Patents

Literature

459 results about "Contact fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

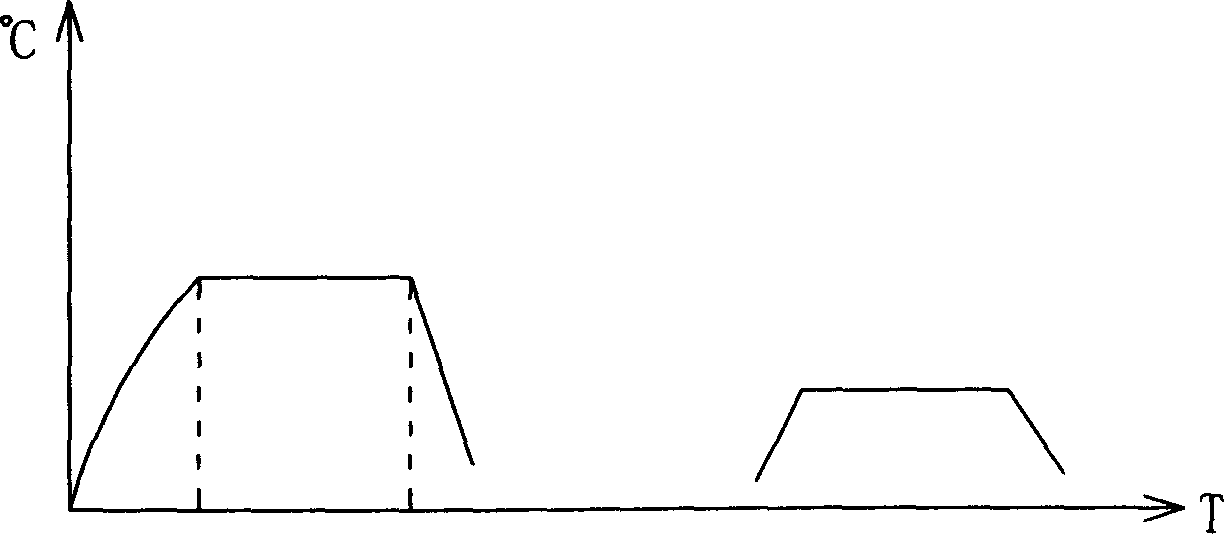

High carbon chromium bearing parts surface chemical heat-treatment process

ActiveCN1804128AHigh surface hardnessIncrease compressive stressSolid state diffusion coatingFurnace typesHigh carbonIn vehicle

The disclosed surface chemical thermal treatment technique for a high-C-Cr bearing comprises: setting parameters, front cleaning, pre-oxidizing, heating, carbonitriding, cooling to diffuse, quenching, and tempering. This invention uses the treatment device in vehicle and motor cycle gear process to form one layer with special tissue and improve contact fatigue strength and surface hardness.

Owner:CHONGQING CHANGJIANG BEARING

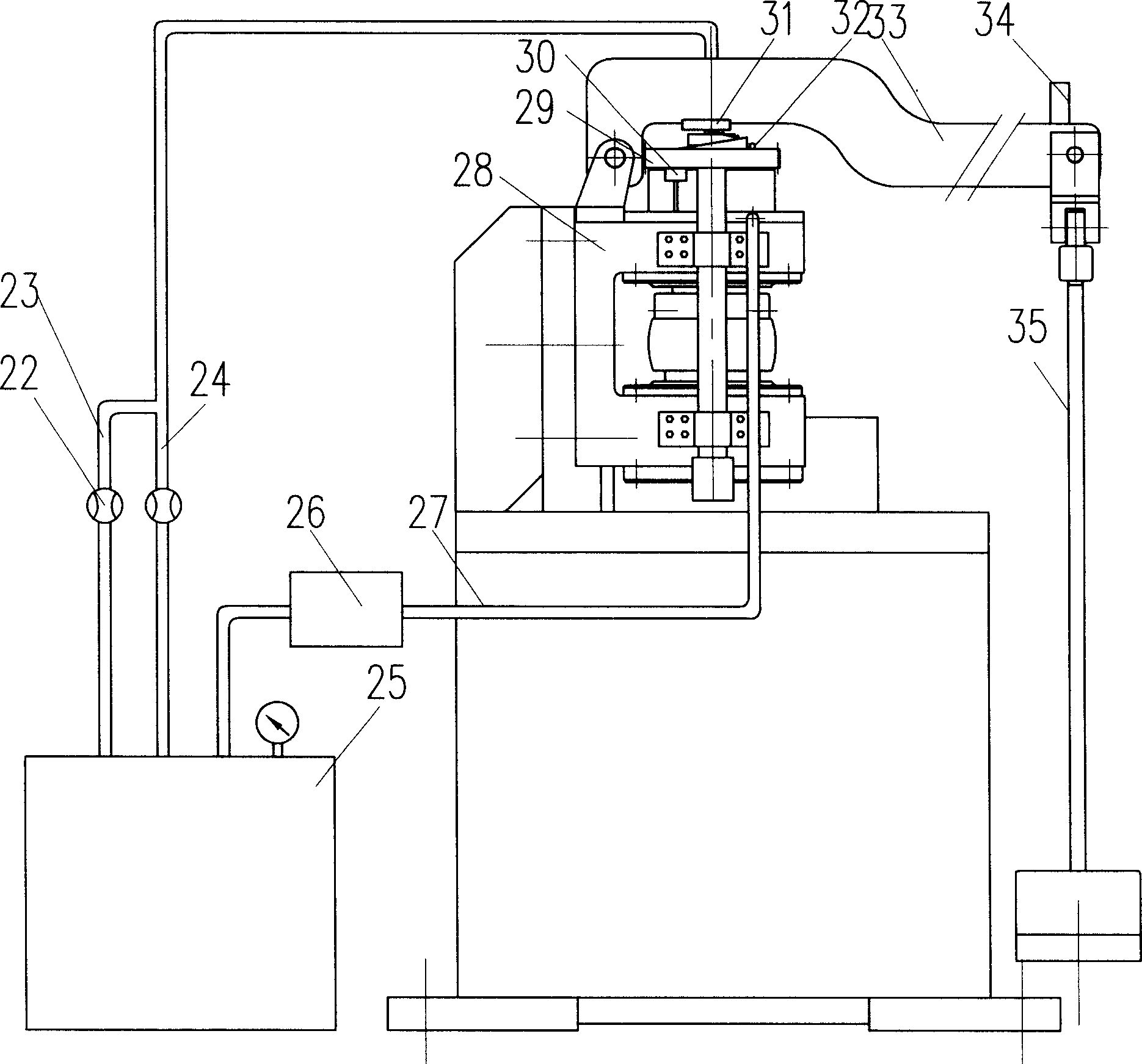

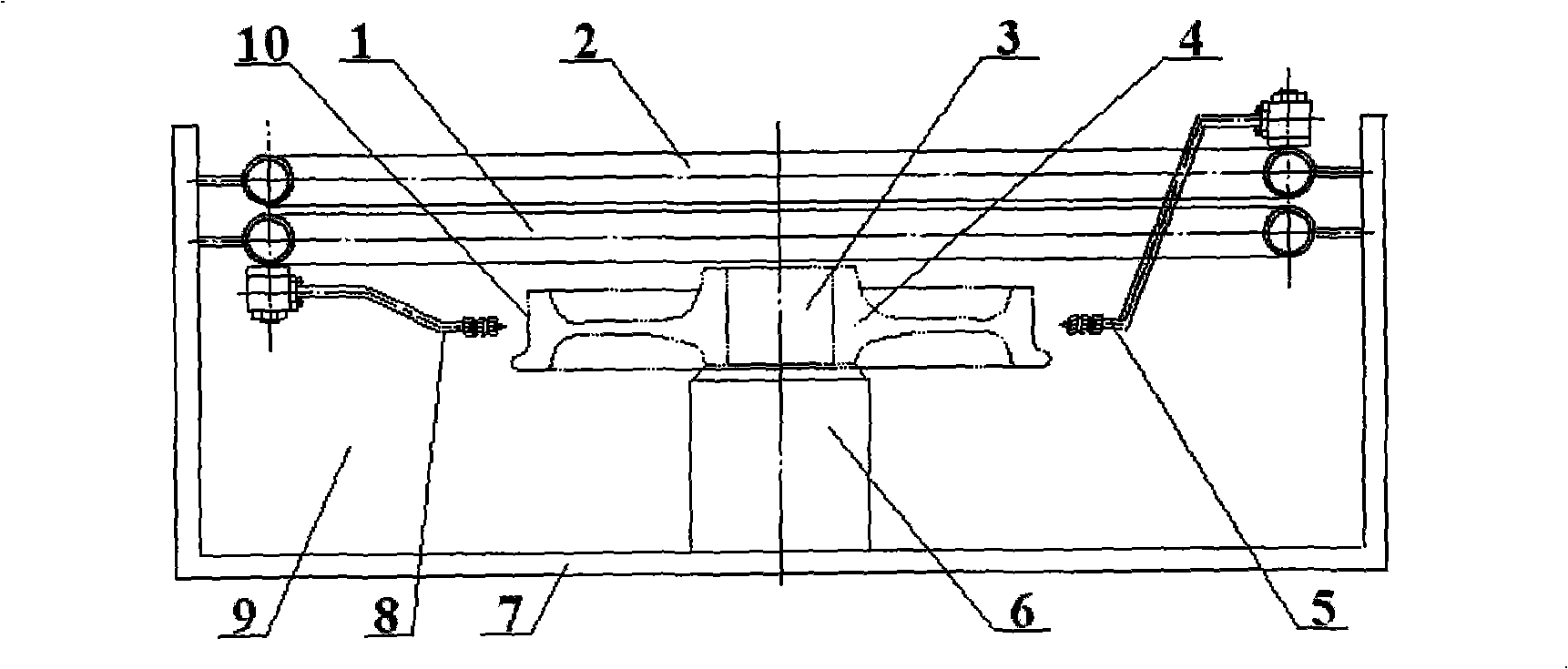

Work condition analogue rolling contact fatigue tester

InactiveCN1715869AReduce the numberReduce fatigue test timeMachine bearings testingUsing mechanical meansTemperature controlInterference fit

The on-line work condition simulating rolling contact fatigue tester includes driving device, loading device, testing device and signal collecting device, and has temperature controlling cavity sleeved on the driving shaft, lower test cavity end interference fitted to the end of the driving shaft and set inside the temperature controlling cavity, test cavity with upper test sample, rolling part, lower test sample, abruptly stopping cam on the upper test sample, and rolling pin thrust bearing on the abruptly stopping cam and matching the pressure block below the loading lever. The present invention can simulate the contact fatigue, friction and wear process of friction pair with or without surface coating for relevant detection, and the instantaneous failure state may be kept by means of abrupt stopping unit.

Owner:YANSHAN UNIV

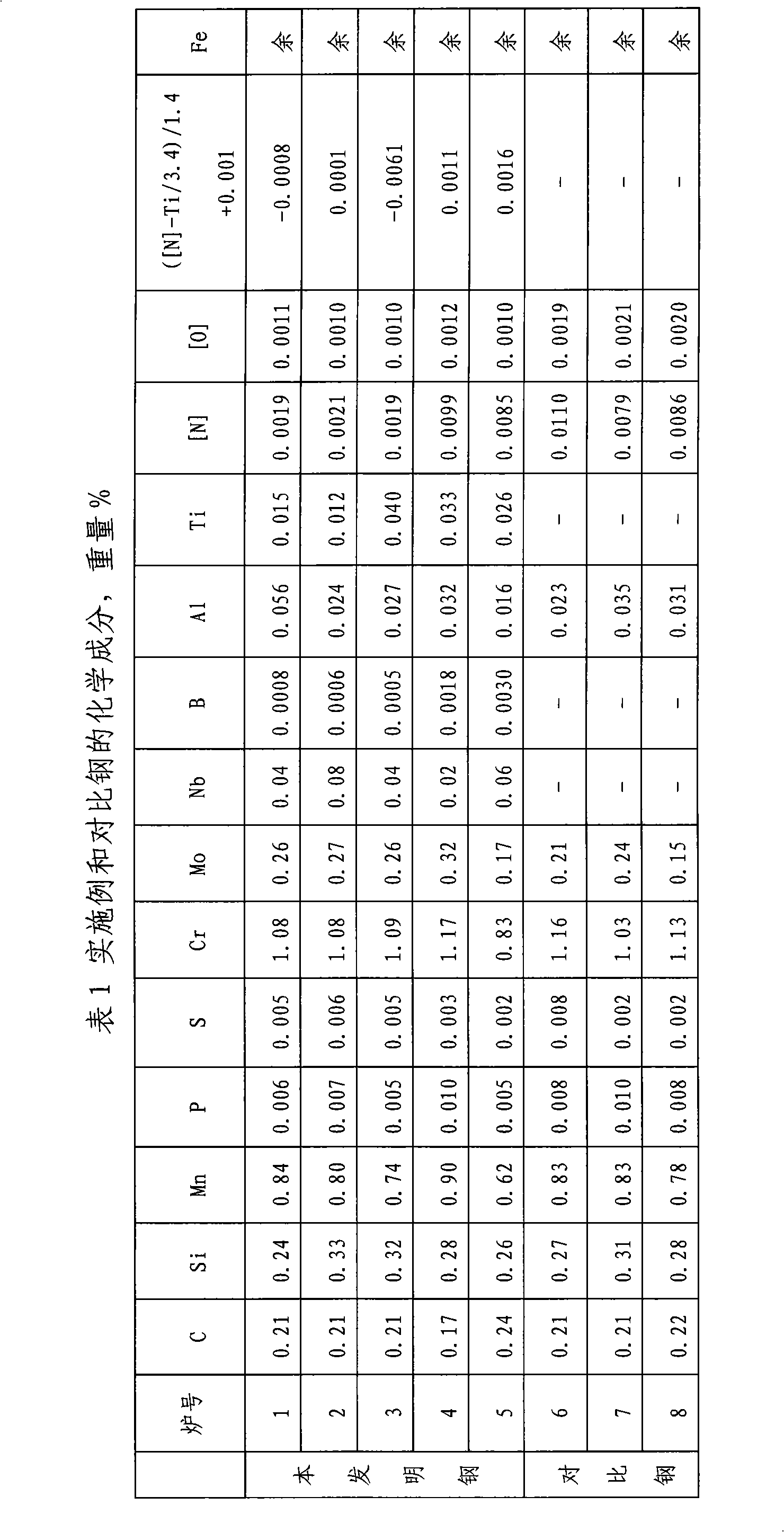

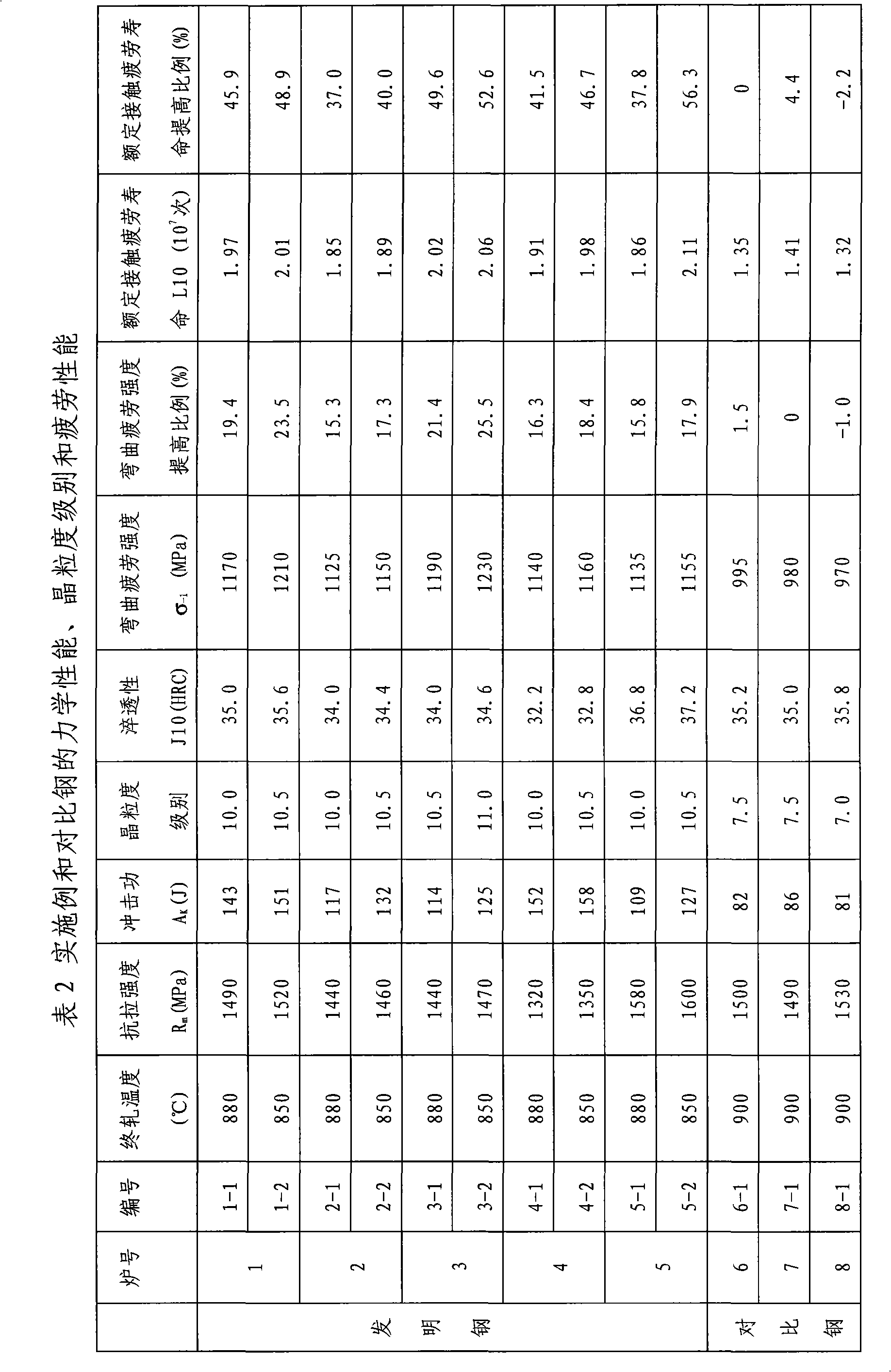

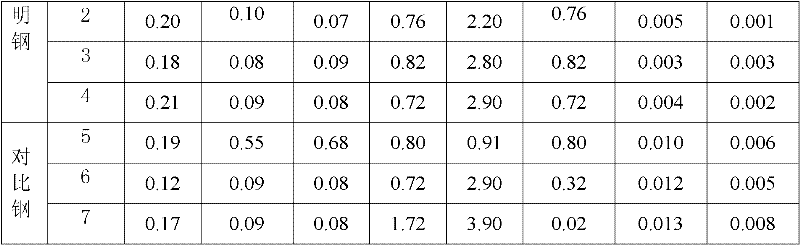

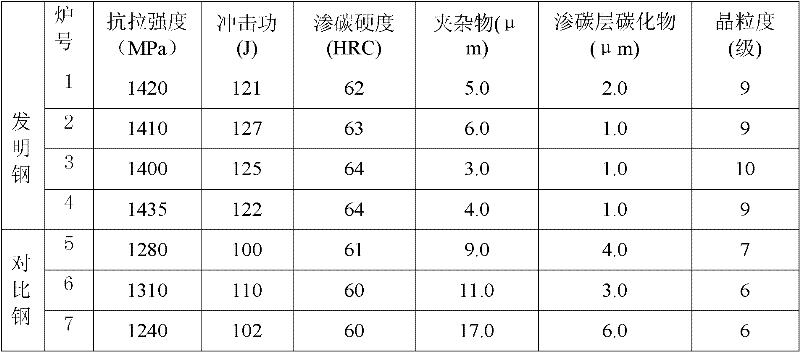

Steel for fine grain carburizing gear and method of manufacturing the same

The invention belongs to the alloy steel field, particularly relating to steel for a fine grain carburization gear and a preparation method thereof. The steel comprises the following chemical compositions in weight percentage: 0.15 to 0.25 percent of C, less than or equal to 0.35 percent of Si, 0.60 to 0.90 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.80 to 1.20 percent of Cr, 0.15 to 0.35 percent of Mo, 0.02 to 0.08 percent of Nb, 0.0005 to 0.0035 percent of B, 0.02 to 0.06 percent of Al, 0.01 to 0.04 percent of Ti, less than or equal to 0.015 percent of [N], less than or equal to 0.0015 percent of [O], the balance being Fe and inevitable impurities. Meanwhile, Ti is more than or equal to 2[N] and B is more than or equal to ([N] minus Ti / 3.4) / 1.4 plus 0.001; and the rolling production process with the finish-to-gage temperature below 900 DEG C is adopted. Compared with the prior carburization gear steel 20CrMoH, the grain size of the steel after carburizing and quenching exceeds ten grade, the bending fatigue resistance(sigama-1) is improved by more than 15 percent and the contact fatigue life(L10) is improved by more than 30 percent.

Owner:CENT IRON & STEEL RES INST

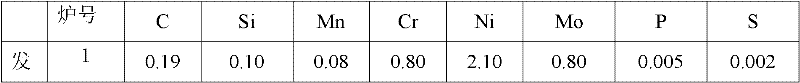

High-toughness carburized bearing steel with ultra-long contact fatigue life and preparation method thereof

The invention relates to a high-toughness carburized bearing steel with ultra-long contact fatigue life and a preparation method thereof, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.16-0.24% of C, at most 0.10% of Si, at most 0.10% of Mn, 0.30-1.50% of Cr, 1.5-4.5% of Ni, 0.30-1.50% of Mo, 0.02-0.10% of Nb, 0.3-0.9% of V, and the balance of Fe and inevitable impurities, wherein [N]+[O]+[H]+P+S<=0.0080%, and Ti<=0.0030%. The invention particularly relates to a high-toughness carburized bearing steel which has the advantages of high shock resistance load, stable dimension and ultra-long contact fatigue life in the serve process. Compared with the prior art, the invention has the advantages of high surface hardness, high core toughness, high dimensional stability, high bending fatigue strength limit and ultra-long contact fatigue life.

Owner:CENT IRON & STEEL RES INST

Carburization-like overloading tooth component tooth surface laser cladding powder material and repairing method thereof

InactiveCN101100746AImprove repair qualityImprove performanceMetallic material coating processesLaser beam welding apparatusLaser power densityAlloy

A process for laser powder-melting onto the surfaces of the teeth parts that are of heavily loaded cemented steel to be repaired is disclosed herewith. The powder of grains = (-140-+260 mesh) comprises (mass%): C 0.80-1.10, Mn 7.50-9.00, Cr 0.90-1.30, Mo 0.20-0.35, B 2.00-3.50, Si 2.50-3.50, and balanced with Fe with impurities of P not more than 0.06 and S not more than 0.04. Laser power density is equal to 1.0 X 108W-109W / m2 per unit of time. The said powder has good re-melting property, self-enhancing and fatigue-resistance performances, so that it can be used to repair worn gears.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Elevator dray driving sliding contact fatigue wear testing machine

InactiveCN1932472AUsing mechanical meansInvestigating abrasion/wear resistanceWear testingPull force

The invention relates to abrasion machine of the elevator towing contacting tiredness. The variable-frequency electric machine drives the towing wheel to rotate by the shaft coupling and the bearing block after the reducer; one end of the cable wire is connected to the arc framework and the other is connected to the draught spring after fixing the two end with the lantern ring by the clap; it changes the pressure and the friction force between the cable wire and the wheel slot by changing the tension force of the cable wire by loading the hand wheel to draw the spring. So it can get the friction force by the fore-and-aft pulling force. So the invention can test the sliding friction and the abrasion character in the different condition to provide the data for designing the elevator towing.

Owner:SHANGHAI JIAO TONG UNIV

Superfinishing large planetary gear systems

ActiveUS20050014597A1Reduces and eliminates lubricant debrisAvoid damageEdge grinding machinesPolishing machinesGear wheelEngineering

Disclosed herein is a new improved large planetary gear system used on the input stage of wind turbine power generators. This improved planetary gear system reduces or eliminates lubricant debris traditionally generated from the gear teeth, thereby eliminating an initiating source for bearing failure. To achieve these results, some and preferably all of the gear teeth within the planetary gear system are superfinished using chemically accelerated vibratory finishing to a surface roughness of approximately 0.25 micron or less. Several objects and advantages of the invention are to provide a gearbox with reduced metal debris, improved bearing life, reduced wear, reduced vibro-frictional noise, improved contact fatigue, improved fretting resistance, improved lubrication, to simplify the run-in process, and to enhance the durability and efficiency of the gearbox.

