Patents

Literature

9484results about How to "Reduce the difficulty of operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

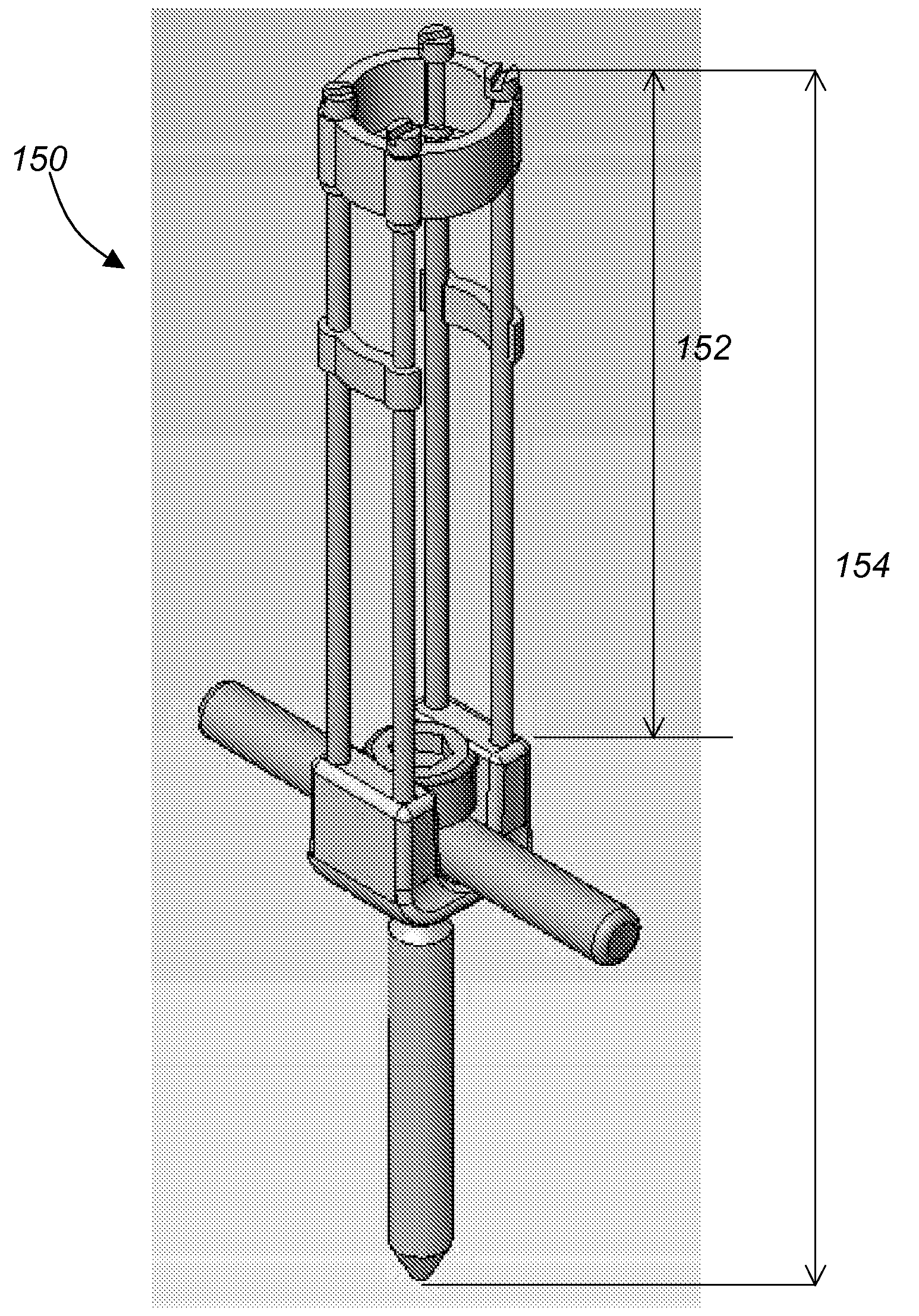

Methods and devices for improving percutaneous access in minimally invasive surgeries

ActiveUS20050065517A1Reduce the difficulty of operationReduce riskInternal osteosythesisCannulasLess invasive surgeryPost operative

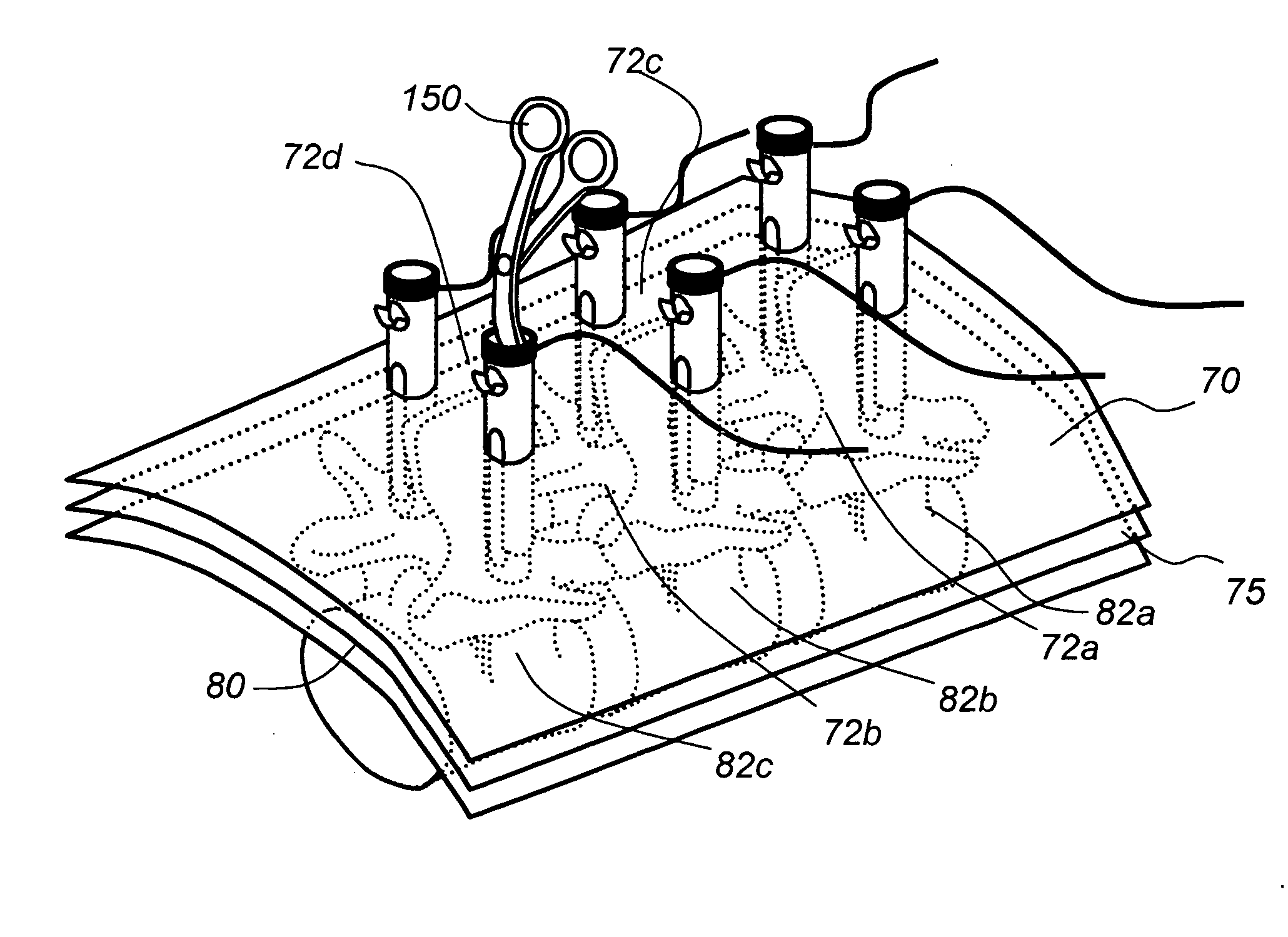

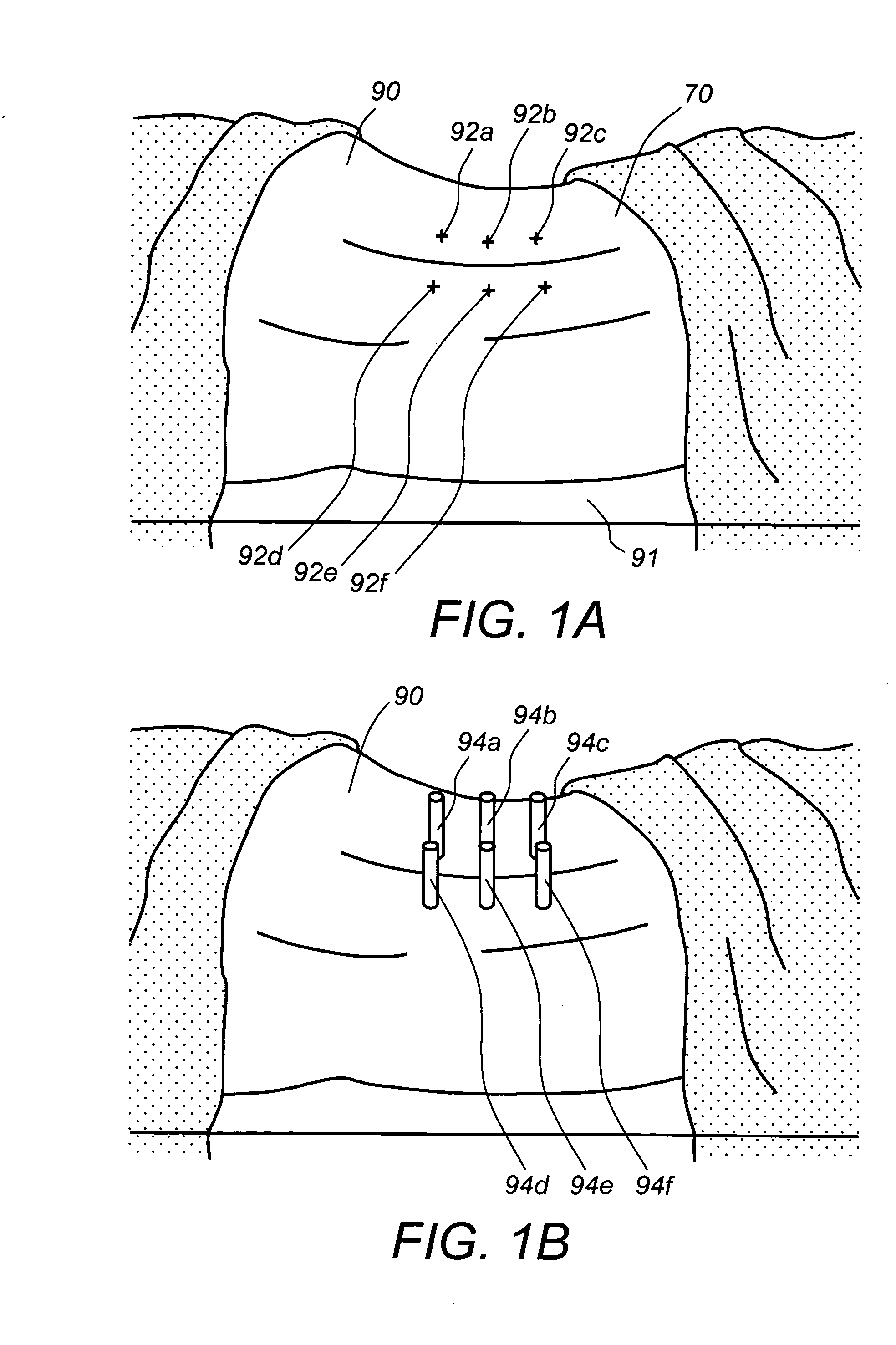

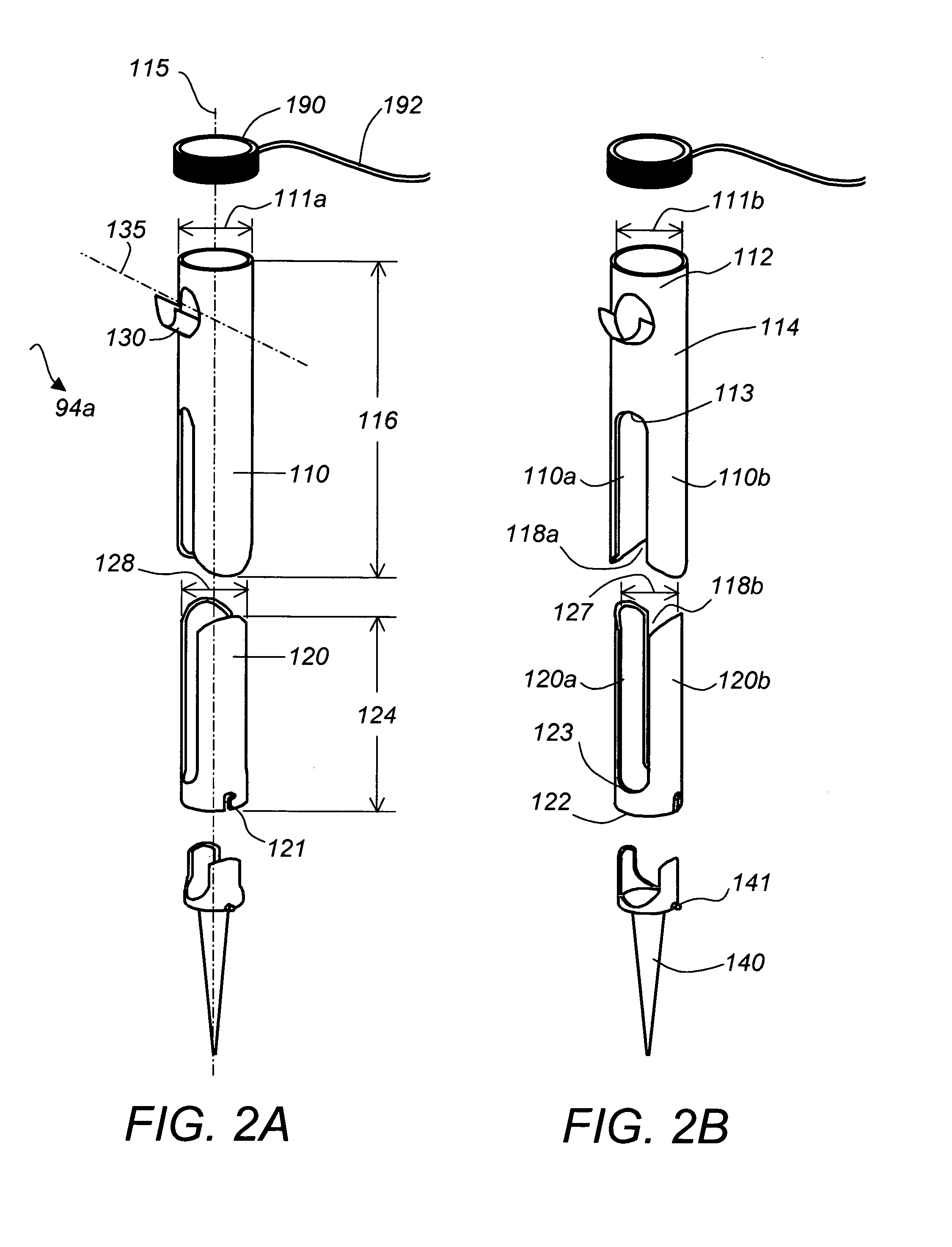

A device for use as a portal in percutaneous minimally invasive surgery performed within a patient's body cavity includes a first elongated hollow tube having a length adjusted with a self-contained mechanism. The first elongated tube includes an inner hollow tube and an outer hollow tube and the inner tube is adapted to slide within the outer tube thereby providing the self-contained length adjusting mechanism. This length-adjustment feature is advantageous for percutaneous access surgery in any body cavity. Two or more elongated tubes with adjustable lengths can be placed into two or more adjacent body cavities, respectively. Paths are opened within the tissue areas between the two or more body cavities, and are used to transfer devices and tools between the adjacent body cavities. This system of two or more elongated tubes with adjustable lengths is particularly advantageous in percutaneous minimally invasive spinal surgeries, and provides the benefits of minimizing long incisions, recovery time and post-operative complications.

Owner:STRYKER EURO OPERATIONS HLDG LLC

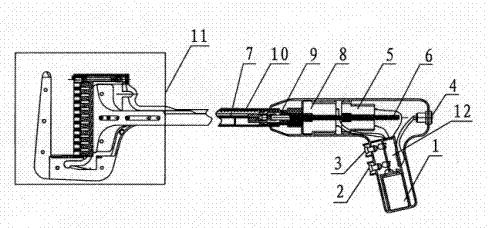

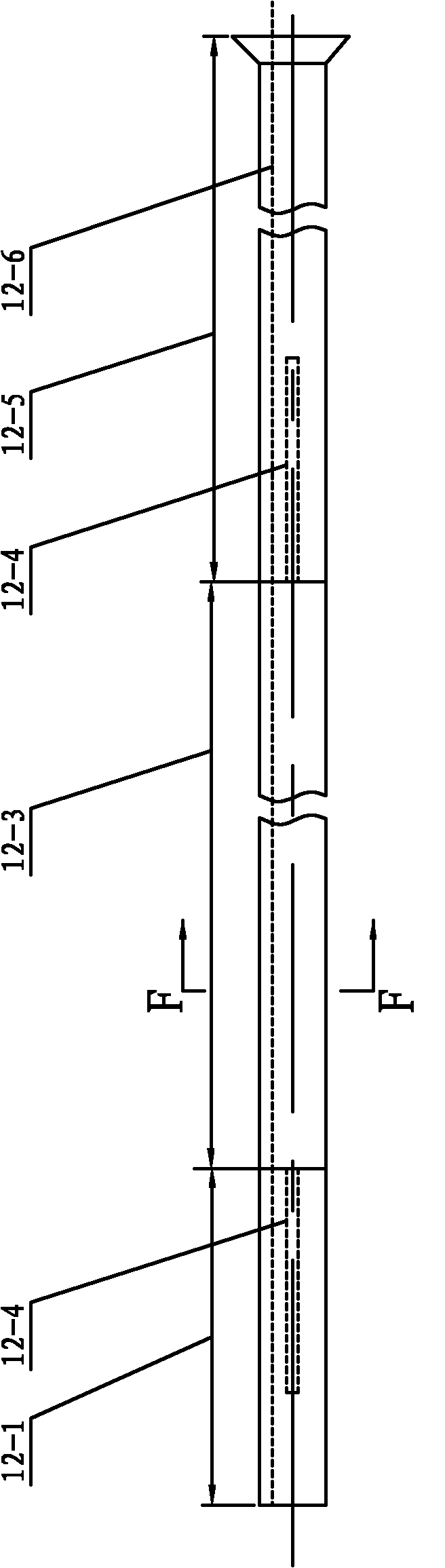

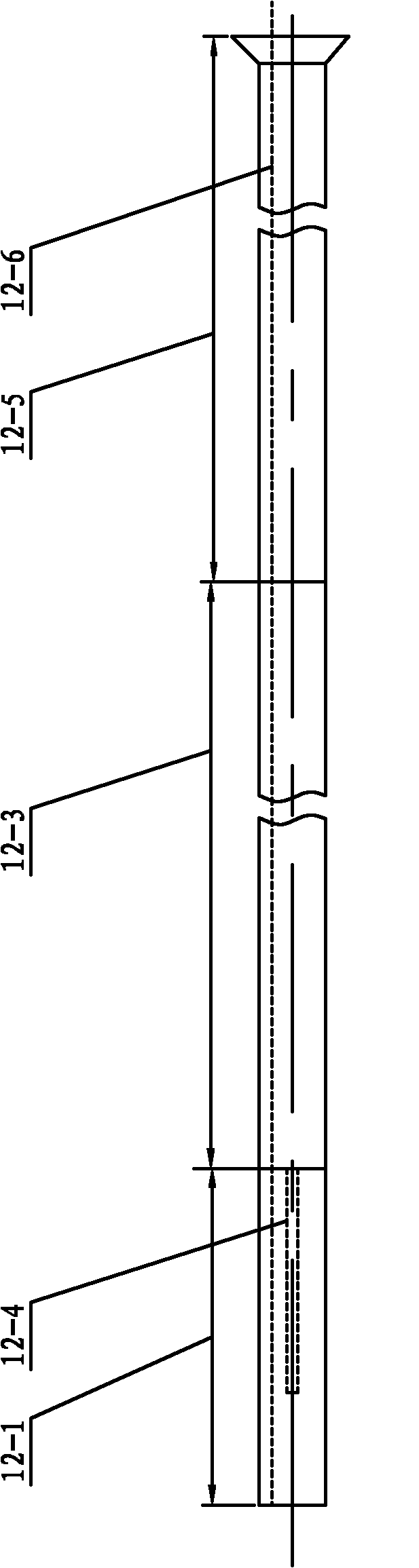

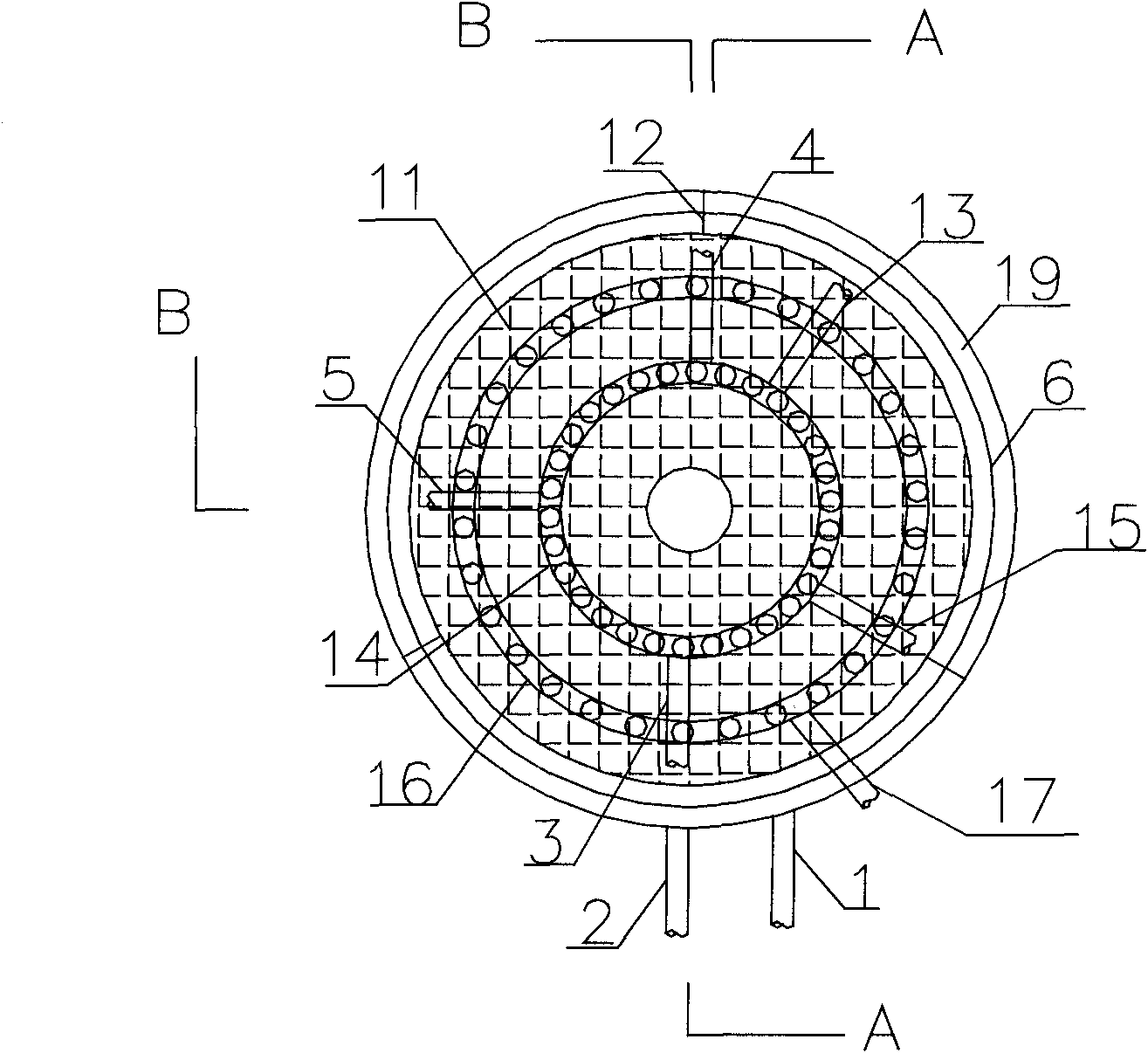

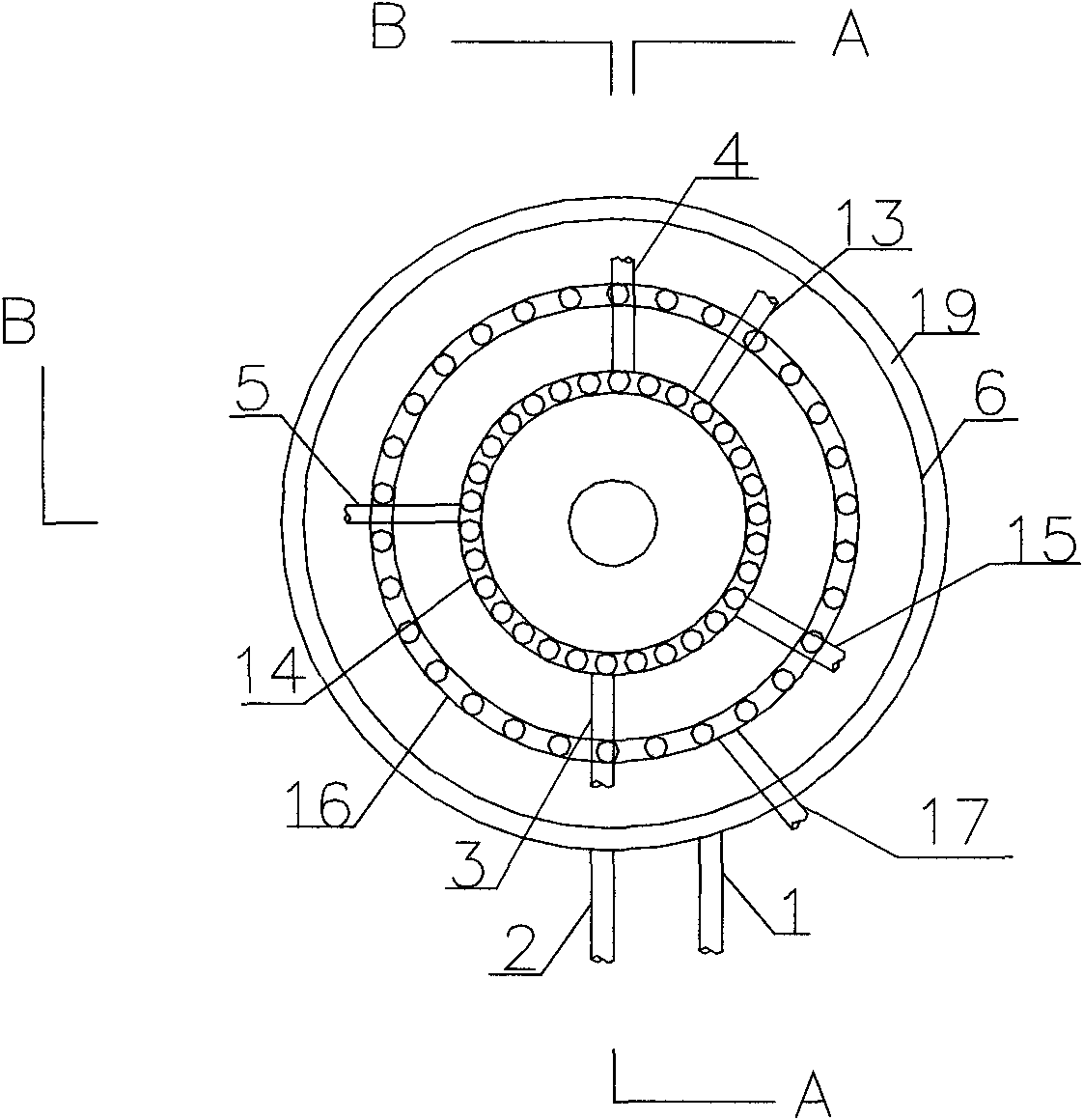

Electric anastomat for surgical department

InactiveCN102247182ARealize automatic operationEasy to operateSurgical staplesElectric driveSurgical department

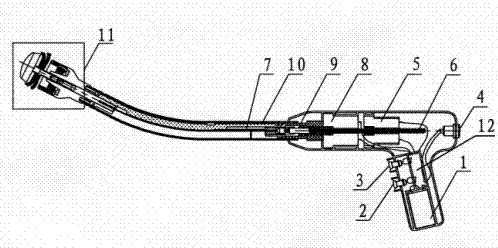

The invention discloses an electric anastomat for a surgical department, comprising an osculating part and a driving device for driving an execution mechanism, wherein the osculating part is provided with a nail supporting seat, a nail bin and the execution mechanism; the driving device is an electric driving device which comprises a power supply, a control panel, a closed driving unit and a percussion driving unit; the closed driving unit consists of a closed motor and a closed driving mechanism; the input end of the closed driving mechanism is connected with the closed motor; the output end of the closed driving mechanism is connected with the execution mechanism of the osculating part; the percussion driving unit consists of a percussion motor and a percussion driving mechanism; the input end of the percussion driving mechanism is connected with the percussion motor; the output end of the percussion driving mechanism is connected with the execution mechanism of the osculating part; the closed motor and the percussion motor are respectively connected with the control panel through leads; and the control panel is connected with the power supply through a lead. According to the electric anastomat disclosed by the invention, the quality of an operation can be improved, the operation difficulty of doctors is reduced and the automatic operation can be realized.

