Patents

Literature

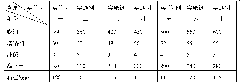

53results about How to "Water evaporates quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coupling compound moulded coal binder and preparation method thereof

InactiveCN101798538AWater evaporates quicklyIncrease production capacitySolid fuelsCross-linkCellulose

The invention discloses a coupling compound moulded coal binder and a preparation method thereof. The coupling compound moulded coal binder is a mixture prepared by mixing bentonite, tackifier, sodium carbonate, kaolin and sodium humate; the mixture comprises the following components in parts by weight: 350-600 parts of the bentonite, 45-55 parts of the tackifier, 3-5 parts of the sodium carbonate, 280-320 parts of the kaolin and 100-125 parts of the sodium humate; the tackifier is prepared by smashing 10-15 parts by weight of polyacrylate, 5-10 parts by weight of acrylamide, 3-5 parts by weight of cellulose, 20-25 parts by weight of cassava stalk, 3-5 parts by weight of modified starch and 0.2-0.5 part by weight of cross-linking agent into 50-100 meshes, and mxing the smashed materials. The preparation method comprises the following steps: preparing the tackifier, stocking, pretreating parts of the components, mixing, stirring and the like. The moulded coal binder has favorable waterabsorbtion performance, the moisture of an extruded and shaped coal bar is quickly evaporated and is easy to dry, thus solving the problems of high raw coal moisture, difficult moulded coal production and low shaping rate in rainy days in the south of China.

Owner:柳州化工股份有限公司 +2

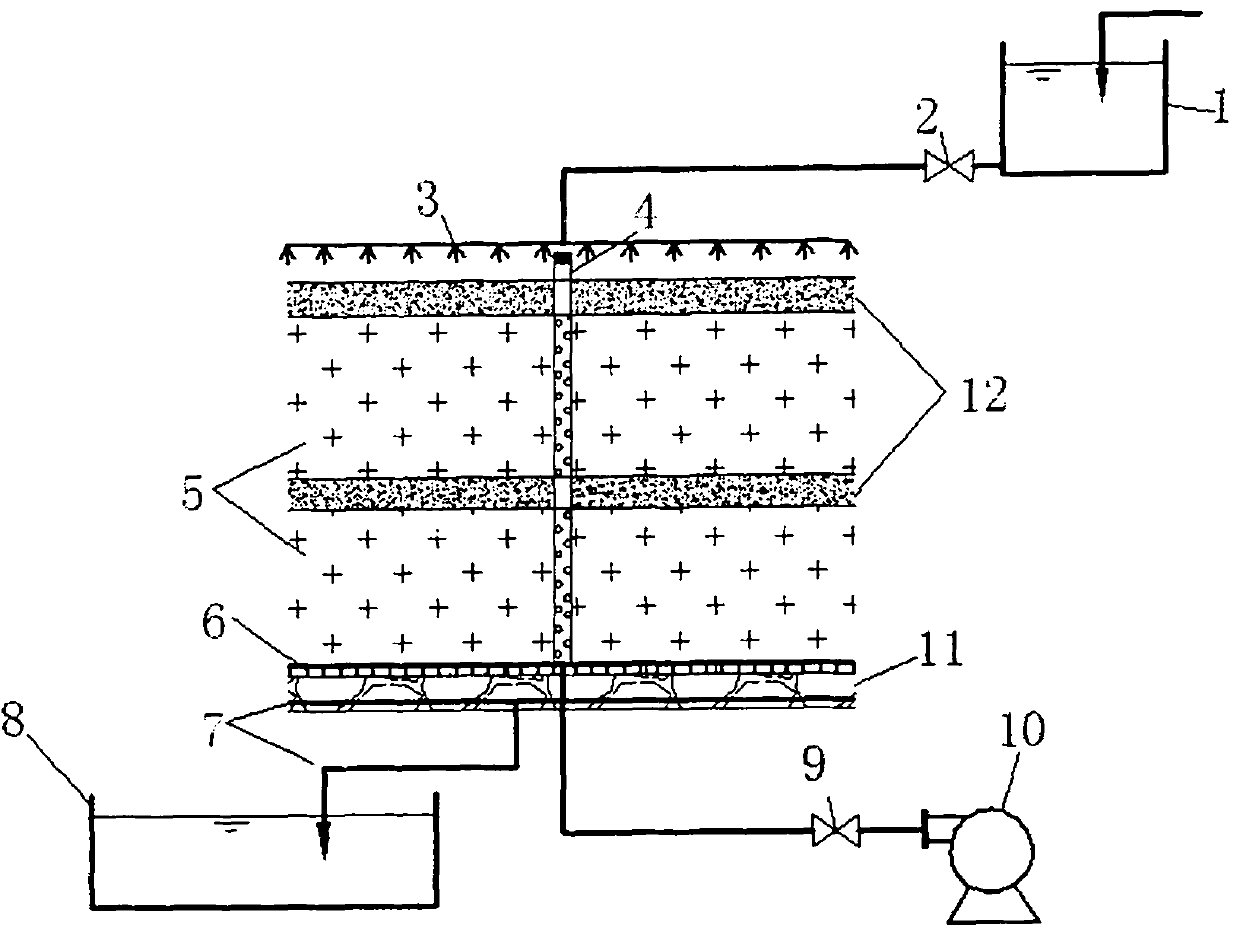

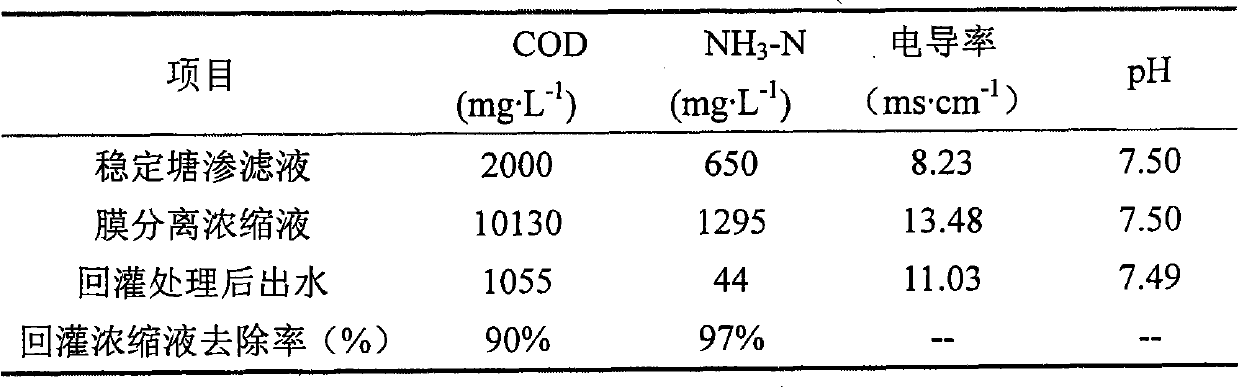

Microaerophilic recirculation treatment method for membrane-separation concentrated solution of garbage leachate

InactiveCN101767877AIncrease temperaturePromote formationTreatment with aerobic and anaerobic processesHigh concentrationOrganic acid

The invention relates to a microaerophilic recirculation treatment method for a membrane-separation concentrated solution of garbage leachate, which comprises the following steps: the concentrated solution is uniformly distributed on the surface layer of the recirculation area via an overhead tank and water distribution pipes, and discharged into a drain pipe via an overlaid soil layer, a garbage landfill layer and a pebble layer; and a forced draft is introduced into the recirculation area to accelerate the organic matters in the concentrated solution and garbage to decompose, and the concentrated solution is finally discharged into a stabilization pond. Since the landfill layer provides a microaerophillic environment, acid fermentation, high concentration and organic acid accumulation are inhibited, thereby accelerating the removal of COD and NH3-N; and the abundant microbial populations in the landfill layer is beneficial to the degradation and stabilization of the landfill layer. Thus, the invention has strong capability for resisting hydraulic load variations and favorable recirculation treatment effect on the concentrated solution.

Owner:GUANGXI UNIV

New tremella cultivation method

The invention discloses a new tremella cultivation method, which comprises the steps of: sawing wood for tremella cultivation into small sections, then, stacking the sawn small wood sections, and then naturally airing the stacked wood sections; loading the wood sections into a plastic bag when arachnoid cracks appear at two ends of the wood sections, tying a bag opening firmly after the wood sections are well bagged, and opening two ends of the plastic bag; and placing the well bagged wood sections into a sterilization stove for sterilization for 12-14 hours at the temperature being of 100 DEG C in the stove, cooling and taking out the wood sections, putting the wood sections into a clean greenhouse subjected to sterilization and insect killing, carrying out inoculation cultivation, and harvesting. The new tremella cultivation method disclosed by the invention is high in yield and free from diseases and pests, the produced tremella is the same as the tremella produced by cut-log cultivation and is high in market value, low in management technological requirement and small in investment quantity.

Owner:张德品

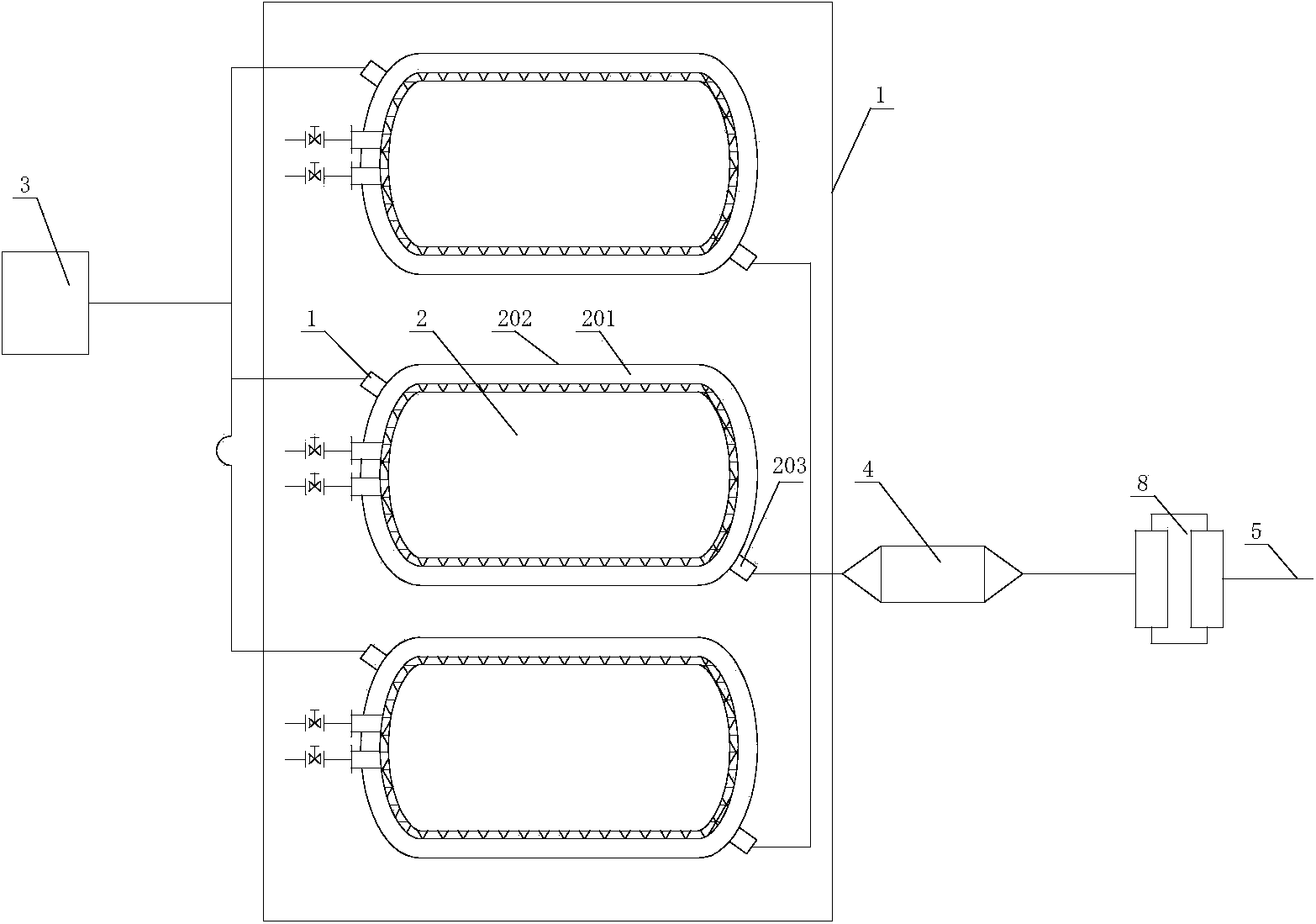

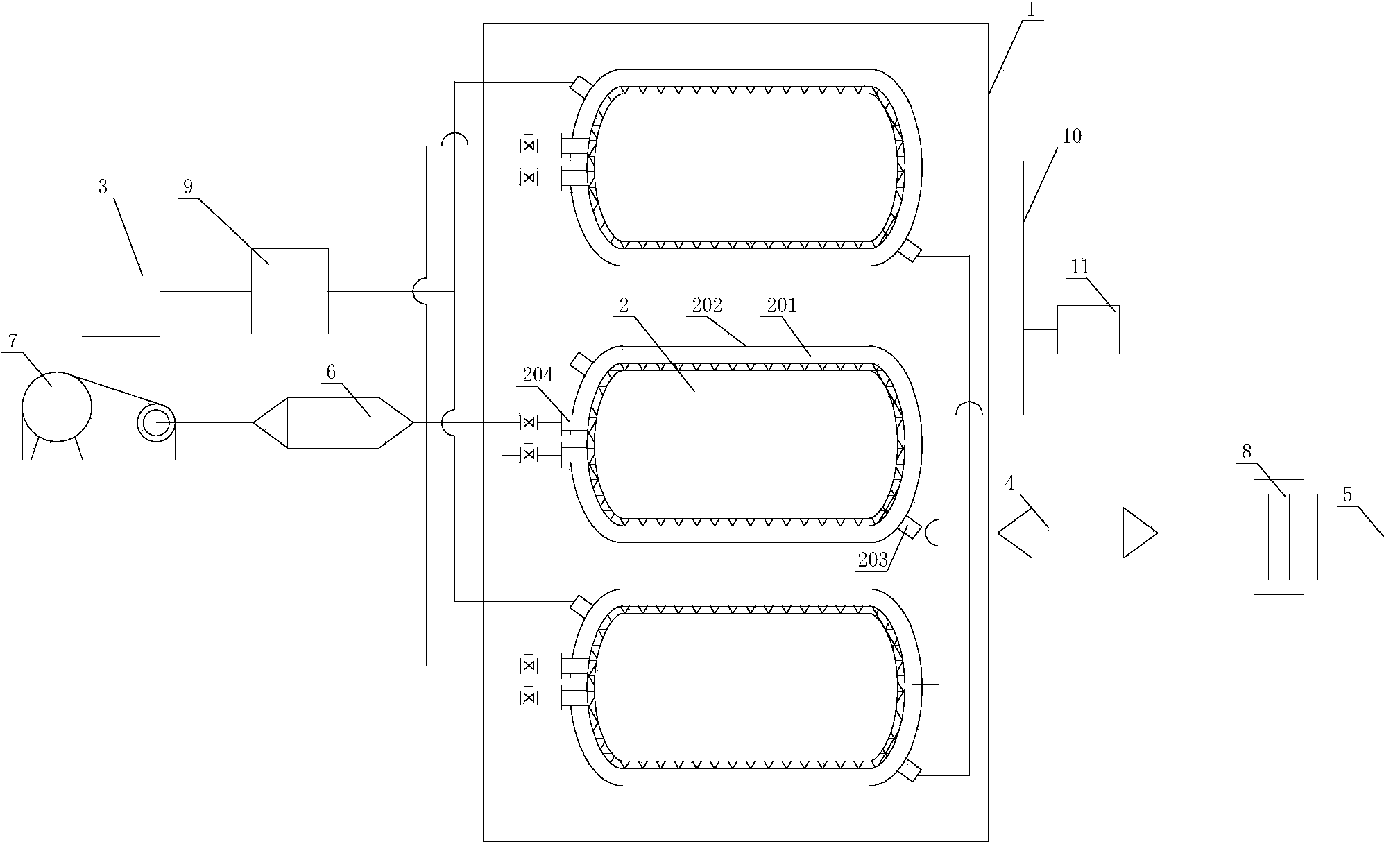

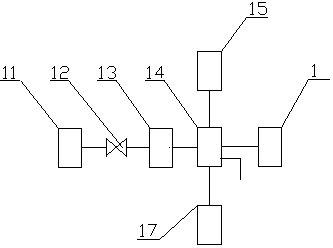

Low-temperature heat-insulation gas cylinder vacuumizing system

InactiveCN103615655AQuick dehydrationReduce energy consumptionPressure vesselsGas cylinderProcess engineering

The invention discloses a low-temperature heat-insulation gas cylinder vacuumizing system. The low-temperature heat-insulation gas cylinder vacuumizing system comprises a plurality of gas cylinders arranged in a vacuum heating chamber, wherein the gas cylinder sandwich layers are communicated with a vacuumizing device, and air inlet joints are arranged on gas cylinder outer containers and are sequentially communicated with a sandwich layer heating tank, a dehumidifier and a compressed air inlet pipe through a pipeline.

Owner:ZHANGJIAGANG FREE TRADE ZONE CHANGJIANG NEW ENERGY EQUIP

Rice mud open-air sprout cultivation method

A method for culturing the rice seedlings transplanted by throwing them in paddy field features that the traditional wet culture method is used as its technological platform, the rice seedlings are cultured in sludge instead of nutritive soil, and said culturing sludge is contained in plastic tray without covering plastic film.

