal gelation properties

InactiveUS6117949AReduce solubilityReduced stabilityPowder deliveryPeptide/protein ingredientsSolubilityPolymer science

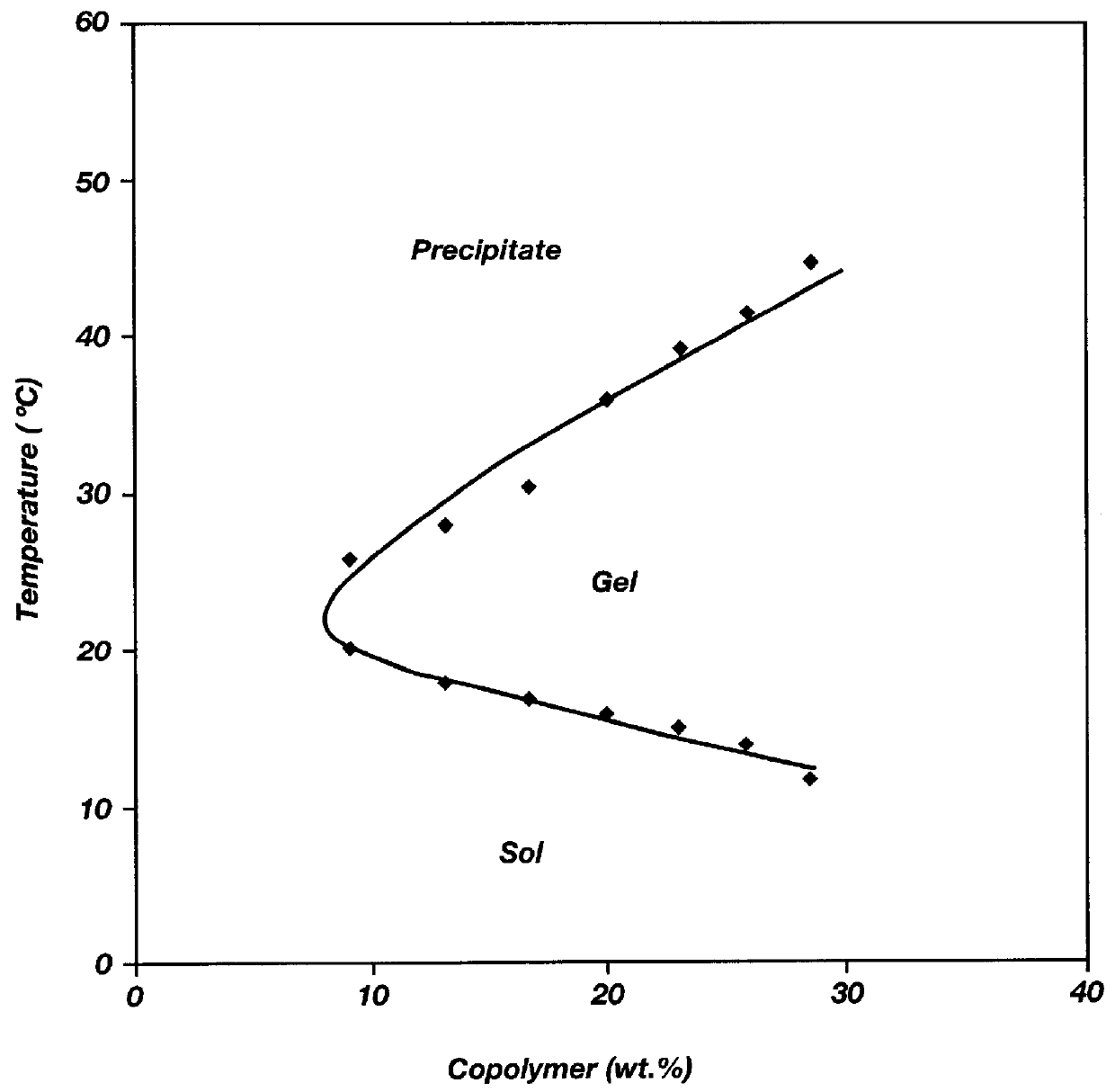

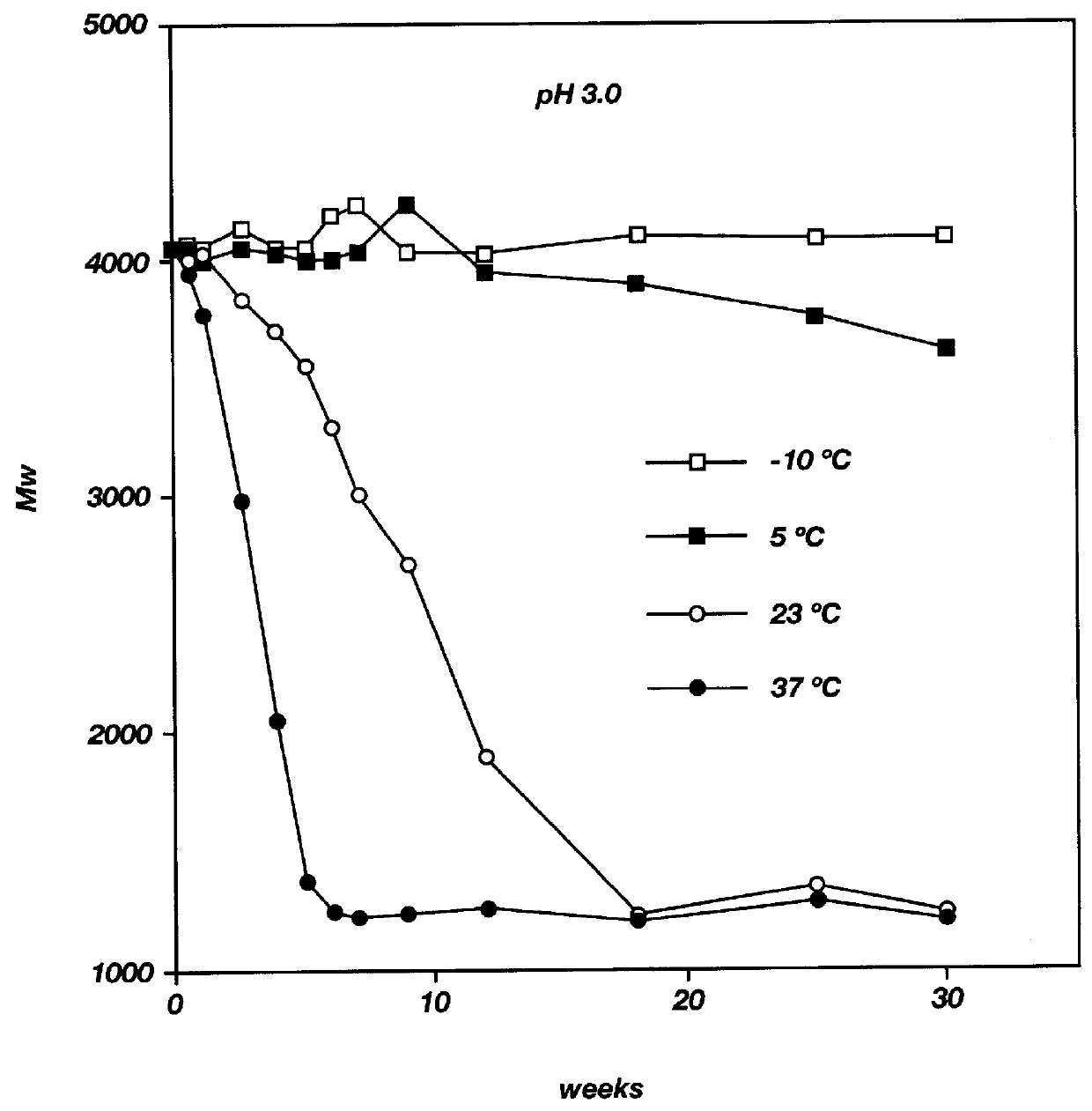

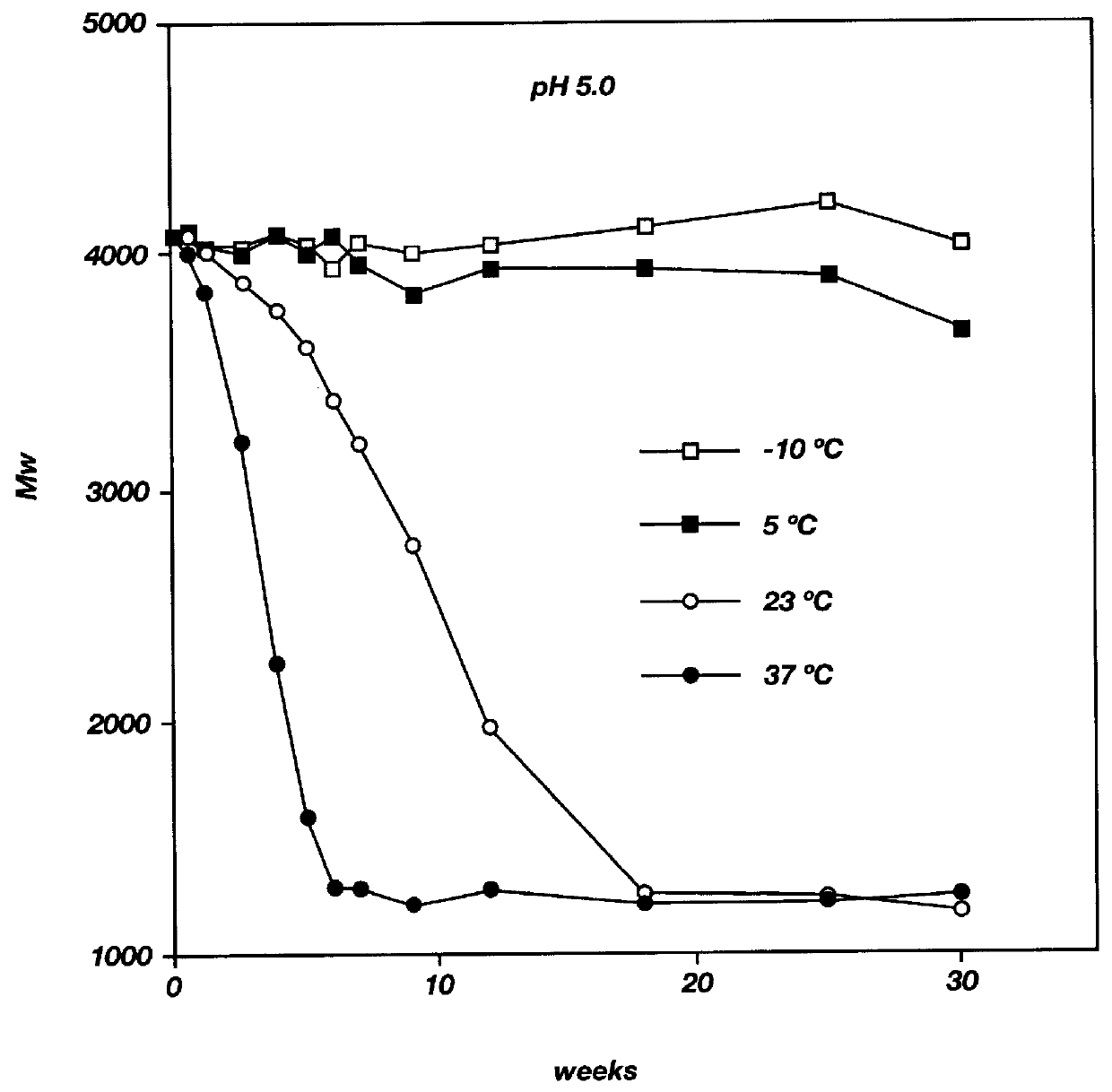

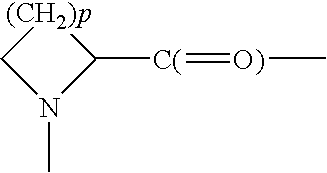

A water soluble biodegradable ABA- or BAB-type triblock polymer is disclosed that is made up of a major amount of a hydrophobic polymer made of a poly(lactide-co-glycolide) copolymer or poly(lactide) polymer as the A-blocks and a minor amount of a hydrophilic polyethylene glycol polymer B-block, having an overall weight average molecular weight of between about 2000 and 4990, and that possesses reverse thermal gelation properties. Effective concentrations of the triblock polymer and a drug may be uniformly contained in an aqueous phase to form a drug delivery composition. At temperatures below the gelation temperature of the triblock polymer the composition is a liquid and at temperatures at or above the gelation temperature the composition is a gel or semi-solid. The composition may be administered to a warm-blooded animal as a liquid by parenteral, ocular, topical, inhalation, transdermal, vaginal, transurethral, rectal, nasal, oral, pulmonary or aural delivery means and is a gel at body temperature. The composition may also be administered as a gel. The drug is released at a controlled rate from the gel which biodegrades into non-toxic products. The release rate of the drug may be adjusted by changing various parameters such as hydrophobic / hydrophilic componenet content, polymer concentration, molecular weight and polydispersity of the triblock polymer. Because the triblock polymer is amphiphilic, it functions to increase the solubility and / or stability of drugs in the composition.

Owner:BTG INT LTD +2

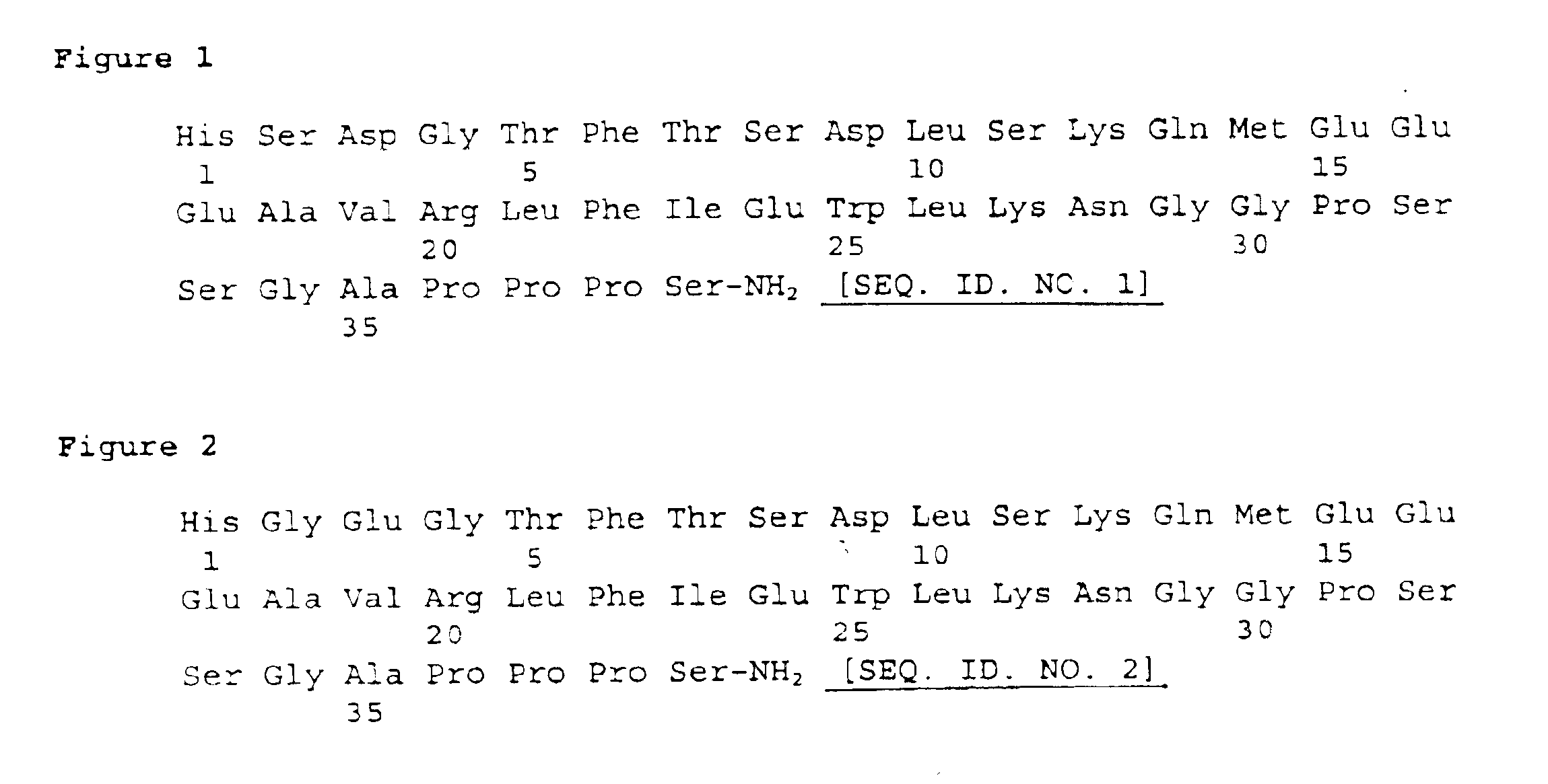

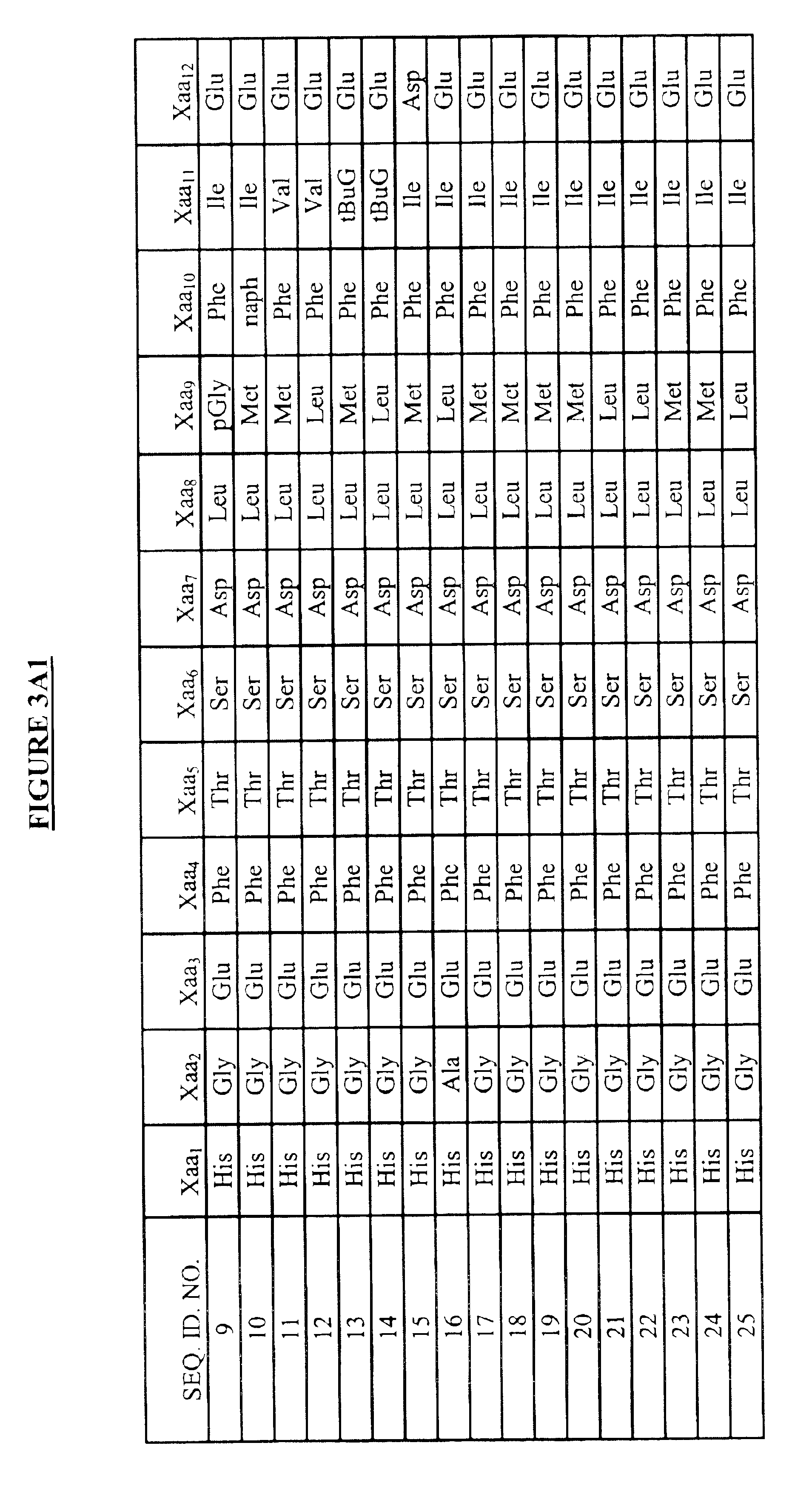

Modified exendins and exendin agonists

InactiveUS6924264B1Increase ratingsDecrease amount of potassiumMetabolism disorderSaccharide peptide ingredientsGastric emptyingPolyethylene glycol

Novel modified exendins and exendin agonist analogs having an exendin or exendin agonist analog linked to one or more polyethylene glycol polymers, for example, and related formulations and dosages and methods of administration thereof are provided. These modified exendins and exendin agonist analogs, compositions and methods are useful in treating diabetes and conditions that would be benefited by lowering plasma glucose or delaying and / or slowing gastric emptying or inhibiting food intake.

