Patents

Literature

57 results about "Cross hatch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cross Hatching definition. Cross-hatching is a drawing method that is used to shade an object or figure; the method utilizes a series of criss-crossing lines that are built up progressively into more complicated tones. Several varieties of cross-hatching may be used but most commonly for developing shadow and depth.

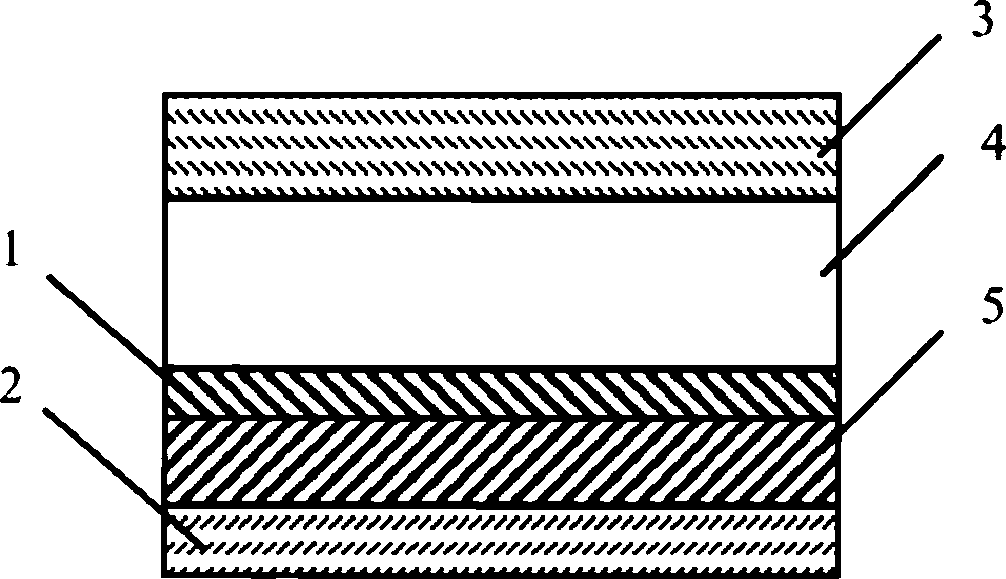

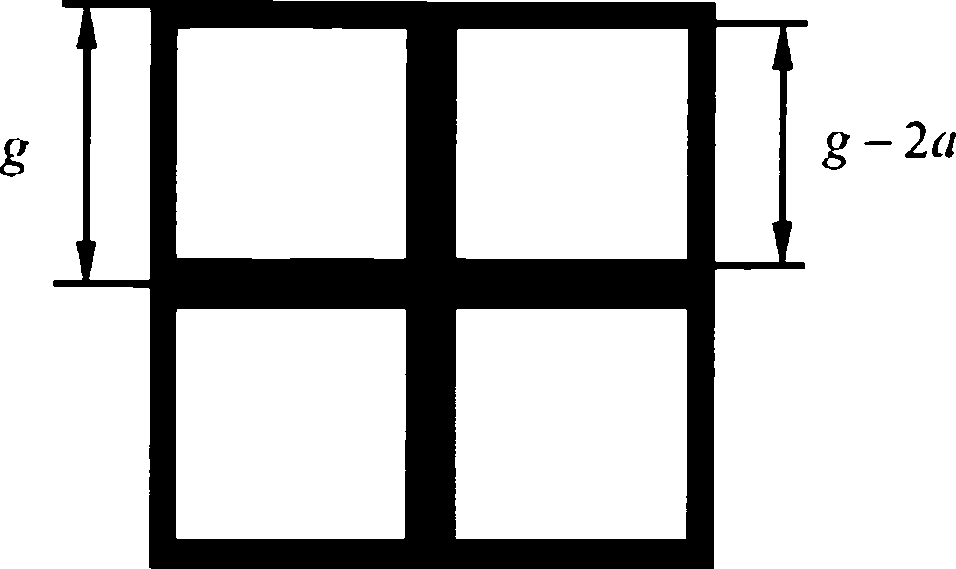

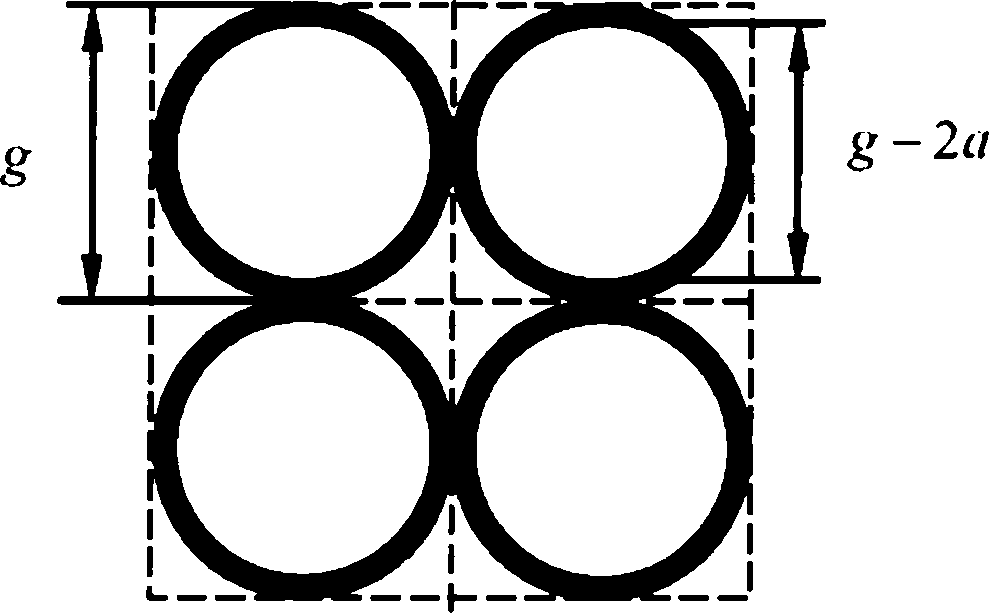

Electromagnetic screening optical window with circular ring metal meshed gate structure

InactiveCN1889822AReduce the occupied areaHigh light transmittanceMagnetic/electric field screeningOptoelectronicsCross hatch

An electromagnetic shielded optical window with ring type of metal cross hatch pattern structure is prepared as arranging ring type of metal cross hatch pattern units in two-dimensional orthogonal mode to from cross hatch pattern array then loading formed array on transparent substrate surface of optical window. The prepared product can be used to carry out electromagnetic shielding in medical treatment and aerospace cause.

Owner:HARBIN INST OF TECH

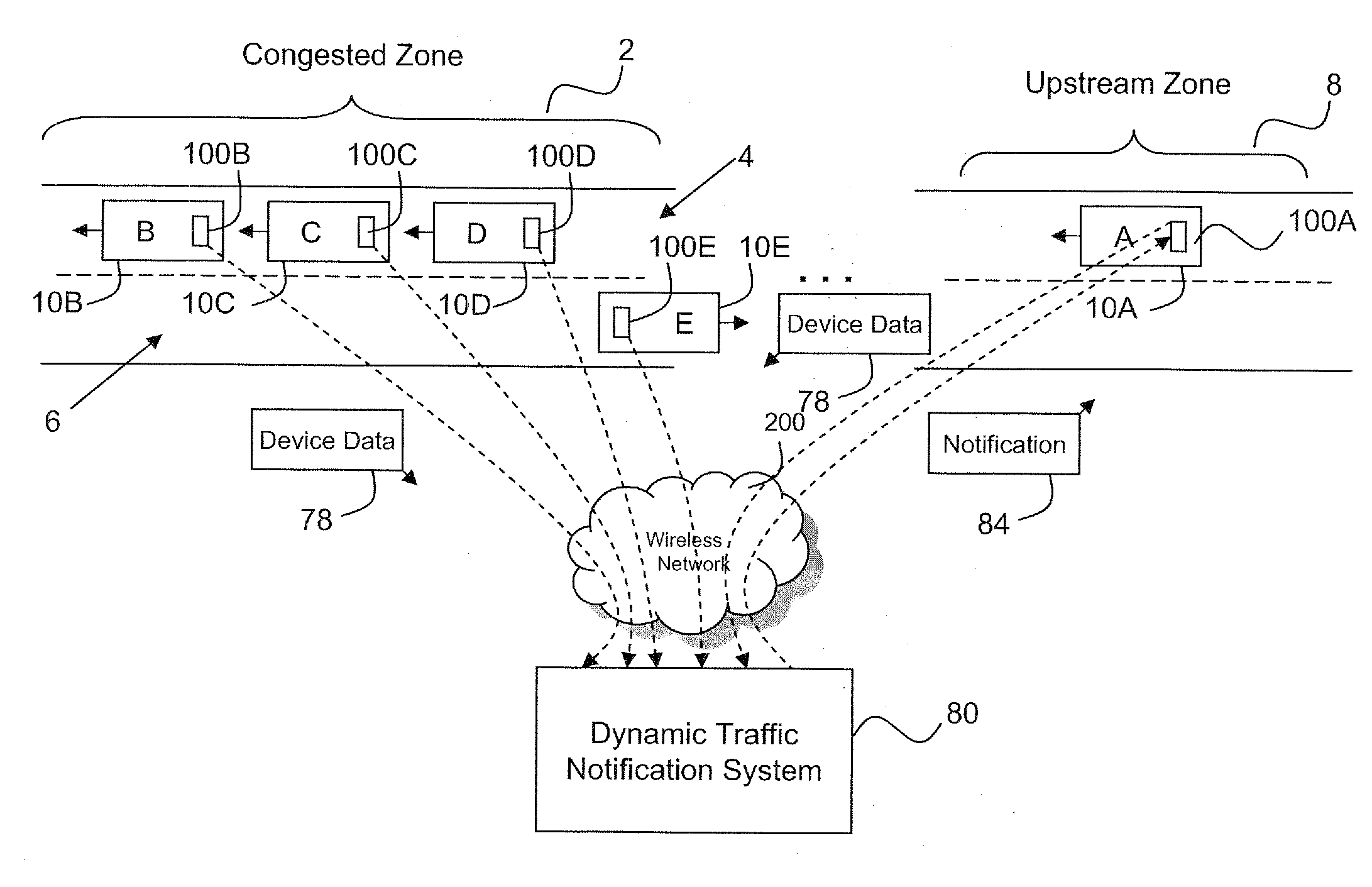

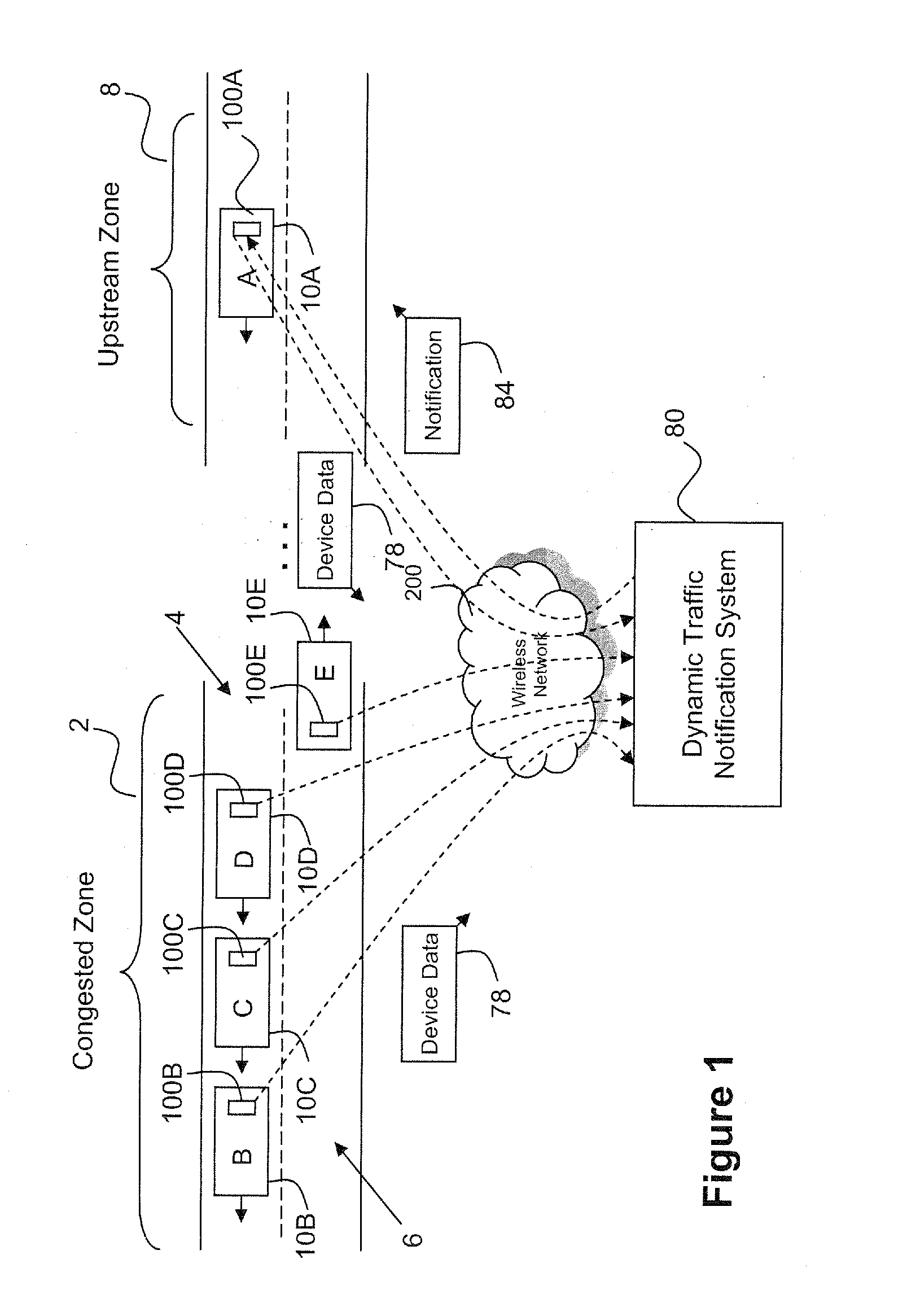

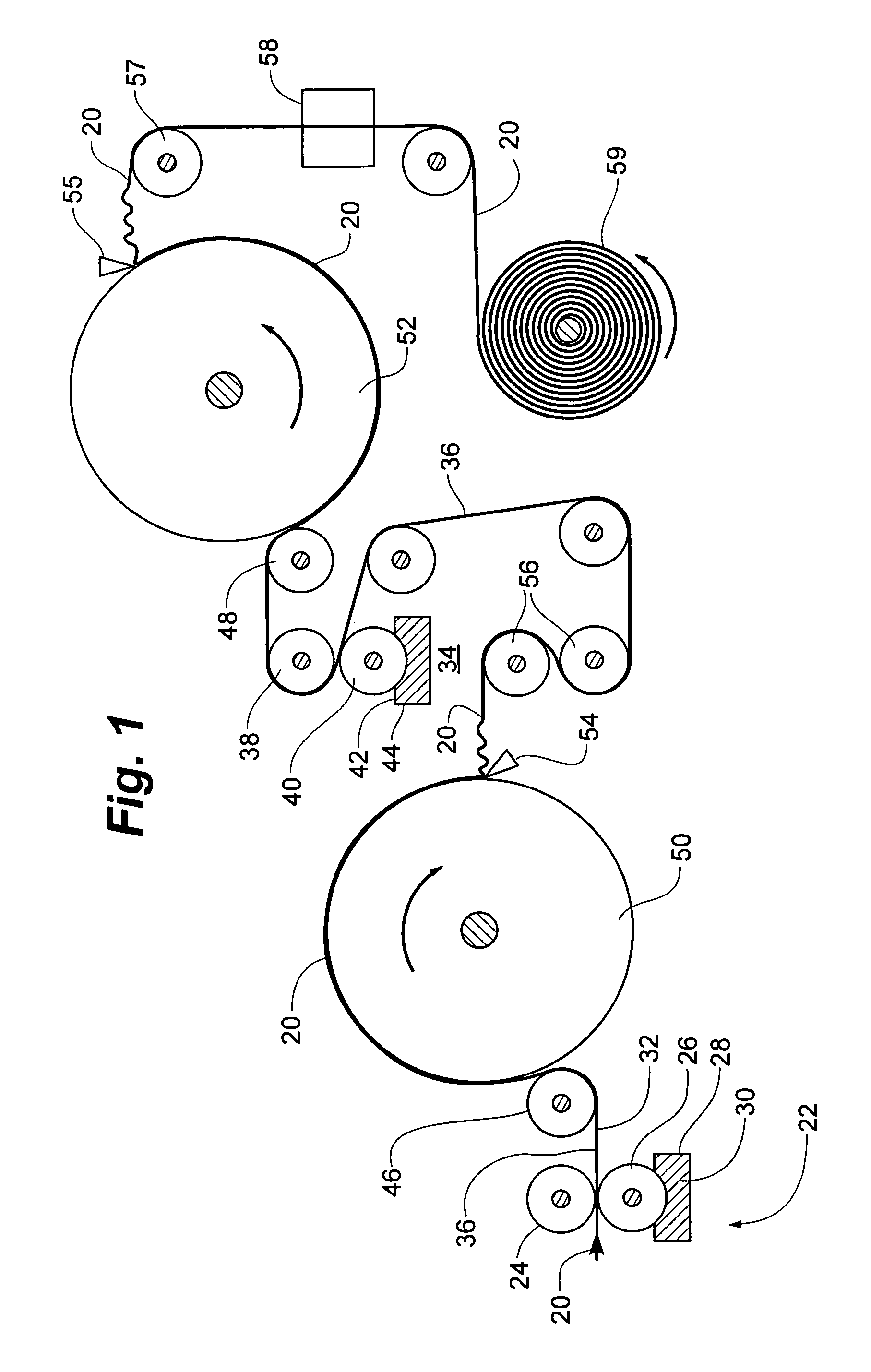

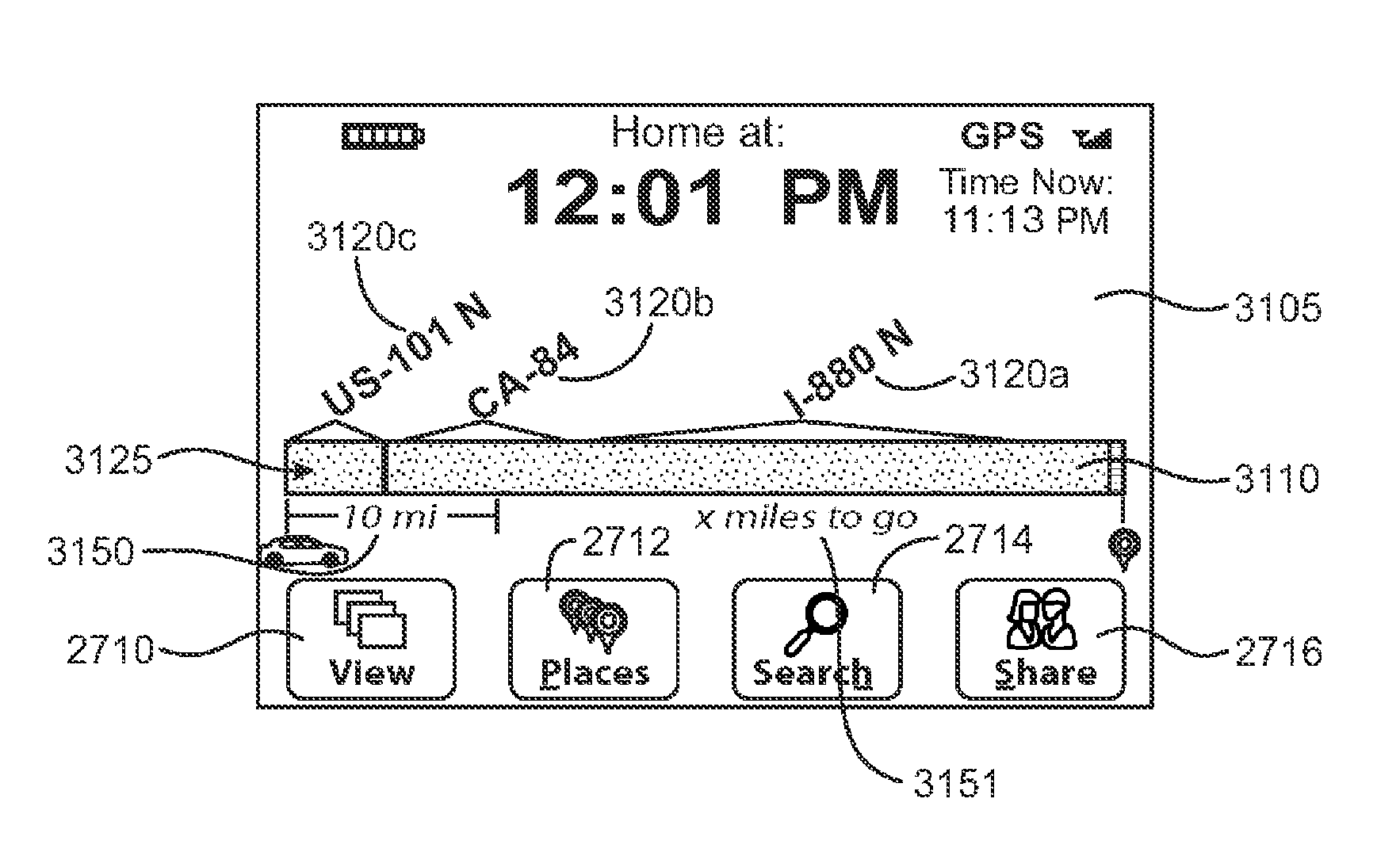

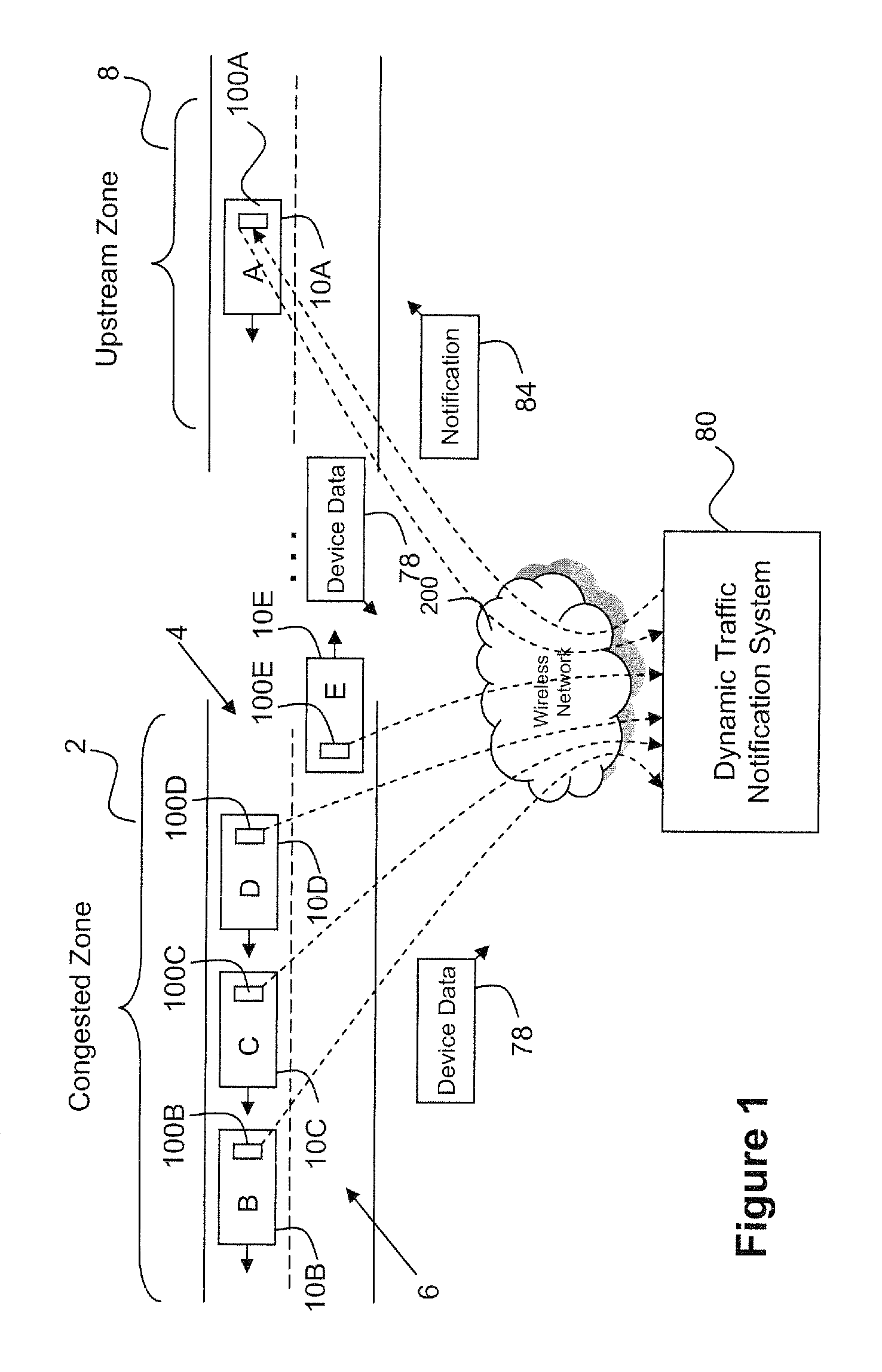

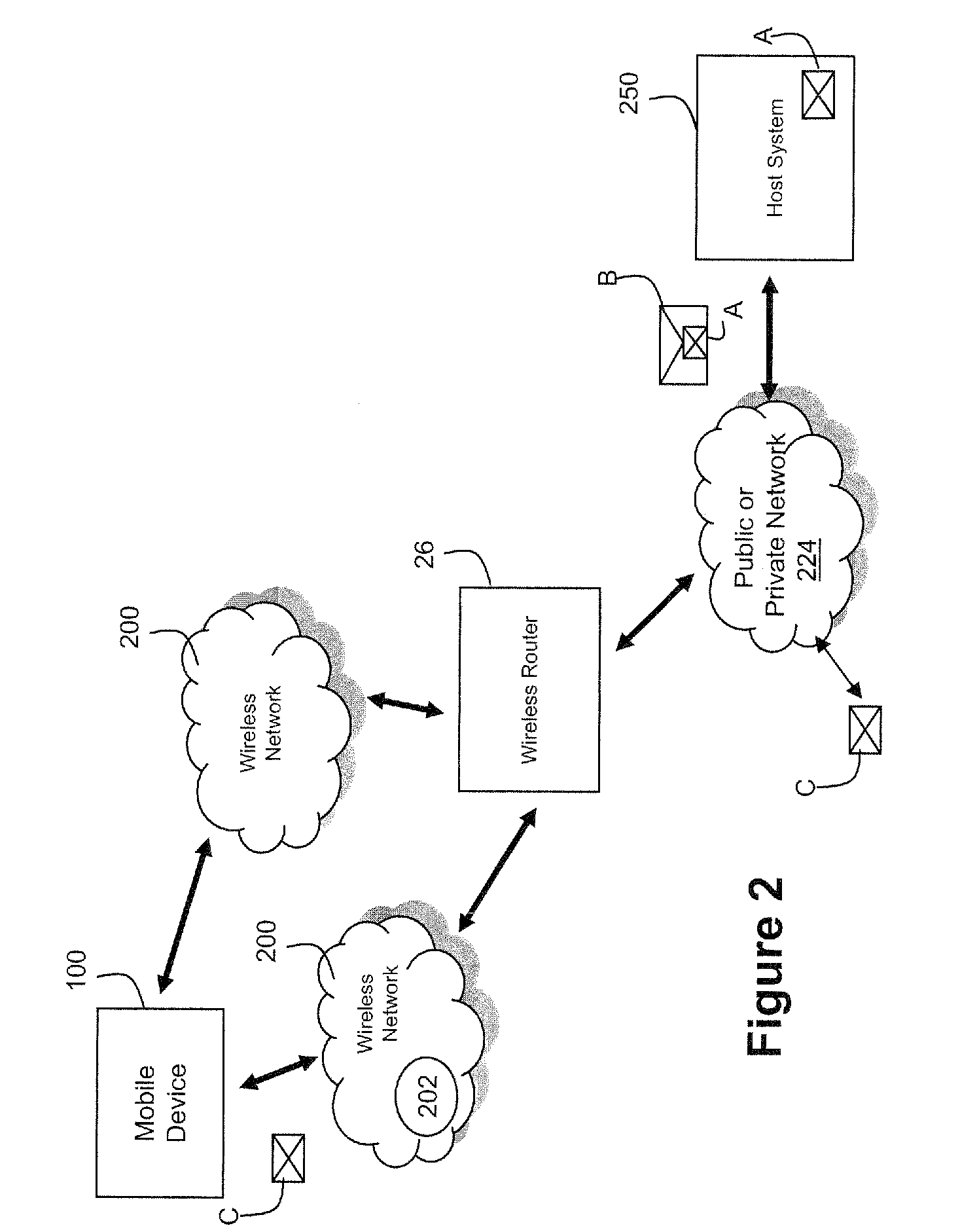

System and method of representing route information

ActiveUS20110208417A1Instruments for road network navigationRoad vehicles traffic controlIncident reportTraffic congestion

A route comprises interconnected road segments that can be traveled to get from a location to a destination. Previously, routes are represented by display of the spatial arrangement of such road segments (e.g., a map). Here, a route is depicted as a linear shape, and portions of the linear shape represent portions of the route, regardless of their spatial arrangement. A scale is applied between a characteristic of the route and the linear shape. Information elements can be depicted at points on the linear shape that correspond, based on the scale, to locations on the route where such information applies. Portions of the linear shape can be colored or cross-hatched according to traffic congestion conditions. Incident reports can be represented by indicators along the linear shape. Alternate routes (detours) can be represented by respective separate linear shapes; lead lines can connect such linear shapes to points of the route linear shape where each such detour would be taken.

