Patents

Literature

122results about How to "Sensitive brakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

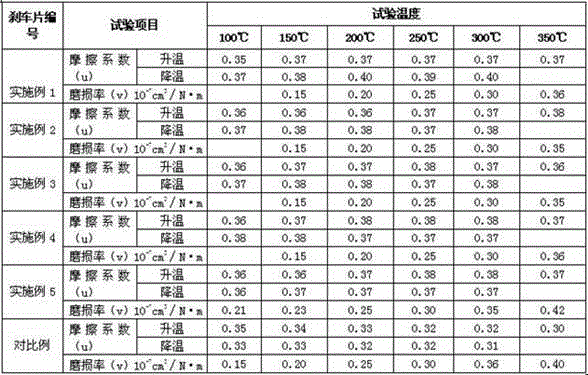

High-performance semi-metallic brake pad

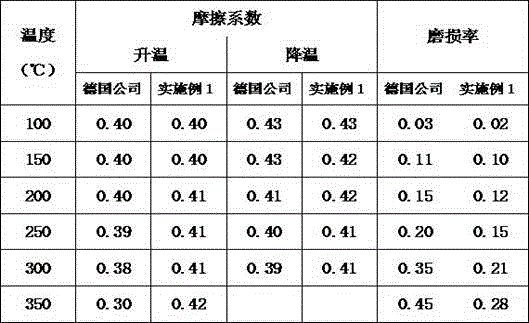

ActiveCN101555915ASensitive brakesReduce brake noiseFriction liningGraphite particleAluminium silicate

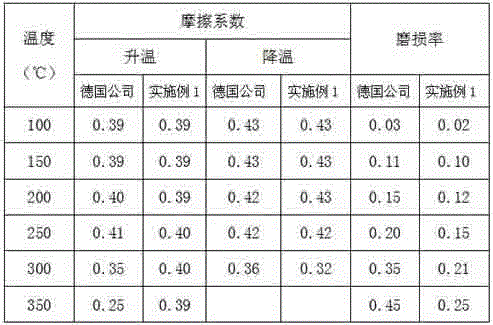

A high-performance semi-metallic brake pad comprises the following components according to weight percentages: 4-6% of nitrile rubber powder, 2-4% of tyre powder, 3-5% of crystalline flake graphite, 6-9% of foam iron powder, 9-13% of boron containing phenolic resin, 8-12% of chopped steel fibre, 2-4% of alumina fibre, 8-11% of red copper fibre, 2-5% of cashew nut oil friction powder, 2-3% of graphite particle, 2-3% of calcined petroleum coke, 7-13% of barite, 3-4% of chromite, 2-3% of magnetite, 2-4% of diatomite, 7-10% of glued aluminium silicate fibre, 3-5% of flake aluminium powder, 2-4% of molybdenum disulfide, 0.2-0.5% of zinc stearate, 0.7-1% of antimony sulphide, 0.5-1% of copper sulphide, and 0.3-0.5% of tungsten carbide. After the brake pad is used, the car brake is sensitive, brake noise is low and comfort performance is good. The brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

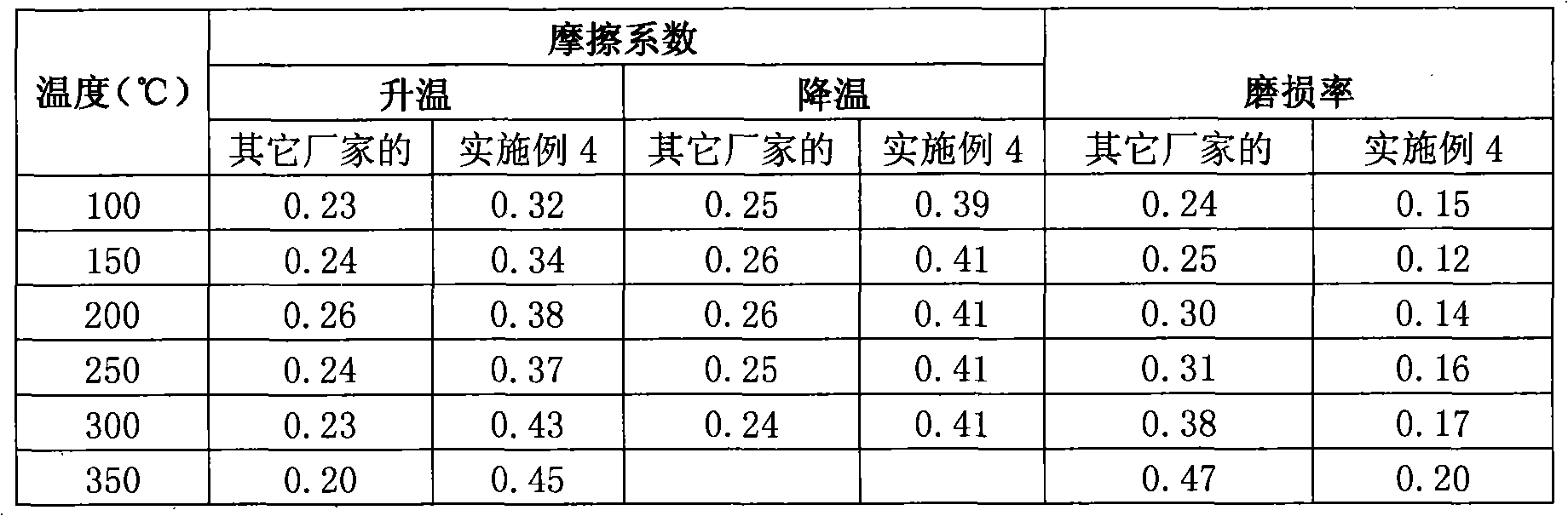

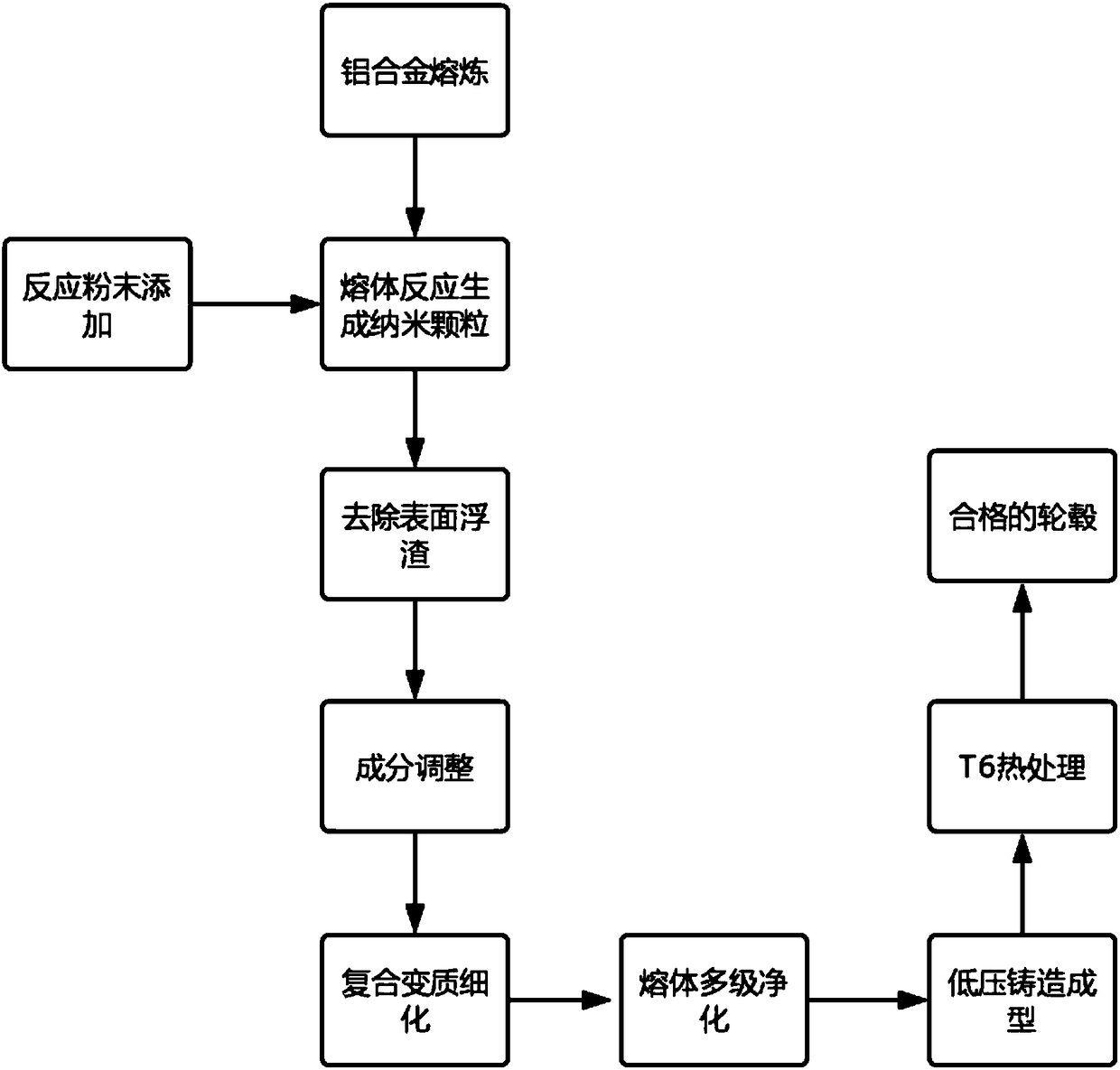

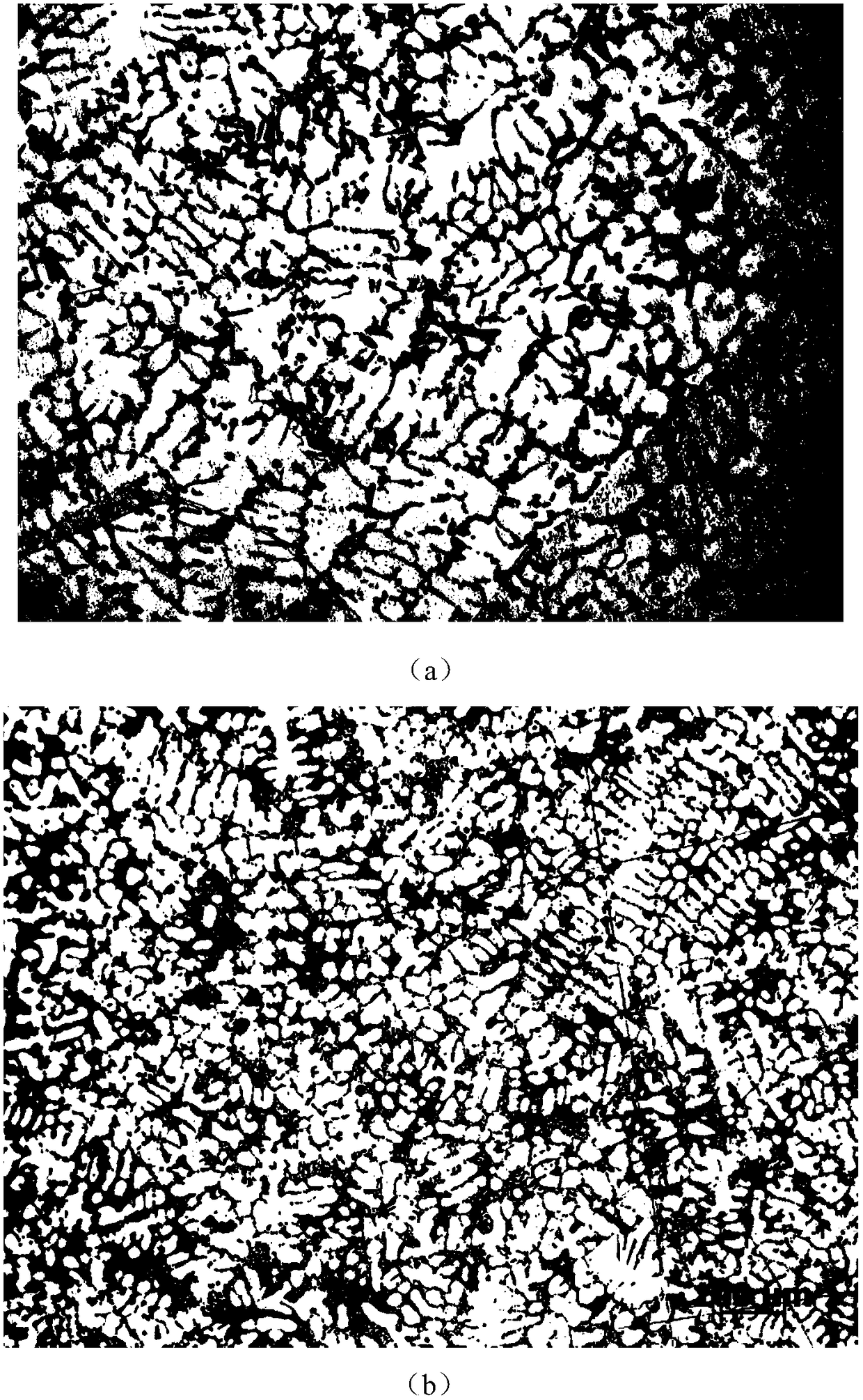

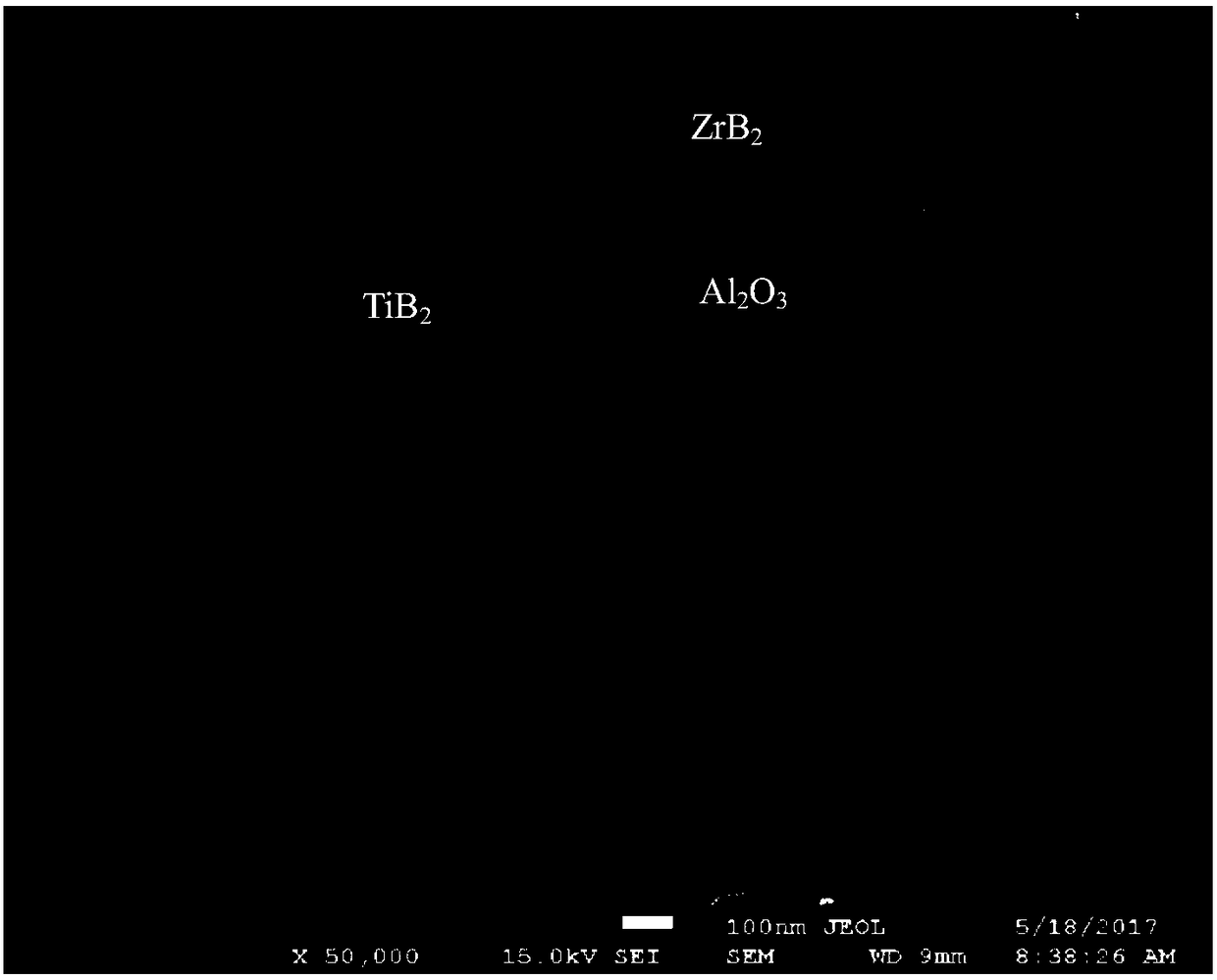

In-situ nanometer intensified aluminum alloy wheel hub for new energy automobile and manufacturing method thereof

ActiveCN108559864AReduce energy consumptionImprove battery lifeHubsWheelsChemical reactionNew energy

The invention relates to an in-situ nanometer intensified aluminum alloy wheel hub with light weight, high strength and fatigue resistance for a new energy automobile and a manufacturing method thereof. Through in-situ chemical reaction of a melted body, nanometer particle compound reinforcement is realized by Orowan reinforcement + refined crystalline reinforcement, long-term compound metamorphism and complex refinement are integrated, and the refined crystalline reinforcement is achieved. The purification technology of nitrogen and argon combined rotary air refining + aluminum-rear earth isadopted, multi-stage deep purification of aluminum melted body is realized, the characteristic that argon is greater than air in density is used for forming a protective layer on the surface of the melted body, and alloy is introduced between the aluminum-rear earth to produce intermediate compounds with the density greater than that of the particles, and therefore the deep high-efficiency purification is effectively achieved. A novel low pressure shaping technology of progressive solidification + rapid crystallization is adopted in the end, due to the fact that crystallization time is shortened, the space between secondary branch crystal arms in a casting microstructure is shortened, the structure is refined and the feeding effect is enhanced, the casting is denser in structure, and the wheel hub with high plasticity, high anti-fatigue performance and high density is obtained.

