Patents

Literature

78results about How to "Dry well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

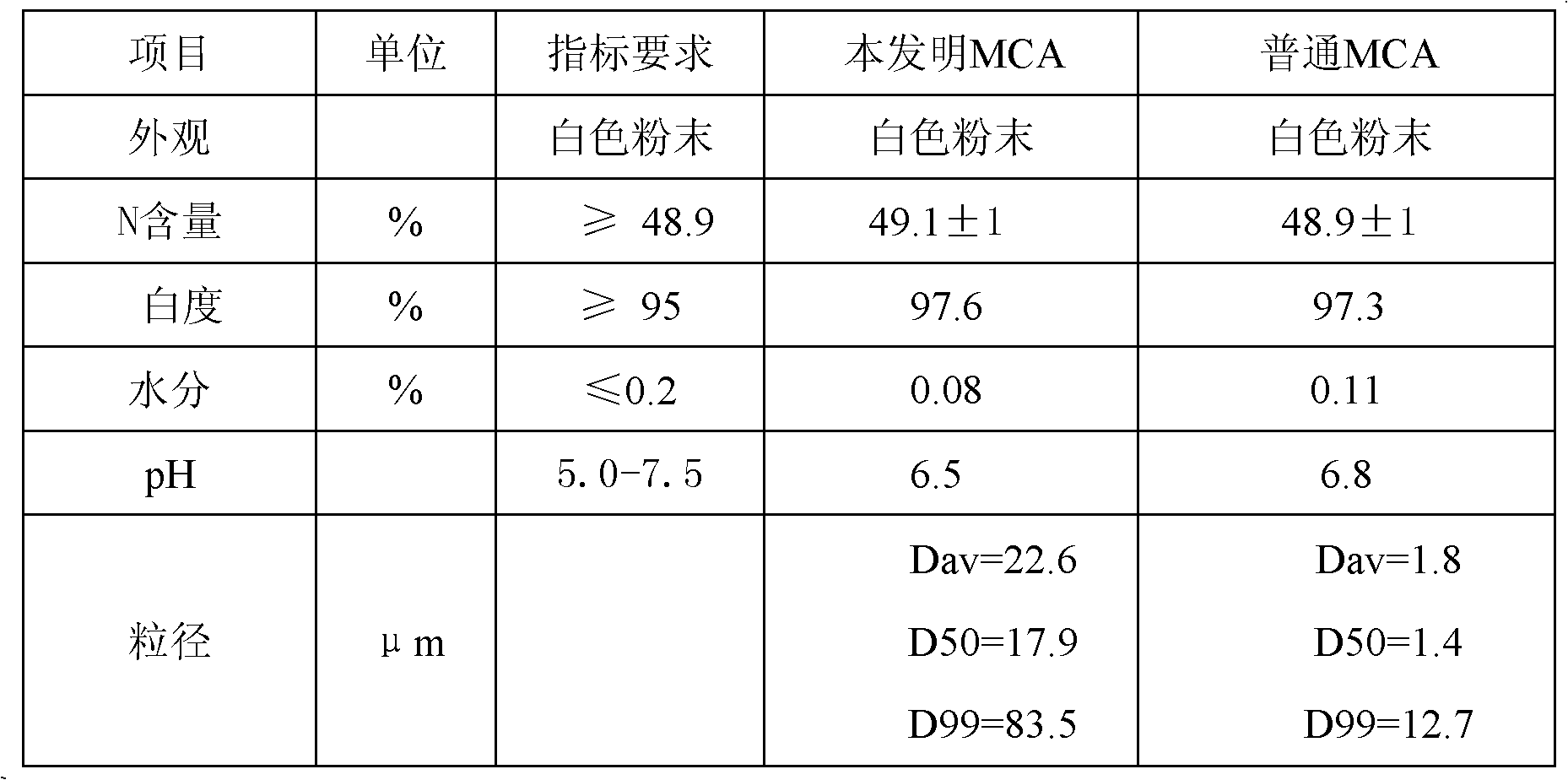

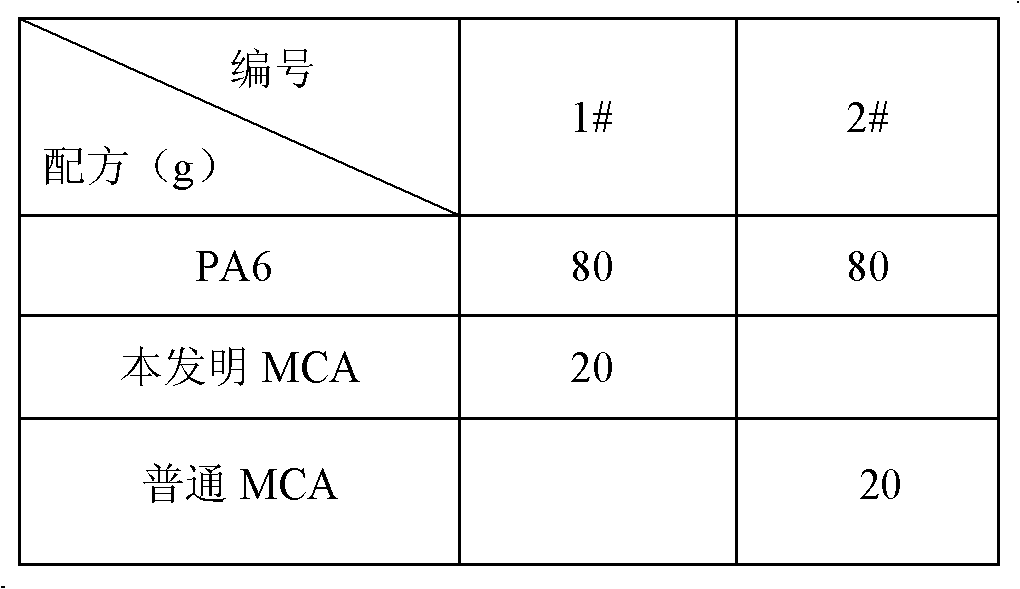

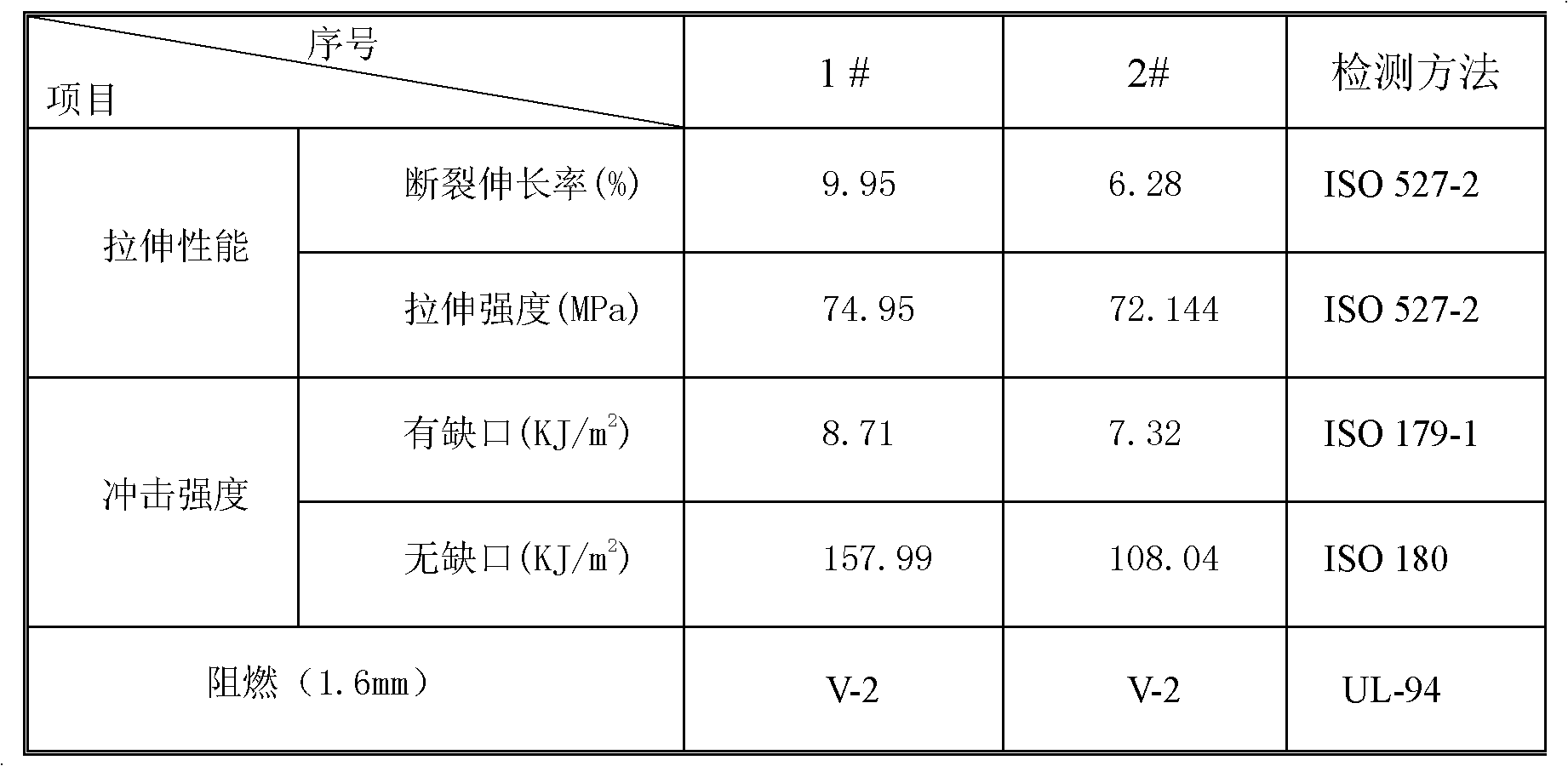

Method for preparing melamine cyanurate with large particle size and wide distribution

The invention discloses a method for preparing melamine cyanurate with large particle size and wide distribution, and belongs to the technical field of preparation of flame retardants. The method comprises the following steps of: preparing raw materials, namely melamine and cyanuric acid in a molar ratio of 1:1.05, adding a solvent, namely water in an amount which is 3 to 6 times the total mass of the melamine and the cyanuric acid into a reaction kettle, adding the cyanuric acid into the reaction kettle, and heating to the temperature of between 60 and 110 DEG C with stirring; adding the melamine and a macromolecular nucleating agent, and reacting at the temperature of between 95 and 110 DEG C for 1.5 to 5 hours with stirring to obtain white slurry; and performing pressure filtering on the slurry, drying, and grinding to prepare white powdered melamine cyanurate with the particle size of 15 to 100mu m. The melamine cyanurate with large particle size and wide distribution is easily subjected to suction filtering and dried, so that production efficiency is improved; and the melamine cyanurate serving as a flame-retardant additive has high dispersibility in a macromolecular materialsubstrate, and the flame-retardant effect and mechanical property of the substrate material are improved.

Owner:JINAN TAIXING FINE CHEM

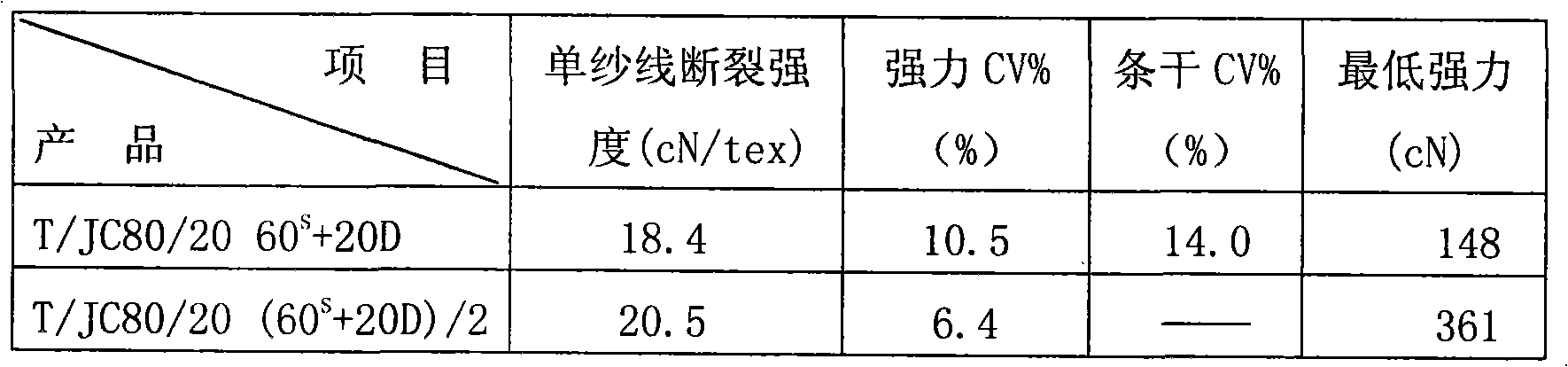

Production method of moisture-absorbing and sweat-discharging fabric

InactiveCN101962850AGood moisture absorption and quick drying effectSkinnyFibre cleaning/opening machinesWoven fabricsBreaking strengthPolyester

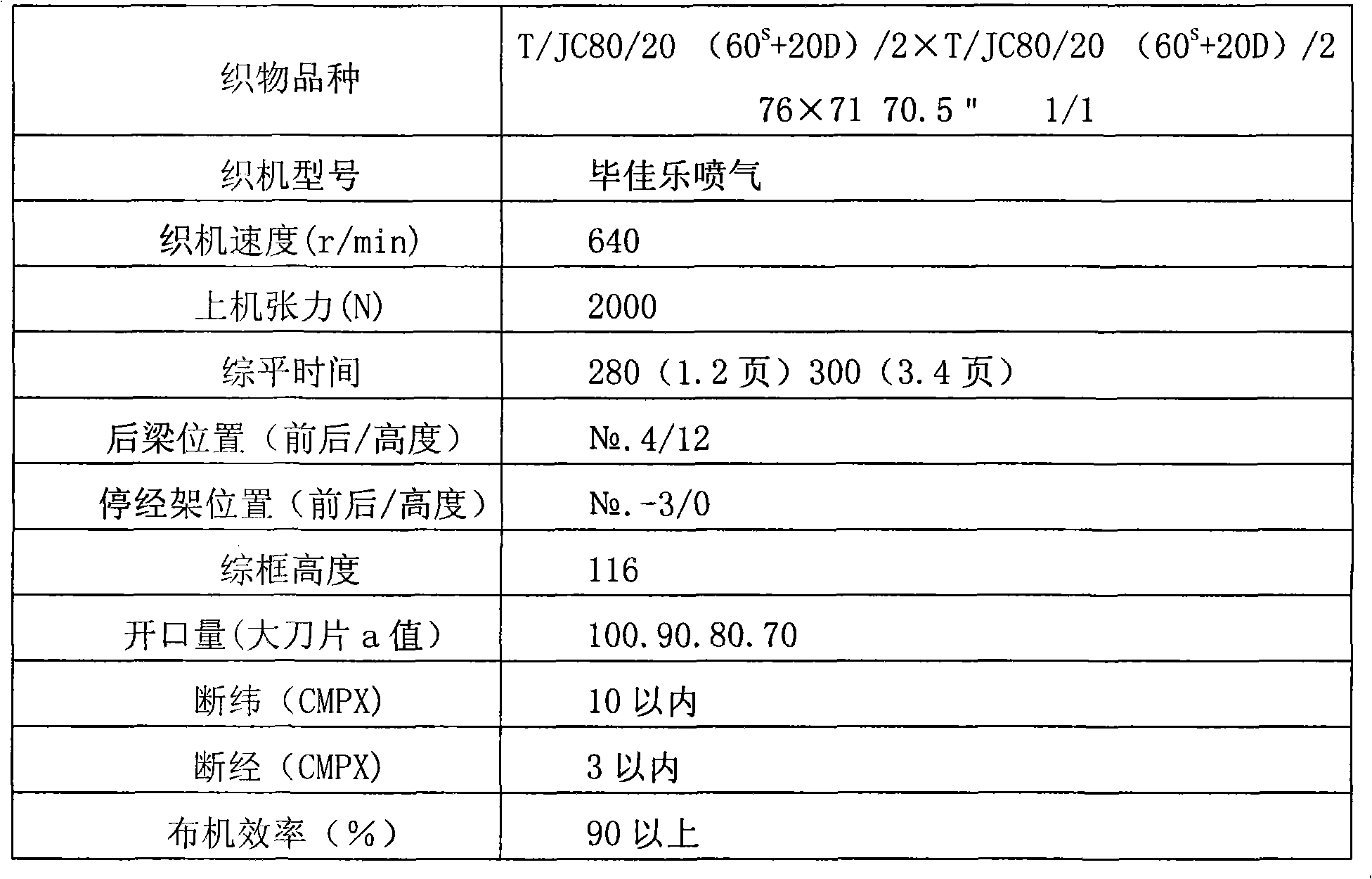

The invention relates to a production method of a moisture-absorbing and sweat-discharging fabric. In the method, the moisture-absorbing and sweat-discharging fabric is produced by using 80 percent of honeycomb moisture-absorbing and quick-drying fibers and 20 percent of cotton fibers as coating fibers and 20D common polyester filaments as core yarns. The method comprises the following steps: subjecting moisture-absorbing and sweat-discharging fibers to cotton opening and cleaning, cotton carding and primary combination, subjecting cotton fibers to cotton opening and cleaning, cotton carding and fine carding, and combining the moisture-absorbing and sweat-discharging fibers and cotton fibers primarily; combining secondarily; spinning a coarse yarn; spinning a fine yarn; winding single yarn; twisting; yarn strand winding; and producing T / JC80 / 20(60s+20D) single yarnbs and T / JC80 / 20(60S+20D) / 2 yarn stands, wherein the breaking strengths of the single yarn and the yarn strand are 18.4cN / tex and 20.5cN / tex respectively, the strength CV values of the single yarn and the yarn strand are 10.5 percent and 6.4 percent respectively, the lowest strength of the single yarn and the yarn strand are 148cN and 361cN respectively, and the yarn levelness of the T / JC80 / 20(60S+20D) single yarn is 14.0 percent; and weaving the yarn and yarn stand by warping, sizing, denting, weaving, finishing and producing a T / JC80 / 20(60s+20D) / 2*T / JC80 / 20(60s+20D) / 2 76*71 70.5''1 / 1. In the invention, the fabric produced by reasonable cotton cleaning and carding processes and proper sizing and weaving processes and by combining two combined yarns has high moisture-absorbing and rapid-drying effects and offers an excellent skinny effect.