Owner:MALIKIE INNOVATIONS LTD

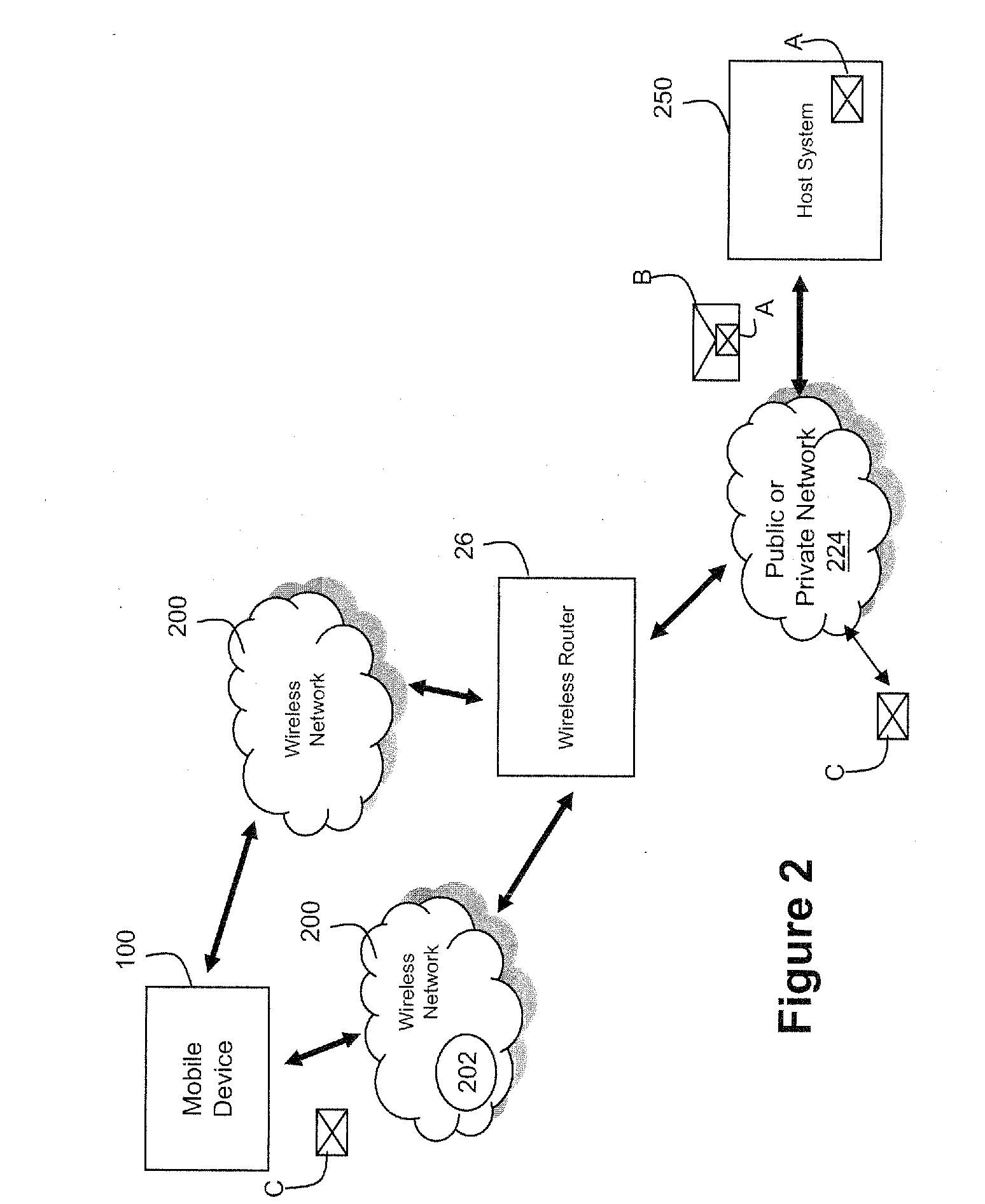

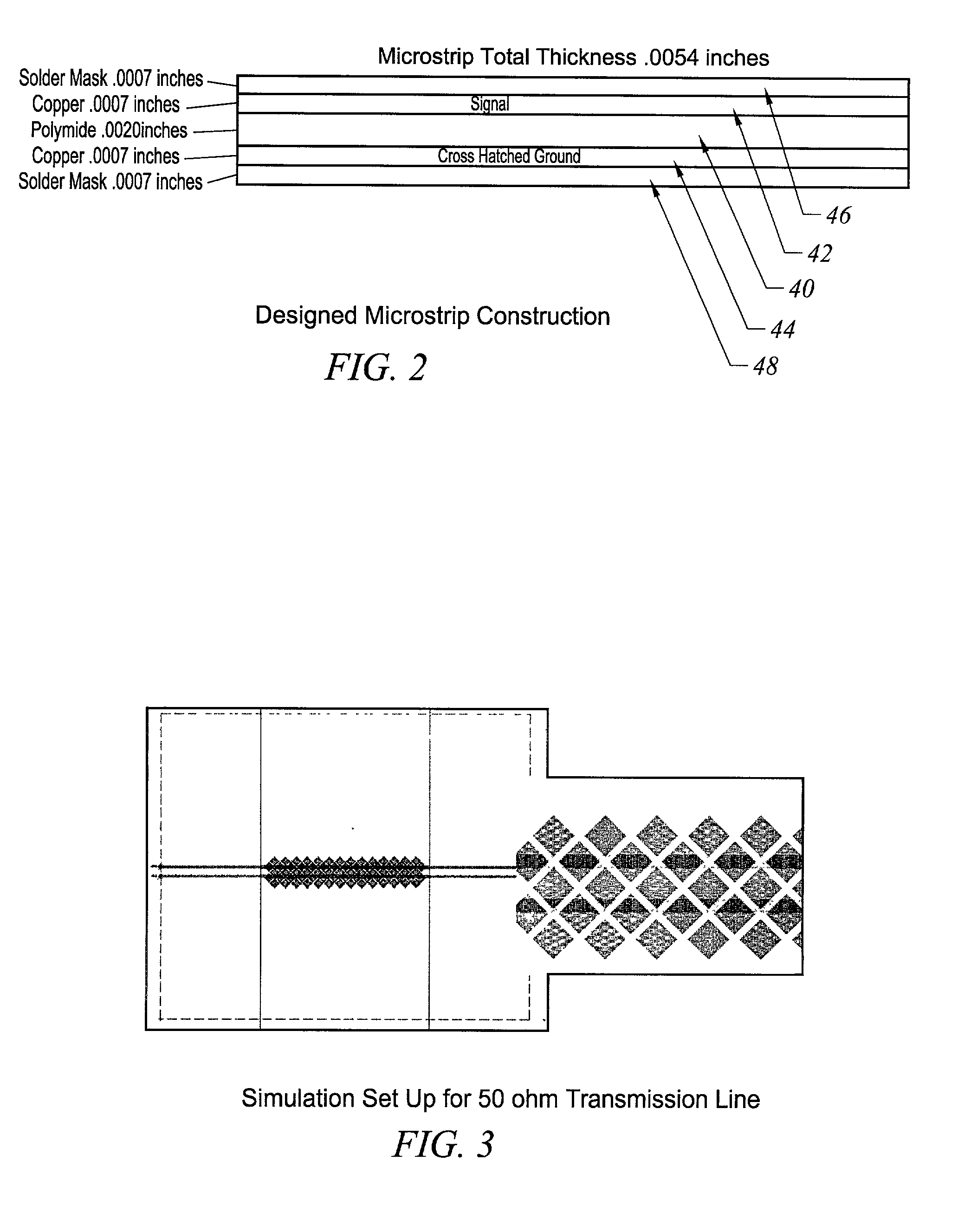

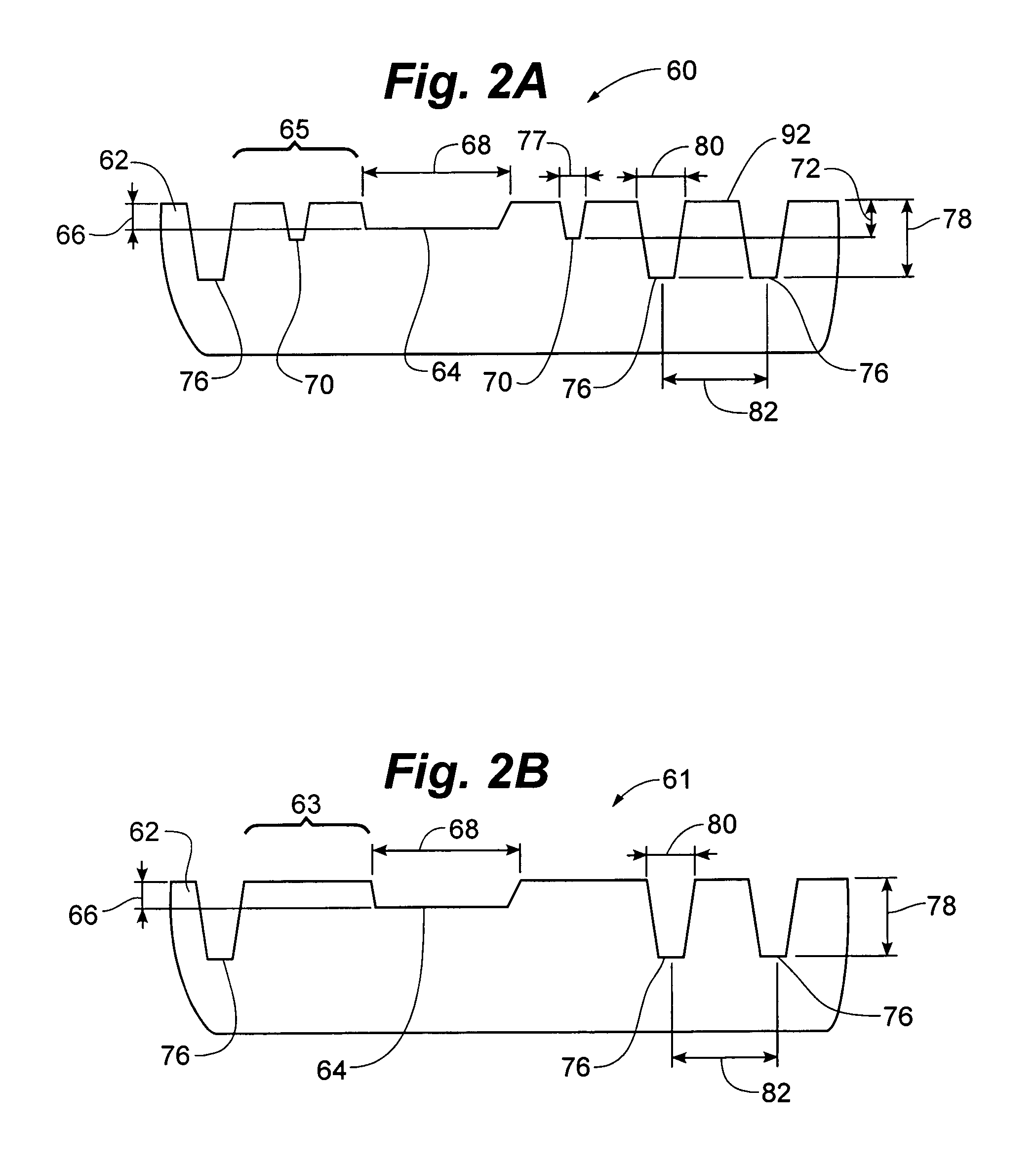

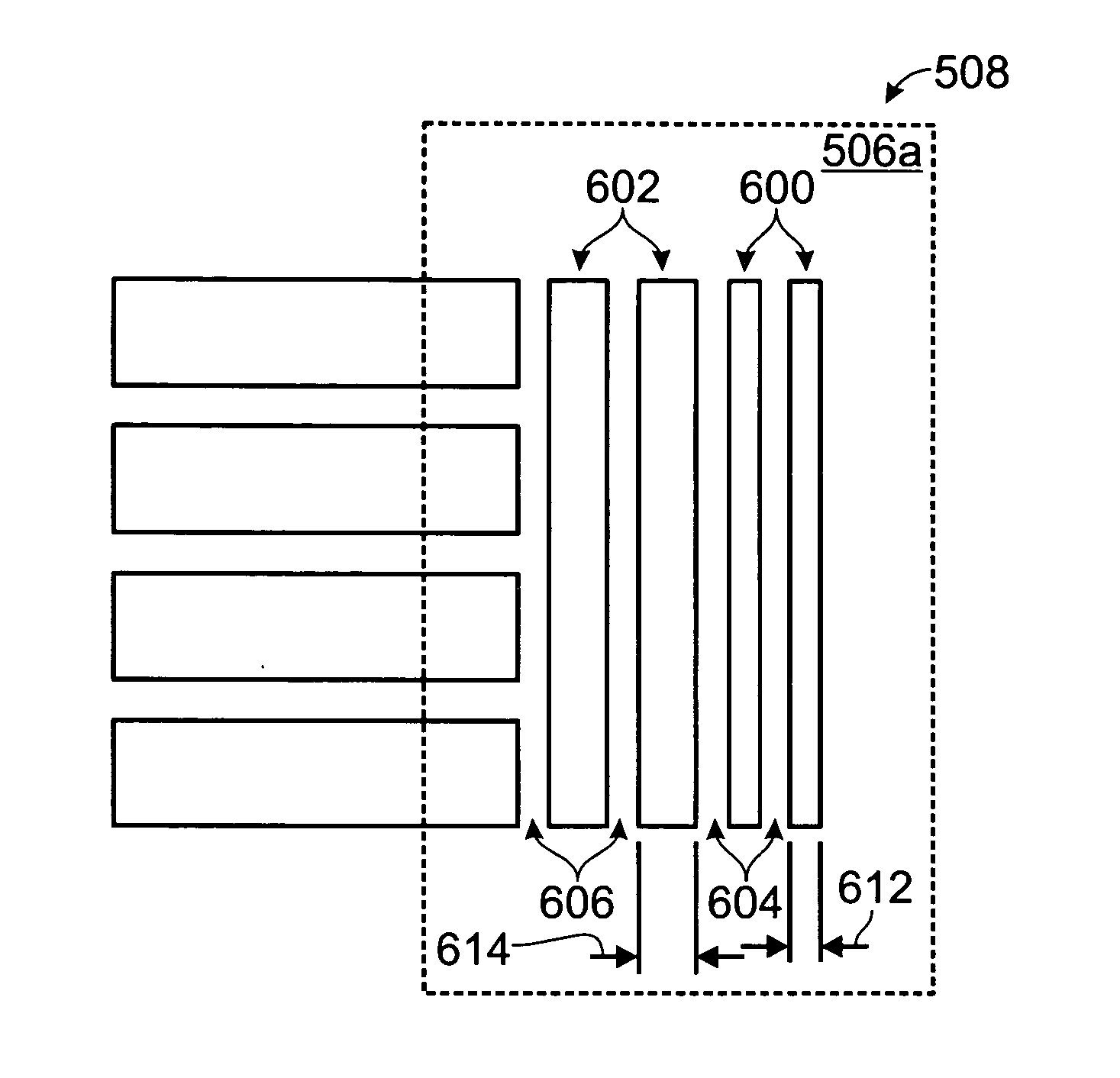

Optical converter flex assemblies

InactiveUS20020126951A1Increase flexibilityLess rigidPrinted circuit assemblingHigh frequency circuit adaptationsElectricityFlexible circuits

Optical to electrical and electrical to optical conversion assemblies provide precise and stable alignment, low loss, unperturbed electrical transmission and high thermal conductivity. Mechanically isolating the ceramic substrate of the conversion assembly relative to the surrounding structures enables good long-term optical alignment. Electrical transmission line connections to and from the optical conversion circuits on the ceramic substrates are made via flexible circuit board designs. The alignment of the components on the substrate relative to the plastic optics is thus preserved. The flexible circuit board includes a cross hatched ground layer, which relieves portions of the metallization below the signal layer and yet is able to maintain the desired transmission line properties. Electrical to optical conversion circuits are provided where the transmission of the electrical signals to the converter circuits is accomplished with minimal loss and with good signal integrity.

