Grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for nuclear power plant and preparation method thereof

A nuclear power plant, irradiation technology, applied in the field of radiation cross-linkable halogen-free flame-retardant cable material and its preparation, 1E grade K2 type radiation cross-linkable halogen-free flame-retardant cable material and its preparation field for nuclear power plant, It can solve the problems of material mechanical properties and processing performance decline, complex composition of flame retardant system, susceptibility to heat and mechanical precipitation, etc., and achieve excellent anti-hydrolysis and anti-oxidation functions, excellent anti-dripping and self-extinguishing properties, and good synergistic flame retardant effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

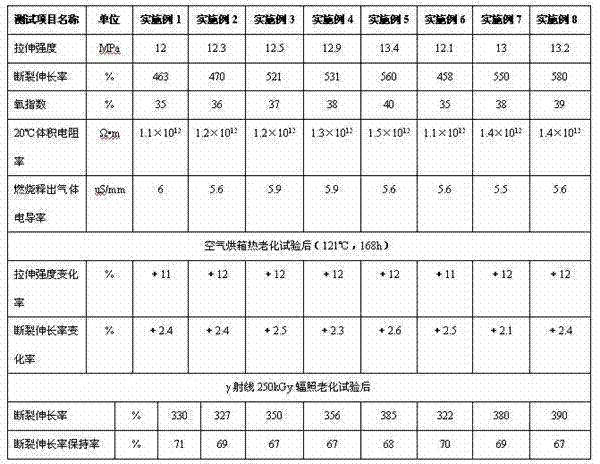

Examples

Embodiment 1

[0044] Raw material weight (kg)

[0045] EVA 100

[0046] Phenoxypolyphosphazene 10

[0047] Mg(OH) 2 25

[0048] Al(OH) 3 25

[0049] ZEO 2

[0050] MMT 2

[0051] Antioxidant 1010 0.25

[0052] Antioxidant 168 0.25

[0053] Antioxidant 300 3

[0054] Liquid paraffin 0.5

[0055] EBS 1

[0056] M-305 0.5

[0057] After weighing the raw materials accurately according to the above proportions, first put the EVA into the high-speed mixer, then add processing aids (liquid paraffin, EBS, M-305), stir at 100-200 rpm for 2-3 minutes, and then add Flame retardant A (phenoxy polyphosphazene), flame retardant B (Mg(OH) 2 , Al(OH) 3 ), flame retardant synergists (ZEO, MMT), basic antioxidants (antioxidant 168, antioxidant 1010), anti-radiation additives (antioxidant 300), high-speed stirring at 300-500 rpm for 3-5 Minutes until the raw materials are uniformly mixed and discharged, the mixed raw materials are dried...

Embodiment 2

[0061] Raw material weight (kg)

[0062] EVA 100

[0063] Phenoxypolyphosphazene 12

[0064] Mg(OH) 2 10

[0065] Al(OH) 3 30

[0066] ZEO 1

[0067] MMT 1

[0068] Antioxidant 1010 1

[0069] Antioxidant 168 1

[0070] Antioxidant 300 2.5

[0071] liquid paraffin 1

[0072] EBS 4

[0074] M-305 1

[0075] After weighing the raw materials accurately according to the above proportions, first put the EVA into the high-speed mixer, then add processing aids (liquid paraffin, EBS, calcium stearate, M-305), and stir at 100-200 rpm for 2- 3 minutes, then add flame retardant A (phenoxy polyphosphazene), flame retardant B (Mg(OH) 2 , Al(OH) 3 ), flame retardant synergists (ZEO, MMT), basic antioxidants (antioxidant 1010, antioxidant 168), anti-radiation additives (antioxidant 300), high-speed stirring at 300-500 rpm for 3-5 Minutes until the raw materials are uniformly mixed and discharged, t...

Embodiment 3

[0079] Raw material weight (kg)

[0080] EVA 100

[0081] Phenoxypolyphosphazene 15

[0082] Mg(OH) 2 10

[0083] Al(OH) 3 25

[0084] ZEO 2.5

[0085] MMT 2.5

[0086] Antioxidant 1010 0.5

[0087] Antioxidant 168 0.5

[0088] Antioxidant 300 2

[0089] liquid paraffin 3

[0091] M-305 0.5

[0092] After weighing the raw materials accurately according to the above proportions, first put the EVA into the high-speed mixer, then add processing aids (liquid paraffin, EBS, calcium stearate, M-305), and stir at 100-200 rpm for 2- 3 minutes, then add flame retardant A (phenoxy polyphosphazene), flame retardant B (Mg(OH) 2 , Al(OH) 3 ), flame retardant synergists (ZEO, MMT), basic antioxidants (antioxidant 1010, antioxidant 168), anti-radiation additives (antioxidant 300), high-speed stirring at 300-500 rpm for 3-5 Minutes until the raw materials are mixed evenly and discharged, the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com