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

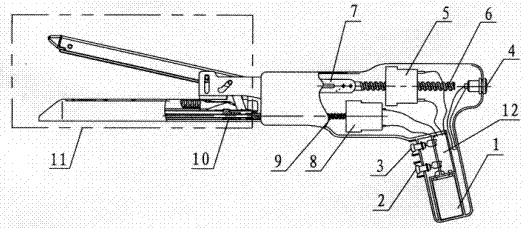

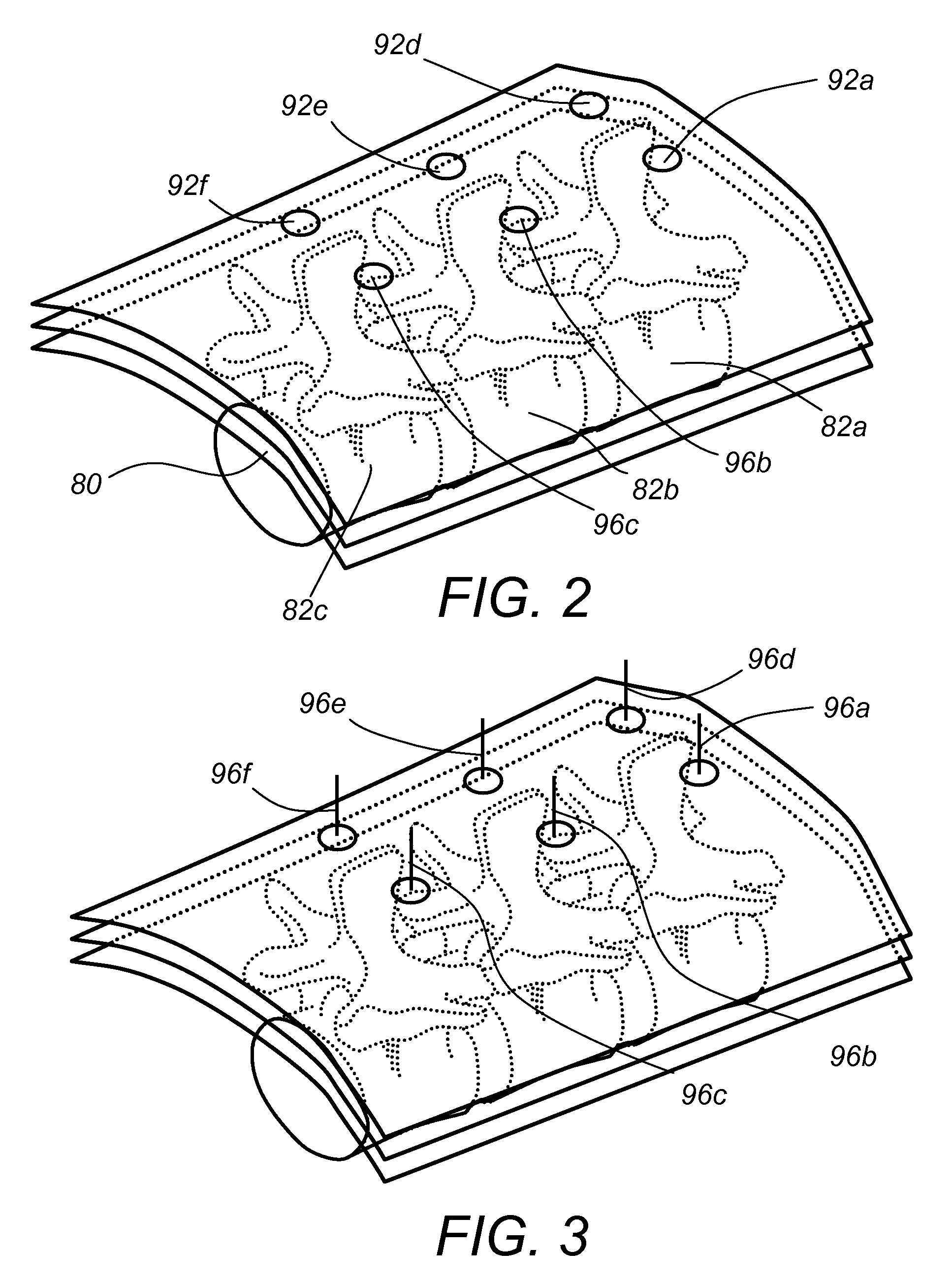

System and method for implanting spinal stabilization devices

InactiveUS20070073294A1Reduce difficulty of operationReduce riskInternal osteosythesisJoint implantsPedicle screwBiomedical engineering

A system and a method for providing minimally invasive access to the spine of a patient and implanting spinal stabilization devices. The system utilizes one or more post-type access devices. The post-type access device includes a cage with an aperture and two or more posts extending from the cage and being removably attached to the cage. The posts are supported at the top of the access device by a support ring structure. A pedicle screw is inserted into the access device and through the cage aperture and the screw-access device assembly is inserted into an opening of the patient's body. The base aperture is dimensioned to securely support the head of the screw. Side openings between the posts allow the insertion and placement of stabilization devices, such as rods, wires, or plates from almost any direction.

