Patents

Literature

8398 results about "Aerospace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerospace is the human effort in science, engineering, and business to fly in the atmosphere of Earth (aeronautics) and surrounding space (astronautics). Aerospace organizations research, design, manufacture, operate, or maintain aircraft or spacecraft. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications.

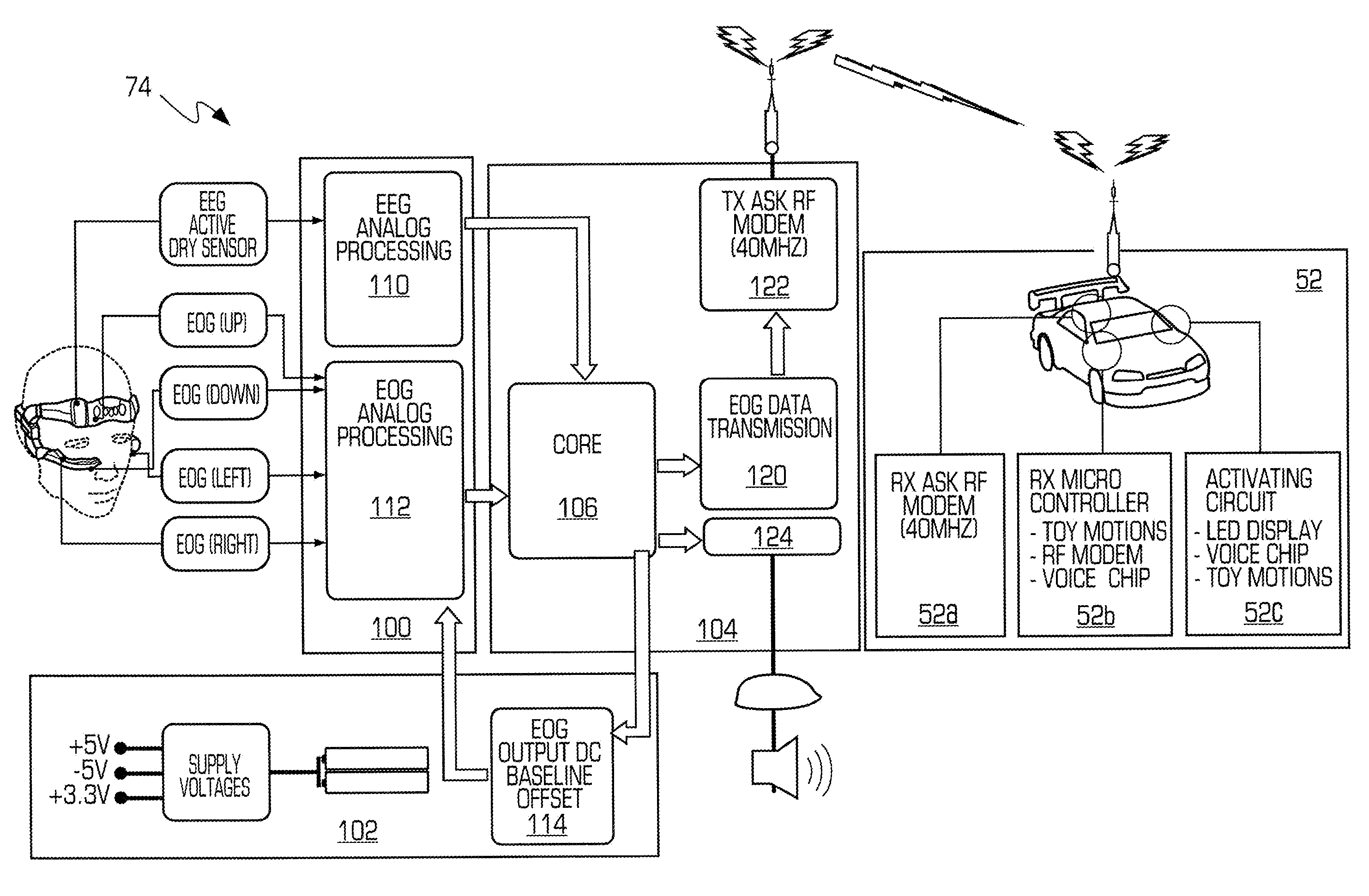

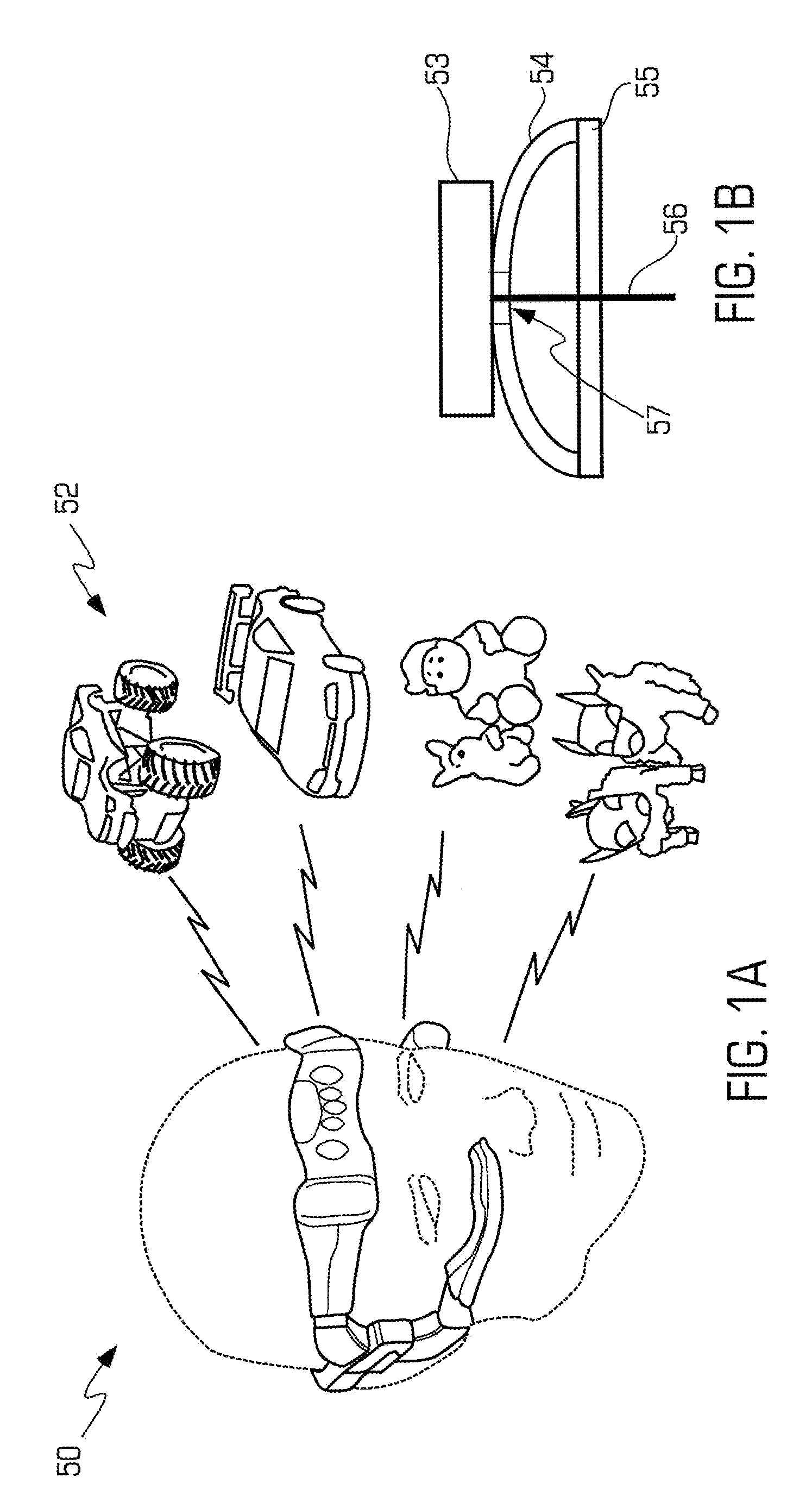

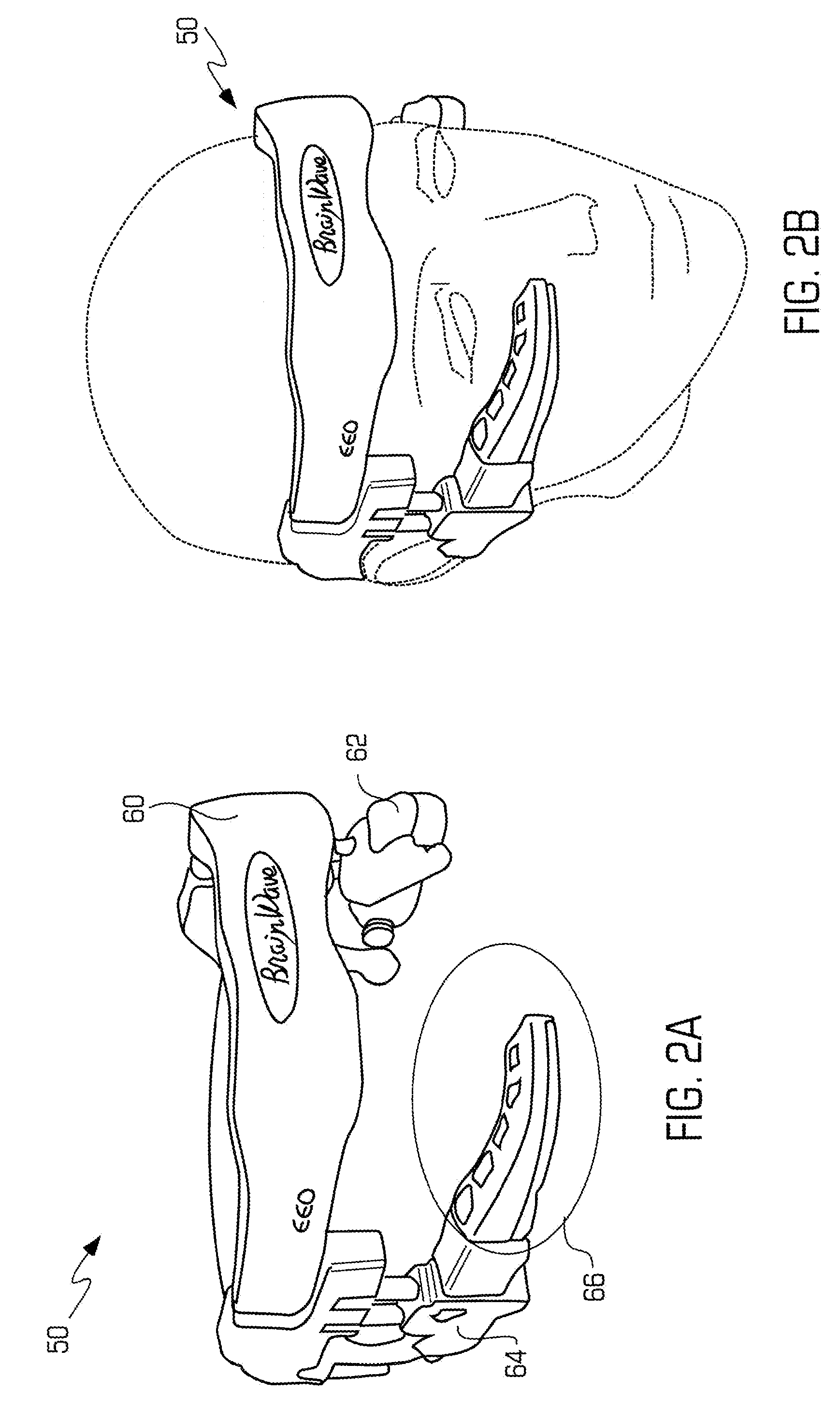

Method and apparatus for quantitatively evaluating mental states based on brain wave signal processing system

A noise-free portable EEG system is provided. The system has hardware and software and can evaluate mental state quantitatively. The quantitative data of mental states and their levels can be applied to various areas of brain-machine interface including consumer products, video game, toys, military and aerospace as well as biofeedback or neurofeedback.

Owner:NEUROSKY

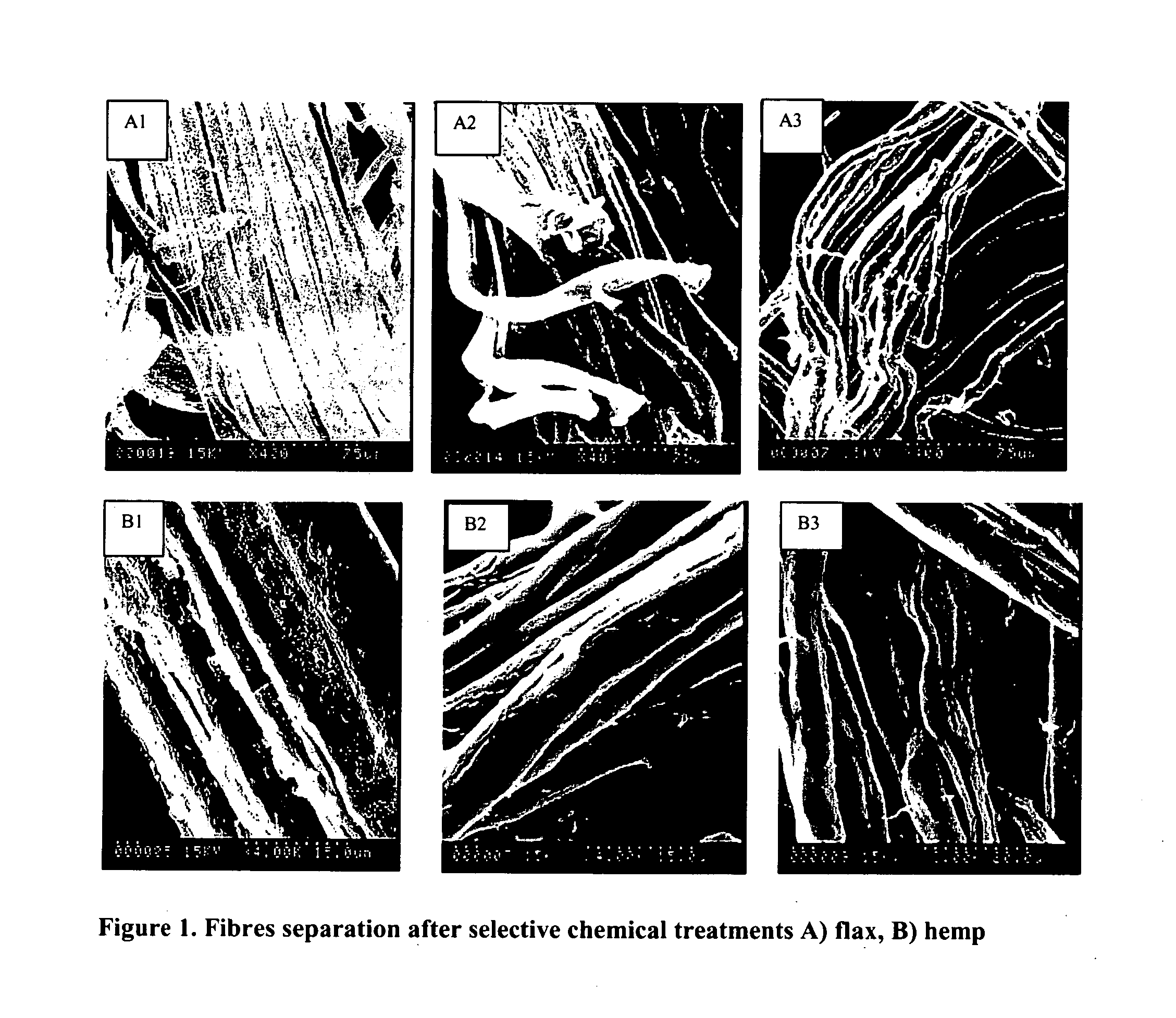

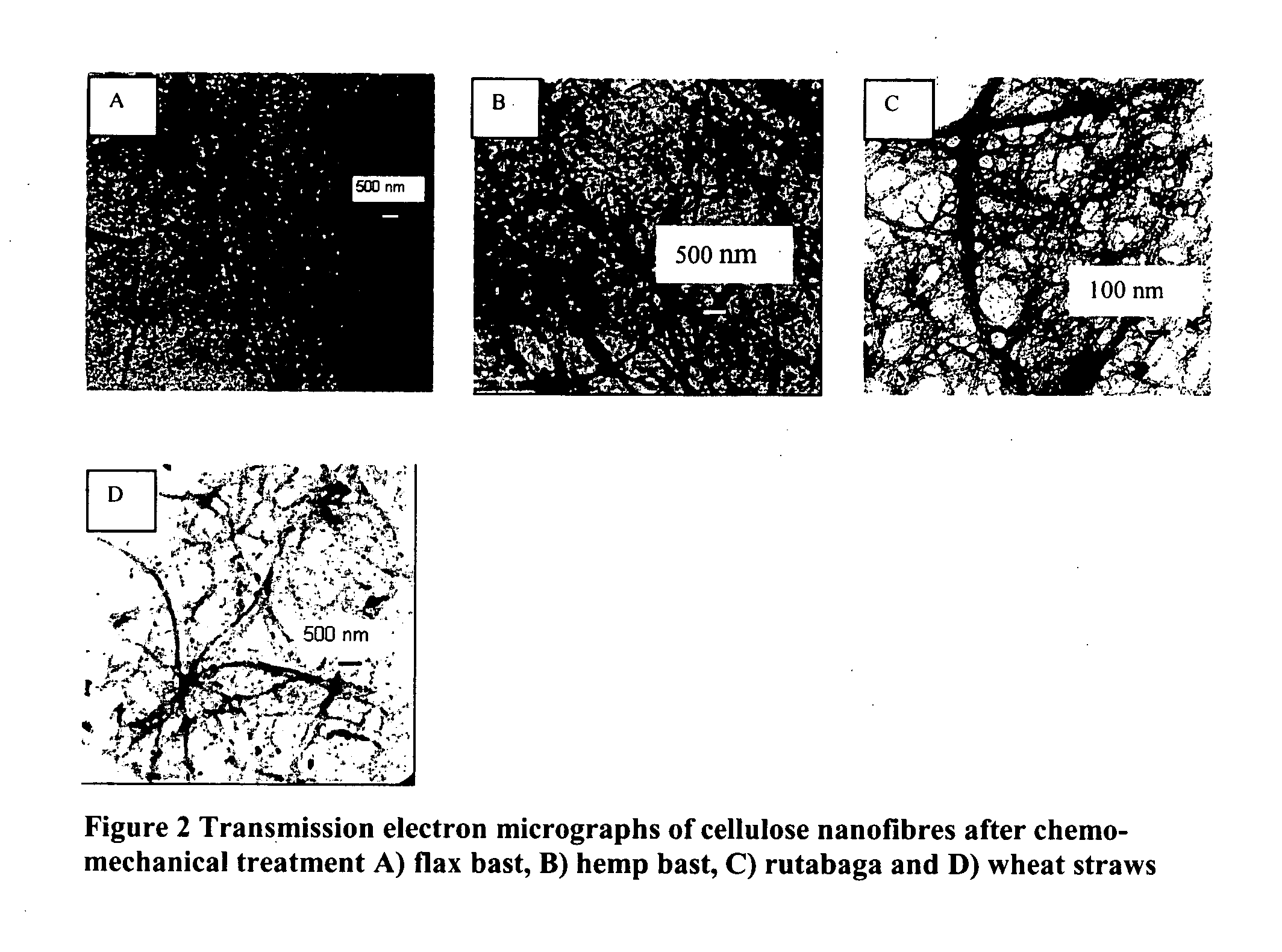

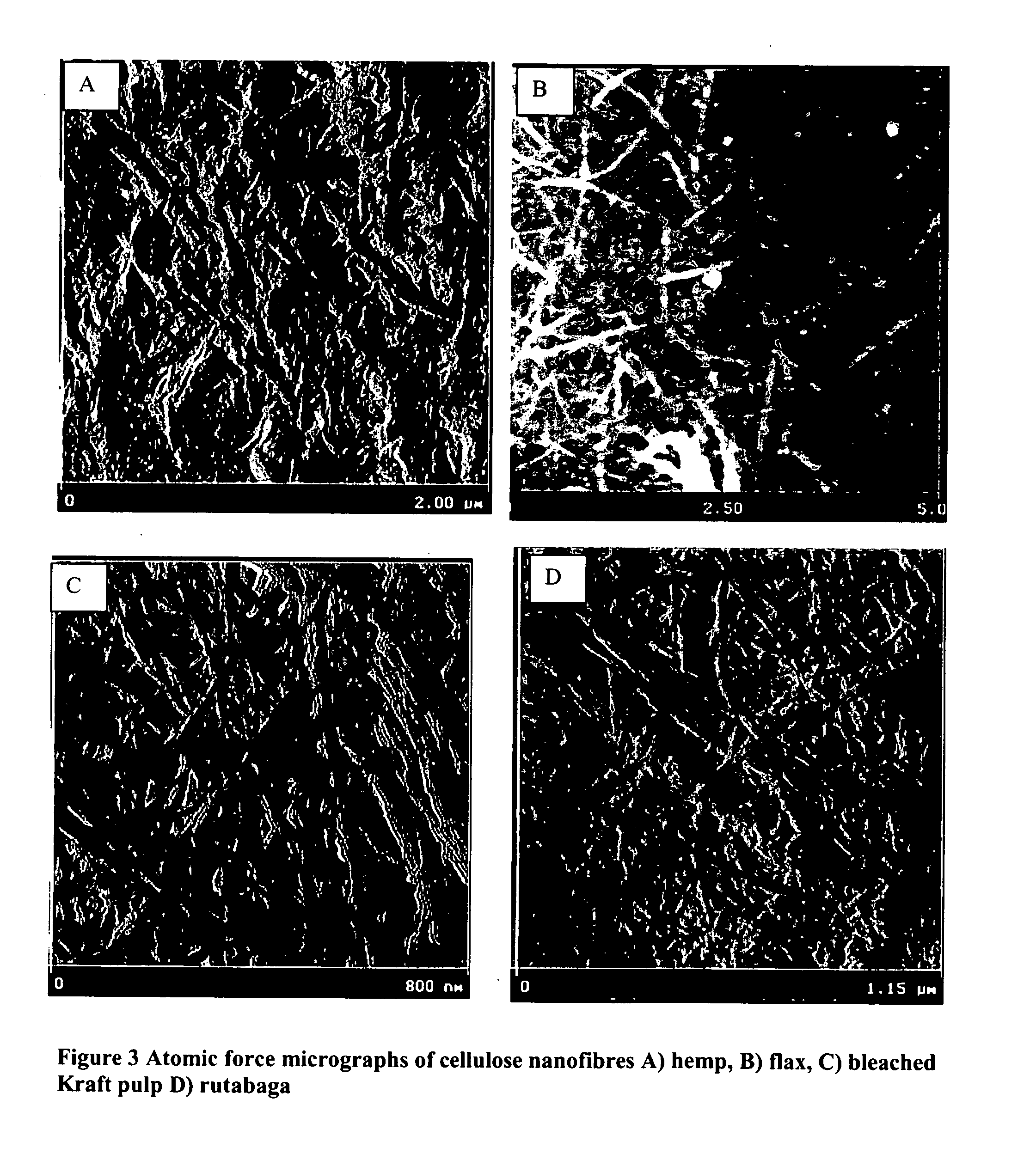

Manufacturing process of cellulose nanofibers from renewable feed stocks

InactiveUS20080146701A1High aspect ratioRaise the potentialMaterial nanotechnologyFats/resins/pitch/waxes removal in pulpCelluloseNatural fiber

Cellulose nanofibers have been processed from renewable feedstock in particularly from natural fibers, root crops and agro fibers, wherein the pulp was hydrolysed at a moderate temperature of 50 to 90 degree C., one extraction was performed using dilute acid and one extraction using alkali of concentration less than 10%; and residue was cryocrushed using liquid nitrogen, followed by individualization of the cellulose nanofibers using mechanical shear force. The nanofibers manufactured with this technique have diameters in the range of 20-60 nm and much higher aspect ratios than long fibers. Due to its lightweight and high strength its potential applications will be in aerospace industry and due to their biodegradable potential with tremendous stiffness and strength, they find application in the medical field such as blood bags, cardiac devices, valves as a reinforcing biomaterial.

Owner:SAIN MOHINI M +1

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

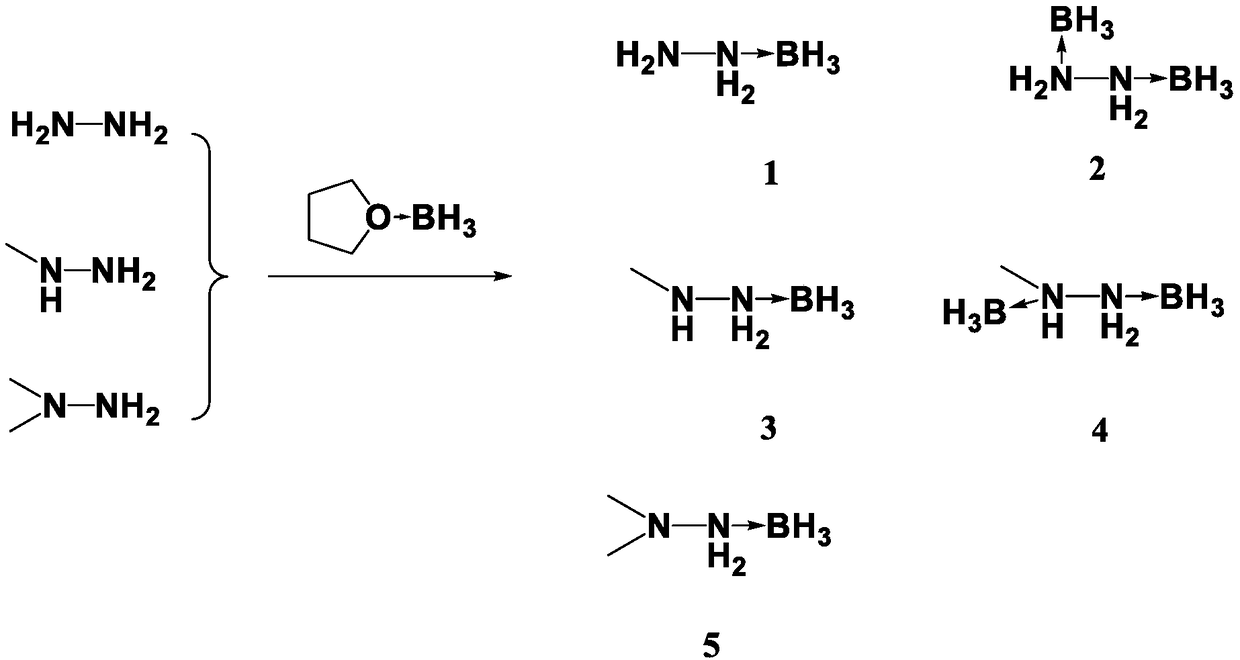

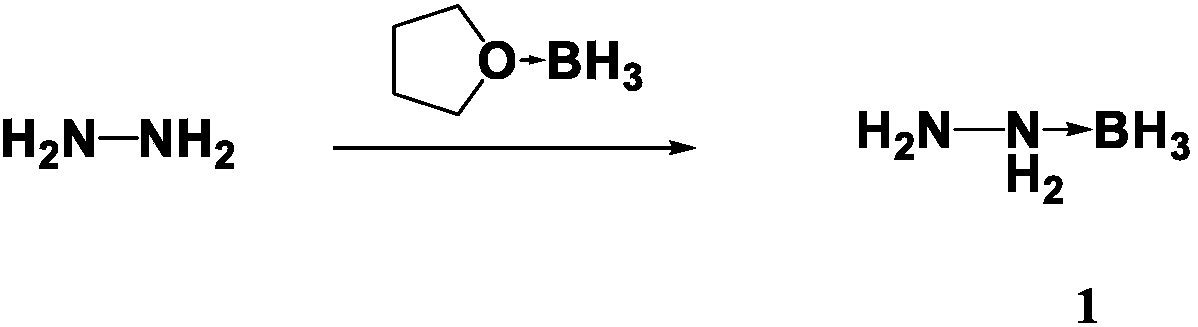

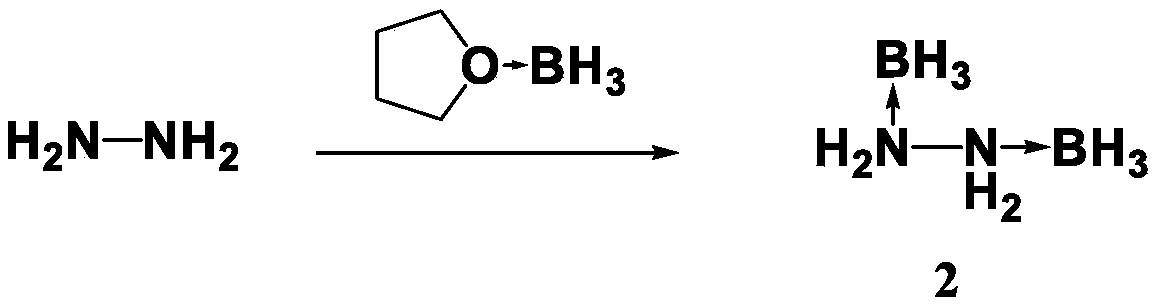

Preparation method for propellant fuel

InactiveCN108910843AShorter ignition delay timeHazard reductionOrganic chemistryHydrazineEvaporationIgnition delay

The invention discloses a preparation method for propellant fuel. The preparation method comprises the following steps: uniformly mixing hydrazine or a methyl derivative thereof with a tetrahydrofuransolution of borane to perform a reaction, and after the reaction, performing rotary evaporation on the tetrahydrofuran solution to obtain a first product; adding a first solvent into the first product, then performing washing, and then performing rotary evaporation to remove the first solvent, so as to obtain a hydrazinoborane derivative. According to the method, hydroboration is carried out on ahighly-volatile hydrazine fuel and a methylated derivative of hydrazine, the obtained borohydride of the hydrazine is a colorless non-volatile liquid or a white solid, has no volatility and greatly reduces hazard of the hydrazine fuel, and is a novel aerospace propellant fuel since the ignition delay time of the hydrazine borofluoride is extremely short.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