Owner:JIHUA 3509 TEXTILE

Coupling compound moulded coal binder and preparation method thereof

InactiveCN101798538AWater evaporates quicklyIncrease production capacitySolid fuelsCross-linkCellulose

The invention discloses a coupling compound moulded coal binder and a preparation method thereof. The coupling compound moulded coal binder is a mixture prepared by mixing bentonite, tackifier, sodium carbonate, kaolin and sodium humate; the mixture comprises the following components in parts by weight: 350-600 parts of the bentonite, 45-55 parts of the tackifier, 3-5 parts of the sodium carbonate, 280-320 parts of the kaolin and 100-125 parts of the sodium humate; the tackifier is prepared by smashing 10-15 parts by weight of polyacrylate, 5-10 parts by weight of acrylamide, 3-5 parts by weight of cellulose, 20-25 parts by weight of cassava stalk, 3-5 parts by weight of modified starch and 0.2-0.5 part by weight of cross-linking agent into 50-100 meshes, and mxing the smashed materials. The preparation method comprises the following steps: preparing the tackifier, stocking, pretreating parts of the components, mixing, stirring and the like. The moulded coal binder has favorable waterabsorbtion performance, the moisture of an extruded and shaped coal bar is quickly evaporated and is easy to dry, thus solving the problems of high raw coal moisture, difficult moulded coal production and low shaping rate in rainy days in the south of China.

Owner:柳州化工股份有限公司 +2

Paper towel with superior wiping properties

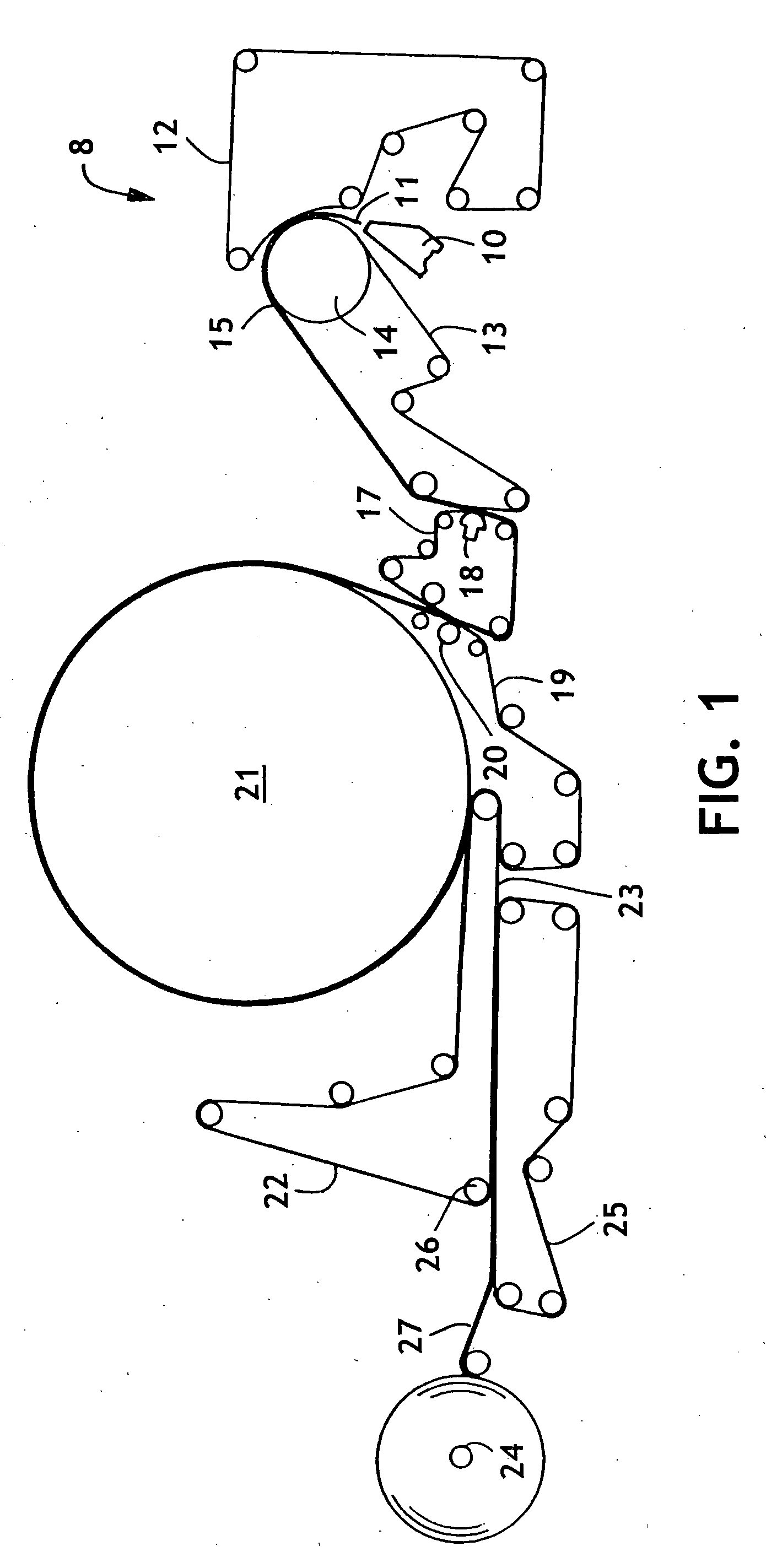

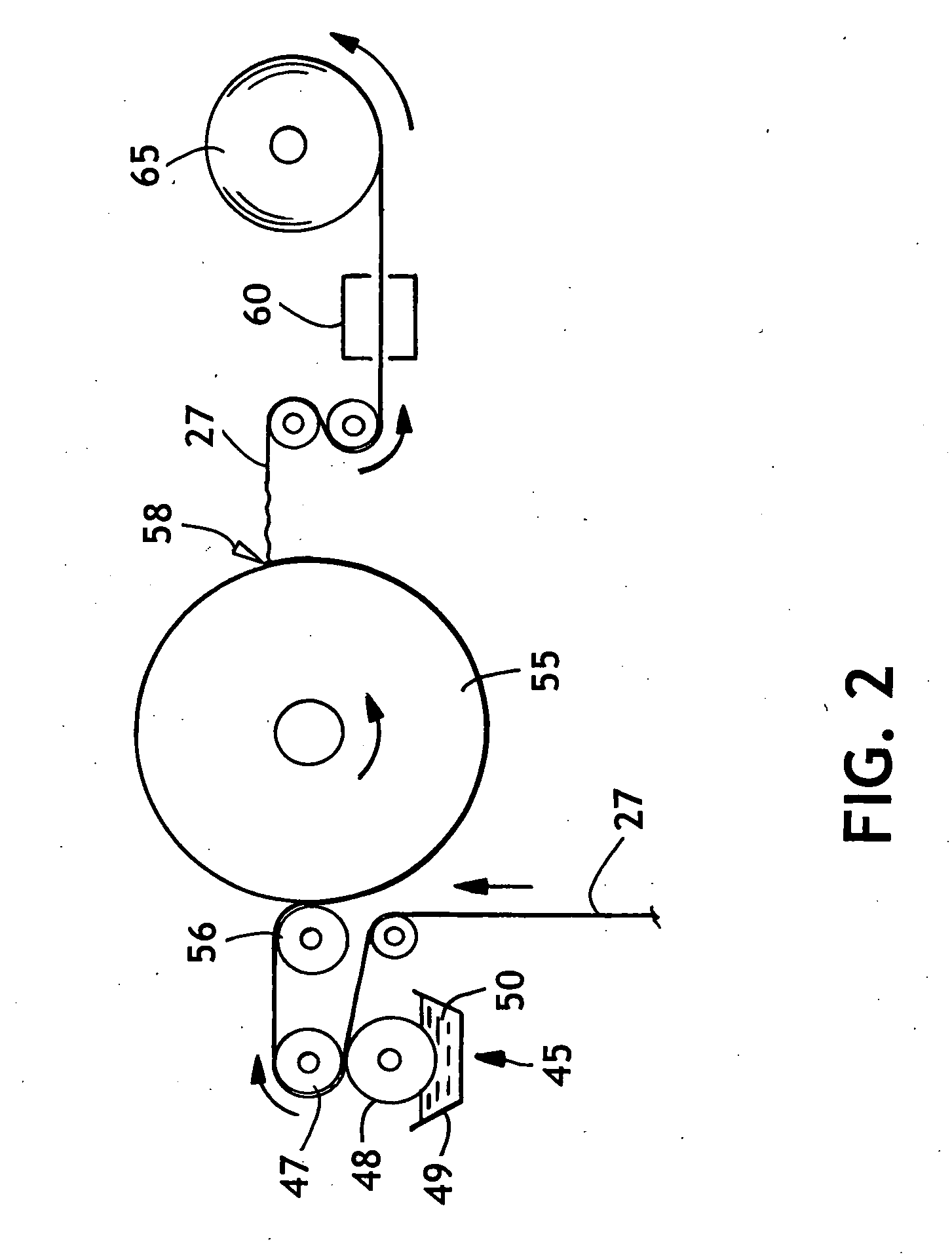

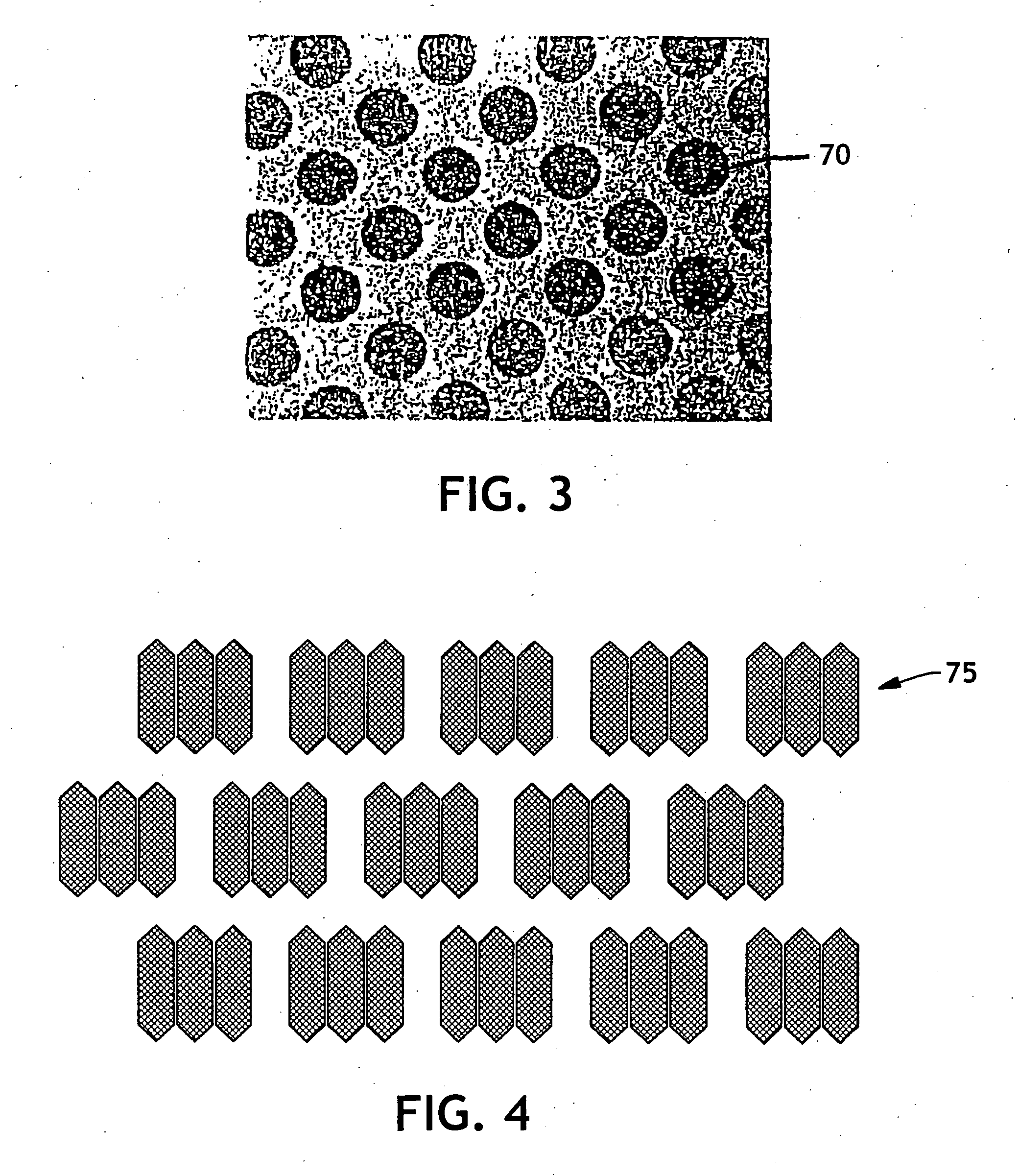

ActiveUS20070000629A1Dry wellSuperior liquid wiping propertyNatural cellulose pulp/paperMechanical working/deformationPaper towelMaterials science

Owner:KIMBERLY-CLARK WORLDWIDE INC

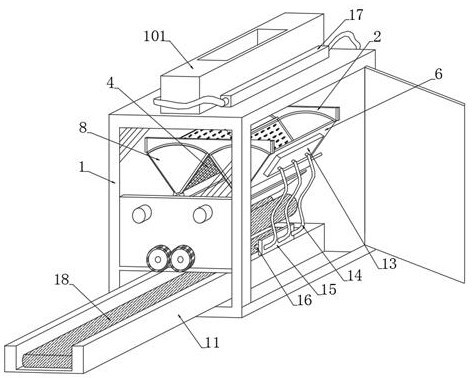

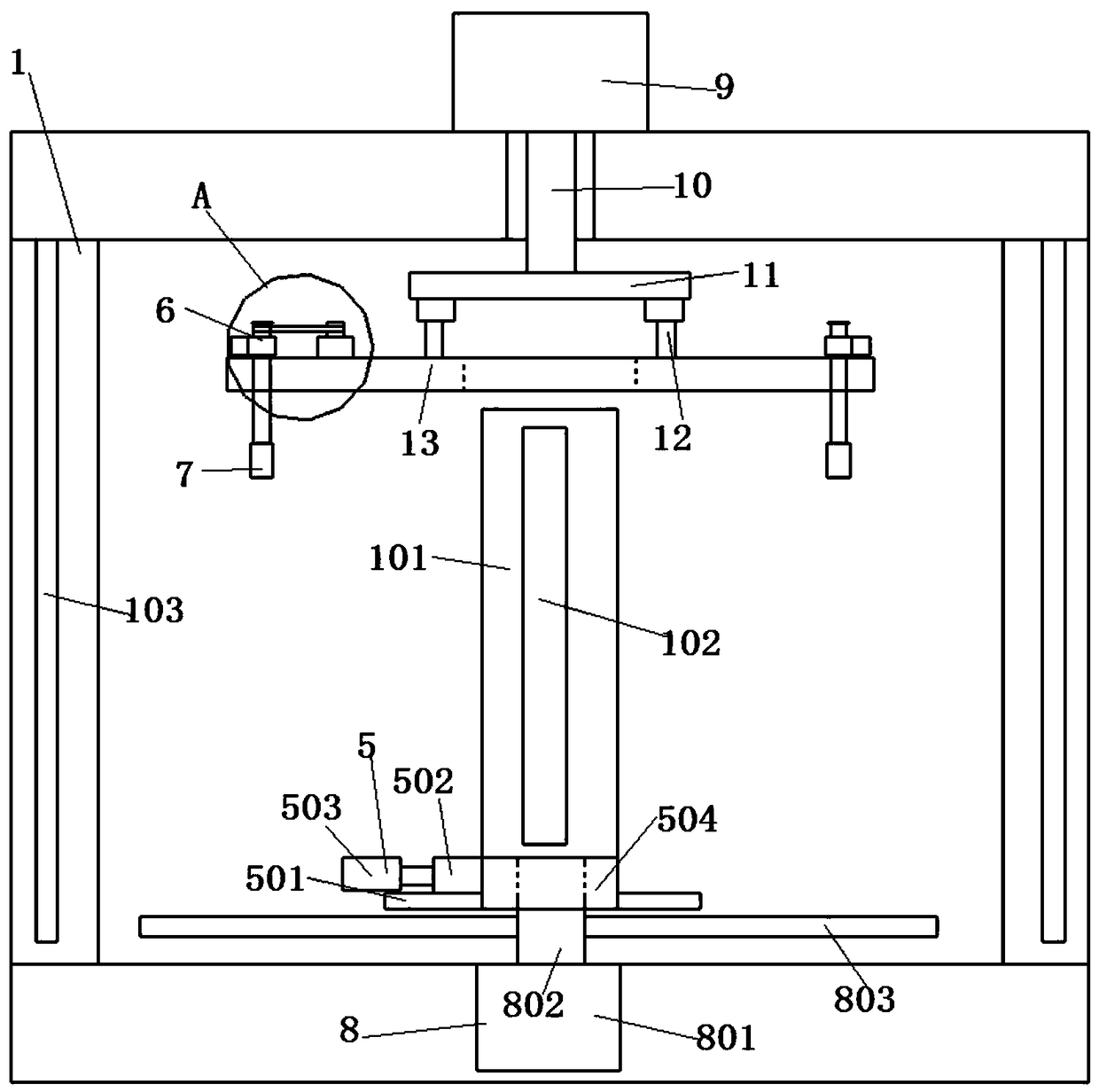

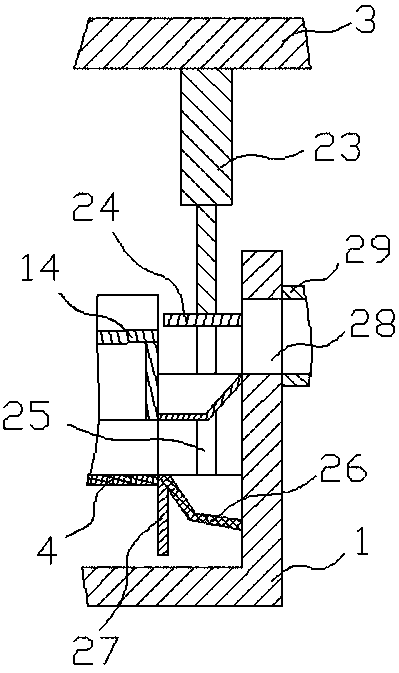

Crushing device for waste concrete regeneration preparation

ActiveCN111632728AImprove the first-level crushing effectImprove crushing effectUsing liquid separation agentDrying gas arrangementsReciprocating motionCrusher

The invention discloses a crushing device for waste concrete regeneration preparation, and belongs to the technical field of waste concrete reutilization. A rolling crushing mechanism is arranged in acrushing box, a pair of extrusion crushing plates extrude and crush concrete blocks in a crushing cavity when moving oppositely, and qualified crushed concrete is guided out through a steel plate screen; the pair of extrusion crushing plates do left-right opposite and reverse reciprocating motion, so that the crushing effect of concrete blocks is effectively improved; semiconductor chilling plates are embedded in the outer ends of the two extrusion crushing plates and used for refrigerating the inner ends of the extrusion crushing plates and heating the outer ends of the extrusion crushing plates, the crushing cavity is matched with the spraying effect when refrigerated, and water mist is cooled at the ultralow temperature to form ice slag; the ice slag and mixed concrete participate in crushing together, the crushing effect is further improved, and meanwhile, generated dust is subjected to dust falling treatment through water mist, the heat guided out is guided into a transmission table with a conveying belt through a hot air conduction mechanism and used for drying concrete aggregate.

