Variable displacement sliding vane pump

a sliding vane pump and variable displacement technology, which is applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of reducing the amount of fluid drawn into the pump, the amount of fluid output of the pump, and the oil pressure as well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

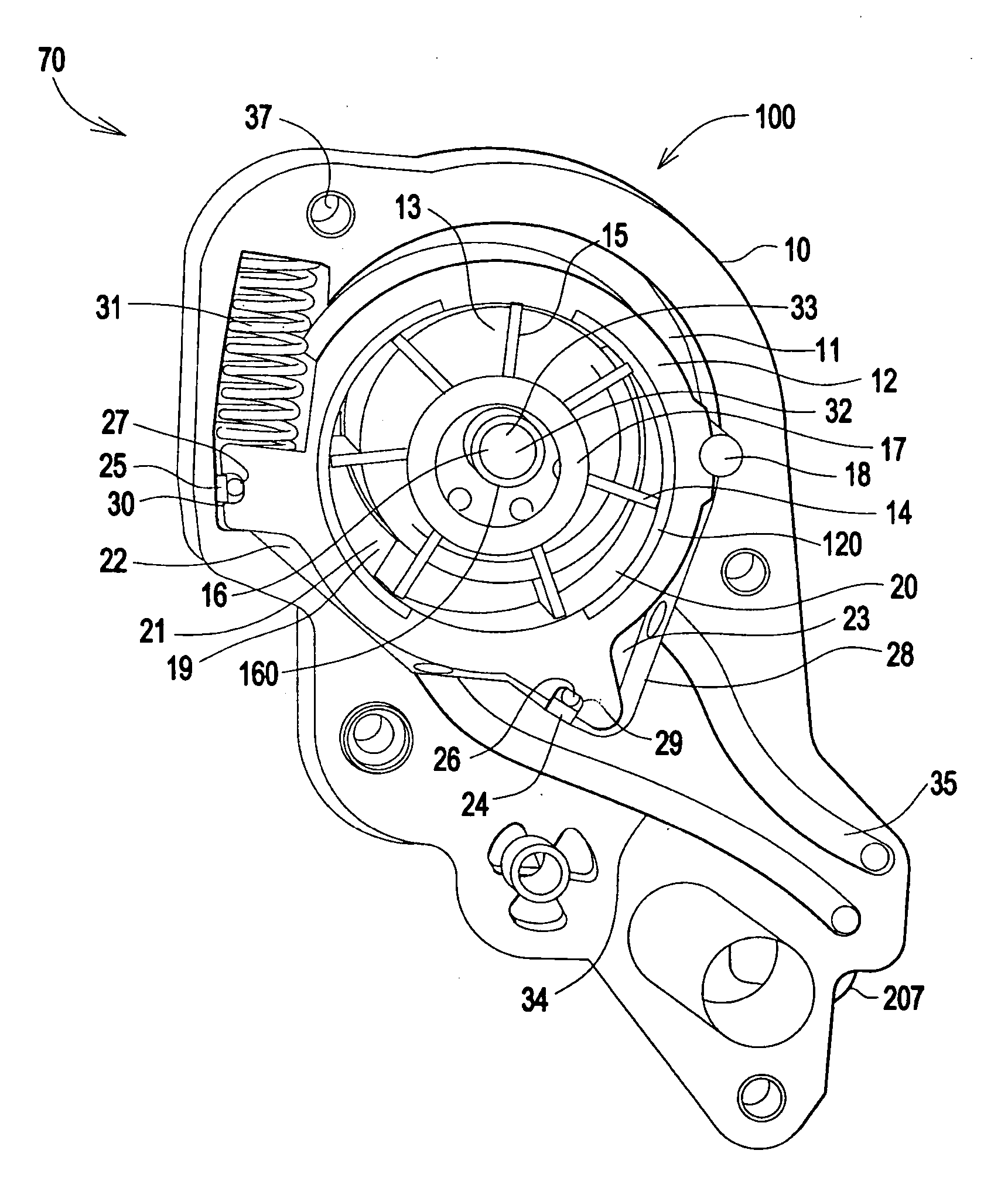

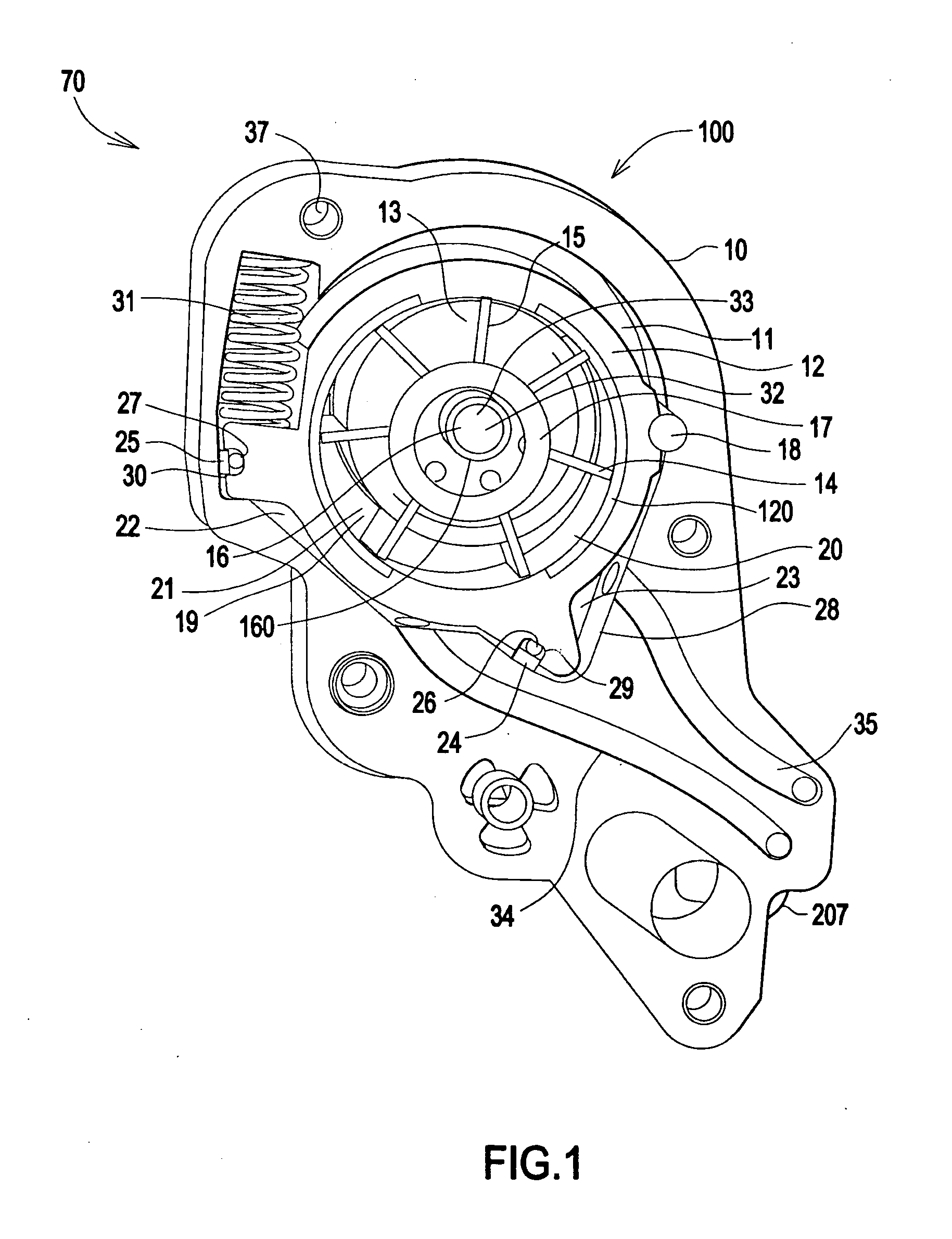

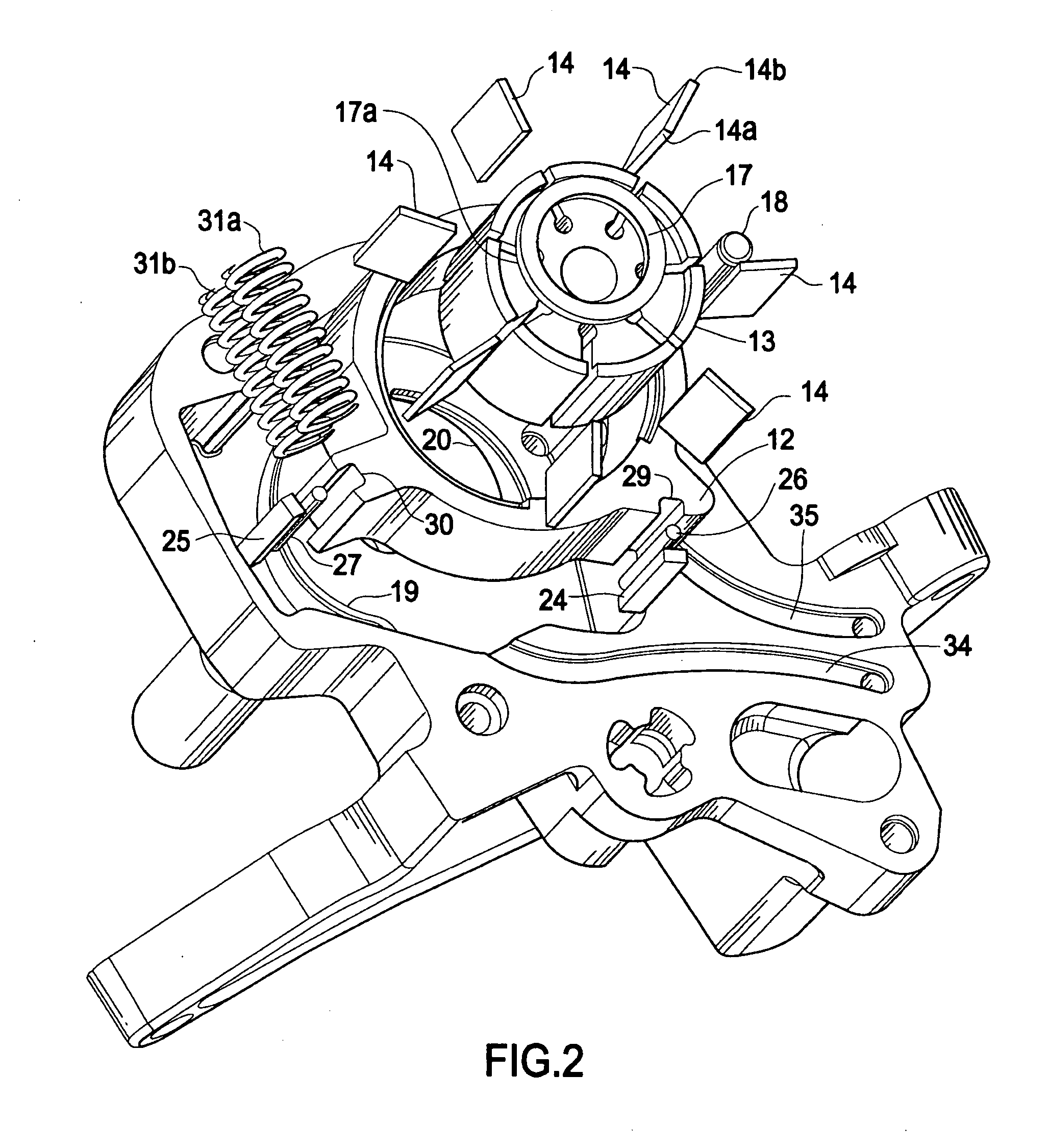

[0020]FIG. 1 is a front view of the pump with outer cover removed. The inventive pump 100 comprises body 10. Body 10 defines a cavity 11 within which is disposed slide 12 and rotor 13. A plurality of sliding vanes 14 are radially disposed about rotor 13. Each vane 14 extends radially from a slot 15 in rotor 13. Each vane 14 is moveable within each slot 15.

[0021] Pump shaft 16 is rotatably mounted in body 10. A splined end 160 of pump shaft 16 engages rotor 13. As rotor 13 rotates vanes 14 are urged outwardly by a pair of vane control rings 17 and centripetal force into a sliding engagement with inner surface 120 of slide 12.

[0022] Slide 12 is pivotally engaged with the body at a pivot member 18. Slide 12 pivots at pivot member 18 within cavity 11 thereby describing an arc which defines the operating range of motion of slide 12.

[0023] The position of each vane 14 is a function of the position of slide 12 with respect to ring 17. Ring 17 occupies a space determined by the ends of v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com