Owner:ASTRAZENECA PHARMA LP

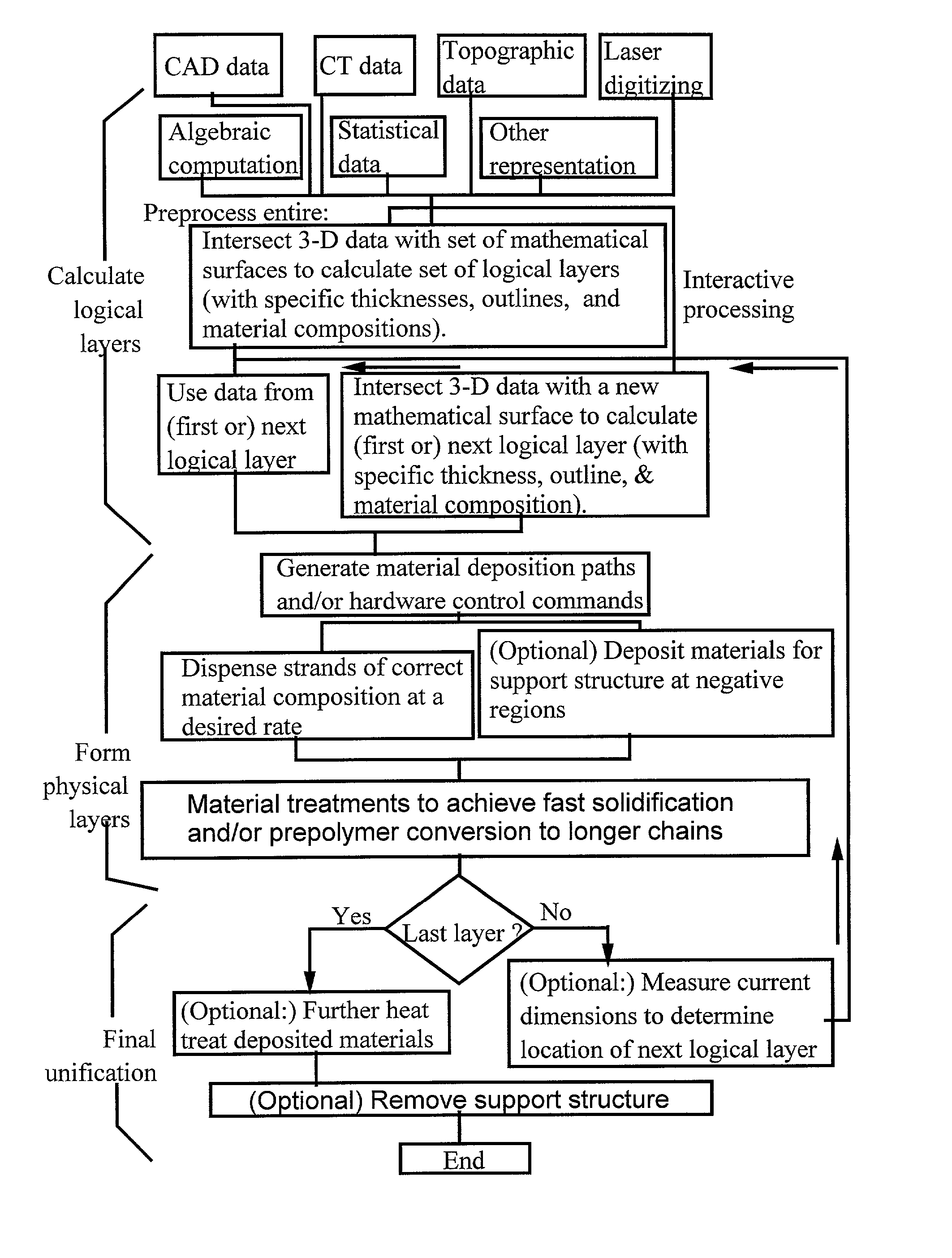

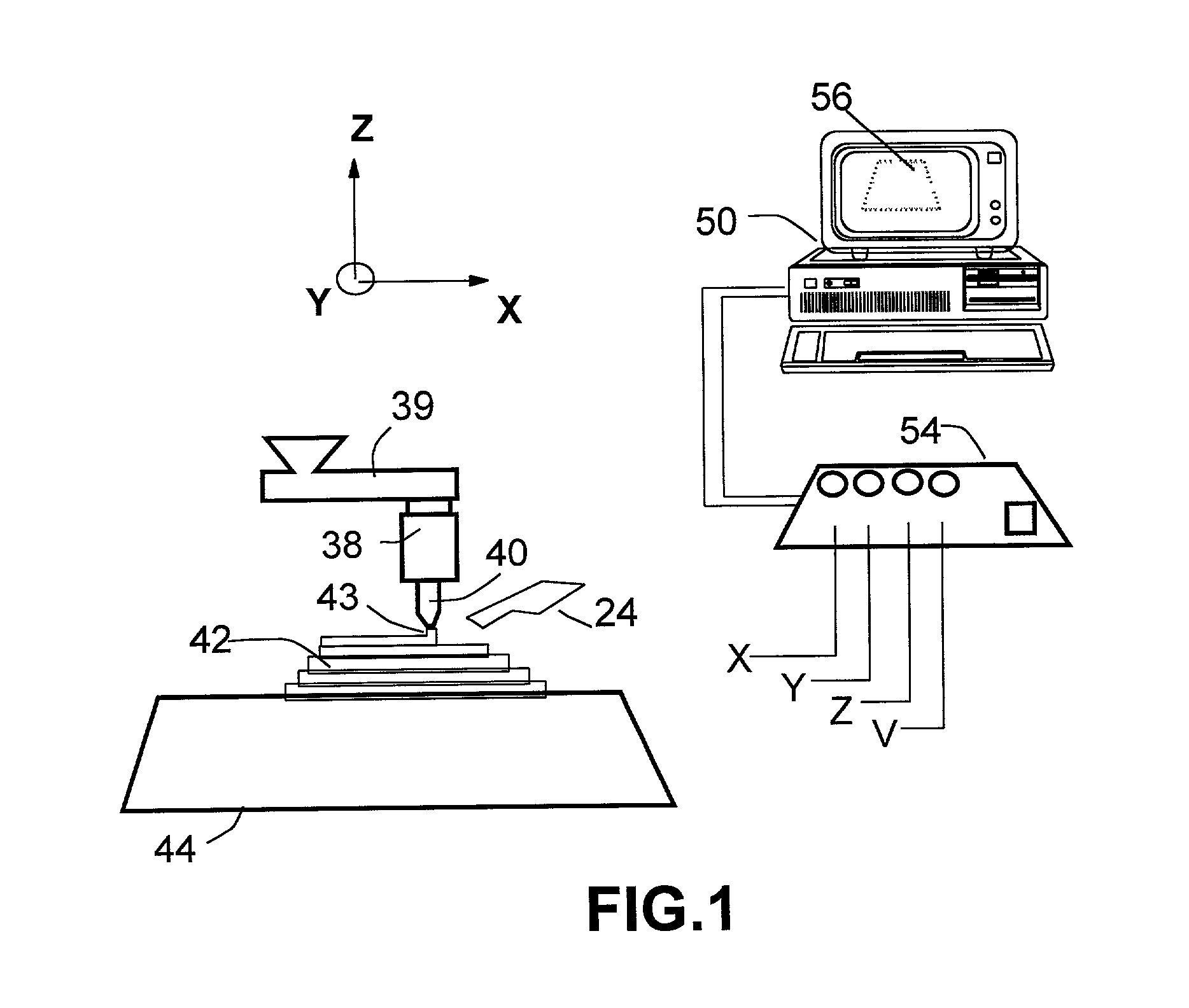

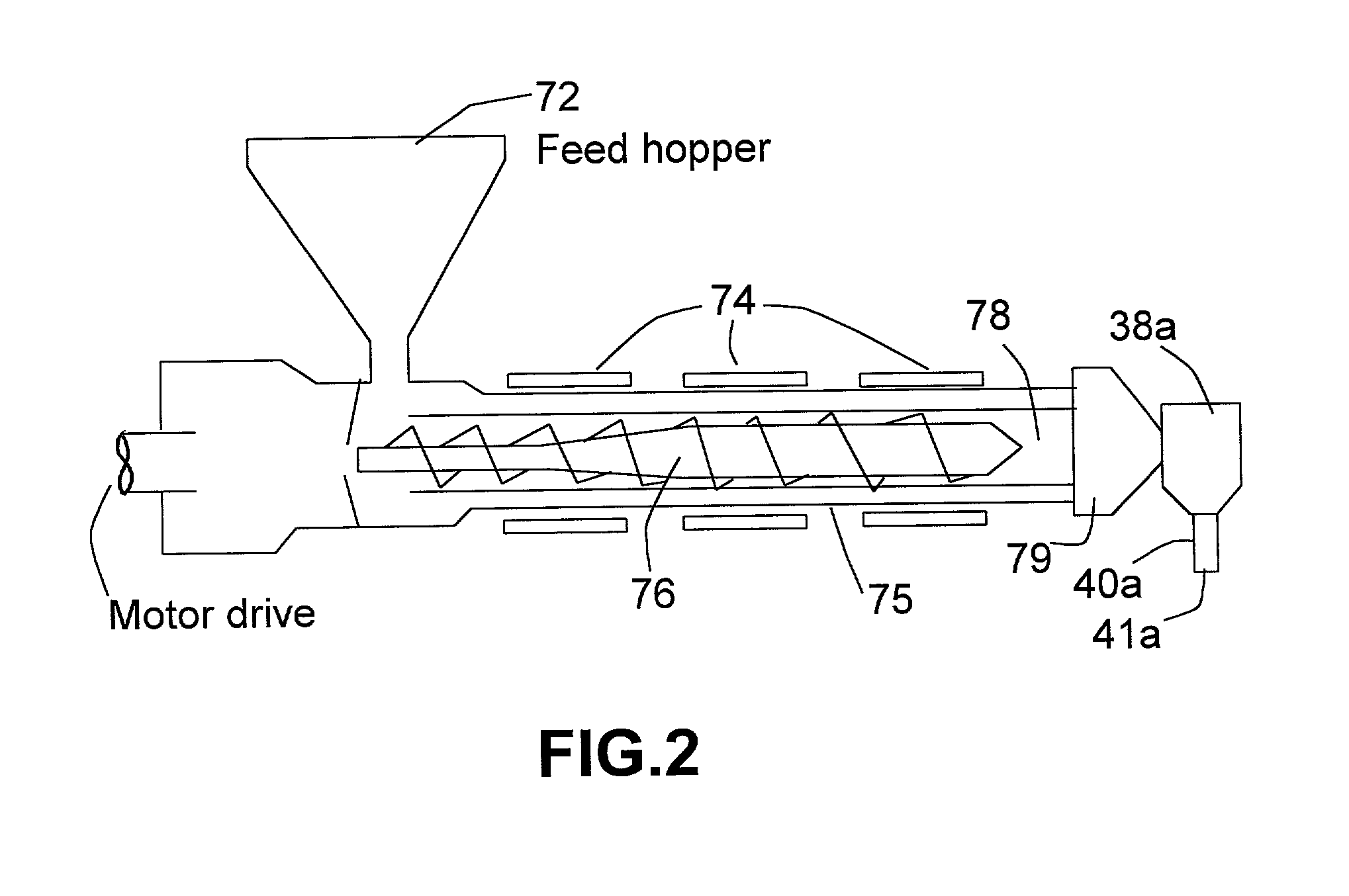

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

Antireflective coatings comprising poly(oxyalkylene) colorants

InactiveUS6048662AReduce the amplitudeImprove anti-reflectionPhotosensitive materialsRadiation applicationsCounterionThin layer

This invention relates to antireflective coatings comprising polymeric polyoxyalkylenated colorants. More particularly, the present invention relates to antireflective coatings for utilization in forming thin layers between reflective substrates and photoresist coatings. Such antireflective coatings are very useful and beneficial within the production and fabrication of semiconductors through photolithographic procedures due to the liquid, non-crystallizing nature of polyoxyalkylenated colorants, and the lack of potentially damaging counterions, metals, and / or electrolytes within the inventive antireflective colored coatings. The inventive coatings may also be applied on lenses, mirrors, and other optical components. Methods of forming such antireflective coatings are also contemplated within this invention.

Owner:MILLIKEN & CO

Effervescent granules and methods for their preparation

InactiveUS6071539AMinimize degradationMelt and soften binderPowder deliveryPill deliveryPlasticizerHot melt

According to the present invent, effervescent granules having a controllable rate of effervescence are provided. Such granules comprise an acidic agent, an alkaline agent, a hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process.

Owner:ETHYPHARM SA

High melting thermoplastic elastomeric alpha-olefin polymers (PRE/EPE effect) and catalysts therefor

InactiveUS6559262B1Activity of fluxional unbridged metallocene polymerization catalystsHigh molecular weightGroup 4/14 element organic compoundsMetallocenesElastomerEthylene Homopolymers

This invention relates generally to low ethylene insertions into I-olefin polymers and processes for production of such polymers using unbridged fluxional metallocenes, primarily substituted aryl indenyl metallocenes, and more particularly to use of unbridged, fluxional, cyclopentadienyl or indenyl metallocene catalyst systems in methods of production of high melting point I-olefin homo- and co-polymers, particularly elastomeric crystalline and amorphous block homo- and co-polymers of I-olefins. The activity of fluxional unbridged metallocene polymerization catalysts containing at least one 2-arylindene ligand is increased 10x or more by the addition of small (typically 0.1-10 wt. %) amounts of ethylene to the polymerization system, which increase is termed the Polymerization Rate-Enhancement effect (PRE), which is measured in terms of an Ethylene Enhancement Factor (EEF) as a dimensionless ratio in the range of from about 1.1 to about 10 or above. The amount of ethylene included in the reaction system can be selected and controlled to be so small as to result in essentially minimal (<2 mole %) incorporation of ethylene units into the resulting elastomeric polymer and the molecular weight may be increased. Amounts of ethylene to generate the PRE effect may be greater than 0.1 wt. % and preferably range up to about 2 wt. %. However, if a polymer with more ethylene is desired, additional ethylene may be incorporated into the polymerization feed, including up to 10 to about 50 mole % based on olefin units. A second important aspect of this invention is the ability to use a PRE activity-enhancing amount of ethylene in an olefin polymerization without substantially affecting the physical properties of the elastomer. In a third important aspect of this invention, I-olefin elastomers are produced through incorporation of ethylene using unbridged fluxional catalyst systems which may not otherwise produce acceptable elastomeric homopolymers. This effect is termed the EPE effect, for Elastomeric Property-Enhancing effect. The EPE amount of ethylene required to produce such elastomers typically overlaps the PRE activity-enhancing amount. Incorporation of up to about 5 mole % or more of ethylene typically will produce an elastomeric polymer using such catalyst systems. Typical useful amounts of incorporated ethylene include about 1 to 3 mole %. Preferred polymers of this invention retain sufficient crystallinity to provide a high melting point (by DSC) of about 80° C., preferably above 100° C., including in the range of from about 120° C. to about 140° C. and above. Novel flexible alpha-olefin homo and copolymers having elongation in excess of 600% and substantially no retained force are disclosed.

Owner:BP CORP NORTH AMERICA INC

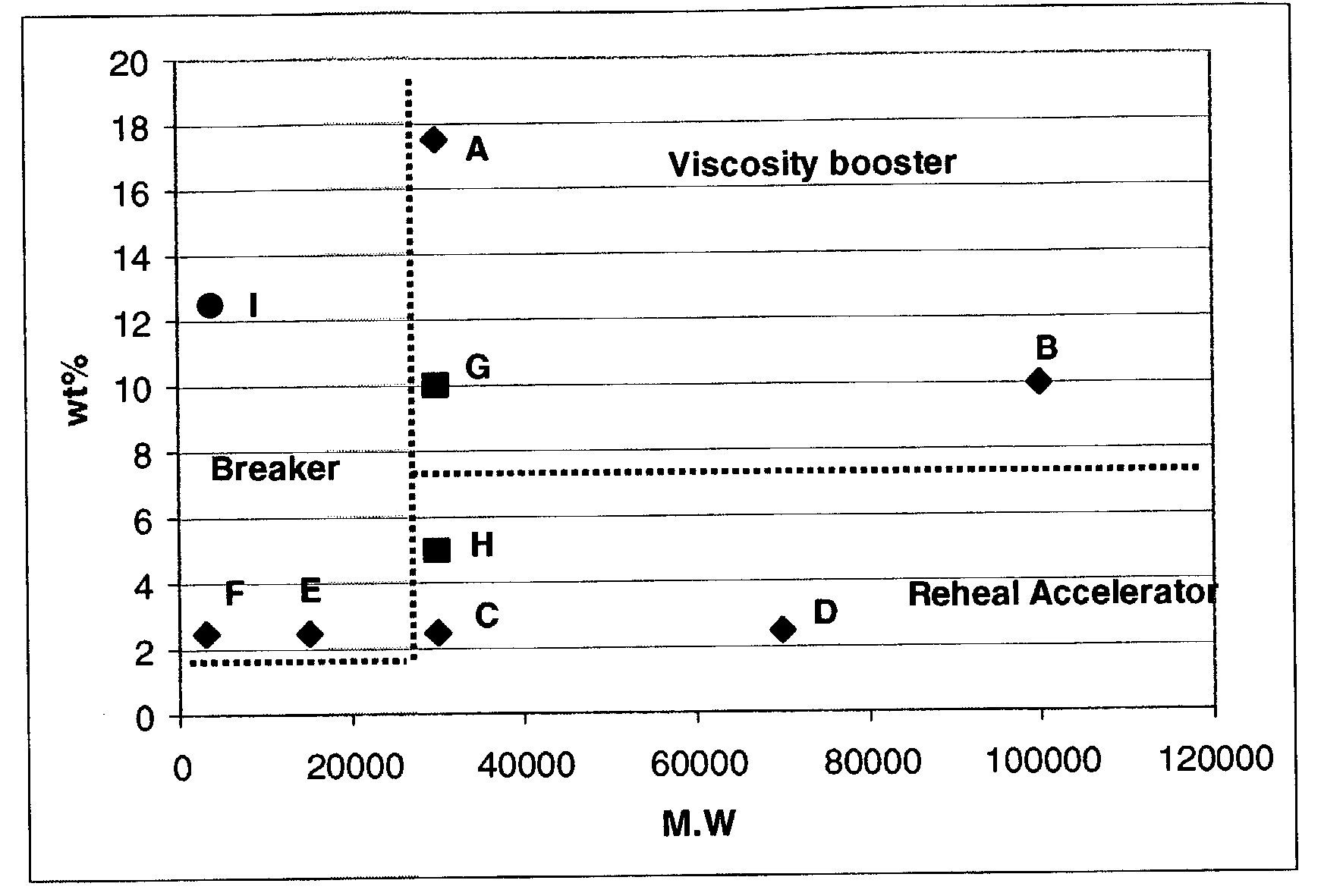

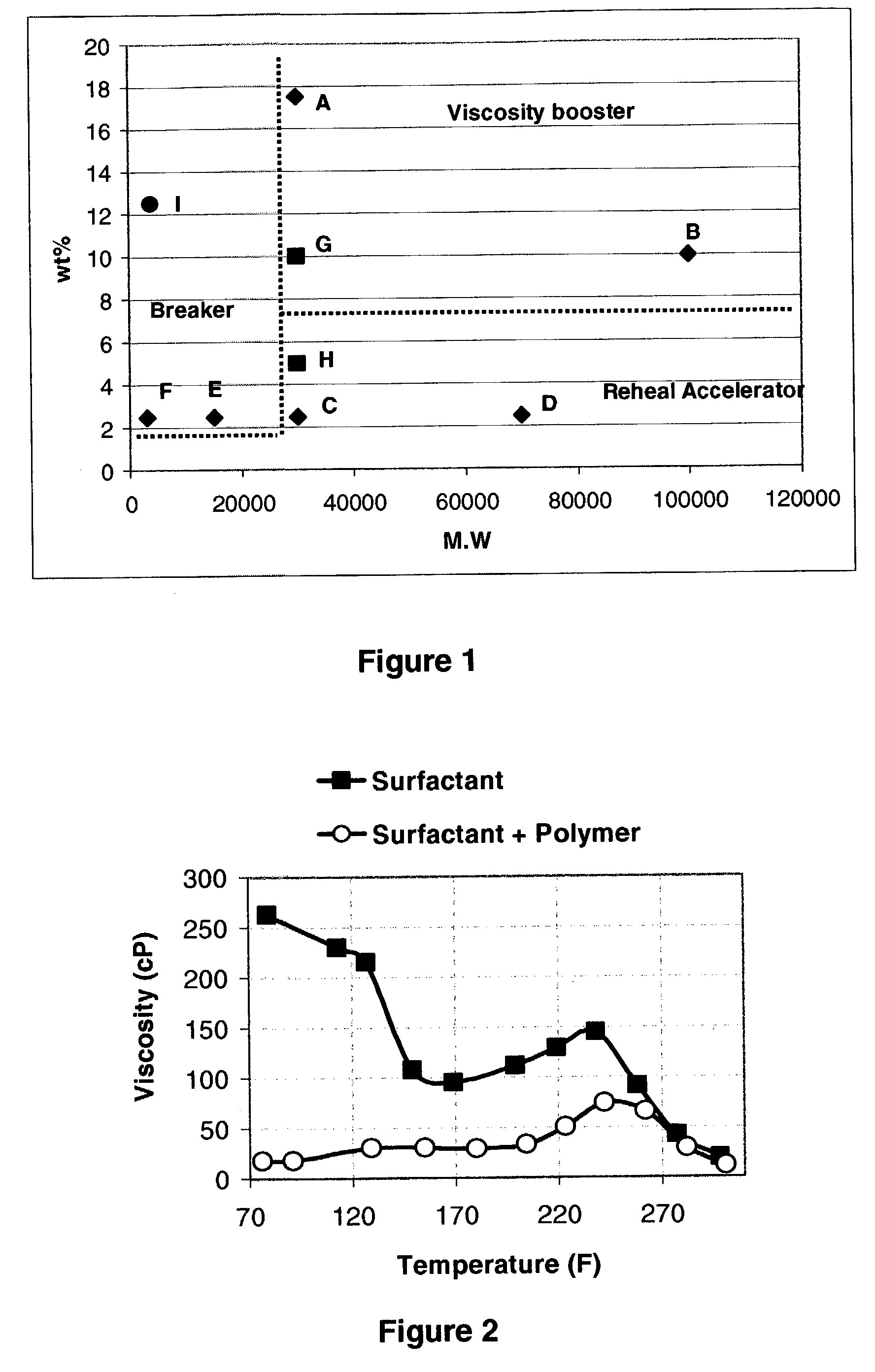

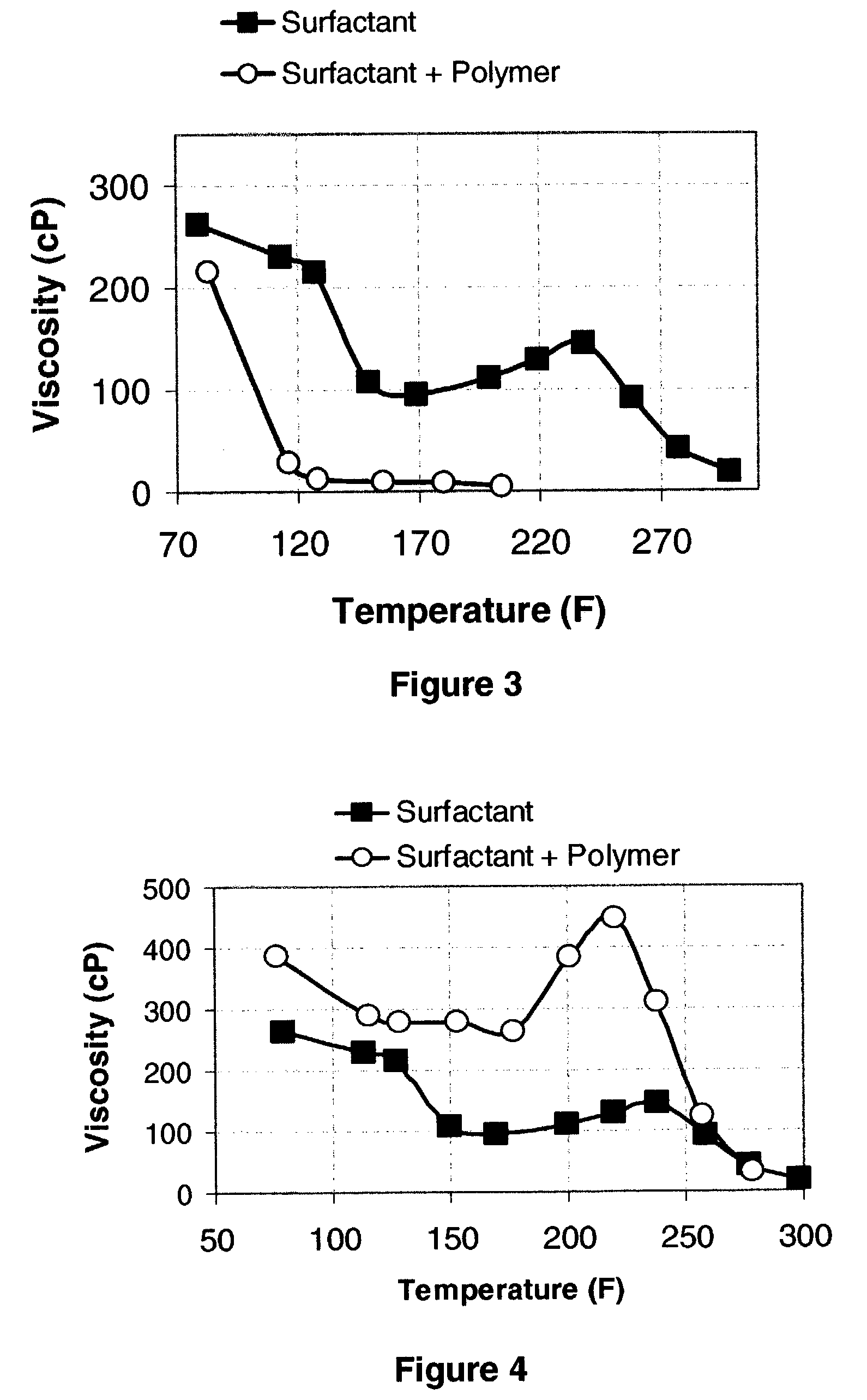

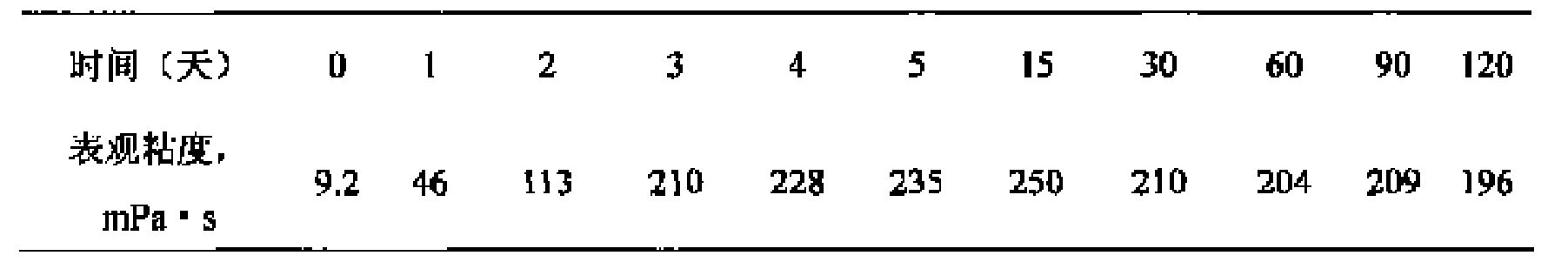

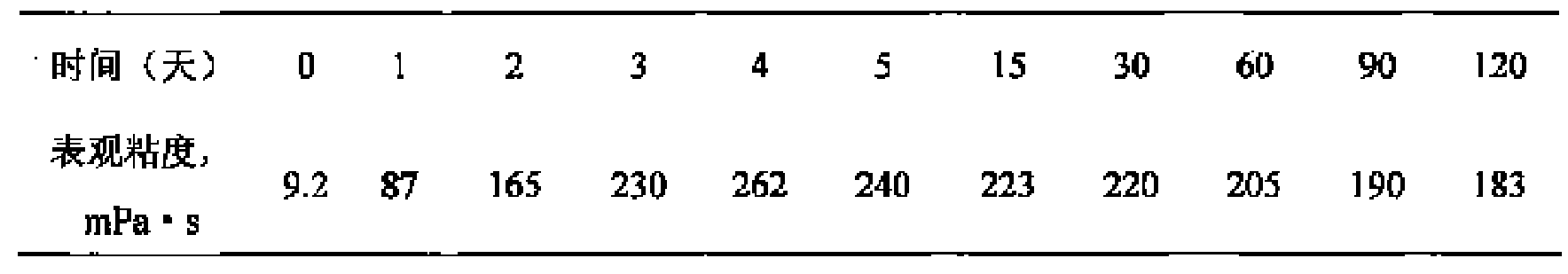

Methods for controlling the rheological properties of viscoelastic surfactants based fluids

InactiveUS7084095B2High viscosityPromote recoveryFlushingDrilling compositionOrganic chemistrySURFACTANT BLEND

It was found that the addition of polymers to viscoelastic surfactant base system allows to adjust the rheological properties of the base fluid. Depending in particular on one side of the ratio of the concentration of added polymer and the concentration of viscoelastic surfactant and on the other side of the molecular weight of the added polymer, the same polymer—or the same type of polymer—may perform different functions such as viscosity enhancer, viscosity breaker or viscosity-recovery enhancer.

