Patents

Literature

494 results about "Constant load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A constant power load is designed to dynamically adjust the load current inversely with the load voltage so that the load power is constant, P = VI.

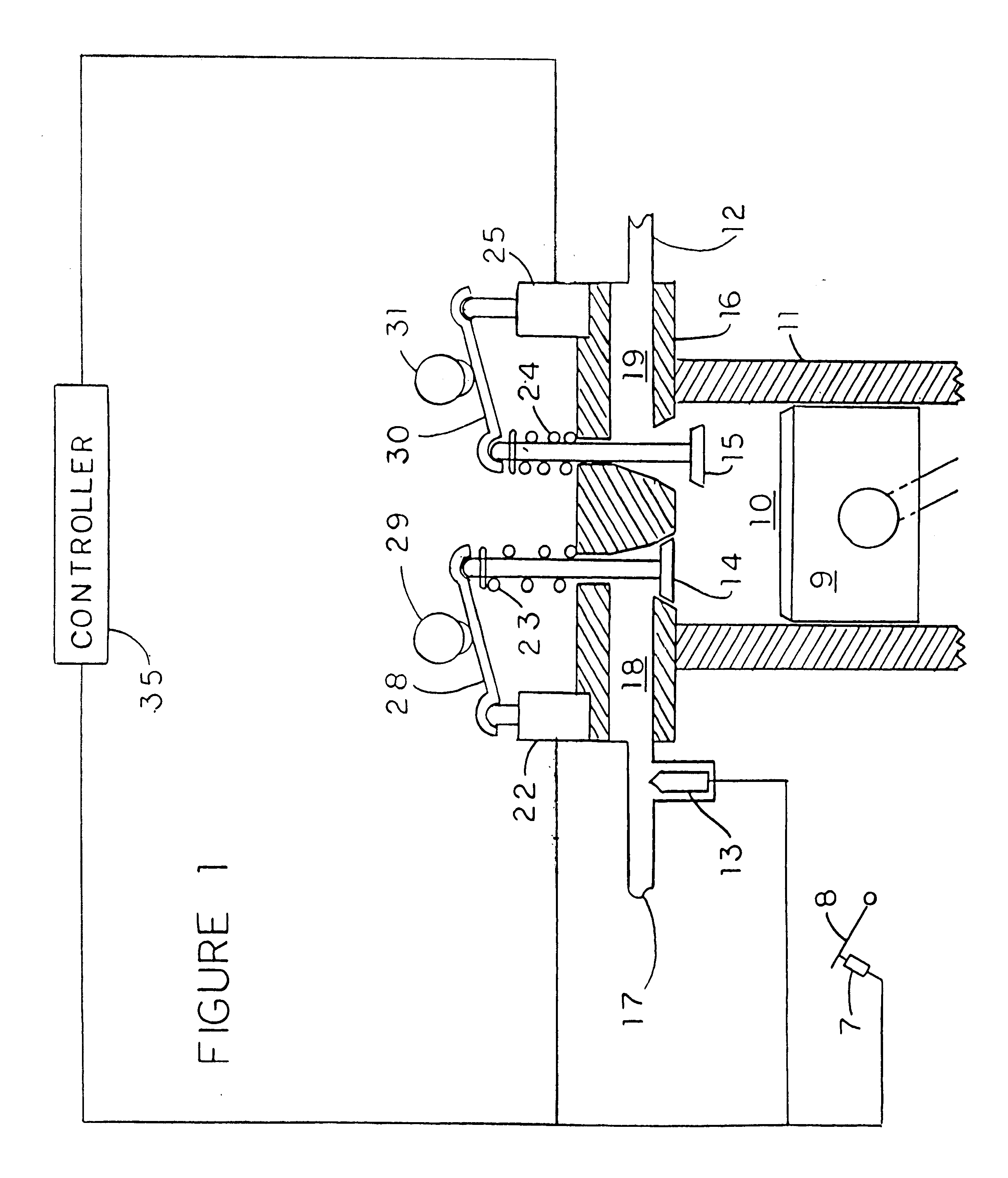

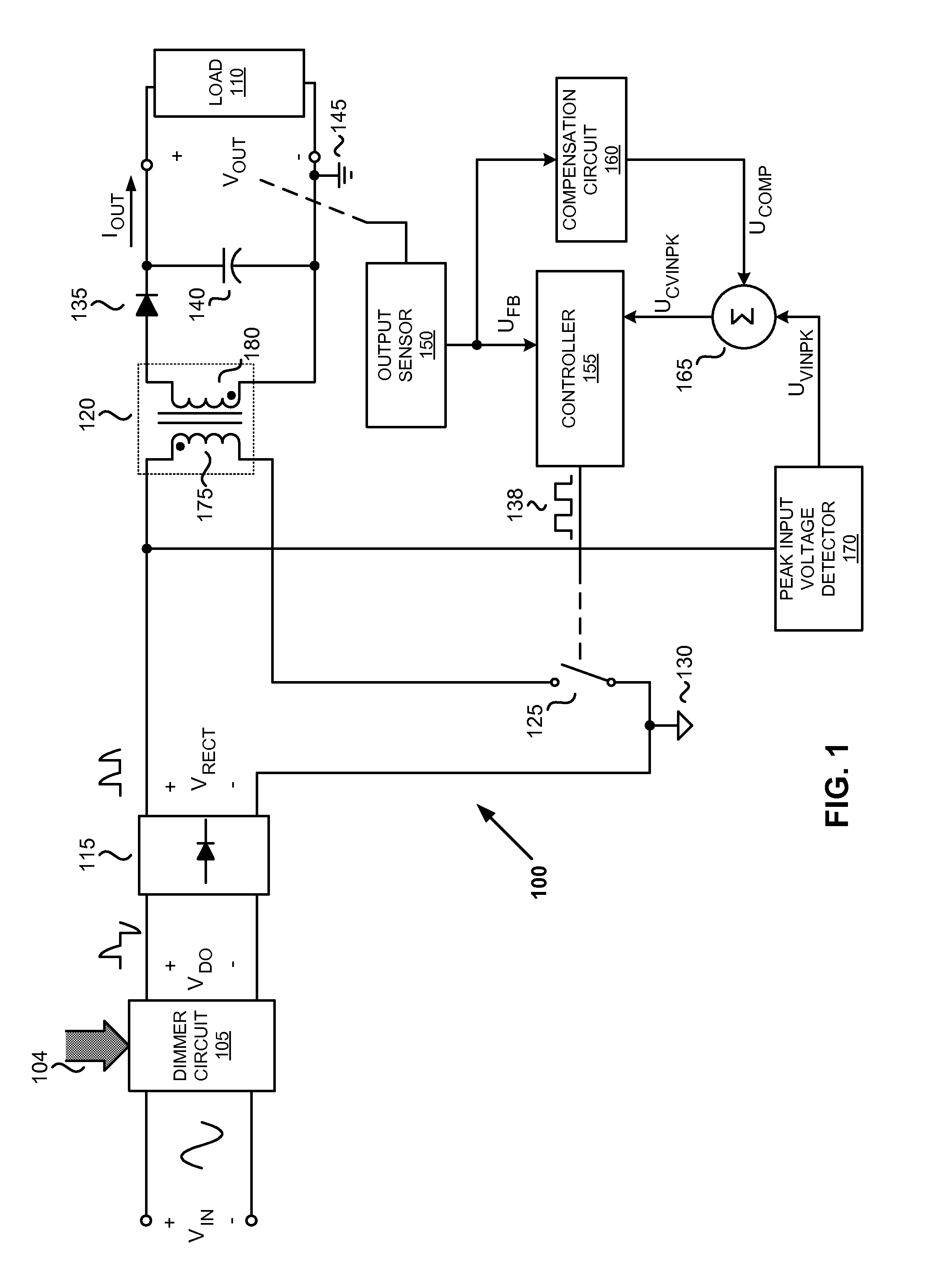

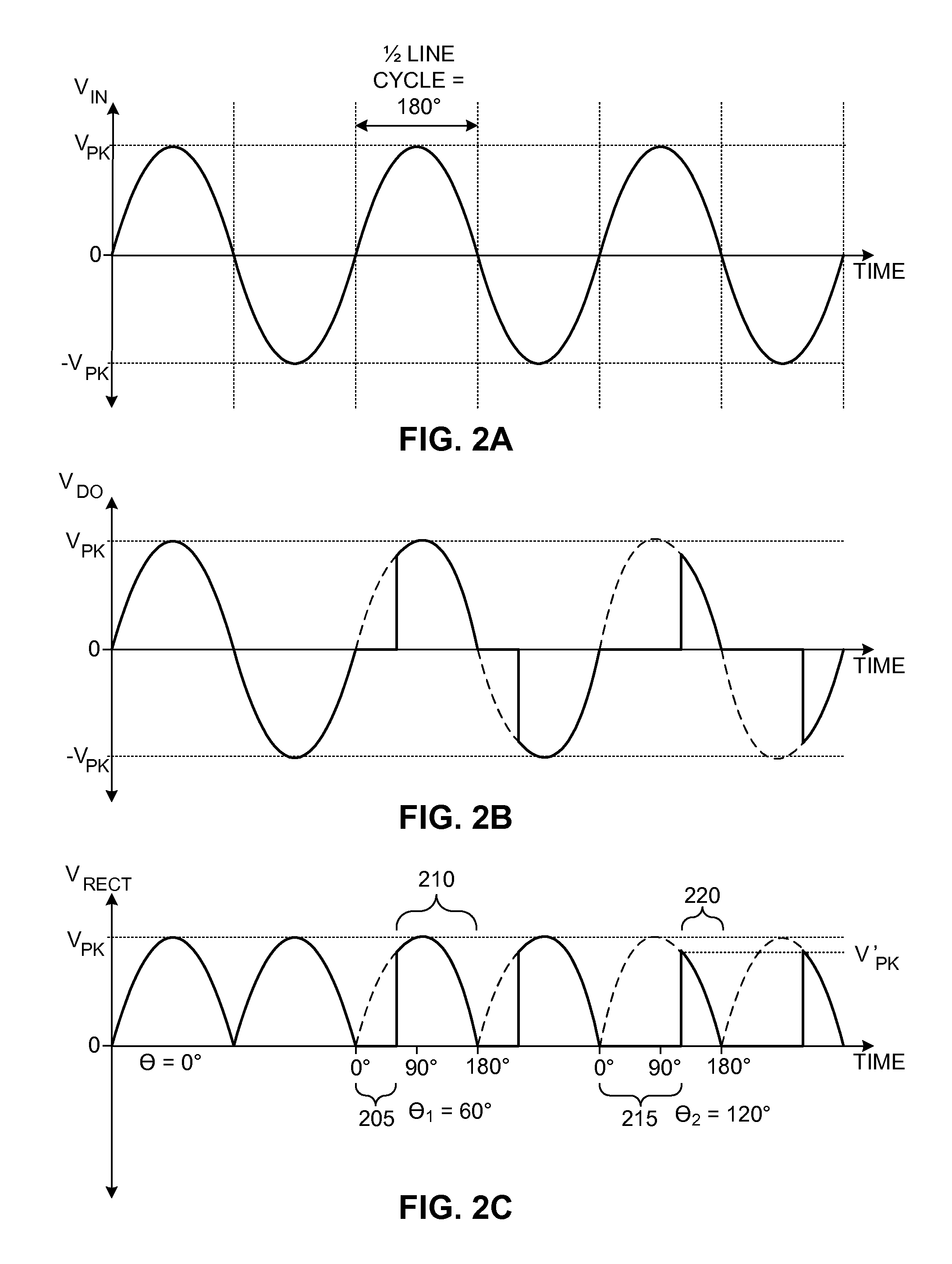

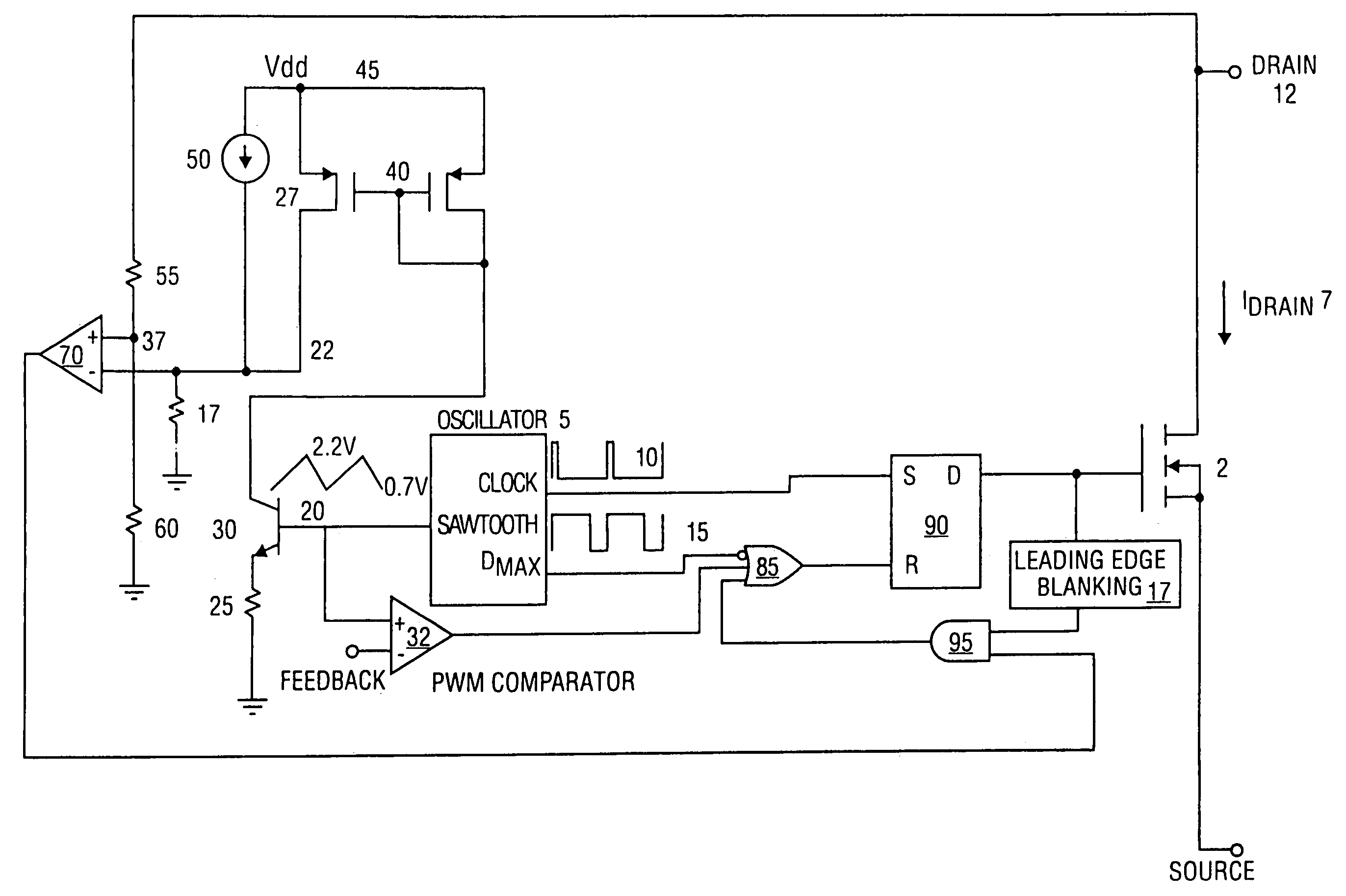

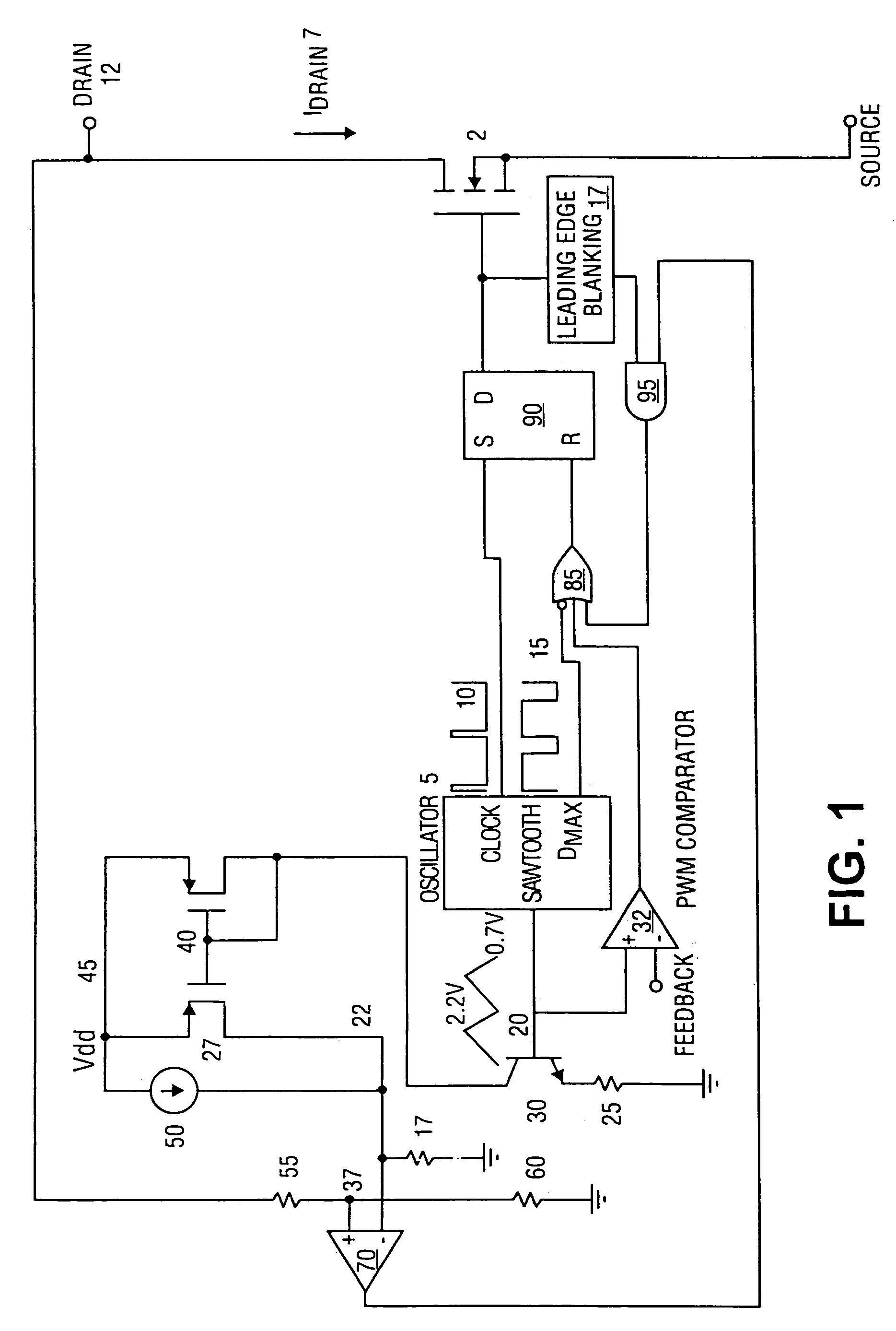

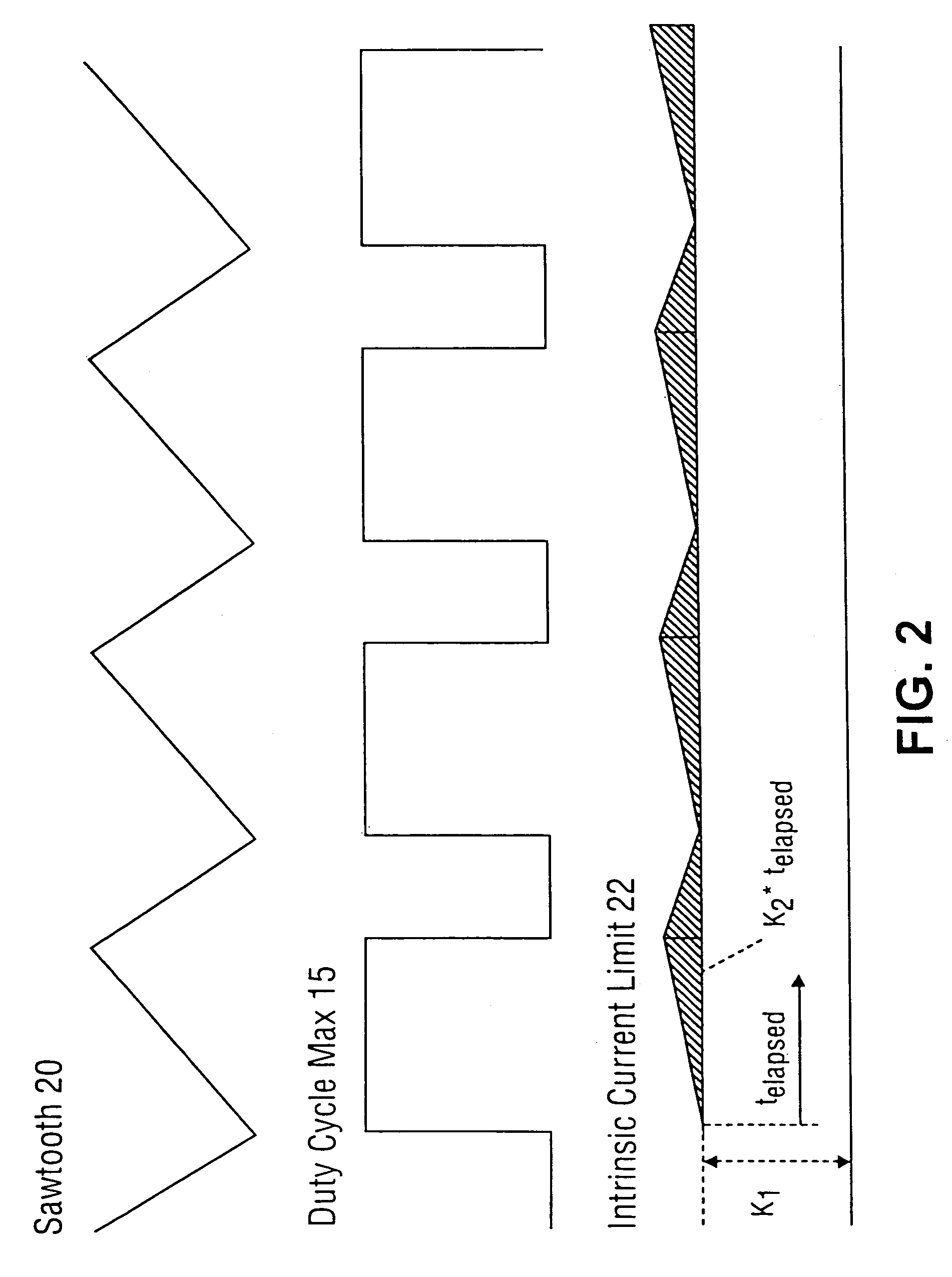

Method and apparatus for maintaining a constant load current with line voltage in a switch mode power supply

InactiveUS20060176716A1TransistorConversion with intermediate conversion to dcConstant loadSignal response

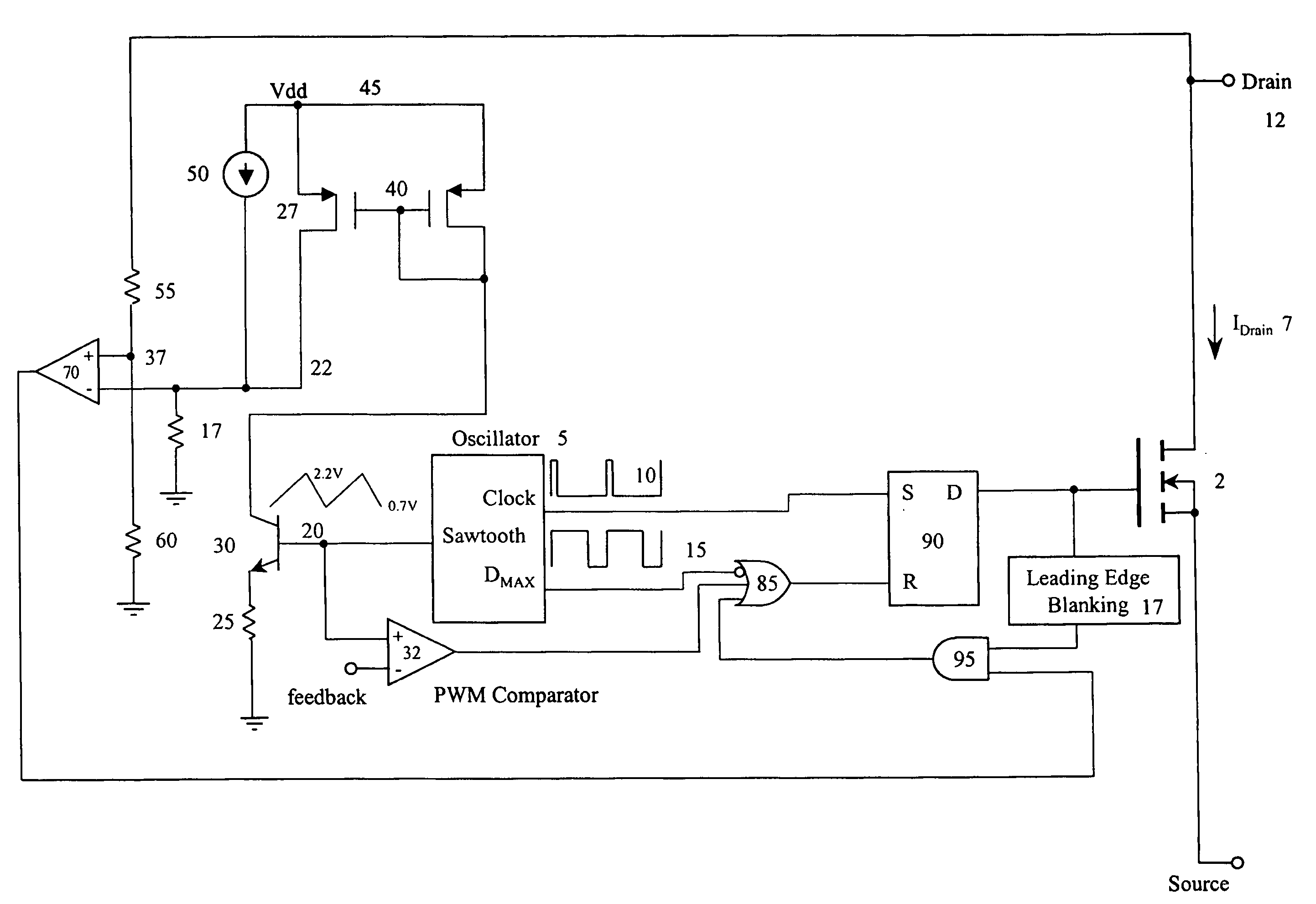

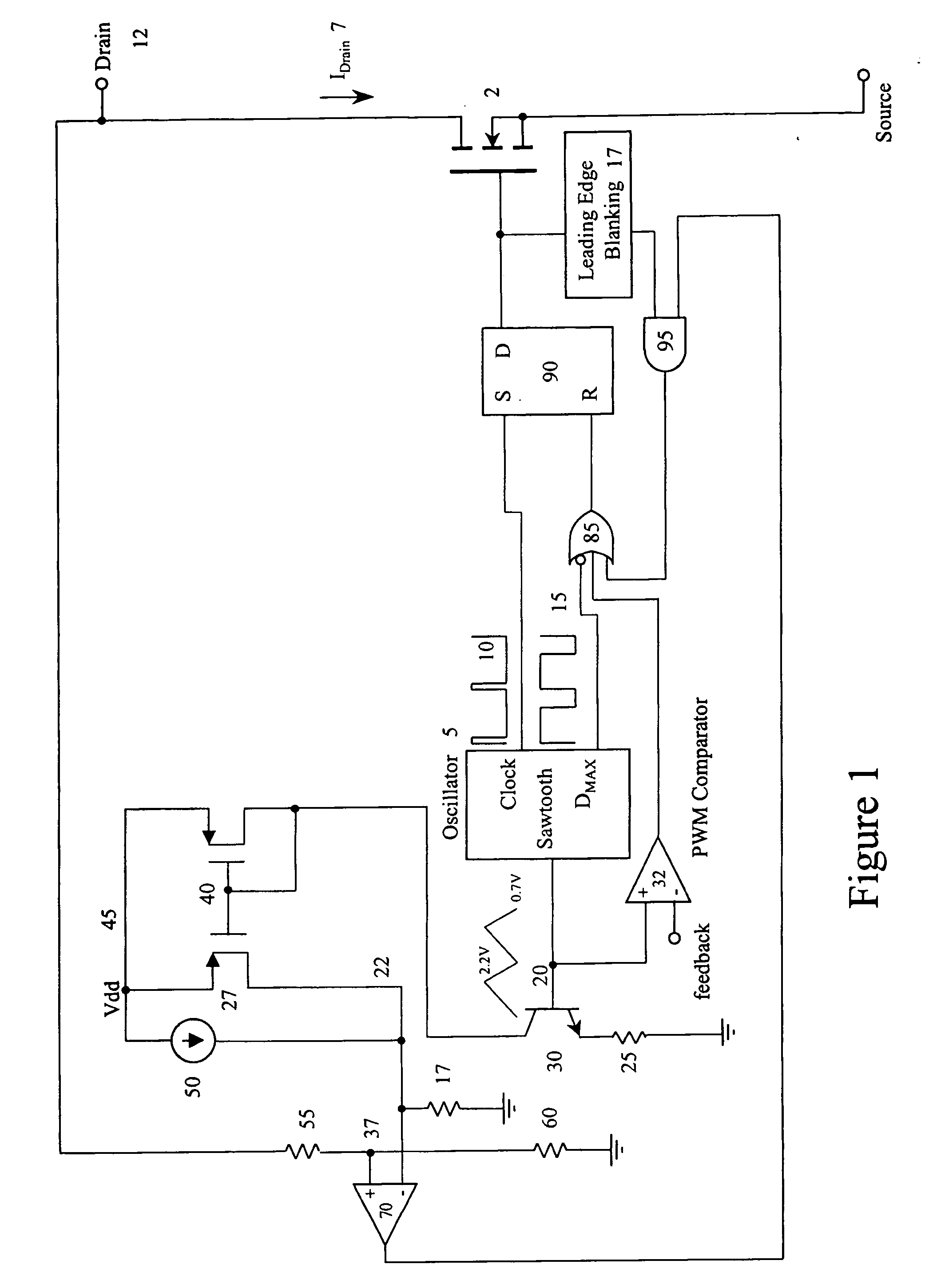

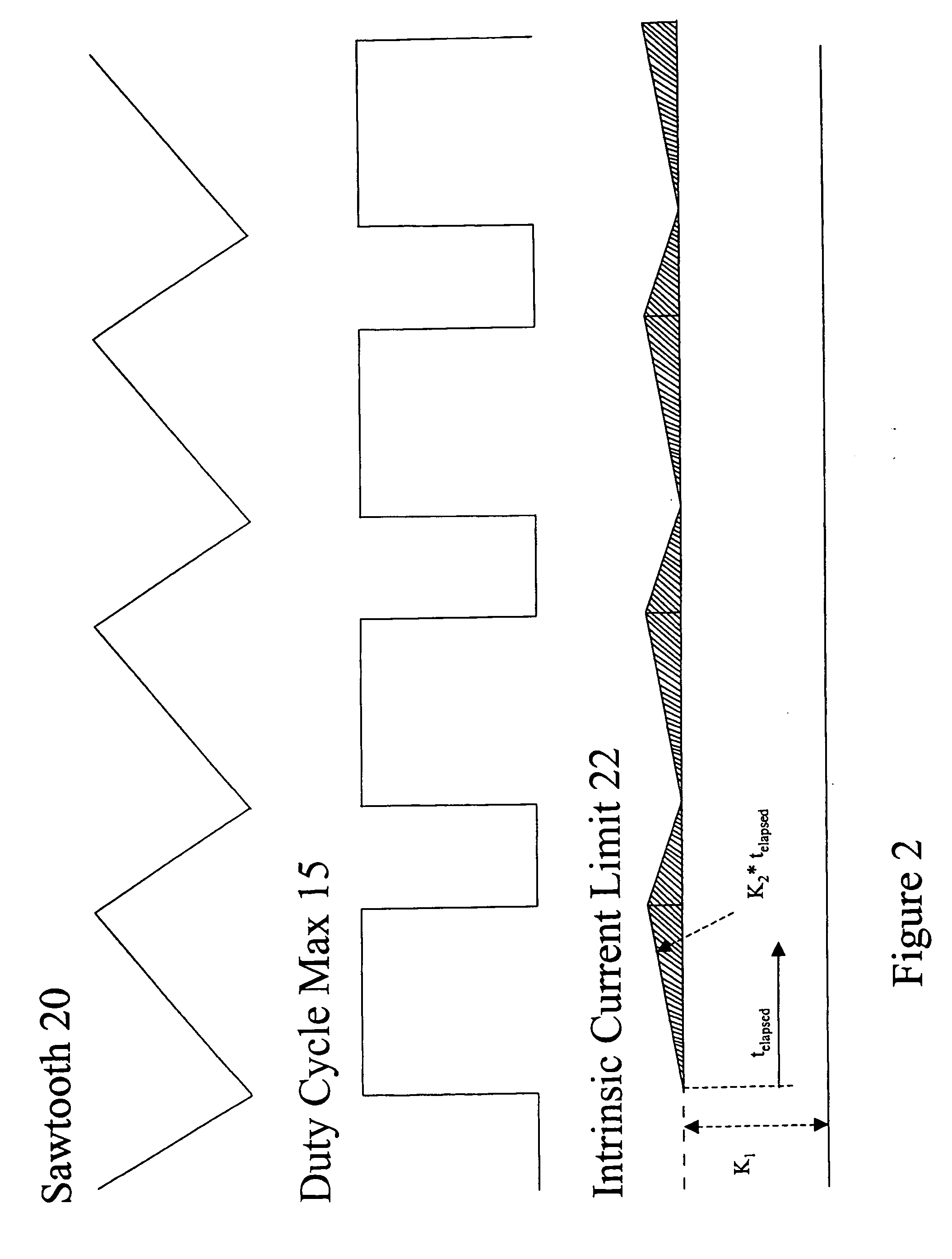

A power supply including a regulation circuit that maintains an approximately constant load current with line voltage. An example circuit includes a switch including first, second and third terminals. The first terminal is coupled or decoupled to the second terminal in response to a control signal received at the third terminal. Voltage sense circuitry is included and is coupled to sense a voltage drop across the switch. The voltage drop is representative of a current in the switch during an on time of the switch. The voltage sense circuitry has a variable current limit threshold that increases between a first level and a second level during the on time of the switch. The control signal is responsive to the variable current limit threshold to regulate a power supply with an output characteristic having an approximately constant output voltage below an output current threshold and an approximately constant output current below an output voltage threshold.

Owner:POWER INTEGRATIONS INC

Engine valve disabler

A method for improving efficiency and reducing emissions of an internal combustion engine. Variable displacement engine capabilities are achieved by disabling engine valves during load changes and constant load operations. Active cylinders may be operated at minimum BSFC by intermittently disabling other cylinders to provide the desired net torque. Disabling is begun by early closing of the intake valve to provide a vacuum at BDC which will result in no net gas flow across the piston rings, and minimum loss of compression energy in the disabled cylinder; this saving in engine friction losses is significant with multiple disablements.

