Patents

Literature

91results about How to "Facilitate blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

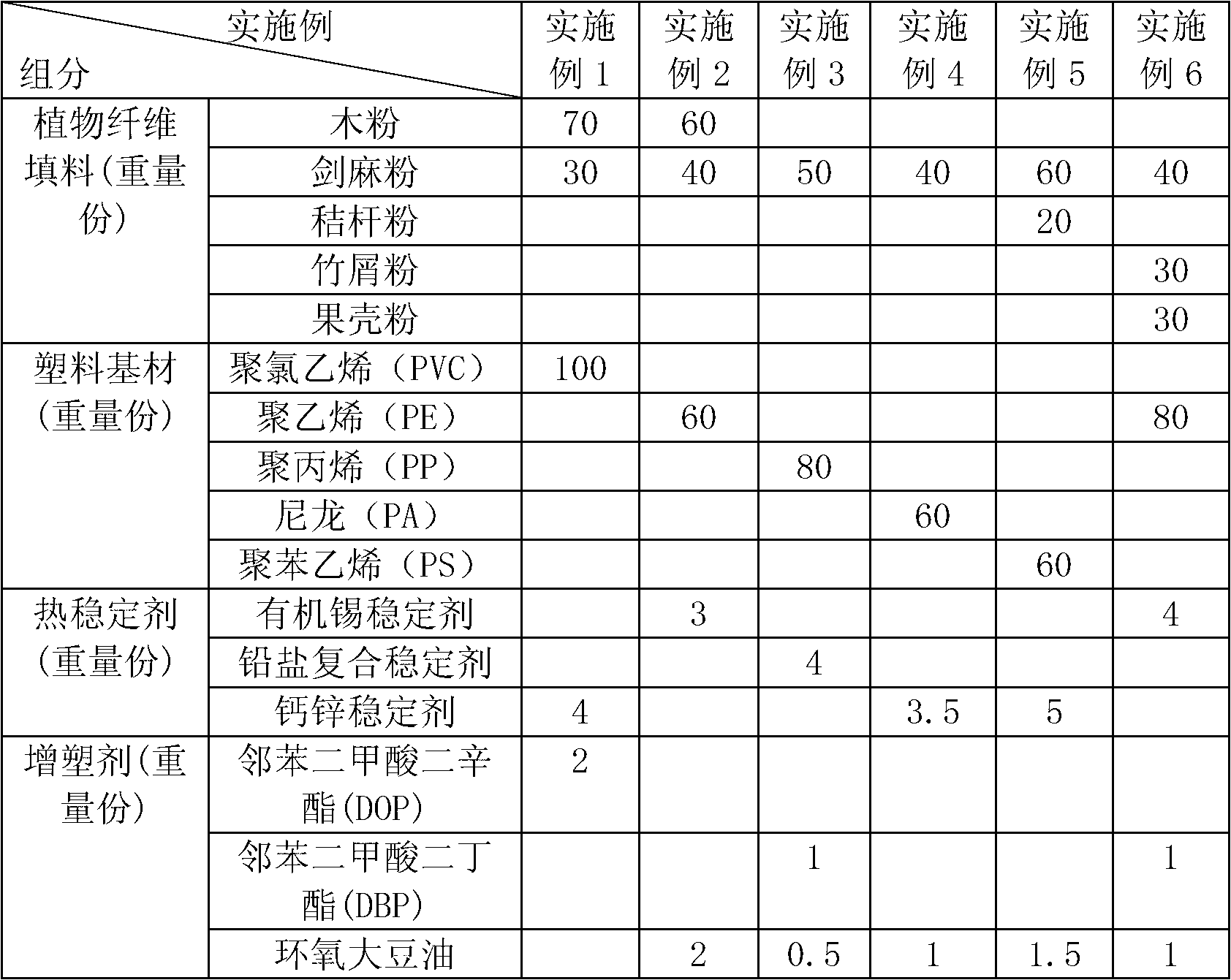

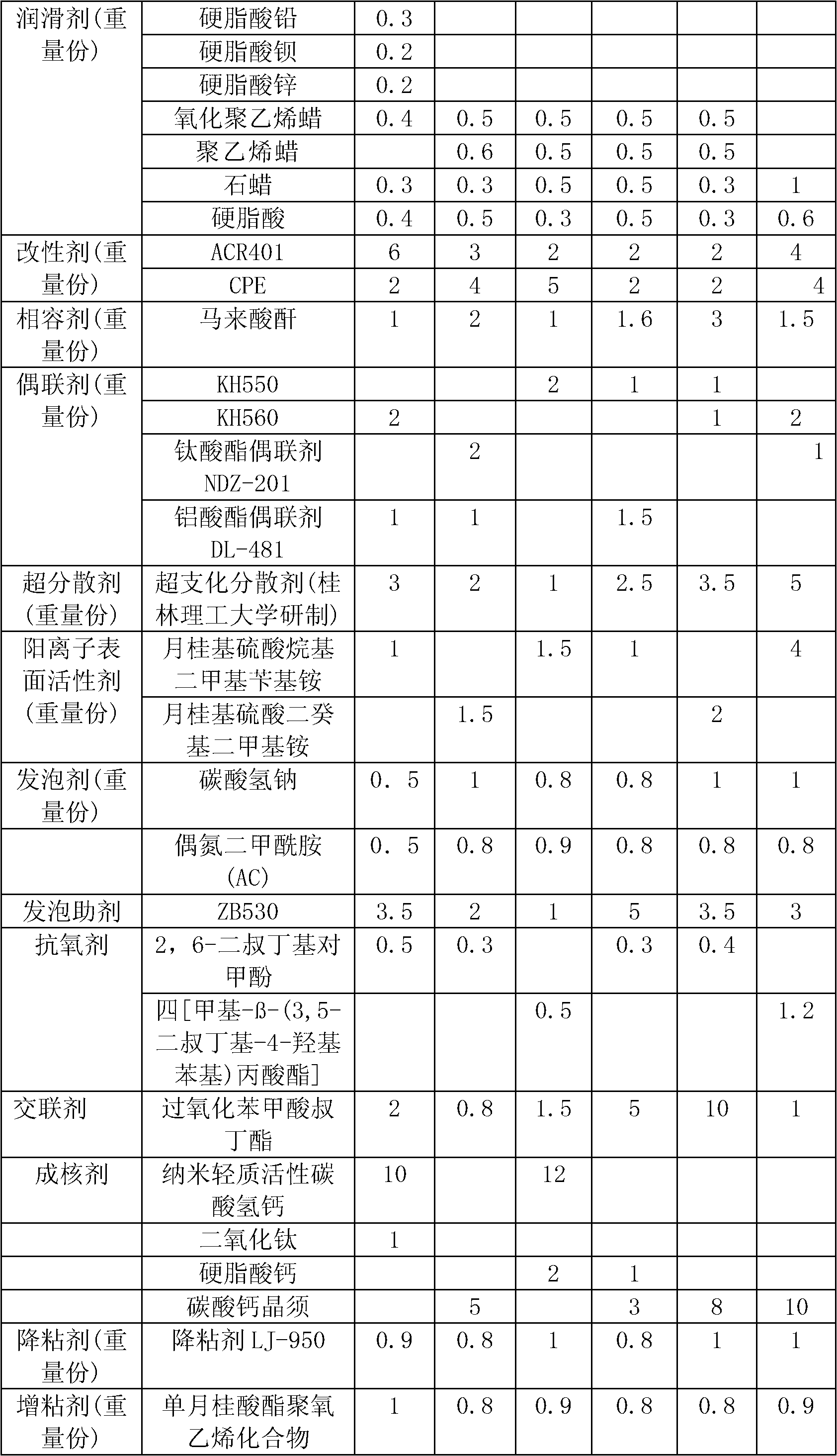

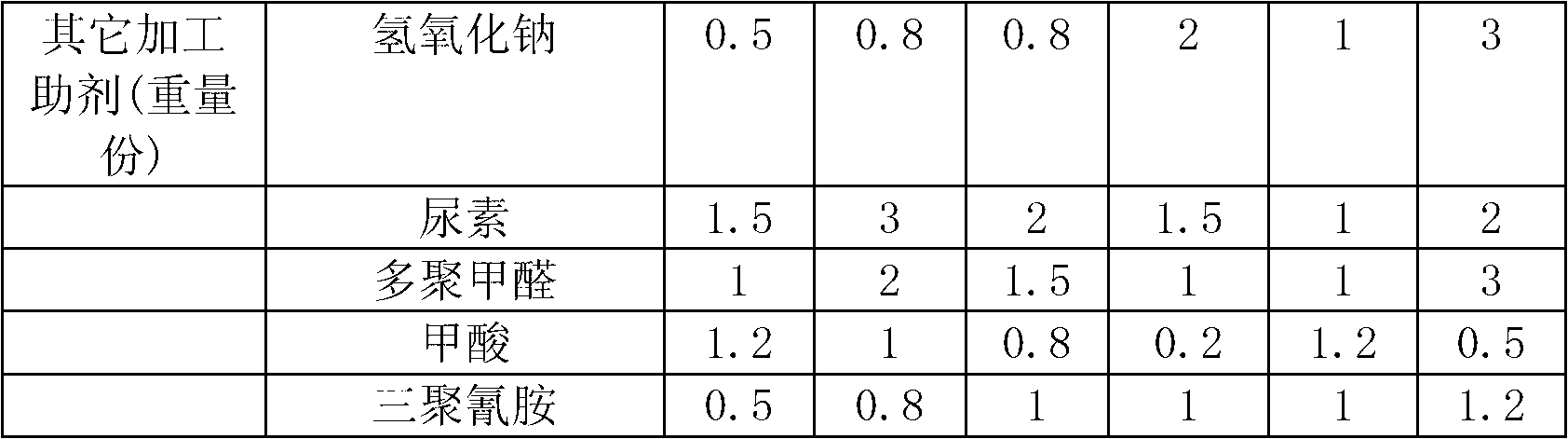

New macromolecule fiber composite material

The invention discloses a new macromolecule fiber composite material which is prepared by the following components in parts by weight, 40-100 parts of plant fiberfill, 60-100 parts of plastic base material, 3.5-5 parts of heat stabilizer, 1-2 parts of plasticizer, 1.6-2 parts of lubricating agent, 4-8 parts of modifying agent, 1-3 parts of compatilizer, 2-3 parts of coupling reagent, 1-5 parts of super dispersing agent, 1-4 parts of positive ion surface active agent, 1-1.8 parts of foaming agent, 1-5 parts of blowing promoter, 0.3-1.2 parts of antioxygen, 1-10 parts of cross-linking agent, 1-20 parts of nucleating agent, 0.8-1 part of viscosity reducer, 0.8-1 part of tackifier and 3.2-13.4 parts of other auxiliaries. The new composite material can not easily cause wet swelling and air shrinkage, and is low in expansibility and water absorbability, so that the prepared product has good stability.

Owner:GUILIN SHUKANG BUILDING MATERIAL

Silicone master batch with high silicone content and preparation method of silicone master batch

The invention relates to silicone master batch with a high silicone content and a preparation method of the silicone master batch and belongs to the technical field of macromolecular materials. The silicone master batch with the high silicone content is prepared from the following raw materials which are mixed through a mixer and extruded and granulated through a twin-screw extruder in percentage by weight: 50-65% of silicone, 5-40% of carrier resin, 5-30% of a compatilizer, 0-10% of filler and 0-5% of auxiliaries, wherein the content of silicone can be higher than 50%. By adding the silicone master batch with the high silicone content provided by the invention, the basic mechanical properties of a material can be maintained well while the rub resistance and processability of the material can be further effectively improved. The production efficiency can be improved to a great extent, and the demand on the processability and rub resistance of materials in industries such as automobiles, electronics and the like can be satisfied.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

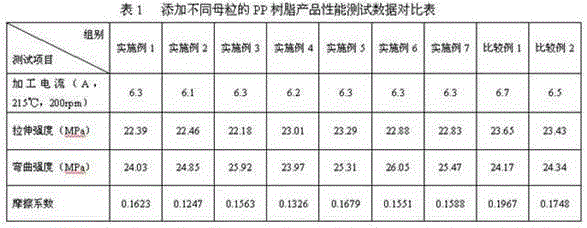

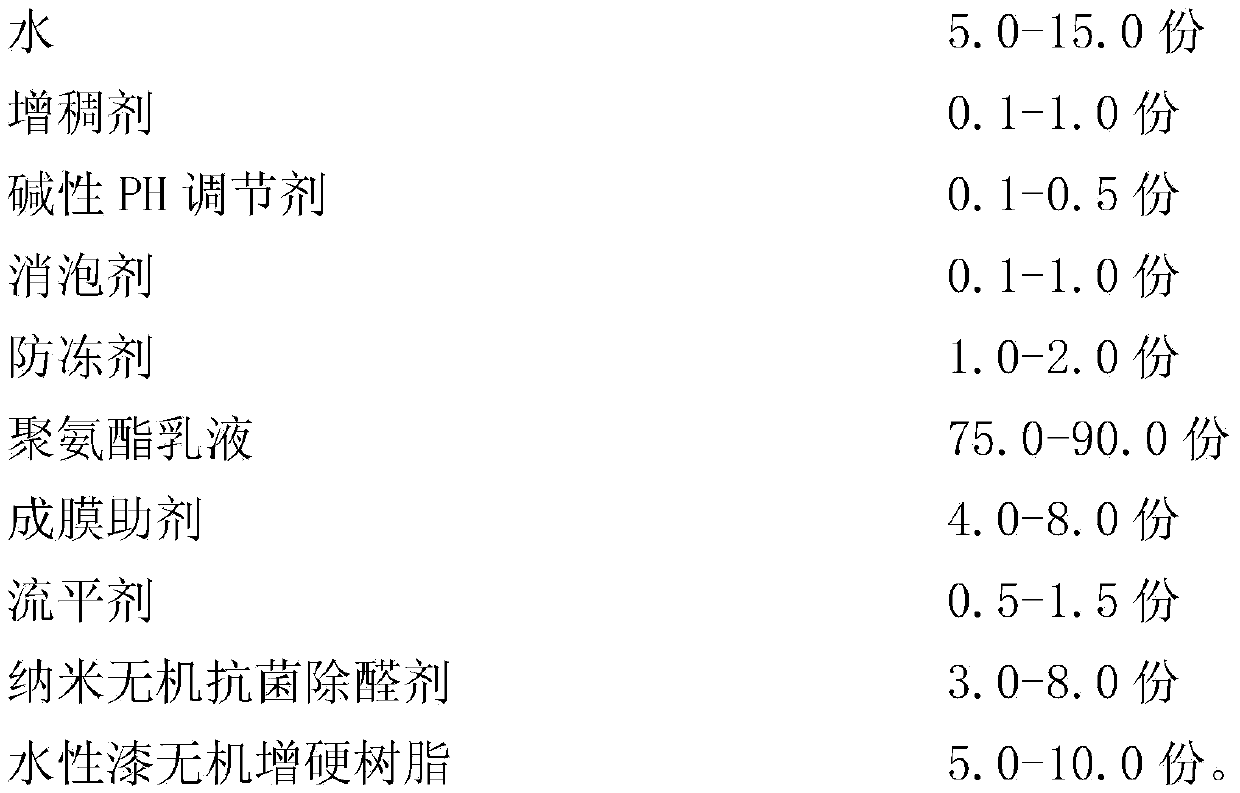

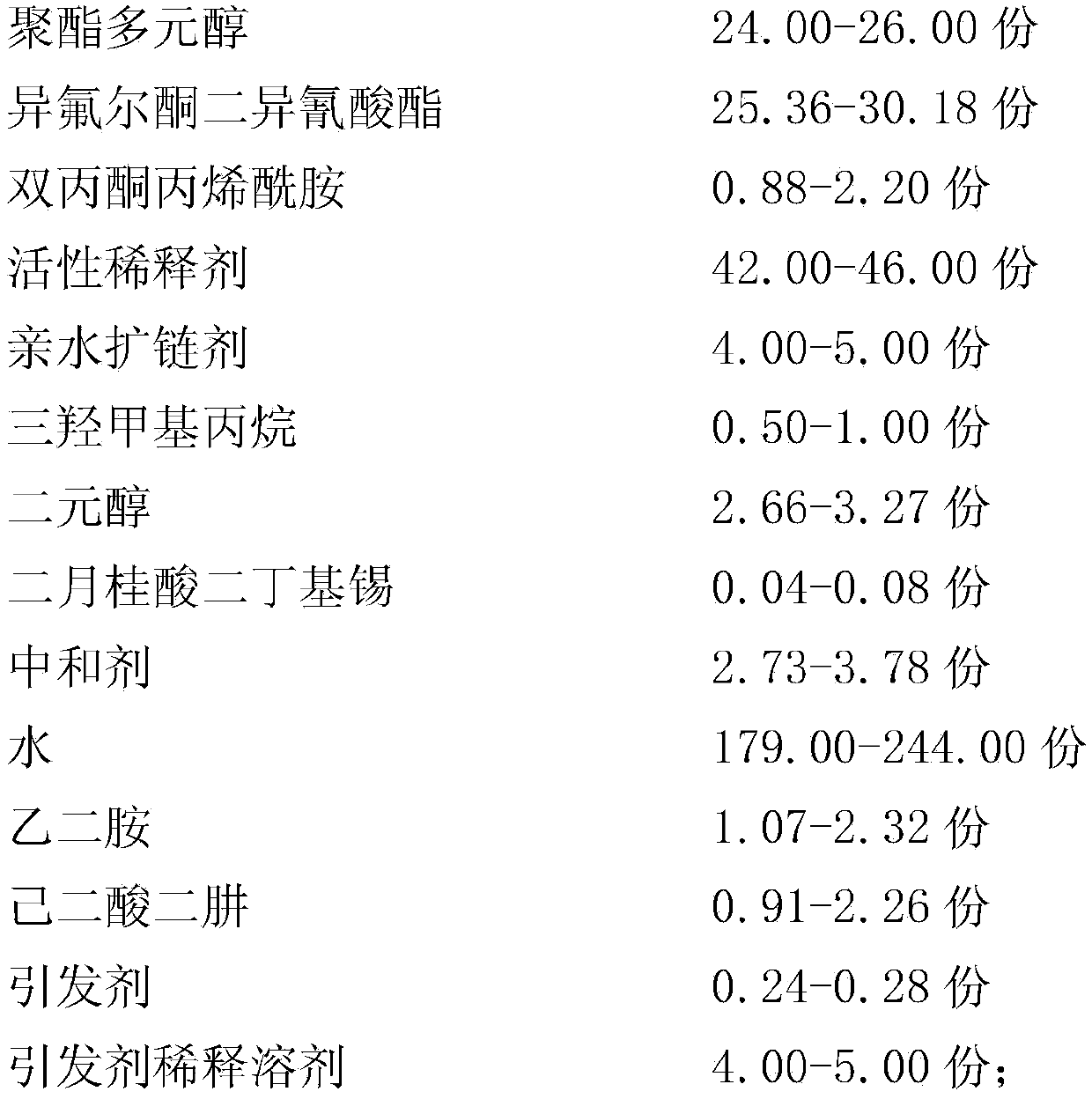

Water-borne woodware coating containing modified polyurethane emulsion and preparation method thereof

ActiveCN105368291AHigh hardnessImprove adhesionPaints with biocidesPolyurea/polyurethane coatingsEnvironmental resistanceEpoxy

The invention provides a water-borne woodware coating containing a modified polyurethane emulsion and a preparation method thereof. The water-borne woodware coating is composed of the following components: water, a thickening agent, a defoaming agent, a pH regulator, an antifreezing agent, a film-forming auxiliary agent, the modified polyurethane emulsion, a levelling agent, a nano inorganic antibacterial aldehyde removing agent, and water-borne paint inorganic hardening resin. The selected modified polyurethane emulsion includes a self-crosslinkable polyurethane acrylate composite emulsion, a core-shell interpenetrated network-structure polyurethane acrylate copolymer emulsion, a silane coupling agent modified polyurethane acrylate composite emulsion, and an epoxy resin modified polyurethane emulsion. The plurality of emulsions are added to the water-borne woodware paint, and thus the coating has the properties of high hardness and adhesion force, and good water resistance, alcohol resistance and pollution resistance; the selected nano inorganic antibacterial aldehyde removing agent has the effects of environmental protection, safety, no toxicity, and long-term bacterial resistance; and the selected water-borne inorganic hardening resin is used for improving the hardness, the adhesion force and the chemical resistance of the water-borne paint.

