Patents

Literature

5365 results about "Tackifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tackifiers are chemical compounds used in formulating adhesives to increase the tack, the stickiness of the surface of the adhesive. They are usually low-molecular weight compounds with high glass transition temperature. At low strain rate, they provide higher stress compliance, and become stiffer at higher strain rates.

Aqueous-based tackifier fluids and methods of use

InactiveUS7131491B2Stabilize the proppant packSynthetic resin layered productsCellulosic plastic layered productsParticulatesTackifier

The present invention relates to aqueous based tackifier fluids and their use in stabilizing particulates in propped fractures. Some embodiments of the present invention provide methods of creating a proppant pack in a subterranean formation, comprising introducing an aqueous servicing fluid comprising proppant particulates, wherein at least some of the proppant particulates are at least partially coated with an aqueous tackifier compound, into a subterranean fracture; and, activating the aqueous tackifier compound so as to form a proppant pack. Other embodiments provide methods of stabilizing a proppant pack comprising introducing an aqueous tackifier compound to at least a portion of an existing proppant pack; and, activating the aqueous tackifier compound so as to stabilize the proppant pack. Other embodiments provide servicing fluids comprising proppant particulates and an aqueous fluid wherein at least some of the proppant particulates are at least partially coated with an aqueous tackifier compound.

Owner:HALLIBURTON ENERGY SERVICES INC

Aqueous tackifier and methods of controlling particulates

Owner:HALLIBURTON ENERGY SERVICES INC

Methods for controlling migration of particulates in a subterranean formation

Method of treating a portion of a subterranean formation comprising: placing a pre-pad fluid into a portion of a subterranean formation wherein the pre-pad fluid comprises a low-viscosity aqueous tackifying composition that comprises an aqueous tackifier compound and an aqueous fluid; placing a fracturing fluid into the portion of the subterranean formation at a pressure sufficient to create or extend at least one fracture therein; and, activating the aqueous tackifier compound with an activator so as to consolidate the unconsolidated particulates. Method of consolidating unconsolidated particulates within a portion of a subterranean formation comprising: placing a foamed low-viscosity aqueous tackifying composition into a portion of a subterranean formation comprising unconsolidated particulates wherein the aqueous tackifying composition comprises an aqueous fluid, a foaming agent, and an aqueous tackifier compound; and, activating the aqueous tackifier compound with an activator so as to consolidate the unconsolidated particulates.

Owner:HALLIBURTON ENERGY SERVICES INC

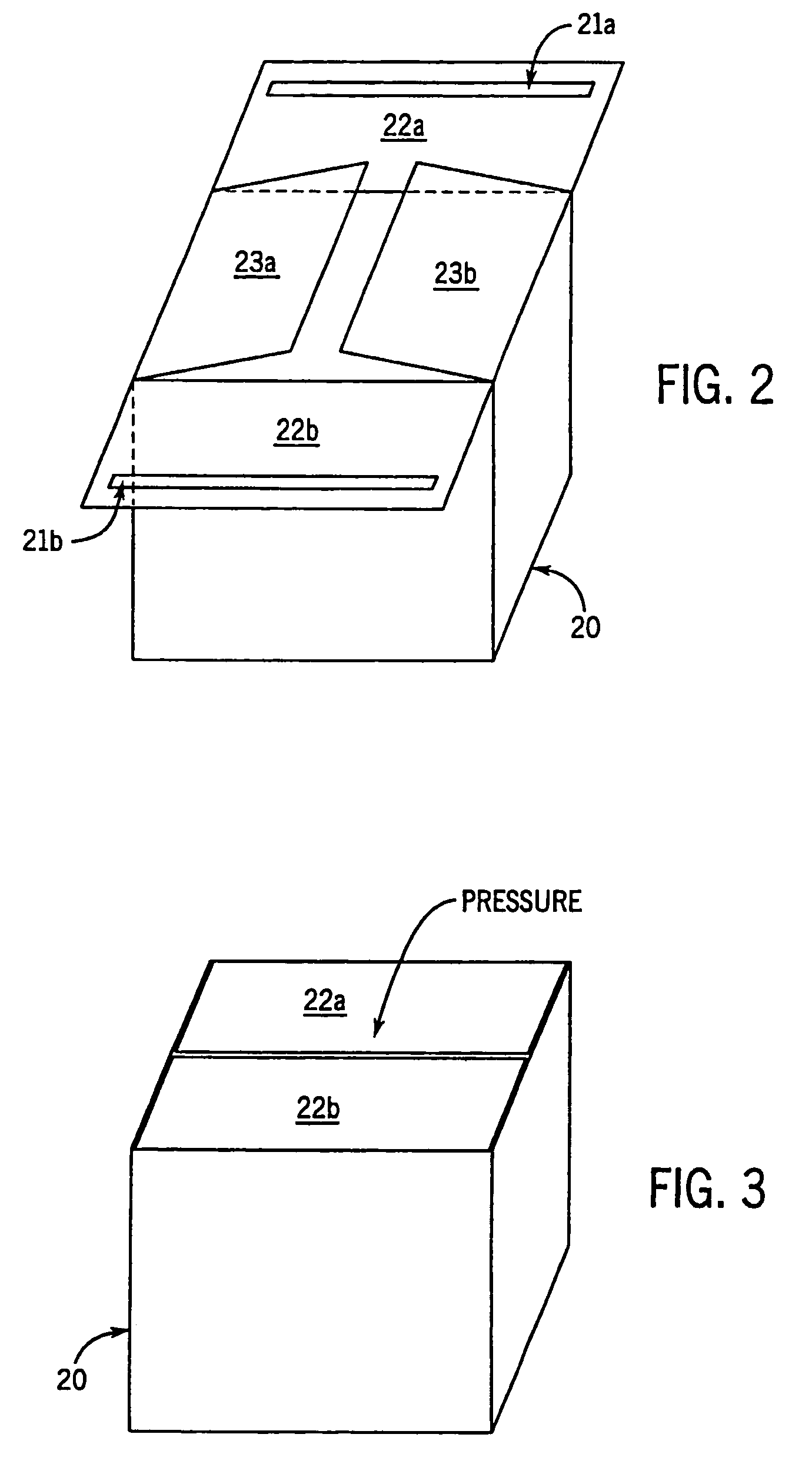

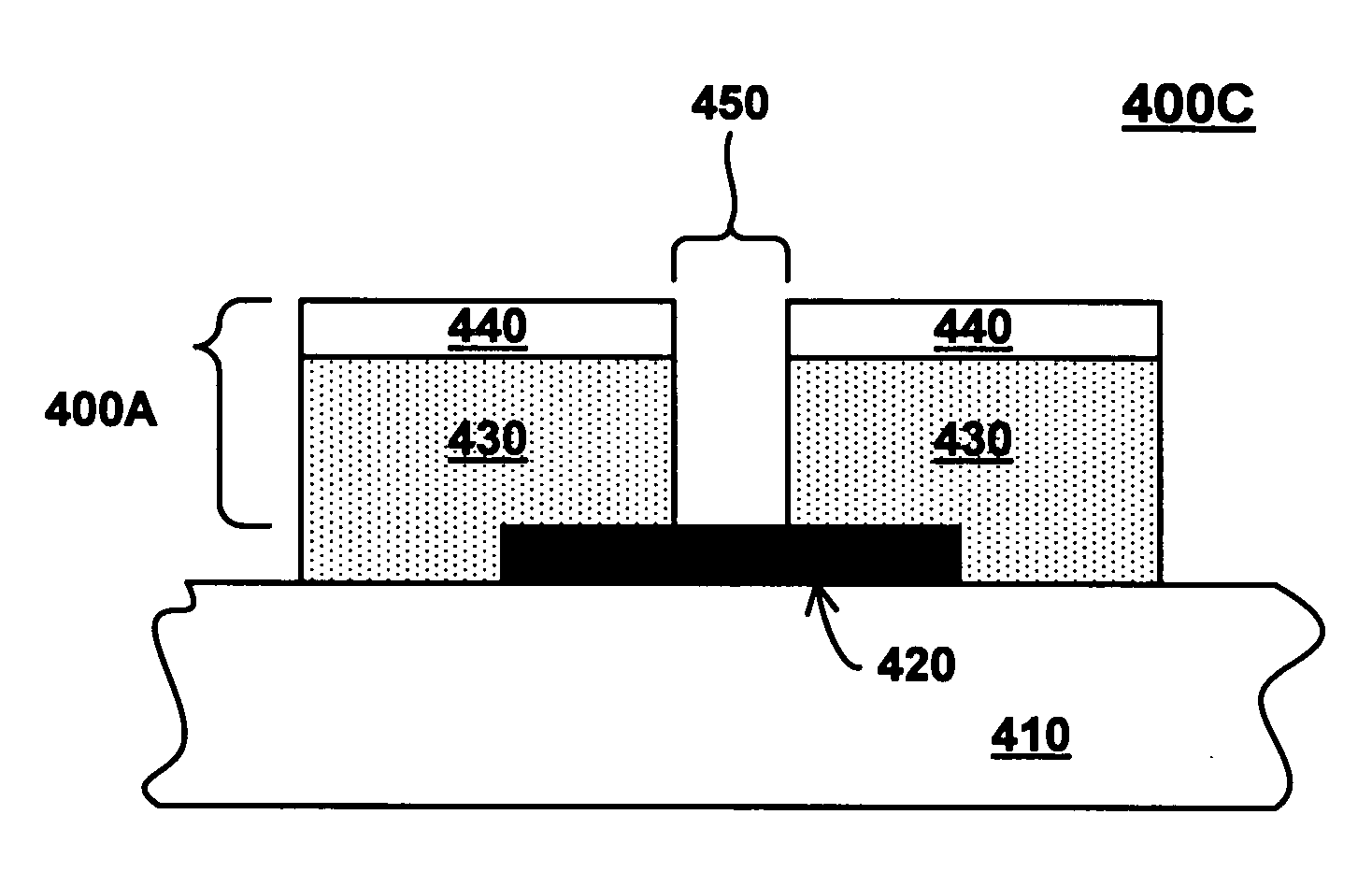

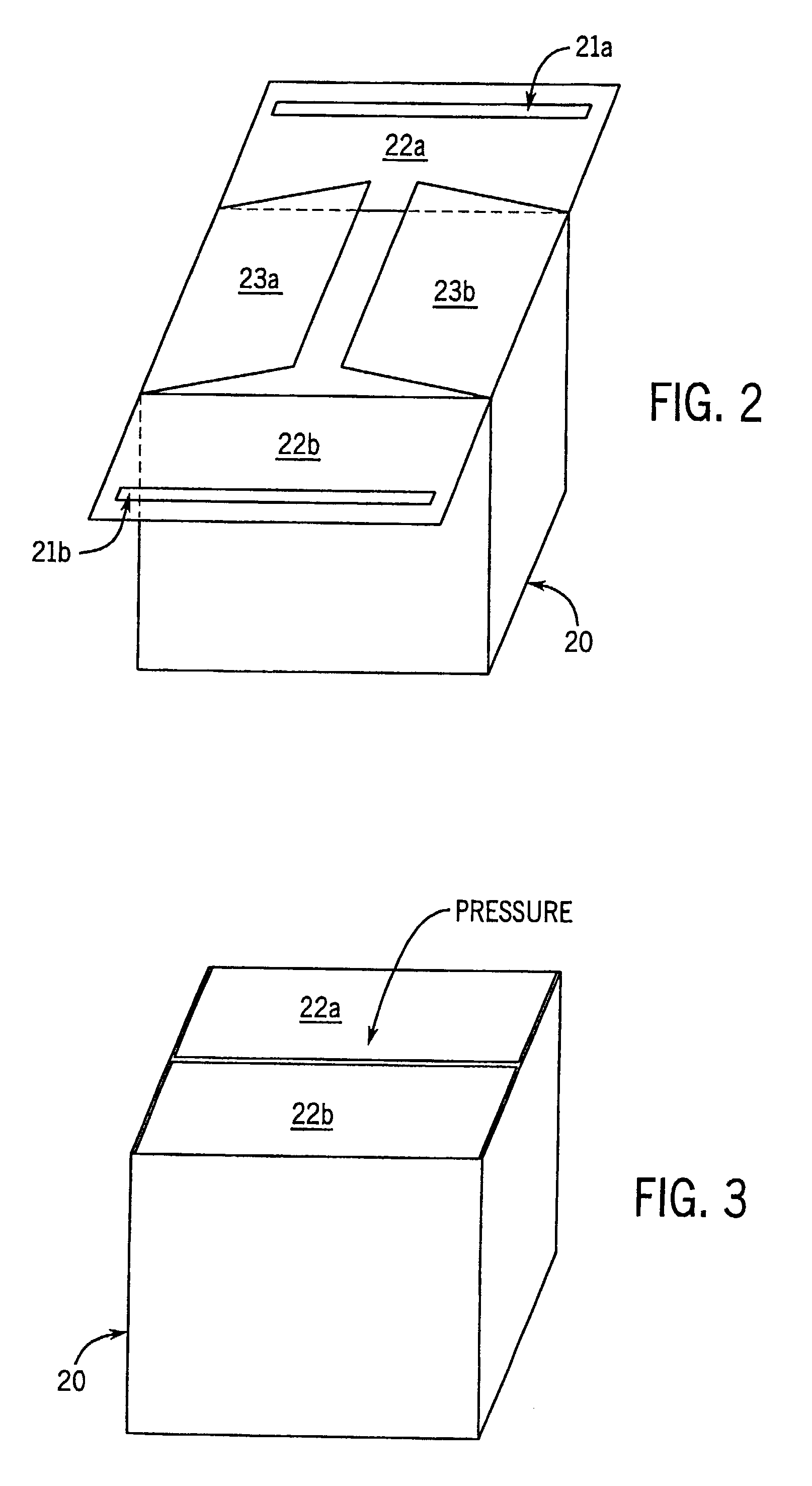

Expandable material

An expandable material and articles incorporating the same are disclosed. The material includes a polymeric admixture; a blowing agent; a curing agent; a tackifier; and optionally, a filler or fiber.

