Non-asbestos micro-metal mineral fiber disk type brake block for automobile

A disc brake pad and mineral fiber technology, applied in friction linings, other chemical processes, chemical instruments and methods, etc., can solve problems such as easy rust, high noise of products, and harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

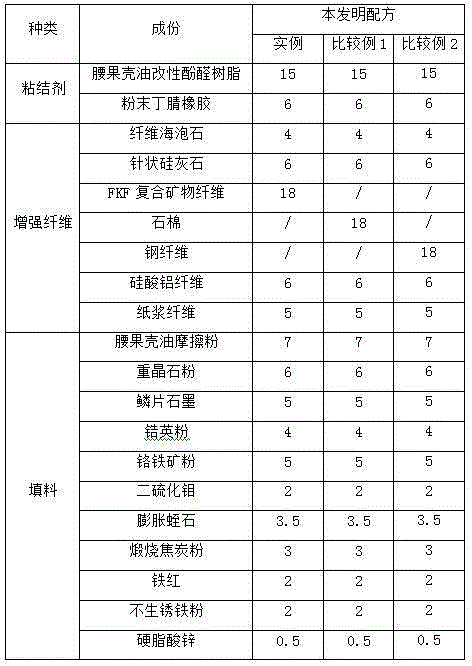

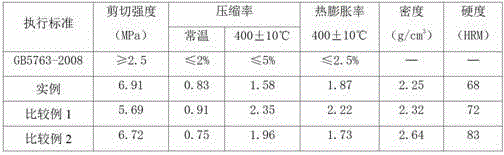

[0082] The invention mainly uses FKF composite mineral fiber as the main reinforcing material. Table 2 is an example of the friction material formulation weight % of the present invention. In Comparative Example 1, asbestos is used as the main reinforcing material, in Comparative Example 2, steel fiber is used as the main reinforcing material, and other components are completely the same. These three groups of tests are comparative tests carried out under the condition that the production process, production equipment, process parameters and product size are exactly the same.

[0083] Table 2 (weight %)

[0084]

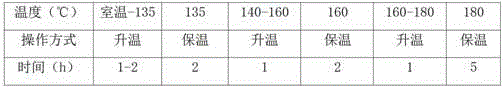

[0085] Process method: first weigh various raw materials according to the ratio of raw materials specified in Table 2, and proceed in steps.

[0086] 1) Batching and mixing: In order to fully and evenly mix the raw materials, batch premixing is usually carried out.

[0087] Premix one: loose fiber. According to the ratio of raw materials in Table 2, weigh zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com