Owner:KIC VENTURES LLC

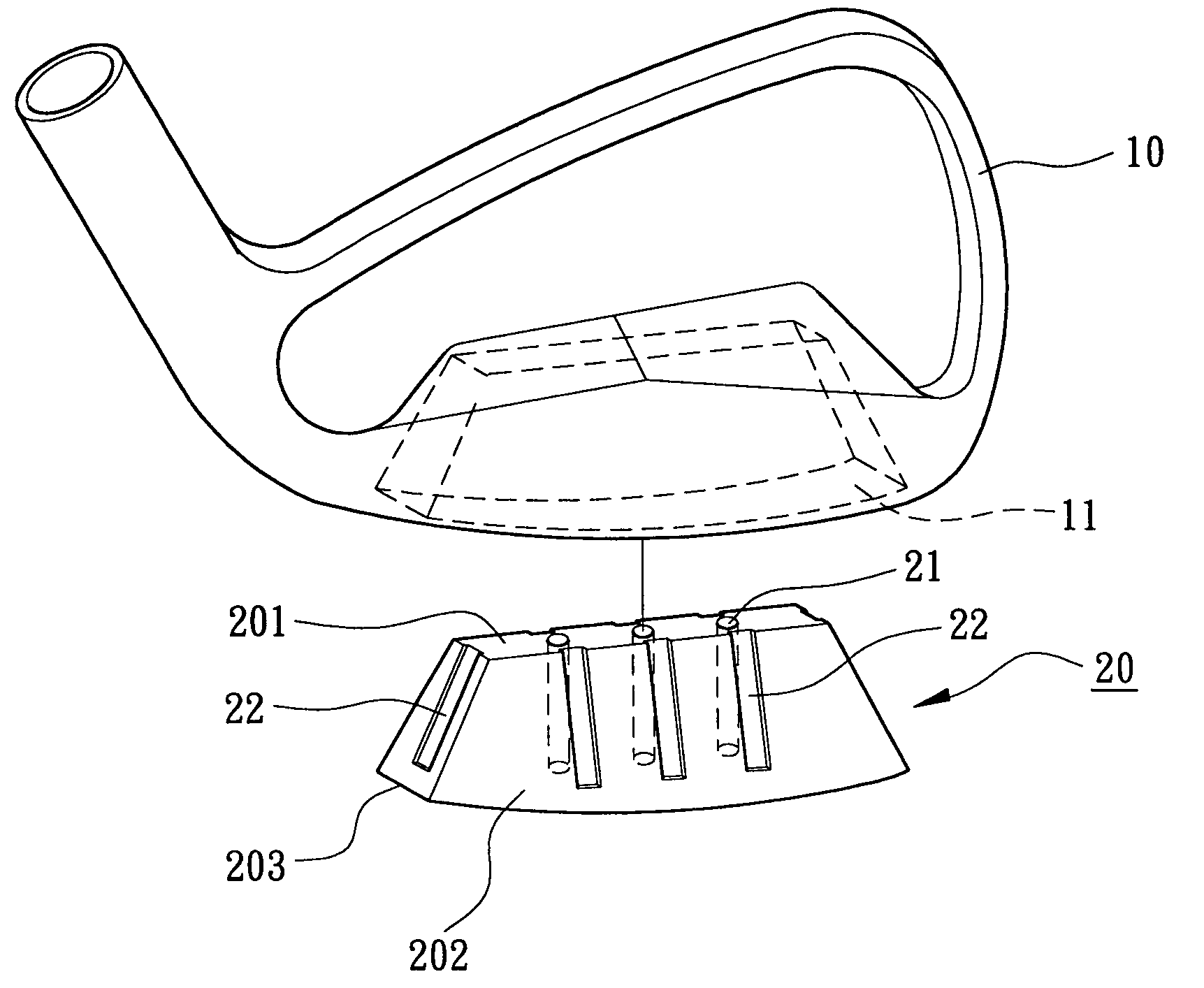

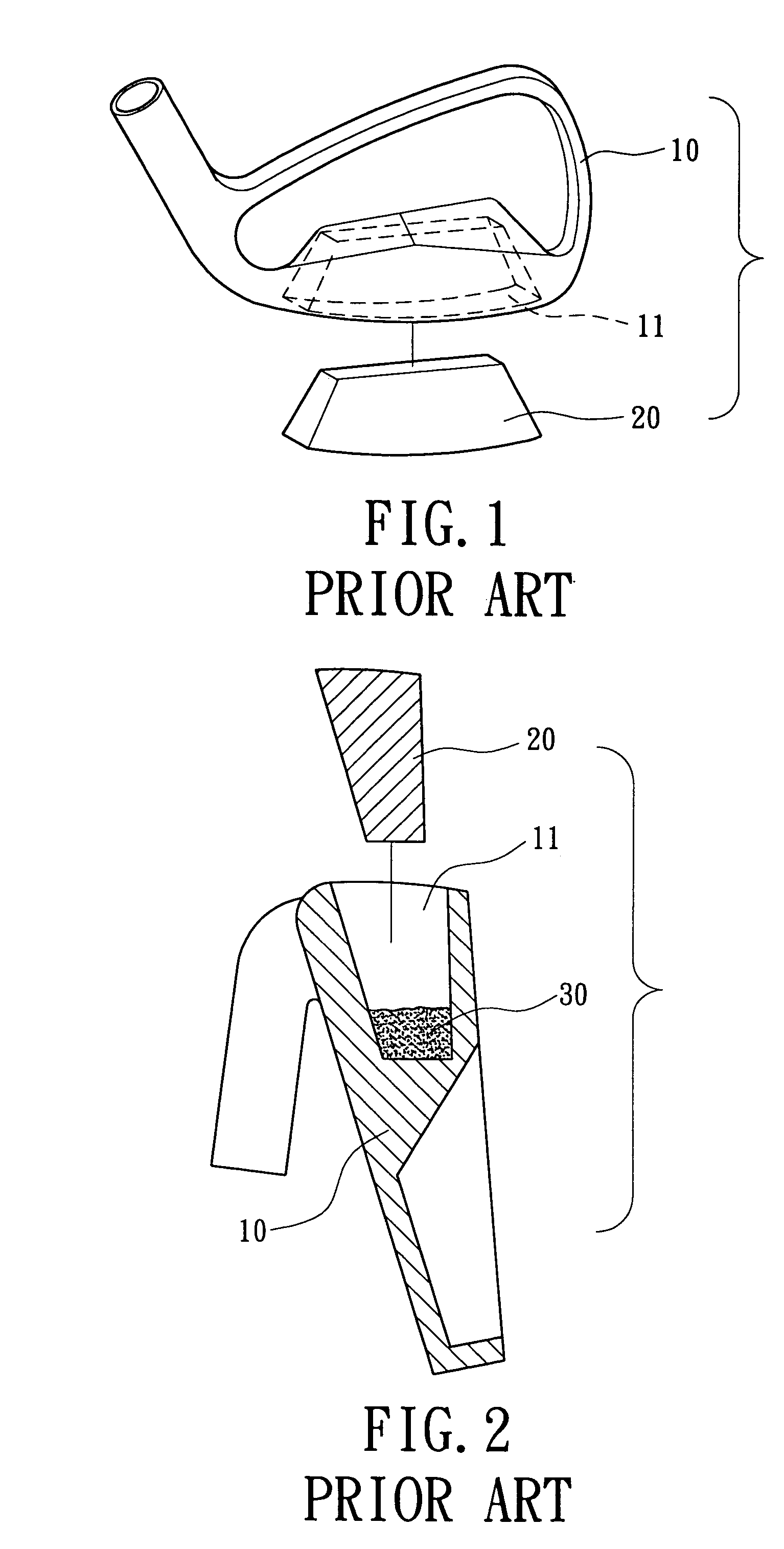

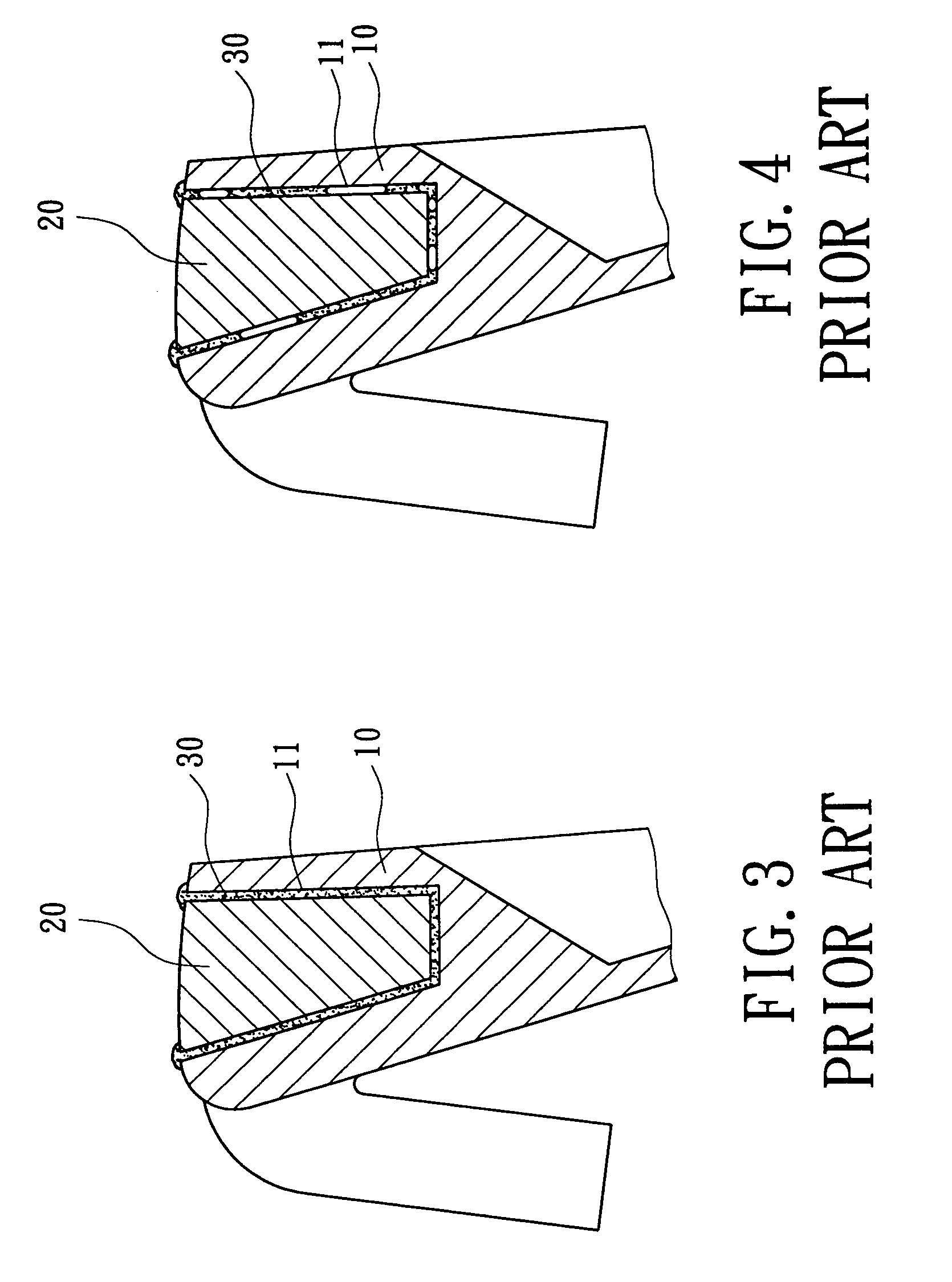

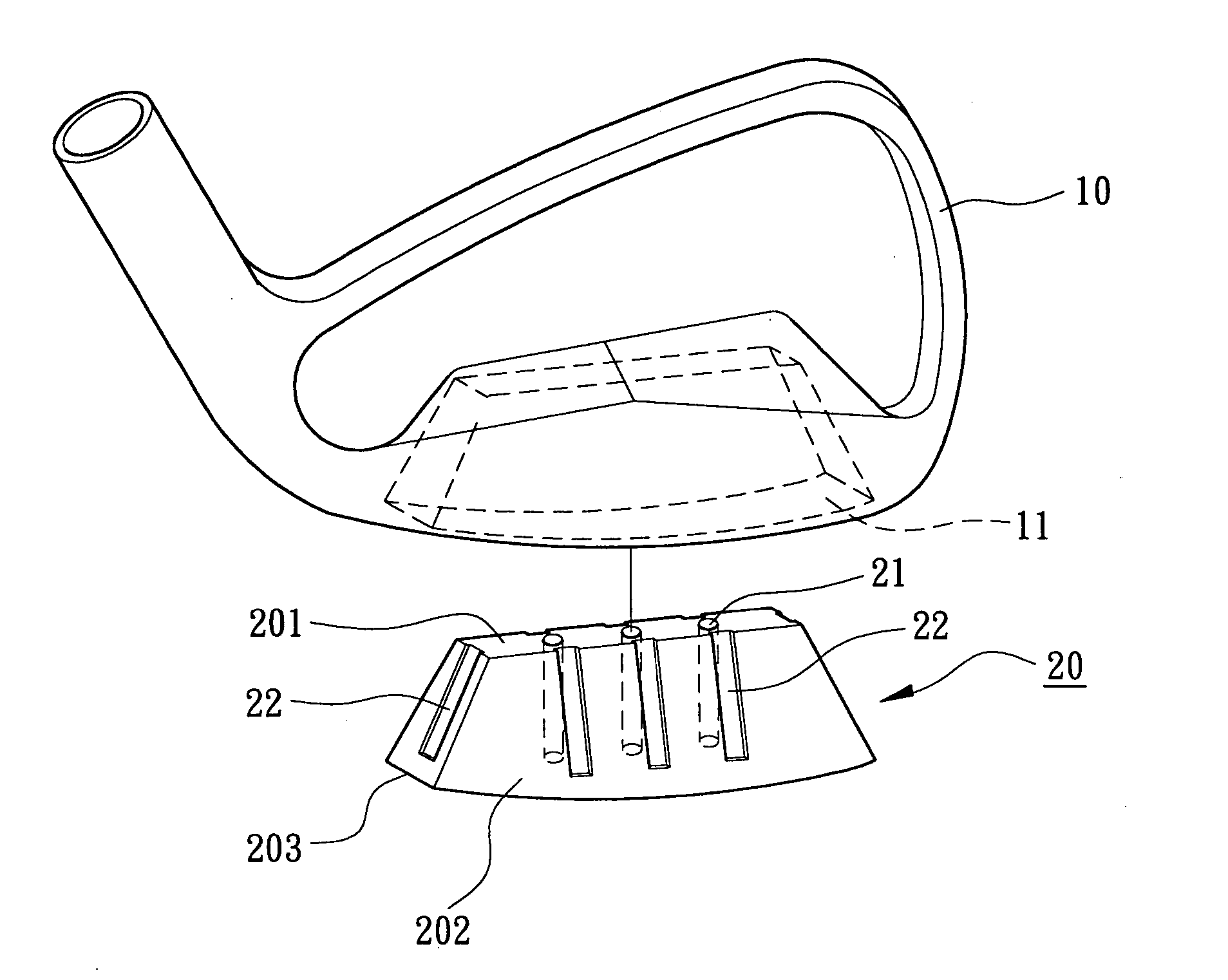

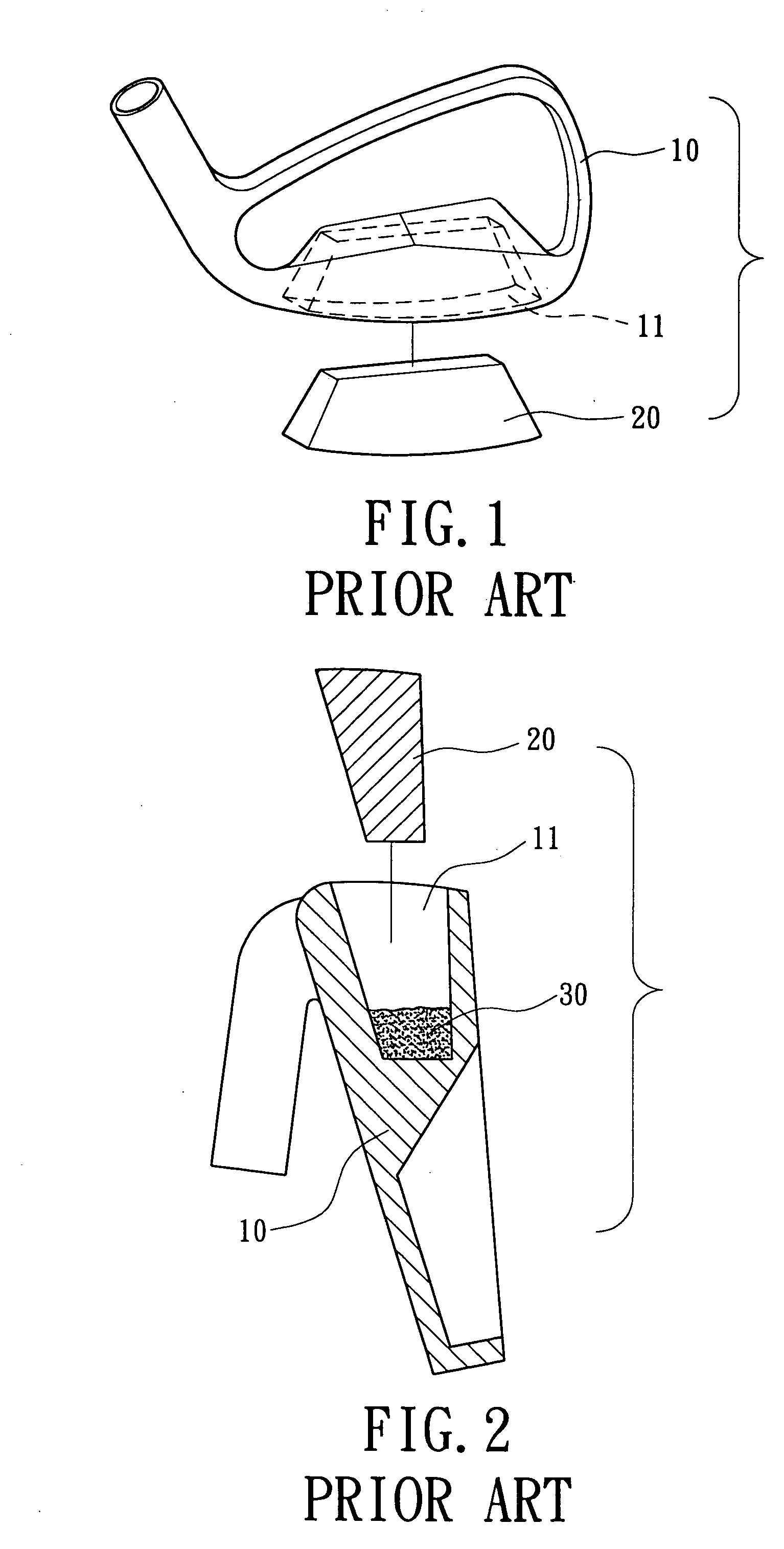

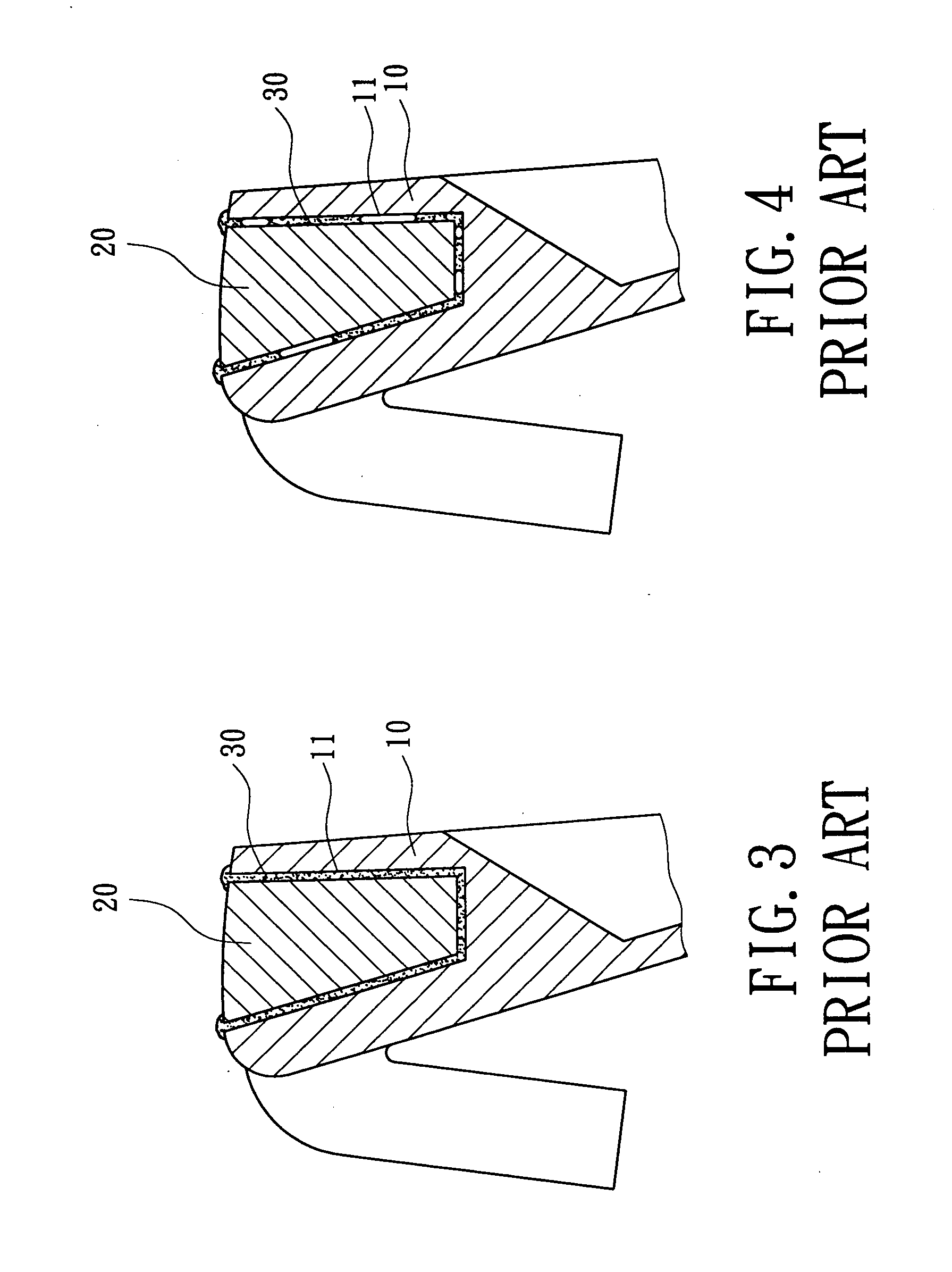

Weight member for a golf club head

InactiveUS7086964B2Improve reliabilityRaise the ratioSoldering apparatusGolf clubsFilling materialsEngineering

A golf club head includes a golf club head body and a weight member mounted in a recession of the golf club head body. The weight member includes at least one compartment for receiving a filling material. The weight member is mounted in the recession of the golf club head body before a brazing process for bonding the weight member with the golf club head body. During the brazing process, the filling material is melted and fills a gap between the weight member and walls delimiting the recession of the golf club head body to thereby increasing bonding strength between the weight member and the walls delimiting the recession of the golf club head body.

Owner:FUSHENG IND CO LTD

Weight member for a golf club head

InactiveUS20050049075A1Improve reliabilityRaise the ratioSoldering apparatusGolf clubsFilling materialsEngineering

A golf club head includes a golf club head body and a weight member mounted in a recession of the golf club head body. The weight member includes at least one compartment for receiving a filling material. The weight member is mounted in the recession of the golf club head body before a brazing process for bonding the weight member with the golf club head body. During the brazing process, the filling material is melted and fills a gap between the weight member and walls delimiting the recession of the golf club head body to thereby increasing bonding strength between the weight member and the walls delimiting the recession of the golf club head body.

Owner:FUSHENG IND CO LTD

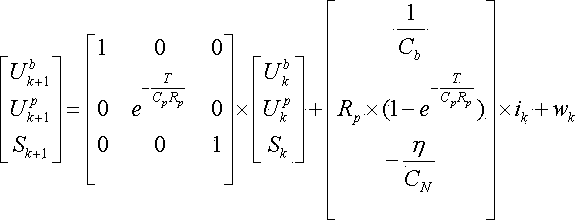

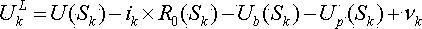

Storage battery state of charge estimation method based on self-adaptive unscented Kalman filtering

InactiveCN103744026AReal-time accurate measurementLow real-timeElectrical testingBattery state of chargeEstimation methods

The invention discloses a storage battery state of charge estimation method based on self-adaptive unscented Kalman filtering. The method comprises that: performance of a storage battery is tested via an HPPC test so that HPPC test data of the storage battery are acquired; parameter identification is performed on the basis of the acquired HPPC test data of the storage battery so that storage battery model parameters are acquired; and an SOC of the storage battery is estimated on the basis of the acquired storage battery model parameters via an AUKF algorithm. According to the storage battery state of charge estimation method based on the self-adaptive unscented Kalman filtering, defects in the prior art that manual amount of labor is large, real-time performance is poor, operation difficulty is high, test and calculation accuracy is low, etc. can be overcome so that advantages of being small in manual amount of labor, great in real-time performance, low in operation difficulty and high in test and calculation accuracy can be realized.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Processing method for acid gas containing H2S

InactiveCN102205202AReduce the overall heightReduce the overall diameterSulfur compoundsDispersed particle separationSulfateProduct gas

The invention provides a processing method for an acid gas containing H2S. The method comprises the following steps that: H2S in the acid gas is transformed into SO2 through burning; the SO2 is subjected to a reaction to generate SO3 in the presence of a catalyst; the SO3 reacts with an alkaline solution to produce a sulfate solution; at last the sulfate solution is processed to obtain a sulfate product. With the method provided by the present invention, the acid gas can be removed so as to meet discharge requirements of environmental protection, and operation difficulty and operation cost are reduced.

Owner:BEIJING FUNGHAN ENG CONSULTING

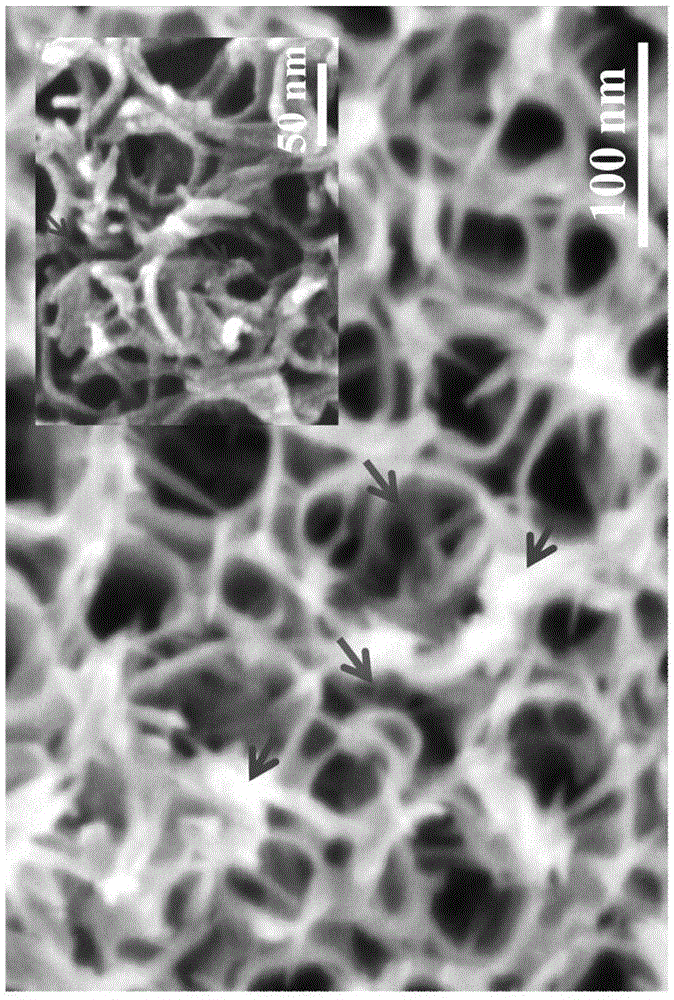

Titanium silicon molecular sieve catalyst as well as preparation method and use thereof

ActiveCN101371989ALarge particle sizeHigh mechanical strengthOrganic chemistryMolecular sieve catalystsMolecular sieveNano al2o3

The invention relates to a titanium silicate molecular sieve catalyst and the preparation method and the application thereof. The catalyst comprises 25-65 percent of titanium silicate molecular sieve and 20-65 percent of nanometer alumina. The mechanical strength is 20-30N / cm<2>. Prepared by an extruded moulding method, the catalyst has the characteristics of high mechanical strength, high catalytic activity and selectivity, and the like, and is especially applied to catalyzing 3-chloropropene oxidation reaction to prepare epichlorohydrin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermo-sensitive discoloration material microcapsule and preparation method thereof

InactiveCN102477290AGood chemical stabilityGood solvent resistanceTenebresent compositionsMicroballoon preparationEmulsionChange color

The invention discloses a thermo-sensitive discoloration material microcapsule and a preparation method thereof. The microcapsule is composed of a core material and a wall material for covering the core material, wherein the core material comprises a thermo-sensitive discoloration compound composed of a chromogenic reagent, a color-developing agent and a solvent; the wall material is a melamine resin pre-polymer; the mass ratio of the thermo-sensitive discoloration compound to the melamine resin pre-polymer is 1:(1-2). The preparation method comprises the following steps of: mixing the chromogenic reagent, the color-developing agent and the solvent to form a thermo-sensitive discoloration solution under the heating condition; adding an emulsifying agent solution into the thermo-sensitive discoloration solution and emulsifying a commixed solution to obtain an emulsion; adjusting the pH value to 3-6 and adding the melamine resin pre-polymer into the emulsion; reacting at a temperature for 60-70 DEG C for 1-1.5 hours and then cooling to 30-40 DEG C; then adding a dispersant; and washing and drying to obtain the thermo-sensitive discoloration microcapsule. According to the method provided by the invention, the influences on human bodies and environments are greatly reduced; the operation is simple, the prepared microcapsule products can fast change color and fade and the effect is obvious, so that the thermo-sensitive discoloration material microcapsule can be widely applied in the fields of anti-counterfeiting textile and printing and the like.

Owner:BEIJING CTA TEX CHEM

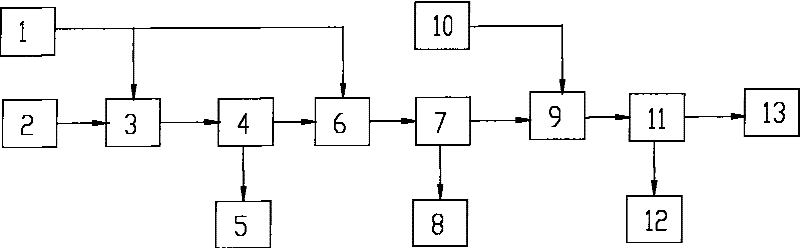

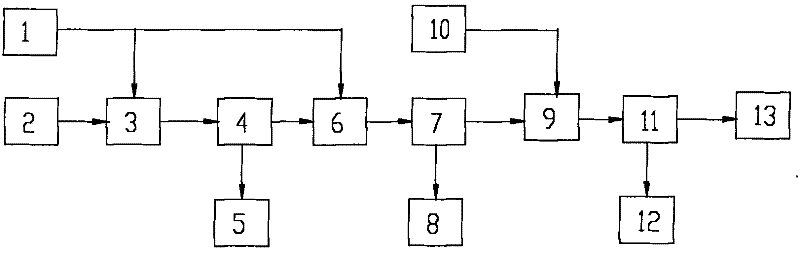

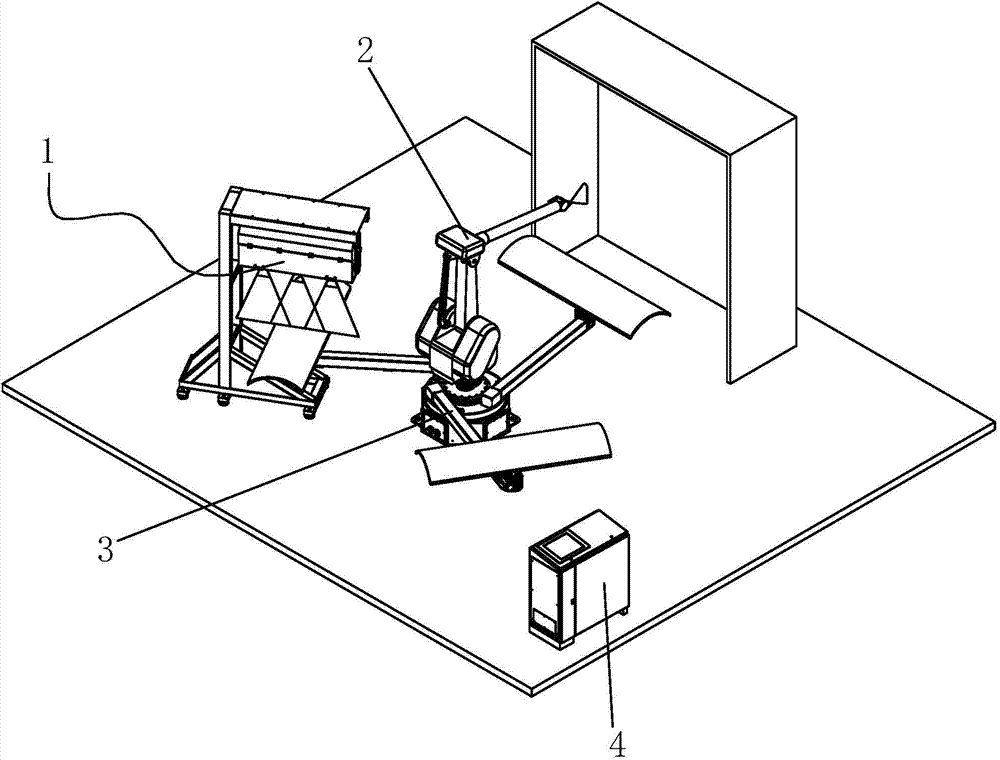

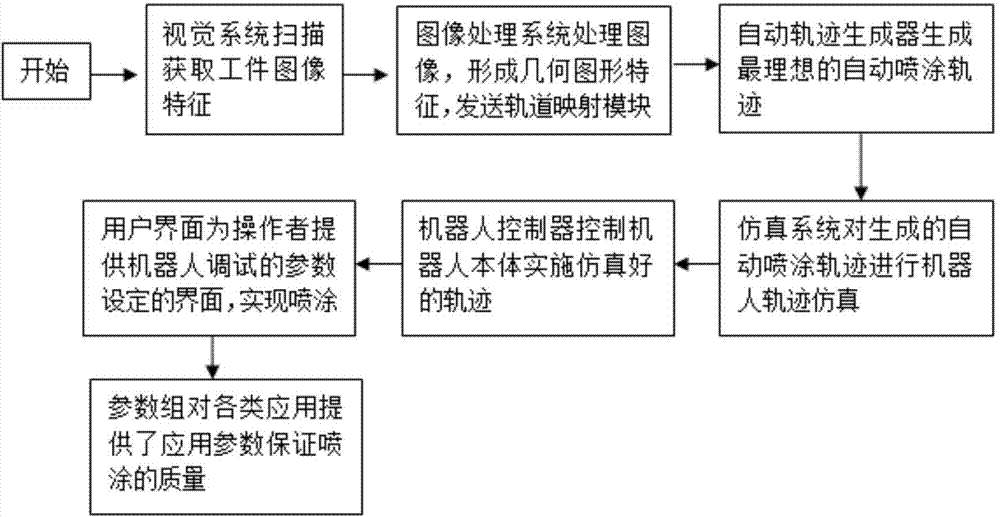

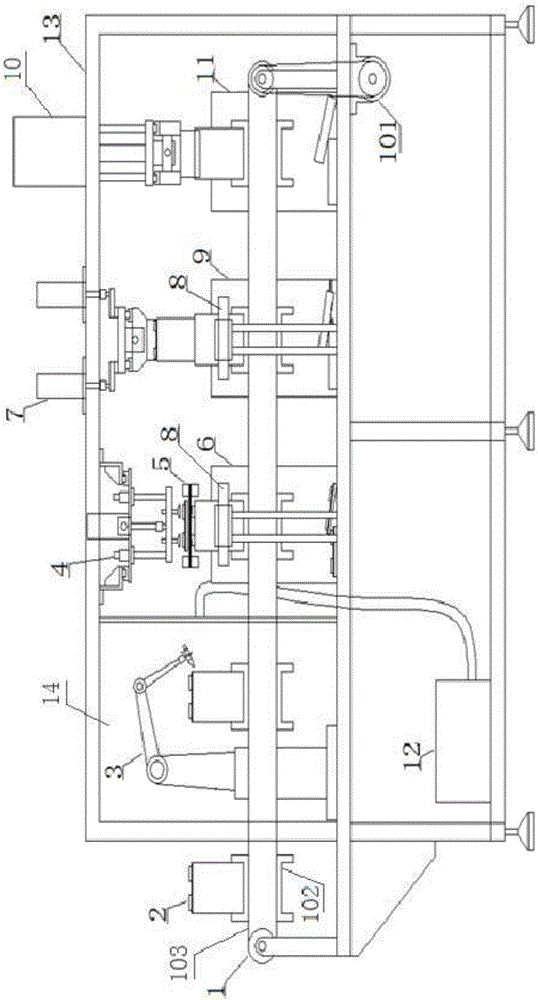

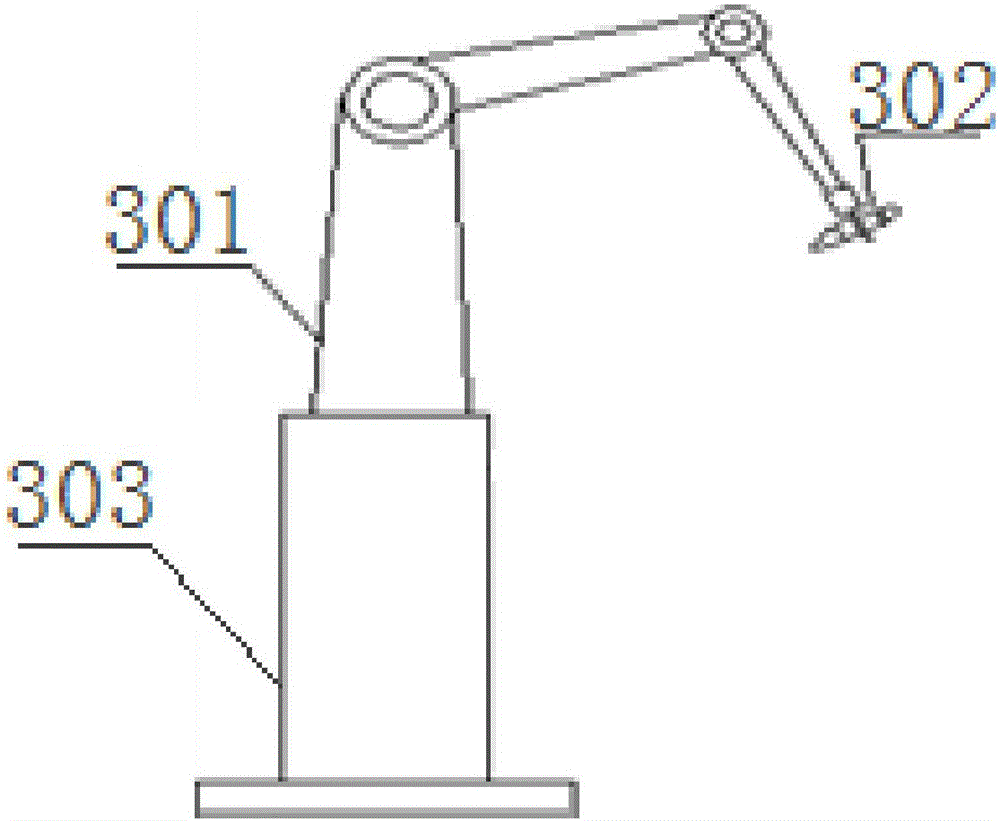

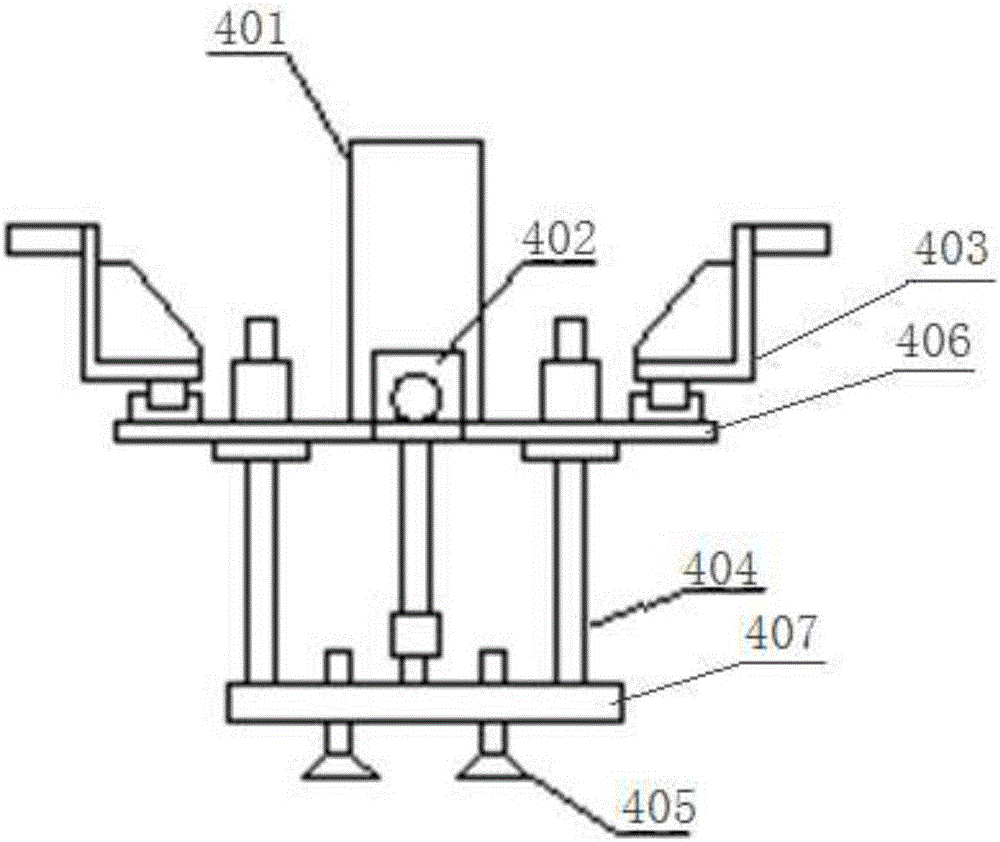

Control method of robot automatic spraying system

The invention discloses a control method for a robot automatic spraying system. The control method of the robot automatic spraying system comprises the following steps of (1) acquiring feature data of a workpiece to be sprayed; (2) processing acquired data by using an image processing system; (3) automatically generating a track; (4) simulating; (5) controlling a user interface; (6) determining a spraying parameter; and (7) performing spraying. The control method of the robot automatic spraying system has the advantages of high automation degree, high machining precision, wide application range and the like. Different workpiece spraying tracks can be generated automatically, the operation difficulty of a user is reduced, the traditional manual programming on single different-model workpieces to be sprayed is replaced, consumed time on spraying is shortened, and the production efficiency is improved.