Owner:OSRO GMBH +1

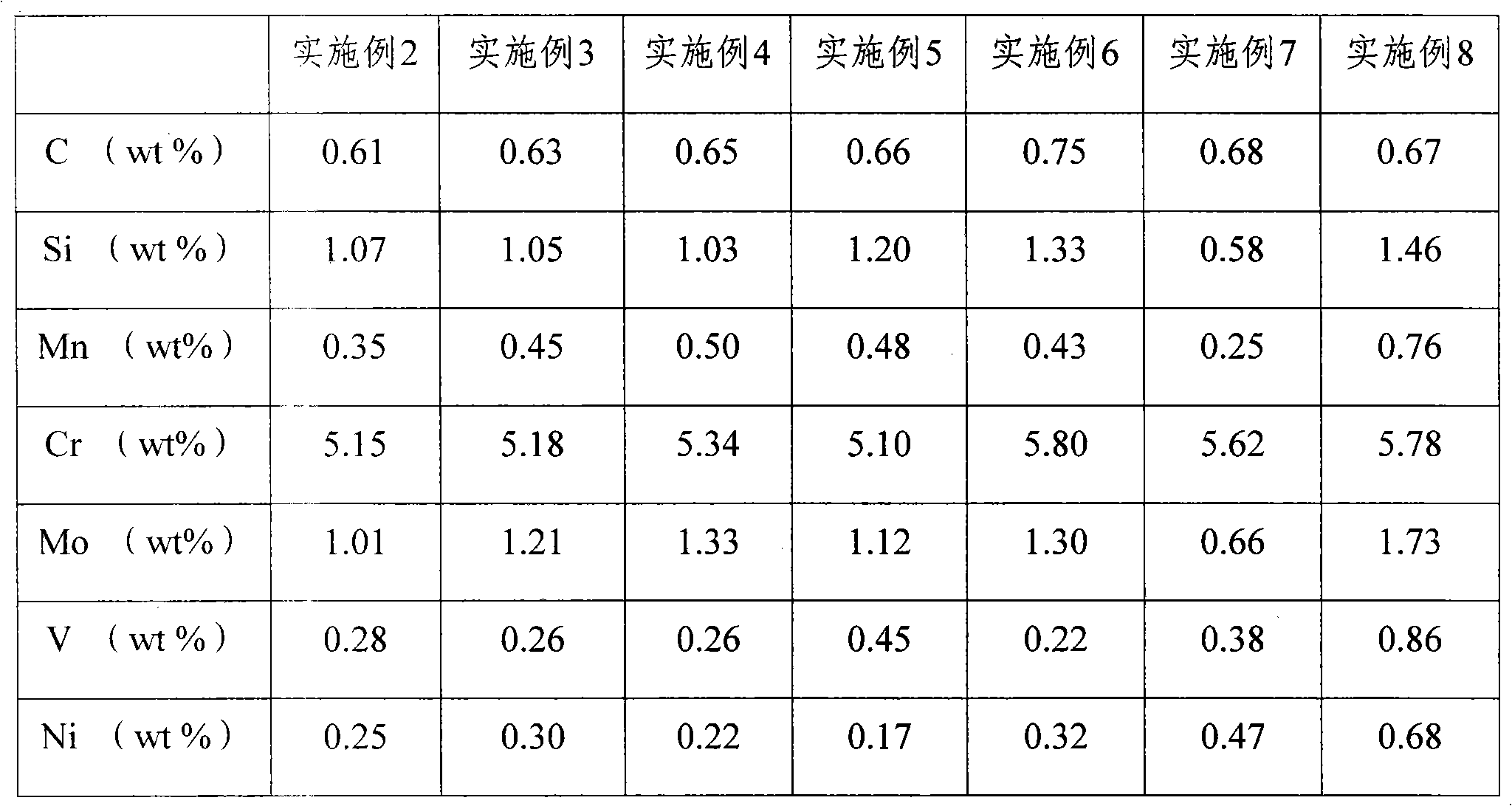

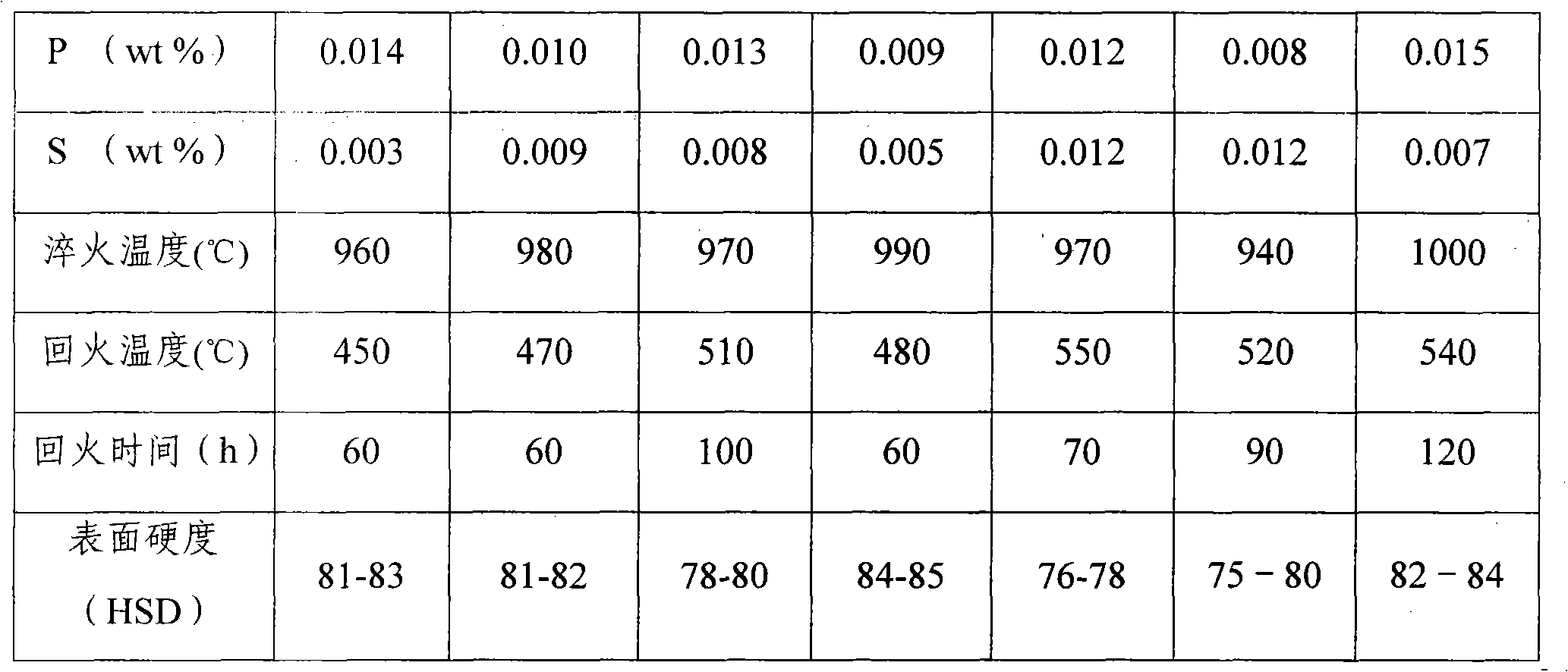

Semi high speed steel cold-rolling intermediate roll and manufacturing method thereof

ActiveCN101956145AImprove performanceGuaranteed performanceRollsMetal rolling arrangementsHardnessWear resistance

The invention discloses a semi high speed steel cold-rolling intermediate roll and a manufacturing method thereof. The semi high speed steel cold-rolling intermediate roll comprises the following chemical components in percentage by weight: 0.50 to 0.90 percent of C, 0.5 to 2.00 percent of Si, 0.20 to 1.00 percent of Mn, 4.50 to 6.00 percent of Cr, 0.50 to 2.00 percent of Mo, 0.20 to 1.00 percent of V, less than or equal to 0.80 percent of Ni, less than or equal to 0.025 percent of S and less than or equal to 0.025 percent of P. The manufacturing method comprises: manufacturing a steel blank of the cold-rolling roll; roughly turning and tempering; quenching at 940 to 1,000 DEG C; and tempering at 450 to 550 DEG C for 30 to 120 hours. The surface hardness of the cold-rolling intermediate roll made of the material is 75 to 85HSD; the mechanical stress resistance, thermal stress resistance, tissue stress resistance, contact fatigue resistance, wear resistance, hot impact resistance and roll shape retaining performance of the semi high speed steel cold-rolling intermediate roll are high, and the comprehensive service performance of the semi high speed steel cold-rolling intermediate roll is high.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Forged (rolled) abrasive austenic permanganic steel and its manufacture

A method for forging abrasive austenic high-manganese steel is carried out by smelting by electric furnace to obtain purified steel liquid with low phosphor and sulfur content, pouring into steel ingot, solid-solution heat treating, forging with temperature between 900-1180 degree and heating speed<300 degree / h, solid-solution treating by forged tailed heat, re-heating to austenic temperature, normal solid-solution treating as forger final heat treatment to obtain single-phase austenic tissue. The austenic high-manganese steel consists of C 1.0-1.3 wt%, Mn 10.0-13.0 wt%, Si<0.5 wt%, S<0.01 wt%, P,0.01 wt%, modifier 0.2-0.6 wt% and Fe residues. sigmab>=1000 MPa, sigmas>=600 MPa, delta5>=30%, aKU>=250J / cm 2. It has better impact, wear and roller contact fatigue resistances.

Owner:YANSHAN UNIV

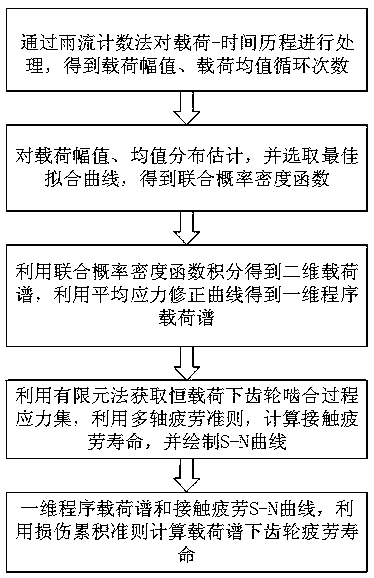

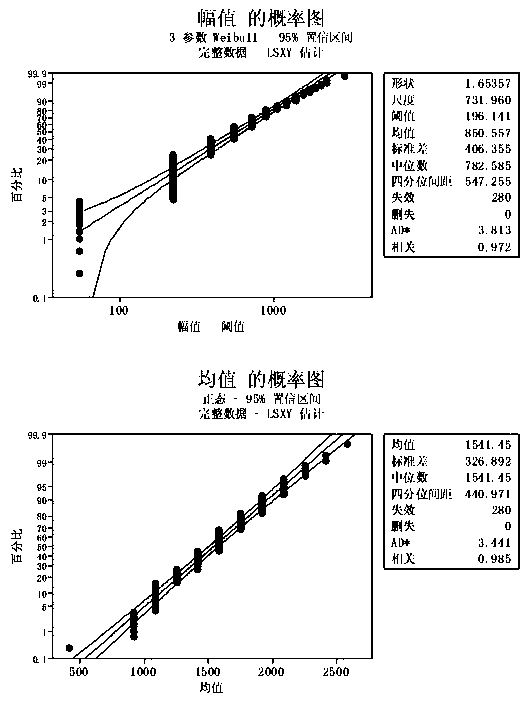

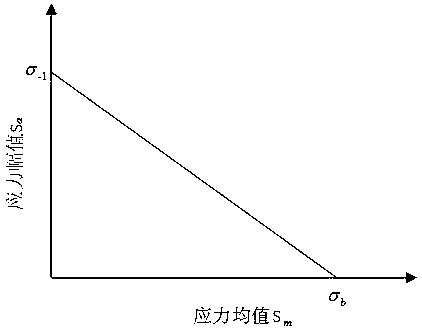

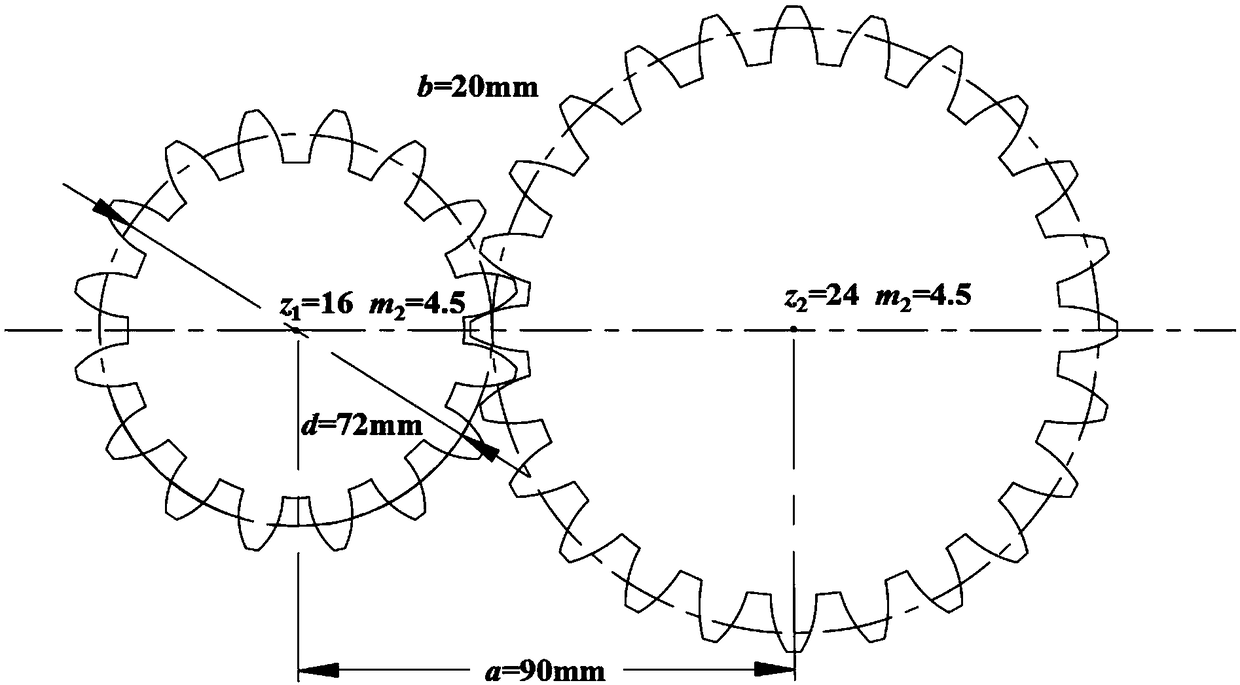

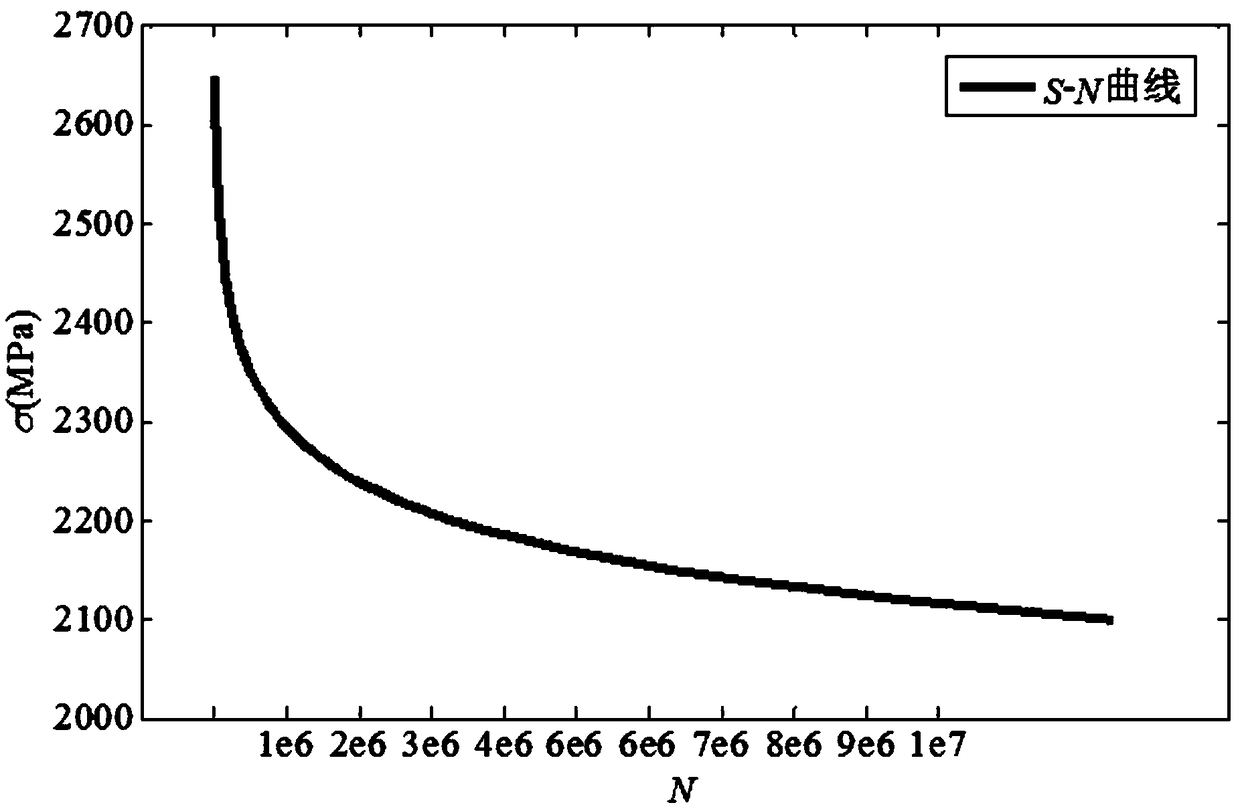

Gear contact fatigue life prediction method based on load spectrum

ActiveCN110147624AImprove accuracyImprove efficiencyGeometric CADDesign optimisation/simulationFatigue damageConstant load

The invention discloses a gear contact fatigue life prediction method based on a load spectrum. The gear contact fatigue life prediction method comprises the following steps: 1, compiling a load spectrum for limited load-time history obtained by measurement, and performing function fitting on the load of the whole life cycle by utilizing a parameter extrapolation method through a statistical result of a rain flow counting method to obtain a two-dimensional load spectrum of the whole life cycle; 2, converting the two-dimensional load spectrum into a one-dimensional load spectrum; 3, simulatingthrough a finite element method to obtain a time-varying stress-strain process of the gear, predicting the contact fatigue life under a constant load by combining a multi-axis fatigue criterion, and drawing the contact fatigue S-N curve of the gear; 4, calculating the contact fatigue life of the gear under the load spectrum according to the Palmgmn-Miner fatigue damage accumulation criterion. Themethod has the advantages that the accuracy of predicting the contact fatigue life of the gear is improved, the test cost is saved, and the efficiency is improved.

