Patents

Literature

883results about How to "Good energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

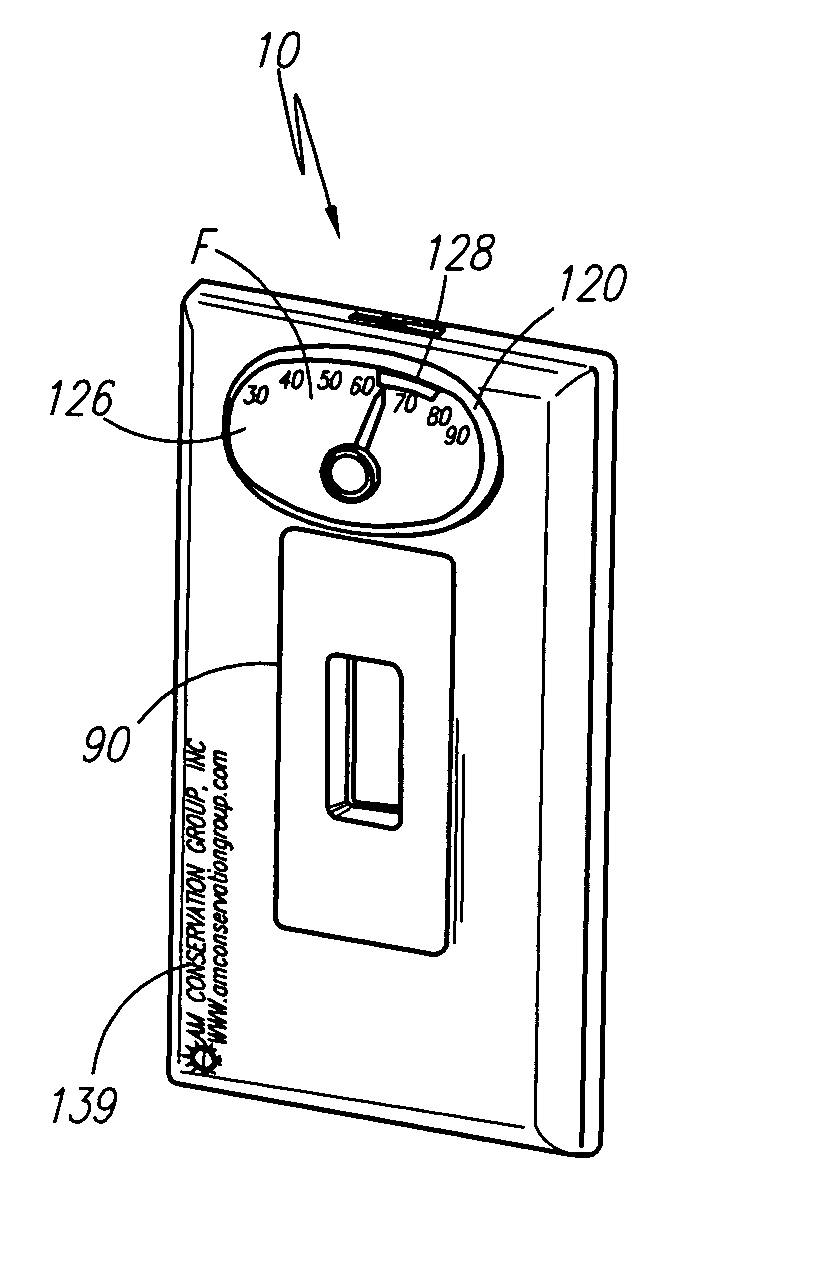

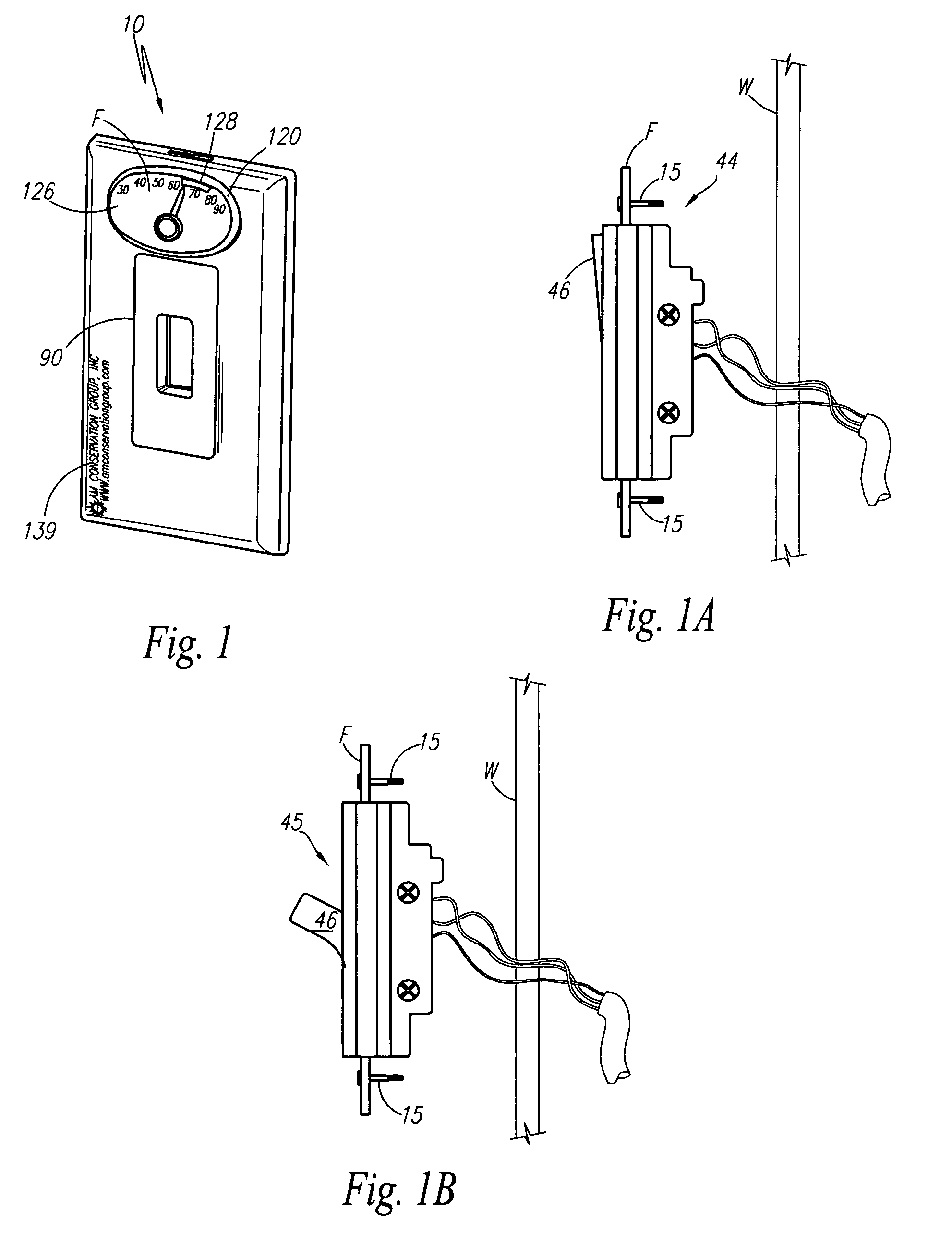

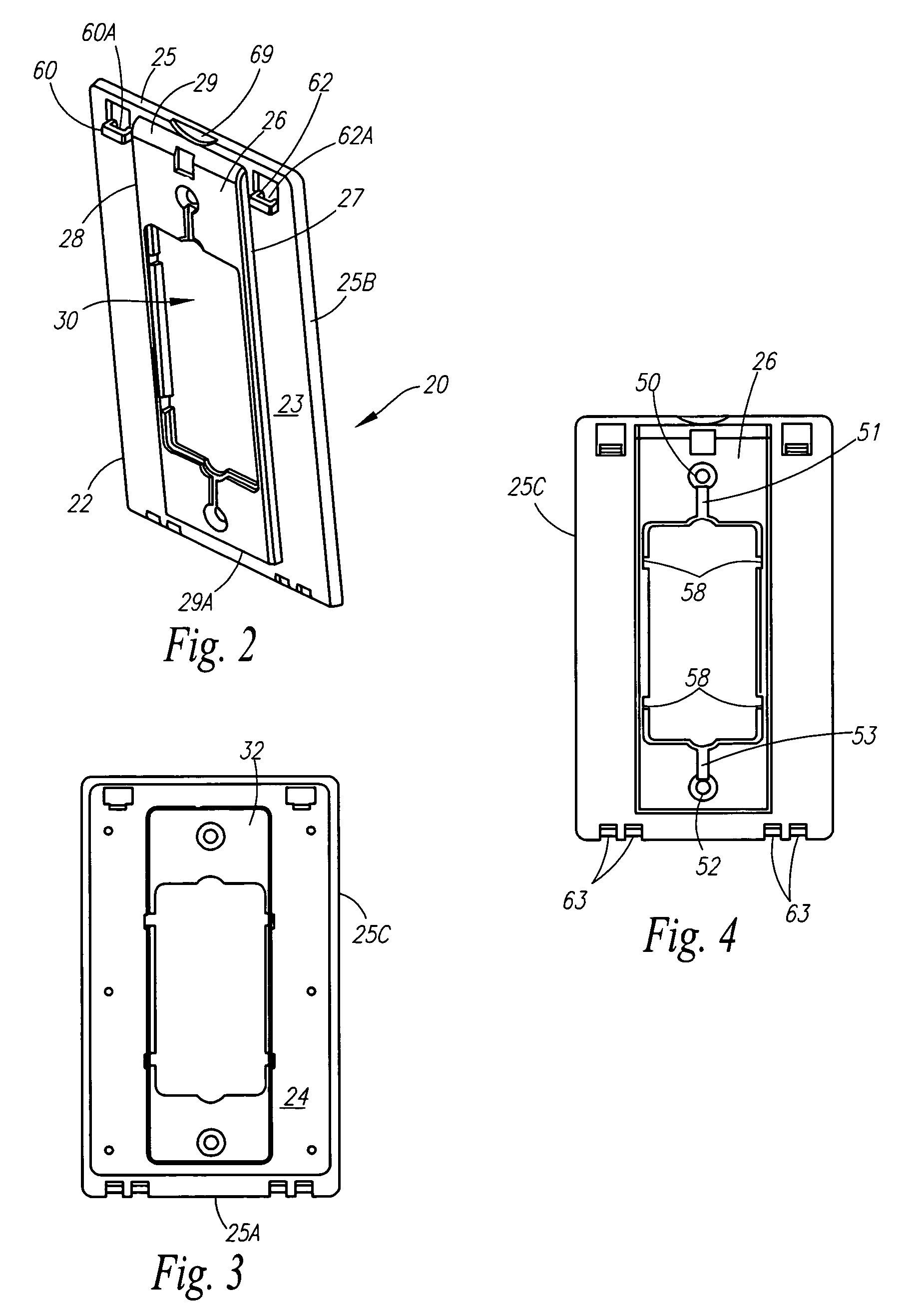

Universal wall plate thermometer

InactiveUS8143520B2Good for conservationGood energyCasings/cabinets/drawers detailsEngineeringLight switch

A light switch cover assembly easily mounted over existing wall type light switches. The cover assembly includes a mounting bracket having an opening provided therethrough which is shapely designed and sizably configured for snug attachment of a bracket plate therein. The bracket plate includes an opening to allow the protruding rocker portion of a light switch to pass therethrough. The bracket plate further includes a plurality of apertures defined therethrough for receipt of mounting screws. A face plate is adapted for removable attachment to the mounting bracket in a snap-fit manner. The face plate includes an opening shapely designed and sizably configured to snugly accommodate a rocker plate therein. The face plate further includes an oblong opening providing a thermometer support enclosure within which a thermometer is swivelably secured.

Owner:FIFTH THIRD BANK

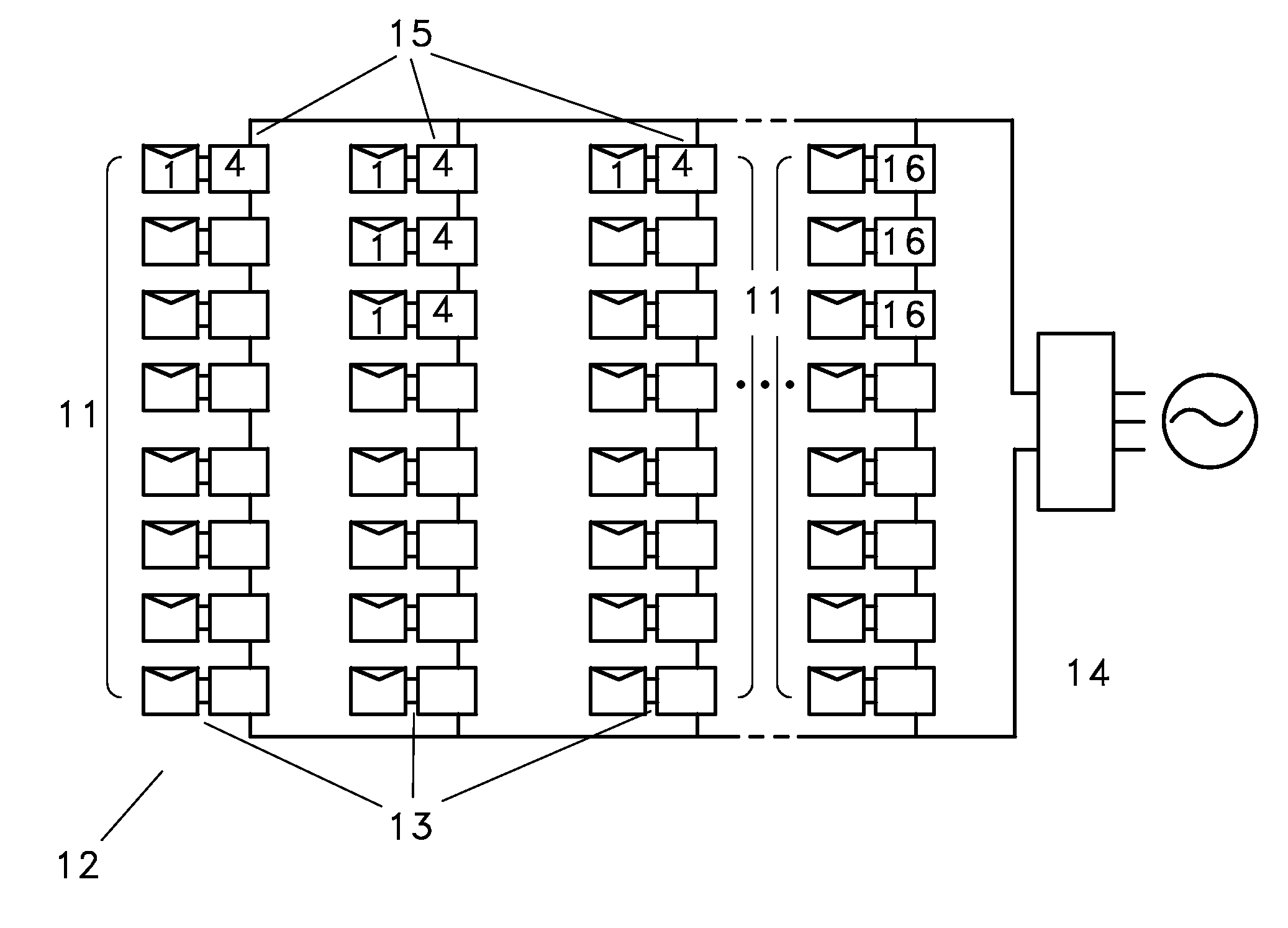

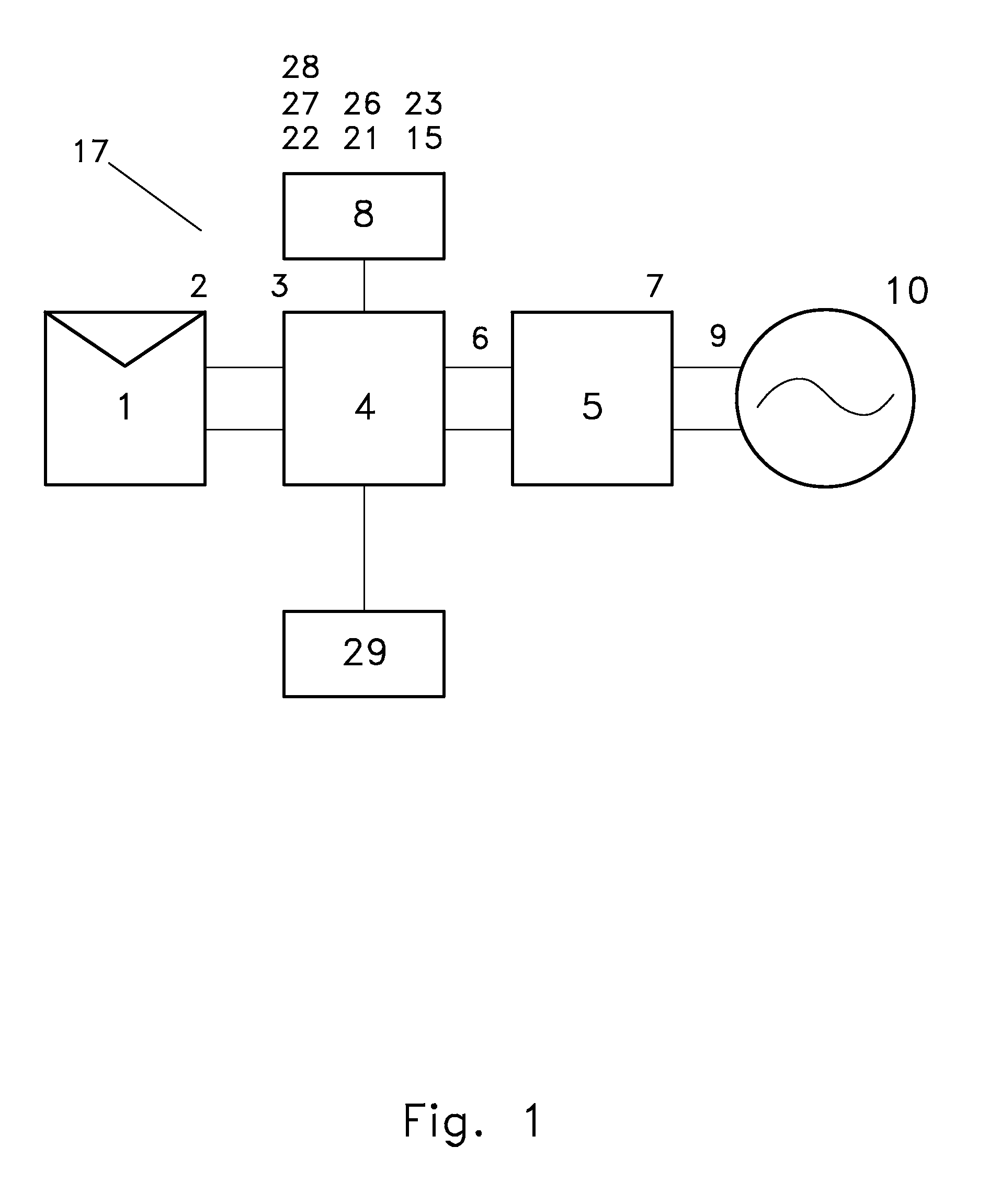

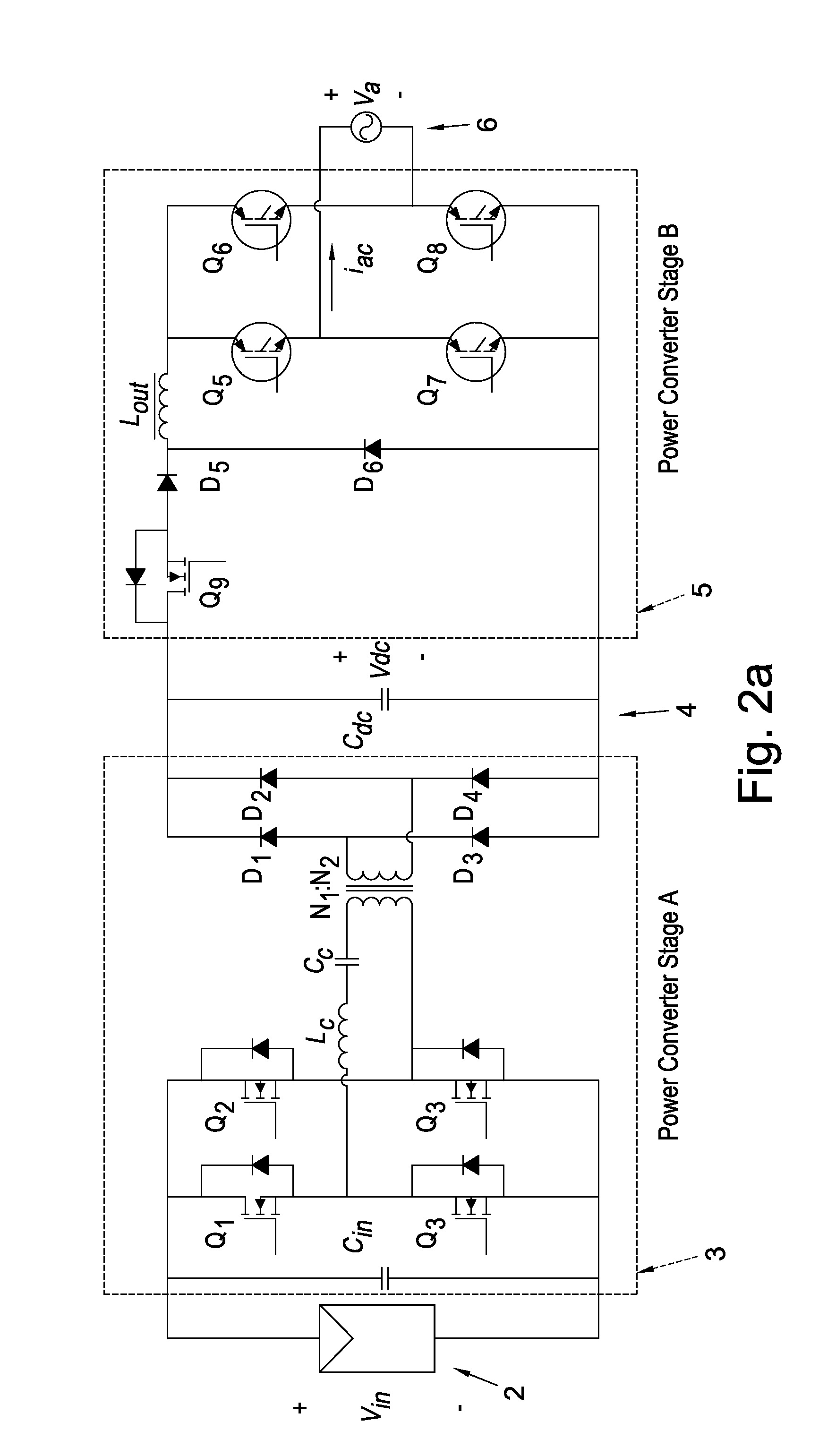

Systems for highly efficient solar power conversion

ActiveUS7605498B2More energyEfficient Power ConversionEnergy industrySingle network parallel feeding arrangementsDc dc converterPower grid

Owner:AMPT

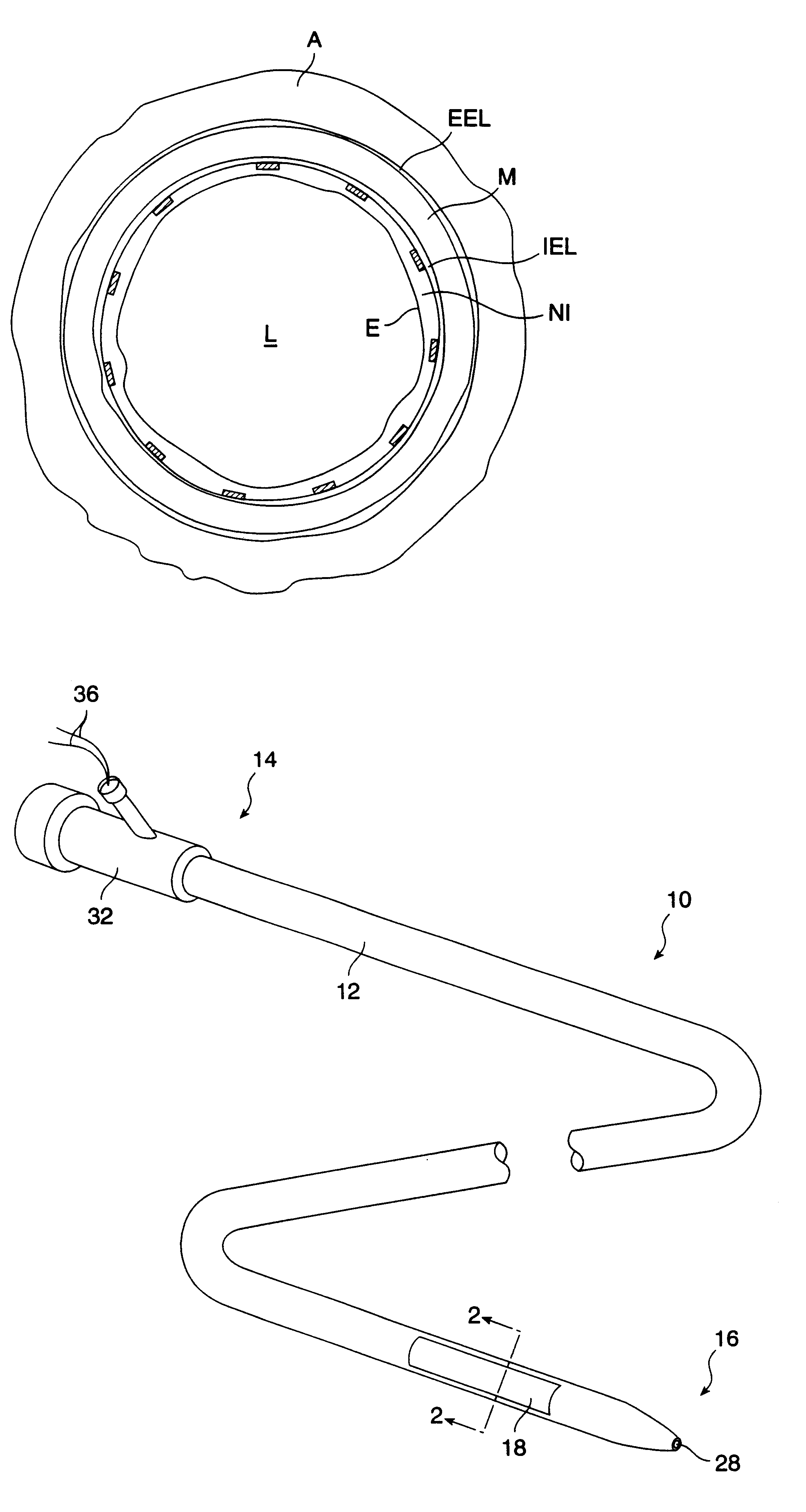

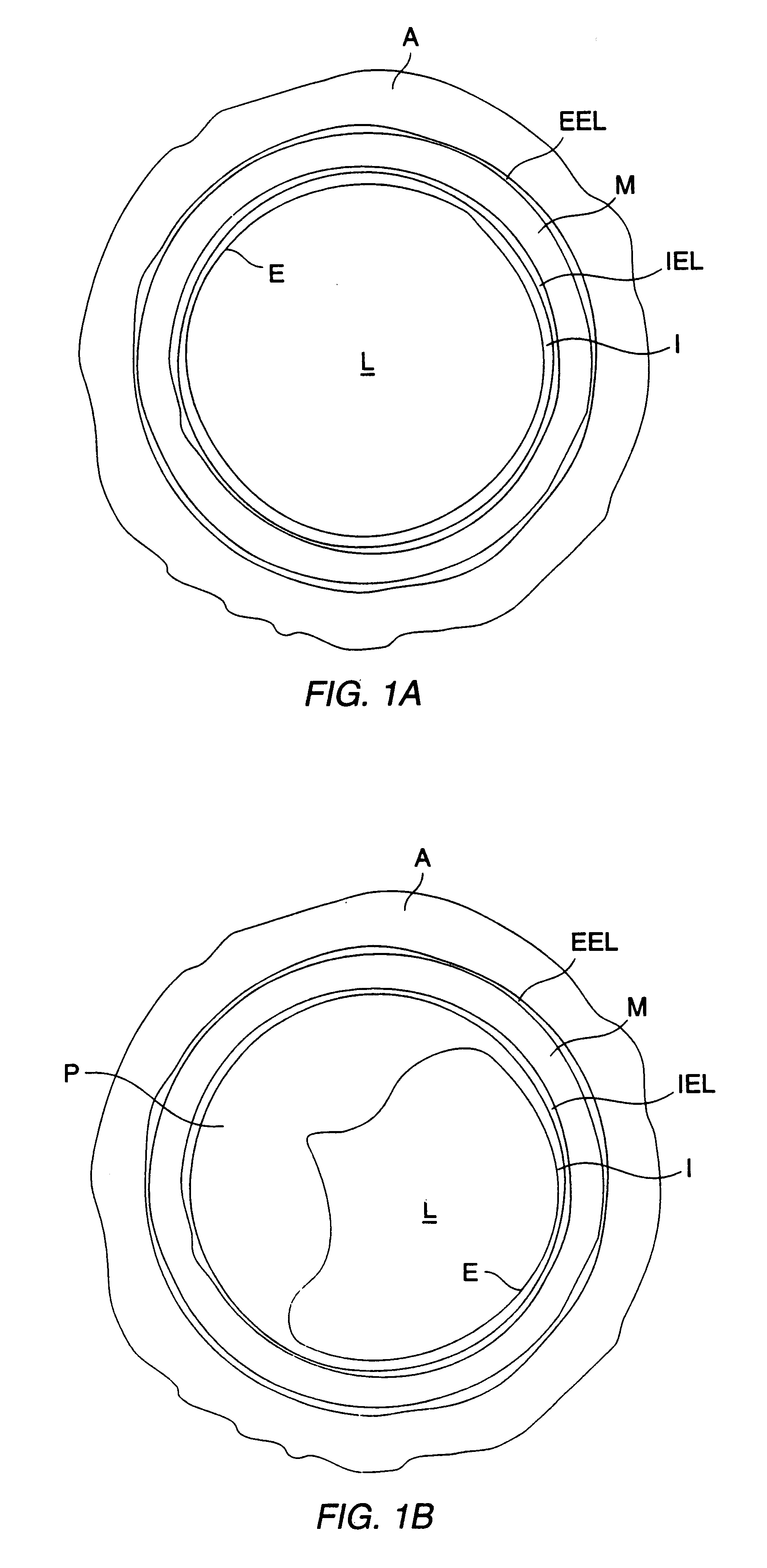

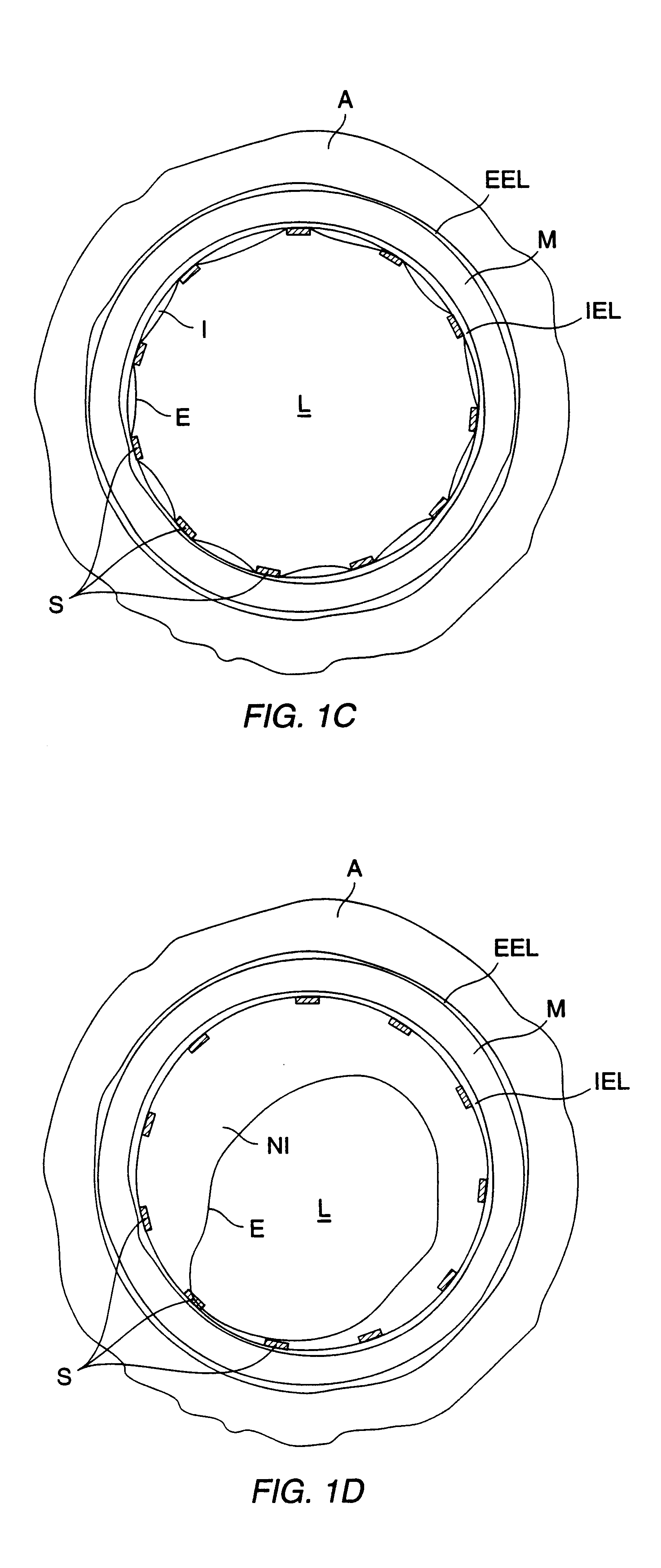

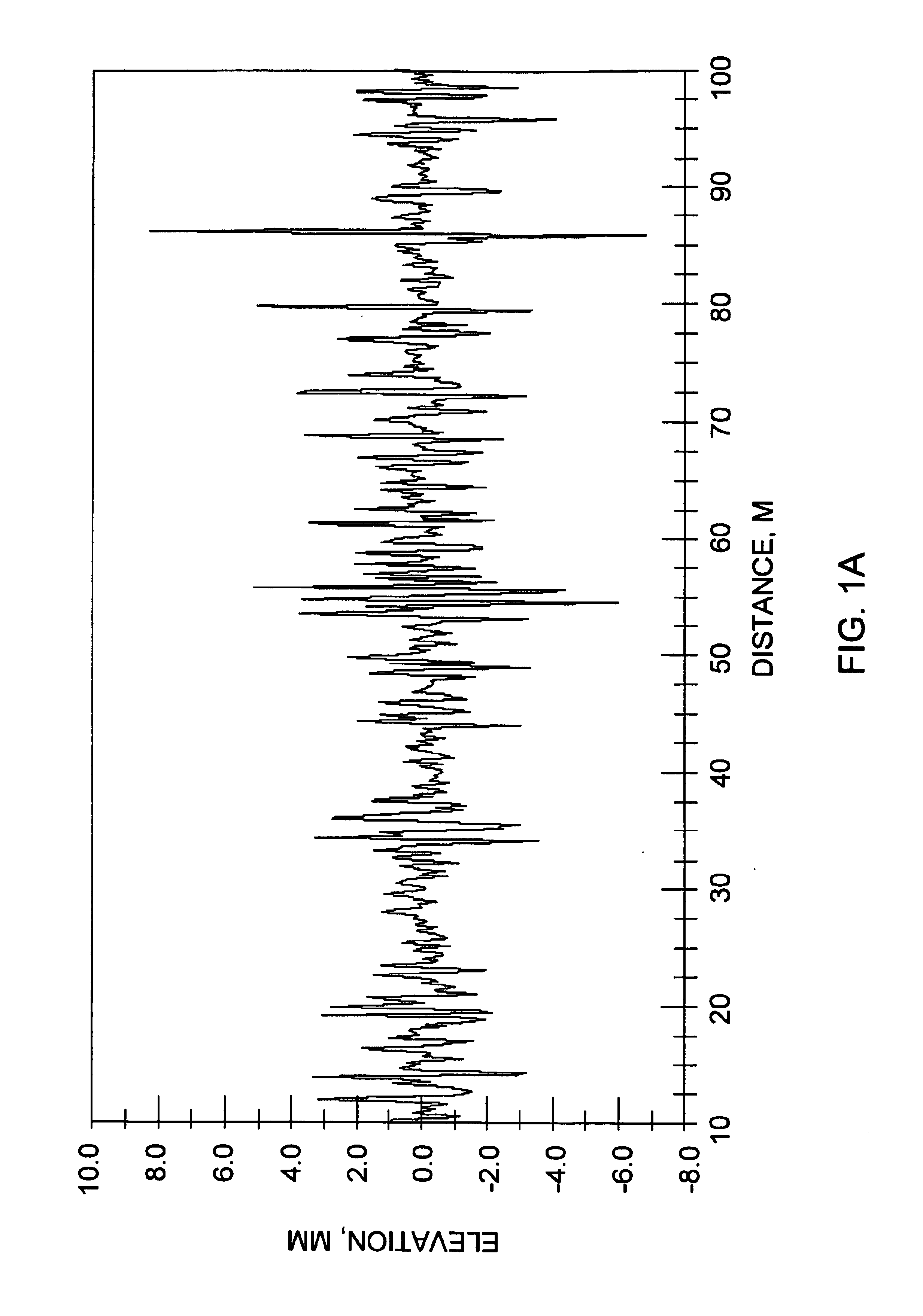

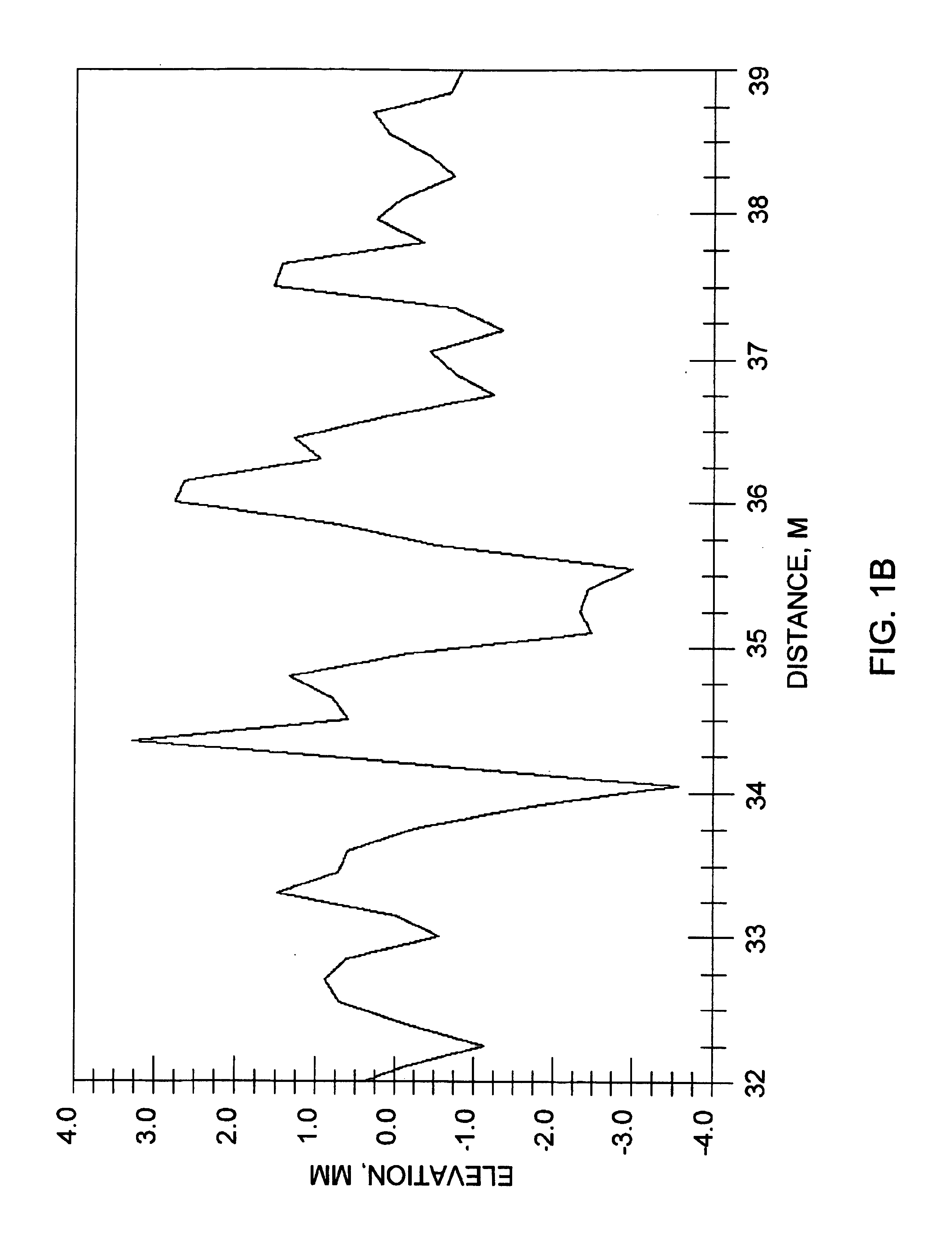

Methods and systems for the inhibition of vascular hyperplasia

InactiveUS6210393B1Limited extentQuick layeringUltrasound therapyStentsSmooth muscleVascular proliferation

Post-interventional neointimal hyperplasia in arteries is treated by the application of ultrasonic energy. Usually, an intravascular catheter having an interface surface is positioned at a target site in the artery which has previously been treated. The interface surface is vibrationally excited to apply energy to the arterial wall in a manner which inhibits smooth muscle cell proliferation in the neointimal layer.