Owner:BLAZE NETWORK PRODS

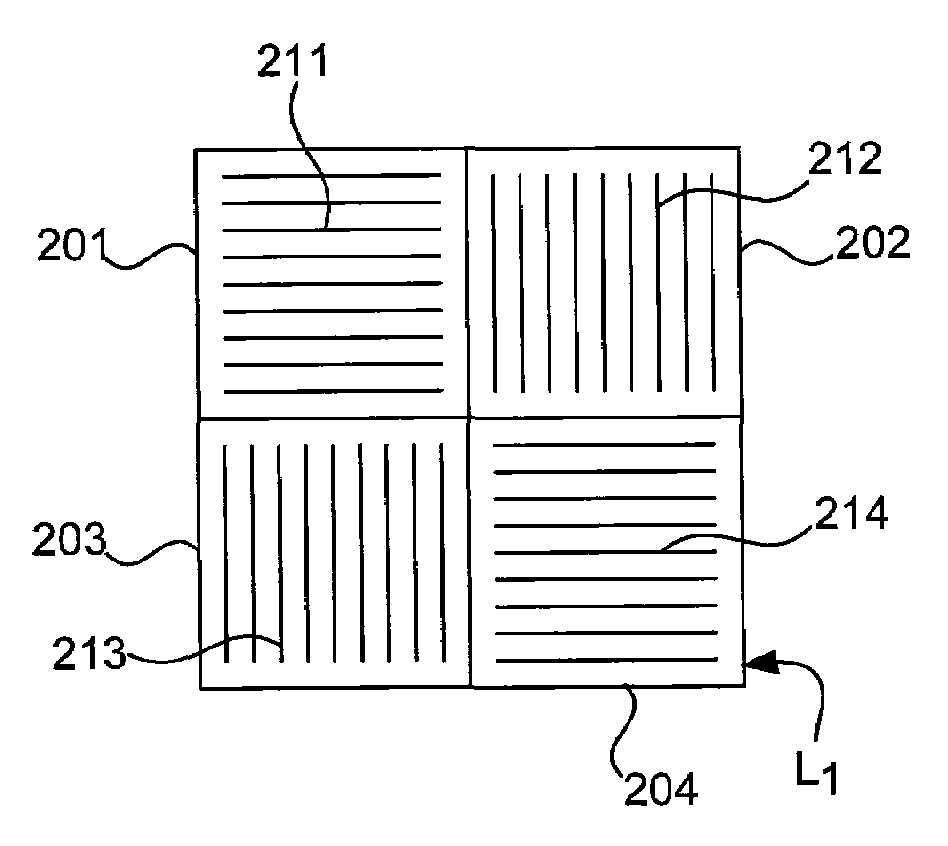

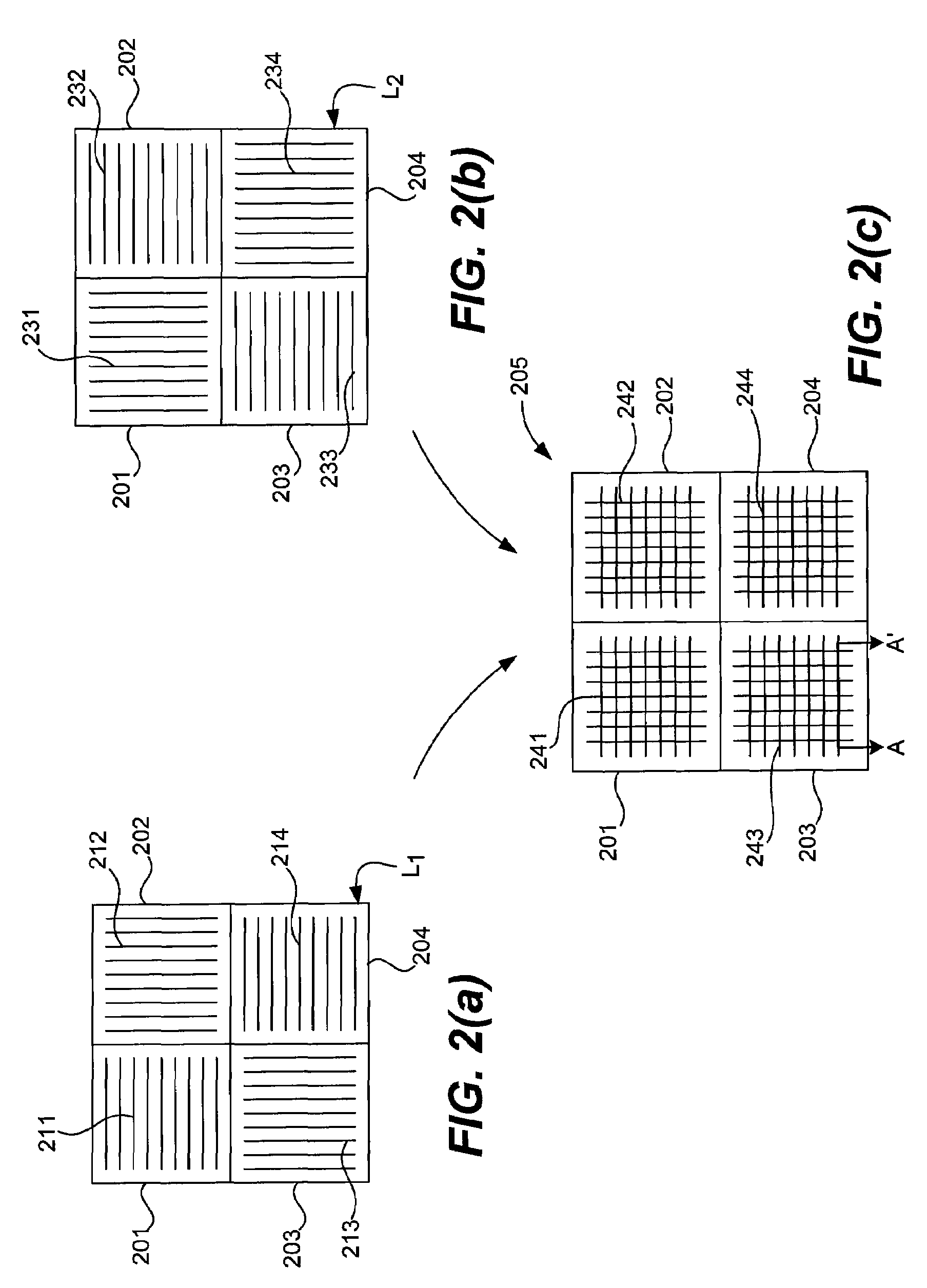

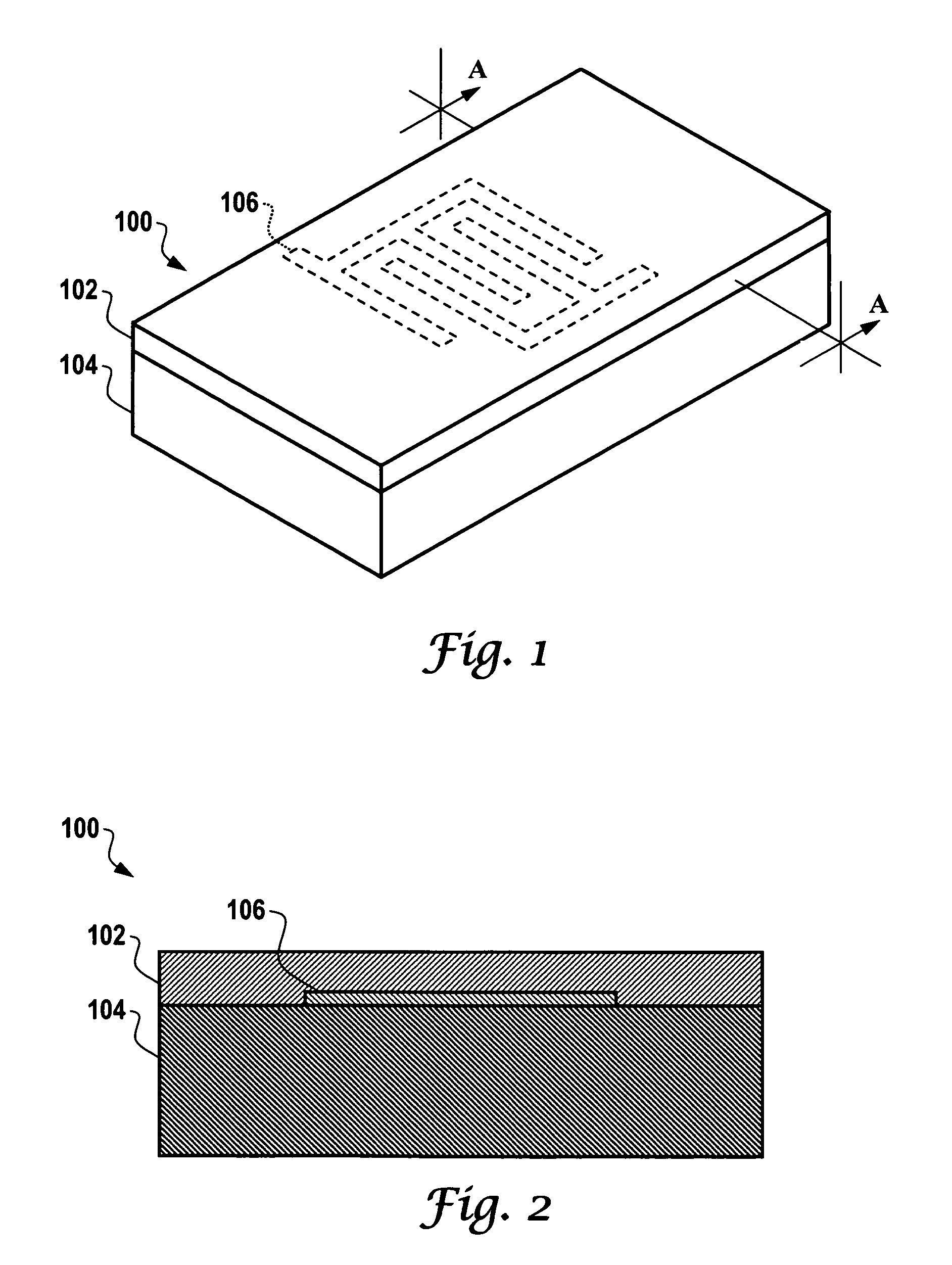

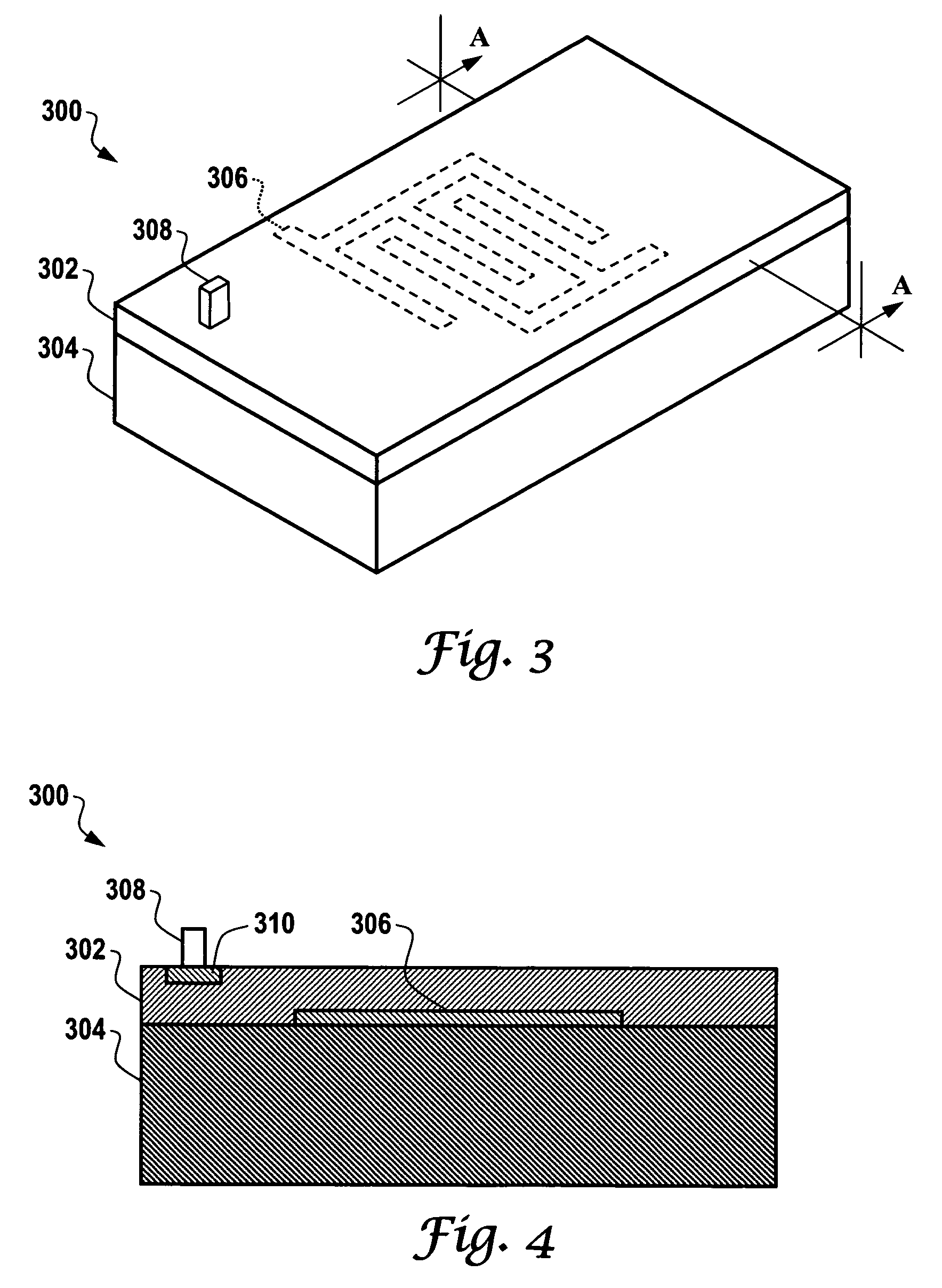

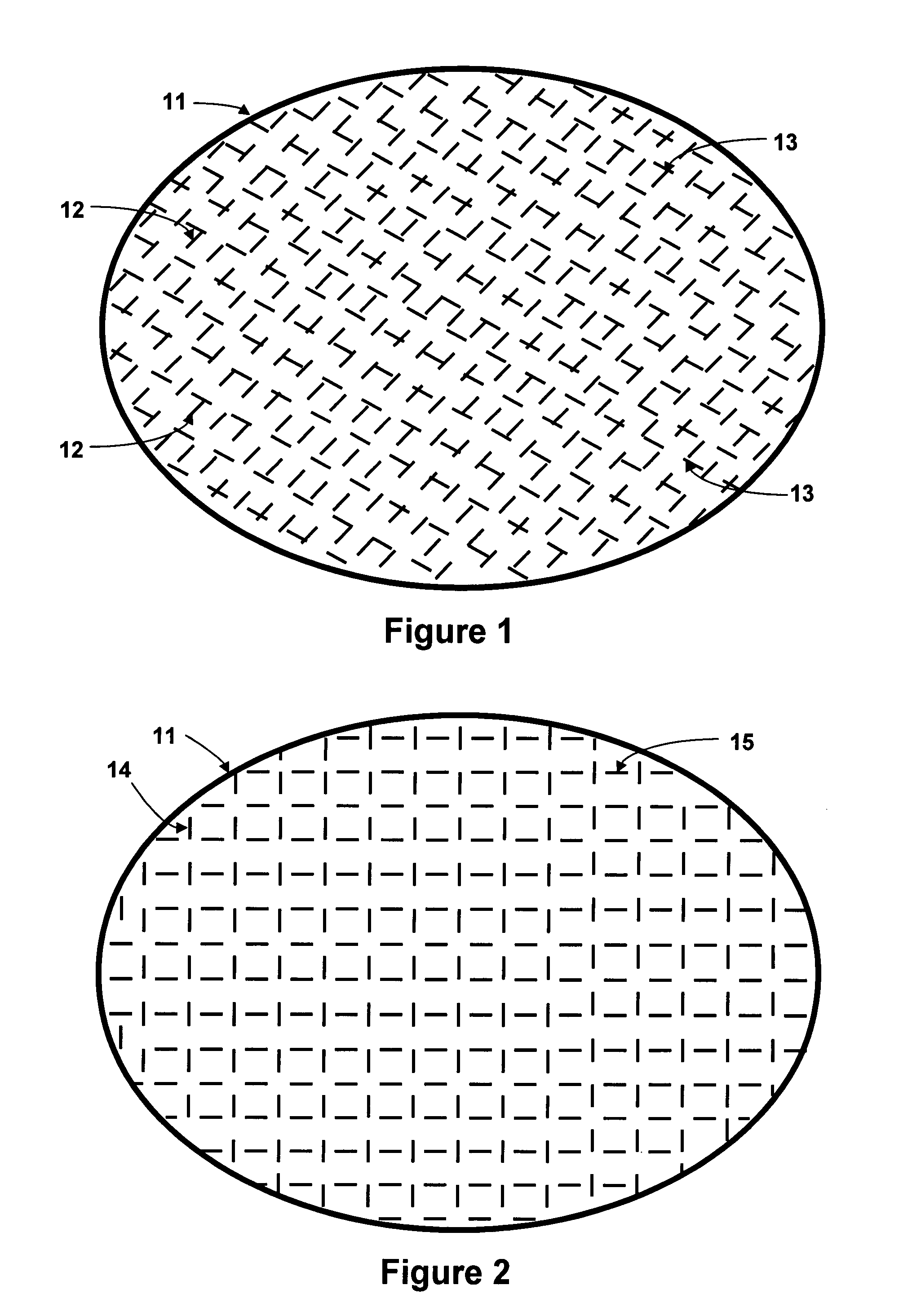

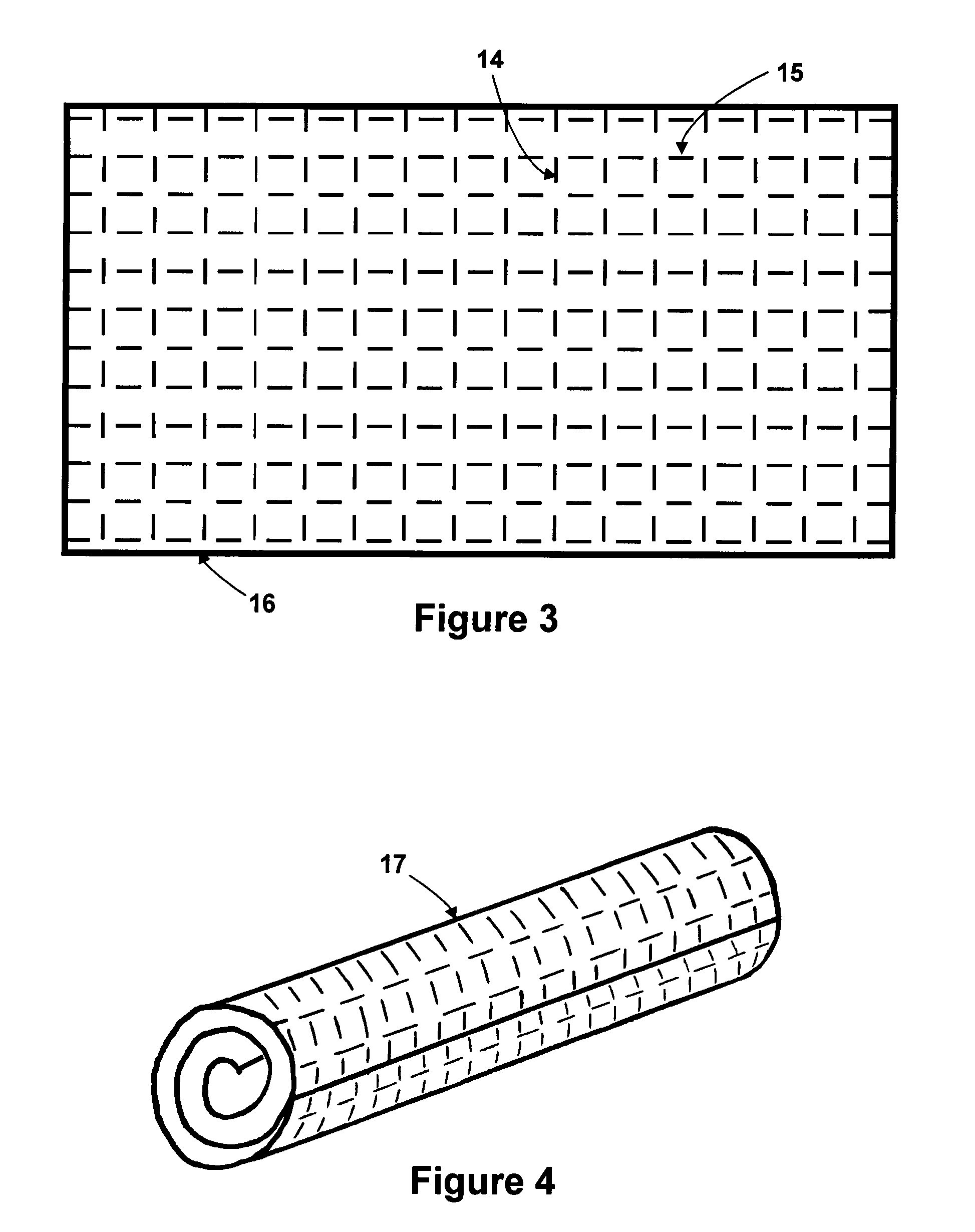

Cross hatched metrology marks and associated method of use

The present invention is directed to novel metrology marks and methods for their use. The marks comprise cross hashed overlay metrology marks formed on a substrate including a plurality of target regions. The mark including a first grating structure formed in one layer of a target region and including a second grating structure formed in another layer of the target region. The periodic features of the first and second grating structures are oriented substantially orthogonal one another to form a cross-hatched metrology target in the target region. Additionally, the patent discloses methods of employing the metrology marks to obtain overlay metrology measurements.

Owner:KLA TENCOR TECH CORP

Absorbent wipe having bonding material logo

InactiveUS6966971B1Reduce bulkReduced Softness RequirementsNon-fibrous pulp additionNatural cellulose pulp/paperCross hatchEngineering

An absorbent printed paper web and methods for making the printed web, the web having a visually discernible larger pattern, which can be a logo, on at least one surface formed essentially only of a paper web and a strengthening, colored bonding material. The printed web having the larger pattern can be made using the same bonding material and process used to print the background pattern. A double recrepe process using an improved Gravure roll may be used to print both logo and background. One method includes using a Gravure roll having deep depressions for printing a geometric background pattern, which can be a cross hatch pattern defining unprinting surface areas between the repeating deep depressions. The Gravure roll can also have shallow depressions in the reverse image of a logo to be printed, where the shallow depressions can have contiguous logo areas much larger than the size of the repeating deep depressions or unprinting surface areas in the background pattern. The shallowly printed regions add strength, and due to interaction with the creping roll and blade, also add bulk and softness to the finished web. The printed web can be printed with a Latex bonding material on one or both web surfaces, not requiring further web printing and compression on a surface after creping. The resulting printed web can carry a product or service logo or trademark, while being strengthened and expanded by the bonding material which also carries the logo or trademark.

Owner:SELLARS ABSORBENT MATERIALS

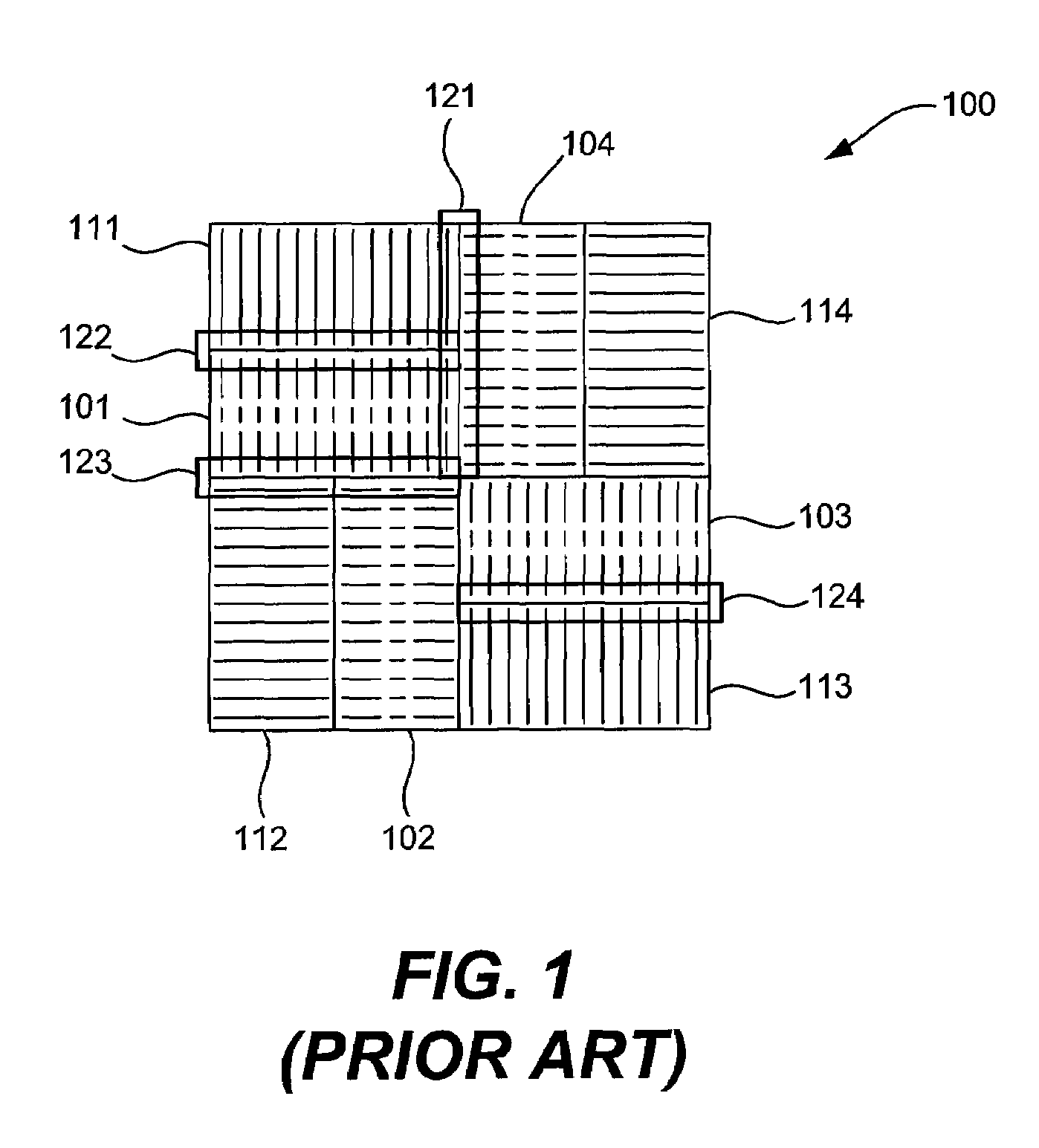

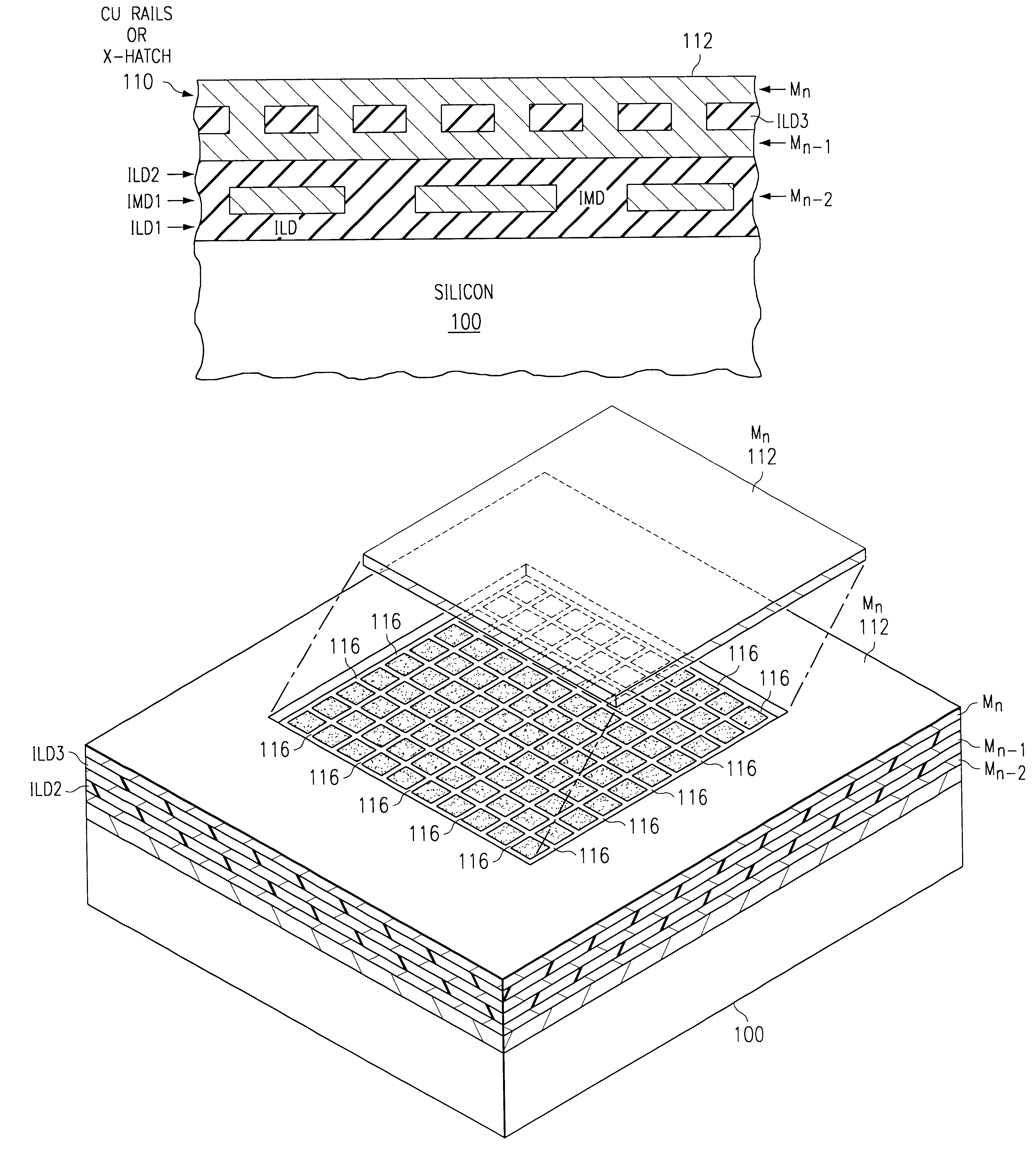

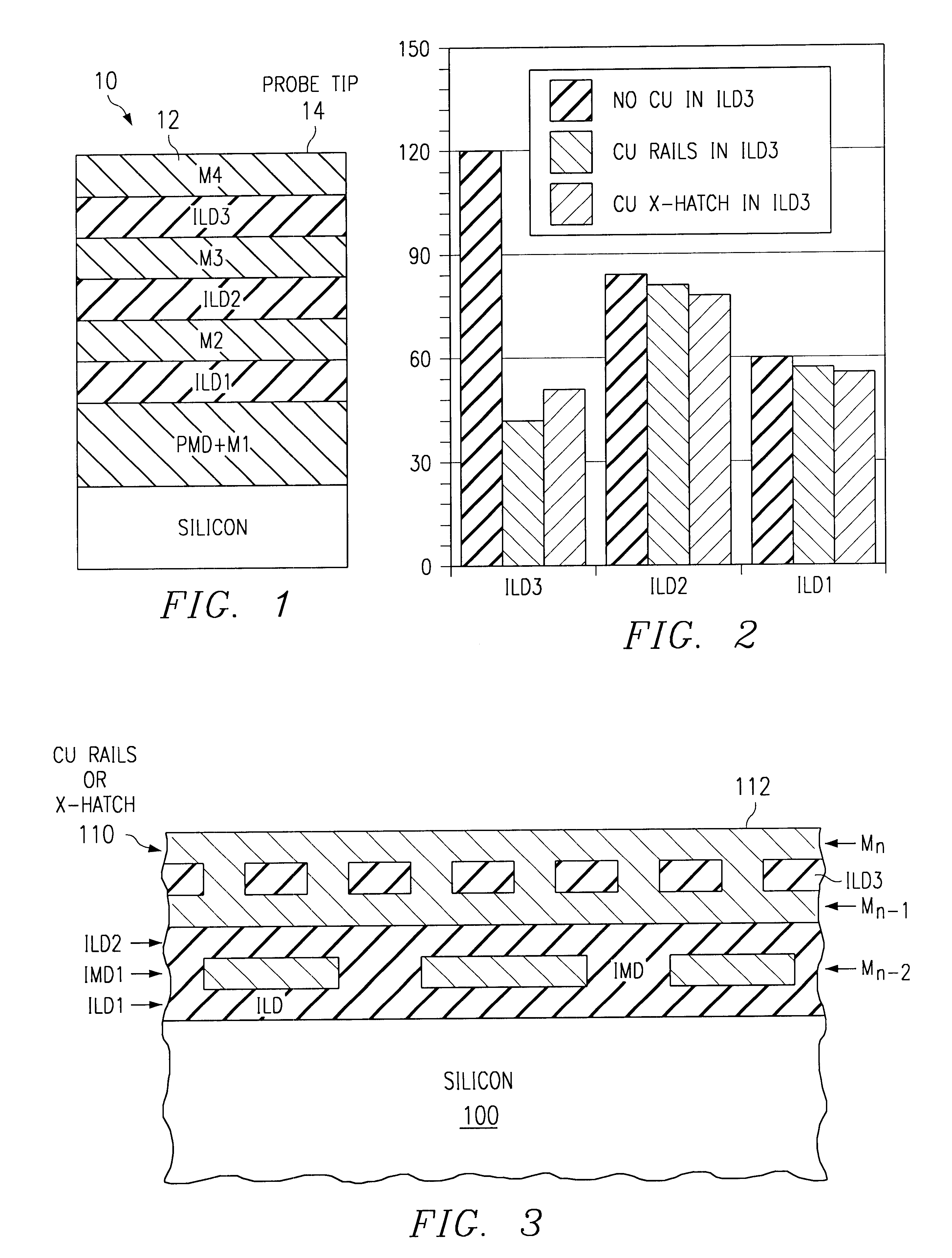

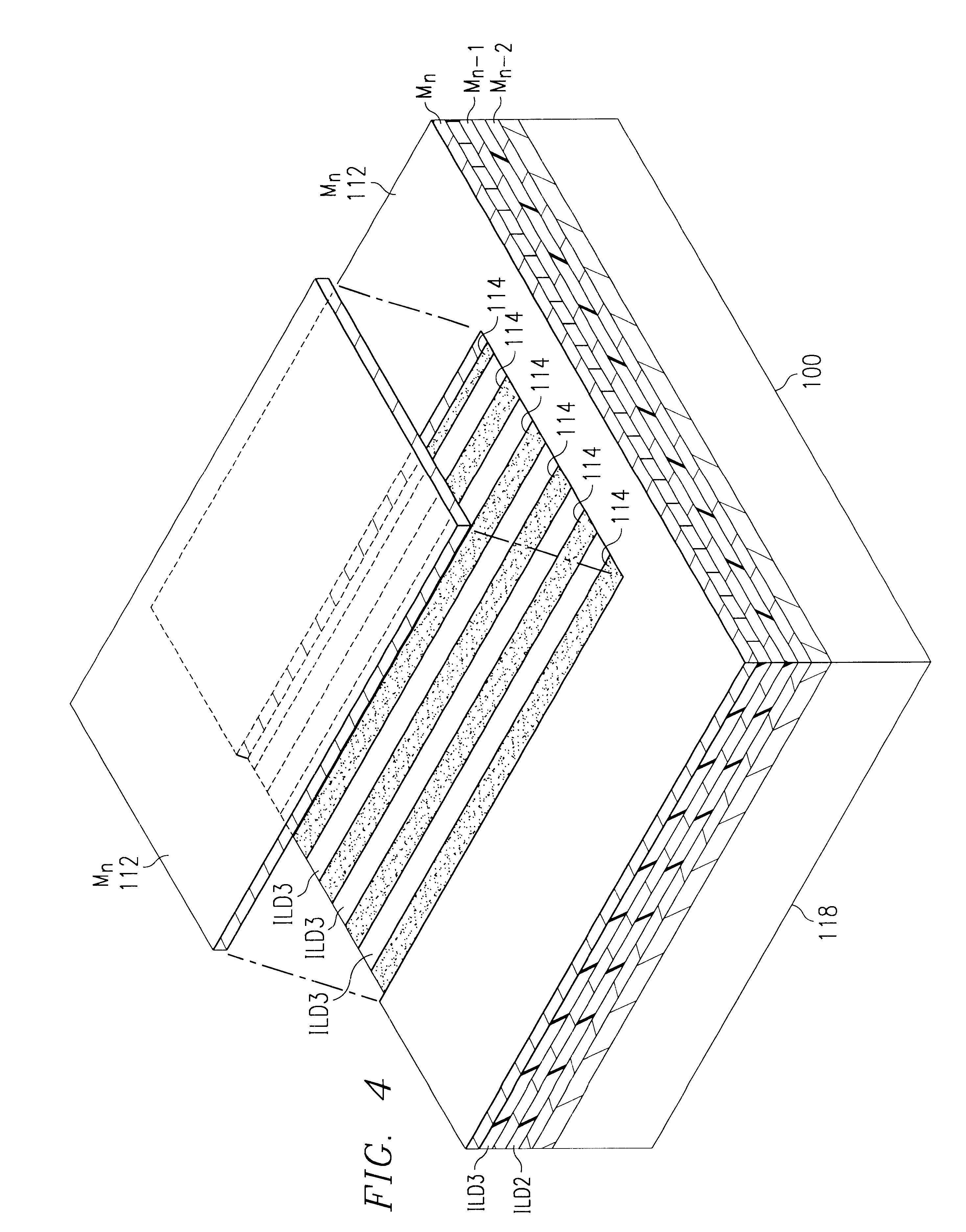

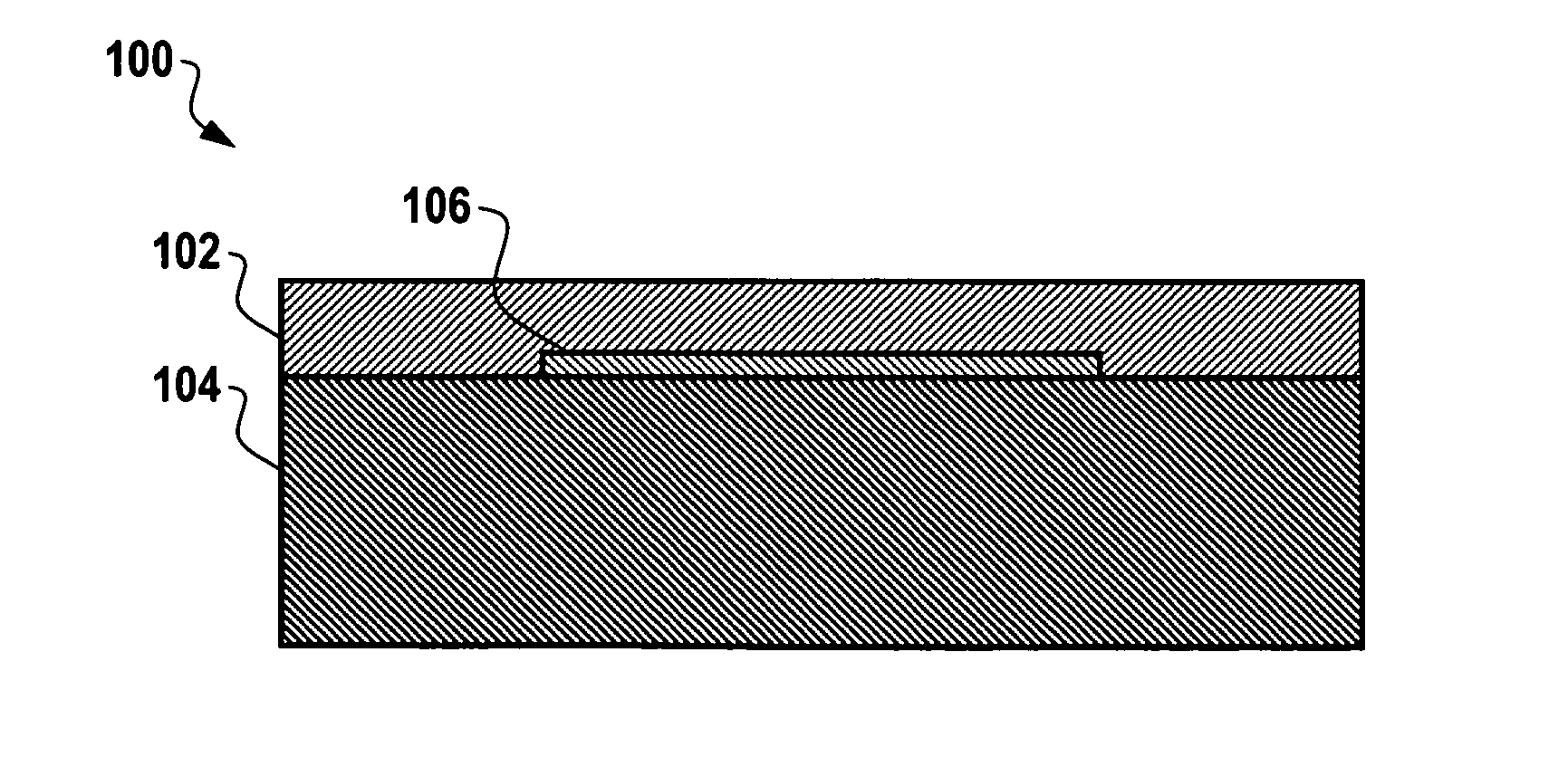

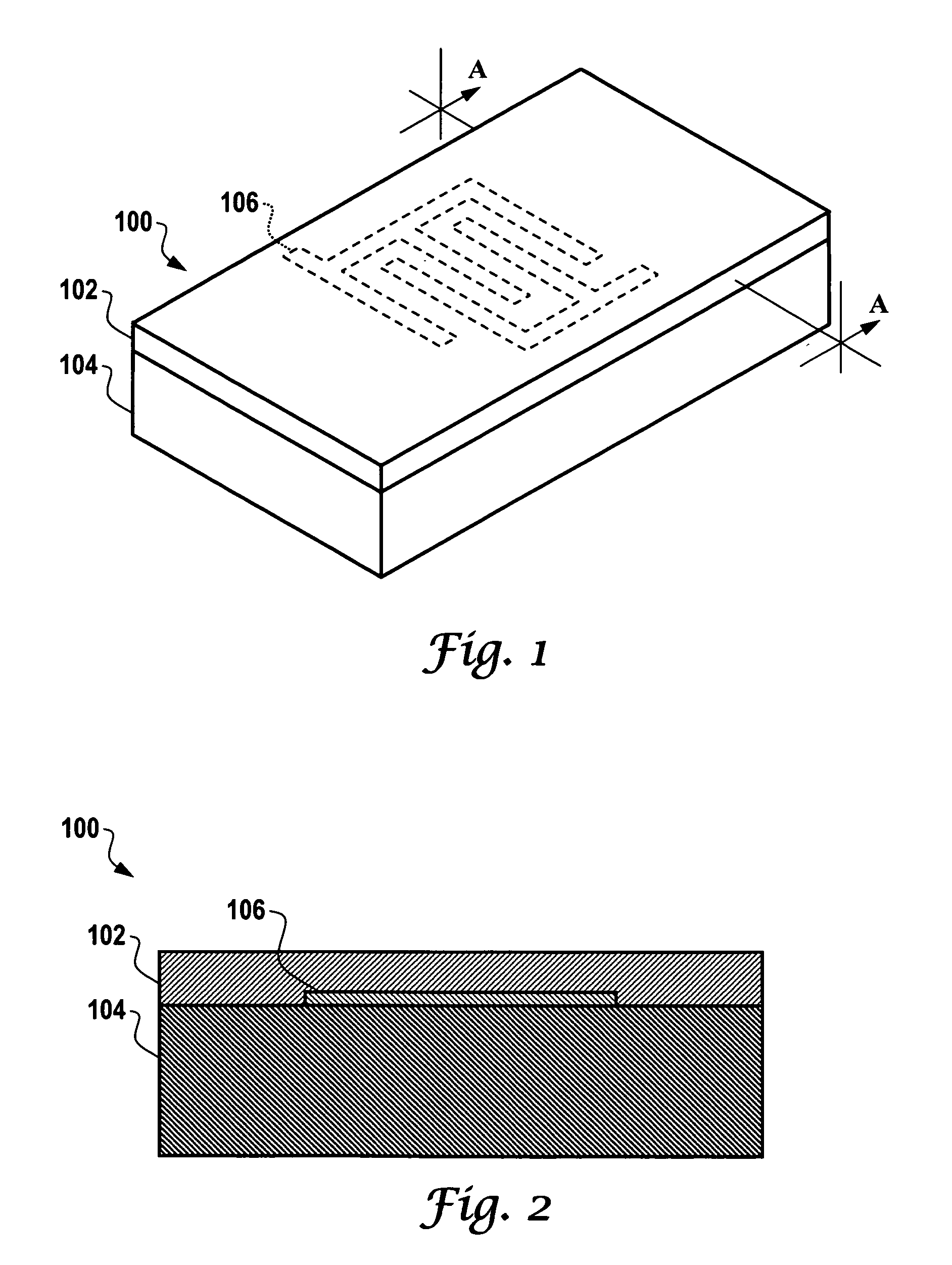

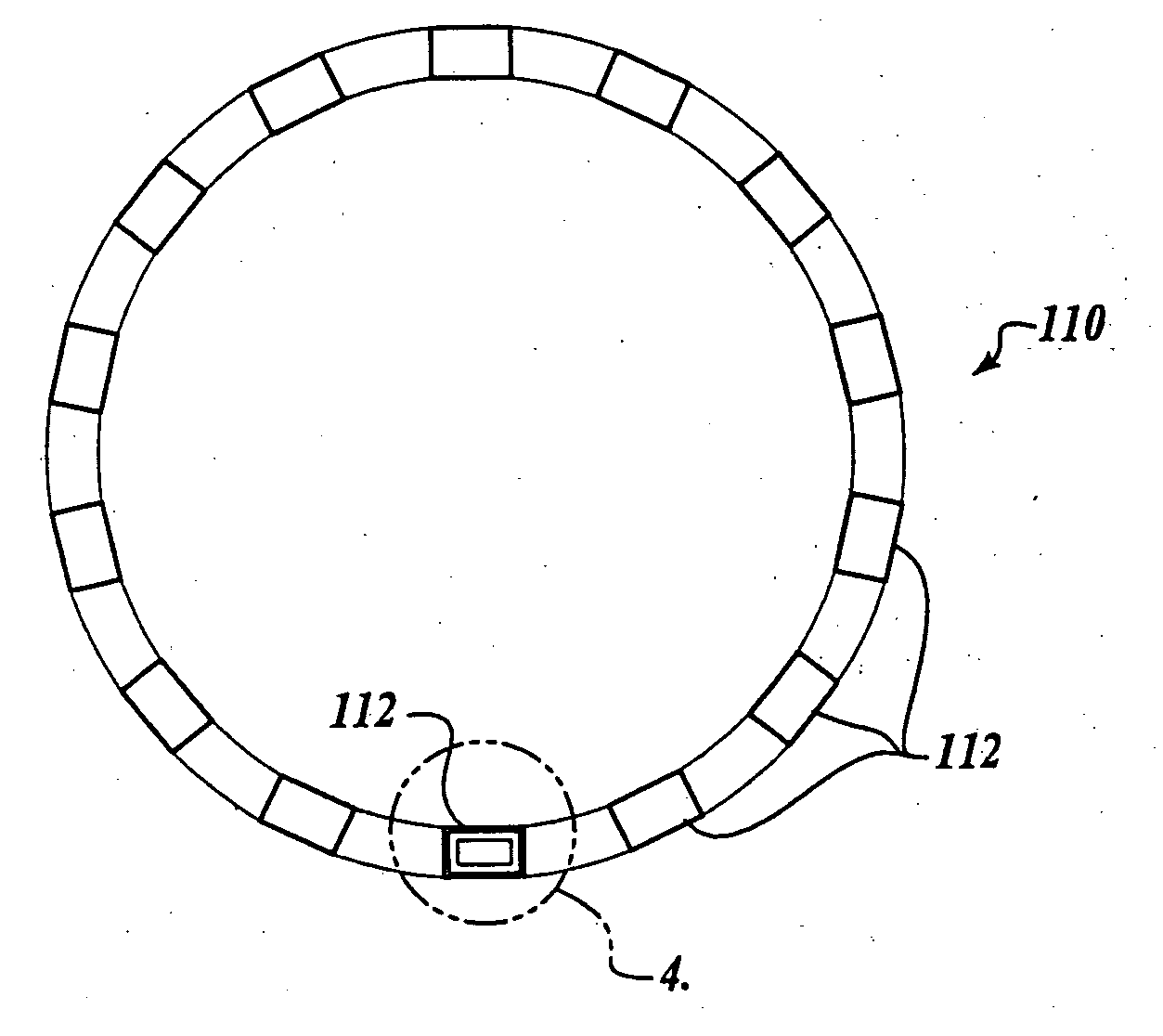

Approach to structurally reinforcing the mechanical performance of silicon level interconnect layers

InactiveUS6586839B2Semiconductor/solid-state device detailsSolid-state devicesStress concentrationMetal interconnect

A conductive via pattern (110) between the uppermost metal interconnect layer (Mn) and next underlying metal interconnect layer (Mn-1) in the bond pad areas strengthens the interlevel dielectric (ILD3) between metal layers (Mn and Mn-1). The conductive via layer (110) may, for example, comprise parallel rails (114) or a grid of cross-hatch rails (116). By spreading the stress concentration laterally, the conductive via layer (110) inhibits micro-cracking from stress applied to the bond pad (112).