Owner:SKSHU PAINT

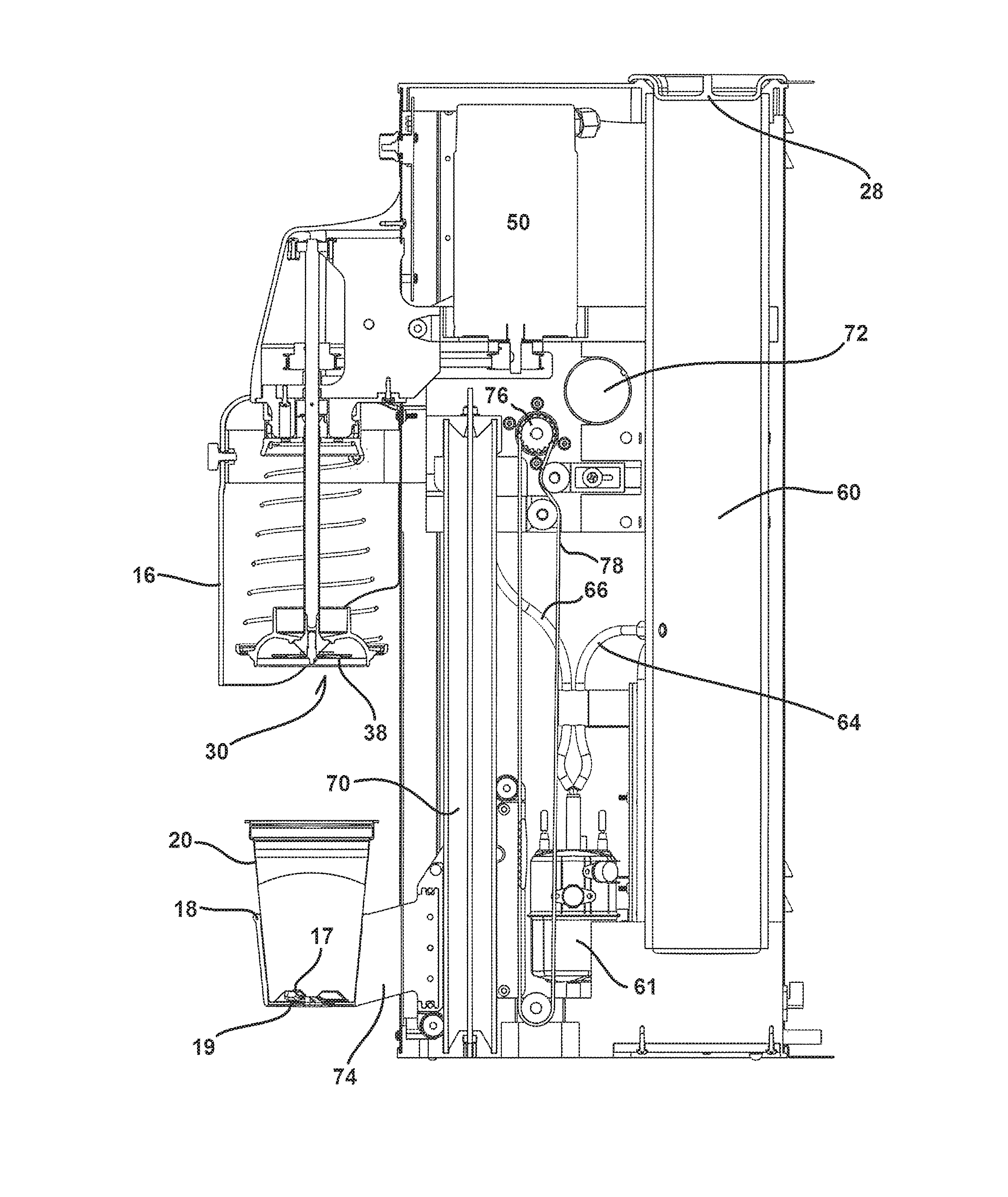

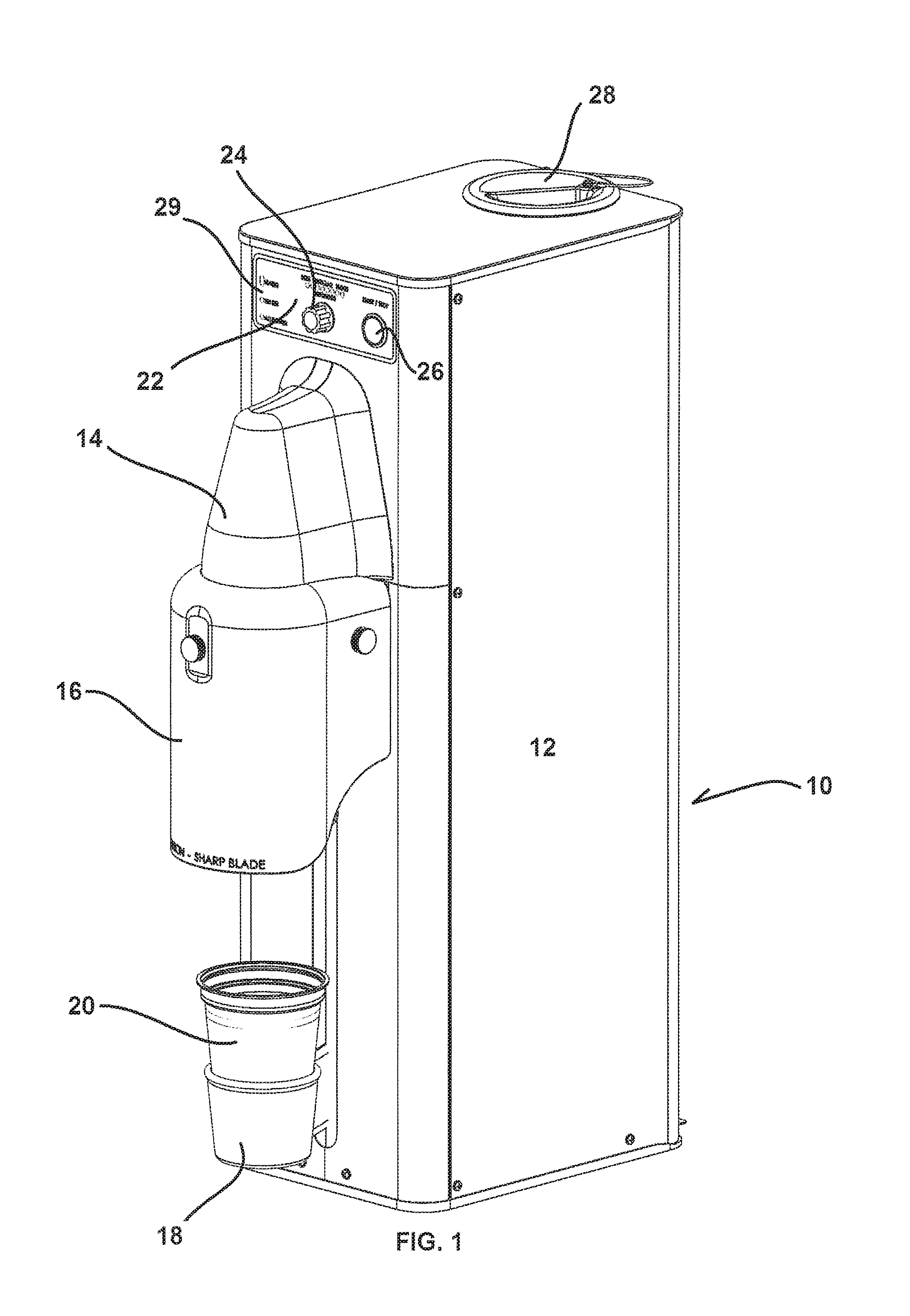

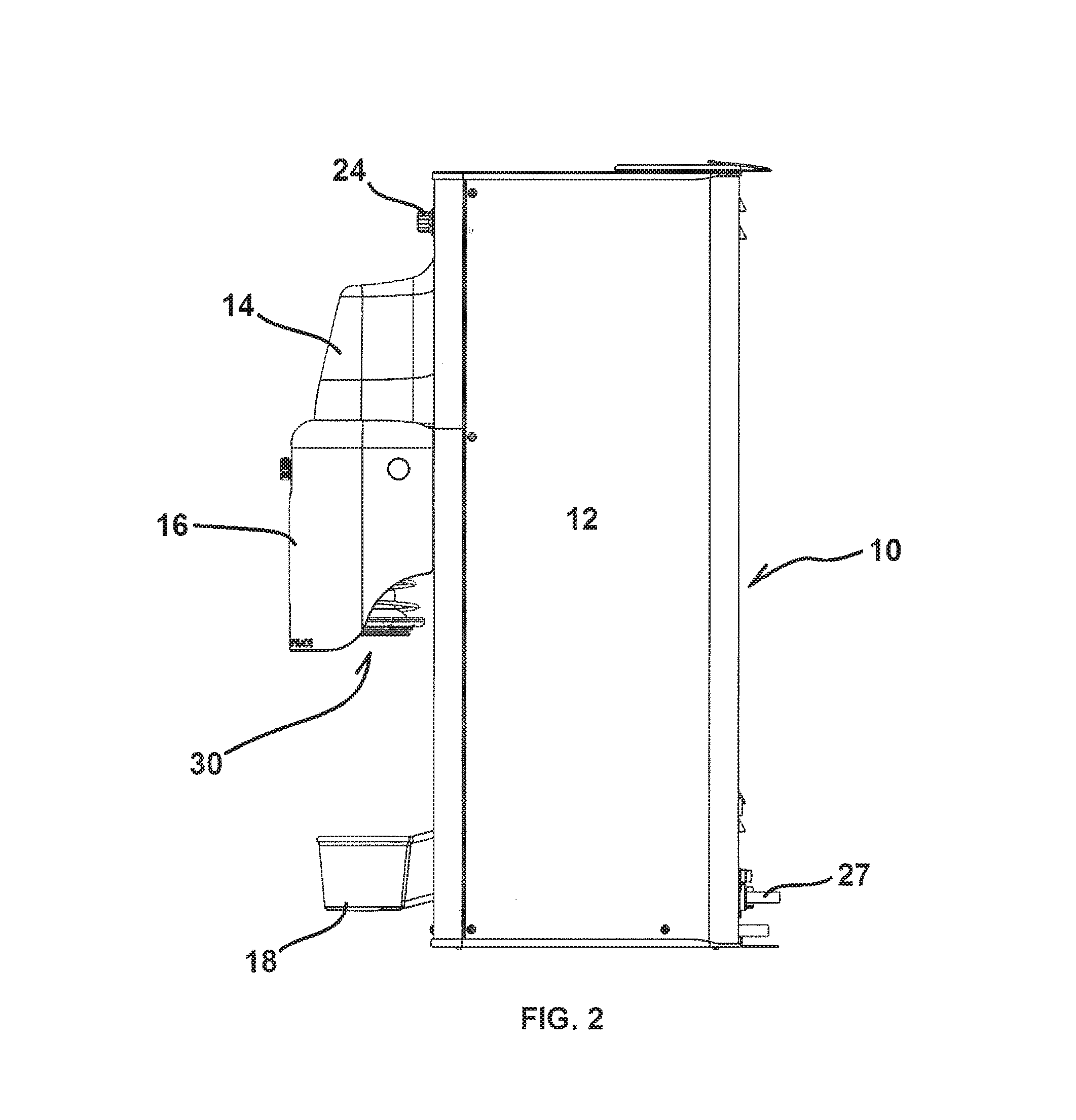

Blender with removable spindle and monitored reservoir

An economical blender with a removable, motor driven spindle assembly to perform blending, a motor driven elevator used to lift a cup with food or beverage up to the spindle assembly and a liquid reservoir which allows liquid to be inserted into the food or beverage during blending. The removable spindle assembly has a quick release coupler and a compression spring which connects the quick release coupler to a cup cover. Blending is accomplished by connecting a motor driven inner spindle drive shaft to a concentric outer spindle drive tube through cogged couplers. The outer spindle drive tube powers a blending tool and, like the blending tool, is removable with the spindle assembly for cleaning.