Owner:PHARMASONICS

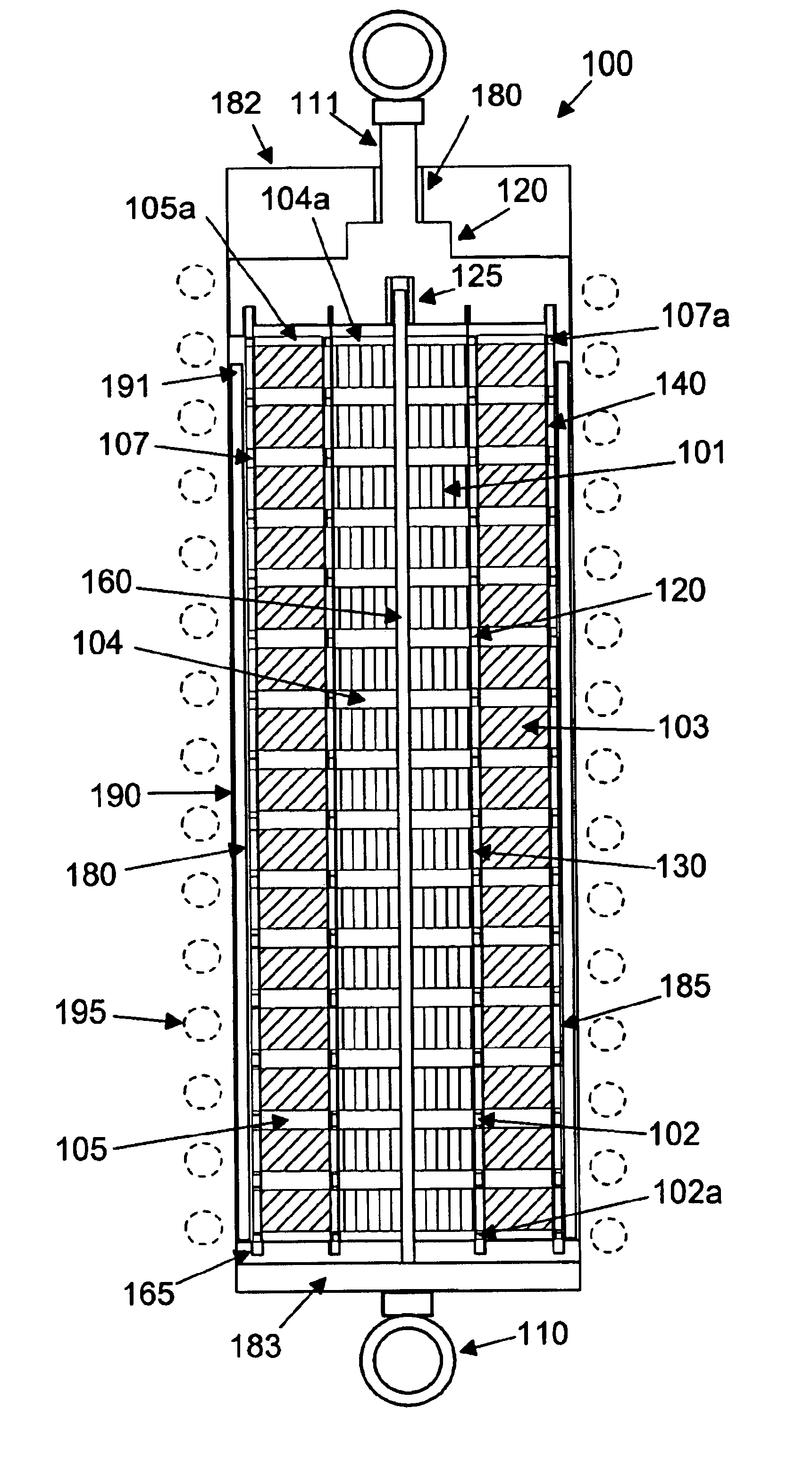

Electromagnetic linear generator and shock absorber

InactiveUS6952060B2Maximizing magnetic flux densityMaximize power generationNon-rotating vibration suppressionMechanical energy handlingElectromagnetic generatorFuel efficiency

An electromagnetic linear generator and regenerative electromagnetic shock absorber is disclosed which converts variable frequency, repetitive intermittent linear displacement motion to useful electrical power. The innovative device provides for superposition of radial components of the magnetic flux density from a plurality of adjacent magnets to produce a maximum average radial magnetic flux density within a coil winding array. Due to the vector superposition of the magnetic fields and magnetic flux from a plurality of magnets, a nearly four-fold increase in magnetic flux density is achieved over conventional electromagnetic generator designs with a potential sixteen-fold increase in power generating capacity. As a regenerative shock absorber, the disclosed device is capable of converting parasitic displacement motion and vibrations encountered under normal urban driving conditions to a useful electrical energy for powering vehicles and accessories or charging batteries in electric and fossil fuel powered vehicles. The disclosed device is capable of high power generation capacity and energy conversion efficiency with minimal weight penalty for improved fuel efficiency.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

Method of generating and recovering gas from subsurface formations of coal, carbonaceous shale and organic-rich shales

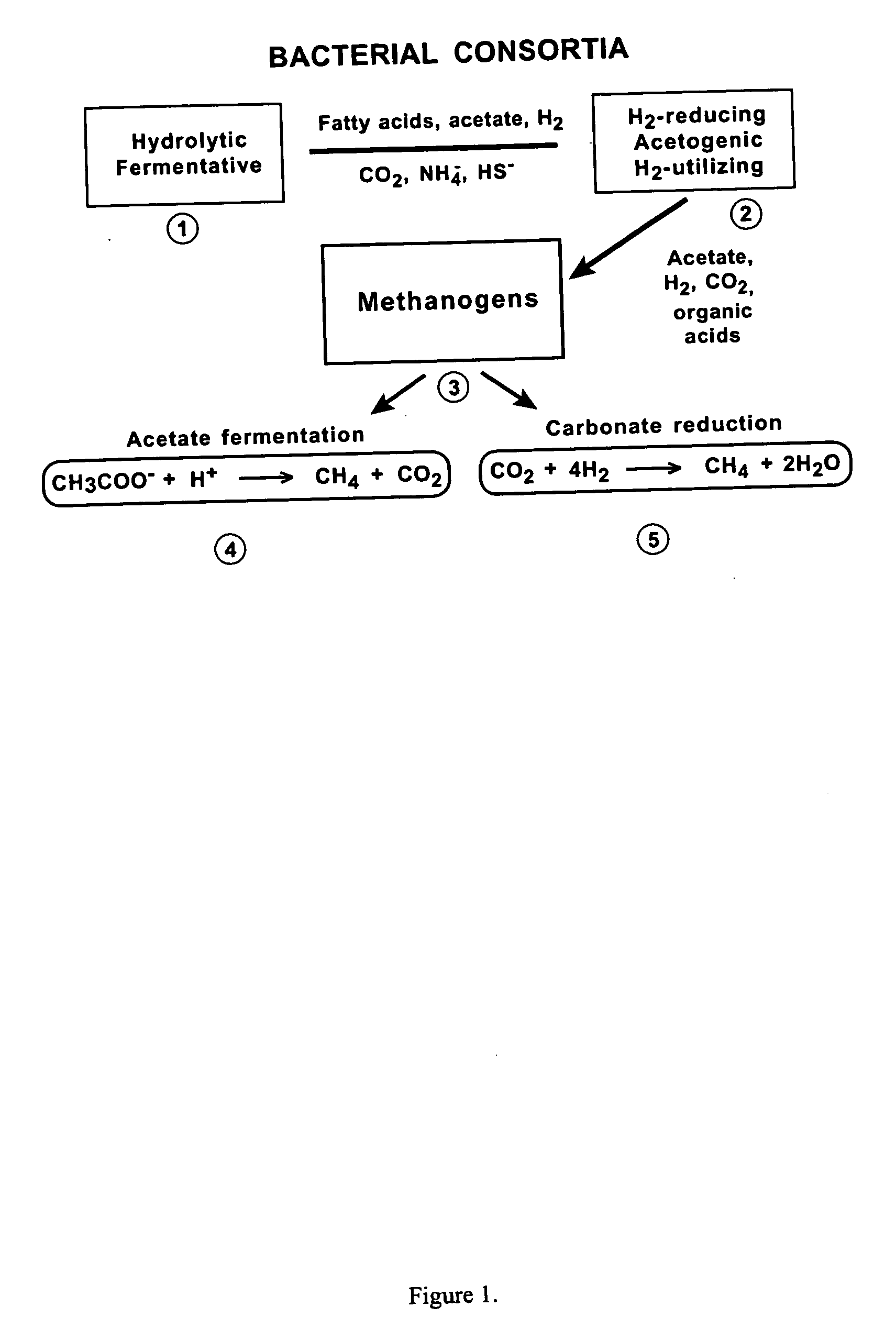

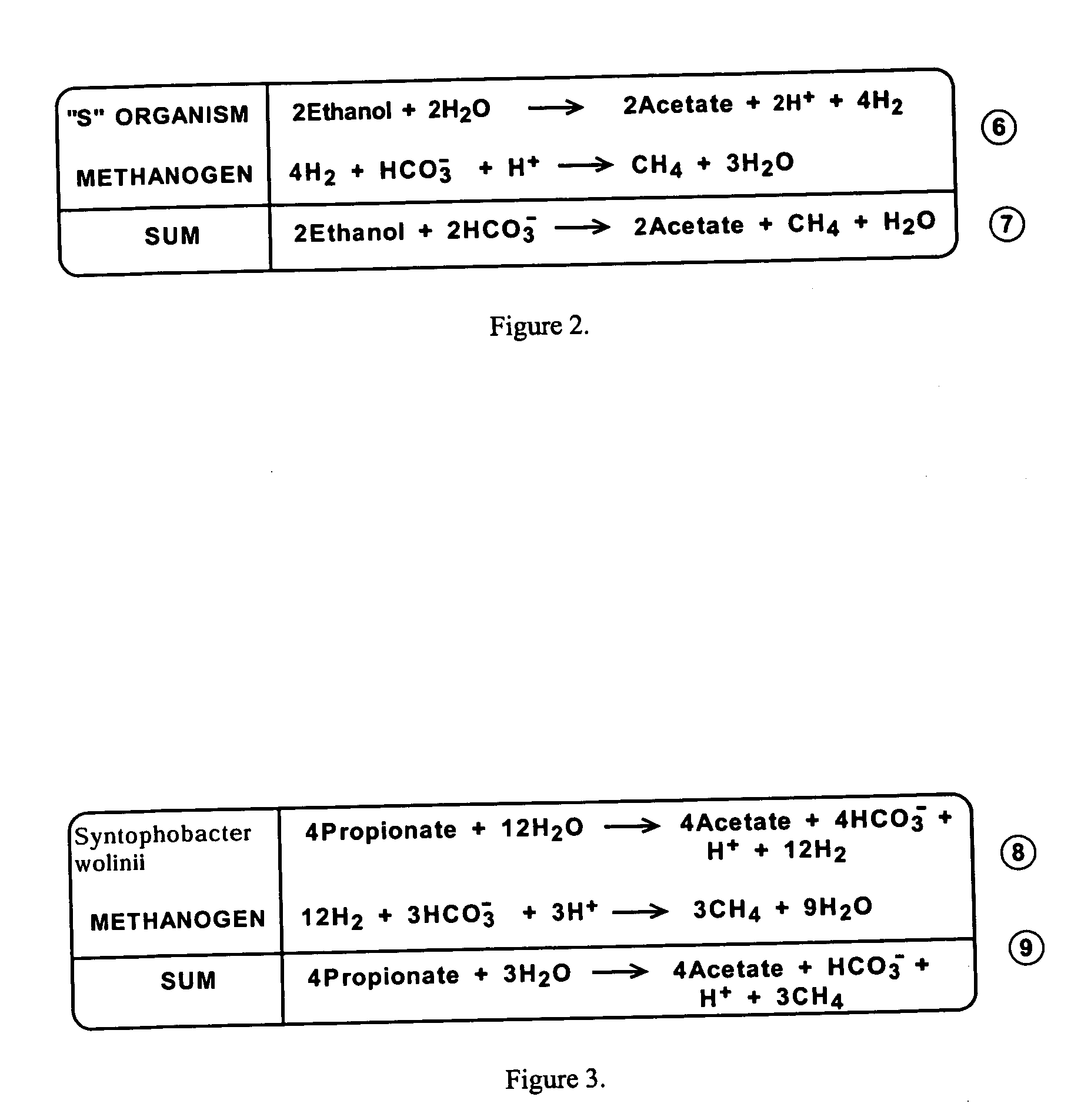

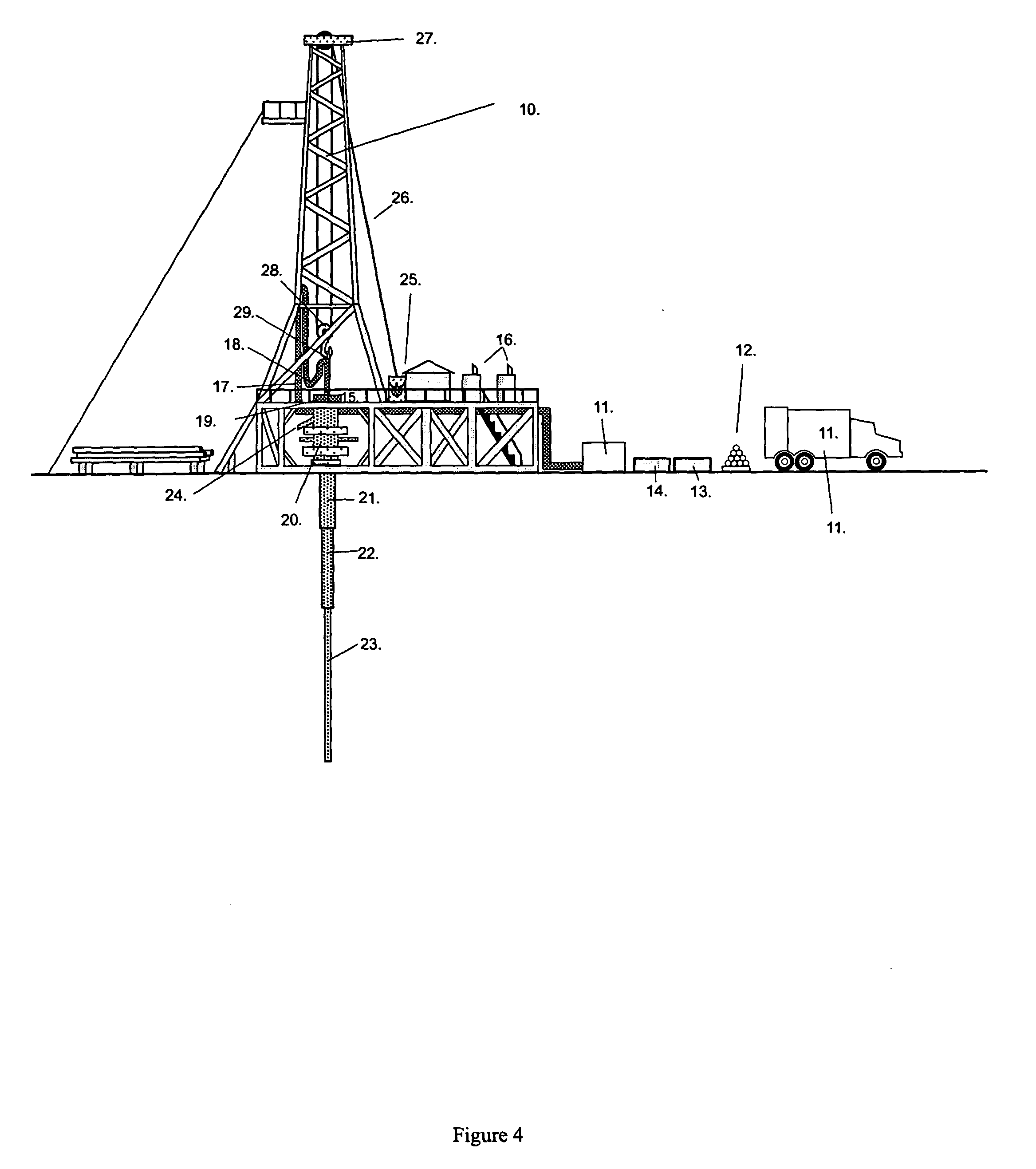

InactiveUS20040033557A1Maximizes bacterial degradationStable and economically favorable and environmentally cleanMicrobiological testing/measurementGas production bioreactorsOrganic compoundCoal

A method of generating and recovering gas from naturally existing subsurface formations Of coal, carbonaceous shale or organic-rich shales comprising the steps Of: injecting into fracture of the subsurface formation, under substantially anaerobic conditions, a consortia of selected anaerobic, biological microorganisms for in situ conversion of organic compounds in said formation into methane and other compounds; and producing methane through at least one well extending from said subsurface formation to the surfaces.

Owner:SCOTT ANDREW R +1

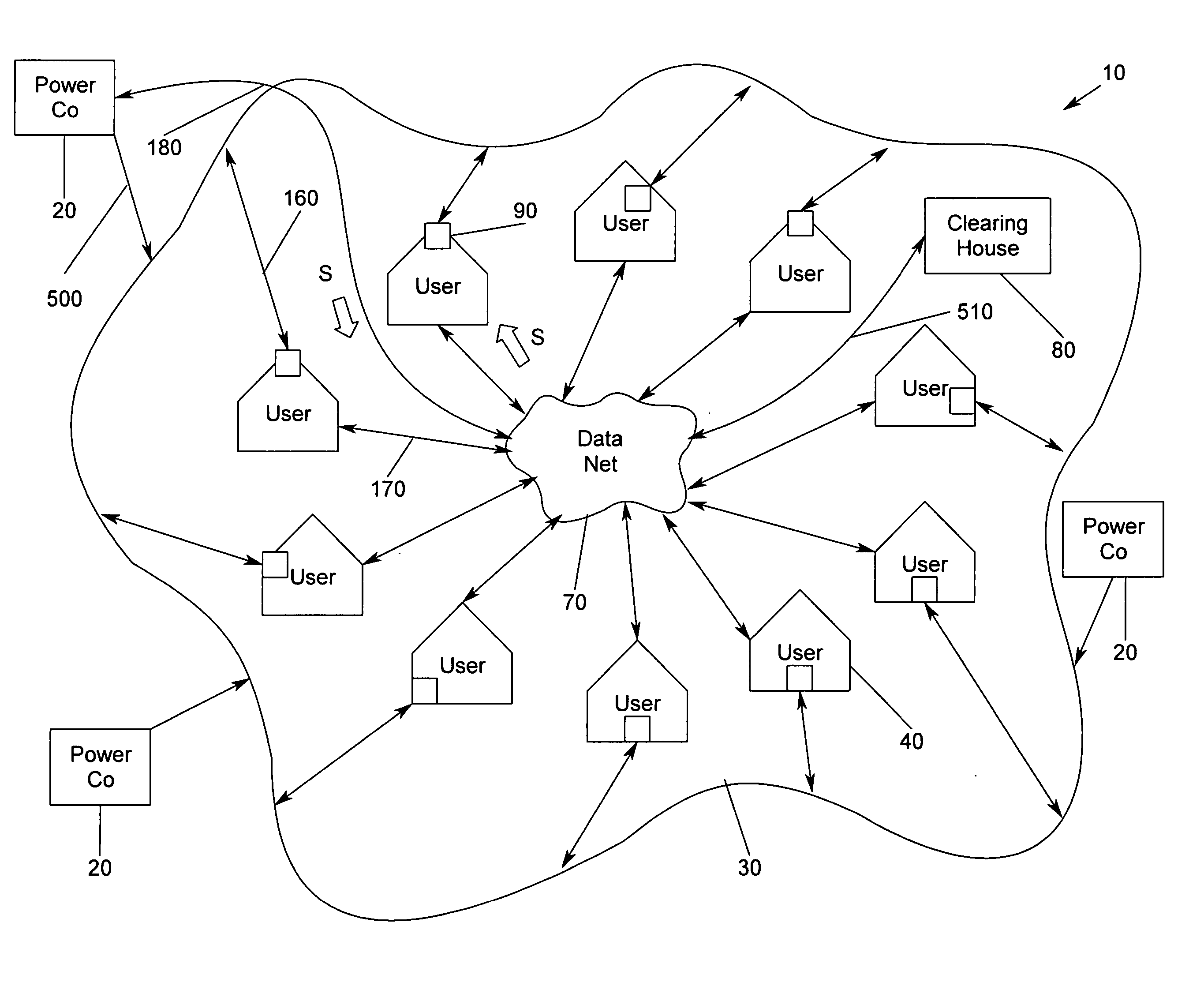

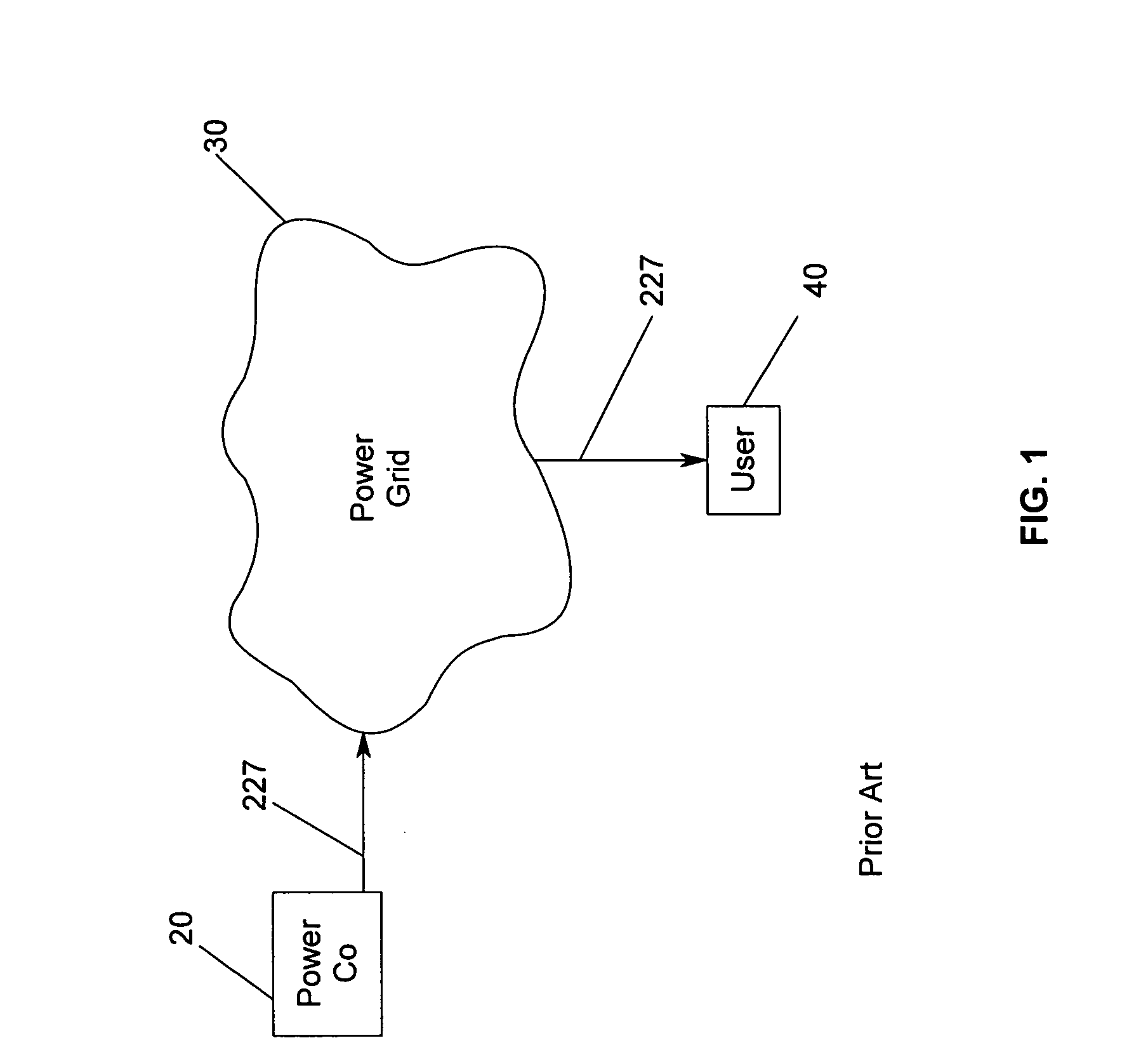

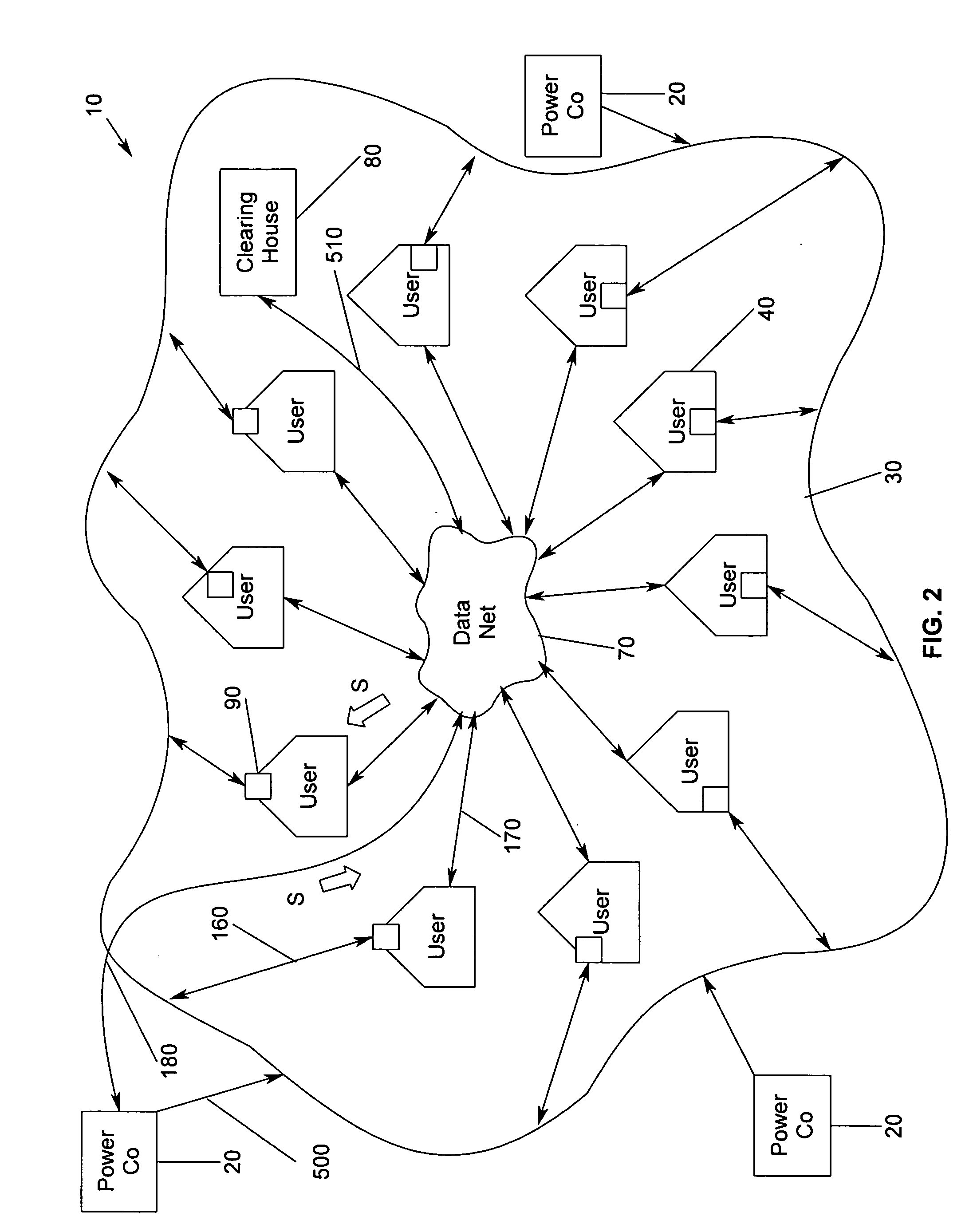

Electric power shuttling and management system, and method

InactiveUS20050125243A1Optimize energy costLow cost optionSubstation/switching arrangement detailsCommerceElectric power transmissionElectricity

A method and apparatus for shuttling, managing, and controlling energy flow between suppliers and users based on bid / ask pricing, wherein individual residential / commercial suppliers are aggregated for the purpose of supply and use, and wherein an electricity transmission utility controls the selection and flow of energy from suppliers to users via a controlling device, such as, for exemplary purposes only, a switch turned on by commands sent over a data net to multiple locations simultaneously.