Owner:TEXAS INSTR INC

UV solidified intaglio printing decorative ink

The present invention relates to a decorative printing ink for gravure printing, its composition is formed from (wt%) 10-50% of oligomer, 10-40% of active diluent, 3-8% of photoinitiator, 0-46% of forming agent whose fineness is less than 10 micrometer, 0.01-1% of retarder and 0-5% of adjuvant. Said UV gravure printing decorative ink possesses reduced oxyinhibition and its solidifying speed is greatly raised, for example, UV light source is 80W / CMX3, at 150M / min. it can be well solidified, and can make cross-hatch with different effects, can print various patterns of imitation metal etching (corning), dioptric, buckle, ice flower and coral form, and its storage stability is good. Said ivnented product is a colorless one, the pigment or colour ink can be added, and the colour pattern can be printed.

Owner:潘治平

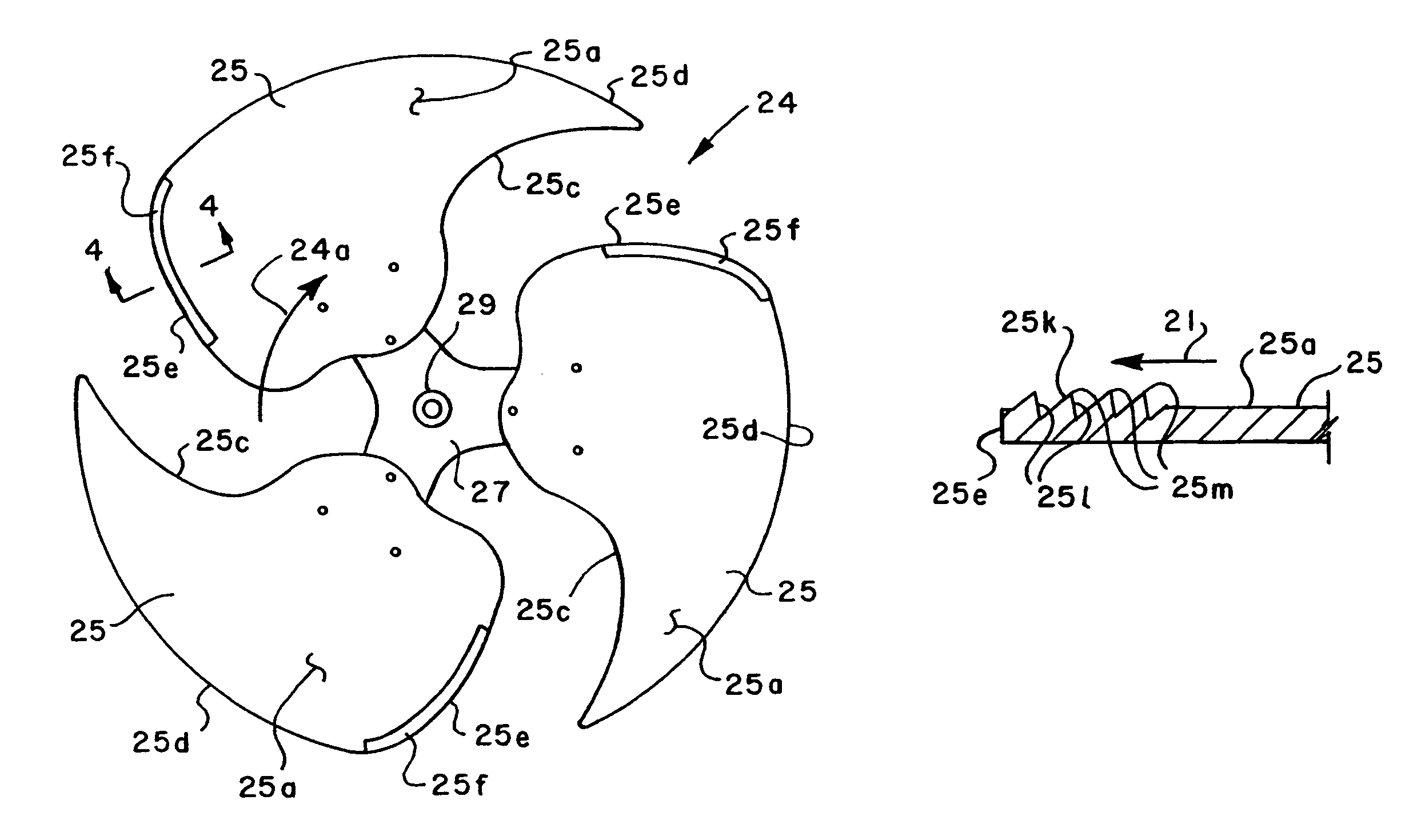

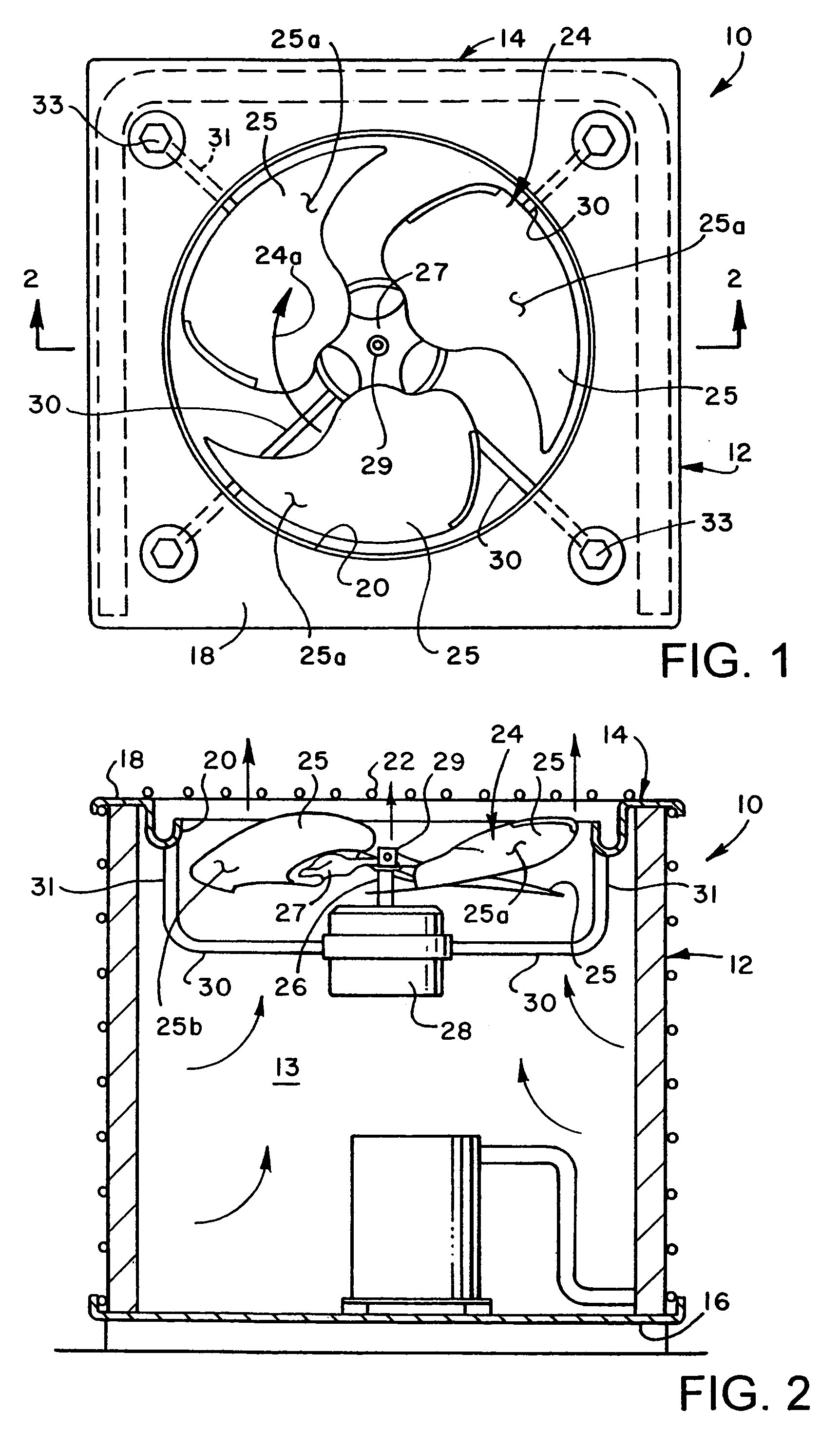

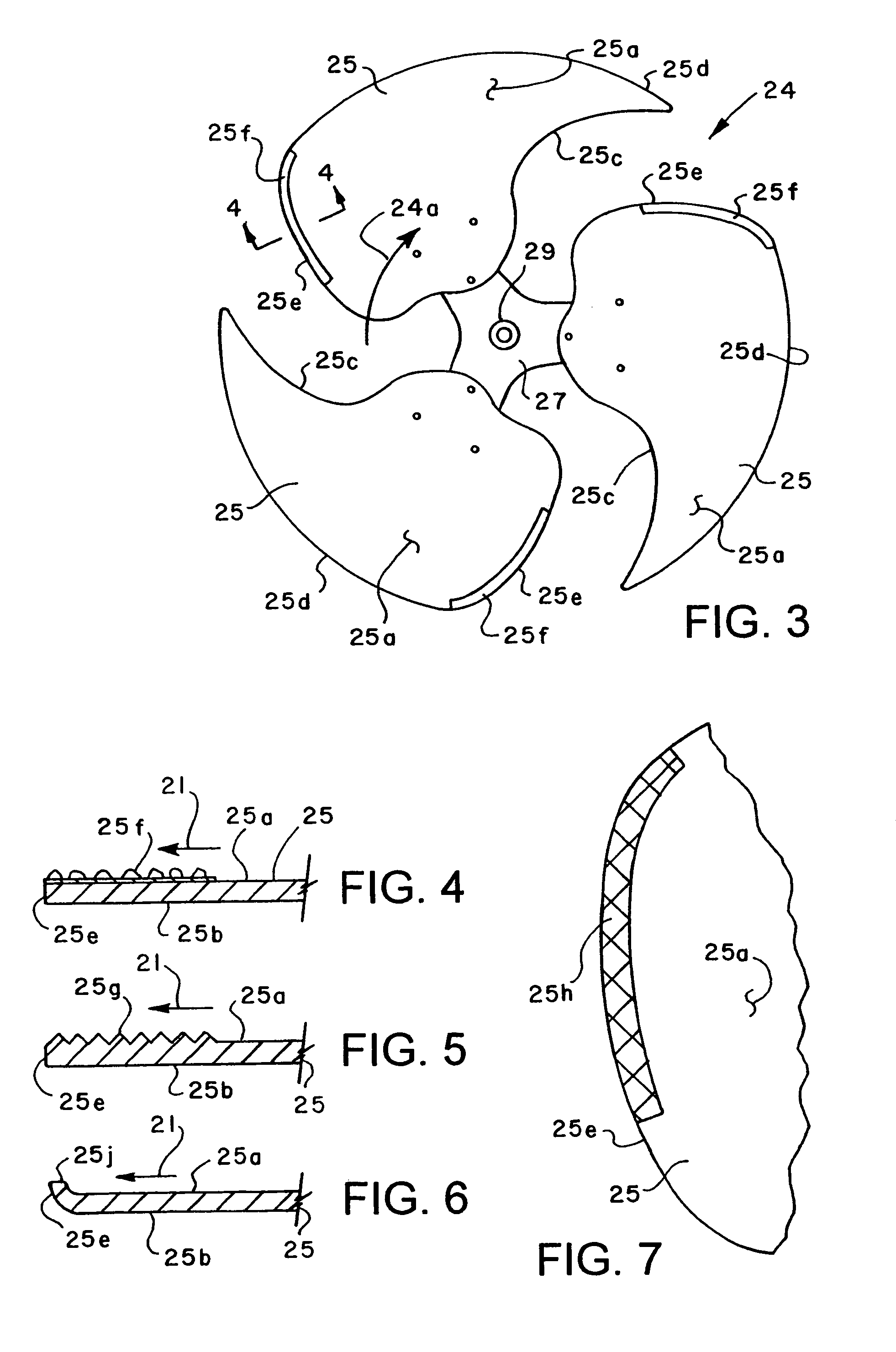

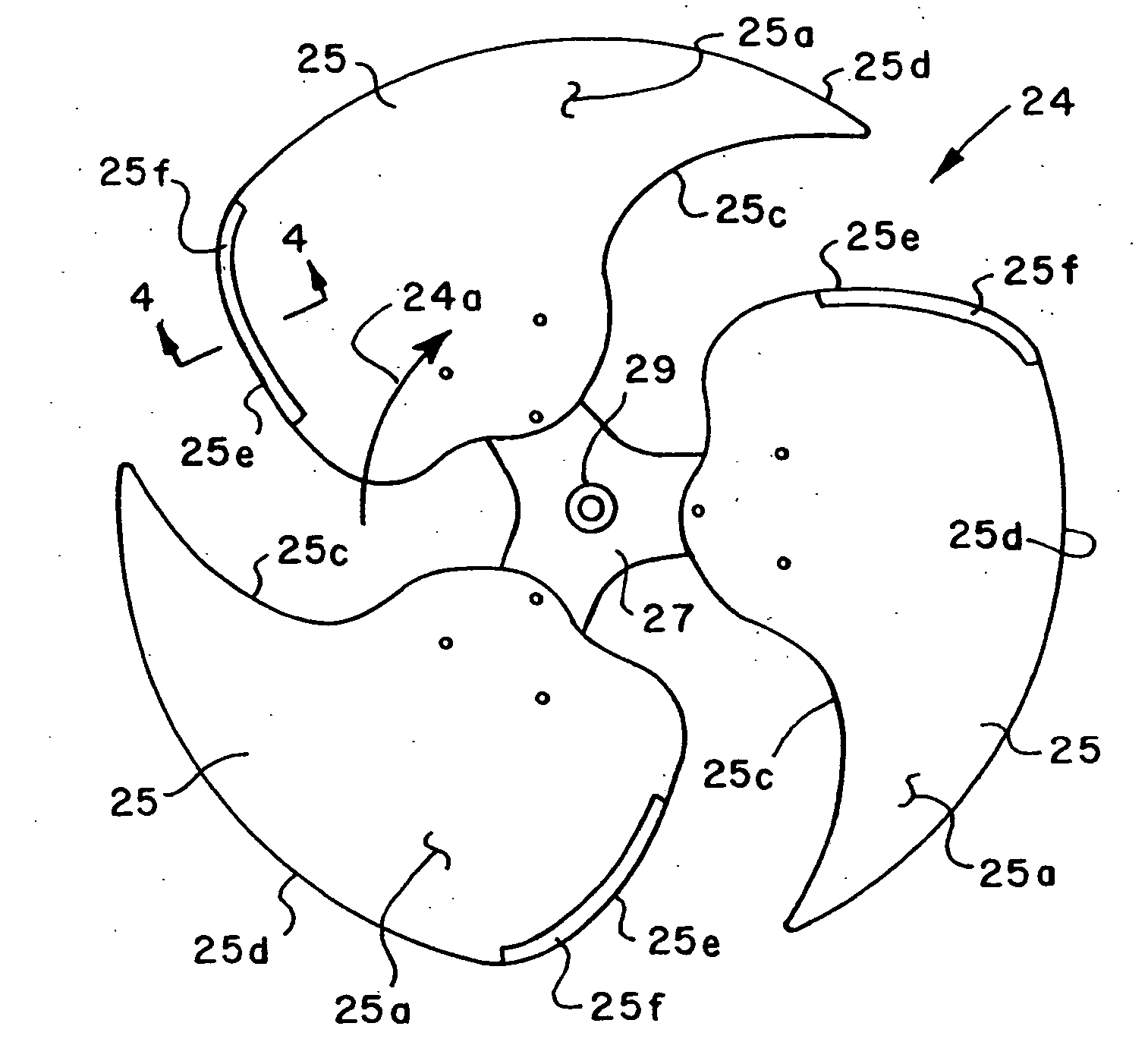

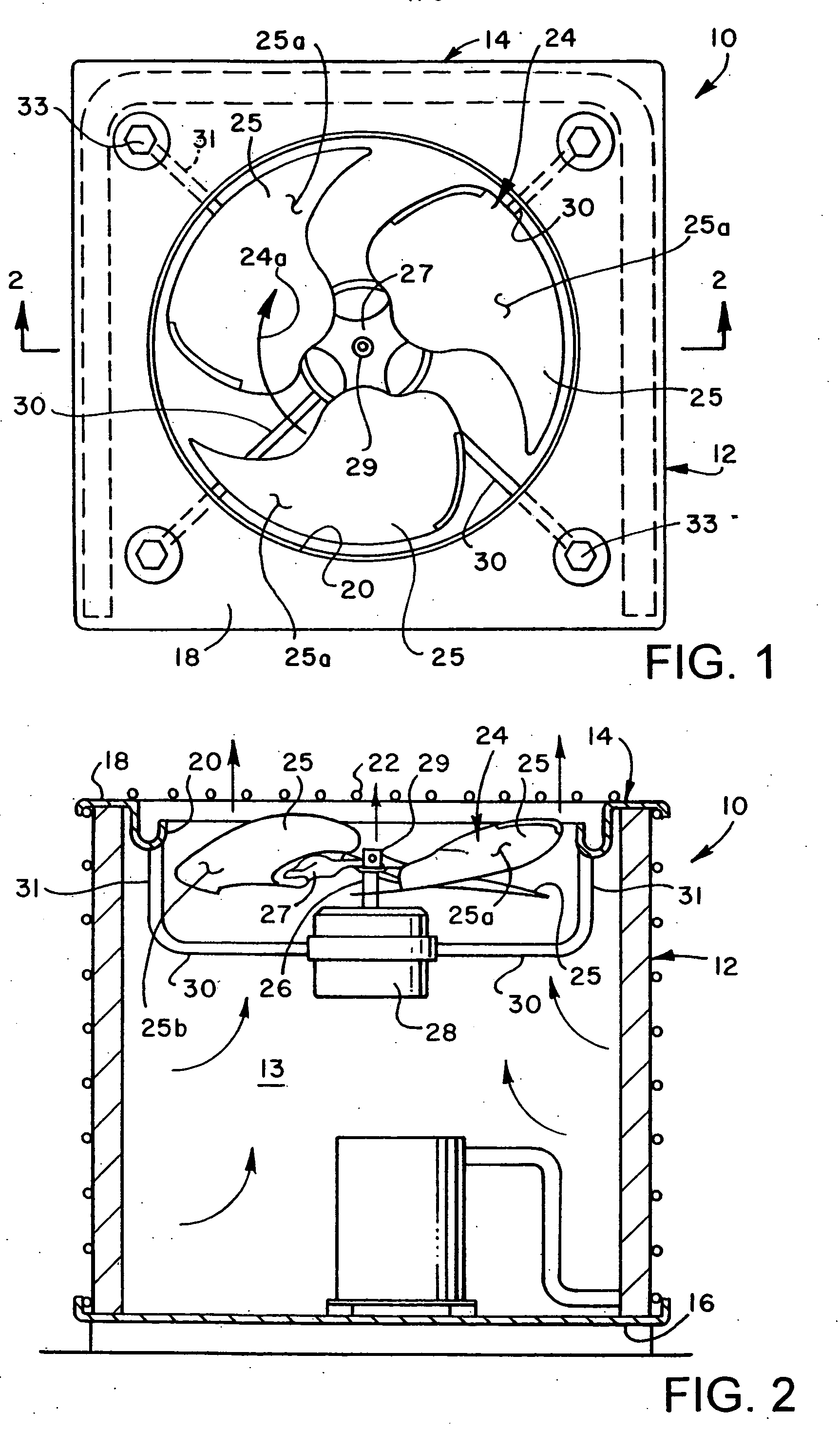

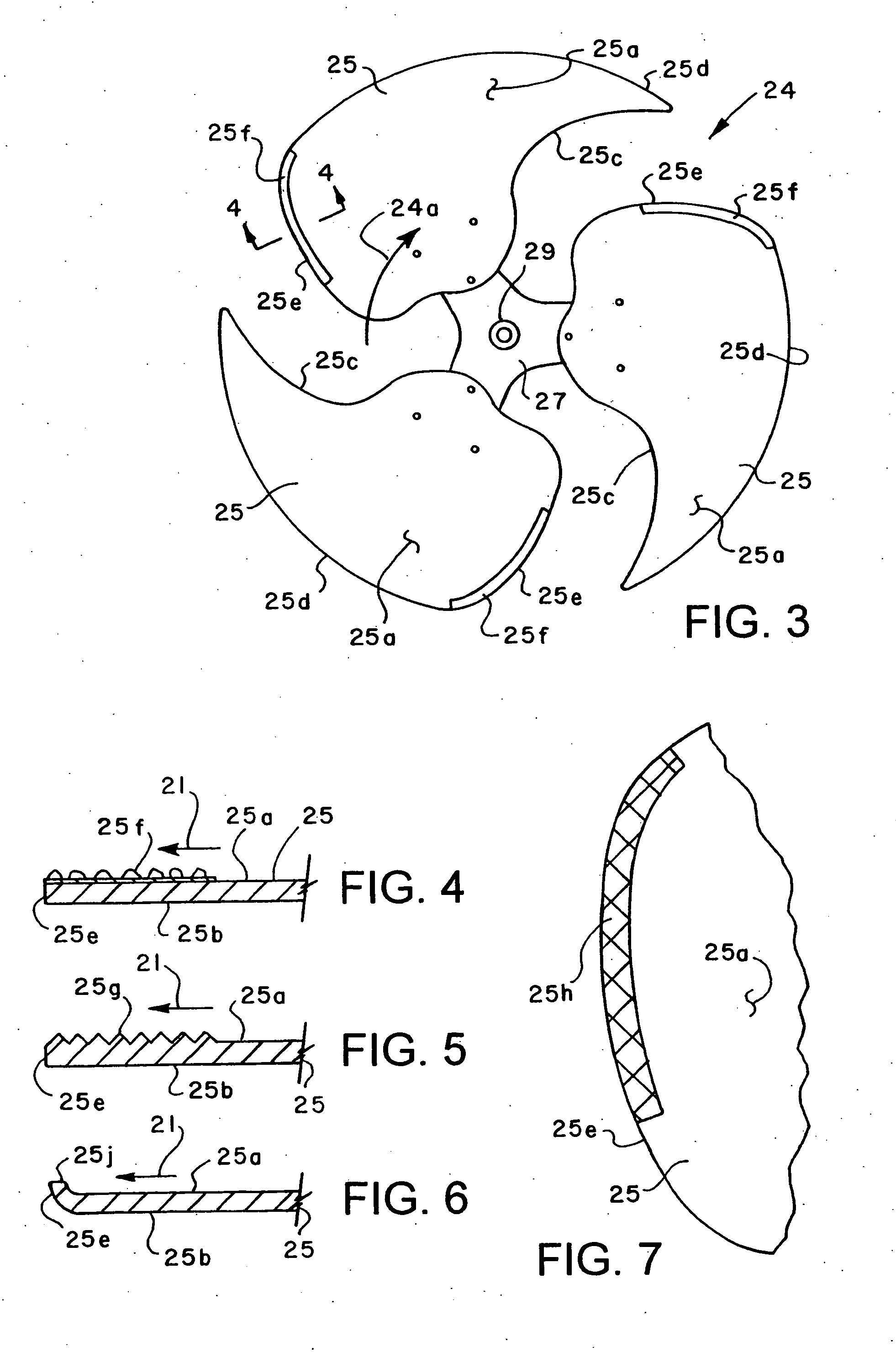

Fan with reduced noise generation

InactiveUS7351041B2Emission reductionReduce noisePropellersPump componentsNoise generationAcoustic emission

Axial flow fan propellers are provided with a roughened portion along the trailing edge of the fan blades on the pressure side of the blade to minimize tonal acoustic emissions generated by laminar boundary layer vortex shedding. The roughened portion may be provided by trip surfaces formed in the blades, by strips of abrasive material adhered to the blades along the trailing edges, respectively, by parallel or cross-hatched serrations in the blades or by upturned or offset trailing edges of the blades. The height of the roughened portion should be about equal to the boundary layer thickness of air flowing over the blade surfaces during operation of the fan. The fan propellers are particularly advantageous in heat exchanger applications, such as residential air conditioning system condenser units.