Owner:CHONGQING UNIV

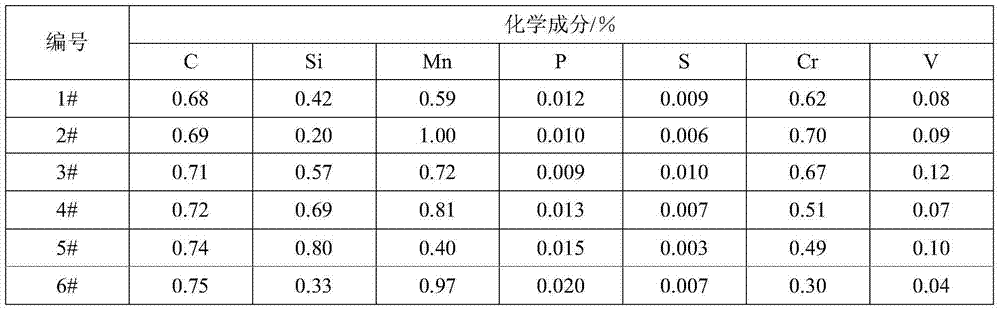

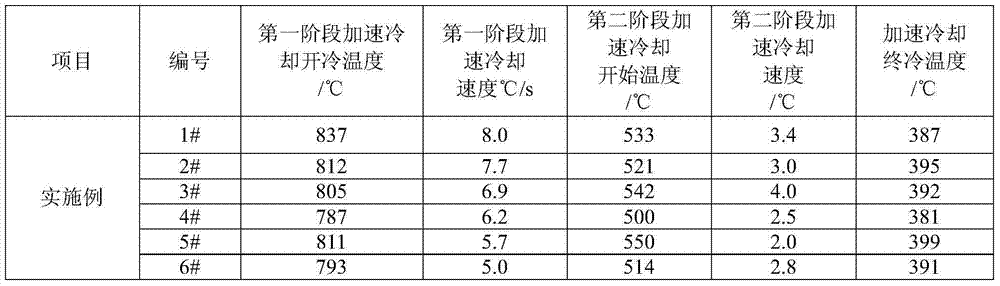

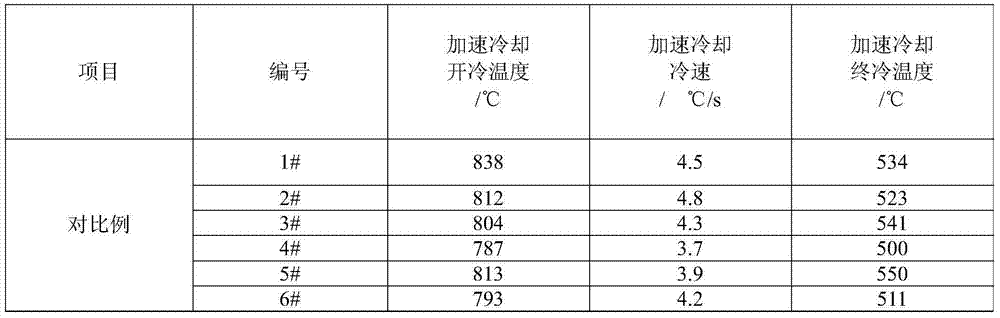

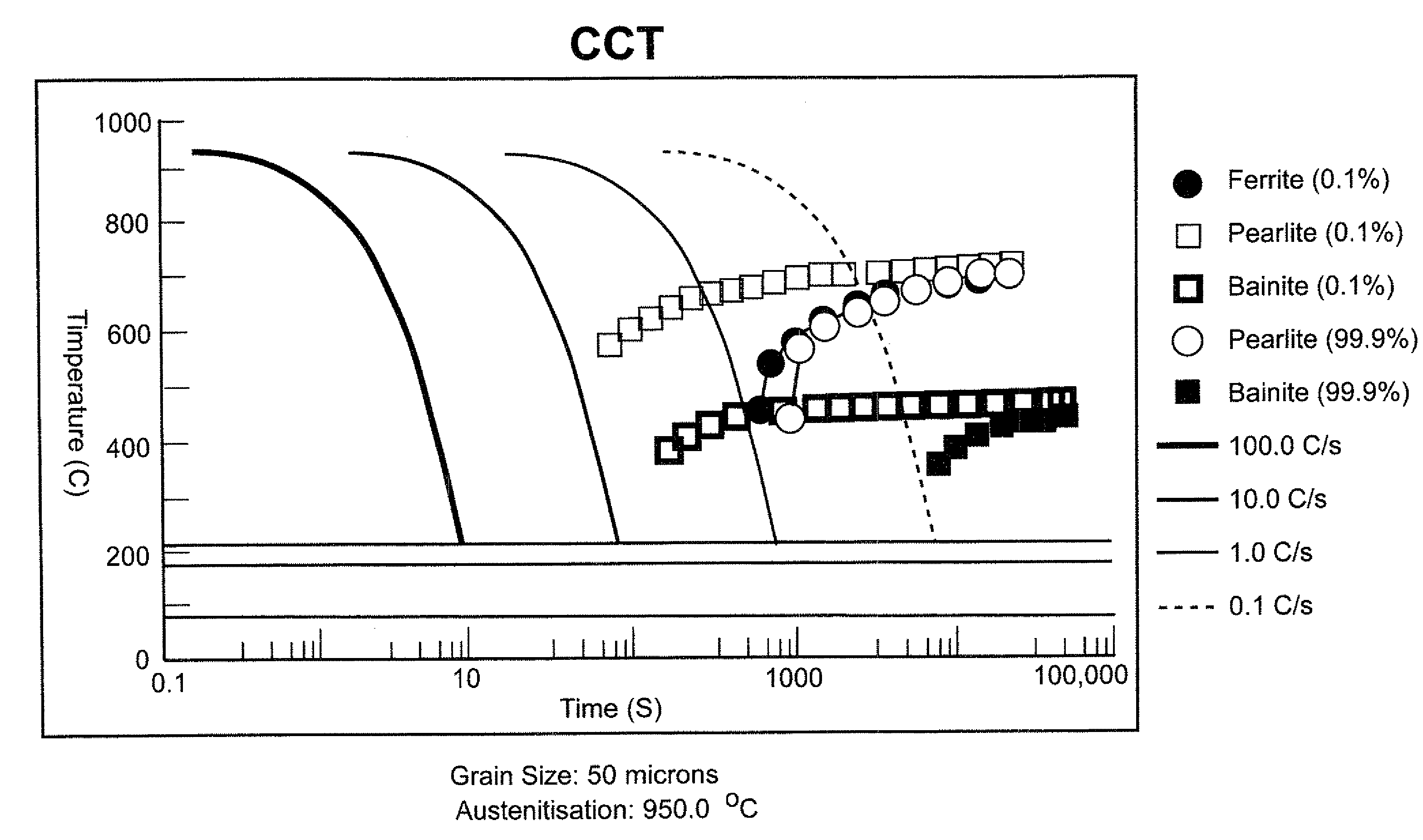

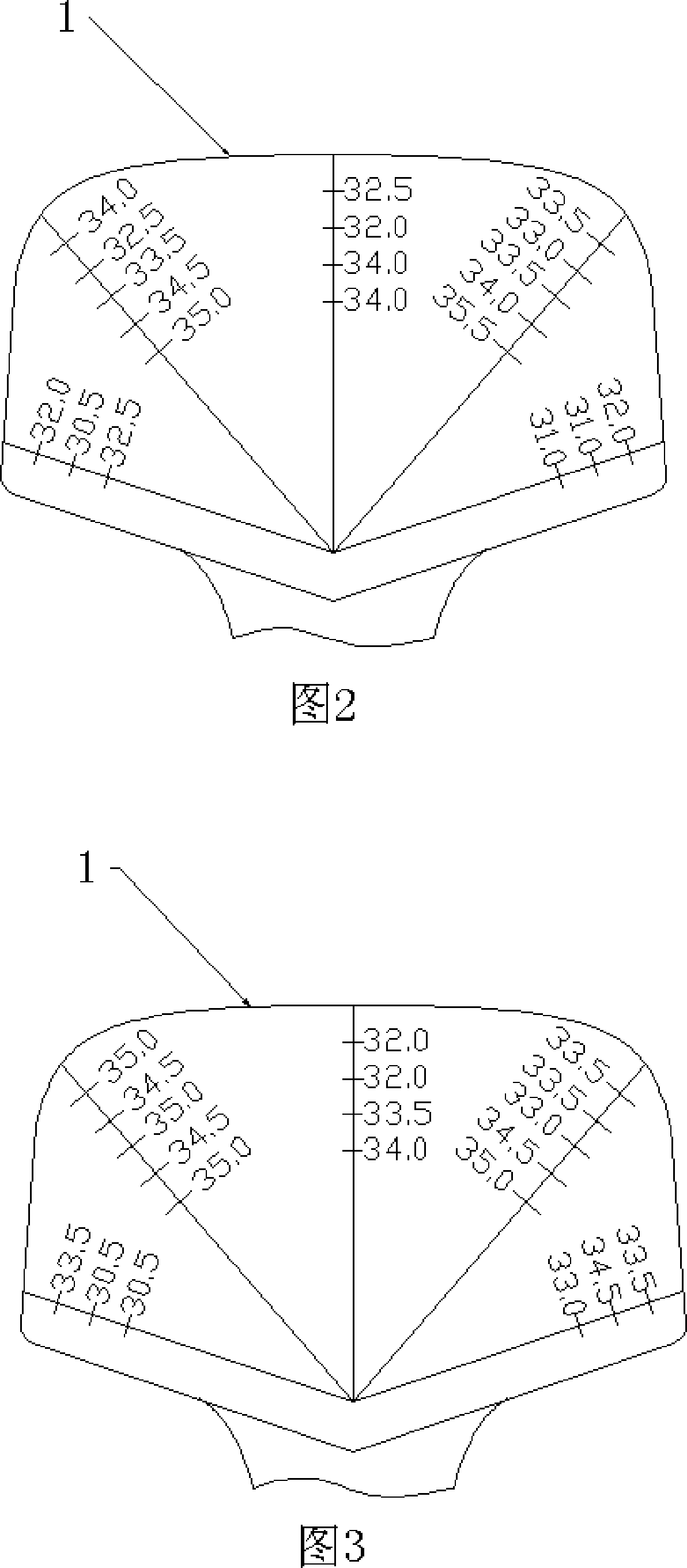

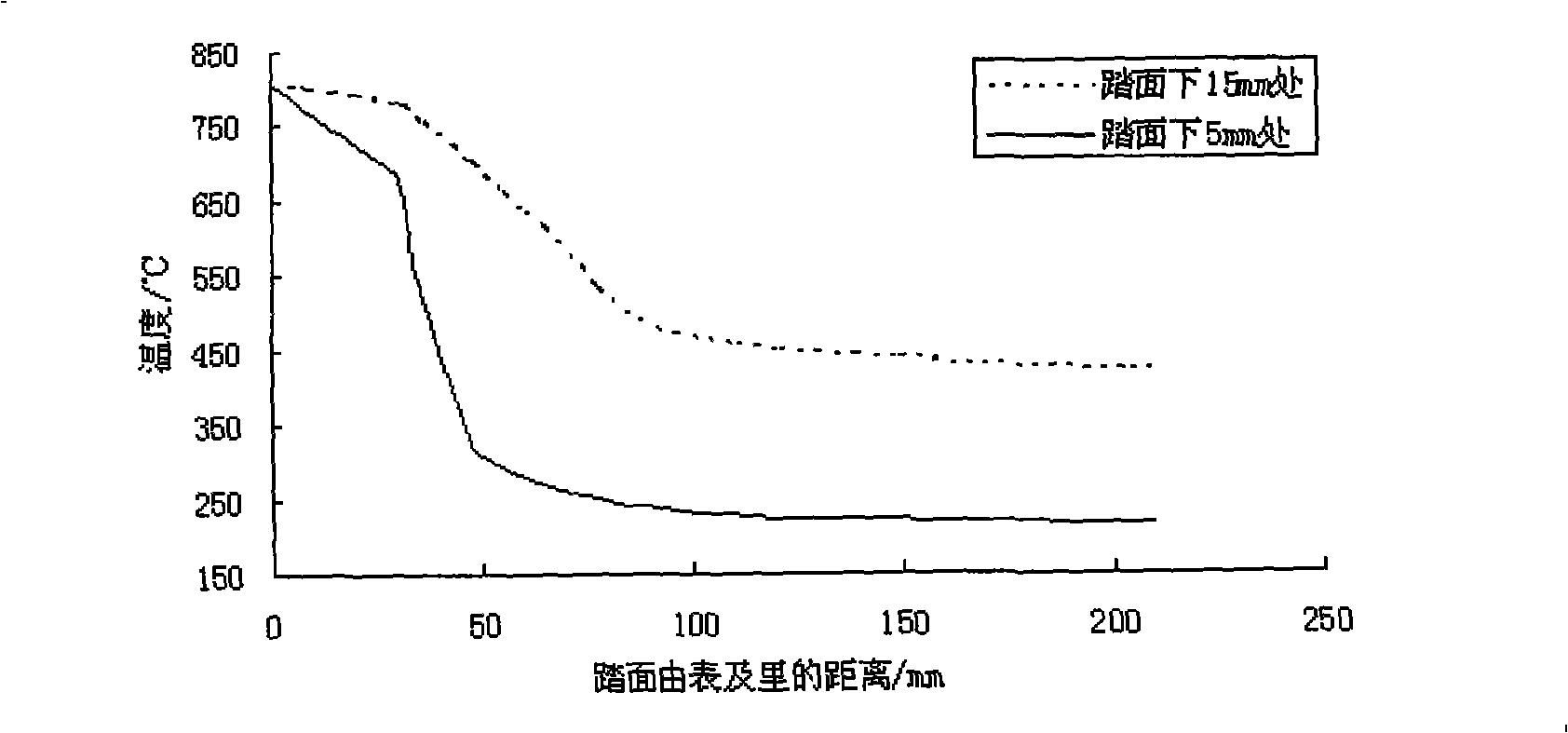

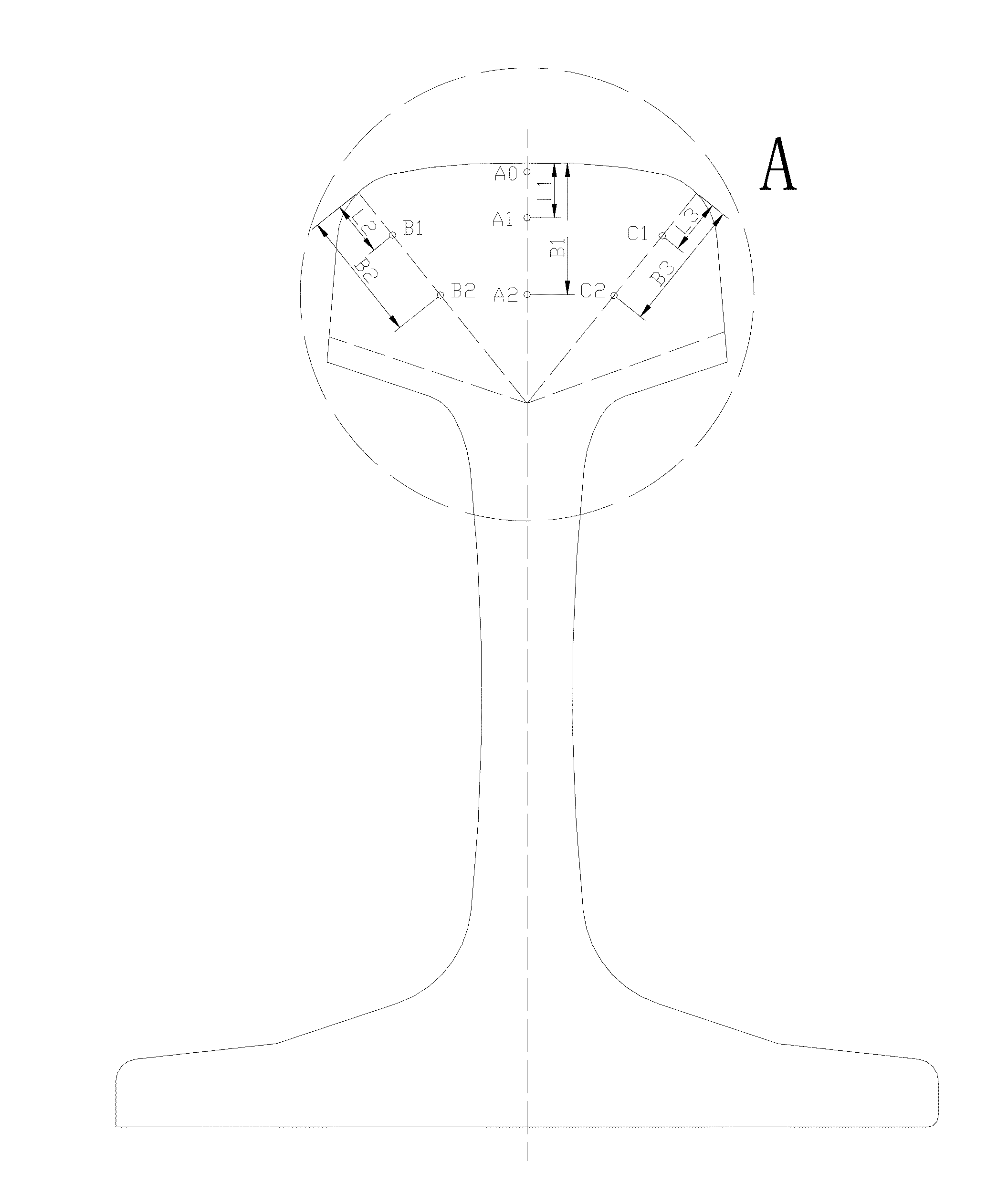

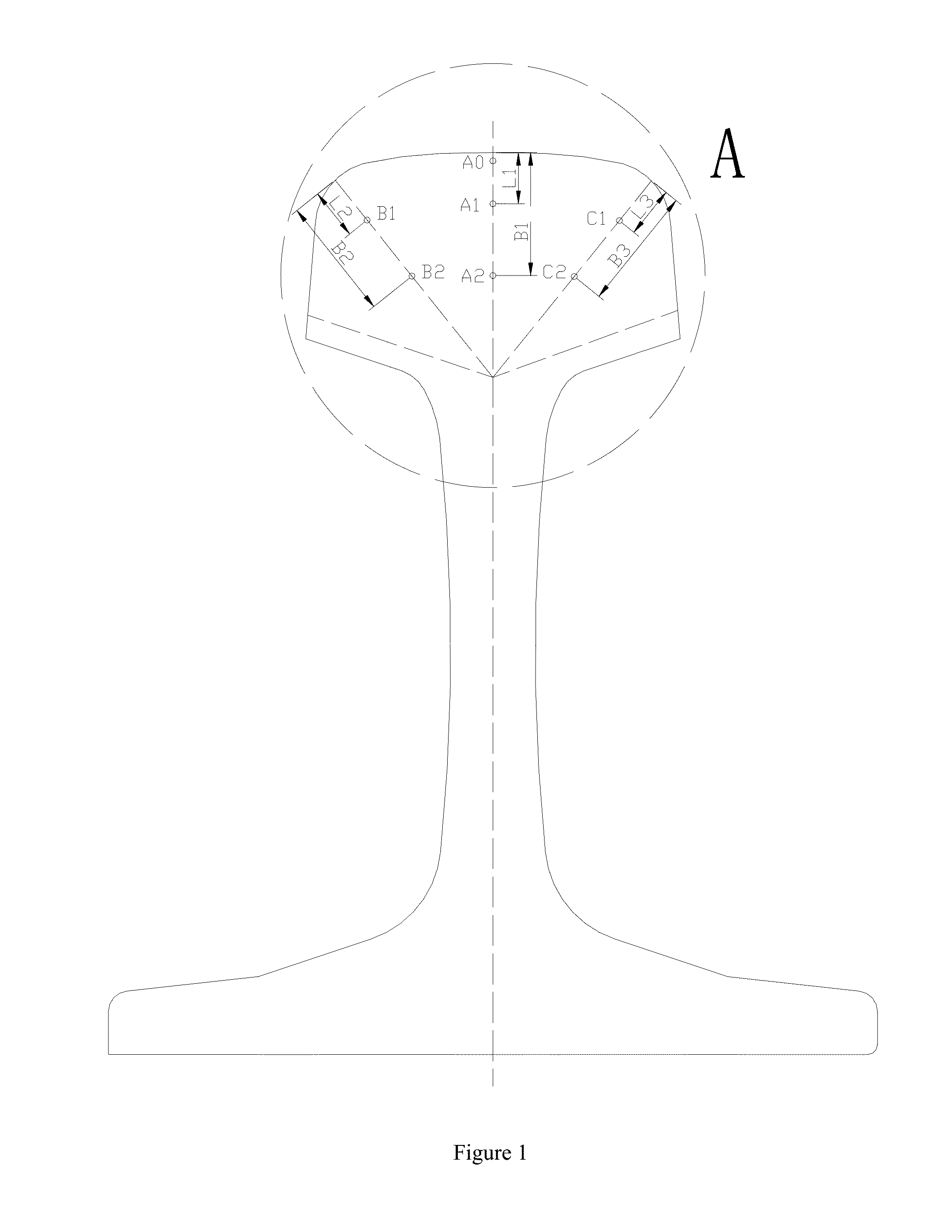

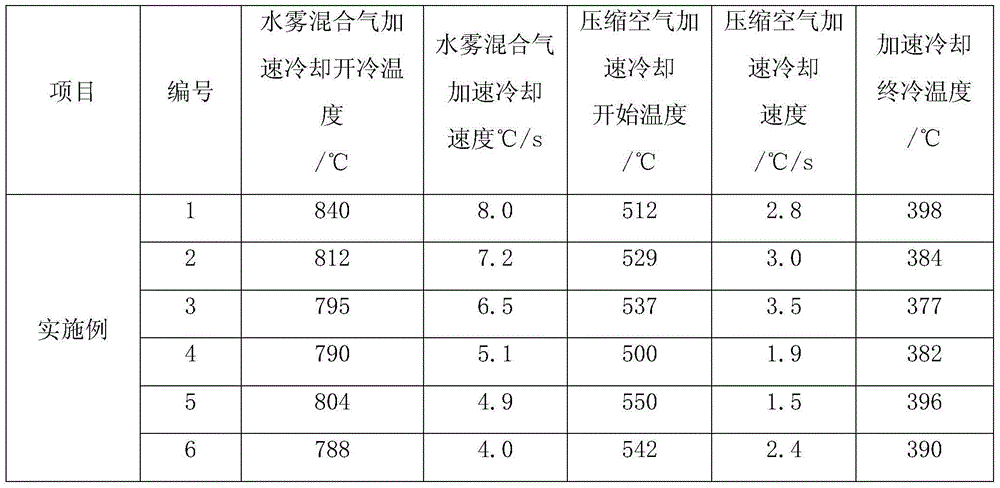

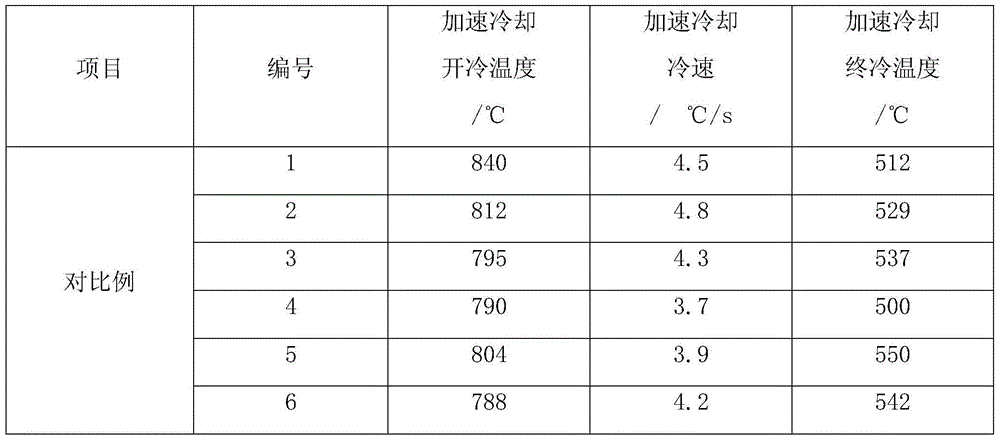

Steel rail with excellent contact fatigue performance and production method thereof

The invention relates to a steel rail with excellent contact fatigue performance and a production method thereof. The steel rail with excellent contact fatigue performance comprises the following elements in percentage by weight: 0.68-0.75% of C, 0.2-0.8% of Si, 0.4%-1% of Mn, 0.3%-0.7 % of Cr, 0.04%-0.12% of V, less than or equal to 0.01% of S, less than or equal to 0.02% of P and the balance of Fe and inevitable impurities. The production method comprises the following steps of carrying out LF refining and RH vacuum treatment in a converter to obtain a square billet, rolling the square billet to form a steel rail of which the cross section is 50-75kg / m, and carrying out accelerated cooling on the rail head part by using the waste heat of the steel rail and adopting a water spray mixed gas with a cooling speed of 5-8 DEG C / s; and when the temperature of the surface of the rail head is cooled to 500-550 DEG C, continuously cooling the rail head by virtue of compressed air with a cooling rate of 2-4 DEG C / s until the temperature of the surface of the rail head is cooled to below 400 DEG C, stopping the accelerated cooling and carrying out air-cooling to room temperature. According to the steel rail disclosed by the invention, the interlamellar spacing in pearlite colonies located at a position from the steel rail head tread to 20mm beneath is 0.07-0.1mu m, the tensile strength of the steel rail is greater than or equal to 1200MPa, the elongation of the steel rail is greater than or equal to 12% and the steel rail has excellent rolling contact fatigue resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

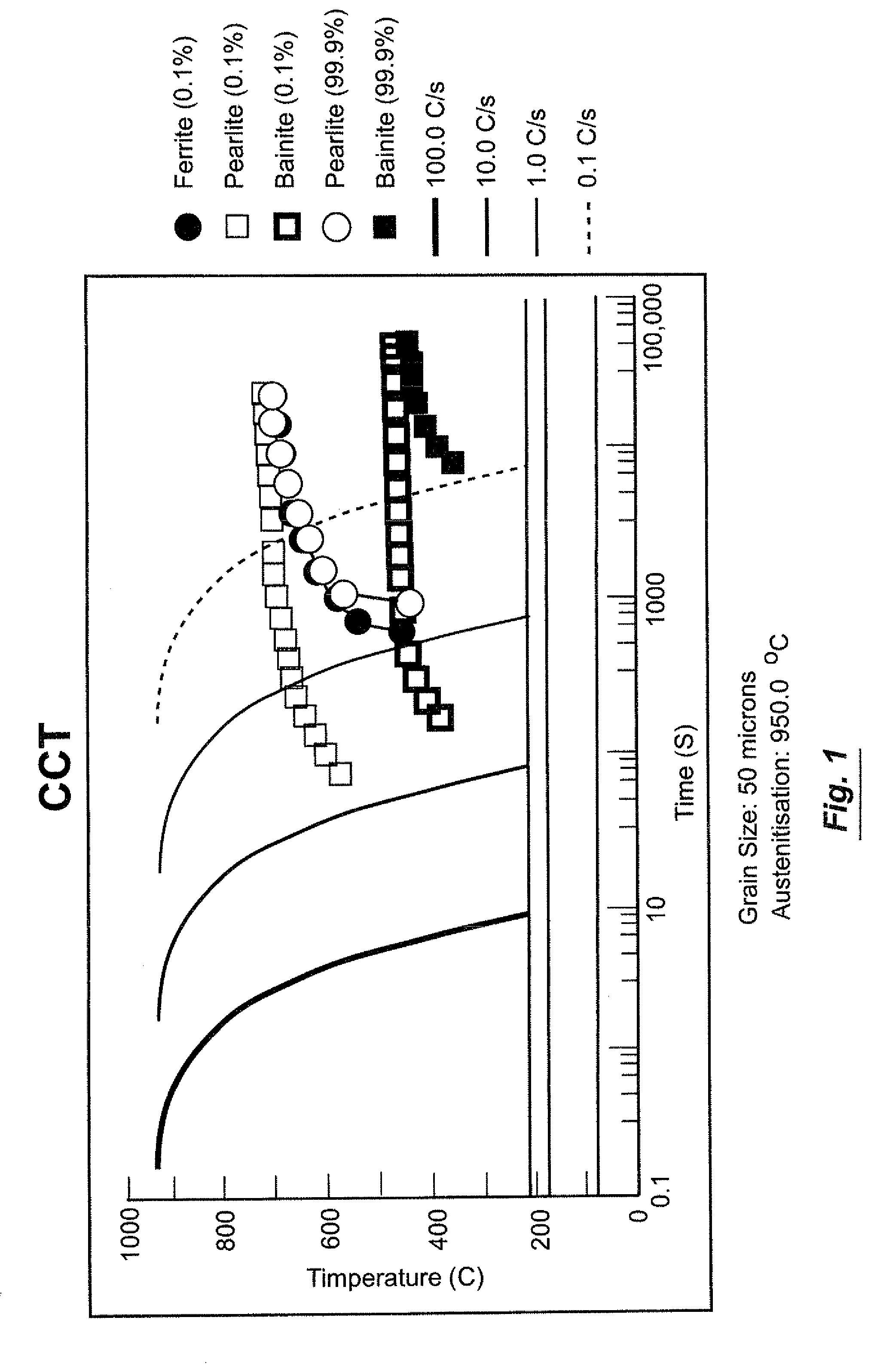

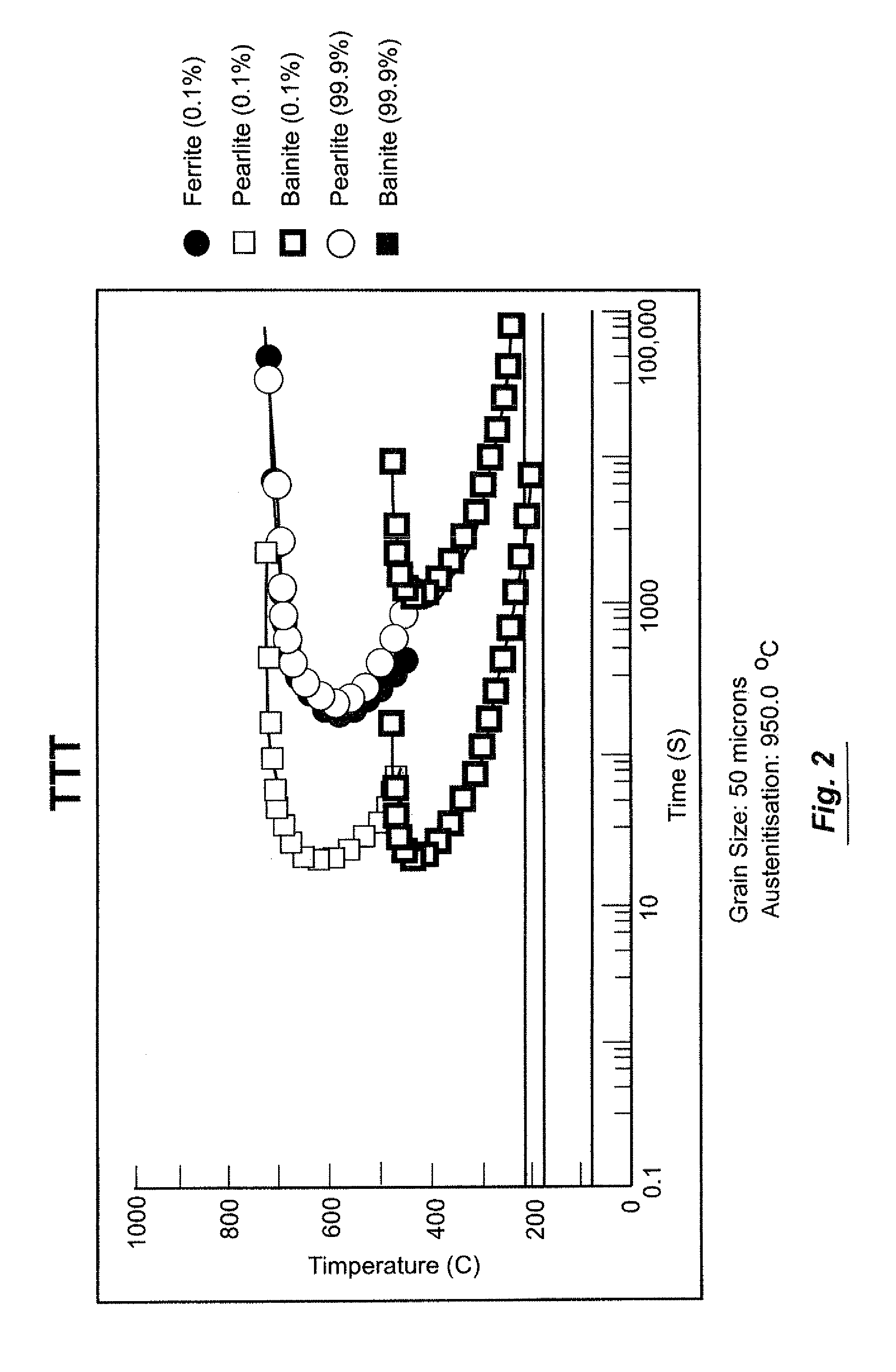

Railroad wheel steels having improved resistance to rolling contact fatigue

Steels having a pearlitic structure and containing 0.65 to 0.80 weight percent carbon, 0.90 to 1.10 weight percent silicon, 0.85 to 1.15 weight percent manganese, 0.001 to 0.030 weight percent phosphorus, 0.009 to 0.013 weight percent niobium, 0.05 to 0.15 nickel, 0.20 to 0.30 weight percent molybdenum, 0.10 to 0.30 weight percent vanadium and 0.005 to 0.040 weight percent sulfur with the remainder of said steel being iron and incidental impurities, can be used to make railway wheels that are particularly resistant to rolling contact fatigue and, hence, shelling.