Owner:兰陵沂州新材料有限公司

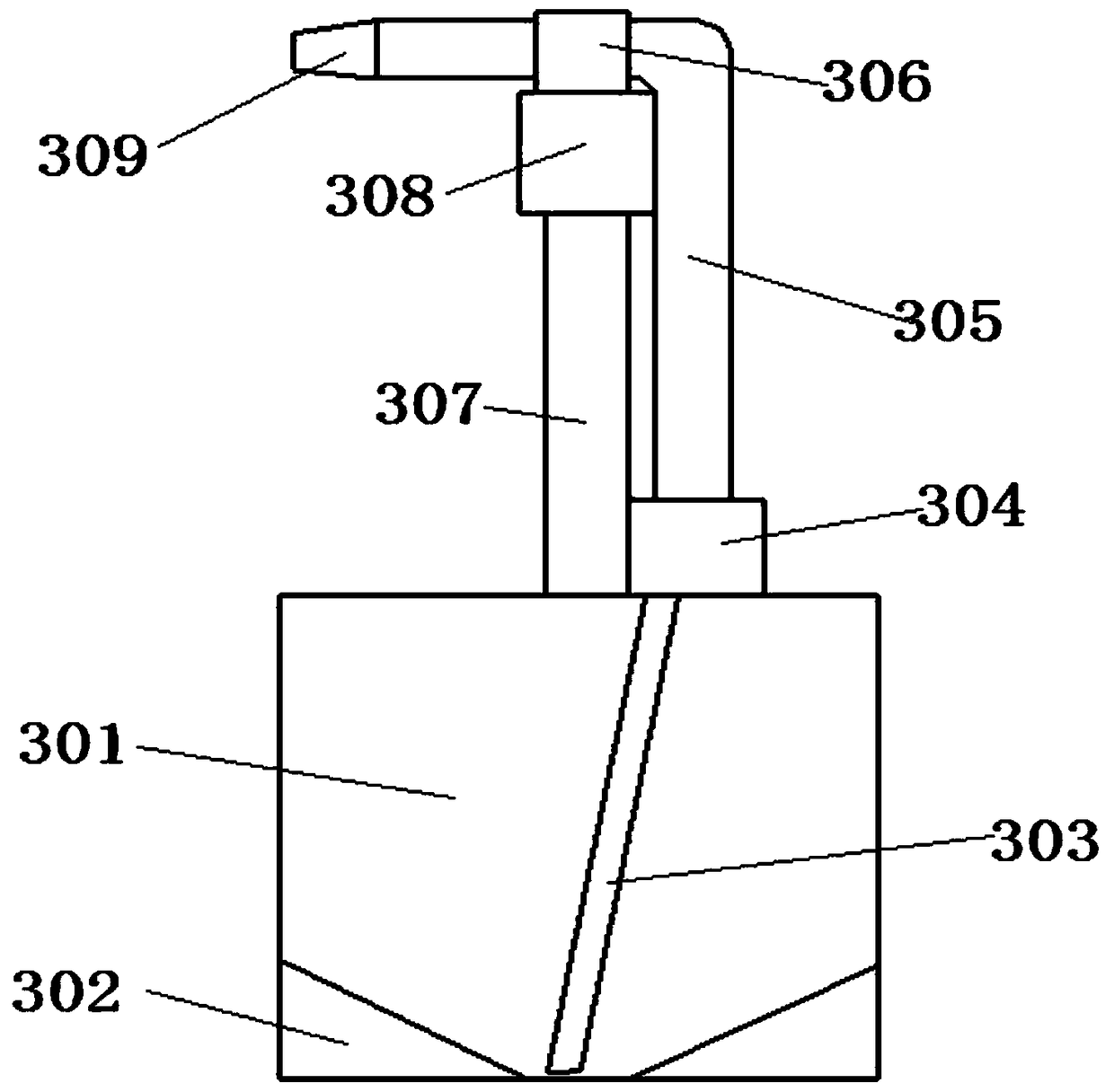

Oil bottle drying device

InactiveCN104197677ADry wellAvoid skewDrying gas arrangementsDrying machines with progressive movementsHandrailEngineering

The invention relates to a tea oil processing device, in particular to an oil bottle drying device which comprises a drying box and a conveying belt. The conveying belt penetrates through the drying box which is divided into a warm air zone and a cold air zone. Air outlets are formed in the box walls of a dryer box of the warm air zone and the cold air zone. The conveying belt penetrates through the warm air zone and the cold air zone in sequence. Handrails are arranged on the left side and the right side of the conveying belt. The handrails comprise blocking plates and pressing plates. The blocking plates are arranged on the two sides of the conveying belt. The pressing plates are vertically connected with the blocking plates. Production personnel place an oil bottle on the conveying belt, the oil bottle is conveyed into the drying box through the conveying belt and enters the warm air zone first, warm air which is sprayed out from the air outlets carries out first-time drying on the oil bottle, then the oil bottle enters the cold air zone for secondary drying, and through the effect of the blocking plates and the pressing plates, oil bottle skewing is effectively avoided.

Owner:HUNAN SHENNONG CAMELLIA OLEIFERA TECH DEV

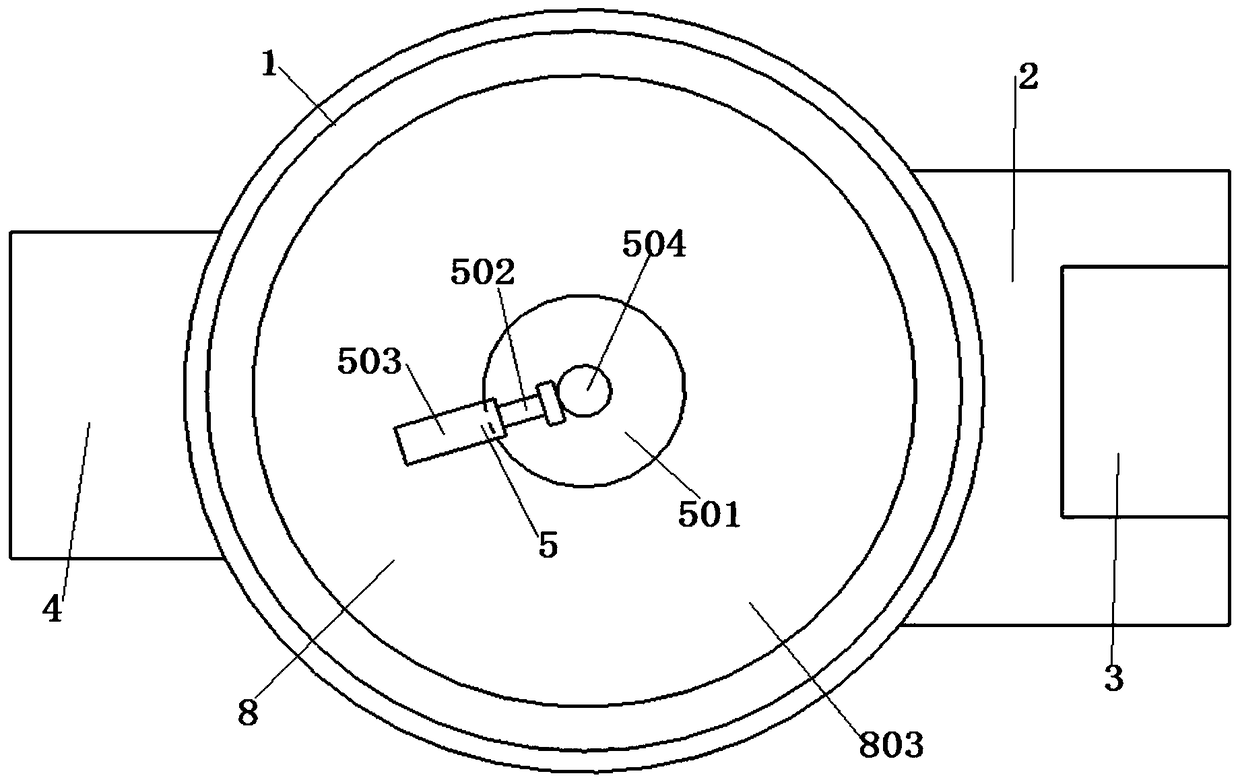

Protective spraying device for PCB (Printed Circuit Board)

ActiveCN109382241AEasy to relaxEasy clampingPretreated surfacesLiquid spraying apparatusEngineeringPrinted circuit board

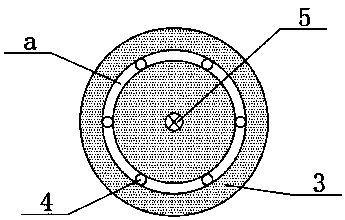

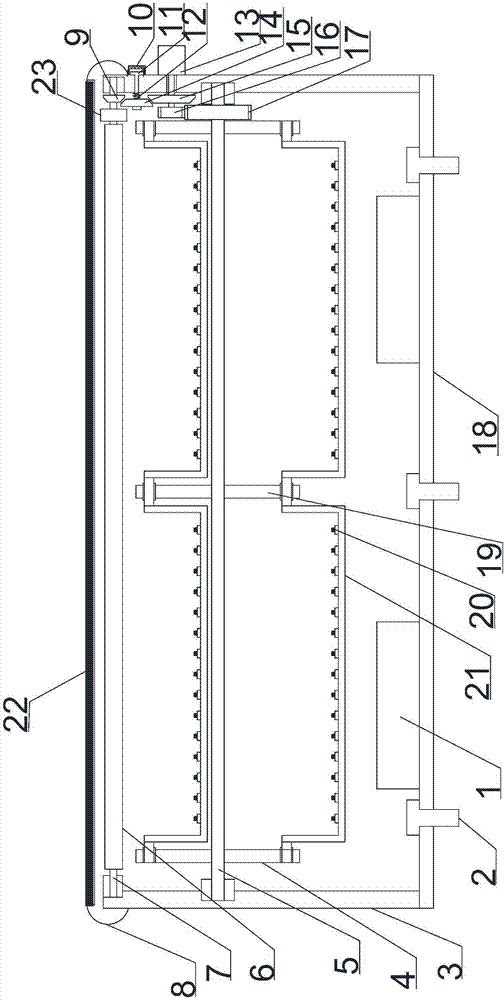

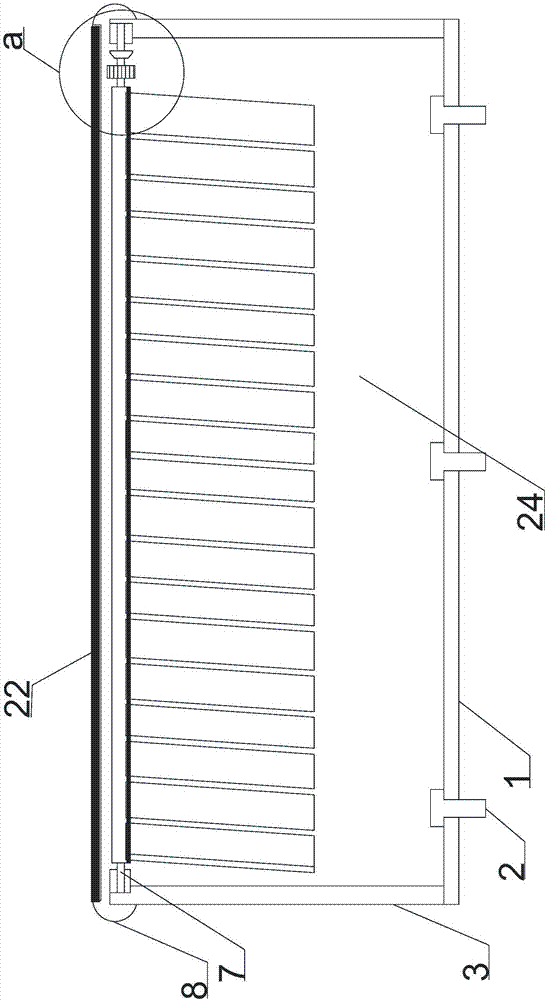

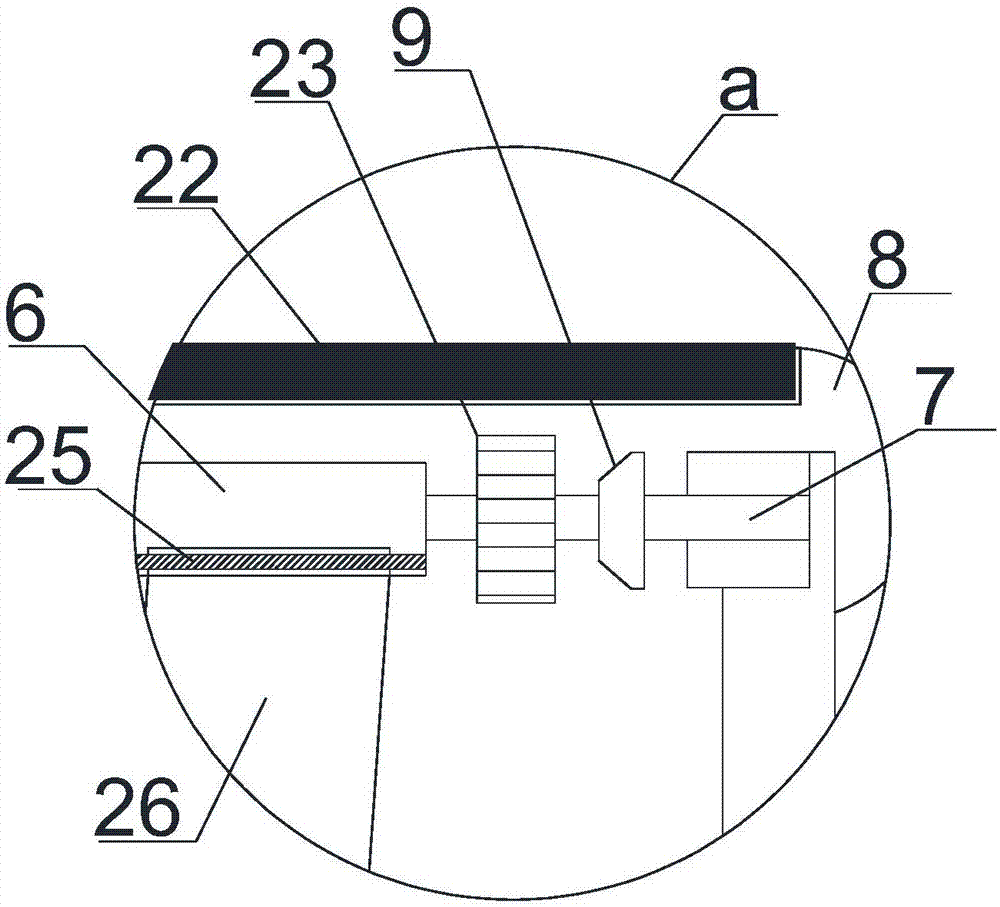

The invention discloses a protective spraying device of a PCB, which comprises a drying cylinder, wherein a spraying chamber is fixedly welded on one side of the drying cylinder, a spraying mechanismis arranged in the spraying chamber, a discharge port is fixedly welded on the other side of the drying cylinder, a connecting plate and a rotating circular plate are arranged in the drying cylinder,the lower end surface of the drying cylinder is provided with an output component, the output component is fixedly connected with a path changing component, the drying cylinder is provided with a first motor, the output end of the first motor is connected with a first rotating shaft penetrating through the upper top surface of the drying cylinder, the lower end of the first rotating shaft is fixedly welded with a connecting plate, the lower part of the connecting plate is fixedly connected with the rotating circular plate through a first electric telescopic push rod, clamping components are evenly distributed at the upper edge position of the rotating circular plate, and a turnover component which is in transmission connection with the clamping components is arranged on the upper end surface of the rotating circular plate. The protective spraying device for PCB (Printed Circuit Board) is convenient for both the quick and highly effective coating and the quick and complete drying of thetwo sides of the coated PCB plate, so that the PCB is efficiently conveyed and the production efficiency of the PCB is improved.