Owner:F REAL FOODS LLC

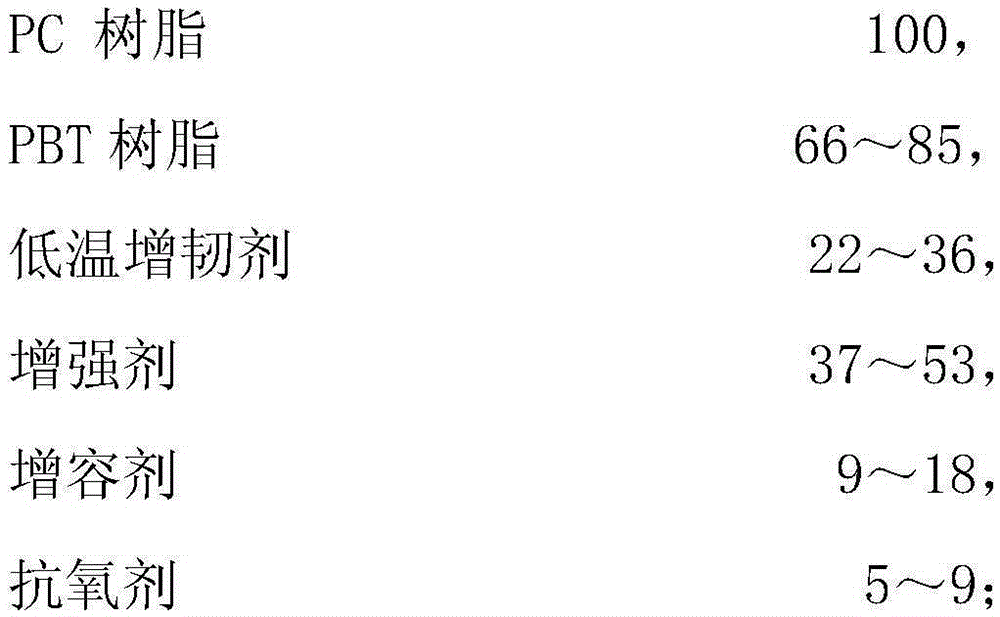

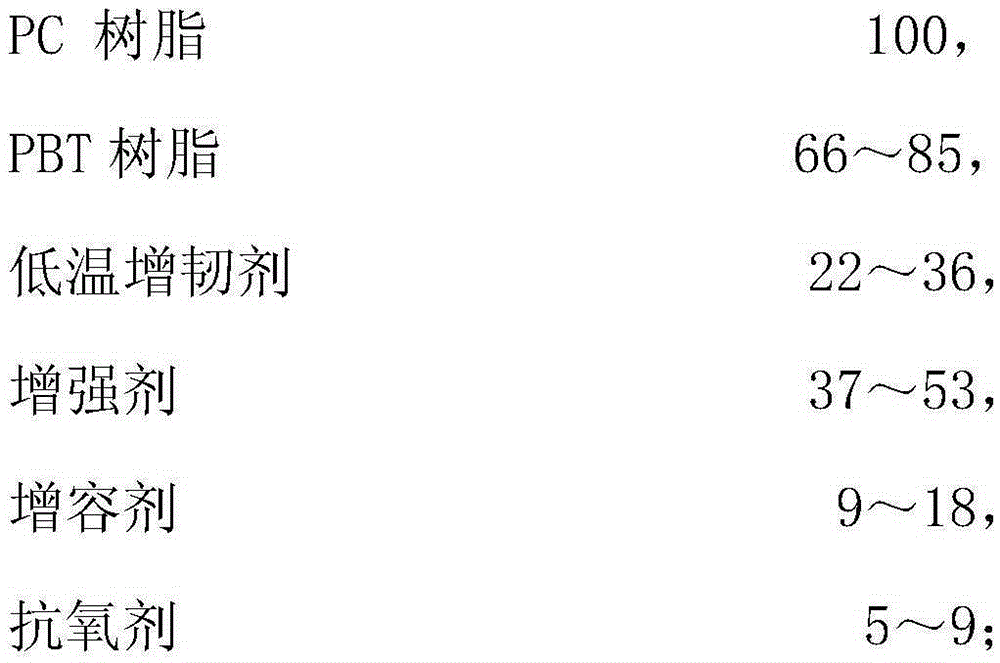

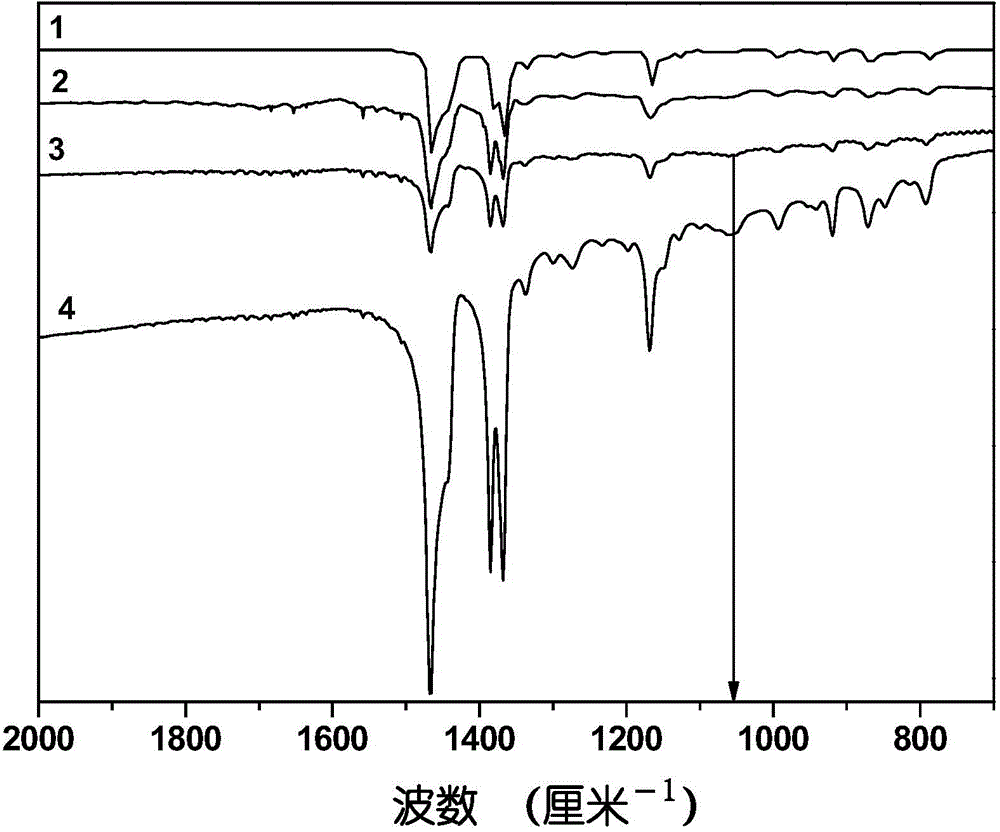

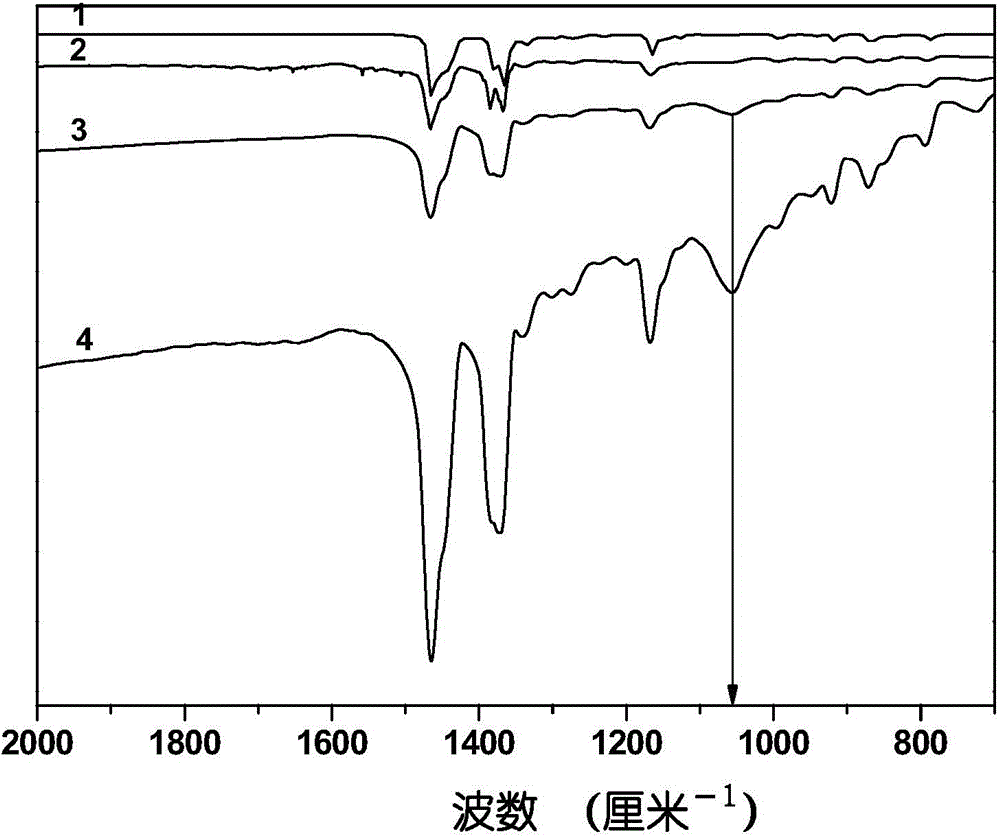

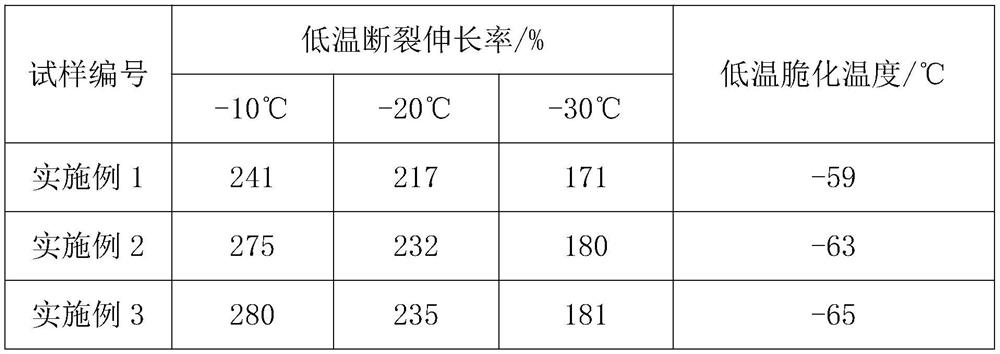

Low-temperature toughened and reinforced PC/PBT (polycarbonate/polybenzothiazole) alloy material and preparation method thereof

The invention relates to a low-temperature toughened and reinforced PC / PBT (polycarbonate / polybenzothiazole) alloy material and a preparation method thereof. The PC / PBT alloy material is prepared from raw materials such as PC resin, PBT, a low-temperature toughening agent, a reinforcing agent, a bulking agent and an antioxidant, wherein the toughening agent is diolefin-styrene-methyl methacrylate (MBS / MIS) which is of a core-shell structure, the reinforcing agent is non-alkali chopped glass fiber, the bulking agent is an ethylene-methyl acrylate copolymer (EMA), and the antioxidant is prepared by compounding an antioxidant 1010 and an antioxidant 168. The preparation process disclosed by the invention is implemented by using single and double screw extruders in cooperation with a two-step extrusion process, the technical characteristic is stepwise feeding, and the preset temperatures of the two extruders are differentiated. Through the implementation of the formula and the process, a low-temperature-resistant and high-strength PC / PBT alloy material which is excellent in performance and good in appearance can be prepared, and the PC / PBT alloy material can be widely used in the aspects of auto parts, bumpers, elevator parts, electrical and electronic engineering, engineering assembly parts for cold regions, and the like.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Rice-husk-based carbon/silicon composite used as rubber filler and preparation method thereof

InactiveCN102212219AReduce resource consumptionSimple preparation processPotassium hydroxideSilicon dioxide

The invention discloses a rice-husk-based carbon / silicon composite used as a rubber filler and a preparation method thereof, and belongs to the technical field of the preparation of carbon / silicon fillers. The method comprises the following steps of: pre-carbonizing a raw material, namely rice husks in a muffle furnace at low temperature so as to remove the moisture and volatile substances from the rice husks, carbonizing in a vacuum sintering furnace, and controlling sintering conditions to obtain a rice-husk-based carbon / silicon composite with high silicon content, wherein the carbon accounts for 65 to 75 percent of the total weight of the carbon / silicon composite, the nitrogen adsorption Brunauer-Emmett-Teller (BET) specific surface area is 12 to 75m<2> / g, and the dibutyl phthalate (DBP) absorption number is 1.7 to 3.8cm<3> / g; and treating the rice-husk-based carbon / silicon composite with high silicon content by using solution of sodium hydroxide or potassium hydroxide, and dissolving out most of silicon dioxide to obtain the rice-husk-based carbon / silicon composite with low silicon content, wherein the carbon accounts for 85 to 98 percent of the total weight of the rice-husk-based carbon / silicon composite, the specific surface area is 120 to 196 m<2> / g, and the DBP absorption number is 2.1 to 3.0cm<3> / g. The rice-husk-based carbon / silicon composite serving as a reinforcingagent and a filler is widely applicable to various models of rubber varieties; moreover, the rice-husk-based carbon / silicon composite is an excellent dual phase filler.

Owner:JIANGNAN UNIV

Olefin copolymer with polar monomer structural units and preparation method of olefin copolymer

The invention relates to an olefin copolymer with polar monomer structural units and a preparation method of the olefin copolymer with the polar monomer structural units. The olefin copolymer is prepared from polar monomers, a monomer 4-methyl-1-pentene and other monomers through copolymerization. The general formula of the olefin copolymer is as shown in the description, wherein n, m and p respectively represent number-average degrees of polymerization of the monomer 4-methyl-1-pentene, the polar monomers and the other monomers in the copolymer, and the monomer structural units are randomly distributed in the sequence and are isotactically distributed in a stereoscopic structure. By introducing polar monomer structural units in a polymer chain, the surface performance of the polymer can be effectively improved when a high melting point is maintained, and the surface energy is improved. The preparation method comprises the step of carrying out copolymerization on the polar monomers, the monomer 4-methyl-1-pentene and the other monomers by virtue of a polymerization catalyst system, so as to prepare the olefin copolymer with the polar monomer structural units, wherein the polymerization catalyst system is capable of polymerizing alpha-olefin into an isotactic polymer and contains transition metal compounds.

Owner:CHINA PETROLEUM & CHEM CORP +1

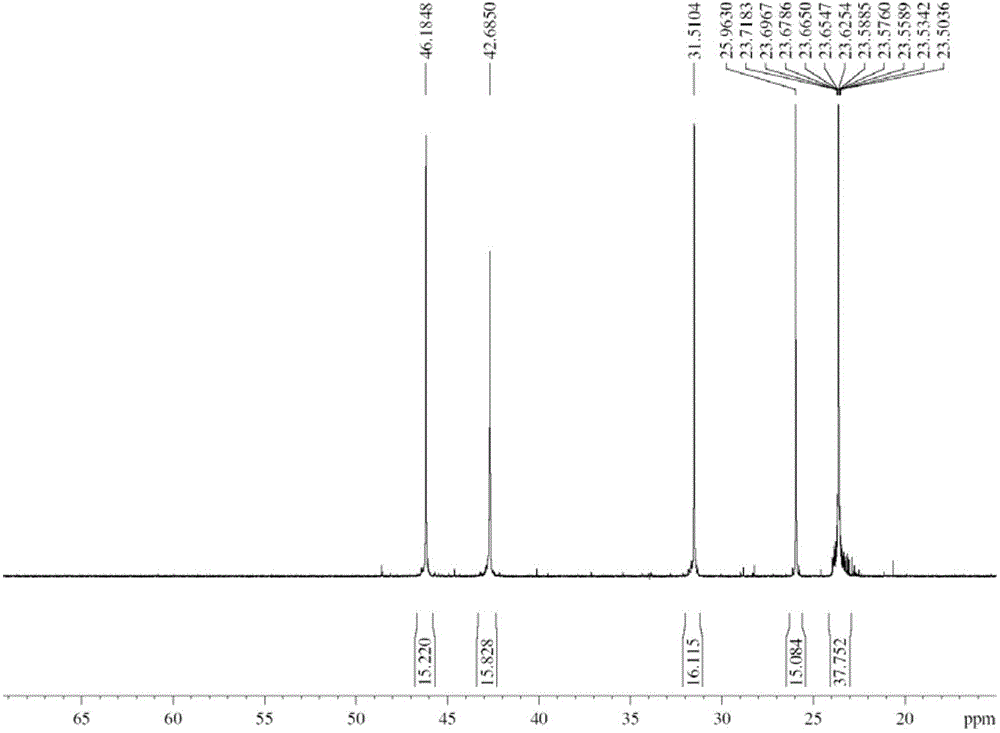

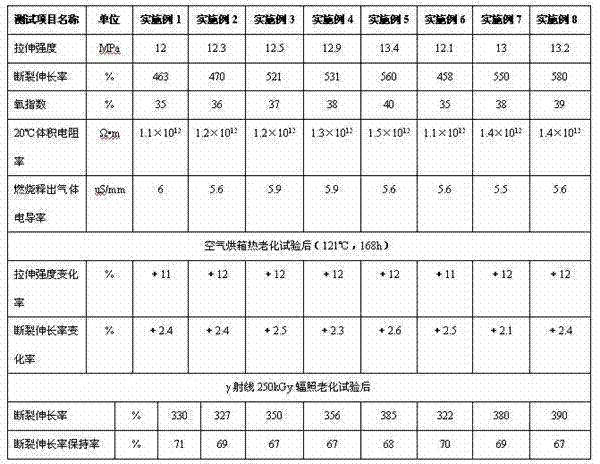

Grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for nuclear power plant and preparation method thereof

ActiveCN103087395AEnvironmental protection is goodReduce pollutionPlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention relates to a grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for a nuclear power plant and a preparation method thereof, belonging to the field of new chemical materials. The cable material comprises raw materials including base resin EVA (ethylene-vinyl acetate copolymer), flame retardants A and B, a flame retardant synergist, basic antioxidants 1010 and 168, a radiation-resistant auxiliary agent 4,4'-thiobis(6-tertiary-butyl-3-methylphenol) and a processing agent; and the preparation method comprises the process steps of material weighing, pretreatment, mixing, extrusion granulation, drying and the like. The cable material is a red-phosphorus-free halogen-free environment-friendly flame-retardant material, phenoxy polyphosphazene is used as a main flame retardant in a flame-retardant system of the cable material, an inorganic flame retardant is auxiliary, the flame-retardant system accounts for a small weight percentage of the material, and the cable material is high in flame-retardant efficiency and excellent in mechanical properties, processability and radiation resistance, so that the cable material is a novel environment-friendly flame-retardant material which has excellent comprehensive properties and is suitable for a nuclear power plant environment.

