Patents

Literature

2308 results about "Variable displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variable displacement is an automobile engine technology that allows the engine displacement to change, usually by deactivating cylinders, for improved fuel economy. The technology is primarily used in large, multi-cylinder engines. Many automobile manufacturers have adopted this technology as of 2005, although the concept has existed for some time prior to this.

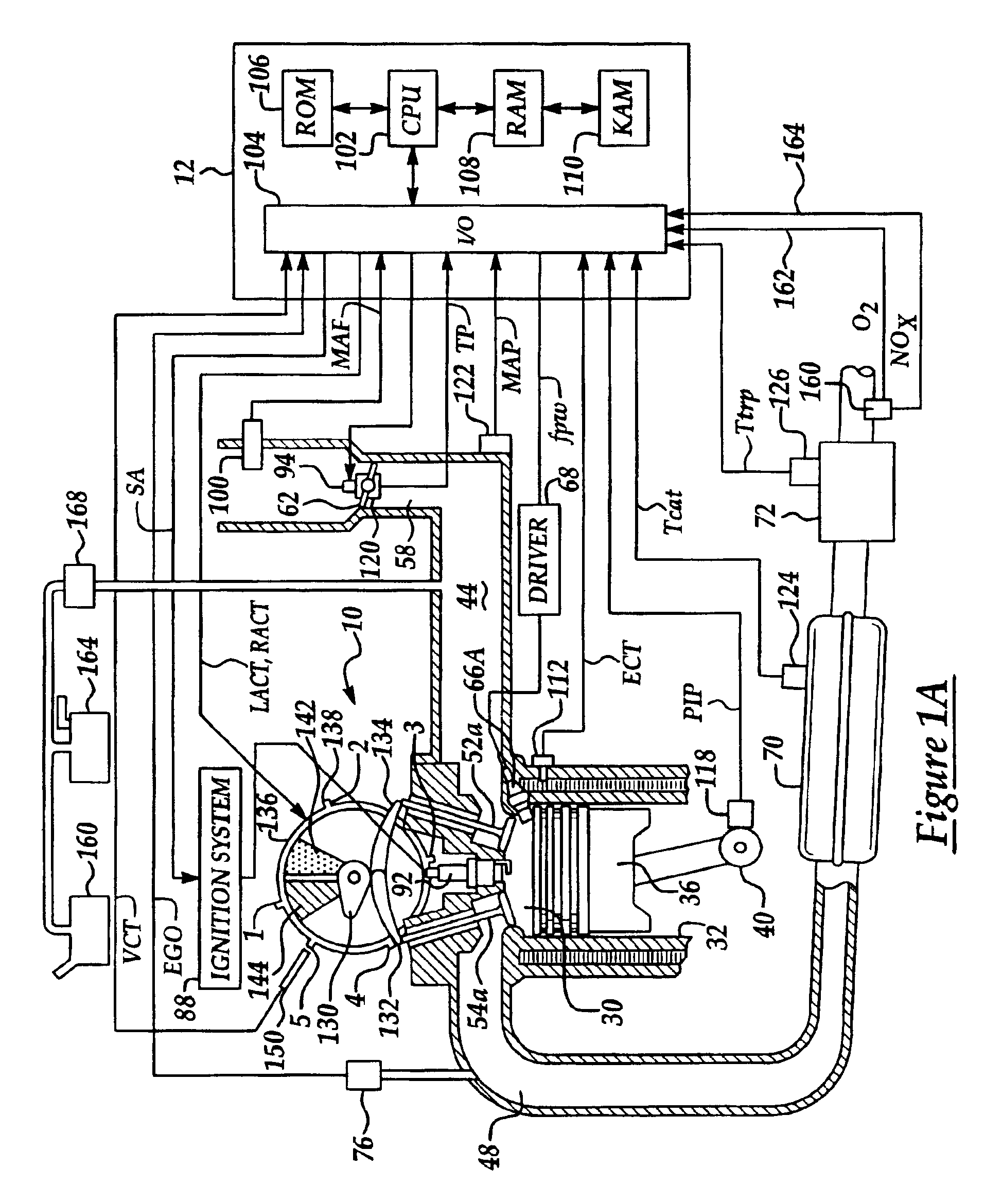

Internal combustion engine control for improved fuel efficiency

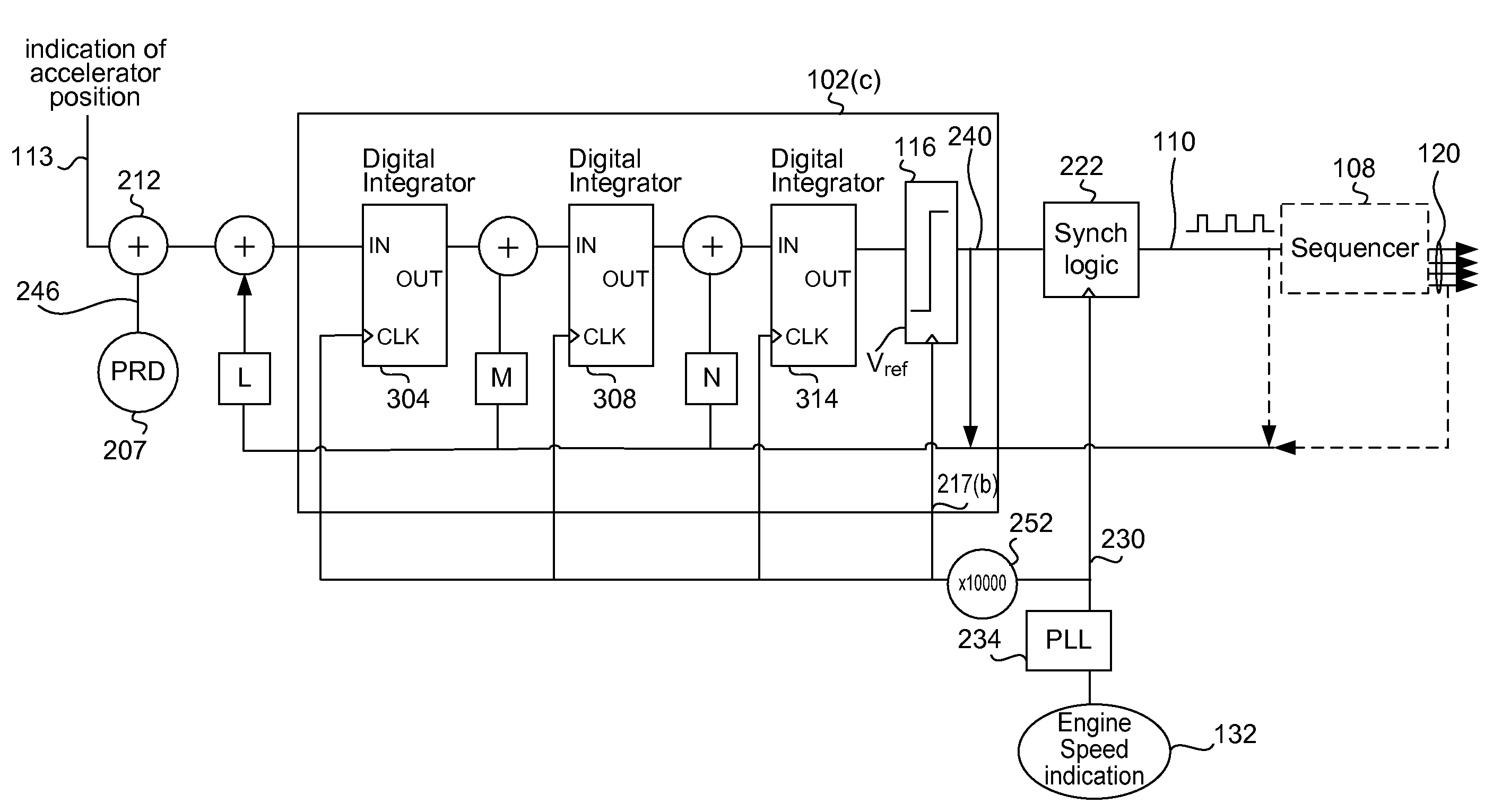

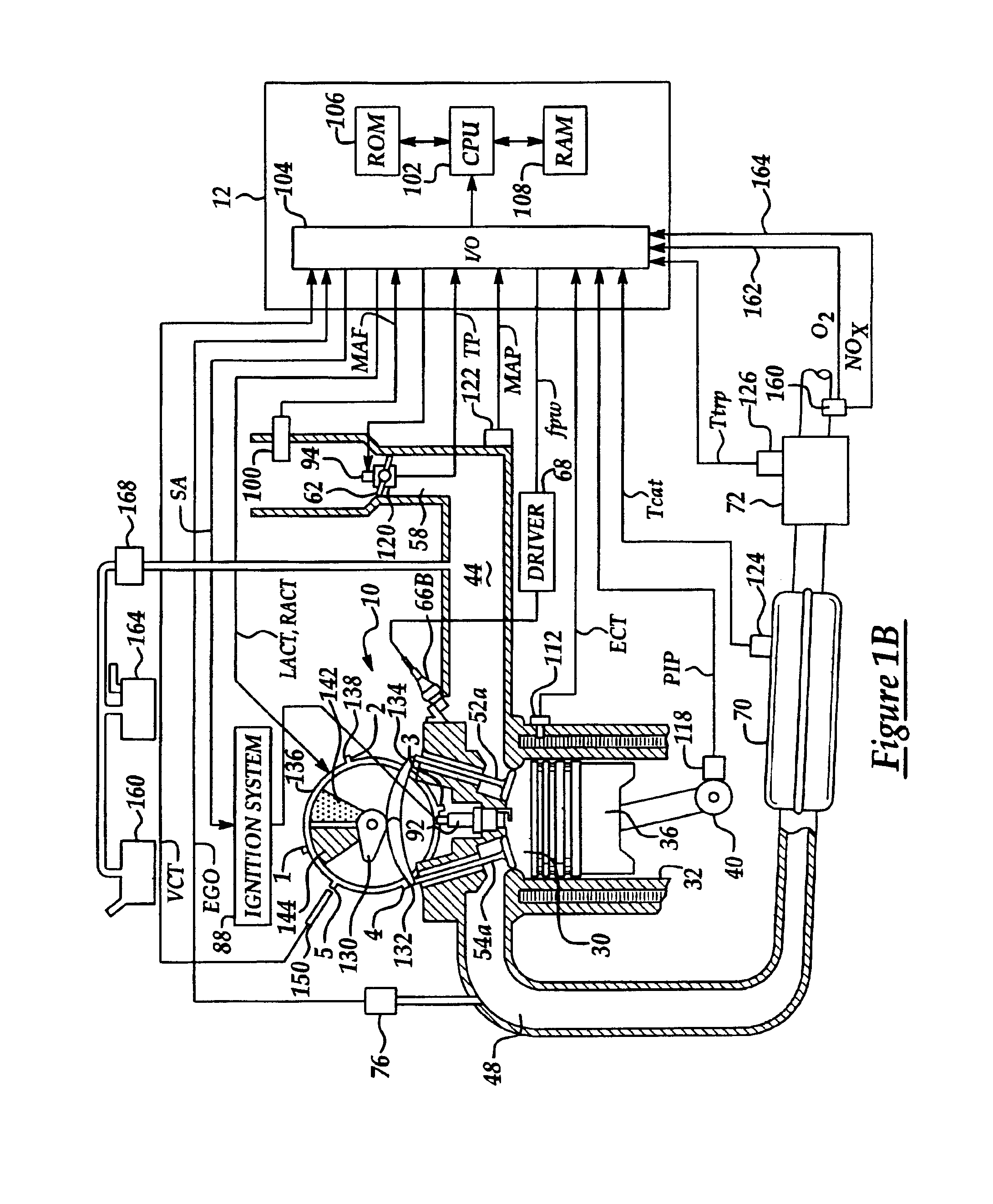

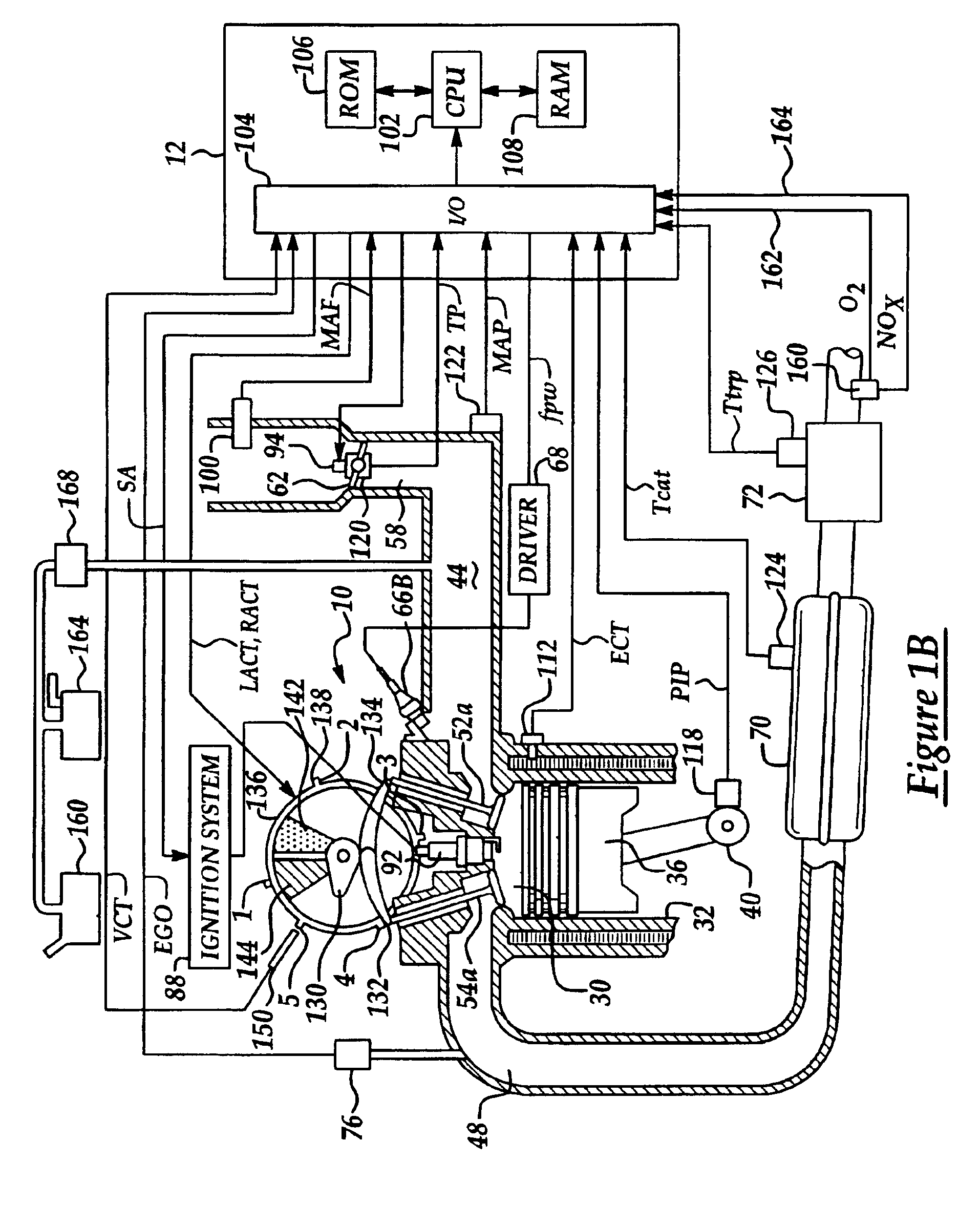

ActiveUS7577511B1Smoother and precise controlReduce probabilityElectrical controlInternal combustion piston enginesExternal combustion engineWork cycle