Owner:信阳市农业科学研究所

A vacuum microwave processing method for crisp persimmon chips

PendingCN107744115AAvoid the problem of partial cokingReduce lossesFood shapingFood dryingMicrowaveFood processing

The invention discloses a vacuum microwave processing method for crisp persimmon chips, and belongs to the technical field of food processing. The objective of the invention is to provide the vacuum microwave processing method for crisp persimmon chips, with the method having advantages of a high production efficiency, a low cost, capability of preparing crisp persimmon chips having rich nutritionand good taste, and the like. The method includes subjecting thin persimmon sheets to staged microwave puffing and drying in vacuum with the vacuum degree being -0.09 MPa to -0.06 MPa.

Owner:HEZHOU UNIV

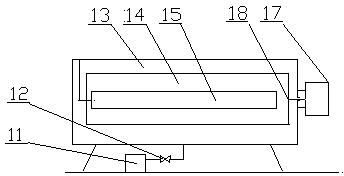

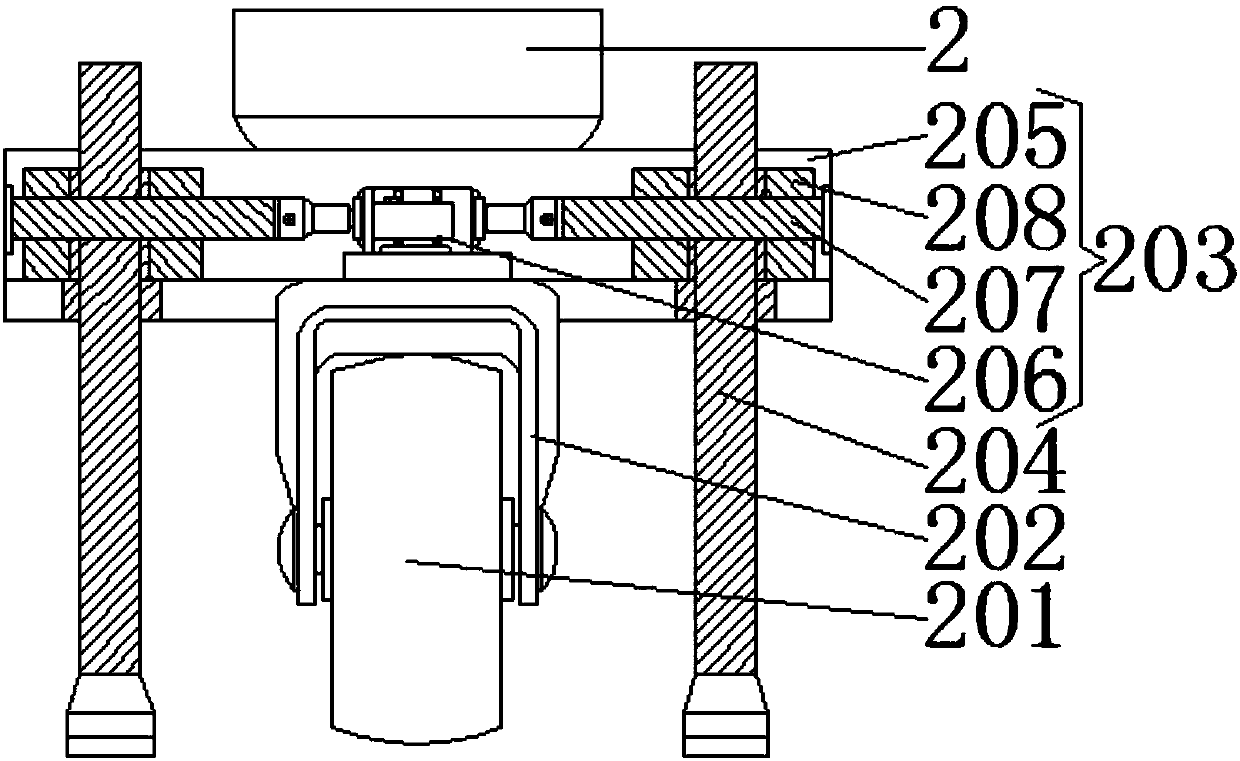

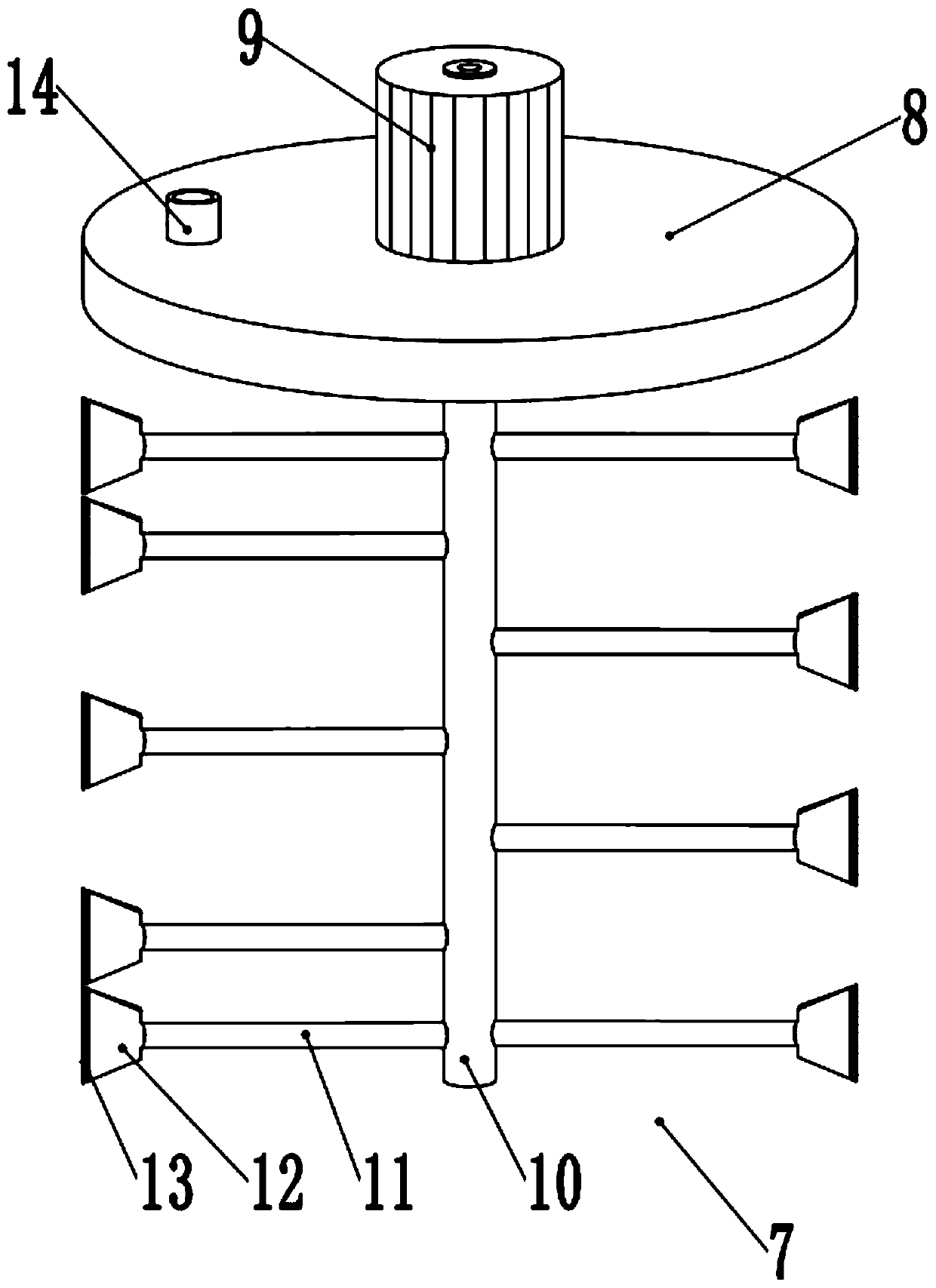

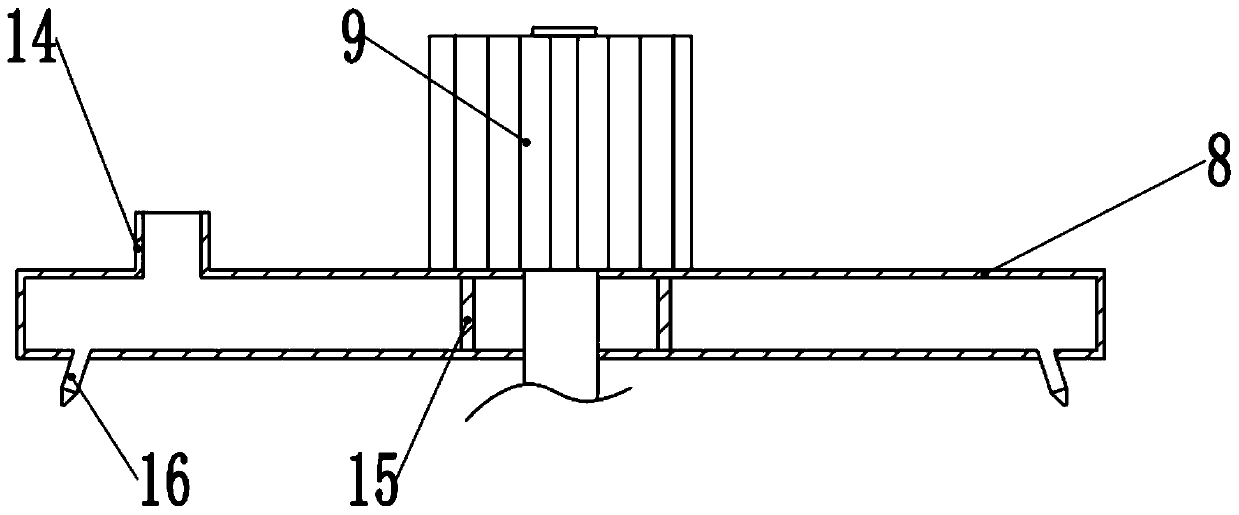

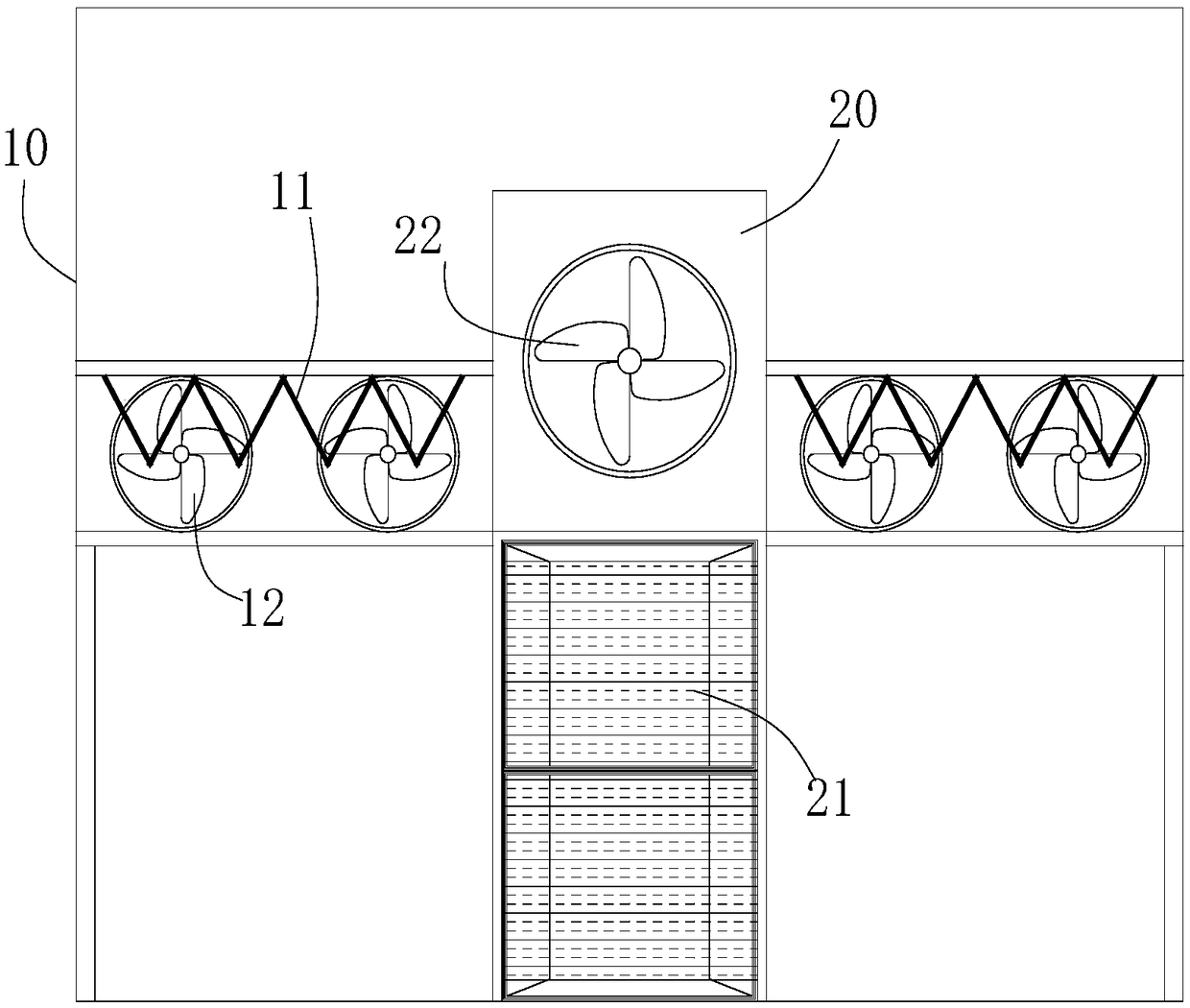

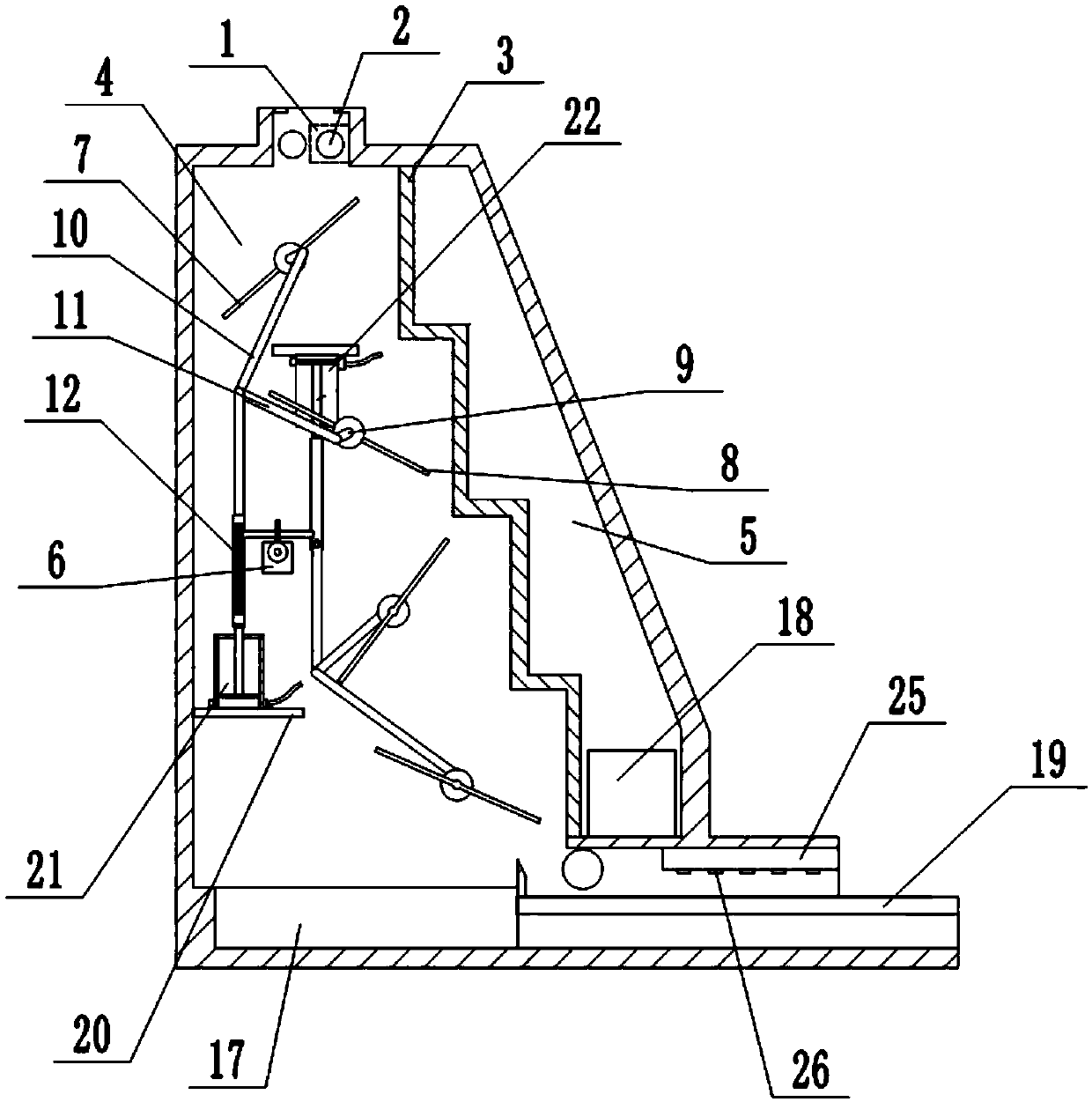

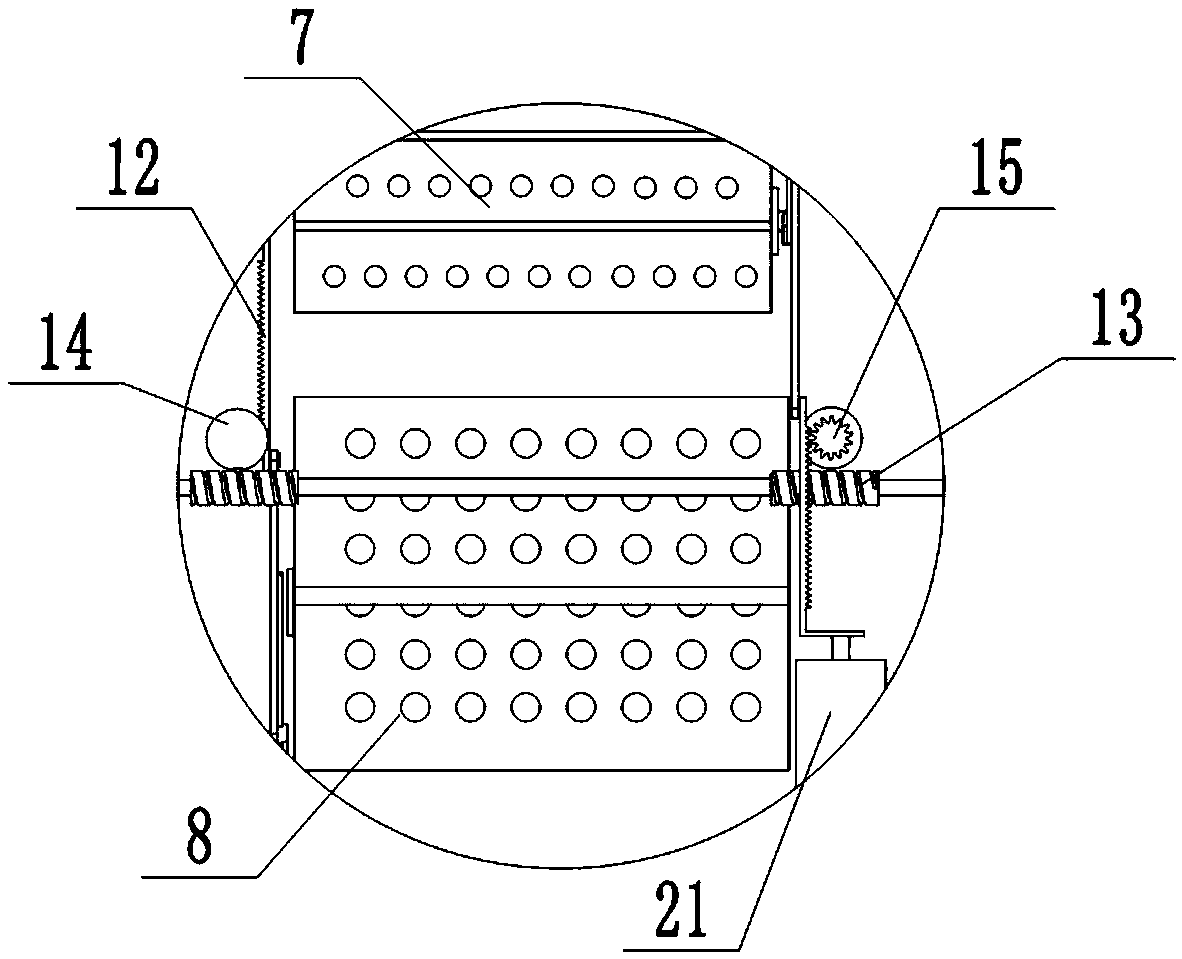

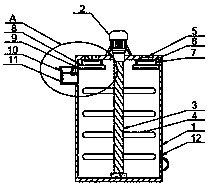

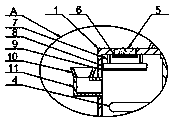

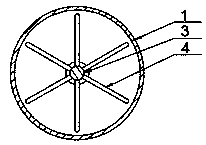

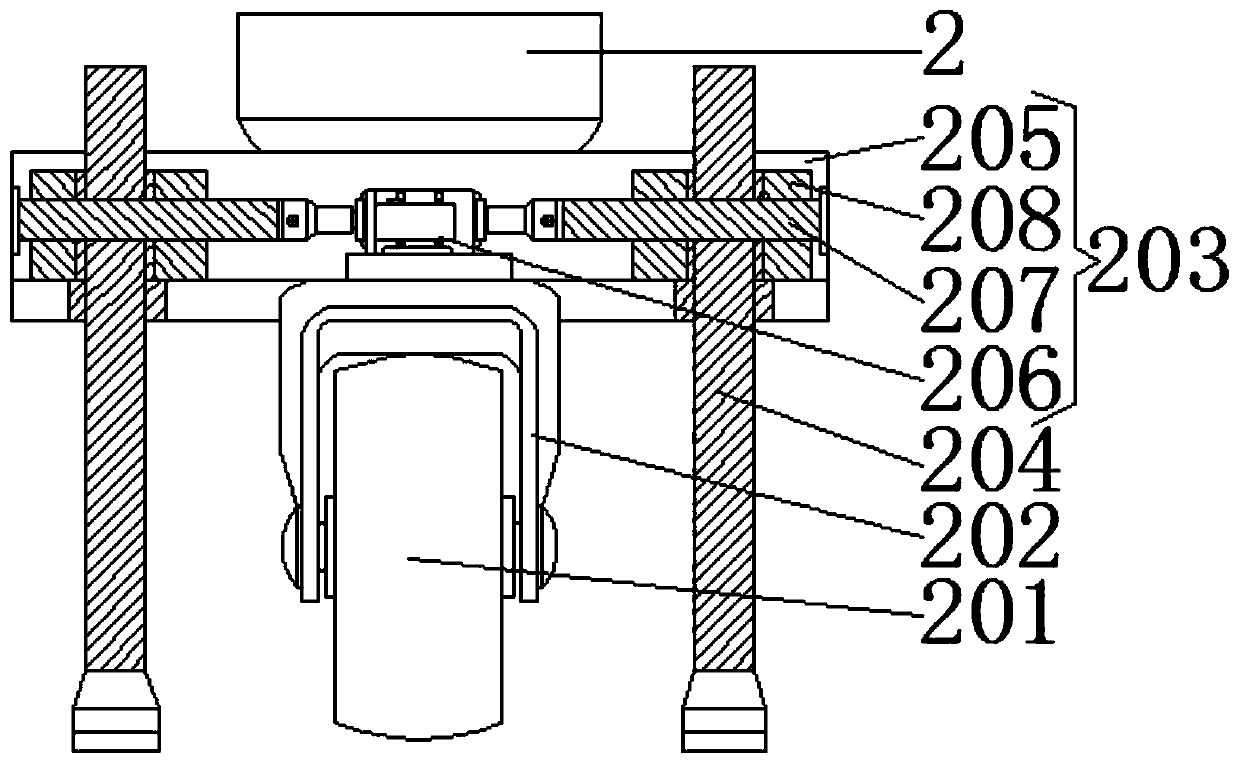

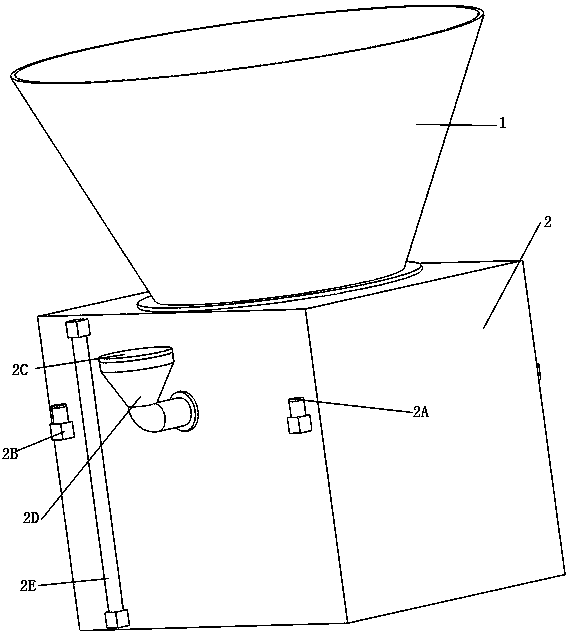

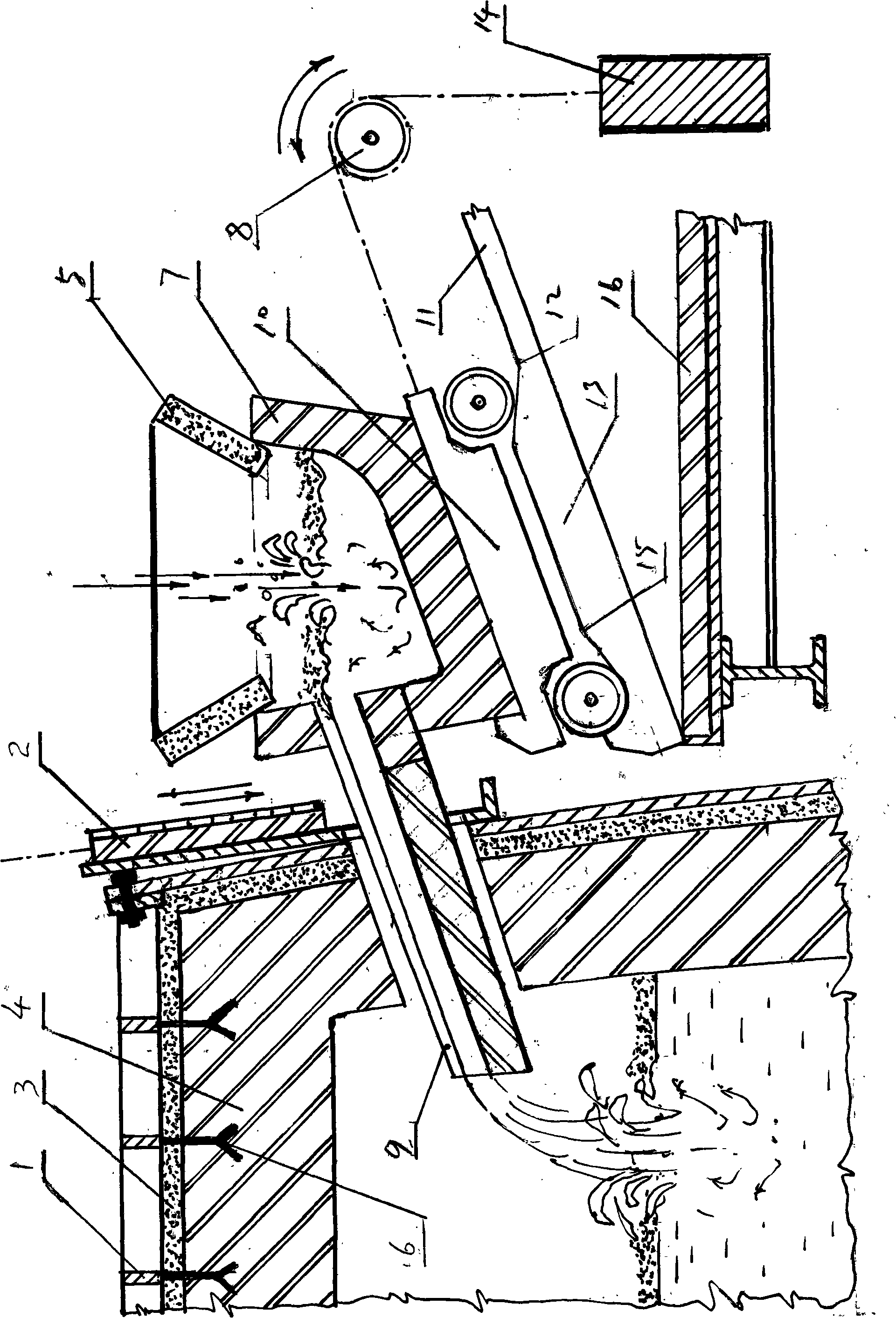

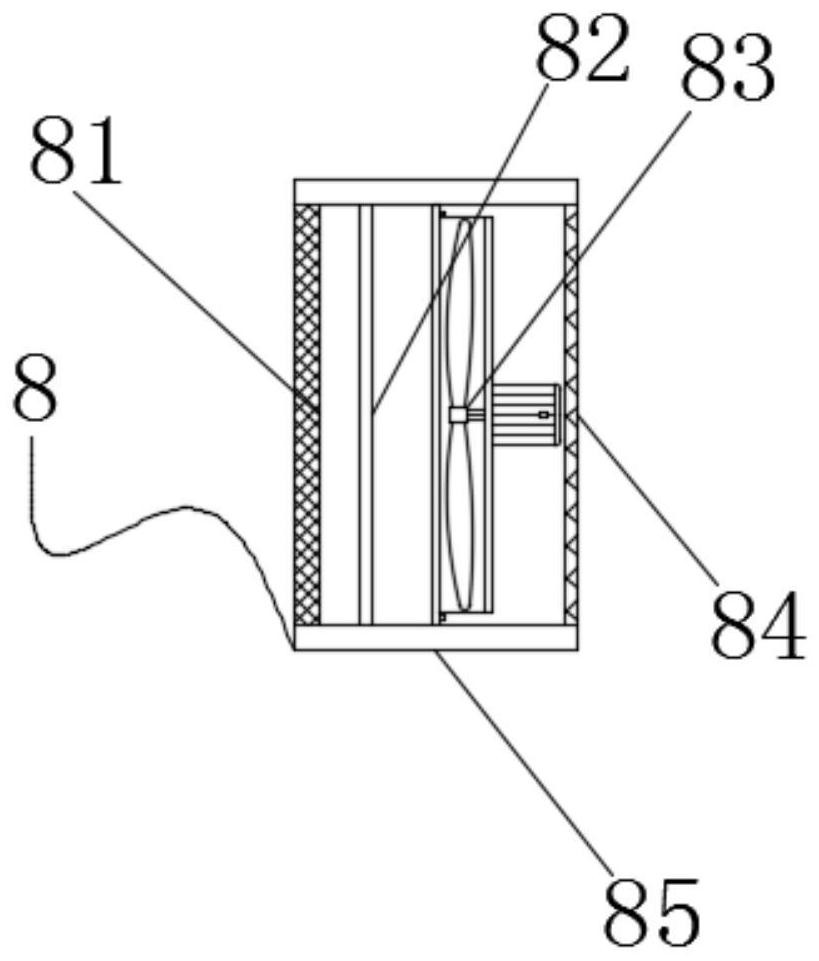

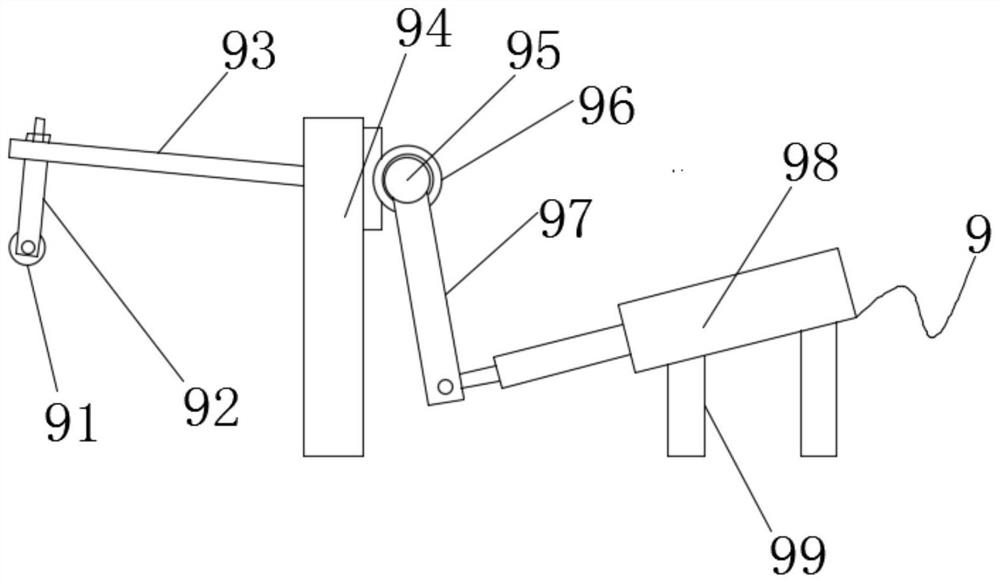

Rapid fresh and wet grain drying method and device

ActiveCN103931761ADry fastWater evaporates quicklyFood processingSeed preservation by dryingInfraredFar infrared

The invention provides rapid fresh and wet grain drying method and device. According to the rapid fresh and wet grain drying method provided by the invention, a method of combining vacuum precooling drying and far infrared heating drying is adopted so as to effectively dry fresh and wet grains with a high speed. With the adoption of the rapid fresh and wet grain drying device, the fresh and wet grains needing drying are put in a grain containing device in a cylinder grid shape, the grain containing device is internally provided with grain scraping plates which are circumferentially distributed, is arranged in a vacuum tank and is driven by a low rotational speed device to rotate so as to ensure that each grain is exposed in vacuum and irradiated by far infrared rays, and a far infrared heating device is installed in the center of the rotary grain containing device and fixed on the vacuum tank. With the adoption of the rapid fresh and wet grain drying method and device, fresh or wet grains are heated by infrared rays in a vacuum state, so that moisture in the grains can be rapidly evaporated until the grains contain safety moisture and the purpose of rapidly drying the fresh and wet grains can be fulfilled.