Owner:JIANGSU UNIV

Novel brake pad material of truck

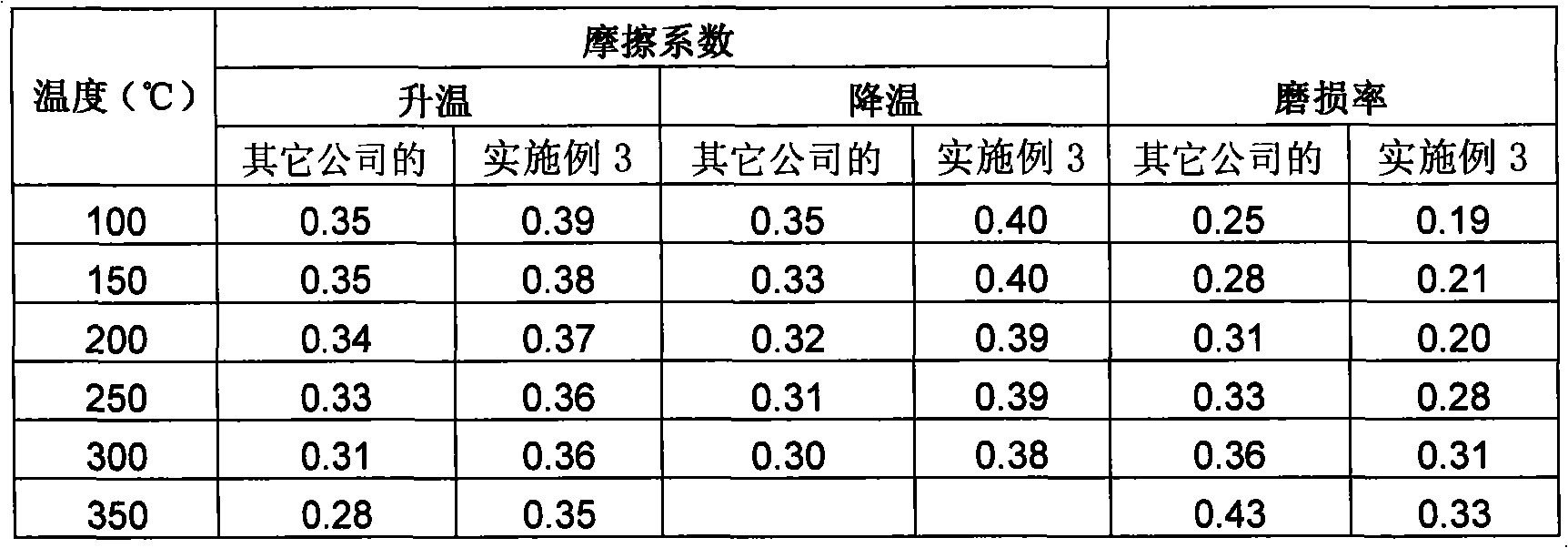

InactiveCN101555399AStable coefficient of frictionStable recovery performanceOther chemical processesFriction liningLow speedEngineering

The invention relates to a frictional material, in particular to a novel brake pad material of truck. The invention provides a novel brake pad material of a truck, wherein the novel brake pad material is used in a dry one-step hot press molding process applied to a nanocopper modified phenolic resin agglutination technology and a parent material modifying and adjusting technology. The raw material mixing ratio of the novel brake pad material is as below: 15%-20% of binder, 30%-50% of framework material, 10%-15% of friction enhancing agent, 5%-10% of anti-friction agent and 20%-30% of filling material. The binder is nanocopper modified phenolic resin, the framework material is mineral fibre and the like, the friction enhancing agent is great-hardness chromium ore power, and the like, the anti-friction agent is low-hardness graphite, and the like, the filling material is BaSO4, coarse whiting, and the like. The novel brake pad material has the advantage that a brake lining has a stable friction factor, stable recovery performance, good heat resistance, no crack performance, low speed sensitivity, good wearability and no braking noise.

Owner:SHANDONG DAWANG XINYI AUTOMOBILE FITTING

High-performance organic fibre brake pad

ActiveCN101555918AStable coefficient of frictionSmall thermal expansionFriction liningLow noiseCellulose

A high-performance organic fibre brake pad comprises the following components according to weight percentages: 5-9% of cashew nut oil friction powder, 4-8% of chromite, 7-10% of barite, 4-7% of calcined petroleum coke, 3-7% of crystalline flake graphite, 3-6% of sepiolite fibre, 4-7% of ceramic fibre, 1.5-3% of antimony sulphide, 4-7% of red copper fibre, 3-5% of glued aluminium silicate fibre, 1-2% of alumina fibre, 8-11% of vermiculite powder, 9-13% of organosilicone phenol-formaldehyde resin, 1-2% of carbon fibre, 5-7% of bastose, 1-2.5% of wood pulp cellulose, 3-6% of viscose fibre, 6-9% of bamboo carbon fibre, 3-5% of nitrile rubber and 0.3-0.5% of zinc oxide. The invention has the advantages of light weight, strong wear resistance, good flexibility, low noise and long service life, and the like, and the friction performance is stable at operating temperature between 100 DEG C and 450 DEG C.

Owner:摩擦一号制动科技(仙桃)有限公司

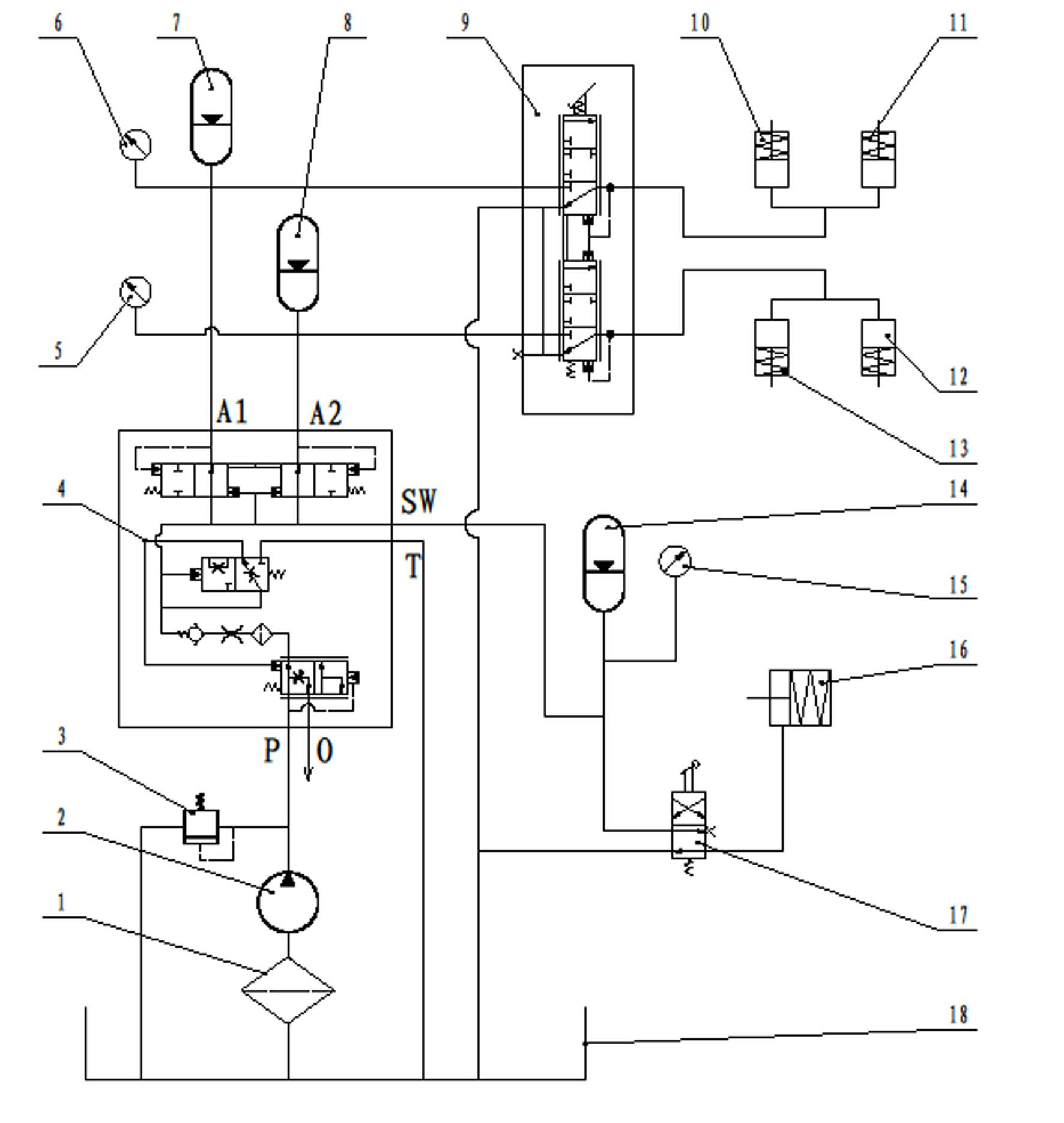

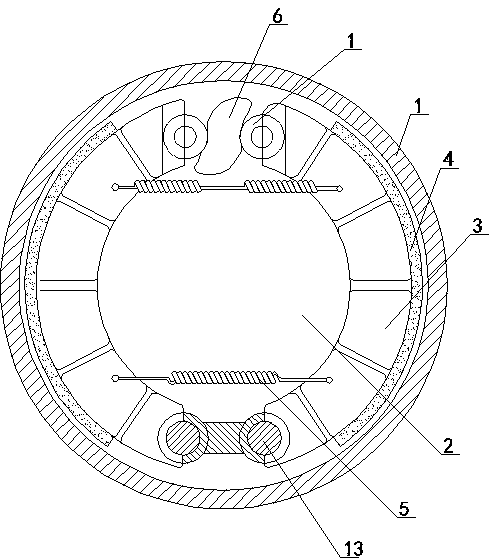

Double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for coal mine explosion-proof vehicle

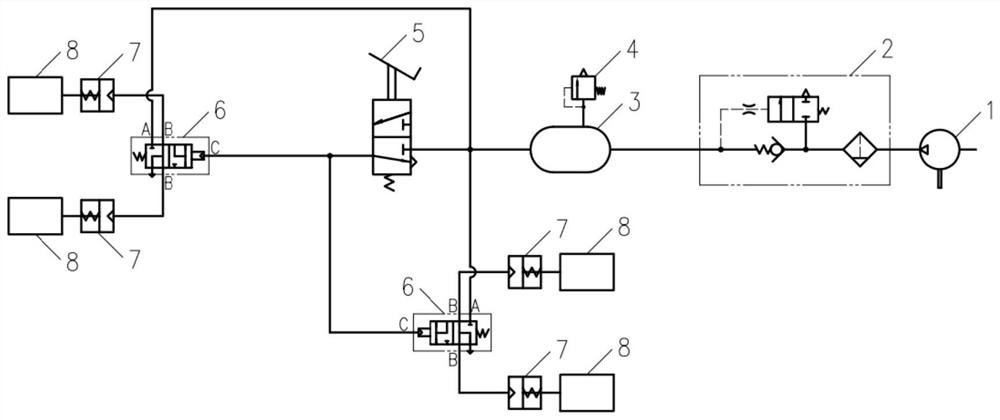

ActiveCN102514562AImprove braking effectReduce labor intensityFluid braking transmissionDouble tubeHydraulic pump

The invention belongs to the technical field of braking devices of coal mine auxiliary conveying machinery, in particular to a double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for a coal mine explosion-proof vehicle. The invention aims to provide an explosion-proof, antipollution, stable, reliable and sensitive brand-new braking system. The braking device comprises a charging valve, wherein an oil feeding opening P of the charging valve is connected with a hydraulic pump, the oil opening A1 and opening A2 of the charging valve are connected with a front brake energy accumulator and a rear brake energy accumulator, and the oil opening SW is communicated with a parking braking oil pipe; the front and rear braking energy accumulators are connected with serial pedal braking valves respectively; the serial pedal braking valves are connected with a front service brake and a rear service brake respectively; parking braking energy accumulators are connected with parking braking valves; and parking braking valves are connected with parking brakes. The braking device meets the conditions for use in a special underground environment, can improve the braking efficiency and working efficiency and safety of the underground explosion-proof vehicle, reduce labor intensity, reduce casualty and accident rates and make underground conveying safer.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Corrosion resistant low noise semi-metallic brake pad

ActiveCN101555916AImprove heat resistanceGood instantaneous high temperature resistanceFriction liningLow noiseFiber

A corrosion resistant low noise semi-metallic brake pad comprises the following components according to weight percentages: 2-4% of nitrile rubber buna, 3-5% of tyre powder, 3-5% of expandable graphite, 9-13% of phenolic resin, 10-15% of stainless steel chopped fibre, 4-7% of red copper fibre, 2-3% of cashew nut oil friction powder, 3-5% of graphite particle, 7-10% of superfine ferric oxide powder, 3-5% of diatomite, 7-12% of acicular wollastonite fibre, 10-15% of barite, 3-5% of chromite, 4-8% of sepiolite fibre, 0.2-0.5% of zinc stearate, 2-3% of zirconite, 3-5% of boron nitride and 2-3% of supramoly; the brake pad has the characteristics of corrosion resistant performance, high frictional coefficient, satisfactory high temperature and thermal decay resistant performance, long service life, and the like. After the brake pad is used, the car brake is sensitive, the braking is stable and brake noise is low, and the brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

Non-asbestos micro-metal mineral fiber disk type brake block for automobile

InactiveCN104533998ASensitive brakesBrake pads require sensitive brakingOther chemical processesFriction liningAcrylonitrileStearic acid

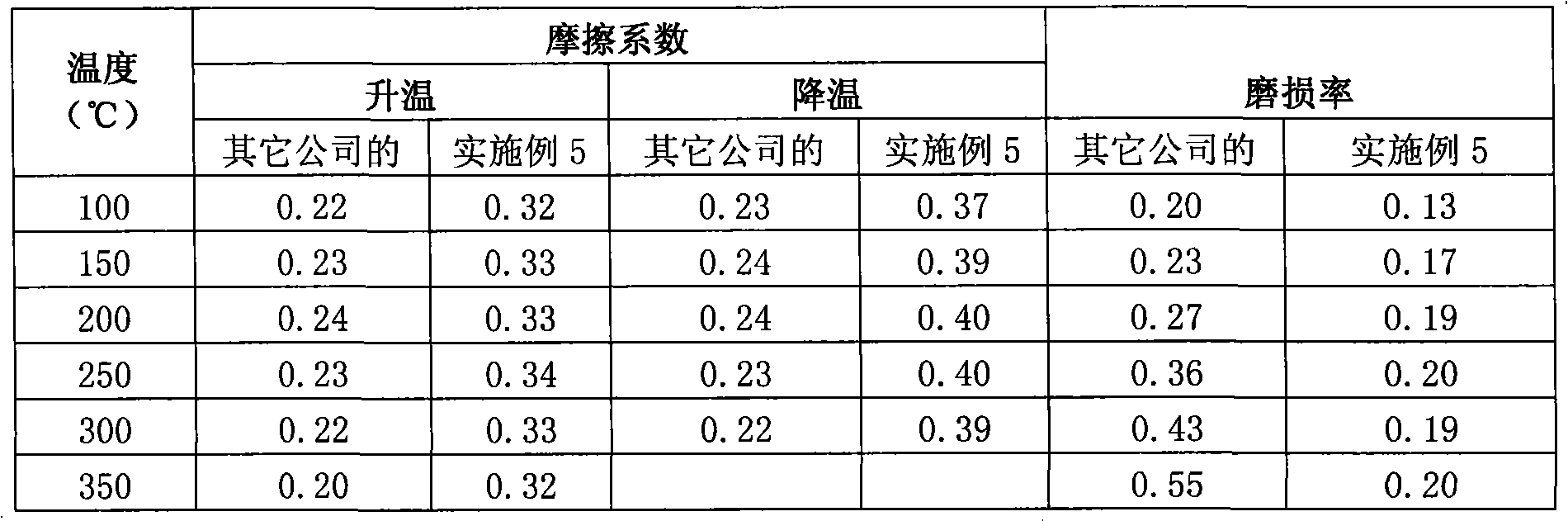

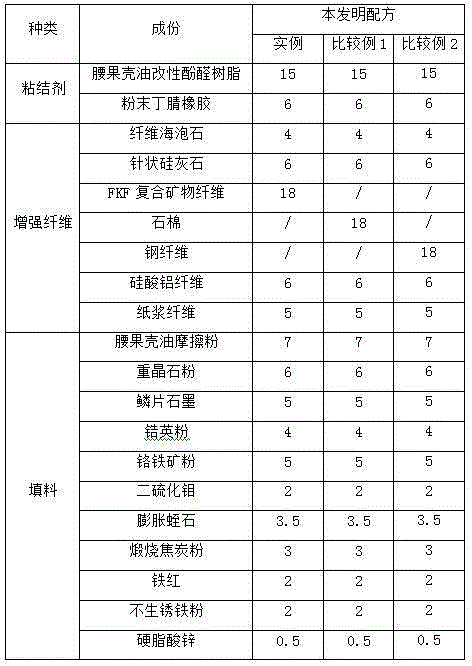

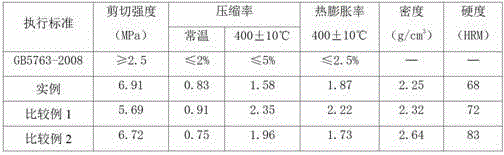

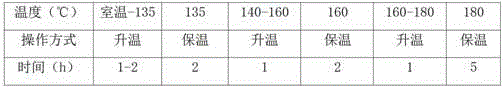

The invention discloses a non-asbestos micro-metal mineral fiber disk type brake block for an automobile. The non-asbestos micro-metal mineral fiber disk type brake block comprises, by weight, 10-20% of cashew nut shell oil modified phenolic resin, 3-8% of powder butadiene-acrylonitrile rubber, 3-8% of fibrous sepiolite, 5-10% of needle-like wollastonite, 15-20% of FKF composite mineral fiber, 5-10% of alumina silicate fiber, 2-6% of paper pulp fiber, 5-10% of cashew nut shell oil friction powder, 5-13% of blanc fixe, 3-15% of crystalline flake graphite, 1-10% of zircon powder, 0.1-0.7% of zinc stearate, 4-7% of chromite ore fines, 1-3% of molybdenum disulfide, 3-6% of expanded vermiculite, 1-5% of calcined coke powder, 1-5% of iron oxide red and 1-6% of rustless iron powder. The production process comprises the steps that the components are pre-mixed and mixed through an automatic mixer, the amount of finally-formed materials is weighted according to the required specification of the disk type brake block, a cold blanket is formed after cooling forming, hot press forming and heat processing are carried out, and the finished product is manufactured through fine machining. The non-asbestos micro-metal mineral fiber automobile disk type brake block has the advantages of being stable in friction abrasion performance, good in mechanical property, excellent in heat recession resisting performance and long in service life.

