Patents

Literature

2791results about "Rotary piston engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

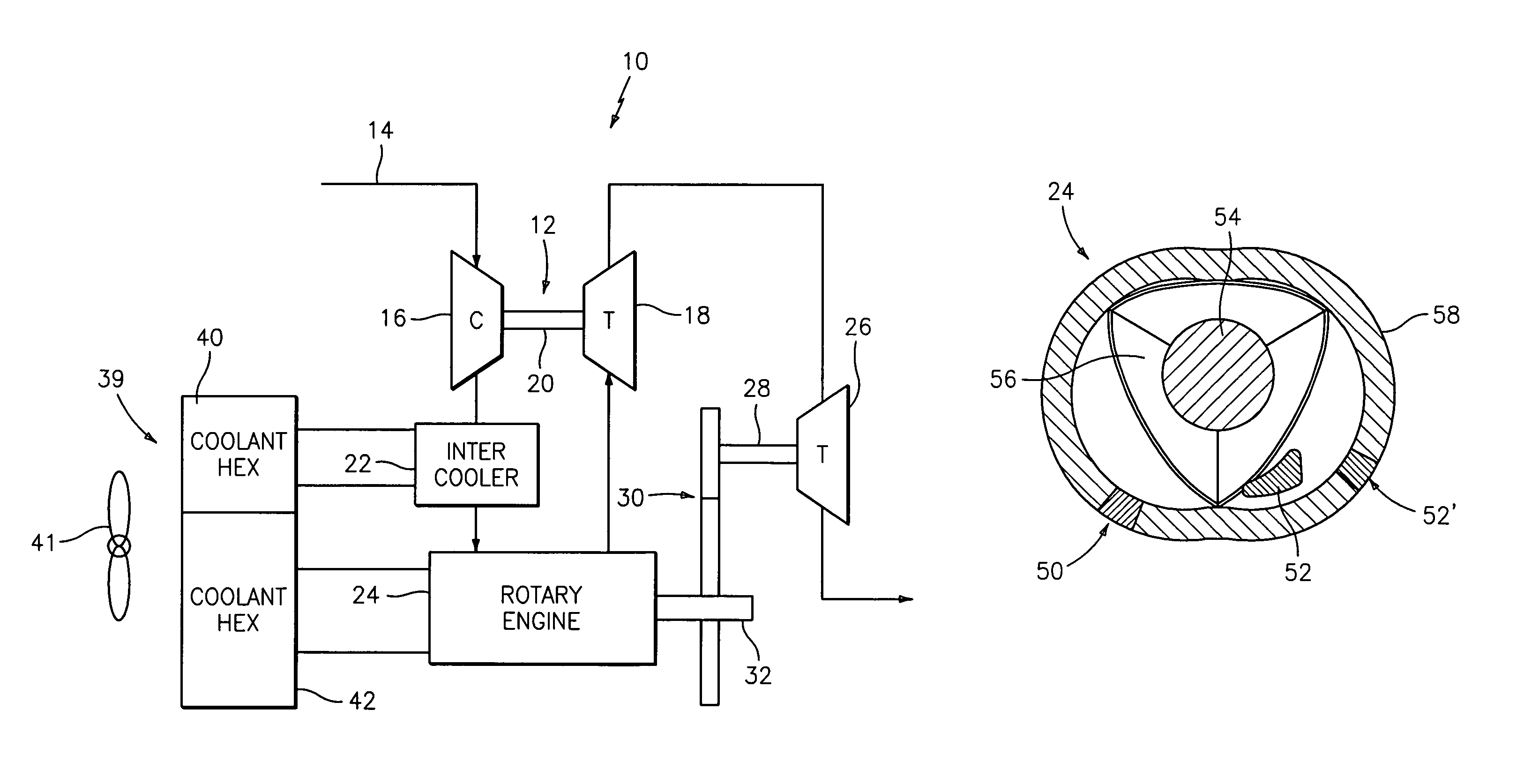

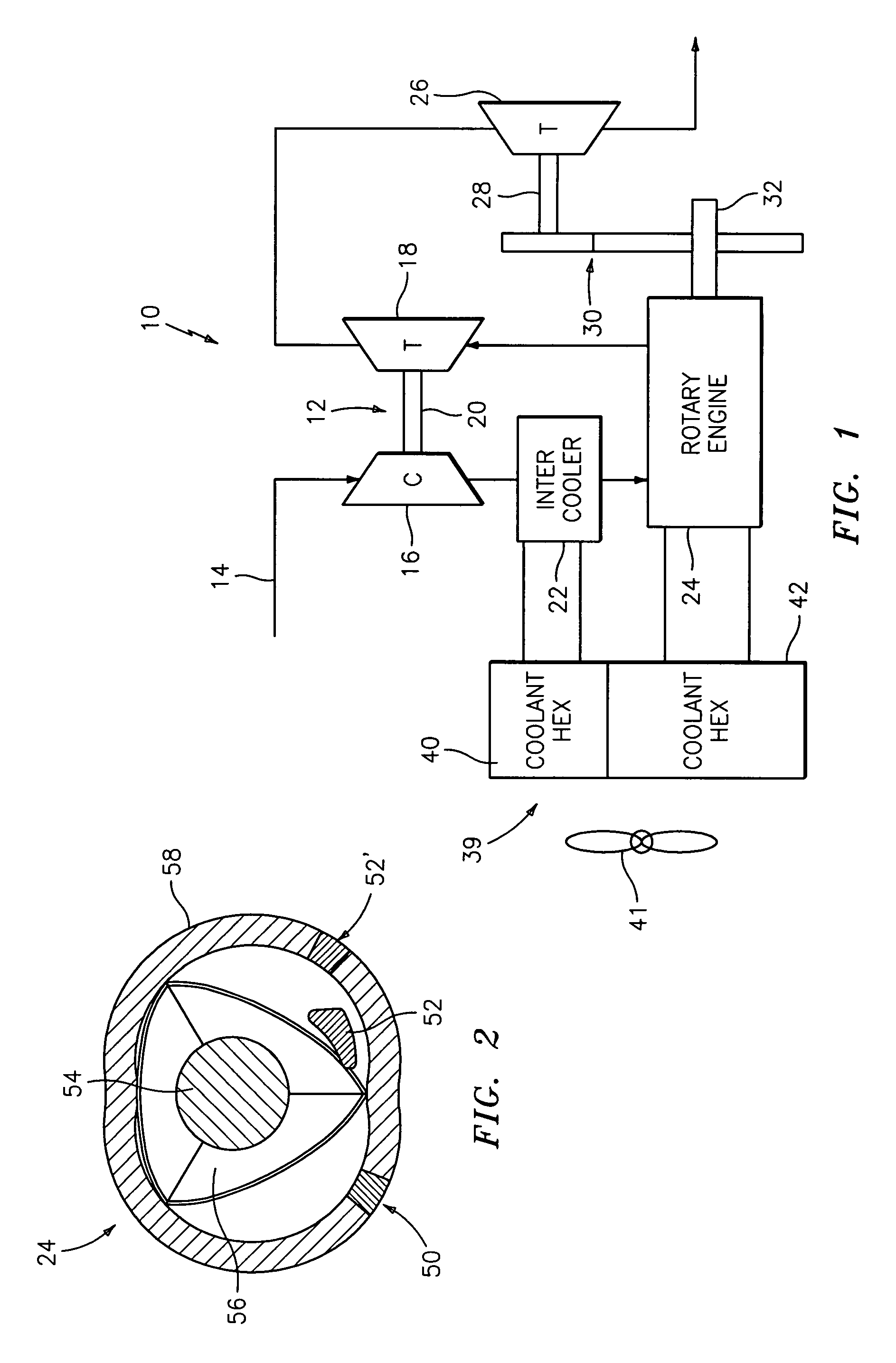

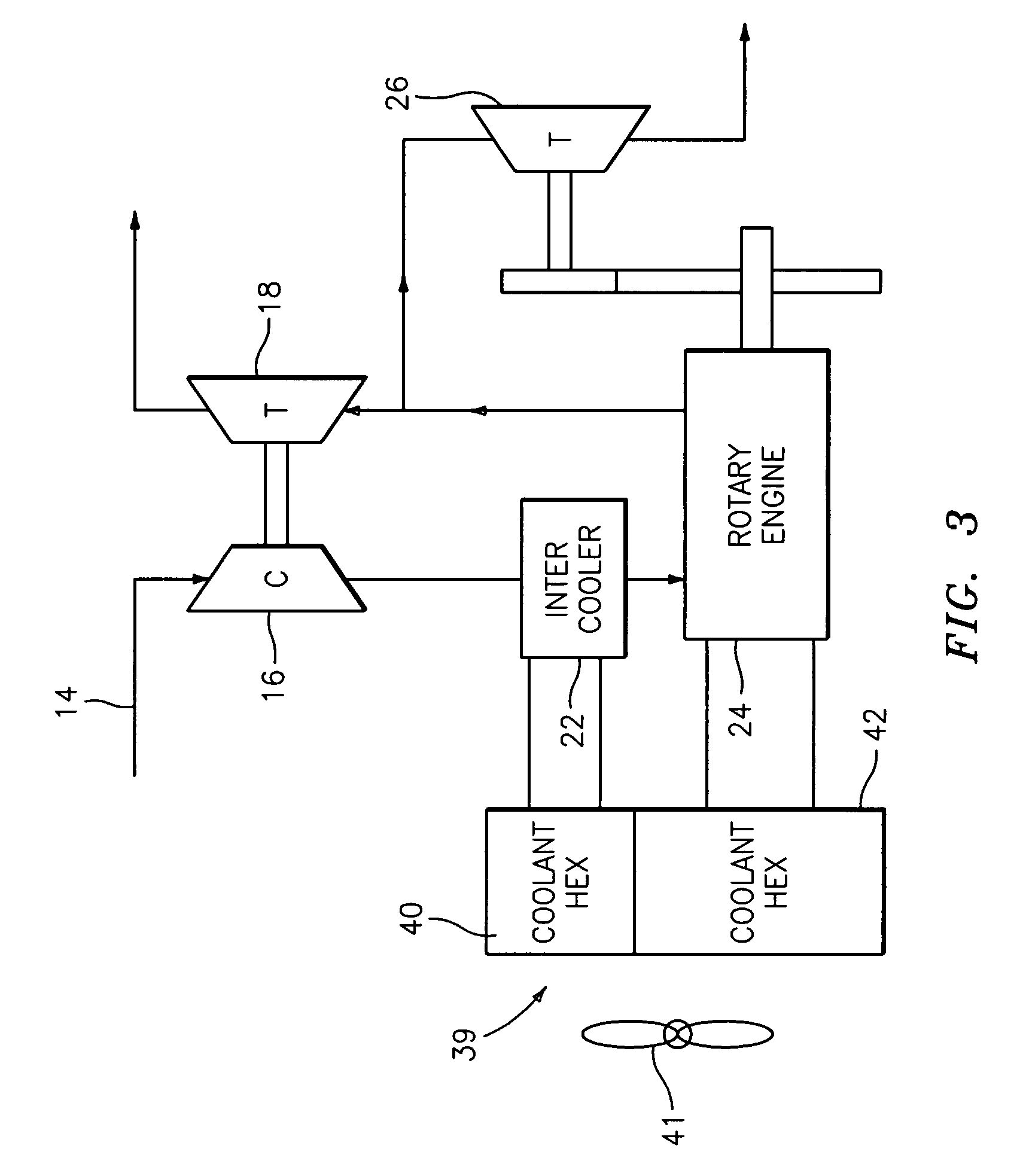

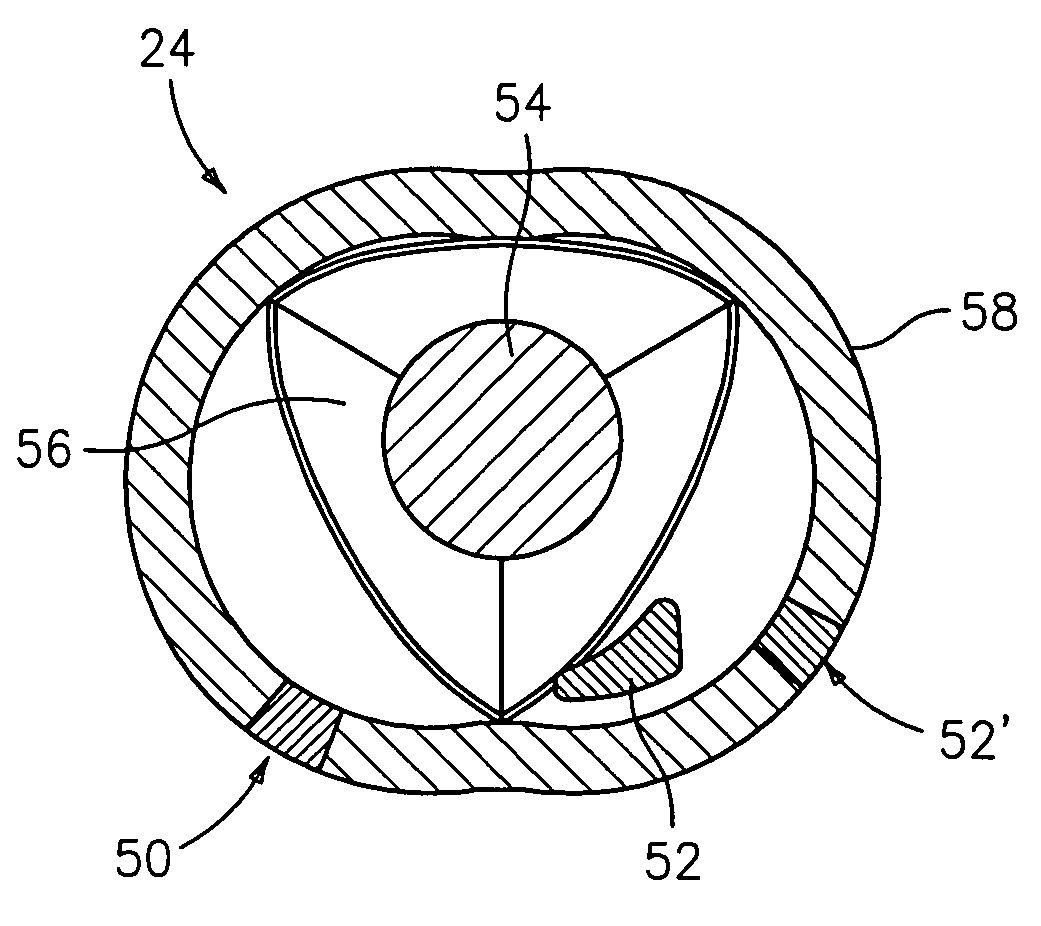

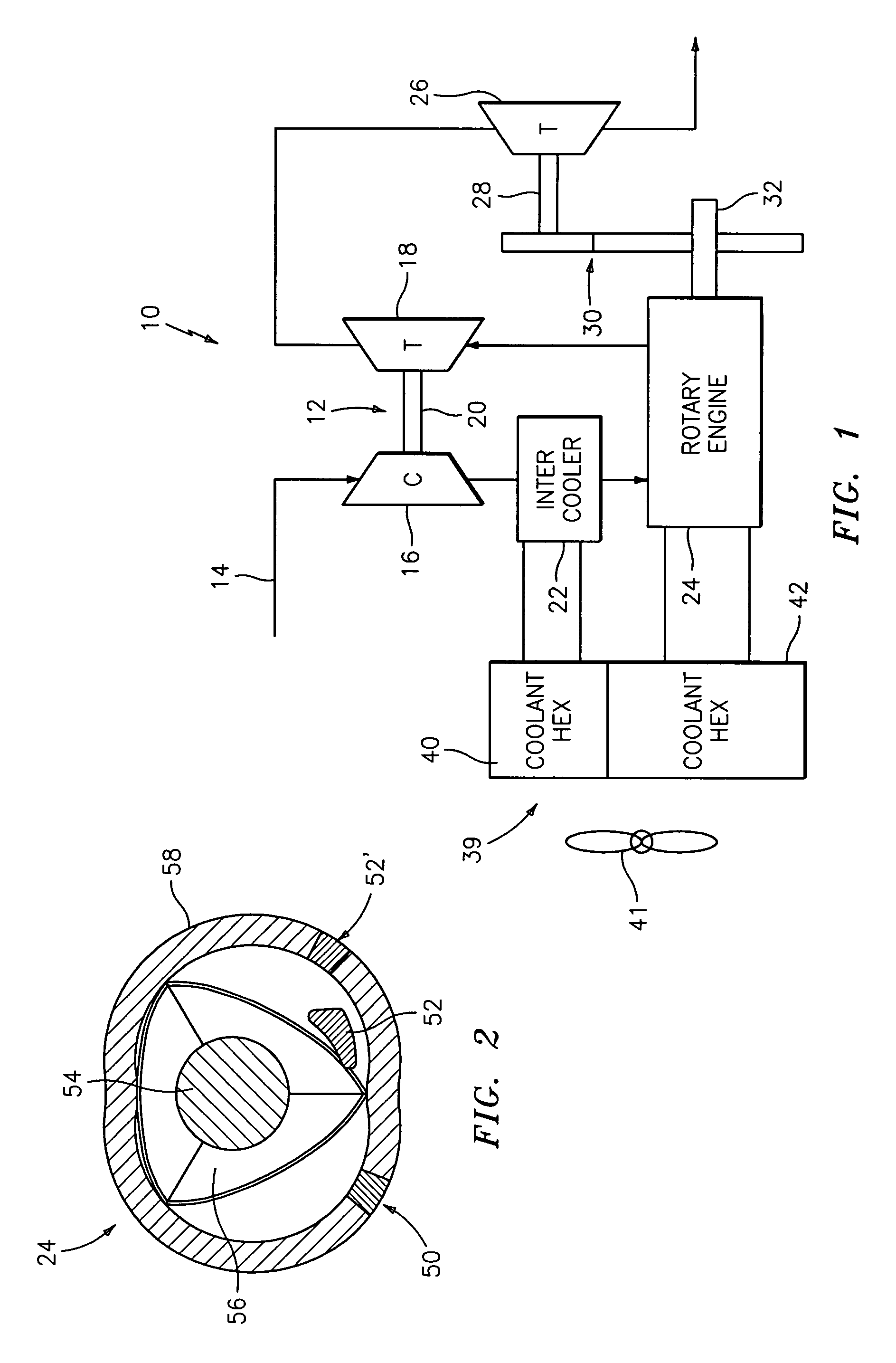

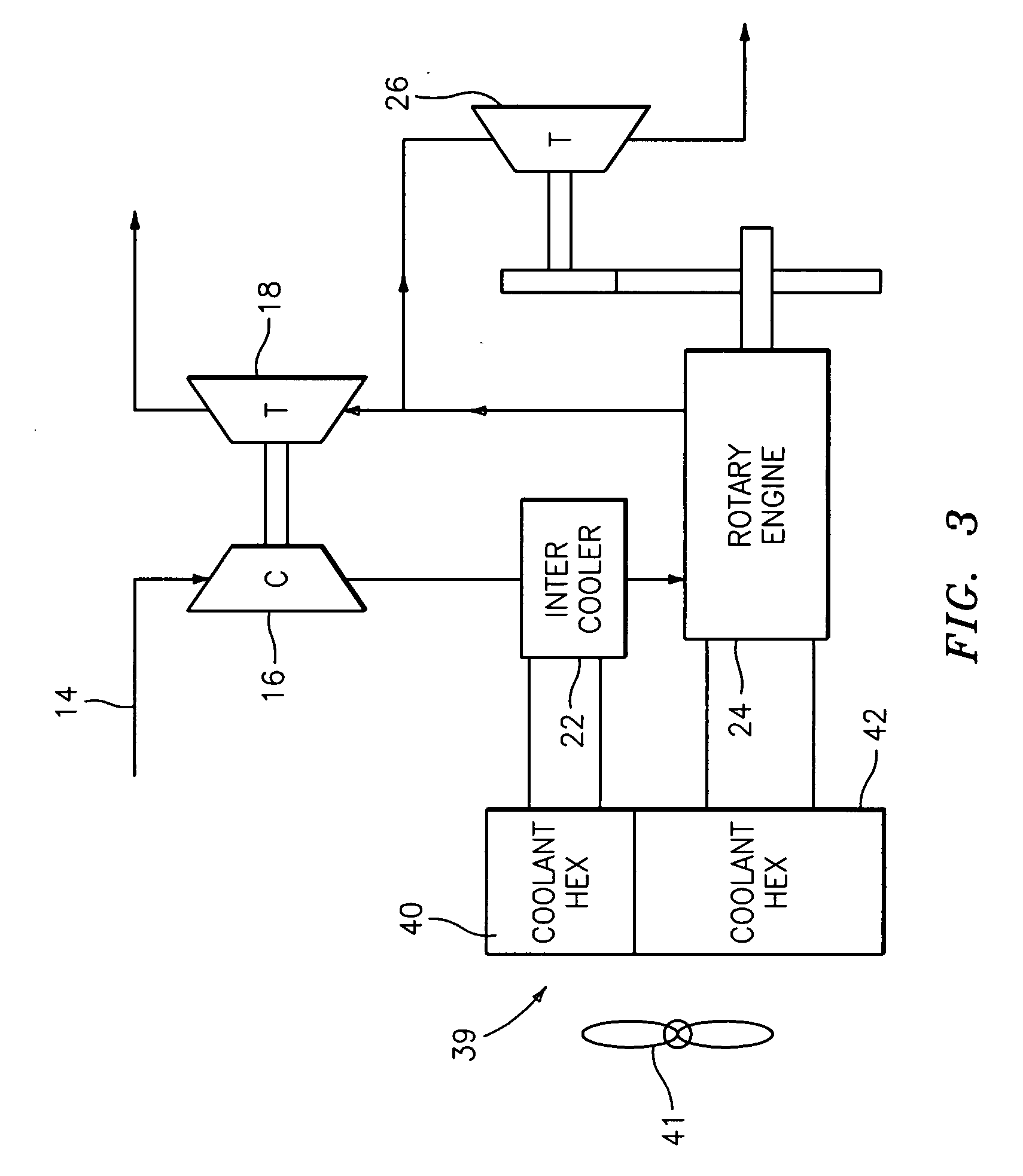

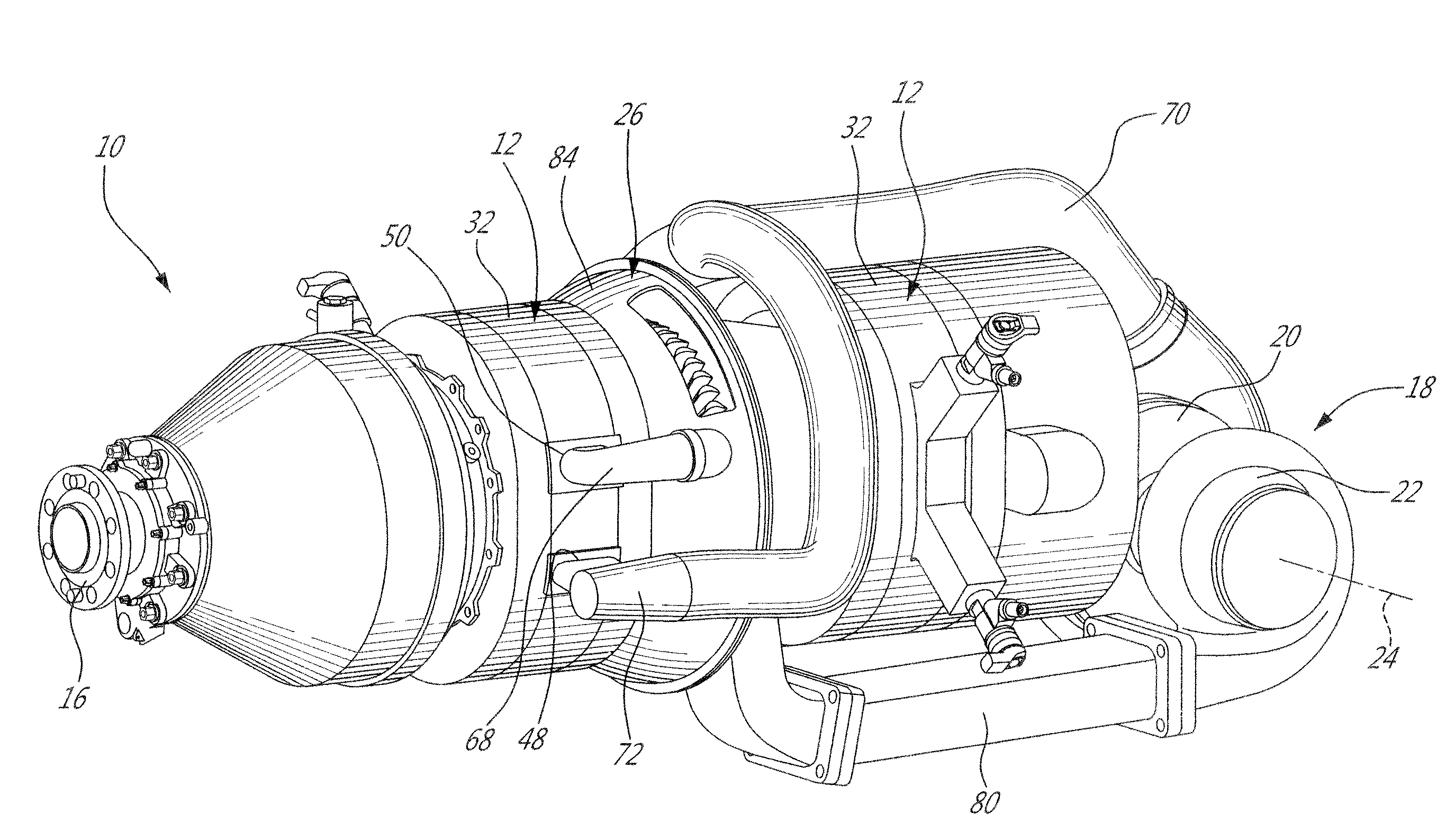

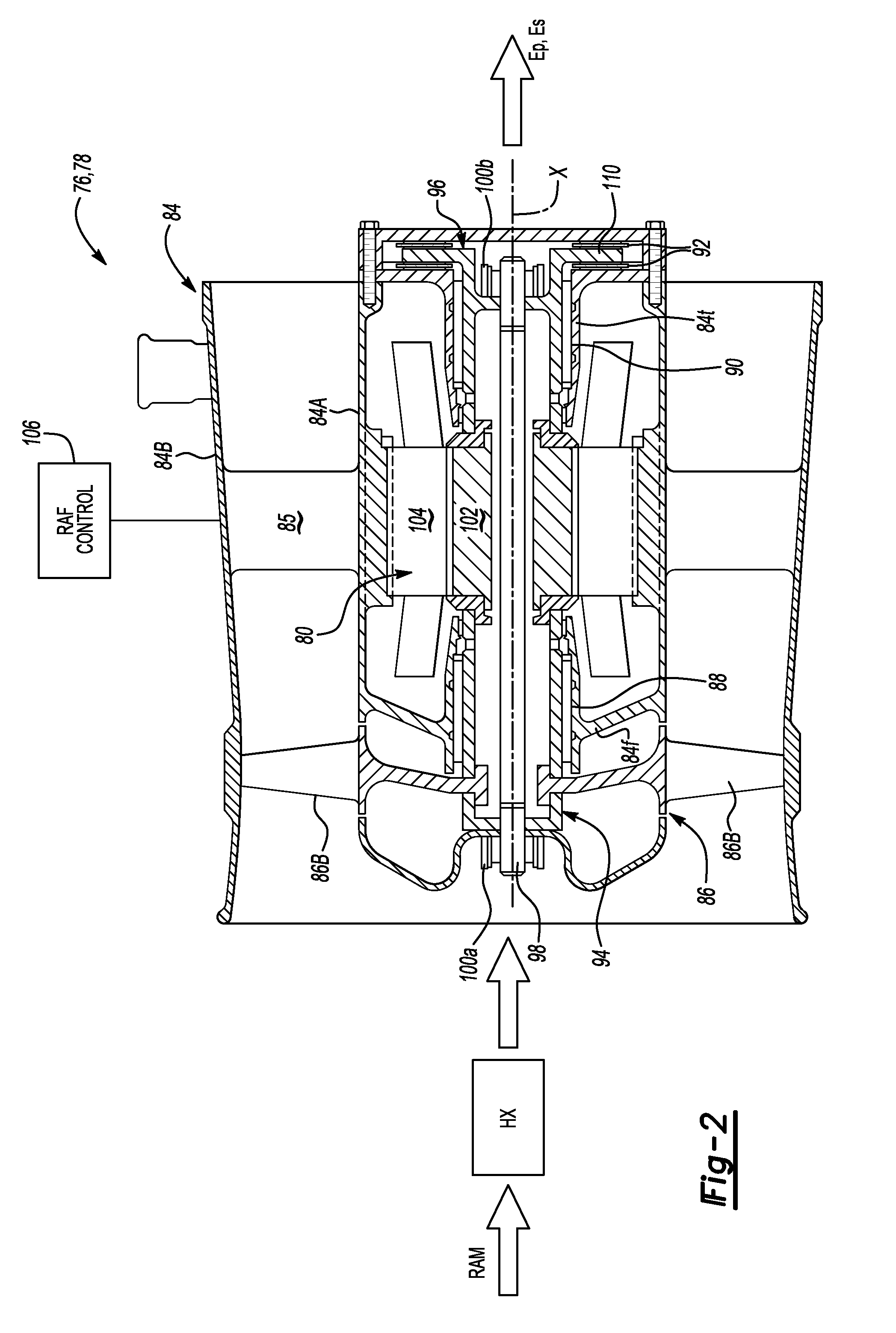

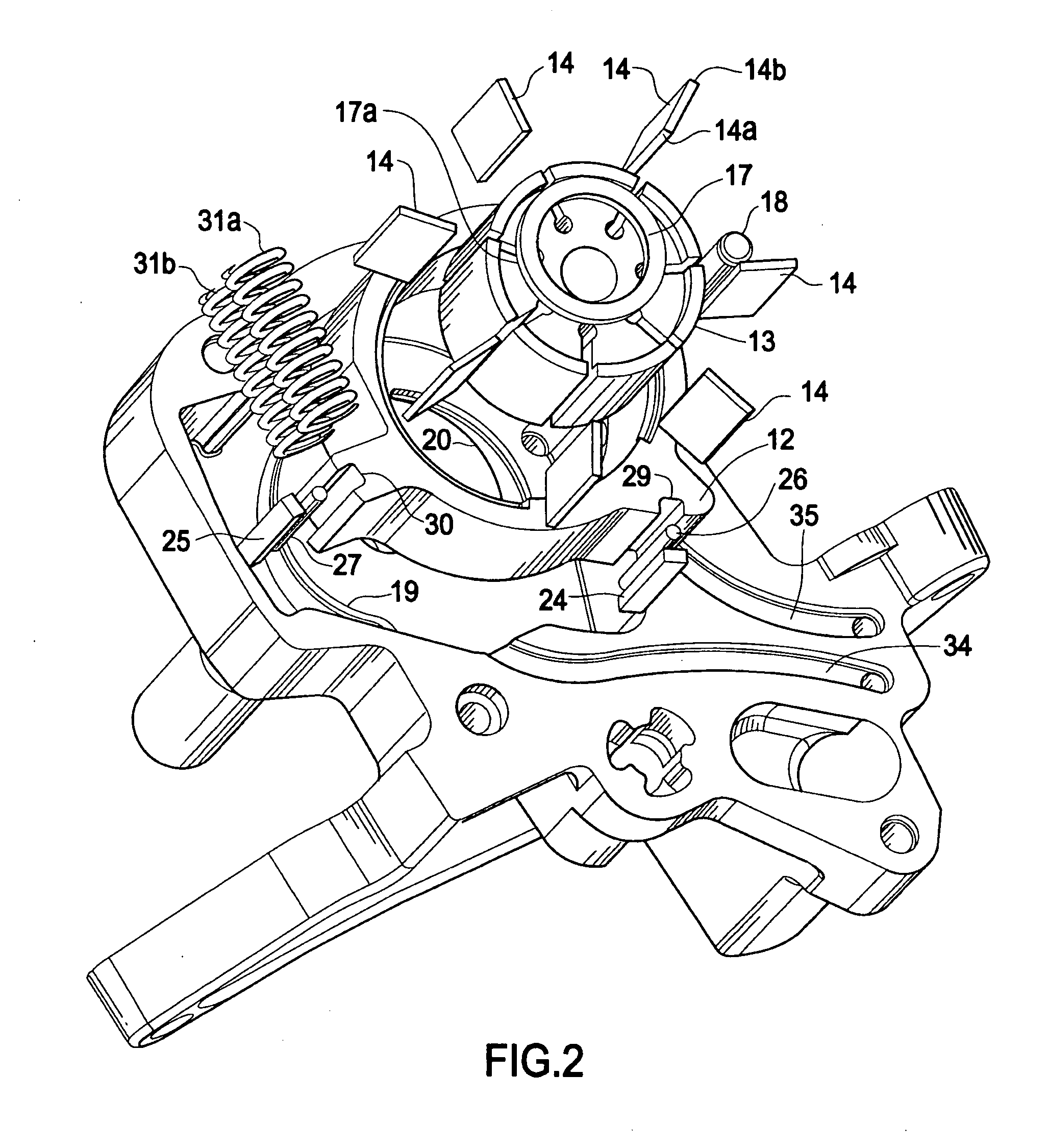

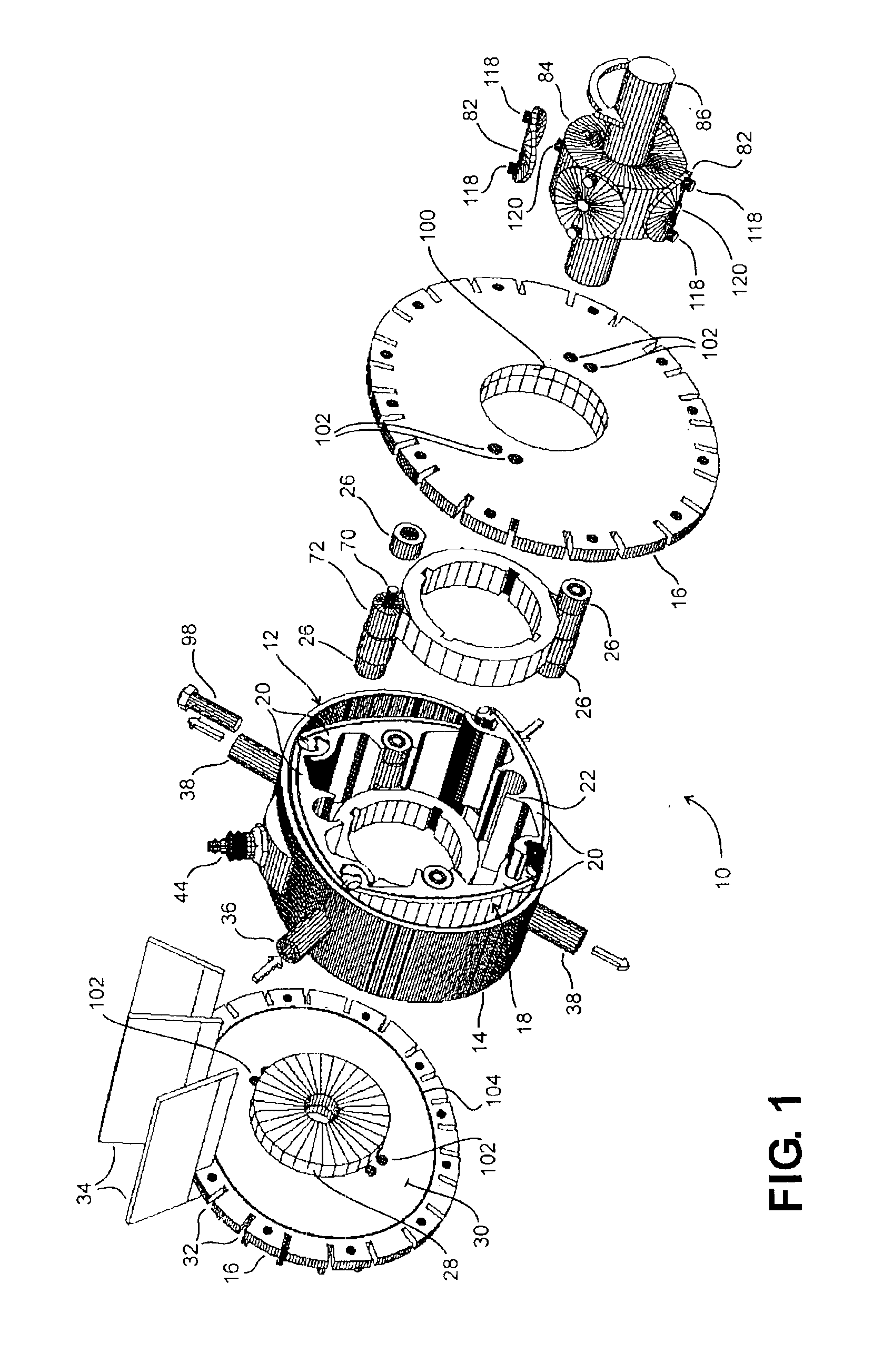

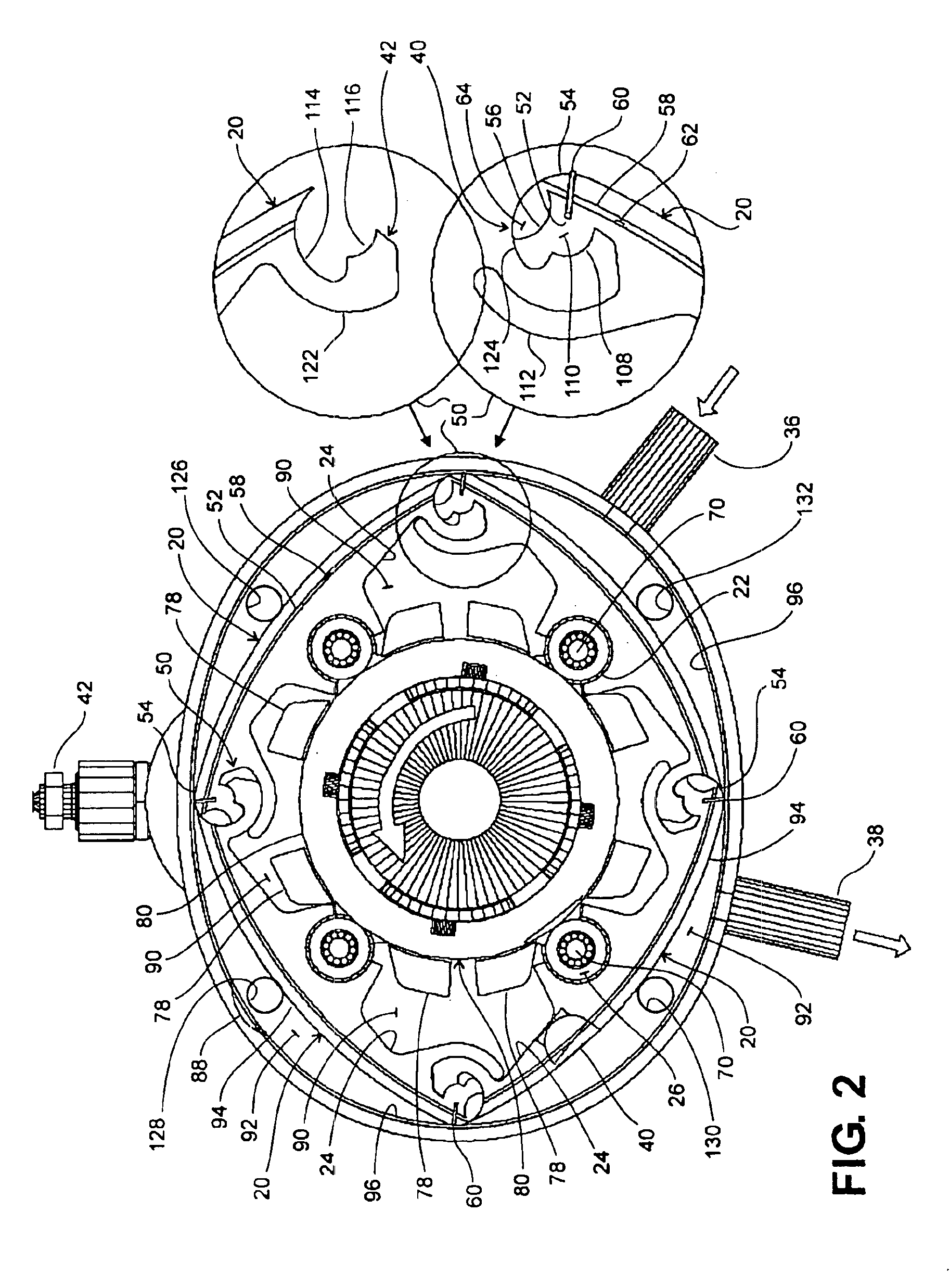

Compound cycle rotary engine

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

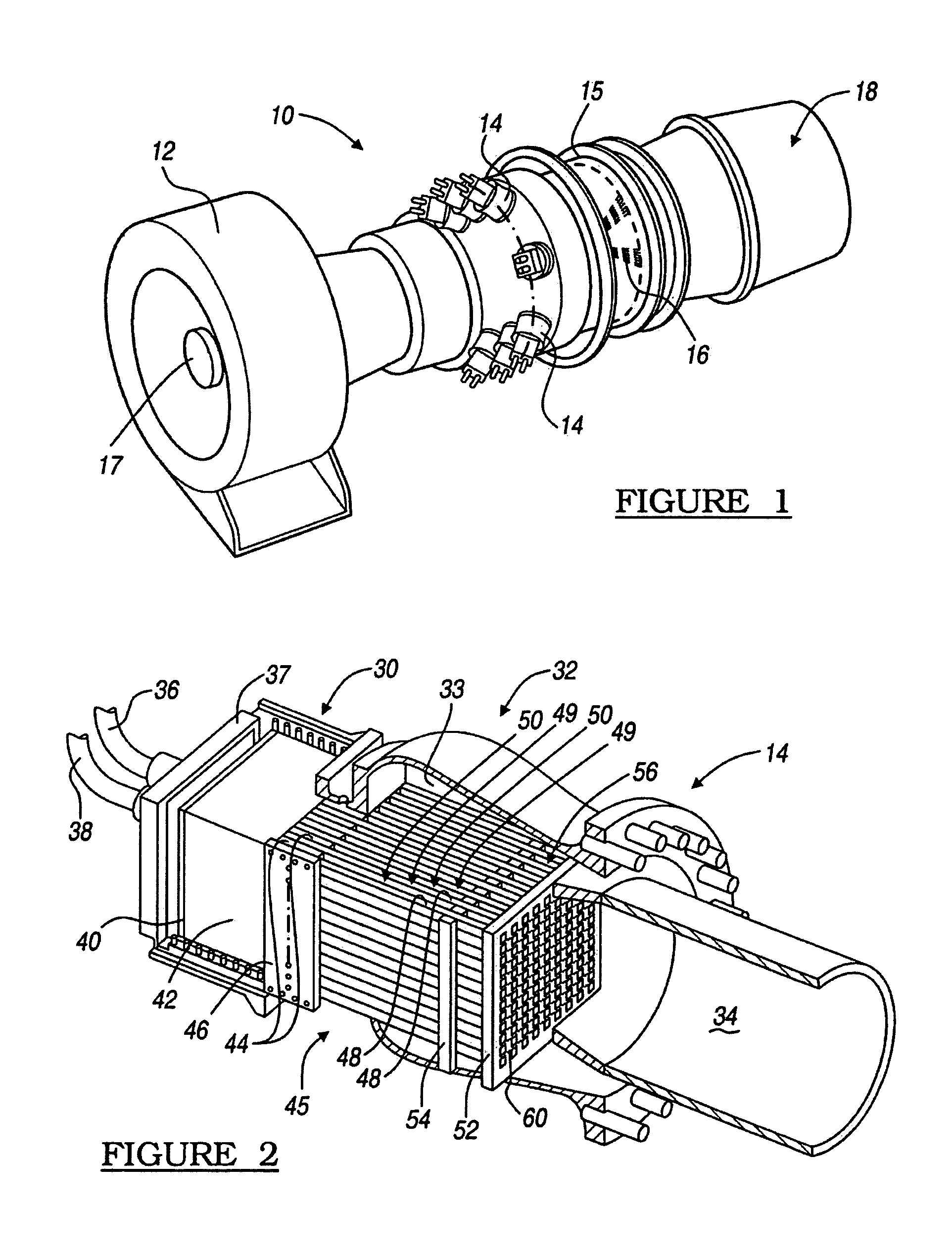

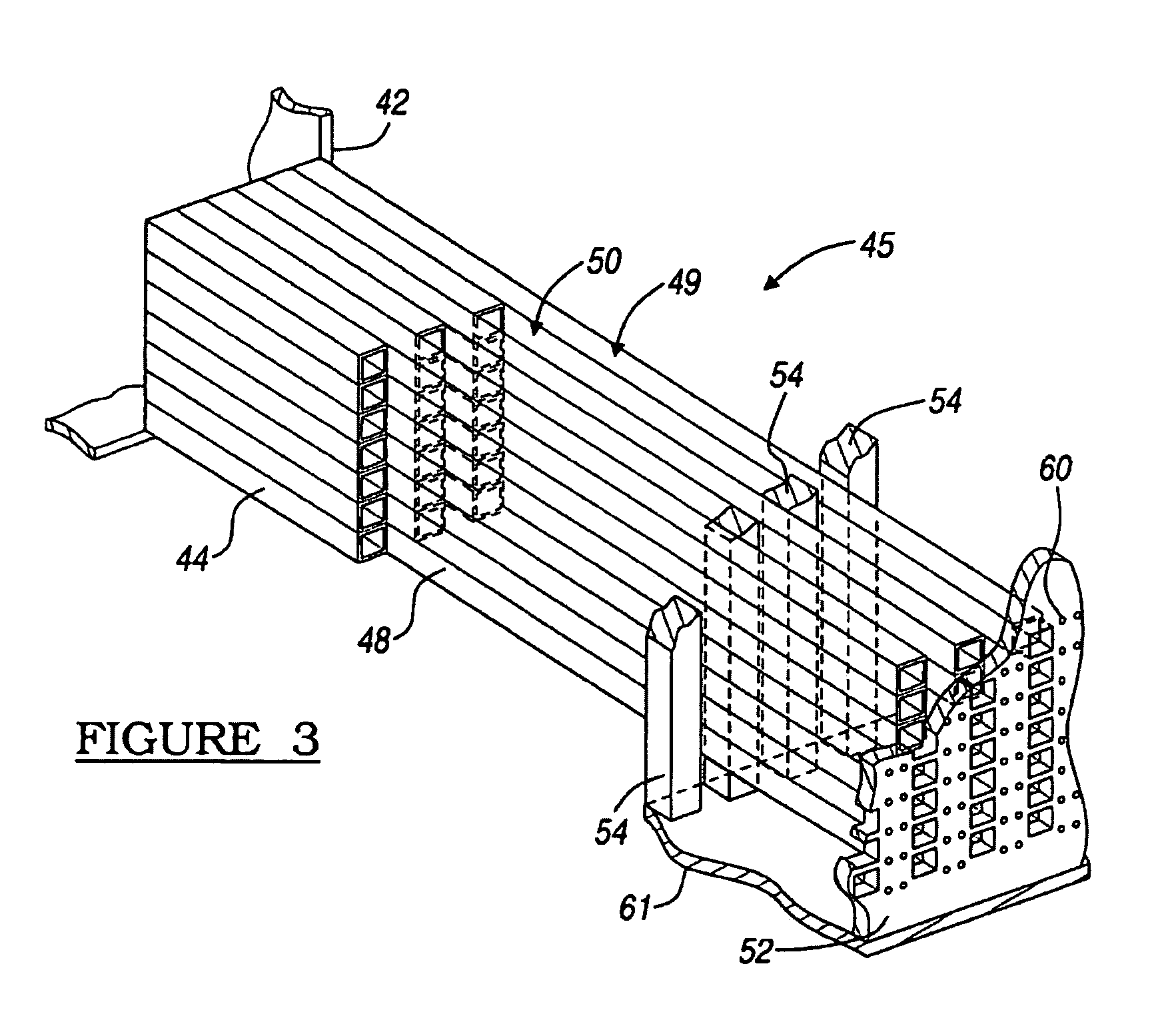

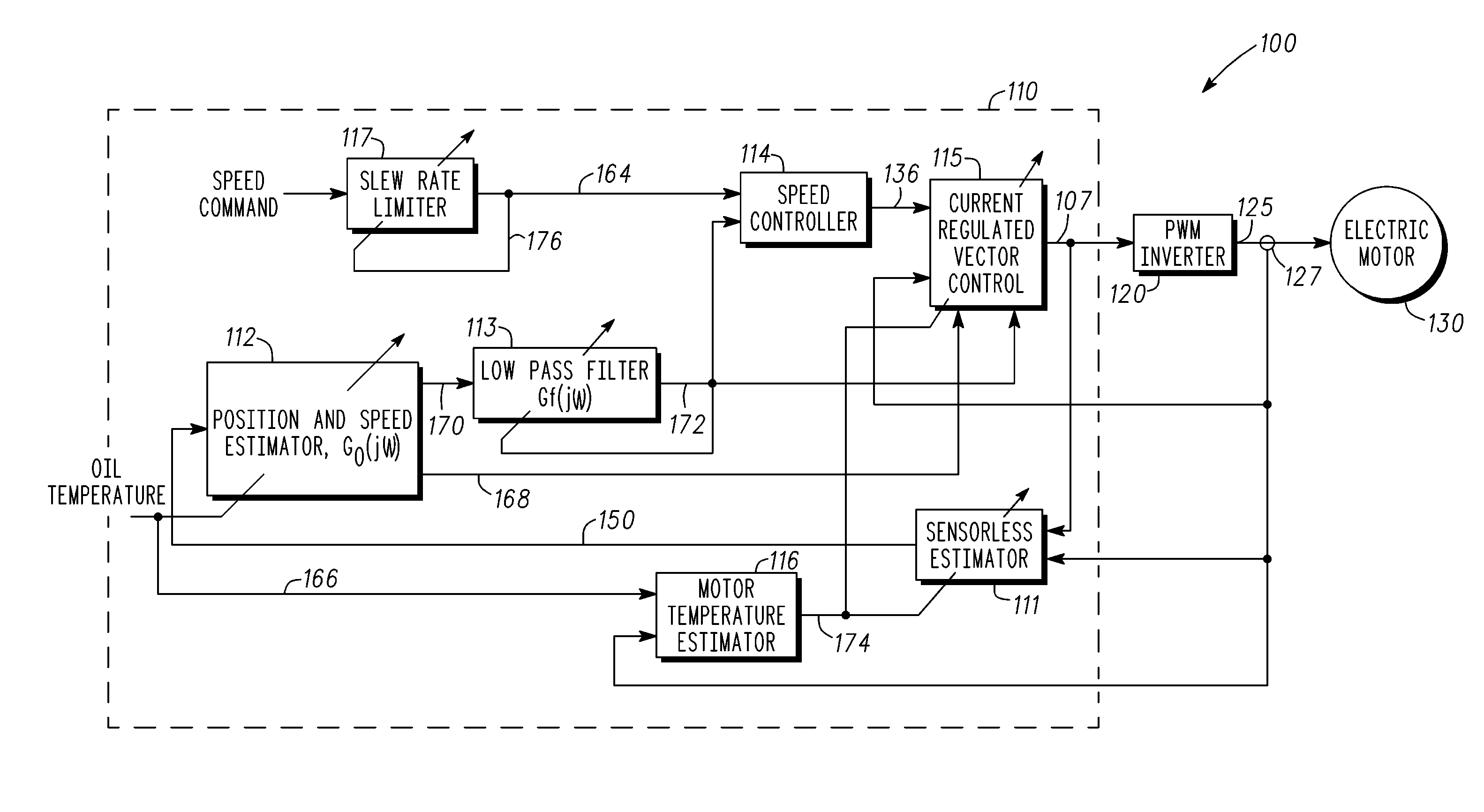

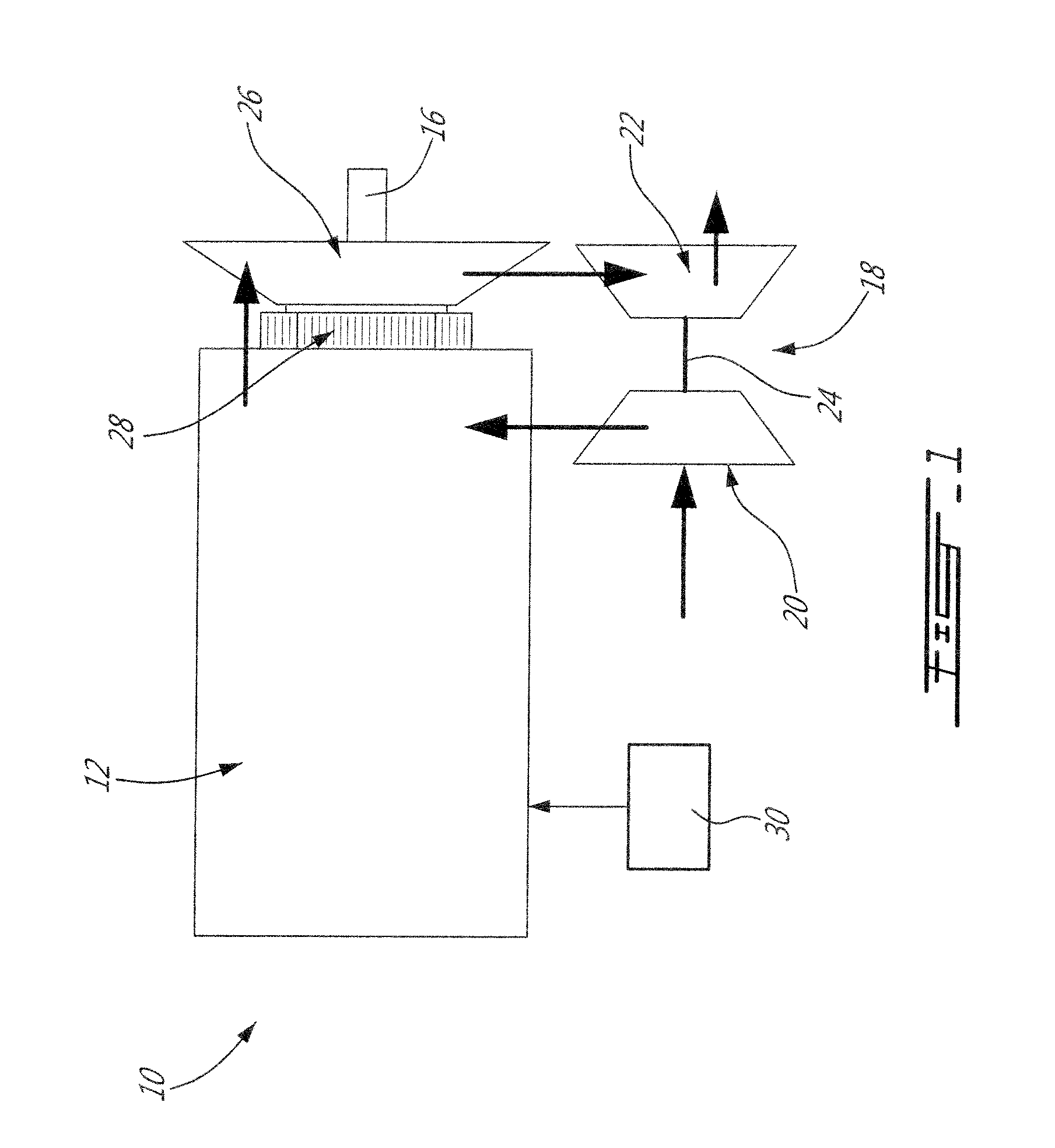

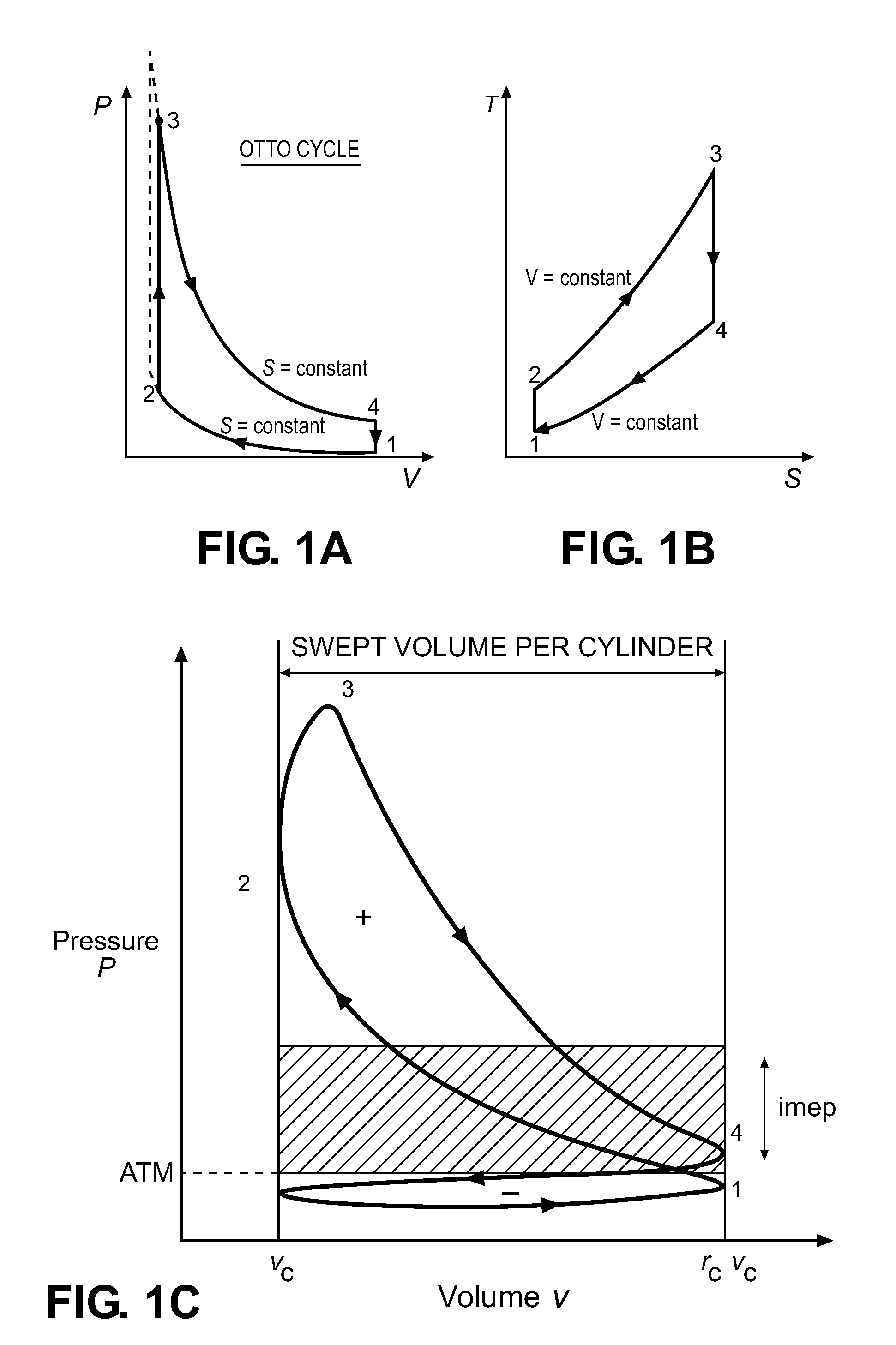

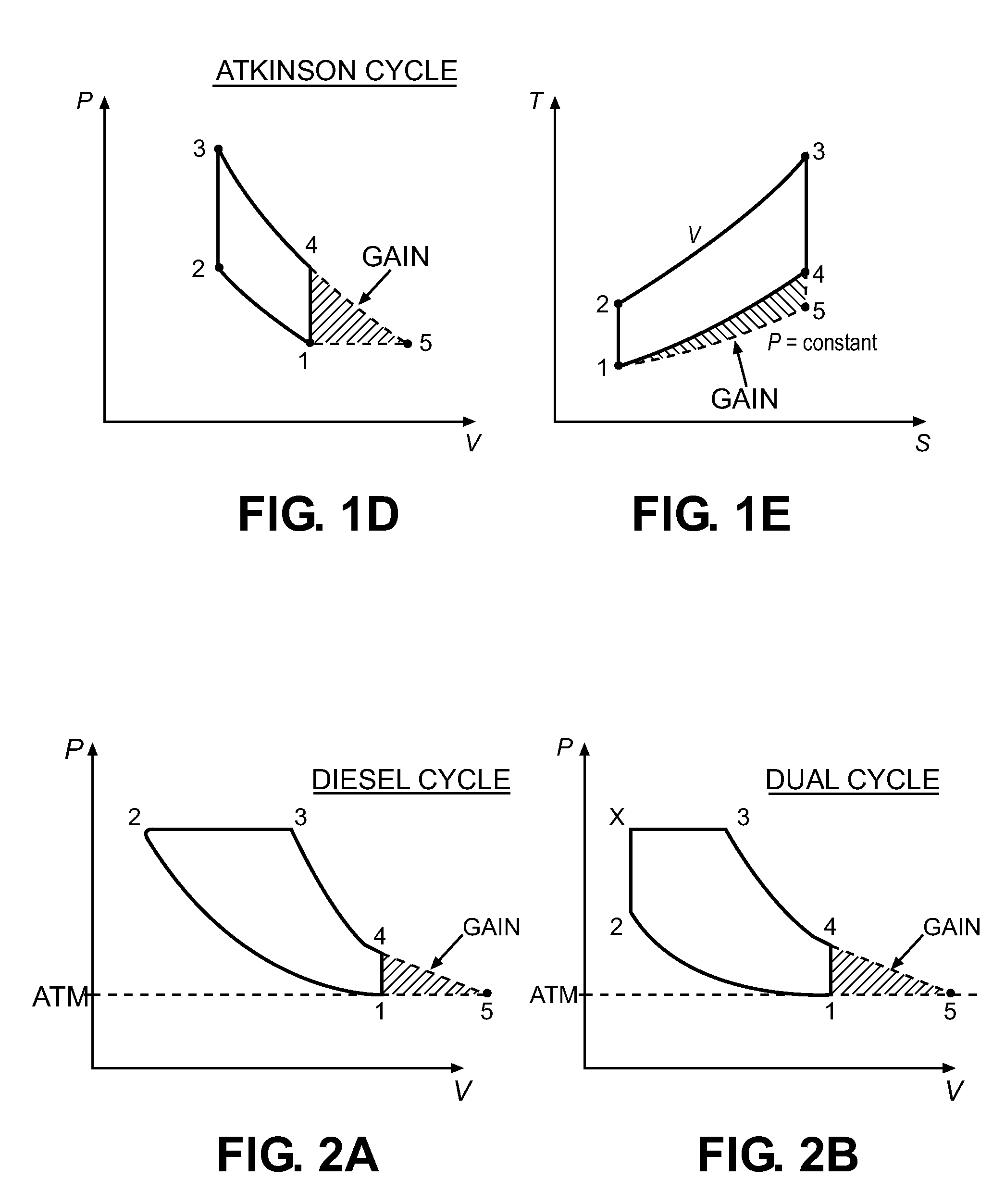

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

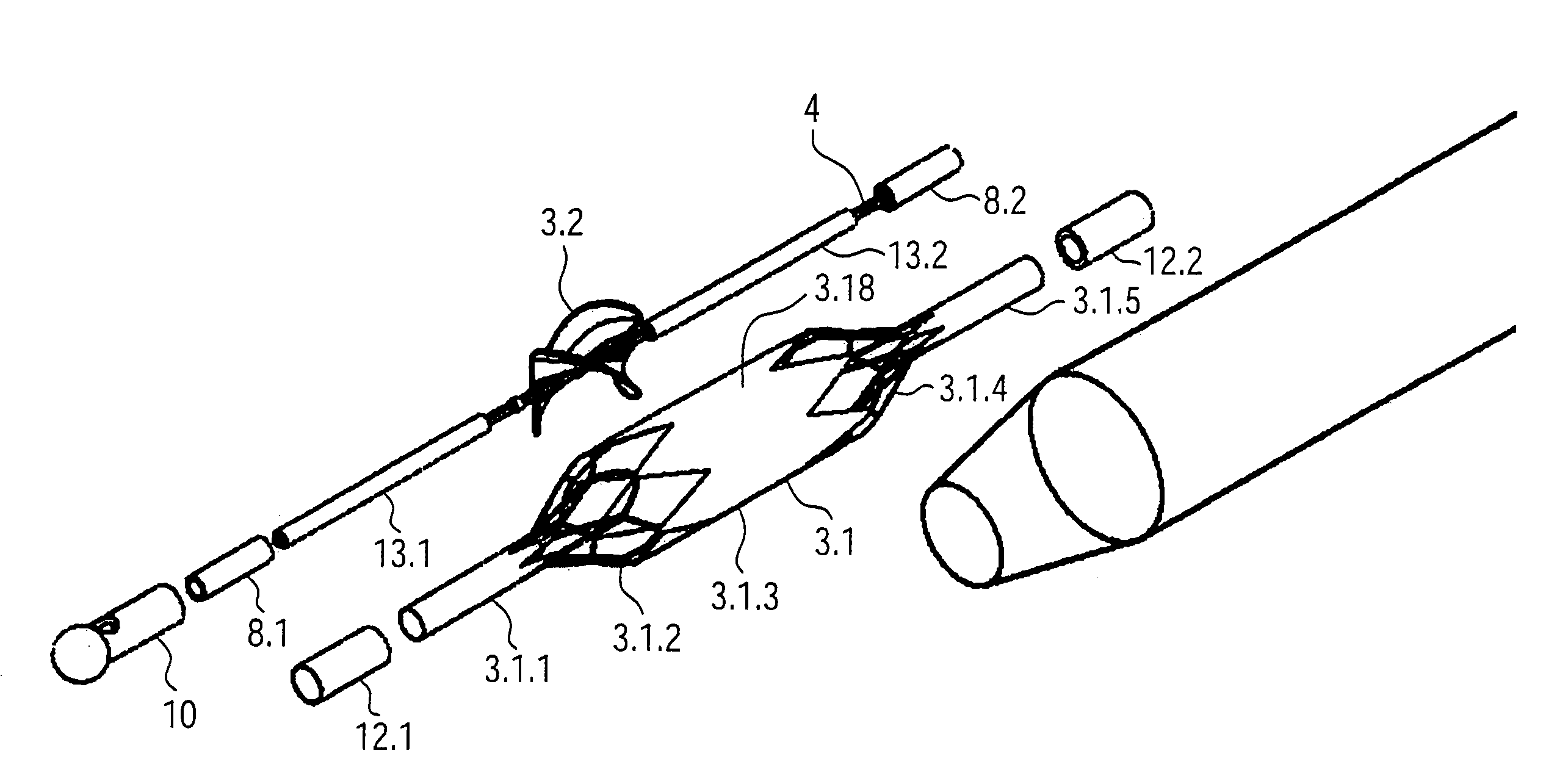

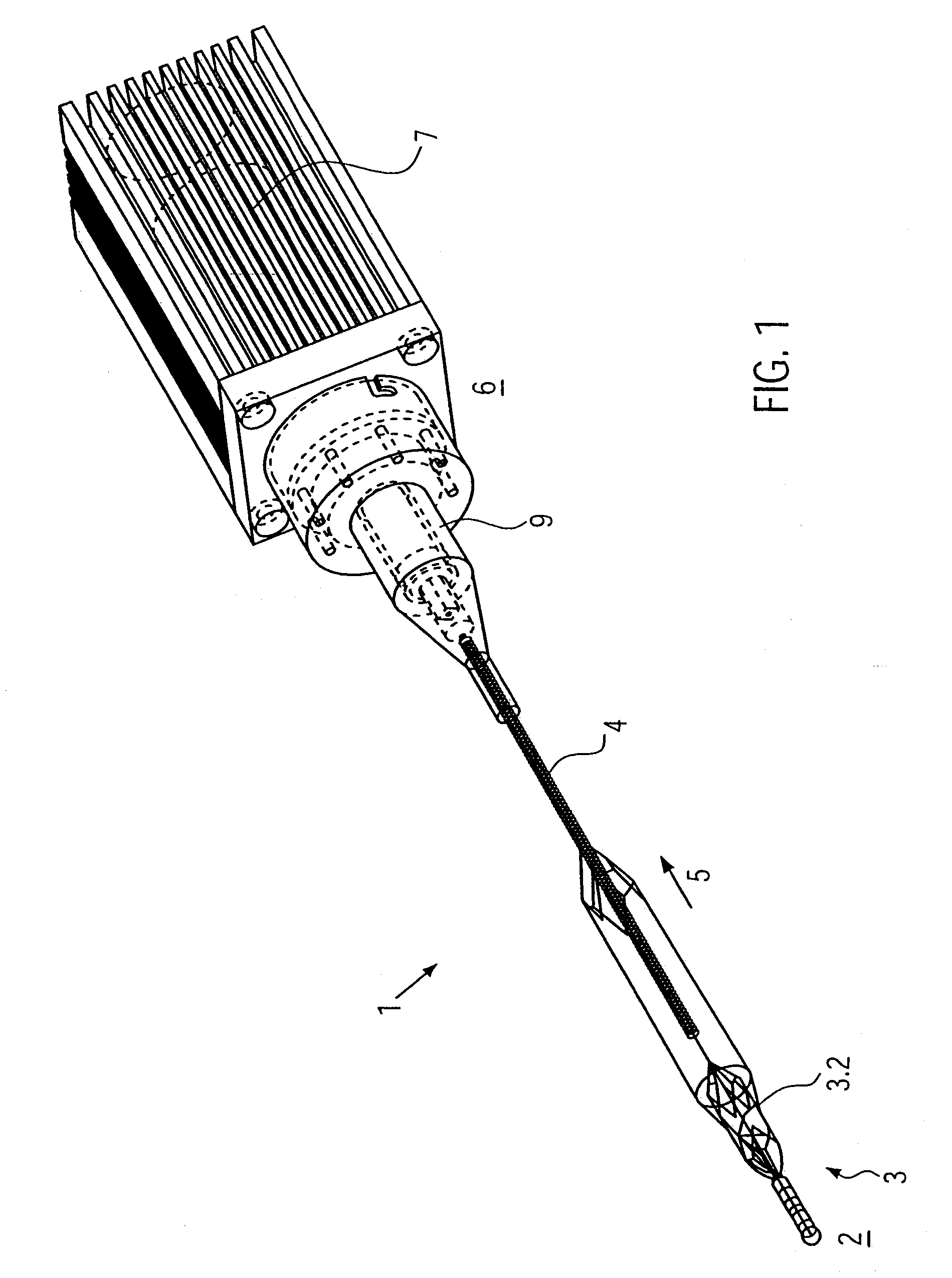

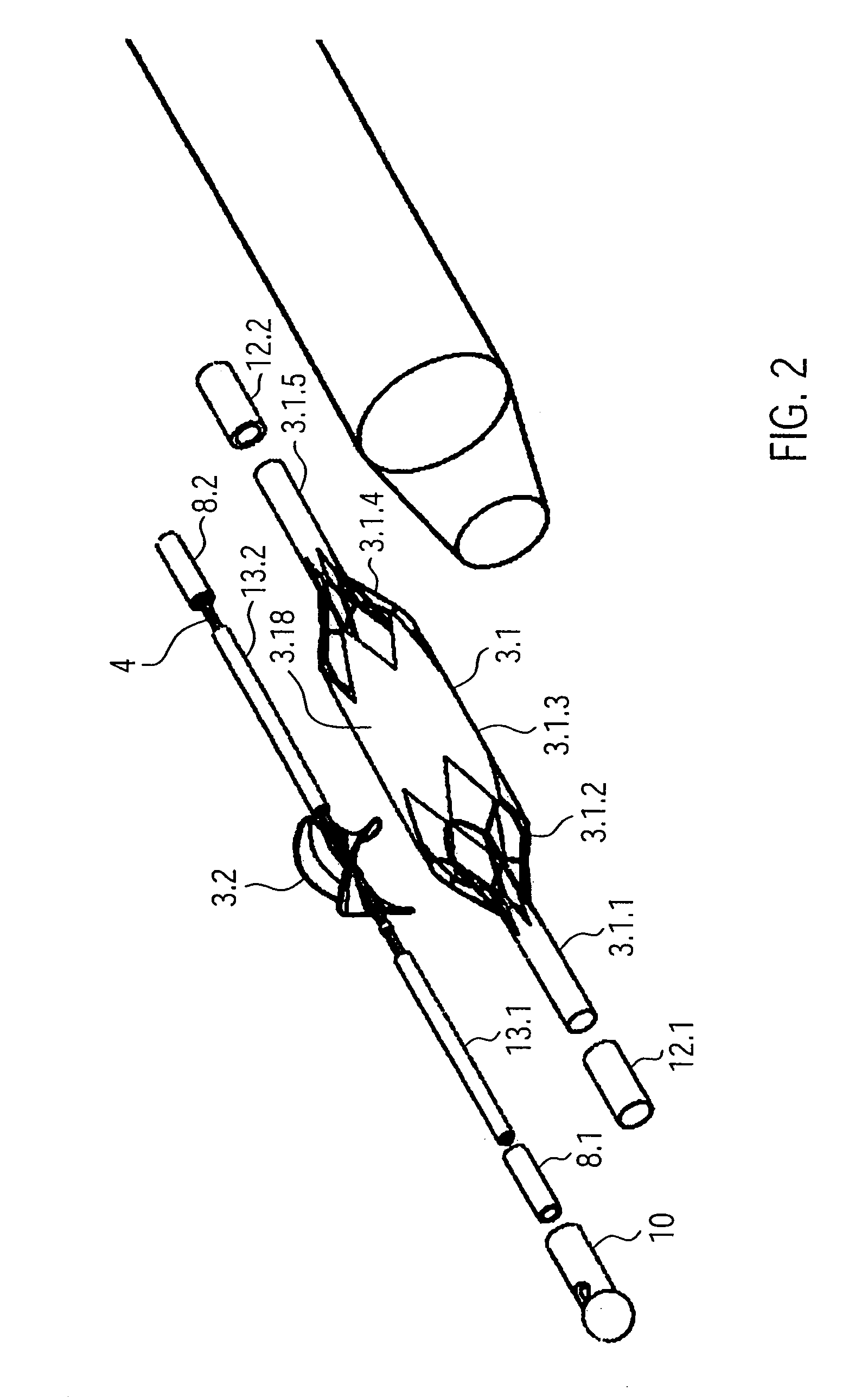

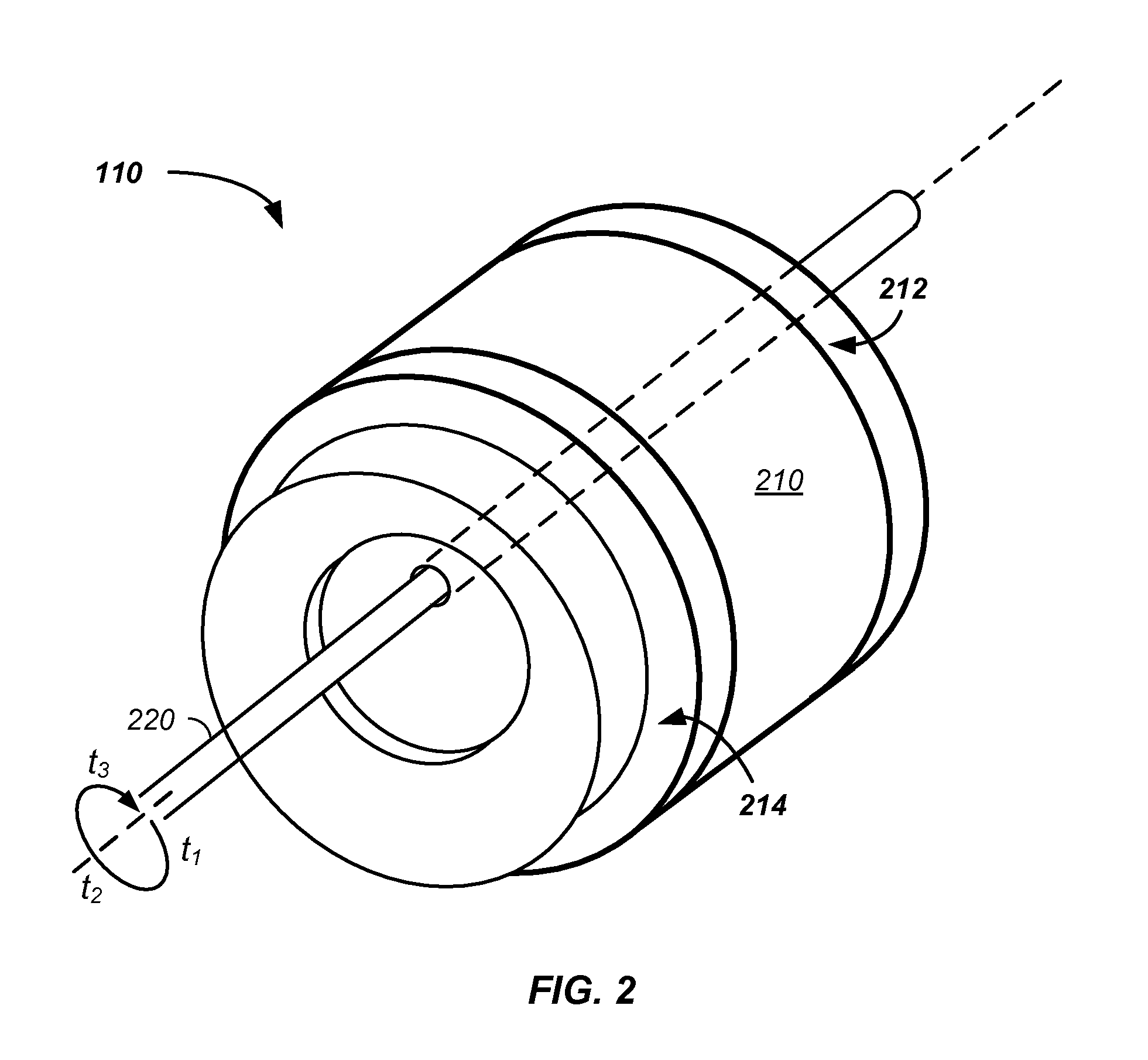

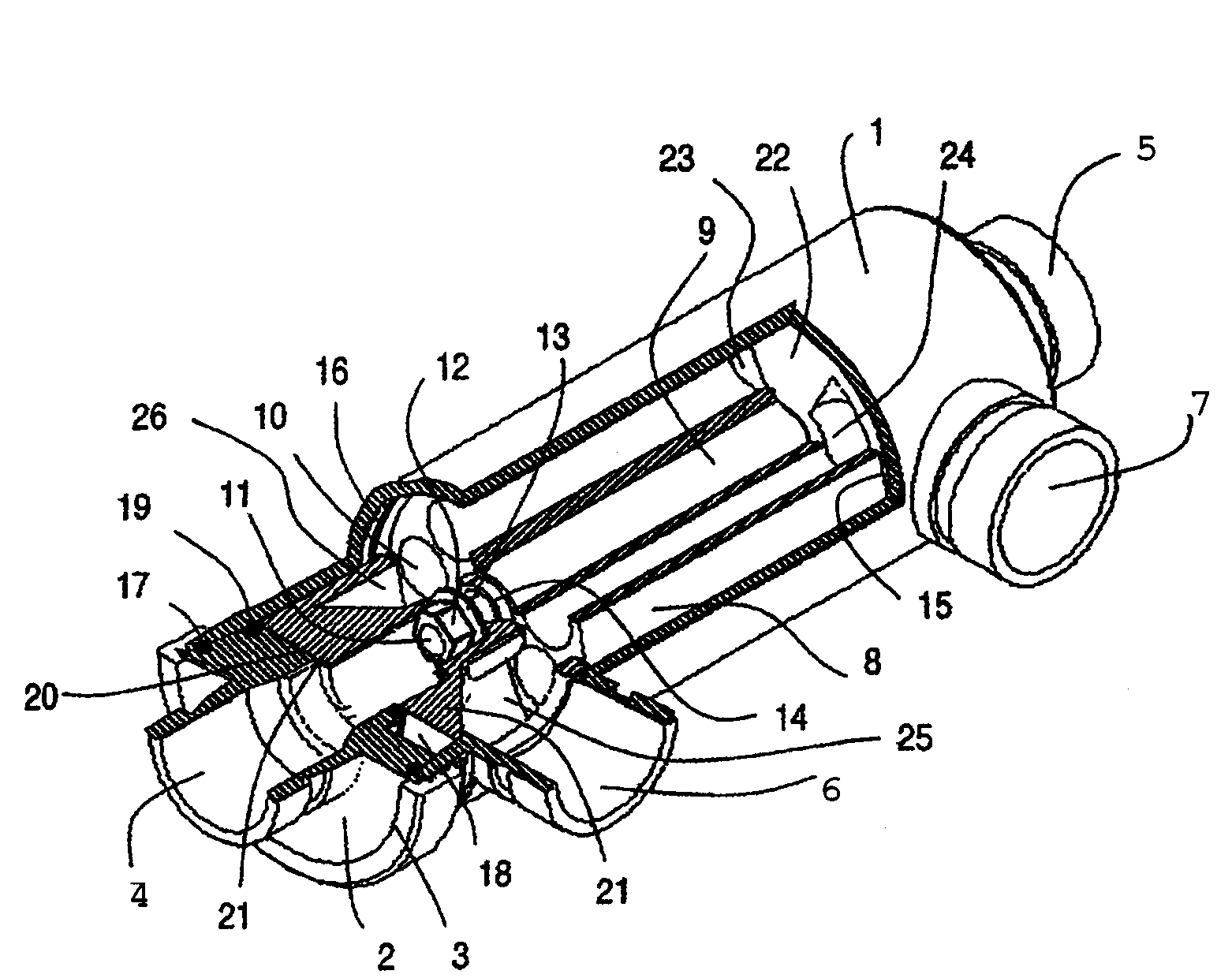

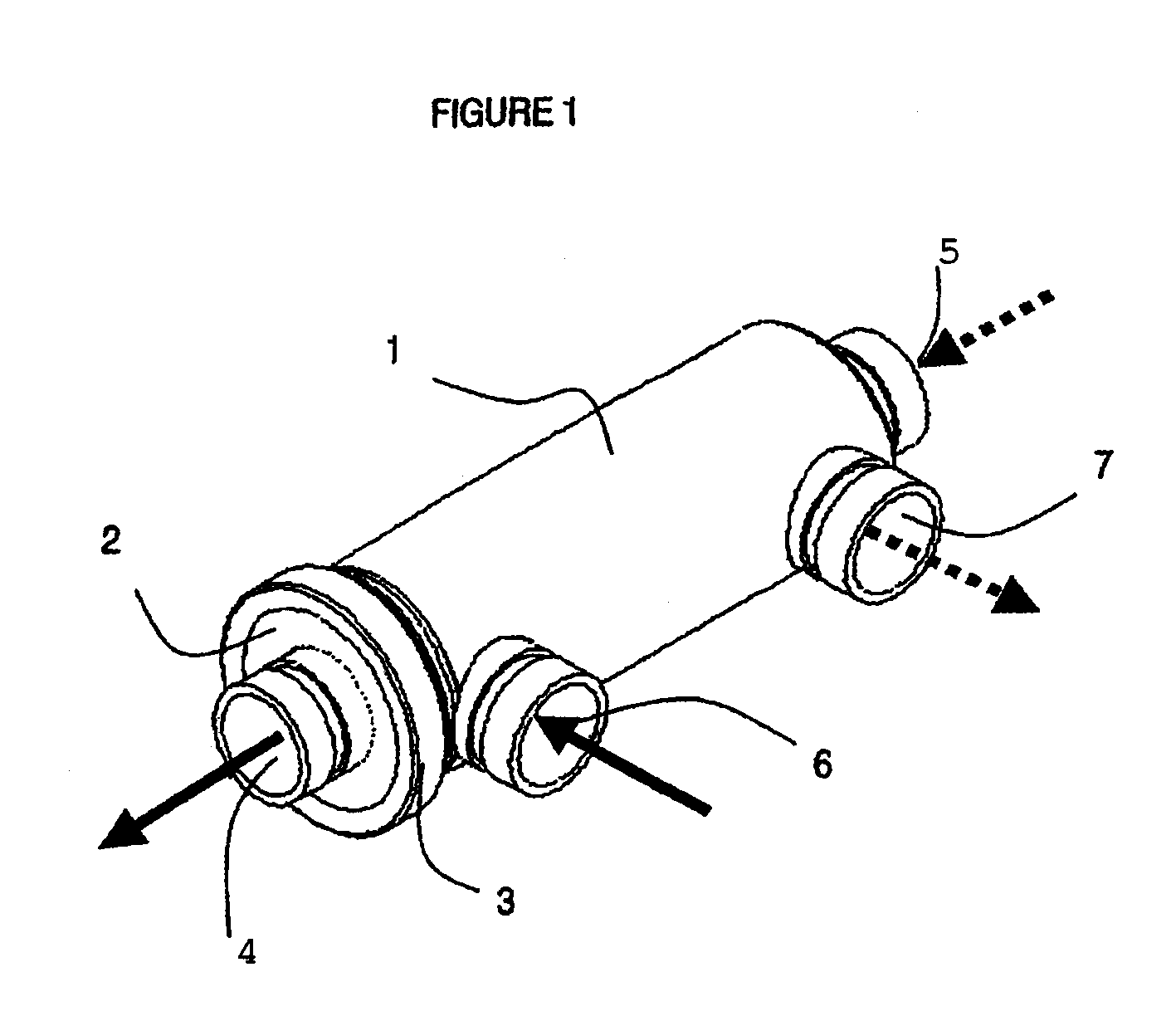

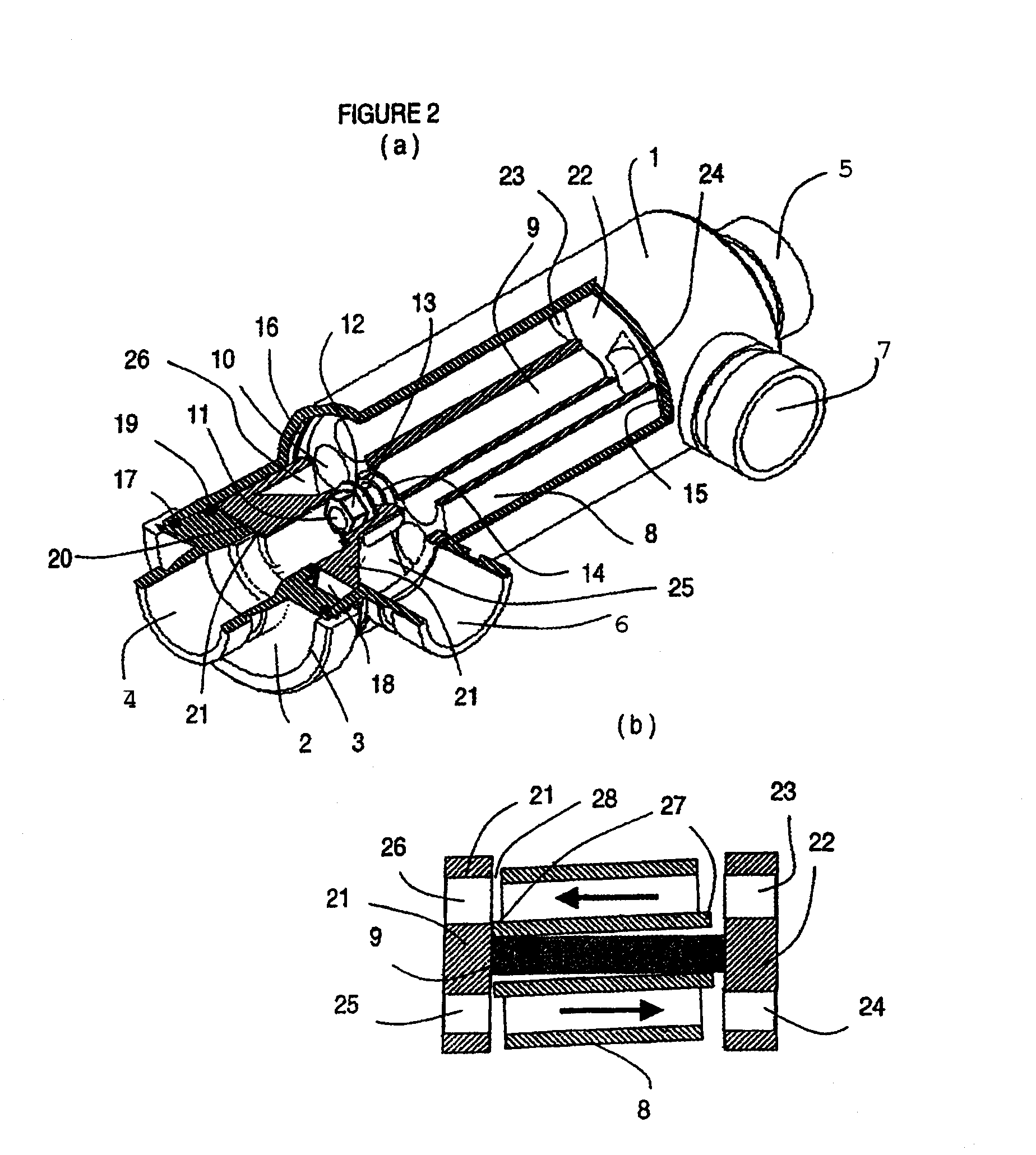

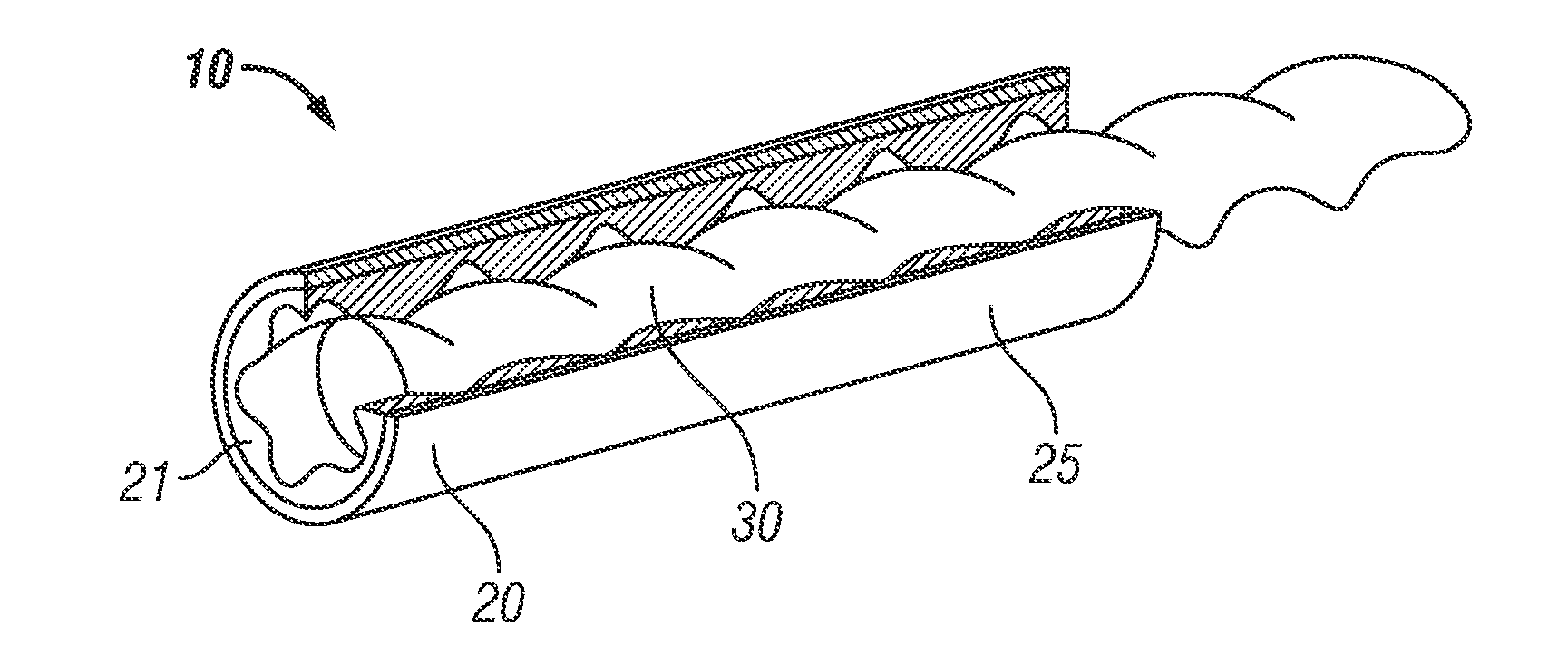

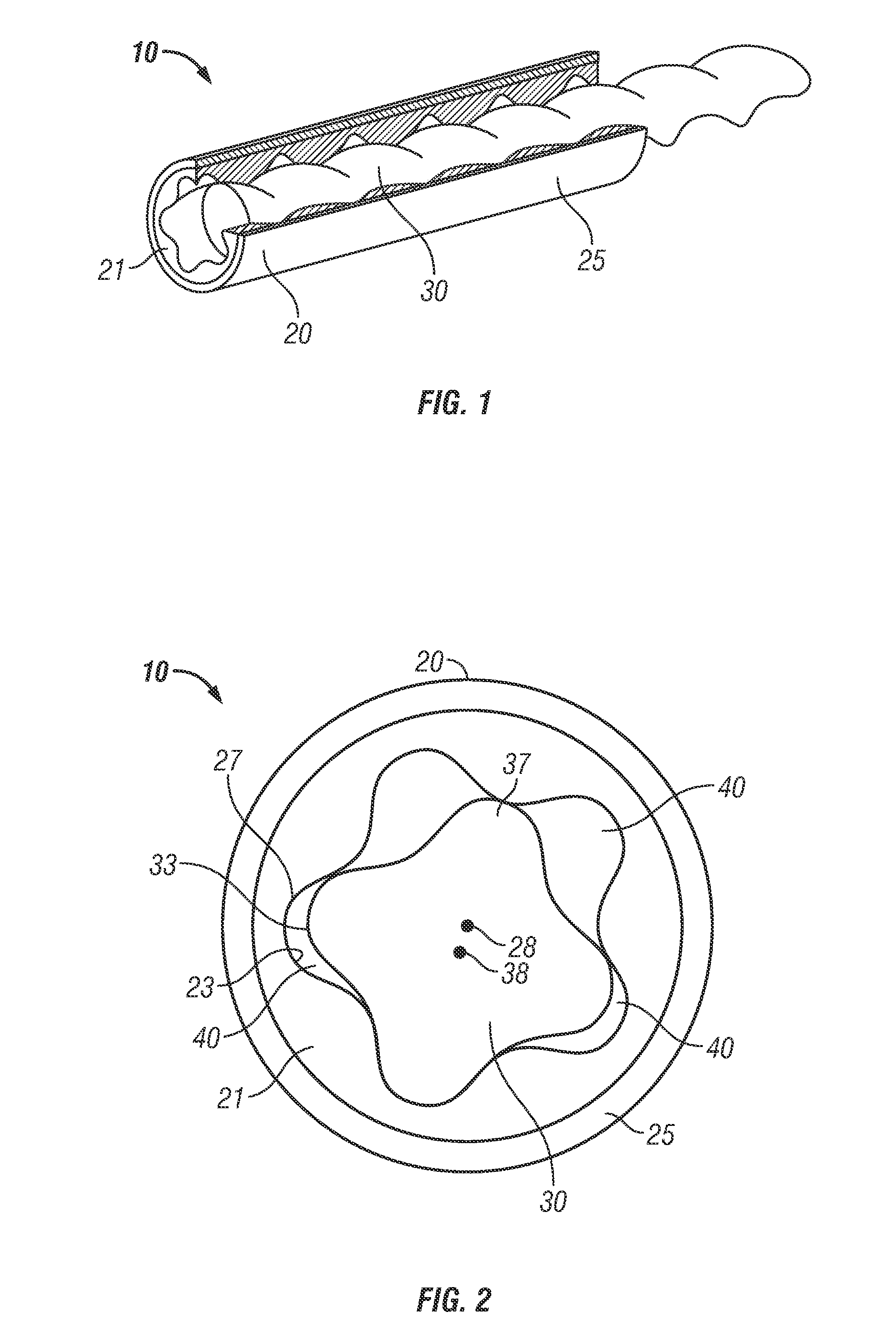

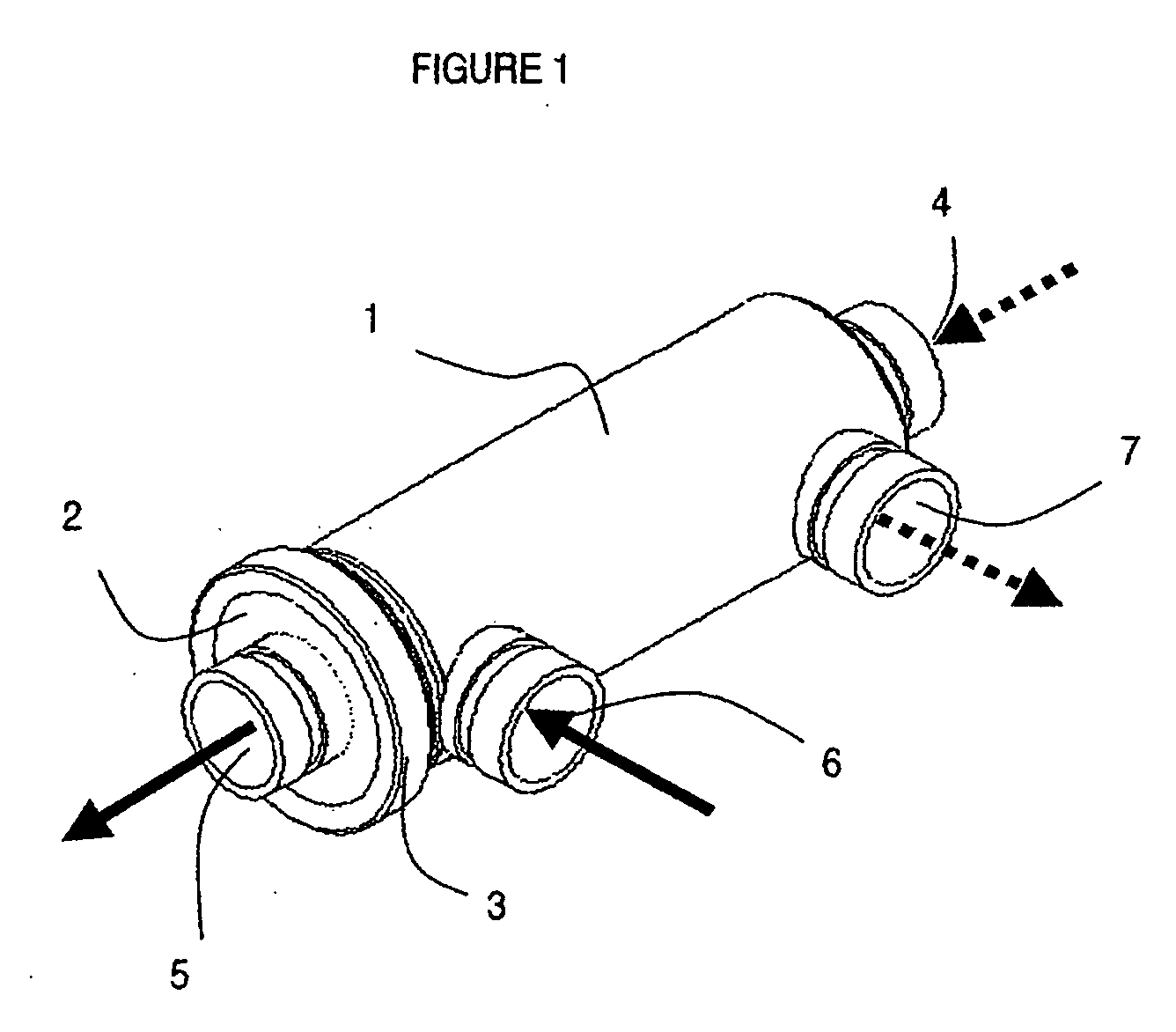

Catheter device

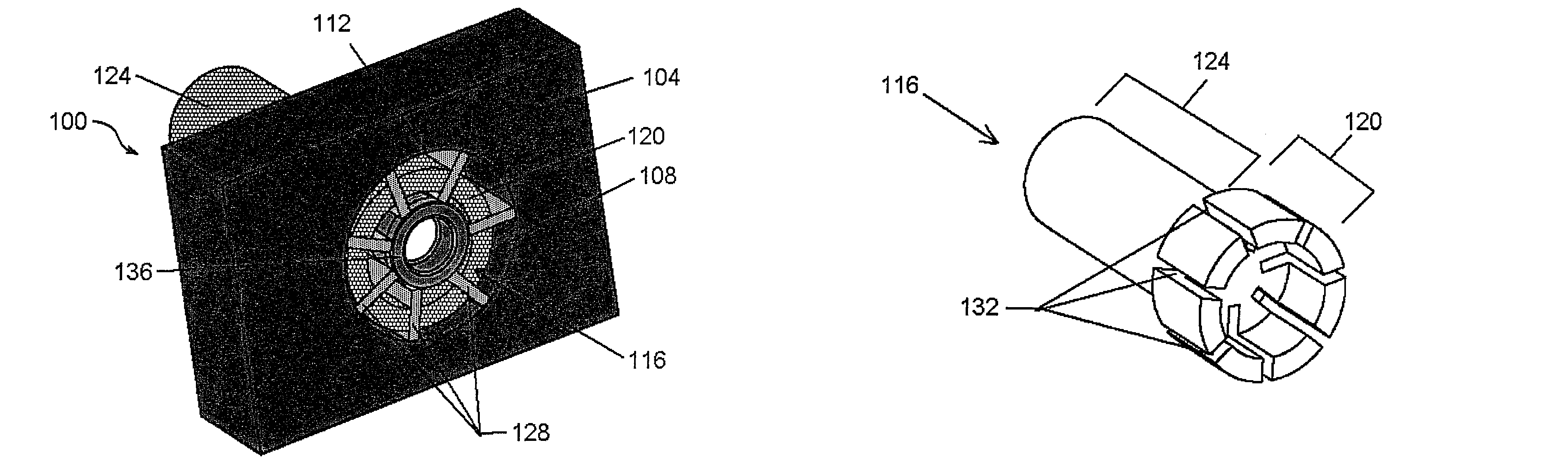

ActiveUS8439859B2Maximum pump performanceImprove performanceStarters with fluid-driven auxillary enginesHeart stimulatorsDrive shaftCatheter device