Owner:VILLALOBOS VICTOR M

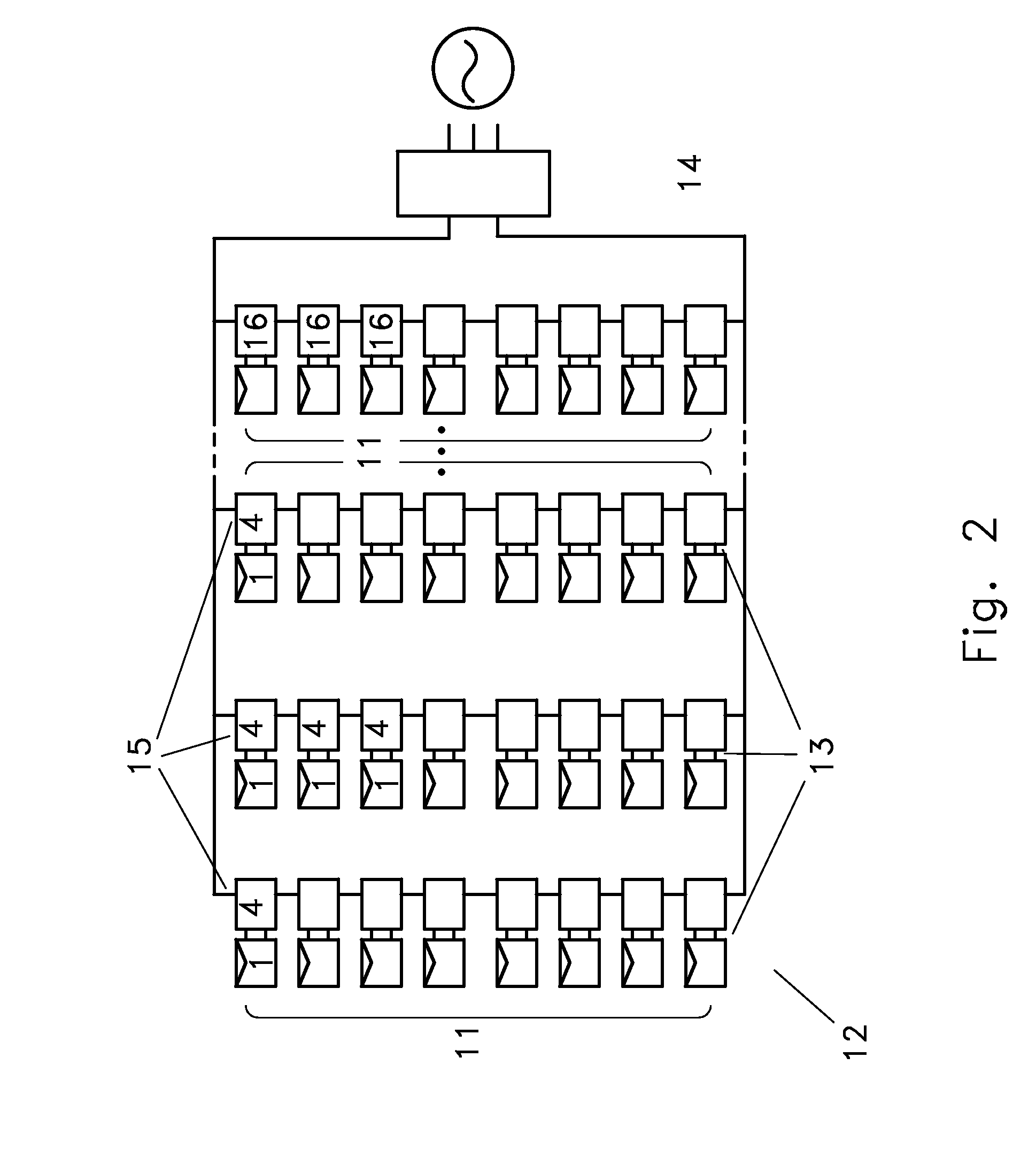

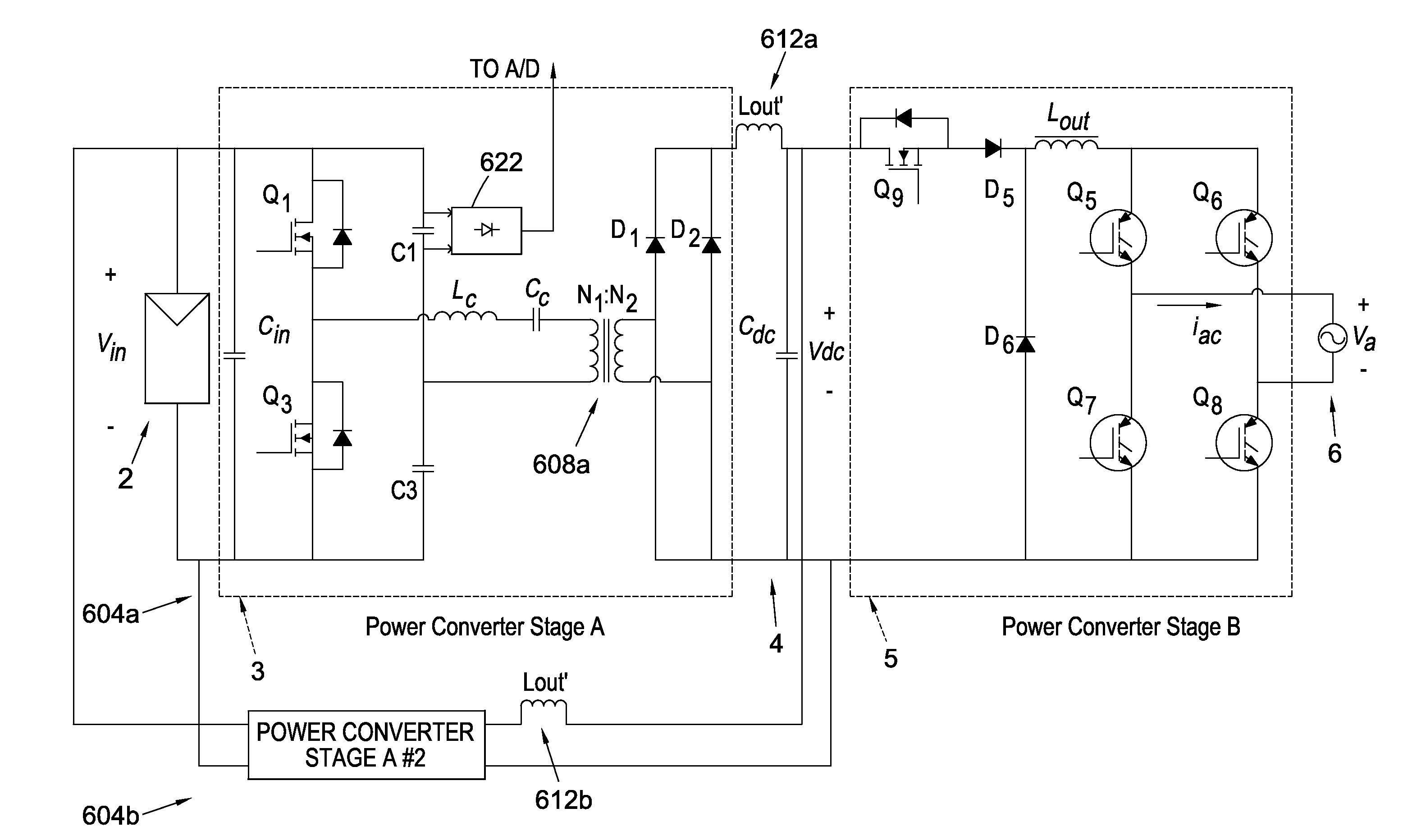

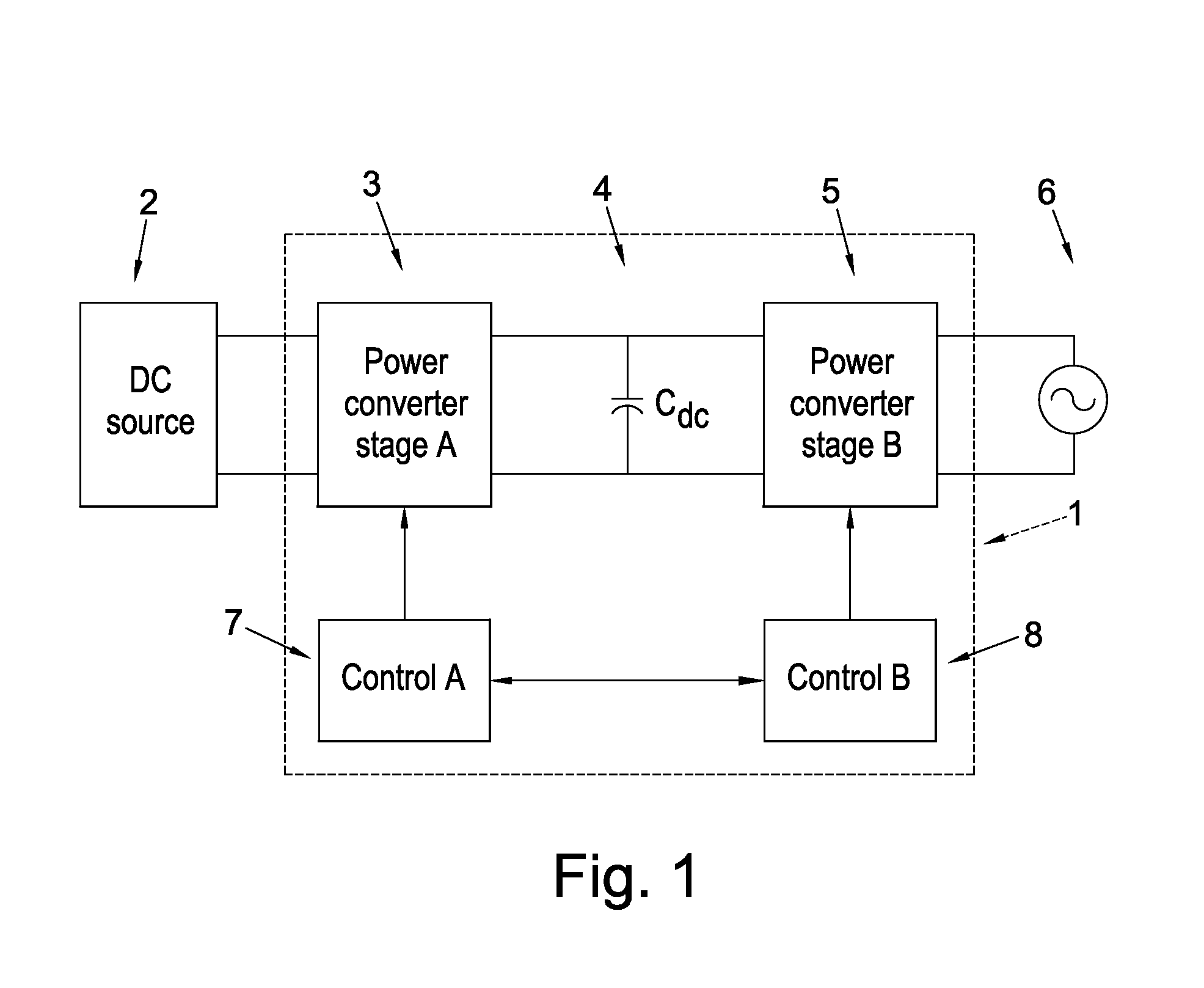

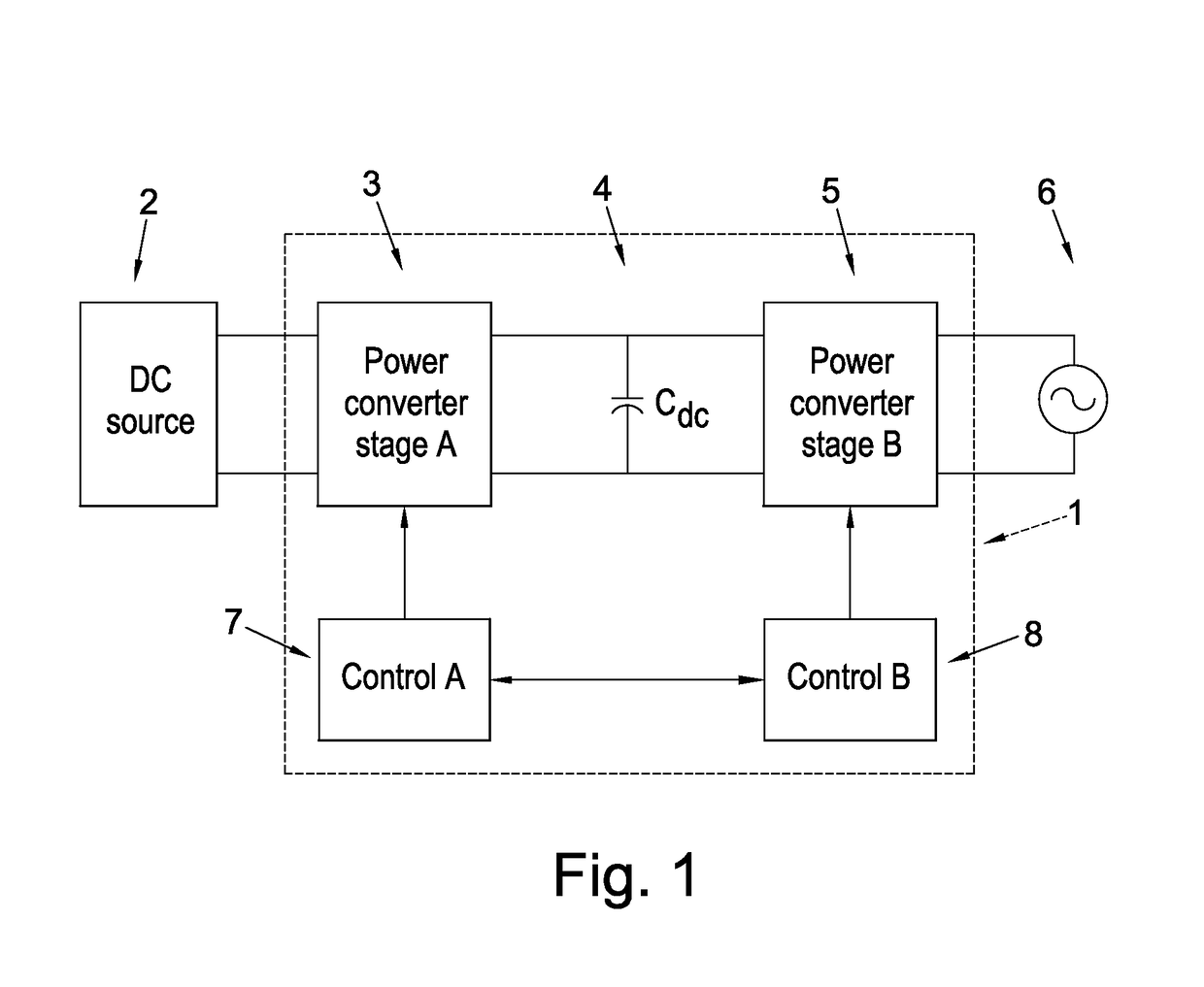

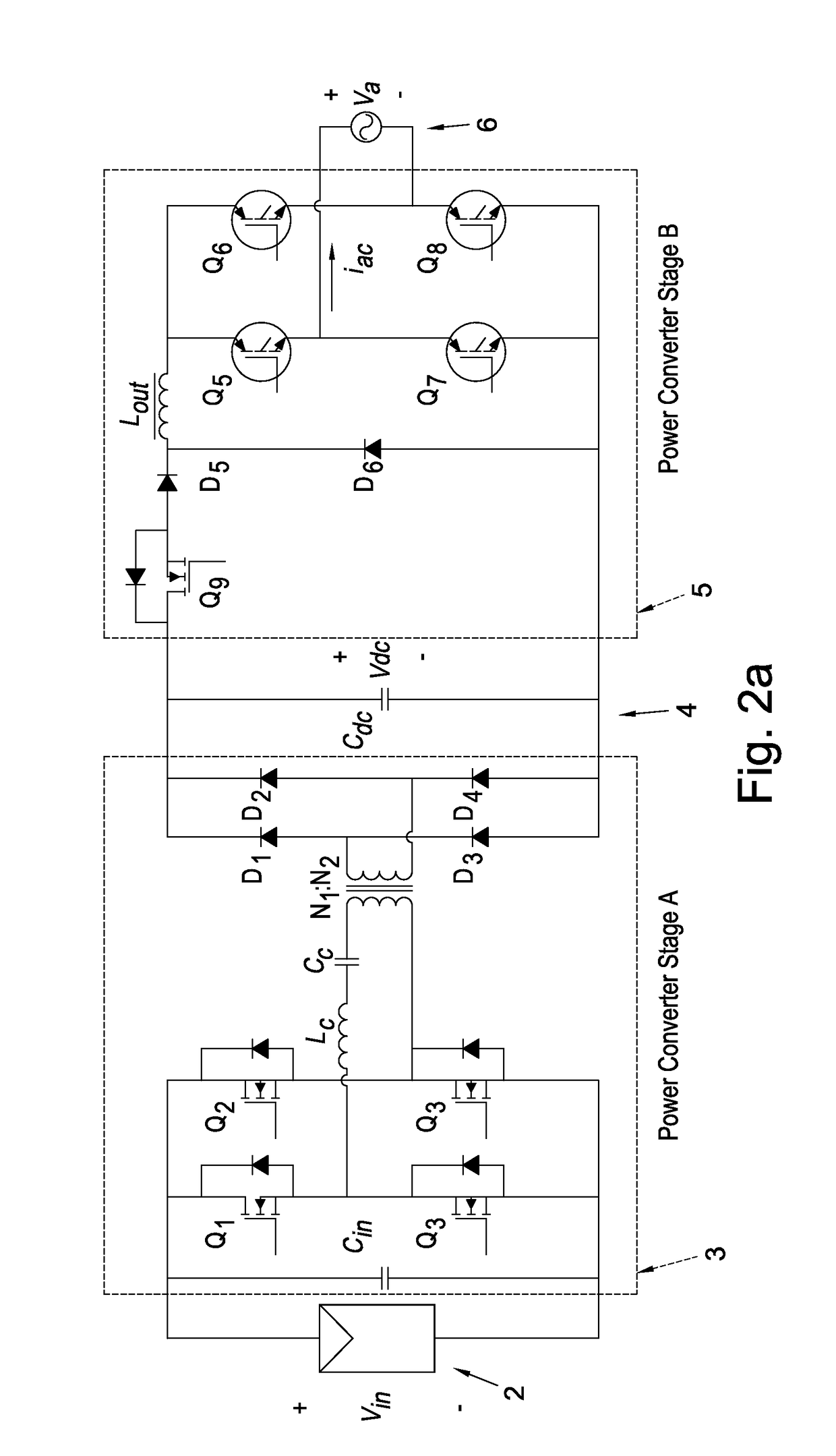

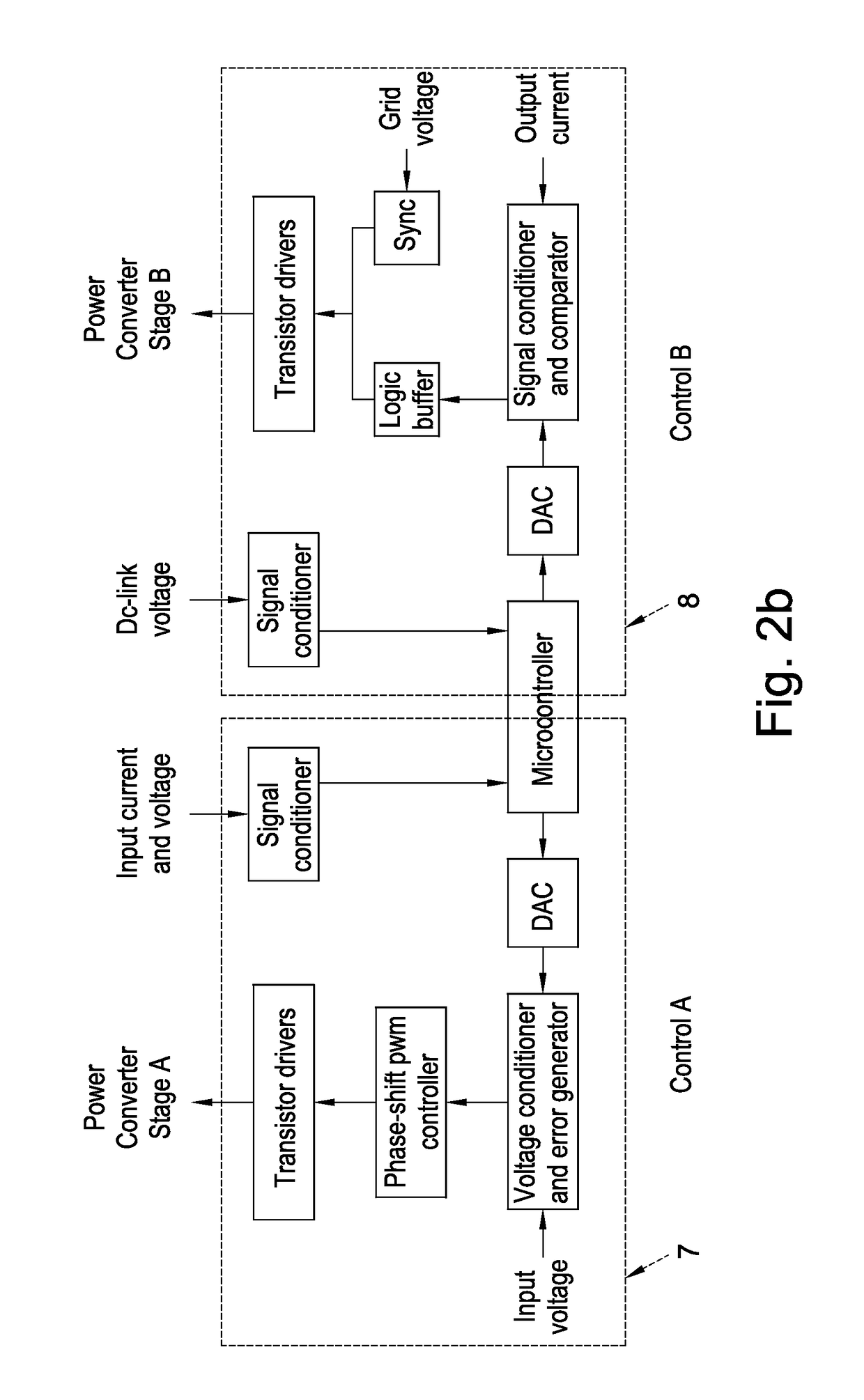

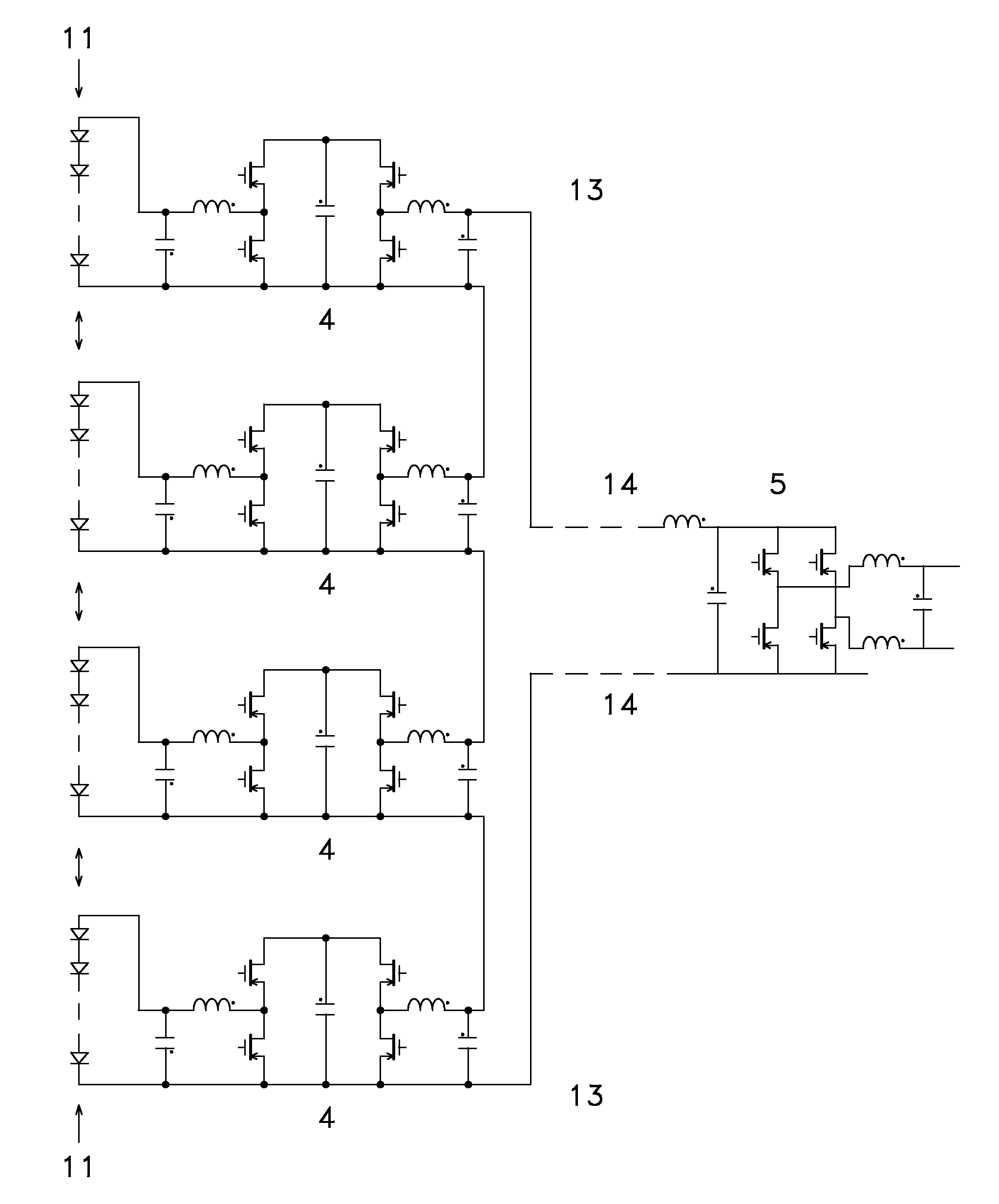

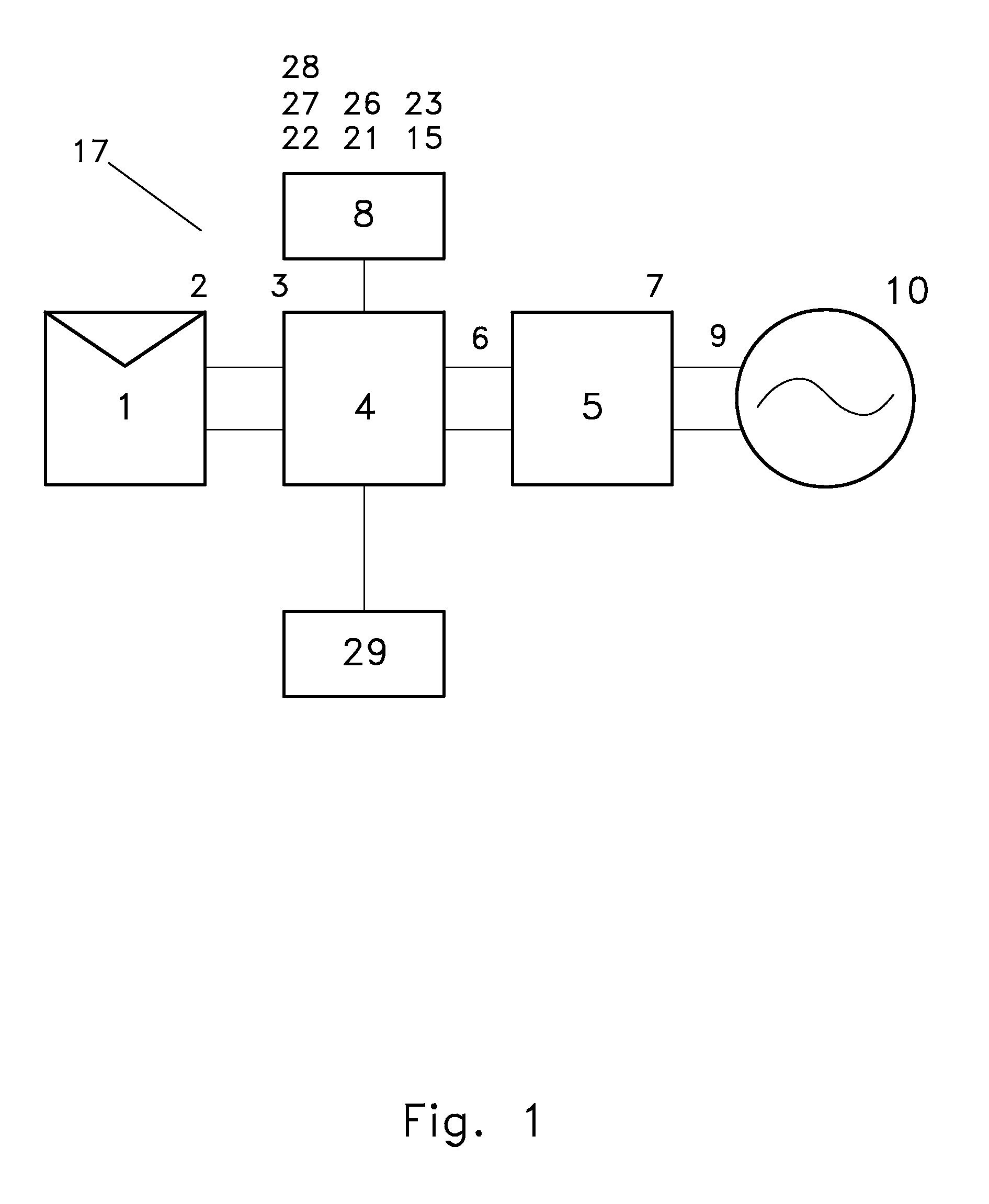

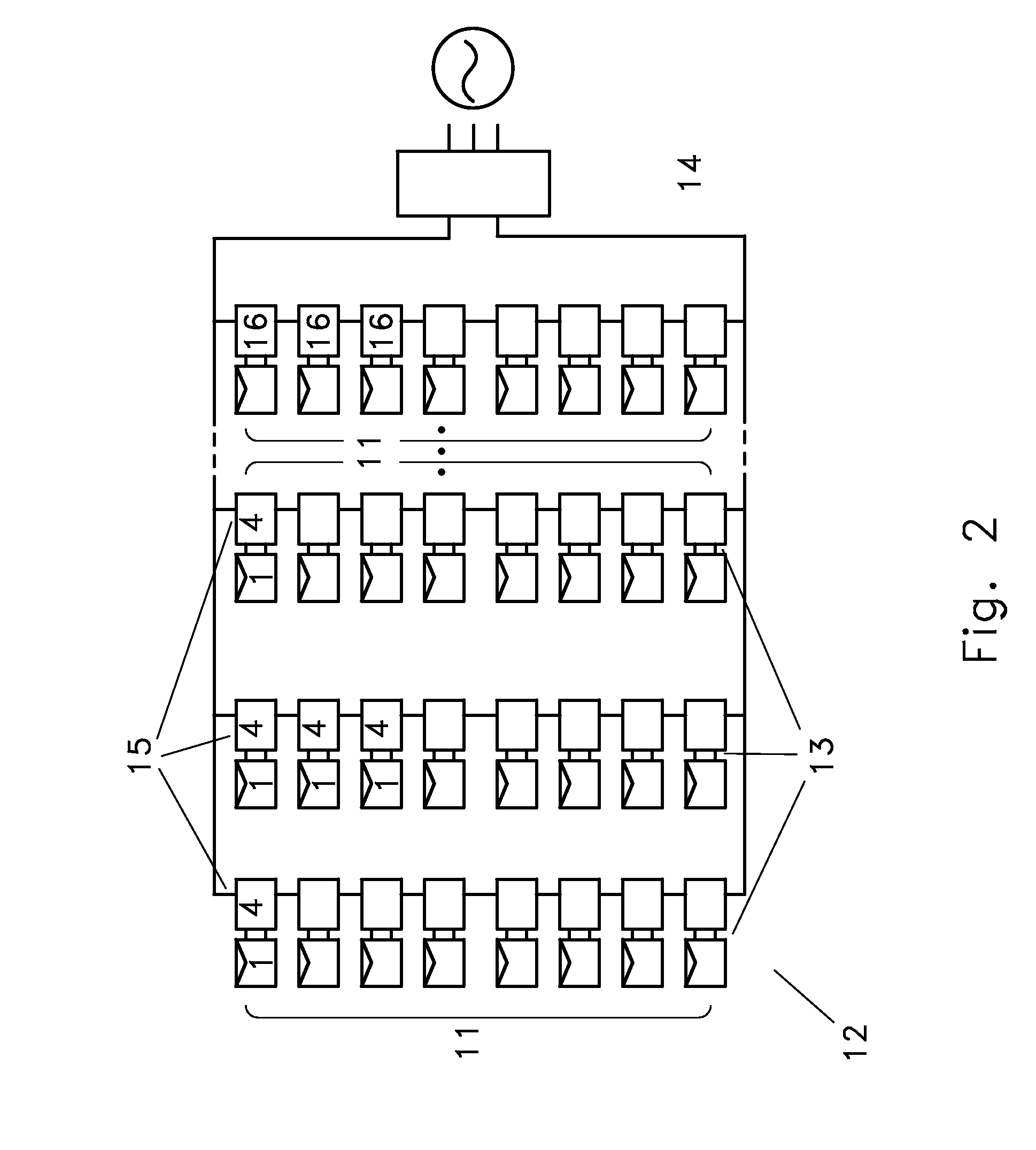

Photovoltaic power conditioning units

ActiveUS20120081934A1High voltage gainGuaranteed uptimeConversion with intermediate conversion to dcDc-dc conversionFailure rateEngineering

We describe a photovoltaic (PV) panel system comprising a PV panel with multiple sub-strings of connected solar cells in combination with a power conditioning unit (microinverter). The power conditioning unit comprises a set of input power converters, one connected to each sub-string, and a common output power conversion stage, to provide power to an ac mains power supply output. Integration of the micro-inverter into the solar PV module in this way provides many advantages, including greater efficiency and reliability. Additionally, embodiments of the invention avoid the need for bypass diodes, a component with a high failure rate in PV panels, providing lower power loss and higher reliability.

Owner:TESLA INC

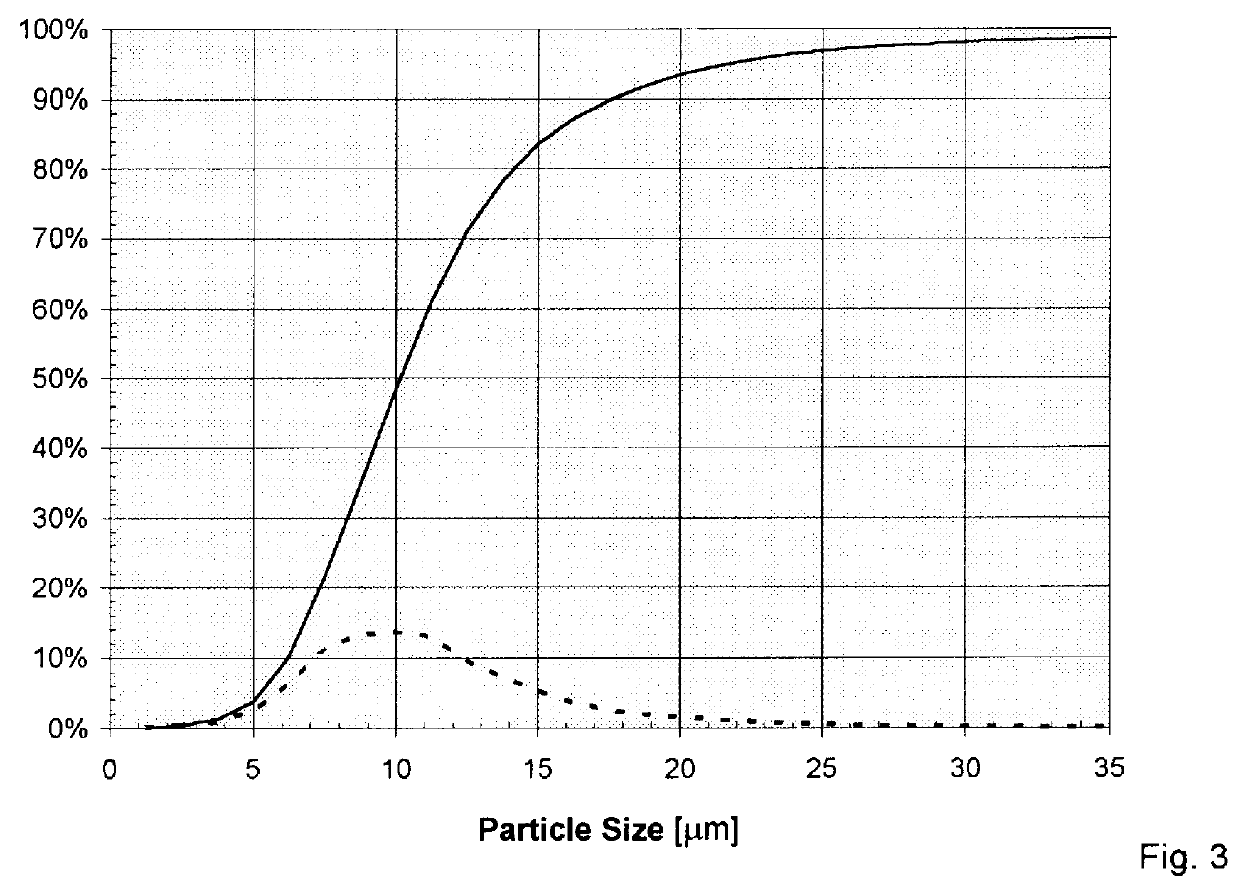

Highly filled polymer composition with improved properties

InactiveUS6362252B1Reduce manufacturing costHigh tensile strengthConductive materialPlastic recyclingPolymer sciencePlasticizer

A highly filled polymer composition with improved properties comprising: a continuous matrix material; a filler material in an amount of 10 to 80 wt. % of said composition; a polymer plasticizer dispersed in said continuous matrix material in an amount of 0.5 to 15 wt. % of said filler; a filler coating material which coats said filler particles in the form of a continuous coating layer thus forming coated filler particles; a diffusion zone around said coated filler particles where said filler coating and said continuous matrix material are mutually diffused into one another wherein said filler coating material is distributed with concentration decreasing in the direction outward from said continuous coating layer. Provided also is a method of preparing the aforementioned composition which guarantees that during extrusion or similar treatment the filler particles are coated with a continuous layer of the filler coating material and that the aforementioned diffusion zone is formed around the coated filler particles. In the manufacture of various products such as pipes, sheets, profiles, etc., the composition of the invention combines high deformation capacity with sufficient strength. Furthermore, the composition of the invention possesses high anticorrosive properties, has low shrinkage, and has high adhesion to metals, wood, plastics, etc.

Owner:NEXT GENERATIONS TECH

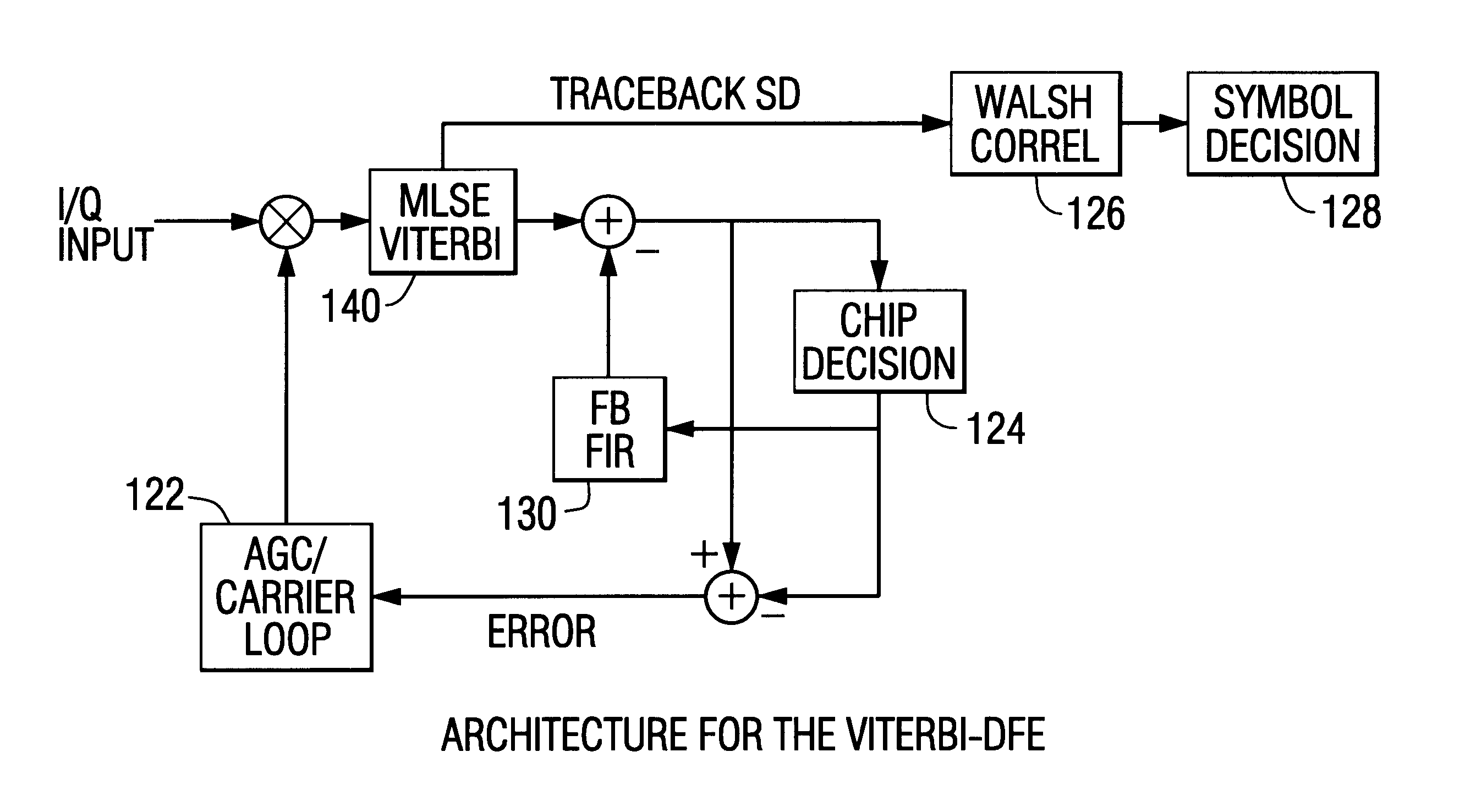

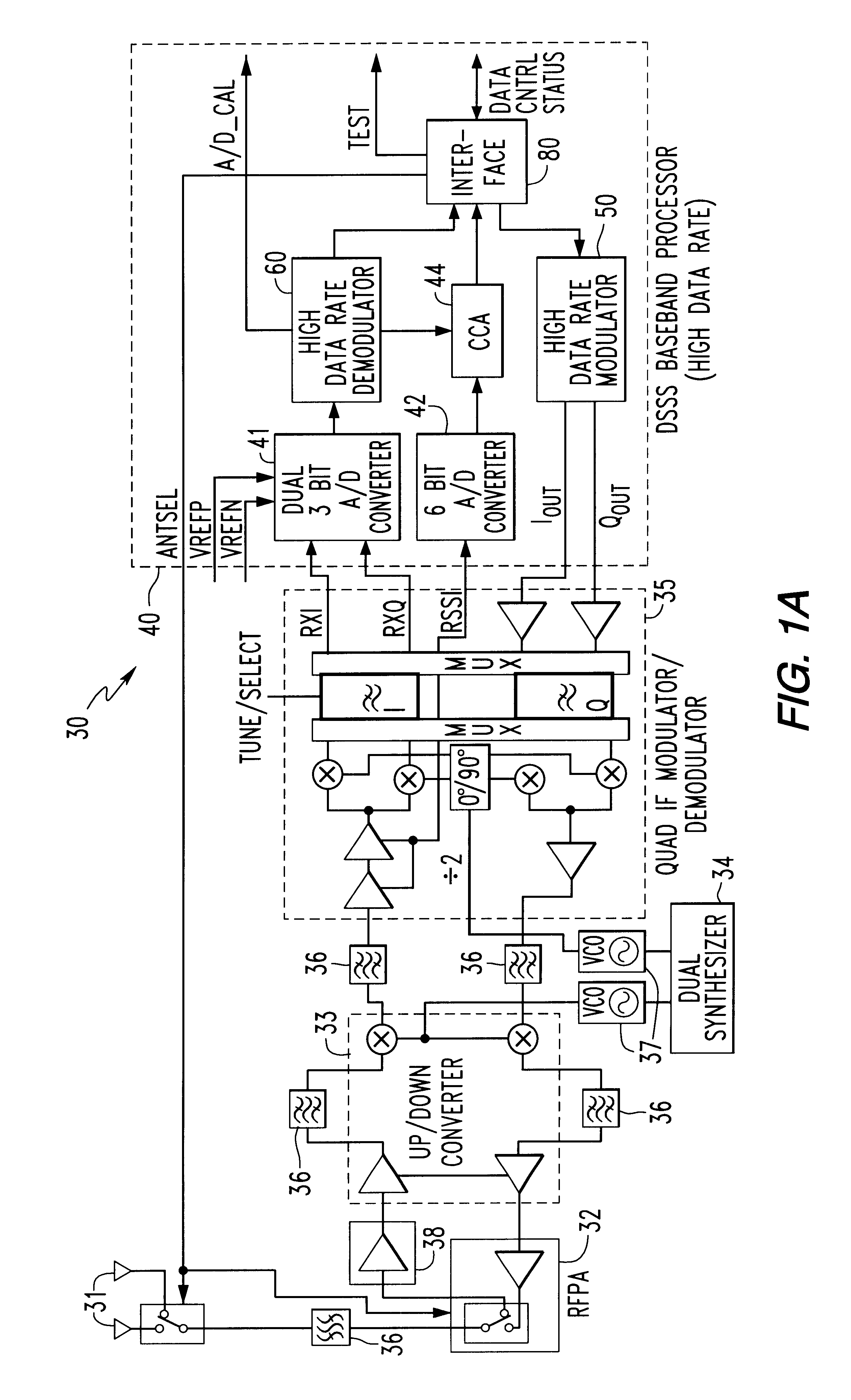

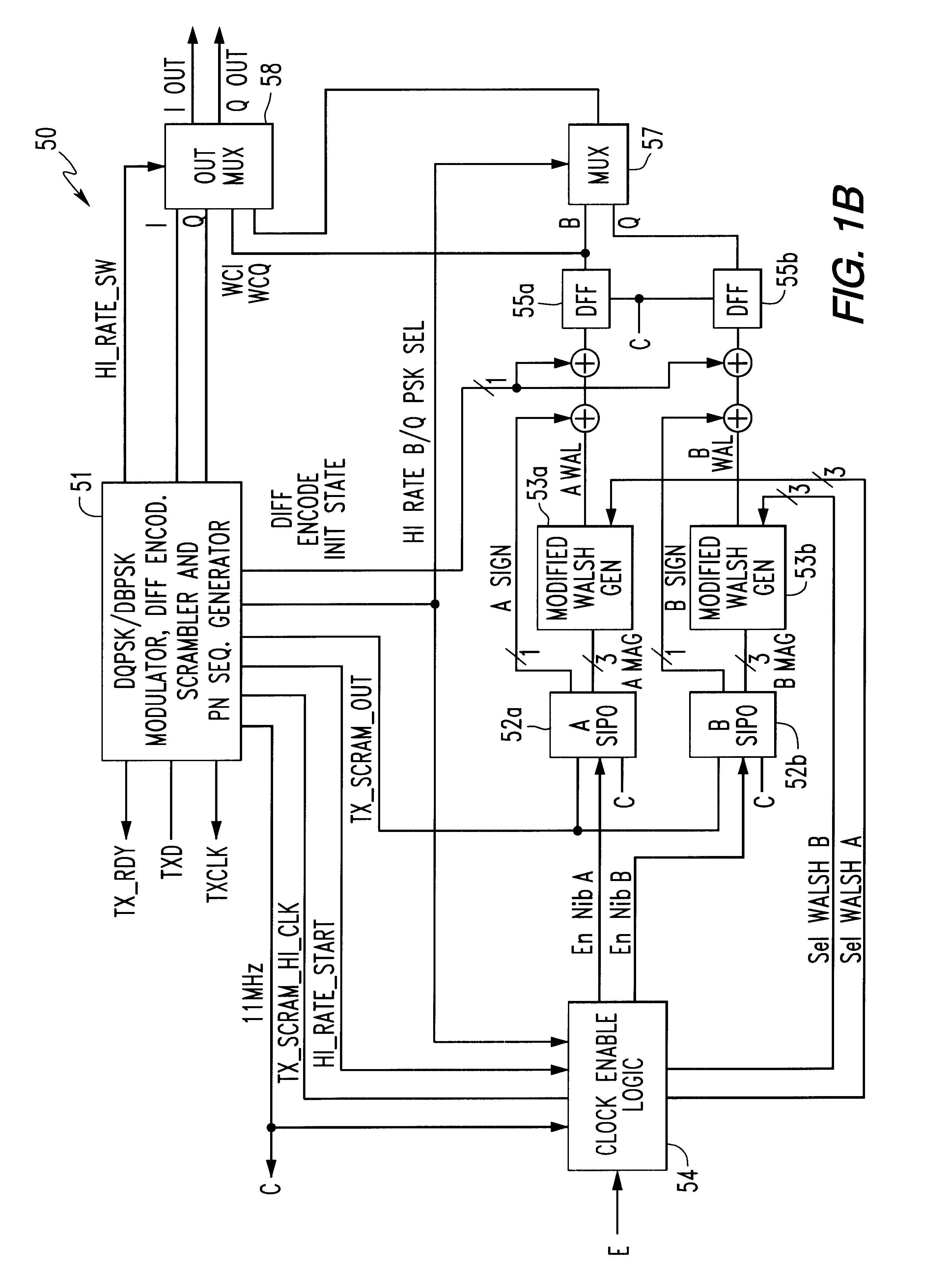

Spread spectrum transceiver for use in wireless local area network and having multipath mitigation

InactiveUS6603801B1Good diversity selection metricGood energySpatial transmit diversityNetwork topologiesFinite impulse responseTransceiver

A method and spread spectrum transceiver for demodulating a spread spectrum signal is disclosed. A spread spectrum phase shift keyed (PSK) modulated information signal is received within a demodulator of a spread spectrum receiver on a signal channel. The information signal includes a sequence of data symbols formed from a plurality of high rate mode chips. A precursor portion of the signal channel is Viterbi detected. A multi-state trellis is formed having a predetermined number of states. A post-cursor portion of the signal channel is feedback equalized with a finite impulse response filter having feedback taps operatively connected to a chip detection circuit that tracks high rate mode chips and a carrier loop circuit for phase and frequency tracking. The information signal is despread within a spread spectrum code function correlator.