Owner:吴焕松

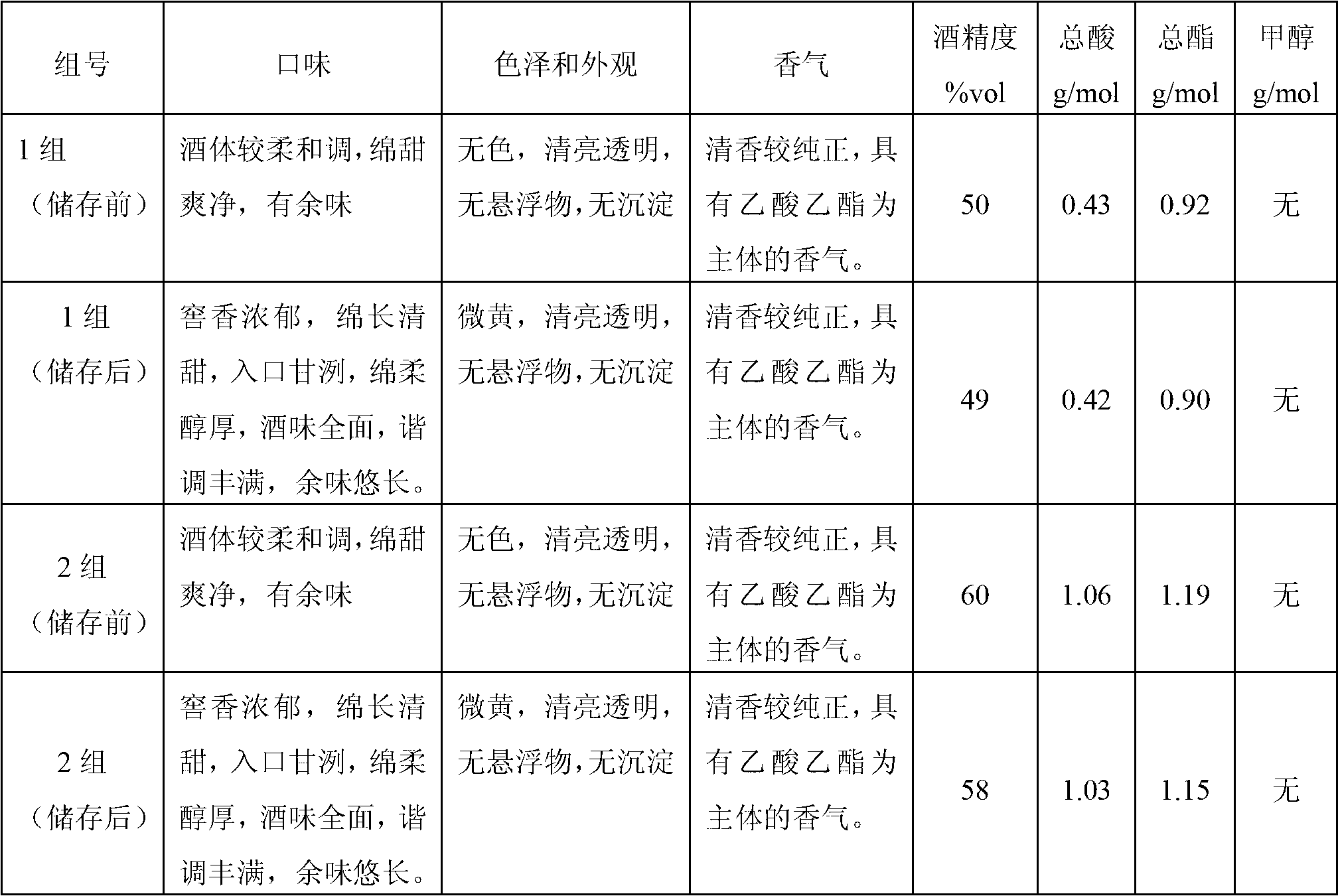

Method for planting liquor underground

InactiveCN102839109AGreat tasteAvoid precision lossAlcoholic beverage preparationAlcohol contentEvaporation

The invention belongs to the technical field of brewage, and particularly relates to a method for planting a liquor underground. The invention aims to provide a method for planting a liquor underground. The technical scheme of the invention is as follows: the method for planting a liquor underground comprises the following steps: containing a liquor in a pottery jar, sealing, and planting underground. According to the method, the pottery jar containing the liquor is planted underground, is strictly isolated from the air and is subjected to anaerobic storage, so that alcohol content loss and overfast water evaporation are avoided, thereby achieving the effect of improving the mouthfeel of the liquor.

Owner:攀枝花市攀欣醇酒厂

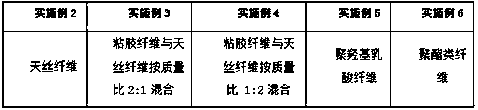

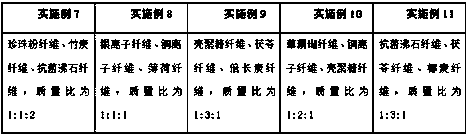

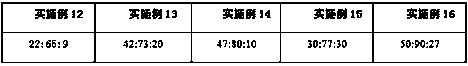

Non-woven fabric with high absorption and production technology and application thereof

ActiveCN108456995AImprove water retentionLose weightCosmetic preparationsToilet preparationsHigh absorptionMass ratio

The invention provides a non-woven fabric with high absorption and a production technology and application thereof. The non-woven fabric is prepared from alginate fiber, skeleton fiber and function fiber; the alginate fiber contains 80-90% of calcium alginate and 10-20% of sodium alginate, and the mass ratio of calcium alginate to sodium alginate in alginate fiber is 8:2-9:1; the water absorptioncapacity of the non-woven fabric is 13-48 times. The non-woven fabric is used for a mask or cotton pads. The breathability of the manufactured non-woven fabric reaches 700-804 CFM, and the fabric is high in comfort level when adopted as the mask and other beauty makeup supplies.

Owner:上海复嫘新材料科技有限公司

Preparing and painting methods of coating of metal mould casting and rising system

ActiveCN104057021AHigh viscosityEasy to sprayMoulding toolsFoundry mouldsSand blastingWorking temperature

The invention relates to preparing and painting methods of a coating of a metal mould casting and rising system. The preparing method comprises the following steps: mixing anhydrous zinc oxide, sodium silicate and anhydrous asbestos powder, after stirring to be uniform, pouring into deionized water with temperature of 65-75 DEG C, and stirring until being completely uniform while pouring. The painting method comprises the following steps: pouring a prepared coating; preheating a mould subjected to sand blasting; painting the mould casting and rising system by using the coating, with thickness of 0.3-0.5 mm; controlling the thickness of the coating of a riser to be 1-3 mm; preheating and fixing, charging the painted metal mould into an insulation furnace for being baked, preheating until the work temperature of the mould is 350-420 DEG C, and keeping for 1-2 hours. According to the coating prepared by adopting the preparing method and the painting method, the casting defects of insufficient casting, cold shut and the like in a production process of the metal mould can be effectively solved. The preparing method and the painting method play a role of well protecting the metal mould, and further ensure that the mould is stable in size and quality.