Owner:福建冠良汽车配件工业有限公司

Friction grain and watering prilling process therefor

The invention discloses a friction granule and the granulation technology thereof. Firstly, resin, toughener, rubber, antifriction, fiber, molding agent, filling, and friction material waste machining material are weight according to a certain proportion, mixed and added into a mixing plant to be stirred by adding water, so a wet mixture is obtained; granulation is carried out on the wet mixture on a granulation device to obtain a granular matter; the granular matter is roasted for many hours under the temperature of 100-200 DEG C to obtain a dried granular material; and at last, the dried granular material is screened according to the requirement to obtain the granular material with needed grit number. The invention utilizes waste materials, reduces the production cost and facilitates the environment protection; in addition, the wearable performance, the vibration resistance and the anti-attenuation of the obtained friction granule are all improved; the brake is sensitive and stable with little noise; and the damage caused for a braking disc drum is little.

Owner:NINGGUO FEIYING AUTO SPARE PARTS +2

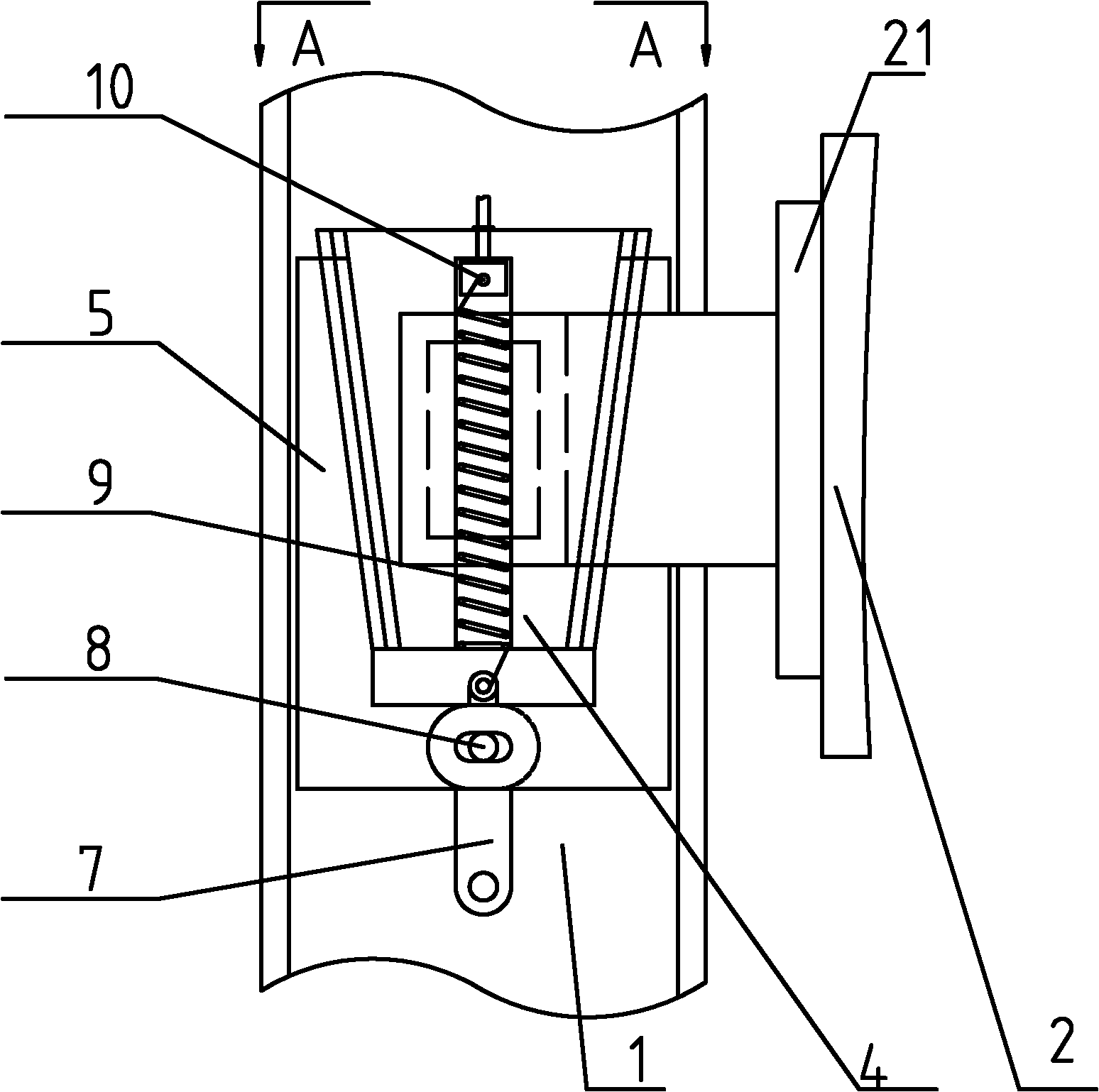

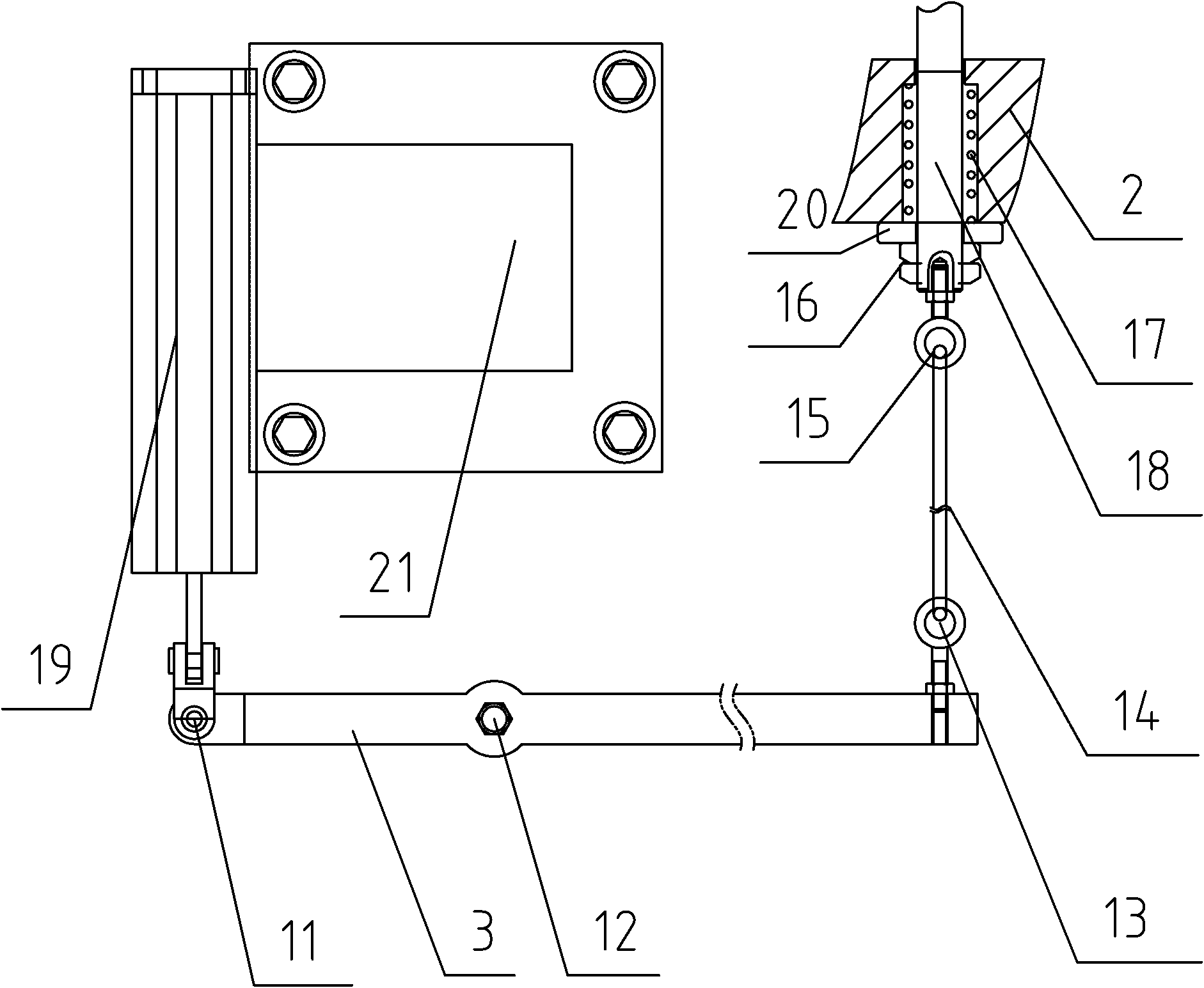

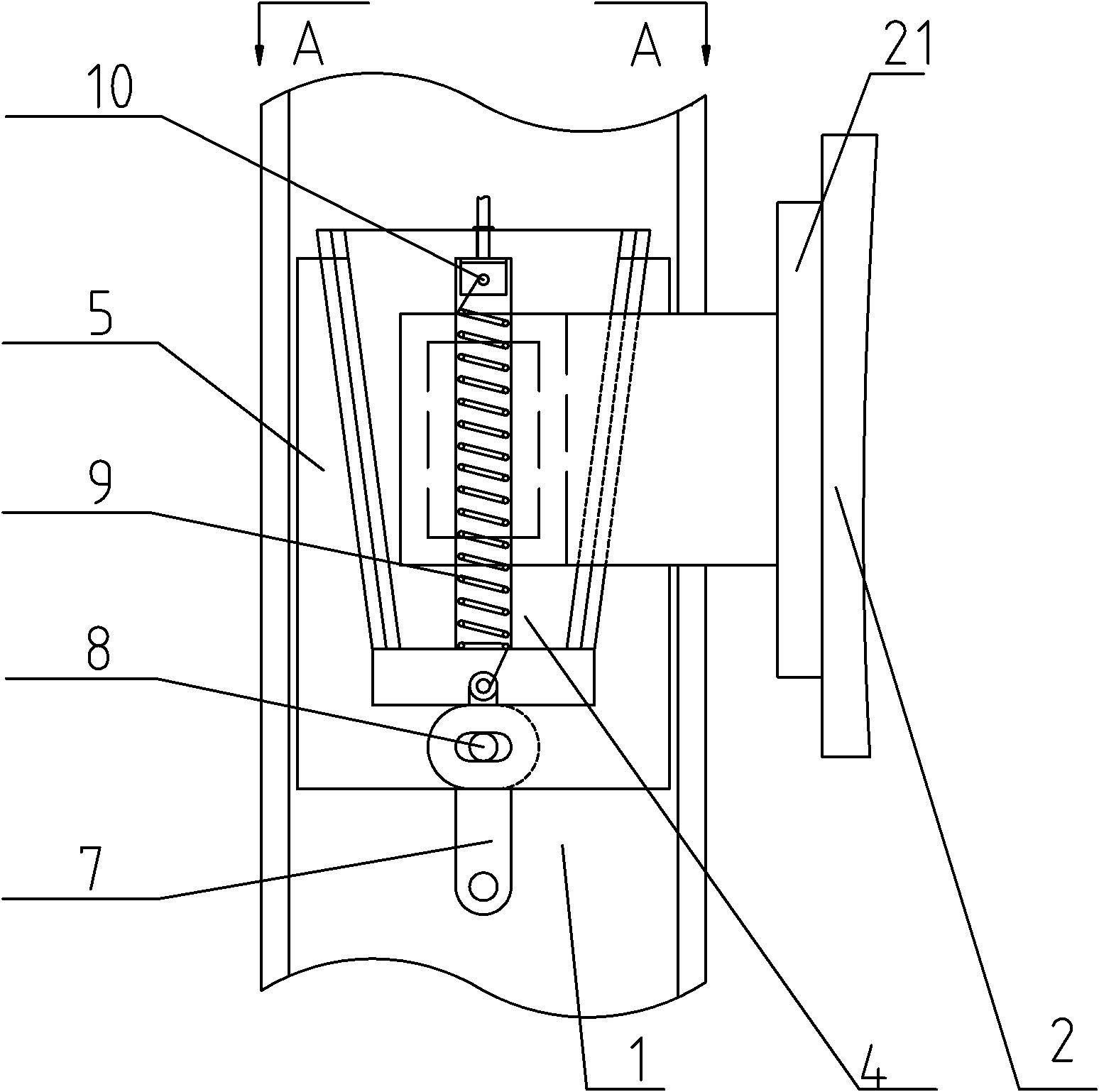

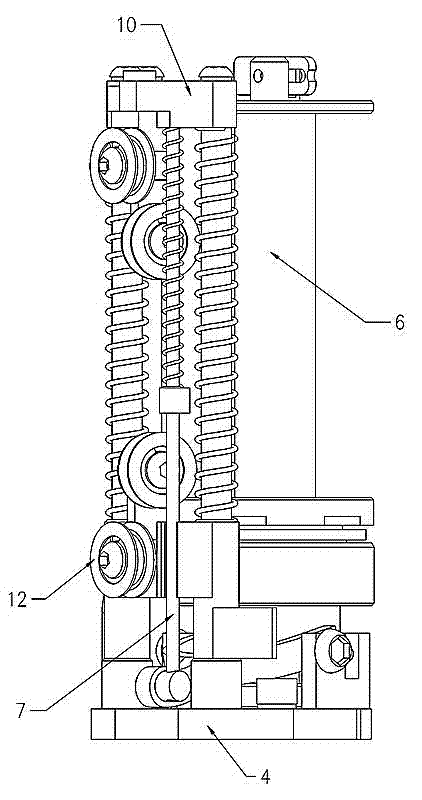

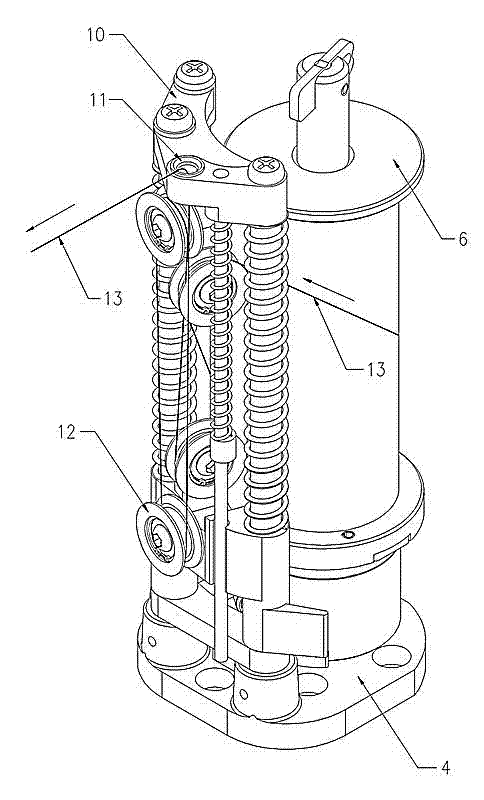

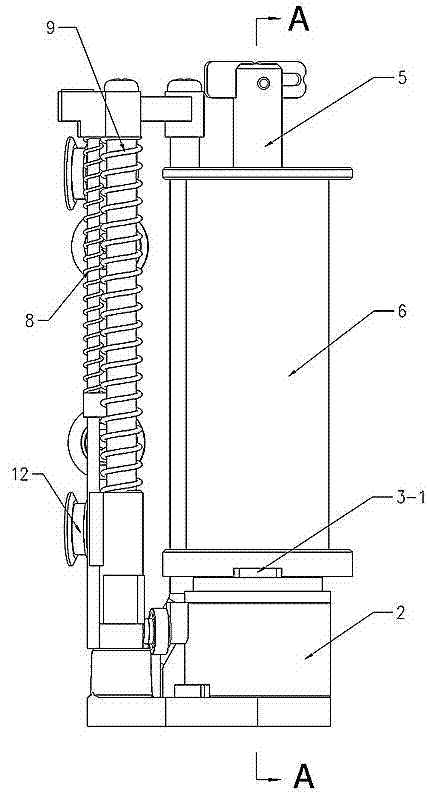

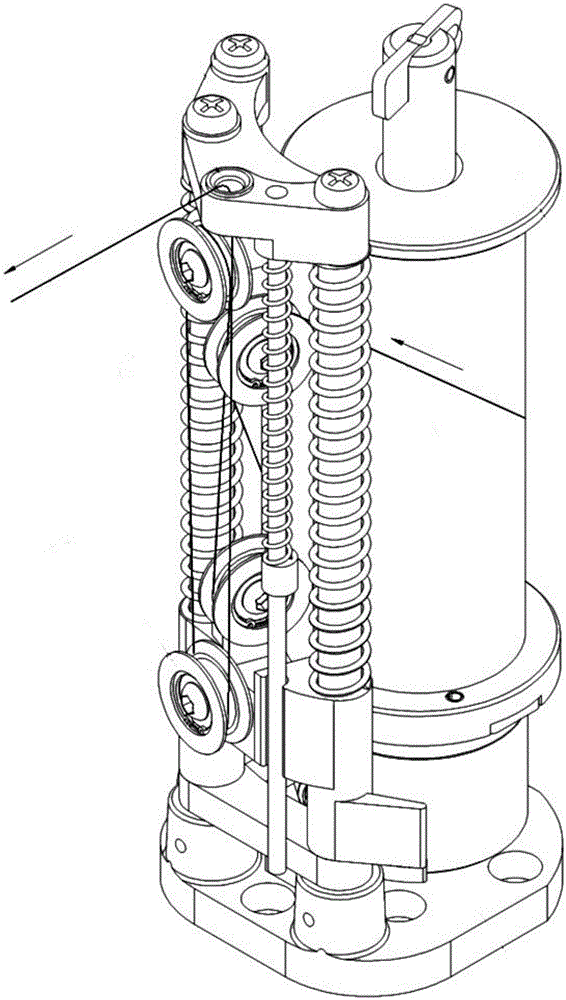

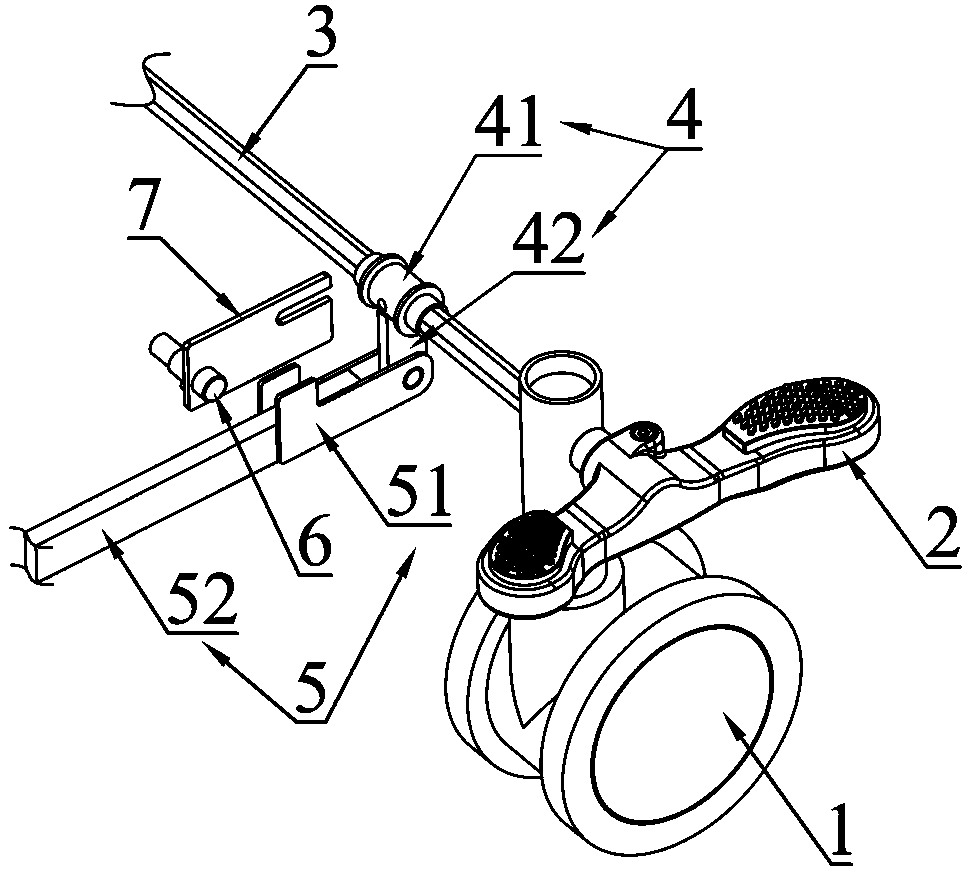

Anti-falling device of vertical elevating equipment

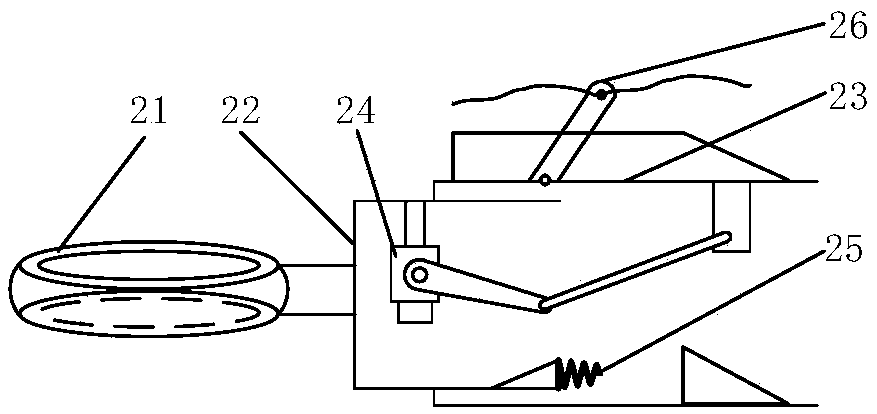

The invention discloses an anti-falling device of vertical elevating equipment, which comprises a brake control connecting lever and a brake locking mechanism which is arranged in a groove-shaped guide rail, wherein the brake locking mechanism comprises a wedge-shaped inner brake block which is fixedly connected with an elevating platform and two wedge-shaped outer brake blocks which are arranged on the two sides of the wedge-shaped inner brake block respectively; one side, which is close to the groove-shaped guide rail, on each wedge-shaped outer brake block is provided with a friction plate; the two wedge-shaped outer brake blocks are hinged with each other through a wedge-shaped outer brake block pin for a waist-shaped hole on the lower part of the two wedge-shaped outer brake blocks; a tension spring is connected on the wedge-shaped outer brake block pin; the upper end of the tension spring is connected on the wedge-shaped inner brake block; the brake locking mechanism is connected at one end of the brake control connecting lever; the other end of the brake control connecting lever is connected to an elevating pull rod; the elevating pull rod is inserted into the hole of the elevating platform; and pressure springs are arranged in the space between the elevating pull rod and the hole of the elevating platform. By the anti-falling device, the problem of insufficient safety of the elevating platform capable of vertically ascending and descending is solved; and the anti-falling device has a simple structure and low cost and can be flexibly braked.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

Micro-copper-formulated ceramic brake pad

InactiveCN103821859ALight weightUniform surface distributionOther chemical processesFriction liningSulfideBoron nitride

A micro-copper-formulated ceramic brake pad is made with aramid pulp, carbon fiber, magnesium hydroxide, copper fiber, brown fused alumina, antimony sulfide, ceramic fiber, superfine iron oxide powder, calcium sulfate whisker, potassium titanate, barite, crystalline flake graphite, calcined petroleum coke, nano hollow float beads, flake aluminum powder, nitrile butadiene rubber powder, cashew nut shell oil modified phenolic resin, zirconite, boron nitride, zinc oxide, and benzoxazine resin. The components are reasonably matched, and advantages of the materials can be given to full play in abrasive materials. The novel fiber materials are reasonably composited, performance defects of the materials can be mutually complemented, and high performance is achieved through mutual connective action. The micro-copper-formulated ceramic brake pad has low content of heavy metals and smaller than 0.5% of copper content and therefore, is very environment friendly.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

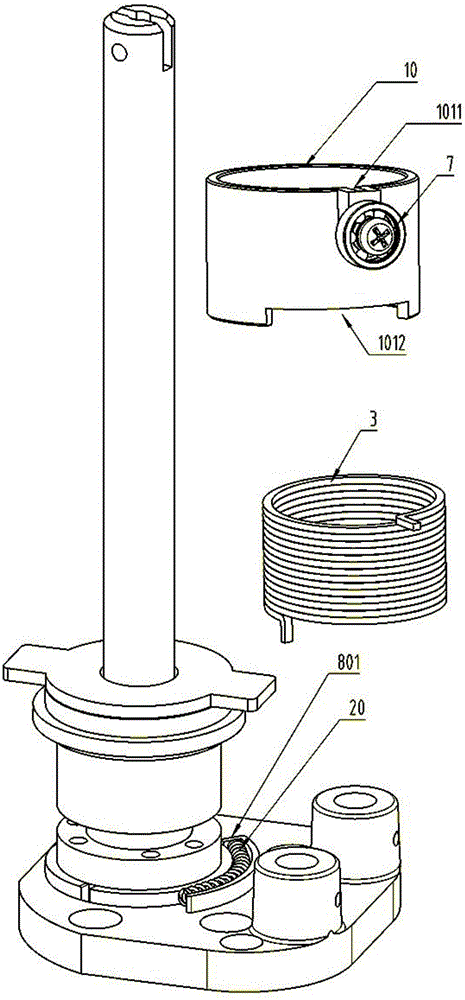

Tension control and torsion spring steel coil brake device for spindle of braiding machine

ActiveCN103173928AShort tension fluctuation rangeSmall tension fluctuation rangeBraidBrakeTorsion spring

A tension control and torsion spring steel coil brake device for a spindle of a braiding machine comprises a steel coil torsion spring, an elastic sleeve, a drill axis, a base and a central shaft, wherein a torque arm above the steel coil torsion spring is inserted in a notch on the elastic sleeve, and a torque arm below the steel coil torsion spring is inserted in a notch of the central shaft; under a free state, the inner wall of the steel coil torsion spring wraps up the outer walls of the drill axis and the central shaft, and a gap is reserved between the elastic sleeve and the steel coil torsion spring, so that the elastic sleeve and the steel coil torsion spring can rotate relatively; a rolling wheel is arranged on a bulge at the upper end of the elastic sleeve, and the circumferential profile of the rolling wheel is closely attached on a wedge of a draw bar; and when the machine is stopped, the tension of braiding wires disappears instantly, the draw bar drops on the base under the action of the spring, during descending, the wedge pushing the rolling wheel is loosen, the elastic sleeve restores rotationally, the steel coil torsion spring returns back to be in a free state, the inner diameter of the helix also wraps up the outer walls of the central shaft and the drill axis, and a lug on the drill axis clamps the spindle to enable the spindle to stop rotating instantly. The tension control and torsion spring steel coil brake device adopts a band-type brake to brake, so that the braking operation is flexible and reliable.

Owner:浙江本发科技有限公司

High-performance friction material composition containing graphene

ActiveCN105909707AReduce deformationSensitive brakesFriction liningActuatorsCalcium silicateFully developed

Provided is a high-performance friction material composition containing grapheme. The composition is characterized in that the composition is made of amino silane, calcium silicate hydrate, polyacrylonitrile fibers, electric-melting zirconia, aramid fibers, hemp fibers, expanded vermiculite, ceramic fibers, magnetite, and graphene based on weight ratio. The composition is characterized by green and environmentally-friendly, good high-temperature resistance and heat fading resistance, good wear-resisting property, stable friction coefficient, and long service life. Through rational matching of various kinds of components, advantages of each material are fully developed in the friction material. The recipe does not have heavy metal substances, and the composition is very friendly to environment.