The catheter device comprises a drive shaft connected to a motor, and a rotor mounted on the drive shaft at the distal end section. The rotor has a frame structure which is formed by a screw-like boundary frame and rotor struts extending radially inwards from the boundary frame. The rotor struts are fastened to the drive shaft by their ends opposite the boundary frame. Between the boundary frame and the drive shaft extends an elastic covering. The frame structure is made of an elastic material such that, after forced compression, the rotor unfolds automatically.

Owner:AIS AACHEN INNOVATIVE SOLUTIONS

Rotary engine expansion chamber apparatus and method of operation therefor

ActiveUS8523547B2Internal combustion piston enginesOscillating piston enginesRotary engineExpansion chamber

Owner:PEKRUL MERTON W

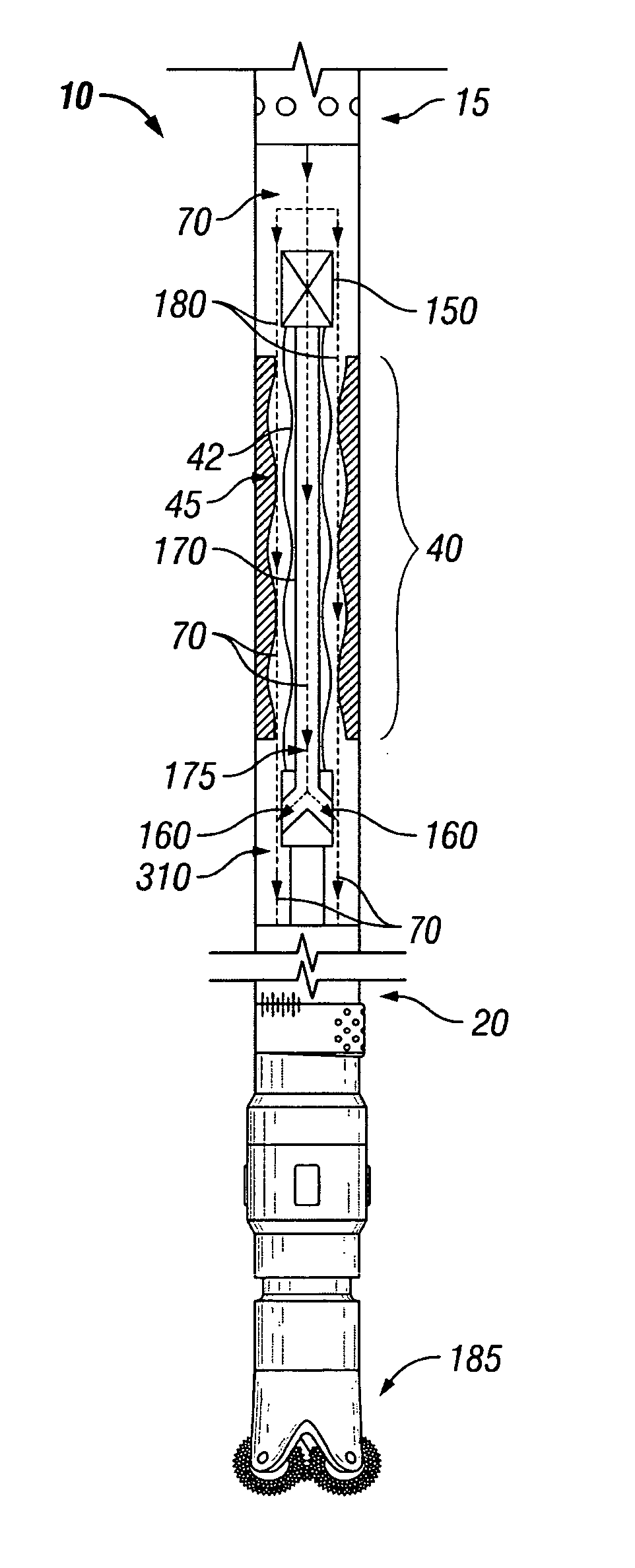

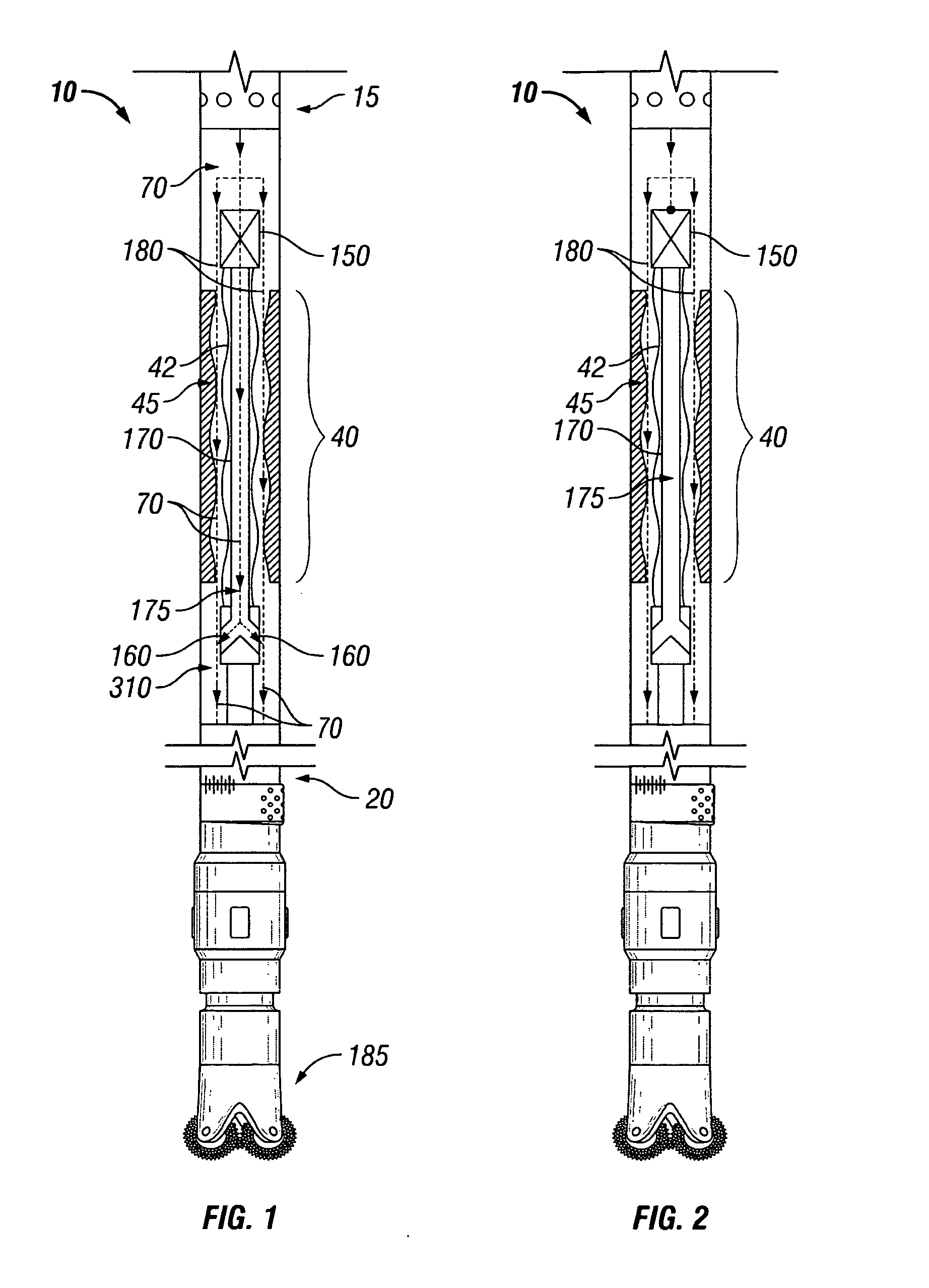

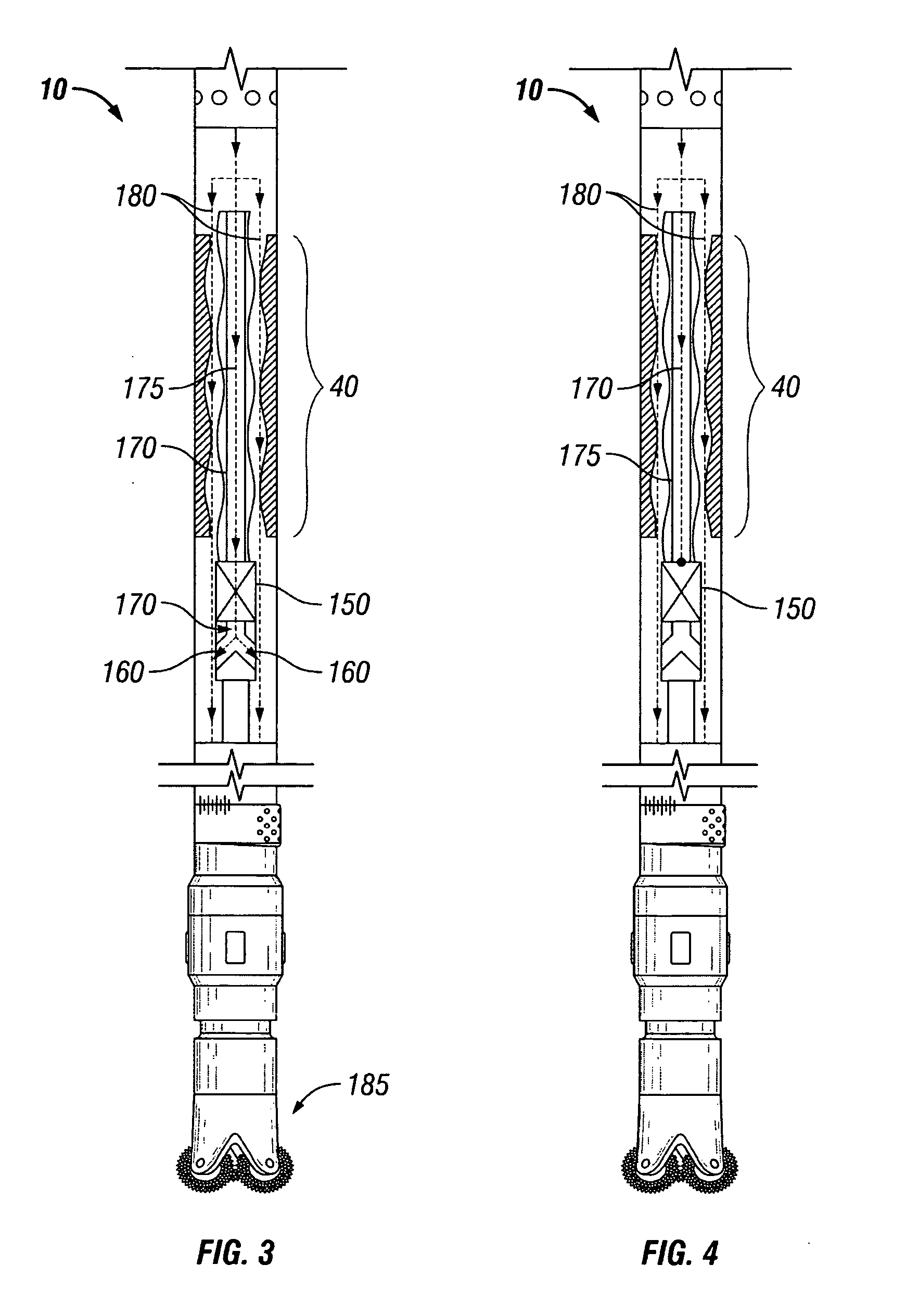

Method and apparatus for shifting speeds in a fluid-actuated motor

ActiveUS20060243493A1Change the rotational speed of the drill bitValve arrangementsFluid removalHydraulic motorControl flow

A method and apparatus for changing the speed of a drill bit down hole in a fluid-actuated motor, including a positive displacement motor and a hydraulic motor, is disclosed. The apparatus comprises a bypass valve installed in the motor for controlling flow through and around the power section of the motor. When closed, the bypass valve forces all fluid to flow through the power section of the motor, imparting maximum speed to the drill bit. When opened, a portion of the fluid flow is allowed to flow around the power section of the motor, thereby reducing the speed of the drill bit. The bypass valve may be opened or closed mechanically, electrically, hydraulically, pneumatically, or by any other means, including a removable plug.