Owner:ZEPHYROS INC

Aqueous-based tackifier fluids and methods of use

InactiveUS20050274517A1Stabilize the proppant packSynthetic resin layered productsCellulosic plastic layered productsParticulatesTackifier

The present invention relates to aqueous based tackifier fluids and their use in stabilizing particulates in propped fractures. Some embodiments of the present invention provide methods of creating a proppant pack in a subterranean formation, comprising introducing an aqueous servicing fluid comprising proppant particulates, wherein at least some of the proppant particulates are at least partially coated with an aqueous tackifier compound, into a subterranean fracture; and, activating the aqueous tackifier compound so as to form a proppant pack. Other embodiments provide methods of stabilizing a proppant pack comprising introducing an aqueous tackifier compound to at least a portion of an existing proppant pack; and, activating the aqueous tackifier compound so as to stabilize the proppant pack. Other embodiments provide servicing fluids comprising proppant particulates and an aqueous fluid wherein at least some of the proppant particulates are at least partially coated with an aqueous tackifier compound.

Owner:HALLIBURTON ENERGY SERVICES INC

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene and a secondary polymer

InactiveUS7262251B2Broad processibilityImprove thermal stabilityOther chemical processesFilm/foil adhesivesWaxPlasticizer

Owner:ATO FINDLEY

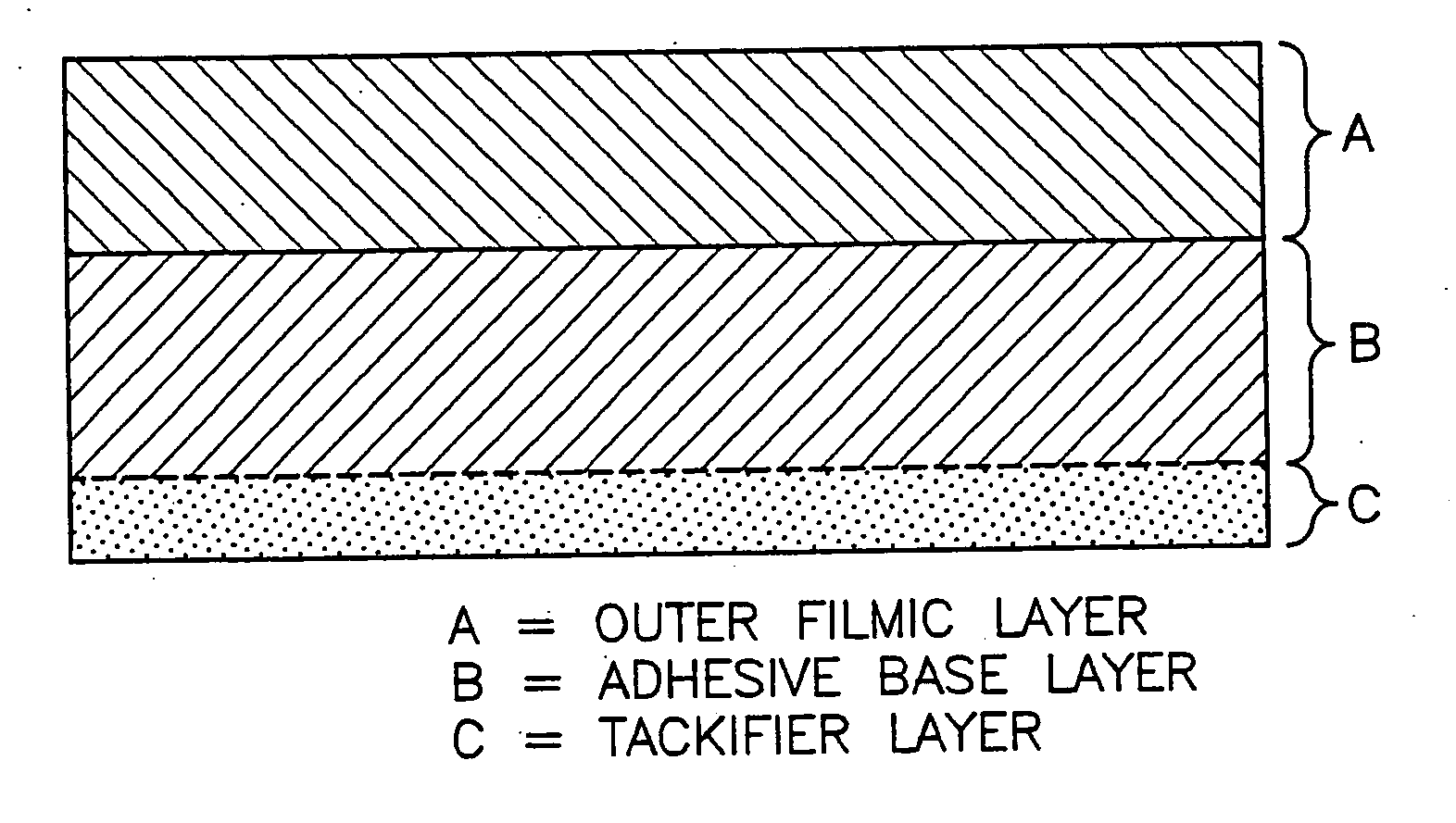

Pressure sensitive adhesive (PSA) laminates

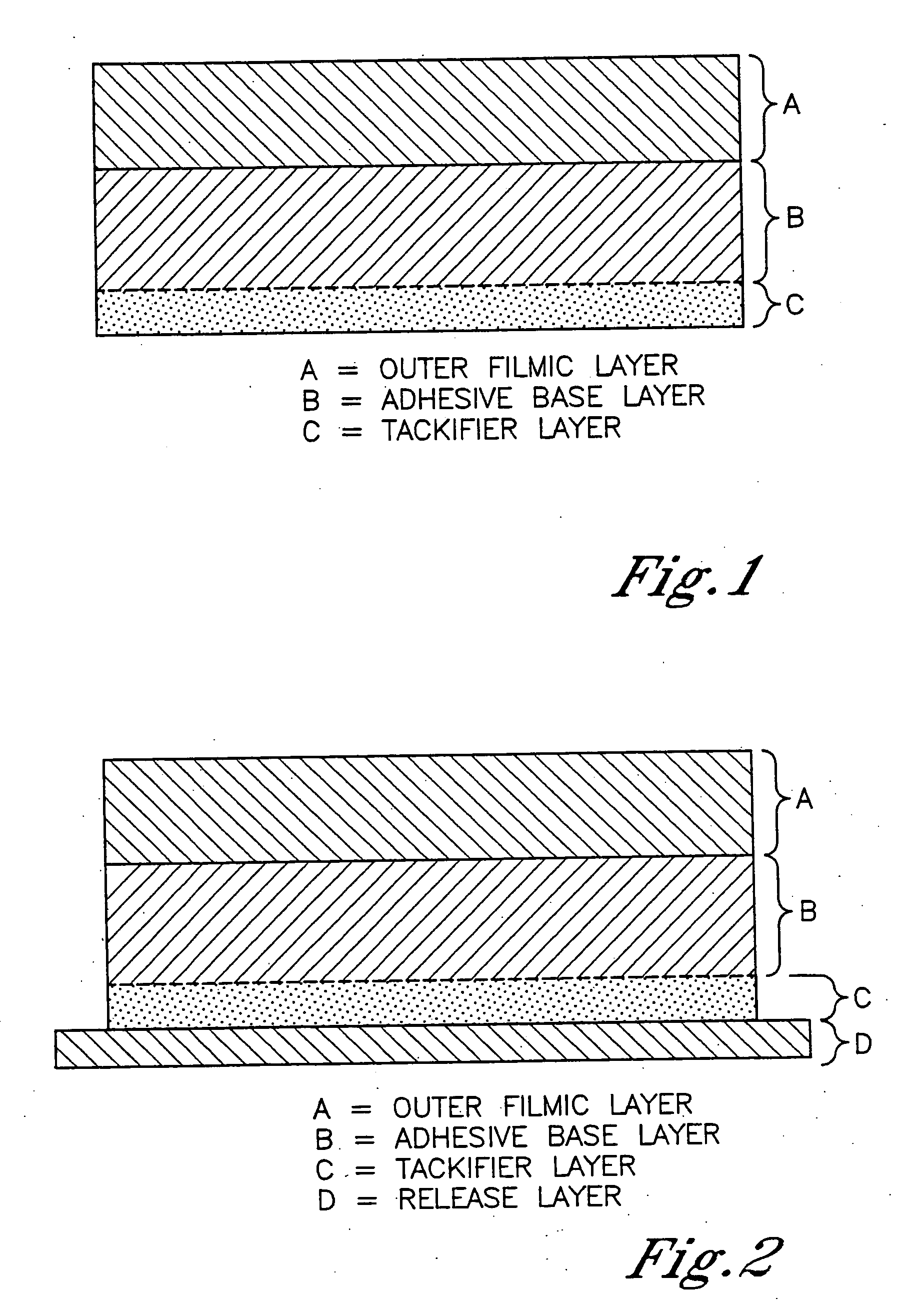

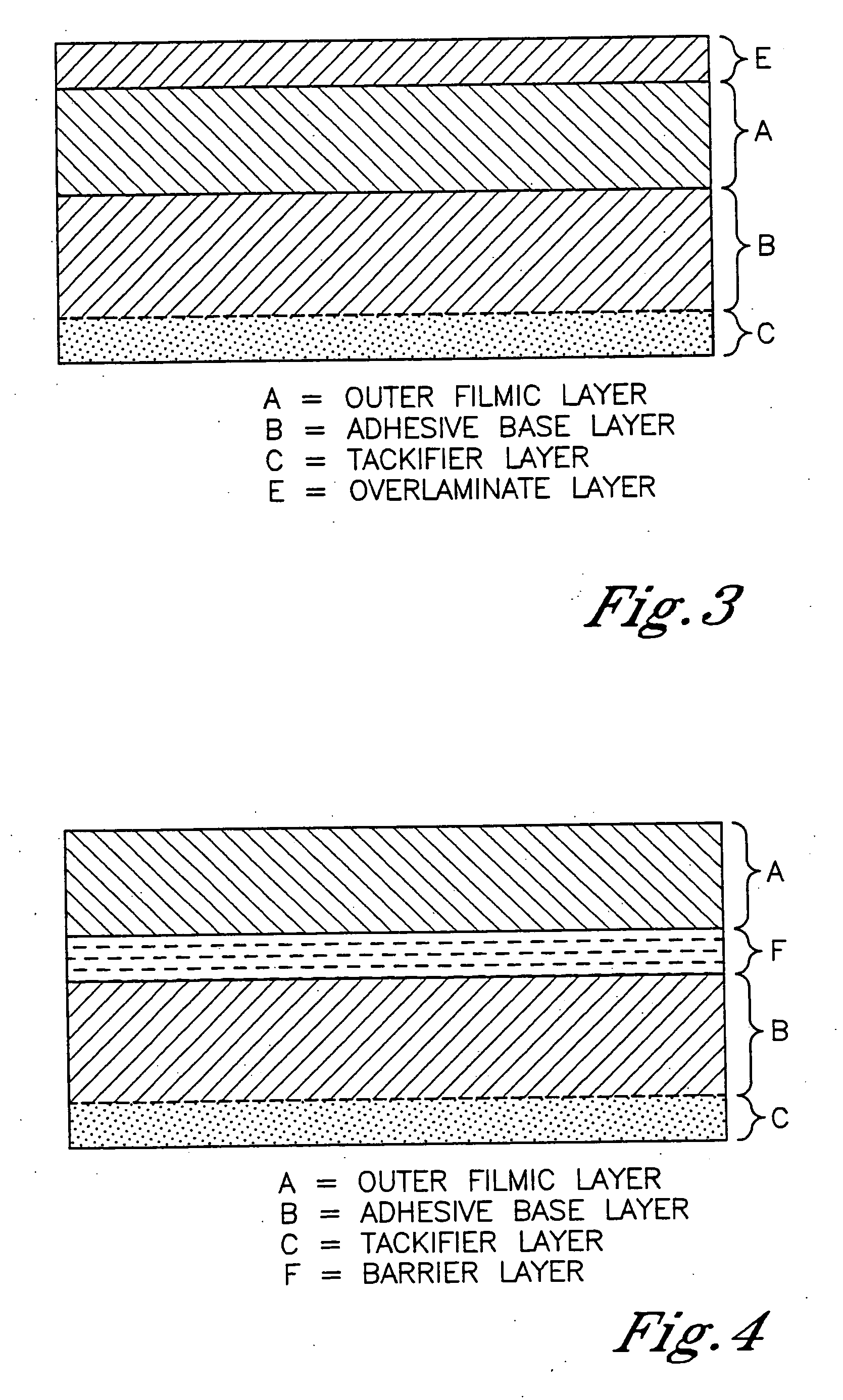

InactiveUS20070231571A1High cohesive strength polymerImprove cohesive strengthFlat articlesThin material handlingTackifierPolymer

A PSA laminate is provided comprising at least one non-adhesive laminate and at least one tackifier layer; wherein the non-adhesive laminate comprises at least one facestock layer and at least one adhesive base layer; wherein the facestock layer comprises at least one facestock material; wherein the adhesive base layer comprises at least one adhesive base polymer; wherein the tackifier layer comprises at least one tackifier; wherein the tackifier composition is not a PSA; and wherein the tackifier layer is applied to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate are also provided as well as articles comprises the PSA laminates.

Owner:EASTMAN CHEM CO

Hot melt sealant and foam-in-place gasketing material

ActiveUS20070042193A1Good balance of propertyImprove adhesionSynthetic resin layered productsOrganic dyesPolymer scienceSealant

A hot melt sealant and foam-in-place gasket composition based on a rubber such as ethylene propylene rubber (EPR) and / or ethylene propylene diene rubber (EPDM) and at least one semicrystalline olefinic polymer. The hot melt composition includes the rubber or a blend of rubbers in an amount of 5% to 50% by weight, at least one semicrystalline olefinic polymer in an amount of 5% to 40% by weight, at least one amorphous poly-α-olefin (APAO) polymer in an amount of 0% to 70% by weight, a compatible tackifier in an amount of 0% to 50% by weight, and a plasticizer in an amount of at least 30% by weight. The composition is particularly useful for foamed gasket applications as a replacement for pressure sensitive adhesive (PSA) coated foam tape.

