Thermal treatment method for high-carbon steel train wheel circular rim surface and heat treatment apparatus

A heat treatment method and high-carbon steel technology, applied in quenching devices, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of increased hardness of the surface of the tread surface, reduce the service life of the wheel, and affect the service life of the wheel, so as to improve the anti-contact fatigue performance , reduce the contact stress level and reduce the effect of tread peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

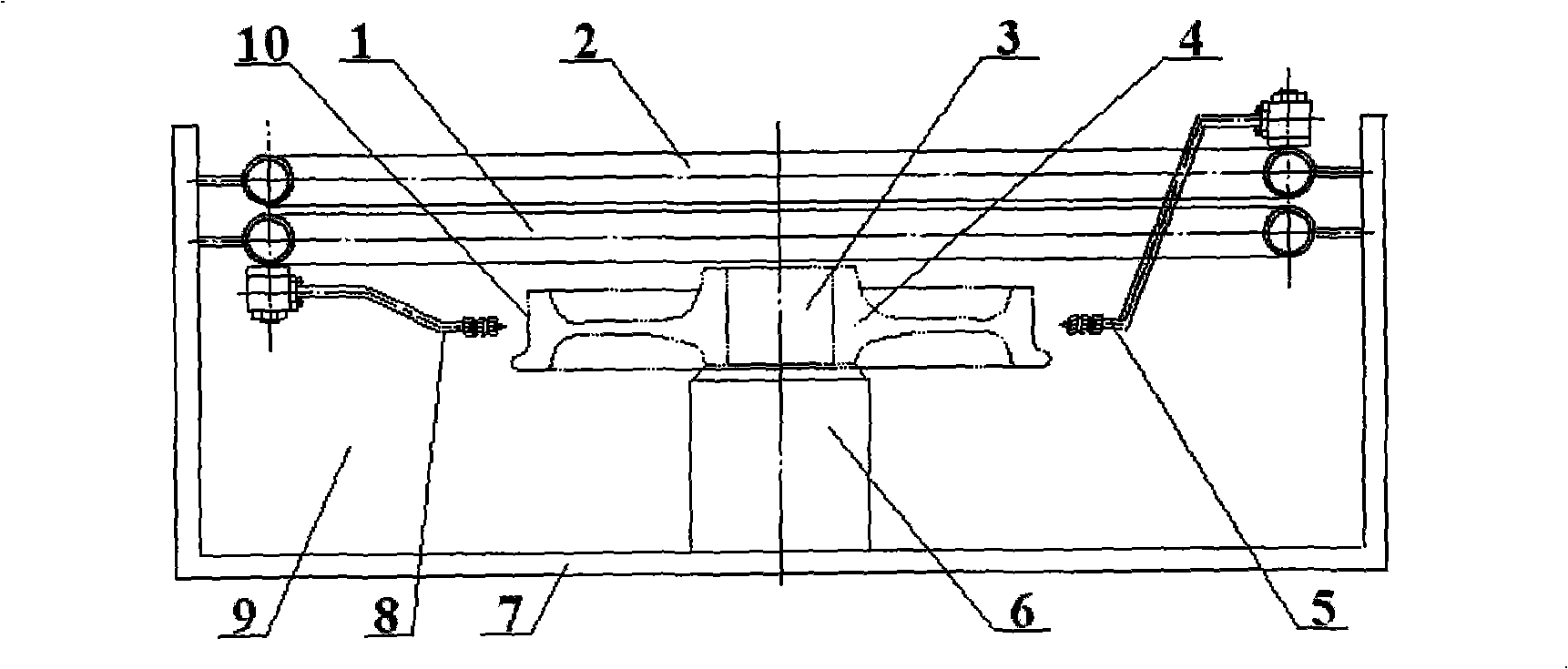

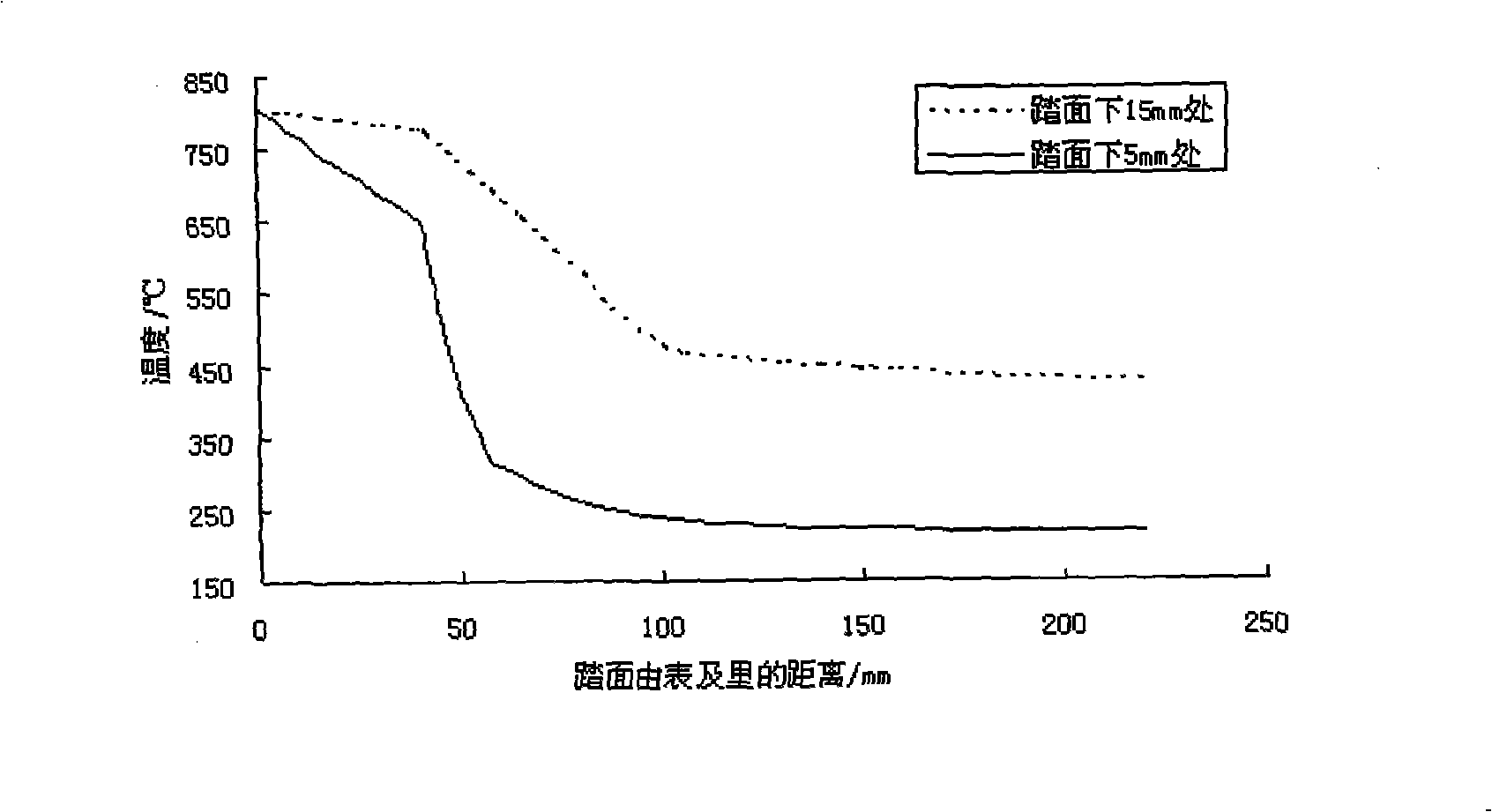

[0052] When the train wheel 4 is heated as a whole, the rim of the train wheel 4 is kept in a high temperature state in the austenite region; the wheel tread 10 is sprayed and cooled for a short time with a small flow of water, so that the wheel tread 10 is lowered by 10mm The temperature in the wheel rim drops to a certain temperature range below A1; the wheel tread 10 is forced to spray water for a long time to cool the wheel tread 10 with a large flow rate, so that the metal inside the wheel rim is accelerated and fully cooled.

Embodiment 2

[0054] Different nozzles are used for spraying water with different flow rates.

[0055] If the same nozzle is used, different flow rates cannot meet the required injection requirements. If a small nozzle is used, the flow rate cannot be satisfied when the flow rate is large; if a large nozzle is used, the injection pressure and range cannot meet the requirements when the flow rate is small.