Owner:摩擦一号制动科技(仙桃)有限公司

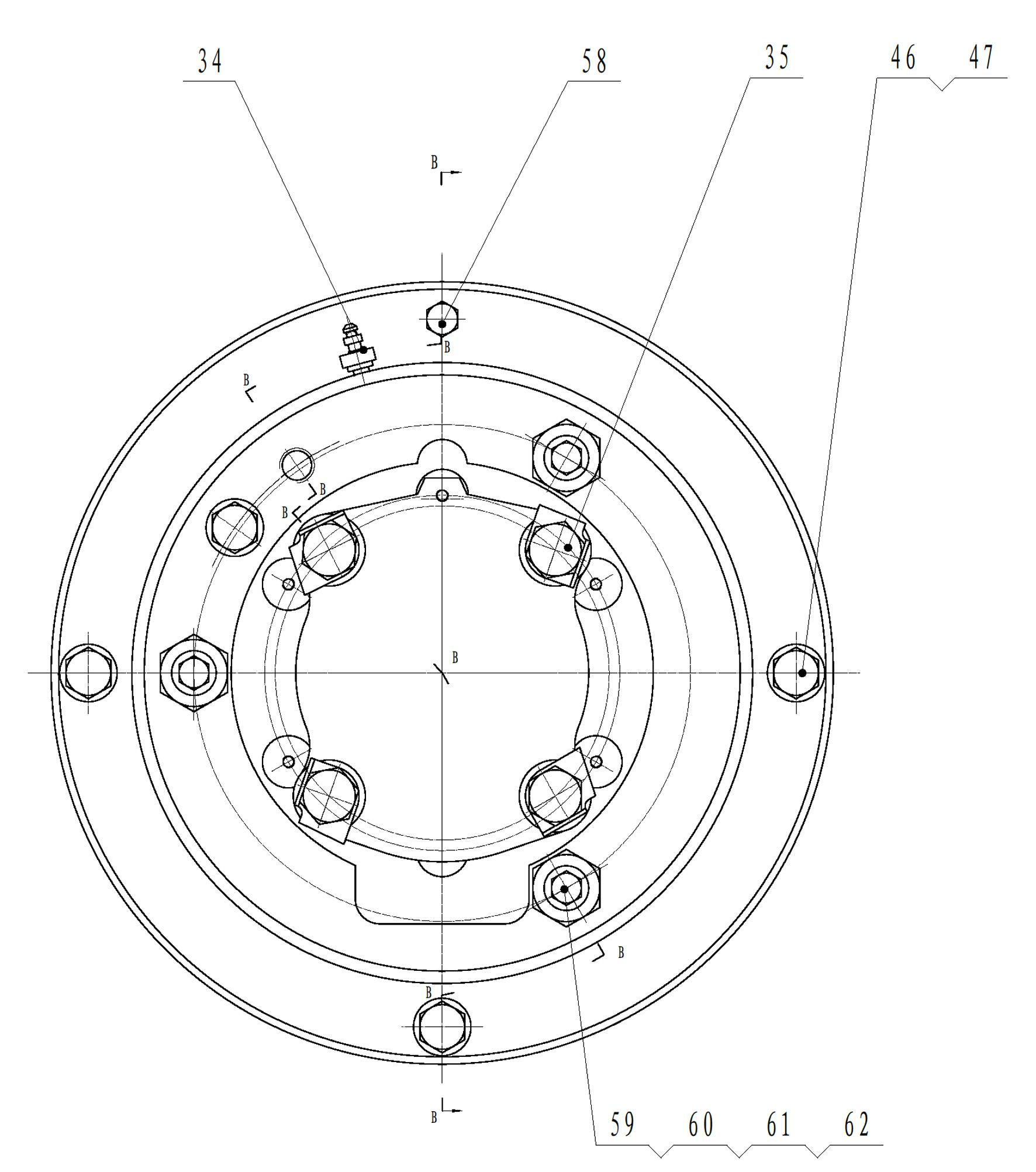

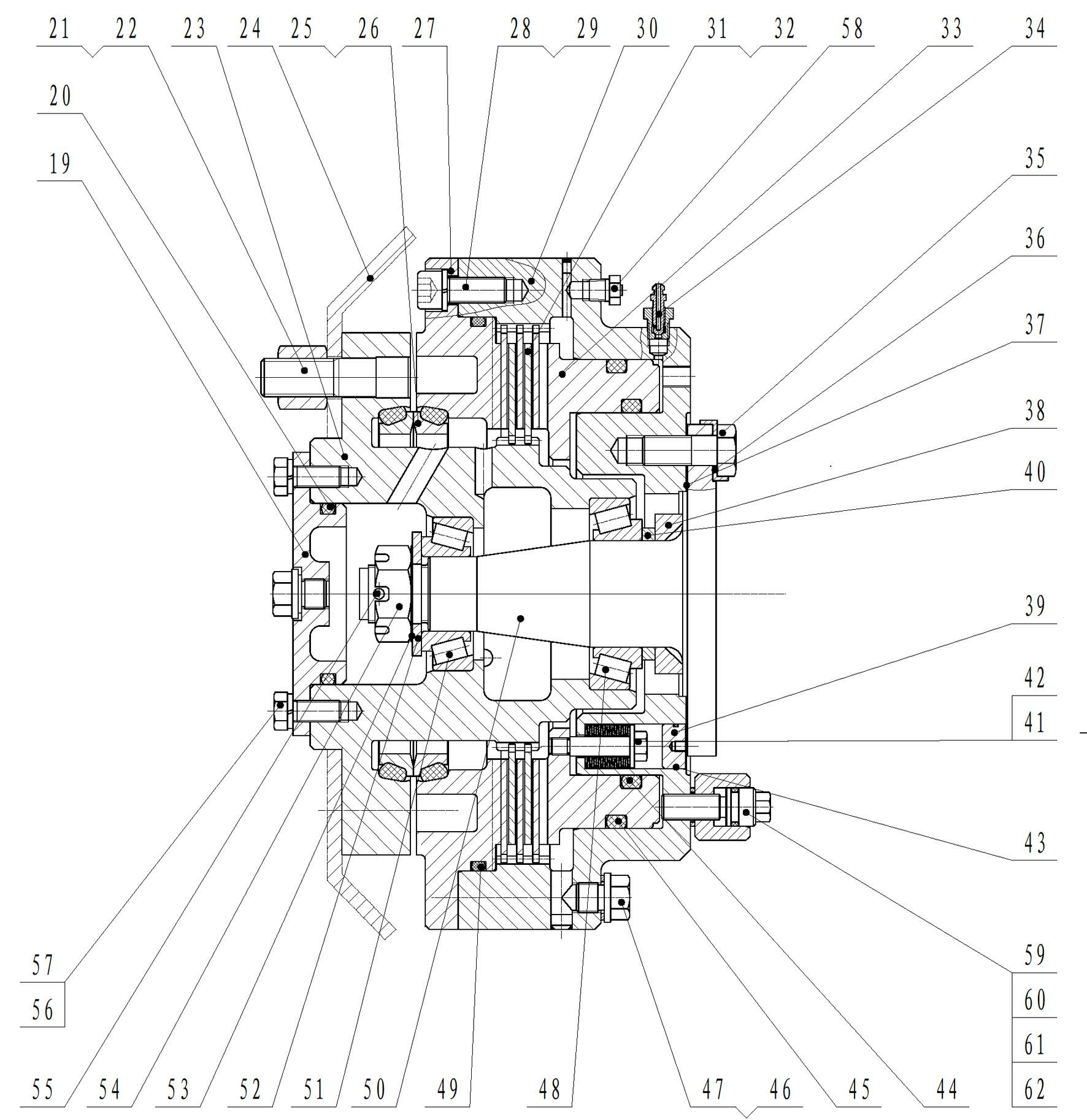

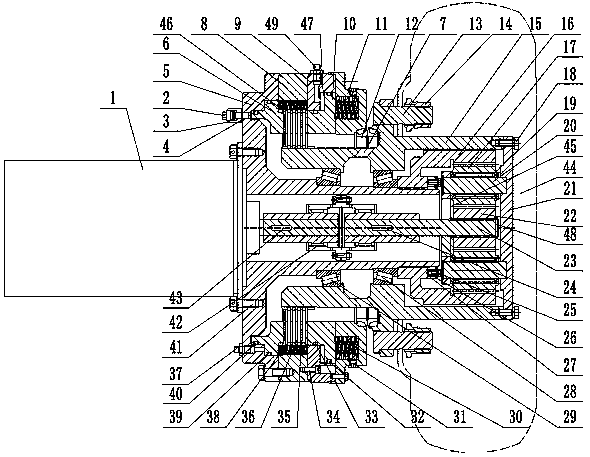

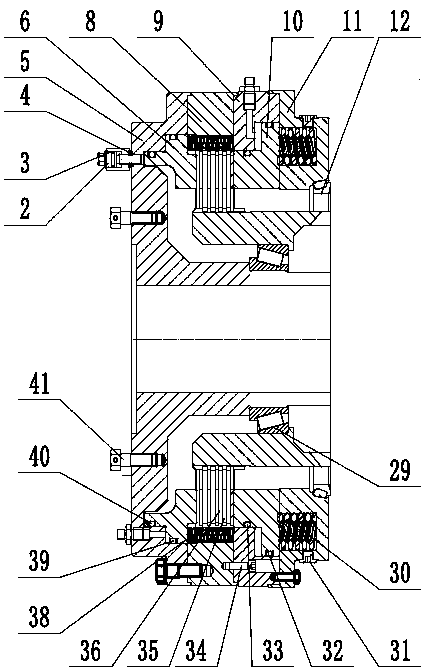

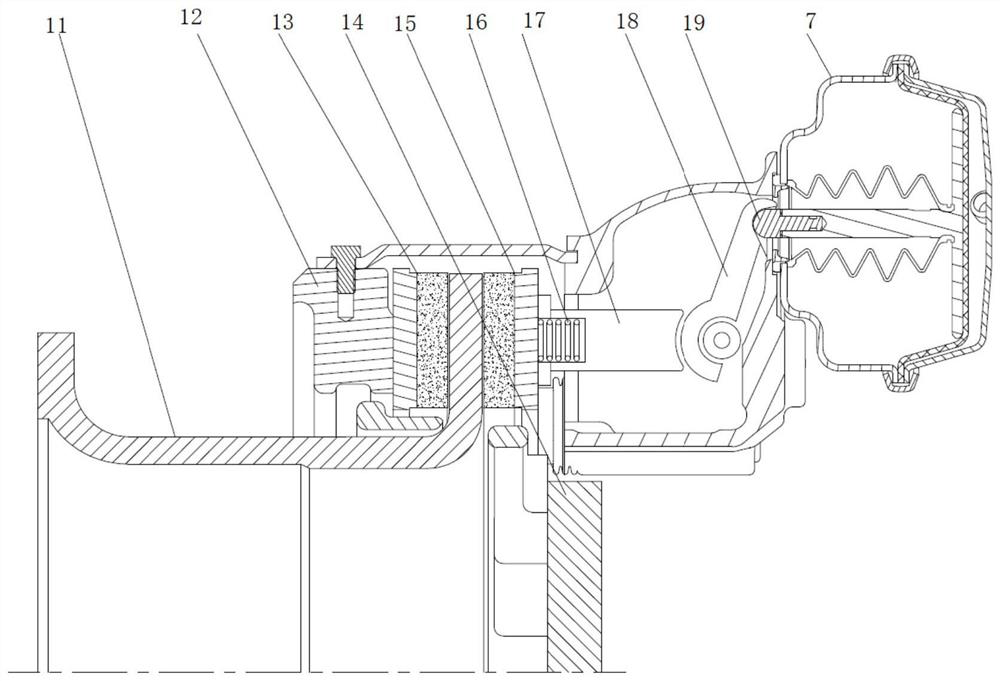

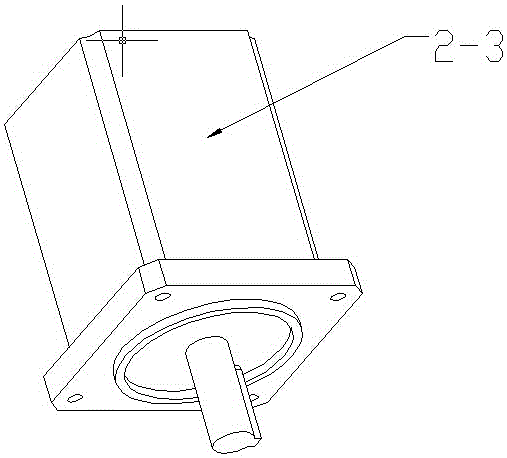

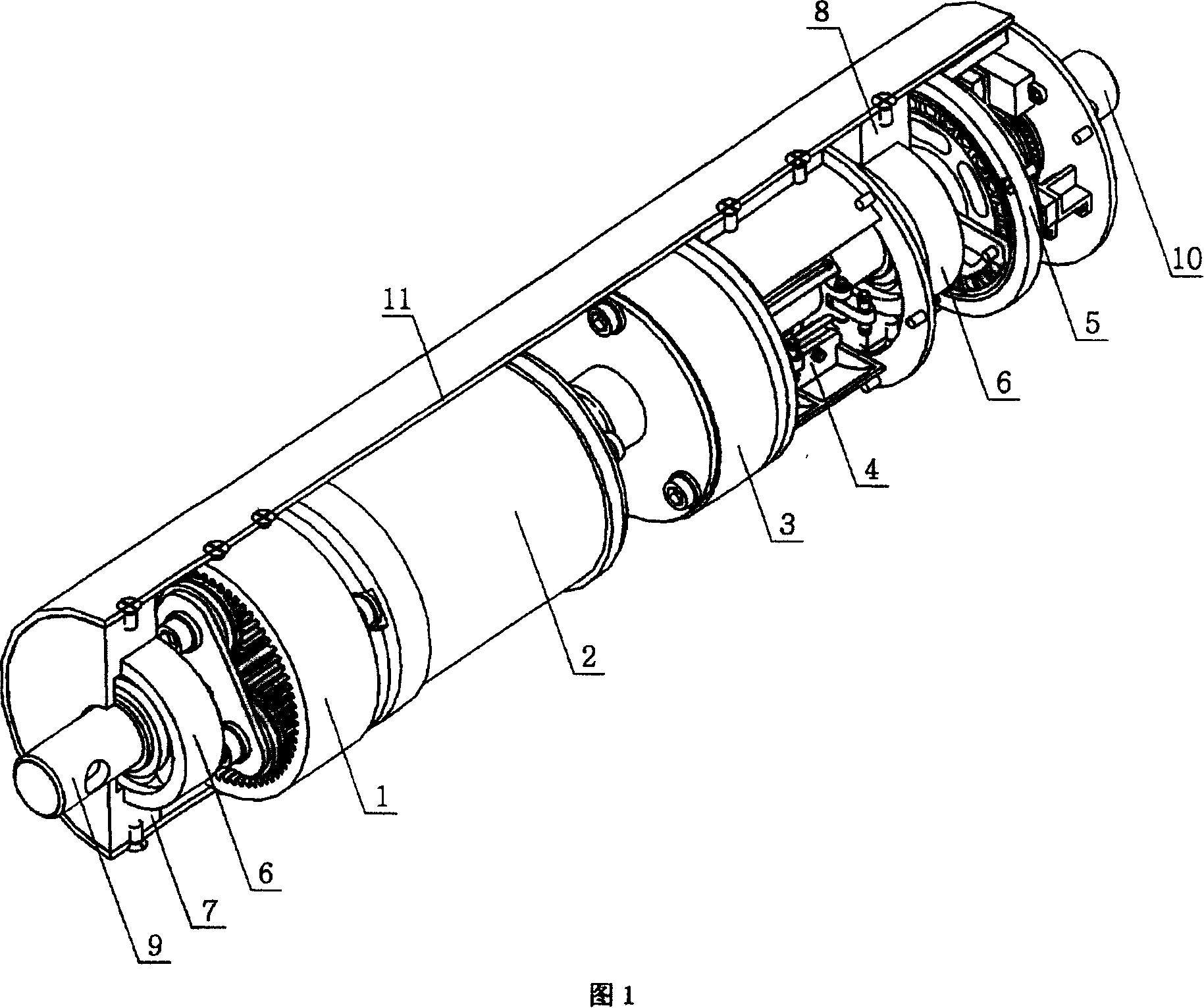

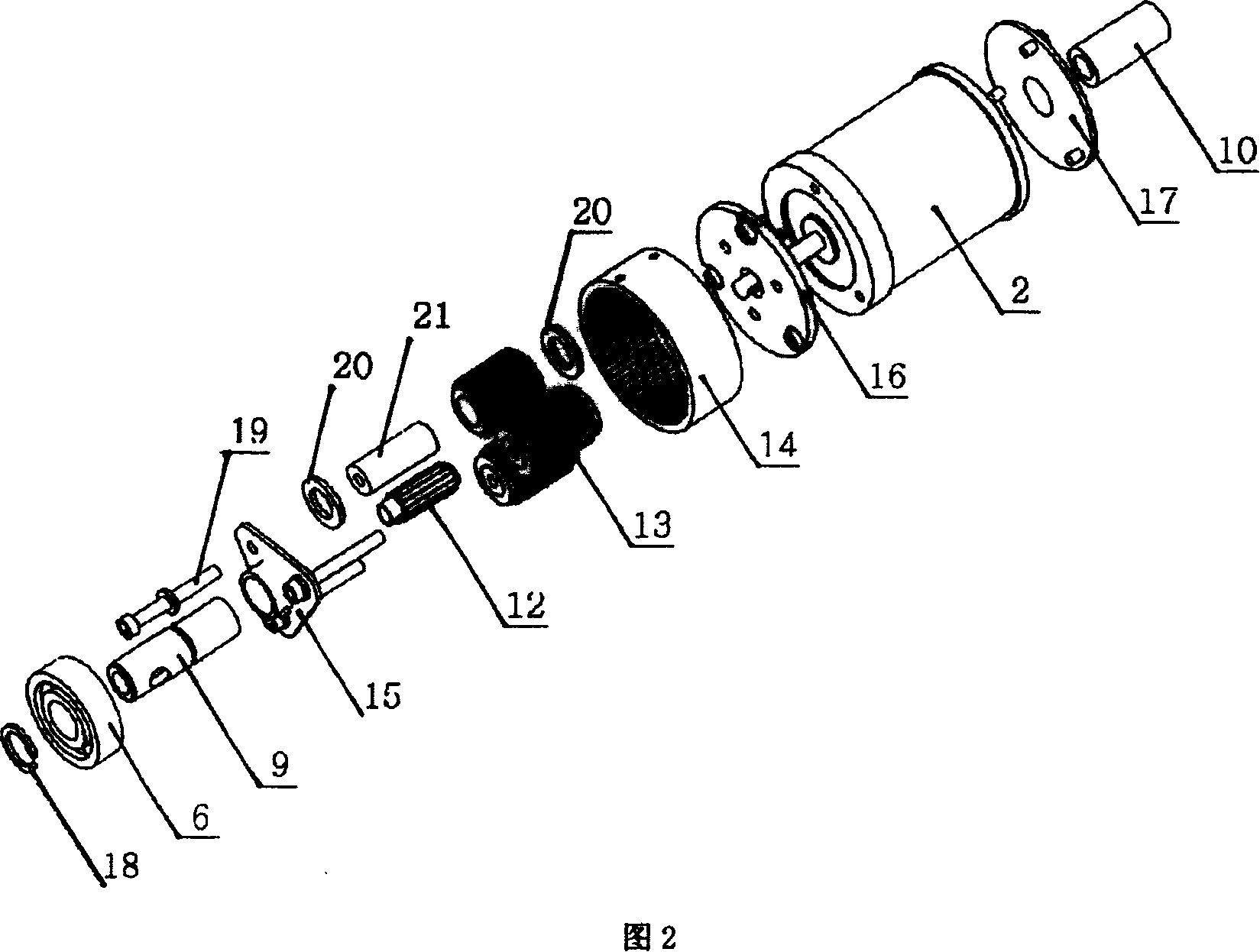

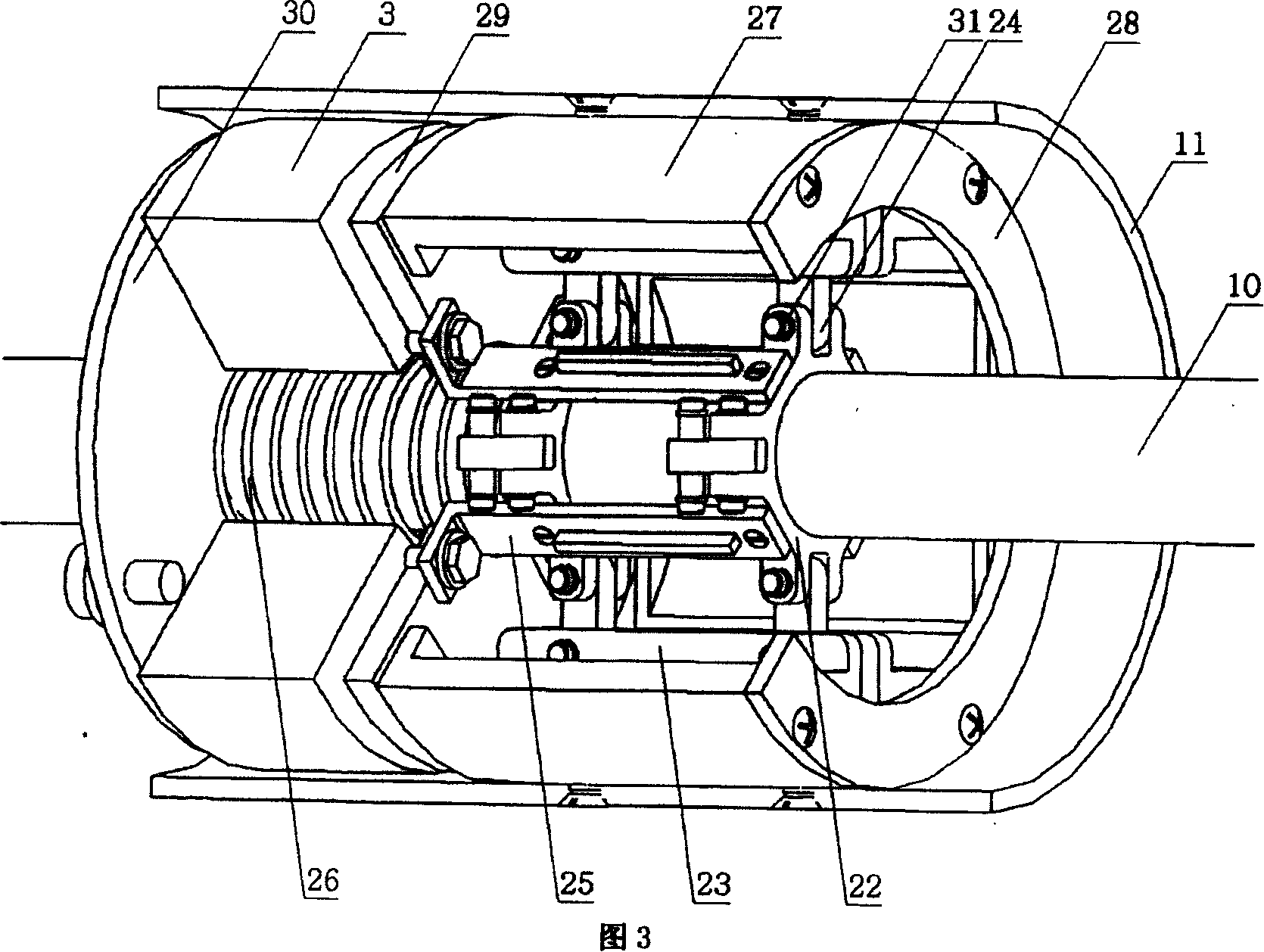

Totally-closed power transmission device used for coal mine explosion-proof electric rubber-wheel vehicle

InactiveCN109027055AGood cooling effectGood lubricityFluid actuated brakesToothed gearingsModular compositionAutomotive engineering

The invention belongs to the technical field of designing and manufacturing of coal mine underground trackless auxiliary equipment, and particularly relates to a totally-closed power transmission device used for a coal mine explosion-proof electric rubber-wheel vehicle. The device comprises a wheel edge transmission speed reduction mechanism, a travel braking mechanism and a parking braking mechanism; the wheel edge transmission speed reduction mechanism is connected with an explosion-proof motor through a coupler, the wheel edge transmission speed reduction mechanism is connected with the travel braking mechanism and the parking braking mechanism, an output shaft of the explosion-proof motor, the coupler, the transmission speed reduction mechanism, the travel braking mechanism and the parking braking mechanism are longitudinally connected in series and fixed and are located on the same central axis, the totally-closed modular combined integrated design is adopted, and the device has the beneficial effects of being compact in structure, convenient to dismount, mount and maintain, pollution-resisting, reliable in explosion-proof property, stable in property, energy-saving, environment-friendly, good in braking cooling effect and the like, and the traveling safety of the rubber-wheel vehicle can be improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