Owner:MOYER DAVID F

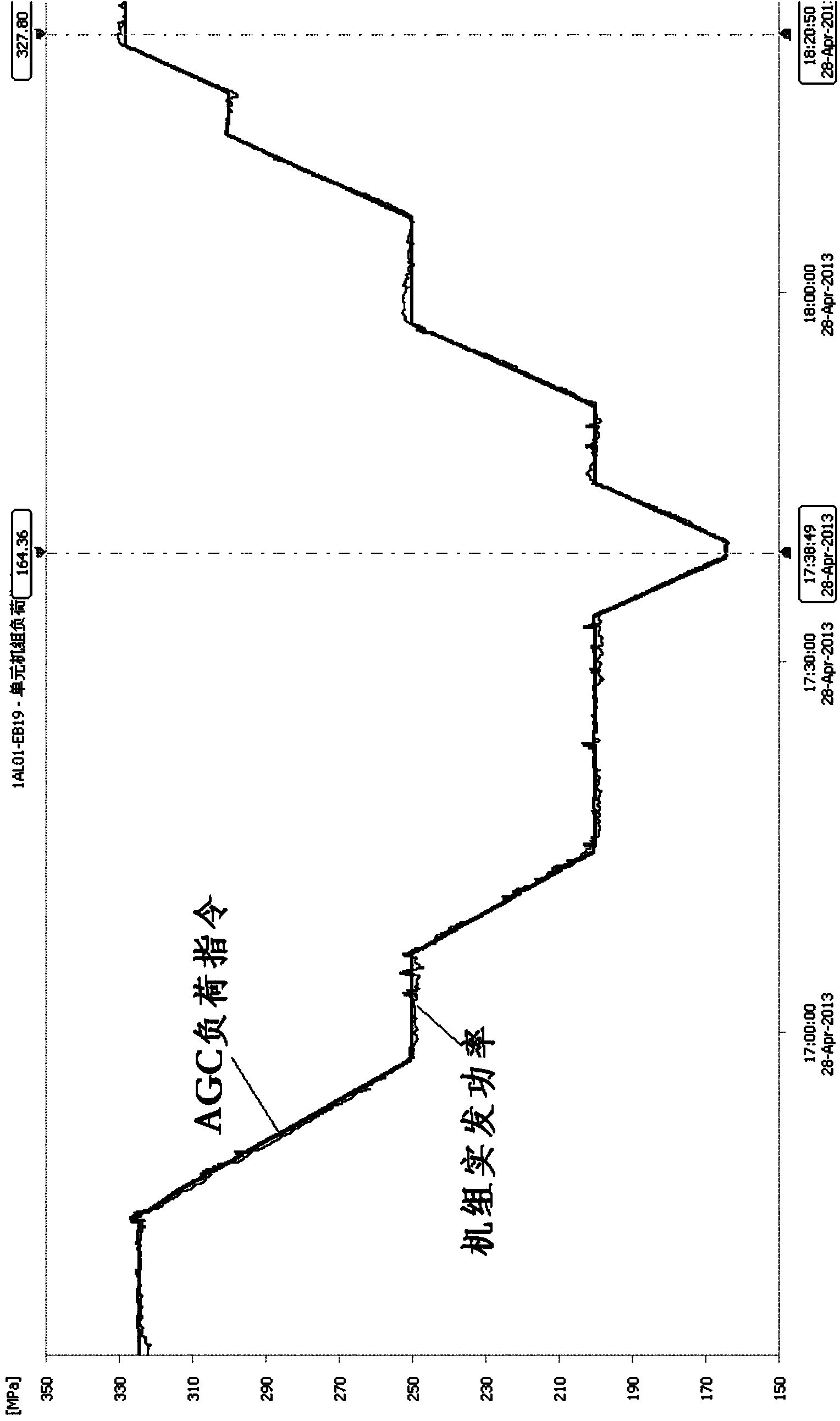

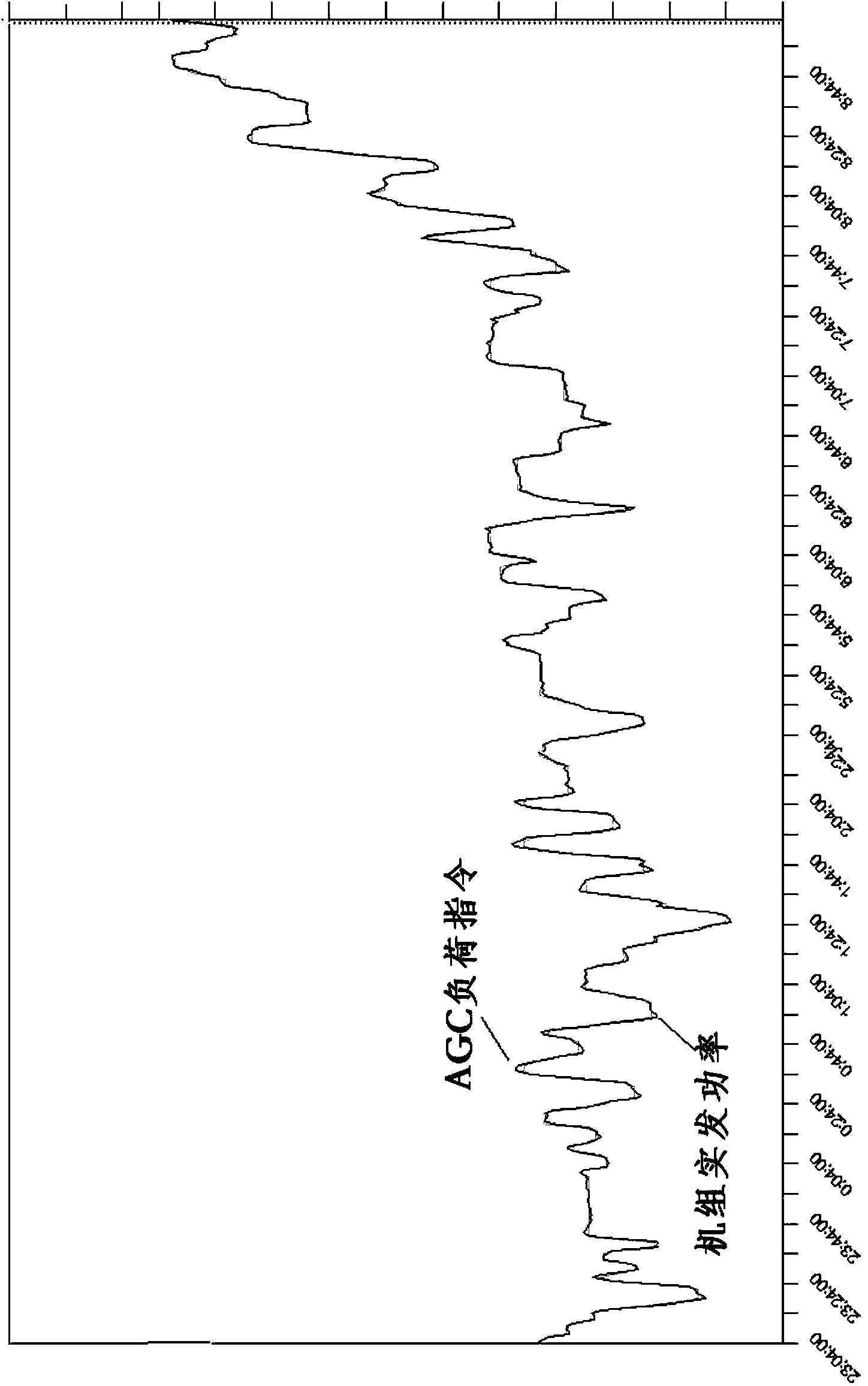

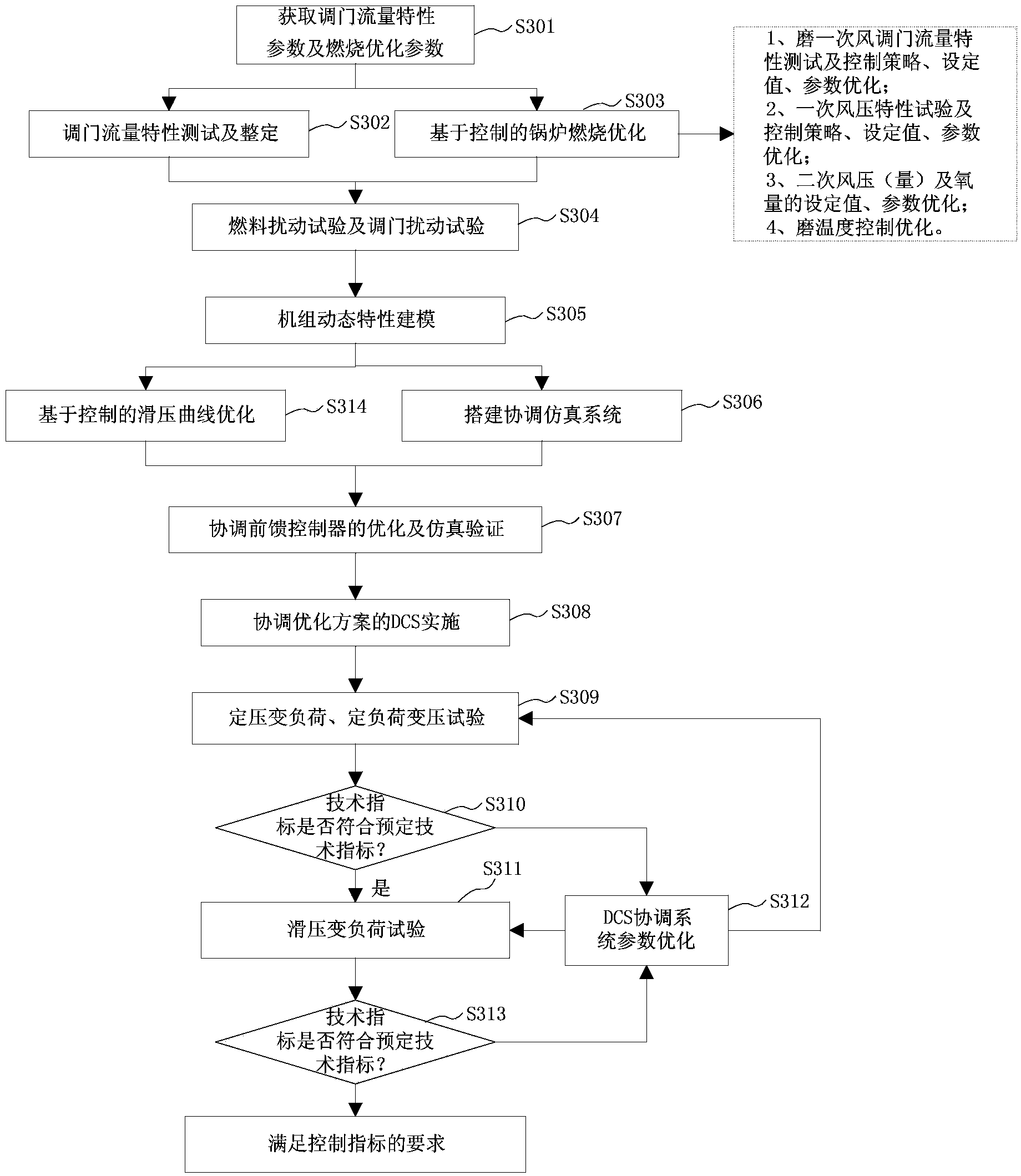

Integral optimization method and system for automatic power generation system of coal-fired unit

ActiveCN103513640AImprove variable load capacityImprove adaptabilityProgramme total factory controlSteam pressureDynamic models

The invention provides an integral optimization method and system for an automatic power generation system of a coal-fired unit. The method comprises the steps of carrying out control valve flow characteristic test and adjustment according to control valve flow characteristic parameters, carrying out combustion optimization on a wind and smoke subsystem and a combustion subsystem, carrying out a fuel disturbance test and a control valve disturbance test to generate typical test parameters, using the typical test parameters to generate a dynamic unit model, constructing a coordinating simulation system according to a coordinating controller and the dynamic unit model, using the dynamic unit model to optimize a feedforward controller and carry out simulation verification on the coordinating simulation system simultaneously, carrying out DCS configuration and parameter debugging in the simulation system, carrying out a constant-voltage slide-voltage variable-load test and a constant-load voltage-transformation test to generate technical indexes of the variable-load rate, the variable-load accuracy, variable-load response time and the main steam pressure accuracy, judging whether the technical indexes meet the preset technical indexes, and if on yes judgment, carrying out a slide-voltage variable-load test to enable the coal-fired unit to operate normally.

Owner:STATE GRID CORP OF CHINA +1

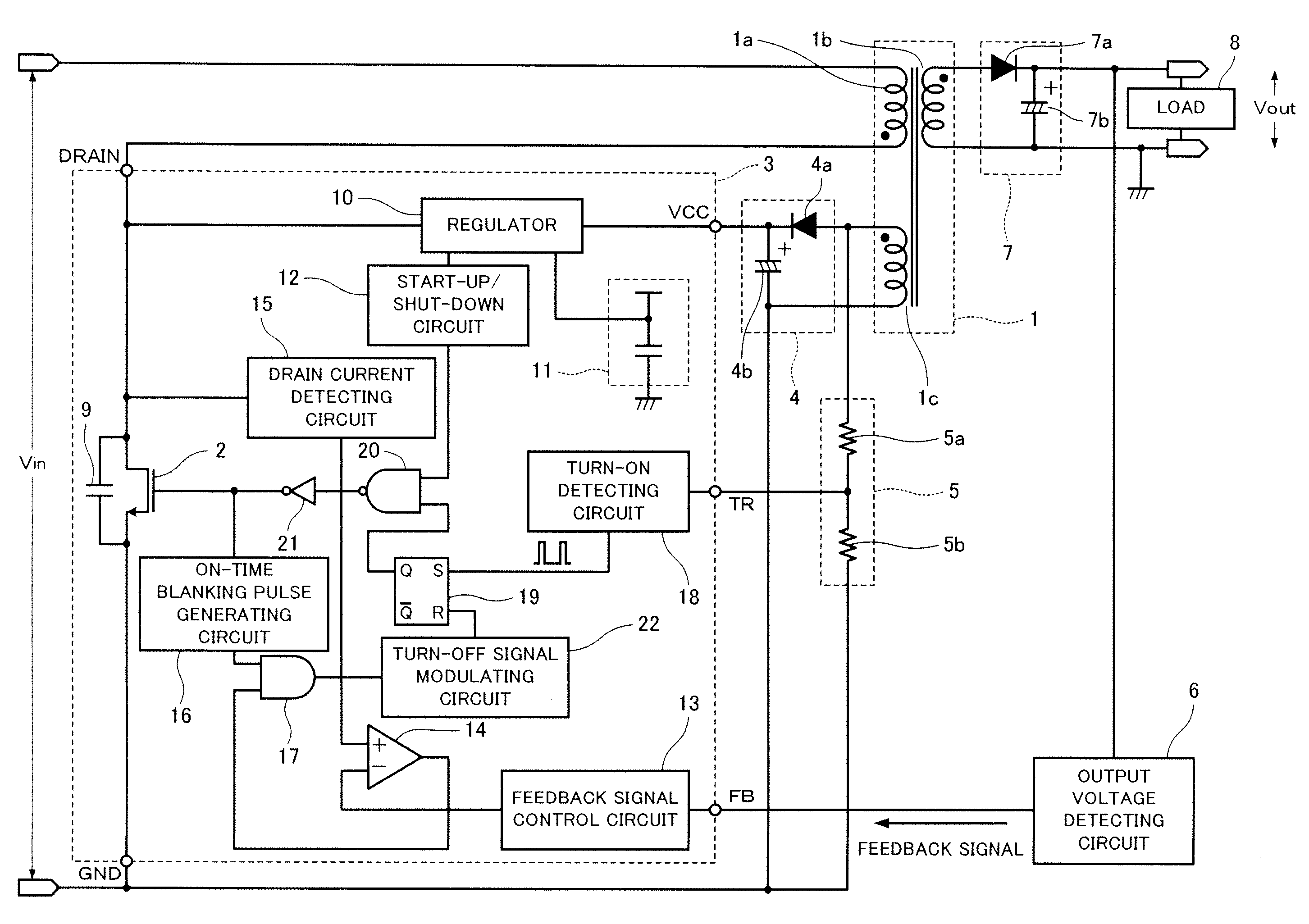

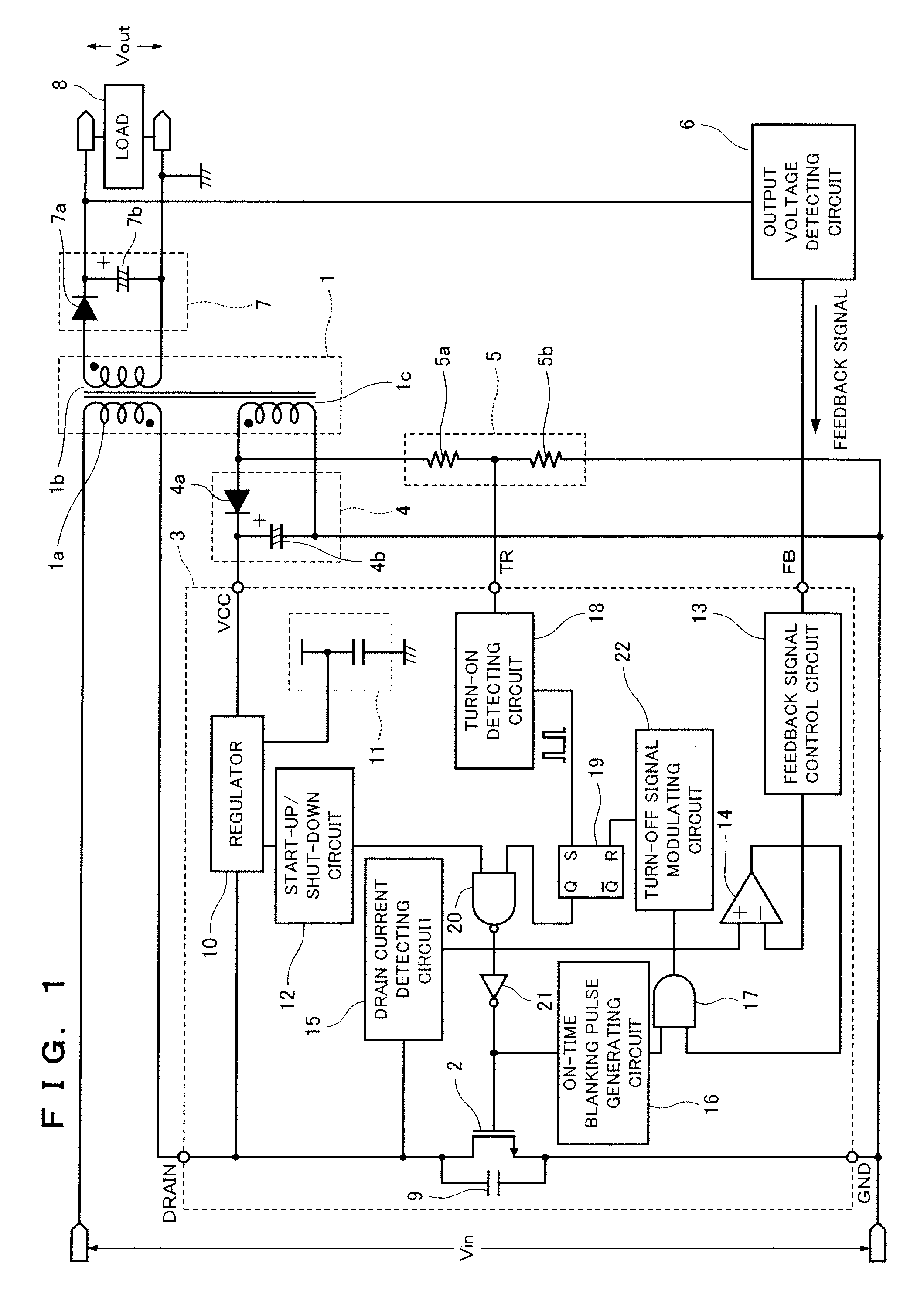

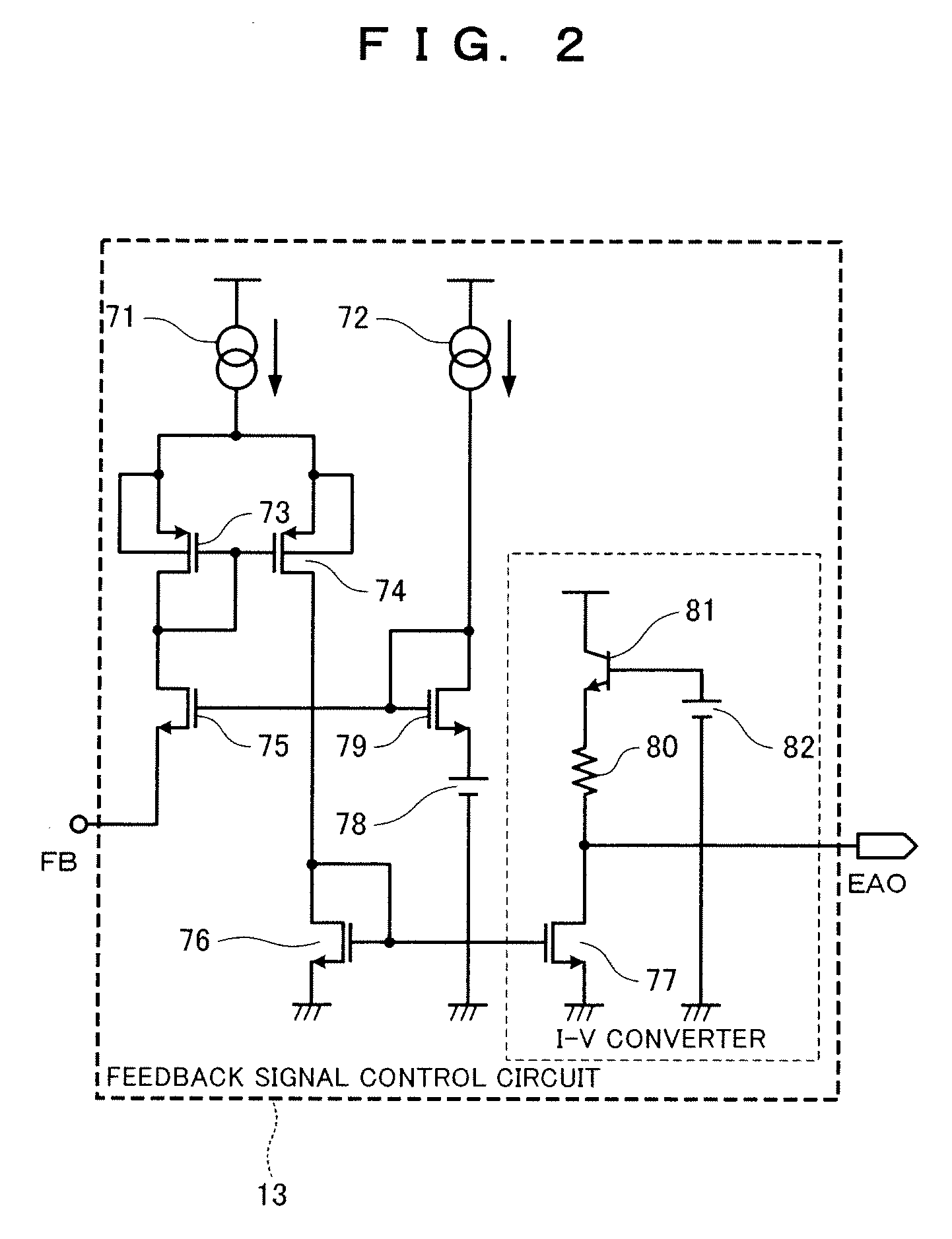

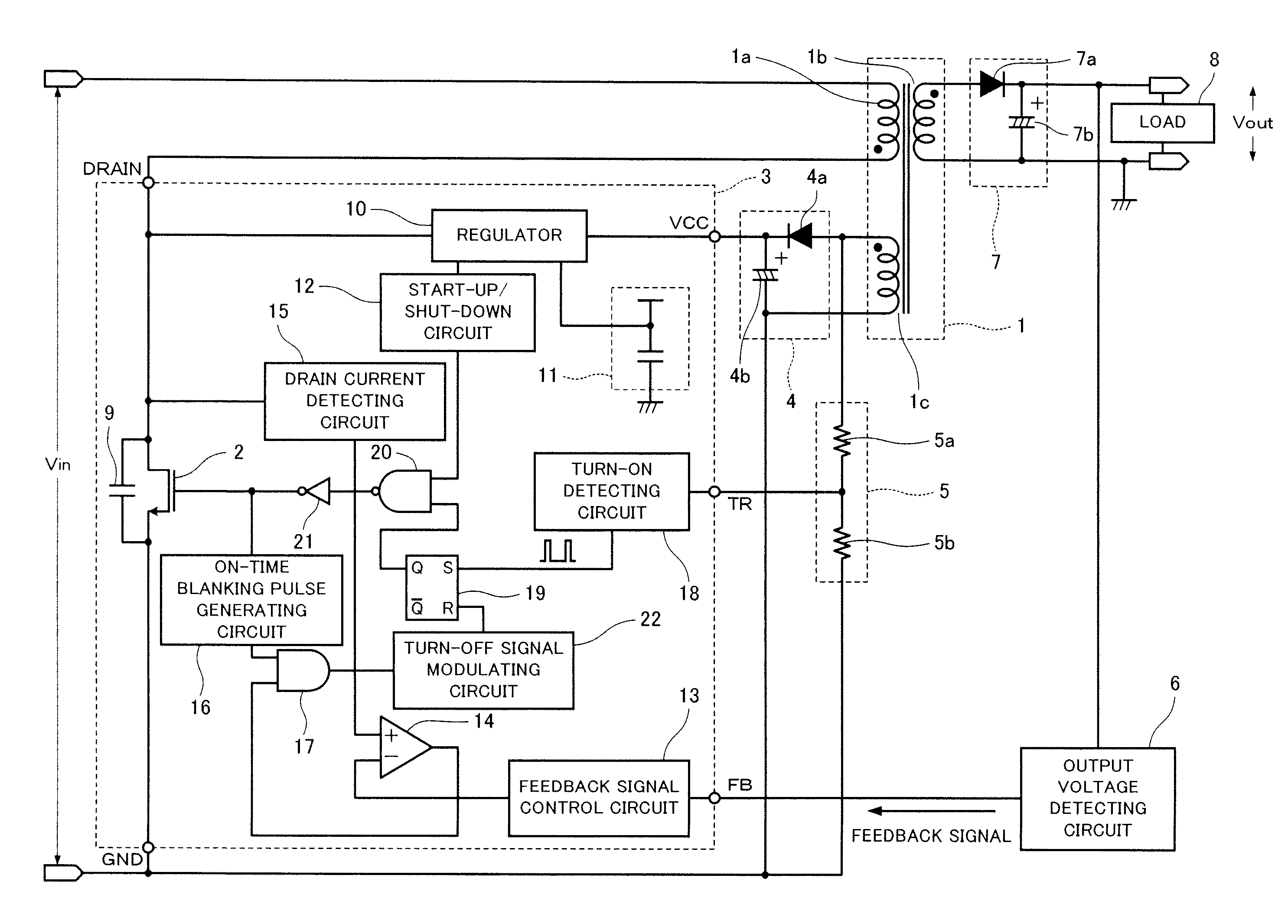

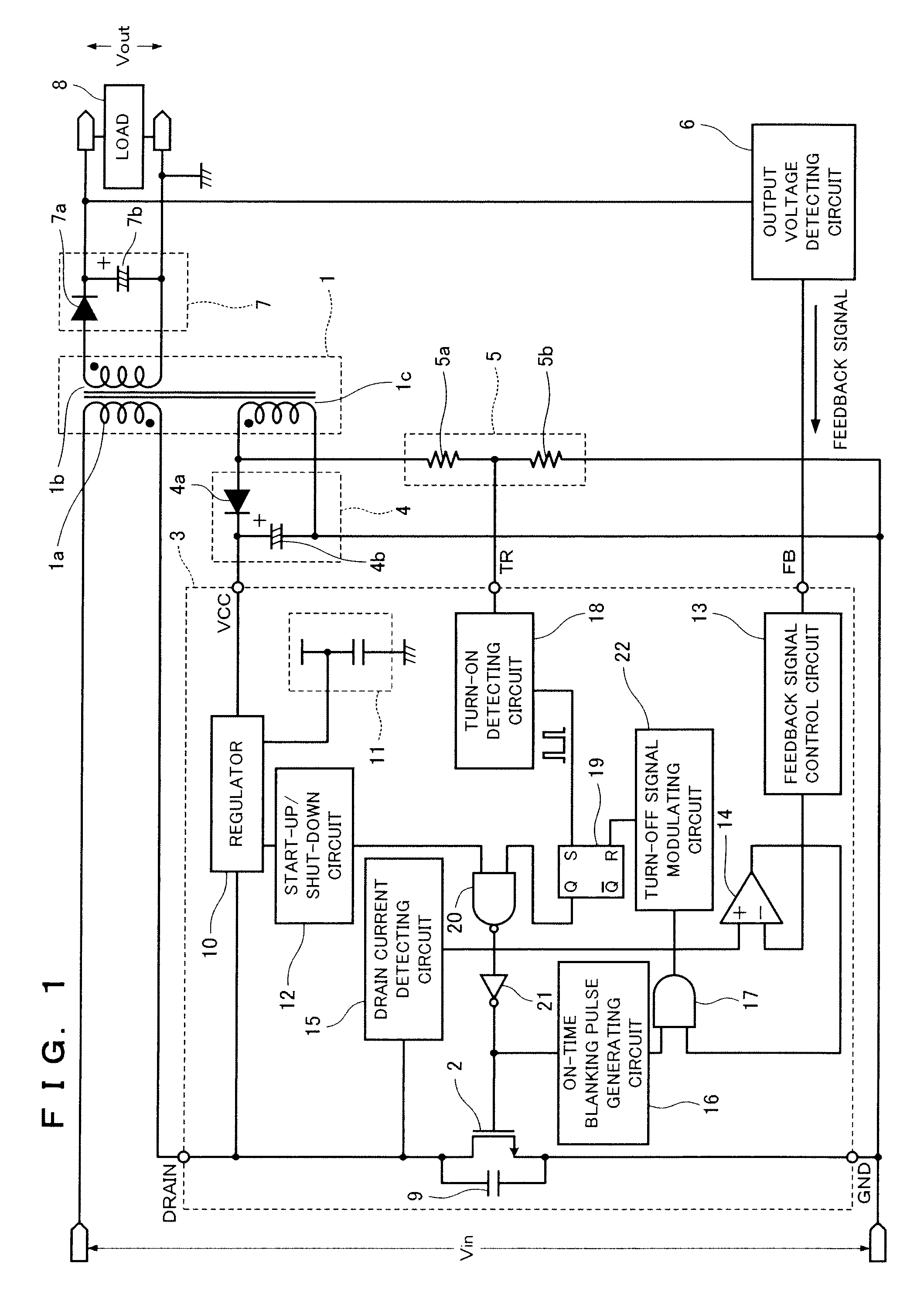

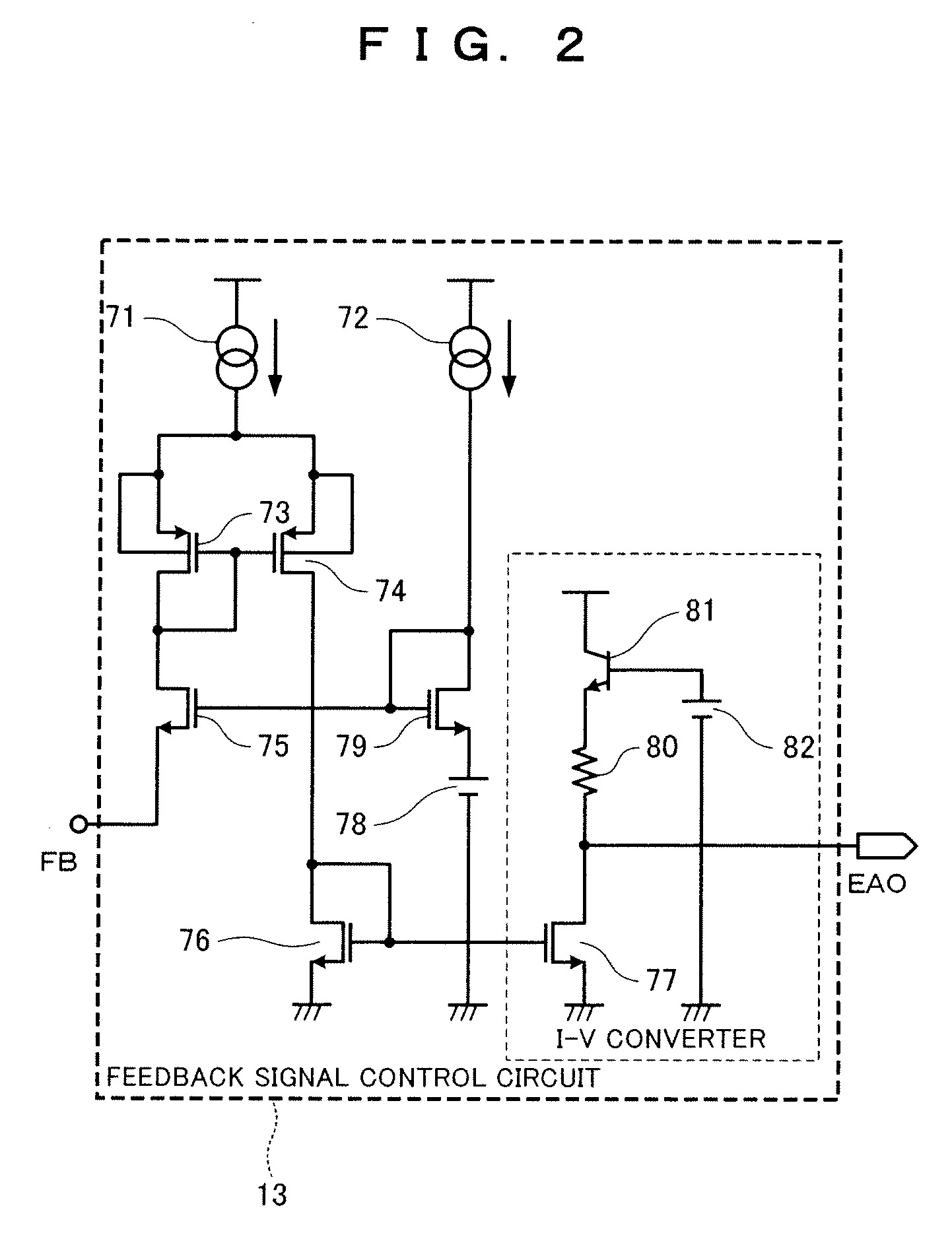

Energy transfer device and energy transfer control semiconductor device

ActiveUS20090147547A1Low costReduce noise valueDc-dc conversionElectric variable regulationConstant loadEnergy transfer

The present invention includes a turn-off signal modulating circuit that periodically varies a turn-off timing of a switching element 2 at a preset modulation time after a current detection by a drain current detecting circuit 15, and by modulating the peak of a current flowing through the switching element 2, diffuses switching noise while preventing concentration of an oscillating frequency at a constant frequency even under a constant input voltage and a constant load.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Energy transfer device and energy transfer control semiconductor device

ActiveUS7778050B2Reduce switching noiseLow costDc-dc conversionElectric variable regulationConstant loadEnergy transfer

The present invention includes a turn-off signal modulating circuit that periodically varies a turn-off timing of a switching element 2 at a preset modulation time after a current detection by a drain current detecting circuit 15, and by modulating the peak of a current flowing through the switching element 2, diffuses switching noise while preventing concentration of an oscillating frequency at a constant frequency even under a constant input voltage and a constant load.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