Owner:NAT OILWELL DHT

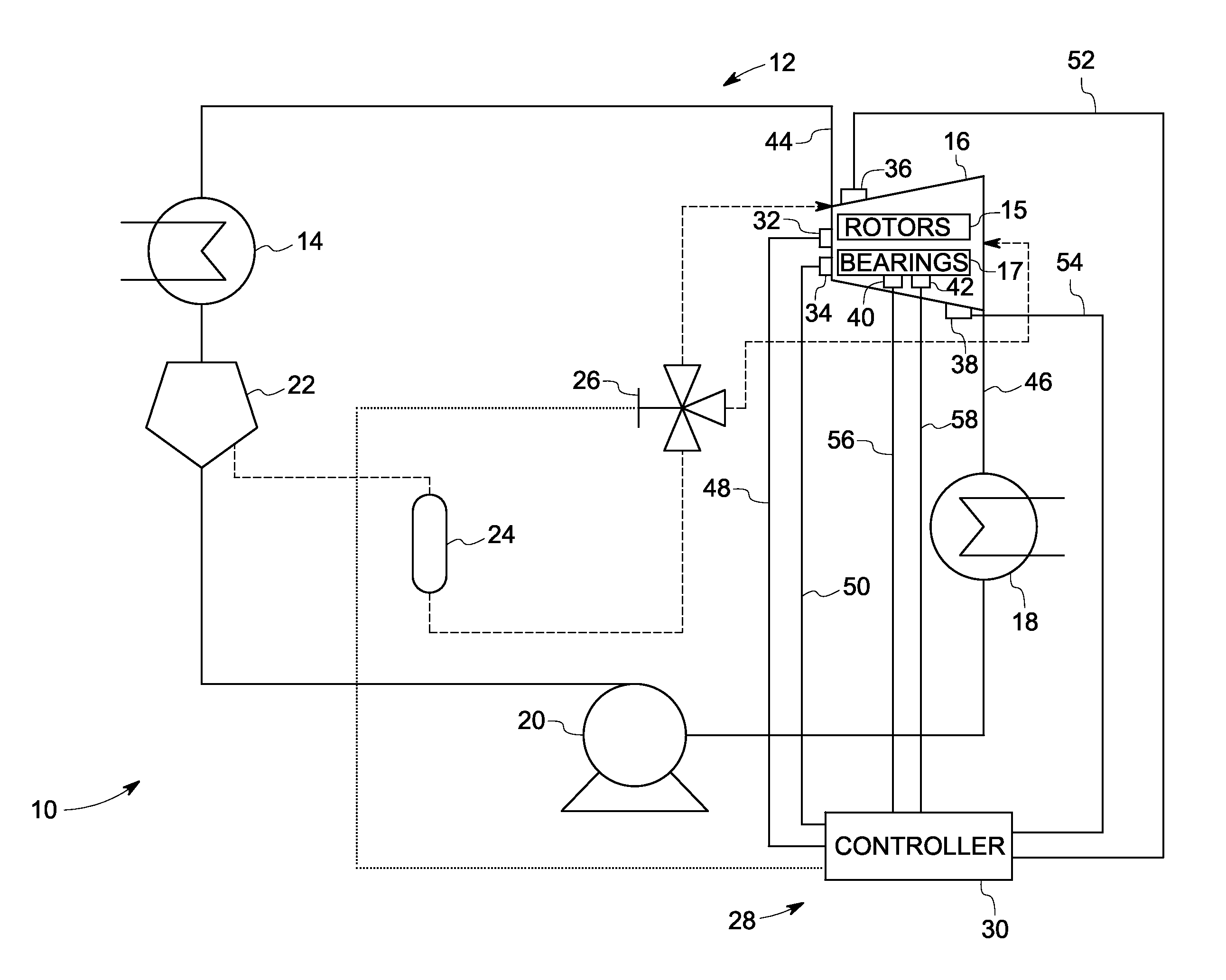

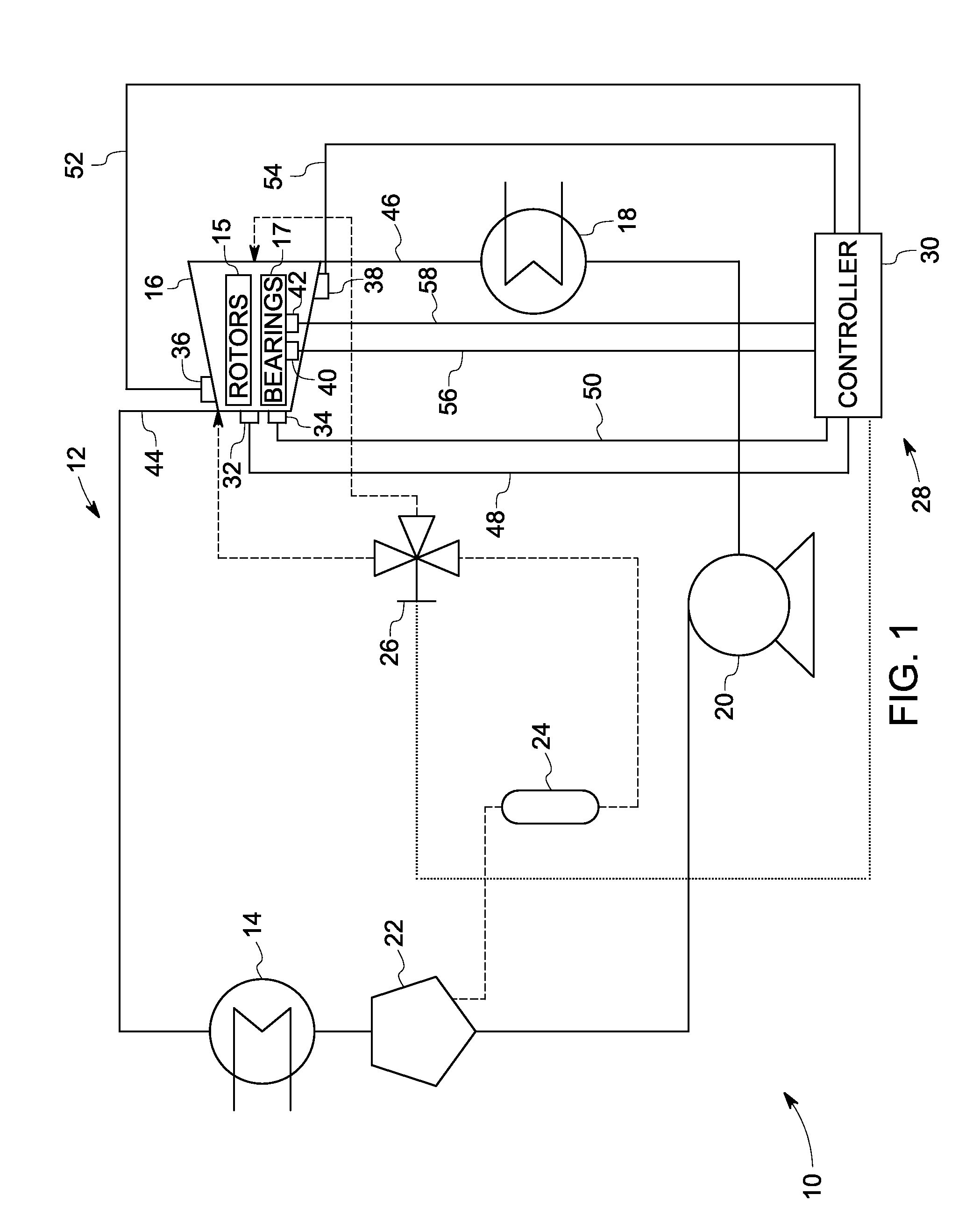

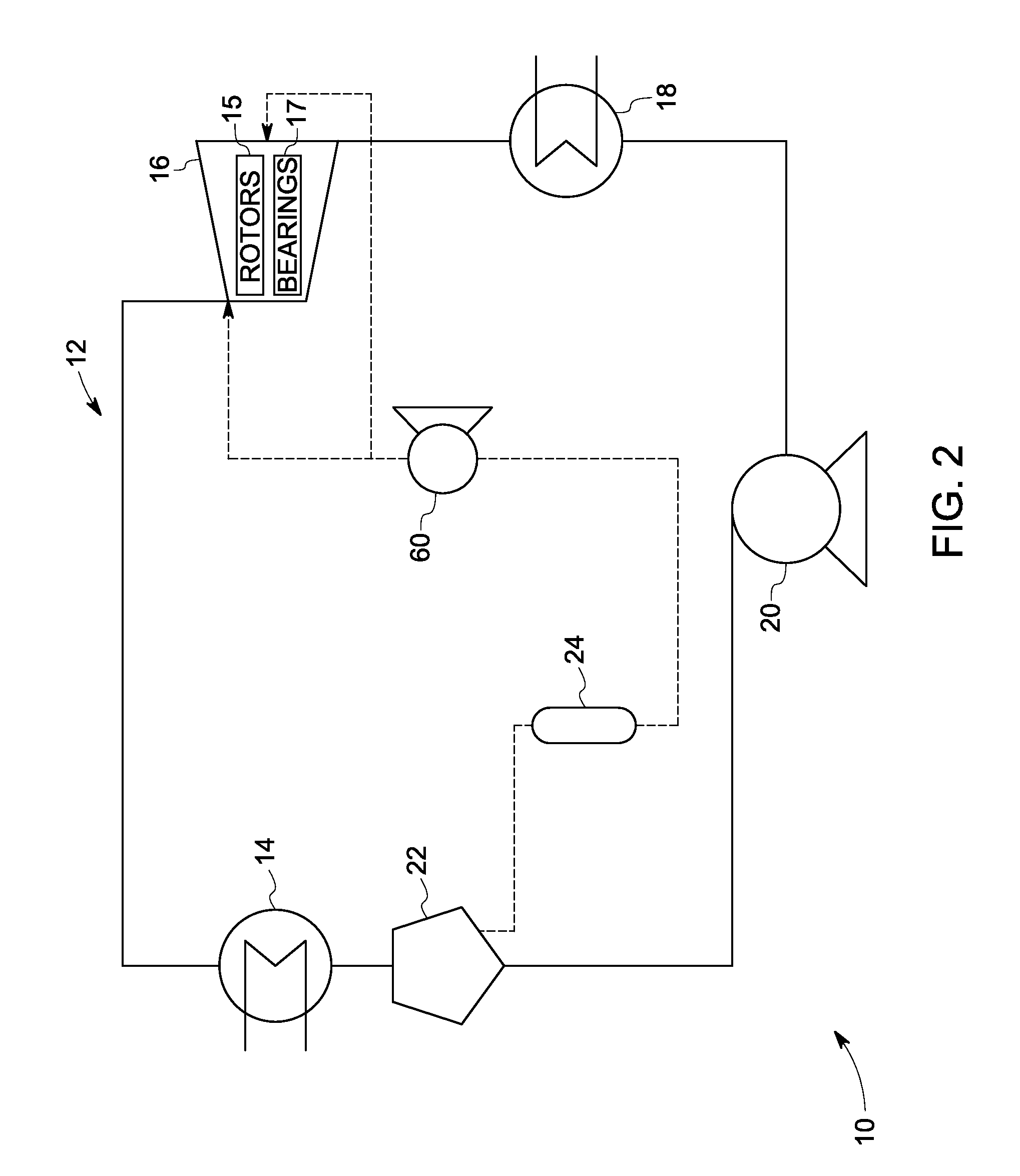

Method for lubricating screw expanders and system for controlling lubrication

A method for lubricating a screw expander includes condensing a mixture of working fluid and lubricant fed from the screw expander, through a condenser. At least a portion of the mixture of working fluid and lubricant fed from the condenser is pressurized from a first pressure to a second pressure through a pump. The method also includes separating the lubricant from the condensed working fluid of the at least portion of the mixture via a separator and feeding the lubricant to the screw expander; or separating the lubricant from the working fluid of the at least portion of the mixture via an evaporator and feeding the lubricant to the screw expander; or feeding the at least portion of the mixture of condensed working fluid and lubricant to the screw expander; or combinations thereof.

Owner:GENERAL ELECTRIC CO

Method and apparatus for injecting a fuel into a combustor assembly

InactiveUS7469544B2Eliminating selectedTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorAutoignition temperature

Owner:THE BOEING CO

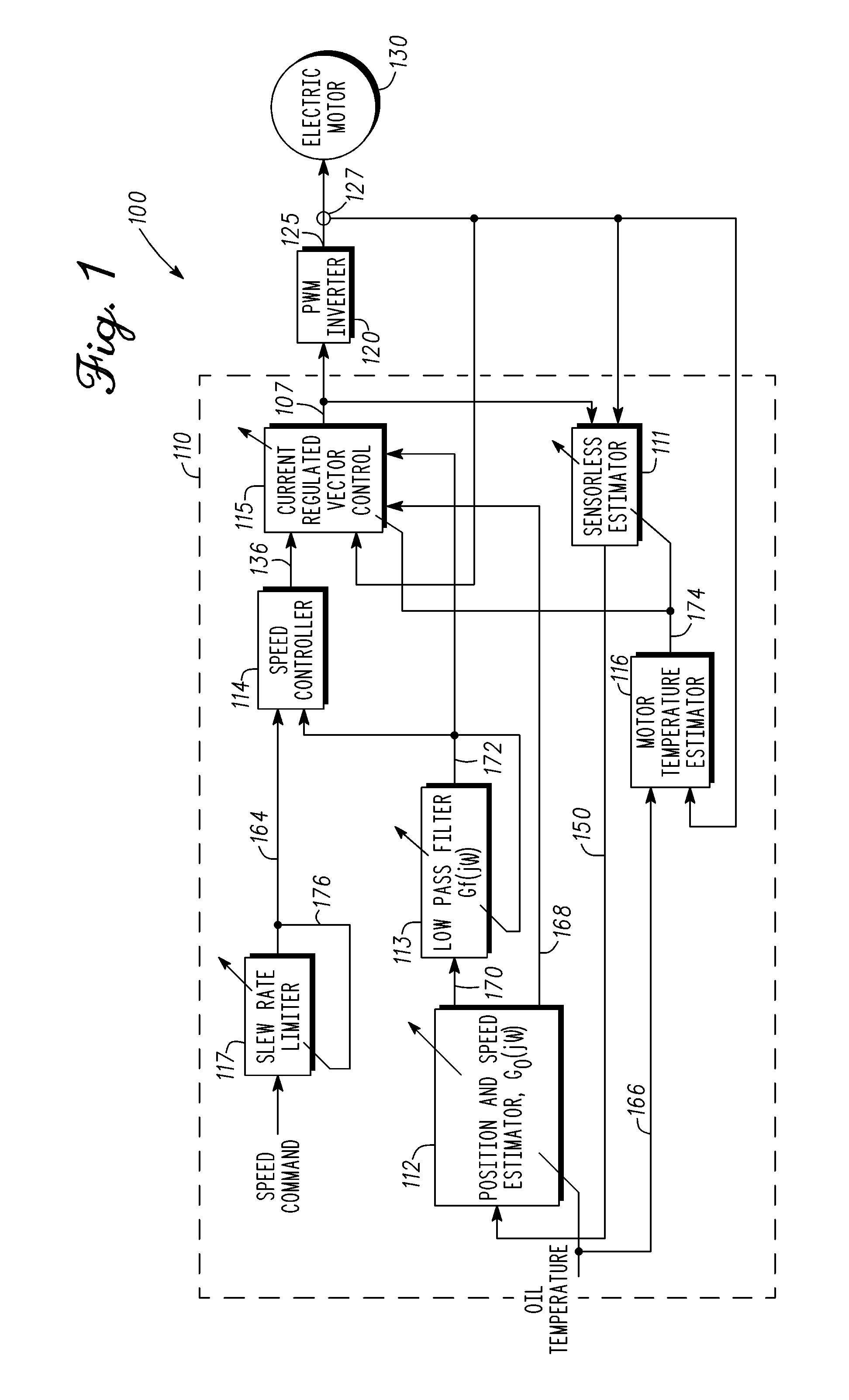

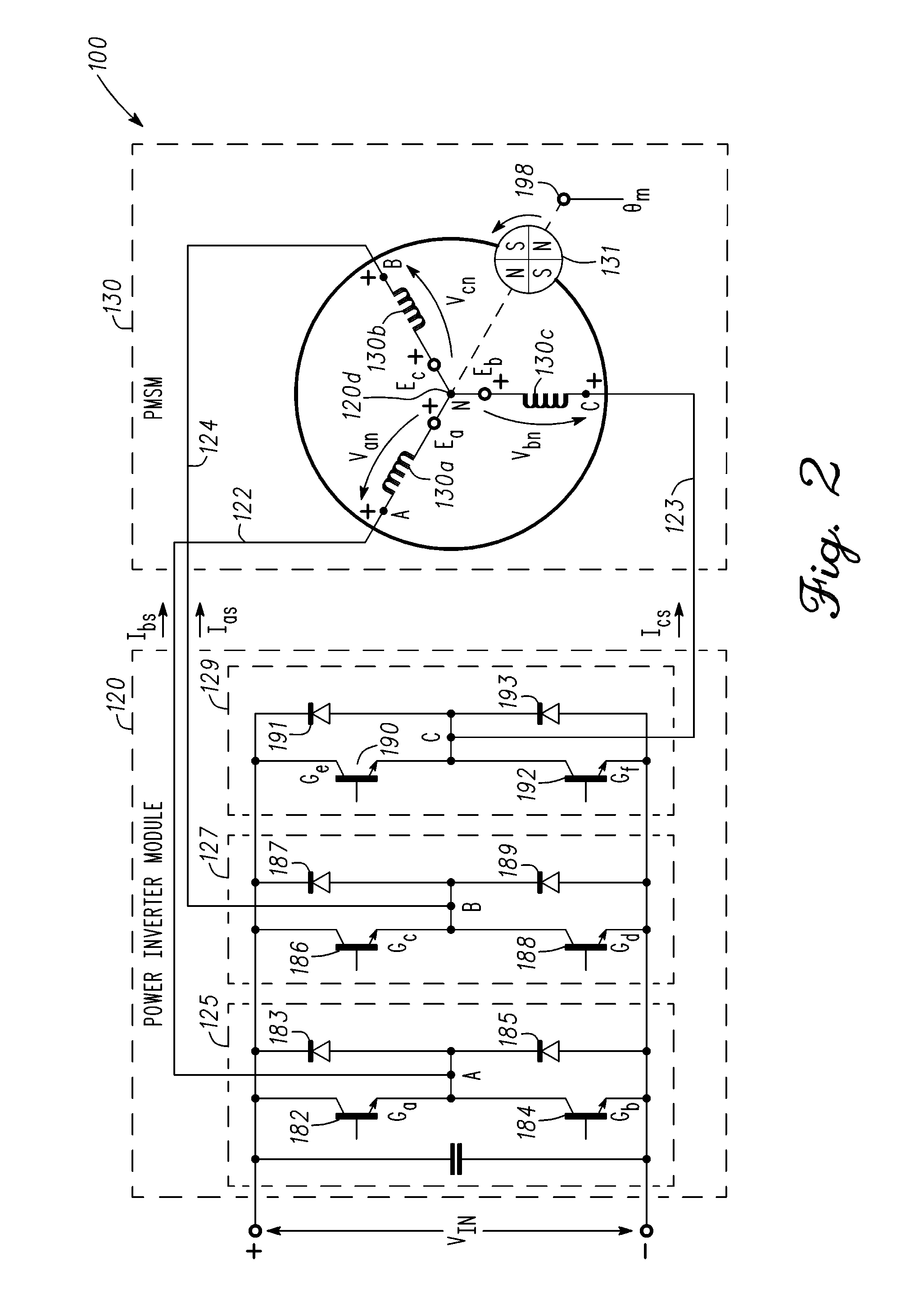

Methods, systems and apparatus for dynamically controlling an electric motor that drives an oil pump

ActiveUS20110084638A1Multiple motor speed/torque controlSingle motor speed/torque controlMotor driveEngineering

Methods, system and apparatus are provided for sensorless control of a vector controlled motor drive system that includes an electric motor used to drive an auxiliary oil pump.

