Patents

Literature

162results about How to "Reduce surface polarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

New macromolecule fiber composite material

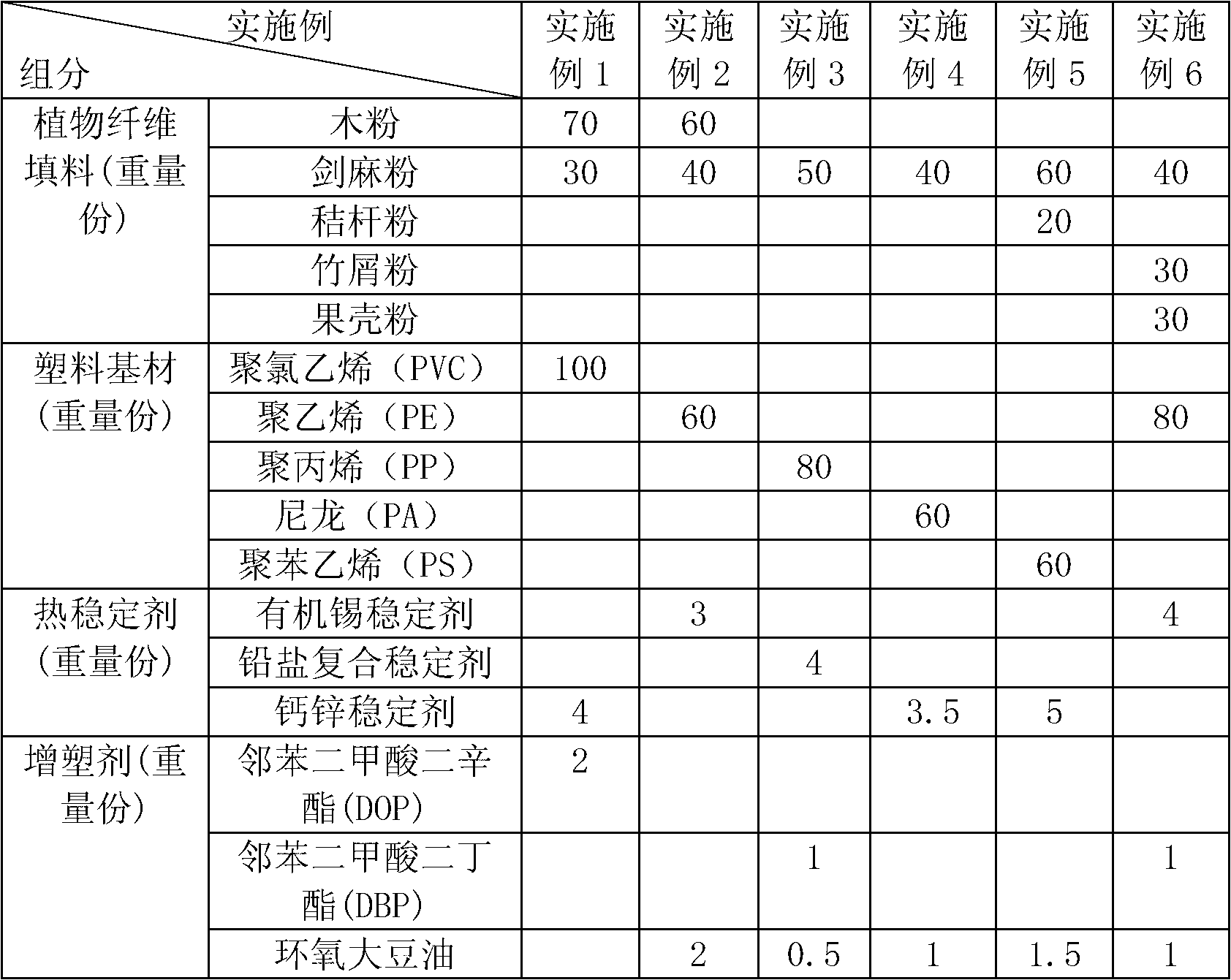

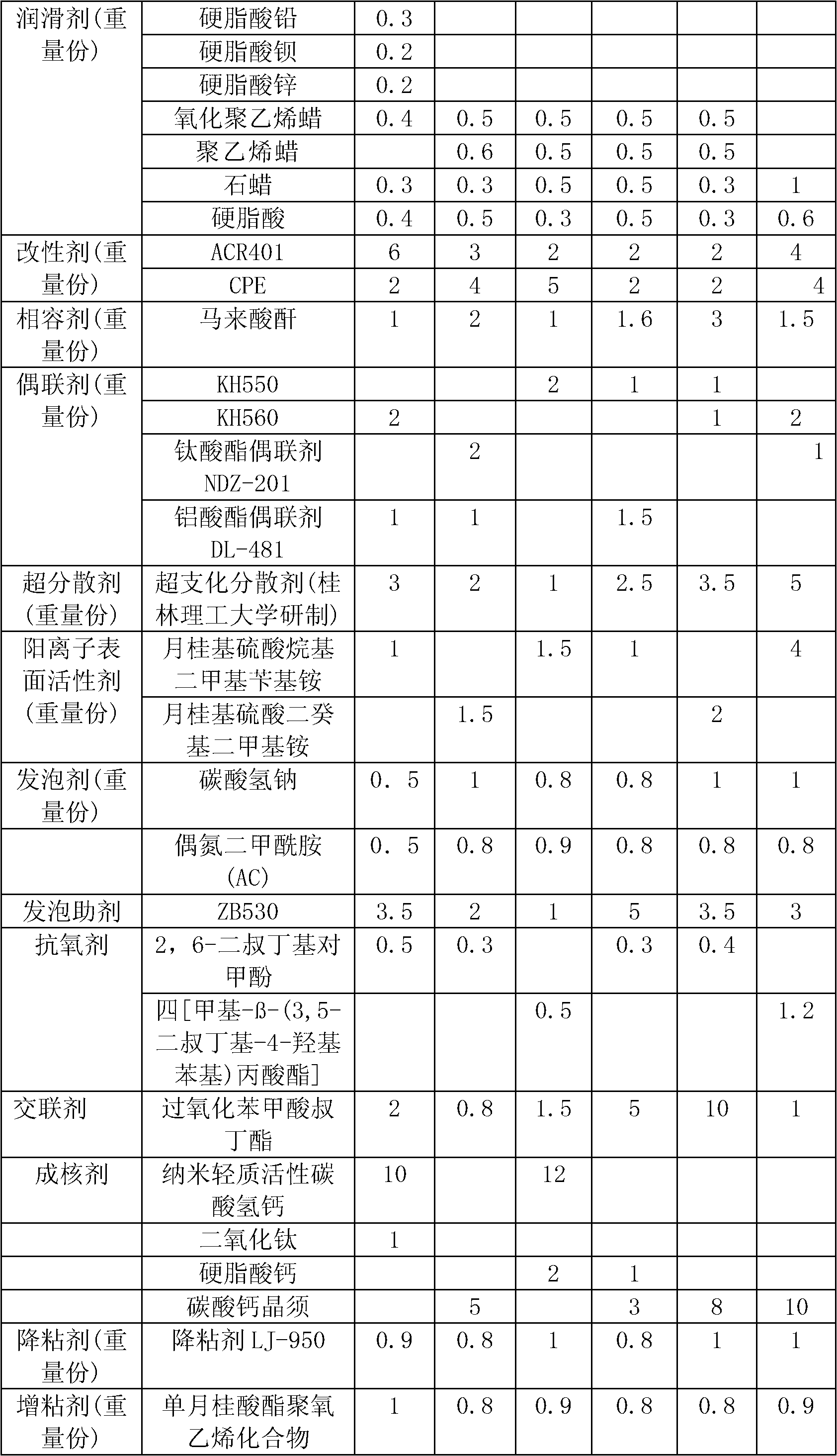

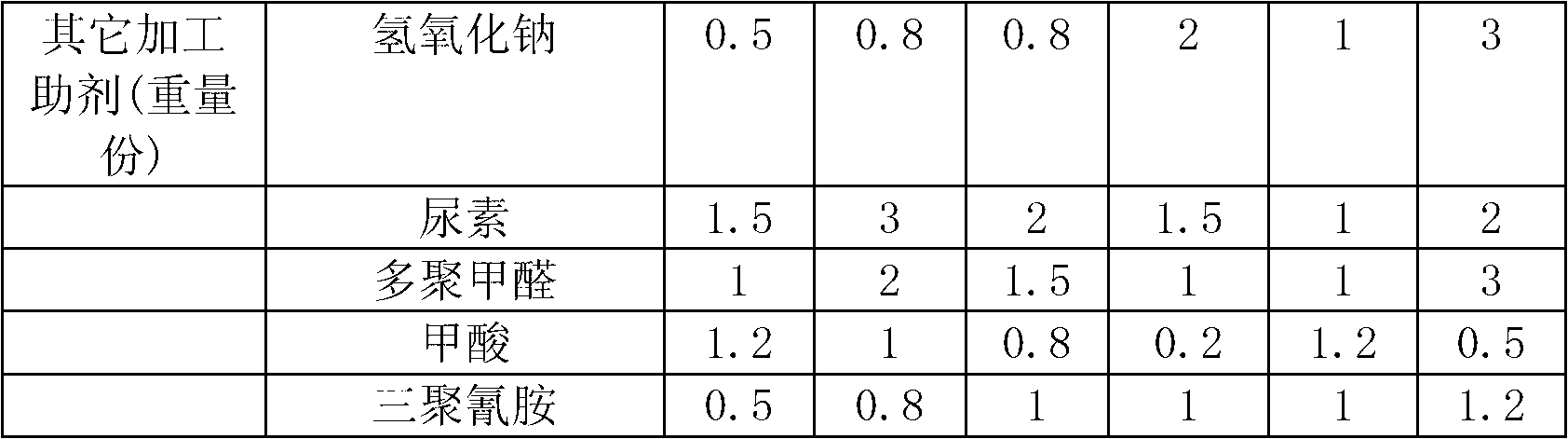

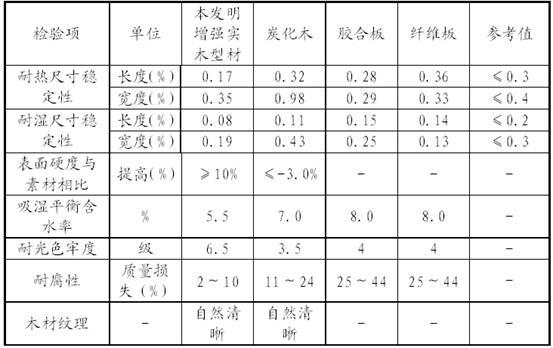

The invention discloses a new macromolecule fiber composite material which is prepared by the following components in parts by weight, 40-100 parts of plant fiberfill, 60-100 parts of plastic base material, 3.5-5 parts of heat stabilizer, 1-2 parts of plasticizer, 1.6-2 parts of lubricating agent, 4-8 parts of modifying agent, 1-3 parts of compatilizer, 2-3 parts of coupling reagent, 1-5 parts of super dispersing agent, 1-4 parts of positive ion surface active agent, 1-1.8 parts of foaming agent, 1-5 parts of blowing promoter, 0.3-1.2 parts of antioxygen, 1-10 parts of cross-linking agent, 1-20 parts of nucleating agent, 0.8-1 part of viscosity reducer, 0.8-1 part of tackifier and 3.2-13.4 parts of other auxiliaries. The new composite material can not easily cause wet swelling and air shrinkage, and is low in expansibility and water absorbability, so that the prepared product has good stability.

Owner:GUILIN SHUKANG BUILDING MATERIAL

Stable enhanced type solid wood profile and production method thereof

ActiveCN101879736AReduce surface hardnessReduce surface strengthWood impregnation detailsSolid woodWeather resistance

The invention provides a production method of a stable enhanced type solid wood profile improved by a wood carbonization and acetylation process, which belongs woodwork production technique. The production method comprises the following steps of: a, drying treatment, wherein the wood moisture content is reduced to be as low as 5.0 to 8.0 percent, the moisture content deviation in the wood thickness is less than 2.0 percent, and the wood internal residual stress is less than 2.0 percent; b, carbonizing treatment; c, acetylation treatment; and d, equalization treatment. The invention also discloses a stable enhanced type solid wood profile prepared by the production method. The solid wood profile prepared by the method is stable, has high corrosion resistance and weathering resistance, high output, long product service life and wide utilization ways, is favorable for realizing flow line production, and is convenient for industrialization.