Owner:INTELLECTUAL VENTURES I LLC +1

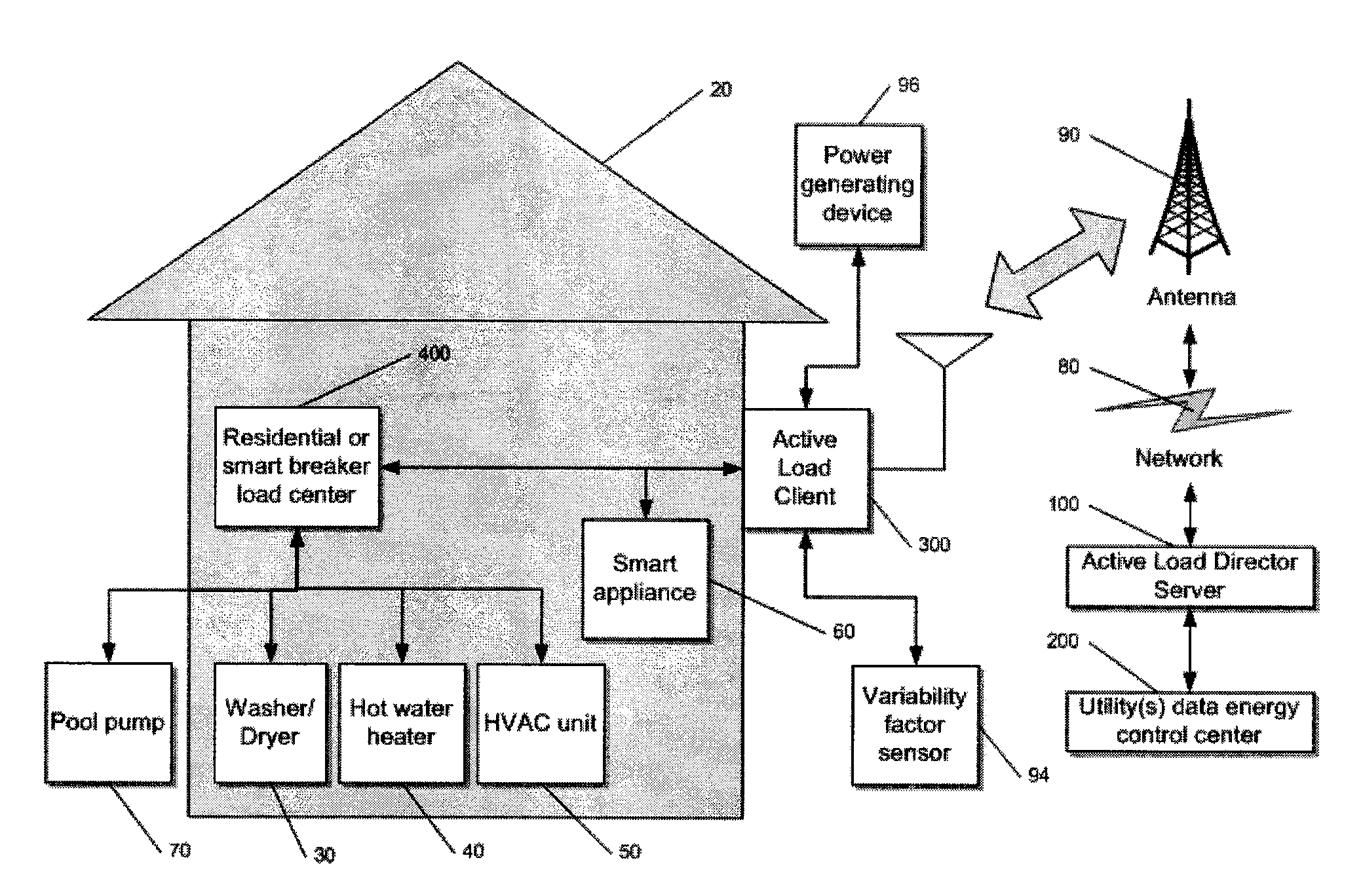

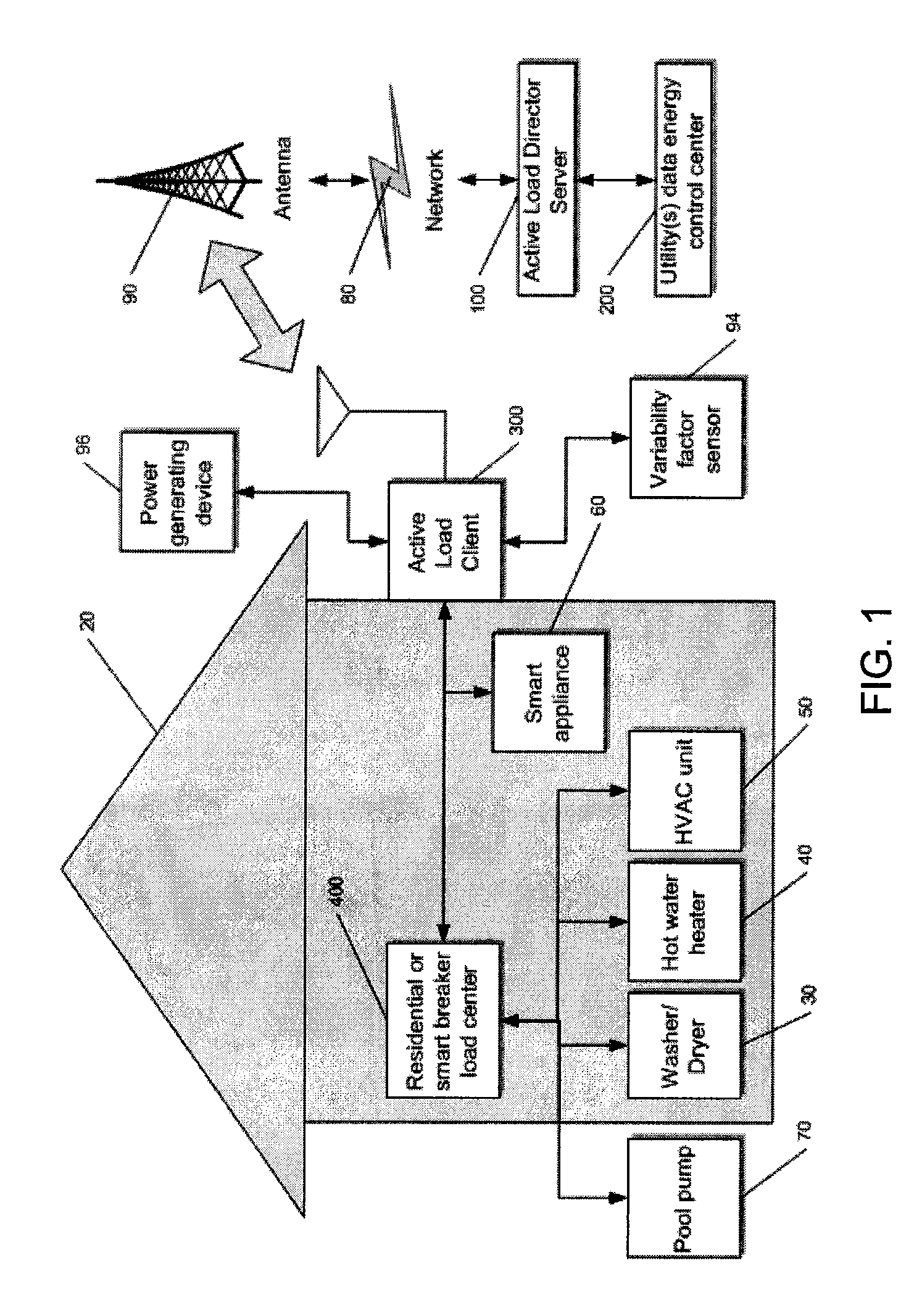

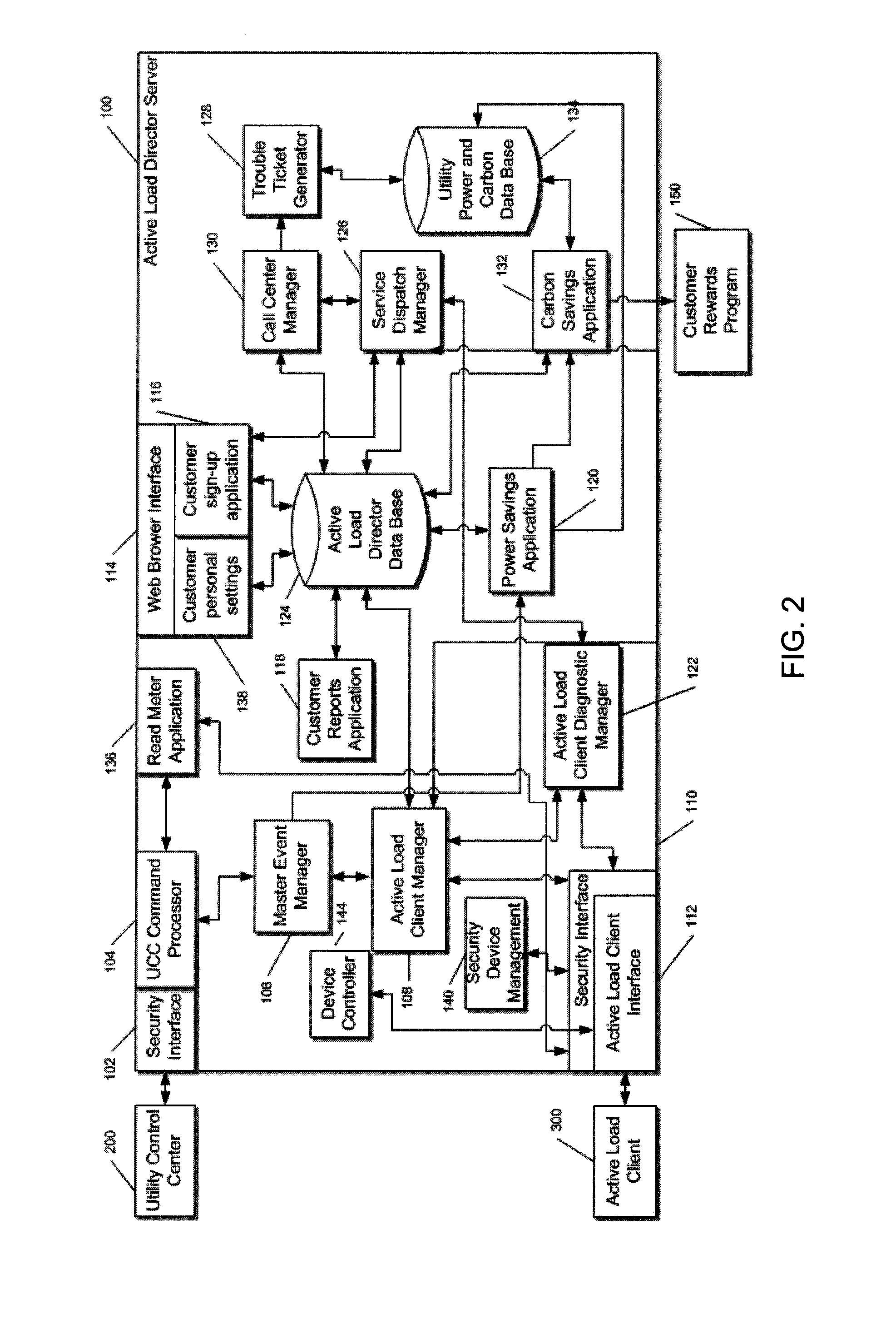

System and method for priority delivery of load management messages on ip-based networks

ActiveUS20100191862A1Easy to controlGood energyElectric devicesSpecial tariff metersNetwork methodReal-time computing

Methods for prioritizing load management messages on IP-based networks utilizing an Active Load Directory and IP capable two-way gateway. The messages being received from, or sent to, the ISP through the gateway contain a blend of regulated and unregulated data. The regulated data is high-priority utility load management data such as, equipment status and load control instructions. The unregulated data consists of Internet messages such as email and web site data. These methods process all regulatory data before unregulated data within strict time limits, providing the greatest possible load management control and energy savings. The methods emulate dedicated network processor memory in a manner that permits the rules for prioritizing, scheduling, and routing to remain the same across both hardware and software implementations.

Owner:LANDISGYR INNOVATIONS INC +1

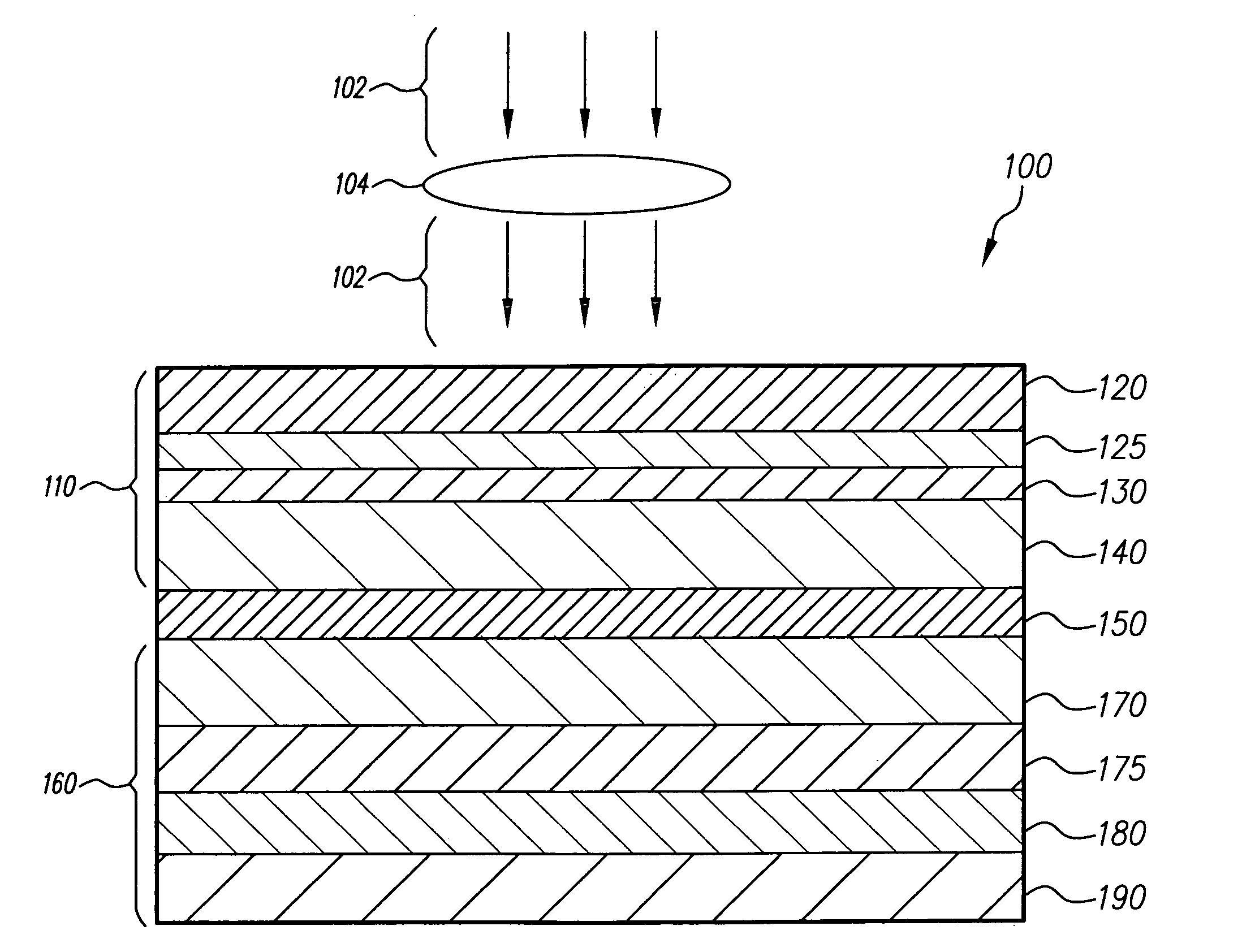

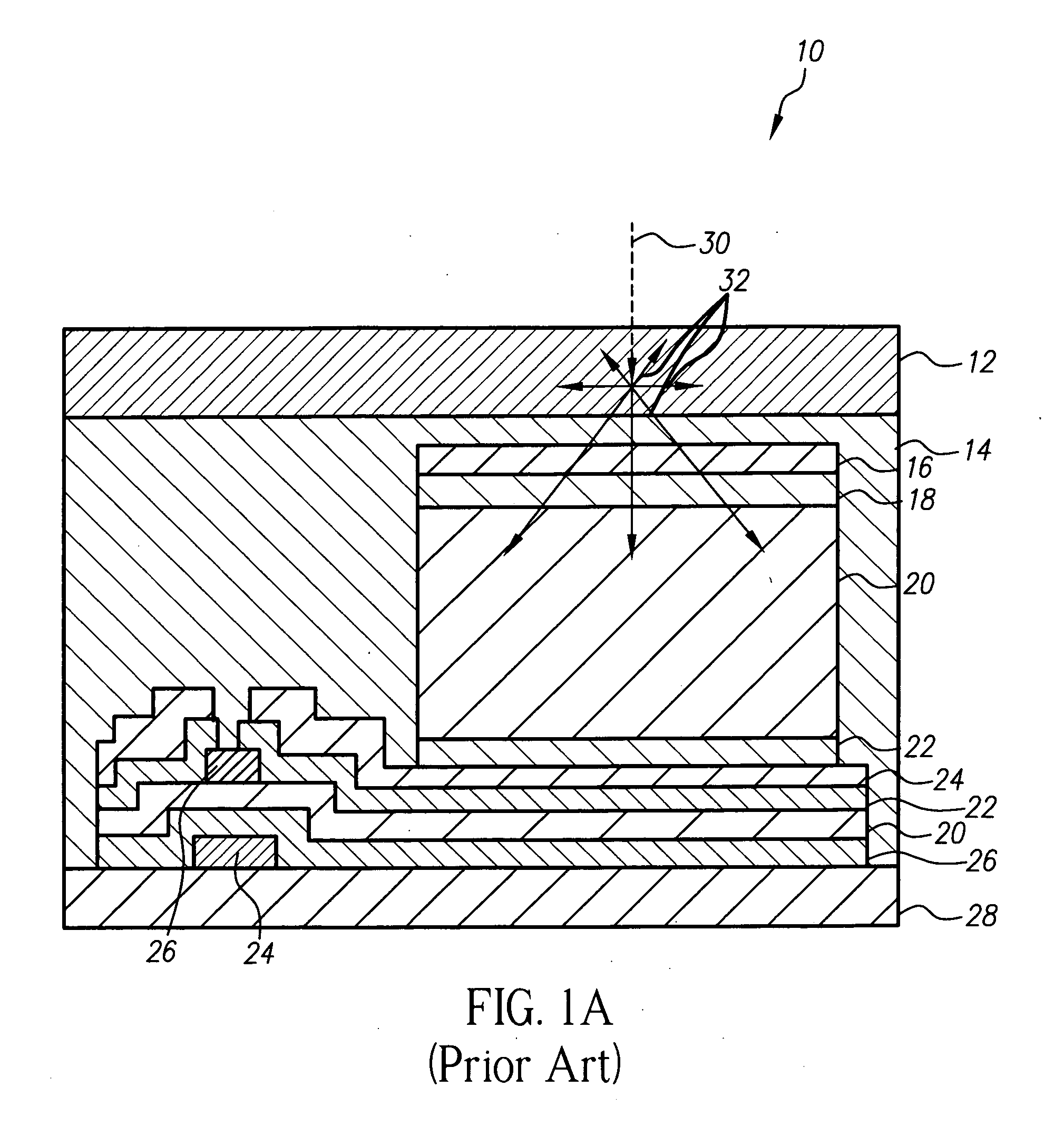

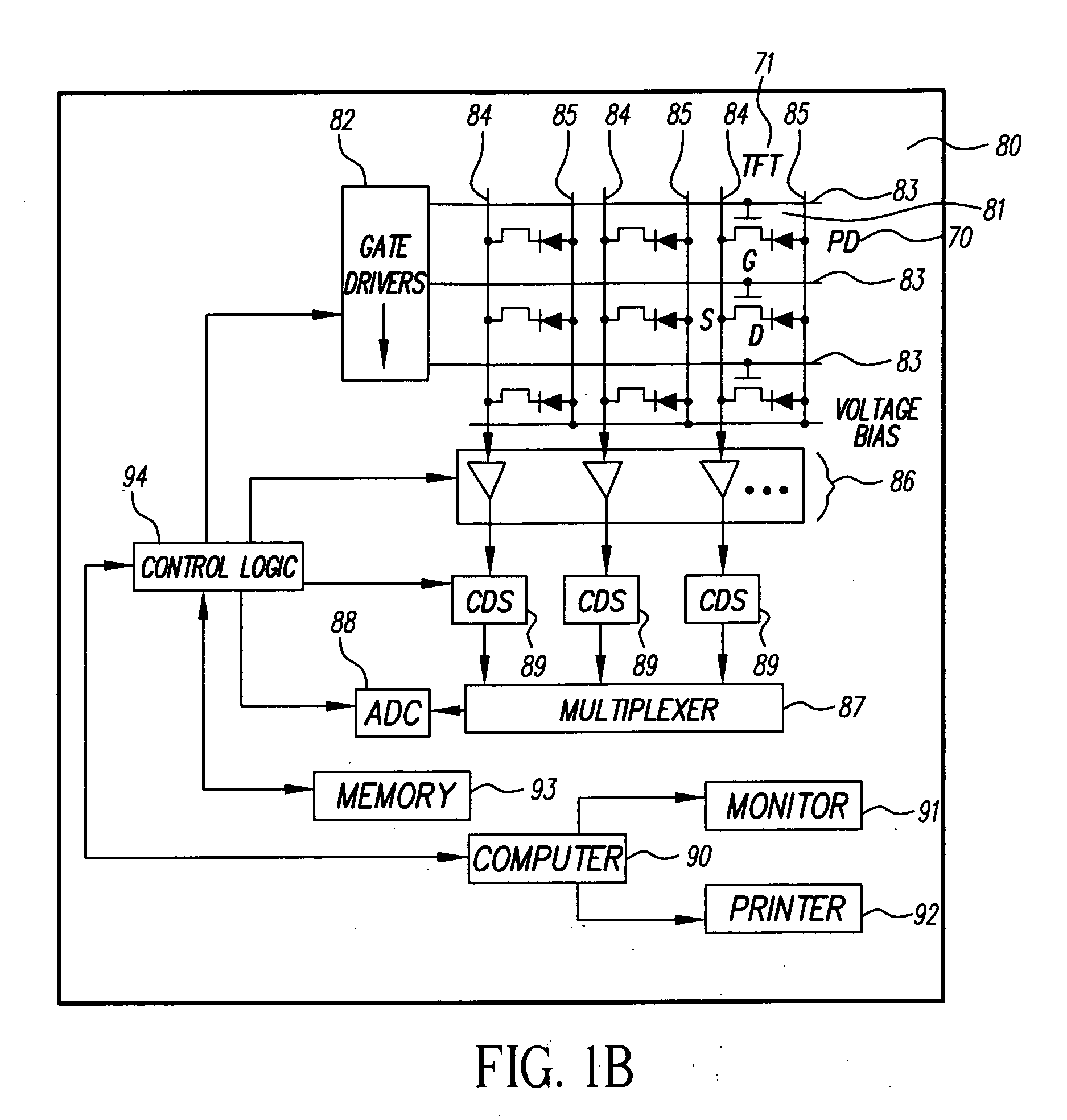

Apparatus for asymmetric dual-screen digital radiography

ActiveUS20080011960A1High detective quantum efficiencyClear imagingSolid-state devicesMaterial analysis by optical meansSoft x rayFluorescence

The present invention relates to radiographic imaging apparatus for taking X-ray images of an object. In various two-panel radiographic imaging apparatus configurations, a front panel and back panel have substrates, arrays of signal sensing elements and readout devices, and passivation layers. The front and back panels have scintillating phosphor layers responsive to X-rays passing through an object produce light which illuminates the signal sensing elements to provide signals representing X-ray images. The X-ray apparatus has means for combining the signals of the X-ray images to produce a composite X-ray image. Furthermore, the composition and thickness of the scintillating phosphor layers are selected, relative to each other, to improve the diagnostic efficacy of the composite X-ray image. Alternatively, a radiographic imaging apparatus has a single panel having arrays of signal sensing elements and readout devices and scintillating phosphor layers that are disposed on both sides of a single substrate. The present invention further relates to various embodiments of indirect dual-screen DR flat-panel imager apparatus that provide single-exposure dual energy imaging.

Owner:CARESTREAM HEALTH INC

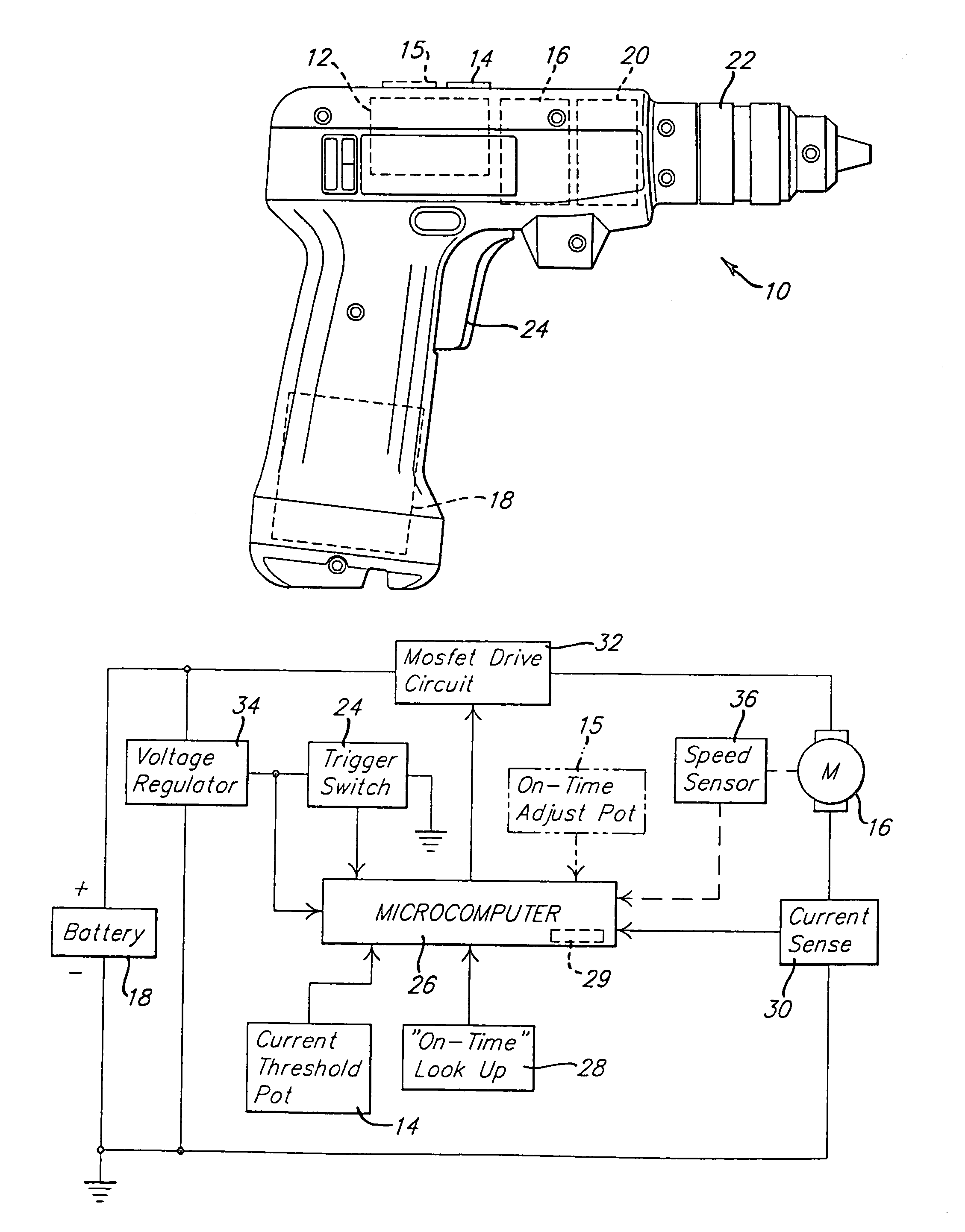

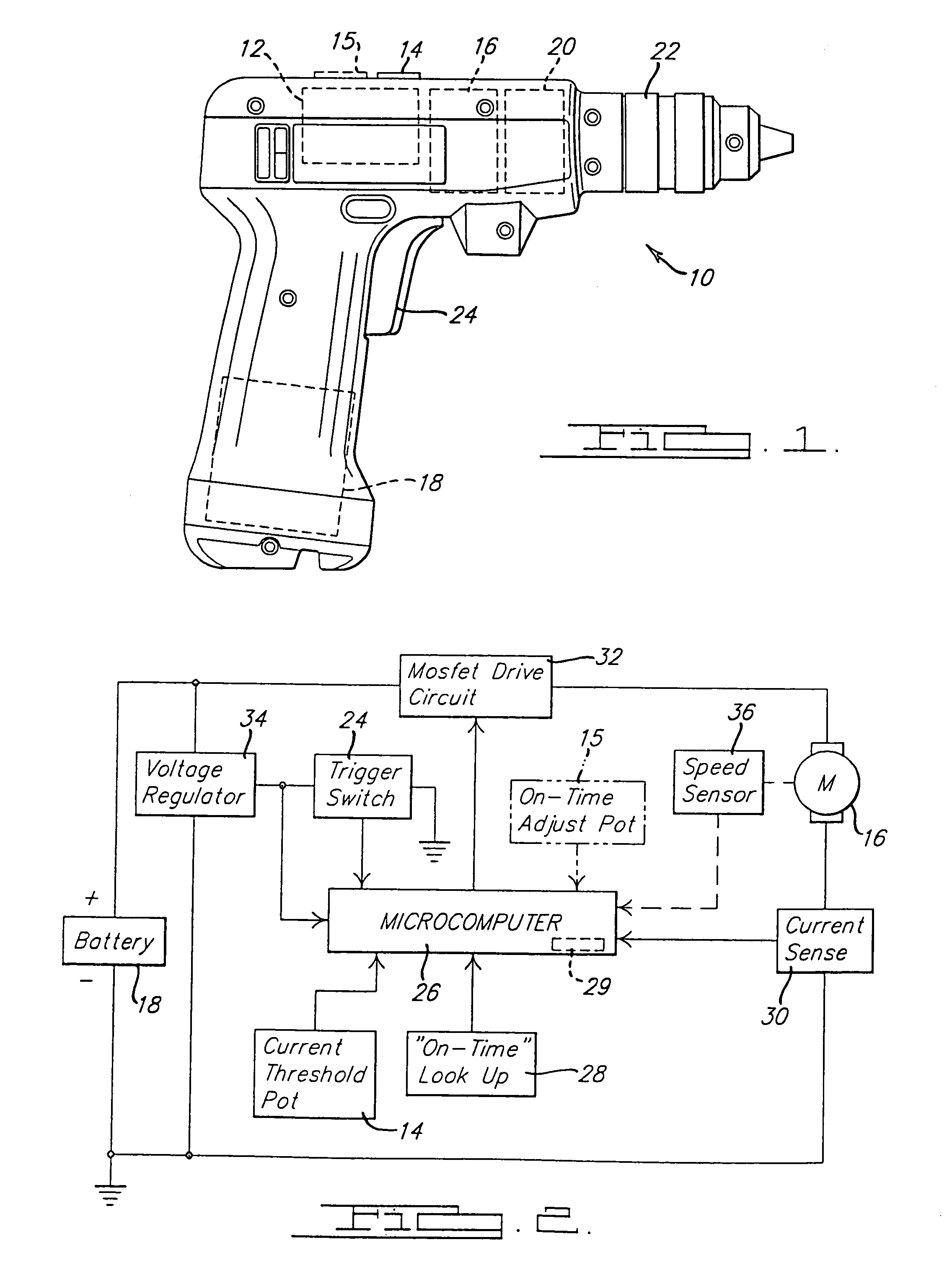

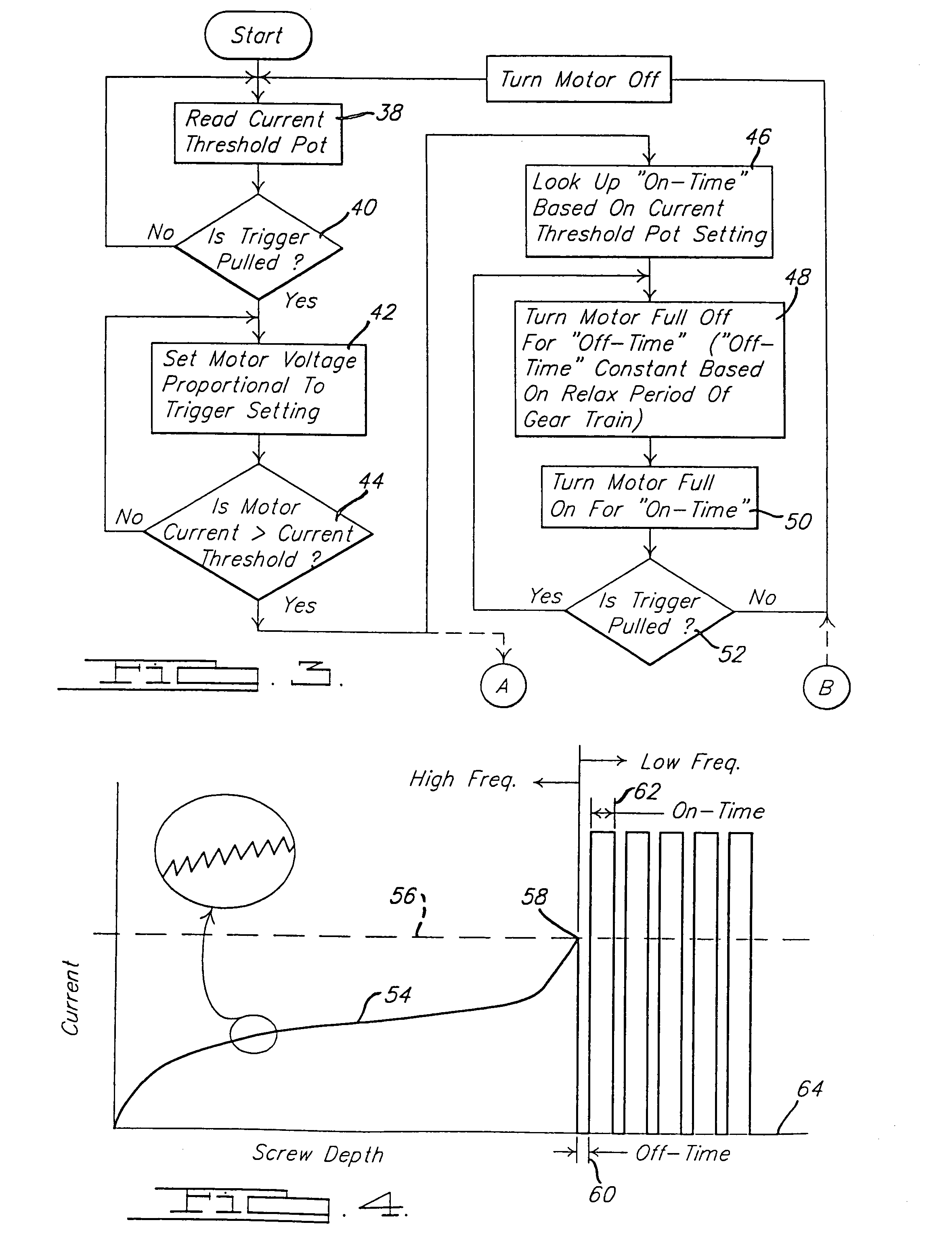

Electrical power tool having a motor control circuit for providing control over the torque output of the power tool

InactiveUS7112934B2Limit magnitudeGreat potential energyDC motor speed/torque controlAsynchronous induction motorsPulsed modeMotor control

A power tool such as an electric drill typically contains a gear train that couples the output spindle of the motor to the tool bit-receiving chuck. The control circuit for the power tool is operable in a ratcheting or pulse mode that causes the output spindle to rotate in discrete incremental amounts. Corresponding methods for controlling the operation of the electric motor of a power tool are also disclosed.