Owner:SCHLUMBERGER TECH CORP

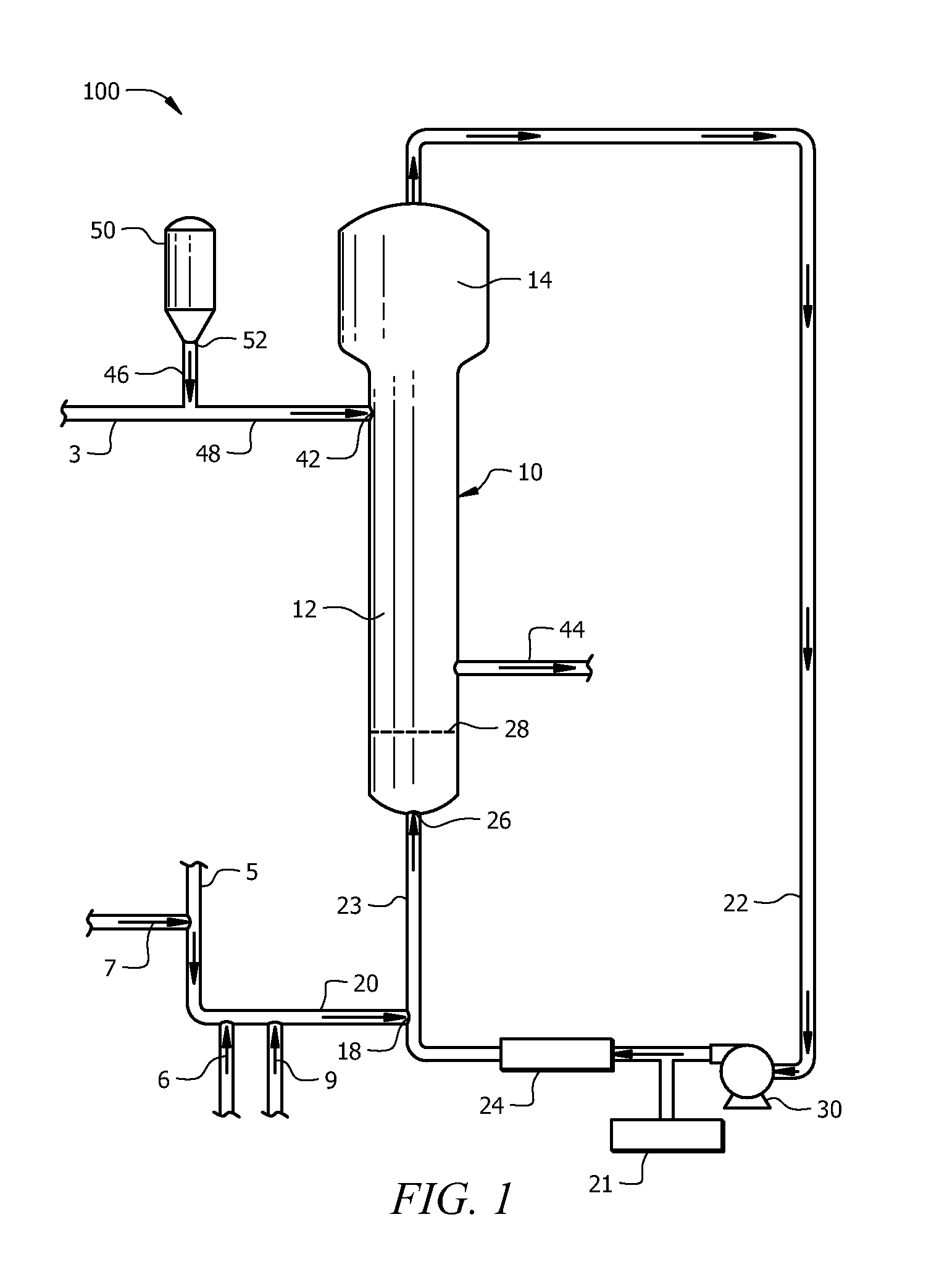

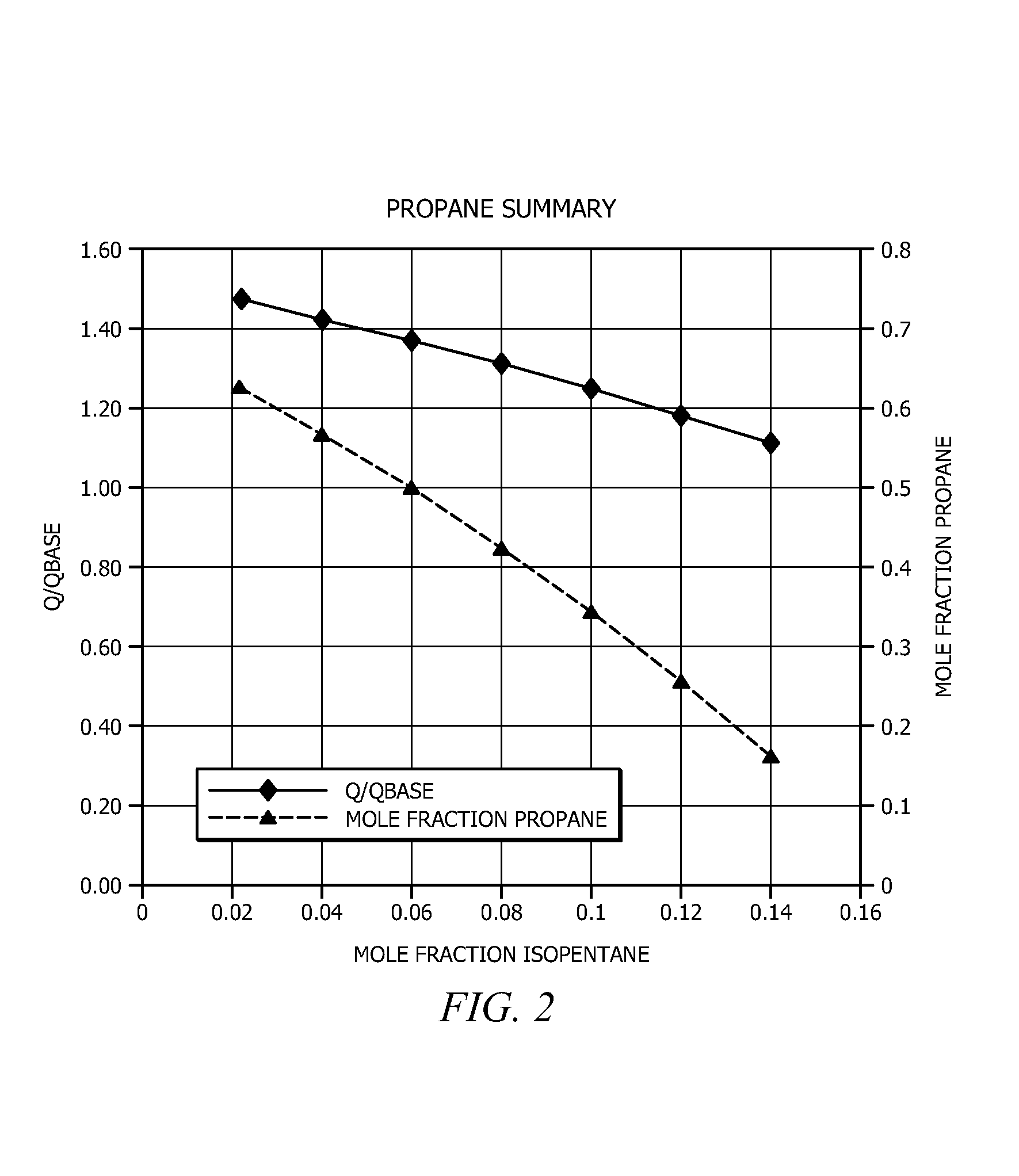

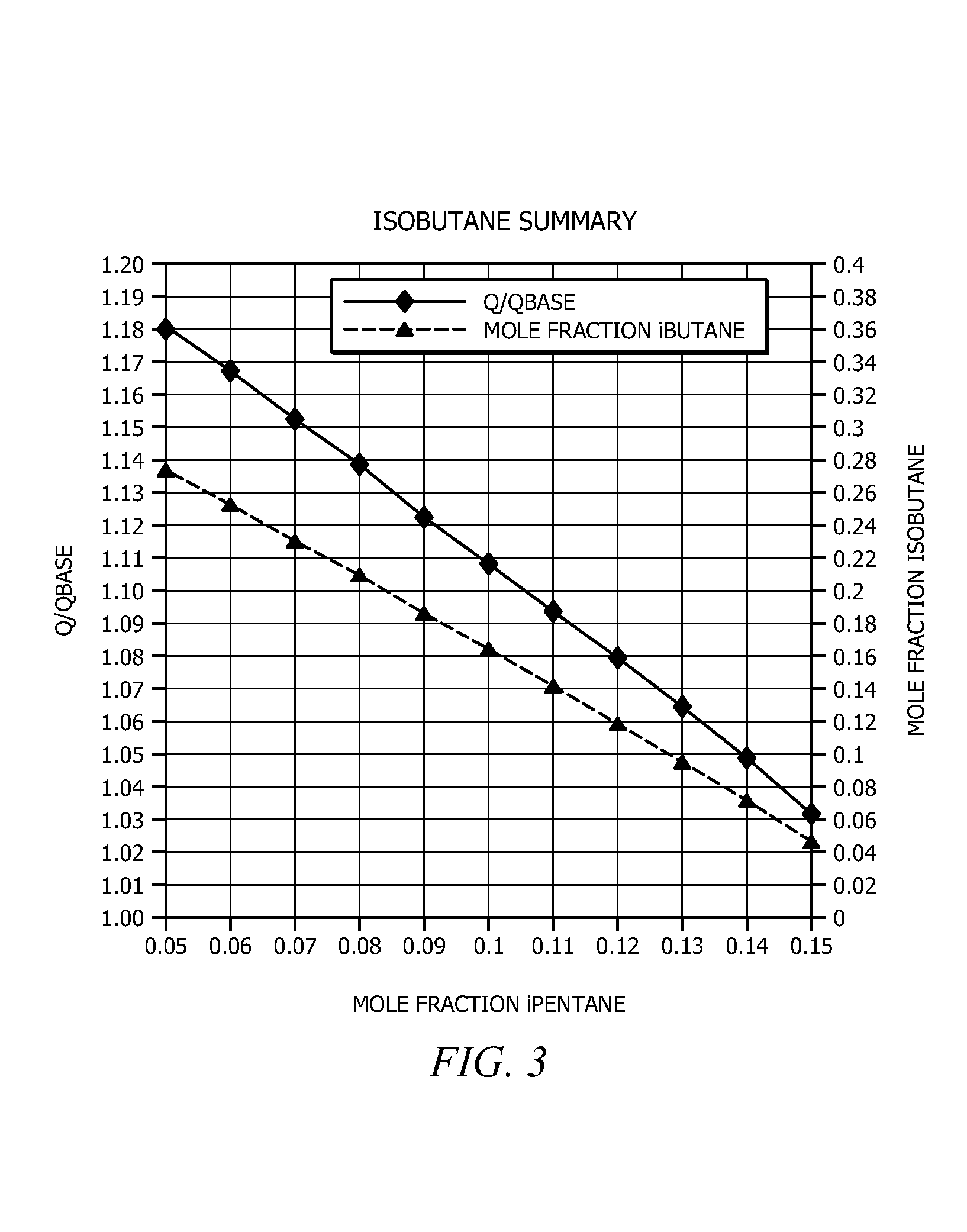

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

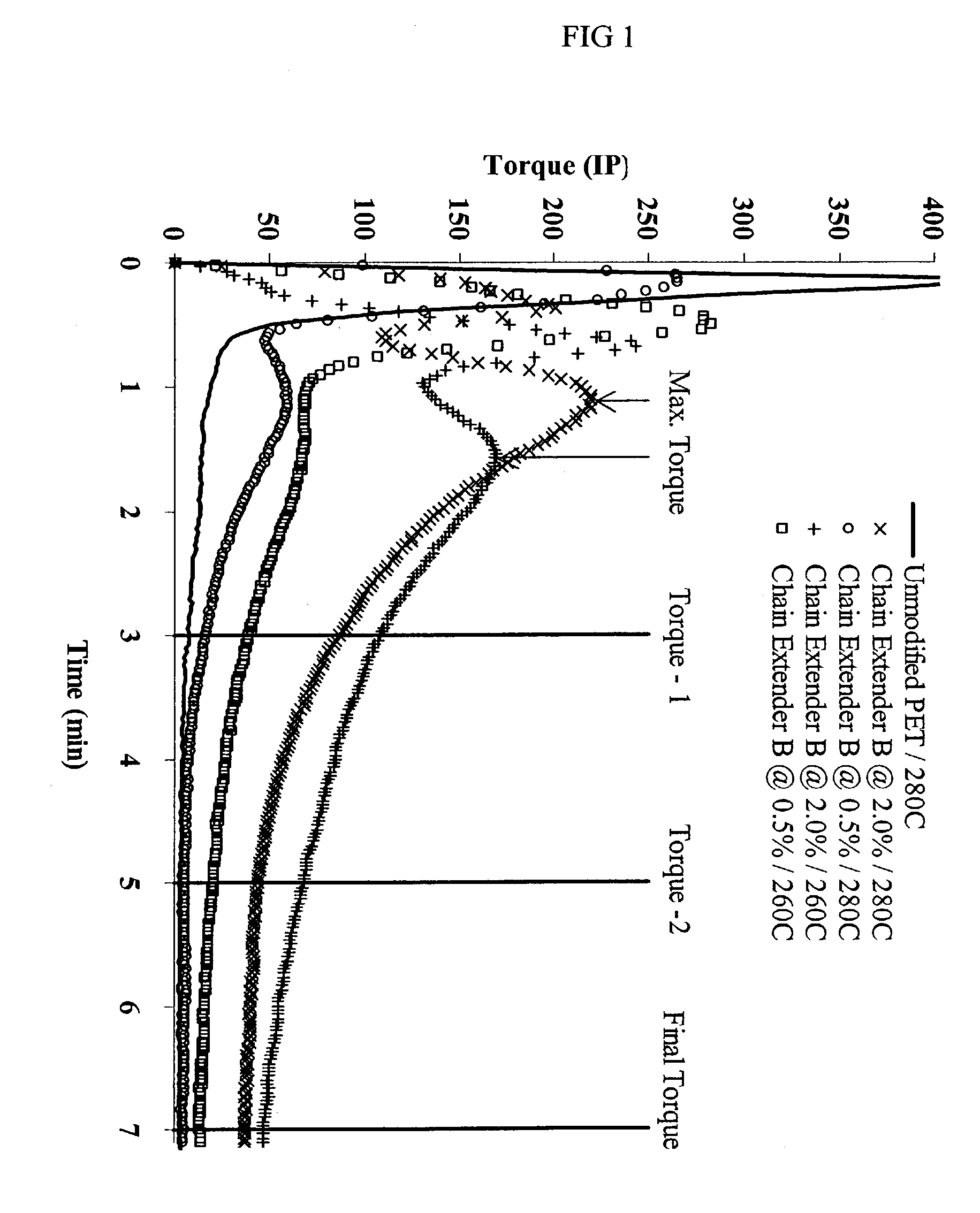

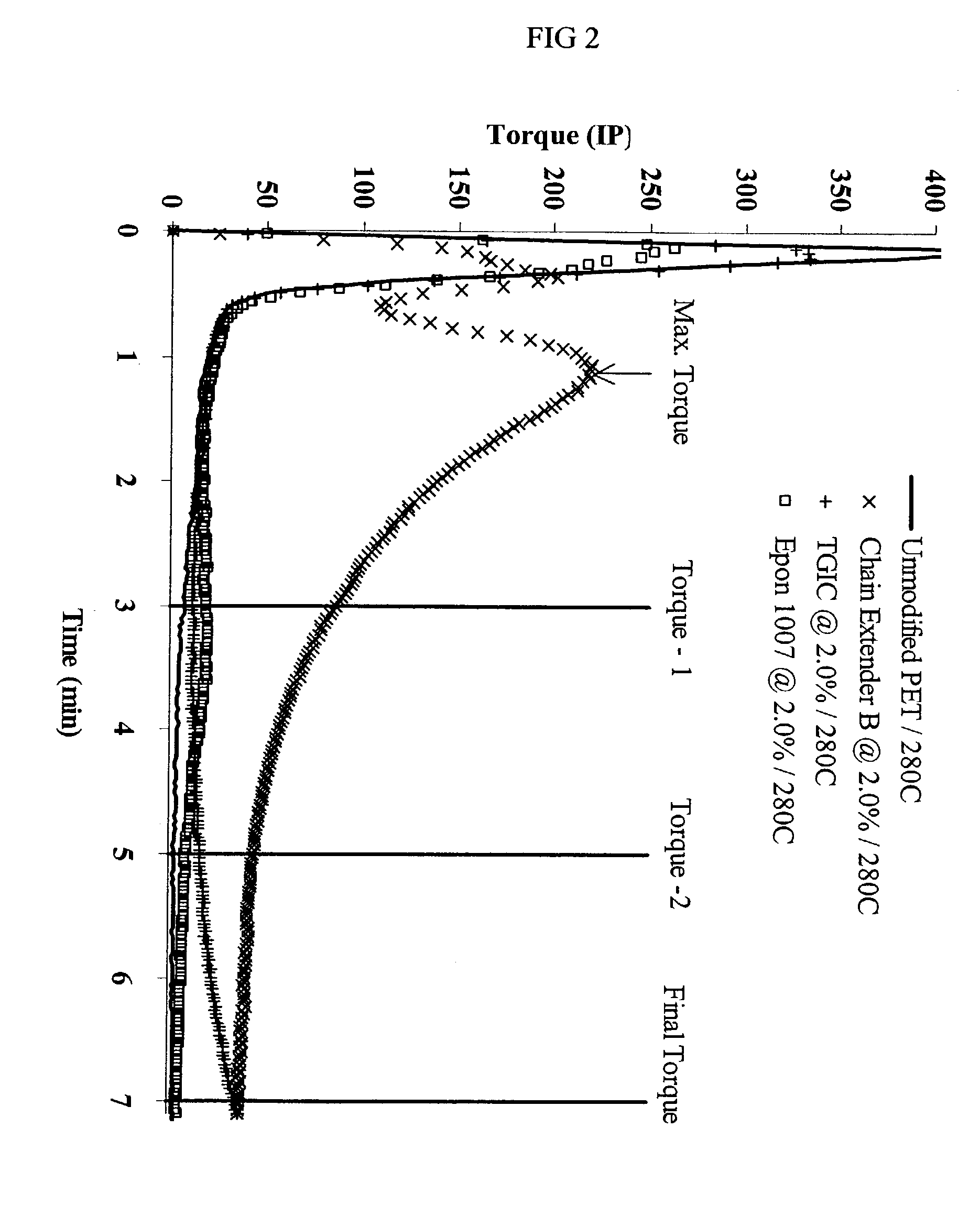

Oligomeric chain extenders for processing, post-processing and recycling of condensation polymers, synthesis, compositions and applications

The invention provides chain extenders made from epoxy-functional (meth)acrylic monomers and styrenic and / or (meth)acrylic monomers. The invention further provides polymeric compositions made from the chain extenders and plastic articles made from the compositions. Finally, the invention provides methods of using the chain extenders to improve the properties of virgin, recycled, and reprocessed condensation polymers.

Owner:BASF CORP +1

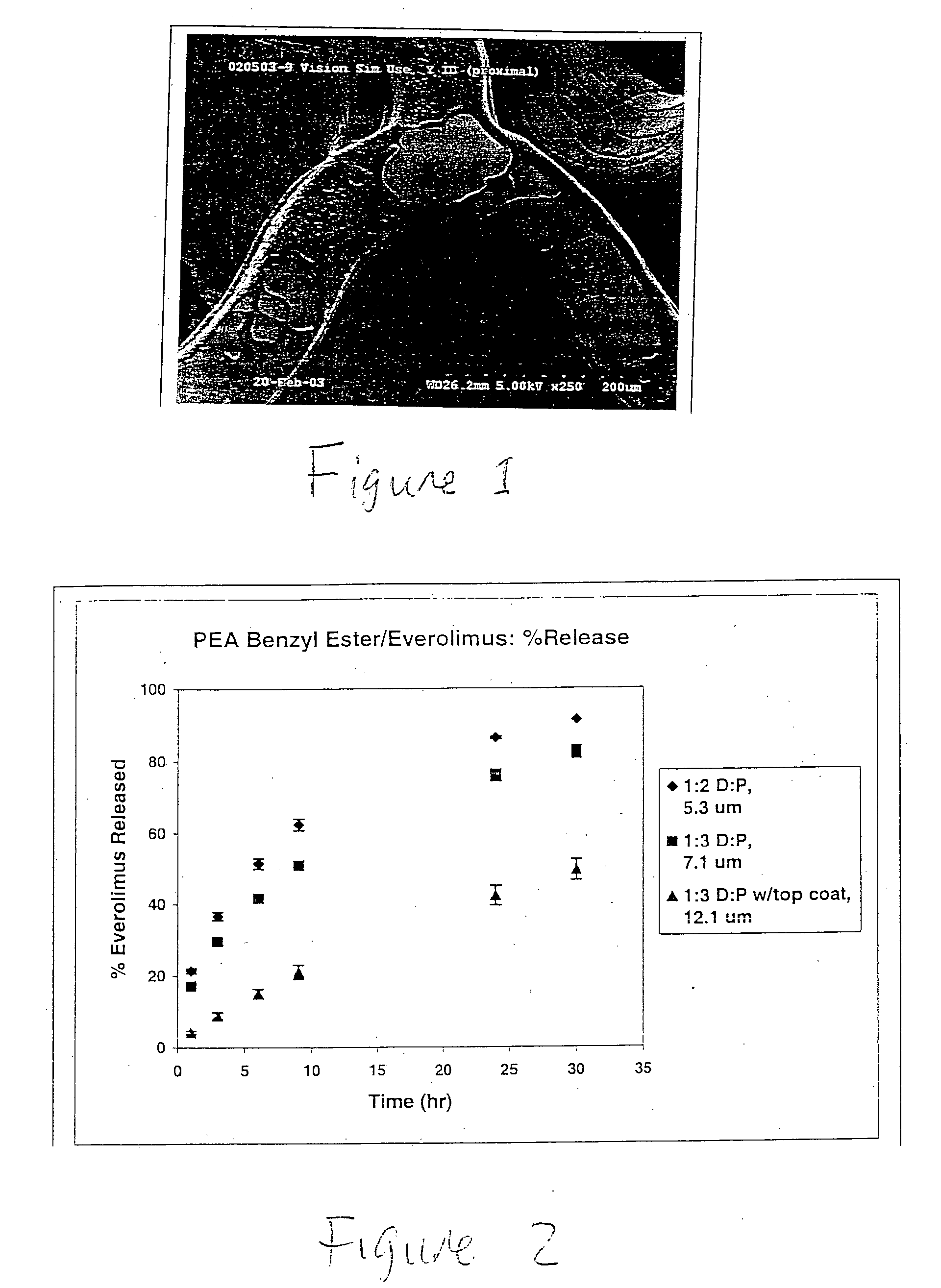

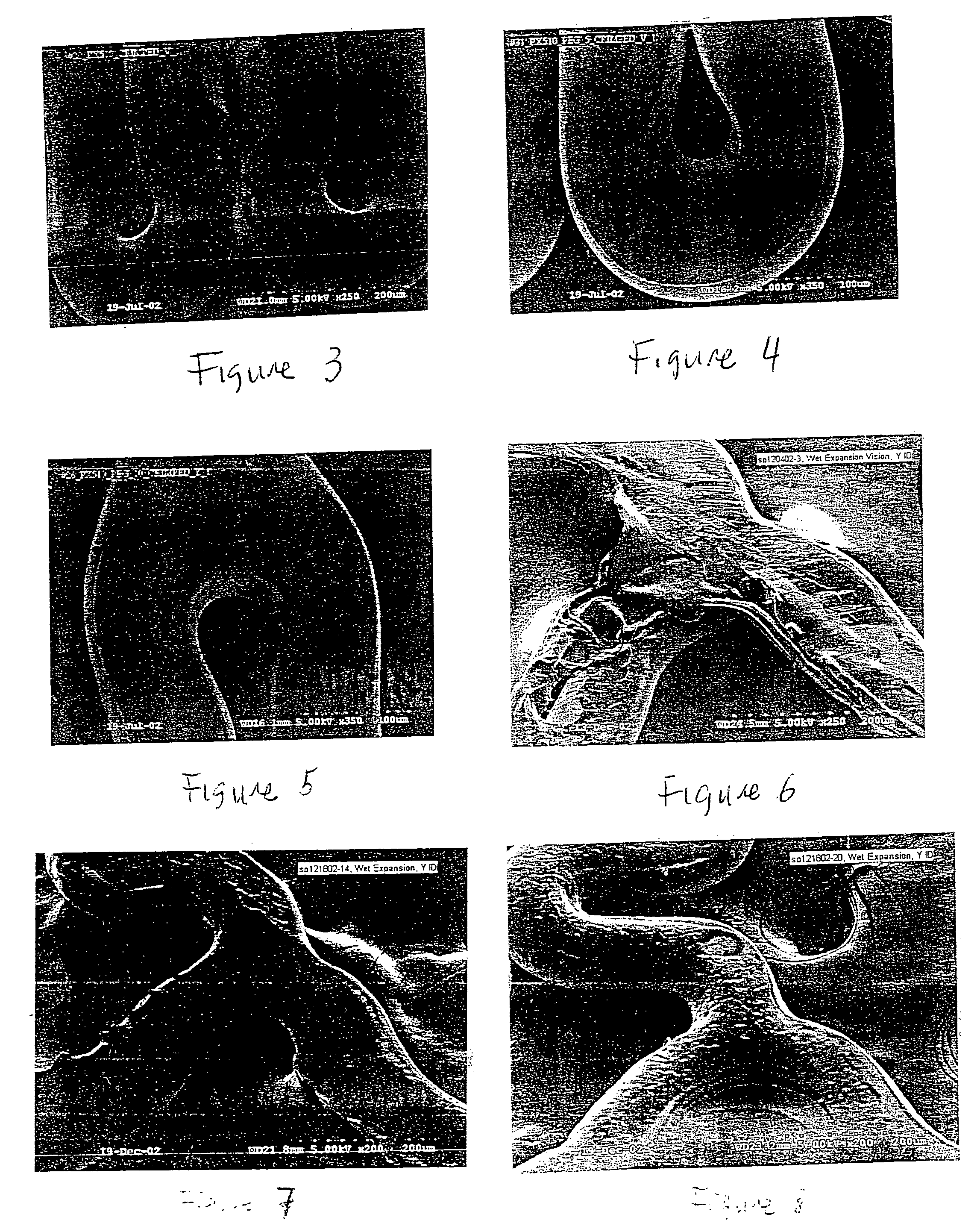

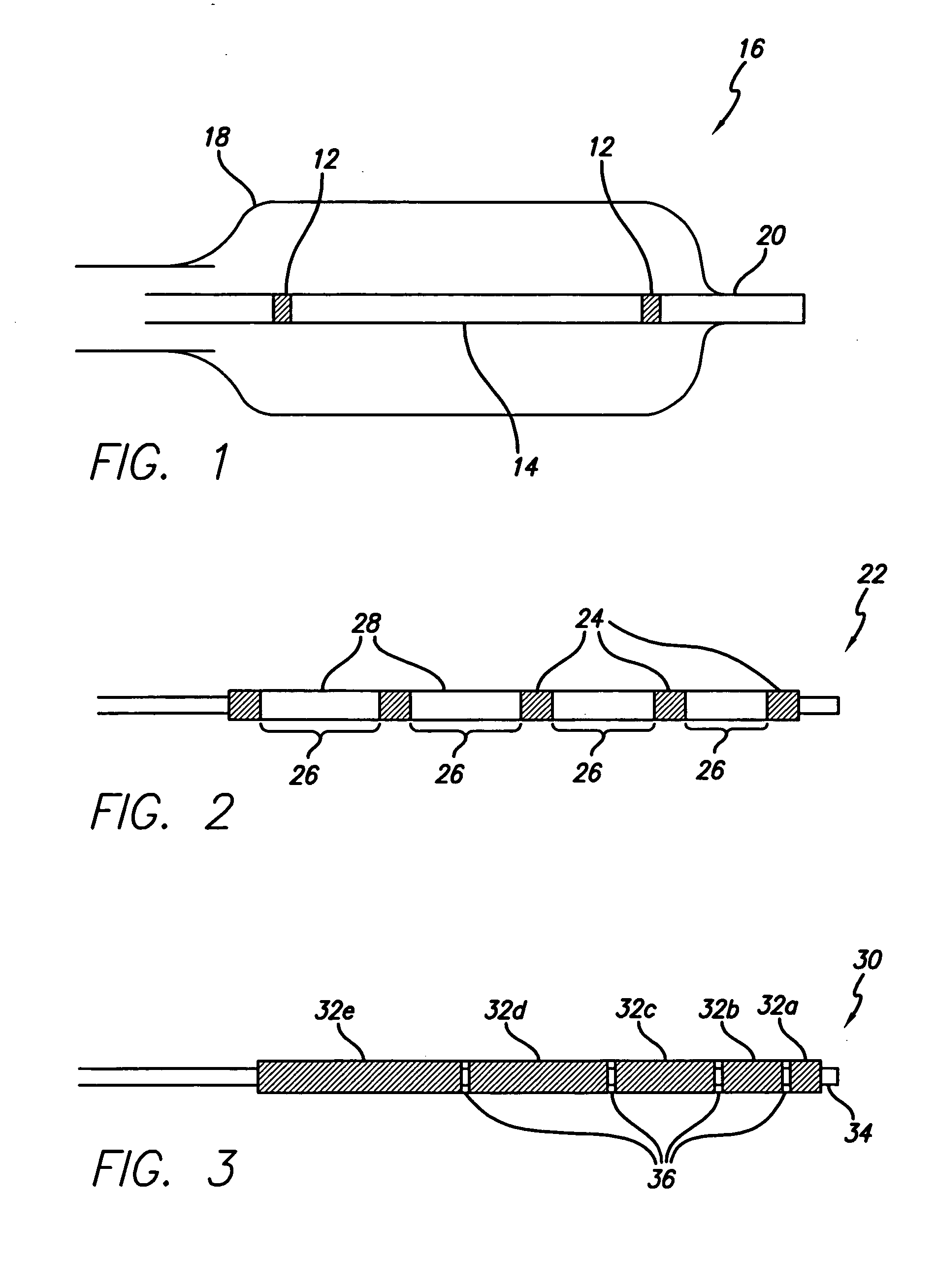

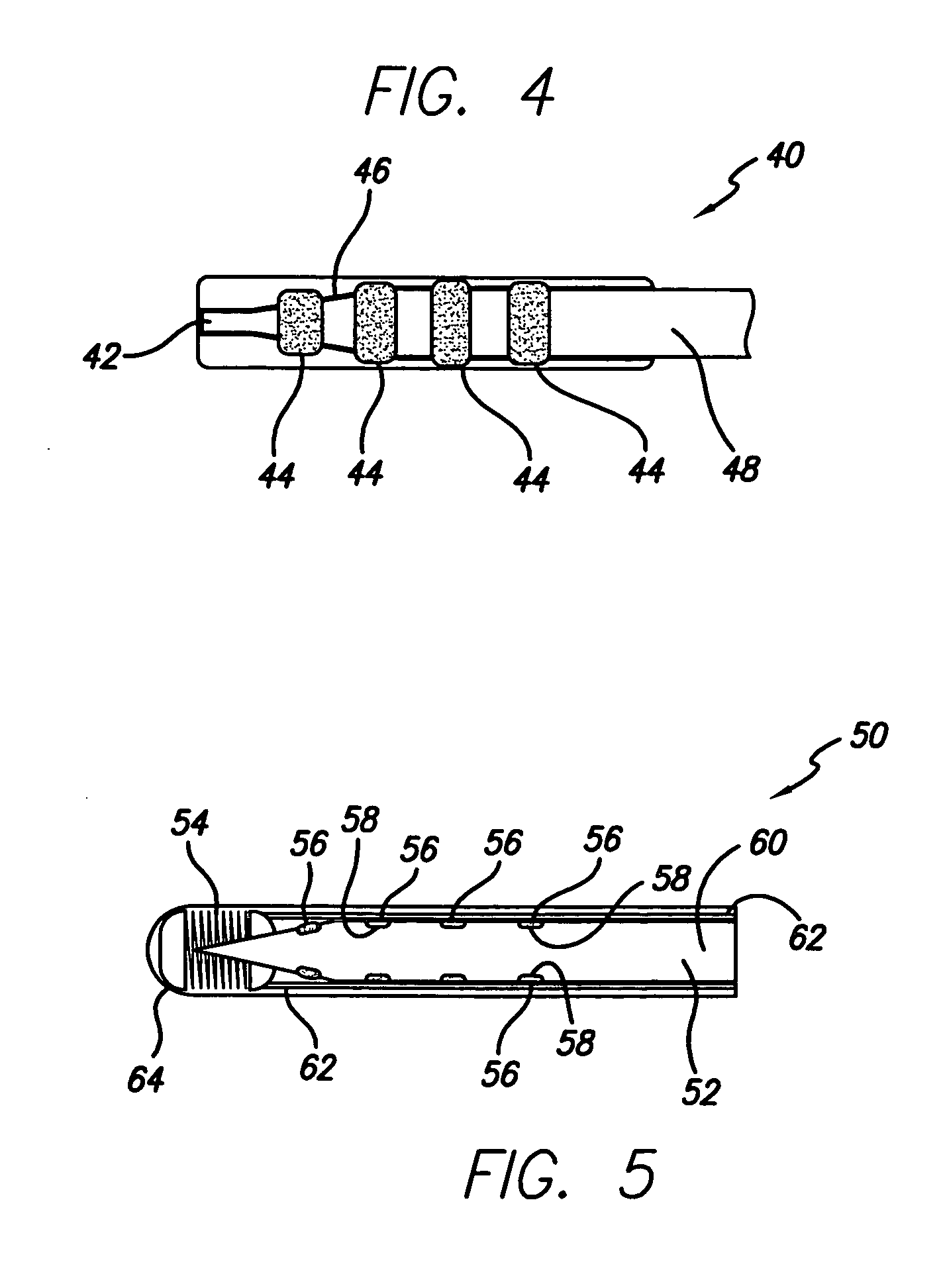

Methods for modulating thermal and mechanical properties of coatings on implantable devices

InactiveUS20050245637A1Narrow molecular weight distributionHigh molecular weightStentsSurgical adhesivesVulnerable plaquePercent Diameter Stenosis

Methods for modulating and enhancing thermal and mechanical properties and biocompatibilities of coatings on implantable devices are disclosed. Implantable devices containing the enhanced thermal and mechanical properties and biocompatibilities are also described. The implantable devices can be used to treat a medical condition such as vulnerable plaque or restenosis.