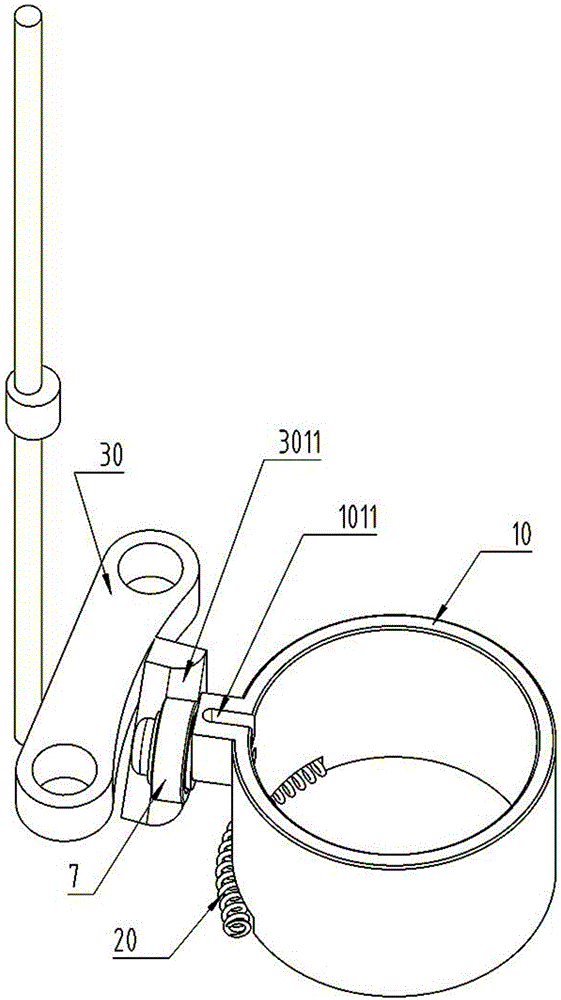

Positioning sleeve part for spindle brake device of braider

The invention discloses a positioning sleeve part for a spindle brake device of a braider. The positioning sleeve part comprises a positioning sleeve, a regulation seat, a steel wire torsion spring, a push-pull piece and a roller, wherein a through hole in the middle part of the positioning sleeve and an outer wall of the positioning sleeve are not positioned on the same axis; a positioning sleeve convex ring is arranged at the lower end of the positioning sleeve; the positioning sleeve convex ring and the through hole in the middle part of the positioning sleeve are positioned on the same axis; the positioning sleeve convex ring is arranged on a pit in the upper end of the regulation seat; a bayonet is formed in the upper end face of the positioning sleeve, and is used for accommodating a steel coil torsion spring cross arm; the roller is fixedly arranged on the outer wall of the positioning sleeve; the regulation seat is a circular ring, and a bayonet is formed in the inner wall of the regulation seat, and is used for accommodating a steel coil torsion spring vertical arm; the regulation seat is fixedly arranged on a convex column of a rack through a screw; through holes are formed in the walls of steel wire torsion spring seats, and are used for accommodating an upper arm or a lower arm of the steel wire torsion spring to fix the steel wire torsion spring seat on the rack; through holes are formed in the two ends of the push-pull piece; one end of the push-pull piece is fixedly arranged on the steel wire torsion spring, and the other end of the push-pull piece is fixedly arranged on the positioning sleeve. The positioning sleeve part has the advantage that the spindle brake is more sensitive, and is more convenient to regulate.