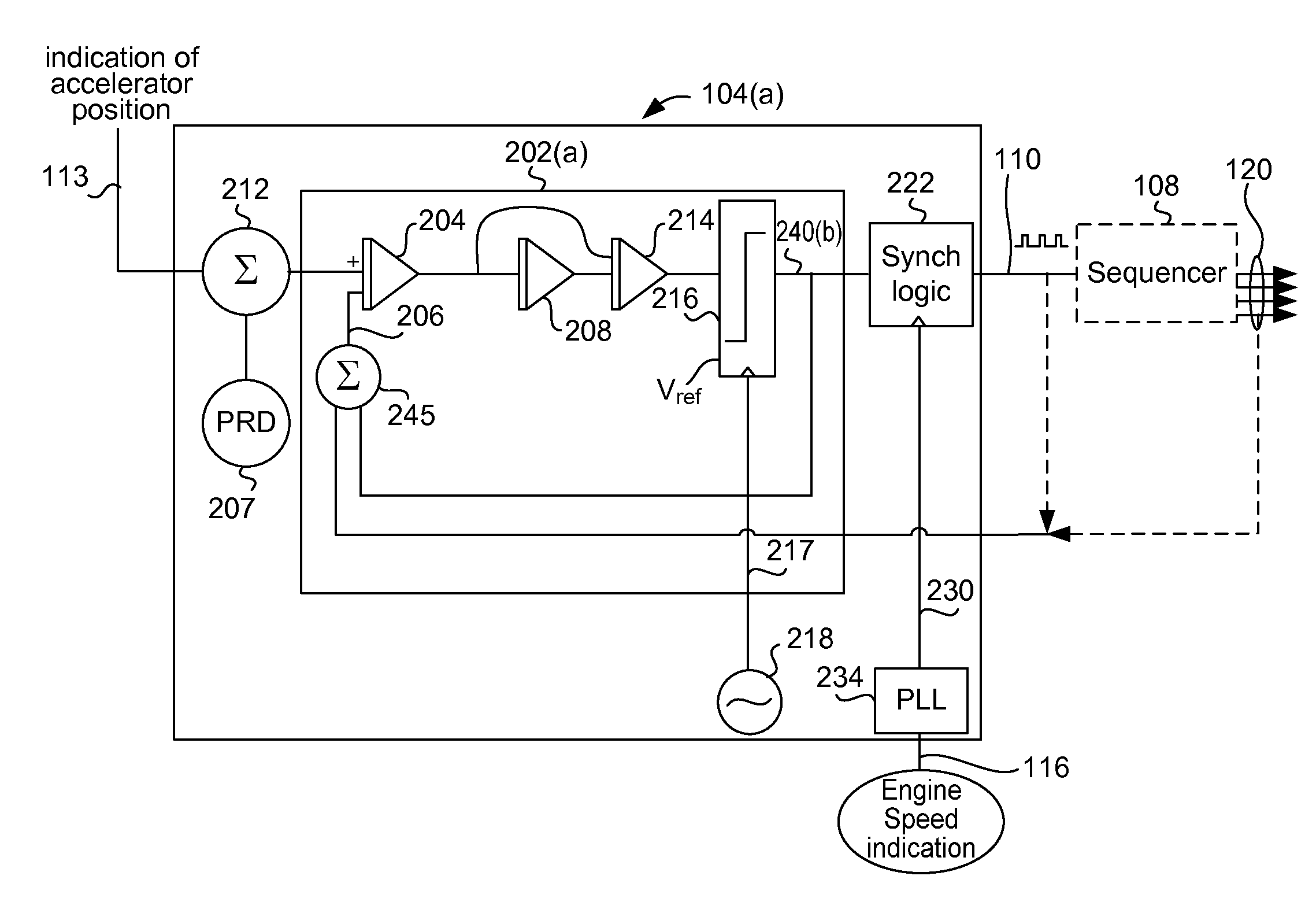

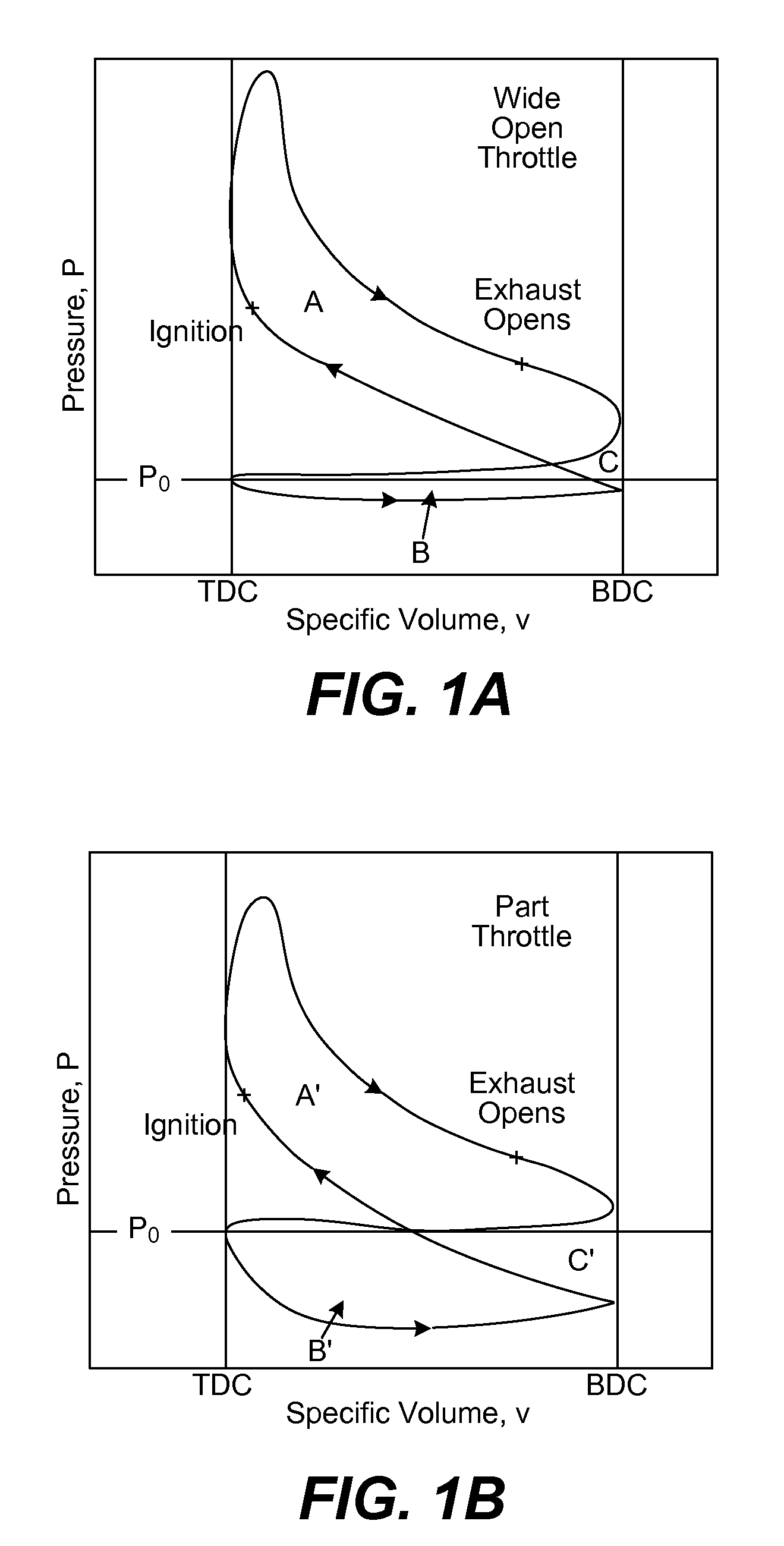

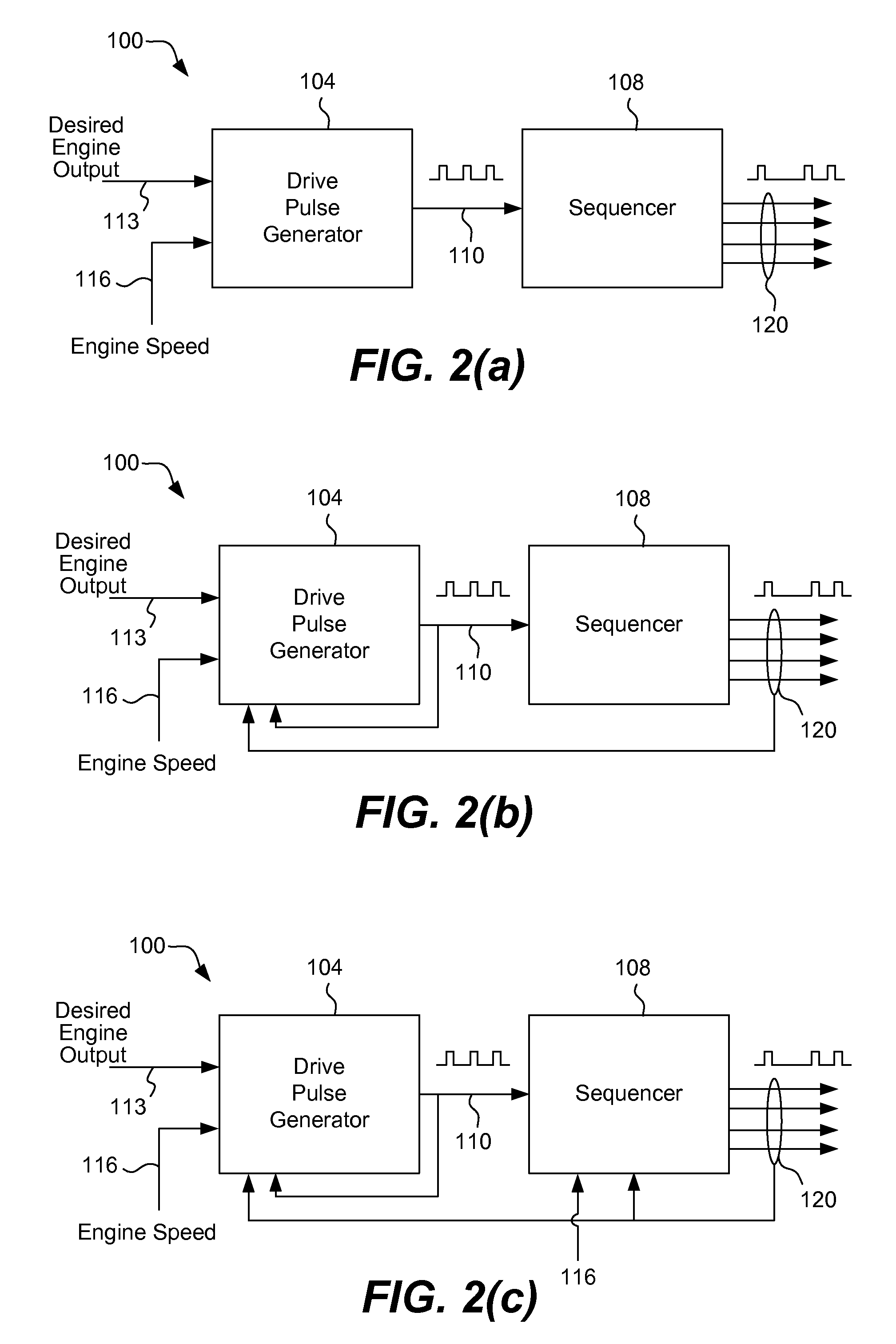

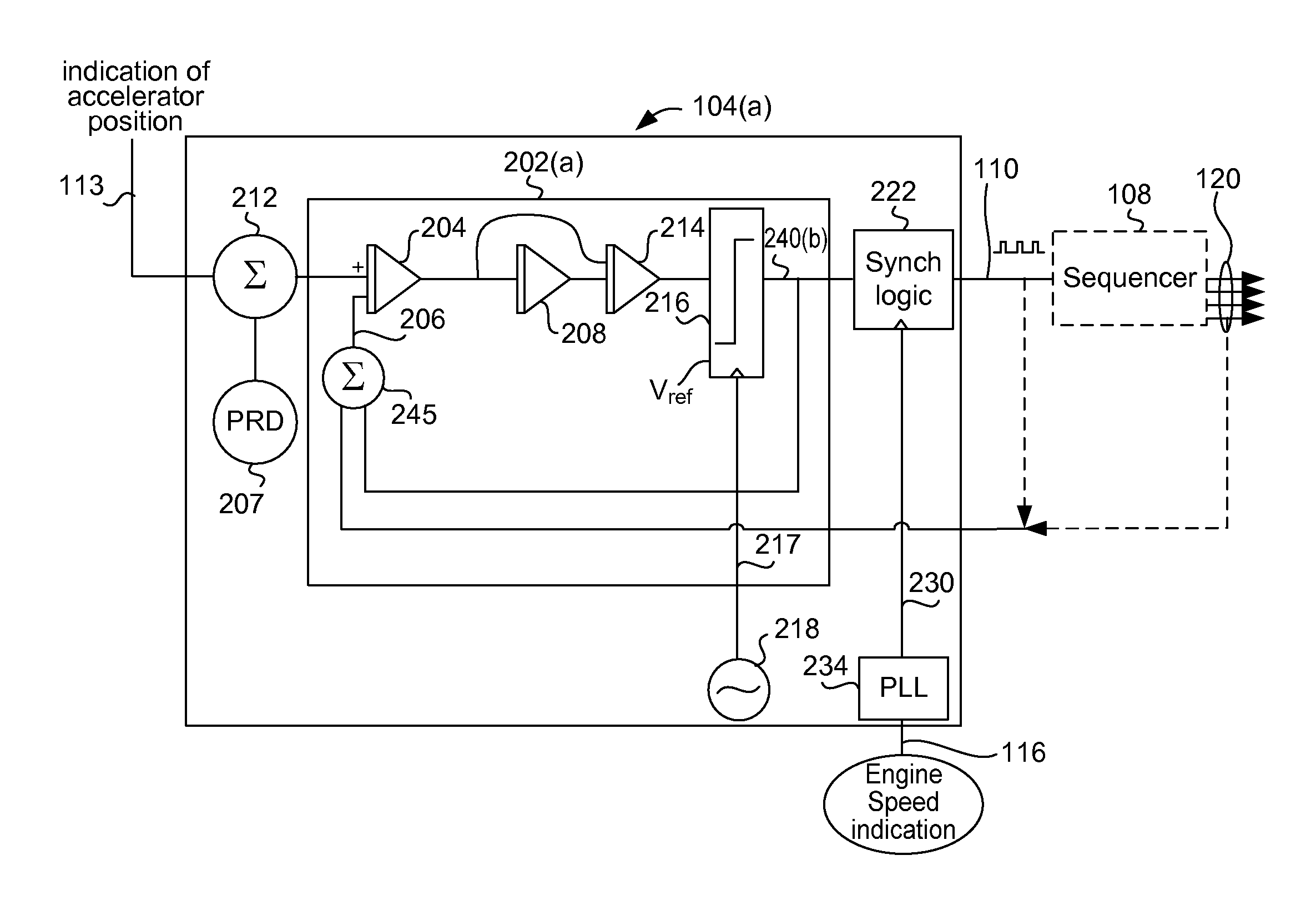

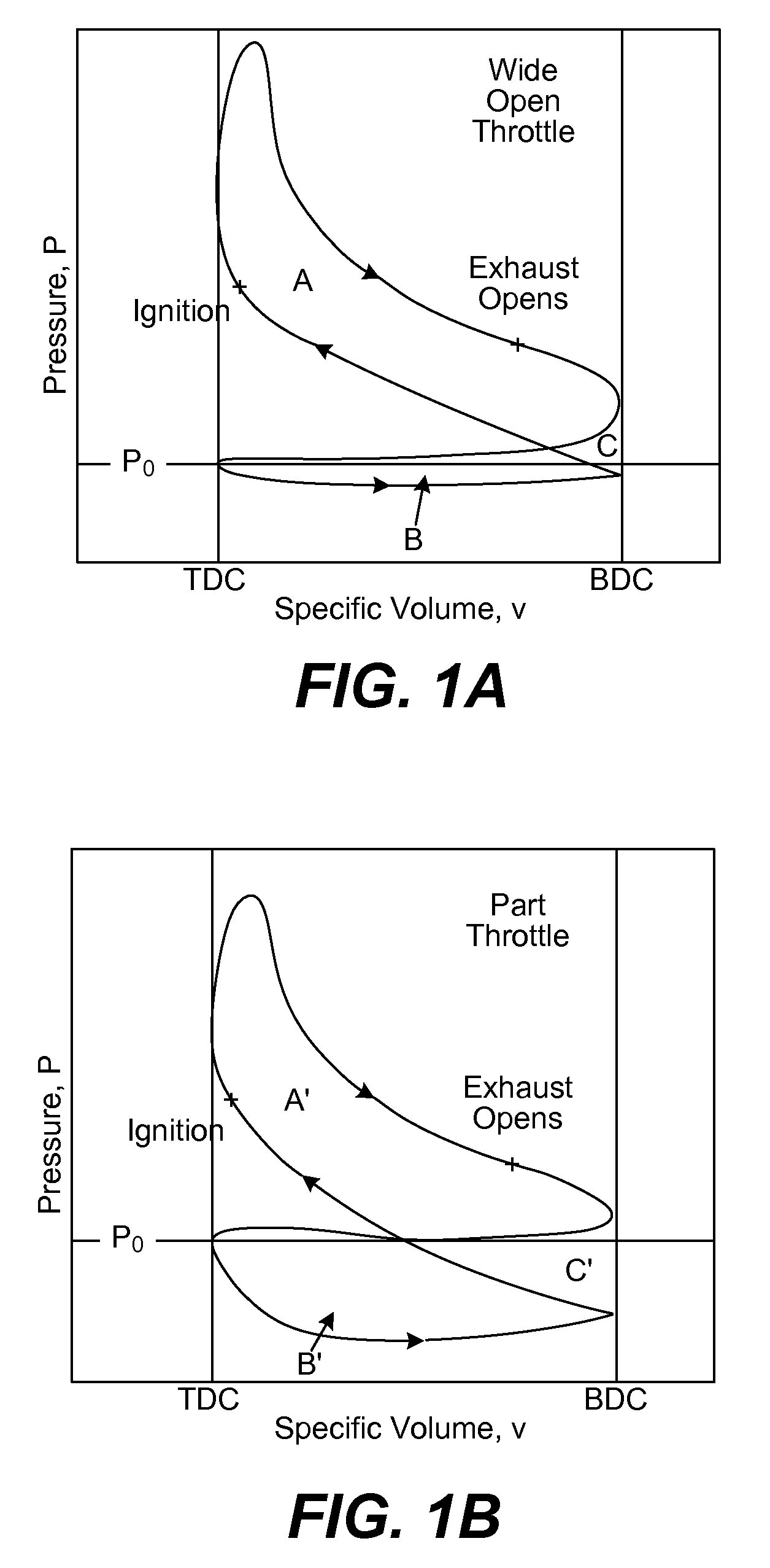

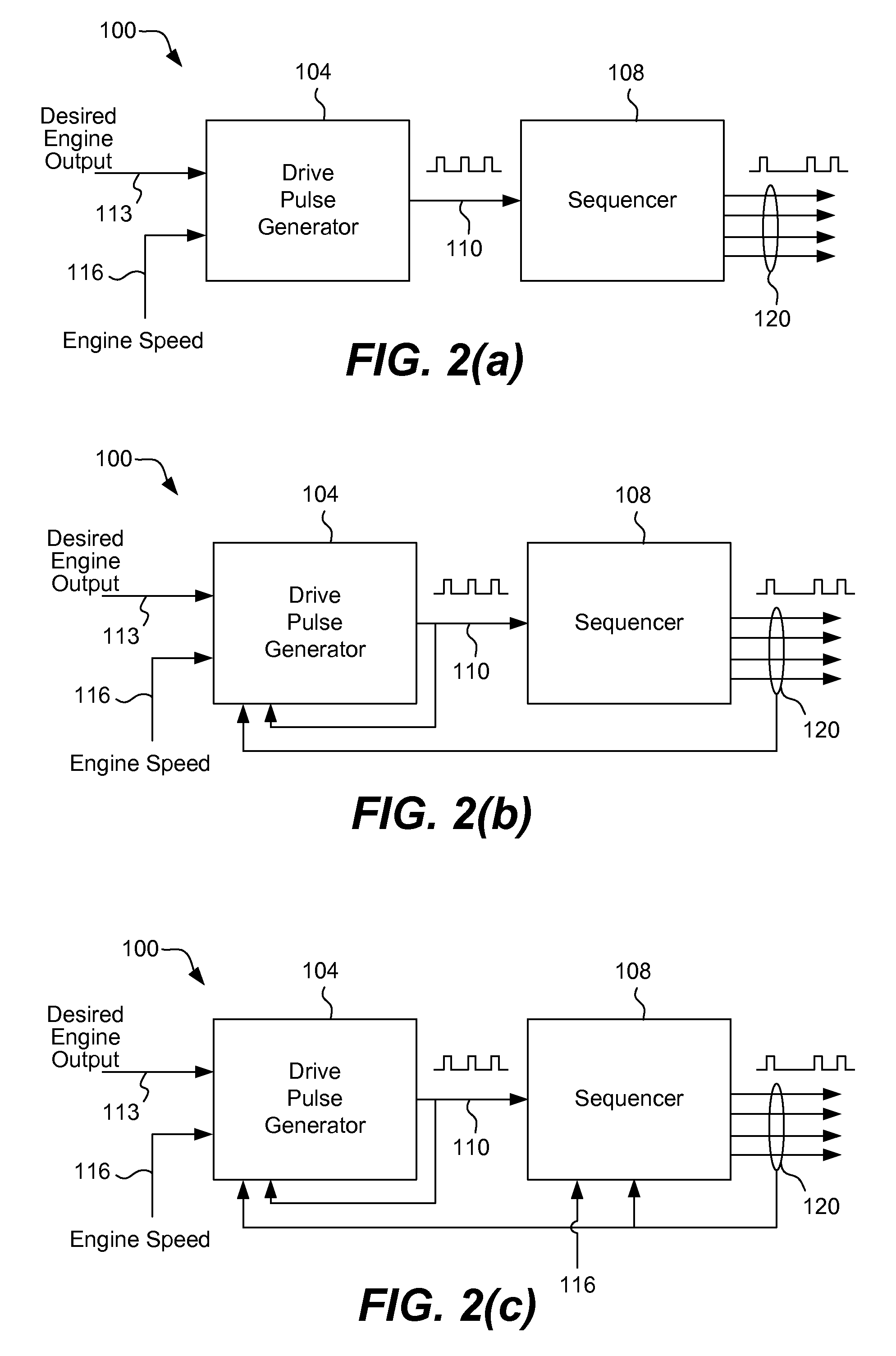

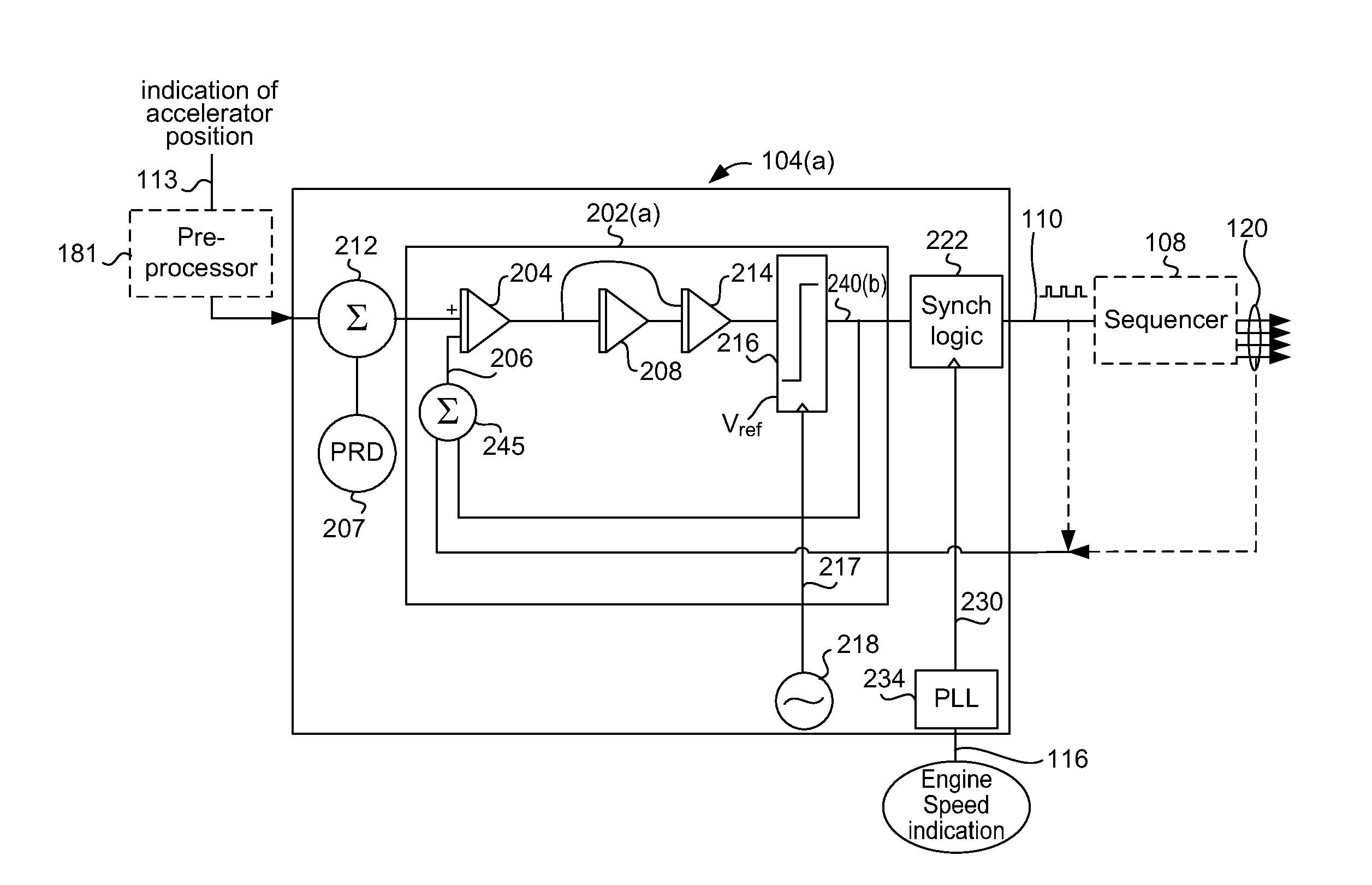

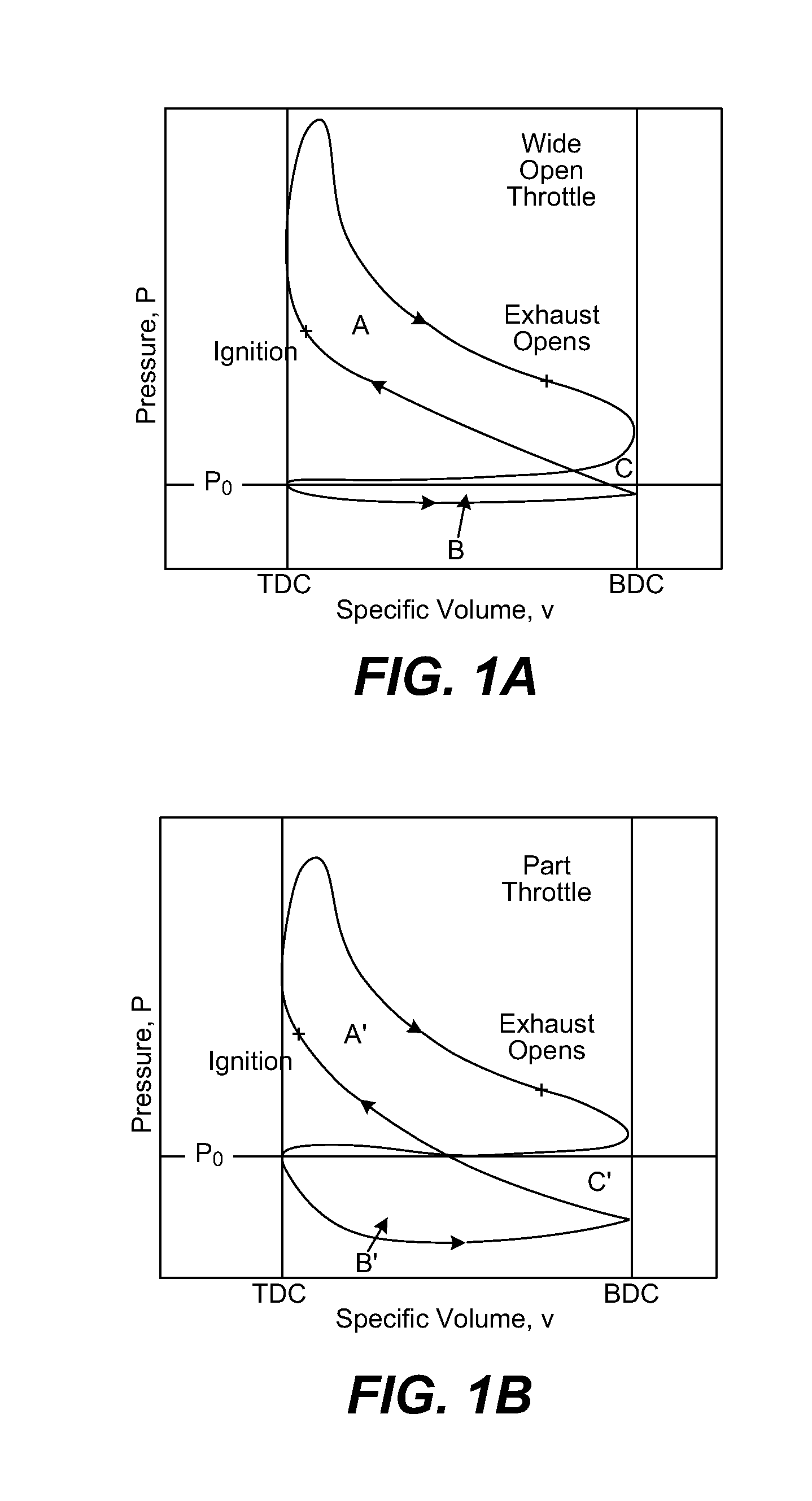

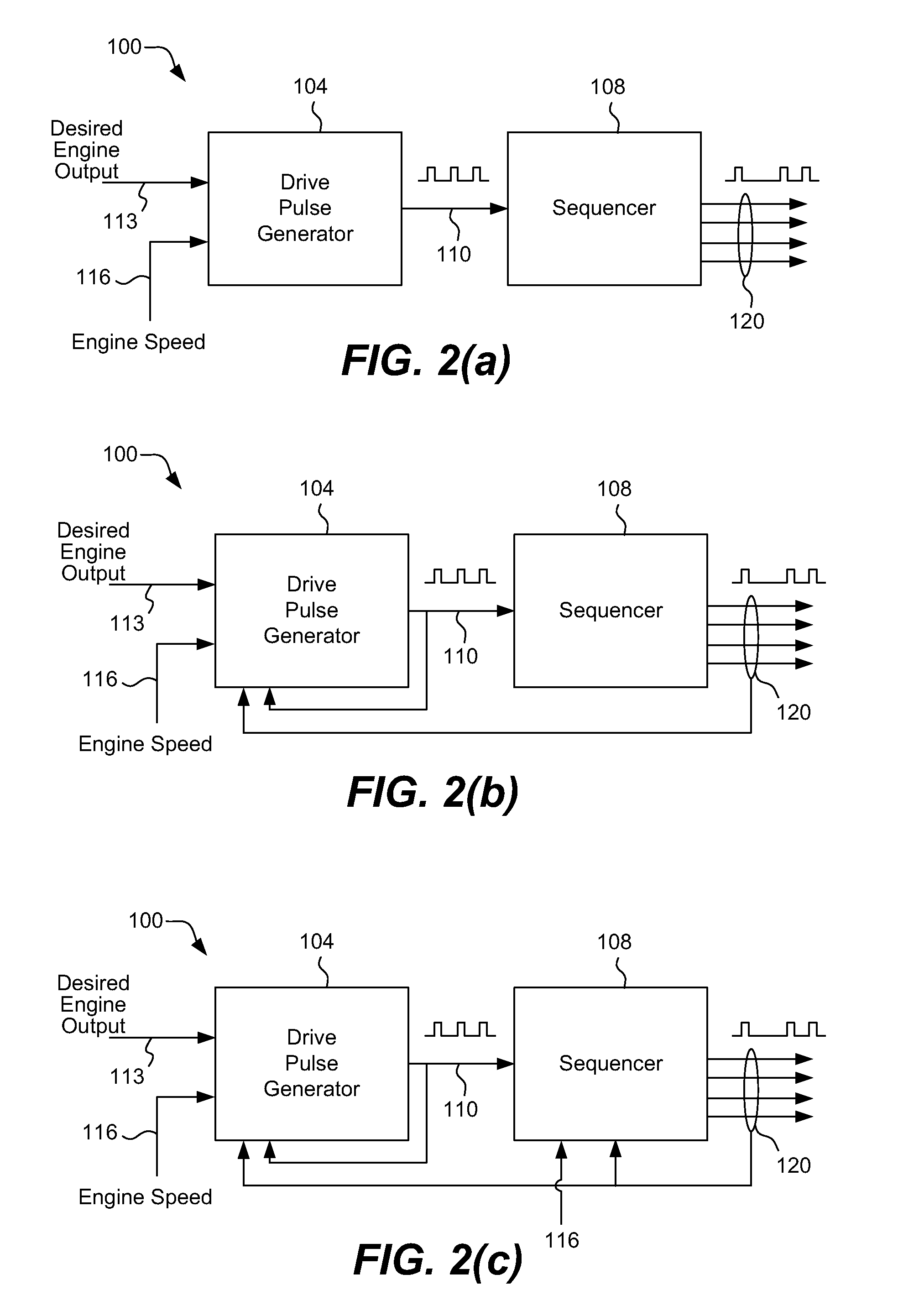

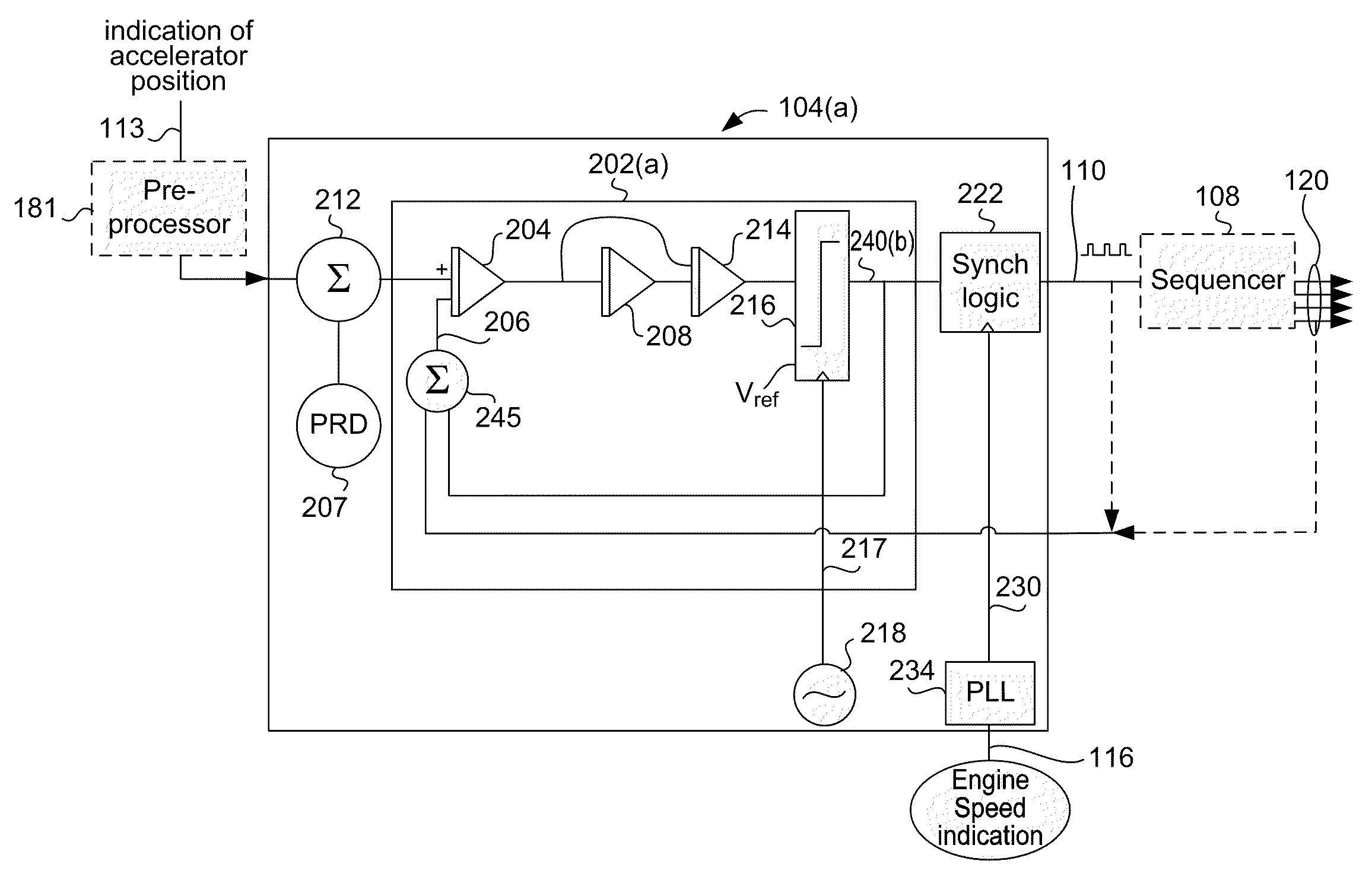

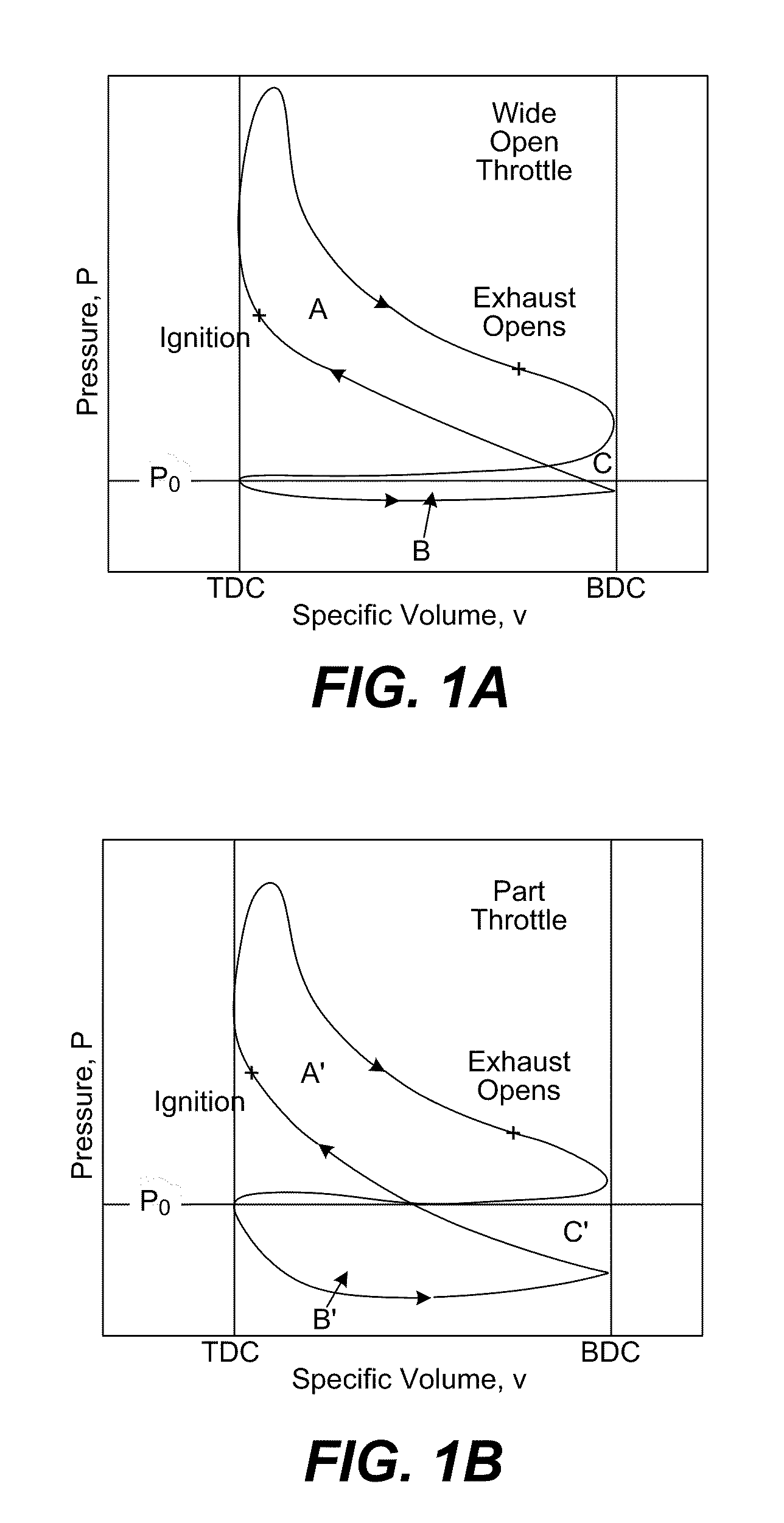

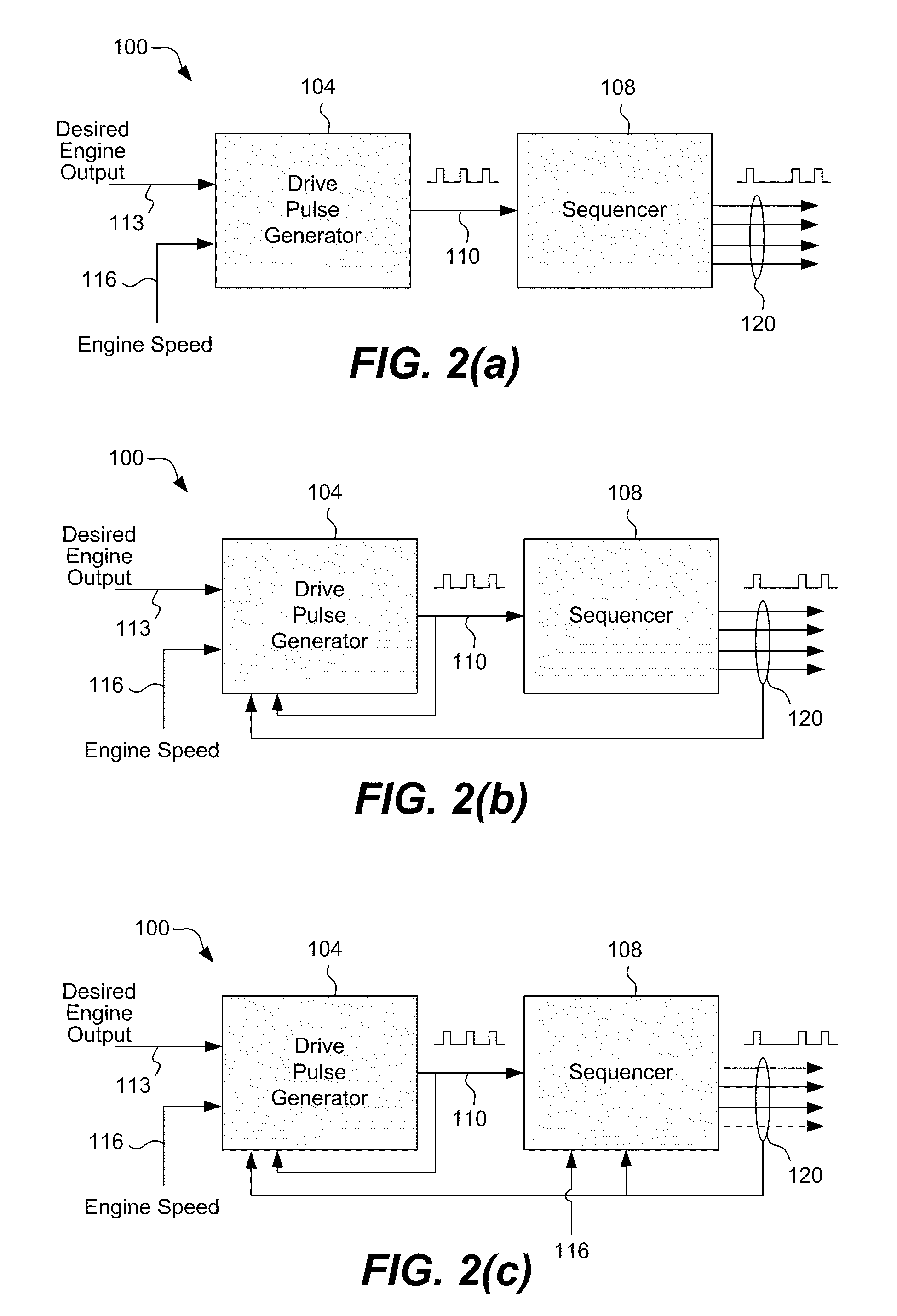

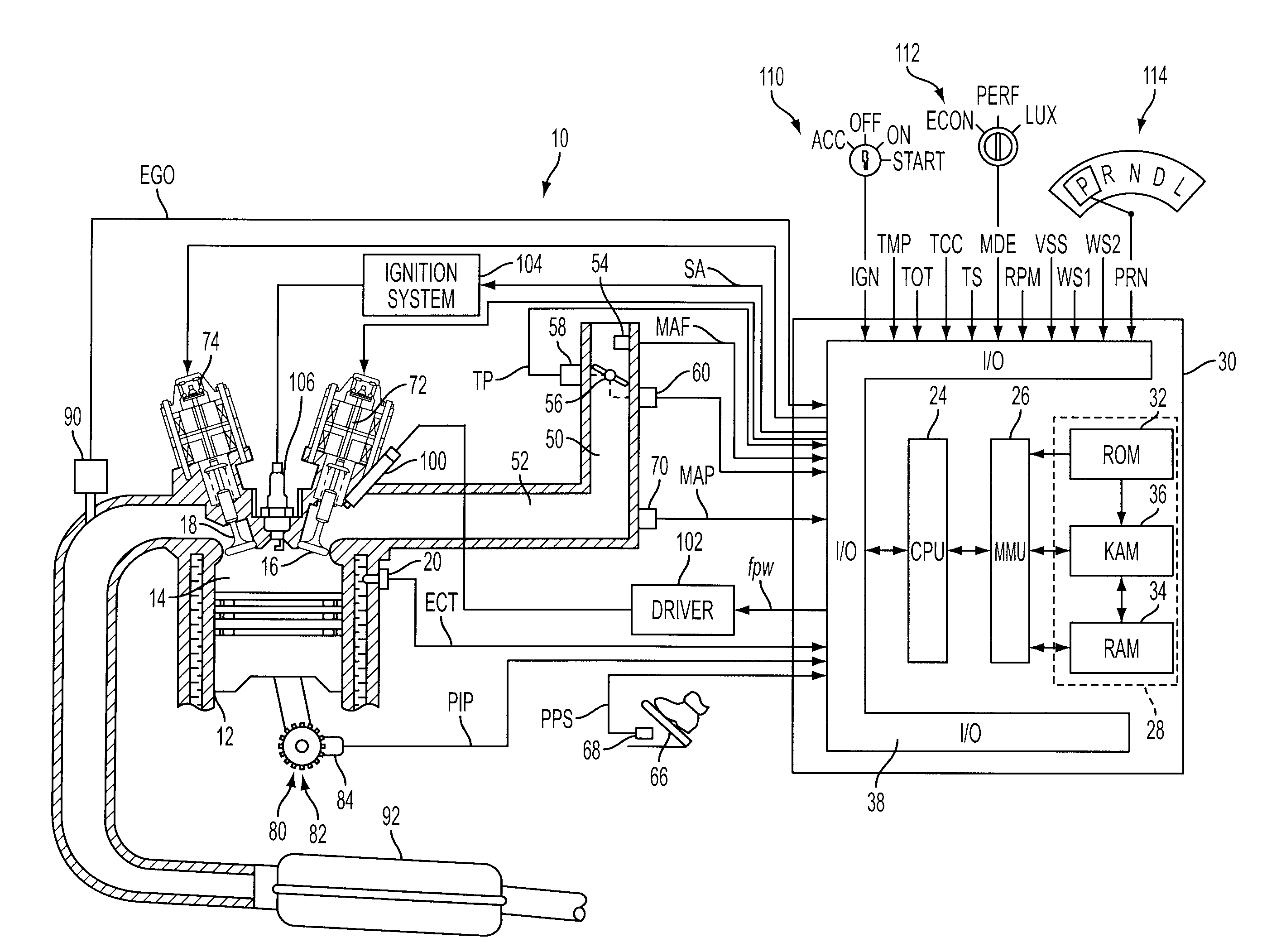

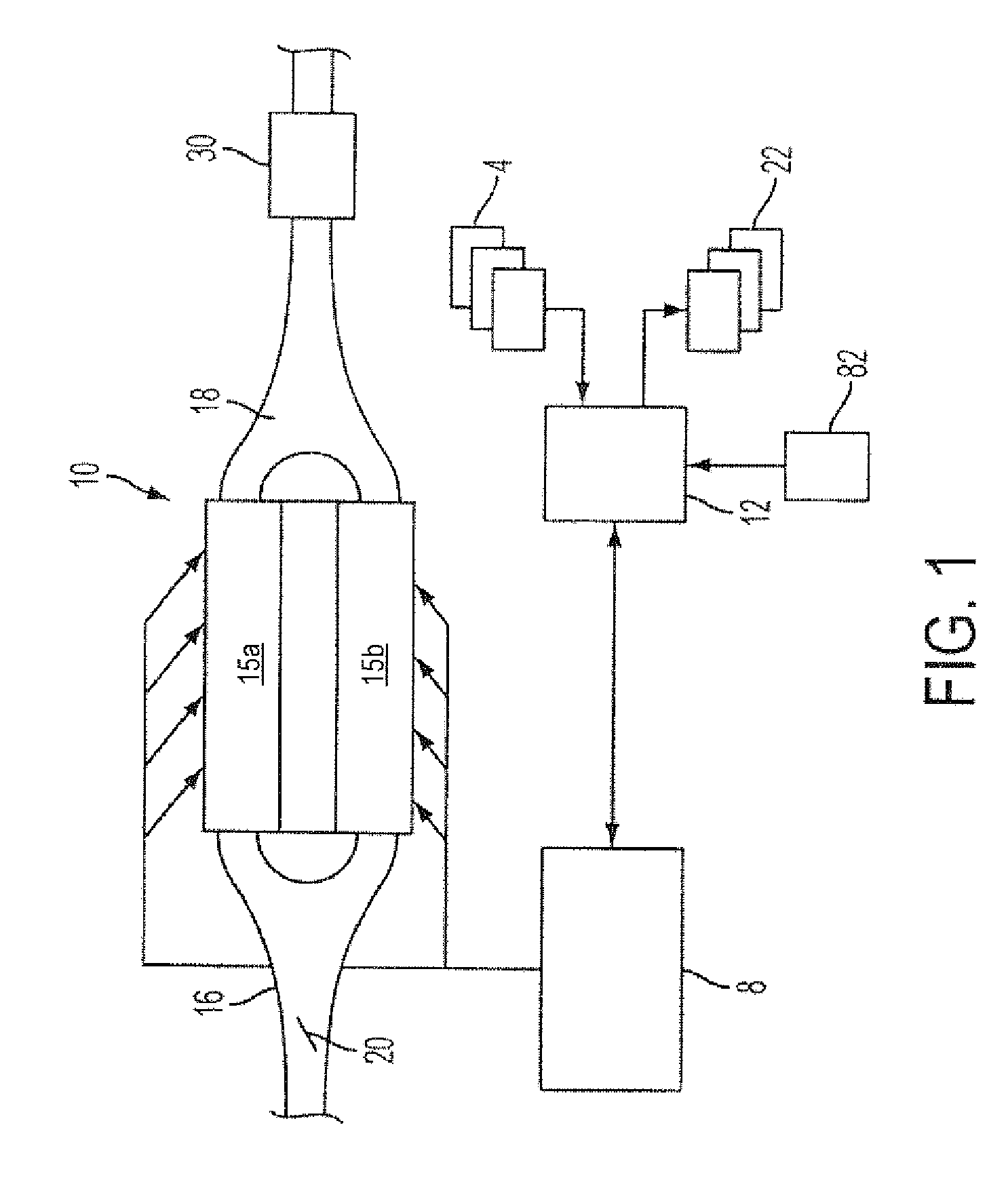

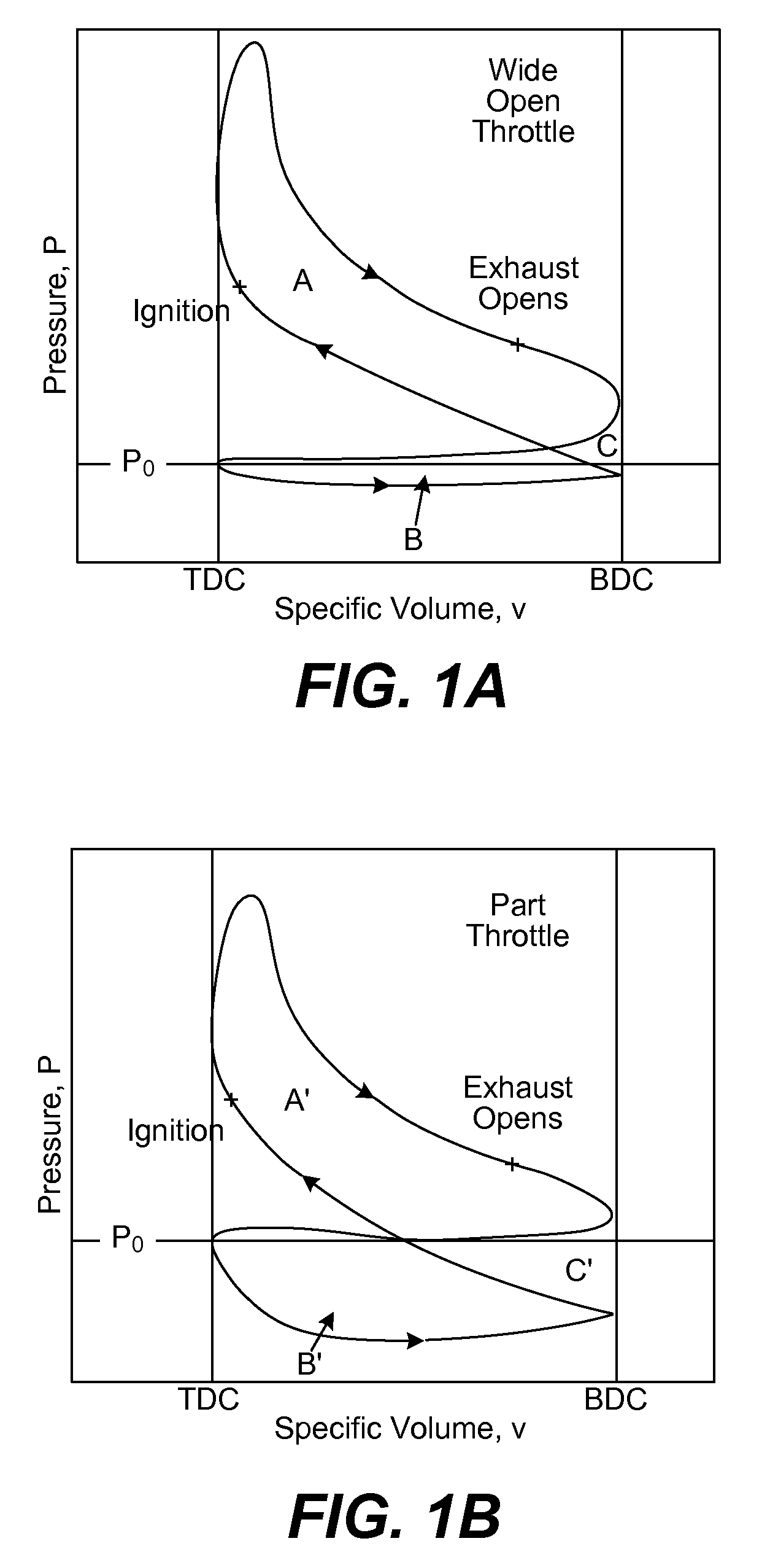

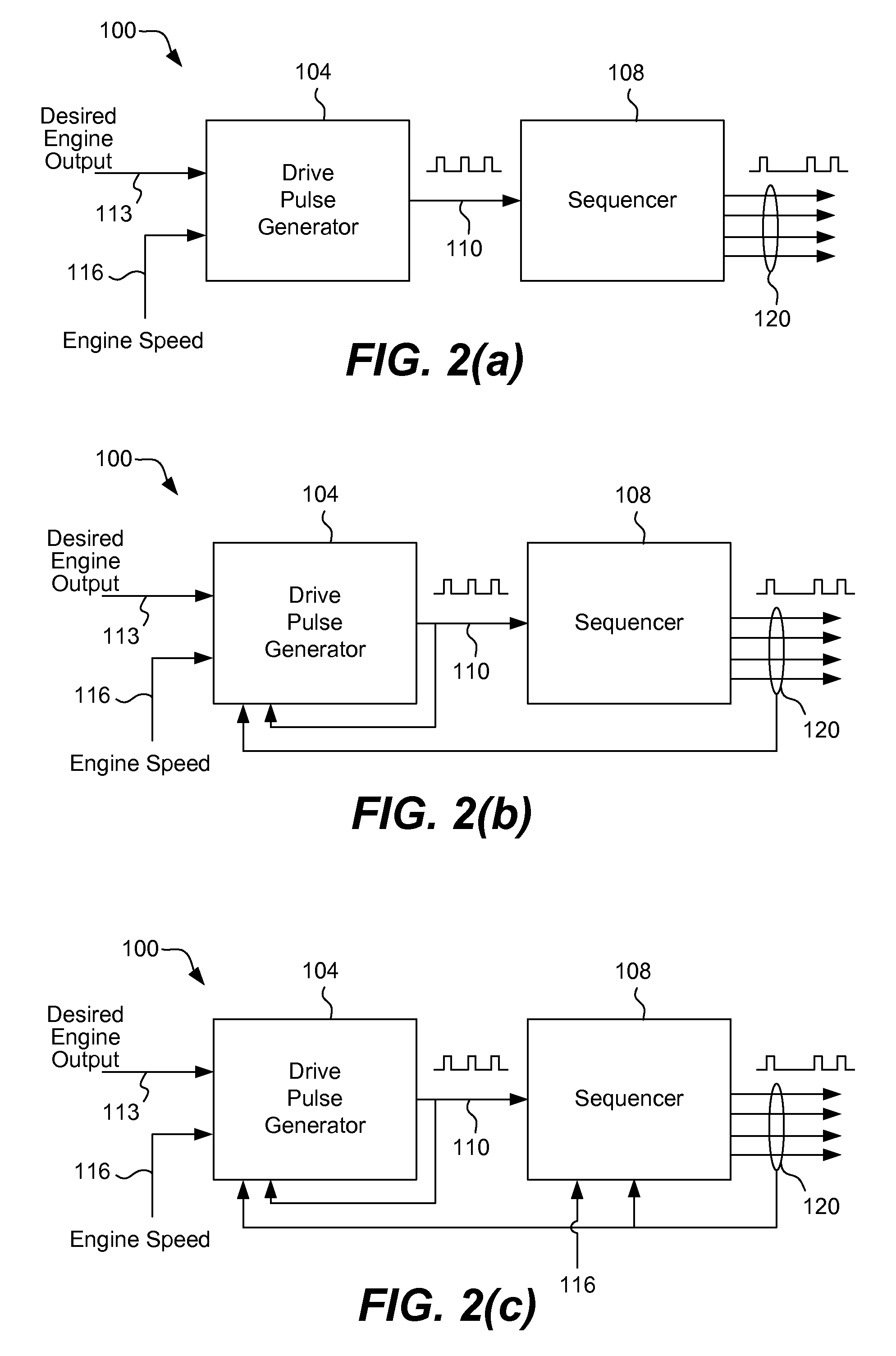

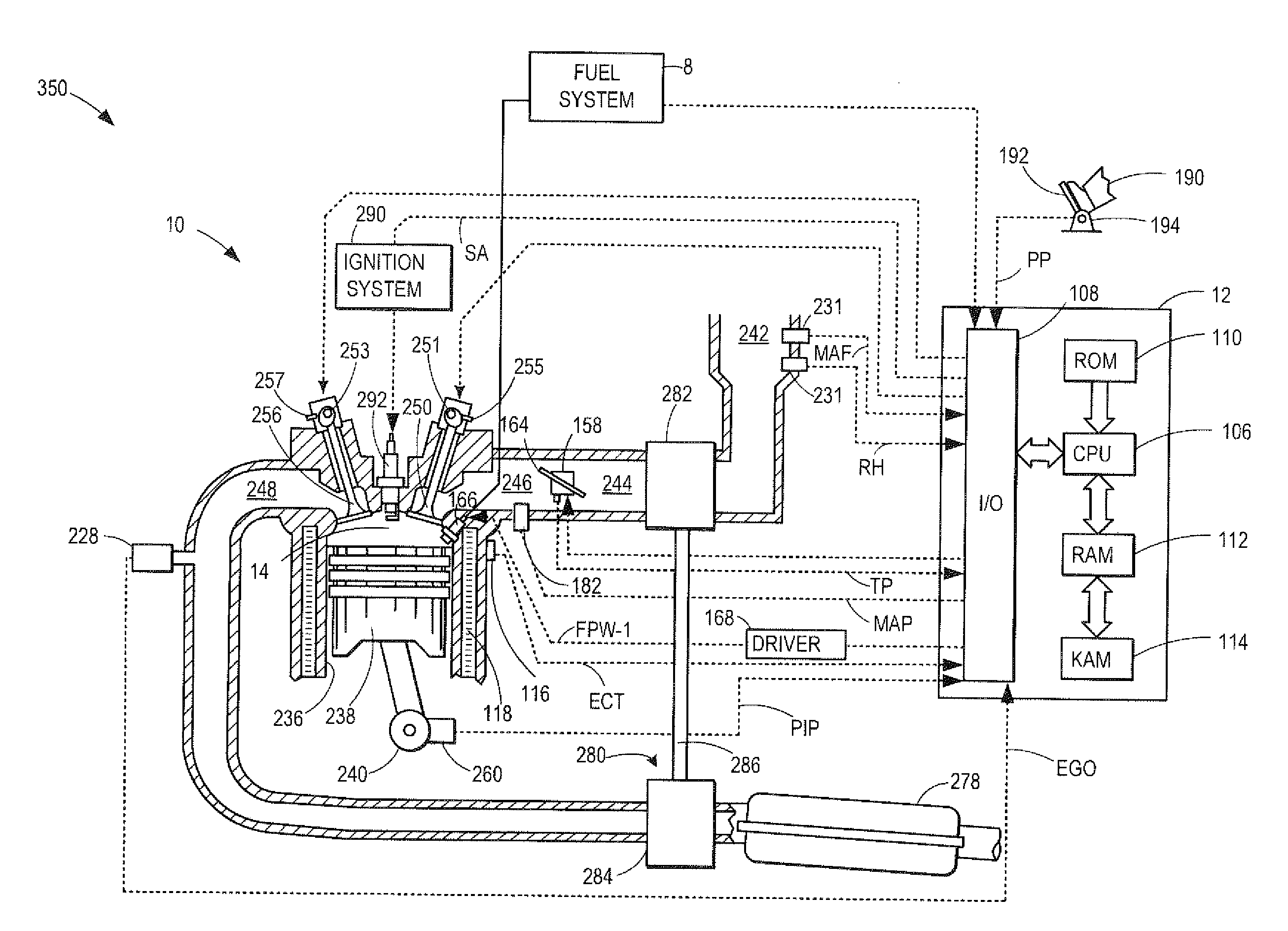

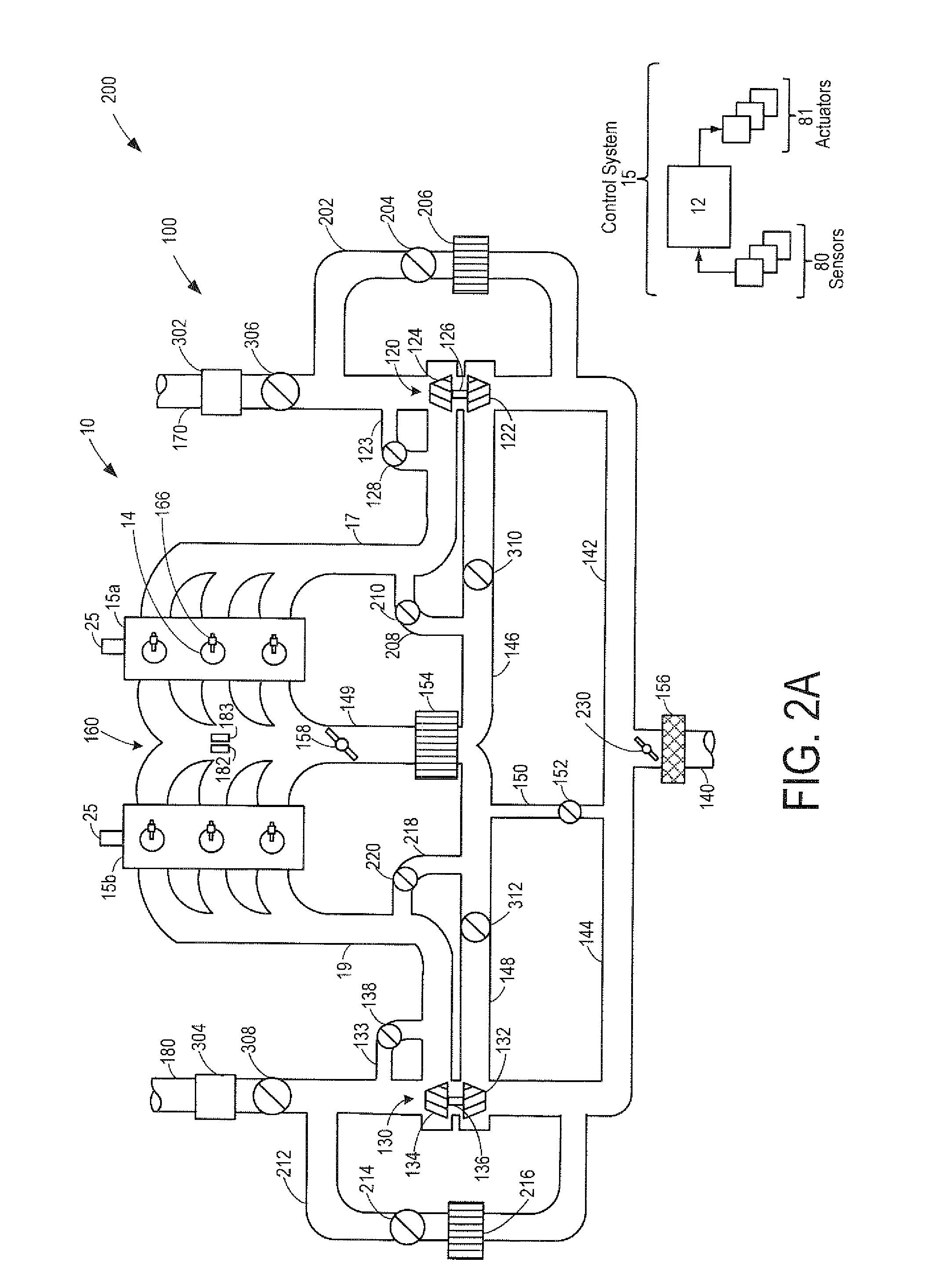

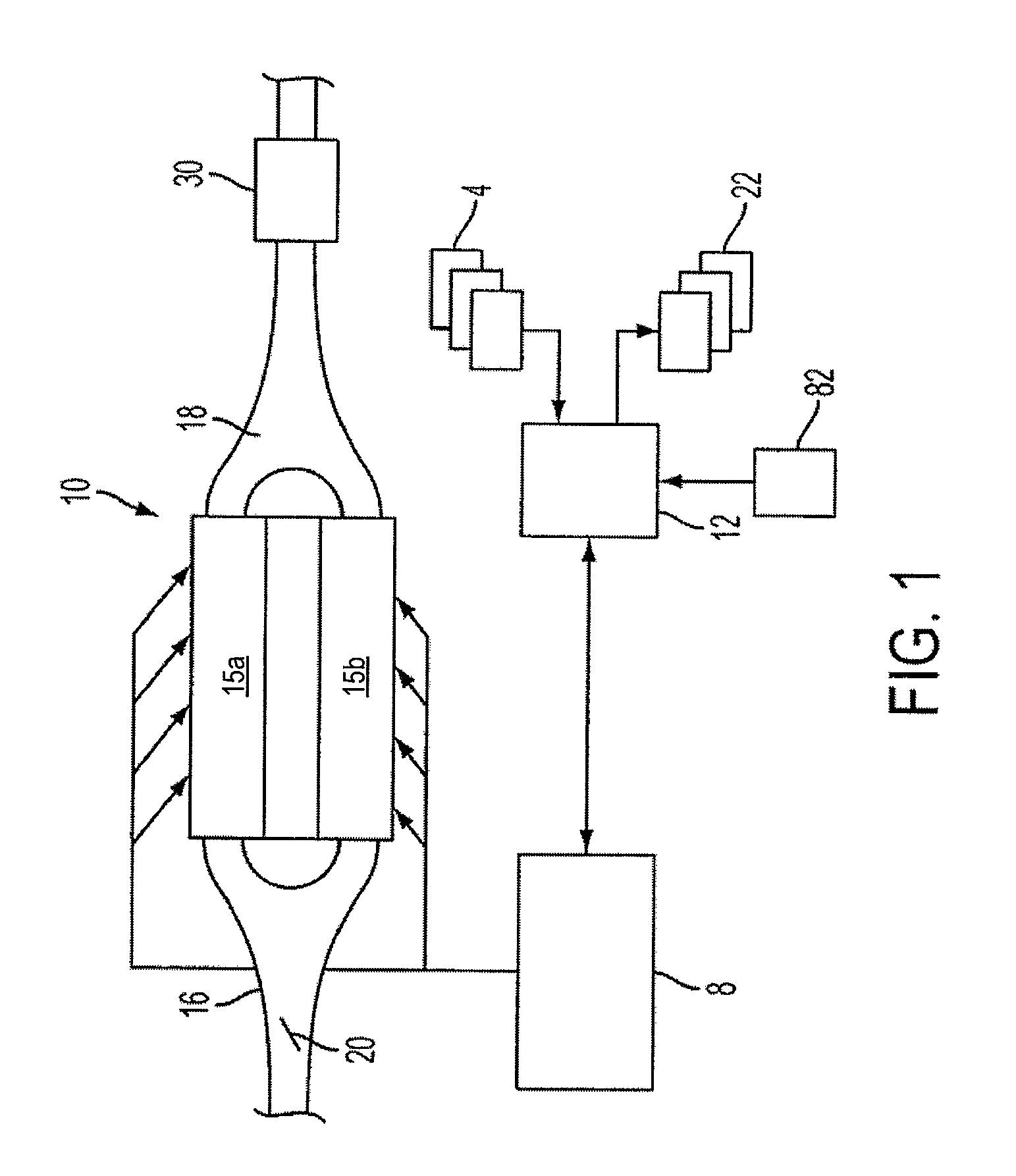

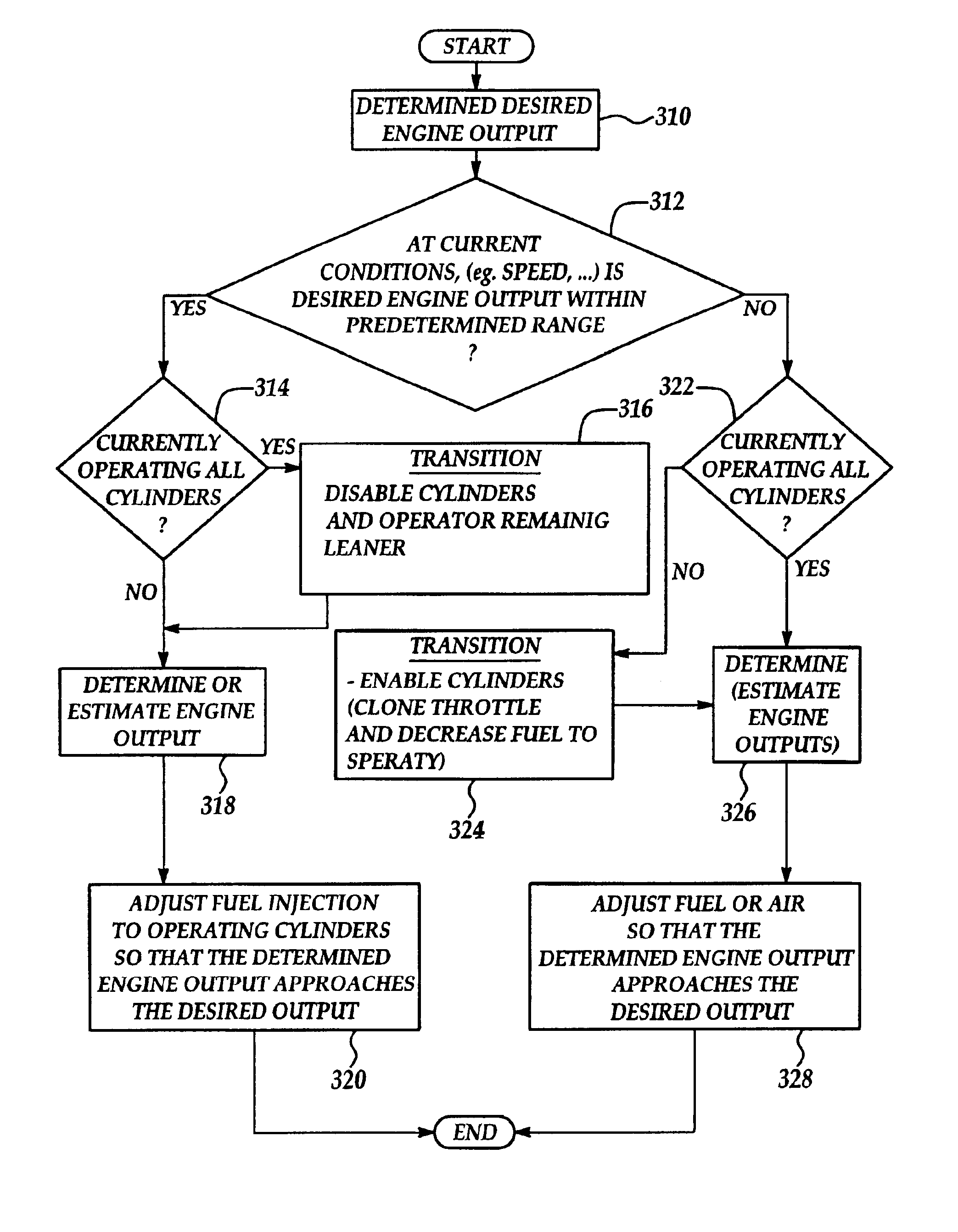

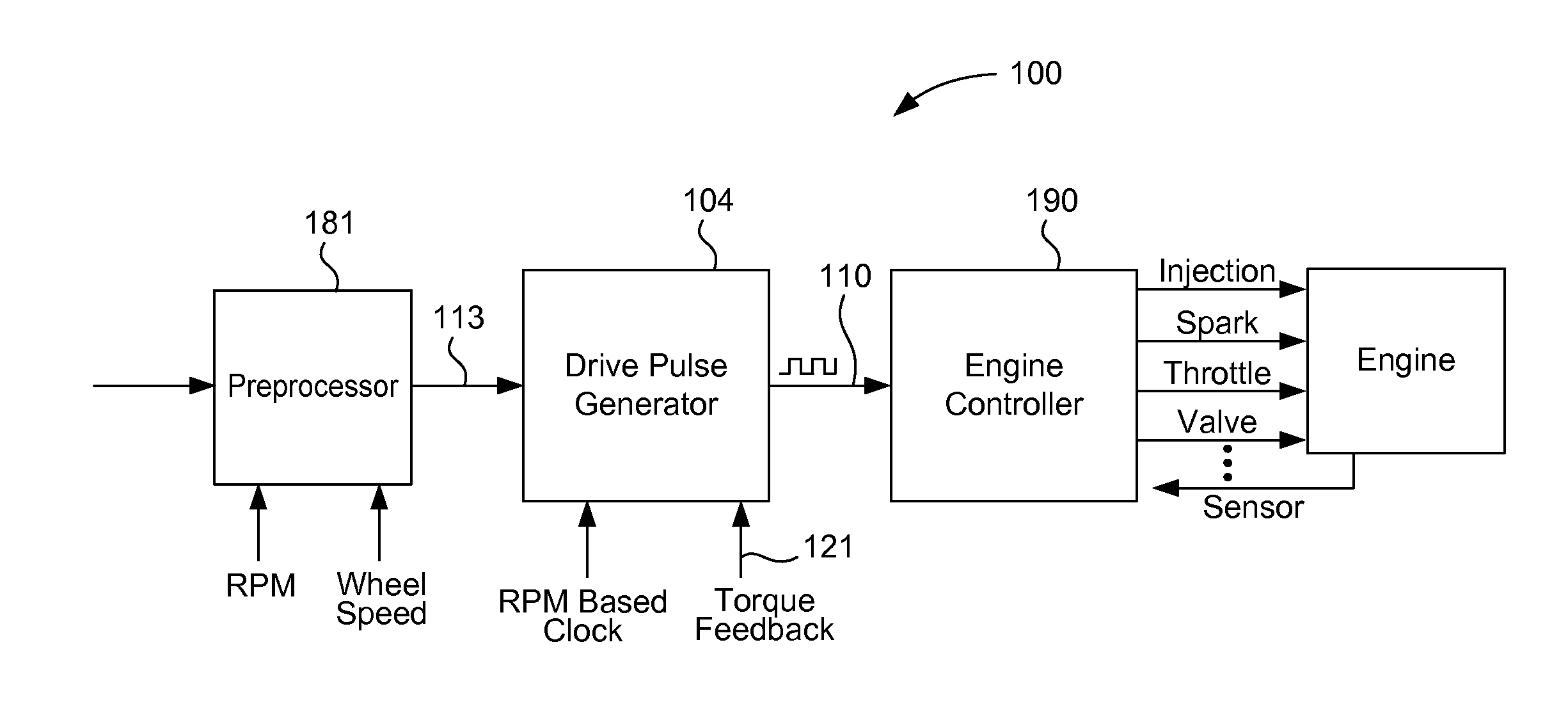

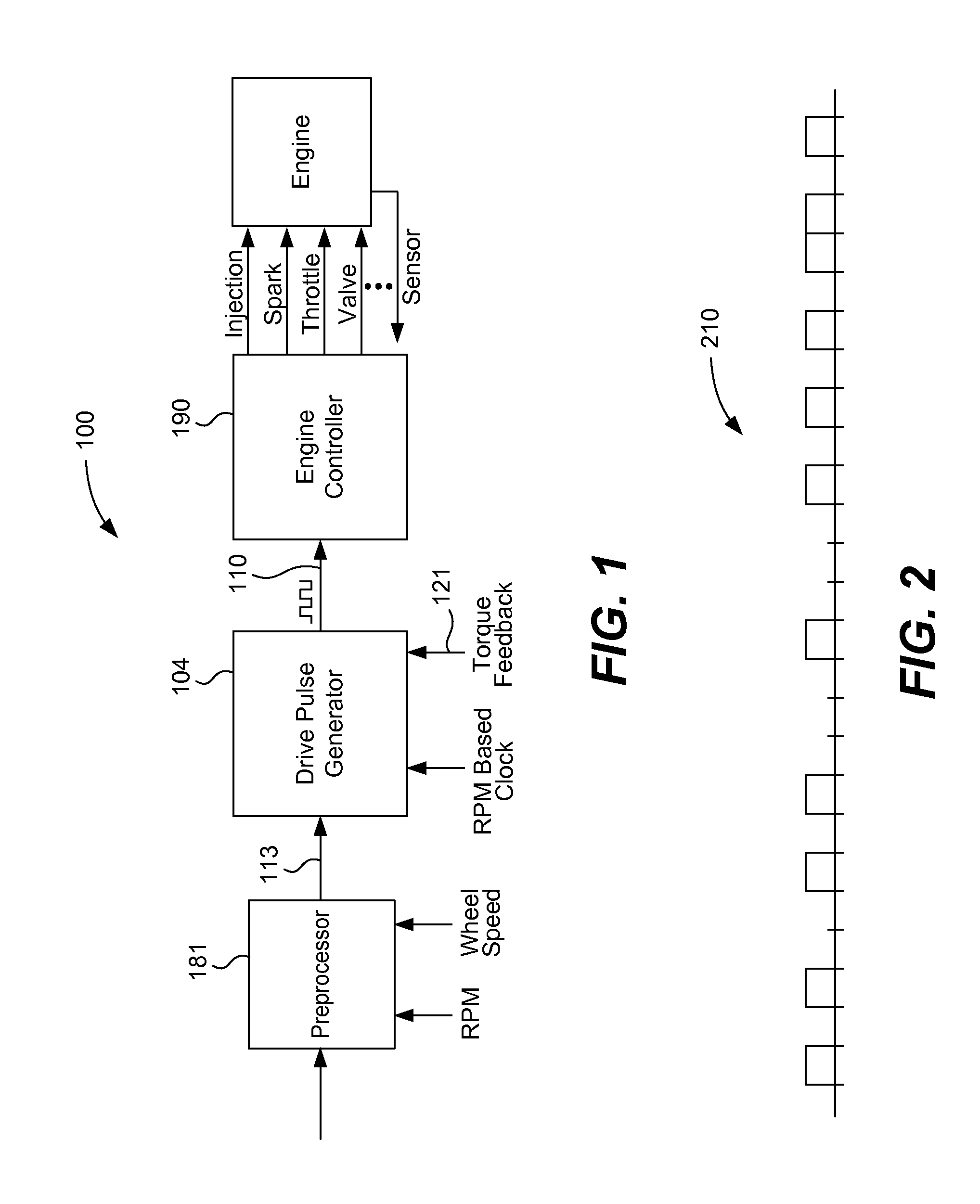

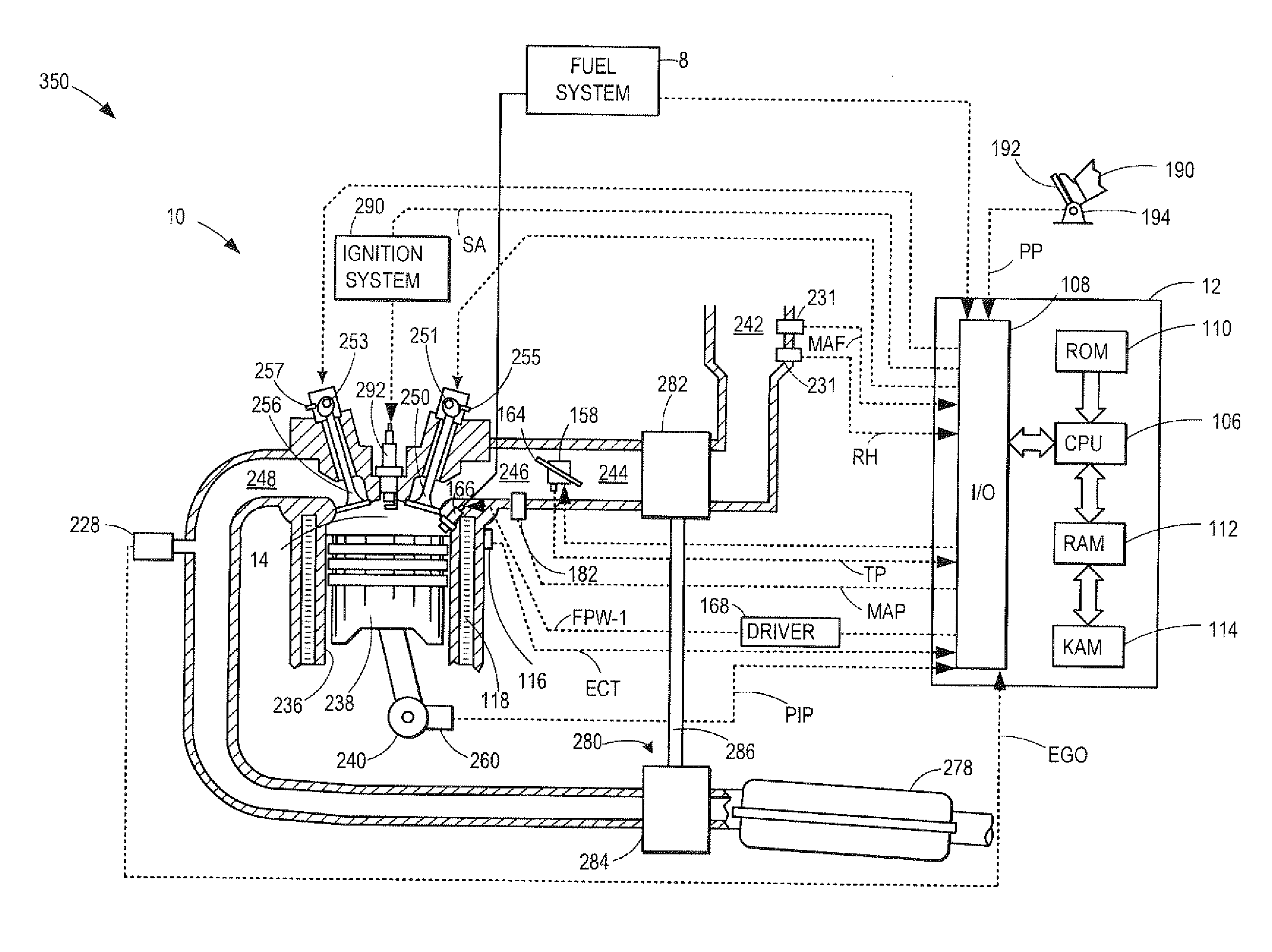

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

Internal combustion engine control for improved fuel efficiency

ActiveUS8131447B2Undesirable vibration reductionConvenient amountElectrical controlInternal combustion piston enginesCombustion chamberWork cycle

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

Internal combustion engine control for improved fuel efficiency

ActiveUS20110208405A1Improve fuel efficiencyUndesirable vibration reductionAnalogue computers for vehiclesElectrical controlCombustionExternal combustion engine

Owner:TULA TECH INC

Skip fire engine control

ActiveUS20110030657A1Improve thermodynamic efficiencyReduce wall wetting lossElectrical controlMachines/enginesCombustionMode control

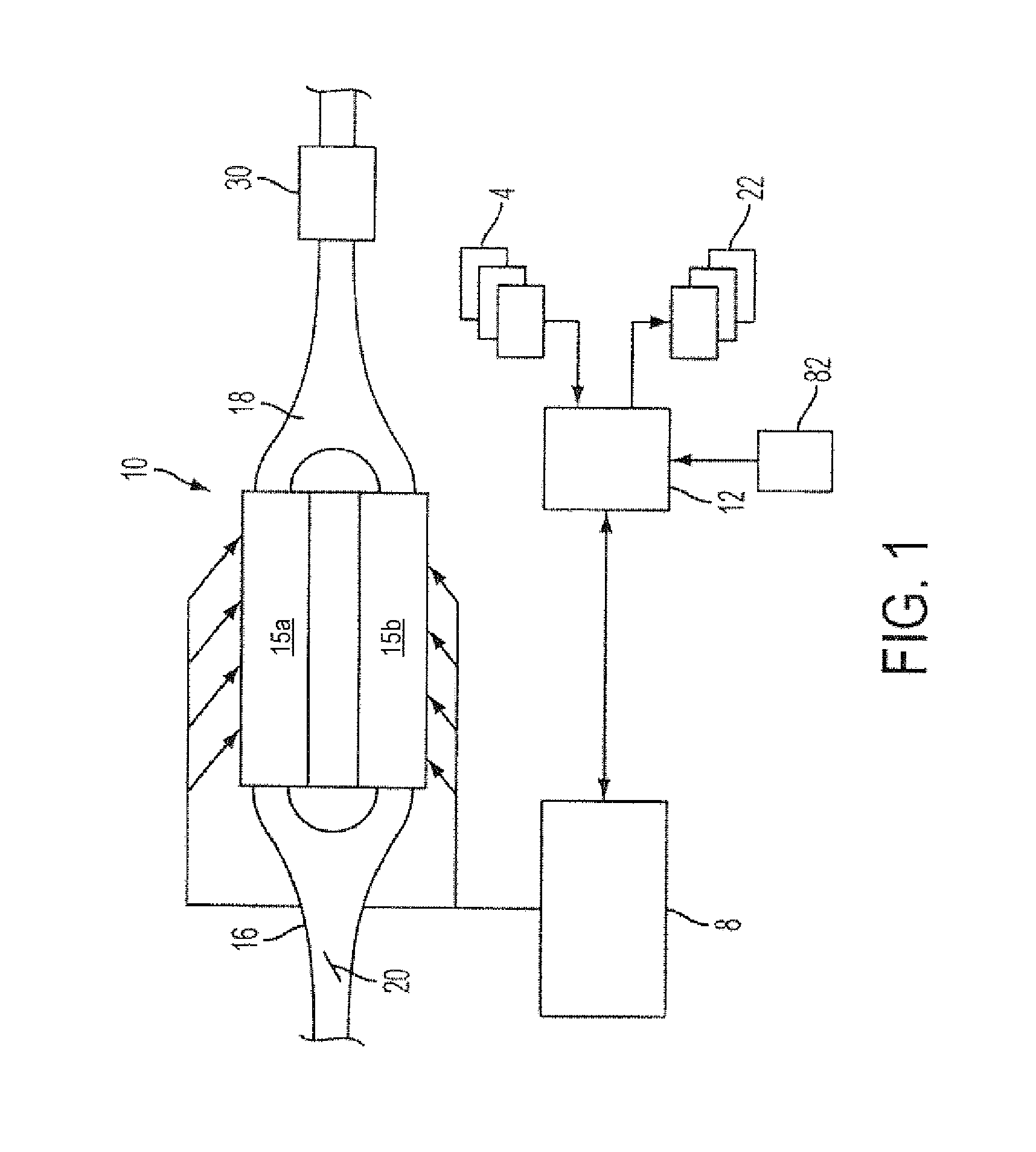

A variety of methods and arrangements for controlling the operation of an internal combustion engine in a skip fire variable displacement mode are described. Generally, an engine is controlled to operate in a skip fire variable displacement mode. In the variable displacement mode, selected combustion events are skipped so that other working cycles can operate at better