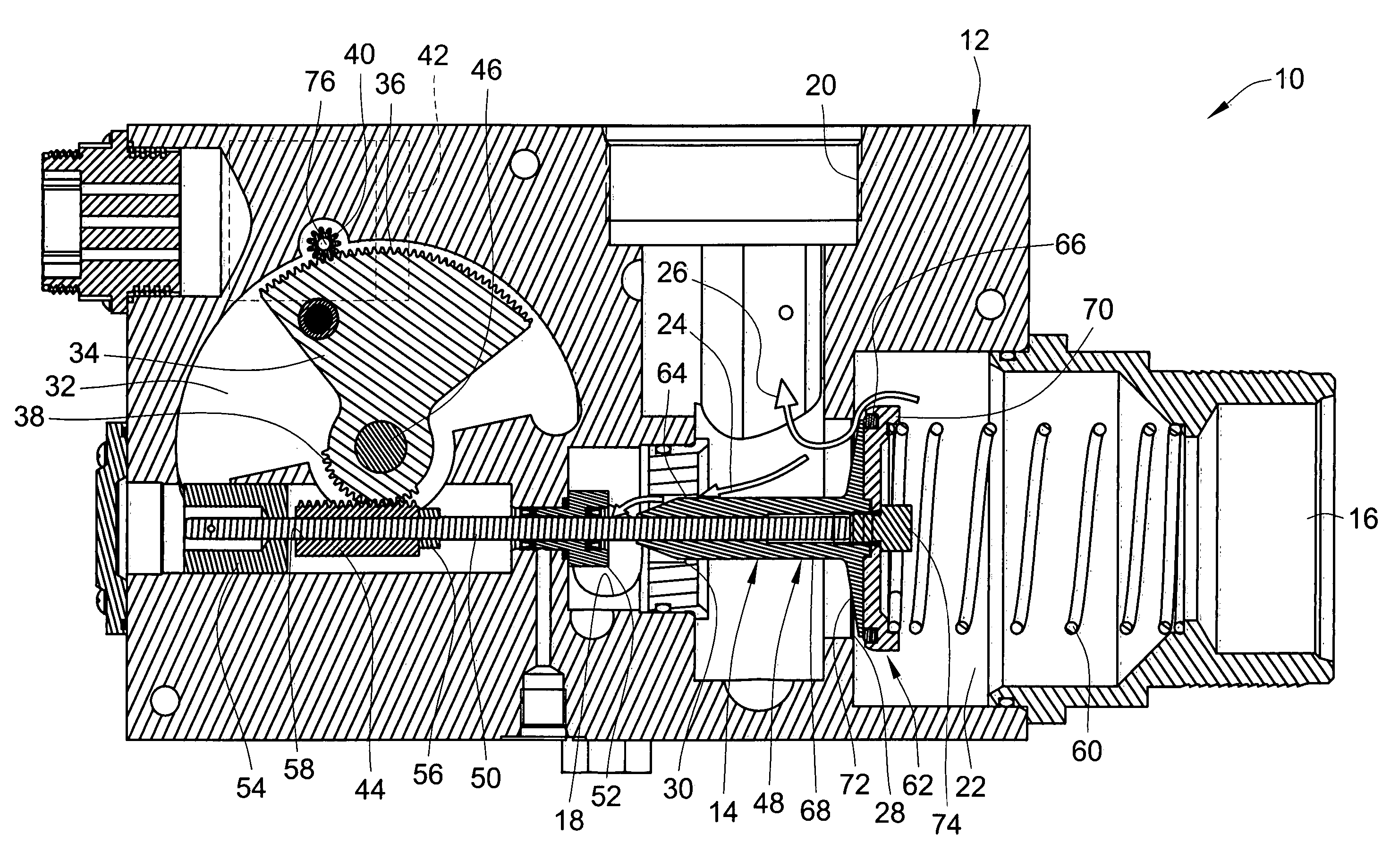

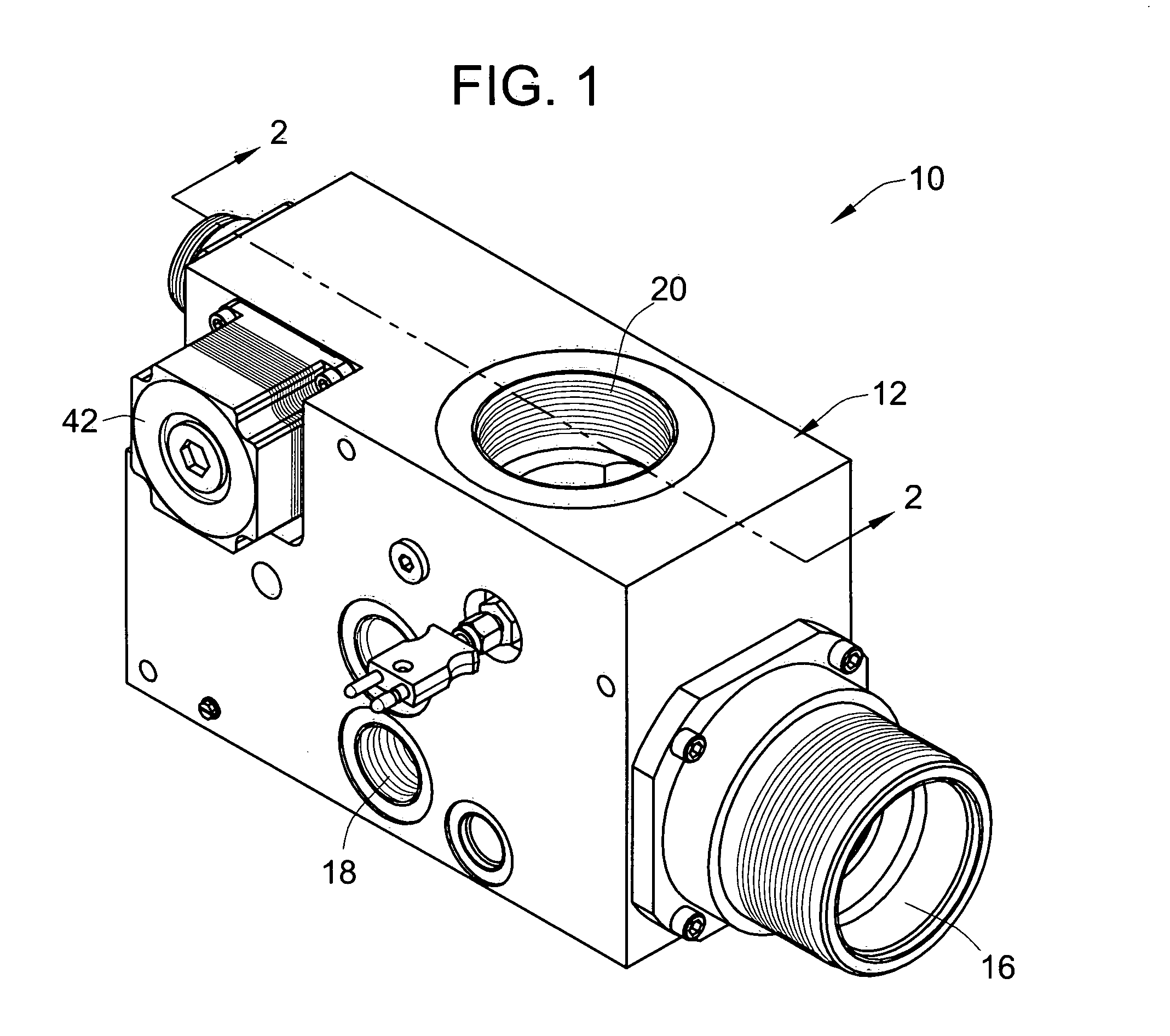

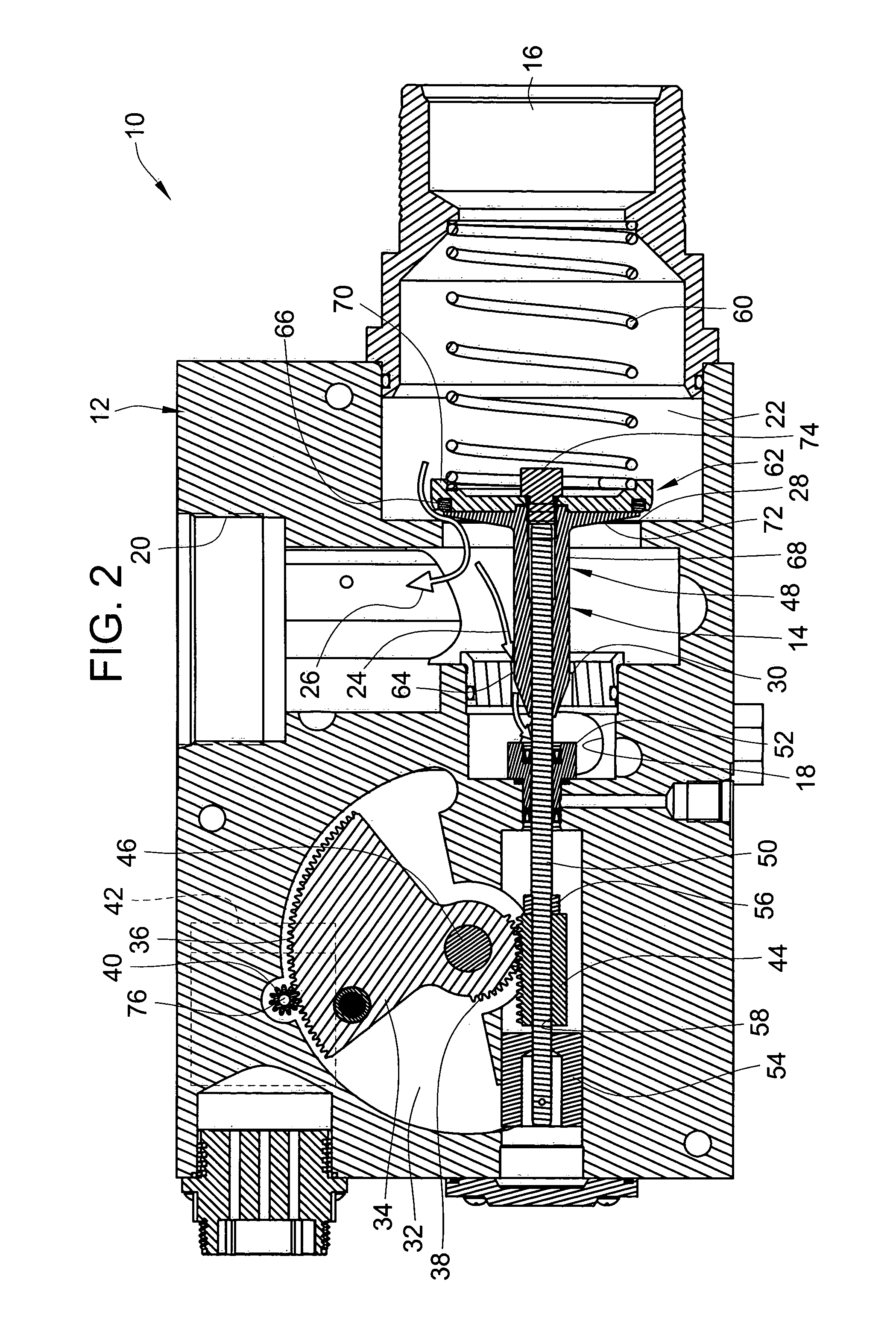

Fluid metering valve

ActiveUS7017884B2Avoid flowEffective controlOperating means/releasing devices for valvesNon-fuel substance addition to fuelConstant loadControl theory

A fluid metering valve includes a gear rack which is slidable on a valve stem in which a spring counteracts the force of an actuator to maintain a constant load on the gear mechanism to prevent backlash. Corresponding stop mechanisms between the gear and the shaft of a rotary actuator come into engagement with each other near a fully closed position of the fluid metering valve for zero calibration purposes upon power loss to the actuator. A single valve member and a single actuator of the fluid metering valve provides for both a shut-off function and a metering function.

Owner:WOODWARD GOVERNOR CO

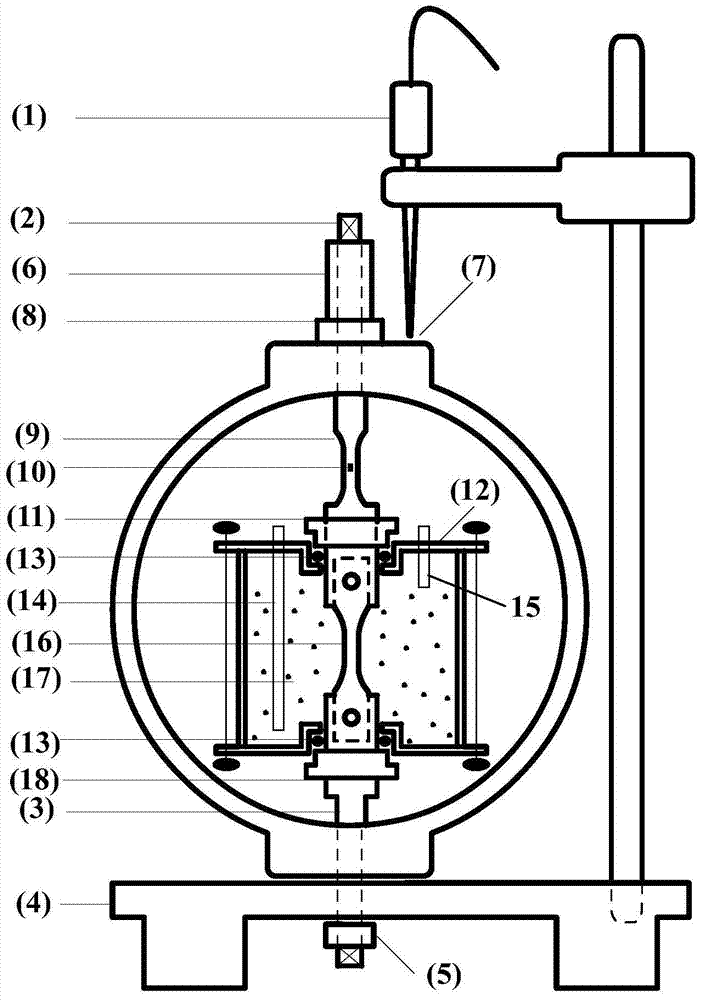

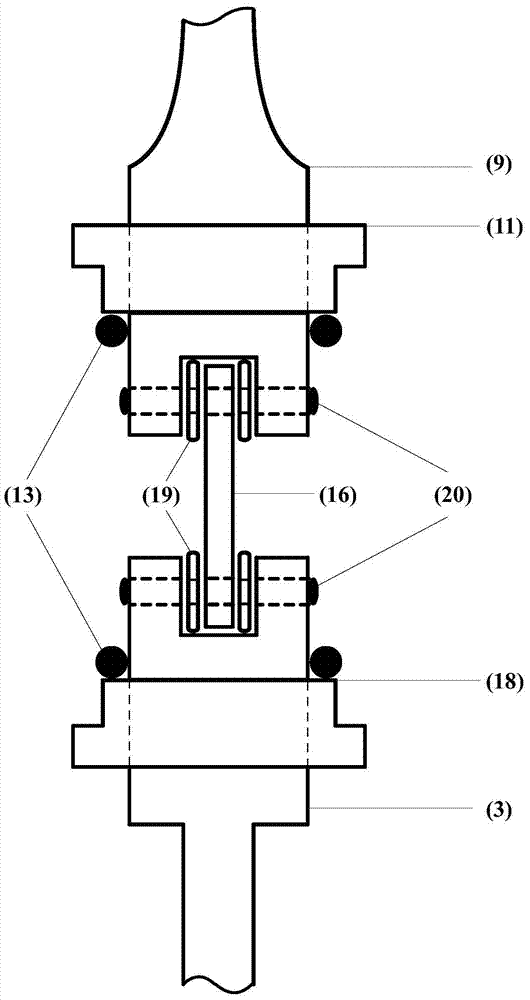

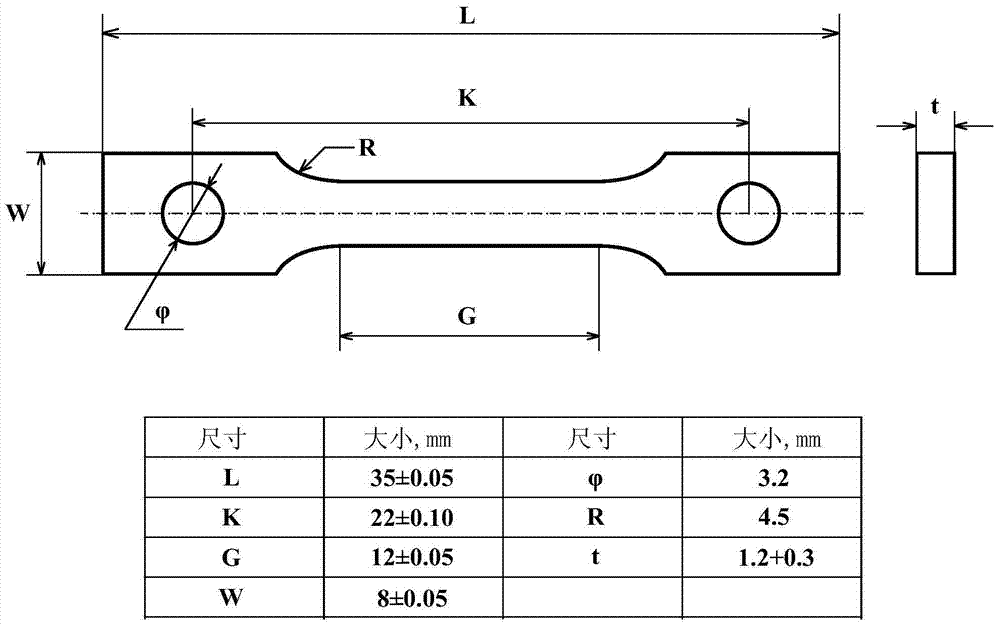

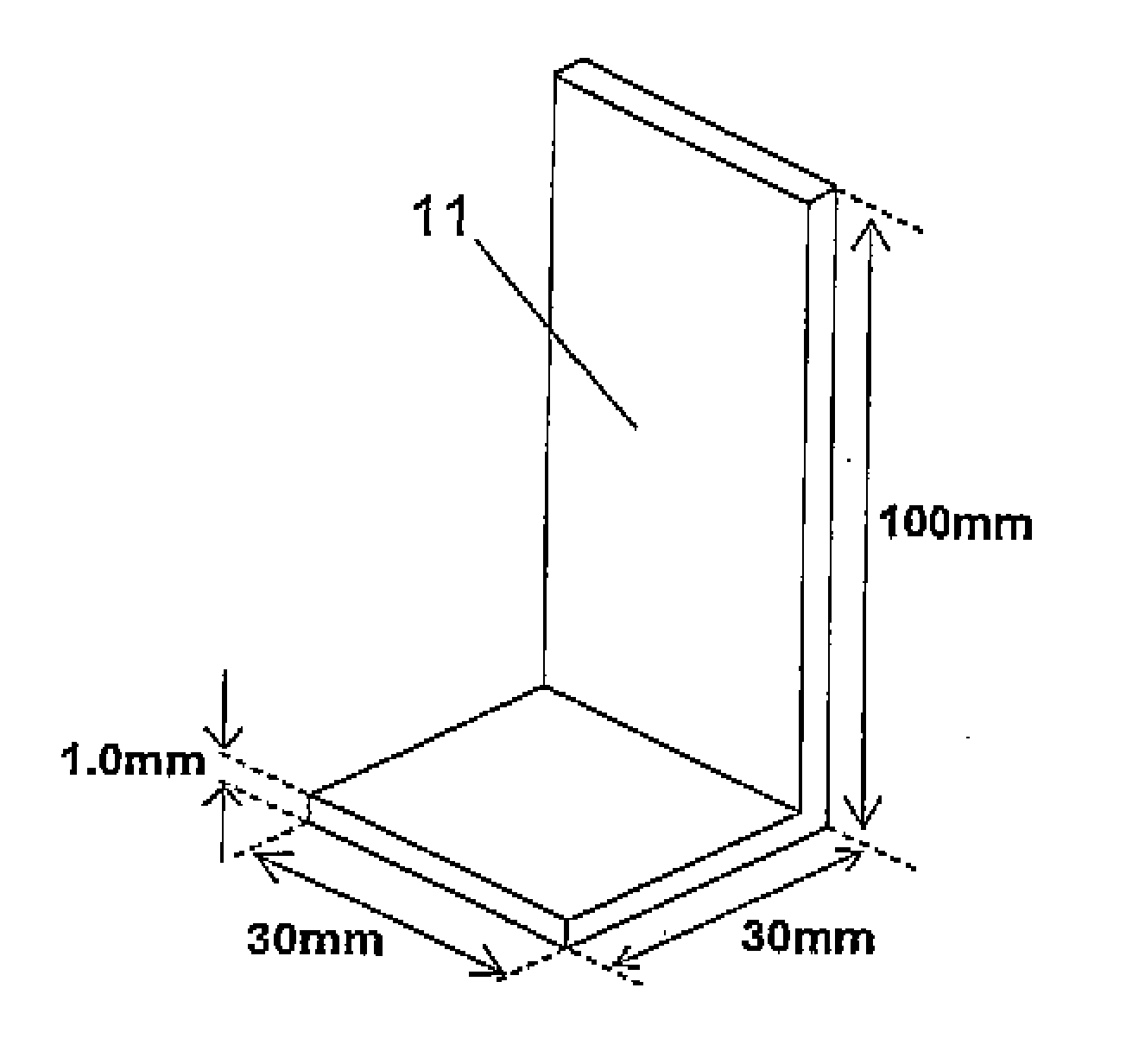

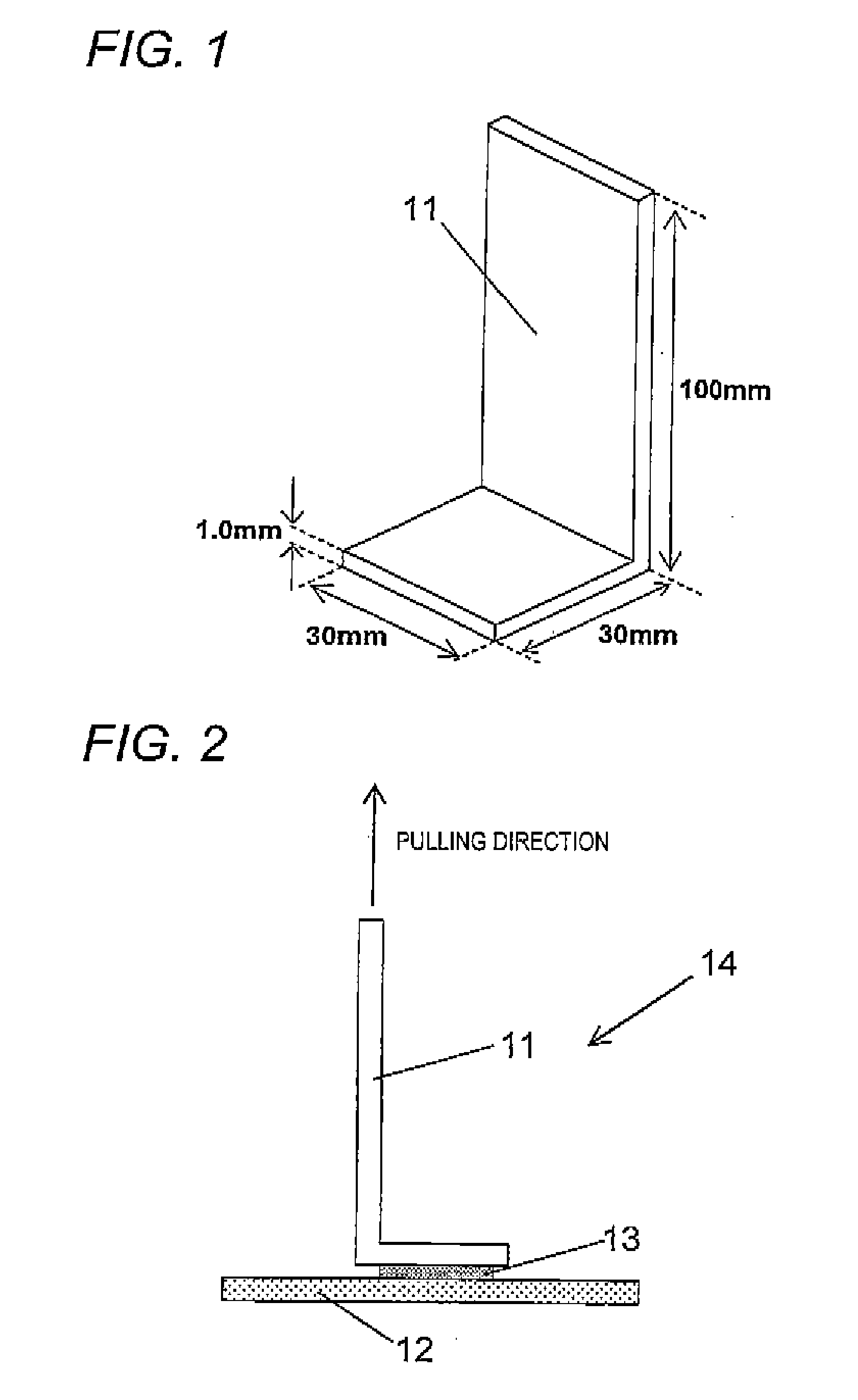

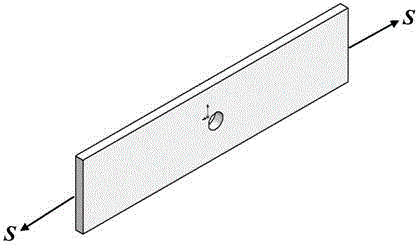

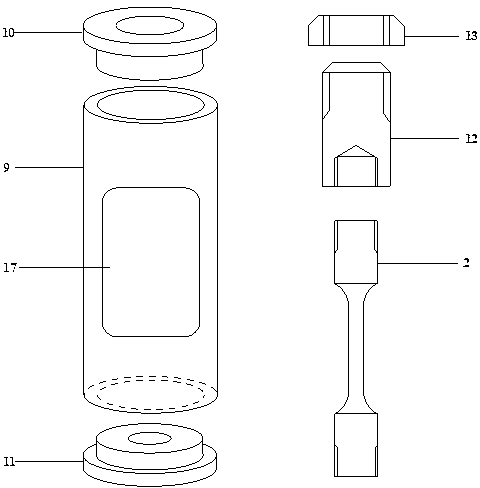

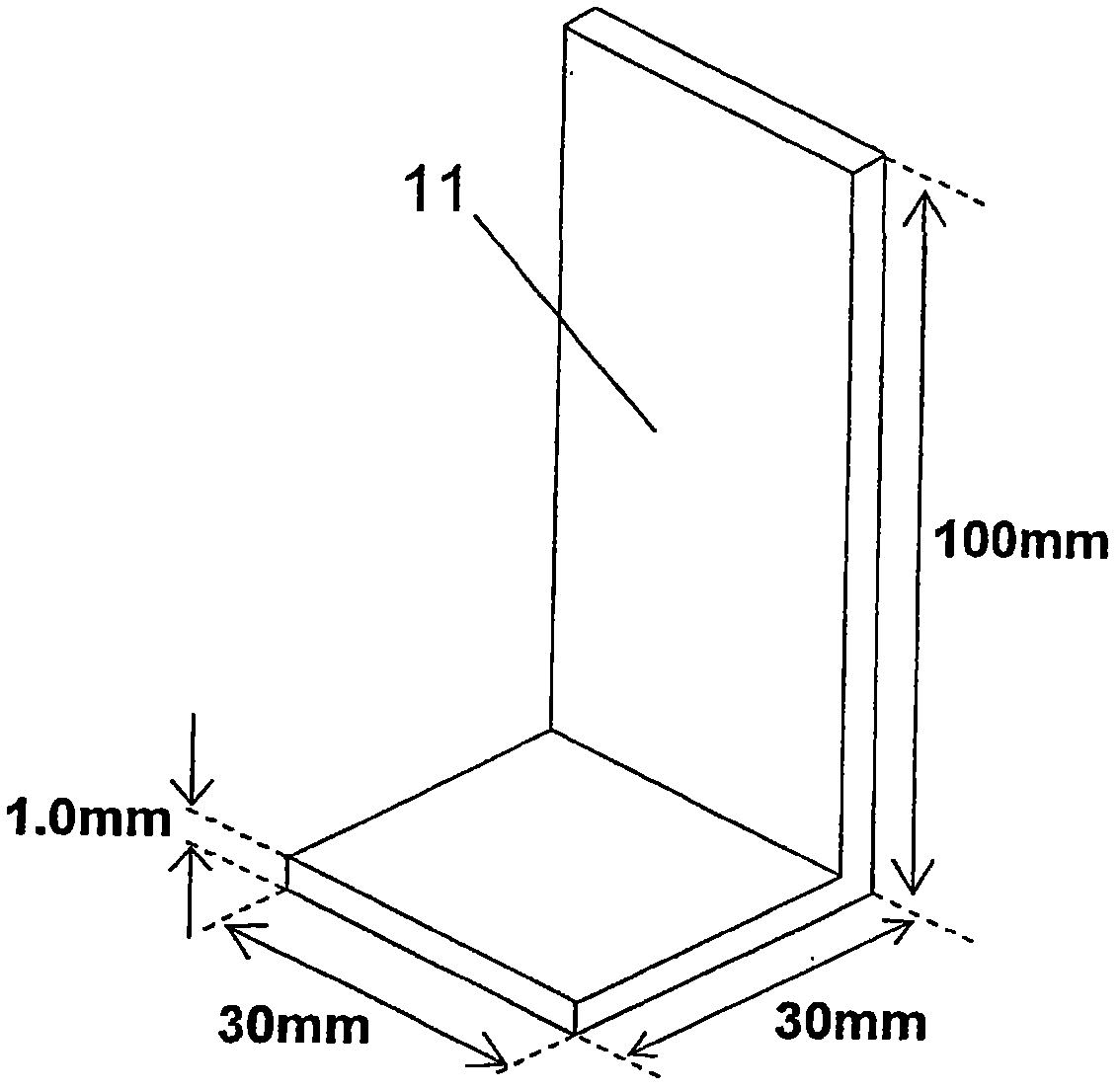

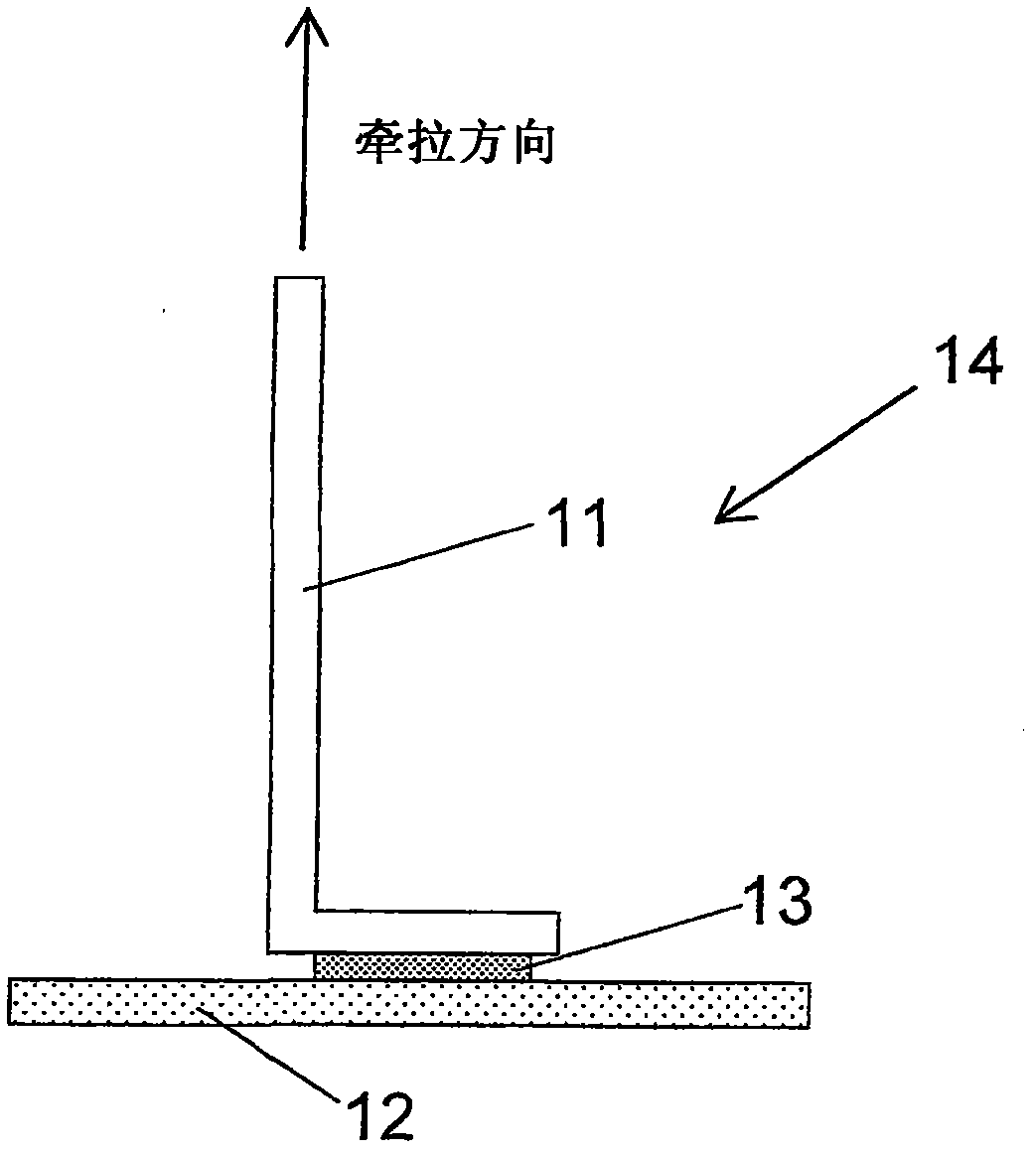

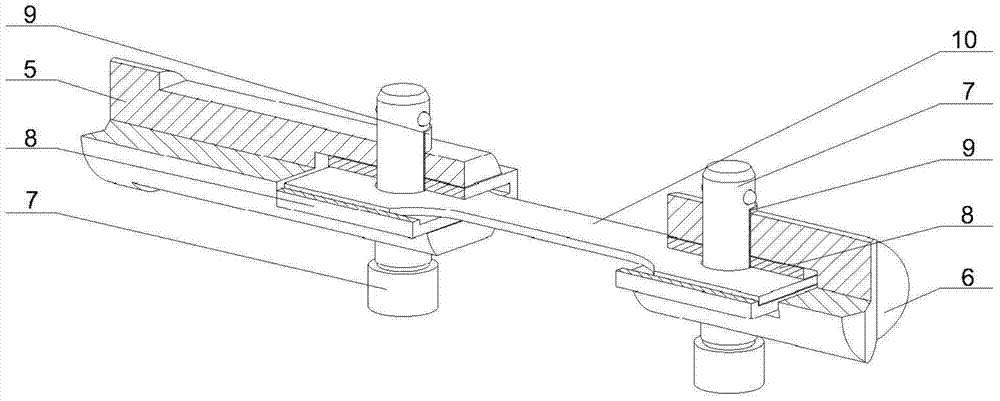

Constant-load stress corrosion testing device of small test sample and testing method thereof

InactiveCN103926146ASmall sizeEasy to processWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesConstant loadAnti stress

The invention relates to a constant-load stress corrosion evaluation method and a constant-load stress corrosion evaluation device of a small test sample. The essentials are as follows: the constant-load stress corrosion testing method and device can be used for testing an anti-stress corrosion cracking property of a thin-wall pipe and a small-size member; the small-size test sample is designed and processed and the level of the loaded stretching stress is accurately controlled; a stress corrosion experiment is carried out in an acidic environment; an anti-sulfide stress corrosion performance and an acting mechanism of the thin-wall pipe and the small-size member in the acidic corrosion environment are evaluated and researched according to an experiment result. With the adoption of the evaluation method and device, the anti-stress corrosion cracking property of the thin-wall pipe and the small-size member, which can not be used for processing a standard test sample, can be determined; the applicability of the material of the member can be obtained according to a testing result, so that the material selection and the applicability evaluation of the thin-wall pipe and the small-size member are carried out.

