Production method of chlortetracycline bisulfate

A technology of bisulfate and production method, applied in the separation/purification of carboxylic acid amide, organic chemistry and other directions, can solve the problems of increasing solvent recovery cost, reducing product competitiveness, increasing manufacturing cost, etc., to shorten production cycle and improve safety Productivity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

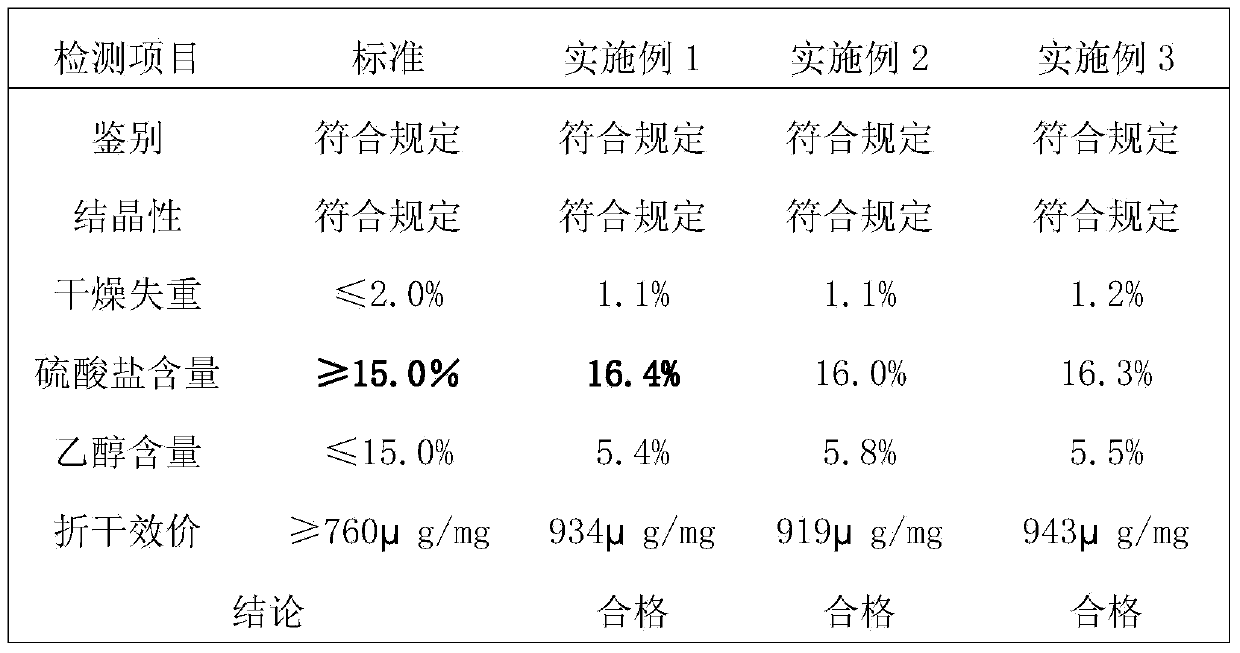

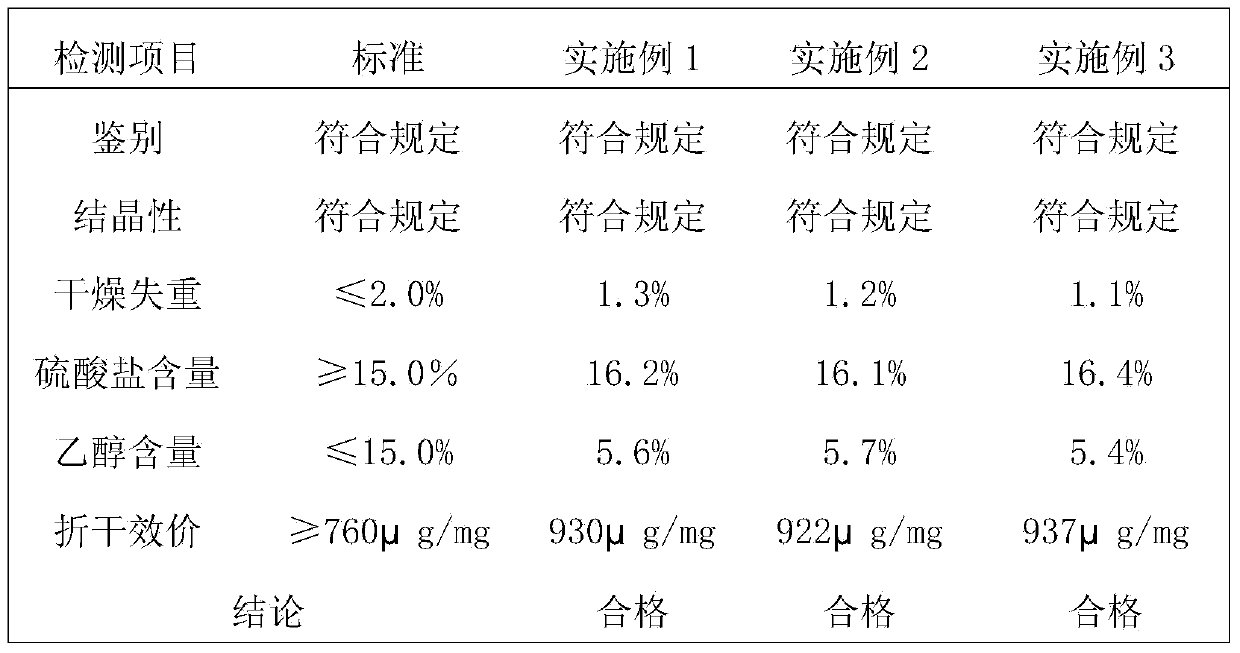

Embodiment 1

[0024] Add 8kg of ethanol to the preparation tank, add 2kg of sulfuric acid dropwise under the temperature of 40°C, after dropping, stir for 10min, and store it at room temperature for later use; After the ethanol mixture is added dropwise, control the temperature at 20°C and stir for 30 minutes, then filter; after filtering, collect the filtrate in a crystallization tank, control the temperature at 35°C and then add 16kg of ethanol dropwise, after the dropwise addition of ethanol, keep it warm for 3 hours, and slowly cool down to 10 Insulate at ℃ for 2 hours; filter to obtain the filter cake, wash the filter cake with 32kg of ethanol, and then filter to obtain the wet powder; dry the wet powder in vacuum, control the temperature at 40°C, and dry at a vacuum degree of -0.07~-0.10Mpa until the weight loss on drying is ≤2.0%. Get aureomycin bisulfate 11.5kg, and the weight yield is 115%. The quality of the product complies with the standards of the United States Pharmacopoeia; a...

Embodiment 2