Owner:ZHEJIANG SHIYOU TIMBER

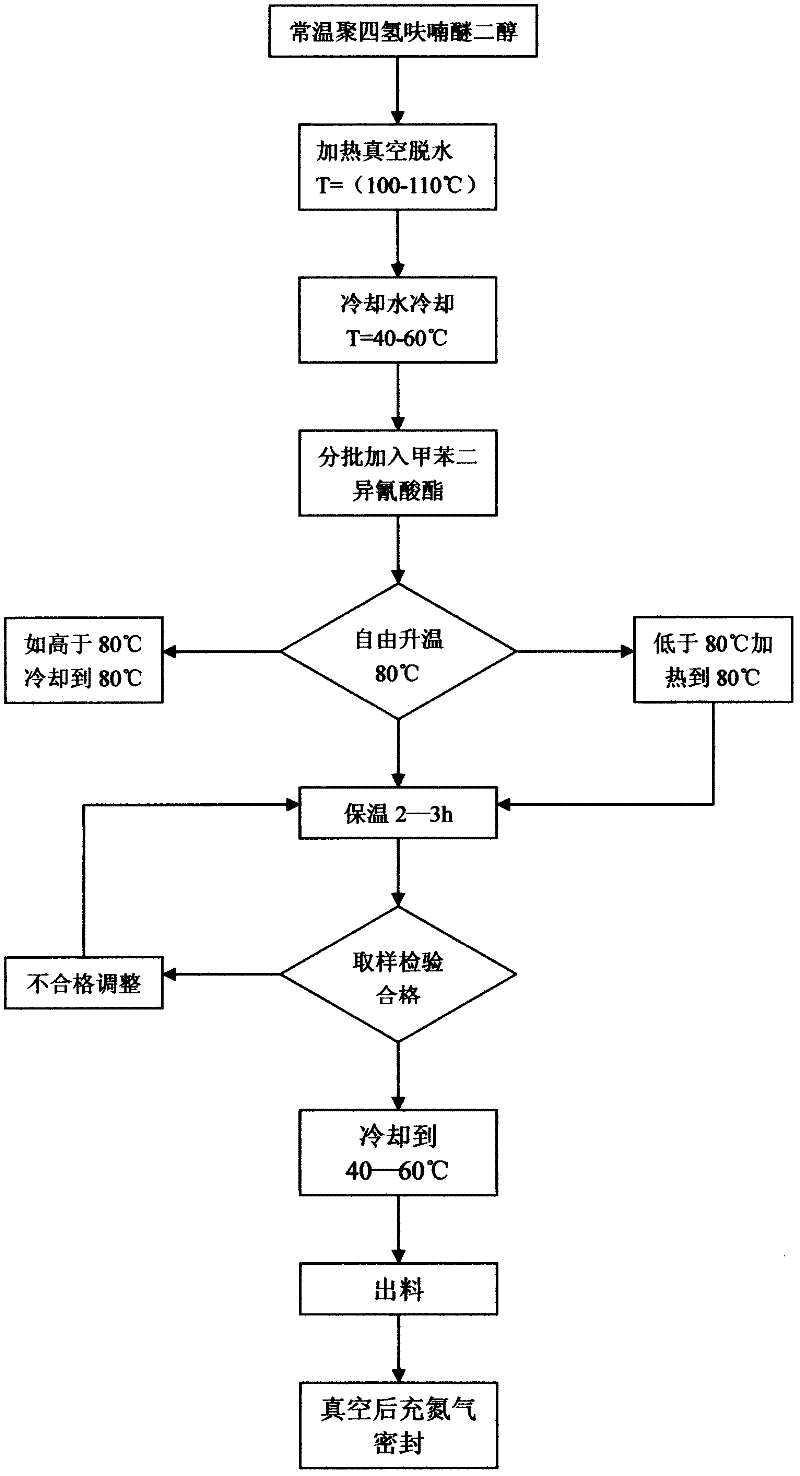

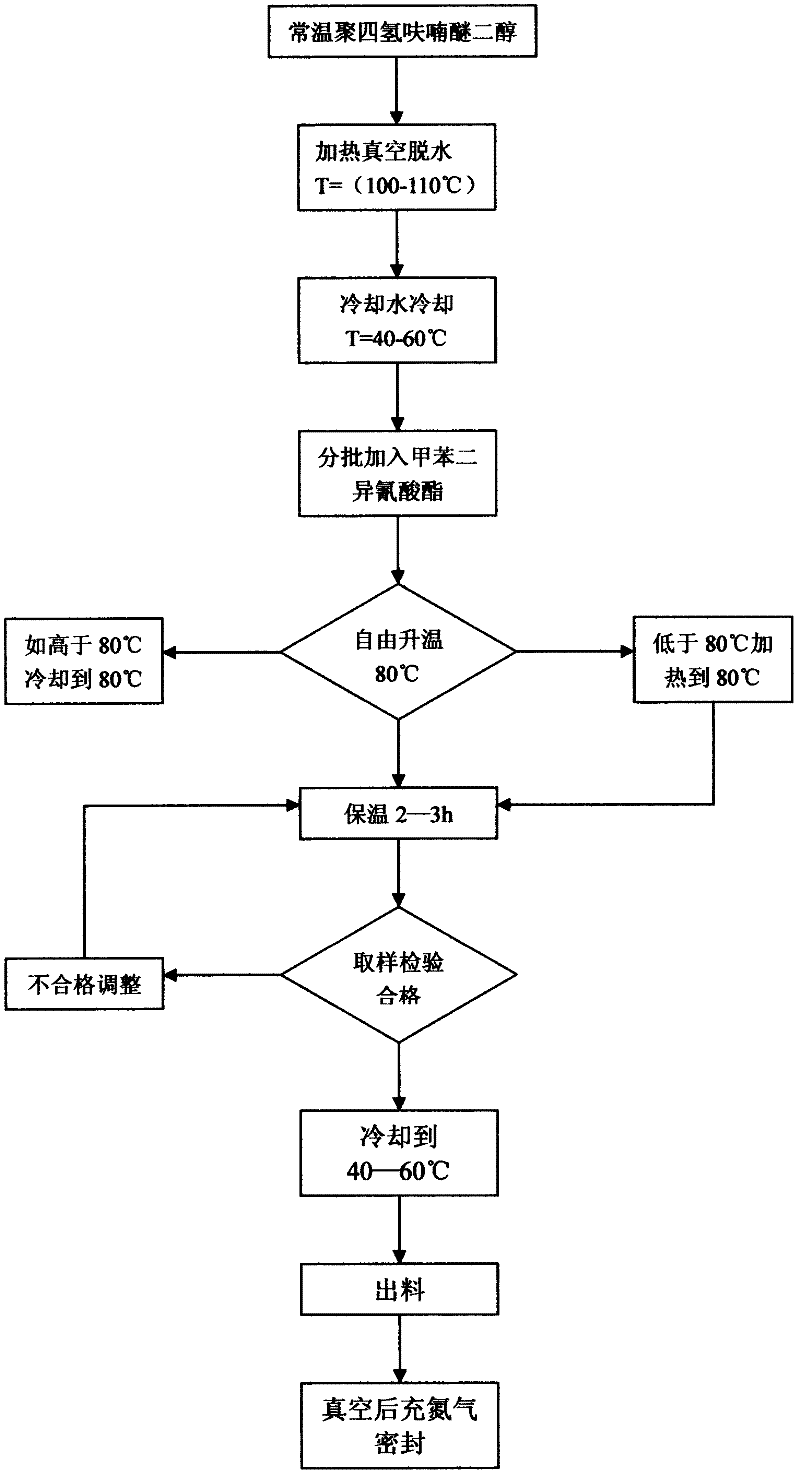

Method for preparing polybutadiene-base water polyurethane and modified emulsion thereof

InactiveCN101235129ASolve the problem of environmental protectionGood compatibilityPolymer scienceAlcohol

The invention discloses a polybutadiene aqueous polyurethane and a preparation method of relative modified emulsion, which is characterized by reacting low polymer polyatomic alcohol and hydroxy-terminated butadiene rubber and isocyanate, adding hydrophilic chain extender and catalyst to be reacted, cooling and emulsifying to obtain polybutadiene aqueous polyurethane, mixing polybutadiene aqueous polyurethane, emulsifier, water and inducer uniformly, adding ethenyl monomer to carry out emulsion polymerization to obtain polybutadiene aqueous polyurethane modified emulsion. The invention uses hydroxy-terminated butadiene rubber to synthesize aqueous polyurethane which can be modified by ethenyl to obtain environment-friendly, stable and low temperature resistant aqueous resin with better mechanical property. The resin can be used in weaving, leather processing, paint and adhesive or the like.

Owner:ANHUI UNIVERSITY

Ammonium nitrate cladding method

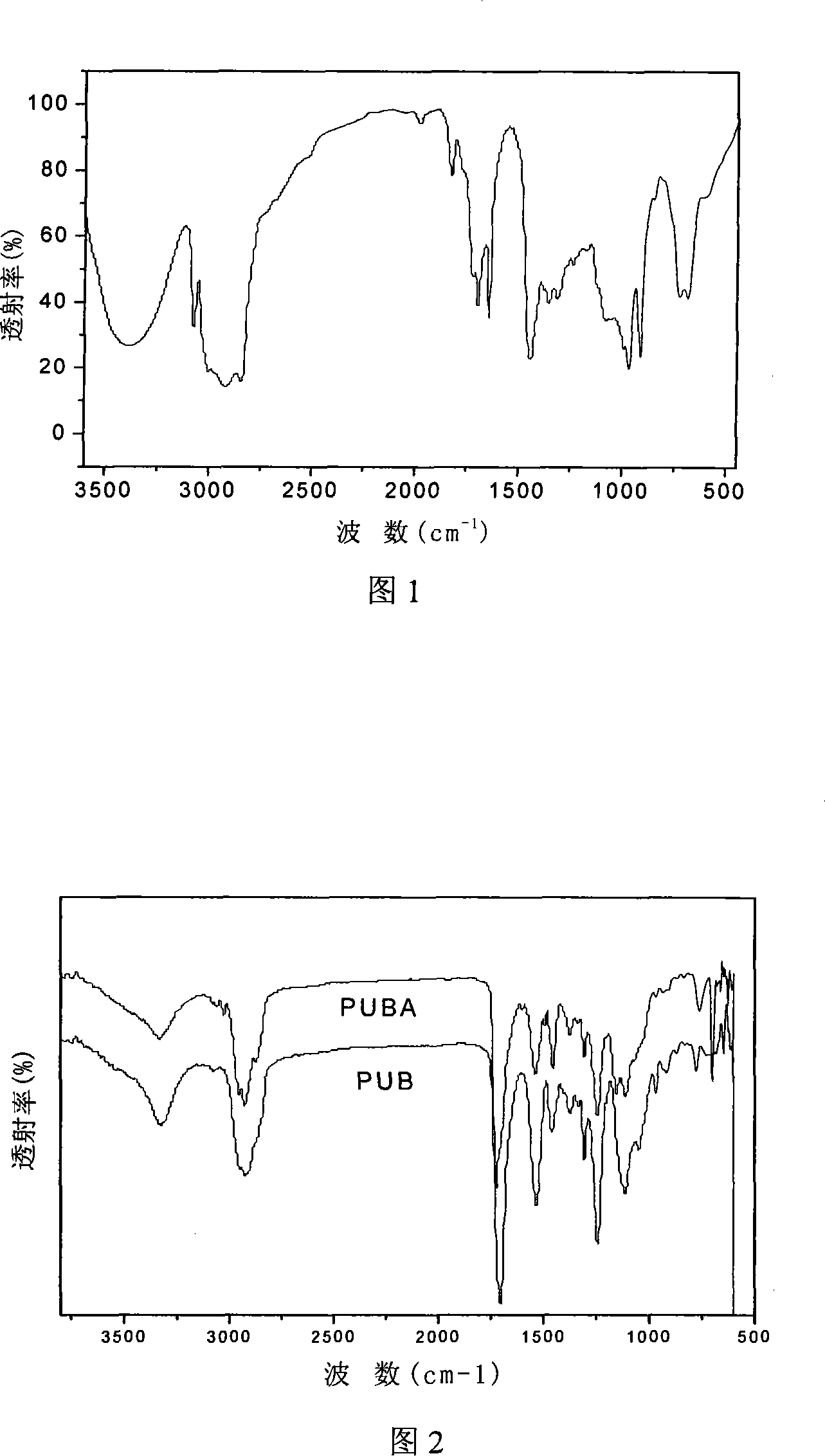

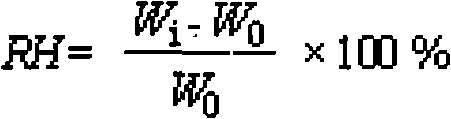

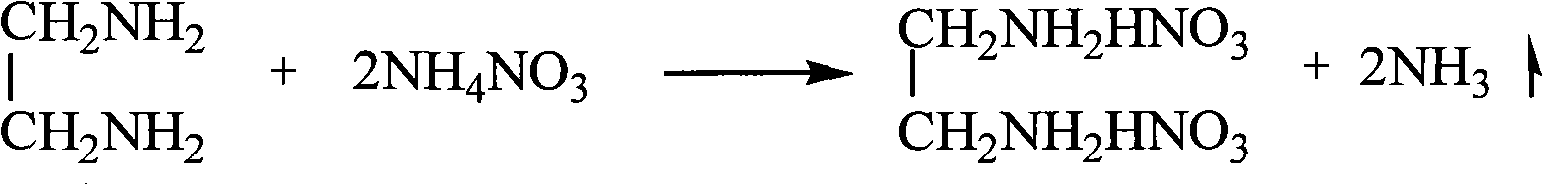

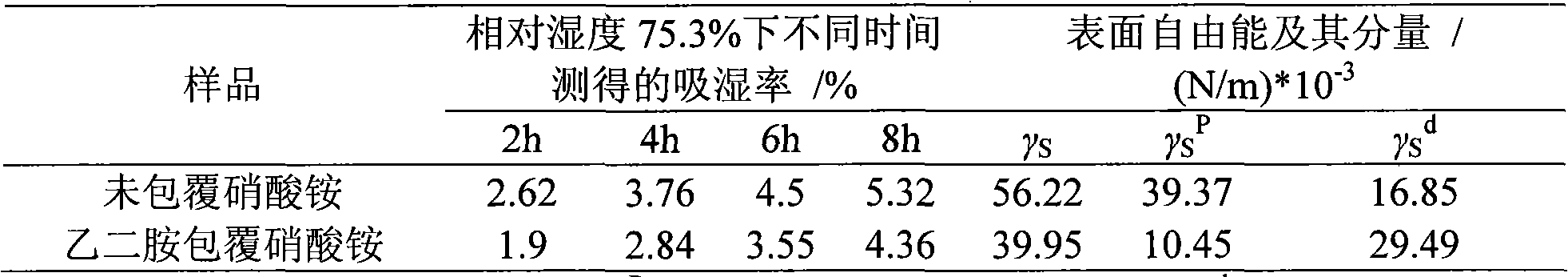

InactiveCN101774870ALow hygroscopicityReduce surface polarityExplosivesPressure gas generationChemical reactionOxidizing agent