Owner:SOUTHWEST PETROLEUM UNIV

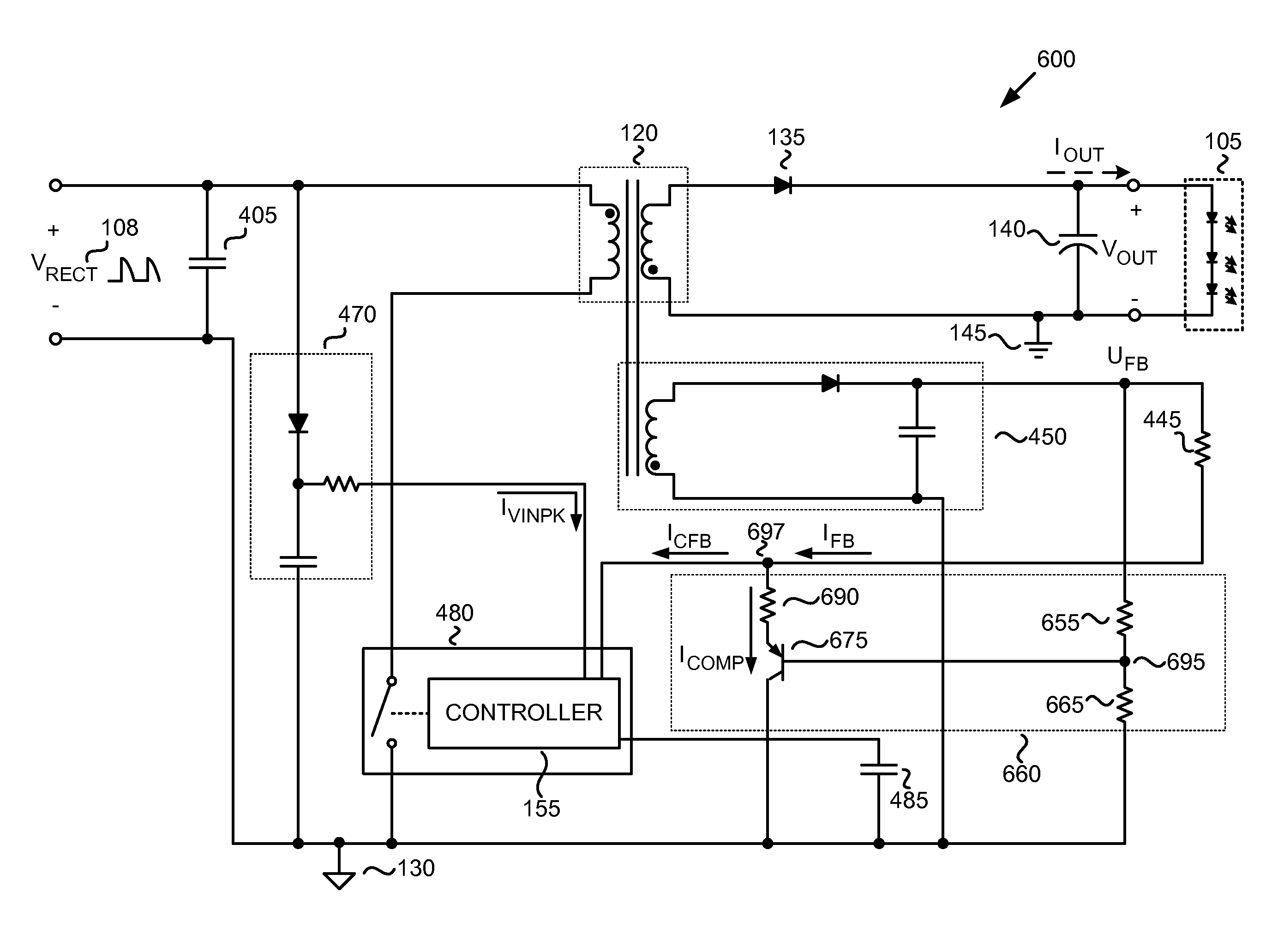

Power converter with compensation circuit for adjusting output current provided to a constant load

A power converter for constant loads includes an energy transfer element, a switch, a controller, and a compensation circuit. The energy transfer element is coupled to receive a rectified voltage having a non-blocked portion and a blocked portion, where an amount of the blocked portion corresponds to a phase angle. The controller is coupled to control switching of the switch to regulate an output current of the power converter in response to a plurality of signals. The plurality of signals includes a peak input voltage signal and a feedback signal, where the peak input voltage signal is representative of a peak input voltage of the power converter and the feedback signal is representative of the output voltage of the power converter. The compensation circuit is coupled to adjust at least one of the plurality of signals in response to the phase angle exceeding a phase angle threshold.

Owner:POWER INTEGRATIONS INC

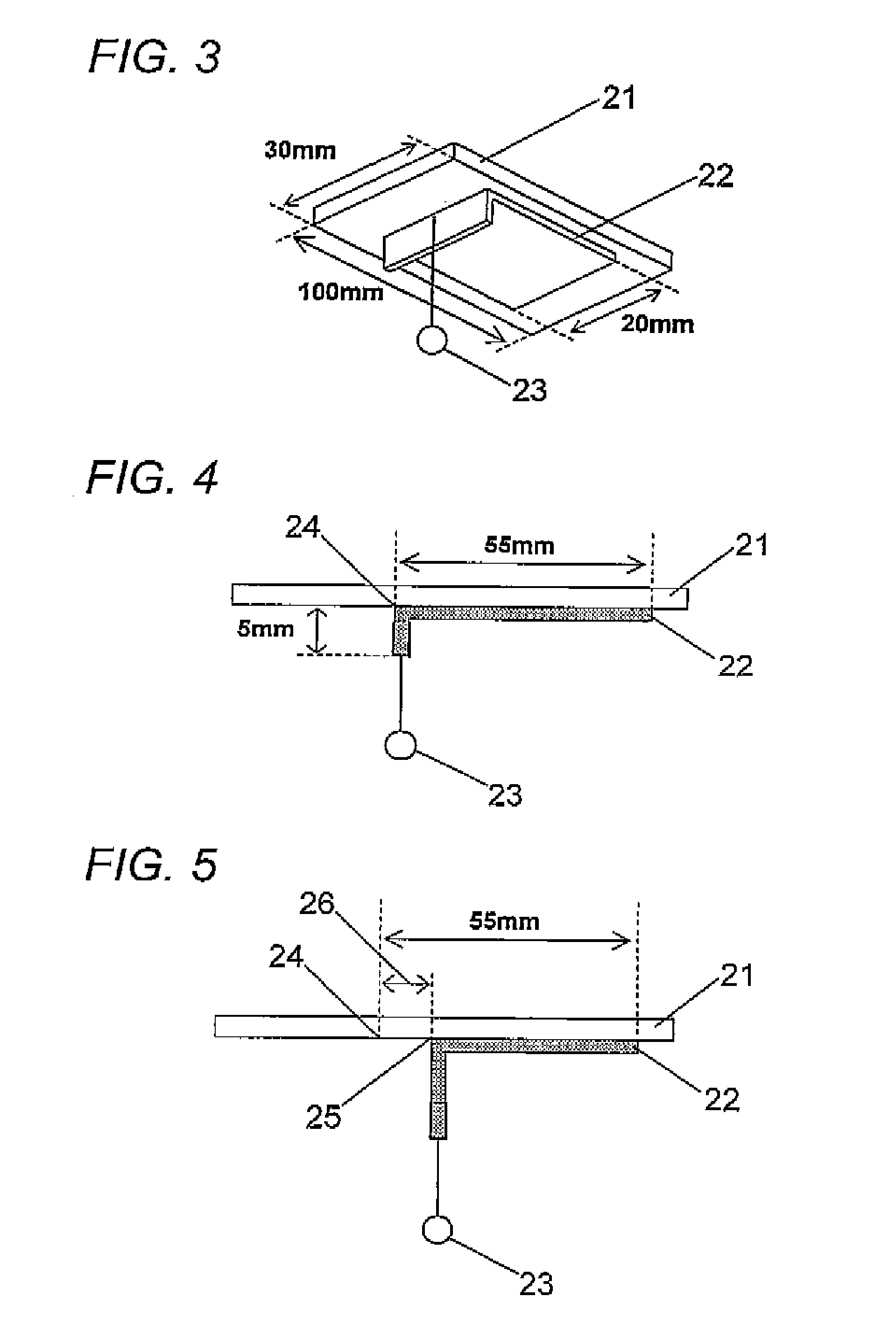

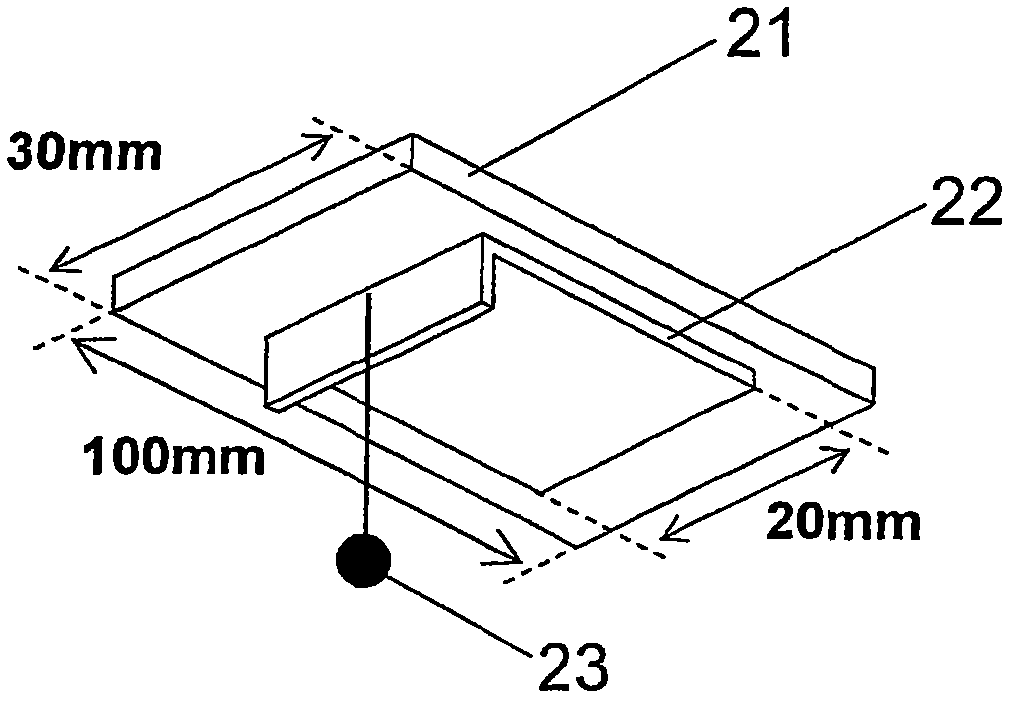

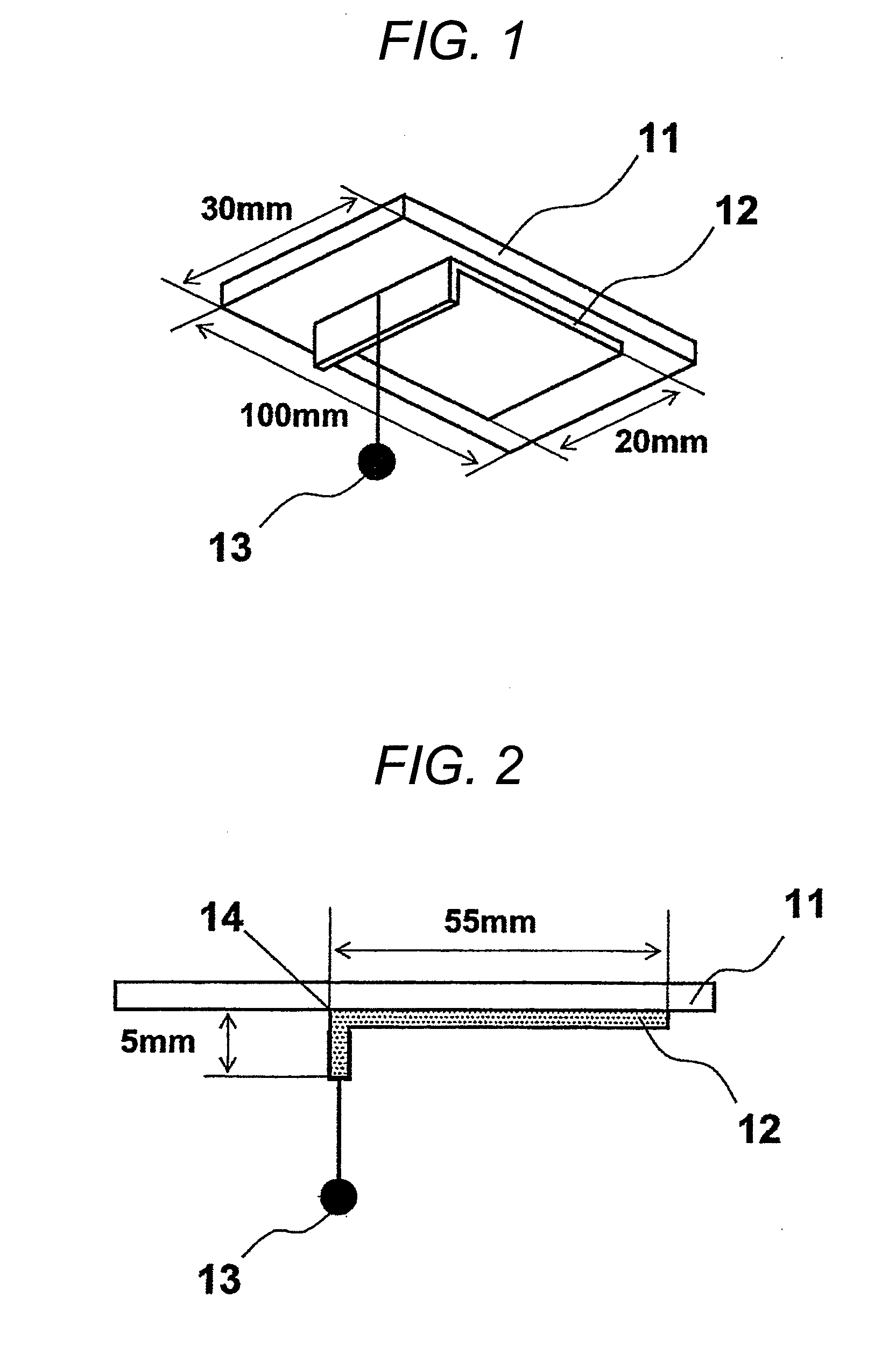

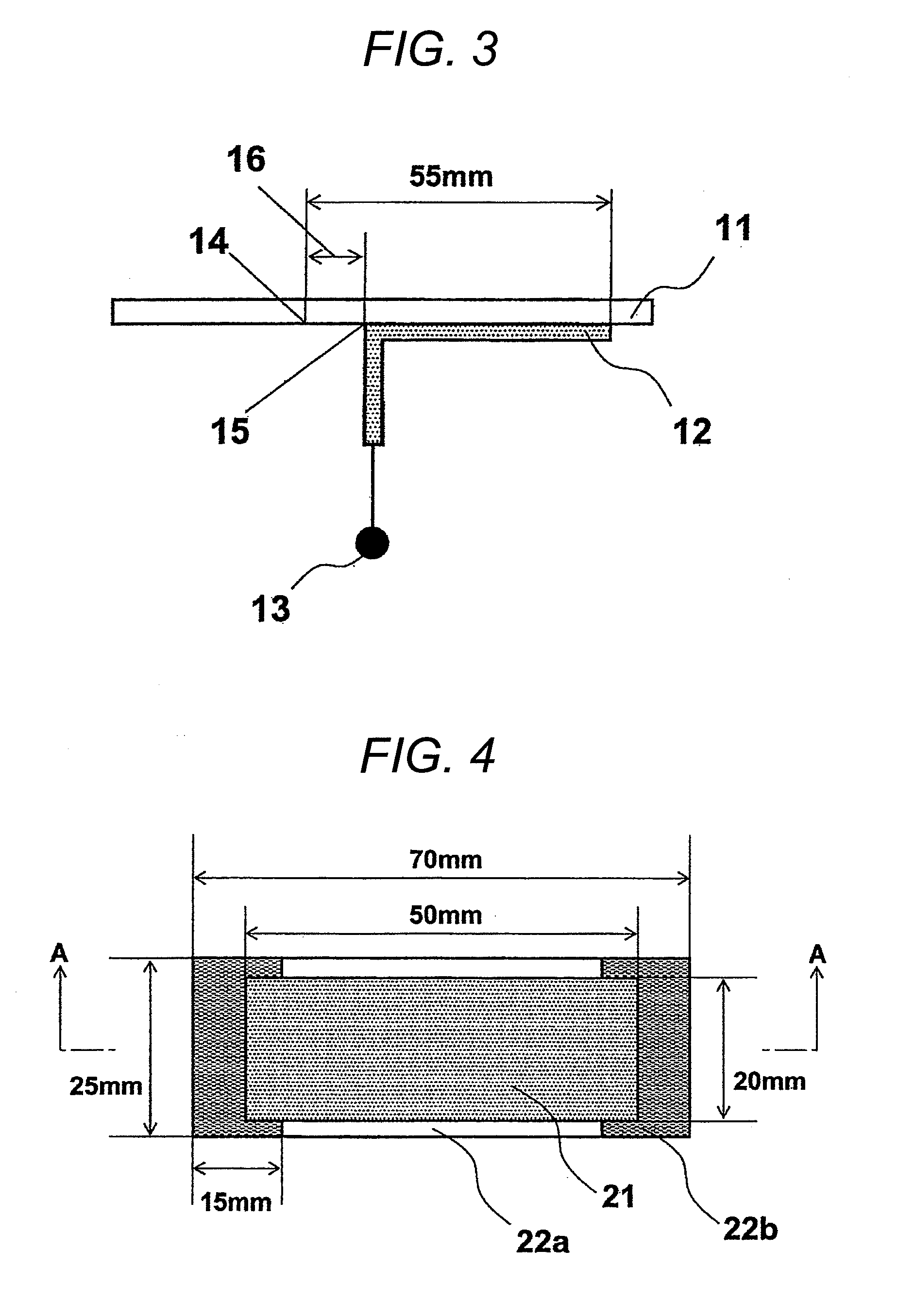

Optical-use pressure-sensitive adhesive sheet

InactiveUS20110111220A1Improve adhesionExcellent in twist-proof adhesivenessMonocarboxylic acid ester polymer adhesivesOpticsConstant loadDynamic viscoelasticity

The present invention provides an optical-use pressure-sensitive adhesive sheet including a pressure-sensitive adhesive layer having, as measured through dynamic viscoelastometry, a storage elastic modulus at 80° C. of at least 2.0×104 Pa and a loss elastic modulus at 80° C. of at least 1.0×104 Pa, in which the pressure-sensitive adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test (under a load of 100 gf for 3 hours), of at most 50 mm.

Owner:NITTO DENKO CORP

Method and apparatus for maintaining a constant load current with line voltage in a switch mode power supply

Owner:POWER INTEGRATIONS INC

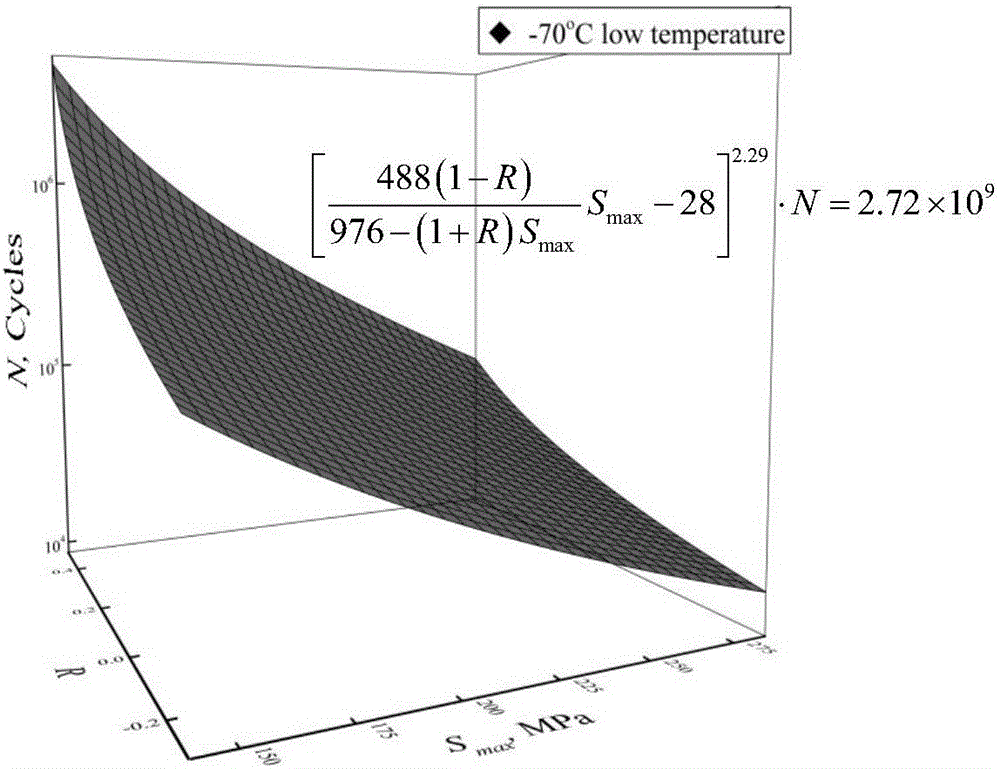

Low-temperature fatigue property characterization and life estimation method

The invention discloses a low-temperature fatigue property characterization and life estimation method. The method comprises three major steps of step 1, through considering the influence of a stress ratio, deriving an S-N-R curved surface characterizing the fatigue property by adopting a Goodman equilife curve based on a three-parameter power function expression, and performing data processing by virtue of a linear regression theory; step 2, through considering an interaction effect of loads under spectrum loading, proposing a corrected spectrum loading fatigue life estimation model based on a Willenborg / Chang model and a crack tip plastic zone theory, and giving out a fatigue damage increment representation method; and step 3, calculating the low-temperature spectrum loading fatigue life of a material by adopting an accumulative damage theory. The method is simple and practical; and a low-temperature fatigue property characterization model can be constructed only by a constant-load fatigue property curved surface and an actually measured flight load spectrum of the material in a low-temperature environment, and the spectrum loading fatigue life is estimated, so that the method has important academic meanings and engineering application values.

Owner:BEIHANG UNIV

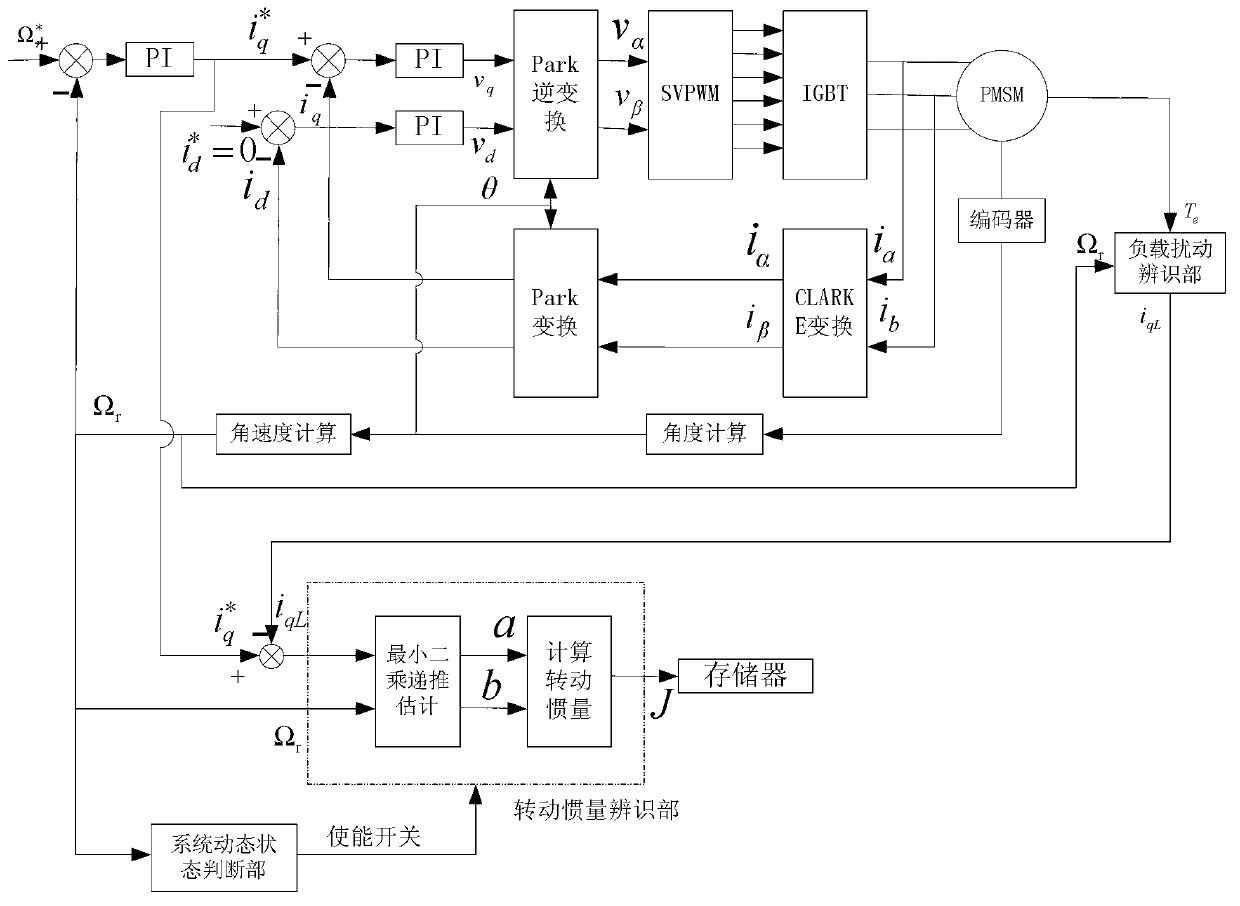

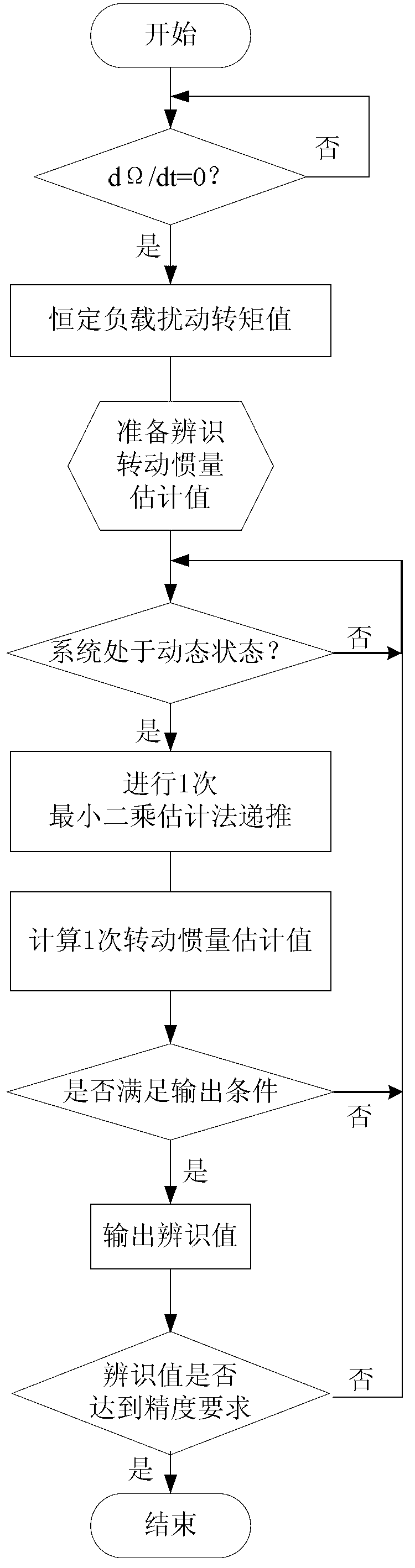

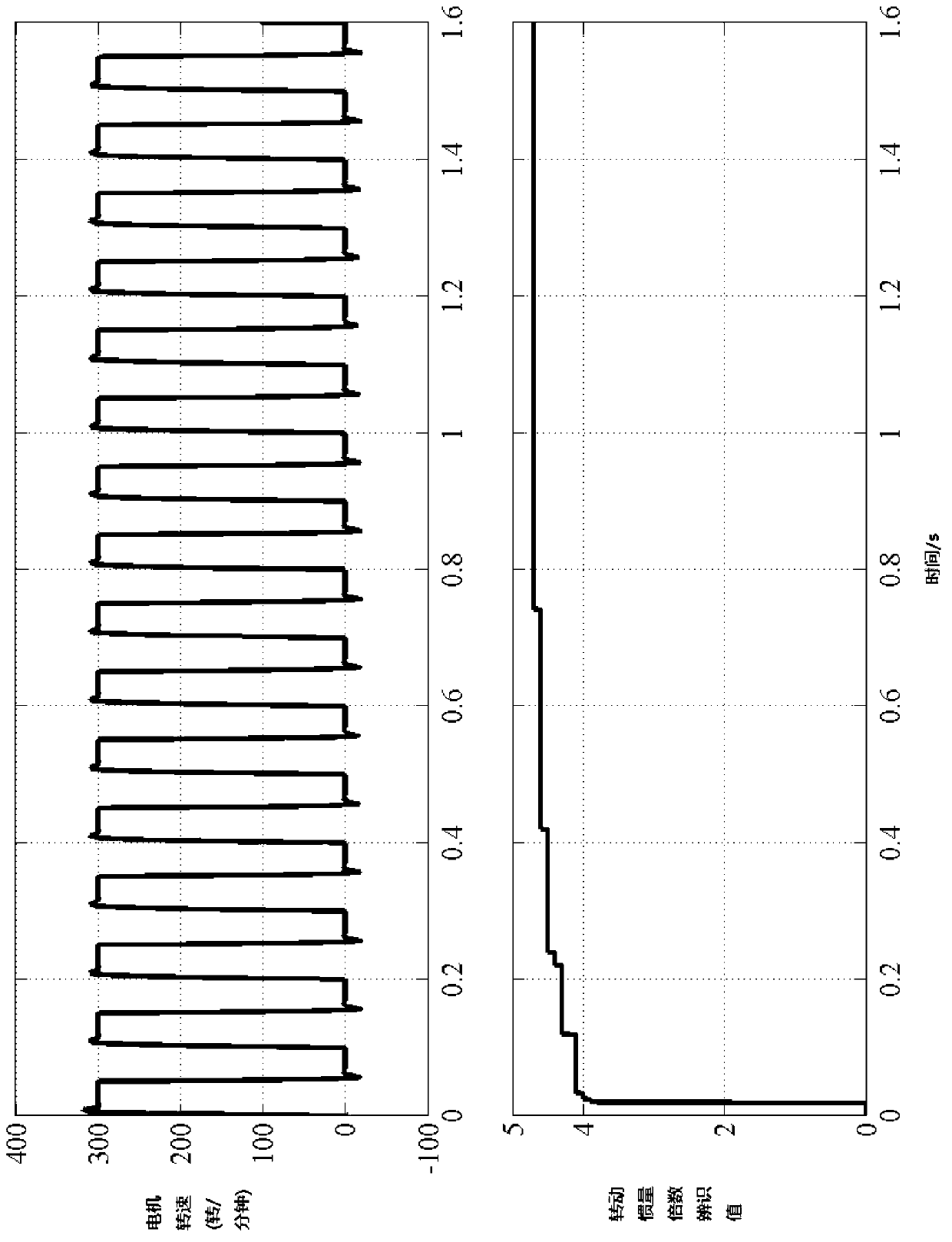

Rotational inertia on-line identification method for alternating current (AC) permanent magnet synchronous motor servo system

ActiveCN103219939AAvoid spaceAvoid the disadvantage of large amount of calculationElectronic commutation motor controlVector control systemsMotor speedConstant load

The invention relates to a rotational inertia on-line identification method for an alternating current (AC) permanent magnet synchronous motor servo system and belongs to the technical field of rotational inertia identification for motors. The method aims to solve the problems that an on-line inertia identification method based on the traditional least square method is high in requirements for storage space and arithmetic speed of digital processing chips. The method adopts a load torque identification part to identify a constant load disturbance torque value TL; a system dynamic state judging part is adopted for judging whether rotation speed of a motor is at a dynamic change stage, and when the rotation speed of the motor is at the dynamic change stage and the rate of change of the rotation speed of the motor is higher than a critical change rate for identification of rotational inertia of the motor, a rotational inertia estimation value is obtained through calculation by utilization of a least square estimation method based on recursion; and when the rotational inertia on-line identification process meets requirements of a preset output rotational inertia estimation value and meets a requirement for precision, the rotational inertia estimation value is output and the rotational inertia on-line identification process is completed. The method is used for rotational inertia on-line identification for the motor servo system.