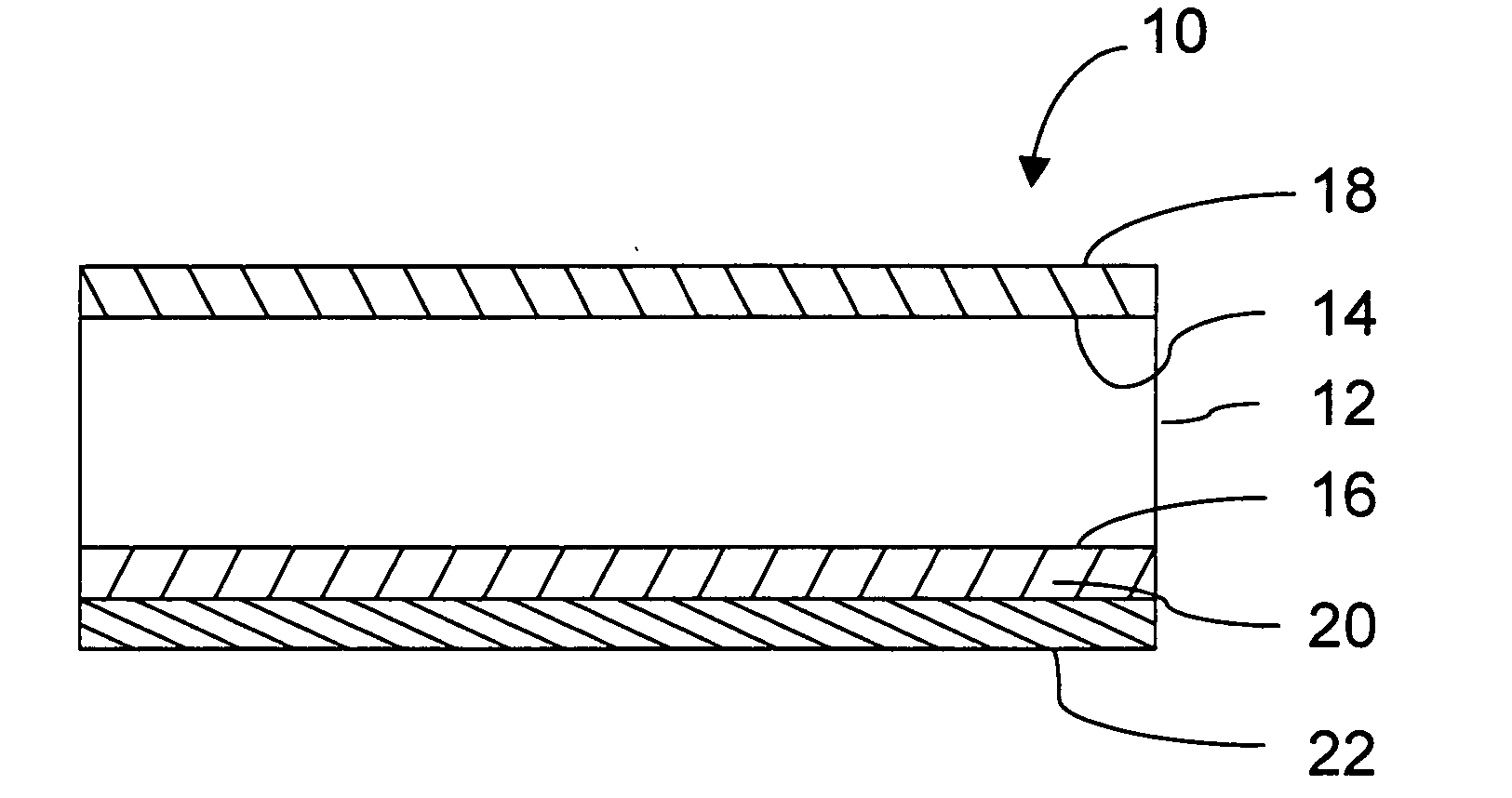

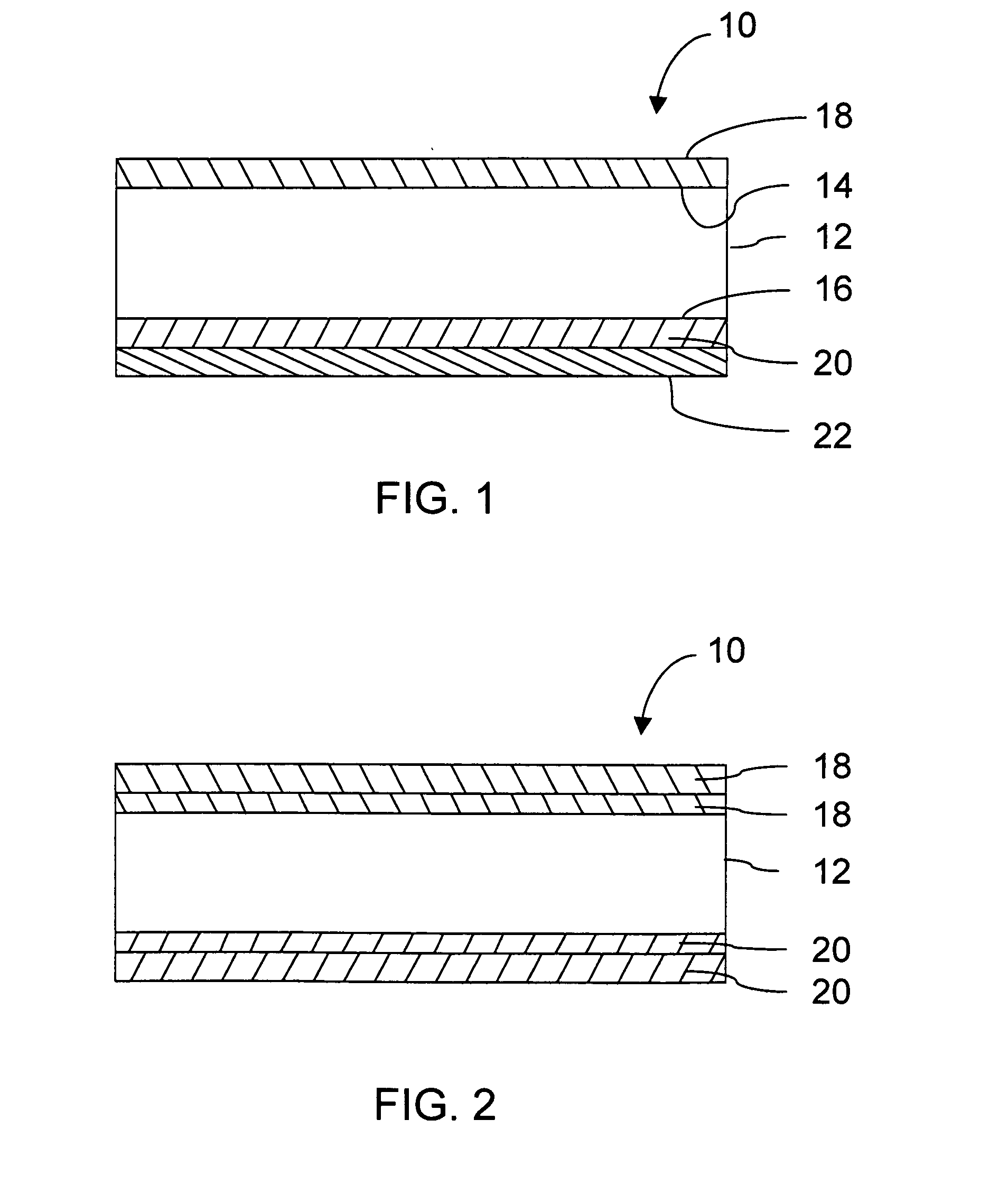

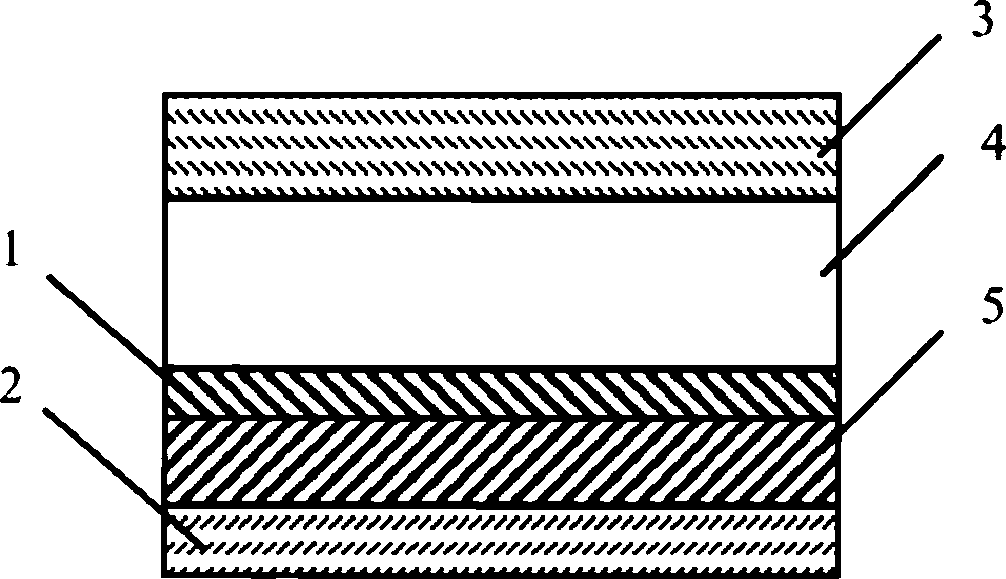

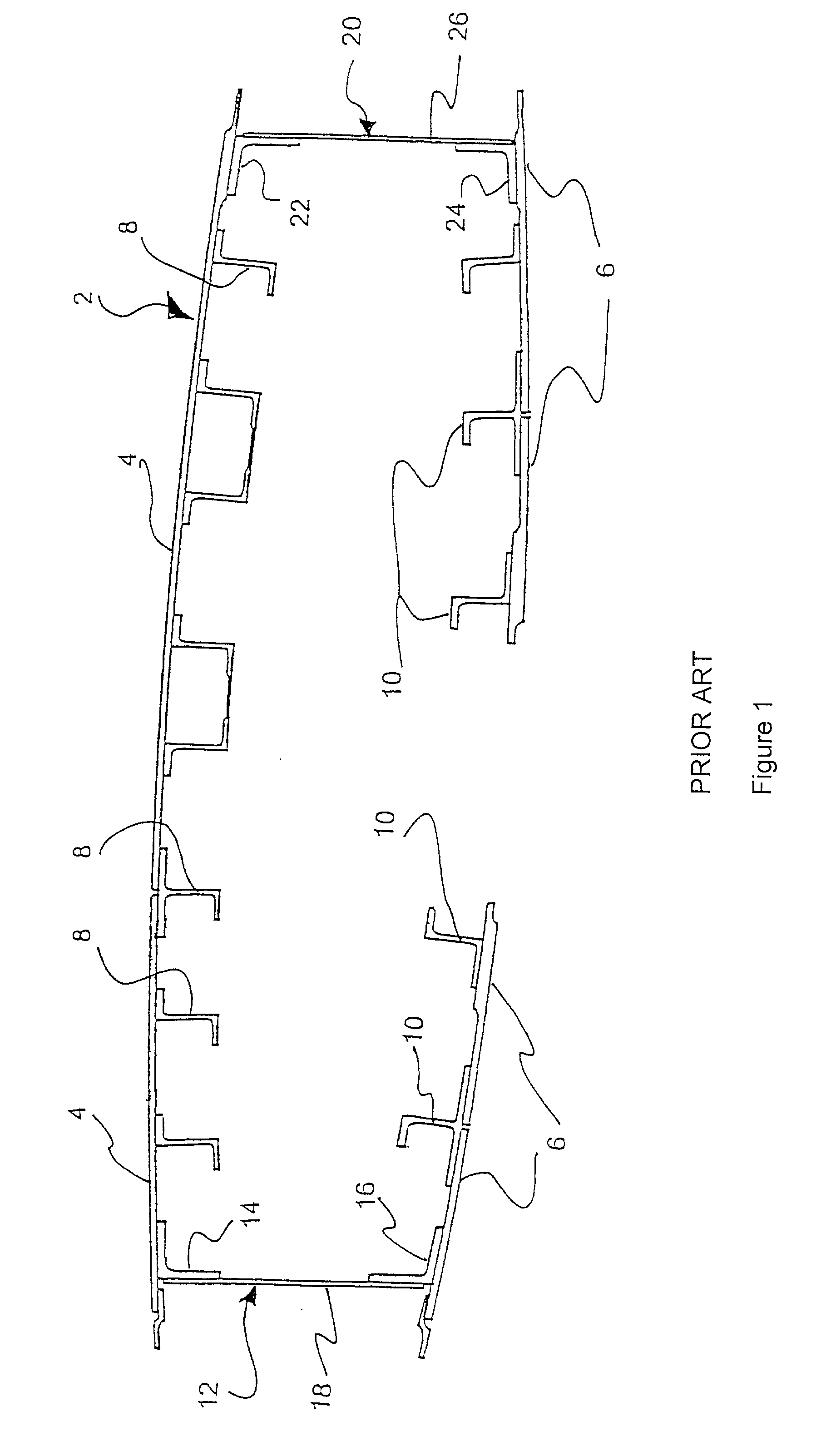

Thermoplastic composite material with improved smoke generation, heat release, and mechanical properties

InactiveUS20100021718A1Reduce fiber contentSynthetic resin layered productsLaminationAviationVolumetric Mass Density

A fiber-reinforced thermoplastic composite material having an advantageous combination of smoke generation, heat release, and mechanical property characteristics. The composite generally comprises a fiber-reinforced thermoplastic core containing discontinuous reinforcing fibers bonded together with one or more thermoplastic resins. The core material may further comprise at least one first skin material applied to a first surface of the core and / or one or more second skin material applied to a second surface of the core material. The thermoplastic core material has a maximum smoke density Ds (4 minutes) of less than 200 as measured in accordance with ASTM E662, a maximum heat release (5 minutes) of less than 65 kW / m2 as measured in accordance with FAA Heat release test FAR 25.853 (a) Appendix F, Part IV (OSU 65 / 65), and an average total heat release (2 minutes) of less than 65 kW / m2 as measured in accordance with FAA Heat release test FAR 25.853 (a) Appendix F, Part IV (OSU 65 / 65). The invention is useful in the manufacture of articles for aircraft, automotive, railcar, locomotive, bus, marine, aerospace and construction in which the certain advantages may be provided over other materials utilized for such applications.