Owner:BLACK & DECKER INC

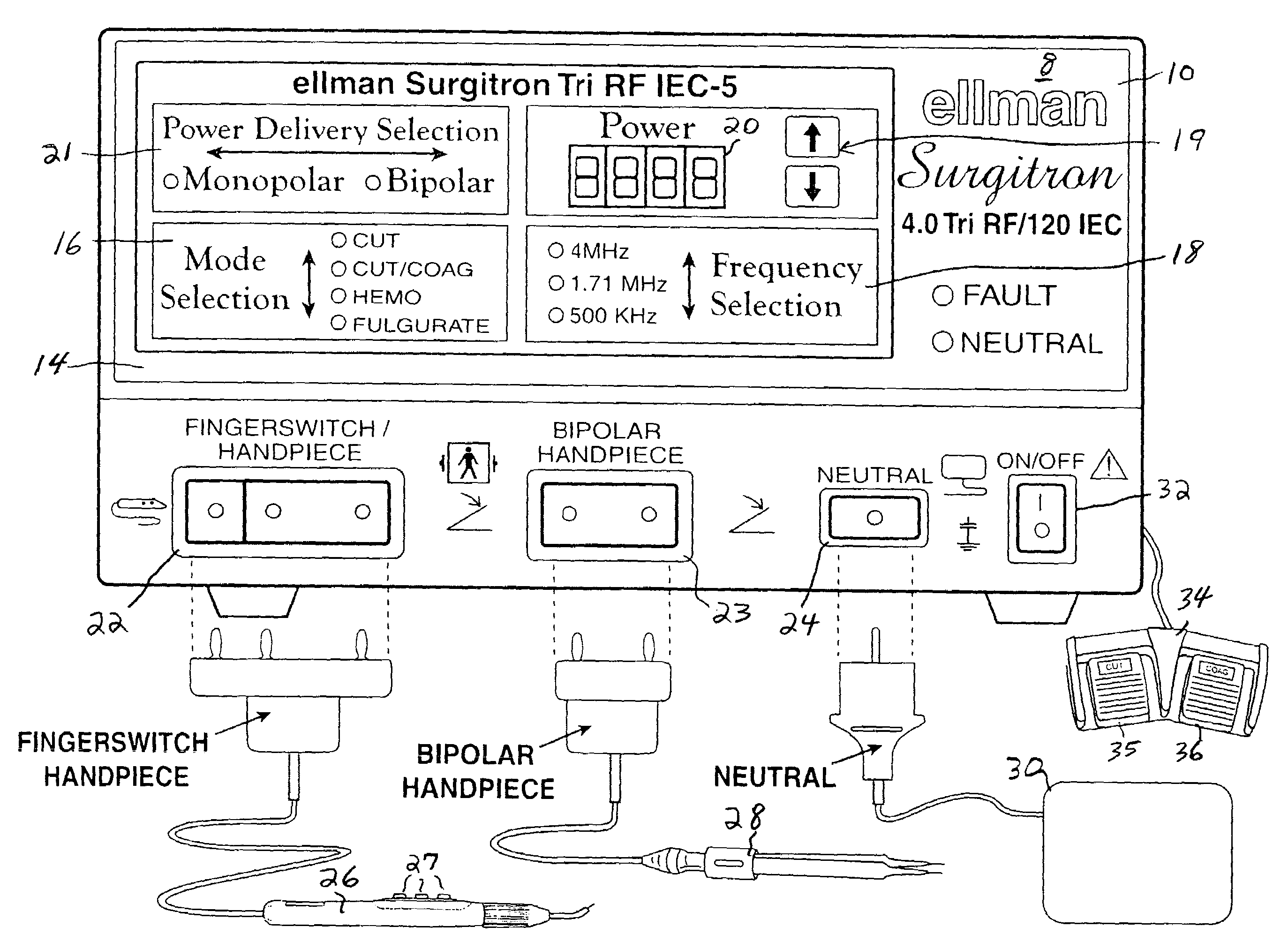

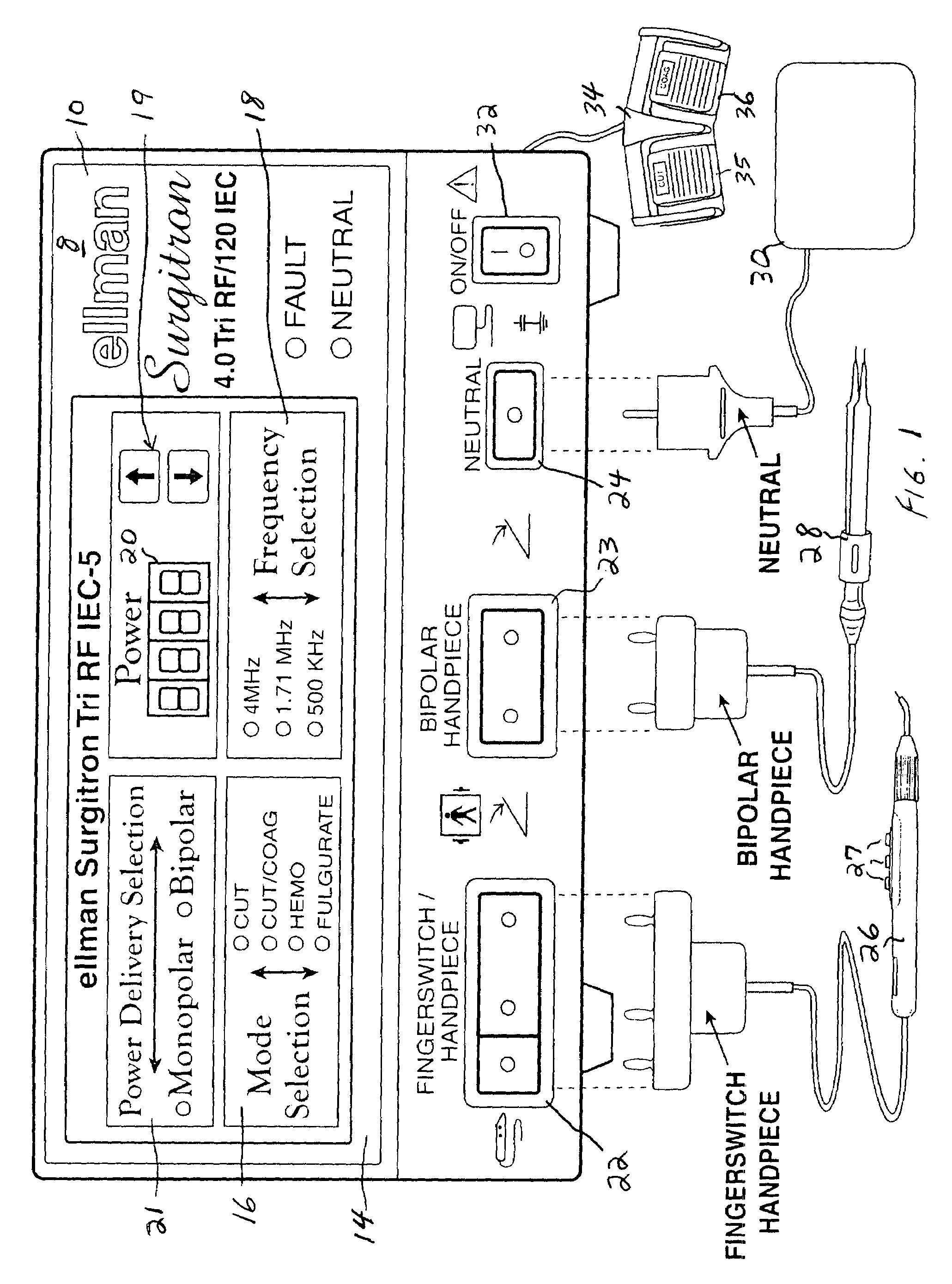

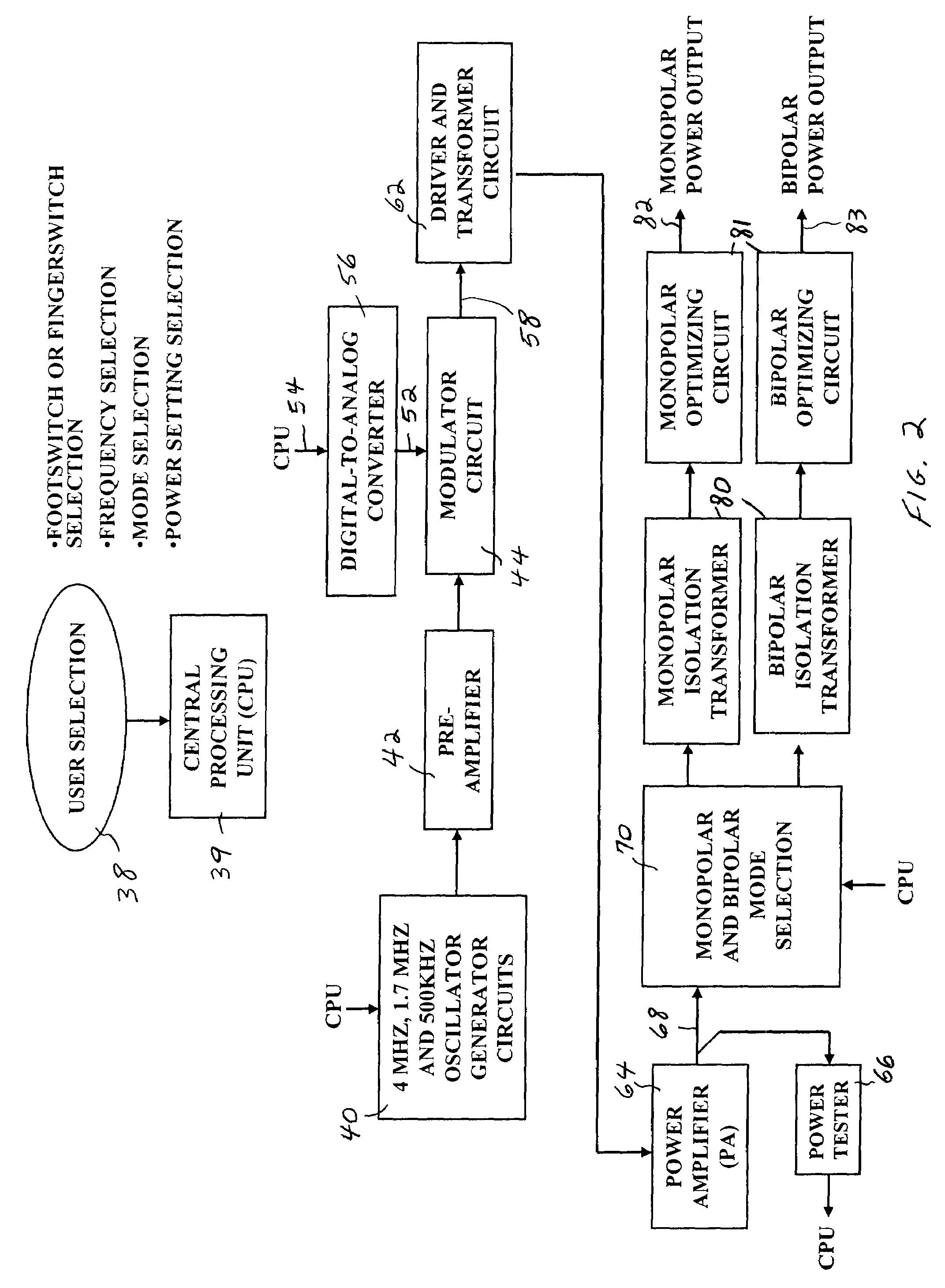

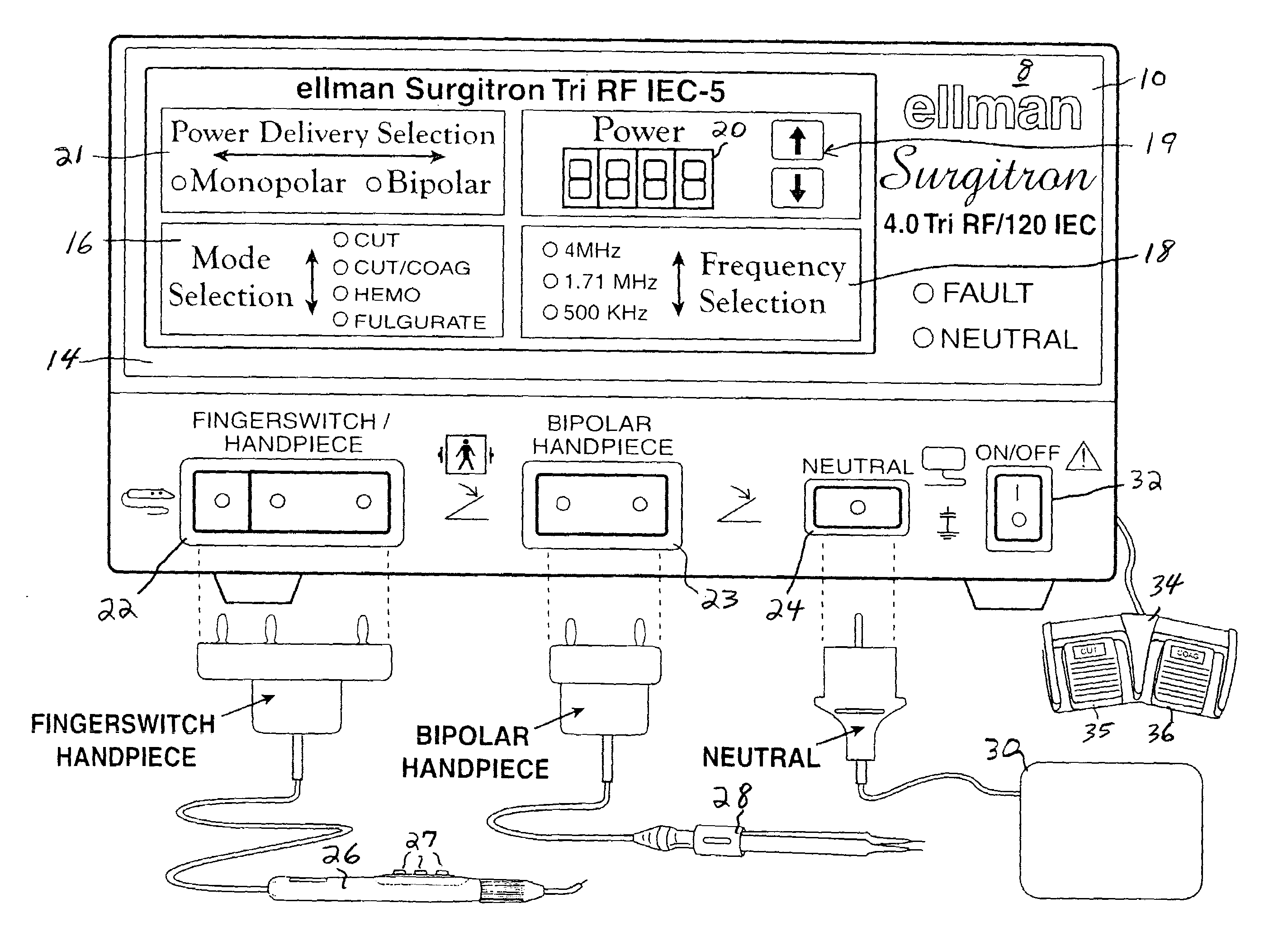

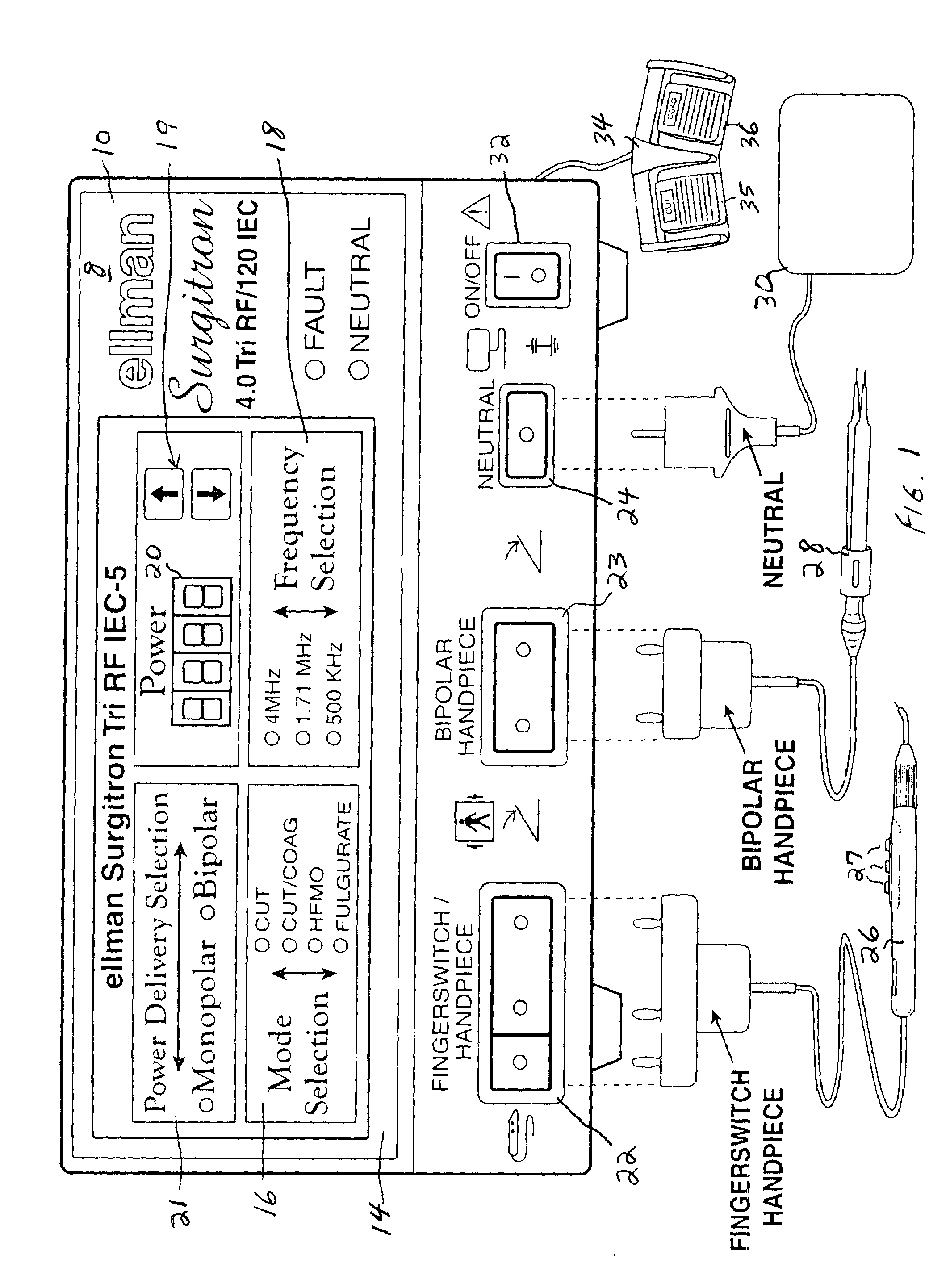

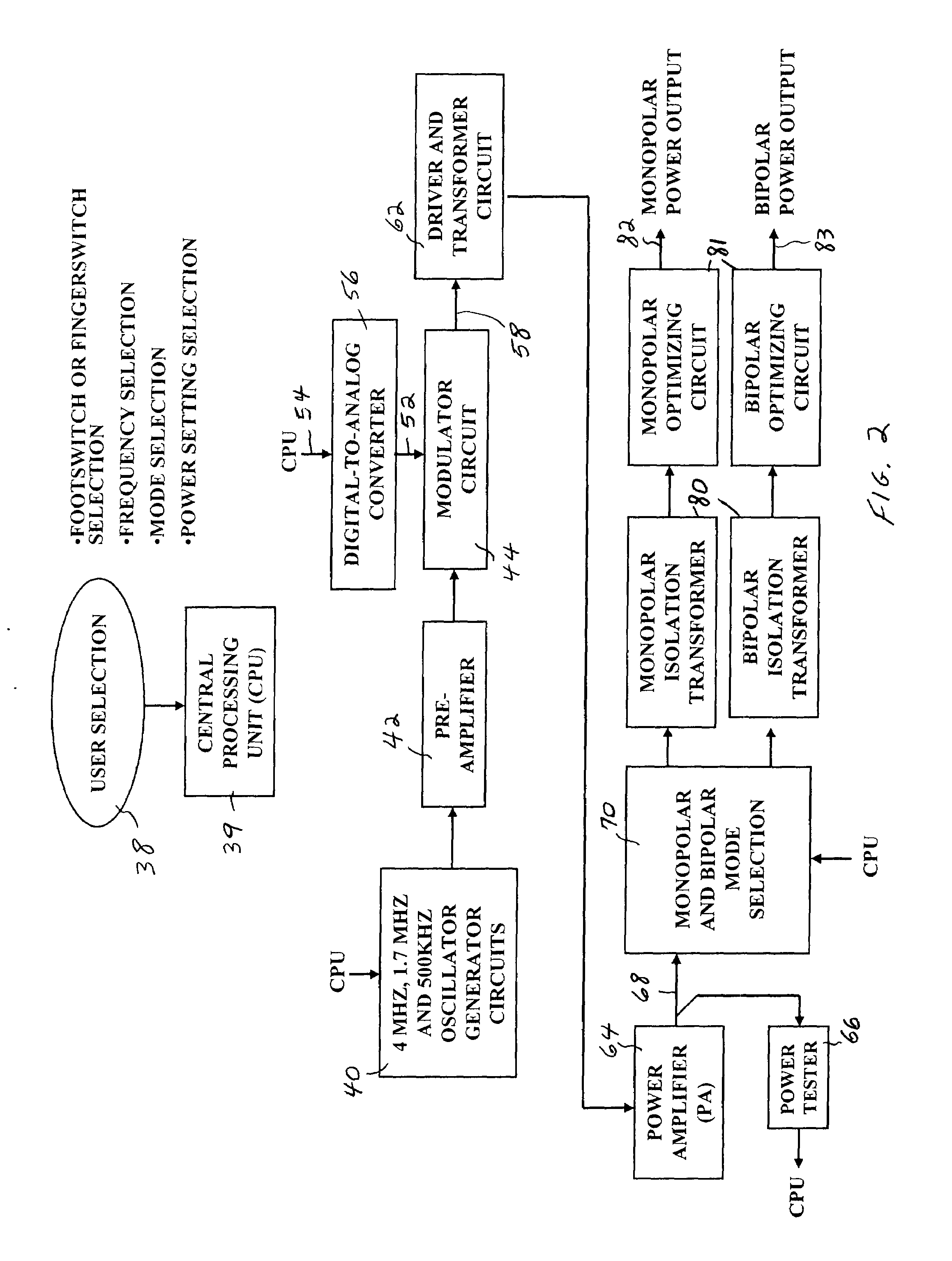

Tri-frequency electrosurgical instrument

ActiveUS8998891B2Good energyReduce leakage currentControlling energy of instrumentSurgical instruments for heatingCarrier signalEngineering

Owner:CYNOSURE

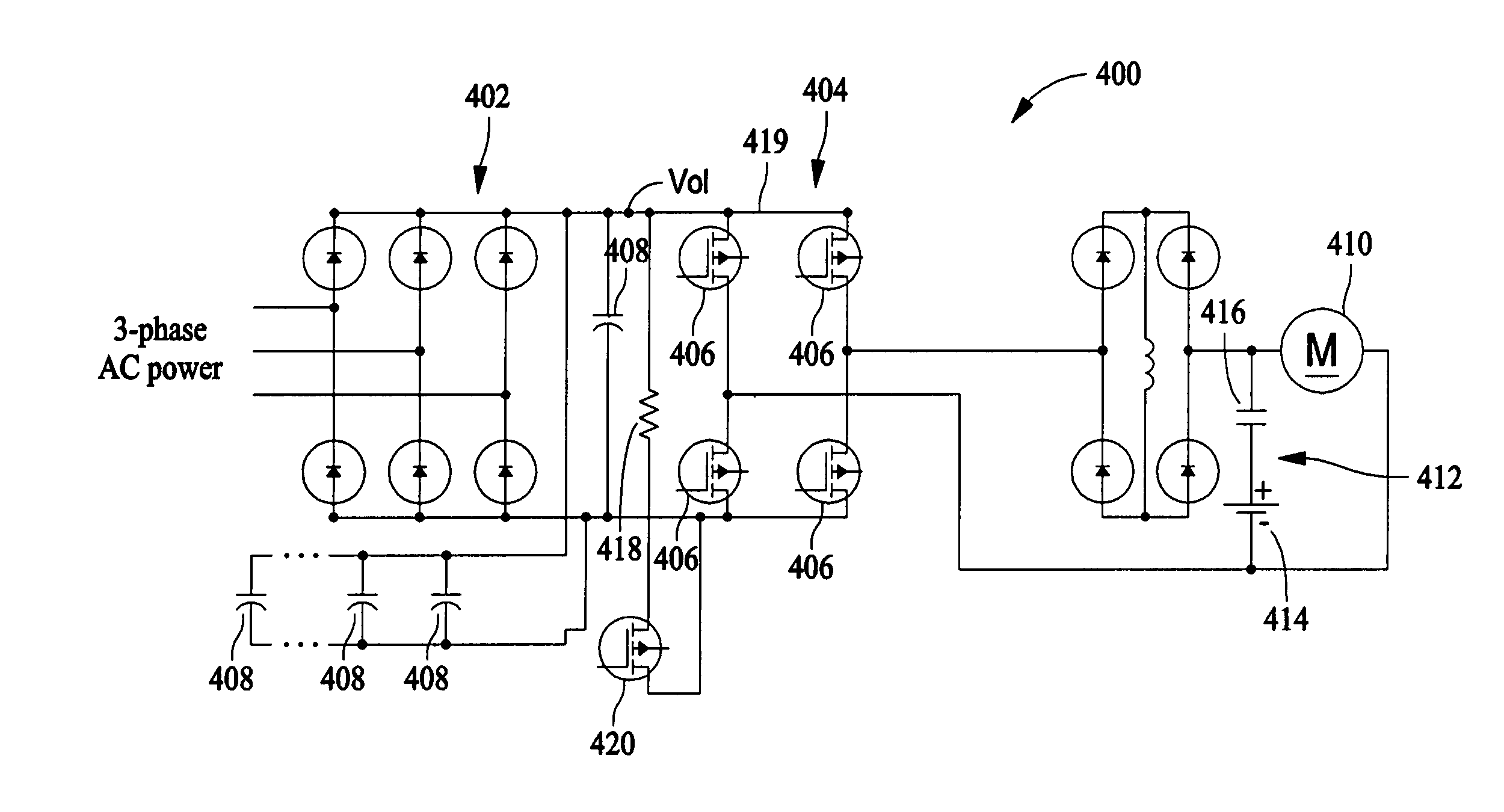

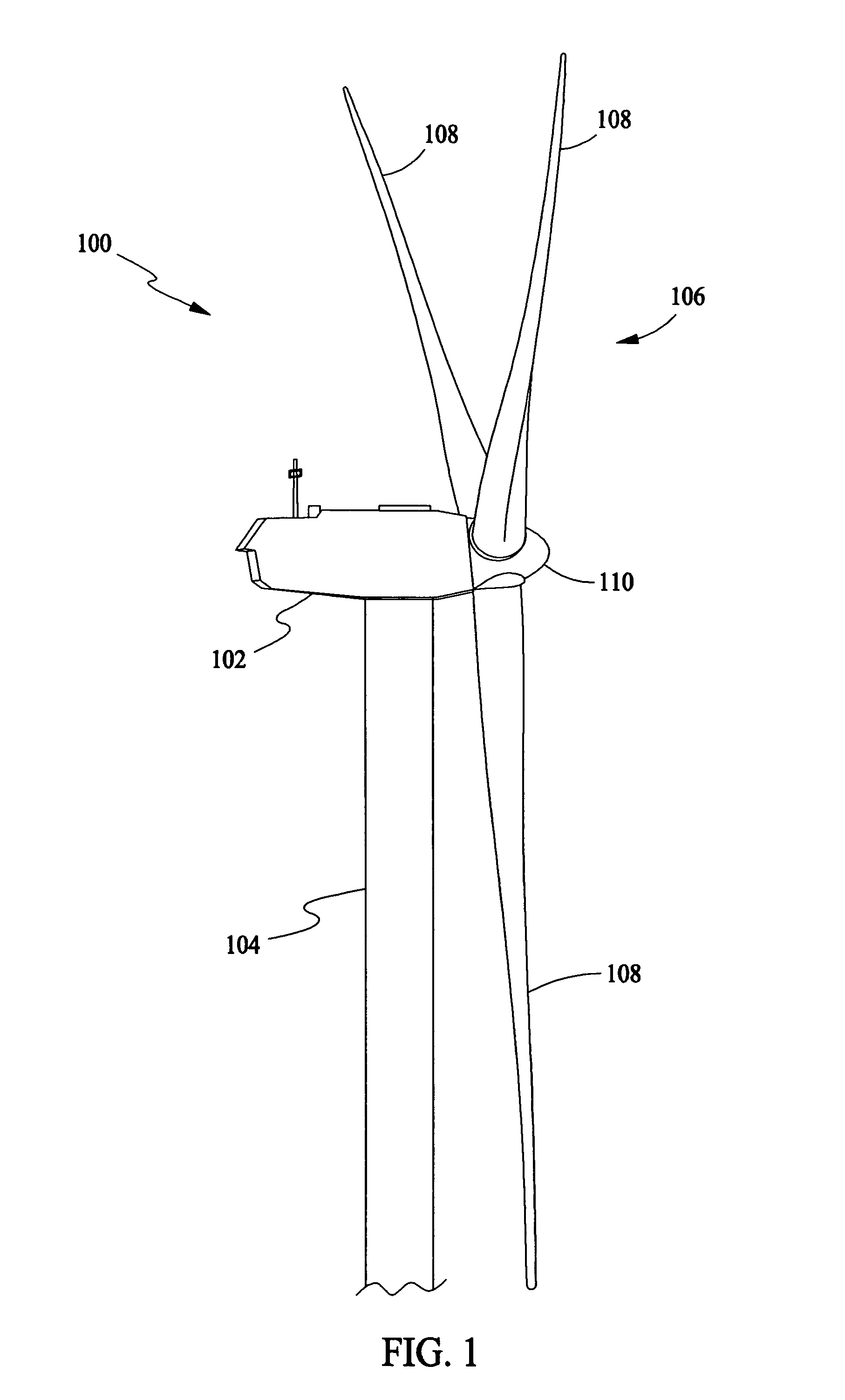

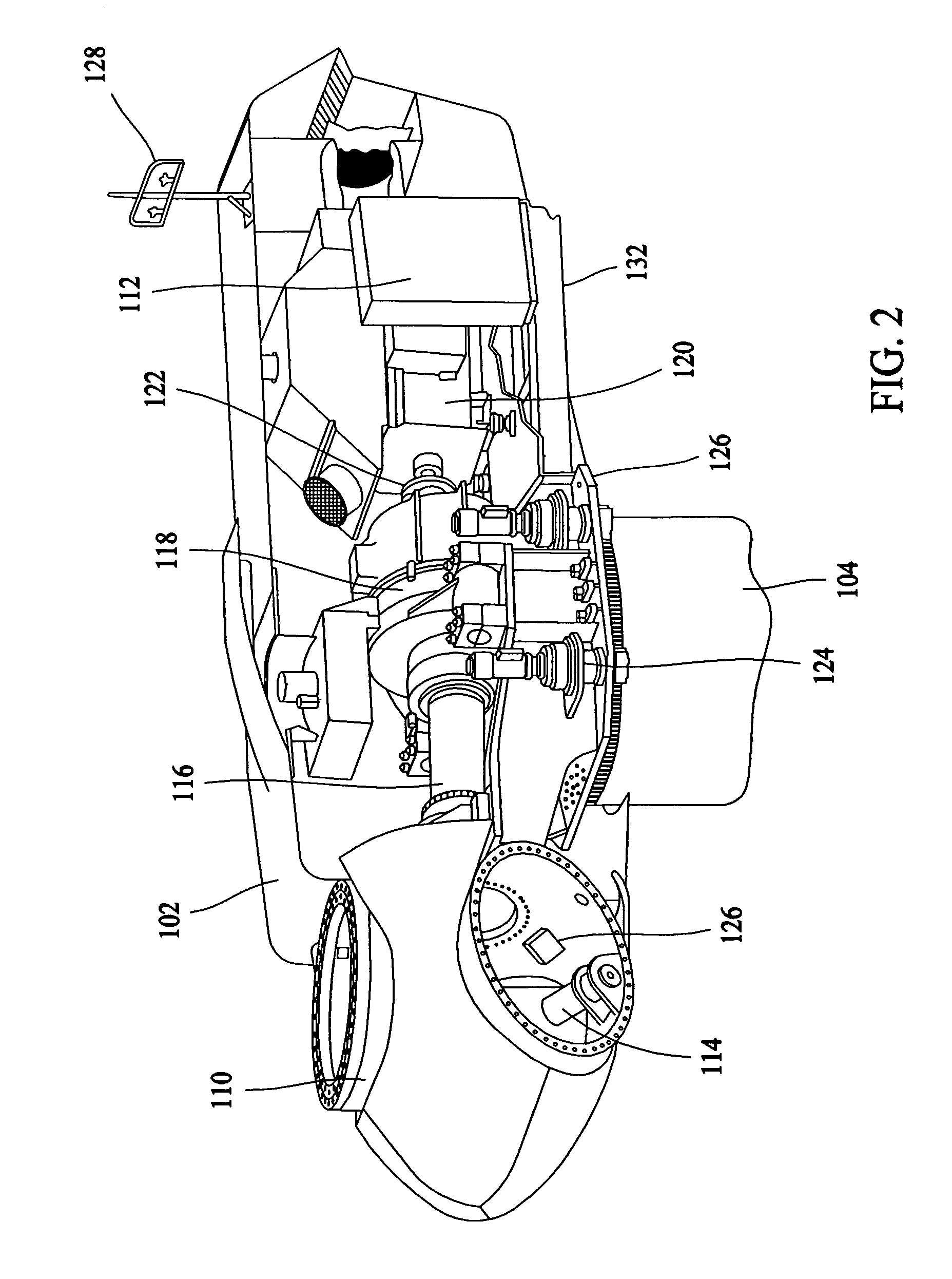

Methods and apparatus for pitch control power conversion

ActiveUS7126236B2Improve availabilityLow costDC motor speed/torque controlWind motor controlMotor driveElectric machine

A method for powering a pitch motor drive system for at least one DC pitch motor of a wind turbine includes rectifying a voltage using a bridge circuit to thereby supply a DC link voltage to a bridge comprising active switching devices, and utilizing at least one link capacitor to smooth the DC link voltage and act as an energy sink and source for the DC pitch motor or motors.

Owner:GE INFRASTRUCTURE TECH INT LLC

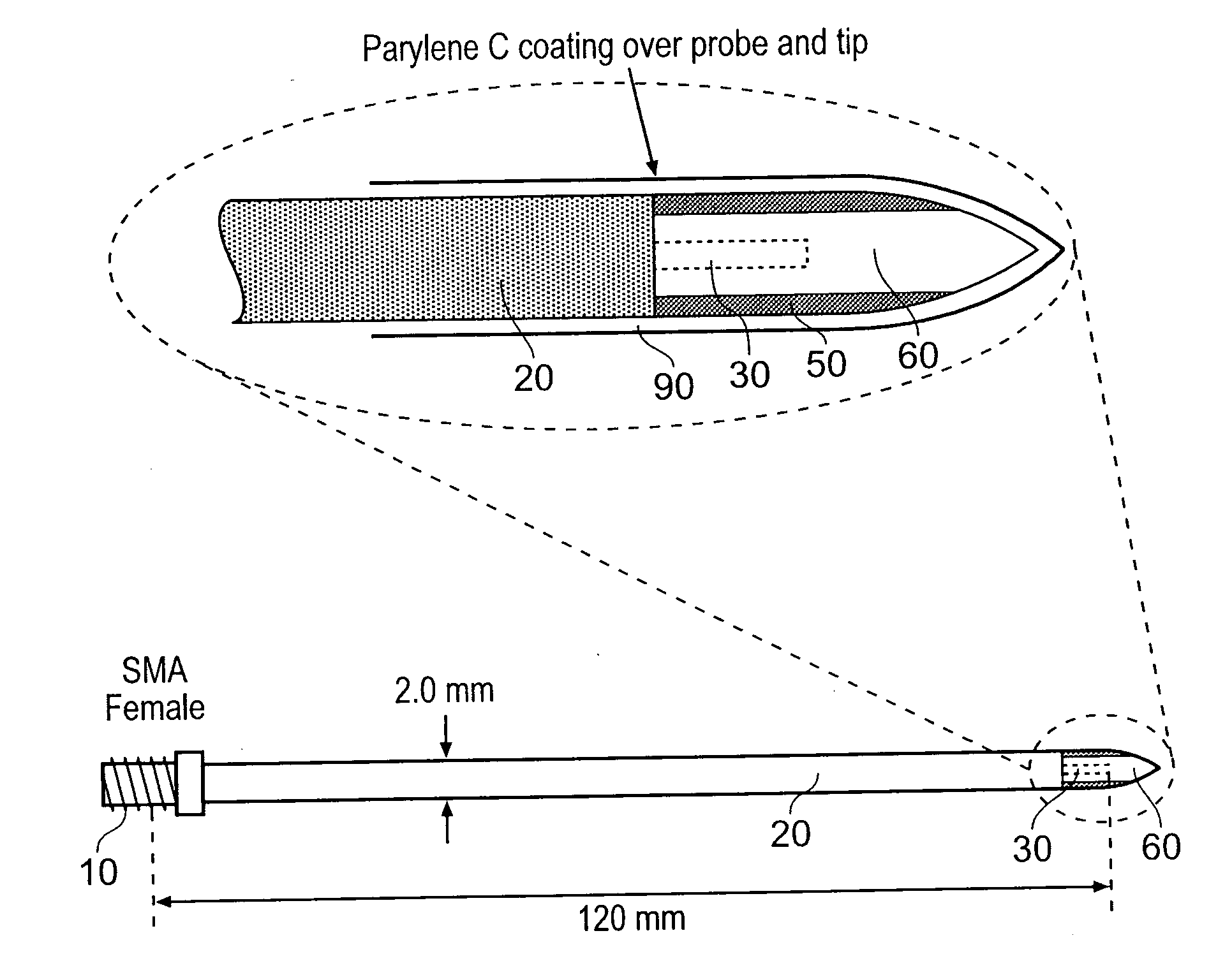

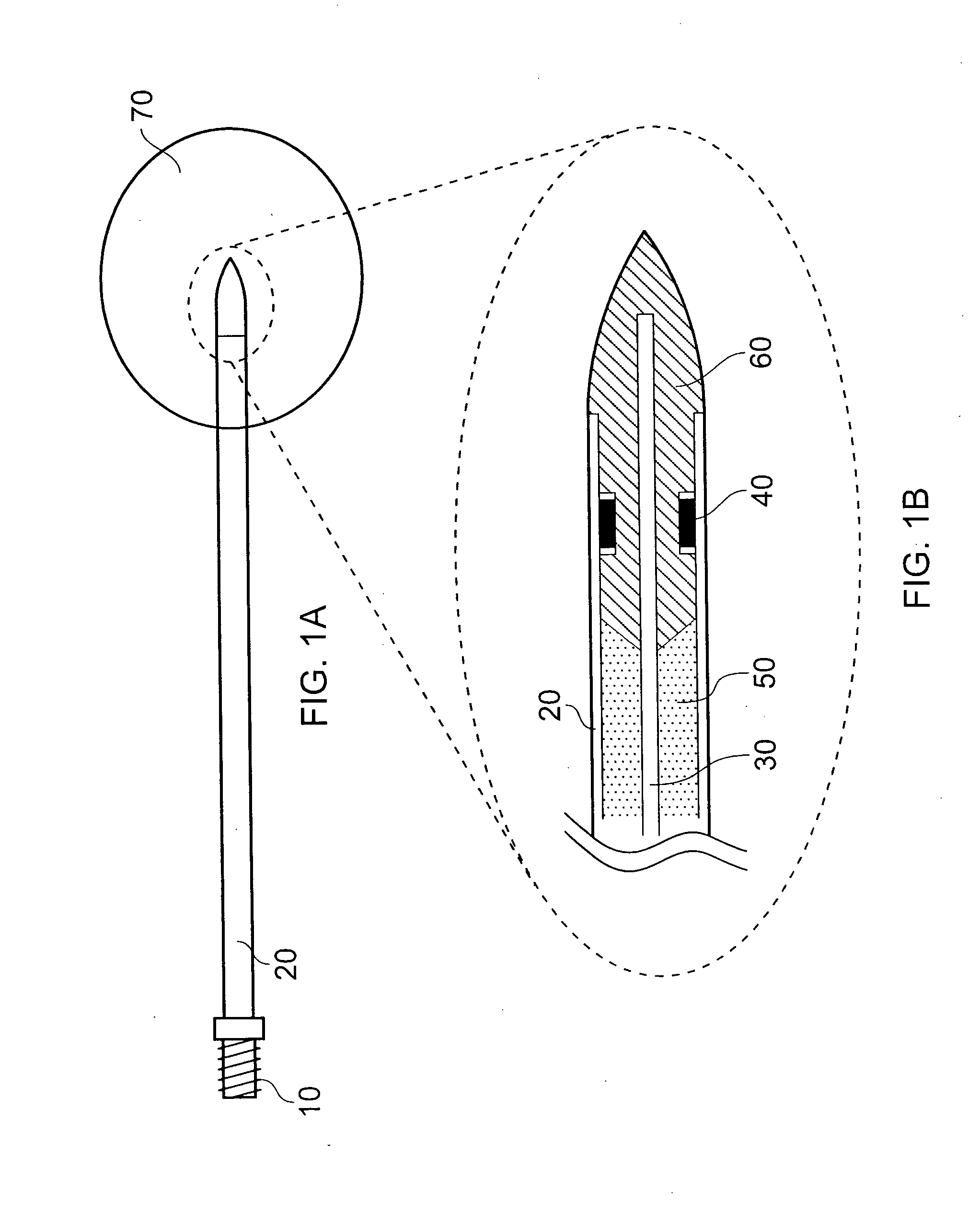

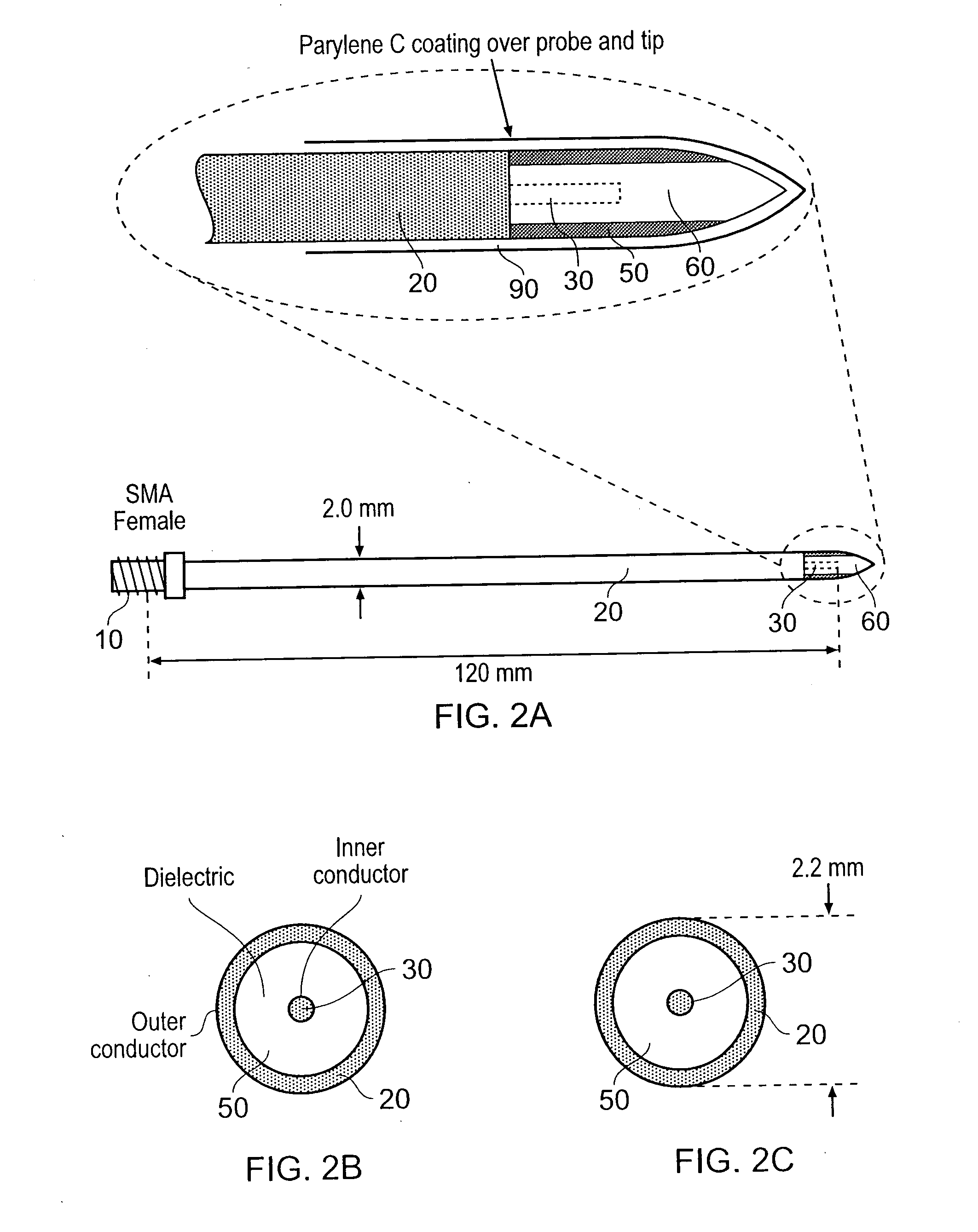

Tissue measurement and ablation antenna

InactiveUS20100228244A1Easy to operateImproving Impedance MatchingSurgical instruments for heatingSurgical instruments using microwavesElectrical conductorMicrowave

A surgical antenna for radiating microwave energy (e.g. frequency 500 MHz to 60 GHz) from a e.g. ceramic insertion tip (60) into biological tissue is disclosed. The tip is provided at the end of an elongate body which delivers the microwave energy to the tip via an inner conductor (30), an outer conductor (20) surrounding the inner conductor and a dielectric material (50) therebetween. The impedance of the insertion tip (60) is selected to improve impedance matching with the complex conjugate of the complex impedance of the tissue at a treatment frequency. For example the insertion tip may act as or include at least one quarter wavelength impedance transformer. By closely matching the antenna's impedance to the tissue, dynamic tuning (if used) can be performed much more efficiently. Impedance matching at the tip can also focus the radiated energy distribution.