Owner:GM GLOBAL TECH OPERATIONS LLC

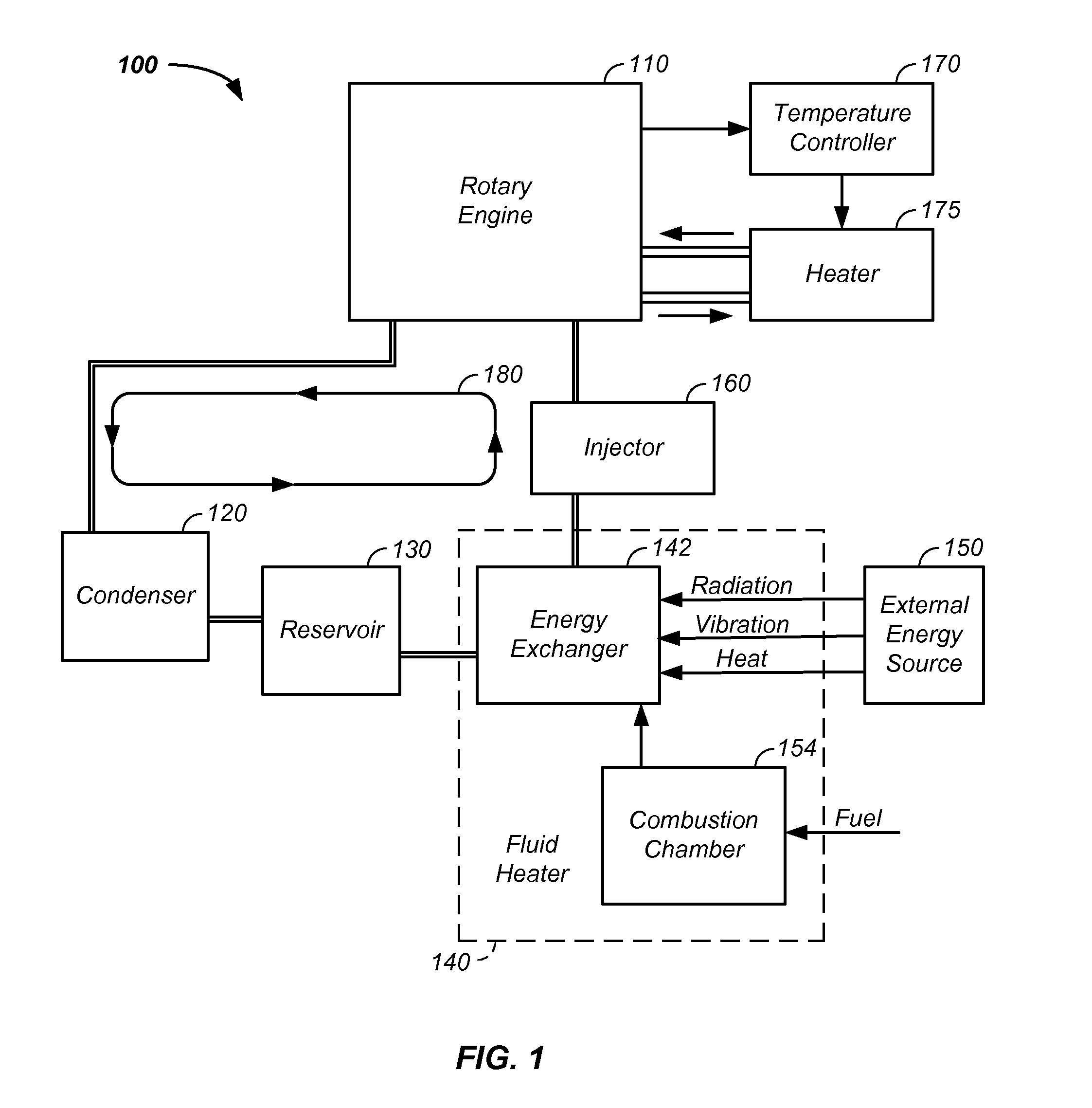

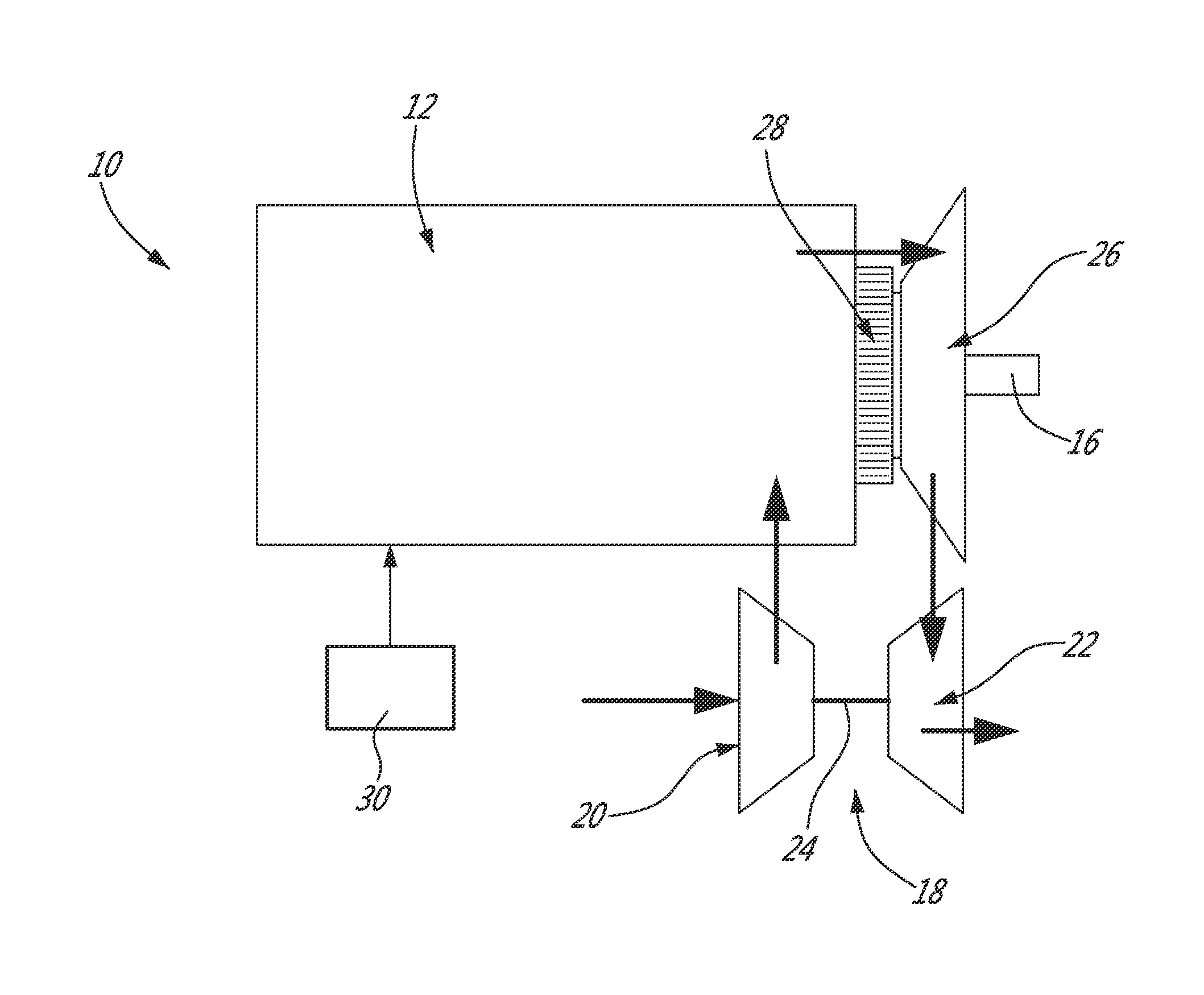

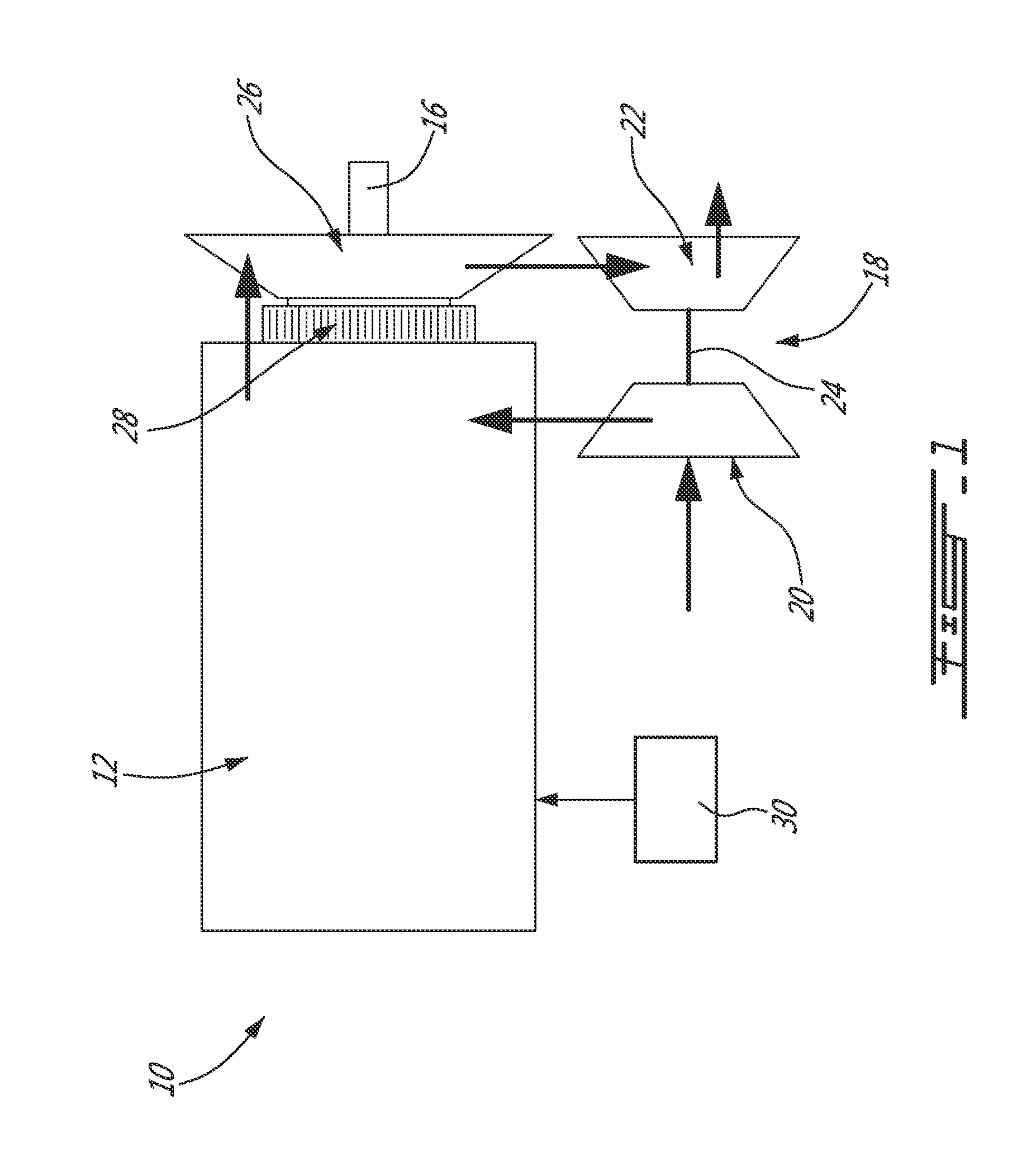

Compound cycle rotary engine

ActiveUS20090007882A1Reduce fuel consumptionHigh power to weightInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

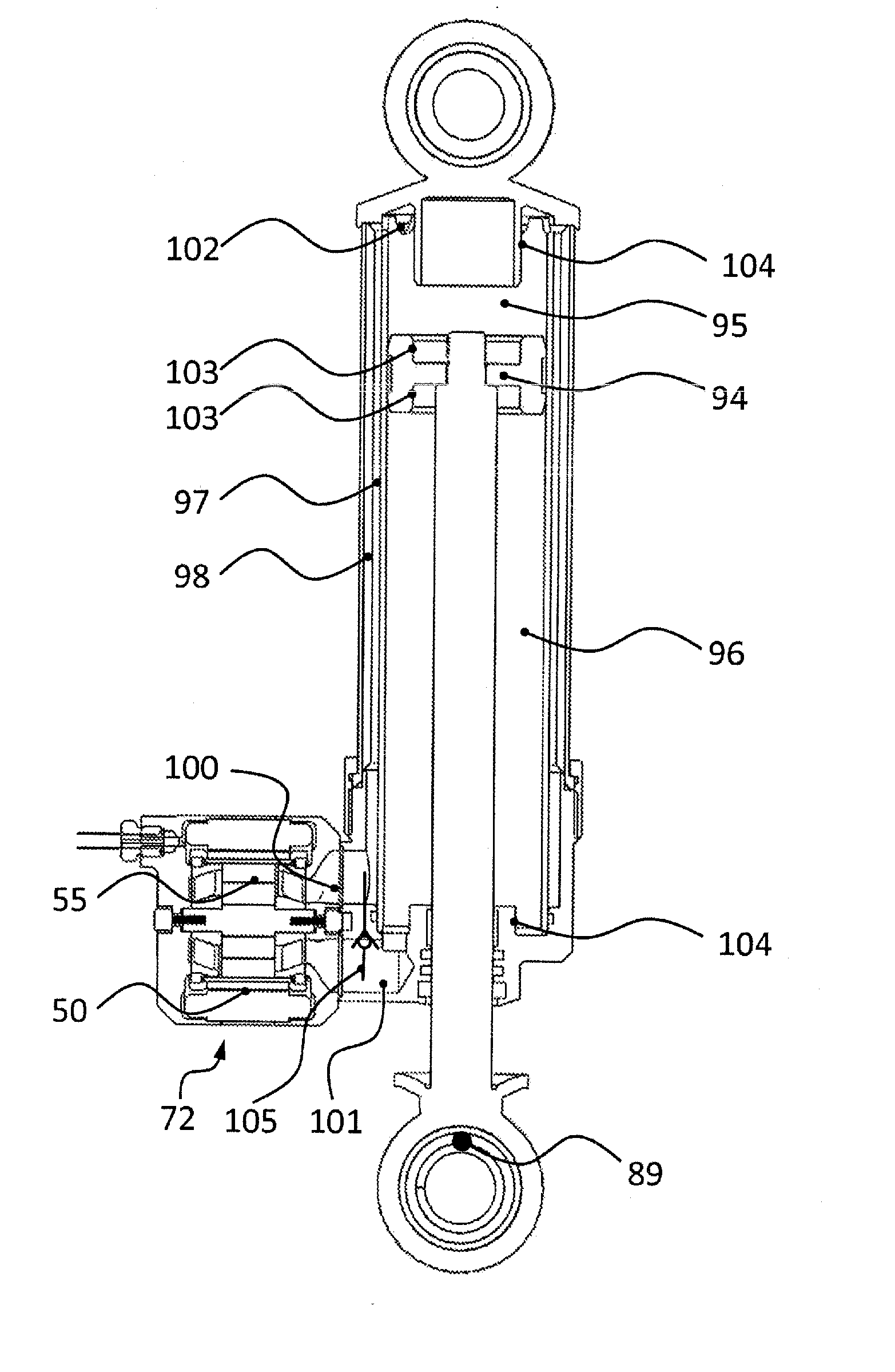

Integrated energy generating damper

A linear energy harvesting device that includes a housing and a piston that moves at least partially through the housing when it is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor drives an electric generator that produces electricity. Both the motor and generator are central to the device housing. Exemplary configurations are disclosed such as monotube, twin-tube, tri-tube and rotary based designs that each incorporates an integrated energy harvesting apparatus. By varying the electrical characteristics on an internal generator, the kinematic characteristics of to the energy harvesting apparatus can be dynamically altered. In another mode, the apparatus can be used as an actuator to create linear movement. Applications include vehicle suspension systems (to act as the primary damper component), railcar bogie dampers, or industrial applications such as machinery dampers and wave energy harvesters, and electro-hydraulic actuators.

Owner:CLEARMOTION INC

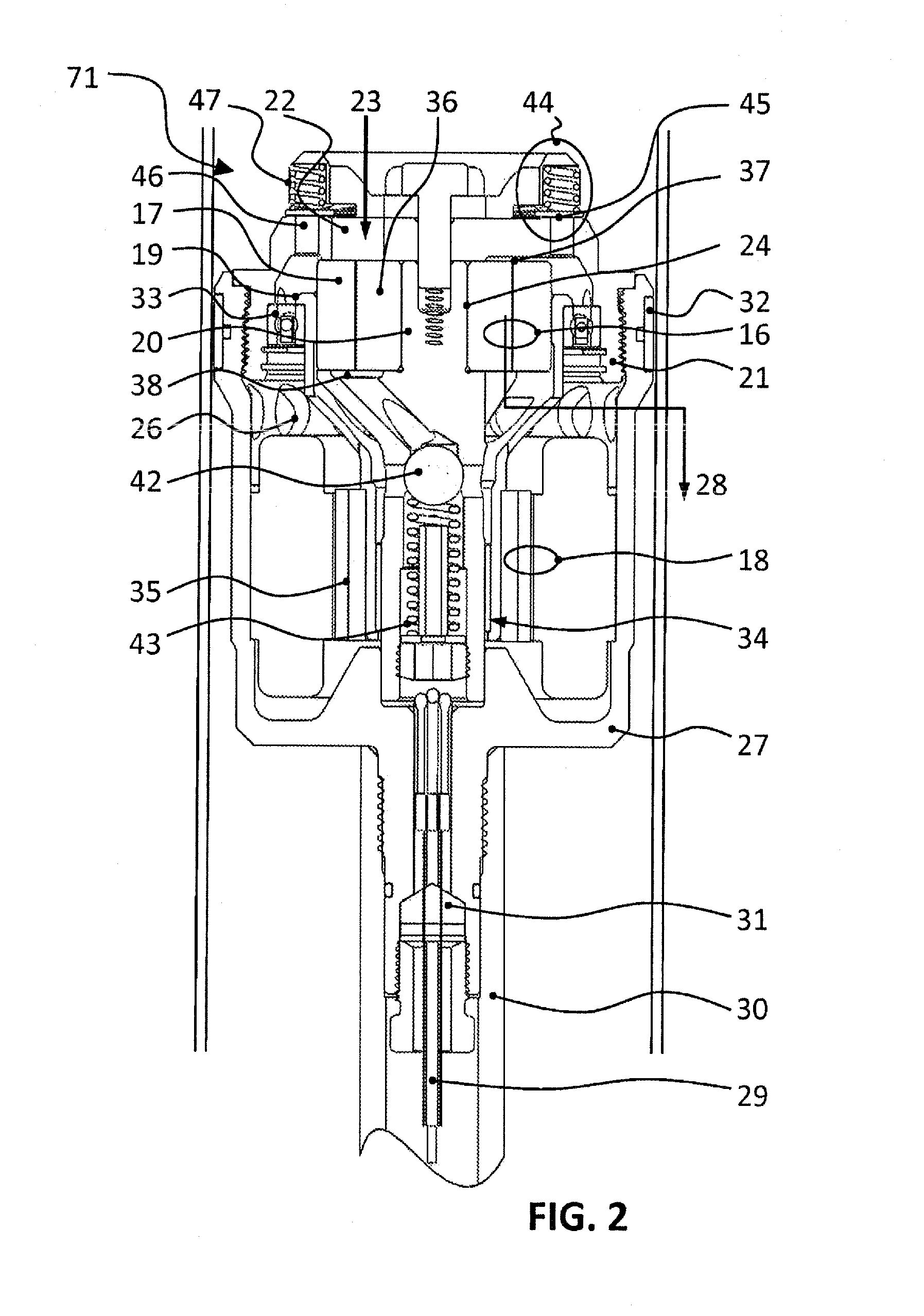

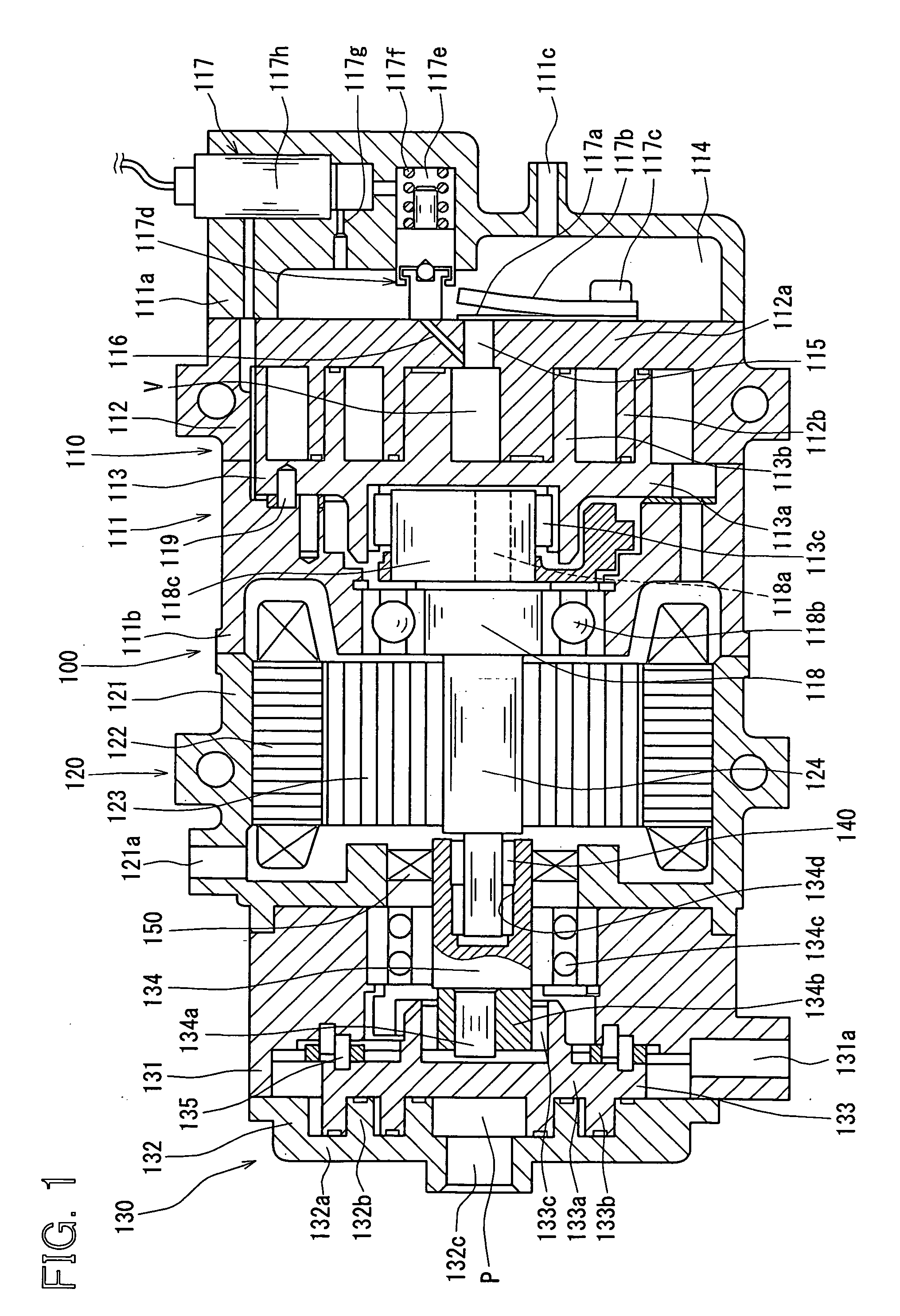

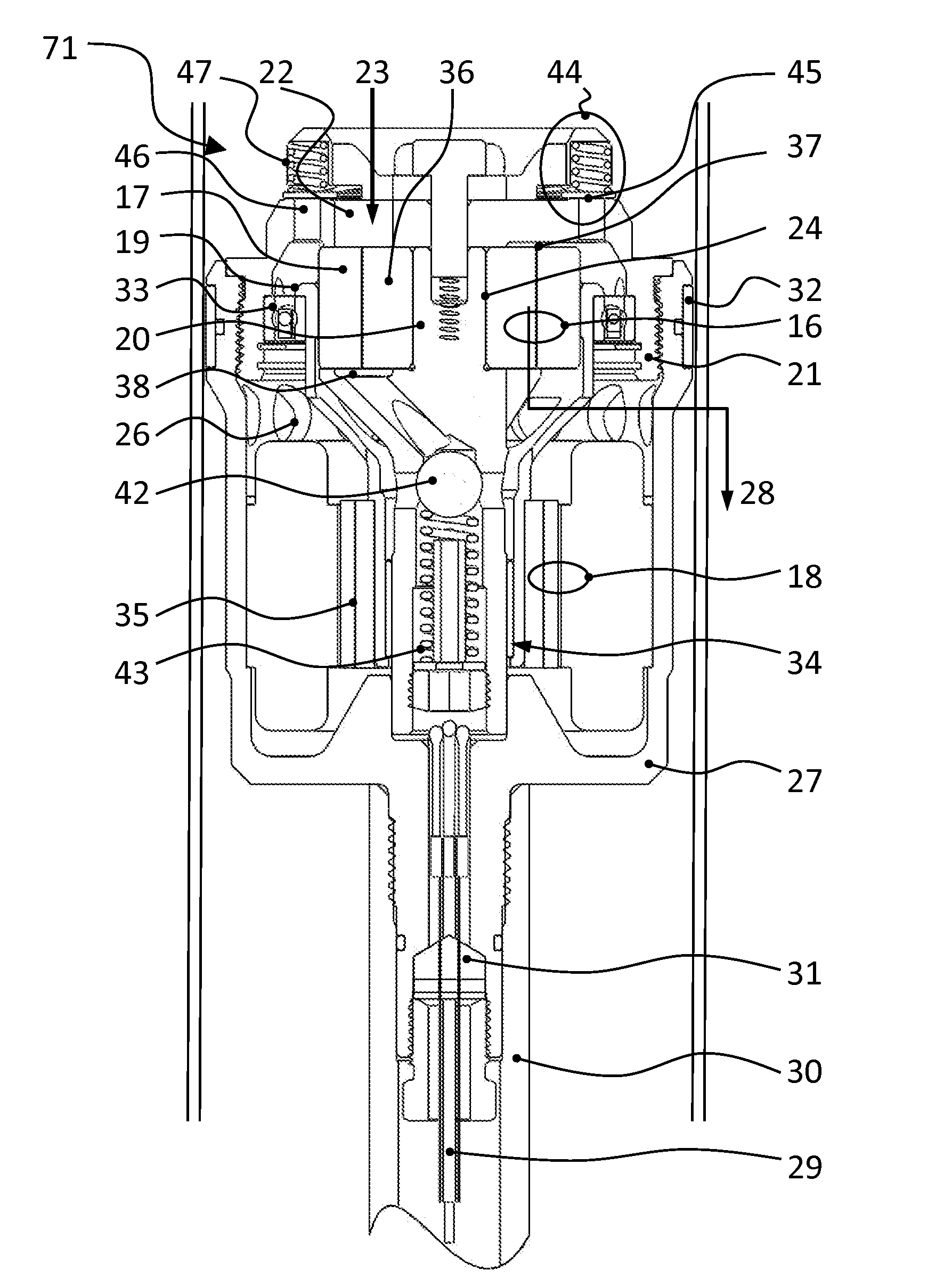

Compound cycle engine

ActiveUS20140020381A1Internal combustion piston enginesWorking fluid for enginesExternal combustion engineTurbocharger

A compound cycle engine having an output shaft; at least two rotary units each defining an internal combustion engine, a velocity turbine, and a turbocharger is discussed. The velocity turbine includes a rotor in driving engagement with the output shaft between two of the rotary units. The exhaust port of each rotary unit is in fluid communication with the flowpath of the velocity turbine upstream of its rotor. The outlet of the compressor of the turbocharger is in fluid communication with the inlet port of each rotary unit. The inlet of the pressure turbine of the turbocharger is in fluid communication with the flowpath of the velocity turbine downstream of its rotor. A method of compounding at least two rotary engines is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

Pressure exchanger

ActiveUS7306437B2Increase capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

Owner:ISOBARIC STRATEGIES INC

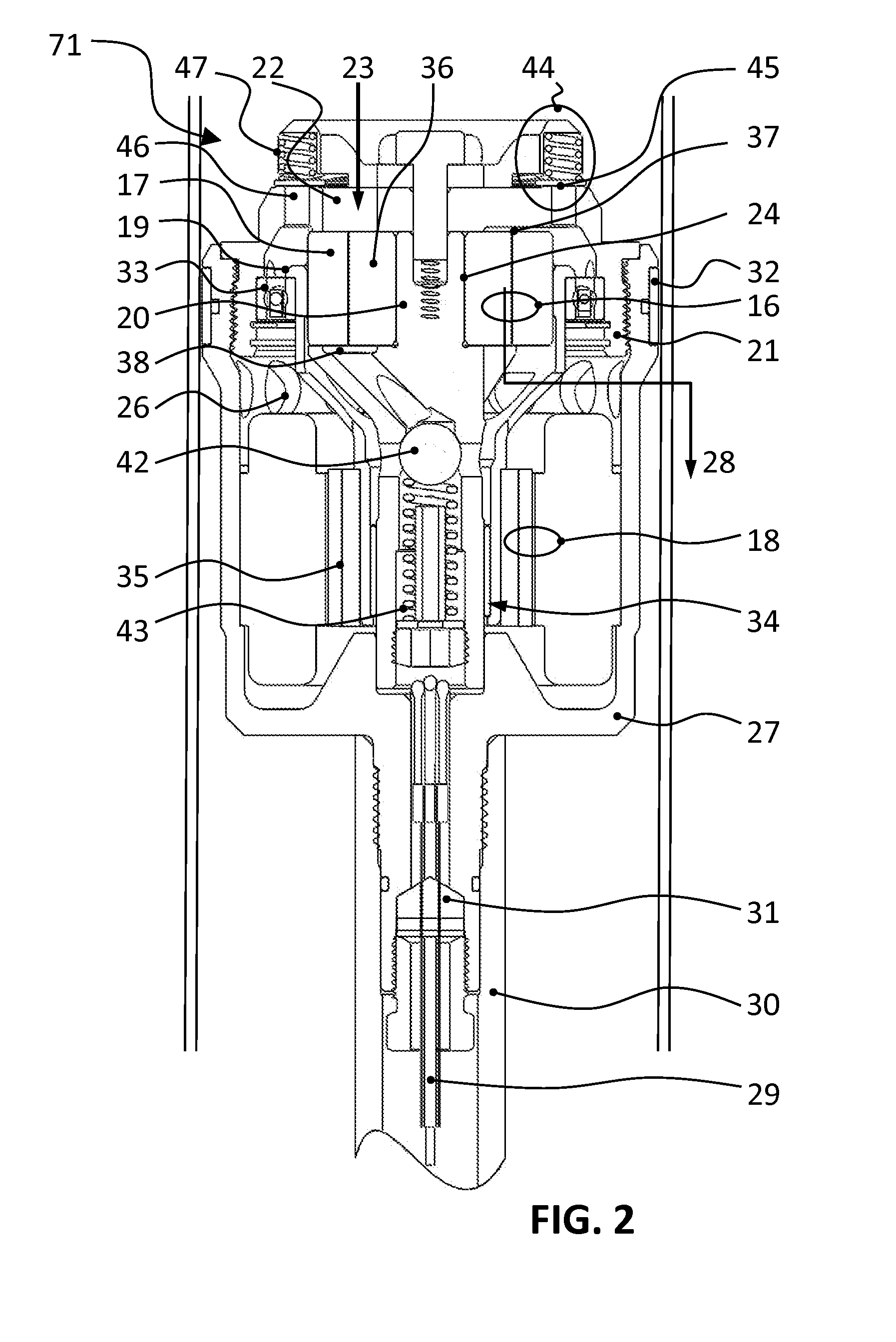

Compound cycle engine

ActiveUS20150275756A1Internal combustion piston enginesPump componentsTurbochargerExternal combustion engine

A compound cycle engine having an output shaft; at least two rotary units each defining an internal combustion engine, a first stage turbine, and a turbocharger is discussed. The first stage turbine includes a rotor in driving engagement with the output shaft between two of the rotary units. The exhaust port of each rotary unit is in fluid communication with the flowpath of the first stage turbine upstream of its rotor. The outlet of the compressor of the turbocharger is in fluid communication with the inlet port of each rotary unit. The inlet of the second stage turbine of the turbocharger is in fluid communication with the flowpath of the first stage turbine downstream of its rotor. The first stage turbine has a lower reaction ratio than that of the second stage turbine. A method of compounding at least two rotary engines is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