Owner:HARBIN INST OF TECH

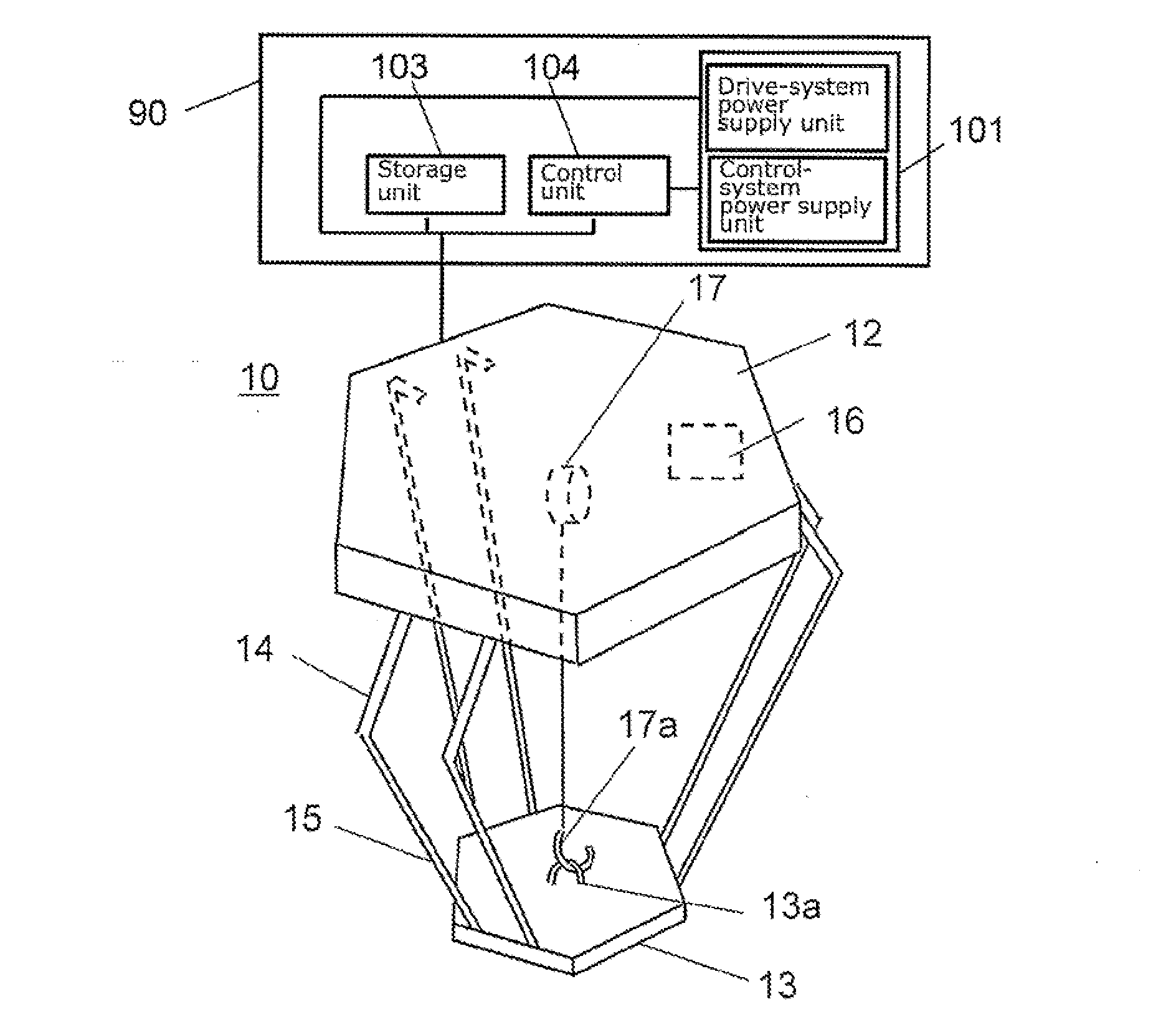

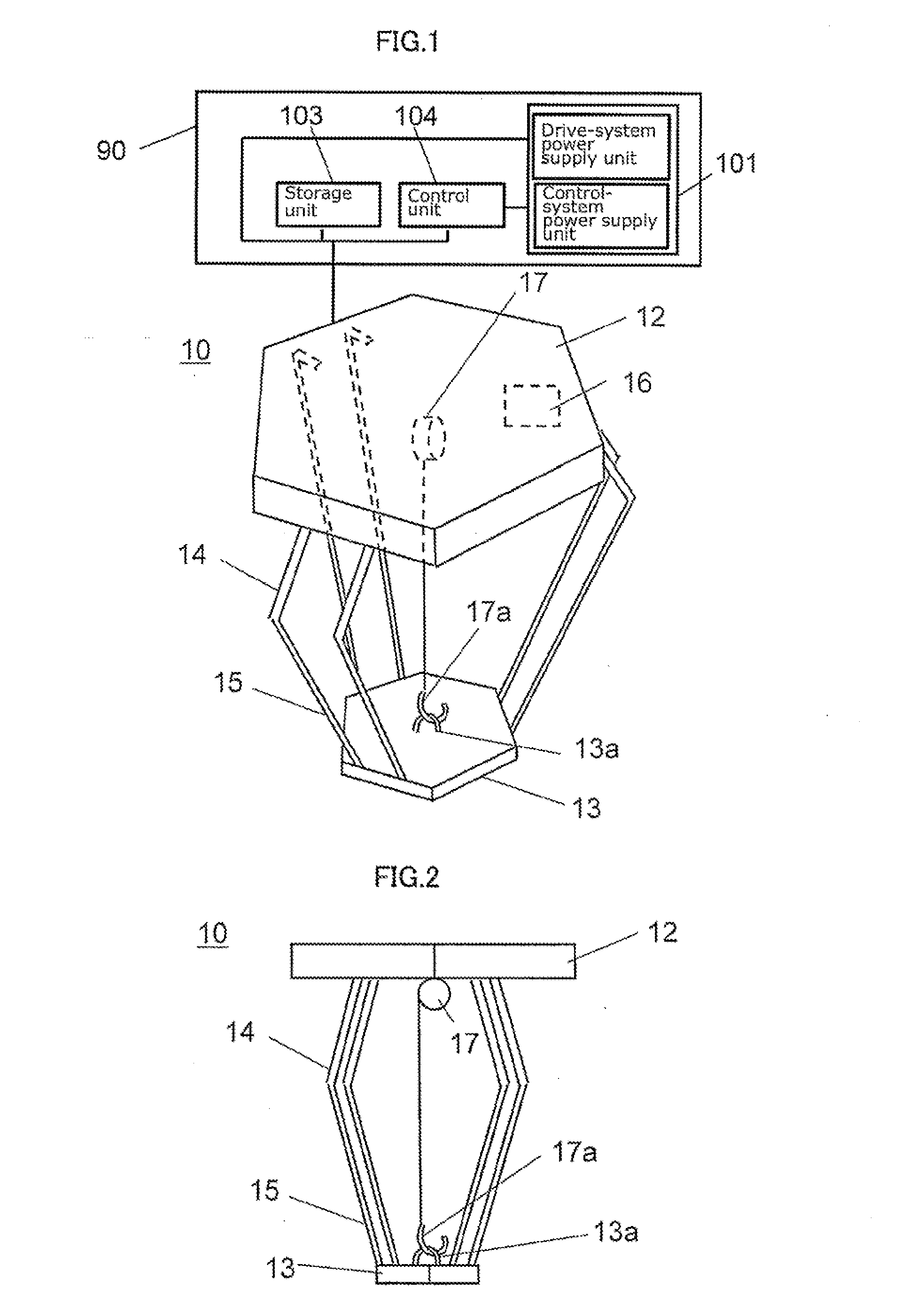

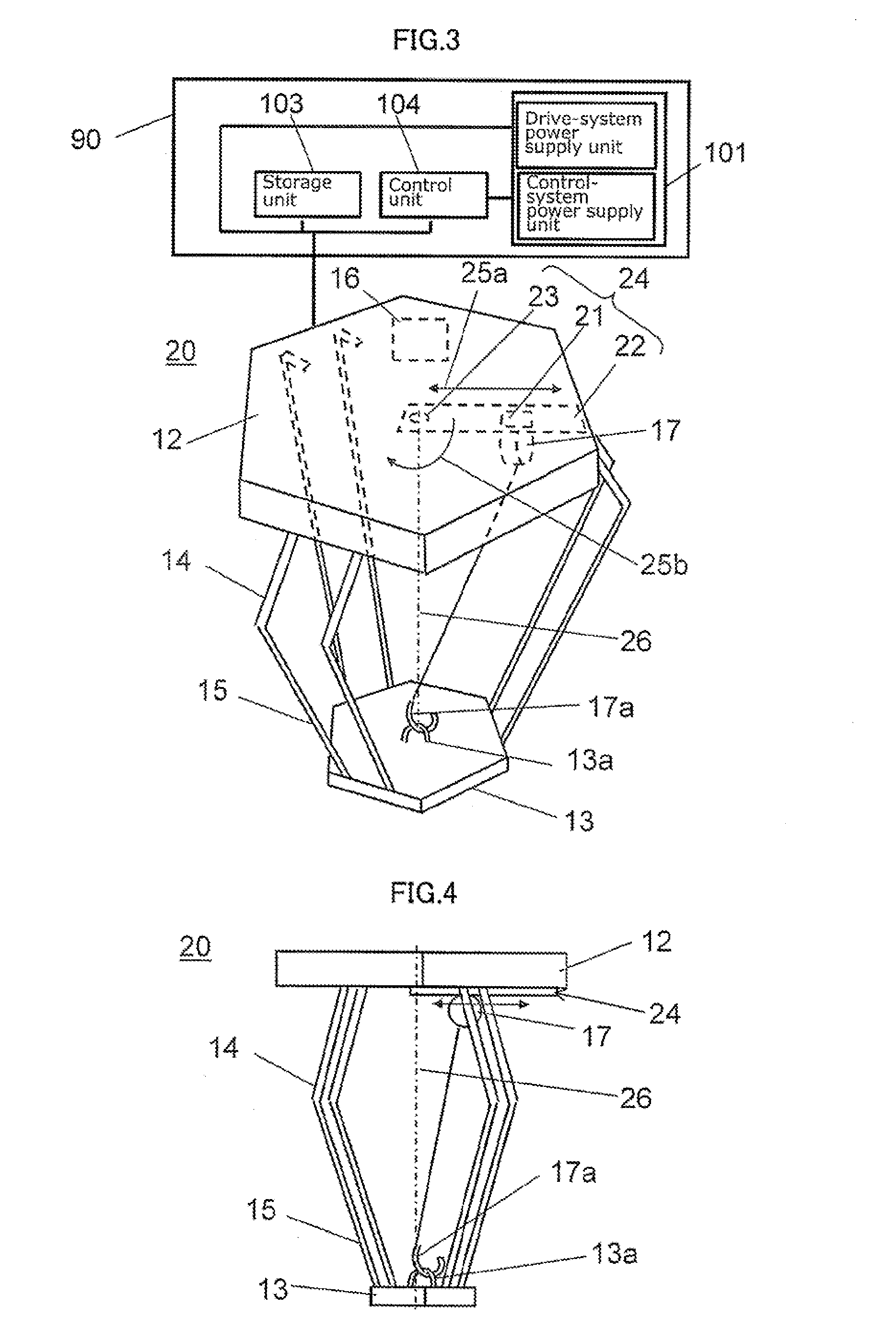

Parallel link robot, and method of teaching parallel link robot

InactiveUS20120078415A1Improve accuracyEasy to operateProgramme-controlled manipulatorMechanical apparatusConstant loadEngineering

A parallel link robot (10) allows holding a movable body (13) in midair by connecting a center portion or a peripheral portion of the movable body (13) and a center portion or a peripheral portion of a base (12), using a suspension unit (17) having elasticity such as a constant load spring.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

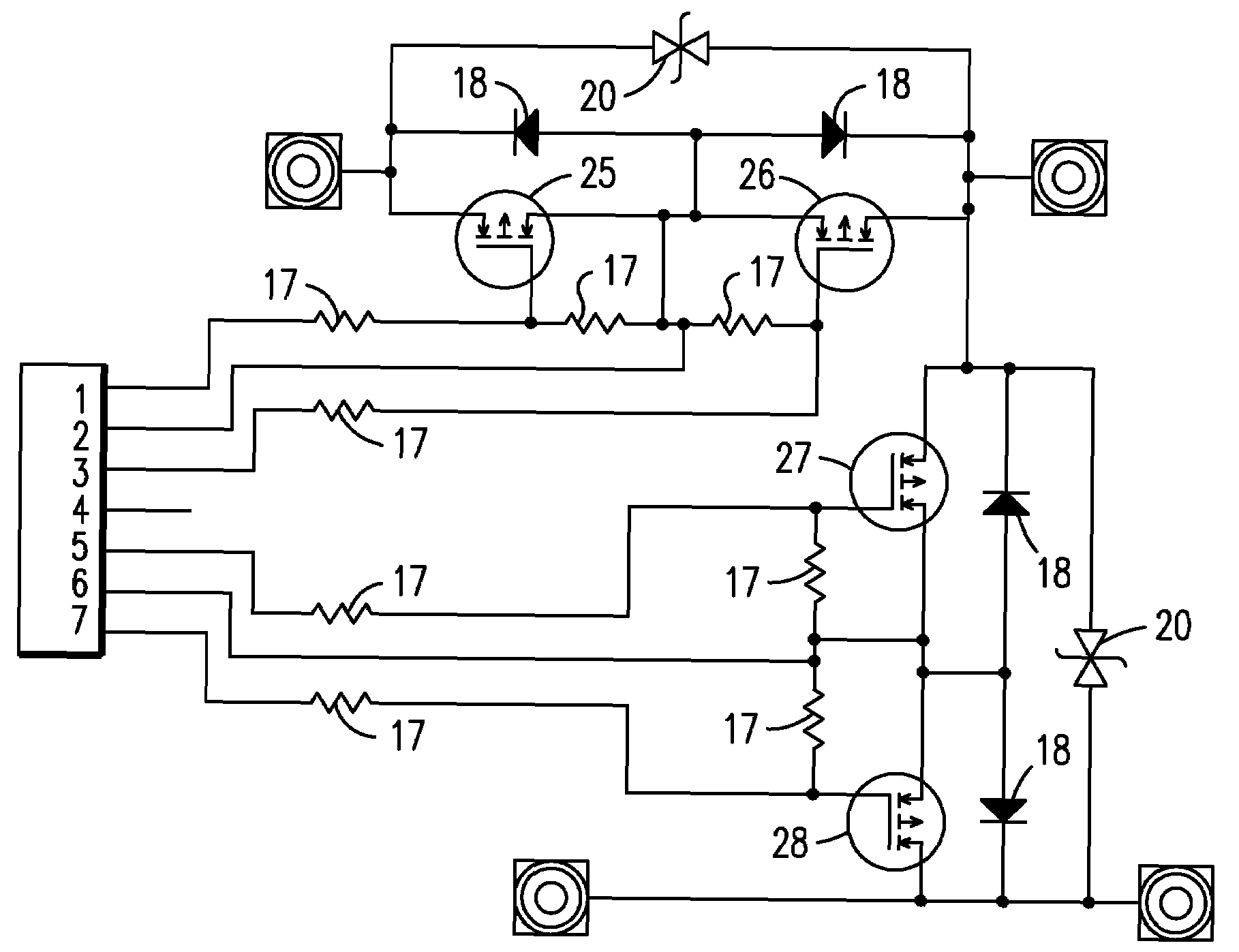

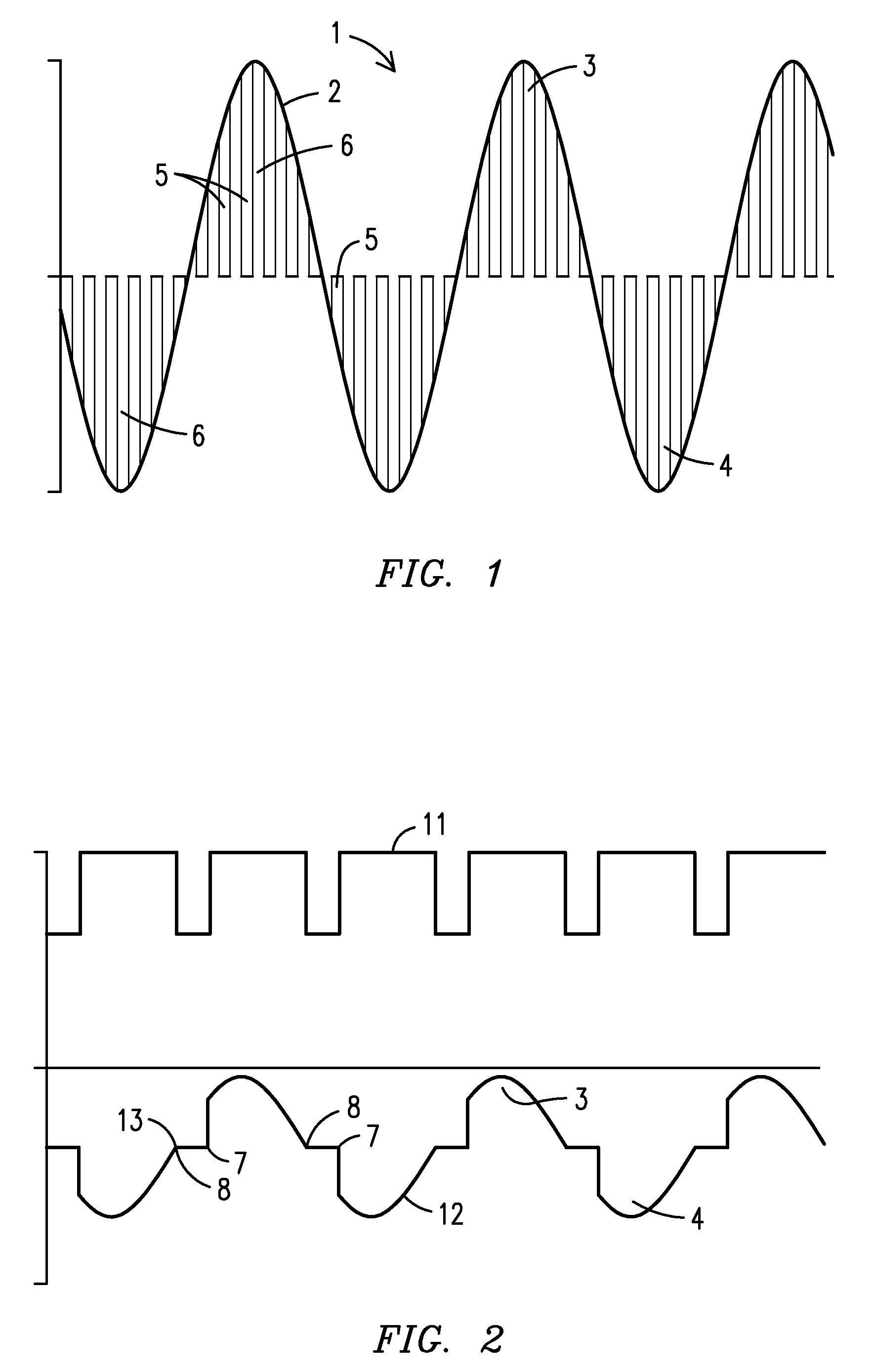

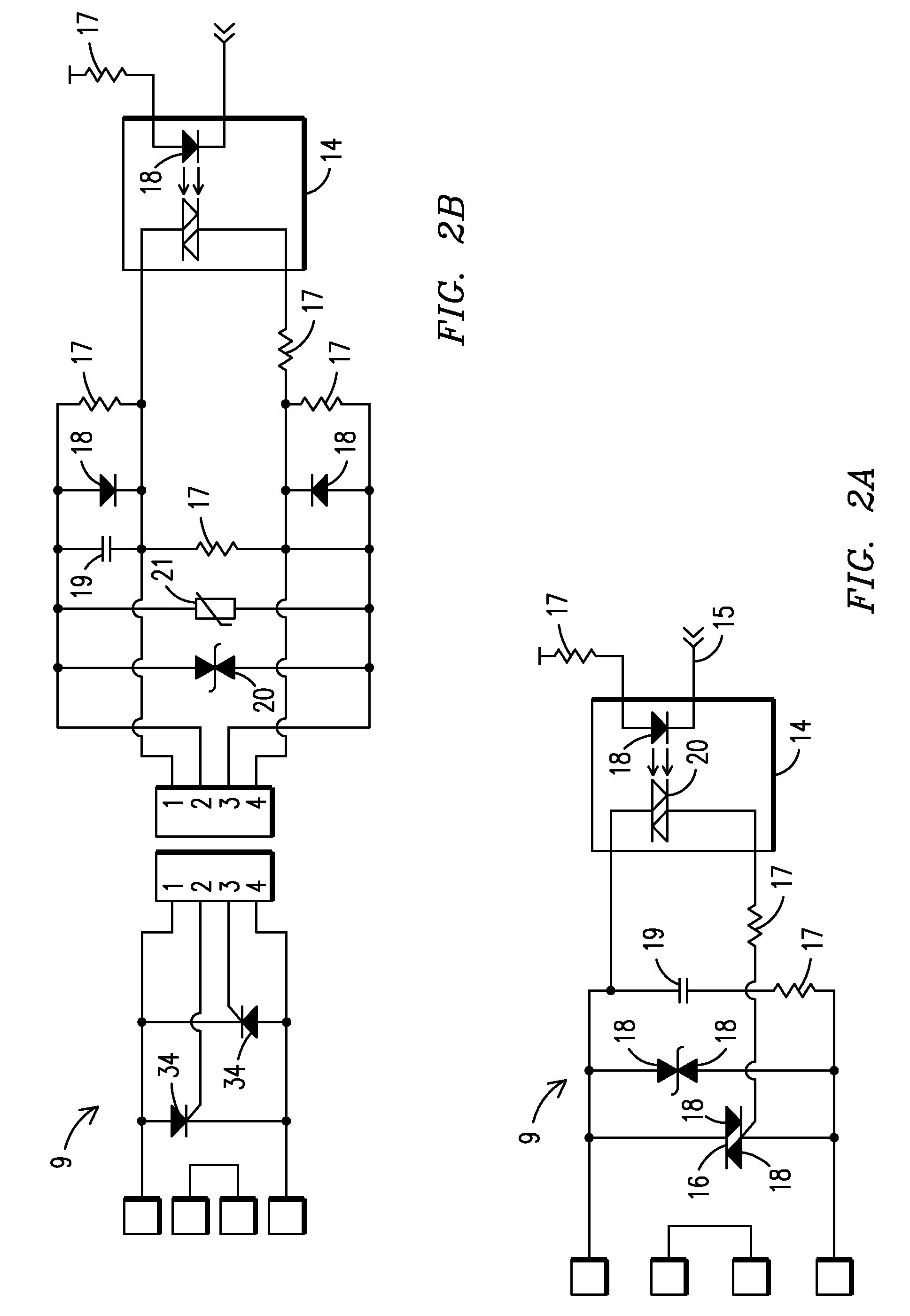

System and method for providing constant loading in ac power applications

ActiveUS20090200981A1Constant loadApply evenlySingle-phase induction motor startersSynchronous motors startersEngineeringField-effect transistor

A system and method for providing constant loading in AC power applications wherein at least one turn-on point (7) of at least one half cycle of a modulating sine wave (2) is determined; at least one turn-off point (8) of said at least one half cycle of a modulating sine wave (2) is determined; and at least one slice (5) located between said at least one turn-on point (7) and said at least one turn-off point (8) is removed. The slices (5) may be removed by utilizing triode alternating current switches, silicone controlled rectifiers, insulated gate bipolar transistors or field effect transistors.

Owner:THE POWERWISE GRP

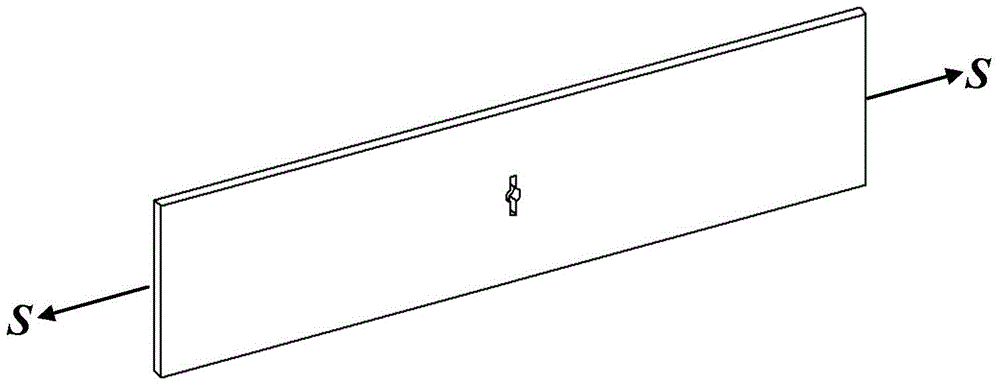

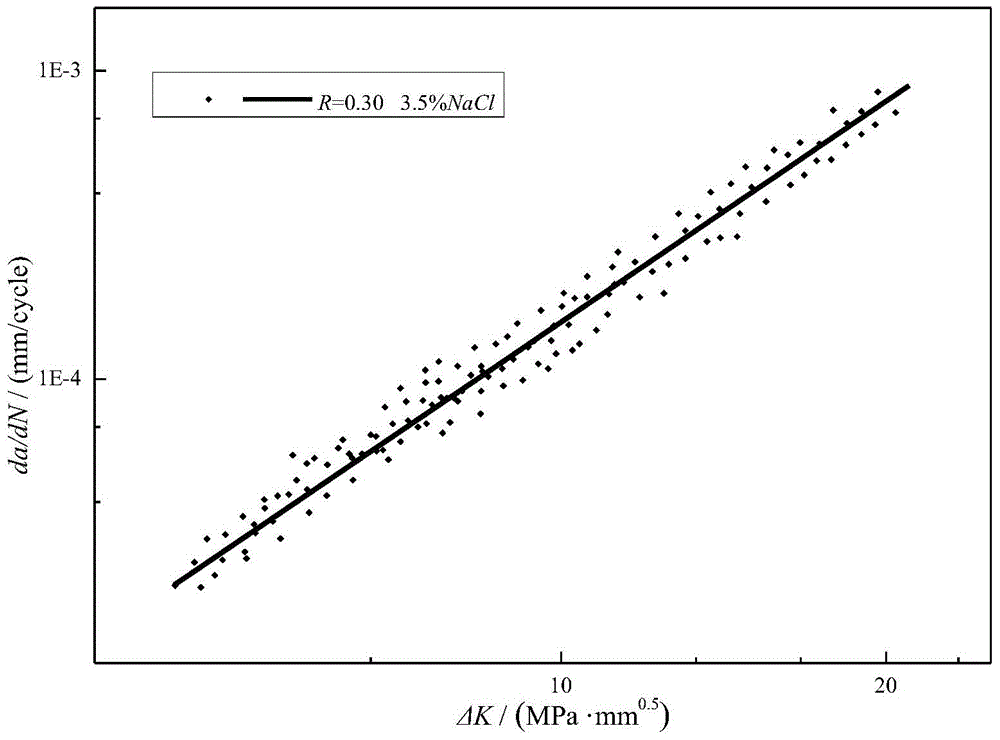

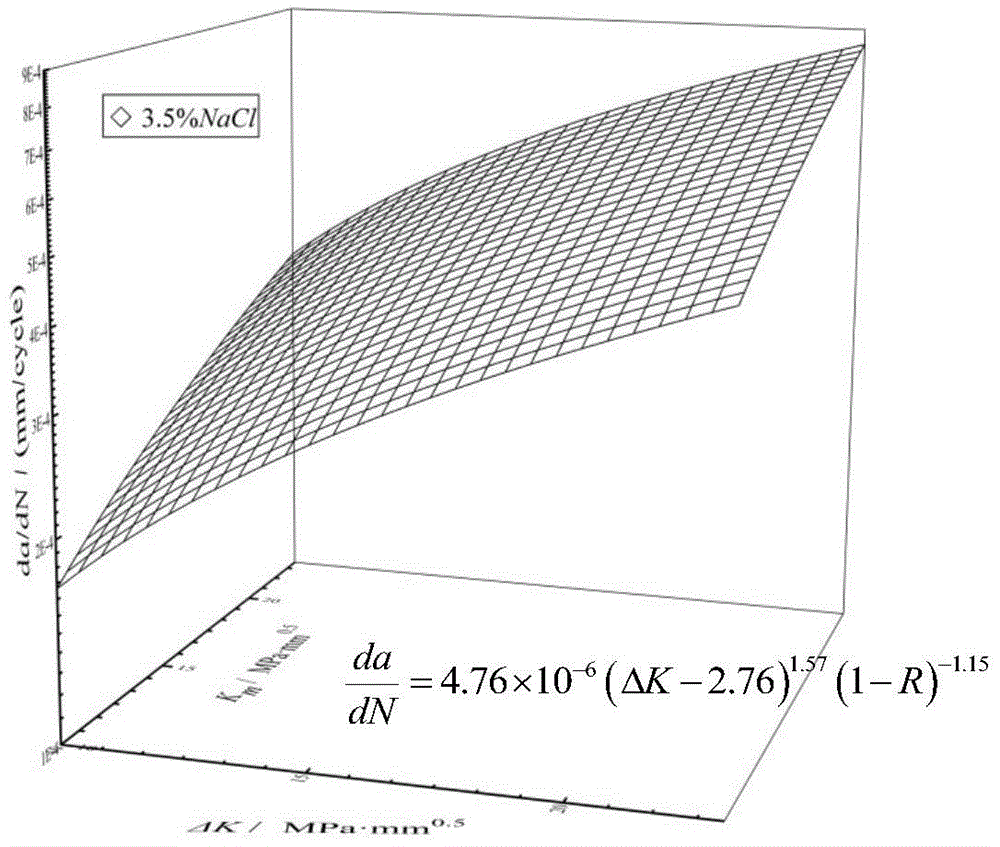

Corrosion crack expansibility characterization and life estimation method

A corrosion crack expansibility characterization and life estimation method comprises the following steps: 1, obtaining the corrosion crack expansibility da / dN-deltaK curve of a material through constant load test; 2, considering influences of corrosion on the fracture threshold value, correcting a Walker formula, fitting the da / dN-deltaK curve through combining a binary linear regression theory, and constructing a corrosion crack expansibility characterization model; and 3, considering the interaction between the retardation effect and load under spectrum load, and estimating the corrosion spectrum-loaded crack expansion life of the material by adopting a Willenborg-Chang model and an accumulation integration technology. The method is simple and practical, allows the corrosion crack expansibility characterization model to be constructed and the spectrum-loaded crack expansion life to be estimated only through using the constant load crack expansibility curve and the actually measured flight load spectrum of the material in corrosion environment, and has great scientific significance and engineering application values.