Owner:BOSTIK INC

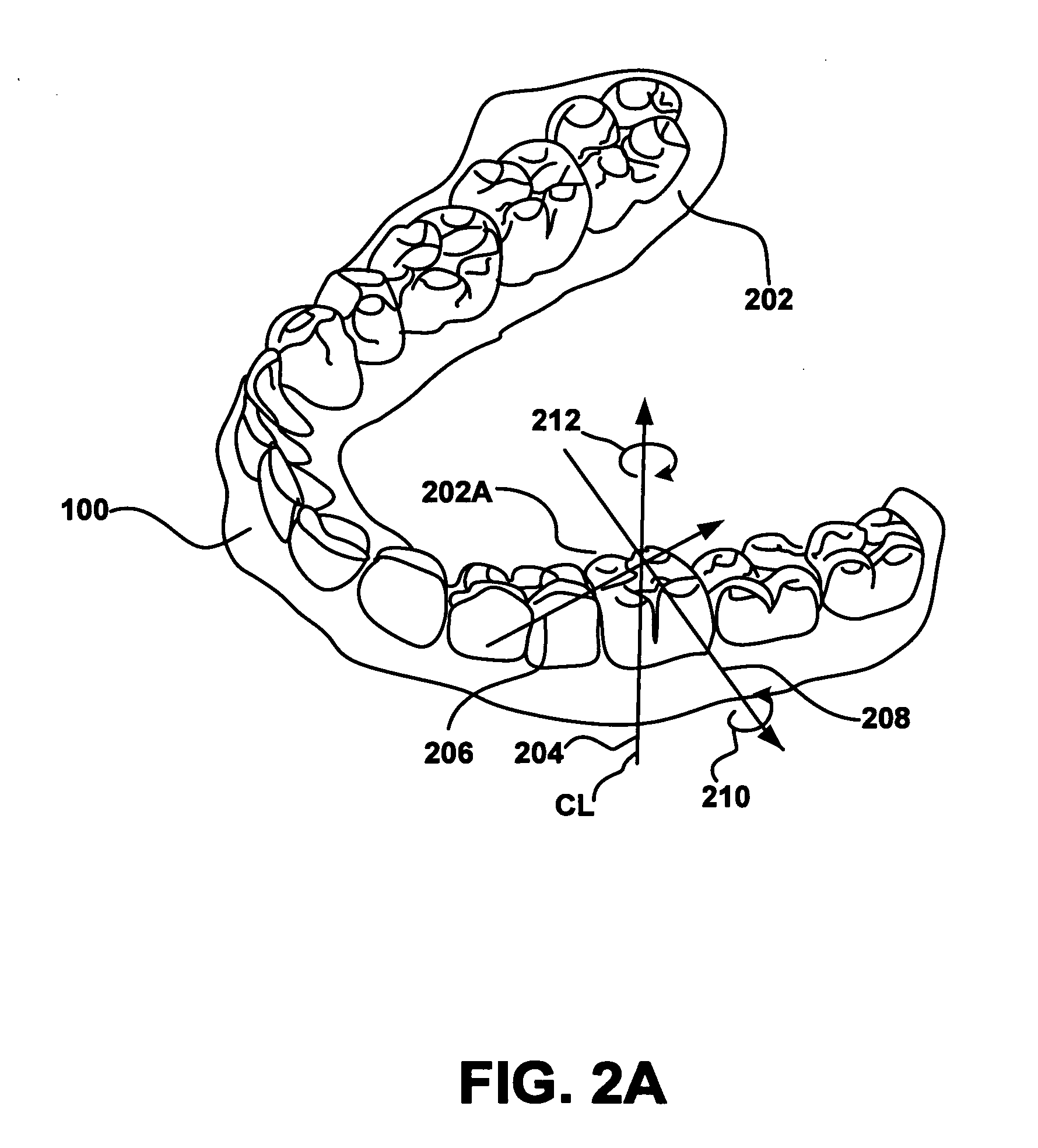

Moisture resistant pressure sensitive adhesives for orthodontic applications

A moisture resistant pressure sensitive adhesive for orthodontic application. Specifically, in accordance with one embodiment, a pressure sensitive adhesive (PSA) composition comprises a polymer base, and at least one bio-compatible hydrophobic tackifier. The PSA composition is structured such that the PSA composition is suitable for use in an oral environment.

Owner:ALIGN TECH

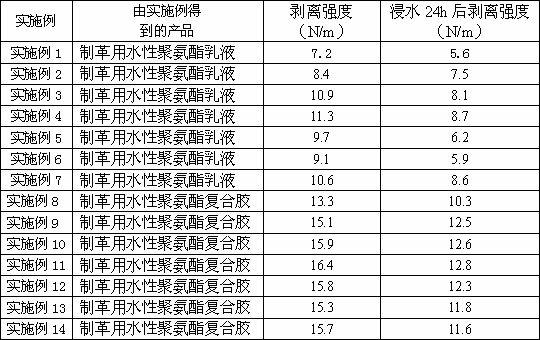

Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

InactiveCN102618202ATroubleshoot MigrationOvercome the problem that the performance cannot fully meet the requirements of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention discloses water-based polyurethane composite adhesive for tanning and a preparation method and application of the composite adhesive, belongs to the technical field of water-based polyurethane composite adhesive preparation methods, and in particular relates to a method for preparing composite adhesive in the fields of artificial leather and synthetic leather. The method for preparing the water-based polyurethane composite adhesive for tanning is characterized by comprising the following steps of: reacting polyol polymer and isocyanate, adding chain extender, hydrophilic chain extender, cross linker, catalyst and solvent, reacting, cooling and emulsifying, to obtain emulsion; and mixing the emulsion, curing agent, wetting agent, tackifier, adsorbent and thickening agent uniformly, and thus obtaining the hot-melt adhesive for artificial leather adhesive layers. The water-based polyurethane composite adhesive for tanning is used for compounding polyvinyl chloride (PVC) / cloth for artificial leather of luggage and clothes. The prepared water-based polyurethane composite adhesive for tanning has high adhesive fastness and good water and solvent resistance, and can be applied to processes of knife coating, roll coating and the like of binding materials of middle layers of artificial leather and synthetic leather in the fields of textiles, leather processing and the like.