Owner:广东领创模架科技有限公司

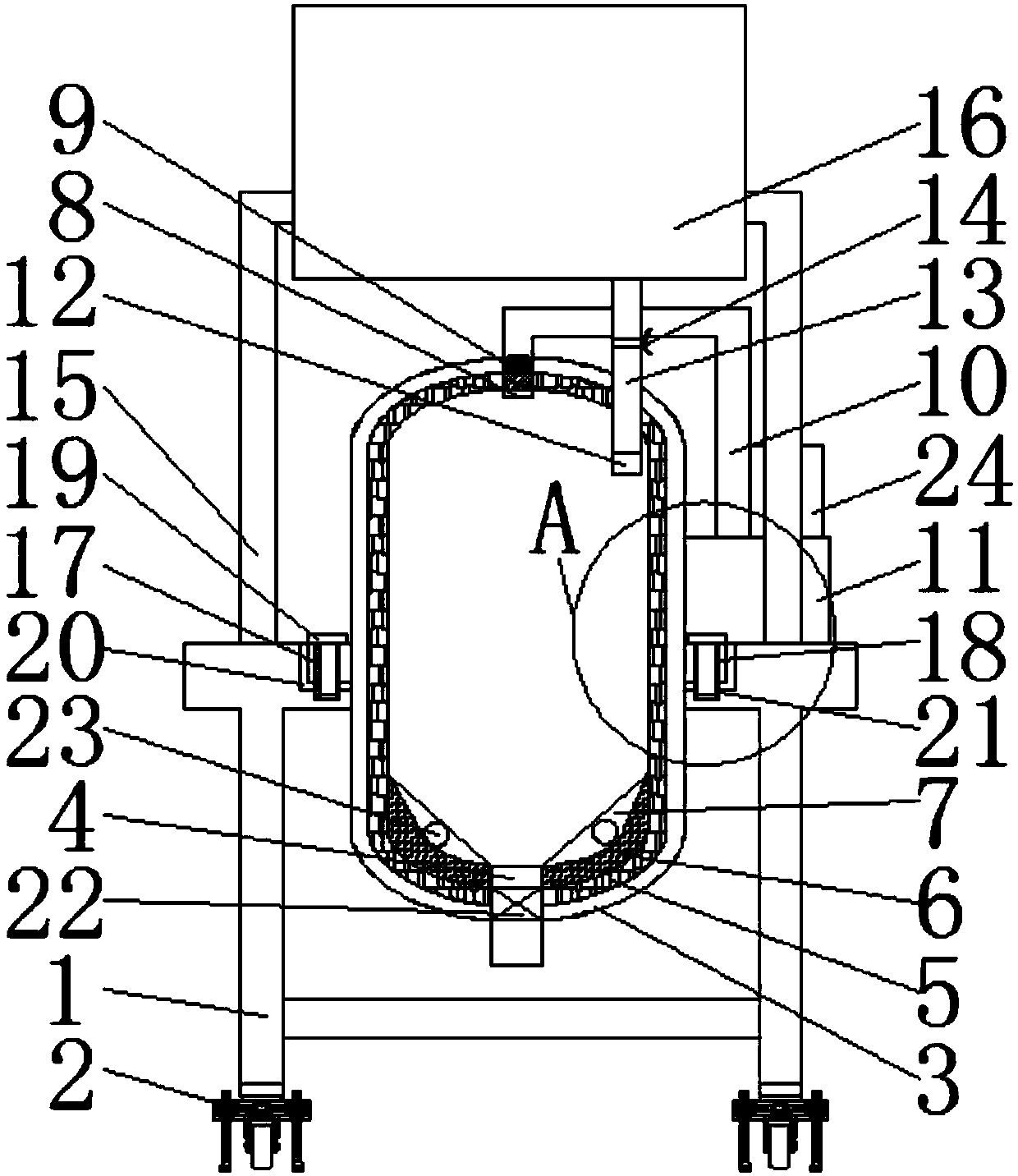

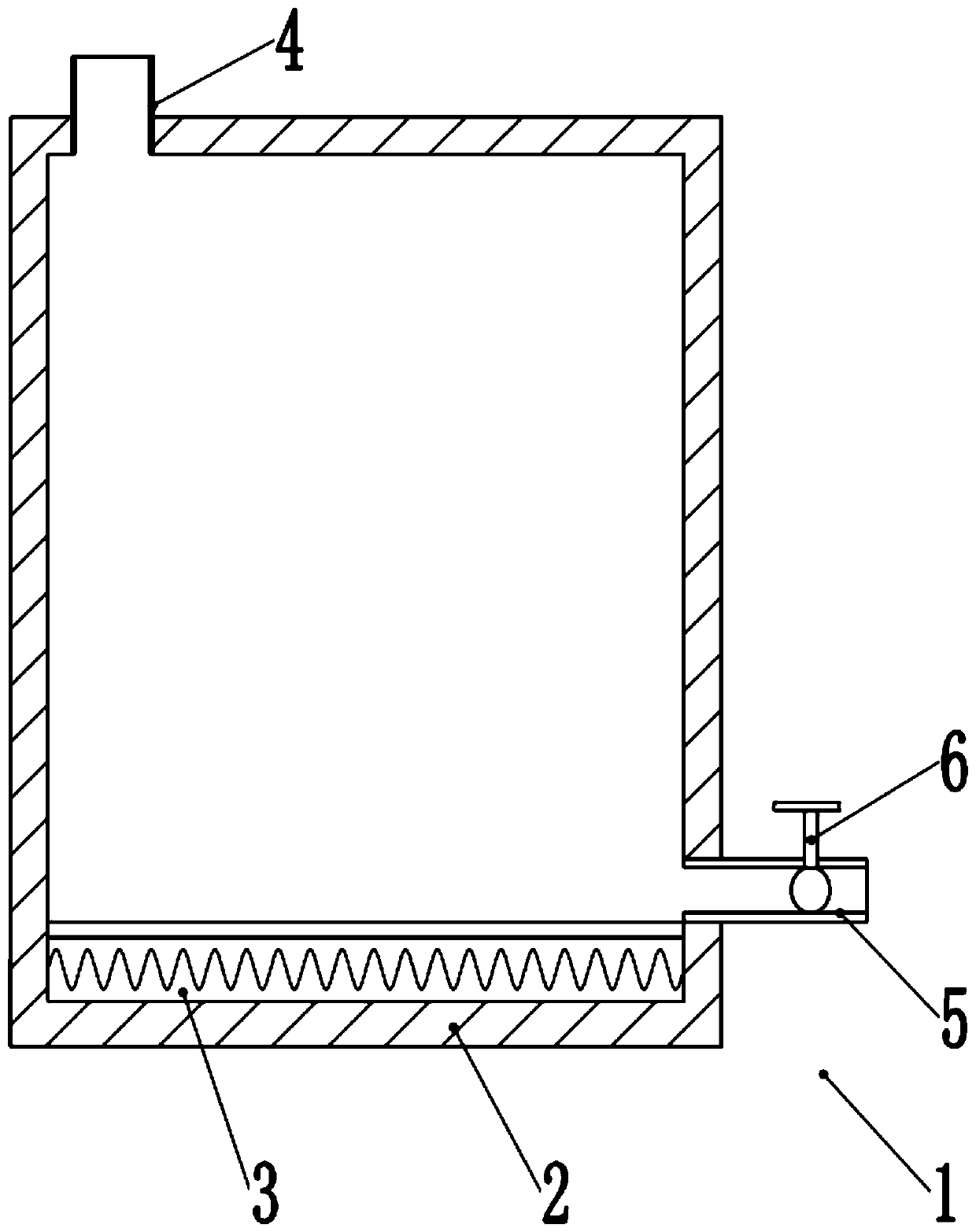

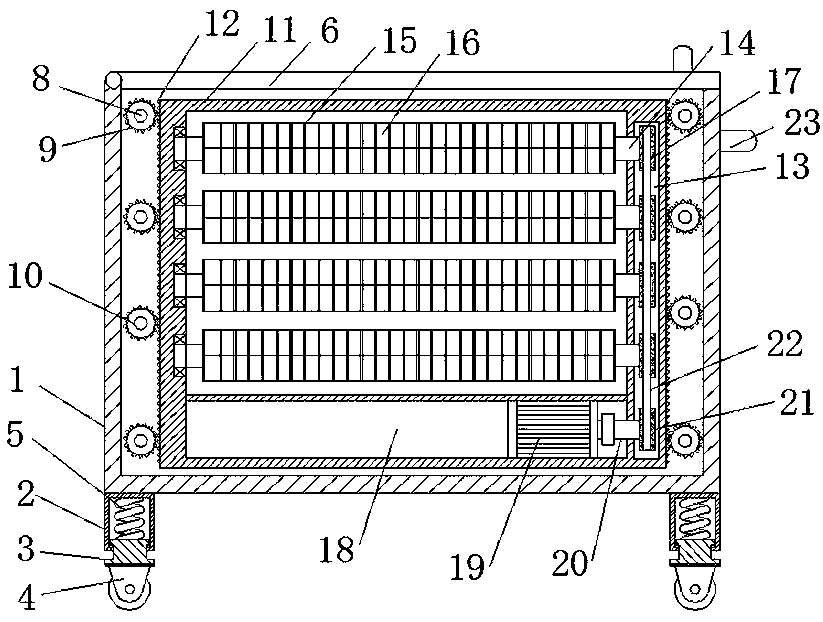

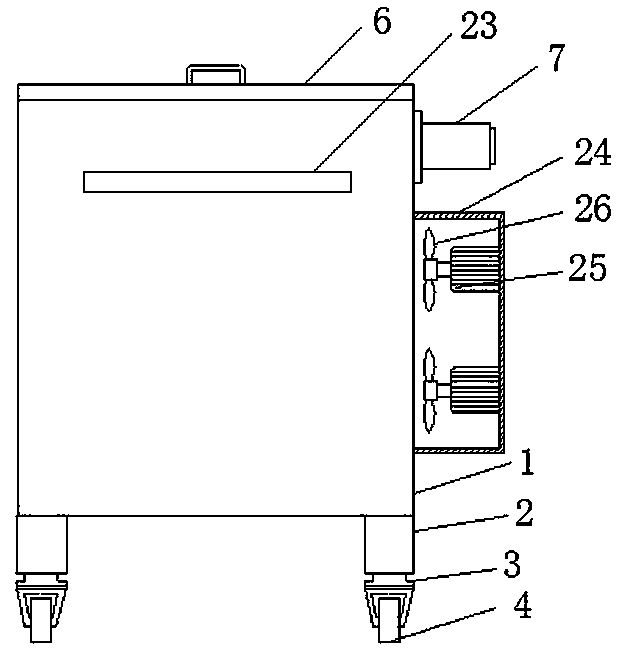

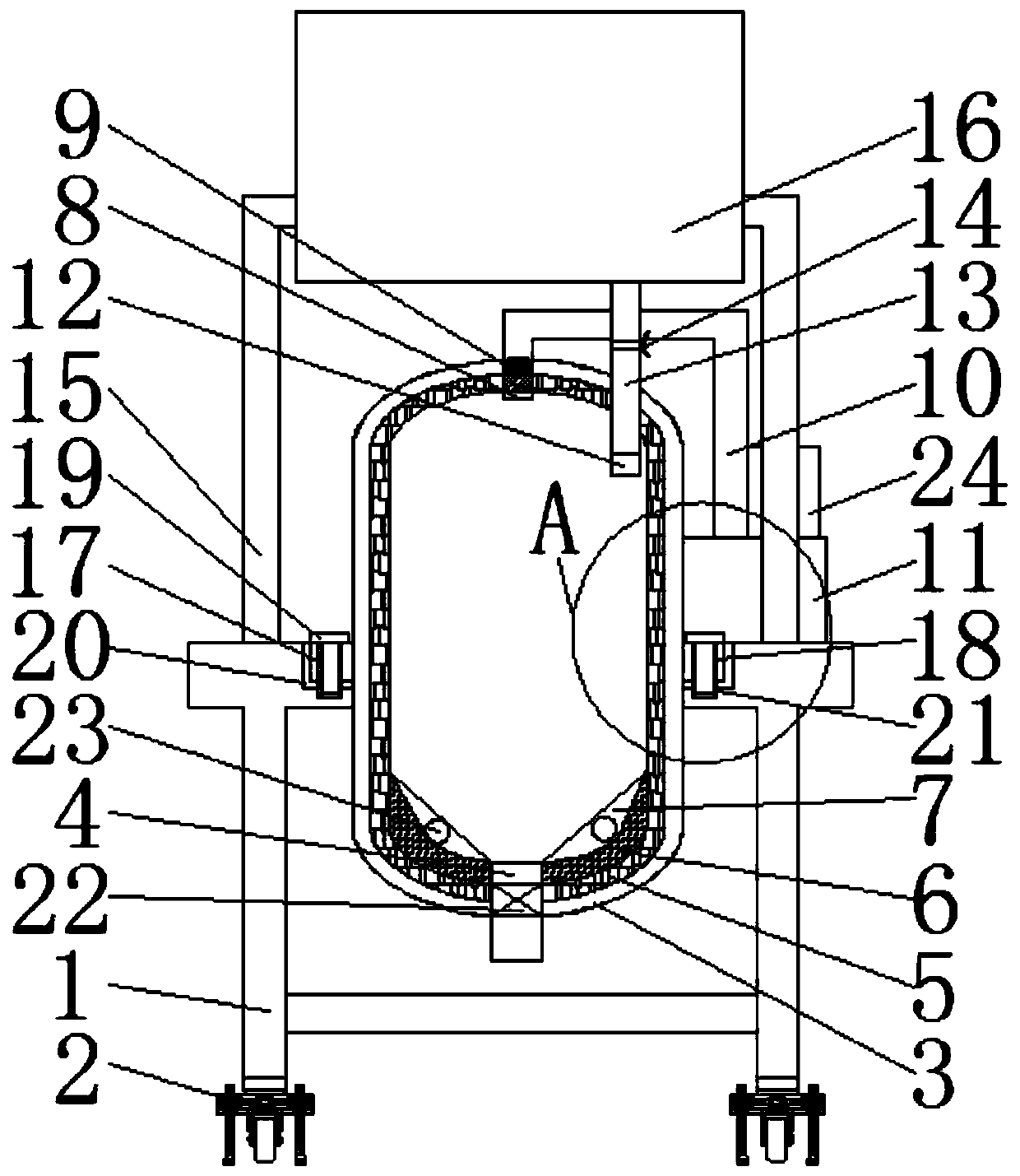

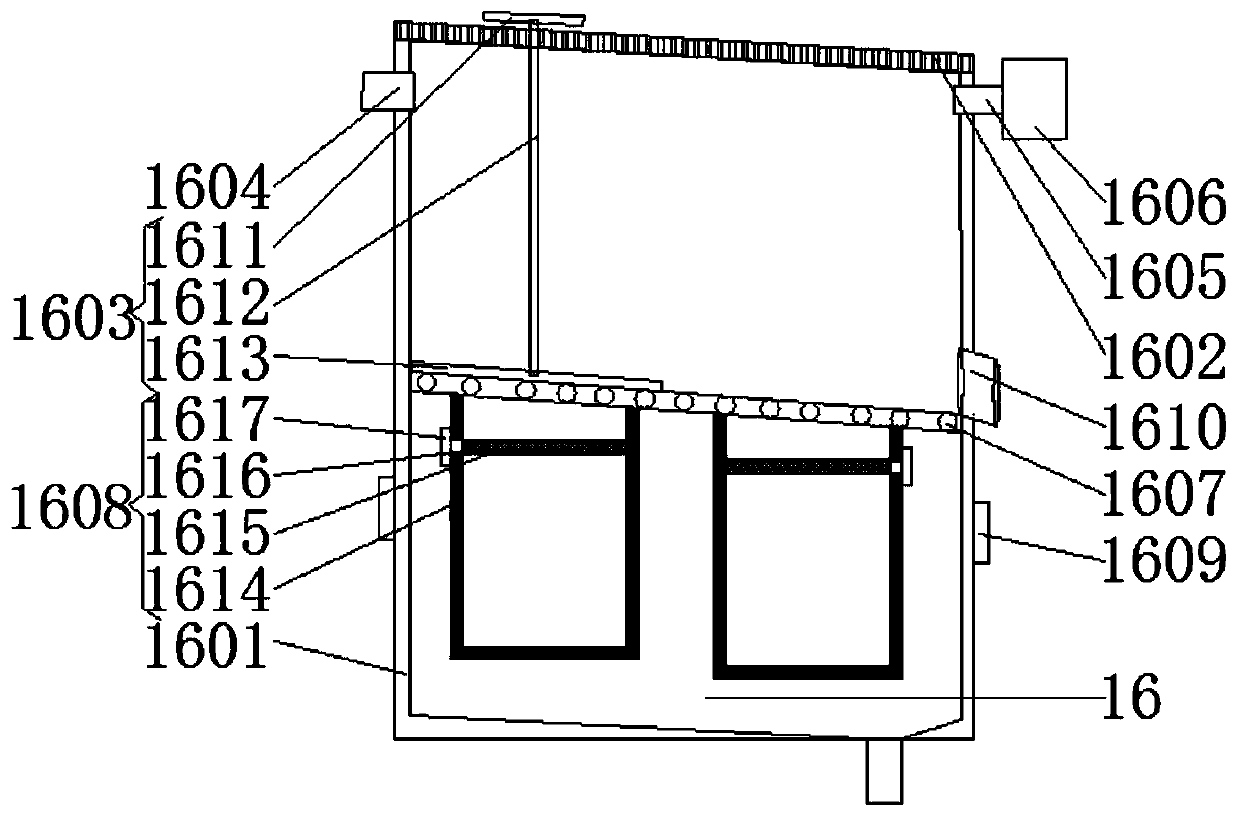

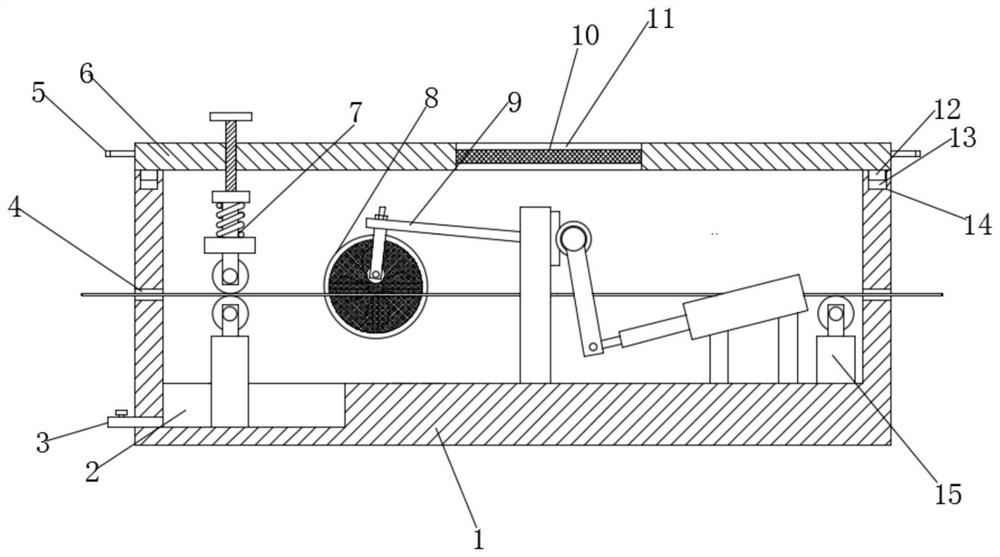

Filtering and crystallizing device for chemical product processing

ActiveCN107670322AWater evaporates quicklyRapid crystallization dryingSolution crystallizationFiltration circuitsFiltrationHeat conducting

A filtering and crystallizing device for chemical product processing comprises an underframe, wherein universal wheels are fixedly connected to symmetrical positions of the bottom of the underframe; acrystallizing barrel is fixedly connected to one side, away from the universal wheels, of the underframe; a thermal insulation layer is arranged on the inner cavity of the crystallizing barrel; heaters are fixedly connected to the bottom of the inner surface of the thermal insulation layer and are positioned on the two sides of a crystal leaking port; heat-conducting sealing layers are fixedly connected to one sides, away from the thermal insulation layer, of the heaters; a filtering device is fixedly connected to one side, away from the underframe, of a supporting frame; one side, near the crystallizing barrel, of the filtering device is communicated with a feed pipe. The invention relates to the technical field of chemical product processing. The filtering and crystallizing device for chemical product processing can quickly evaporate moisture of a chemical product to quickly crystallize and dry the chemical product and can reasonably control the temperature to prevent crystallization evaporation, so that the processing efficiency is improved; multiple filtration is performed on the chemical product, so that a filtrate is pure and the quality of a processed product is guaranteed;through integrated arrangement, the product loss is reduced.

Owner:安徽海蓝生物科技有限公司

Method for preparing briquette binder from kitchen waste and cattle manure

The invention discloses a method for preparing a briquette binder from kitchen waste and cattle manure and belongs to the technical field of preparation of briquette binders. The method comprises the following steps: adding sodium humate, bentonite and crushed maize straw into filtered leftovers, mixing and stirring, adding vinasse, fermenting and then centrifuging, spray drying supernatant, then mixing the supernatant with precipitate for later use, taking the cattle manure and peanut shell, drying and crushing the cattle manure and the peanut shell, then mixing the dried and crushed cattle manure and peanut shell with filtered biogas liquid, then carrying out composting treatment, uniformly mixing the compost with the mixture for later use and polymethyl acrylate, and drying to obtain the briquette binder. According to the method for preparing the briquette binder from the kitchen waste and the cattle manure, the kitchen waste and the cattle manure are used as raw materials of the briquette binder; the raw materials are easily available and environmental-friendly; when the prepared briquette binder is used for preparing pyrolysis briquette, the briquette is high in cold intensity and heat intensity; the tar yield during pyrolysis of the briquette can also be obviously increased; the prepared briquette binder is high in heat intensity and heat stability and excellent in water resistance and humidity resistance; the admixing amount and the ash content of the briquette in the using process are reduced; the briquette binder has a broad application prospect.

Owner:袁春华

Device and process for recovering residual honey in honey barrel

InactiveCN110606461AAvoid damageSpeed up meltingDischarging meansBottle emptyingDrive motorEngineering

The invention relates to the technical field of honey, and particularly relates to a device and process for recovering residual honey in a honey barrel. The device comprises a heater, a pressurizing pump, a stirring scraping device, a water pump, a filtering device and an evaporator, wherein the interior of the stirring scraping device comprises a hollow disc, the top of the hollow disc is provided with a driving motor through a bolt, an output shaft of the driving motor is connected with a rotating shaft, the two sides of the rotating shaft are provided with rotating rods, one ends, away fromthe rotating shaft, of the rotating rods are provided with scraping plates, one sides of the scraping plates are provided with rubber plates, and the hollow disc is provided with a second water inletpipe. The device and process have the beneficial effects that the honey attached to the honey barrel can be scraped, the honey on the inner wall of the honey barrel is scraped clean, the inner wall of the honey barrel is prevented from being damaged, the honey attached to the inner wall of the honey barrel is accelerated to be melted, the stirring scraping device can conveniently scrape the residual honey in the honey barrel, impurities in the honey can be removed, and the quality of honey recovery is improved.

Owner:安徽泓顺源生物科技有限公司

Preparation method for zinc citrate

InactiveCN105218357AHigh purityKeep dryCarboxylic acid salt preparationSpontaneous combustionSulfate

The invention relates to a preparation method for zinc citrate. The preparation method comprises the following steps: (1) a salt forming reaction step: adding citric acid, zinc oxide, an initiator and water in a molar ratio of 1 to 15 to (0.5-0.6) to (0.02-0.05) into a reaction kettle to obtain a mixture, heating the mixture to 70-80 DEG C while stirring, reacting the mixture for 5-7 hours for releasing carbon dioxide, thereby obtaining zinc citrate; and (2) a drying step: centrifugally separating the zinc citrate obtained in the step (1) to obtain granular zinc citrate, putting the granular zinc citrate into a drying sieve to dry in a drying oven, and sieving the granular zinc citrate after drying the granular zinc citrate, thereby obtaining a finished product zinc citrate. According to the preparation method, citric acid is used to replace sodium citrate and zinc oxide is used to replace zinc sulfate; the obtained product is zinc citrate which is single, high in purity, granular and easy to dry after being separated, so that spontaneous combustion risks are relieved; and the obtained product does not need to crush, so that much dust is avoided.

Owner:TIANJIN CHEM REAGENT RES INST

Baking oven and baking method

InactiveCN109362816AGuaranteed dry moldingSpeed up circulationOven air-treatment devicesFood processingProcess engineeringRefrigerant

The invention discloses a baking oven. The baking oven includes a baking oven housing and a heat pump device; a drying chamber is arranged in the baking oven housing; a plurality of heaters are installed in the drying chamber, and a plurality of exhaust fans are installed on the baking oven housing; the heat pump device includes a heat pump housing and a compressor, an evaporator, a condenser, anexpansion valve and a heat pump main fan separately arranged in the heat pump housing; the compressor, the evaporator, the condenser and the expansion valve are successively connected to form a refrigerant cycle processing return circuit; the heat pump housing is also provided with an air duct, an air inlet of the air duct is connected to an air outlet of the drying chamber, and an air outlet of the air duct is connected to an air inlet of the drying chamber; and the condenser is located in the air duct, and the heat pump main fan is located at the air inlet of the air duct. The invention alsodiscloses a baking method. The baking oven has the characteristics of fast heating speed, rapid circulation of internal air, high drying efficiency and adjustable humidity, and can ensure that the dried meat threads / slices in the baking oven are dried and shaped under the condition of the same temperature and humidity.

Owner:广东真美食品股份有限公司

Quick cloth color fixation device

ActiveCN109554869AReduce moisture contentAvoid the problem of color difference between front and backLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsConveyor beltTurbine

The invention relates to the field of cloth processing, in particular to a quick cloth color fixation device which comprises a machine. A feed tank and a conveyor belt are arranged on the machine, a first motor and second rollers are arranged on the feed tank, and a first roller is connected with an output shaft of the first motor; a gas outlet plate is fixedly connected into the machine, gas delivery holes are densely formed in the gas outlet plate, the inside of the machine is divided into a turnover chamber and a steam chamber by the gas outlet plate, a second motor is arranged in the turnover chamber, first turning plates and second turning plates are rotationally connected into the turnover chamber and are connected with turntables and rotary rods, first connecting rods and second connecting rods are connected onto the rotary rods and are fixedly connected with a rack, worms are connected with an output shaft of the second motor and mesh with turbines, and gears are connected withthe turbines; a steam machine is arranged in the steam chamber. According to the technical scheme, the quick cloth color fixation device has the advantage that the problems of incomprehensive cloth steaming effects and color difference between the front and back surfaces of cloth in the prior art can be solved by the aid of the quick cloth color fixation device.

Owner:象山平悦环保科技有限公司

Knitted fabric instant drying water absorption ventilating color separating platemaking printing technology

ActiveCN106592275AWith multiple clothing functionsImprove breathabilityDyeing processOther printing apparatusScreen printingEngineering

The invention discloses a knitted fabric instant drying water absorption ventilating color separating platemaking printing technology. The printing technology comprises the steps of pattern designing, color separating, rotary screen platemaking, rotary screen printing, baking, molding and tidying, finished product test and examination and warehousing. According to the knitted fabric instant drying water absorption ventilating color separating platemaking printing technology, the instant drying water absorption ventilating knitted fabric can quickly lead sweats on the skin to the outside of the clothes and presents the sweats in flower-shape patterns, the flower-shape patterns formed during movement of the sweats have a dynamic sense, the knitted fabric has no patterns and present a pure color when there are no sweats, and the dynamic flower-shape patterns slowly disappear after the sweats gradually evaporate. The color separating platemaking printing technology can provide a shell fabric with multiple functions, and bring new prospects for the development of the shell fabric.