The invention relates to an ammonium nitrate cladding method, which belongs to the technical field of ammonium nitrate surface modification and the technical field of propelling agents, in particular to a method for cladding ammonium nitrate through the chemical reaction with the surface of the ammonium nitrate and application effect of the clad ammonium nitrate to the propelling agents. The method comprises the following steps: dripping cladding agents dissolved in a polar solvent into a mixed system of ammonium nitrate particles and a non-polar solvent so that the cladding agents are attached to the surface of the ammonium nitrate and take the chemical reaction with the surface of the ammonium nitrate; then, removing the solvent and drying the materials to obtain the chemical reaction type clad ammonium nitrate; uniformly mixing the cladd ammonium nitrate and other ingredients of a propelling agent recipe in a container to obtain propelling agent medicine slurry; then, casting the propelling agent medicine slurry into a mold in vacuum; and heating and solidifying the propelling agent medicine slurry to obtain a composite propelling agent medicine block. The invention has the advantages that consumption of the cladding agents is little, the combining force with the surface of clad oxidizers is strong, the hydroscopic property of the clad ammonium nitrate is reduced, the surface polarity is reduced, and the mechanical property of the propelling agents is obviously improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Heat-conduction electronic potting adhesive and preparation method thereof

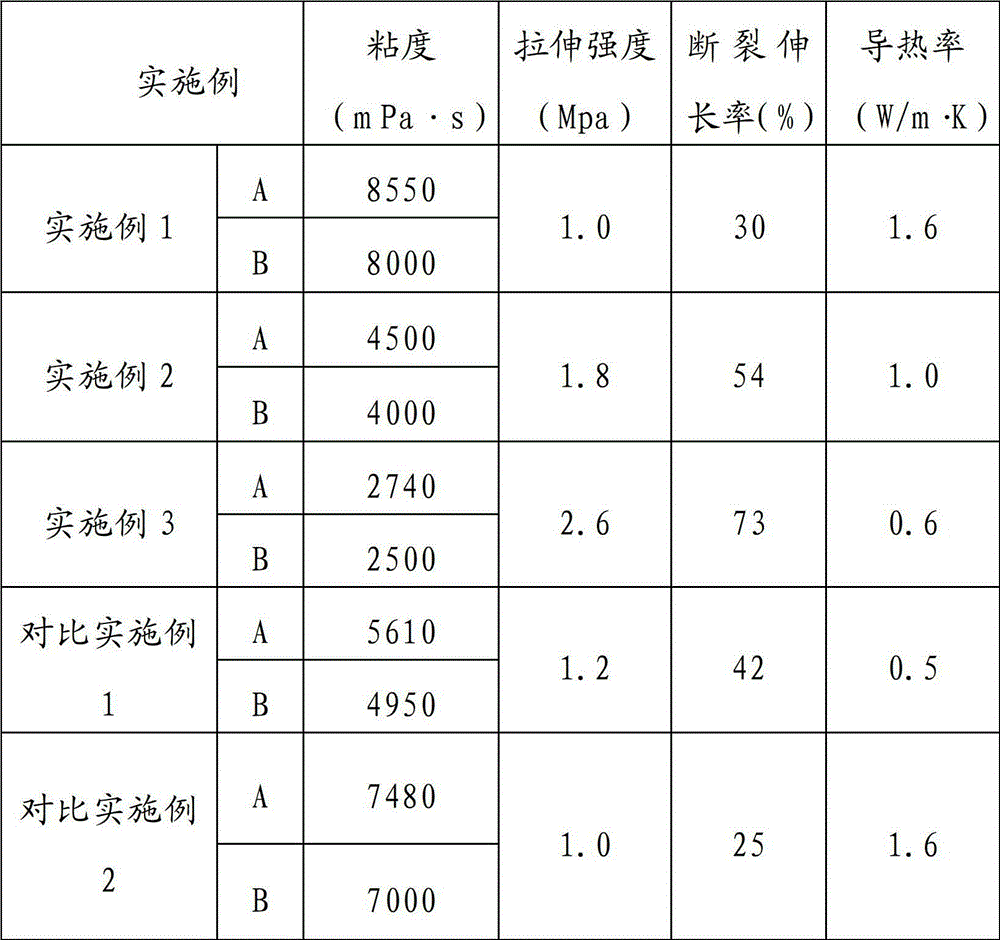

InactiveCN102942895AMeet potting requirementsEffective protectionNon-macromolecular adhesive additivesAdhesiveUltimate tensile strength

The invention relates to the field of a potting adhesive and particularly relates to a low-viscosity heat-conduction electronic potting adhesive applicable to each electronic element and a preparation method thereof. The heat-conduction electronic potting adhesive is formed by a component A and a component B in a weight ratio from 100: 90 to 100: 110; the component A comprises the following raw materials in weight percentage of 39.20-79.60% of heat-conduction inflaming retarding powder, 0.80-2.00% of color matching agent, 0.40-1.00% of silane coupling agent, 16.20-43.80% of liquid silicon oil and 3.00-14.50% of silane cross-linking agent; and the component B comprises the following raw materials in weight percentage of 39.20-79.60% of heat-conduction inflaming retarding powder, 18.00-57.80% of liquid silicon oil, 0.20-1.00% of silane coupling agent, 1.00-1.96% of color matching agent and 0.04-1.00% of catalyst. The low-viscosity heat-conduction electronic potting adhesive has lower viscosity, excellent mobility, good heat-conduction performance and high inflaming retarding grade; the potting requirement of a seam less than 0.02 mm can be met and the construction is convenient; and after the heat-conduction electronic potting adhesive is cured, the strength is good, and the dustproof, moisture-proof and vibration-proof performances are good, the electronic element can be effectively protected and the service life of the electronic element is prolonged.