Owner:SICHUAN INST OF ATOMIC ENERGY +1

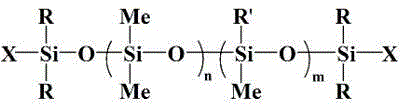

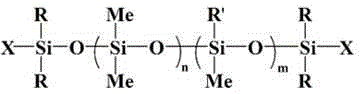

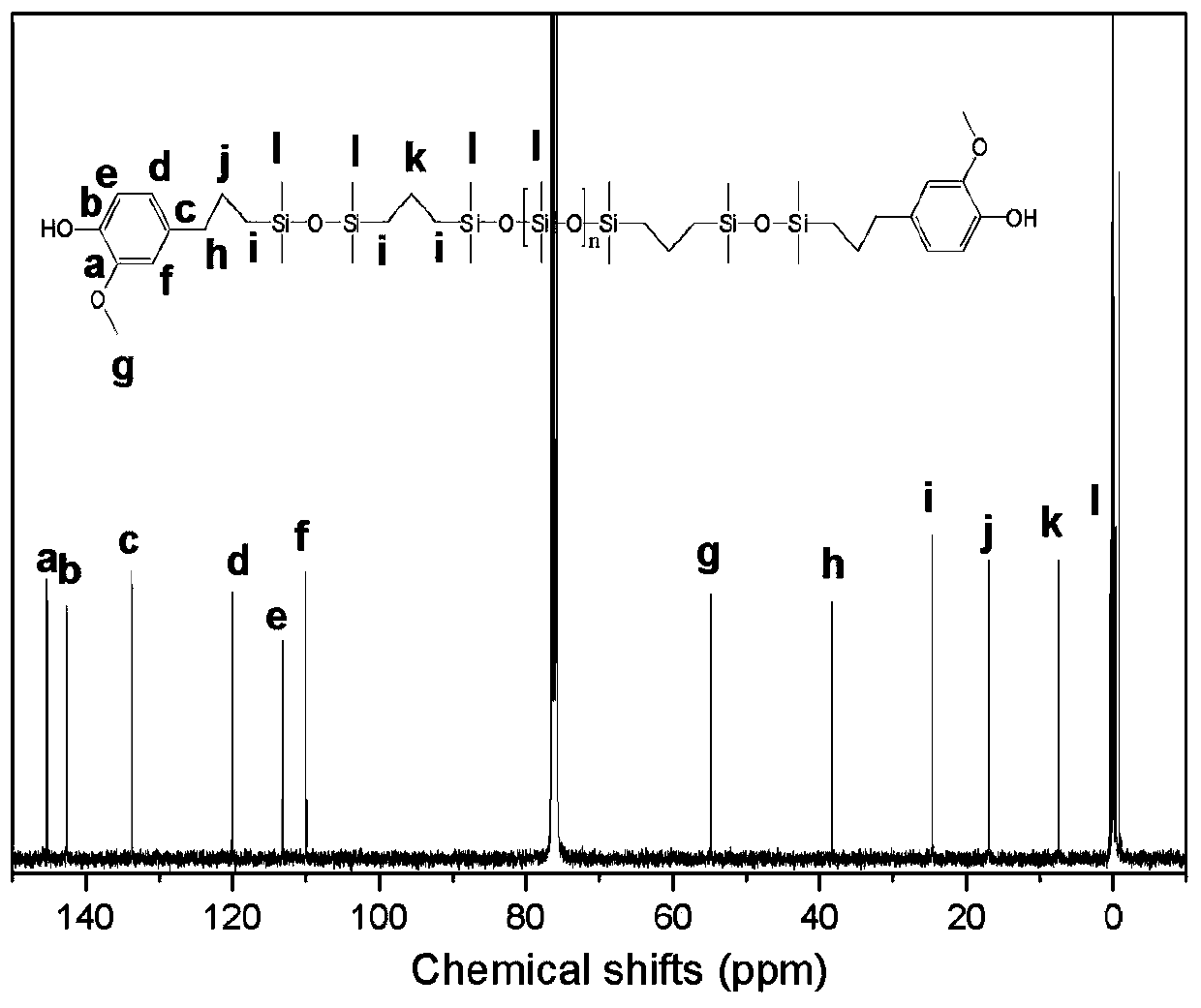

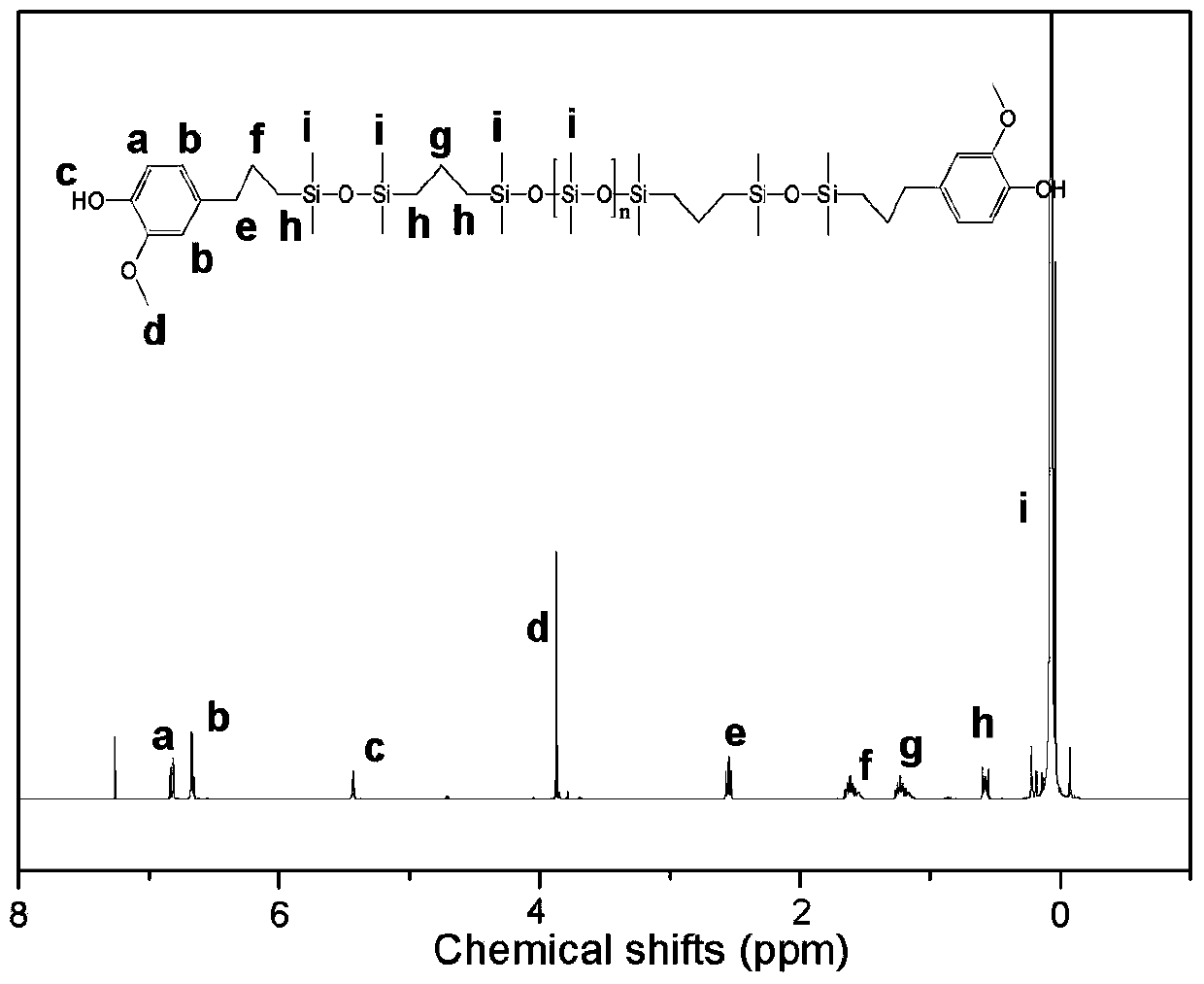

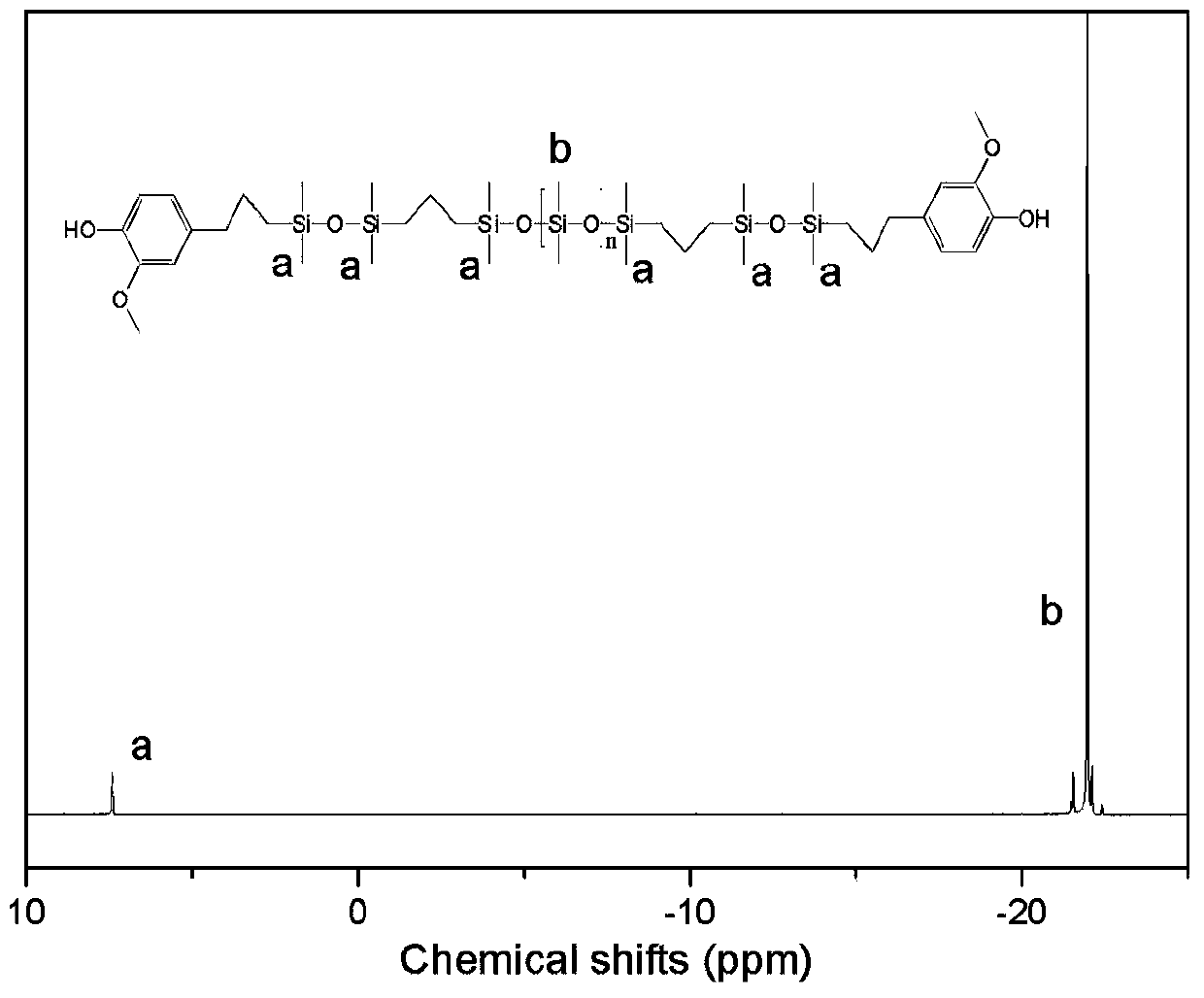

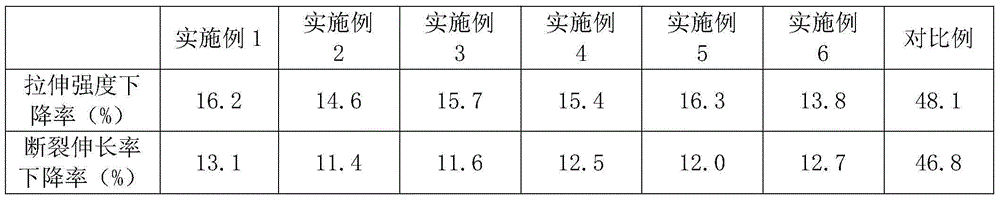

Phenol-terminated polysiloxane, preparation method thereof, and polysiloxane-polycarbonate copolymer

The invention discloses phenol-terminated polysiloxane, a preparation method thereof, and a polysiloxane-polycarbonate copolymer. The method includes the following steps: a) catalyzing a reaction of tetramethyldisiloxane and an allyl-containing phenolic compound by using a transition metal catalyst A to prepare phenol-modified hydrogen-containing silane having a phenol group at one end and a silicon-hydrogen bond at one end; b) performing separation by using reduced-pressure rectification to obtain phenol-modified hydrogen-containing silane with purity of >=99%; and c) catalyzing B by using atransition metal catalyst, performing a hydrosilylation reaction on the pure phenol-modified hydrogen-containing silane and polysiloxane with a vinyl end group to obtain the polysiloxane containing aphenol group at the end group. The content of the free allyl-containing phenol compound in the phenol-terminated polysiloxane is 100 ppm or less, the phenol group capping rate is 98% or more, and theresidual metal platinum content is <= 5 ppm. The phenol-terminated polysiloxane is used for preparing the modified polycarbonate, and the obtained polysiloxane-polycarbonate copolymer has a high polysiloxane content, and excellent heat resistance and yellowing resistance.

Owner:WANHUA CHEM GRP CO LTD +1

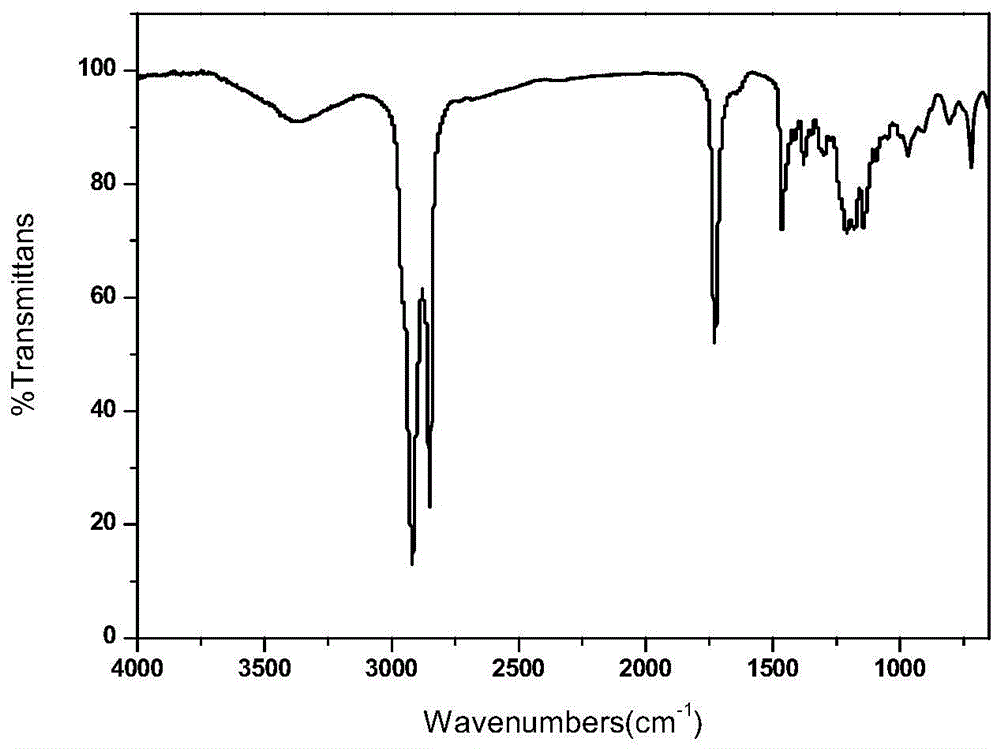

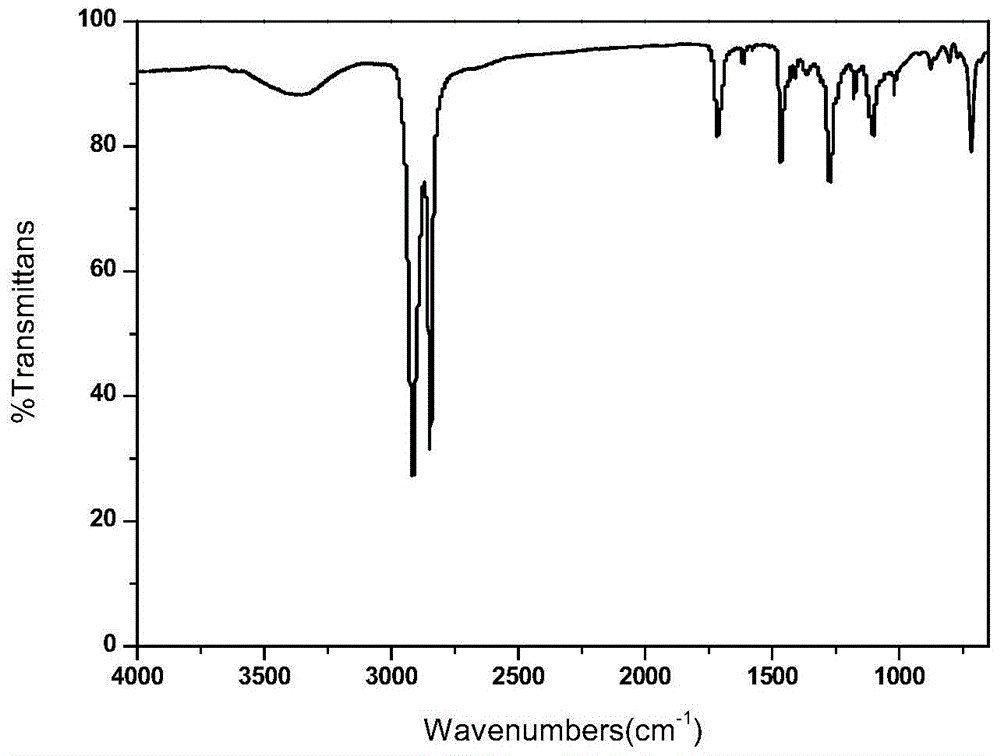

Preparation method of radiation-resistant organic silicon packaging adhesives

InactiveCN105086920AGood compatibilityImprove radiation resistanceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesCross-linkMethacrylate

The invention provides a preparation method of radiation-resistant organic silicon packaging adhesives. The method includes the following steps that (1) a titanate coupling agent is dispersed in an n-butanol aqueous solution with the mass fraction being 80%, modified liquid is obtained after room-temperature stirring, nano cerium oxide is added into the modified liquid for magnetic stirring, pressure reduction and rotary evaporation are carried out on the mixture after reflux condensation, the mixture is dried till the weight is constant, the mixture is obtained and ground, and accordingly modified nano cerium oxide is obtained; (2) by mass, poly (methyl phenyl siloxane), PEEK, ethyl methacrylate and the modified nano cerium oxide obtained in the step (1) are added into an internal mixer for mixing, the mixture is moved into a single-screw extruding machine to be melted and extruded, and a granular material is obtained after cooling and granulation; (3) by weight, a cross-linking agent, a tackifier and the particle material obtained in the step (2) are added into a high mixing machine for high-speed mixing, high-speed mixing continuous being carried out after an inhibitor is added, medium-speed mixing is carried out after a catalyst is added, and the radiation-resistant organic silicon packaging adhesives are obtained after discharging. The organic silicon packaging adhesives prepared through the method are good in radiation resistance.