Owner:ENPING KAM HING TEXTILE & DYEING

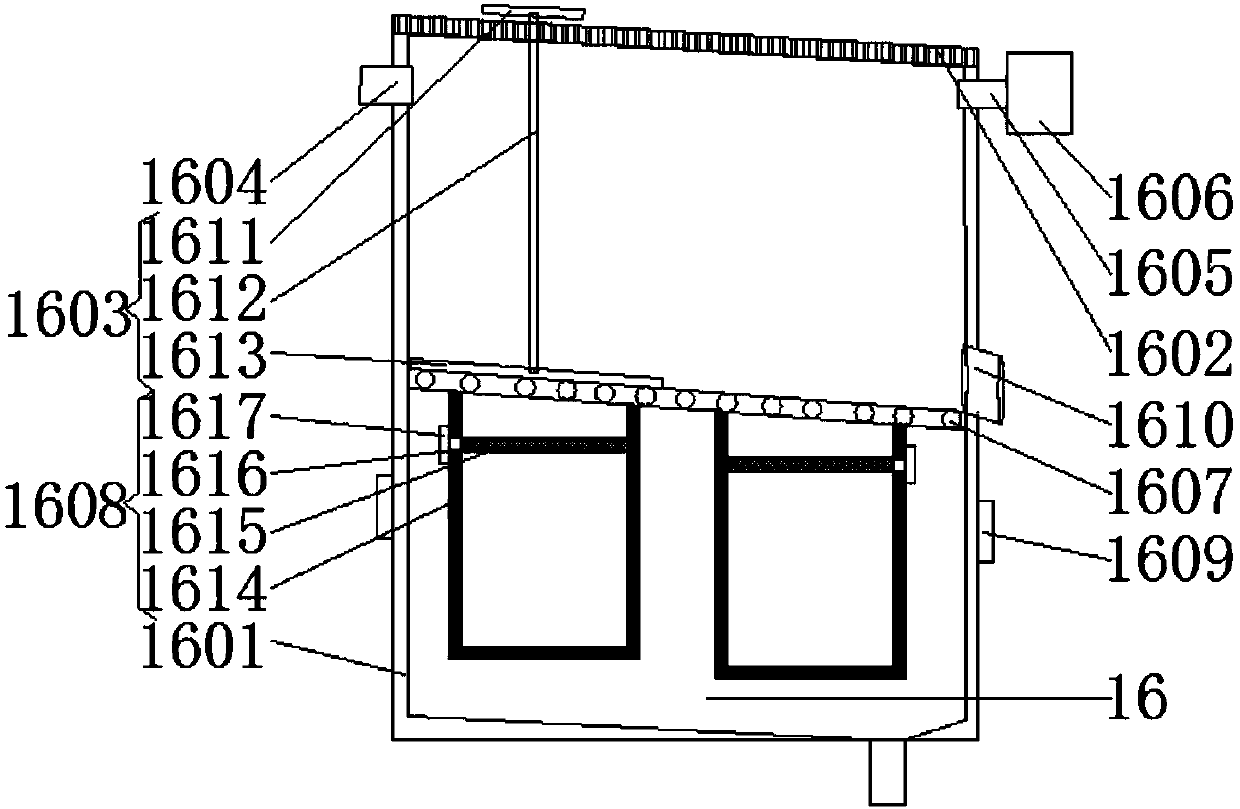

Holding rack for holding mobile phone display screen

InactiveCN110269405AAchieve circumferential swingEasy accessVariable dimension cabinetsFeetSmall amplitudeMotor drive

The invention discloses a holding rack for holding mobile phone display screens. The holding rack comprises a cabinet body, a telescopic block, holding plates and a holding rack, gear racks are arranged at the left end and the right end of the holding rack, and the holding rack is meshed and connected with a driven gear and a driving gear through the gear racks. The holding rack is reasonable in structural design and high in practicality, during working, dust can be effectively prevented under the effect of a sealing cover, and the yield is increased. A belt driving wheel drives a belt driven wheel to rotate so as to drive transmission shafts to rotate, so small-amplitude circumferential swinging of the holding plates is realized. Meanwhile, third motors and fan blades can quickly evaporate water on display screens, the production efficiency is greatly improved, a first motor drives the driving gear to rotate through rotating shafts, lifting of the holding plates is achieved through the gear racks, the display screens can be conveniently taken and placed, time is shortened, the display screens can be prevented from being damaged due to collision of the device through telescopic blocks and springs, and moving is convenient and fast under the effect of a pushing handle and moving wheels.