Owner:希美埃(芜湖)机器人技术有限公司

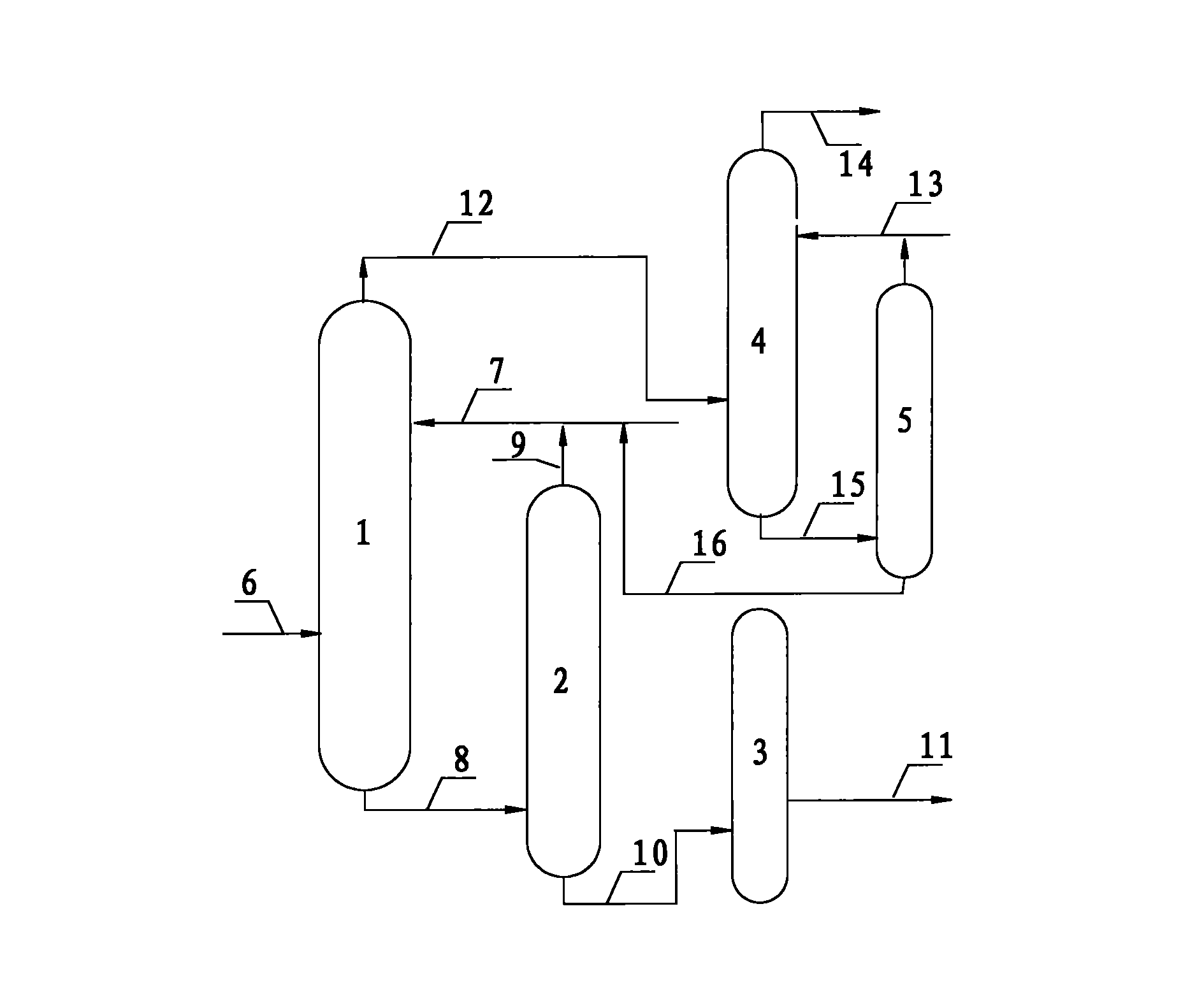

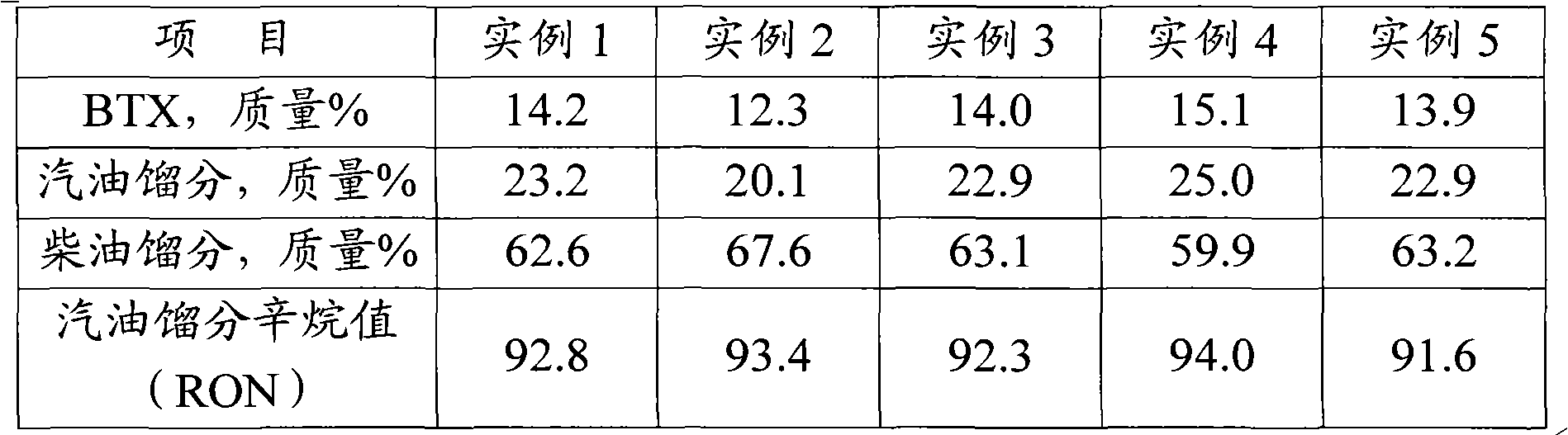

Method for producing light aromatic hydrocarbons and high-quality oil products from catalytically cracked diesel

ActiveCN103214332AEasy to handleReduce the difficulty of operationHydrocarbon purification/separationHydrocarbonsAlkanePolycyclic aromatic hydrocarbon

The invention discloses a method for producing light aromatic hydrocarbons and high-quality oil products from catalytically cracked diesel. The method comprises the following steps of 1, carrying out extraction of catalytically cracked diesel by an extraction solvent to obtain polycyclic aromatic hydrocarbon-rich extract oil and alkane-rich raffinate oil, 2, carrying out hydrofining and hydrocracking of the polycyclic aromatic hydrocarbon-rich extract oil under the hydrogenation reaction conditions to obtain light aromatic hydrocarbons and a high-octane number gasoline fraction. The method can realize production of light aromatic hydrocarbons, high-cetane number diesel and high-octane number gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

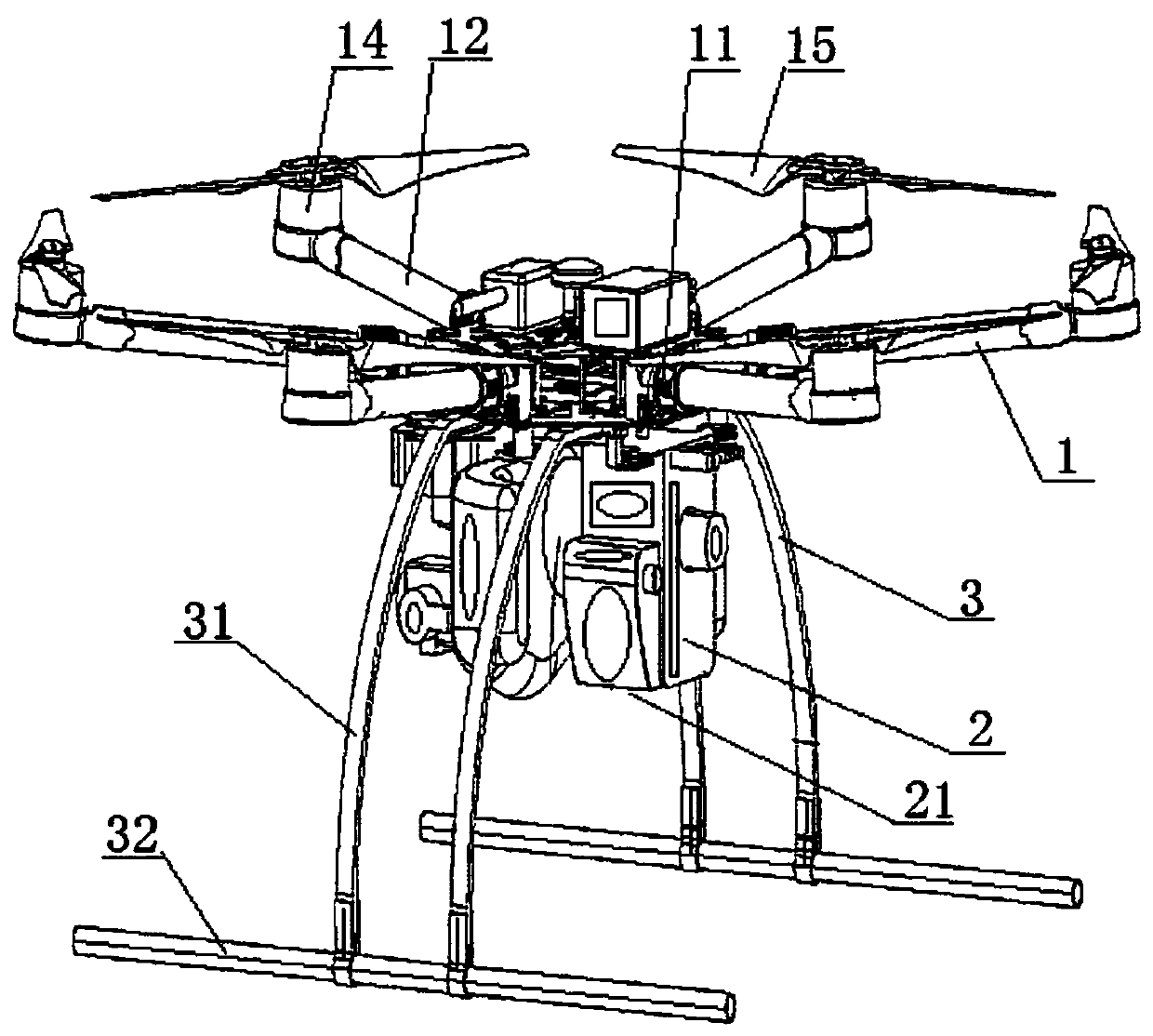

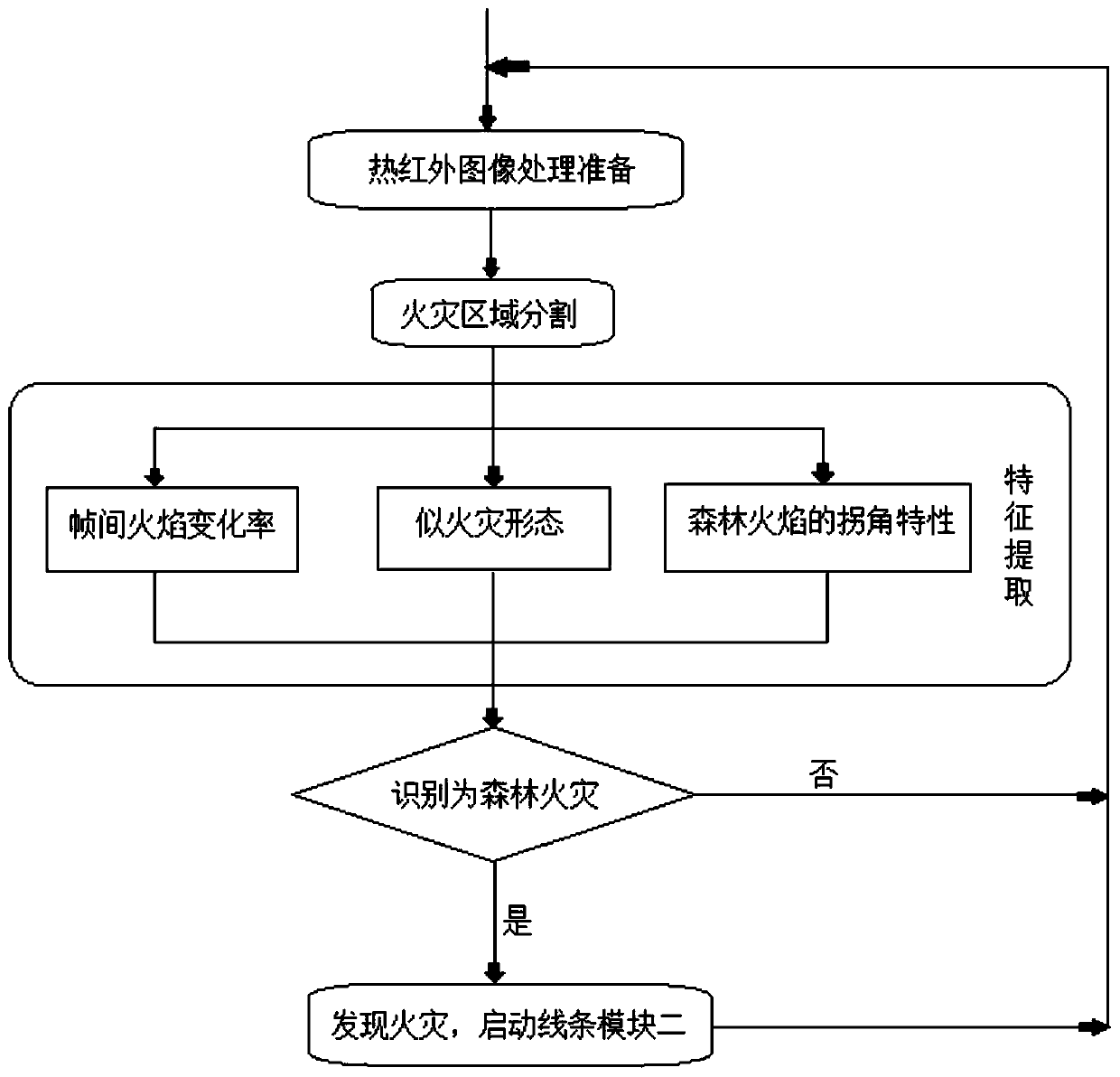

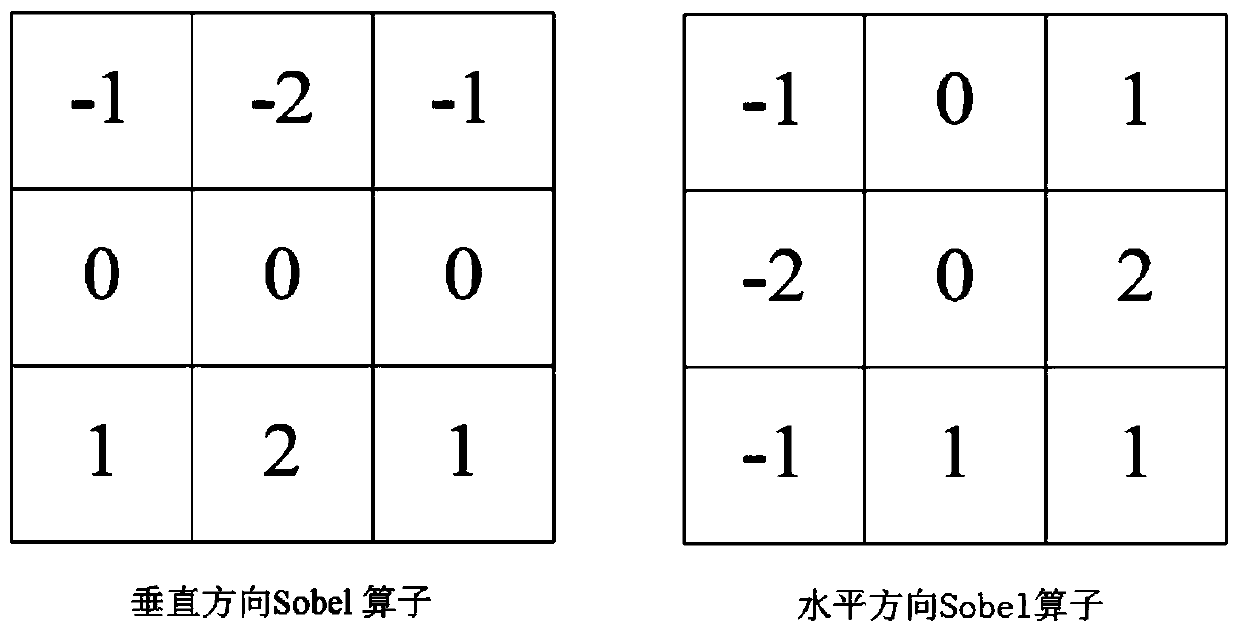

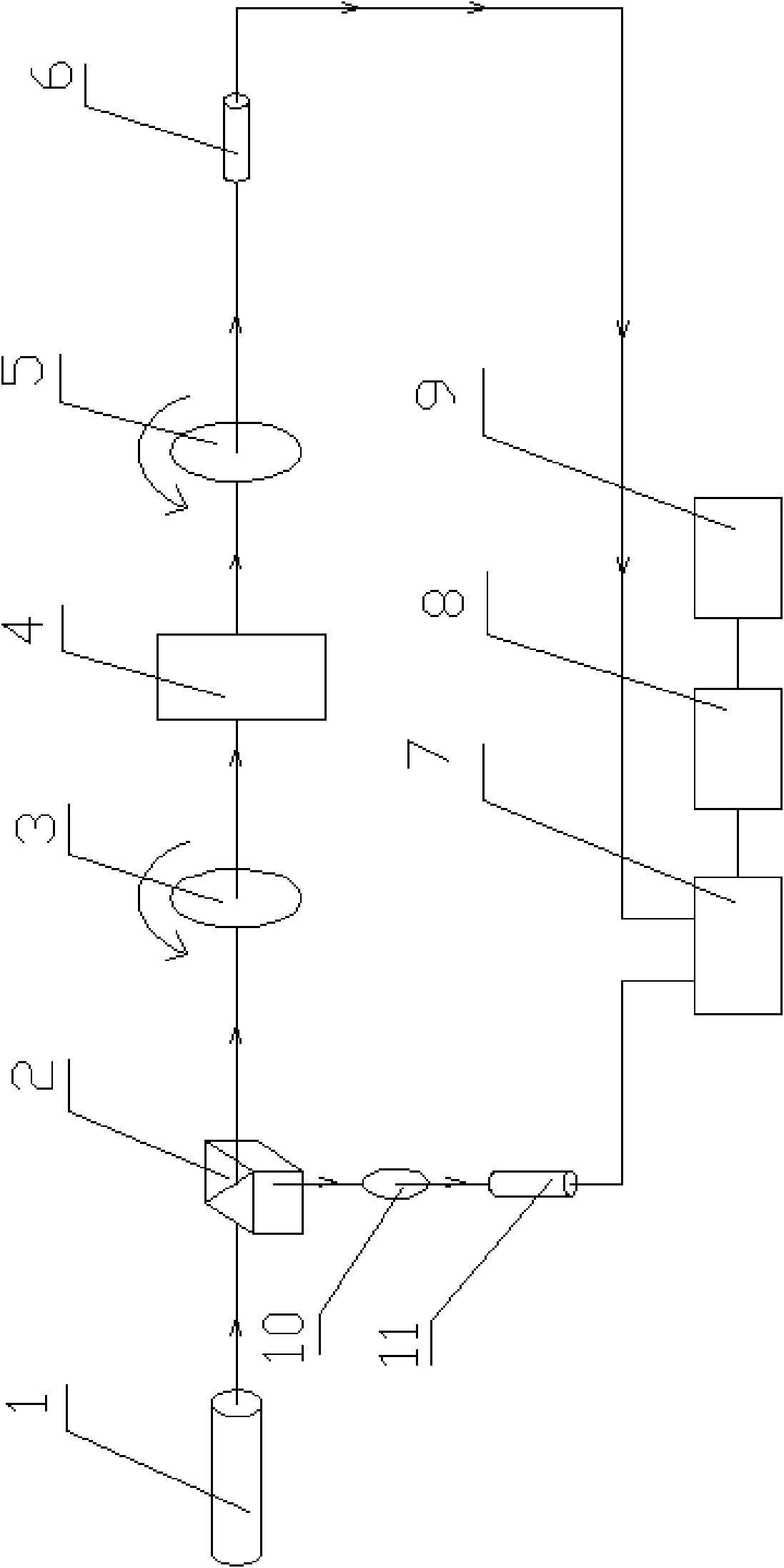

Unmanned aerial vehicle cruising and monitoring system for forest fire

PendingCN110047241AReduce weightExtended flight timeForest fire alarmsCharacter and pattern recognitionEngineeringFlight time

The invention provides an unmanned aerial vehicle cruising and monitoring system for forest fire. The weight of the unmanned aerial vehicle is reduced, flight time is prolonged, an unmanned aerial vehicle cruising range is enlarged, route planning is carried out for fire monitoring, and an unmanned aerial vehicle flight control system is combined with a geographic information system. The route planning not only guarantees monitoring quality and monitoring full coverage but also considers the hardware parameters and the flight safety of the cruising unmanned aerial vehicle, a rotary head carries a thermal infrared imager and a colorful high-definition camera, the thermal infrared characteristics of the image of the forest fire are fully utilized, and an automatic monitoring and identification method for forest fire information is designed. Even if the forest fire monitoring distance of the unmanned aerial vehicle is long, fire characteristics can be accurately captured. A colorful high-definition image is compressed and transmitted back to a ground command post, a high-definition fire video image can be quickly transmitted to the ground, a fire position can be accurately reported, so that convenience is brought to the ground command post in accurately judging a fire situation and organizing people to fight the fire, and precious fire-fighting time is saved.

Owner:刘秀萍

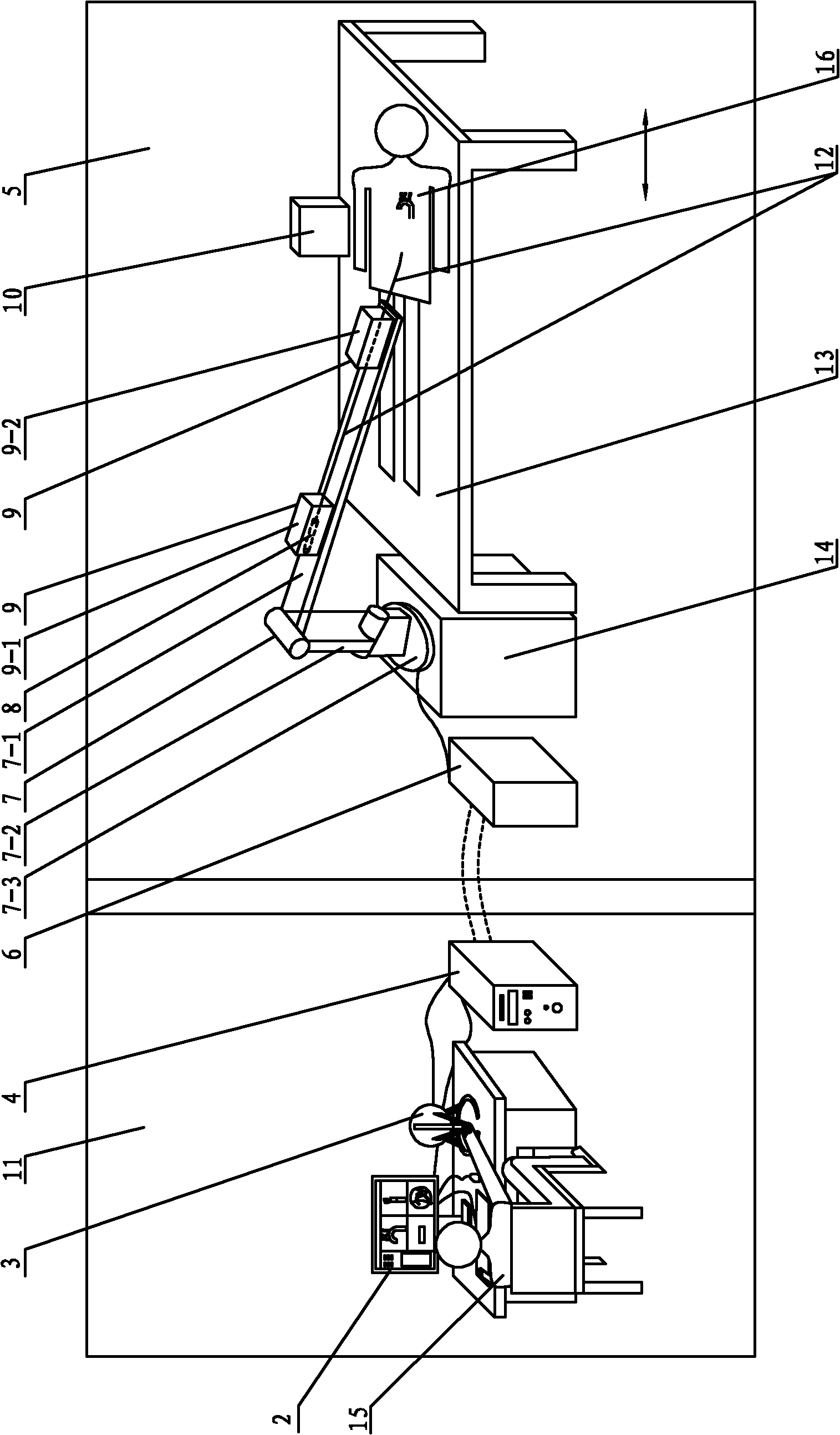

Catheter robot system for minimally invasive interventional operation in blood vessel

ActiveCN102028549AReduce the difficulty of operationGuaranteed accuracyDiagnosticsSurgical robotsRobotic systemsControl signal

The invention discloses a catheter robot system for a minimally invasive interventional operation in a blood vessel, relating to a robot system for assisting the minimally invasive interventional operation in the blood vessel, which aims to lower the radiation hazard to patients and doctors on site, realize compartmental interventional operation at different sites and feed back the conveying force of a catheter. A main hand handle and a computer mainframe are arranged in a control room; a control cabinet, a catheter handle, master and slave intervention devices, a magnetic field generator and a controllable catheter are arranged in an operation room; a pose signal of the main hand handle is delivered to the control cabinet after processed by the computer mainframe; the control cabinet is internally provided with a motion control card and a driver; the motion control card receives a command to send an instruction to the driver; the driver delivers a control signal to the motors of the master and slave intervention devices, thereby controlling the intervention devices to realize the pushing / pulling, rotation and bending operations of the controllable catheter; a pose sensor acquires pose information on a controllable bent section, and the pose signal is delivered by the motion control card to the computer mainframe for signal processing. The invention is used for the minimally invasive interventional operation in the blood vessel.