thermodynamic efficiency. More specifically, selected “skipped” working cycles are not fired while other “active” working cycles are fired. Typically, fuel is not delivered to the working chambers during skipped working cycles. In one aspect of the invention, a firing pattern is determined that is not fixed but the active working cycles are selected to favor the firing of working chambers that have recently been fired at least in part to reduce wall wetting losses. In another aspect of the invention, when an active working cycle follows a skipped working cycle in the same working chamber, the quanta of fuel injected for delivery to the working chamber is increased relative to the quanta of fuel that would be delivered to the working chamber when the active working cycle follows another active working cycle in the same working chamber in order to compensate for wall wetting losses that occur during skipped working cycles.

Owner:TULA TECH INC

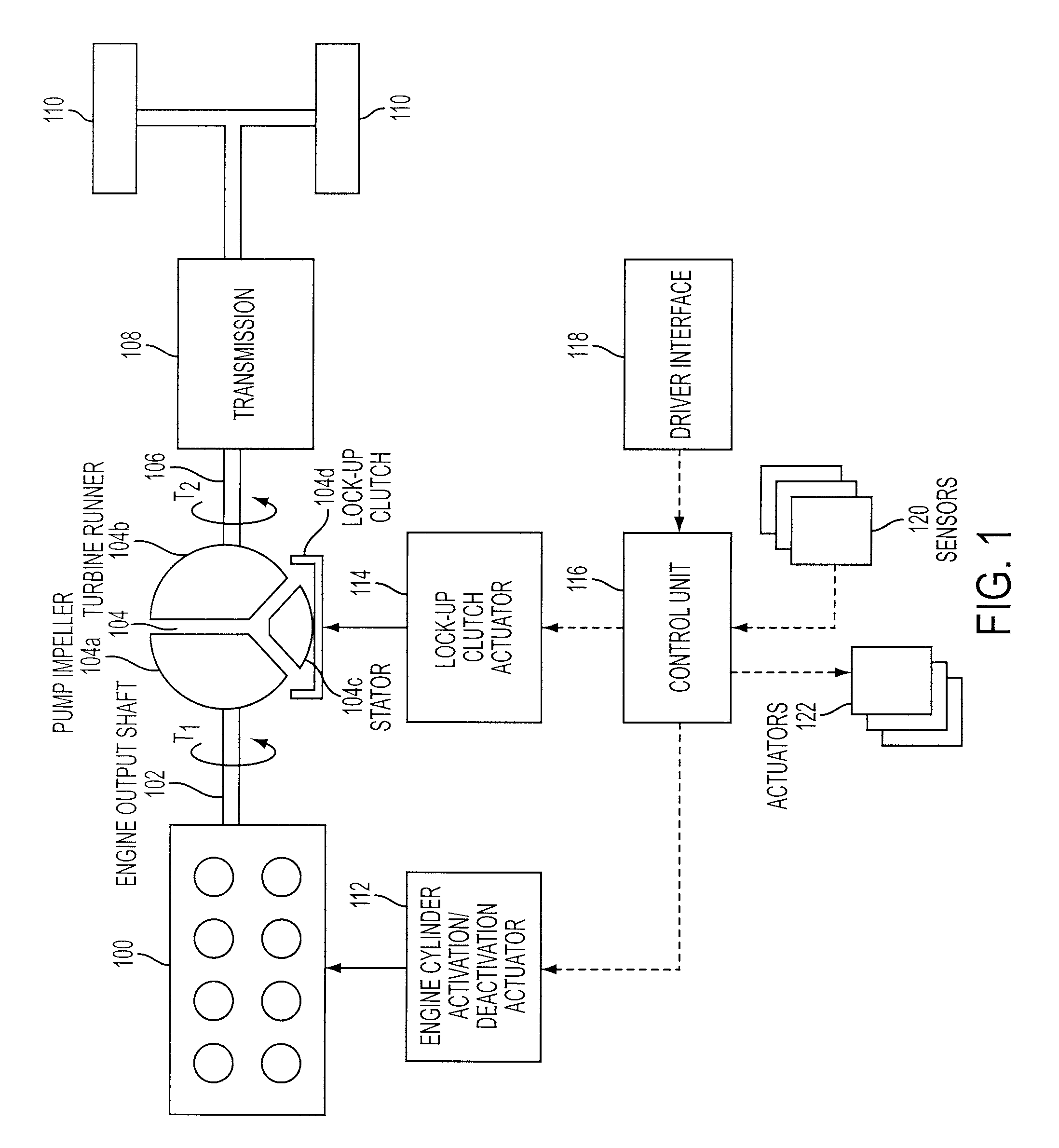

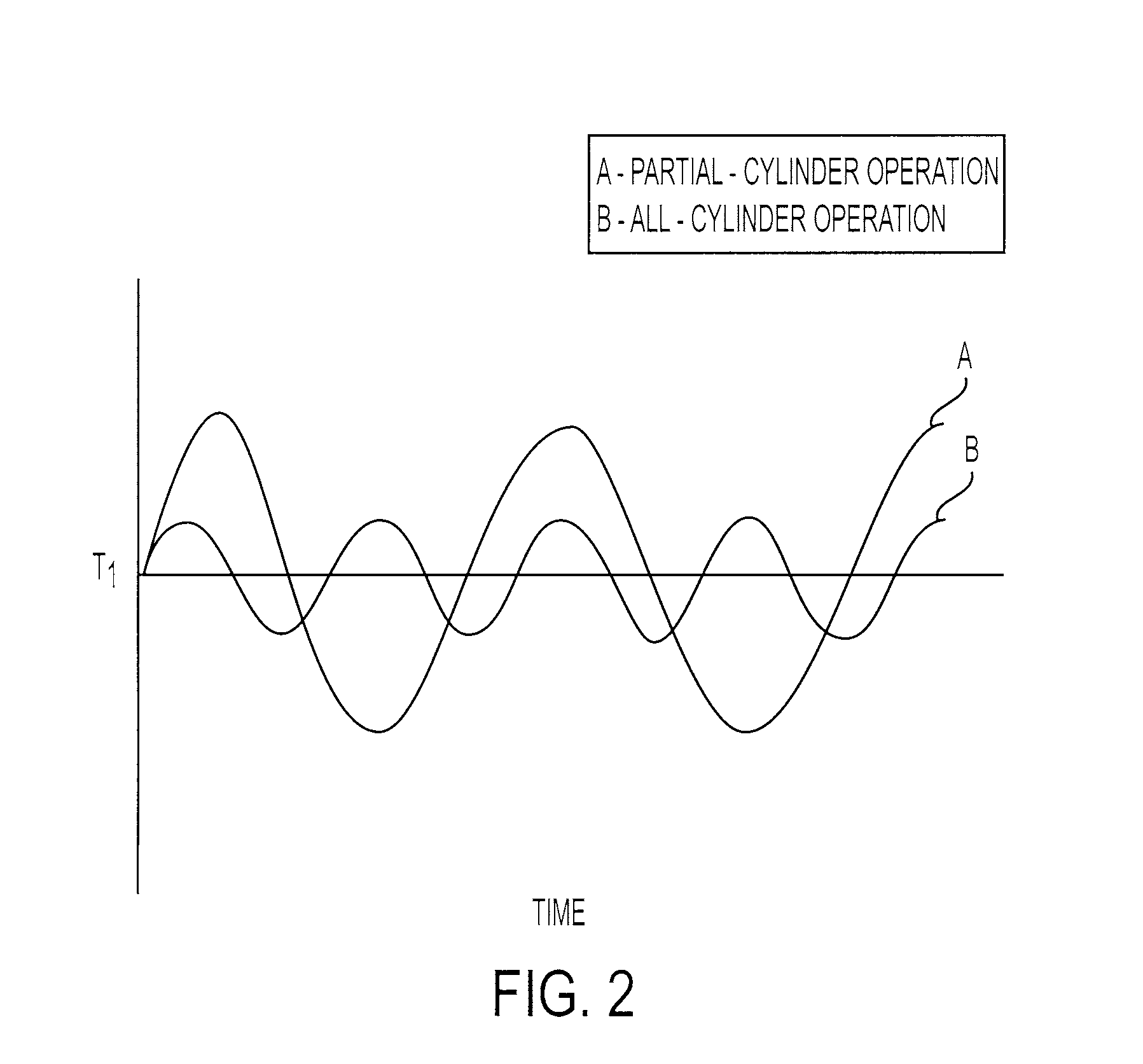

Variable Displacement Engine Operation With NVH Management

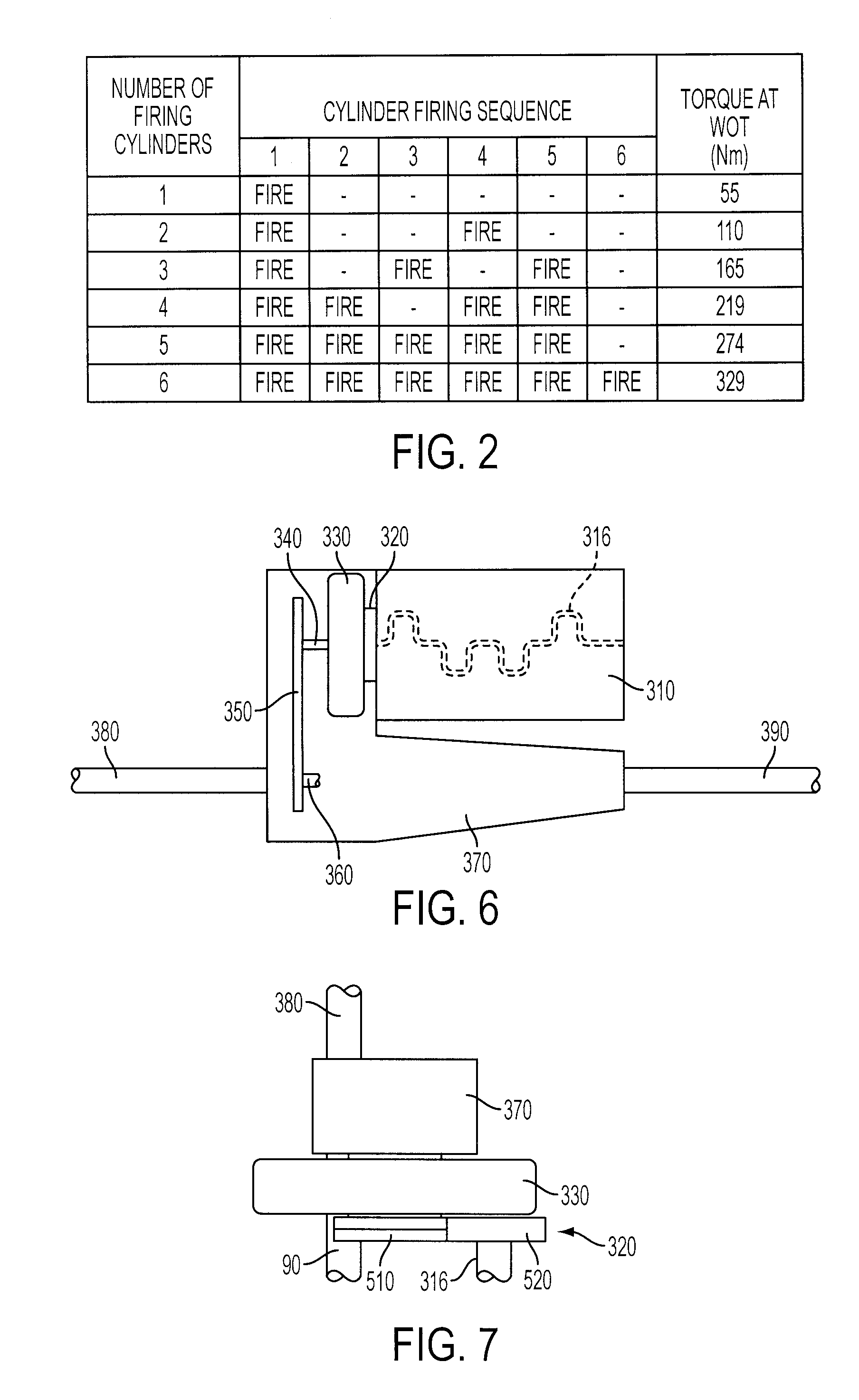

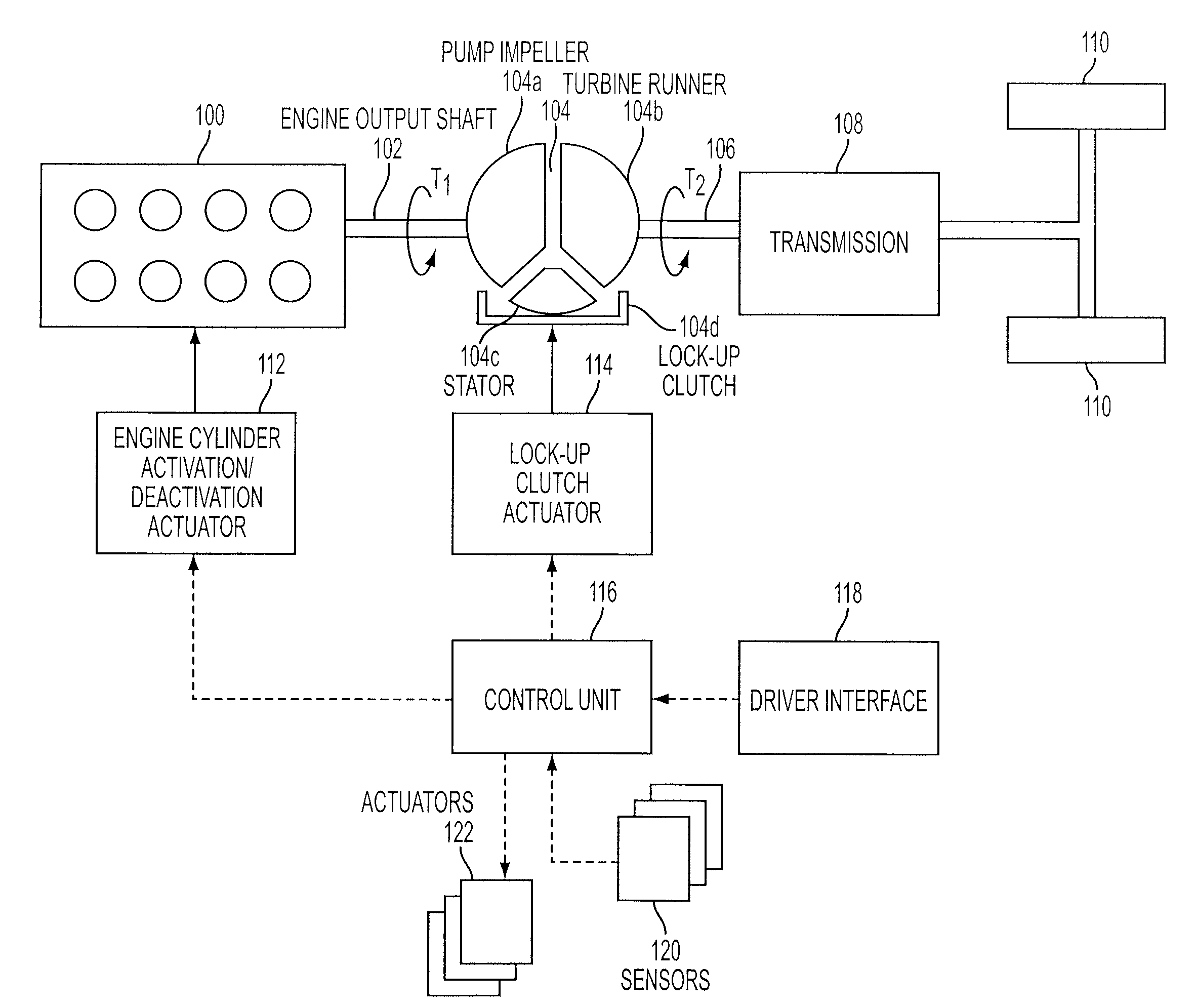

InactiveUS20080154468A1Reduce and eliminate torque reactionNo backlashAnalogue computers for vehiclesDigital data processing detailsClose couplingDrivetrain

A system and method for controlling an internal combustion engine operable with a first cylinder firing frequency and a second cylinder firing frequency to reduce or eliminate transmission of torsional vibrations associated with the second cylinder firing frequency to reduce or eliminate constraints on reduced displacement mode operation using a closely coupled drive train component rotating in an opposite direction relative to rotating components of the engine. A close coupling device allows the inertia of the counter-rotating elements to reduce or eliminate the torque reaction of the drivetrain associated with acceleration and deceleration of the engine crankshaft in response to the second cylinder firing frequency in the reduced displacement mode.