Owner:YANTAI DARBOND TECH

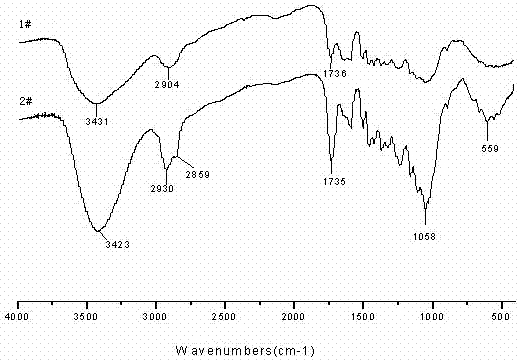

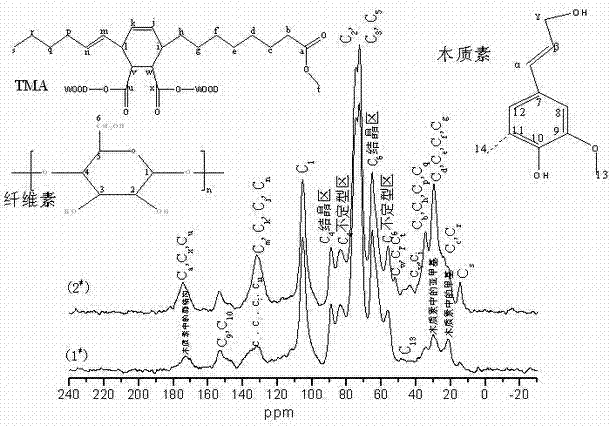

Preparation method of nano-SiO2/cellulose composite separating membranes

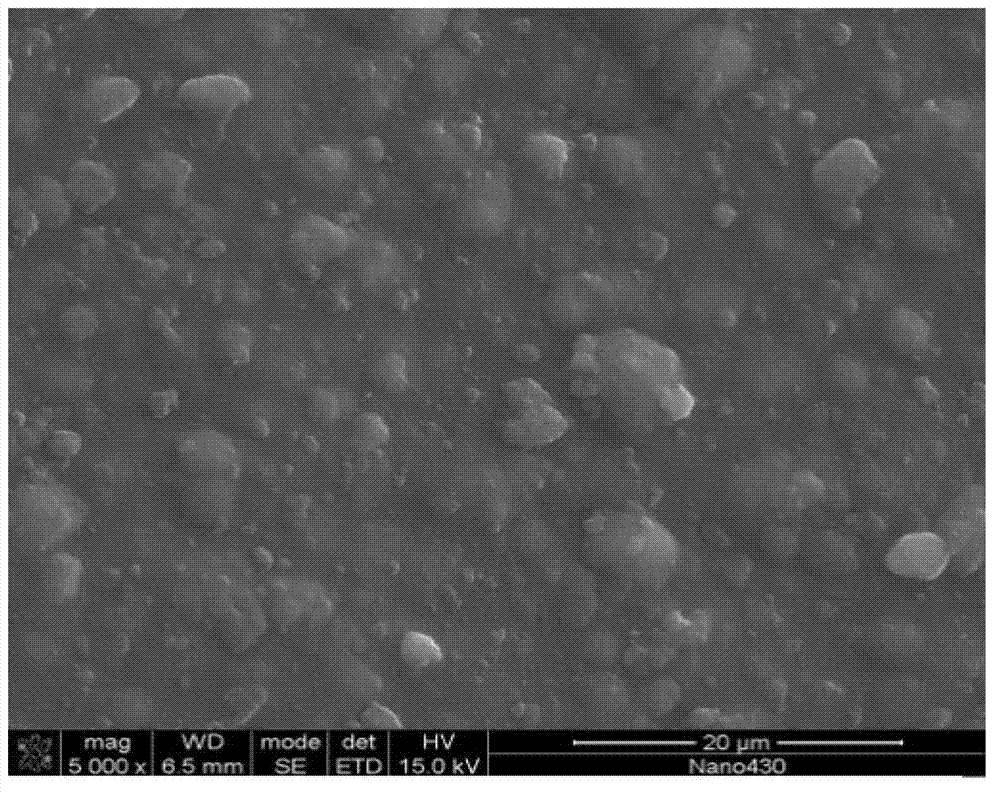

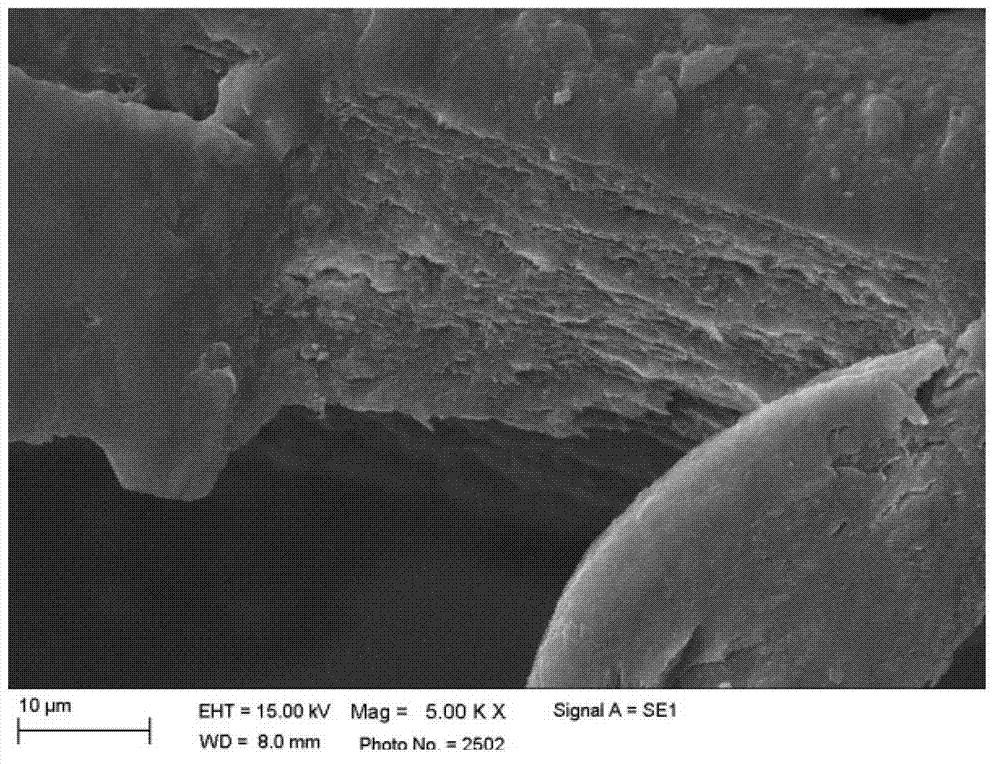

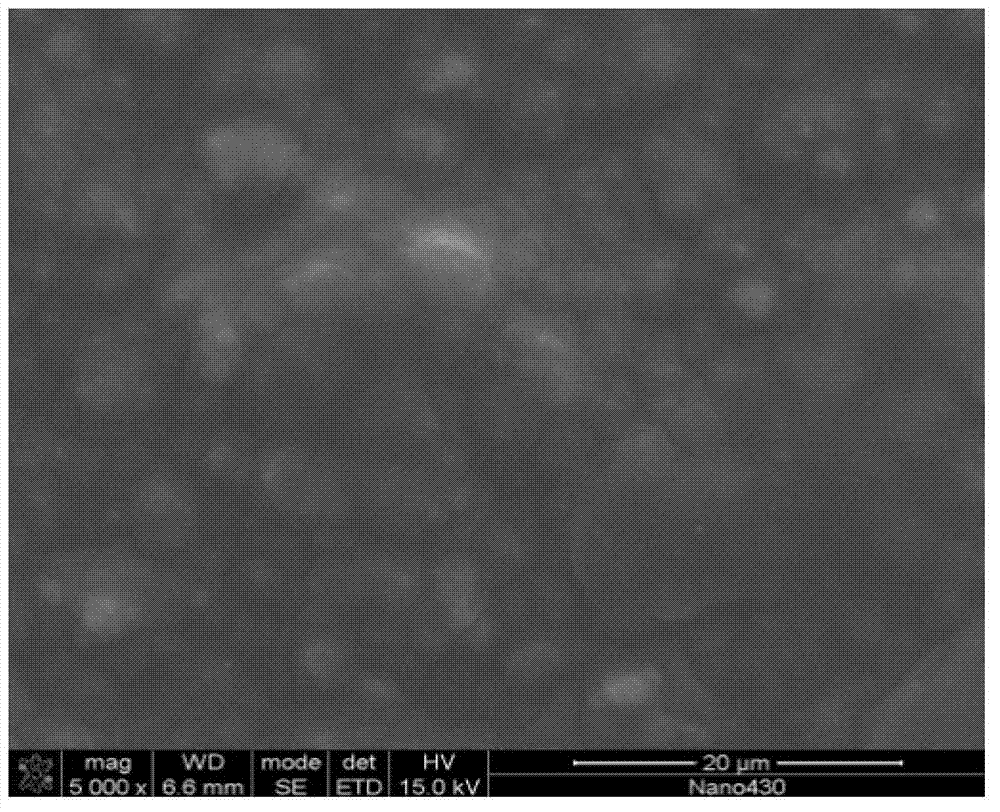

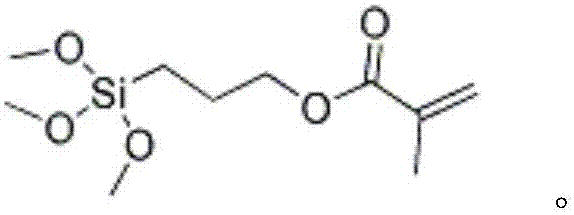

The invention discloses a preparation method of nano-SiO2 / cellulose composite separating membranes, which comprises the following steps: (1) dissolving cellulose in ionic liquid so as to form a membrane-casting solution; (2) preparing nano-SiO2; (3) carrying out modification on the nano-SiO2 by using a silane coupling agent gamma-(2, 3-epoxy propoxy) n-propyltrimethoxysilane; and (4) dispersing the modified nano-SiO2 in the membrane-casting solution obtained in sep (1) so as to obtain a mixed membrane-casting solution; and preparing the mixed membrane-casting solution into a membrane and drying the membrane so as to obtain a nano-SiO2 / cellulose composite separating membrane. According to the invention, the dispersion and uniformity of nano-SiO2 particles in cellulose membranes are improved, and the mechanical strength and thermal stability of the cellulose membranes are further enhanced.

Owner:OLANSI HEALTHCARE CO LTD

Functional master batch for antisticking BOPA film and production process thereof

The invention relates to a functional master batch for an antisticking BOPA film and a production method thereof, and the master batch is used to prepare a biaxial stretching BOPA film. The functional master batch is prepared by the following raw materials by weight: 90-95% of PA; and 5-10% of cage-shaped polyhedral oligomeric silsesquioxane (POSS), wherein the typical molecular formula of POSS is R7R' (SiO1.5)8, and the beneficial effects are that POSS is used as an antisticking agent, and fine aggregated micro-areas are formed on the surface of the BOPA film by the nano effects of POSS, which increase the roughness of the film surface and decrease the friction coefficient between films; on the other hand, the addition of POSS can reduce the surface polarity of the BOPA film, increase the hydrophobicity of the BOPA film, decrease the penetration of water, and thus improve the barrier property of the BOPA film, and has no adverse effect on mechanical properties; additionally, no other additive is required to be added during the production process of the master batch.

Owner:GUANGDONG MODERN HIGH TECH FIBER CO LTD

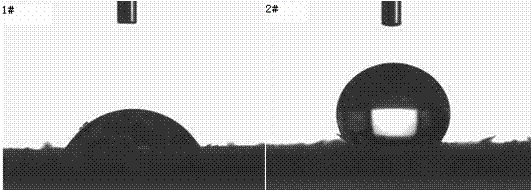

Method for manufacturing methyl malei-eleostearate anhydride modified wood fiber

InactiveCN102206917AAbundant and cheap resourcesReduce surface polarityVegetal fibresFiberCooking & baking

The invention discloses a method for manufacturing methyl malei-eleostearate anhydride modified wood fiber by virtue of reaction of wood fiber and methyl malei-eleostearate anhydride. The method comprises the following steps of: firstly, with dimethyl formamide as solvent, carrying out reaction on the wood fiber and methyl malei-eleostearate anhydride at the temperature of 25-130 DEG C for 2-12 hours, wherein the dosage of dimethyl formamide is 20ml per g of the wood fiber, and the dosage of methyl malei-eleostearate anhydride is 2.5-15 times that of the wood fiber; and secondly, extracting reaction products with mixed solvent for 16 hours, removing unreacted small molecular compound, and baking, thus the methyl malei-eleostearate anhydride modified wood fiber is obtained. Catalyst pyridine is added in the first step preferably. The method disclosed by the invention has the advantages of being rich in resources, being low in cost and being environmentally-friendly. The surface polarity of the modified wood fiber manufactured by adopting the method disclosed by the invention is reduced, and the surface hydrophobicity is improved, thus the interface compatibility with synthetic resin is enhanced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for manufacturing bamboo redwood

InactiveCN102528892ALarge specific surface areaImprove accessibilityWood working apparatusFlat articlesFiberResin adhesive

A method for manufacturing bamboo redwood includes steps of selecting and cutting off materials, and radially splitting a bamboo barrel into 10 to 15 equal parts by a bamboo cutting machine; removing bamboo green parts, bamboo yellow parts and bamboo joints by a bamboo slicer, and preparing bamboo chips in certain sizes; grinding the bamboo chips, dividing the bamboo chips into threads, subjecting bamboo bundles to activating treatment: applying dyeing adhesive; dipping the bamboo bundles in dyeing phenolic resin adhesive solution for 3 minutes to 5 minutes in a pressurization manner, manually paving dyed adhesive-dipped bamboo bundles longitudinally to form a plate blank with a certain thickness; feeding the blank into a hot press to realize solidifying and forming, and preparing a reconstructed bamboo plate; and finally splitting and sawing the bamboo plate according to needs, and processing and using the bamboo plate. The dyeing phenolic resin adhesive solution contains from 20 to 40% of solid. The crystallinity of bamboo fibers and the specific surface areas of the bamboo bundles are reduced by means of pressurized activating treatment, accessibility and leaching resistance of dye are improved, imitated redwood bamboo furniture and decorative materials are manufactured, and additional values of reconstructed bamboo are increased by 40% at least under the condition that cost is seldom increased.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

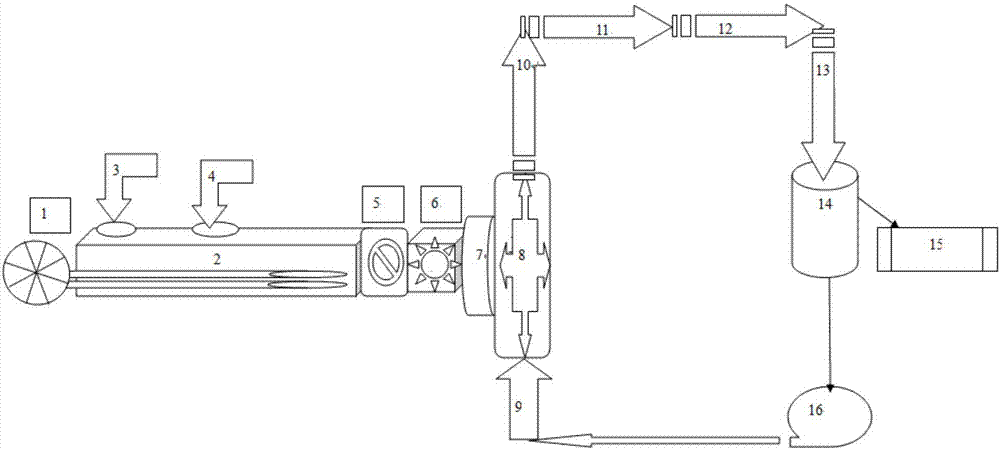

Degradable antifouling thermoplastic micro-airbag polymer elastomer material and preparation thereof

The invention relates to a degradable antifouling thermoplastic micro-airbag polymer elastomer material which is prepared from the following ingredients in percentage by weight: 88 to 98% of polymer raw material, 0.05 to 0.5% of nucleating agent, 0.4 to 2% of foaming agent and 0.1 to 10% of environment-friendly degradable organic perfluorosebacamidine material. A preparation method specifically comprises the steps: (1) feeding the polymer raw material, the nucleating agent and the environment-friendly degradable organic perfluorosebacamidine material from a feeding opening in the front end of a twin-screw extruder, feeding the foaming agent from a feeding opening in a middle section of the twin-screw extruder, hot melting and fully mixing all the raw materials, then sending into a static mixer to be further homogenized and then controlling pressure and quantitatively conveying by a melt pump; (2) sending hot melt sent out by the melt pump into an underwater pelletizing chamber to be pelletized, bringing out by technological water to be separated and screening and drying the particles to obtain a target product. Compared with the prior art, the degradable antifouling thermoplastic micro-airbag polymer elastomer material disclosed by the invention effectively achieves performance of antifouling, soiling-resistant, oil-resistant, contamination-resistant, attractive and good touch and is especially suitable for being applied to the fields of shoe materials, food package and the like.