Owner:江阴市诺科生物新材料科技有限公司

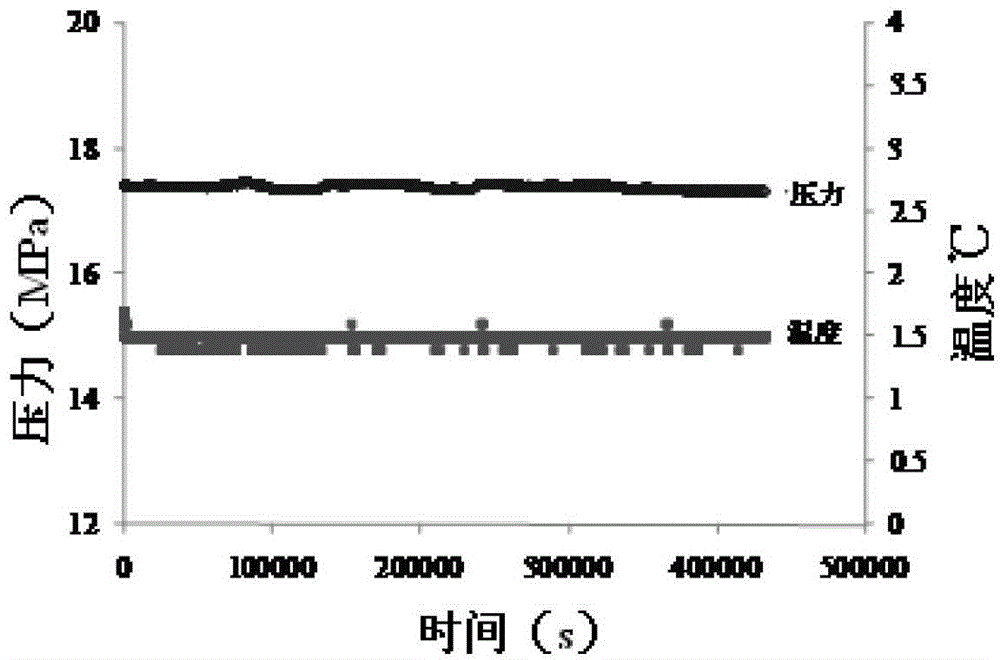

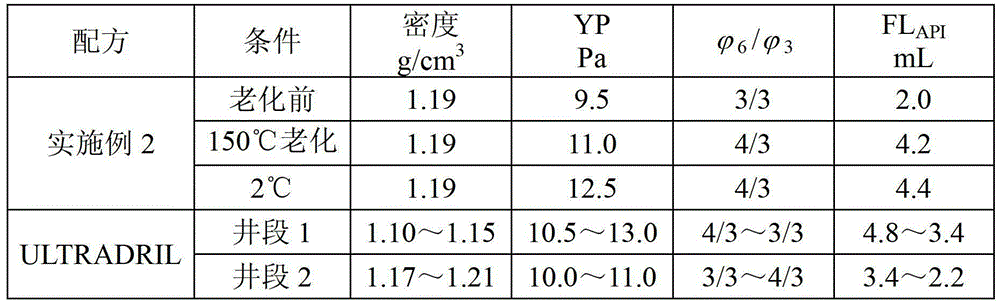

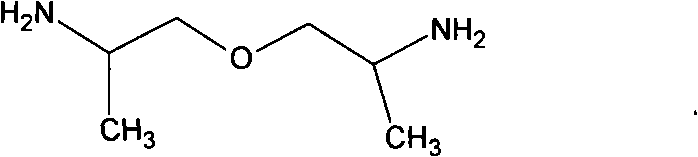

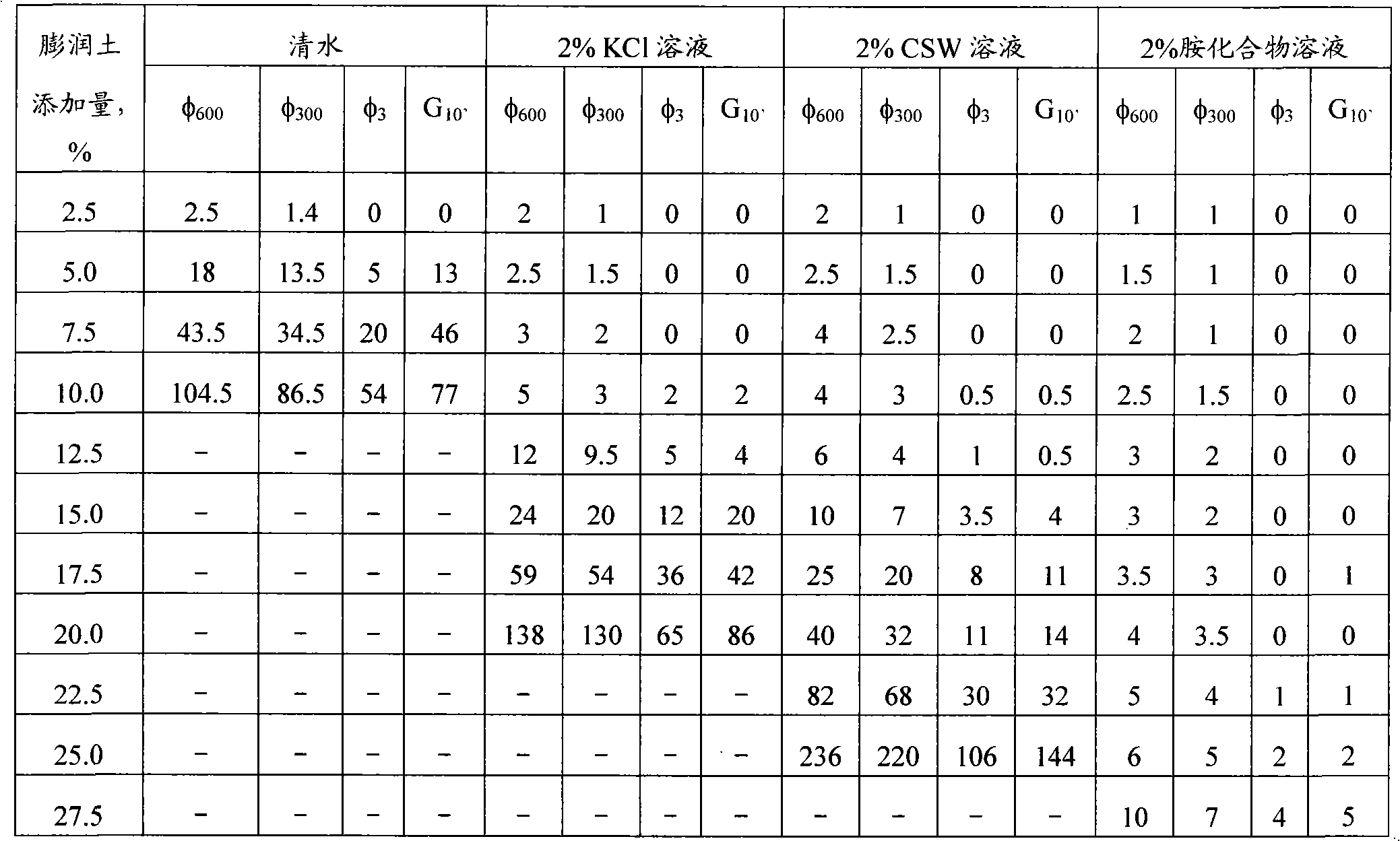

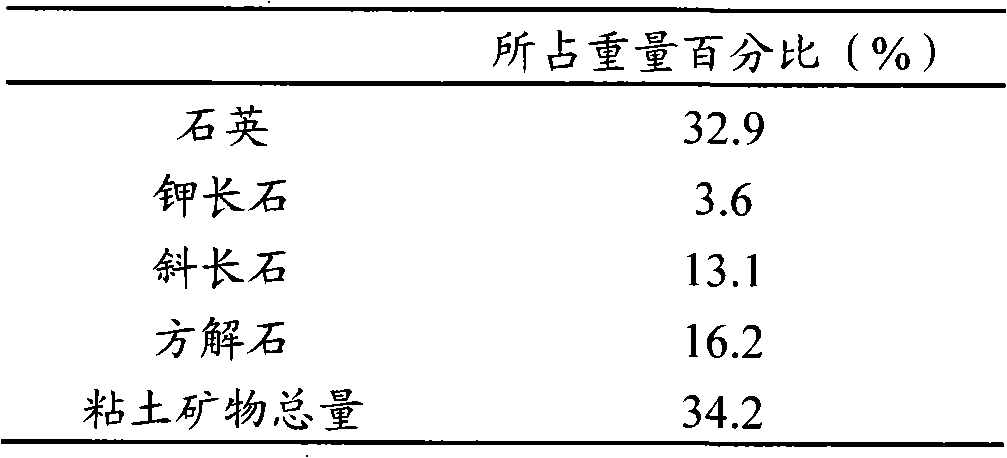

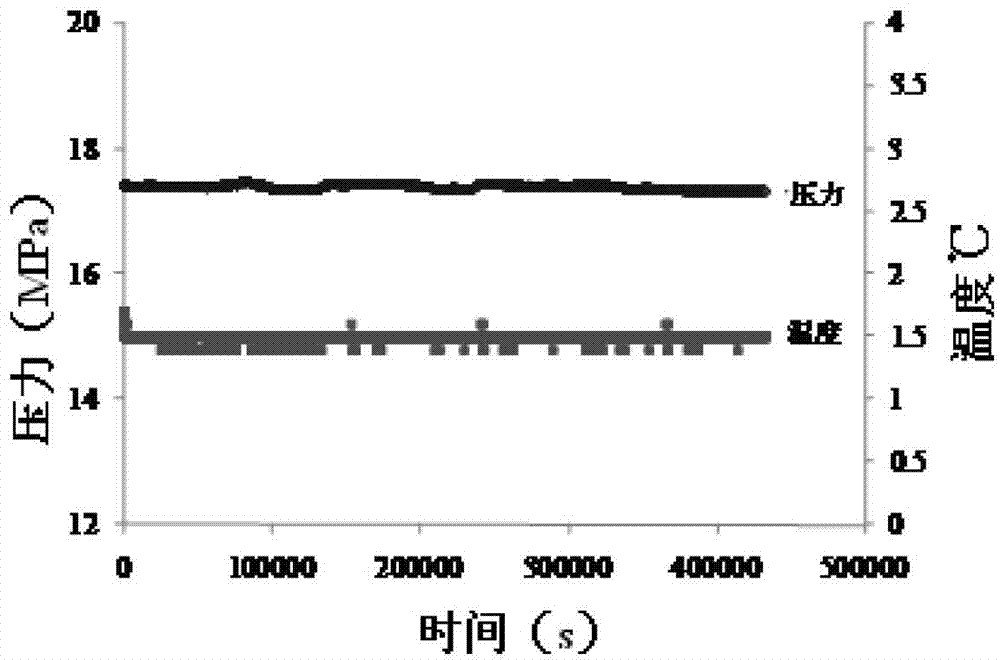

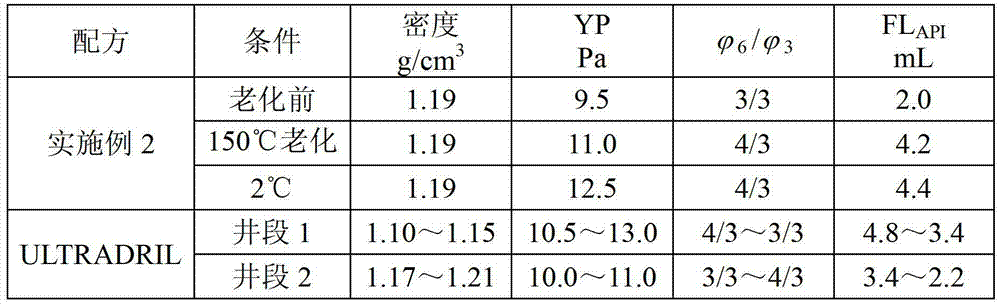

Strong-inhibition water-base drilling fluid

The invention discloses a strong-inhibition water-base drilling fluid which comprises the following components in parts by mass: 100 parts of water, 0.2-4 parts of polyamine inhibitor, 0.1-1 part of coating inhibitor, 10-25 parts of hydrate inhibitor, 0.1-1 part of tackifier, 0.5-5 parts of fluid loss agent and 0.5-3 parts of liquid lubricant. The polyamine inhibitor is an amino polymer polymerized from polyether diamine and epoxy alkane; and the mol ratio of the polyether diamine to the epoxy alkane is 1-10:1-20. The drilling fluid disclosed by the invention can effectively inhibit wellbore instability of deepwater shallow strata, and has equivalent inhibition capability to an oil-base drilling fluid. The drilling fluid disclosed by the invention can solve the problem of generation of hydrate in deepwater drilling, and is applicable to 3000m-deep drilling operation. The drilling fluid disclosed by the invention has favorable low temperature-high temperature stability, and is applicable to a deepwater large-temperature-difference environment (2-150 DEG C).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Methods for controlling migration of particulates in a subterranean formation

Method of treating a portion of a subterranean formation comprising: placing a pre-pad fluid into a portion of a subterranean formation wherein the pre-pad fluid comprises a low-viscosity aqueous tackifying composition that comprises an aqueous tackifier compound and an aqueous fluid; placing a fracturing fluid into the portion of the subterranean formation at a pressure sufficient to create or extend at least one fracture therein; and, activating the aqueous tackifier compound with an activator so as to consolidate the unconsolidated particulates. Method of consolidating unconsolidated particulates within a portion of a subterranean formation comprising: placing a foamed low-viscosity aqueous tackifying composition into a portion of a subterranean formation comprising unconsolidated particulates wherein the aqueous tackifying composition comprises an aqueous fluid, a foaming agent, and an aqueous tackifier compound; and, activating the aqueous tackifier compound with an activator so as to consolidate the unconsolidated particulates.

Owner:HALLIBURTON ENERGY SERVICES INC

High-efficiency oil-based flushing spacer liquid and preparation method thereof

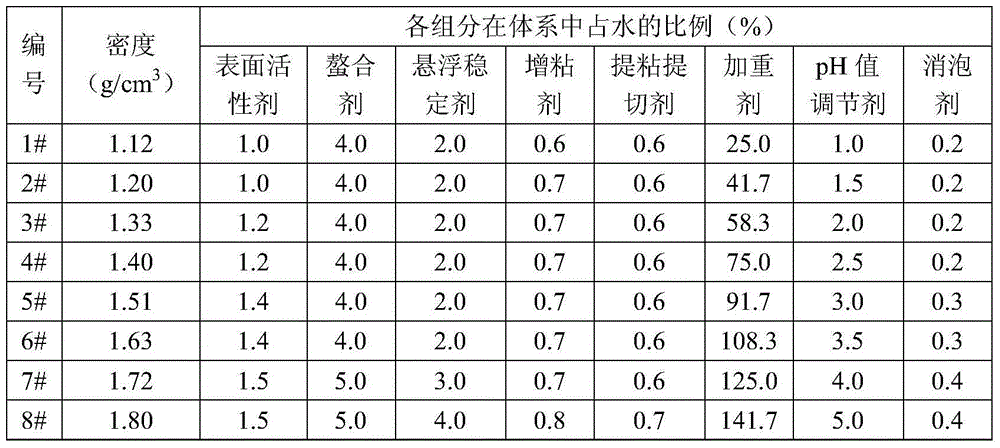

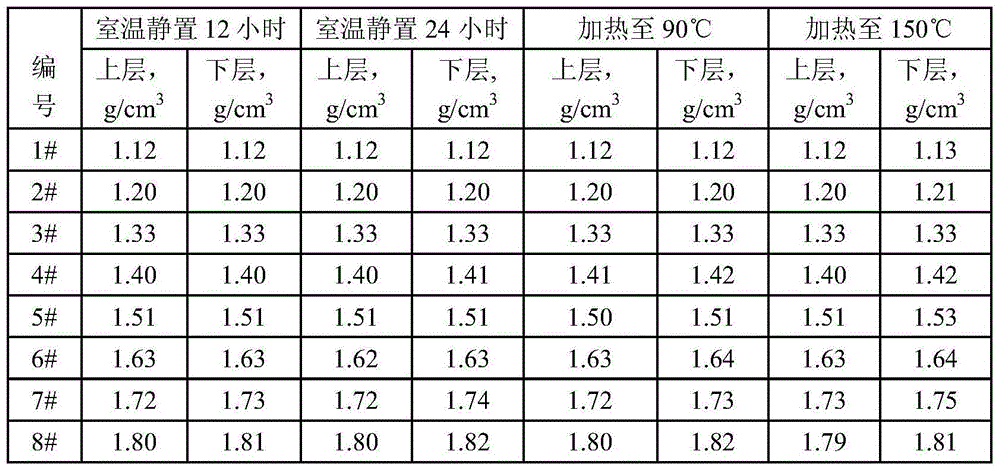

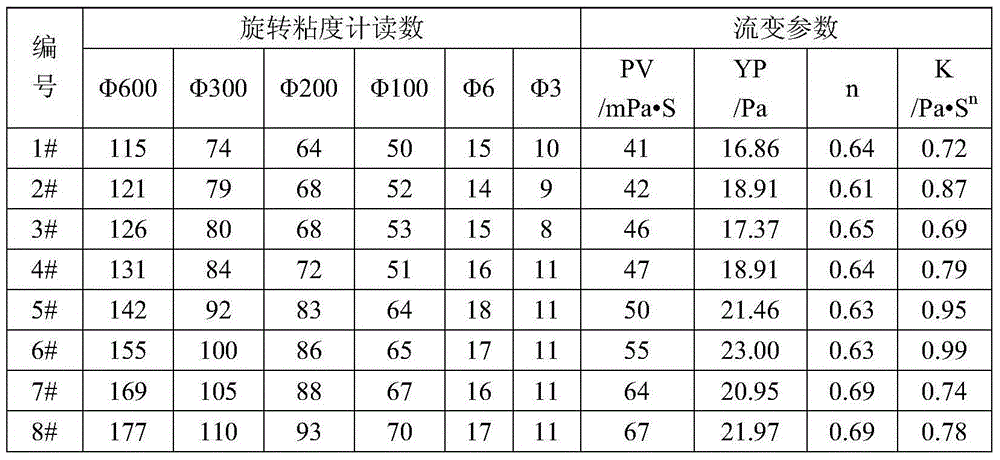

The invention relates to a high-efficiency oil-based flushing spacer liquid. The flushing spacer liquid is prepared from the following components in parts by weight: 100 parts of clear water, 1.0-1.5 parts of a surfactant, 4.0-5.0 parts of a chelating agent, 2.0-4.0 parts of a suspension stabilizer, 0.6-0.8 part of a tackifier, 0.5-0.75 part of a viscosity enhancer, 25-15 parts of a weighting agent, 1.0-5.0 parts of a pH regulator, and 0.2-0.4 part of a defoaming agent. The invention provides a special high-efficiency flushing spacer liquid for oil-based drilling fluid, which has dual functions of flushing and spacing, is high in flushing efficiency, wide in density adjusting range and good in suspension stability, and can effectively improve the conditions of interfacial cementation and improve the quality of well cementation.

Owner:SHENYANG POLYTECHNIC UNIV

Radiation-curable adhesive compositions

InactiveUS20050182150A1Low levelDesirable fogging behaviorImpression capsMacromolecular adhesive additivesPolymer scienceOrganic chemistry

A radiation-curable adhesive composition comprising at least one tackifier resin and at least one radiation-curable composition is provided wherein the tackifier resin comprises monomer repeating units from at least one aromatic monomer and at least one acrylate monomer. Processes to produce the radiation-curable adhesive composition as well as articles comprising the radiation-curable adhesive compositions are also provided.

Owner:EASTMAN CHEM CO

Adhesive polyethylene compositions and multi-layer laminated films using the same

InactiveUS6210765B1Improve adhesion strengthHigh heat sealing strength heatWrappers shrinkageShrinkage connectionsElastomerPolyamide

Disclosed is a specific adhesive polyethylene composition comprising [1] a modified ethylene / alpha-olefin copolymer resin or elastomer obtained by modifying a specific ethylene / alpha-olefin copolymer resin or elastomer, each of which comprises ethylene and an alpha-olefin of 3 to 20 carbon atoms, with an unsaturated carboxylic acid or anhydride, ester, amide, imide or metallic salt derivative of a unsaturated carboxylic acid thereof, [2] an unmodified ethylene / alpha-olefin copolymer resin and / or an unmodified ethylene / alpha-olefin copolymer elastomer and [3] a tackifier. Also disclosed is a multi-layer laminated film of 3 or more layers in which a layer of the above composition is interposed between an ethylene polymer layer and either a polyamide resin layer, an ethylene / vinyl alcohol copolymer layer or a layer of a mixture of polyamide resin and ethylene / vinyl alcohol copolymer. The adhesive polyethylene composition shows excellent adhesion strength to ethylene polymers, polyamide resins and ethylene / vinyl alcohol copolymers, high heat-sealing strength and heat resistance. The multi-layer laminated film shows excellent strength, heat resistance and gas barrier properties, and besides this film has heat shrinkability, so that the film is suitably used as a shrink film.