Owner:LENNOX IND INC

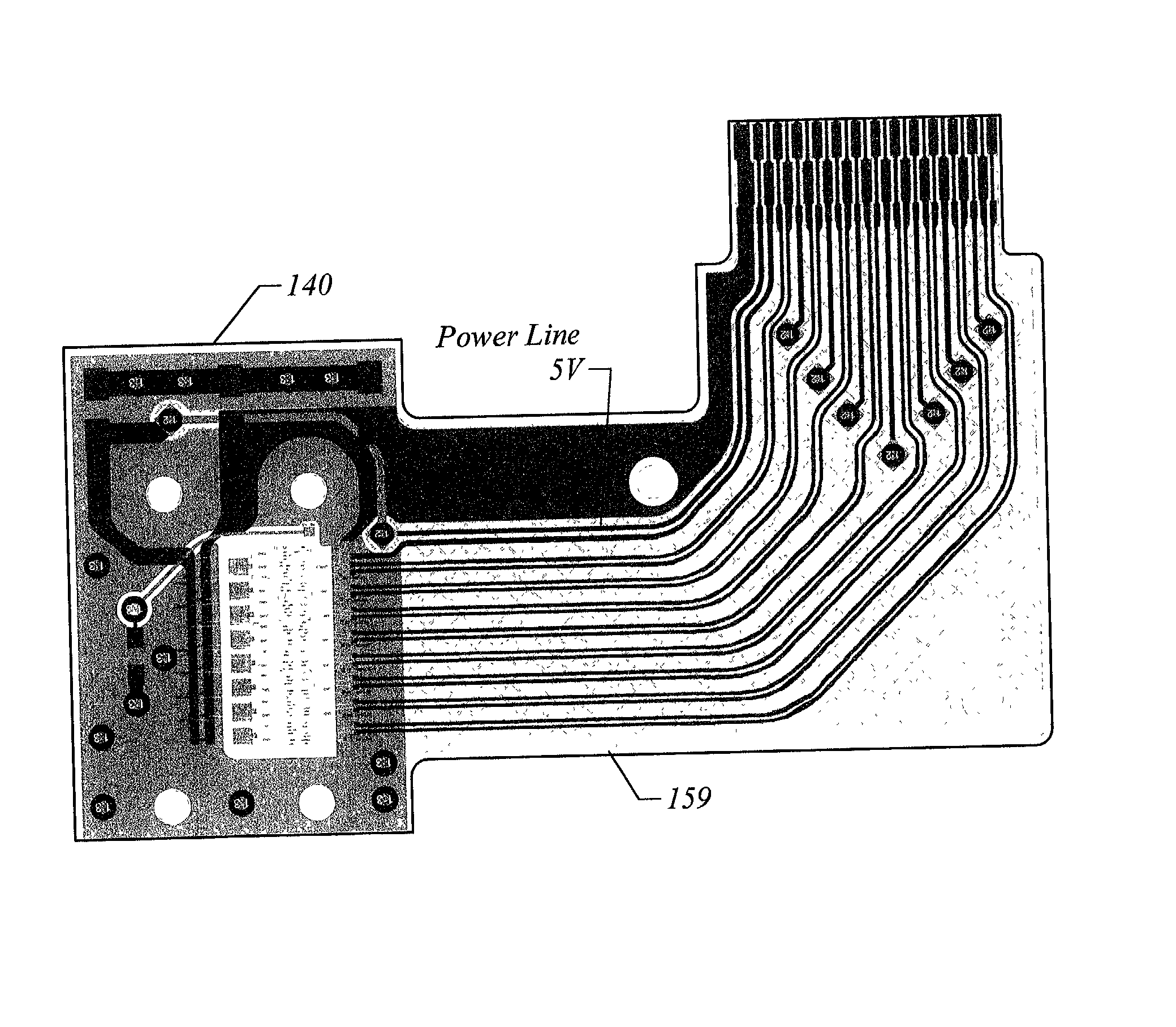

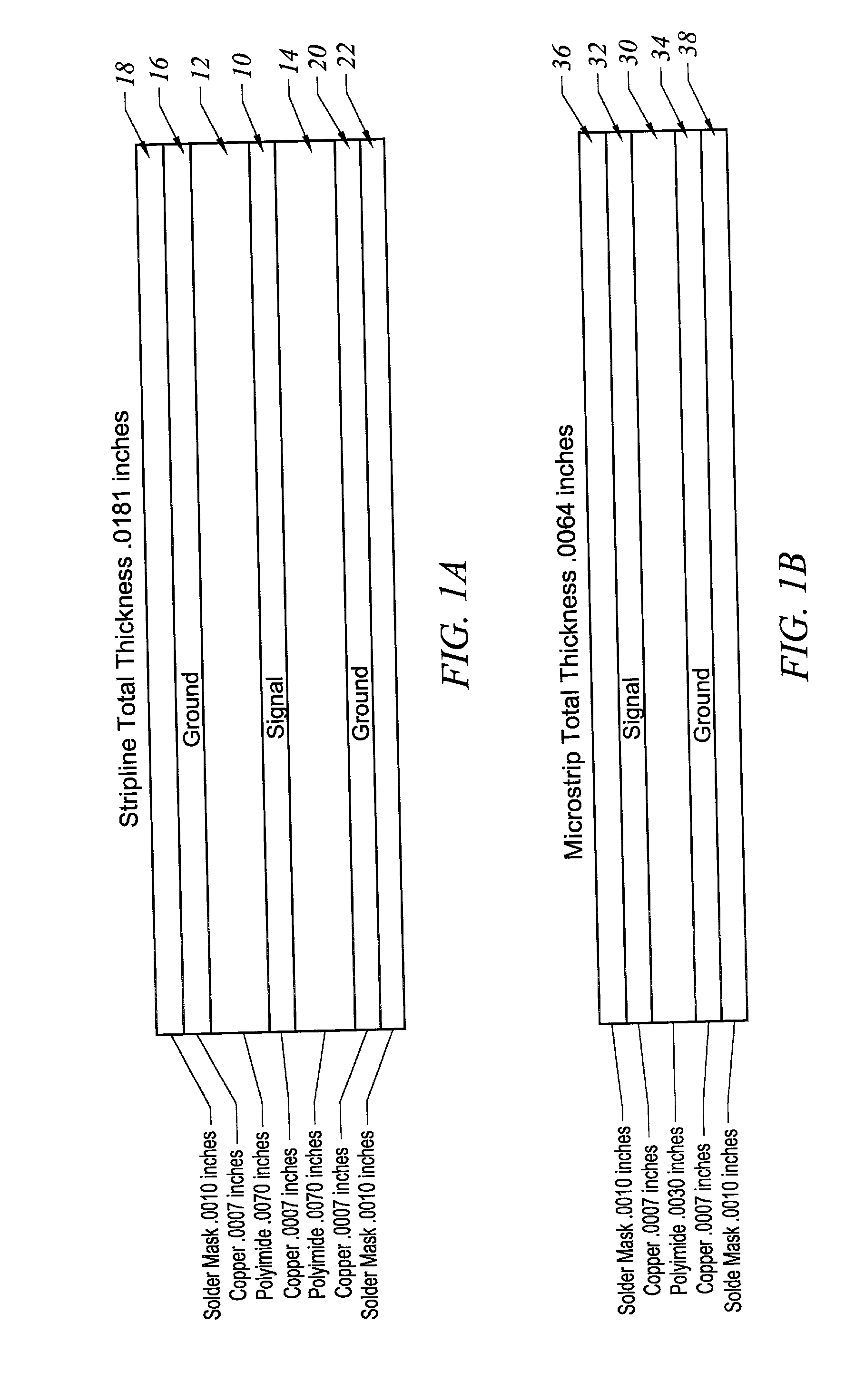

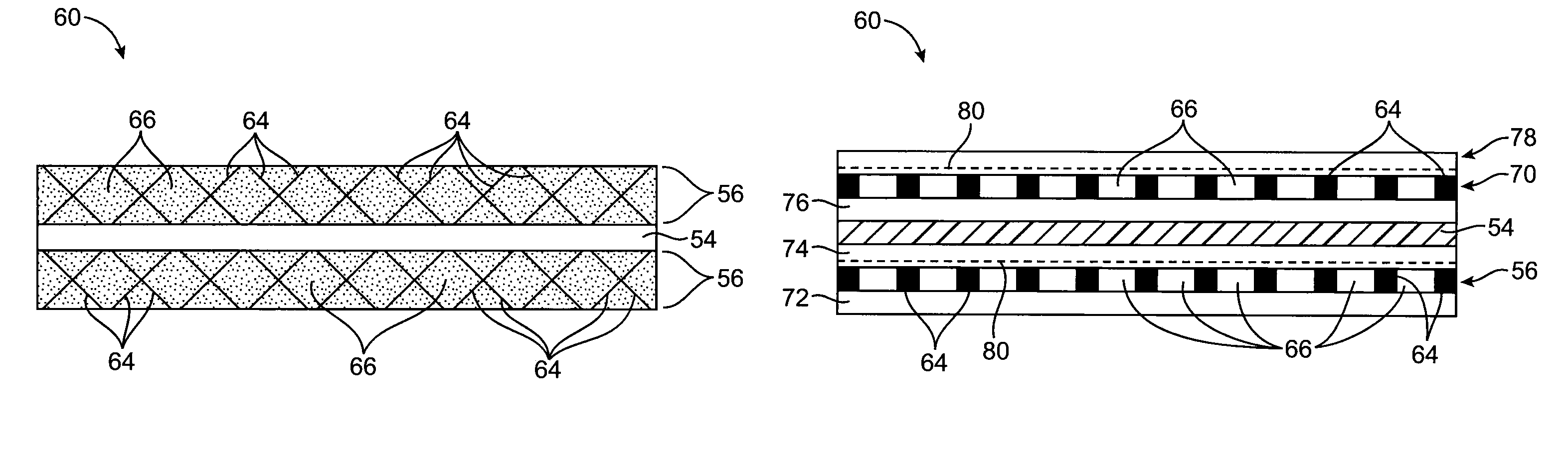

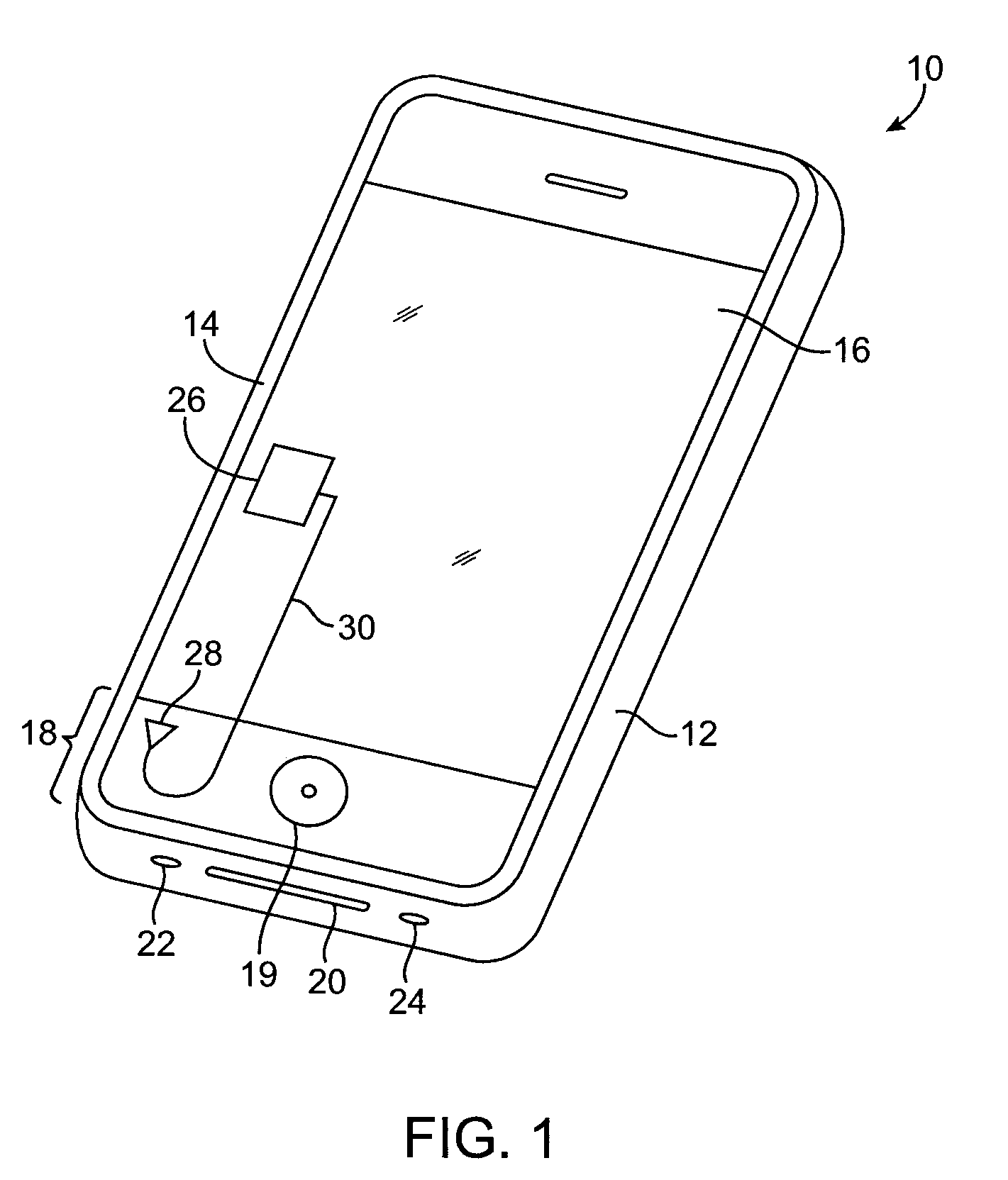

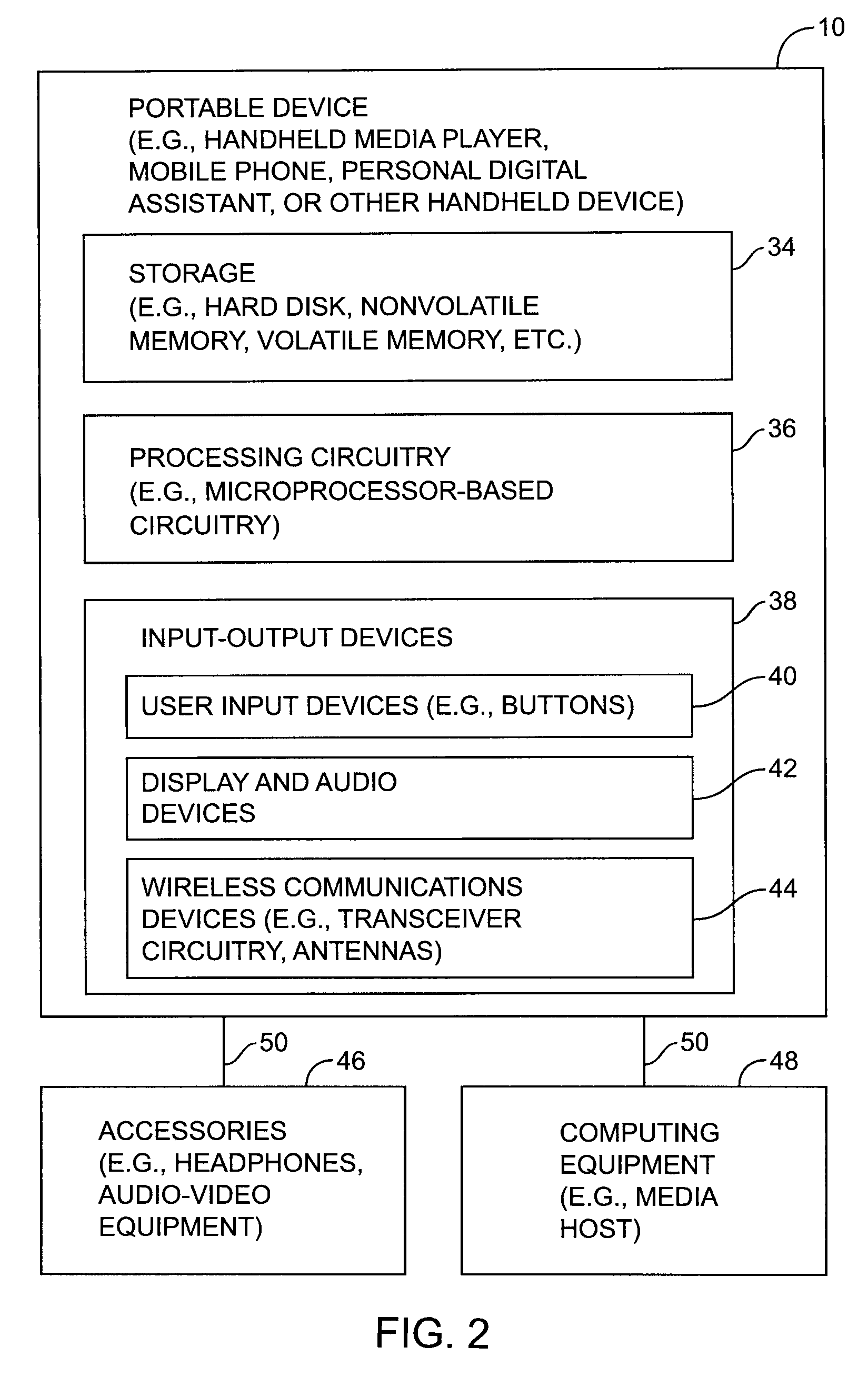

Transmission line with a cross-hatched ground plane that is either filled with conductive paint or covered by a conductive foil

ActiveUS8058954B2Increase flexibilityImprove conductivityMultiple-port networksPrinted circuit manufactureElectrical conductorCross hatch

Transmission lines for electronic devices such as microstrip and stripline transmission lines may be provided that include patterned conductive lines and a conductive paint in the patterned conductive lines. The transmission lines may include one or more planar ground conductors. The ground conductors may include conductive lines arranged in a crosshatch pattern with spaces between the conductive lines. The ground conductors may also include conductive paint in spaces within the crosshatched pattern. The ground conductors may form one or more ground planes for the transmission lines.