Owner:ABBOTT CARDIOVASCULAR

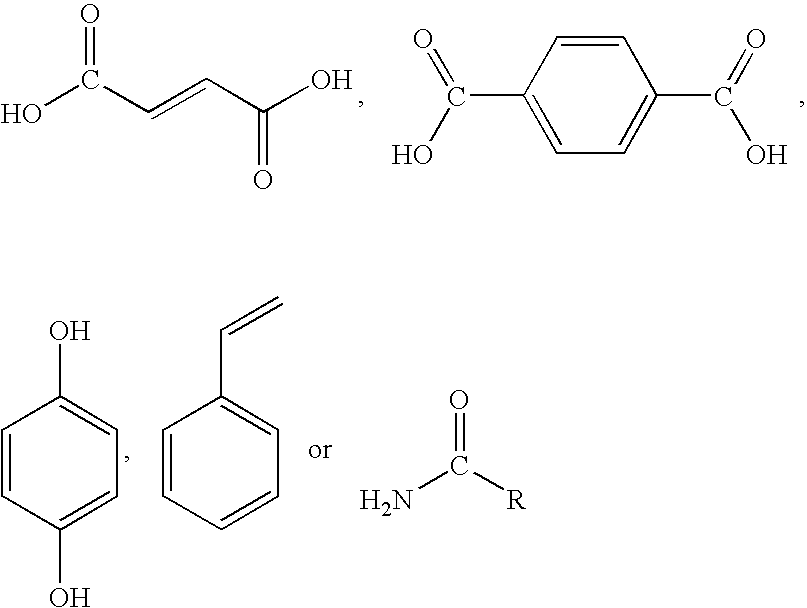

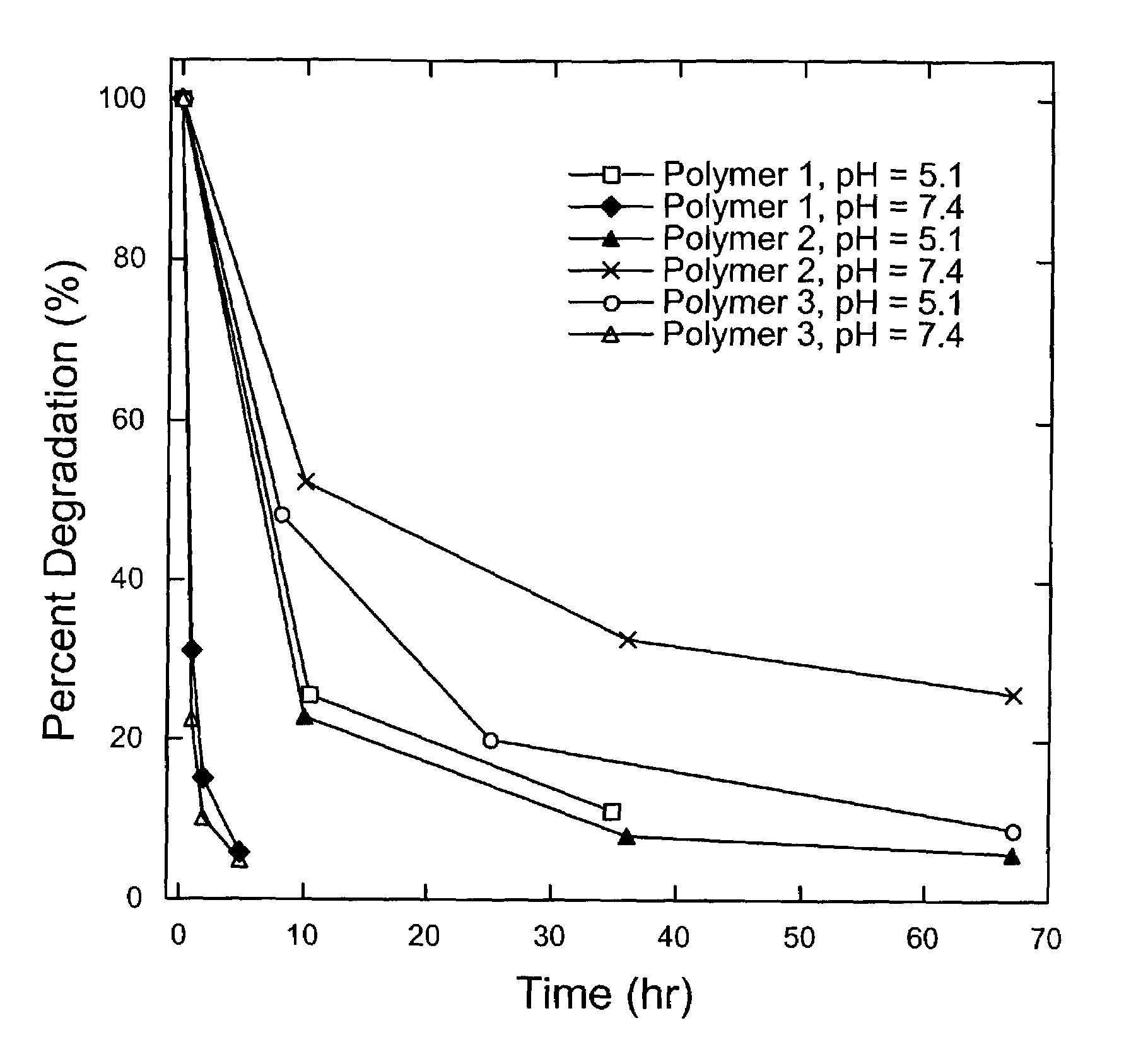

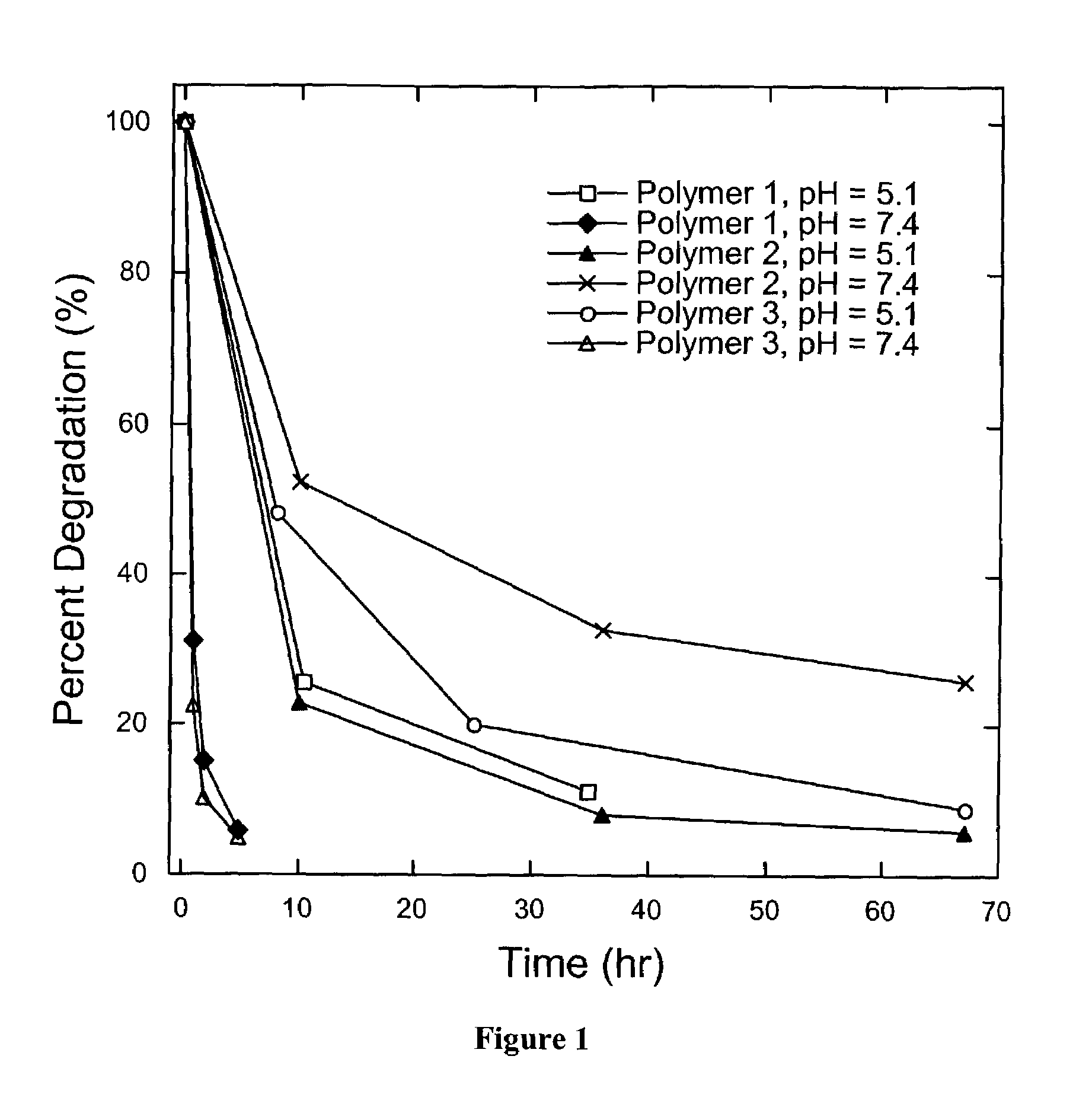

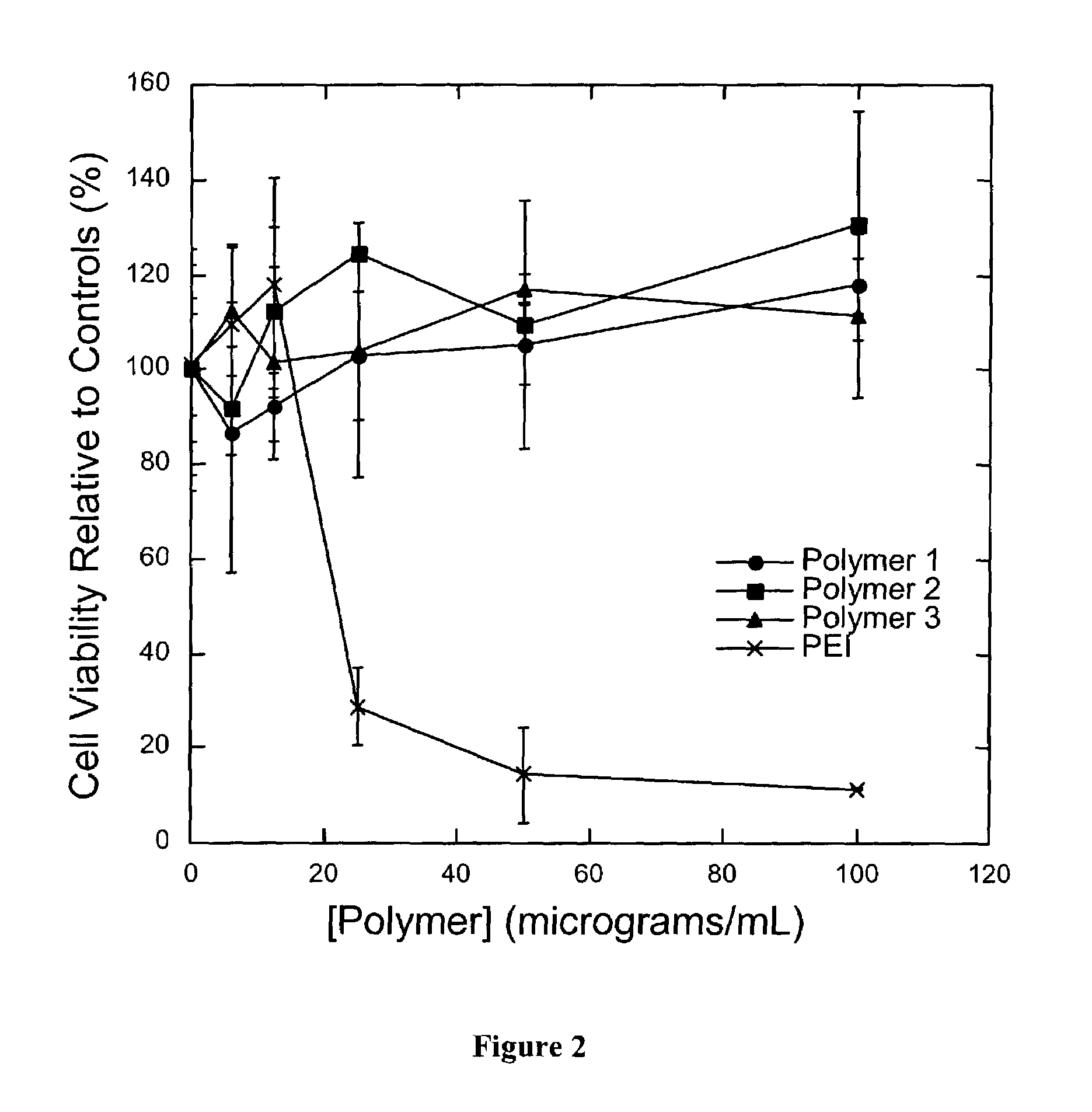

Biodegradable poly(beta-amino esters) and uses thereof

InactiveUS7427394B2High molecular weightHigh transfection efficiencyAntibacterial agentsOrganic active ingredientsAmino estersNucleotide

Poly(β-amino esters) prepared from the conjugate addition of bis(secondary amines) or primary amines to a bis(acrylate ester) are described. Methods of preparing these polymers from commercially available starting materials are also provided. These tertiary amine-containing polymers are preferably biodegradable and biocompatible and may be used in a variety of drug delivery systems. Given the poly(amine) nature of these polymers, they are particularly suited for the delivery of polynucleotides. Nanoparticles containing polymer / polynucleotide complexes have been prepared. The inventive polymers may also be used to encapsulate other agents to be delivered. They are particularly useful in delivering labile agents given their ability to buffer the pH of their surroundings. A system for preparing and screening polymers in parallel using semi-automated robotic fluid delivery systems is also provided.

Owner:MASSACHUSETTS INST OF TECH

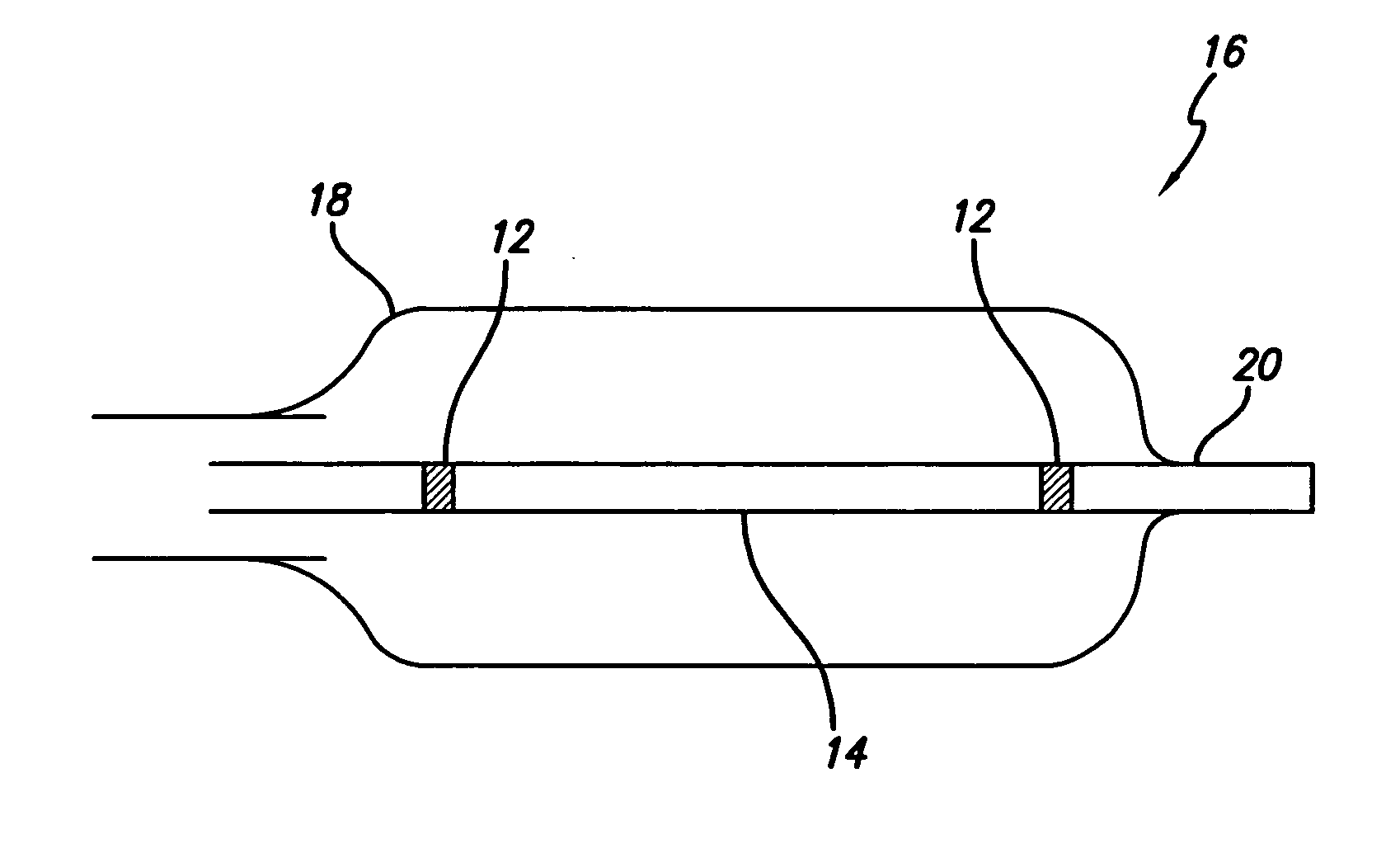

Progenitor endothelial cell capturing with a drug eluting implantable medical device

InactiveUS20050271701A1Increased formationSmooth migrationStentsHeart valvesProgenitorDrug-Coated Stents

A medical device for implantation into vessels or luminal structures within the body is provided. The medical device, such as a stent and a synthetic graft, is coated with a pharmaceutical composition consisting of a controlled-release matrix and one or more pharmaceutical substances for direct delivery of drugs to surrounding tissues. The coating on the medical device further comprises a ligand such as an antibody or a small molecule for capturing progenitor endothelial cells in the blood contacting surface of the device for restoring an endothelium at the site of injury. In particular, the drug-coated stents are for use, for example, in balloon angioplasty procedures for preventing or inhibiting restenosis.

Owner:ORBUSNEICH MEDICAL PTE LTD

Effervescent granules and methods for their preparation

InactiveUS6649186B1Improve stabilityParticular regionPowder deliveryNervous disorderHYDROMORPHONE HYDROCHLORIDEAlpha adrenergic blockade

Disclosed here are effervescent granules having a controllable rate of effervescence. In some embodiments, the such granules comprise an acidic agent, an alkaline agent, a pharmacologically active agent, hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process. The present invention also provides a thermal heat process for preparing a pharmacologically active agent containing effervescent granule. In certain aspects, the granules contain pharmacologically active agents such as narcotics, antidiarrheal agents, antiviral agents, anxiolytic agents, a cholesterol lowering agent, an alpha adrenergic blocking agent, a phenanthrene derivative. By way of example, some of the narcotics that may be included in the granules and in the process of preparing the granules include, by way of example: phenanthrene derivatives (e.g., morphine sulfate), and morphine derivatives (e.g., hydromorphone hydrochloride).

Owner:ETHYPHARM SA

Effervescent granules and methods for their preparation

InactiveUS6488961B1Improve stabilityParticular regionPowder deliveryBiocideAnesthetic AgentHYDROMORPHONE HYDROCHLORIDE

Disclosed here are effervescent granules having a controllable rate of effervescence. In some embodiments, the such granules comprise an acidic agent, an alkaline agent, a pharmacologically active agent, hot-melt extrudable binder capable of forming a eutectic mixture with the acidic agent and, optionally, a plasticizer. The effervescent granules are made by a hot-melt extrusion process. The present invention also provides a thermal heat process for preparing a pharmacologically active agent containing effervescent granule. In certain aspects, the granules contain pharmacologically active agents such as narcotics, antidiarrheal agents, antiviral agents, anxiolytic agents, a cholesterol lowering agent, an alpha adrenergic blocking agent, a phenanthrene derivative. By way of example, some of the narcotics that may be included in the granules and in the process of preparing the granules include, by way of example: phenanthrene derivatives (e.g., morphine sulfate), and morphine derivatives (e.g., hydromorphone hydrochloride).