Owner:ANHUI SHENZE ELECTRONICS TECH

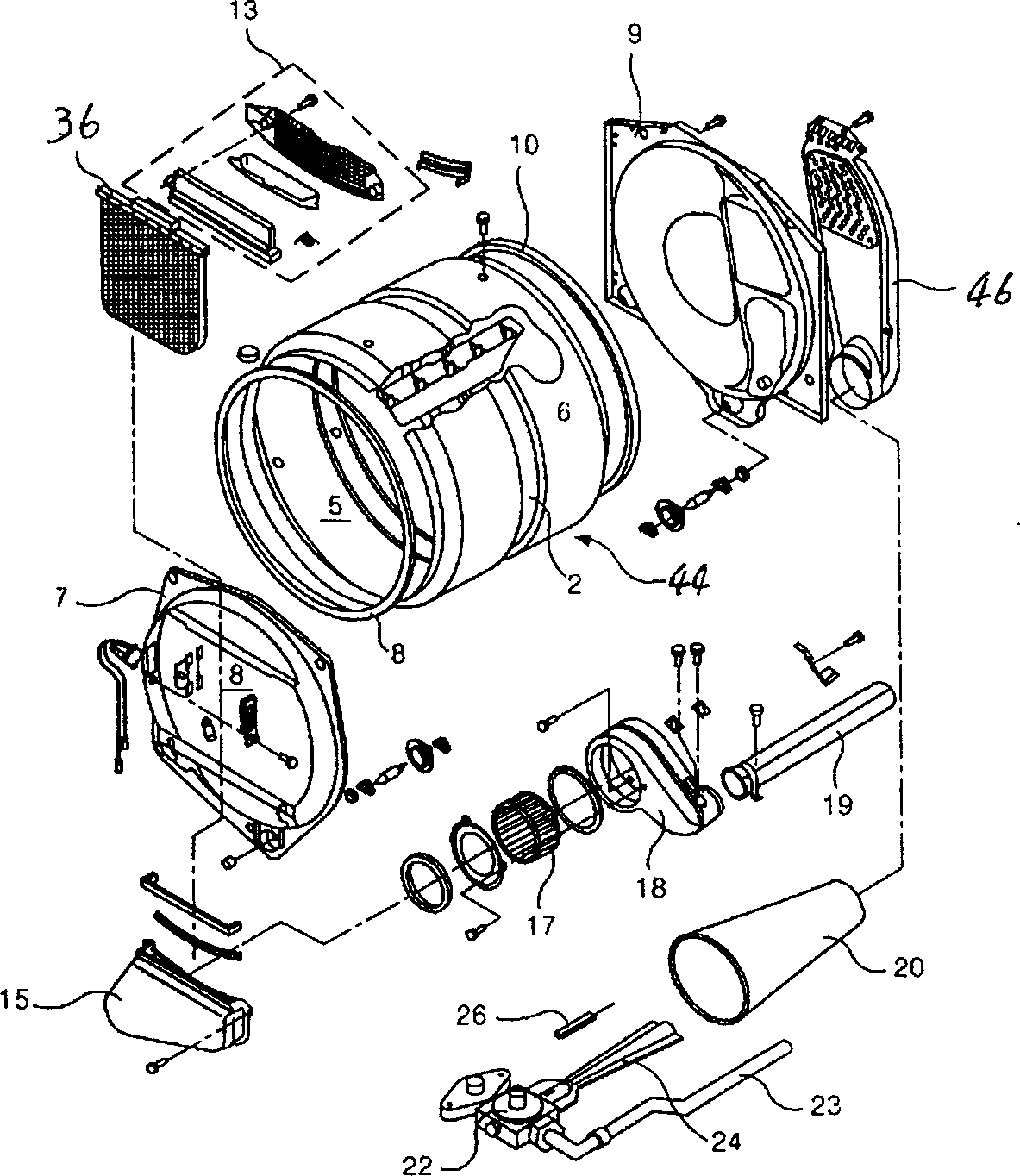

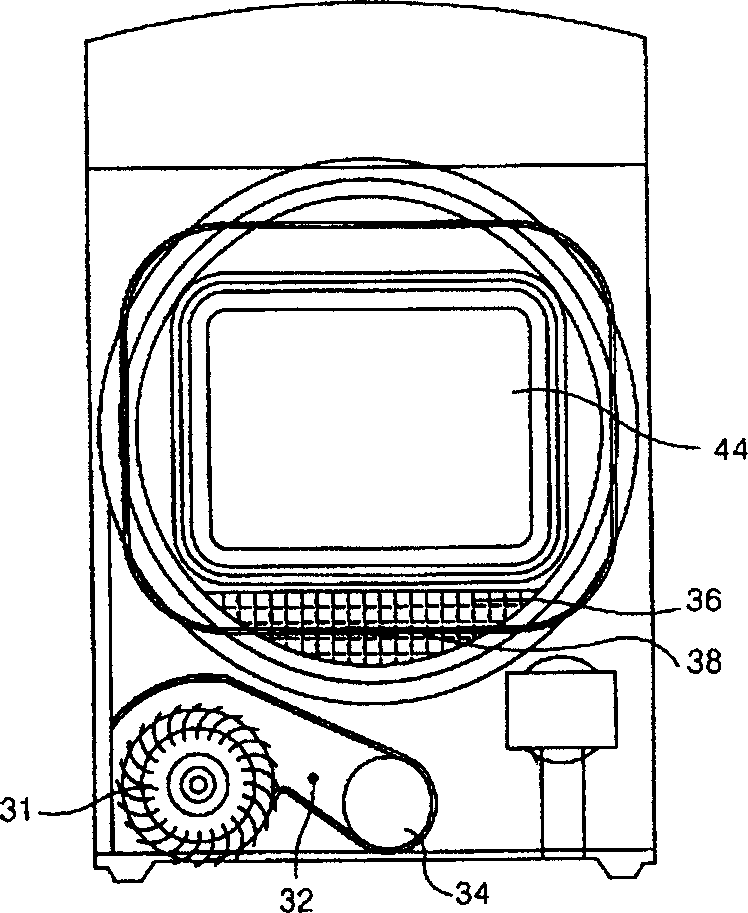

Drying machine and control method thereof

InactiveCN1467335AAvoid damageExtended drying timeLaundry dryer apparatusTextiles and paperControl theoryExhaust pipe

A baker features structurally that a mainboard for controlling baker and a switch board for controlling the driver of drum. Its control method includes such steps as monitoring the rotation speed of controllable exhaust blower, sensing the blocking degree of gauze filter and exhaust pipe, speeding up the rotation of exhaust blower to increase the air flow in drum if the gauze filter and exhaust pipe has been blocked, and controlling the heat generated by heater to prevent the heater from being turned off due to overheat.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

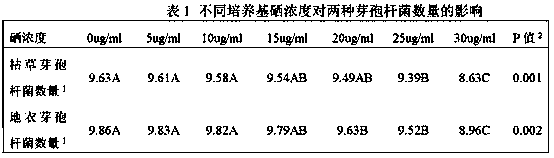

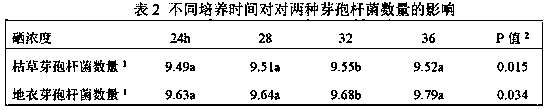

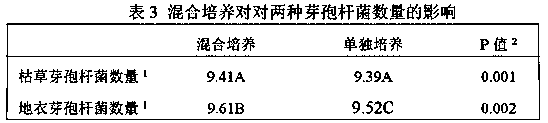

Fodder composite selenium-rich probiotic bacillus solid preparation and preparation method thereof

InactiveCN108977397AHigh content of organic seleniumImprove conversion rateBacteriaAnimal feeding stuffBacillus licheniformisAdditive ingredient

The invention relates to a fodder composite selenium-rich probiotic bacillus solid preparation and a preparation method thereof. Each gram of the composite selenium-rich probiotic bacillus solid preparation contains the following ingredients: Bacillus licheniformis with the content being 9.41'109 CFU / g, Bacillus subtilis with the content being 9.65'10<9> CFU / g, 48.25 microgrammes of organic selenium and 1.83 microgrammes of inorganic selenium. The preparation method of the fodder composite selenium-rich probiotic bacillus solid preparation comprises the following steps of (1) selection of theculture, (2) preparation of a beef extract-peptone medium, (3) activation of the culture and obtaining of seed liquid, (4) first fermentation, (5) secondary fermentation, (6) drying and (7) grinding and packaging. The composite selenium-rich probiotic bacillus preparation is green and environmentally friendly, not only contains the probiotic bacillus, but also is rich in organic selenium, and achieves the effect of joint actions by combining the double effects of organic selenium and the probiotic bacillus.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY MEDICINE ANHUI ACAD OF AGRI SCI

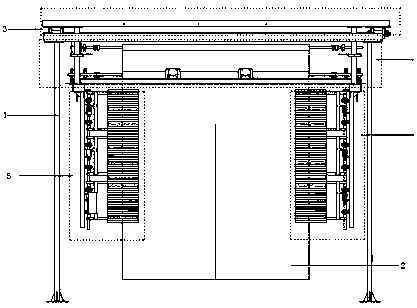

Vehicle wiping method and vehicle wiping device with automatic cleaning function

PendingCN108372845AReduce stretchExtended service lifeVehicle drying apparatusCleaning apparatus for railwaysEngineeringPiston rod

The invention relates to a vehicle wiping method and a vehicle wiping device with an automatic cleaning function. The vehicle wiping device comprises a framework, a towel front and back moving part and a towel water extruding and automatic cleaning part, wherein the towel front and back moving part comprises a movable trolley which is moved back and forth corresponding to the framework; a supportframe is arranged on the movable trolley; a towel coiling shaft for fixing a towel is connected with the support frame; the towel water extruding and automatic cleaning part comprises a towel top coiling and down uncoiling device, a water extruding device and a cleaning spray head, the towel top coiling and down uncoiling device comprises the towel coiling shaft and a drive part of the towel coiling shaft for driving the towel coiling shaft to rotate, the water extruding device comprises a fixed coiling shaft and a movable coiling shaft under the towel coiling shaft, the movable coiling shaftis connected with a piston rod of a water squeezing air cylinder, and the cleaning spray head is arranged on the movable trolley. The vehicle wiping device has the advantages that the vehicle body wiping effect is good, and the operation speed is quick.

Owner:盛利

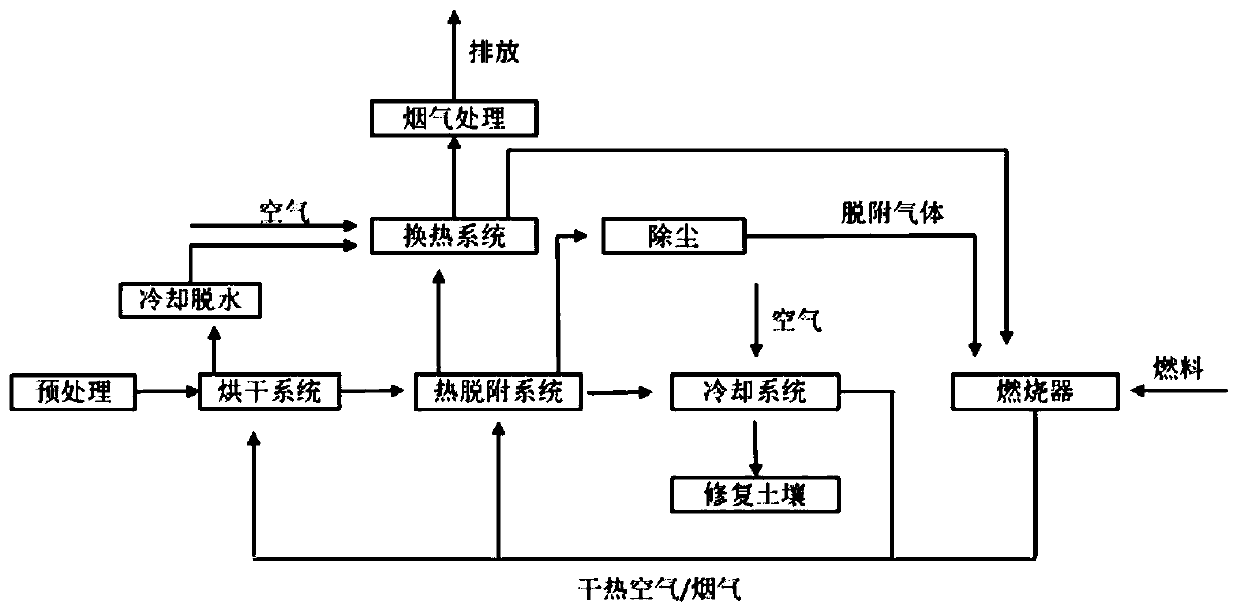

Method for treating organic contaminated soil through thermal desorption

ActiveCN111545558AEfficient use ofAvoid lostContaminated soil reclamationIncinerator apparatusCombustorFlue gas

The invention relates to a method for treating organic contaminated soil through thermal desorption. The method comprises the following steps: (1) crushing, sieving and drying organic contaminated soil, sending the organic contaminated soil into a thermal desorption furnace for thermal desorption to obtain repaired soil and desorption gas, cooling the repaired soil to complete the treatment, removing dust from the desorption gas, and sending the desorption gas into a combustor for combustion; (2) feeding the high-temperature flue gas discharged from the combustor into the thermal desorption furnace as a heat source to heat the organic contaminated soil to obtain low-temperature flue gas; and (3) carrying out heat exchange between the obtained low-temperature flue gas and combustion-supporting air fed into the combustor, treating the low-temperature flue gas by a flue gas treatment system, and discharging the flue gas after the flue gas meets the standards. The energy utilization rate is increased, the soil is repaired, and secondary pollution is avoided.

Owner:SHANGHAI RES INST OF CHEM IND

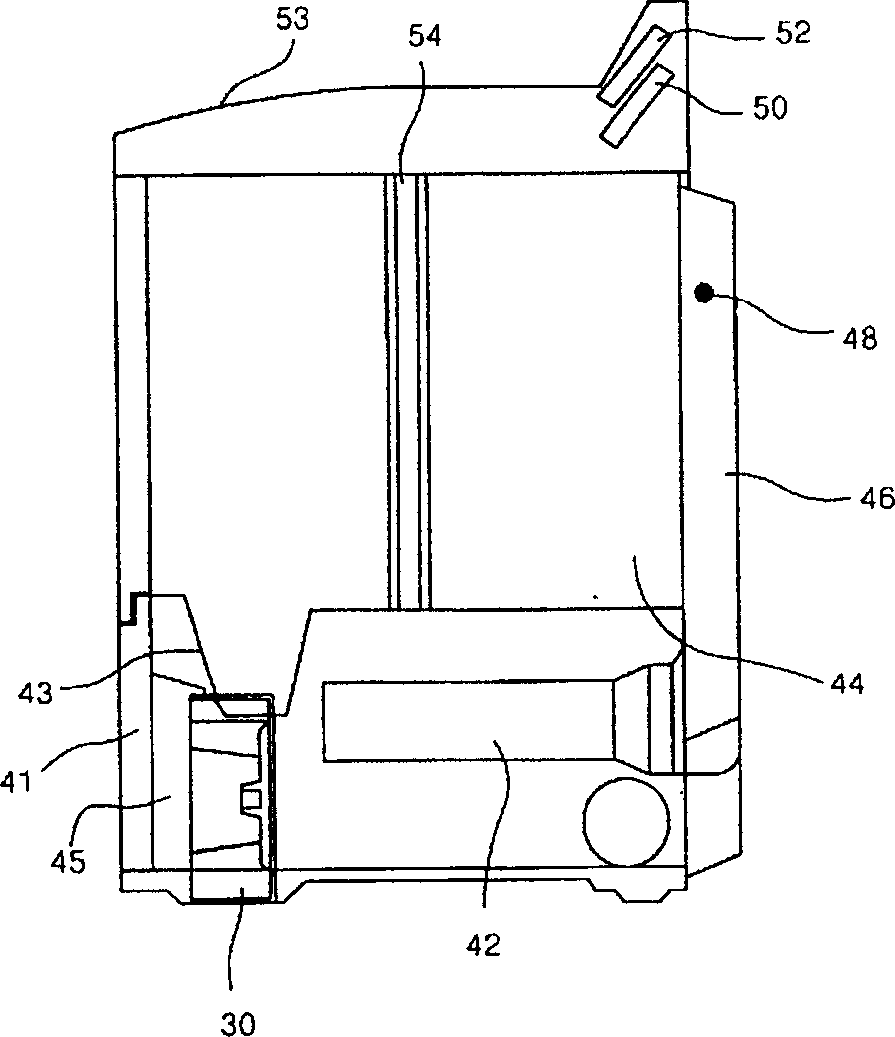

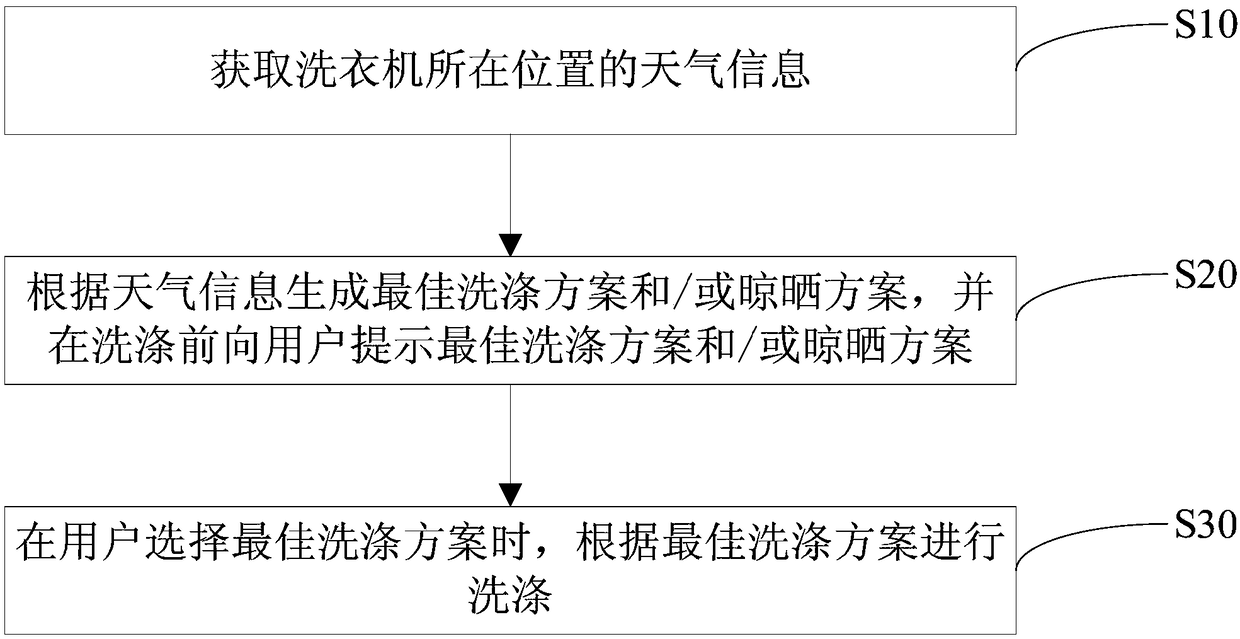

Washing machine control method based on weather information and washing machine

InactiveCN109505090AImprove experienceDry wellControl devices for washing apparatusOther drying apparatusMachine controlProcess engineering

The invention belongs to the relevant technical field of washing machines and discloses a washing machine control method based on weather information and a washing machine. The washing machine controlmethod comprises the steps that weather information of a position the washing machine is located is obtained, and an optimum washing scheme and / or air-drying scheme is generated according to the weather information before washing and is prompted to a user. Before clothes washing of the user, the optimum washing scheme and / or air-drying scheme can be generated according to the weather informationof a position the washing machine is located and prompted to the user so that the user can know outside weather information in real time and select the optimum washing scheme and / or air-drying schemematched with the weather information, user experience can be effectively improved, the washing machine control method can be suitable for users who do not see outdoor weather before washing or havingvisual disturbance and can ensure that washed clothes obtain optimum air-drying, and no contamination problem exists.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

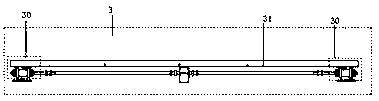

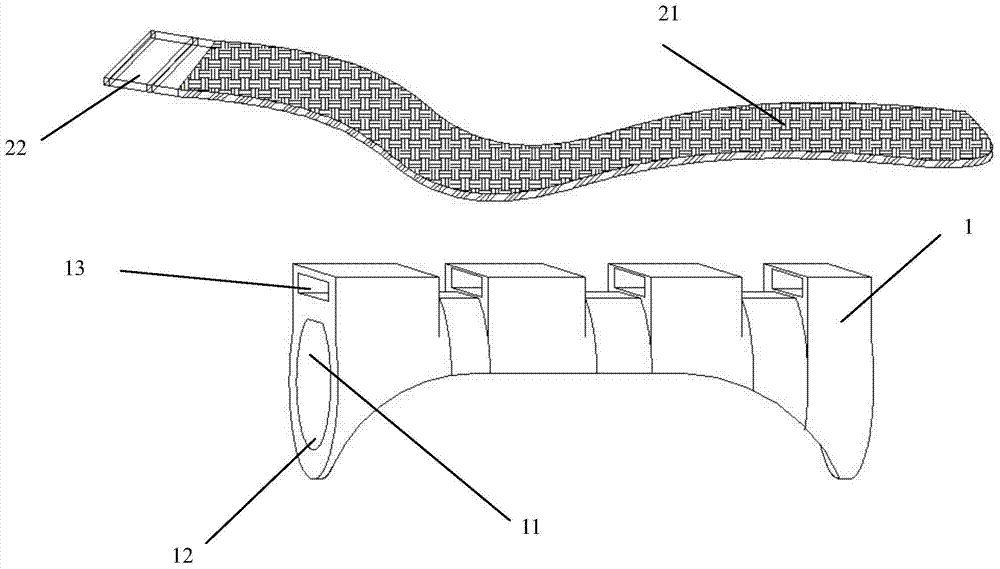

Double-line clothesline fixing rack

InactiveCN104514130AEasy to tieEasy to disassembleTextiles and paperClothes-linesEngineeringClothes line

The invention discloses a double-line clothesline fixing rack which comprises a fixing rack main body, wherein the fixing rack main body comprises a clothesline passing hole, arc-shaped parts and band holes; the hollow clothesline passing hole is formed in the middle of the fixing rack main body; each arc-shaped part is arranged at an opening in each of the two ends of the clothesline passing hole; a plurality of protruded band holes are formed in the outer side of the fixing rack main body; a binding band can be arranged in the band holes in a penetrating manner; a fixing ring is arranged at one end of the binding band. According to the double-line clothesline fixing rack, a double-line clothesline can be very conveniently bound so as to air clothes, and air can flow between two layers of the clothes, so that the airing speed can be increased, and a better airing effect can be achieved; the double-line clothesline fixing rack is used in daily lives.