Owner:MITSUI CHEM INC

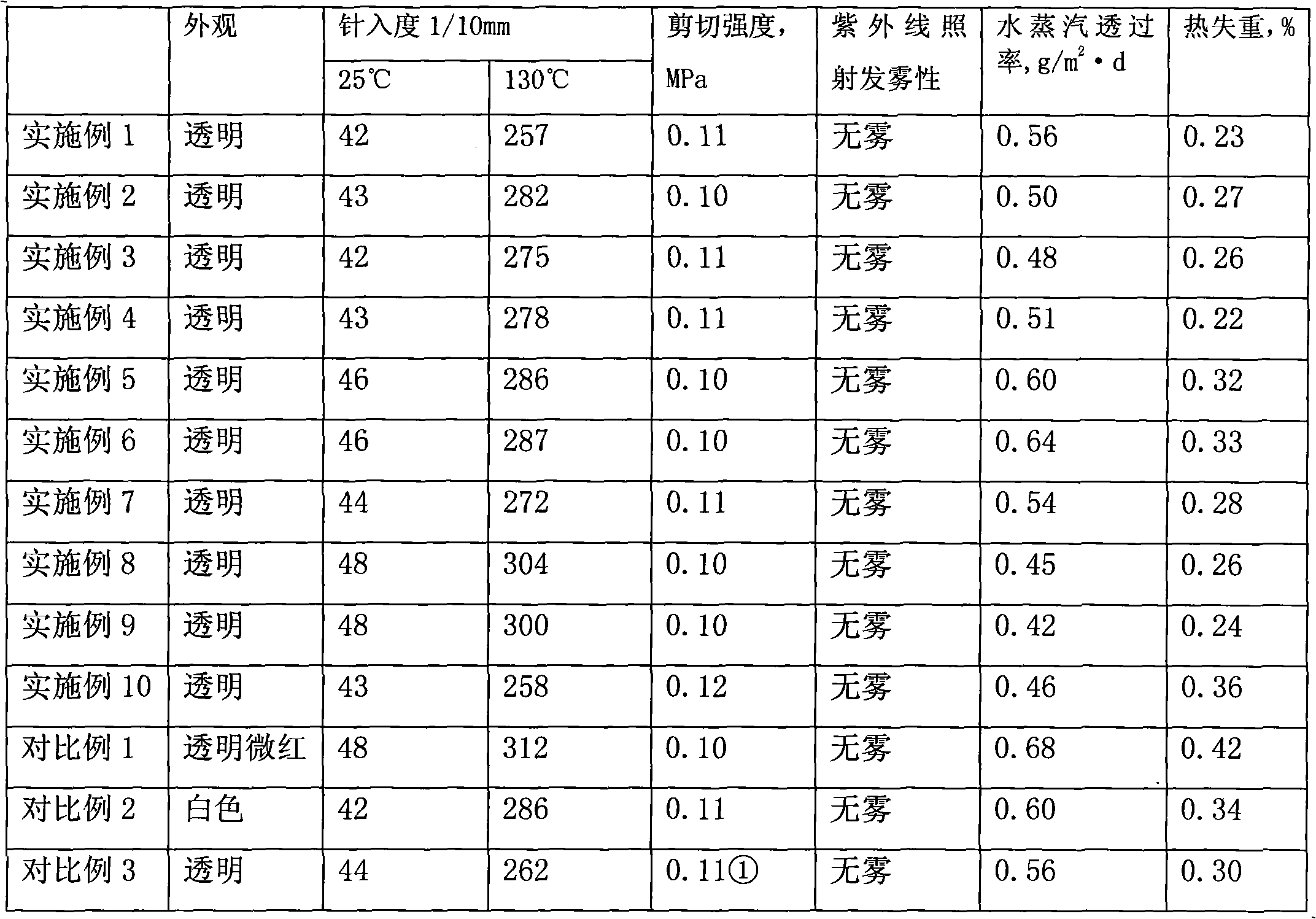

Self-adhesive waterproof coiled material having high initial stickiness and preparation method thereof

ActiveCN103361025AEfficient productionEfficient production lineNon-macromolecular adhesive additivesBituminous material adhesivesBasementAnti ageing

Owner:XIANYANG DONGFANG YUHONG BUILDING MATERIAL CO LTD

Stretchable hot-melt adhesive composition with temperature resistance

InactiveUS20050054779A1Improve tensile propertiesHigh bonding strengthPersonal careSynthetic resin layered productsPolymer sciencePlasticizer

An adhesive composition including an atactic polymer, an isotactic polymer, and an elastomeric base polymer. The composition may also include a high softening point tackifier resin, a low softening point additive and / or other additives, such as an antioxidizing agent, a plasticizer, mineral oil, color pigment, filler, polymer compatibilizer, or a combination of any of these additives. Facing layers, particularly stretchable and / or elastomeric substrates, can be bonded with the adhesive composition. The adhesive composition maintains high bond strength, even at body temperature and after initial stretching. Such adhesive compositions and laminates can be made according to a method of the invention.

