Patents

Literature

2312 results about "Petroleum coke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum coke, abbreviated coke or petcoke, is a final carbon-rich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokes. Petcoke is the coke that, in particular, derives from a final cracking process—a thermo-based chemical engineering process that splits long chain hydrocarbons of petroleum into shorter chains—that takes place in units termed coker units. (Other types of coke are derived from coal.) Stated succinctly, coke is the "carbonization product of high-boiling hydrocarbon fractions obtained in petroleum processing (heavy residues)." Petcoke is also produced in the production of synthetic crude oil (syncrude) from bitumen extracted from Canada’s oil sands and from Venezuela's Orinoco oil sands.

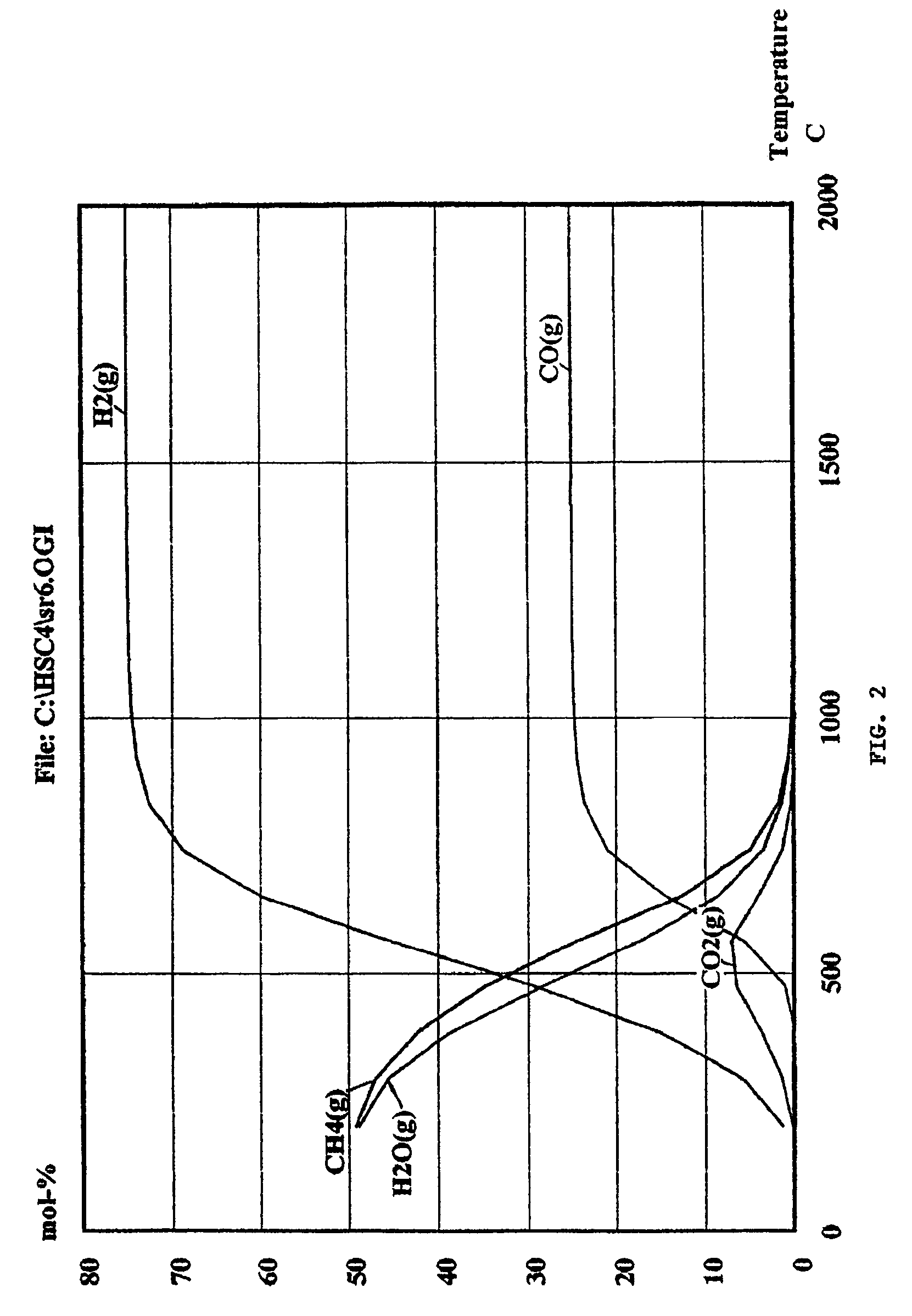

Catalytic steam gasification of petroleum coke to methane

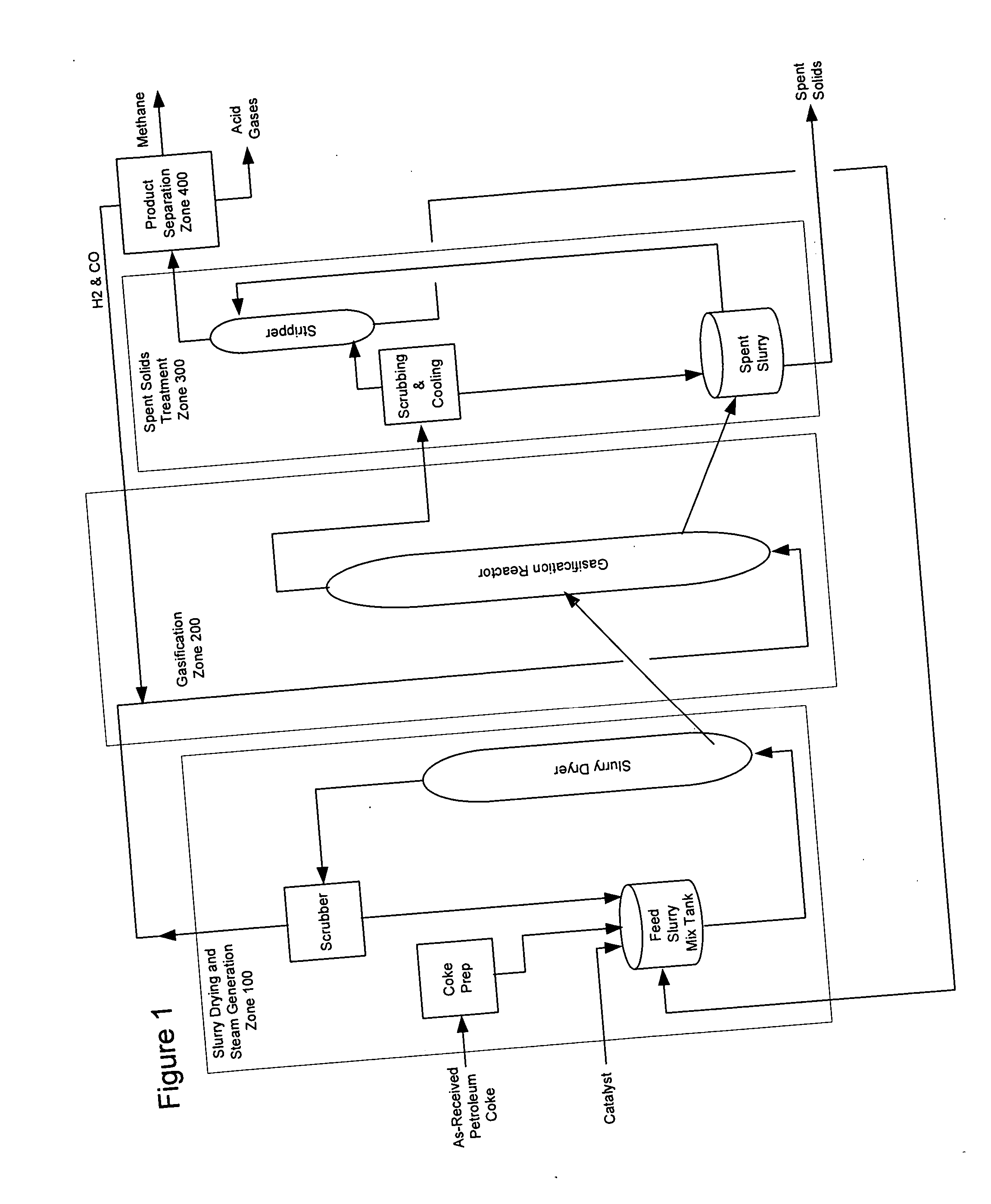

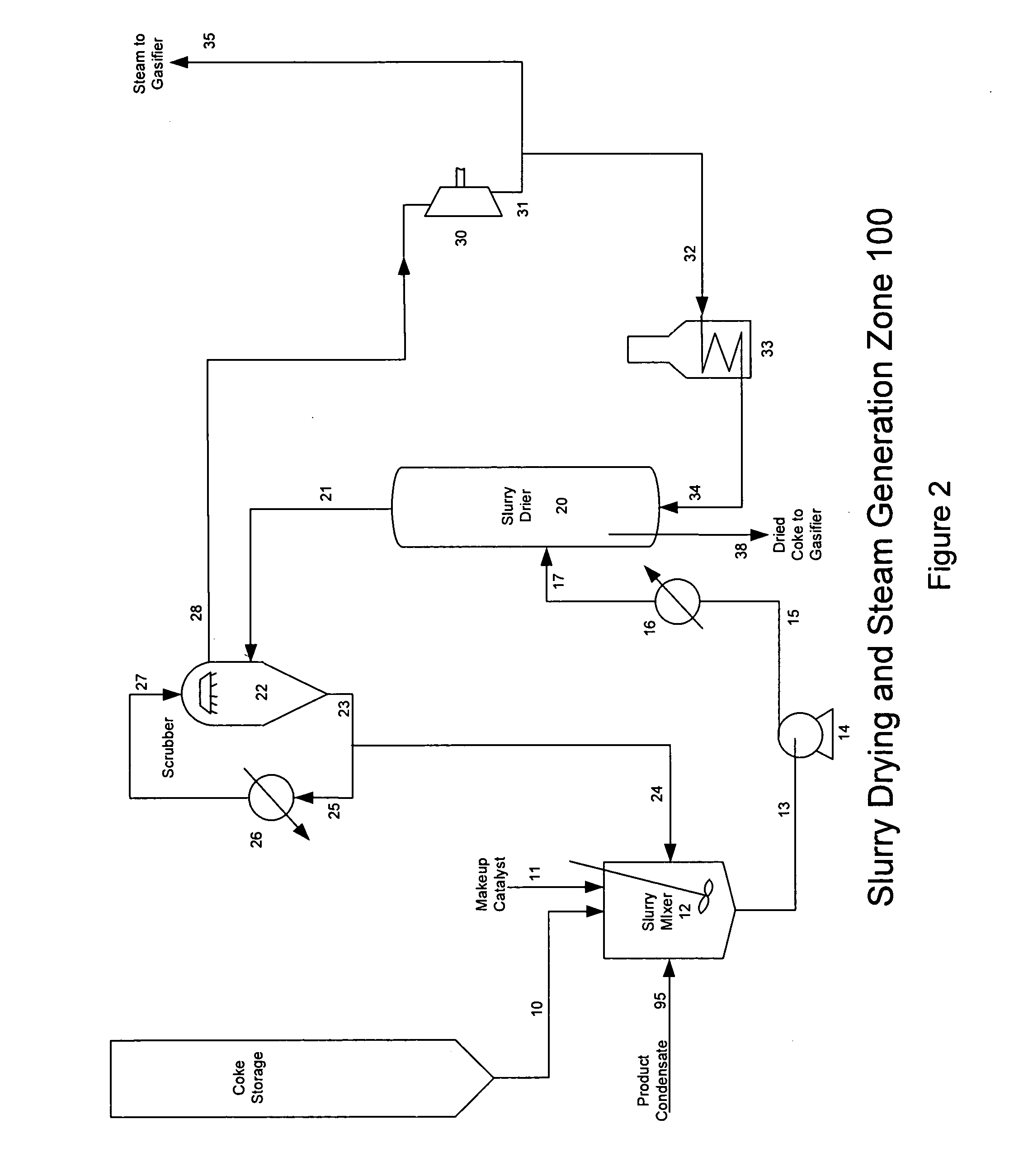

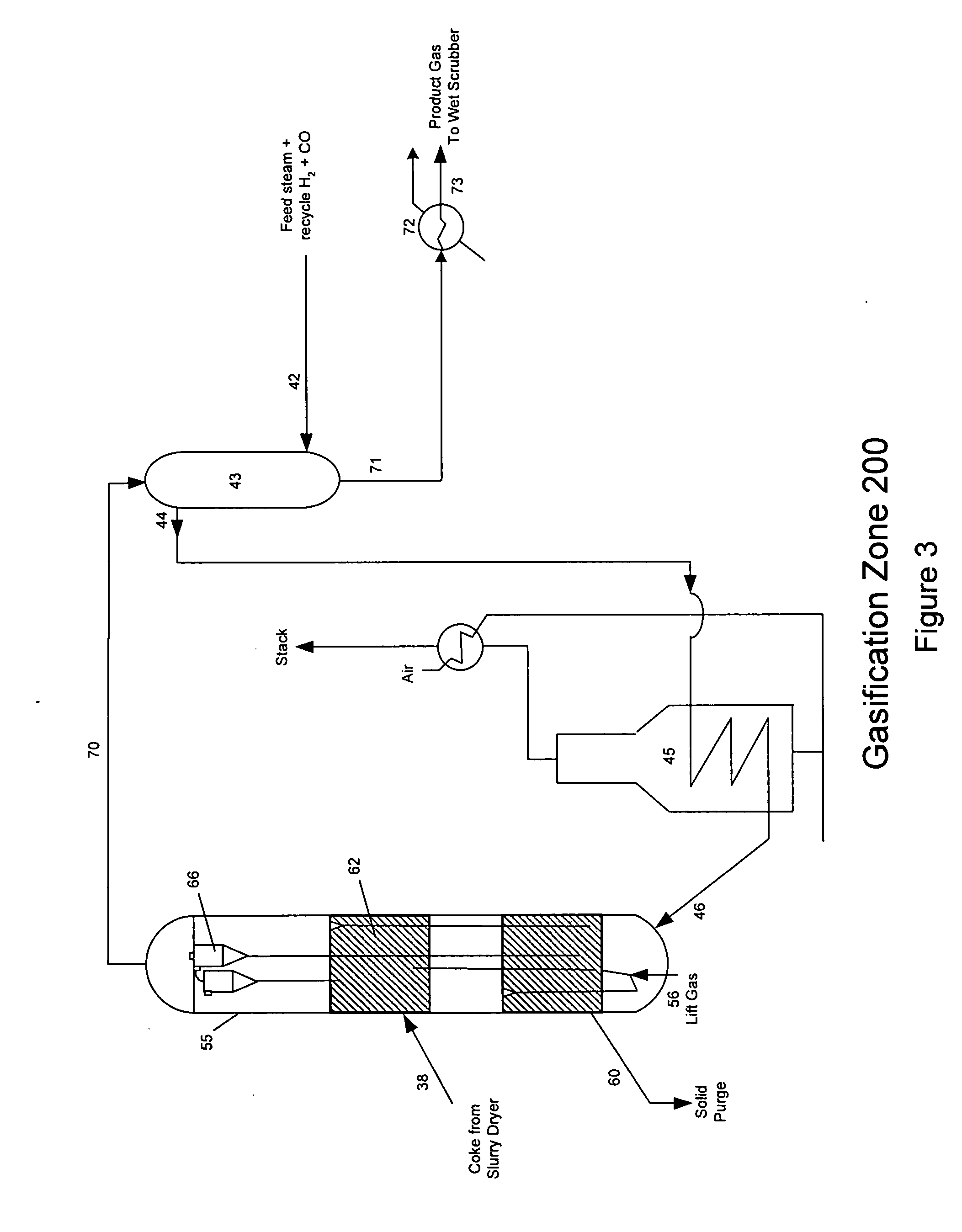

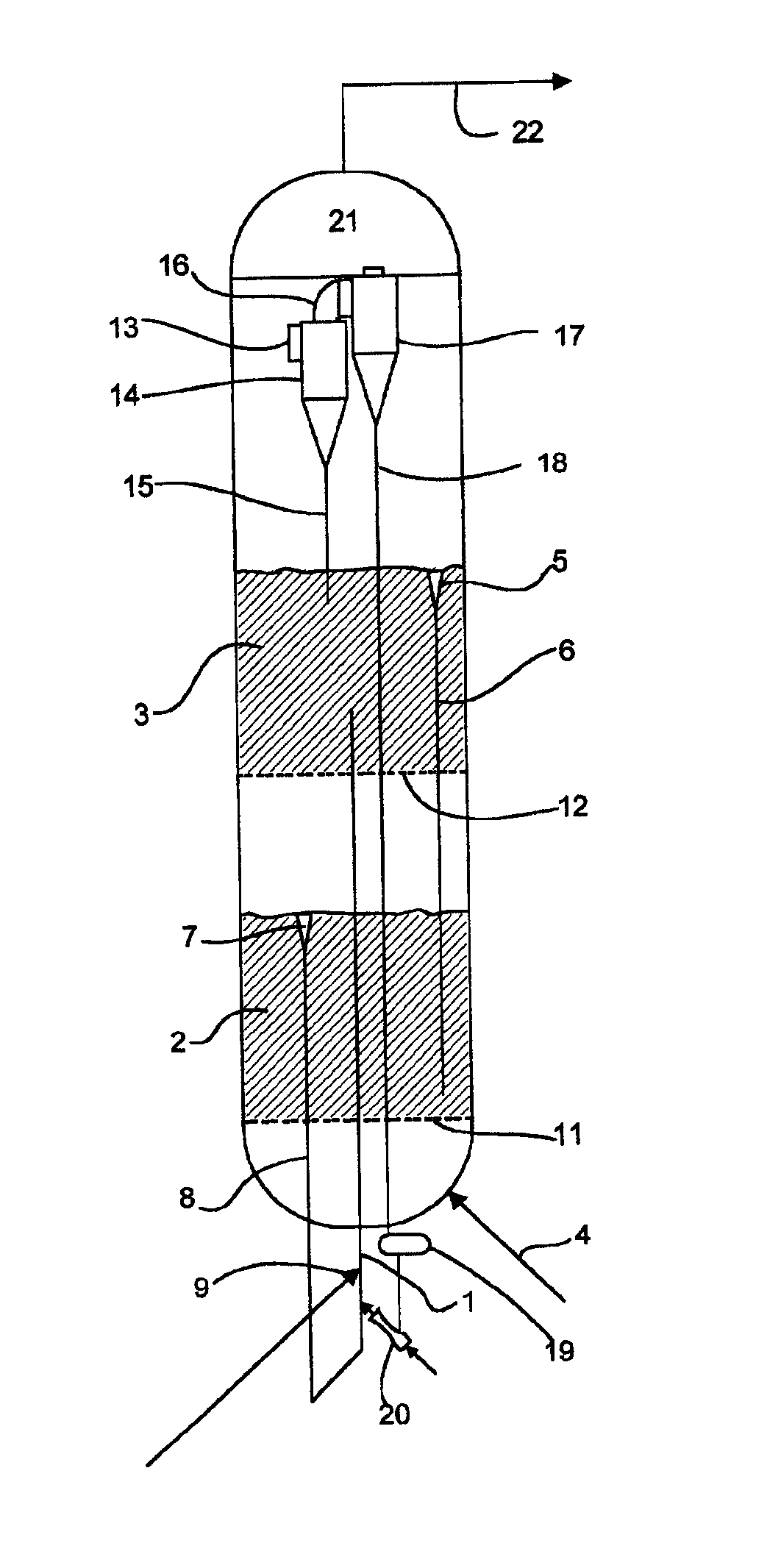

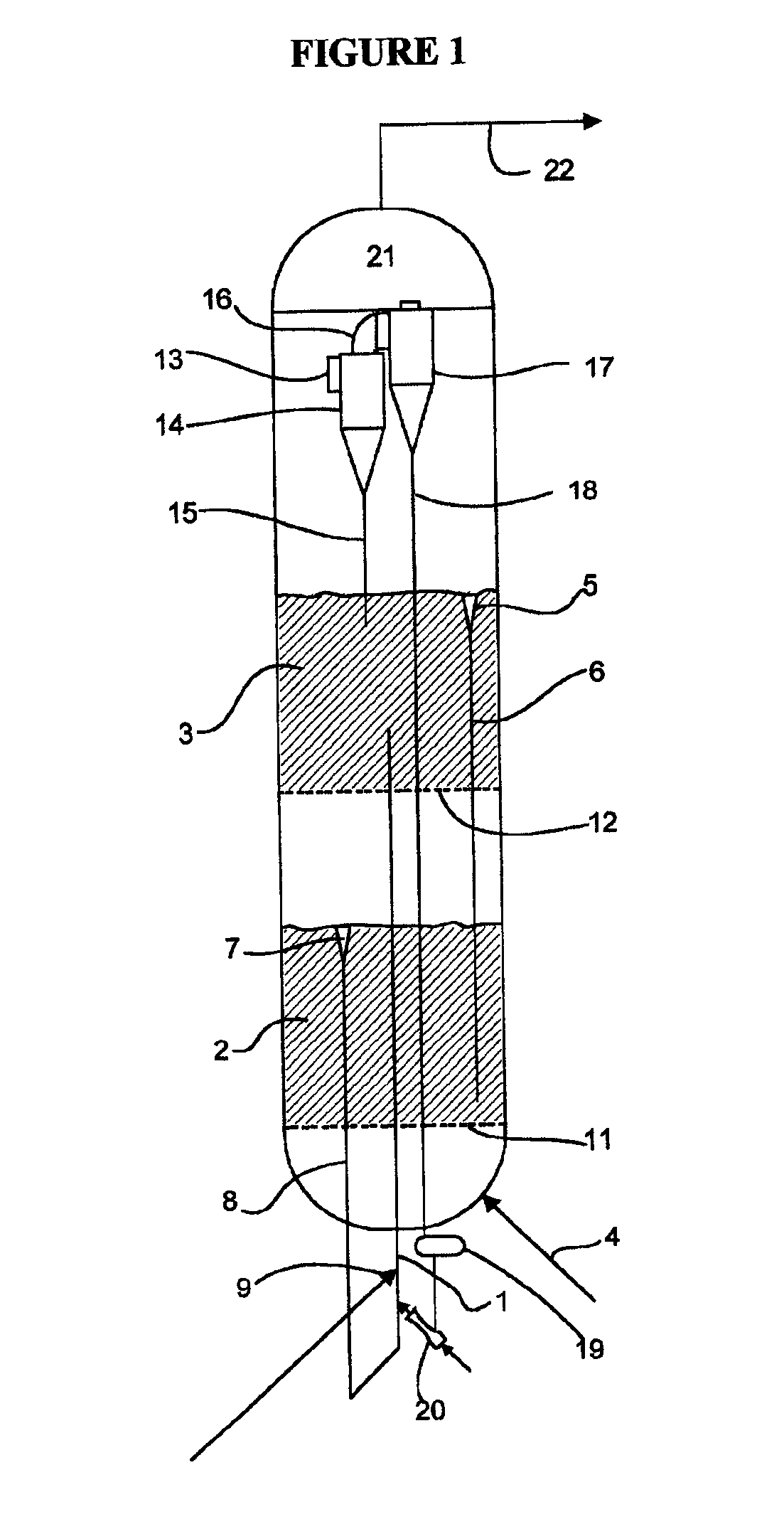

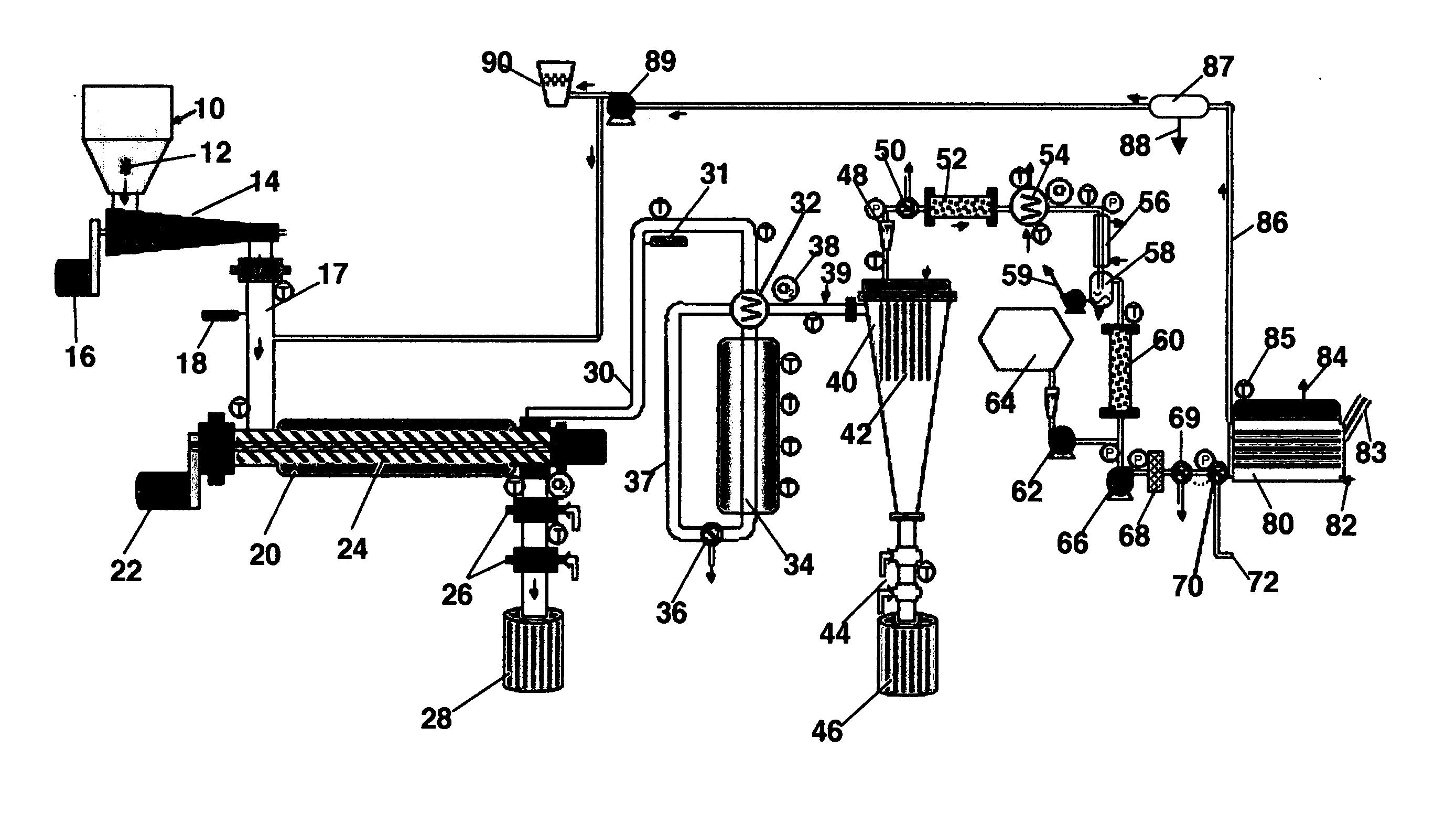

The present invention provides a catalytic steam gasification process for gasifying petroleum coke. The solids composition within the gasification reactor of the disclosed invention is maintained by controlling the catalyst composition of the feed. The process utilizes sour water from the raw gasification product gases to recover and recycle catalyst. Fine particles generated in the handling of coke are advantageously utilized to increase the efficiency of the process.

Owner:SURE CHAMPION INVESTMENT LTD

Biomass Char Compositions for Catalytic Gasification

InactiveUS20090217575A1Efficient utilization of carbonEfficient comprehensive utilizationProductsReagentsParticulatesHydrogen

Particulate compositions are described comprising an intimate mixture of a biomass char producedfrom the combustion of a biomass, such as switchgrass or hybrid poplar, with at least a second carbonaceous material, such as petroleum coke or coal, and, optionally a gasification catalyst, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Compositions for Catalytic Gasification of a Petroleum Coke

InactiveUS20090090056A1Cost-effective and high-yielding productionPromote gasificationHydrogenGaseous fuelsParticle compositionMethane gas

The present invention relates to particulate compositions of a lower ash type petroleum coke containing at least two preselected components (alkali metal and calcium) that exhibit an efficient, enhanced-yielding gasification to value added gaseous products, particularly when used in a steady-state integrated gasification process. The compositions of the present invention are particularly useful for catalytic gasification of petroleum coke at moderate temperatures ranging from about 450° C. to about 900° C. Advantageously, the compositions can be readily incorporated into fluidized bed gasification units, and can result in a cost-effective, high-yielding production of methane gas from petroleum coke.