Owner:DALIAN NATIONALITIES UNIVERSITY

Method for preparing briquette binder from kitchen waste and cattle manure

The invention discloses a method for preparing a briquette binder from kitchen waste and cattle manure and belongs to the technical field of preparation of briquette binders. The method comprises the following steps: adding sodium humate, bentonite and crushed maize straw into filtered leftovers, mixing and stirring, adding vinasse, fermenting and then centrifuging, spray drying supernatant, then mixing the supernatant with precipitate for later use, taking the cattle manure and peanut shell, drying and crushing the cattle manure and the peanut shell, then mixing the dried and crushed cattle manure and peanut shell with filtered biogas liquid, then carrying out composting treatment, uniformly mixing the compost with the mixture for later use and polymethyl acrylate, and drying to obtain the briquette binder. According to the method for preparing the briquette binder from the kitchen waste and the cattle manure, the kitchen waste and the cattle manure are used as raw materials of the briquette binder; the raw materials are easily available and environmental-friendly; when the prepared briquette binder is used for preparing pyrolysis briquette, the briquette is high in cold intensity and heat intensity; the tar yield during pyrolysis of the briquette can also be obviously increased; the prepared briquette binder is high in heat intensity and heat stability and excellent in water resistance and humidity resistance; the admixing amount and the ash content of the briquette in the using process are reduced; the briquette binder has a broad application prospect.

Owner:袁春华

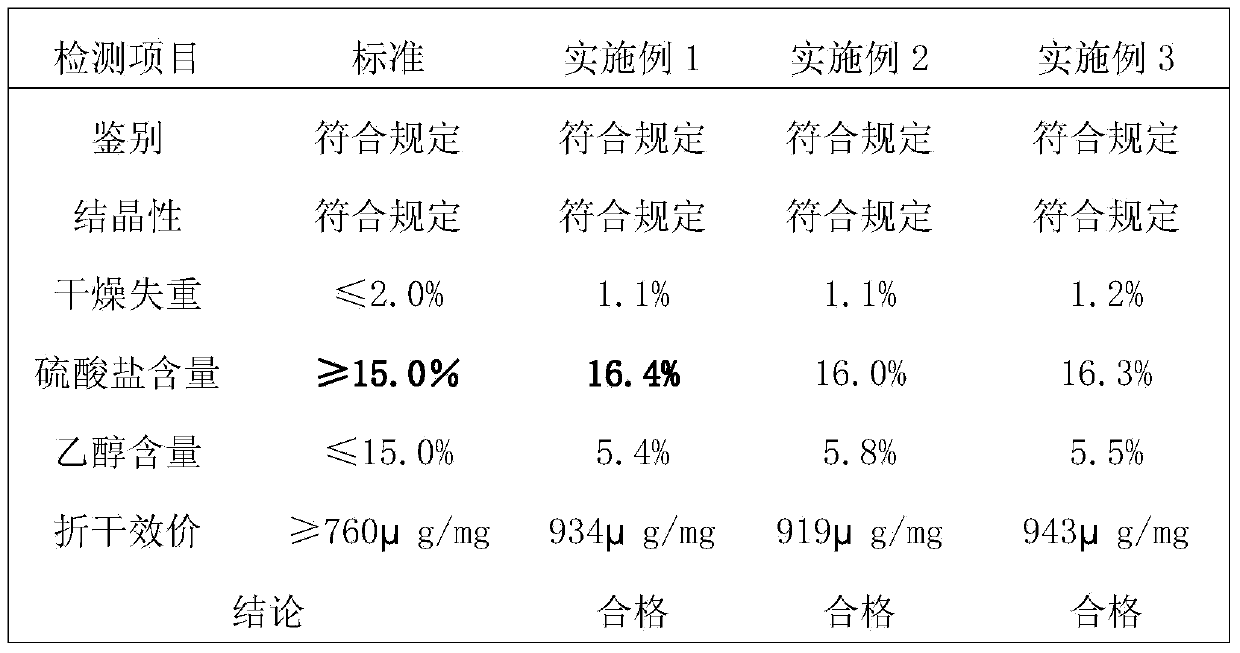

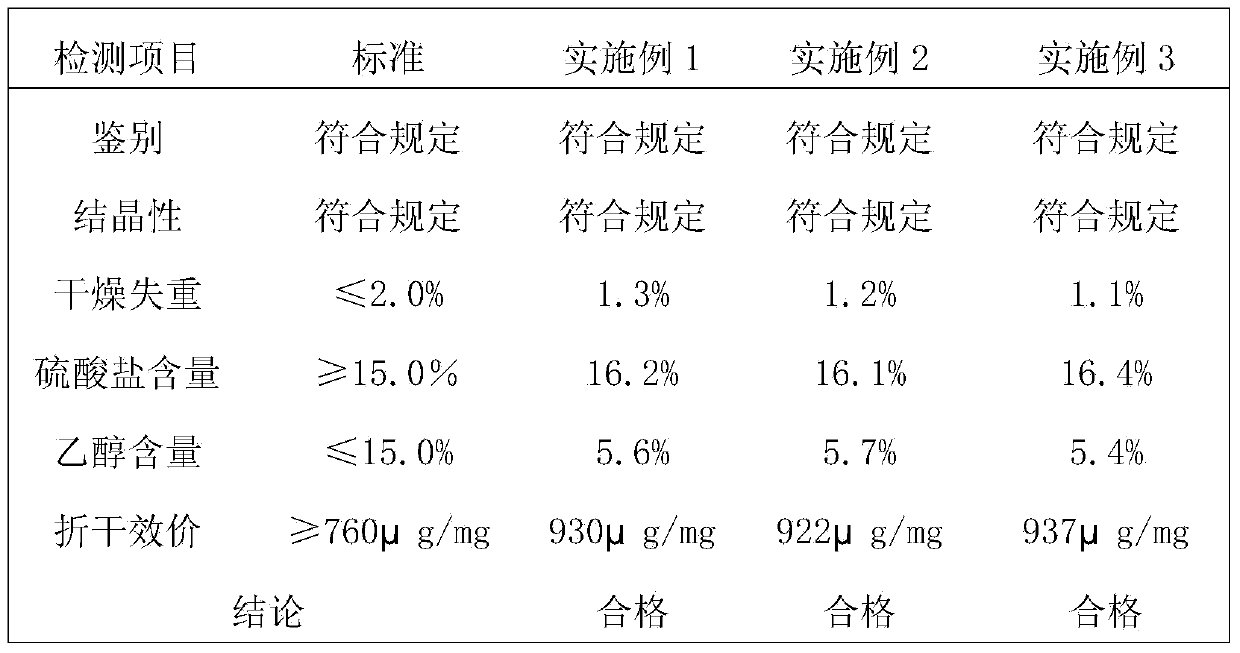

Production method of chlortetracycline bisulfate

ActiveCN103739514AResidue reductionLow ethanol toxicityCarboxylic acid amide separation/purificationChlortetracycline bisulfateSolvent

The invention discloses a production method of chlortetracycline bisulfate. The production method comprises the following steps: dropping a well prepared sulfuric acid / ethanol mixed solution in an ethanol suspension of a chlortetracycline base to dissolve the chlortetracycline base, filtering, then performing crystal growth by using ethanol, filtering, further washing with the ethanol, filtering, and finally performing vacuum drying to obtain the chlortetracycline bisulfate. According to the preparation method disclosed by the invention, the operation procedure is simplified, the production period is shortened, a single solvent is used to facilitate the recovery and the mechanical application of the solvent, the production cost is reduced, and the safety in production, the yield and the product quality are further improved. The chlortetracycline bisulfate prepared by the preparation method disclosed by the invention has the advantages of high yield, high titer, low solvent residue and good stability.

Owner:FUJIAN FUKANG PHARMA

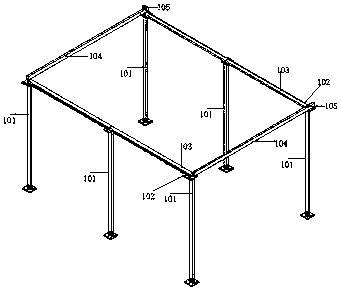

Rapid drying frame for subway door plate

The invention discloses a rapid drying frame for a subway door plate. The rapid drying frame comprises a supporting plate, an upper bottom plate, a lower bottom plate, air suction boxes, air suction holes, sliding grooves, airing frames, hooks, an air suction pipe and an exhaust fan. The upper end and the lower end of the supporting plate are fixedly provided with the upper bottom plate and the lower bottom plate correspondingly. The six parallel air suction boxes are fixedly installed between the upper bottom plate and the lower bottom plate. The left planes and the right planes of the air suction boxes are evenly provided with the air suction holes. The corresponding positions, between every two adjacent air suction boxes, of the upper bottom plate and the lower bottom plate are provided with sliding grooves correspondingly. Every two corresponding sliding grooves are internally provided with one airing frame in a sliding mode. Each airing frame is internally provided with two hooks in a rotating mode. The air suction pipe is fixedly installed to the lower plane of the lower bottom plate. The air suction pipe is connected with an air suction opening of the exhaust fan. The rapid drying frame has the advantages of being good in drying effect and high in drying speed, not damaging product quality and the like.

Owner:安徽枫帆轨道装备有限公司

Surface cleaning device for electronic element

InactiveCN109954724AAvoid components getting wet or even short circuitDry wellDrying gas arrangementsCleaning using gasesAir heaterEngineering

The invention relates to the technical field of cleaning equipment, in particular to a surface cleaning device for an electronic element. The surface cleaning device comprises a worktable, an air heater and a dust collector; the center of the top end of the worktable is provided with a turning plate; the left side of the top end of the workable is fixedly provided with a left oil cylinder; the topend of the left oil cylinder is provided with a left lifting rod and is fixedly connected with a first fixed plate; the top end of the first fixed plate is fixedly provided with the air heater; the right side of the top end of the worktable is fixedly provided with a right oil cylinder; the top end of the right oil cylinder is provided with a right lifting rod and is fixedly connected with a second fixed plate; a supporting plate is arranged inside the second fixing plate; the supporting plate is slidably connected with the inner wall of the second fixed plate; the top end of the left side ofthe supporting plate is fixedly provided with the dust collector; the right end of the supporting plate is fixedly connected with a gear rack; the inner side of the gear rack is provided with a gear;and the gear is engaged with the gear rack. The surface cleaning device provided by the invention can implement hot air drying and dust removal for the surface of the electronic element, achieves a good cleaning effect and is worthy of popularization.

Owner:GUILIN SHIHUAN WASTE GAS TREATMENT EQUIP

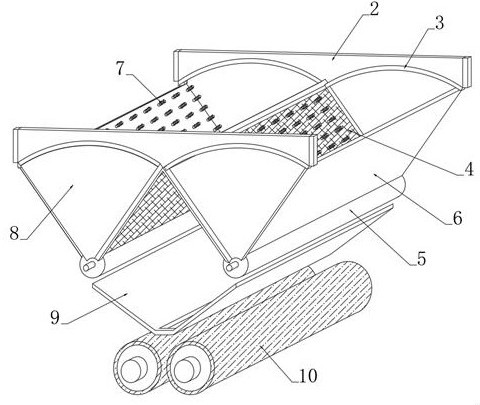

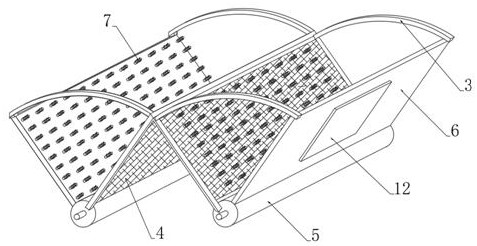

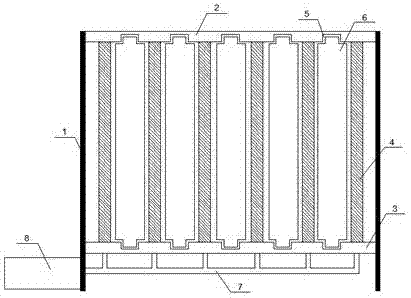

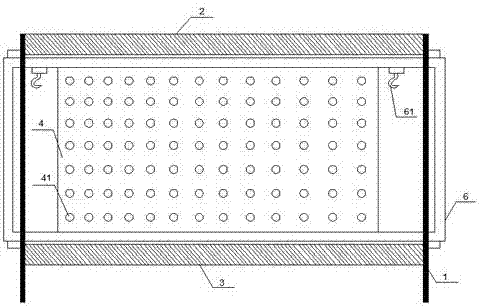

Gill type energy-saving solar sun-curing greenhouse

InactiveCN107388755ANovel structureDry wellFood processingClimate change adaptationStart stopGreenhouse

The invention discloses a gill type energy-saving solar sun-curing greenhouse. The gill type energy-saving solar sun-curing greenhouse comprises a supporting mounting module, gill type start-stop modules and an uniform-rotation sun-curing module, wherein the supporting mounting module comprises a mounting bottom plate; the two ends of the mounting bottom plate are vertically equipped with supporting mounting plates; the upper ends of the supporting mounting plates are horizontally equipped with limiting mounting covers; the upper ends of the limiting mounting covers are embedded with solar cell panels; the gill type start-stop modules are embedded into limiting mounting covers below the solar cell panels; each gill type start-stop module comprises guide rotary shaft groups which are horizontally equipped through bearing sleeves symmetrically arranged at the two sides of the lower end of each limiting mounting cover; the uniform-rotation sun-curing module is arranged inside the supporting mounting module; and the uniform-rotation sun-curing module comprises a rotatably mounted sun-curing structure and a switching transmission structure. The gill type energy-saving solar sun-curing greenhouse has the advantages of being novel and delicate in structure, energy-saving and environmentally friendly, controllable in sun-curing period, good in sun-curing effect, stable and efficient in structural transmission and the like.

Owner:吴鑫锋

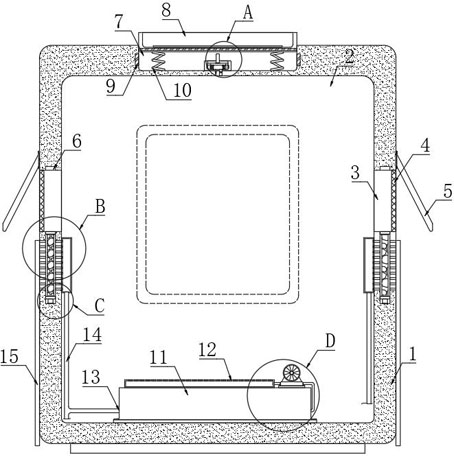

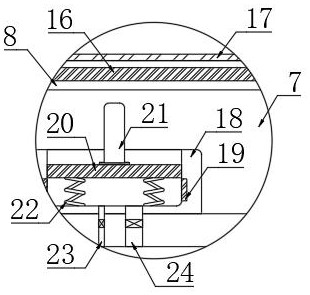

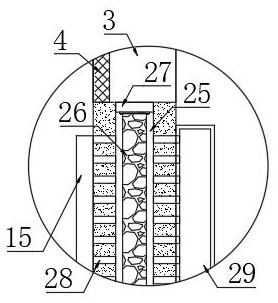

Damp-proof power distribution cabinet for rainy areas

ActiveCN113363827AAutomatic riseActive coolingGas treatmentDispersed particle filtrationActivated carbonMechanical engineering

The present invention discloses a damp-proof power distribution cabinet for rainy areas. The cabinet comprises a shell, an installation chamber is arranged in the shell, ventilation openings are formed in the inner walls of the two sides of the installation chamber respectively, a filter screen is installed in each ventilation opening, a sliding groove is formed in the inner bottom of each ventilation opening, a limiting groove is formed in the inner top of each ventilation opening, an activated carbon plate is arranged in each sliding groove, the upper end and the lower end of each activated carbon plate are fixedly connected with sliding strips, and each sliding strip is slidably connected with the inner wall of the corresponding sliding groove. According to the power distribution cabinet, the activated carbon plate can be lifted in rainy days, active heat dissipation is carried out while wet air is dried, the heat dissipation effect is good, a heat collection structure is further arranged, collected heat can be used for evaporation of water on the drying layer after raining, and the drying effect of the drying layer is guaranteed.