Owner:KIMBERLY-CLARK WORLDWIDE INC

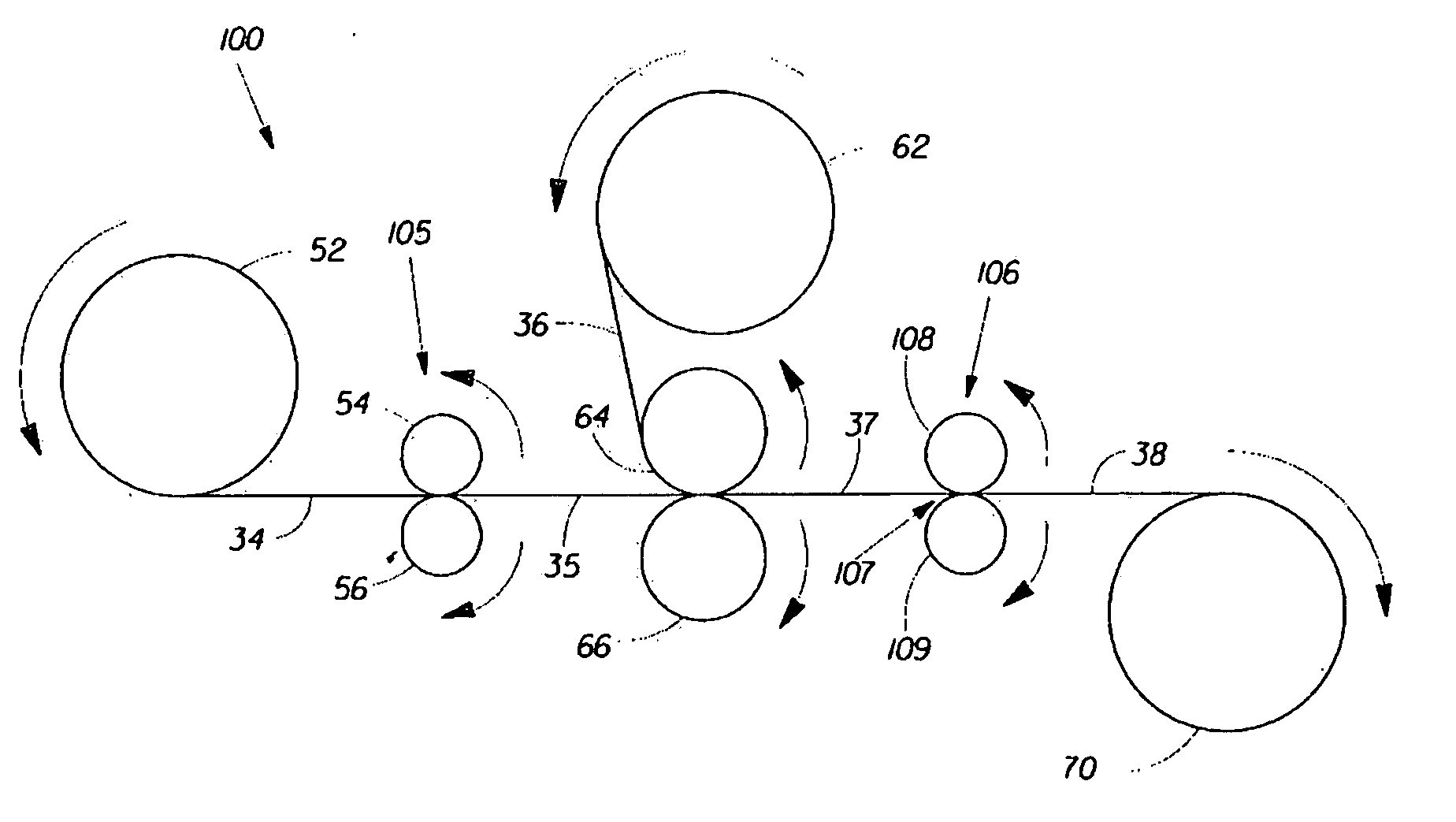

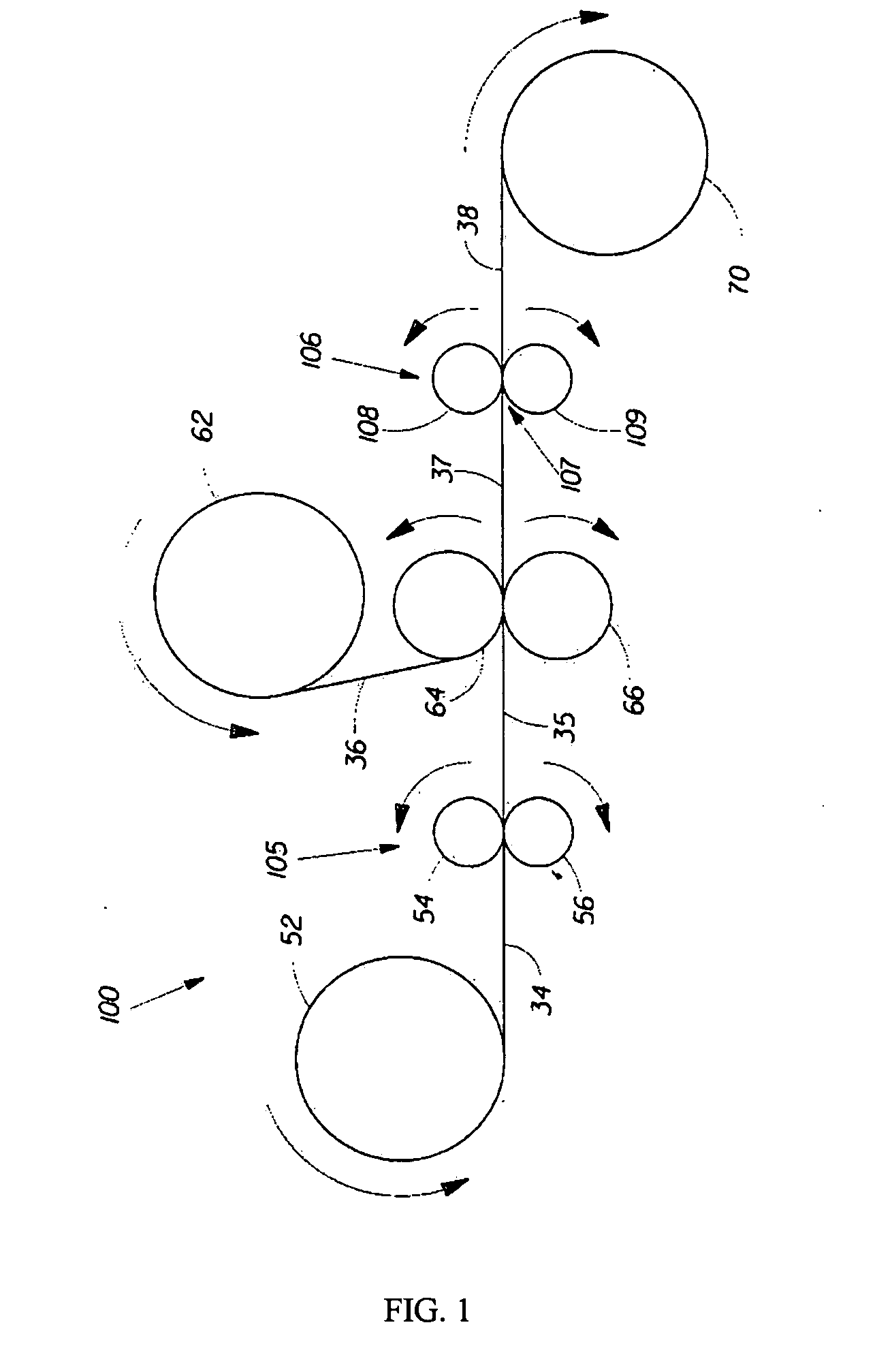

Method of gravure printing elastomeric compositions

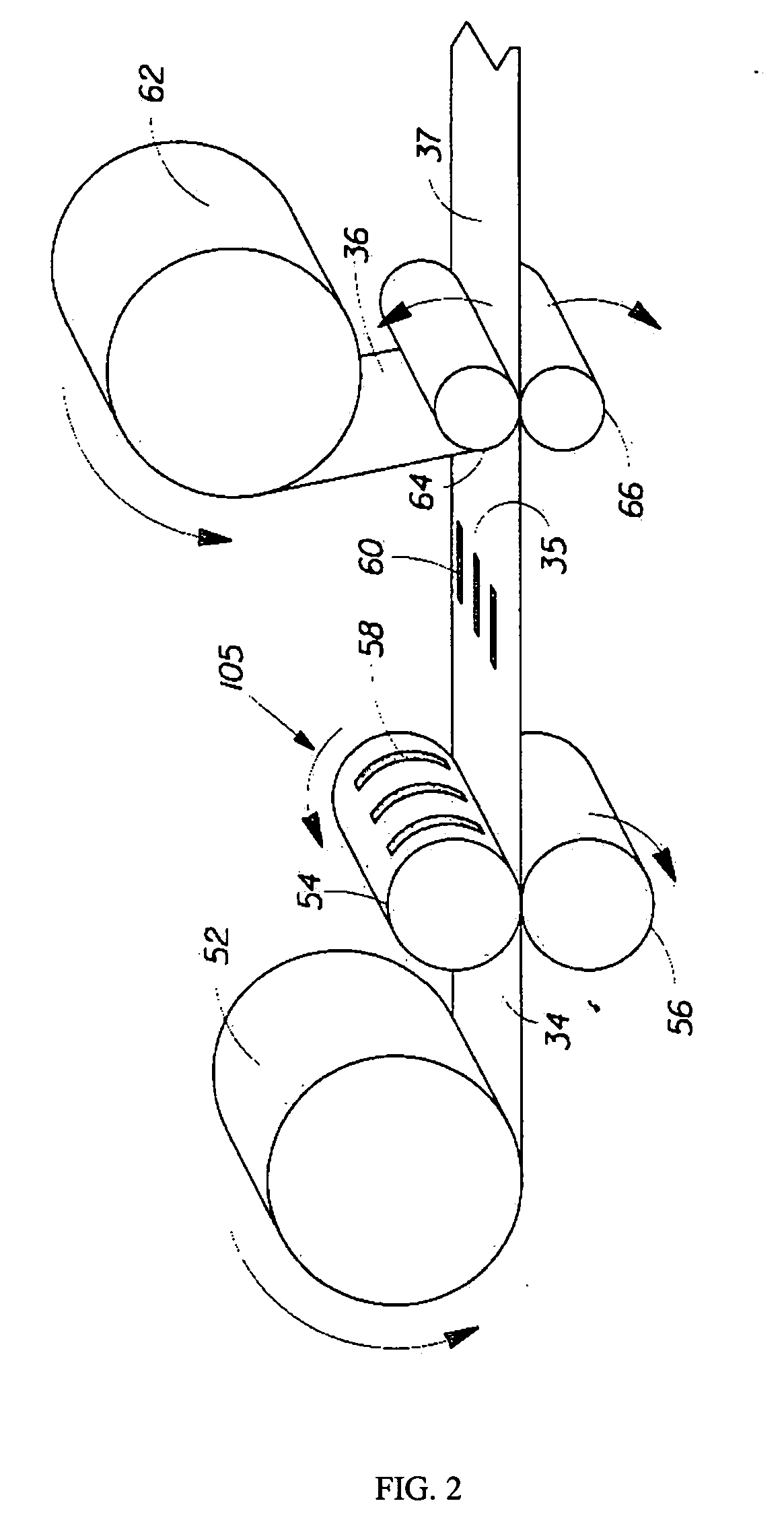

The present invention relates to a process of manufacturing a stretch composite, said method comprising: a) providing a first substrate in a machine direction, wherein said substrate has opposing first and second surfaces; b) providing a gravure printing roll having an exterior surface that comprises one or more cells wherein at least a portion of the surface is relatively cool; c) depositing a molten, non-adhesive, elastomeric composition onto the exterior surface of the gravure printing device which comprises a gravure printing roll, wherein said composition is characterized as having a peel force of less than about 3 N / cm; d) causing said composition to be pushed into said cells; and e) contacting said first surface of said substrate with said gravure printing roll and substantially completely transferring said elastomeric composition from said cells of said exterior surface on said gravure printing roll to said first surface; wherein said process is substantially free of tackifier.

Owner:THE PROCTER & GAMBLE COMPANY

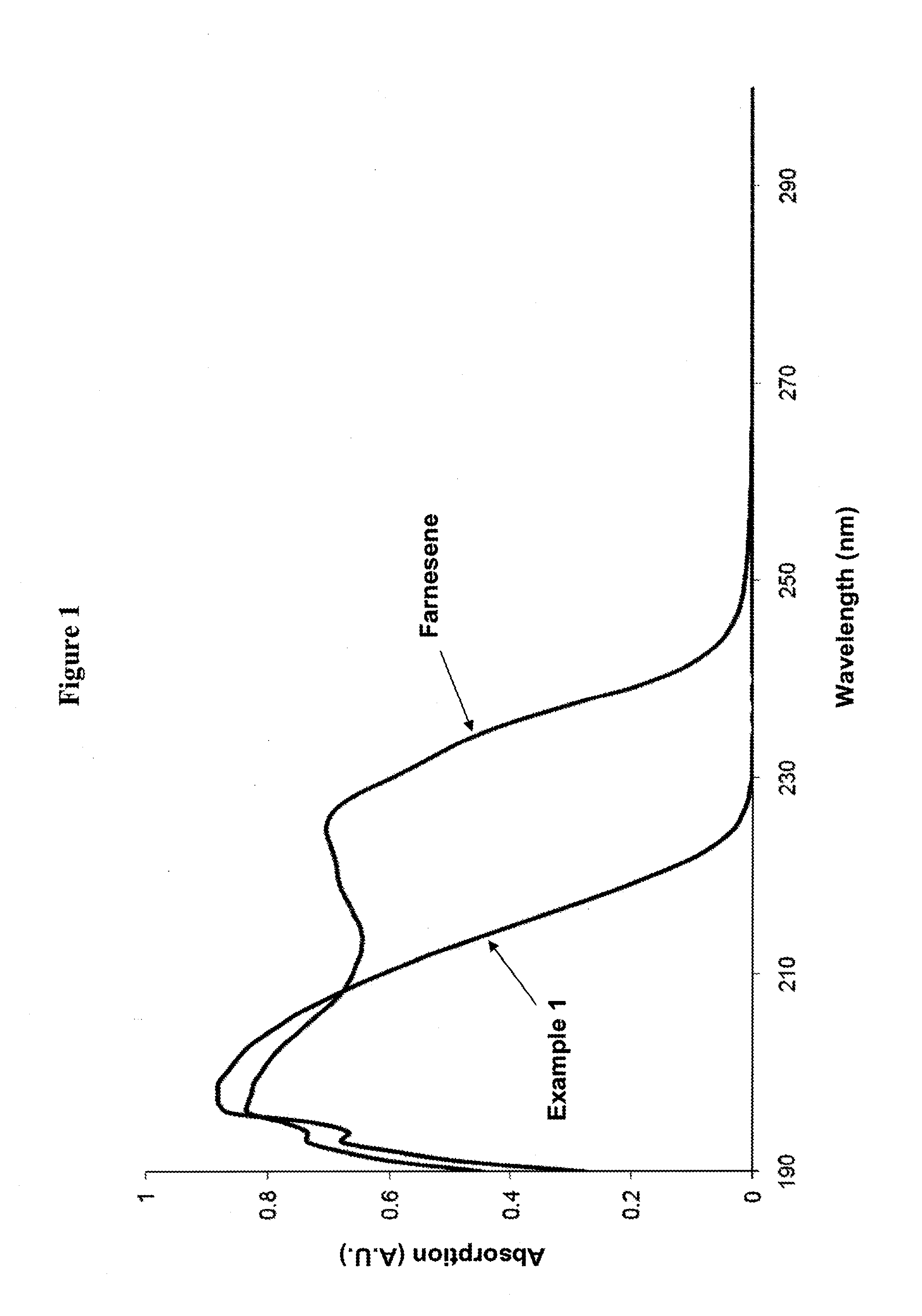

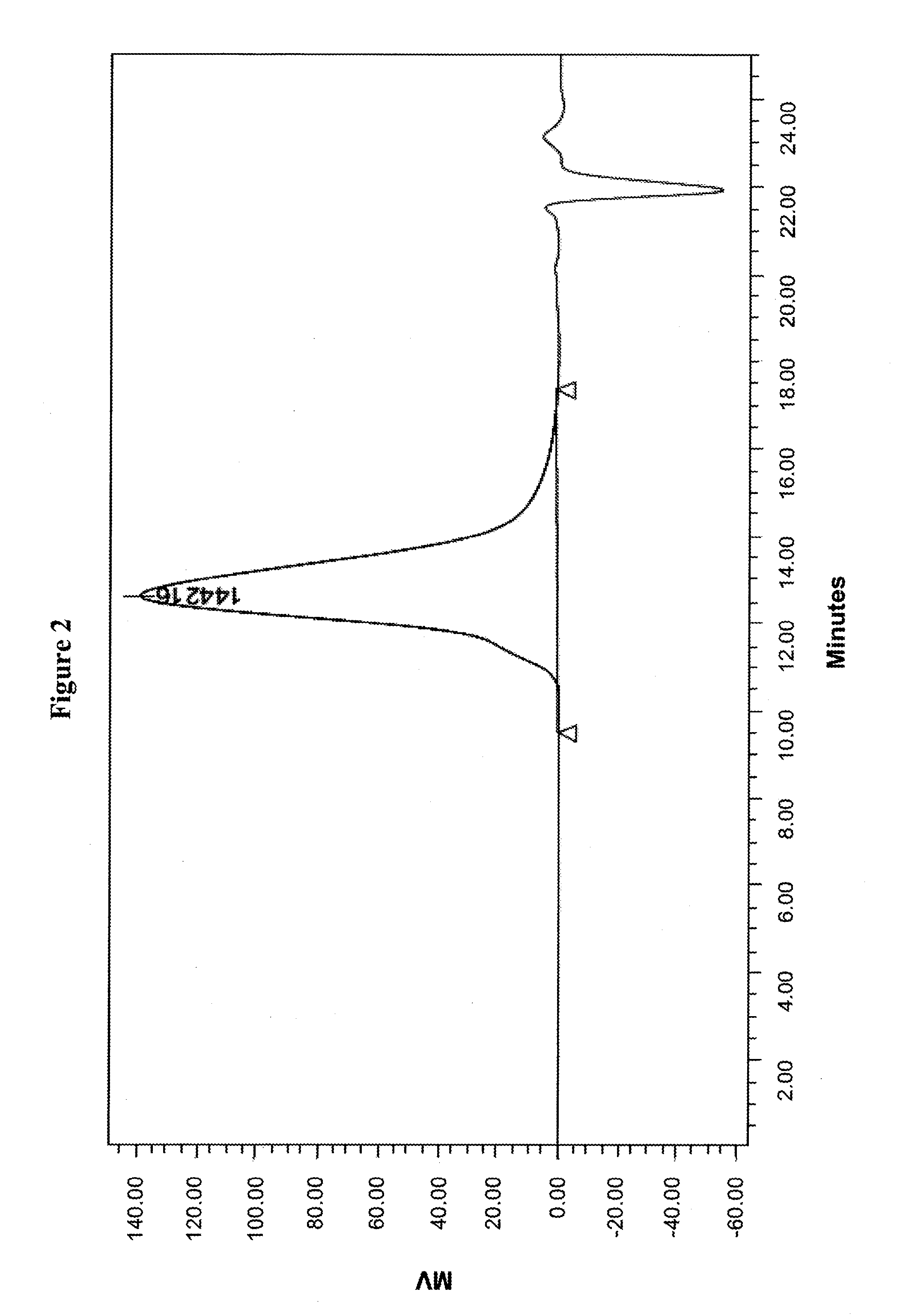

Adhesive compositions comprising a polyfarnesene

Adhesive composition comprises a polyfarnesene and a tackifier. The polyfarnesene can be a farnesene homopolymer derived from a farnesene (e.g., α-farnesene or β-farnesene) or a farnesene interpolymer derived from a farnesene and at least a vinyl monomer. In some embodiments, the at least one vinyl monomer is ethylene, an α-olefin such as styrene, or a substituted or unsubstituted vinyl halide, vinyl ether, acrylonitrile, acrylic ester, methacrylic ester, acrylamide or methacrylamide, or a combination thereof. The composition disclosed herein can be used as a hot melt adhesive, a pressure sensitive adhesive or the like.

Owner:AMYRIS INC

Water-based drilling fluid composition containing amine compound

The invention provides a water-based drilling fluid composition containing an amine compound, which comprises the following components: a 0.5 to 5 weight percent of water-based amine compound as shown in formula I: RHN-Y-[OY']X-NHR', wherein Y, Y',x, R and R' are as defined in a manual; 0.1 to 1.0 weight percent of water-based tackifier which is selected from one or more types of xanthan gum, acrylamide-acrylic copolymer and hydroxyl ethyl cellulose; 0.5 to 5 weight percent of water-based fluid loss agent which is selected from one or more types of modified lignite, acrylic polymer, modified starch and modified cellulose; 2 to 12 weight percent of water-based inhibitor which is selected from one or more types of potassium chloride, potassium sulfate, formic acid, formic acid sodium, potassium chloride and epoxypropyltrimethylammonium chloride; and the composition can also further comprises coating agent, weighting agent, lubricant, borehole stabilizer and the like. The water-based drilling fluid composition has good inhibiting performance to clay shale drilling cuttings.