Owner:TRANSPORTATION TECH CENT

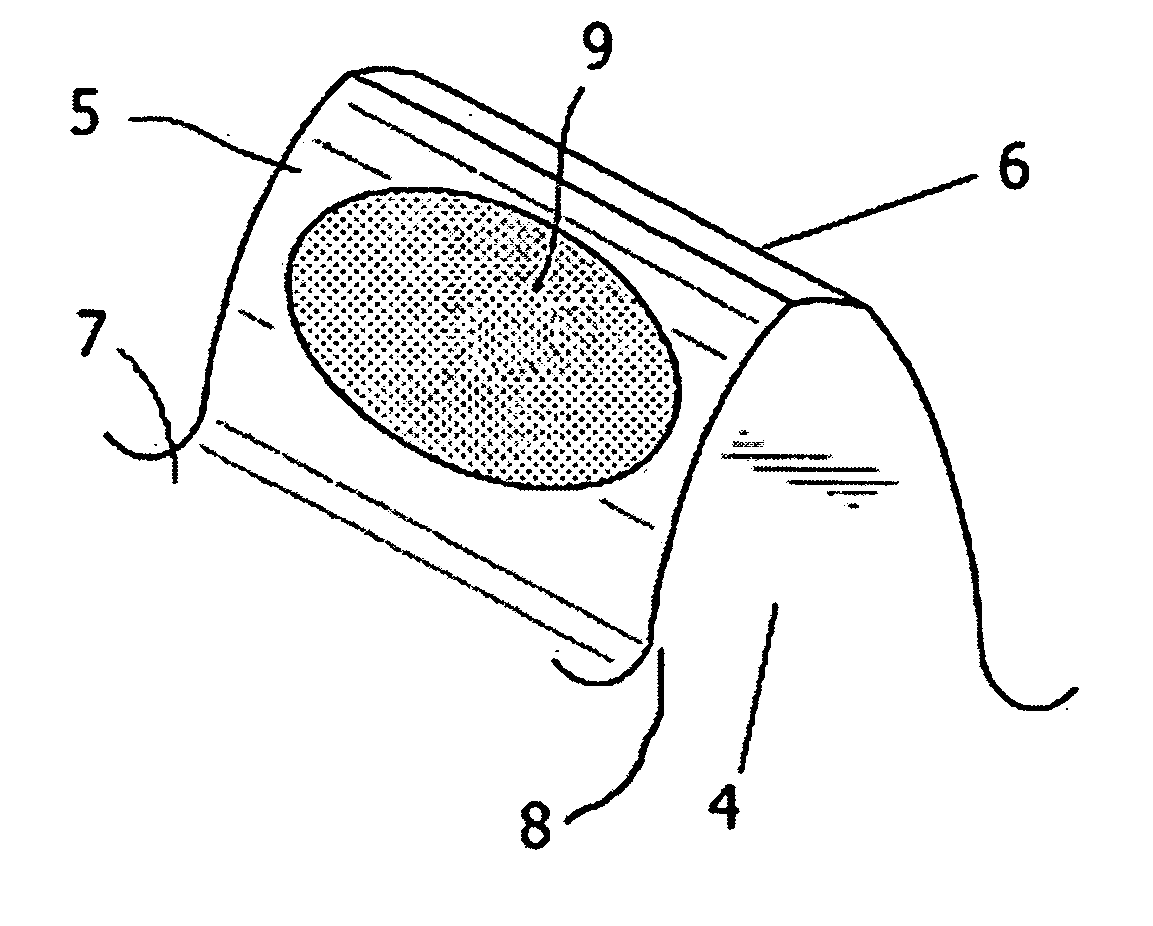

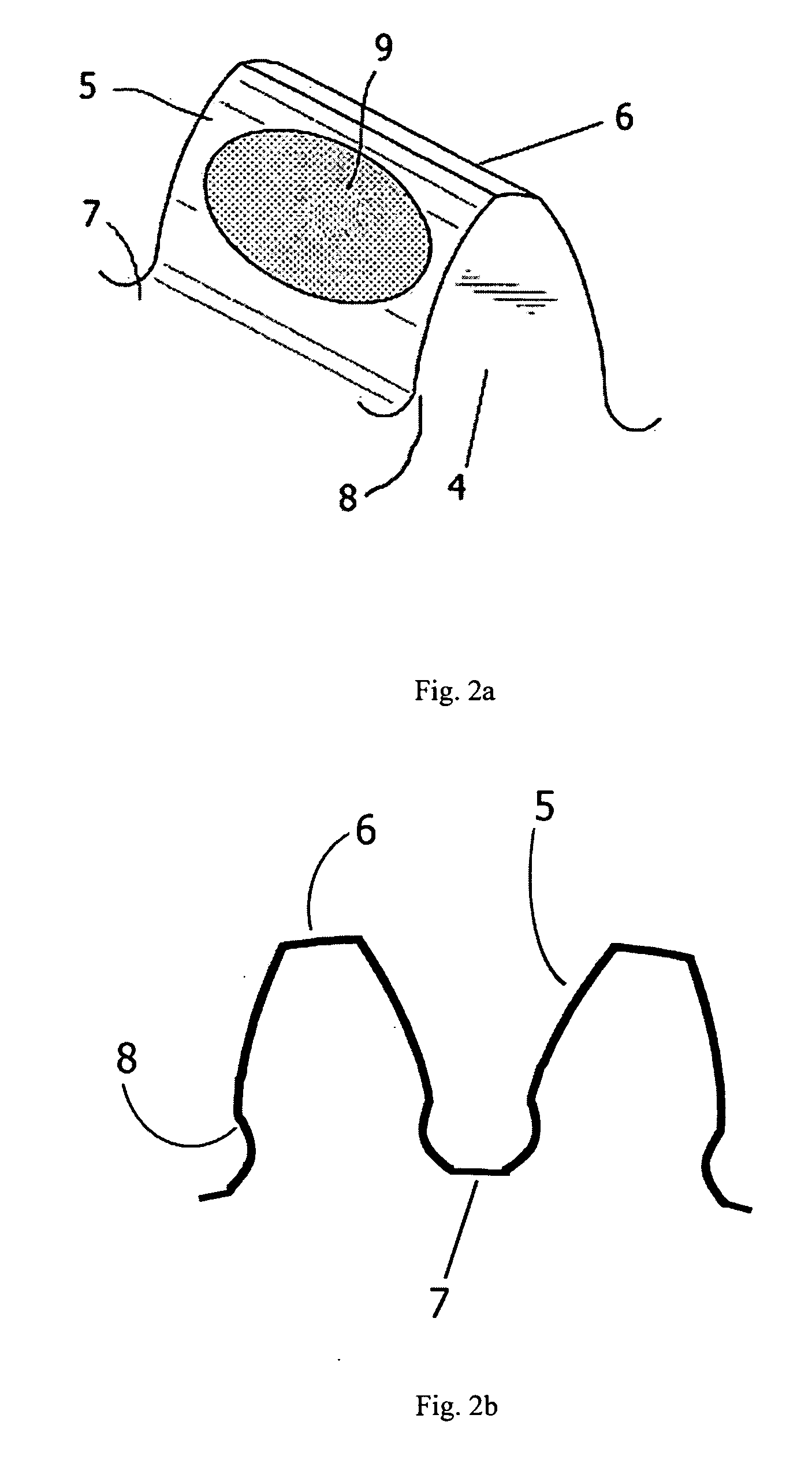

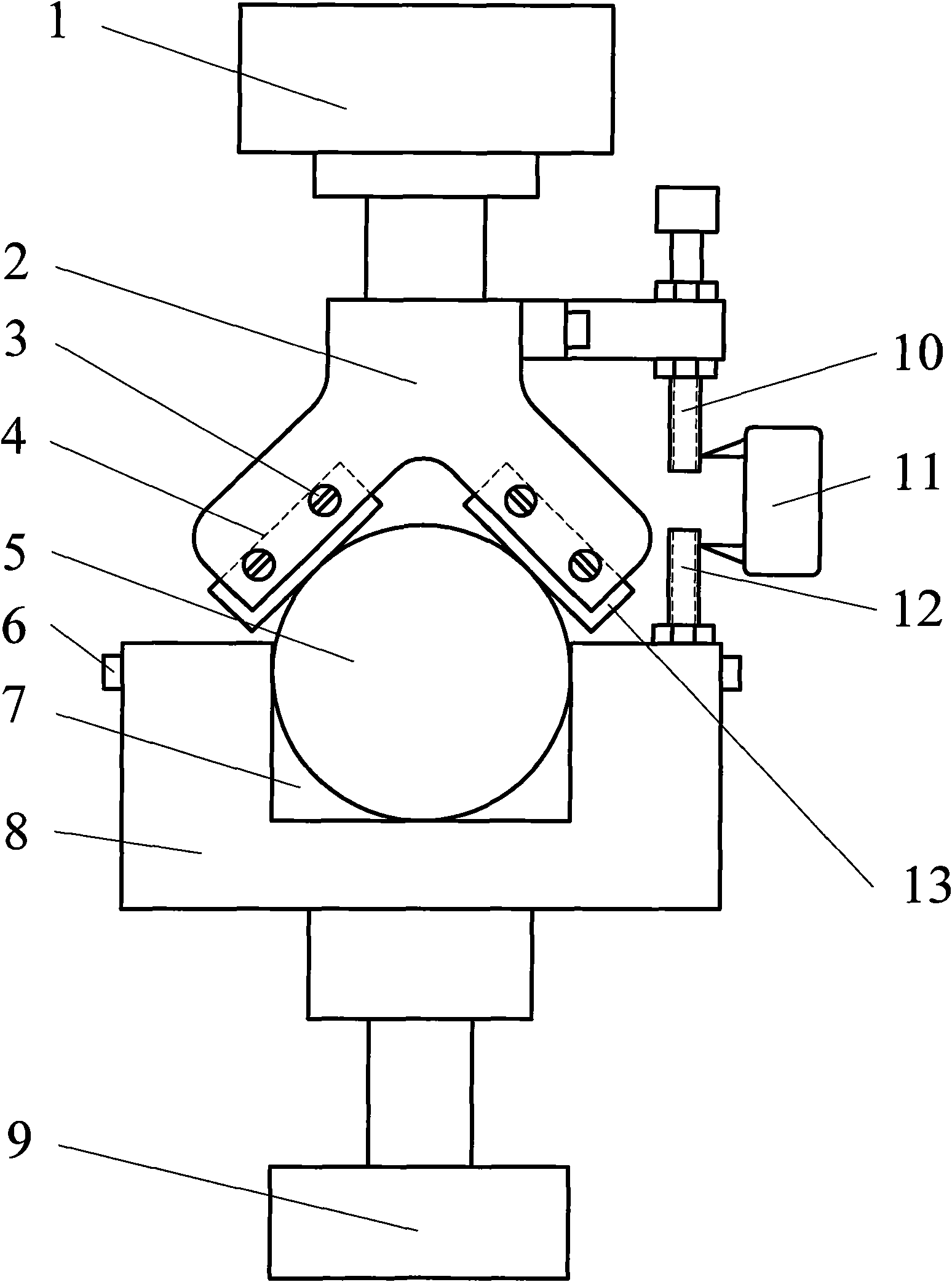

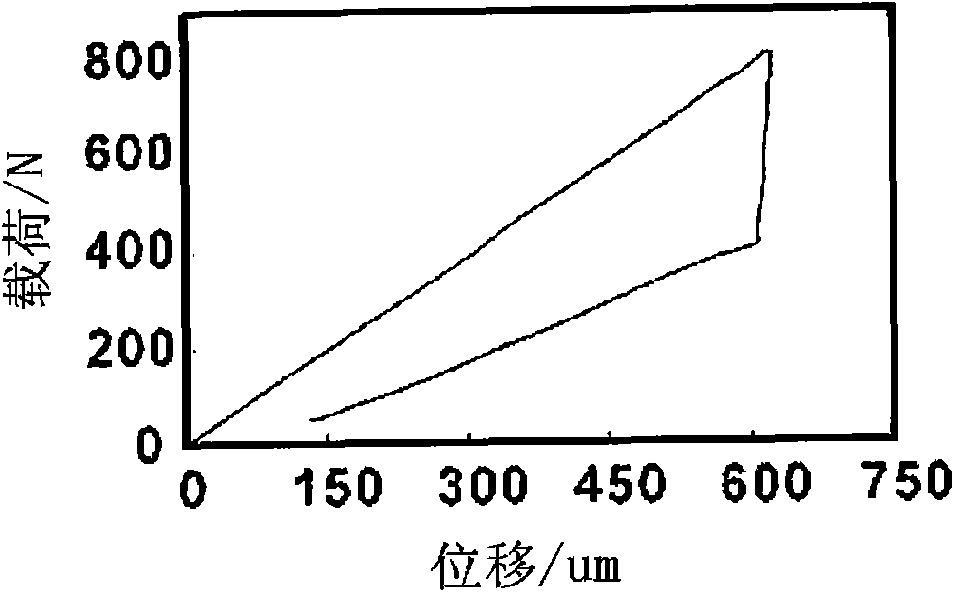

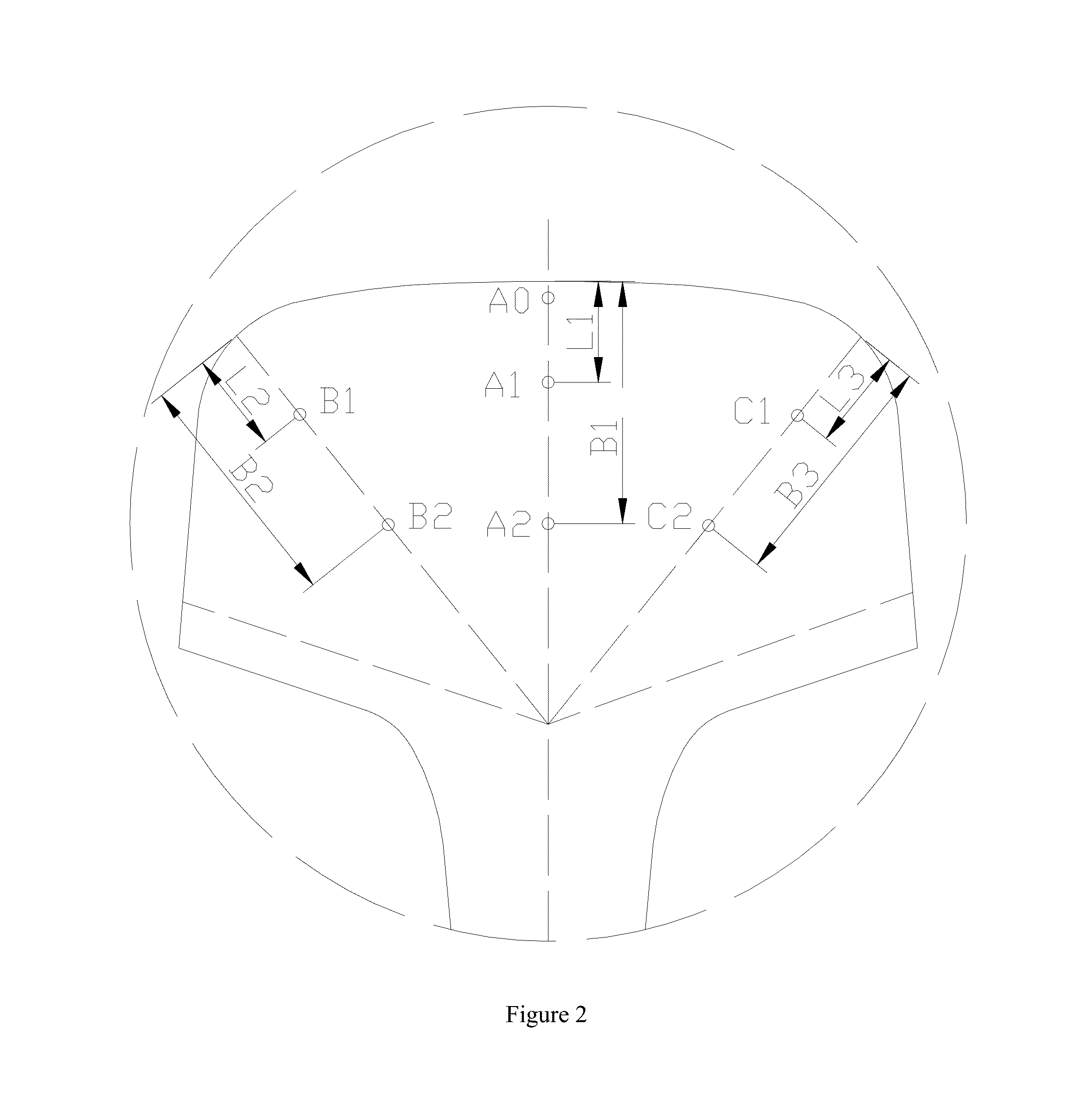

Bidirectional final motion test fixture and bidirectional final motion test method thereof

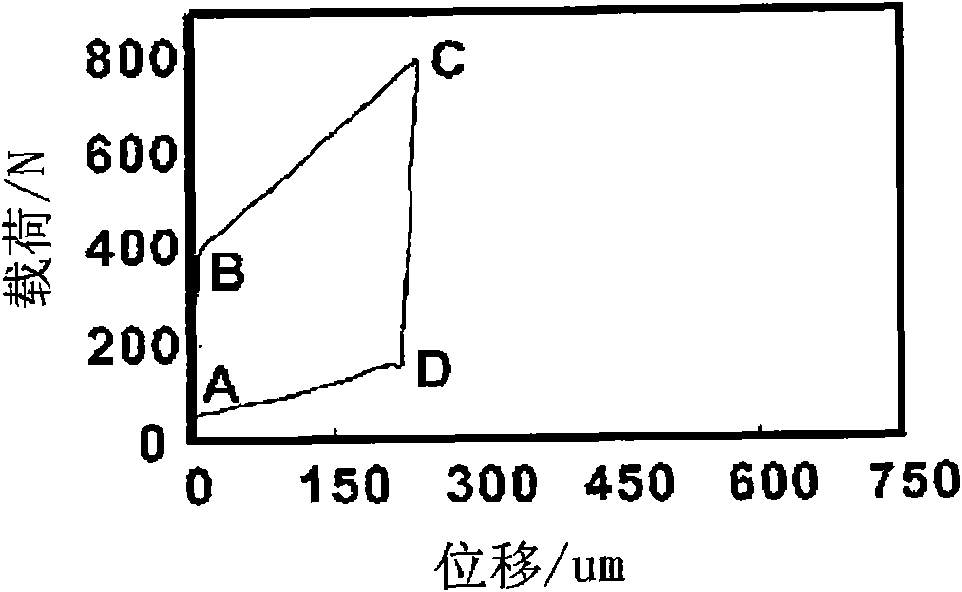

InactiveCN101608986ARealize two-way inchingShorten the lengthUsing mechanical meansMaterial strength using repeated/pulsating forcesFrettingEngineering

The invention relates to a bidirectional micro motion test fixture and a bidirectional micro motion test method thereof. The fixture is mainly in the structure that: a planar test-piece fixture (2) is in an inversed V shape, the opposite surfaces of the left and right sides of the lower part are all opened with a groove (4) fit to a planar test-piece (13), and the wall of the groove (4) is provided with a puller screw (3); a spherical test-piece fixture (8) is opened with a spherical test-piece cavity (7) fit to a spherical test-piece (5), and the wall of the spherical test-piece cavity (7) is provided with a puller screw (6); and the vertical axes of the spherical test-piece cavity (7), a piston (9) and the planar test-piece fixture (2) are coincided. One side of the upper part of the planar test-piece fixture (2) is connected with an upper vertical screw (10) while the spherical test-piece fixture (8) is connected with a lower vertical screw (12), and a displacement sensor is connected with the upper vertical screw (10) and the lower vertical screw (12). The test fixture can effectively simulate bidirectional fretting under spherical / surface contact condition, test tribology properties and estimate contact fatigue life of a coating under spherical / surface bidirectional micro motion condition on the existing hydraulic servo micro motion test platform.

Owner:SOUTHWEST JIAOTONG UNIV

Steel rail and producing method thereof

InactiveCN101148736AReduce rateNo contact fatigue cracksFurnace typesHeat treatment process controlChemical compositionTrace element

The present invention relates to metallurgy technology, and is especially one kind of steel rail with high contact fatigue resistance and its production process. The steel rail has the chemical composition comprising C 0.61-0.73 %, Si 0.20-0.50 %, Mn 0.80-1.30 %, and Fe and other trace elements for the rest. It has tensile strength Rm over 1080 MPa, fracture toughness KIC over 45 MPa.m1 / 2, excellent contact fatigue resistance and high comprehensive use effect. Its production process includes the on-line treatment of rolled steel rail, including simultaneous quenching and cooling to the rail head, the rail web and the rail base.

Owner:PANZHIHUA IRON AND STEEL

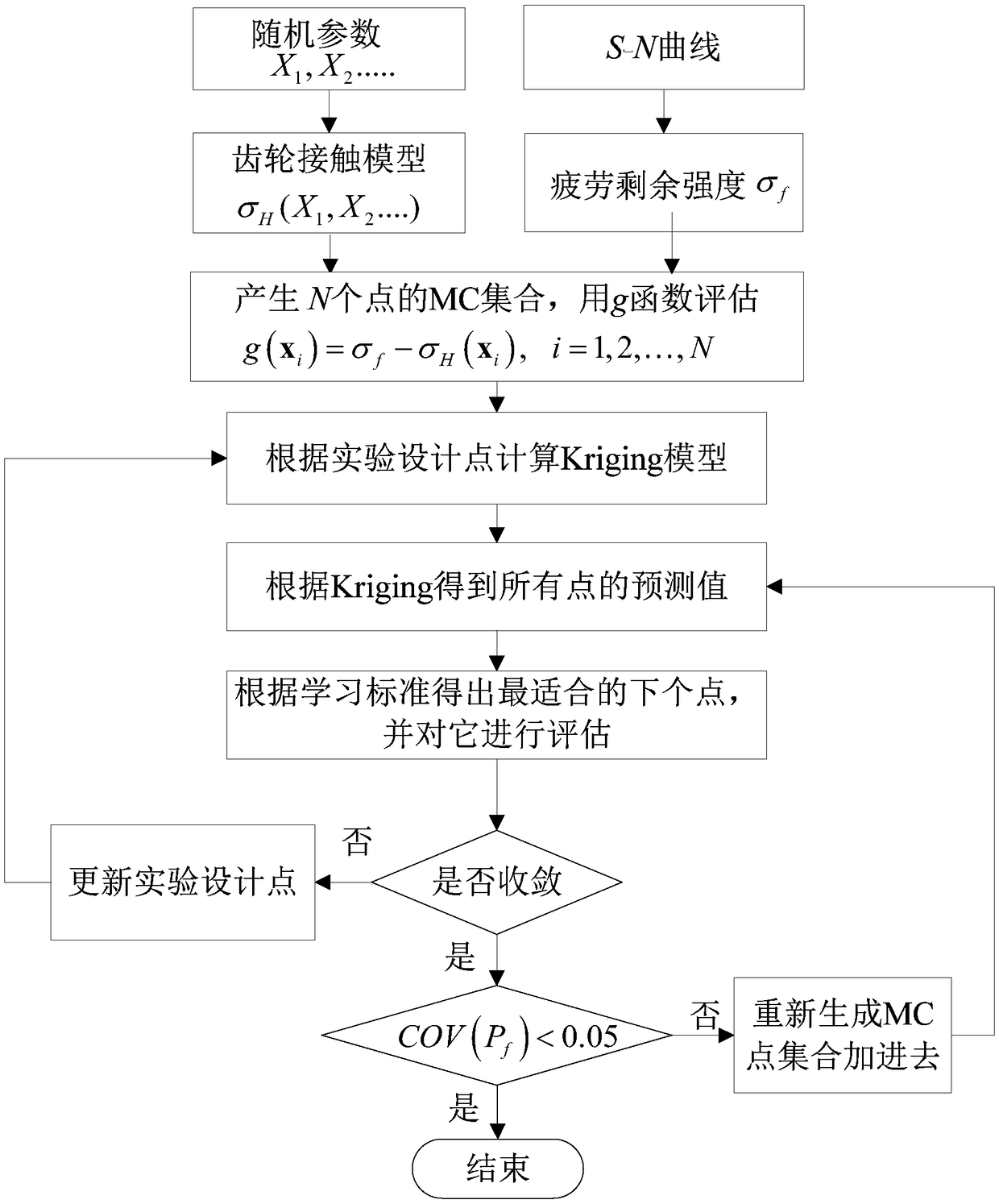

A gear contact fatigue reliability analysis method

ActiveCN109165425AAccurate and reliableGuaranteed reliabilityDesign optimisation/simulationSpecial data processing applicationsDistribution characteristicEngineering

The invention discloses a gear contact fatigue reliability analysis method. Firstly, the contact stress model of gear is established, the residual fatigue strength after a certain cycle is obtained onthe basis of a fatigue S-N curve, and then the function of gear contact fatigue failure is constructed. Then, according to the distribution characteristics of the random parameters, the Monte Carlo method is used to generate point set, the initial Kriging model is constructed by randomly selecting N points as the experimental design points, and then the sample points which are closest to the limit state surface or have the largest error are obtained by active learning strategy, and the sample points are added to the original experimental design points as the best sample points, and the Kriging model is updated until convergence. According to the convergent Kriging model, the approximate value of the function corresponding to all the sample points is obtained, and the failure probability is calculated by Monte Carlo method. Finally, an example is given to verify the feasibility of the proposed method. The gear contact fatigue reliability analysis method of the invention is more efficient and practical.