Owner:DONGGUAN XINXING ORGANIC SILICON TECH

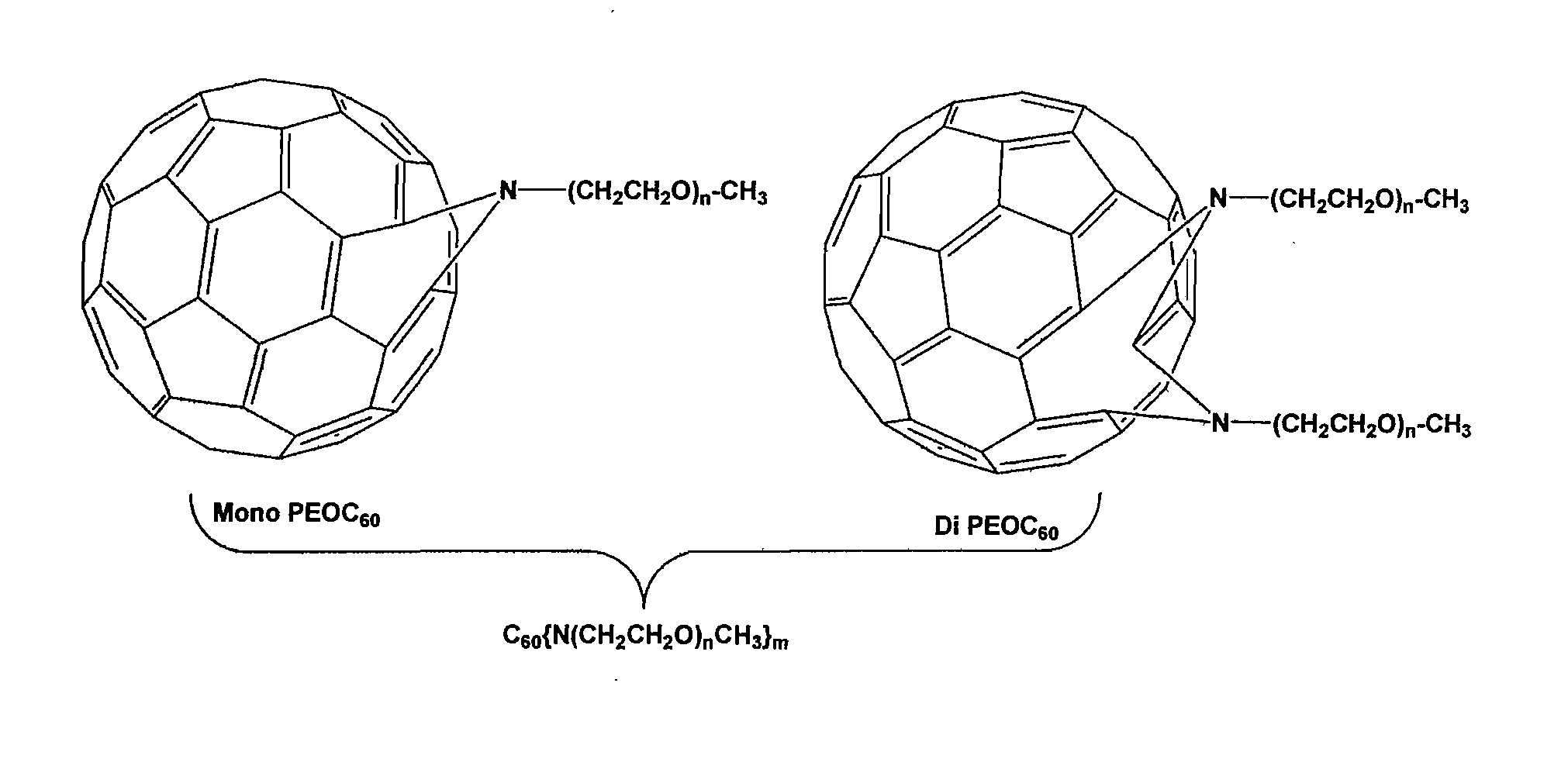

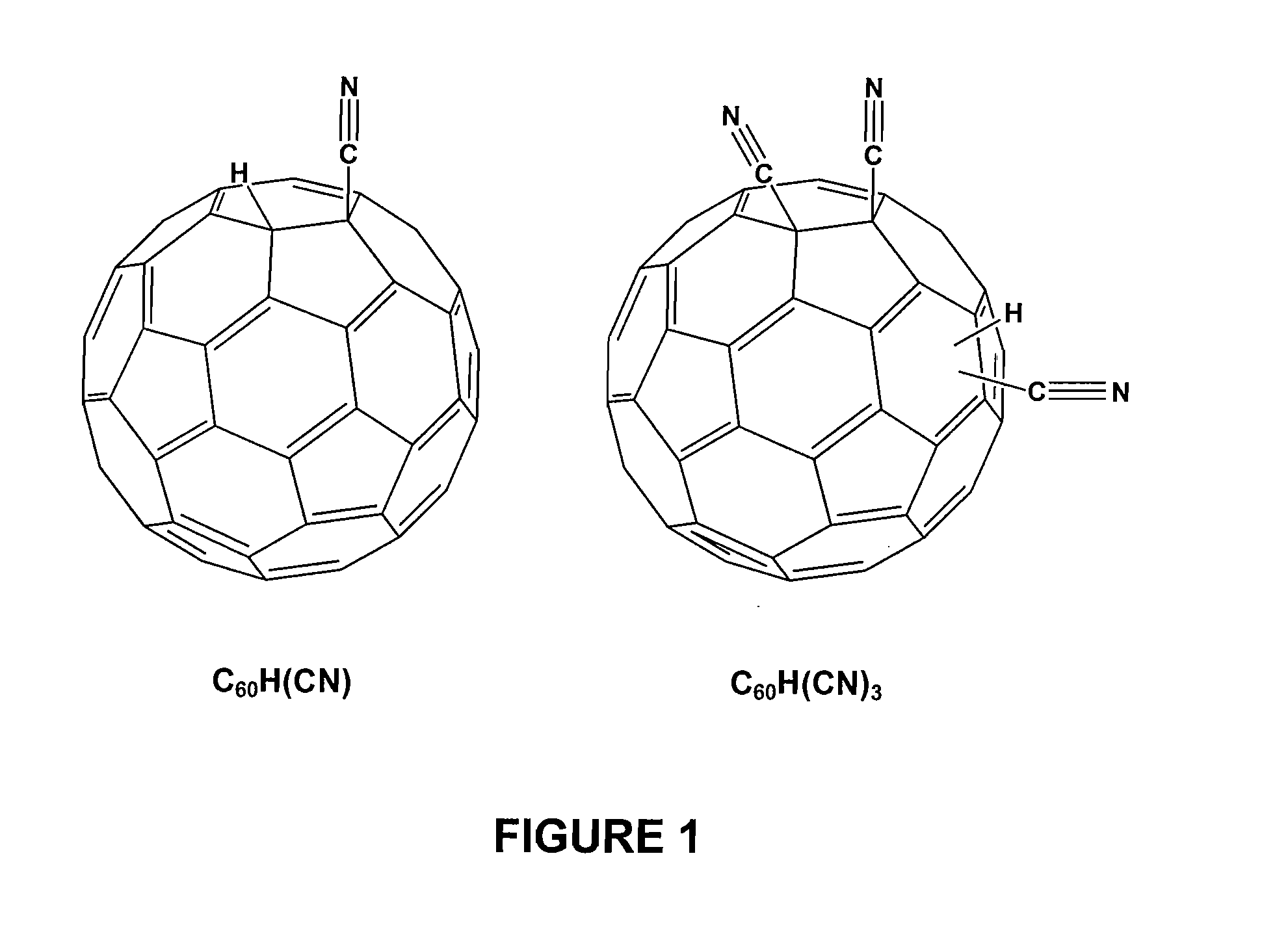

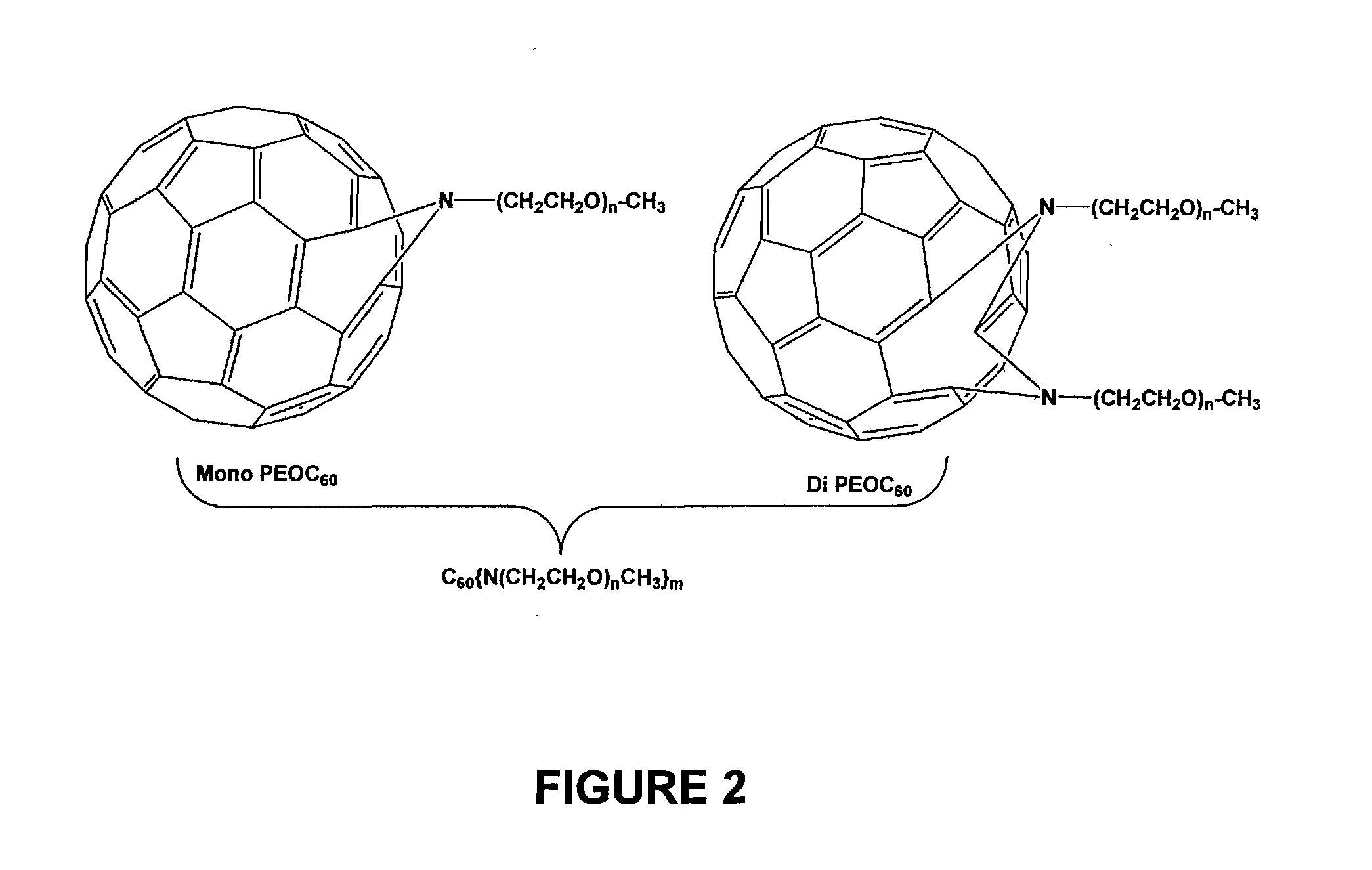

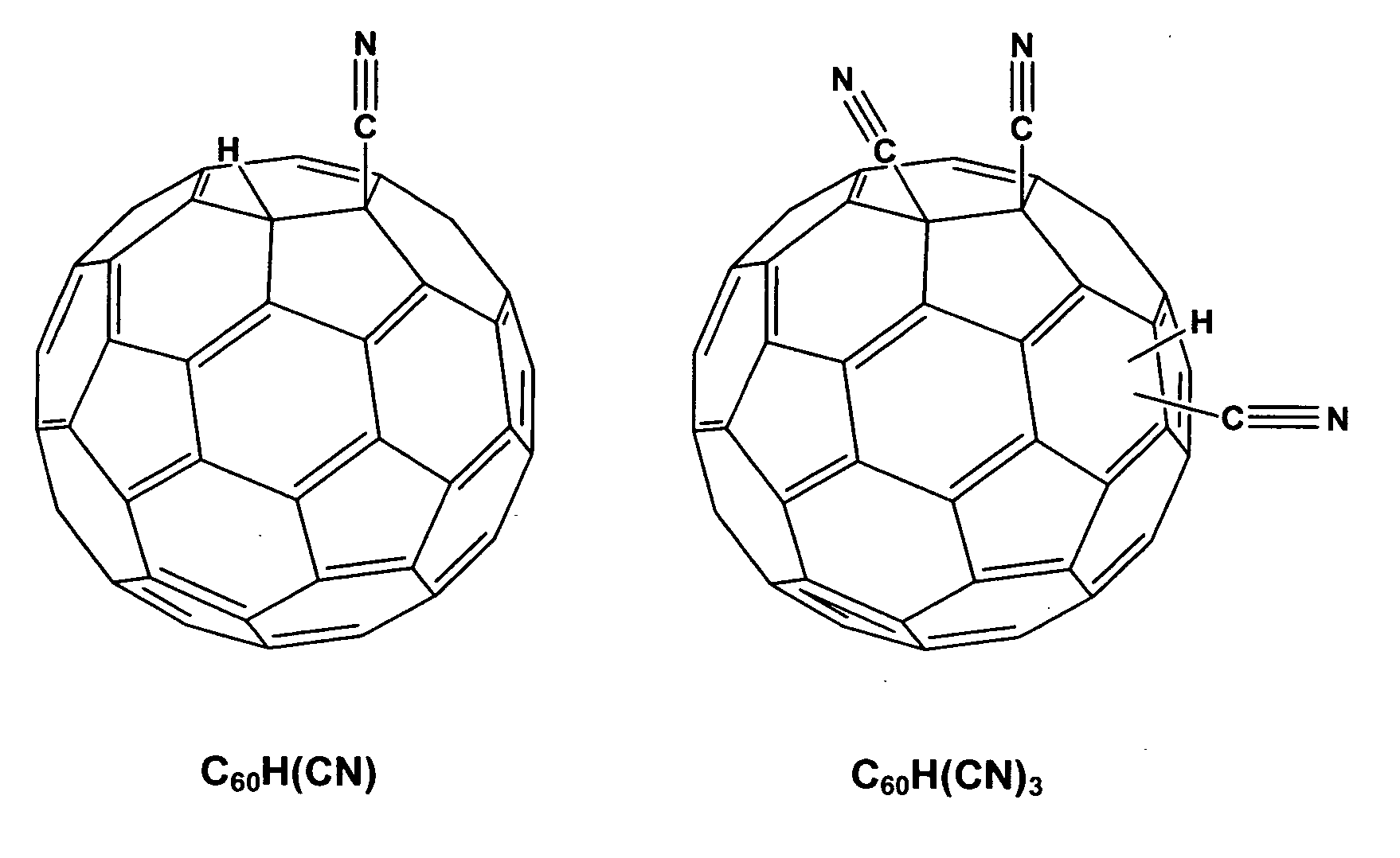

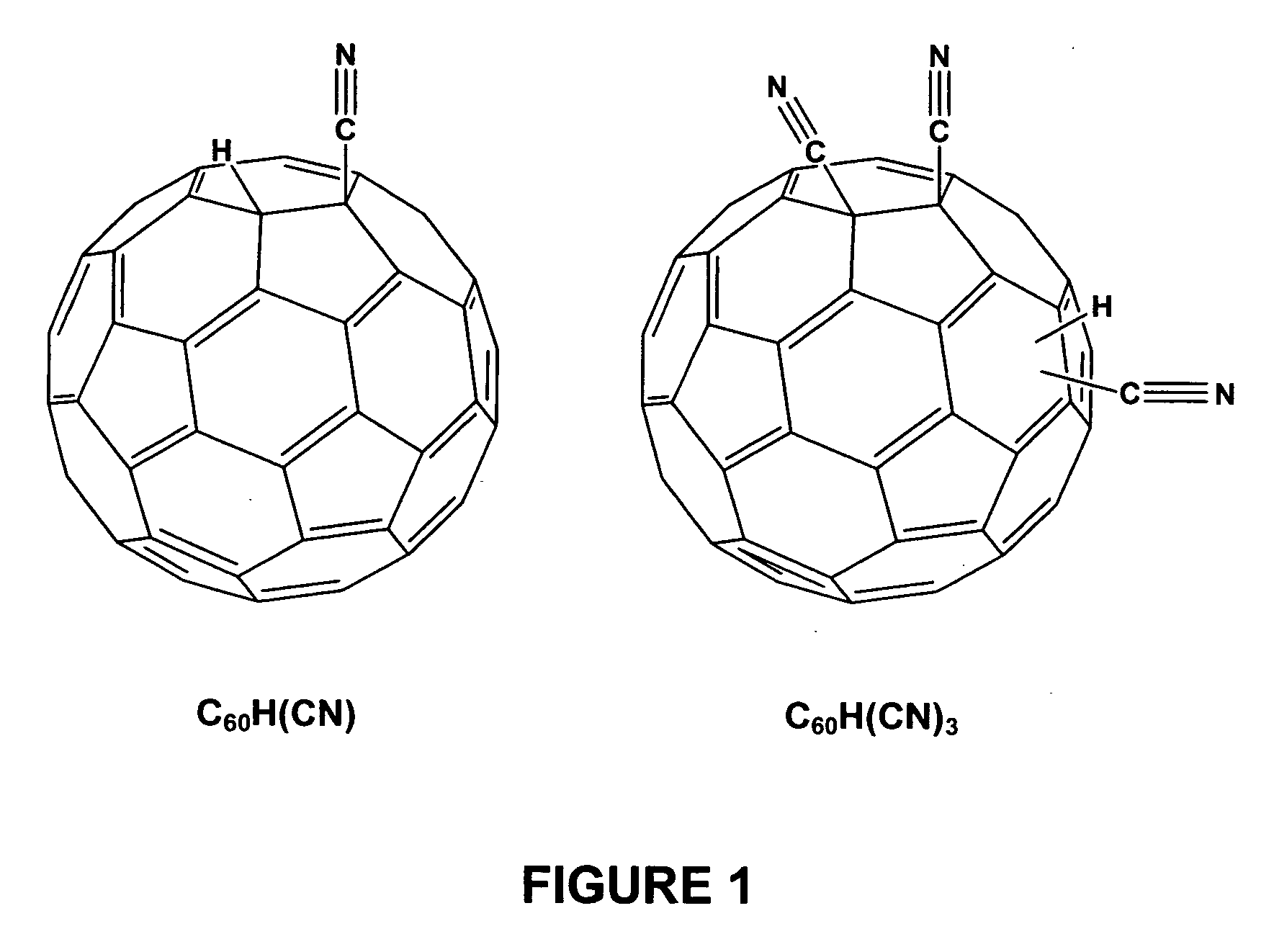

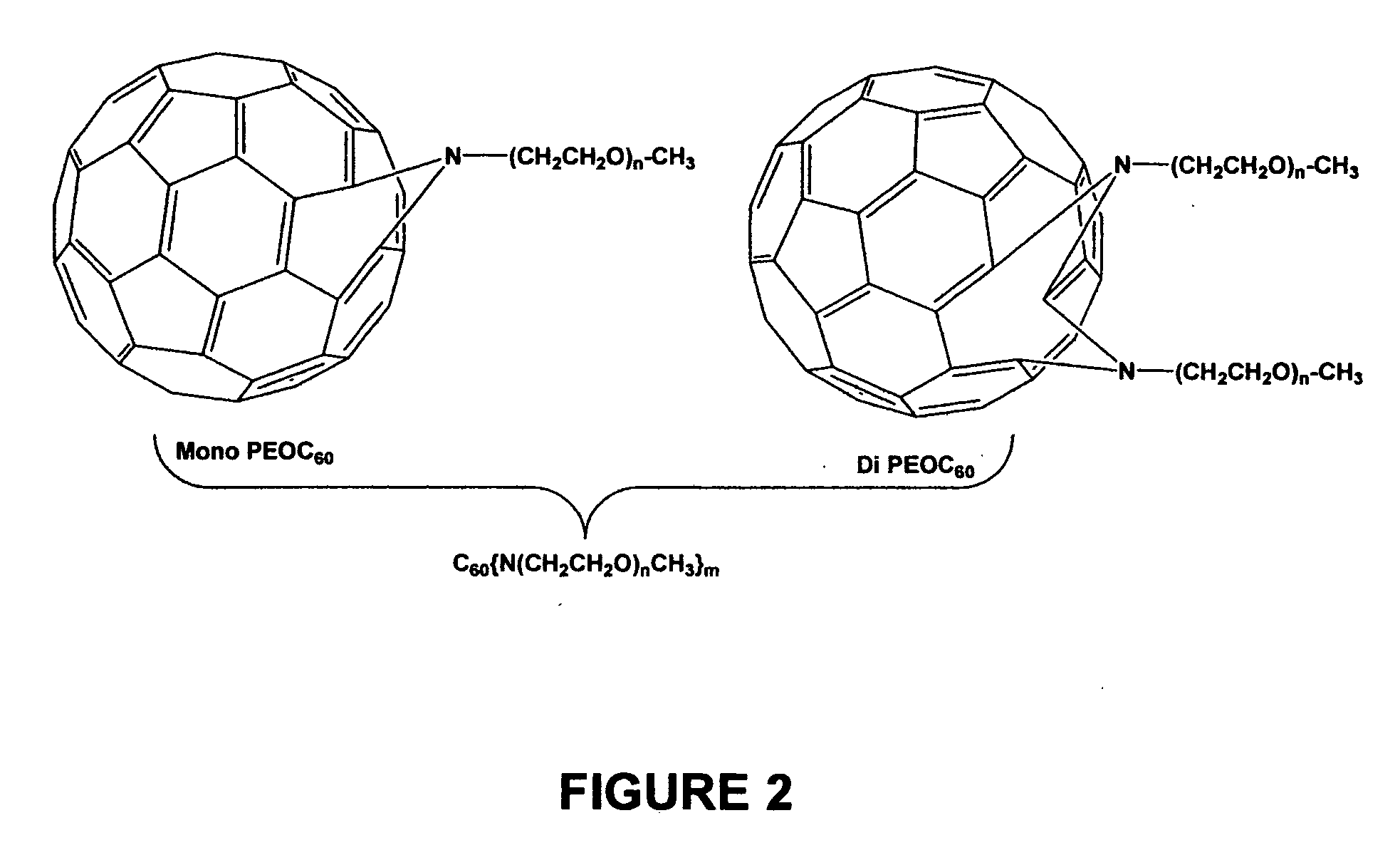

Hydrogen cyano fullerene containing proton conducting membranes

InactiveUS20080015268A1Facilitate blendingFacilitates blending of a host polymerMaterial nanotechnologySolid electrolytesMembrane configurationOxide

The components of and a proton conducting membrane (PCM) produced from a host polymer and an attached or physically blended in hydrogen cyano fullerene proton-source agent, with the physical blending of the host polymer and hydrogen cyano fullerene further promoted by a poly(ethylene oxide) attached fullerene mixing agent.

Owner:RGT UNIV OF CALIFORNIA

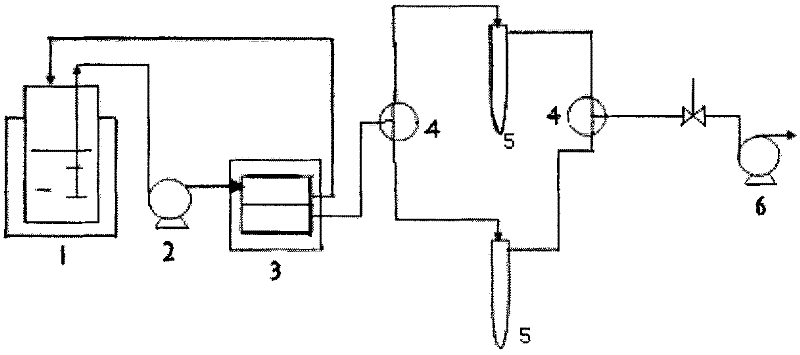

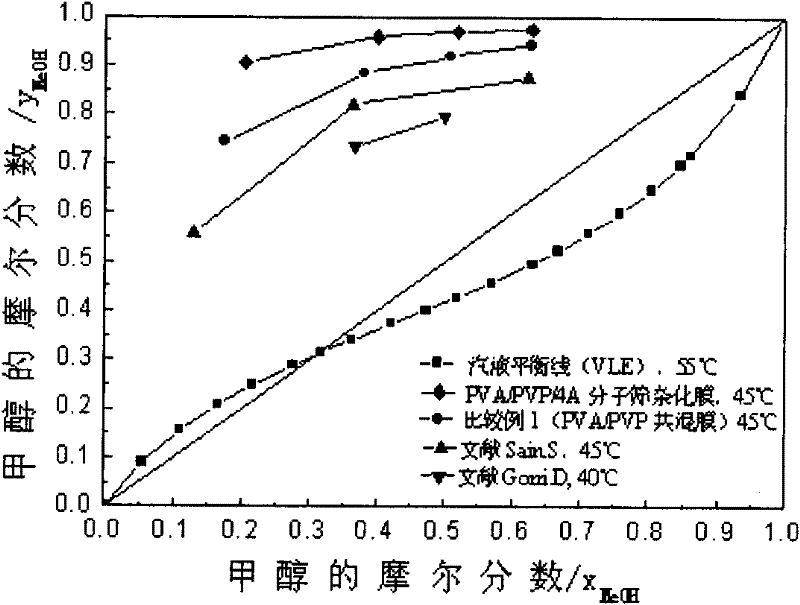

Organic-inorganic hybrid membrane for pervaporation separation of methanol/methyl acetate azeotropic system and preparation method thereof

InactiveCN102266729ANo separation performanceImprove toughnessSemi-permeable membranesOrganic compound preparationWater bathsSeparation coefficient

The invention discloses an organic-inorganic hydrid film used for pervaporation separation of a methanol / methyl acetate azeotropic system and a preparation method thereof. The preparation method comprises the following processes of: (1) heating and stirring polyvinyl alcohol (PVA), polyvinylpyrrolidone (PVP), a 4A molecular sieve and a solvent of dimethyl sulfoxide according to proportions in a constant-temperature water bath to obtain a PVA / PVP / 4A molecular sieve mixing solution; and (2) weighing DAS (Dialdehyde Starch) according to a proportion, dissolving into the dimethyl sulfoxide, stirring in a dark place and dissolving, then adding the equivalent PVA / PVP / 4A molecular sieve mixing solution obtained in the step (1) to the solution, and uniformly stirring to obtain a casting film solution. The casting film solution is filtered and defoamed, and then the film is scraped from glass and dried. The dried film is placed below a high-pressure mercury lamp and irradiated for 30-60 min toensure that coupling reaction is completed so as to obtain a 4A molecular sieve-filled DAS-crosslinking polyvinyl alcohol / polyvinylpyrrolidone organic-inorganic hydrid film. The organic-inorganic hydrid film has favorable mechanical strength and chemical stability and a higher pervaporation separation coefficient and can effectively break azeotropic components and has better separation degree than the traditional method.