Owner:湖北省欧盛科技有限公司

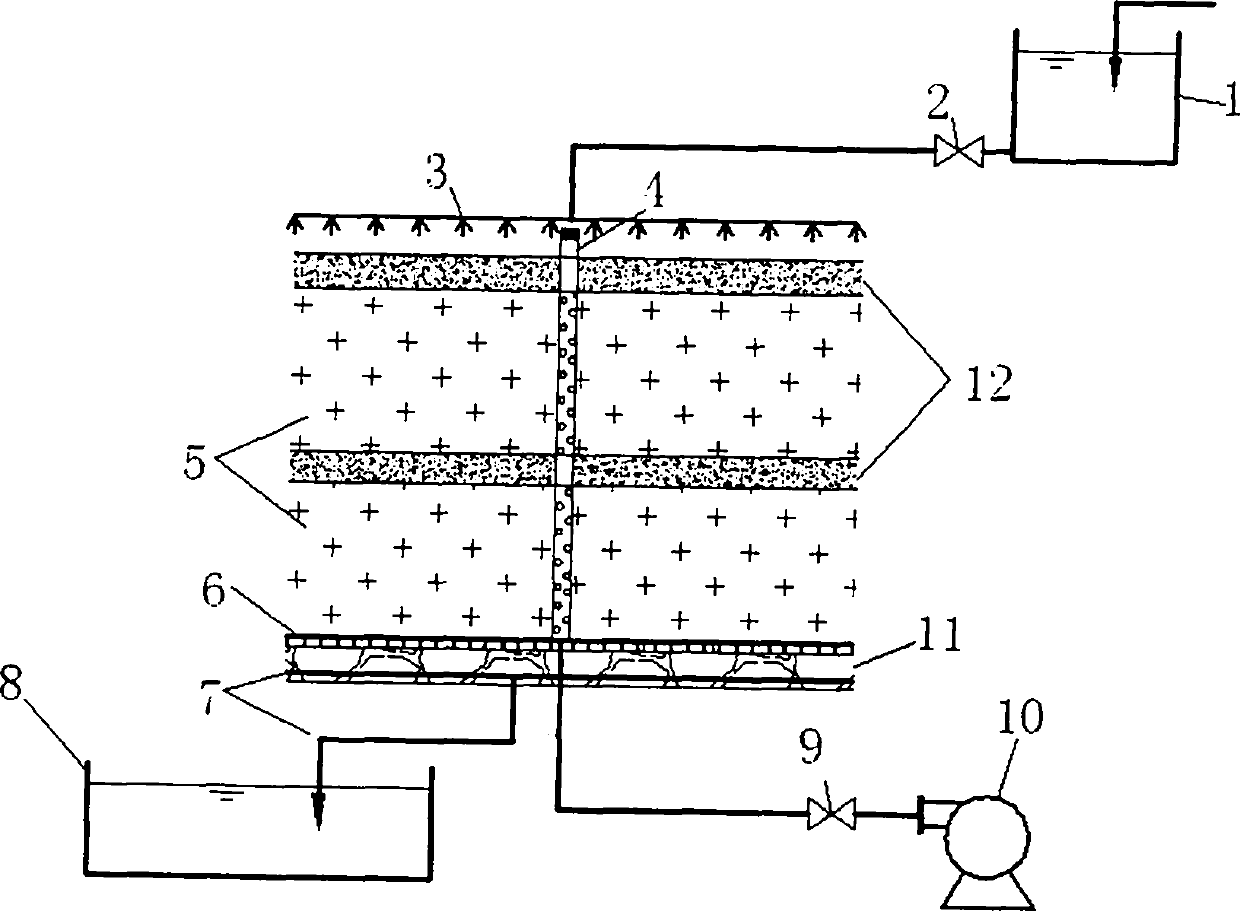

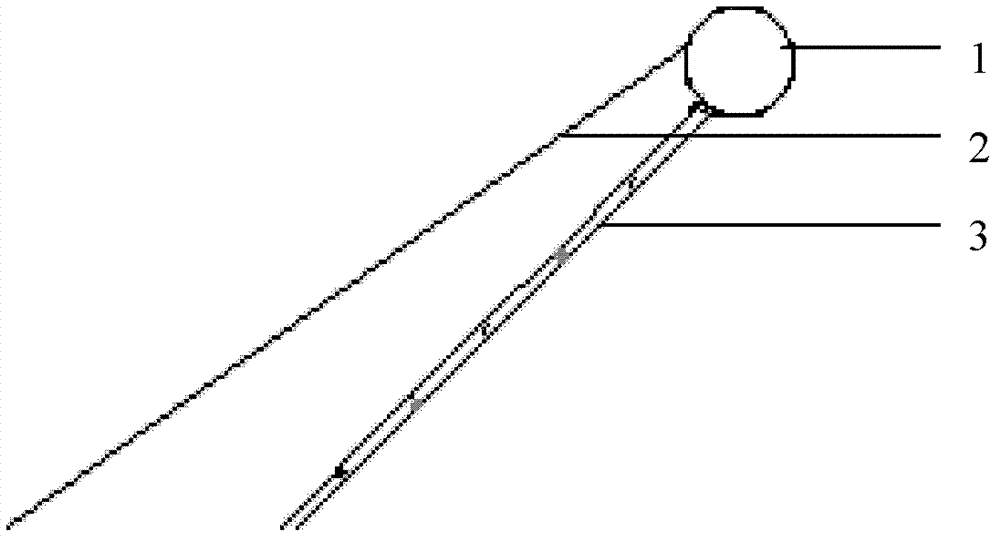

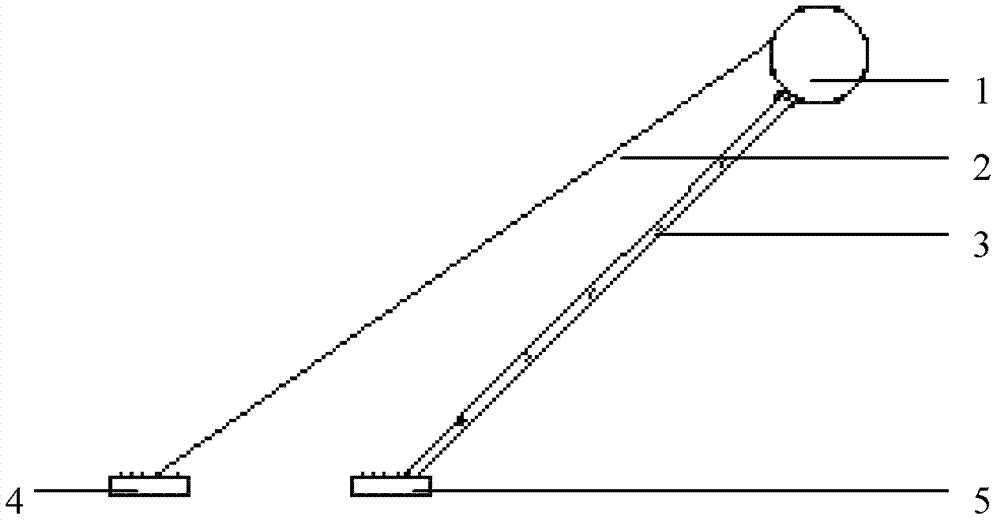

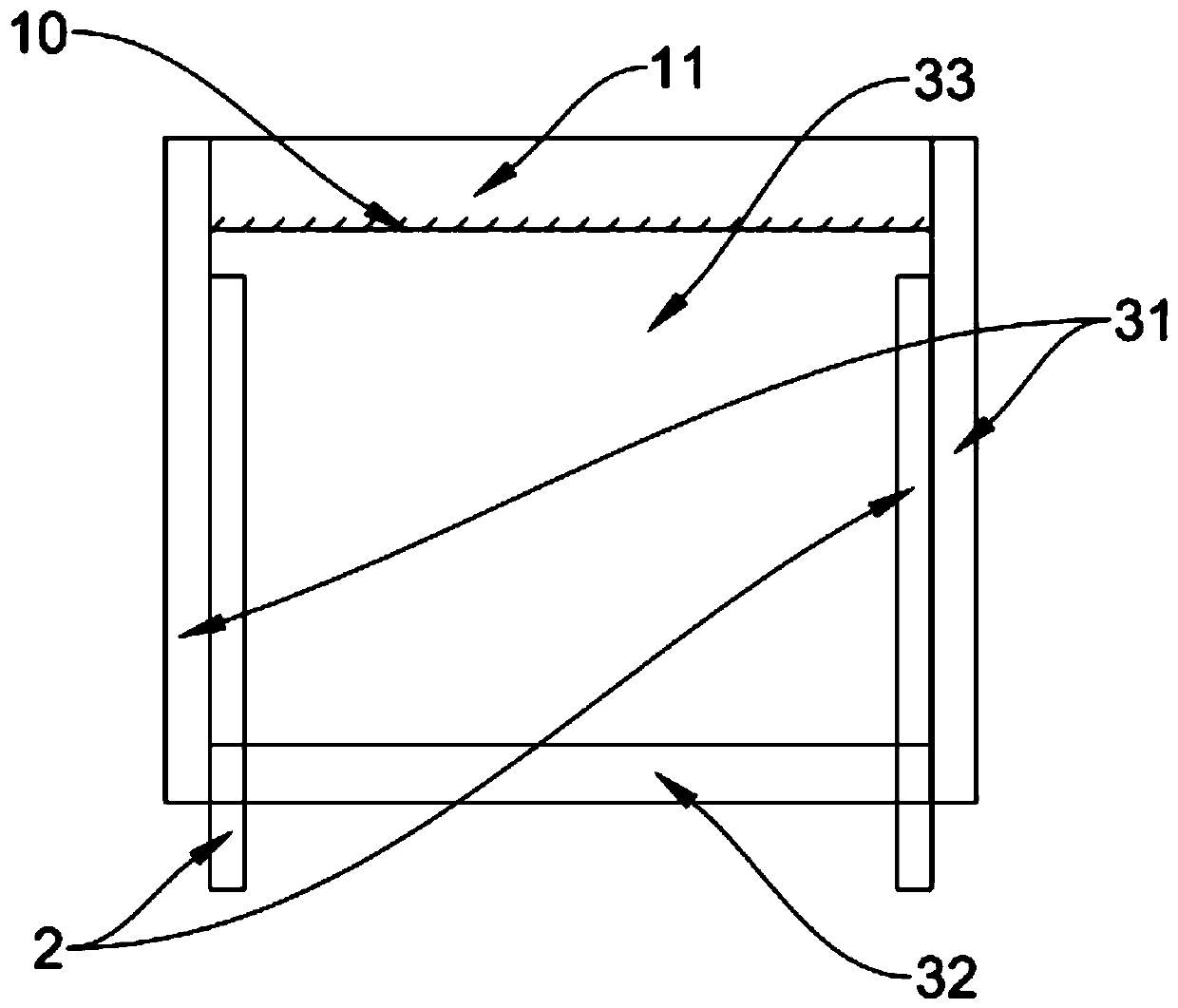

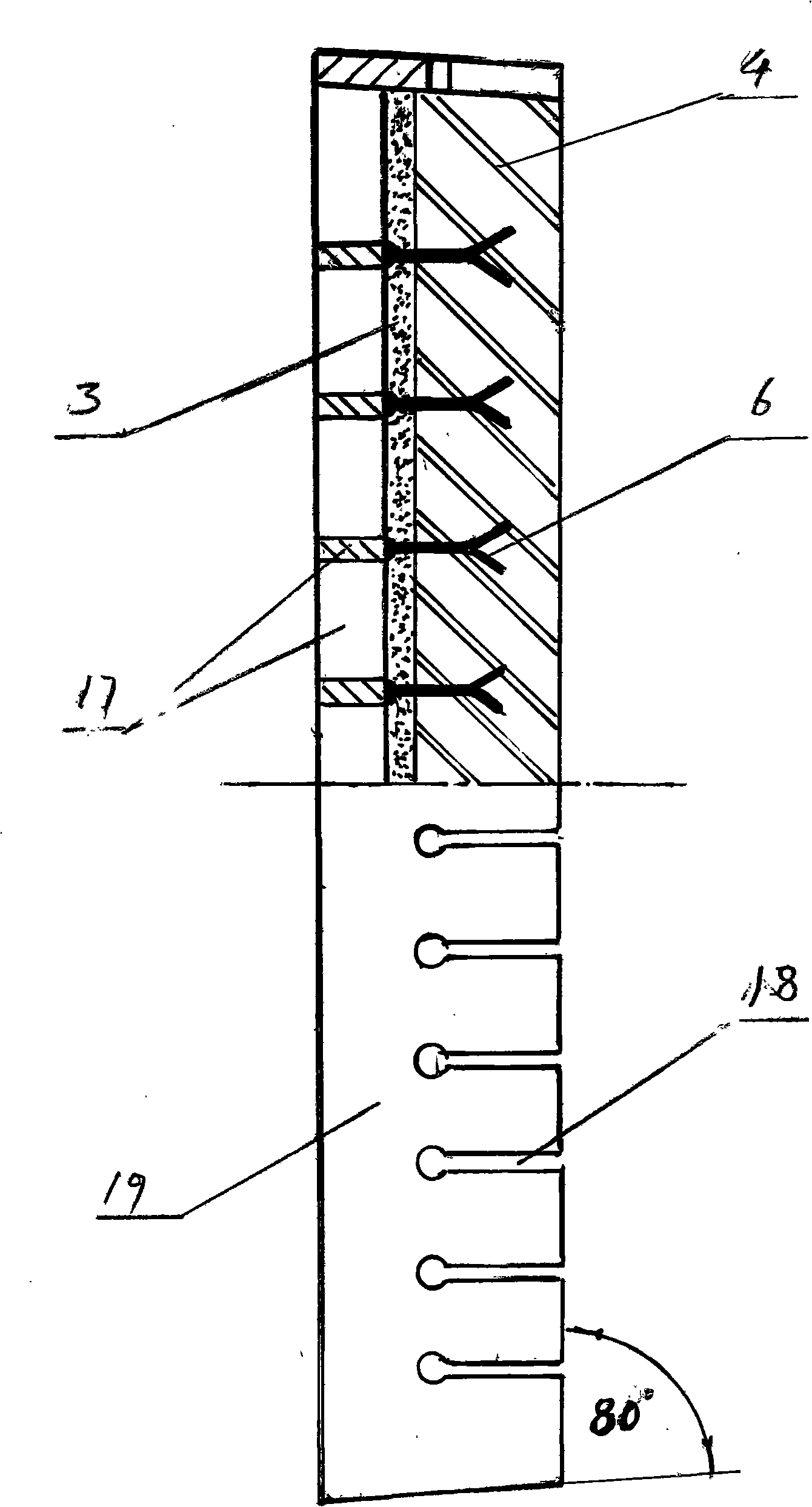

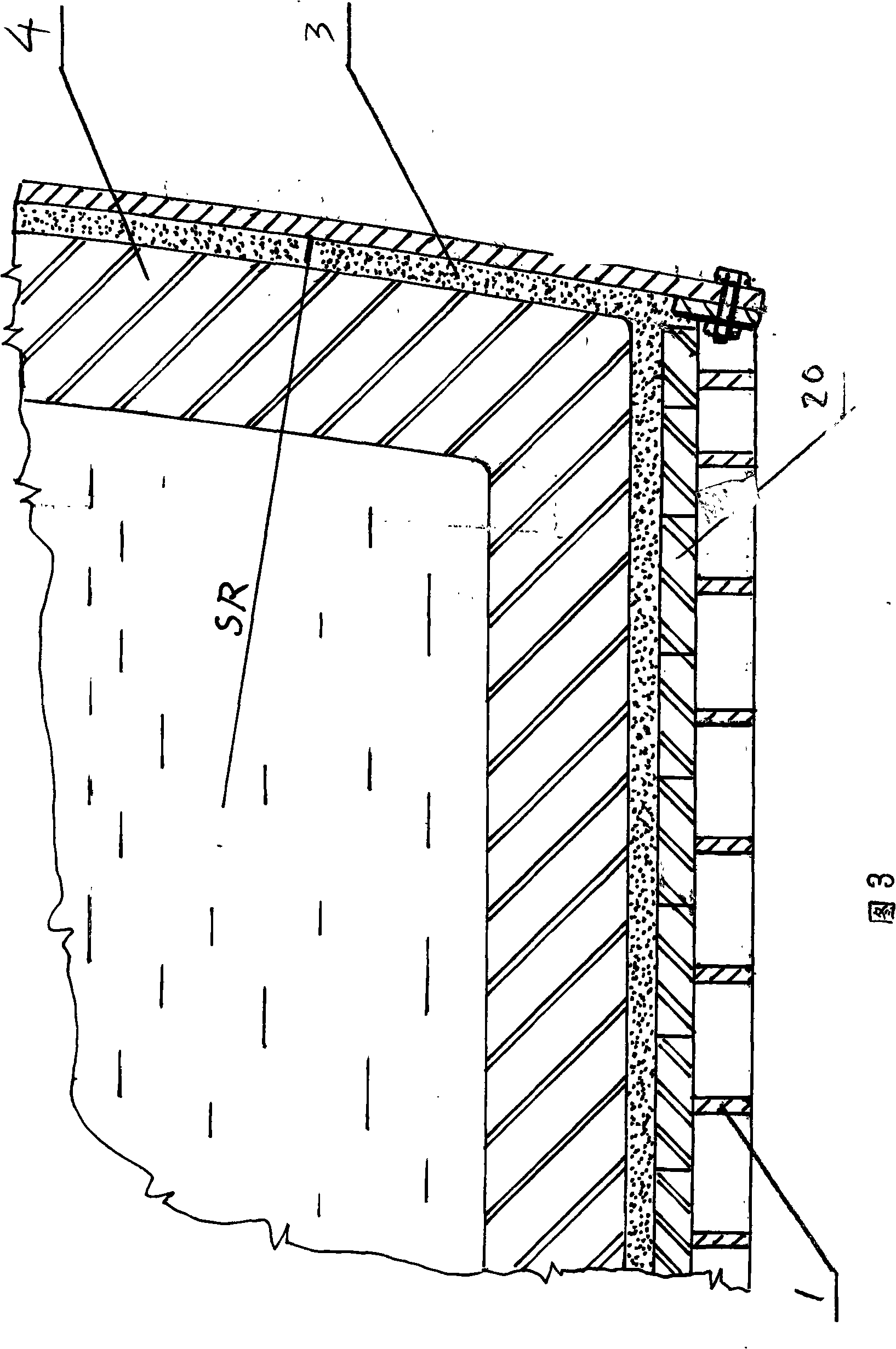

Manufacturing method for seawater desalination or sewage purification apparatus

ActiveCN102897860AImprove purification efficiencySimple manufacturing methodGeneral water supply conservationSeawater treatmentAdhesiveTransmittance

The invention relates to a manufacturing method for a seawater desalination or sewage purification apparatus. The method comprises that: (1) silica sand and a first adhesive are uniformly mixed at a temperature of 100-200 DEG C, and the obtained mixture contacts a curing agent and a black silica sand coloring agent to form a black adhesive layer on the surface of the silica sand; (2) a second adhesive and the silica sand prepared from the step (1) are uniformly mixed and subjected to curing molding to obtain a second plate-like member; (3) a first plate-like member is obliquely arranged above the second plate-like member, wherein one end of the first plate-like member is higher than the other end, and the material of the first plate-like member is a light transmittance material; and (4) a plurality of openings are arranged on a pipeline, wherein partial or all seawater or sewage inside the pipeline can flow onto the second plate-like member through the pipeline position and the opening direction. The manufacturing method has the following characteristics that: the method is simple and easy to perform; production operating cost is saved; sand with characteristics of low cost and wide source is successfully applied in seawater desalination or sewage purification; and the method can be widely applied in the field of water resource treatment.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Vacuum microwave processing method for instant Chinese yam chips

InactiveCN109892583AReduce lossesFast processingFruits/vegetable preservation by dehydrationFlavorHeating time

The invention discloses a vacuum microwave processing method for instant Chinese yam chips, and belongs to the technical field of food processing. Chinese yam chips are given special flavor through soaking and seasoning, and then rapid processing of the low-temperature and non-fried instant Chinese yam chips is achieved by utilizing the characteristics of low puffing temperature, short heating time, fast water evaporation and less loss of nutrients of products of vacuum microwave drying technology. By means of the method, nutrient loss of Chinese yam can be effectively reduced, and the methodhas the advantages that production efficiency is high, the cost is low, nutrition is rich and taste is good. The vacuum microwave processing method includes the step that seasoned Chinese yam chips are subjected to two-stage microwave drying under the vacuum degree of -0.09 Mpa.

Owner:HEZHOU UNIV

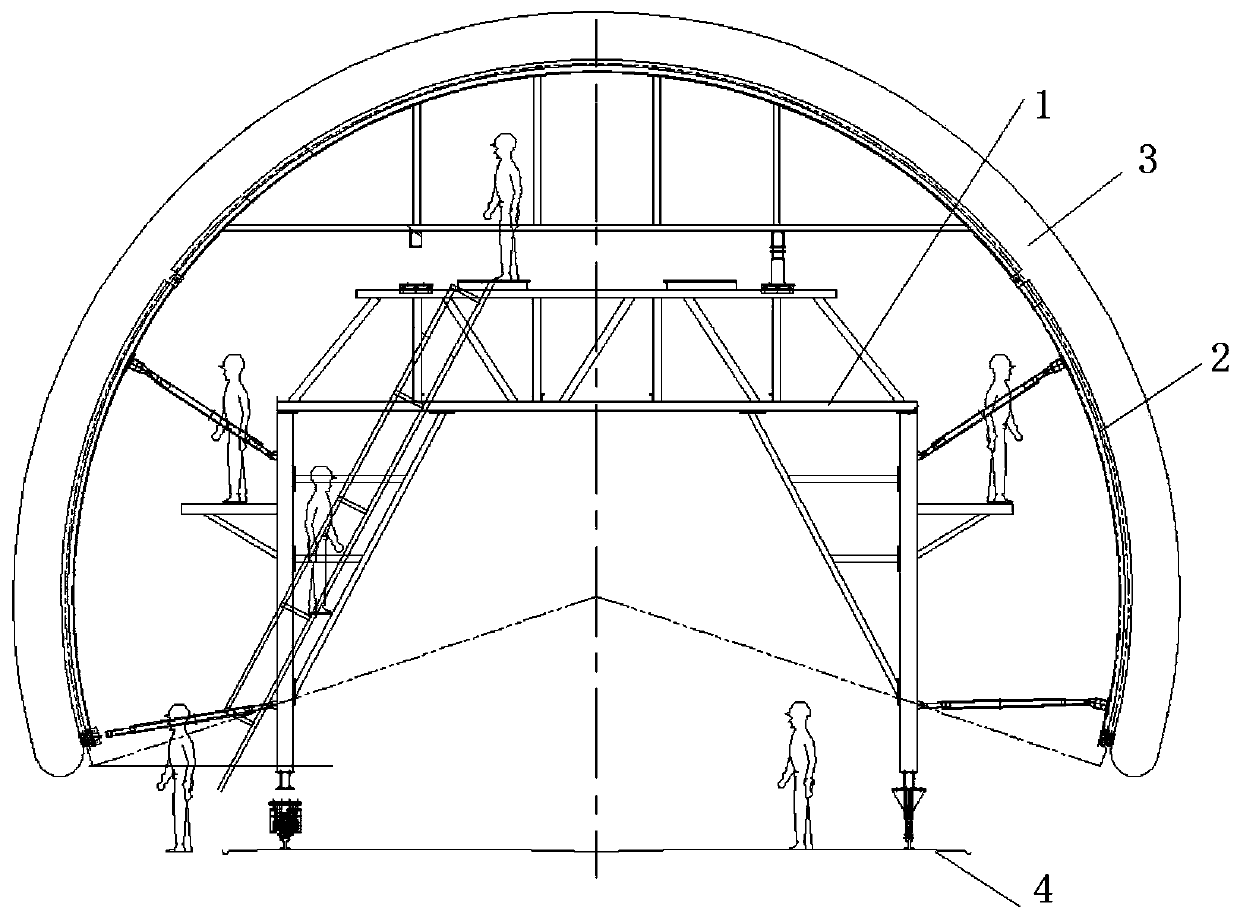

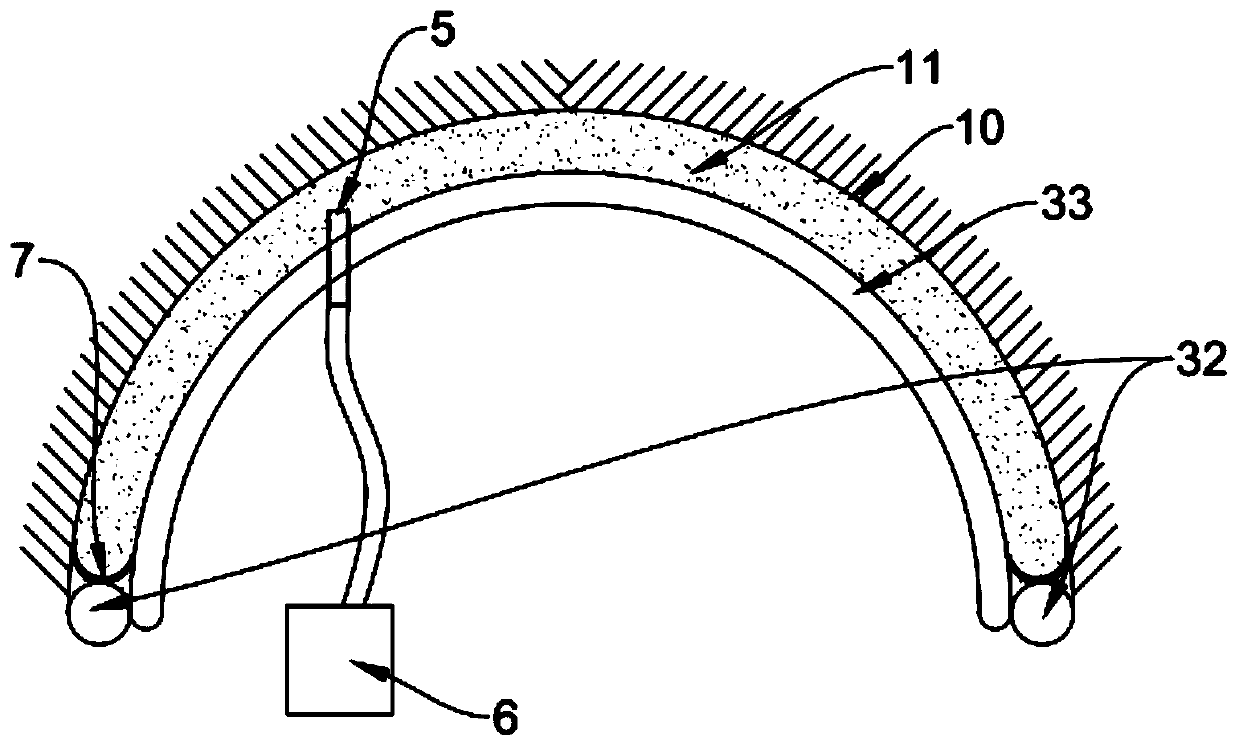

Efficient constant-temperature and constant-humidity tunnel automatic maintenance equipment

InactiveCN111365023AAchieve conservationSave waterUnderground chambersTunnel liningThermodynamicsWater resources

The invention discloses efficient constant-temperature and constant-humidity tunnel automatic maintenance equipment. The equipment comprises at least two maintenance trolleys arranged at an interval,each maintenance trolley is provided with a support matched with the shape of the arch face of a tunnel, a sealing air bag is fixed between every two adjacent supports, after the sealing air bags areinflated, a sealed space is formed between the sealing air bags and the inverted arch surface of the tunnel, the sealing space is connected with a steam generator, and the steam generator injects steam into the sealing space to maintain the inverted arch surface of the tunnel. According to the efficient constant-temperature and constant-humidity tunnel automatic maintenance equipment, the sealingspace is formed between the inflated air bags and the inverted arch face of the tunnel, steam is inflated into the sealing space, steam is used for maintenance, the problem that in the prior art, water resources are wasted is solved, and the problem that in the prior art, the requirements for water pressure, water amount, tunnel height, tunnel depth and the like are limited is solved.