Owner:MEDICAL DEVICE INNOVATIONS

Photovoltaic power conditioning units

ActiveUS8472220B2Easy to controlGood energyConversion with intermediate conversion to dcDc-dc conversionFailure rateEngineering

We describe a photovoltaic (PV) panel system comprising a PV panel with multiple sub-strings of connected solar cells in combination with a power conditioning unit (microinverter). The power conditioning unit comprises a set of input power converters, one connected to each sub-string, and a common output power conversion stage, to provide power to an ac mains power supply output. Integration of the micro-inverter into the solar PV module in this way provides many advantages, including greater efficiency and reliability. Additionally, embodiments of the invention avoid the need for bypass diodes, a component with a high failure rate in PV panels, providing lower power loss and higher reliability.

Owner:TESLA INC

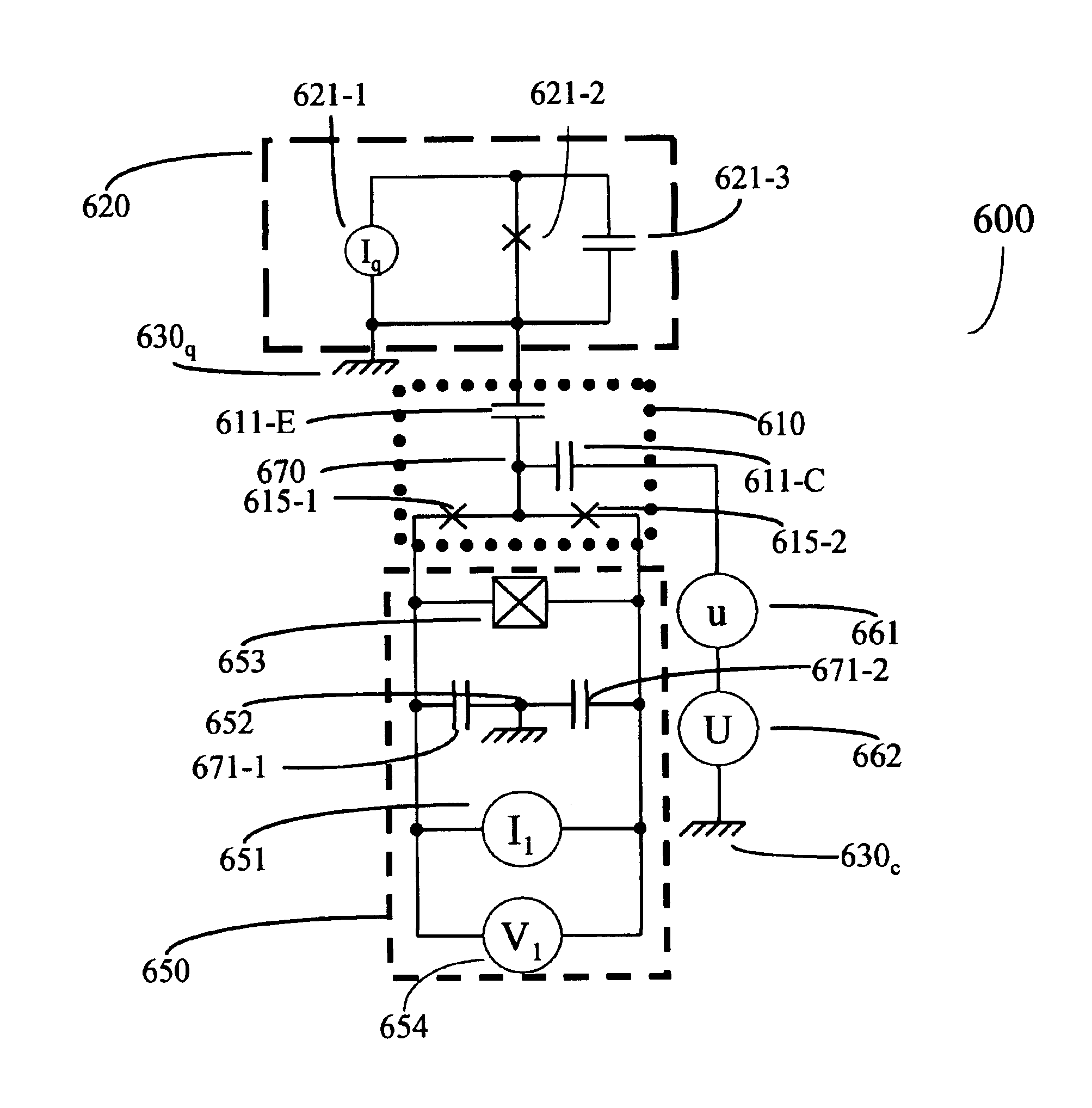

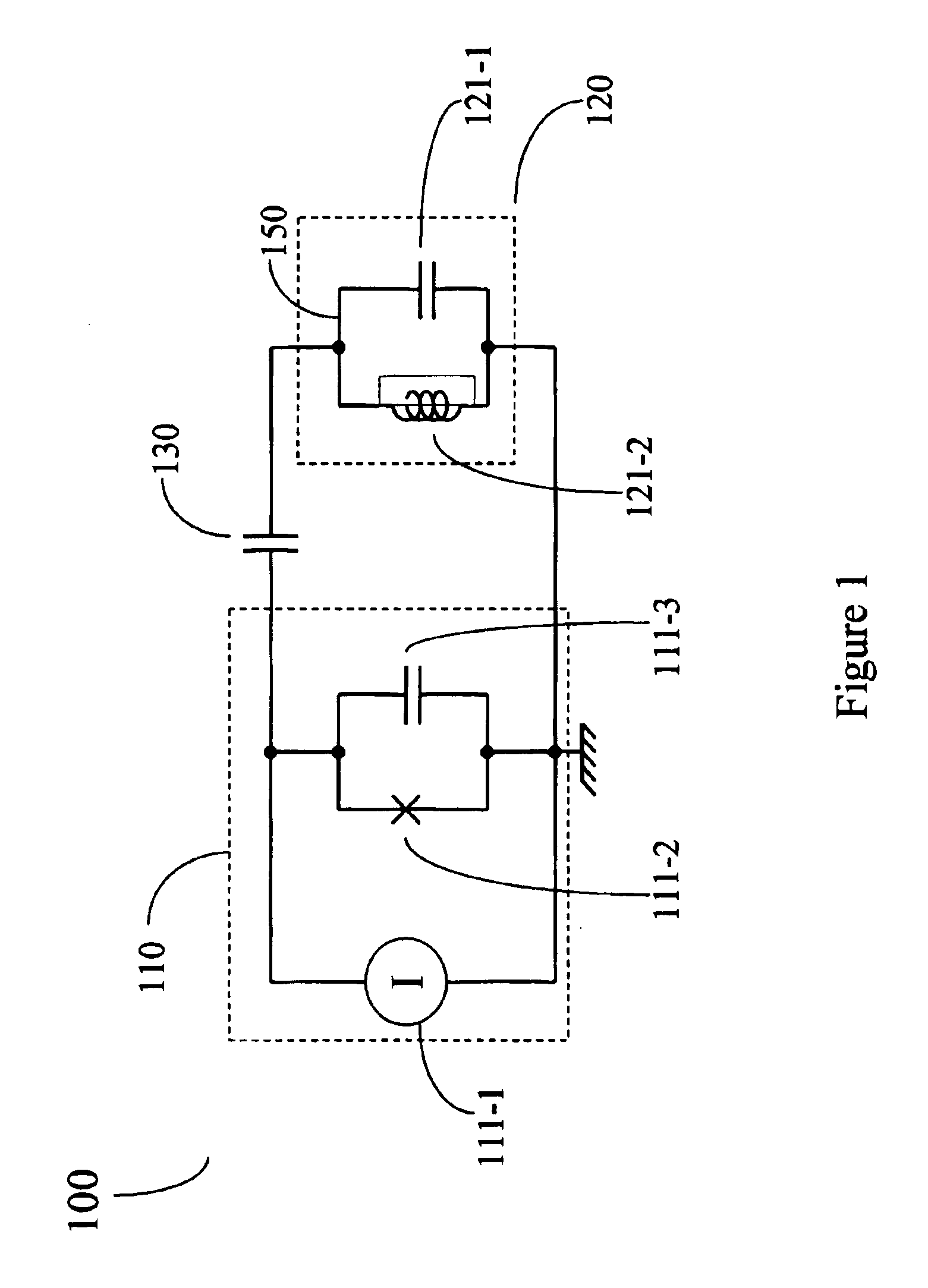

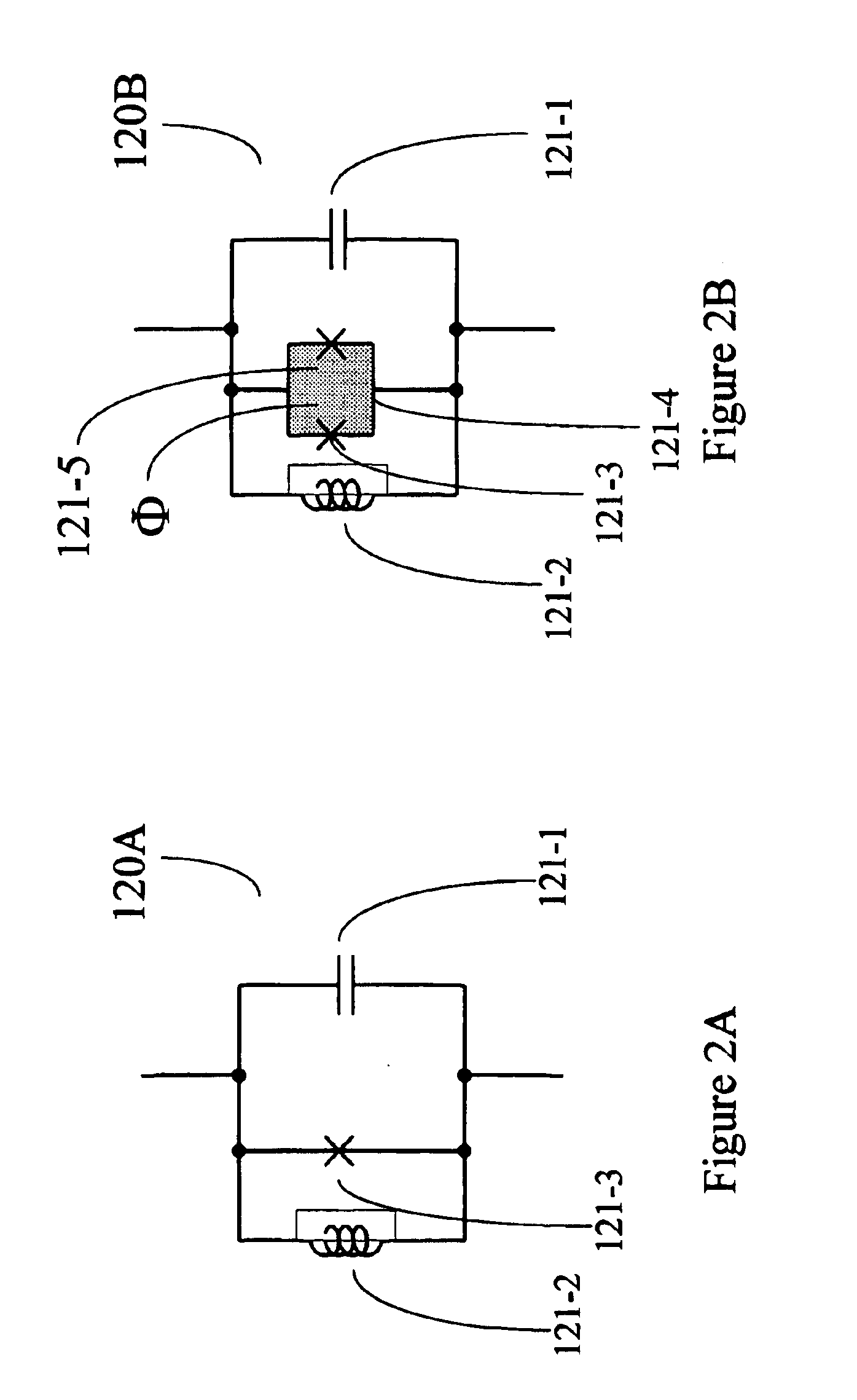

Resonant controlled qubit system

Methods for coupling a superconducting qubit to a resonant control circuit. An interaction term between the qubit and the circuit initially has a diagonal component. A recoupling operation is applied to the qubit. The circuit is tuned so that a frequency of the qubit and circuit match. A second recoupling operation transforms the term to have only off-diagonal components. A method for entangling a state of two qubits coupled to a bus with a control circuit. An interaction term between at least one of the qubits and the circuit has a diagonal component. A recoupling operation is applied to at least one of the qubits such that the term has only off-diagonal components. The frequency of the circuit is tuned to the frequency of the first qubit, and then tuned to the frequency of the second qubit. The recoupling operation is reapplied to at least one of the qubits.

Owner:D WAVE SYSTEMS INC

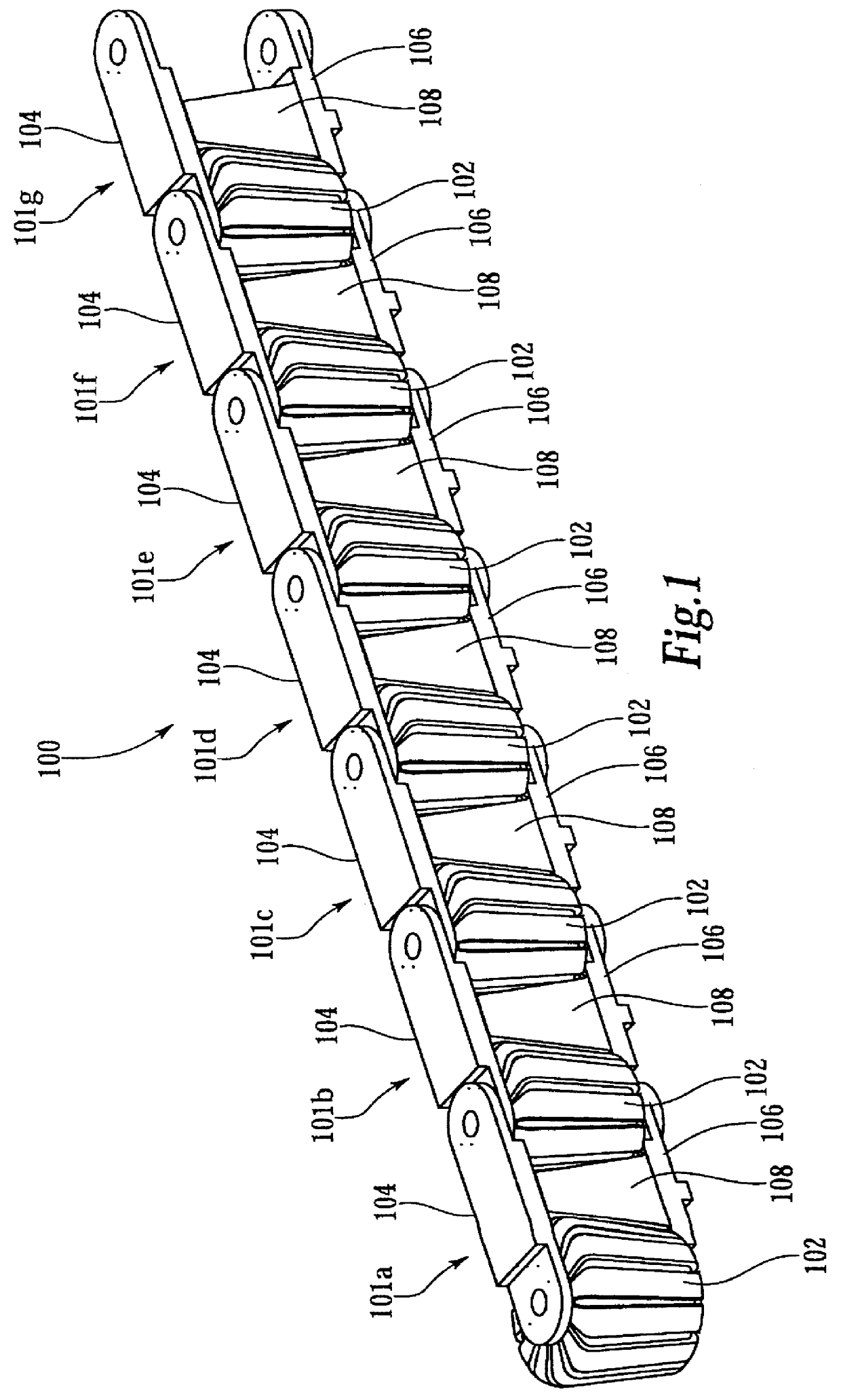

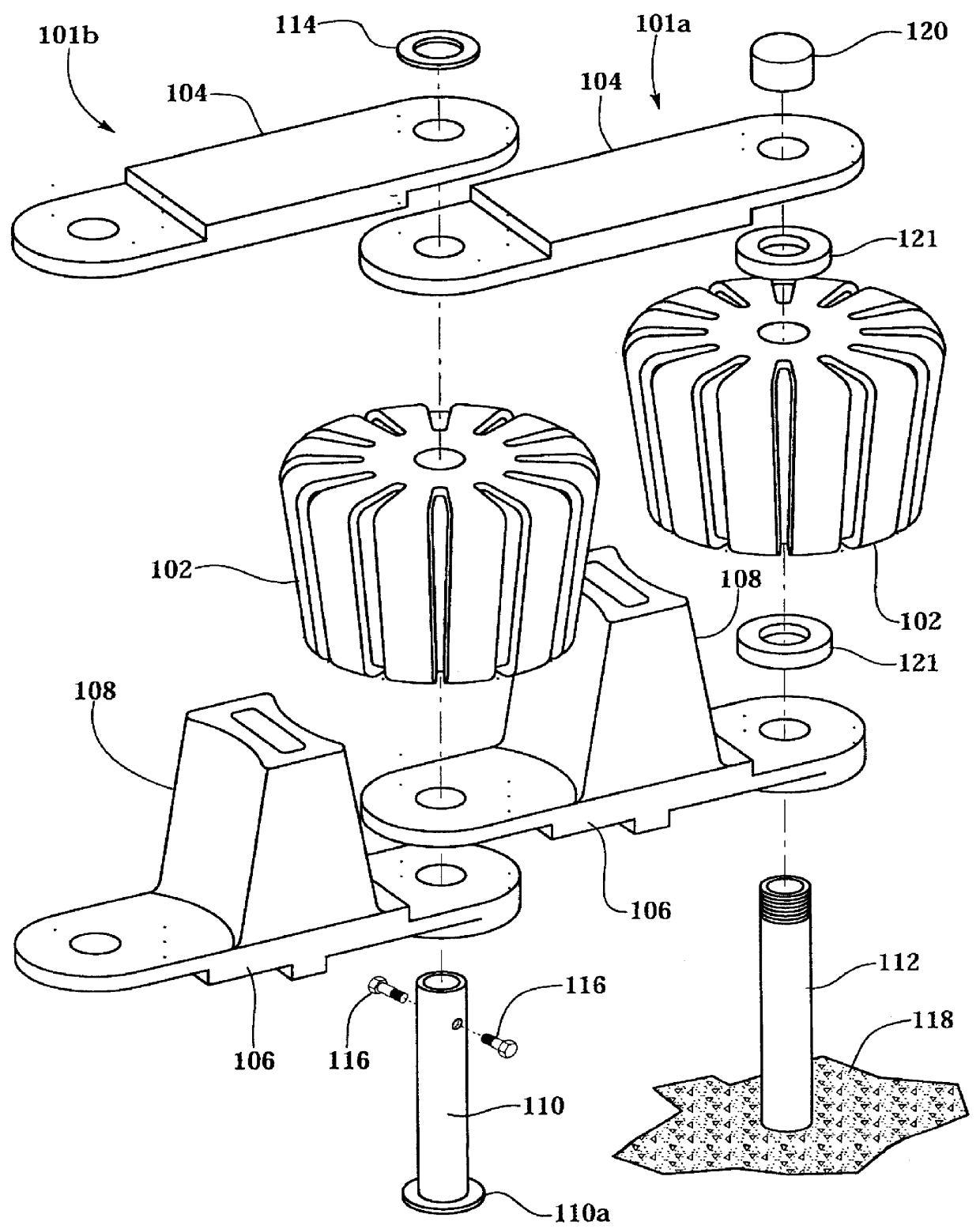

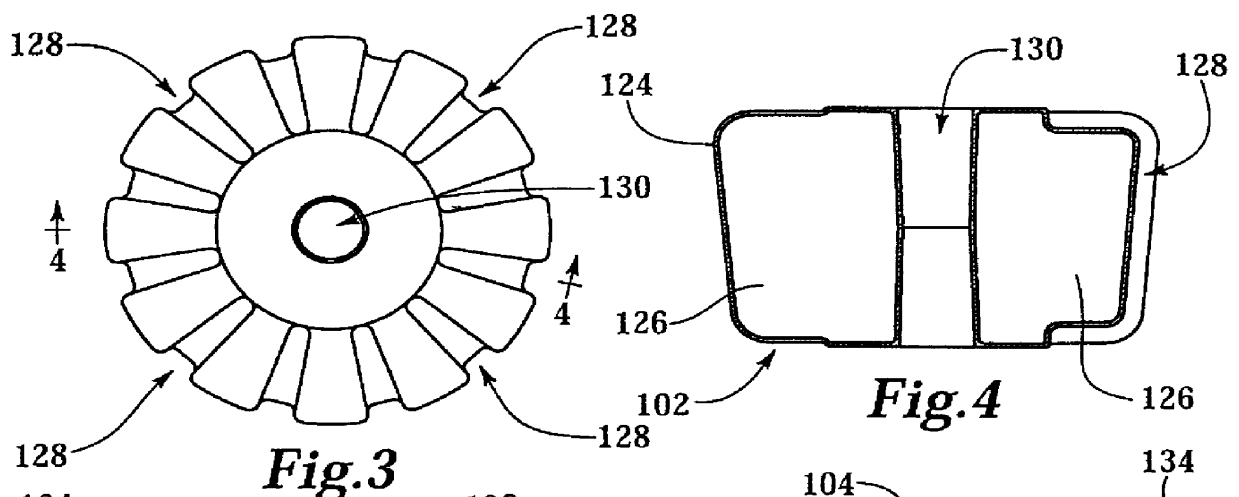

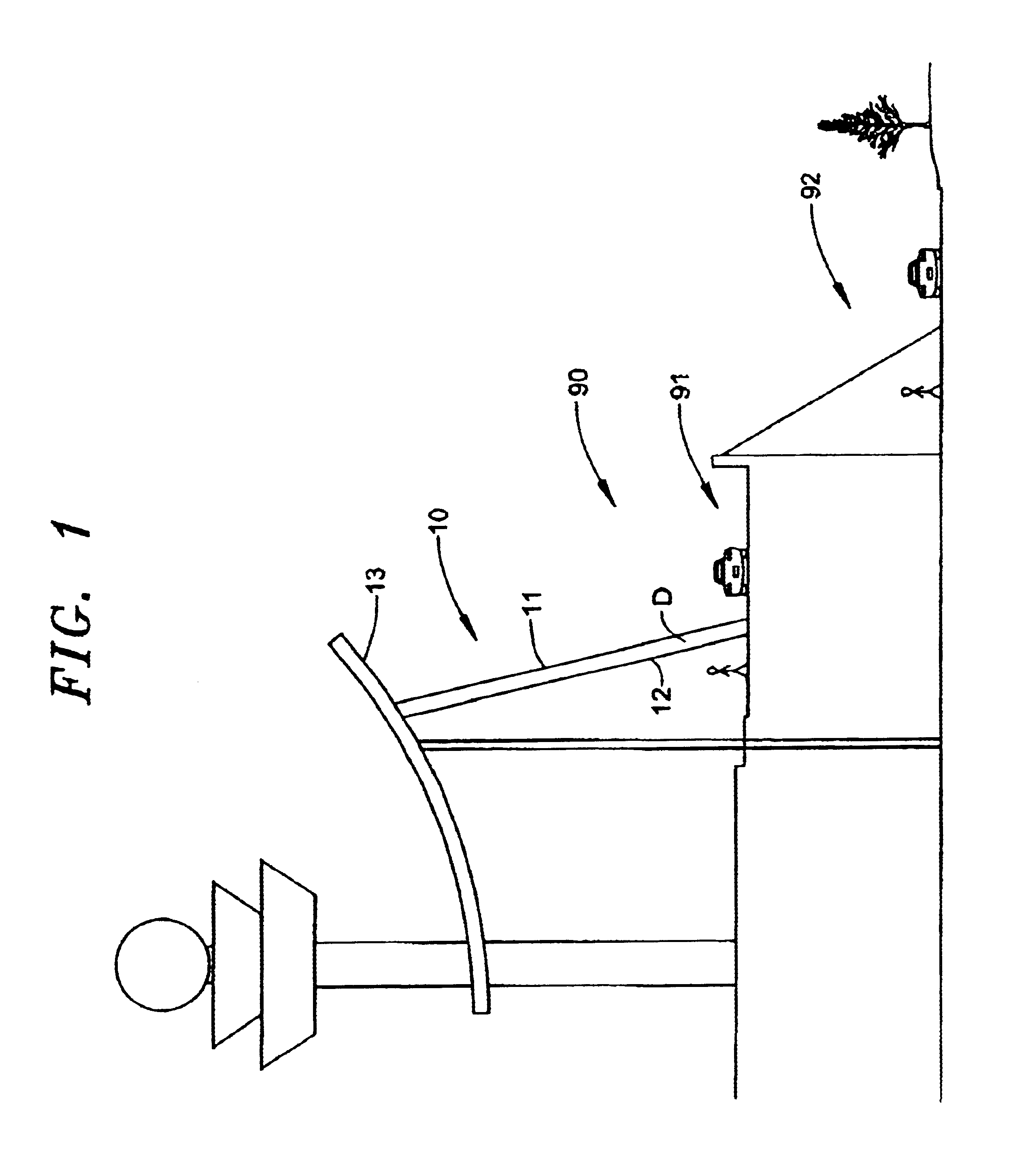

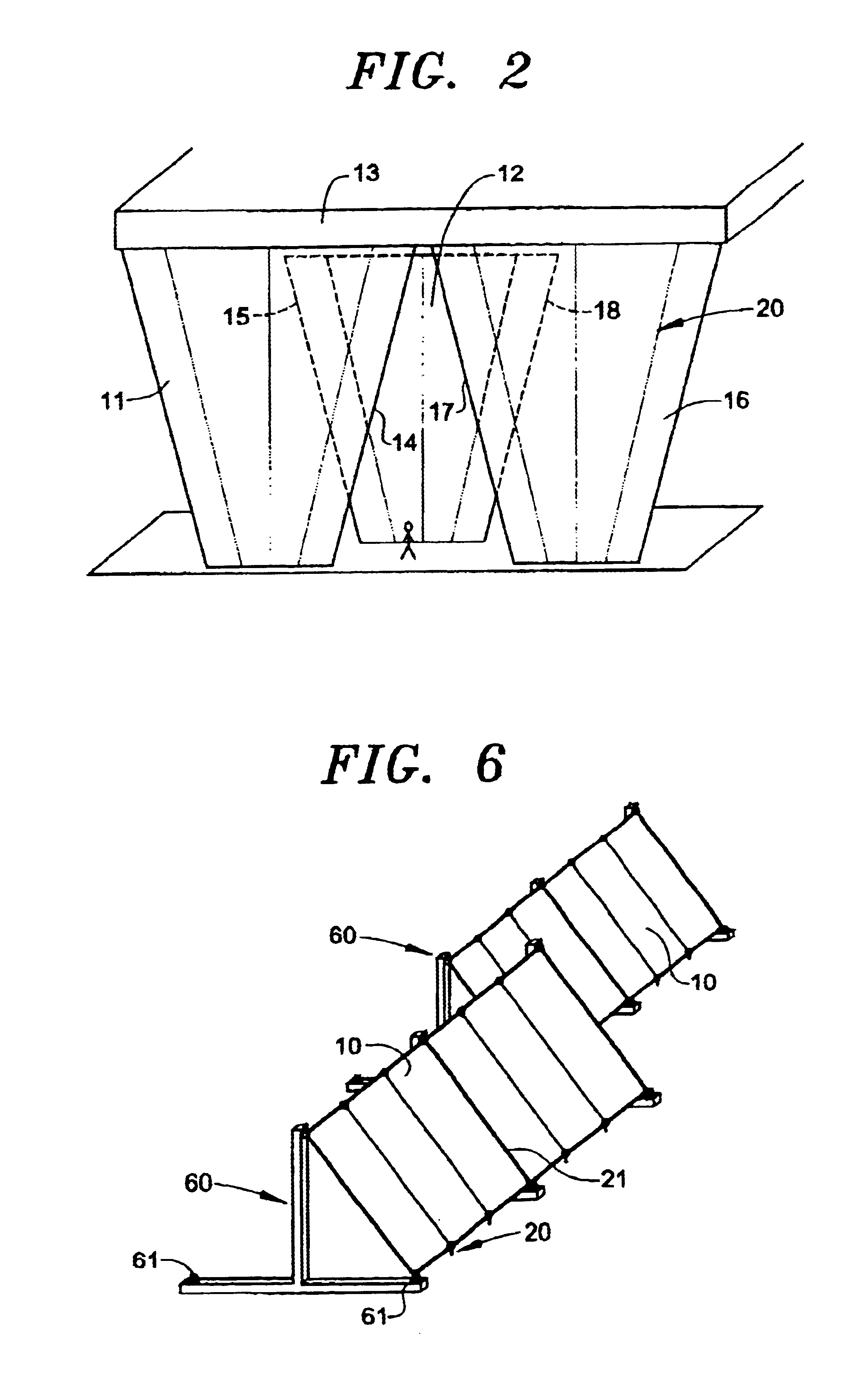

Vehicle barrier system

A barrier vehicle system for an amusement race track is formed from a chain of pivotally coupled barrier modules. Each barrier module has a top and a bottom link separated by a spacer structurally joined with the top and bottom links to create a rigid structure when assembled. A pin extends through the top and bottom links, to one side of the spacer. An resilient, deformable barrel is journalled on the pin. To assist in attenuating high energy impacts, an extendable, energy-absorbing mechanism is attached to one end of the barrier, and the other end of the barrier is anchored to the ground.

Owner:FESTIVAL FUN PARKS +1

Production method for tea vinegar drink

The invention discloses a production method for a tea vinegar drink, and relates to the technical field of processing of drinks. The tea vinegar drink is mainly prepared from tea, momordica grosvenori, white sugar, mountain spring water and acetic acid bacterium. The production method comprises the following steps: after the momordica grosvenori is smashed, the tea, the momordica grosvenori, the white sugar, the mountain spring water and the acetic acid bacterium are respectively weighed, and the weighed raw materials are placed in a pot and boiled to obtain an extract liquid; an acetic acid bacterium strain accounting for 2-3 percent of the total weight of the raw materials is -inoculated, covered and fermented, the product temperature is controlled to be 16-28 DEG C, and the fermentation lasts 10-25 days; acid adjustment is performed on a fermented and obtained feed liquid, the total acid content of the feed liquid is controlled within a range of 0.3-1 g / 100ml, and the soluble solid is controlled within a range of 3-5 percent; the tea vinegar drink is obtained via vacuum and sterile filling after the liquid is sterilized. The invention discloses the tea vinegar drink integrating multiple functions of nutrition and health care, vegetal syrup is used as an acetic acid bacteria culture medium for fermentation, the produced tea vinegar drink contains various spicy substances and nutrient ingredients of the tea, the momordica grosvenori and acetate acid, and is good in flavor and high in quality.

Owner:广西三江县康百氏实业有限公司

Tri-frequency electrosurgical instrument

ActiveUS20090062786A1Good energyReduce leakage currentControlling energy of instrumentSurgical instruments for heatingCarrier signalEngineering

Owner:CYNOSURE

Systems for Highly Efficient Solar Power Conversion

ActiveUS20090218887A1More energyEfficient Power ConversionDc network circuit arrangementsEnergy industryDc dc converterPower grid

A high efficiency photovoltaic DC-DC converter achieves solar power conversion from high voltage, highly varying photovoltaic power sources to harvest maximum power from a solar source or strings of panels for DC or AC use, perhaps for transfer to a power grid at high power levels with coordinated control possible for various elements. Photovoltaic DC-DC converters can achieve efficiencies in conversion that are extraordinarily high compared to traditional through substantially power isomorphic photovoltaic DC-DC power conversion capability that can achieve 97%, 98%, 99.2% efficiency, or even only wire transmission losses. Switchmode impedance or voltage conversion circuit embodiments may have pairs of photovoltaic power interrupt switch elements and pairs of photovoltaic power shunt switch elements to first increase voltage and then decrease voltage as part of the desired photovoltaic DC-DC power conversion.

Owner:AMPT

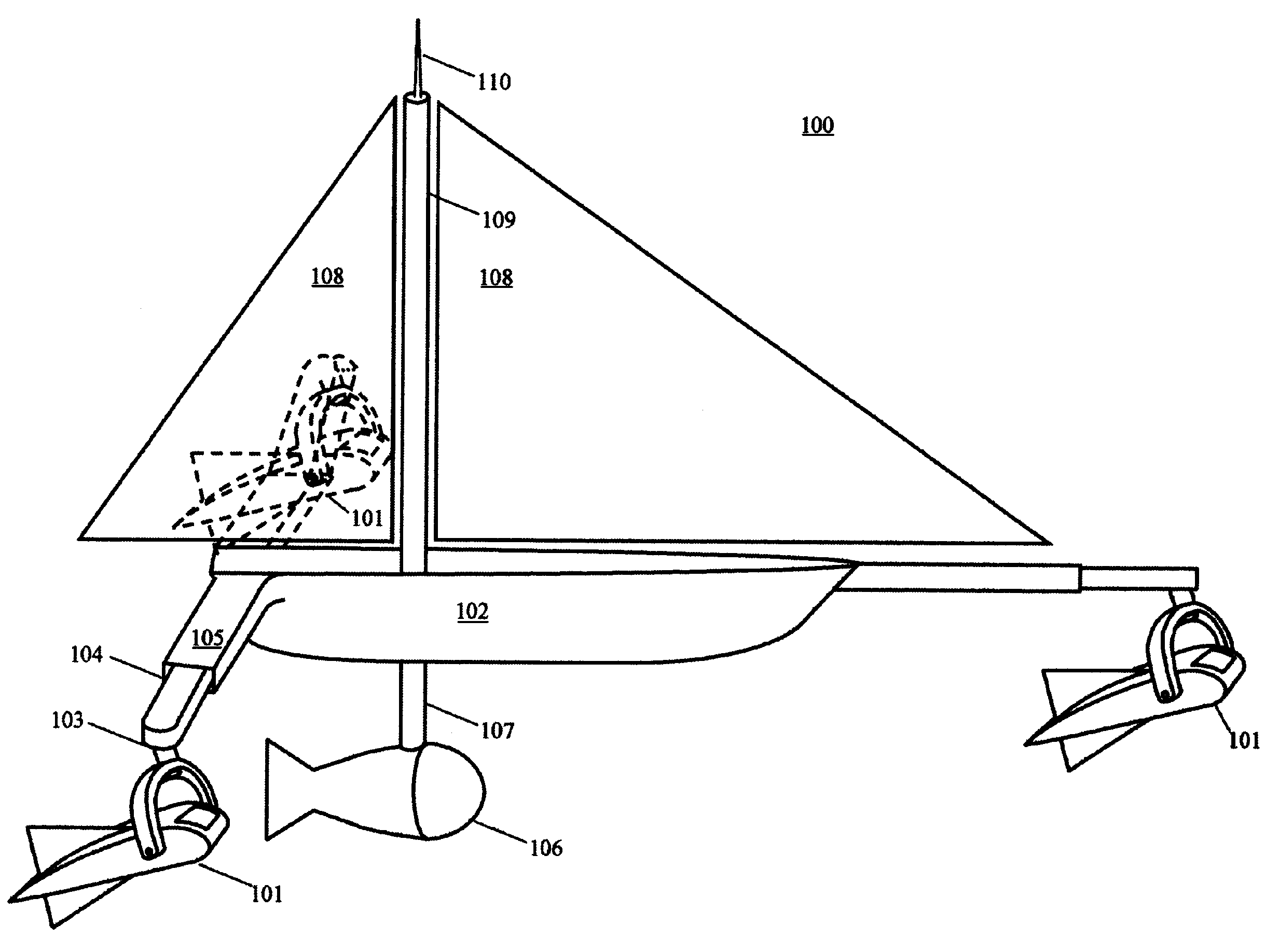

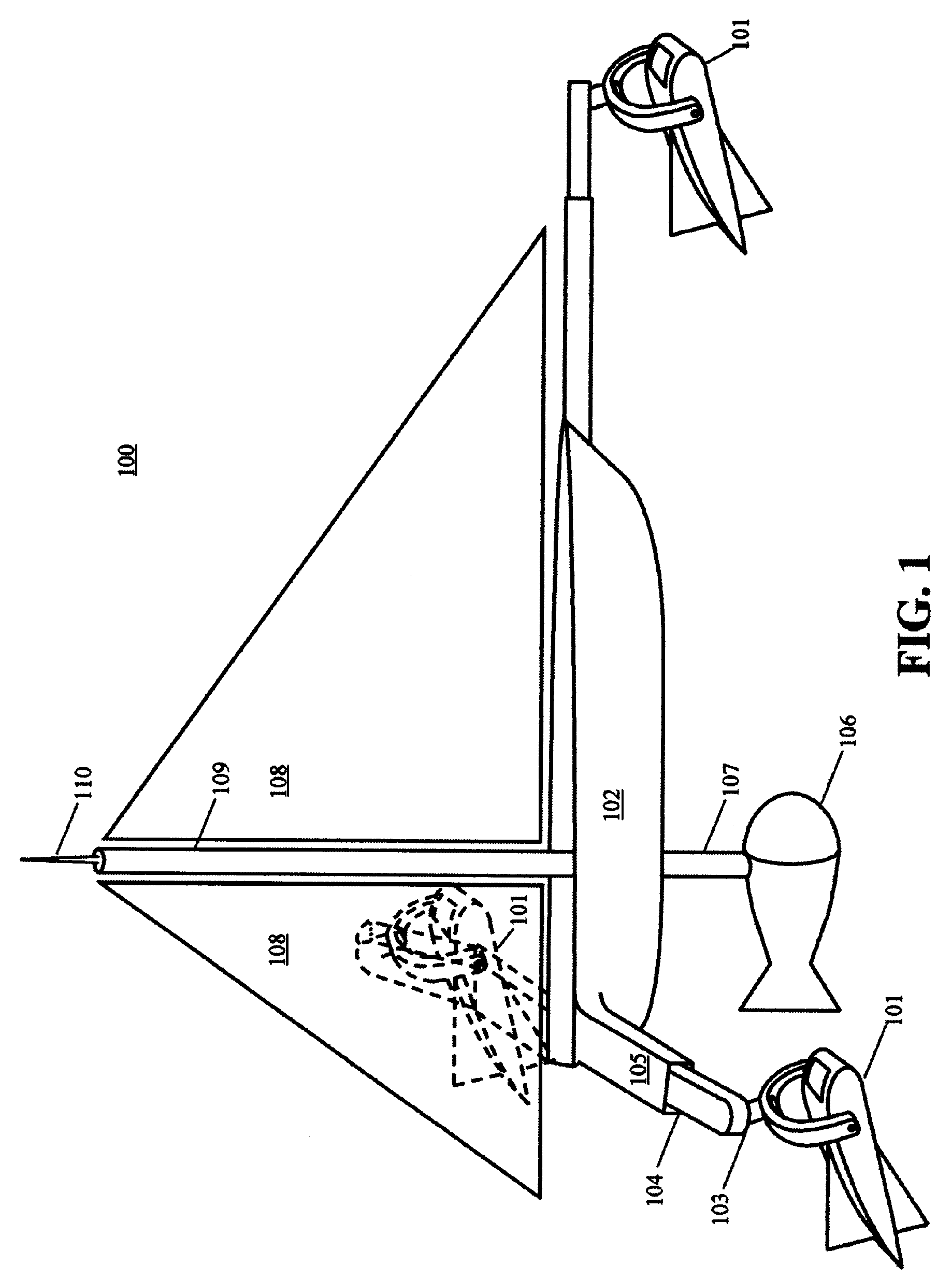

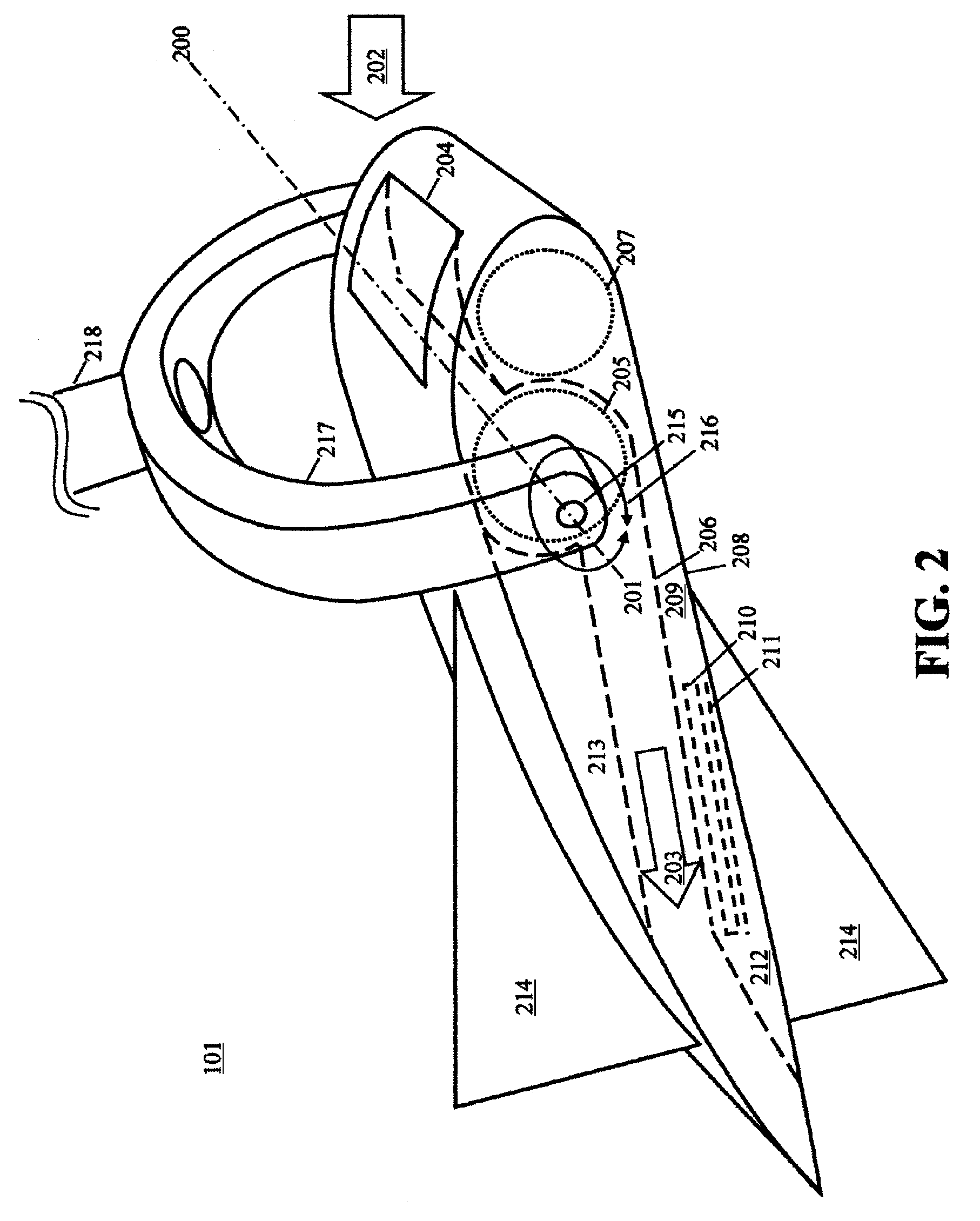

Turbine-integrated hydrofoil

InactiveUS7298056B2Good energyFacilitates maintaining overall stability and guidanceElectrolysis componentsAuxillariesPower overEngineering