Owner:杭州唯精医疗机器人有限公司

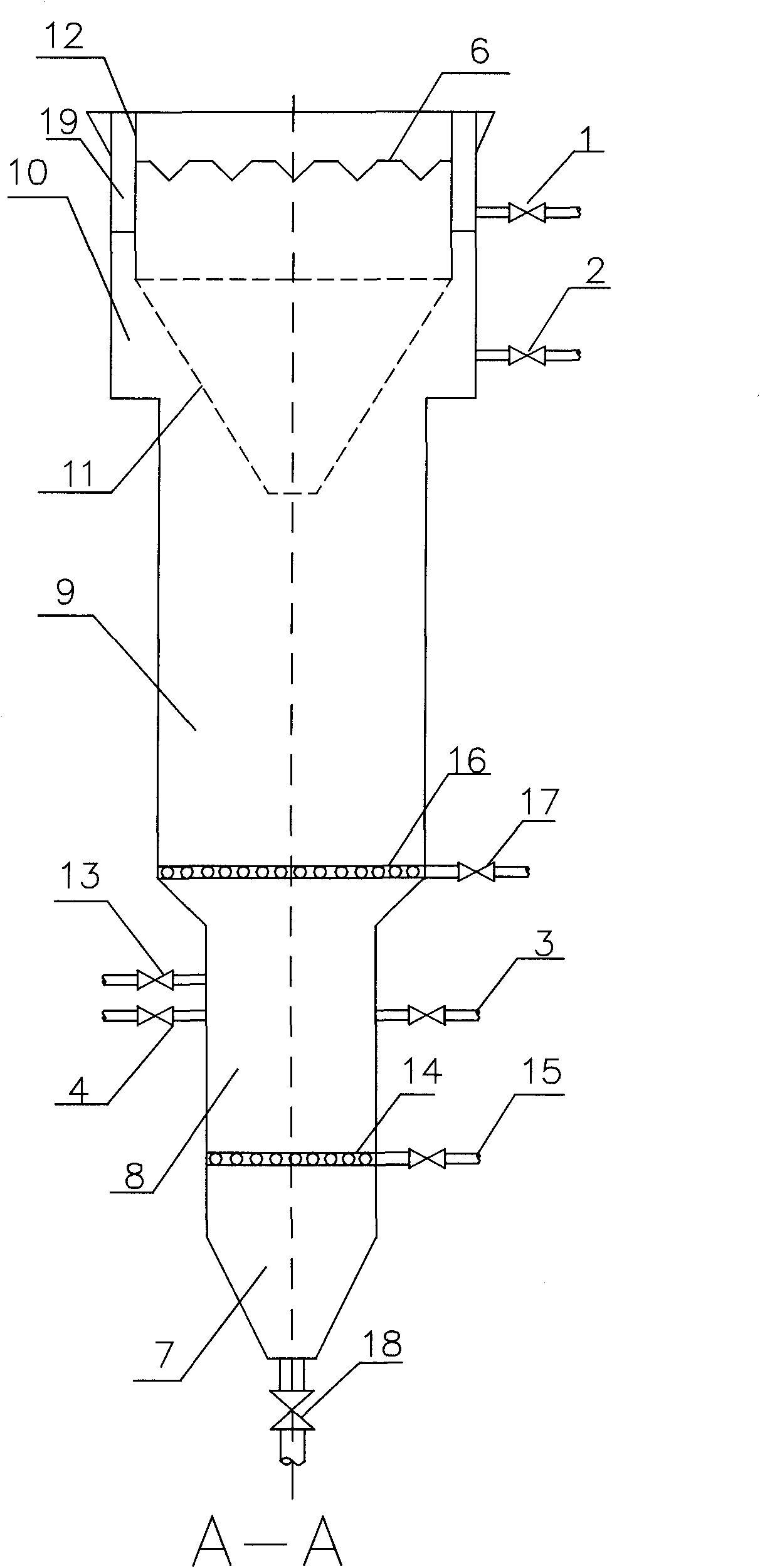

Integrated nitrogen and phosphorus recovery device in struvite method

InactiveCN101817581AImprove recycling efficiencyAvoid churnWater/sewage treatment by flocculation/precipitationPhosphorus compoundsTrappingStruvite Crystals

The invention discloses an integrated nitrogen and phosphorus recovery device in a struvite method, which relates to the field of environmental engineering water treatment and is a reactor for treating nitrogen and phosphorus-containing wastewater in a physicochemical method. Substances nitrogen and phosphorus in the wastewater are removed in a magnesium ammonium phosphate (struvite) form, and the substances are recovered and reused. The reaction device is in an integrated form, which comprises a precipitation zone, a mixing reaction zone, a crystal growth zone and a crystal trapping and water discharging zone from bottom to top sequentially, the mixing reaction zone is provided with a first-grade aerator, which is mainly a wastewater and reagent fully mixing and reacting zone; the crystal growth zone is provided with a second-grade aerator, which is mainly a struvite growth zone; in the precipitation zone, large-grain struvite crystals are mainly precipitated; and the crystal trapping and water discharging zone recovers the struvite crystals by a filter screen. In addition, the device uses external reflux to reinforce and to control the supersaturated rate of the struvite reaction, thus promoting the crystal growth. The device has simple technological process and has the advantages of short hydraulic retention time, high nitrogen and phosphorus recovery efficiency, high recovery pureness, little occupied area, low operation and maintenance cost and the like.

Owner:TONGJI UNIV

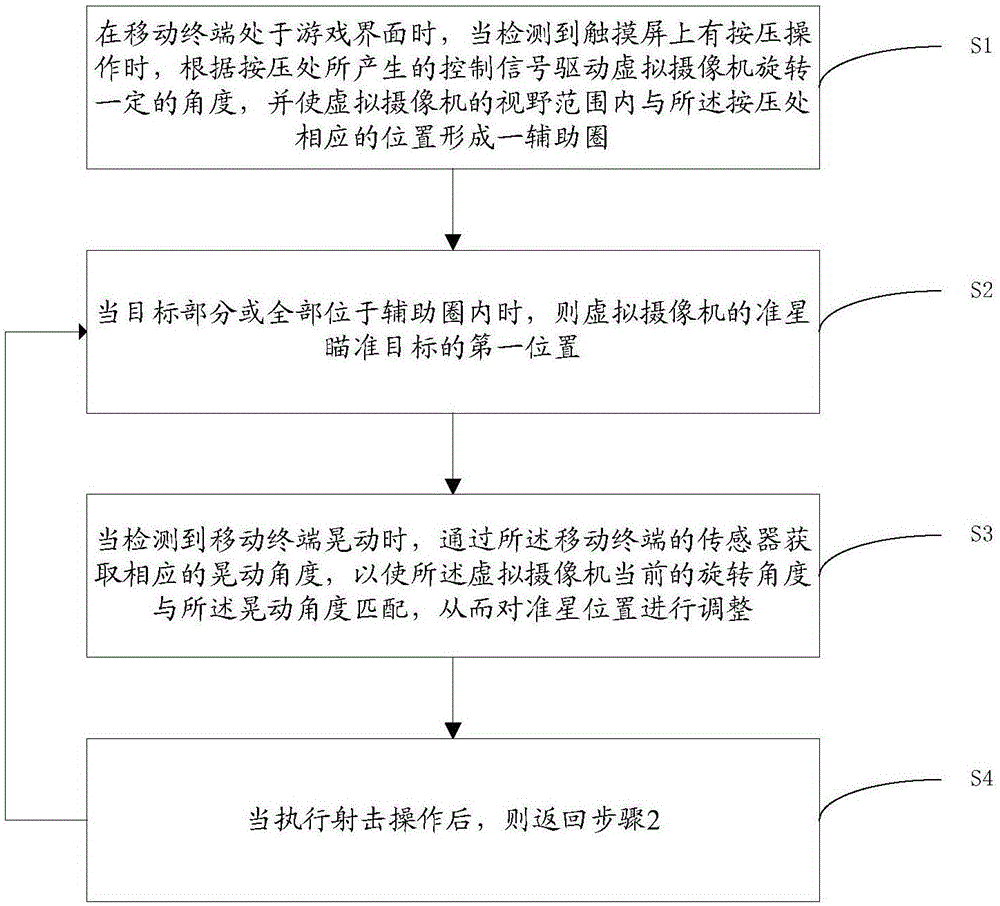

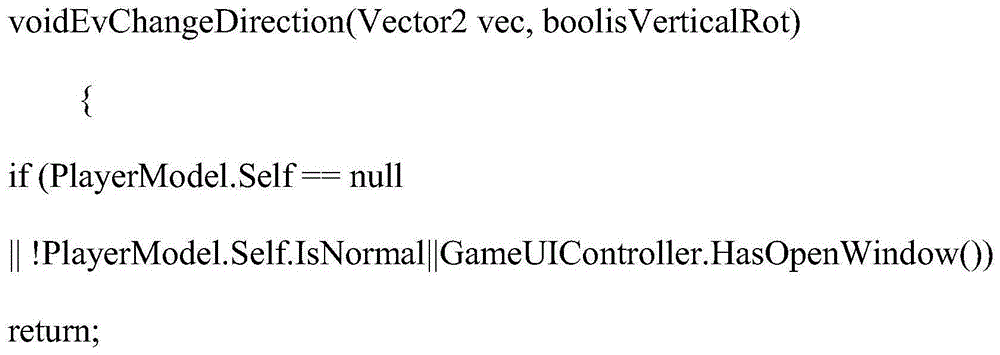

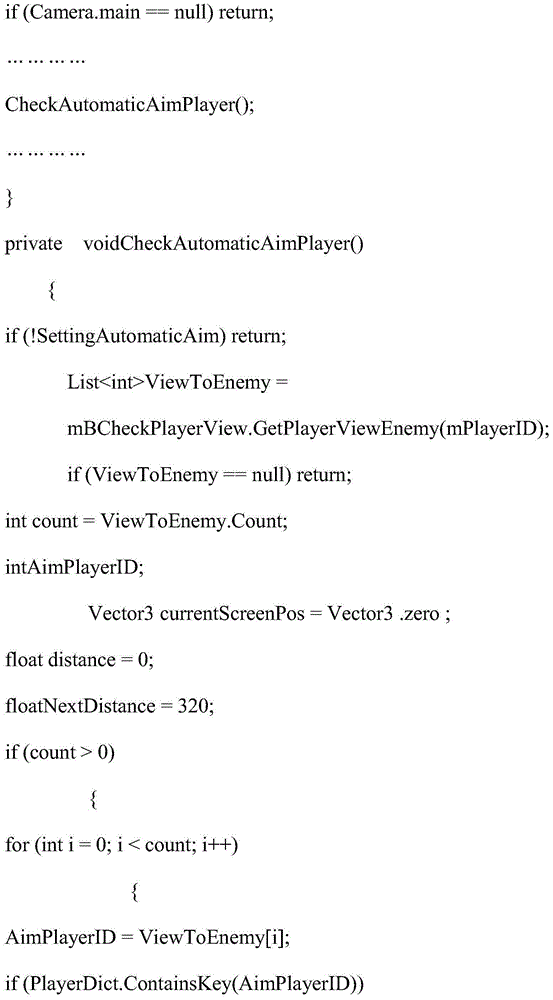

Method and device for automatic aiming of shooting games

InactiveCN105148520AReduce the difficulty of operationImprove aiming accuracyVideo gamesInput/output processes for data processingVirtual cameraVideo camera

The invention relates to a method for automatic aiming of shooting games. The method is applied to a mobile terminal with a touch screen. The method comprises the following steps: when the mobile terminal is on a game interface and when it is detected that there is pressing operation on a touch screen, a virtual camera is driven according to control signals generated at the pressed position to rotate through a certain angle, and an auxiliary ring is formed at the position within the view field of the virtual camera corresponding to the pressed position; when part or all of a target is located in the auxiliary ring, a front sight of the virtual camera aims at a first position of the target; when it is detected that the mobile terminal shakes, the corresponding shaking angle is obtained through a sensor of the mobile terminal, so that the current rotating angle of the virtual camera is matched with the shaking angle, and accordingly the position of the front sight is adjusted. The invention further relates to a device for automatic aiming of shooting games. According to the method and device for automatic aiming of shooting games, the operation difficulty can be effectively reduced, and the aiming accuracy is improved.

Owner:SHANGHAI JIAYOU NETWORK TECH CO LTD

Hill-starting assisting control method and device

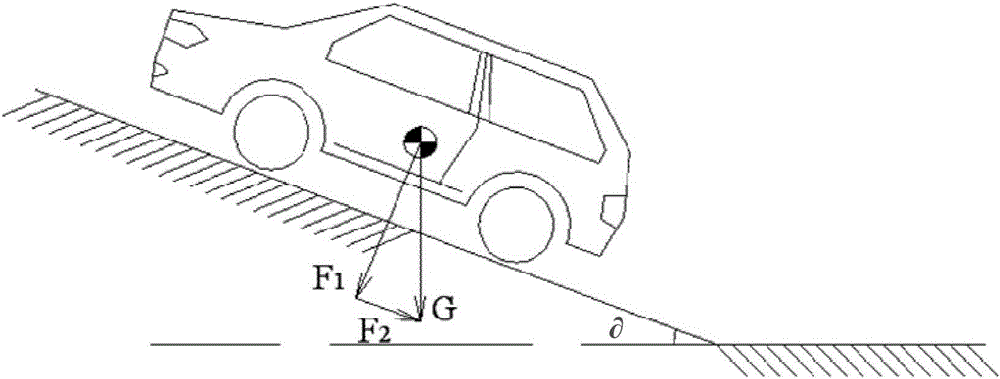

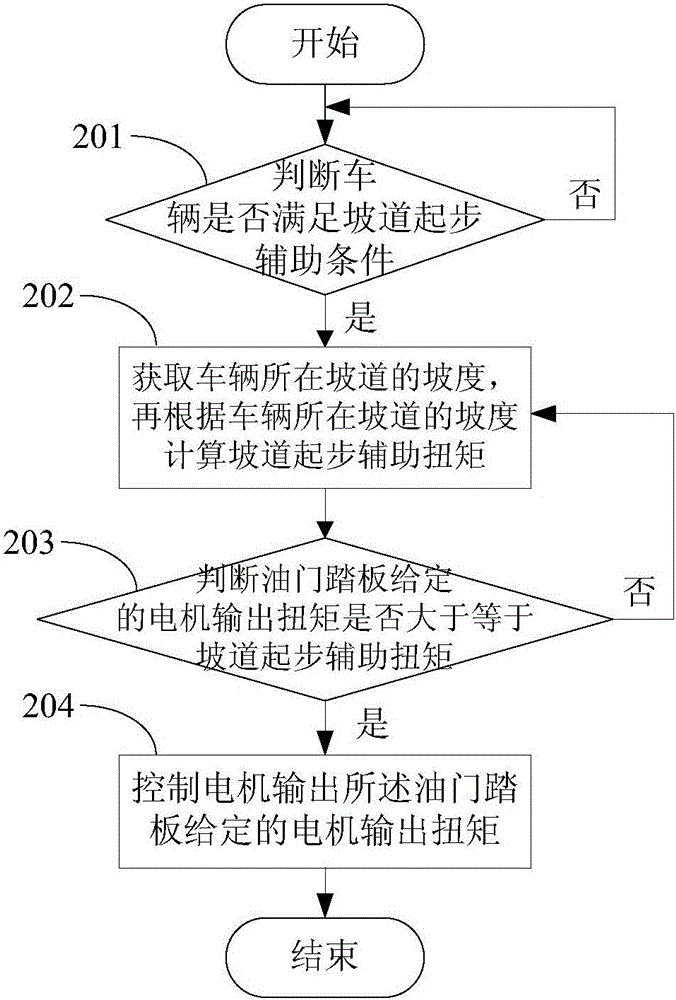

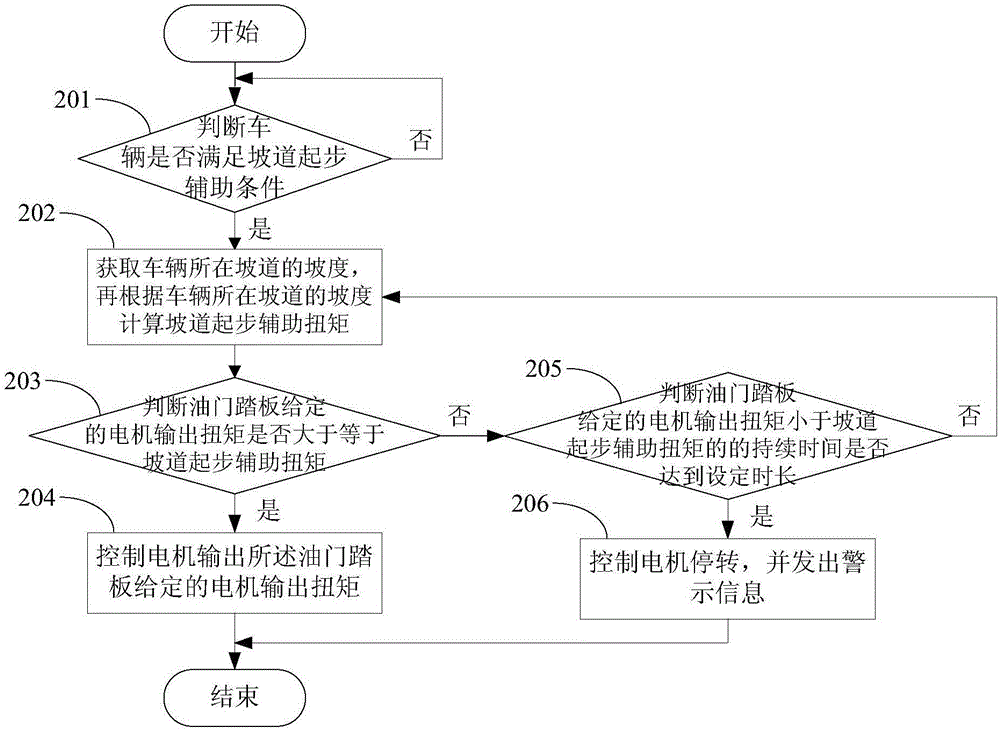

InactiveCN105711590AReduce the difficulty of operationAchieving a safe startSpeed controllerElectric energy managementEngineeringStatics

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

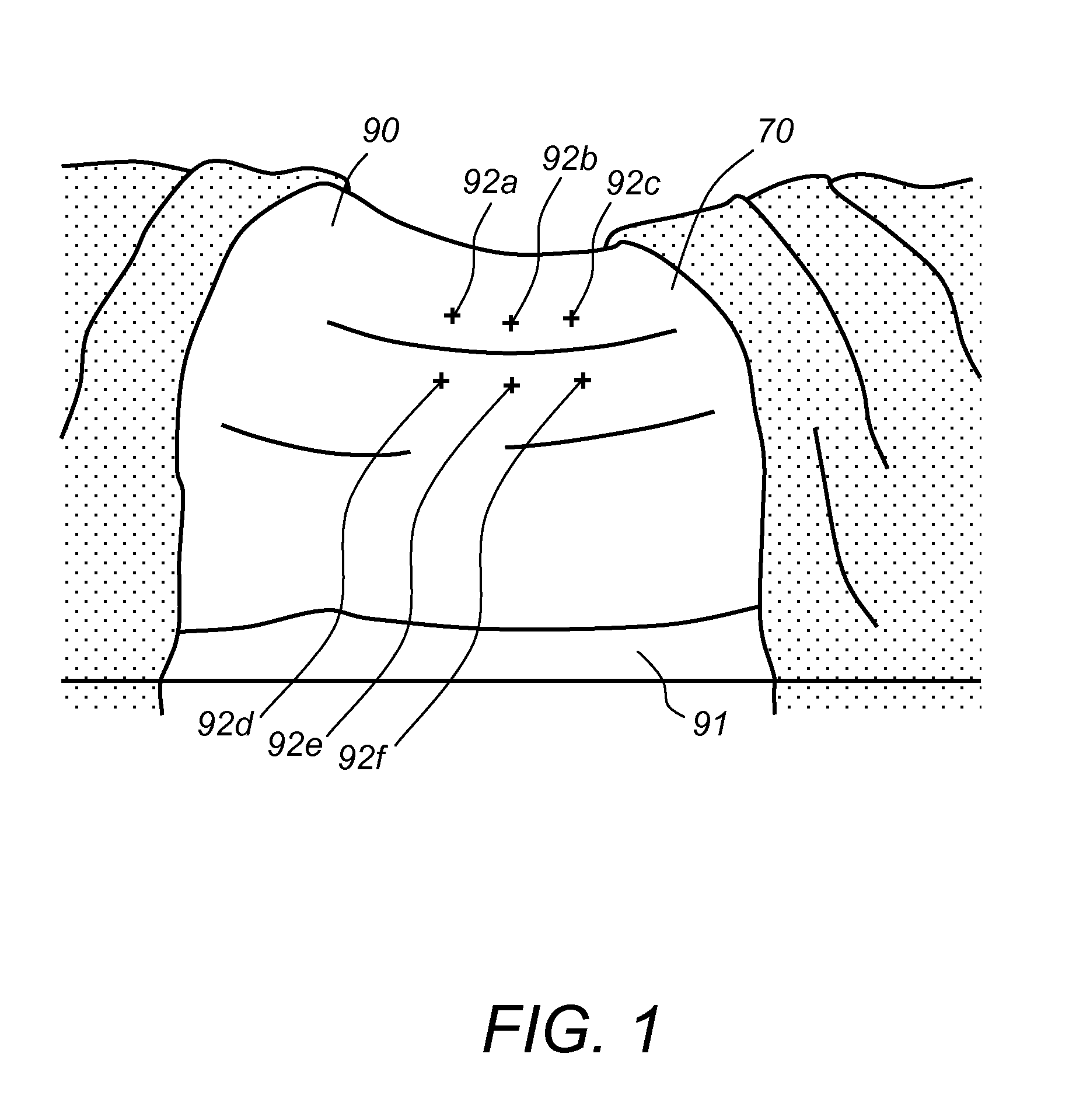

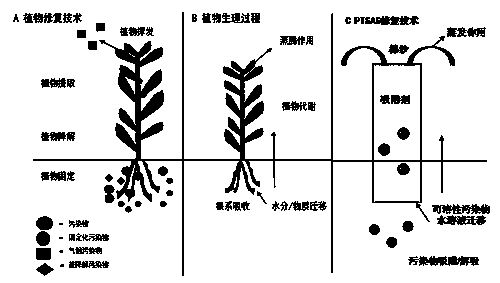

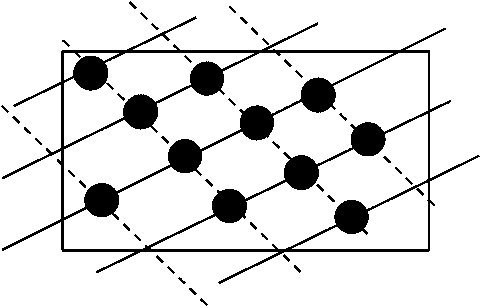

In-situ self-sustaining contaminated soil restoring device based on plant bionics and method

ActiveCN103736719AEnriched fixationSustainable transpiration pullContaminated soil reclamationPipe fittingFilling materials

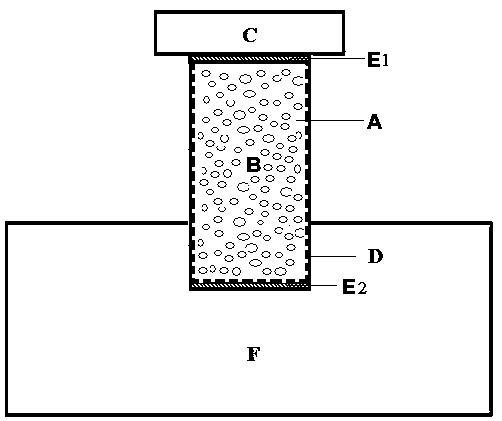

The invention provides an in-situ self-sustaining contaminated soil restoring device by simulating the capillary phenomenon and the transpiration function of a plant and a method for restoring soil by utilizing the device. The restoring device comprises the following members: a main body, filling materials, an evaporator and accessories, wherein the main body is a hollow pipe fitting which is tightly filled with the filling materials; the filling materials are supported by depending on the accessories; the evaporator is arranged at the top end of the main body pipe fitting; the accessories are mainly of supporting materials for mounting other members. The specification of the restoring device is selected and the distribution density and depth are selected according to soil contamination conditions, and then the restoring device is inserted into the soil, so that contaminants in the soil are driven to move by utilizing the capillarity phenomenon and the transpiration function of the restoring device so as to be transferred into the restoring device. Thus, the contaminants in the soil are effectively removed.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Method for forming composite material pipe mold element by pressurizing air bags with assistance of resin film transfer

InactiveCN104070687AGet rid of usingReduce manufacturing costTubular articlesManufacturing cost reductionManufacturing technology

The invention belongs to the technical field of manufacture engineering, relates to a manufacture technology method of a high-performance composite material pipe mold element, and particularly relates to a method for forming a composite material pipe mold element by pressurizing air bags with assistance of resin film transfer. According to the invention, a dry state fiber fabric and a thermoset resin adhesive film act as a base of a material, so that the method has the multiple advantages of reducing the manufacture cost obviously, improving the production efficiency effectively, expanding the application range of the manufacture technology extremely and the like. Compared with the traditional prepreg-autoclave technology, the fiber / adhesive film pre-dipping process is saved, so that on one hand, the using of a pre-dipping machine is prevented, and the cost of production equipment is reduced obviously, and on the other hand, the reduction of manufacture links improves the production efficiency effectively; additionally, most importantly, as for manufacture of pipe mold elements with the dry state fiber structure incapable of being treated by the pre-dipping mode, such as fiber 2.5D / 3D braided structure, the technology provided by the invention can also be used, and the technology application range is expanded extremely.