Owner:HUNAN UNIV

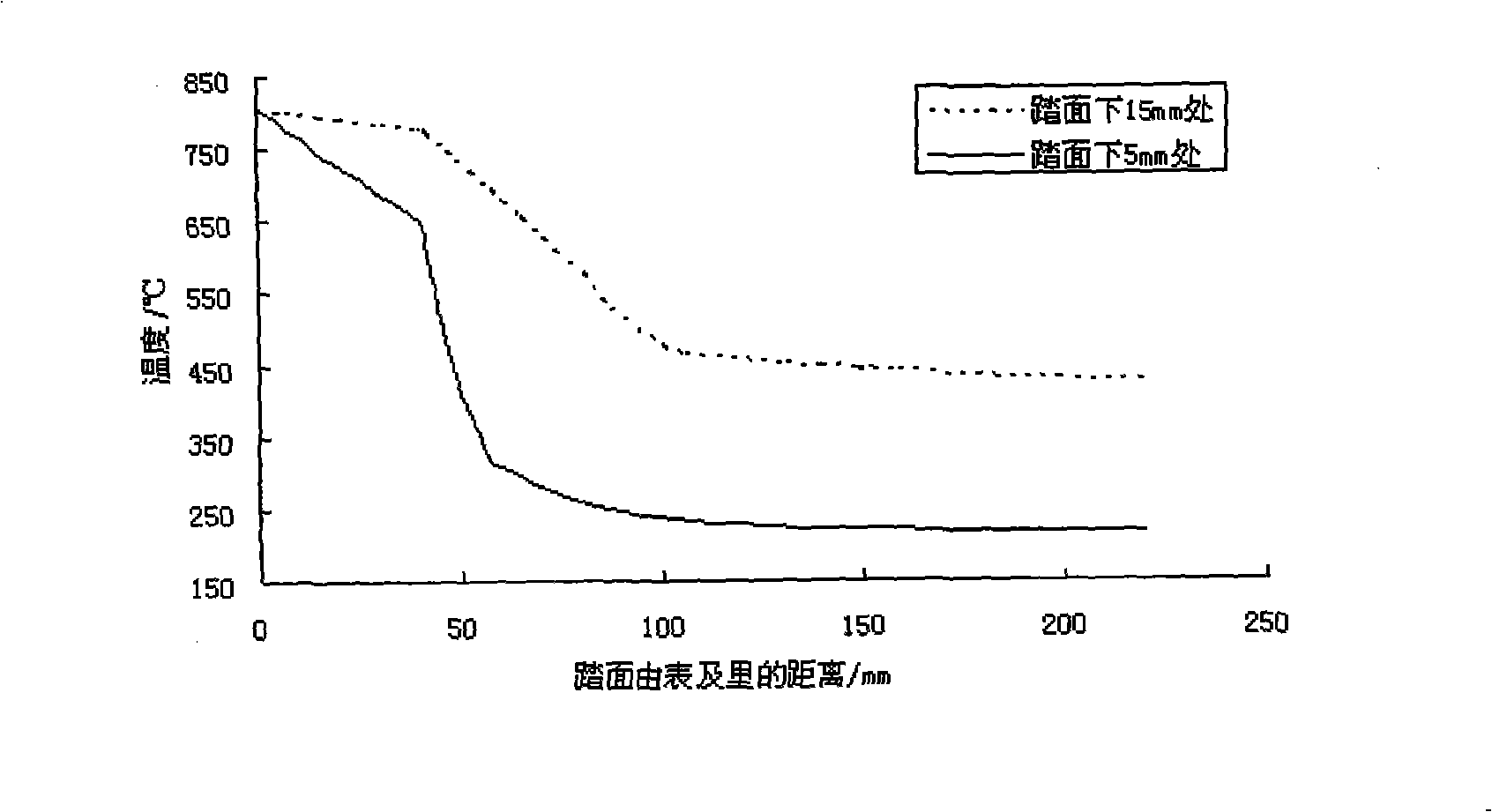

Thermal treatment method for high-carbon steel train wheel circular rim surface and heat treatment apparatus

ActiveCN101270408AReduce the difficulty of operationFurnace typesHeat treatment furnacesHigh carbonEngineering

The invention discloses a heat treatment method of a wheel rim surface of the train wheel with high carbon steel. The method is carried out as follows: during the cooling process, the wheel tread of train wheel is firstly cooled by spraying water with small flow in short time, then large flow in long time. The invention also discloses a heat treatment device of using the method. An water feed tubular tube comprises a water feed tubular tube with large flow and a water feed tubular tube with small flow, the water feed tubular tube with large flow is communicated with a plurality of nozzles with large flow, and the water feed tubular tube with small flow is communicated with a plurality of nozzles with small flow. Adopting the technical proposal can improve the contacting fatigue resistance of train wheel, reduces the tread spalling of train wheel; obtains the appropriate geometric matching relation between wheels and rails as soon as possible, increases the contact area, decreases the contact stress level; promotes the wear resistance of the internal part of wheel rim, thereby promoting the service life of wheel; can not increase the operation difficulty of the heat treatment and cooling technology of wheels.

Owner:MAANSHAN IRON & STEEL CO LTD

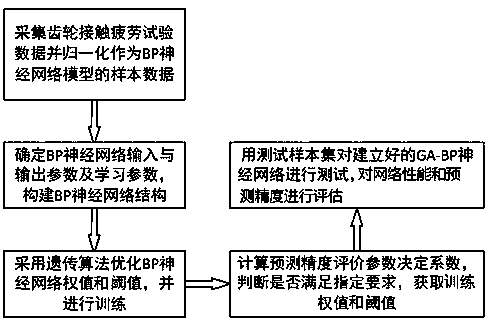

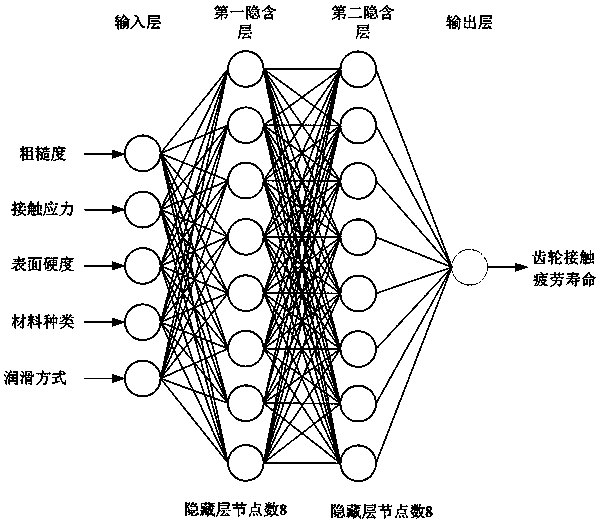

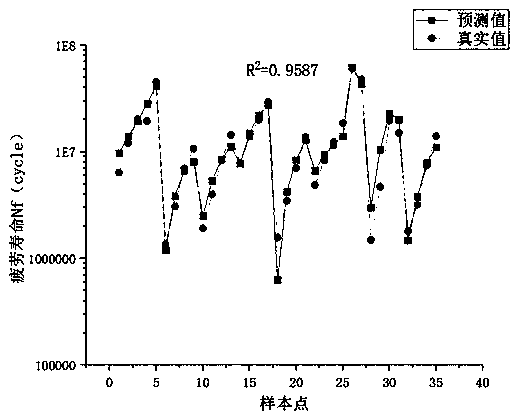

Gear contact fatigue life prediction method based on GA-BP neural network

PendingCN111324989AAchieve forecastLow costDesign optimisation/simulationNeural architecturesAlgorithmPhysical model

The invention discloses a GA-BP neural network-based gear contact fatigue life prediction method. The method comprises the following steps of 1, collecting gear contact fatigue test data and normalizing the gear contact fatigue test data as sample data of a BP neural network model; 2, constructing a structure of a BP neural network; 3, optimizing the weight and threshold of the BP neural network by using a genetic algorithm, and training the BP neural network; 4, calculating a prediction precision evaluation parameter determination coefficient, and obtaining an optimization weight and a threshold when the prediction precision evaluation parameter determination coefficient meets a set value; and 5, testing the established GA-BP neural network by using the test sample set. Compared with an existing gear contact fatigue life prediction method based on a physical model, the gear contact fatigue life prediction method is low in cost and high in prediction precision, does not need to be derived according to a failure mechanism, achieves prediction of the gear fatigue life, improves the prediction accuracy, is easy to use, and provides a new technical means for design and manufacturing ofgears.

Owner:CHONGQING UNIV

Railroad wheel steels having improved resistance to rolling contact fatigue

Steels having a pearlitic structure and containing 0.65 to 0.80 weight percent carbon, 0.90 to 1.10 weight percent silicon, 0.85 to 1.15 weight percent manganese, 0.001 to 0.030 weight percent phosphorus, 0.009 to 0.013 weight percent niobium, 0.05 to 0.15 nickel, 0.20 to 0.30 weight percent molybdenum, 0.10 to 0.30 weight percent vanadium and 0.005 to 0.040 weight percent sulfur with the remainder of said steel being iron and incidental impurities, can be used to make railway wheels that are particularly resistant to rolling contact fatigue and, hence, shelling.

Owner:TRANSPORTATION TECH CENT

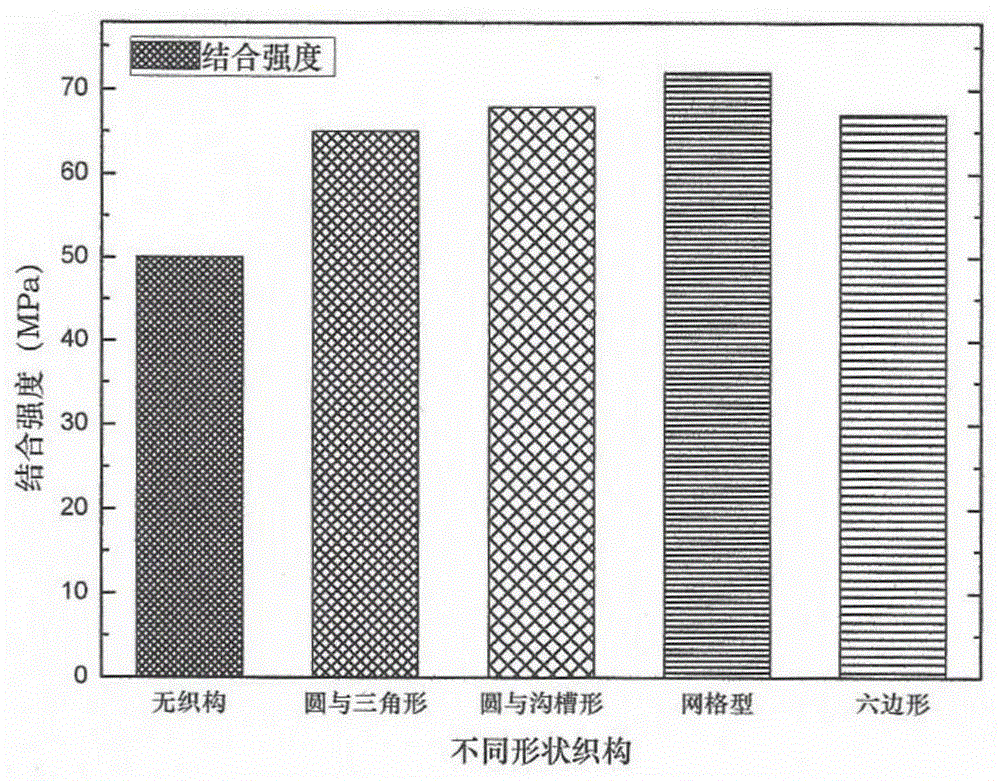

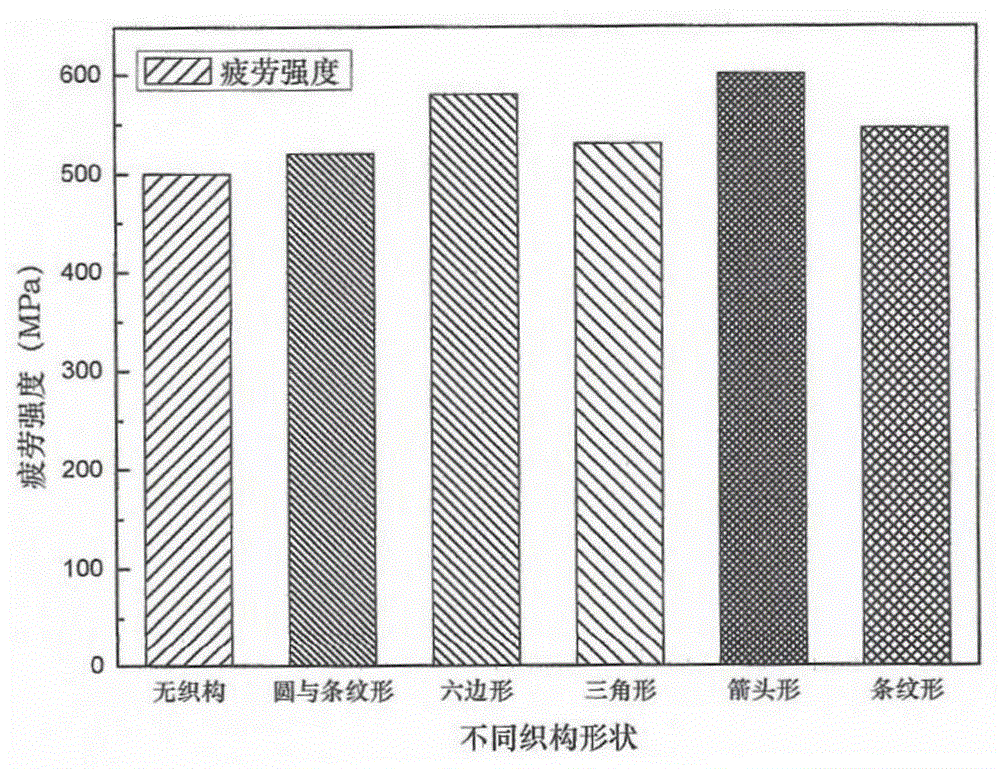

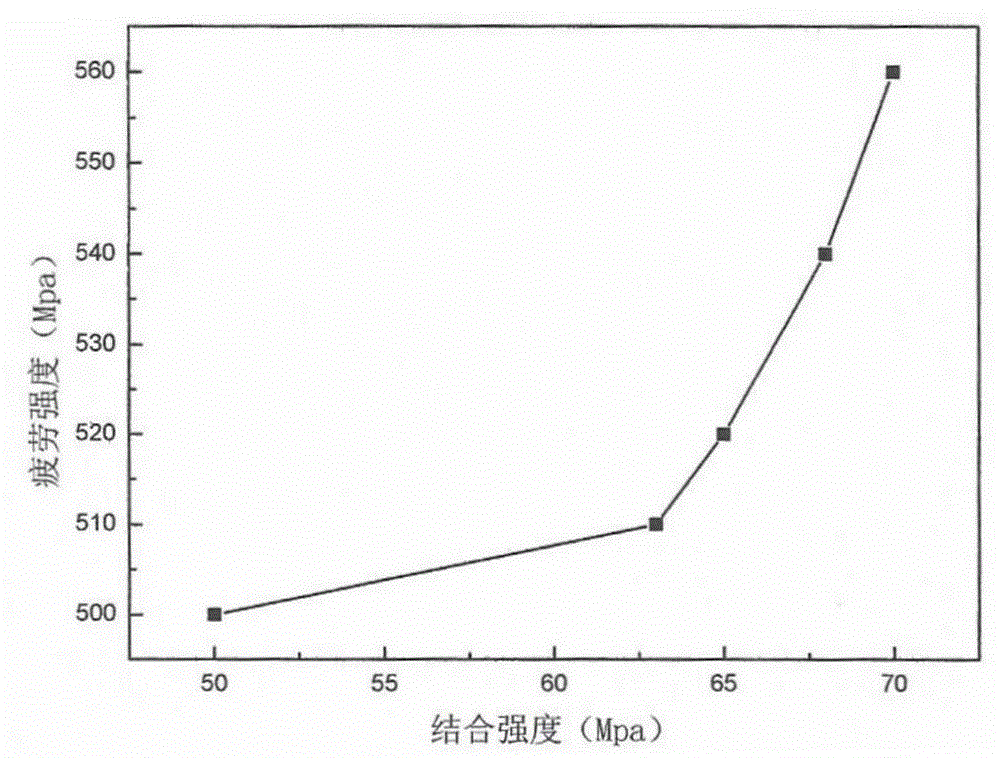

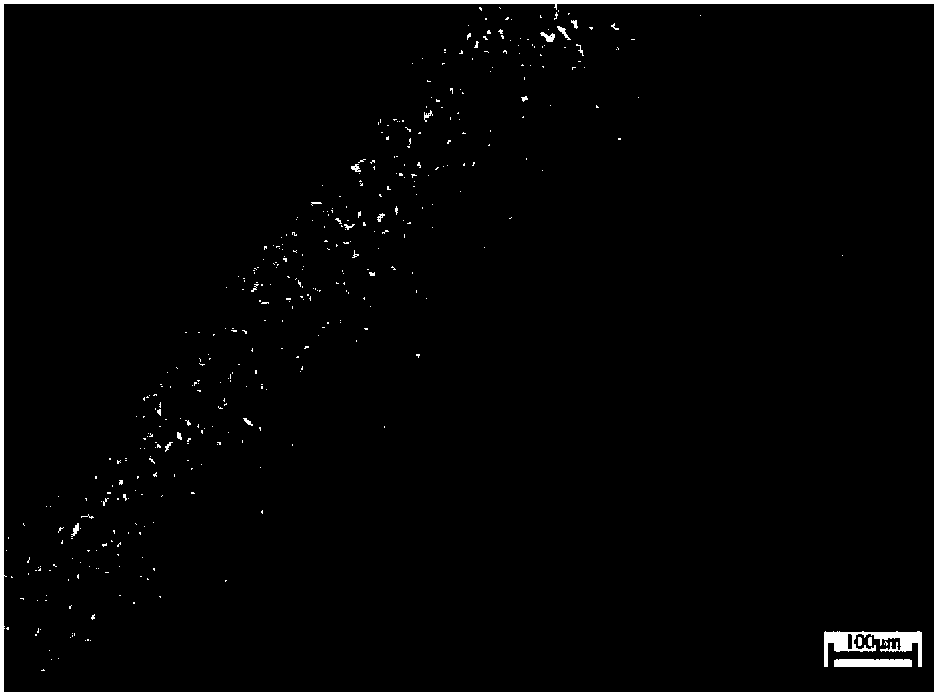

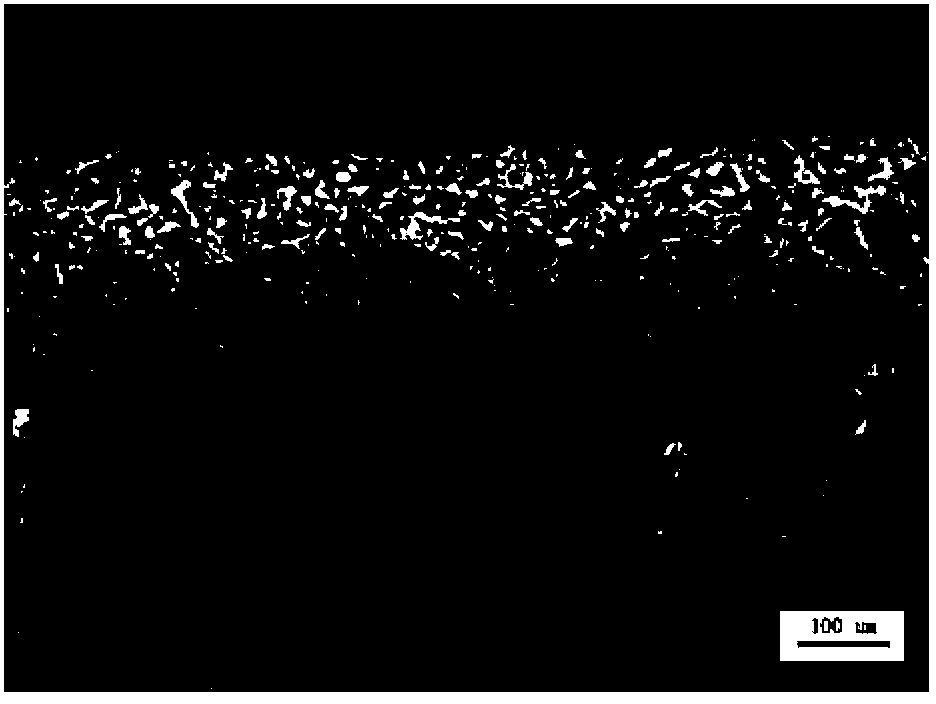

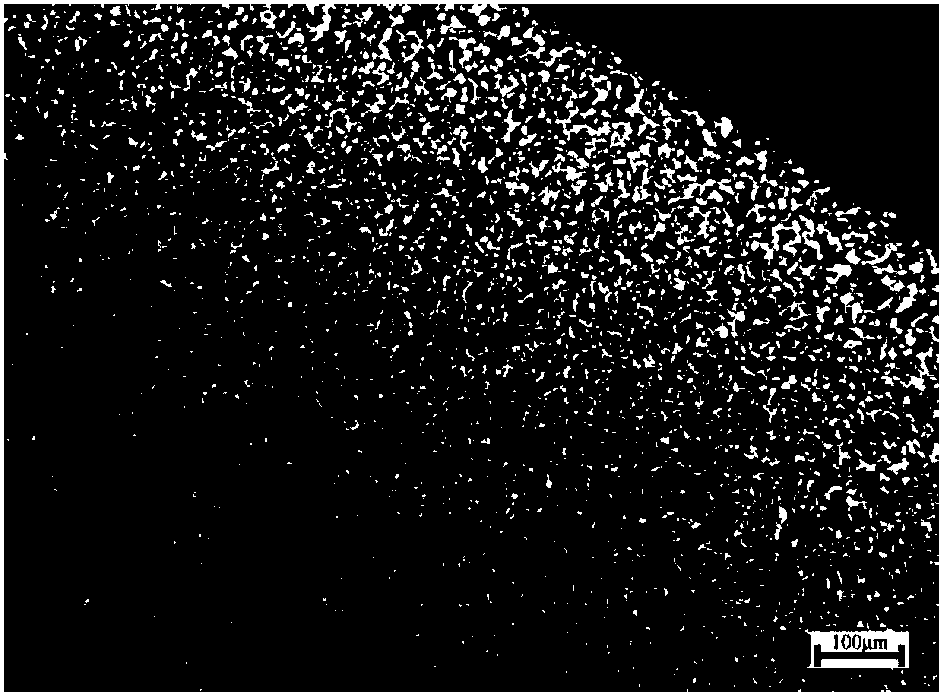

Method for improving fatigue strength of coating layer by double-layer texture coupling effect

InactiveCN106637182AHigh bonding strengthImproved resistance to contact fatiguePressure inorganic powder coatingCoated surfaceUltimate tensile strength

The invention provides a method for improving fatigue strength of a coating layer by a double-layer texture coupling effect; and the method prepares texture patterns on the surface of a basal body and the surface of the coating layer through biologic bionics simulation. The method adopts texture as a method for combining a spraying pretreatment with aftertreatment, improves the bonding strength of the coating layer through texture, improves the contact fatigue resistance of the coating layer through surface texture, and prolongs the service life of the coating layer.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Rolling piston and manufacturing method thereof for rotary type cold compressor

ActiveCN101158356ASufficient supplyFair priceRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorHigh energy

The invention provides a rolling piston used for a rotary refrigeration compressor and the manufacture method thereof. The material of the rolling piston is a precise steel pipe made of GCr15 bearing steal cold rolled; the manufacture method of the invention is that (1) the GCr15 bearing steal is selected to be cold rolled to the steel pipe meeting required internal diameter, external diameter and thickness of the rolling piston; (2) the steel pipe is cut according to the length of the rolling piston material; (3) the cut steel pipe is disposed by hot controllable gas; (4) all surfaces of the steel pipe are kibbled; (5) the steel pipe is disposed by heat stabilization; (6) all surfaces of the steel pipe are finely grinded. The invention has the advantages that the made rolling piston has obvious predominance on the anti-wear performance and high contact fatigue life. The work load of the cutting process can be reduced by 50%, and the utilization ratio of the steel material can reach more than 90%, thus reducing the manufacture cost. The invention saves the casting method, avoids the environmental pollution and high energy consumption, and is a good energy-saving method with environmental protection.