Owner:INTEGRATED POWER TECH CORP

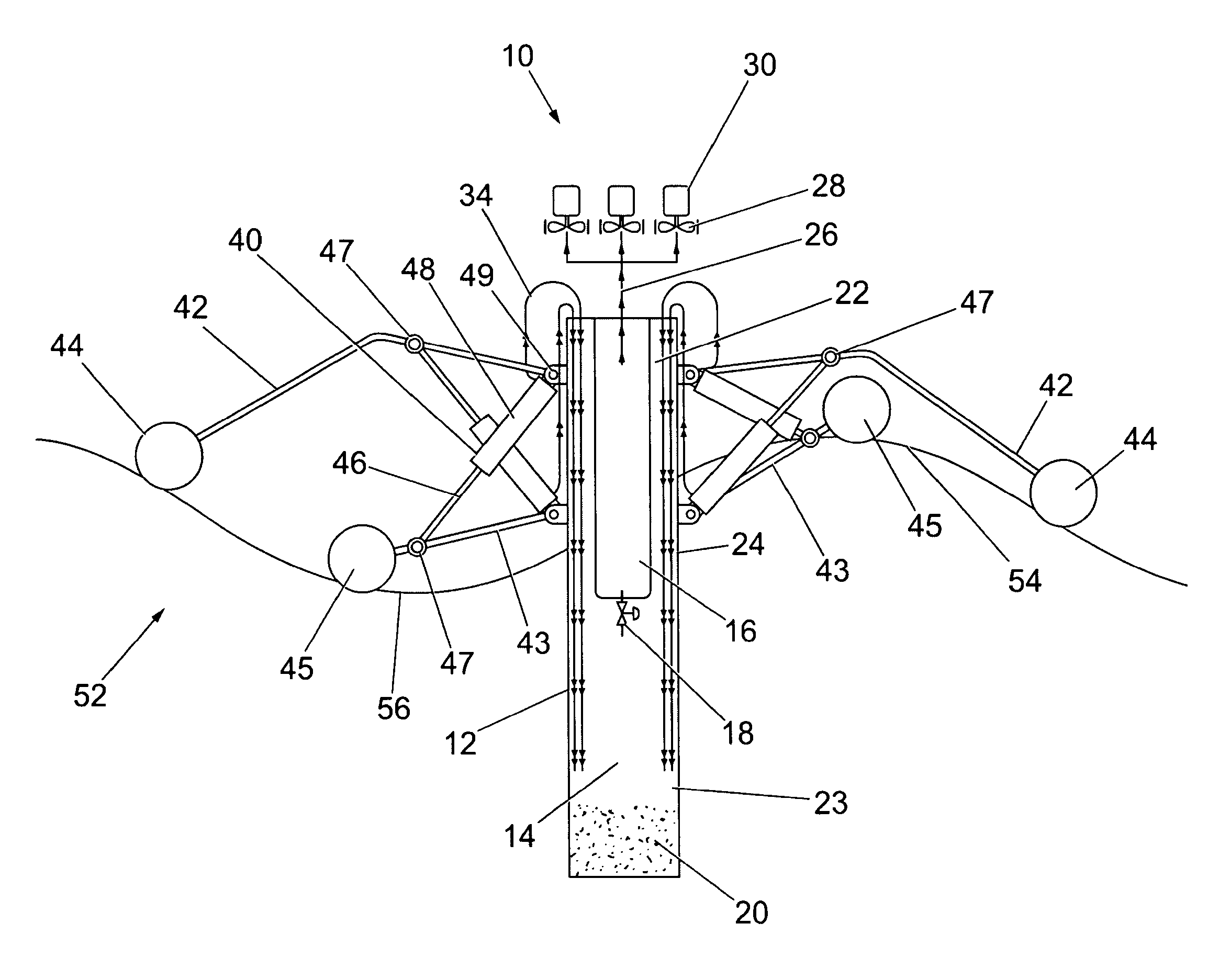

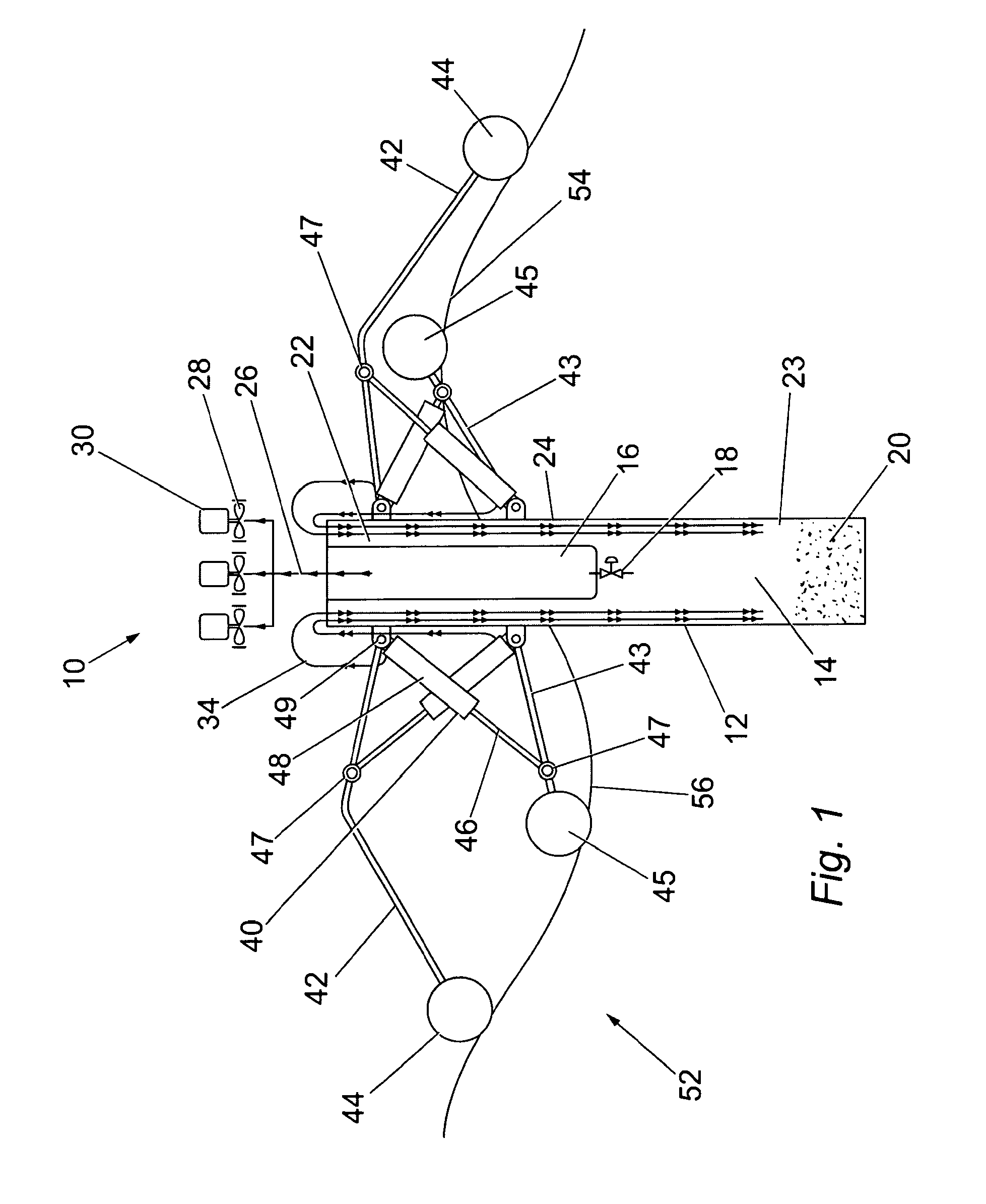

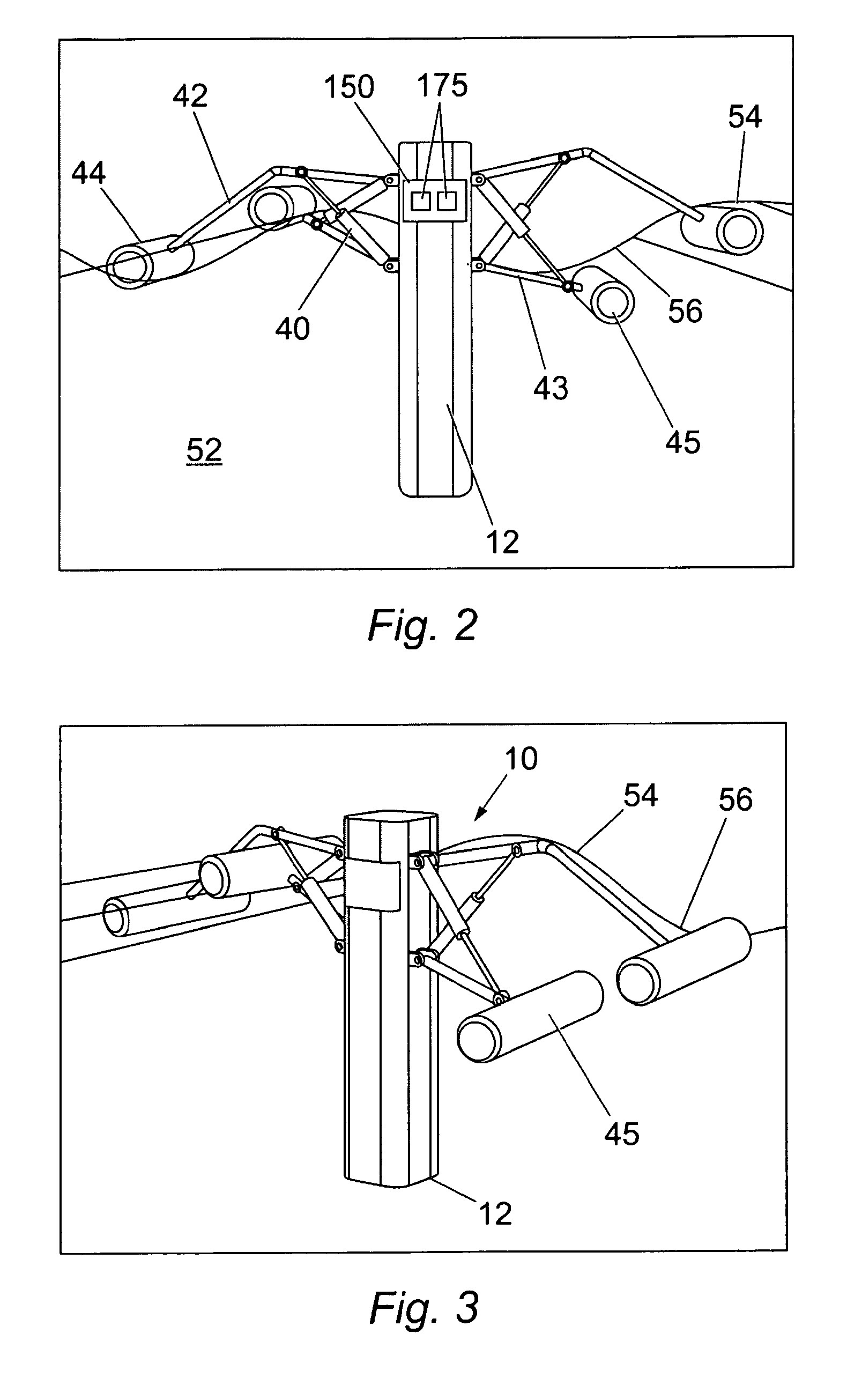

Method and apparatus for energy generation from wave motion

InactiveUS7808120B2Precise positioningGood electric energy returnMachines/enginesEngine componentsEnergy transferMotion generation

A method and apparatus for generating electric energy from the motion of the waves. The apparatus comprises at least one member which is moved by the motion of the waves. The apparatus also comprises an energy transfer mechanism coupled to the or each member. The energy transfer mechanism converts the kinetic energy from movement of the or each member to potential energy by pressurization of a fluid. The apparatus further comprises a first chamber, arranged to store the pressurized fluid and a conversion means for converting the potential energy stored in the pressurized fluid into electric energy. The apparatus can be arranged such that any substantially vertical displacement of the or each member causes actuation of the or each corresponding energy transfer mechanism.

Owner:GREEN OCEAN ENERGY

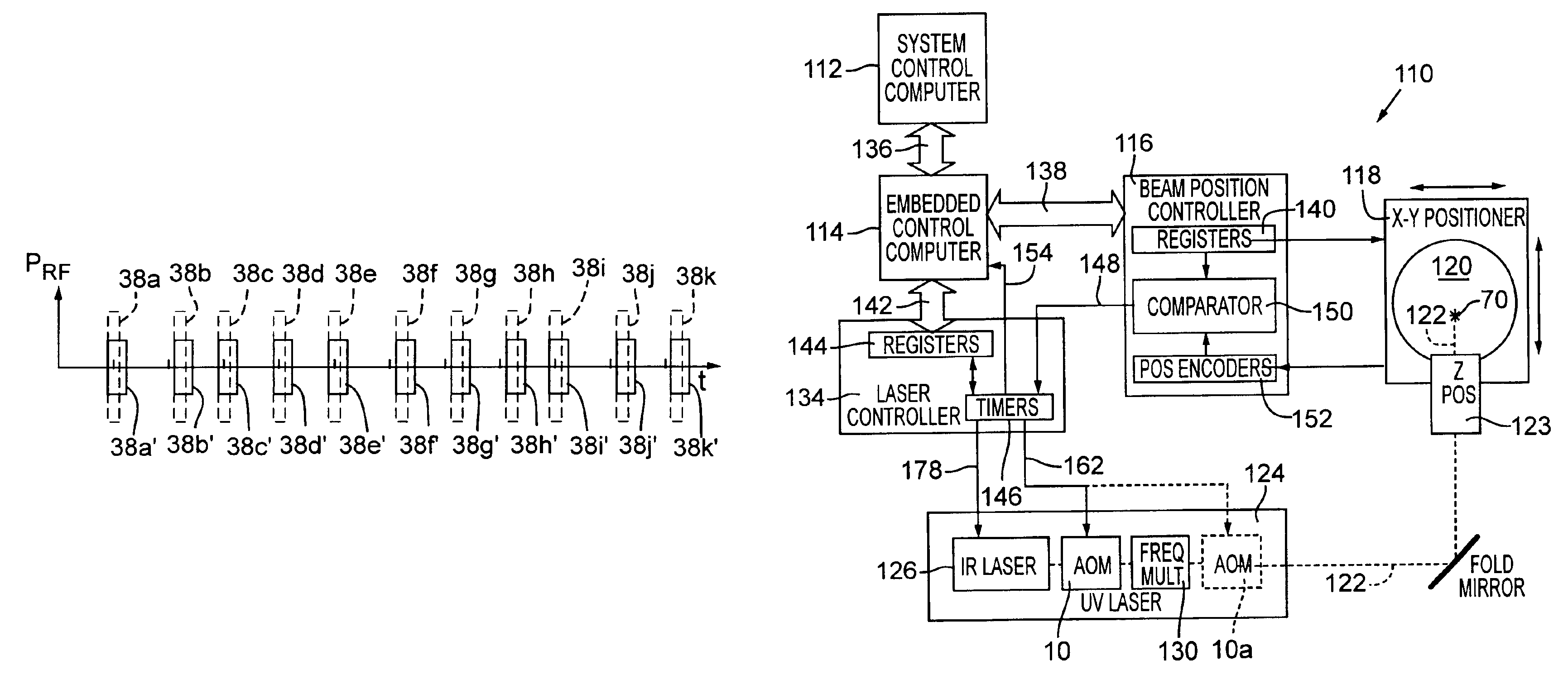

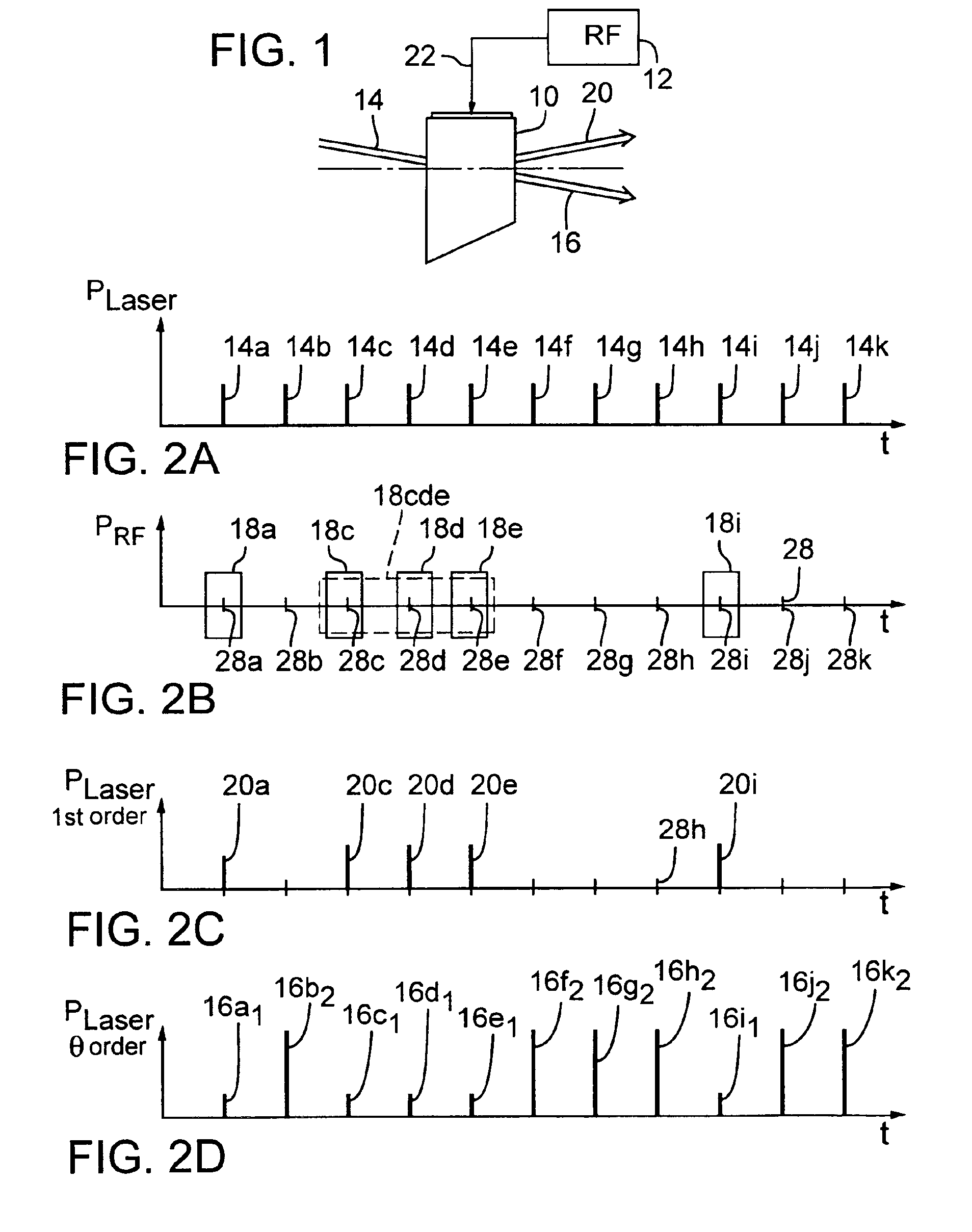

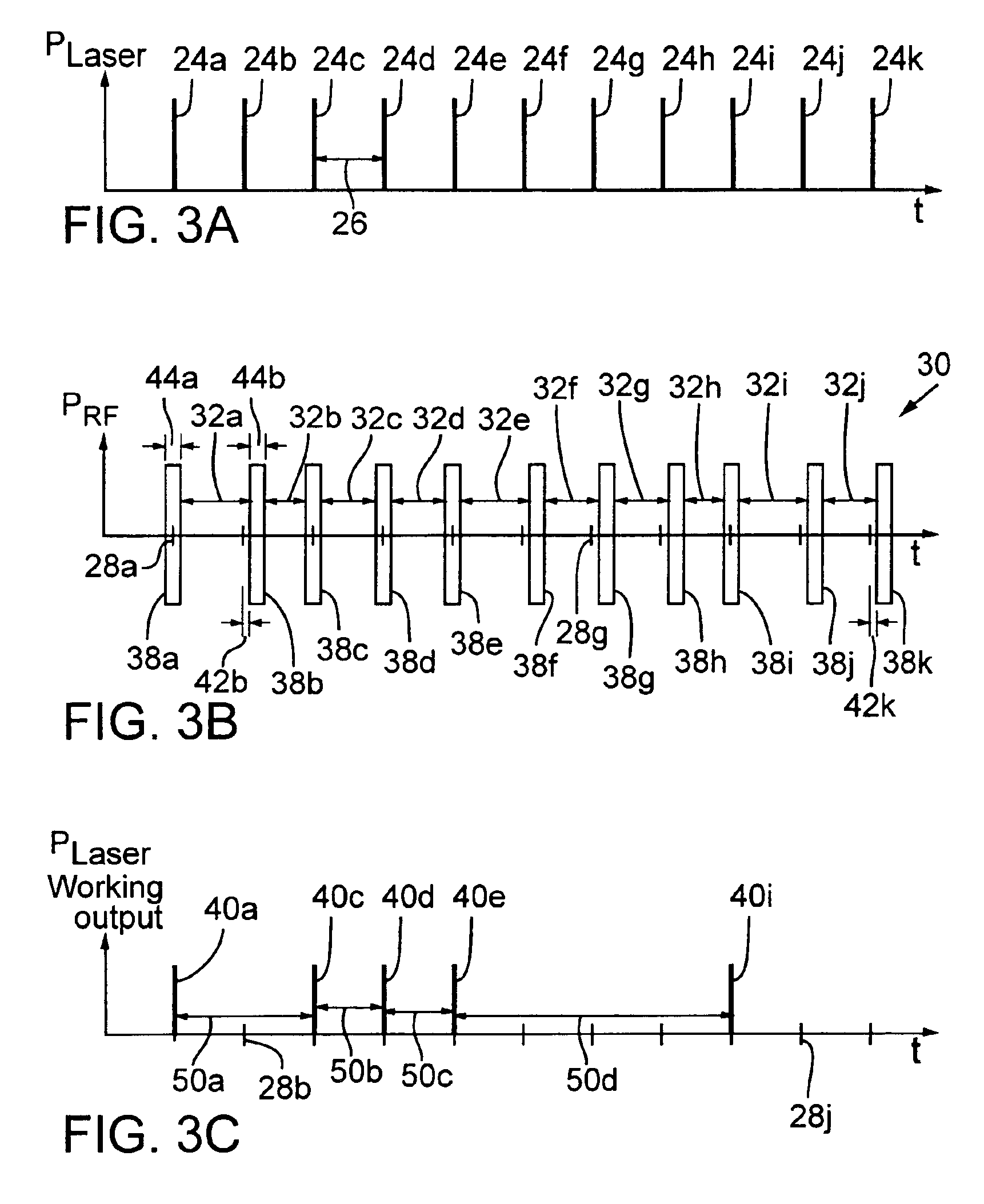

Laser pulse picking employing controlled AOM loading

ActiveUS6947454B2Constant RF powerConstant thermal loadingExcitation process/apparatusSemiconductor/solid-state device manufacturingPulse energyOptoelectronics

A laser (126) and an AOM (10) are pulsed at substantially regular and substantially similar constant high repetition rates to provide working laser outputs (40) with variable nonimpingement intervals (50) without sacrificing laser pulse-to-pulse energy stability. When a working laser output (40) is demanded, an RF pulse (38) is applied to the AOM (10) in coincidence with the laser output (24) to transmit it to a target. When no working laser output (40) is demanded, an RF pulse (38) is applied to the AOM (10) in noncoincidence with the laser output (24) so it gets blocked. So the average thermal loading on the AOM (10) remains substantially constant regardless of how randomly the working laser outputs (40) are demanded. The AOM (10) can also be used to control the energy of the working laser output (40) by controlling the power of the RF pulse (38) applied. When the RF power is changed, the RF duration (44) of the RF pulse (38) is modified to maintain the constant average RF power. Consistent loading on the AOM (10) eliminates deterioration of laser beam quality and laser beam pointing accuracy associated with thermal loading variation on the AOM (10) and is advantageous for applications such as IC chip link processing where stable working laser outputs (40) with variable output intervals (50) are needed.

Owner:ELECTRO SCI IND INC

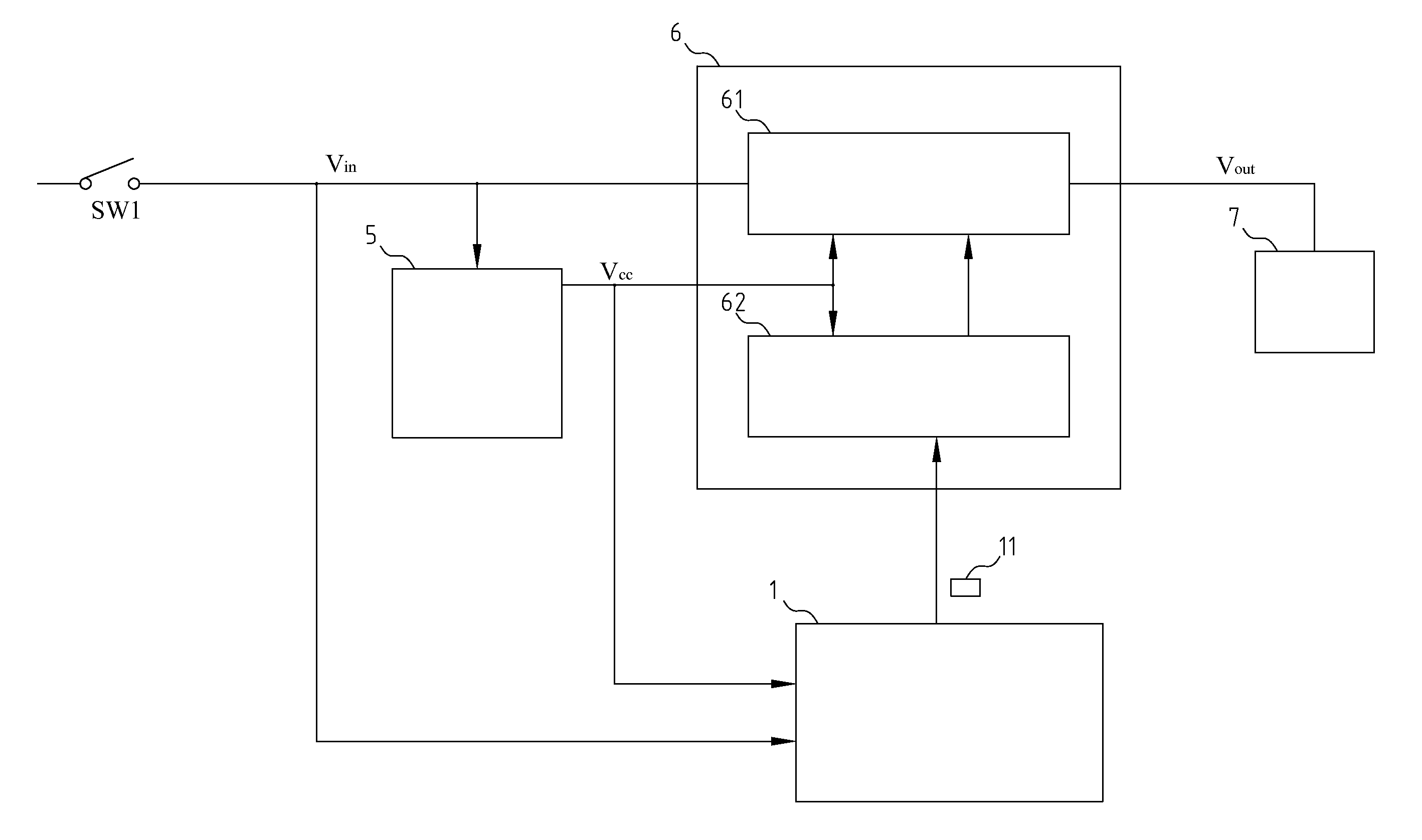

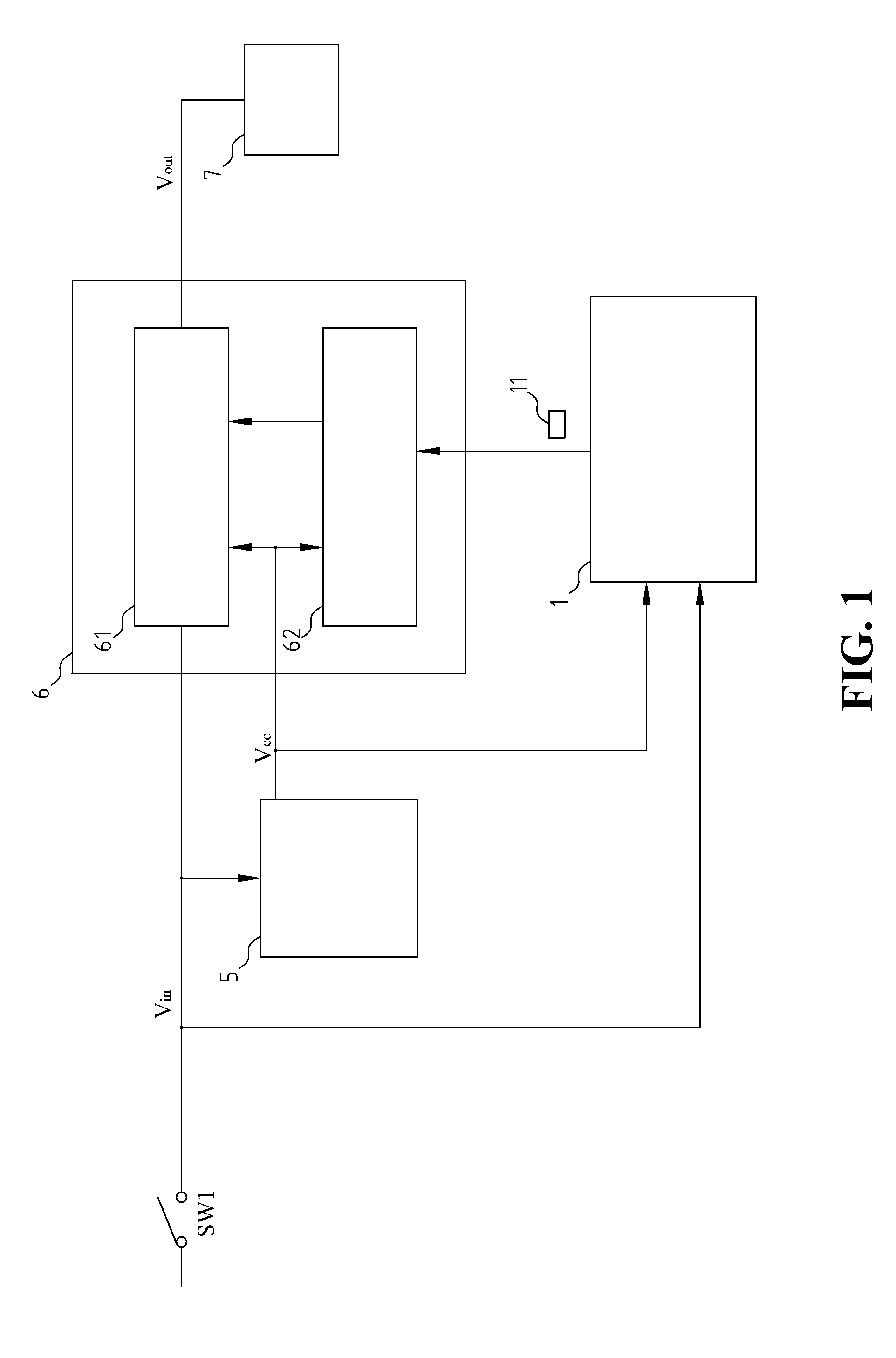

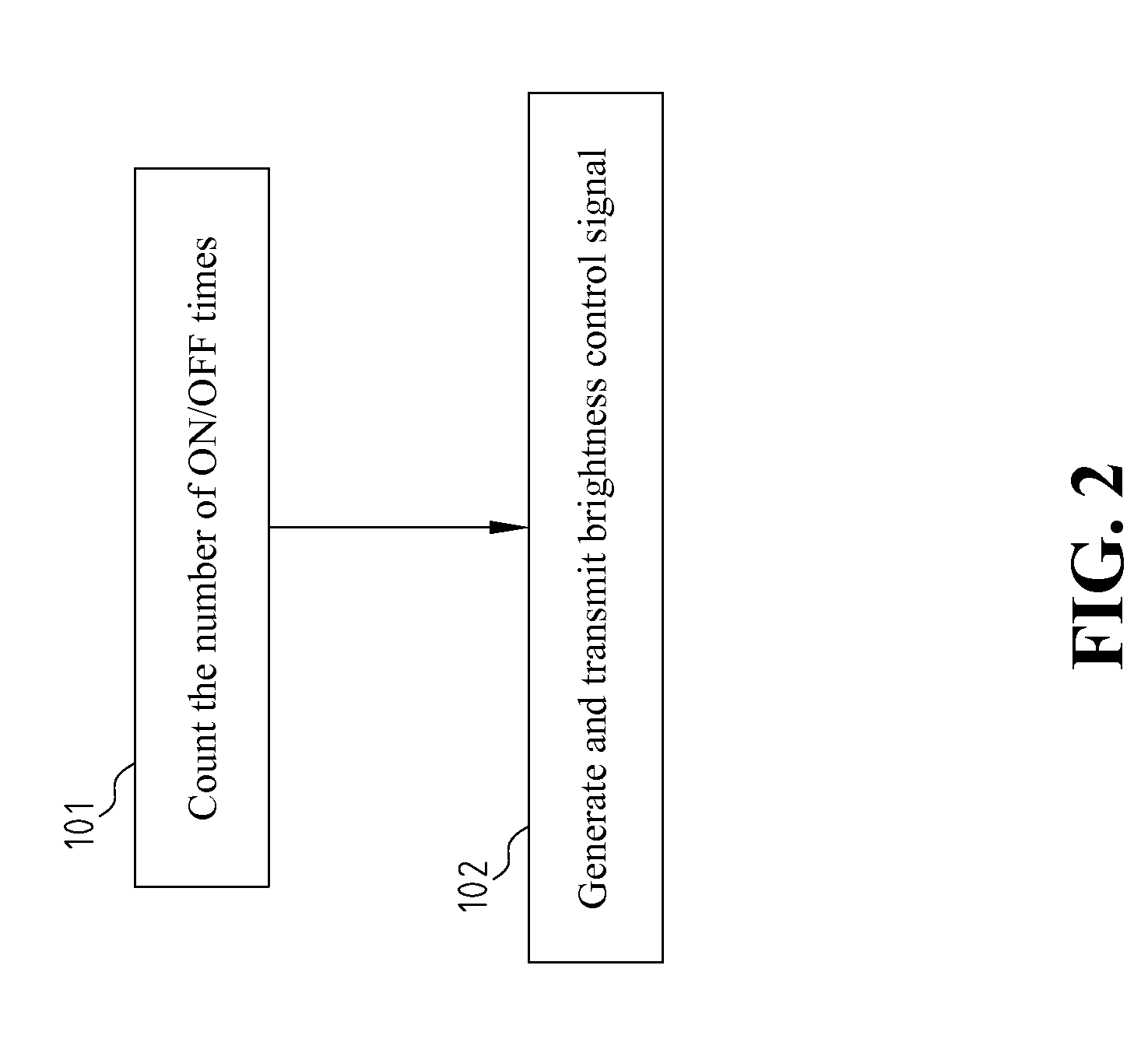

Apparatus and method for driving and adjusting light

InactiveUS20090322255A1Good effectGood energyElectrical apparatusElectroluminescent light sourcesEffect lightEngineering

An apparatus and method for driving and adjusting light is provided, applicable to the LED lighting environment. Without the necessity to change the existing wiring and lighting devices, the driving and light adjusting apparatus of the present invention can cooperate with LED driver, by counting the number of switch ON / OFF times, to enable the LED driver to adjust light so that the LED lighting device is capable of light adjustment in addition to lighting.