[0026] Add 12kg of ethanol to the preparation tank, and add 3kg of sulfuric acid dropwise under the control temperature of 40°C. After the dripping is completed, stir for 15min, and store it for later use at normal temperature; After the ethanol mixture is added dropwise, control the temperature at 25°C and stir for 30 minutes, then filter; after filtering, collect the filtrate in a crystallization tank, control the temperature at 40°C and then add 20kg of ethanol dropwise, after the dropwise addition of ethanol, keep it warm for 3 hours, and slowly cool down to 12 Insulate at ℃ for 2 hours; filter to obtain the filter cake, wash the filter cake with 40kg of ethanol, and then filter to obtain the wet powder; vacuum-dry the wet powder at a controlled temperature of 45°C and a vacuum degree of -0.07~-0.10Mpa until the drying weight loss ≤ 2.0%, to obtain Chlortetracycline hydrogen sulfate 11.2kg, weight yield is 112%. The quality of the product complies with the standards of the...

Embodiment 3

[0028] Add 16kg of ethanol to the preparation tank, add 4kg of sulfuric acid dropwise under the control temperature of 40°C, after dropping, stir for 20min, store it at room temperature for later use; After the ethanol mixture is added dropwise, control the temperature at 30°C and stir for 30 minutes, then filter; after filtering, collect the filtrate in a crystallization tank, control the temperature at 45°C and then add 24 kg of ethanol dropwise, after the dropwise addition of ethanol, keep warm for 3 hours, and slowly cool down to 15 Insulate at ℃ for 2 hours; filter to obtain the filter cake, wash the filter cake with 48kg of ethanol, and then filter to obtain wet powder; vacuum dry the wet powder at a controlled temperature of 50°C and vacuum degree of -0.07~-0.10Mpa until the drying weight loss ≤ 2.0%, Get aureomycin bisulfate 11.1kg, and the weight yield is 111%. The quality of the product complies with the standards of the United States Pharmacopoeia; after being store...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com