Owner:AVIC COMPOSITES

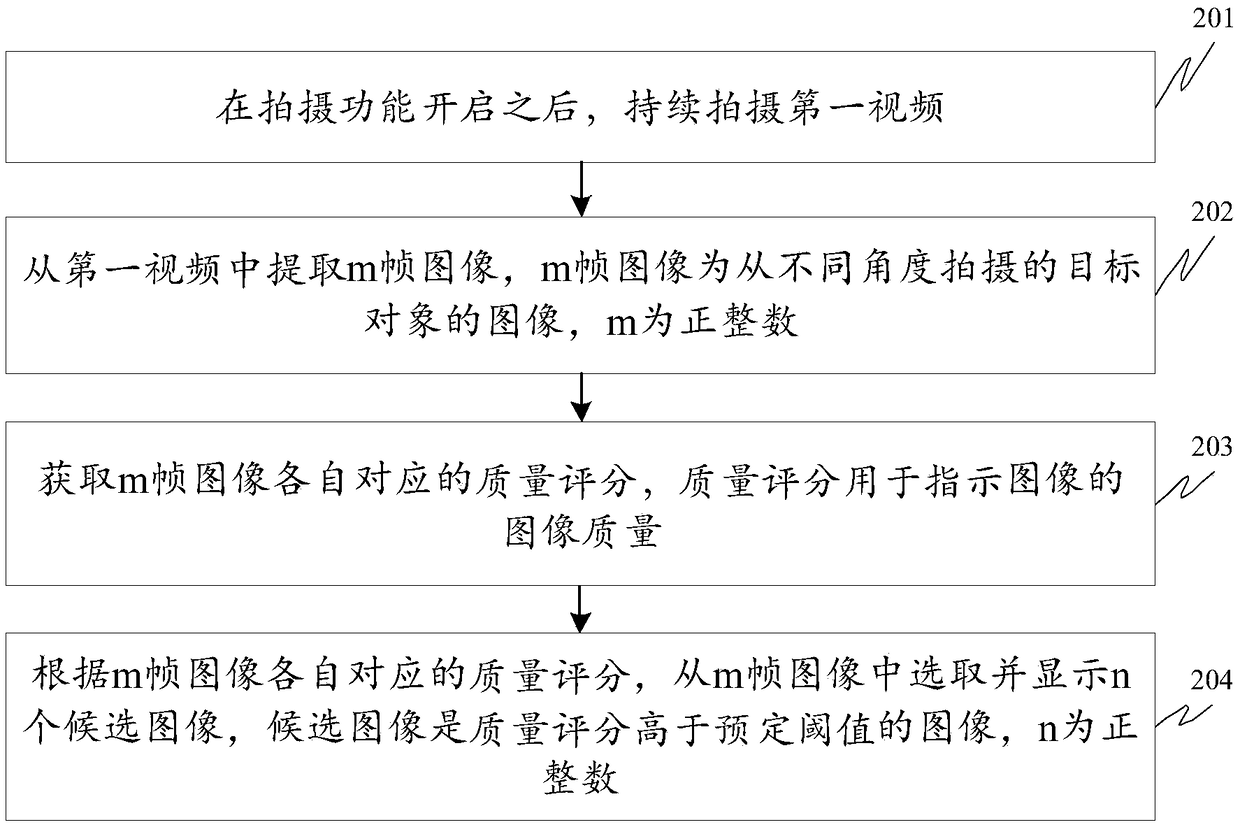

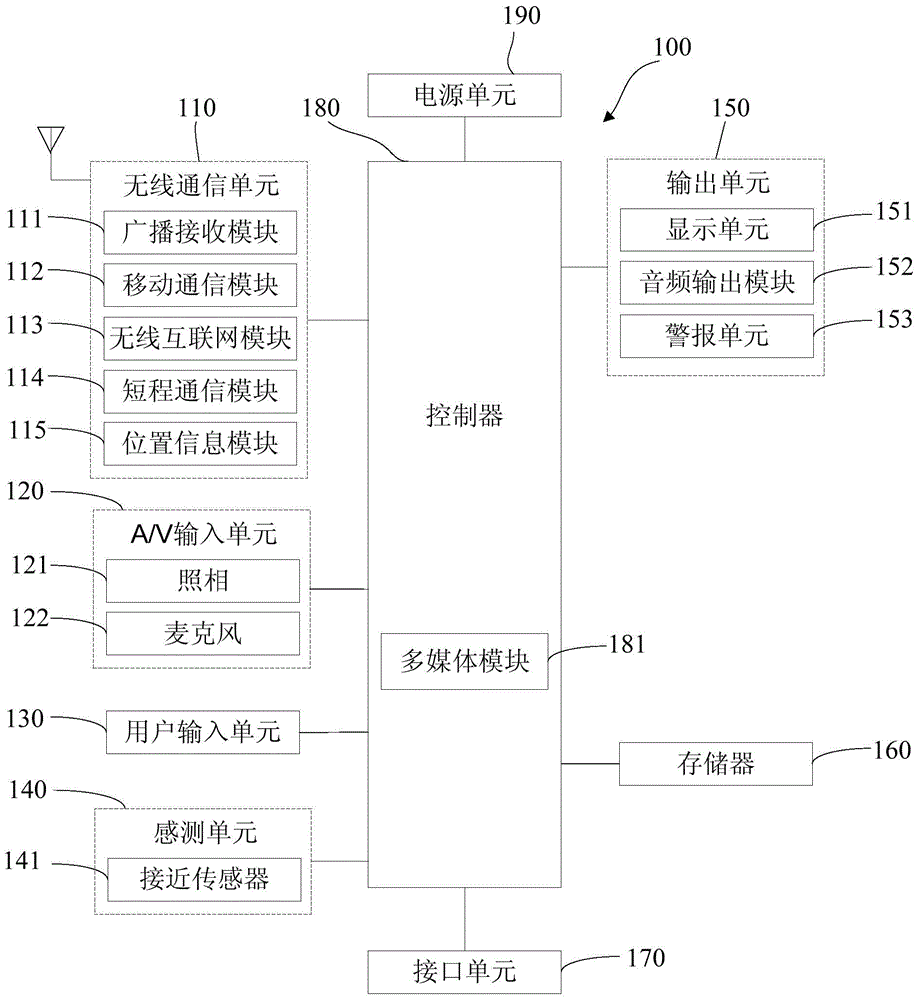

Image processing method and device, terminal and storage medium

ActiveCN108234870AAvoid manual adjustment of shooting parametersReduce the difficulty of operationTelevision system detailsImage enhancementImaging processingImaging quality

The invention discloses an image processing method and device, a terminal and a storage medium, and belongs to the technical field of terminals. The method comprises the steps of keeping on shooting afirst video after a shooting function is enabled; extracting m frames of images from the first video, wherein the m frames of images are images of a target object shot in different angles; obtainingrespective corresponding quality score of the m frames of the images, wherein the quality score is used for indicating image quality of the image; selecting and displaying n candidate images from them frames of images based on respective corresponding quality score of the m frames of the images, wherein the candidate images are images with the quality score higher than a preset threshold. N high-quality candidate images which include the target object are output automatically through the terminal, and the subsequent users can select images satisfies the prospection from the displayed n candidate images, so that users are avoided adjusting shooting parameters every time the users shoot images, and the operational difficulty in shooting high-quality images is reduced greatly.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

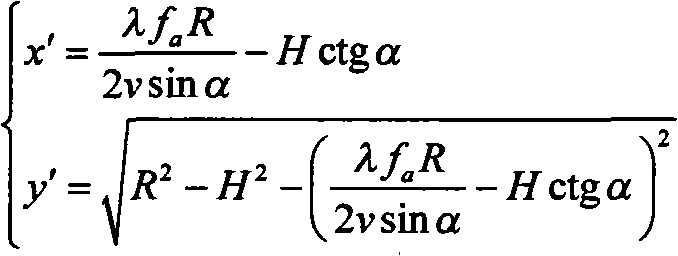

Method for evaluating simulation imaging of multi-mode synthetic aperture radar

ActiveCN101907704AAvoid modificationAvoid debuggingRadio wave reradiation/reflectionSystems designWork pattern

The invention discloses a method for evaluating the simulation imaging of a multi-mode SAR (Synthetic Aperture Radar), which mainly solves the problems of poor adaptability to different operating modes, complex experiment process and long experiment time in the prior art. The method comprises the following steps of: firstly, selecting an operating mode, inputting the parameters of a radar and the motion parameters of a carrier, loading a simulation scene and setting coordinates; secondly, setting a simulation radar echo signal according to a system environment; thirdly, imaging the radar echo signal to obtain a slant-range image; fourthly, geometrically correcting the slant-range image by using a three-dimensional geometric correction method to obtain a ground-range image; and finally, evaluating the quality of the ground-range image, and feeding back and correcting system parameters according the evaluation results so as to provide a feasible basis for a latter semi-physical simulation experiment. The method is applicable to three operating modes including a side looking mode, a slant looking mode and a scanning mode; only a plurality of parameters need to be input during operation, so that the experiment process can be simplified, the experiment time is saved, and the method can be used in a ground simulation experiment of SAR system design.

Owner:XIDIAN UNIV

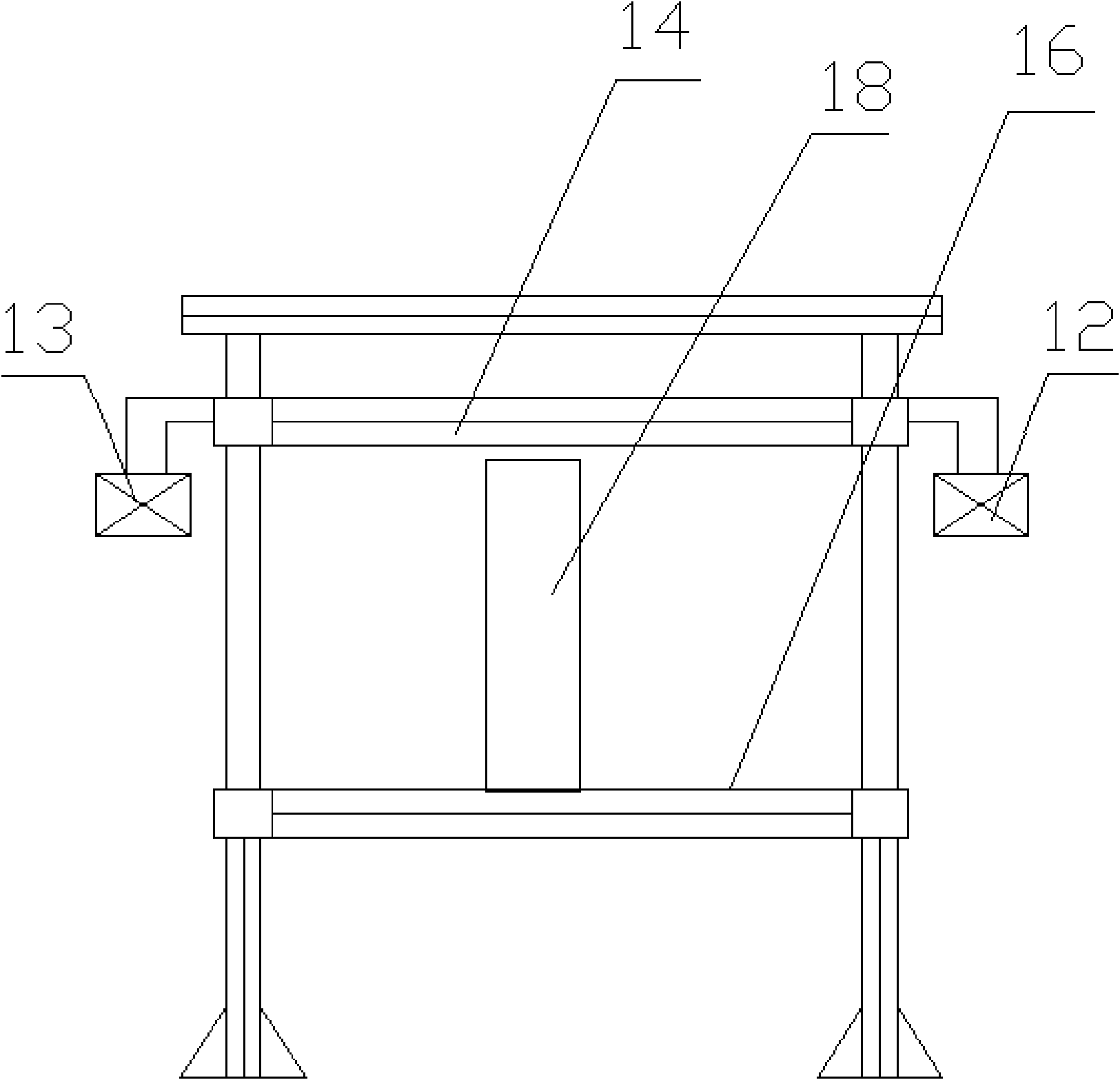

Device and method for measuring stress of optical glass

ActiveCN101592537ASize relaxedEasy to measureForce measurement by measuring optical property variationMaterial analysis by optical meansStress measuresMeasurement device

The invention provides a stress measuring device with higher precision, which can measure the size, direction and distribution of the stress of optical glass. The stress measuring device of the optical glass comprises a communicated light path interferometer and a stander, wherein the stander comprises a frame and a plane scanning test platform arranged on the frame; and a laser receiving unit and a laser emitting unit of the communicated light path interferometer are arranged on the stander, and can synchronously move front and back, and up and down. The stress measuring device achieves the quantitive measurement of the stress size and the stress uniformity of the optical glass; in addition, the precision is greatly improved, the resolution reaches 0.01nm, and the size of the measurable optical glass is greatly widened. The stress measuring device can better measure the stress optical coefficient of the optical glass; and compared with the other polarized stress meter measuring devices with weight application, the measuring precisions of the pressure and the stress of load are obviously improved, and the measuring precision of the stress optical coefficient can reach 0.03*10<-12> / Pa.

Owner:CDGM OPTICAL GLASS

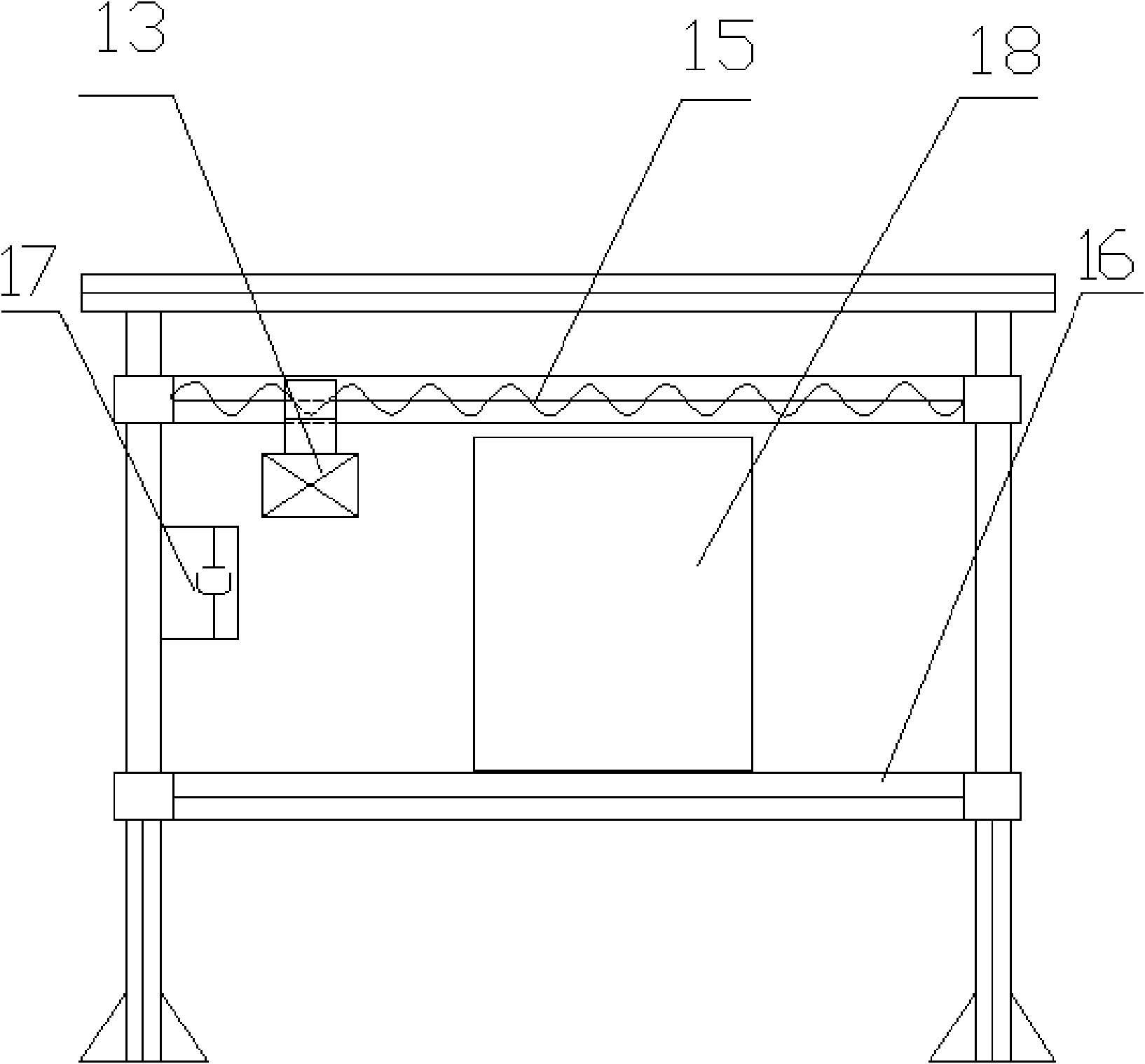

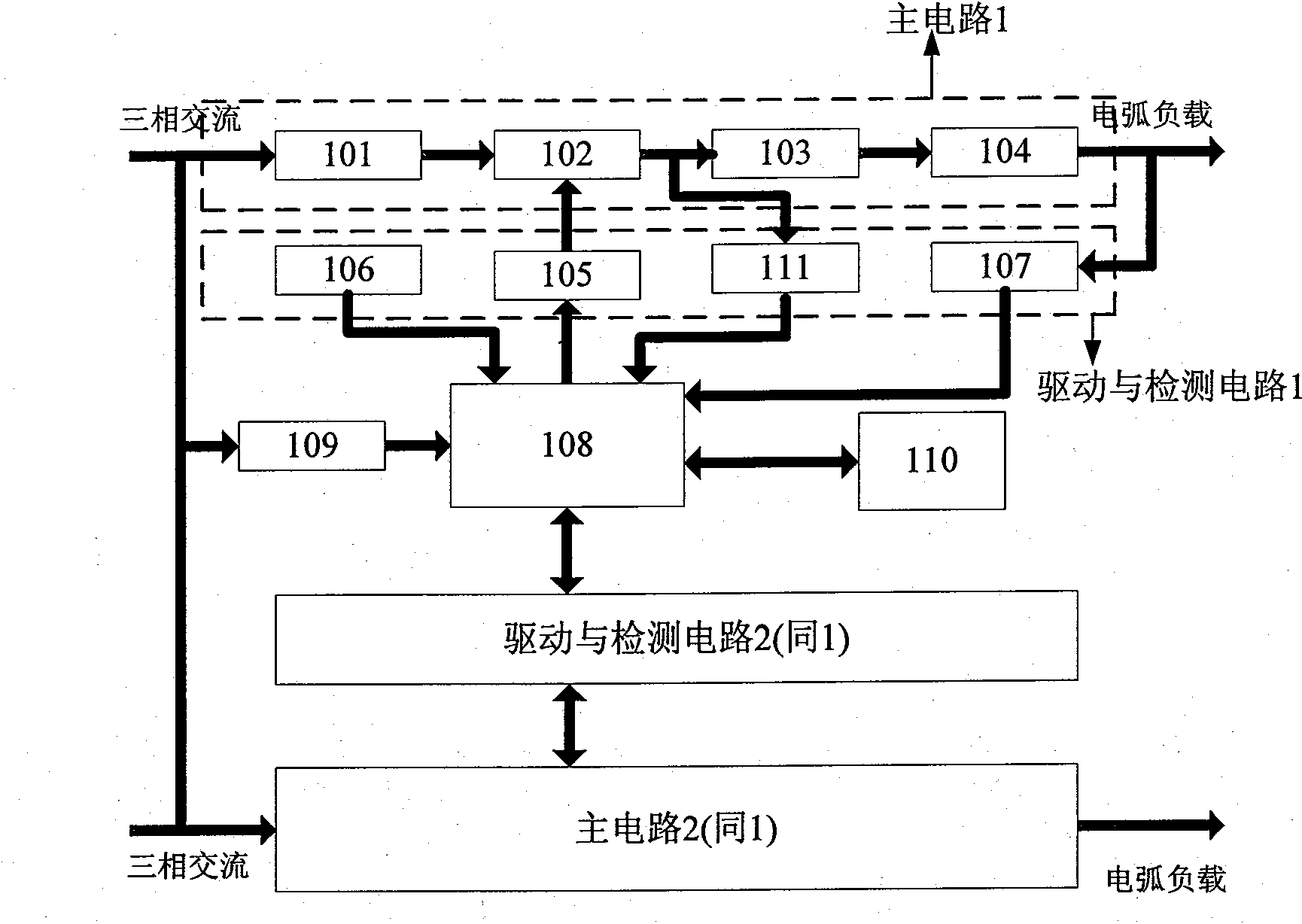

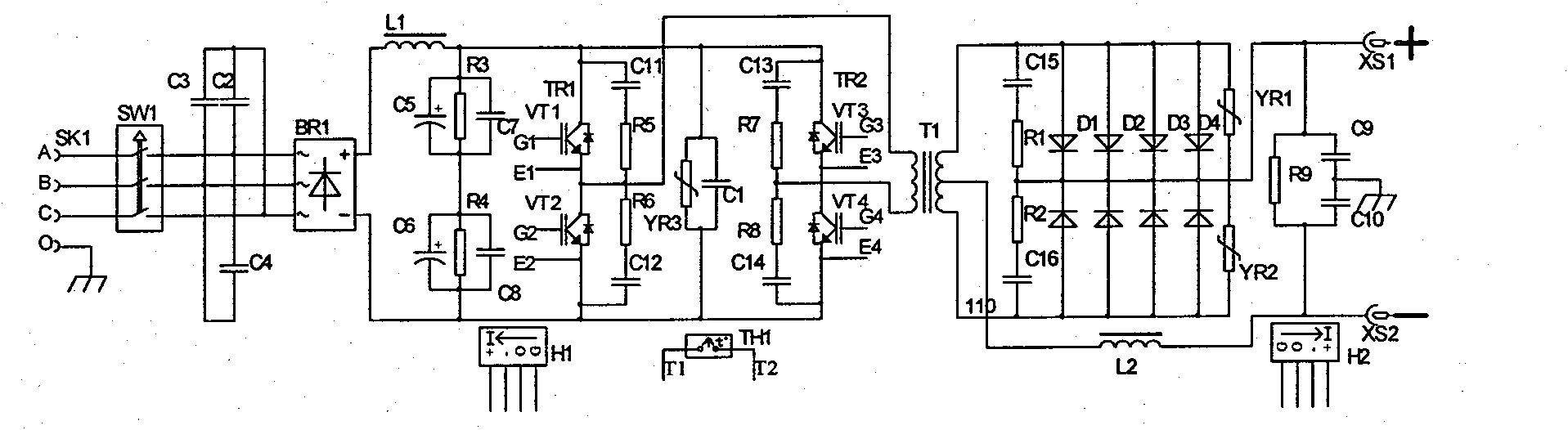

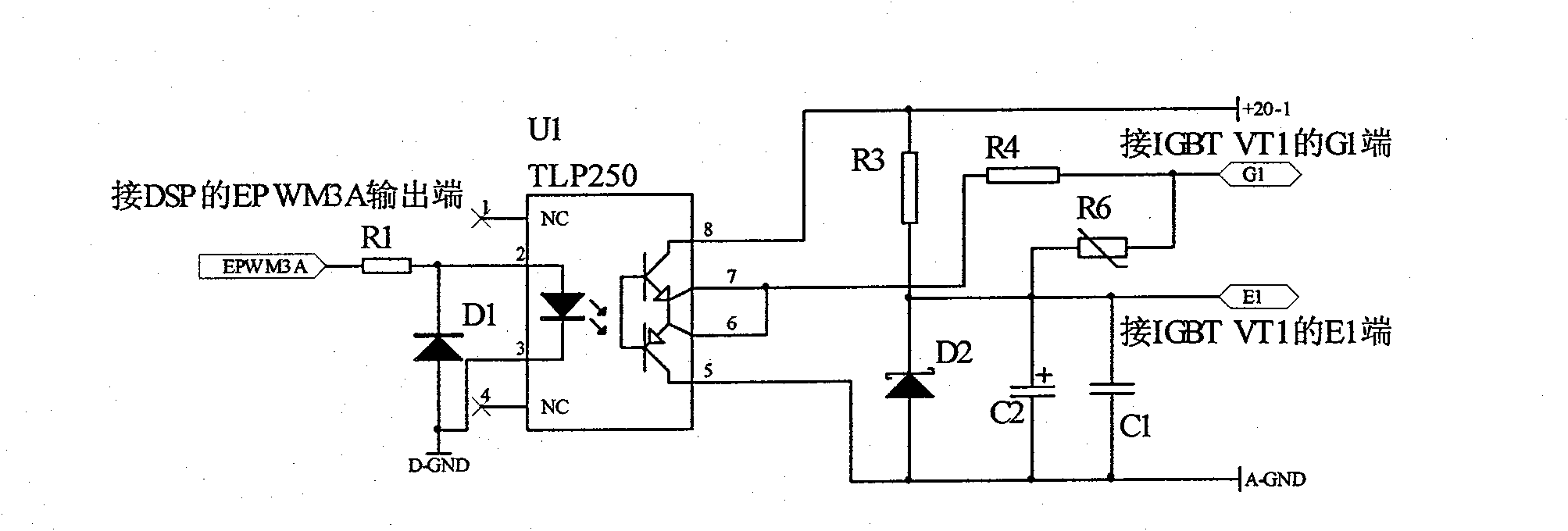

Aluminium alloy twin-wire dipulse welding method and welding power supply thereof

InactiveCN101791733AImprove consistencyImprove dynamic response performanceArc welding apparatusSoft switchingWelding power supply

The invention discloses an aluminium alloy twin-wire dipulse welding method and a welding power supply thereof. The specific method is as follows: carrying out low frequency modulation on pulse wave shapes on the basis of high frequency to obtain periodically varied pulse bursts; and carrying out efficient and superior welding on aluminium alloy through the active phase match of two branches of the pulse bursts. The welding power supply comprises IGBT soft switching main circuits which are integrated into a whole, a DSP control circuit and a man-machine interactive system. The invention puts forward realizing dipulse aluminum alloy welding on a twin-wire welding machine for the first time, realizes all digital control, directly generates eight branches of PWM signals by utilizing a software module, controls the two main circuits, and reduces the control problems caused by communication; and simultaneously, the two main circuits are concentrated on the same welding machine so that the overall structure is much smaller than the master-slave mode welding machine, in addition methods such as instantaneous energy control and the like are adopted to realize the fine control of dipulse.

Owner:SOUTH CHINA UNIV OF TECH

Lithium ion battery automatic dismantling device

ActiveCN106058357ANo deviationTimely recyclingWaste accumulators reclaimingBattery recyclingElectrical batteryEngineering

The invention provides a lithium ion battery automatic dismantling device comprising a frame and a circulation carrier for transferring a waste battery; the frame bottom located at one side of the circulation carrier is successively fixedly provided with a cover plate recycling box, an electric core recycling box, and an outer shell recycling box; the bottom of the frame is successively fixedly provided with a cutting manipulator for annular cutting of a waste battery shell body and two outer shell clamping mechanisms for clamping and fixing the waste battery shell body along the running direction of the circulation carrier; the top of the frame is successively erected with a cover plate recycling mechanism for clamping a waste battery cover plate, an electric core taking-out mechanism for clamping a waste battery electric core, and an outer shell transfer mechanism for clamping the waste battery shell body along the running direction of the circulation carrier; the cover plate recycling mechanism and the electric core taking-out mechanism are respectively located at the top ends of the two outer shell clamping mechanisms; an electrode ear cutting mechanism for cutting a waste battery electrode ear is arranged between the cover plate recycling mechanism and the outer shell clamping mechanism. The automation degree is improved, the work efficiency is increased, and the intensity of work is reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

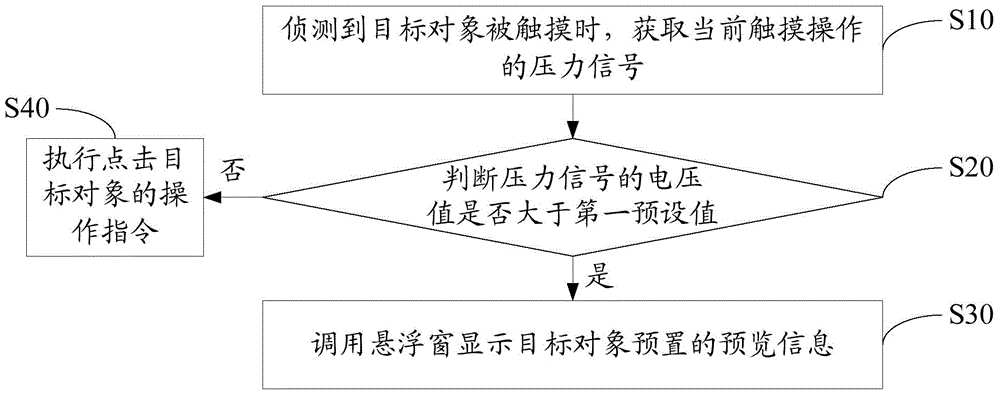

Method and device for previewing object information

InactiveCN104915141AReduce the difficulty of operationInput/output processes for data processingComputer visionArtificial intelligence

The invention discloses a method and a device for previewing object information. The method for previewing the object information comprises the following steps: obtaining the pressure signal of a current touch operation when a target object is detected to be touched; judging whether the voltage value of the pressure signal is greater than a first preset value; if yes, calling a suspension window to display preset previewing information of the target object; if not, carrying out an operational order for clicking the target object. The invention also discloses a device for previewing the object information. The operation difficulty of object browsing is reduced.