Owner:NANTONG DE NEW MATERIAL CO LTD

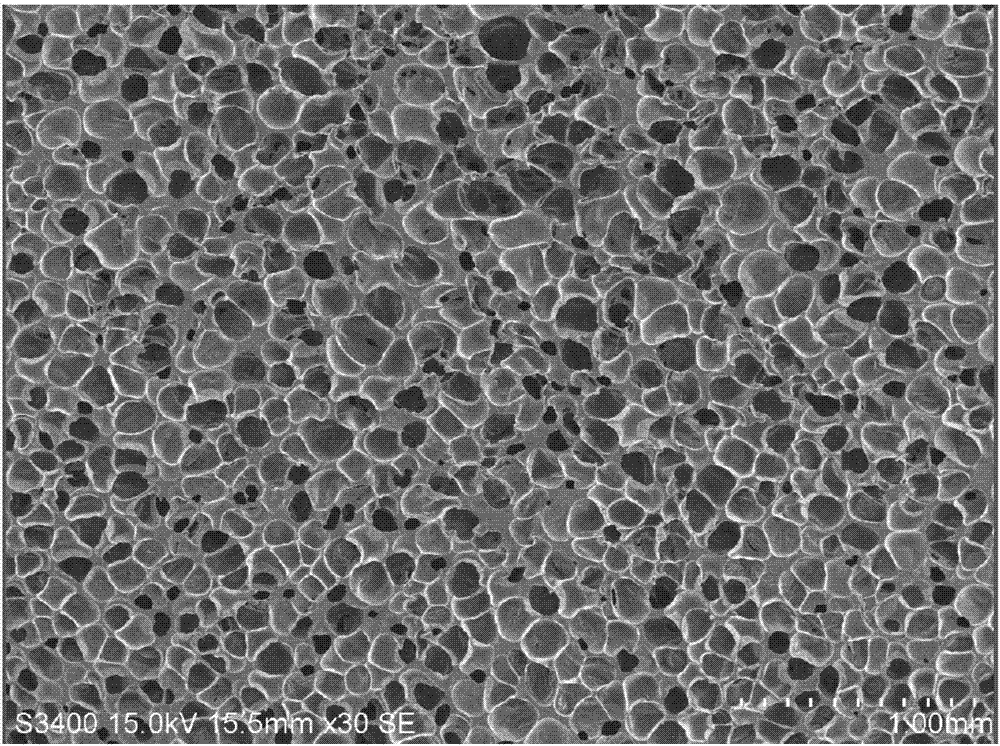

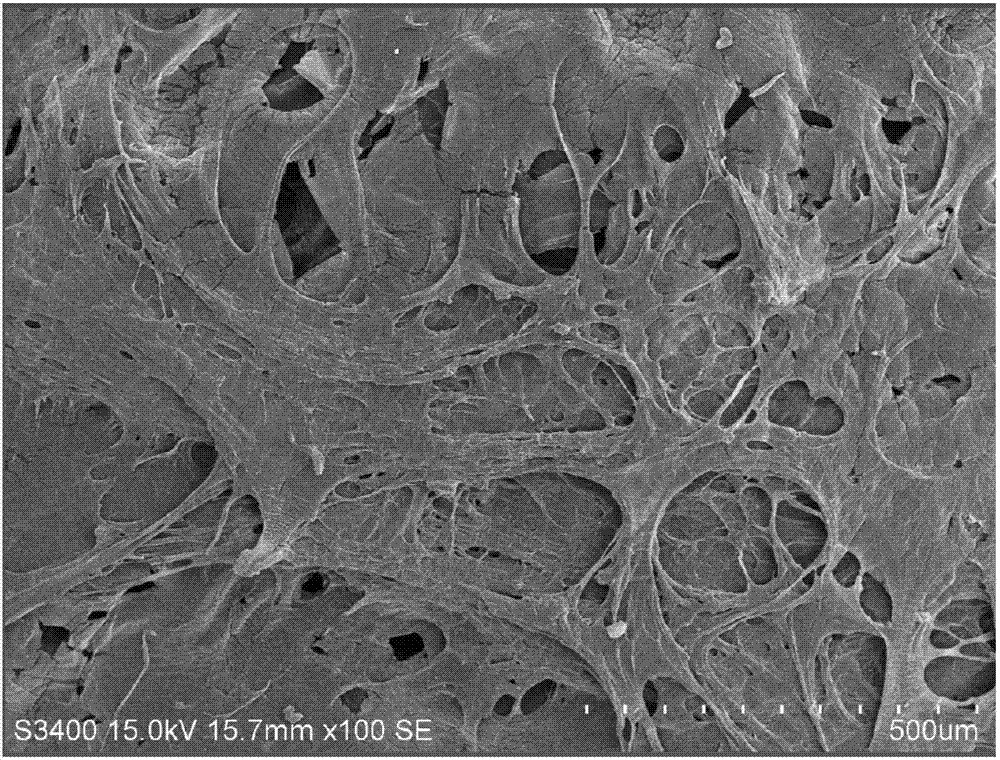

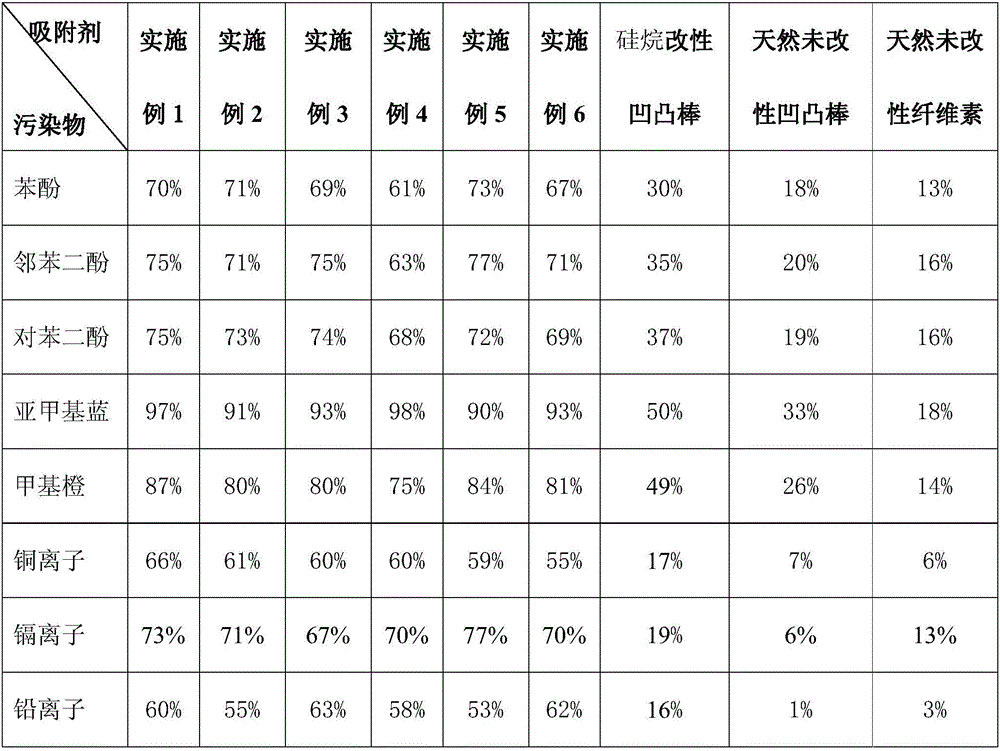

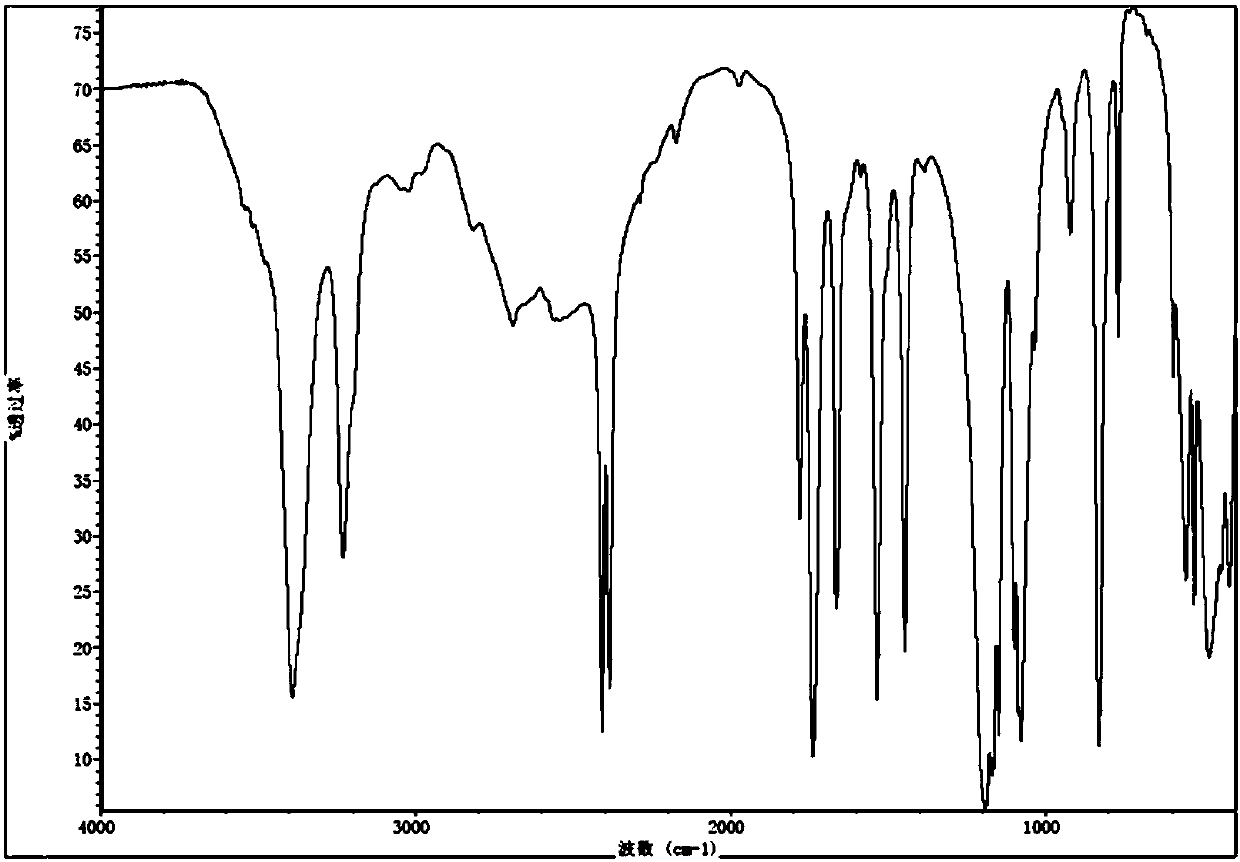

Preparation method of composite adsorption microspheres of attapulgite cellulose

ActiveCN106179249AReduce pollutionSimple processOther chemical processesAlkali metal oxides/hydroxidesCelluloseMicrosphere

The invention discloses a preparation method of composite adsorption microspheres of attapulgite cellulose. The method comprises the following steps: carrying out preprocessing and surface modification on attapulgite; preparing an ionic liquid cellulose solution; preparing the composite adsorption microspheres of the attapulgite cellulose. A preparation process is simple and convenient, adopted ionic liquid solvent is safe and nontoxic, and the prepared composite microspheres of the attapulgite cellulose are porous, have good dispersibility, biocompatibility and thermostability, have the advantages of high adsorption capability, large adsorption capacity, high removal efficiency and stable property on contaminants in water and can be easily recovered. The problems that the attapulgite is poor in adsorption capability and difficult to recover, a cellulose adsorbent is weak in mechanical strength and low in thermostability and the like are solved, meanwhile, the preparation method has the advantages of wide raw material resources, low cost, no secondary pollution and high practical value since the renewable resources including cellulose and the attapulgite are fully utilized, and can be used for the advanced treatment of contaminants in water, and the problems of energy crisis and environment pollution are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Elastic fluorocarbon paint and formula thereof

The invention relates to a formula of elastic fluorocarbon paint. The formula comprises the following ingredients: 40-50% of fluorocarbon resin, 15-20% of elastic resin, 0.3-0.5% of a wetting agent, 0.3-0.5% of a dispersant, 0.5-1% of a leveling agent, 15-20% of aluminium powder, 0.1-0.2% of an antifoaming agent, 0.1-0.5% of an anti-settling agent, 0-0.5% of a drier and 15-20% of a solvent. Long straight chain and low branched chain of a high-molecular elastic cross-linking agent react with a fluorine-containing polymer to form a highly-straight-chain and low-branched-chain polymer, the structure of which is jagged. The ultimate embodiment of properties is reflected in appropriate surface strength, excellent elasticity, telescopic springback function, high tensile strength and fracture resistance, low surface polarity and strong resistance to soiling and weatherability.