Owner:CNPC DRILLING RES INST

Transparent butyl hot-melt sealant and preparation method thereof

ActiveCN101805569AHigh strengthGood construction performanceNon-macromolecular adhesive additivesOther chemical processesSealantFumed silica

The invention relates to a transparent butyl hot-melt sealant, which is prepared with the following raw materials in parts by weight: 1-20 of butyl rubber, 10-80 of polyisobutylene, 5-30 of plasticizer, 3-10 of tackifier, 3-10 of softener, 0.1-5 of stabilizer, 5-30 of filler and 0.1-5 of adhesion promoting agent. The matching use of the butyl rubber and the polyisobutylene with different molecular weights facilitates the improvement of the strength and workability of the transparent butyl hot-melt sealant. The filler is selected from fumed silica or precipitated silica, which ensures the appearance transparency of the product. Due to the addition of the stabilizer and the strict control of the production process, the appearance transparency and the physical and chemical properties of the product are enhanced. The use of the active group substituted alkoxy silane as a coupling agent improves the adhesion of the product to glass, aluminum and other substrates.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

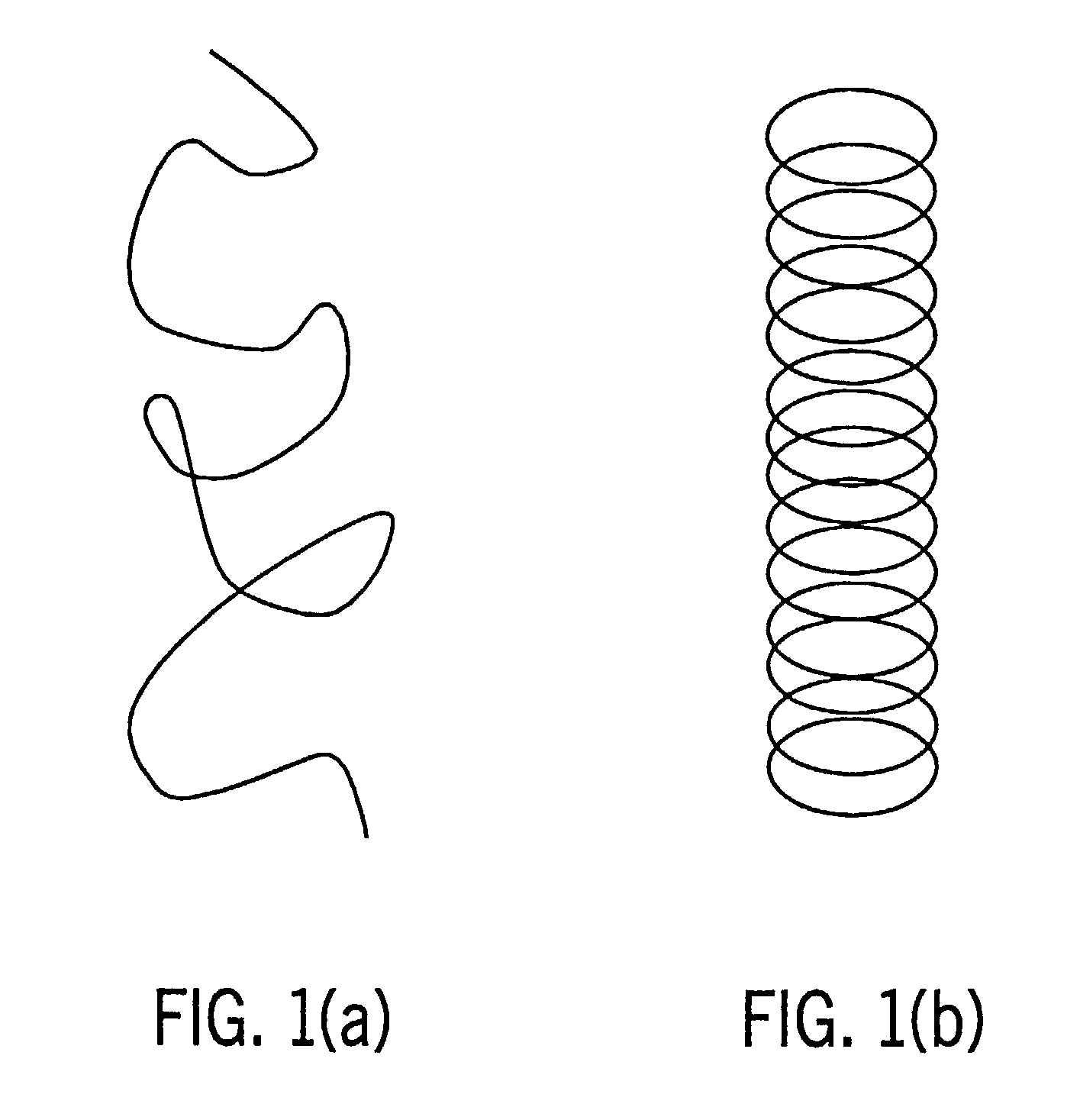

Acrylic amide modified graft copolymer, preparation method and application thereof

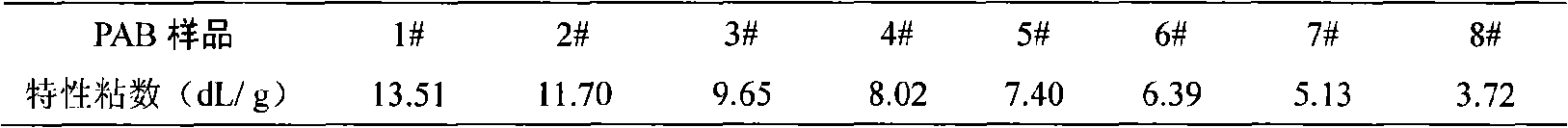

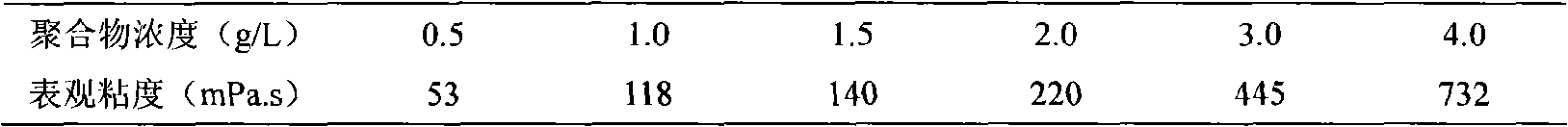

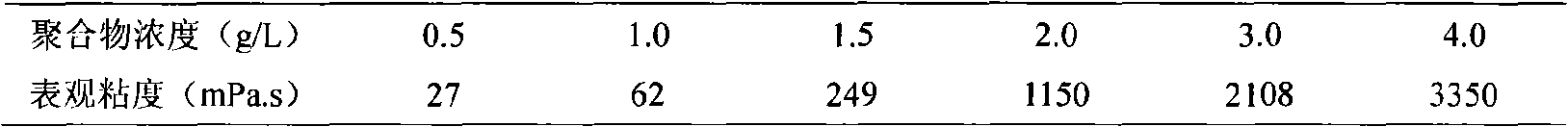

The invention discloses an acrylamide modified graft copolymer and a preparation method and usage thereof. The invention is characterized in that 20 parts of acrylamide, 1-20 anionic monomer and / or cationic monomer, 0.1-15 macromonomer, 0.05-10 ionic lyophobic monomer and 50-1000 deionized water are added into a three-necked reaction bottle, the pH value is adjusted to be 3-9, N2 is introduced for 30min, then 0.002-0.5 part of initiator persulfate is added at 30-75 DEG C, the reaction lasts 8-36h, then copolymer PAB is obtained, and finally water is used for dilution to obtain strong PAB solution. During polymerization, no surfactant is used, and the macromonomer with a long chain and the ionic lyophobic monomer with intermolecular association function are introduced into the copolymer PAB, so the capabilities of cooperative tackification and salt-resistance between the rigid conformation of a molecular chain and the intermolecular association can be played optimally, the PAB exhibits unique solution property and has higher colloidal viscosity in high saline solution than in fresh water, and the PAB obtains the capabilities of tackification, salt resistance, low surface tension and strong molecular association and can be used for the oil-displacing acrylamide modified graft copolymer. The copolymer is prepared into water solution with mass concentration of 0.2-3.0g / L and surfactant concentration of 0.01-2 mmol / L, then the water solution is added into a mixing vessel by a stirring device, and then a polymer oil-displacing agent with tackification, salt resistance and cutting resistance is obtained. The PAB has the functions of both a tackifier and a macromolecule surfactant. The copolymer PAB is prepared into water solution which has mass concentration of 0.05-7%, so the macromolecule surfactant with excellent surface activeness can be obtained and then applicable to an emulsifier, an emulsion splitter, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