Owner:江苏电博仕能源装备有限公司

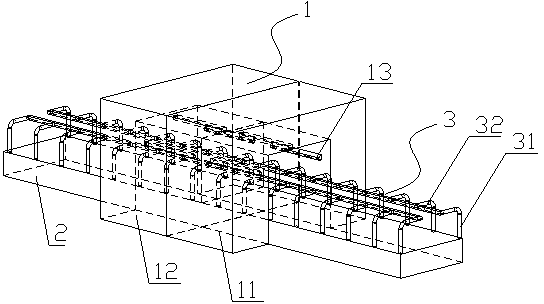

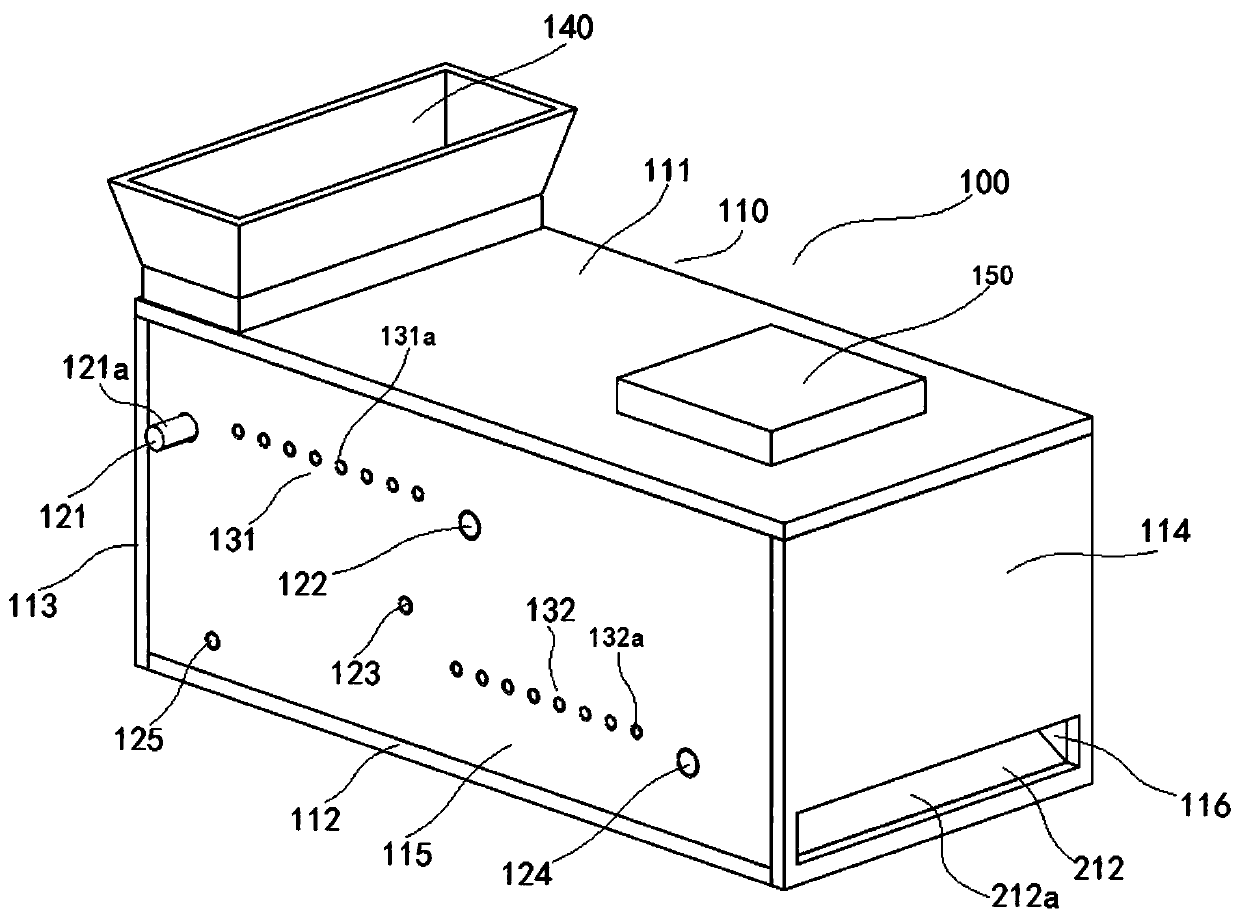

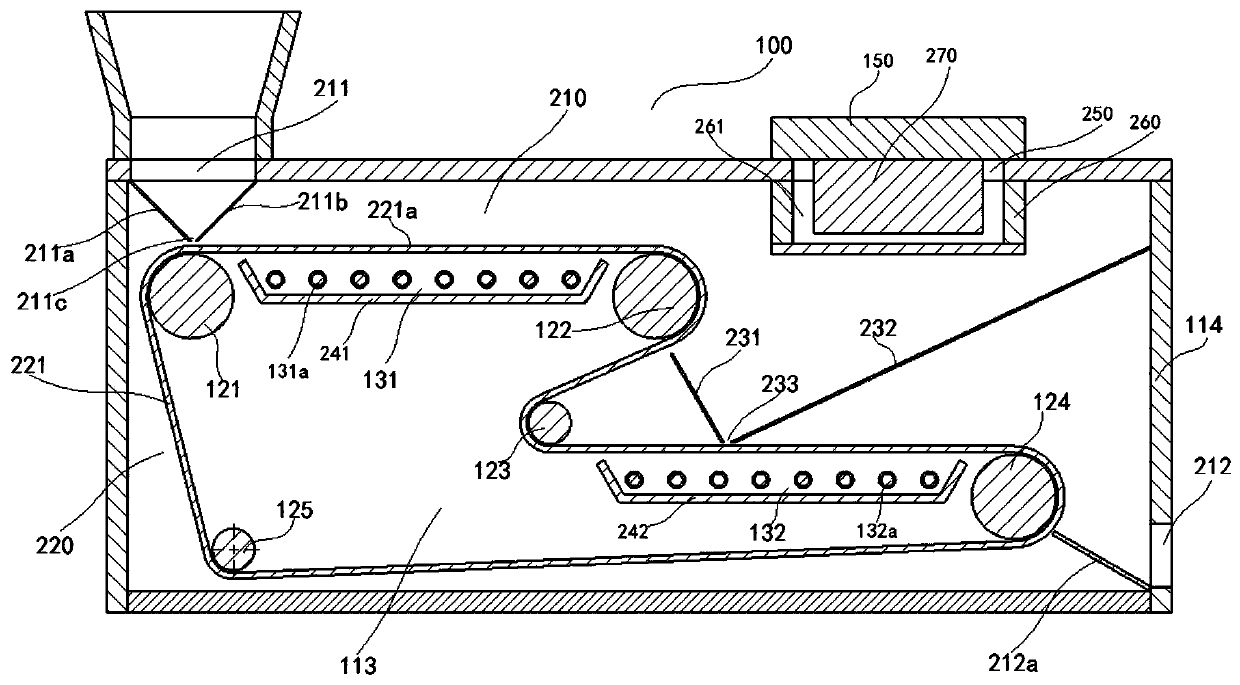

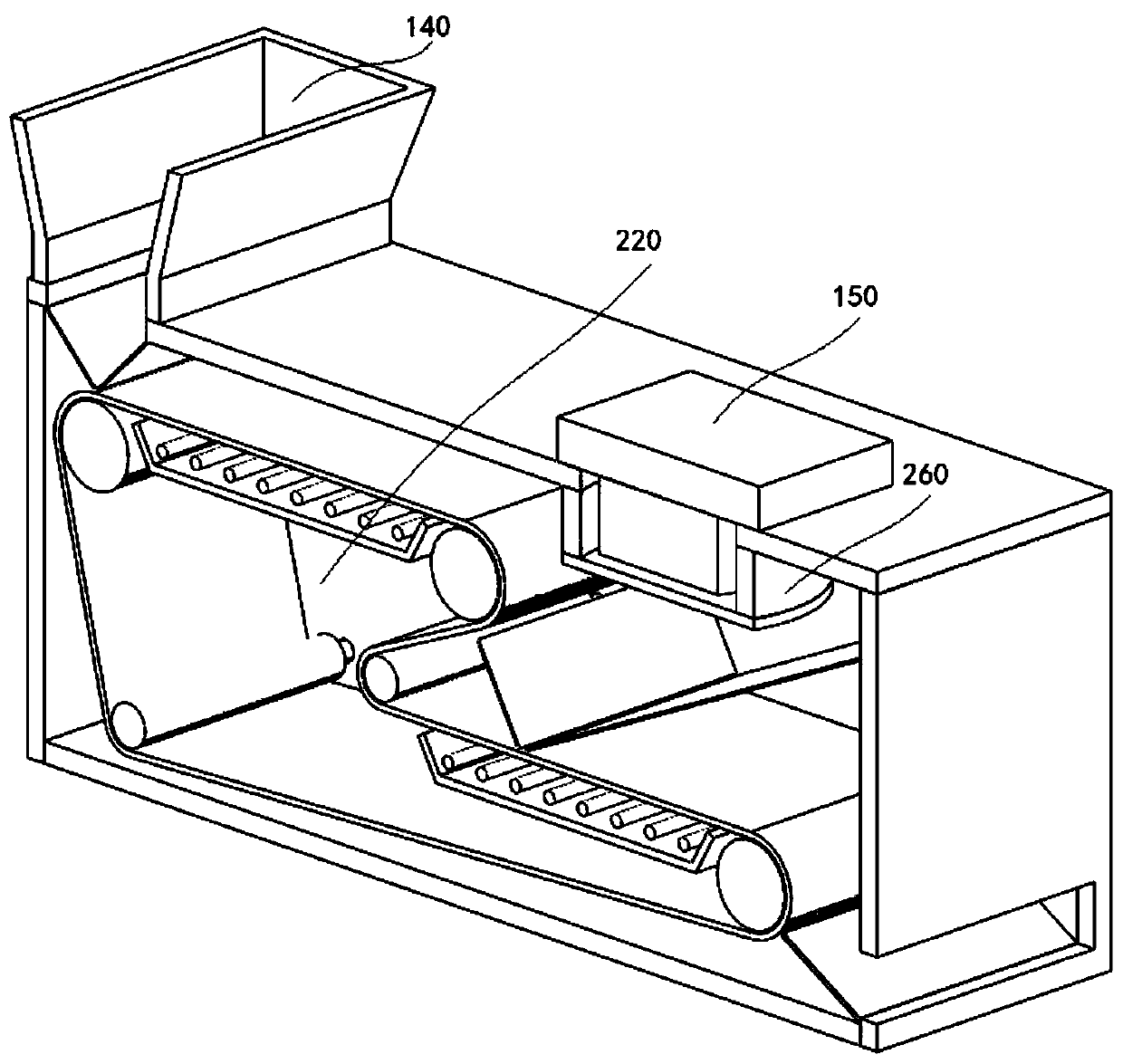

Drying device for pesticide preparation and pesticide production device

InactiveCN111288782AImprove drying effectSimple processShaking/oscillating/vibrating mixersDispersed particle filtrationAgricultural scienceAgricultural engineering

The invention relates to the technical field of pesticide production equipment, and particularly relates to a drying device for a pesticide preparation and a pesticide production device. The drying device comprises a drying device body, wherein the drying device body comprises a cuboid-shaped drying box body, and a drying cavity is formed in the drying box body; a feeding port and a discharging port which communicate with the drying cavity are formed in the drying box body, and a drying device is arranged between the feeding port and the discharging port in the drying cavity; the drying devicecomprises a transmission mechanism and a conveying belt, the transmission mechanism is used for driving the conveying belt to rotate circularly, and the conveying belt is used for conveying to-be-dried materials entering from the feeding port to the discharging port; and the transmission mechanism comprises a driving roller, a first driven roller, a first tensioning roller, a second driven rollerand a second tensioning roller which are sequentially arranged in the running direction of the conveying belt, and the driving roller is used for transmitting external power. According to the dryingdevice, the pesticide can be better dried in the pesticide preparation process.

Owner:王菲

High-efficiency method of extracting vanadium through sodium treatment

The invention relates to a high-efficiency method of extracting vanadium through sodium treatment, and belongs to the technical field of vanadium extraction of chemical engineering. The method comprises the following steps of uniformly mixing a vanadium-containing material and sodium salt to obtain a mixed material, and then preparing a bonding solution from sodium hydroxide, a binder and water; furthermore, adding the bonding solution into the above mixed material, and carrying out pelletizing to obtain wet pellets; and finally, conducting drying to obtain dry pellets, roasting the dry pellets at a high temperature, and then adding water and leaching. The method has the advantages that the stability of pelletizing and drying process is good, the equipment malfunction rate is low, the water content of the wet pellets is low so the wet pellets are easy to dry, thus achieving low drying cost; and meanwhile, the roasting process is conducted without adding tail slag, clinker and the like,thus improving the capacity of single roasting equipment by one time or more so as to reduce the production cost.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

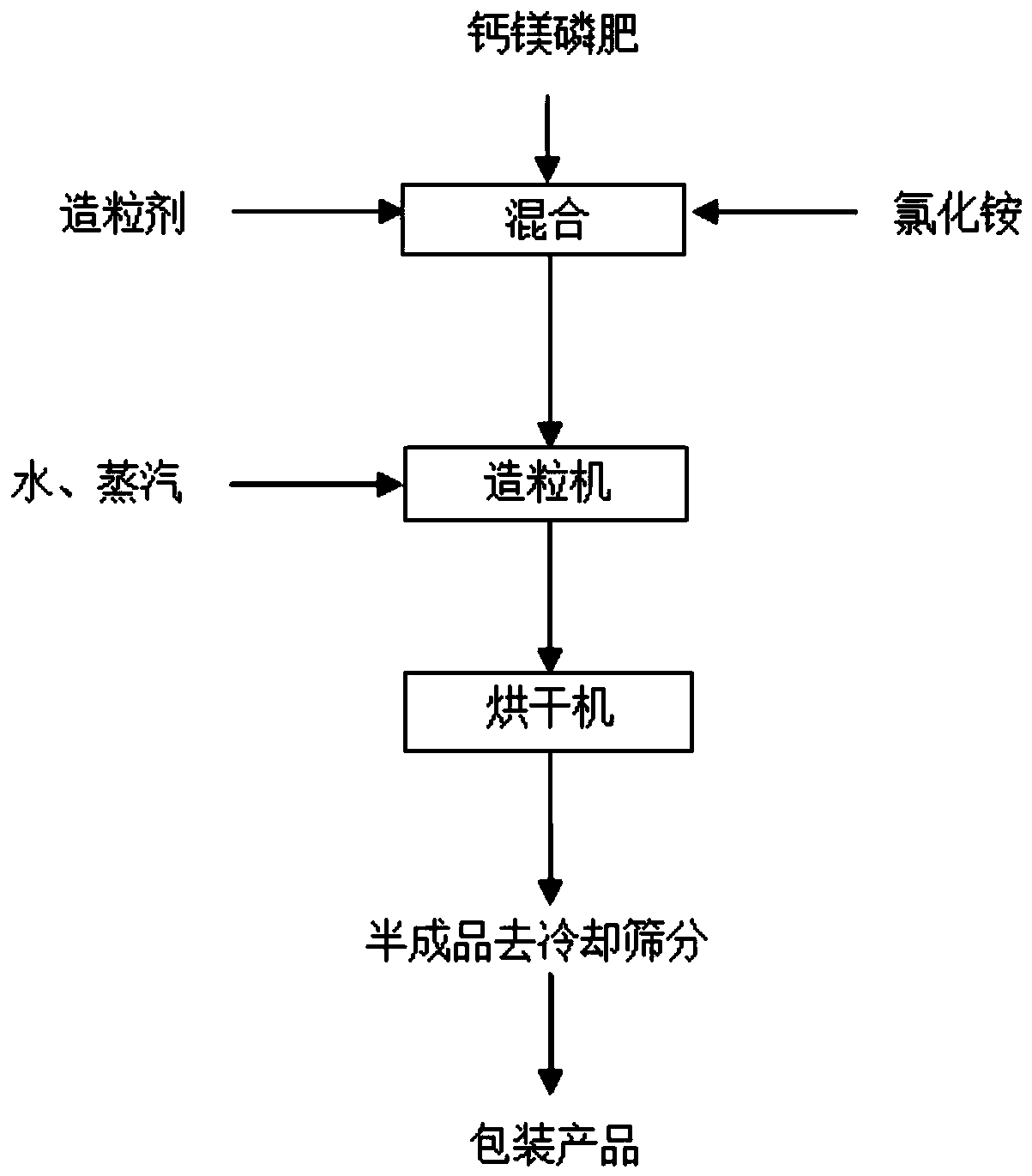

Special fertilizer for preparing granular rice from sandy raw materials and preparation method and application of special fertilizer

InactiveCN109942338AIncrease costPromote photosynthesisRice cultivationFertilizer mixturesPhosphate fertilizerCalcium magnesium phosphate

The invention relates to a special fertilizer for preparing granular rice from sandy raw materials and a preparation method and application of the special fertilizer. A calcium-magnesium-phosphate fertilizer, ammonium chloride and a granulating agent are mixed in the weight ratio of (30-70):(30-70):(1-10); the mixture is added into a granulator for granulation, then the granulated particle material is transferred into a drying machine for drying, the dried particle material is transferred into a cooling screening machine for cooling and screening, and the special fertilizer is obtained. Compared with the prior art, the calcium-magnesium-phosphate fertilizer and the ammonium chloride are put together, and a small quantity of granulating agent is added, so that granulation is easy, nutritional requirements of paddy rice are met, and the use quantity of other chemical fertilizers can be replaced and reduced.

Owner:SHANGHAI RES INST OF CHEM IND

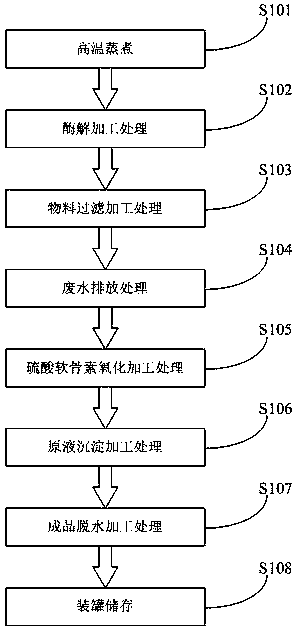

Production process of chondroitin and bone paste

InactiveCN111269334APollution suppressionAvoid pollutionOrganic active ingredientsSenses disorderJoint arthralgiaEngineering

The invention provides chondroitin and bone pulp. The chondroitin and bone pulp comprises the following raw materials in parts by weight: bone pulp, cartilage, water, sodium hydroxide, protease, sodium chloride, alcohol, hydrochloric acid and enzymolysis powder. The production process of chondroitin and bone paste comprises the following steps: high temperature cooking, enzymatic processing treatment, material filtration processing treatment, wastewater discharge treatment, chondroitin sulfate oxidation processing treatment, stock solution precipitation processing treatment, dehydrating the finished product, canning and storing. The production efficiency is high, the utilization rate is high, the chondroitin produced and processed by the method is a clinically common medicine and is used for treating neuropathic headache, neuralgia, arthralgia, migraine, arteriosclerosis and the like and is easy to dehydrate, dry and process and low in production cost and can be produced or processed in batch, and the generated wastewater is properly treated so as to avoid environmental pollution, inhibit generation of waste gas and noise and improve the production and processing efficiency.