Owner:SURE CHAMPION INVESTMENT LTD

Petroleum Coke Compositions for Catalytic Gasification

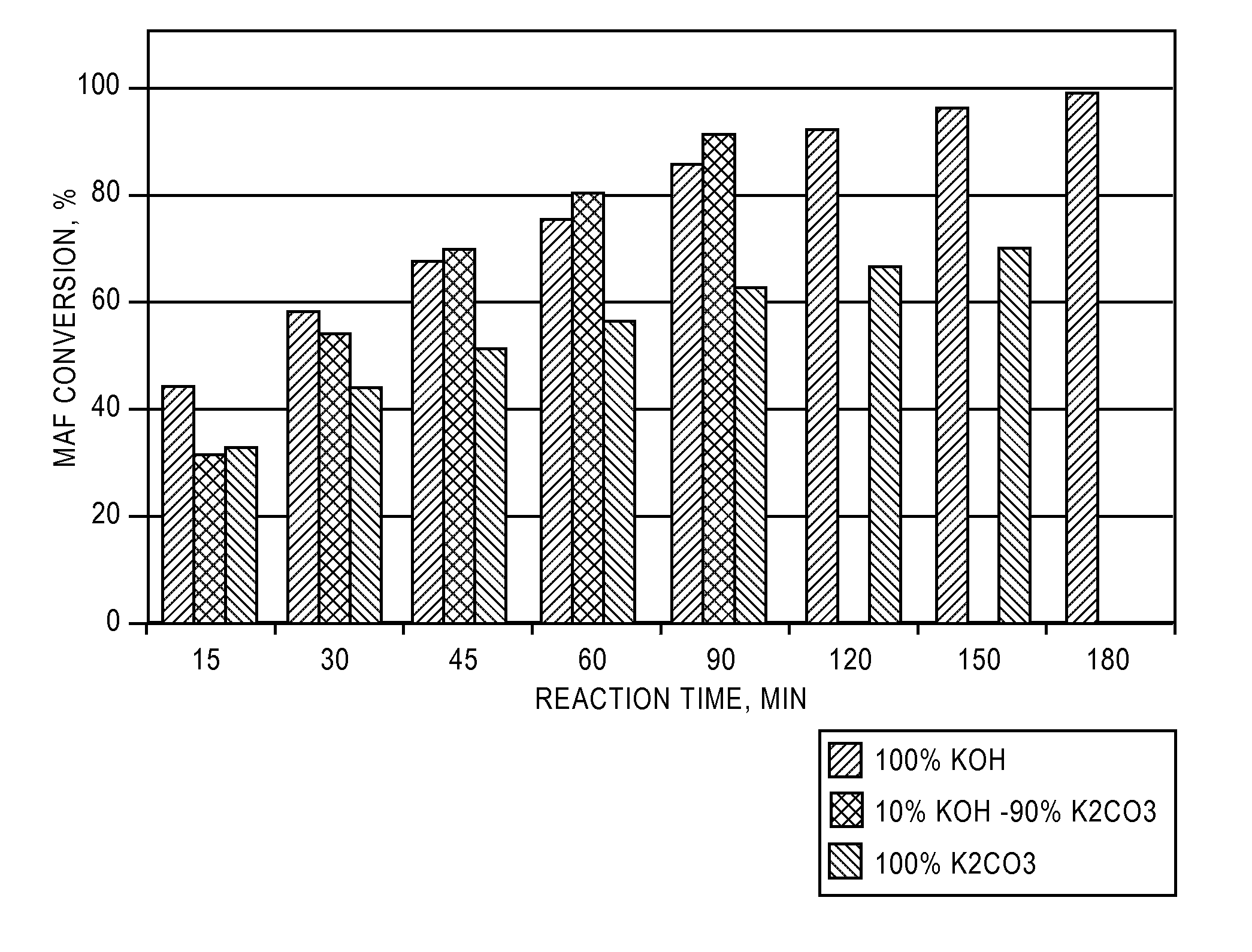

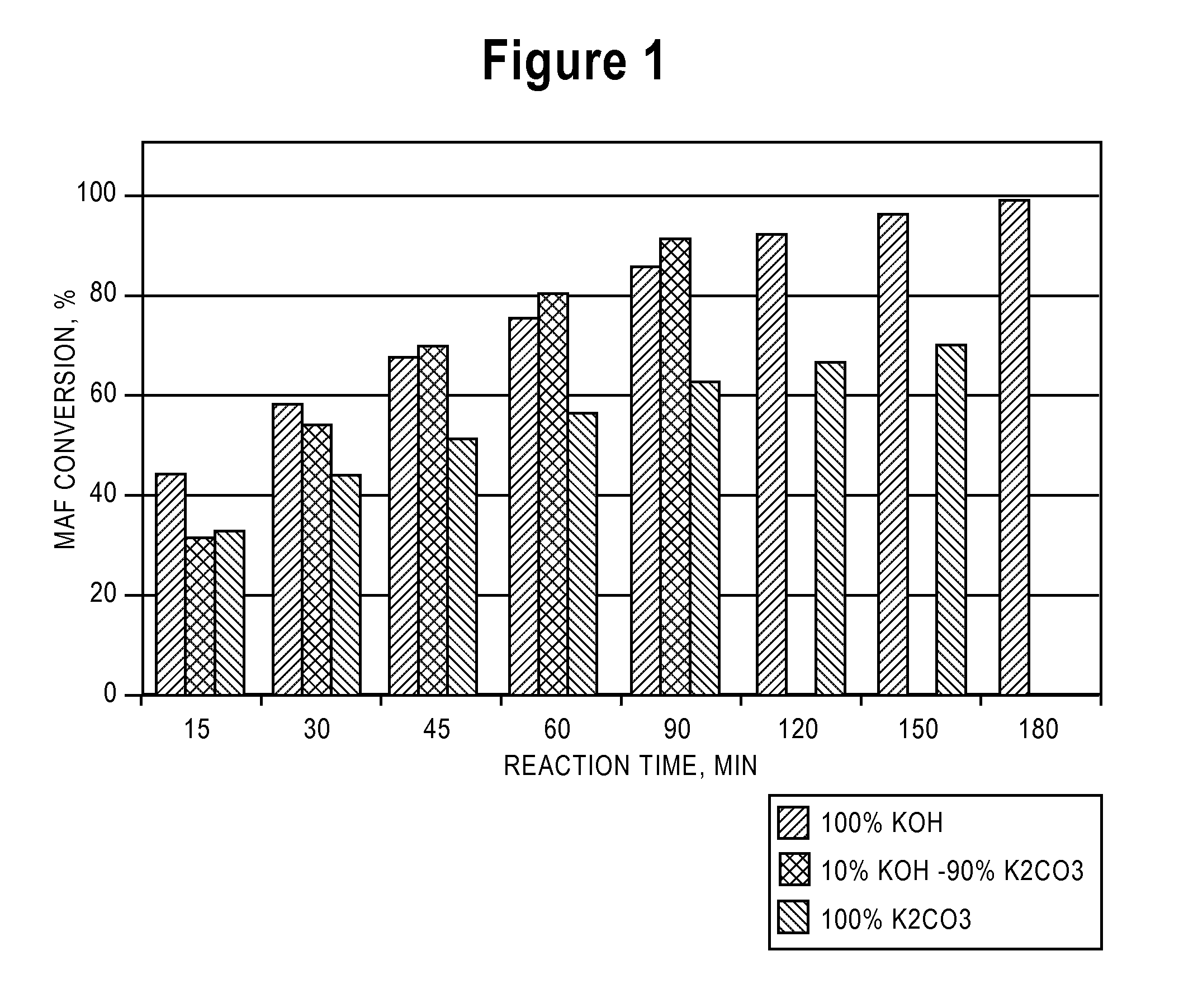

Particulate compositions are described comprising an intimate mixture of a petroleum coke and an alkali metal gasification catalyst, where the alkali metal gasification catalyst comprises a combination of an alkali metal hydroxide and one or more other alkali metal compounds are loaded onto coke for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

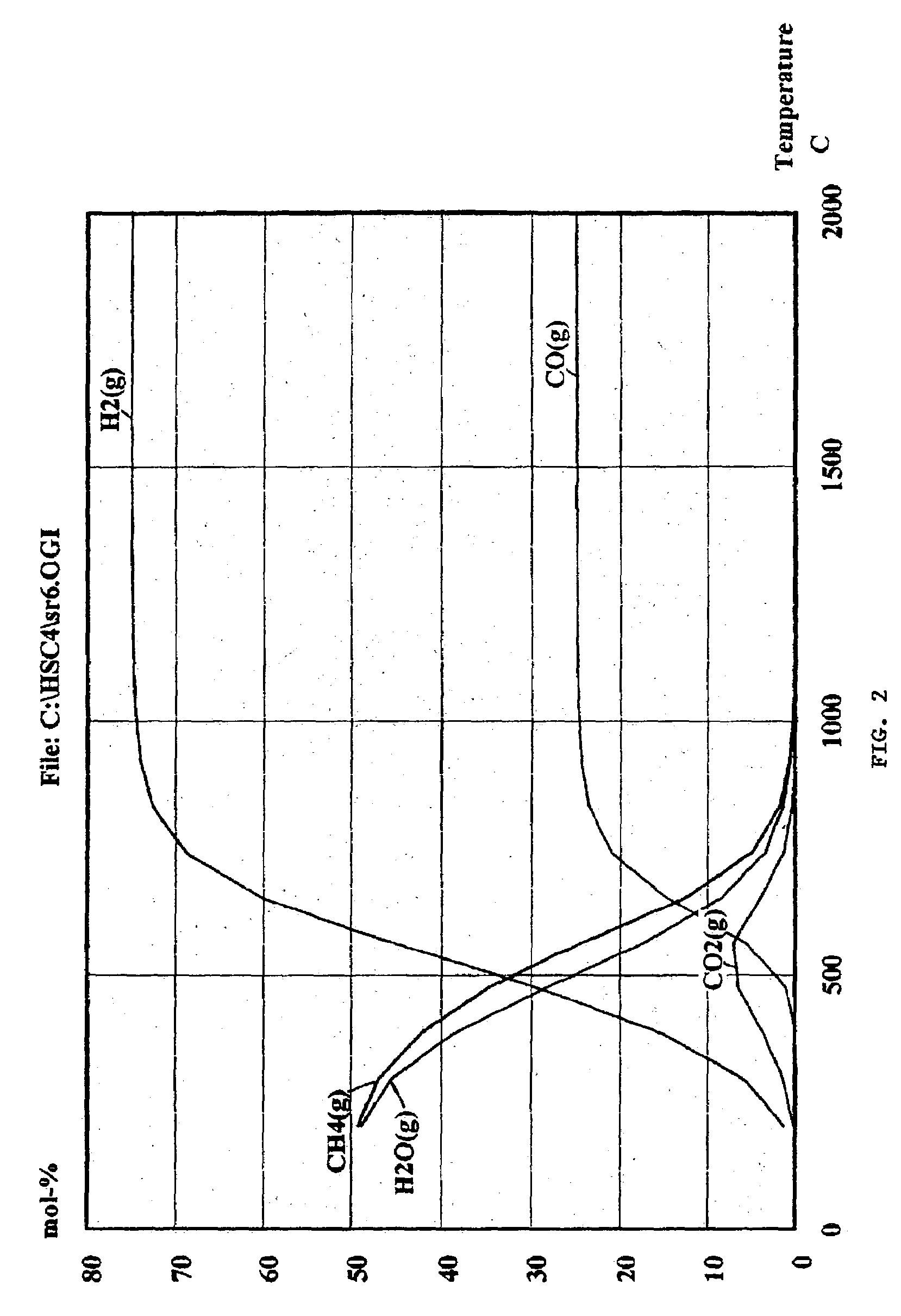

Conversion of petroleum residua to methane

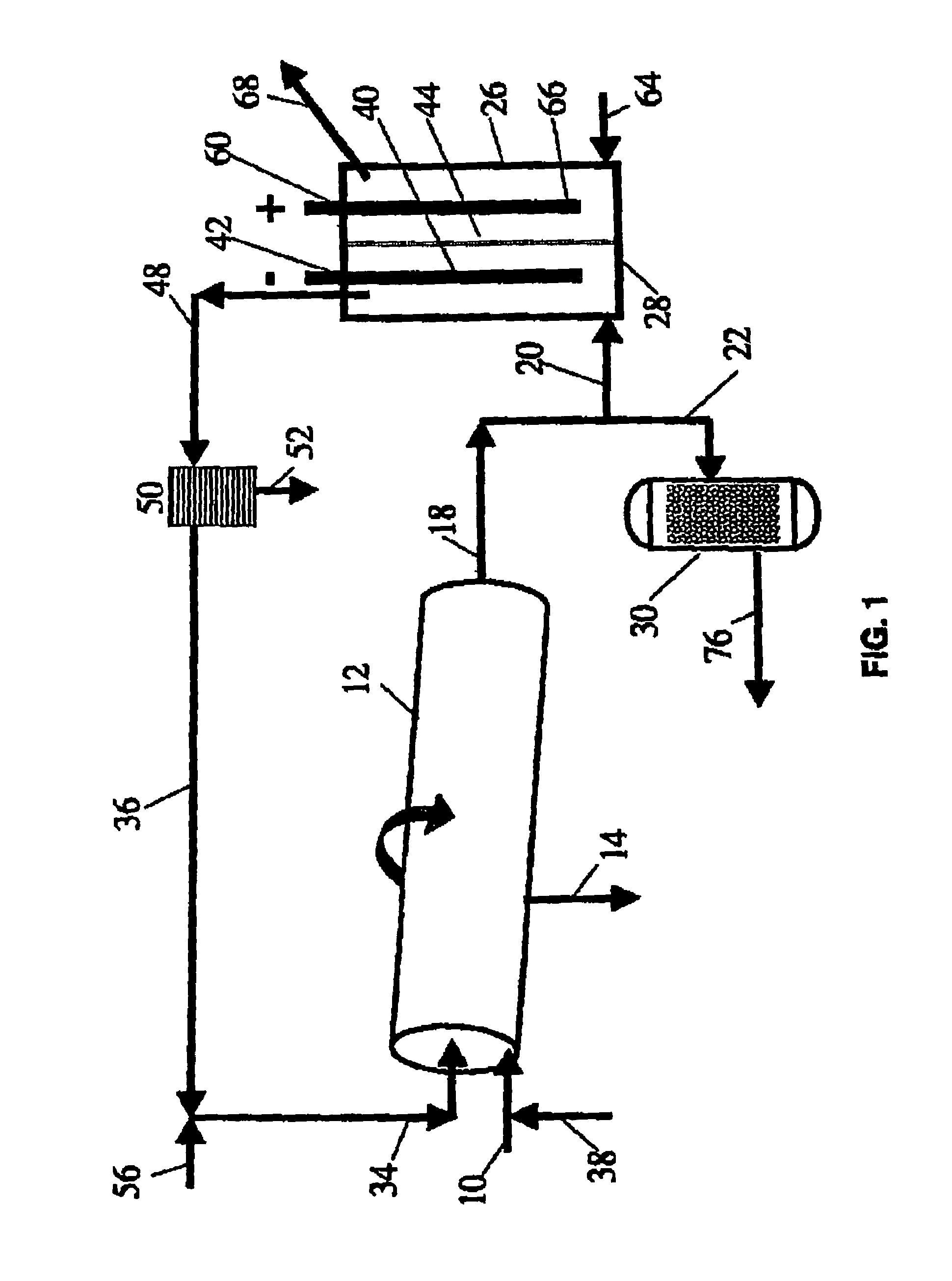

InactiveUS6955695B2Eliminate needReduce usageThermal non-catalytic crackingElectrolysis componentsParticulatesGas phase

This invention discloses improvements on previous inventions for catalytic conversion of coal and steam to methane. The disclosed improvements permit conversion of petroleum residua or heavy crude petroleum to methane and carbon dioxide such that nearly all of the heating value of the converted hydrocarbons is recovered as heating value of the product methane. The liquid feed is distributed over a fluidized solid particulate catalyst containing alkali metal and carbon as petroleum coke at elevated temperature and pressure from the lower stage and transported to the upper stage of a two-stage reactor. Particulate solids containing carbon and alkali metal are circulated between the two stages. Superheated steam and recycled hydrogen and carbon monoxide are fed to the lower stage, fluidizing the particulate solids and gasifying some of the carbon. The gas phase from the lower stage passes through the upper stage, completing the reaction of the gas phase.

Owner:PETRO2020

Petroleum Coke Compositions for Catalytic Gasification

InactiveUS20090166588A1Improve efficiencyReduce moisture contentOther chemical processesMixing methodsPtru catalystThermodynamics

Particulate compositions are described comprising an intimate mixture of a petroleum coke, coal and a gasification catalyst, where the gasification catalyst is loaded onto at least the coal for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

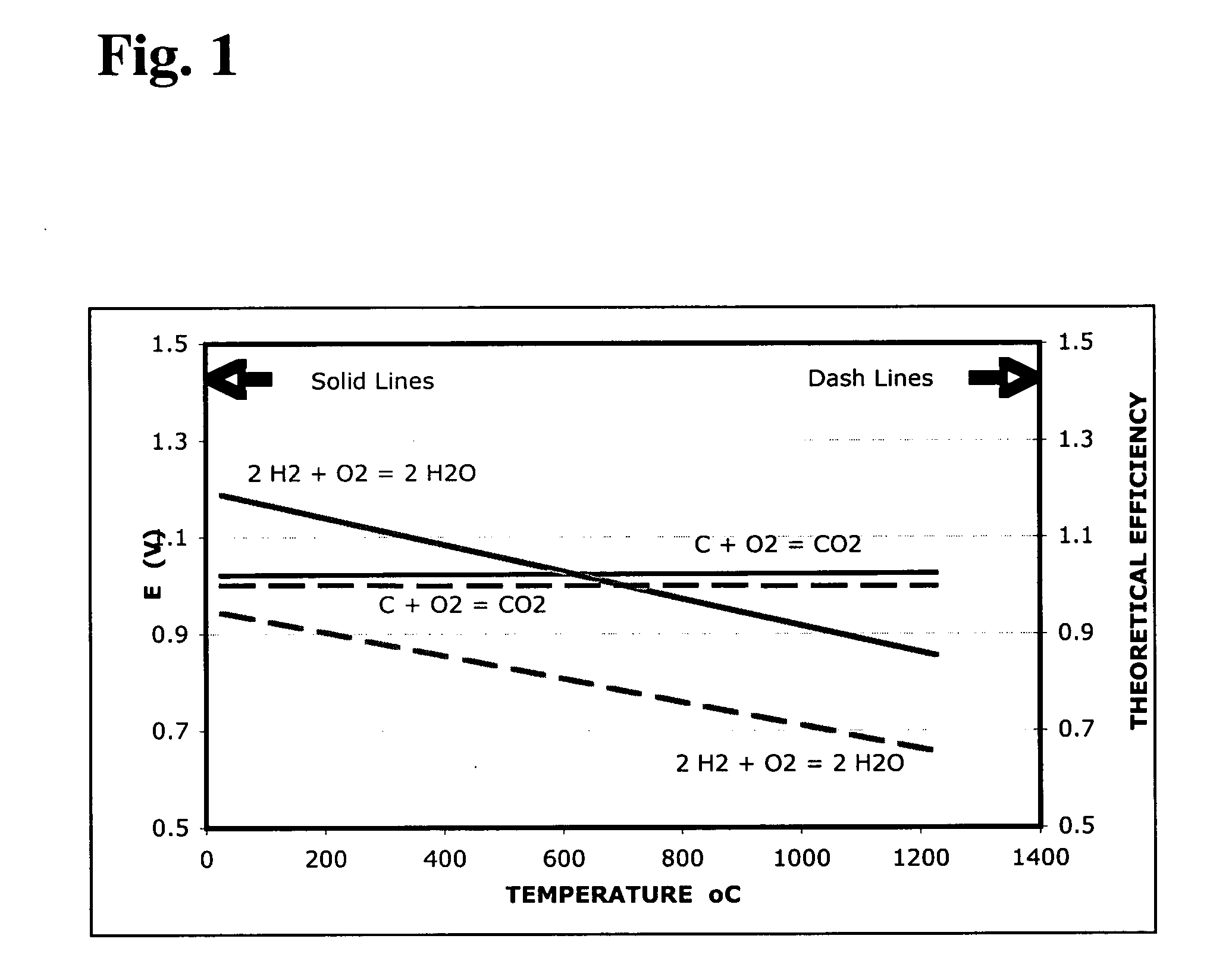

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

Biomass Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a biomass, such as switchgrass or hybrid poplar, a non-biomass carbonaceous material, such as petroleum coke or coal, and a gasification catalyst, where the gasification catalyst is loaded onto at least one of the biomass or non-biomass for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Particulate Compositions

ActiveUS20090229182A1Efficient use ofBiofuelsGas modification by gas mixingPtru catalystPetroleum coke

Particulate compositions are described comprising a carbonaceous material, such as petroleum coke and / or coal, treated or otherwise associated with a gasification catalyst, where the catalyst is at least in part derived from a leachate from a biomass char, for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