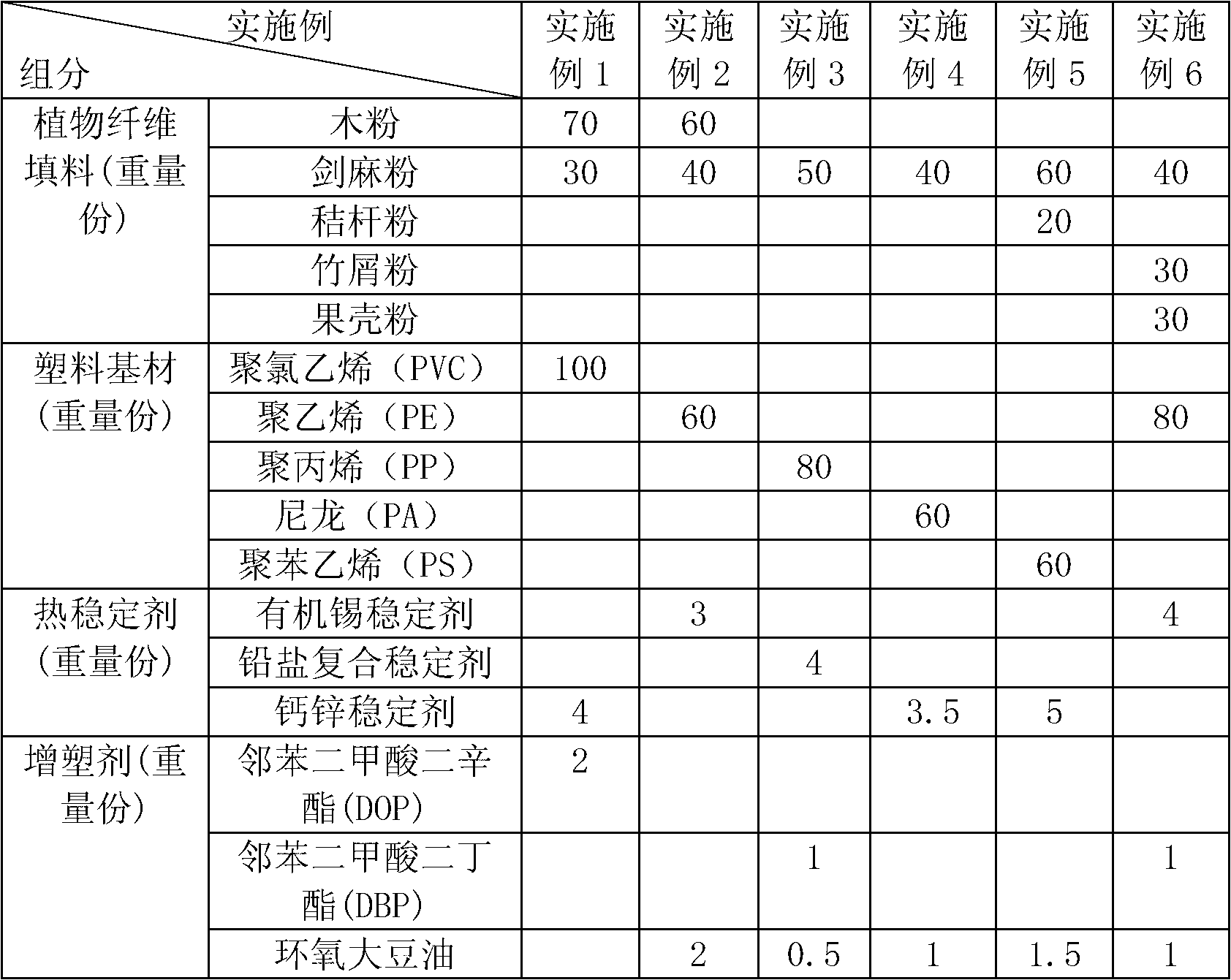

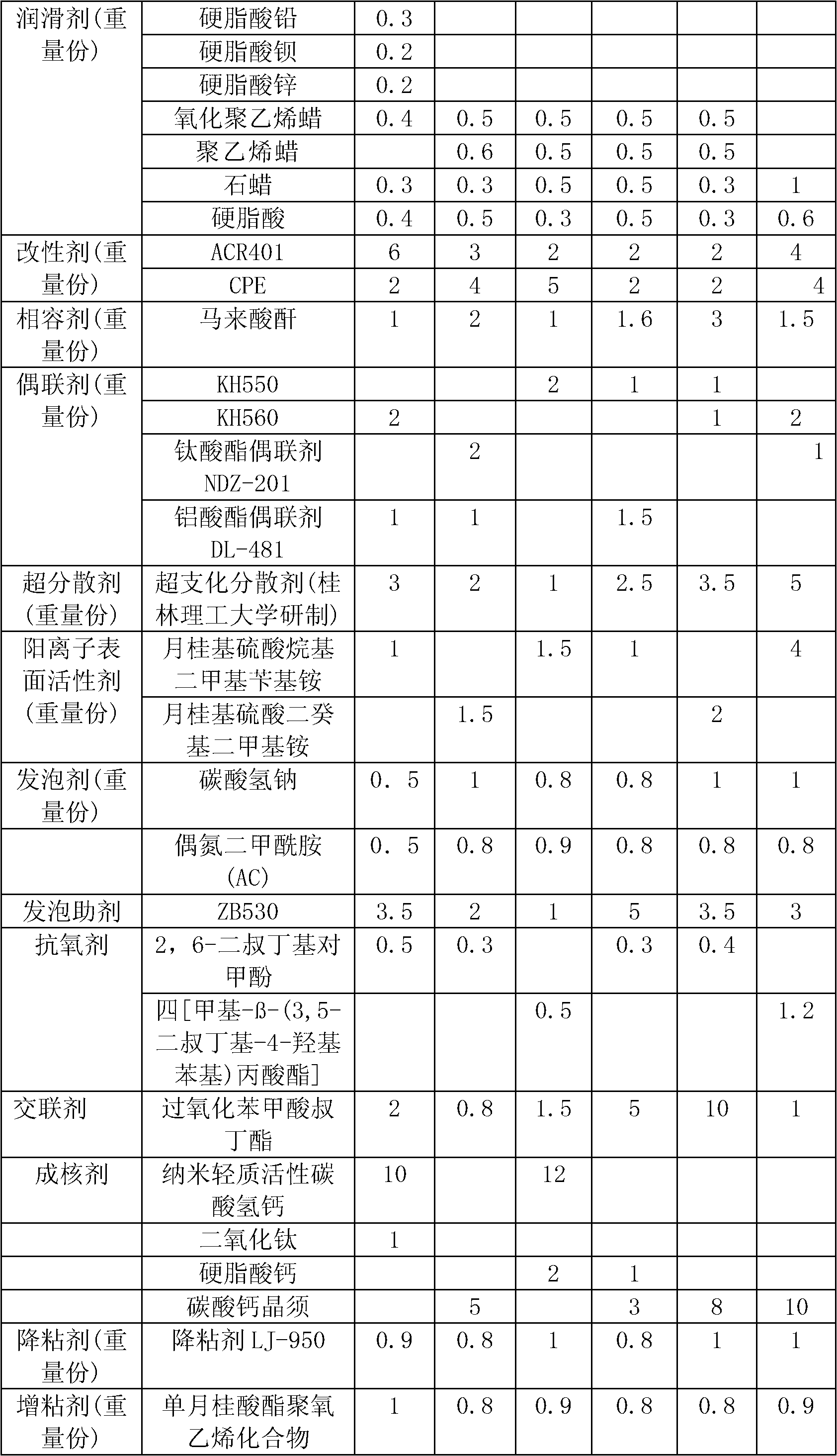

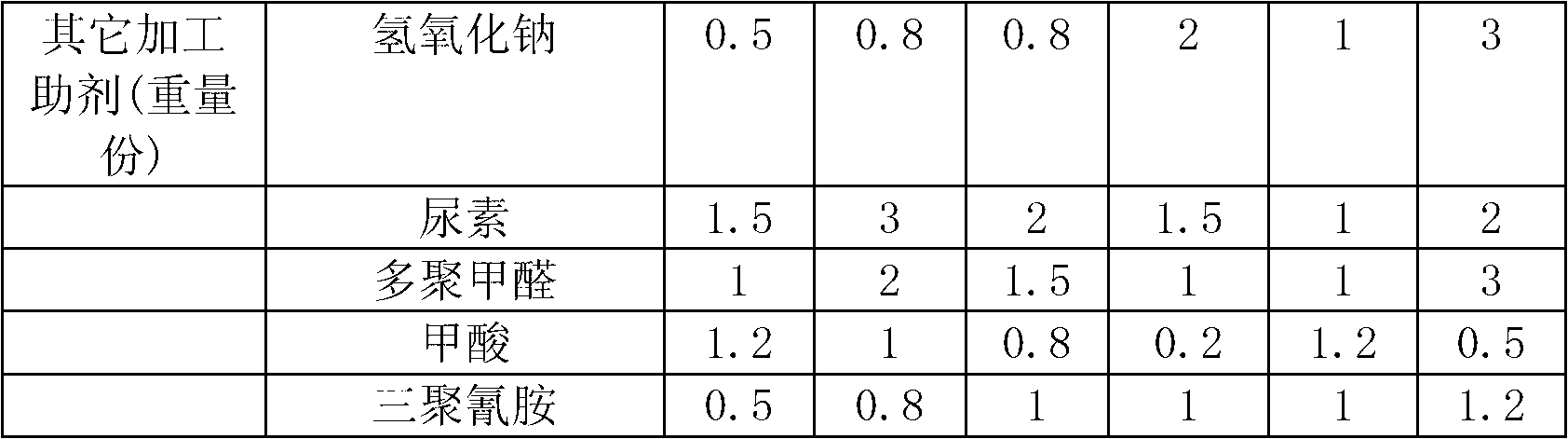

New macromolecule fiber composite material

The invention discloses a new macromolecule fiber composite material which is prepared by the following components in parts by weight, 40-100 parts of plant fiberfill, 60-100 parts of plastic base material, 3.5-5 parts of heat stabilizer, 1-2 parts of plasticizer, 1.6-2 parts of lubricating agent, 4-8 parts of modifying agent, 1-3 parts of compatilizer, 2-3 parts of coupling reagent, 1-5 parts of super dispersing agent, 1-4 parts of positive ion surface active agent, 1-1.8 parts of foaming agent, 1-5 parts of blowing promoter, 0.3-1.2 parts of antioxygen, 1-10 parts of cross-linking agent, 1-20 parts of nucleating agent, 0.8-1 part of viscosity reducer, 0.8-1 part of tackifier and 3.2-13.4 parts of other auxiliaries. The new composite material can not easily cause wet swelling and air shrinkage, and is low in expansibility and water absorbability, so that the prepared product has good stability.

Owner:GUILIN SHUKANG BUILDING MATERIAL

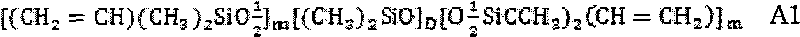

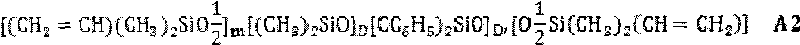

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

Ultraviolet curing pressure sensitive adhersive for polyethylene protective film and preparation method thereof

ActiveCN101649165AStrong adhesionStrong initial adhesionOrganic non-macromolecular adhesiveTectorial membraneSolvent

The invention discloses an ultraviolet curing pressure sensitive adhersive for the polyethylene protective film and a preparation method thereof. The ultraviolet curing pressure sensitive adhersive comprises the following components by weight percent: 30-80% of acrylate prepolymer, 0.03-4.5% of photoinitiator, 0.2-2.5% of photocuring crosslinking agent, 3-25% of tackifier and 5-40% of solvent. Theultraviolet curing pressure sensitive adhersive disclosed in the invention has good adhesive force to the polyethylene film and can realize good balance among initital adhesive force, peeling strength and cohesive force.

Owner:无锡达美新材料有限公司

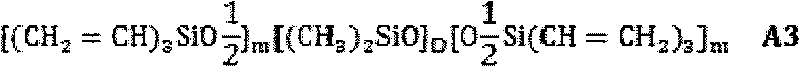

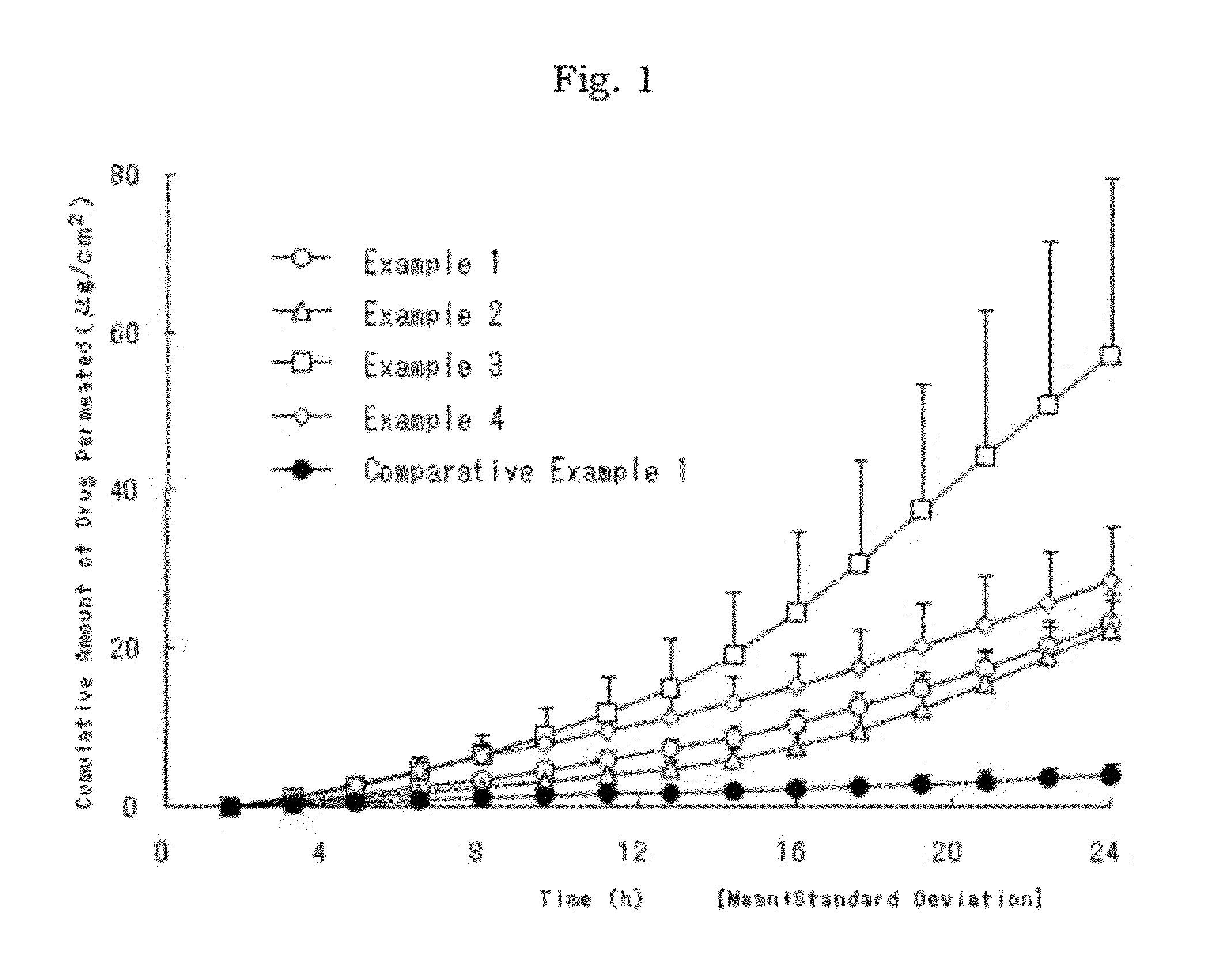

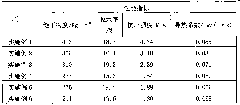

Anti-inflammatory analgesic adhesive patch for external use

ActiveUS20120283671A1Promote absorptionLess irritatingAntipyreticAnalgesicsAdditive ingredientTackifier

An external patch containing diclofenac hydroxyethylpyrrolidine prepared by laminating an adhesive layer on a backing, wherein said adhesive layer is characterized by comprising 5-50% by weight of styrene•isoprene•styrene block copolymer, 20-50% by weight of a tackifier resin, 5-70% by weight of a softening agent, and 0.5-20% by weight of one or more solubilizers selected from N-methyl-2-pyrrolidone, propylene glycol and dimethyl sulfoxide as essential ingredients, and 0.5-20% by weight of diclofenac hydroxyethylpyrrolidine as an active ingredient. The patch has excellent transdermal absorption, less skin-irritation and excellent stability of the drug.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD +1

Manufacturing method of aerated concrete

ActiveCN101823864AIncreased durabilityExcellent mechanical propertiesSolid waste managementCeramicwareCalcium hydroxideFoaming agent

The invention discloses a manufacturing method of aerated concrete, which comprises the following steps of: preparing liquid feed liquid; precuring; mixing an amorphous silicon material and water to prepare amorphous silicon material slurry; then mixing the amorphous silicon material slurry, the liquid feed liquid, a crystalline silicon material, one of calcined lime or calcium hydroxide or lime milk, dihydrate gypsum or semi-hydrated gypsum, ordinary portland cement, feldspar materials, strength intensifier, calcined lime digestion regulator, bubble regulator, lubrication tackifier, water repellent, a foaming agent and water; stirring the mixture at the speed of between 800 and 1,500rpm for 3 to 7 minutes to prepare foam slurry; and performing standing curing and still kettle curing to prepare the aerated concrete. The product obtained by the manufacturing method has the characteristics of light weight, high strength, flame retardance, heat preservation, heat insulation, hydrophobic property, long service life, impact resistance, small shrinkage, and the like; moreover, the material sources are wide, and the products are simple and convenient to process and manufacture.

Owner:吴智深 +2

Strong-inhibition water-base drilling fluid

The invention discloses a strong-inhibition water-base drilling fluid which comprises the following components in parts by mass: 100 parts of water, 0.2-4 parts of polyamine inhibitor, 0.1-1 part of coating inhibitor, 10-25 parts of hydrate inhibitor, 0.1-1 part of tackifier, 0.5-5 parts of fluid loss agent and 0.5-3 parts of liquid lubricant. The polyamine inhibitor is an amino polymer polymerized from polyether diamine and epoxy alkane; and the mol ratio of the polyether diamine to the epoxy alkane is 1-10:1-20. The drilling fluid disclosed by the invention can effectively inhibit wellbore instability of deepwater shallow strata, and has equivalent inhibition capability to an oil-base drilling fluid. The drilling fluid disclosed by the invention can solve the problem of generation of hydrate in deepwater drilling, and is applicable to 3000m-deep drilling operation. The drilling fluid disclosed by the invention has favorable low temperature-high temperature stability, and is applicable to a deepwater large-temperature-difference environment (2-150 DEG C).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene

InactiveUS7067585B2High bond strength retentionGood adhesionOther chemical processesFilm/foil adhesivesWaxPlasticizer

A hot melt adhesive composition is based on an isotactic polypropylene random copolymer (RCP). The composition contains about 4%–50% by weight of the RCP copolymer, about 20%–65% by weight of a compatible tackifier, about 0%–40% by weight of a plasticizer, about 0%–3% by weight of a stabilizer, about 0%–40% by weight of a wax, and optionally about 0%–60% by weight of an atactic poly-α-olefin (APAO). The adhesive composition may be used in a number of applications such as, for example, in disposable nonwoven hygienic articles, paper converting, flexible packaging, wood working, carton and case sealing, labeling and other assembly applications.

Owner:BOSTIK INC

Elastomeric bicomponent fibers comprising block copolymers having high flow

InactiveUS20070004830A1Strong flow abilityIncrease chanceWorking-up pitch/asphalt/bitumen by chemical meansSynthetic resin layered productsElastomerFiber

Bicomponent fibers comprising a thermoplastic polymer and an elastomeric compound are made which can be continuously extruded from the melt at high production rates. The elastomeric compound has high flow and consists essentially of a selectively hydrogenated block copolymer and a tackifier resin, an alpha-olefin copolymer, an alpha-olefin terpolymer, a wax or mixtures thereof. In one embodiment the block copolymer has at least one polystyrene block of molecular weight from 5,000 to 7,000 and at least one polydiene block of molecular weight from 20,000 to 70,000 and having a vinyl content of greater than 60 mol %. In a second embodiment the block copolymer has a vinyl content of less than 60 mol %. The bicomponent fibers are useful for the manufacture of articles such as woven fabrics, spun bond non-woven fabrics or filters, staple fibers, yarns and bonded, carded webs.

Owner:KRATON POLYMERS US LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com