Owner:APPLE INC

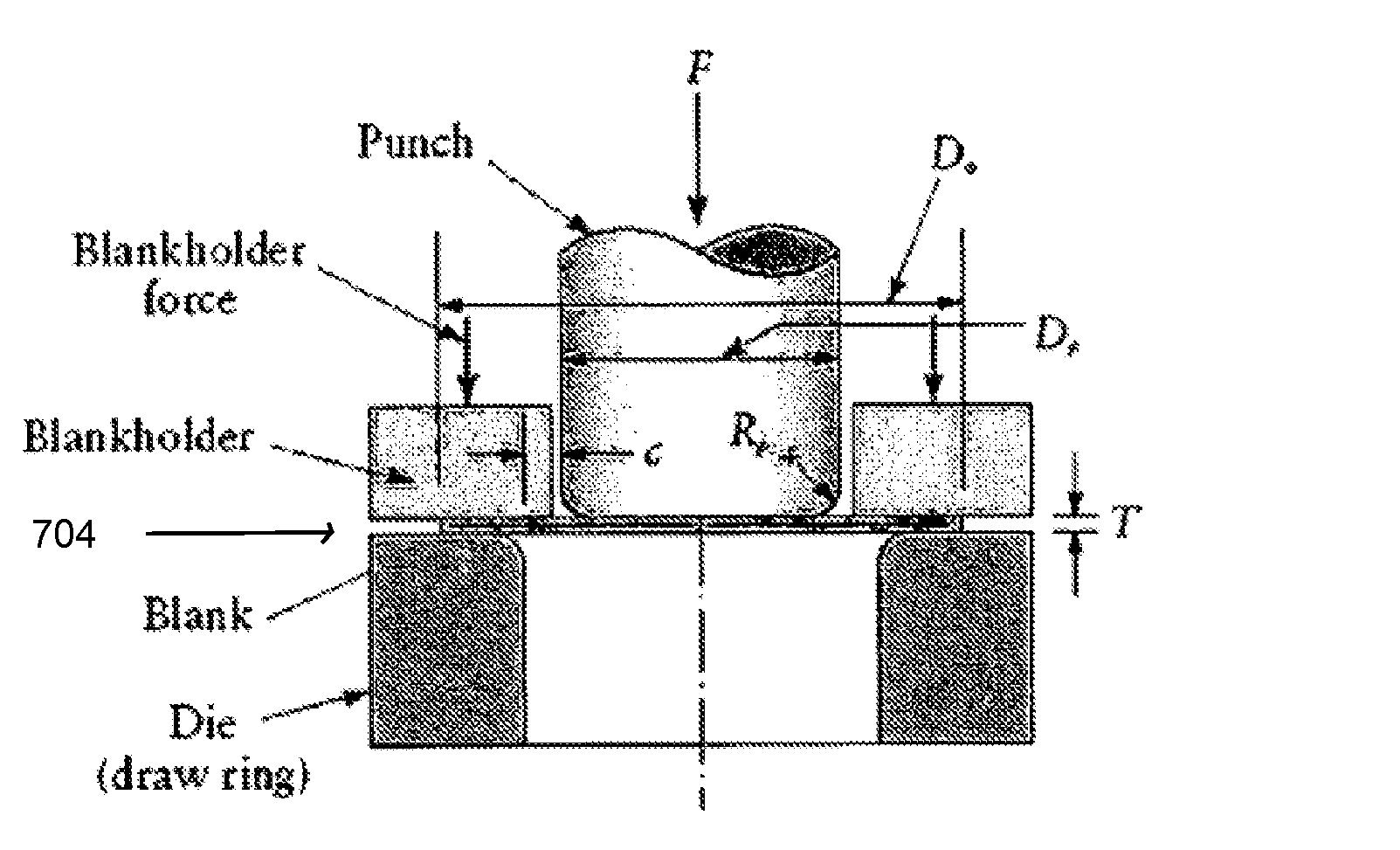

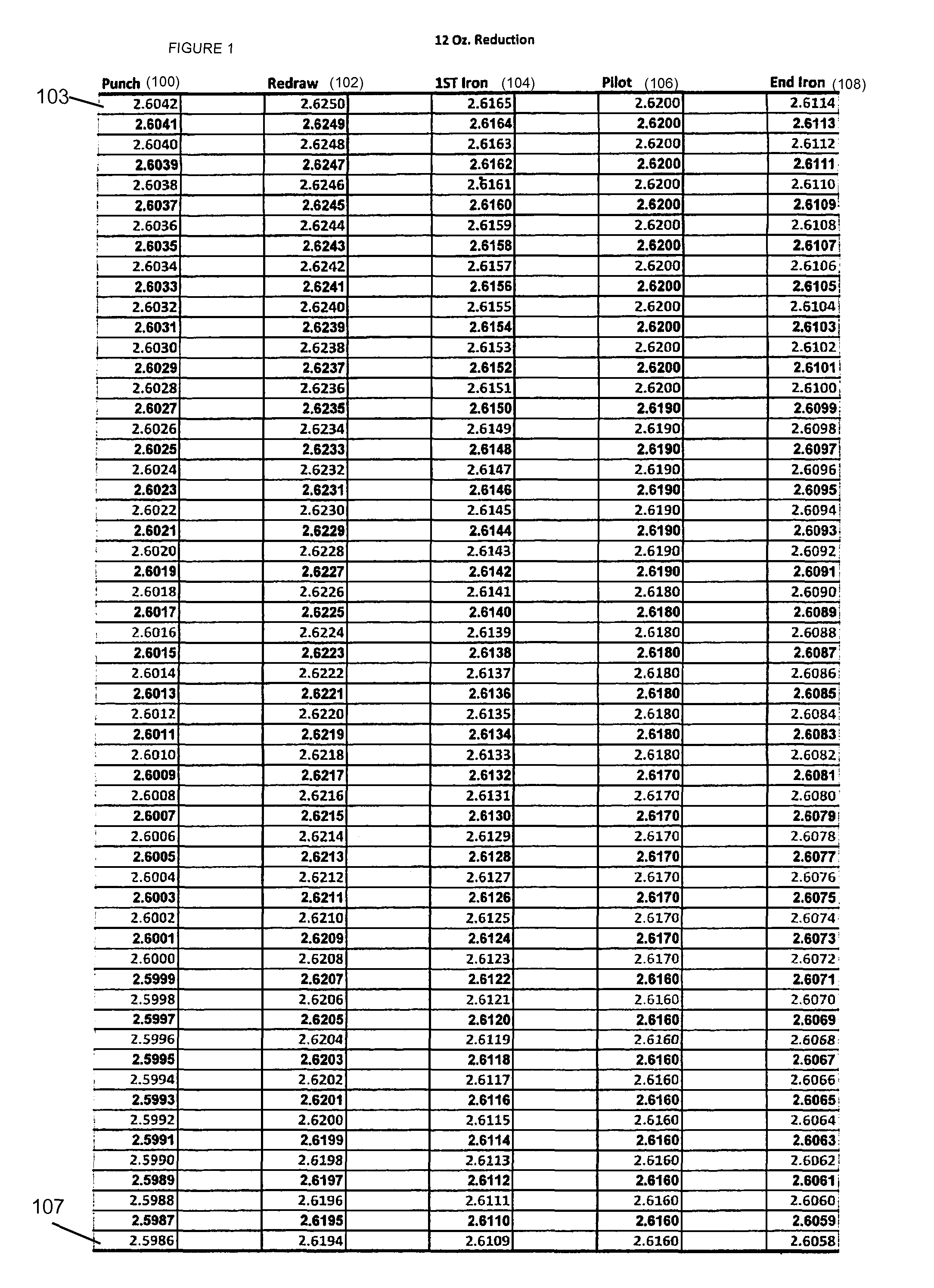

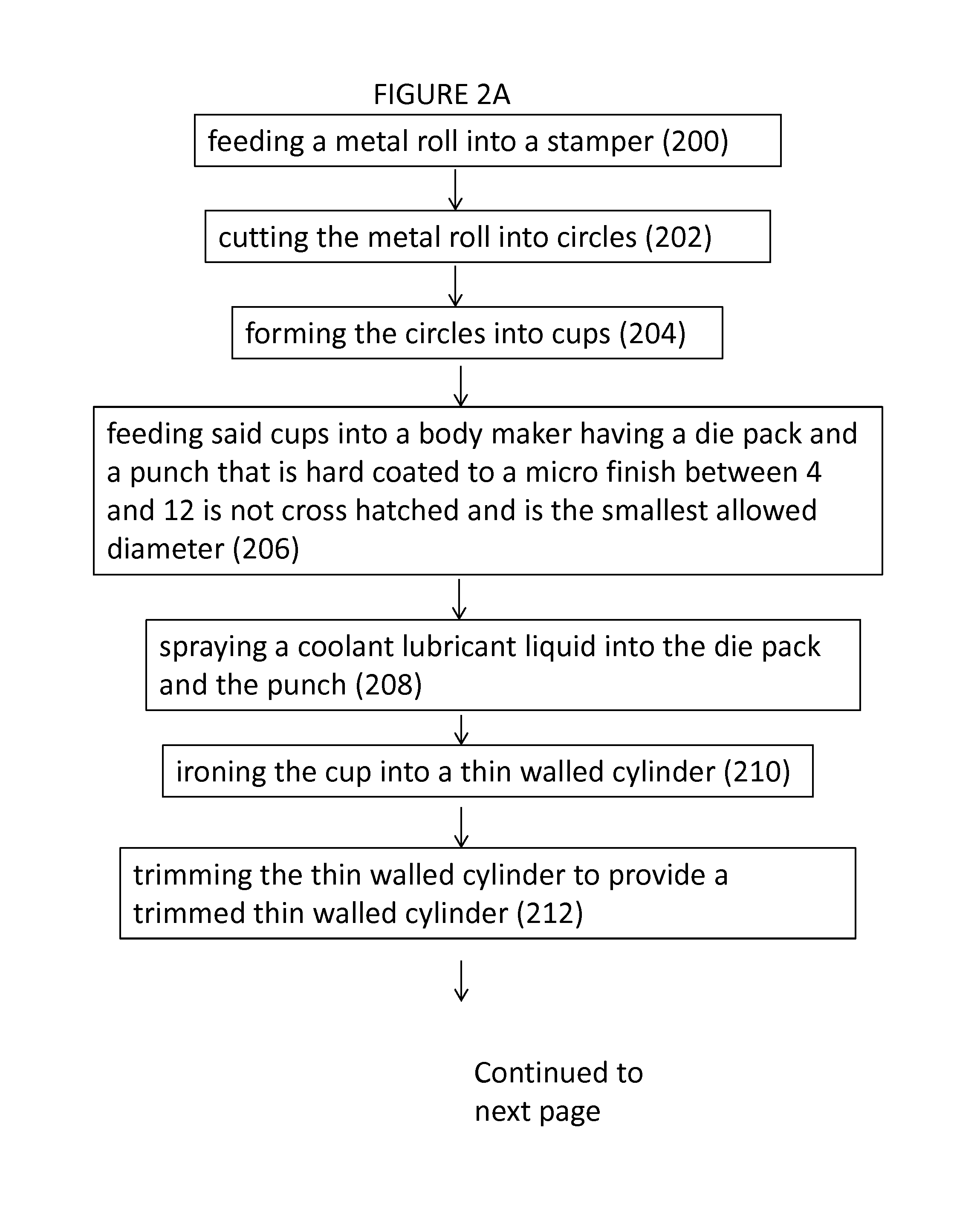

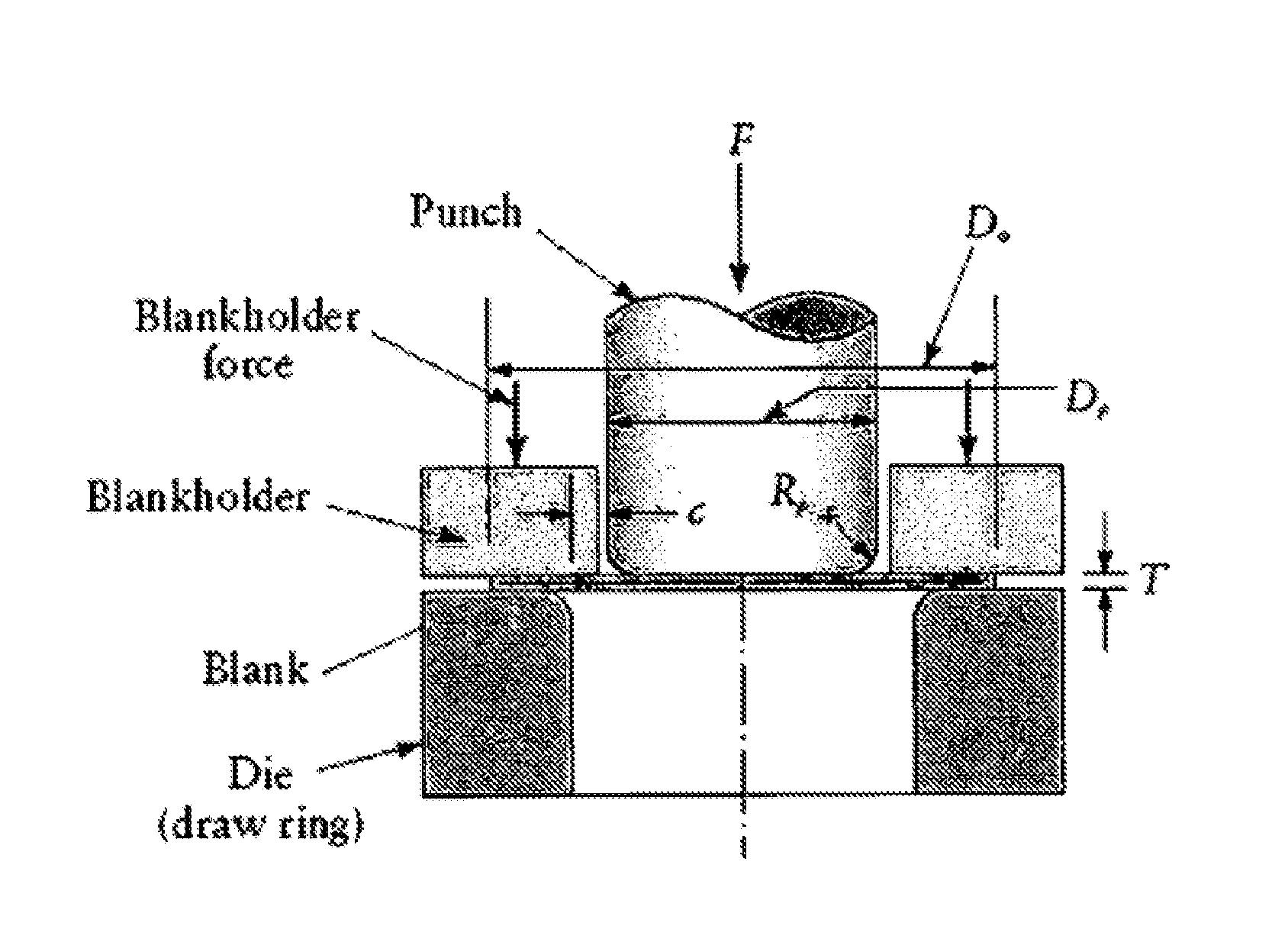

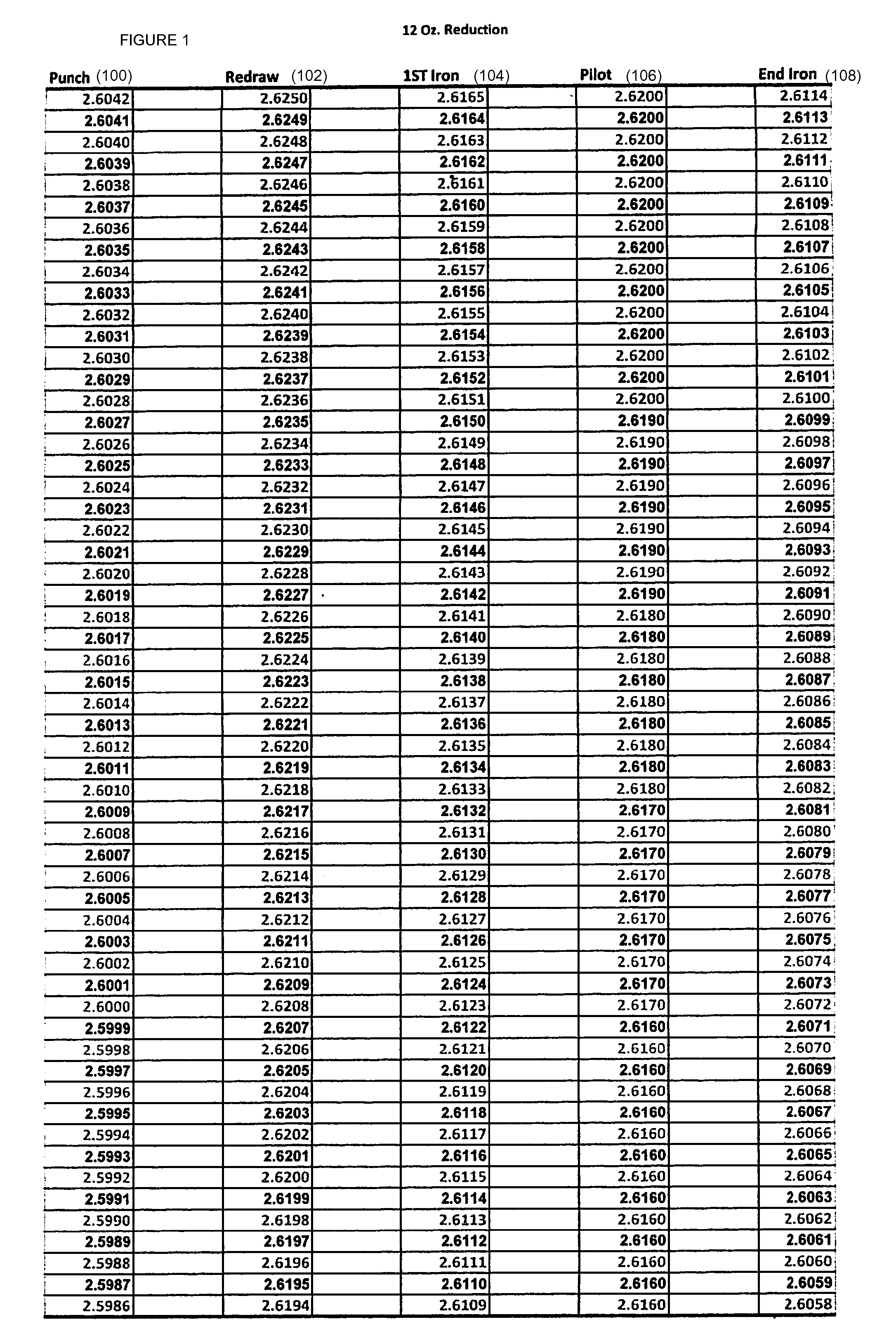

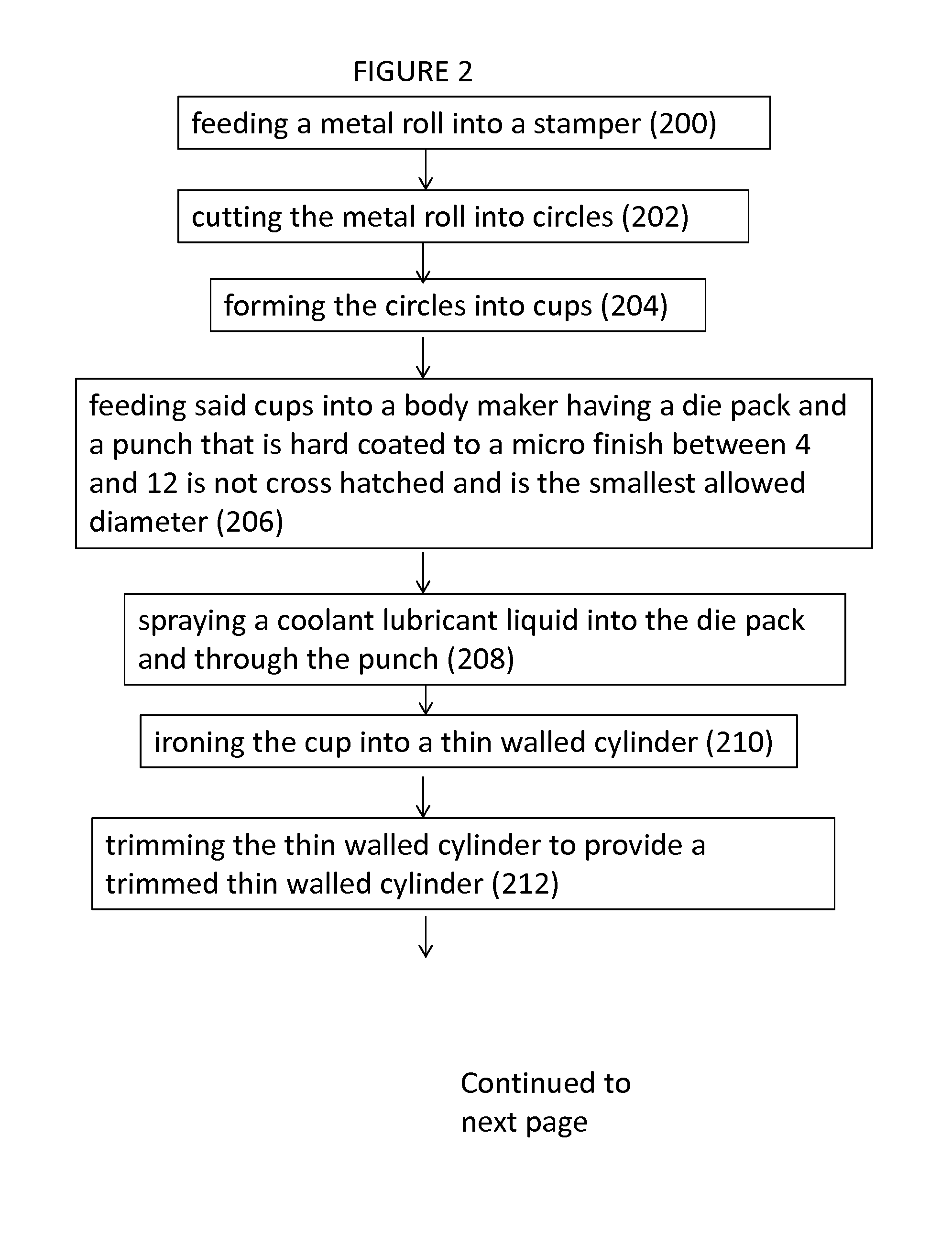

Methods and processes of manufacturing two piece cans

A method of drawing and ironing metal into a can comprising the steps of: feeding a metal roll into a stamper; cutting the metal into circles; forming the circles into cups; feeding the cups into a body maker having a die pack with at least three dies and a punch hard coated to a micro finish between 4 and 12, not cross hatched and is the smallest allowed diameter; spraying a coolant lubricant liquid into the die pack and through the punch; ironing the cup into a thin walled cylinder; trimming the thin walled cylinder; washing, rinsing, drying and decorating the trimmed thin walled cylinder; spray coating the inside of the can with a protective coating; necking the trimmed thin walled cylinder; forming a lip on the top of the tapered thin walled cylinder; testing the trimmed thin walled cylinder for defects; and palletizing the thin walled cylinder.

Owner:FARNHAM ENTERPRISES

Methods and processes of manufacturing two piece cans

A method of drawing and ironing metal into a can for beverages, food and products, the method comprising the steps of: feeding a metal roll into a stamper; cutting the metal into circles; forming the circles into cups; feeding said cups into a body maker, wherein said body maker has a die pack having at least three dies and a punch, wherein the at least three dies and the punch are hard coated to a micro finish between 4 and 12, and the punch is not cross hatched and is the smallest allowed diameter; spraying a coolant lubricant liquid into the die pack and the through the punch; ironing the cup into a thin walled cylinder; trimming the thin walled cylinder to provide a trimmed thin walled cylinder; washing, rinsing and drying the trimmed thin walled cylinder; decorating the trimmed thin walled cylinder; spray coating the inside of the can with a protective coating; necking the trimmed thin walled cylinder to provide a tapered thin walled cylinder; forming a lip on the top of the tapered thin walled cylinder; testing the trimmed thin walled cylinder for defects; and palletizing the thin walled cylinder.

Owner:FARNHAM ENTERPRISES

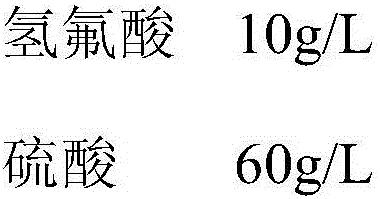

Chromium based ceramic composite coating process and piston ring thereby

InactiveCN1424436ATypical layered structureIncrease contentElectrolytic coatingsCeramic compositePiston ring

A plated composite Cr-base ceramic layer of piston ring is prepared through electroplating hard Cr layer on piston ring in the liquid containing CrO3, H2SO4, 3-valence Cr and catalyst AFC, chemically and physical generating cross hatches, inlaying ceramic microparticles, covering, sealing, and repeating several times. Its advantages are high power to bear heat load and mechanical load, and high antiwear performance.

Owner:ASIMCO SHUANGHUAN PISTON RING YIZHENG

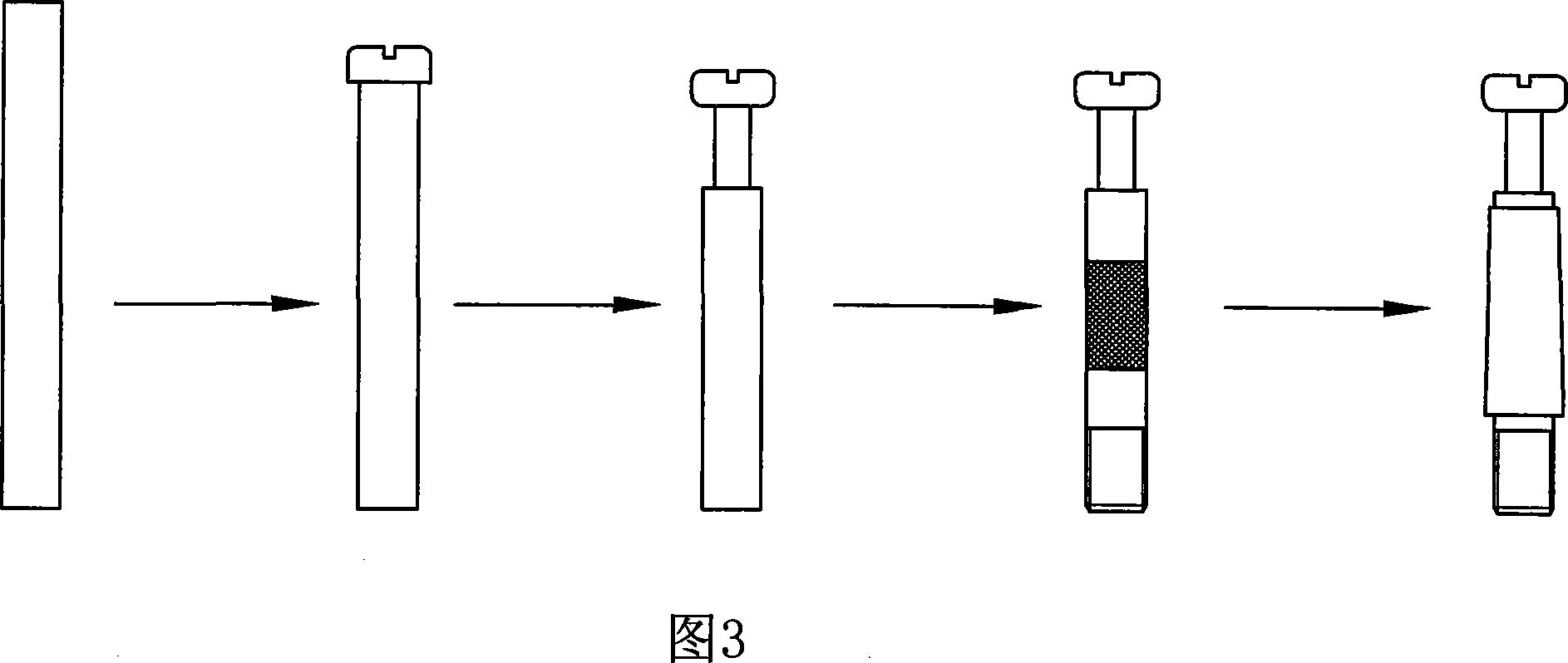

Connection rod and production process and dedicated device for processing half-product of connection rod

The present invention involves a connecting rod for furniture, its productive technology and the special device used for processing connecting rod half-finished product. The connecting rod includes thin rod and plastic-wrapping body, the top head surface of thin rod is equipped with flight and the screw-plug end of thin rod is processed with external screw thread, the plastic-wrapping body is wrapped on the outer surface of then thin rod wall, the thin rod wall which is wrapped with plastic-wrapping body is processed with cross hatch, the screw-plug end of thin rod is processed with multidiameter which consists of transition part and core rod, the diameter of multidiameter is reduced from outer to inner, the outer screw thread is processed on the outer wall on the core rod. Compared with the prior connecting rod, the connecting rod in the invention has small integral size and lower manufacturing cost; the production process of the invention is simplified, the efficient production is higher and the production cost is reduced; the special device of the invention uses non-cutting working, no produce waste is generated during the process, the flow production can be realized more easily and the processing efficiency is improved after the special device is used in cold heading machine.

Owner:吴建荣

System and method of representing route information

ActiveUS8924142B2Instruments for road network navigationRoad vehicles traffic controlIncident reportTraffic congestion

A route comprises interconnected road segments that can be traveled to get from a location to a destination. Previously, routes are represented by display of the spatial arrangement of such road segments (e.g., a map). Here, a route is depicted as a linear shape, and portions of the linear shape represent portions of the route, regardless of their spatial arrangement. A scale is applied between a characteristic of the route and the linear shape. Information elements can be depicted at points on the linear shape that correspond, based on the scale, to locations on the route where such information applies. Portions of the linear shape can be colored or cross-hatched according to traffic congestion conditions. Incident reports can be represented by indicators along the linear shape. Alternate routes (detours) can be represented by respective separate linear shapes; lead lines can connect such linear shapes to points of the route linear shape where each such detour would be taken.

Owner:MALIKIE INNOVATIONS LTD

Method of making a surface acoustic wave device

InactiveUS7165298B2Securely holdPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyAdhesiveSensing applications

Owner:HONEYWELL INT INC

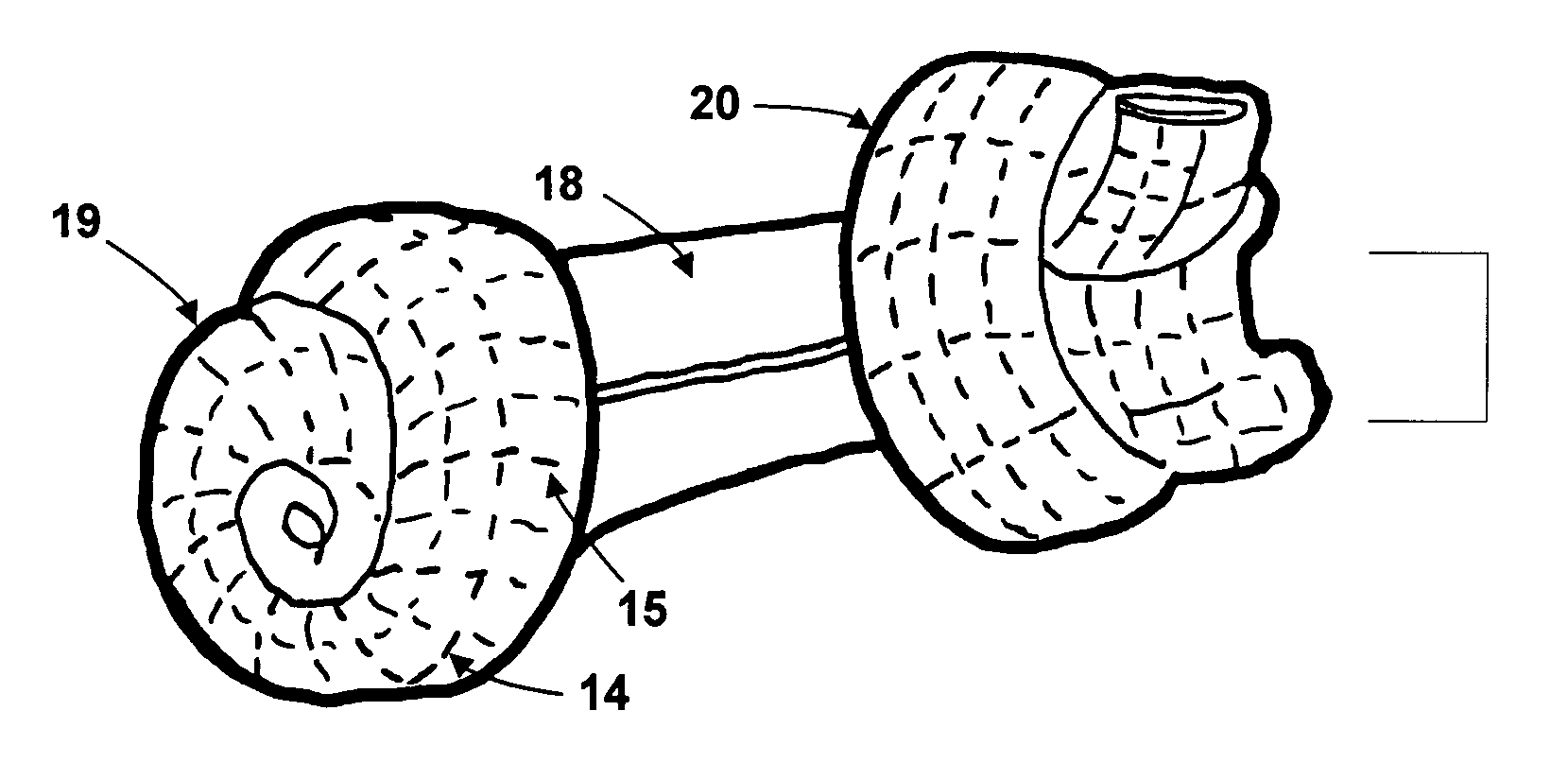

Animal chew

InactiveUS7678402B1Facilitate the small piecesAnimal feeding stuffBakery productsEngineeringCross hatch

A novel dog chew is disclosed made of raw hide which has a large plurality of closely spaced perforations cut there through during manufacture of the dog chew. Typically the perforations are created in first rows that are generally parallel to each other and in second rows that are also generally parallel to each other, and the first rows intersect the second rows to create a cross hatching pattern. The intersecting sets of perforations created by the cross hatch pattern define a large number of small sections on the rawhide. The small sections of the dog chew individually break off when chewed by a dog instead of large pieces that may choke the dog.

Owner:MARINO DAVID C

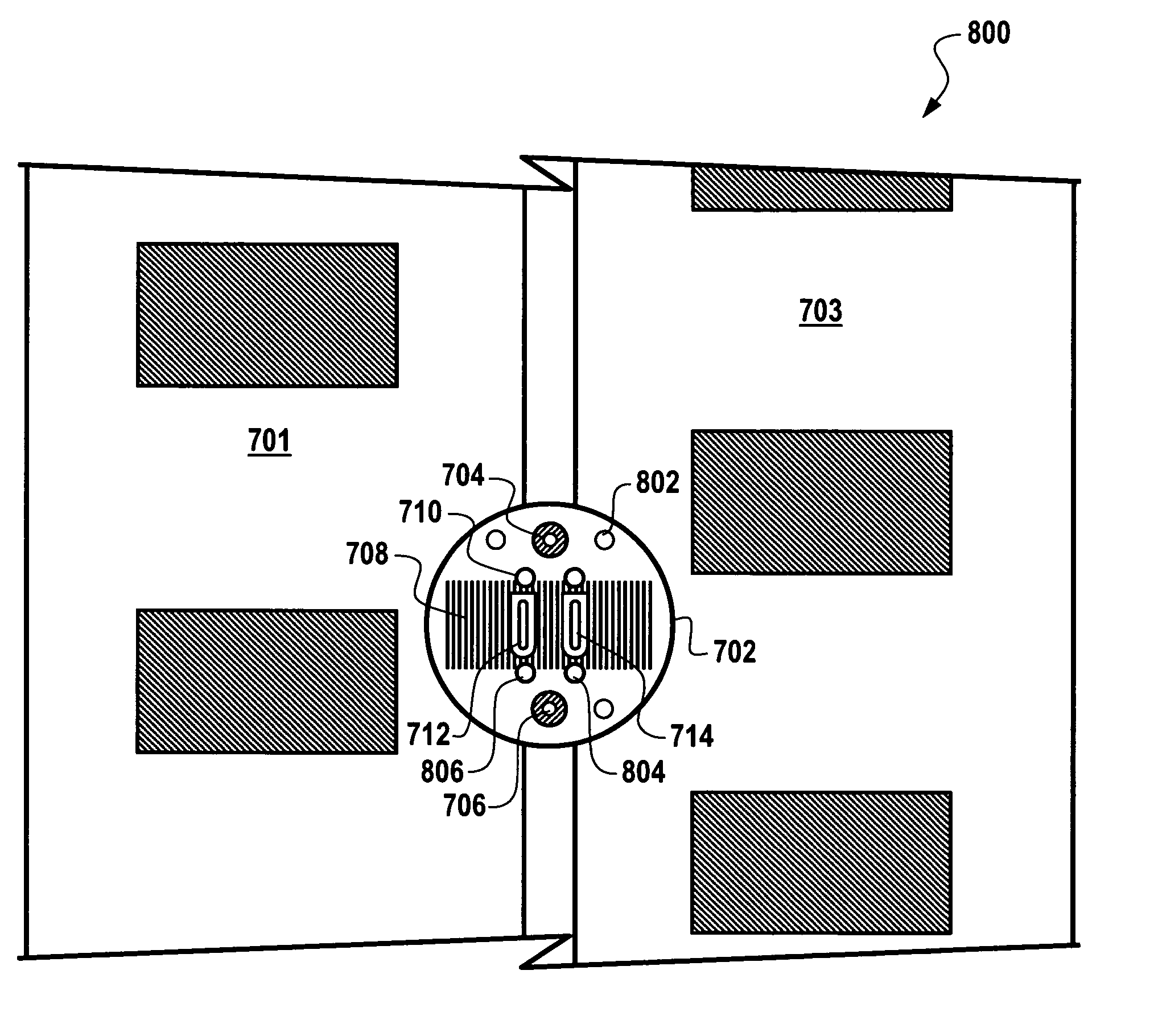

Surface acoustic wave die methods and systems

InactiveUS20060055286A1Securely holdPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyAdhesiveSensing applications

A surface acoustic wave die system and method are disclosed herein, including a surface acoustic wave sensor comprising one or more surface acoustic wave die disposed and hermetically sealed between a base and a cover. An adhesive is generally for securing one or more of the surface acoustic wave die to the base, which is configured with a pattern of cross hatches formed thereon in order to permit the adhesive to adhere to the base. The adhesive is placed under a location wherein surface acoustic wave die is to be located. The surface acoustic wave die is thereafter pressed into the adhesive, whereby upon a subsequent curing of the adhesive, the surface acoustic wave die is held securely in place, while remaining flexible as required by sensing applications associated with the surface acoustic save sensor.