Owner:ETHYPHARM SA

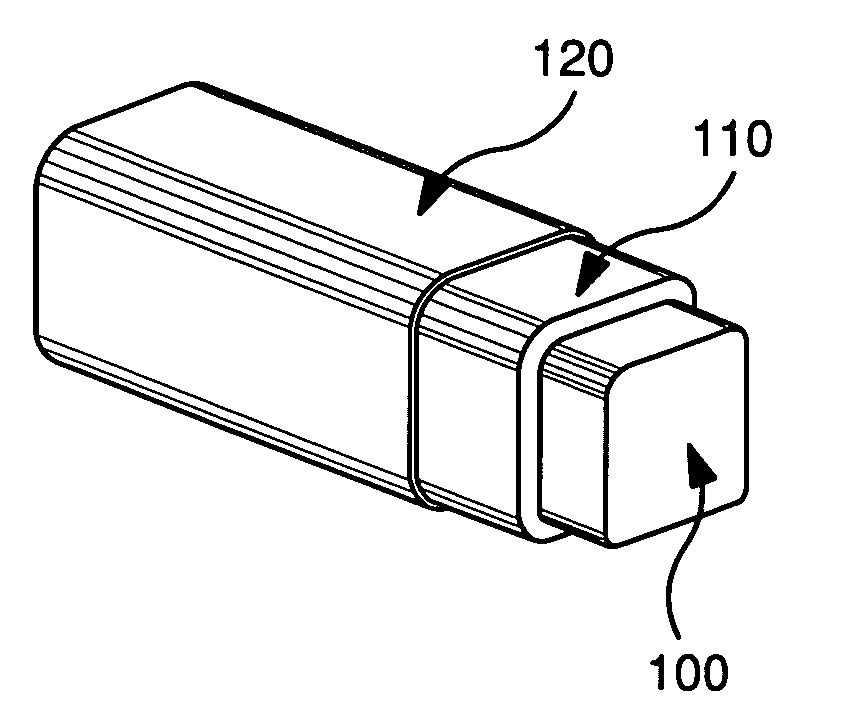

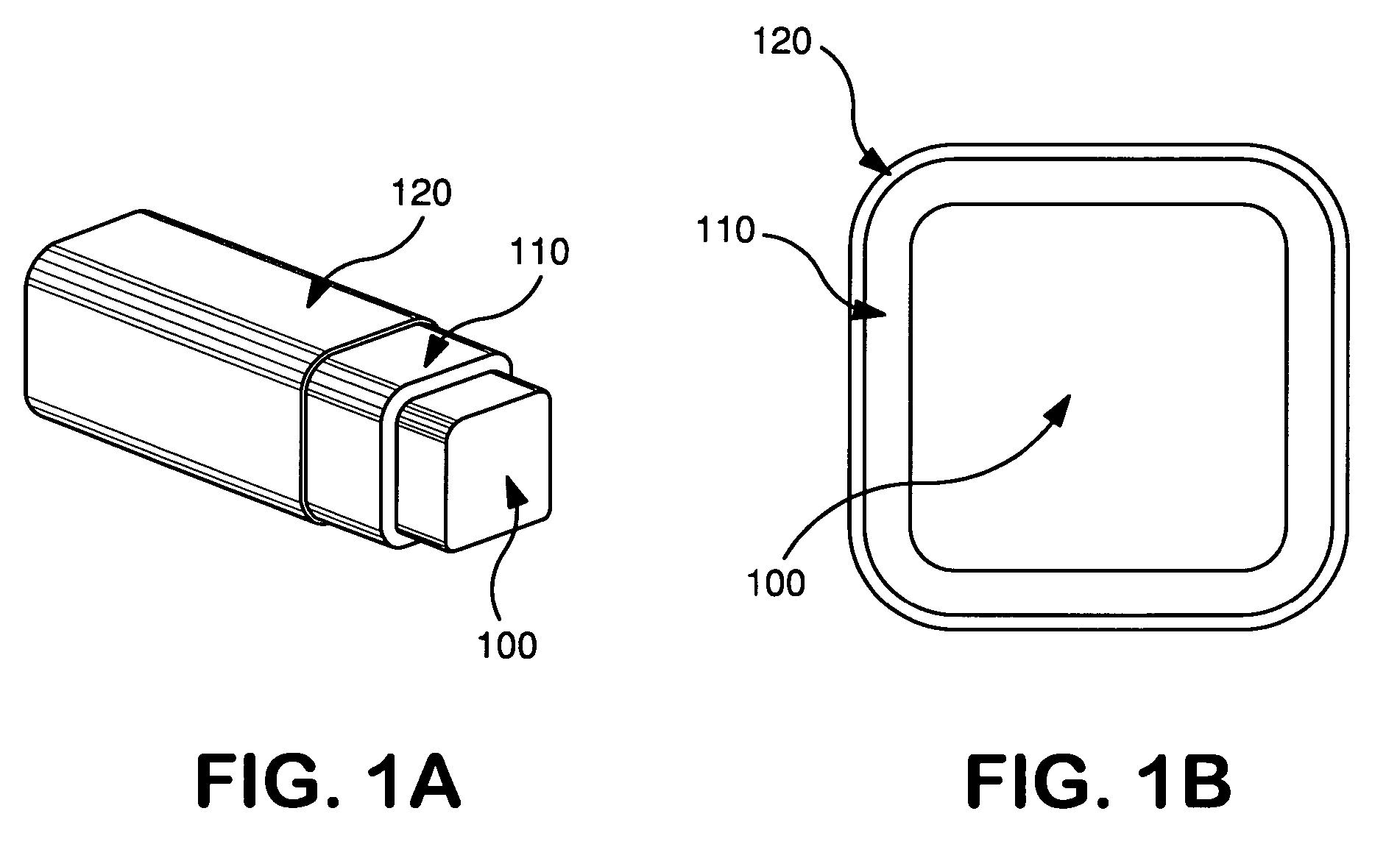

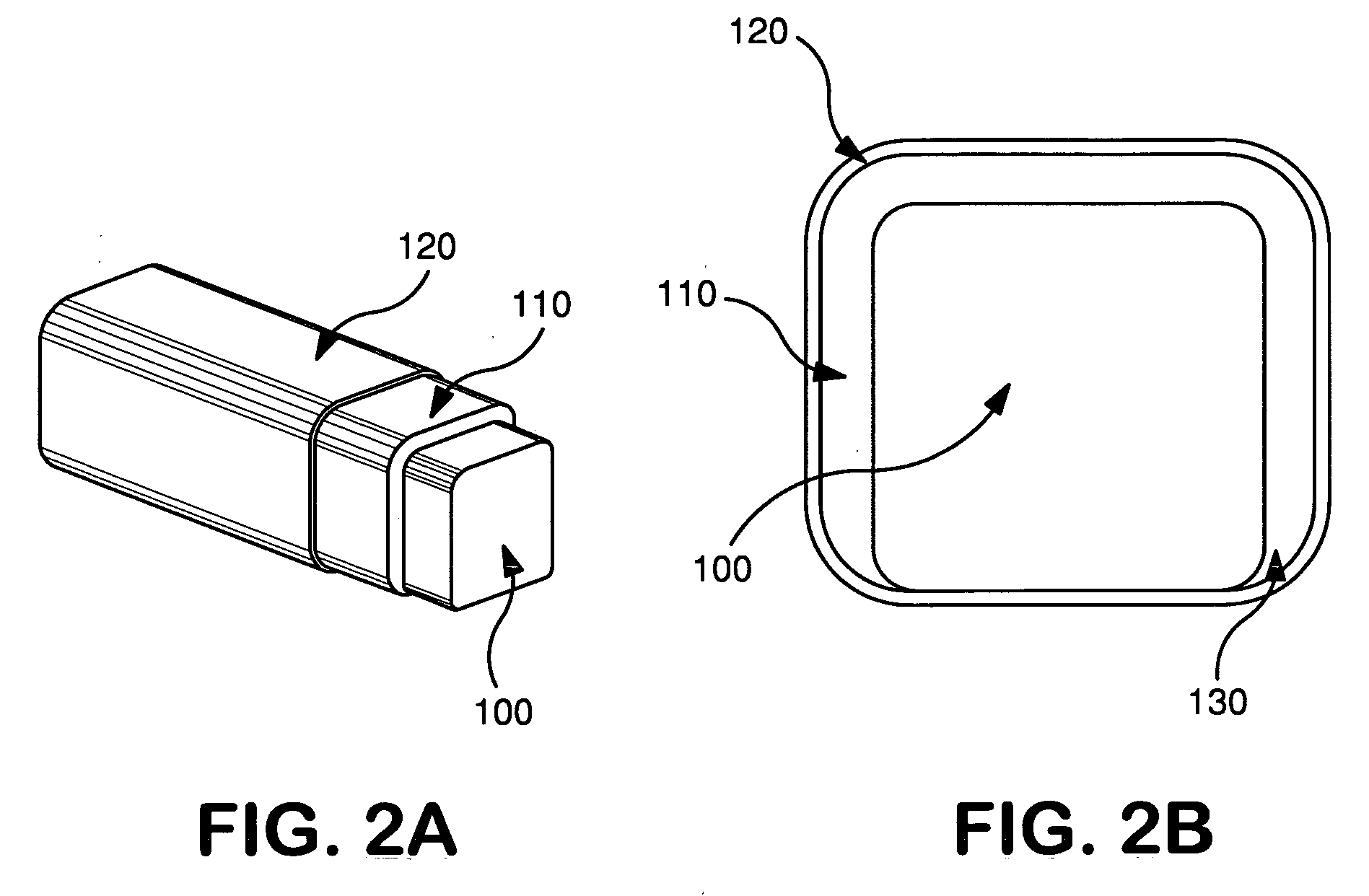

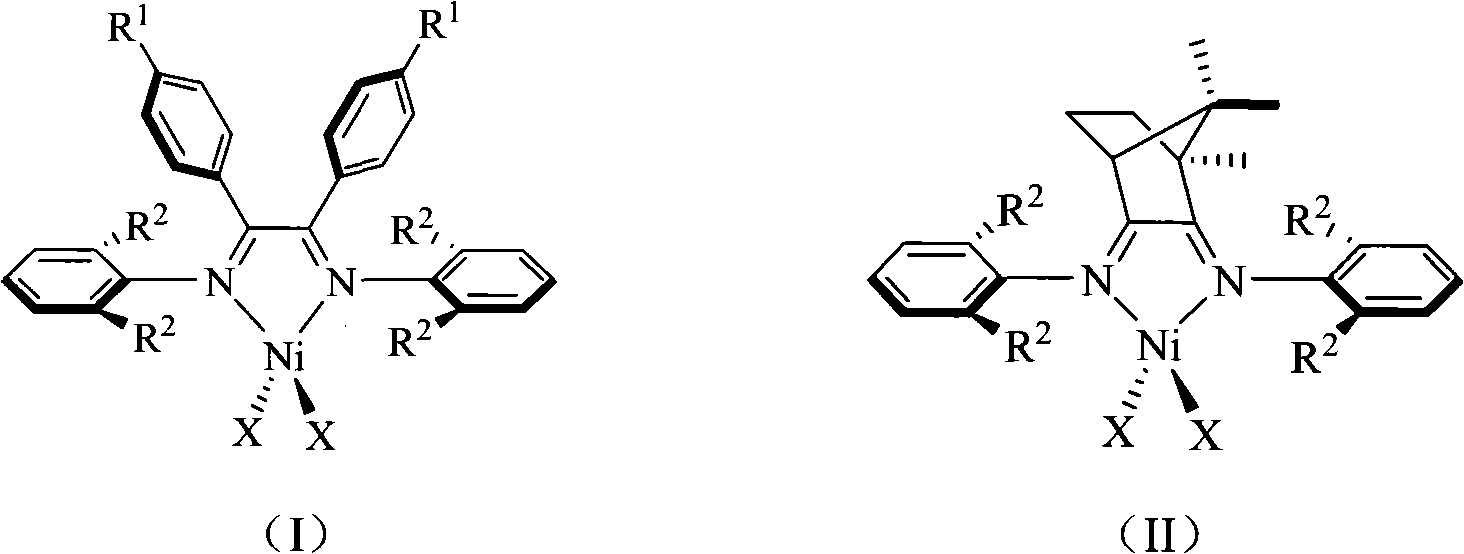

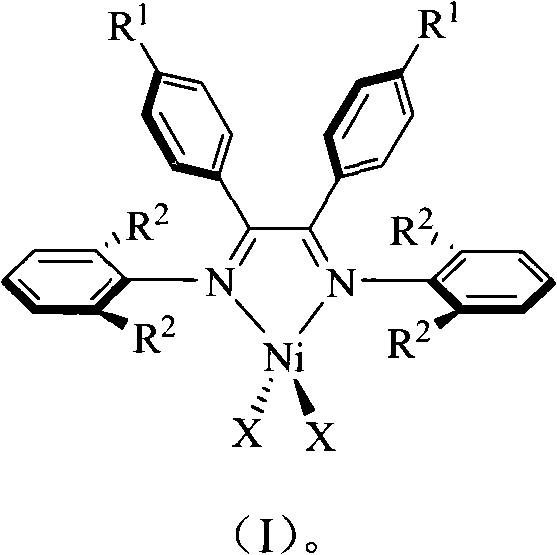

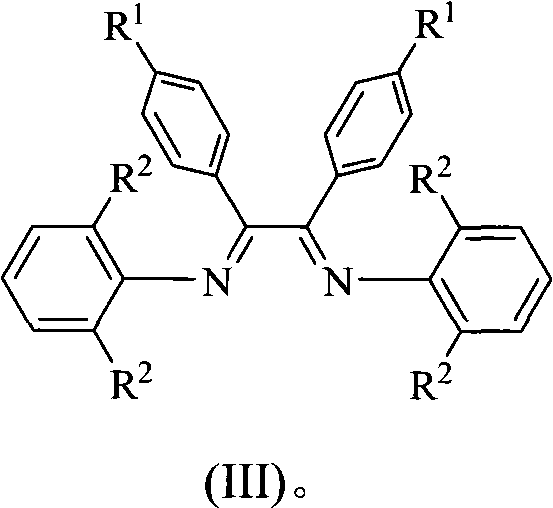

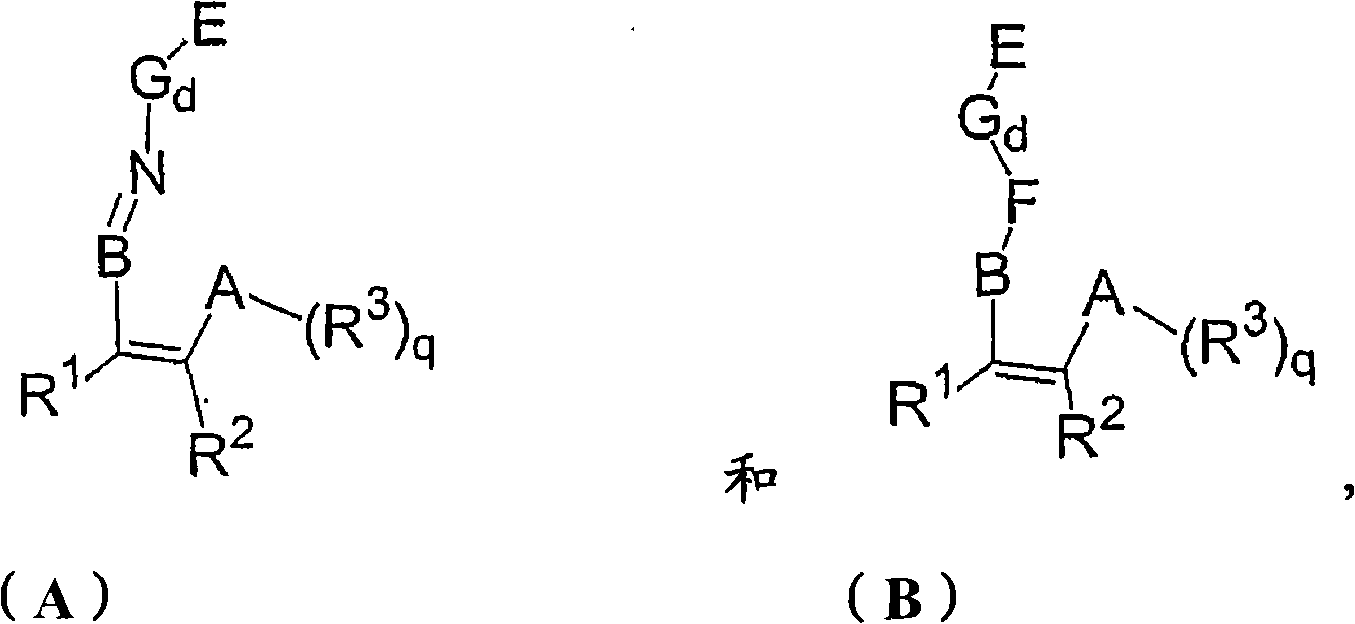

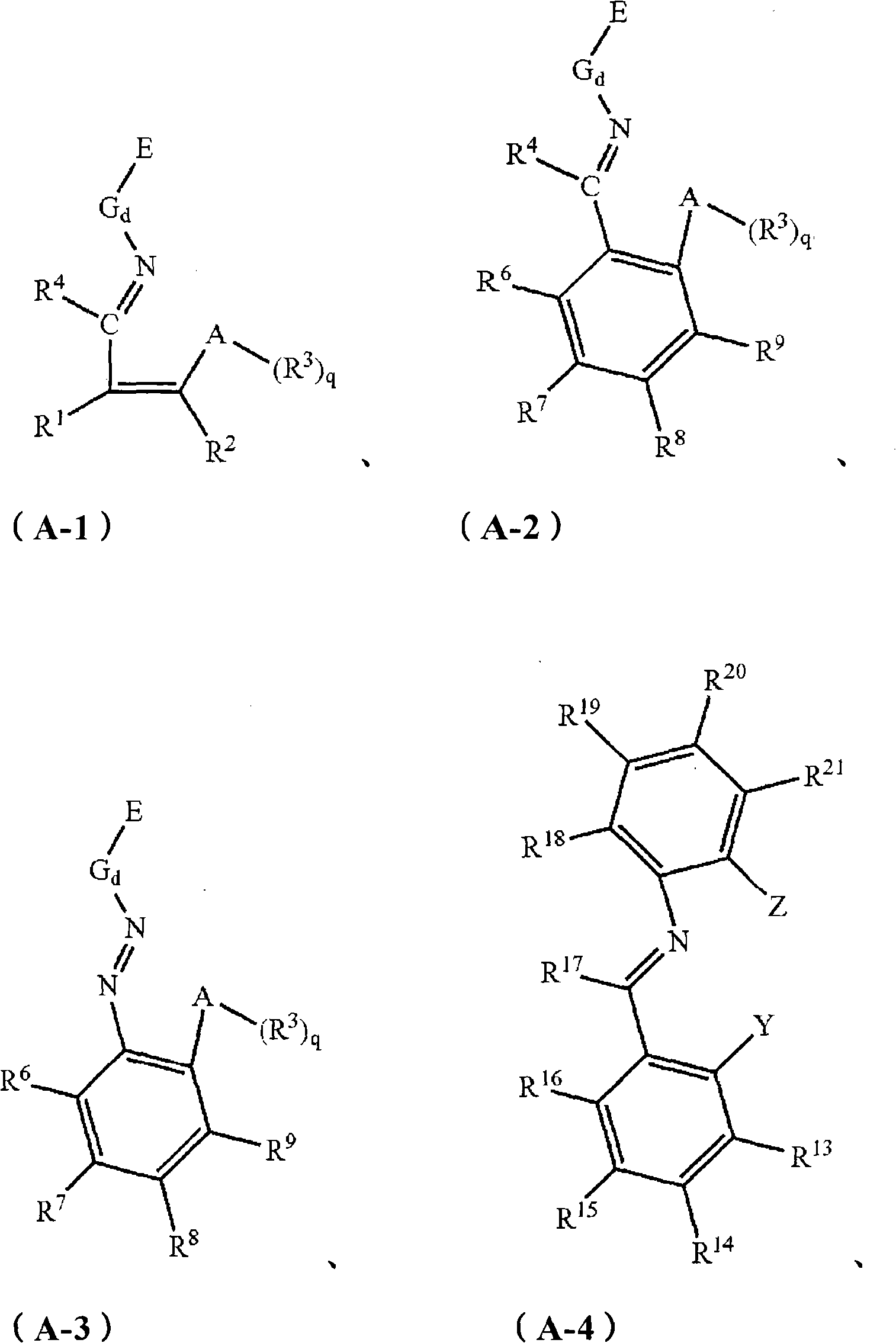

Alpha-nickel diimine compound olefin polymerization catalyst, preparation method and method for preparing branched polyethylene

InactiveCN101812145AEasy to prepareLow costNickel organic compoundsBulk chemical productionPolymer scienceDiimine

The invention discloses an alpha-nickel diimine compound olefin polymerization catalyst, a preparation method and a method for preparing branched polyethylene. The structural formula of the alpha-nickel diimine compound olefin polymerization catalyst is shown as the formula (I) and the formula (II). The alpha-nickel diimine compound olefin polymerization catalyst has simple preparation method and low cost, and ethylene can be catalyzed to polymerize with high activity at a temperature not lower than 80 DEG C to obtain high molecular weight polyethylene. The polyethylene prepared from the alpha-nickel diimine compound olefin polymerization catalyst by catalyzing has high molecular weight, and the molecular weight can reach higher than 102x kg / mol within the range of 0-80 DEG C.

Owner:SUN YAT SEN UNIV

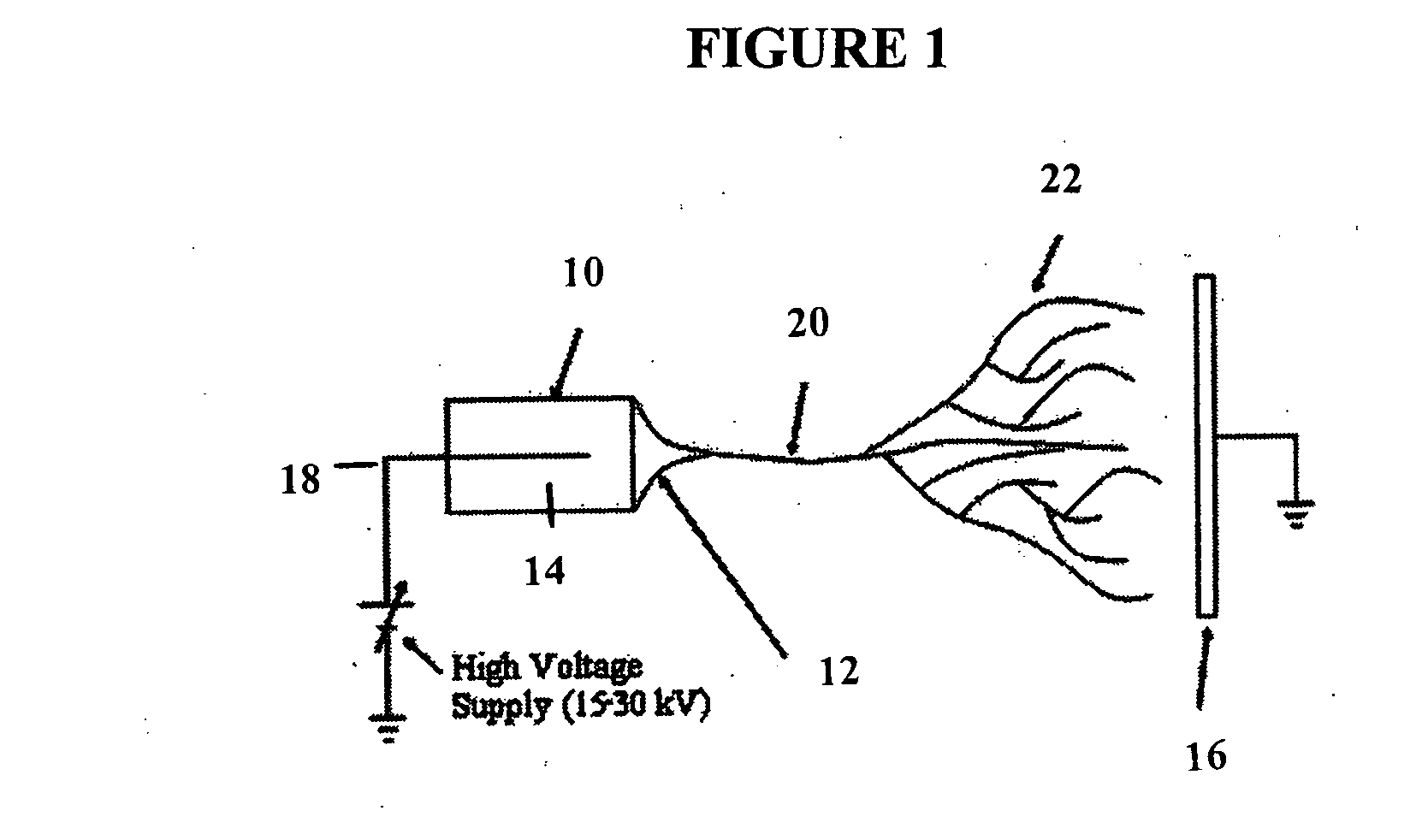

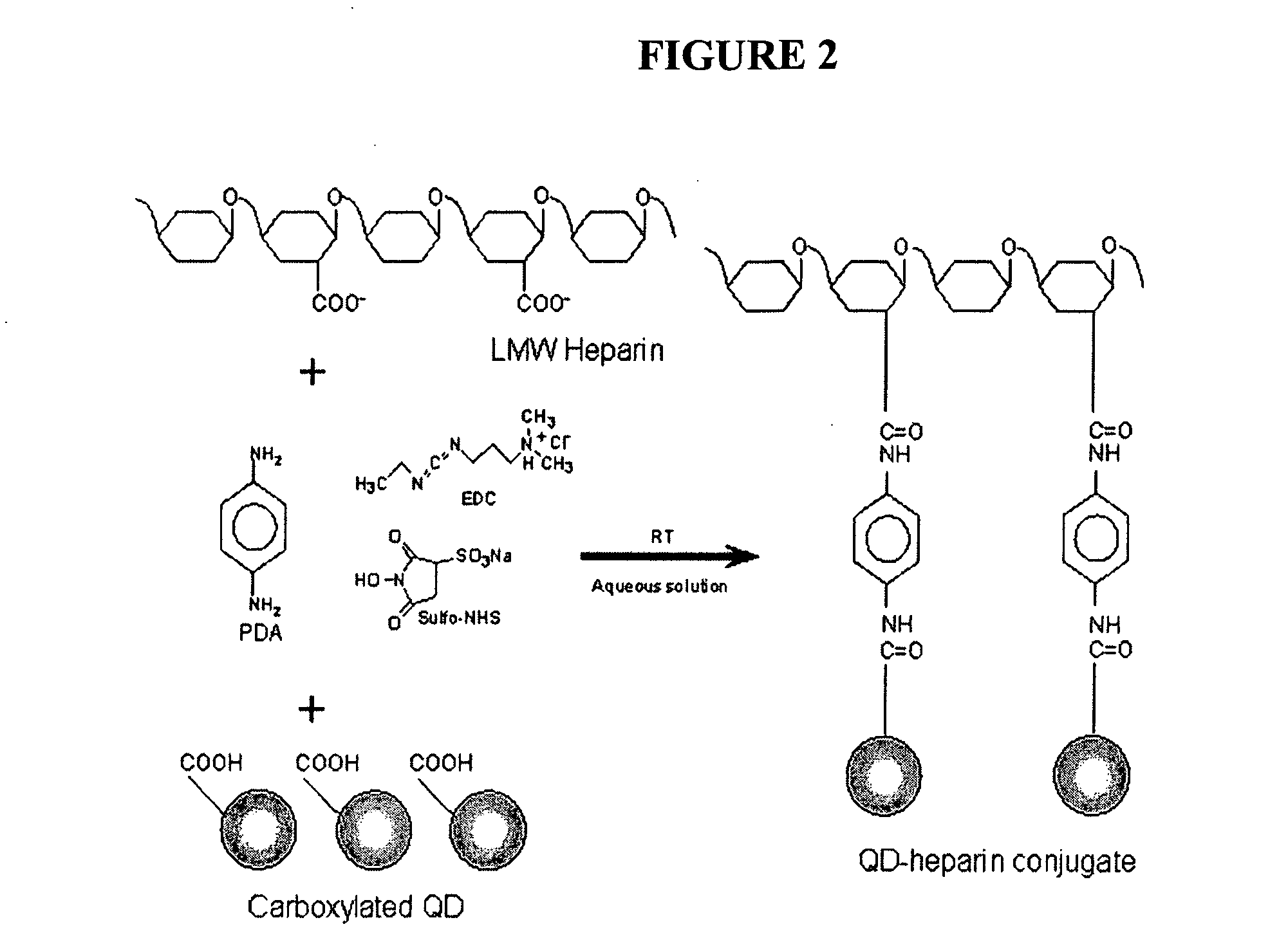

Electrospun cell matrices

InactiveUS20060204539A1Function increaseFiber sizeMonocomponent protein artificial filamentElectro-spinningElectrospinningUltimate tensile strength

The invention is directed to compositions and methods for preparing electrospun matrices comprising at least one natural biological material component and at least one synthetic polymer material. The natural component makes the matrices highly biocompatible while the molecular weight polymer component can impart additional strength mechanical strength to the scaffold and / or improve ease of manufacture by increasing viscosity and spinning characteristics of the solution during electrospining.