Owner:NUBIA TECHNOLOGY CO LTD

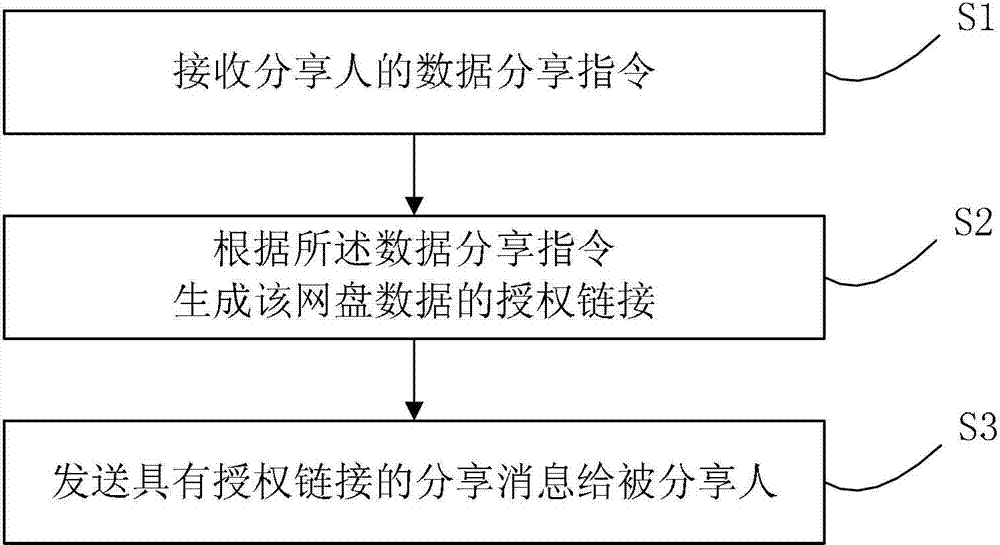

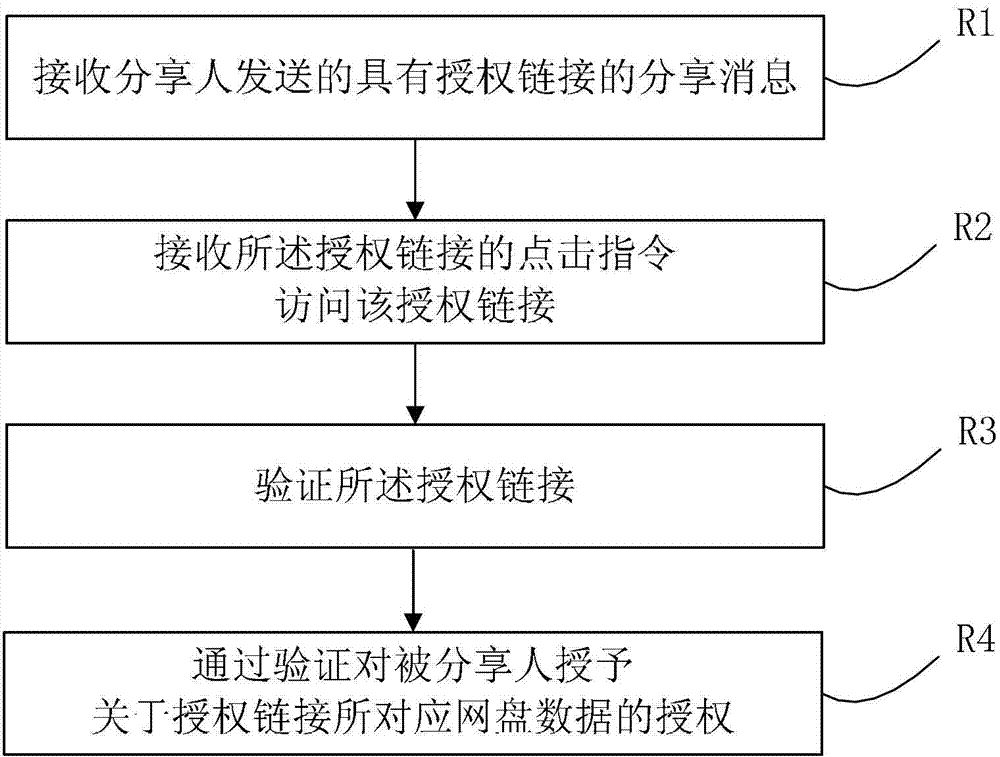

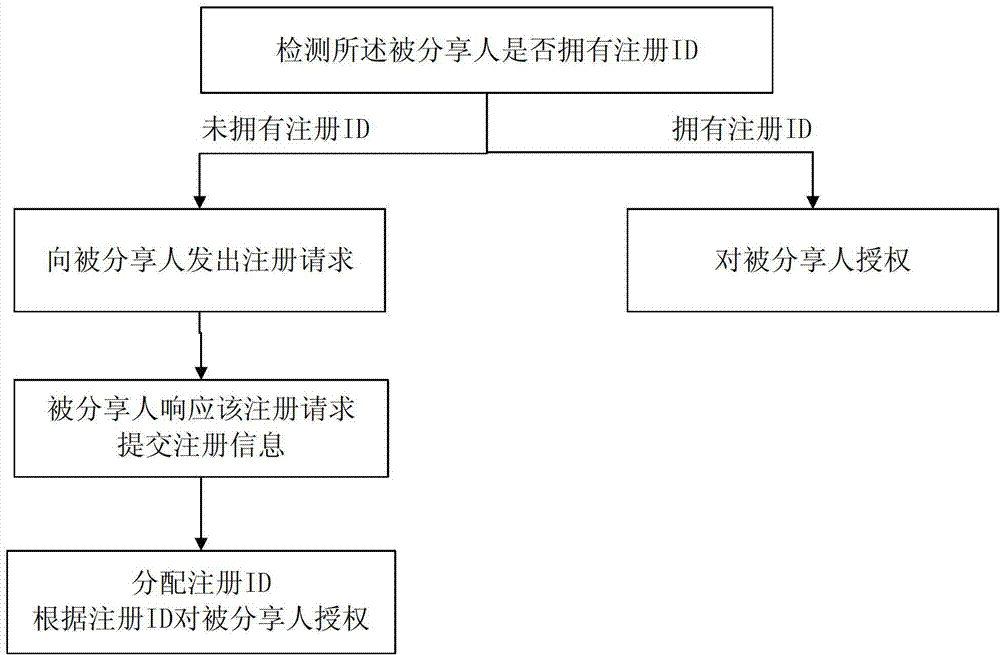

Method and system for sharing network disk data

ActiveCN103248680AReduce the difficulty of operationAchieve sharingTransmissionData sharingAuthorization

The invention provides a method and system for sharing network disk data. The method comprises the following steps: receiving the data sharing instruction of a sharing person, which includes to-be-shared information of the network disk data; generating an authorization link of the network disk data according to the data sharing instruction; receiving the sharing message including the authorization link and sent by the sharing person; verifying the authorization link; and granting a to-be-shared person the authorization of the network disk data corresponding to the related authorization link. The method and the system are used for generating the corresponding authorization link which is used for verifying the authorization according to the to-be-shared network disk data and sending the sharing message including the authorization link to the to-be-shared person. The method and the system actively realize the sharing of the network disk dada under the condition that the sharing person does not need to consider whether the to-be-shared person has a registered ID (Identification) or registers an ID at all, reduce the operation difficulty, and provide convenience for a user.

Owner:XIAOMI INC

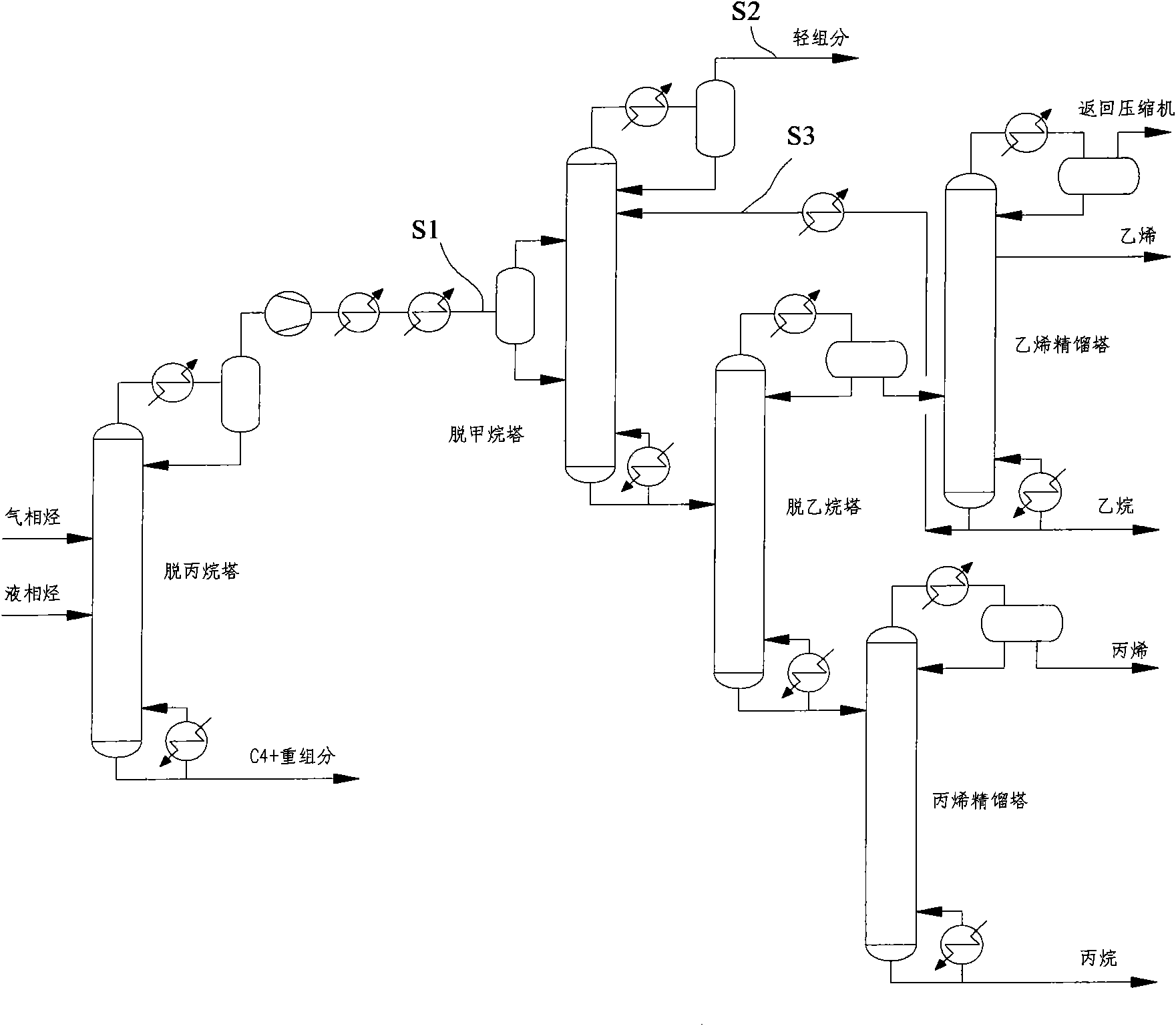

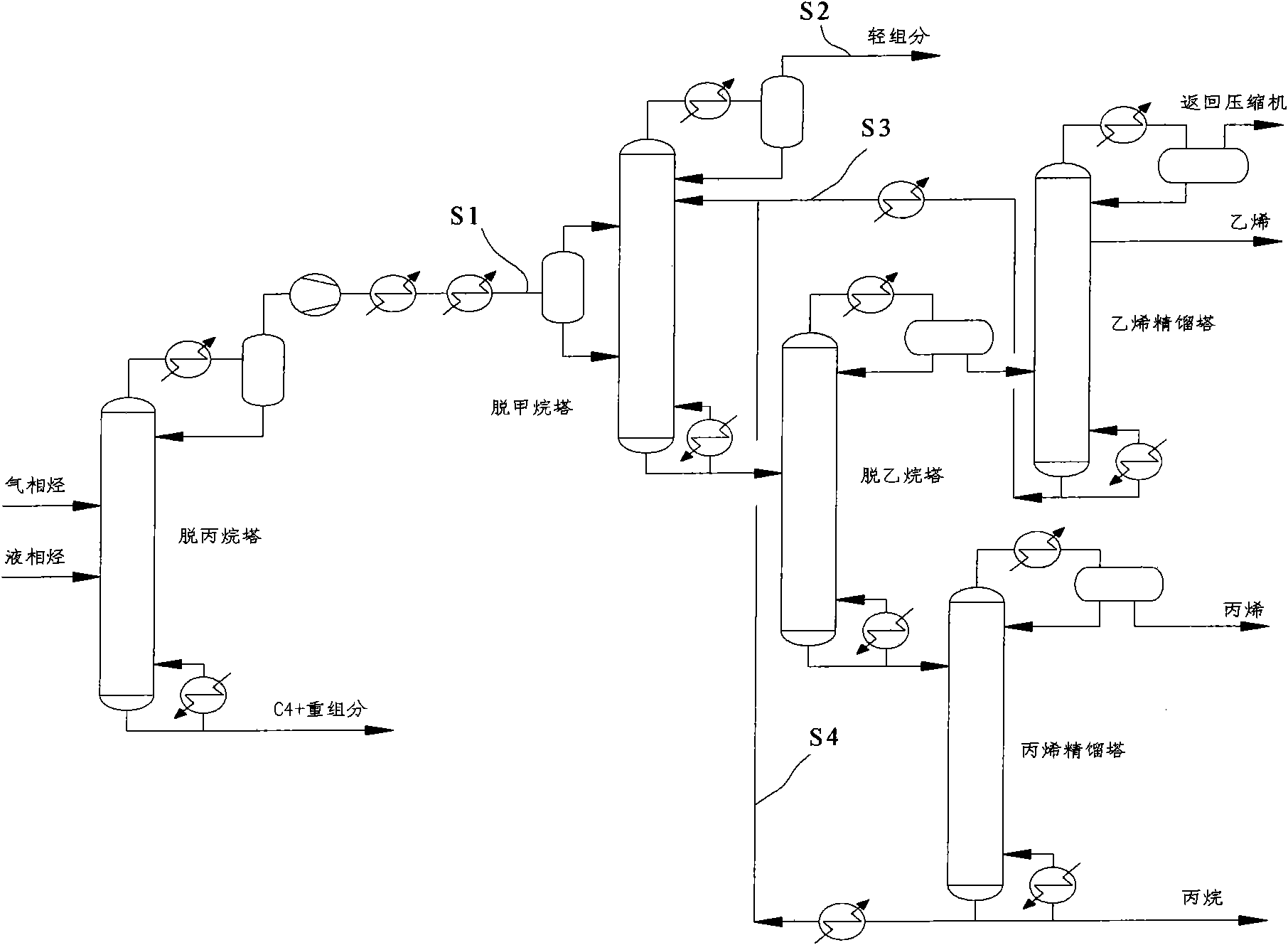

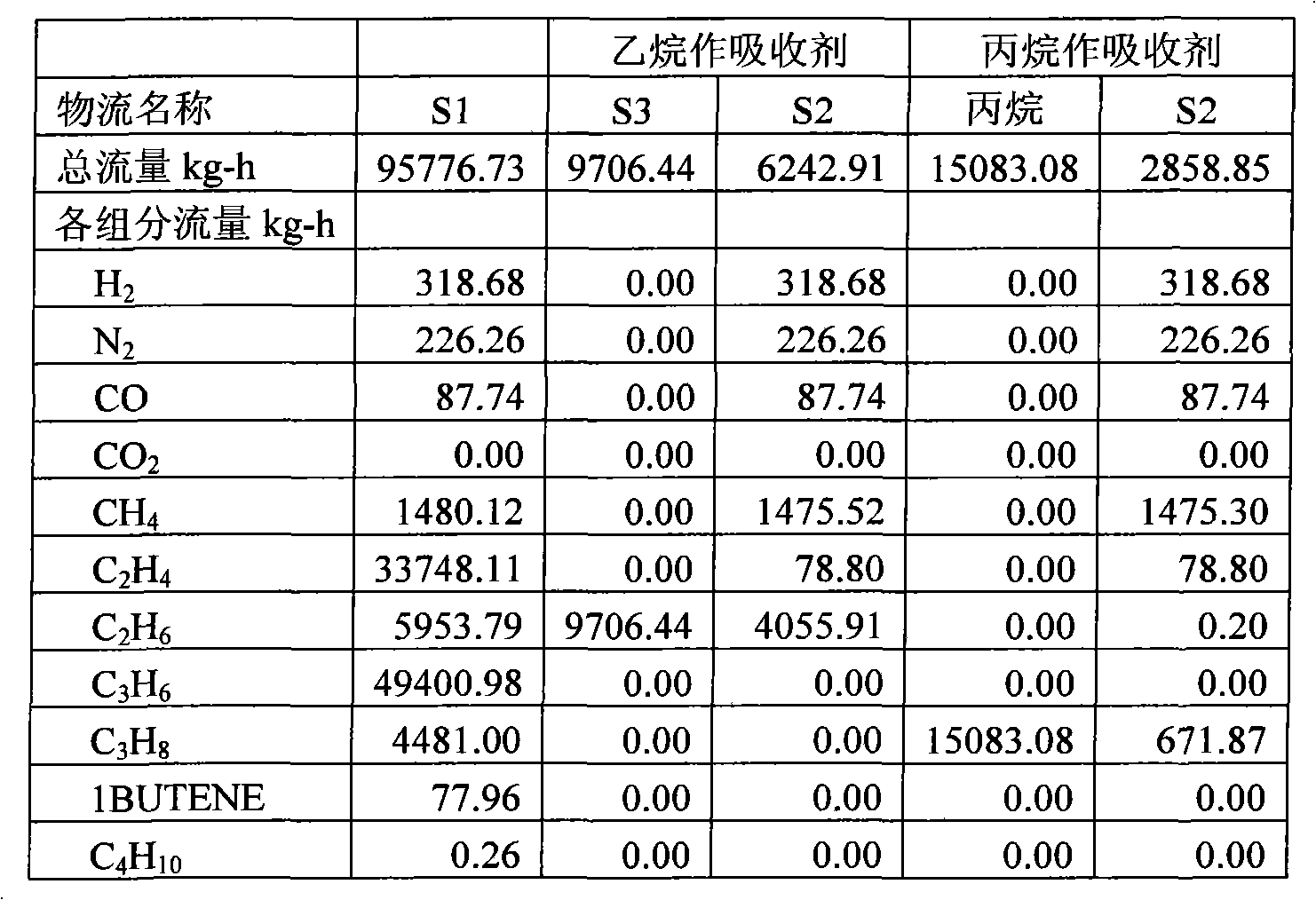

Separation method for producing light olefins from oxygenated chemicals

InactiveCN101973831AReduce investmentReduce the difficulty of operationGaseous fuelsEthylene productionGas phaseMethane

The invention discloses a separation method for producing light olefins from oxygenated chemicals. In the method, a product from a reactor for producing the light olefins from the oxygenated chemicals and / or a product generated from olefins catalytic cracking are mixed, and the mixture is treated by a series of pretreatment steps of heat recovery, compression, purification, cooling and the like and is separated into gas-phase hydrocarbon and liquid-phase hydrocarbon; the gas-phase hydrocarbon and the liquid-phase hydrocarbon respectively enter different column plates of a depropanizing column to be in (C3-)-(C4+) separation; after being subjected to further compressing and cooling, light components of C3 and below on the top of the depropanizing column enter the depropanizing column, and ethane is used as an absorbent on the top of the depropanizing column to enhance the recovery rate of the ethane; C2-C3 at the bottom of the depropanizing column enter a deethanizing column to separate C2 and C3; the C2 enters an ethylene rectifying column, ethylene is produced through side drawing, noncondensable gas on the top of the ethylene rectifying column returns to a compressor, after totally cooling, the ethane at the bottom of the column is recovered as an absorbent of a demethanizing column or partly as fuel gas; and C3 enters a propylene rectification tower, propylene is recovered on the tower top, and propane is recovered at the tower bottom, as an LPG (Liquid Petroleum Gas) byproduct. The invention has the advantages of high ethylene yield, low energy consumption, little investment and the like, and the byproduct can be effectively utilized.

Owner:EAST CHINA ENG SCI & TECH

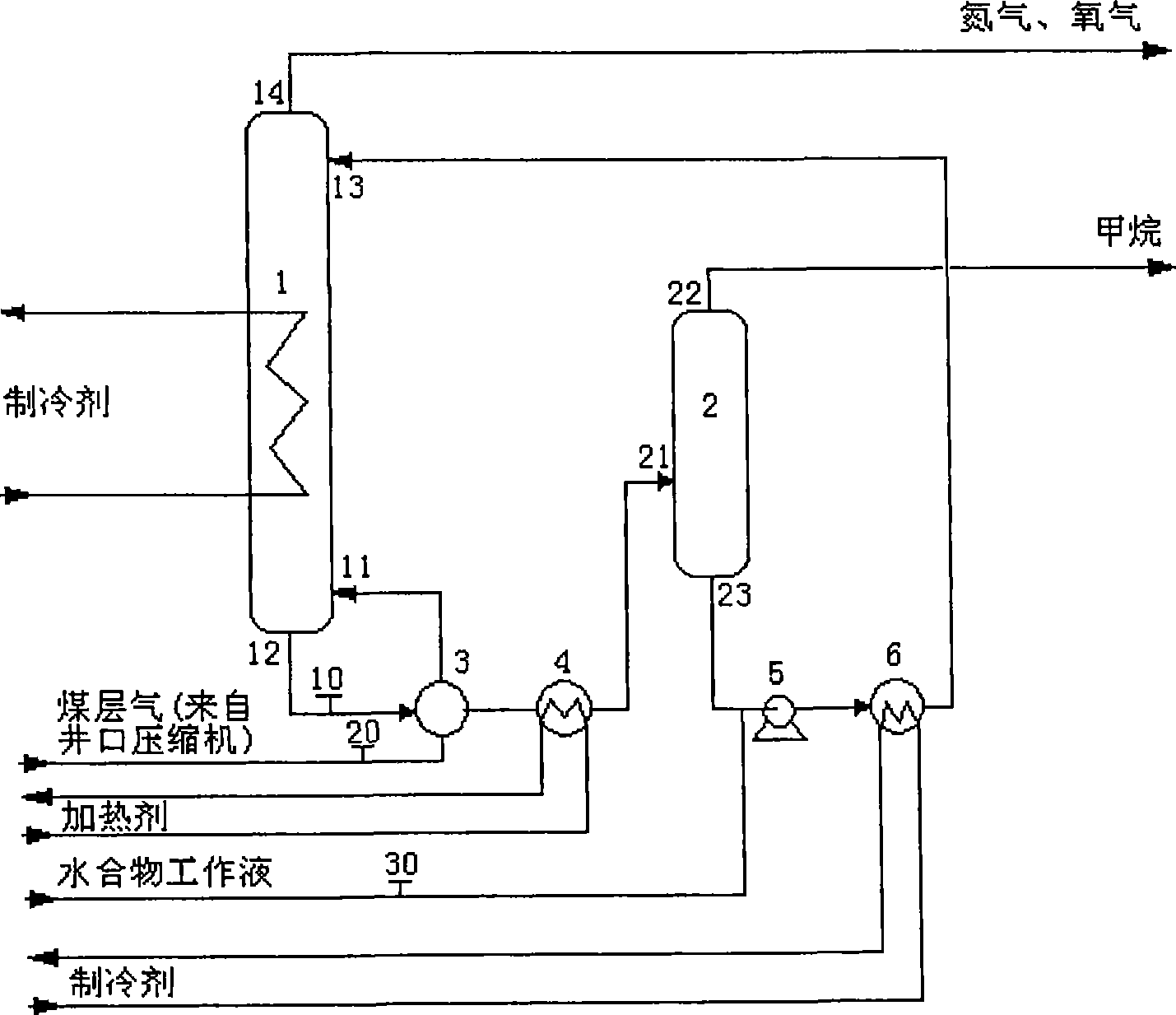

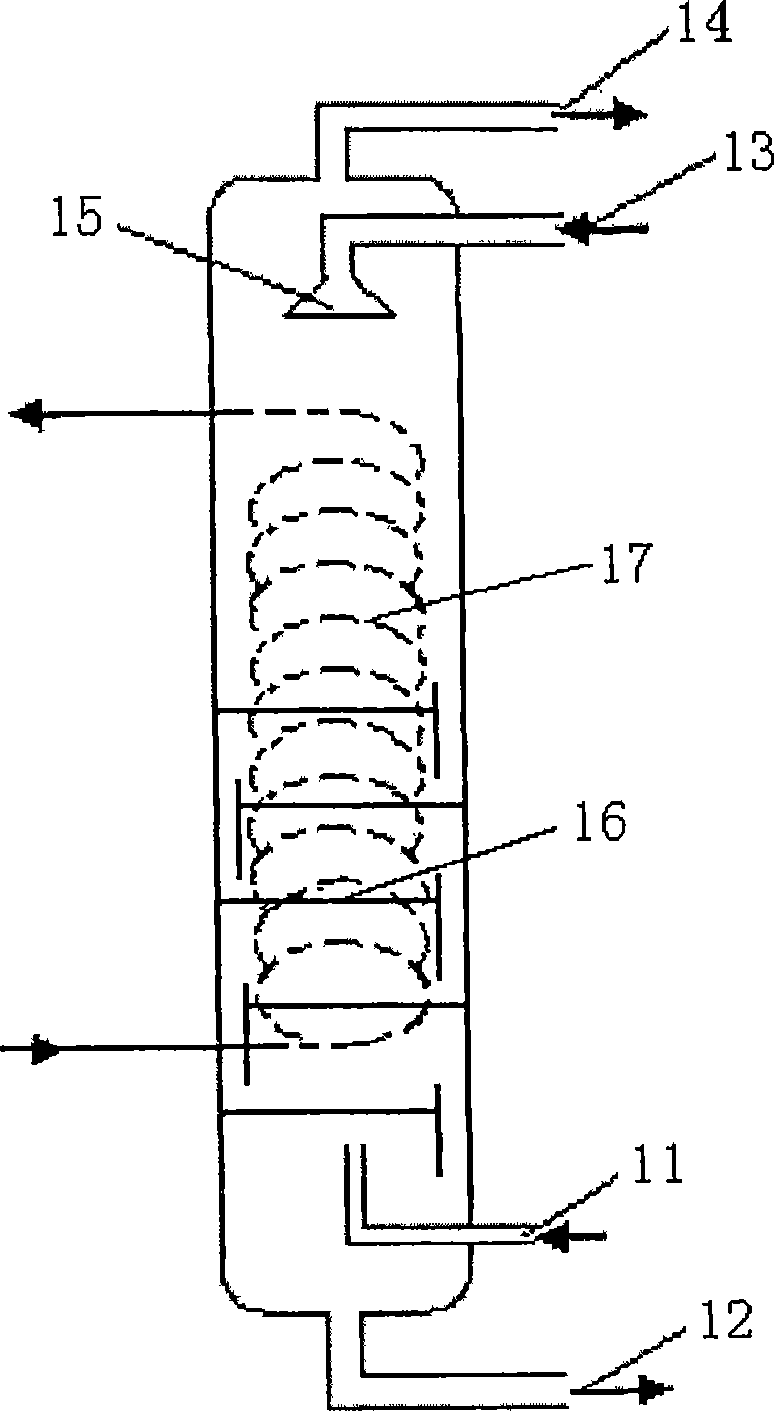

Method and device for low-pressure processing of coal bed gas

InactiveCN101530719AReduce concentrationEmission reductionDispersed particle separationAbsorption purification/separationHydration reactionHigh concentration

