Aluminium alloy twin-wire dipulse welding method and welding power supply thereof

A welding power supply and double pulse technology, which is applied in the field of aluminum alloy high-speed arc welding processing, aluminum alloy double wire double pulse welding, can solve problems such as unstable welding, achieve good consistency, save volume, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the implementation method and scope of protection of the present invention are not limited thereto.

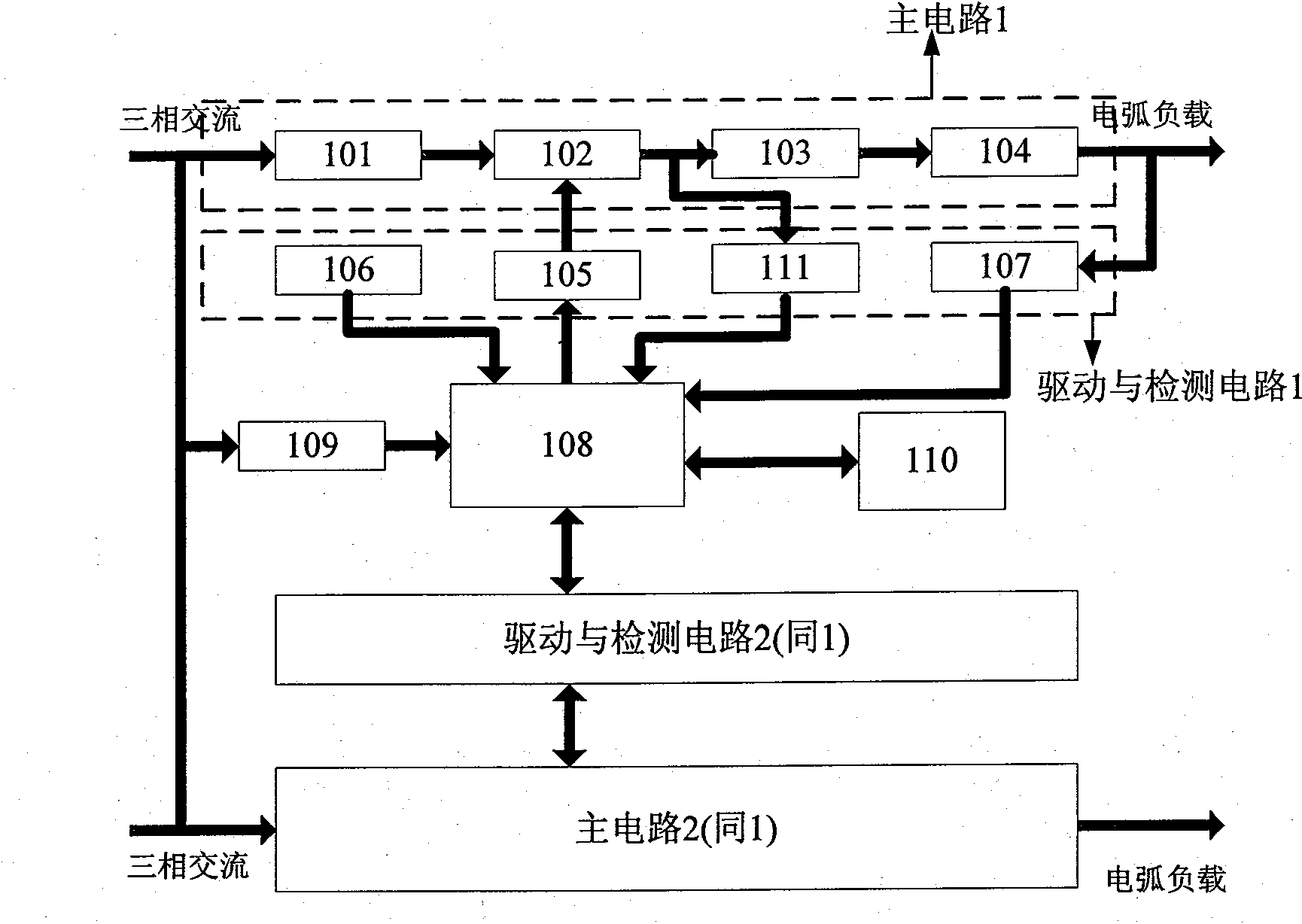

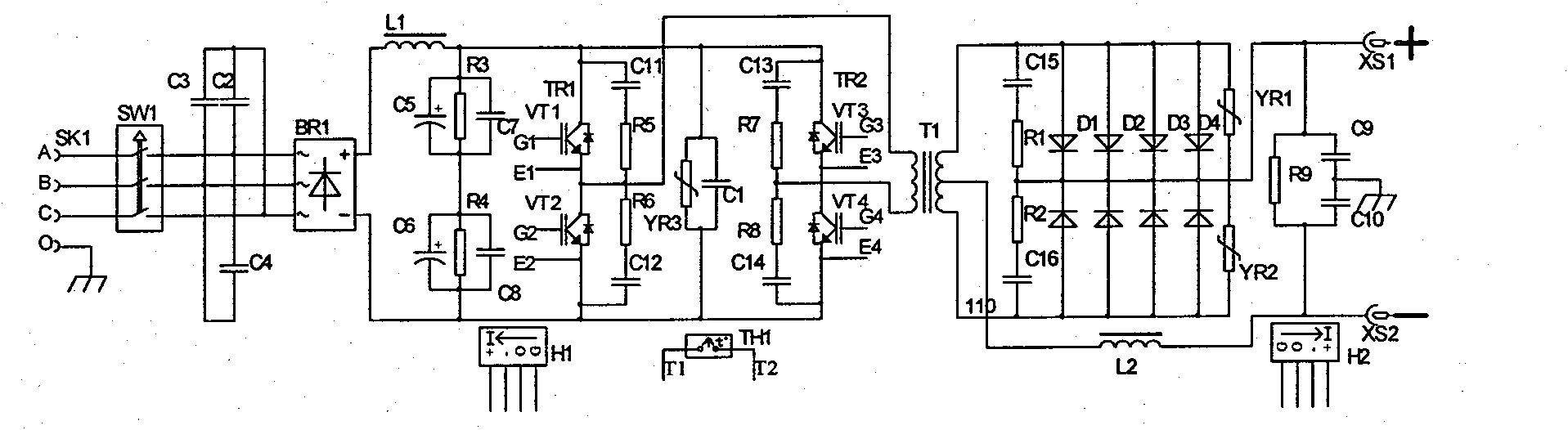

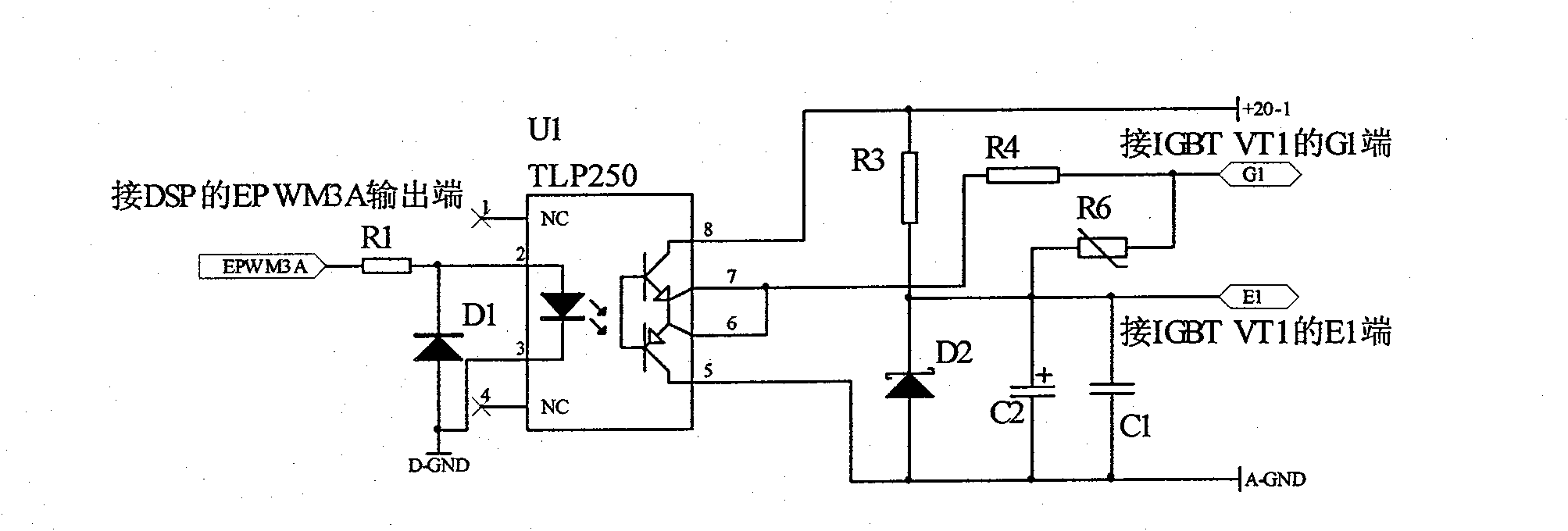

[0068] Such as figure 1 As shown, it is a multifunctional digital double wire soft switch welding power supply of the present invention, which consists of a main circuit 1 and a main circuit 2, a drive and detection circuit 1 and a drive and detection circuit 2, a DSP controller 108, and an overvoltage and undervoltage protection detection module 109, and a human-computer interaction system 110 constitutes. Wherein, the main circuit 1 and the main circuit 2 have the same structure and composition, and the same is true for the driving and detecting circuit 1 and the driving and detecting circuit 2 . Taking the main circuit 1 as an example, it is composed of a rectification and filtering module 101 , a high-frequency inverter module 102 , a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com