Owner:WAKE FOREST UNIV

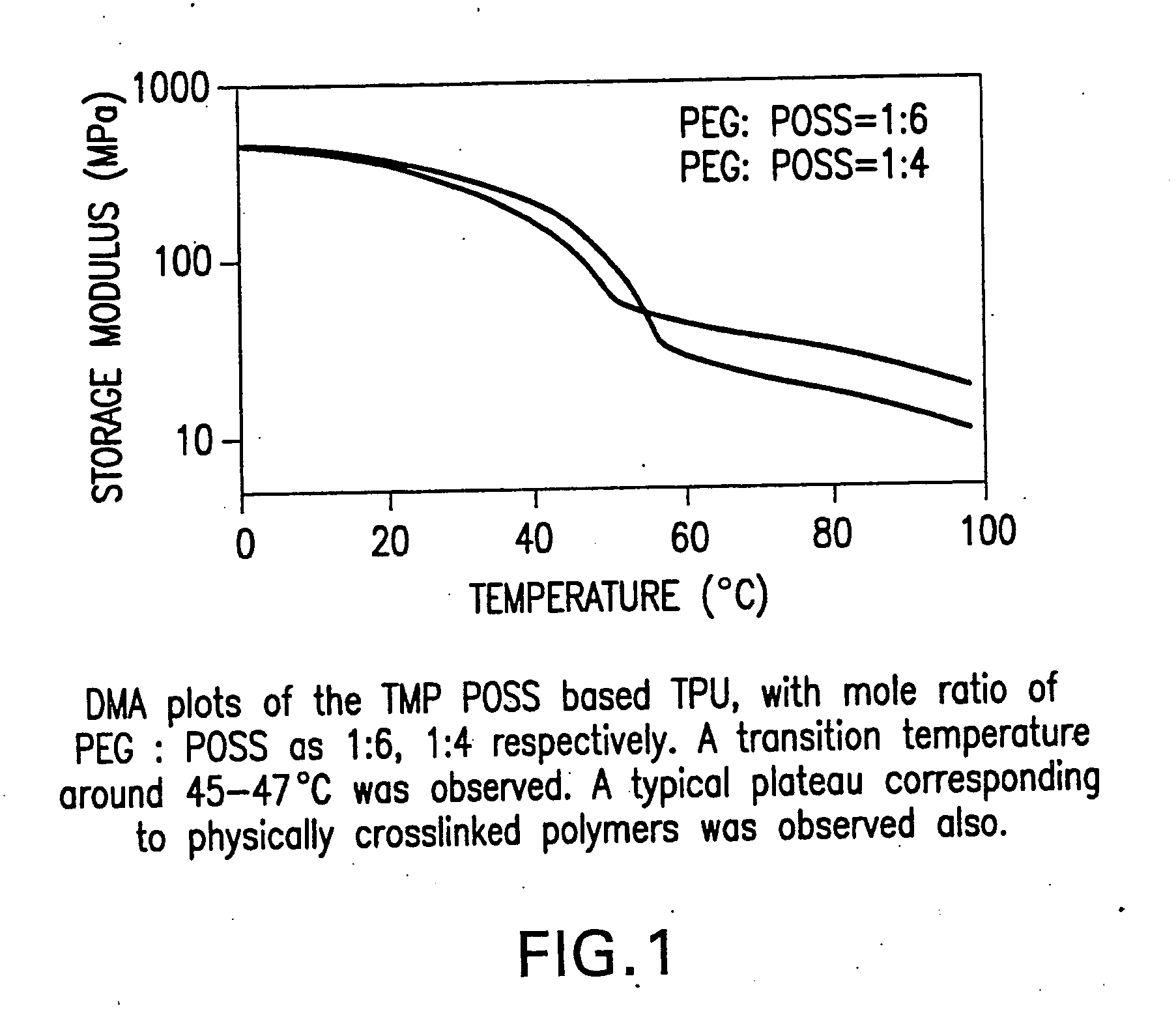

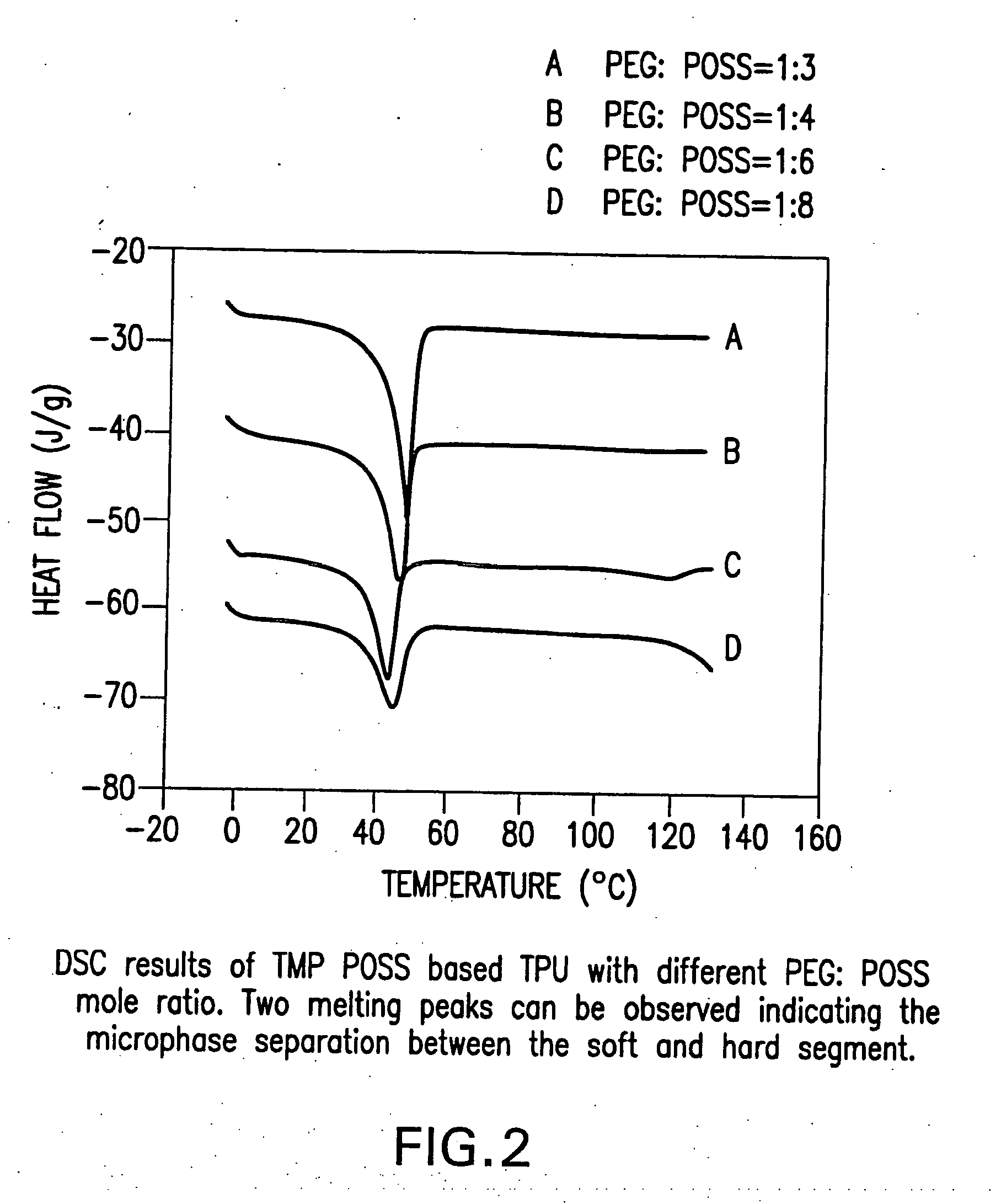

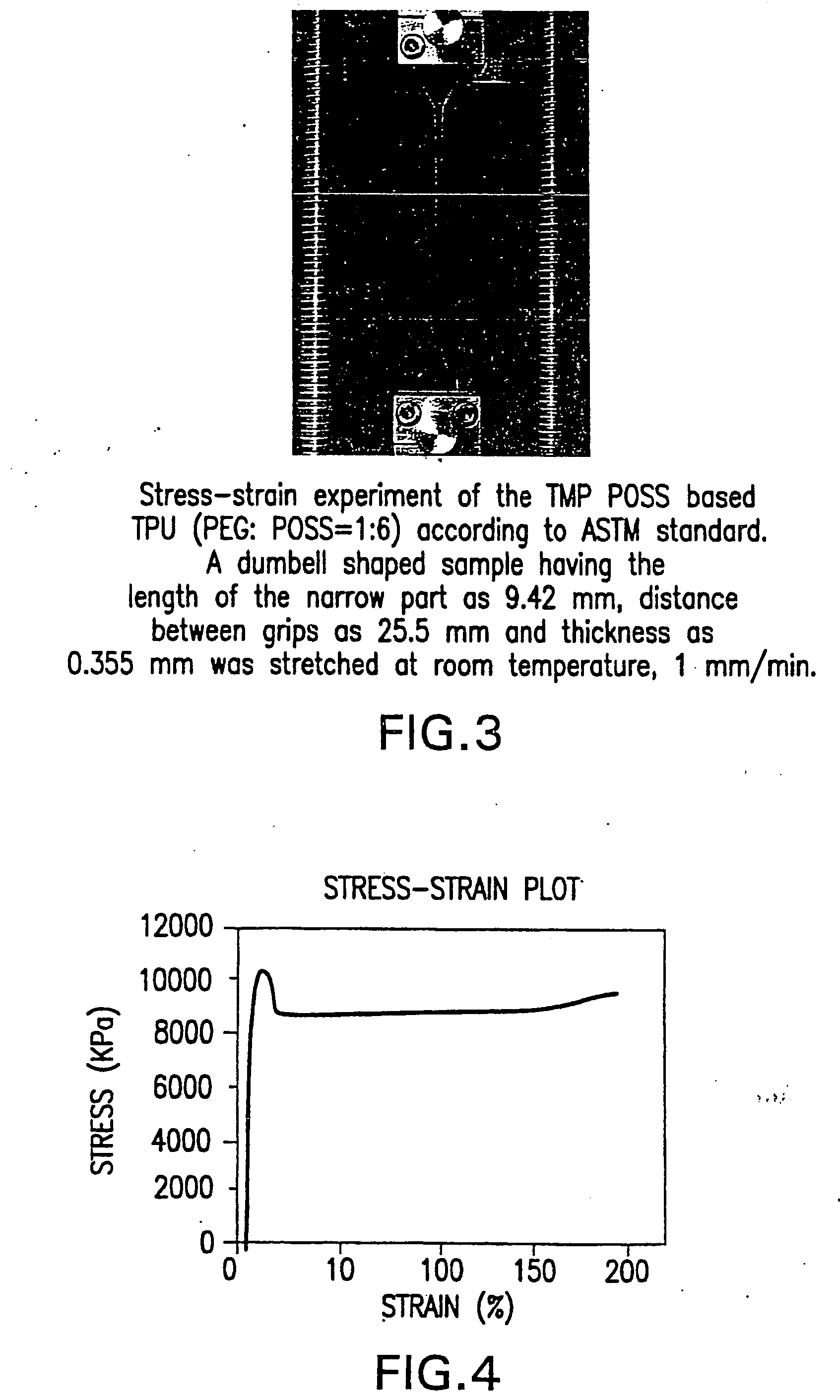

Shape memory polymers based on semicrystalline thermoplastic polyurethanes bearing nanostructured hard segments

InactiveUS20050245719A1Sharp and tunable transition temperatureAbove melting pointPolymer scienceAdhesive

Thermoplastic polyurethanes having an alternating sequence of hard and soft segments in which a nanostructured polyhedral oligosilsesquioxane diol is used as a chain extender to form a crystalline hard segment constituting SMPs. The polyurethanes are formed by reacting a polyol, a chain extender dihydroxyl-terminated polyhedral oligosilsesquioxane and a diisocyanate. The polyurethanes have multiple applications including for example, implants for human health care, drug delivery matrices, superabsorbant hydrogels, coatings, adhesives, temperature and moisture sensors, etc.

Owner:UNIV OF CONNECTICUT

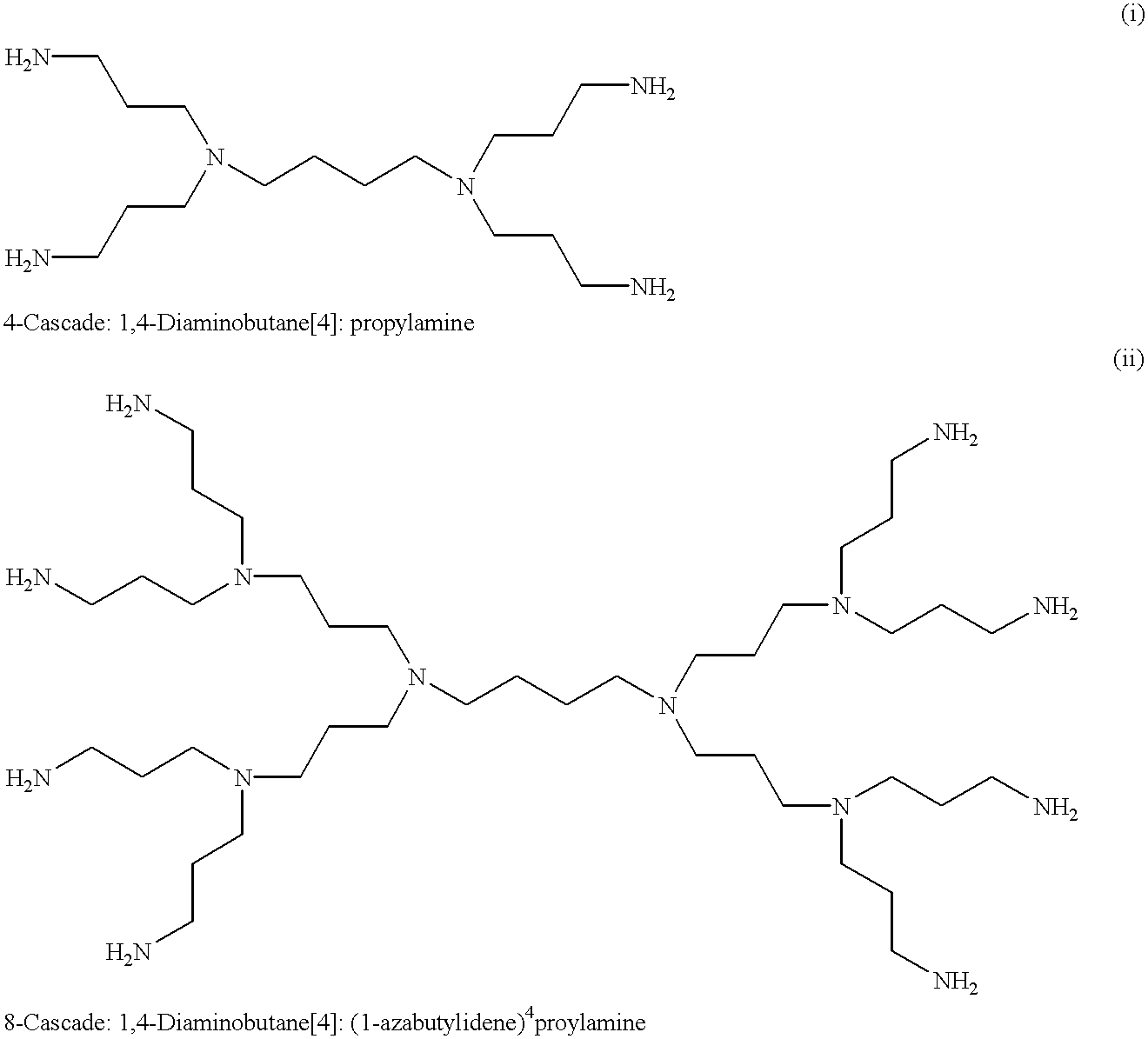

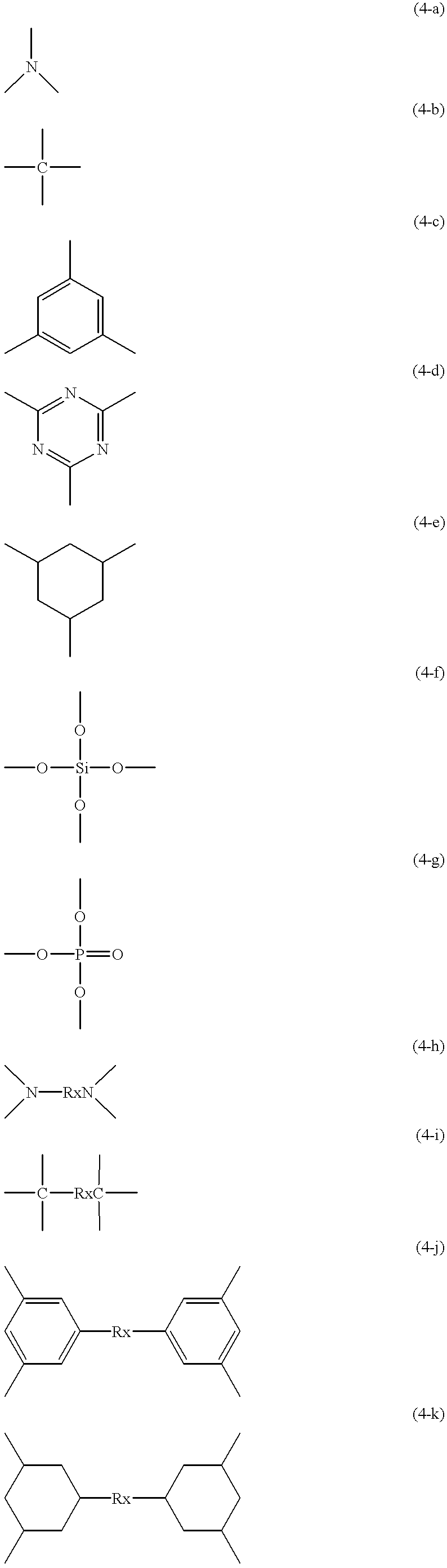

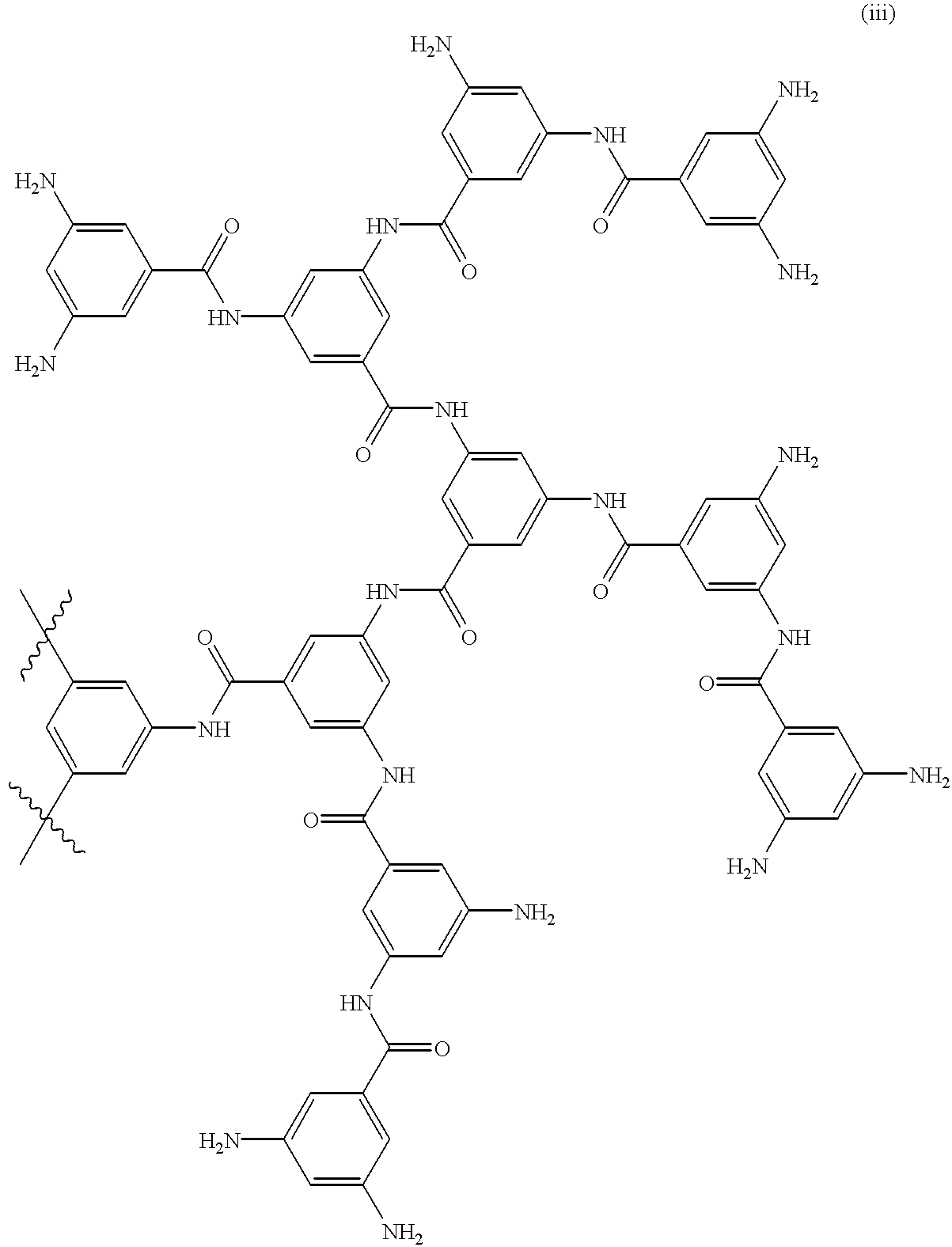

Vinyl-group-containing dendrimer and curable composition

A vinyl-group-containing dendrimer useful in coating and printing and is curable by any one of conventional triggers such as heating, ultraviolet light, infrared light, electron beams and gamma rays, the composition comprising a vinyl-group-containing dendrimer (A) comprising a core portion, branching portions, branches and at least 4 terminal portions and having a vinyl group as a terminal portion and a long-chain group and a curable unsaturated-group-containing compound (B), and the composition comprising a vinyl-group-containing dendrimer (A) obtained by reacting a polyfunctional compound (a) having at least three active-hydrogen-containing groups in a terminal per molecule and having at least five active hydrogen atoms per molecule with a long-chain-group-containing compound (b) having a functional group reactive with an active hydrogen atom so as to leave part of the active hydrogen atoms, thereby obtaining a long-chain-group-containing multi-branched compound (X), and reacting the long-chain-containing multi-branched compound (X) with a vinyl-group-containing compound (c) having a functional group reactive with an active hydrogen atom and a curable unsaturated-group-containing compound (B).

Owner:TOYO INK SC HOLD CO LTD

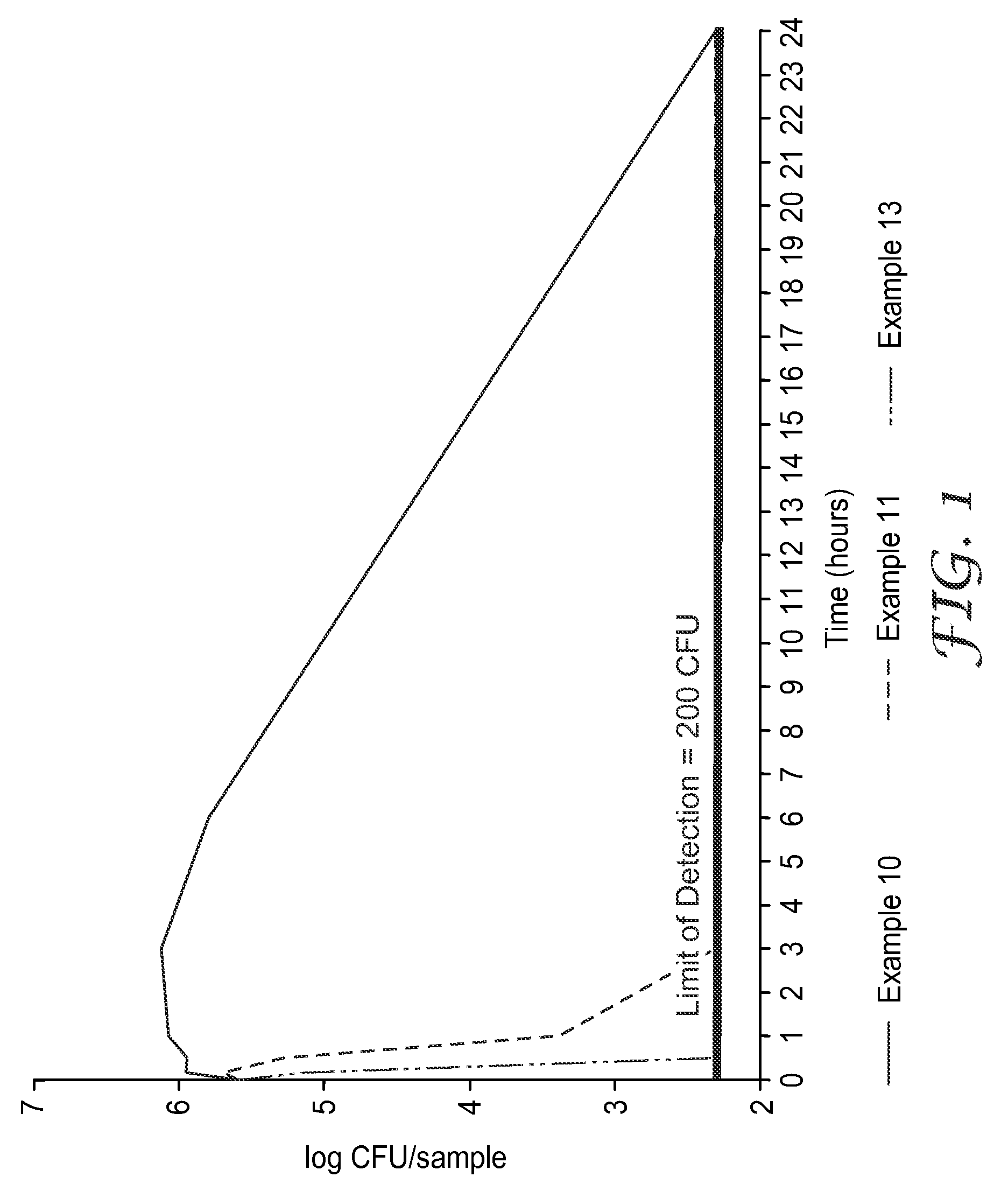

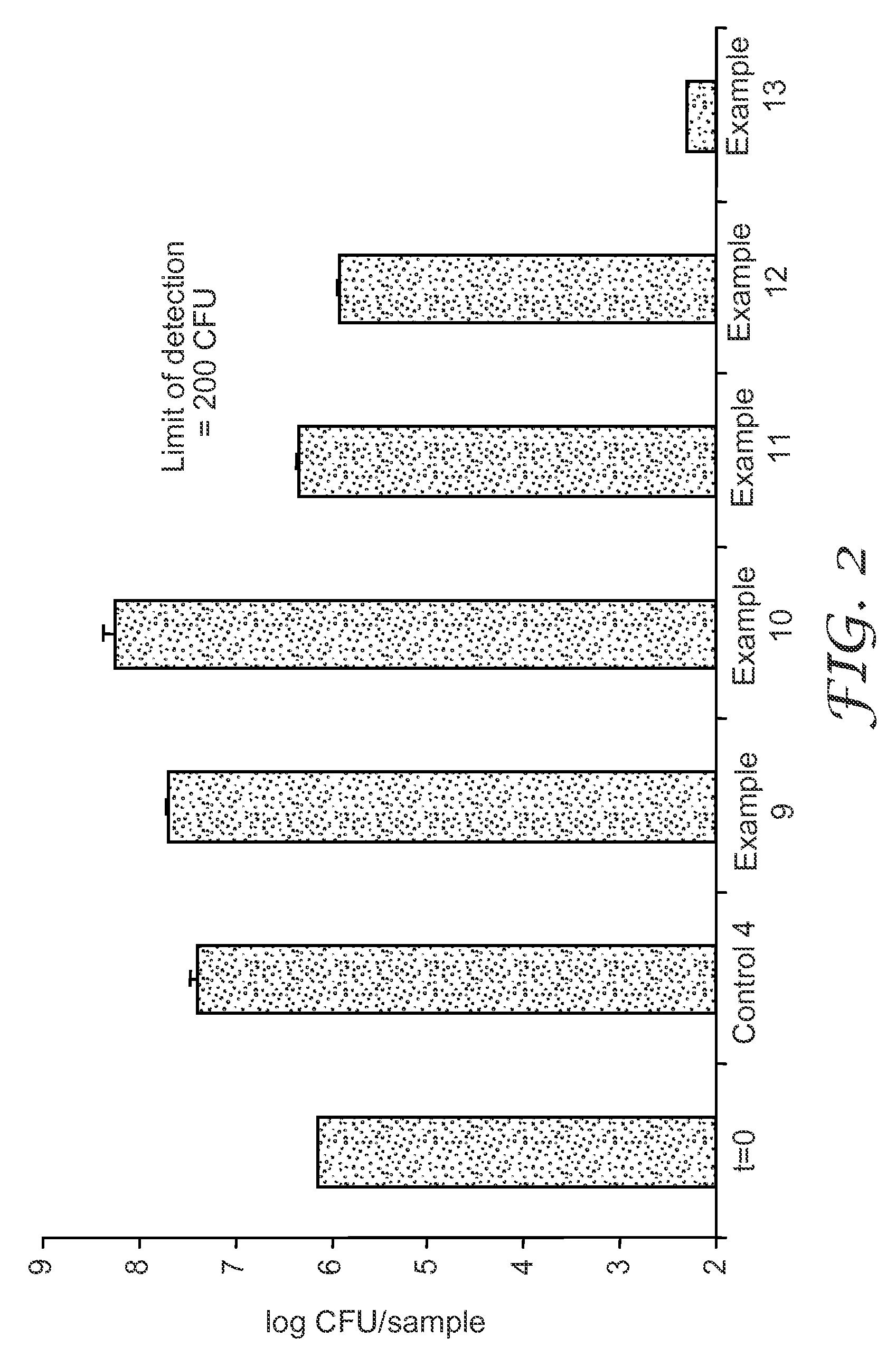

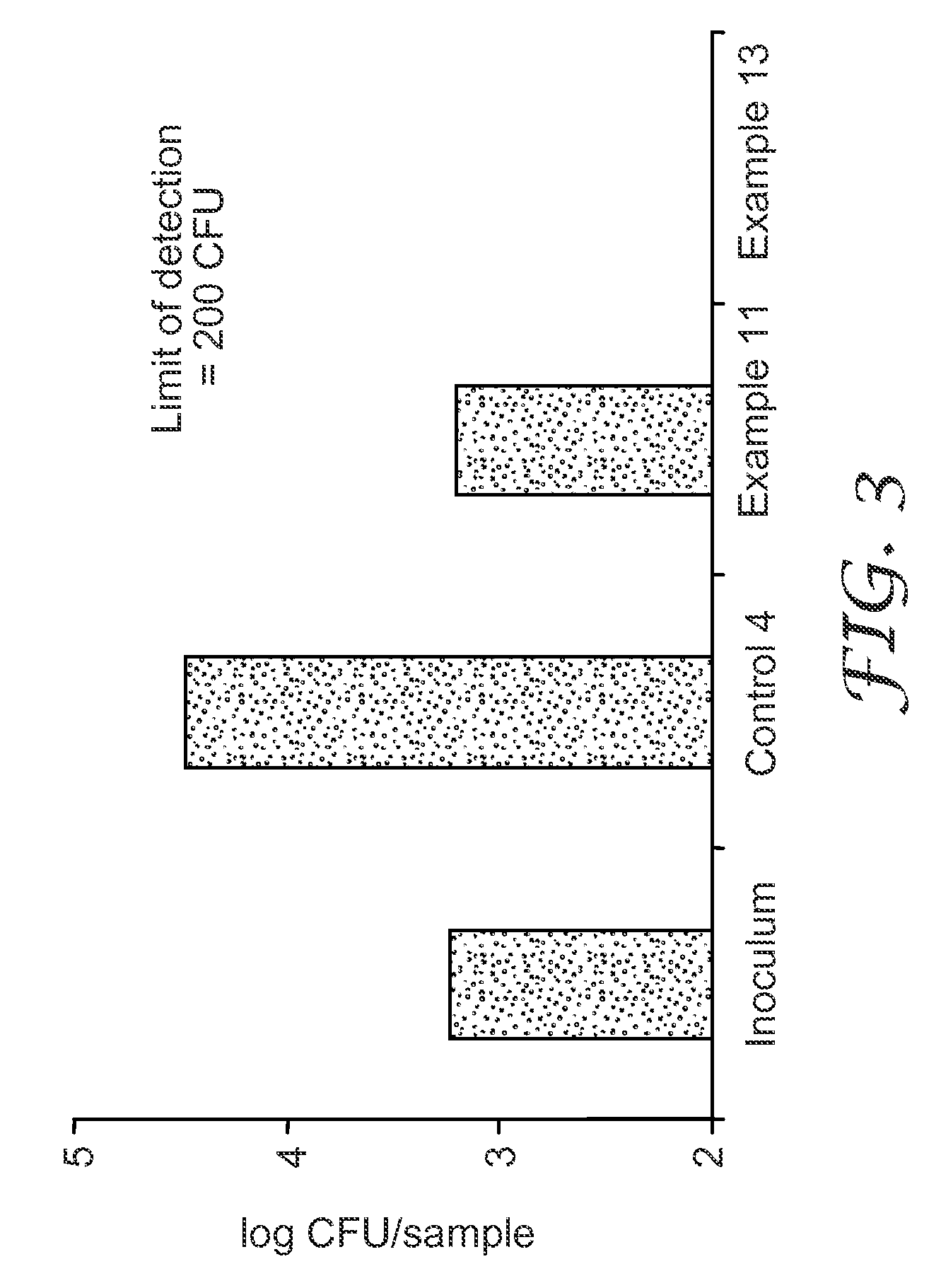

Antimicrobial disposable absorbent articles

InactiveUS20080200890A1Small amountImprove mechanical propertiesBiocideSurgeryPolyesterPersonal care

Disposable absorbent articles comprising an absorbent material and a degradable thermoplastic polymer composition comprising an aliphatic polyester and an antimicrobial composition. The antimicrobial composition includes an antimicrobial component and an enhancer component. The aliphatic polyester and antimicrobial composition are formed into webs by melt extrusion, such as nonwovens and films, that are incorporated into disposable absorbent articles, such as disposable infant diapers, adult incontinence articles, feminine hygiene articles such as sanitary napkins, panty liners and tampons, personal care wipes and household wipes to provide odor control, control of microbial growth, and control of microbial toxin production.