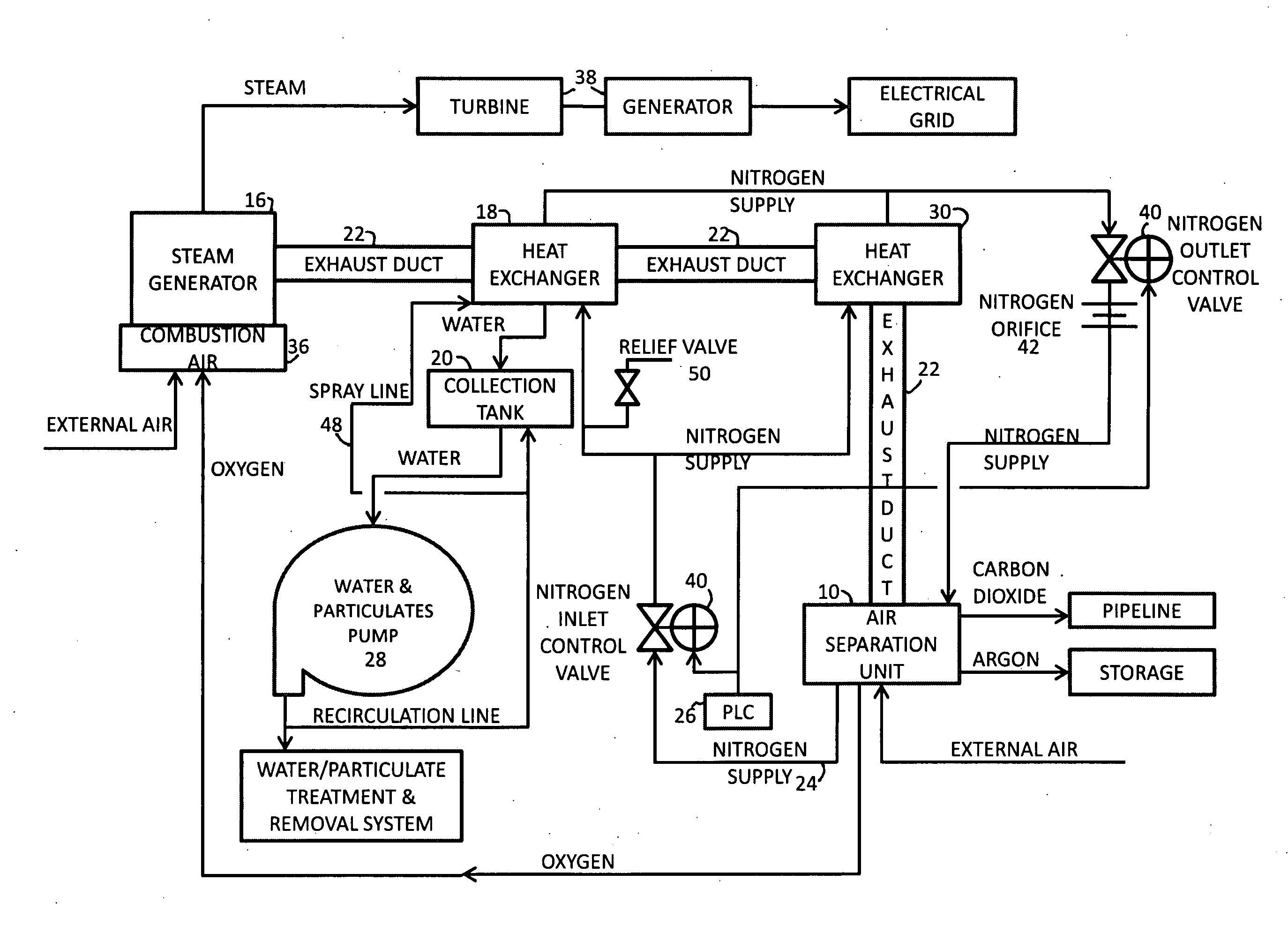

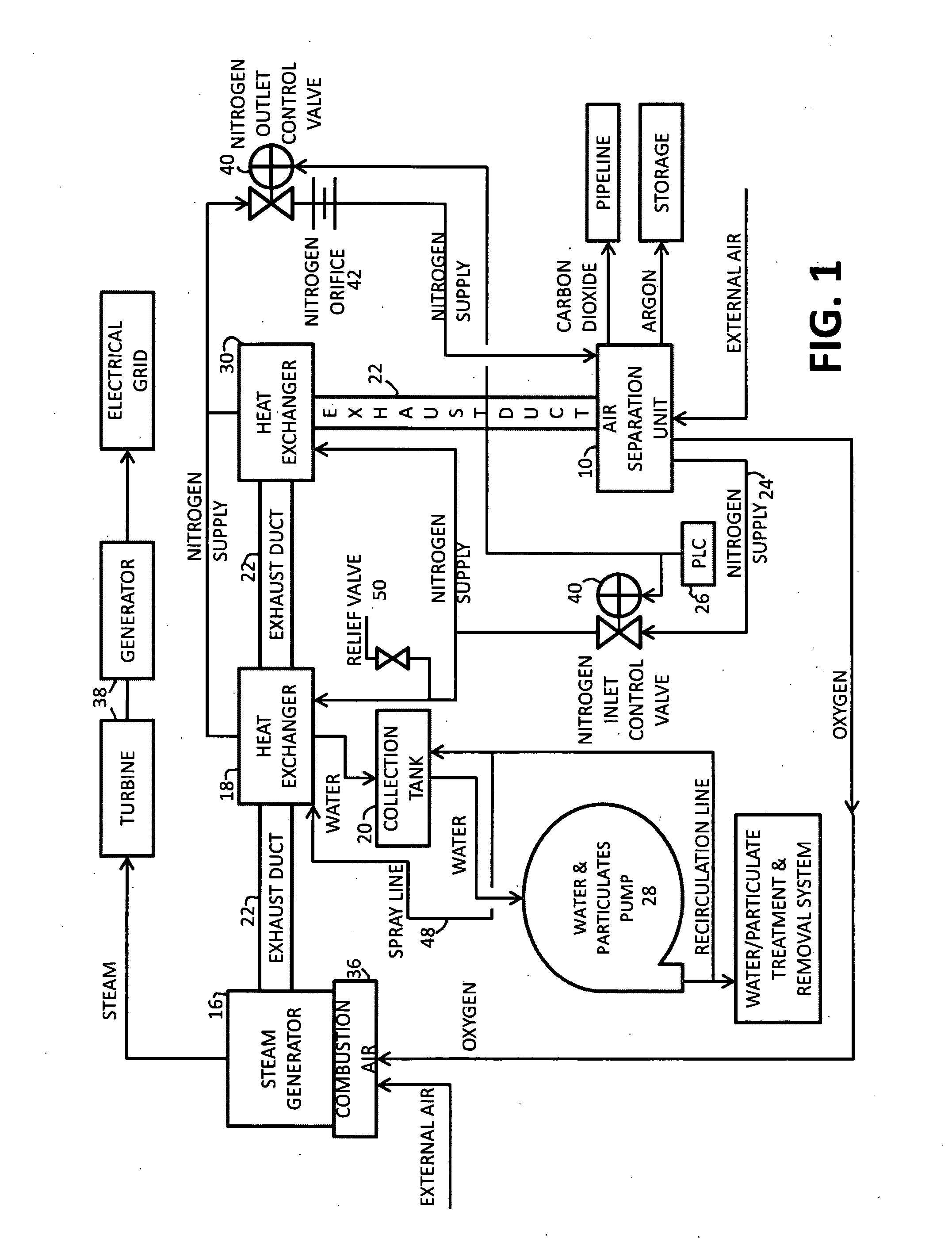

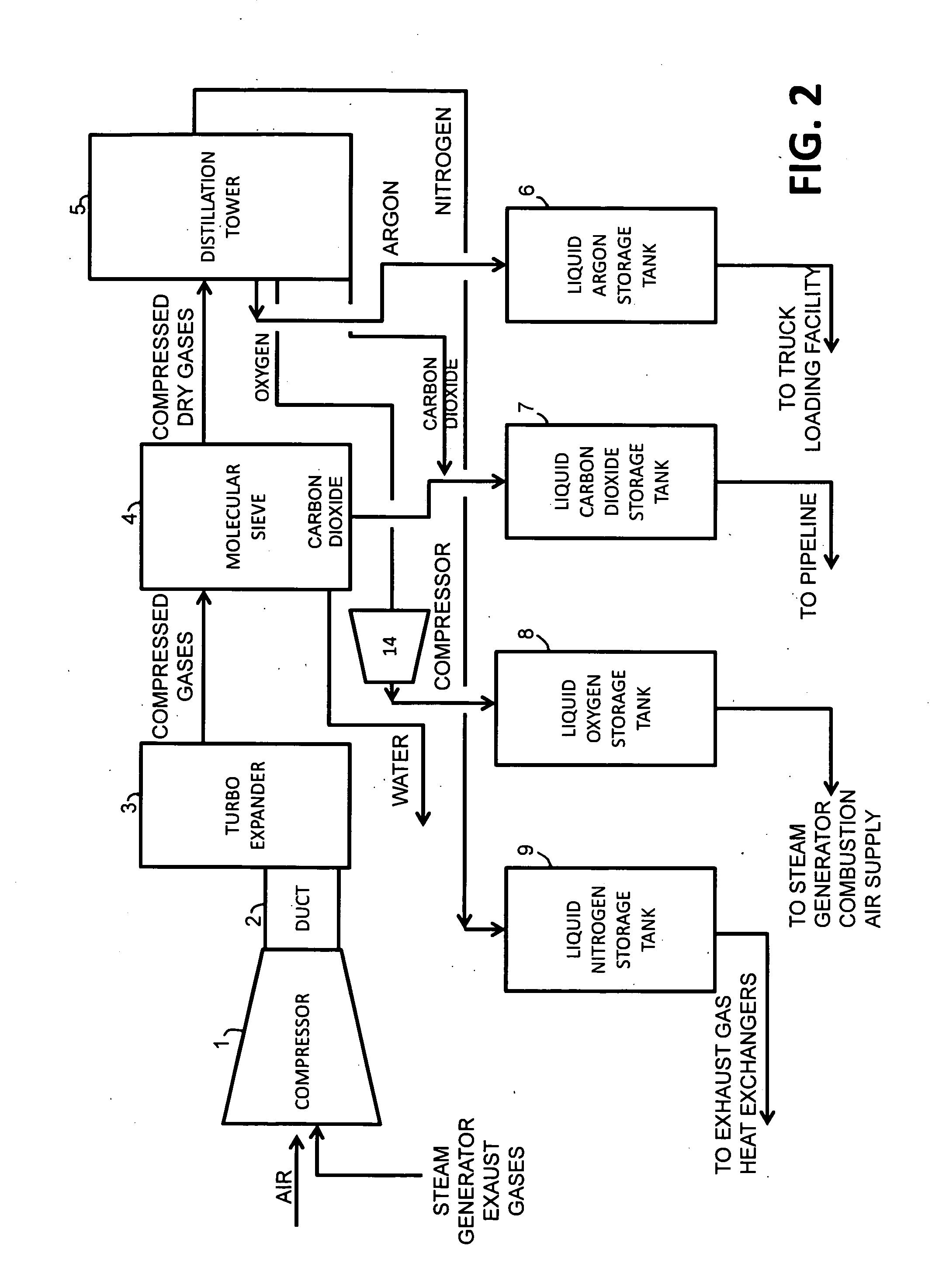

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

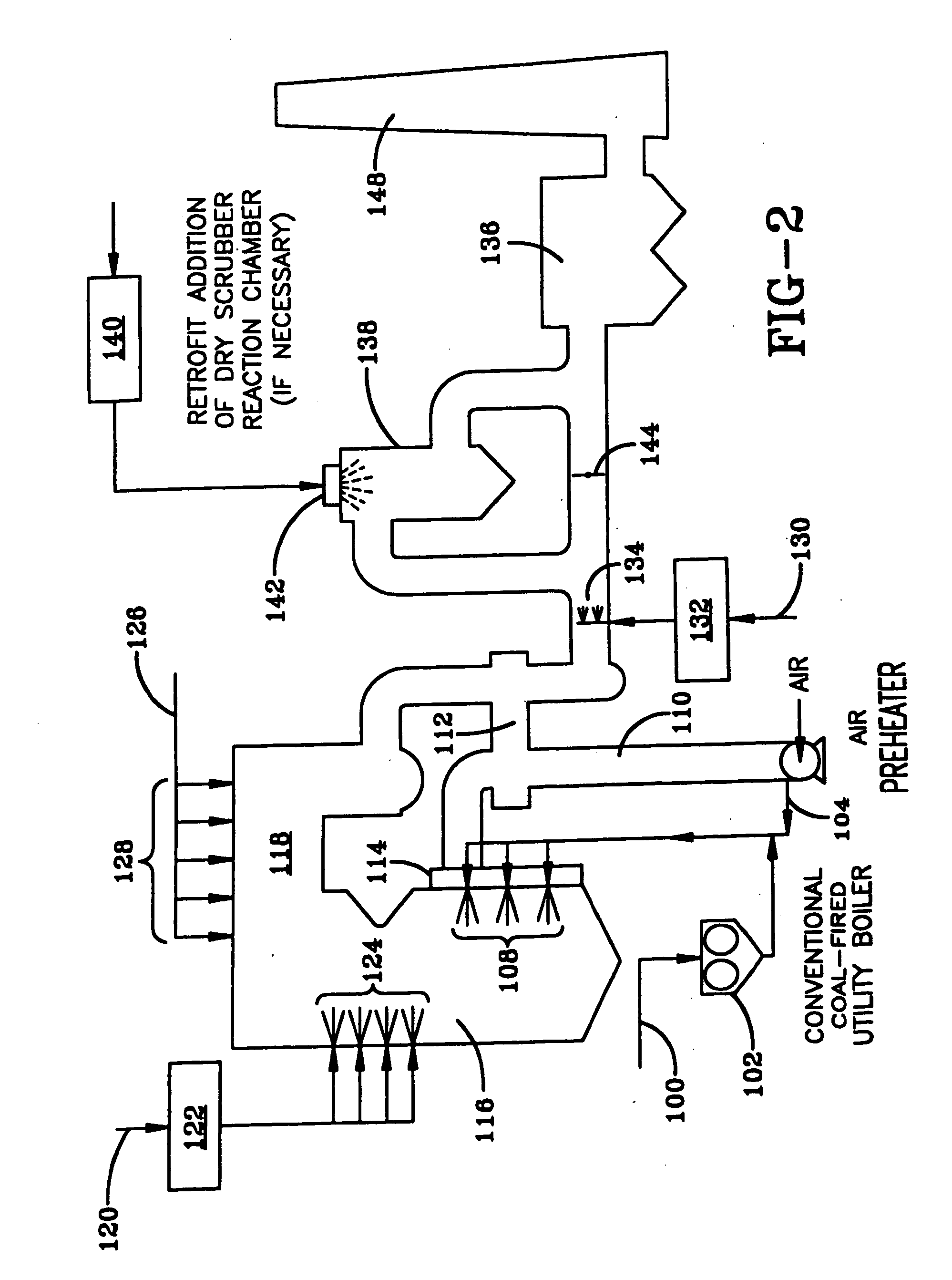

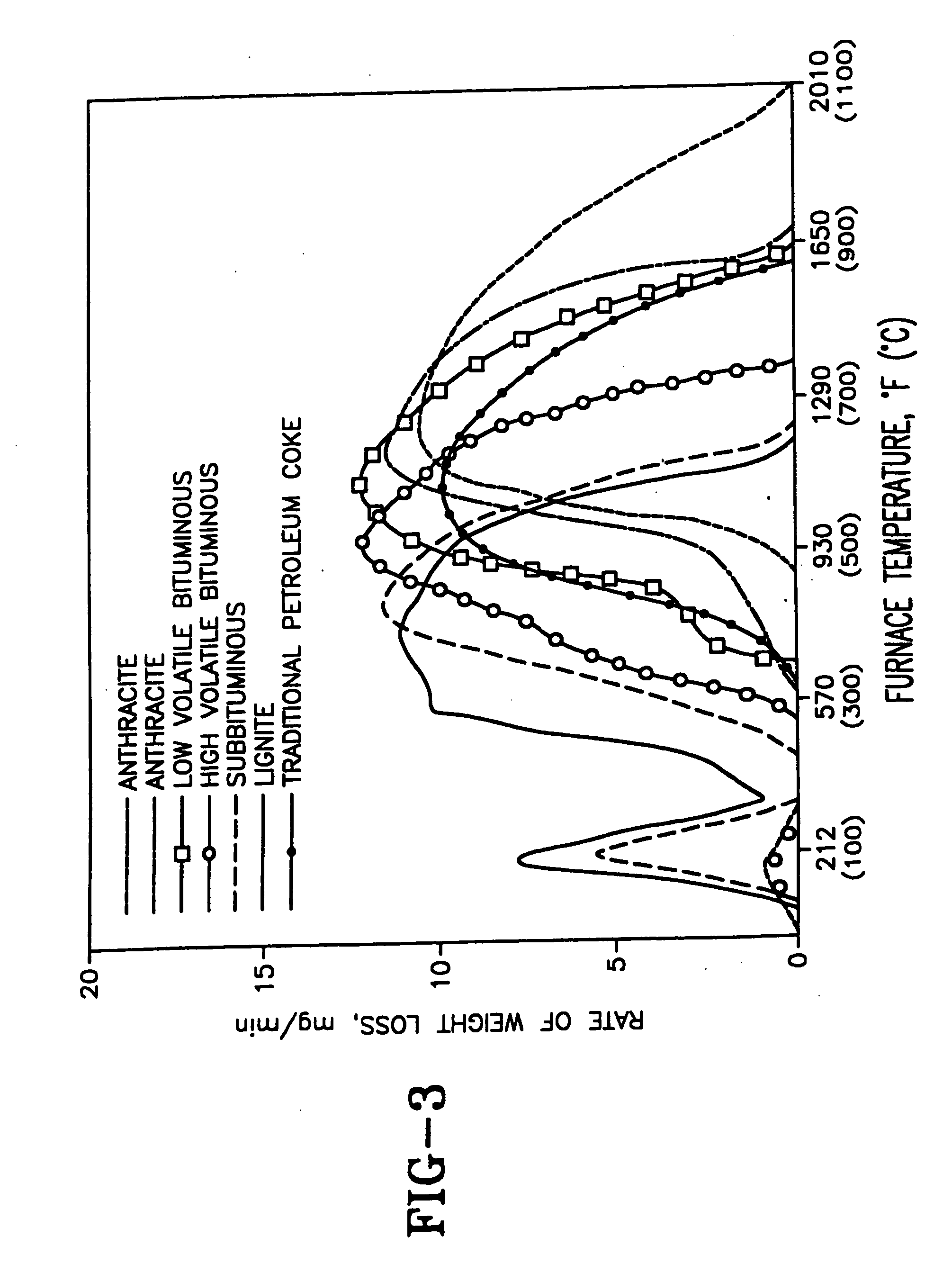

Production and use of a premium fuel grade petroleum coke

InactiveUS20060032788A1Thermal non-catalytic crackingLiquid organic insulatorsCombustionSufficient time

A premium “fuel-grade” petroleum coke is produced by modifying petroleum coking technology. Coking process parameters are controlled to consistently produce petroleum coke within a predetermined range for volatile combustible material (VCM) content. The invention includes a process of producing a coke fuel, the method comprising steps: (a) obtaining a coke precursor material derived from crude oil and having a volatile organic component; and (b) subjecting the coke precursor material to a thermal cracking process for sufficient time and at sufficient temperature and under sufficient pressure so as to produce a coke product having volatile combustible materials (VCMs) present in an amount in the range of from about 13% to about 50% by weight. Most preferably, the volatile combustible materials in the coke product typically may be in the range of from about 15% to about 30% by weight. The present invention also provides methods for (1) altering the coke crystalline structure, (2) improving the quality of the coke VCM, and (3) reducing the concentration of coke contaminants. Fuels made from the inventive coke product and methods of producing energy through the combustion of such fuels are also included. Finally, novel environmental control techniques are developed to take optimal advantage of the unique characteristics of this upgraded petroleum coke.

Owner:ETTER ROGER G

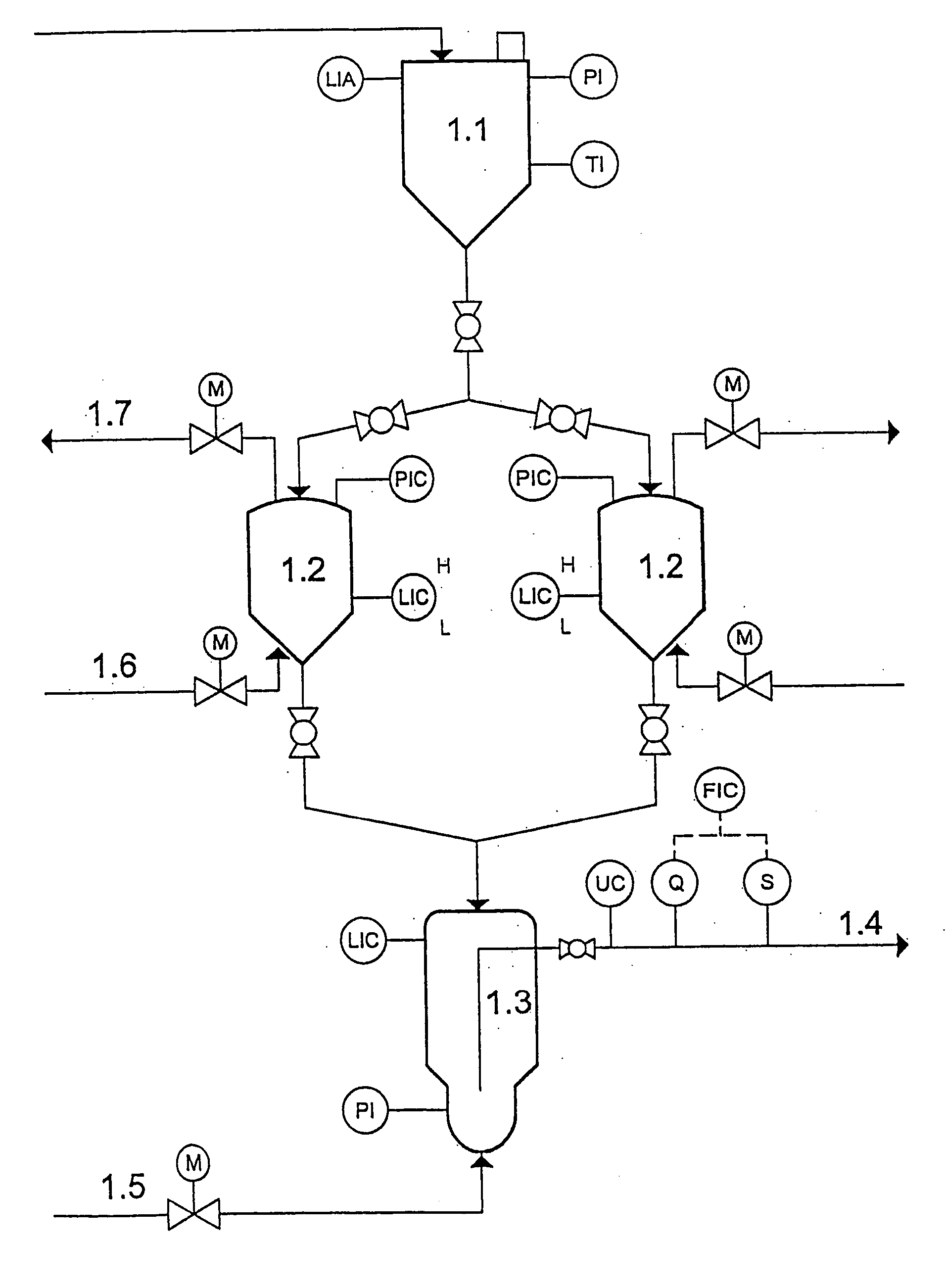

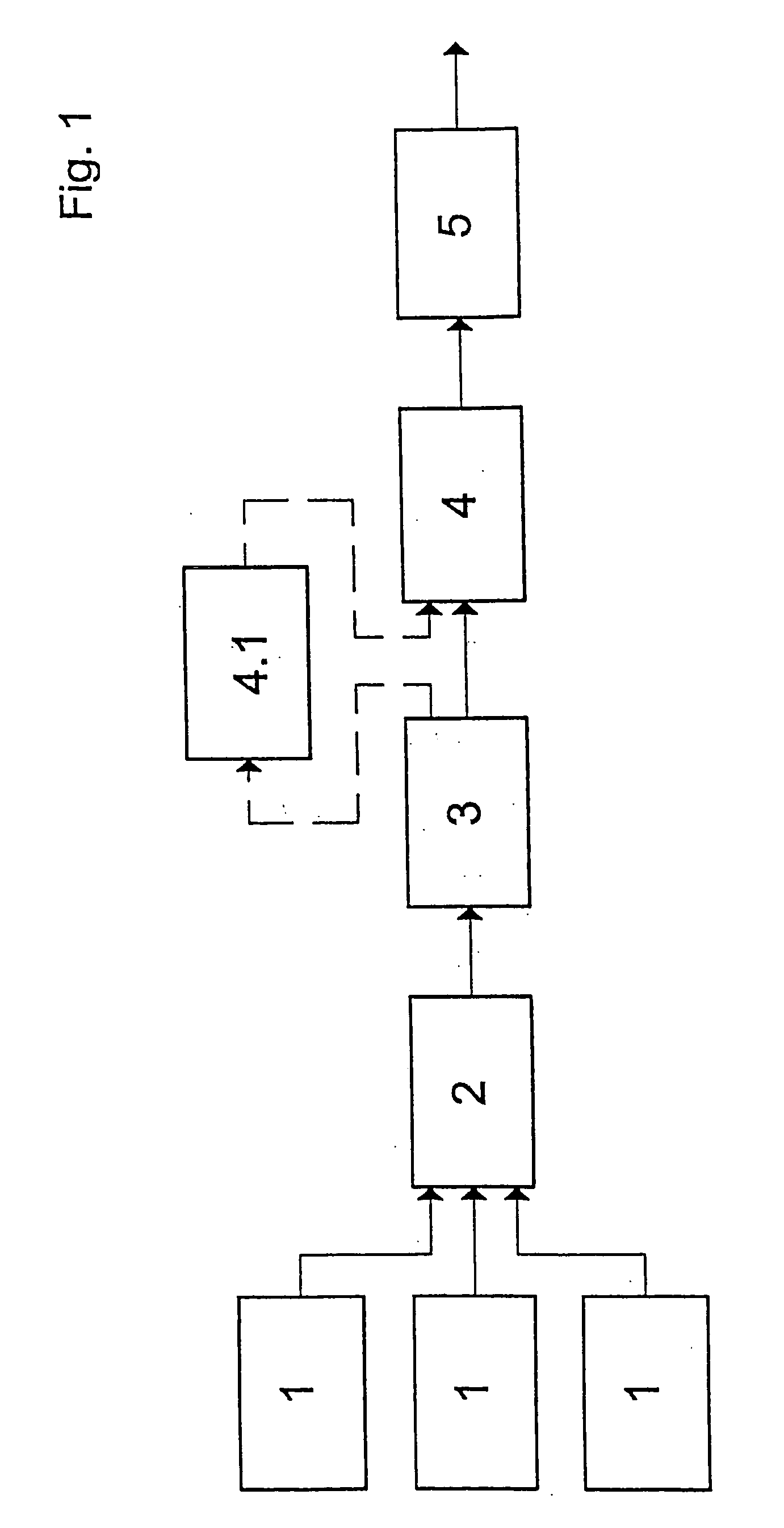

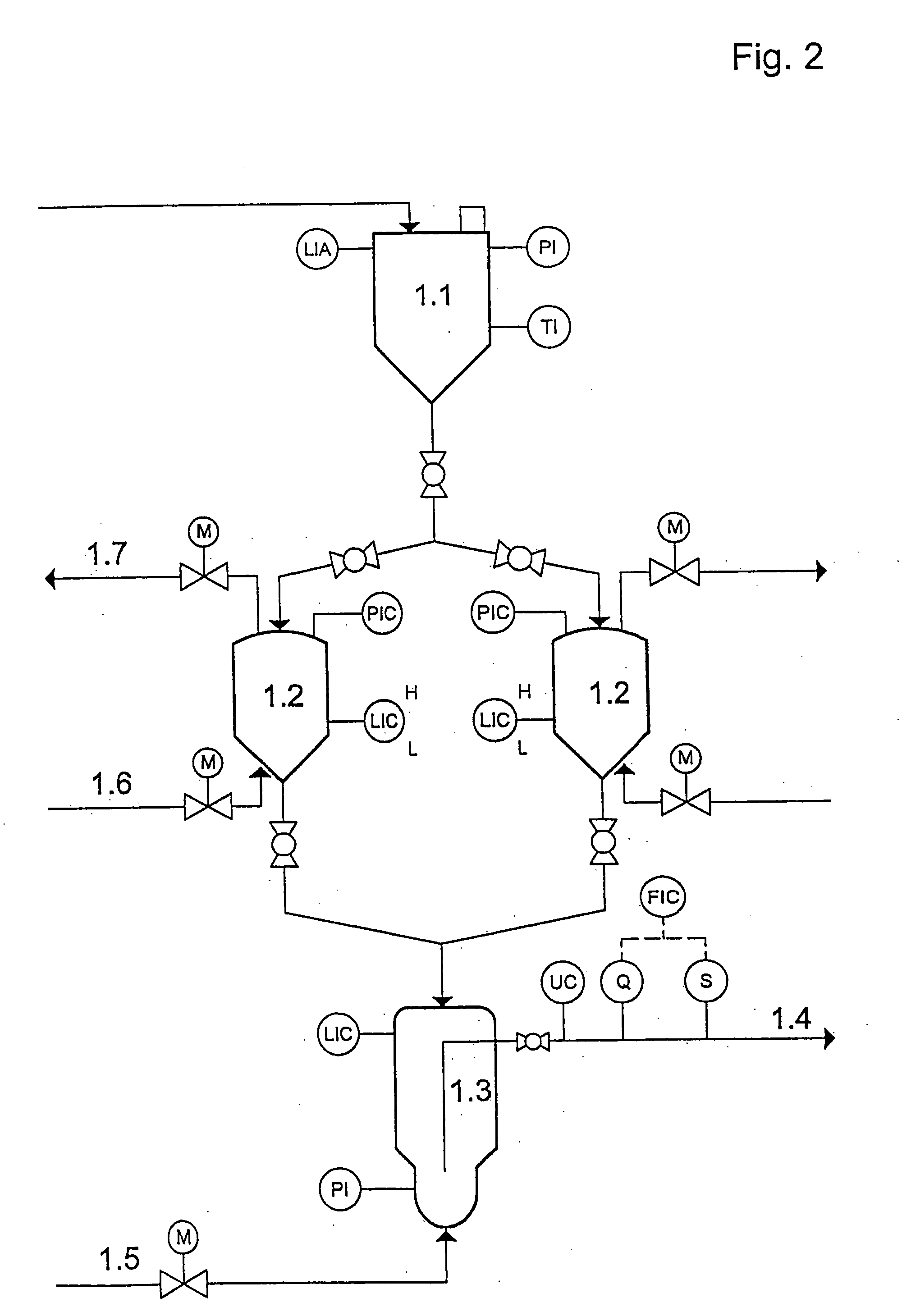

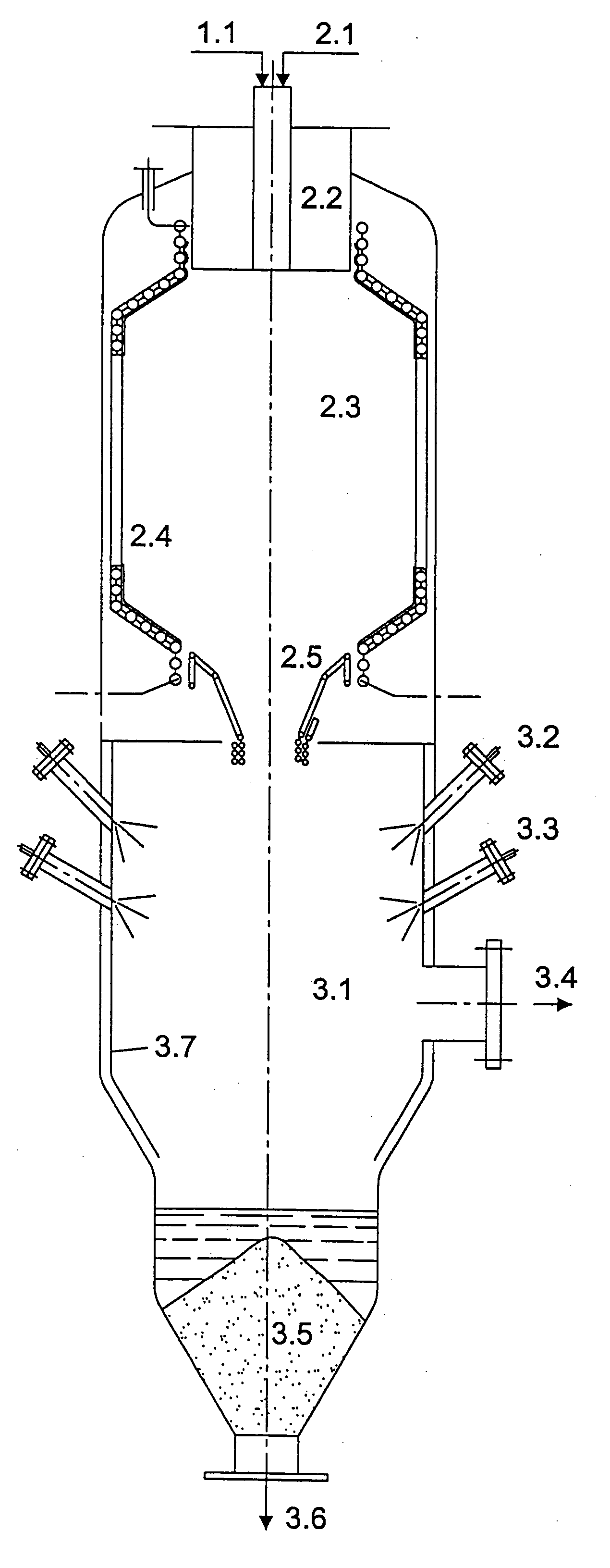

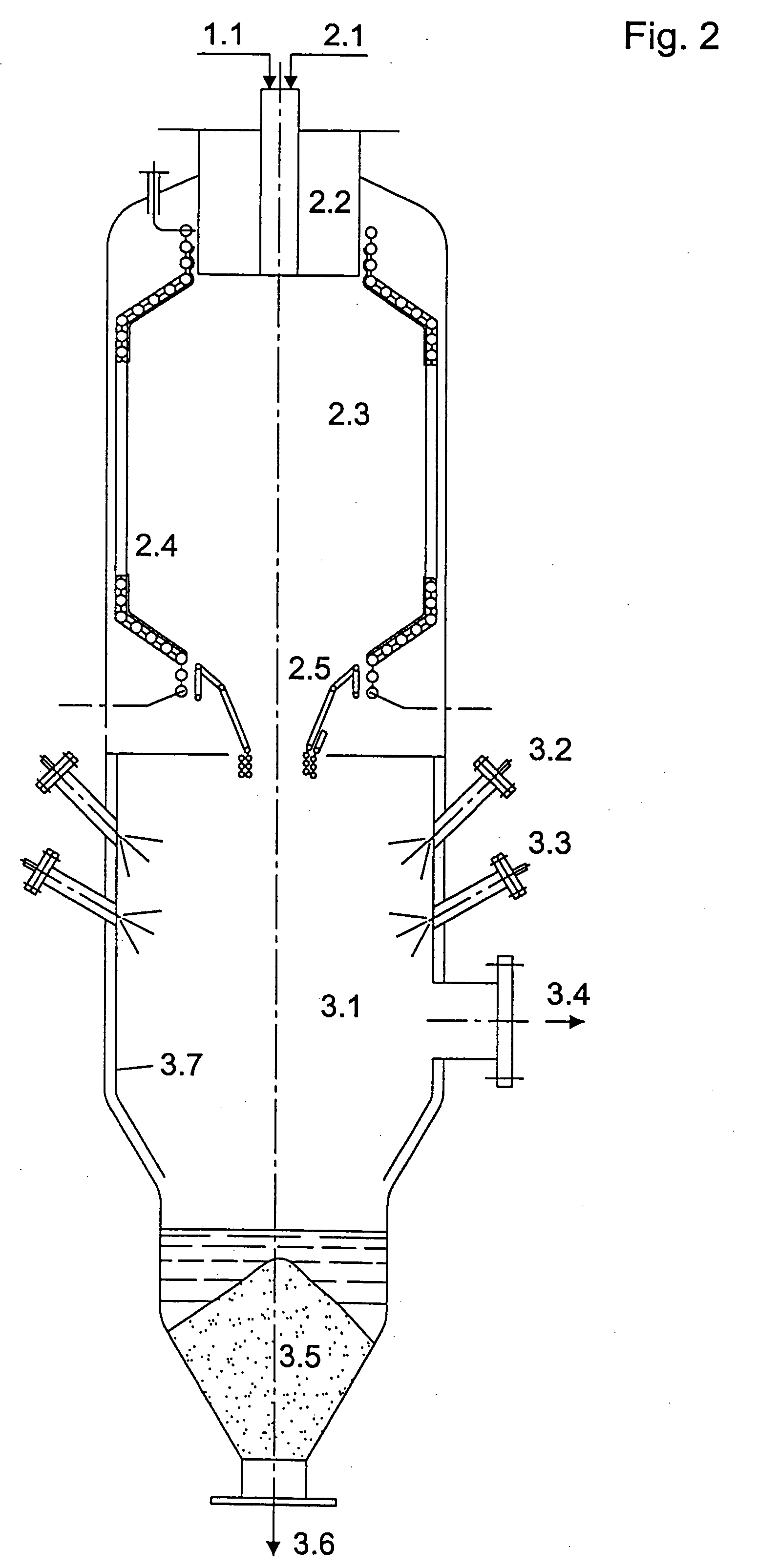

Method and device for high-capacity entrained flow gasifier

A method and device for the gasification of pulverized fuels from solid fuels such as bituminous coals, lignite coals, and their cokes, petroleum cokes, coke from peat or biomass, in entrained flow, with an oxidizing medium containing free oxygen, by partial oxidation at pressures between atmospheric pressure and 80 bar, and at temperatures between 1,200 and 1,900° C., at high reactor capacities between 1,000 and 1,500 MW. The method uses the following steps: metering of the fuel, gasification reaction in a gasification reactor with cooled reaction chamber contour, quench-cooling, crude gas scrubbing, and partial condensation.