Owner:无棣县兴亚生物科技有限公司

Paint rolling equipment capable of automatically feeding and treating paint

The invention relates to the technical field of bamboo and wood product paint rolling processing, and discloses paint rolling equipment capable of automatically feeding and treating paint. The paint rolling equipment comprises a paint rolling equipment main body, a support is fixedly mounted in the paint rolling equipment main body, an extrusion plate is slidably connected in the support, a material storage groove is fixedly mounted in the support, an elastic rod is fixedly connected to the interior of the material storage groove, a material guide pipe is fixedly connected to the bottom of the material storage groove, a through hole is formed in the outer wall of the paint rolling equipment main body, and a steel ball is slidably connected to the interior of the through hole. The steel ball is extruded, so that the extrusion plate in the support is driven to vertically move downwards to extrude the material storage groove in the support to shrink, paint in the material storage groove is discharged onto a liquid outlet plate on the outer wall of the paint rolling equipment main body from the material guide pipe, and then the paint is uniformly smeared through rolling of the paint rolling equipment main body, so that in the paint rolling process, the effect of automatic feeding of the paint rolling equipment main body is achieved.

Owner:国峻

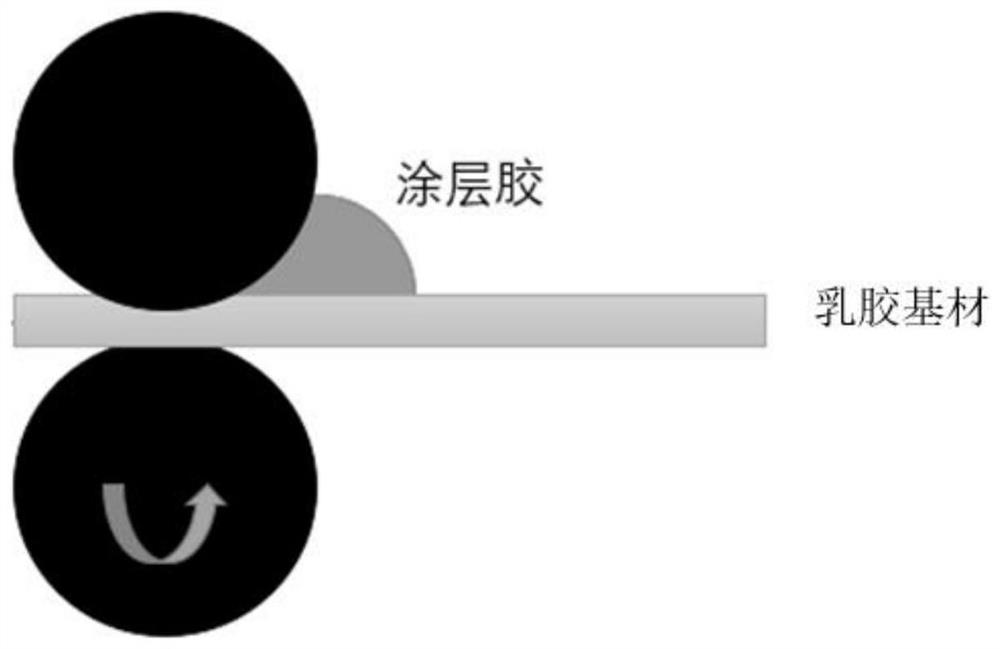

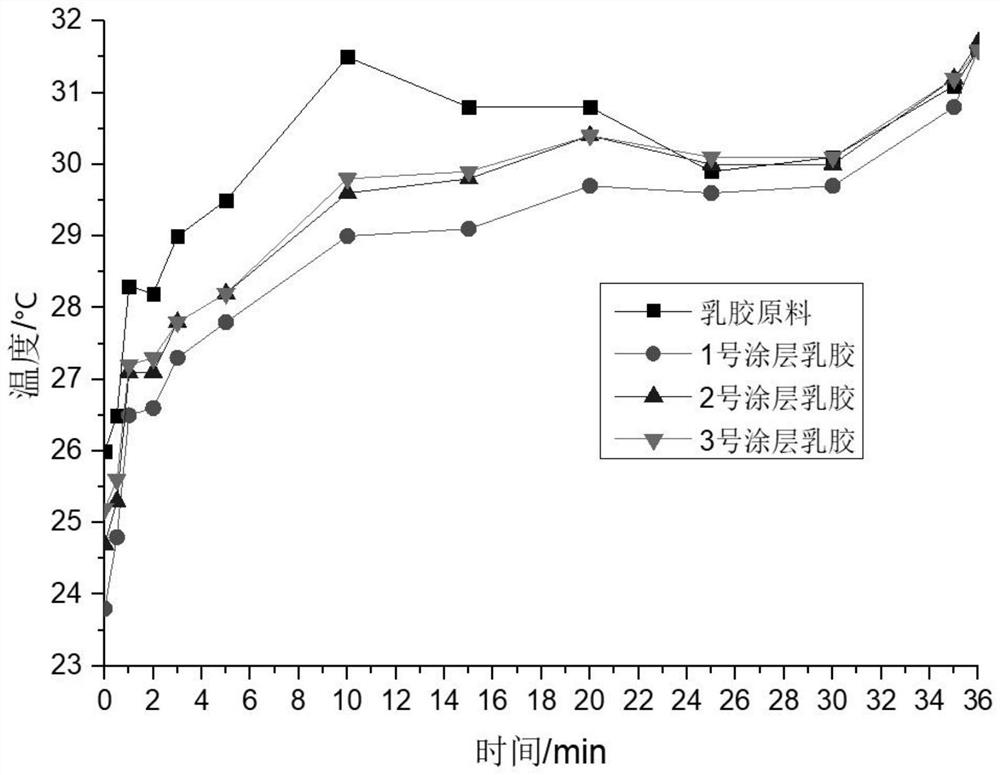

Cool breathable latex product and preparation method thereof

InactiveCN113549243AImprove wear resistanceImprove tensile propertiesPillowsStuffed mattressesParaffin waxPolymer science

The invention provides a cool breathable latex product and a preparation method thereof. According to the cool breathable latex product and the preparation method thereof provided by the invention, coating glue containing phase-change microcapsules coats a surface layer of the latex product and a pore structure below the surface layer by adopting a roller coating mode, and substances such as paraffin in the phase-change microcapsules absorb heat to keep a temperature constant, so a cool feeling during contact is brought to a human body. According to the coating technology, a compact film cannot be formed on the surface of latex, so inconvenience caused by heat dissipation and sweat evaporation of the compact film formed by an existing gel technology is avoided; and the technology does not damage an original latex structure, does not block pores in the surface layer of the latex, retains the breathable characteristic of the latex, and enables a user to feel cool and air-breathable.

Owner:武汉中科先进材料科技有限公司

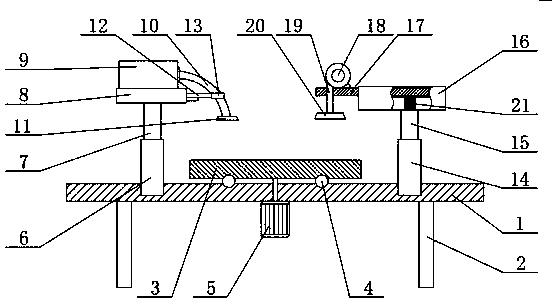

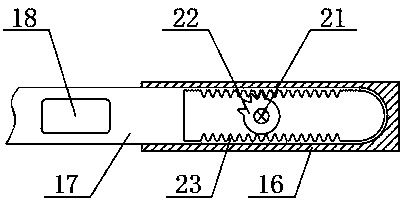

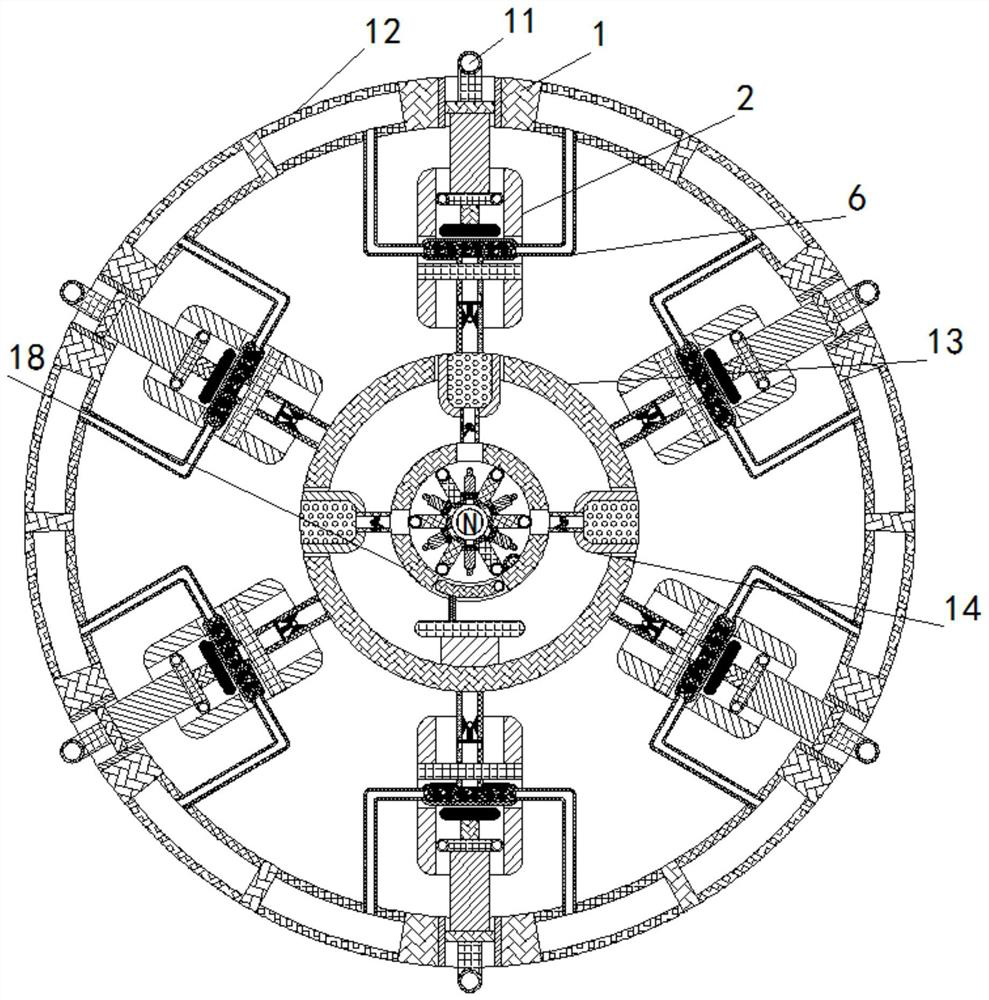

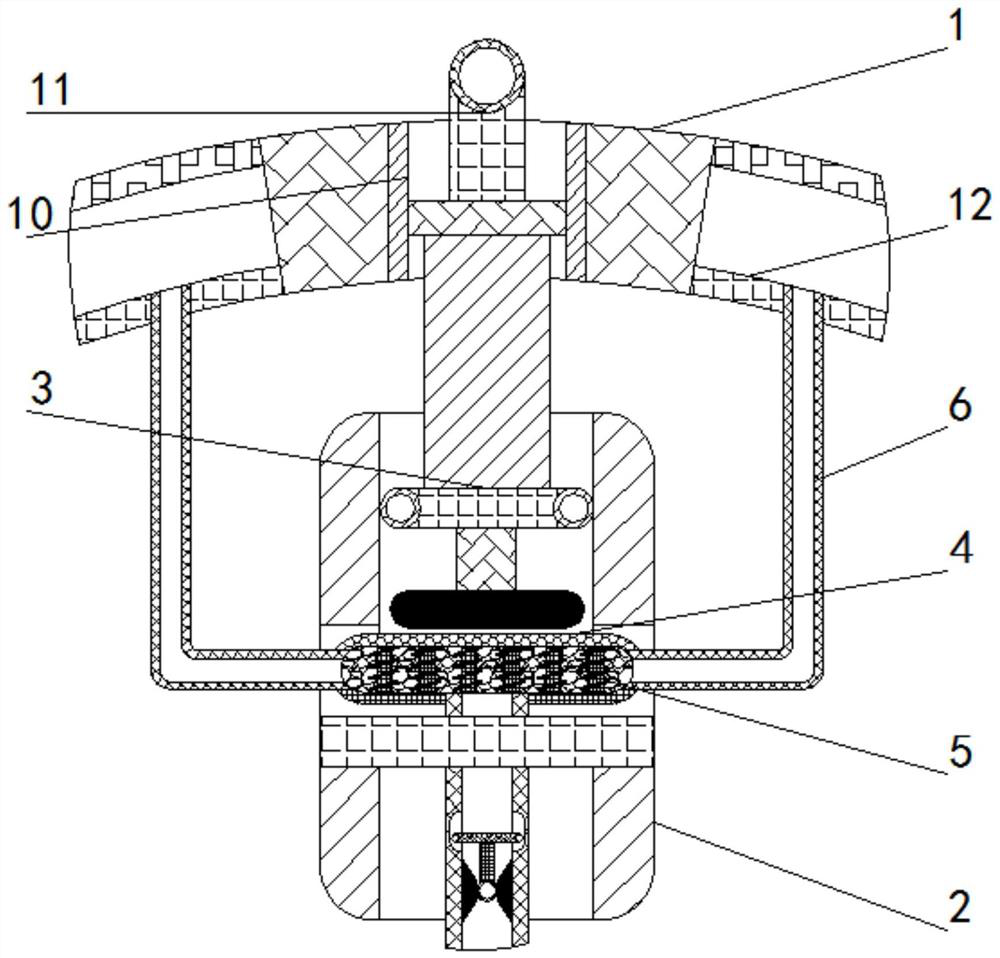

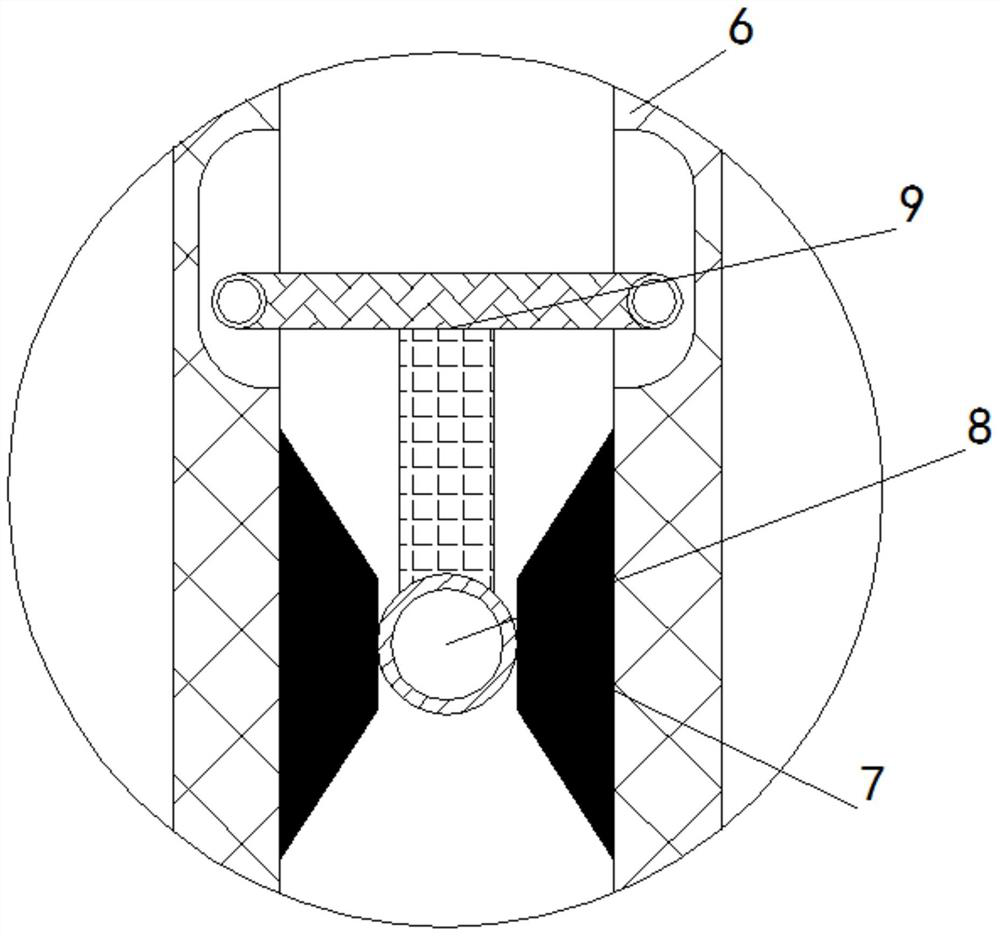

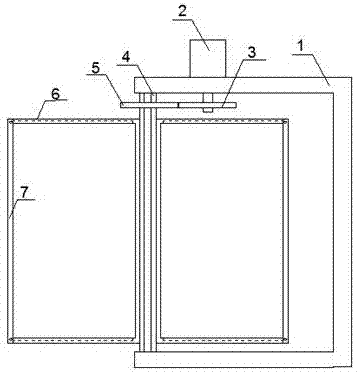

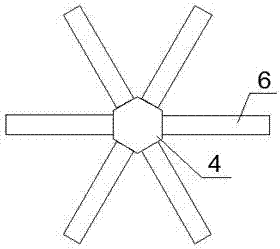

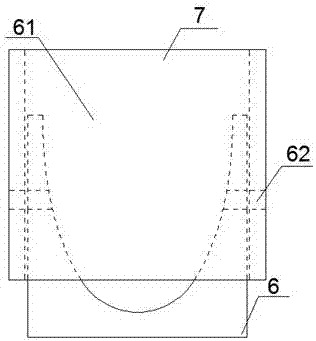

Rotary airing sun-cure frame

InactiveCN107185784ADry wellReduce energy consumptionPretreated surfacesCoatingsGear wheelEngineering

The invention discloses a rotary airing sun-cure frame. The rotary airing sun-cure frame comprises a rack, a servo motor, a first gear, a rotating frame body, a second gear, supporting frame bodies, limiting grooves, threaded holes and limiting rods; the servo motor is fixedly mounted on the upper plane of the rack; the first gear is fixedly mounted on an output shaft of the servo motor; the rotating frame body is rotatably mounted at the left end of the rack through a bearing; the second gear is fixedly mounted on the surface of the rotating frame body; the six supporting frame bodies are uniformly and fixedly mounted on the surface of the rotating frame body; the semi-elliptical limiting grooves are formed in the upper inner walls and the lower inner walls of the supporting frame bodies correspondingly; the side walls of the two ends of the limiting grooves are provided with the corresponding threaded holes; the limiting rods are also provided with the threaded holes corresponding to the threaded holes in the limiting grooves; and the limiting rods are fixed to the supporting frame bodies in the mode that bolts penetrate through the threaded holes. The rotary airing sun-cure frame has the advantages of being good in airing effect, small in energy consumption and the like.