Owner:AZDEL INC

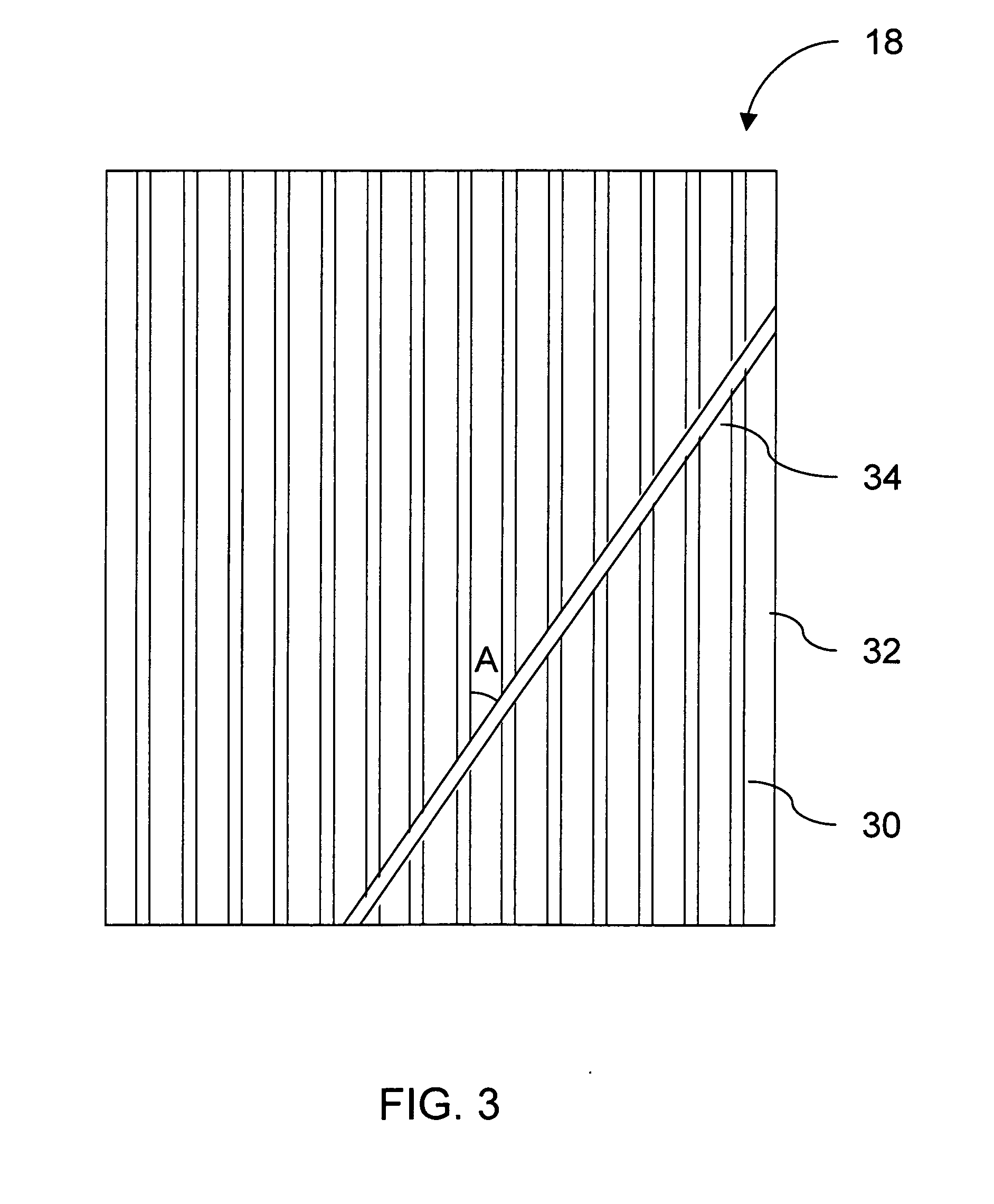

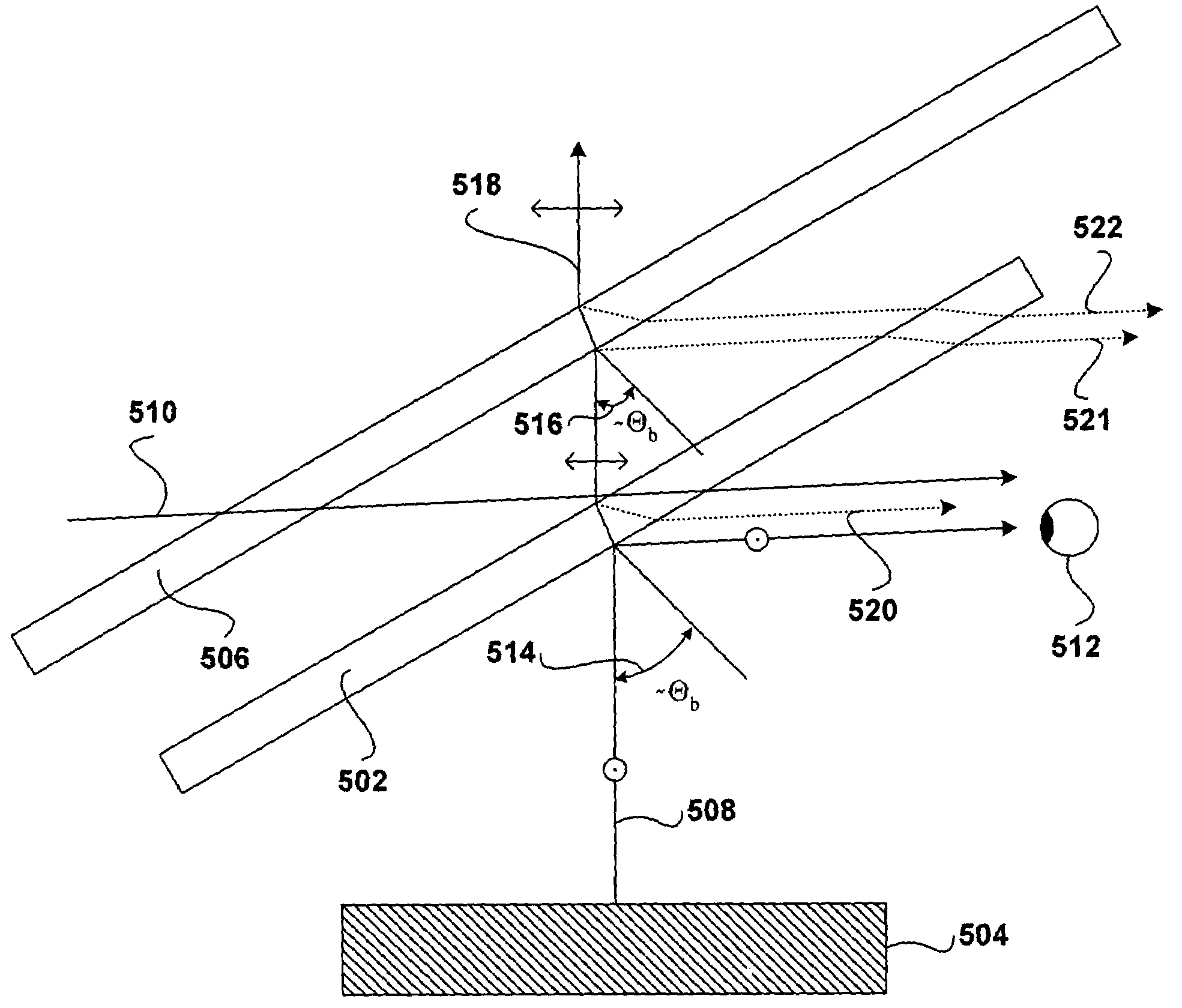

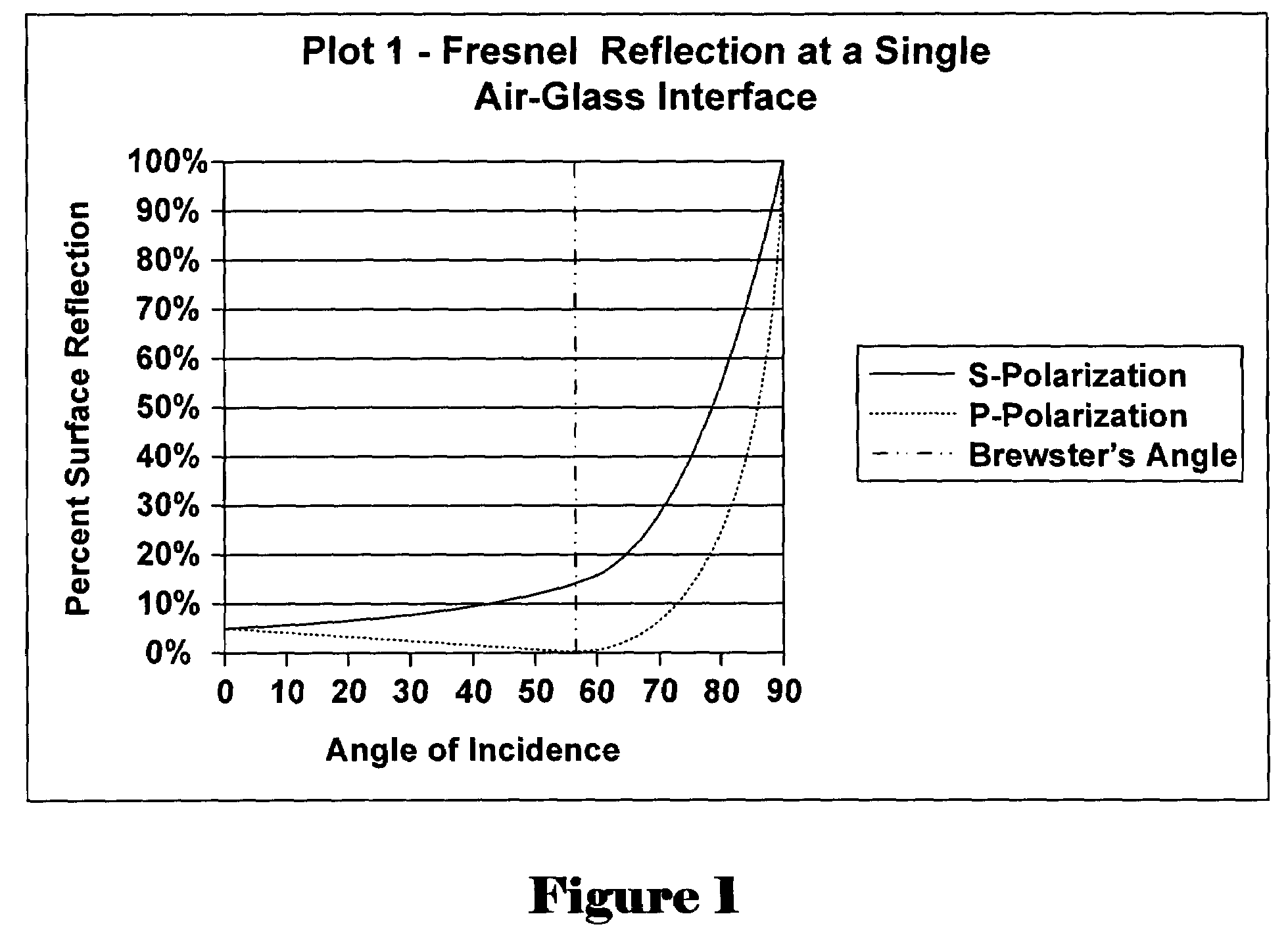

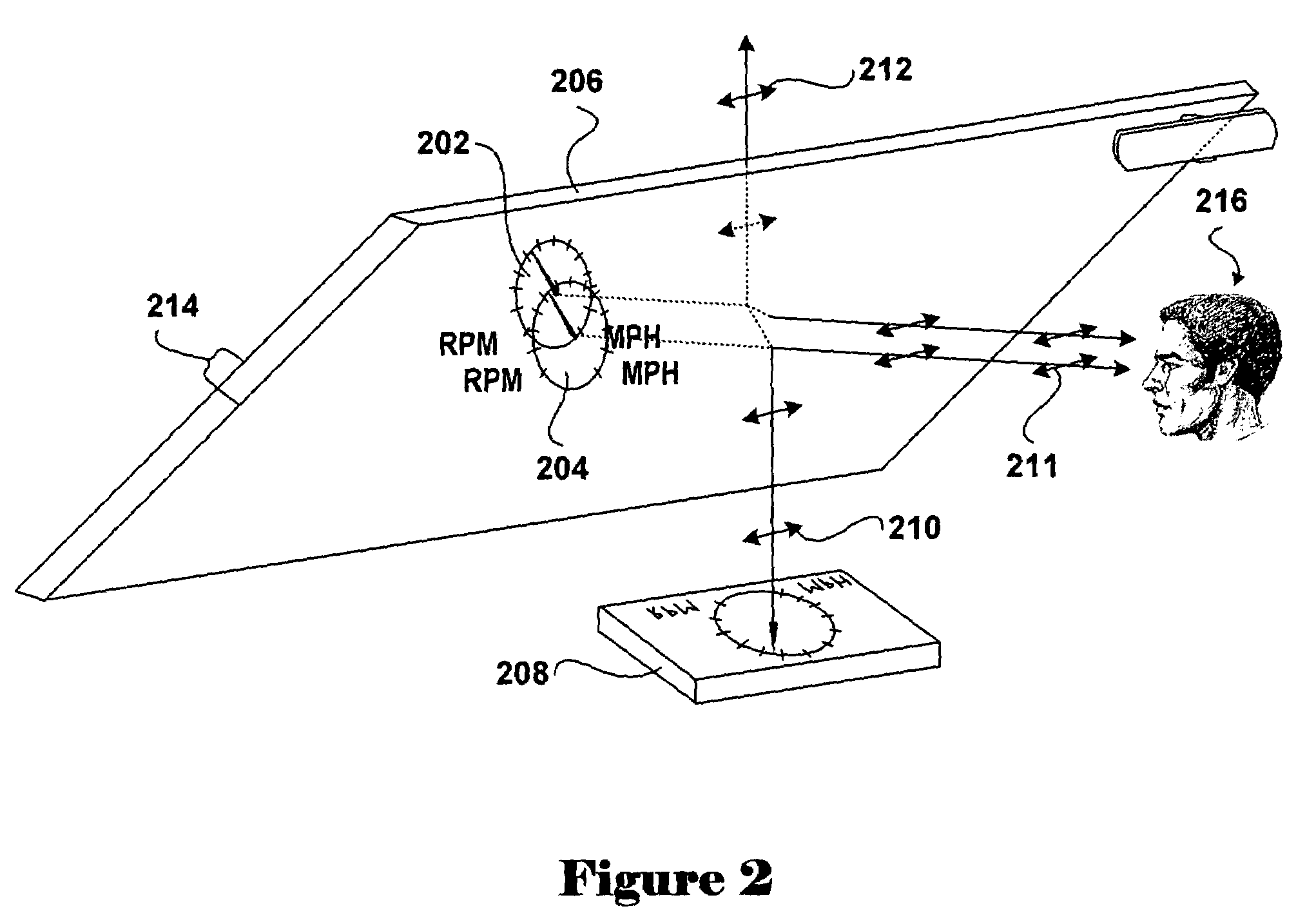

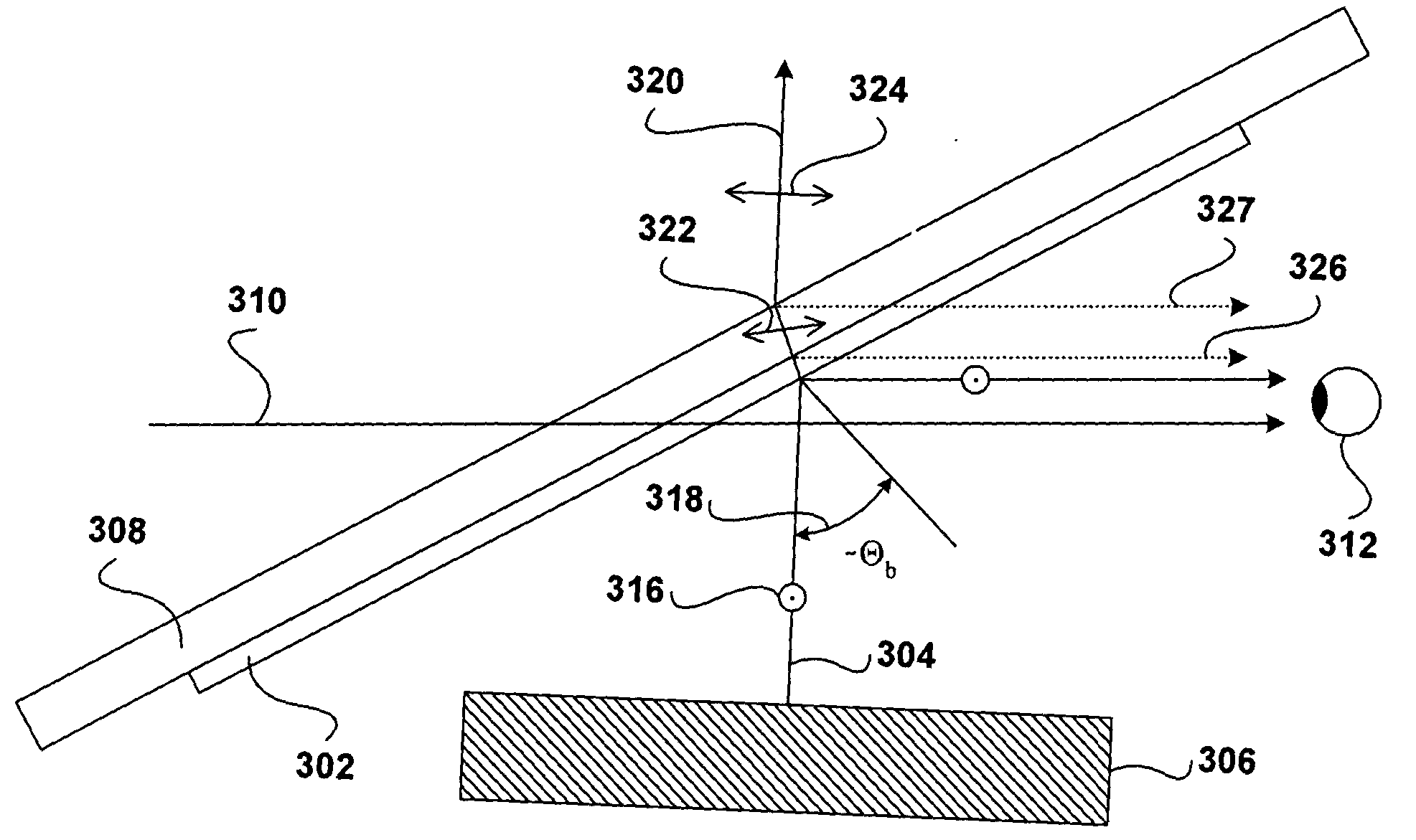

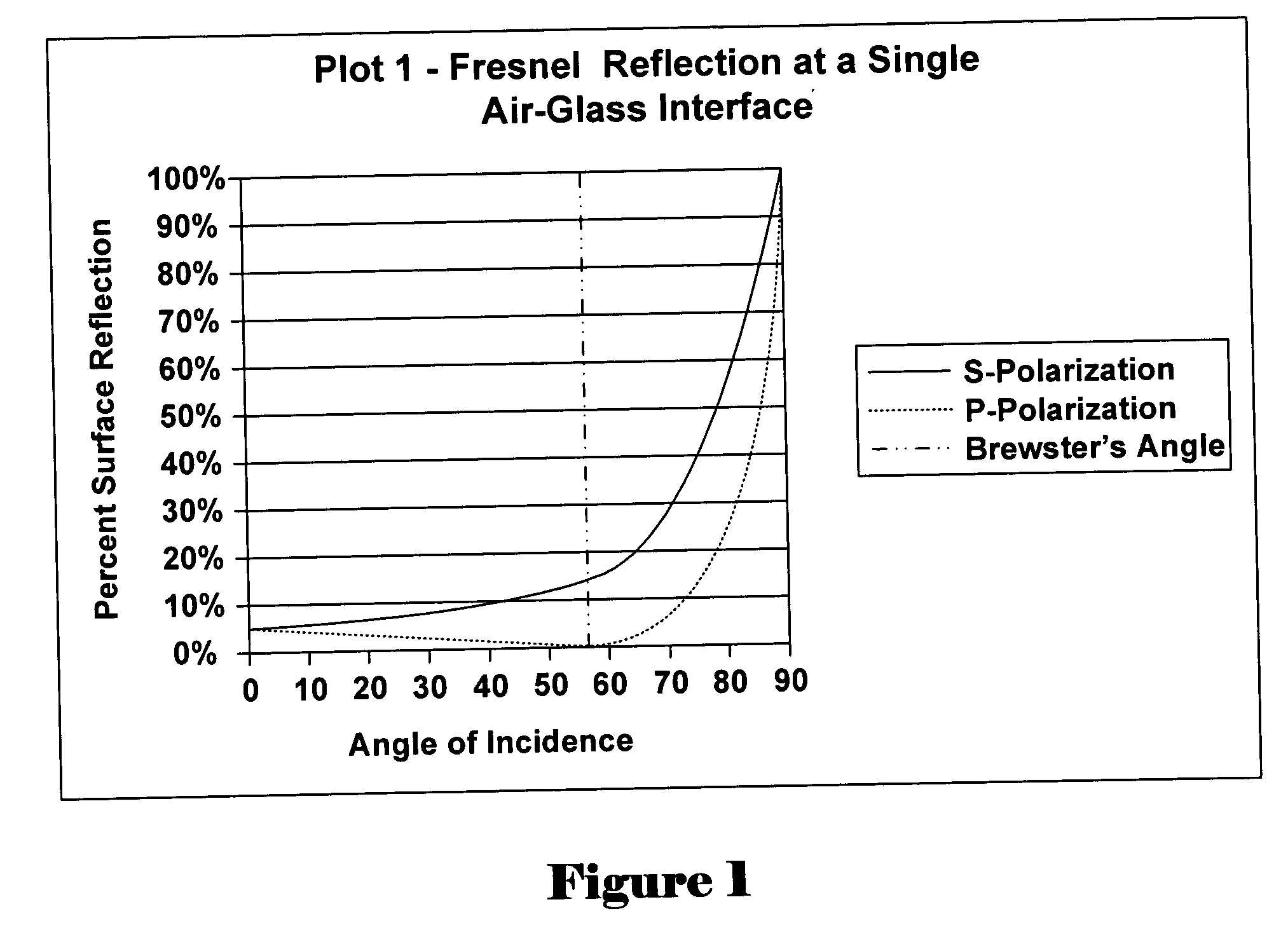

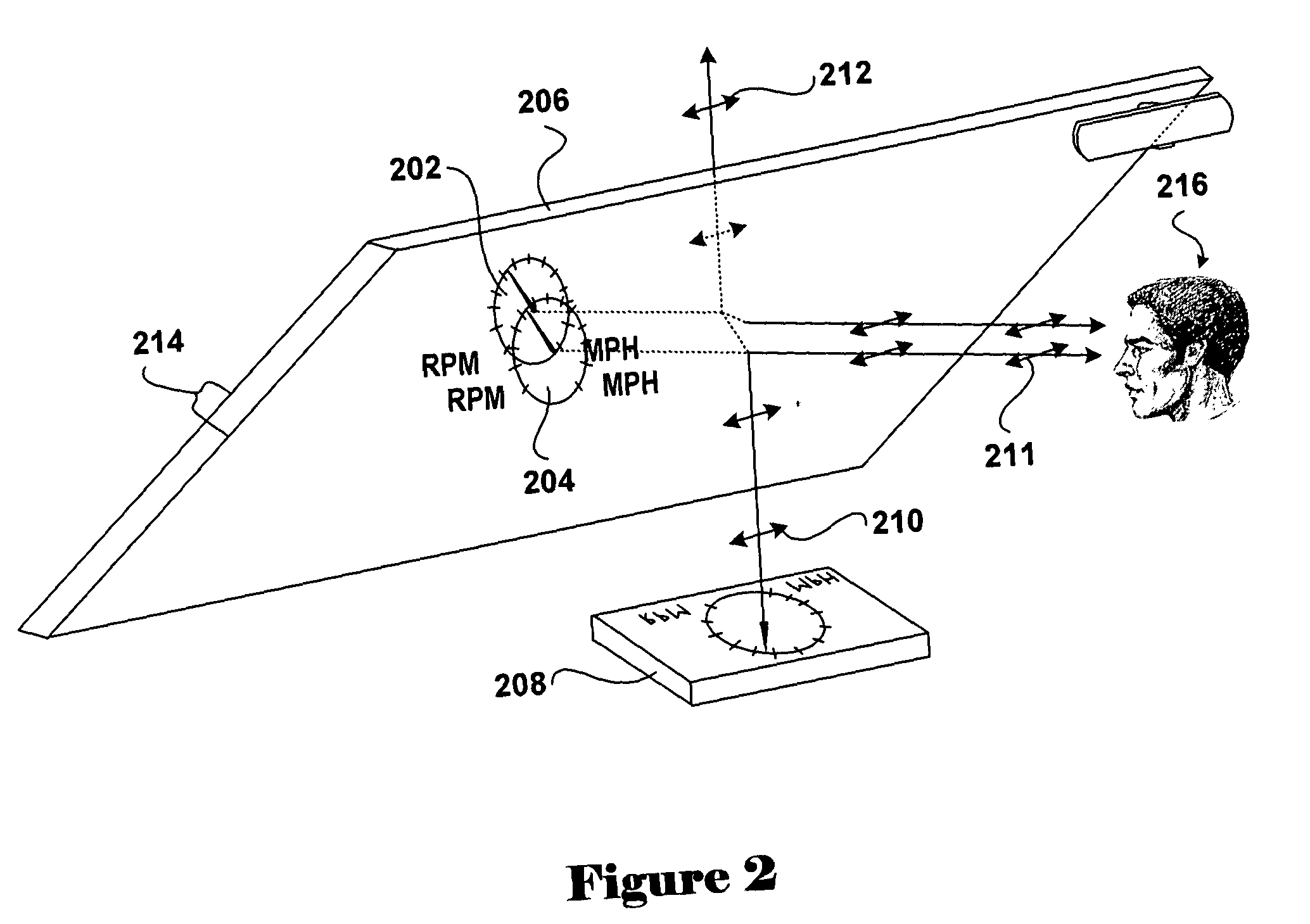

Visual display system for displaying virtual images onto a field of vision

An optically transparent, ghost-free visual display system that superimposes a virtual image comprising graphical or textual information onto a field of vision. Embodiments of the visual display system utilize illumination and optical components that introduce a virtual image onto a field of vision while minimally obstructing and / or attenuating other objects within the field of vision. Embodiments of the visual display system can be used in numerous applications, including head-up displays (“HUDs”) for automotive, tracked and rail-mounted vehicles, marine, aerospace applications, see-through speech prompt displays, and see-through projection displays.

Owner:BIG BUDDY PERFORMANCE

Article comprising a fine-grained metallic material and a polymeric material

InactiveUS20060135282A1Strength-to-weight ratio can be improvedGood damping propertiesWalking sticksMaterial nanotechnologyPolymer scienceHigh stiffness

Lightweight articles comprising a polymeric material at least partially coated with a fine-grained metallic material are disclosed. The fine-grained metallic material has an average grain size of 2 nm to 5,000 nm, a thickness between 25 micron and 5 cm, and a hardness between 200 VHN and 3,000 VHN. The lightweight articles are strong and ductile and exhibit high coefficients of restitution and a high stiffness and are particularly suitable for a variety of applications including aerospace and automotive parts, sporting goods, and the like.