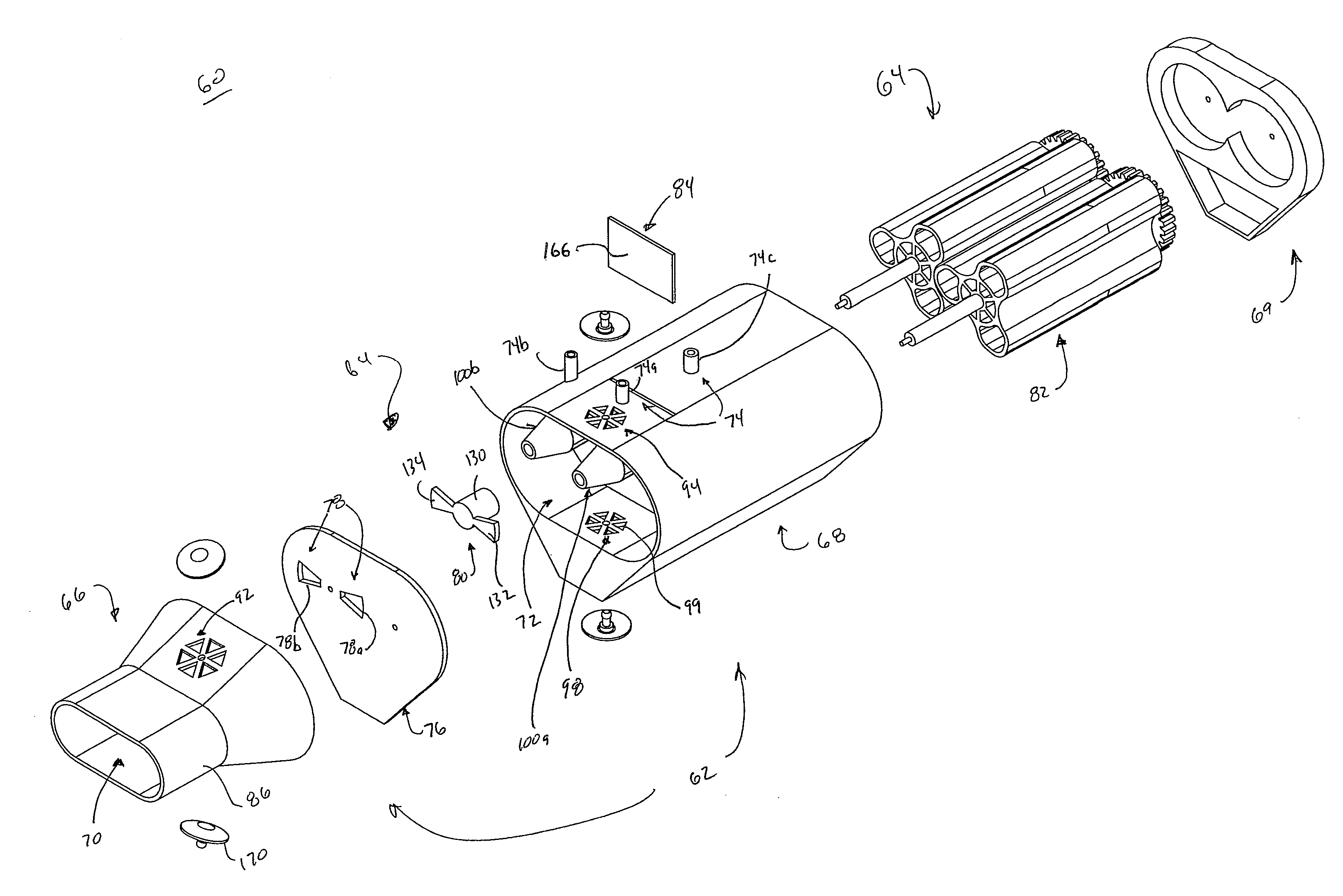

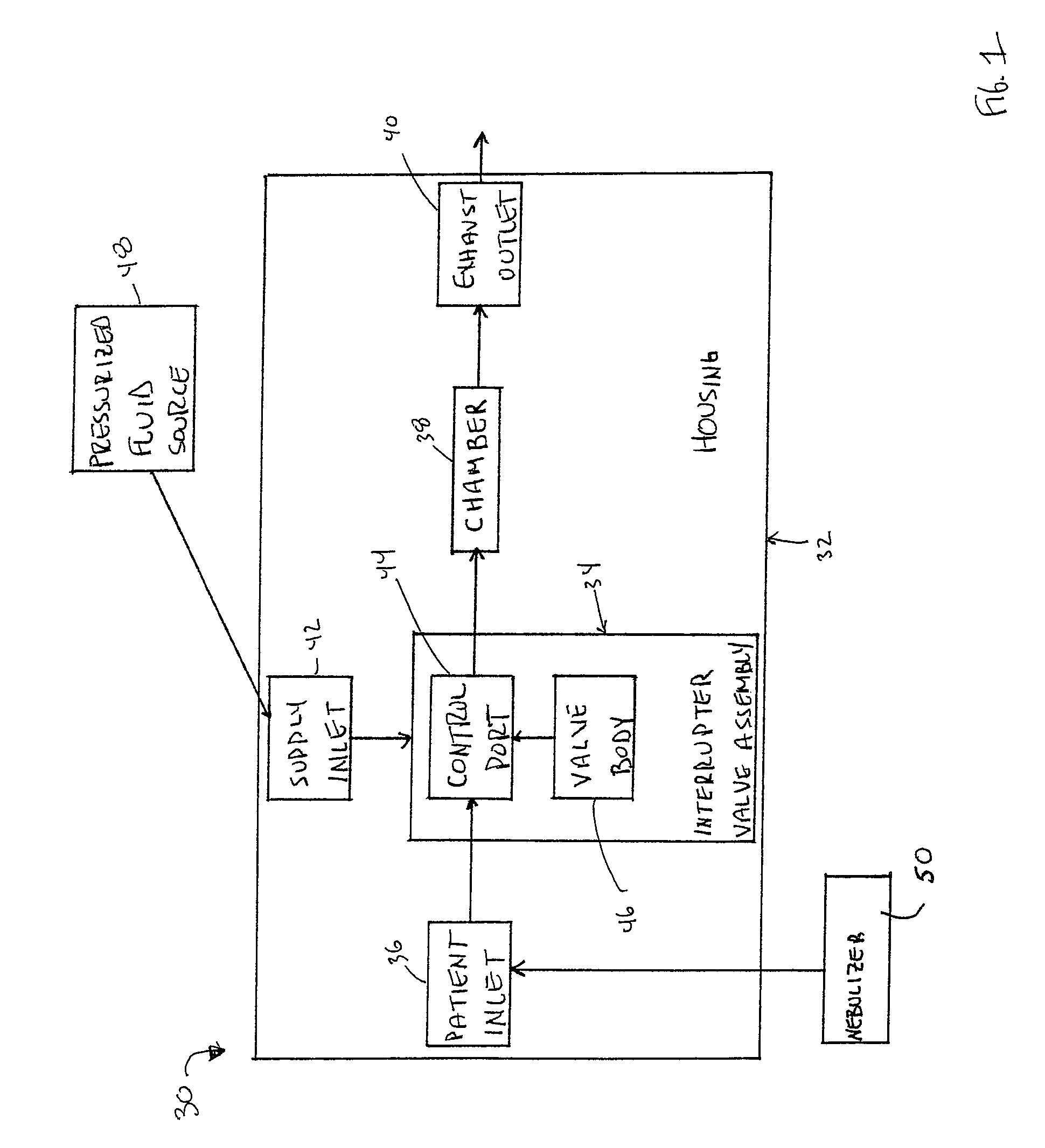

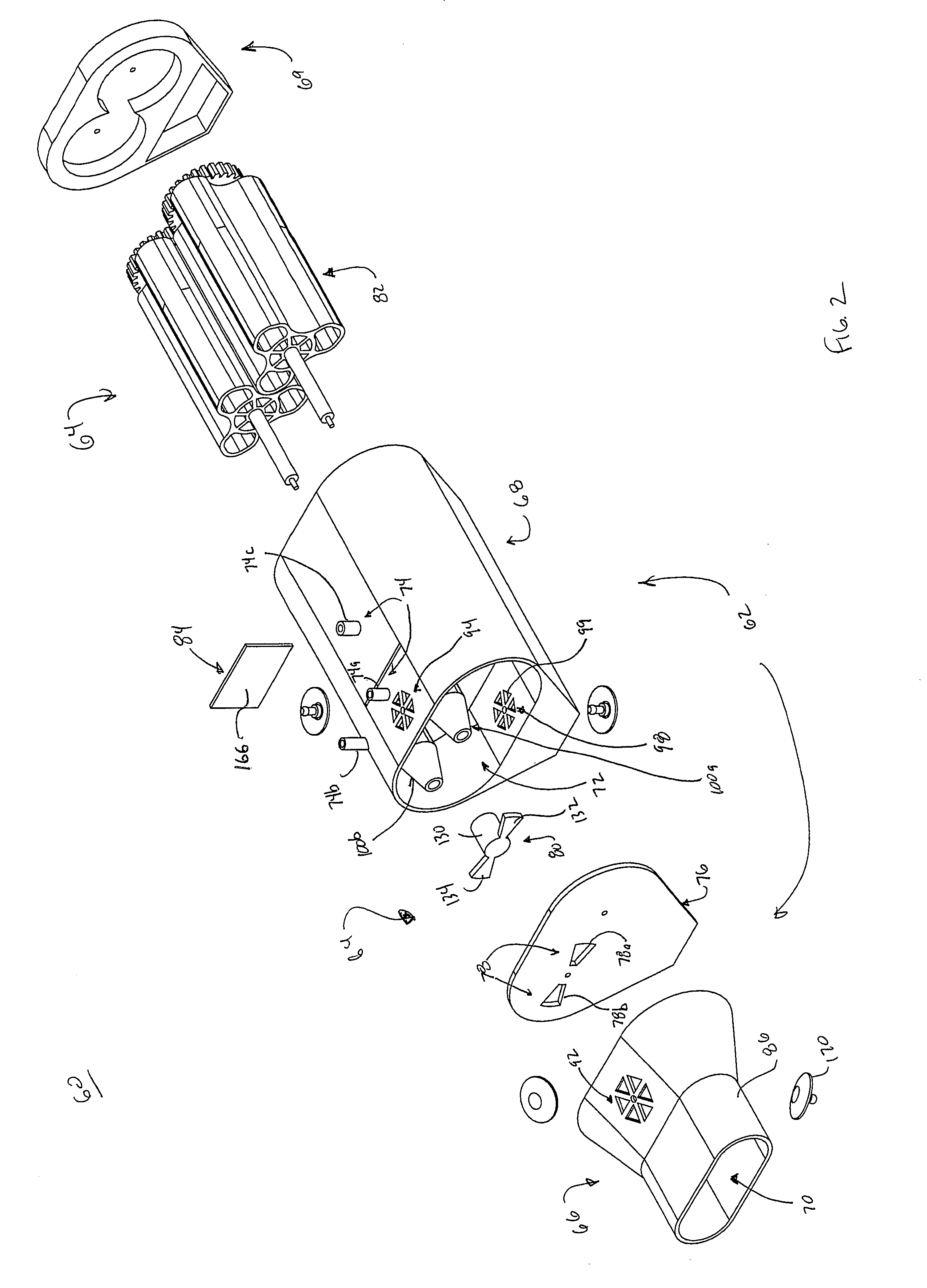

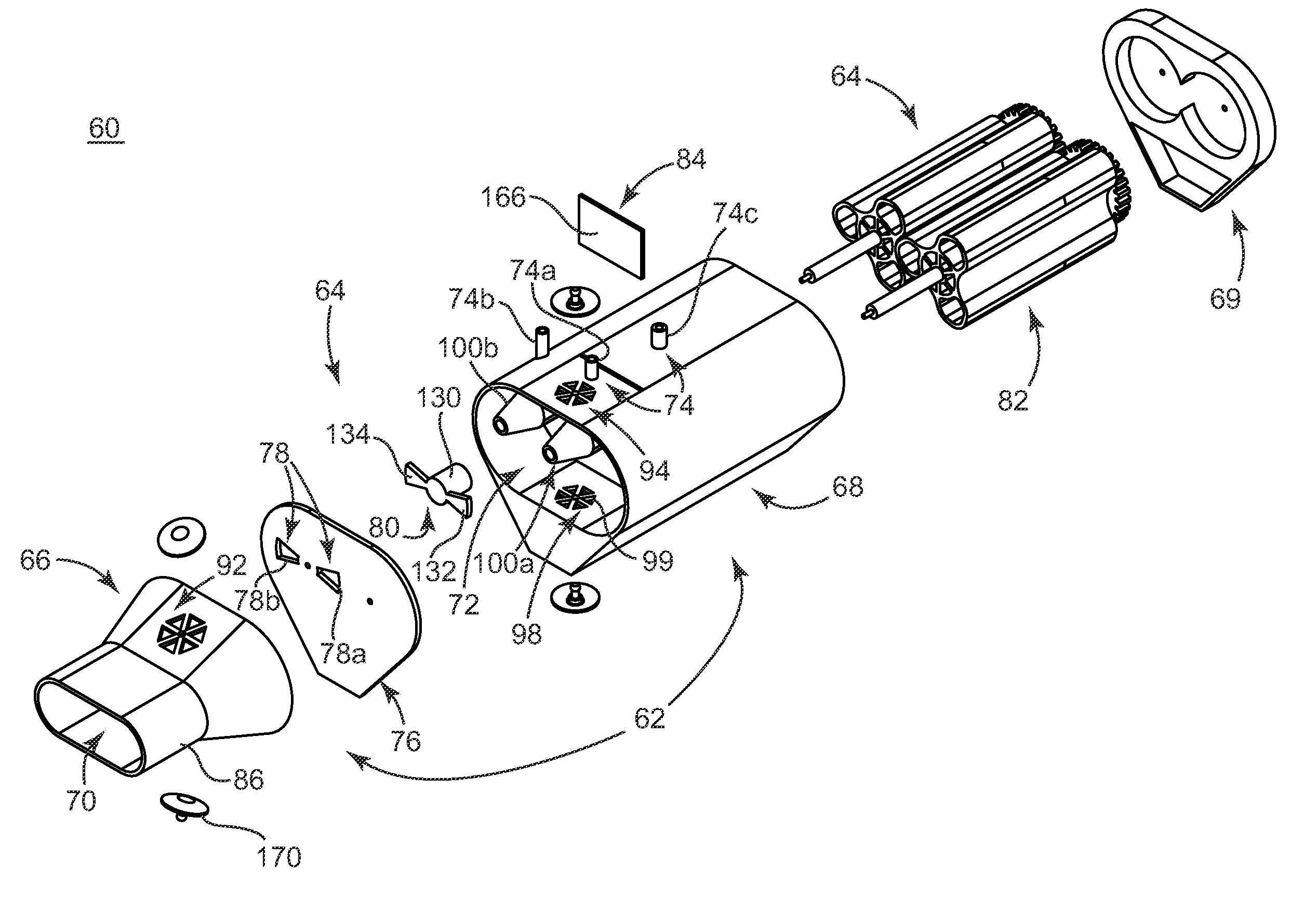

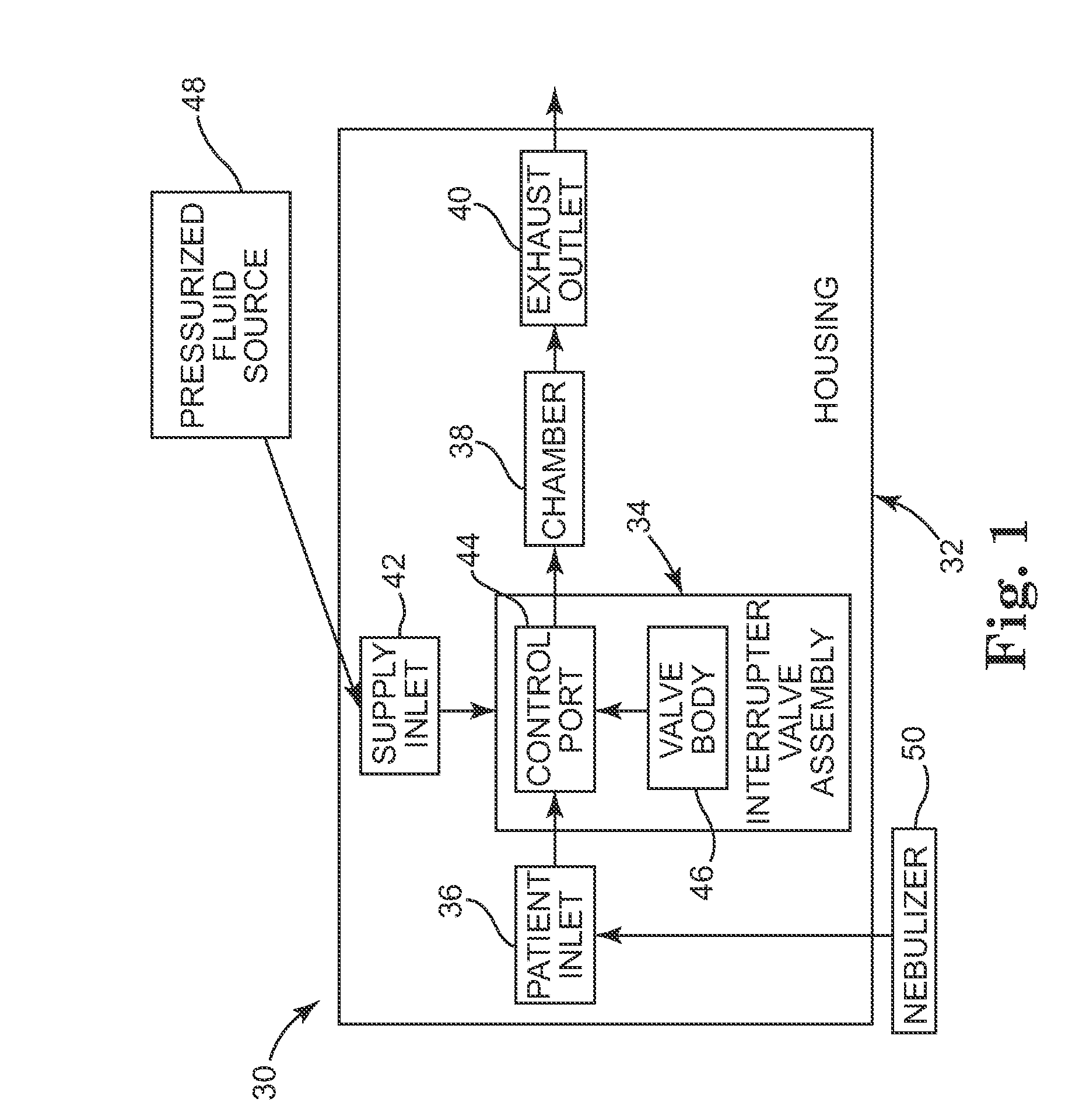

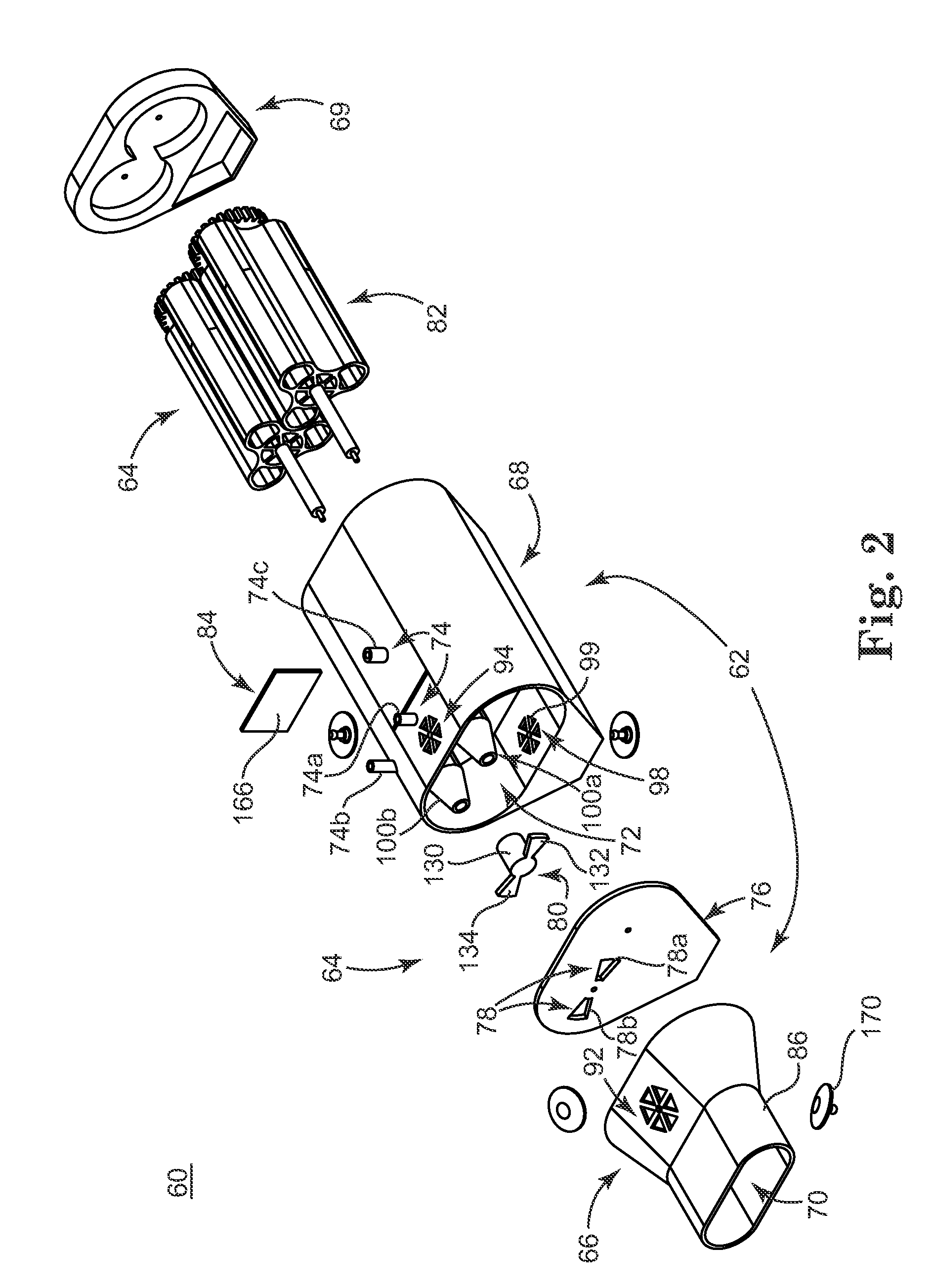

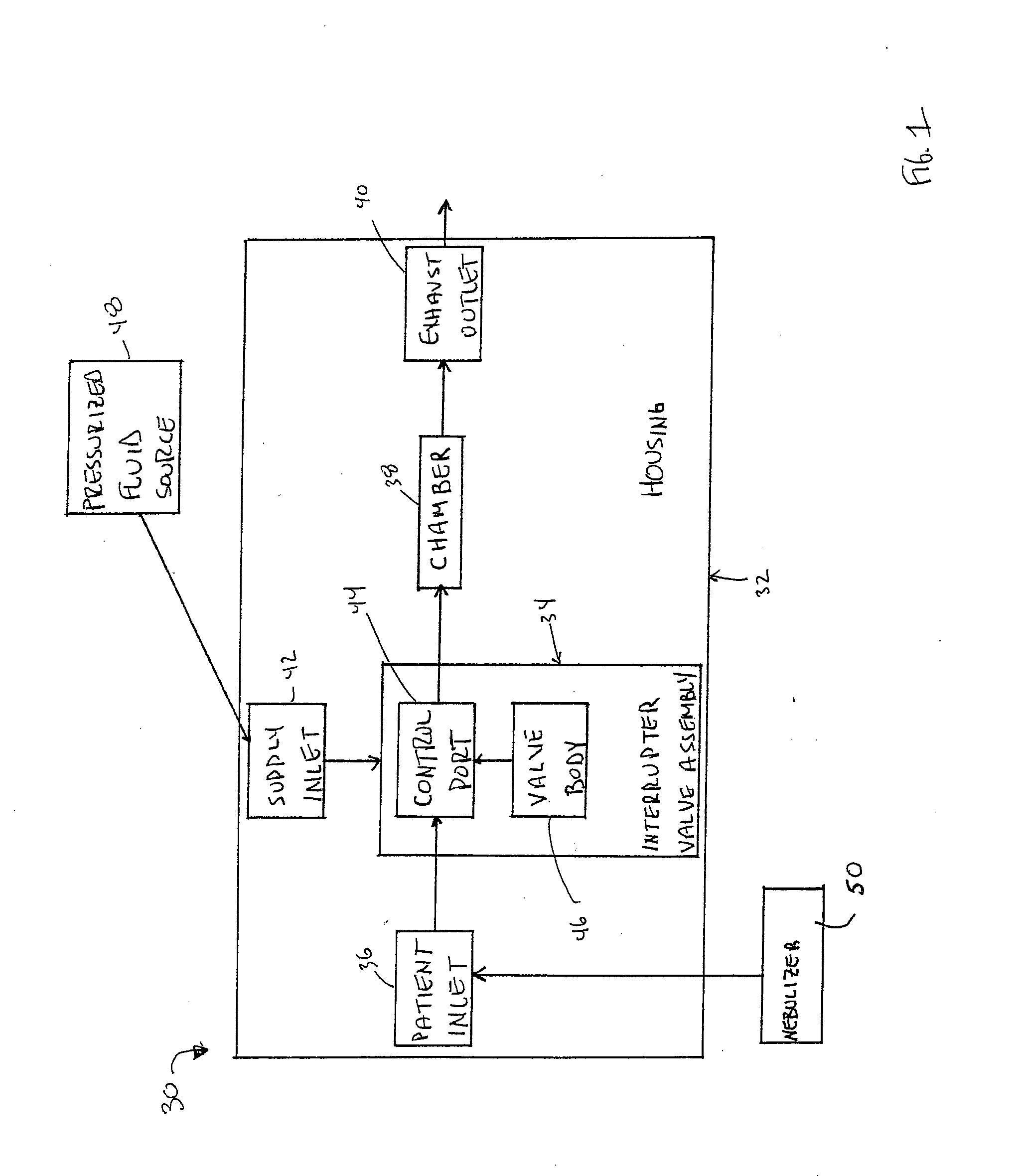

Respiratory therapy device and method

ActiveUS7779841B2Facilitate one or more additional therapiesRespiratorsBreathing masksPositive pressureEngineering

A respiratory therapy device including a housing and an interrupter valve assembly. The housing includes a patient inlet, an exhaust outlet, a chamber, and a supply inlet. The interrupter valve assembly is associated with the housing and includes a control port fluidly connecting the patient inlet and the first chamber, and a valve body adapted to selectively obstruct fluid flow through the control port. In a passive mode, positive fluid flow to the supply inlet does not occur, and the interrupter valve assembly interacts with exhaled air create an oscillatory PEP effect. In an active mode, fluid flow to the supply inlet occurs and the interrupter valve assembly operates to create a CHFO effect. The respiratory device can serve as a passive oscillatory PEP device, and when connected to a positive pressure source, as an active device.

Owner:SUNMED GRP HLDG LLC

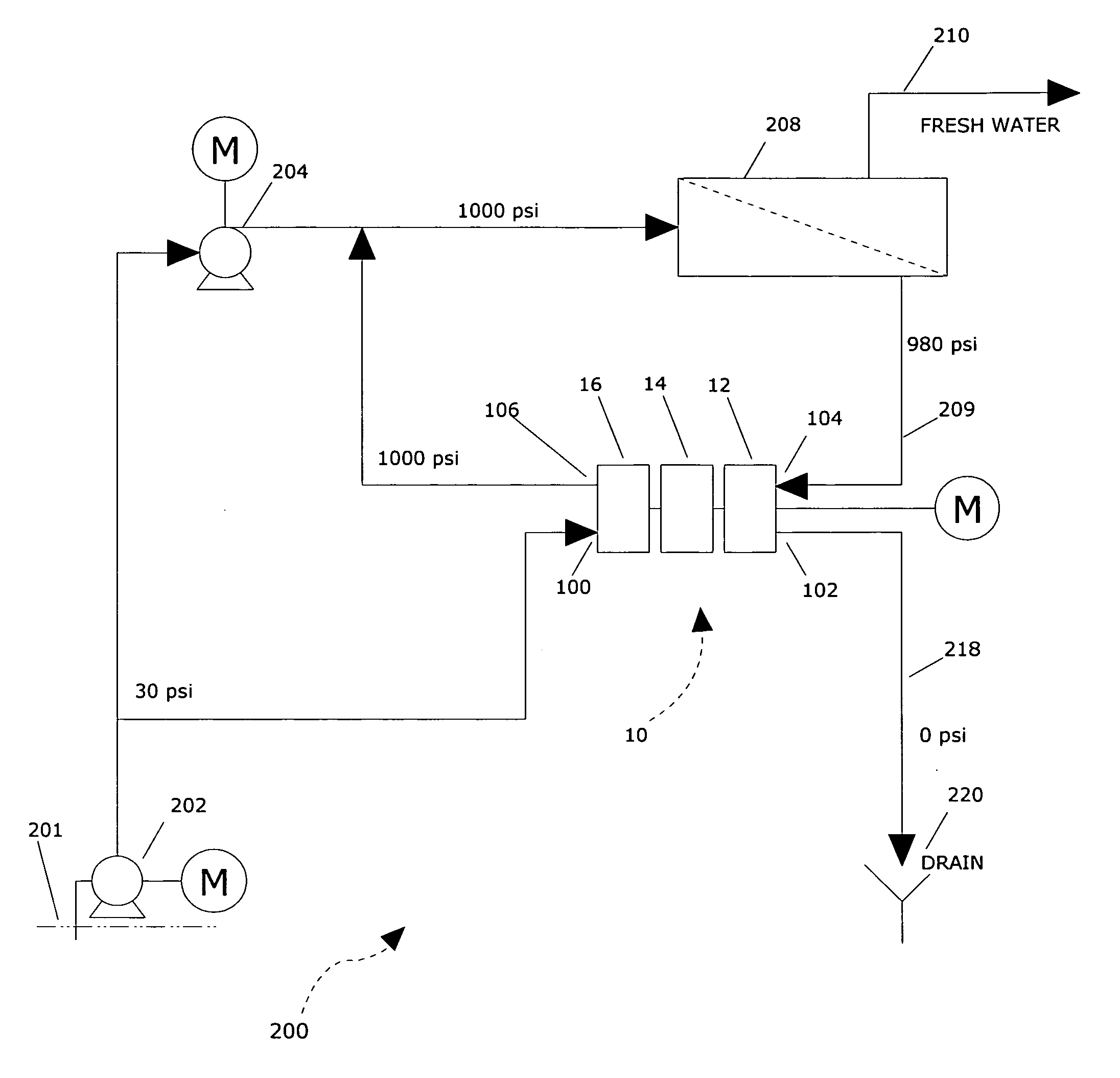

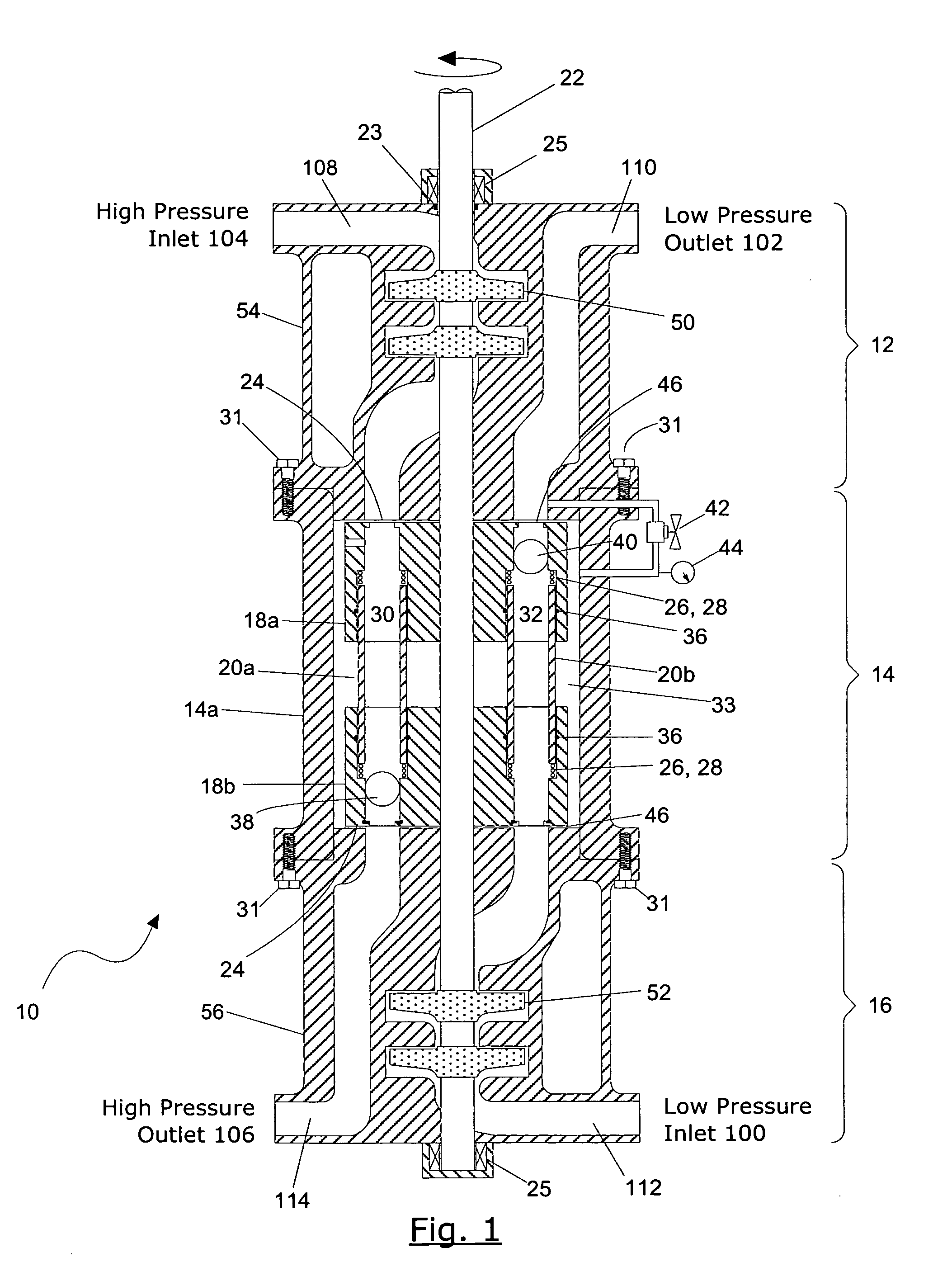

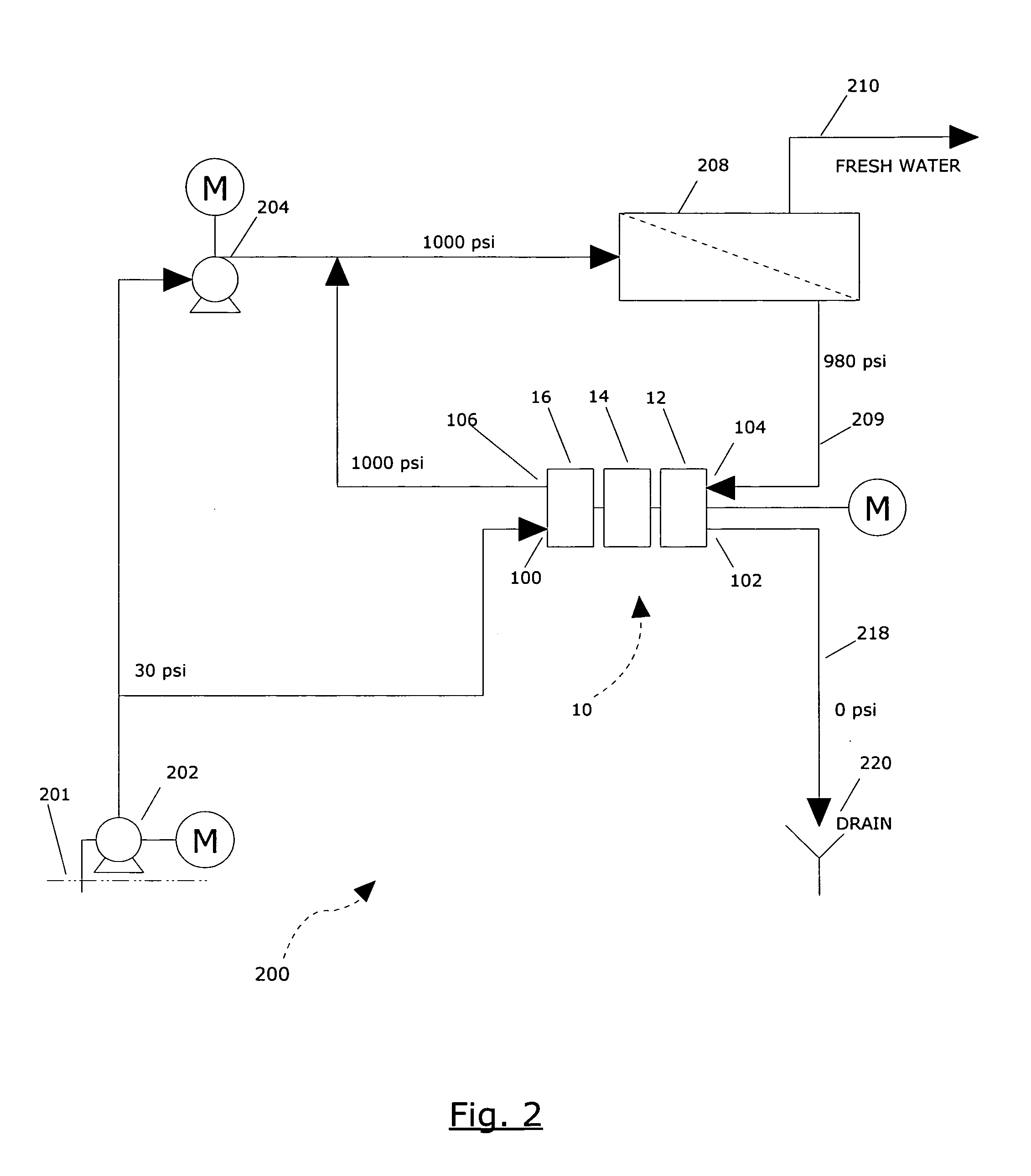

Pressure exchange apparatus with integral pump

InactiveUS20060037895A1Increase pressureRotary/oscillating piston combinations for elastic fluidsPump componentsEngineeringMechanical engineering

A pressure exchange device is provided that utilizes an integral high pressure boost pump that is in fluid communication with a pressure exchange unit. An optional low pressure boost pump unit may also be provided. The pressure exchange unit comprises a rotating rotor assembly inside a housing to transfer the pressure of a fluid from one high pressure fluid to another low pressure fluid.

Owner:SHUMWAY SCOTT

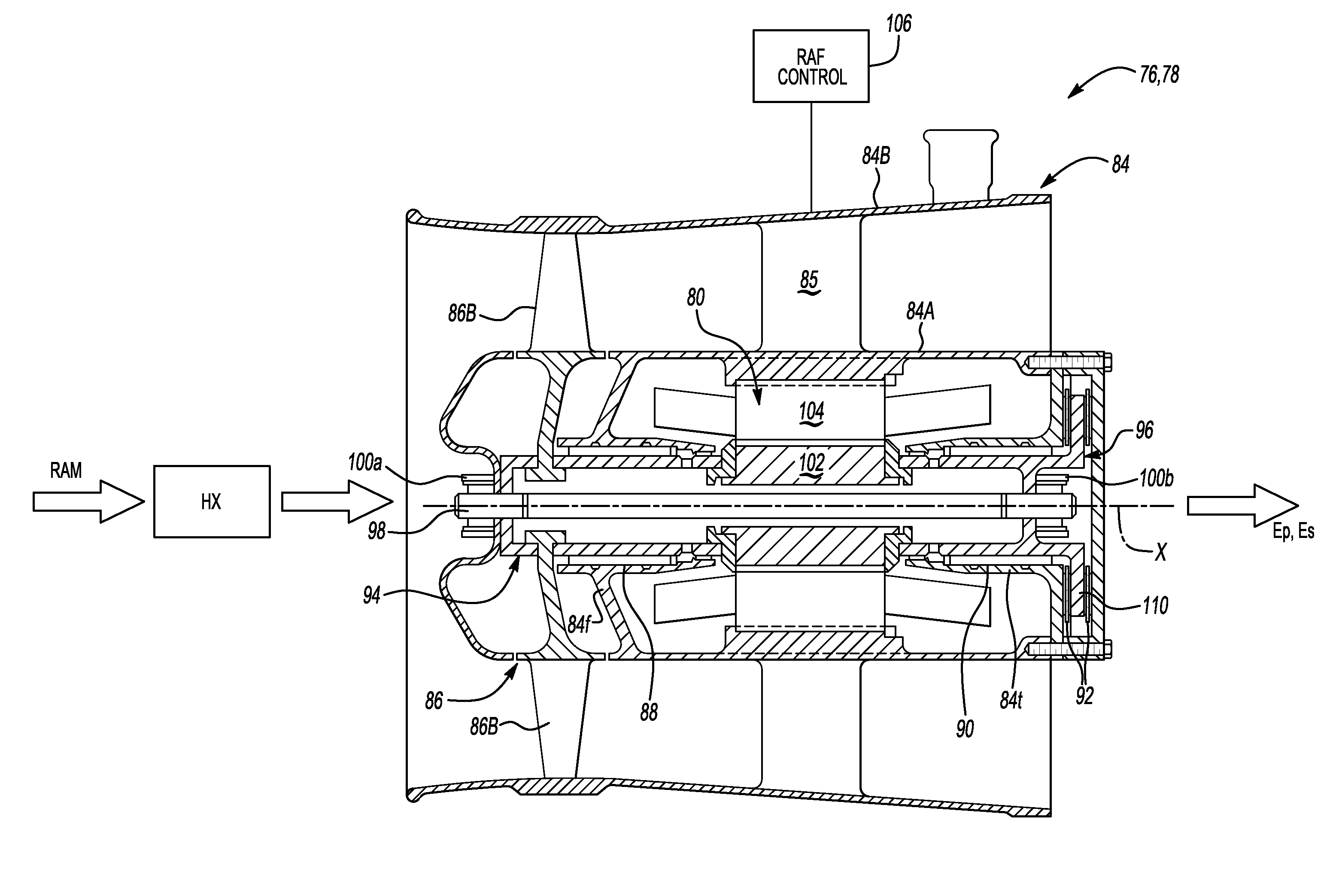

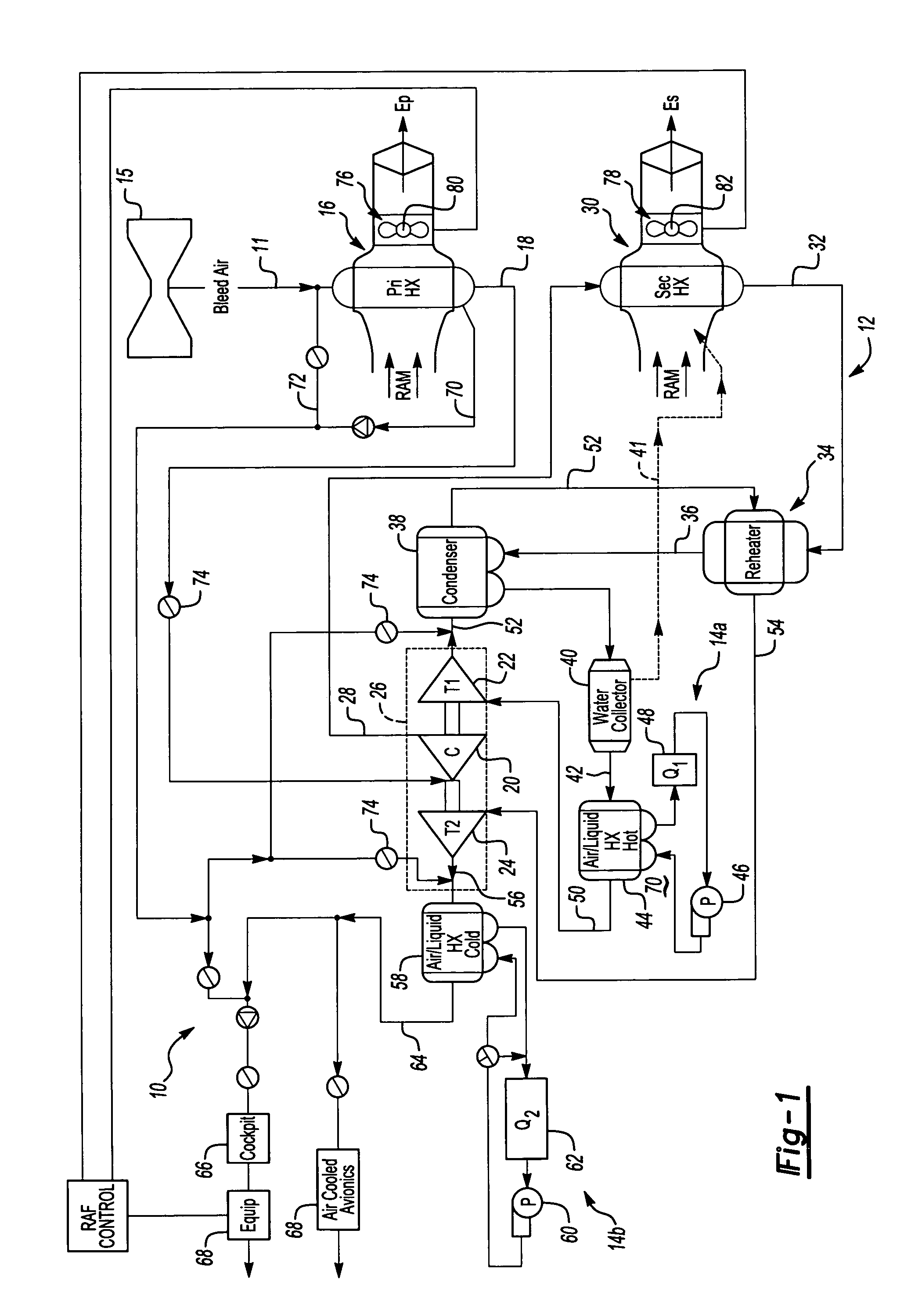

RAM fan system for an aircraft environmental control system

InactiveUS7757502B2Reduce noiseEasy to operateDomestic cooling apparatusSteam/vapor condensersAir cycle machineControl system

An environmental control system includes a RAM air fan system downstream of a respective heat exchanger in the relatively high temperature RAM exhaust. The RAM air fan includes a RAM air fan electric motor such that the RAM air fan is driven at a speed independent of an air cycle machine. A fan rotor is completely supported by hydrodynamic foil journal and thrust bearings. As the RAM air fan is driven by the RAM air fan electric motor the RAM air fan is installed in the environmental control system as a self-contained system.