Owner:浙江本发科技有限公司

Novel automobile brake device

PendingCN107985279AImprove braking effectPedal power is smallBraking element arrangementsFoot actuated initiationsPiston rodBrake pad

The invention discloses a novel automobile brake device. The novel automobile brake device comprises a front wheel, a rear wheel and a main oil cylinder and is characterized in that the transverse piston of the main oil cylinder is hinged to a brake bottom rod through an L-shaped piston rod, and the brake bottom rod is provided with a pedal; the main oil cylinder is filled with brake and connectedwith a front wheel oil cylinder and a rear wheel oil cylinder through pipelines; a second piston rod is fixed to the second piston of the front wheel oil cylinder, the second piston rod are connectedto two symmetrical arc-shaped front brake pads, a circle of front brake drum is arranged outside the front brake pads, the two front brake pads are hinged to the second piston rod, a plurality of outwardly-radial springs are connected between each front brake pad and a protruding standing column in the middle of the second piston rod, and the front wheel is arranged outside the front brake drum.The novel automobile brake device is good in brake effect, and force needed for braking is small.

Owner:ZHEJIANG BELORD DRIVE TECH

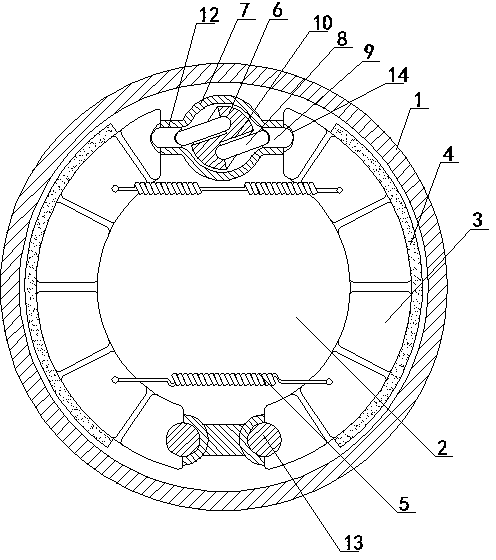

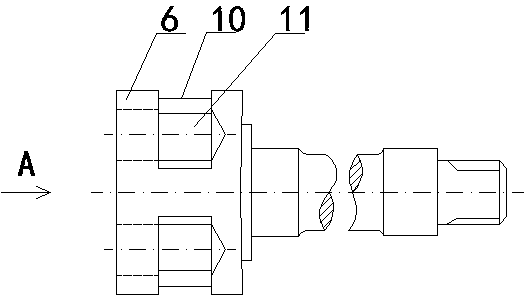

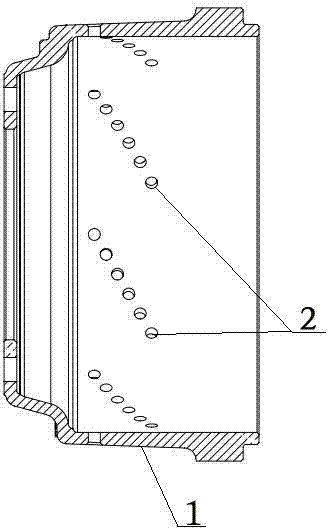

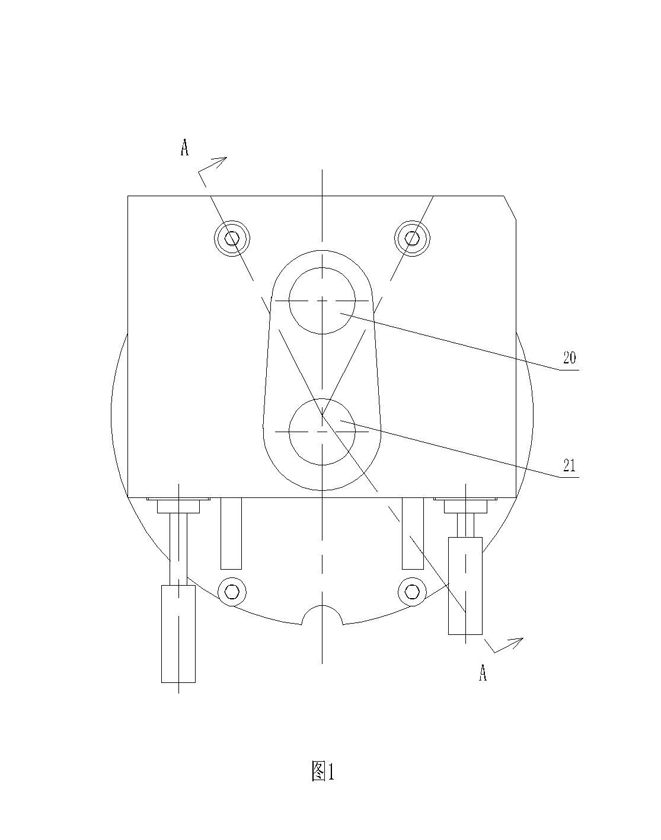

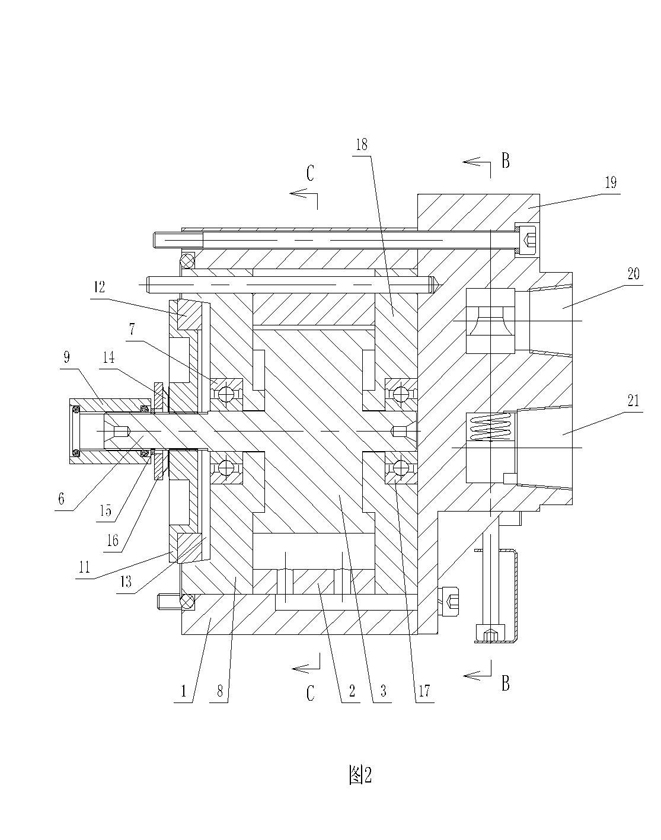

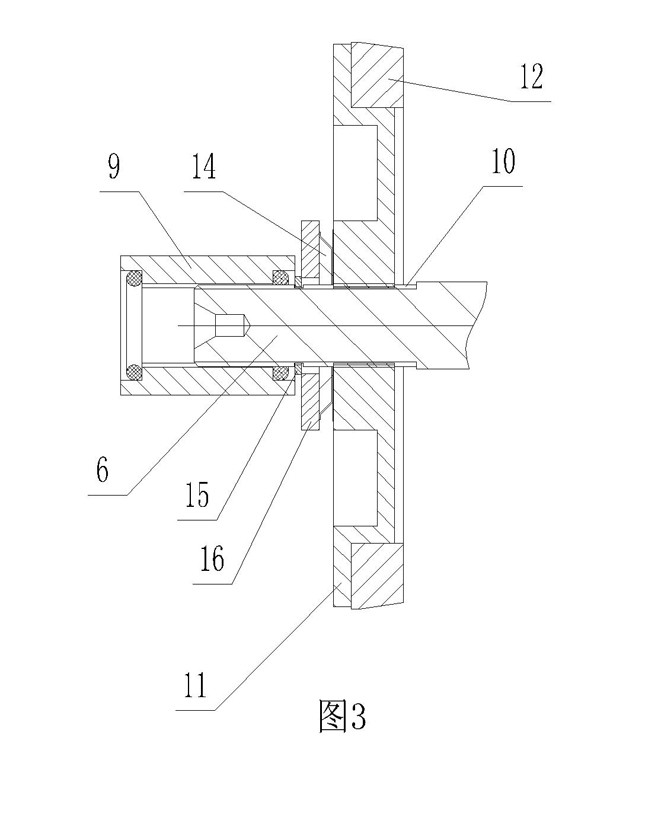

Actuating expanding device for automobile drum brake and drum brake

InactiveCN103899683AFlexible returnSensitive brakingBraking membersBrake actuating mechanismsDrum brakeEngineering

The invention discloses an actuating expanding device for an automobile drum brake and the drum brake comprising the actuating expanding device, and belongs to the production field of brakes. The actuating expanding device is characterized in that two radial deep grooves which are symmetrically distributed are formed in the head end of a centre driving shaft, an axial concave arc face is formed in the bottom of each groove, a connecting rod is inserted and connected into each radial deep groove, the two ends of each connecting rod are both convex arc faces, one end of each connecting rod is in sliding fit with the corresponding axial concave arc face, the outer side of the head end of the center driving shaft is sleeved with a guiding part which is fixedly arranged, the two ends of the guiding part are respectively provided with a round guiding hole, a top rod in sliding fit with each round guiding hole is arranged in each round guiding hole, one end of each top rod is a concave arc face and in sliding fit with the convex arc faces at the outer ends of the connecting rods, and the other end of each top rod is convex arc face. A stress arc face is machined at the top end of a brake shoe of the brake and in sliding fit with the top rods. Compared with the prior art, the actuating expanding device is large in expanding angle and flexible in expanding and returning; the drum brake has the advantages of being stable in braking, short in braking distance and the like.

Owner:周广如

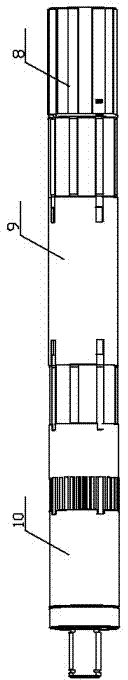

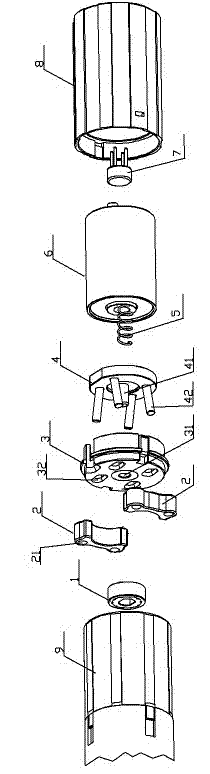

Brake assembly of mute tubular motor

A brake assembly of a mute tubular motor is installed on the tail portion of the tubular motor and comprises a brake disk, brake pads, a fixing base, an armature base, a spring, an electromagnet and a brake cover. The brake cover is meshed with a shell of the tubular motor through teeth, the brake disk is fixed to a rotary shaft of the tubular motor, the brake pads are arranged around the periphery of the brake disk, the spring is installed in a spring groove in the center of the electromagnet, the fixing base is meshed with the inner wall of the brake cover through teeth, one side of the armature base makes contact with the spring, and the spring keeps applying push force to the armature base. A sliding shaft is arranged in the center of the armature base, and the sliding shaft penetrates through a positioning hole of the fixing base. Multiple sets of splayed oblique shafts are arranged on the armature base, and the oblique shafts penetrate through kidney-shaped holes in the fixing base and stretch into oblique holes in the brake pads. The brake assembly is simple in structure and easy to machine; the tubular motor is braked sensitively by a control circuit in the mode that the electromagnet is attracted to the armature base, and the brake pads are further controlled to be unfolded and tightened up through the oblique shafts. Friction plates of the brake assembly are abraded in an integral contact mode, the friction degrees in all positions are the same, and therefore the brake assembly is good in braking effect, longer in service life and low in noise.

Owner:NINGBO HAIYU ELECTROMECHANICAL

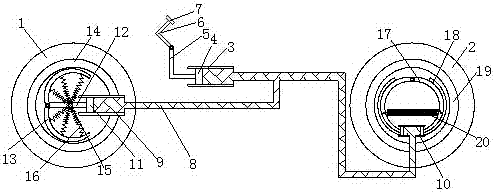

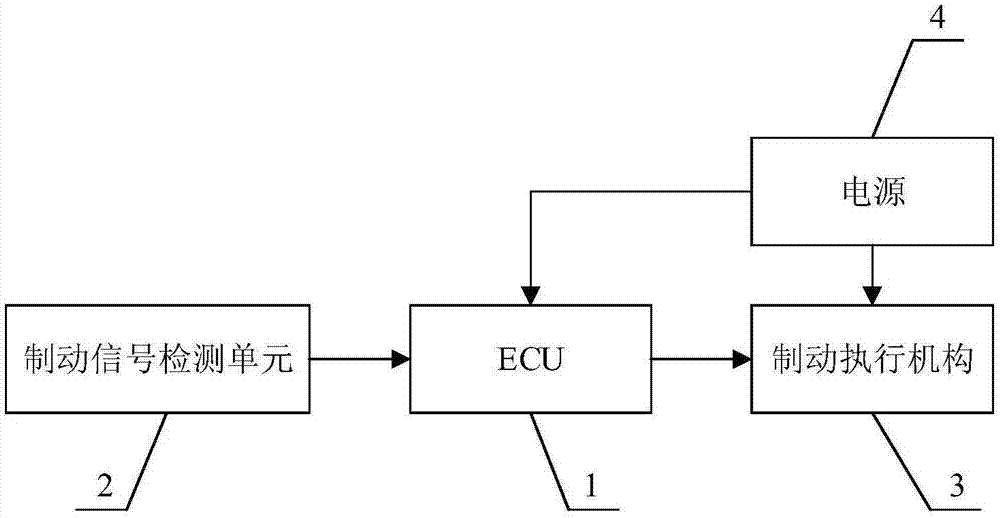

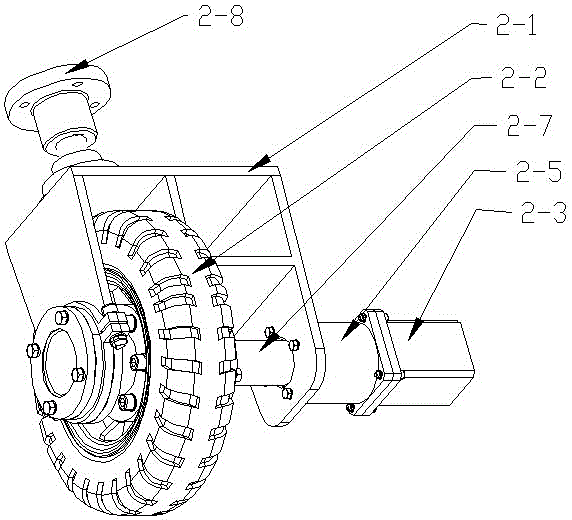

Electric control brake system used for trailer

PendingCN107878434AImprove ride comfort performanceSensitive brakesBraking action transmissionAutomatic initiationsElectric controlBraking system

The invention discloses an electric control brake system used for a trailer. The electric control brake system comprises an electric control unit (1), a brake signal detection unit (2), a brake execution mechanism (3) and a power source (4). The signal input end of the electric control unit (1) is connected with the signal output end of the brake signal detection unit (2), the signal output end ofthe electric control unit (1) is connected with the signal input end of the brake execution mechanism (3), and the power source (4) is connected with the power input ends of the electric control unit(1) and the brake execution mechanism (3). The electric control brake system is sensitive in braking and stable in brake direction, brake sideslips are unlikely to happen, no braking is conducted inthe trailer backing process, and the braking characteristic is adjustable.

