Braking integrated pneumatic motor

A technology of air motors and housings, applied in the direction of rotating or swinging piston engines, engine components, machines/engines, etc., can solve the problems of complex structure, hidden safety hazards in hoisting work, high production costs, etc., and achieve high safety performance and braking effect Good, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

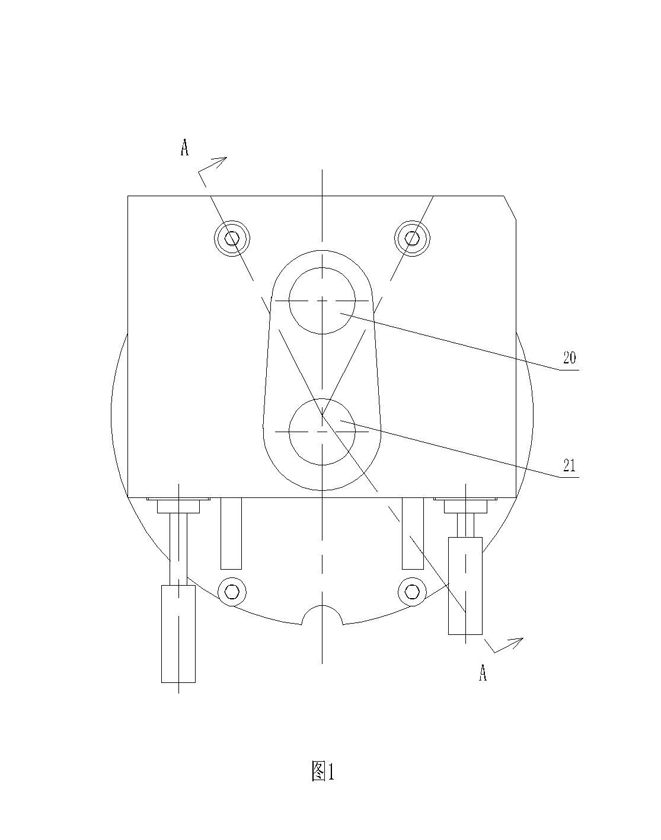

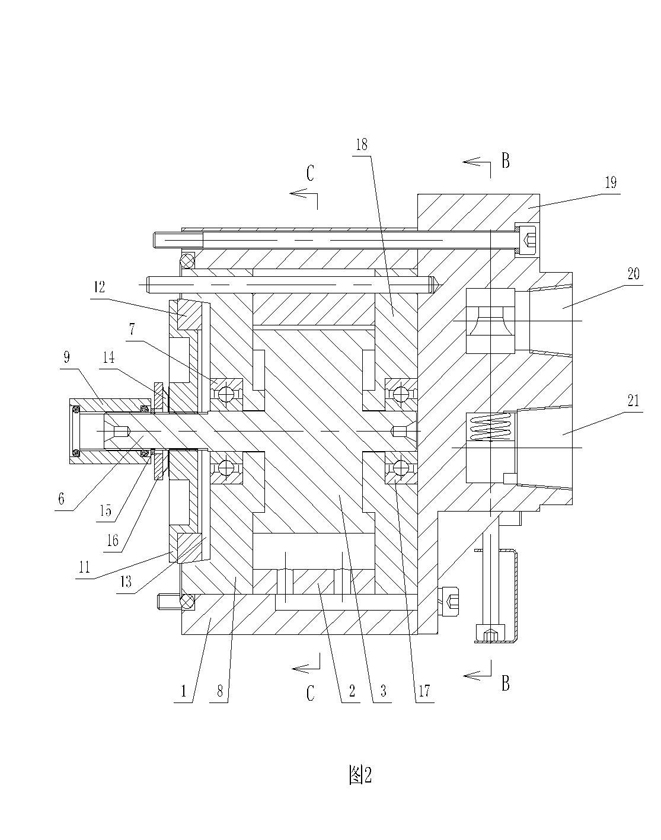

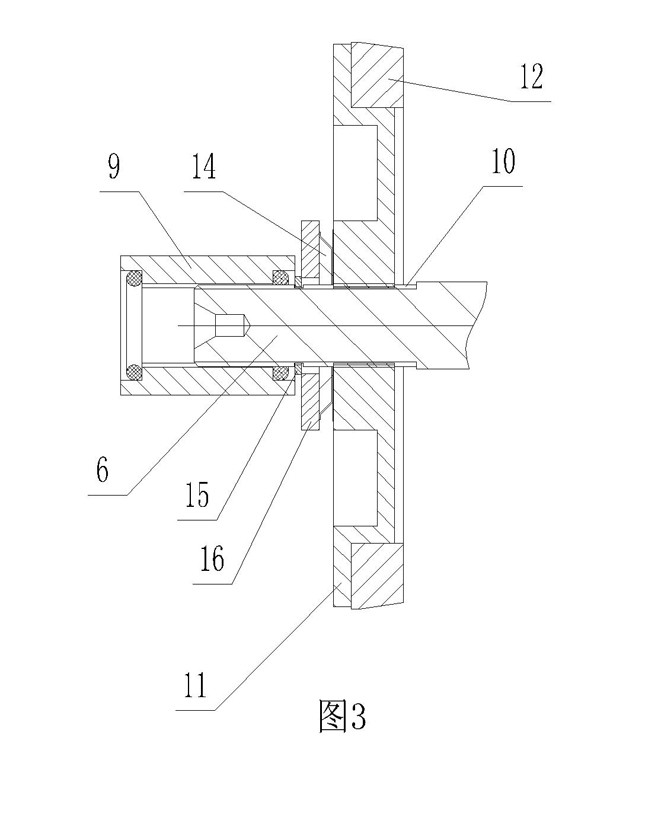

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the air motor with brake integration of the present invention includes a stator 2 installed in the housing 1, an eccentric is arranged in the stator 2, a rotor is installed in the stator 2, and a blade groove 4 is arranged on the rotor 3, and the blade groove 4 The blade 5 is fitted inside and the blade 5 can move radially. The output shaft 6 of the rotor 3 is supported on the front end cover 8 of the housing 1 through a bearing 7. The front end of the output shaft 6 extends outward from the front end cover 8. The output shaft The front end sleeve of 6 is provided with a shaft sleeve 9, and a section of external spline 10 is provided on the output shaft 6 between the front end cover 8 and the shaft sleeve 9, and a brake seat 11 with an internal spline is arranged on the external spline 10. , the rear end of the brake seat 11 is provided with a friction plate 12, and the front end of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com