Owner:SIEMENS AG

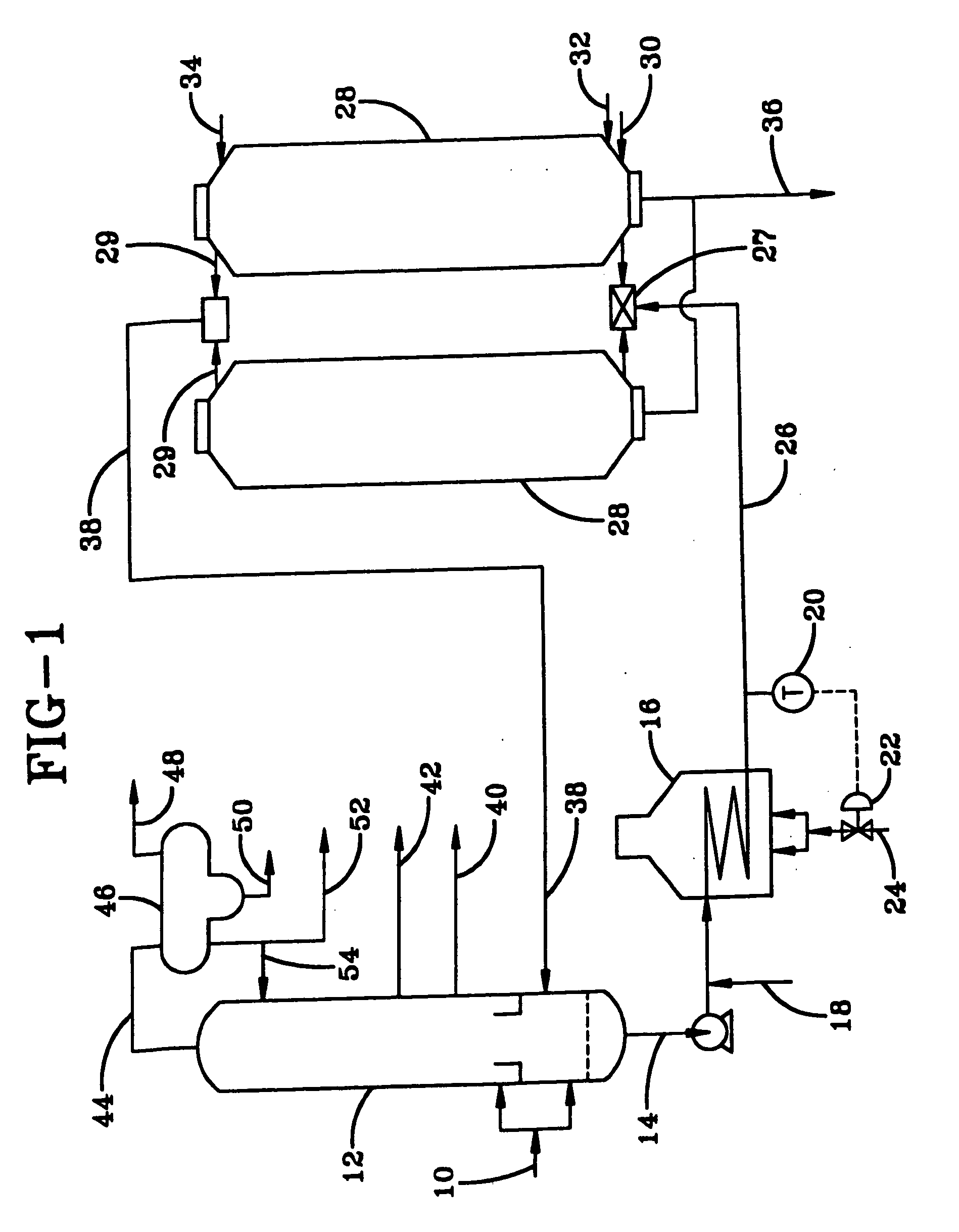

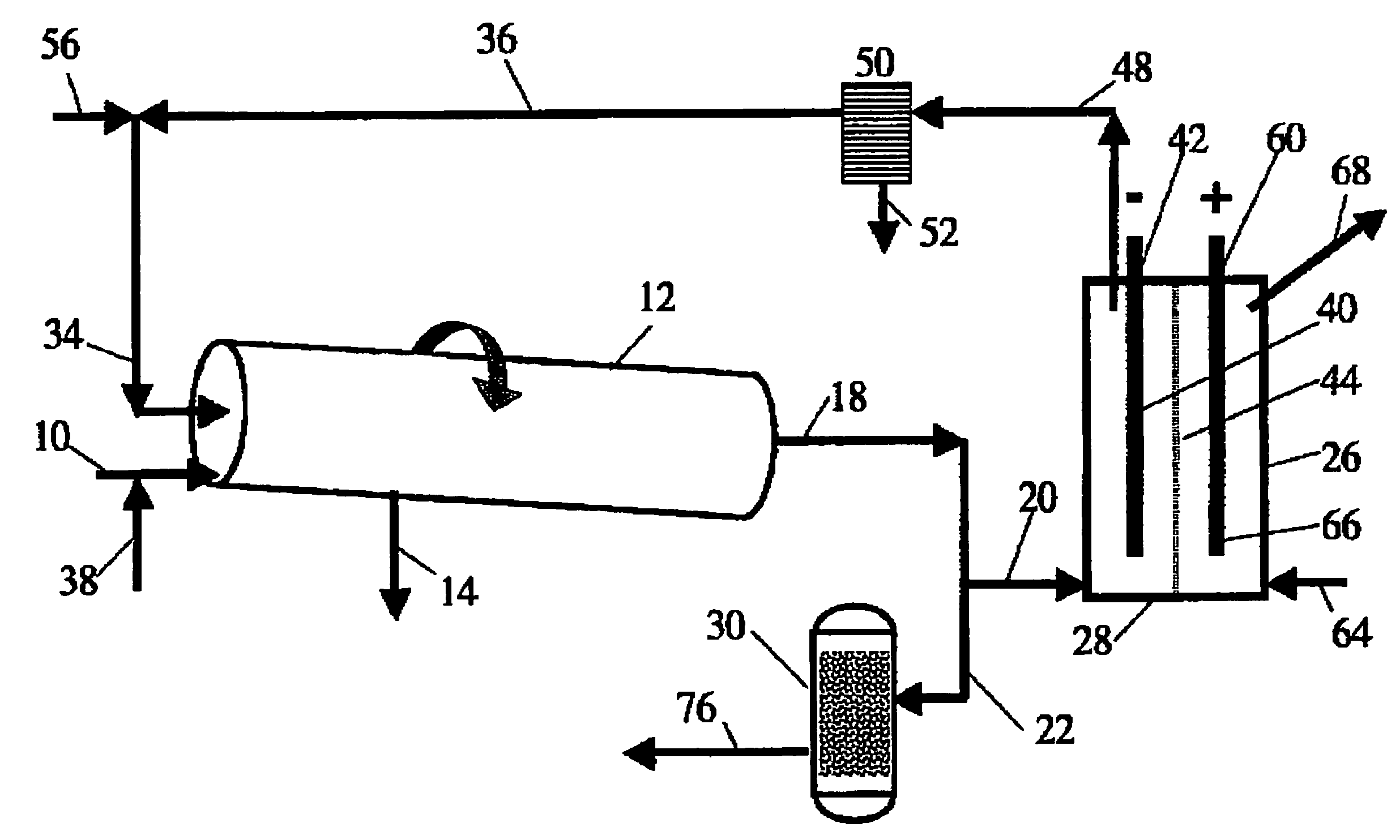

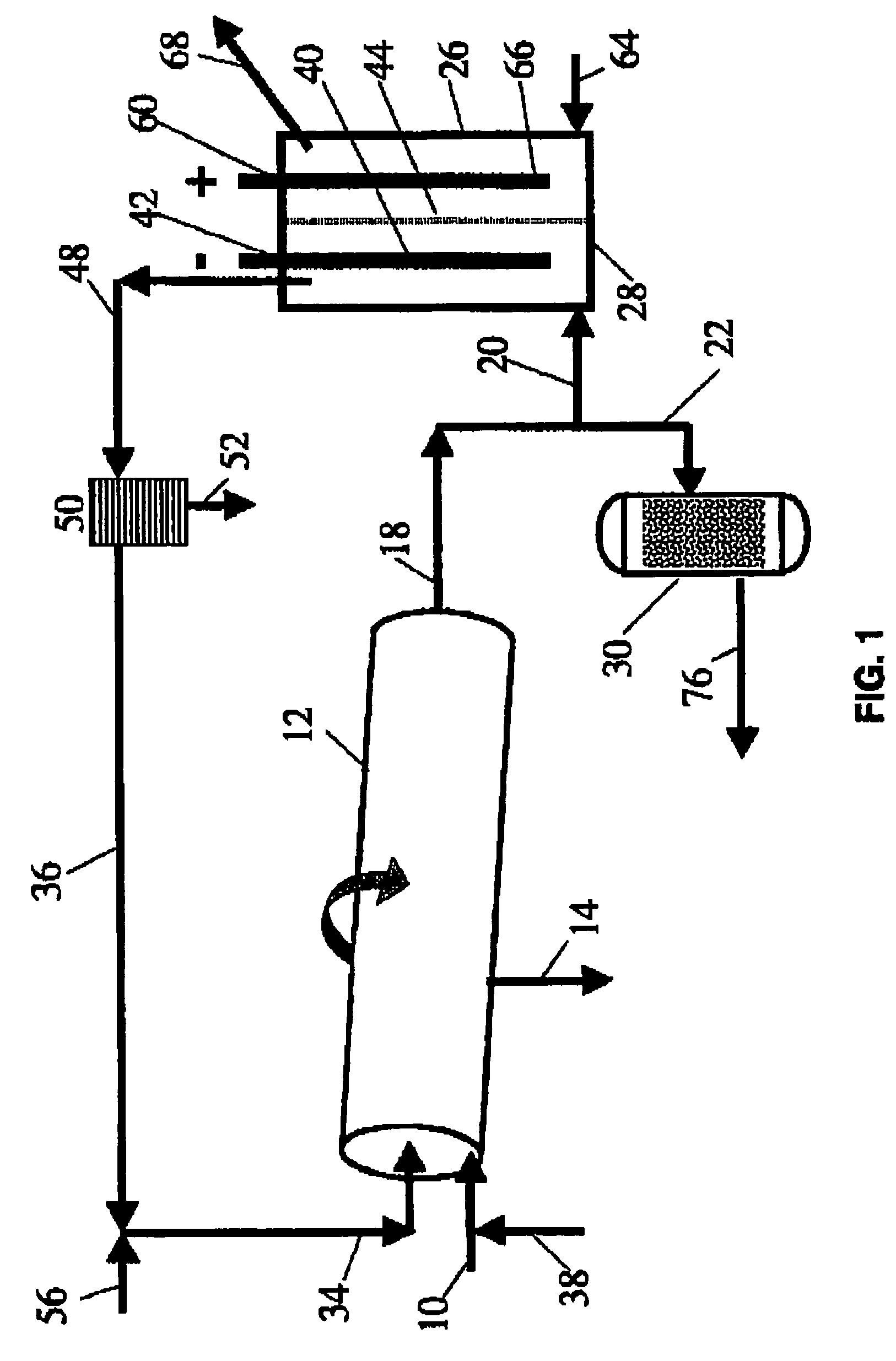

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

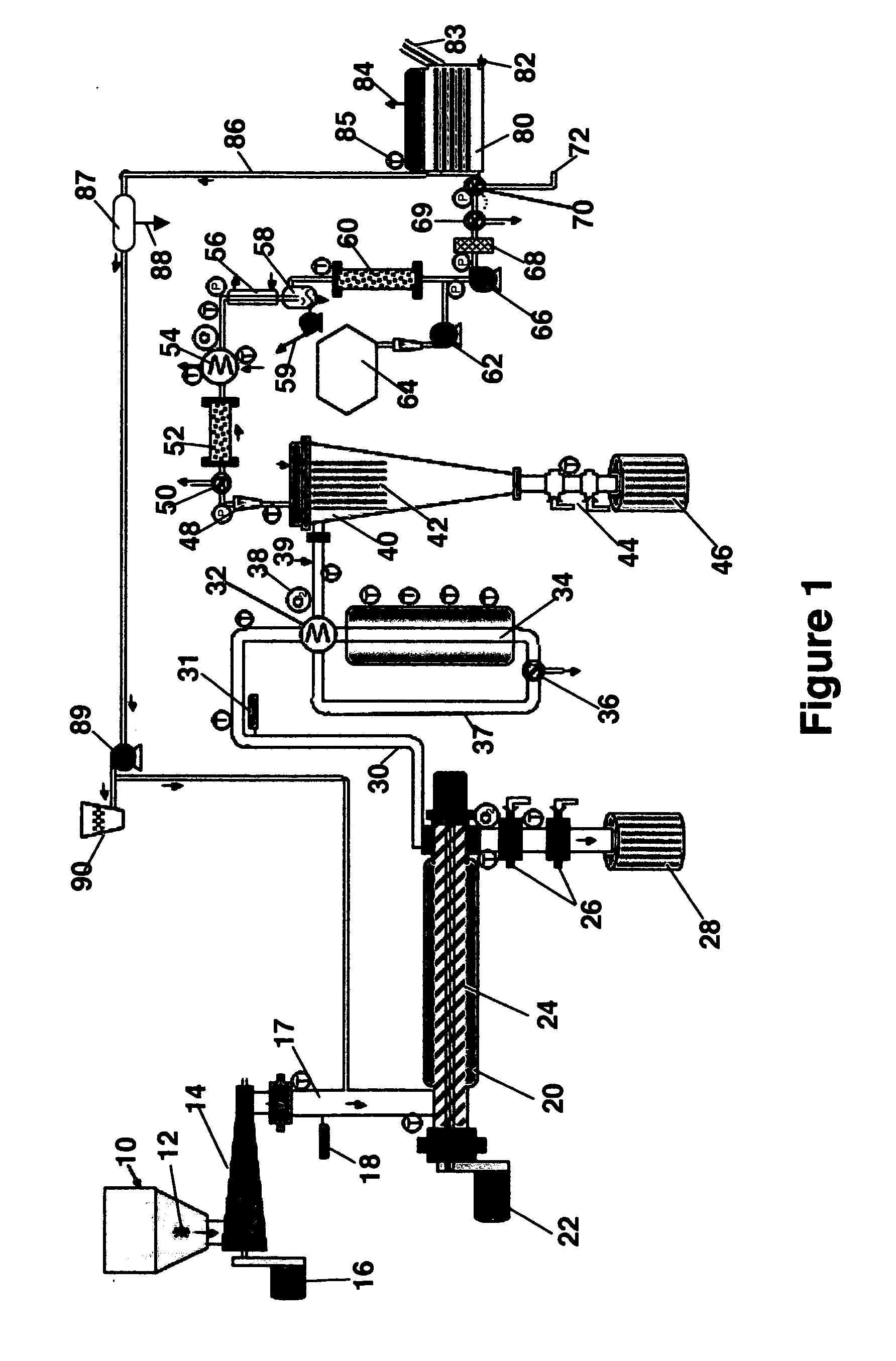

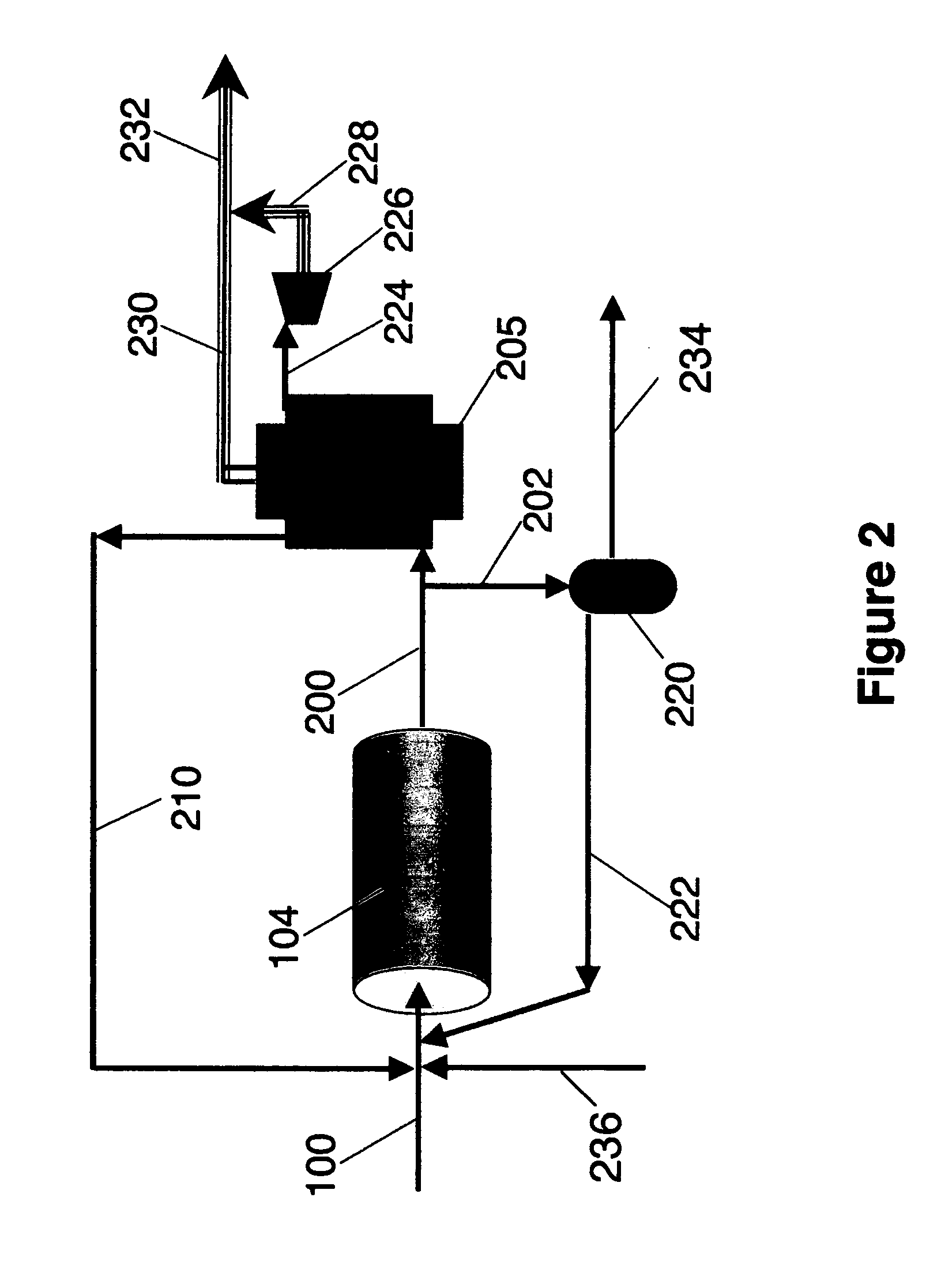

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

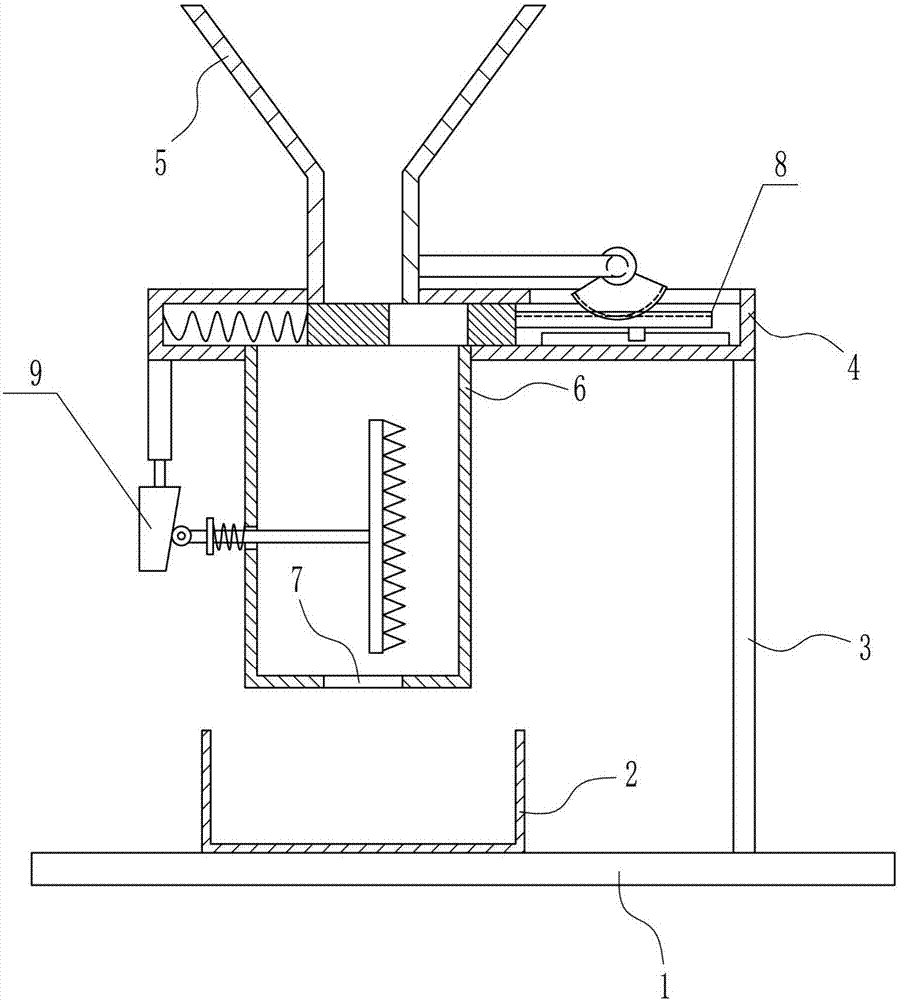

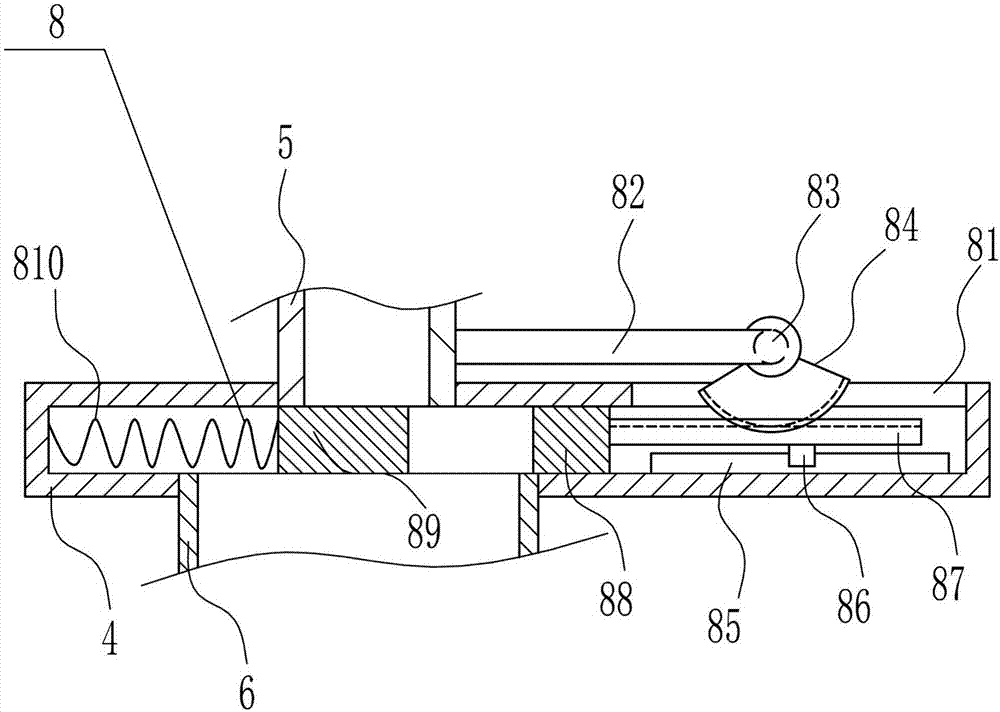

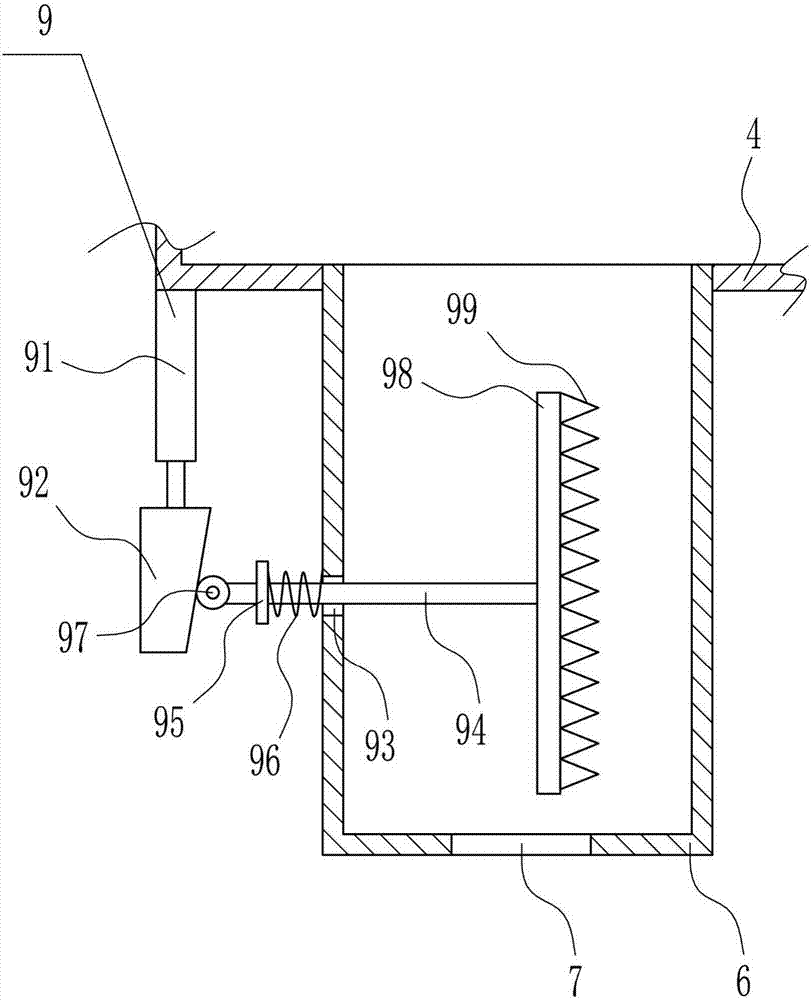

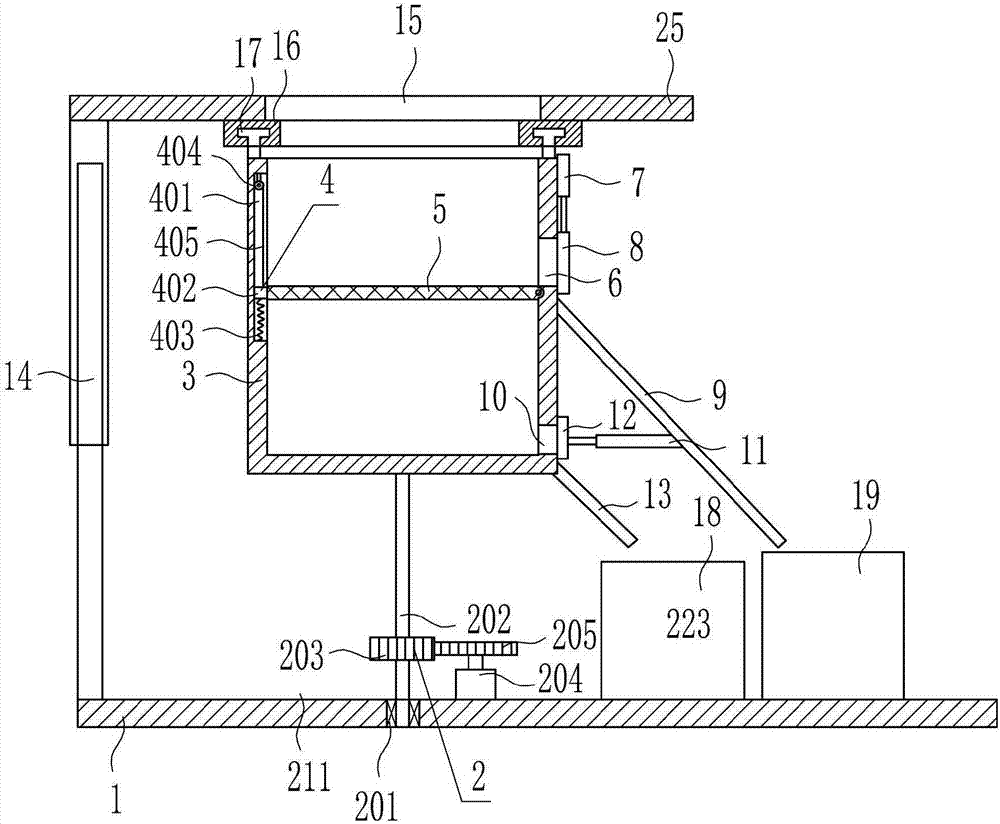

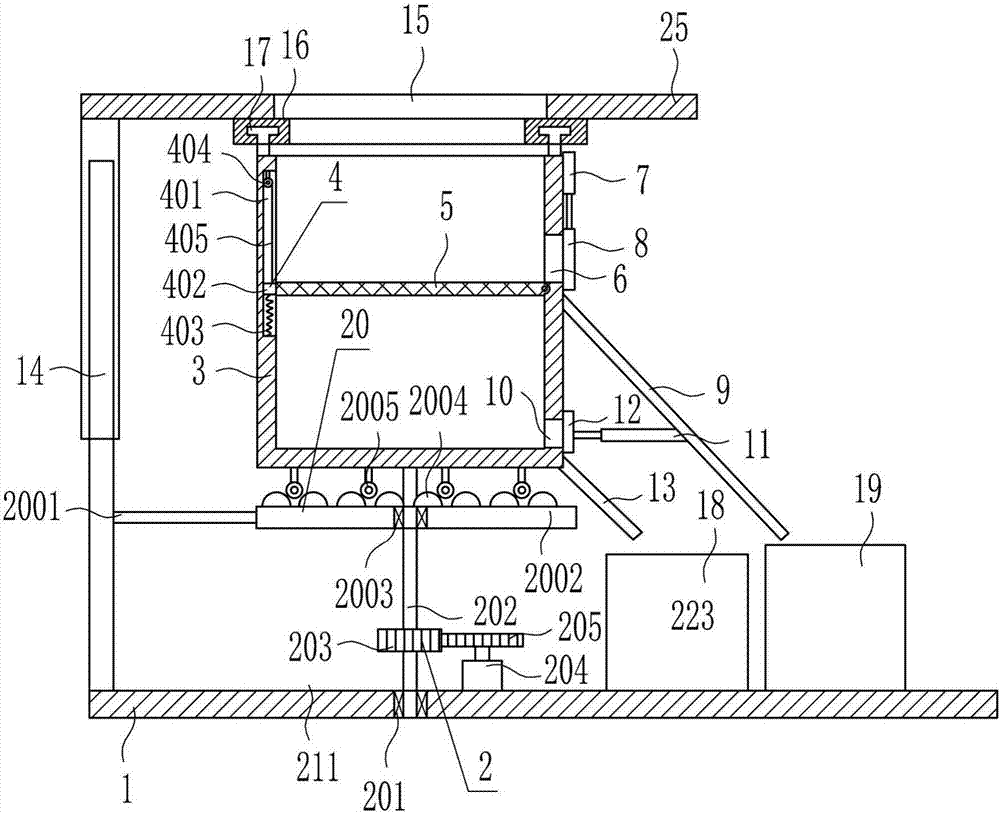

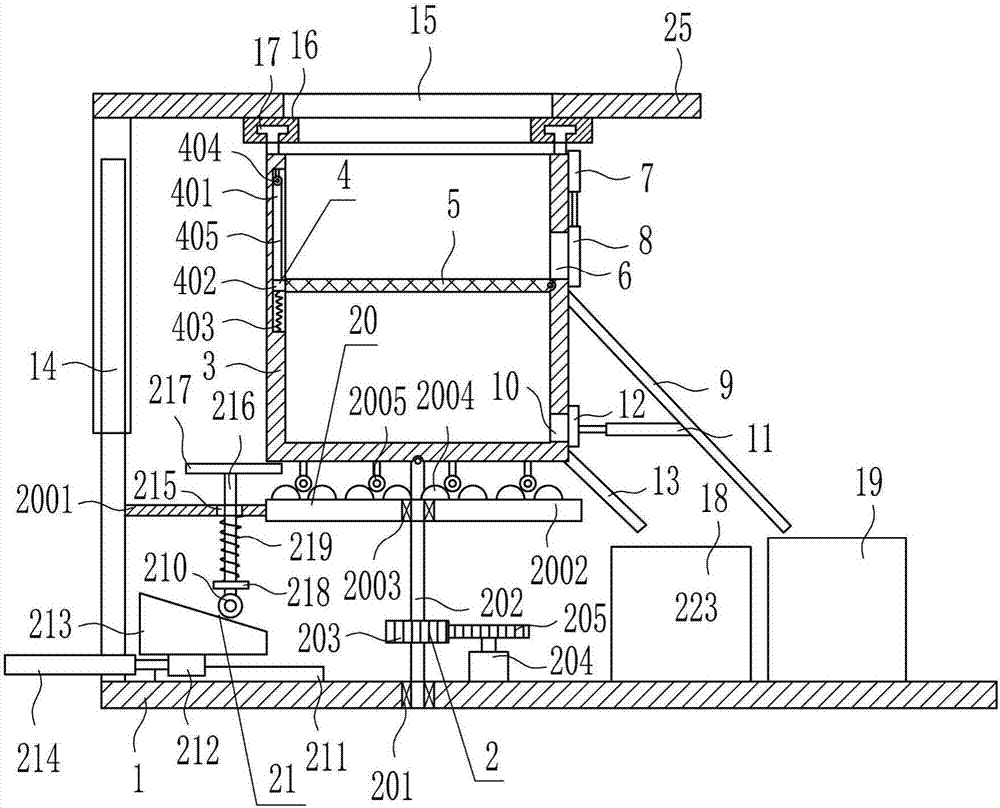

Crushing equipment special for petroleum coke and capable of achieving intermittent discharging

The invention relates to a crushing equipment for petroleum coke, in particular to a special crushing equipment for petroleum coke capable of intermittent feeding. The technical problem to be solved by the present invention is to provide a special petroleum coke crushing equipment capable of intermittent feeding, which is fast in crushing speed, high in working efficiency, not easy to be injured in the crushing process, and easy to operate. In order to solve the above technical problems, the present invention provides such a special crushing equipment for petroleum coke capable of intermittent feeding, which includes a bottom plate, a collection frame, a right side plate, a shell, a lower hopper, a crushing frame, etc.; the top of the bottom plate passes through The collection frame is installed by bolt connection, the right side plate is installed on the top right side of the bottom plate by bolt connection, the shell is installed on the top of the right plate by bolt connection, and an intermittent feeding device is installed in the shell. The present invention filters the petroleum coke dropped from the crushing frame through the filter frame, so that the petroleum coke that is not broken completely can be filtered in the filter frame.