Owner:HAMILTON SUNDSTRAND CORP

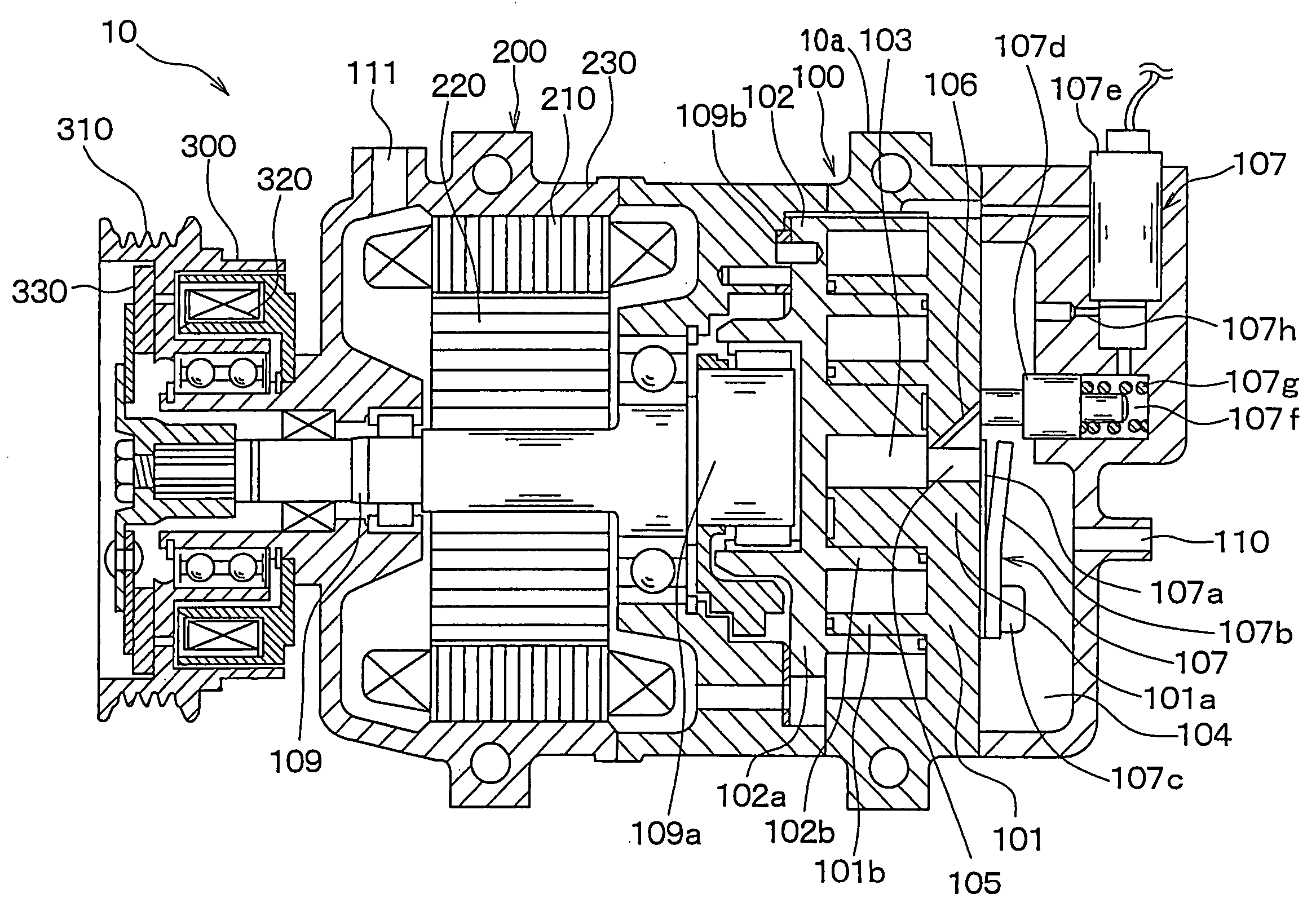

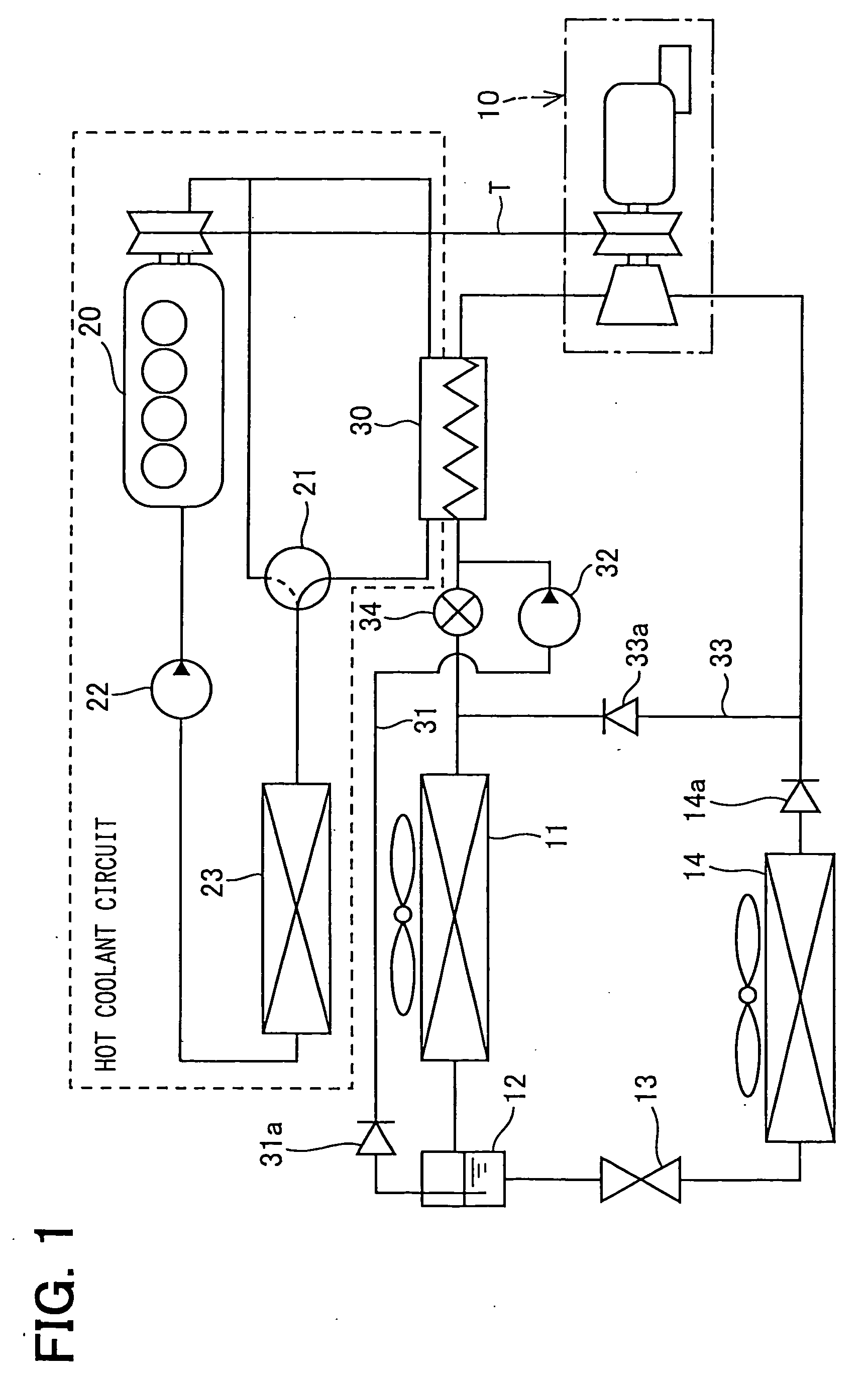

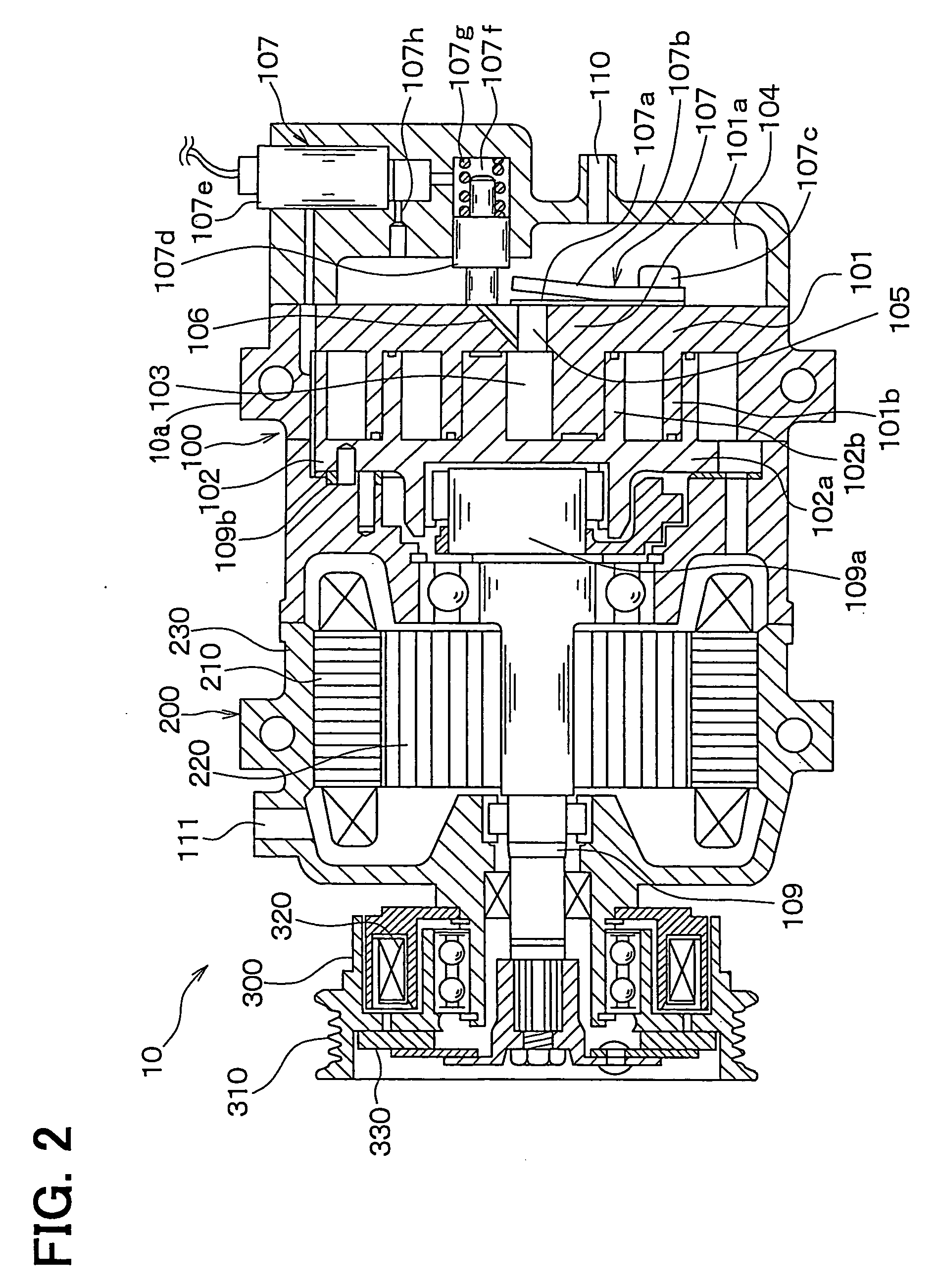

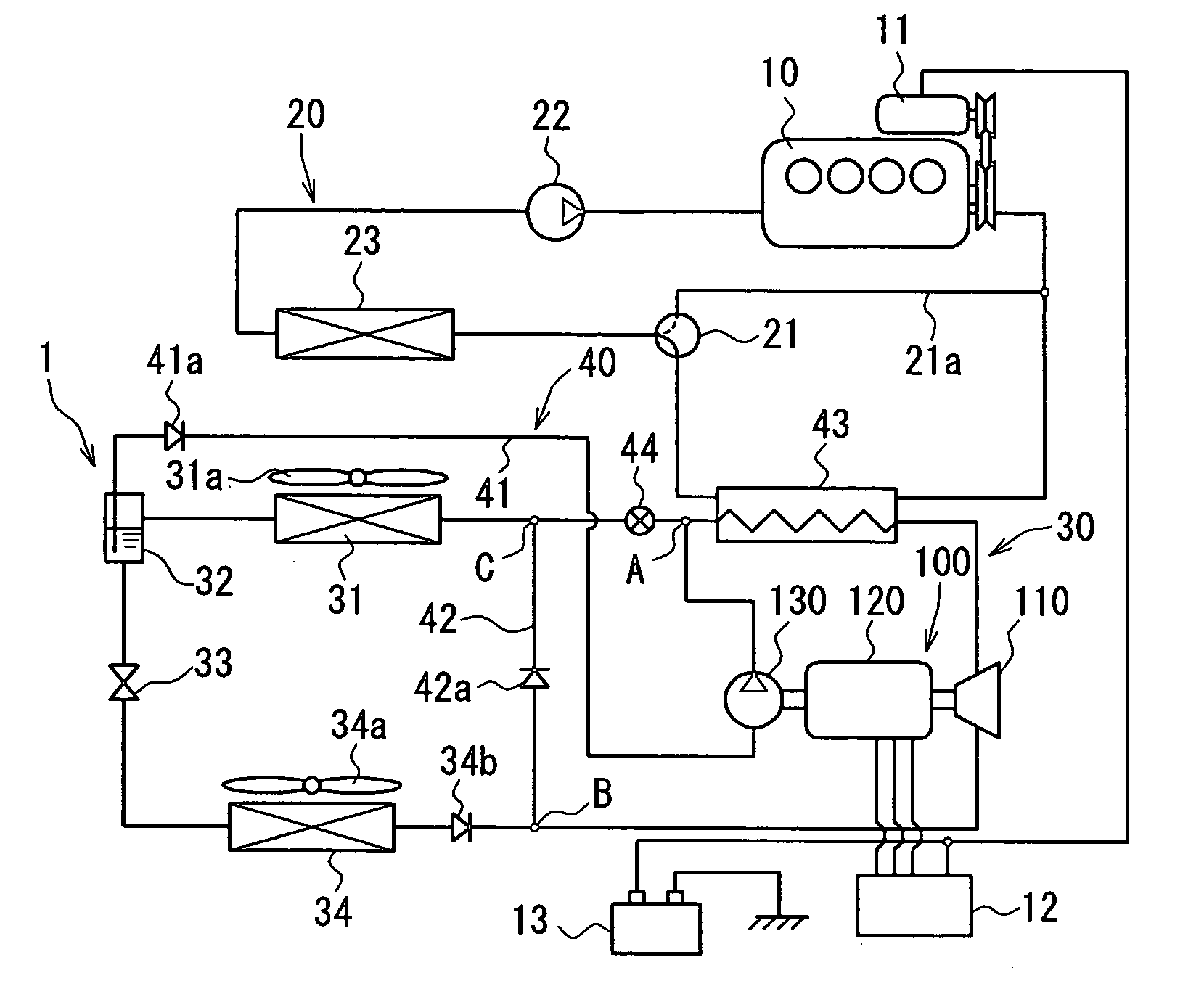

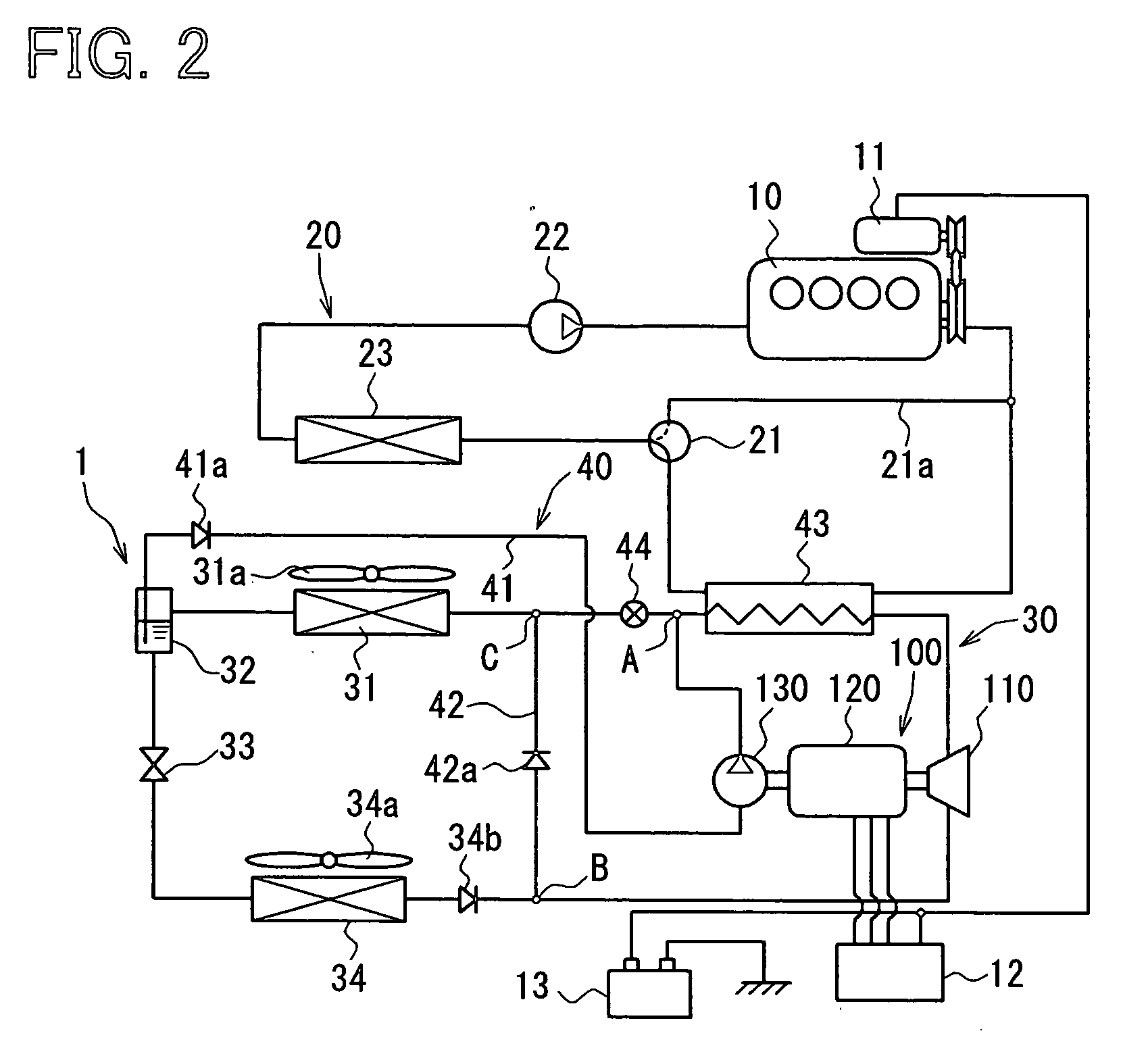

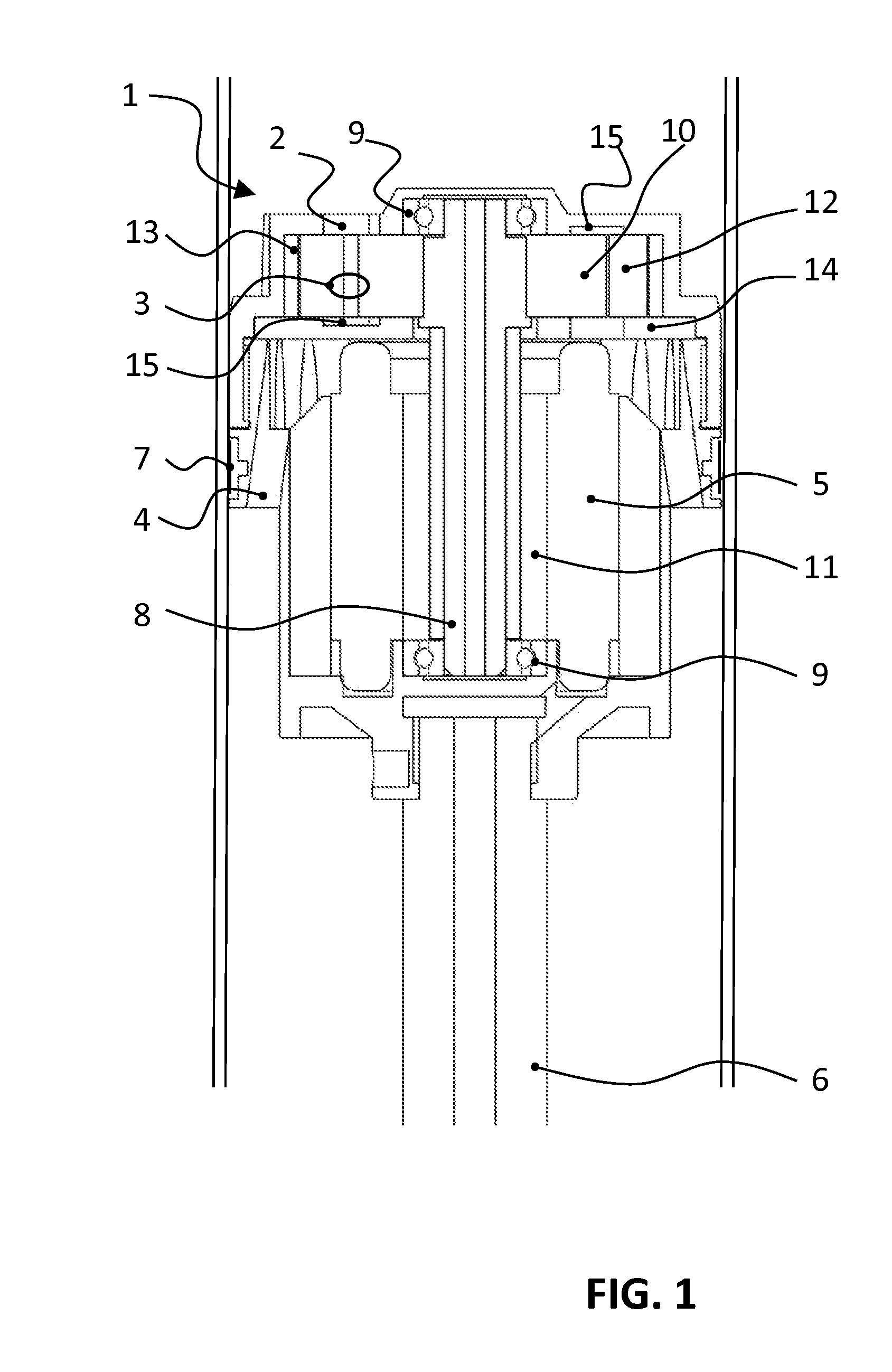

Fluid machine operable in both pump mode and motor mode and waste heat recovering system having the same

InactiveUS20040184923A1Increase and decreases volumePreventing backflow of fluidInternal combustion piston enginesPositive displacement pump componentsHigh pressure chamberCheck valve

A check valve is provided to each discharge port, which communicates between a corresponding working chamber and a high pressure chamber in an integrated compressor / expander apparatus. A valve mechanism, which is opened in a motor mode, is provided to communicate between the working chamber and the high pressure chamber.

Owner:DENSO CORP +1

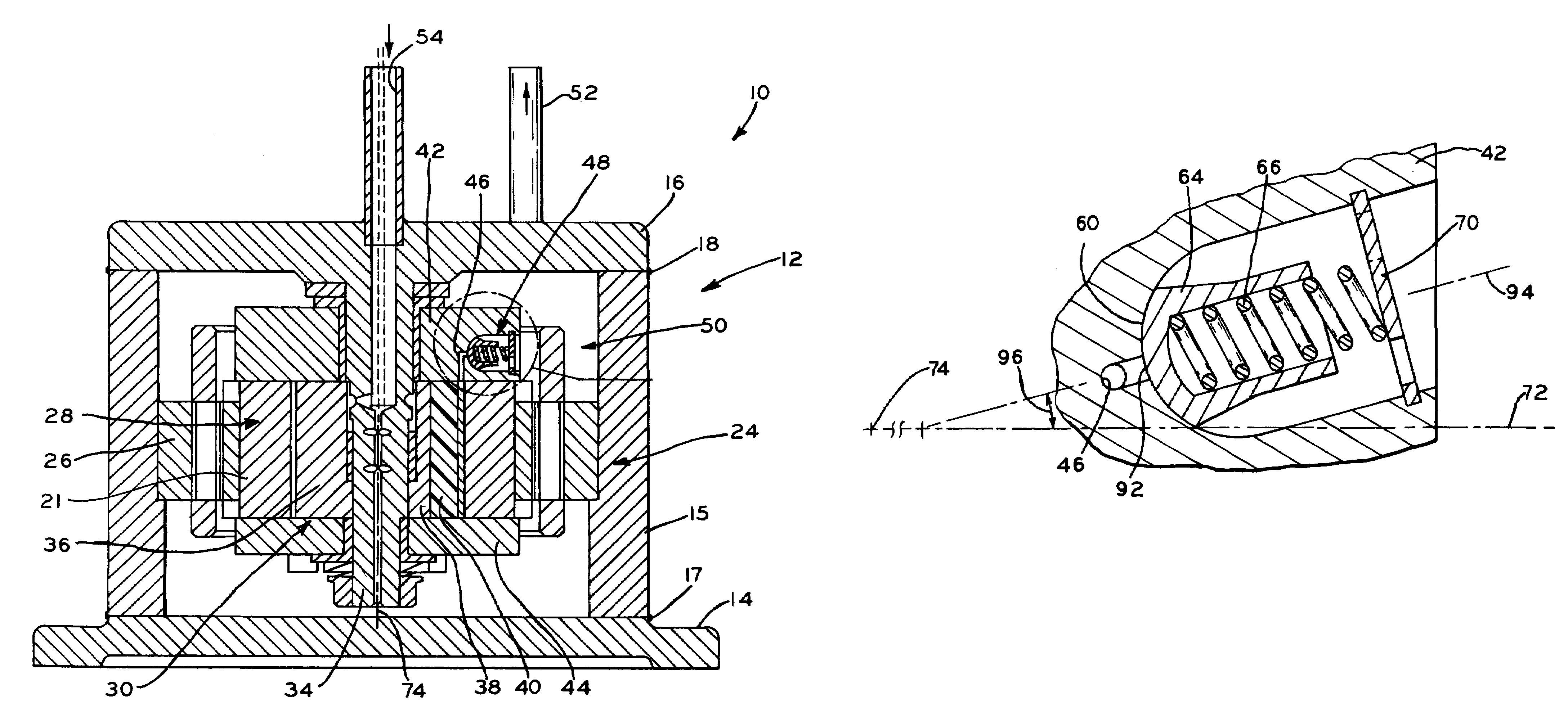

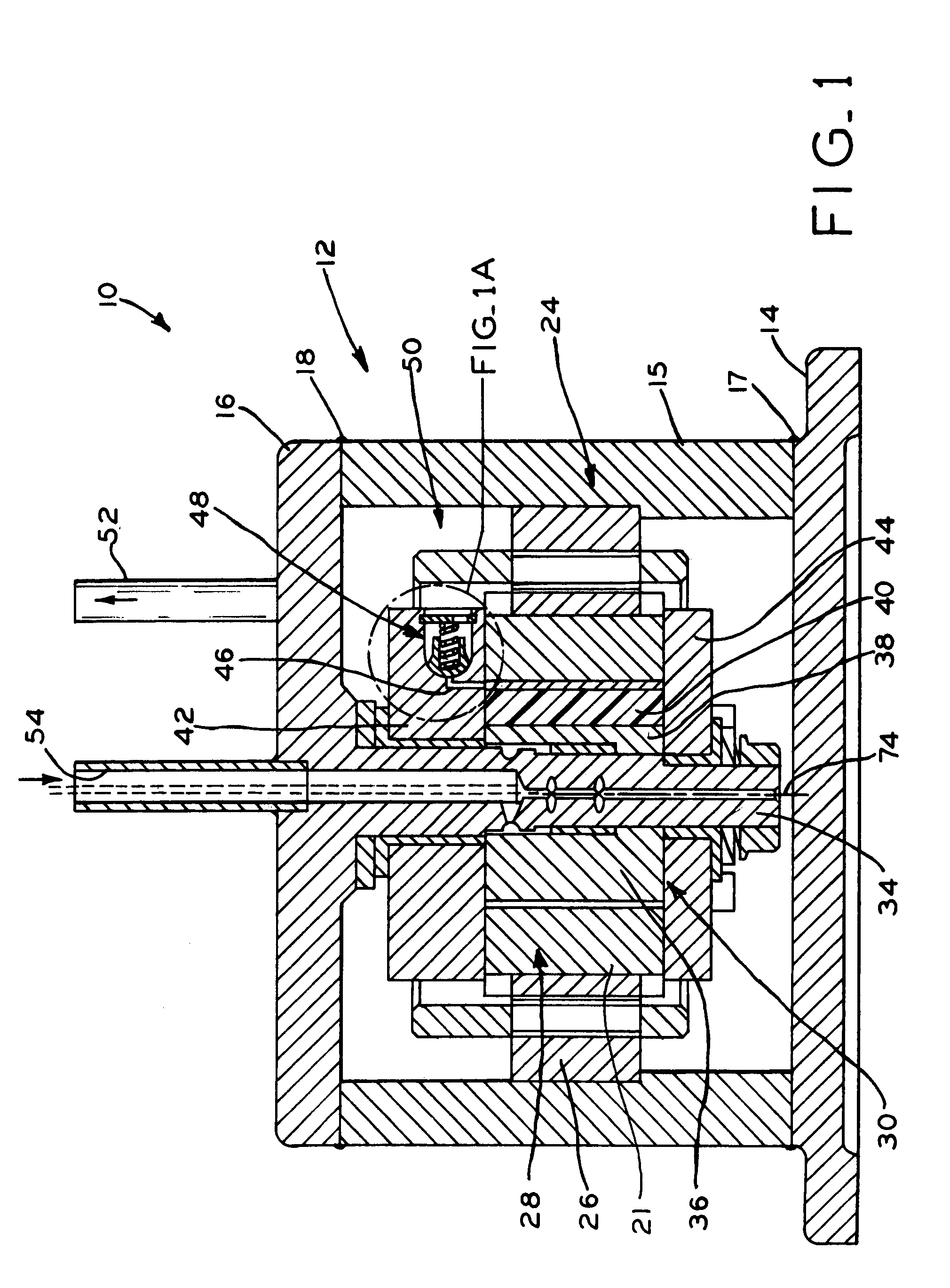

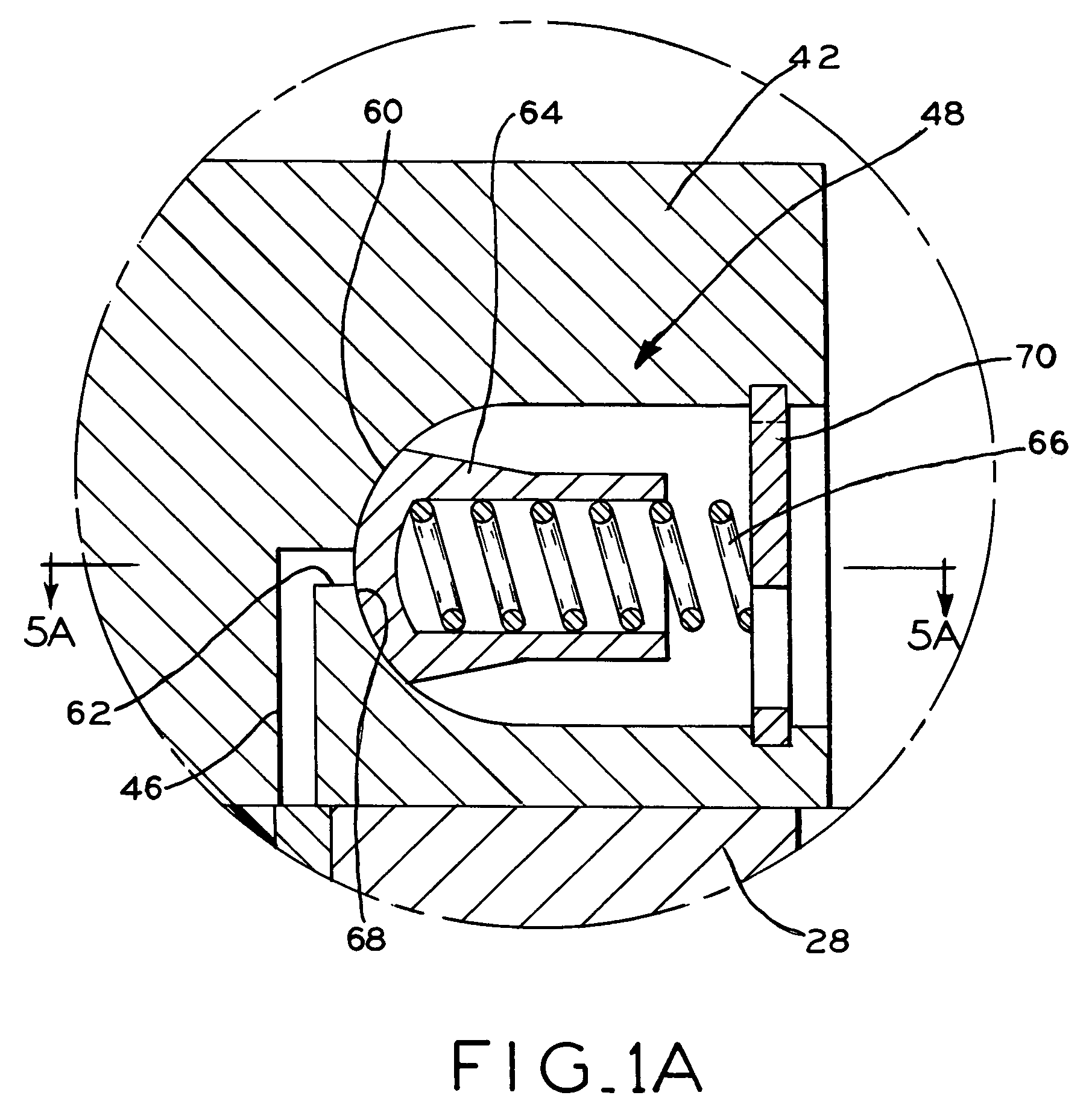

Rotary compressor having a discharge valve

InactiveUS7344367B2Improper seatingInsufficient compressionCheck valvesEqualizing valvesEngineeringMechanical engineering

A rotary compressor having a housing, a rotor positioned within the housing defining a compression chamber, the rotor rotatable about an axis of rotation, a discharge port in the rotor in fluid communication with the compression chamber, and a valve assembly mounted to the rotor to regulate the pressure of the fluid within the compression chamber. In one embodiment, the valve assembly is canted or obliquely aligned with respect to the axis of rotation of the rotor and a radial axis perpendicular to and intersecting the axis of rotation. Aligning the valve assembly in this way allows the displacement of the valve head of the valve assembly to be substantially collinear with forces acting on the valve head.