Owner:安徽枫帆轨道装备有限公司

Orange pomace and peel drying method

The invention discloses an orange pomace and peel drying method. The orange pomace and peel drying method is characterized by comprising the steps of performing rolling, namely feeding orange peels, kernels and pomace into a peel pressing oil machine to be rolled, feeding rolled orange peels and pomace into a smashing machine to form particle pulp with particle size ranging 8mm to 12mm, standing the particle pulp in a tank with a stirring device, adding 0.5-1% by total orange peel and pomace weight of lime, performing stirring for 30-40 minutes for standby application, feeding the orange peels and pomace mixed with the lime into a belt presser to squeeze the orange peels and pomace with 3-4 kilogram pressure, collecting the pressed orange peels and pomace for standby application, feeding the squeezed orange peels and pomace into a flashing type drying machine to be dried for 5-10 minutes at the temperature ranging from 400 DEG C to 40 DEG C and performing bagging, weighing, opening sealing and storage on dried orange peels and pomace. The dried orange peels and pomace are golden yellow in color and luster and free of bitter taste and can serve as a food and a feed additive, and the product usage is greatly improved.

Owner:NANCHONG JIAMEI FOOD IND CO LTD

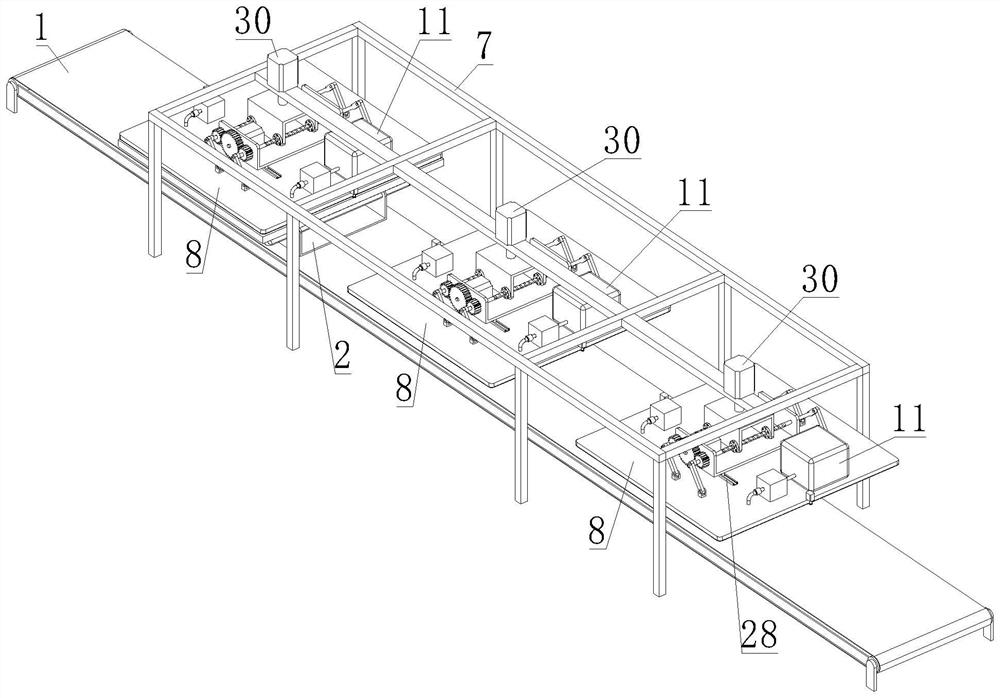

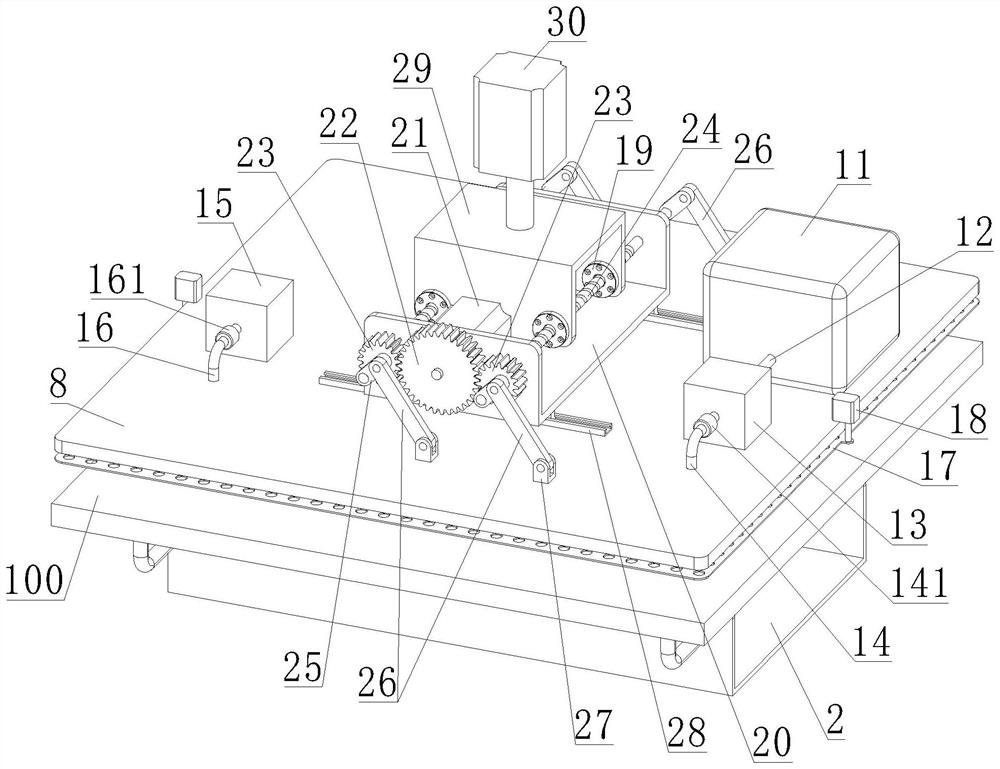

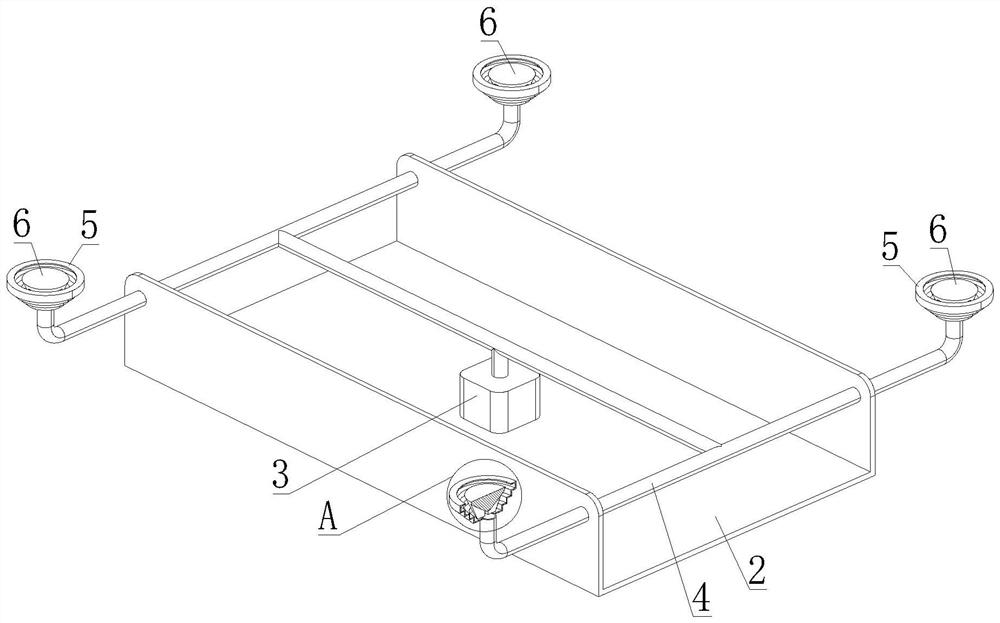

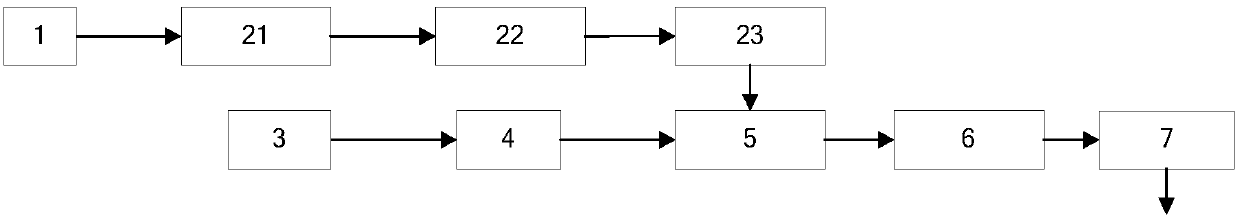

Wooden furniture production device and production method thereof

ActiveCN114505192AIncrease ejection speedIncrease diversityPretreated surfacesLiquid spraying apparatusWood plankIndustrial engineering

The invention relates to the field of furniture production, in particular to a wooden furniture production device and a production method thereof. The device comprises a rack, multiple sets of paint spraying and drying mechanisms sequentially arranged on the rack, a fixing mechanism used for fixing a wood board, and a conveying mechanism capable of driving the fixing mechanism to sequentially move to the position below the multiple sets of paint spraying and drying mechanisms. The paint spraying and drying mechanism comprises a flow dividing box, an output head, a paint box, a connecting pipe b, a conveying pump, a connecting pipe c, a hot air output device, a connecting pipe a, a power mechanism used for driving the flow dividing box to move in a wave mode in the plane so that paint and hot air can be evenly sprayed out through the output head, and a lifting mechanism a used for driving the power mechanism to ascend and descend. A plurality of discharge holes are formed in the bottom of the flow dividing box in an array manner. According to the device, multiple rounds of paint spraying and drying treatment can be carried out, each round of paint spraying and drying treatment process is carried out under the condition that a wood board is not moved, the paint thickness is uniform, the bubbling phenomenon is avoided, and the paint spraying quality is high.

Owner:HUNAN UNIV OF TECH

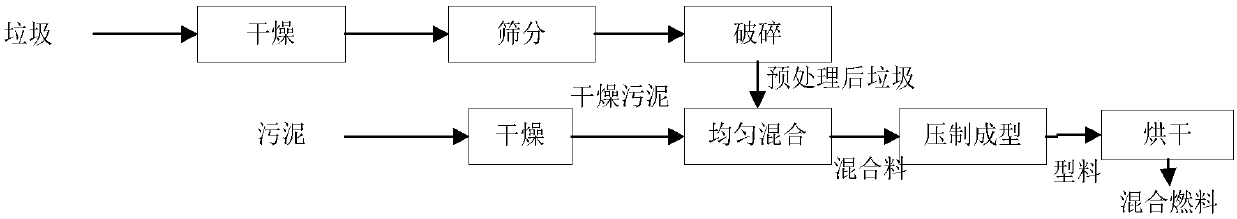

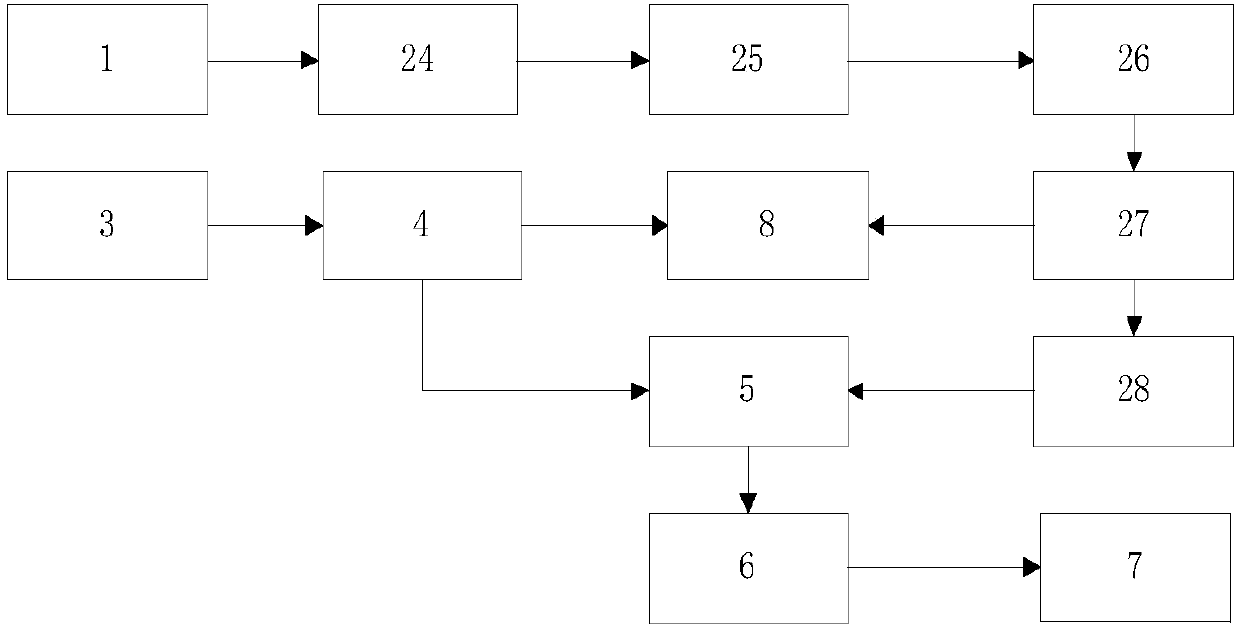

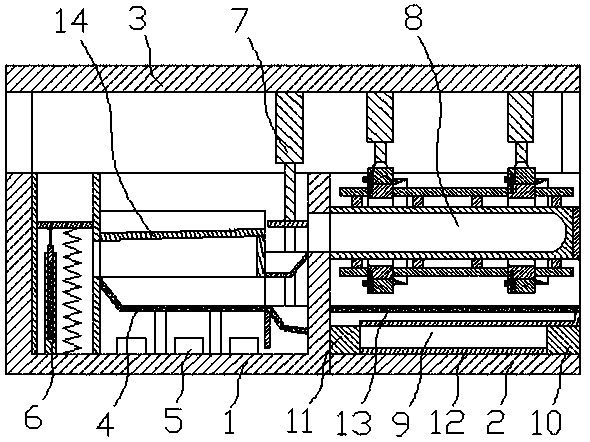

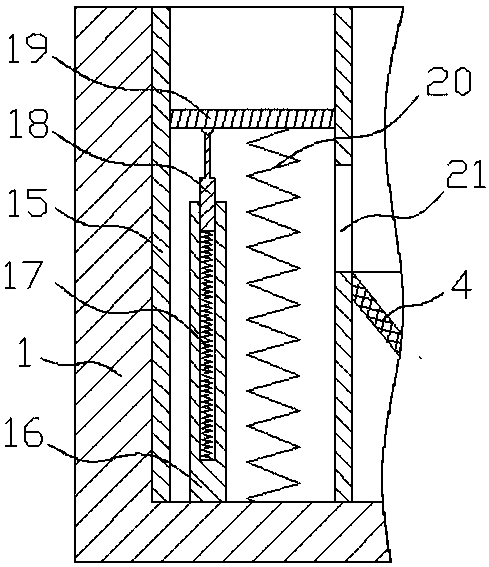

Preparation method and preparation system for garbage and sludge mixed fuel

PendingCN107557105ARealize resource utilizationHigh calorific valueBiofuelsSolid fuelsMixed fuelPre treatment

The invention relates to a preparation method and a preparation system for garbage and sludge mixed fuel. The method comprises the following steps: performing drying, crushing and screening pretreatment on garbage so as to obtain pretreated garbage; drying sludge until the moisture content is 50-60wt% so as to obtain dried sludge; uniformly mixing the pretreated garbage with the dried sludge so asto obtain a mixture; molding the mixture to obtain a molded material; and drying the molded material, thereby obtaining the mixed fuel. According to the method disclosed by the invention, productionof dioxin and fly ash can be effectively reduced, bad smell, sewage and the like produced in the storage or transporting process can be reduced, the cost is saved, and the fuel product is high in strength and high in stability.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

Washing and wipe-drying machine available for discharging and collecting at same station

InactiveCN108414321AReduce manpower consumptionSimple structurePreparing sample for investigationFood treatmentTextileButt joint

The invention relates to a washing and wipe-drying machine available for discharging and collecting at a same station. The washing and wipe-drying machine comprises a washing frame, a wipe-drying frame and an upper supporting frame above the washing frame and the wipe-drying frame. A washing mesh trough is arranged in the washing frame through supporting rods, a washing lifting device is fittinglyarranged on the right side of the washing mesh trough, a right side plate of the washing frame is provided with a wipe-drying feeding port matched with the washing lifting device, a wipe-drying device matched with the wipe-drying feeding port is arranged in the washing frame, and a washing vibration source is arranged in the washing frame. A collection trough matched with the washing lifting device is arranged above the washing mesh trough, the wipe-drying device comprises a wipe-drying cloth pipe in butt joint with the wipe-drying feeding port, two cloth pipe inclination adjusting cylindersin bilateral abreast arrangement are fittingly hinged to the upper portion of the wipe-drying cloth pipe, and the right end of the wipe-drying cloth pipe is a sealed concave arc block. By structural design of the wipe-drying device and structural design of the collection trough, washed and wipe-dried potatoes can be re-transported to a discharging position, so that discharging and collecting at the same station is realized, and labor consumption is greatly saved.

Owner:DONGGUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com