Owner:NINGBO UNIV

Production technology of activation and oxidation double-modified scrap tire rubber powder modified asphalt

InactiveCN107383901AEtching phenomenon is obviousImprove surface roughnessBuilding insulationsPolymer scienceSurface oxidation

The invention discloses a production technology of activation and oxidation double-modified scrap tire rubber powder modified asphalt. According to the production technology, low temperature plasma activation is carried out on desulfurated scrap tire rubber powder, the obtained rubber powder is then sequentially treated by etching and surface oxidation, and the scrap tire rubber powder modified asphalt is prepared by adopting a wet process under the action of a high speed shearing machine. After the rubber powder is subjected to low temperature plasma activation, the specific surface area of the rubber powder is enlarged, so that the effective contact area between the rubber powder and asphalt is increased, and the rubber powder is promoted to be blended with the asphalt; on the other hand, oxygen containing functional groups can be introduced, the contents of -OH groups and C=C double bonds in the rubber powder are increased, and surface oxidation treatment is then carried out, so that the content of active groups on the surface of the rubber powder is further increased, the compatibility of the rubber powder and the asphalt is improved, the softening point of the modified asphalt is obviously increased, and the pavement performance of the modified asphalt is greatly improved.

Owner:安徽中宏橡塑有限公司

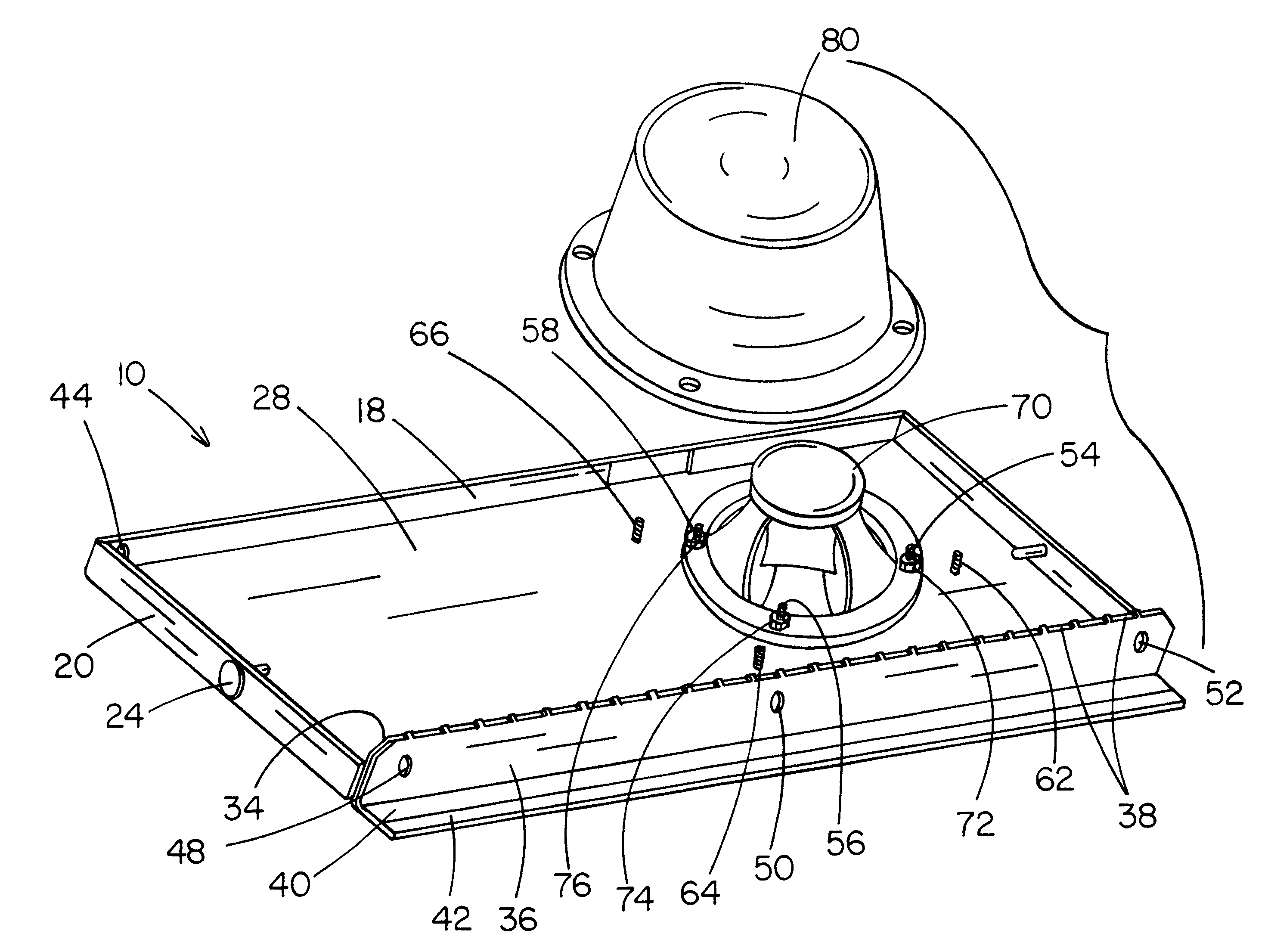

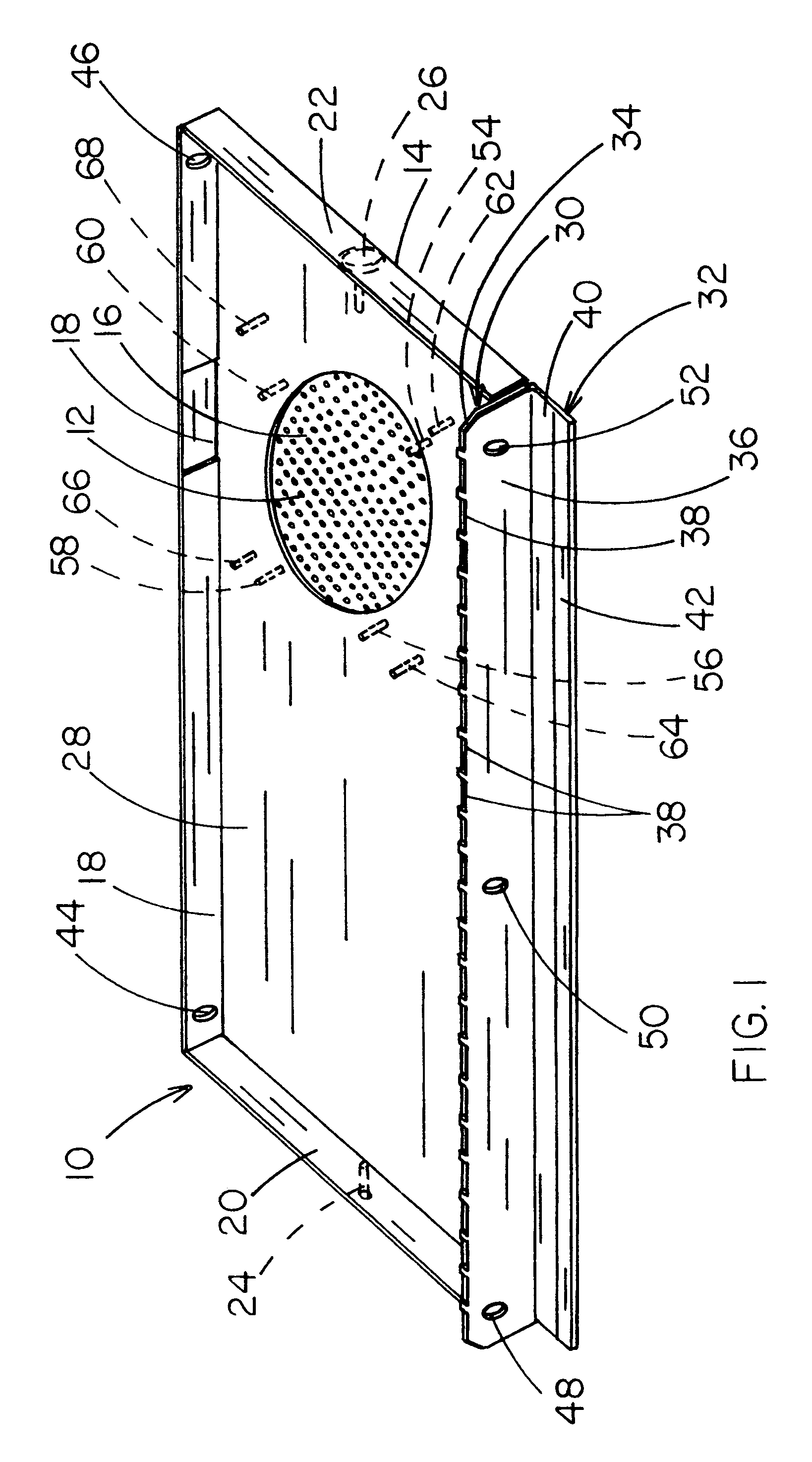

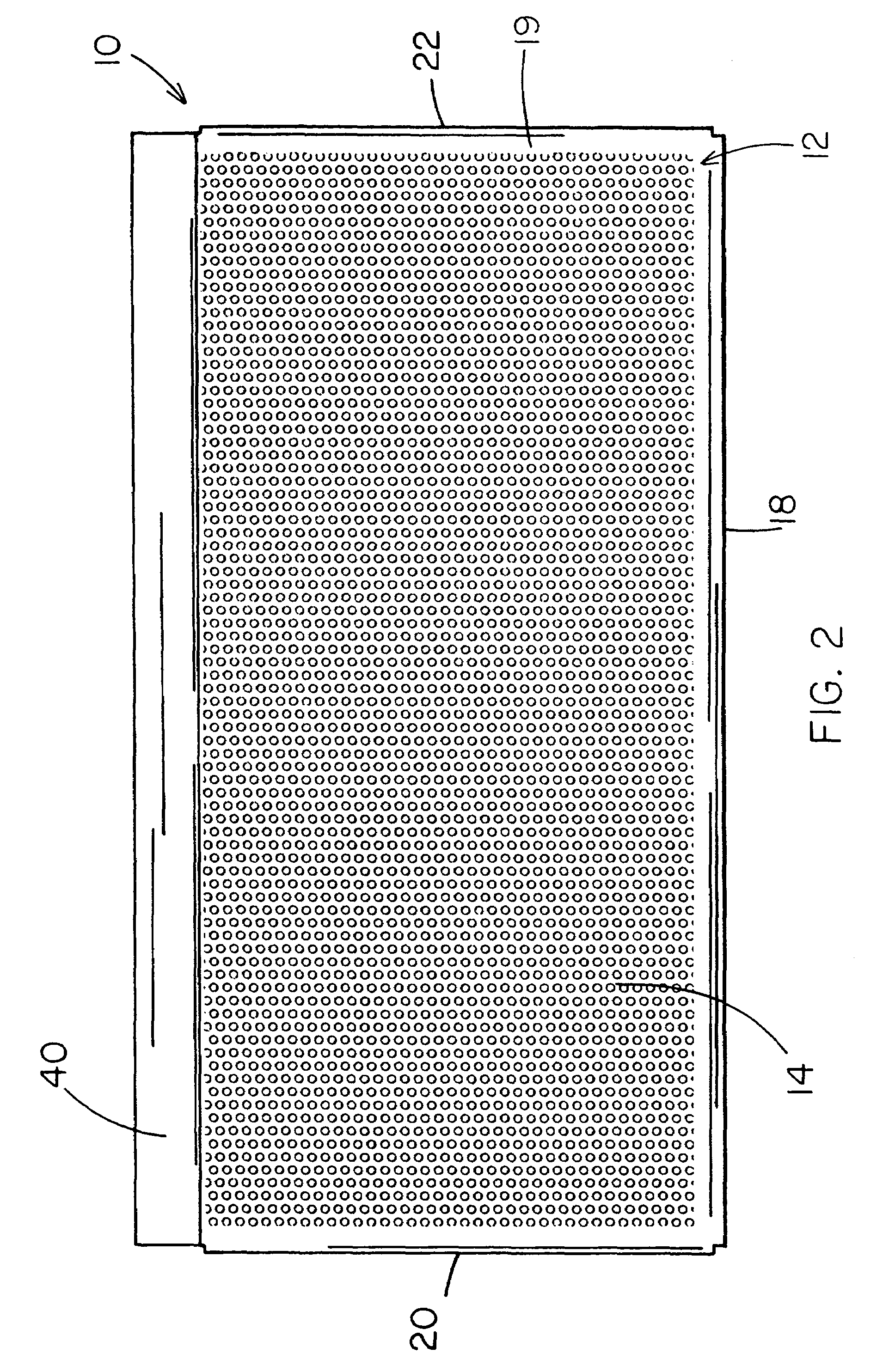

Lay-in tile speaker system

InactiveUS7643647B2Improve acousticsFree spaceMicrophonesLoudspeaker transducer fixingSupporting systemPartial alignment

Owner:LOWELL MFG

High-efficiency oxygen-insulation water-insulation blended full-degradable plastic film and preparation method thereof

The invention discloses a high-efficiency oxygen-insulation water-insulation blended full-degradable plastic film. The high-efficiency oxygen-insulation water-insulation blended full-degradable plastic film is prepared from, by weight, 60 to 65 parts of corn starch, 7 to 9 parts of nano montmorillonite, 0.6 to 0.7 part of peanut oil, 1.2 to 1.4 parts of tetrabutyl titanate, 12 to 14 parts of ramie straw, 27 to 30 parts of polyvinyl alcohol, 1 to 2 parts of xanthan gum, 2 to 4 parts of sodium carboxymethylcellulose, 14 to 15 parts of polyethylene glycol, 7 to 9 parts of poly propylene carbonate, 4 to 6 parts of Pulullan, and 2 to 3 parts of ethyl silicon oil. According to a preparation method, synergistic effect of polyving akohol, polyethylene glycol, and poly propylene carbonate is realized; so that the melting point of polyving akohol is reduced, better blending with a starch master batch is realized, barrier property of plastic film is improved, and oxygen insulation and water insulation effects are excellent. The high-efficiency oxygen-insulation water-insulation blended full-degradable plastic film can be taken as food packaging bags and preservative film, and is capable of insulating oxygen and water, and realizing fresh-keeping effects; and prepared products are capable of satisfying using requirements and can be degraded rapidly after abandoning.

Owner:TONGLING FOUNDER PLASTICS TECH

Preparation method of antimony doped nanometer stannic oxide powder

ActiveCN107758741AFacilitate blendingLower surface energyMaterial nanotechnologyAntimony oxides/hydroxides/oxyacidsDispersityAlcohol

The invention discloses a preparation method of an antimony doped nanometer stannic oxide powder. The preparation method comprises the following steps: (1) mixing an antimonic salt and a tin salt, dissolving in an ethyl alcohol solution, and conducting ultrasonic concussion for 10-20 minutes at the room temperature to obtain a solution A; sequentially dissolving butanetetracarboxylic acid and ammonium dihydrogen phosphate into deionized water to obtain a solution B; (2) mixing the solution A and the solution B, conducting ultrasonic concussion for 5-10 minutes at the room temperature, adding alkali and diethanol amine at the stirring state, enabling the pH of the solution to reach 8-9, heating to 65-75 DEG C, reacting for 2-4 hours to obtain a precipitate precursor; and (3) washing, dryingand calcining the precipitate precursor to obtain the antimony doped nanometer stannic oxide powder. The prepared antimony doped nanometer stannic oxide powder is even in particle size distribution and good in dispersity, the average particle size of the prepared antimony doped nanometer stannic oxide powder is less than 120 nm, the electrical resistivity is less than 25 ohm.cm, the specific surface area is 4-6 m<2> / g, and the electrical conductivity is excellent.

Owner:广西生富锑业科技股份有限公司

Environment-friendly adhesive

InactiveCN107841261ASimple production processImprove product qualityStarch derivtive adhesivesMacromolecular adhesive additivesAdhesiveRosin

The invention discloses an environment-friendly adhesive and relates to the technical field of adhesives. A preparation method comprises the following steps: (1) carrying out phenolation modificationon starch; (2) modifying rosin resin; (3) synthesizing the environment-friendly adhesive. The environment-friendly adhesive prepared by the preparation method does not contain formaldehyde and has notoxin and no odor; a production technology is simple and the quality of a product is excellent; the environment-friendly adhesive has the advantages of good bonding property and good construction property, rapid drying speed, strong adhesive force and high bonding strength; the starch is subjected to the phenolation modification so that a prepared phenolated starch solution has good film forming,gelling, sizing, thickening and blending properties and the like; the environment-friendly adhesive has great viscosity and typical pseudoplastic performance; the bonding strength of the adhesive canbe effectively improved.

Owner:枞阳县新天地高新材料有限公司

Flexible composite polymer thin film containing carbon nanotubes and nano silver, and preparation method thereof

ActiveCN109659071ASimple preparation processHigh feasibilityNon-insulated conductorsApparatus for manufacturing conducting/semi-conducting layersBenzeneCarbon nanotube

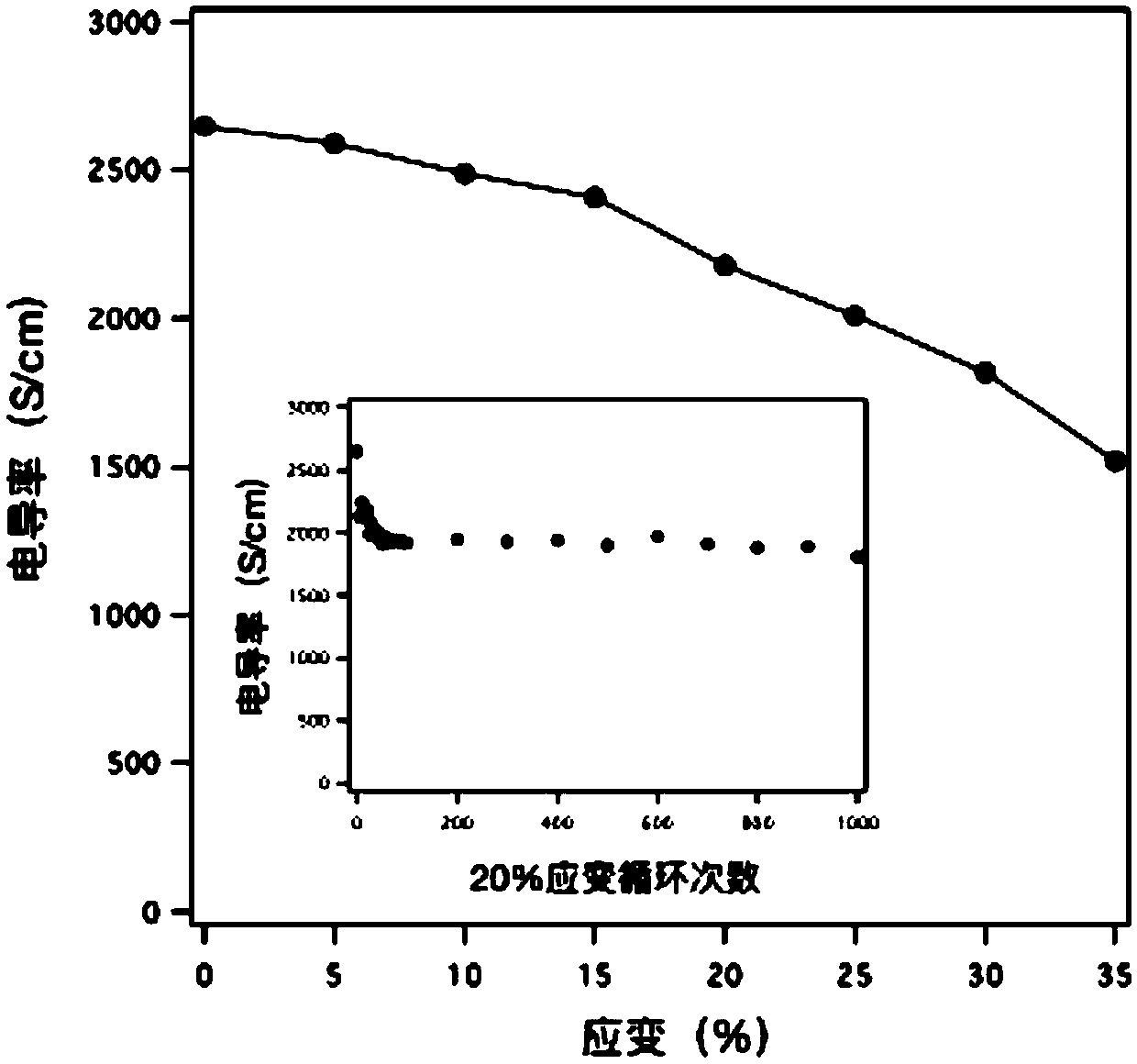

The invention provides a flexible composite polymer thin film containing carbon nanotubes and nano silver. The flexible composite polymer thin film is prepared from raw materials including the carbonnanotubes, silver nanoparticles, an ionic liquid, nano silver wires and polyvinylidene fluoride, wherein the one-dimensional carbon nanotubes are effectively dispersed among the benzene-modified silver nanoparticles (AgNP), the ionic liquid (IL) and the nano silver wires (AgNF), and form a continuous three-dimensional interpenetrating conductive network; and the interpenetrating conductive networkis loaded in a polyvinylidene fluoride (PVDF) base material to form a stretchable highly-conductive flexible composite polymer thin film. The prepared flexible composite polymer thin film has a conductivity ranging from 1500 to 2000 S / cm. The invention further provides a preparation method of the flexible composite polymer thin film containing the carbon nanotubes and the nano silver.