Owner:TECUMSEH PROD CO

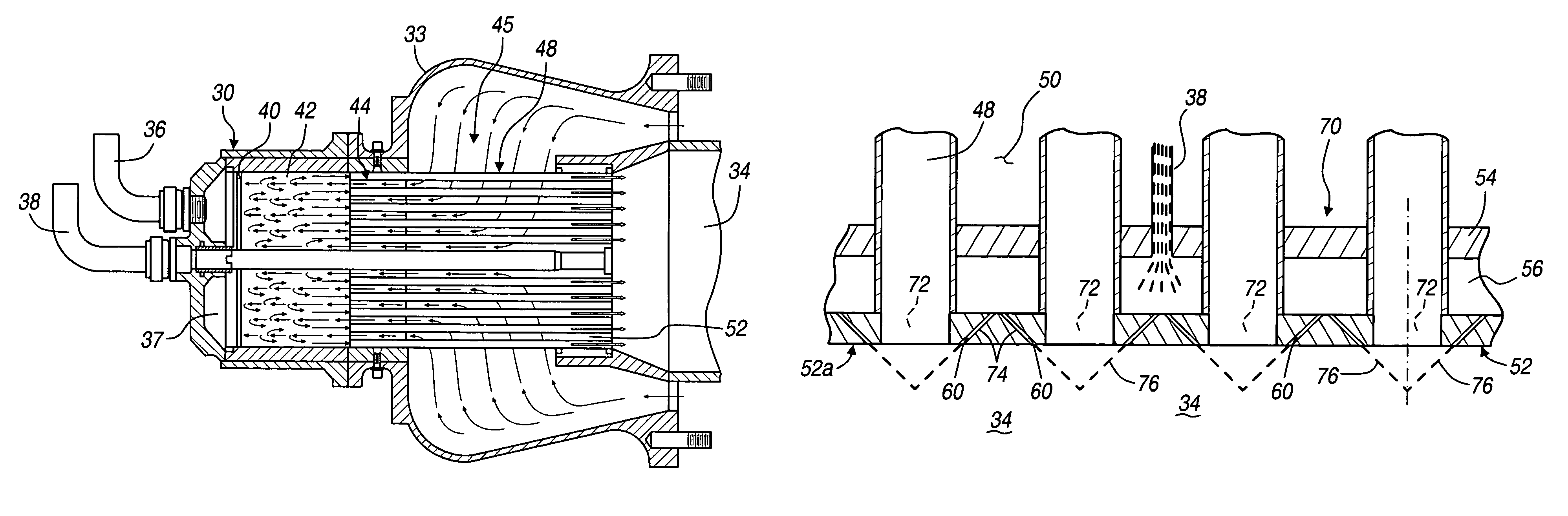

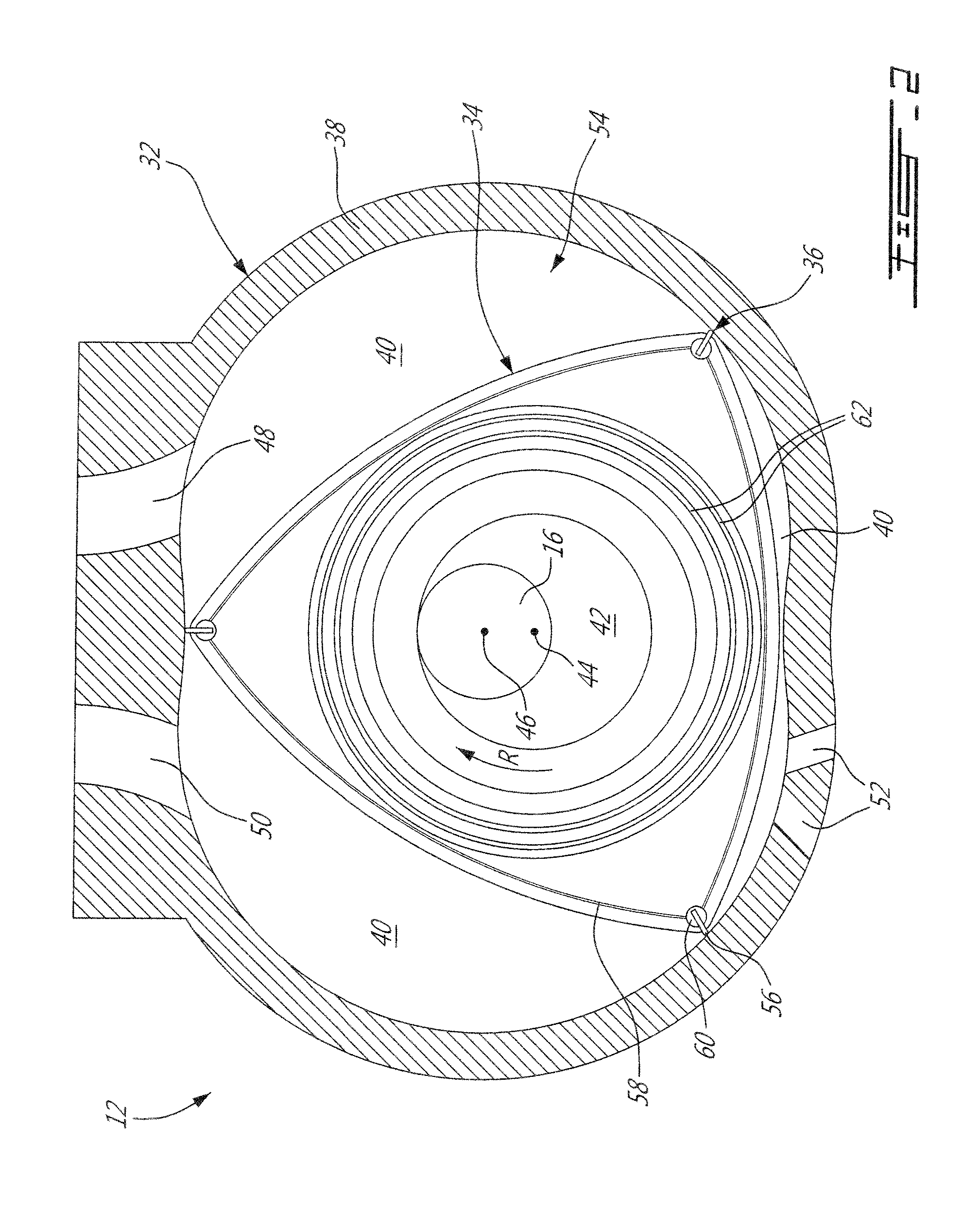

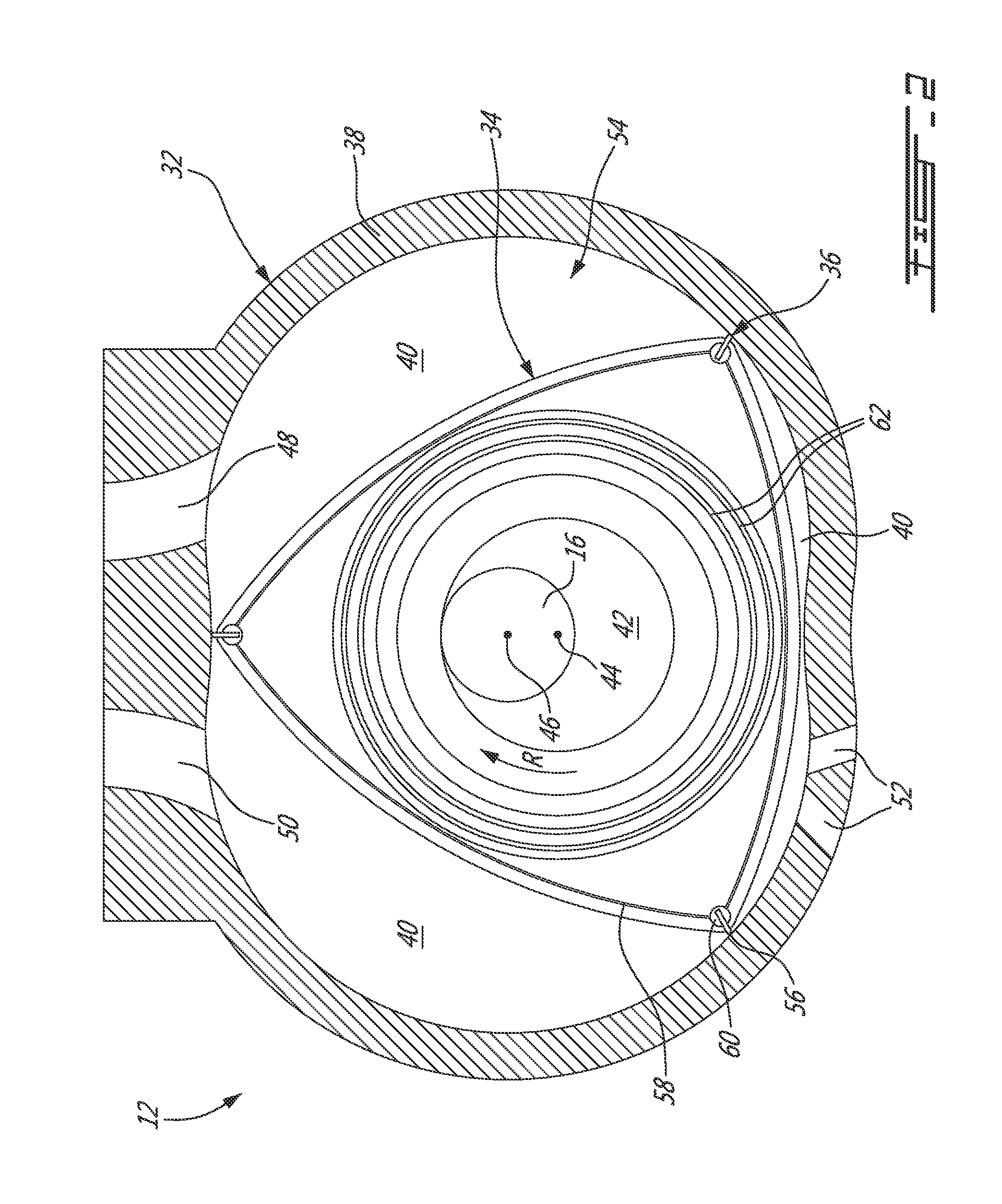

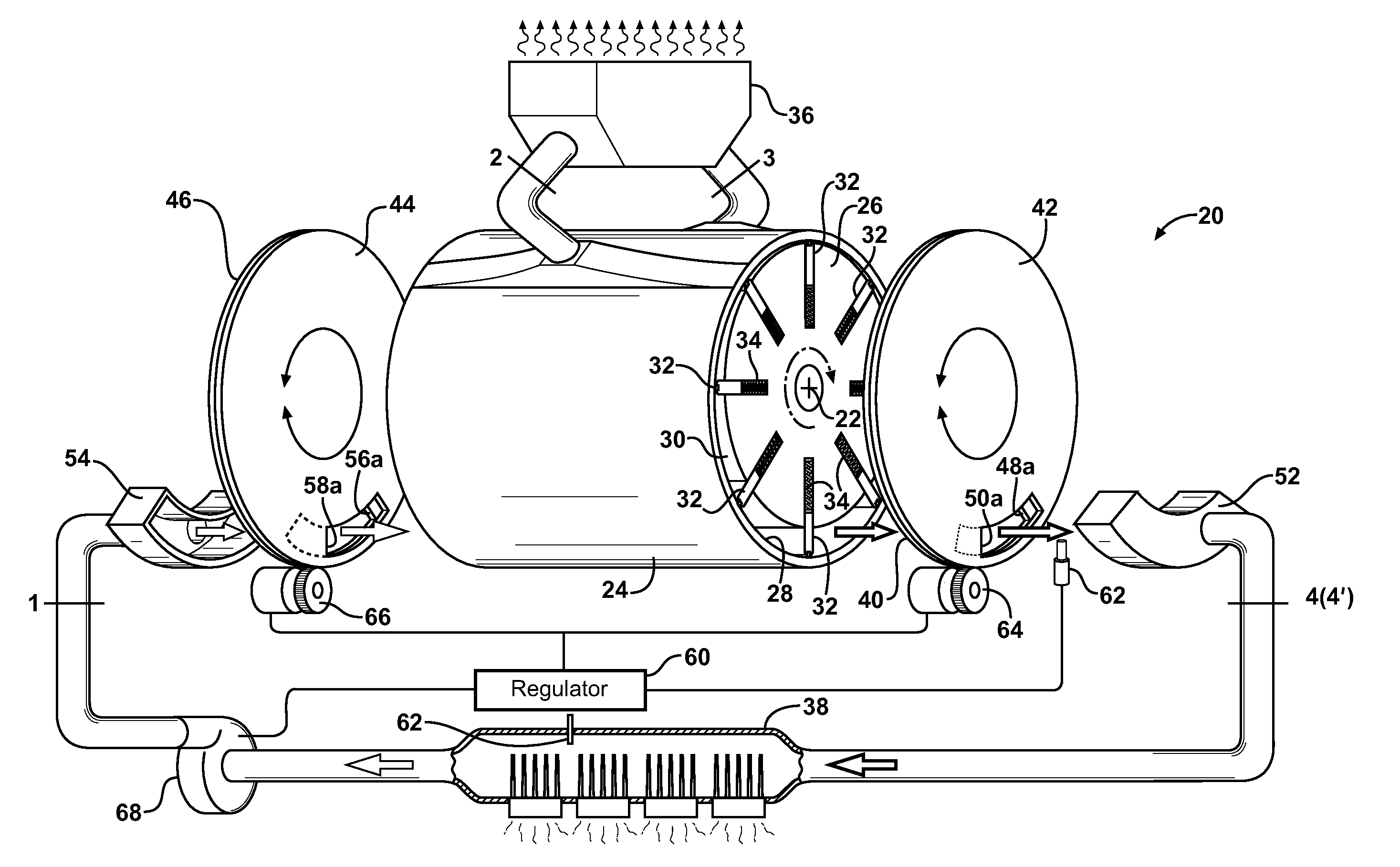

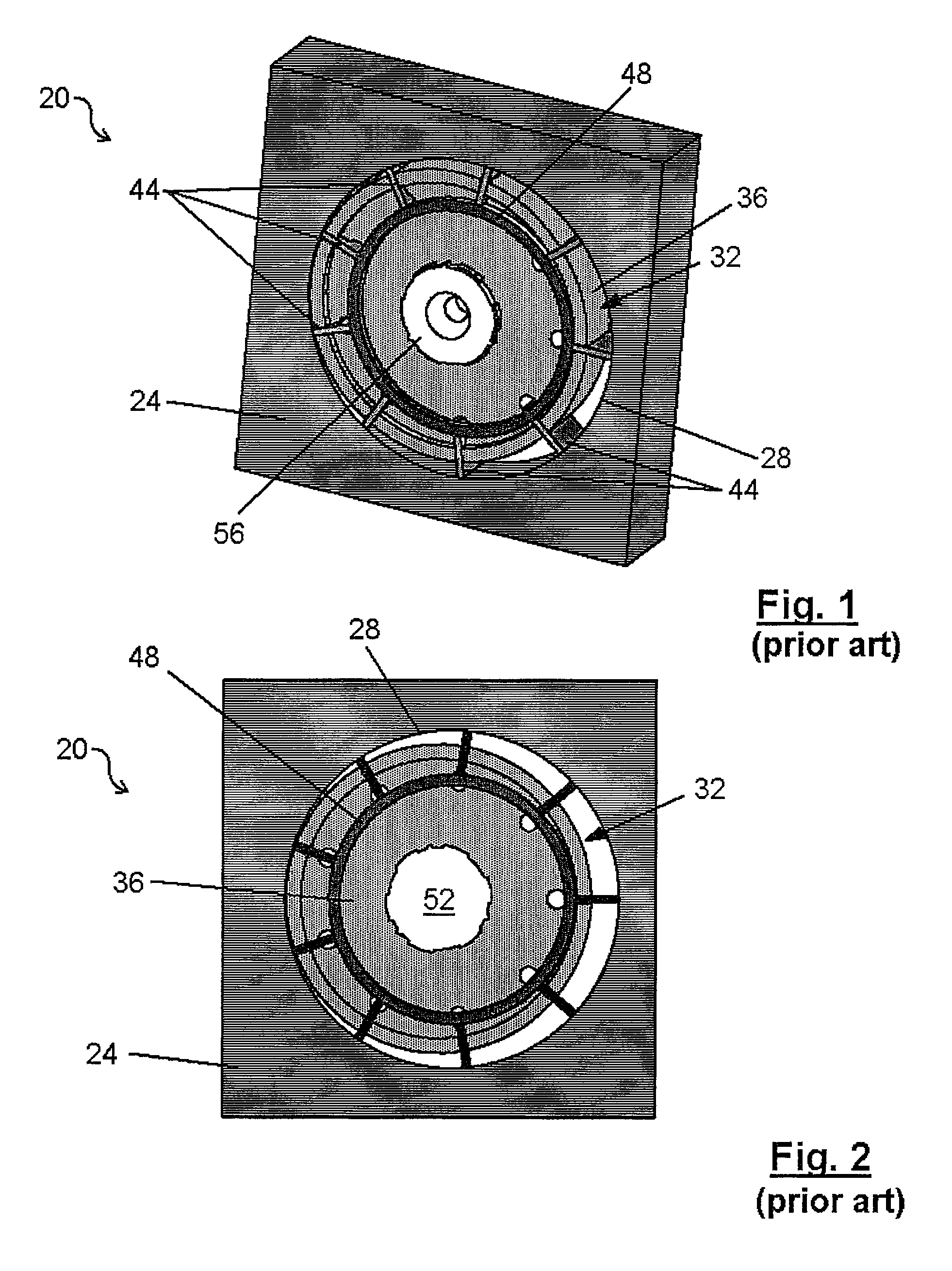

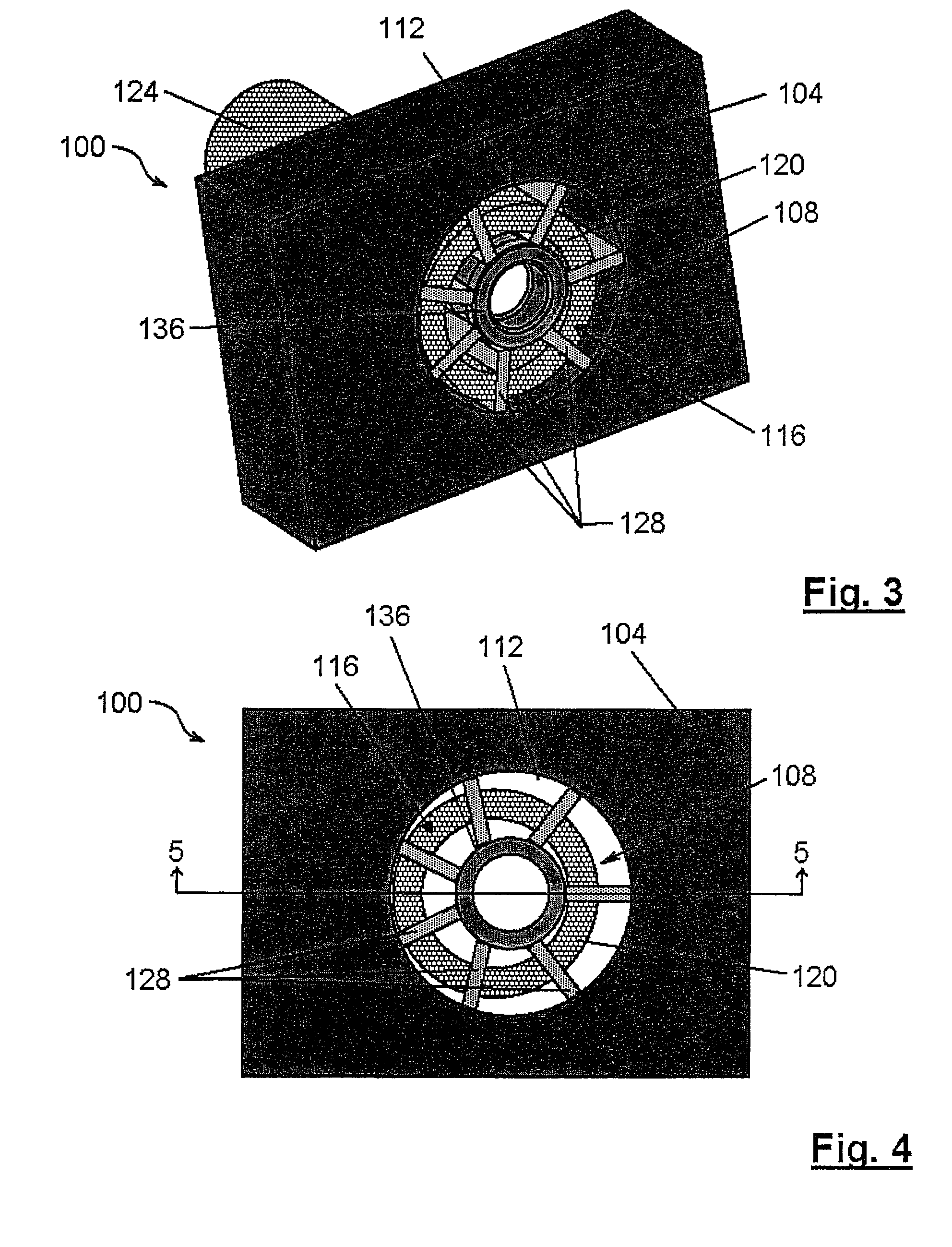

High efficiency positive displacement thermodynamic system

ActiveUS8424284B2Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

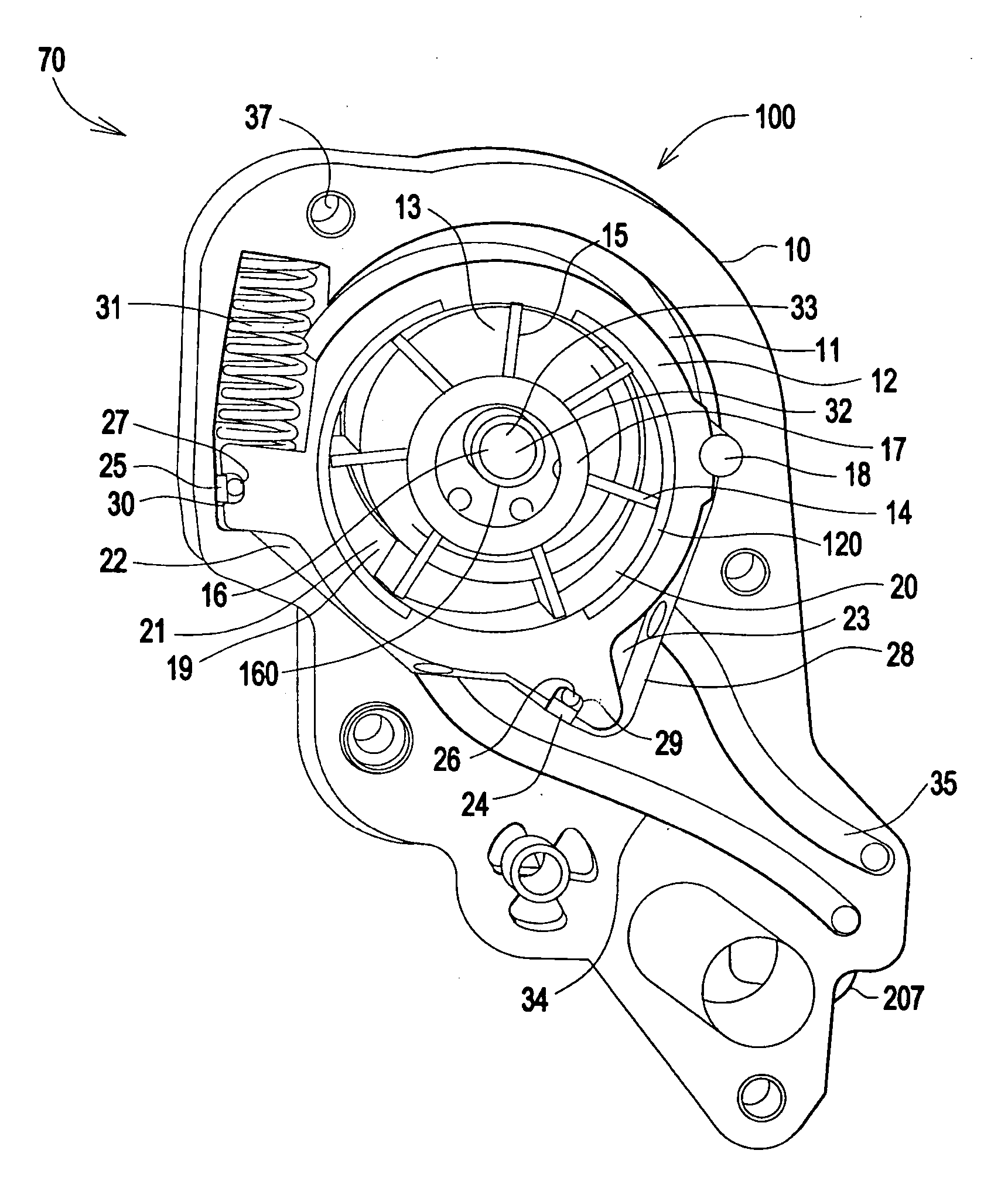

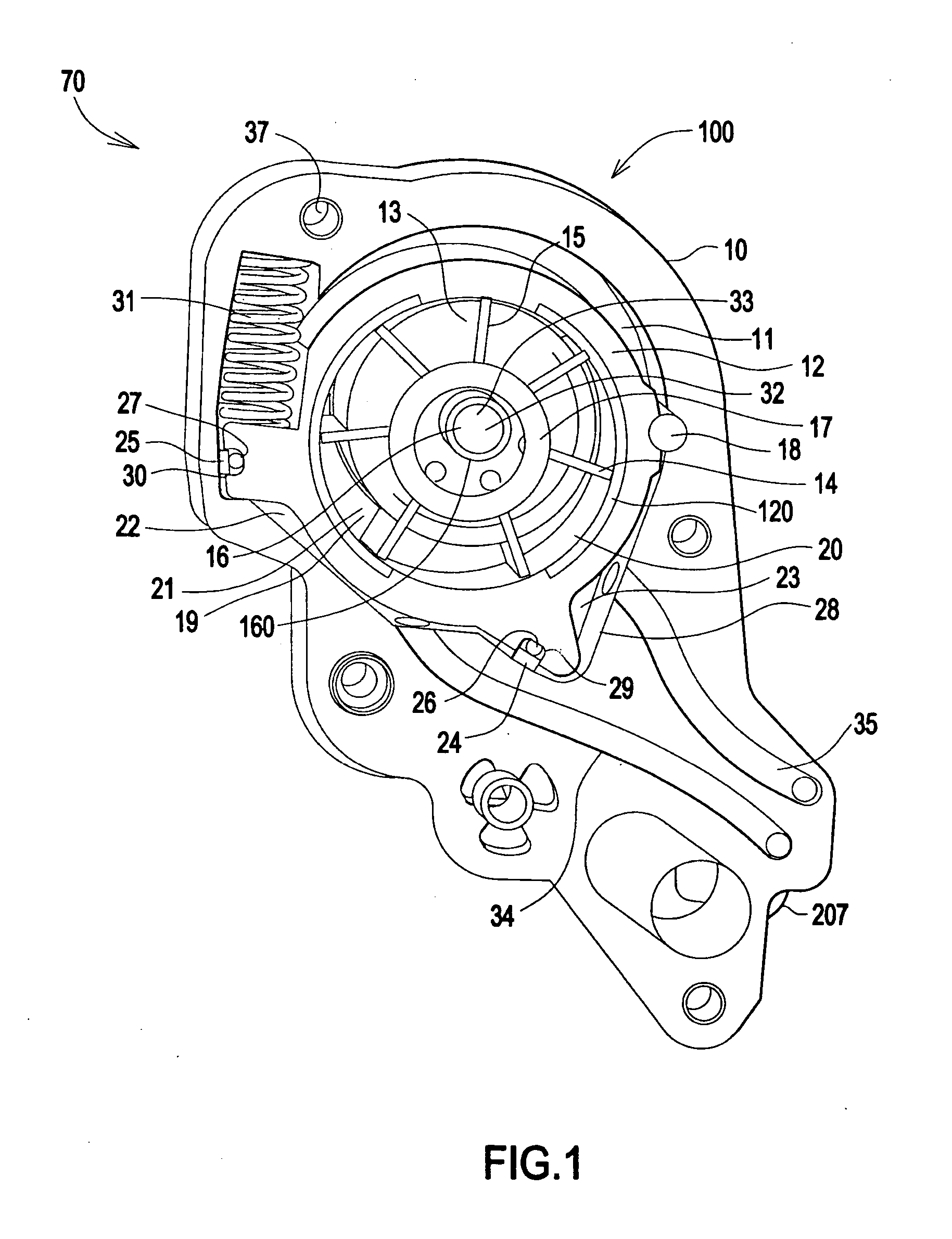

Variable displacement sliding vane pump

InactiveUS20070224067A1Oscillating piston enginesSealing arrangement for pumpsDrive shaftEngineering

A variable displacement sliding vane pump comprising a pump body, inlet and outlet ports formed in said pump body, a drive shaft rotatably mounted in said pump body, a rotor driven by said drive shaft and co-axially aligned therewith, a plurality of radially extending vanes slidably disposed in said rotor, a pivot disposed in said pump body, a slide pivotally disposed on said pivot in said pump body and having a central axis eccentric to the axis of said rotor, a plurality of fluid chambers defined by said rotor, said vanes, and said slide that are successively connected to said inlet and outlet ports, a spring acting on said slide to urge said slide in one direction, a first chamber and a second chamber, each suitable for receiving a fluid pressure and each disposed between said pump body and an outer surface of said slide, the first chamber in fluid communication with a pump outlet discharge pressure, and a valve operable to selectively pressurize and depressurize the second chamber.

Owner:STACKPOLE POWERTRAIN INT ULC

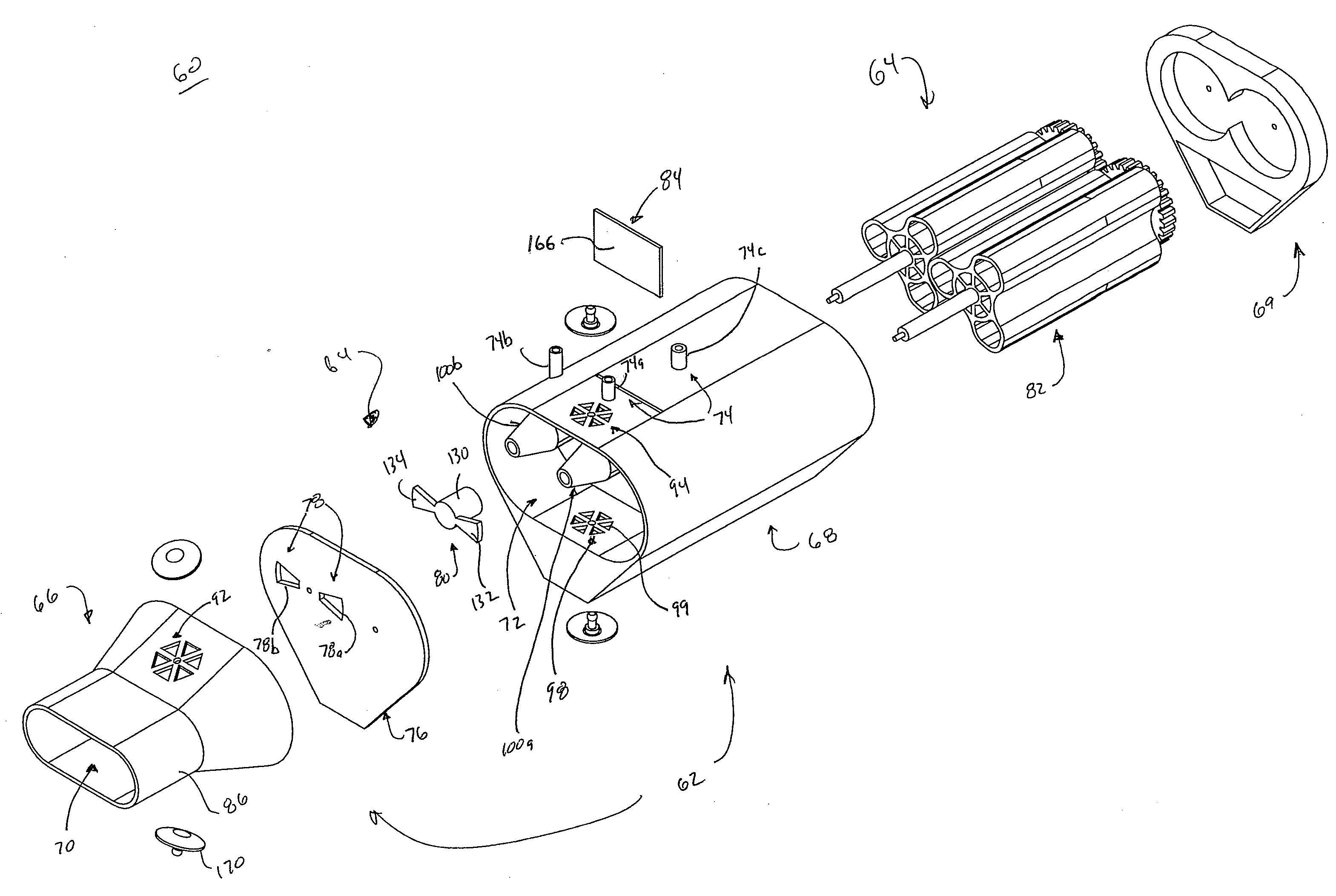

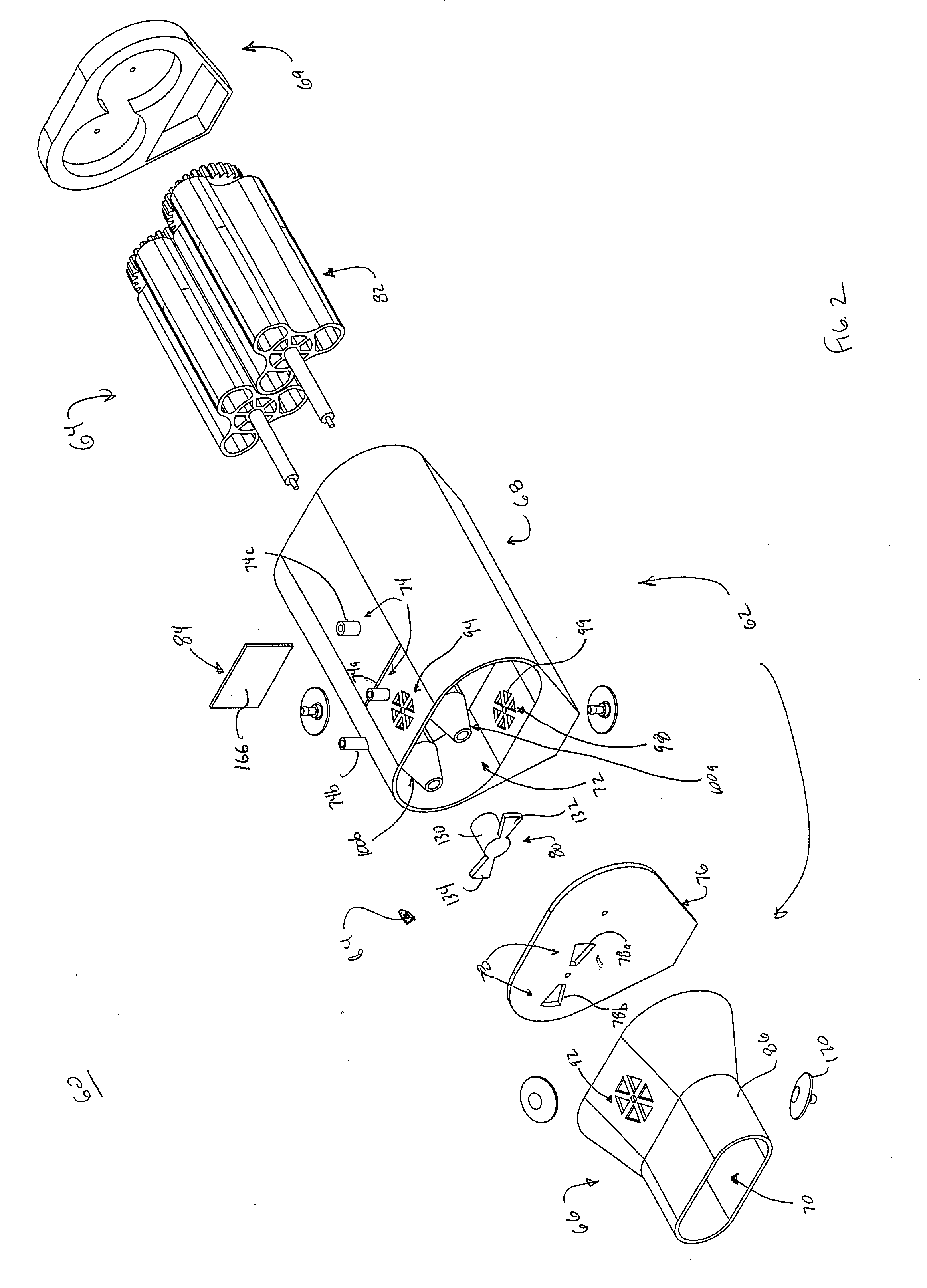

Passive respiratory therapy device

A respiratory therapy device including a housing and an interrupter valve assembly. The housing is sized for handling by a patient and defines a patient breathing passage extending from a patient end and through which a patient inhales and exhales air. The interrupter valve assembly is carried by the housing and includes a control port, a valve body, and a drive mechanism. Expiratory airflow is released from the patient breathing passage through the control port. The valve body is sized to at least partially obstruct fluid flow through the control port. The drive mechanism moves the valve body relative to the control port in response to the expiratory airflow such that the valve body repeatedly transitions between a position of maximum obstruction and a position of minimum obstruction relative to the control port to create an oscillatory positive expiratory pressure effect.

Owner:SUNMED GRP HLDG LLC

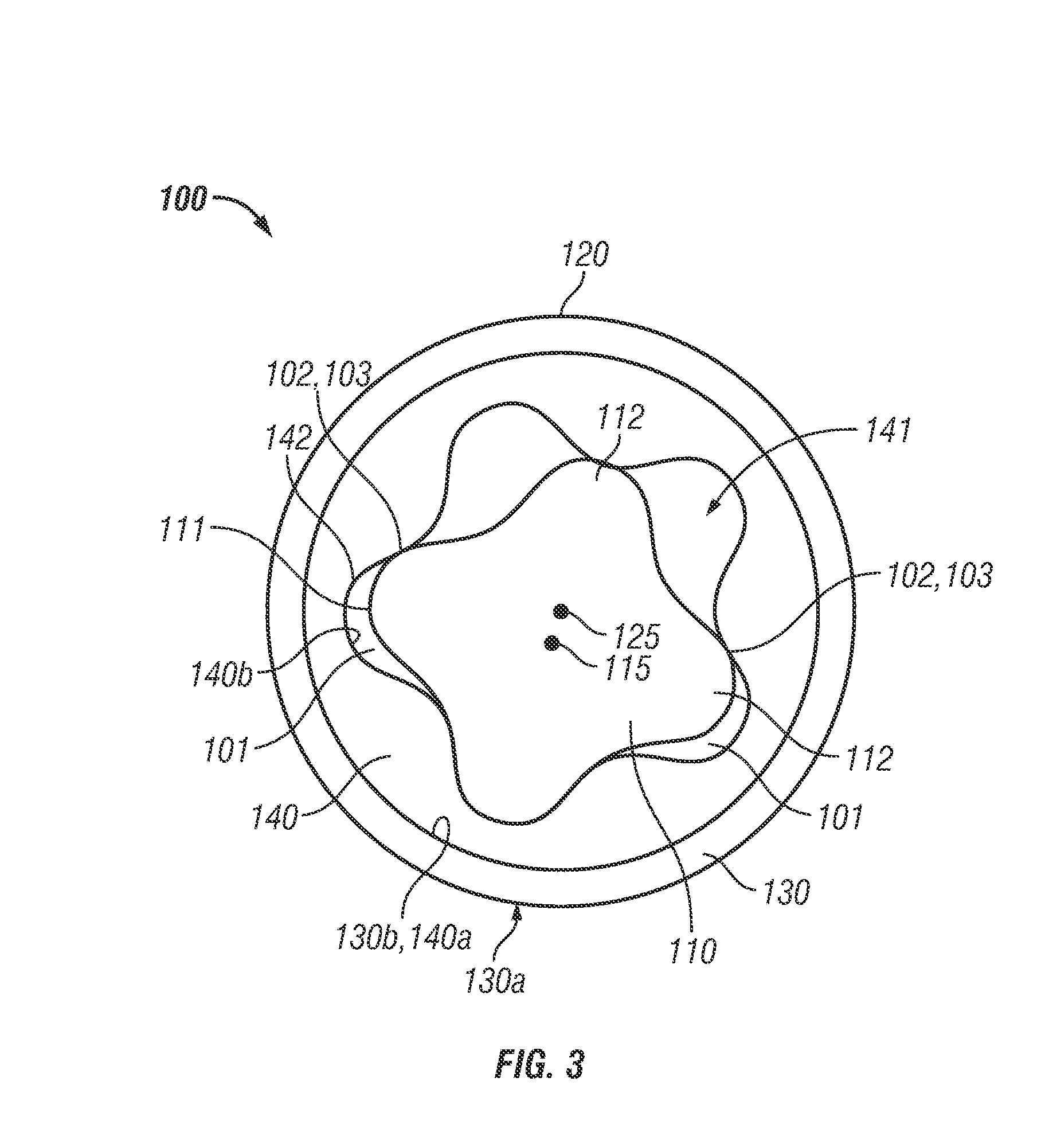

Reinforced Stators and Fabrication Methods

ActiveUS20130149182A1Readily apparentAdditive manufacturing apparatusOscillating piston enginesEngineeringMechanical engineering

A stator for a progressive cavity pump or motor comprises a tubular housing having a central axis. In addition, the stator comprises a stator insert coaxially disposed within the housing. The stator insert has a radially outer surface that engages the housing and a radially inner surface defining a helical-shaped through bore extending axially through the stator insert. The stator insert includes an insert body and an insert liner attached to the insert body. The insert body is radially positioned between the housing and the insert liner. The insert body comprises a reinforcement structure and a plurality of voids dispersed within the reinforcement structure.

Owner:NAT OILWELL VARCO LP

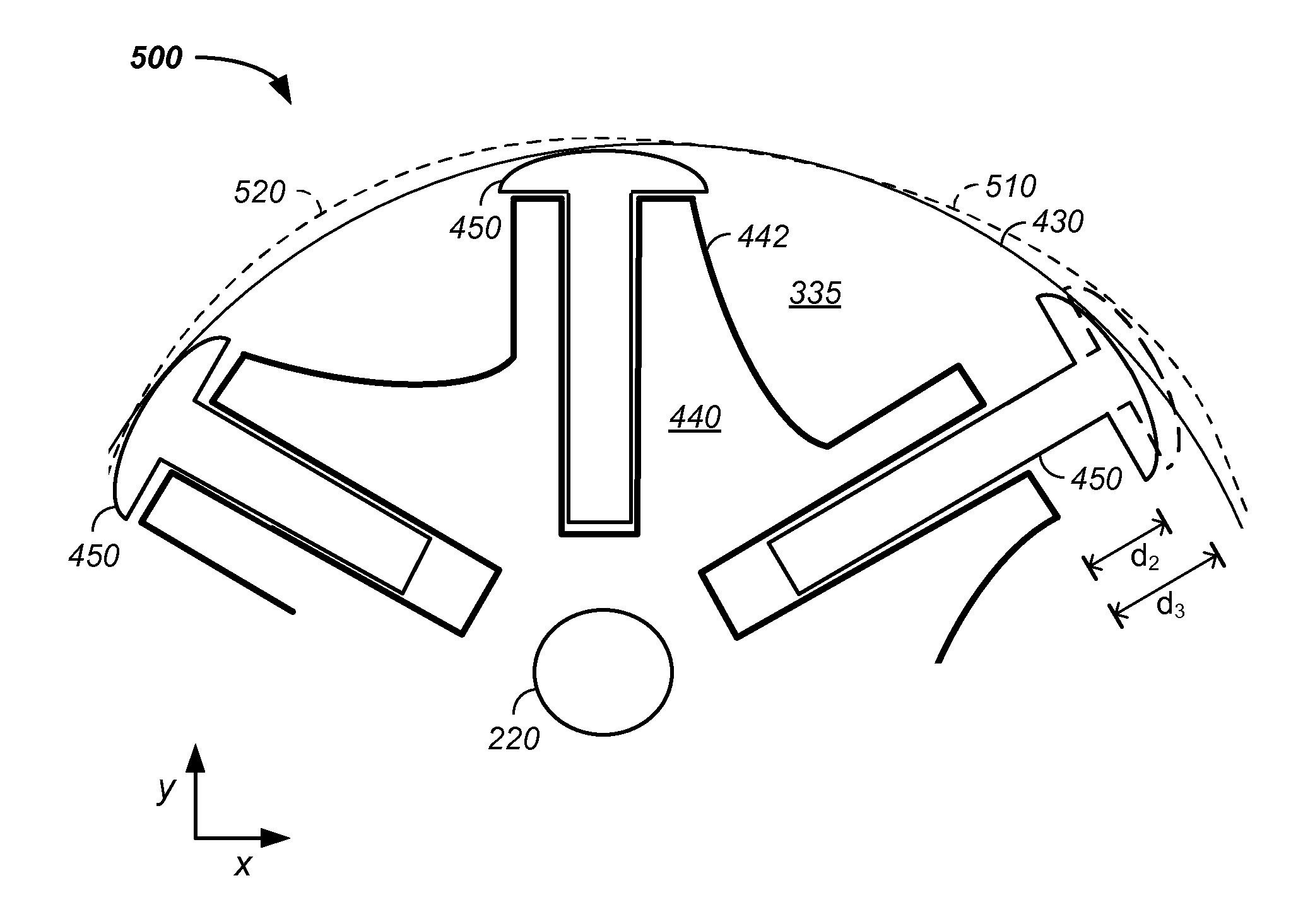

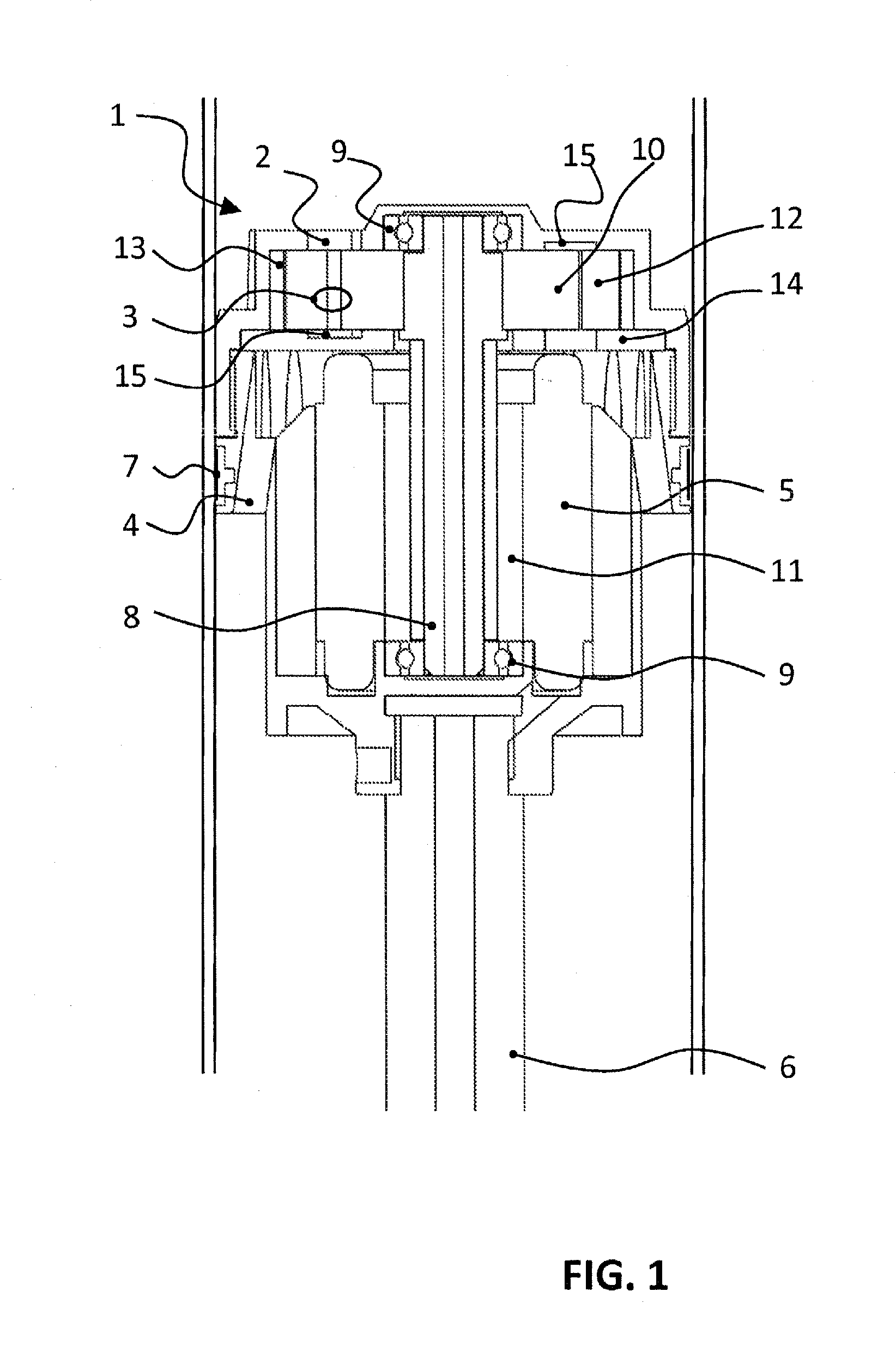

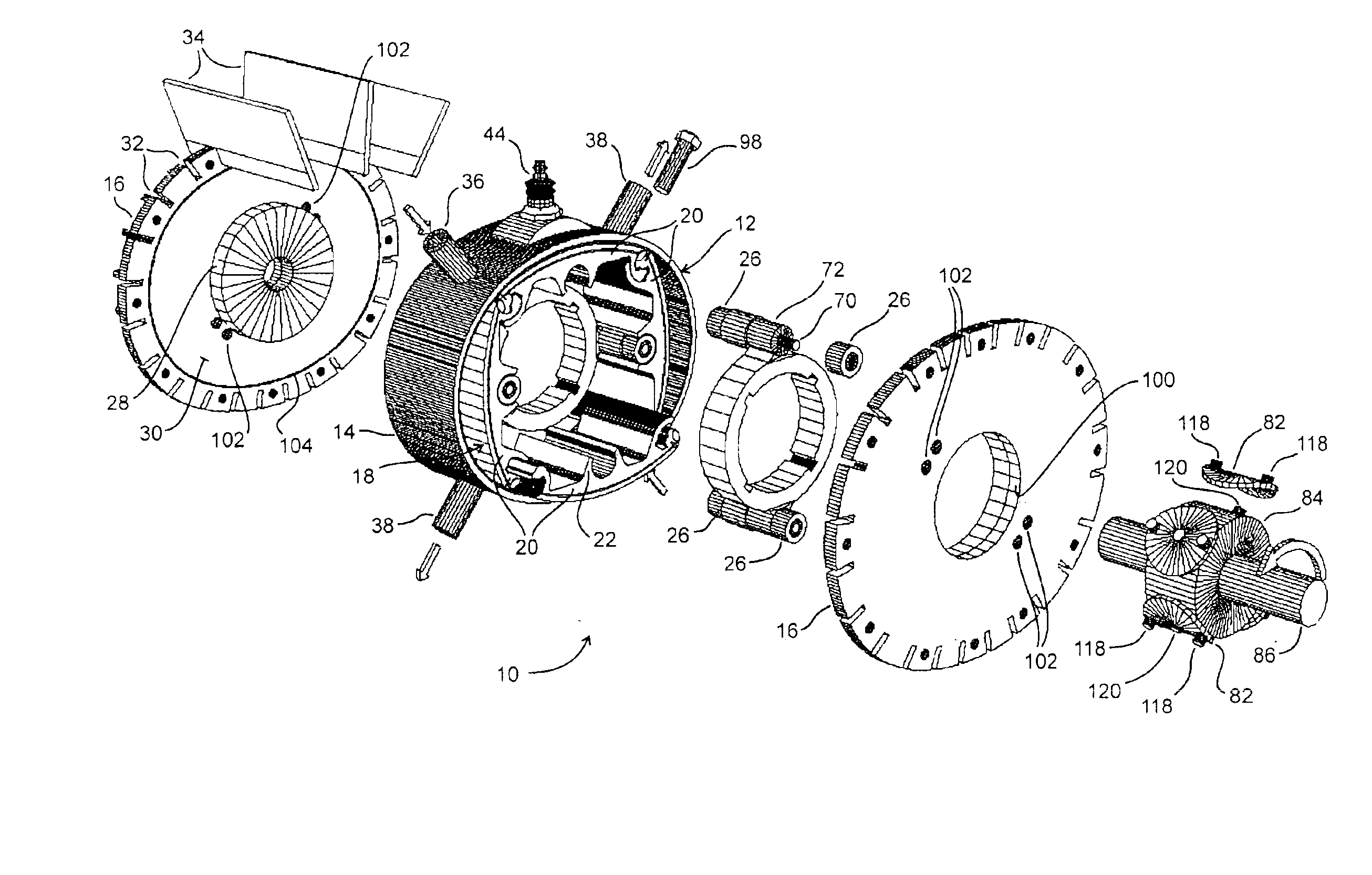

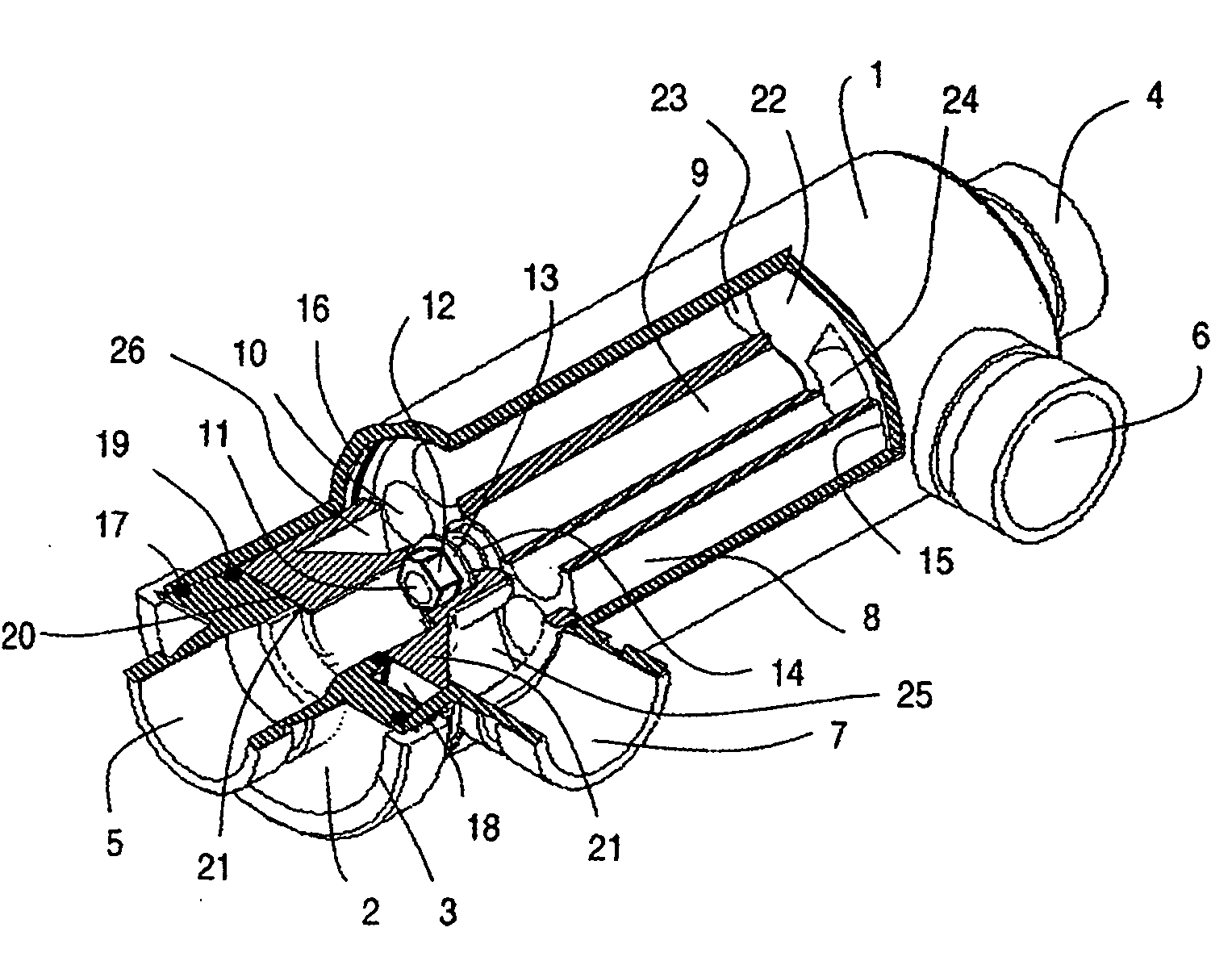

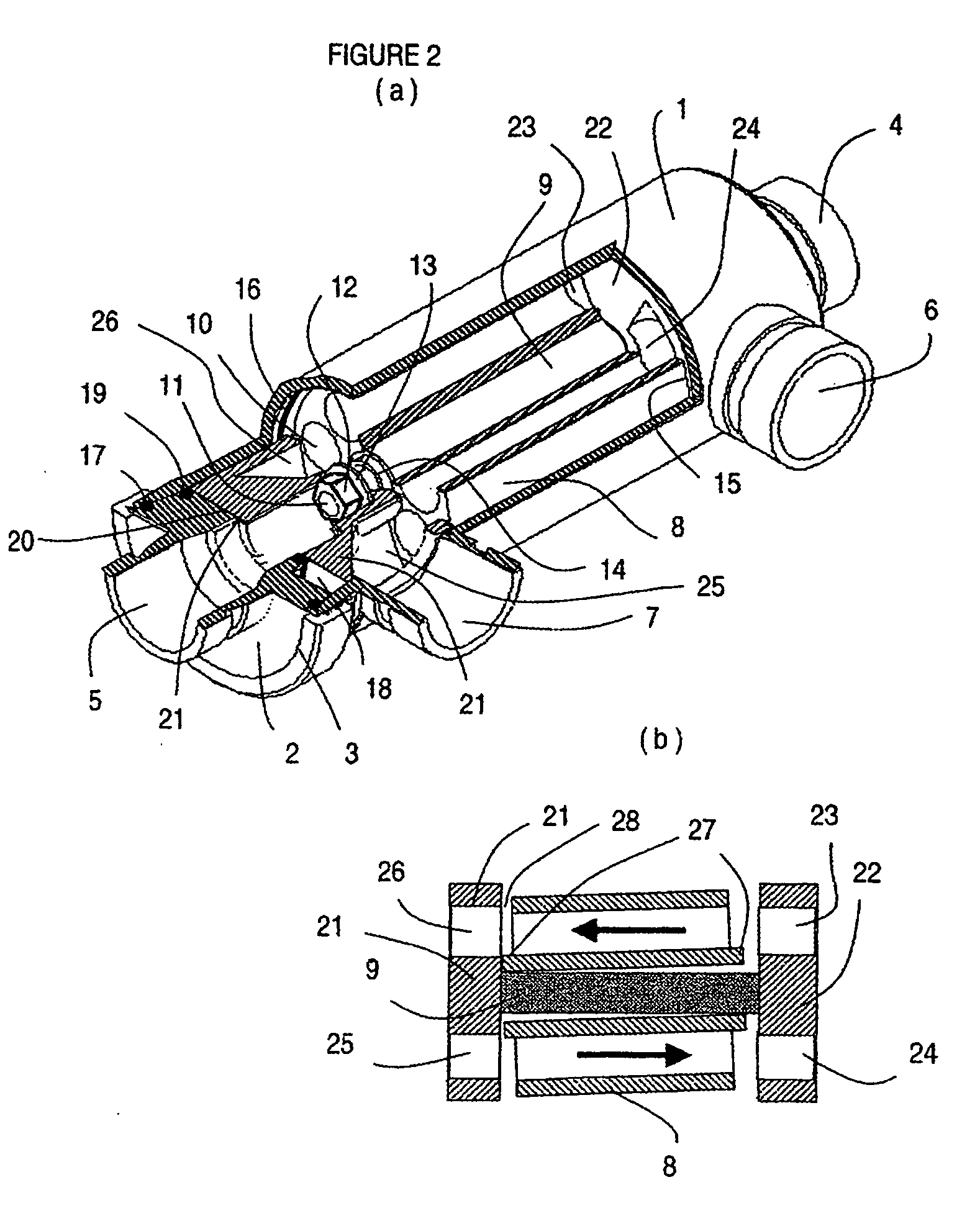

Quasiturbine (Qurbine) rotor with central annular support and ventilation

InactiveUS6899075B2Minimizing surface to volume ratioReduce flow turbulenceInternal combustion piston enginesOscillating piston enginesQuasiturbineWheel and axle

The Quasiturbine (Qurbine in short) uses a rotor arrangement peripherally supported by four rolling carriages, the carriages taking the pivoting blade pressure-load of the blades forming the rotor, and transferring the load to the opposite internal contoured housing wall. The present invention discloses a central, annular, rotor support for the rotor geometry defined by the pivoting blades and associated wheel-bearings, while still maintaining the important center-free engine characteristic. The pressure-load on each pivoting blade is taken by its own set of wheel-bearings rolling on annular tracks attached to the central area of the lateral side covers forming part of the stator casing. This central, annular, rotor support could generally apply to all the family of Quasiturbine rotor arrangements and particularly to the limit case here considered, where the previous carriage design is replaced by a cylindrical pivoting blade joint as presented in the present patent, and for which an efficient solution of the five bodies rotary engine sealing problem is given.