Owner:FORD GLOBAL TECH LLC

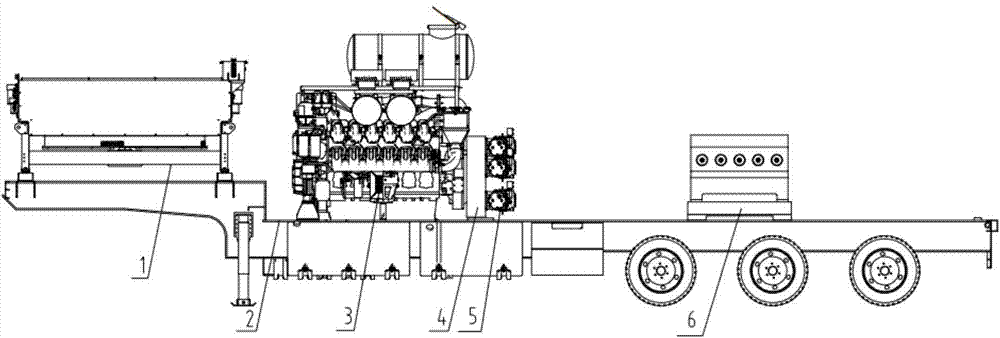

Fracturing transmission and high-pressure discharging system

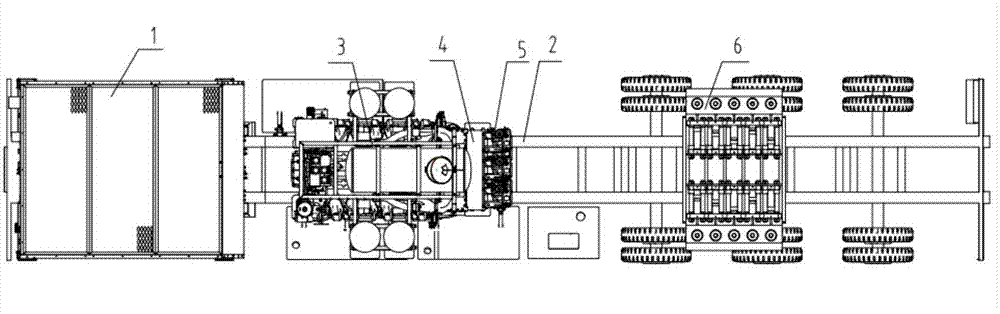

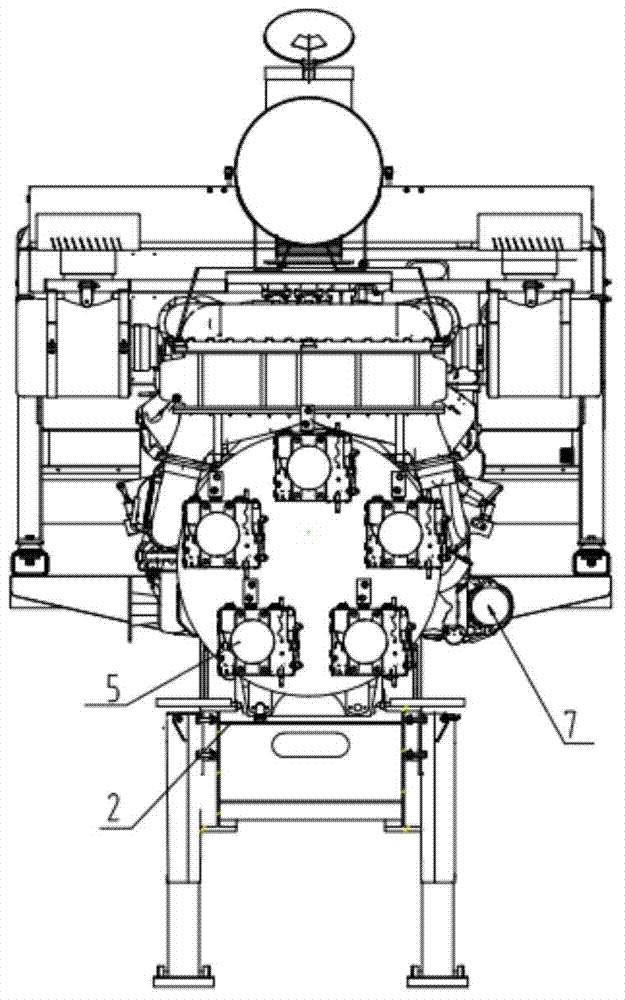

InactiveCN104727797AExpand the range of selectionSave layout spaceFluid removalTransfer caseEngineering

The invention relates to a fracturing transmission and high-pressure discharging system. The fracturing transmission and high-pressure discharging system comprises a chassis and is characterized in that a high-power engine, a transfer case, a plurality of variable displacement plunger pumps and a double-acting fracturing pump are arranged on the chassis, the output end of the high-power engine is connected with the input end of the transfer case, the output end of the transfer case comprises a plurality of power take-off ports, and each power take-off port is connected with one variable displacement plunger pump; the variable displacement plunger pumps drive the double-acting fracturing pump through a hydraulic system. The fracturing transmission and high-pressure discharging system further comprises a system radiator and a heat dissipation plunger pump used for driving the system radiator, and the heat dissipation plunger pump is connected with one power take-off port of the transfer case. The power take-off ports of the transfer case and the variable displacement plunger pumps are arranged annularly. The fracturing transmission and high-pressure discharging system has the advantages that hydraulic driving replaces mechanical transmission, and working vibration is reduced; the layout space of a whole vehicle is saved, and meanwhile, operating efficiency and the stability of the whole vehicle are improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

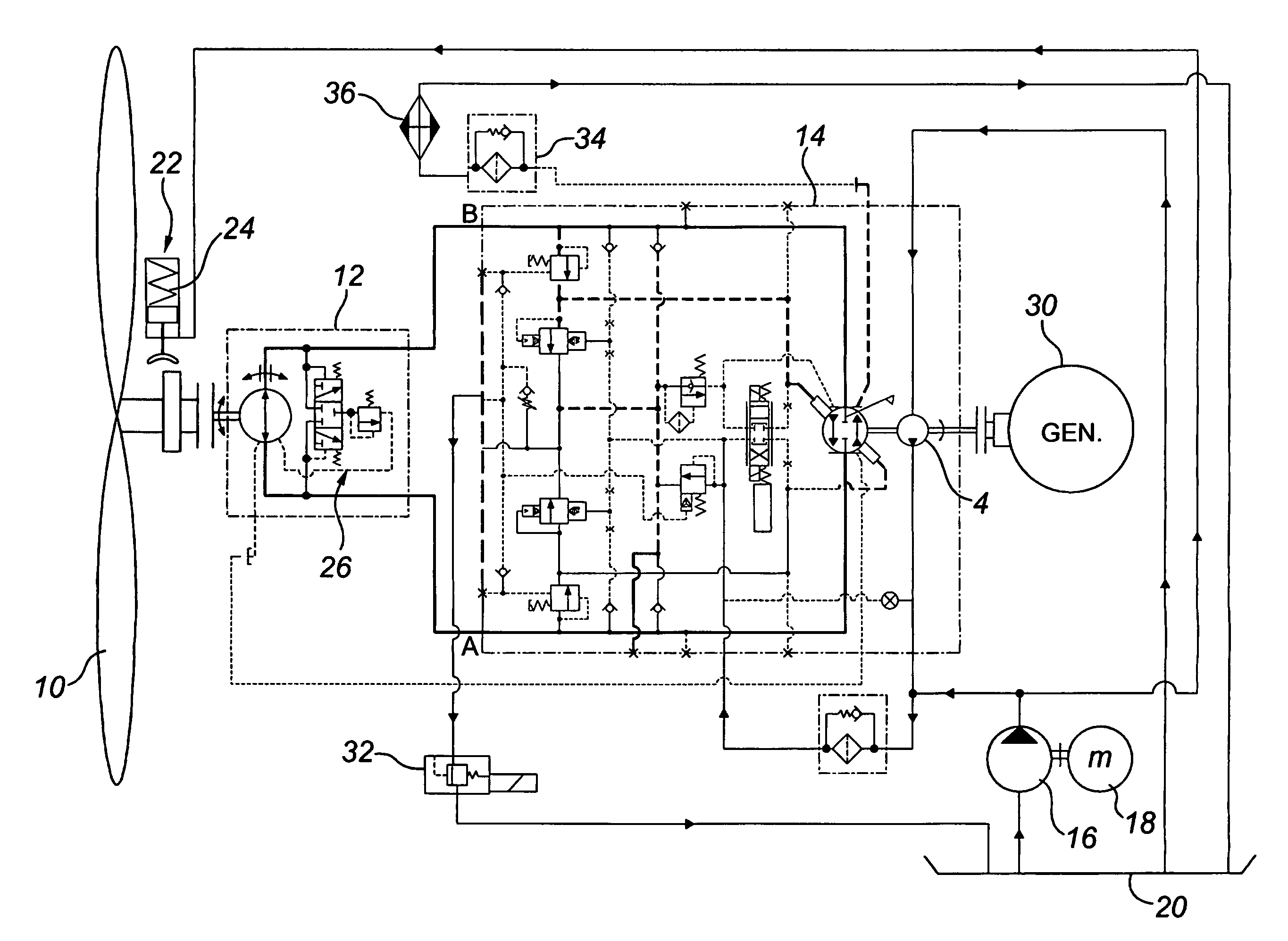

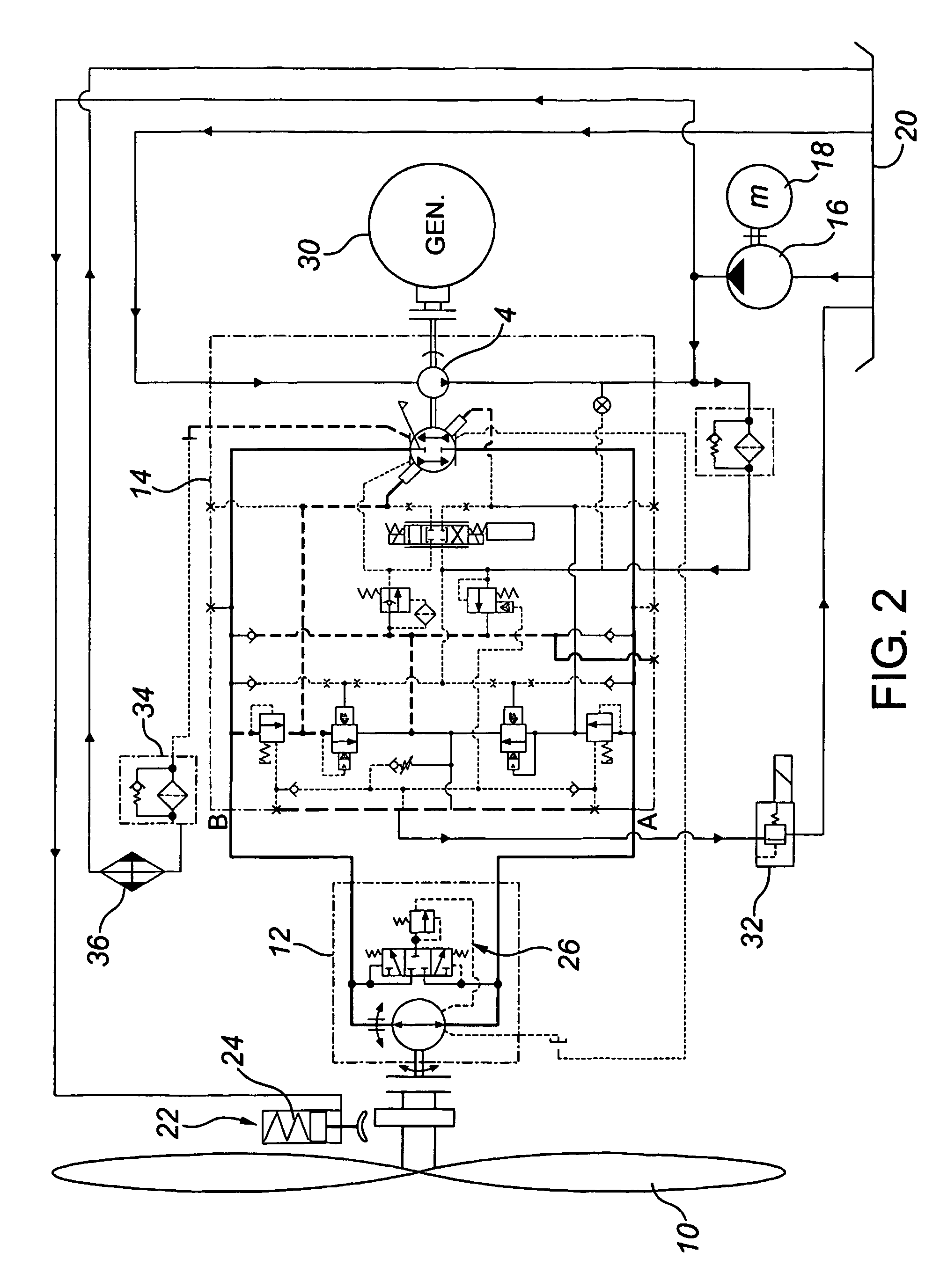

Wind turbine with hydraulic transmission

InactiveUS7418820B2Guaranteed normal transmissionAbsorb more horsepowerWind motor controlEngine fuctionsNacelleLow speed

Owner:MACKAY GARY

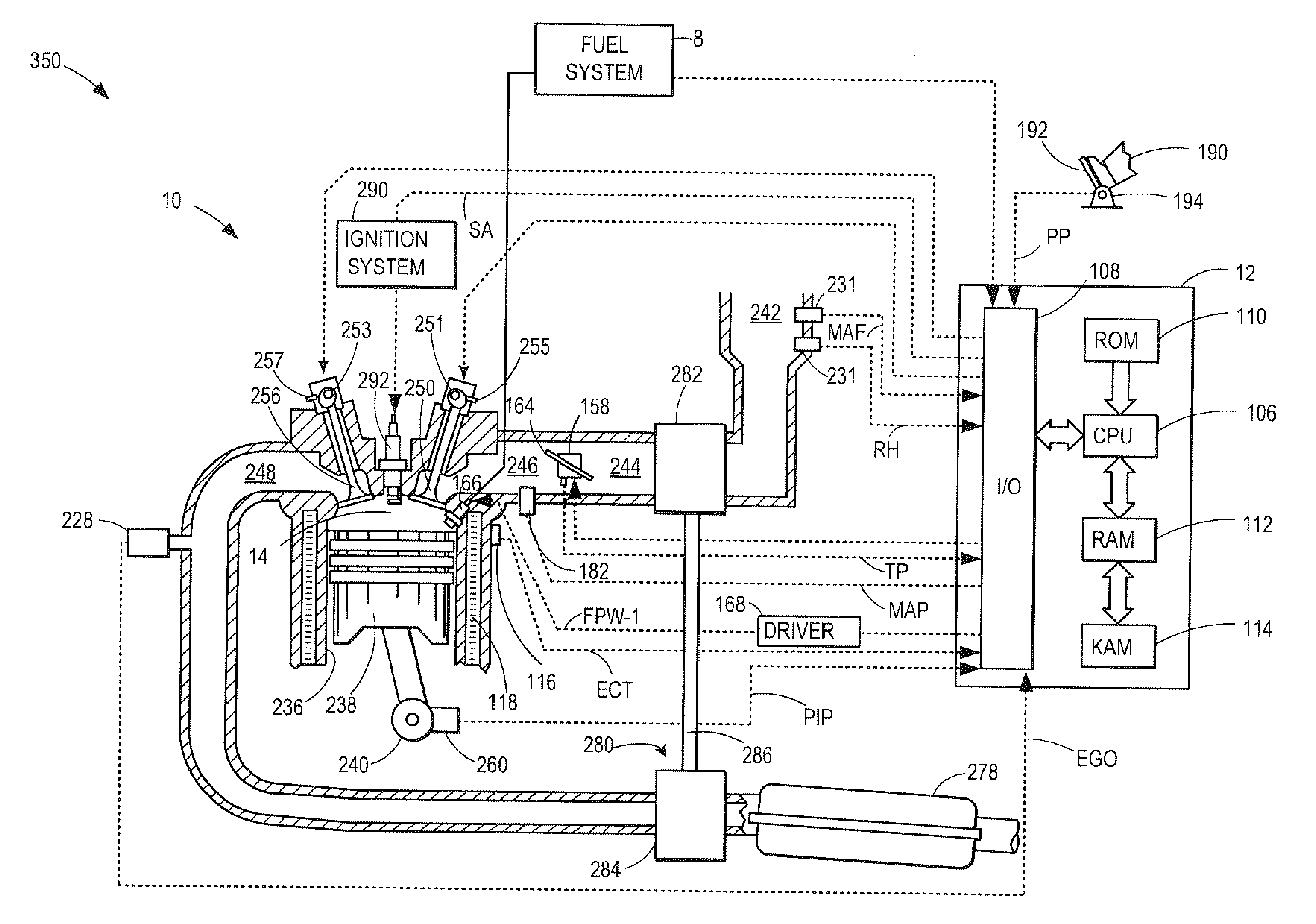

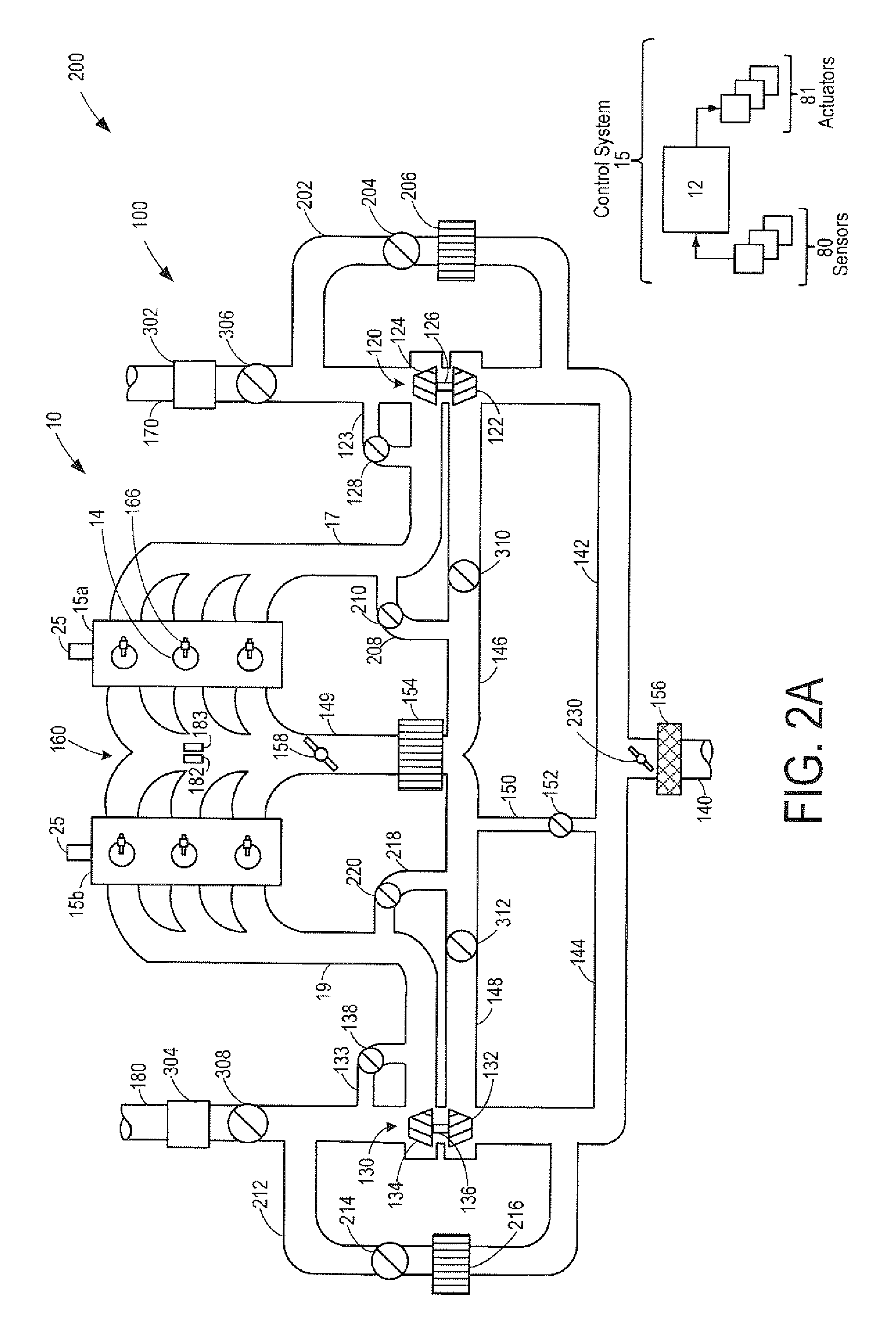

Methods and Systems for Variable Displacement Engine Control

ActiveUS20120285161A1Reliable detectionGood correlationElectrical controlInternal combustion piston enginesEngineeringThrottle

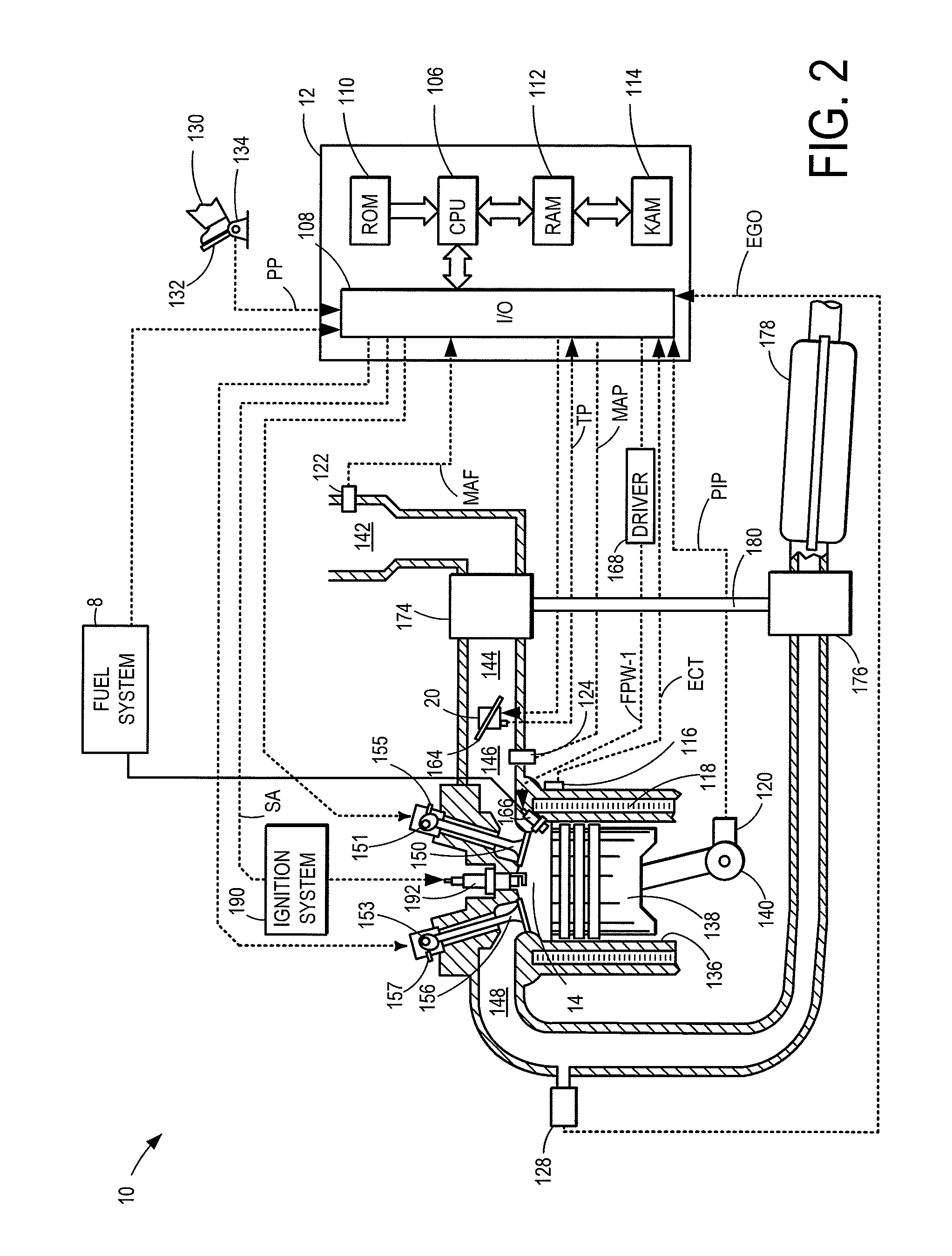

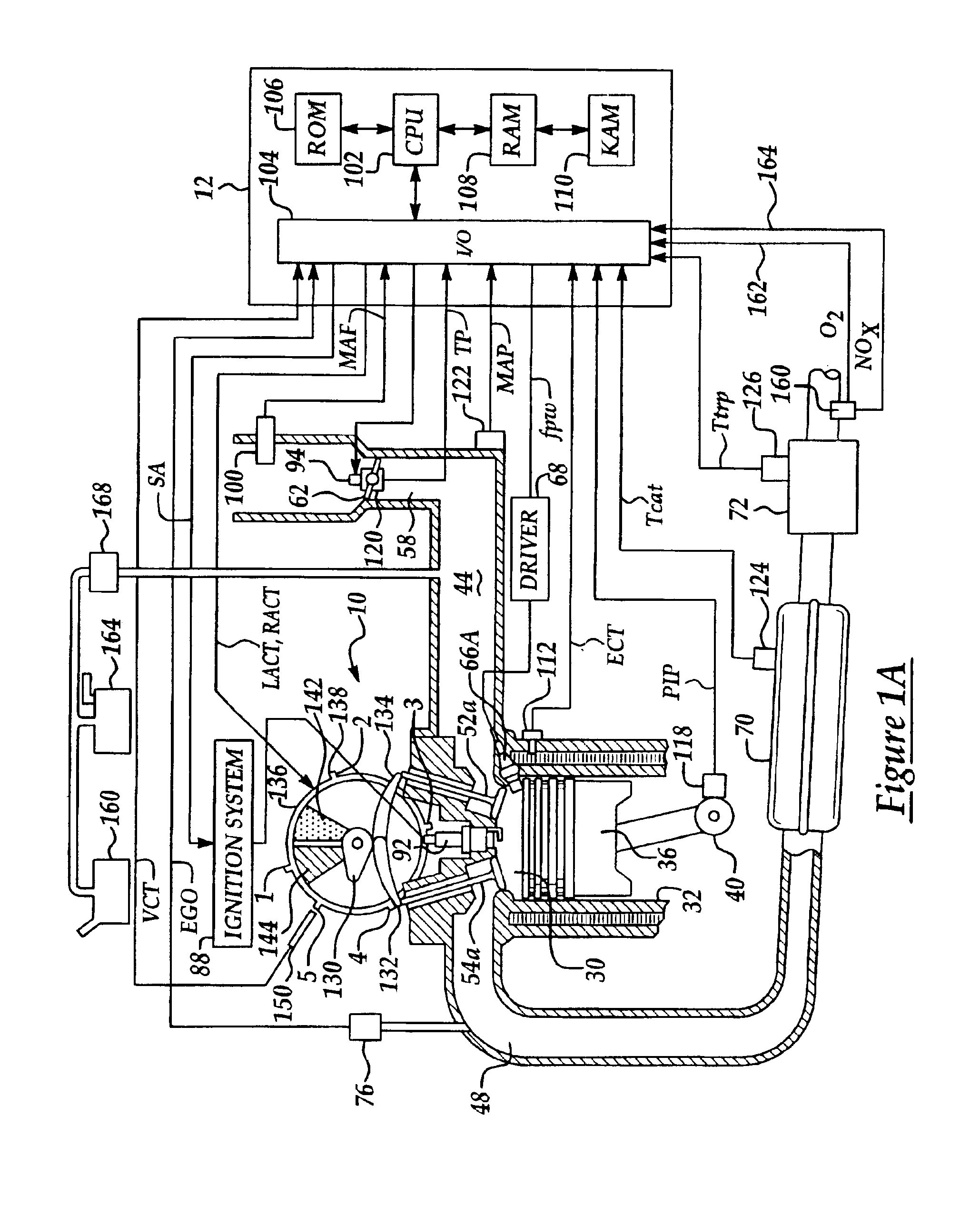

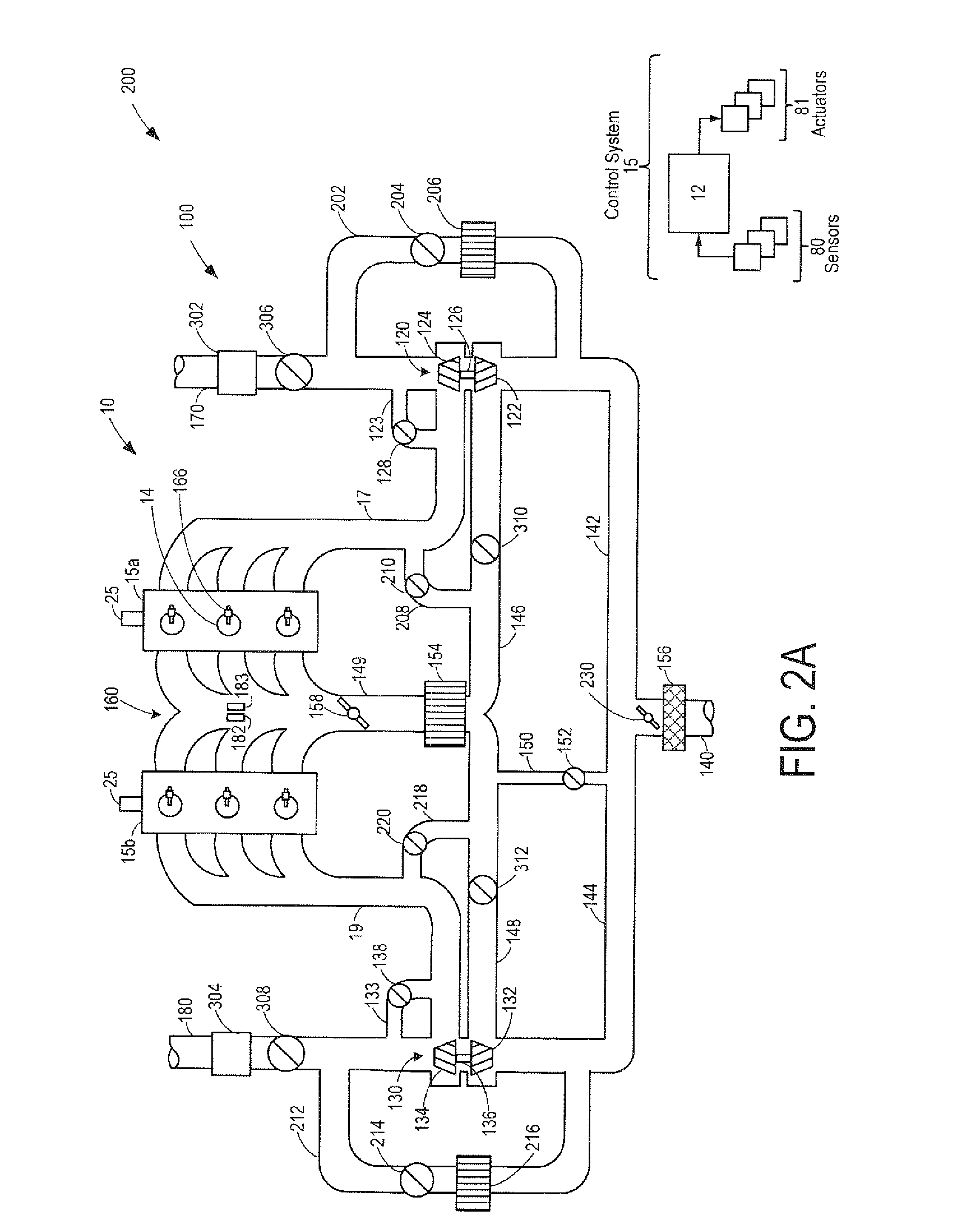

Methods and systems are provided for selecting a group of cylinders for selective deactivation, in a variable displacement engine system, based at least on a regeneration state of an exhaust catalyst. The position of one or more valves and throttles may be adjusted based on the selective deactivation to reduce back-flow through the disabled cylinders while also maintaining conditions of a downstream exhaust catalyst. Pre-ignition and knock detection windows and thresholds may also be adjusted based on the deactivation to improve the efficiency of knock and pre-ignition detection.

Owner:FORD GLOBAL TECH LLC

Skip fire internal combustion engine control

ActiveUS20120143471A1Reduce generationAnalogue computers for vehiclesElectrical controlFire controlInternal combustion engine

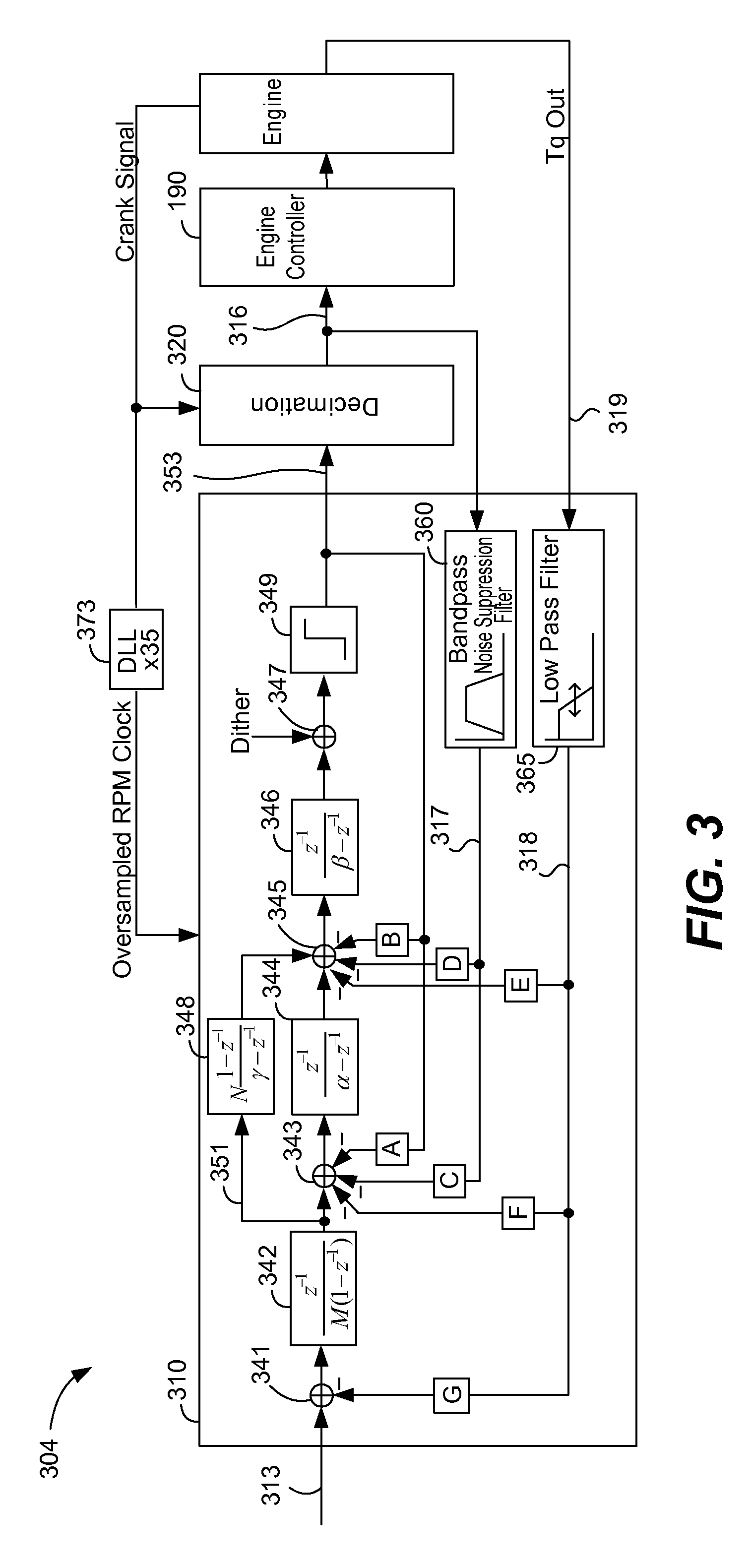

A variety of methods and arrangements for controlling the operation of an internal combustion engine in a skip fire variable displacement mode are described. In general, a firing control unit determines working chamber firings during operation of the engine that are suitable for delivering a desired engine output. In one aspect, the firing control unit is arranged to isolate the generation of firing sequences having frequency components in a frequency range of concern and to alter the firing sequence in a manner that reduces the occurrence of frequency components in the frequency range of concern. In another aspect, a filter is arranged to filter a feedback signal to provide a filtered feedback signal that is used in the determination of the working chamber firings. In preferred embodiments, the frequency characteristics of the filter are variable. In various embodiments, the frequency characteristics of the filter vary as a function engine speed and / or a transmission gear ratio.

Owner:TULA TECH INC

Internal combustion engine control for improved fuel efficiency

ActiveUS20100010724A1Smoother and precise controlReduce probabilityElectrical controlInternal combustion piston enginesCombustionWork cycle

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

Methods and Systems for Variable Displacement Engine Control

ActiveUS20110265454A1Control flowHigh catalytic efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringThrottle

Methods and systems are provided for selecting a group of cylinders for selective deactivation, in a variable displacement engine system, based at least on a regeneration state of an exhaust catalyst. The position of one or more valves and throttles may be adjusted based on the selective deactivation to reduce back-flow through the disabled cylinders while also maintaining conditions of a downstream exhaust catalyst. Pre-ignition and knock detection windows and thresholds may also be adjusted based on the deactivation to improve the efficiency of knock and pre-ignition detection.