Owner:北京睦邦仁科技有限公司

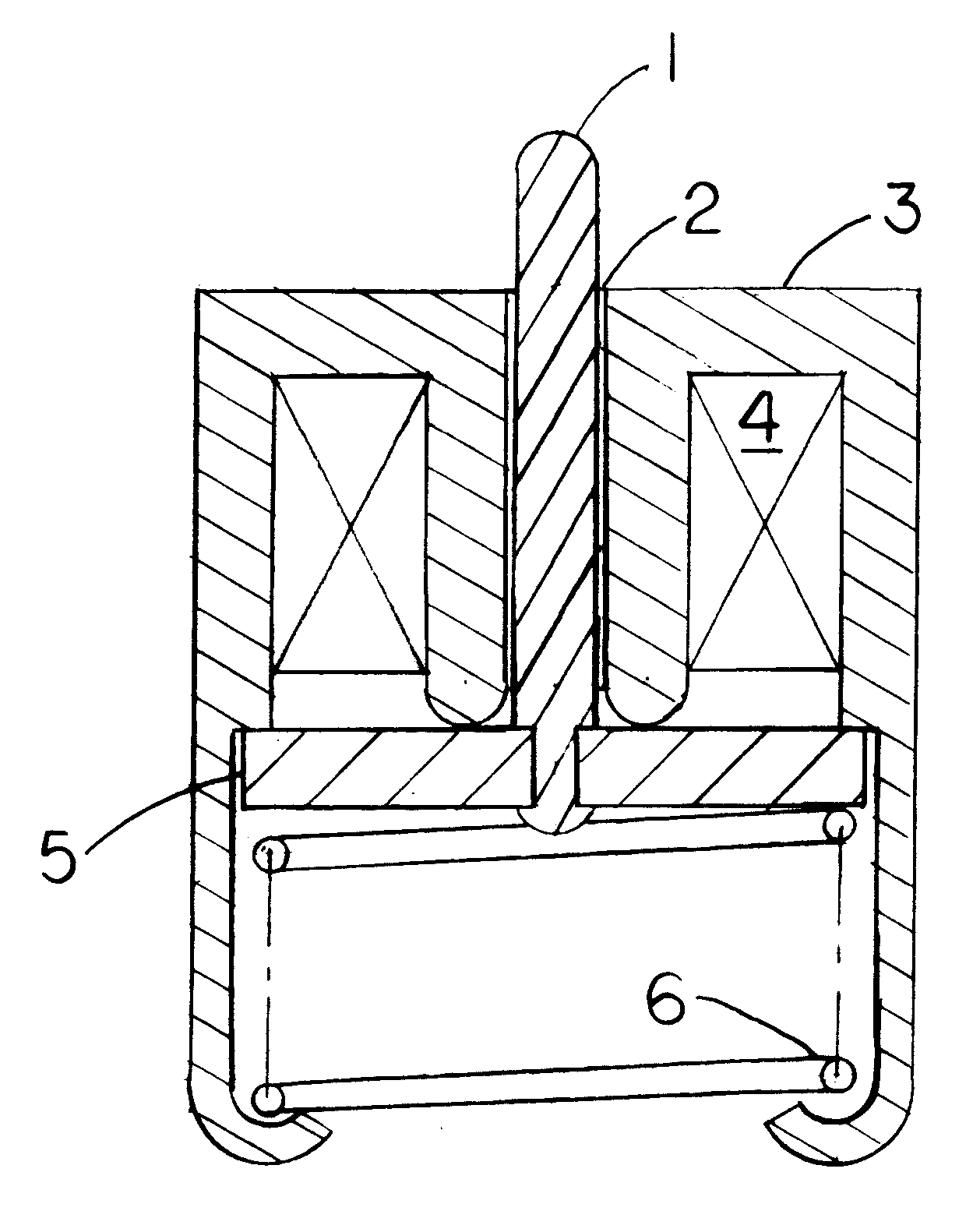

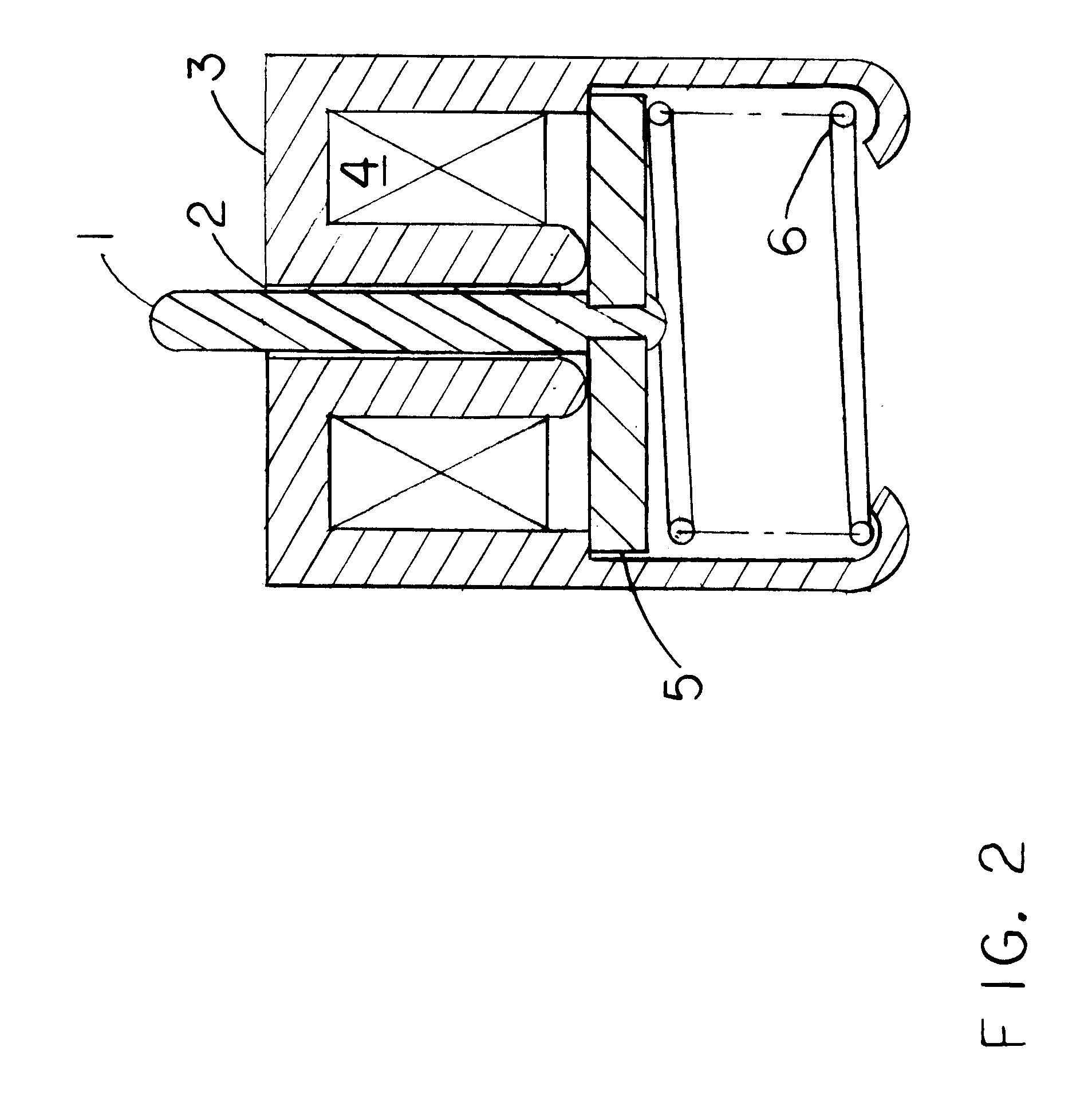

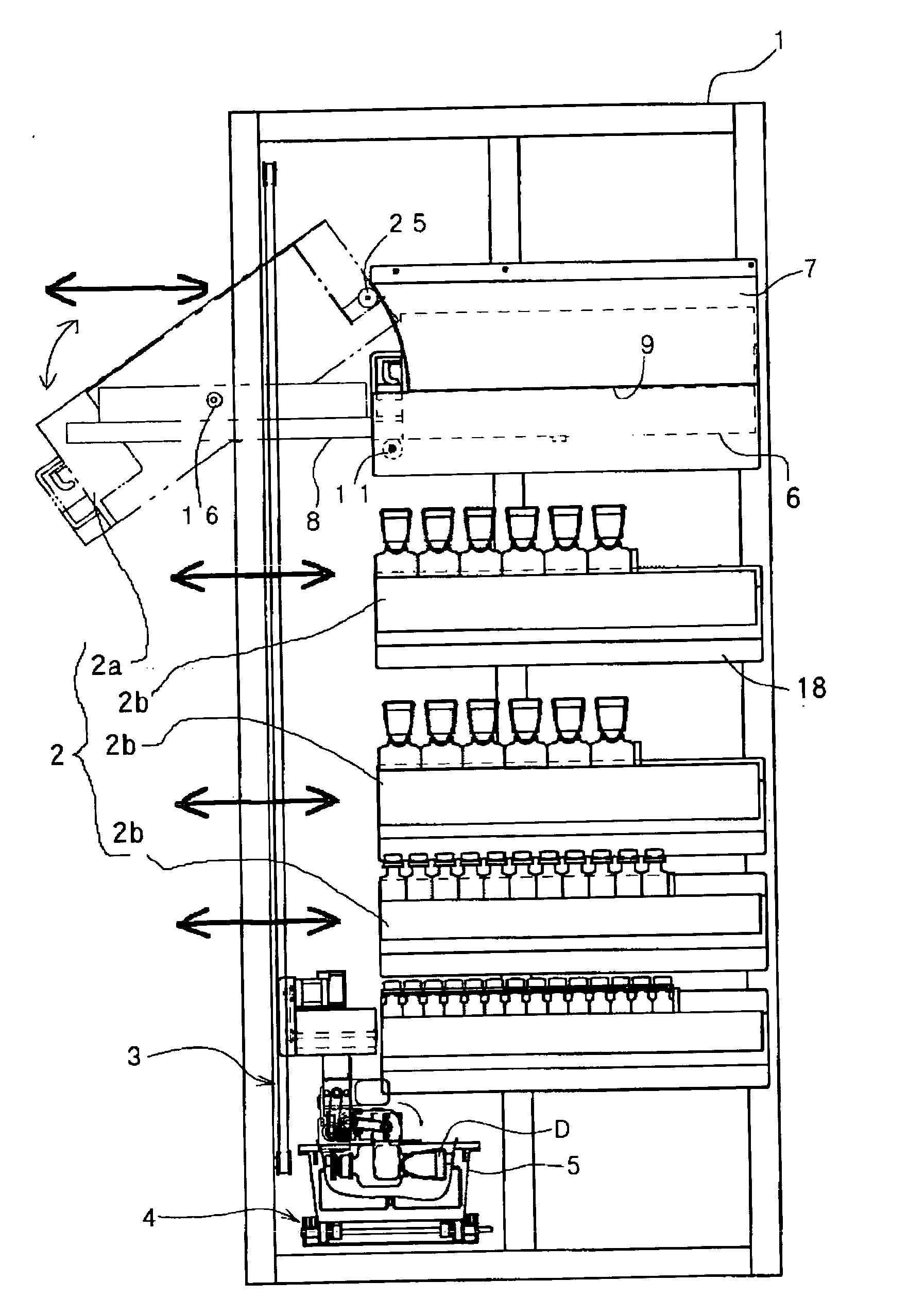

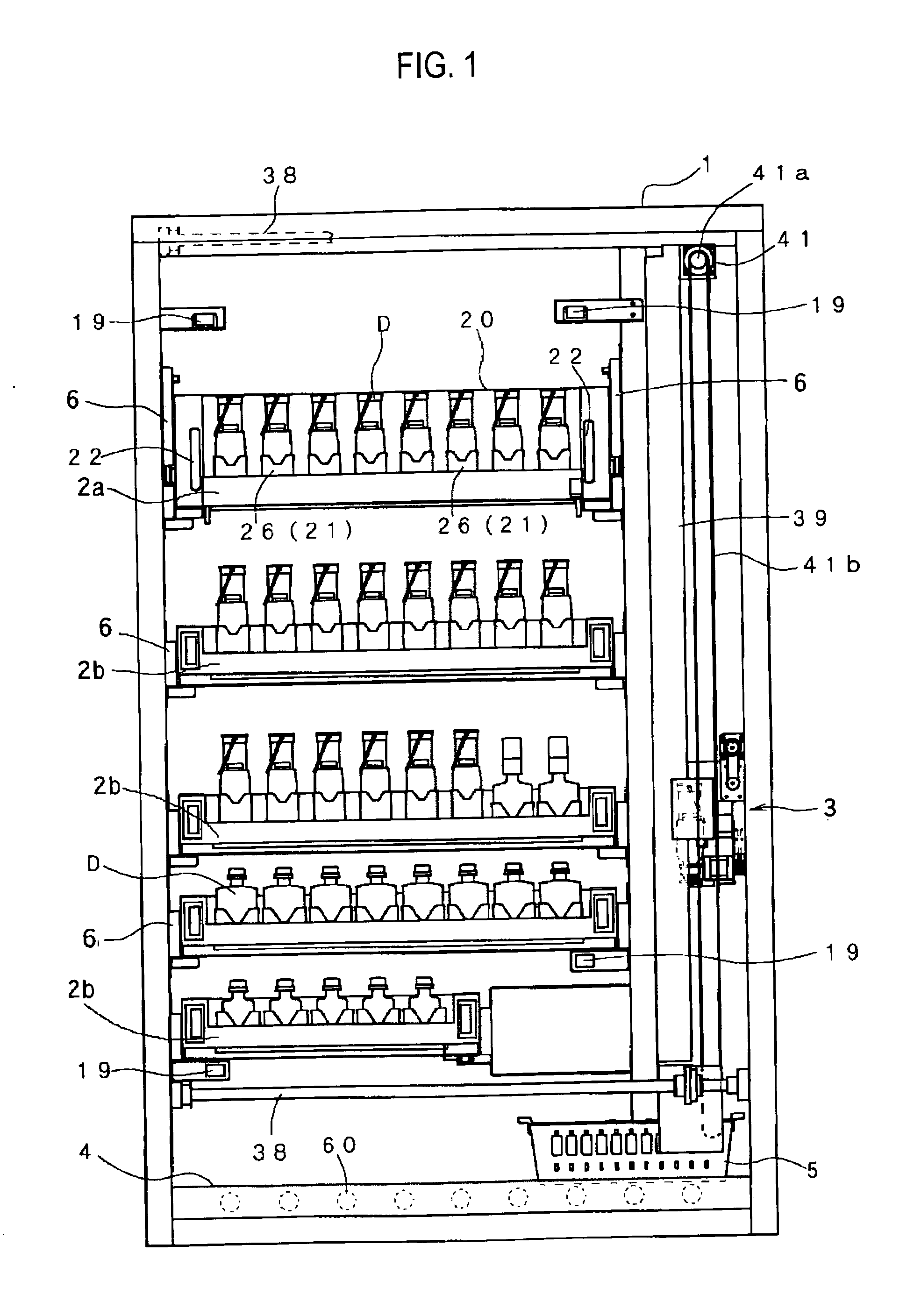

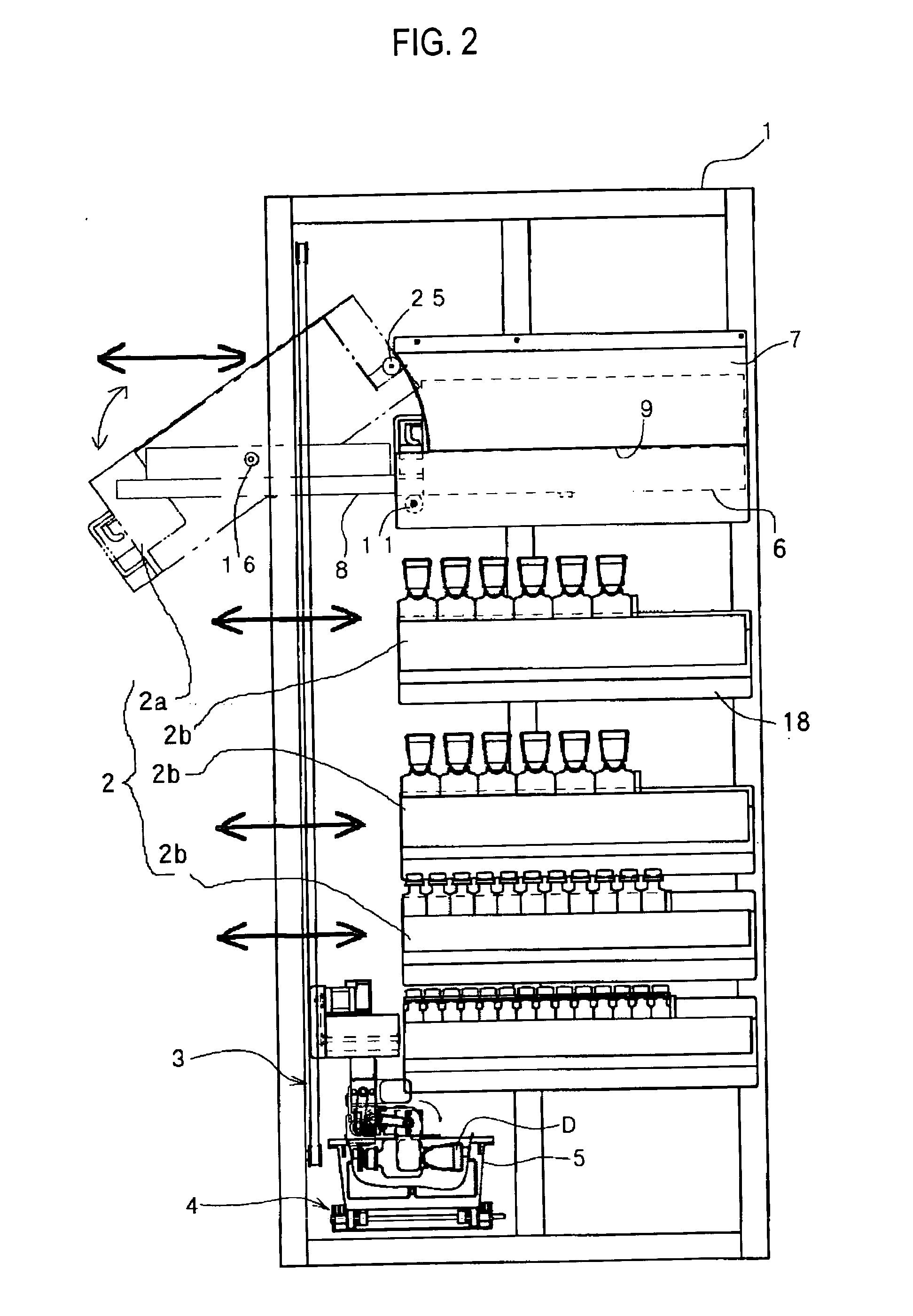

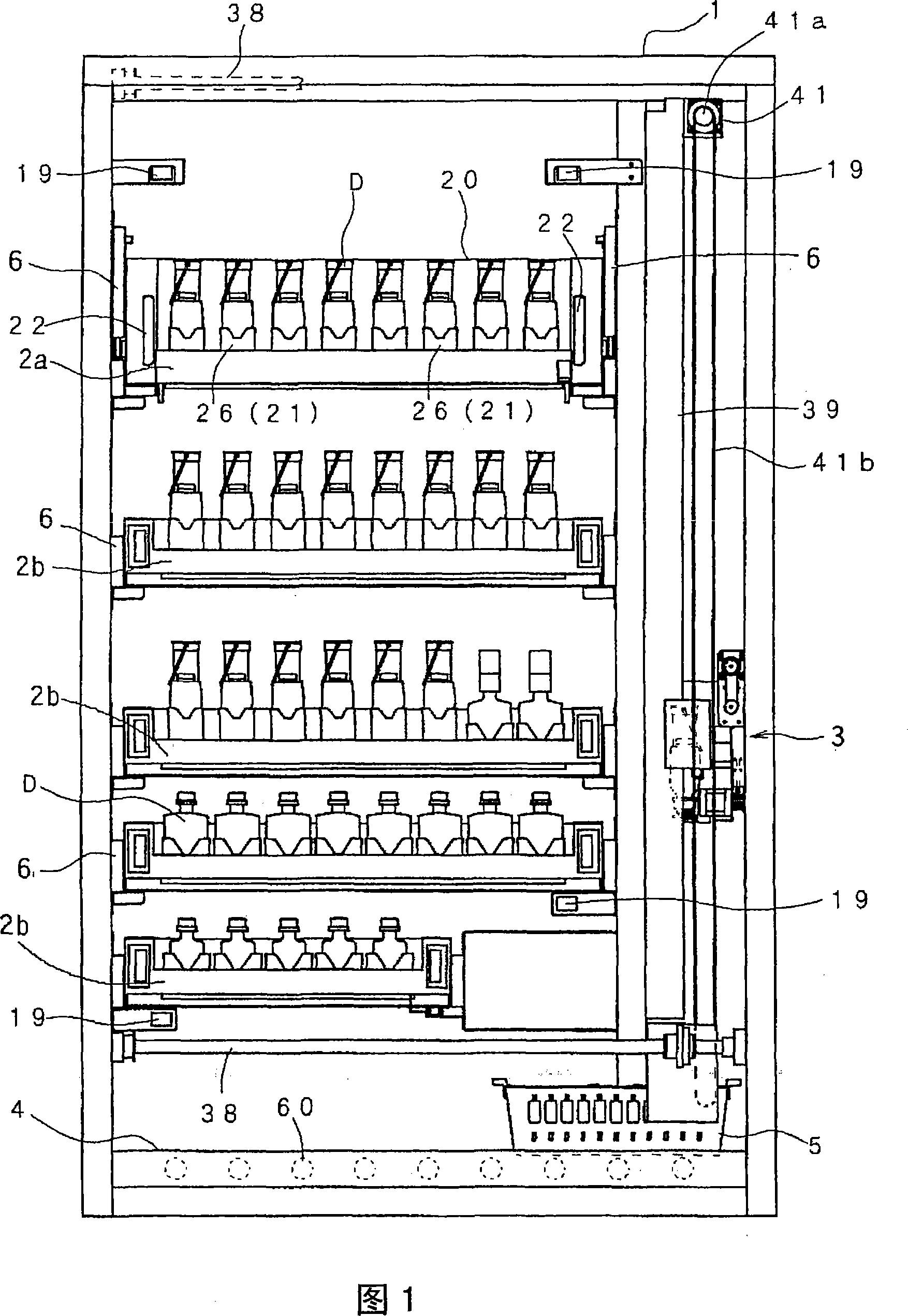

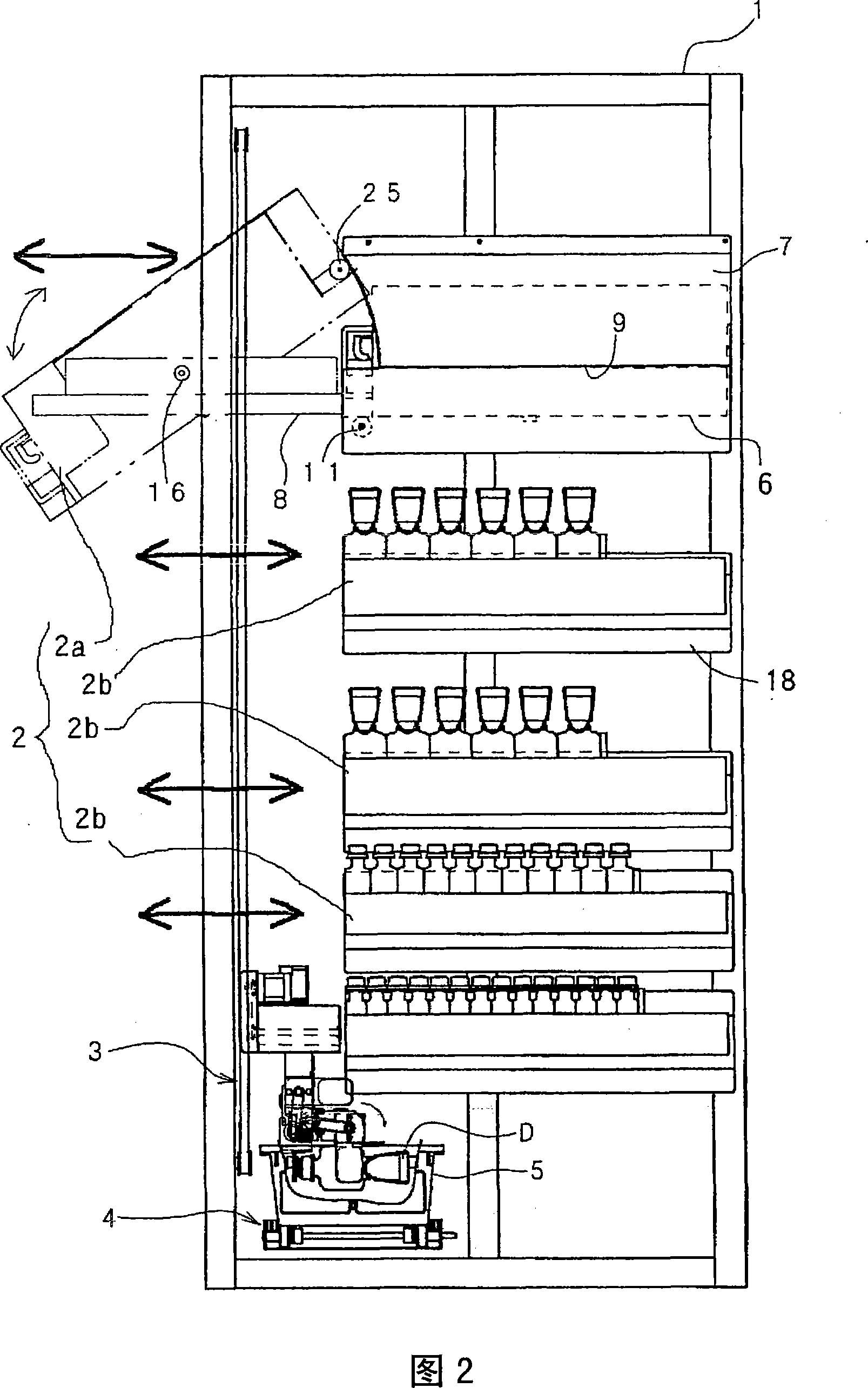

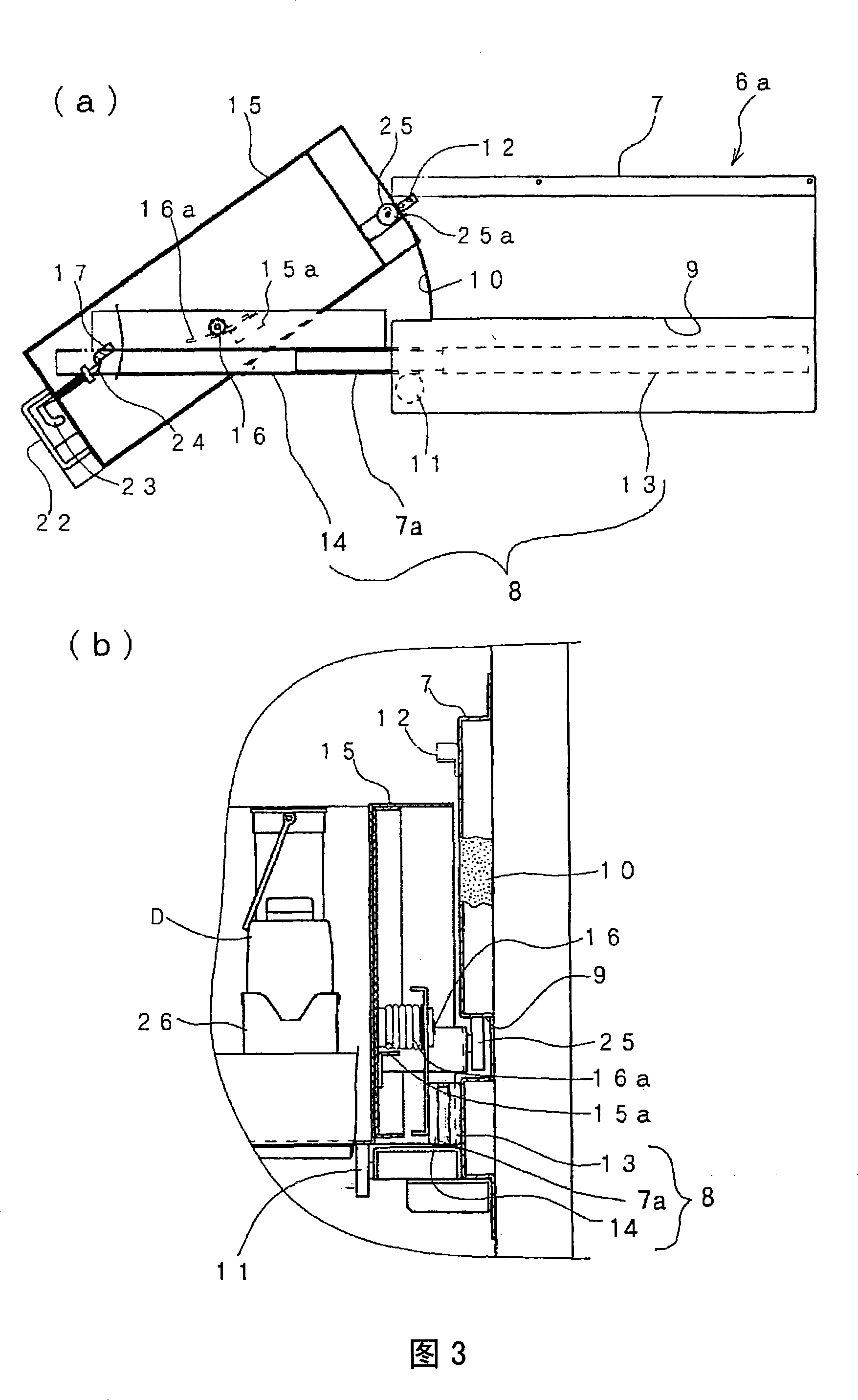

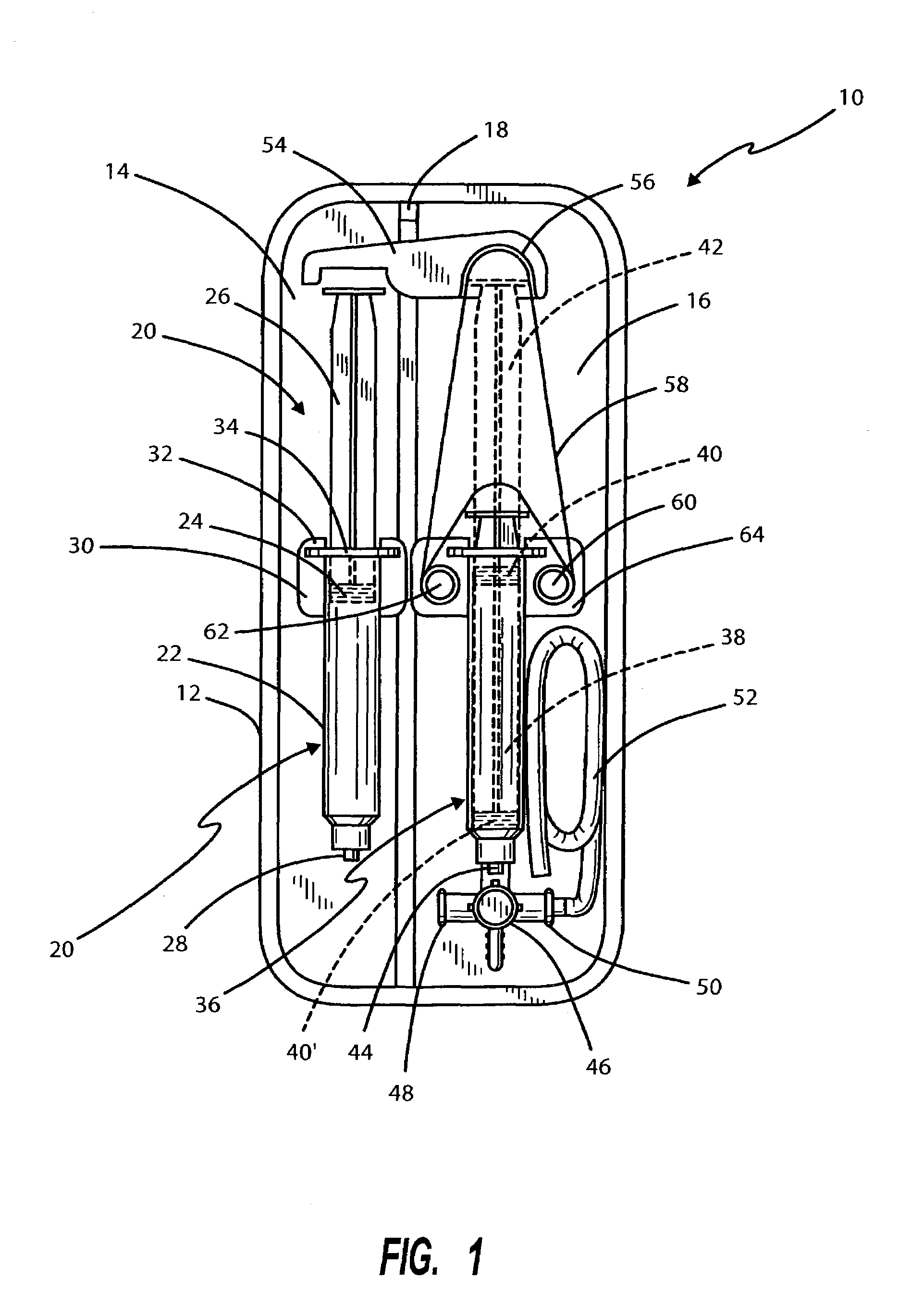

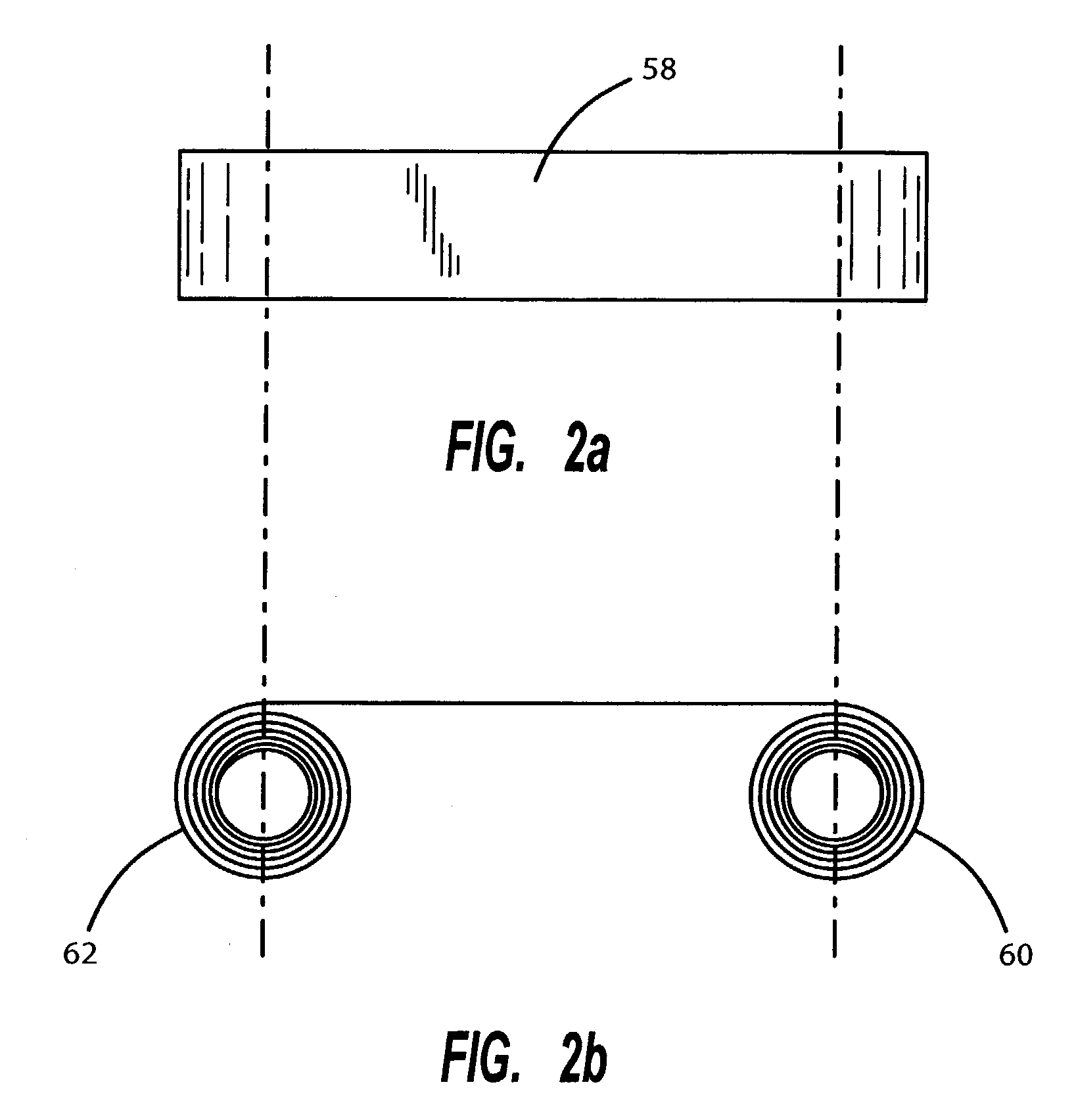

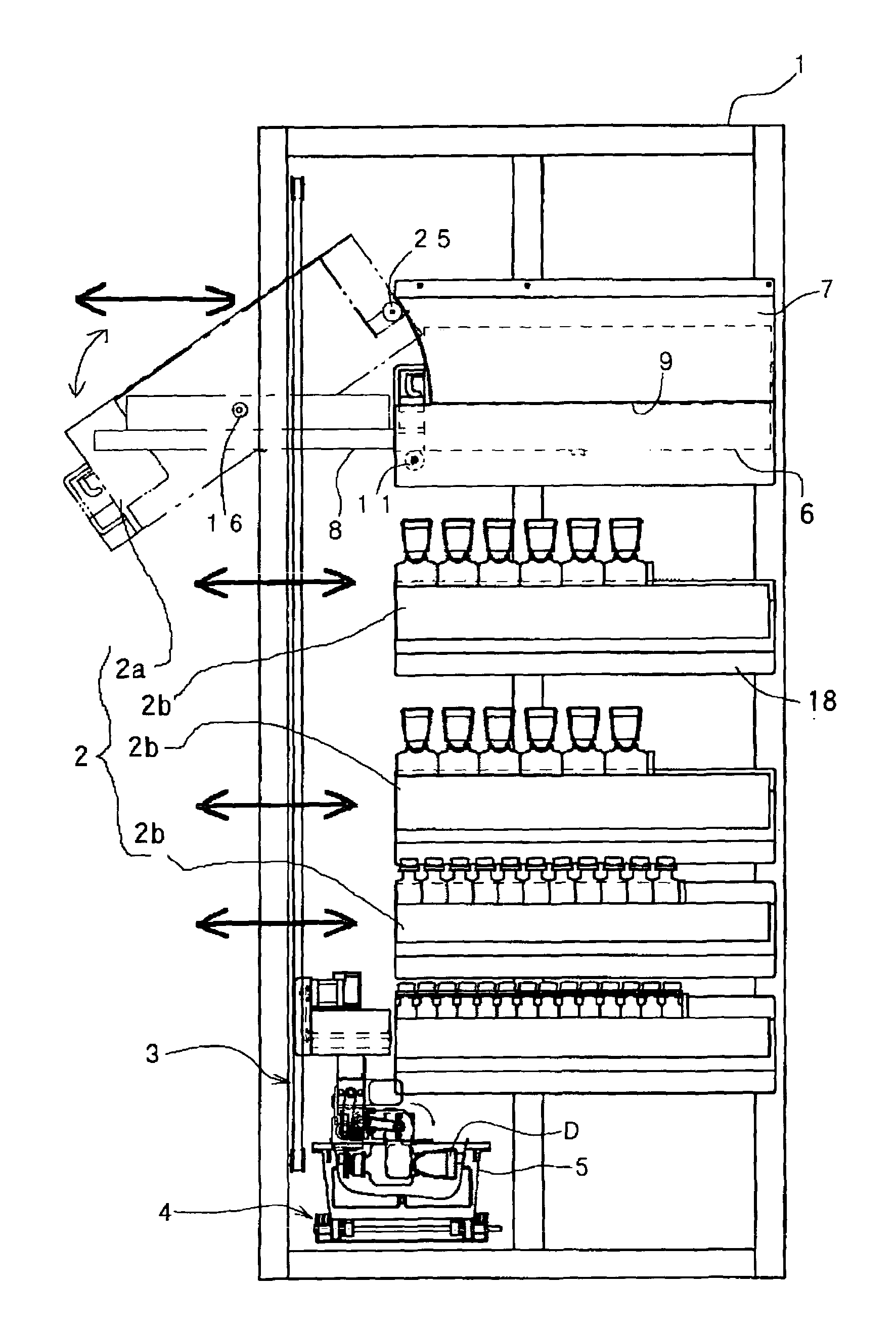

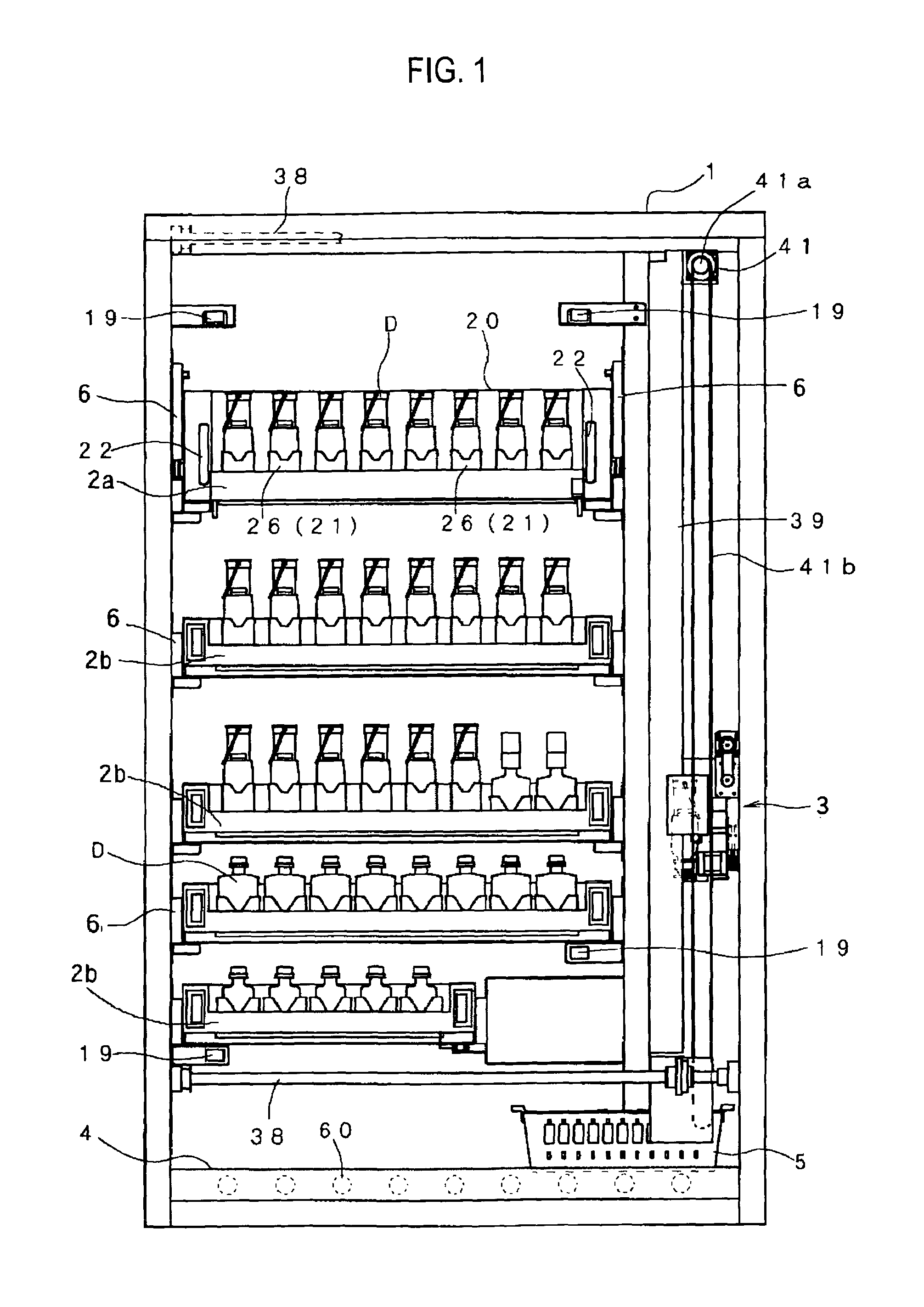

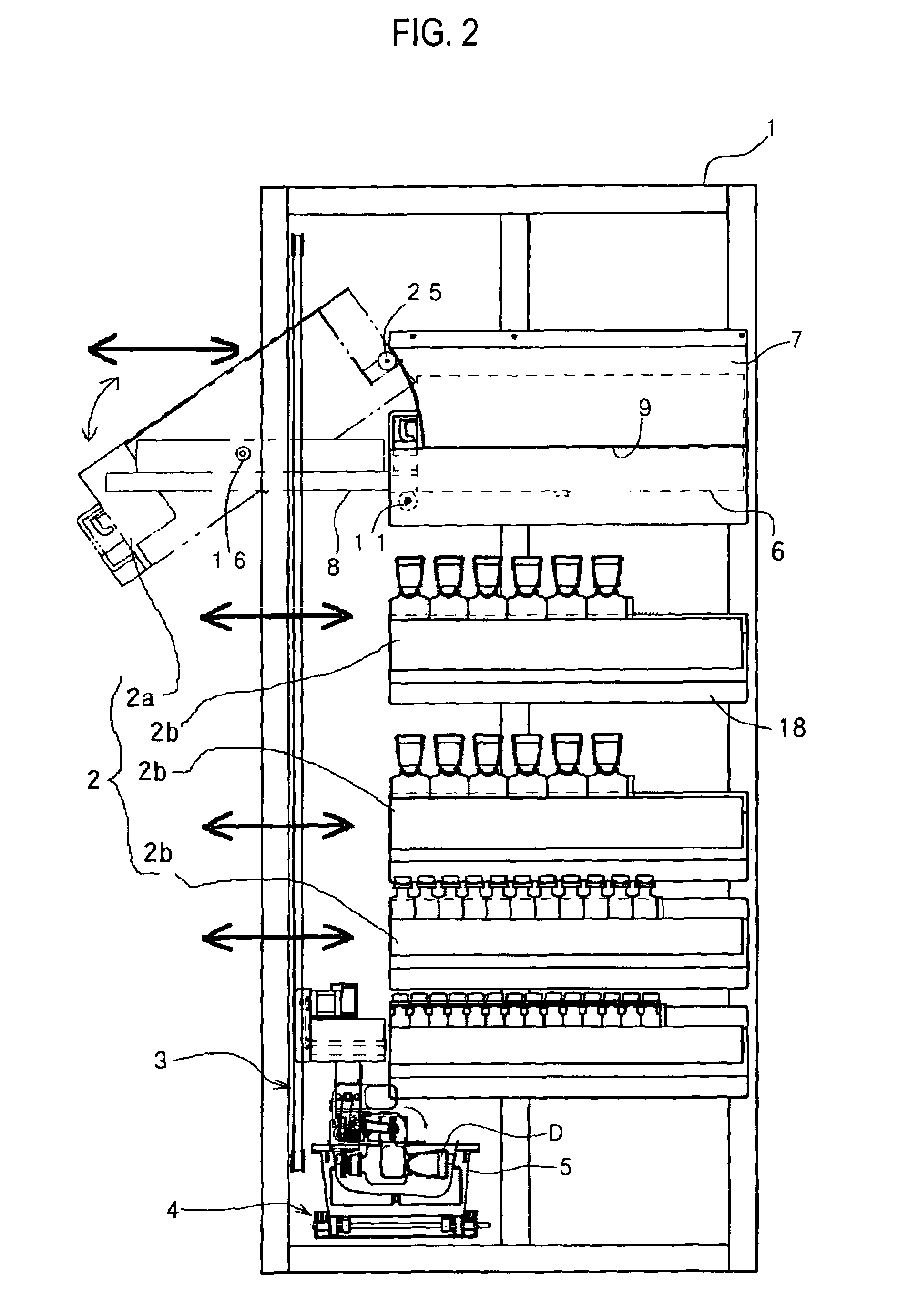

Medicine dispensing device

InactiveUS20070221680A1Compact configurationEasy to replenishCabinetsStorage devicesConstant loadMagnetic tape

A medicine dispensing device has a device body (1), shelf members (2) arranged in the vertical directions in the device body (1), and a medicine conveyance member (3) for conveying medicines (D), received in the shelf members (2), on one by one basis from the front face side of the device body (1). A shelf member (2) has cassettes (26) in which medicines (D) are received in line, a pusher (31) for pushing the medicines in the cassettes (26) toward the front face side of the device body (10), and a constant load spring (32) for applying a constant load to the medicines (D) received in the cassettes (26) through the pusher (31). To fill the cassettes (26) with the medicines (D), the shelf member (2) can be pulled out from the front face side of the device body (1) and then positioned by pivoting the shelf member (2) so as to face obliquely downward.