Embodiment 3

[0057] The technological process of the heat treatment method of train wheel 4 of the present invention is:

[0058] First the train wheel 4 is placed in the horizontal quenching table 9;

[0059] When heating, the rim heating temperature of the train wheel 4 is 800°C to 810°C;

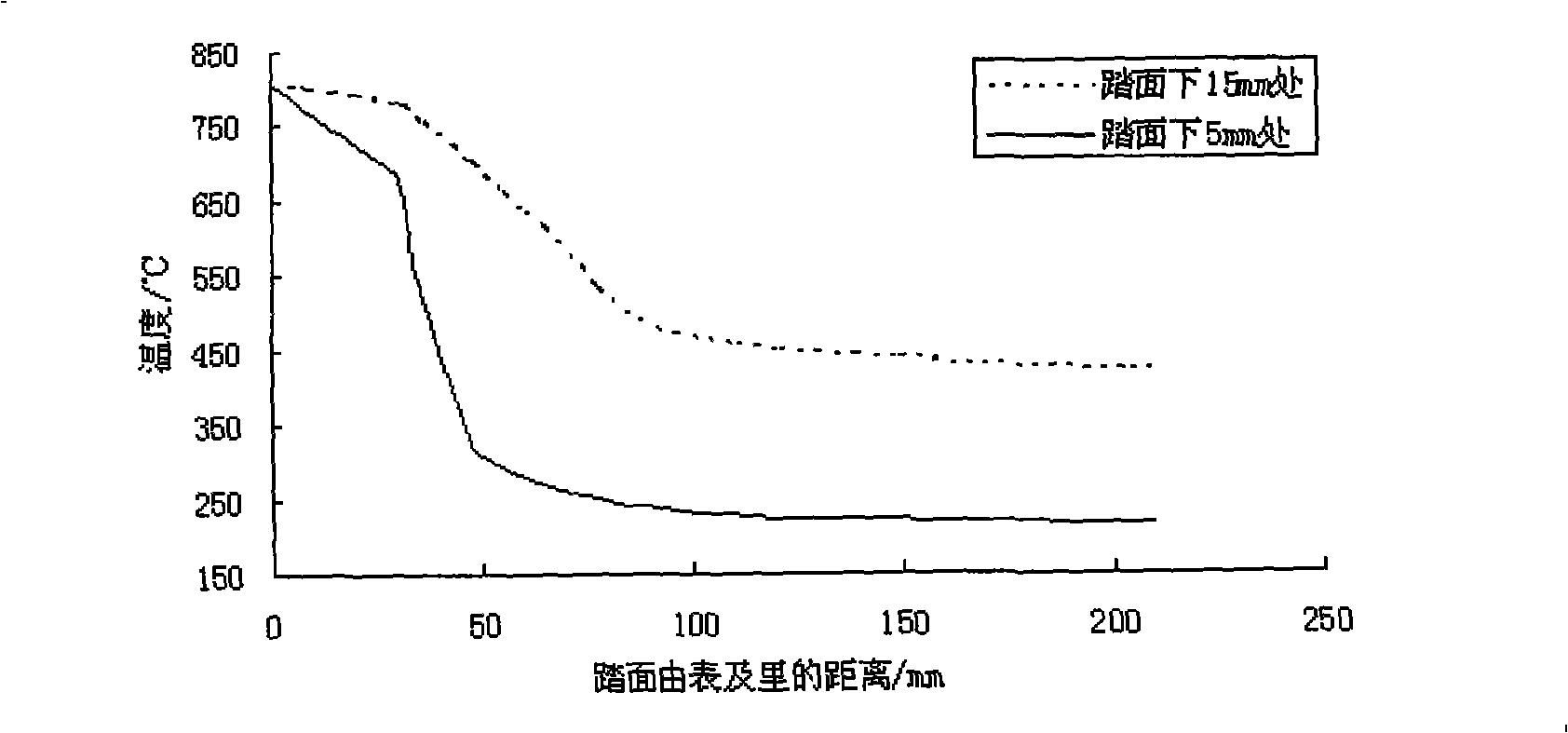

[0060] Then with a group of small flow nozzles 5 arranged around the wheel tread 10, water is sprayed to the rotating wheel tread 10, and the cooling time is controlled by spraying water for a short time, so that the temperature at 5mm below the wheel tread 10 is reduced to 650°C-690°C. ℃ temperature range, at this time, a layer of reticular ferrite-pearlite structure is formed on the surface layer of the wheel tread 10;

[0061] At the same time, control the cooling time so that the temperature inside the rim of the wheel and within the range of 10 mm to 45 mm below the tread surface of the wheel still exceeds Ac3, and the tissue transformation has not yet occurred;

[0062] Switch nozzles, and use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com