Owner:FORD GLOBAL TECH LLC

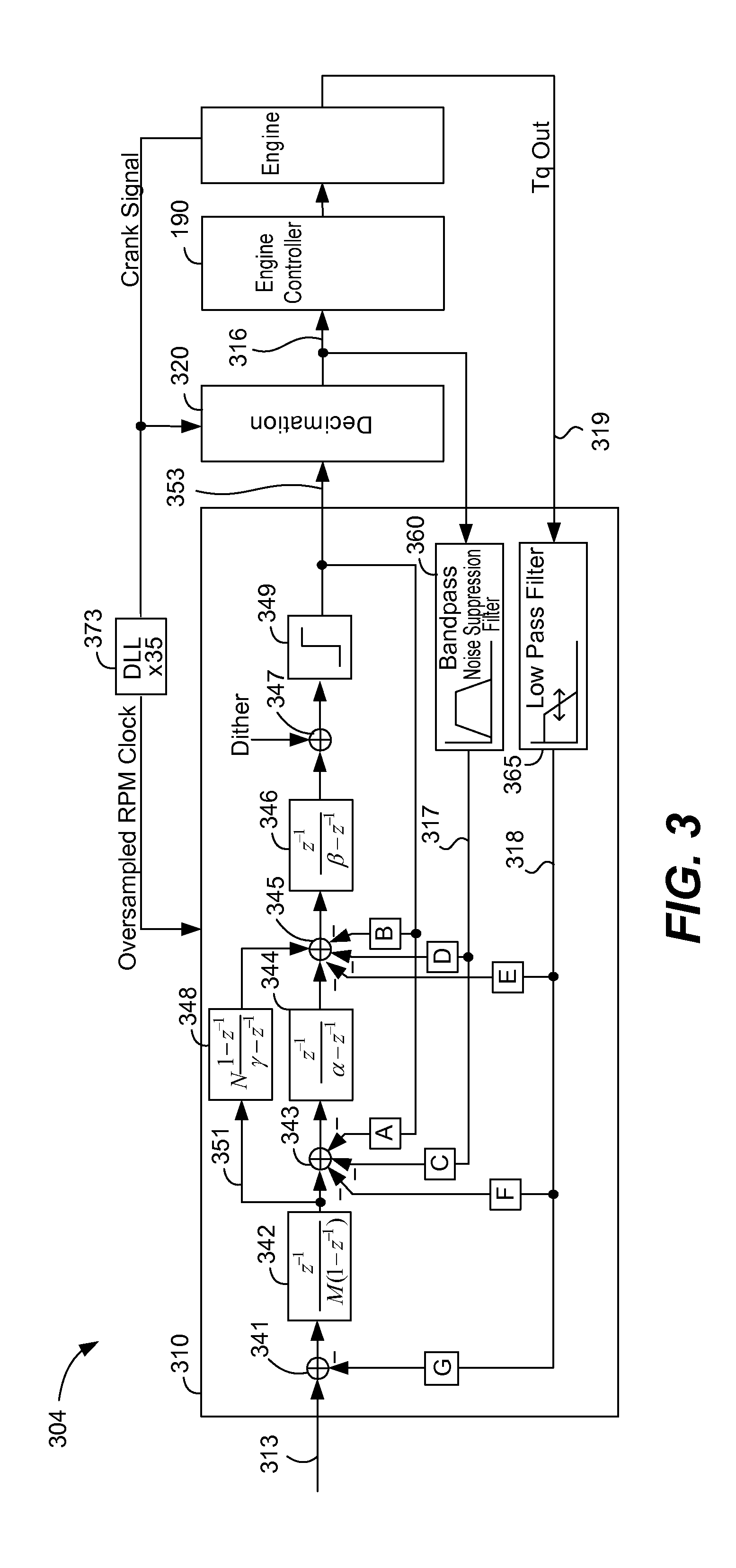

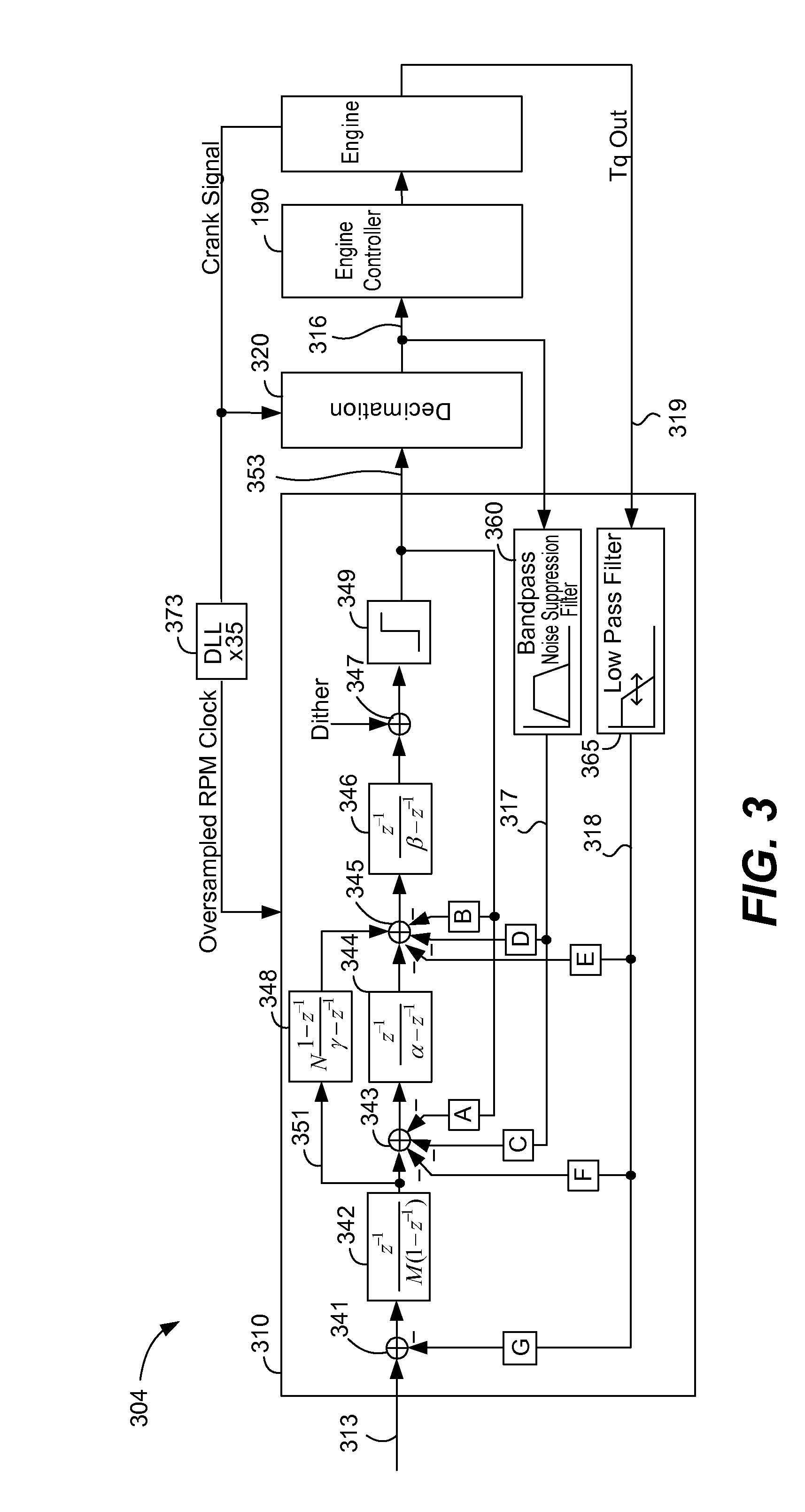

Skip fire internal combustion engine control

ActiveUS8869773B2Reduce generationAnalogue computers for vehiclesElectrical controlFire controlExternal combustion engine

A variety of methods and arrangements for controlling the operation of an internal combustion engine in a skip fire variable displacement mode are described. In general, a firing control unit determines working chamber firings during operation of the engine that are suitable for delivering a desired engine output. In one aspect, the firing control unit is arranged to isolate the generation of firing sequences having frequency components in a frequency range of concern and to alter the firing sequence in a manner that reduces the occurrence of frequency components in the frequency range of concern. In another aspect, a filter is arranged to filter a feedback signal to provide a filtered feedback signal that is used in the determination of the working chamber firings. In preferred embodiments, the frequency characteristics of the filter are variable.

Owner:TULA TECH INC

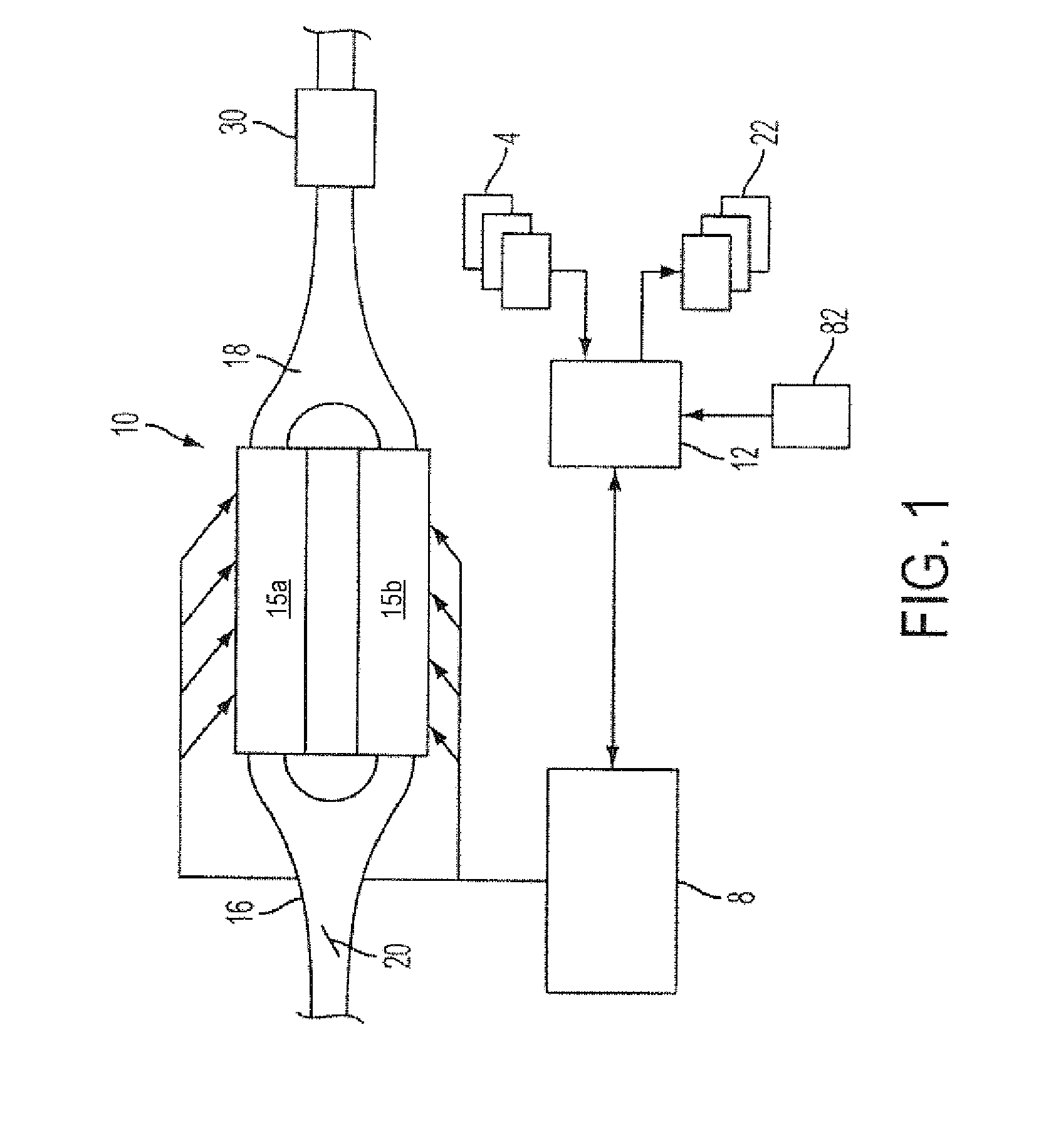

Engine valve disabler

A method for improving efficiency and reducing emissions of an internal combustion engine. Variable displacement engine capabilities are achieved by disabling engine valves during load changes and constant load operations. Active cylinders may be operated at minimum BSFC by intermittently disabling other cylinders to provide the desired net torque. Disabling is begun by early closing of the intake valve to provide a vacuum at BDC which will result in no net gas flow across the piston rings, and minimum loss of compression energy in the disabled cylinder; this saving in engine friction losses is significant with multiple disablements.

Owner:MOYER DAVID F

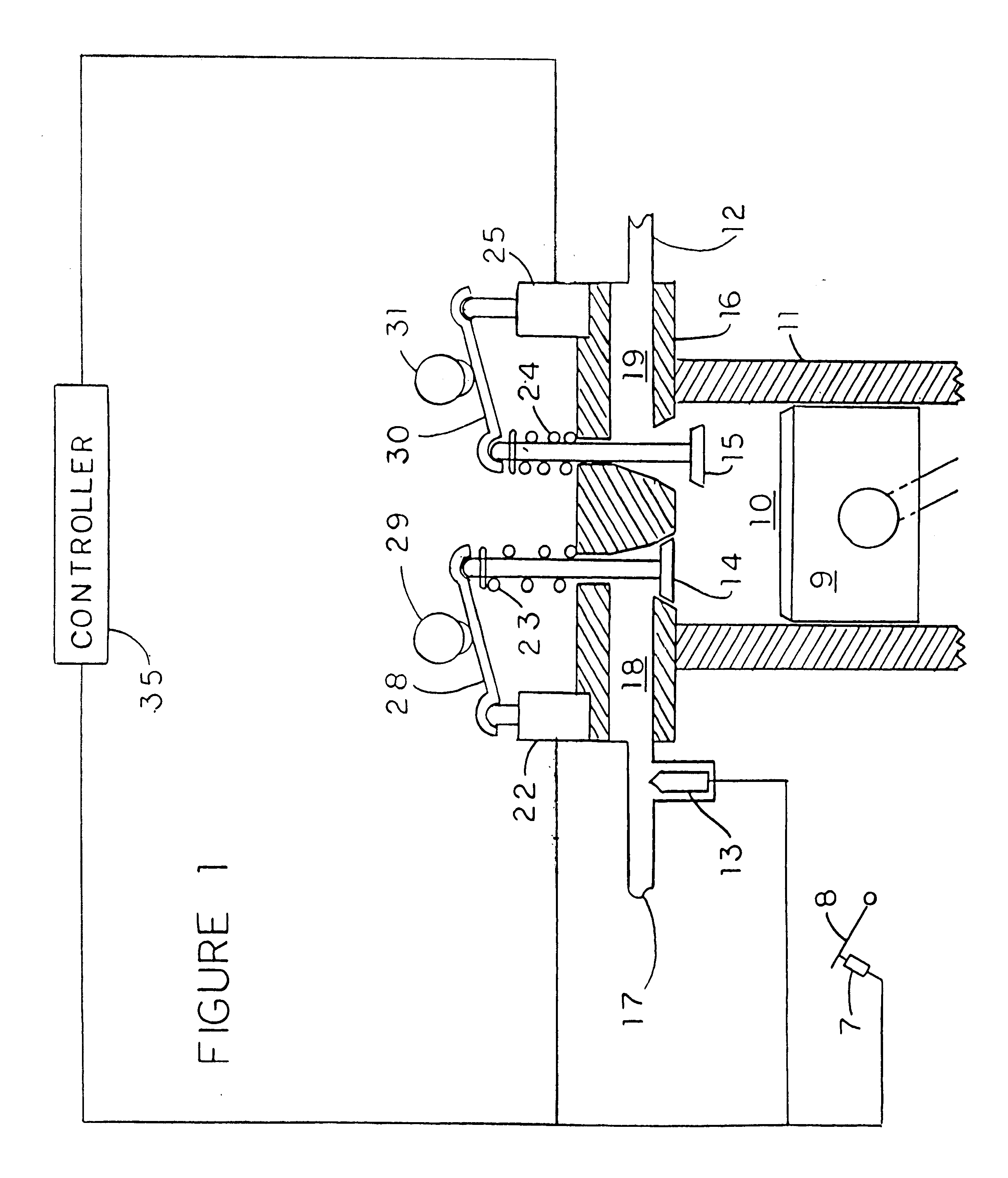

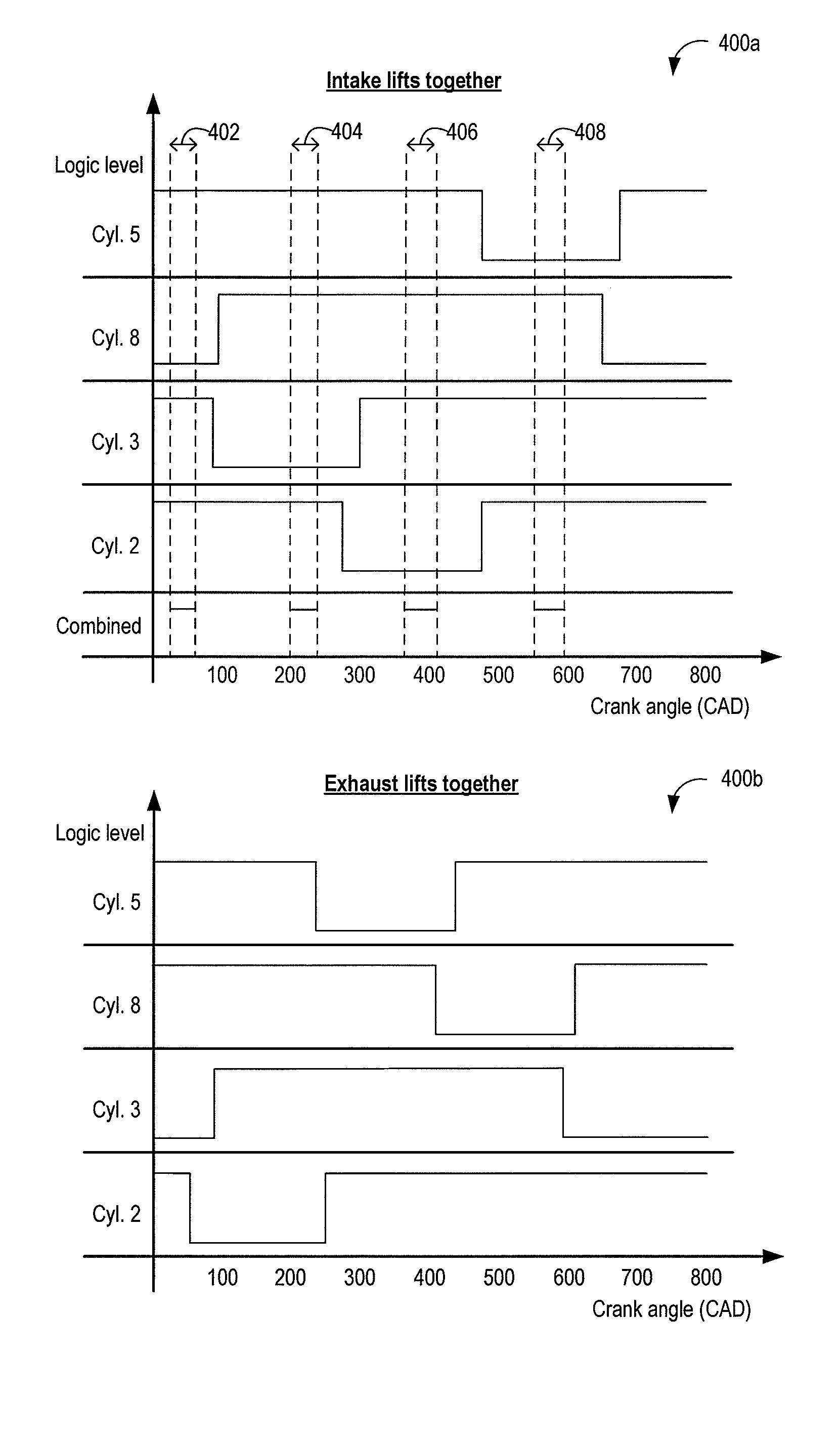

Methods for variable displacement engine diagnostics

InactiveUS7546827B1Improve fuel economyReduce controlValve arrangementsElectrical controlEngineeringCylinder Valve

Methods and systems are provided for monitoring cylinder valve deactivation in an engine operating with a plurality of cylinder valves. One example method comprises, sensing a plurality of cylinder valve positions of a plurality of cylinder valves; and combining the plurality of sensed positions to form a combined cylinder valve signal. The method may further include identifying valve degradation and differentiating valve degradation among the plurality of cylinder valves based on the combined cylinder valve signal and an expected value of the signal, and further based on a crank angle at which the expected value differs from the combined signal.

Owner:FORD GLOBAL TECH LLC

Idle speed control for lean burn engine with variable-displacement-like characteristic

InactiveUS6769398B2Easy to operateDegradation of combustionElectrical controlIdling devicesAdaptive learningIdle speed control

A method is disclosed for controlling operation of a engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air-fuel mixture and a second group of cylinders pumping air only (i.e. without fuel injection.) In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: auto speed control, sensor diagnostics, air-fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, and default operation. In addition, the engine control method also disables the split air / lean operating mode under preselected operating conditions.

Owner:FORD GLOBAL TECH LLC

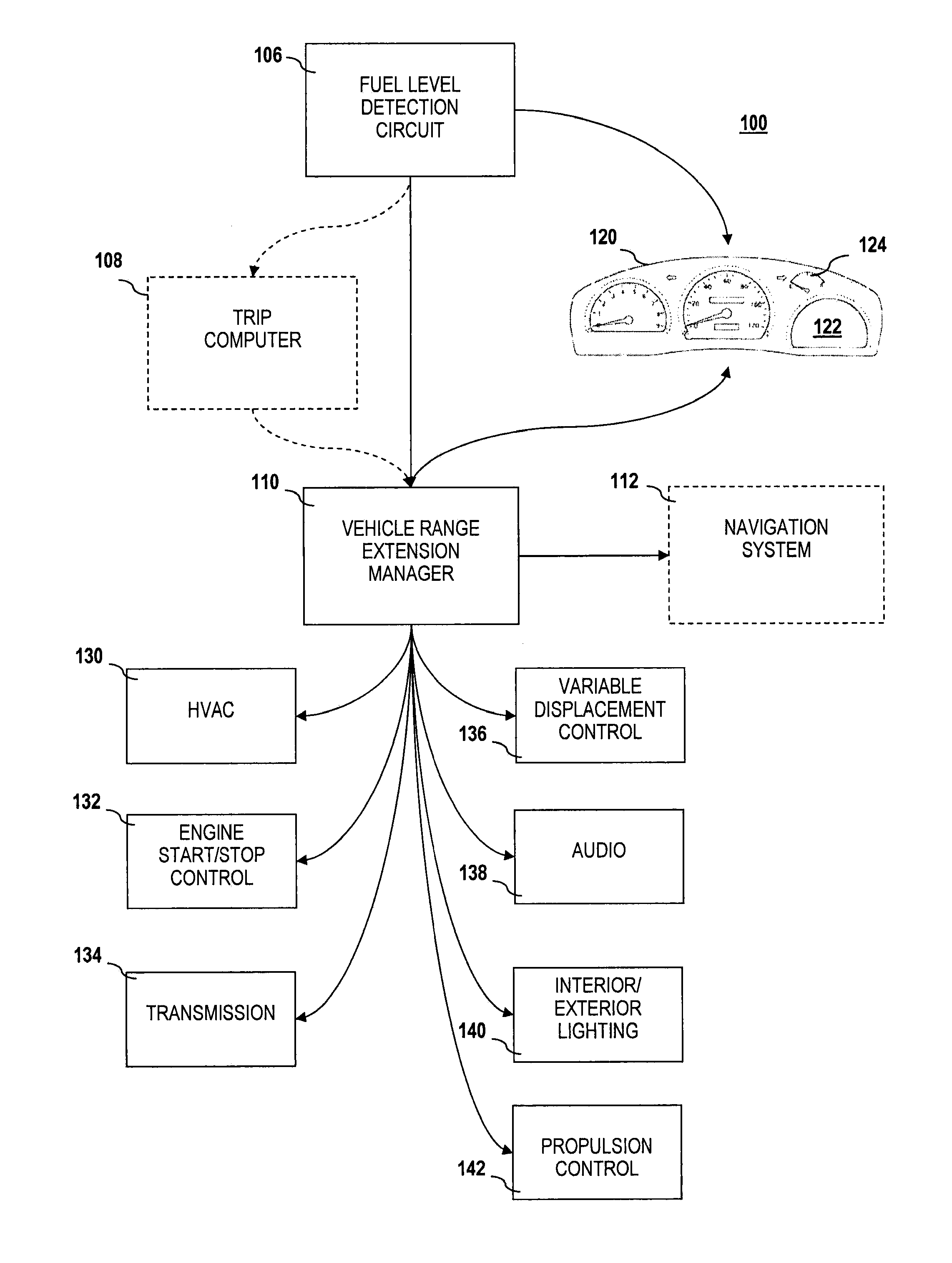

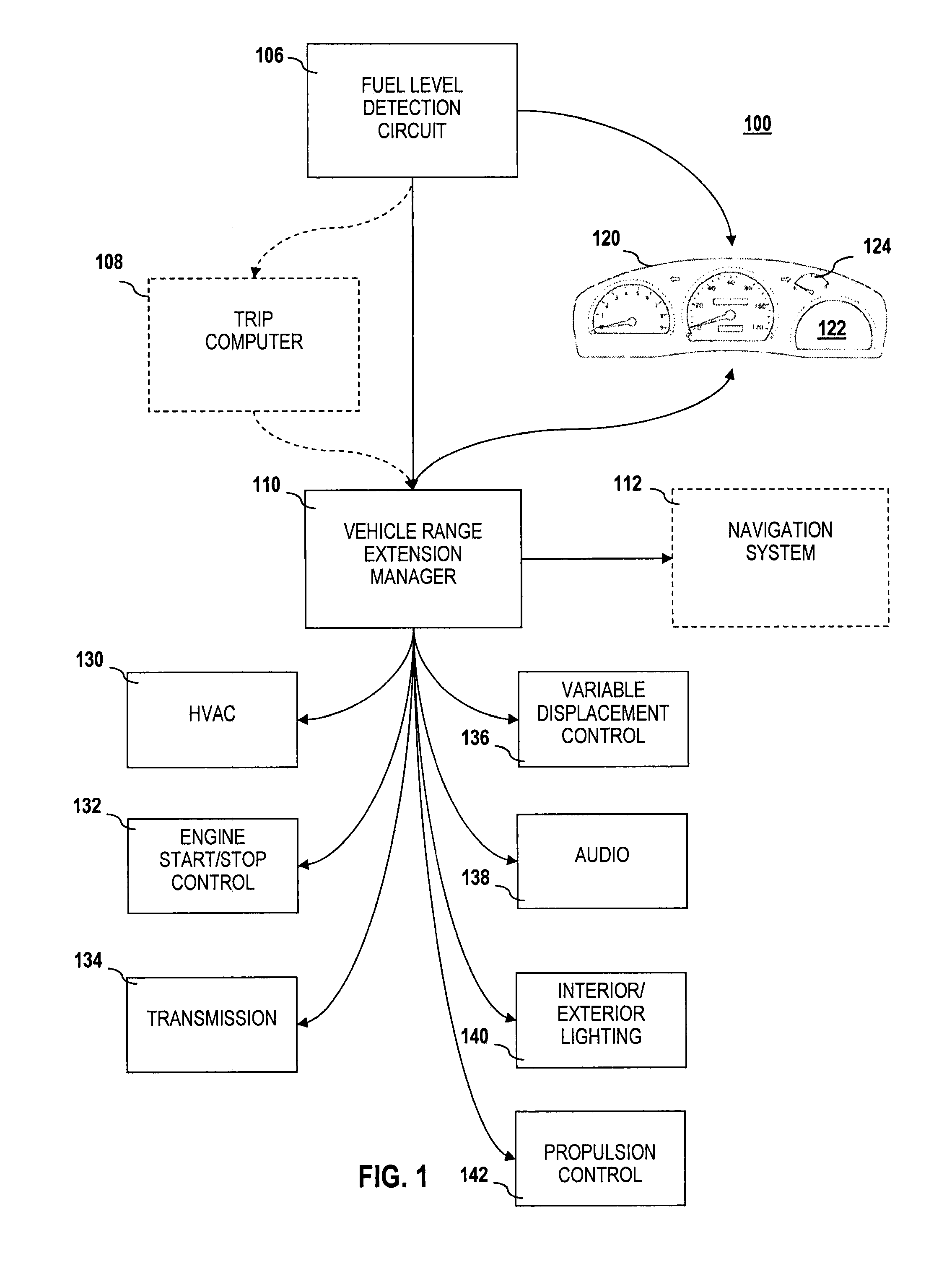

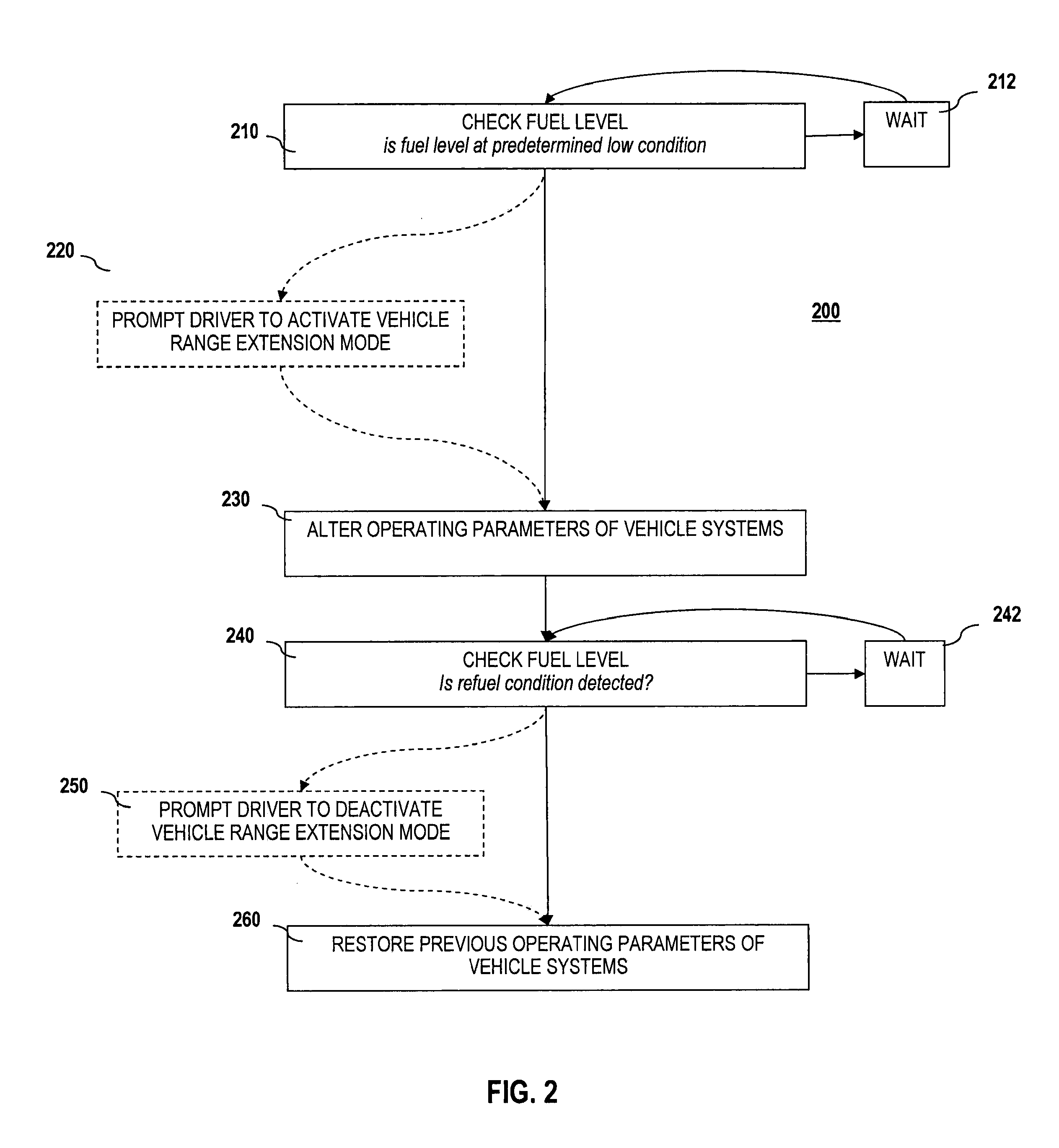

System and method for vehicle range extension on detection of a low fuel condition

ActiveUS20110153141A1Increasing vehicle rangeImprove propulsion system efficiencyVehicle testingAnalogue computers for vehiclesStart stopDriving range

The technology described herein provides a system and method for automatically increasing the remaining driving range of a vehicle when a low fuel or other condition is detected by altering the operating parameters of one or more vehicle systems to improve propulsion system efficiency and thereby lower fuel consumption. The vehicle range extending system is capable of altering the operating parameters of any vehicle system, including for example variable displacement settings, start-stop technology settings, and HVAC operation. The disclosed technology can also provide information to the driver, suggesting which system operating parameters should be altered to reduce the fuel consumption rate.