Owner:SAINT HILAIRE ROXAN +3

Fluid machine

InactiveUS20060254309A1Useless of driving forceAmount of collected is increasedOscillating piston enginesClimate change adaptationEngineeringHigh pressure

A fluid machine has a scroll type expansion device which is operated by a high temperature high pressure refrigerant. The refrigerant is heated by use of waste heat from an engine for a vehicle. The fluid machine further has a motor generator for generating electric power when it is driven by a rotational force produced at the expansion device, wherein a rotating shaft of the motor generator is coupled to a movable scroll of the expansion device via a crank mechanism. A biasing member is provided for biasing the crank mechanism in a direction that the movable scroll wrap is separated from a contact in a circumferential direction with a fixed scroll wrap. Pressure of the refrigerant in a working chamber in the center portion is thereby equalized to the pressure in the outer peripheral portion, at a startup period of the expansion mode.

Owner:DENSO CORP +1

Respiratory Therapy Device and Method

ActiveUS20080110451A1Facilitate one or more additional therapiesRespiratorsBreathing masksPositive pressureEngineering

A respiratory therapy device including a housing and an interrupter valve assembly. The housing includes a patient inlet, an exhaust outlet, a chamber, and a supply inlet. The interrupter valve assembly is associated with the housing and includes a control port fluidly connecting the patient inlet and the first chamber, and a valve body adapted to selectively obstruct fluid flow through the control port. In a passive mode, positive fluid flow to the supply inlet does not occur, and the interrupter valve assembly interacts with exhaled air create an oscillatory PEP effect. In an active mode, fluid flow to the supply inlet occurs and the interrupter valve assembly operates to create a CHFO effect. The respiratory device can serve as a passive oscillatory PEP device, and when connected to a positive pressure source, as an active device.

Owner:SUNMED GRP HLDG LLC

Reduced rotor assembly diameter vane pump

InactiveUS7997882B2Reduce the overall diameterReduce radial sizeOscillating piston enginesSealing arrangement for pumpsWorking fluidDrive shaft

A vane pump with a reduced rotor diameter is provided. The reduced rotor diameter allows a reduction in the overall size of the pump which allows the pump to be used in circumstances wherein sufficient packaging volume does not exist for conventional vane pumps. Further, the reduced rotor diameter permits operation of the pump at a higher speed, in comparison to conventional vane pumps, for a given working fluid and pump rate. The rotor includes an integrally formed drive shaft and a cylindrical rotor head. Both fixed displacement and variable displacement embodiments are shown.

Owner:MAGNA POWERTRIAN INC (US)

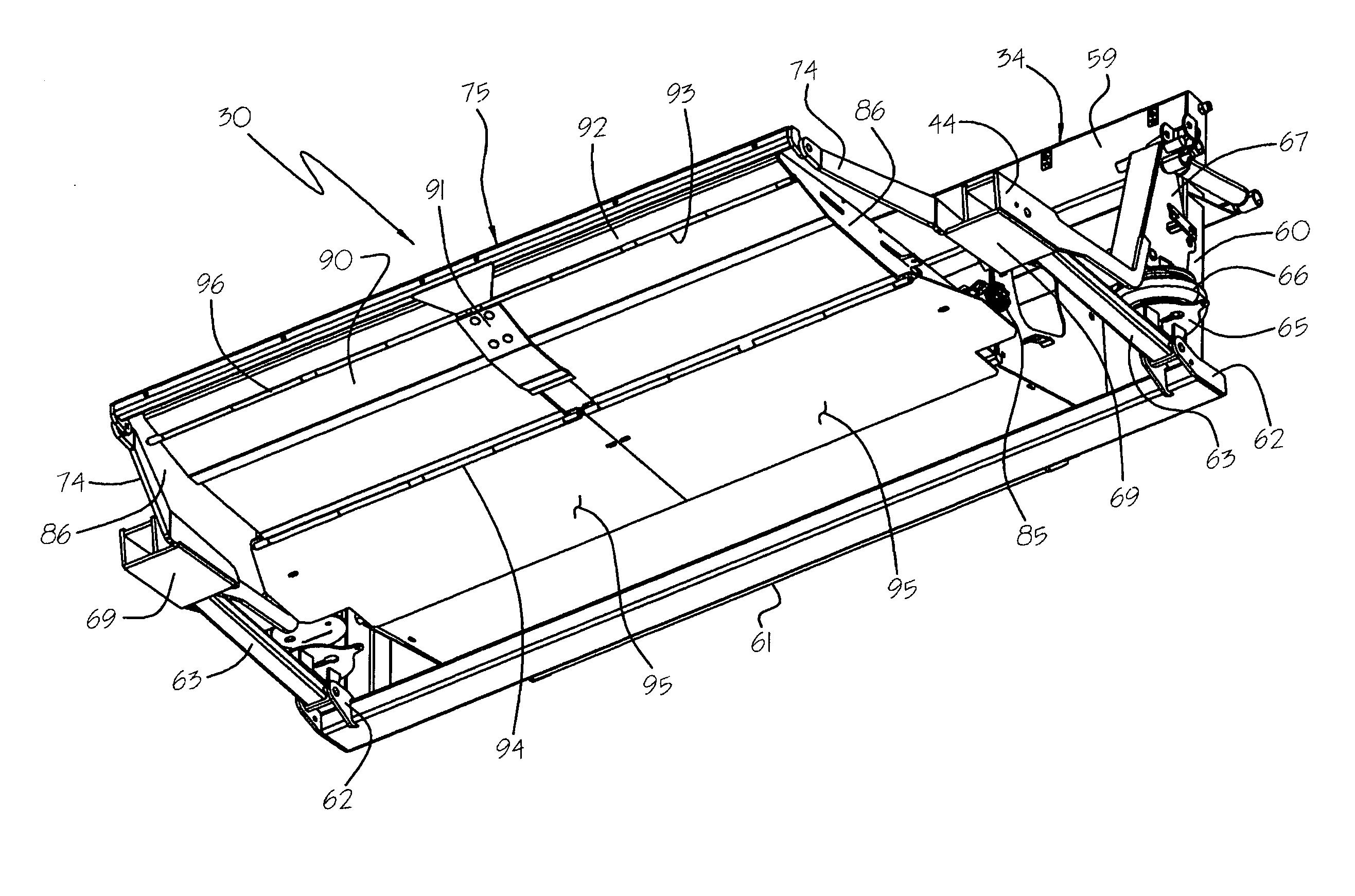

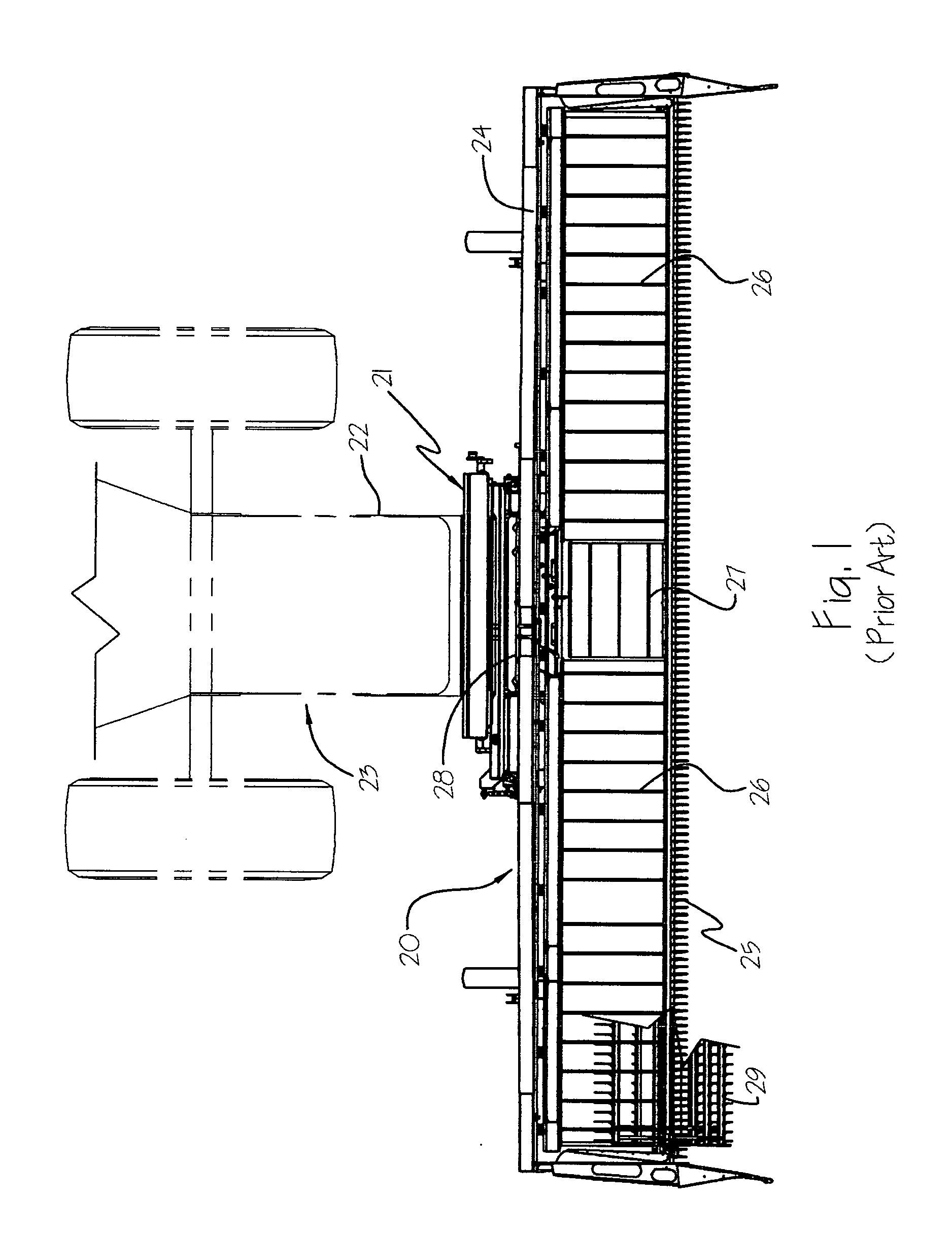

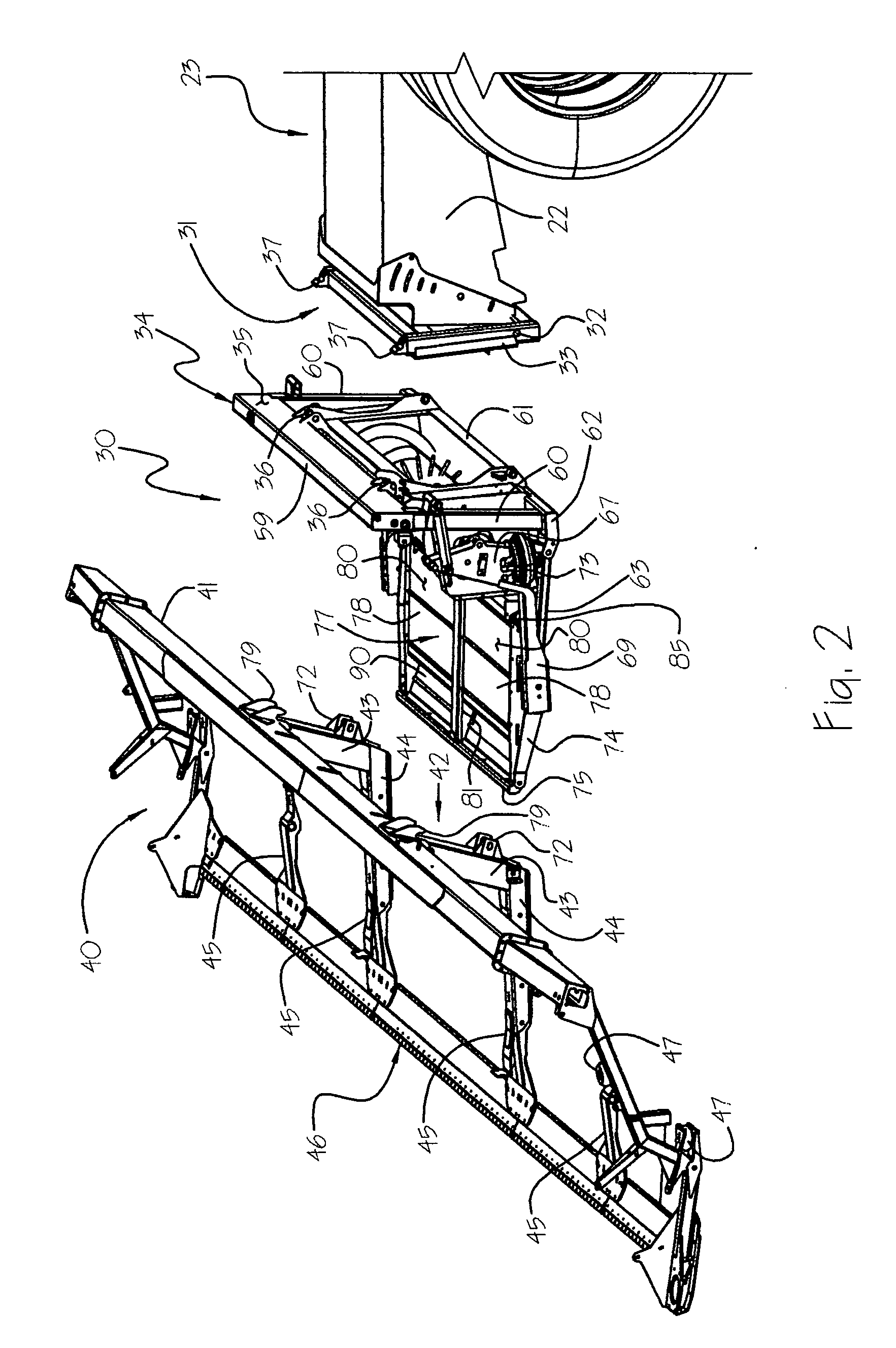

Rock trap for combine header

ActiveUS20080161077A1Design economyEfficient designOscillating piston enginesMowersEngineeringTrap door

A rock trap disposed in a feeder adapter of a combine directly behind a sickle bar of a combine header and in an area in front of a rearwardly directed conveyor located for receiving cut crop from transversely directed conveyor of the header. The rock trap has a trap door which can be selectively opened so as to drop beneath the header rocks collected therein.

Owner:HONEY BEE MFG

Pressure exchanger

ActiveUS20060032808A1Improve flow capacityIncrease momentumRotary/oscillating piston combinations for elastic fluidsGeneral water supply conservationCavitationMomentum

A pressure exchanger for transferring pressure energy from a relatively high-pressure fluid stream to another relatively low-pressure fluid stream is provided. A ducted rotor is positioned on a central axle between two end covers inside a pressure vessel with a coaxial inlet and outlet pair that is in communication with a pair of low pressure ports having inclination forming an inlet tangential velocity vector in the direction of rotor rotation and an outlet tangential velocity vector in opposite direction imparting a rotational momentum on rotor. A pair of high-pressure ports is adapted for flow without inclination and imparts no momentum to rotor and flow can be varied without impacting the rotor's RPM. The end covers have a sloped surface following a flat sealing area that increases the clearance in the direction of rotation causing increased outflow during depressurization and lower duct pressure before duct is exposed to low pressure port and furthermore causing increased inflow during the pressurization phase before duct is exposed to the high pressure port, which will dissipate pressure energy as opposed to producing cavitation or pressure waves with result wear and noise.

Owner:ISOBARIC STRATEGIES INC

Integrated energy generating damper

A linear energy harvesting device that includes a housing and a piston that moves at least partially through the housing when it is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor drives an electric generator that produces electricity. Both the motor and generator are central to the device housing. Exemplary configurations are disclosed such as monotube, twin-tube, tri-tube and rotary based designs that each incorporates an integrated energy harvesting apparatus. By varying the electrical characteristics on an internal generator, the kinematic characteristics of the energy harvesting apparatus can be dynamically altered. In another mode, the apparatus can be used as an actuator to create linear movement. Applications include vehicle suspension systems (to act as the primary damper component), railcar bogie dampers, or industrial applications such as machinery dampers and wave energy harvesters, and electro-hydraulic actuators.

Owner:CLEARMOTION INC

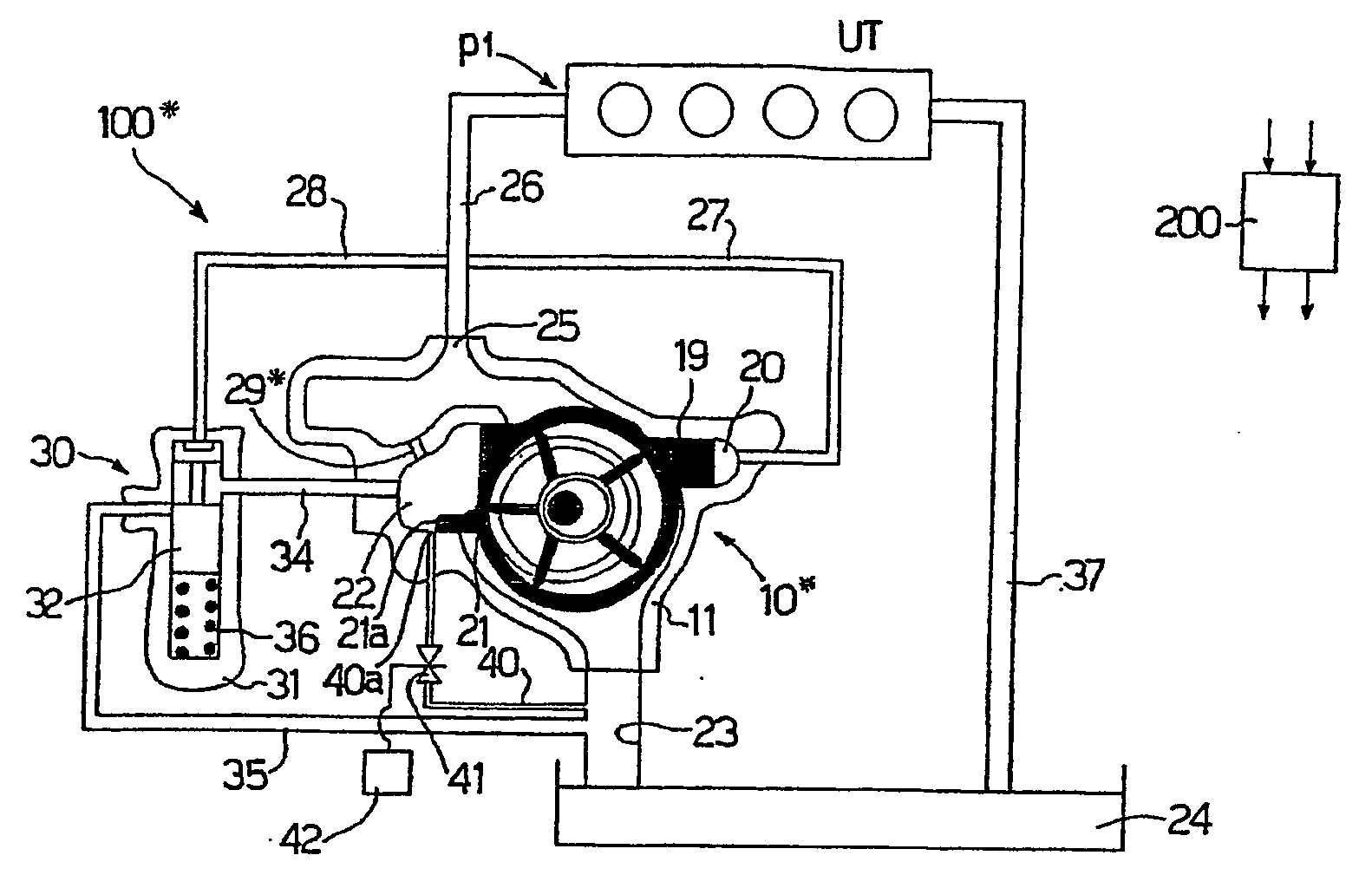

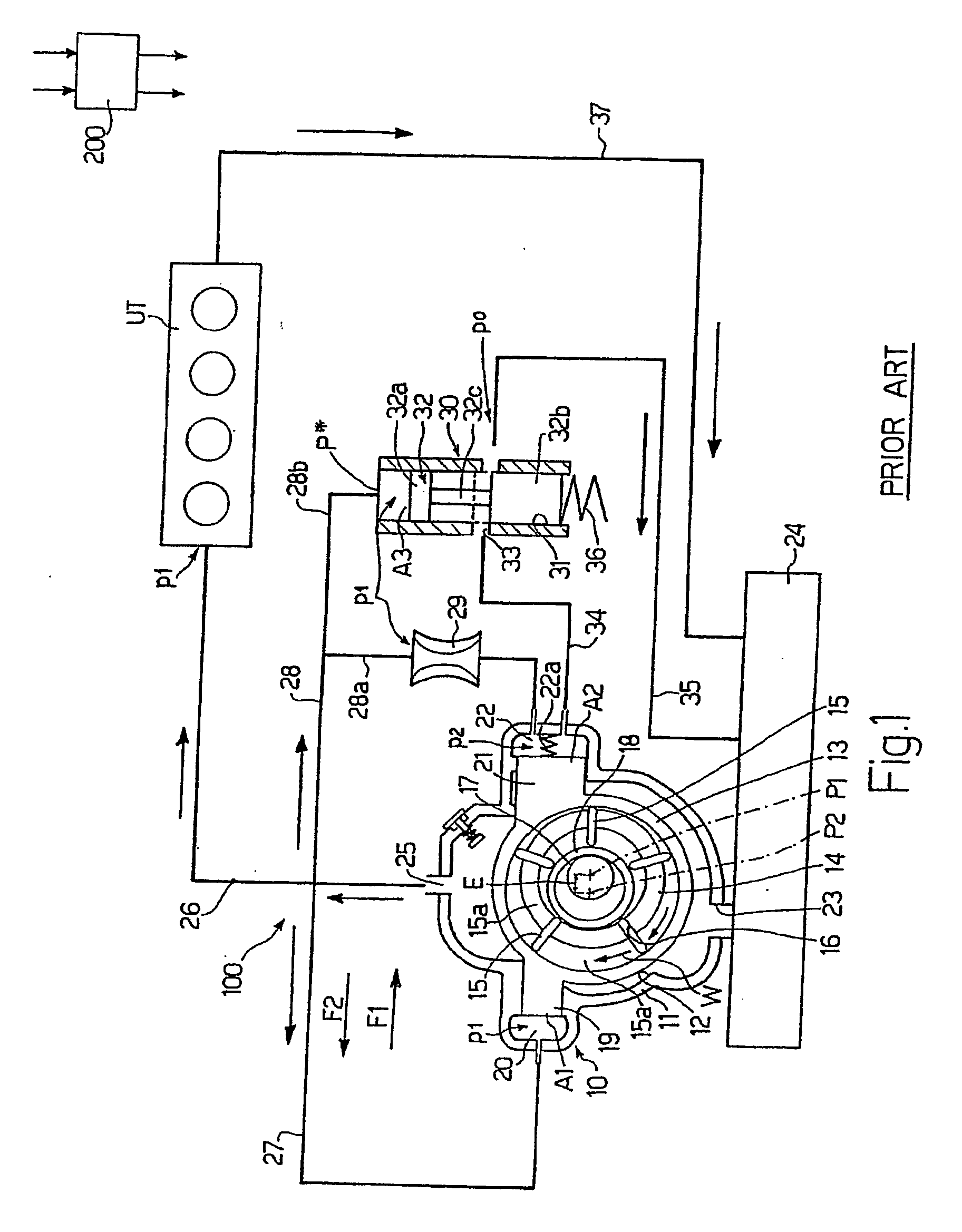

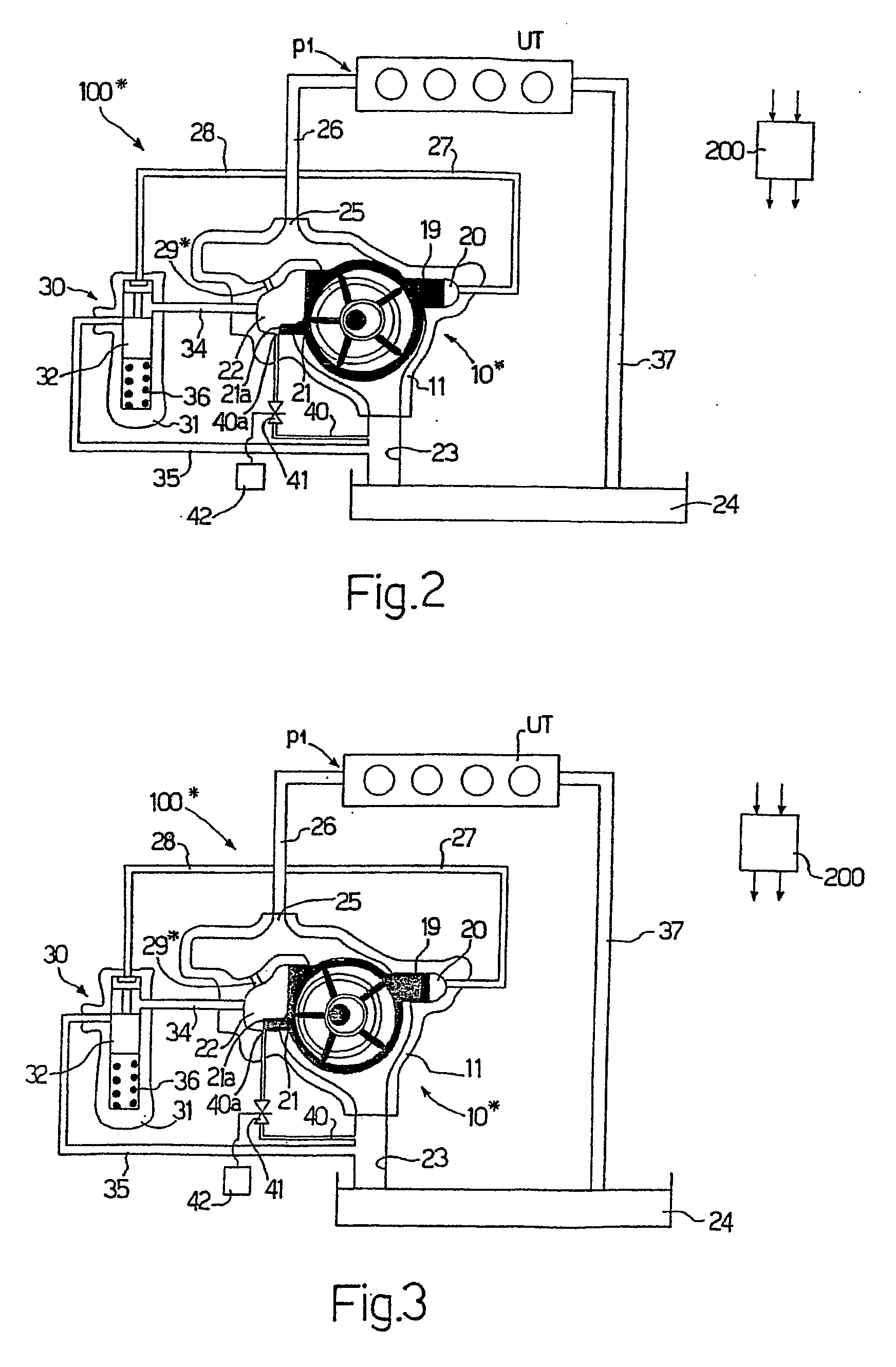

Pumping System

A pumping system (100*) having a pump (10*), such as a variable-displacement vane pump (10*) or a gear pump. The pump (10*) in turn has hydraulic pressure-control dissipating devices (29, 30) for imparting to the oil in a first control chamber (22) a pressure (p2) lower than the pressure of a second chamber (20). The system (100*) is characterized in that the first control chamber (22) of the pump (10*) has a channel (40) connecting the first control chamber to an oil inlet (23). And the channel (40) has an opening / closing device (41) controlled selectively by an engine operating parameter, such as oil temperature.

Owner:PIERBURG PUMP TECH ITAL

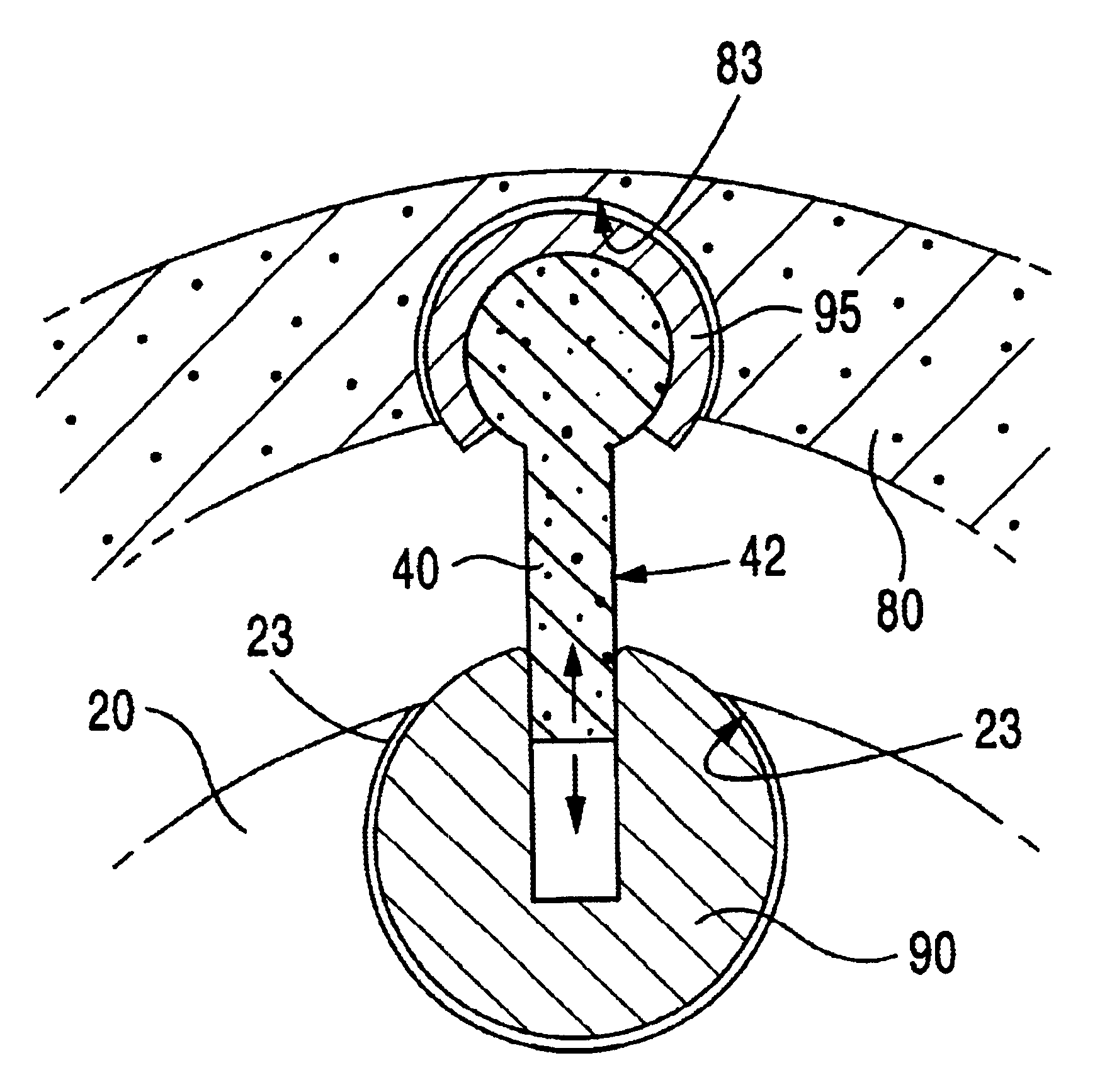

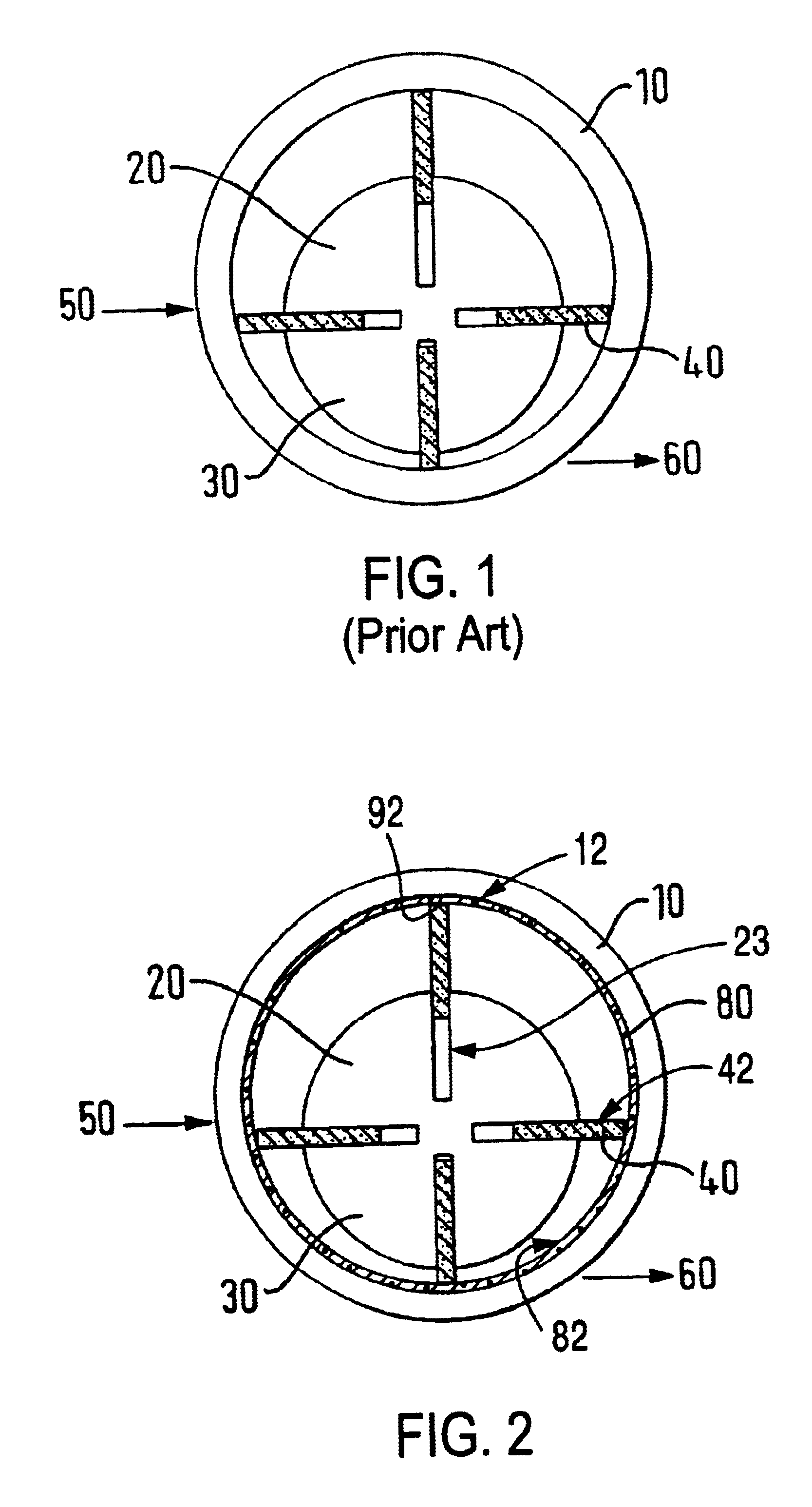

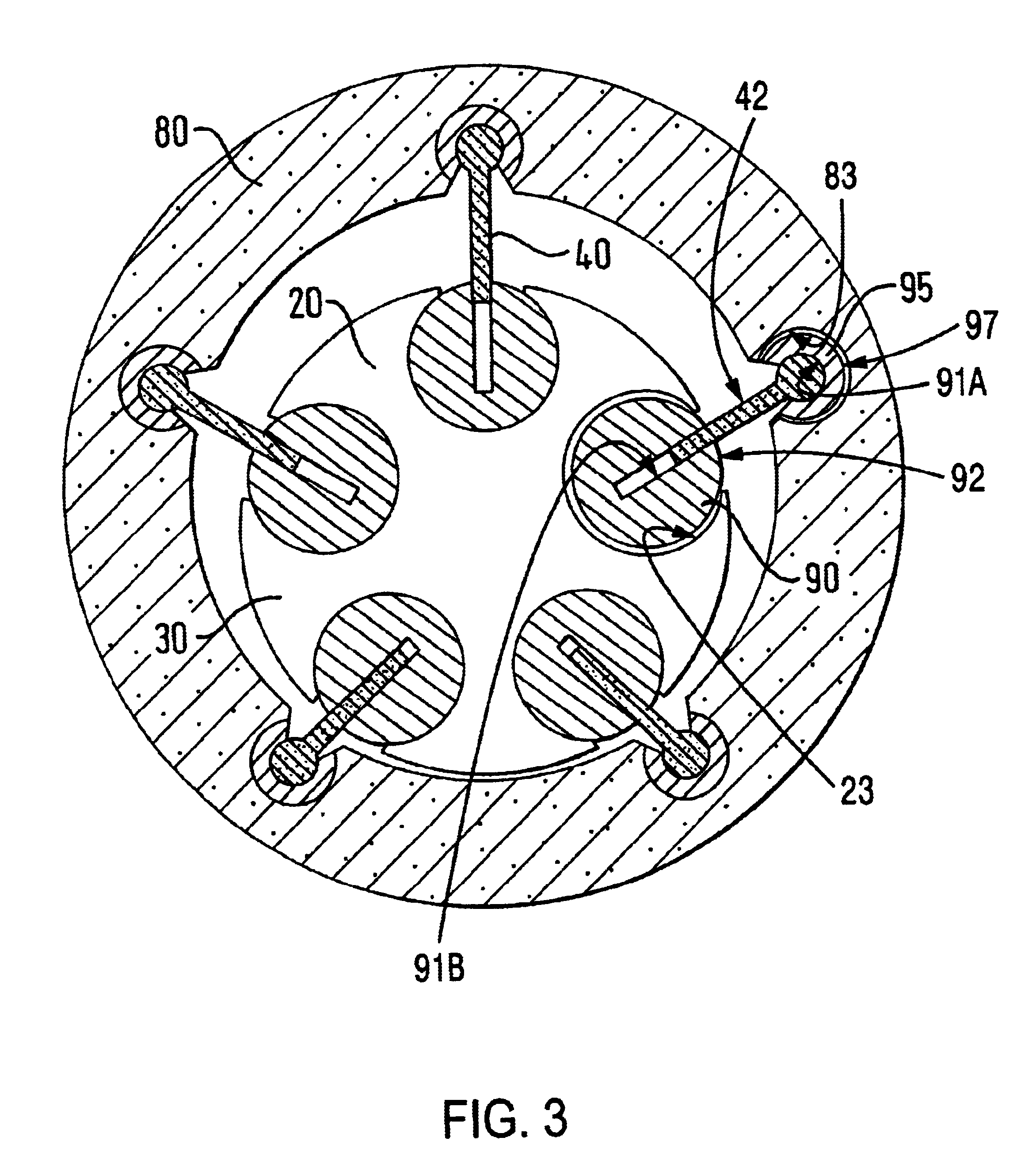

Rotary pump

InactiveUS6666671B1Shorten speedReduce wear rateOscillating piston enginesSealing arrangement for pumpsRotary pumpFree rotation

A rotary pump for pumping compressible fluid comprising an eccentrically mounted rotor 20 and a stator 10. The stator 10 comprises a stator inner liner 80 that is free to rotate, driven directly or in response to rotation of the rotor 20 such that the relative velocity between the outer surface of the rotor 20 and the inner surface of the stator 10 is reduced. The vanes 40 are held at each end by sockets 90, 95 in the rotor 20 and stator 10. The vane 40 and socket 90, 95 coupling provides fluid sealing without liquid lubricant. Opposing solid lubricant and hard surfaces are used on contact surfaces between the elements.

Owner:IC INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com