Owner:INTEGRAN TECH

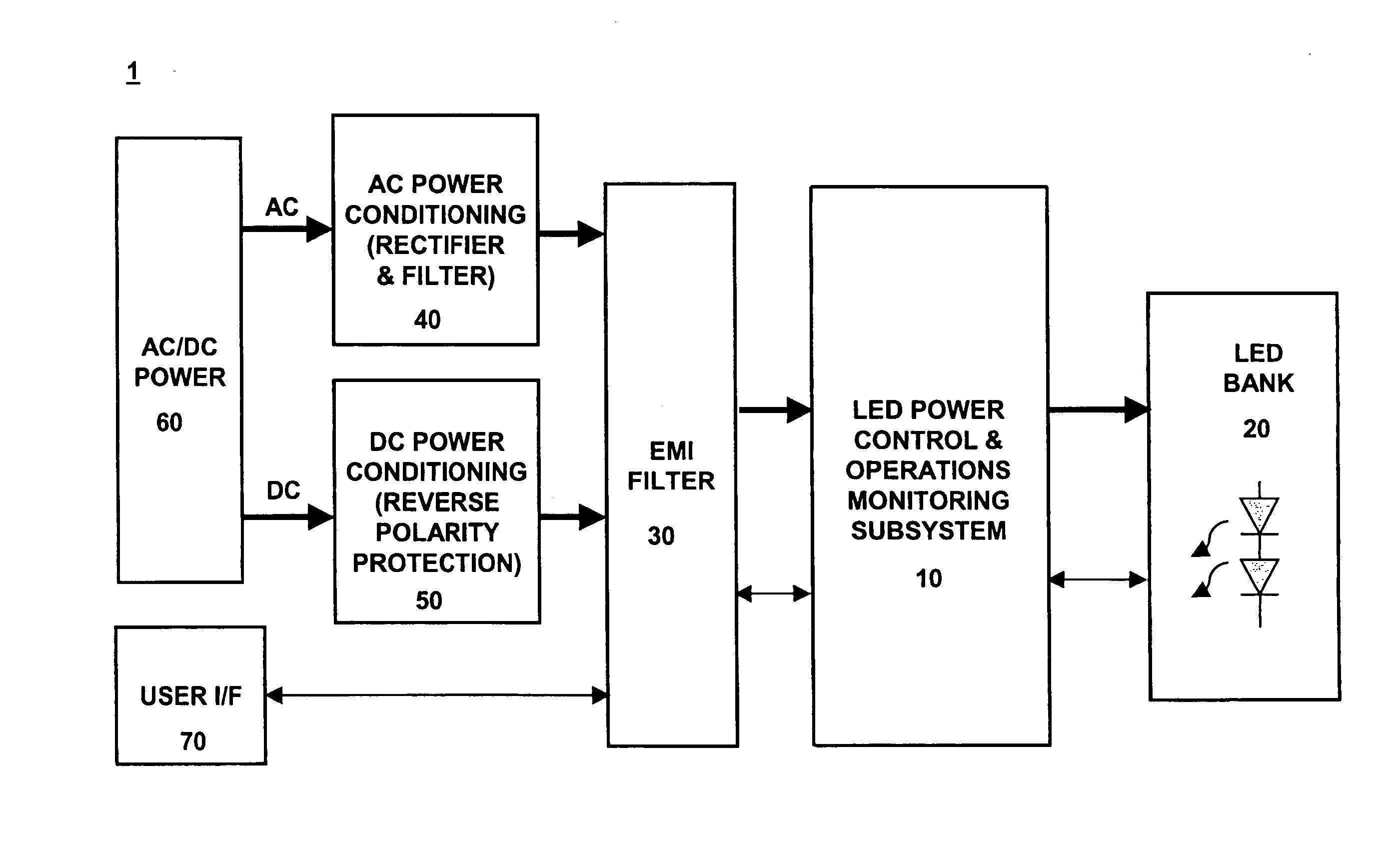

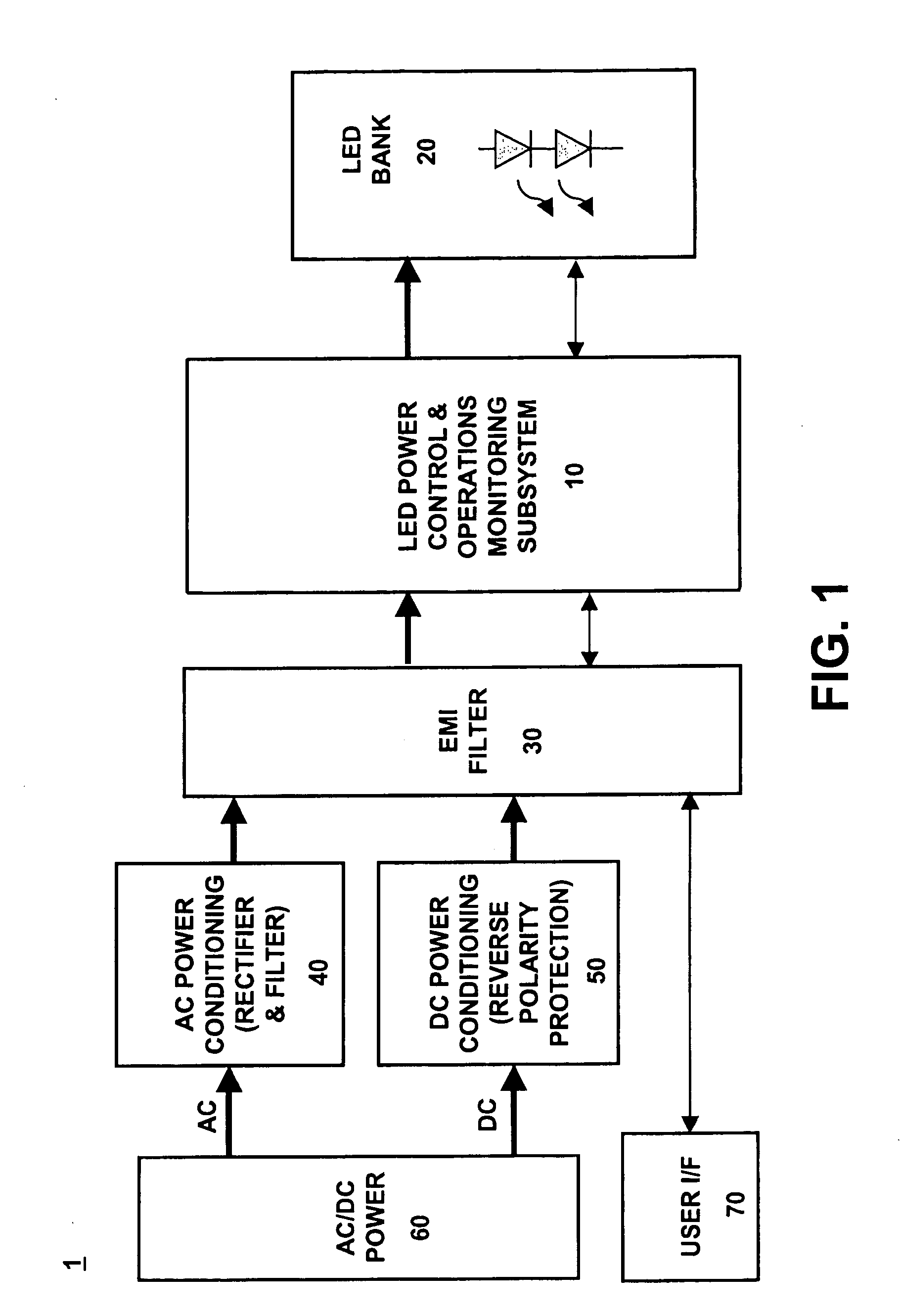

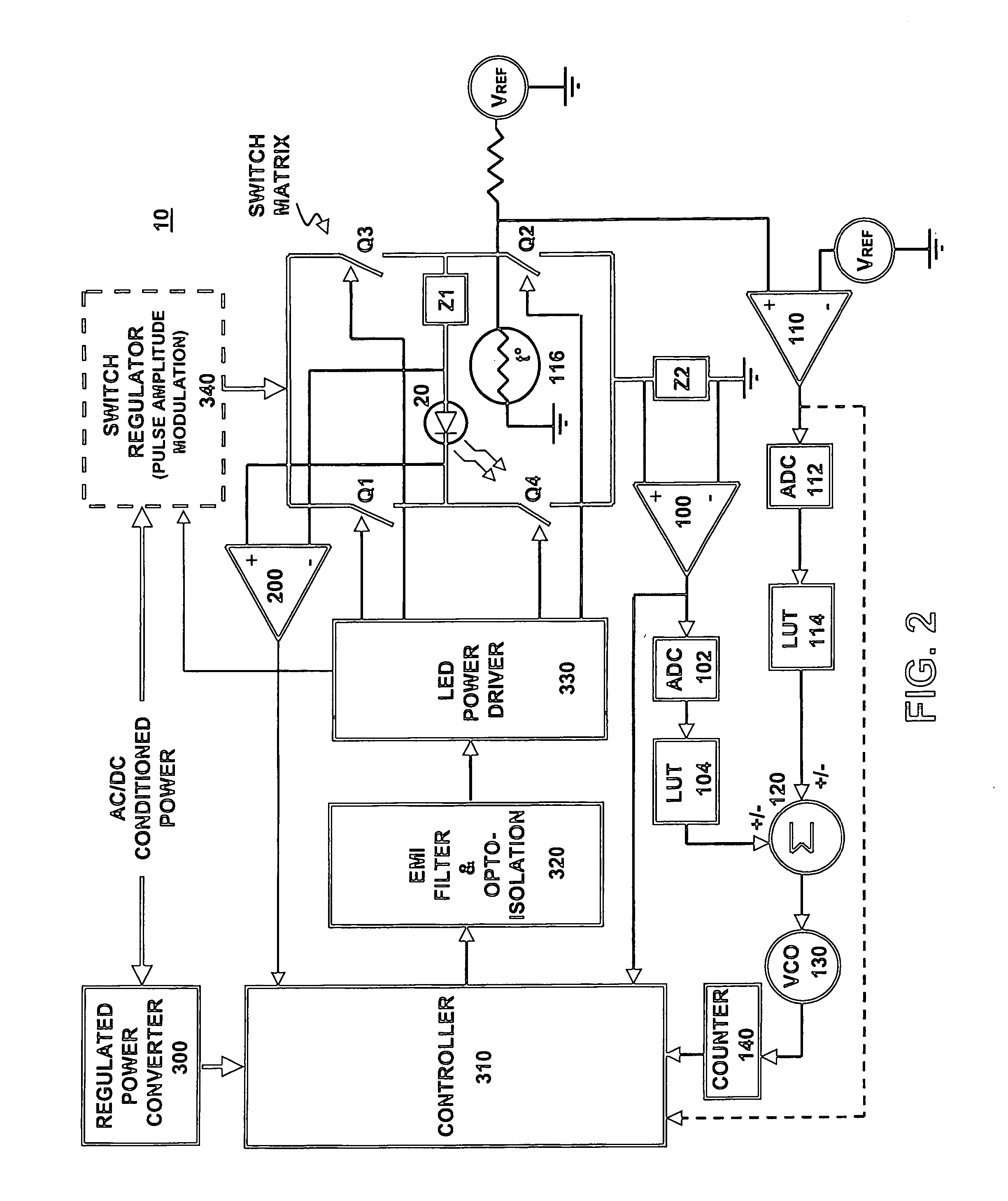

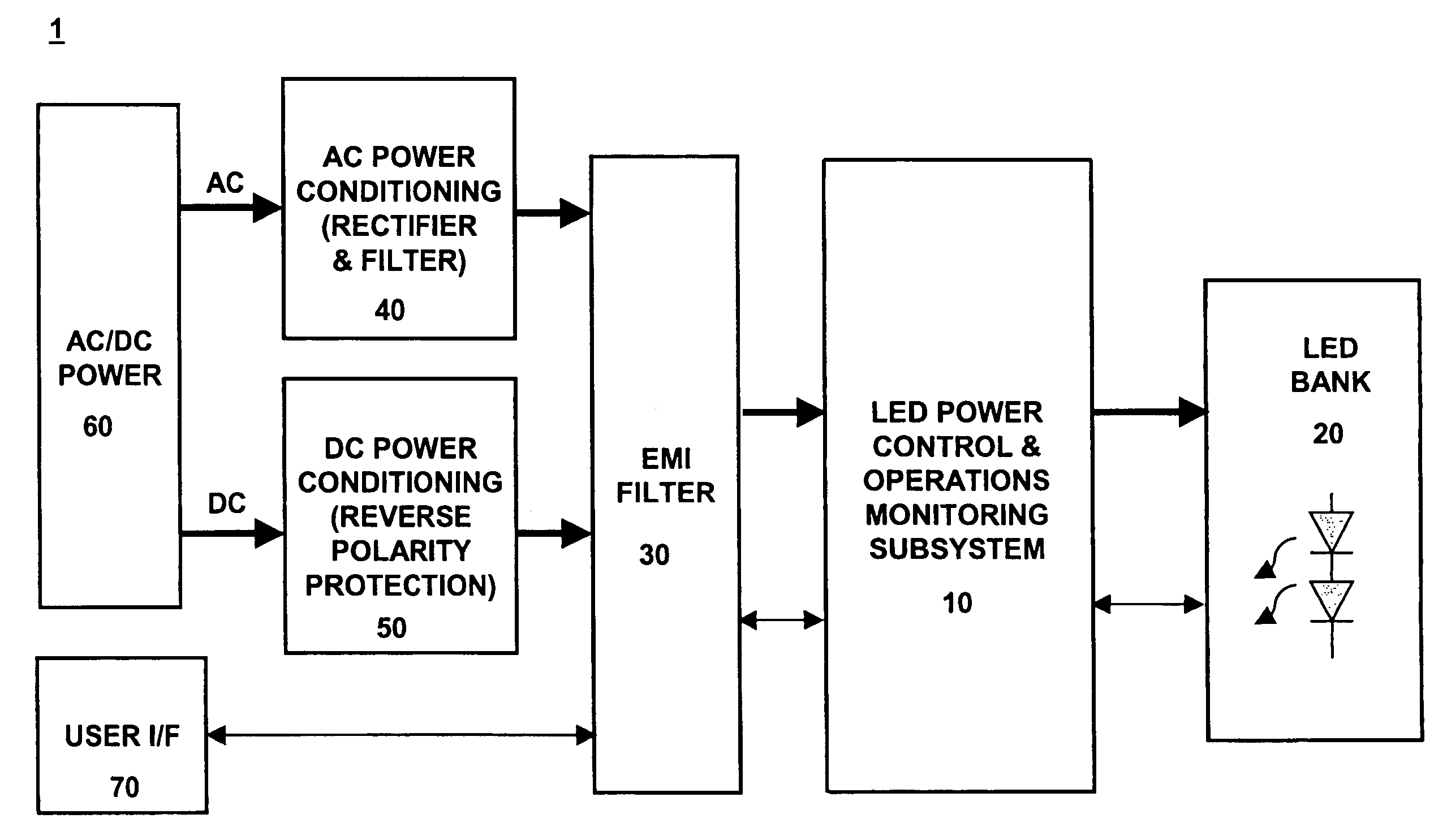

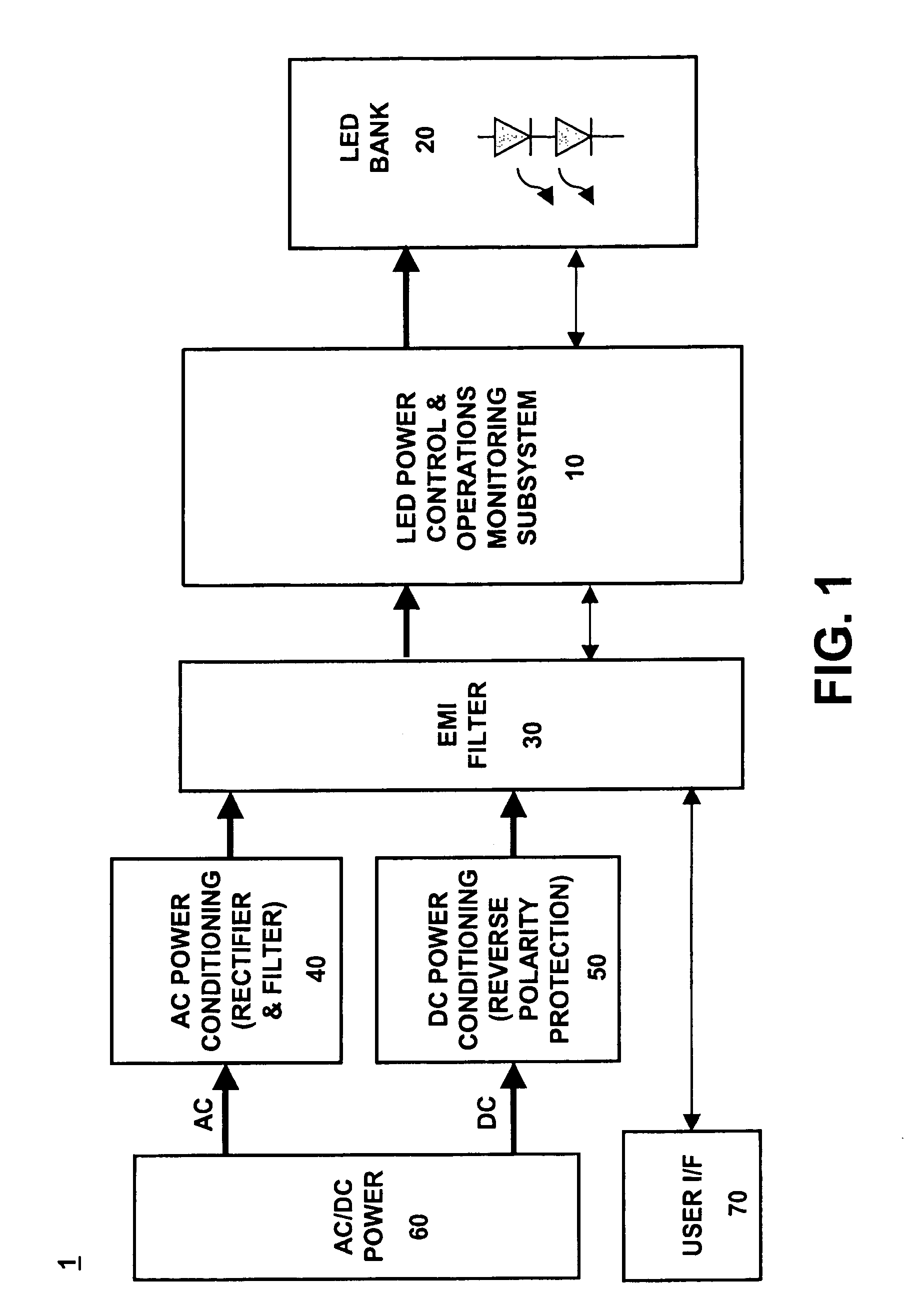

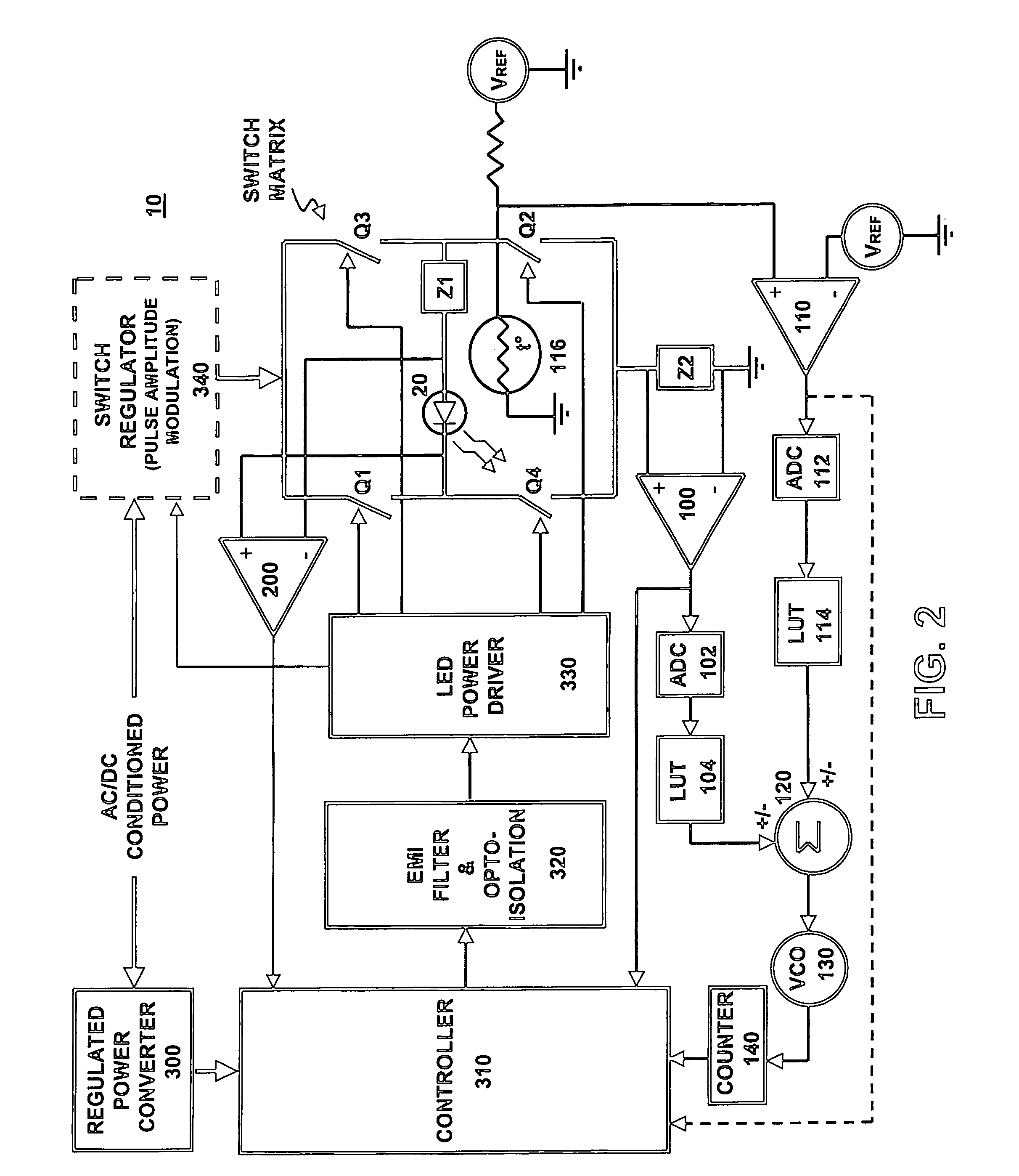

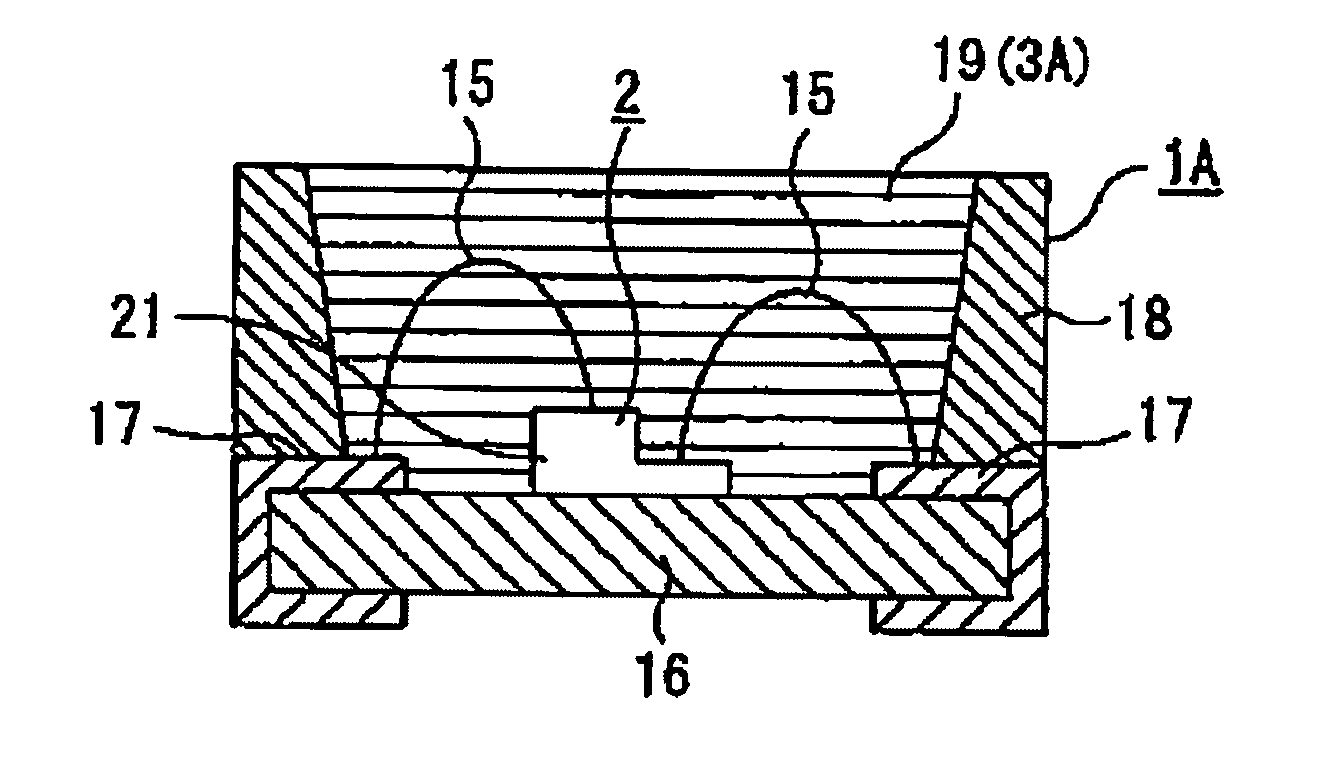

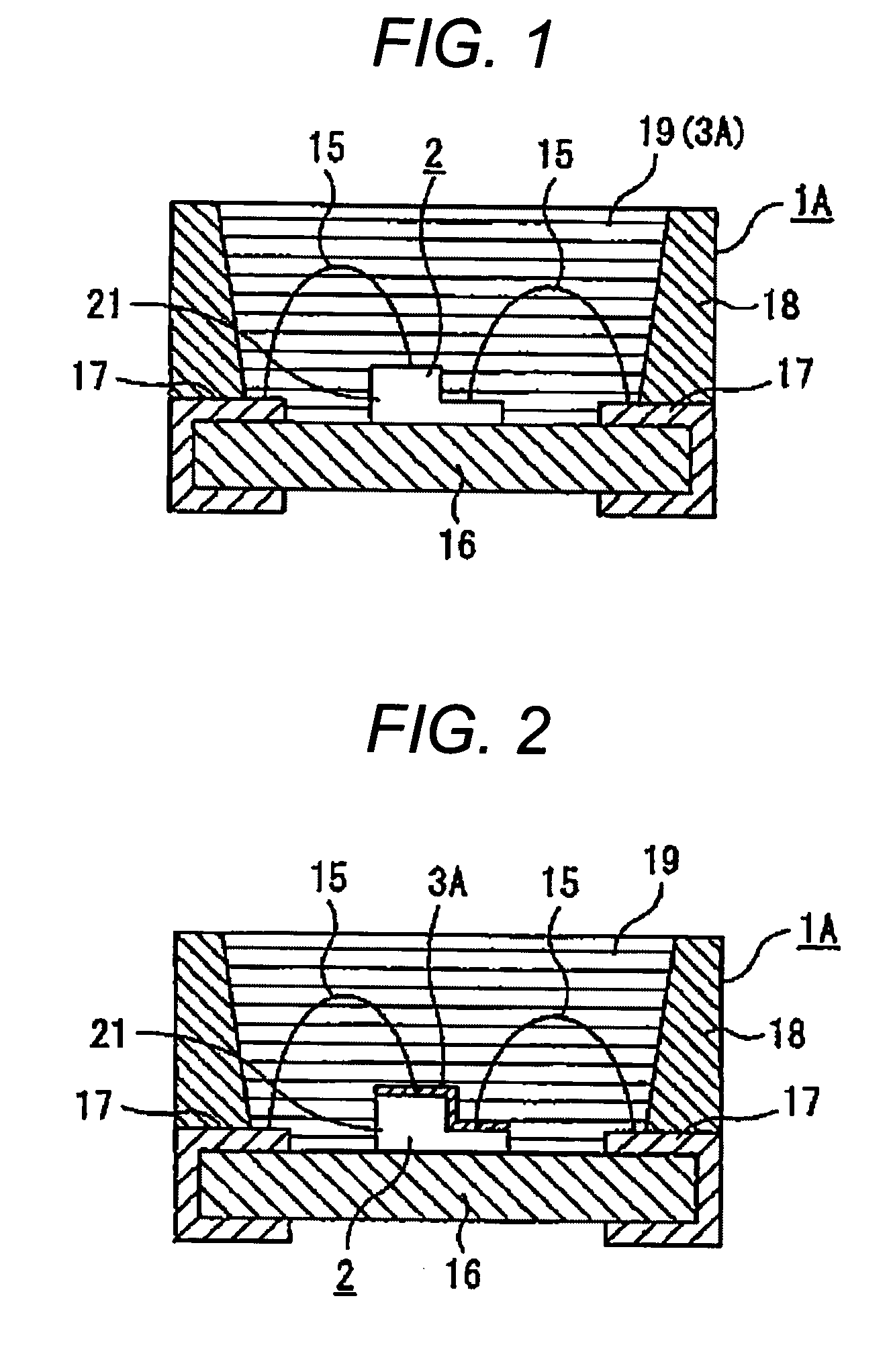

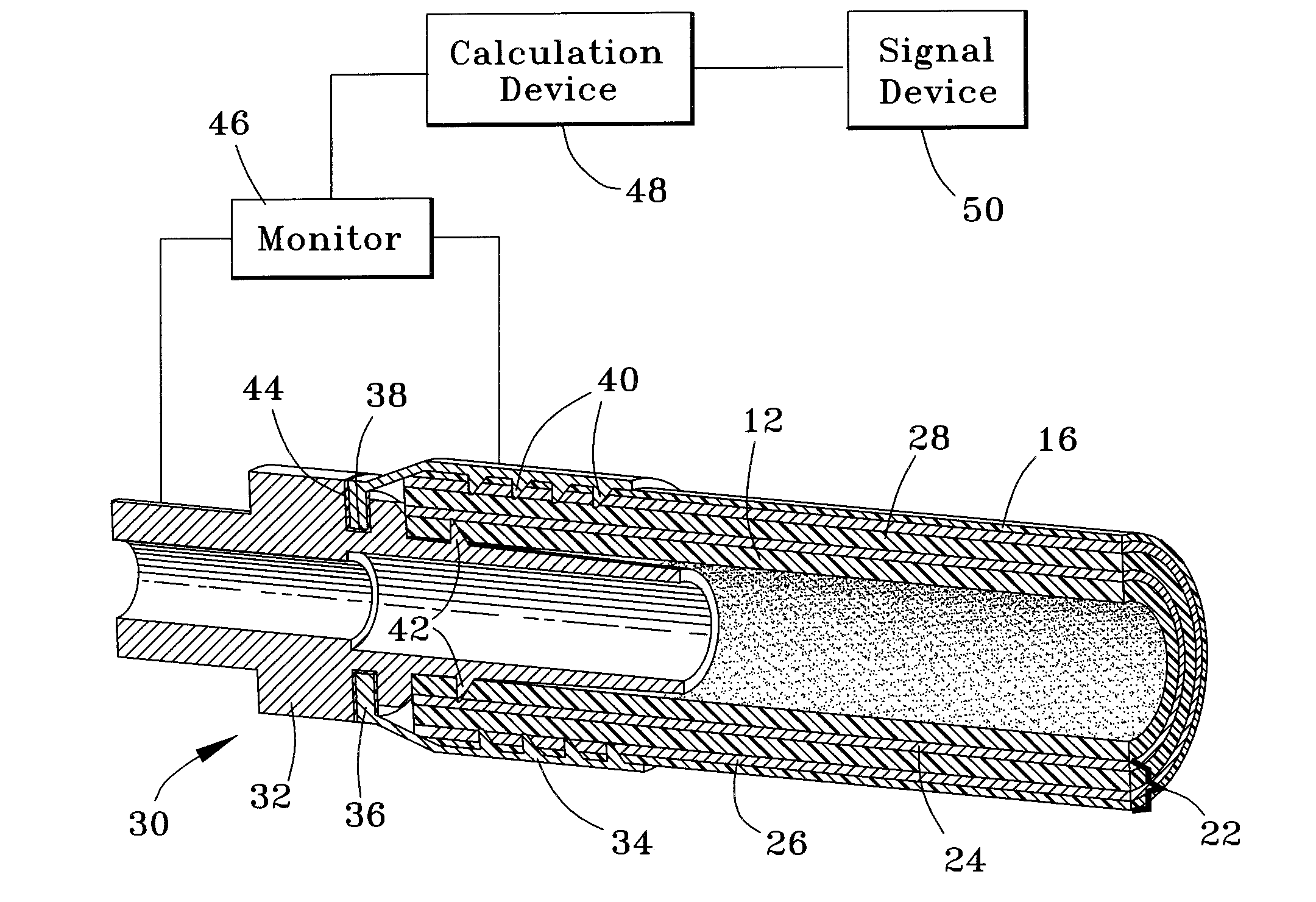

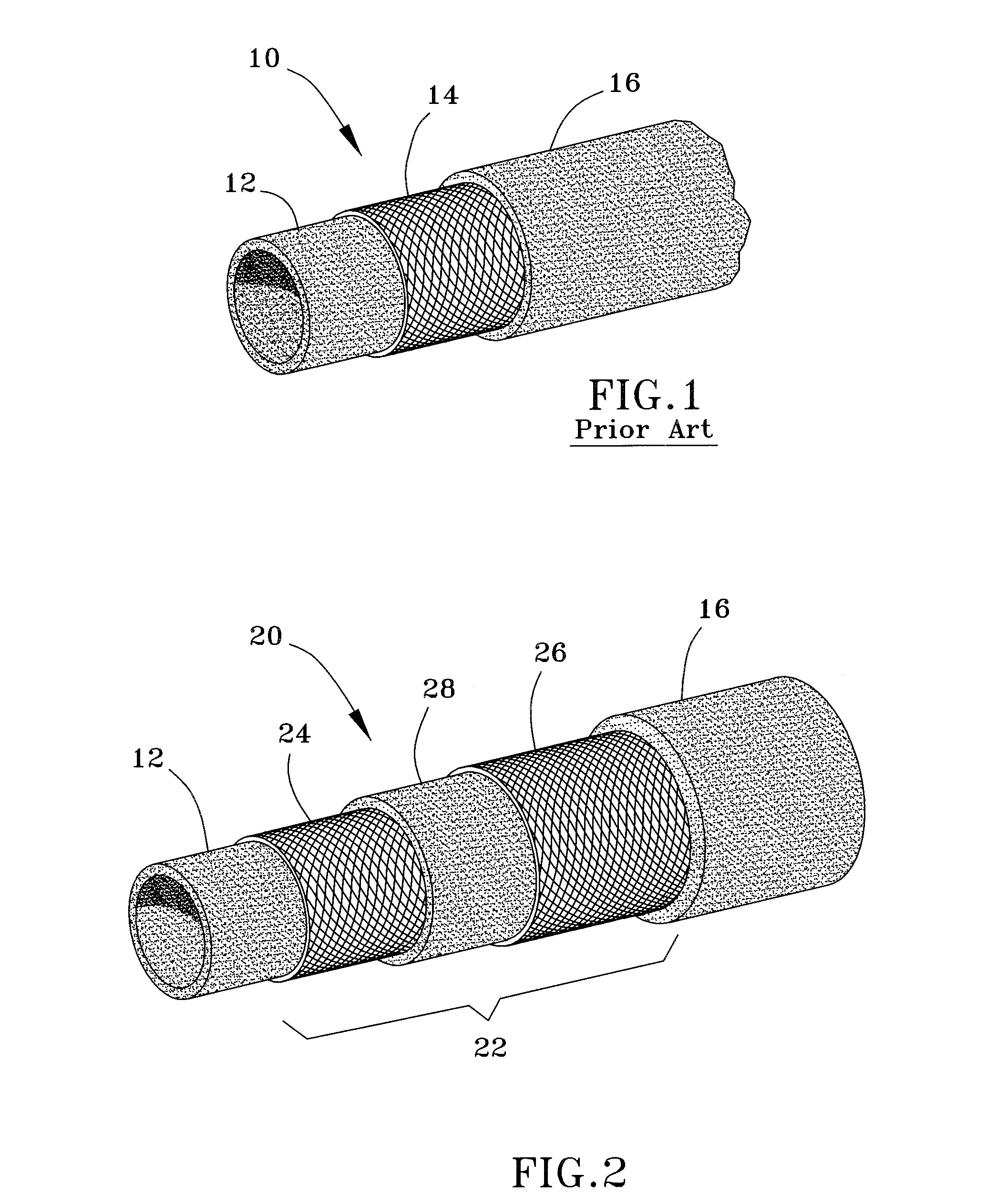

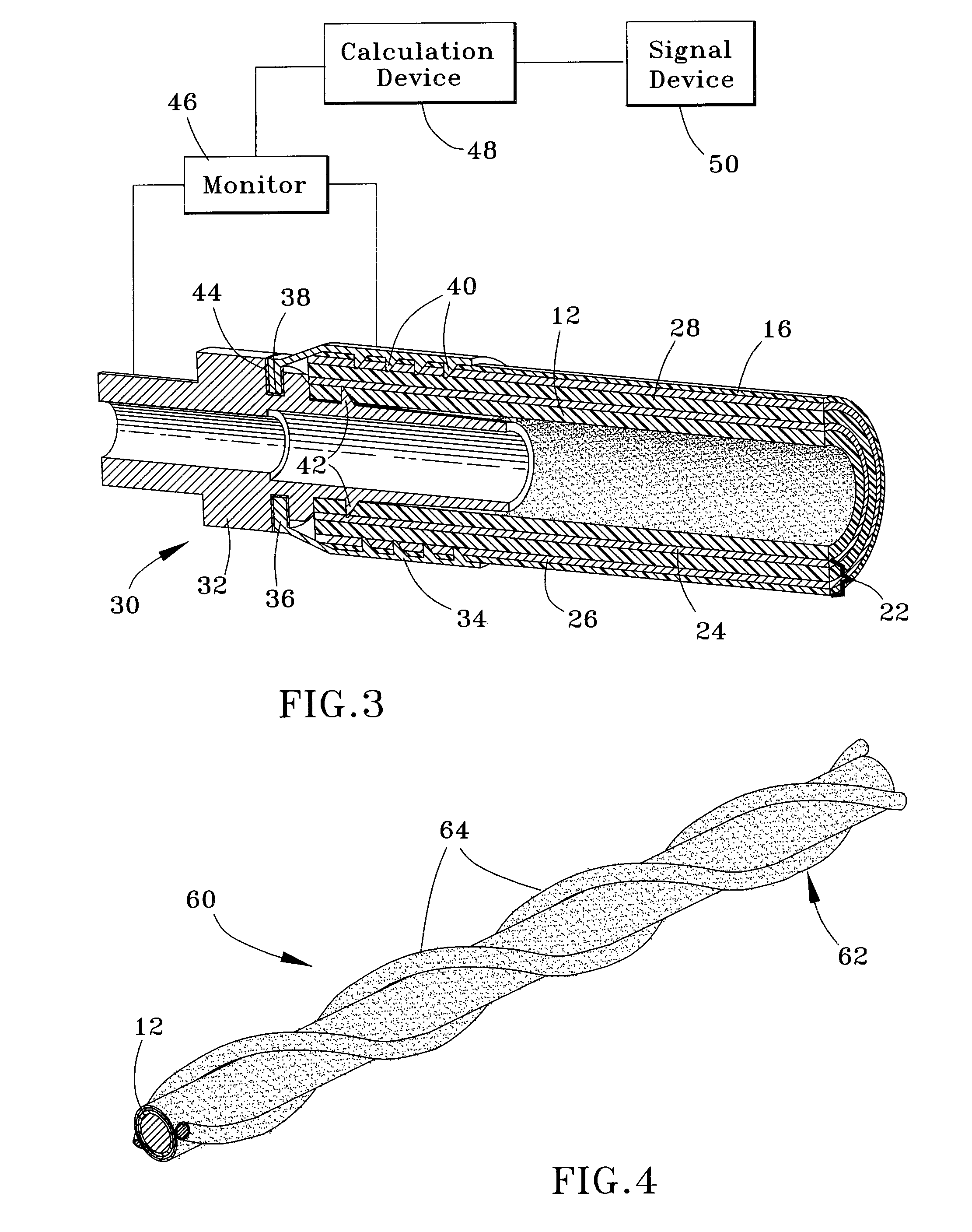

Aerospace light-emitting diode (LED)-based lights life and operation monitor compensator

ActiveUS20070040696A1Electrical apparatusStatic indicating devicesEngineeringUltimate tensile strength

A system (10) and method for monitoring the operational life and / or performance of one or more light-emitting diodes (LEDs) (20) based on sensed parameters are disclosed. The remaining life of each LED may be predicted by counting the clock cycles during which the LED-based light is activated. LED current and / or temperature measurements may be used to control the clock signal and, thus, to compensate the predicted life value. Furthermore, operational characteristics of the LED-based light may be monitored based on LED current and / or voltage measurements. Such characteristics may include performance (e.g., intensity) and failure conditions (e.g., open or short circuits).

Owner:HONEYWELL INT INC

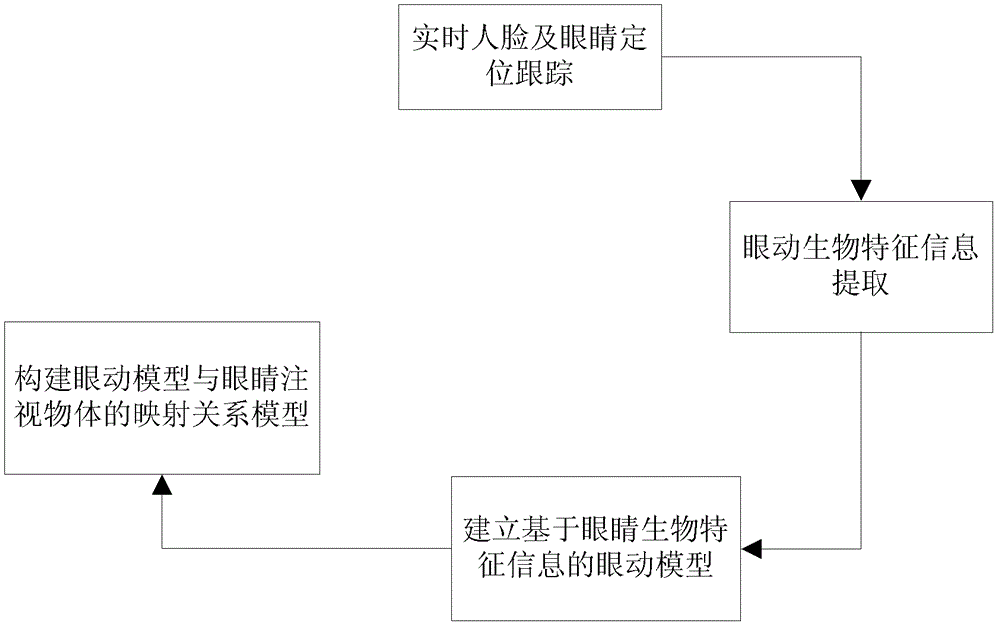

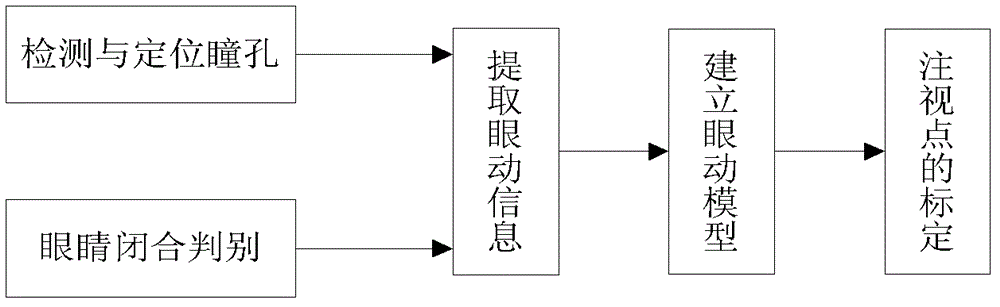

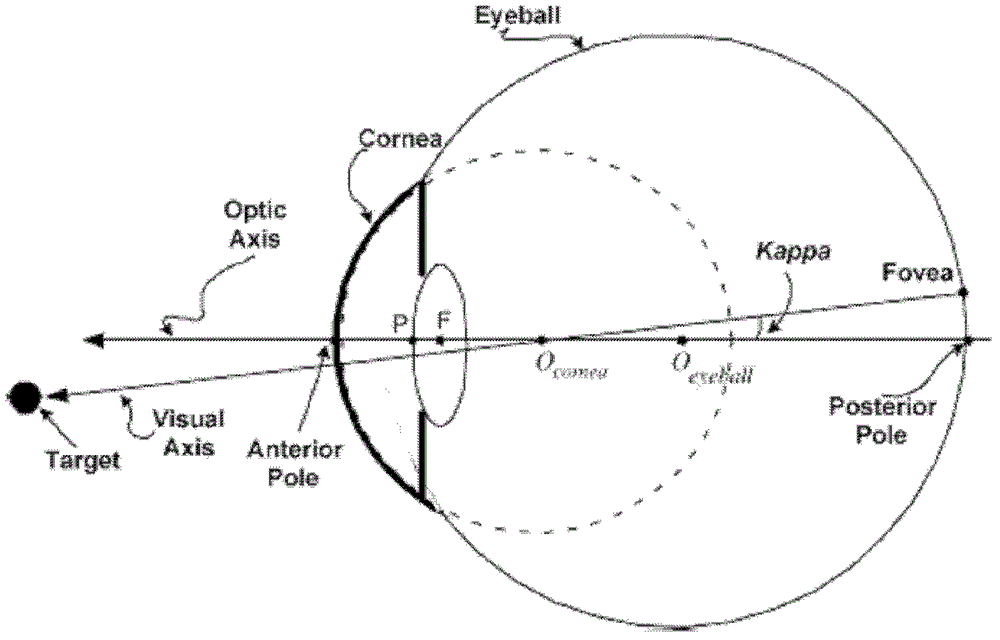

Non-contact free space eye-gaze tracking method suitable for man-machine interaction

ActiveCN102749991AAccurate detectionPrecise positioningInput/output for user-computer interactionCharacter and pattern recognitionJet aeroplaneAviation

The invention provides a non-contact free space eye-gaze tracking method suitable for man-machine interaction. The method comprises the steps of positioning and tracking a face and eyes in real time, extracting eye movement biological characteristic information, building an eye movement model based on the eye movement biological characteristic information, building a mapping relational model of the eye movement model and an eye-gazed object and the like. The non-contact free space eye-gaze tracking method suitable for the man-machine interaction relates to multiple crossed fields of image processing, computer vision, pattern recognition and the like and has wide application prospect in the fields of new-generation man-machine interaction, disabled people assisting, aerospace relating field, sports, automobile and airplane driving, virtual reality, games and the like. In addition, the method has great practical significance for improvement of the life and self-care level of disabled people, building of a harmonious society and improvement of independent innovative capability in the national high-and-new technical fields of the man-machine interaction, unmanned driving and the like.