Owner:FCA US

Skip fire internal combustion engine control

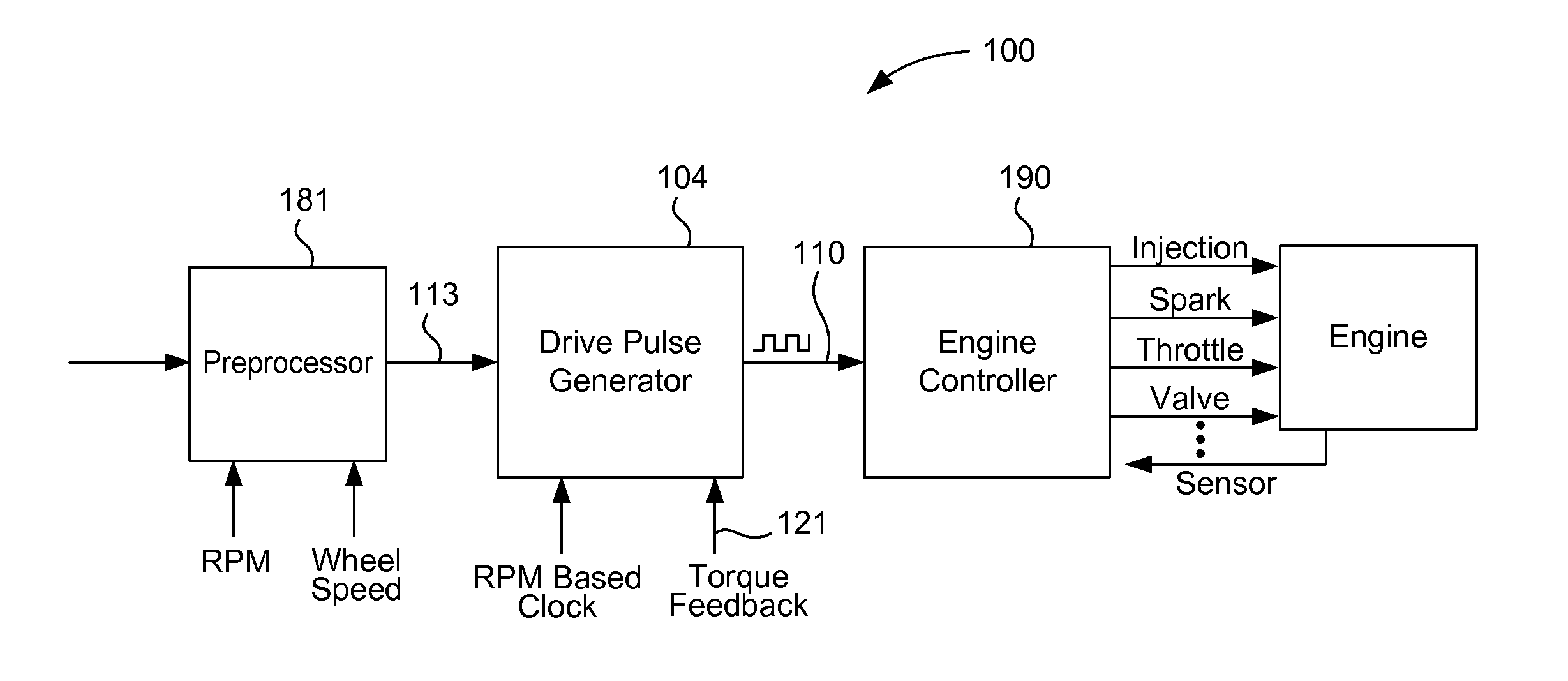

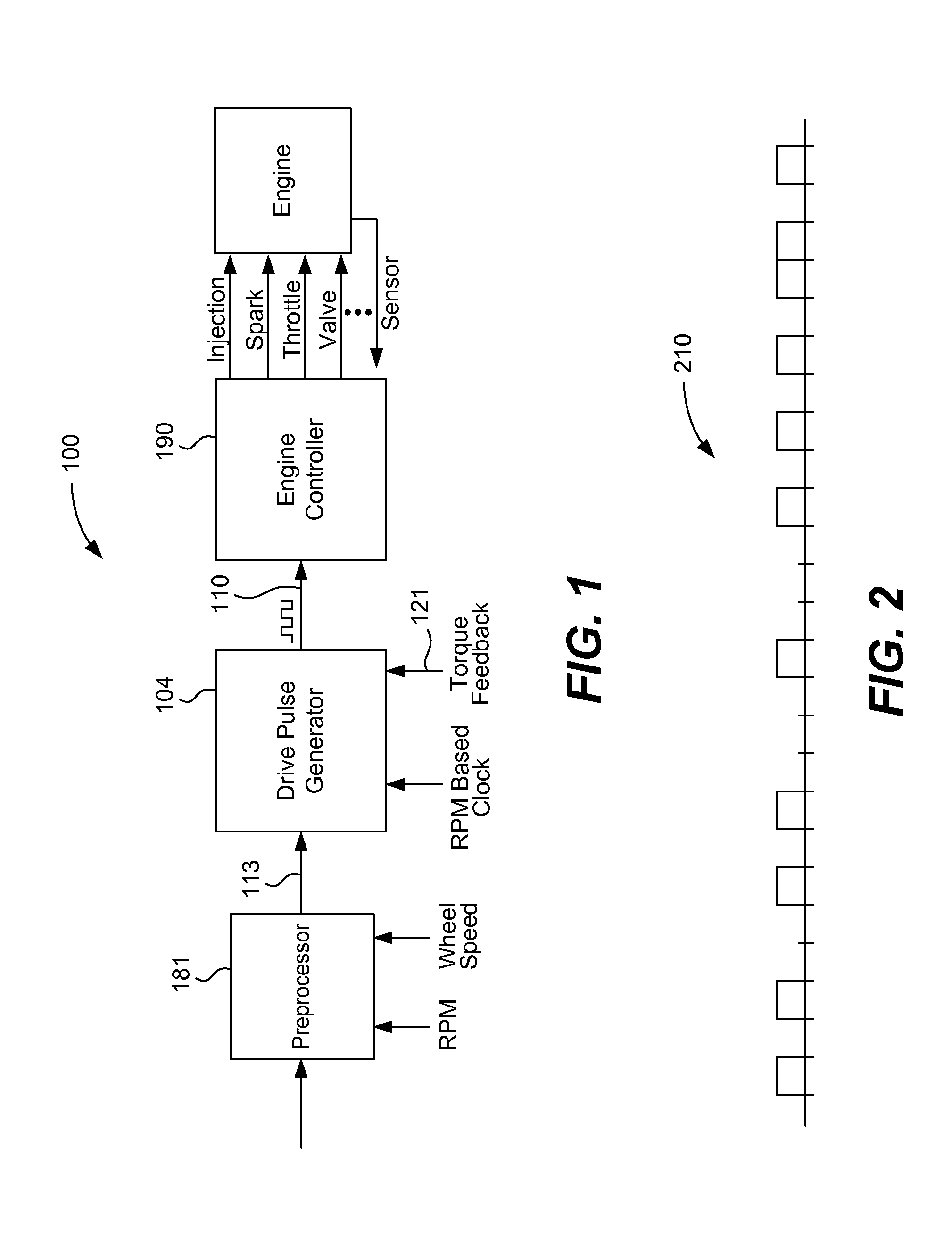

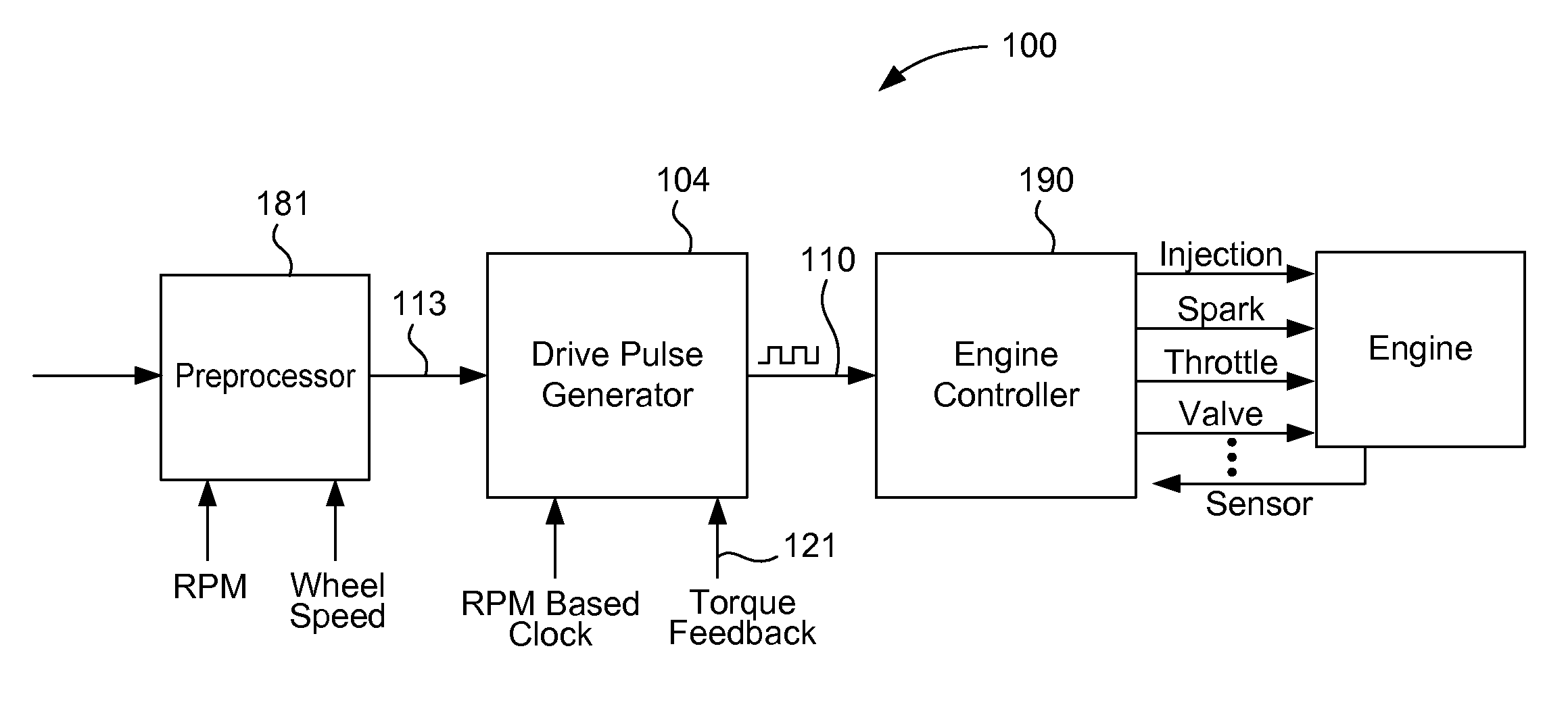

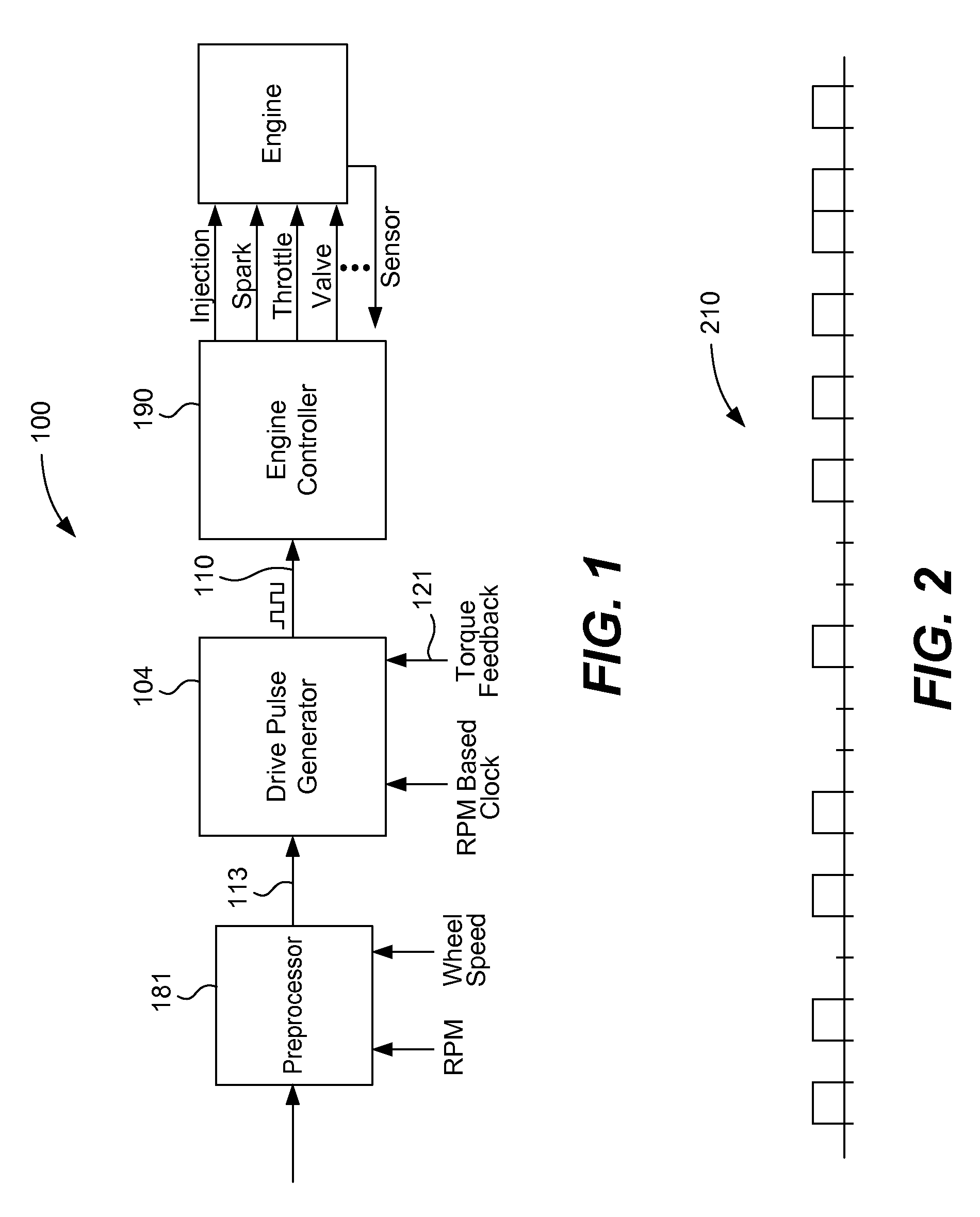

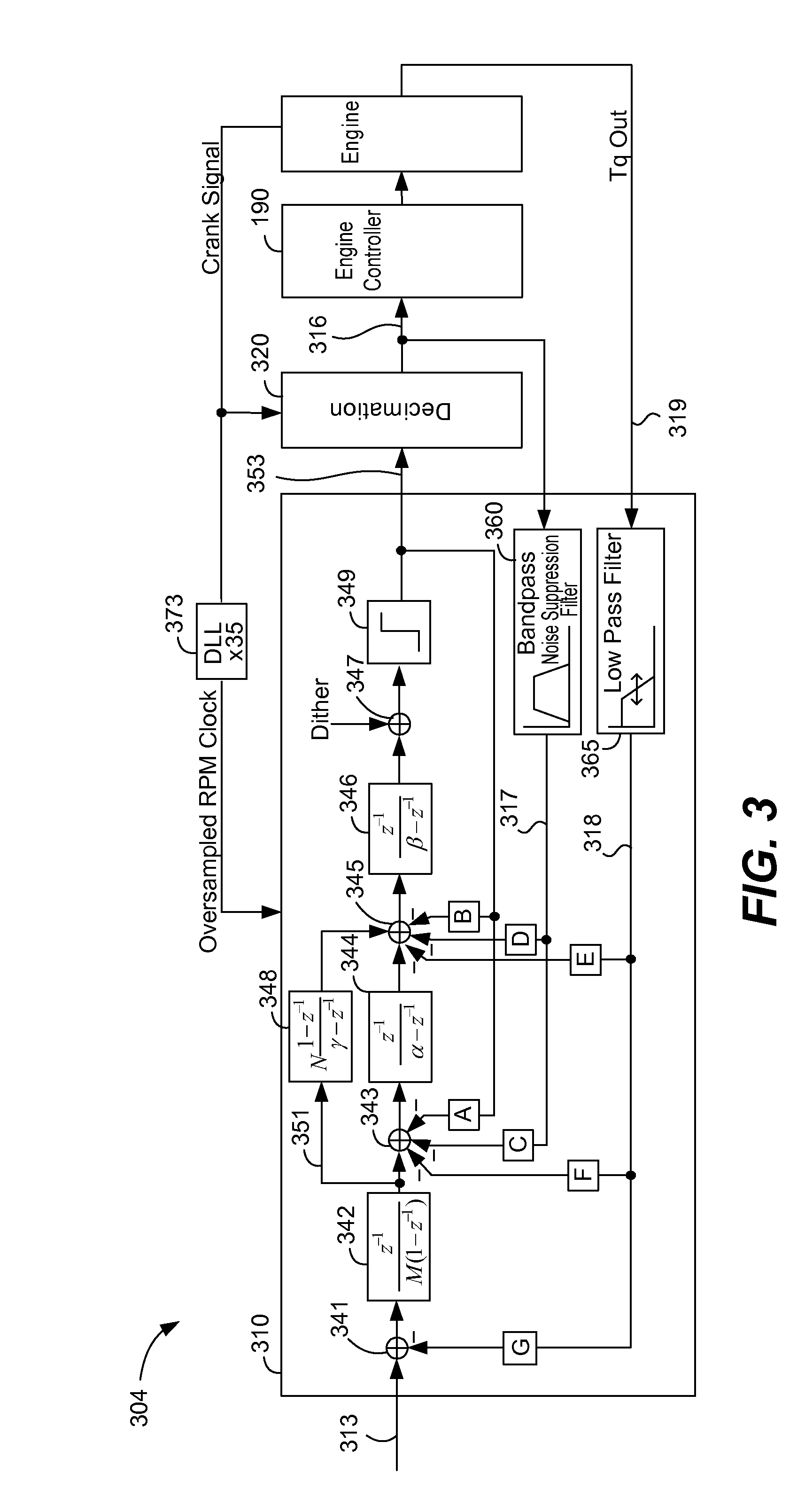

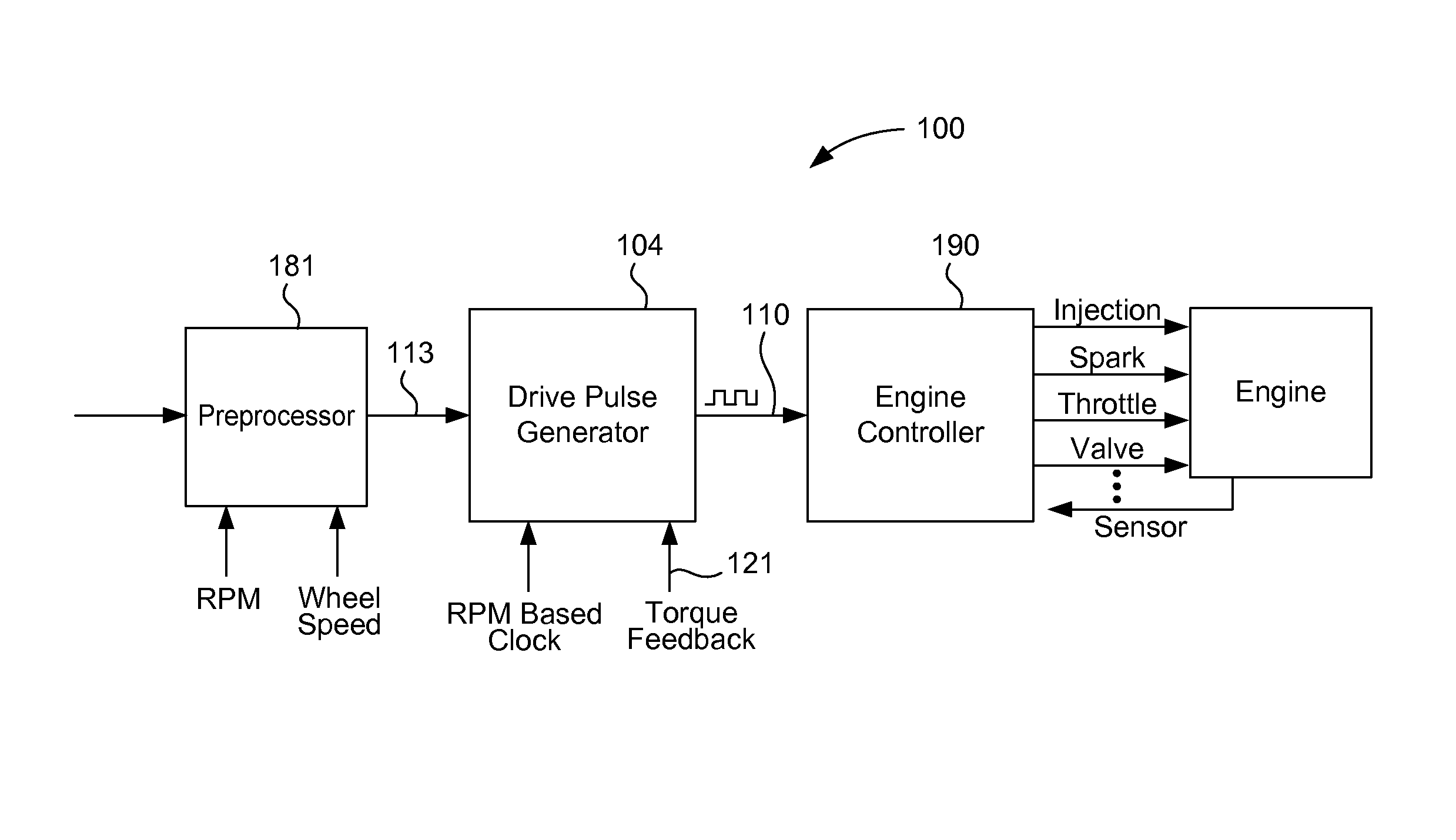

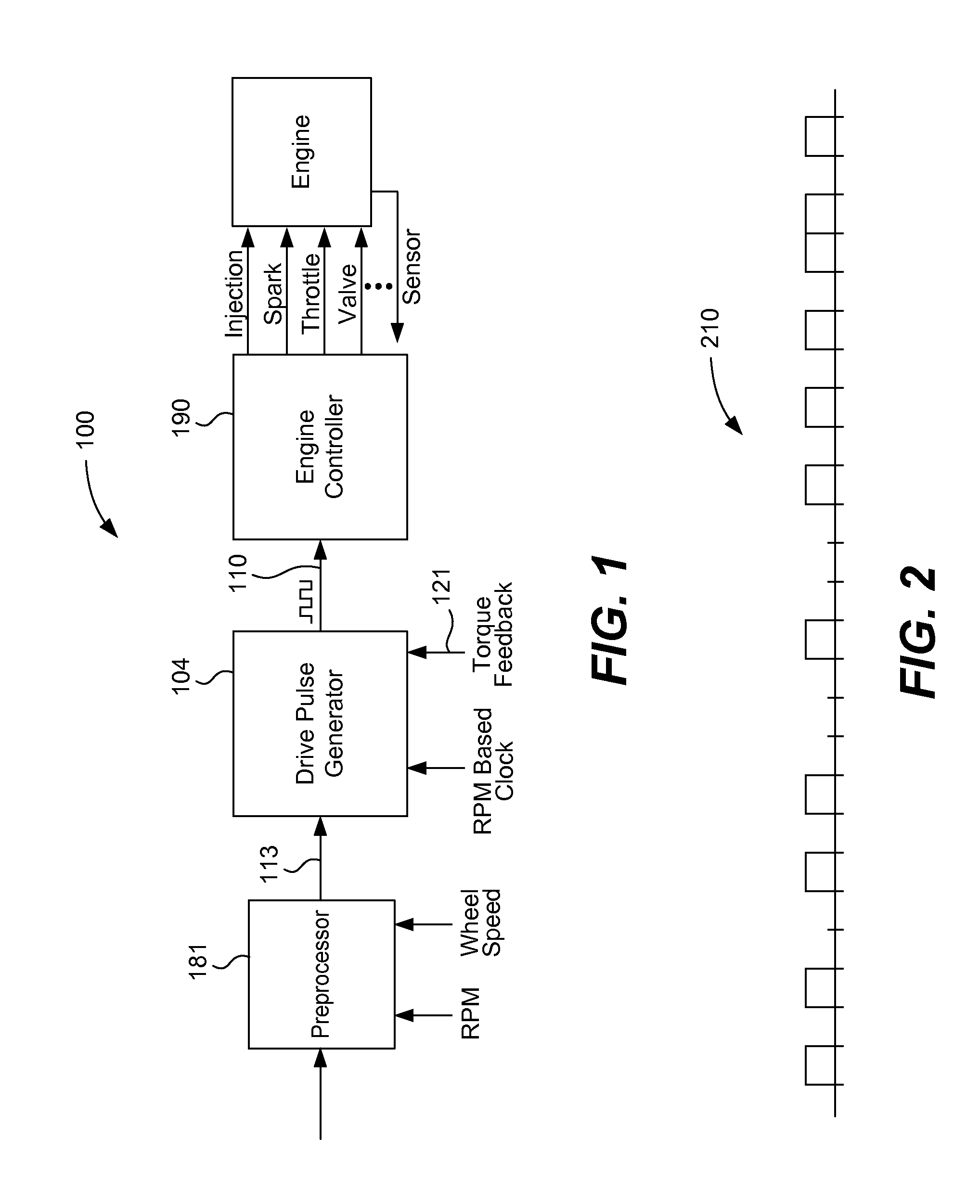

ActiveUS20120109495A1System stabilityAnalogue computers for vehiclesElectrical controlInternal combustion engineControl theory

A variety of methods and arrangements for controlling the operation of an internal combustion engine in a skip fire variable displacement mode are described. In one aspect, the working chamber firing that are selected to deliver the desired engine output are determined at least in part based on torque feedback. The torque feedback may be an indication of the torque output of the engine or the torque experienced at some other location in the drive train. In some embodiments, the torque feedback signal is filtered to remove high frequency components of the torque feedback signal in order to help stabilize the system. In another aspect, other operational parameters are used as feedback in the determination of the firing sequence. In yet another aspect, a filter is arranged to filter a feedback signal to provide a filtered feedback signal that is used in the determination of the working chamber firings.

Owner:TULA TECH INC

Variable displacement engine powertrain fuel economy mode

InactiveUS7785230B2Reduce fuel usageImprove noiseAnalogue computers for vehiclesDigital data processing detailsOperator interfaceDriver/operator

A vehicle drive system for adjusting vehicle fuel economy is described. In one example, the vehicle drive system includes an operator interface for adjusting vehicle operation so as to increase or decrease fuel consumption according to a driver preference.

Owner:FORD GLOBAL TECH LLC

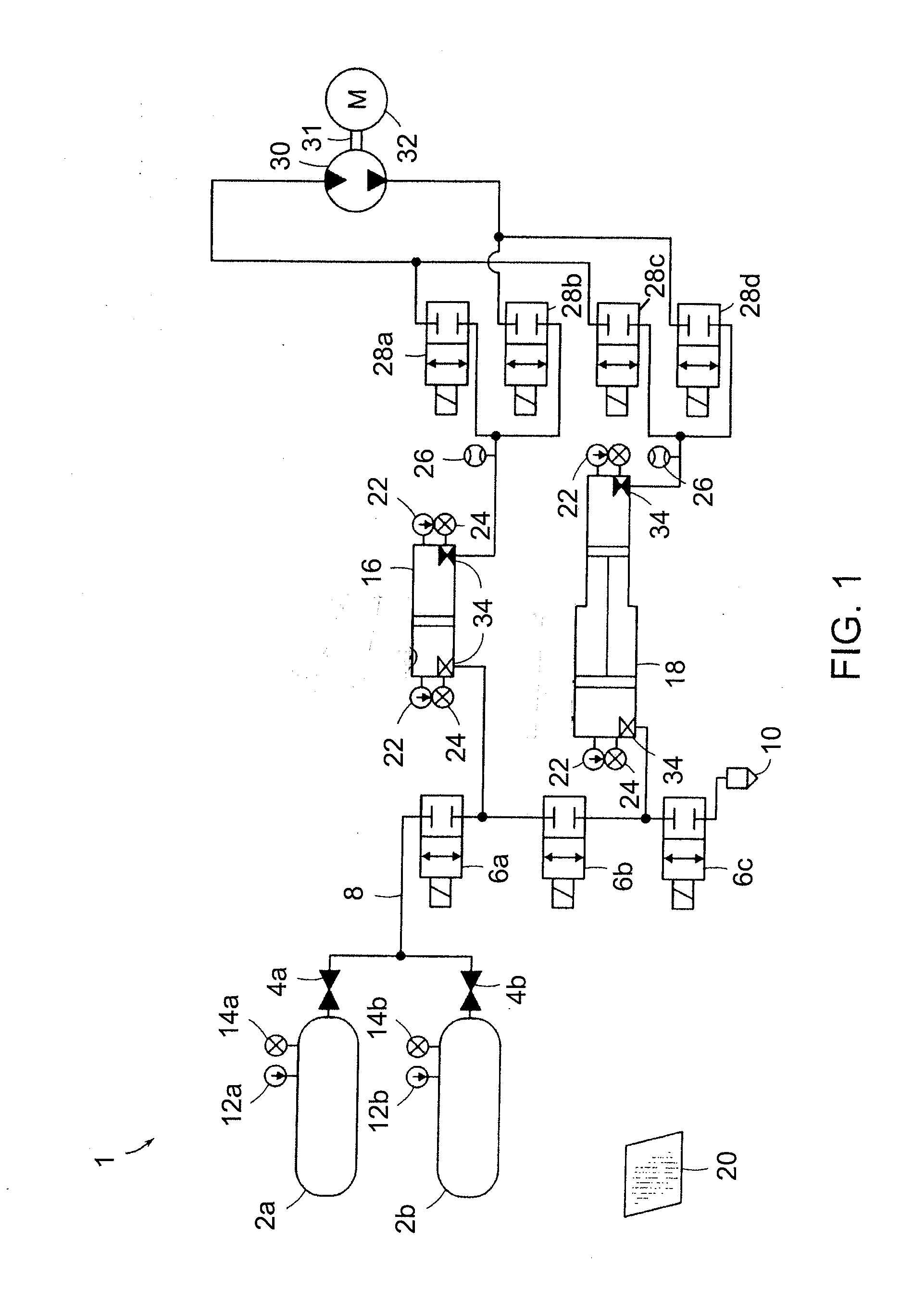

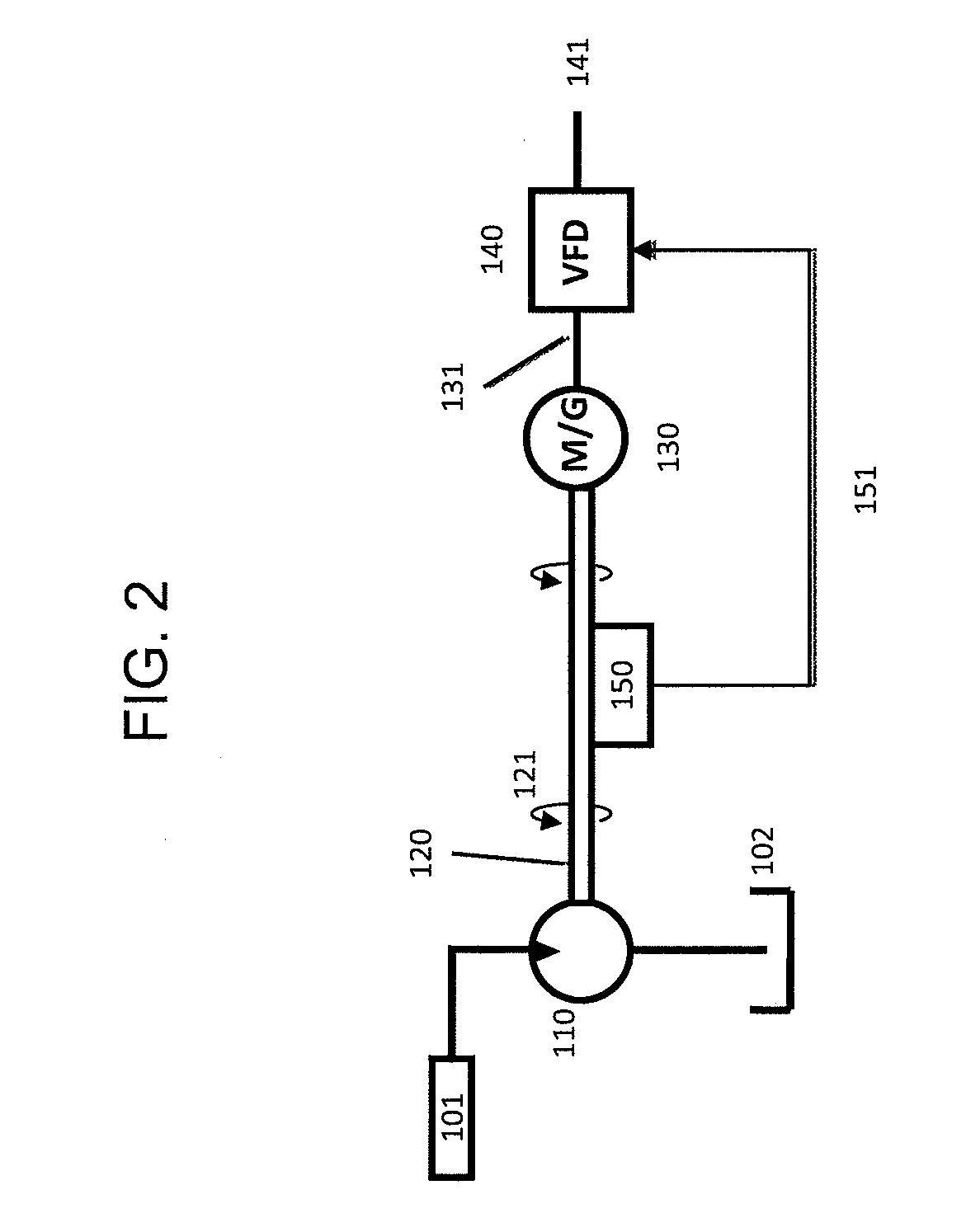

Systems and Methods for Improving Drivetrain Efficiency for Compressed Gas Energy Storage

InactiveUS20100229544A1Improve efficiencyIncreasing electric motorElectrical storage systemFluid couplingsHydraulic motorConstant power

Generally, the invention relates to power generation and energy storage. In particular, to systems and methods for providing constant power from hydraulic inputs having widely-varying pressures. More particularly, the invention relates to hydraulic-pneumatic energy storage and recovery systems that include either a fixed or variable displacement hydraulic motor and control systems that allow a user to maintain constant power from the fixed or variable displacement hydraulic motor.

Owner:SUSTAINX

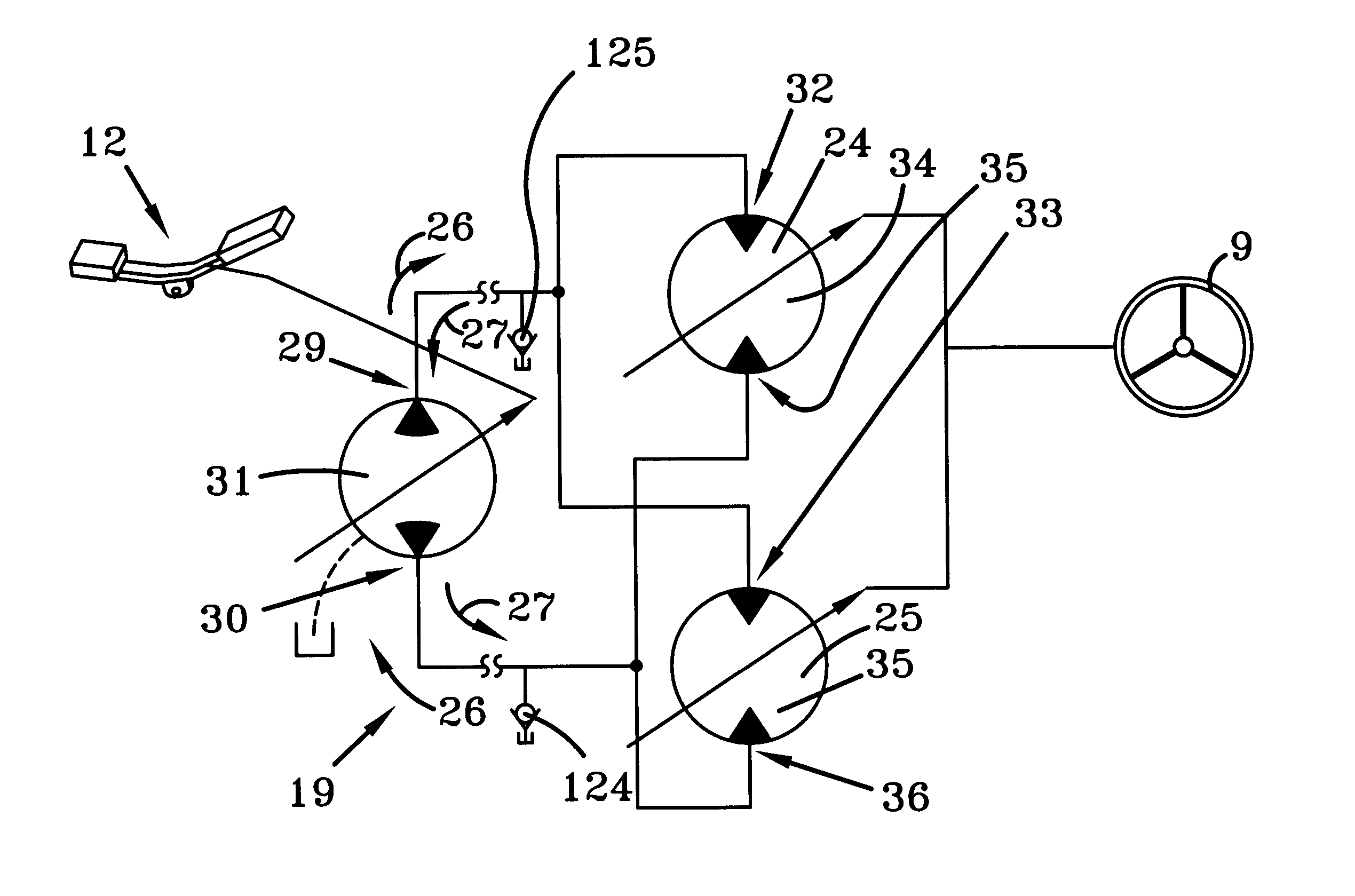

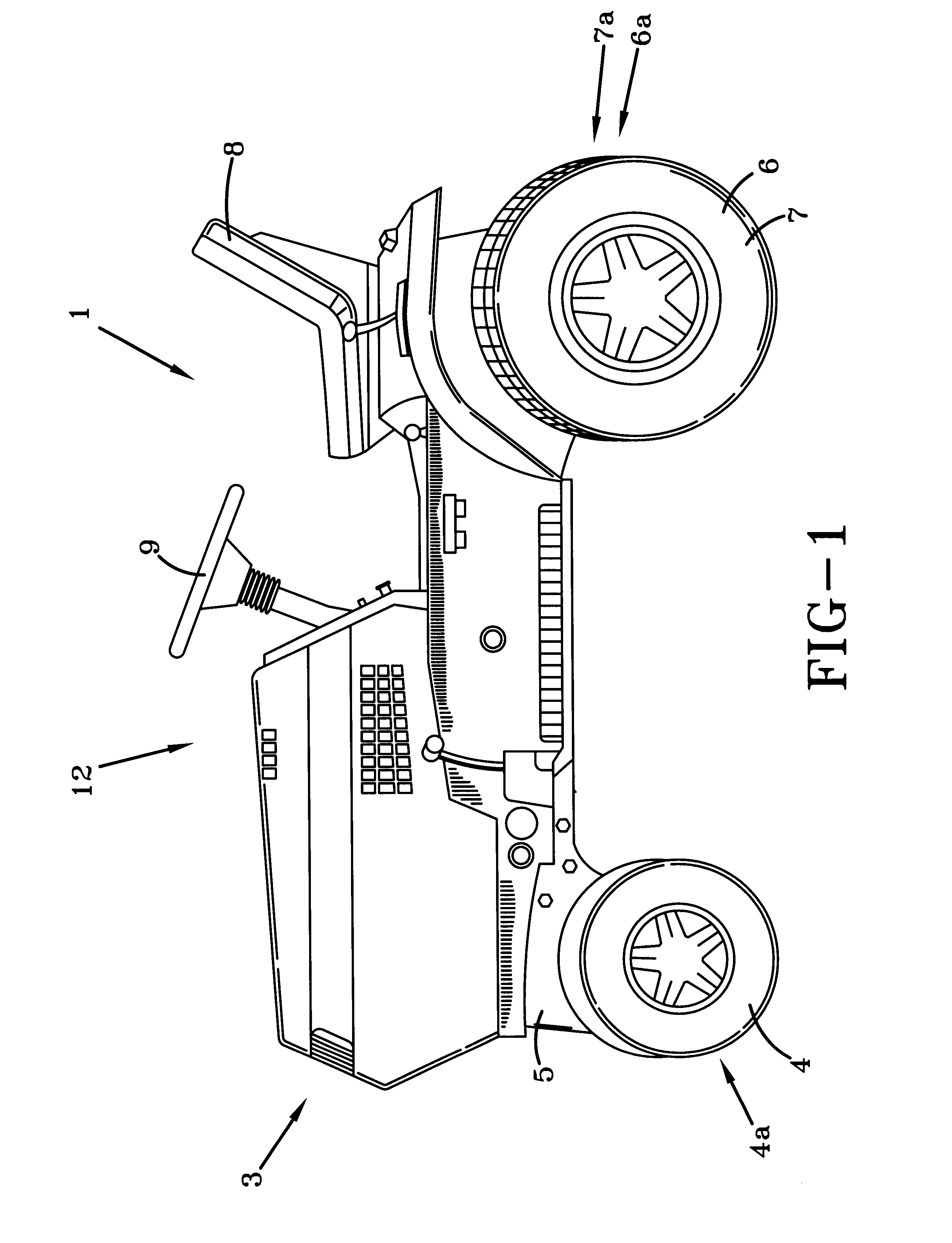

Zero turn radius or ZTR vehicle with a one-pump two motor mechanism

InactiveUS6601663B2Steering precisionMotor depositionNon-deflectable wheel steeringHydraulic motorEngineering

A Zero Turn Radius vehicle is provided that utilizes a drive system including a single hydraulic variable displacement pump and dual variable displacement hydraulic motors connected respectively one to each of two ground engaging wheels for use in steering and propelling the vehicle. The configuration of the drive system allows for proper ZTR steering of the in the forward and reverse directions.

Owner:MTD PRODUCTS

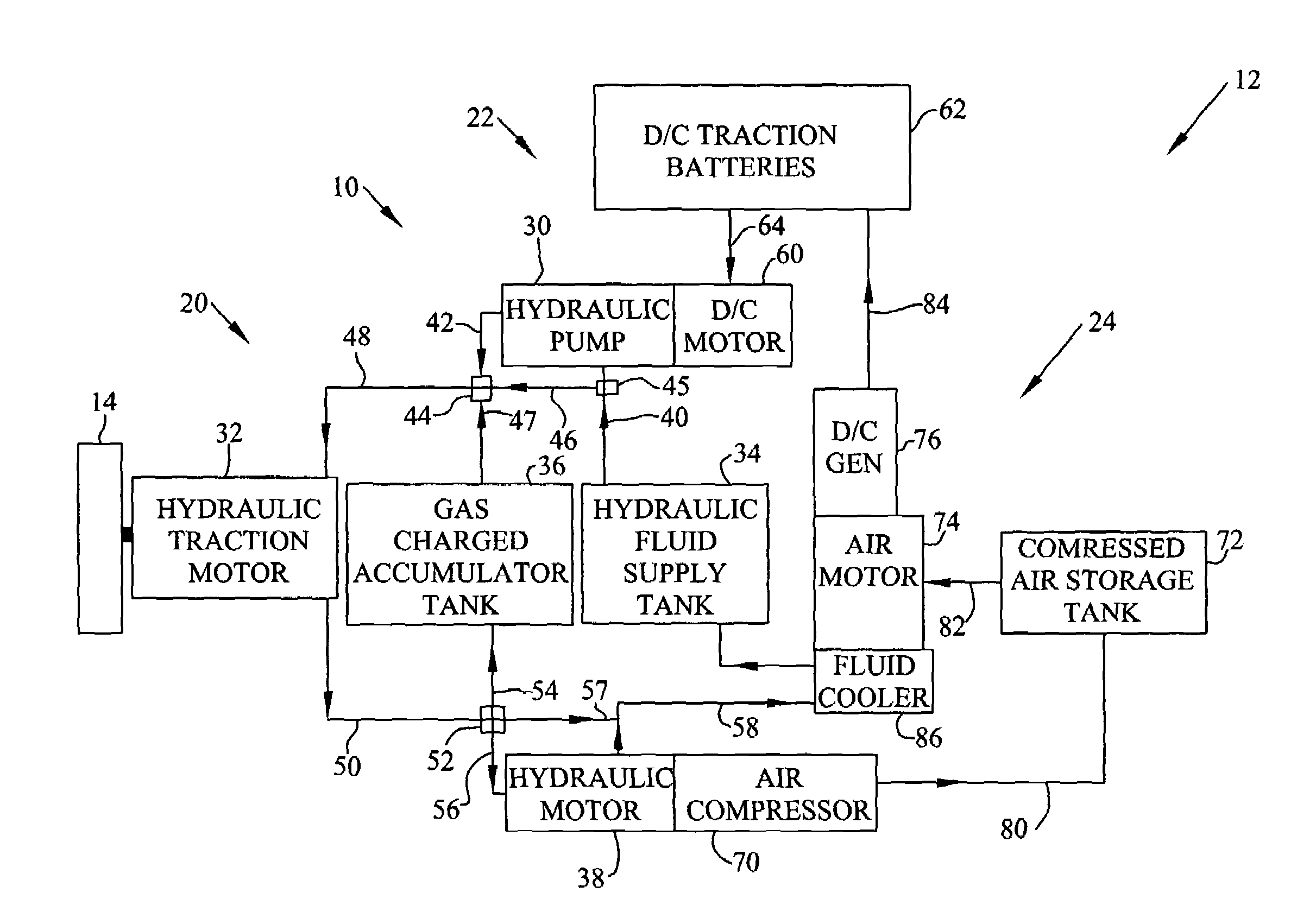

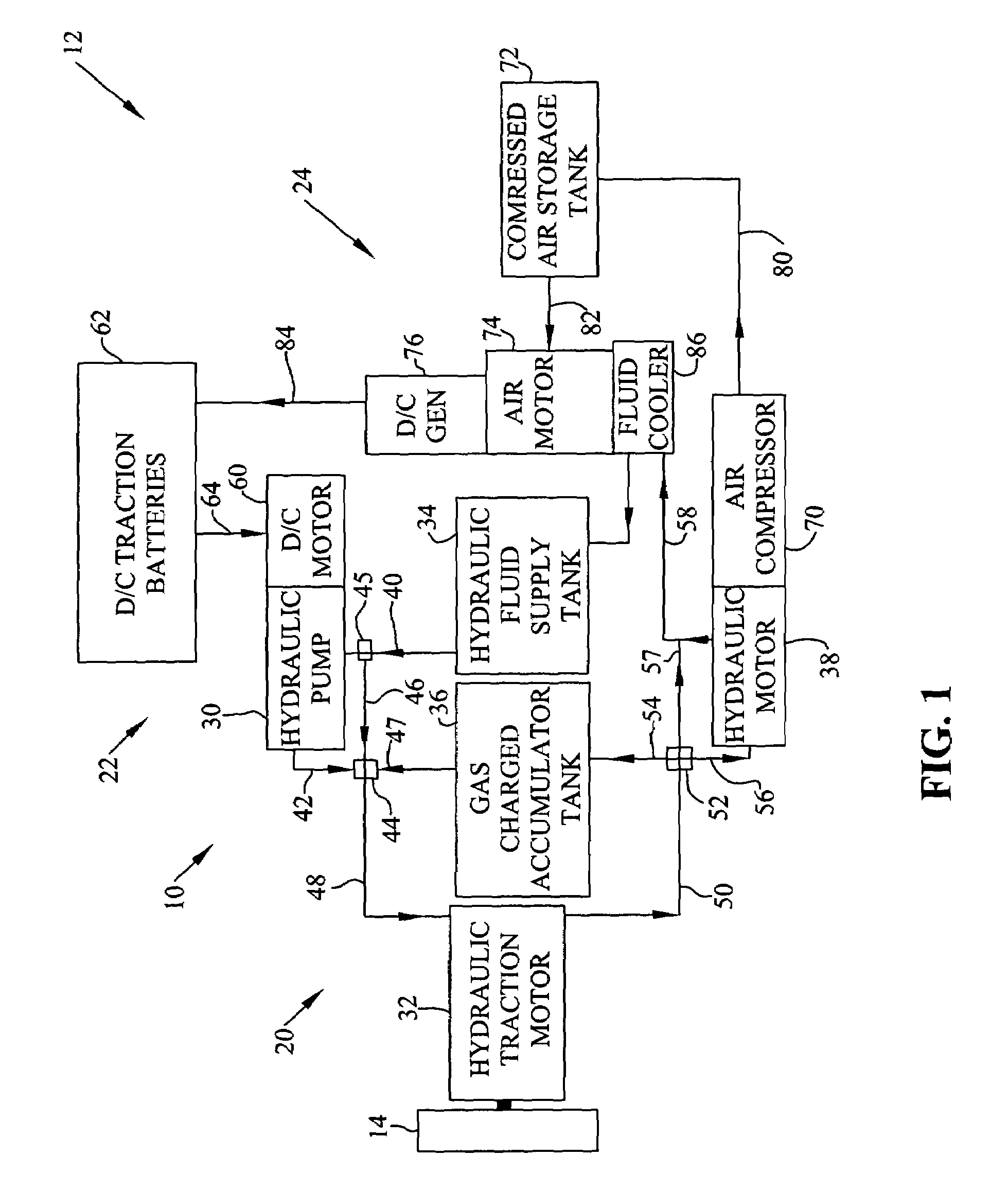

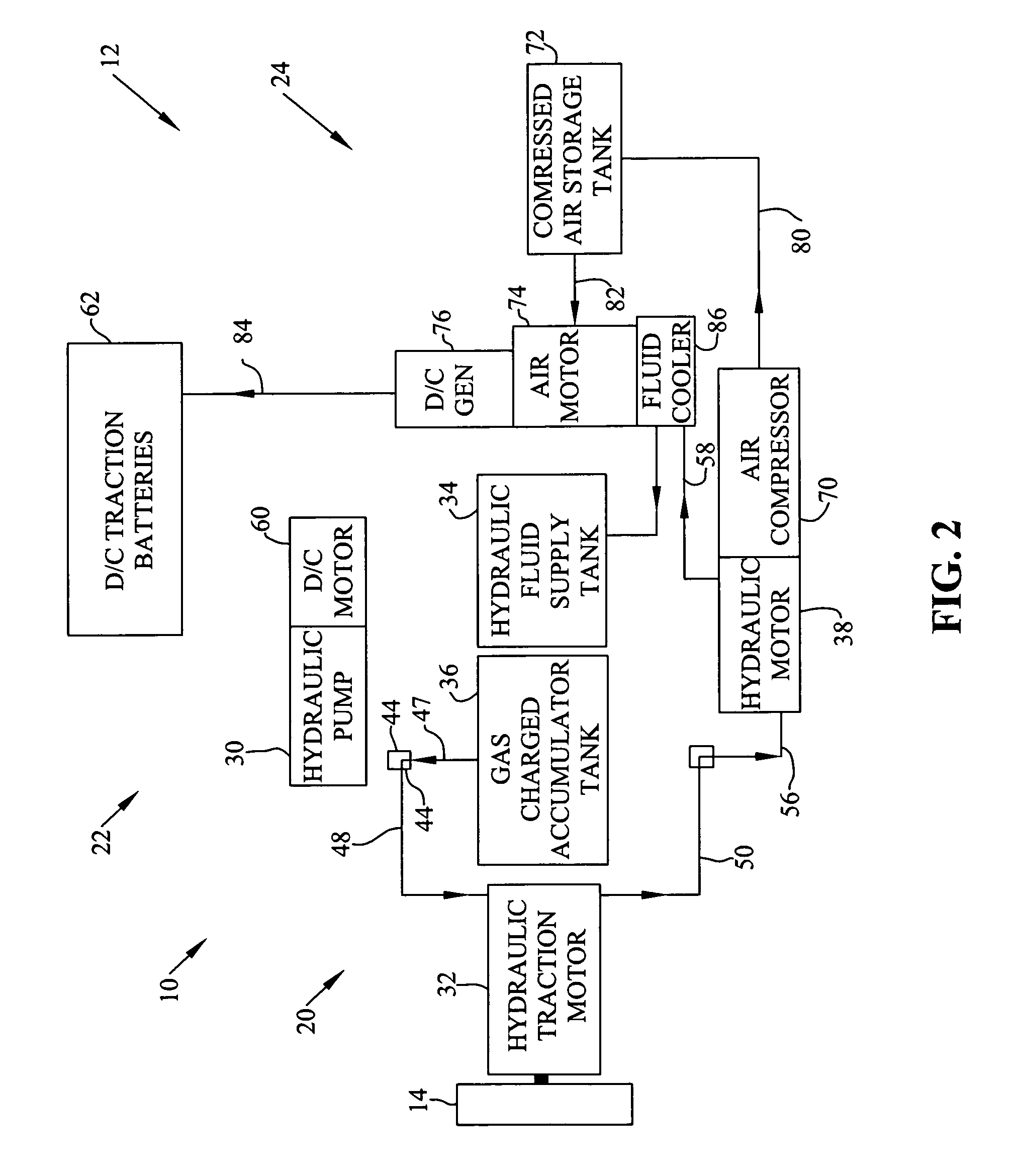

Vehicle system to recapture kinetic energy

A fluid drive system that can be used to drive a vehicle and has energy regeneration and storage capabilities. The fluid drive system includes an electrical energy supply source mounted on the vehicle, at least one electrical motor electrically connected to the electrical supply source, and a hydraulic pump driven that may be of the variable displacement type by the electrical motor. The fluid drive system may also include a low pressure hydraulic fluid supply tank supplying fluid to the hydraulic pump, at least one pneumatically charged accumulator tank for storing pressurized hydraulic fluid, a combination hydraulic motor and pump that may also be of the variable displacement type being alternately driven by the hydraulic pump and the pneumatically charged accumulator tank; and an electrical regeneration system for regenerating the electrical energy supply. The electrical regeneration system may be powered by hydraulic fluid from the combination electrical motor and pump. The combination hydraulic motor and pump propels the vehicle during acceleration and speed maintaining operations and may also serves as a braking mechanism during deceleration of the vehicle. The combination hydraulic motor and pump may also pump hydraulic fluid into the pneumatically charged accumulator tank during at least a portion of the time that the vehicle is decelerating. The combination hydraulic motor and pump may further pump hydraulic fluid for powering the electrical regeneration system when the pneumatically charged accumulator tank is fully pressurized. The electrical regeneration system also has the ability to recharge the electrical energy supply while the vehicle is stopped using stored recovered kinetic energy.