Owner:华碳研发(深圳)有限公司

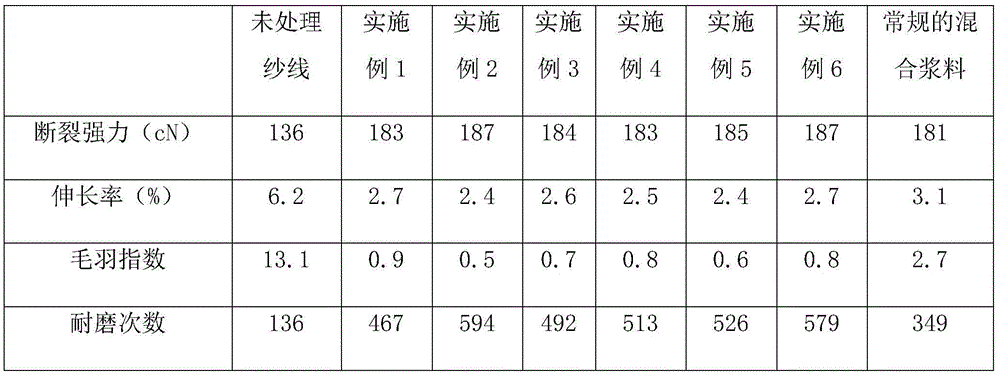

Nanometer titanium dioxide modified starch mixed slurry for textile use

The invention provides nanometer titanium dioxide modified starch mixed slurry for textile use. The nanometer titanium dioxide modified starch mixed slurry comprises starch, PVA (polyvinyl acetate), acrylic ester, soybean protein, an organic silicone emulsion, sodium hydroxide, nanometer titanium dioxide and water; and the specific preparation method comprises the following steps: adding acetate starch to 5%-7% of nanometer titanium dioxide solution, and stirring at a high speed for 30-50 minutes so as to disperse the starch evenly, then adding the PVA, the acrylic ester, the soybean protein and the organic silicone emulsion, and adding sodium hydroxide to adjust the pH value to be 7-10; stirring at the speed of 150-200r / min for 30 minutes, heating to 80-90 DEG C and stirring at a constant temperature for 2-3 hours, so as to obtain the nanometer titanium dioxide modified starch mixed slurry for textile use. The sizing property of the nanometer titanium dioxide modified starch mixed slurry for textile use exceeds the sizing property of a mature formula with relatively high PVA content; and the nanometer titanium dioxide modified starch mixed slurry is good in degradation property and small in environmental burden, and can be applied to the sizing process of yarns and fabric.

Owner:SUZHOU WILDER IND & TRADE

Polymer quaternary phosphonium salt antibacterial material and preparation method thereof

ActiveCN103739786BEasy to cleanImprove antibacterial functionBiocideFungicidesEscherichia coliPhosphonium

The invention discloses a high polymer quaternary phosphonium salt antibacterial material and a preparation method thereof. The high polymer quaternary phosphonium salt antibacterial material is prepared by bonding halogenacylhalide type monomers onto macromolecules of an ethylene-vinyl alcohol copolymer (EVOH) through grafting reaction and further performing quaternary phosphonium reaction with trialkylphosphine. The high polymer quaternary phosphonium salt antibacterial material disclosed by the invention has the advantages of broad-spectrum, high-efficient and lasting antibacterial function and good safety, can be shaped and processed into products with the antibacterial function alone, and mixed with polyethylene, polypropylene and other non-polar resin and other types of resin for being shaped and processed into the products with the antibacterial function, and further has broad application prospects. The sterilization efficiency of the high polymer quaternary phosphonium salt antibacterial material prepared by the preparation method disclosed by the invention against escherichia coli, staphylococcus aureus and a variety of bacteria is more than 99%, and the mildew-resistant grade against aspergillus niger, aspergillus terreus and a variety of mildew is 1-0 grade.

Owner:JINYU HENAN PACKAGING

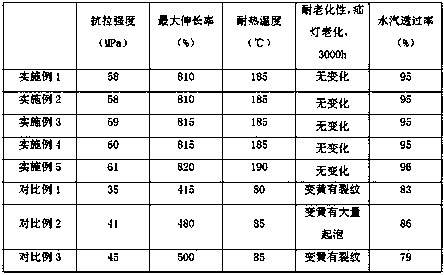

Composite rubber glove and preparation method thereof

InactiveCN108659665AGood mechanical propertiesPromote mutual integrationGlovesCarboxyl rubber coatingsMaleic anhydrideAcrylic acid

The invention provides a composite rubber glove and a preparation method thereof. According to the invention, the rubber layer is formed by spraying rubber cement on the surface of the lining of a fiber glove, so that the composite rubber glove is obtained. The rubber cement is prepared by taking maleic anhydride grafted ethylene-propylene terpolymer, sucrose polyester modified isoprene rubber, and acrylic acid modified nitrile rubber as main raw materials, and straw powder and wollastonite powder are added, so that the composite rubber glove has good mechanical property, heat resistance, aging resistance and air permeability.

Owner:高勐

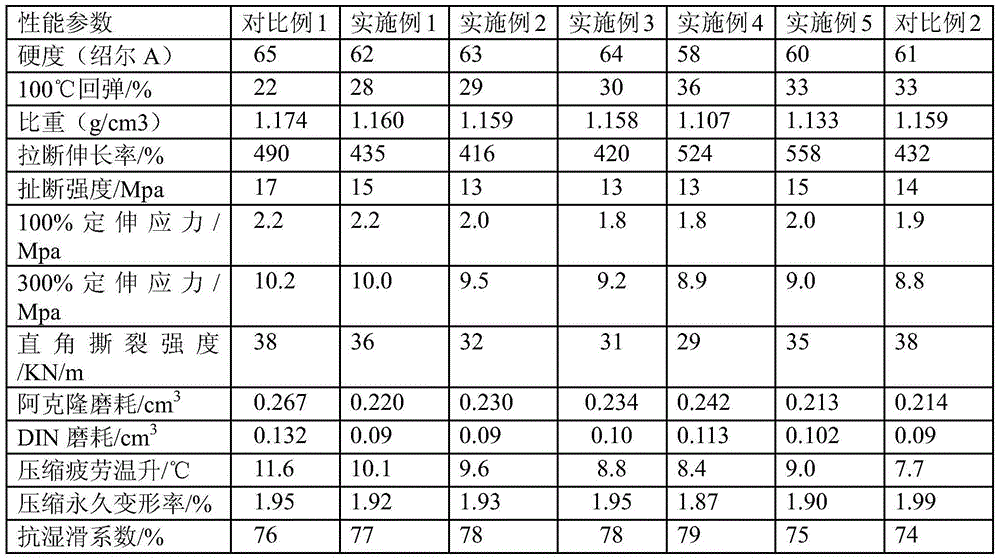

White carbon black reinforced rubber composition for semi-steel tire treads

InactiveCN105273250AReduce rolling resistanceLow heat generationSpecial tyresRolling resistance optimizationReinforced rubberSemi-steel

The invention relates to a white carbon black reinforced rubber composition for semi-steel tire treads, and belongs to the technical field of tire and rubber processing. The composition comprises, by mass, 50-60 parts of HVPBR, 40-50 parts of NR, and 50-70 parts of white carbon black; and a processing assistant and a filler can be added according to routine tread rubber performances. The high wet skid resistance and the low rolling resistance of the HVPBR containing a branched structure are used, the branched structure is in favor of realizing rubber and white carbon black blending and realizing processing performances and the mechanical strength of the NR, and the HVPBR, the NR and the white carbon black are compounded and are used in the production of tire treads. Compared with synthetic rubber materials for traditional semi-steel tire treads, high vinyl polybutadiene (HVPBR) has the advantages of low cost, improvement of the compatibility of the white carbon black and the rubber material, improvement of the processing performances, guaranteeing of excellent wet skid resistance, reduction of the rolling resistance and the dynamic heating of the treads, and no obvious traction loss.

Owner:CHINA PETROLEUM & CHEM CORP

Hydro cyano and cyano fullerene derivatives

InactiveUS20060191843A1Facilitate blendingFacilitates blending of a host polymerMaterial nanotechnologyPigmenting treatmentChemistryMembrane configuration

Owner:RGT UNIV OF CALIFORNIA

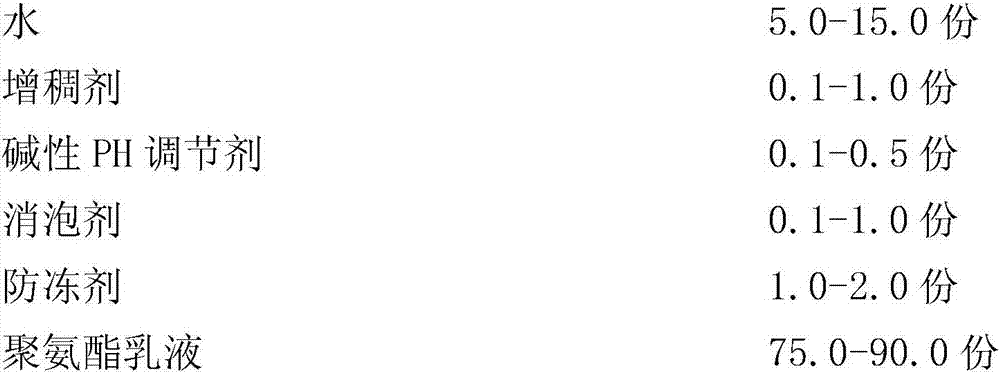

Waterborne wood paint containing modified polyurethane emulsion and preparation method of waterborne wood paint

ActiveCN107189615AHigh hardnessImprove adhesionAntifouling/underwater paintsPaints with biocidesCross-linkEpoxy

The invention provides waterborne wood paint containing modified polyurethane emulsion and a preparation method of the waterborne wood paint. The waterborne wood paint containing the modified polyurethane emulsion is prepared from the following components: water, a thickener, a de-foaming agent, a pH (Potential of Hydrogen) regulator, an anti-freezing agent, a film-forming auxiliary agent, the modified polyurethane emulsion, a flatting agent, a nano inorganic antibacterial formaldehyde removing agent and waterborne paint inorganic hardening resin, wherein the selected modified polyurethane emulsion is prepared from self-cross-linked polyurethane acrylate composite emulsion, polyurethane acrylate copolymerized emulsion with a core-shell interpenetrating network structure, silane coupling agent modified polyurethane acrylate composite emulsion and epoxy resin modified polyurethane emulsion. The emulsions are added into the waterborne wood paint, so that the waterborne wood paint has very high rigidity and adhesive force and good water resistance, alcohol resistance and pollution resistance; the nano inorganic antibacterial formaldehyde removing agent is selected, so that the waterborne wood paint has environment-friendly, safe and toxin-free, and long-period antibacterial effects. The waterborne paint inorganic hardening resin is used for improving the rigidity, adhesive force and chemical resistance properties of the waterborne paint.

Owner:SKSHU PAINT

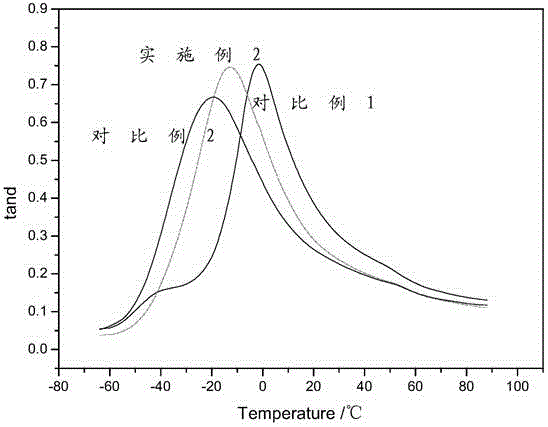

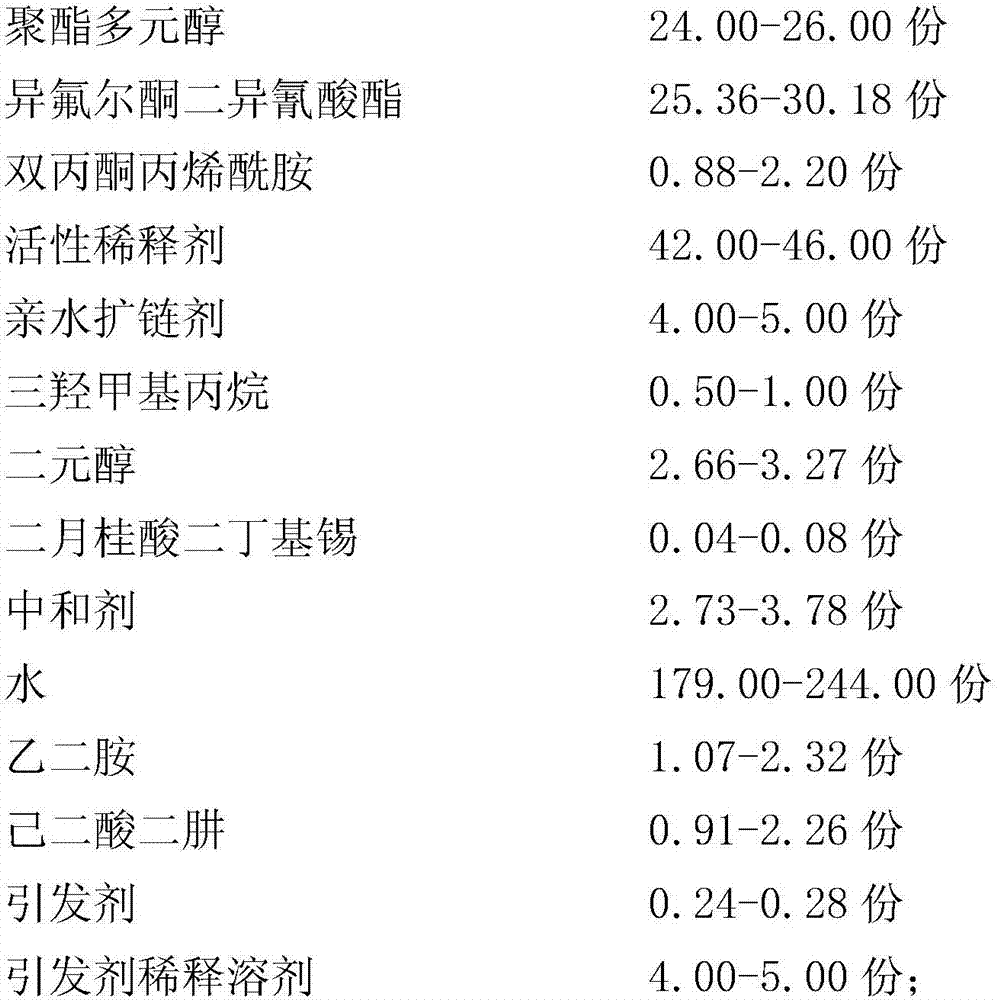

Copper-aluminum-manganese alloy/ polymer/ carbon nanotube damping material and preparation method

ActiveCN109277571AReduce the proportionPrecise control of hole structure parametersMaterials preparationEnergy absorption

The invention discloses a copper-aluminum-manganese alloy / polymer / carbon nanotube damping material and a preparation method and belongs to the technical field of damping material preparation. The damping material comprises a porous copper-aluminum-manganese memory alloy framework and a thermoplastic elastomer. The thermoplastic elastomer is acquired by blending polyacrylate rubber, polyvinyl chloride and carbon nanotubes together. The thermoplastic elastomer is loaded in pores of the copper-aluminum-manganese memory alloy framework. The pore diameter of the porous copper-aluminum-manganese memory alloy framework ranges between 0.355 Mu m and 1.43 Mu m, and the pore rate of the porous copper-aluminum-manganese memory alloy framework ranges between 70% and 90%. The porous copper-aluminum-manganese shape memory alloy with high anti-martensite stabilization capacity and with pores communicating with each other is adopted as the framework. The thermoplastic elastomer generated by a polyacrylate composite material (ACM) polymer, a polyvinyl chloride (PVC) polymer and carbon nanotubes (CNT) is infiltrated into the communicating pores. According to the composite material, the proportionof the damping alloy can be effectively reduced; and disadvantages of the polymer damping material that the strength is not enough and dimensional stability is poor can also be remedied. By adopting the porous copper-aluminum-manganese shape memory alloy framework, pore structure parameters can be controlled accurately; and in addition, the porous copper-aluminum-manganese shape memory alloy framework has the advantages of being great in energy absorption, high temperature resistance and good in dimensional stability.