Owner:YUYAMA MFG CO LTD

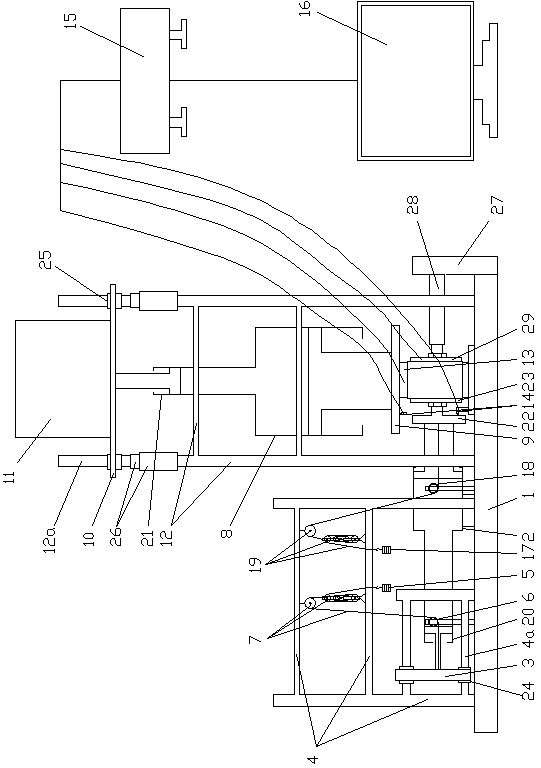

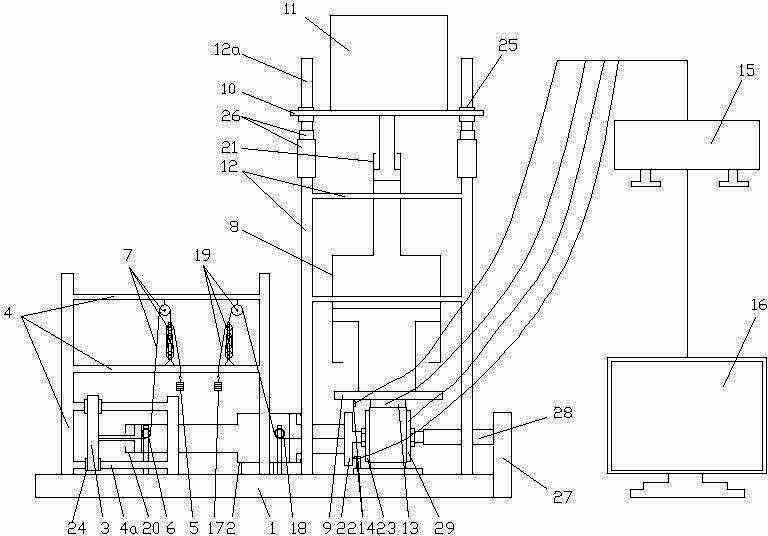

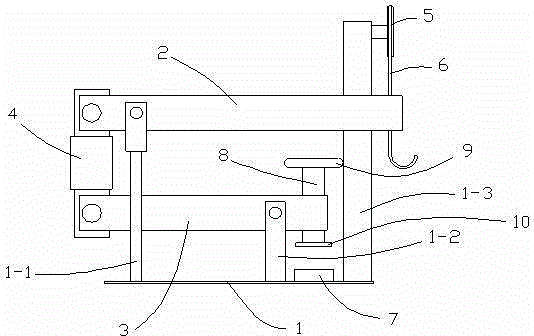

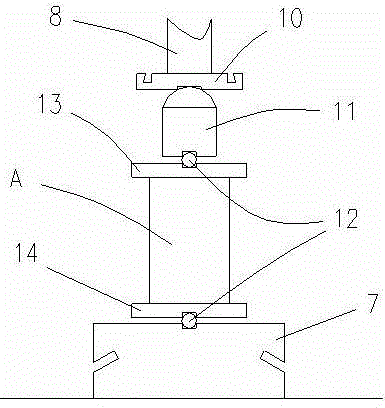

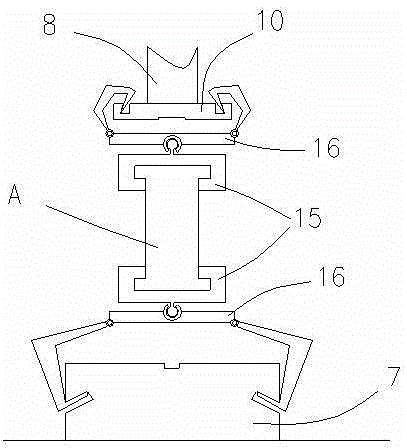

Multifunctional true triaxial rock creepmeter

InactiveCN102621012AMany experimental functionsPracticalInvestigating material ductilityConstant loadStress path

The invention discloses a multifunctional true triaxial rock creepmeter, comprising a base, a test piece mounting base arranged on the base, two groups of horizontal direction stress loading systems with the same structure, a vertical direction stress loading system and a creep data measuring system. The multifunctional true triaxial rock creepmeter disclosed by the invention can carry out a single-axis pulling and pressing creep test and also can carry out a true triaxial compression, pulling and pressing combined creep and unloading-creep test which simulates three-dimensional stress state and loading and unloading stress path of a natural geological rock mass and an engineering rock mass and maintain tension stress states in one or two directions unloaded to the rock; and test function is more comprehensive, practicability is stronger, and a pulling and pressing combined creep and stable pressing and pulling stress conversion unloading-creep test is realized; a pull pressure loading system can provide a pressure which is high enough to meet creep test requirements of most rock materials, and a long-term constant load can be provided; and the multifunctional true triaxial rock creepmeter disclosed by the invention has the characteristics of having a simpler structure, hardly consuming energy source in a test process and having low test cost.

Owner:CHONGQING UNIV

Medicine dispensing device

InactiveCN1976671AConvenient supplementCompact structureCoin-freed apparatus detailsPharmaceutical product form changeConstant loadDrug product

A medicine dispensing device has a device body (1), shelf members (2) arranged in the vertical directions in the device body (1), and a medicine conveyance member (3) for conveying medicines (D), received in the shelf members (2), on one by one basis from the front face side of the device body (1). A shelf member (2) has cassettes (26) in which medicines (D) are received in line, a pusher (31) for pushing the medicines in the cassettes (26) toward the front face side of the device body (1), and a constant load spring (32) for applying a constant load to the medicines (D) received in the cassettes (26) through the pusher (31). To fill the cassettes (26) with the medicines (D), the shelf member (2) can be pulled out from the front face side of the device body (1) and then positioned by pivoting the shelf member (2) so as to face obliquely downward.

Owner:YUYAMA MFG CO LTD

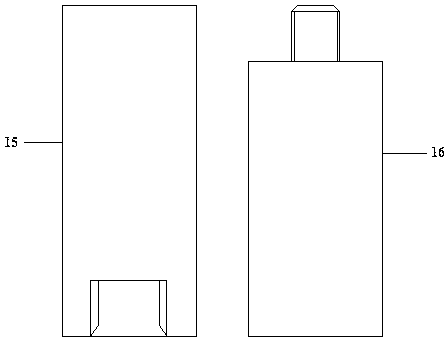

High-temperature high-pressure constant load stress corrosion experiment method and device

InactiveCN102706750ARealistic simulation of mechanical damageStability test methodWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMetallic materialsStressed state

The invention discloses a high-temperature high-pressure constant load stress corrosion experiment method and device. The technical scheme are that constant load stress corrosion experiment of metal materials can be conducted in certain stress state under the combined action of high-temperature high-pressure gaseous phase and liquid phase corrosion media, and subjected to combined action of the constant stress, and high-temperature high-pressure gaseous phase and liquid phase corrosion media in experiment process, and evaluation and research on the applicability and action mechanism of the metal material can be conducted under high-temperature high-pressure corrosive environment and tension stress state according to the experiment results. Damage to strength, plasticity and flexibility of the metal materials can be determined in high-temperature high-pressure gaseous phase and liquid phase corrosive environments under the action of any load by utilizing the experiment method and device, the mechanical property damage degree of the metal materials can be obtained in certain stress state and special corrosion environment according to the test result, thus conducting preference of the metal materials and applicability evaluation.

Owner:SOUTHWEST PETROLEUM UNIV

Optical-use pressure-sensitive adhesive sheet

ActiveCN102051133AStripping does not produceImprove bond reliabilityMonocarboxylic acid ester polymer adhesivesOpticsConstant loadPeel force

The invention provides an optical-use adhesive sheet excellent in adhesiveness under bending, twisting or distorting stress. The optical-use adhesive sheet has an adhesive layer having a storage elastic modulus at 80 DEG C of at least 2.0X10 4 Pa and a loss elastic modulus at 80 DEG C of at least 1.0X10 4 Pa, the optical-use adhesive sheet is characterized in that the adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test, of at most 50 mm. In the L-shape peel test, an L-shaped stainless steel clamp is adhered with an acrylicresin plate through the adhesive sheet, the acrylicresin plate and the stainless steel clamp are processed for 15 minutes at 50 DEG C under 5 atm, and then, the stainless steel clamp is drawn along a direction vertical to a surface of the acrylicresin plate so as to test the peel force. In the constant-load peel test, a double-faced adhesive sheet is adhered on the acrylicresin plate, then, the acrylicresin plate and the double-faced adhesive sheet are processed for 10 minutes at 50 DEG C under 5 atm, and then, a load of 100gf is applied along the direction vertical to the surface of the acrylicresin plate on a tail end in a length direction of the adhesive sheet so as to test the peel distance of the adhesive sheet after 3 hours.

Owner:NITTO DENKO CORP

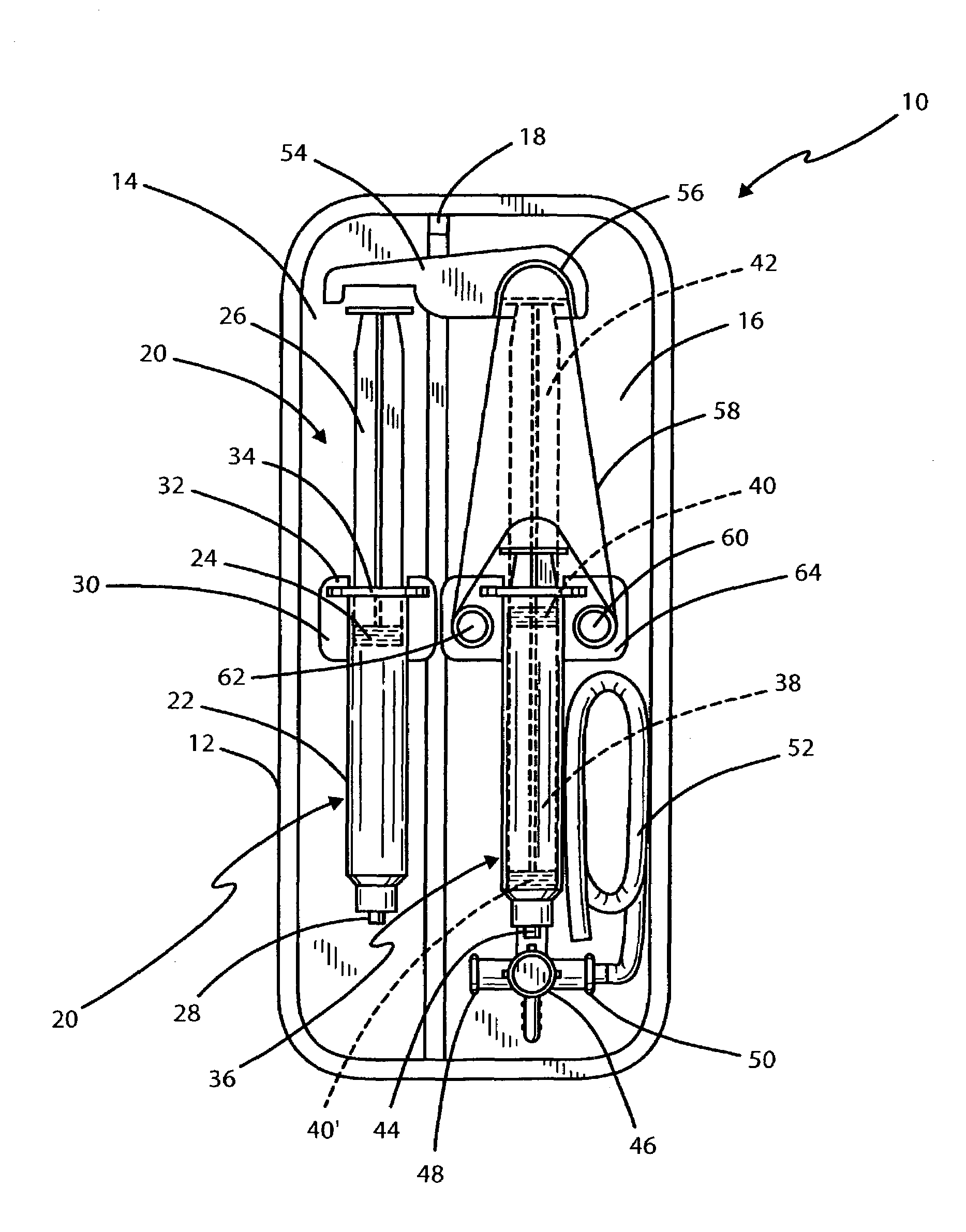

Drug delivery apparatus

A drug to be infused into a patient is contained in a syringe or vial having a displaceable plunger for ejecting the drug out through an injection port into an administration set. Motion of the plunger of the drug delivery syringe / vial is controlled by a driver syringe having a piston or plunger for ejecting either a compressible or an incompressible fluid through a flow resistance element. Motive power for the piston of the drive syringe is provided by a constant load spring. A suitable linkage is provided for coupling the piston of the drive syringe to the plunger of the drug delivery syringe. Several types of flow rate control elements for use with the driver syringe are disclosed.

Owner:KAZEMZADEH FARHAD

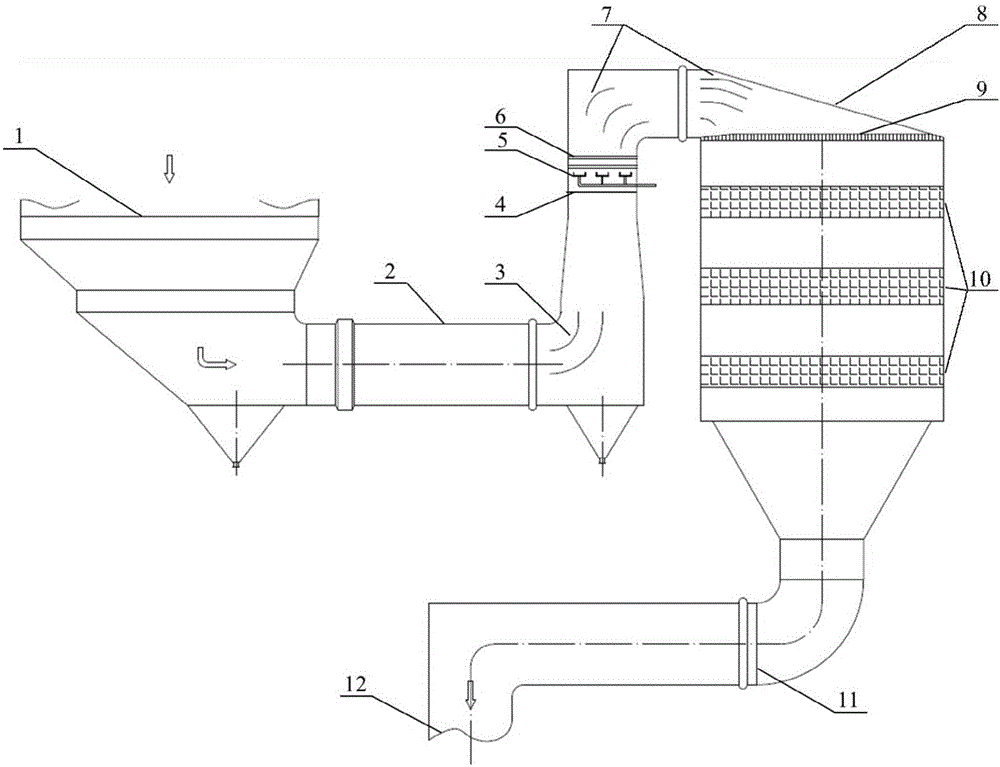

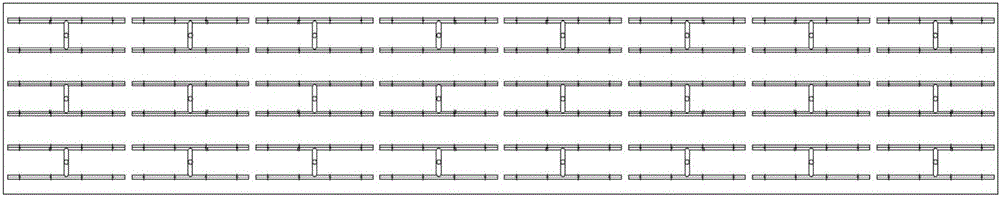

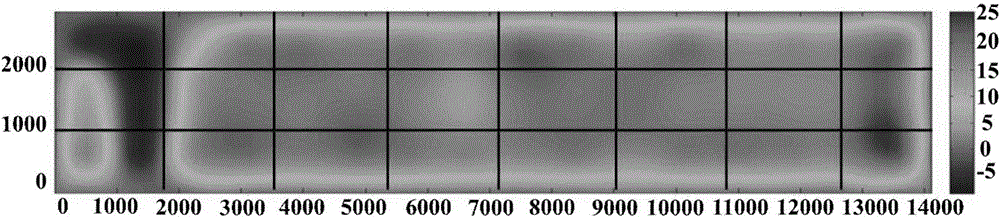

SCR denitration system ammonia spraying optimization method based on weight valve regulation and control

InactiveCN105126616AMake targeted adjustmentsReduce escapeDispersed particle separationConstant loadFlue gas

The invention discloses an SCR denitration system ammonia spraying optimization method based on weight valve regulation and control. The method is divided into four steps: measurement of flue gas flow field characteristics, analysis of flue gas flow field regional flow characteristics, determination of ammonia spraying weight valves and pertinence adjustment of opening degrees of the ammonia spraying valves. The method comprises the particular steps: firstly, measuring the flue gas flow field characteristics of a flue transverse section in front of an ammonia spraying grille of an SCR denitration system under a condition of constant load; then combining with a distribution condition of spray nozzles of the ammonia spraying grille, and analyzing flue gas flow field regional flow continuous distribution characteristics matched with the ammonia spraying spay nozzle distribution; according to the flue gas flow field regional flow characteristics under various load conditions, obtaining the weights of the ammonia spraying valves; and finally, adjusting the opening degrees of all the valves according to the valve weight difference, simultaneously, with the help of a flue gas analyzer, measuring the NOx outlet concentration on an outlet section of the SCR denitration system, and timely feeding back the adjustment effect of the opening degrees of the ammonia spraying valves. The method can ensure good ammonia nitrogen mixing equivalent ratio, effectively improves the denitration efficiency, decreases the ammonia escape and reduces the ammonia amount.

Owner:南京奥麦科仪器自动化有限公司

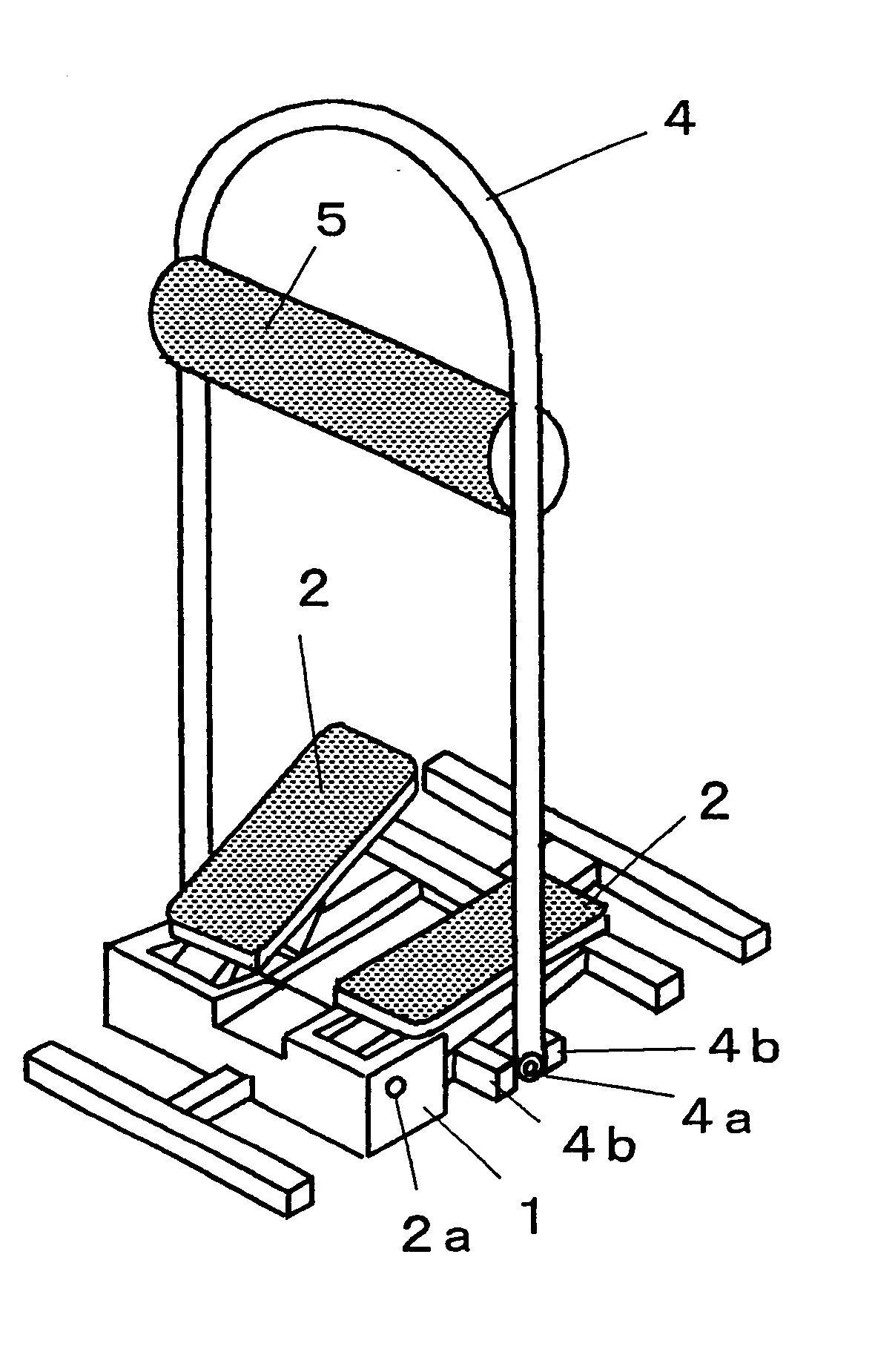

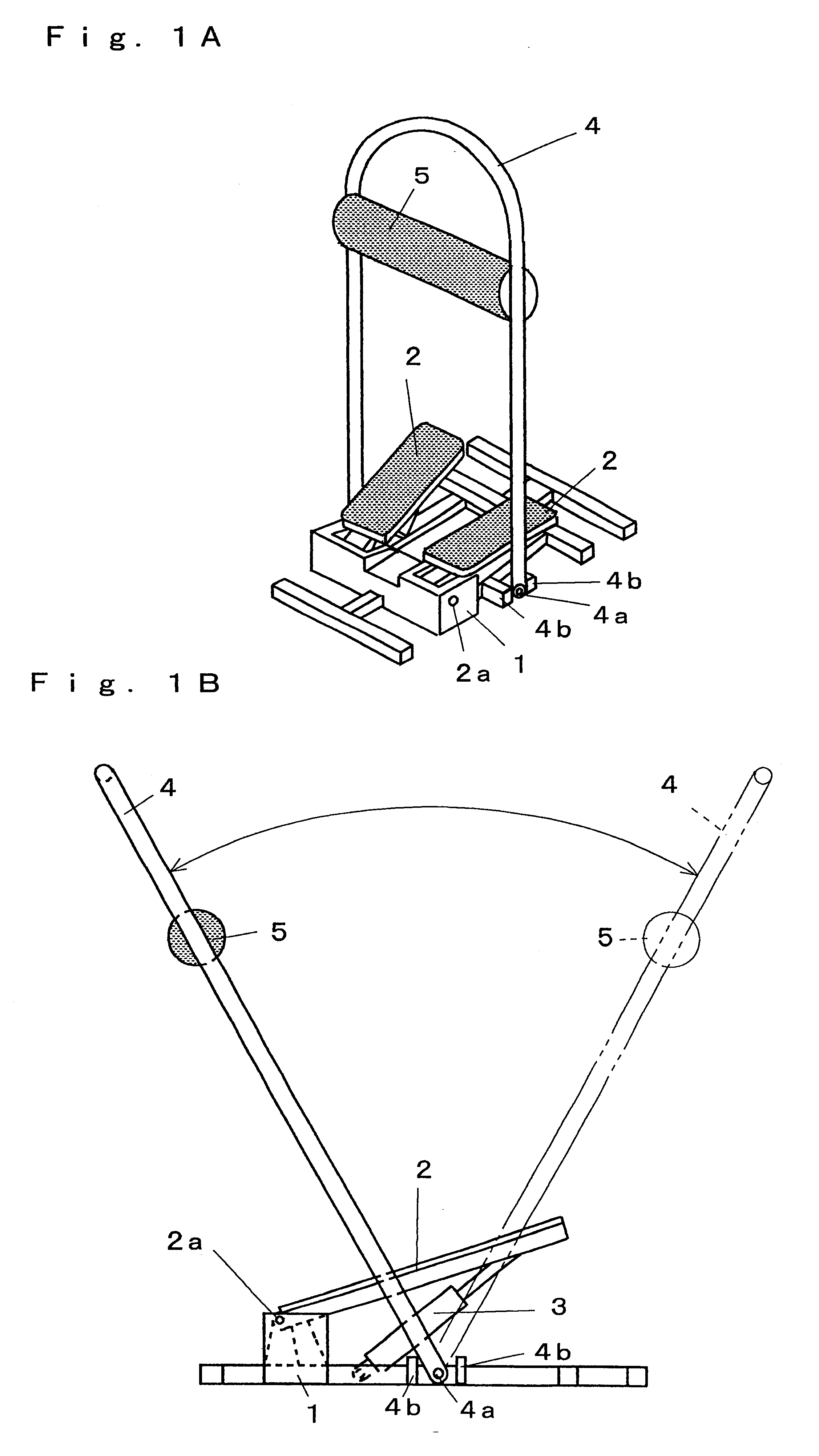

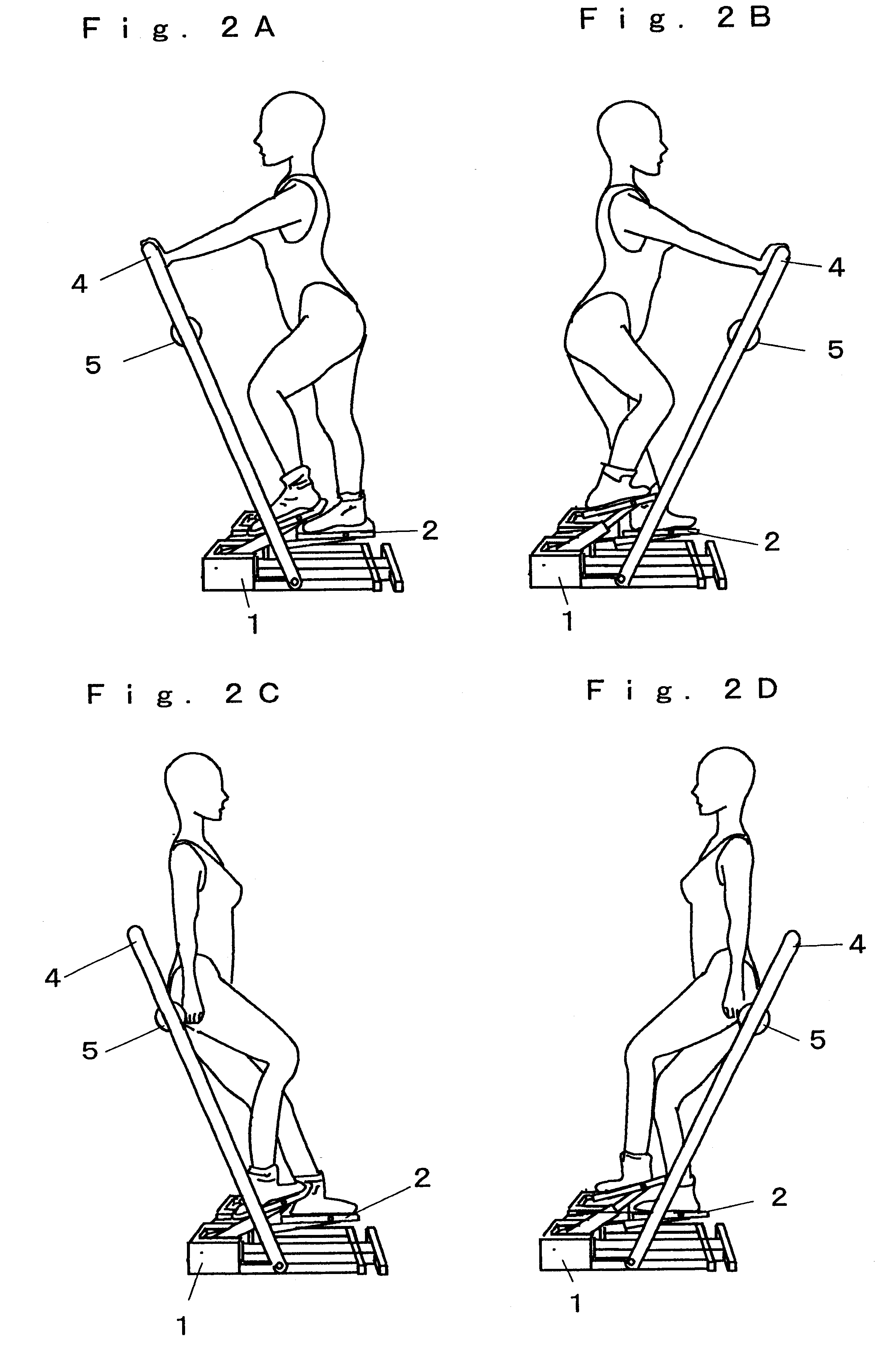

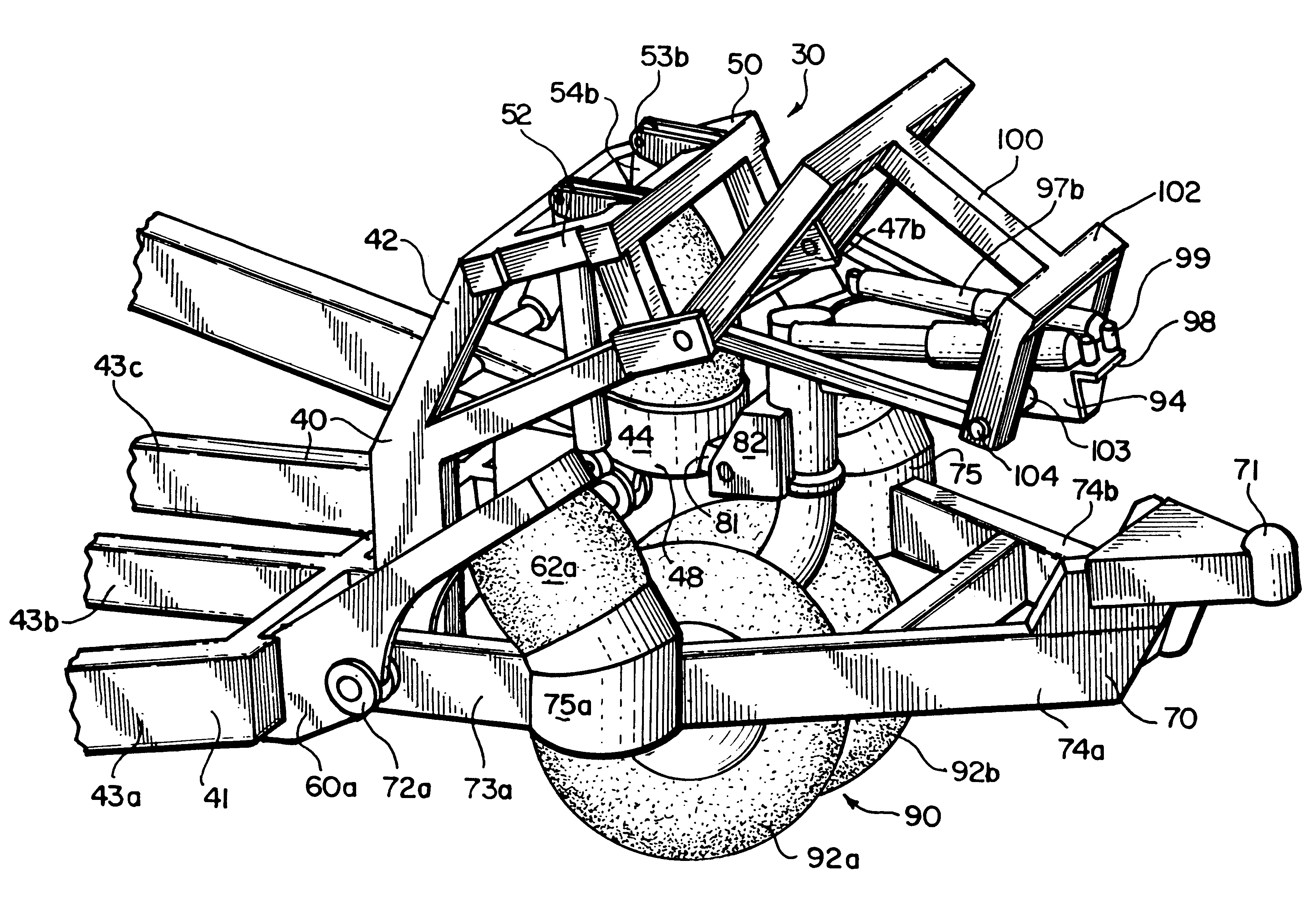

Fitness machine

InactiveUS6258012B1Movement coordination devicesMuscle exercising devicesConstant loadReciprocating motion

A fitness machine to provide a wide range of workout motions to the user. The machine is comprised of a base; and a pair of foot platforms adapted to alternately make vertically reciprocating motions. There may further be provided a support which is adapted to reverse an orientation with respect to said stepping platforms between positions forwardly and rearwardly thereof. Cylinders may be provided to support the foot platforms such that a constant load resistance is given while changing their stepping stroke by means of linkage combination of a hydraulic system. The foot platforms are set at laterally inclined positions.