Owner:PARKER I L L C +1

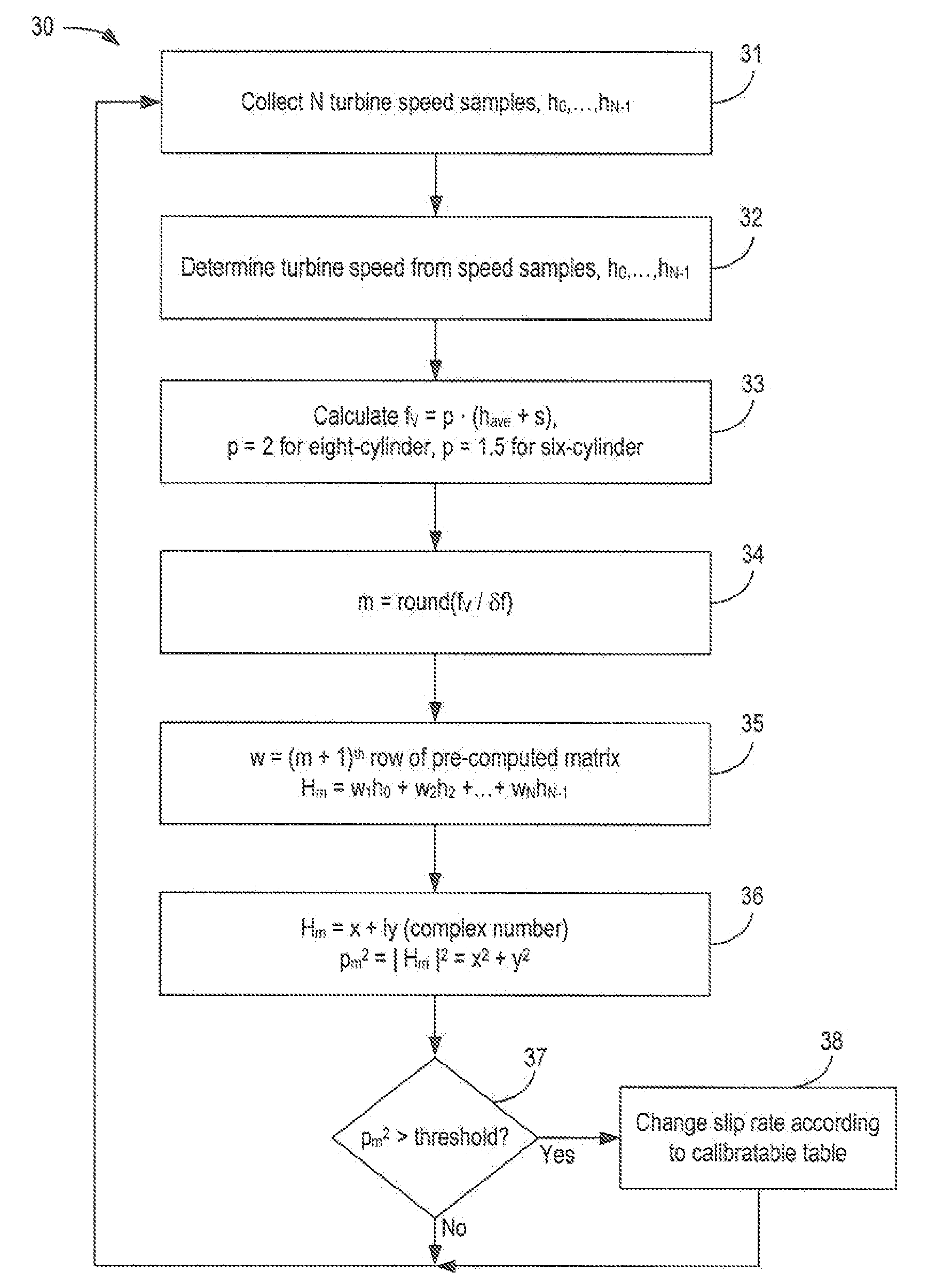

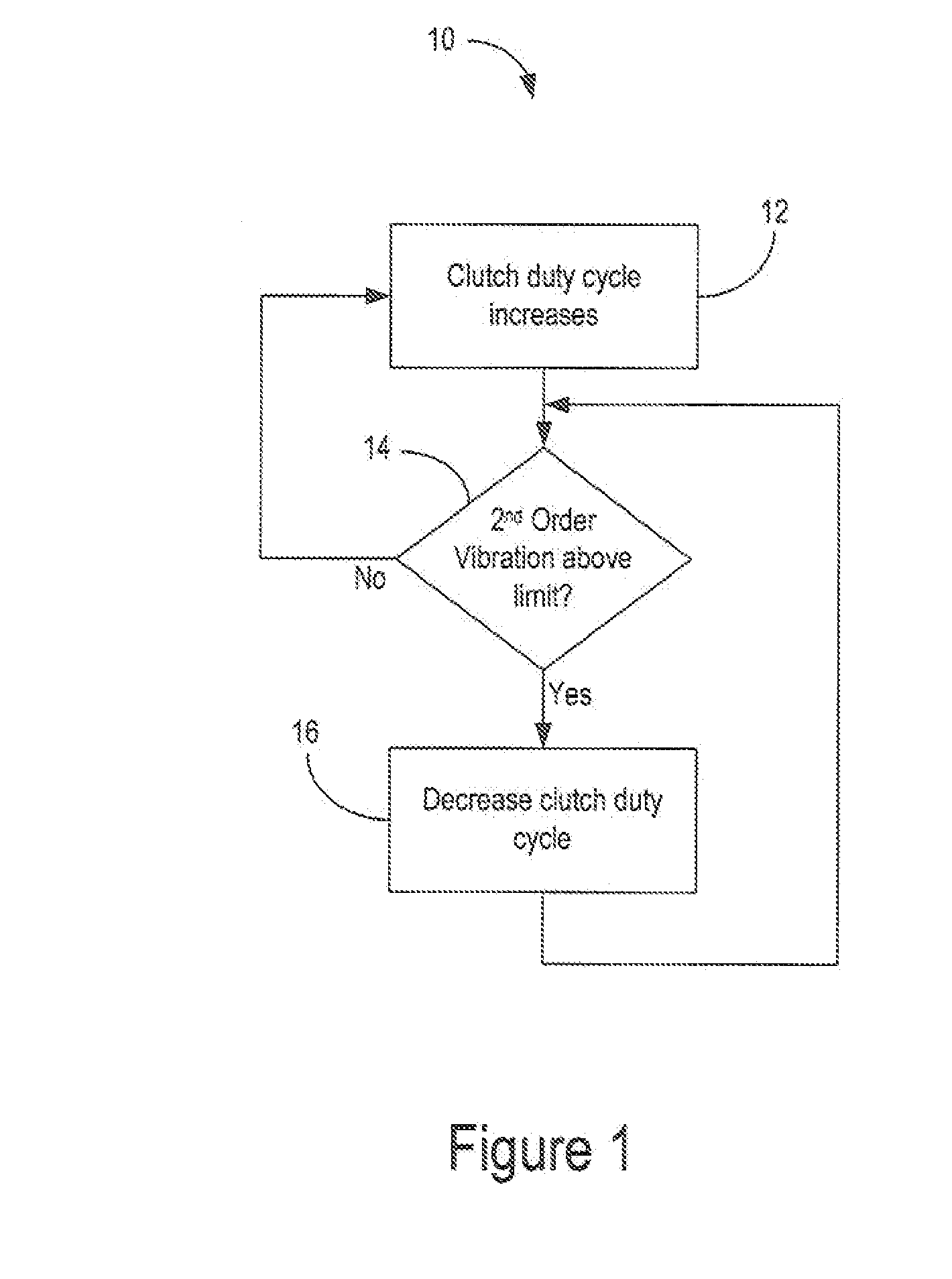

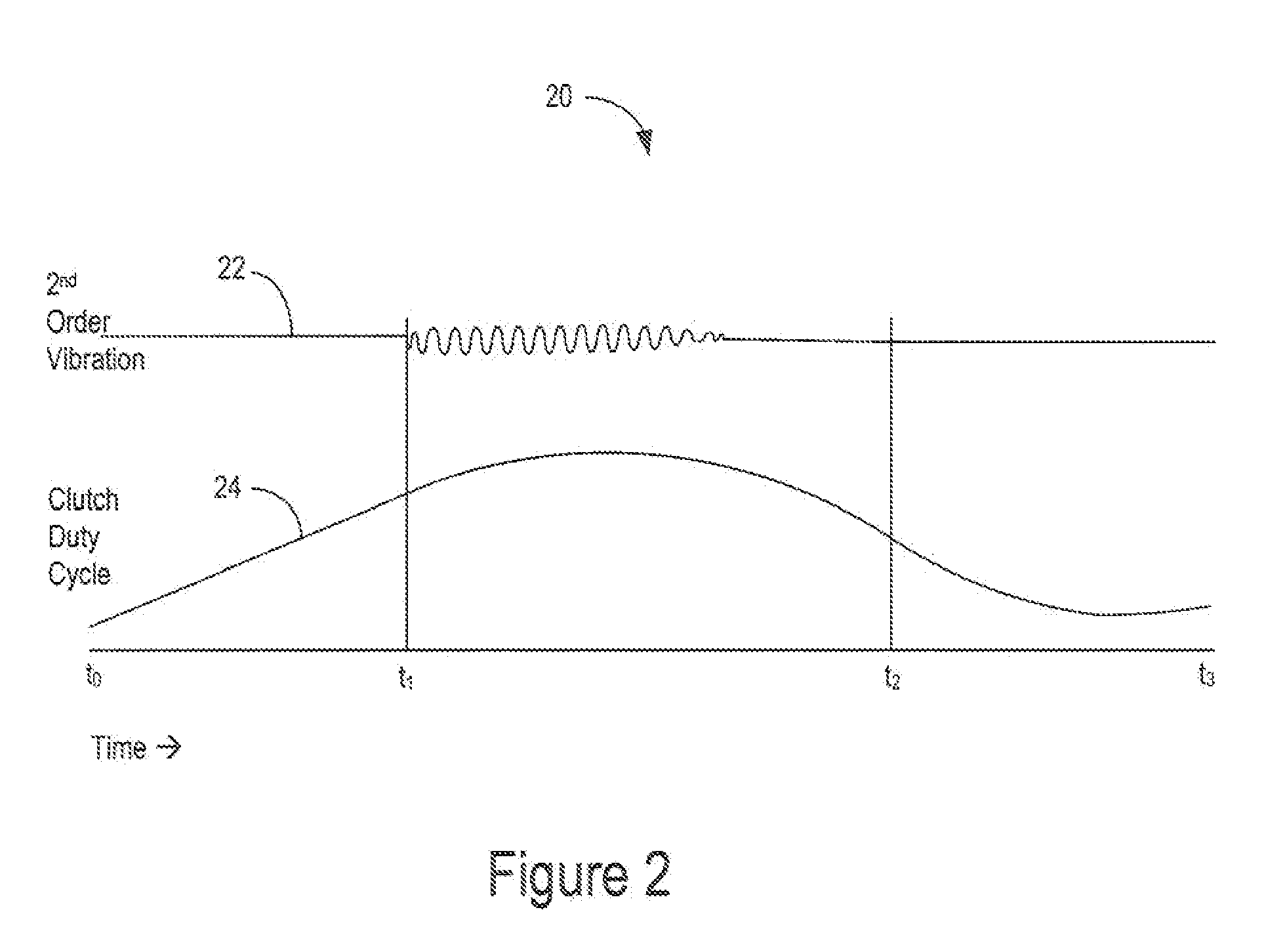

Systems and methods for detecting and reducing high driveline torsional levels in automobile transmissions

ActiveUS20080288146A1Improve the level ofReduce distractionsDigital data processing detailsGearing controlDrivetrainFuel efficiency

The present disclosure provides systems and methods to detect and reduce any high driveline torsional levels, such as due to the cylinder deactivation in variable displacement system engines or aggressive lock-up strategies for fuel efficiency, in automobile transmissions. The present disclosure utilizes a controller in an automobile to operate a computationally thrifty method for quickly detecting noise and vibration disturbances in the transmission. This quick detection enables fuel economic calibrations that aggressively reduce the disturbances by controlling slip in a launch device of the transmission. As problem disturbances arise, they are detected before occupants notice objectionable behavior. Once detected, the disturbances are reduced, such as by increasing launch device slip, which effectively intercepts the objectionable disturbances before they are transferred through the entire drivetrain. The present disclosure can also apply to launch devices in Dual Clutch Transmissions and Electronically-controlled Manual Transmissions.

Owner:FCA US

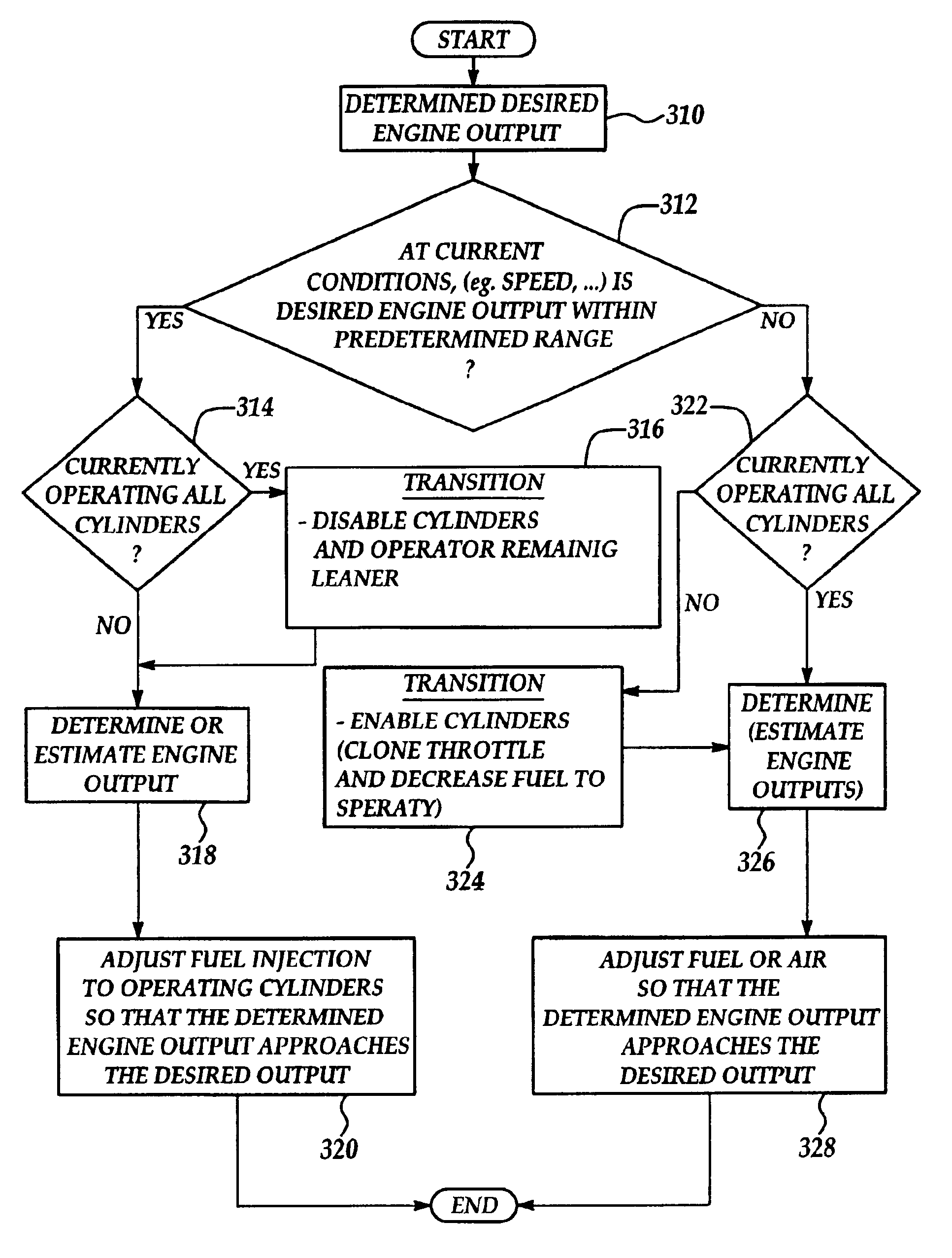

Method to improve fuel economy in lean burn engines with variable-displacement-like characteristics

InactiveUS6758185B2Easy to operateOverall engine torque fallsElectrical controlNon-fuel substance addition to fuelTemperature controlAdaptive learning

Owner:FORD GLOBAL TECH LLC

Skip fire internal combustion engine control

ActiveUS9020735B2System stabilityAnalogue computers for vehiclesElectrical controlExternal combustion engineInternal combustion engine

A variety of methods and arrangements for controlling the operation of an internal combustion engine in a skip fire variable displacement mode are described. In one aspect, the working chamber firing that are selected to deliver the desired engine output are determined at least in part based on torque feedback. The torque feedback may be an indication of the torque output of the engine or the torque experienced at some other location in the drive train. In some embodiments, the torque feedback signal is filtered to remove high frequency components of the torque feedback signal in order to help stabilize the system. In another aspect, other operational parameters are used as feedback in the determination of the firing sequence. In yet another aspect, a filter is arranged to filter a feedback signal to provide a filtered feedback signal that is used in the determination of the working chamber firings.

Owner:TULA TECH INC

Methods and Systems for Variable Displacement Engine Control

ActiveUS20110265771A1Improve engine boostReducing pumping lossesElectrical controlInternal combustion piston enginesEngineeringThrottle

Methods and systems are provided for selecting a group of cylinders for selective deactivation, in a variable displacement engine system, based at least on a regeneration state of an exhaust catalyst. The position of one or more valves and throttles may be adjusted based on the selective deactivation to reduce back-flow through the disabled cylinders while also maintaining conditions of a downstream exhaust catalyst. Pre-ignition and knock detection windows and thresholds may also be adjusted based on the deactivation to improve the efficiency of knock and pre-ignition detection.

Owner:FORD GLOBAL TECH LLC

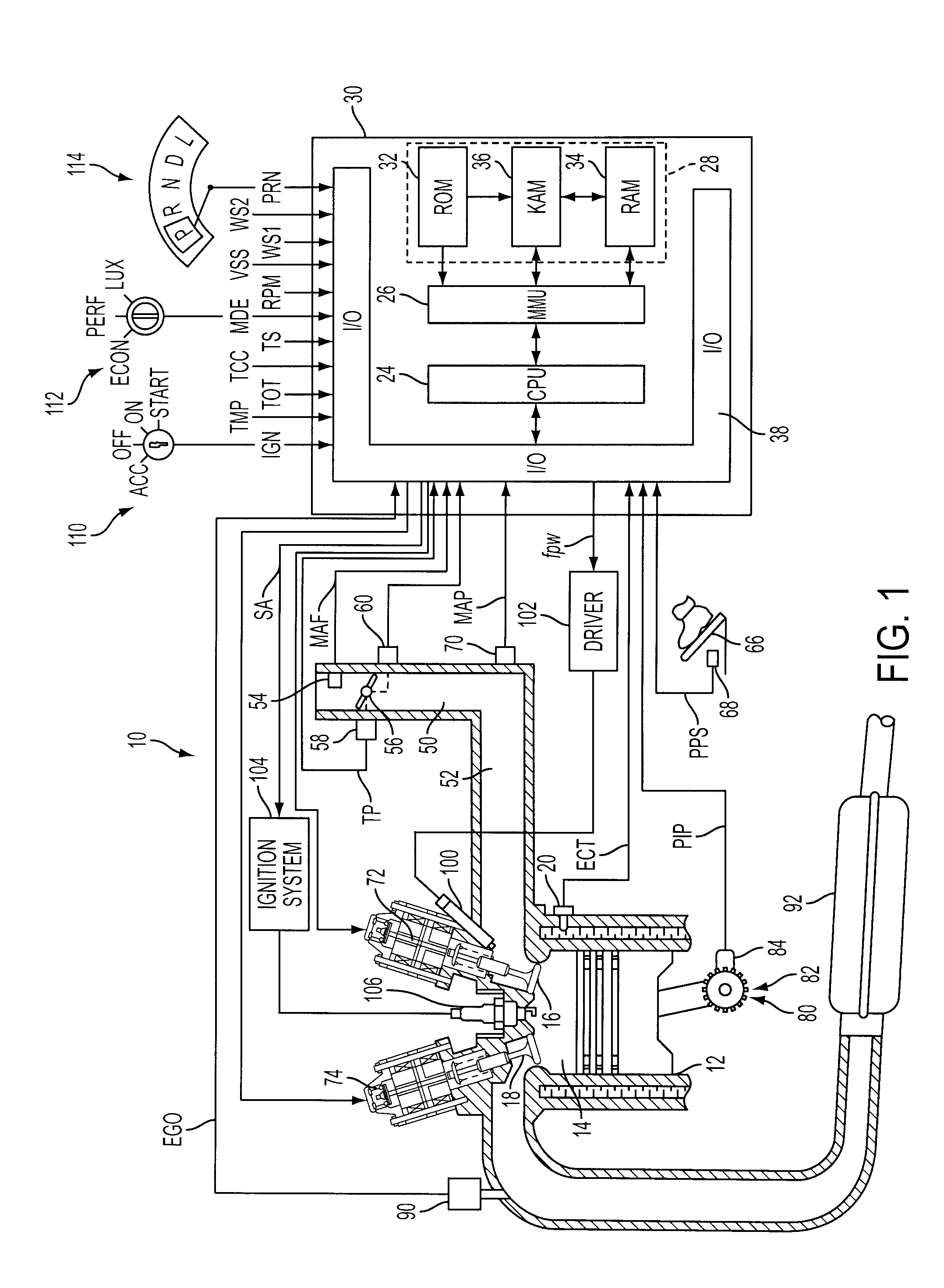

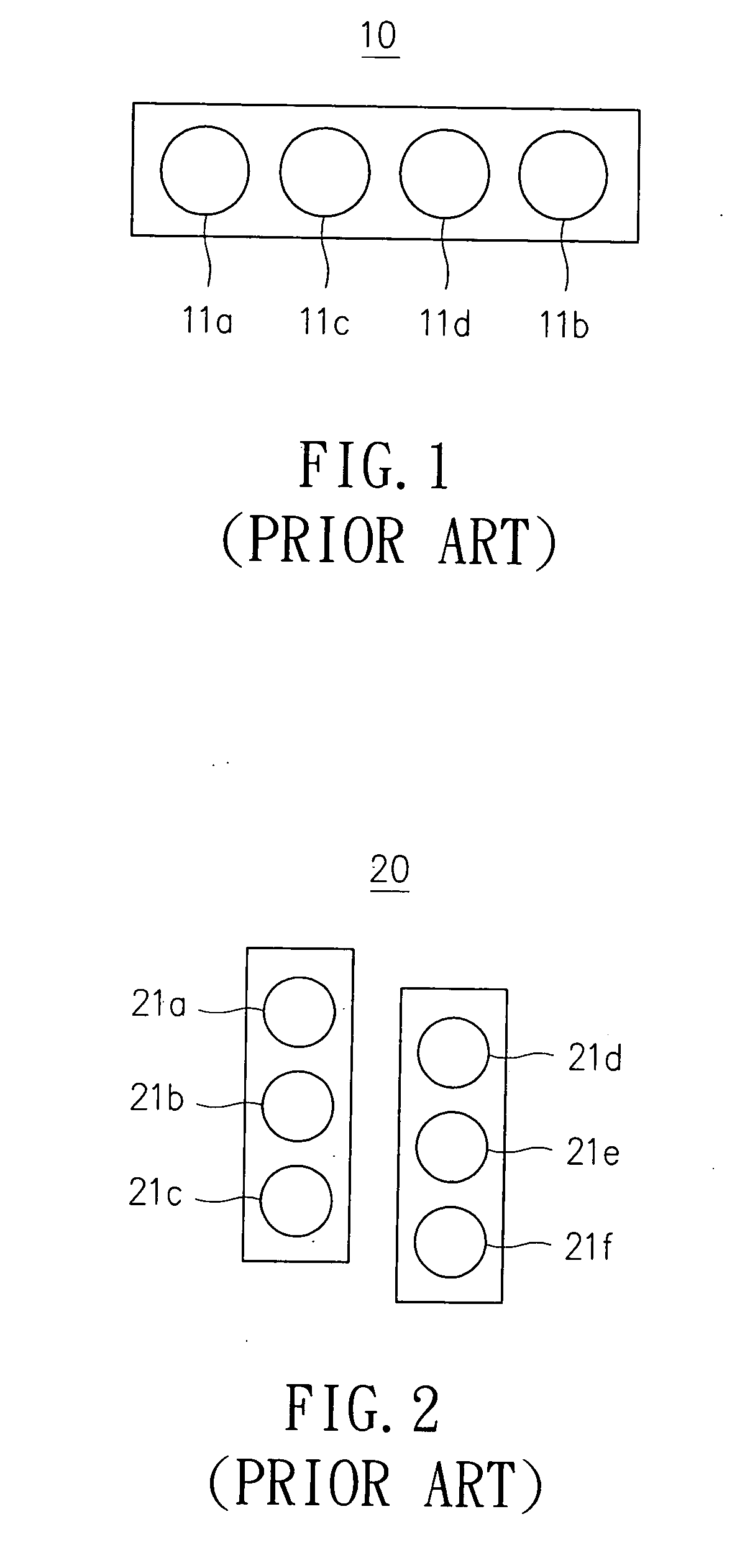

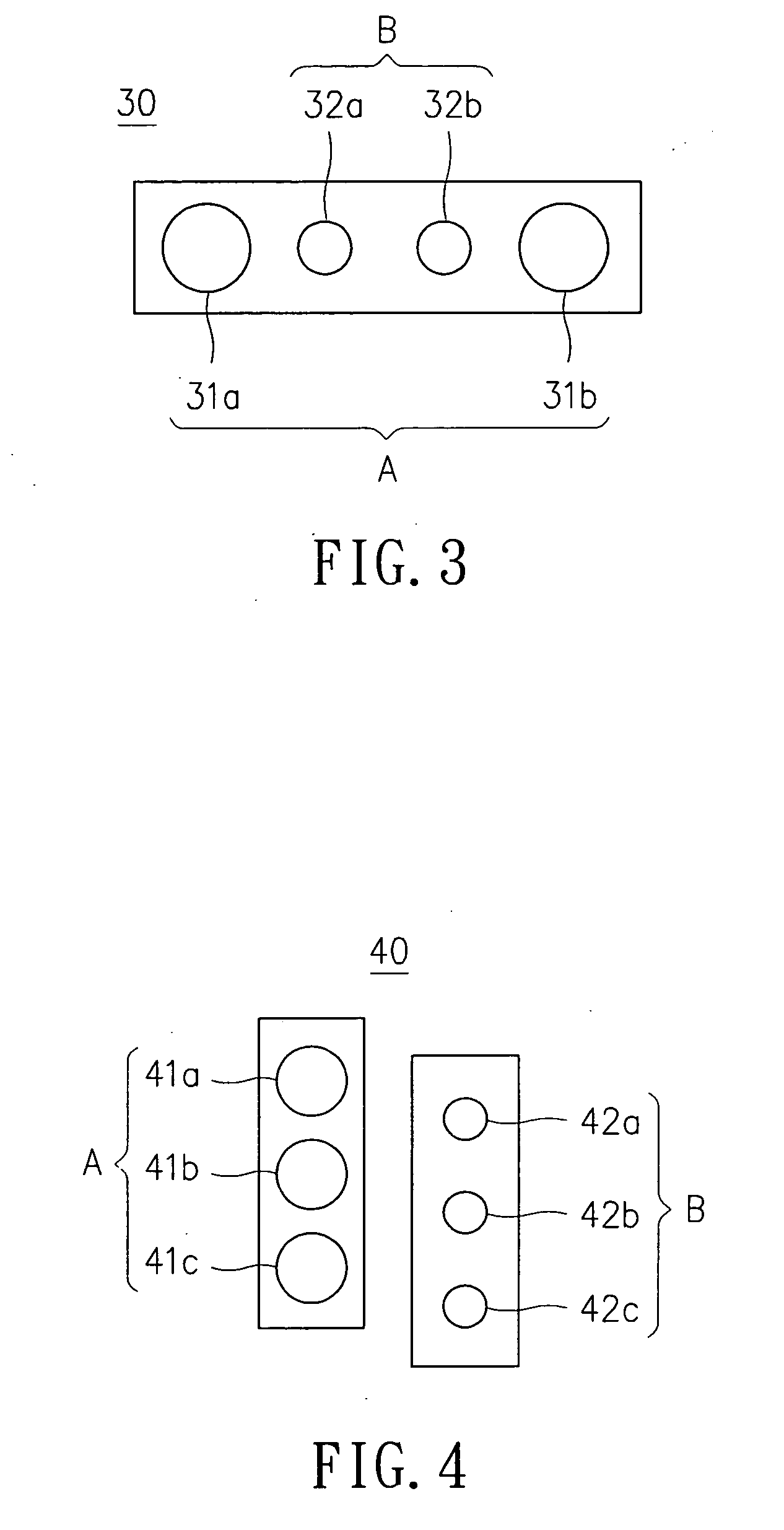

Multi-stage variable displacement engine

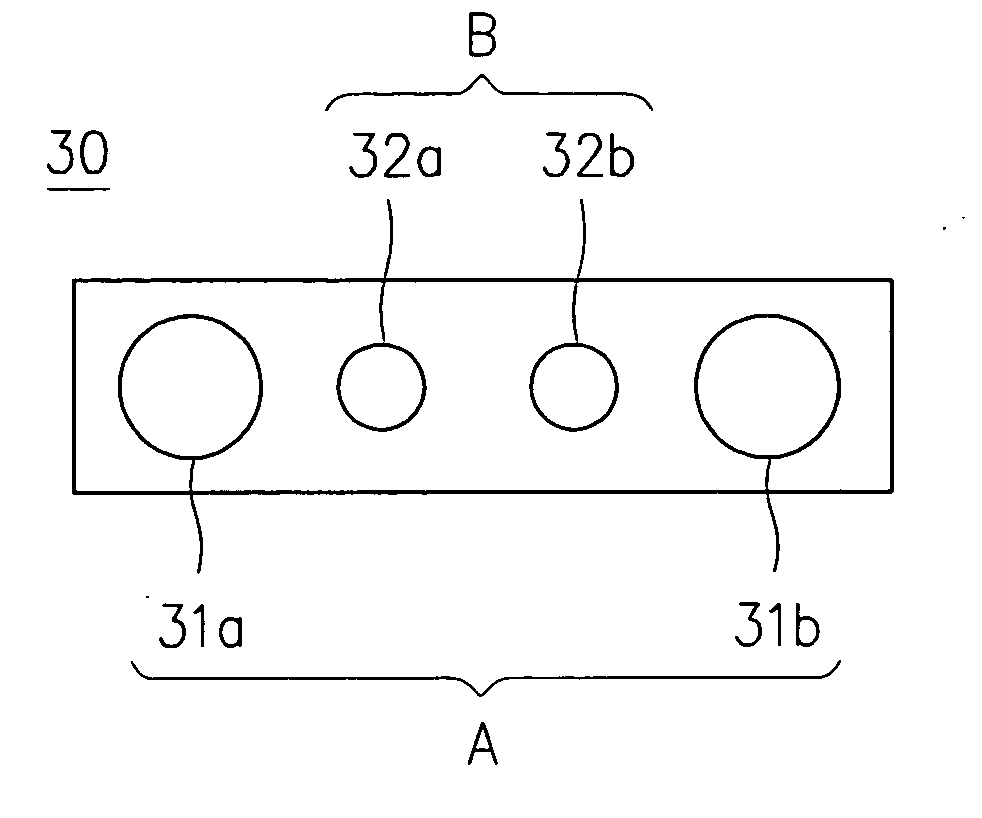

InactiveUS20070131183A1Improve efficiencyReduce fuel consumptionInternal combustion piston enginesCylinder headsCurrent loadFiring order

The present invention relates to an uneven cylinder displacement arrangement of a multi-stage variable displacement engine. By arranging a plurality of cylinders of at least two different cylinder bores or at least two different strokes in an engine while grouping the plural cylinders into at least two cylinder groups, e.g. grouping odd-numbered cylinders in an ignition sequence of the engine into a first group while grouping even-numbered cylinders in an ignition sequence of the engine into a second group, the engine is enabled to have multi-stage displacement capability adapted to various operation speeds for reducing fuel consumption since the displacement of the engine can be varied by using the ignition sequence to control and select which groups are to be ignited for matching the current load of the engine. In a preferred embodiment of the invention, there are two kinds of cylinders of different cylinder bores arranged in an engine which are grouped into two cylinder groups by the control of the ignition sequence of the engine, whereas the cylinder bore of a cylinder grouped in one of the two cylinder group is the same as another cylinder of the same cylinder group, but is different to those grouped in another cylinder group.