Owner:ANHUI HUAHUA BRIDGE EQUIP CO LTD

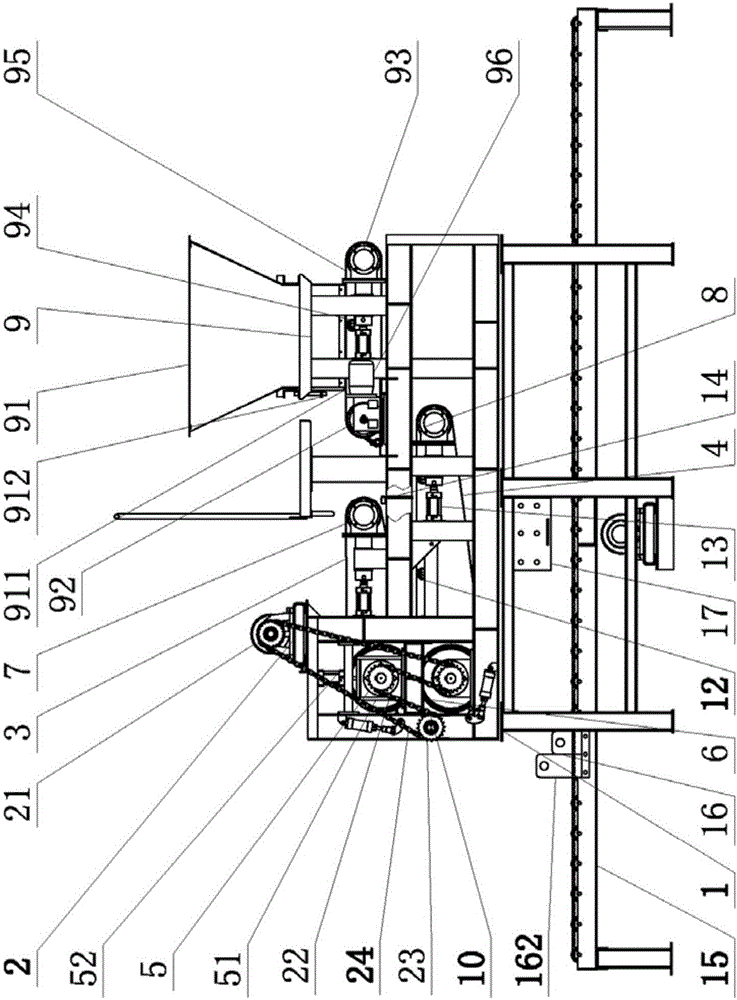

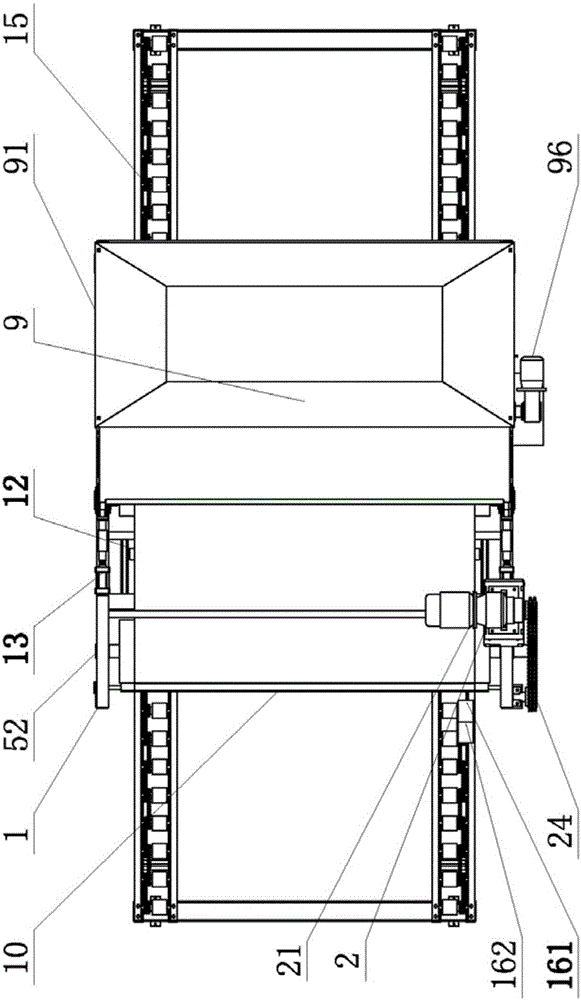

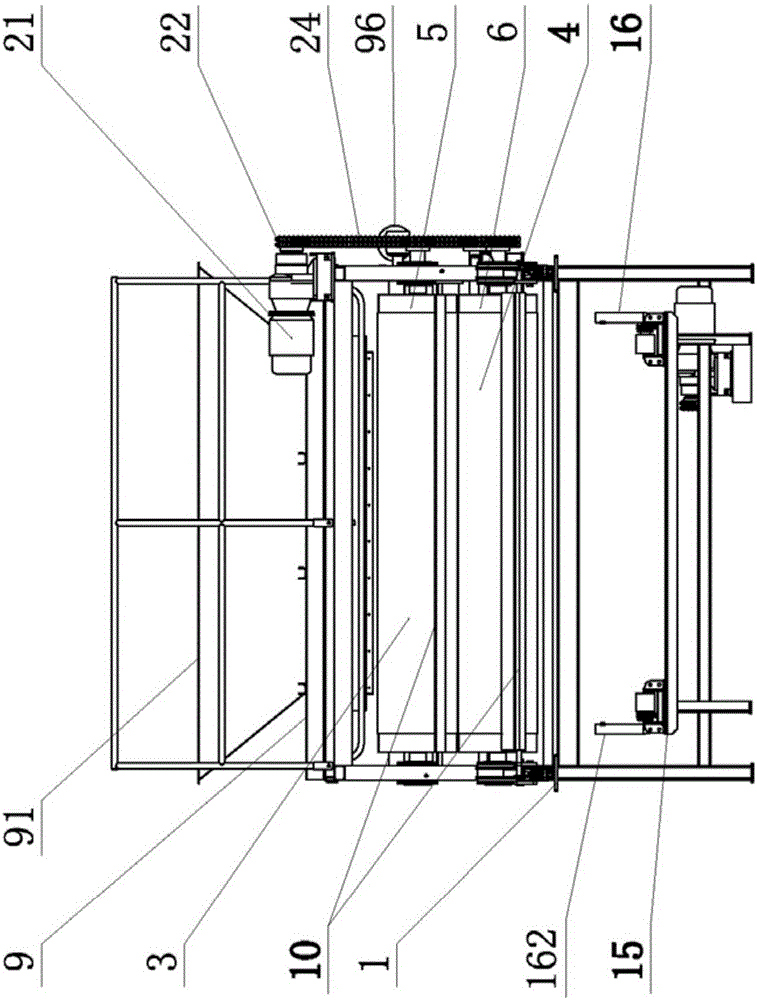

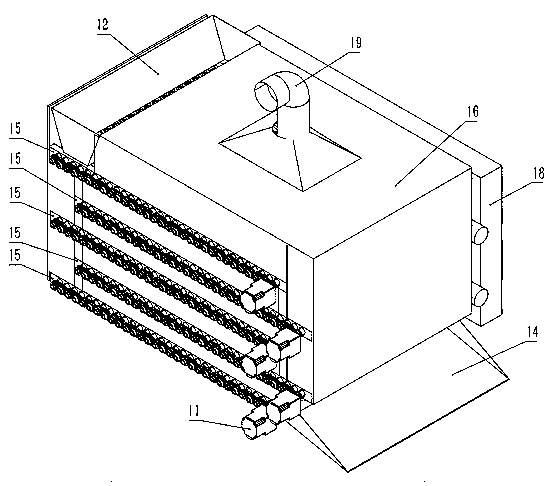

Belt-type fermented material sheeting and loading all-in-one machine

The invention relates to a belt type fermentation material tabletting and plate loading all-in-one machine which comprises a rack, a driving device, an upper material pressing belt, a lower material pressing belt, an upper material pressing belt driving roller, a lower material pressing belt driving roller, an upper material pressing belt redirection roller, a lower material pressing belt redirection roller, a material distributing device, a discharging scraper, a plate sending device, a sensor and a controller. The driving device, the upper material pressing belt driving roller, the lower material pressing belt driving roller, the upper material pressing belt redirection roller, the lower material pressing belt redirection roller, the material distributing device, the discharging scraper, the plate sending device, the sensor and the controller are installed on the rack. The upper material pressing belt is wound and installed between the upper material pressing belt driving roller and the upper material pressing belt redirection roller, and the lower material pressing belt is wound and installed between the lower material pressing belt driving roller and the lower material pressing belt redirection roller. The driving device, the material distributing device, the plate sending device and the sensor are electrically connected with the controller. The belt type fermentation material tabletting and plate loading all-in-one machine can continuously and stably roll organic materials with high water content into pieces, and plate loading is completed synchronously.

Owner:GUANGXI LIYUANBAO SCI & TECH

Graphite drying equipment for producing lithium batteries

InactiveCN110762949AWater evaporates quicklyDry graphite works wellDrying solid materials with heatDrying gas arrangementsElectric machineryStructural engineering

The invention discloses graphite drying equipment for producing lithium batteries, and particularly relates to the technical field of lithium battery production. The graphite drying equipment comprises a box, and a motor is fixedly arranged at the top end of the box. The bottom end of an output shaft of the motor stretches into the box, and a vertical rod is arranged in the box. The bottom end ofthe vertical rod is connected with the bottom end in the box through a bearing. The bottom end of the output shaft of the motor is fixedly connected with the top end of the vertical rod, and a plurality of stirring sheets are fixedly arranged at the outer end of the vertical rod. Two air heaters are embedded into the top end of the box, and two drying lamps are symmetrically arranged in the box. The vertical rod is arranged between the two drying lamps, and two supporting columns are fixedly arranged at the top end of each of the two drying lamps. The top ends of the four supporting columns are fixedly connected with the top end in the box, and second filtering screens are arranged at the bottom ends of the two drying lamps. The two second filtering screens are arranged at the tops of thestirring sheets. The graphite drying equipment is good in effect, water in graphite evaporates fast, and the processing cost is reduced.

Owner:江苏创优佳新能源科技有限公司

A filter and crystallization device for chemical product processing

ActiveCN107670322BWater evaporates quicklyRapid crystallization dryingSolution crystallizationFiltration circuitsThermal insulationFiltration

Owner:安徽海蓝生物科技有限公司

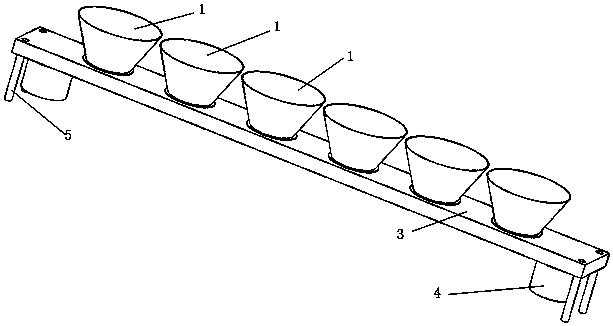

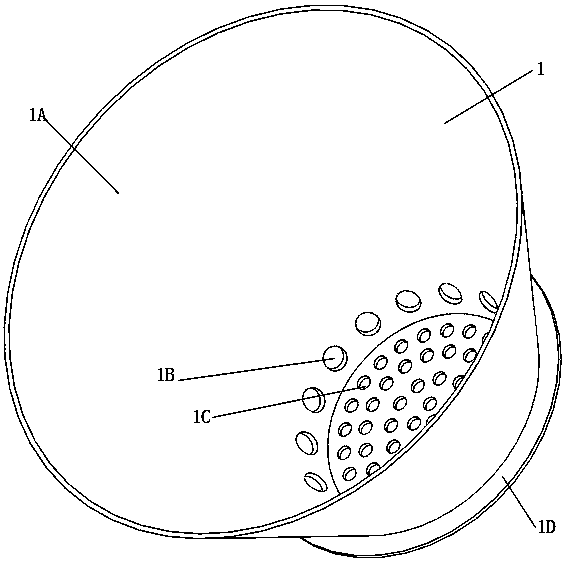

Capillary nutrient bowl

InactiveCN108450181AWater evaporates quicklySelf-acting watering devicesReceptacle cultivationWater storageEvaporation

A capillary nutrient bowl absorbs water of a water storage room to a high-level nutrient bowl using capillarity and buoyancy laws and cotton and hemp products in high water-absorbing capacity. Air holes are on the bottom of the nutrient bowl. A filter element is arranged on the bottom of the nutrient bowl. Through arranging a water outlet, water evaporation can be reduced, to prevent fertilizer loss and meanwhile stimulate roots to grow downward. A buoyancy rule is used to ensure relative constant of distance of the bottom of the nutrient bowl and a water surface, to ensure water supply and prevent overhydration. The capillary nutrient bowl can effectively use various water bodies, and through covering effect of the nutrient bowl, some small ponds are prevented to be dried up under burningsun. For some pot flowers, watering every day is not needed. The nutrient bowl prevents defects that floor is polluted since air holes on the bottom leak mud when watering a common flowerpot.

Owner:ZHANGJIAJIE INST OF AERONAUTICAL ENG

Quick-drying type glass cleaning agent

InactiveCN109929696AImprove decontamination abilityFast cleaningOrganic detergent compounding agentsBenzoic acidEvaporation

The invention relates to the technical field of cleaning agents, in particular to a quick-drying glass cleaning agent which comprises 10-50 parts of silicon oil powder, 20-30 parts of nitrilo trimethylene -triamine, 1-10 parts of propylene glycol benzoic acid, 2-10 parts of water-soluble siloxane, 5-15 parts of a surfactant, 1-8 parts of essence and the balance of water. The quick-drying glass cleaning agent is prepared from 10 parts of the silicon oil powder, 20 parts of the nitrilo trimethylene -triamine, 1 part of the propylene glycol benzoic acid, 2 parts of the water-soluble siloxane, 5 parts of the surfactant, 1 part of the essence and the balance of the water or 50 parts of the silicon oil powder, 30 parts of the nitrilo trimethylene -triamine, 10 parts of the propylene glycol benzoic acid, 10 parts of the water-soluble siloxane, 15 parts of the surfactant, 8 parts of the essence and the balance of the water. The glass cleaning agent produced by the production method disclosed by the invention is high in decontamination capability and high in cleaning speed; after being used, the water evaporation speed is high, so that the working effect and the using effect are greatly improved.

Owner:CHANGZHOU HEDA OIL PUMP

A microwave curing method for concrete

The invention provides a microwave curing method for concrete. The method comprises: (1) after the concrete is poured and pounded into shape, the surface is covered with a layer of film, and left to stand for initial setting for 2 to 3 hours; (2) after the initial setting is completed, use a movable Type microwave device for preliminary microwave curing for 0.5-1h, the temperature is controlled at 35-45°C, and the microwave frequency is 400-6000MHz; (3) followed by deep microwave curing for 0.5-2h, the temperature is controlled at 55-65°C, 400-6000MHz; (4) Finally, the concrete is naturally cooled to room temperature, and the curing is completed. The invention can realize synchronous heating of the inside and outside of the concrete, avoid microstructure damage of the concrete caused by the stress difference caused by excessive temperature difference in the maintenance process, and ensure that the concrete has a standard strength while realizing rapid solidification of the concrete.

Owner:GUANGXI ACAD OF SCI +2

Metal mixing device

The invention discloses an auxiliary device for metallurgy and steelmaking, in particular to a metal mixing device, comprising a metal mixer, a metal charging relay tank and a tank vehicle, wherein the track of the tank vehicle is installed on the upper part of a track platform; the track is inclined and rises gradually from the furnace to the outside; the chute of the metal charging relay tank is parallel to the track; the size of the cross section of the chute matches with that of the metal charging port in the metal mixer; the tail of a driving chain of the tank vehicle is equipped with a balance weight with the mass equal to that of the tank vehicle; and a driving chain wheel of the tank vehicle is a reversible chain wheel. The invention is a metal mixing device with small metal charging port and high water evaporating speed, and is capable of casting furnace brick lining and saving baker energy.

Owner:HEBEI WENFENG STEEL & IRON

Drying device for sunshade net

InactiveCN114857865AAdjustable spacingEasy to dryDispersed particle filtrationDrying solid materials without heatStructural engineeringMechanical engineering

The invention discloses a sunshade net drying device, and belongs to the technical field of sunshade net production, the sunshade net drying device comprises a box body, the two sides of the box body are provided with notches for the sunshade net to penetrate through, the upper end of the box body is provided with a sealing cover, the rear side wall of the box body is provided with an air inlet mechanism, and the box body is internally provided with a dewatering mechanism; a sunshade net is dewatered through the dewatering mechanism, moisture of the sunshade net is squeezed out through a pressing roller, follow-up drying is facilitated, the drying effect is improved, the drying efficiency is improved, meanwhile, the distance between a first supporting roller and the pressing roller can be adjusted, and the drying efficiency is improved. And the beating mechanism continuously beats the surface of the sunshade net, so that the sunshade net forms photovoltaic motion, air flow on the moisture surface of the sunshade net is accelerated, moisture evaporation of the sunshade net is faster, and the drying efficiency of the sunshade net is improved.

Owner:BENGBU TIANWANG FISHING NEED SUPPLIES

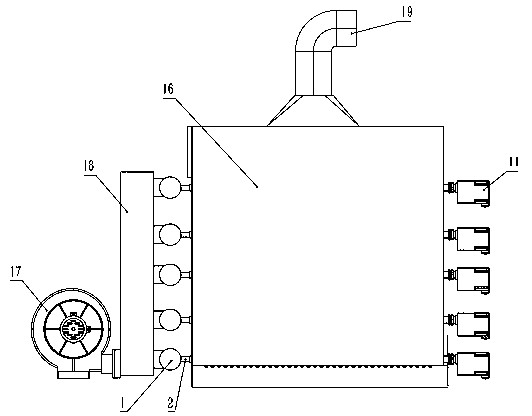

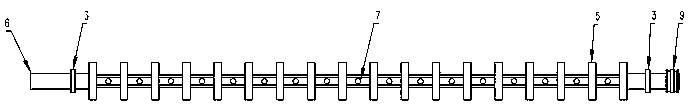

Roller piece crossing combined conveying type supporting pipe exhaust dryer

InactiveCN109883179AWater evaporates quicklyImprove efficiencyDrying gas arrangementsDrying machines with progressive movementsTransmission beltEvaporation

The invention discloses a roller piece crossing combined conveying type supporting pipe exhaust dryer. The major characteristic of the dryer is a roller piece crossing combined type conveying mechanism which is formed by transversely laying multiple supporting pipes in a longitudinal and horizontal direction; the two ends of the supporting pipes are provided with bearings respectively; the bearings are fixed on bearing supports at the two ends respectively; one end of each supporting pipe is provided with a double-groove transmission wheel; each supporting pipe is provided with roller pieces;the roller pieces on one supporting pipe and the roller pieces on the adjacent supporting pipe are orderly arranged and installed in a crossing manner; and a high-pressure fan is connected to one endof a heat exchanger box of the dryer and is used for sending hot air with a set temperature into the supporting pipes and then exhausting the hot air from exhaust holes of the supporting pipes. By adopting the roller piece crossing combined conveying type supporting pipe exhaust dryer, when the dryer runs, under transmission of a motor and a transmission belt, all the supporting pipe components roll in one direction, exhausting of the hot air from the exhaust holes is multi-directional, and a material can be multi-directionally heated at a close range when passing through a space above supporting pipes, so that water evaporation of the material is fast, the efficiency is improved, and the quality is guaranteed.

Owner:陈伦浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com