Owner:NINGBO YONGWEI GROUP

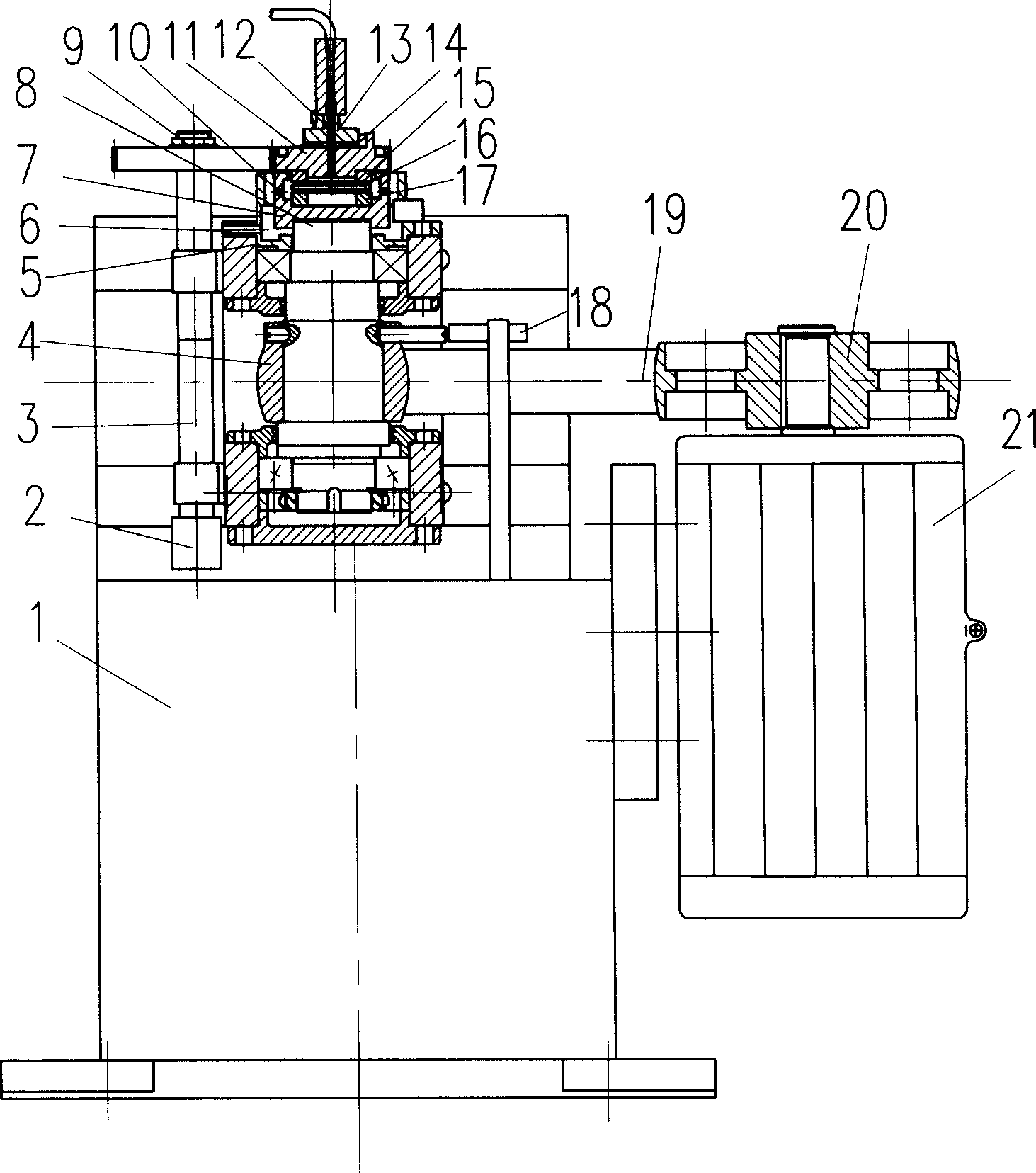

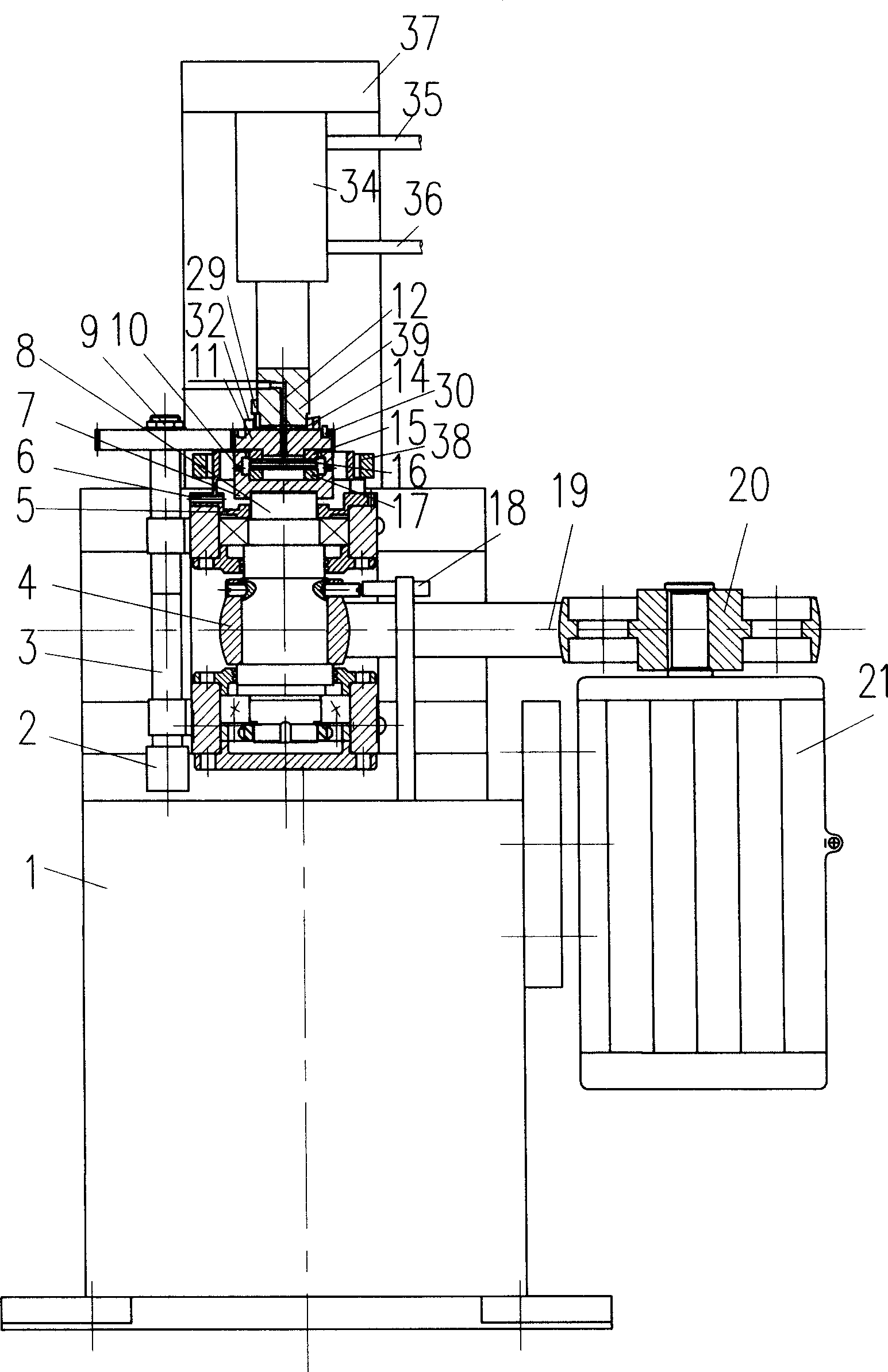

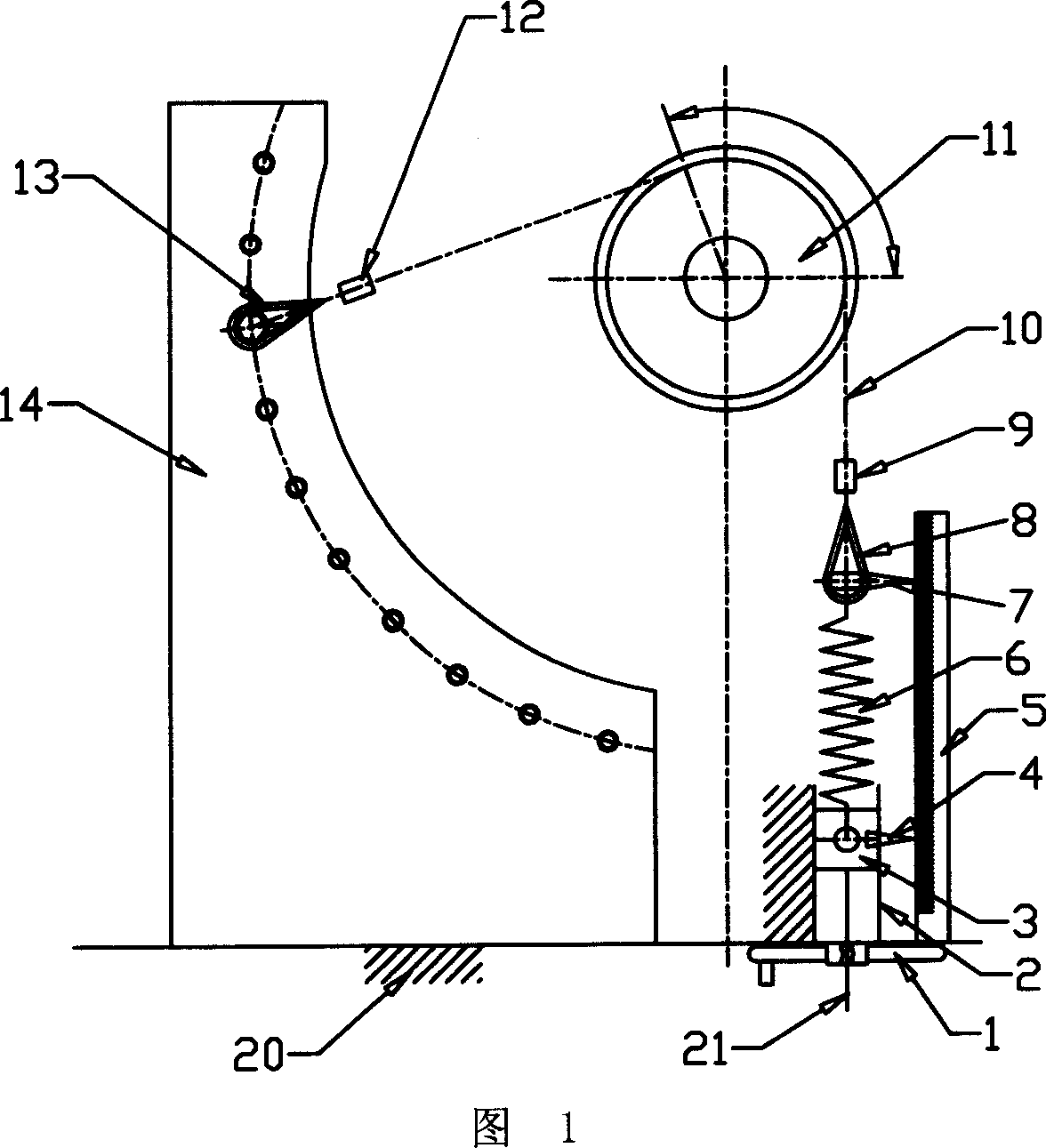

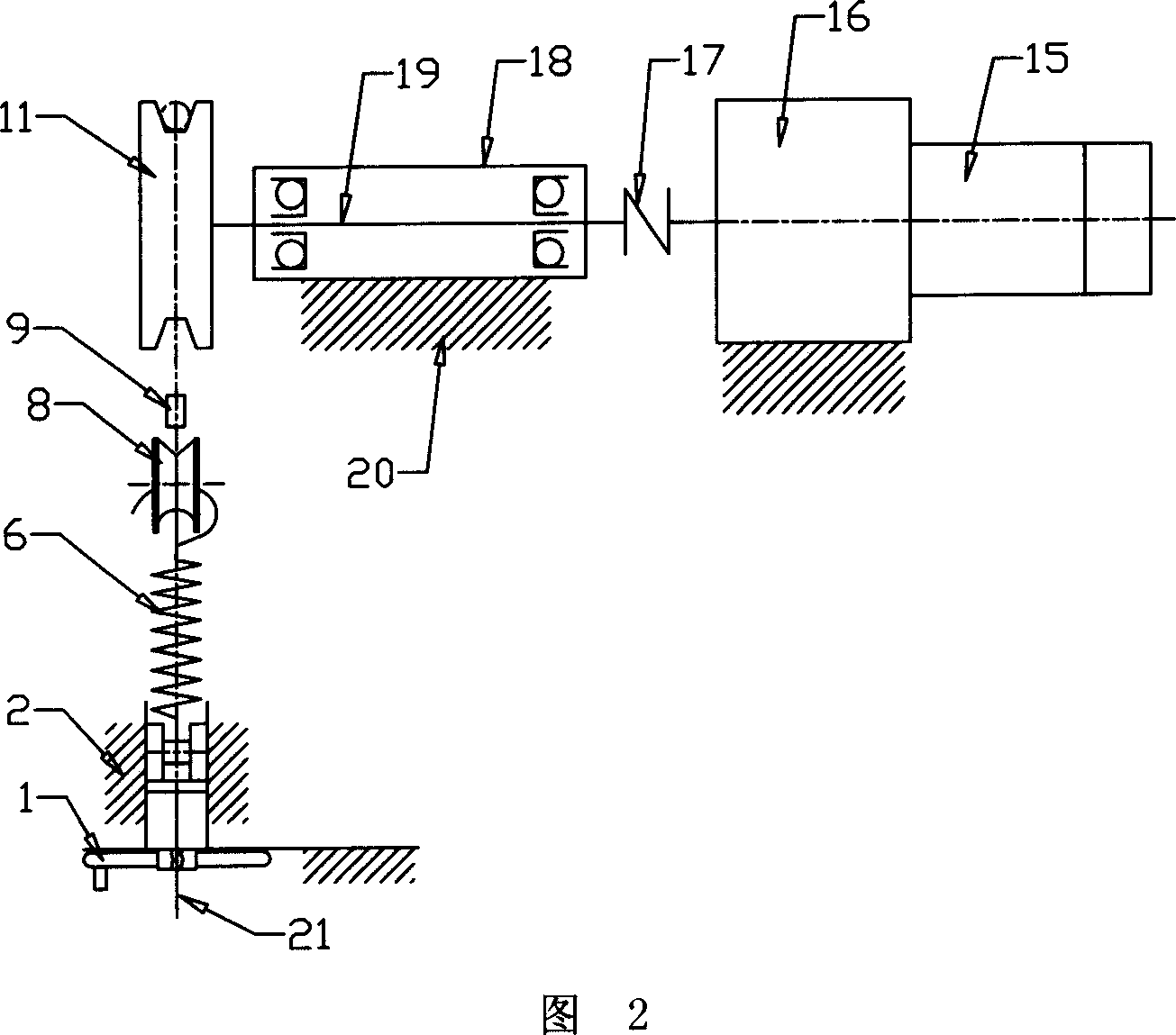

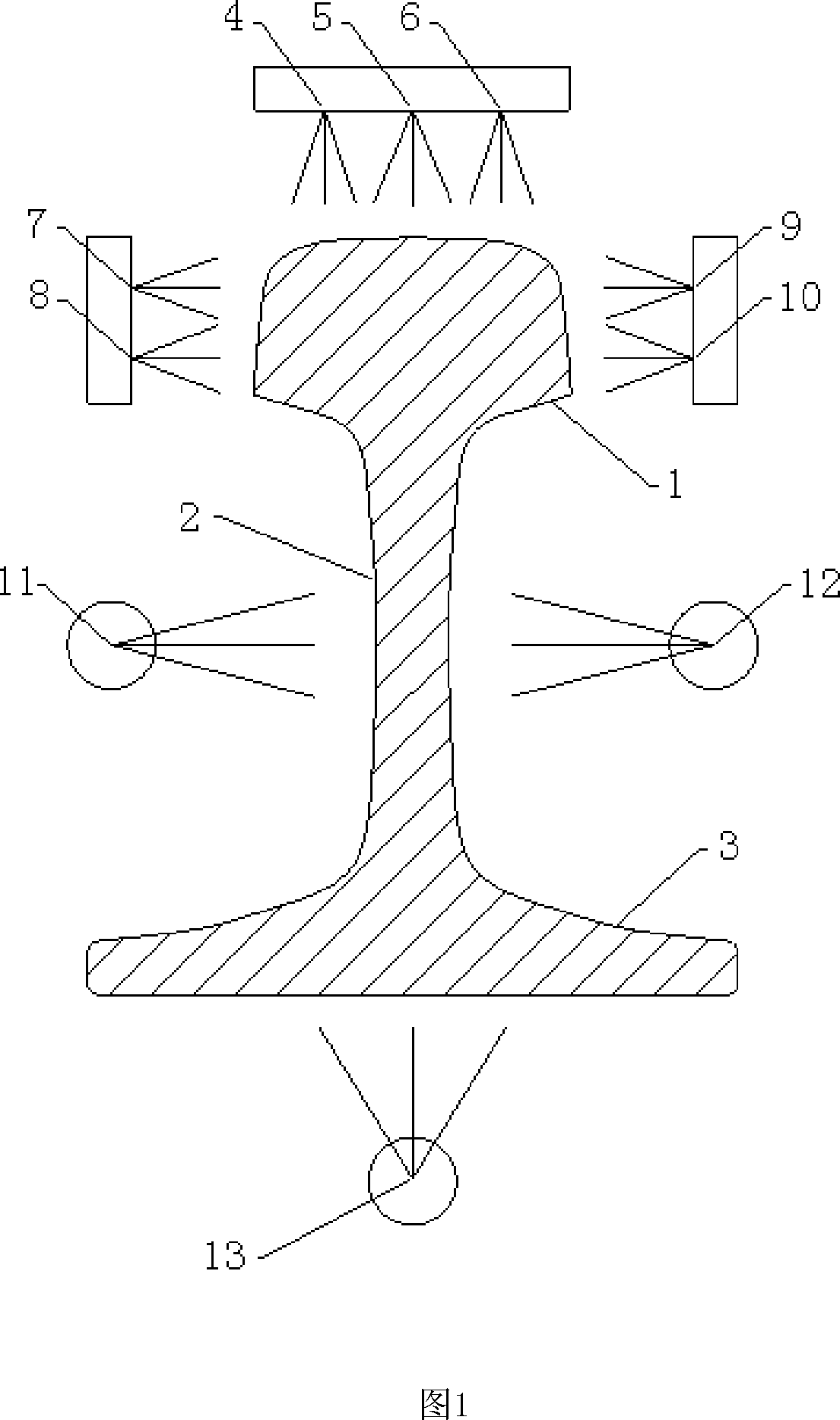

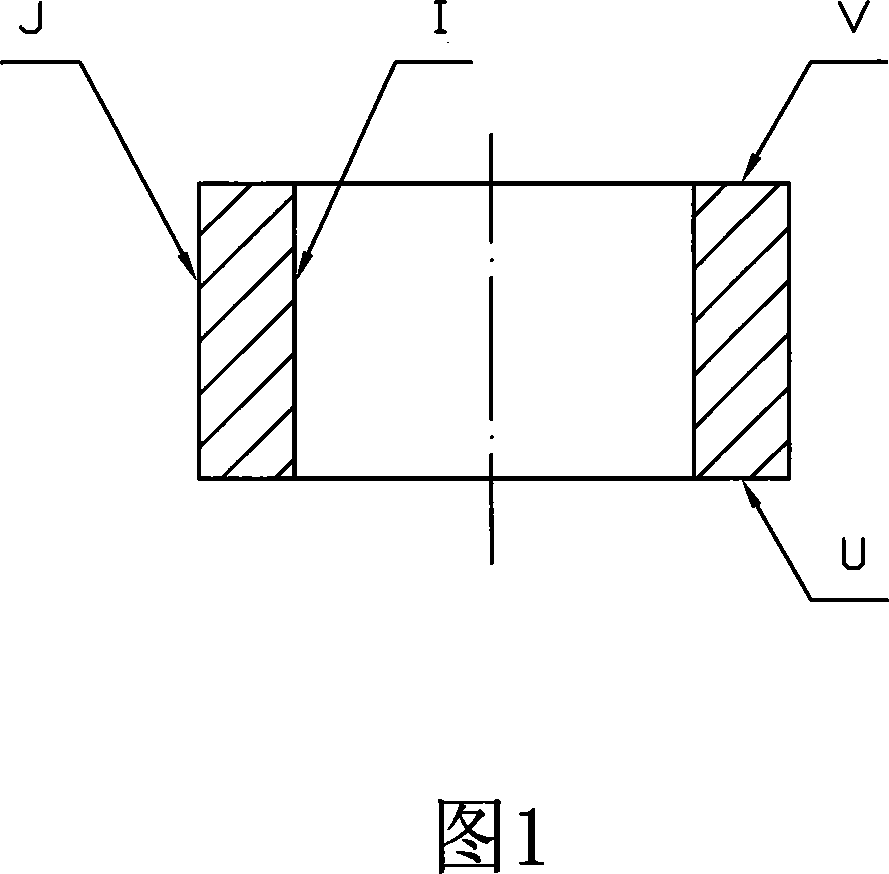

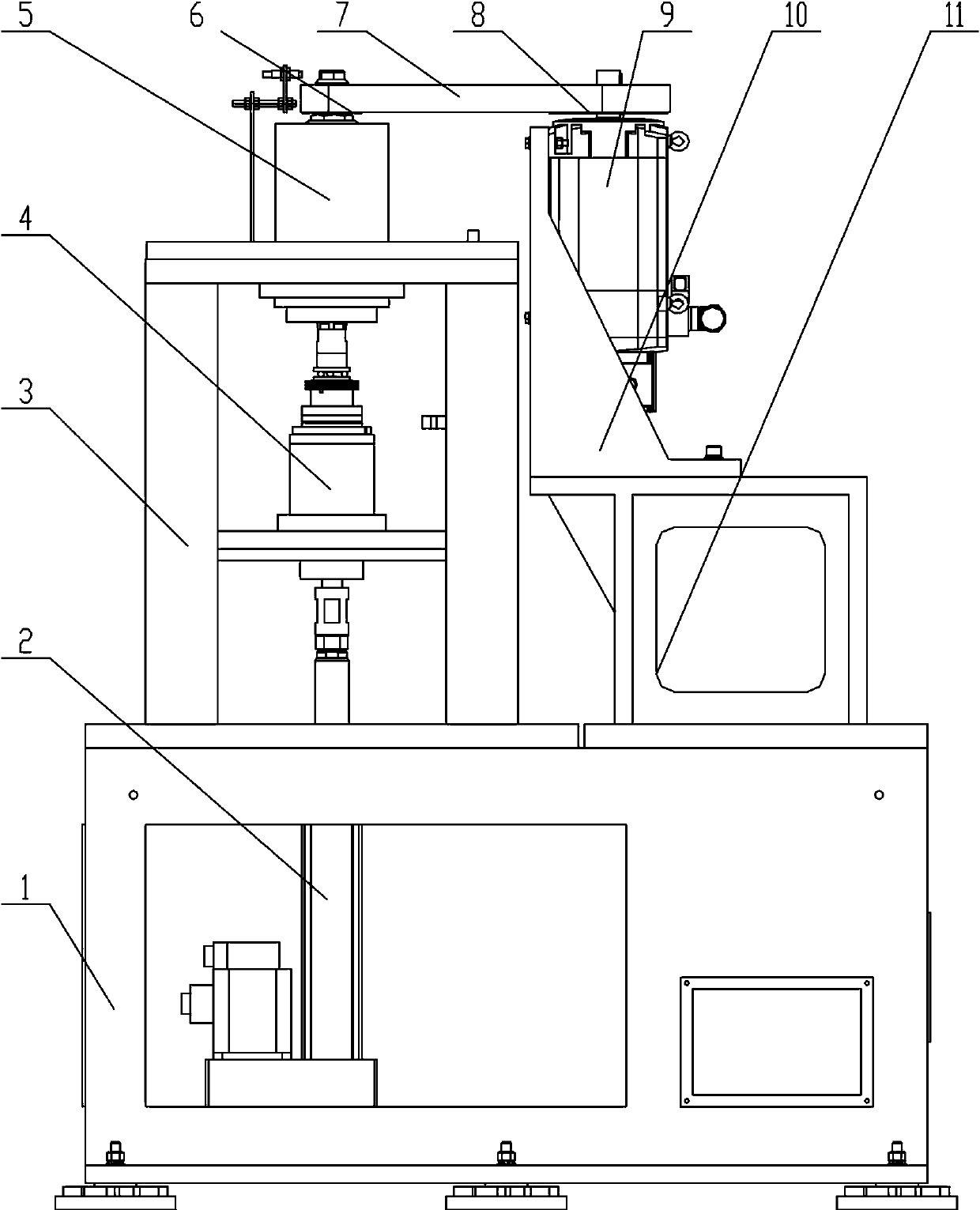

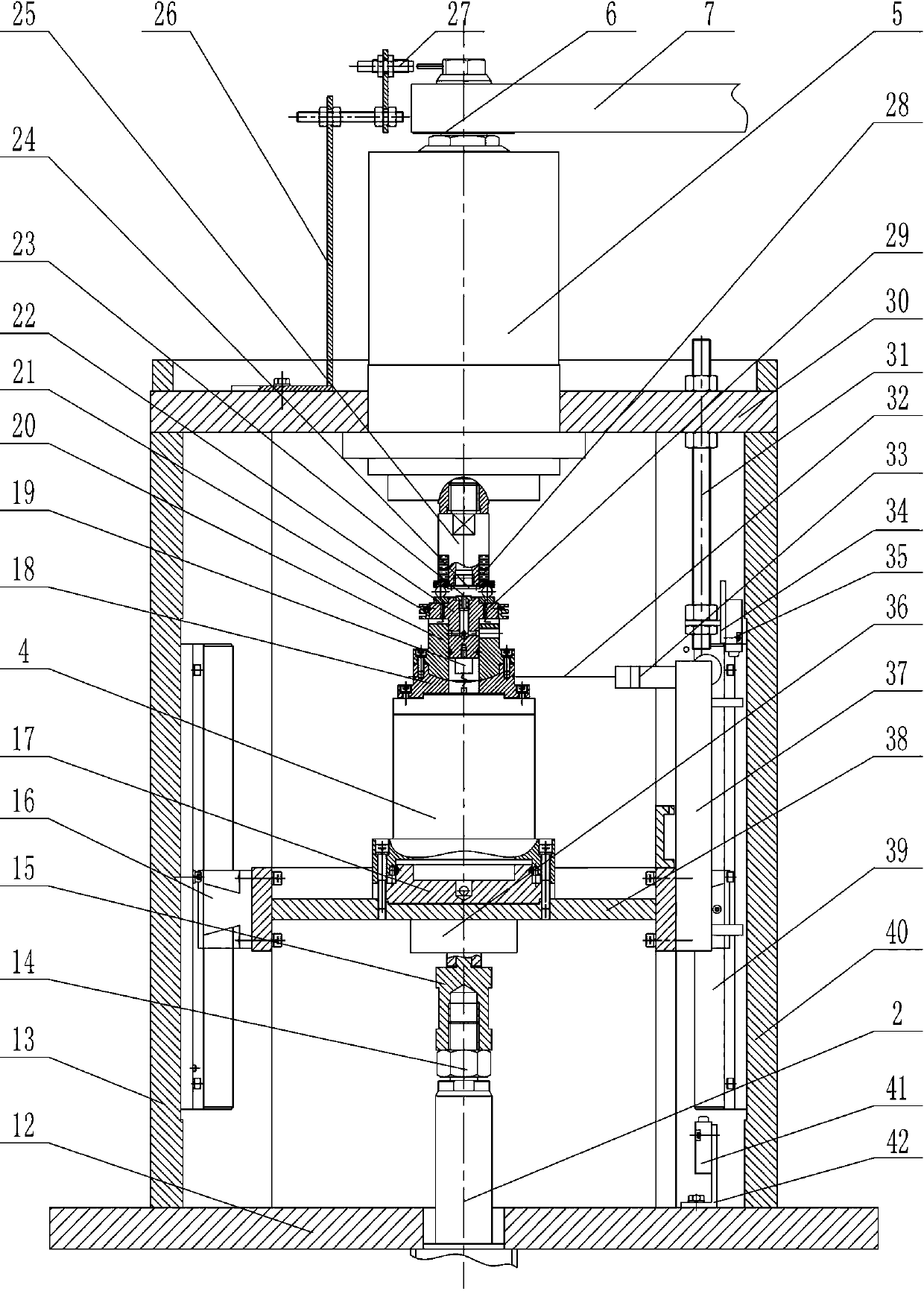

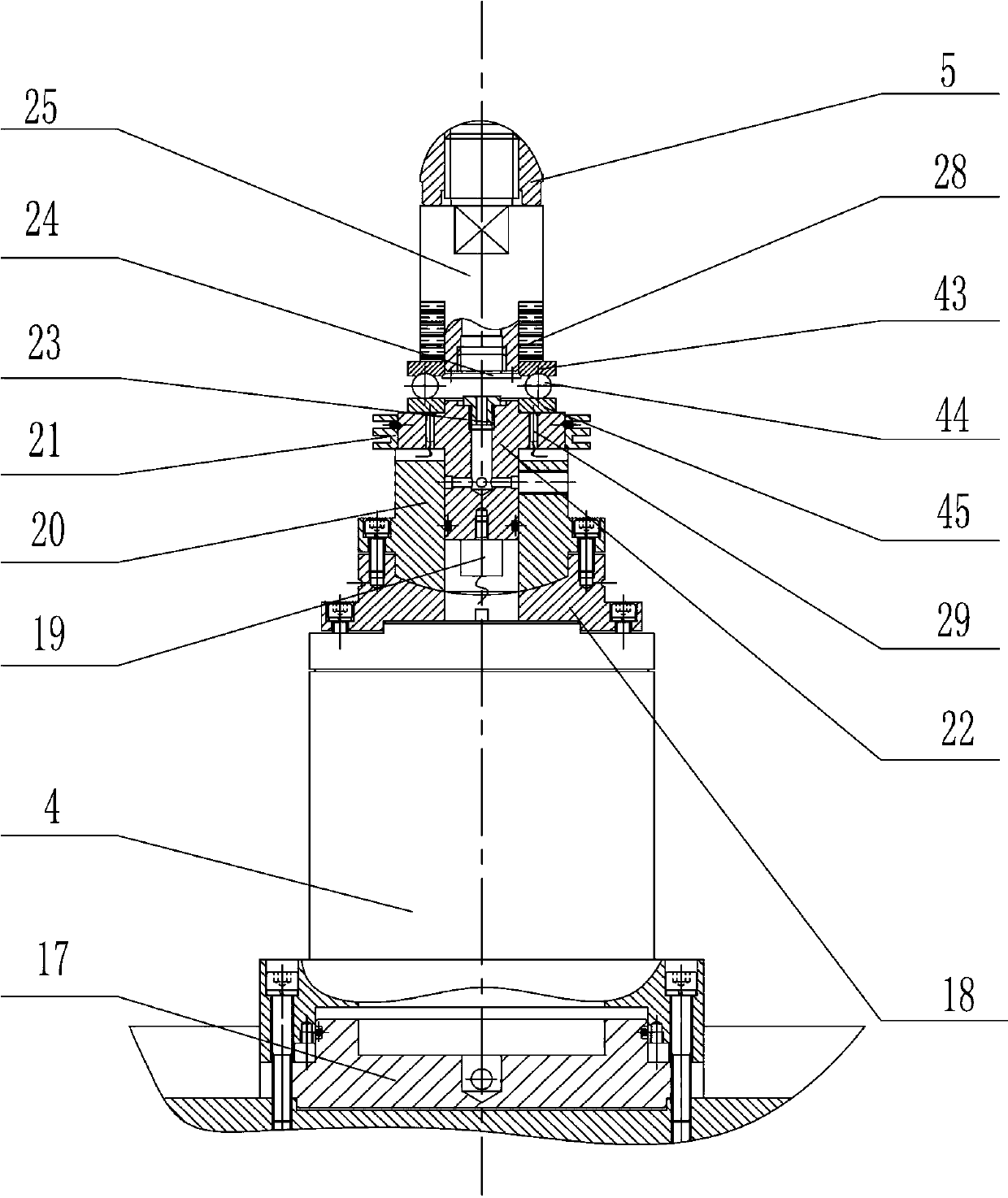

High-speed rolling contact fatigue testing machine

InactiveCN103344553AUse cleanEasy to controlUsing mechanical meansMaterial analysisRolling contact fatigueEngineering

The invention discloses a high-speed rolling contact fatigue testing machine. The high-speed rolling contact fatigue testing machine is characterized in that a driving pulley (6) arranged on the upper end of the output shaft of a servo motor (9) is in transmission connection with a driven pulley (8) arranged on the upper end of a static pressure main shaft (5), and the static pressure main shaft (5) is fixed on an upper beam (30) arranged on a rack (3); a servo electric cylinder (2) is connected with a pressure sensor (36) fixed on the lower surface of a moving beam through a connecting piece (15) of the pressure sensor; the upper end of a hydraulic supporting platform (4) is fixed on a sphere base lower part (18), a lower test specimen base (21) is connected with a sphere base upper part (20), and the lower test specimen base (21) is connected with a test specimen base ring (45) in a clearance fit mode. The high-speed rolling contact fatigue testing machine provided by the invention has the advantages that the rolling contact of a bearing material under a high speed and heavy load working condition is simulated, the key parameter of rolling contact fatigue of a testing material can realize accurate detection, and finally, the data support is provided for evaluating the rolling contact fatigue property of the bearing material.

Owner:YANSHAN UNIV

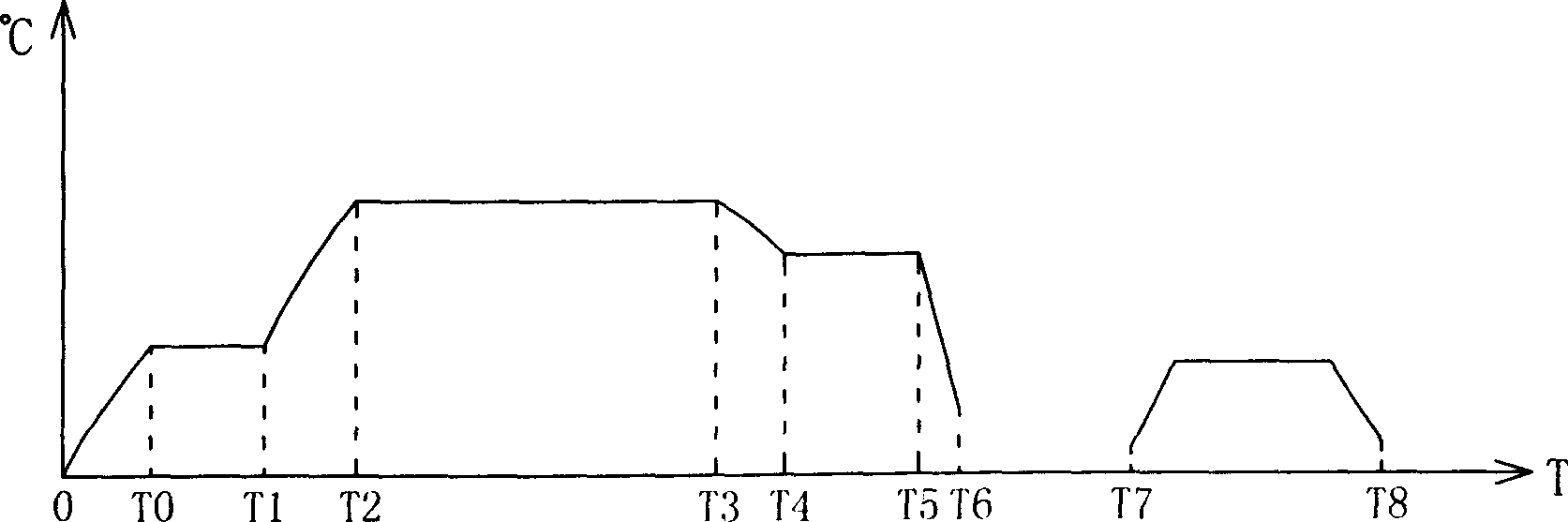

Heat treatment method for diesel engine cam

InactiveCN101476029AReduce distortionReach hardnessSolid state diffusion coatingFurnace typesMechanical equipmentCam

The invention discloses a diesel engine cam thermal treatment method comprising a carburizing step, a quenching step and a tempering step.After the carburizing step, a pit cooling method is adopted for reducing the deformation of the cam because of the heat treatment process, two times of alkaline bath quenching are adopted for not only reducing thermal stress and deformation, but also having functions of thinning heart crystal grains and eliminating network carbide for satisfying metallography requirement in the first quenching process of the cam, and having a function of assuring to obtain cryptocrystal martensite, residual austenite and partial of granule carbide on the surface for satisfying performance requirements of rigidity, wearing resistance property, contact fatigue degree and the like of the cam surface in the second quenching process of the cam;simultaneously, the cam heart can obtain lath martensite and fine homogeneous ferrite, and the mechanical property of the cam heart can be improved; according to the invention, design requirements of heat rigidity, wearing resistance property, fatigue strength, mechanical property of the cam heart and deflection can all be satisfied, therefore, the manufactured cams can be extensively used in large-scale heavy-duty mechanical equipment.

Owner:CHONGQING YUEJIN MACHINERY

Preparation method of wear-resistant coating on surface of roller

InactiveCN103820780AUniform claddingLayer depth controllableRollsMetallic material coating processesMachined surfaceAlloy

The invention discloses a preparation method of a wear-resistant coating on the surface of a roller. The preparation method is characterized by comprising the steps: (1) pretreating the surface of the roller; (2) selecting an alloy powder, and regulating an automatic powder feeding device; (3) regulating a light beam: selecting a 10*1mm broadband integral mirror, and regulating a defocusing amount to focus laser spots in a rectangular shape; (4) selecting a CO2 laser to carry out laser cladding on a wear and etch resistant coating, automatically feeding the alloy powder into a laser molten pool by adopting a synchronous powder feeding device, enabling a high-power focusing laser beam and an automatic powder feeding hole to be axially fed along the roller, rotating by setting a rotational speed, and forming a uniform and dense laser cladding layer on the processing surface of roller; (5) carrying out flaw detection after cladding. With the adoption of the preparation method, a strengthening layer formed by laser cladding can be used for remarkably improving the rigidity, the wear resistance and the contact fatigue resistance on the surface of the roller of a hot rolled plate.