Owner:3M INNOVATIVE PROPERTIES CO

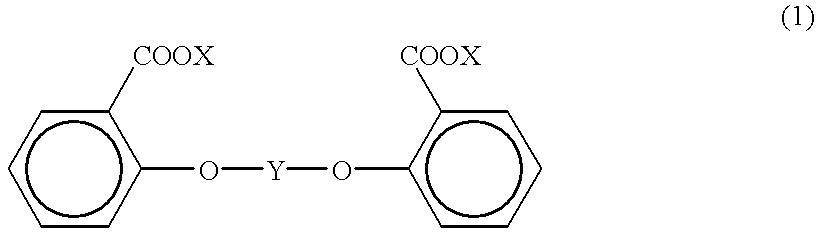

Process for producing aromatic polycarbonate

An aromatic polycarbonate and an active-hydrogen compound are subjected to the transesterification reaction in the presence of a transesterification catalyst under a reduced pressure condition followed by reaction with a salicylic acid ester derivative expressed by the following chemical formula (1),{wherein X is methyl or ethyl, and Y is a carbonyl group or a divalent functional group expressed by the following formula (2),(where Z is an alkylene group having a carbon number of 1 to 30, an arylene group having a carbon number of 6 to 30 or an aralkylene group having a carbon number of 7 to 30)}.An aromatic polycarbonate having a high molecular weight can be produced by this process.

Owner:TEIJIN LTD

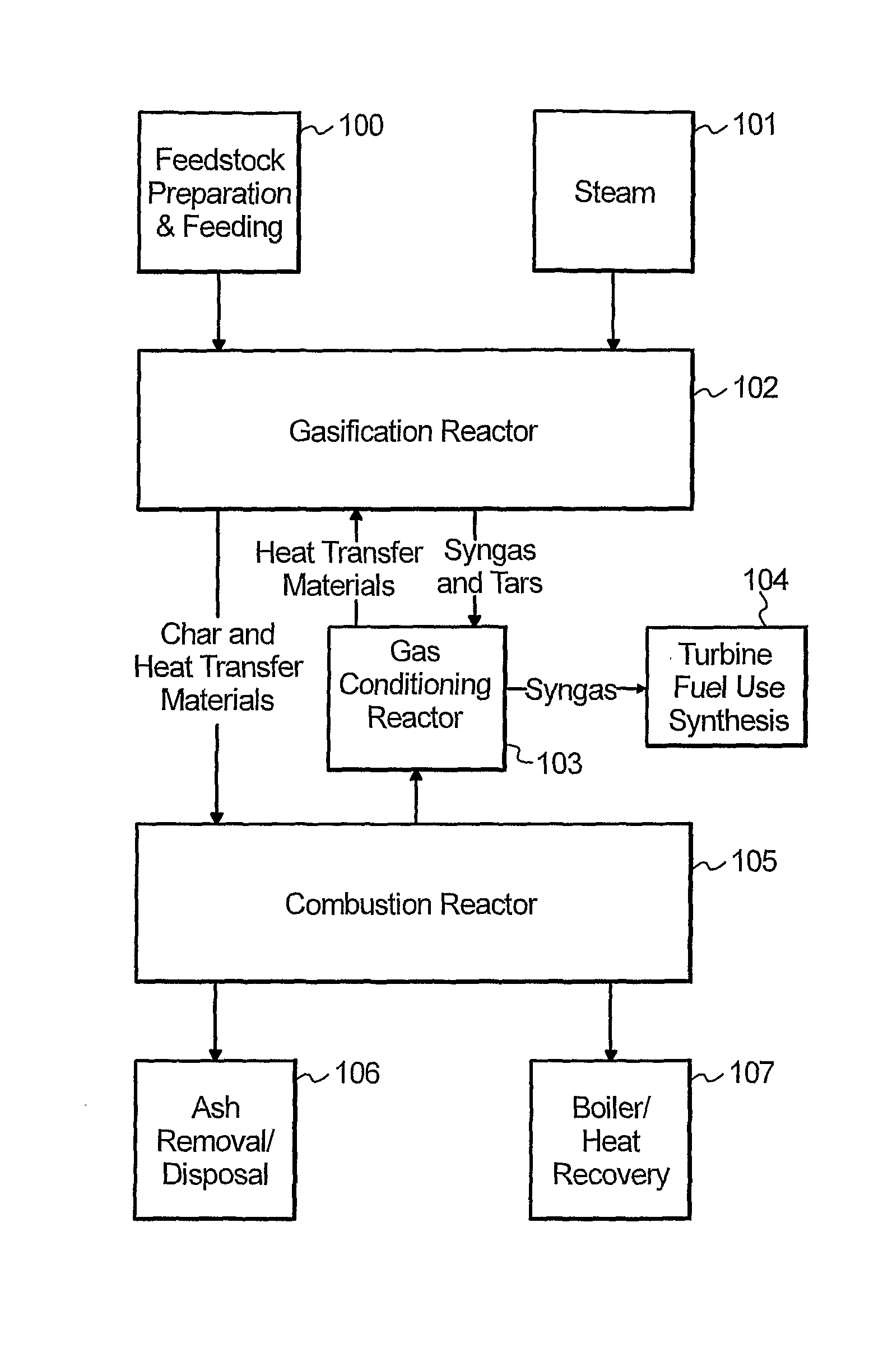

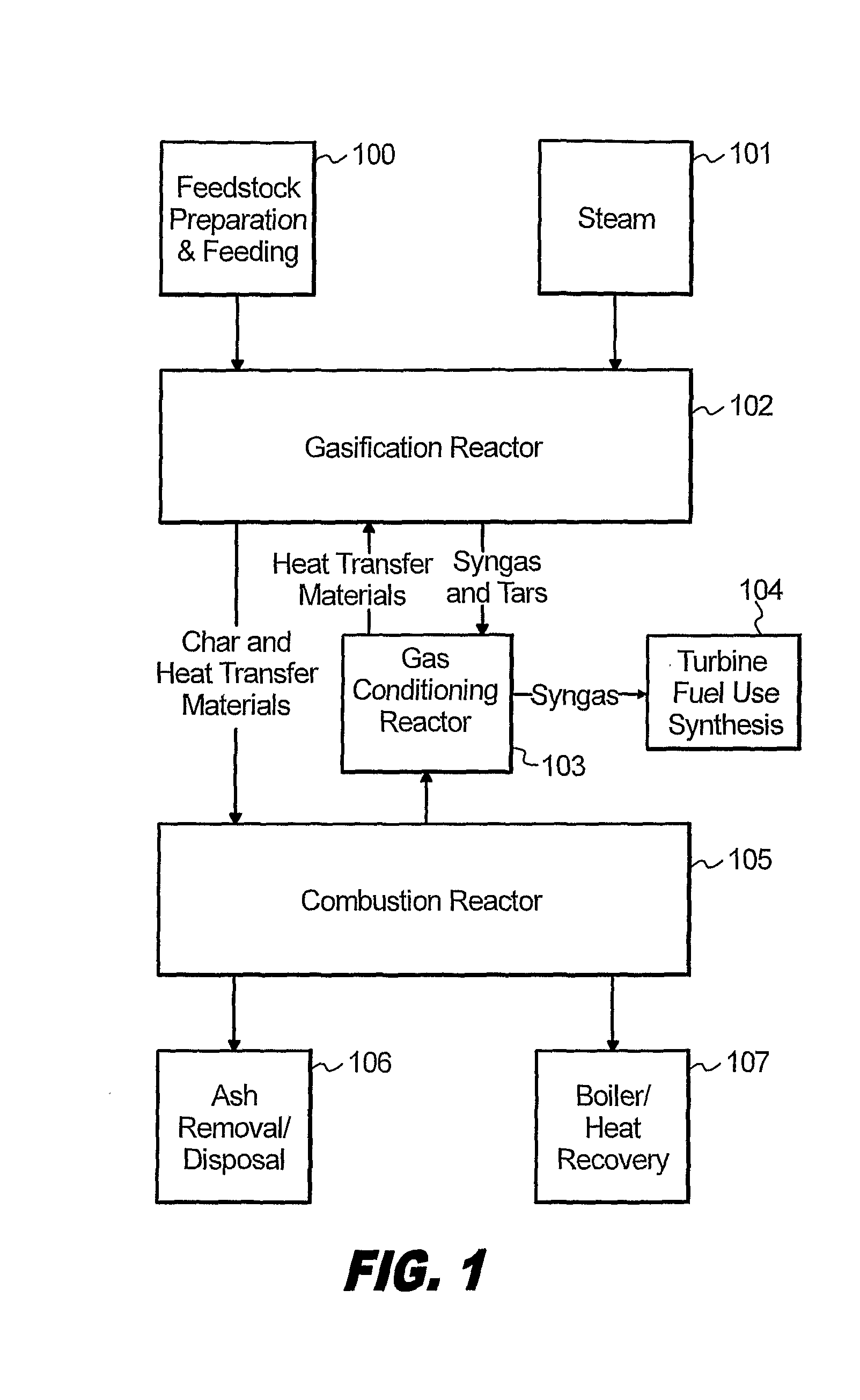

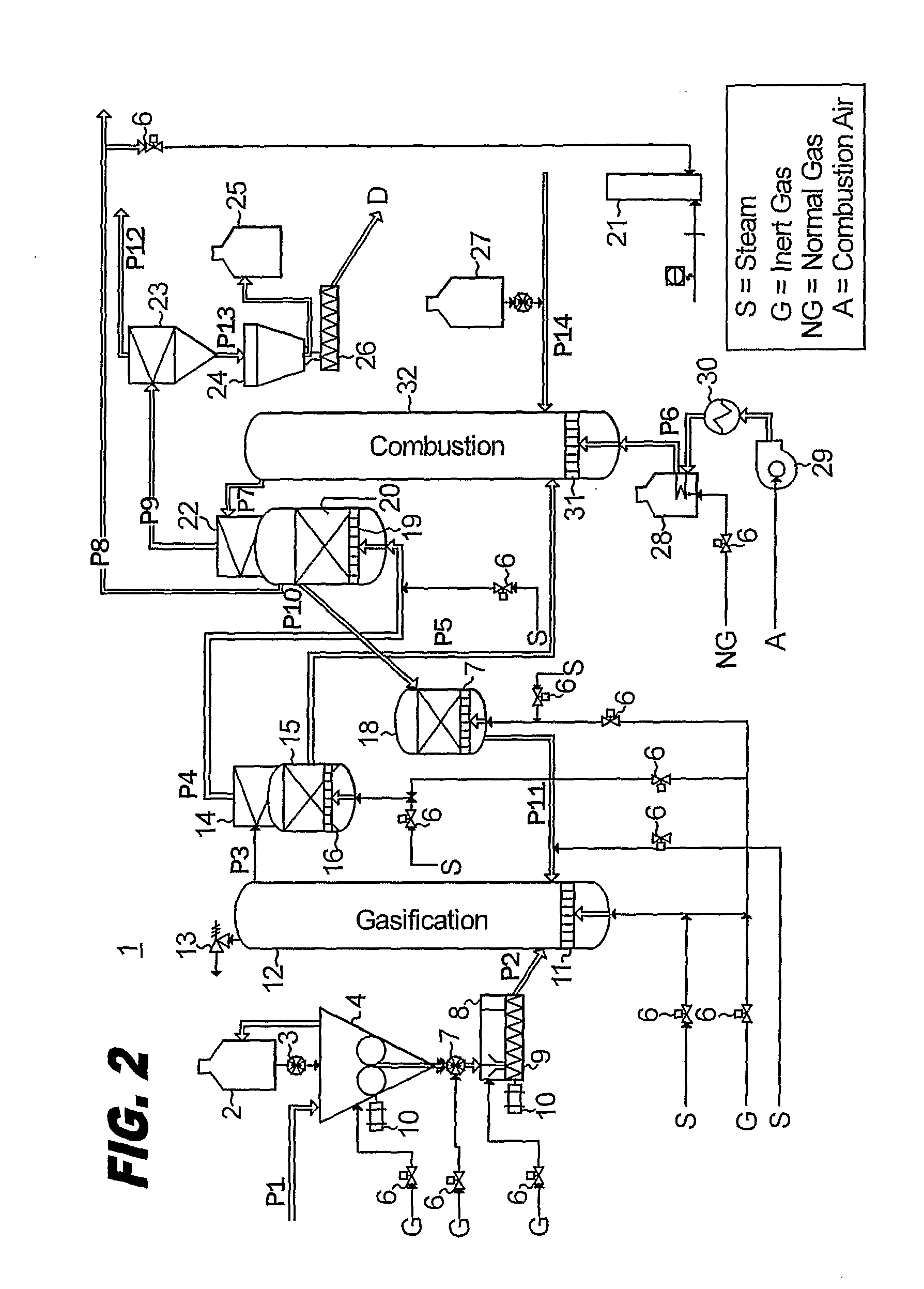

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

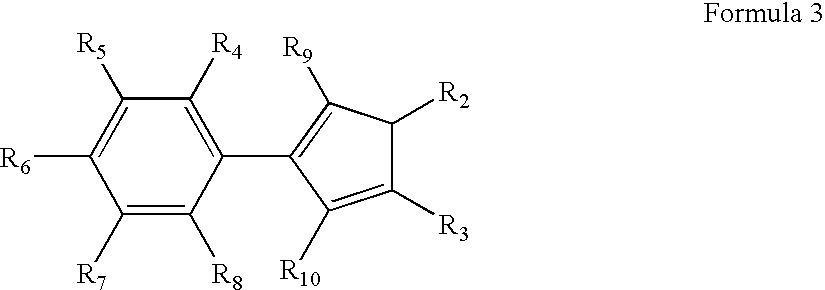

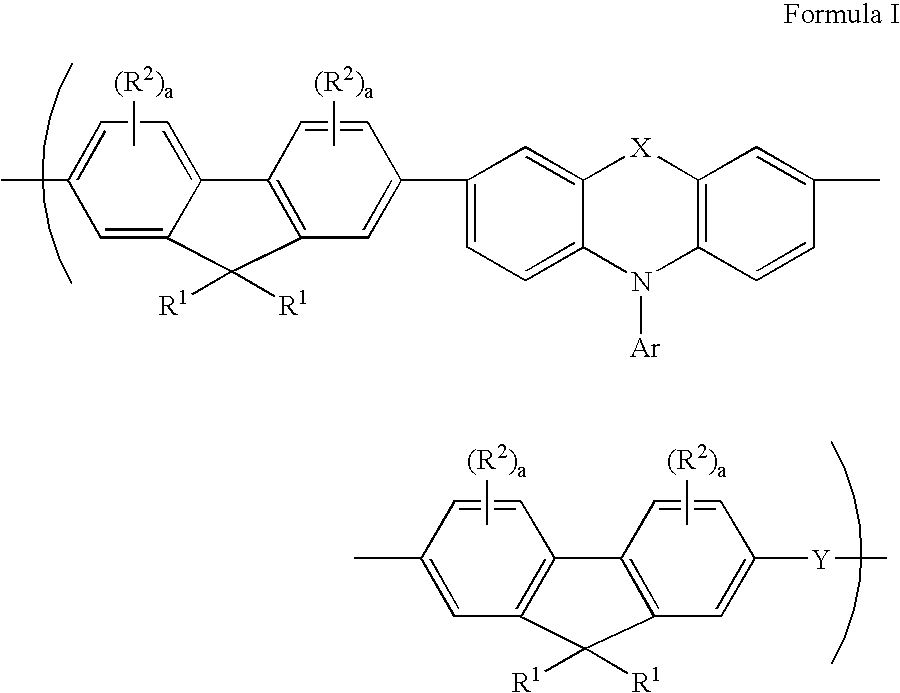

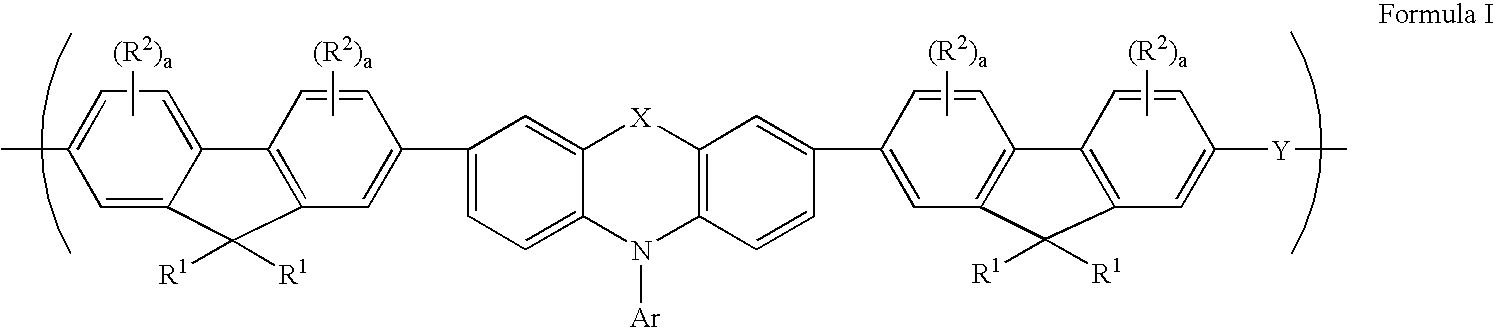

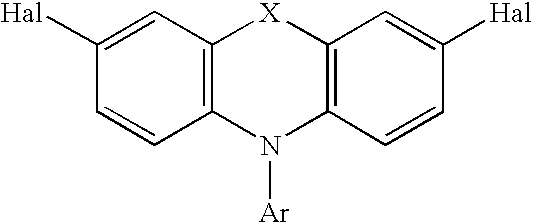

Tricyclic arylamine containing polymers and electronic devices therefrom

InactiveUS20040127666A1Improve conductivityImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingArylMedicinal chemistry

A composition comprising a polymer comprising a repeat unit of Formula I.: wherein R<1 >is independently in each occurrence H, C1-40 hydrocarbyl or C3-40 hydrocarbyl containing one or more S, N, O, P or Si atoms, or both of R<1 >together with the 9-carbon on the fluorene, may form a C5-20 ring structure which may contain one or more S, N, or O atoms; R2 is independently in each occurrence C1-20 hydrocarbyl, C1-20 hydrocarbyloxy, C1-20 thioether, C1-20 hydrocarbyloxycarbonyl, C1-20 hydrocarbylcarbonyloxy, or cyano; a is independently in each occurrence, 0 or 1; X is O, S, SO2, C(R<3>)2 or N-R<3 >wherein R<3 >is aryl or substituted aryl of C6 to C40, aralkyl of C6 to C24, or alkyl of C1 to C24. Preferably R<3 >is aryl of C6 to C24 and more preferably R<3 >is an alkylated aryl group of C6 to C24; Ar is an aryl or heteroaryl group of C6 to C40 or substituted aryl or heteroaryl group of C6 to C40, preferably C6-C24, and most preferably C6-C14. Y is a conjugated moiety that can vary in each occurrence of the repeat unit.

Owner:DOW GLOBAL TECH LLC

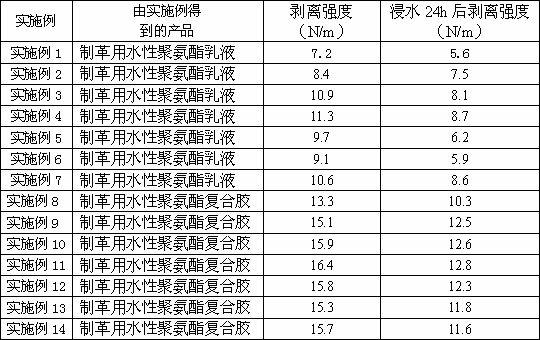

Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

InactiveCN102618202ATroubleshoot MigrationOvercome the problem that the performance cannot fully meet the requirements of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention discloses water-based polyurethane composite adhesive for tanning and a preparation method and application of the composite adhesive, belongs to the technical field of water-based polyurethane composite adhesive preparation methods, and in particular relates to a method for preparing composite adhesive in the fields of artificial leather and synthetic leather. The method for preparing the water-based polyurethane composite adhesive for tanning is characterized by comprising the following steps of: reacting polyol polymer and isocyanate, adding chain extender, hydrophilic chain extender, cross linker, catalyst and solvent, reacting, cooling and emulsifying, to obtain emulsion; and mixing the emulsion, curing agent, wetting agent, tackifier, adsorbent and thickening agent uniformly, and thus obtaining the hot-melt adhesive for artificial leather adhesive layers. The water-based polyurethane composite adhesive for tanning is used for compounding polyvinyl chloride (PVC) / cloth for artificial leather of luggage and clothes. The prepared water-based polyurethane composite adhesive for tanning has high adhesive fastness and good water and solvent resistance, and can be applied to processes of knife coating, roll coating and the like of binding materials of middle layers of artificial leather and synthetic leather in the fields of textiles, leather processing and the like.

Owner:江阴市诺科生物新材料科技有限公司

Process for increasing the molecular weight of polyamides

A process for condensing polyamides to increase their molecular weight, using a compound having at least two carbonate units comprises using a polyamide which, as a result of its preparation, comprises from 5 to 500 ppm of phosphorus in the form of an acidic compound, and adding, to the polyamide, from 0.001 to 10% by weight of a salt of a weak acid, thus eliminating the inhibiting action of the phosphorus compound.

Owner:EVONIK DEGUSSA GMBH

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059144AThe load is easy to controlEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkeneMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

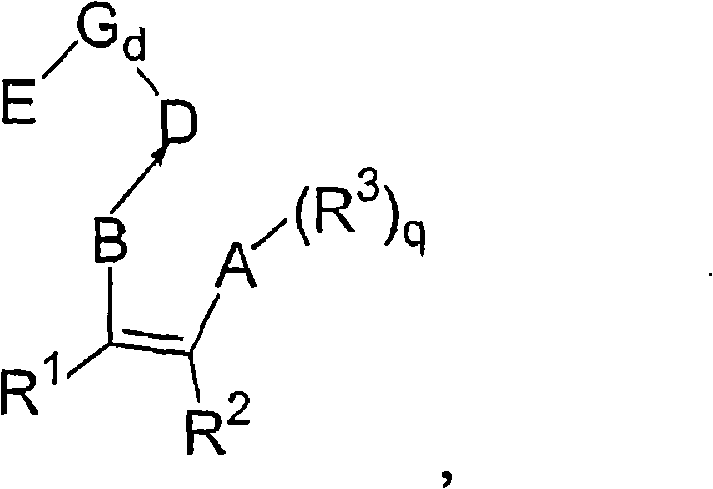

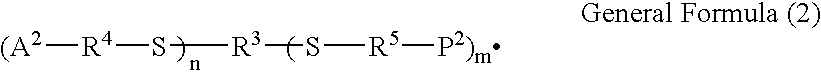

Ink composition and image recording method and image recorded matter using same

ActiveUS20080241485A1Excels dispersivityExcels stabilityMeasurement apparatus componentsDecorative surface effectsEpoxyPolymer science

An ink composition containing at least a polymerizable composition, a pigment, and a polymer represented by General Formula (1):where R1 represents an (m+n)-valent organic linking group, R2 represents a single bond or divalent organic linking group; A1 represents a monovalent organic group having a pigment adsorption structure that contains at least one selected from organic pigment structure, heterocyclic structure, acidic group, group having a basic nitrogen atom, urea group, urethane group, group having a coordinating oxygen atom, hydrocarbon group having 4 or more carbon atoms, alkoxysilyl group, epoxy group, isocyanate group, and hydroxyl group; the n groups A1 and bonds or groups R2 may independently be the same or different; “m” is 1 to 8, “n” is 2 to 9, and m+n is 3 to 10; P1 represents a polymer skeleton; and the m skeletons P1 may be the same or different.