Owner:CENT SOUTH UNIV

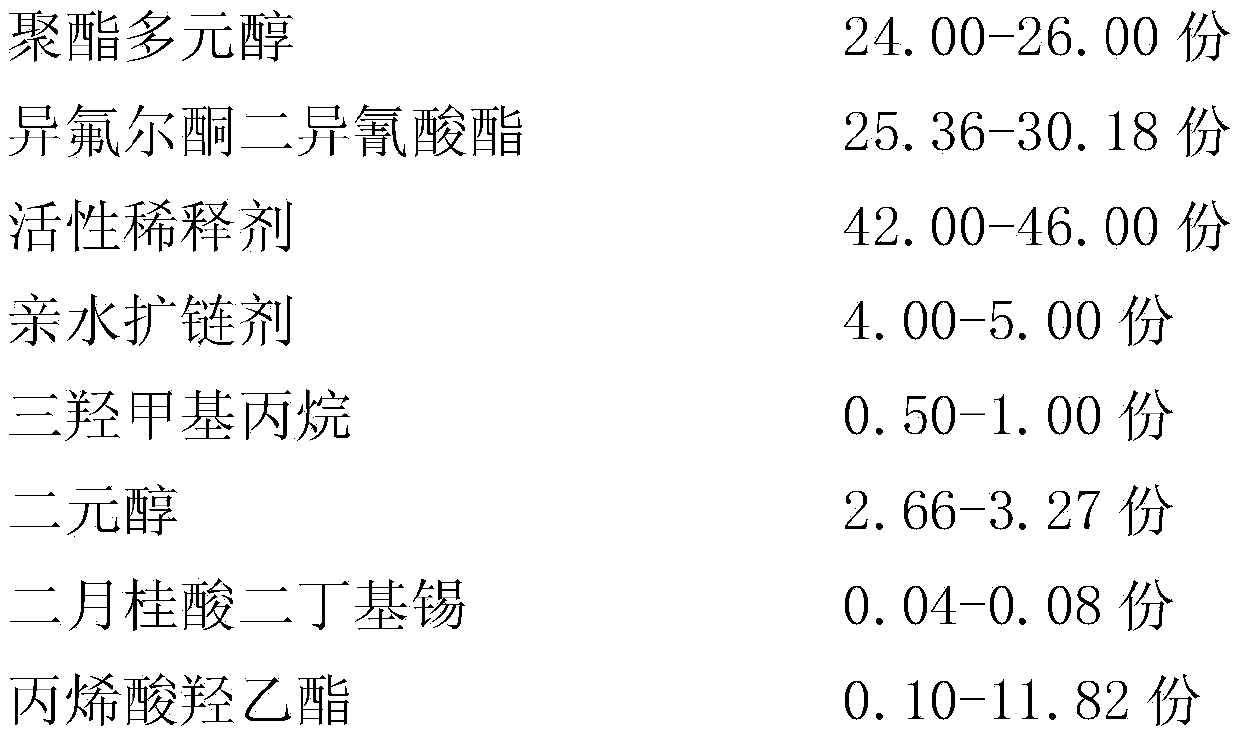

Self-repairing polyurethane heat insulation film as well as preparation method and application thereof

ActiveCN112321878AHigh transparencyWith heat insulation effectFireproof paintsPolyurea/polyurethane coatingsPolymer scienceInsulation layer

The invention discloses a self-repairing polyurethane heat insulation film as well as a preparation method and application thereof. The heat insulation film is formed by sequentially arranging a thermoplastic polyurethane film layer, a heat insulation layer and a self-repairing coating. The thermoplastic polyurethane film layer is prepared from the following raw materials: TPU master batch and modified nano indium antimony oxide. The raw material formula of the heat insulation layer comprises tungsten trioxide powder, a dispersing agent, a photoinitiator, polyurethane acrylate, tridecafluorooctyl methacrylate, 2-(perfluorooctyl) ethyl methacrylate, hollow glass beads and a cross-linking agent. The heat insulation film is good in heat insulation performance, capable of reducing light transmission and heat transfer and generating heat insulation, inflaming retarding and abrasion resisting effects, has a self-repairing function, is good in scratch resistance and has a wide application prospect in the aspect of automobile safety protection films.

Owner:ZHEJIANG SHICHUANG OPTICAL FILM MFG

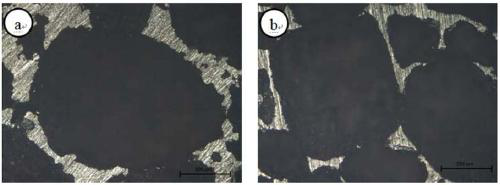

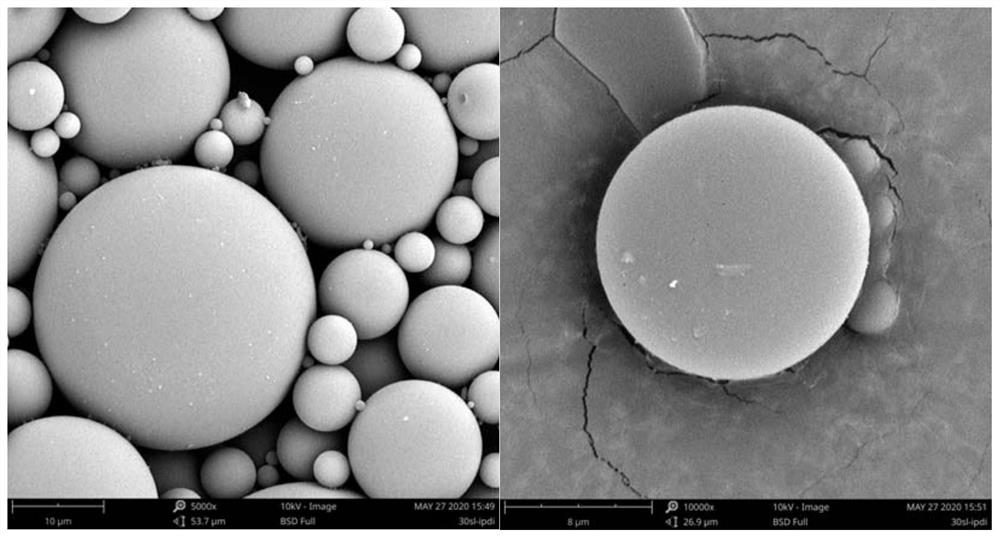

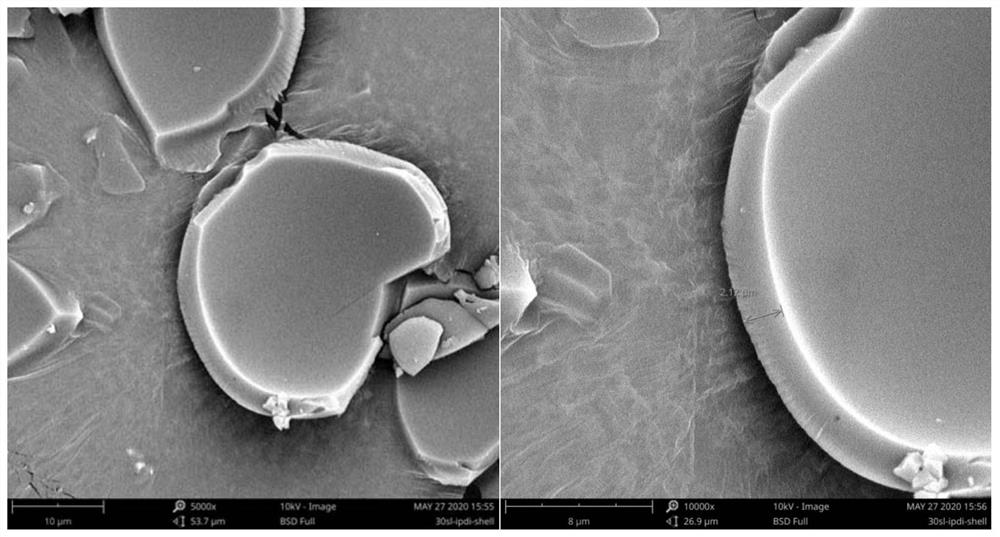

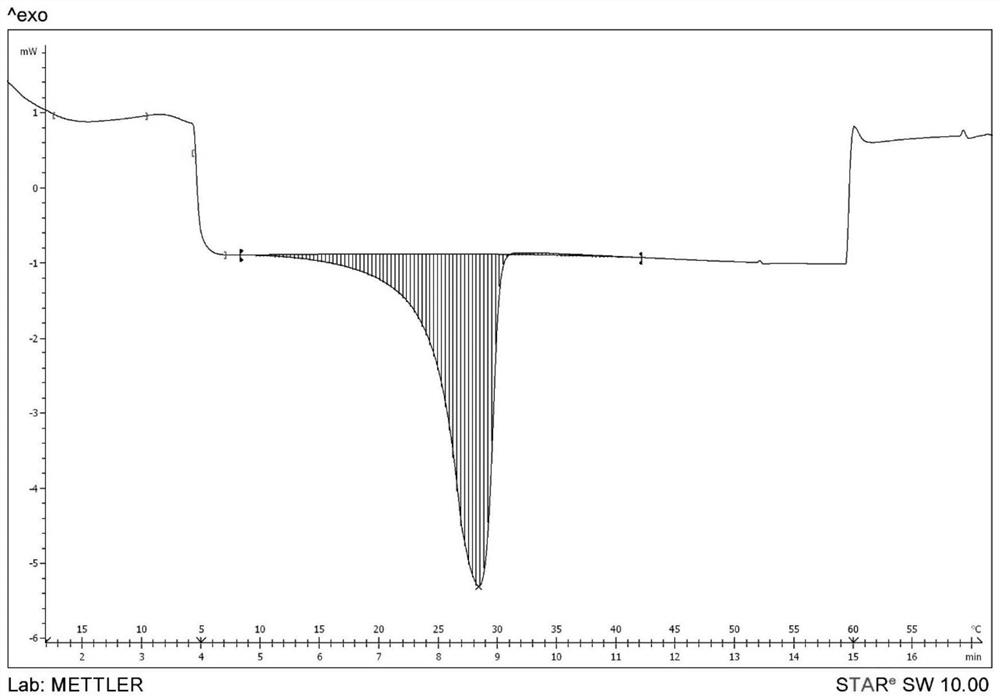

Phase-change energy-storage microcapsule with shear thickening effect, and preparation method and application thereof

InactiveCN111804249AIncrease enthalpyHas a shear thickening effectHeat-exchange elementsMicroballoon preparationAlkanePolymer science

The invention discloses a phase-change energy-storage microcapsule with a shear thickening effect, and a preparation method and application thereof. Alkanes with different melting points are taken ascore materials, and the phase-change energy-storage microcapsule taking polyurethane as a shell material is prepared by an emulsifier-free emulsion polymerization method. By changing the types of thecore materials, the working temperature and the heat storage performance can be changed. The core-shell structure of the phase-change energy-storage microcapsule has phase-change energy storage and shear thickening properties at the same time. The phase-change microcapsule material is technically endowed with the shear thickening property, the application range of the phase-change microcapsule material is effectively widened, and the phase-change microcapsule material has a wide application prospect in the wearable field.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Light high-strength ABS wood-plastic foamed board and preparation method thereof

InactiveCN111073327AImprove reaction binding abilityImprove mechanical propertiesFoaming agentAcid anhydride

The invention provides a light high-strength ABS wood-plastic foamed board and a preparation method thereof. The wood-plastic foamed board is prepared from the following components in parts by weight:20-30 parts of ABS resin particles, 10-20 parts of maleic anhydride grafted ABS resin particles, 40-60 parts of wood flour, 5-10 parts of coated flame-retardant polypropylene fibers, 5-7 parts of modifier and 2-5 parts of foaming agent and 0-6 parts of a filler. Reasonable raw material selection and self-made pretreatment of part of raw materials are carried out, the reaction combination effect between the materials is effectively improved and the performance effect is higher; and the ABS is adopted as a board substrate, the comprehensive quality is good, the applicability is high, the prepared board is light, high in strength and excellent in corrosion resistance, mildew resistance, acid and alkali resistance, water resistance, heat preservation, flame retardance and the like, the mechanical property is remarkably improved, and the popularization and application value is high.

Owner:安徽智晟通讯科技有限公司

SBR sole material for shoes of old people and preparation method of SBR sole material

InactiveCN105542260AImprove compatibilityImproves elasticity and shock absorptionSolesOlder peopleGlass microsphere

The invention provides an SBR sole material for shoes of old people. The SBR sole material is prepared from the following components in parts by weight: 40-60 parts of SBR, 9-14 parts of IIR, 6-7 parts of a compatilizer, 8-9 parts of hollow glass microsphere, 6-8 parts of softening oil, 10-12 parts of a filling material, 3-6 parts of a reinforcing agent, 0.6-1.1 parts of an anti-aging agent, 0.5-1 part of a vulcanizing agent, 0.7-1.2 parts of vulcanizing accelerator, 0.5-1 part of a coupling agent, 2-3 parts of zinc oxide and 1-2 parts of stearic acid. The invention further provides a preparation method of the sole material. The provided sole material has better vibration reduction performance and shock resistance, and can better meet requirements of the shoes of old people.

Owner:SUZHOU JINGRO TECH

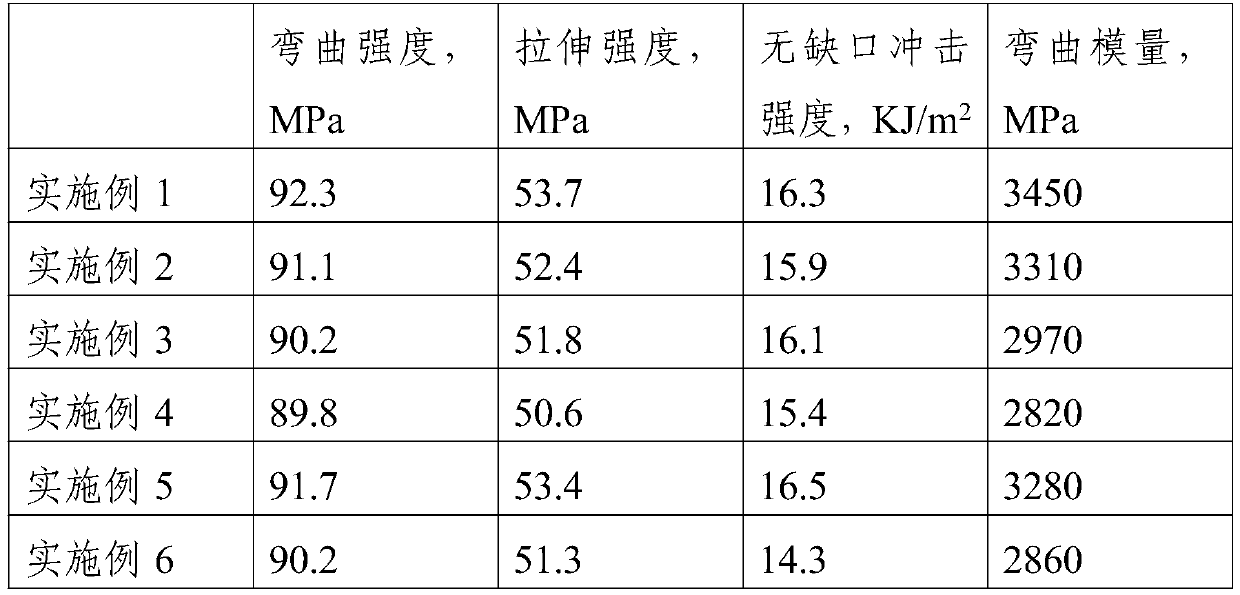

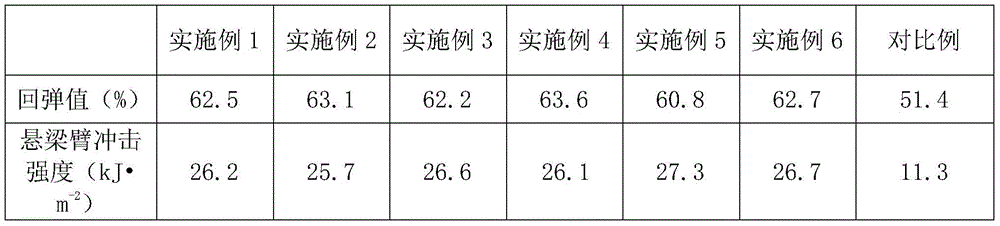

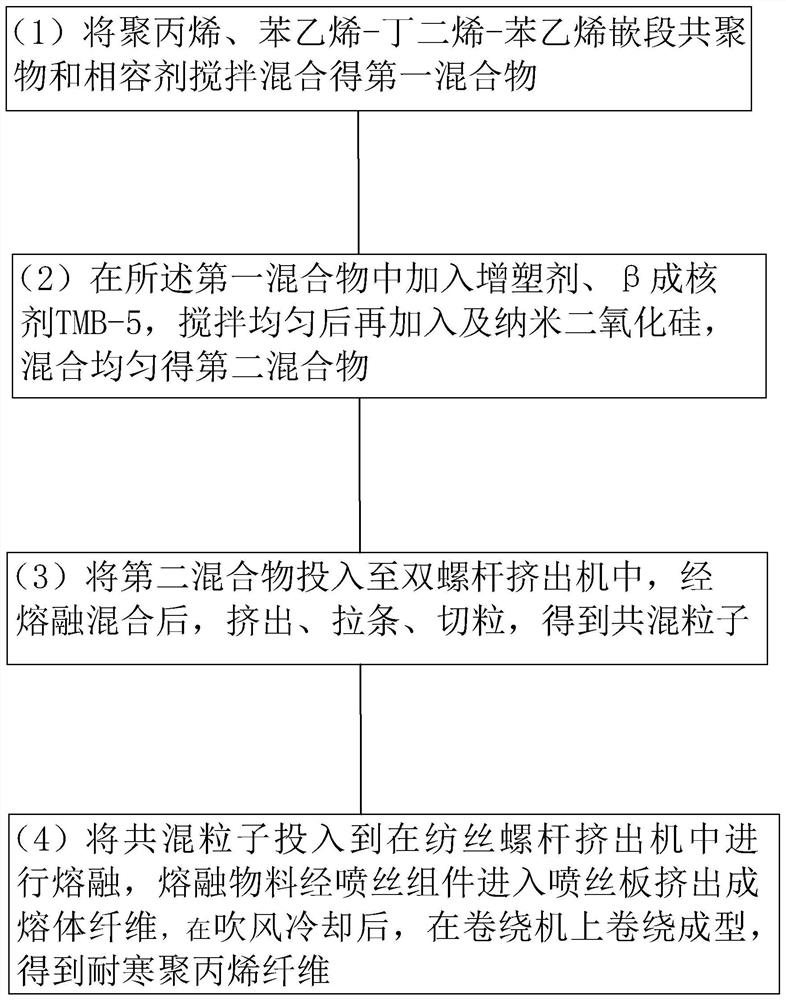

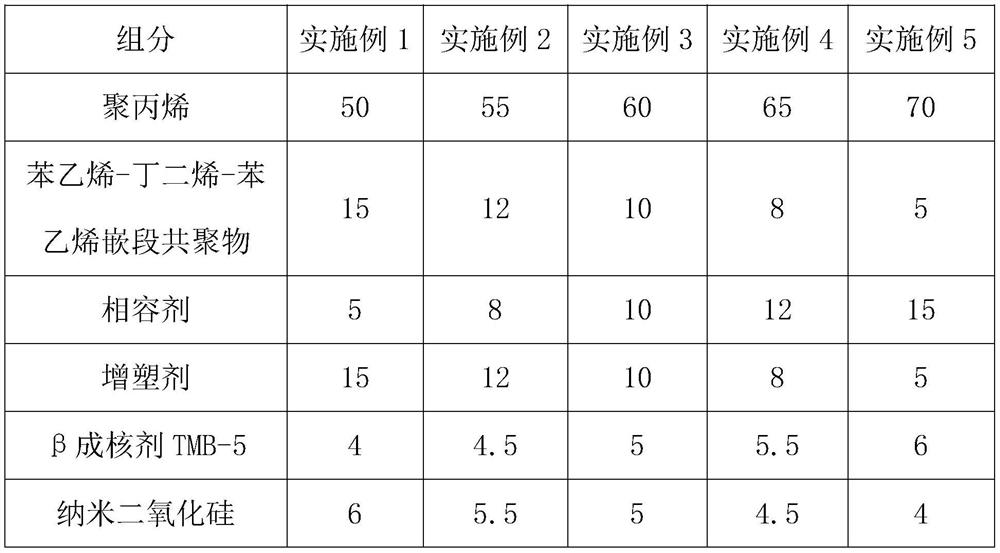

Cold-resistant polypropylene and preparation method thereof

The invention relates to the field of polypropylene fibers, and particularly discloses cold-resistant polypropylene and a preparation method thereof. The cold-resistant polypropylene is prepared fromthe following raw materials in parts by weight: 50-70 parts of polypropylene, 5-15 parts of a styrene-butadiene-styrene block copolymer, 5-15 parts of a compatilizer and 5-16 parts of a plasticizer. The cold-resistant polypropylene disclosed by the invention can be used in a low-temperature environment and has the advantage of prolonging the service life of polypropylene at a low temperature.

Owner:慈溪金轮复合纤维有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com