Owner:冷国强

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7132183B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesGasification processes detailsWaste oilHigh pressure

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing hazardous waste, carbonaceous-containing medical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300–2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

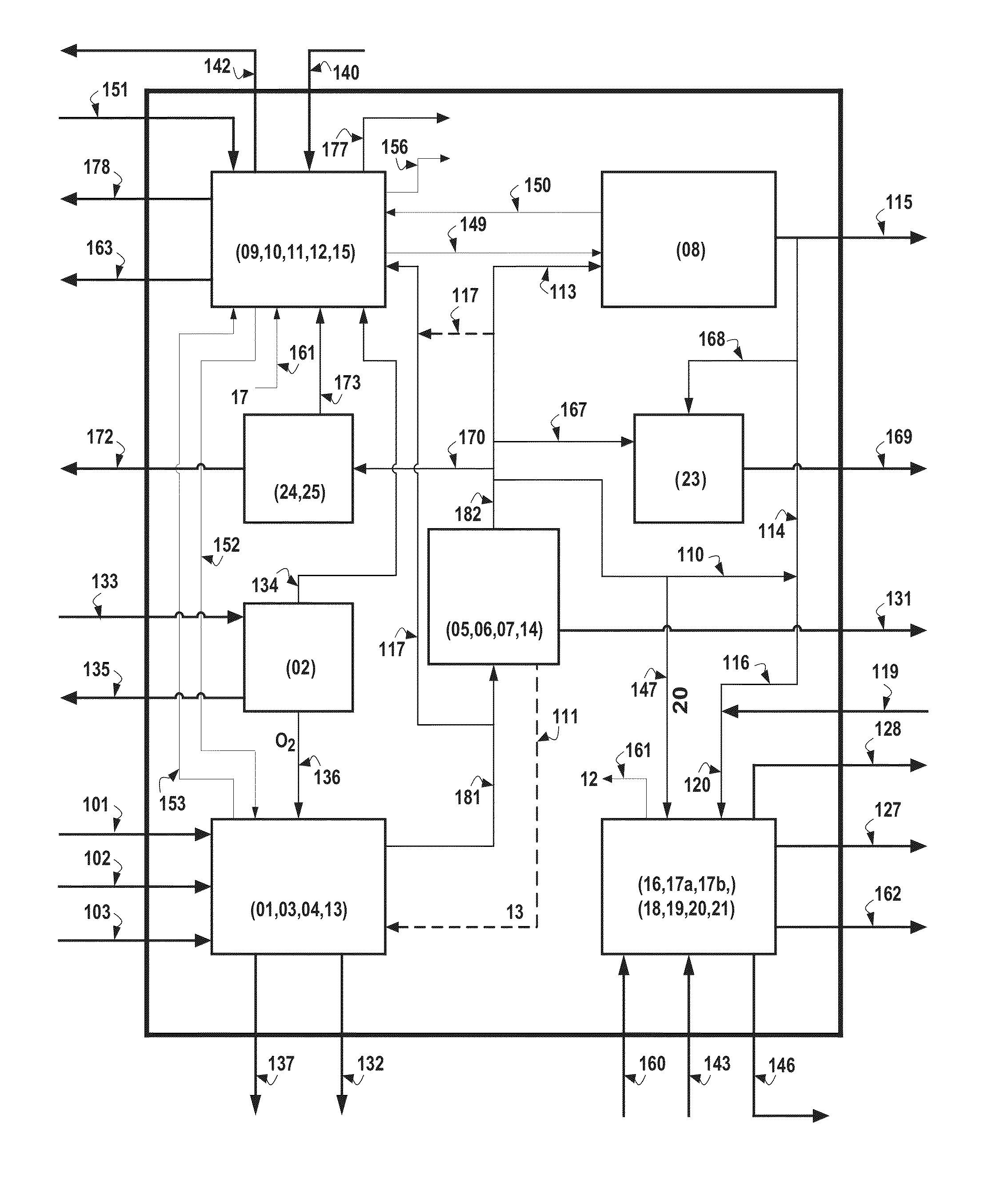

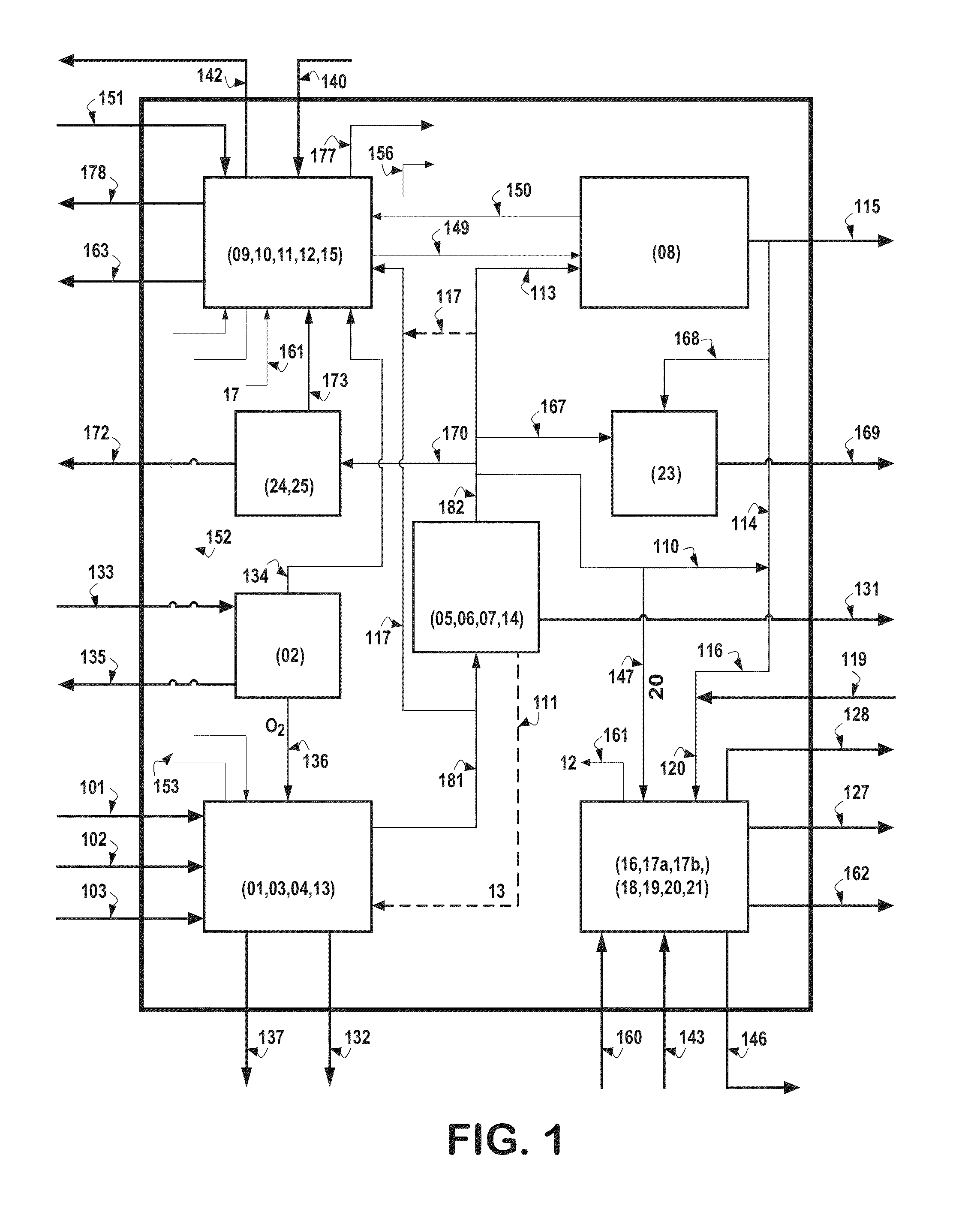

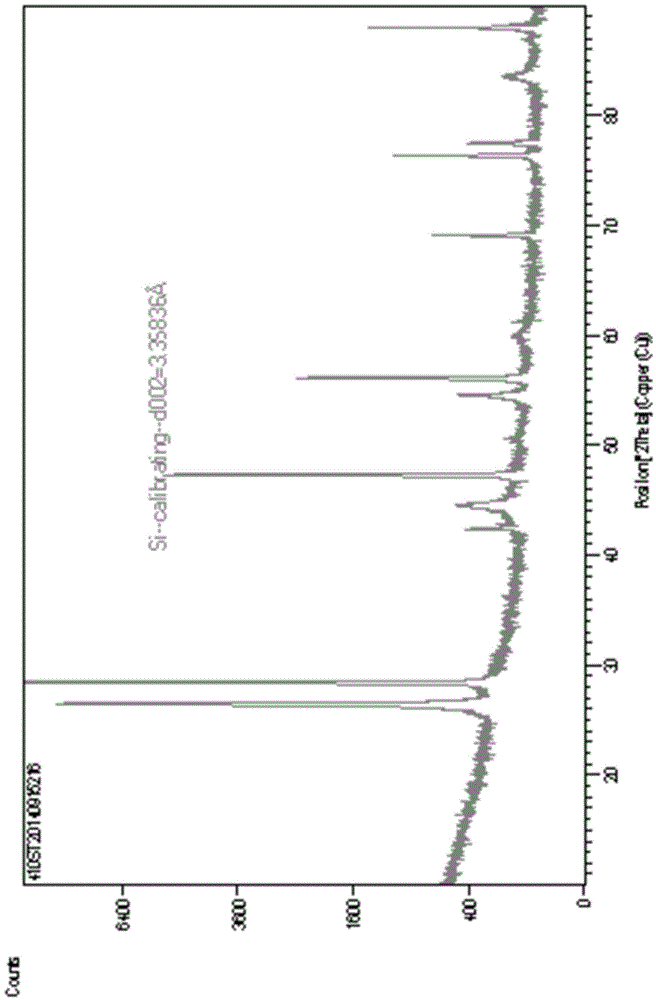

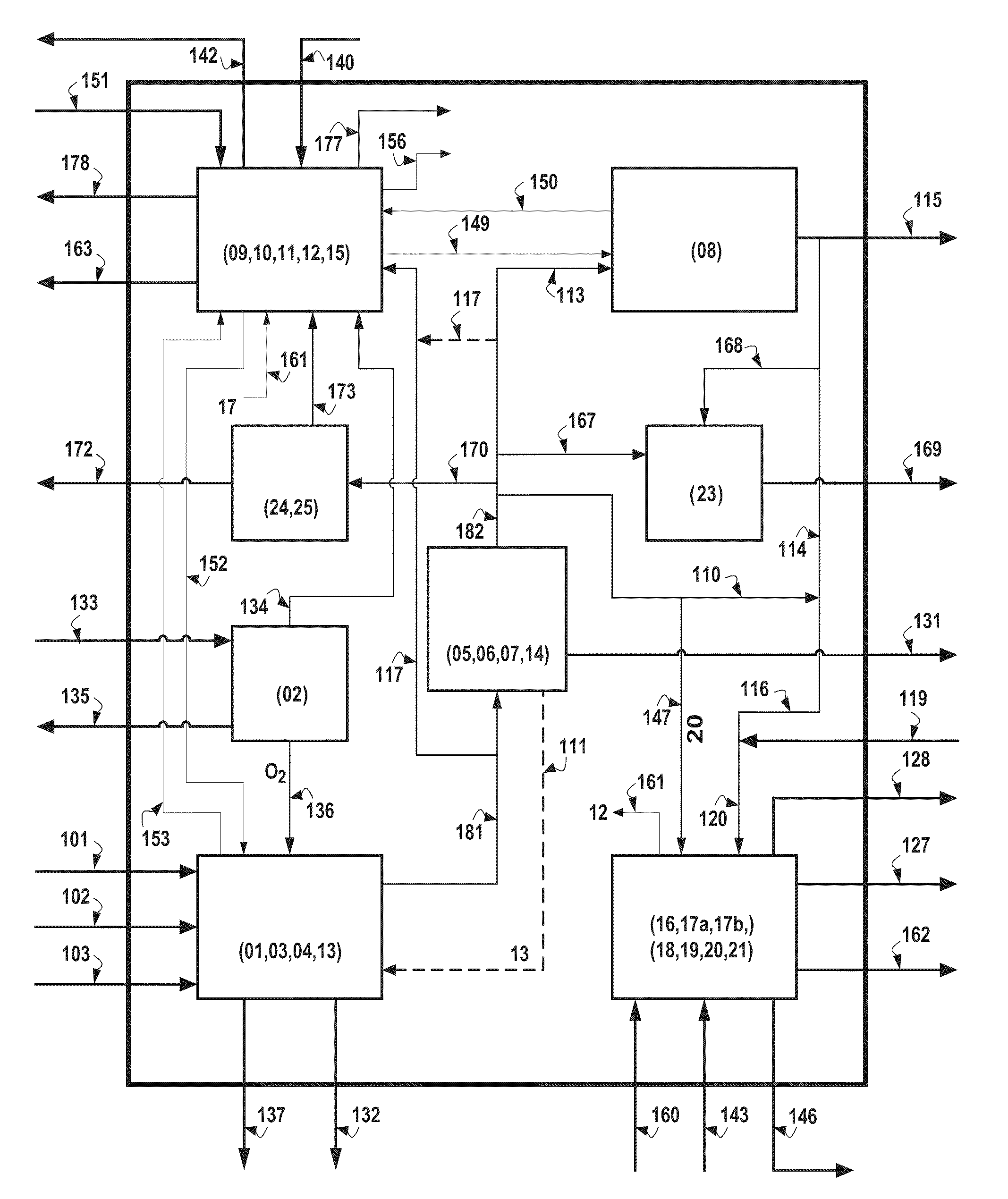

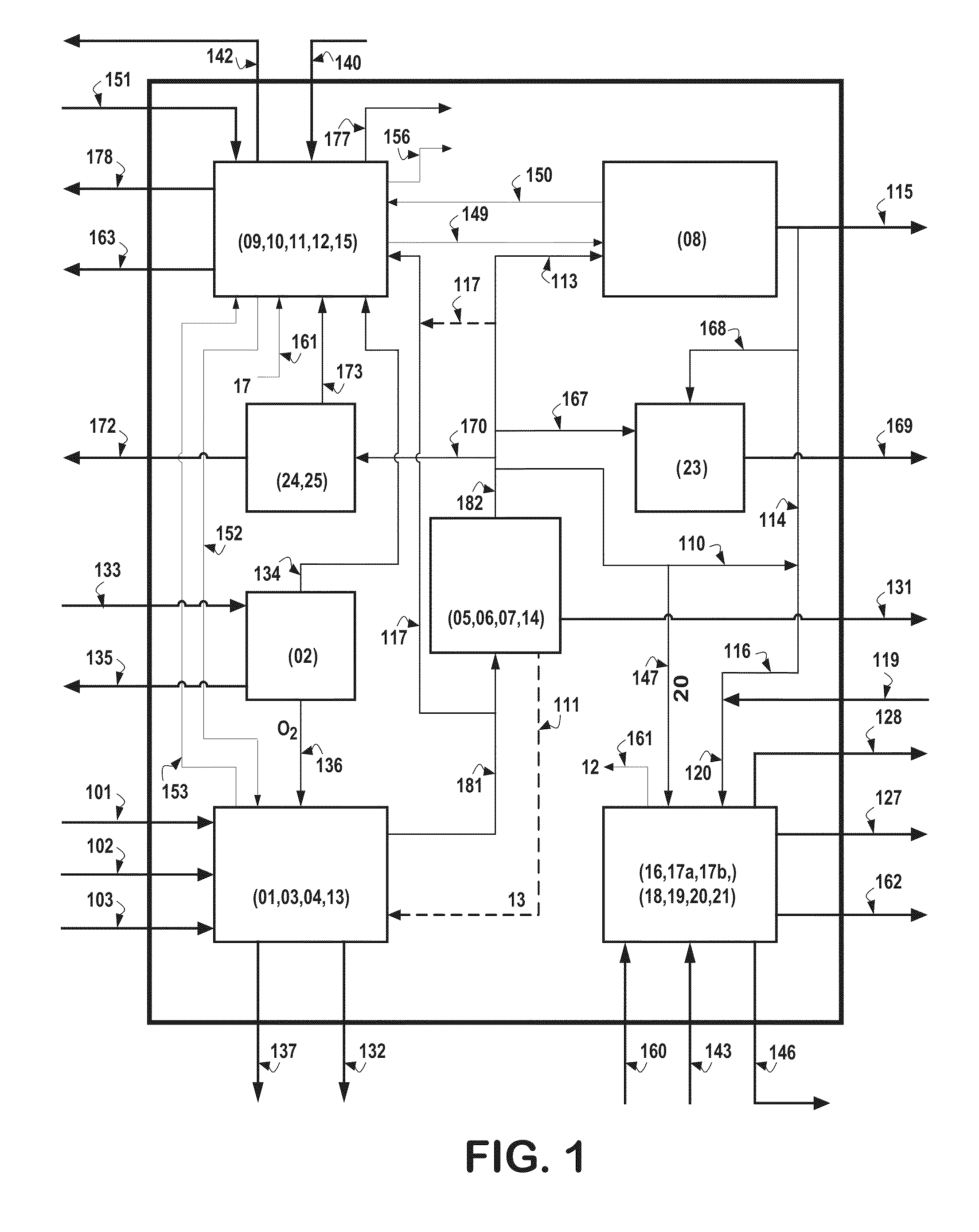

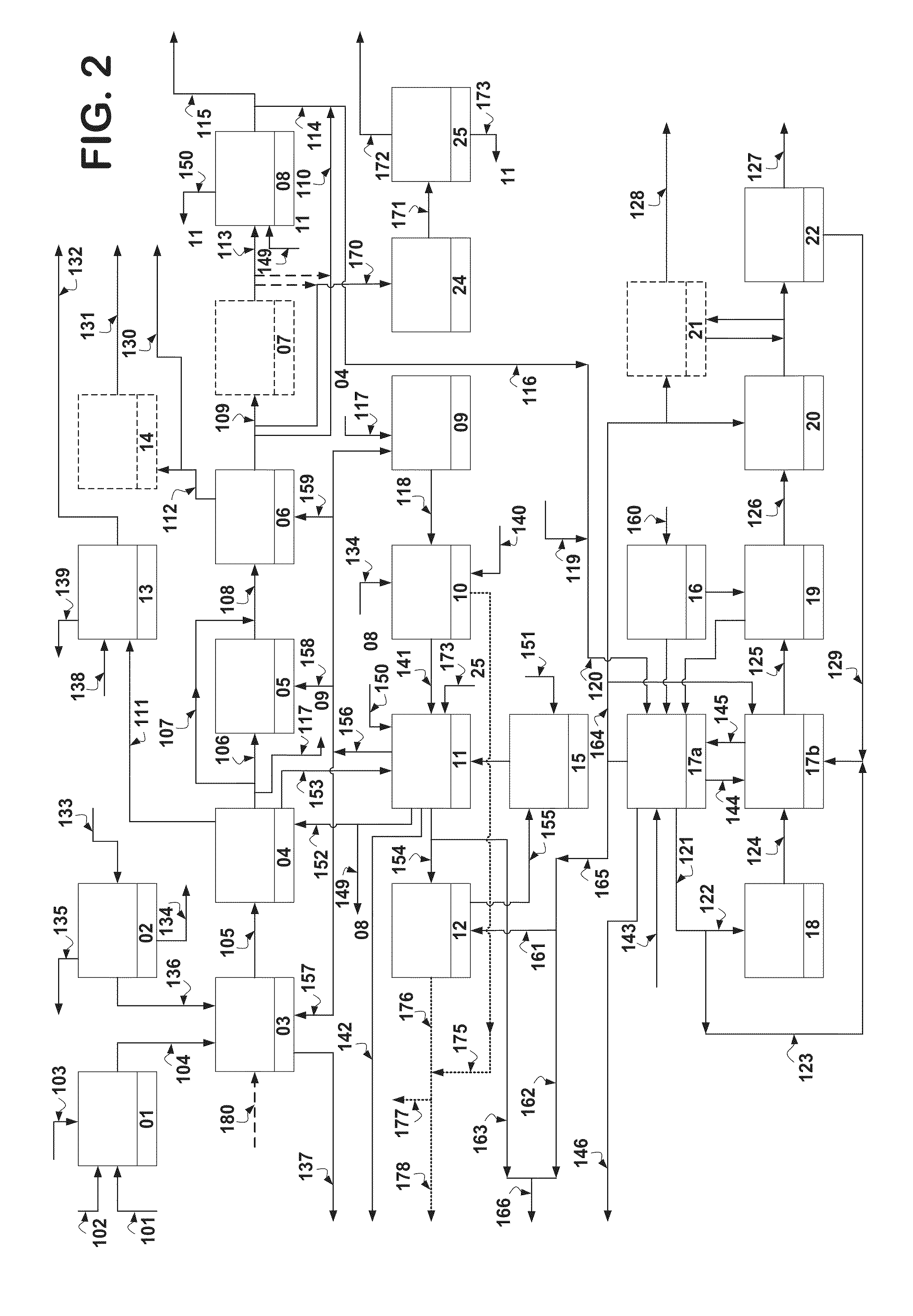

Gasification and steam methane reforming integrated polygeneration method and system

InactiveUS8409307B2Improve reliabilityMaximize reliabilityCombustible gas catalytic treatmentGas modification by gas mixingProcess engineeringPetroleum

This invention is a process and system for providing hydrogen at a high level of reliability from a gasification system by integrating it with SMR. Carbonaceous feedstock such as petroleum coke or coal or biomass is gasified to co-produce SNG, fuel gas, hydrogen, power and steam in conjunction with hydrogen production through steam methane reforming. Carbon dioxide may also be recovered in this process. The integrated schemes are designed in a way that maximizes the reliability of production of high value products such as hydrogen through gasification and minimizes the impact of high natural gas prices on hydrogen production by SMR.