Owner:广东百泰科技有限公司

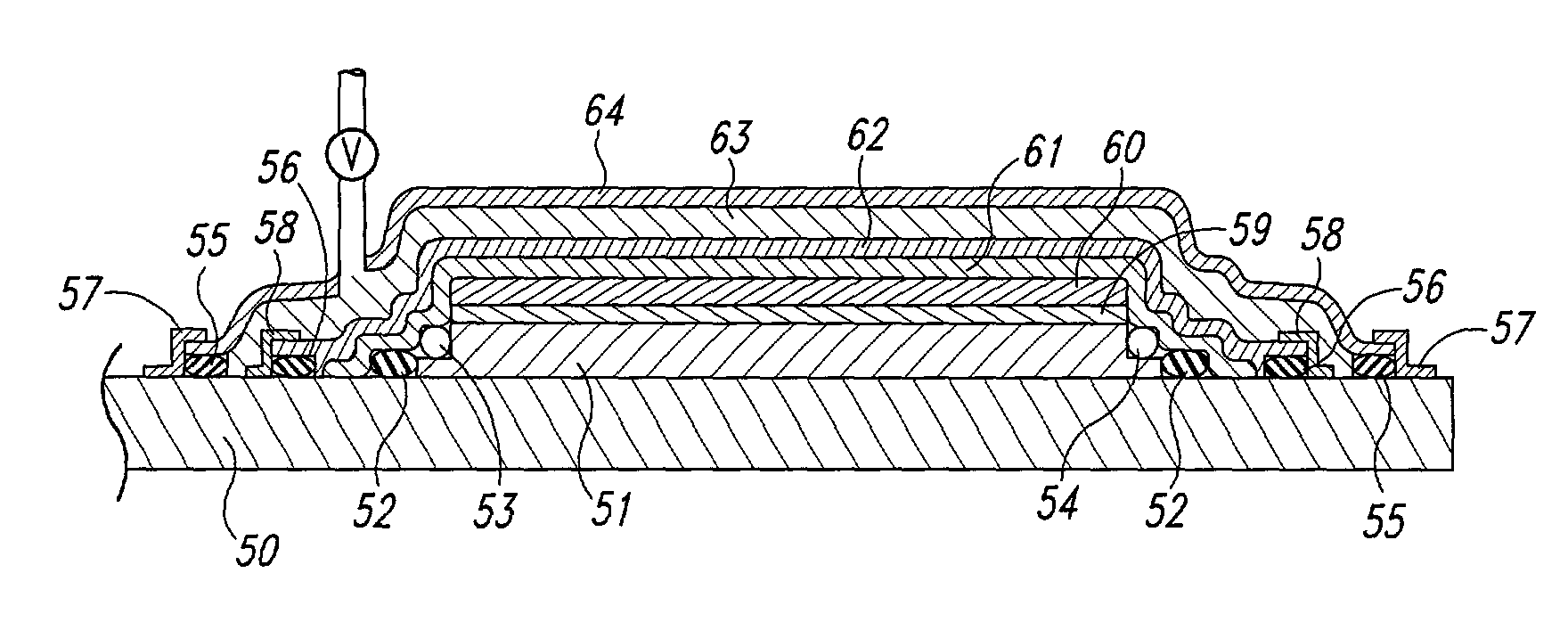

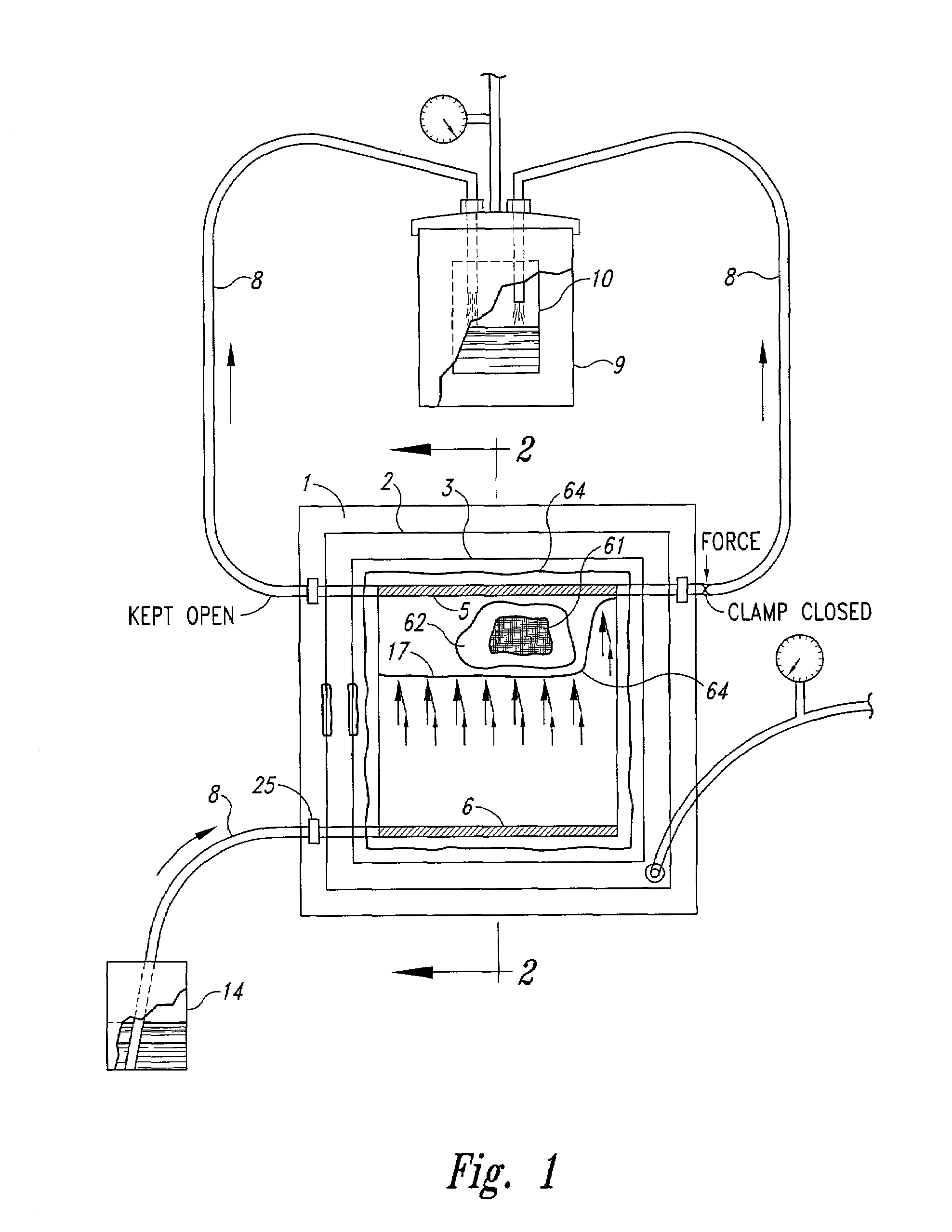

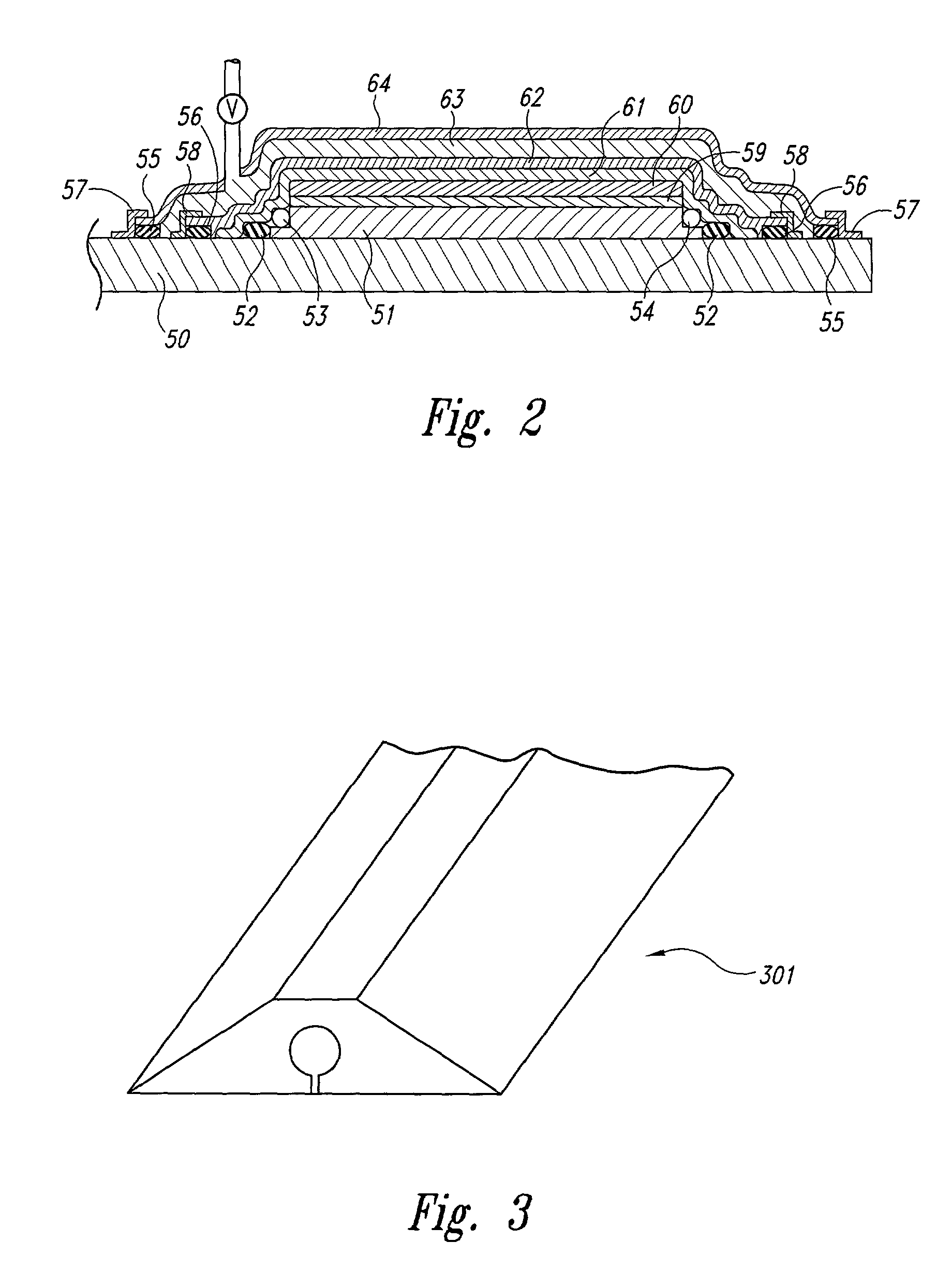

Double bag vacuum infusion process

InactiveUS7413694B2Reduce porosityMinimal surface porositySynthetic resin layered productsLaminationMedia controlsFiber

The double bag vacuum infusion process of the present invention provides a low cost method for producing complex composite assemblies without an autoclave. It also enables the production of highly innovative structures. The quality of the composites produced using such an infusion process are comparable to composites made using prepregs, hand layup or fiber placement, and autoclave curing. Double bagging provides vacuum integrity, controls bag relaxation while flow media controls the flow front to allow high quality aerospace-grade products.

Owner:THE BOEING CO

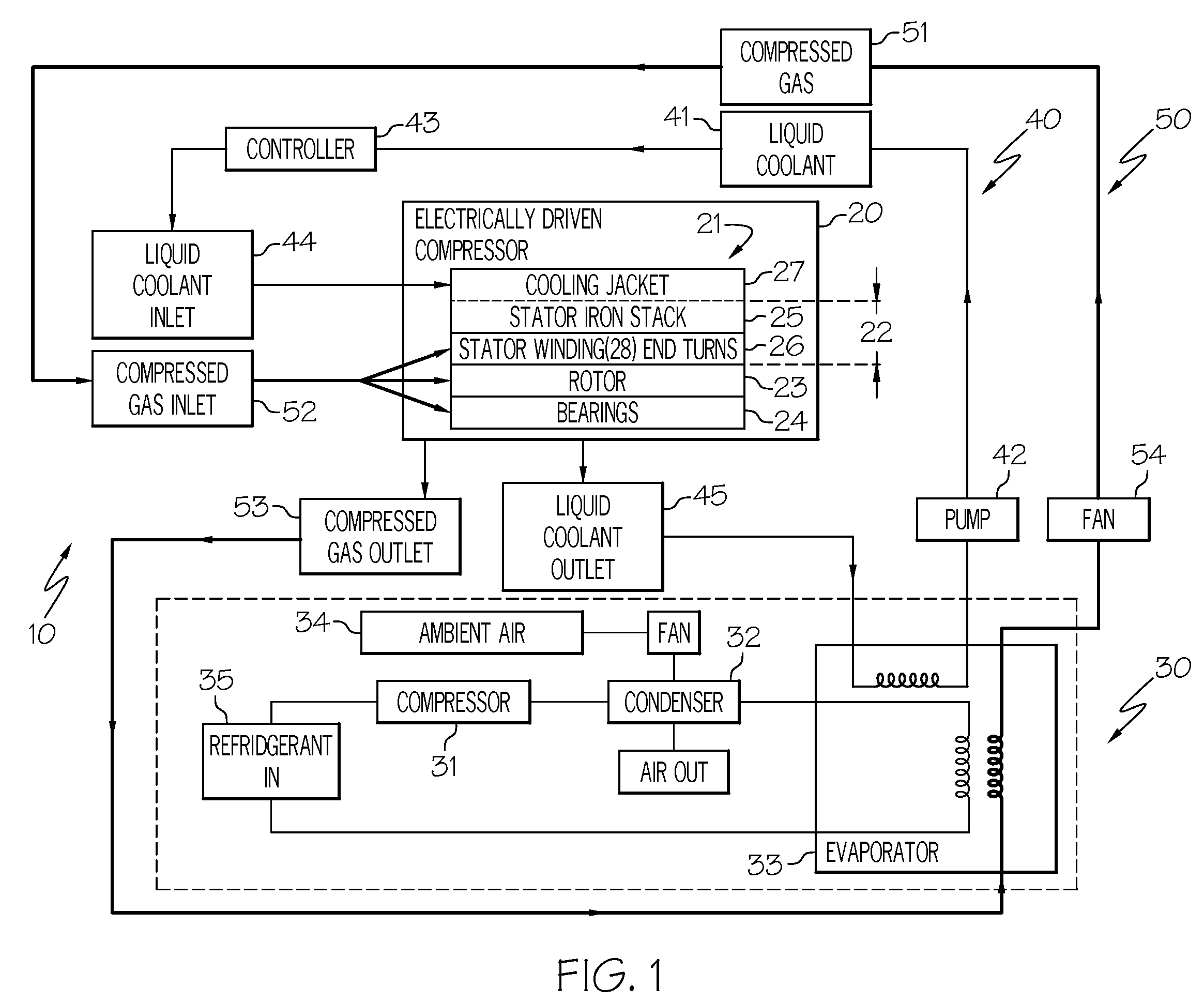

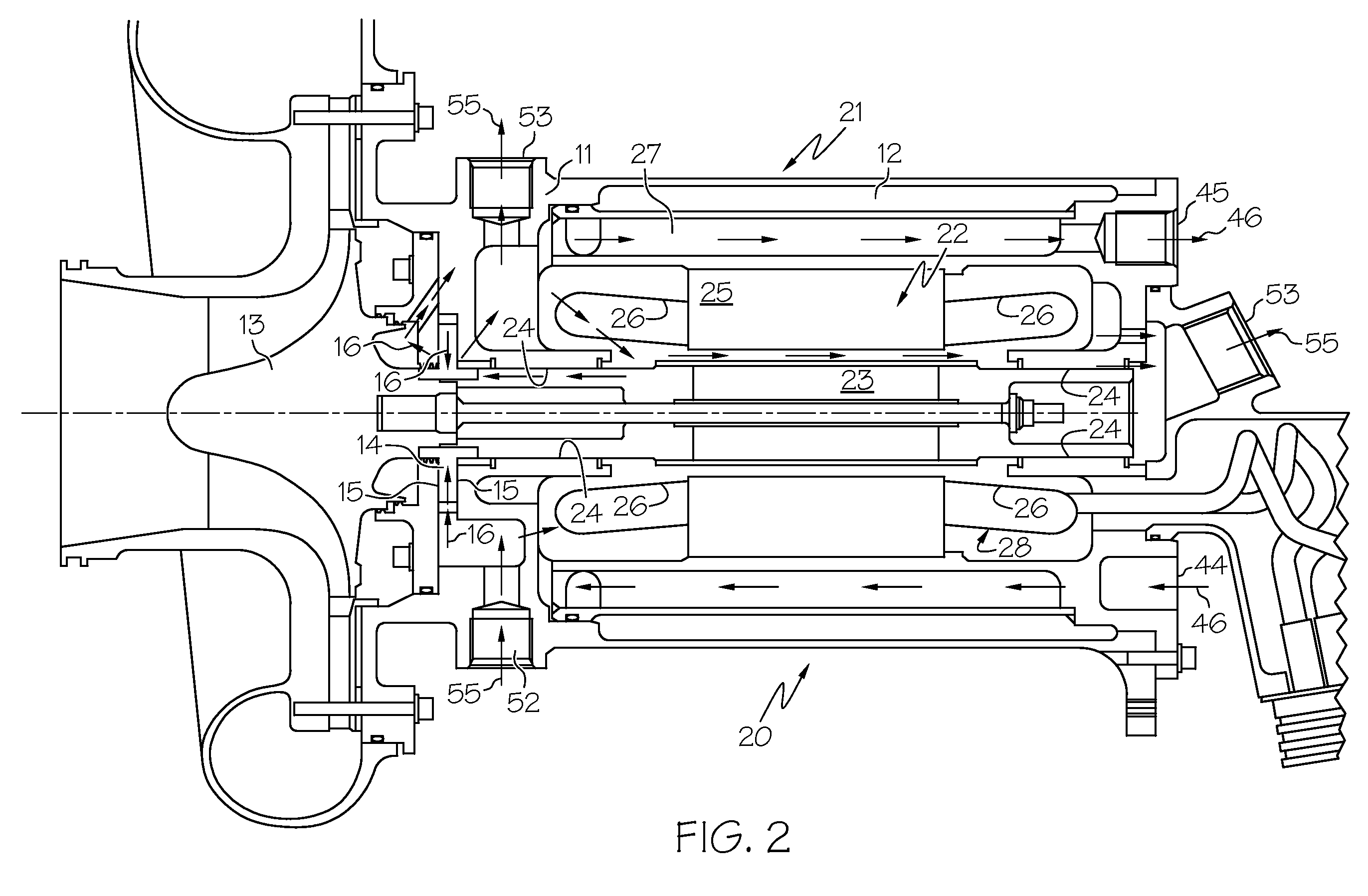

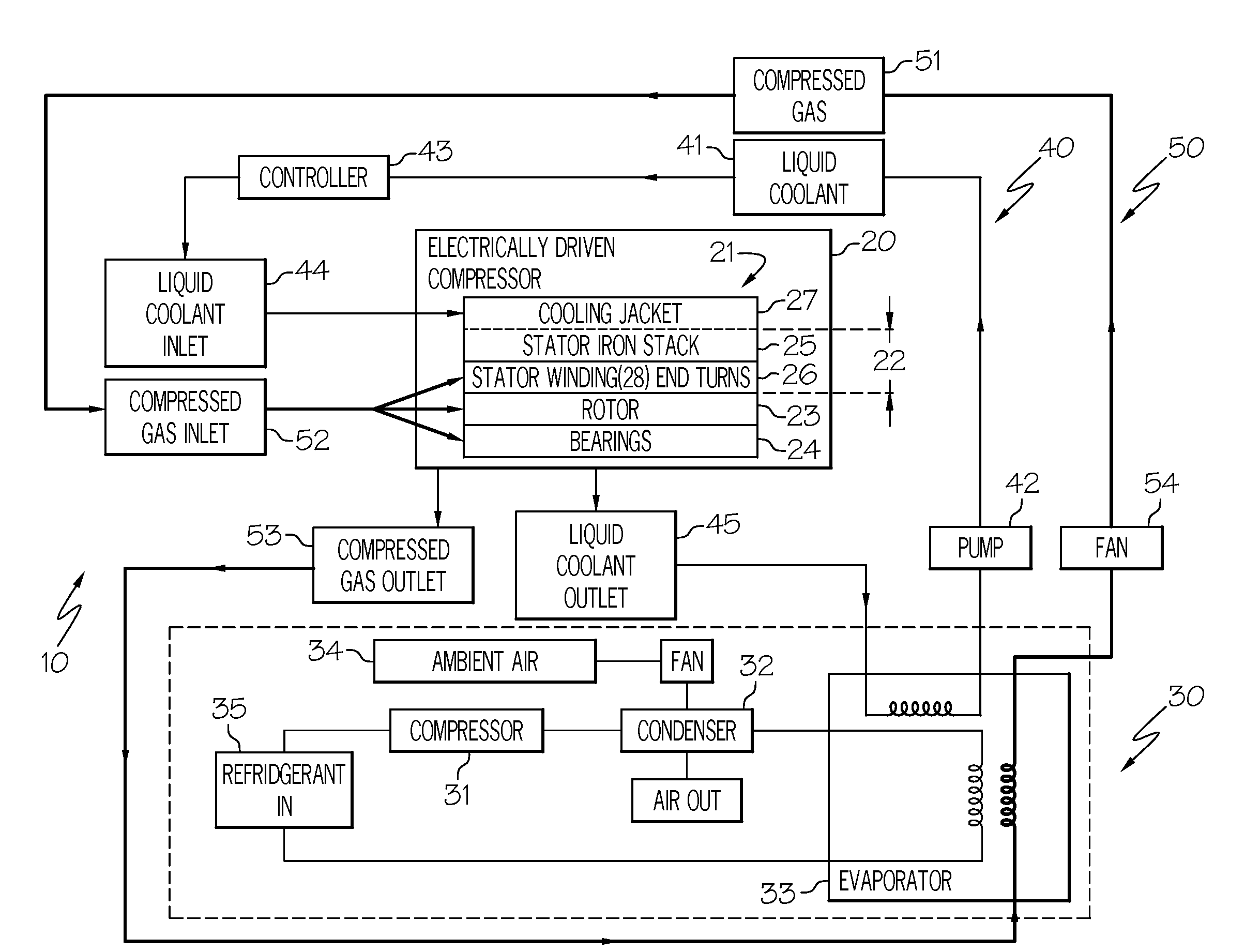

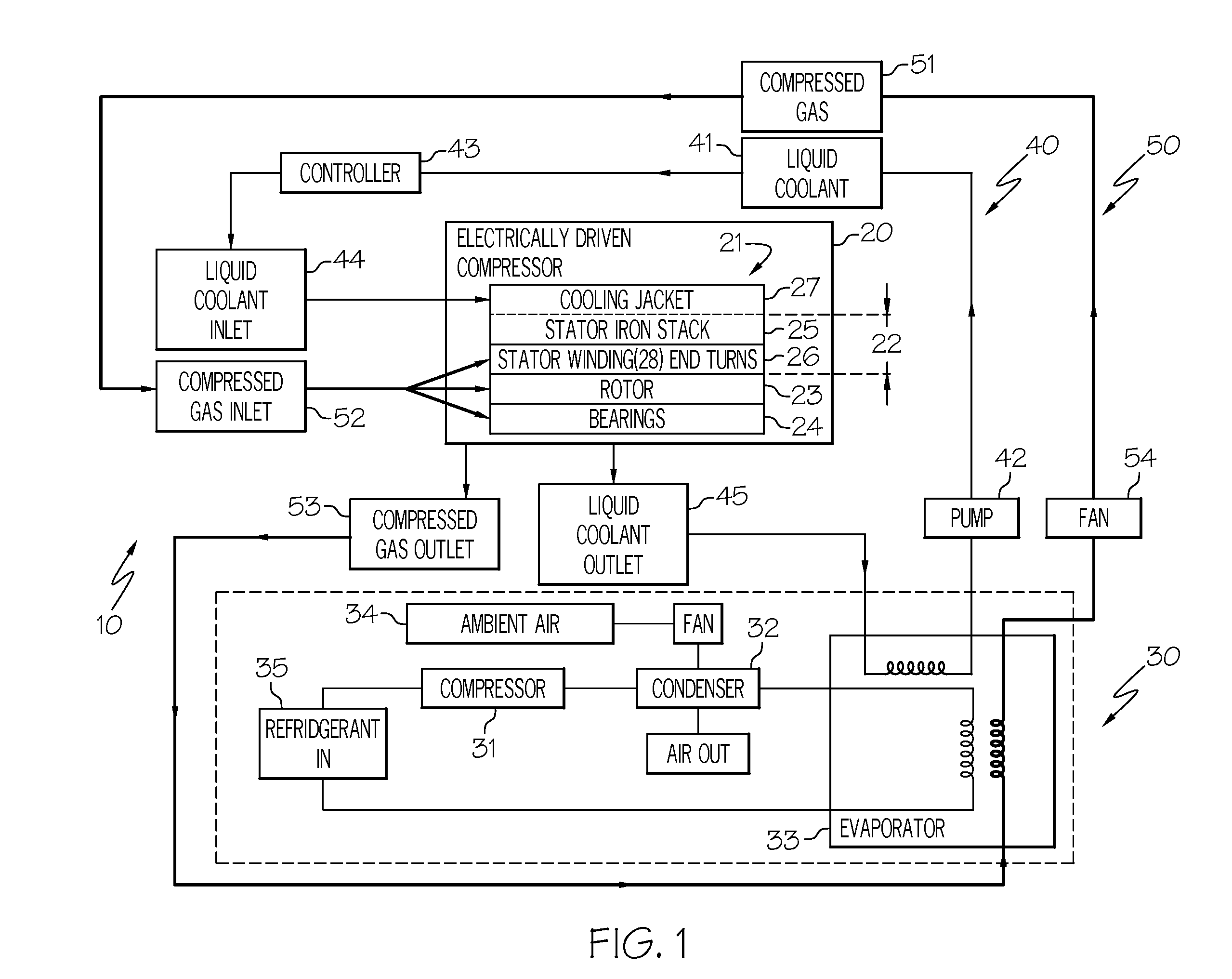

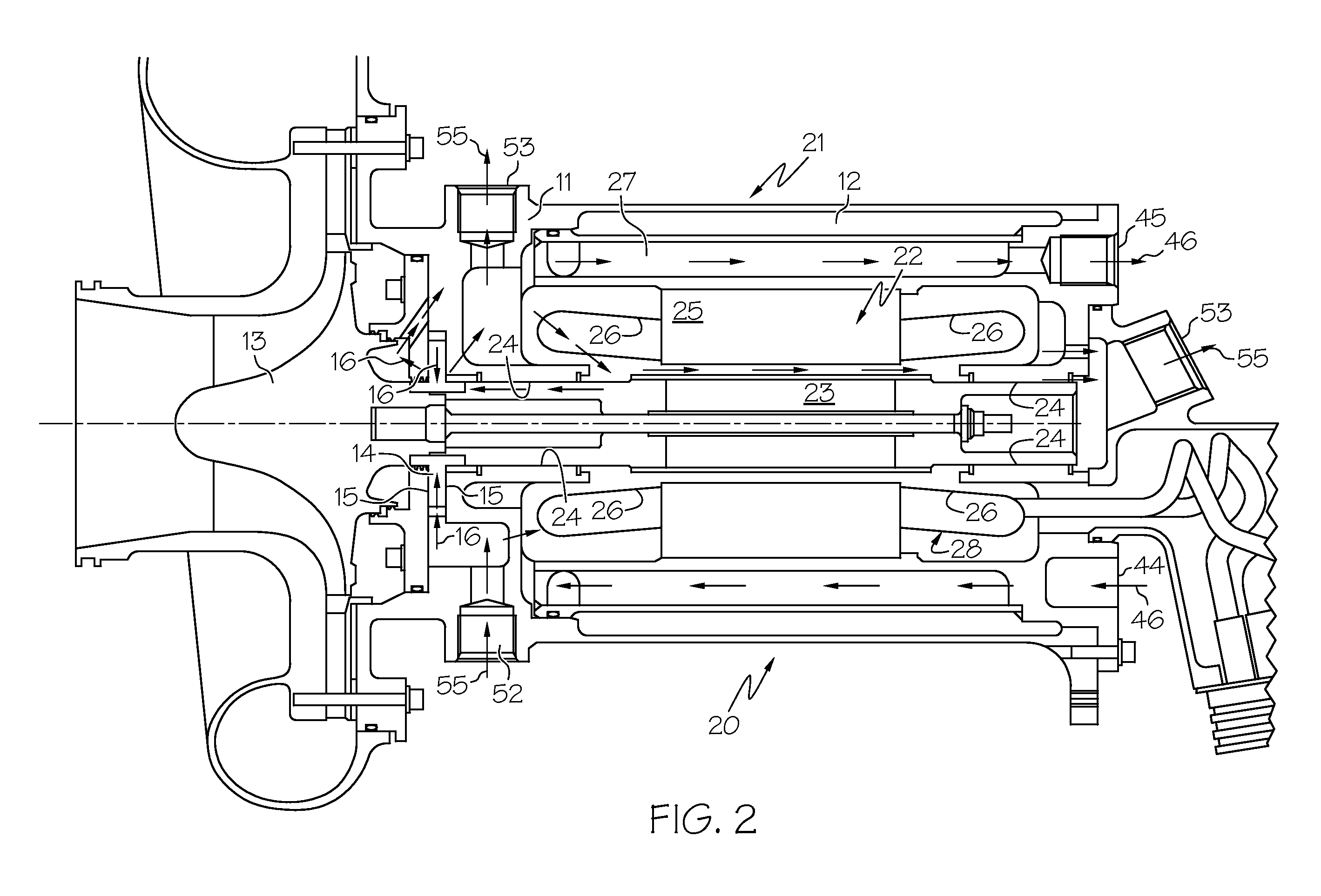

Thermal and secondary flow management of electrically driven compressors

Owner:HONEYWELL INT INC

Nanometer multiple-layer composite thermal insulation material and preparation method thereof

ActiveCN101799099AEasy to useInhibition of high temperature radiative heat transferThermal insulationPipe protection by thermal insulationAdhesiveMetal foil

The invention discloses a nanometer multiple-layer composite thermal insulation material and a preparation method thereof. The nanometer multiple-layer thermal insulation composite material is formed by alternatively overlapping an infrared reflecting screen and a spacer; the ratio of total layer amounts n of the infrared reflecting screens and the spacers to the total thickness of the nanometer multiple-layer composite thermal insulation material is 0.5-4; the infrared reflecting screen is a metal foil or a metal plated foil; the spacer is a thermostability nanometer porous aerogel composite thermal insulation material; the infrared reflecting screen and the spacer are combined by being adhered with thermostability adhesives or in puncturing connection by thermostability sewing threads. The invention also comprises the preparation method of the nanometer multiple-layer composite thermal insulation material. The nanometer multiple-layer composite thermal insulation material of the invention has low density, favorable mechanical property and favorable high-temperature thermal insulation property, lowers requirements on the vacuum degree by a VIP plate when being used as vacuum thermal insulation plate core materials, does not need getter and can satisfy harsh high-efficiency thermal insulation using requirements on materials by aviation, aerospace and civil fields. The method of the invention can prepare thermal insulation material members with large size and complex shape.