Owner:FUJIFILM CORP

Polymeric marker with high radiopacity for use in medical devices

InactiveUS20050255317A1Overcomes shortcomingImprove fill ratePowder deliverySurgeryPolymer resinRadiopaque agent

High radiopacity is achieved in a polymeric marker by combining a polymeric resin, a powdered radiopaque agent having uniformly shaped particles of a specific particle size distribution, and a wetting agent. The method to produce the marker calls for the blending and pelletization of these materials followed by extrusion onto support beading. The resulting supported tubing is subsequently cut to length with the beading still in place. After ejection of the beading remnant the marker is slipped into place on the device to be marked and attached by melt bonding. Marking of a guide wire allows lesions to be measured while the marking of balloon catheters allow the balloon to be properly positioned relative to a lesion.

Owner:ABBOTT CARDIOVASCULAR

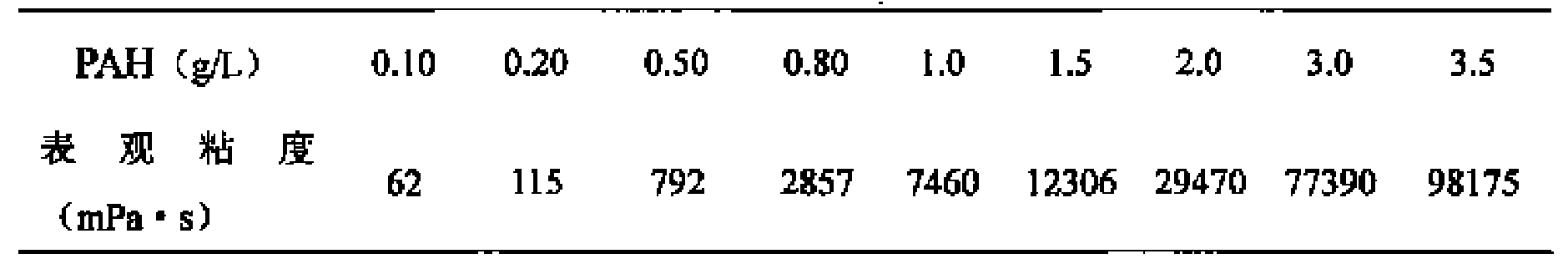

Temperature-resistant salt-resistant efficient gel, and preparation and use thereof

InactiveCN101475667AImprove solubilityGood viscosity increasing effectDrilling compositionSulfite saltAging resistance

The invention discloses a temperature resistant salt tolerant high efficiency gel and a preparation method and application thereof. The preparation method is characterized in that the preparation method comprises the following steps: preparing a comb-shaped associated copolymer PAH containing macromonomers and functional hydrophobic monomers into an aqueous solution having the concentration of 0.1 to 4g / L, the crosslinking agent concentration of 0.01 to 1.0g / L, the surfactant concentration of 0.01 to 8mmol / L and the sodium sulfite thermal stabilizer concentration of 0.005 to 1.0g / L; adding the aqueous solution into a mixing container with a stirring device; stirring the aqueous solution evenly at the room temperature; regulating the pH value of the solution to be equal to between 4 and 11, and obtaining a temperature resistant salt tolerant high efficiency gel polymer solution system used for tertiary oil recovery and scavenge, displacement modification, profile modification or water shutoff. The polymer solution system has micro-crosslinking to form the gel during the flowage inside the oil reservoir. The gel has good elasticity, not easy dehydration, stable gelling performance, and excellent tackification, temperature resistance, salt tolerance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

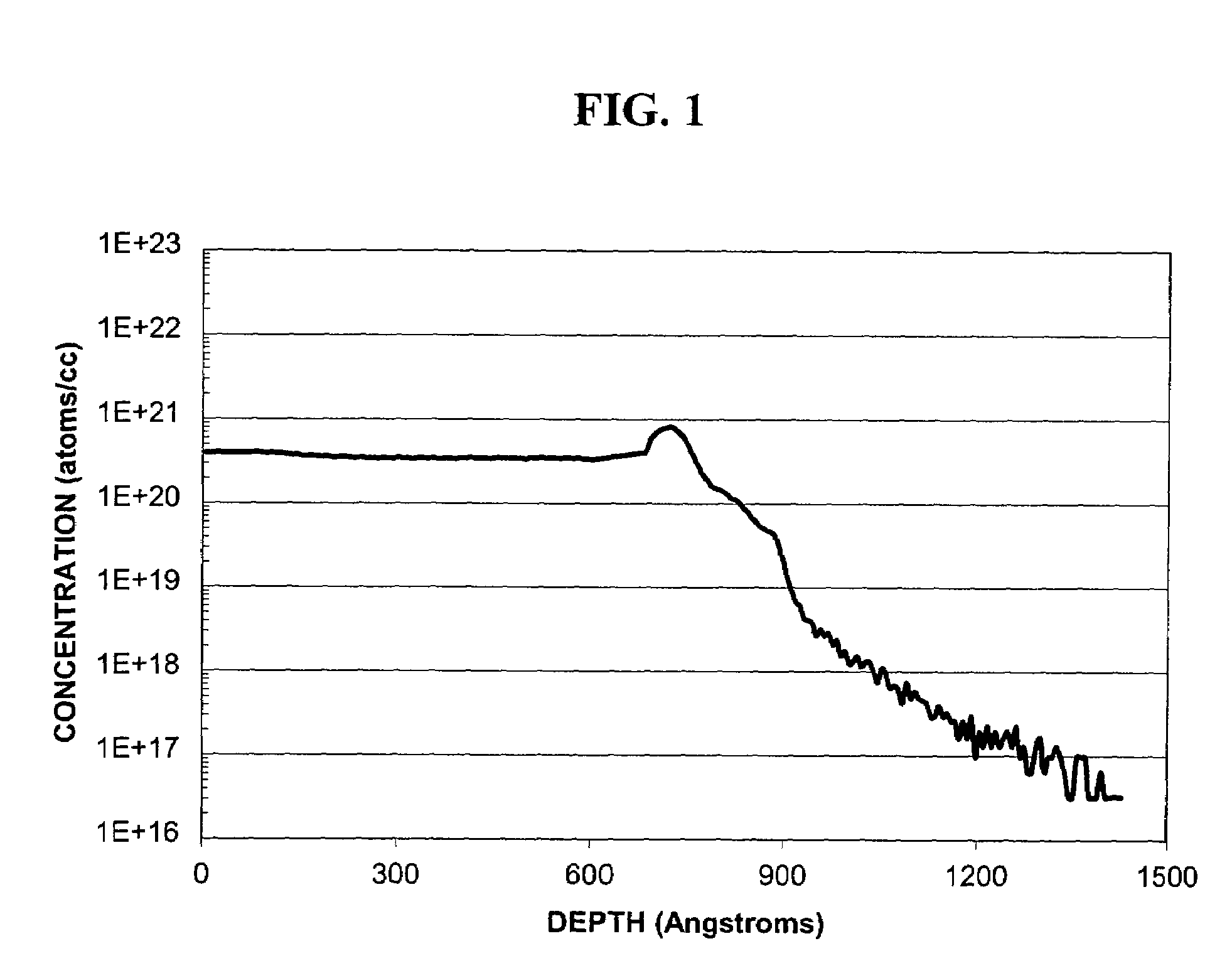

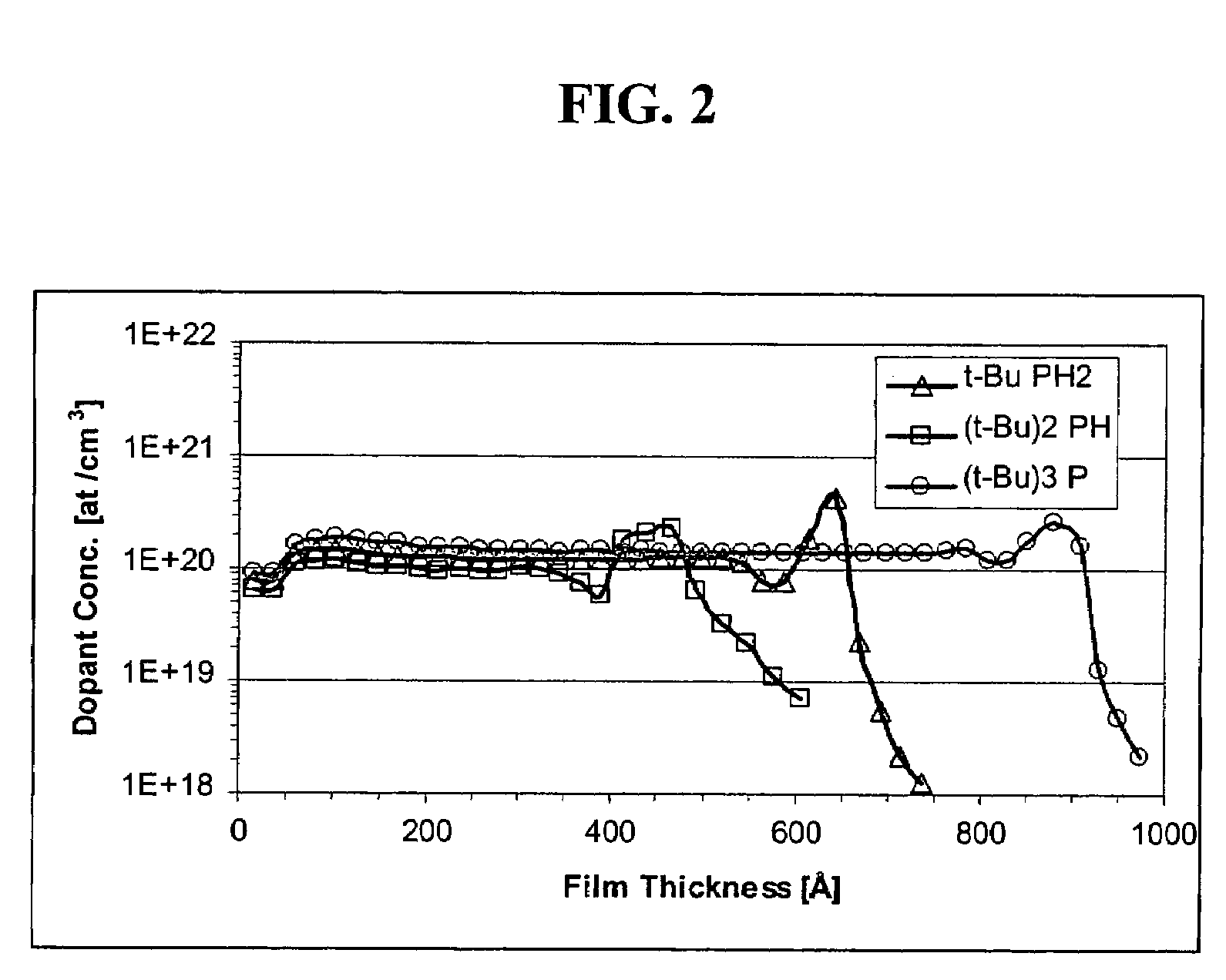

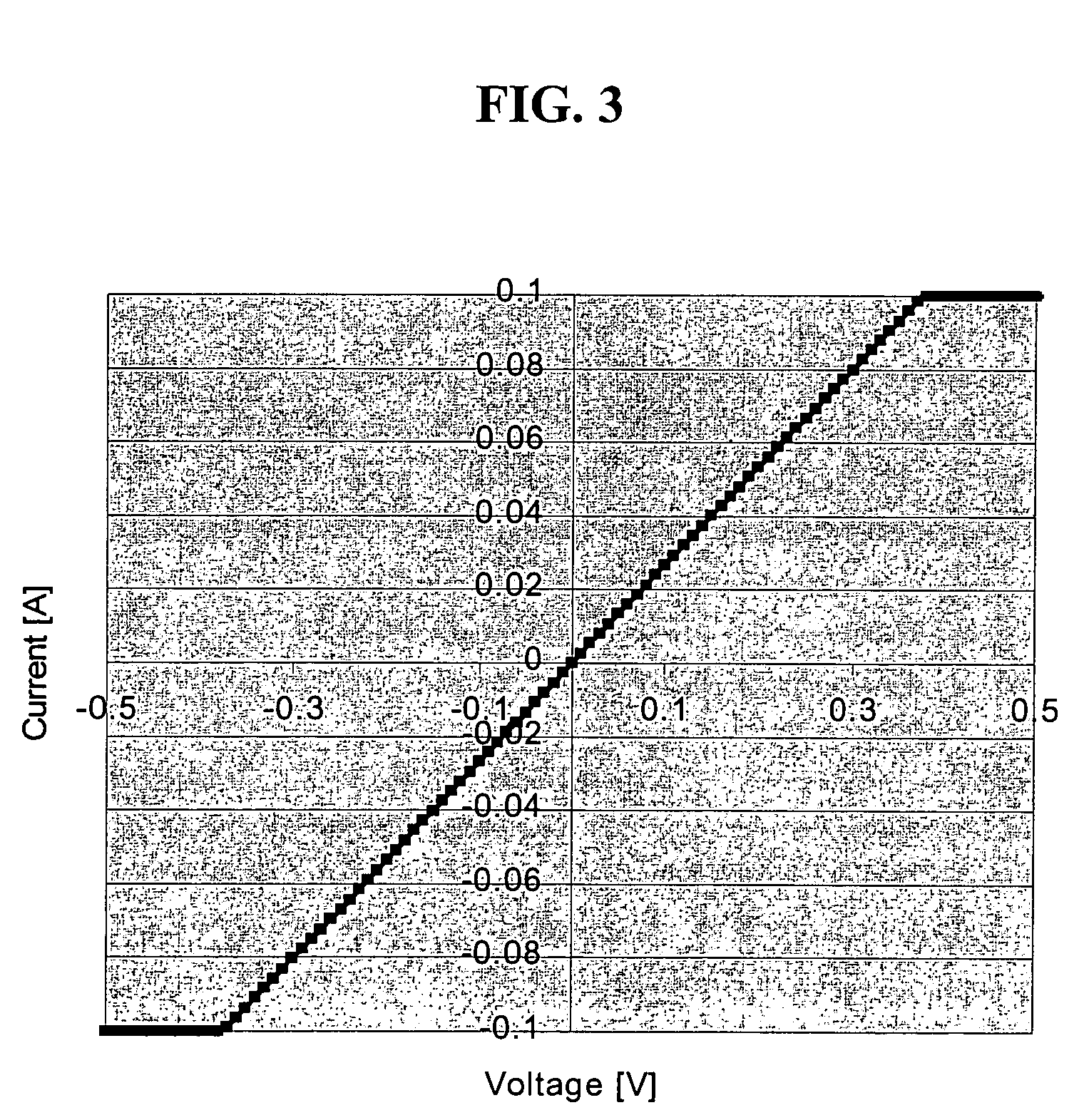

Methods of forming a doped semiconductor thin film, doped semiconductor thin film structures, doped silane compositions, and methods of making such compositions

ActiveUS7314513B1Reduce volatilityHigh molecular weightOther chemical processesSemiconductor/solid-state device manufacturingIsomerizationElectron

Methods for forming doped silane and / or semiconductor thin films, doped liquid phase silane compositions useful in such methods, and doped semiconductor thin films and structures. The composition is generally liquid at ambient temperatures and includes a Group IVA atom source and a dopant source. By irradiating a doped liquid silane during at least part of its deposition, a thin, substantially uniform doped oligomerized / polymerized silane film may be formed on a substrate. Such irradiation is believed to convert the doped silane film into a relatively high-molecular weight species with relatively high viscosity and relatively low volatility, typically by cross-linking, isomerization, oligomerization and / or polymerization. A film formed by the irradiation of doped liquid silanes can later be converted (generally by heating and annealing / recrystallization) into a doped, hydrogenated, amorphous silicon film or a doped, at least partially polycrystalline silicon film suitable for electronic devices. Thus, the present invention enables use of high throughput, low cost equipment and techniques for making doped semiconductor films of commercial quality and quantity from doped “liquid silicon.”

Owner:ENSURGE MICROPOWER ASA

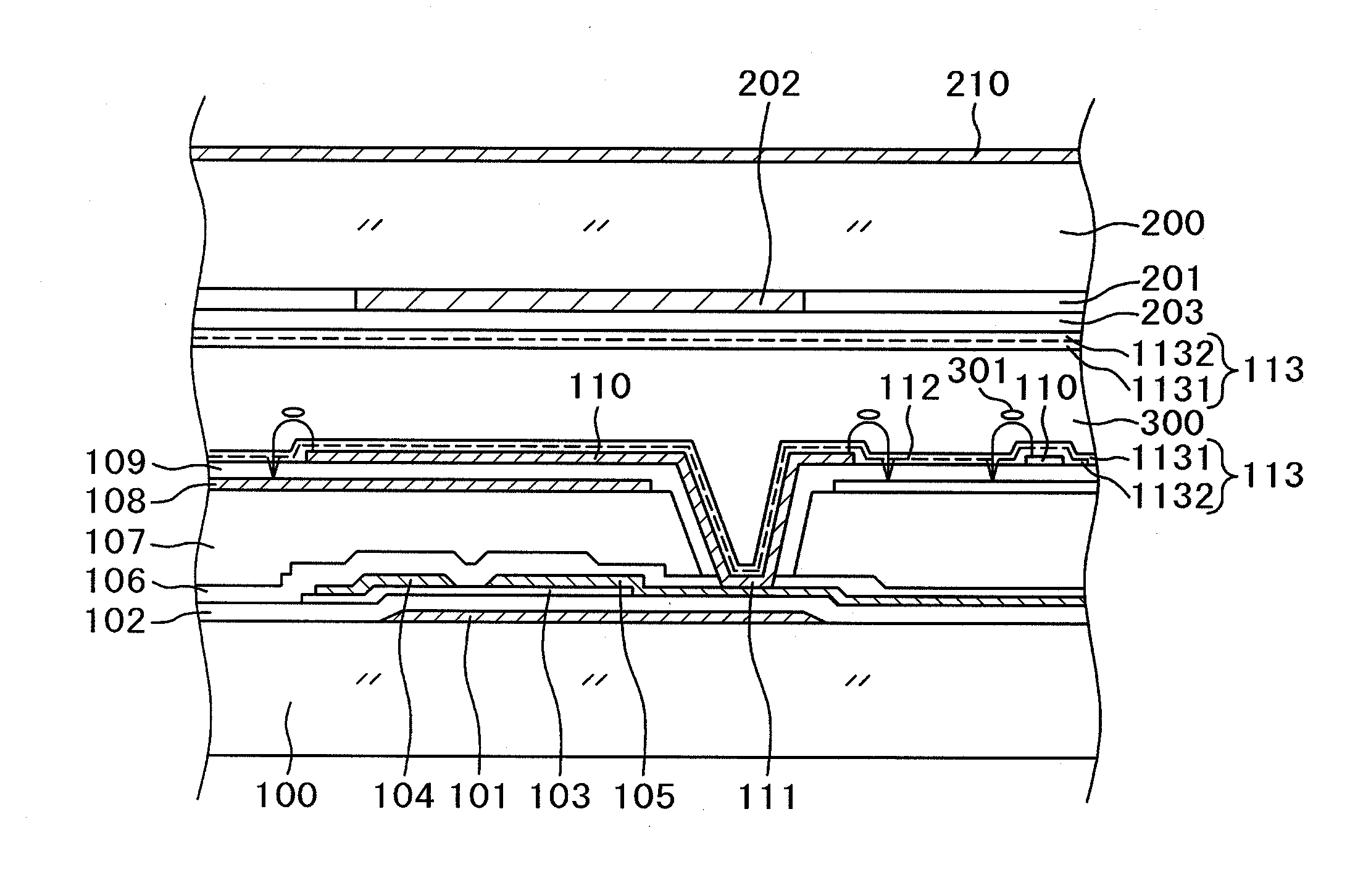

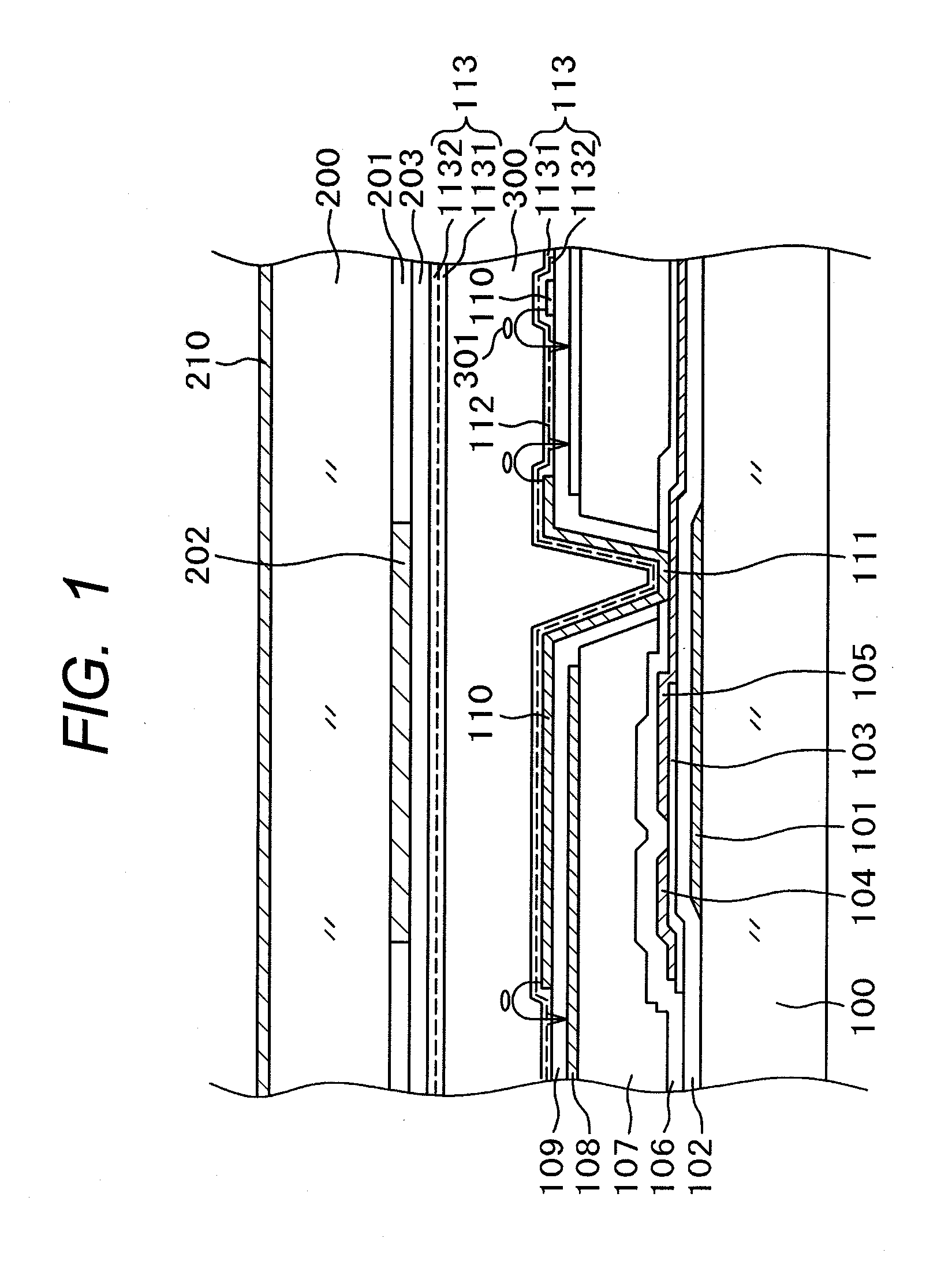

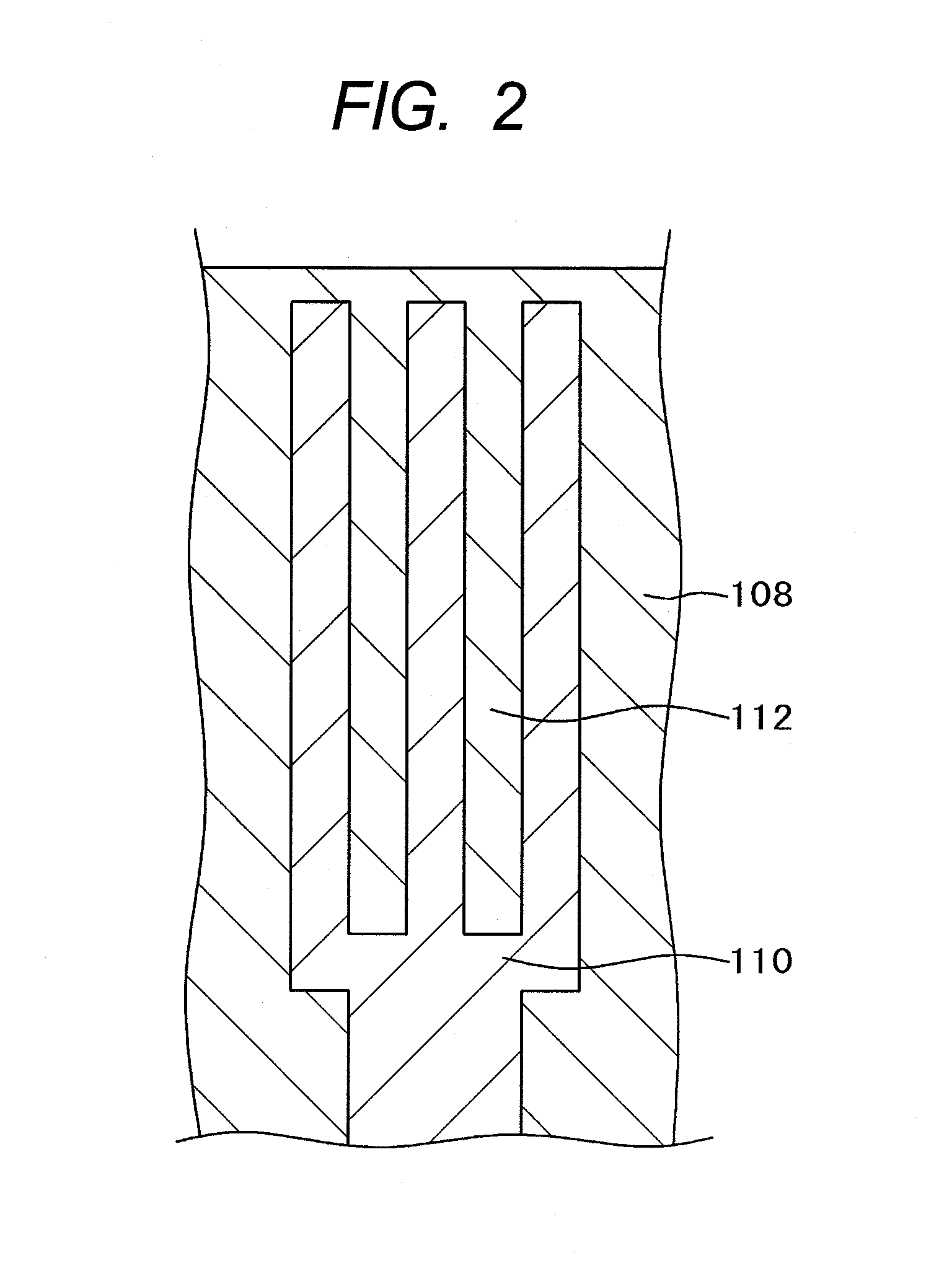

Liquid crystal display device

ActiveUS20110199565A1High film strengthLess afterimageLiquid crystal compositionsSolid-state devicesLiquid-crystal displayUltraviolet lights

This invention enables forming a photo-alignment film having a large LC anchoring strength in an IPS type liquid crystal display device. An alignment film is adapted to have a two-layer structure including a photo-alignment film and an alignment film with enhanced film strength. The photo-alignment film is formed of a precursor of polyamide acid ester, 80 percent or more of which is polyamide acid ester including cyclobutane. The alignment film with enhanced film strength is formed of a precursor of polyamide acid. After irradiating the substrate with ultraviolet light for photo-alignment, the substrate is heated. Thus, it is possible to achieve a high LC anchoring strength of the alignment film as the whole for photo-alignment, without degrading the mechanical strength of the alignment film with enhanced film strength.

Owner:JAPAN DISPLAY INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com