Owner:HONEYWELL INT INC

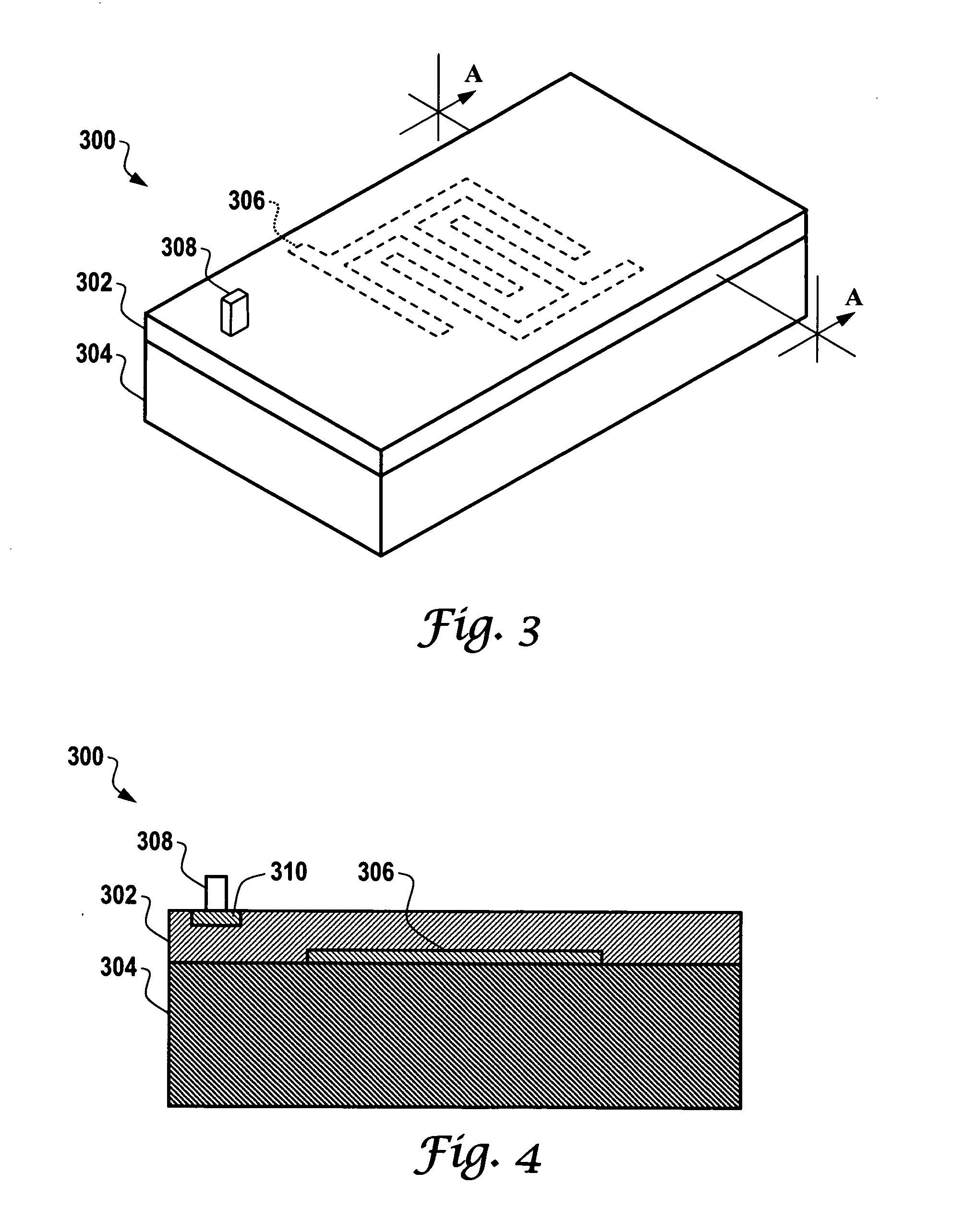

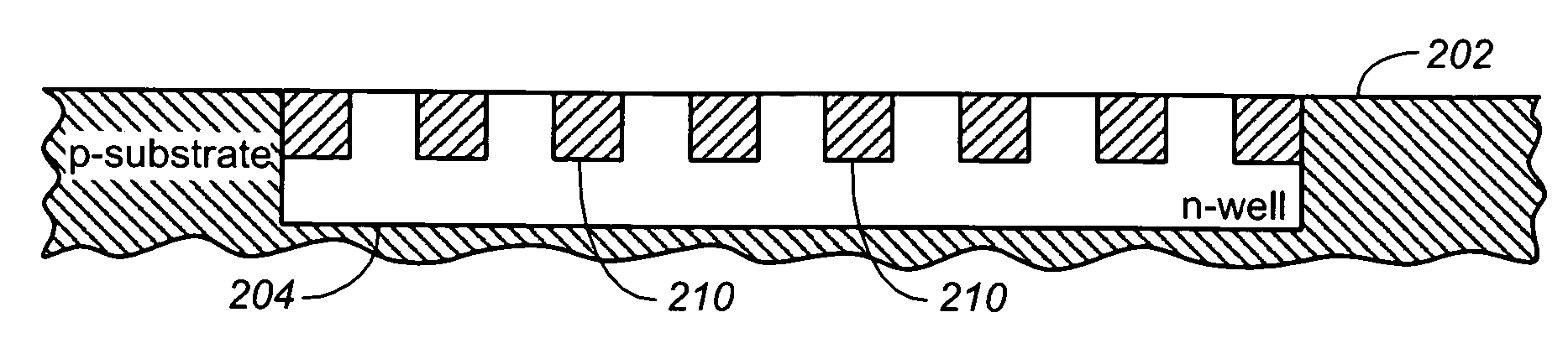

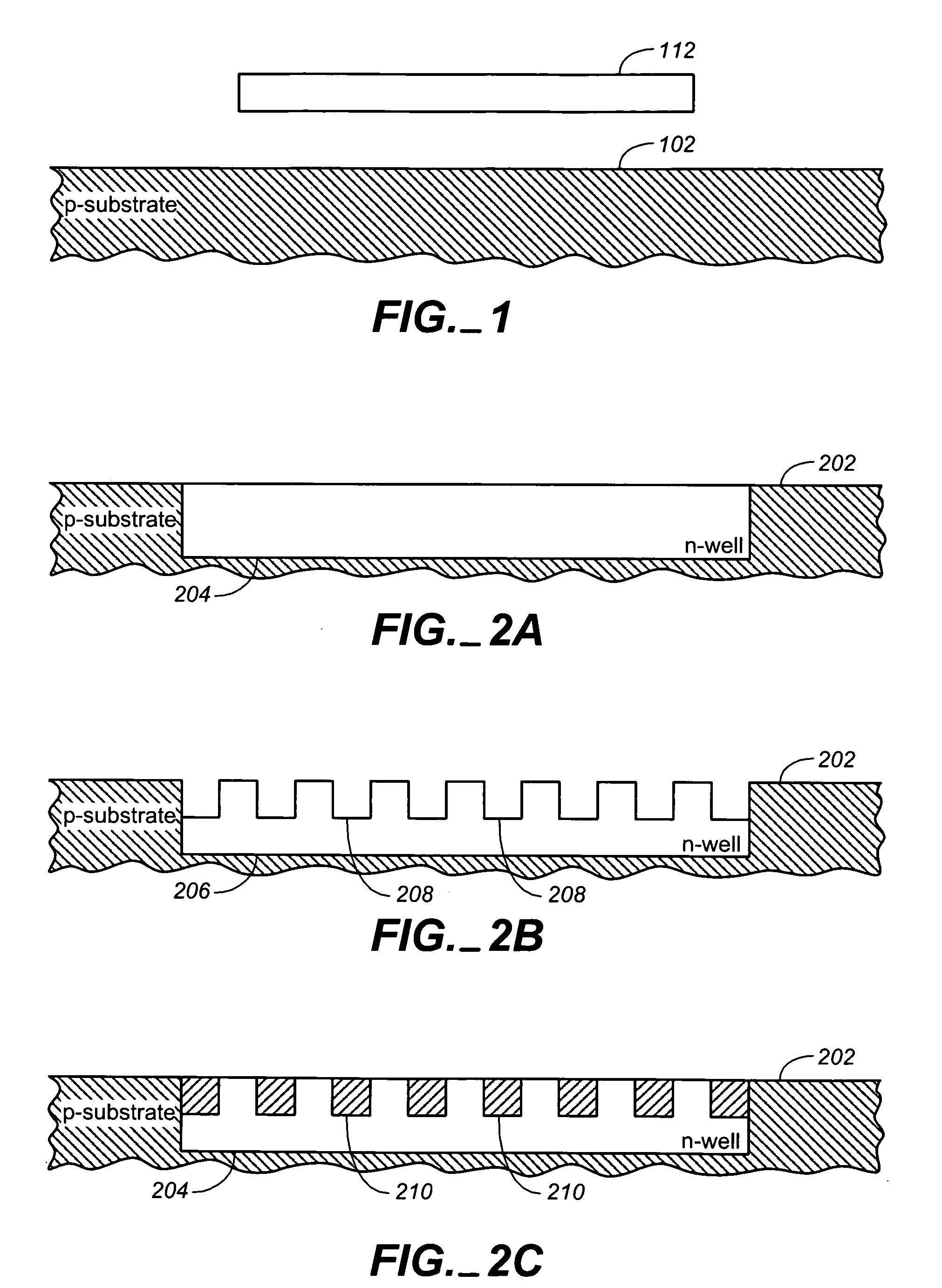

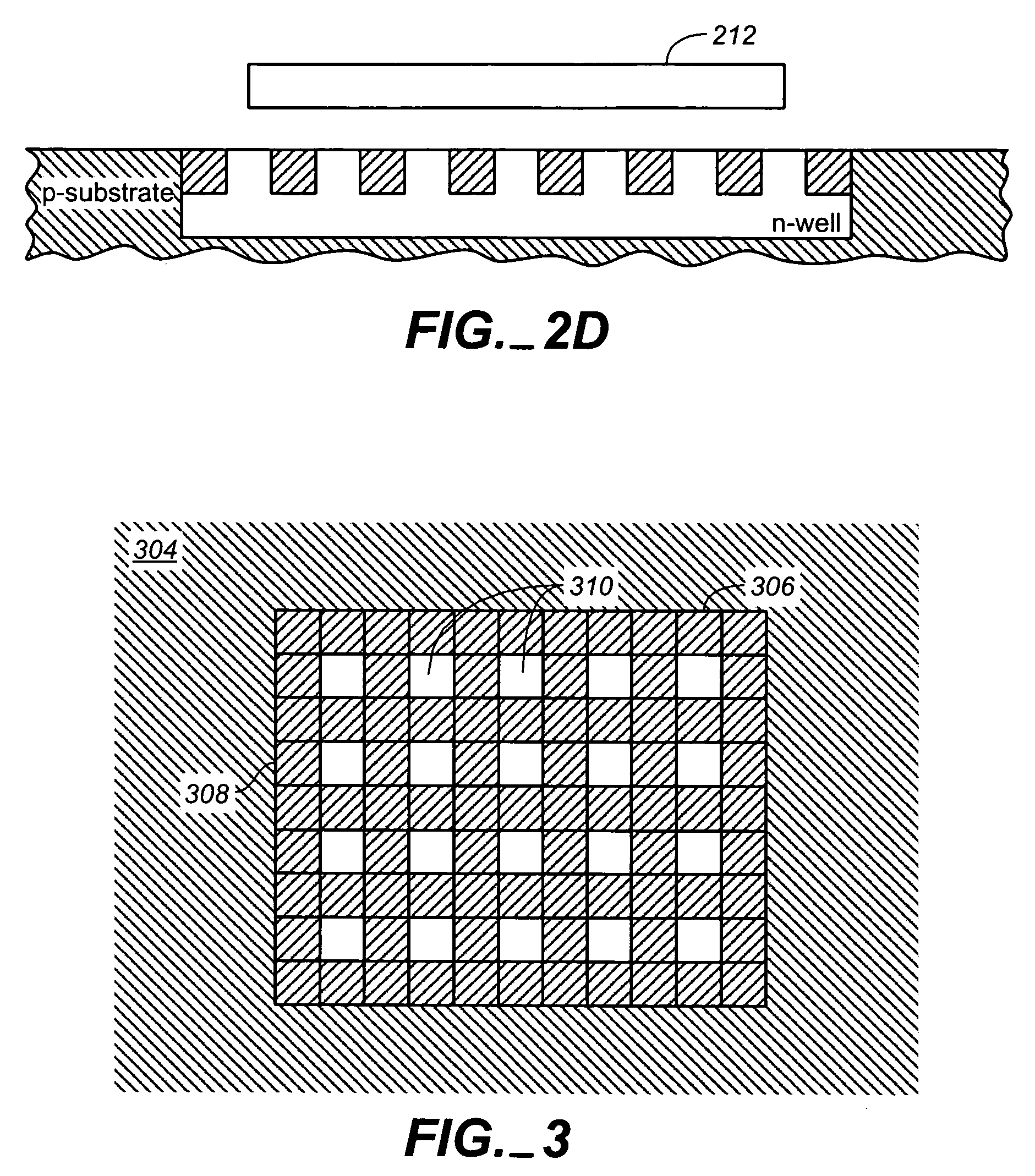

Technique and methodology to passivate inductively coupled surface currents

ActiveUS20060128112A1Reduce parasitic capacitanceReduces substrate noiseSolid-state devicesSemiconductor/solid-state device manufacturingDielectricParasitic capacitance

A deep n-well is formed beneath the area of an inductor coil. The use of a deep n-well lessens the parasitic capacitance by placing a diode in series with the interlayer dielectric cap. The deep n-well also reduces substrate noise. Once the n-well is implanted and annealed, a cross hatch of shallow trench isolation is patterned over the n-well. The shallow trench isolation reduces and confines the inductively coupled surface currents to small areas that are then isolated from the rest of the chip.

Owner:BELL SEMICON LLC

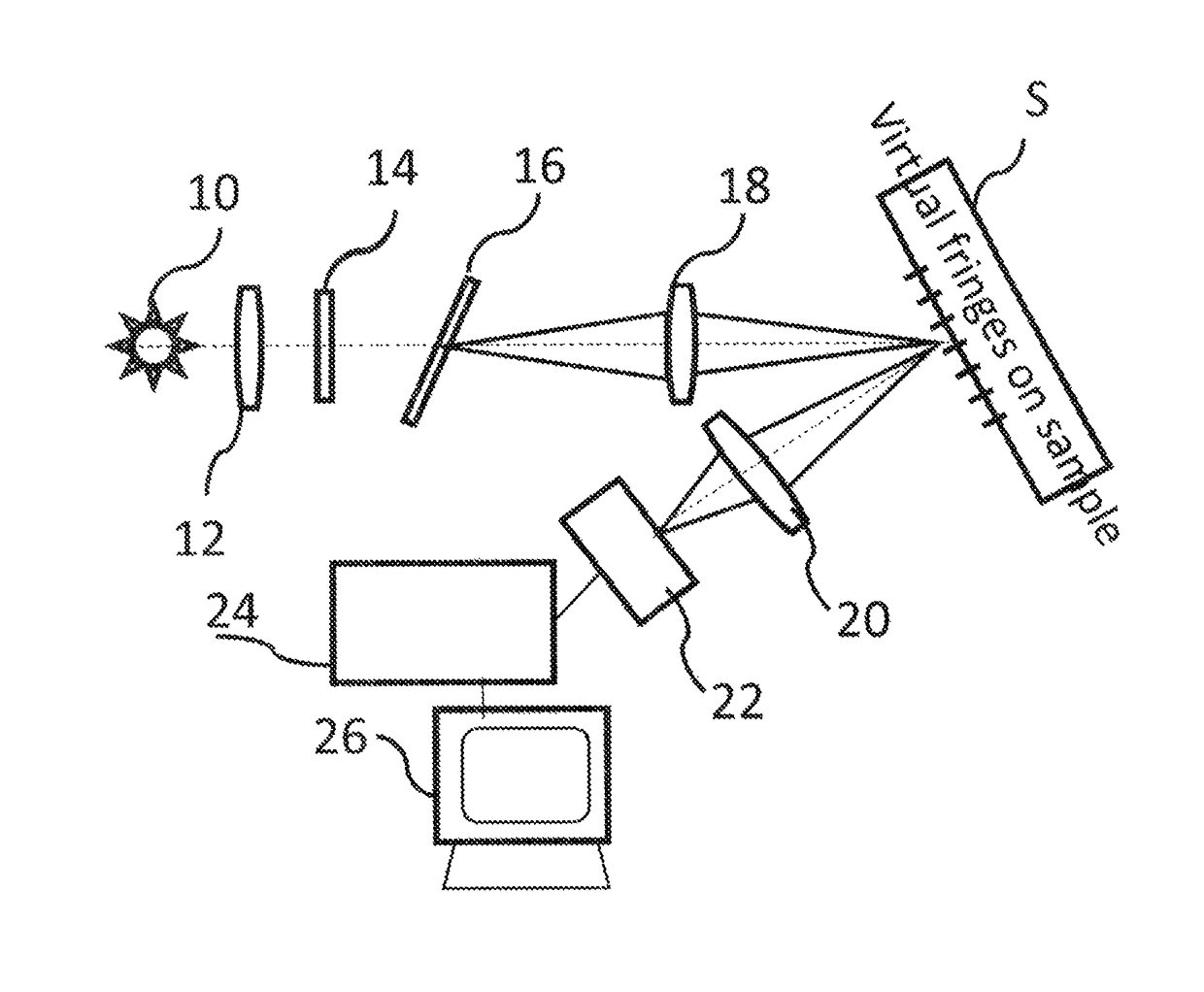

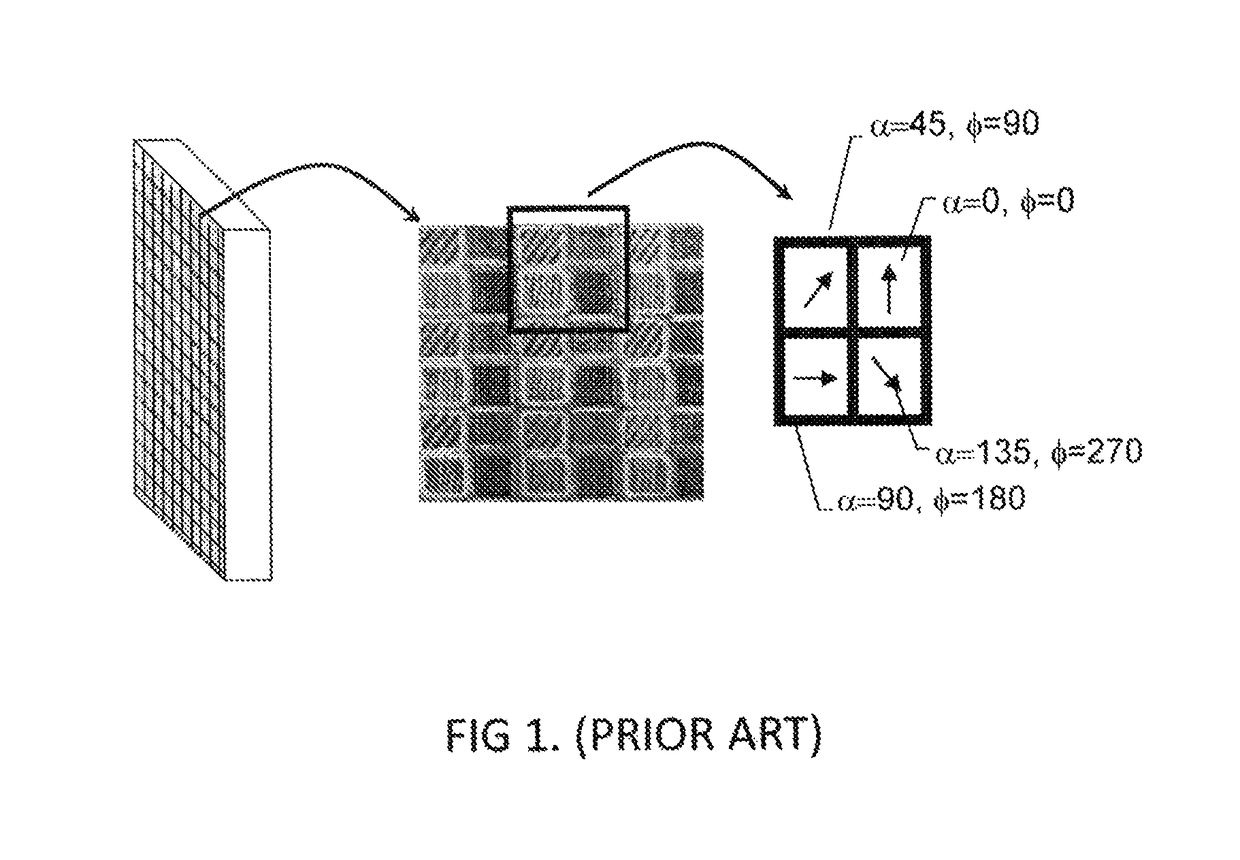

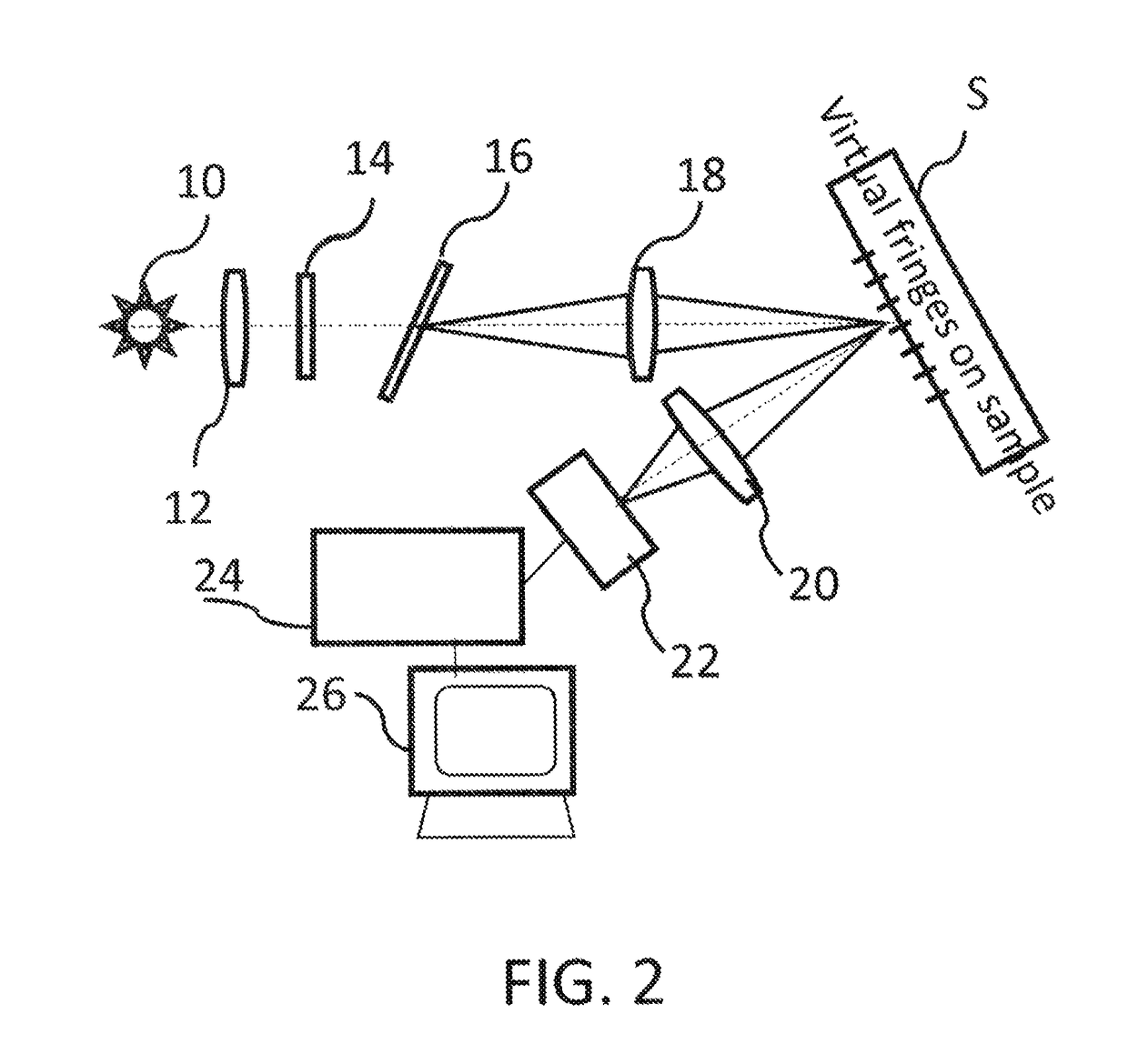

Single snap-shot fringe projection system

ActiveUS9958251B1Negates vibration-immune natureReduce noiseInterferometersUsing optical meansMeasurement testCross hatch

A cycloidal diffraction waveplate is combined with a pixelated phase mask (PPM) sensor in a dynamic fringe-projection interferometer to obtain phase-shifted interferograms in a single snap-shot camera operation that provides the phase information required to measure test surfaces with micrometer precision. Such mode of operation enables a portable embodiment for use in environments subject to vibration. A shifting mechanism coupled to the cycloidal waveplate allows temporal out-of-phase measurements used to remove noise due to test-surface characteristics. Two or more pixels of each unit cell of the PPM are combined to create super-pixels where the sum of the phases of the pixels is a multiple of 180 degrees, so that fringes are eliminated to facilitate operator focusing. By assigning colors or cross-hatch patterns to different ranges of modulation measured at the detector, the areas of best focus within the field of view are identified quantitatively to ensure measurements under best-focus conditions.

Owner:ONTO INNOVATION INC

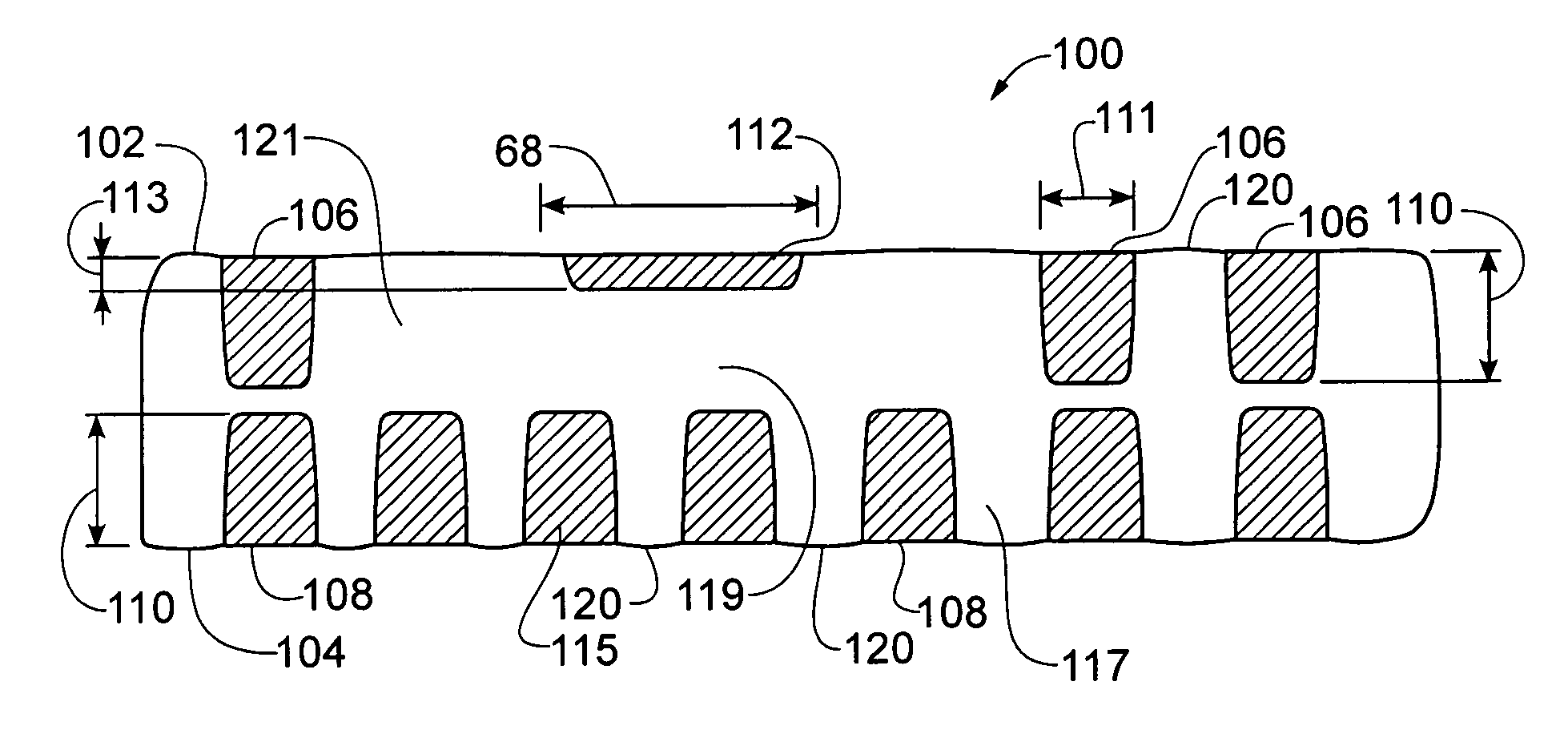

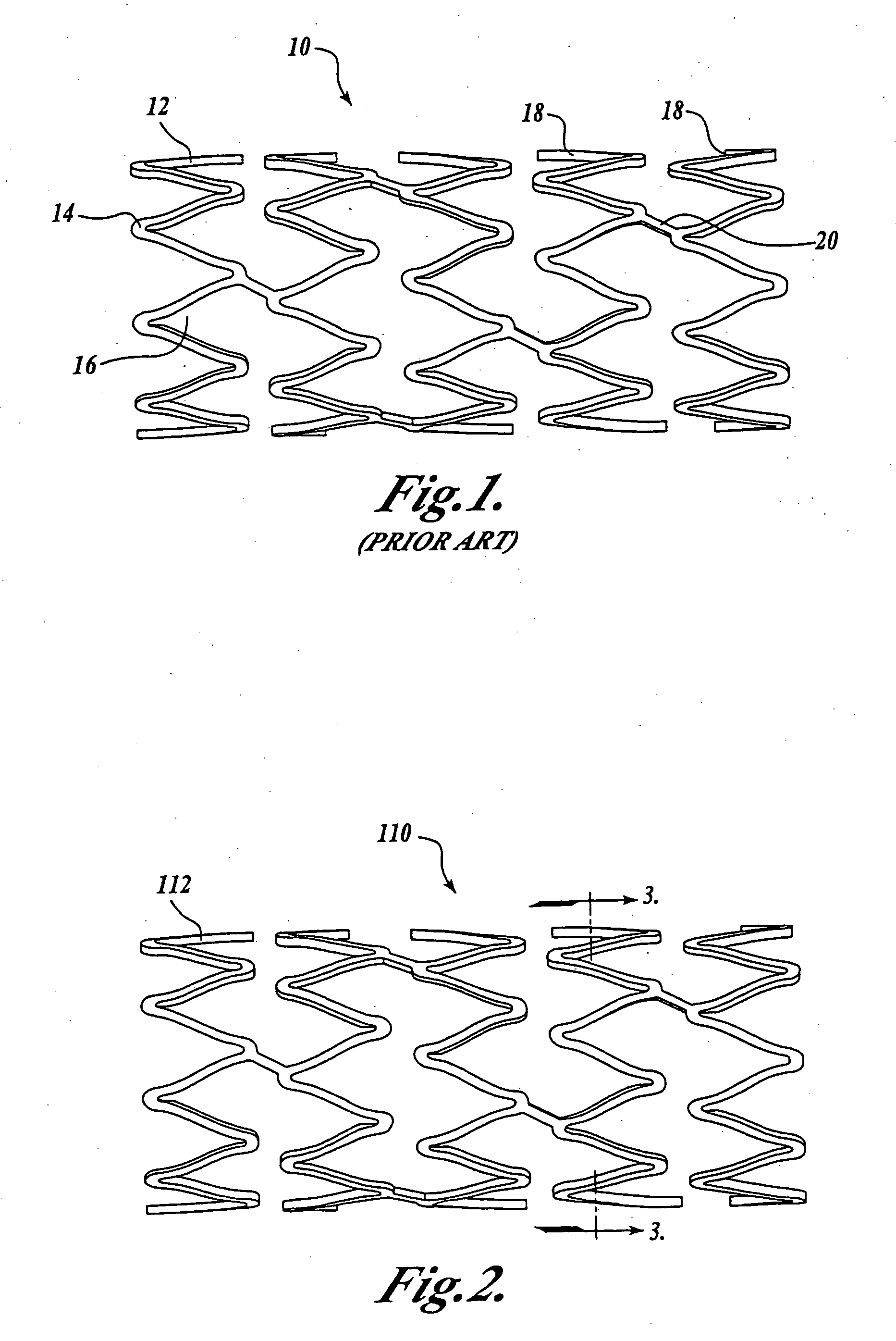

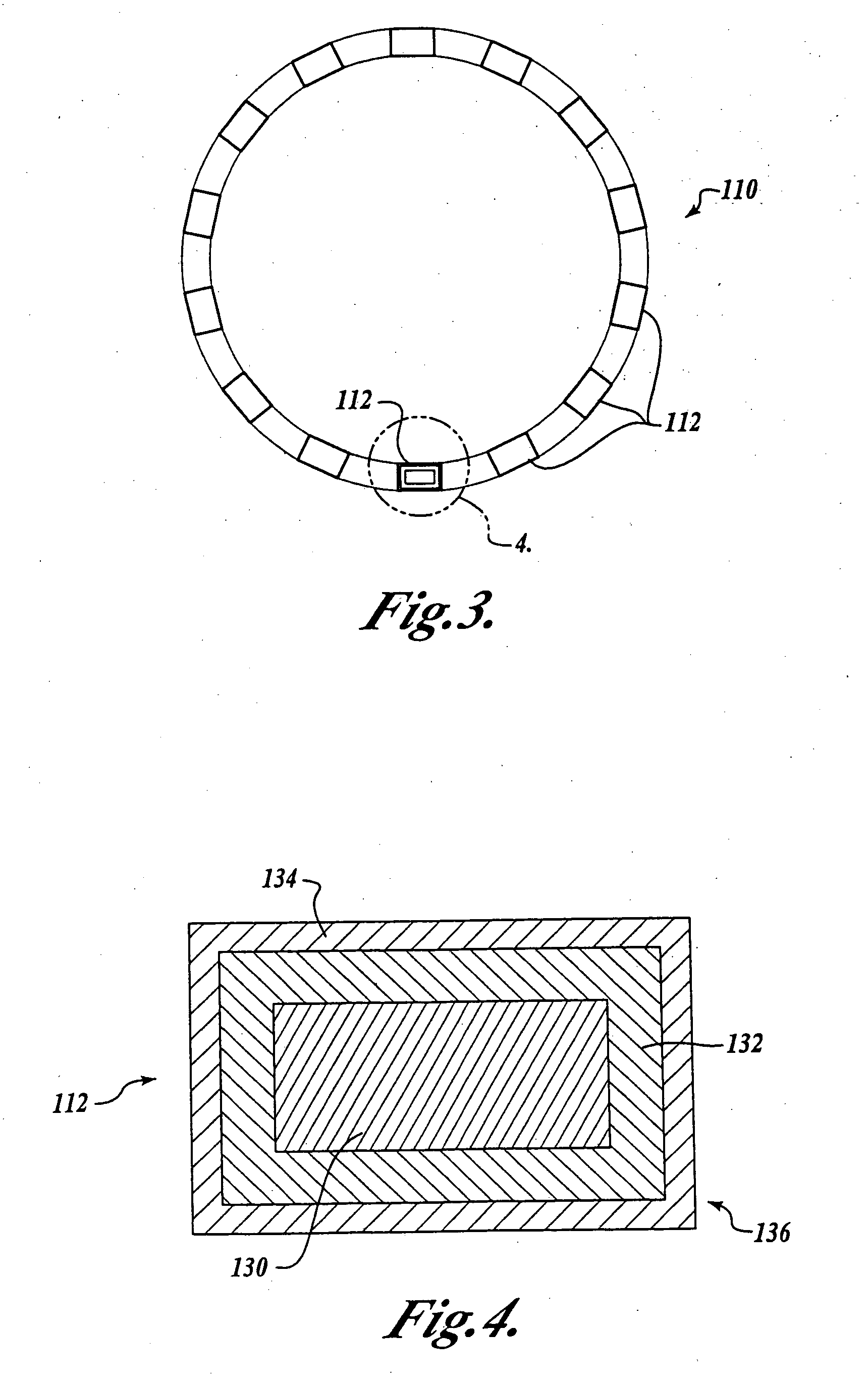

Medical device having radio-opacification and barrier layers

A medical device such as a coronary stent is provided that can be visualized in-vivo while further aiding in the prevention of restenosis. The medical device comprises a core having a first layer disposed thereon. The first layer is made from a material that is radio-opaque so that the medical device may be visualized in-vivo. An outer layer is disposed onto and surrounds at least a portion of the first layer to provide a barrier layer between the radio-opaque inner layer and blood and / or tissue disposed within the patient's vessel. The outer surface of the outer layer may include a textured surface of micro-pores, grooves, cross-hatched lines to receive a therapeutic agent. Drugs and treatments which utilize anti-thombogenic agents, and anti-proliferation agents may be readily deployed from the textured outer surface of the outer layer of the medical device.