Owner:NAT UNIV OF DEFENSE TECH

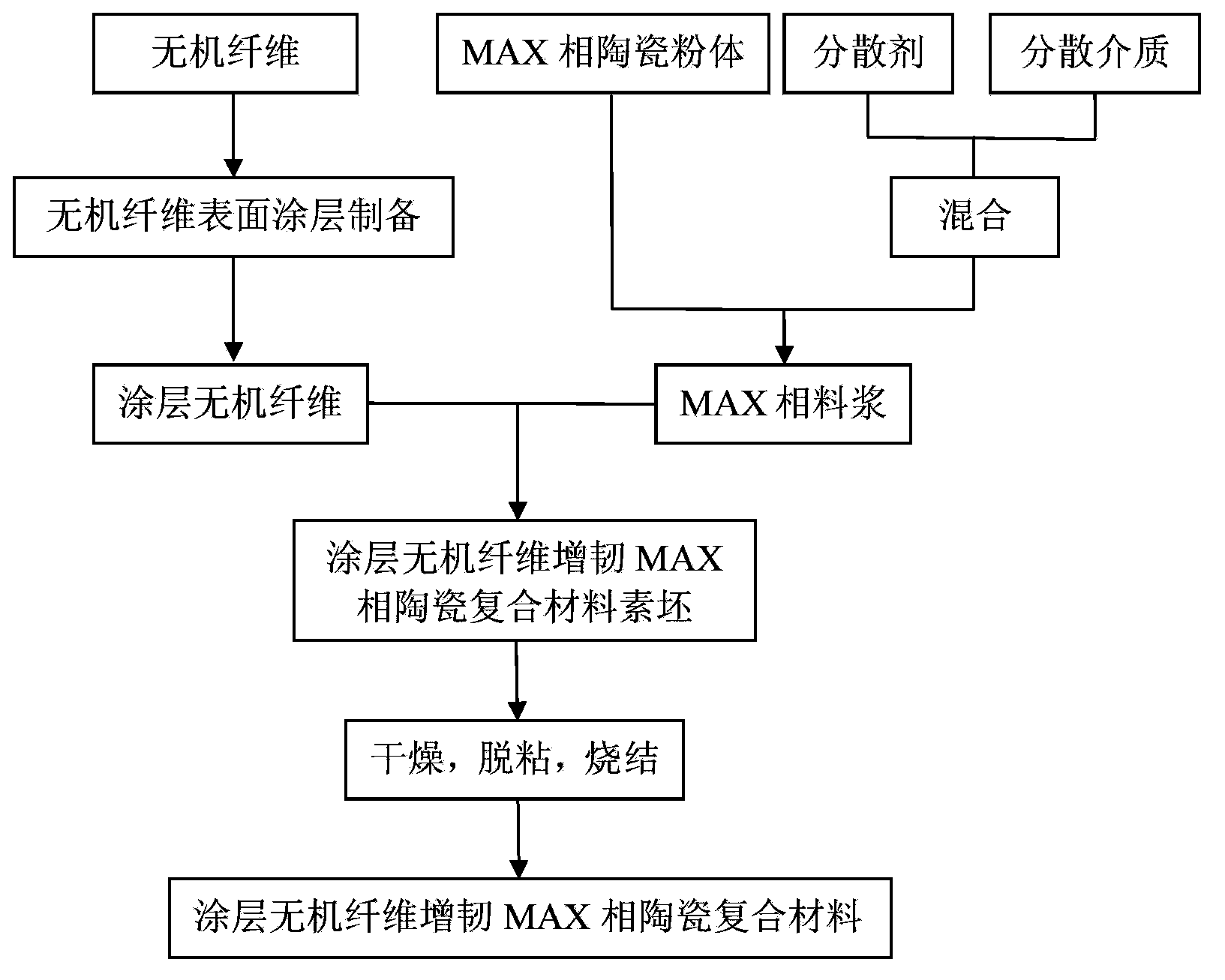

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

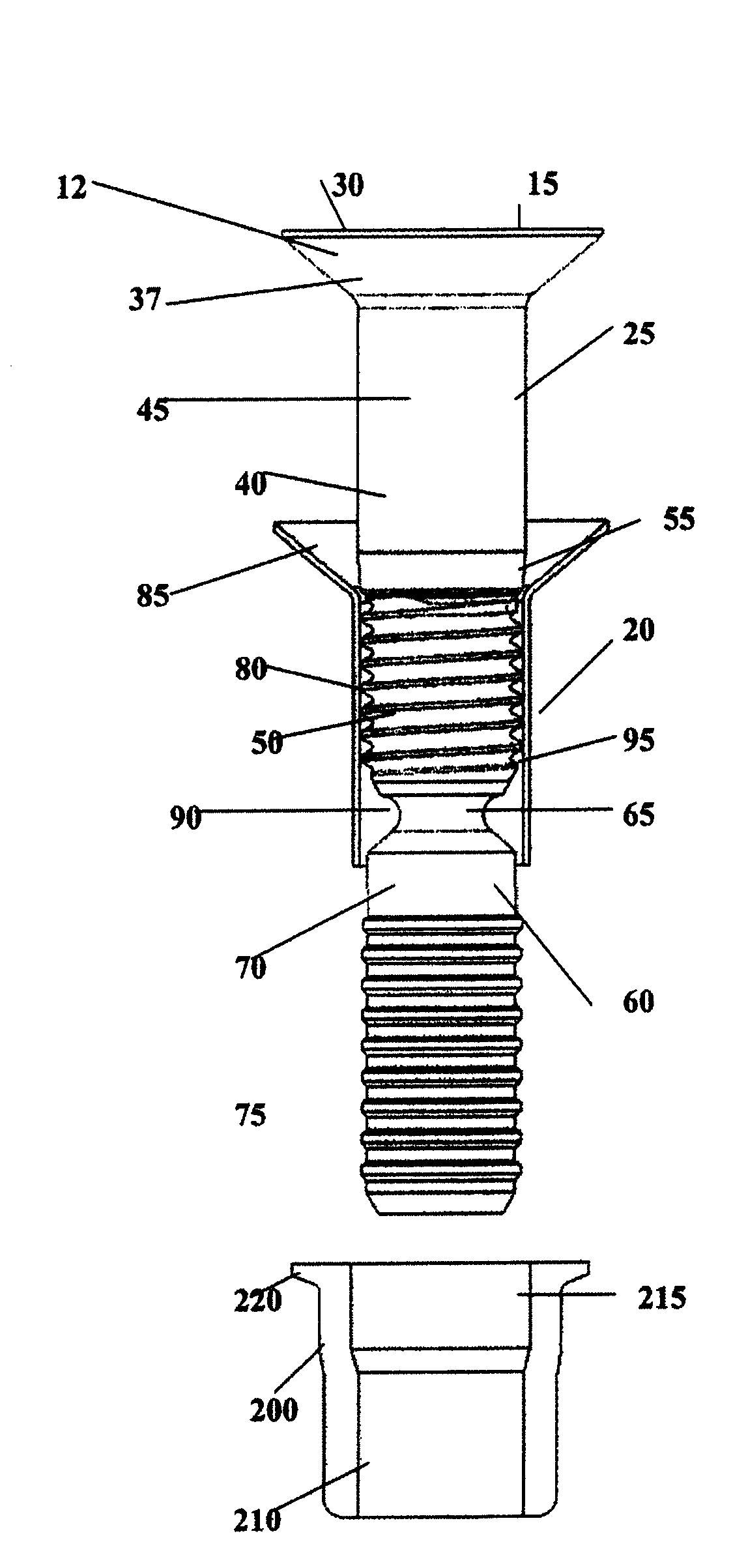

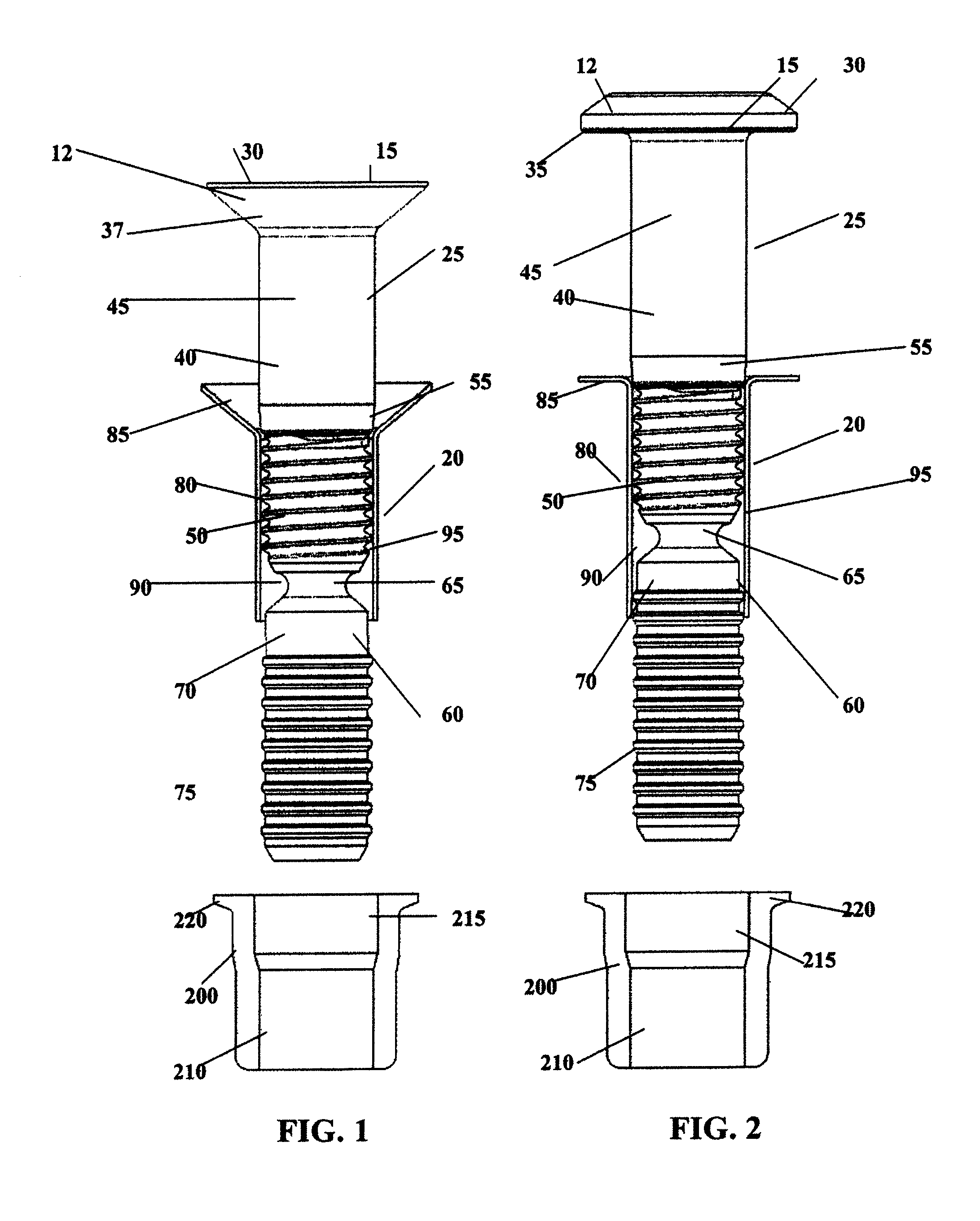

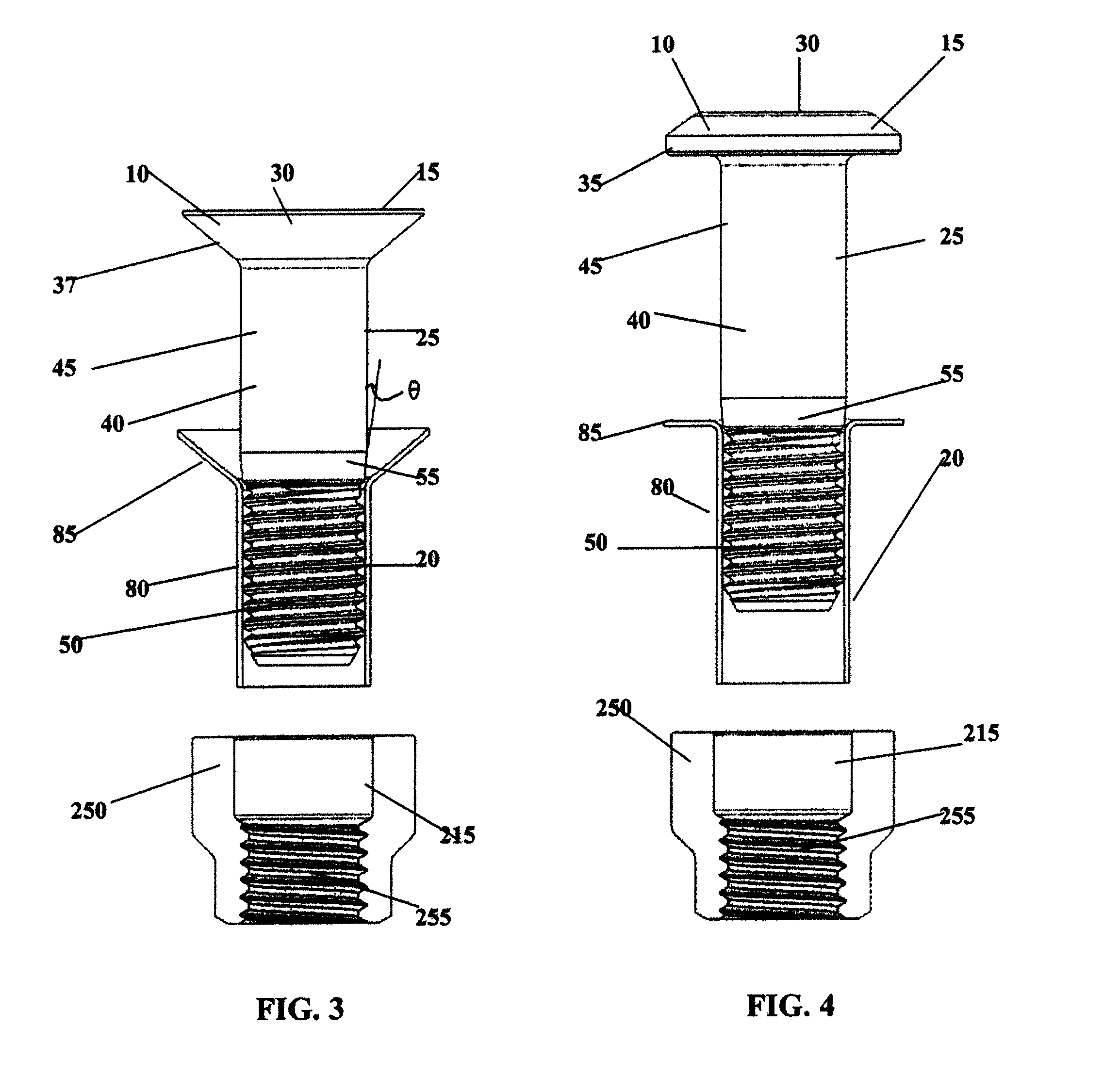

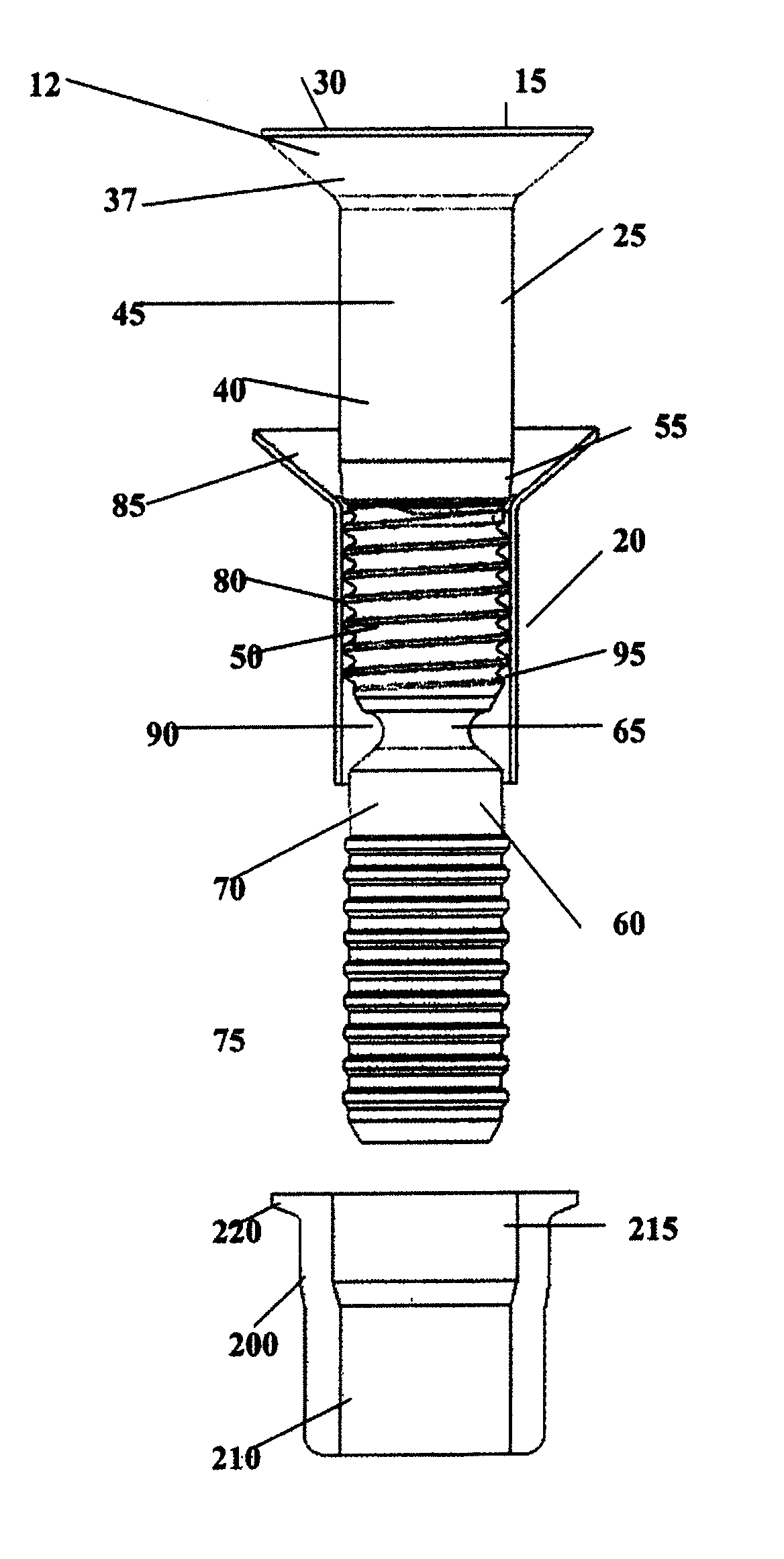

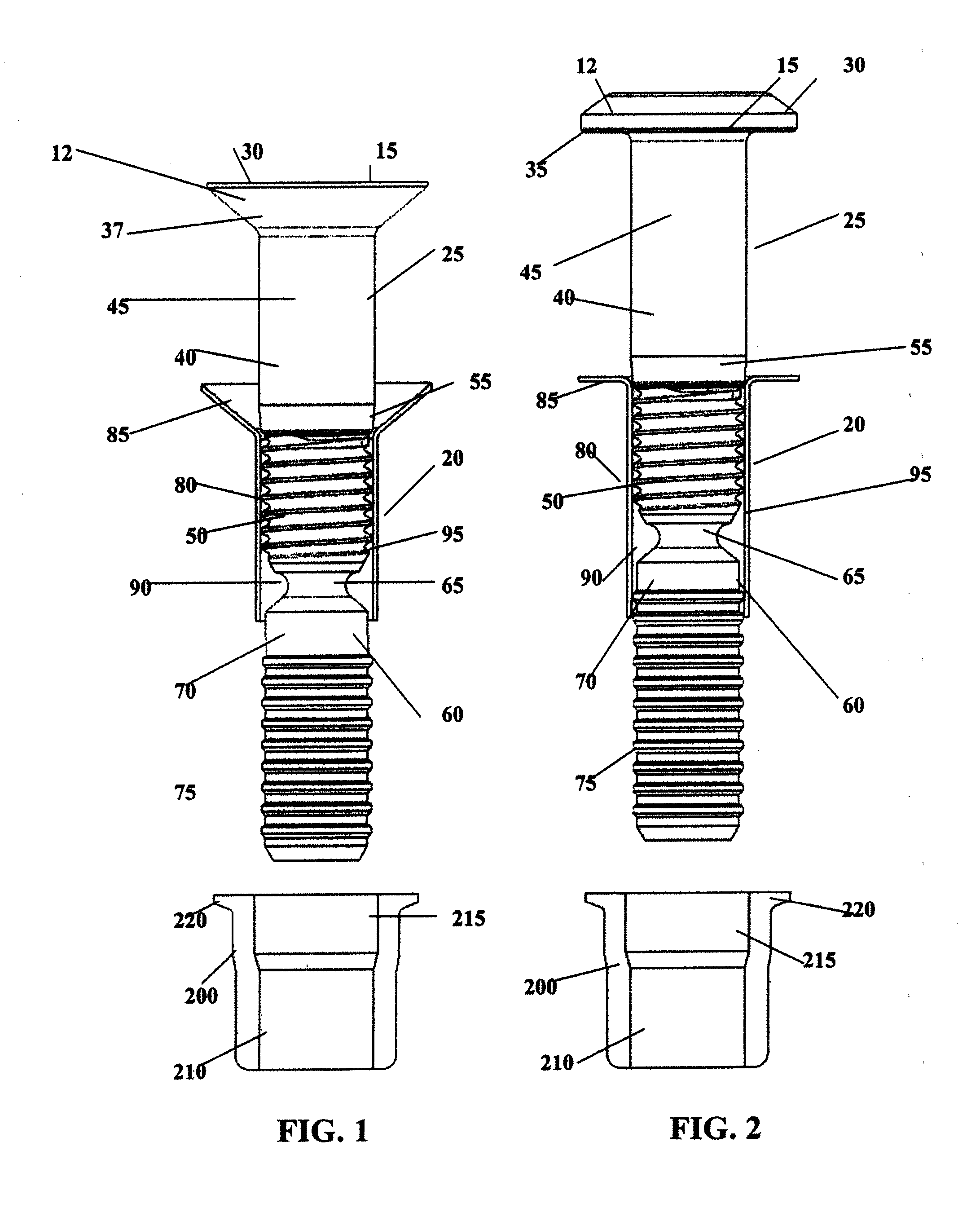

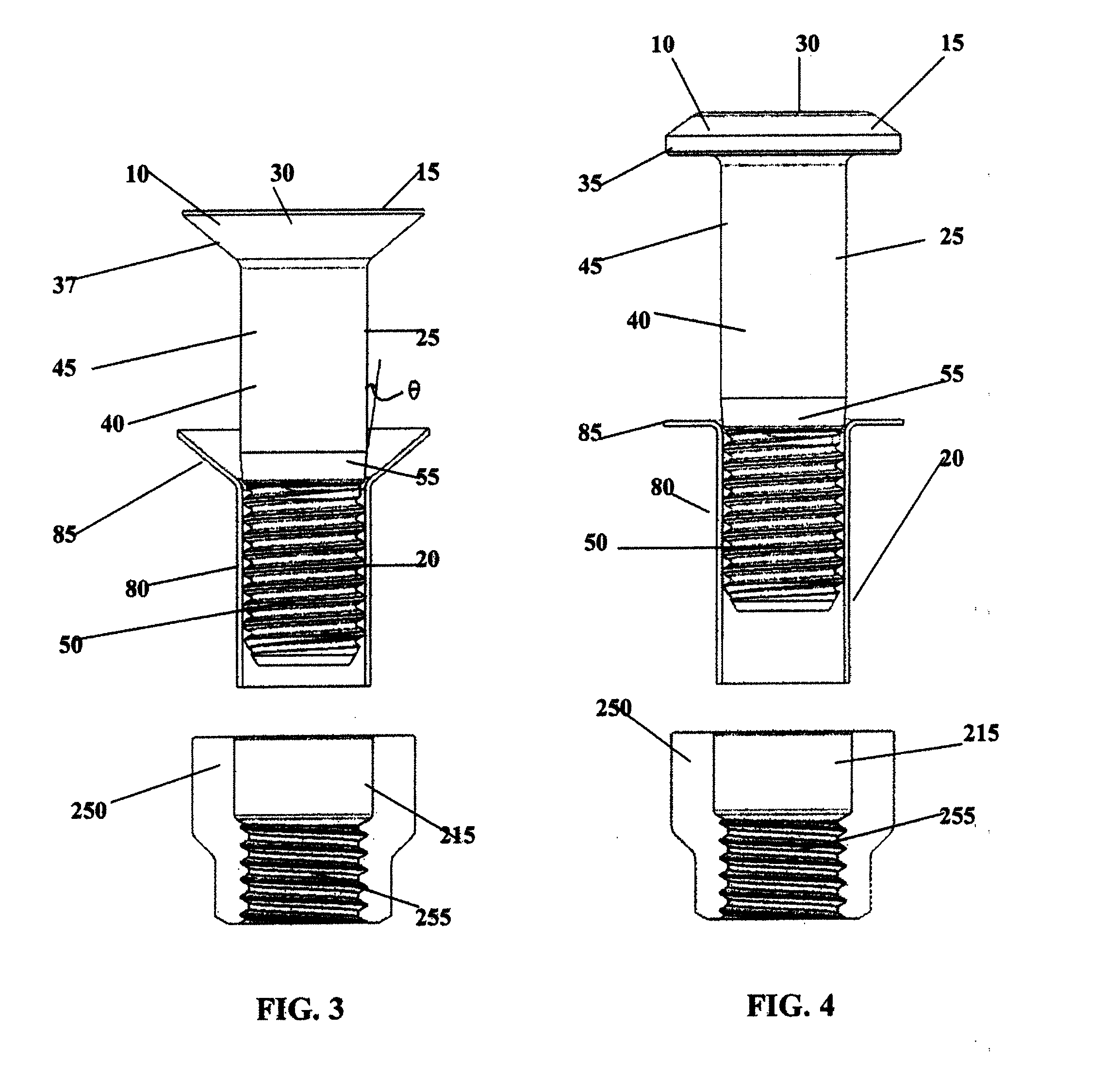

High performance sleeved interference fasteners for composite applications

A fastener adapted to pass through aligned holes through workpieces is disclosed. The fastener includes a pin member having a transition portion wherein the diameter of the transition portion decreases radially as it extends from the smooth cylindrical shank portion to the threaded portion. The fastener may also comprise a sleeve member and a clamping means. The clamping means includes a collar, a nut, or any other possible clamping means. In exemplary embodiments, the workpieces can be formed with a plurality of materials, the materials including composite, metallic, or composite / metallic structures, any combination thereof. In particular embodiments, the fastener has interference capability of 0.0005 to 0.0100 inches in composite structures without risk of composite delamination or damage. As a result of the fastener interference, gaps between the fastener and the structure are eliminated thereby providing good electrical conductivity between components. As a result, the potential for electrical sparks is reduced, providing a safer fastener for use with aerospace applications.

Owner:ALCOA GLOBAL FASTENERS

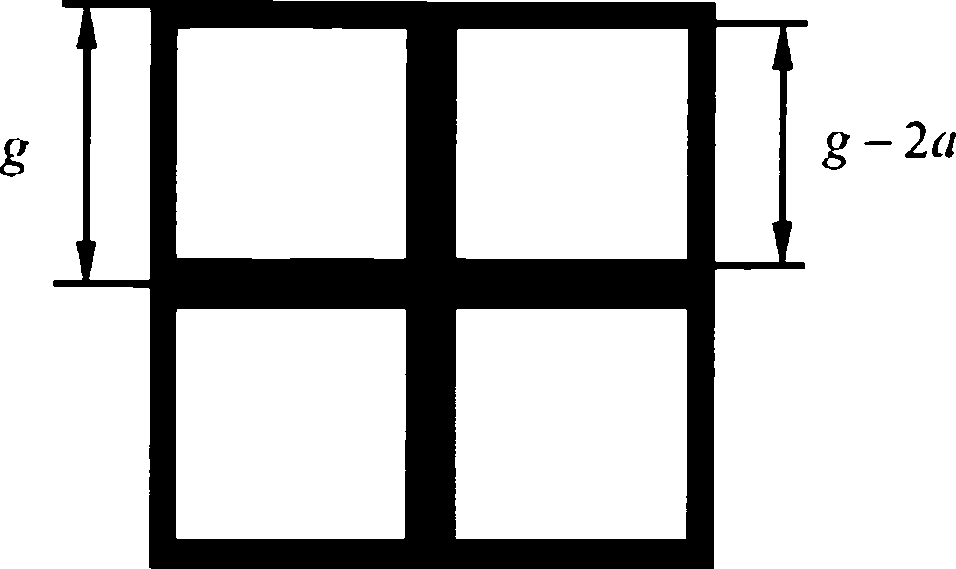

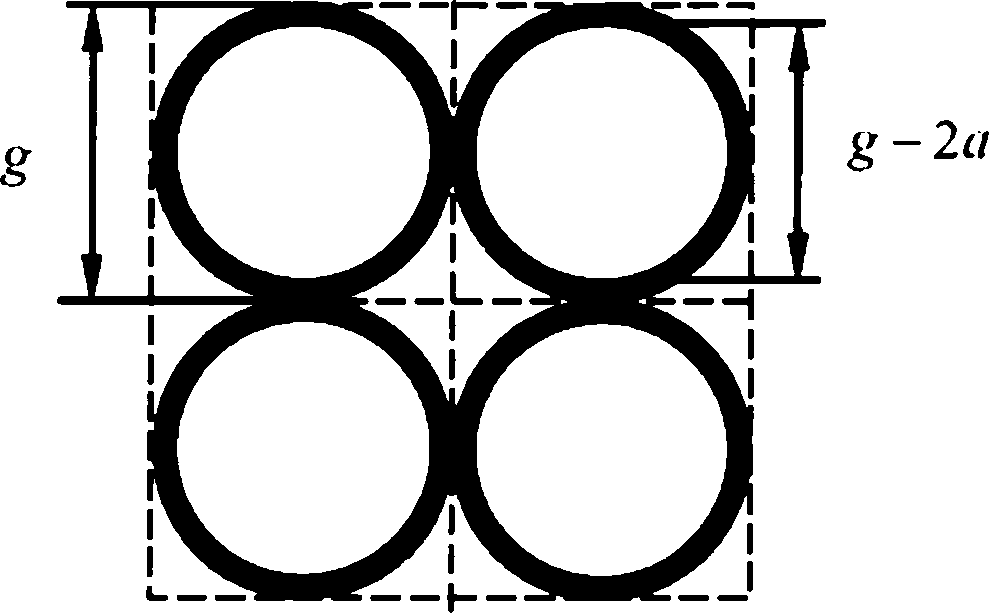

Electromagnetic screening optical window with circular ring metal meshed gate structure

InactiveCN1889822AReduce the occupied areaHigh light transmittanceMagnetic/electric field screeningOptoelectronicsCross hatch

An electromagnetic shielded optical window with ring type of metal cross hatch pattern structure is prepared as arranging ring type of metal cross hatch pattern units in two-dimensional orthogonal mode to from cross hatch pattern array then loading formed array on transparent substrate surface of optical window. The prepared product can be used to carry out electromagnetic shielding in medical treatment and aerospace cause.

Owner:HARBIN INST OF TECH

Silicon dioxide aerogel material and preparation method thereof

The invention relates to a silicon dioxide aerogel material and a preparation method thereof. The method comprises the following steps: by using water glass as silicon source, adding an acid-containing organic solvent free of chlorine ions and fluorine ions to generate a precipitate of sodium ions, potassium ions and other metal salt ions, filtering to remove the precipitate to obtain high-purity silica sol, carrying out a sol-gel process, aging, acidifying, modifying, and drying to obtain the silicon dioxide aerogel material. The acidification before modification enhances the surface reaction activity of the silicon gel, thereby obviously enhancing the modification effect and efficiency. The method has the advantages of low cost and simple and efficient technique, is beneficial to mass high-efficiency production, is free of chlorine ions and fluorine ions in the whole technical process, and enhances the equipment operation safety and reliability; and the product can be used for heat preservation and thermal insulation of nuclear power and liquefied natural gas equipment and pipelines with higher requirement for corrosion resistance, and can also be used for thermal insulation in the field of aerospace, petrochemical engineering, track transportation, ships, automobiles, construction and the like.