Owner:SHINA CO LTD

Method for preparing human umbilical cord mesenchymal stem cells

The invention relates to a method for preparing human umbilical cord mesenchymal stem cells, which comprises the steps of collection, transportation, handover, separation, freezing, recovering, primary culture and subculture of umbilical cords. The method has simple process, ensures low production cost, good freezing effect, little cell damage, low toxic side effect and no harm to human body and reduces the residual of the freezing protection liquid in the recovered cells of tissue blocks; and the prepared mesenchymal stem cells can be applied to the clinical treatment of various diseases.

Owner:江苏省北科生物科技有限公司 +1

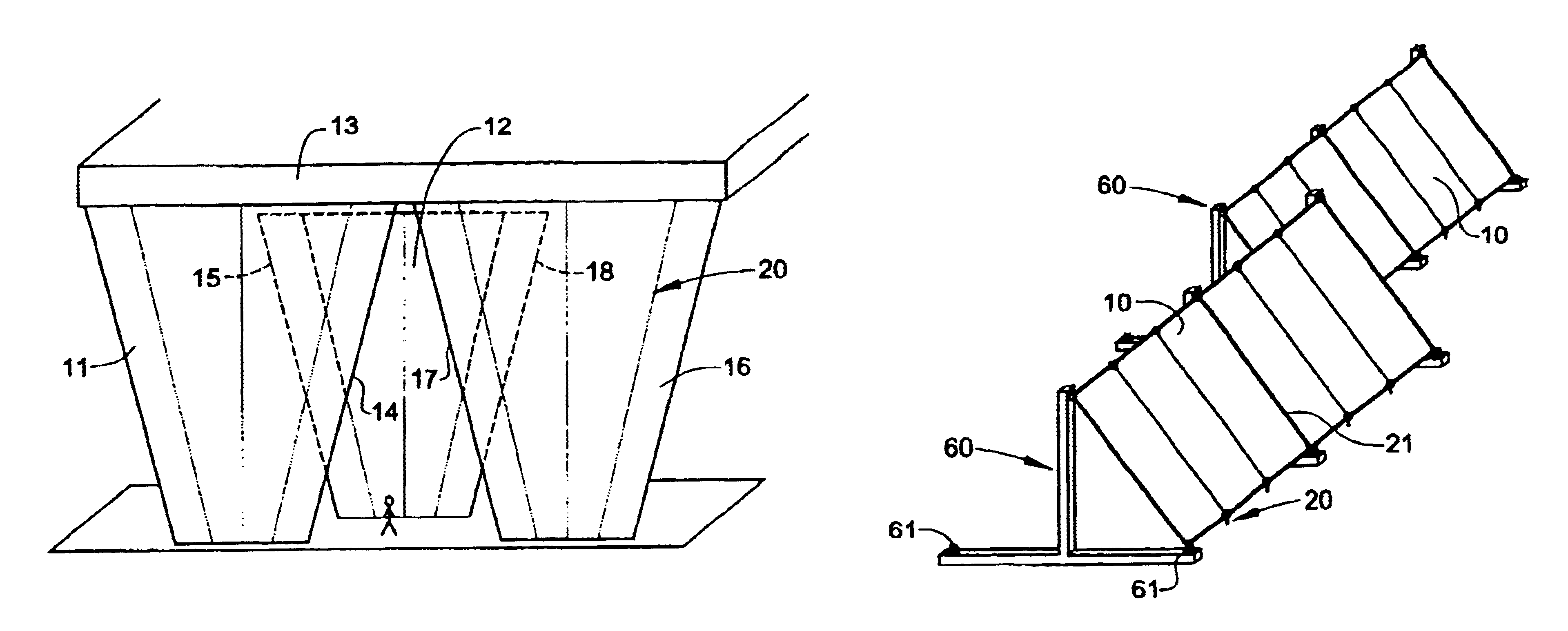

Blast curtain

InactiveUS6886299B2Consume energySafely dissipatedHuman health protectionArmourVisibilityEngineering

A flexible blast curtain will reduce casualties and property damage in the event of a terrorist bombing by intercepting flying debris and dissipating over pressure through deflection of the curtain. The blast curtain may be attached directly to buildings or mounted on frames anchored in close proximity to buildings. The curtain provides complete visibility and easy pedestrian ingress and egress for the buildings.

Owner:TARGUS INT

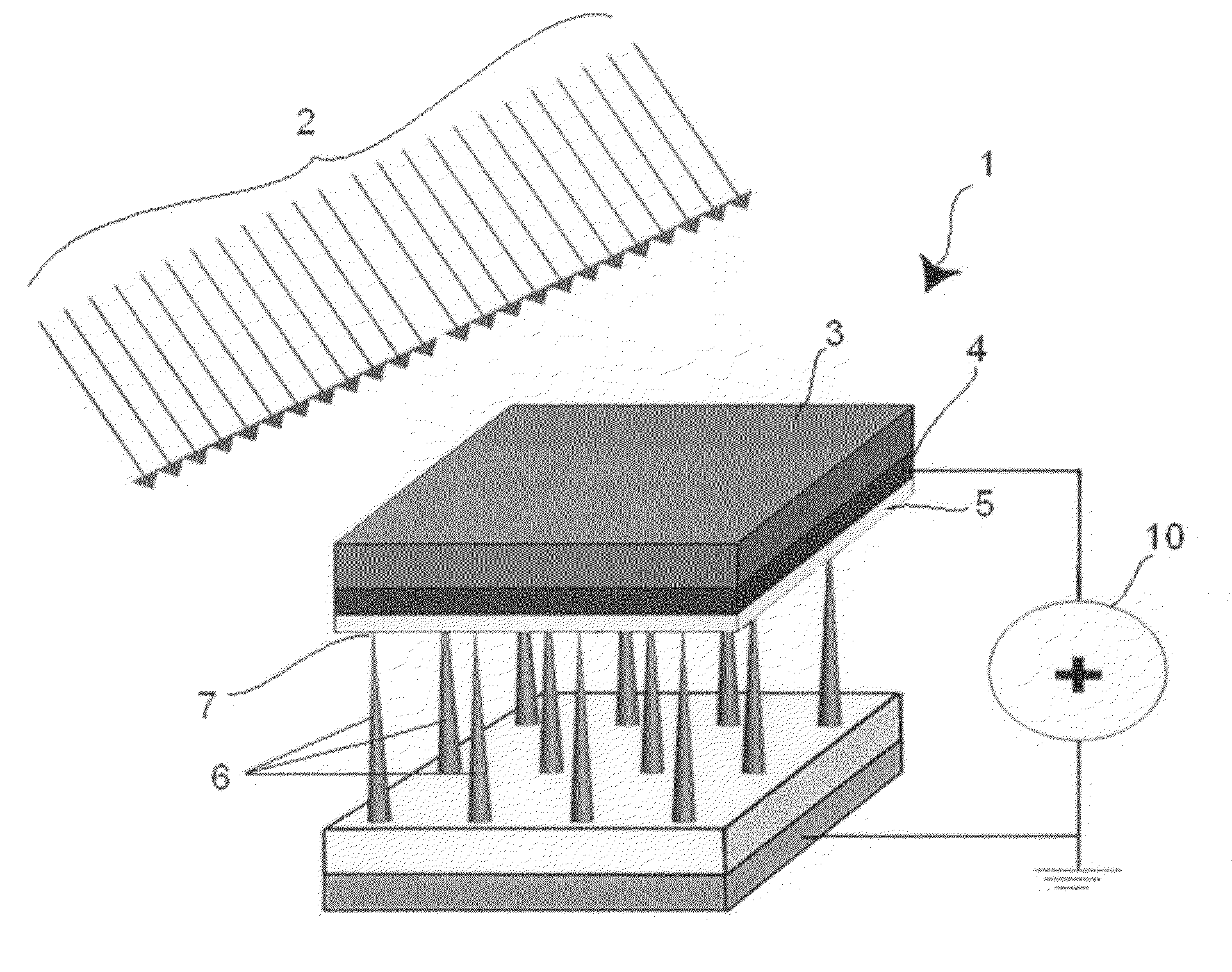

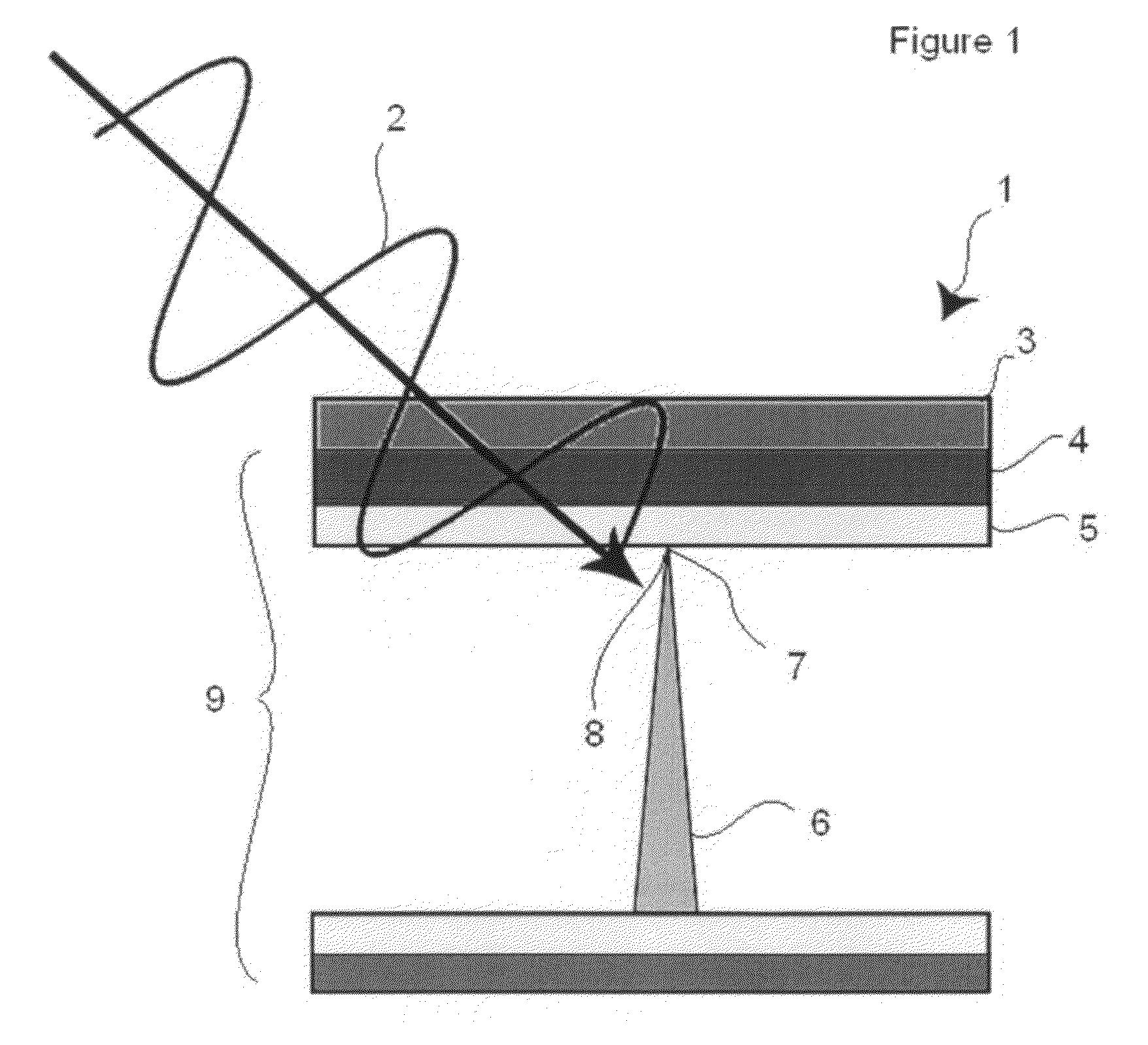

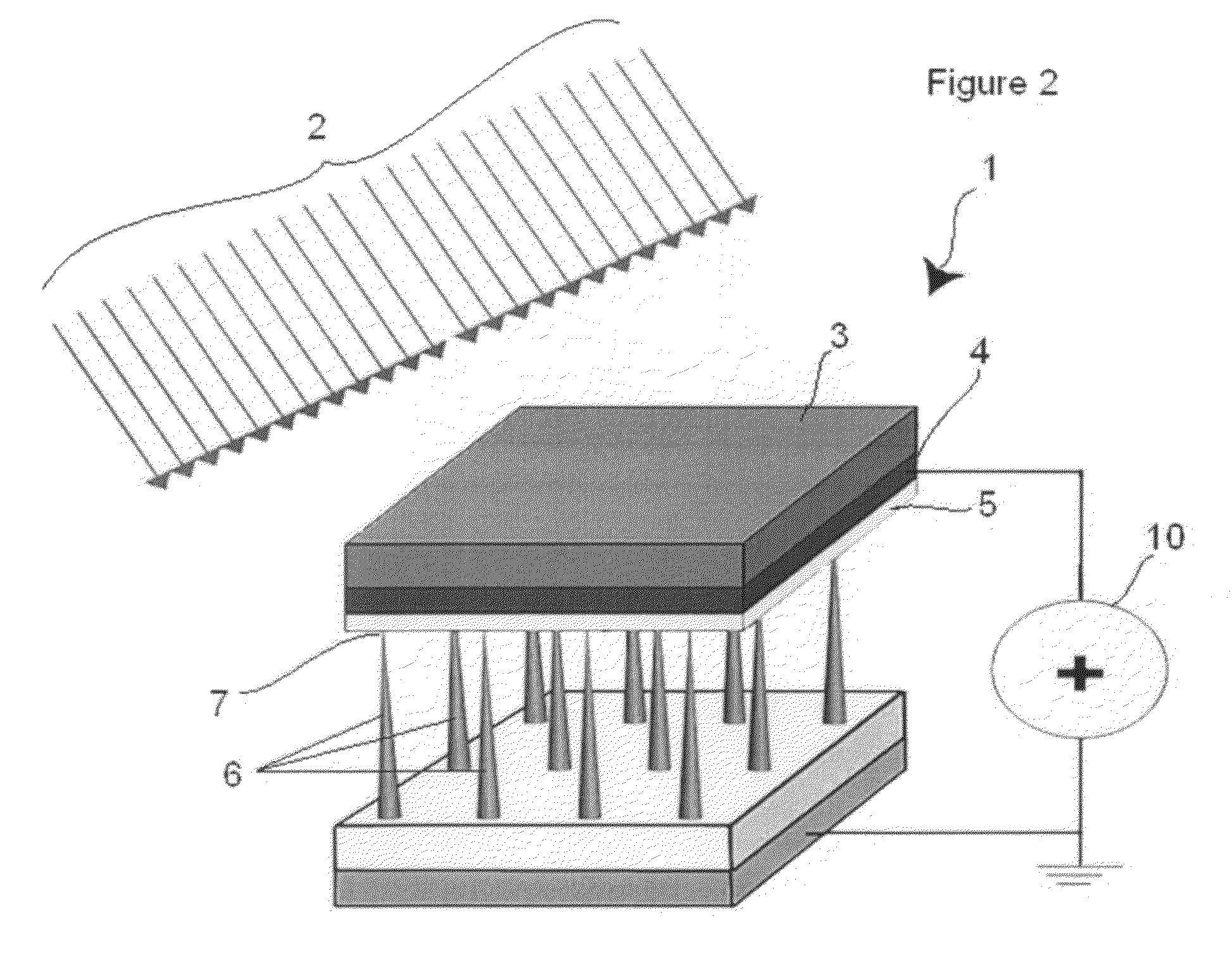

Apparatus and system for a single element solar cell

InactiveUS20090308443A1High densityGood energyNanoinformaticsSolid-state devicesNanowireElectrical conductor

A device for receiving and converting incident radiation into DC current, the device including a transparent conductor, at least one point-contact diode, the at least one point-contact diode having a nanowire / mCNT providing a receiving antenna function and a rectification function, a thin insulating layer situated between the transparent conductor and the nanowire / mCNT, and a point contact junction at which the nanowire / mCNT contacts the thin insulating layer.

Owner:SCITECH ASSOCS HLDG

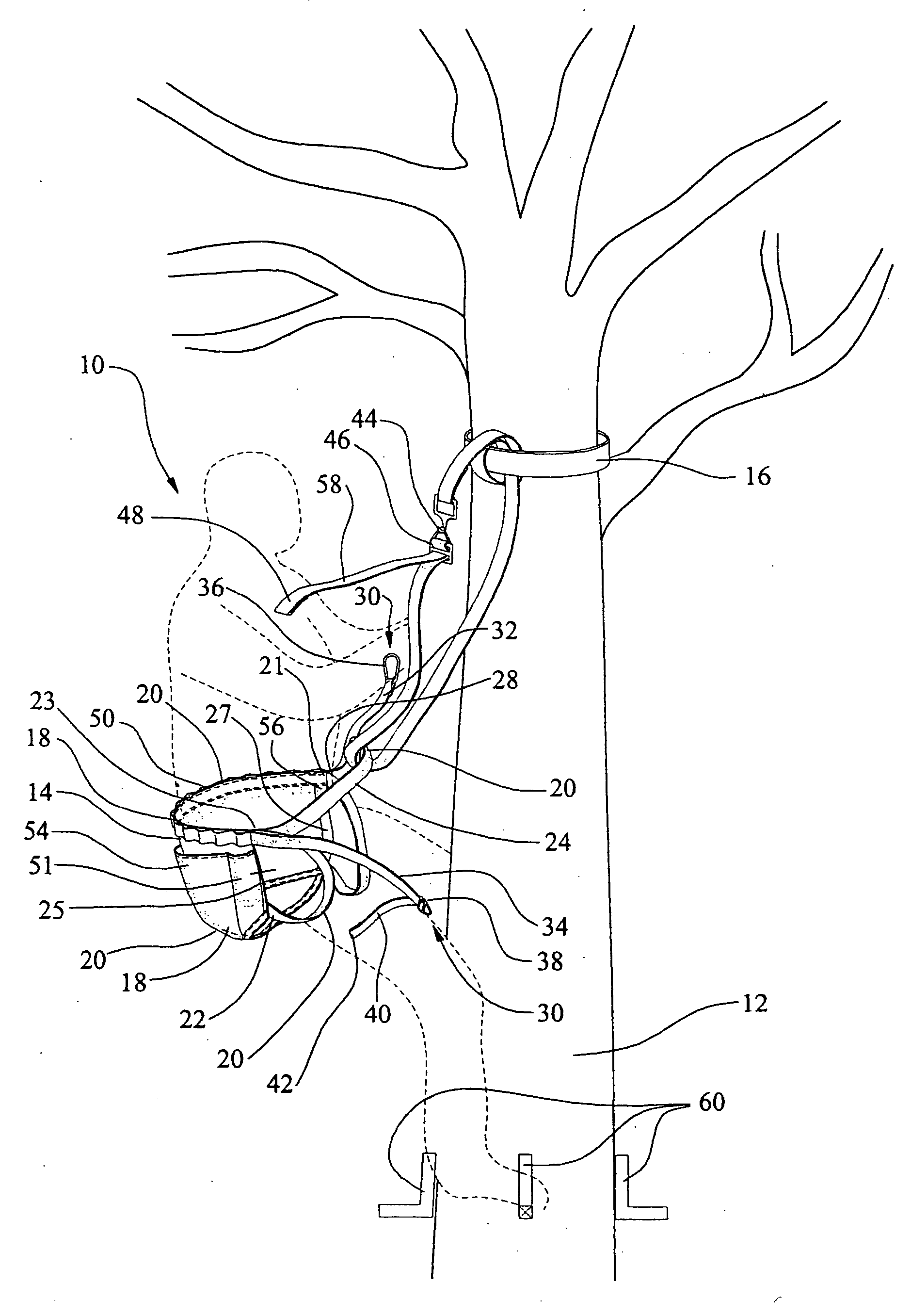

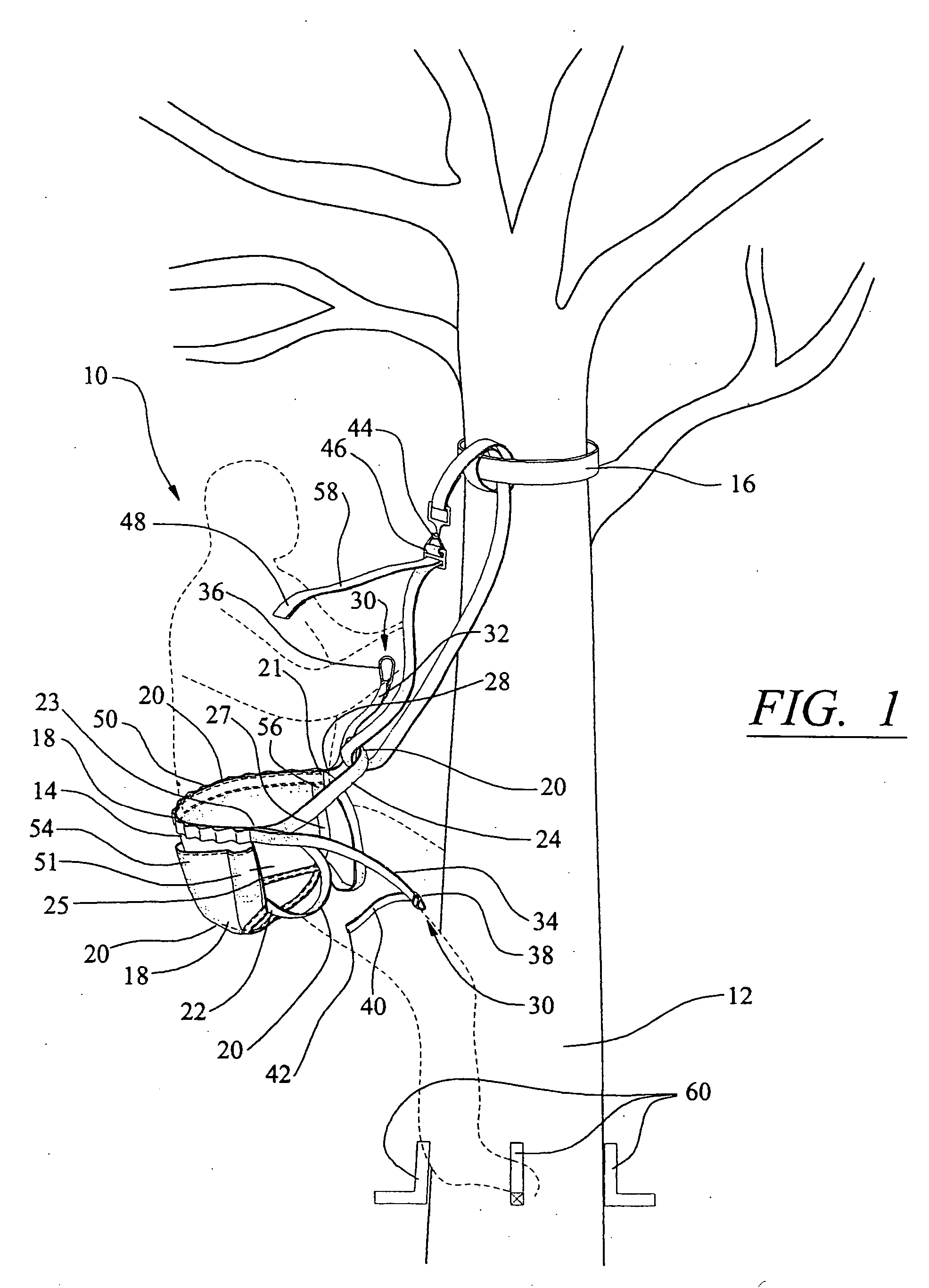

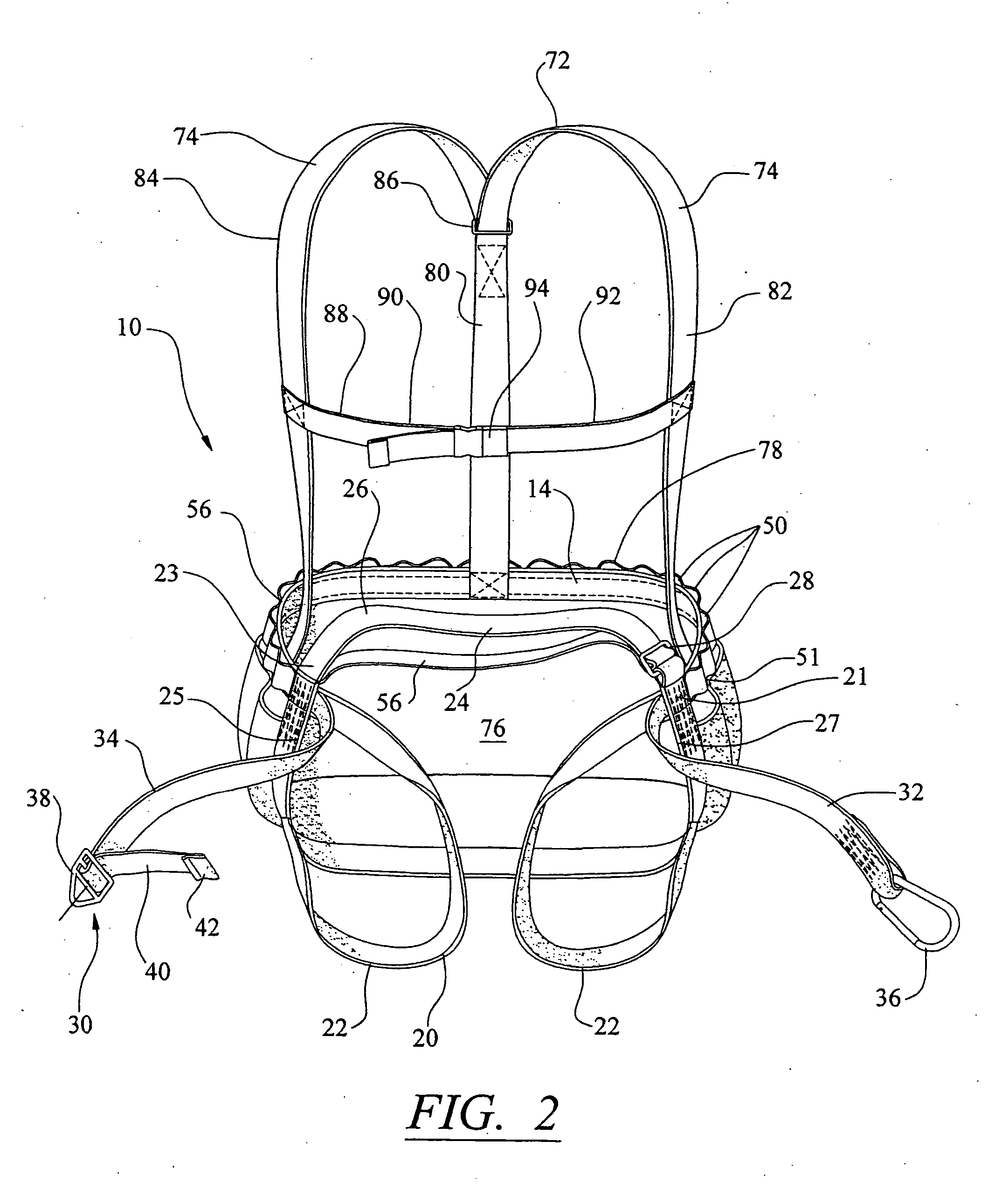

Support harness

ActiveUS20060169534A1Prevent fallingFacilitate self-extractionAnimal huntingSafety beltsEngineeringCable harness

A harness system for supporting a person off of a ground surface. The harness system may include a seat supported by a strap attached to the seat. The strap may form one or more leg containing loops for keeping a person securely positioned in the harness. The harness may also include a climbing strap for securing the harness loosely to a support device, such as a tree, while a person climbs a support device. The harness may be secured to a person by tightening a waist strap around the person's waist. The harness system may include a fall restraint device and should straps enabling the harness system to qualify as a fall arrest system.

Owner:TROPHYLINE

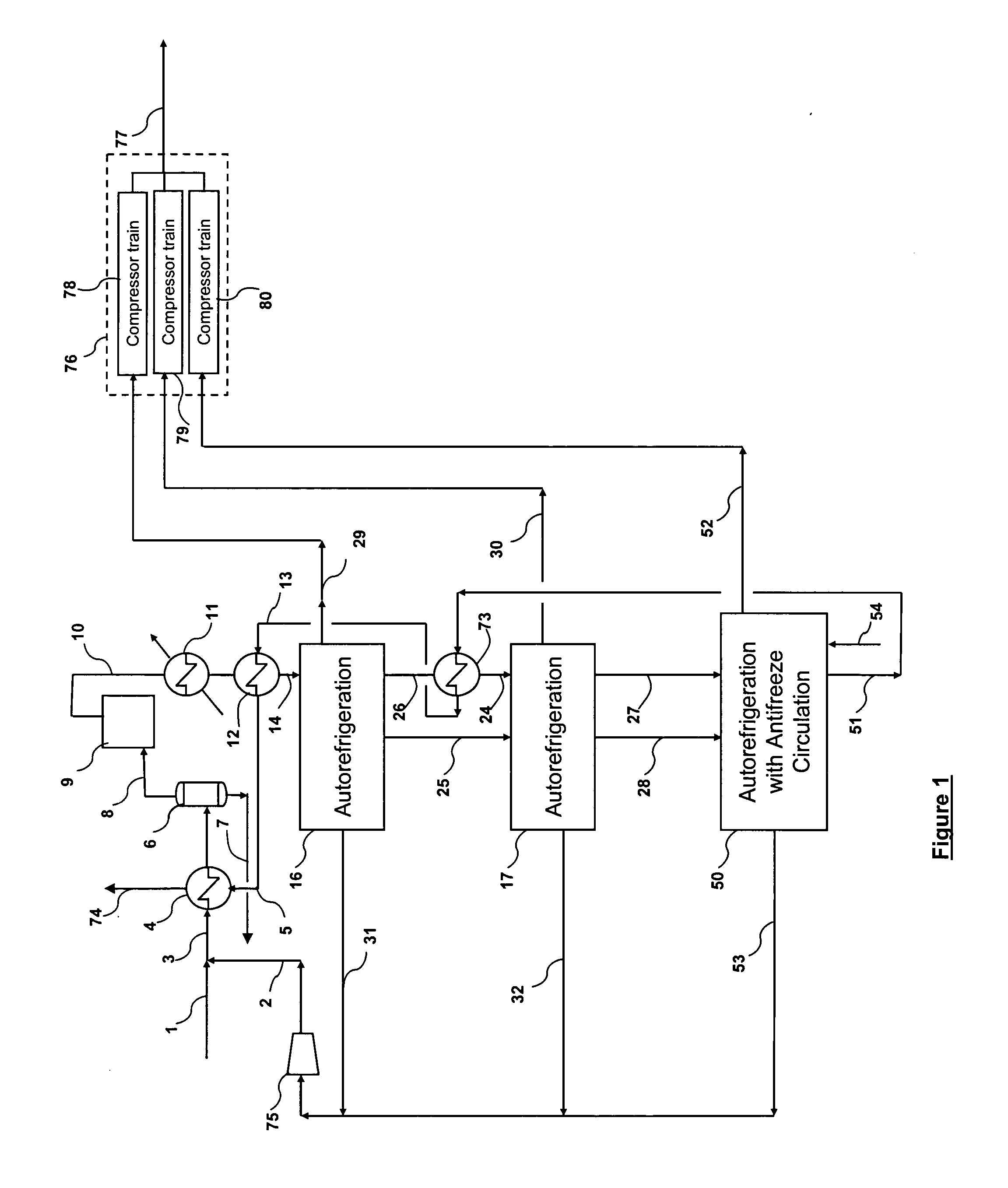

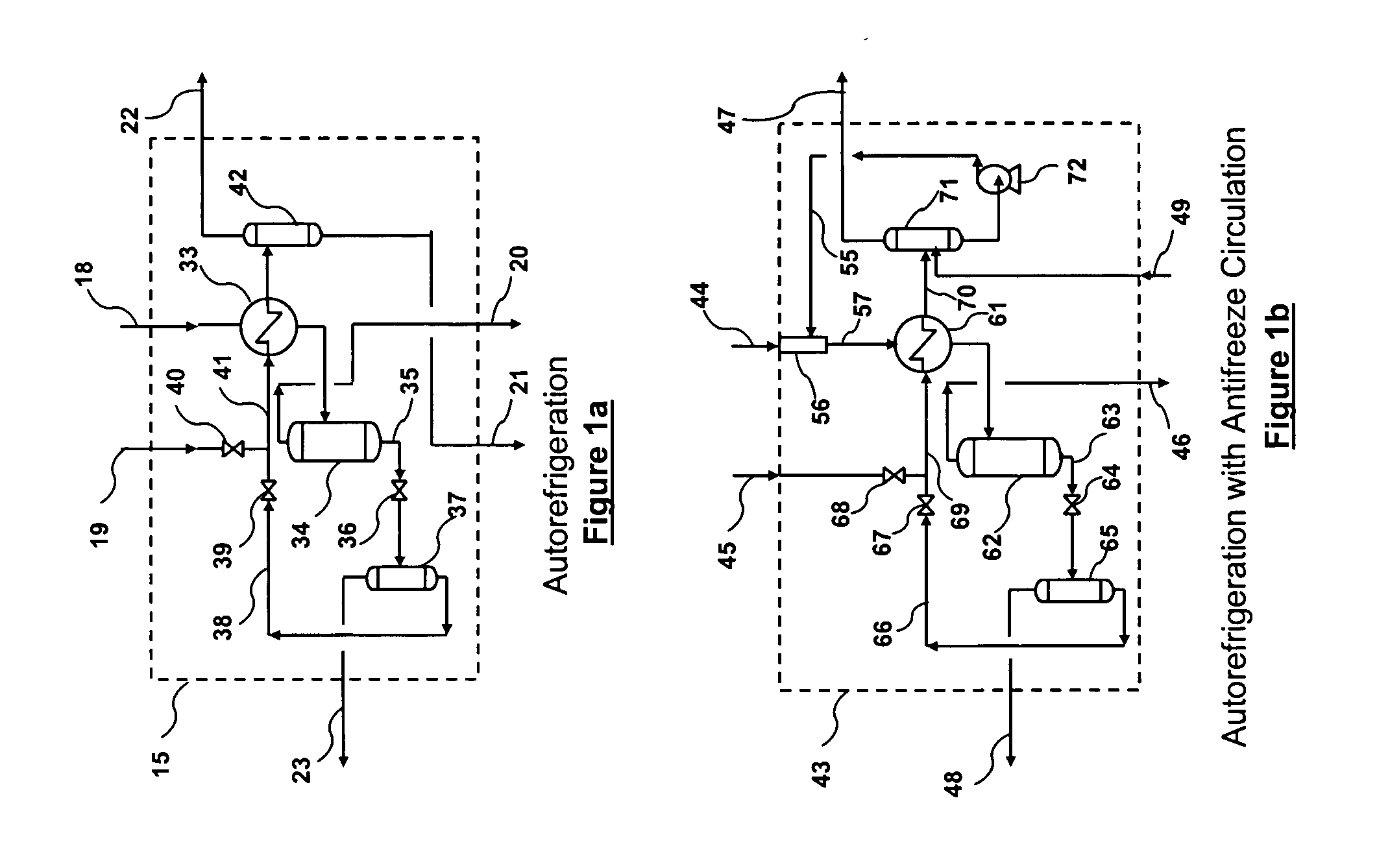

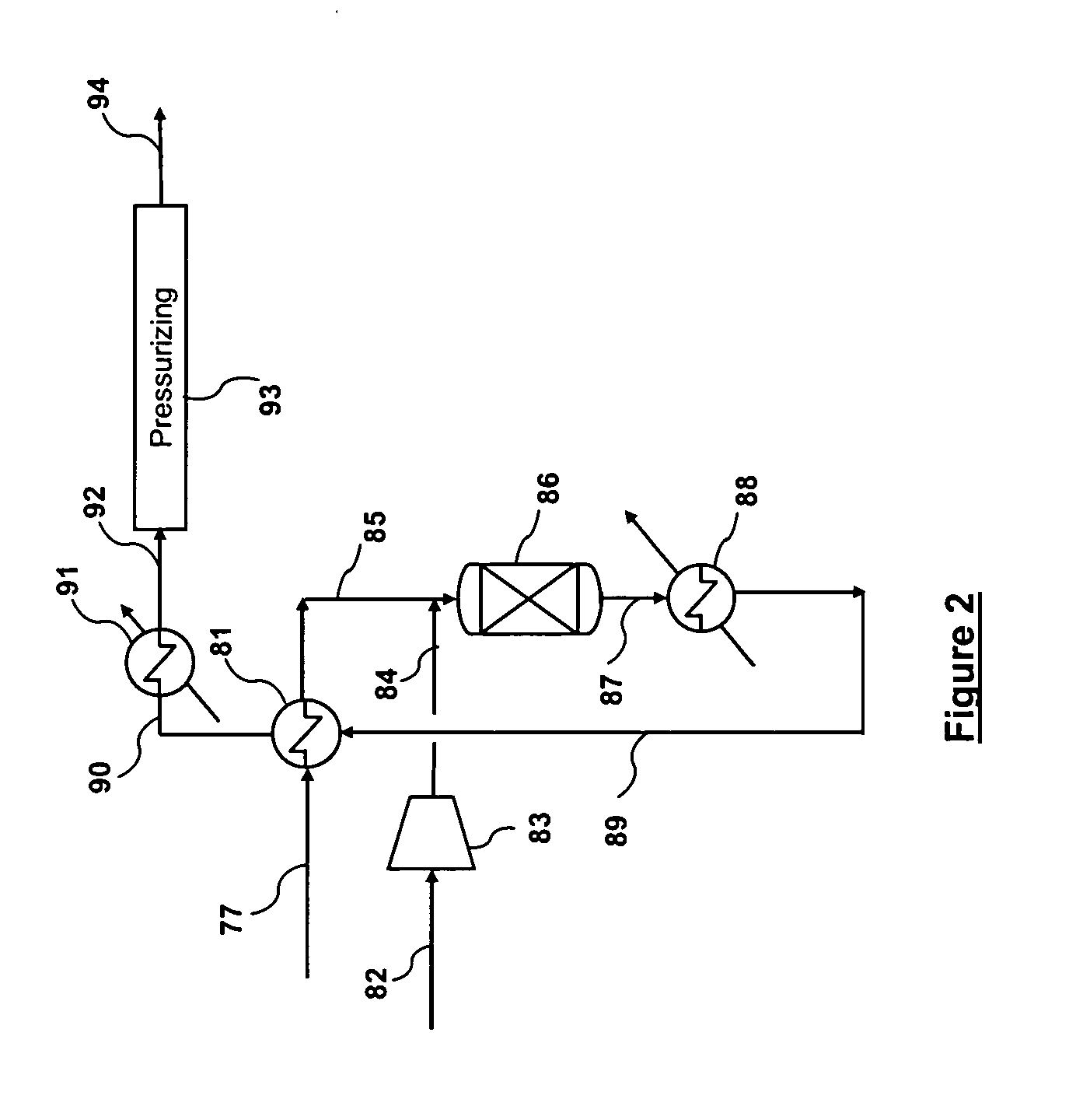

Multi-stage cryogenic acid gas removal

InactiveUS20070221541A1Alleviate power needsIncrease the number ofSolidificationLiquefactionPetroleumPetroleum coke

A relatively simple and energy efficient multiple stage cryogenic process for the purification of a hydrogen-rich stream by the removal of acid gases, mainly CO2 and H2S, by method of autorefrigeration and delivering or producing those acid gases, mainly CO2, at pressure sufficiently high for disposal by containment, commonly known as sequestration. Autorefrigeration is comprised of (a) condensing acid gases from the syngas stream by cooling the syngas, (b) separating the liquefied acid gases from the syngas, and (c) evaporating the liquefied acid gases at a pressure lower than that of the syngas to provide cooling. The process is composed of multiple autorefrigeration stages to generate multiple acid gas product streams with a pressure as high as practical in each stream so as to lessen the power needed to pressurize the acid gas streams for sequestration. The final autorefrigeration stage utilizes an antifreeze liquid that allows the final stage to operate below the freezing point of CO2; thus allowing more acid gas removal. The antifreeze liquid is an alcohol or a mixture of alcohols with a freezing point lower than about minus 110 degrees F. and a boiling point higher than about 100 degrees F. The process includes hydrogen recovery and recycle as well as recovery of the energy contained in the sulfur bearing compounds. The process is especially well suited for CO2 removal / sequestration from a coal (or petroleum coke) gasification process.

Owner:TENNESSEE VALLEY AUTHORITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com