Owner:上海奥泽涂料有限公司

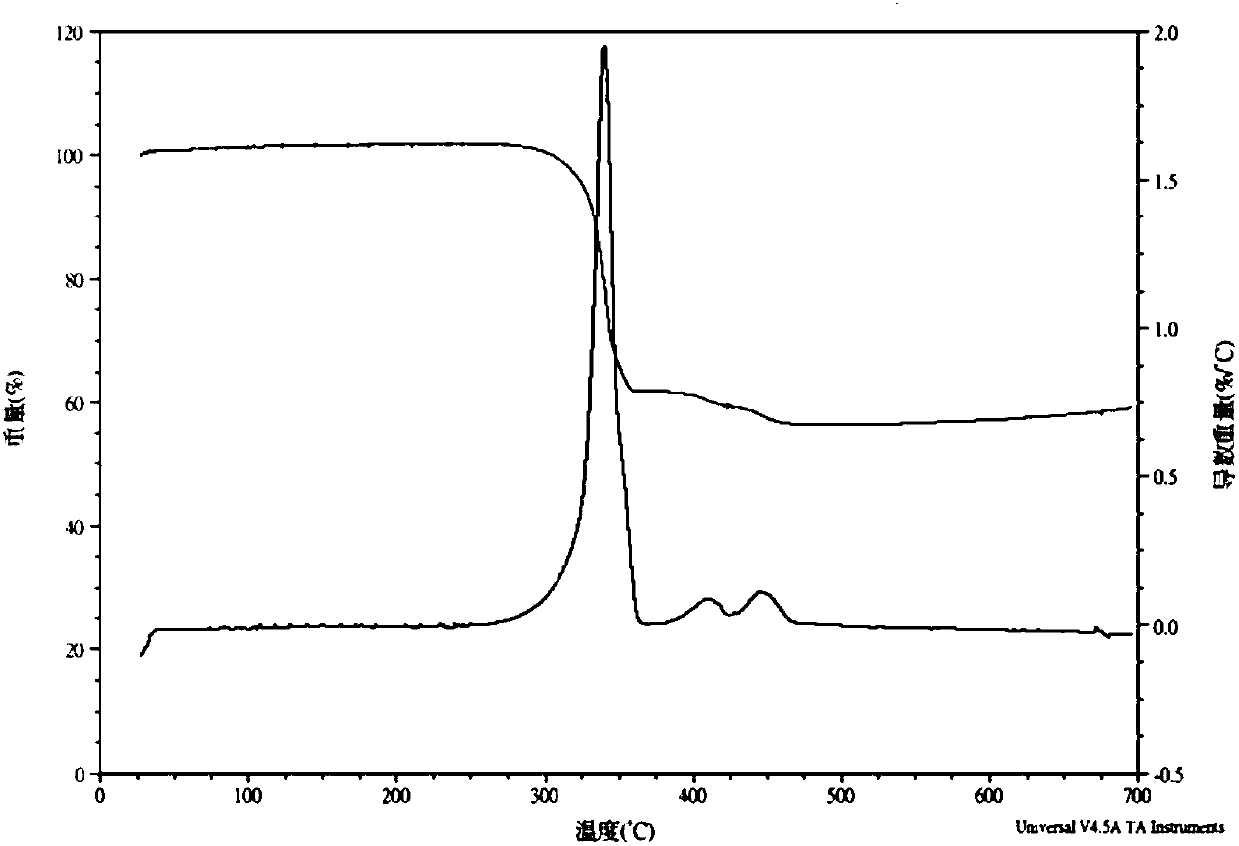

Modified aluminum hypophosphate flame retardant and preparation method thereof

The invention relates to the field of flame retardants, in particular to a modified aluminum hypophosphate flame retardant. A preparation method of the modified aluminum hypophosphate flame retardantcomprises the following steps: 1) adding aluminum hypophosphate and a dispersing agent in a reaction kettle and fully stirring, so that a solution is uniformly dispersed; 2) adding an adhesive and a modifying agent, raising the temperature, stirring and fully reacting to obtain a crude product; and 3) washing, filtering and drying the crude product to obtain the modified aluminum hypophosphate flame retardant. The modified aluminum hypophosphate flame retardant prepared by the preparation method provided by the invention can effectively solve the problems of low aluminum hypophosphate heat resistance, low compatibility, low dispersing performance and the like.

Owner:广东顺德同程新材料科技有限公司

Preparation method for modified magnesium-aluminium hydrotalcite cable fillers

InactiveCN108314821AImprove corrosion resistanceImprove high temperature resistancePlastic/resin/waxes insulatorsHeat resistanceHydrotalcite

The invention discloses a preparation method for modified magnesium-aluminium hydrotalcite cable fillers and belongs to the technical field of preparation of cable fillers. The preparation method disclosed by the invention has the beneficial effects that firstly a tetraethoxysilane hydrolysis method is utilized for preparing silica sol, and since the silica sol contains silicon dioxide, oxygen inthe air can be effectively isolated from a base material to prevent contact; in addition, bismaleimide resin has heat resistance, and is easily cured on the polyethylene surface to form a triazine-ring structure, so that the compatibility of self-made magnesium-aluminium hydrotalcite with the base material is improved; meanwhile, the self-made magnesium-aluminium hydrotalcite particles are uniformly dispersed on the surface of the base material, so that the surface temperature of the base material is reduced and the flame-retardant effect is achieved; furthermore, in the heat-absorbing and decomposing process of the self-made magnesium-aluminium hydrotalcite, an alkali porous composite oxide is obtained, and can be combined with a carbonized product on the surface of the base material to form a protective film, so that the invasion of heat and oxygen can be effectively prevented, the flame retardance of the cable fillers can be further improved and the application prospect is wide.

Owner:谢新昇

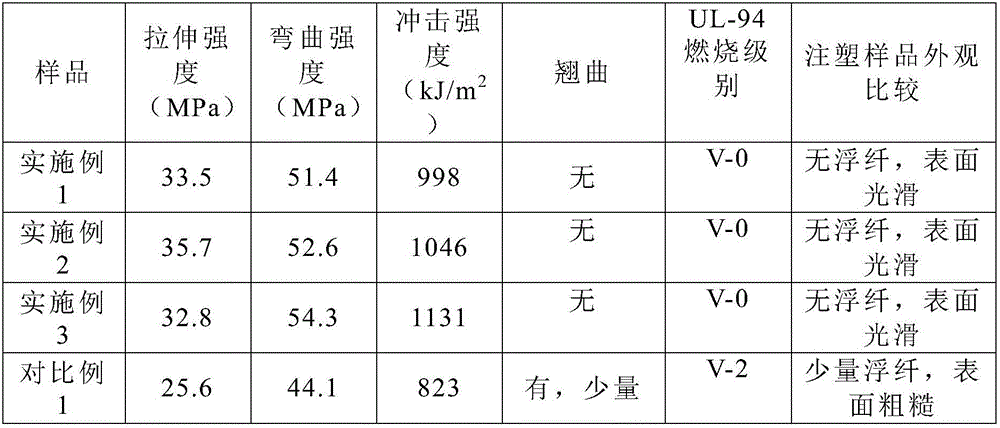

High-smoothness long-glass-fiber flame-retardant toughened polypropylene blend material and preparation method thereof

The invention belongs to the technical field of high-polymer composite materials, and relates to a high-smoothness long-glass-fiber flame-retardant toughened polypropylene blend material and a preparation method thereof. The preparation method comprises the following steps: A. preparing the following components in parts by mass: 50-70 parts of polypropylene resin, 10-25 parts of synergic toughener master batch, 0.5-2.0 parts of chain extender, 2-5 parts of anti-floating fiber agent and 25-40 parts of main toughener master batch; B. blending: adding the components in the step A into an extruder, and blending to obtain a blend; and C. preparation: drawing the blend in the step B out of the head of an extruder, cooling, blow-drying, and granulating to obtain the high-smoothness long-glass-fiber flame-retardant toughened polypropylene blend material. The high-smoothness long-glass-fiber flame-retardant toughened polypropylene blend material is especially suitable for medium / high-end furniture supplies with higher requirements for product shape structure and appearance, cost, processibility and the like.

Owner:STARWAY INTERNATIONAL HOME LIVING CO LTD

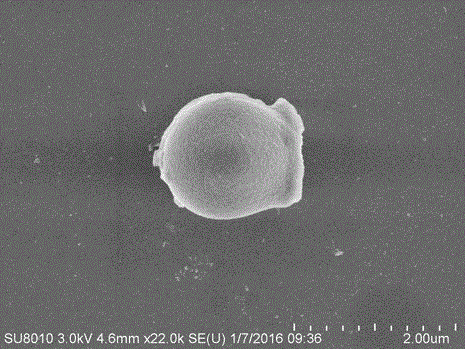

Multi-gradient functionalized microcapsule titanium phosphate flame retardant and preparation method thereof

InactiveCN105542229AEfficient flame retardant propertiesHigh mechanical strengthMicroballoon preparationMicrocapsule preparationTitanium phosphateCrosslinked polymers

The invention discloses a multi-gradient functionalized microcapsule titanium phosphate flame retardant and a preparation method thereof. The multi-gradient functionalized microcapsule titanium phosphate flame retardant comprises a core material and a wall material for wrapping the core material, wherein the core material is titanium phosphate; the wall material is double-layered, the inner wall is an intumescent flame retardant prepared from a carbon source modifier, an acid source modifier and a gas source modifier in a mole ratio being (1-2):(1-2):(1-2) through reaction, and the outer wall is an organosilicon cross-linked polymer. The preparation method of the flame retardant comprises the following steps: titanium phosphate powder is prepared firstly; then the titanium phosphate powder is dispersed in a solvent, and the carbon source modifier, the acid source modifier and the gas source modifier are added for the reaction for inner wall wrapping; the outer wall is wrapped with the organosilicon cross-linked polymer finally, and the flame retardant is obtained. According to the flame retardant, the organosilicon cross-linked polymer with high carbon formation amount, water resistance, molten droplet avoidance and heat resistance is taken as the outer wall, the intumescent flame retardant is taken as the inner wall, the titanium phosphate powder with carbon formation catalysis characteristic is taken as the core material, so that the prepared microcapsule titanium phosphate flame retardant has more efficient flame retardance and can show a multi-functional multi-gradient flame retardant effect in a burning process.

Owner:GUANGDONG UNIV OF TECH

Active carbon and modification method as well as application thereof in processing water containing endocrine disrupters

InactiveCN101513999AChange surface chemistryBest adsorption interfaceWater/sewage treatment by sorptionPerturbateurs endocriniensAbsorption capacity

The invention provides active carbon and modification method as well as application thereof in processing water containing endocrine disrupters. The active carbon is arranged in a muffle furnace silica tube; under the room temperature, hydrogen is pumped into the muffle furnace at first for 0.5 to 1.5 hours; the hydrogen flowing speed is 40 to 60ml / minute; then under the protection of the same hydrogen flow, the temperature of the muffle furnace is raised to 500-900 DEG C by the speed of 10 DEG C / minute and then the temperature is maintained for 1 to 5 hours; after the temperature is reduced to 30 DEG C, hydrogen pumping is stopped; then the air is pumped continuously for one hour by the flux of 40 to 60ml / minute; then the active carbon is taken out, and is added into a container together with muriatic acid with a volume by volume concentration of 35 percent according to a weight percentage of 10 percent for boiling and reflowing for 2 to 4 h; then de-ionized water is used for leading the sample of the active carbon to be detected without chloridion to obtain the modified active carbon. The modified active carbon prepared by the invention is used as a sorbent in the treatment process and has larger absorption capacity and renewable performance than that of raw carbon, and can realize to completely remove the endocrine disrupters under lower carbon inputting amount.

Owner:HARBIN ENG UNIV

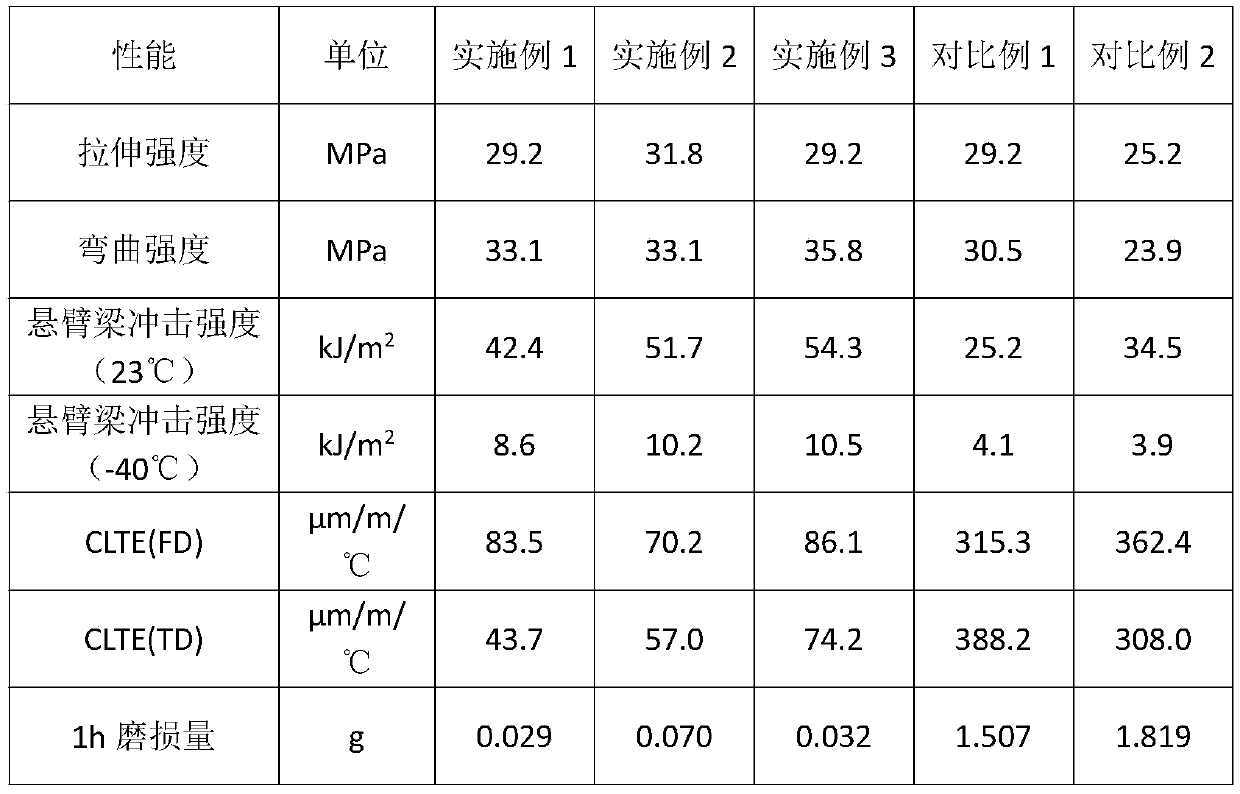

Preparation method and application of polypropylene composite material

PendingCN111548567ALow coefficient of linear expansionImprove impact toughnessPolypropylene compositesGlass fiber

The invention provides a preparation method and application of a polypropylene composite material. The polypropylene composite material is characterized by comprising the raw materials in parts by mass: 62-75 parts of polypropylene resin, 30-45 parts of modified glass fibers, modified talcum powder and modified master batch, 1-2 parts of a lubricant, and 1-10 parts of maleic anhydride grafted polyethylene, wherein the ratio of the modified glass fibers to the modified talcum powder to the modified master batch is (22-25):(11-14):(3-5). The preparation method comprises the steps: preparing themodified glass fibers, the modified talcum powder and the modified master batch, adding the polypropylene resin, the modified glass fibers, the modified talcum powder, the lubricant, the modified master batch and the maleic anhydride grafted polyethylene into a high-speed mixer according to a ratio, mixing, melting, blending and extruding through a double-screw extruder, and carrying out water-cooling drawing, air-drying and dicing to obtain the polypropylene composite material. The polypropylene composite material disclosed by the invention has the advantages of low linear expansion coefficient, high cold resistance and the like, can be used for injection molding of injection molded parts generating friction with metals, and can also be applied to injection molding of household appliancesand automobile parts.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +2

Prepn process of naometer calcium carbonate with non-polar surface

InactiveCN1636878AEvenly dispersedAvoid reunionCalcium/strontium/barium carbonatesPolypropylene compositesNucleation

The preparation process of nano calcium carbonate with non-polar surface includes dispersing nano calcium carbonate particles in hot polypropylene solution homogeneously via high speed stirring; adding reactive monomer as modifier and initiating in-situ reaction of the reactive monomer with initiator under heat action to form macromolecular compatibilizing agent; and crystallizing polypropylene on the surface of nano calcium carbonate by means of the heterogeneous nucleation action of nano calcium carbonate on polypropylene under high speed stirring and slowly lowering temperature to obtain nano calcium carbonate particles with non-polar surface coated with reactive monomer grafted polypropylene. The composite nanometer calcium carbonate / polypropylene material with the nano calcium carbonate of the present invention added has high calcium carbonate dispersivity, raised interface adhesion, etc.