Owner:NANJING UNIV OF SCI & TECH

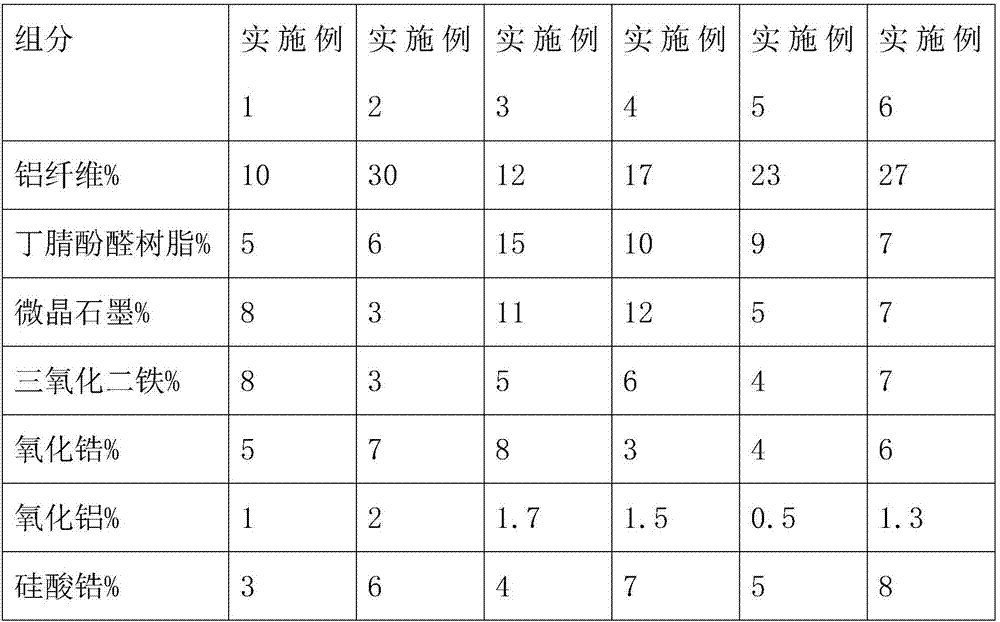

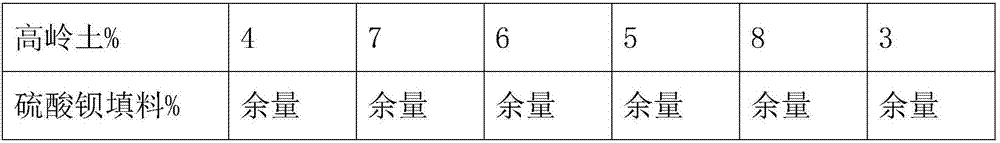

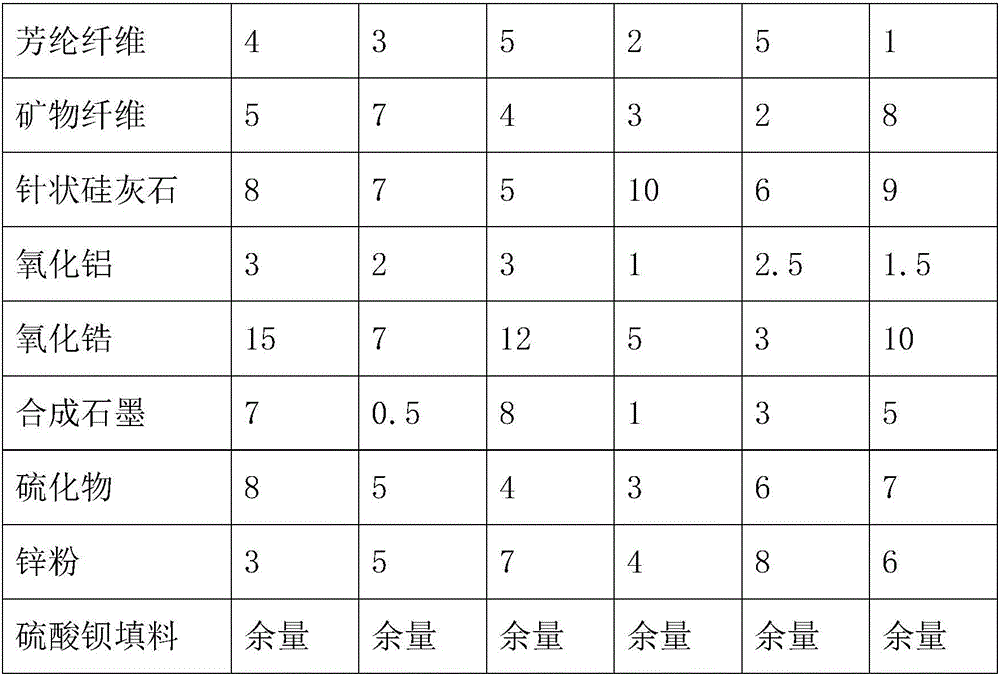

Novel fiber copper-free composition for automobile brake pad, application and preparation method thereof

ActiveCN107461436AHigh thermal conductivityAvoid thermal decayOther chemical processesFriction liningAluminiumFiber

The invention discloses a novel fiber copper-free composition for an automobile brake pad, application and a preparation method thereof, and relates to the technical field of automobile brake pad preparation. According to the novel fiber copper-free composition for the automobile brake pad, aluminum fibers, kaolin, butyronitrile phenolic resin and amorphous graphite are used cooperatively. According to the novel fiber copper-free composition for the automobile brake pad, the aluminum fibers are added in a brake pad formula, and the aluminum fiber has high heat conductivity, so that friction heat produced during a braking process can be remarkably conducted, and the occurrence of a heat fading phenomenon is avoided.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

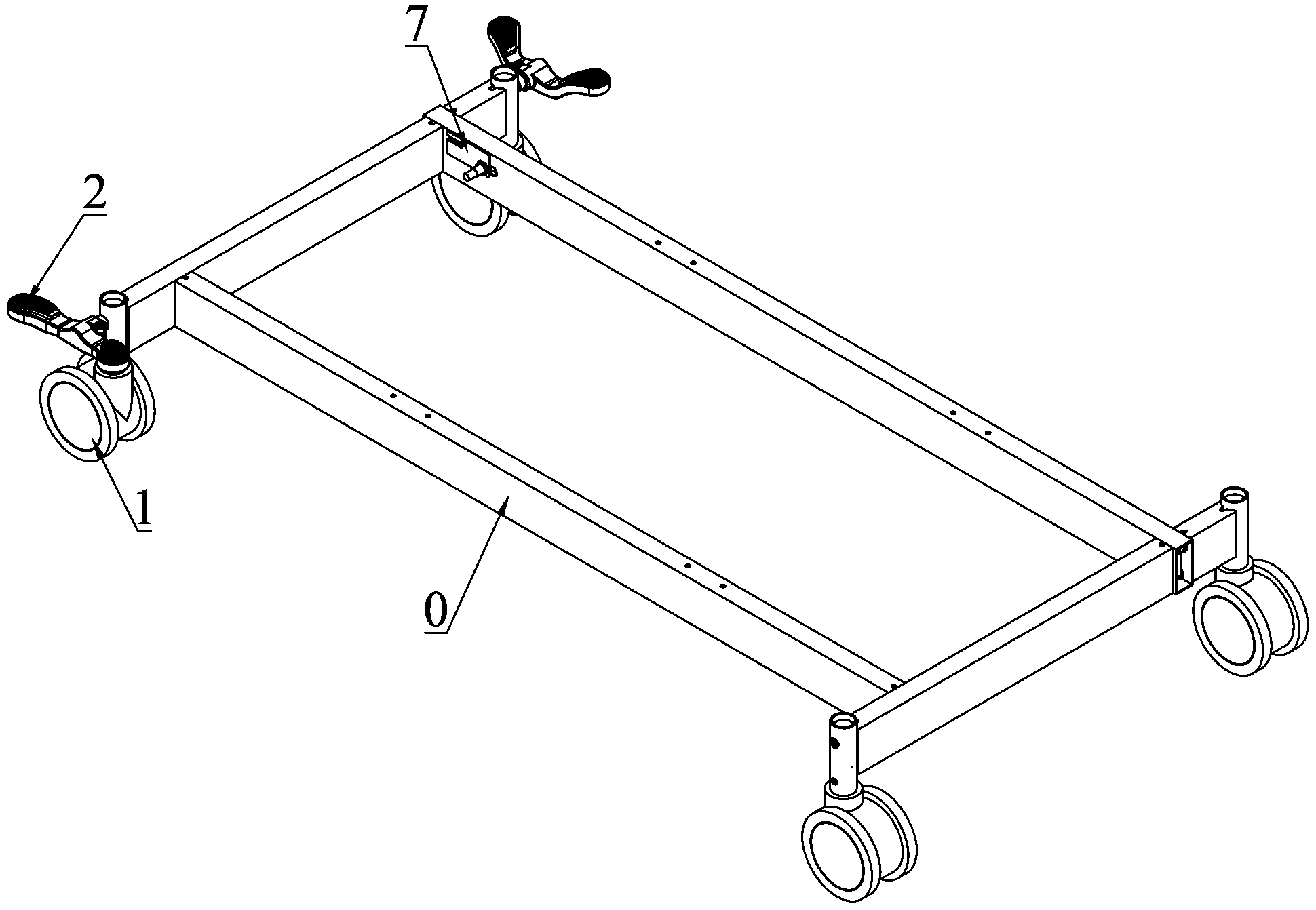

Hospital bed brake warning mechanism and hospital bed with same

ActiveCN104257475AFully understand the real-time braking statusSimple structureNursing bedsProximity sensorEngineering

The invention provides a hospital bed brake warning mechanism and a hospital bed with the same and relates to the technical field of brake devices of hospital beds. The hospital bed brake warning mechanism and the hospital bed aim at solving the problems that the existing wheel hospital beds are high in cost and free of warning function. The hospital bed brake warning mechanism comprises central control pedal plates, hexagonal rods, swing pieces and a central control connecting rod; the hexagonal rods are arranged on two castors of a hospital bed in a straddled mode respectively; the two central control pedal plates sleeve two ends of the hexagonal rods respectively; each central control pedal plate is provided with a stamping portion for a human foot to stamp so as to enable the hexagonal rods to rotate; the central control connecting rod is perpendicularly arranged between the two hexagonal rods; two ends of the central control connecting rod are connected with the hexagonal rods through the swing pieces respectively; each swing piece is formed by a hexagonal sleeve and a connecting piece; each hexagonal sleeve sleeves the corresponding hexagonal rod through a hexagonal inner hole formed inside the hexagonal sleeve; one end of each connecting piece is fixedly connected with the corresponding hexagonal sleeve; the other end of each connecting piece is hinged to the central control connecting rod; the hospital bed brake warning mechanism also comprises an proximity sensor and a warning device; the proximity sensor is used for detecting the position of the central control connecting rod. According to the hospital bed brake warning mechanism, the accidental injury to the personnel due to the fact that the hospital bed is located in the non-braking state can be effectively avoided.

Owner:江西美格尔医疗设备有限公司

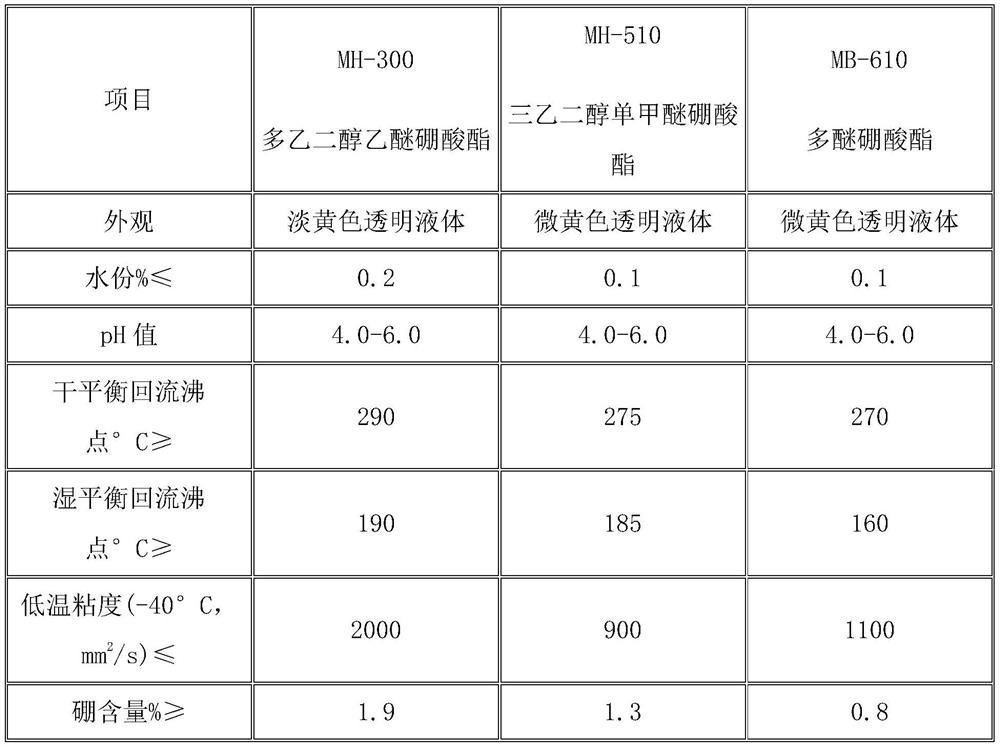

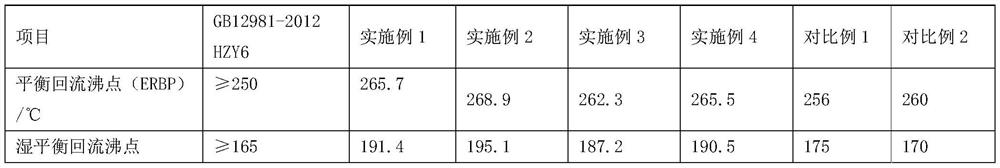

Borate type synthetic brake fluid with ultralow low-temperature viscosity and preparation method thereof

InactiveCN111961521AThe purity of raw materials is highly controllableEfficient and simple productionLubricant compositionEthyleneglycol monobutyl etherEther

The invention provides a borate type synthetic brake fluid with ultralow low-temperature viscosity. The borate type synthetic brake fluid consists of triethylene glycol monomethyl ether borate, triethylene glycol monomethyl ether, triethylene glycol monobutyl ether, an antioxidant, a corrosion inhibitor and a pH value regulator. The invention also provides a preparation method of the borate type synthetic brake fluid with ultralow low-temperature viscosity. According to the invention, the lower limit of low-temperature fluidity of an existing borate type brake fluid is broken through; meanwhile, Class6 in International Standard ISO4925:2005 Road vehicles-specification of non-petroleum-base brake fluids for hydraulic systems and HZY6 grade product specification requirements in national standard GB12981-2012 Motor Vehicle Brake Fluids are met, and it can also be guaranteed that braking is sensitive and timely under extremely cold weather conditions; the dry boiling point and the wet boiling point are high and stable, and air resistance is not prone to occurring; the lubricity is good, and the braking is stable; corrosion to metal materials of a brake system is small, swelling to rubber parts is small, and oxidation resistance and thermal stability are excellent.

Owner:上海中孚油品集团有限公司

Environmentally friendly high performance grinding material composition

ActiveCN105907370AReduce deformationSensitive brakesOther chemical processesFriction liningEnvironmental resistanceEnvironmentally friendly

The invention discloses an environmentally friendly high performance grinding material composition. The composition comprises fused magnesia, fused zirconia, aramid fibers, tyre powder, expanded vermiculite, ceramic fibers, magnetite, multiwalled carbon nanotubes, boron-containing phenolic resin and benzoxazine resin. The composition has the characteristics of environmental friendliness, high temperature heat fading resistance, wear resistance, stable friction coefficient and long service life. Through reasonable matching of a plurality of components, advantages of various materials are fully performed in the friction material. The composition does not contain heavy metal substances and is environmentally friendly.

Owner:摩擦一号制动科技(仙桃)有限公司

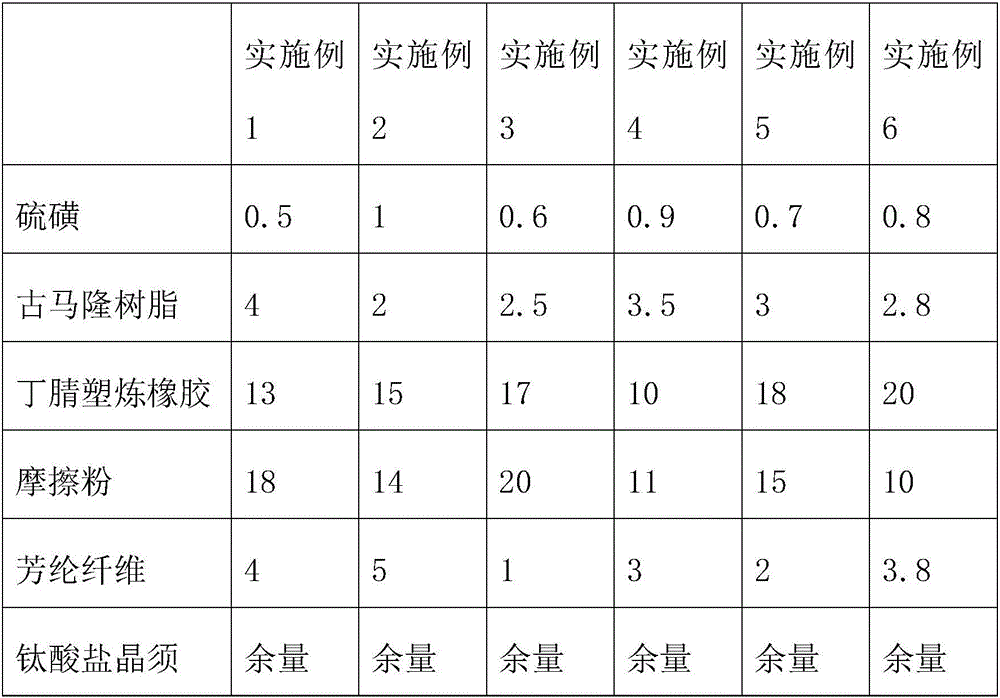

High-strength heat-resistant rubber-based composite for automobile brake pad and application and preparation method thereof

InactiveCN107435703AHigh strengthIncrease temperature resistanceOther chemical processesFriction liningCoumaronesHigh intensity

The invention discloses a high-strength heat-resistant rubber-based composition for automobile brake pads, an application and a preparation method thereof, and relates to the technical field of preparation of automobile brake pads. The formula of the high-strength heat-resistant rubber-based composition for automobile brake pads provided by the invention contains a high-component reinforcing whisker material and a coumarone resin material used in conjunction. The high-strength heat-resistant rubber-based composition for automobile brake pads provided by the invention solves the problem that the high heat generated during the braking process easily causes thermal recession of existing rubber-based brake pads, leading to brake failure and endangering life safety.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Spiral ventilation radiating brake drum

InactiveCN104265815AExtended service lifeReduce weightBraking drumsSlack adjustersAgricultural engineering

The invention relates to a spiral ventilation radiating brake drum which comprises a brake drum body. A brake friction face is arranged in the middle of the brake drum body, 4-10 rows of radiating holes series evenly distributed spirally are formed in the brake friction face, each row of radiating hole series comprises 4-8 radiating holes, and each row of radiating hole series are arranged linearly in the cross section of the brake drum body. The brake drum is light in weight, reduces the steps in the radiating process aspect of the existing brake drum, reduces production cost and greatly improves the braking capability foremost.