Owner:PRAXAIR TECH INC

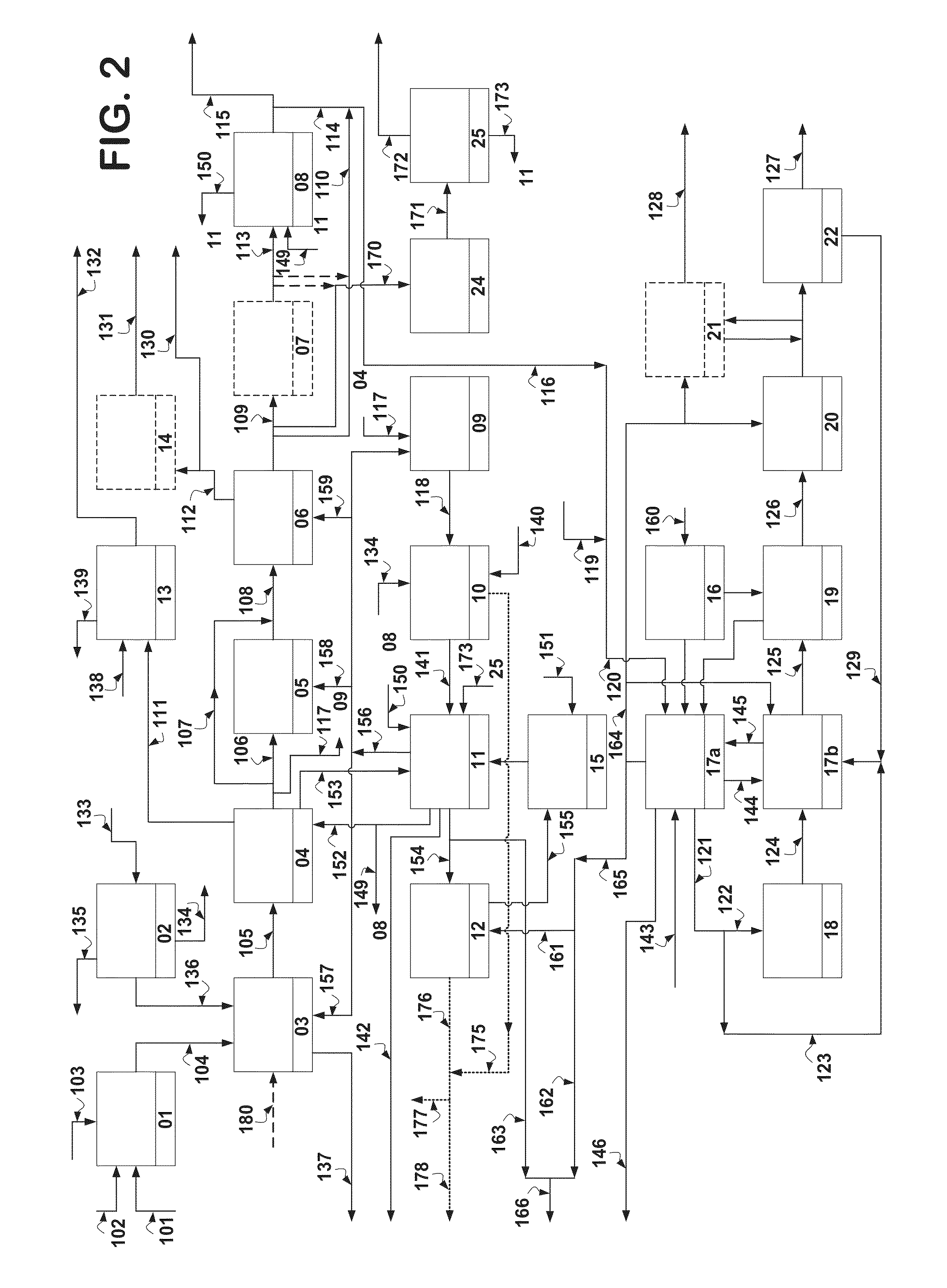

Preparation method of anode material for power lithium ion battery

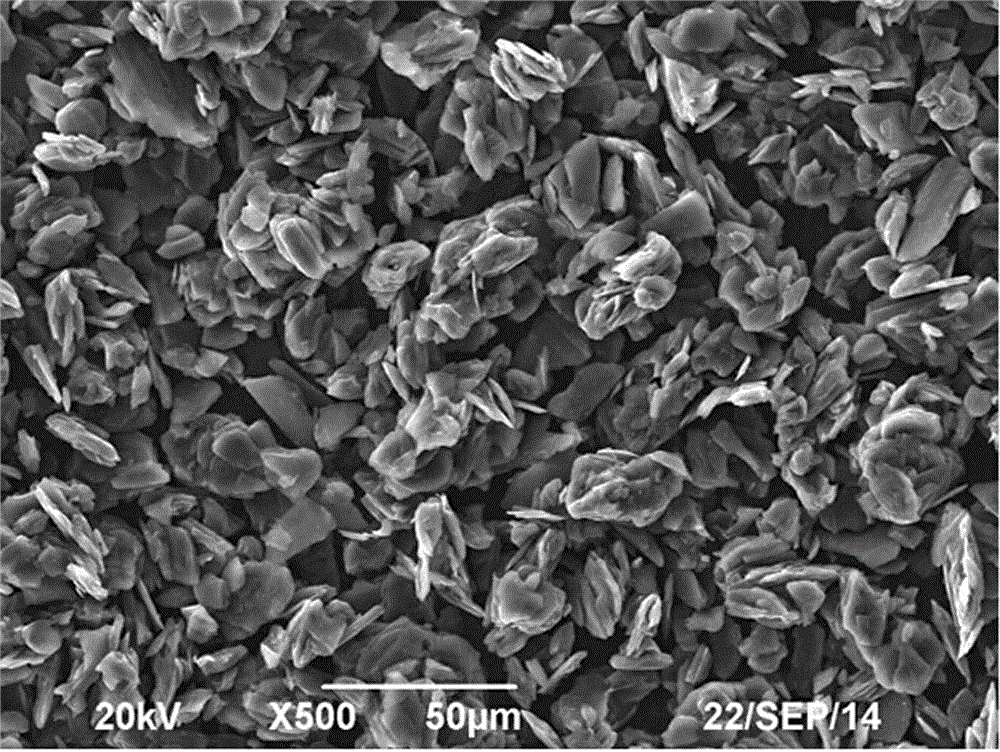

InactiveCN104659366AImprove electrochemical performanceIncrease capacityCell electrodesSecondary cellsCarbonizationDischarge rate

The invention discloses a preparation method of an anode material for a power lithium ion battery. The preparation method comprises the following steps: by adopting petroleum coke ground until the grain size is 1-6mu m, calcined petroleum coke or needle coke as a raw material, adding additives, adding a mixture to a reaction kettle to carry out first high-temperature carbonization coating under the protection of the inert atmosphere, then grinding the mixture with a grinder until the grain size is 5-13mu m, then carrying out superhigh-temperature graphitization at a temperature above 3200 DEG C, adding one or a mixture of petroleum asphalt, coal asphalt and resin to a material obtained after graphitization, and then enabling the mixture to enter a carburization furnace to undergo second coating under the protection of the inert atmosphere to obtain the anode material for the power lithium ion battery, namely a spheroidal artificial graphite material which is formed through bonding after being coated with granules and undergoes two-time coating and three-time high-temperature treatment. The preparation method has the advantages that the discharge rate property of the anode material is improved, the low temperature properties of the anode material are improved, and the latest requirements of the market for the product are further met.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

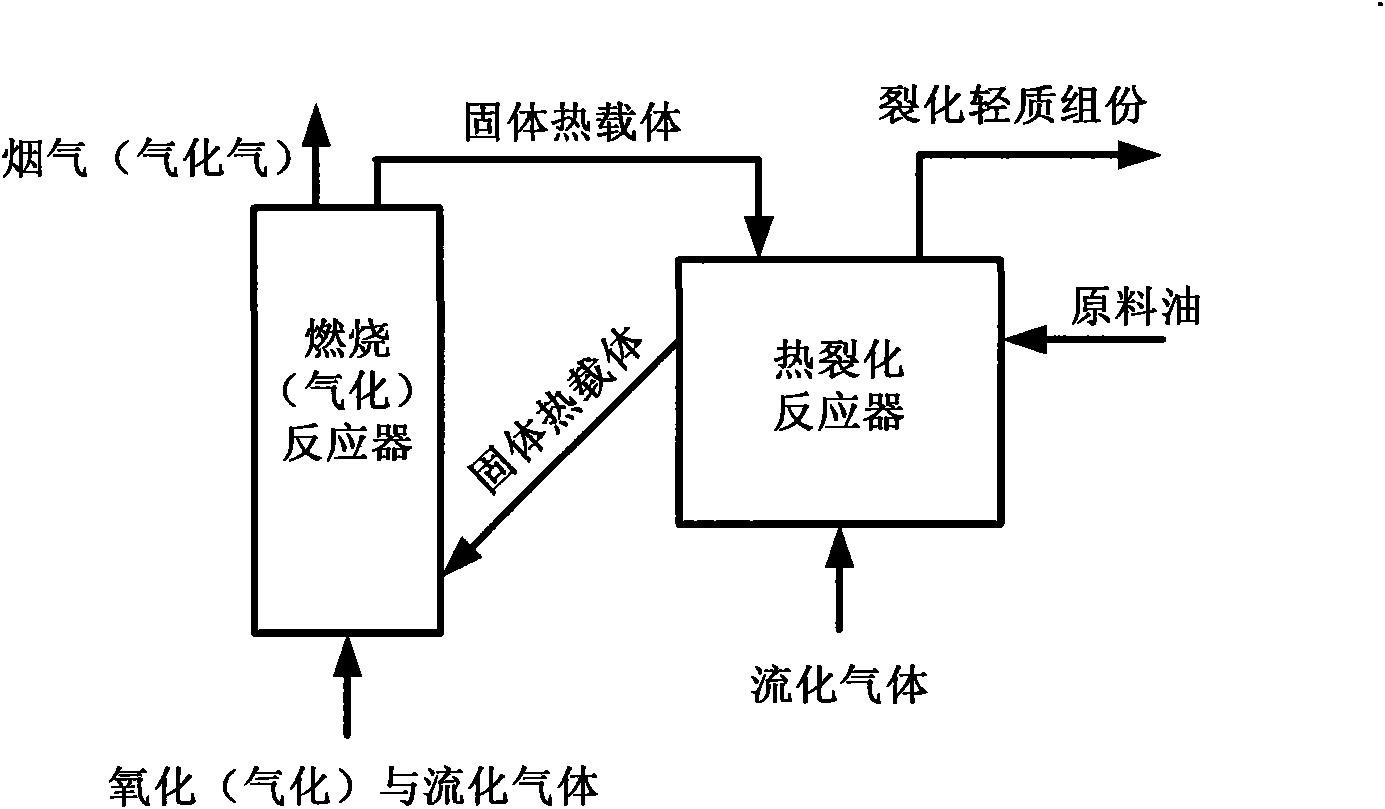

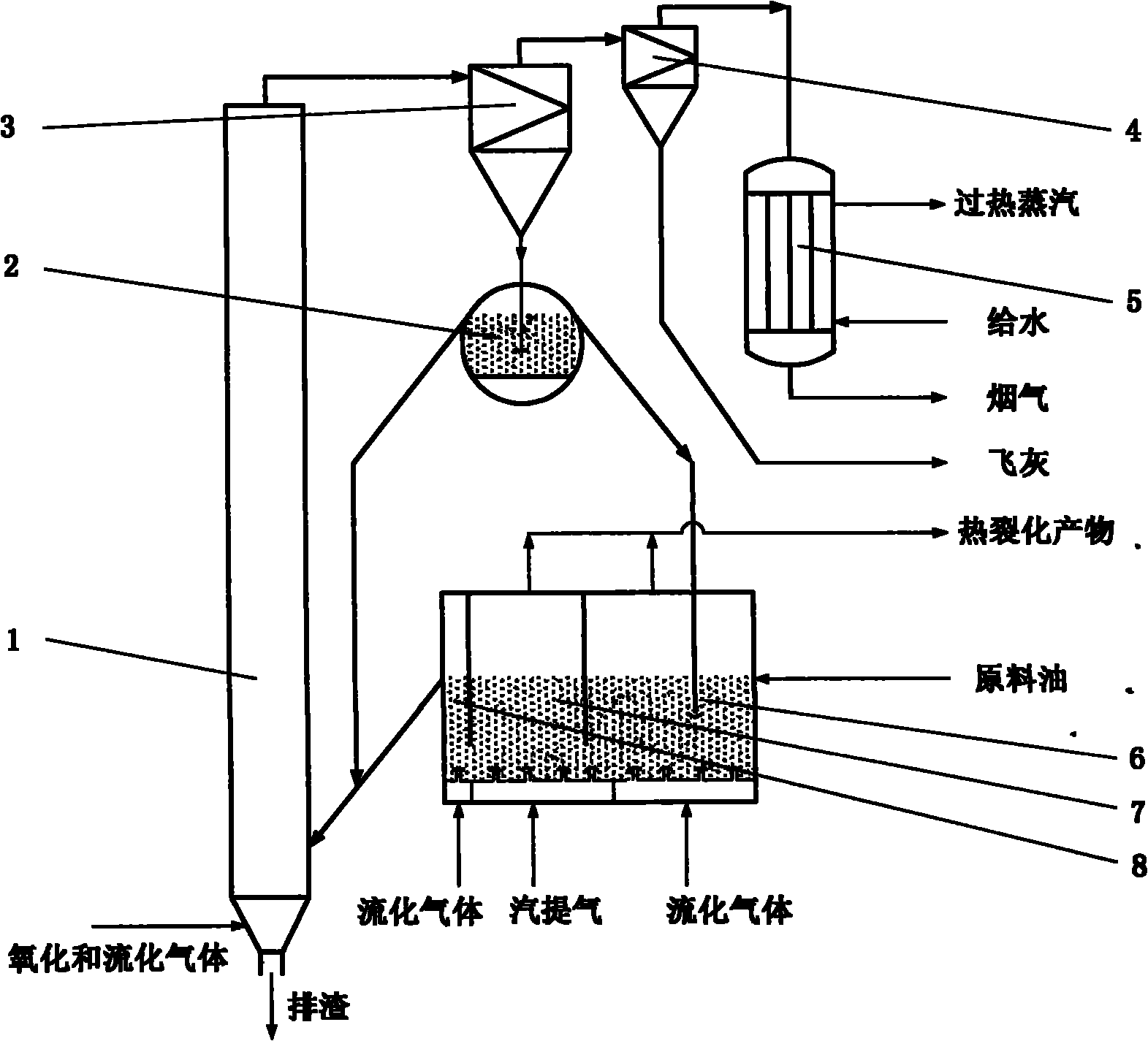

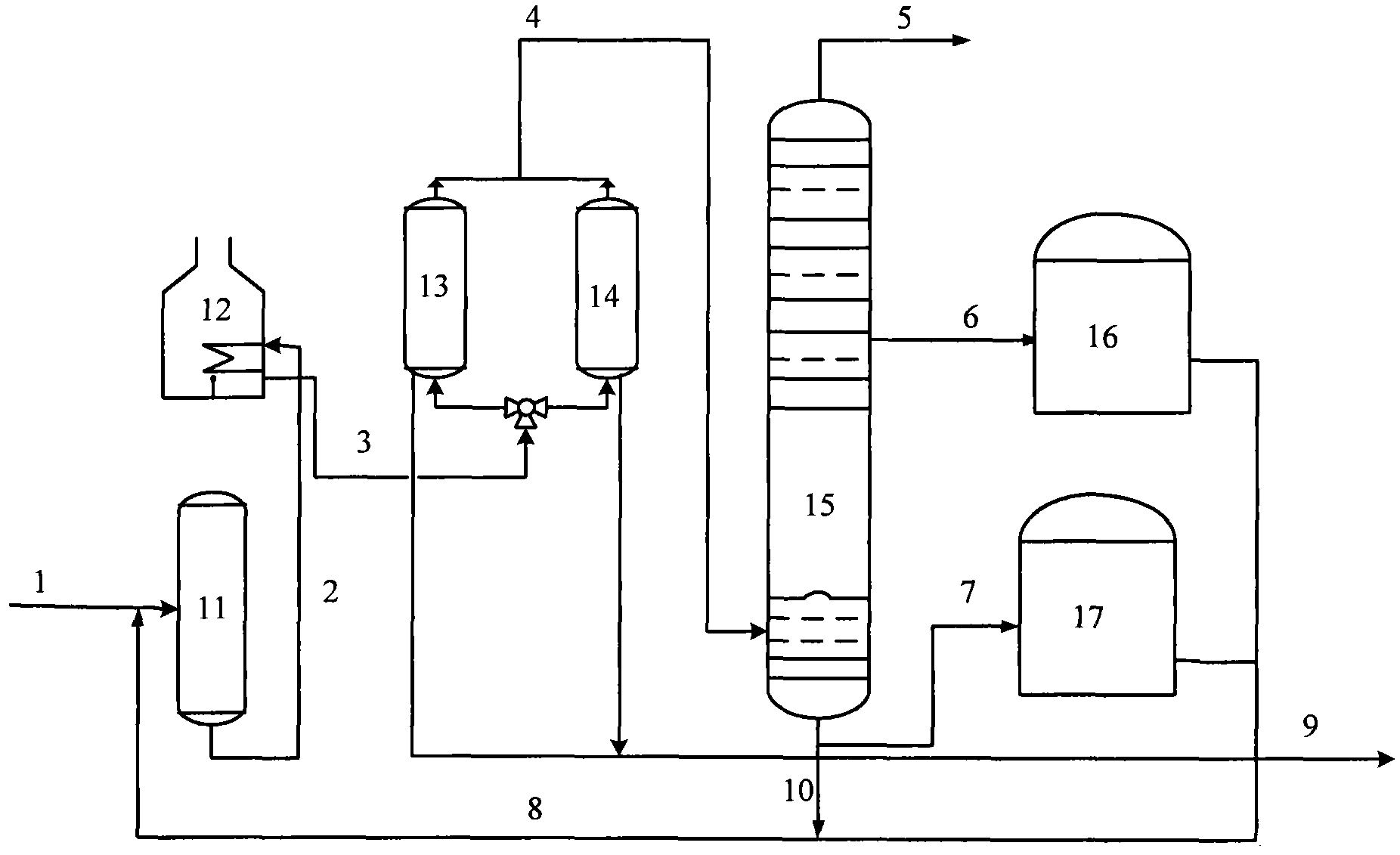

Heavy oil lightening method and device

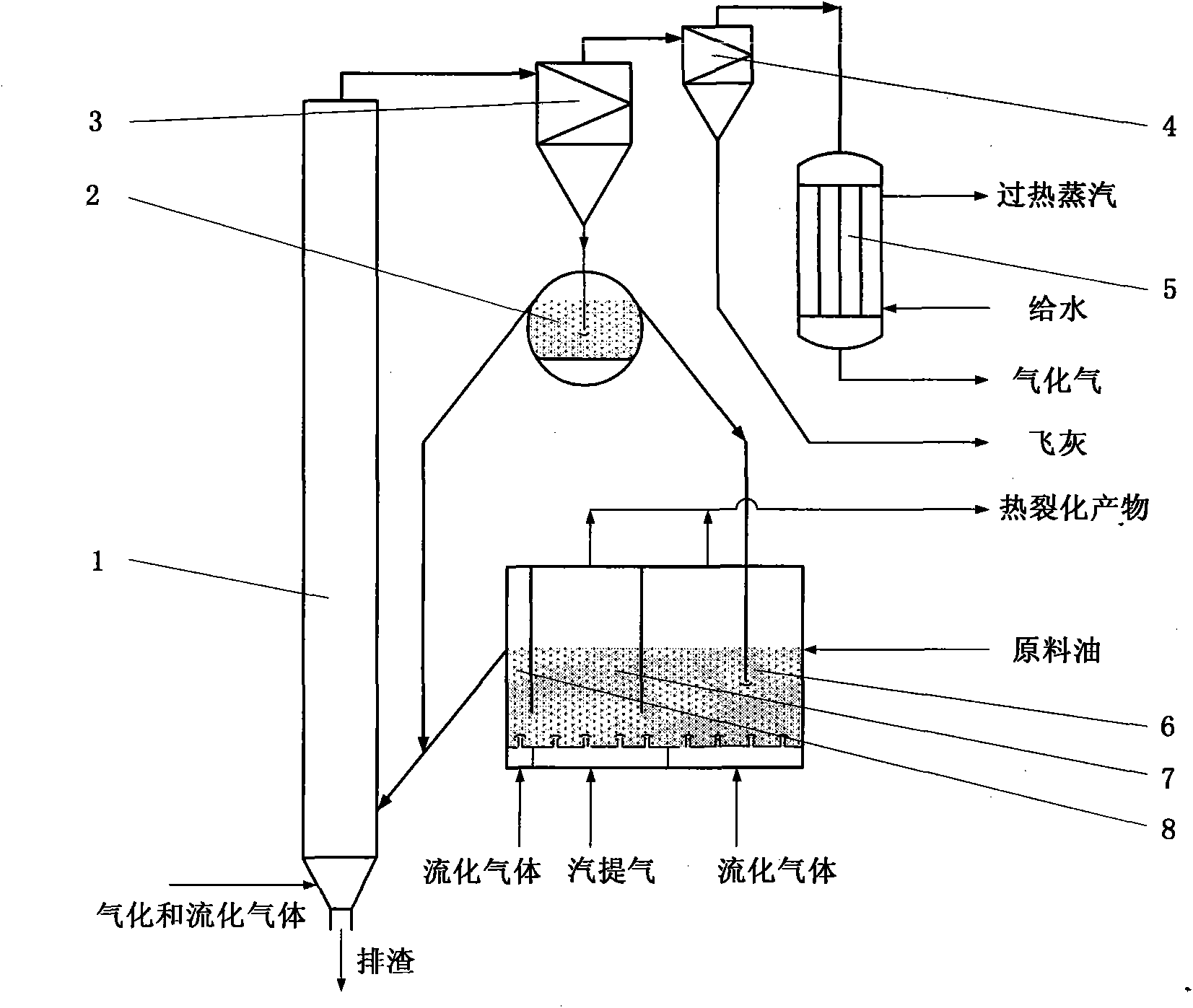

InactiveCN102115675AAchieve conversionEfficient conversionThermal non-catalytic crackingEnergy inputHeat carrierCombustion

The invention relates to a heavy oil lightening method and technique. The method comprises steps as follows: raw oil is introduced into a thermal cracking reactor through a feed system, and mixed with a high-temperature solid heat carrier from a combustion (gasifying) reactor, so that the raw oil is subjected to fluidizing heat exchange with the solid heat carrier and carries out thermal cracking reaction on the surface of the solid heat carrier; the cracking gas generated by the thermal cracking reaction and a light component product are subjected to steam stripping by fluidizing medium gas and enter a subsequent absorption and stabilization system and a purification and separation system, heavy coke (petroleum coke) is attached to the surface of the solid heat carrier and enters the combustion (gasifying) reactor via a material returning valve, and an oxidizing (gasifying) and fluidizing gas is introduced to realize combustion (gasifying) reaction in the fluidization elevation process of the petroleum coke; and after the reaction product (fume or gasified gas) and the solid heat carrier are separated by a gas-solid separator, the fume (gasified gas) is led into a waste heat recovery system and a gas purification system, the high-temperature solid heat carrier is distributed by a distribution valve and respectively enters the thermal cracking reactor and the combustion (gasifying) reactor for cyclic use, and the collected fly ash can be used after further processing, thereby complete high-value conversion and use of the heavy oil.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

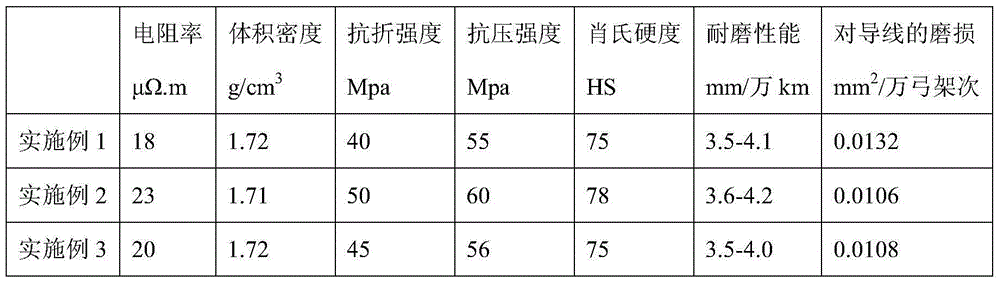

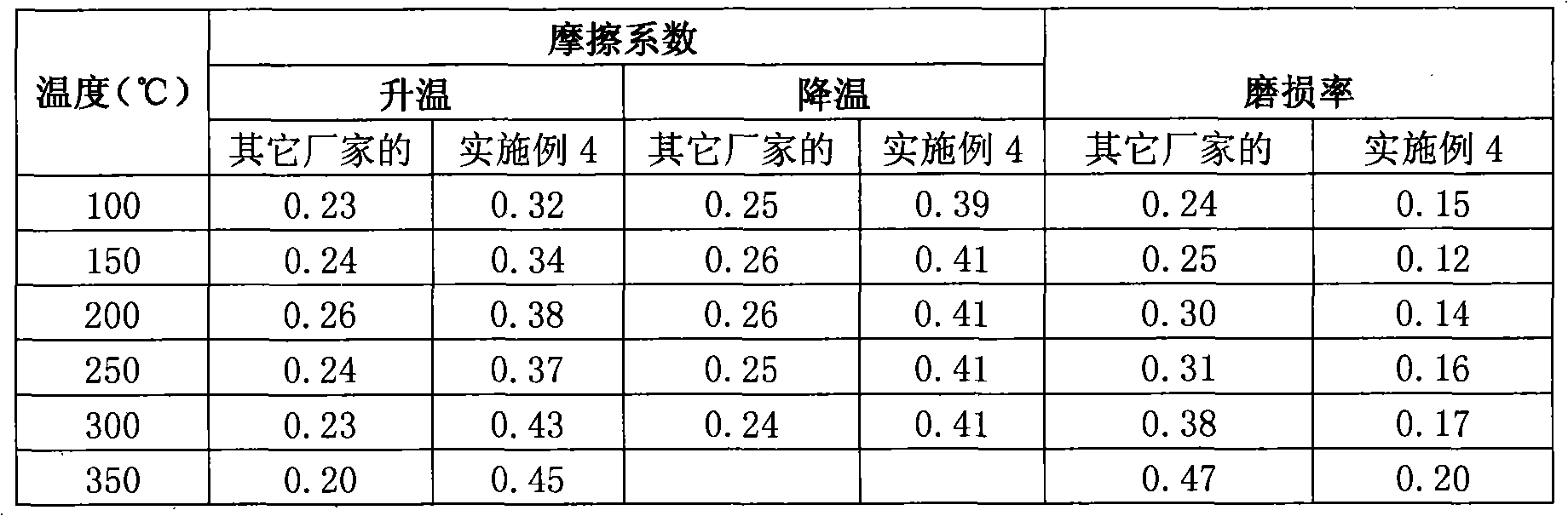

Carbon contact strip of pantograph and manufacturing method thereof

The invention discloses a carbon contact strip of a pantograph and a manufacturing method thereof. The carbon contact strip is prepared from following raw materials, by weight, 28-43 parts of petroleum coke powder, 25-28 parts of asphalt coke powder, 10-12 parts of sprayed carbon black, 2-5 parts of sulfur, 3-5 parts of boron nitride, 5-8 parts of carbon fiber, 4-6 parts of natural graphite, 5-7 parts of artificial graphite, 1-3 parts of calcium chloride powder and 30-35 parts of modified asphalt. The carbon contact strip is high in mechanical strength, is good in self-lubricating performance and electric arc resistance and is wear-resistant. The carbon contact strip can be not only used in various locomotives in railway main lines with speed per hour being 120-250 km / h, but also used in motor train units and high-speed trains with speed per hour being higher than 250 km / h. The carbon contact strip is free of limit of environment and climate conditions.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