Owner:浙江圣润纳米科技有限公司

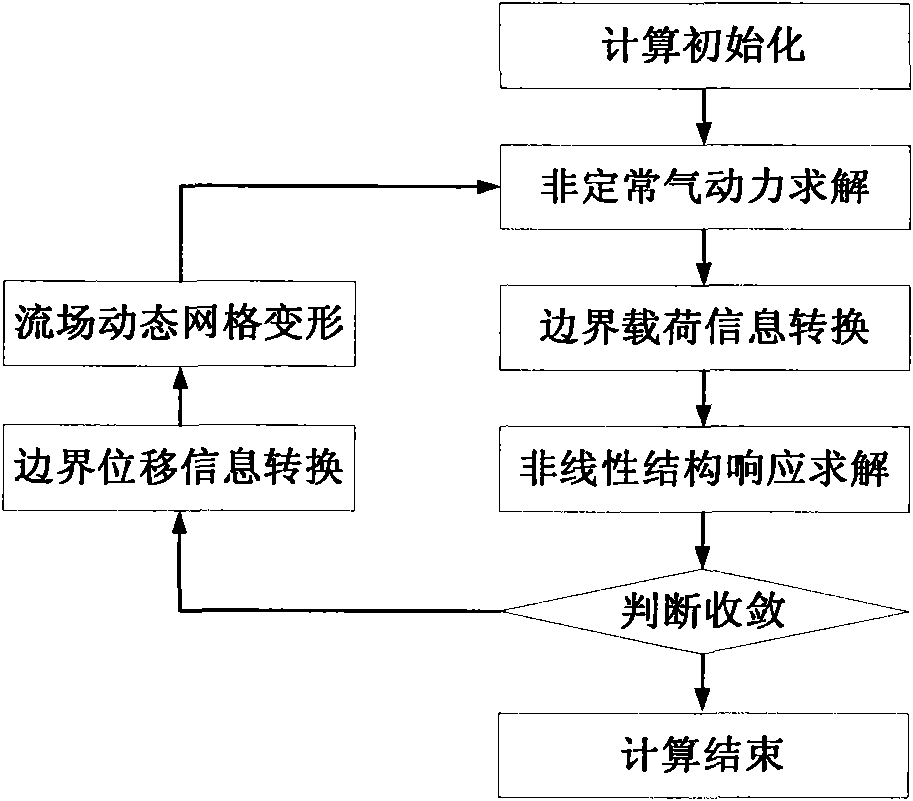

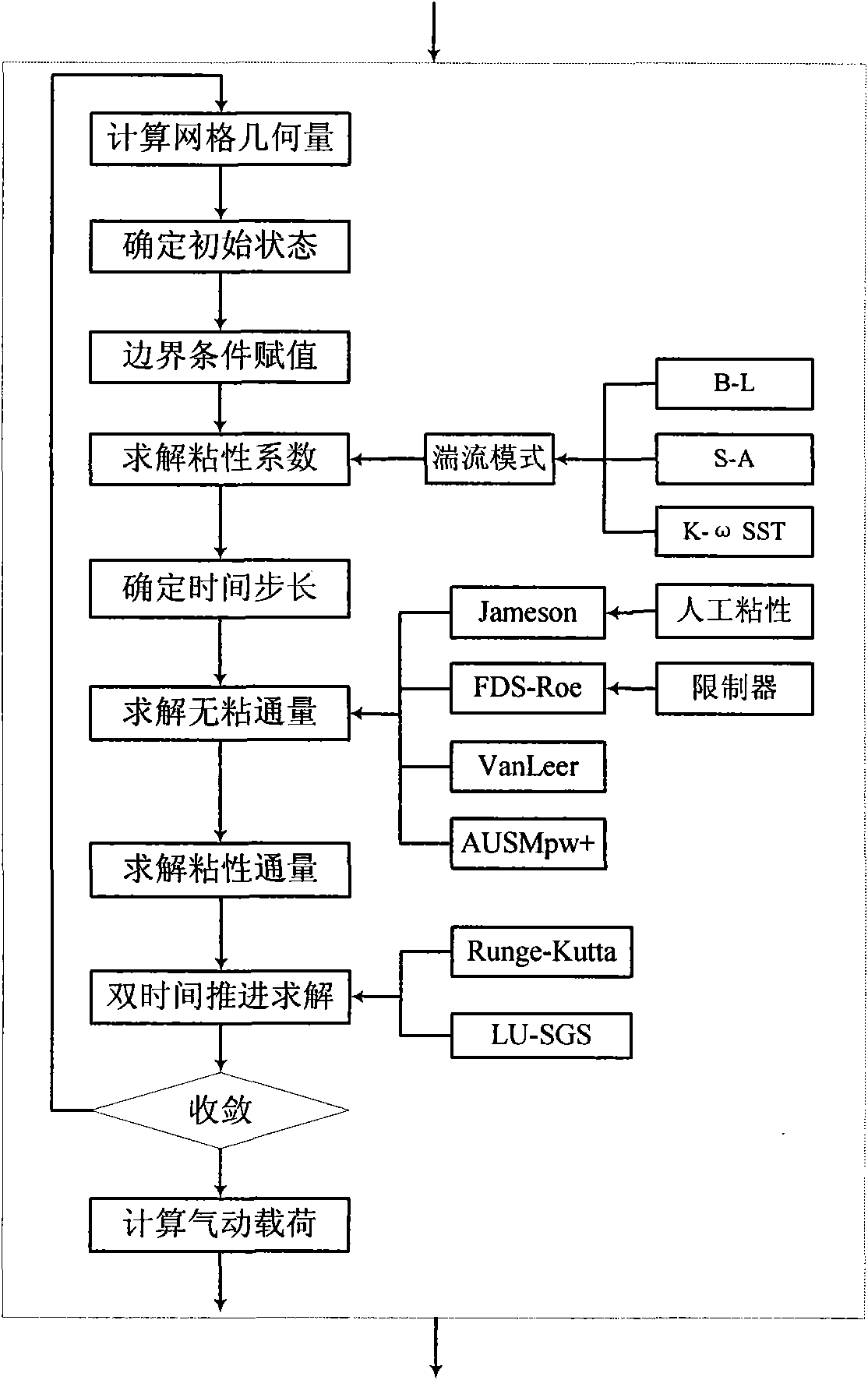

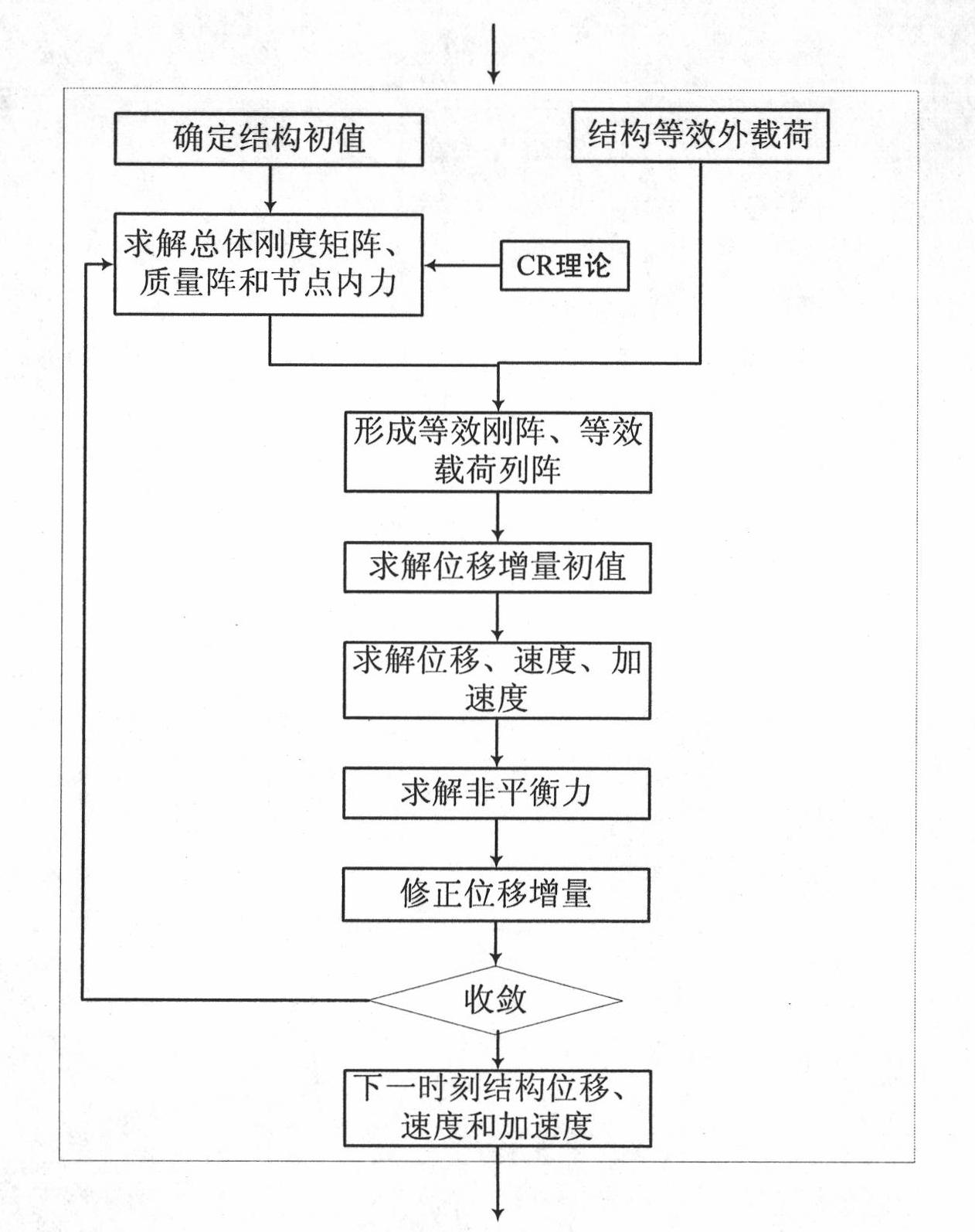

CFD (computational fluid dynamics)/CSD (circuit switch data) coupled solving nonlinear aeroelasticity simulation method

InactiveCN102012953ACapable of nonlinear couplingSpecial data processing applicationsAviationCircuit Switched Data

The invention discloses a CFD (computational fluid dynamics) / CSD (circuit switch data) coupled solving nonlinear aeroelasticity simulation method, comprising: firstly, carrying out calculation initialization; then solving the CFD of unsteady aerodynamic force; converting boundary load information; solving the CSD of nonlinear structure dynamic response; judging whether to exist computation or notby taking the response of structural finite-element mesh point displacement as a convergence criteria; if not exiting, carrying out the dynamic mesh deformation of a flow field after the surface displacement information of a computation model is converted; and then, continuing to compute until the convergence criteria is satisfied, thus finishing computation. By means of the simulation method disclosed by the invention, the problem of pneumatic nonlinearity and structural nonlinearity coupling and the problem of geometric large deformation dynamic mesh can be solved; and the simulation methoddisclosed by the invention can be applied on the nonlinear aeroelasticity analysis of aerospace aircrafts and the nonlinear aeroelasticity analysis of civil high-rise buildings and bridges.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Visual display system for displaying virtual images onto a field of vision

An optically transparent, ghost-free visual display system that superimposes a virtual image comprising graphical or textual information onto a field of vision. Embodiments of the visual display system utilize illumination and optical components that introduce a virtual image onto a field of vision while minimally obstructing and / or attenuating other objects within the field of vision. Embodiments of the visual display system can be used in numerous applications, including head-up displays (“HUDs”) for automotive, tracked and rail-mounted vehicles, marine, aerospace applications, see-through speech prompt displays, and see-through projection displays.

Owner:BIG BUDDY PERFORMANCE

Nanometer cellulose/polyvinyl alcohol gel composite material

ActiveCN102786642ALarge specific surface areaHigh porosityChemical industryChemical industryPolyvinyl alcohol

The invention relates to a nanometer cellulose / polyvinyl alcohol gel composite material, which is characterized by comprising hydrogel and aerogel. A preparation method of the nanometer cellulose / polyvinyl alcohol gel composite material comprises the following process steps of 1, nanometer cellulose preparation by a chemical combination mechanical treatment method; 2, composite hydrogel preparation; and 3, composite aerogel preparation. The nanometer cellulose / polyvinyl alcohol gel composite material has the advantages that the composite aerogel belongs to a porous amorphous solid material consisting of nanometer level colloid particles or high-polymer molecules, and a unique open nanometer level porous structure and a continuous three-dimensional reticular structure are adopted, so the density is extremely low, the specific surface area is high, and the porosity is high, wherein the solid phase of the aerogel accounts for 0.2 percent to 20 percent of the total volume percentage, the characteristics of high adsorption catalytic capability, low thermal conductivity, low sound resistance, low refractive index and the like are shown, and wide application prospects are realized in the fields of aviation, spaceflight, chemical industry, metallurgy, energy-saving building and the like.

Owner:SHANDONG LVSEN WOOD PLASTIC COMPOSITE

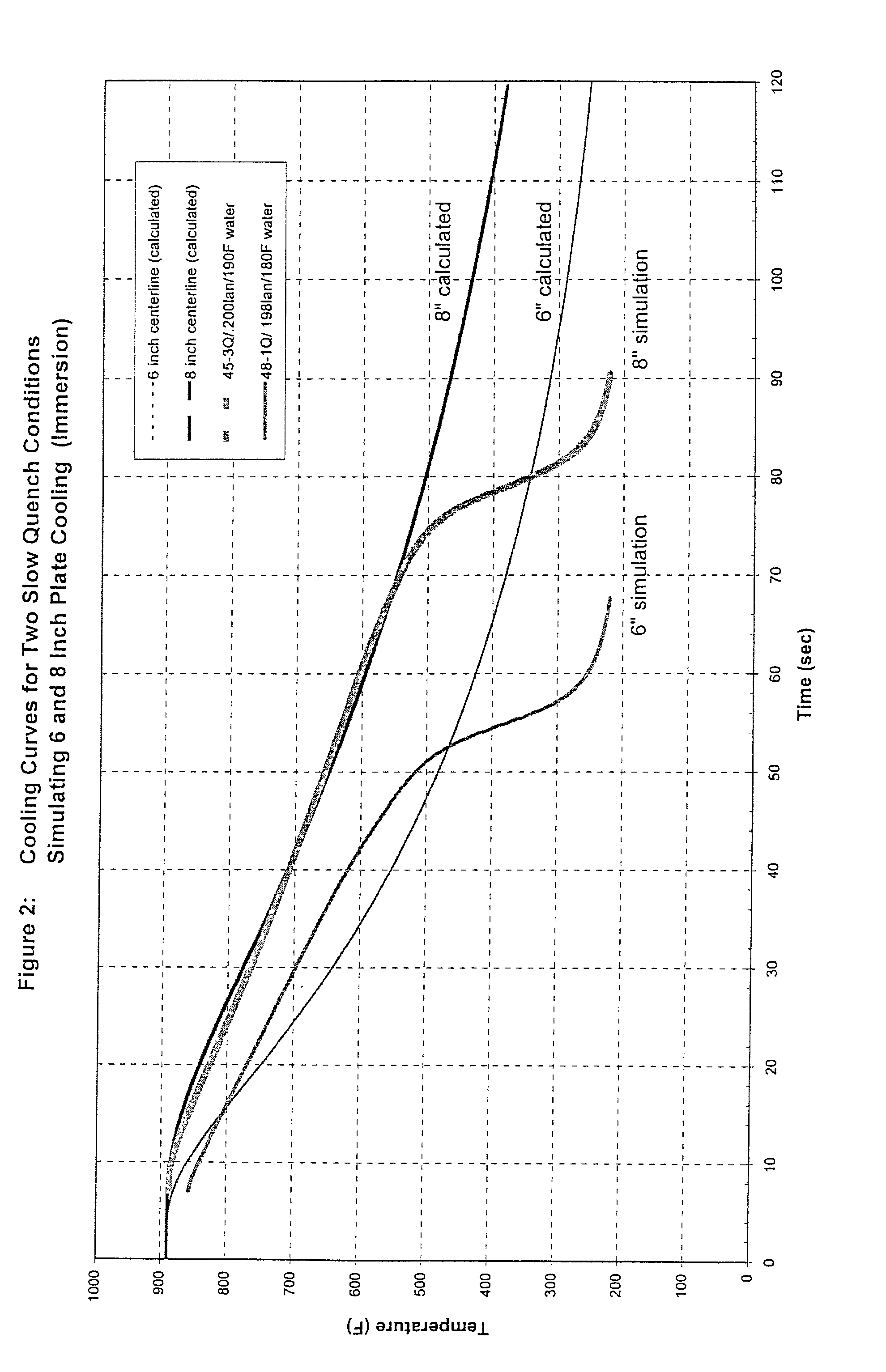

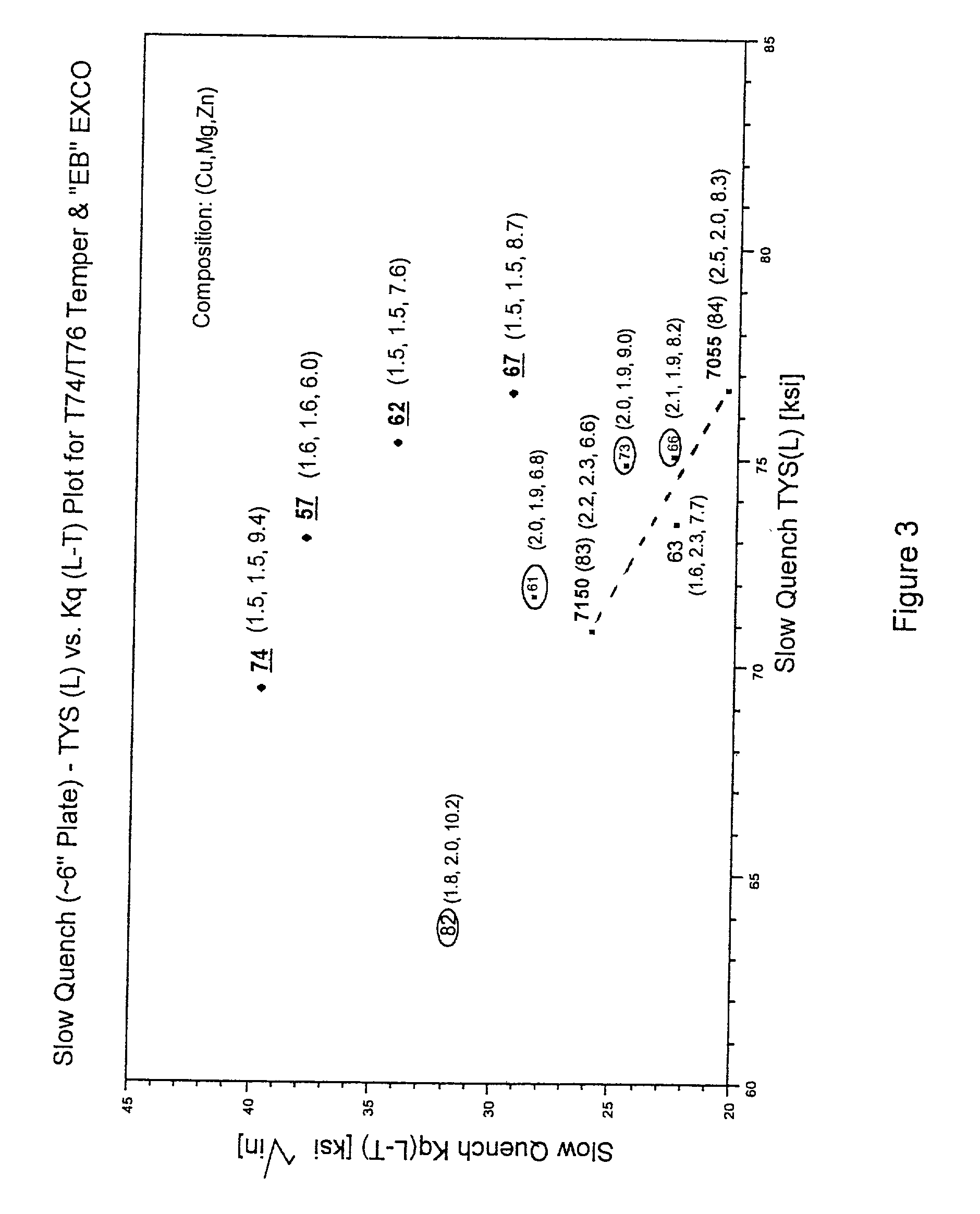

Aluminum alloy having superior strength-toughness combinations in thick gauges

A 7XXX series aluminum alloy having reduced quench sensitivity suitable for use in aerospace structural components, such as integral wing spars, ribs, extrusions and forgings comprises, in weight %: 6 to 10 Zn, 1.3 to 1.9 Mg, 1.4 to 2.2 Cu, wherein Mg<=Cu+0.3, one or more of 0 to 0.4 Zr, up to 0.4 Sc, up to 0.2 Hf, up to 0.4 Cr, up to 1.0 Mn and the balance Al plus incidental additions including Si, Fe, Ti and the like plus impurities. By controlling the Mg content to 1.3 to 1.7 wt. %, limiting Mg<=Cu+0.3 and 6.5<=Zn<=8.5, the alloy provides significantly improved combined strength and fracture toughness in heavy gauges. For example, in a six-inch thick plate there is provided a combination of about 75 ksi quarter-plane tensile yield strength (L) with a fracture toughness (L-T) of about 33 ksi{square root}in which progresses by artificial aging / tempering to a combined strength and fracture toughness of about 67 ksi tensile yield strength (L) and a fracture toughness (L-T) of about 40 ksi{square root}in. The alloy product possesses equally attractive combinations of strength and fracture toughness when intentionally quenched slowly following solution heat treatment so as to lessen dimensional distortion, particularly in shapes of varying cross section.

Owner:ARCONIC INC

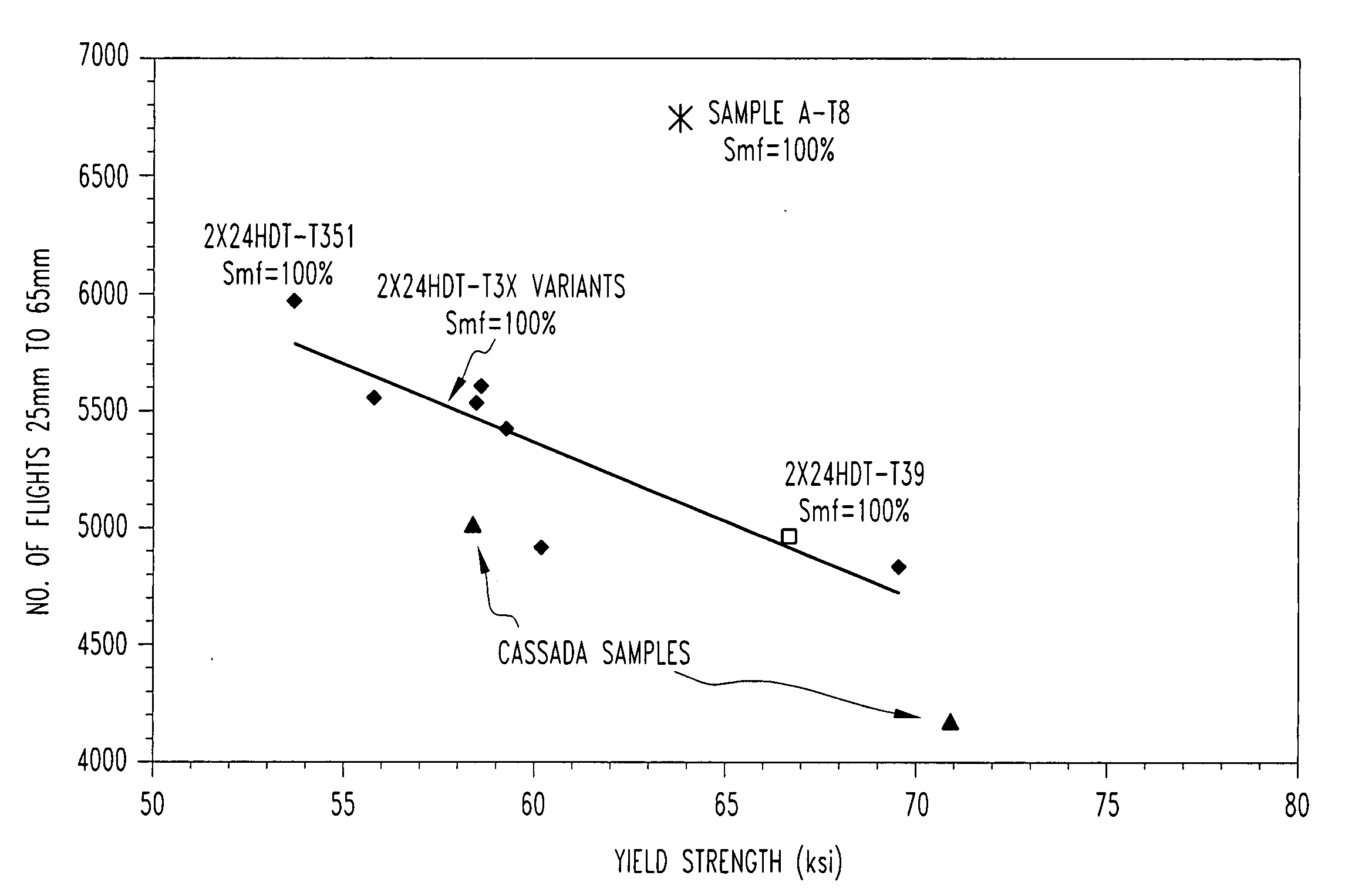

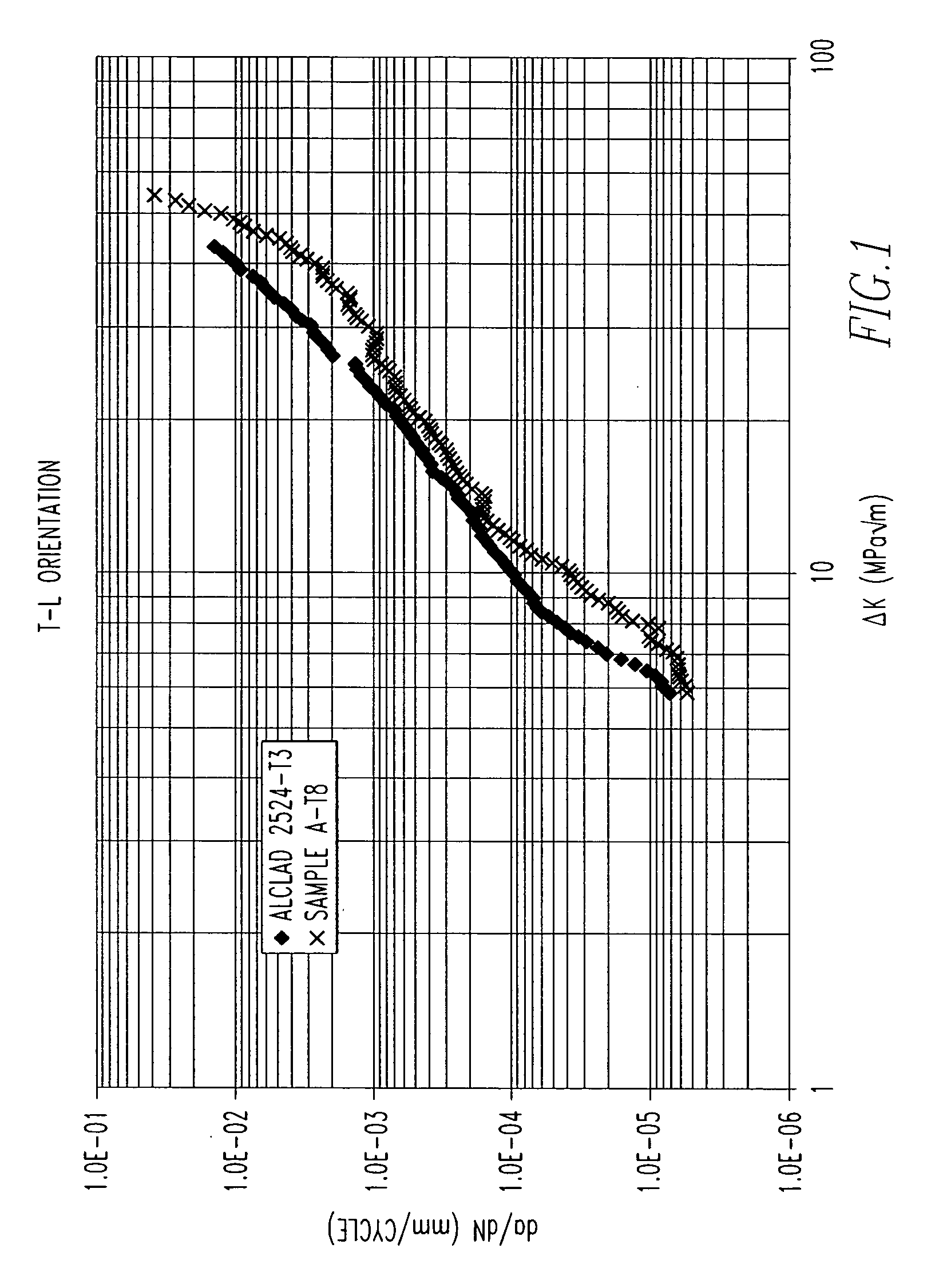

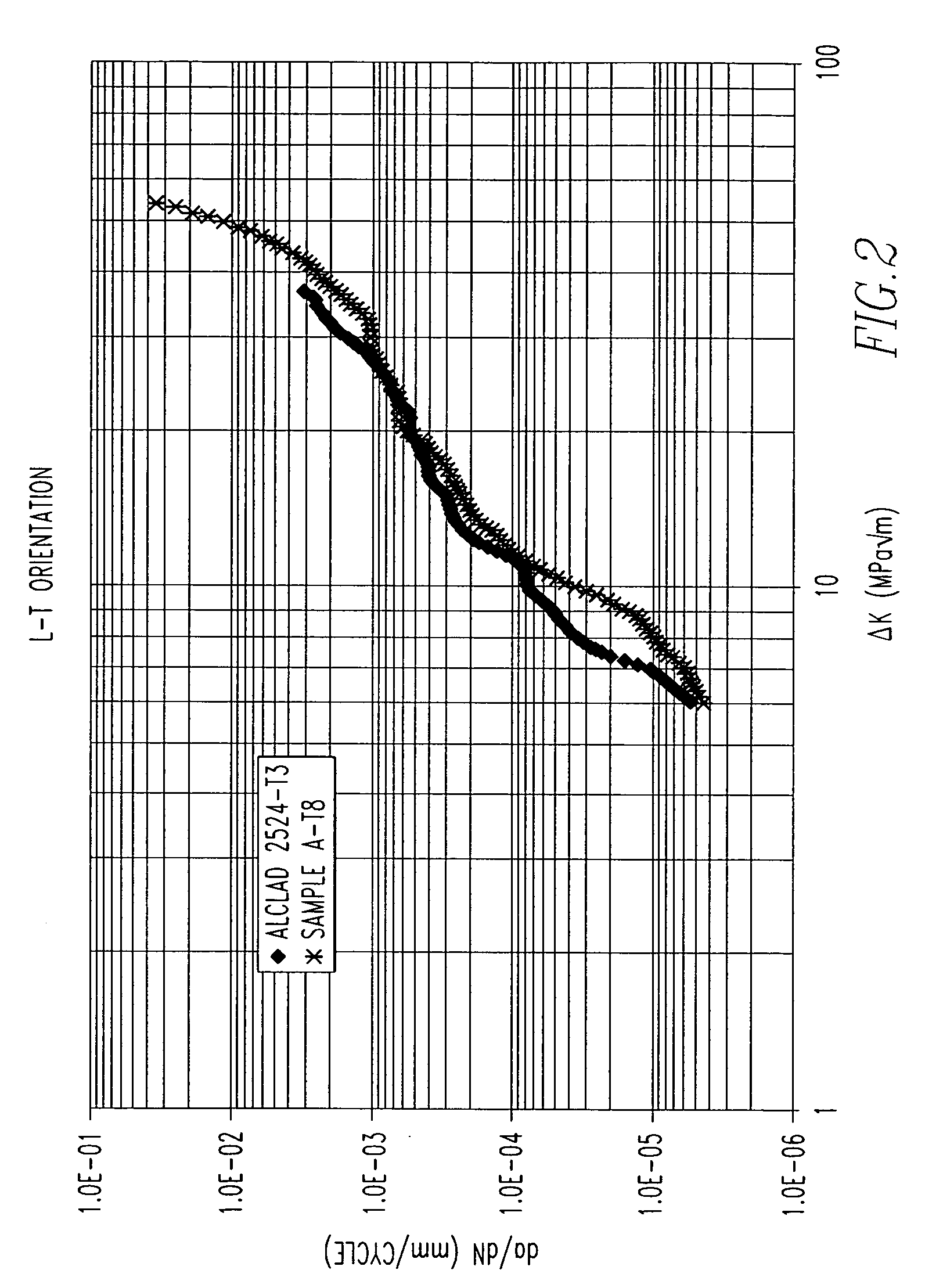

2000 Series alloys with enhanced damage tolerance performance for aerospace applications

The invention provides a 2000 series aluminum alloy having enhanced damage tolerance, the alloy consisting essentially of about 3.0-4.0 wt % copper; about 0.4-1.1 wt % magnesium; up to about 0.8 wt % silver; up to about 1.0 wt % Zn; up to about 0.25 wt % Zr; up to about 0.9 wt % Mn; up to about 0.5 wt % Fe; and up to about 0.5 wt % Si, the balance substantially aluminum, incidental impurities and elements, said copper and magnesium present in a ratio of about 3.6-5 parts copper to about 1 part magnesium. The alloy is suitable for use in wrought or cast products including those used in aerospace applications, particularly sheet or plate structural members, extrusions and forgings, and provides an improved combination of strength and damage tolerance.