Owner:吴立松

High-strength and highly fatigue-resistant steel rail and production method thereof

InactiveUS20160194729A1Improve wear resistanceHighly contact-fatigue-resistantFurnace typesQuenching agentsManufacturing technologyChemical composition

The present invention relates to a high-strength, highly wear-resistant, and highly contact-fatigue-resistant steel rail and a production method thereof, and belongs to the field of black steel manufacturing technology. The present invention provides a high-strength and highly fatigue-resistant steel rail, comprising the following chemical components by weight percentage: C: 0.76%˜0.86%; Si: 0.6%˜1%; Mn: 0.7%˜1.5%, Cr: 0.1%˜0.5%, and 0.8%≦Mn %+Cr %≦1.6%; V: 0.05%˜0.3%, Ni: 0.1%˜0.35%, and 0.15%≦V %+Ni %≦0.4%; Mo: ≦0.03%; P: ≦0.02%; S: ≦0.015%; Fe and inevitable impurities: the remaining content, wherein, the metallurgical structure of the steel rail is fine pearlite+A, where, A is proeutectoid ferrite or proeutectoid cementite, and A≦2%. The tensile strength of the obtained steel rail is 1,260 MPa˜1,420 MPa.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Steel rail with surface decarburized layer smaller than 0.3mm and manufacturing method of steel rail

ActiveCN104233073AExtended service lifeHigh hardnessWork treatment devicesFurnace typesFurnace temperatureChemical composition

The invention provides a steel rail with a surface decarburized layer smaller than 0.3mm and a manufacturing method of the steel rail. The steel rail comprises the following chemical components in percentage by weight: 0.60-0.66% of C, 0.10-0.30% of Si, 0.8-1.2% of Mn, 0.2-0.5% of Cr, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.0002% of hydrogen, less than or equal to 0.0020% of oxygen and the balance of Fe and unavoidable impurities. The manufacturing method comprises the steps of smelting and continuously casting; refining, and carrying out vacuum treatment by using VD for longer than 25min, wherein the content of hydrogen is lower than 2.0PPm; and carrying out blank casting treatment, namely carrying out hot delivery and hot charging, wherein the blank casting temperature is higher than 760 DEG C, a heating zone in a heating furnace is at a weak-oxidative atmosphere, the furnace temperature at the heating zone is 1250-1320 DEG C, the air coefficient at the heating zone is 1.0-1.20, a soaking zone is at a reducing atmosphere, the furnace temperature at the soaking zone is 1150-1250 DEG C, and the air coefficient at the soaking zone is 0.80-1.00. The surface decarburized layer of the steel rail is smaller than 0.3mm, so that the polishing quantity of an upper rail of a high-speed rail can be reduced; and the structure of the surface layer of the steel rail is refined, so that the hardness of the surface layer can be favorably improved, the surface contact fatigue injury of the steel rail can be reduced, and the service life of the steel rail can be prolonged.

Owner:ANGANG STEEL CO LTD

Forging method of bearing ring

ActiveCN102756070AFine and evenly distributedImprove contact fatigue lifeEngine componentsTO-18Heating time

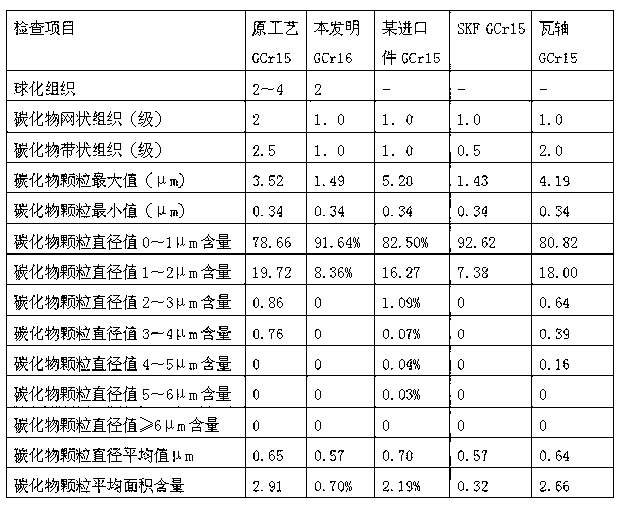

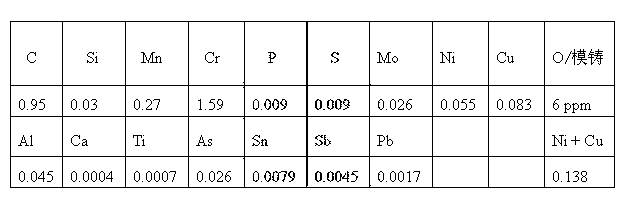

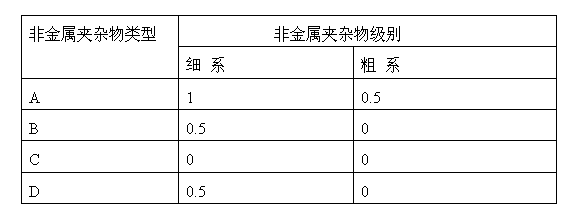

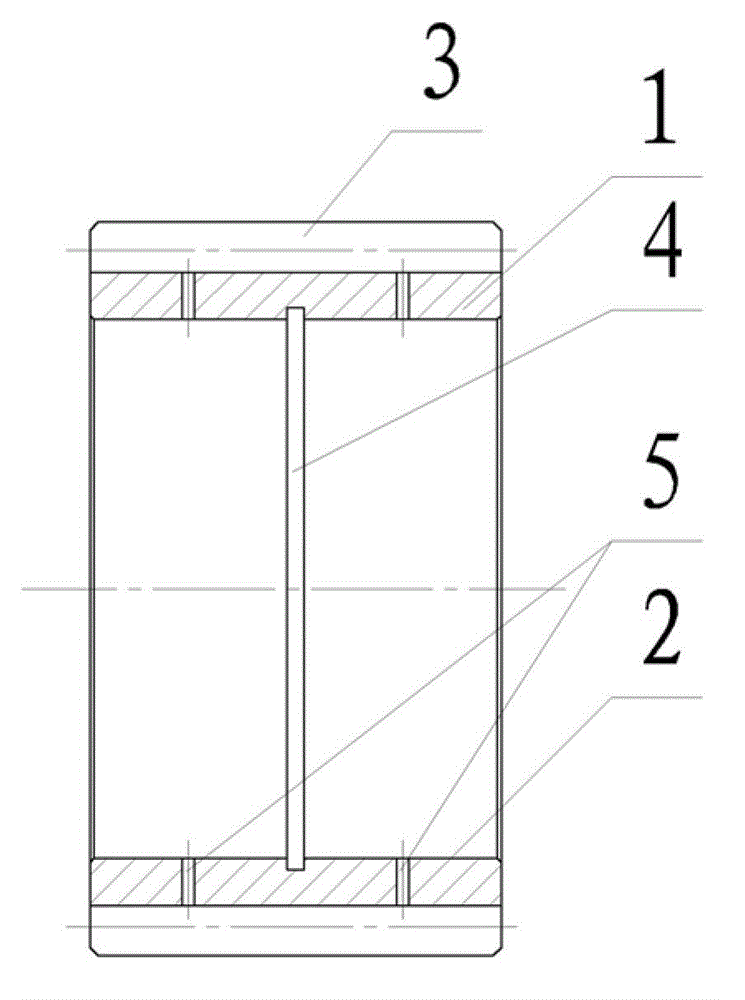

The invention relates to a forging method of a bearing ring. The forging method is characterized by comprising the following steps of heating, raising the temperature, preserving the temperature, forging, quickly cooling and naturally cooling, wherein in the heating step, a bearing ring blank is heated from common temperature to the temperature of 900 DEG C; in the temperature raising step, the temperature of the bearing ring blank is raised from 900 DEG C to 1150 DEG C; in the temperature preserving step, the temperature of the bearing sleeve blank is preserved for 0.5 to 1 hour at 1150 DEG C; and in forging step, the bearing ring forged is at 930 to 980 DEG C; and in the quickly cooling step, the forged bearing ring is dipped into a cooling medium for being quickly cooled to reach 700 DEG C. According to the forging method, the cooling medium is water; the quick cooling is carried out for 7 to 18 seconds; the heating is carried out for 4 to 7 seconds; and the temperature raising time is 2 to 3 seconds; and the forging is carried out for 4 to 7 seconds. With the adoption of the forging method, spherical, small and uniformly distributed quenching structures of carbide can be obtained, and the dimension of carbide particle is not greater than 5 um to the maximum, thus reaching the value below the critical value of cracking initiated by amorphous impurity; and the contact fatigue life of a bearing is prolonged.