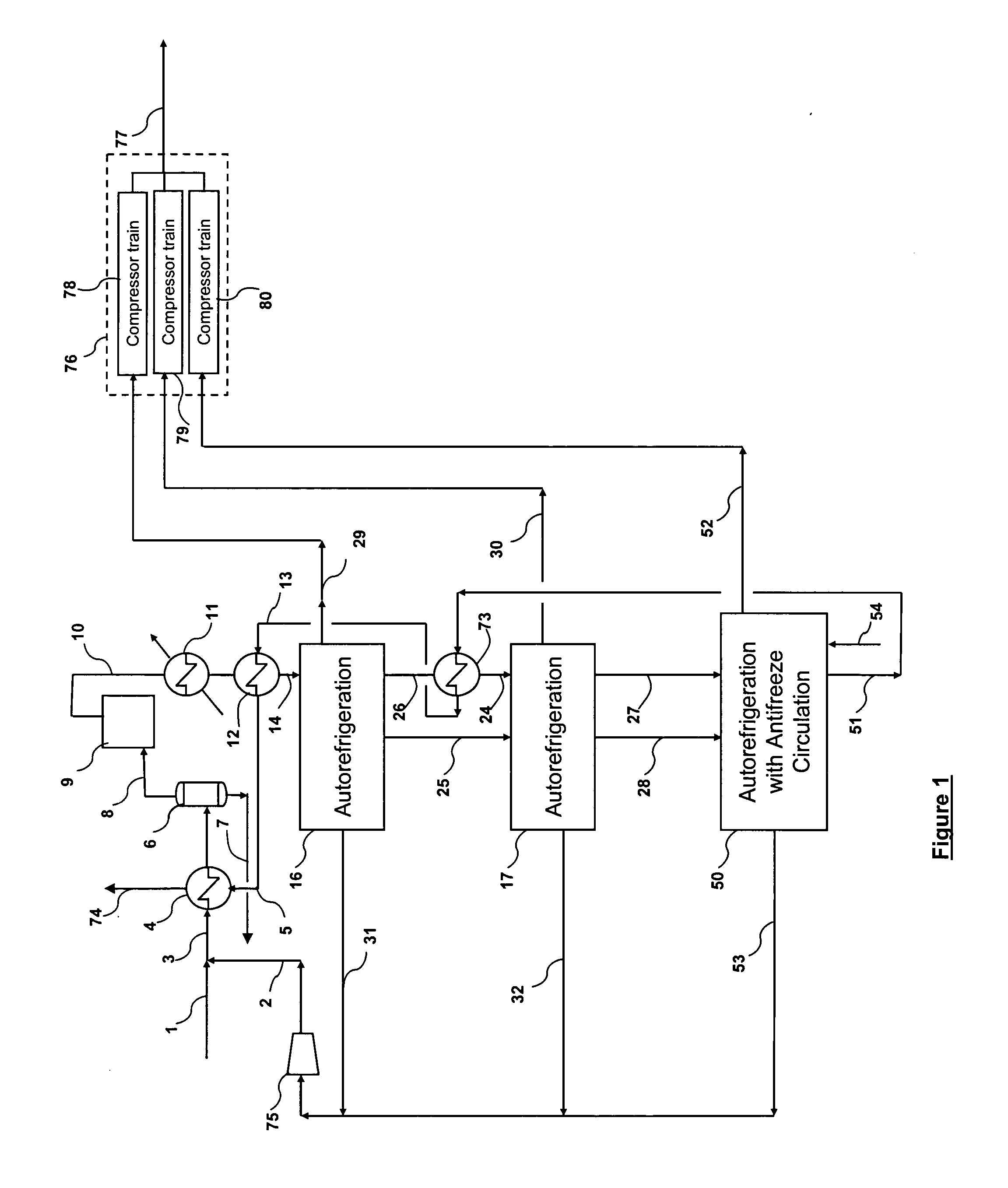

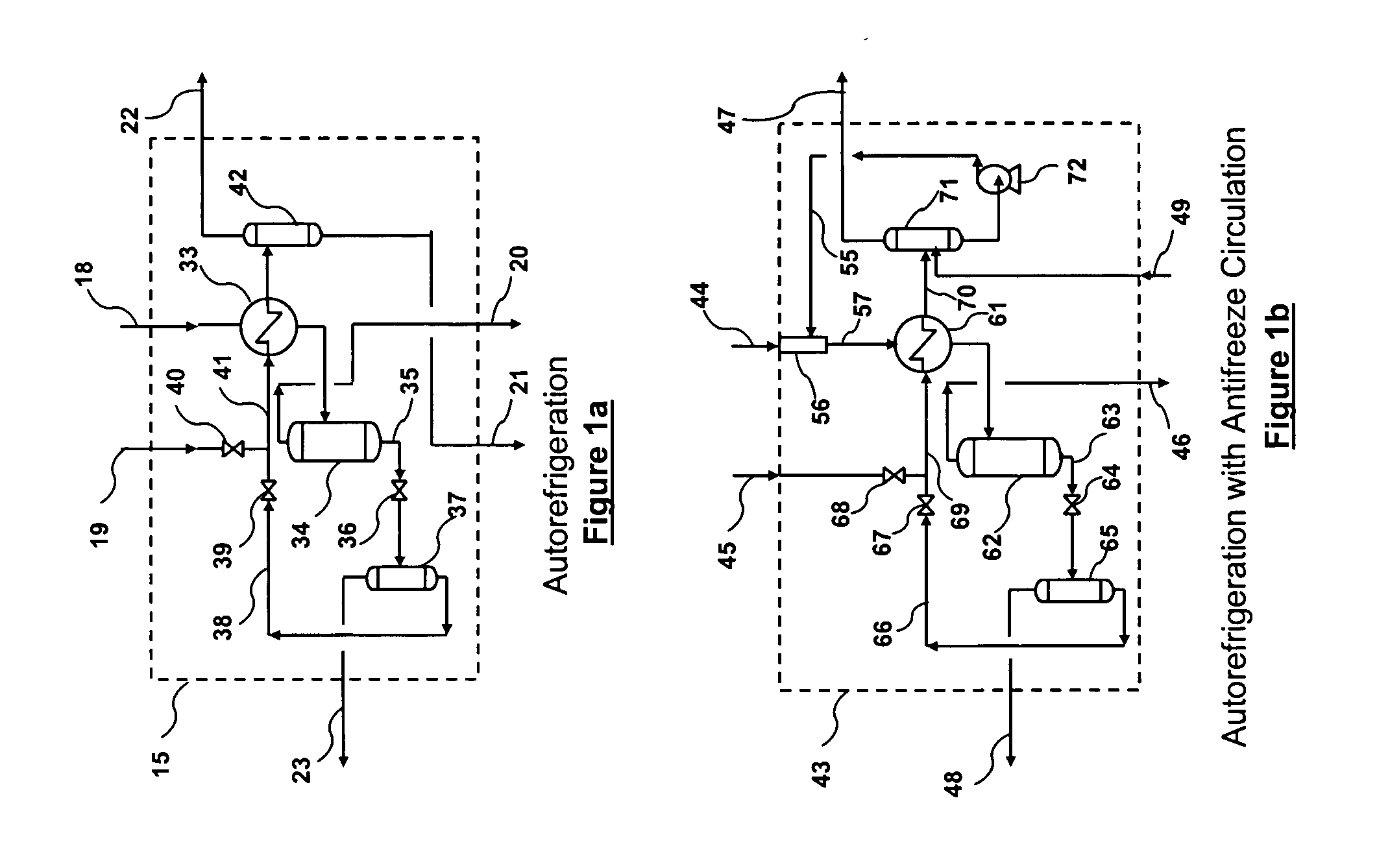

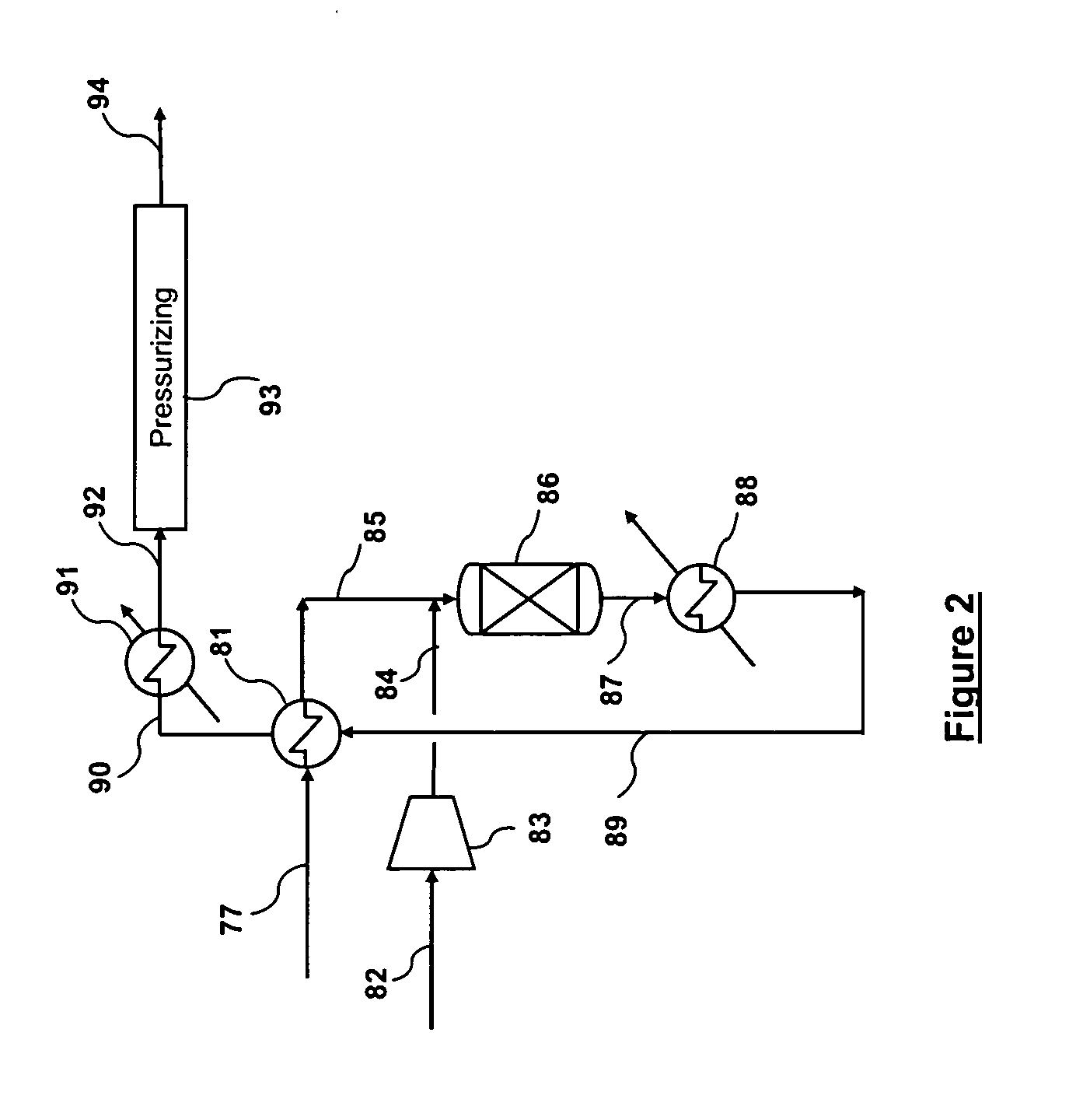

Multi-stage cryogenic acid gas removal

InactiveUS20070221541A1Alleviate power needsIncrease the number ofSolidificationLiquefactionPetroleumPetroleum coke

A relatively simple and energy efficient multiple stage cryogenic process for the purification of a hydrogen-rich stream by the removal of acid gases, mainly CO2 and H2S, by method of autorefrigeration and delivering or producing those acid gases, mainly CO2, at pressure sufficiently high for disposal by containment, commonly known as sequestration. Autorefrigeration is comprised of (a) condensing acid gases from the syngas stream by cooling the syngas, (b) separating the liquefied acid gases from the syngas, and (c) evaporating the liquefied acid gases at a pressure lower than that of the syngas to provide cooling. The process is composed of multiple autorefrigeration stages to generate multiple acid gas product streams with a pressure as high as practical in each stream so as to lessen the power needed to pressurize the acid gas streams for sequestration. The final autorefrigeration stage utilizes an antifreeze liquid that allows the final stage to operate below the freezing point of CO2; thus allowing more acid gas removal. The antifreeze liquid is an alcohol or a mixture of alcohols with a freezing point lower than about minus 110 degrees F. and a boiling point higher than about 100 degrees F. The process includes hydrogen recovery and recycle as well as recovery of the energy contained in the sulfur bearing compounds. The process is especially well suited for CO2 removal / sequestration from a coal (or petroleum coke) gasification process.

Owner:TENNESSEE VALLEY AUTHORITY

Method and device for producing synthesis gases by partial oxidation of slurries prepared from fuels containing ash and full quenching of the crude gas

ActiveUS20070062117A1Improve usabilityGuaranteed uptimeMuffle furnacesGasifier mechanical detailsPartial oxidationSlurry

A method and device for the gasification of solid fuels such as bituminous coals, and cokes such as those from bituminous coals, lignite coals, and biomasses, as well as petroleum cokes, that are ground fine and mixed with water or oil to obtain fuel-in-liquid suspensions, so-called slurries, and their gasification together with an oxidizing medium containing free oxygen, by partial oxidation at pressures between atmospheric pressure and 100 bar, and at temperatures between 1200 and 1900° C. in an entrained flow reactor. The method includes slurry preparation and infeed to the reactor, gasification in an entrained flow reactor with cooled reaction chamber contour, full quenching of the crude gas to saturation temperature that may be 180-260° C. depending on the gasification pressure, and wet or dry dust separation. The crude gas is pretreated so that it can be fed to further technological steps such as crude gas conversion, H2S and CO2 removal, and synthesis.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Gasification and steam methane reforming integrated polygeneration method and system

InactiveUS20100158792A1Improve reliabilityMaximizes reliability of productionCombustible gas catalytic treatmentGas modification by gas mixingProcess engineeringPetroleum coke

This invention is a process and system for providing hydrogen at a high level of reliability from a gasification system by integrating it with SMR. Carbonaceous feedstock such as petroleum coke or coal or biomass is gasified to co-produce SNG, fuel gas, hydrogen, power and steam in conjunction with hydrogen production through steam methane reforming. Carbon dioxide may also be recovered in this process. The integrated schemes are designed in a way that maximizes the reliability of production of high value products such as hydrogen through gasification and minimizes the impact of high natural gas prices on hydrogen production by SMR.

Owner:PRAXAIR TECH INC

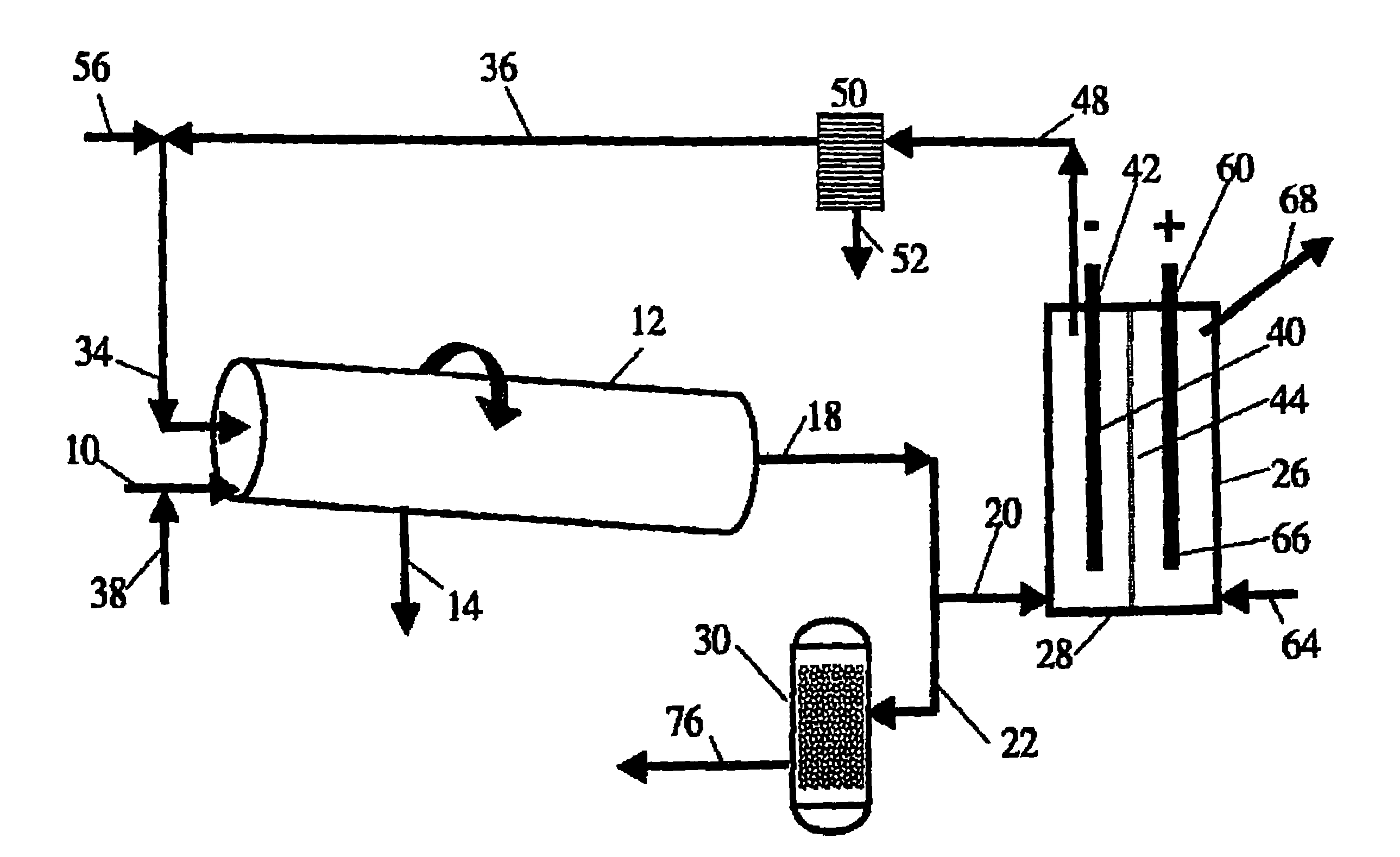

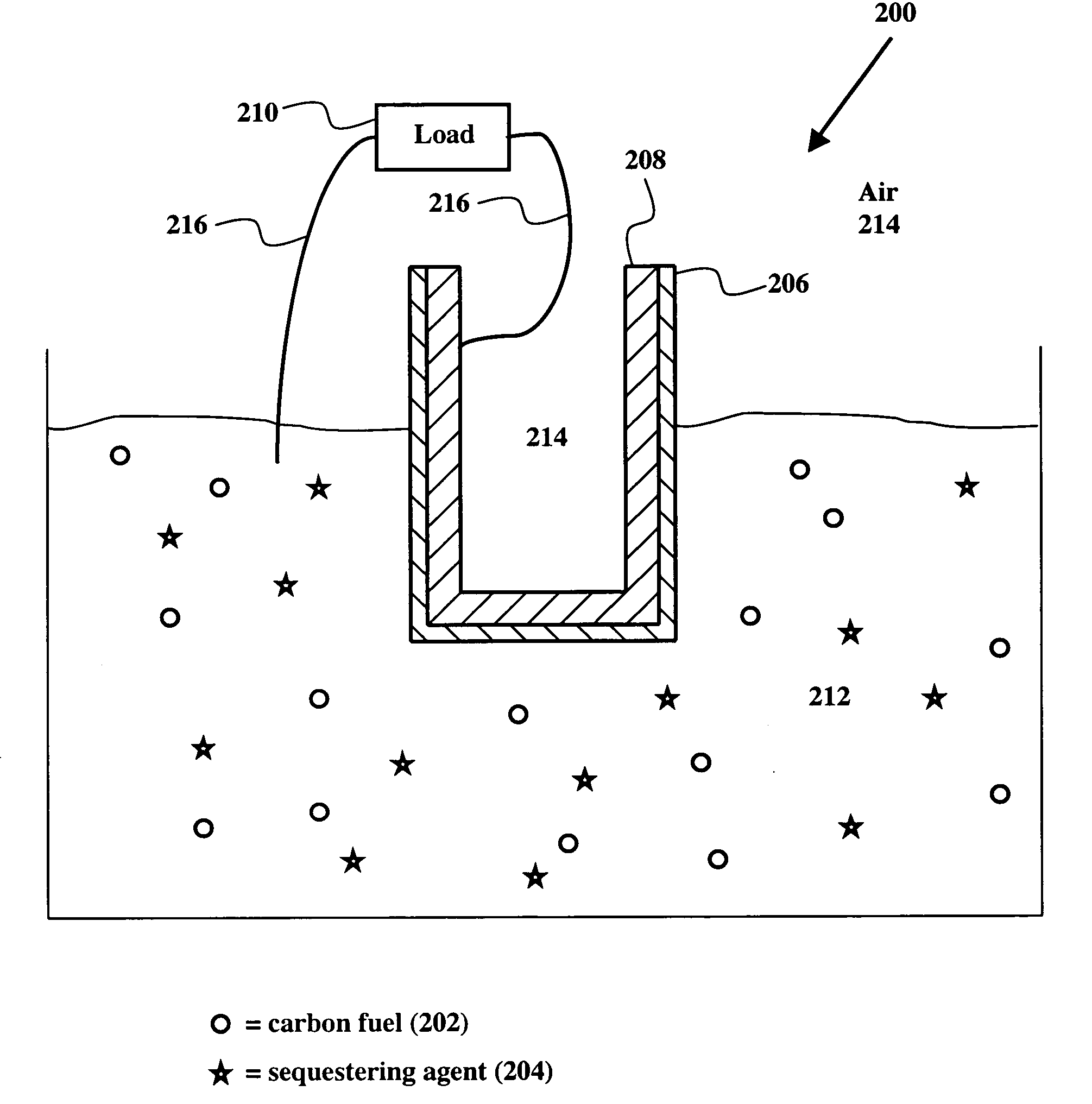

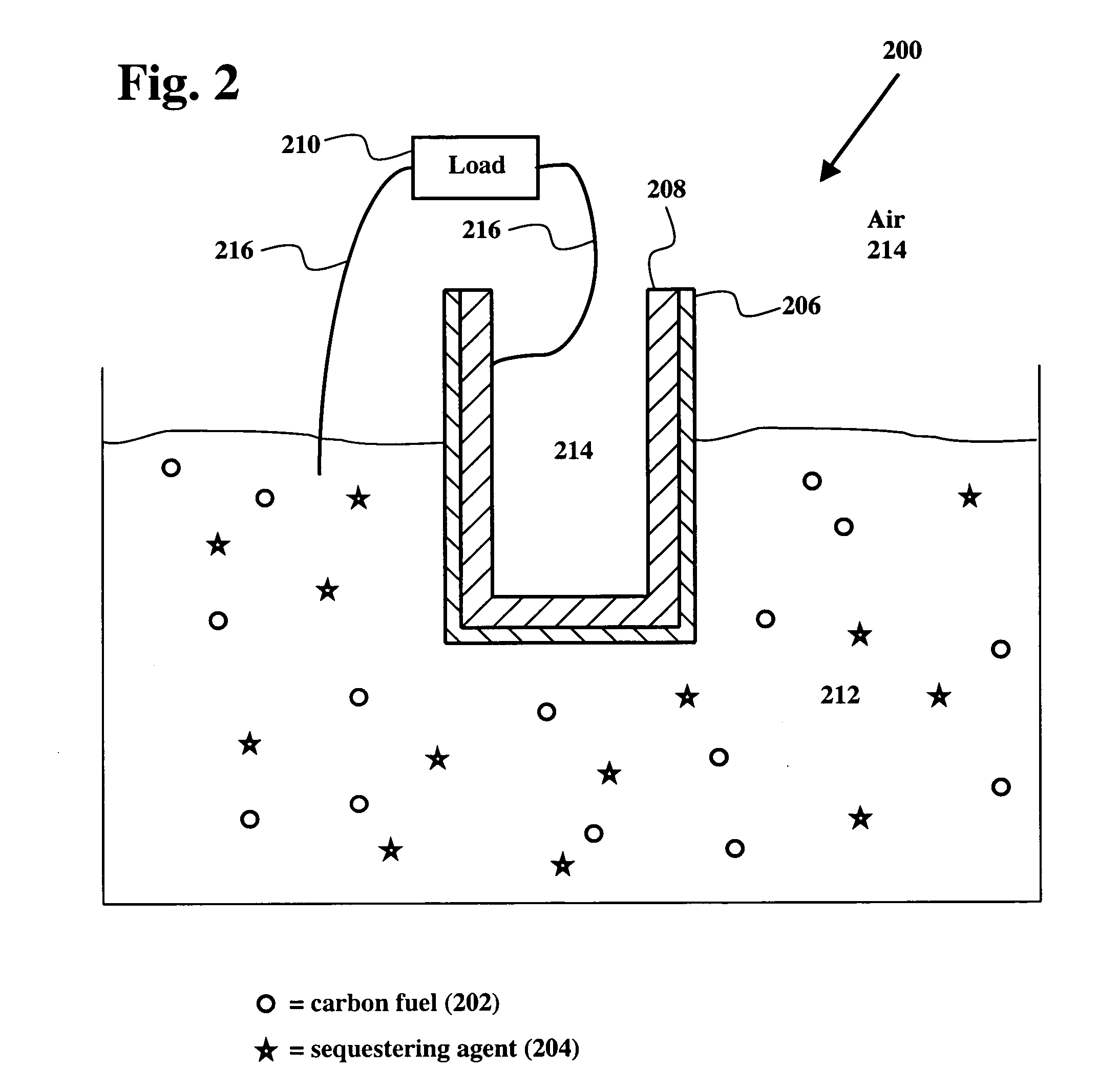

Direct carbon fuel cell with molten anode

This invention discloses a method of converting carbon-containing materials directly to electrical energy without the need for intermediate processing steps. An embodiment comprises the use of a conductive molten medium with dispersed particles of carbon material as the anode in a fuel cell with a solid oxide electrolyte which enables conversion of carbon-containing materials (such as pulverized coal, charcoal, peat, coke, char, petroleum coke, oil sand, tar sand, waste plastics, biomass, and carbon produced by pyrolysis of carbonaceous substance) directly into electrical energy in a single step process. The anode optionally may have a dispersed second solid phase that getters CO2 and SO2 gases that are produced during the anodic reaction. Hence, this invention facilitates near-zero emissions and dramatically reduces the release of environmentally harmful emissions. More importantly, this direct route to electrical energy eliminates Carnot cycle constraints and offers high thermodynamic efficiency.