Owner:SUN YAT SEN UNIV

Anti-bacterial Lyocell fiber and preparation method thereof

InactiveCN105177746AImprove antibacterialImproves UV resistanceMonocomponent cellulose artificial filamentArtifical filament manufactureFiberCellulose pulp

The invention discloses anti-bacterial Lyocell fiber and a preparation method of the anti-bacterial Lyocell fiber. The anti-bacterial Lyocell fiber contains nano ZnO of which the mass content is 0.1 to 10 percent, wherein the fineness of the anti-bacterial Lyocell fiber is 1.1 to 4.3 dtex, the strength of the anti-bacterial Lyocell fiber is 1 to 5 cN / dtex, and the elongation at break of the anti-bacterial Lyocell fiber is 8 to 20 percent. A preparation method comprises the steps of uniformly mixing the nano ZnO subjected to surface modification treatment with NMMO (N-Methylmorpholine-N-Oixde) water solution of which the mass concentration is 70 to 87 percent to obtain ZnO-contained NMMO solution; then dissolving cellulose pulp; obtaining the anti-bacterial Lyocell fiber through spinning. The production technology is easy to control and is environment-friendly and pollution-free, industrial production is easy to realize, the nano ZnO is uniformly dispersed in a product, and the anti-bacterial performance of the product is good.

Owner:SHANDONG YINGLI IND

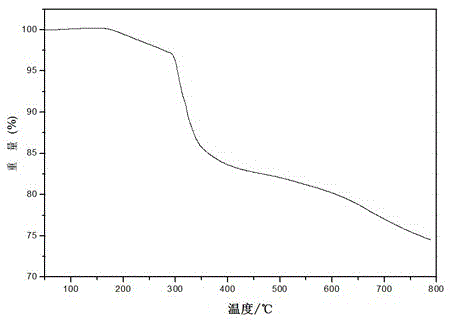

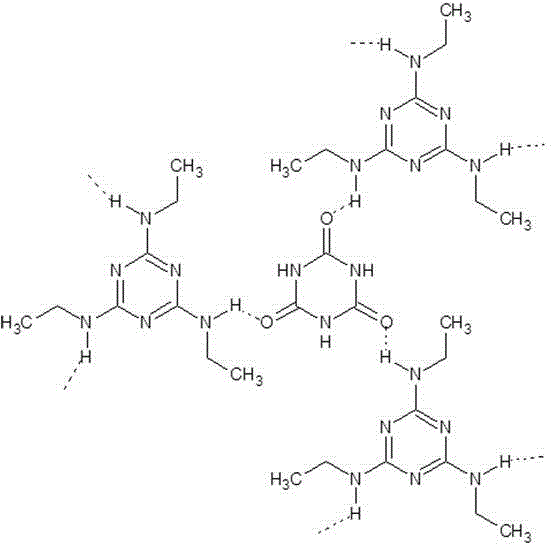

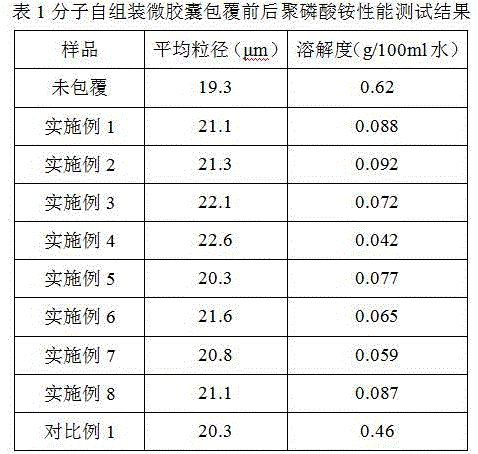

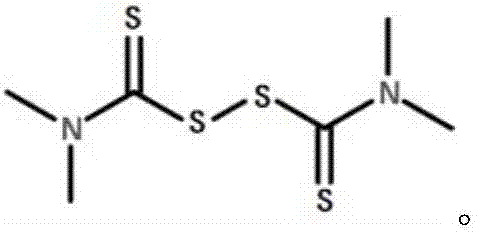

Method for preparing microcapsule-coated ammonium polyphosphate through in-situ polymerization molecular self-assembly

ActiveCN105566684ARaw material safetyRaw materials are easy to getIn situ polymerizationCyanuric acid

The invention discloses a method for preparing microcapsule-coated ammonium polyphosphate through in-situ polymerization molecular self-assembly. The method includes mixing formalin with melamine, increasing the temperature for condensation reaction after adjusting pH value of the mixture to 8-9, lowering the temperature after reaction, adding water and ammonium polyphosphate, stirring the mixture for 1-2 hours, adding cyanuric acid, increasing the temperature for in-situ polymerization reaction, coating the ammonium polyphosphate with a microcapsule, and performing filtering and drying after reaction to obtain the microcapsule-coated ammonium polyphosphate. The method has the advantages that the technological operation process is simple, ammonium polyphosphate coating rate is high, water solubility of the ammonium polyphosphate is reduced greatly, high dispersity and compatibility of the ammonium polyphosphate and polymer materials are achieved after coating, and flame retarding effect is remarkable; moreover, adhesion of the ammonium polyphosphate and resin to the inner wall of a reaction kettle is avoided during reaction, the reaction kettle is easy to clean, raw material utilization rate is increased and heat transfer efficiency of the reaction kettle is improved.

Owner:山东青科华创化工科技有限公司

Modified coconut shell and natural rubber composite cable sheath material

InactiveCN104194239ALow hydroxyl contentImprove hydrophobicityRubber insulatorsInsulated cablesFiberVulcanization

The invention discloses a modified coconut shell and natural rubber composite cable sheath material which is characterized by comprising the following raw materials in parts by weight: 100 parts of natural rubber, 8-10 parts of maleic anhydride, 30-40 parts of coconut shell fiber, 15-20 parts of kieselguhr, 5-10 parts of nylon PA, 10-15 parts of calcined clay, 30-40 parts of white carbon black, 20-30 parts of carbon black, 20-40 parts of attapulgite, 4-4.5 parts of zinc oxide, 1.5-2 parts of sulfur, 1-2 parts of vulcanization accelerant N-cyclohexyl-2-benzothiazole sulfonamide, 3-4 parts of bi(3-triethoxy silylation propyl) tetrasulfide and 1.5-2 parts of stearic acid, wherein the particle size of the coconut shell fiber is 20-30mm. The modified coconut shell and natural rubber composite cable sheath material is good in physical and mechanical properties and relatively excellent in thermo-oxidative aging resistance, ozone resistance and ultraviolet resistance.

Owner:ANHUI LAND GRP

Modified bamboo charcoal fiber-rubber composite sole material, preparation method and application

ActiveCN107417998AImprove toughness and strengthHigh tensile strengthSolesFibre typesButadiene-styrene rubberOxide

The invention discloses a modified bamboo charcoal fiber and rubber composite material, a preparation method therefor and an application of the modified bamboo charcoal fiber and rubber composite material. The composite material is prepared from the following ingredients in parts by weight: 100 parts of natural rubber, cis-butadiene rubber and styrene-butadiene rubber blended rubber, 15-35 parts of modified bamboo charcoal fibers, 1.2-3.3 parts of sulfur, 2.5-4 parts of zinc oxide, 0.9-1.3 parts of stearic acid and 1.2-2 parts of accelerant TMTD. The preparation method comprises the steps of using the natural rubber, cis-butadiene rubber and styrene-butadiene rubber blended rubber as a raw material, carrying out milling and plastifying on the modified bamboo charcoal fibers, processing aids and the blended rubber in mixing and milling procedures of the raw material, and carrying out procedures such as vulcanization, thereby preparing a modified bamboo charcoal fiber containing rubber composite material and products. The composite material and the products thereof, prepared by the method, can serve as a shoe sole material and can meet the requirements of novel shoe soles on light weight and low cost.

Owner:贝克兰(厦门)新材料有限公司

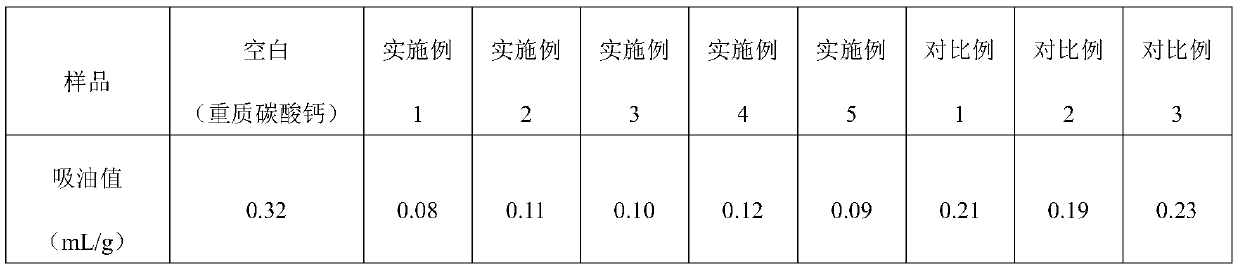

Heavy calcium carbonate modifier and modification method thereof

ActiveCN110845871AReduce surface polarityImprove compatibilityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEnvironmental chemistryAlkyl phosphate

The invention relates to a heavy calcium carbonate modifier and a modification method thereof, wherein the heavy calcium carbonate modifier comprises at least one of fatty alcohol-polyoxyethylene ether, fatty acid polyoxyethylene ether and fatty alcohol alkyl phosphate. According to the modifier, adsorption and organic coating of part of polar groups on the surface of heavy calcium carbonate powder can be realized by utilizing various groups on the surface of the modifier, and the oil absorption value and the surface polarity of heavy calcium carbonate are remarkably reduced, so that the compatibility, the dispersity and the stability of the heavy calcium carbonate powder in an organic matrix are effectively improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

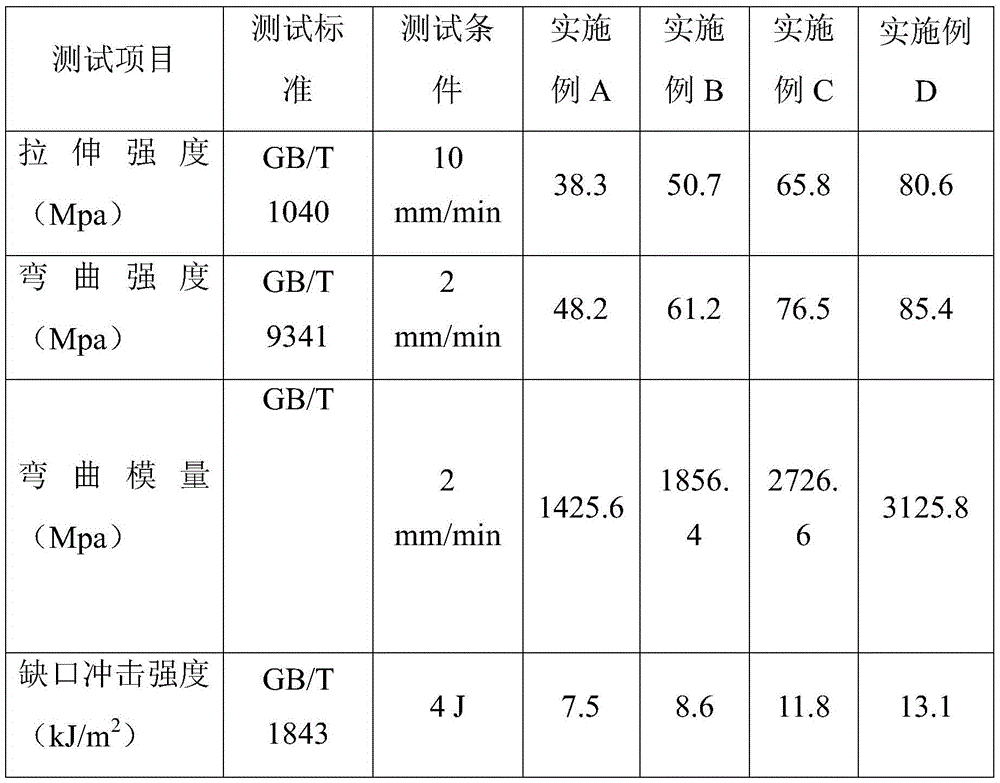

Functionalized boron nitride nanosheet/polypropylene composite material and preparation method thereof

The invention provides a functionalized boron nitride nanosheet / polypropylene composite material. The composite material comprises the following components in parts by weight: 50-70 parts of polypropylene, 5-20 parts of a functionalized boron nitride nanosheet, 5-15 parts of an alkali-free glass fiber yarn, 0-5 parts of grafted PP, 5-10 parts of barium sulfate, 0.1-0.5 part of an antioxidant and 0.1-1 part of other aids. The invention further provides a preparation method of the functionalized boron nitride nanosheet / polypropylene composite material. By virtue of pi-pi action stacked functionalization modification, the surface energy and the surface polarity of a BN nanosheet can be decreased, the dispersion degree of the BN nanosheet in a polypropylene resin matrix can be improved, and therefore, the agglomeration phenomenon is reduced; by decreasing two-phase interfacial tension, the wettability, the consistency and the bonding force between the BN nanosheet and polypropylene resin are improved, and therefore, the mechanical strength of the composite material is improved.