Owner:YOSHIMURA SHINICHIRO

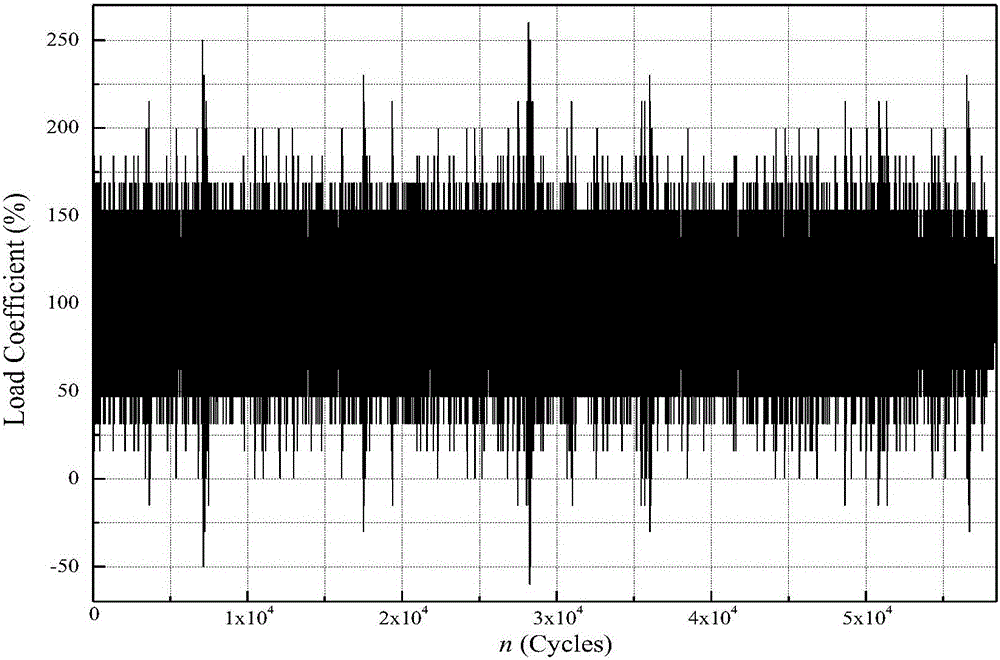

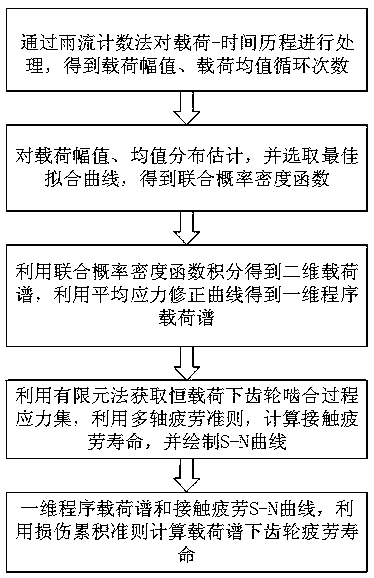

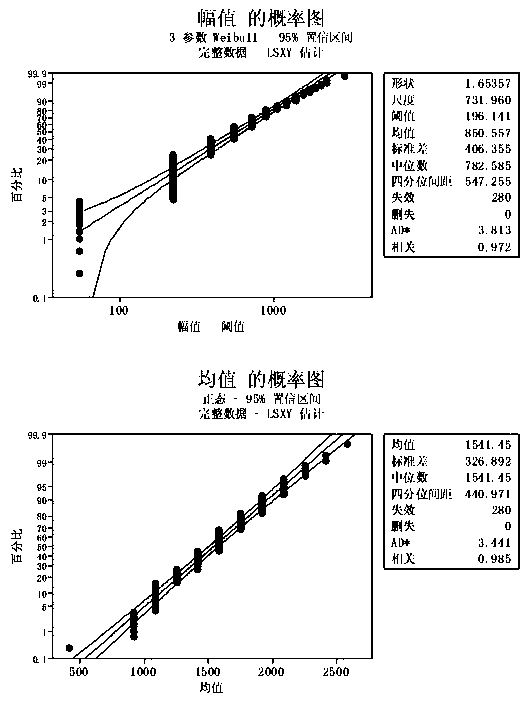

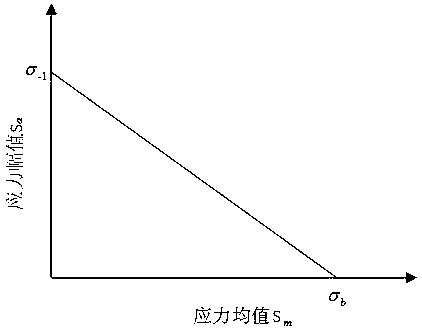

Gear contact fatigue life prediction method based on load spectrum

ActiveCN110147624AImprove accuracyImprove efficiencyGeometric CADDesign optimisation/simulationFatigue damageConstant load

The invention discloses a gear contact fatigue life prediction method based on a load spectrum. The gear contact fatigue life prediction method comprises the following steps: 1, compiling a load spectrum for limited load-time history obtained by measurement, and performing function fitting on the load of the whole life cycle by utilizing a parameter extrapolation method through a statistical result of a rain flow counting method to obtain a two-dimensional load spectrum of the whole life cycle; 2, converting the two-dimensional load spectrum into a one-dimensional load spectrum; 3, simulatingthrough a finite element method to obtain a time-varying stress-strain process of the gear, predicting the contact fatigue life under a constant load by combining a multi-axis fatigue criterion, and drawing the contact fatigue S-N curve of the gear; 4, calculating the contact fatigue life of the gear under the load spectrum according to the Palmgmn-Miner fatigue damage accumulation criterion. Themethod has the advantages that the accuracy of predicting the contact fatigue life of the gear is improved, the test cost is saved, and the efficiency is improved.

Owner:CHONGQING UNIV

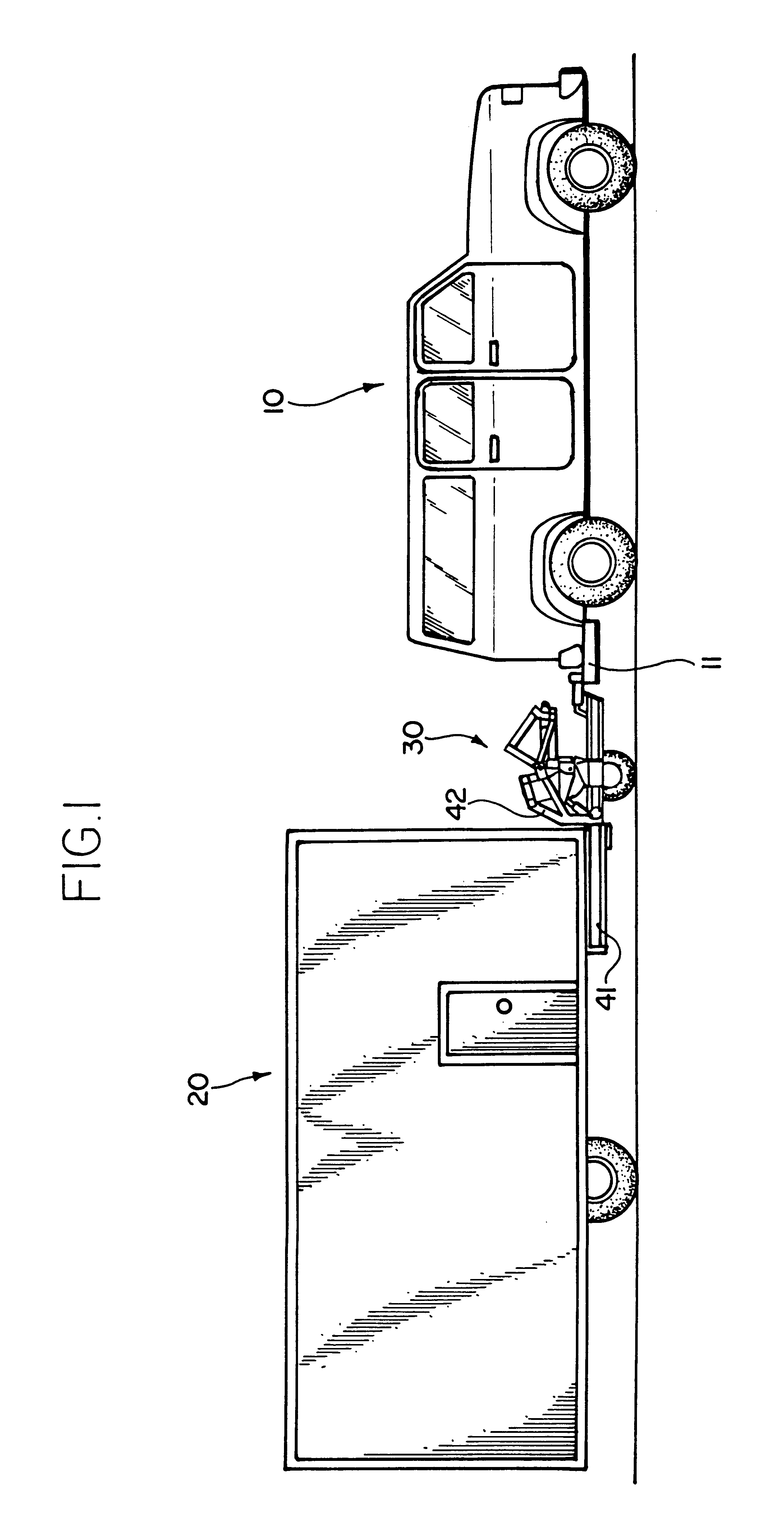

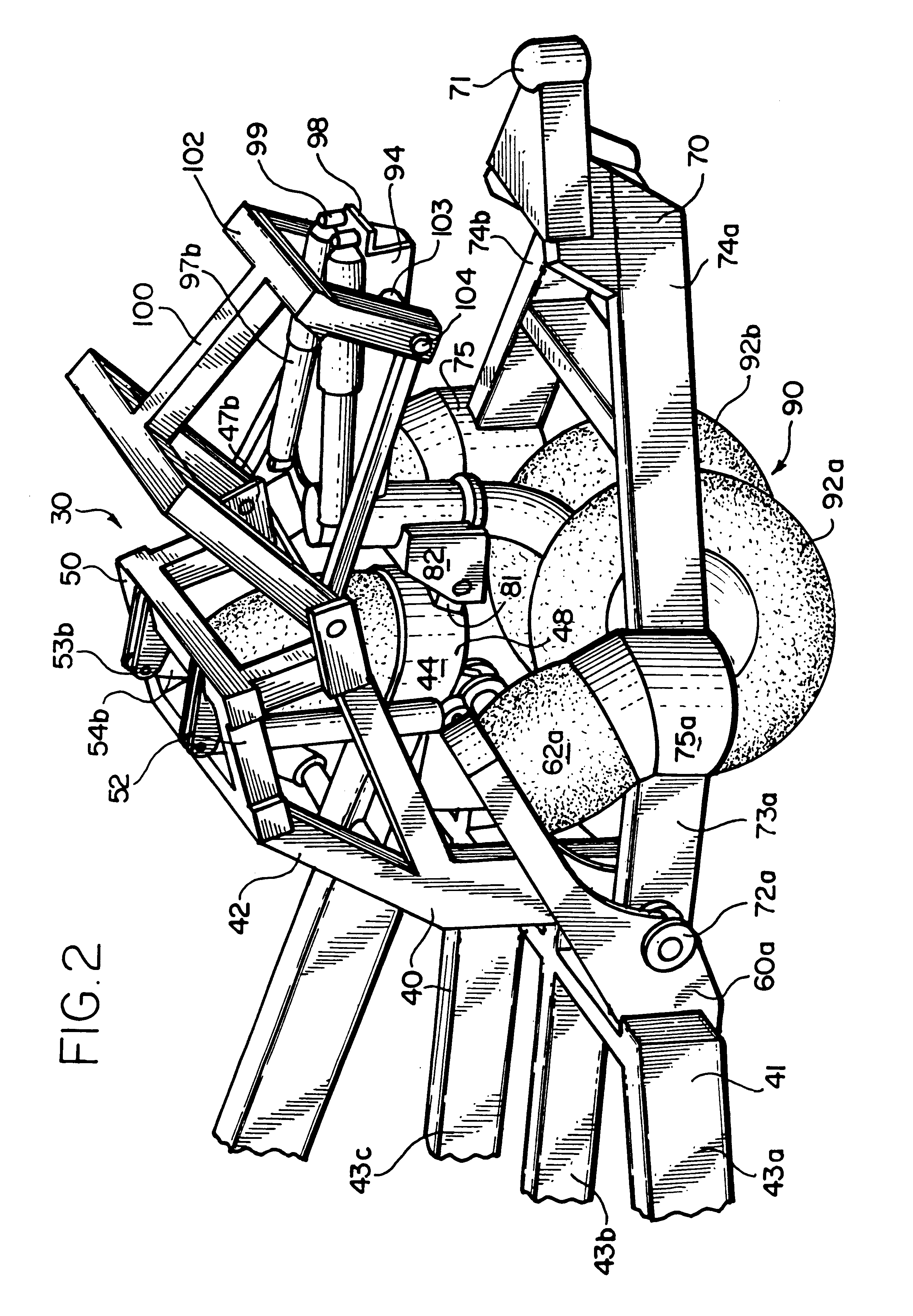

Trailer hitch assembly

InactiveUS6182997B1Easy to adjustEasy to liftTractor-trailer combinationsTowing devicesConstant loadEngineering

Towing apparatus for connecting a trailer with a towing vehicle. The towing apparatus is adapted to bear part of the weight of the trailer, thus lessening the load on the towing vehicle. This is accomplished by providing a wheel assembly on the towing apparatus which is operatively connected to an adjustable main spring which supports most of the weight of the trailer which would normally bear on the hitch of the towing vehicle. Unlike conventional towing systems, wherein the trailer tongue is rigidly attached to the trailer, the towing apparatus of the present invention employs a pivotally-mounted trailer tongue which is maintained in a horizontal position by an adjustable secondary spring or springs. The use of main and secondary springs presents a relatively constant load to the trailer hitch, even when the trailer is being towed across rough or uneven surfaces.

Owner:EZ TOW A DELAWARE

Medicine dispensing device

A medicine dispensing device has a device body (1), shelf members (2) arranged in the vertical directions in the device body (1), and a medicine conveyance member (3) for conveying medicines (D), received in the shelf members (2), on one by one basis from the front face side of the device body (1). A shelf member (2) has cassettes (26) in which medicines (D) are received in line, a pusher (31) for pushing the medicines in the cassettes (26) toward the front face side of the device body (10), and a constant load spring (32) for applying a constant load to the medicines (D) received in the cassettes (26) through the pusher (31). To fill the cassettes (26) with the medicines (D), the shelf member (2) can be pulled out from the front face side of the device body (1) and then positioned by pivoting the shelf member (2) so as to face obliquely downward.

Owner:YUYAMA MFG CO LTD

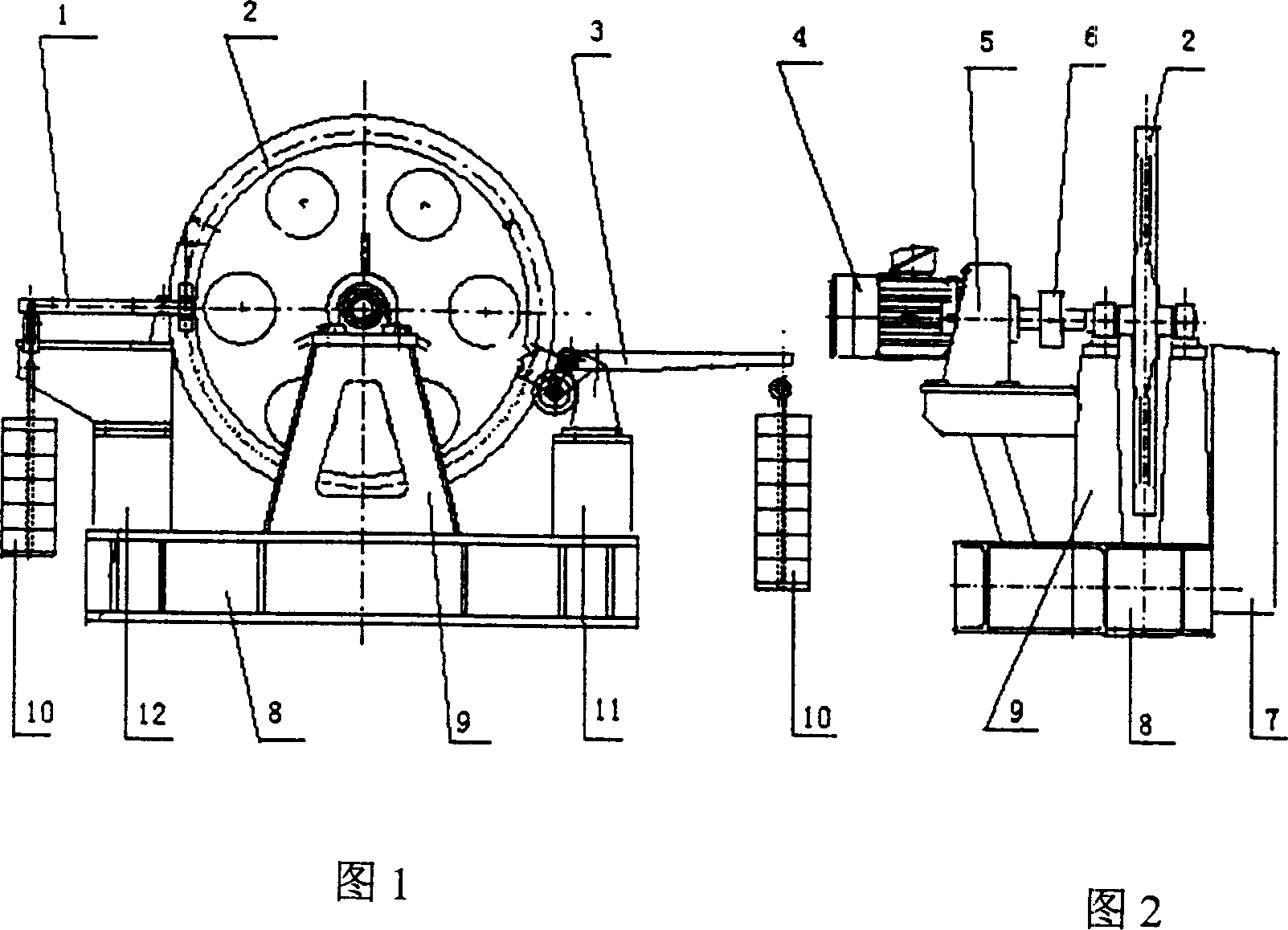

Rolling and friction composite testing machine

InactiveCN1529145APressure does not affectWeight CalibrationInvestigating abrasion/wear resistanceConstant loadPositive pressure

The invention is a kind of testing machine which combines rolling and friction, the driving electric motor is connected with speed reducing box, big wheel with the same shaft through coupler, and carries on speed adjusting through the converter in control box, there set friction piece loading device and rolling piece loading device on the bracket at two side of the big wheel respectively, the load of friction piece realizes constant load experience through lever weights, the friction piece is locked with clamper, the weight of the weights fixes the pulling point at the tail part of the lever through guiding wheel by the steel cable, and it is supported by the lever supporting point, the vertical load is changed into the positive pressure of the tested friction piece, the size of the load is adjusted by the weights and the suspending point of the weights. The loading device of rolling piece realizes the constant load experience with the lever weights system. The invention can realize the character of constant load, the structure is simple, the load is stable. It has compound testing function.

Owner:SHANGHAI JIAO TONG UNIV

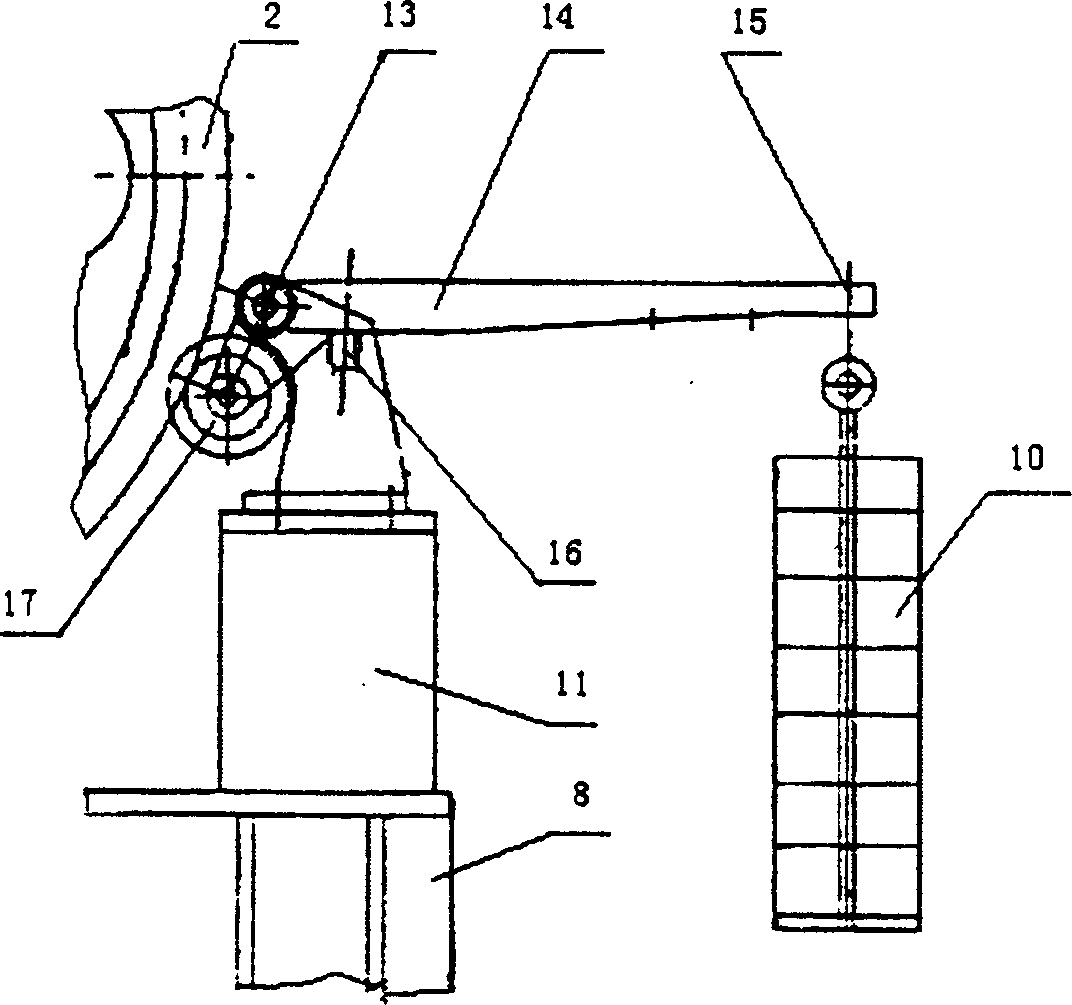

Concrete lever type tension-compression creep device provided with static pulley

InactiveCN104677745ASimple structureStable structureMaterial strength using tensile/compressive forcesConstant loadTension compression

The invention relates to a concrete lever type tension-compression creep device provided with a static pulley. The concrete lever type tension-compression creep device consists of a support device, a loading device and a test piece connecting device; the concrete lever type tension-compression creep device adopts a double-level mechanism to realize tension and compression. The concrete lever type tension-compression creep device has the beneficial technical effects that the device is simple and reliable in structure, is capable of applying a continuous and constant load onto a test piece, and is small in floor space; and two test functions including a tension test and a compression test can be provided by a set of device.

Owner:CHONGQING JIAOTONG UNIVERSITY

Optical pressure-sensitive adhesive sheet, optical film and display device

ActiveUS20120100359A1Increased durabilityObscures visibilitySynthetic resin layered productsAmide/imide polymer adhesivesDynamic viscoelasticitySheet film

The present invention provides an optical pressure-sensitive adhesive sheet in which white turbidity is not caused by humidification and durability is excellent as well. The present invention provides an optical pressure-sensitive adhesive sheet, comprising: a pressure-sensitive adhesive layer in which a moisture ratio after storage under an environment of 60° C. and 95% RH for 120 hours is 0.65 wt % or more, and a shear storage elastic modulus at 85° C. which is measured by a dynamic viscoelastic measurement is 5.0×104 to 5.0×105 Pa, wherein a peeling distance measured by the constant-load peel test is 30 mm or less when an adherend is a polyethylene terephthalate plate, and the peeling distance measured by the following constant-load peel test is 30 mm or less when the adherend is an acrylic plate.

Owner:NITTO DENKO CORP

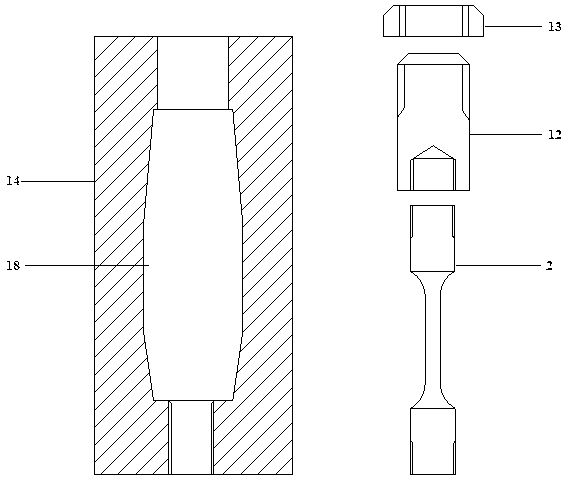

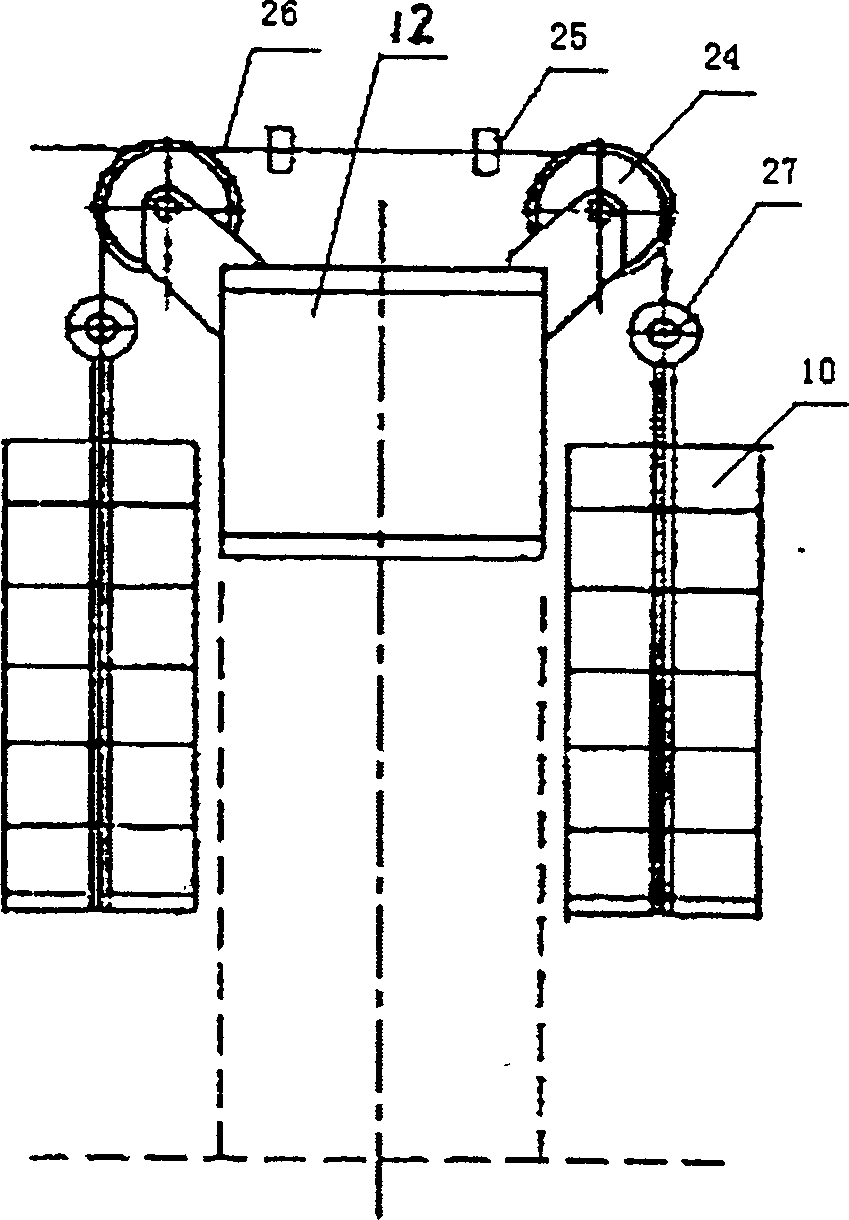

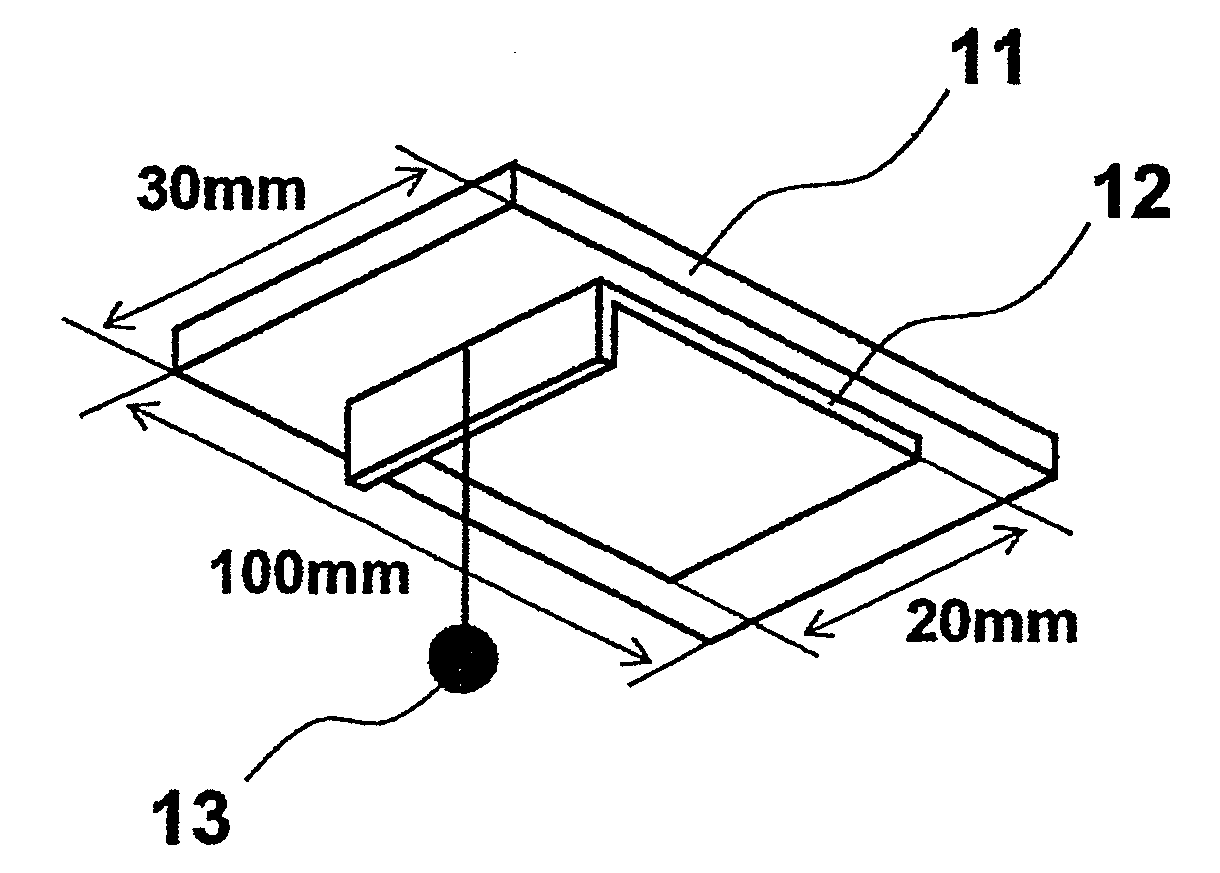

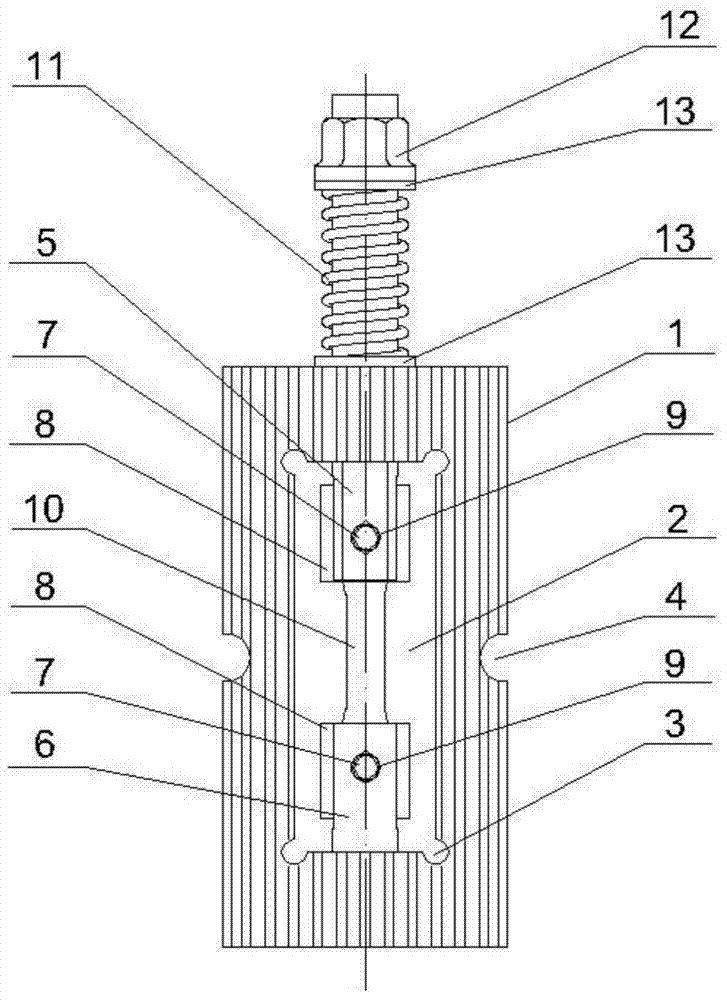

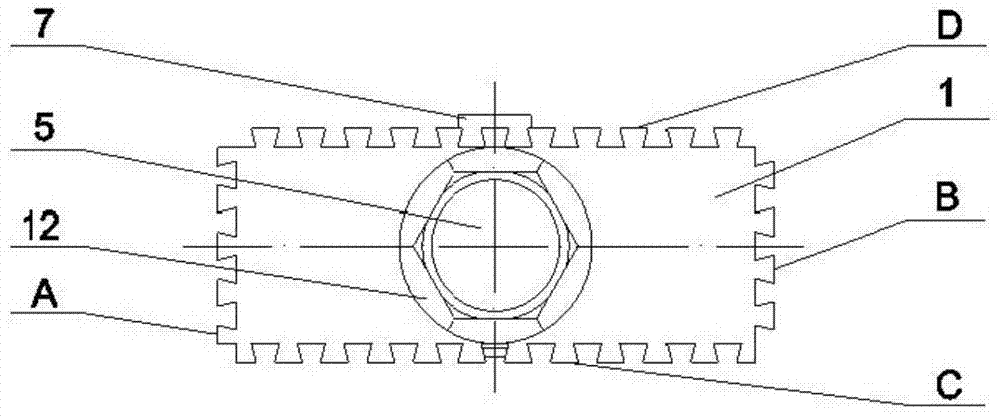

Constant-load tensile test device

ActiveCN104749029AEasy to carryEasy to assemble and disassembleMaterial strength using tensile/compressive forcesConstant loadMetallic materials

The invention belongs to the technical field of metal material test equipment and relates to a constant-load tensile test device. The constant-load tensile test device is characterized in that a rectangular cavity is formed in a force-bearing framework with A, B, C and D side surfaces, wherein circular-arc-shaped grooves capable of dispersing load on four right angles of the rectangular cavity are formed in four vertexes of the rectangular cavity; a sleeve type upper chuck is arranged on a perpendicular central axis at the inner side of an upper beam of the force-bearing framework; a threaded end of the upper chuck penetrates through the force-bearing framework and is provided with an insulating gasket, a loading spring and a loading nut in a sleeved mode; a lower chuck of a sleeve structure is arranged on a perpendicular central axis at the inner side of a lower beam of the force-bearing framework; a threaded end of the lower chuck is fixedly connected with the force-bearing framework; U-shaped slot structures are arranged at the clamping ends of the upper chuck and the lower chuck respectively; insulating gaskets are arranged in the centers at the two sides of each U-shaped slot structure. The constant-load tensile test device is small and light, easy to carry, assemble and fix, freely spliced to realize batch test of a tested part, safe and reliable, simple and convenient in a manual loading mode, and accurate and constant in loaded load.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com