The invention relates to a method for low-pressure processing of coal bed gas, comprising the steps of: introducing the coal bed gas into a hydration reactor from the bottom part of a hydration reactor so as to be contacted with hydrate working liquid in the hydration reactor, leading methane contained in the coal bed gas and water in the hydrate working liquid to generate hydration reaction to form a hydrate which is removed from the coal bed gas; meanwhile, the purified gas is obtained after the methane in the coal bed gas is removed; wherein the operation pressure of the hydration reactor is 0.11-0.85MPa, and the temperature is 3-18 DEG C. The formed hydrate can be further introduced into a hydrate decomposition device for decomposition, thereby obtaining the methane with high concentration. The invention simultaneously relates to a device for realizing the method for low-pressure processing of the coal bed gas. The invention can safely purify the oxygen-containing coal bed gas under lower pressure and remove the contained methane to be lower than 0.05 molar fraction, thereby reducing the emission of the methane, reducing the greenhouse effect and simultaneously avoiding the risk of explosion.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

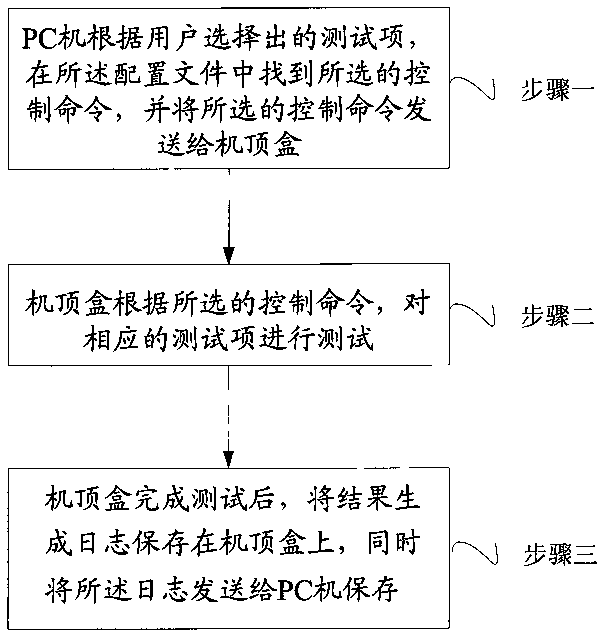

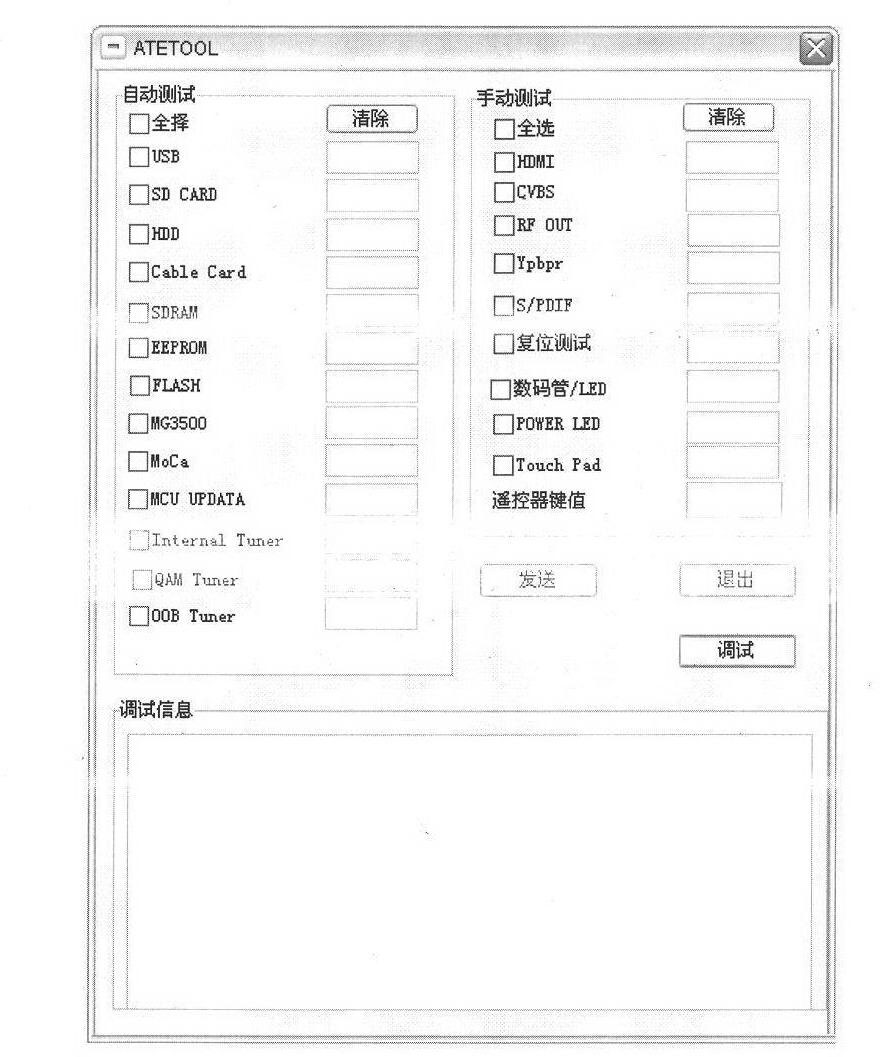

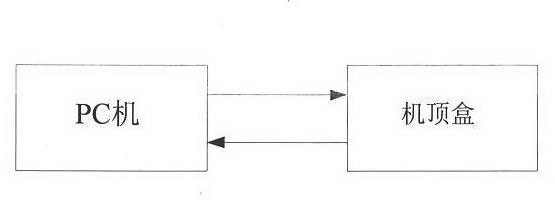

Test method of set-top box and test system thereof

InactiveCN102665094AEasy to operateSmall amount of software codeTelevision systemsTest executionSet top box

The invention relates to the set-top box field, especially to a test method of a set-top box and a test system thereof. The method comprises the following steps that: a configuration file is stored in a PC machine in advance, wherein the configuration file includes a plurality of control commands and each control command corresponds to one test item, and the PC machine generates a test interface including a plurality of test items; after a user selects a test item that needs to be tested on the test interface, the PC machine finds a selected control command in the configuration file according to the test item selected by the user and sends the selected control command to a set-top box; the set-top box tests a corresponding test item according to the selected control command; and after the test by the set-top box is completed, the result is generated into a log that is then stored in the set-top box; and meanwhile, the log is sent to the PC machine for storage. According to the invention, test interface software is developed on a PC machine and matched test execution software is developed on a set-top box; the software code scale is small; and besides, characteristics of simpleness, easiness of maintenance, easiness of operation and high portability are realized.

Owner:SHENZHEN JIUZHOU ELECTRIC

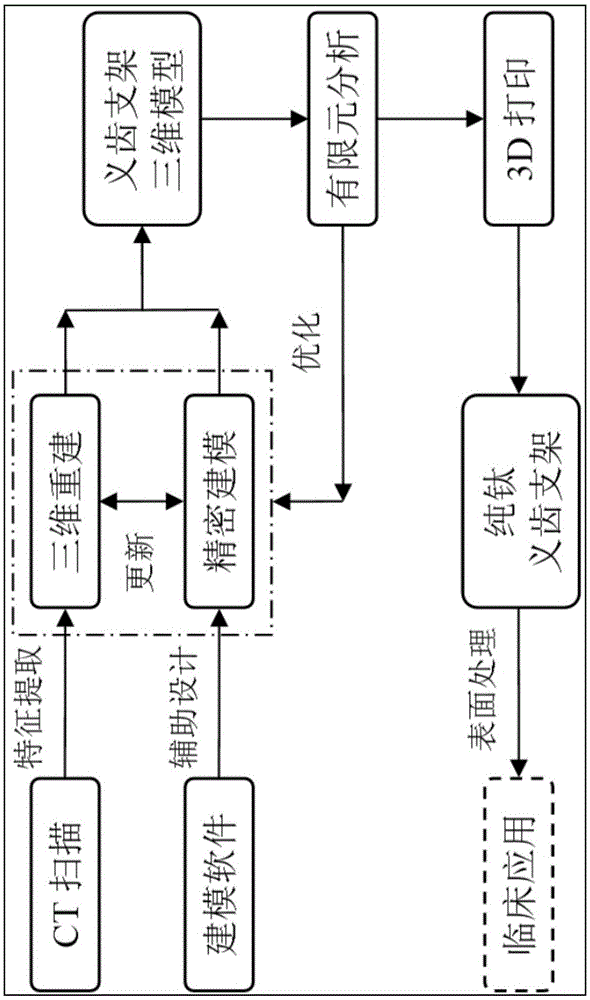

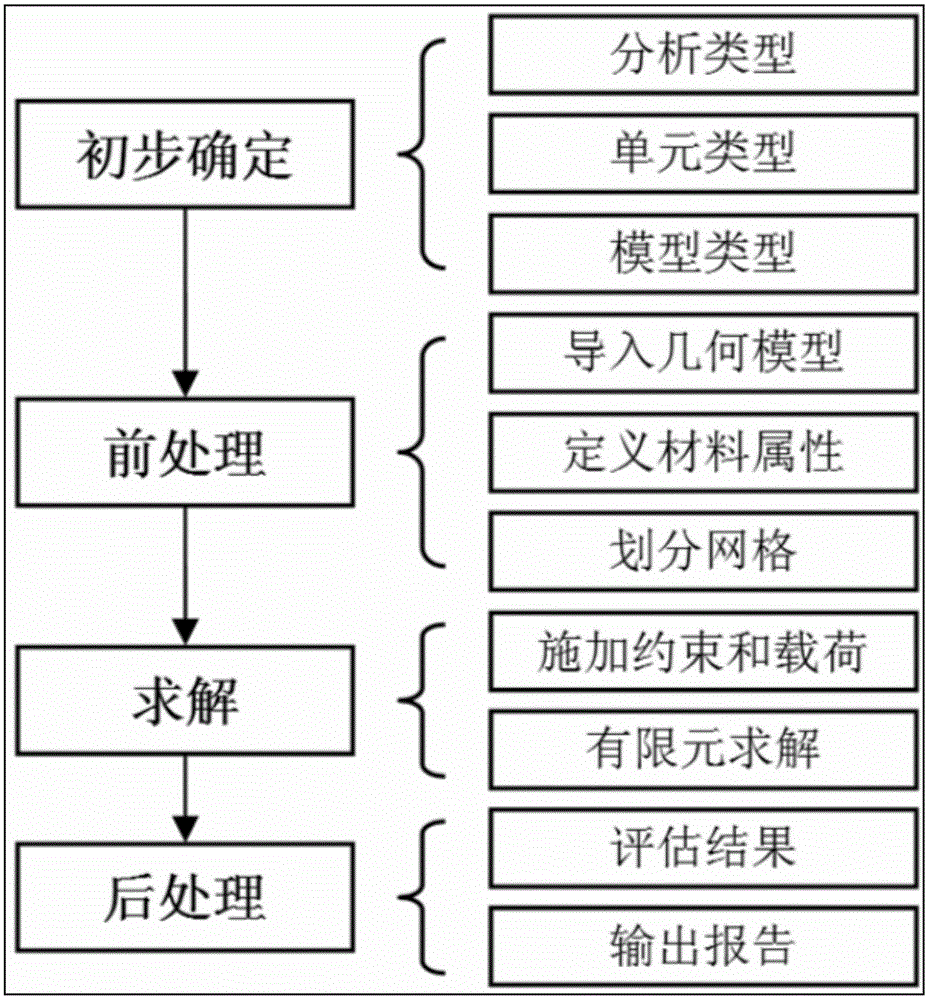

Method for preparing false tooth support through 3D printing laser stereo-lithography technology

InactiveCN104999078AGuaranteed comfortGuaranteed service lifeAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing cost reductionFinite element technique

The invention discloses a method for preparing a false tooth support through a 3D printing laser stereo-lithography technology. According to the method for preparing the false tooth support through the 3D printing laser stereo-lithography technology, the individual false tooth support most suitable for a patient is printed through the 3D printing laser stereo-lithography technology; the comfort level and the service life of the false tooth support are ensured by means of a finite element technology; the operation difficulty of a physician is lowered; the manufacturing cost is reduced; the manufacturing period is shortened. The surface of the false tooth support is processed through an anodizing and / or electrochemical deposition method so that the surface of the false tooth support can have more excellent synosteosis features and biology activity, osteoblast growth and surface calcification are facilitated, and the satisfaction of the patient is improved. The method is suitable for the field of medical devices.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

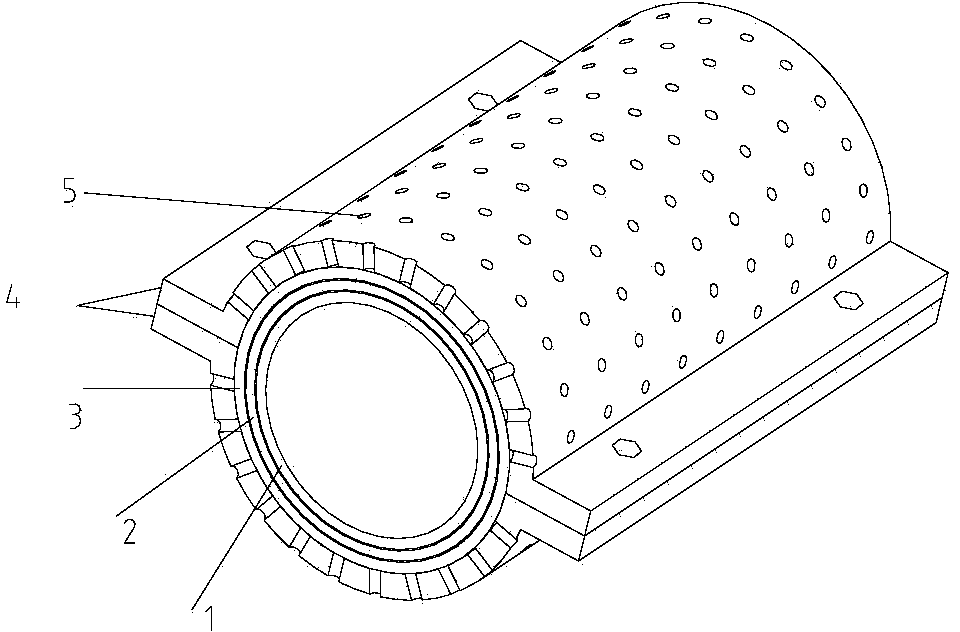

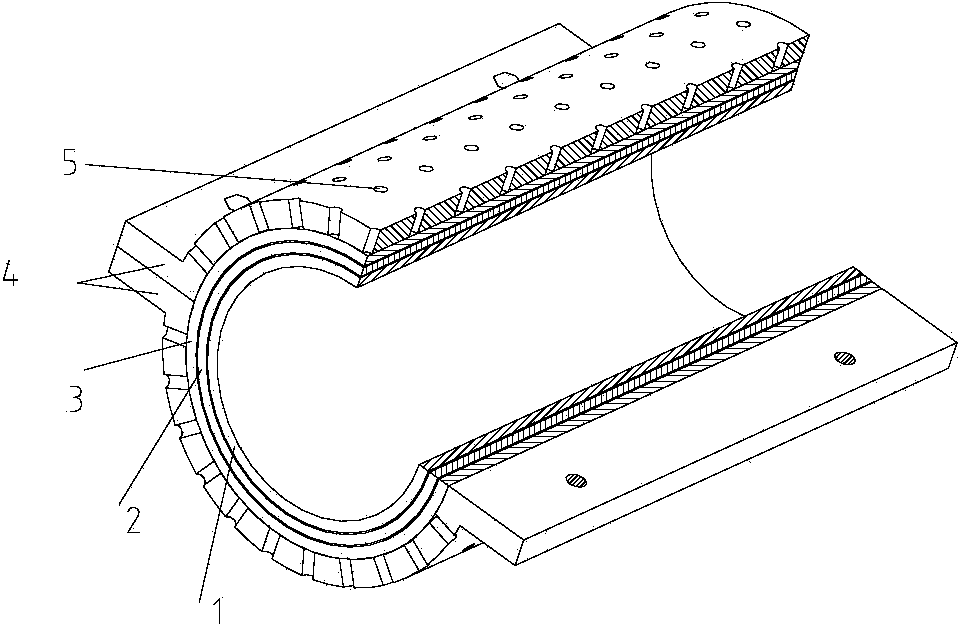

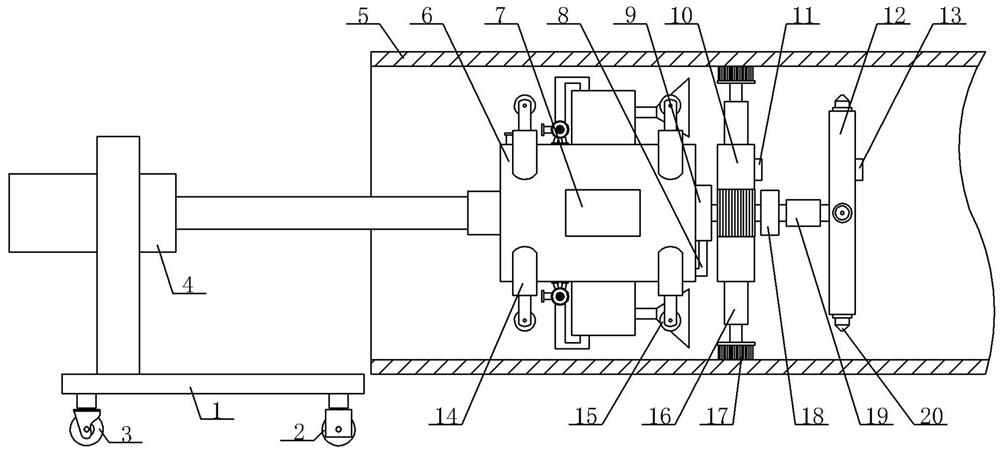

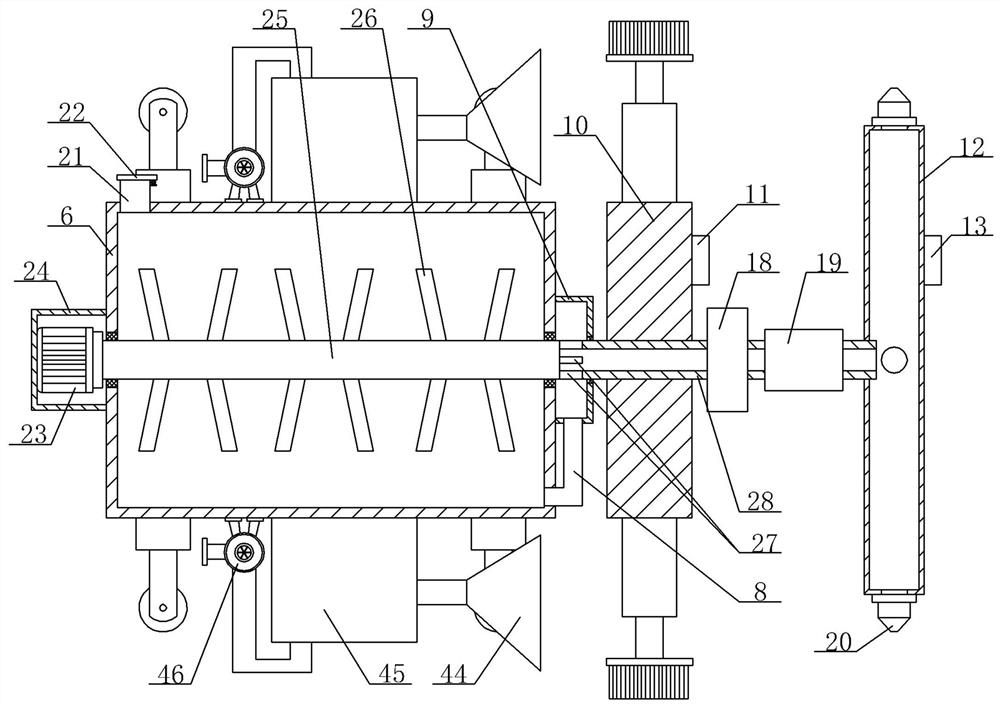

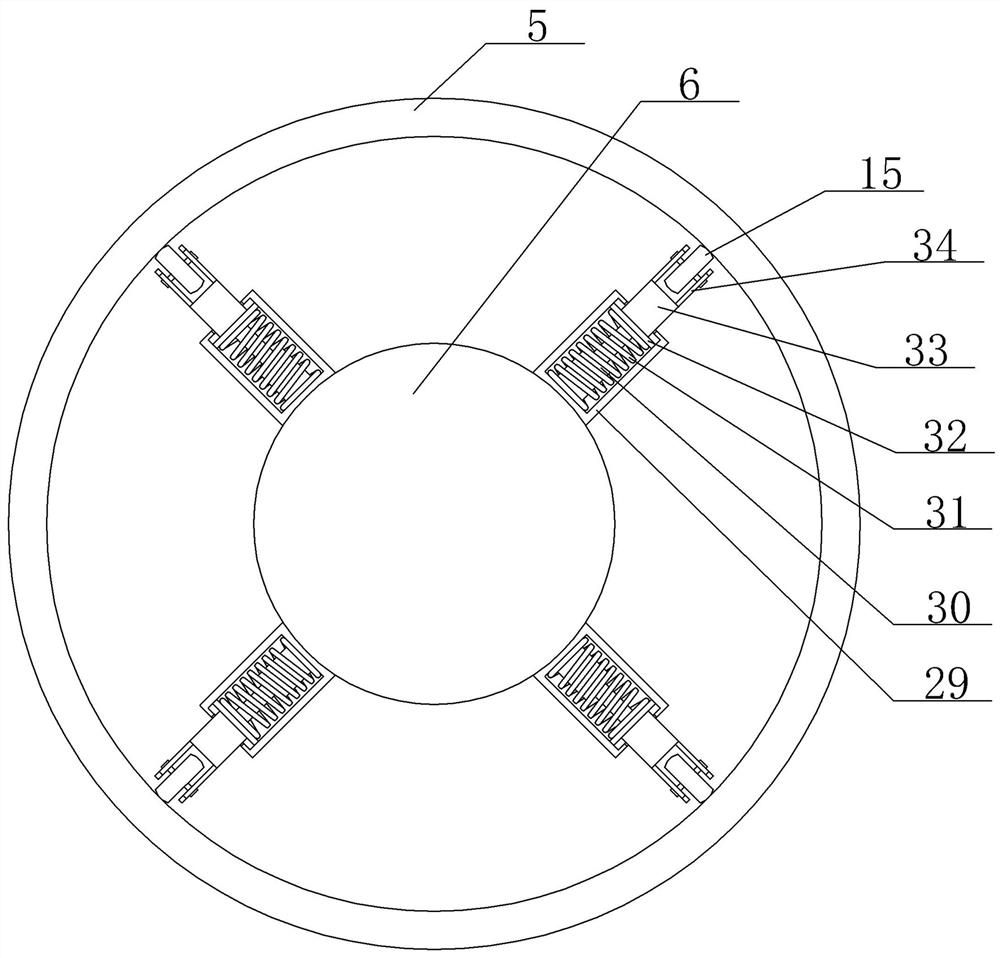

Petrolatum spraying equipment for pipeline corrosion prevention

ActiveCN111889281AEasy to moveReasonable designHollow article cleaningSpray boothsSprayerElectric machinery

The invention relates to petrolatum spraying equipment for pipeline corrosion prevention. The petrolatum spraying equipment for pipeline corrosion prevention comprises a pipeline, a spraying device and a traction device, the spraying device comprises a coating barrel, walking mechanisms are arranged at the two ends of the outer side wall of the coating barrel, a stirring shaft is rotationally arranged in the coating barrel, a plurality of stirring paddles are arranged on the stirring shaft at intervals, one end of the stirring shaft extends out of the coating barrel and is in transmission connection with a driving motor, the other end of the stirring shaft extends out of the coating barrel and is fixedly connected with a hollow rotating shaft, a plurality of feeding holes are formed in theouter side wall of one end, close to the coating barrel, of the rotating shaft, sealing covers rotationally cover the outer part of the end, the sealing covers are fixedly arranged on the outer end walls of the corresponding coating barrels, the bottoms of the sealing covers communicate with the inner bottoms of the coating barrels through feeding pipes, the other end of the rotating shaft communicate with spraying discs, a plurality of sprayers are arranged on the spraying discs in the circumferential direction, a pressure control valves, a feeding pump and rotating discs are arranged on therotating shaft, and multiple sets of cleaning brushes are arranged on the rotating discs in the circumferential direction at intervals. Automatic cleaning and spraying operation of the pipeline can be achieved, and the spraying efficiency and the spraying quality can be greatly improved.

Owner:开封新奥燃气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com