Owner:DIRECT CARBON TECH

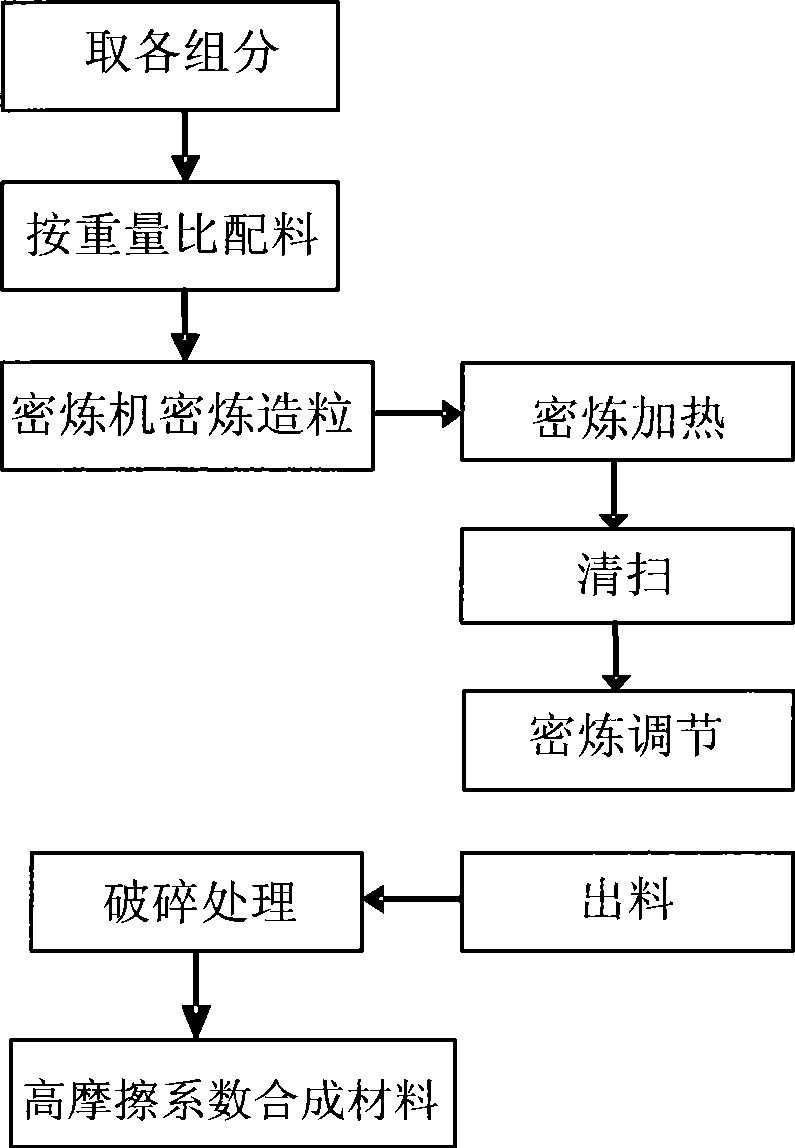

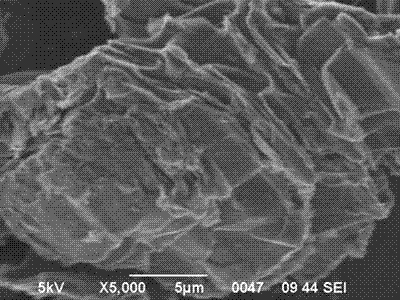

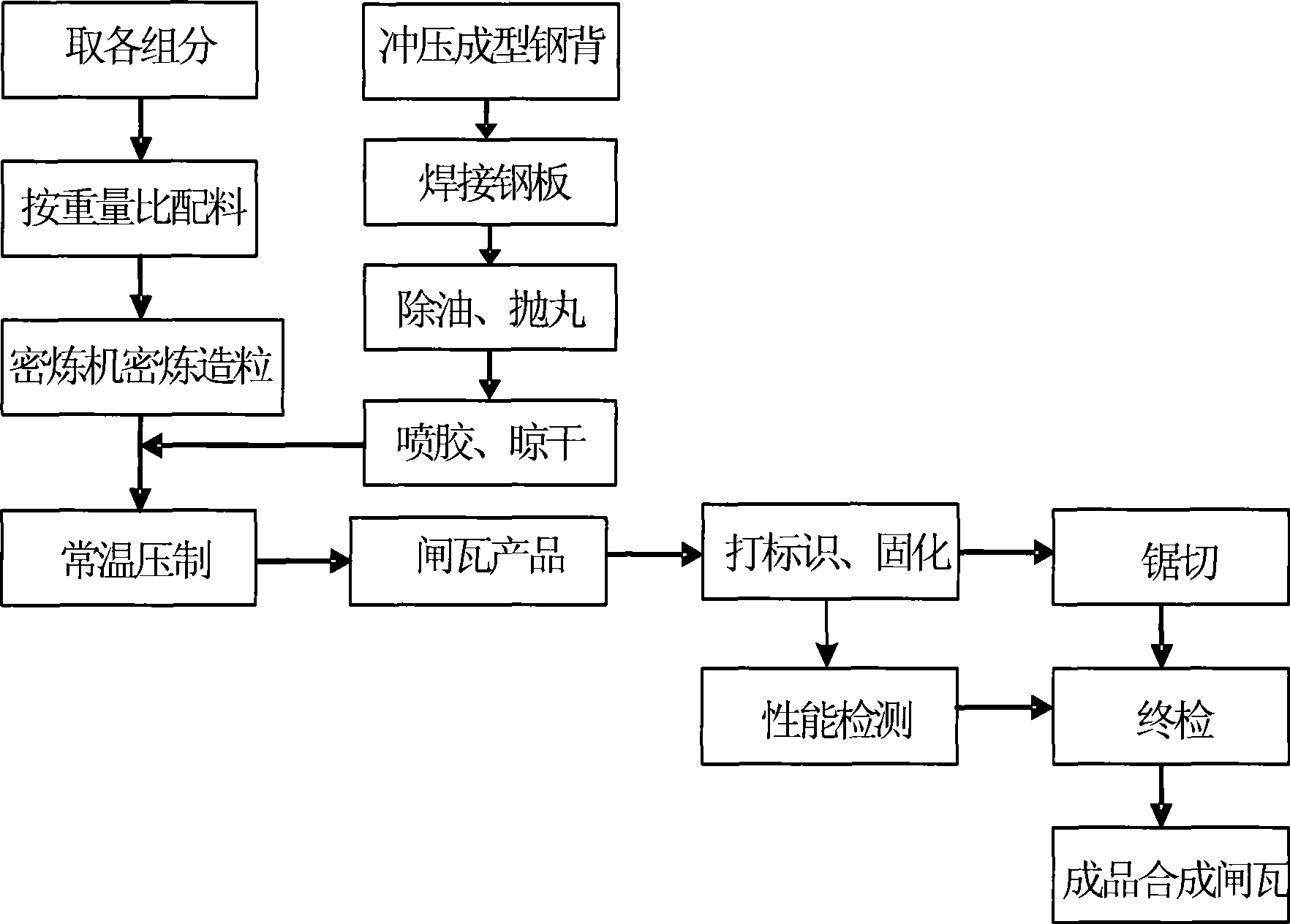

High friction coefficient synthetic materials and preparation method thereof

The invention discloses a high friction coefficient composite material and a manufacturing method thereof, wherein the material is prepared through material sealing and grain-making processing by the following compositions in weight percentage: 8 to 13 percent of butadiene-acrylonitrile rubber, 2 to 10 percent of styrene-butadiene rubber, 5 to 10 percent of cresol methyl-stage phenol-formaldehyde resin modified, 15 to 30 percent of steel fiber, 10 to 15 percent of magnesia, 5 to 10 percent of calcined petroleum coke, 2 to 5 percent of silicon carbide, 10 to 25 percent of mineral fiber, 5 to 10 percent of calcium hydroxide, 10 to 20 percent of barium sulfate, 5 to 10 percent of graphite, 1 to 5 percent of supramoly, 1 to 5 percent of carbon black, 1 to 3 percent of sulfur and 1 to 3 percent of accelerant. The material can be applied in a plurality of situations to prepare friction components, has stable friction performance and good abrasion resistance, effectively inhibits the phenomena of metal inlay, cracking, chip off-falling and so on, reduces the damage on vehicle wheels, has good impact resistance and good weathering resistance, can be used in the environment with large temperature variation for a long time, and has the application characteristics of wide application region and large difference of the regional environment.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

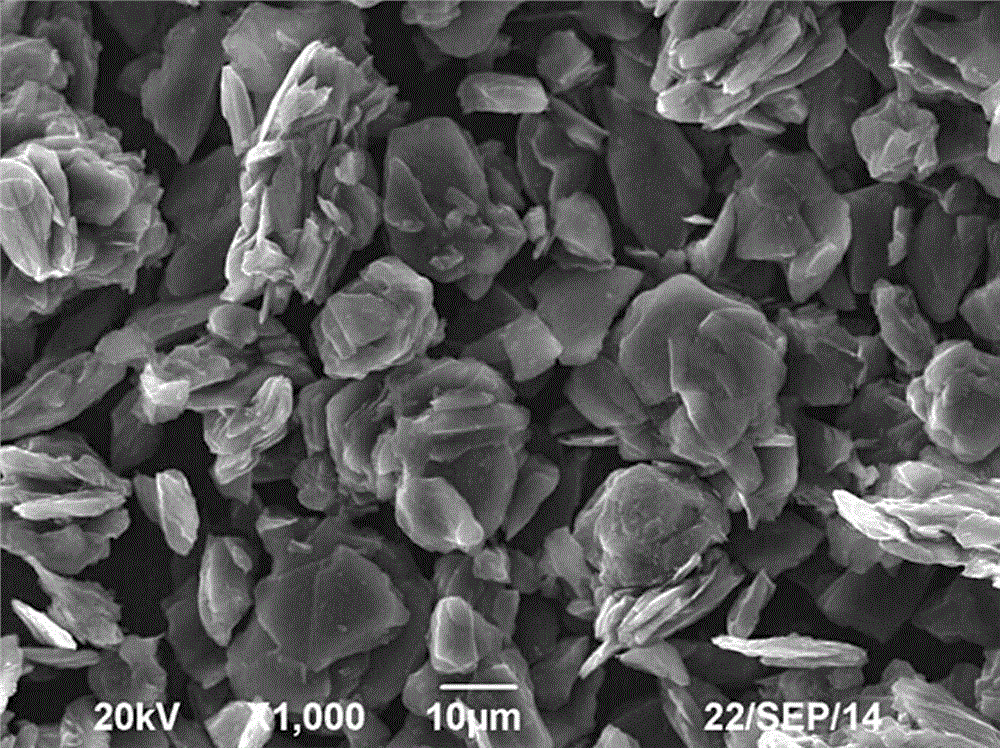

Preparation method of asphalt liquid phase coated modified artificial graphite lithium battery cathode material

ActiveCN103682350AImprove first-time efficiencyHigh specific capacityCell electrodesDischarge efficiencyPhysical chemistry

The invention provides a preparation method and an application of an asphalt liquid phase coated modified artificial graphite lithium battery cathode material. The method comprises the steps of mechanically grinding petroleum coke, mixing with an appropriate amount of (3-8%) asphalt powder after stage treatment, performing reaction for 6-10h in a moderate temperature reaction kettle at 500-650 DEG C, performing reshaping stage treatment again, performing reaction for 36-72h at 2400-3000 DEG C for high-temperature graphitization treatment, finally obtaining an unmodified artificial graphite material through stage treatment, then further dissolving the unmodified artificial graphite material and asphalt in a dispersing agent, stirring to obtain uniform mixing liquid, preparing the uniform mixing liquid into composite powder with a closed cycle spray dryer, heating for 1-5h at 700-1100 DEG C, and finally obtaining the asphalt liquid phase coated modified artificial graphite material. After the asphalt liquid phase coated modified artificial graphite prepared by the method is applied to a lithium battery, the artificial graphite shows excellent electrochemical properties such as high first charge-discharge efficiency, high specific capacity and good cycle performance.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

High friction composite brake shoe for railway freight car and manufacture method thereof

ActiveCN101391611AHigh compressive strengthHigh impact strengthBraking membersBrake arrangement with braking memberFiberEngineering

The invention discloses a high friction composite brake shoe for a railway wagon and a manufacturing method thereof. The composite brake shoe comprises: a steel back and a brake shoe body which is fixed on the steel back, wherein, the brake shoe body is prepared by materials which are synthesized by various components with the following weight ratio: 8 to13 parts of nitrile butadiene rubber, 2 to10 parts of styrene butasiene rubber, 5 to10 parts of cresol modified A-stage phenolic resin, 15 to 30 parts of steel fiber, 10 to 15 parts of magnesium oxide, 5 to 10 parts of calcined petroleum coke, 2 to 5 parts of silicon carbide, 10 to25 parts of mineral fiber, 5 to 10 parts of calcium hydride, 10 to 20 parts of barium sulfate, 5 to 10 parts of graphite, 1 to 5 parts of molybdenum disulfide, 1 to 5 parts of carbon black, 1 to 3 parts of sulfur and 1 to 3 parts of enhancer. The brake shoe can be used in the railway heavy-duty high-speed wagon and has stable friction performance and better wear resistance; the brake shoe can effectively inhibit the phenomena of metal inlay, cracks, dropping blocks and the like and reduce the damages on wheels; and the brake shoe is characterized by better impact resistance performance and good weatherability.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

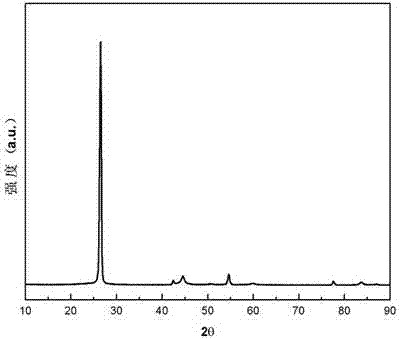

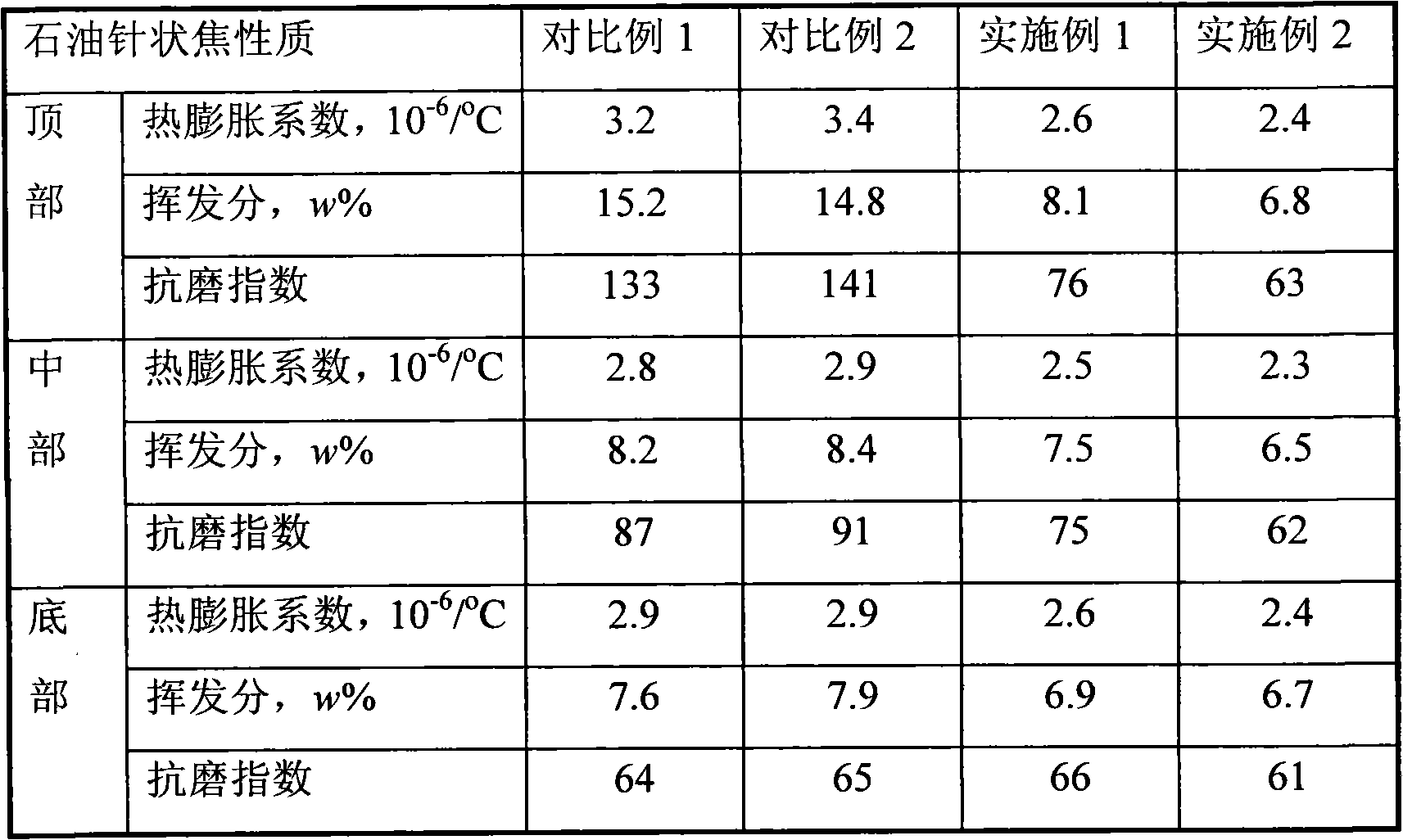

Production method of homogeneous petroleum needle coke

ActiveCN103184057AImproved Anti-wear IndexSolve for uniformityTreatment with plural serial stages onlyCoking carbonaceous materialsHeating furnaceTower

The invention relates to a production method of a homogeneous petroleum needle coke. The method comprises the steps of: (1) heating the raw material for needle coke production to a relatively low temperature of 400-480DEG C by a heating furnace, then leading the raw material into a coking tower to make the coking raw material form flowable intermediate phase liquid crystals; (2) when the low temperature fresh raw material charging stage is completed, gradually raising the temperature of a heating furnace outlet, and at the same time, charging the coking heating furnace with a fresh raw material and heavy distillate oil from a fractionating tower; and (3) when the materials in the coking tower reach a curing coking temperature, charging the coking heating furnace with the coking intermediate distillate oil generated in step (1), and simultaneously raising the coking heating furnace feed temperature to make the internal temperature of the coking tower reach 460-510DEG C, thus finishing high temperature curing of petroleum coke. The method provided in the invention can make the properties of needle coke at different parts inside the coking tower more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

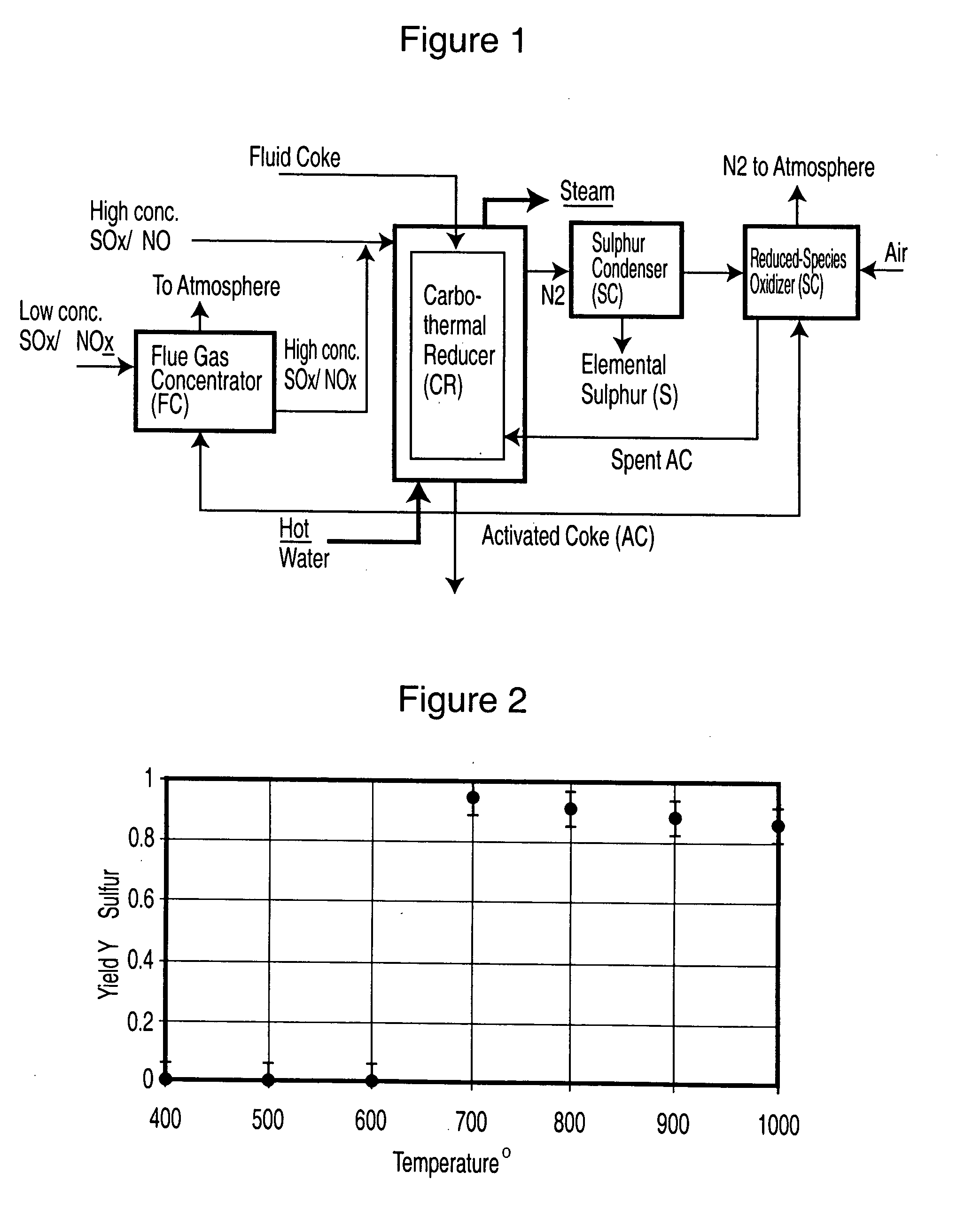

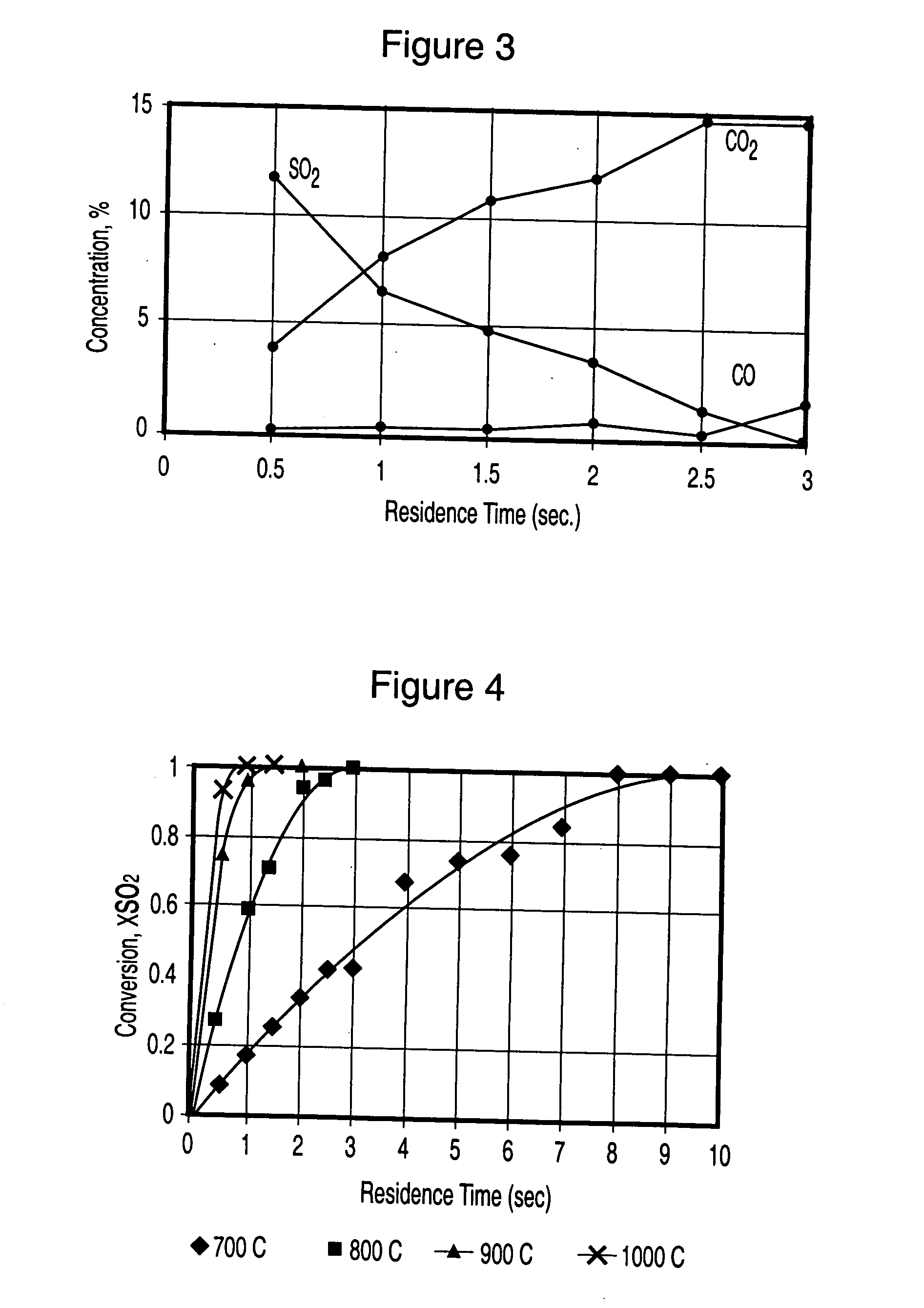

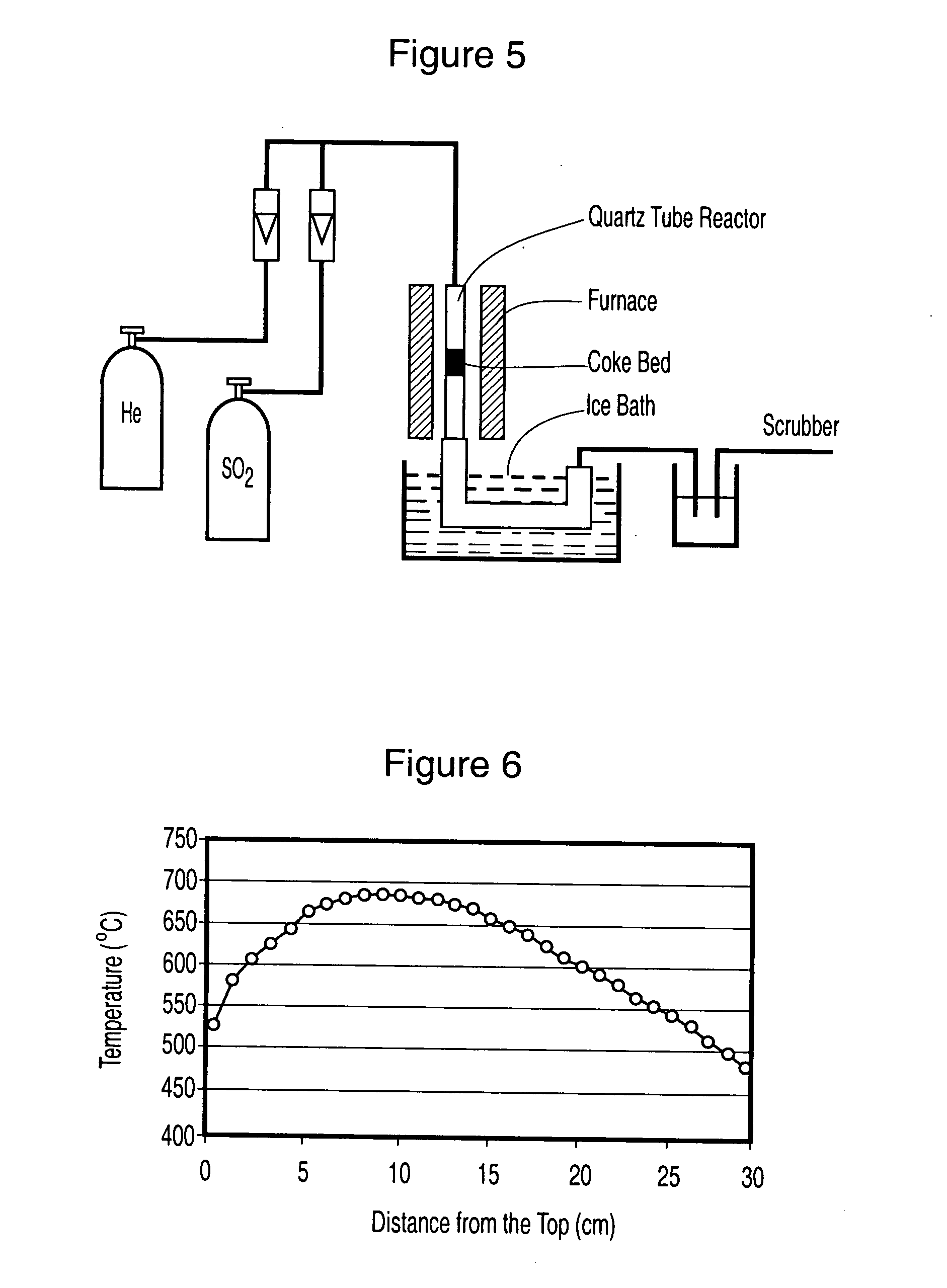

Production of sulphur and activated carbon

A petroleum coke-based combined De-SOx and De-NOx process is described comprising use of four key units, namely, a flue gas concentrator (FC), a carbothermal reducer (CR), an elemental sulphur condenser (SC) and an oxidizer for reduced sulphur and nitrogen species (RO). The two major reactants in this process are the petroleum coke, preferably, and a flue gas containing SOx / NOx. The major products are elemental sulphur from the SC and activated coke from the CR. The process provides for SOx and NOx abatement in an economically viable way while the activated coke produced has a wide range of applications, particularly, in environmental protection.

Owner:CHAR TECH INC

High-efficient petroleum coke screening device

InactiveCN106914414AImprove screening efficiencyImprove filtering effectSievingScreeningPetroleumPetroleum coke

The invention relates to a petroleum coke screening device, in particular to a high-efficient petroleum coke screening device. The technical problem to be solved by the invention is to provide a high-efficient petroleum coke screening device with the features of lower manufacture cost and capabilities of saving time and labor, improving screening efficiency and reducing screening cost. In order to solve the technical problem, the invention provides the high-efficient petroleum coke screening device comprising a bottom plate, a rotating device, a screening barrel, a vertical moving device, a filter screen, a first electric pushing rod, a first baffle plate, a first U-shaped discharging plate, a second electric pushing rod, an annular sliding rail, a first sliding block, a first collecting frame and a second collecting frame, wherein the rotating device is arranged on the top part of the bottom plate, and the screening barrel is arranged on a rotating part of the rotating device. The high-efficient petroleum coke screening device has the advantages that the screening barrel is enabled to rotate and vertically shake at the same time, so that petroleum coke is screened, therefore the time and labor can be saved, the screening efficiency can be improved, and the manufacture cost is lower.

Owner:冷国强

High-performance semi-metallic brake pad

ActiveCN101555915ASensitive brakesReduce brake noiseFriction liningGraphite particleAluminium silicate

A high-performance semi-metallic brake pad comprises the following components according to weight percentages: 4-6% of nitrile rubber powder, 2-4% of tyre powder, 3-5% of crystalline flake graphite, 6-9% of foam iron powder, 9-13% of boron containing phenolic resin, 8-12% of chopped steel fibre, 2-4% of alumina fibre, 8-11% of red copper fibre, 2-5% of cashew nut oil friction powder, 2-3% of graphite particle, 2-3% of calcined petroleum coke, 7-13% of barite, 3-4% of chromite, 2-3% of magnetite, 2-4% of diatomite, 7-10% of glued aluminium silicate fibre, 3-5% of flake aluminium powder, 2-4% of molybdenum disulfide, 0.2-0.5% of zinc stearate, 0.7-1% of antimony sulphide, 0.5-1% of copper sulphide, and 0.3-0.5% of tungsten carbide. After the brake pad is used, the car brake is sensitive, brake noise is low and comfort performance is good. The brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com