Owner:DEQING TIANMA BEARING CO LTD

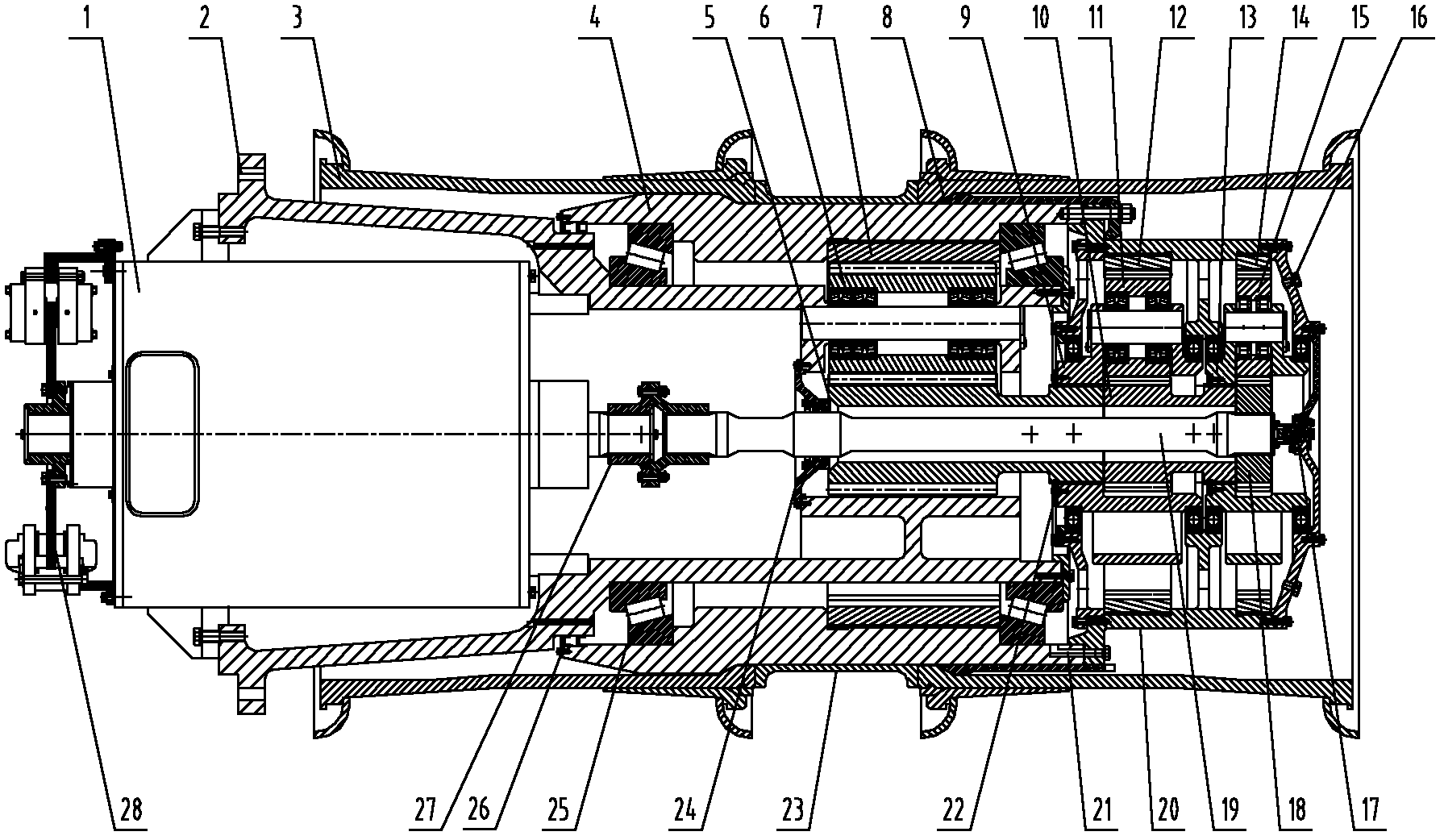

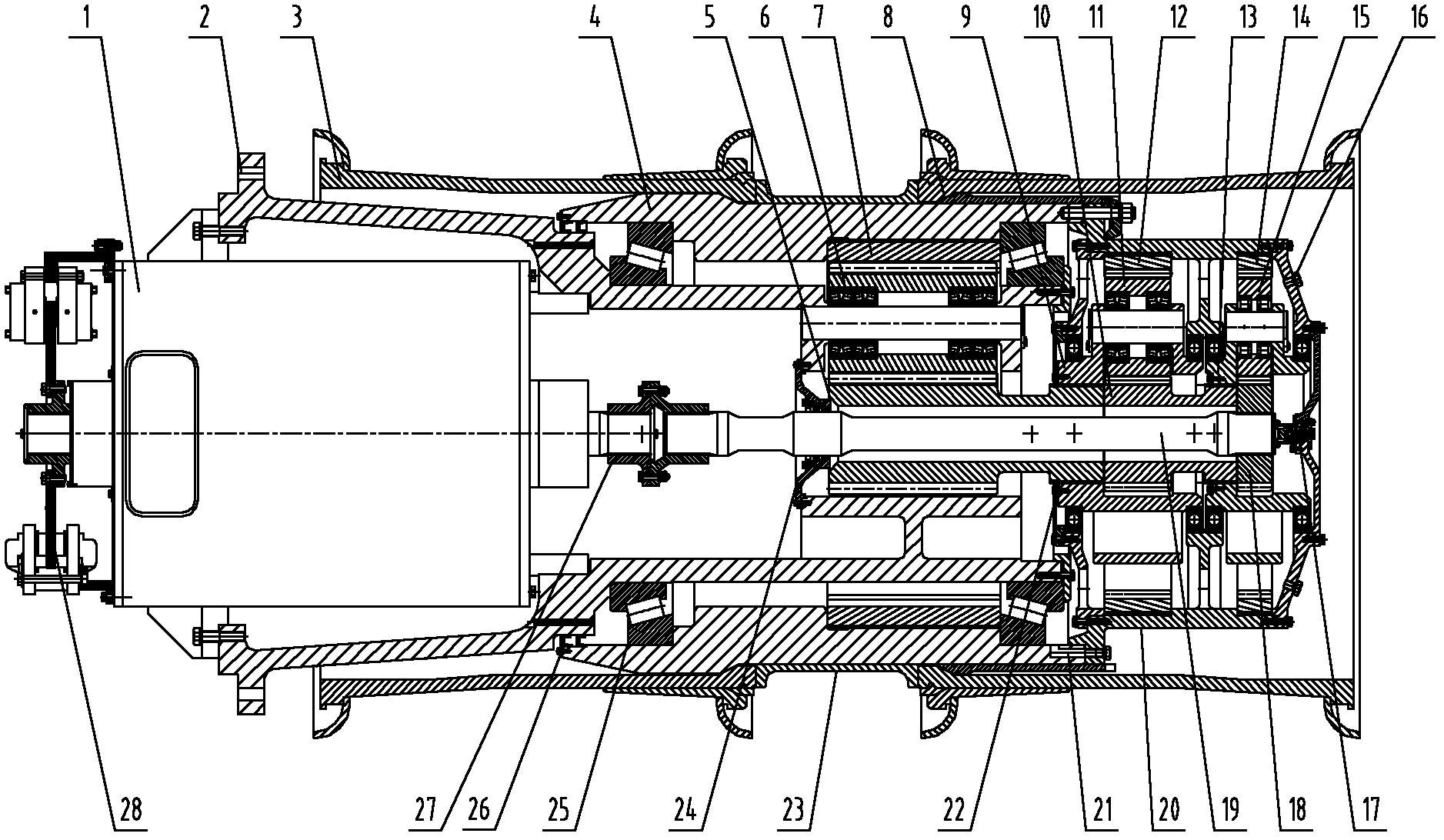

Mine vehicle axle wheel reductor planetary gear and manufacture method thereof

ActiveCN102979884AGood contact fatigue strengthImprove reliabilityPortable liftingGear lubrication/coolingGear wheelReduction drive

The invention relates to a mine vehicle axle wheel reductor planetary gear and a manufacture method thereof. The manufacture method comprises the following processing steps of: (1) forging to obtain a gear ring; (2) roughly turning; (3) carrying out preheat treatment; (4) finely turning; (5) carrying out ultrasonic flaw detection; (6) hobbing; (7) boring a plurality of oilholes in the wall of a planet wheel inner hole in the middle of the gear ring along the radial direction of the planet wheel inner hole; (8) carburizing for heat treatment; (9) performing plain grinding on two end faces of the gear ring to the required size and then grinding the planet wheel inner hole of the gear ring to the required size; (10) grinding the gear; (11) carrying out magnetic powder inspection; (12) strengthening shot peening at gear root; and (13) carrying out manganese phosphating. The planetary gear produced by adopting the manufacture method, disclosed by the invention has the advantages that the contact fatigue strength is better, the reliability is greatly enhanced and the service life is greatly prolonged; and according to the manufacture method provided by the invention, shot peening strengthening is adopted in processing the gear root, and the stress state of the gear root is changed, so that the gear root bending strength of the planetary gear is remarkably enhanced, the strength of the planetary gear is enhanced and the service life of the planetary gear is prolonged.

Owner:WUXI WEIFU CHINA ITAL GEAR

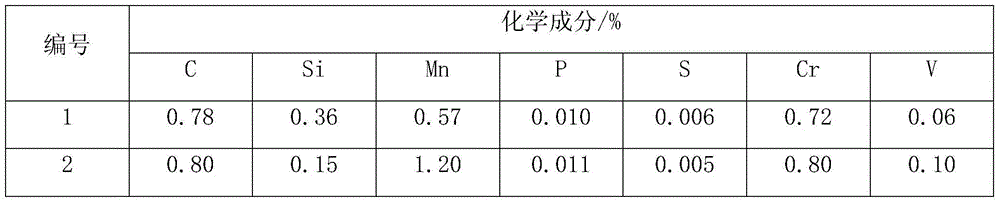

Vanadium-chromium micro-alloyed superfine pearlite steel rail

The invention relates to a steel rail, and in particular relates to a vanadium-chromium micro-alloyed superfine pearlite steel rail. The technical problem to be solved by the invention is to provide the vanadium-chromium micro-alloyed superfine pearlite steel rail. The vanadium-chromium micro-alloyed superfine pearlite steel rail comprises the following components in percentage by weight: 0.78-0.86% of C, 0.15-0.70% of Si, 0.4-1.20% of Mn, 0.3-0.8% of Cr, 0.04-0.12% of V and less than or equal to 0.01% of S. A production method of the vanadium-chromium micro-alloyed superfine pearlite steel rail comprises the following steps: applying a water-mist gas mixture to the rail head part of the steel rail with waste heat after finishing rolling, wherein the cooling rate is 4-8DEG C / s; applying compressed air when the surface layer temperature of the rail head is reduced to 500-550 DEG C at a cooling rate of 1.5-3.5DEG C / s; and performing air cooling to room temperature when the temperature is less than 400 DEG C. The steel rail disclosed by the invention has excellent wear-resistant performance and good contact fatigue resistance, and is suitable for road segments with too fast wear and prominent fatigue problems of heavy haul railways.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

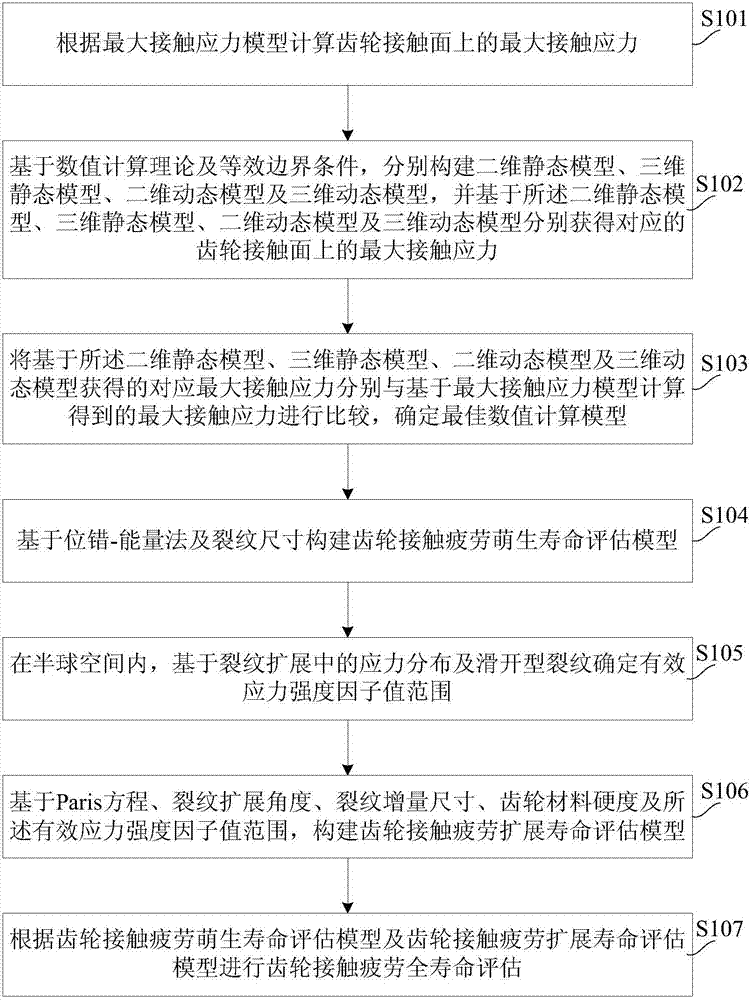

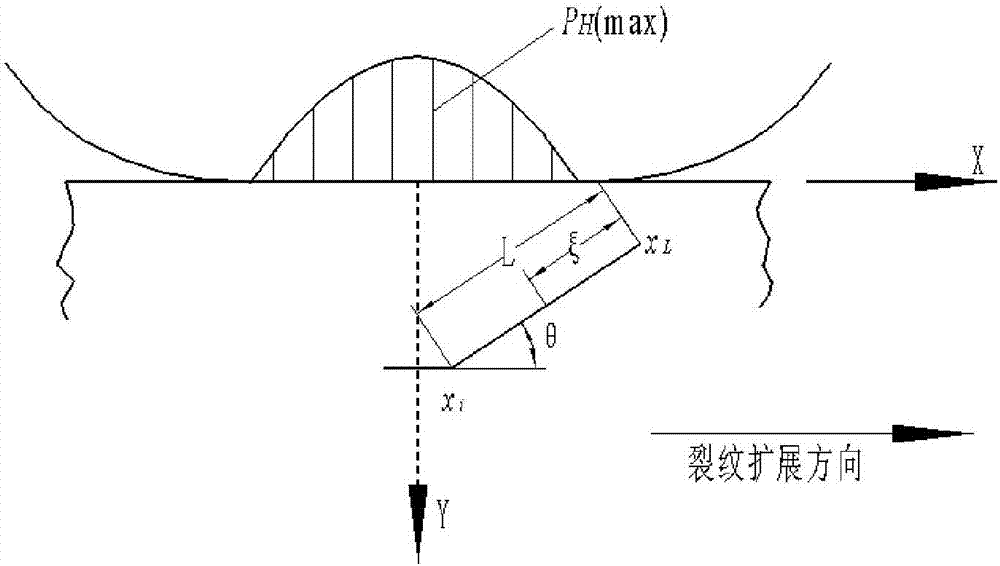

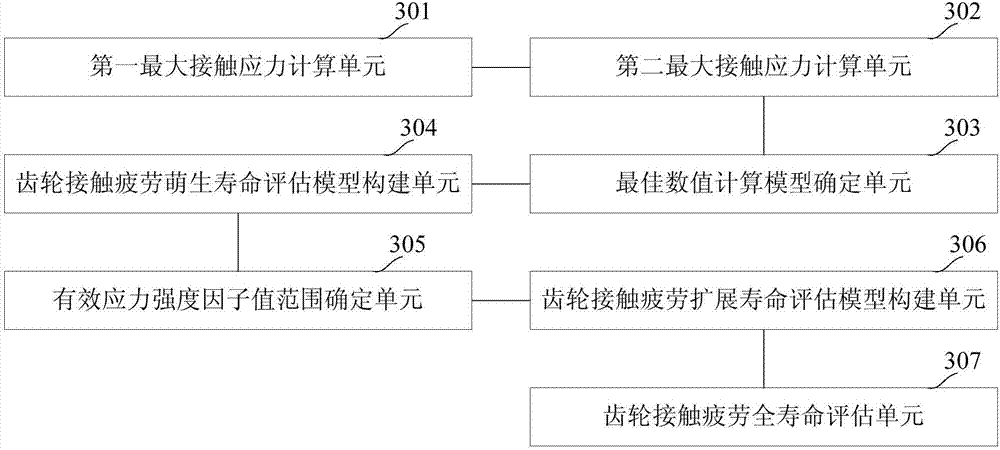

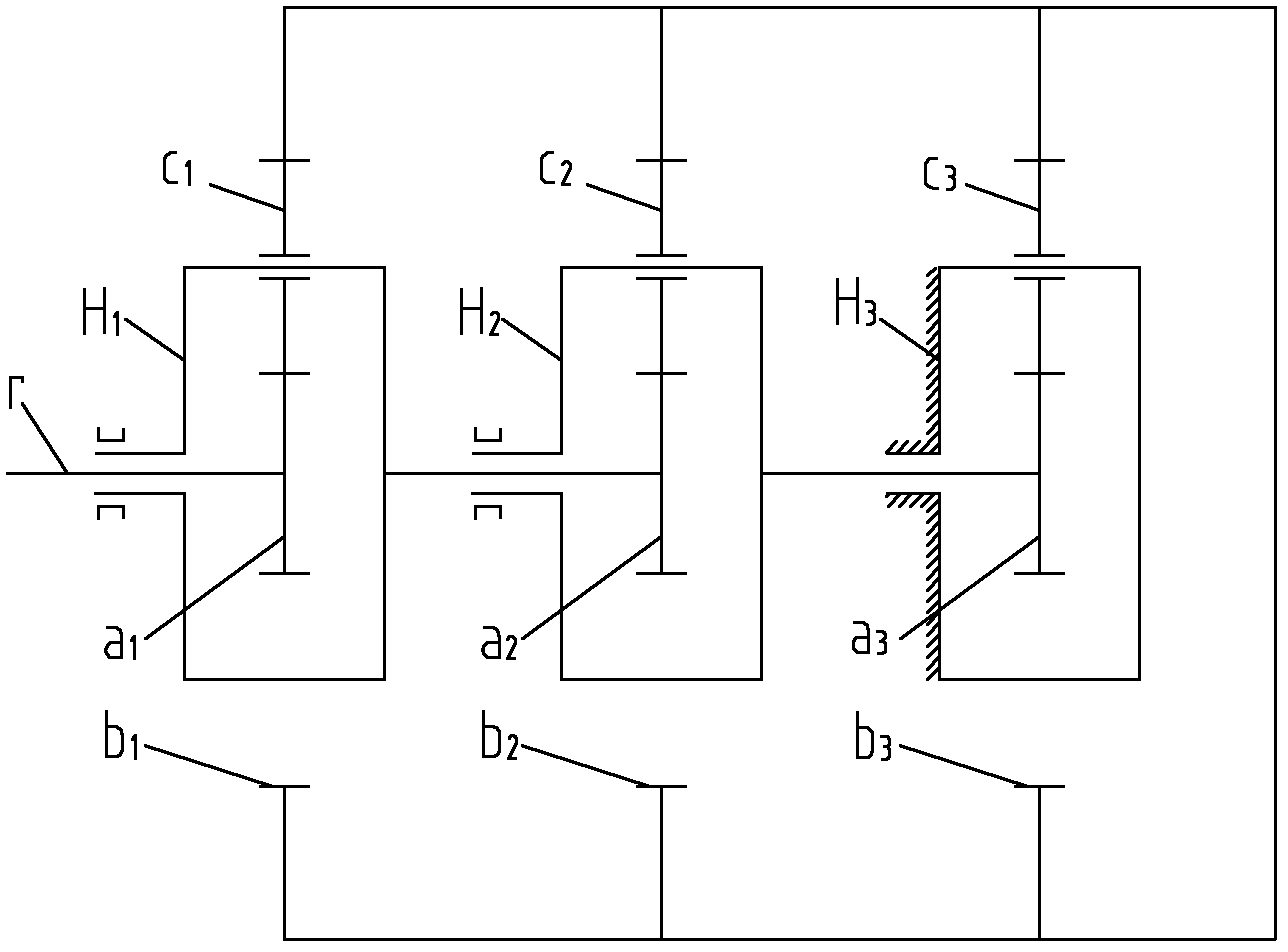

Evaluation method and device for full gear contact fatigue life

ActiveCN106979861AReduce dependenceMachine gearing/transmission testingDesign optimisation/simulationDynamic modelsEngineering

The invention provides an evaluation method and device for the full gear contact fatigue life based on crack producing and expanding. The method comprises that a maximal contact stress in a gear contact surface is calculated according to a maximal contact stress model; 2D static, 3D static, 2D dynamic and 3D dynamic models are constructed on the basis of a numerical calculation theory and an equivalent boundary condition, and maximal contact stress of corresponding gear contact surfaces are obtained on the basis of the models; the maximal contact stresses obtained on the basis of the four models are compared with the maximal contact stress obtained via the maximal contact stress model, and an optimal numerical calculation model is determined; a gear contact fatigue producing life evaluation model is constructed; the range of effective stress intensity factor values is determined; a gear contact fatigue expanding life evaluation model is constructed; and the full gear contact fatigue life is evaluated according to the gear contact fatigue producing life evaluation model and the gear contact fatigue expanding life evaluation model.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

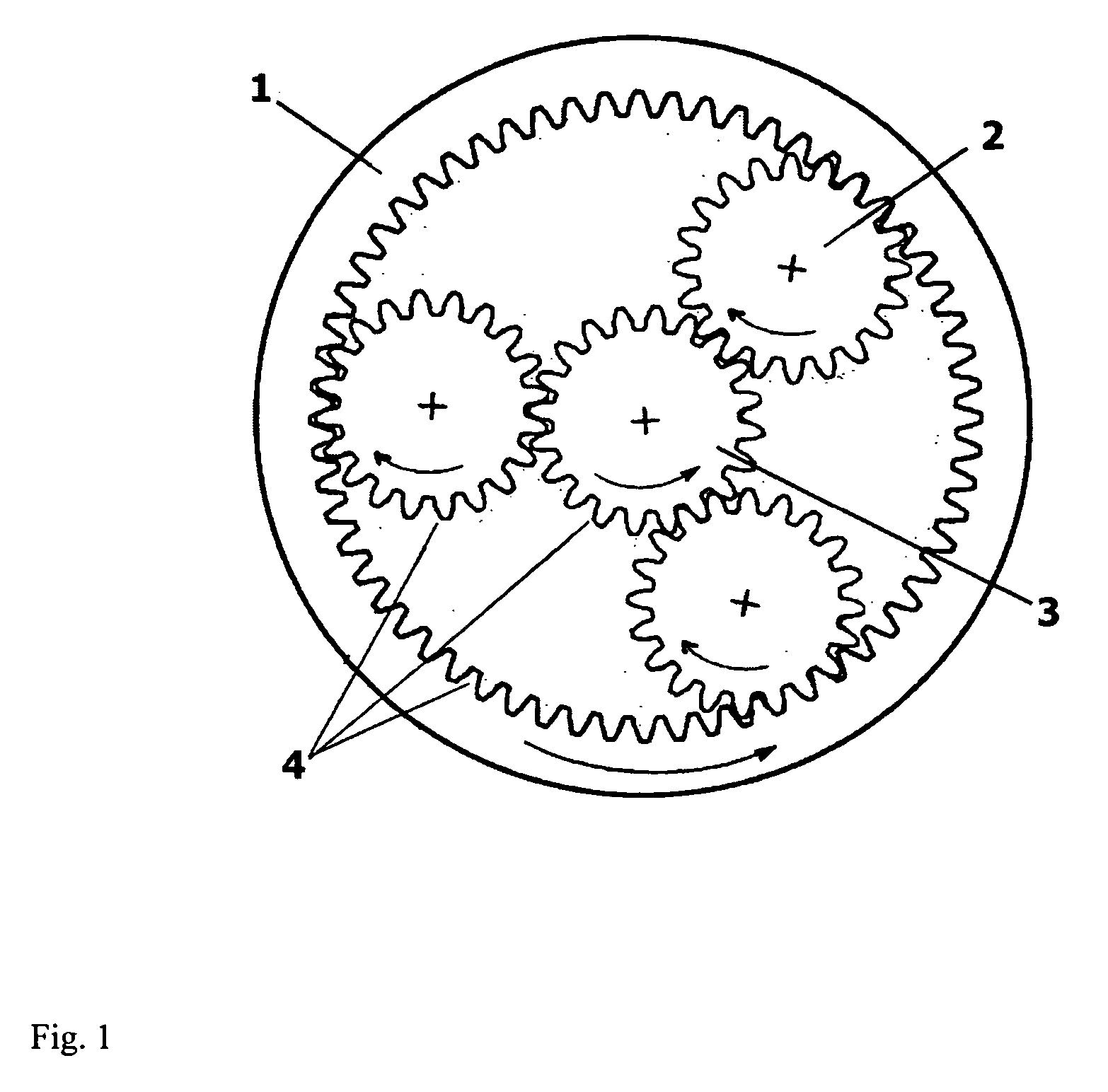

Hub reductor for mine electric drive heavy-duty car

The invention is suitable for the field of mechanical transmission devices, in particular to the field of transmission devices for large-tonnage mining dump trucks with electric wheels, and provides a hub reductor for a mine electric drive heavy-duty car. The hub reductor is characterized by adopting three stages of planetary reducing mechanisms; the first-stage and the second-stage planetary reducing mechanisms are differential gear trains; the third-stage planetary reducing mechanism is an ordinary gear train; in first-stage transmission and second-stage transmission, sun gears are power input components, and planet carriers and gear rings are power output components; and in third-stage transmission, a sun gear is a power input component, a planet carrier is fixed, and a gear ring is a power output component. The invention has the benefits that the transmission ratio changes within a large range, so as to transmit even larger torque; one more stage of planetary reducing mechanism is adopted for providing driving torque required by driving the heavy duty car, so that the bending fatigue stress and the contact fatigue stress of a last stage gear are reduced, which ensures higher safety factor; and the axial space utilization rate of the whole hub reductor is improved while the radial space is fully used, so that the integral radiating area is enlarged to achieve integral thermal balance better.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com