Owner:山西汤荣机械制造股份有限公司

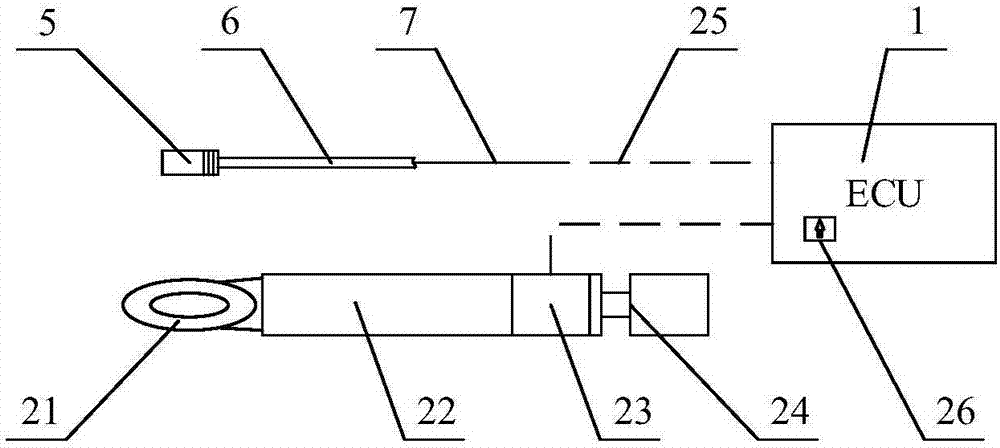

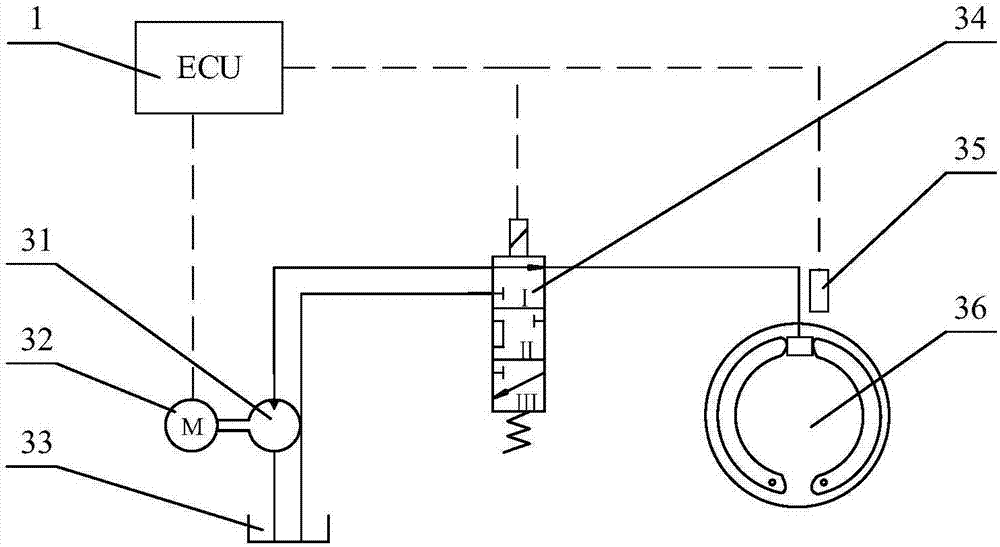

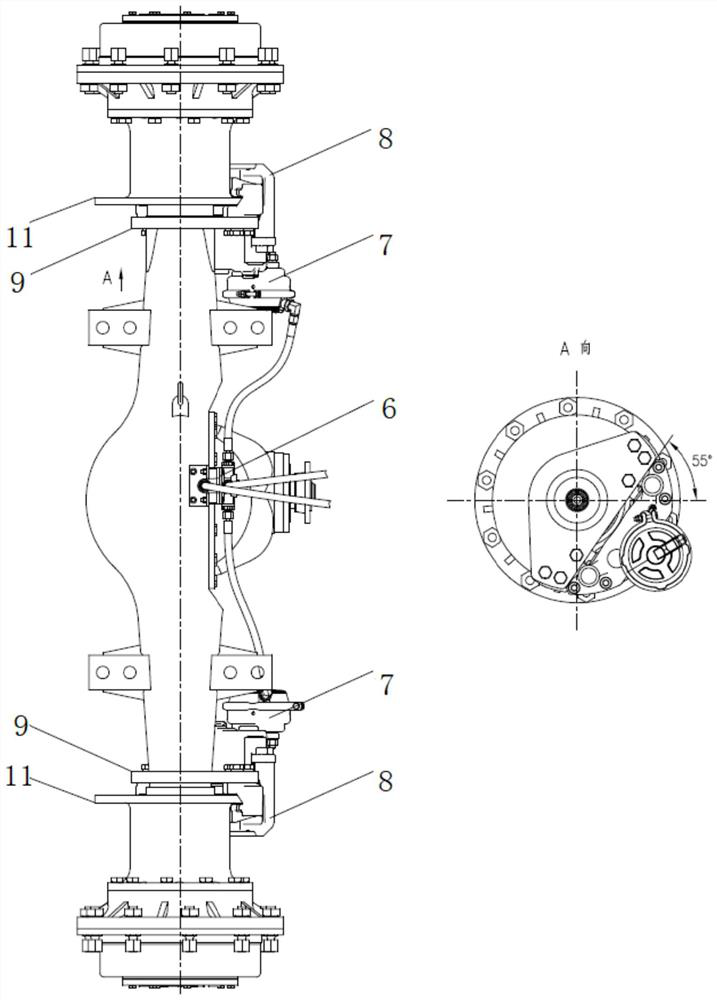

Active trailer braking system

PendingCN108407783ASensitive brakingAvoid hysteresisAutomatic initiationsElectricityElectric machine

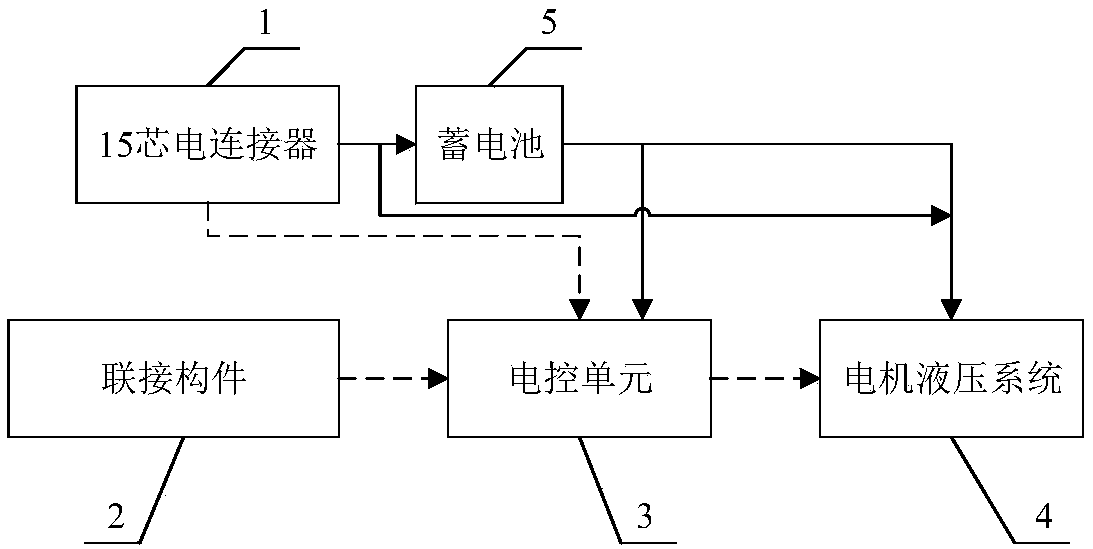

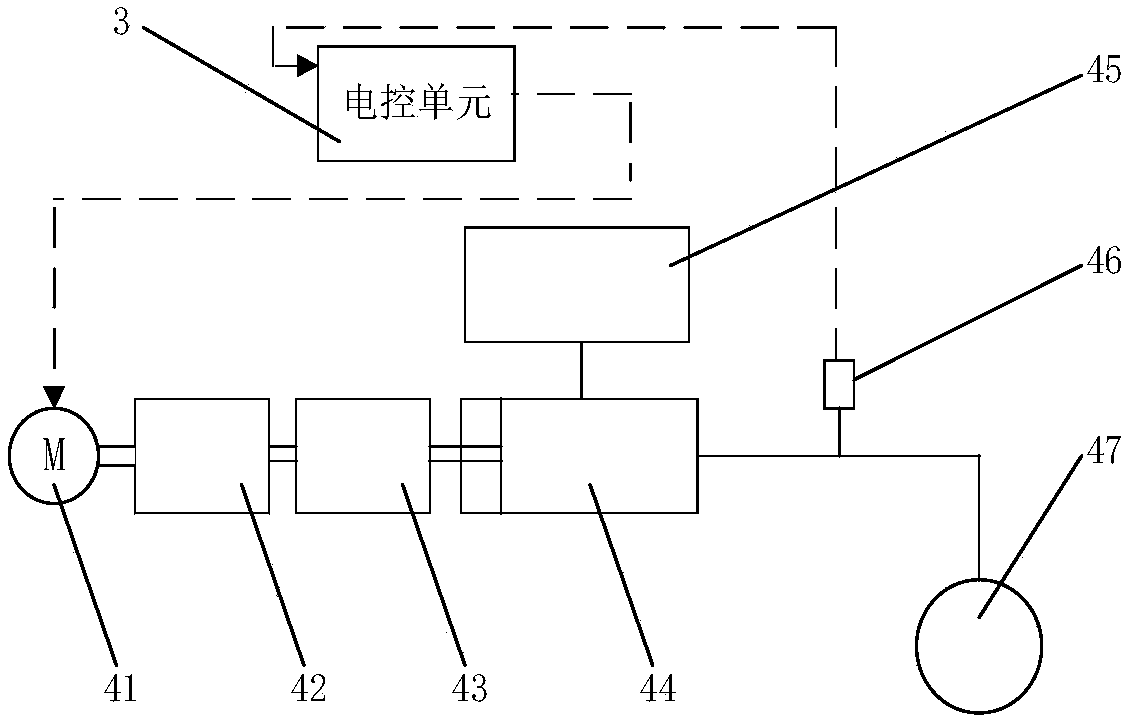

The invention discloses an active trailer braking system. The active trailer braking system comprises a 15-core electric connector (1), a connecting member (2), an electric control unit (3), a motor hydraulic system (4) and a storage battery (5); a signal input end of the electric control unit (3) is connected with signal output ends of the connecting member (2) and the 15-core electric connector(1); a signal output end of the electric control unit (3) is connected with a signal input end of the motor hydraulic system (4); a power supply output end of the 15-core electric connector (1) is connected with power supply input ends of the storage battery (5) and the motor hydraulic system (4); and a power supply output end of the storage battery (5) is connected with power supply input ends ofthe electric control unit (3) and the motor hydraulic system (4). The active trailer braking system has the advantages of sensitive braking, no braking during backing and adjustable braking characteristic.

Owner:NANJING UNIV OF SCI & TECH

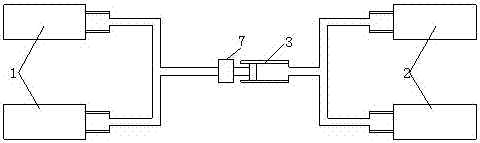

Service brake system for wheel loader

PendingCN111791858AImprove securityAvoid brake failureBraking element arrangementsBraking action transmissionRelay valveAir brake

The invention discloses a service brake system for a wheel loader. The system comprises an air compressor, an unloading valve, an air cylinder and a safety valve. The air compressor is connected withthe air cylinder through the unloading valve; the safety valve is arranged on the air cylinder and is used for limiting the highest pressure of the system. The service brake system is characterized byfurther comprising an air brake valve, a relay valve, a brake air chamber and a brake, an outlet of the air cylinder is connected with an air inlet of the air brake valve and an air inlet of the relay valve, an air outlet of the air brake valve is connected with a control air pressure input port of the relay valve, and an air outlet of the relay valve is connected with the brake through the brakeair chamber. The system cancels the brake fluid to thoroughly solve a gasification problem of the brake fluid and improve the safety of the service brake system. The relay valve is used in the system, the position is reasonably arranged, the inflation time of a brake air chamber is shortened, the brake lag time is shortened, and brake is more sensitive.

Owner:龙工(上海)机械制造有限公司

Automatic guide part conveying device

InactiveCN105082979ASensitive brakesPrecise positioningMotor depositionVehiclesVehicle frameControl engineering

The invention provides an automatic guide part conveying device. The automatic guide part conveying device comprises a drive system, an anti-collision system, a power supply system, a frame chassis and a center controller. The operating state of the drive system is controlled through the center controller to guarantee stable operation of the device. The drive system comprises four independent drive units and the drive frame chassis. Motors are arranged in the drive units and can independently finish steering and driving. The drive frame chassis finishes part conveying. The power supply system comprises a battery jar, and power supply is achieved through a battery in the battery jar. The anti-collision system comprises a mechanical anti-collision system. The center controller controls the motors arranged in the driving units to slow down for collision prevention, or the mechanical anti-collision system automatically avoids obstacles. As the automatic guide part conveying device monitors the operating states of the four drive units, information is fed back to the center controller for operation of the device through a feedback system, the operating states are determined through processing, positioning is more accurate, vibration is low, and limitation from regions is avoided.

Owner:LUOYANG INST OF SCI & TECH

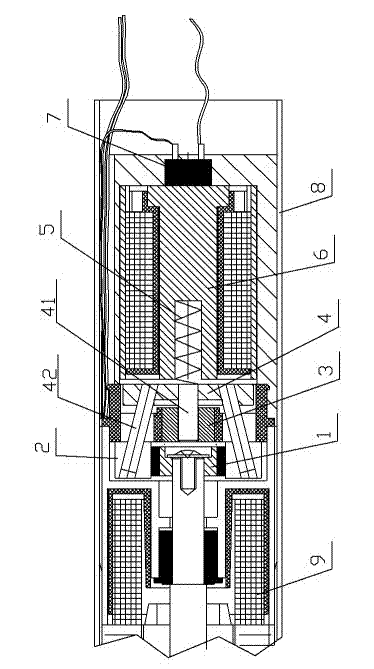

Tube-type electric motor

InactiveCN101141084APrecise positioningExtended service lifeBrake actuating mechanismsMechanical energy handlingLow speedProjection screen

The invention relates to a high performance tubular electric machine, comprising a tubular engine casing, and a drive assembly, a brake assembly and a travel control assembly which are supported in the tubular engine casing by a beari9ng seat; wherein the brake assembly comprises an electric machine right axis securing fitting, a right axis, an electromagnet right axis securing fitting, an electromagnet and a leverage braking mechanism; The electric machine right axis securing fitting is fixed at the right end surface of the low-speed electric machine and used for supporting one end of the right axis; the electromagnet right axis securing fitting is fixed at the right axis, the electromagnet is fixed at the electromagnet right axis securing fitting; the leverage braking mechanism is arranged at the right axis and arranged in the cavity which is arranged between the right axis and the tubular engine casing, the electromagnet drives the leverage braking mechanism to break. Trough the connecting-rod principle, the invention increase the elasticity of the pressure spring to reduce the power of the electromagnet, thereby the invention has the advantages of low energy consumption, quick starting, novel design of the brake assembly, rational structure, quick break speed, good break effect and long service time, therefore, the invention is capable of being widely used in various products such as dynamo-electric dropping door, sunshade system and projection screen, etc.

Owner:KELIYA MACHINE TECH SHANGHAI

Braking integrated pneumatic motor

InactiveCN102071974ACombination design is compactSmall sizeSafety/regulatory devicesRotary piston enginesEngineeringPneumatic motor

The invention discloses a braking integrated pneumatic motor, belonging to the technical field of pneumatic motors. The pneumatic motor comprises a stator installed in a shell and a rotor eccentrically arranged in the stator, wherein blade grooves are arranged on the rotor; and blades are arranged in the blade grooves in a matching manner and can move in the radial direction. The pneumatic motor is characterized in that an output shaft of the rotor is supported on a front end cover of the shell via bearings 1; the front end of the output shaft extends out of the front end cover; shaft sleevesare arranged at the front end of the output shaft; a section of outer splines are arranged on the output shaft between the front end cover and the shaft sleeves; braking bases are arranged on the outer splines in a matching manner; friction plates are arranged at the rear ends of the braking bases; wedge-shaped grooves are arranged at the front end of the front end cover and are matched with the friction plates; and resetting devices are arranged between the shaft sleeves and the braking bases. The pneumatic motor is sensitive to respond and has good braking effect, high safety property, highlifting speed and compact structure.

Owner:陈树忠

Composite double-layered brake pad and preparation method thereof

InactiveCN110594323AGood resistance to high temperature and thermal recessionImprove noise reductionOther chemical processesFriction liningFiberInsulation layer

The invention provides a composite double-layered brake pad and a preparation method thereof. The brake pad comprises steel backs and a brake pad body, and the brake pad body consists of a bonding heat-insulation layer and a friction layer. The preparation method comprises the following steps: uniformly dispersing materials of the friction layer and the bonding heat-insulation layer through a high-speed disperser respectively; then sequentially feeding the raw materials into a forming die; compounding the steel backs and then placing the steel backs into a vulcanizing press to be pressed; andremoving burrs to obtain the composite double-layered brake pad. The brake pad has the characteristics of environmental friendliness, good high-temperature heat fading resistance, good noise reductionperformance, stable friction coefficient, long service life and the like. The bonding heat-insulation layer plays a role in fixing the friction layer, improving the strength of the friction layer andisolating heat; a plurality of new fiber materials in the friction layer not only can mutually make up for the defects of respective properties, but also can cooperate to form high properties such asrapid heat dissipation, stable friction coefficient, reduction of deformation of the brake pad and the like; and by the brake pad, the excellent friction layer and an excellent transfer film are formed, and thus, an automobile brakes sensitively and is stable in braking.

Owner:SAFETY ZHONGSHAN AUTO SPARE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com