Owner:GUANGDONG WAYLAM ENG PLASTICS

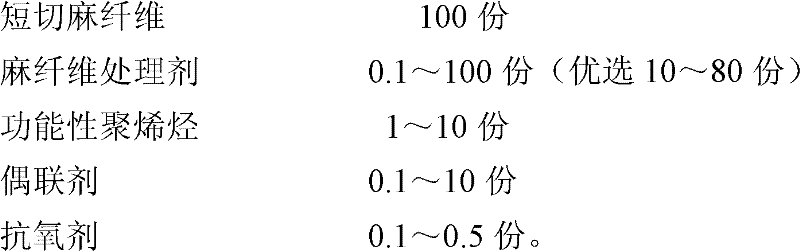

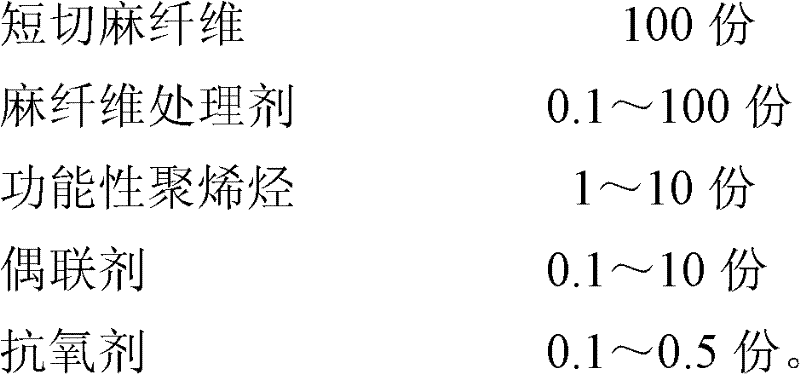

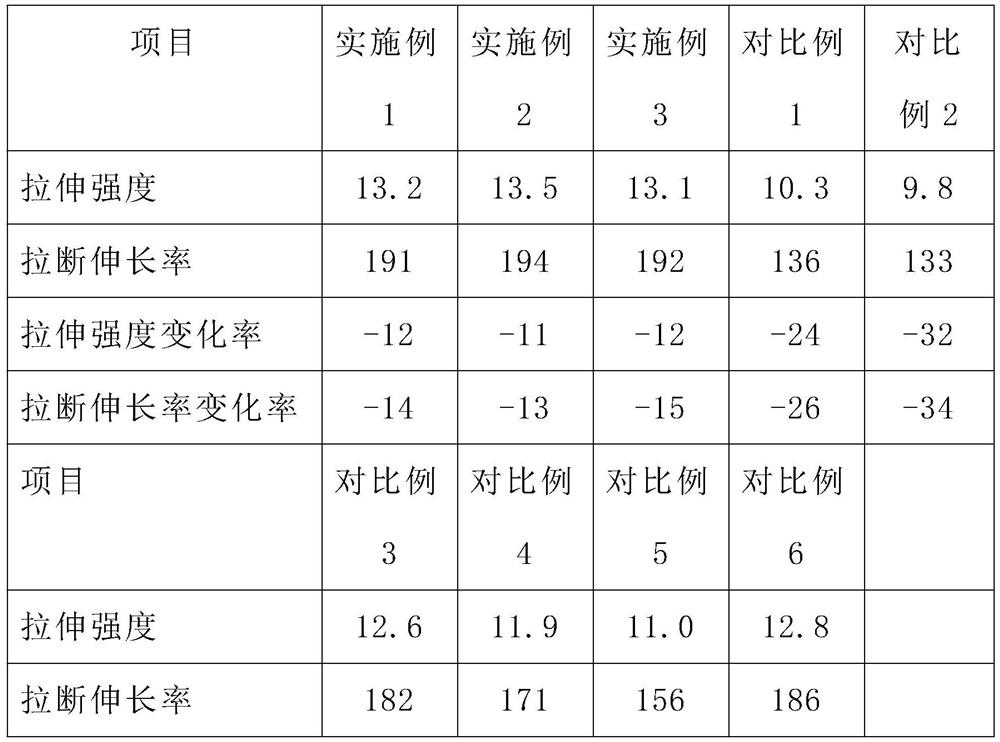

Bast fibers for plastics reinforcement and preparation method thereof

The present invention refers to bast fibers for plastics reinforcement and preparation method thereof. The bast fibers are composed of the following components by weight ratio; 100 pts.wt. chopped bast fibers, 0.1˜100 pts.wt. bast fiber treating agent, 1˜10 pts.wt. Functional Polyolefin wax, 0.1˜10 pts.wt. coupling agent and 0.1˜0.5 pts.wt. antioxidant. The method includes the steps of: firstly, cut chopped bast fibers and soak them in sodium hydroxide solution, agitate the mixture, after rinse and drying of water, soak the fibers in the aqueous solution of bast fiber treating agent, then dry them and obtain surface-treated chopped bast fibers; secondly, add in order the chopped fibers, the coupling agent, the Functional Polyolefin wax and the antioxidant to a preheated kneader, agitate the mixture and thus obtain bast fibers for plastics reinforcement. Chopped bast fibers according to the invention present good color, rigidity and heat resistance, as well as excellent compatibility with plastics, and can be used in the preparation of high-performance short-bast-fiber\plastic composites, as reinforcement in the plastic matrix.

Owner:BILIC FORTUNE TECH

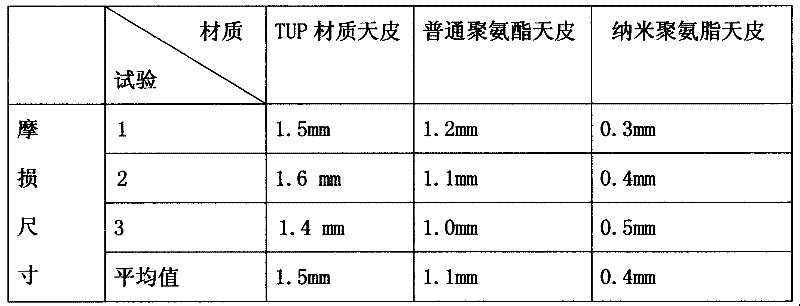

Nano-wear-resistant polyurethane heel lift composite material and preparation method

InactiveCN102501422AHigh mechanical strengthImprove mechanical propertiesLayered productsWear resistantHardness

The invention relates to a nano-wear-resistant polyurethane heel lift composite material and a preparation method. By means of nano composite technology, a polyurethane heel lift is modified, and the mechanical strength and the comprehensive performance of the materials are improved. Materials on an upper material layer A and materials on a lower material layer B are successively filled into a mould by a filling machine according to a certain time interval, are extruded by a flat vulcanizing machine at a certain pressure and a certain pressure, and are solidified into a whole to obtain the nano-wear-resistant polyurethane composite heel lift, the wear resistance and flexibility of the lower material layer B of the heel lift are improved, the upper material layer A has good hardness and strength and is stably engaged with a pinned top piece, the hydrolysis resistance, the impact strength and the like of the heel lift are further improved, the service life of the heel lift is effectively prolonged, noise generated by knocking the ground with the heel lift in use is lower, and quality in use of women's leather shoes is improved.

Owner:黎宏域

Fibrilia for plastic reinforcing and method for manufacturing the same

InactiveCN102232099AReduce surface polarityLow water absorptionVegetal fibresThin material handlingFiberPolyolefin

The present invention discloses a fibrilia for plastic reinforcing and a method for manufacturing the same. The fibrilia contains the following components in part by weight: 100 chopped fibrilias, 0.1 to 100 fibrilia agents, 1 to 10 functional polyolefins, 0.1 to 10 coupling agents and 0.1 to 0.5 antioxygens. The method comprises the steps of: cutting off the chopped fibrilias; immersing the cut chopped fibrilias into a sodium hydroxide solution and stirring the solution; washing out the chopped fibrilias after taking out them from the solution; drying the obtained chopped fibrilias; then immersing the dried chopped fibrilias into solution with the fibrilia agents; drying to obtain the chopped fibrilias with surface treatment; adding the chopped fibrilias, the coupling agents, the functional polyolefins and the antioxygens into a preheated kneader in order; and stirring to obtain the fibrilia for plastic reinforcing. The chopped fibrilias manufactured by the present invention has goodcolor, good rigidity, good heat resistance, and good compatibility with the plastic, thus the chopped fibrilias can be used for manufacturing chopped fibrilias / plastic composite materials with high performance, and can play a reinforcing role in plastic substrates.

Owner:BILIC FORTUNE TECH

Preparation method of nano calcium carbonate modified composite emulsion for paper coating

InactiveCN107489058AImprove hydrophilic abilityReduce surface polarityCoatings with pigmentsPaper/cardboardPolyethylene glycolDissolution

The invention discloses a preparation method of a nano calcium carbonate modified composite emulsion for paper coating. The preparation method is characterized by comprising the following steps: adding absolute ethyl alcohol into a silane coupling agent; stirring uniformly; adjusting pH; performing magnetic stirring for hydrolysis to obtain modified liquid; adding absolute ethyl alcohol into nano calcium carbonate; performing ultrasonic dispersion; adding the modified liquid; heating for reacting to obtain surface-modified nano calcium carbonate; adding an ethanol aqueous solution into nano titanium dioxide powder; adding dispersing agents sodium hexametaphosphate and polyethylene glycol; grinding and performing ultrasonic dispersion to obtain nano titanium dioxide dispersion liquid; adding solvents absolute ethyl alcohol and acetic acid into chitosan; stirring for dissolution; uniformly mixing with the nano titanium dioxide dispersion liquid to obtain composite antibacterial liquid; uniformly mixing a styrene-acrylic emulsion, a polyvinyl acetate emulsion and a carboxymethylcellulose solution with the obtained materials to obtain a composite emulsion.

Owner:ANHUI HONGYANG PACKAGING GRP

Butadiene styrene rubber-based right-angled civil defense door sealing rubber strip and preparation method thereof

ActiveCN111763363AImprove hydrophilicityGood dispersionSealing arrangementsPolymer scienceEthylene-propylene-diene-monomer

The invention discloses a butadiene styrene rubber-based right-angled civil defense door sealing rubber strip and a preparation method thereof. The sealing rubber strip comprises natural rubber, butadiene styrene rubber, ethylene propylene diene monomer, an anti-aging agent, auxiliary agents and the like. The auxiliary agents comprise modified graphene oxide, an additive and dopamine. The sealingrubber strip comprises the following raw materials in parts by weight: 25-30 parts of natural rubber, 45-50 parts of butadiene styrene rubber, 5-10 parts of ethylene propylene diene monomer, 3-6 partsof an anti-aging agent, 10-14 parts of auxiliary agents, 4-6 parts of silicon dioxide, 0.5-1 part of sulfur, 4-6 parts of dicumyl peroxide, 1-2 parts of an accelerant and 1-2 parts of an age resister. According to the butadiene styrene rubber-based right-angle civil air defense door sealing rubber strip and the preparation process thereof disclosed by the invention, the process design is reasonable, the component proportion is proper, and the prepared sealing rubber strip has excellent mechanical properties and excellent aging resistance, is convenient to store, can be applied to the fields of civil air defense doors and the like, and has a wide application range and high practicability.

Owner:盐城耀晖人防防护设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com