Owner:IND TECH RES INST

Wave energy conversion system

InactiveUS7042112B2Easy extractionHigh yieldGas turbine plantsPiston pumpsThermal energyForms of energy

Owner:SEAWOOD DESIGNS

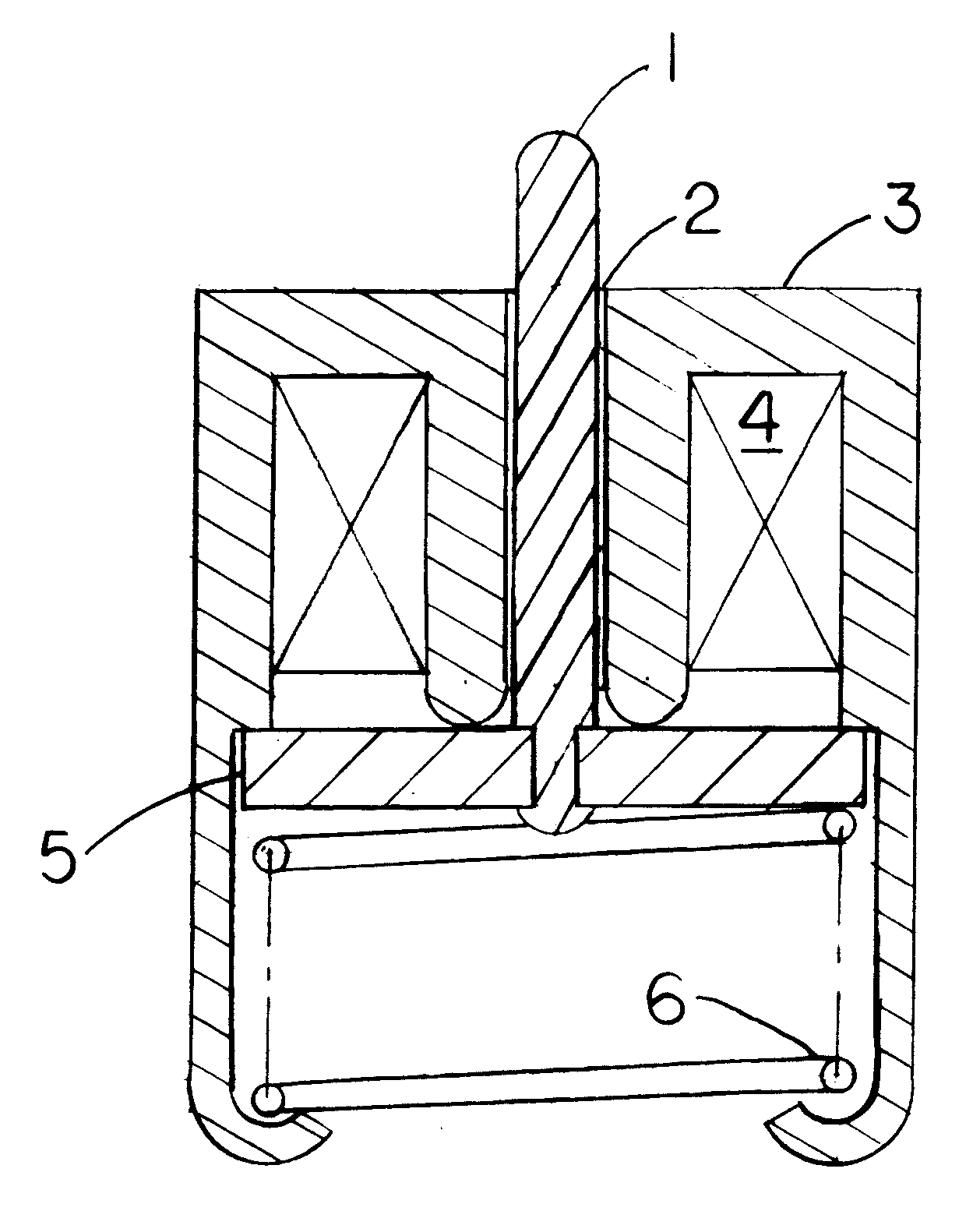

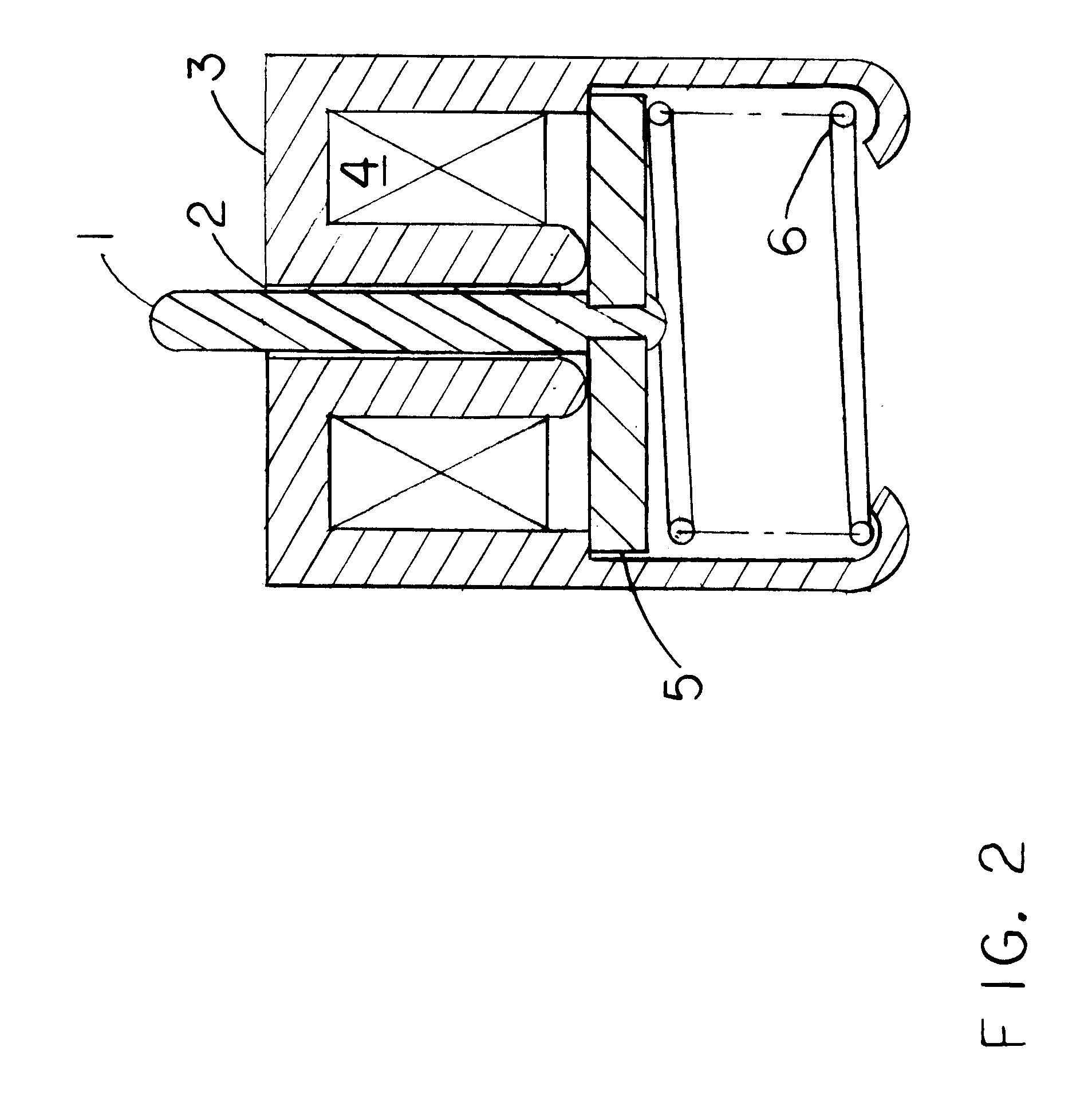

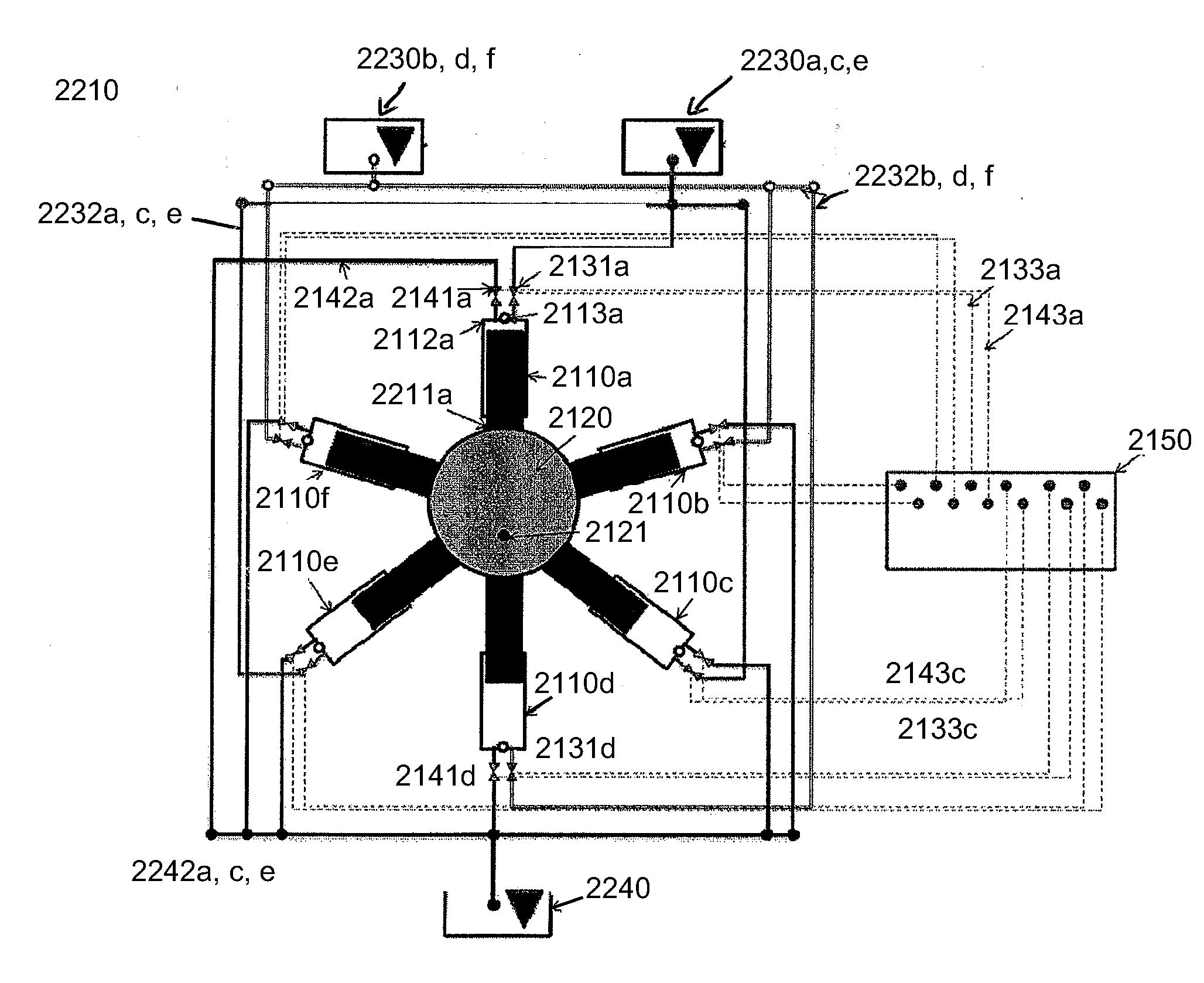

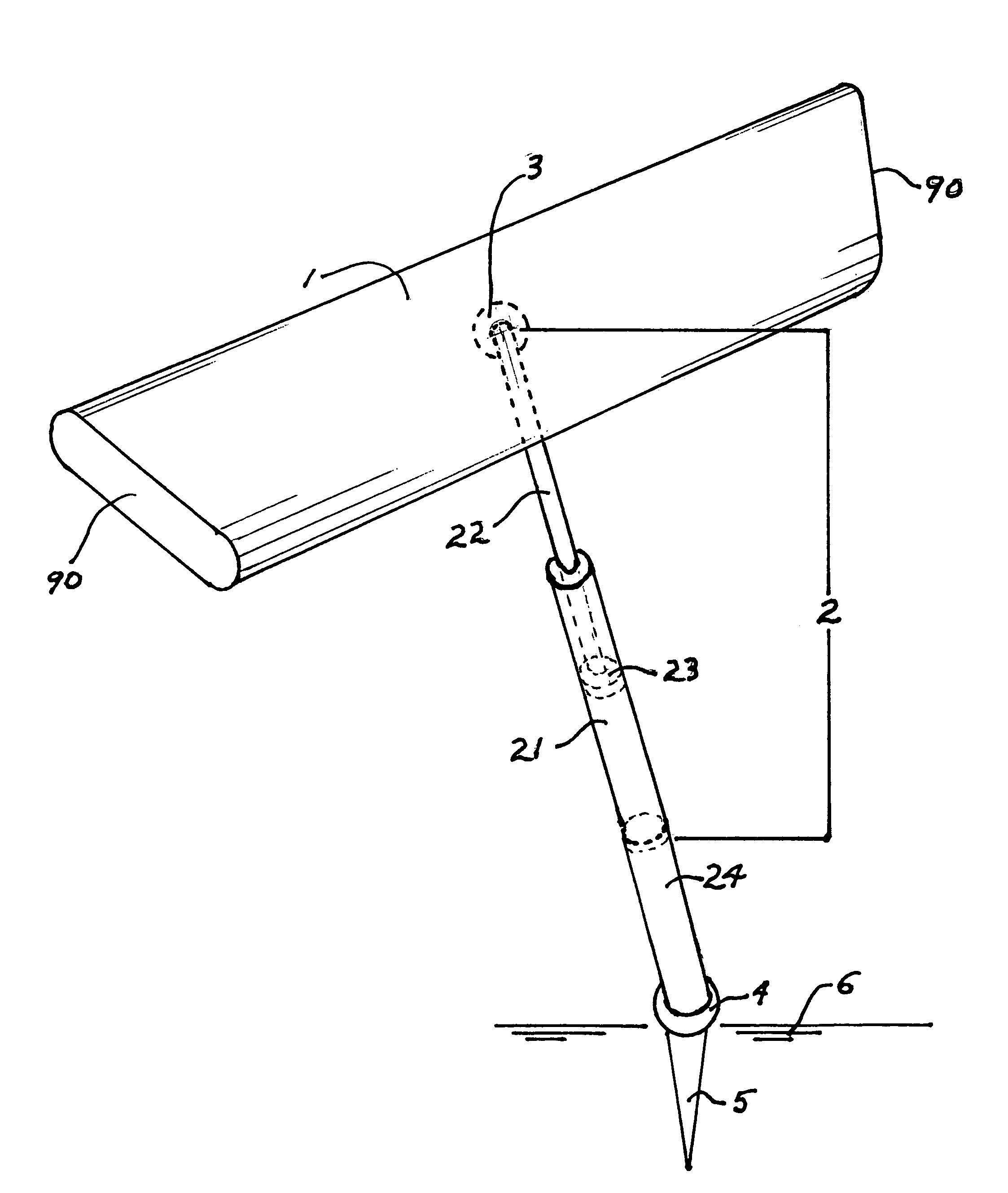

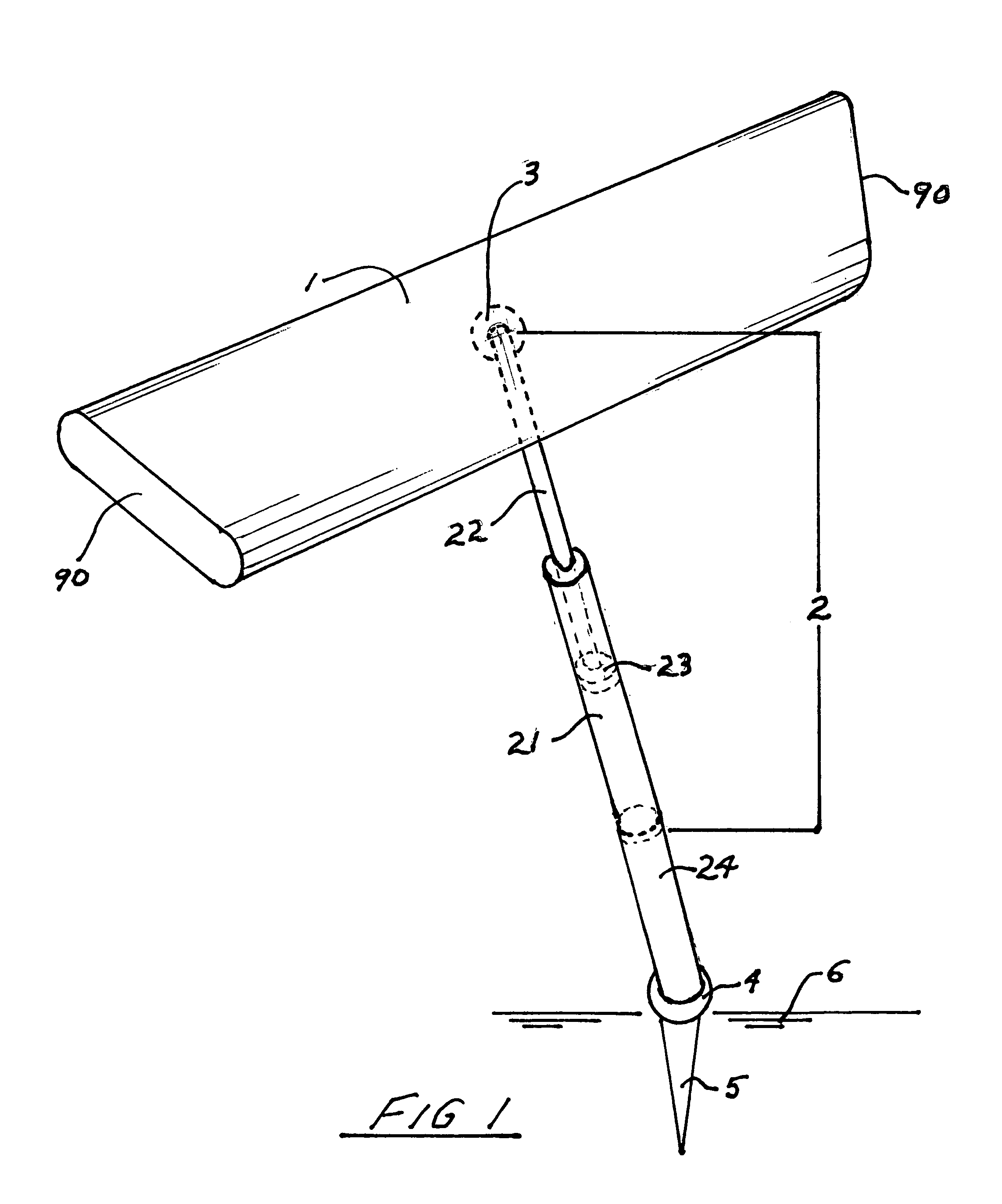

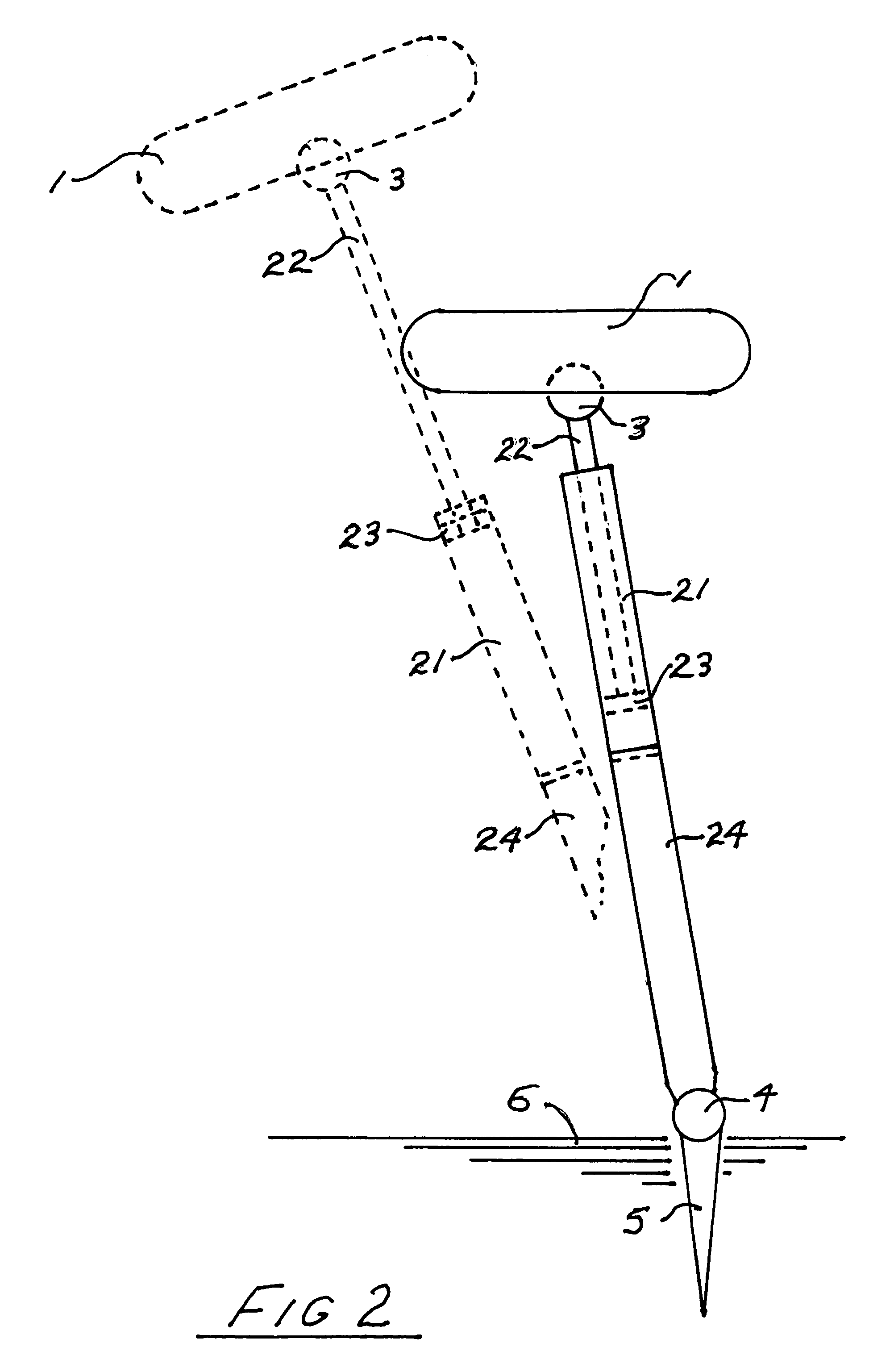

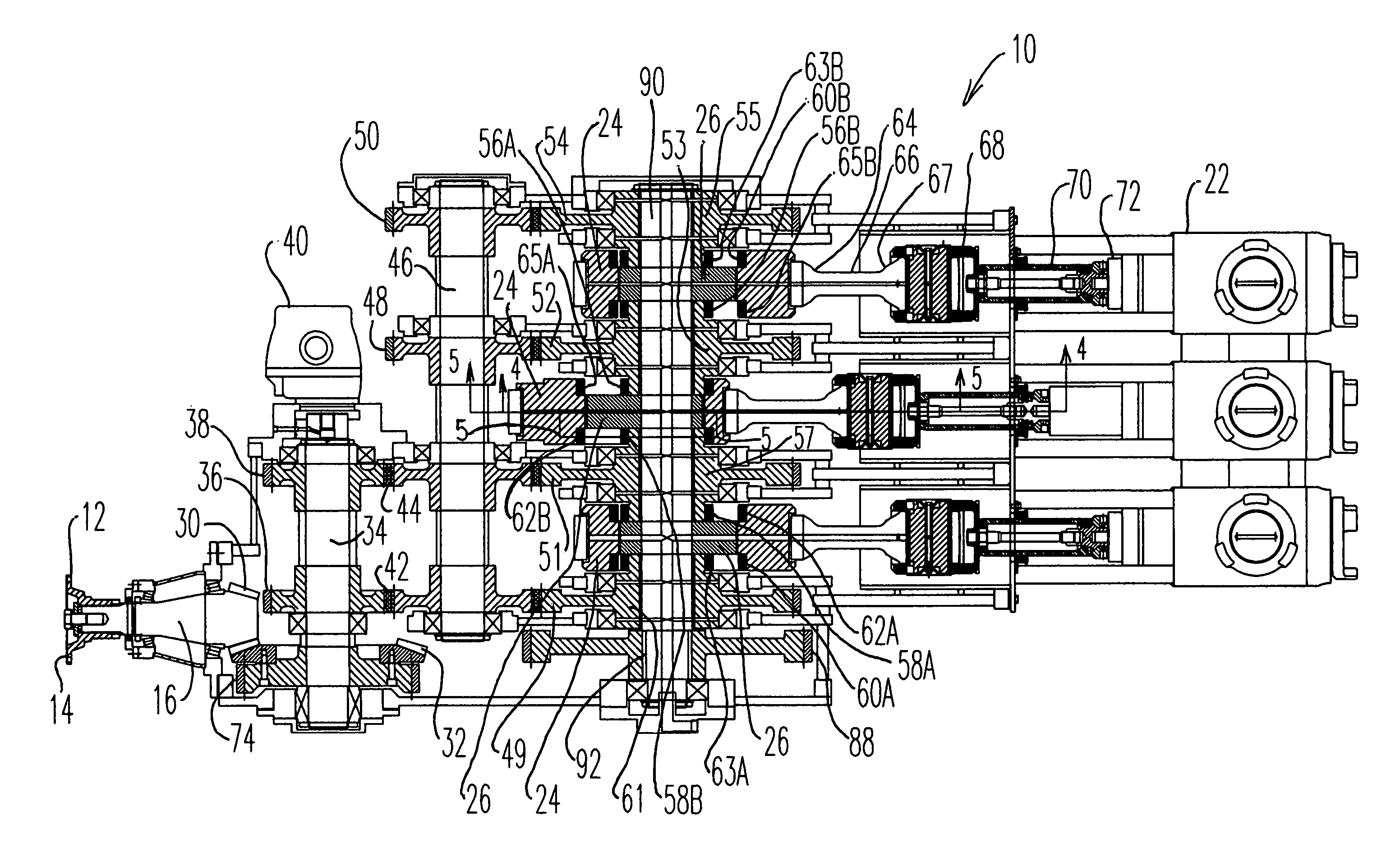

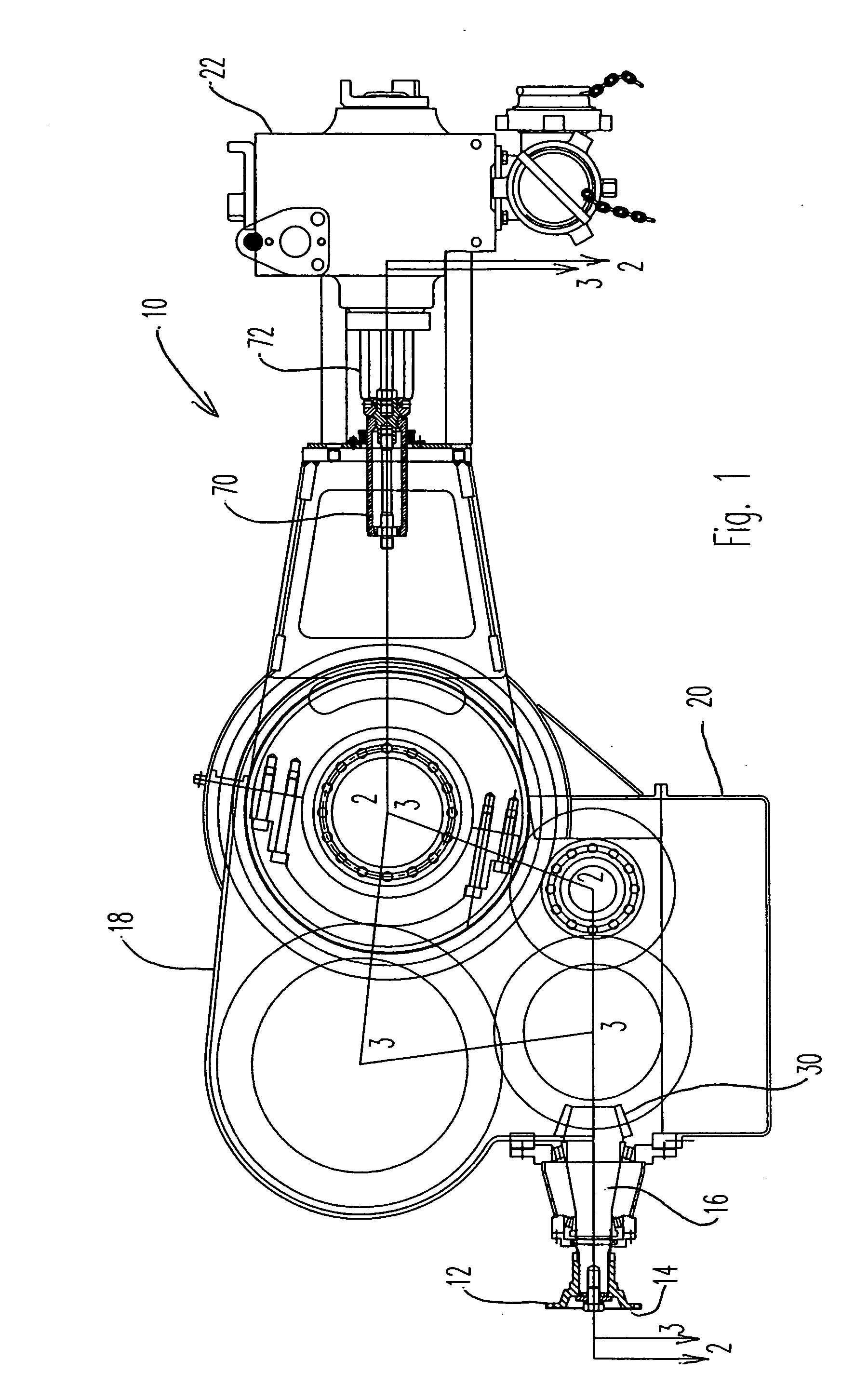

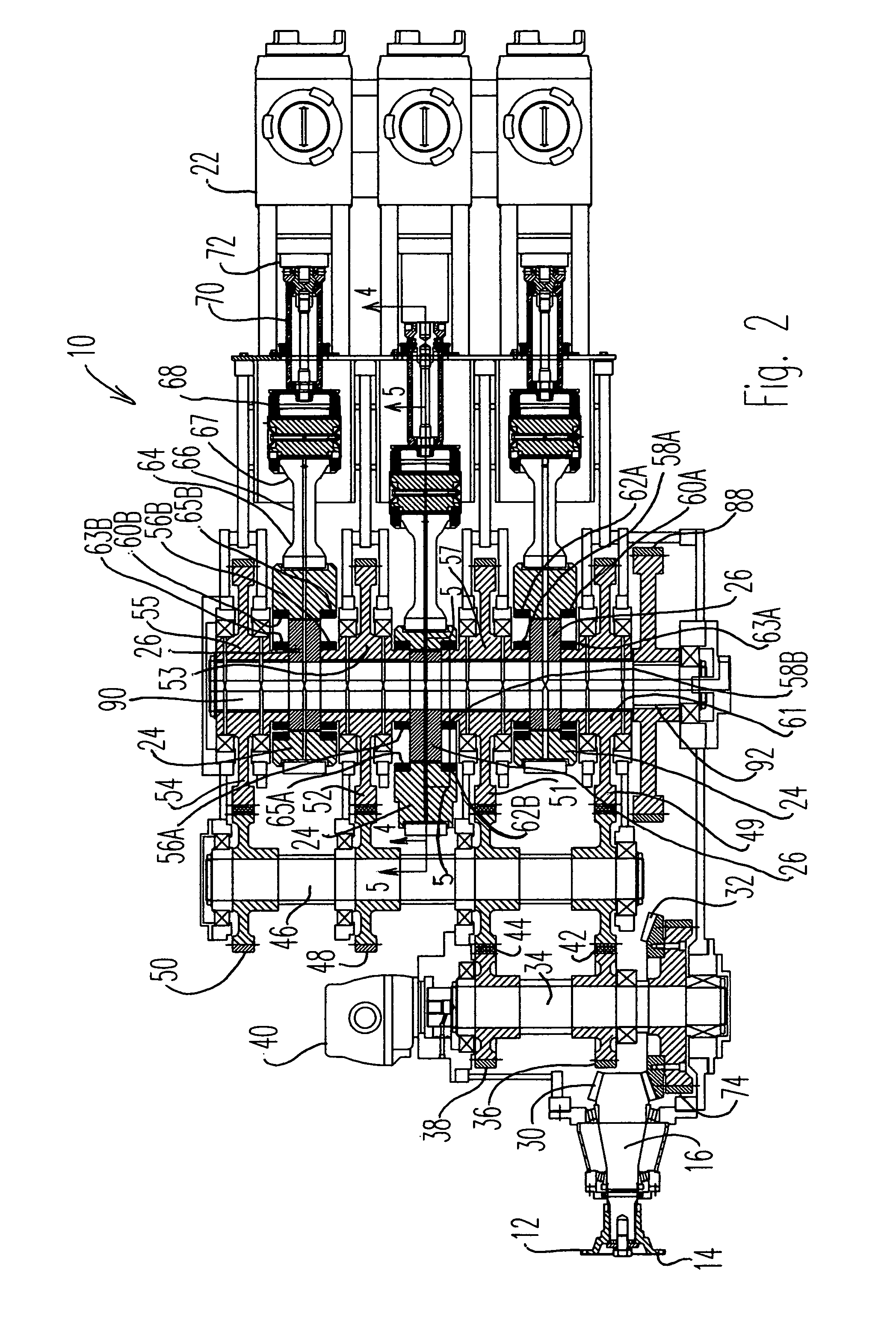

Variable displacement reciprocating pump

A variable displacement reciprocating pump with pumping rate that is adjustable from zero to maximum stroke while the pump is running. Stroke is varied by changing relative position of pairs of eccentric inner and outer cams that drive the pump's plungers. The pump's input drive shaft drives two gear trains: a first gear train that turns the inner cams and a second gear train that turns the outer cams. These cams normally revolve together with no relative motion occurring between them. A rotary actuator is positioned in the first gear train to rotate the inner cams relative to the outer cams and thereby changes the pump's stroke. A computerized system of sensors and control valves allows the pump to be automatically controlled or limited to any one or combination of desired output flow, pressure and horsepower.

Owner:SERVA CORP

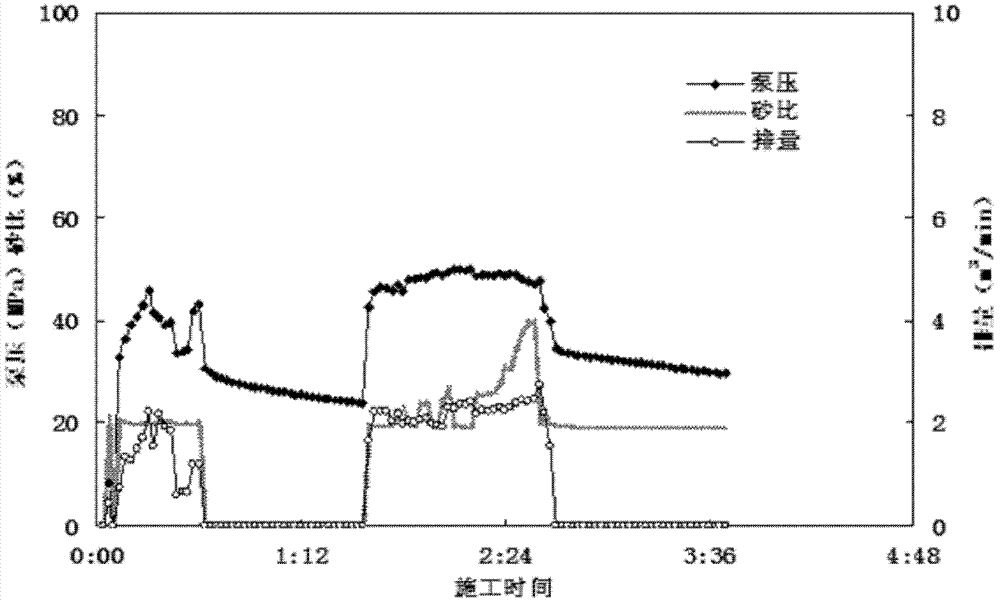

Fracturing method for comprehensively controlling fracture height

InactiveCN103089224AGuaranteed construction successAvoid invalid extensionFluid removalFracturing fluidWell control

The invention discloses a fracturing method for comprehensively controlling fracture height. The method includes: injecting reversing agent to form an artificial isolating layer, using clean fracturing fluid, controlling construction scale, designing construction pumping programs of variable displacement and low displacement, using a combination of supporting agent with different grain sizes, and adjusting the pumping programs according to construction pressure monitoring results. The fracturing method for comprehensively controlling fracture height is simple in process, convenient to operate, evident in construction effect, capable of being widely used in renovation construction of oil-gas reservoirs with a thin target reservoir stratum and small stress difference between the reservoir stratum and the isolating layer, and capable of well controlling vertical extension of fractures so as to avoid ineffective extension of a communication water layer, a gas layer or in the vertical direction, lower using amount of the fracturing fluid and the supporting agent, reduce cost of fracturing construction and improve effect of fracturing modification yield increase.

Owner:CHINA PETROLEUM & CHEM CORP +1

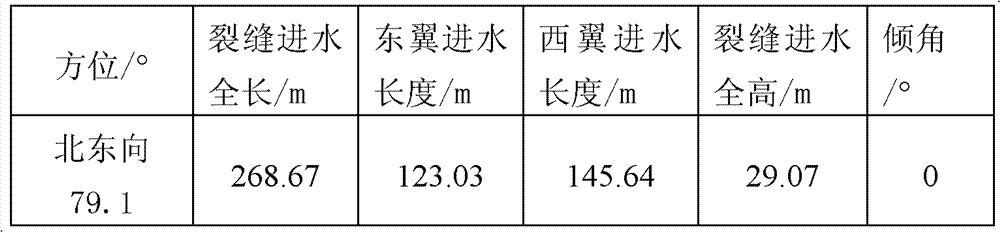

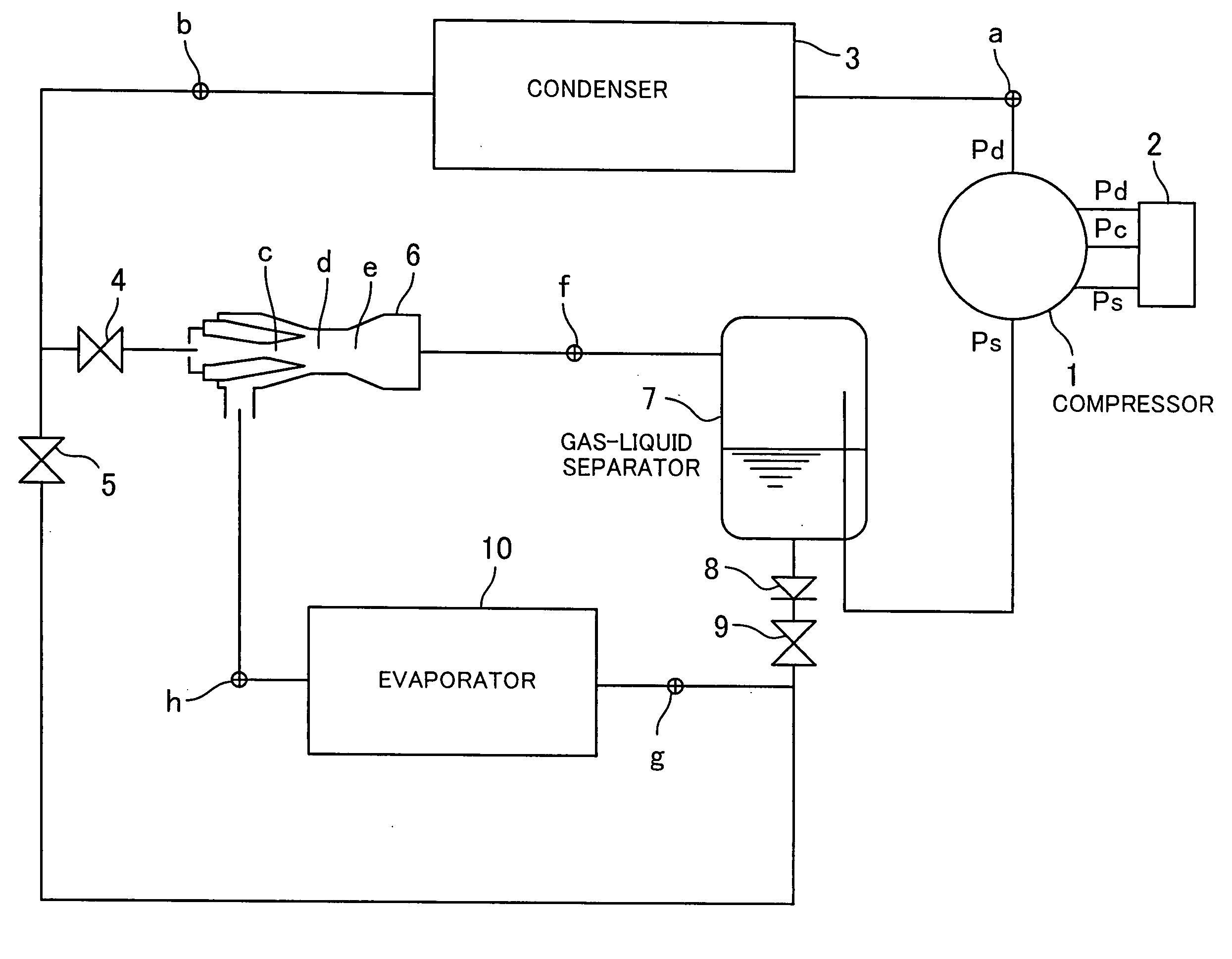

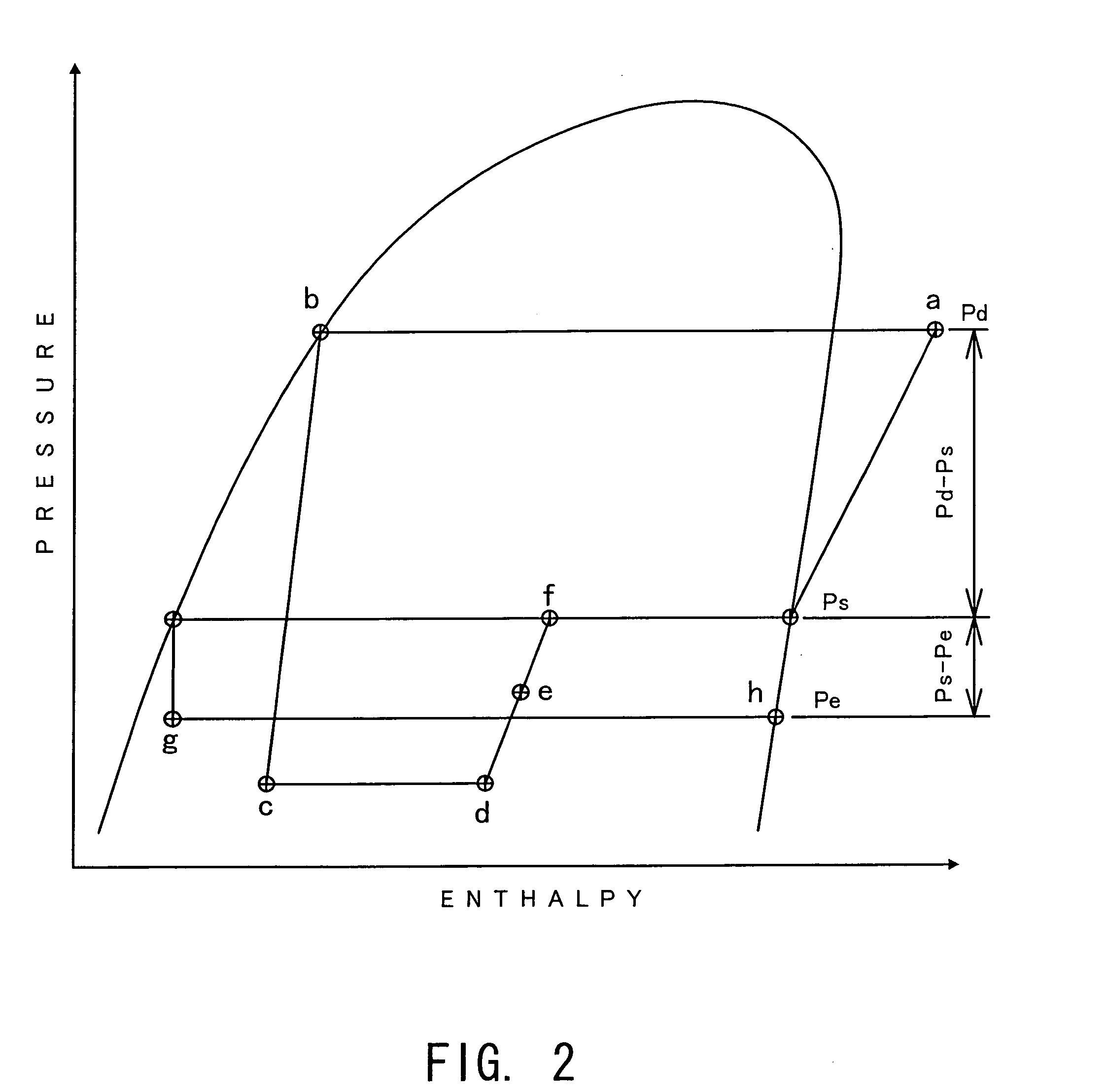

Refrigeration cycle

InactiveUS20050011221A1Low costAir-treating devicesCompression machines with non-reversible cycleMobile vehicleVapor–liquid separator

The object of the present invention is to provide a refrigeration cycle for an automotive air conditioner, which is reduced in costs and uses an ejector. A variable displacement compressor driven by an engine for driving an automotive vehicle is used as a compressor, and the capacity of the compressor is controlled by a capacity control valve such that the differential pressure between discharge pressure and suction pressure of refrigerant becomes equal to a predetermined differential pressure determined by an external signal. Pressure substantially equal to pressure applied across the compressor is applied across the ejector, and therefore to control the differential pressure across the compressor is to control the differential pressure across the ejector. A differential pressure valve disposed between a gas-liquid separator and an evaporator is set to a differential pressure approximately proportional to the differential pressure across the ejector. A differential pressure set to the differential pressure valve is estimated from the differential pressure across the compressor which corresponds to the differential pressure across the ejector, and the differential pressure can be directly and accurately determined from the external signal for controlling the capacity control valve.

Owner:TGK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com