Owner:ARCONIC TECH LLC

Aerospace light-emitting diode (LED)-based lights life and operation monitor compensator

A system (10) and method for monitoring the operational life and / or performance of one or more light-emitting diodes (LEDs) (20) based on sensed parameters are disclosed. The remaining life of each LED may be predicted by counting the clock cycles during which the LED-based light is activated. LED current and / or temperature measurements may be used to control the clock signal and, thus, to compensate the predicted life value. Furthermore, operational characteristics of the LED-based light may be monitored based on LED current and / or voltage measurements. Such characteristics may include performance (e.g., intensity) and failure conditions (e.g., open or short circuits).

Owner:HONEYWELL INT INC

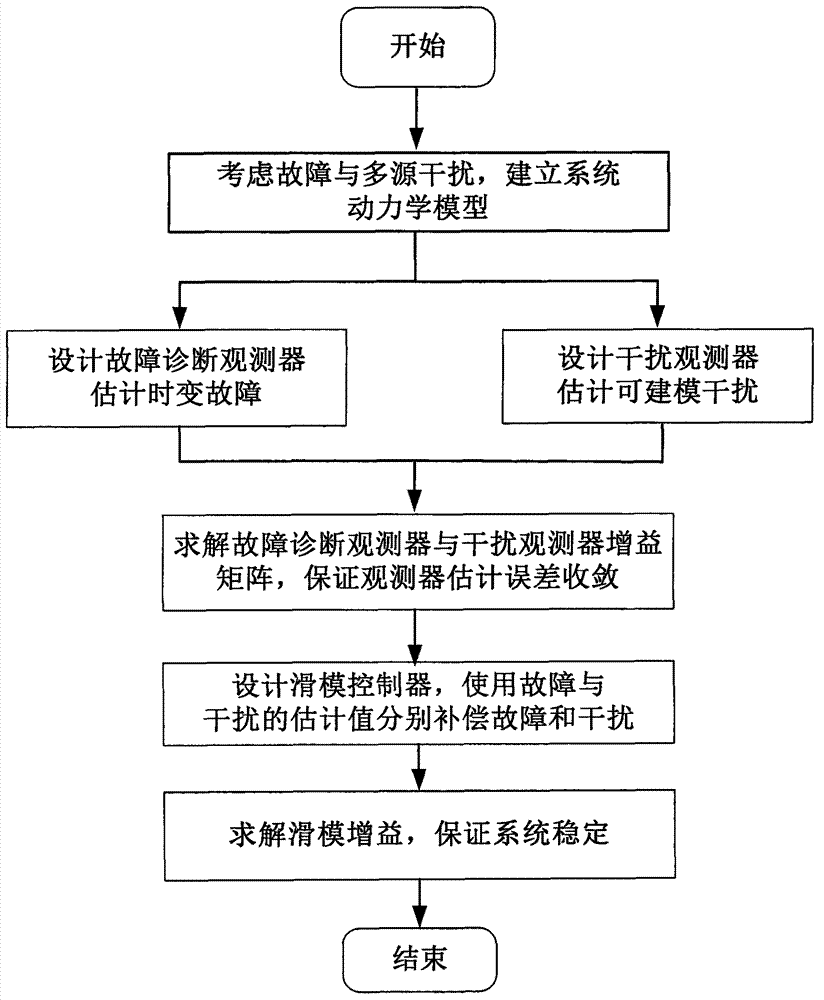

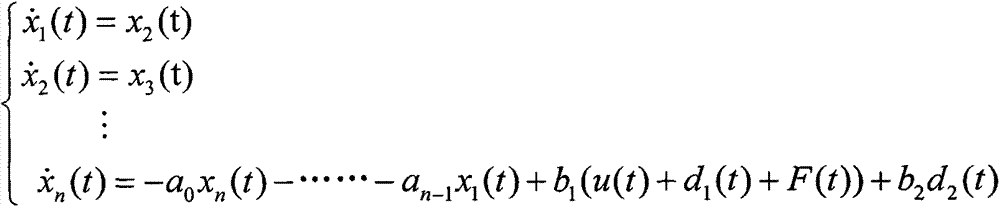

Sliding-mode control method with anti-interference fault-tolerance performance

Provided is a sliding-mode control method with anti-interference fault-tolerance performance. A sliding-mode controller with anti-interference fault-tolerance performance is designed and is specific to a system containing faults and interferences. Firstly, faults and multi-source interferences in the system are considered, so that a dynamical model of the system is established. Secondly, a fault diagnosis observer and a disturbance observer are designed to estimate the faults and interferences capable of being modeled. Thirdly, the gain matrix of the disturbance observer and the fault diagnosis observer is solved. Then, the sliding-mode controller is designed to offset faults and interferences respectively by using the estimated value of faults and interferences. Finally, stability of the controller is analyzed and the sliding-mode yield value is determined on the premise that the system input is saturated. According to the sliding-mode control method with anti-interference fault-tolerance performance, the anti-interference and fault-tolerance performance of the system are guaranteed, the buffeting of the sliding-mode control is improved, and the sliding-mode control method can be applied to the attitude control system of the fields of aviation, aerospace and deep space exploration.

Owner:BEIHANG UNIV

Curable polysiloxane composition, and polysiloxane cured product, optical member, member for aerospace industry, semiconductor light-emitting device, illuminating device and image display device using the same

ActiveUS20110098420A1Improve heat resistanceImprove light resistanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceLight emitting device

The present invention provides a curable polysiloxane composition which is excellent in light resistance (particularly ultraviolet resistance) and adhesion and has a sufficient heat resistance / hydrothermal resistance and film-forming property and which generates little foaming at curing and does not generate cracks, peeling, coloring, and foaming even when used for a long period of time. A curable polysiloxane composition which comprises a specific hydrosilyl group-containing polysiloxane compound, a specific polysiloxane compound comprising two or more silanol groups in one molecule, and a dehydrogenative condensation reaction catalyst.

Owner:MITSUBISHI CHEM CORP

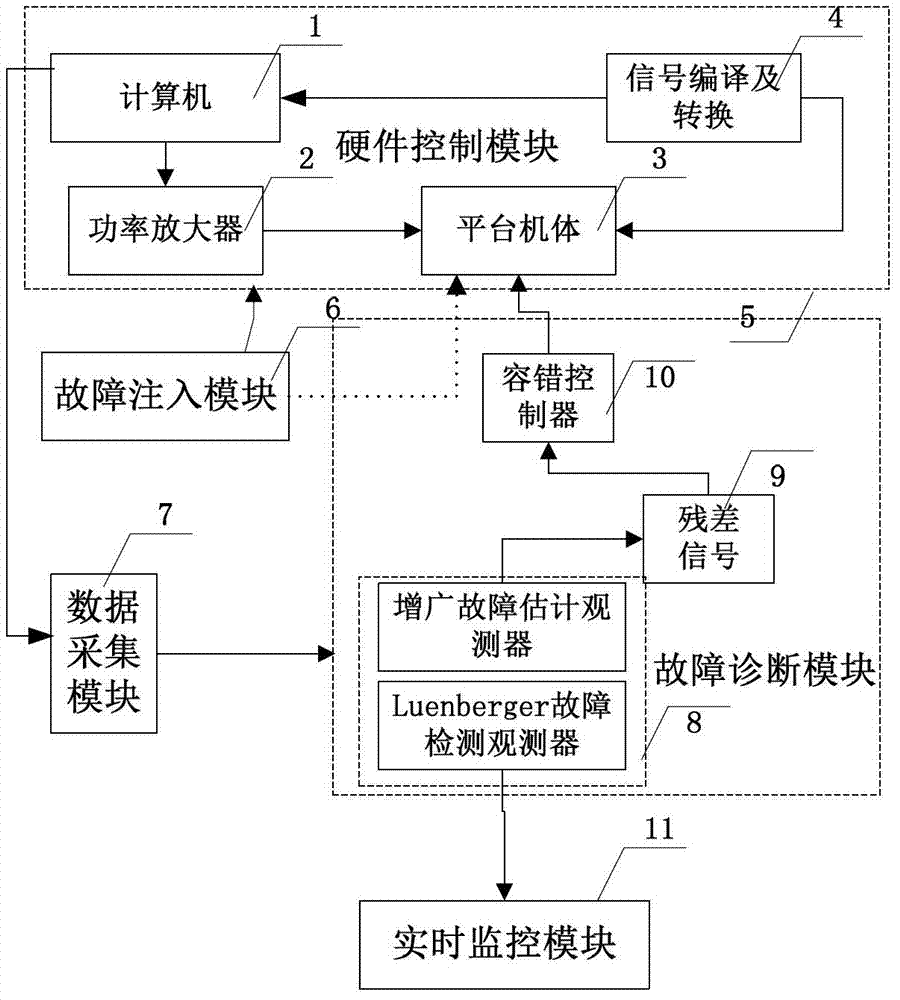

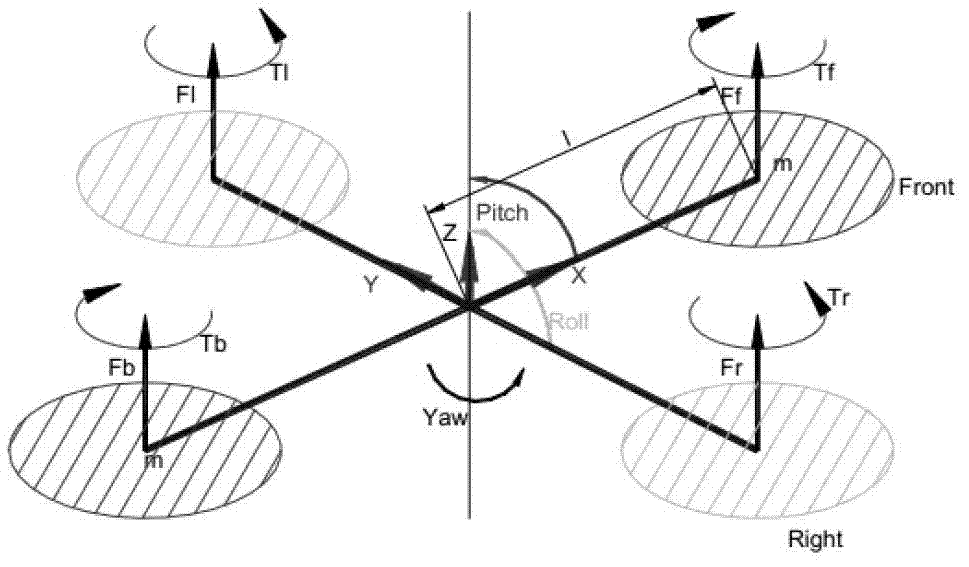

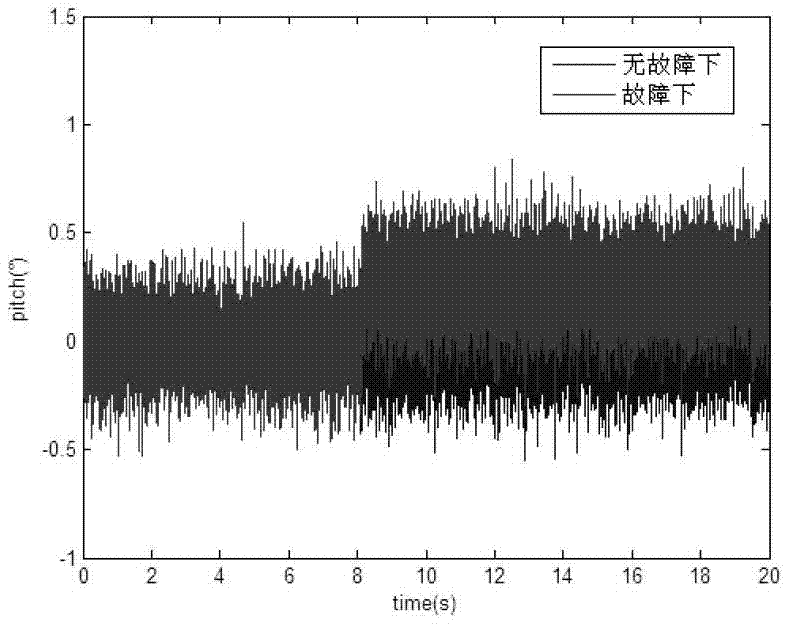

A plurality of united observer based fault diagnosis and fault-tolerant control device and method

ActiveCN102854874AAvoid serious coupling problemsAvoid errorsElectric testing/monitoringAviationDiagnosis methods

The invention discloses a plurality of united observer based fault diagnosis and fault-tolerant control device and a method and belongs to the field of aerospace. The plurality of united observer based fault diagnosis and fault-tolerant control device comprises following modules of a fault injection module, a fault diagnosis module, a real time monitoring module and a hardware control module. According to the method, the problem that traditional observer based fault diagnosis methods are limited by conditions is mainly solved, the operation is simple, the implementability is high, and the method can be used for diagnosing faults of actuating mechanisms of a four rotor wing helicopter and verifying feasibility of state monitoring.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

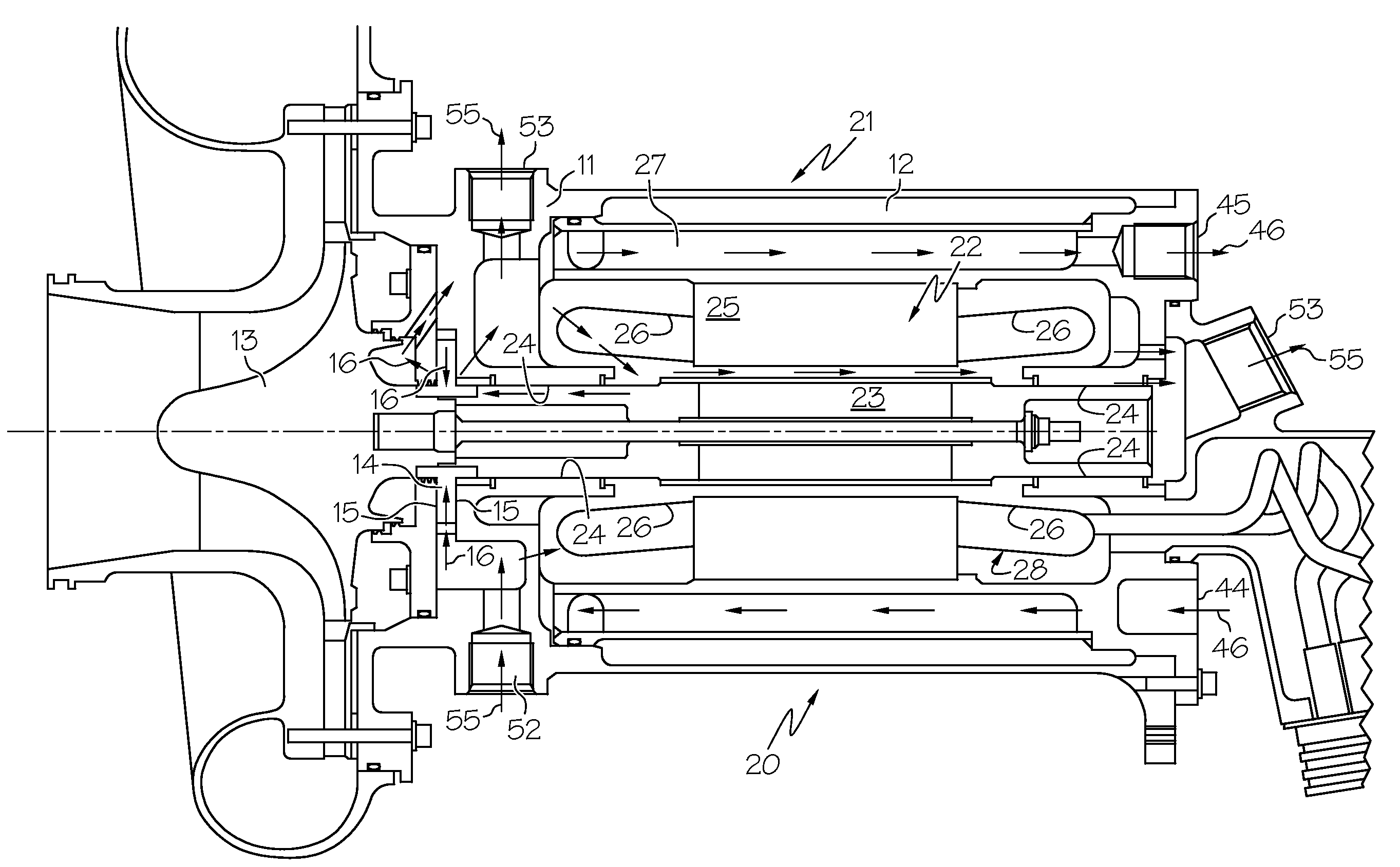

Thermal and secondary flow management of electrically driven compressors

A cooling system for an electrical motor or generator includes a first cooling loop, a second cooling loop, and a heat exchange system. The first cooling loop may extract heat from an iron stack and winding of the electrical motor or generator. The second cooling loop may extract heat from end turns of the stator winding, the rotor, and the bearings independently from and simultaneously to the first cooling loop. At least the first cooling loop may pass through the heat exchange system. A liquid coolant may circulate in the first cooling loop and a compressed gas, such as compressed air or compressed refrigerant in vapor form, may circulate in the second cooling loop. The cooling system and method for an electrical motor or generator may be suitable for, but not limited to, applications in the aircraft and aerospace industries, such as driving a cabin air compressor of an aircraft.

Owner:HONEYWELL INT INC

Polymer blend and compositions and methods for using the same

A polymer blend having at least one polysulfide component and at least one polythioether component is disclosed. The polymer blend offers numerous advantages, including the ability to compatibilize formulations based on either polysulfide chemistry or polythioether chemistry alone. Compositions comprising the polymer blend, particularly sealant formulations for use in aerospace applications, are also disclosed, as are multilayer sealant assemblies and methods for repairing the same.

Owner:PRC DE SOTO INT INC

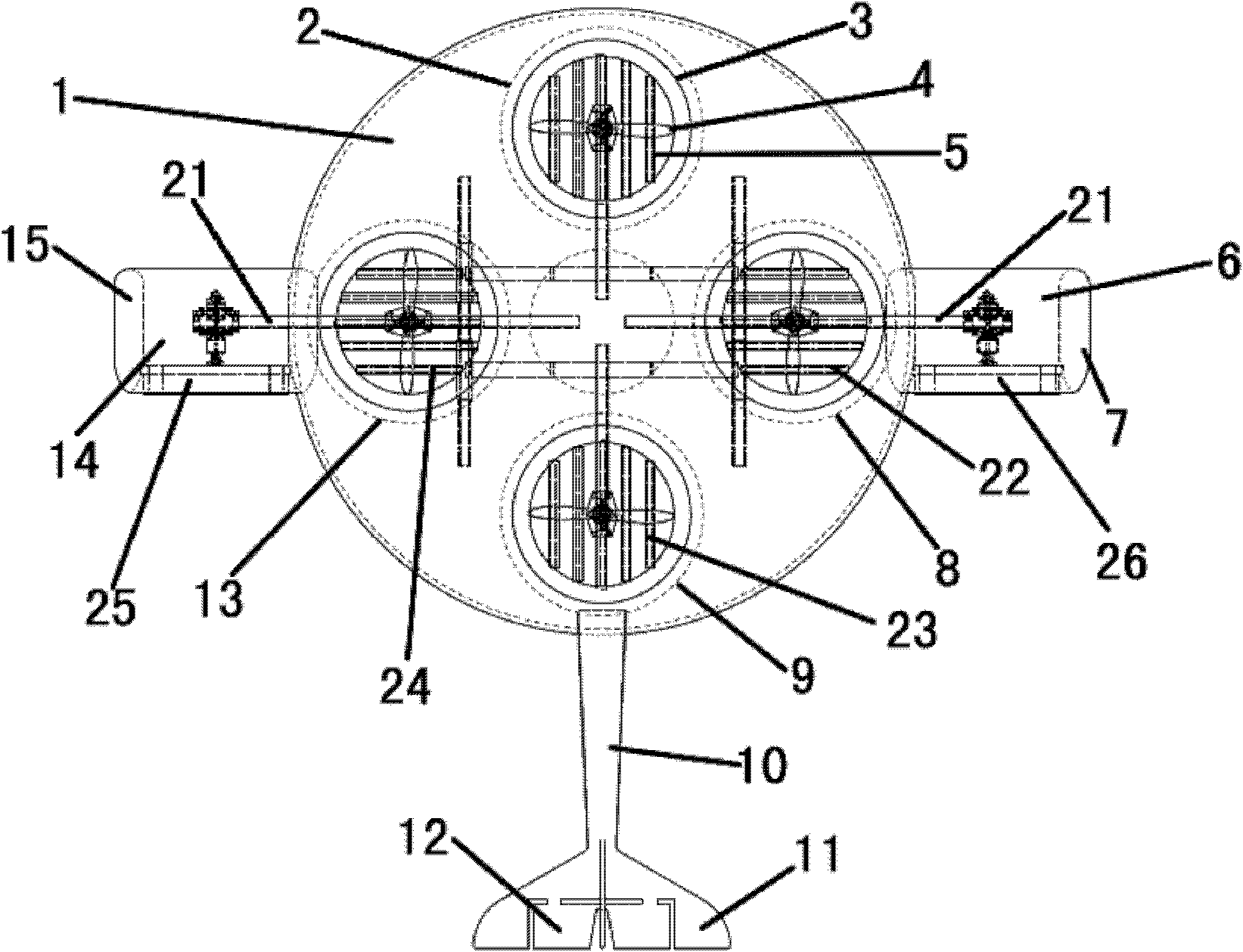

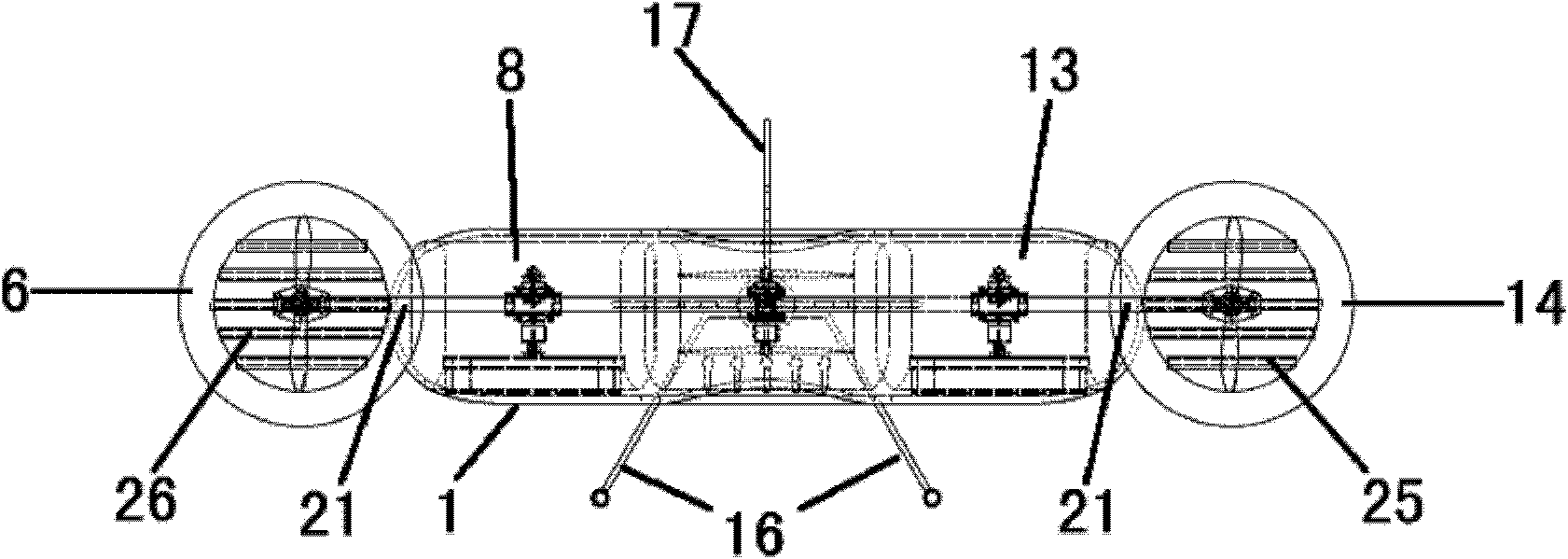

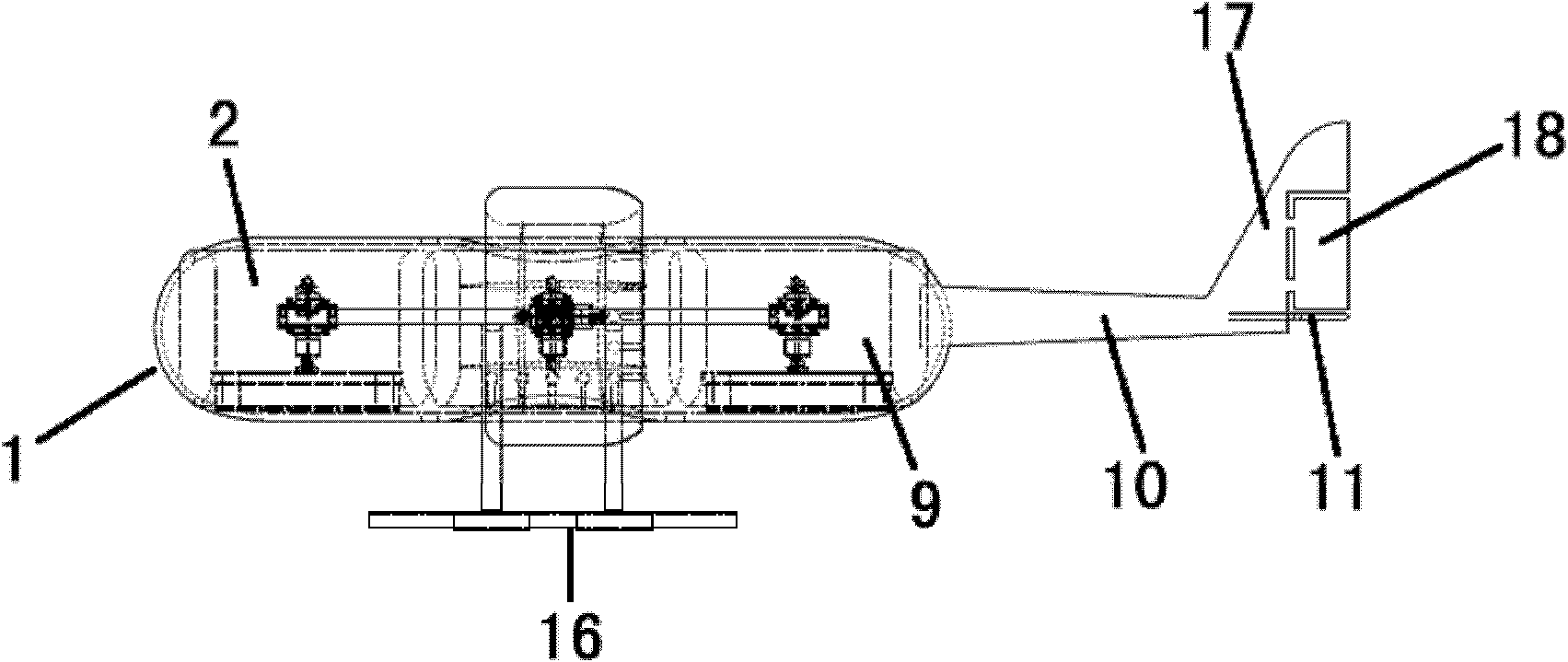

Distributed power multi-rotor VTOL (vertical take off and landing) aircraft and control method thereof

InactiveCN102114914AImprove reliabilityImprove stabilityPower plant typeRotocraftPower unitAerospace

The invention relates to the field of aerospace engineering, specifically discloses a distributed power multi-rotor VTOL (vertical take off and landing) aircraft and a control method thereof. The aircraft comprises an aircraft body, a plurality of lift power units, a plurality of thrust power units, and a central flight control computer system, wherein the aircraft body is provided with a cowling covering outside the aircraft body; the lift power units and the thrust power units are uniformly arranged on the aircraft body and used for adjusting the attitude and speed of the aircraft; and the central flight control computer system is connected with the lift power units and the thrust power units and used for controlling the lift power units and the thrust power units to adjust the attitude and speed of the aircraft. Through uniformly setting a plurality of lift power units on the aircraft, the reliability, stability and disaster-tolerant capacity of the aircraft are improved, so that the aircraft still can fly normally when the components such as engines or rotors of the aircraft have mechanical failures, thereby reducing crash risk of the aircraft.

Owner:文杰

High performance sleeved interference fasteners for composite applications

ActiveUS20080075555A1Minimizing installation forceImprove interferenceRivetsNutsAviationMulti material

A fastener adapted to pass through aligned holes through workpieces is disclosed. The fastener includes a pin member having a transition portion wherein the diameter of the transition portion decreases radially as it extends from the smooth cylindrical shank portion to the threaded portion. The fastener may also comprise a sleeve member and a clamping means. The clamping means includes a collar, a nut, or any other possible clamping means. In exemplary embodiments, the workpieces can be formed with a plurality of materials, the materials including composite, metallic, or composite / metallic structures, any combination thereof. In particular embodiments, the fastener has interference capability of 0.0005 to 0.0100 inches in composite structures without risk of composite delamination or damage. As a result of the fastener interference, gaps between the fastener and the structure are eliminated thereby providing good electrical conductivity between components. As a result, the potential for electrical sparks is reduced, providing a safer fastener for use with aerospace applications.

Owner:ALCOA GLOBAL FASTENERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com