Owner:BOSTON SCI SCIMED INC

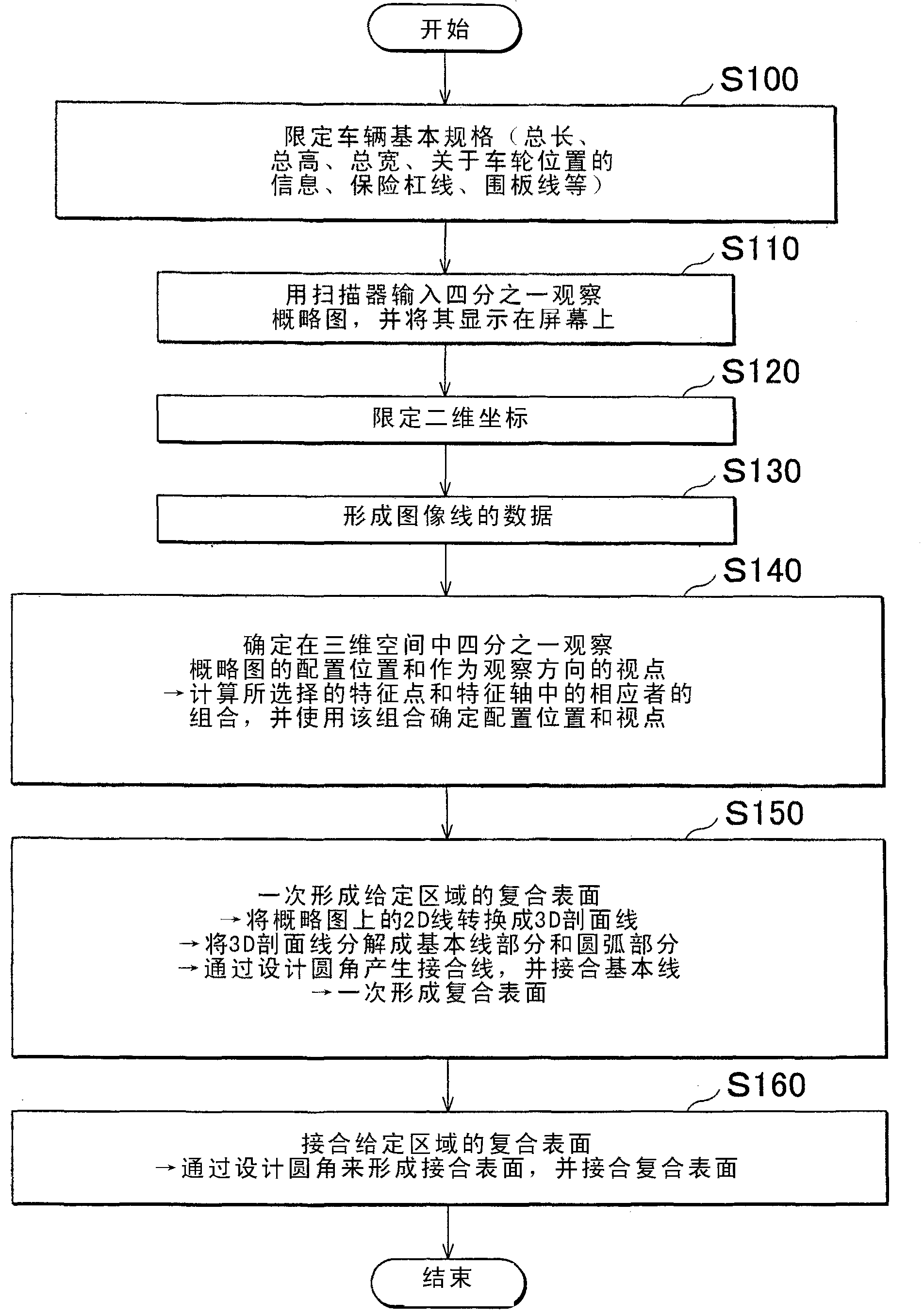

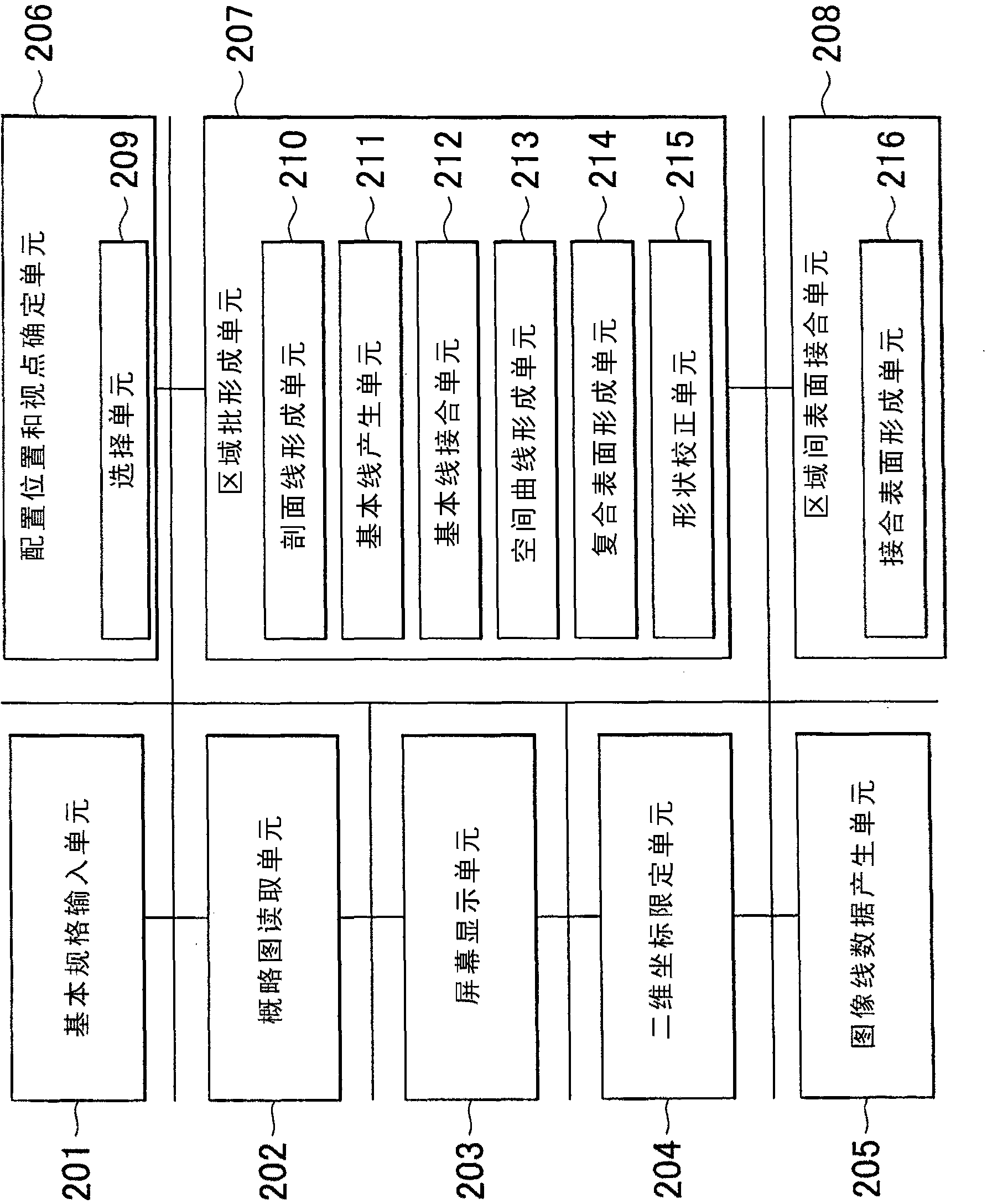

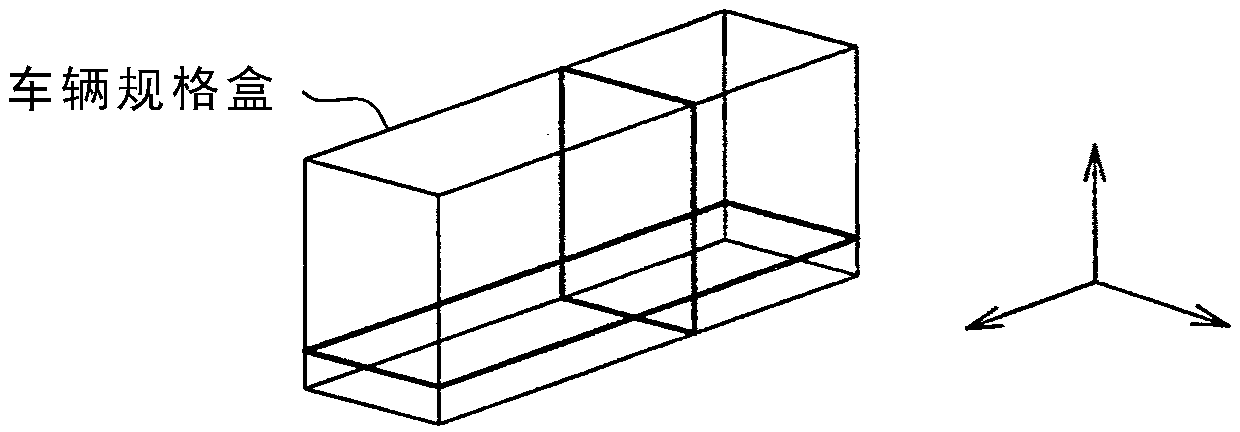

Method for creating three-dimensional shape data, apparatus for creating three-dimensional shape data, and computer-readable storage medium

InactiveCN102985950AImprove qualityReliable determinationGeometric image transformation3D-image renderingComputer graphics (images)Algorithm

A three-dimensional shape data creating method associates characteristic points and characteristic axes on an image of a sketch drawn by a designer, or the like, with given points and given axes in a vehicle specs box, and determines the placement position and viewpoint direction of the sketch in a three-dimensional space by selecting combinations (point and point, axis and axis, and point and axis) having the minimum error in correspondence (step S140). Then, complex surfaces of given regions depicted in the sketch are created at a time in the three-dimensional space, by forming each cross-section line in a given region depicted in the sketch from a basic line and a fillet joint line (step S150), and a fillet joint surface is created between adjacent ones of the created complex surfaces of the given regions so as to join the complex surfaces (step S160).

Owner:TOYOTA JIDOSHA KK

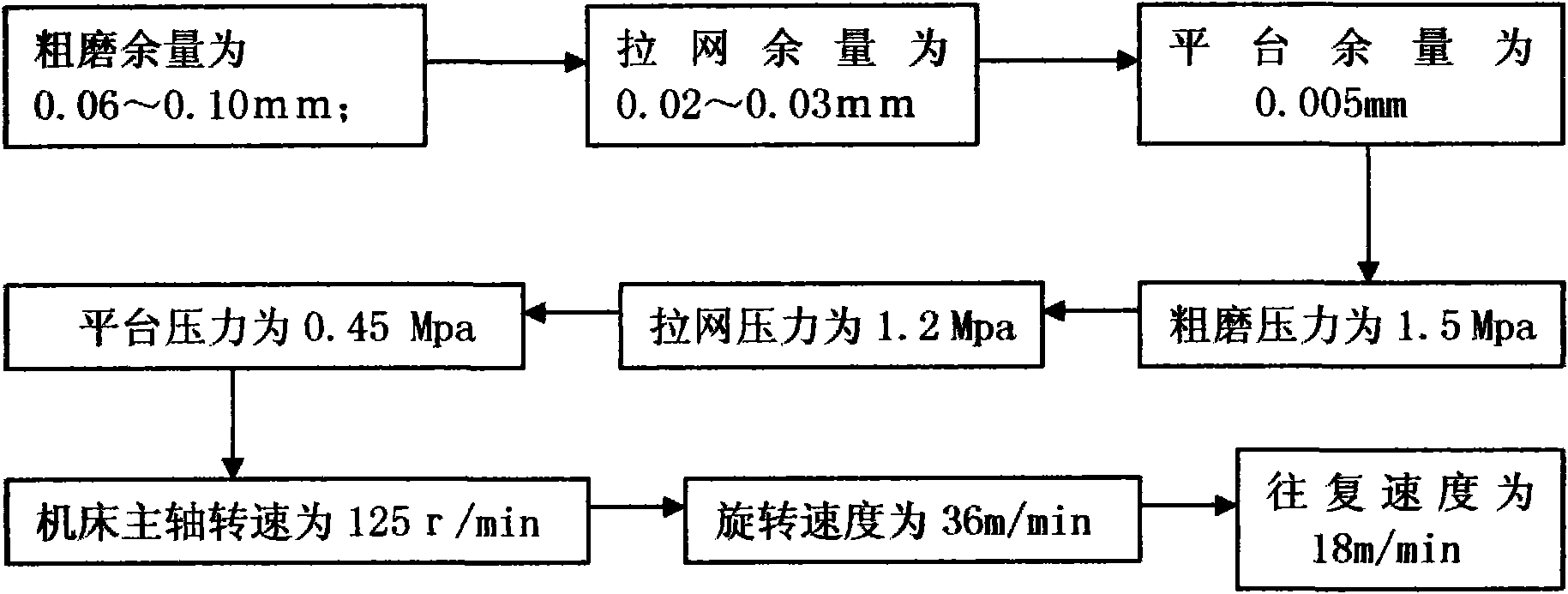

Three-dimensional detection method of plateau honing cross hatches in inner hole of cylinder liner

The invention relates to a three-dimensional detection method of plateau honing cross hatches in inner hole of a cylinder liner. Developing image analysis, feature recognition and digital processing technology lay good foundation for the development of surface roughness measurement and provide capacity of surface three-dimensional analysis. The method is characterized in that: three-dimensional parameters are acquired from regional surface rather than from profile track; statistic information exacted by three-dimensional analysis has high robustness and reliability; the advantages of excellentstatistic property, small error; and the like are achieved, and parameter values can reflect a real surface state.

Owner:韦星野

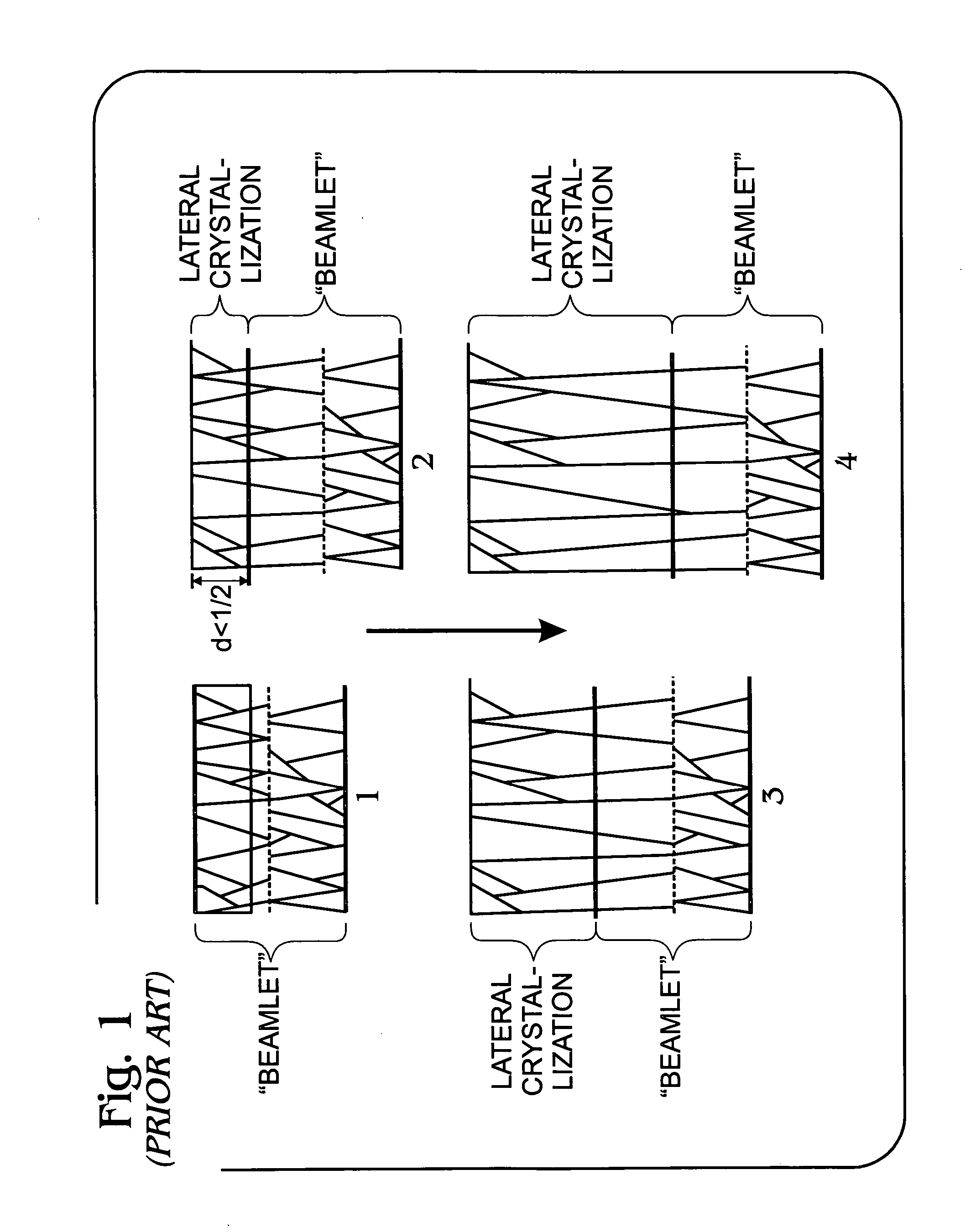

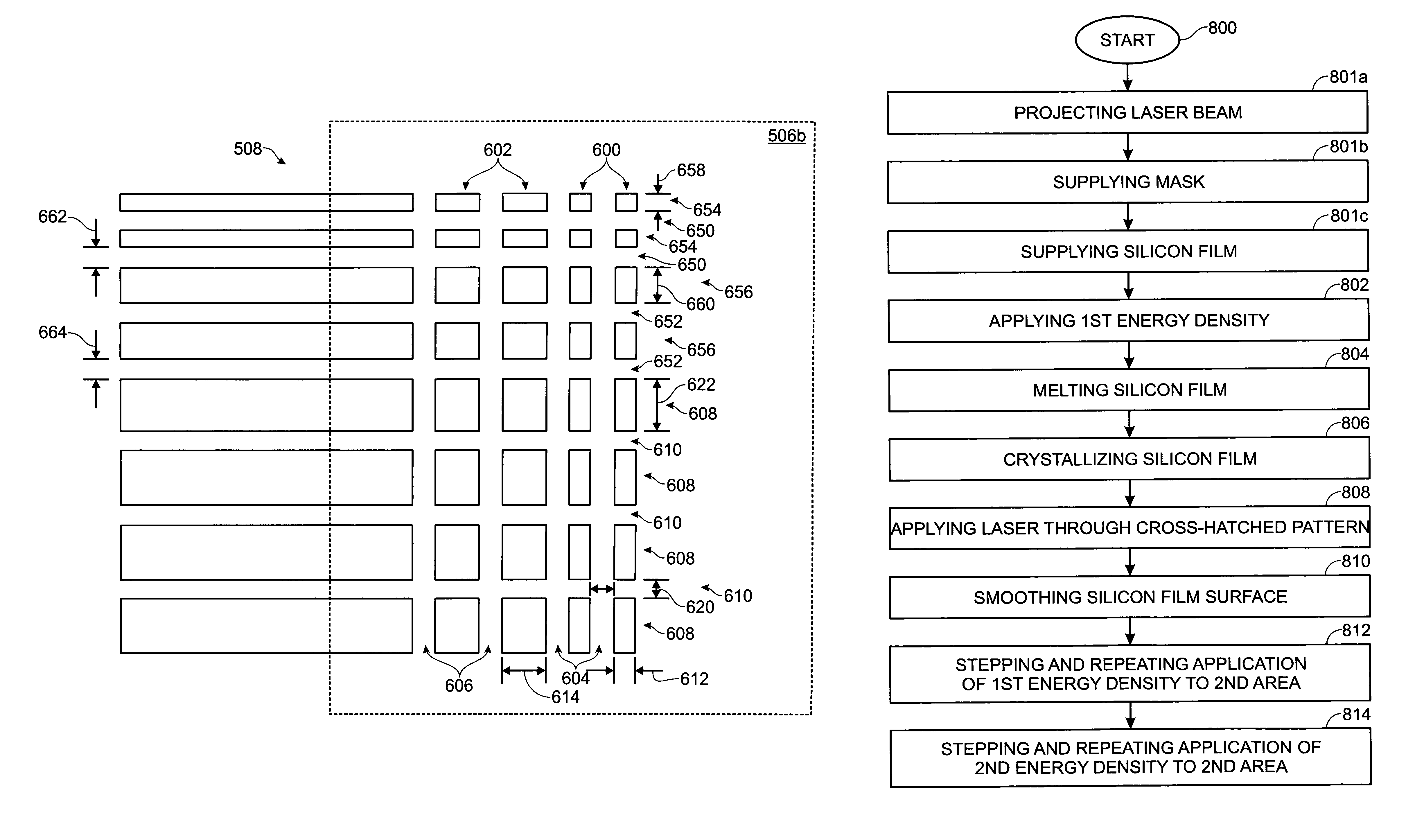

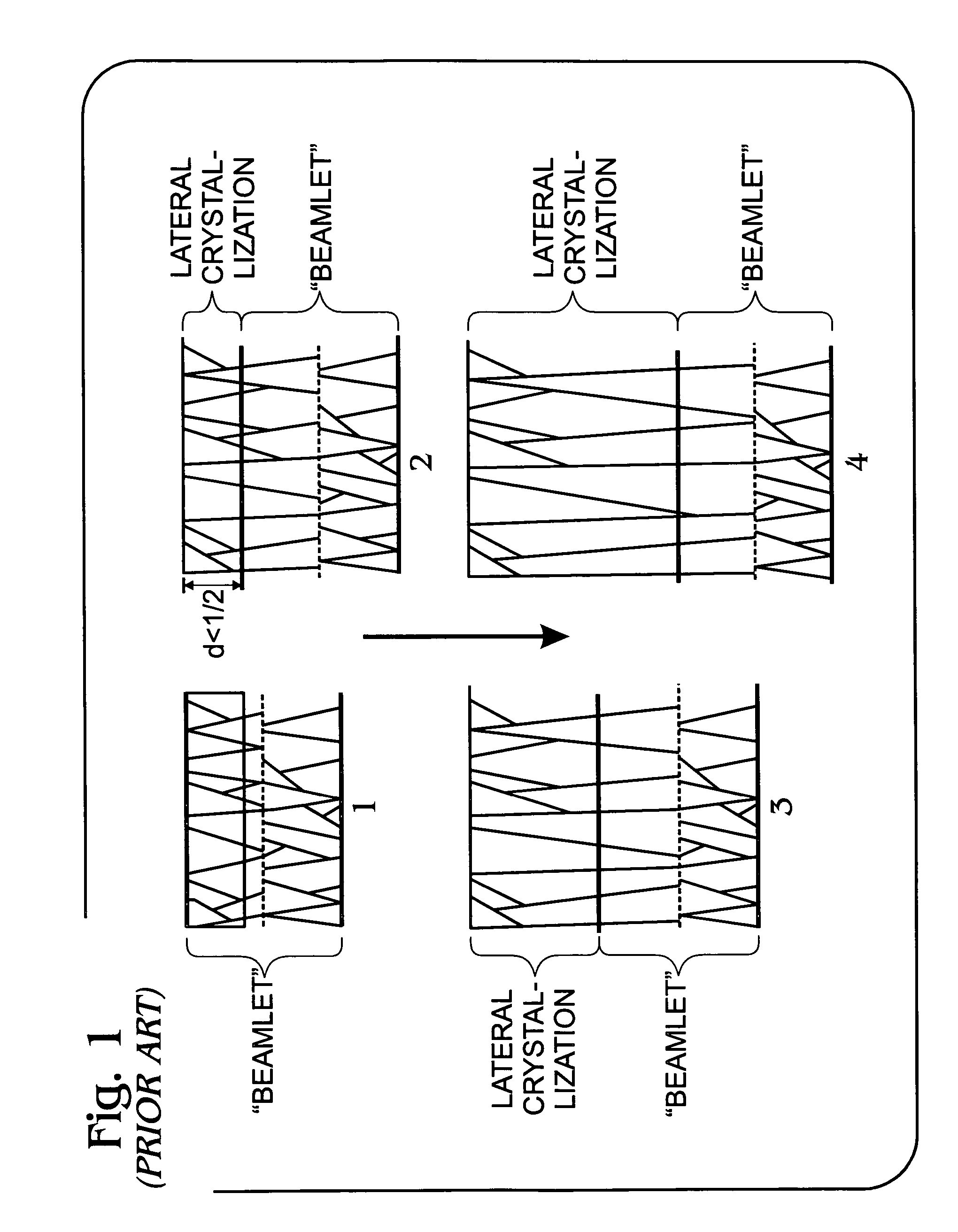

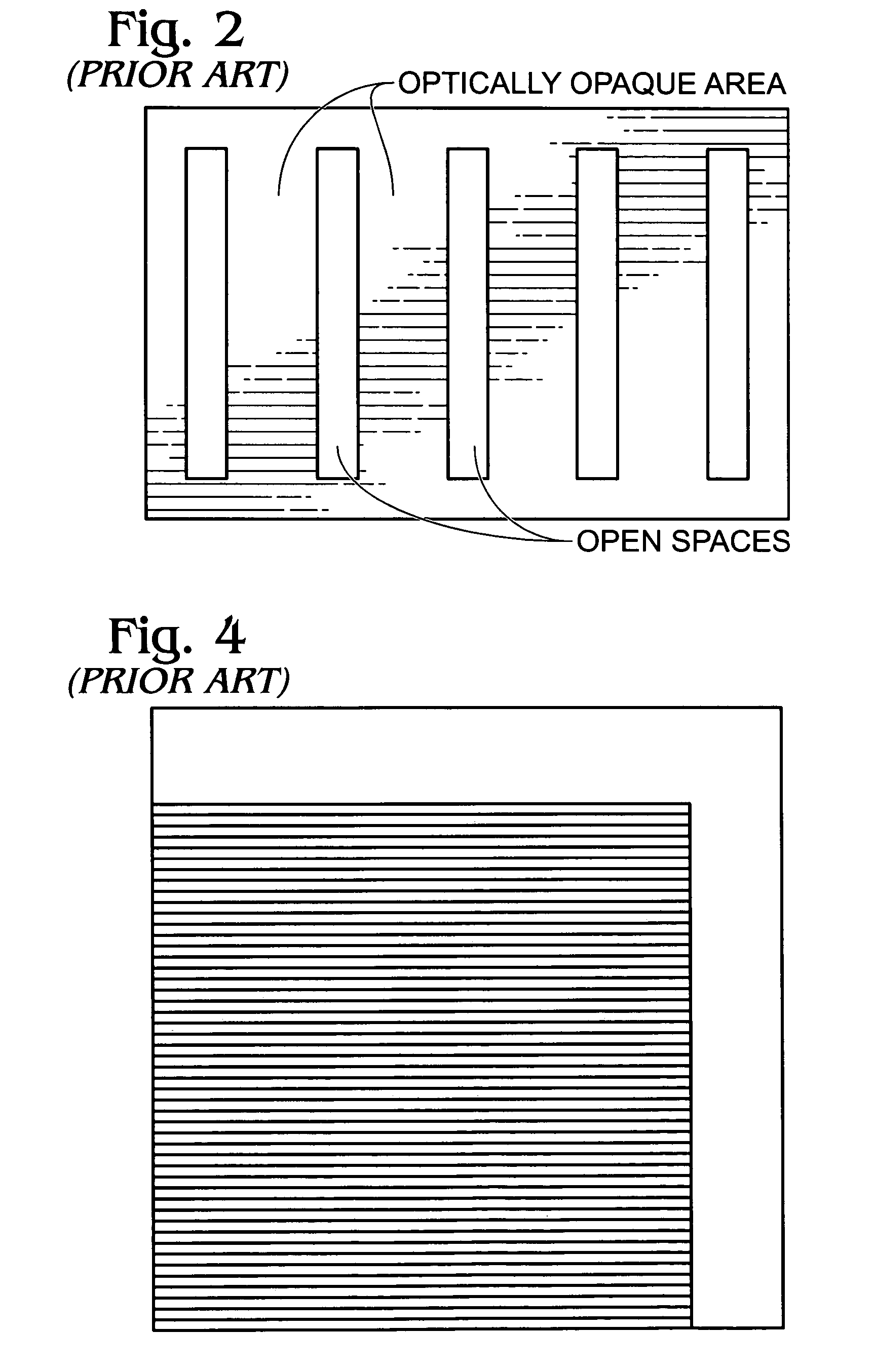

Method for optimized laser annealing smoothing

InactiveUS20050009352A1Reduce mask edge diffraction patternDiffraction reductionSemiconductor/solid-state device manufacturingLaser beam welding apparatusVertical edgeLight energy

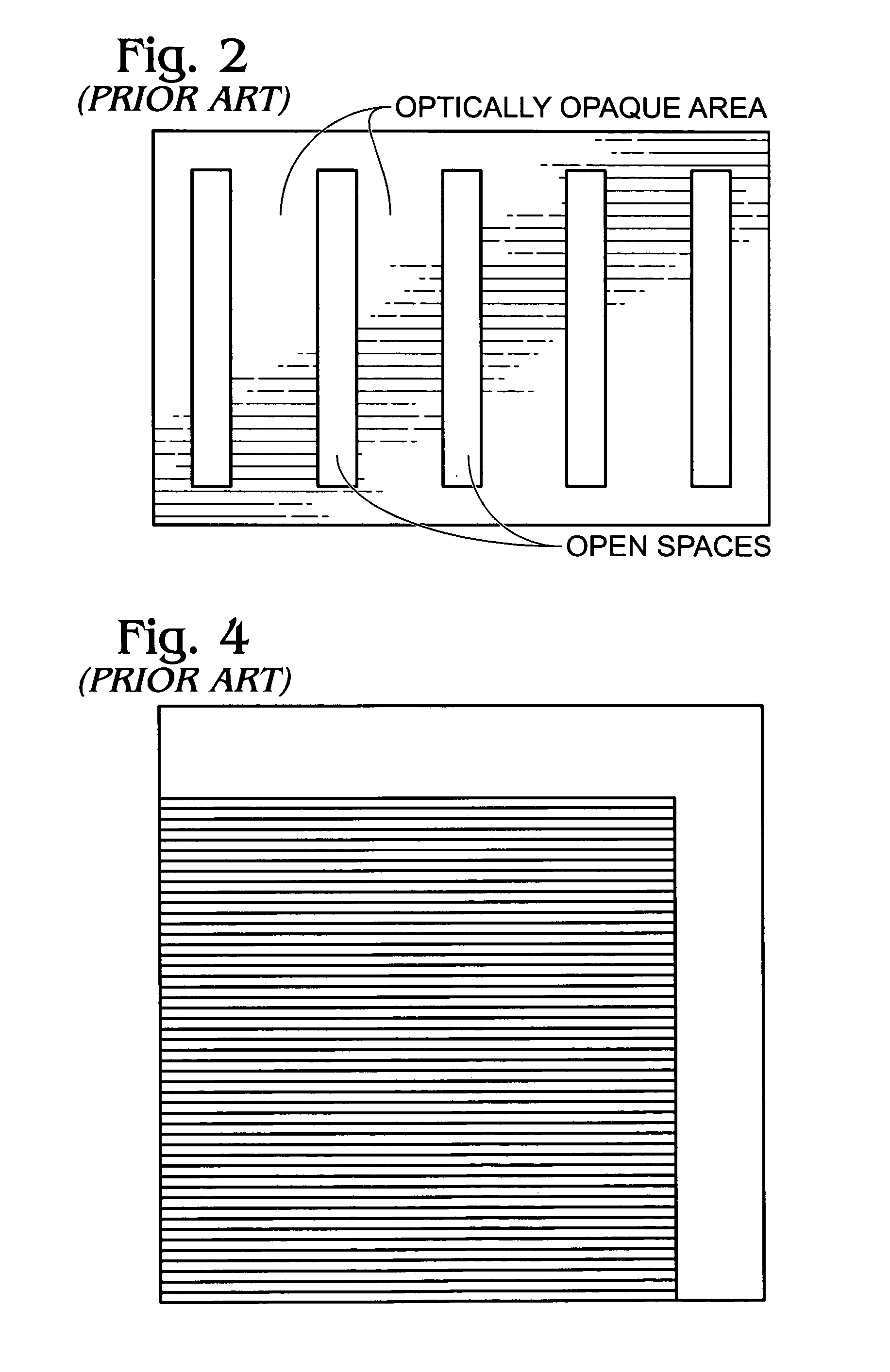

A laser annealing mask is provided with cross-hatched sub-resolution aperture patterns. The mask comprises a first section with aperture patterns for transmitting approximately 100% of incident light, and at least one section with cross-hatched sub-resolution aperture patterns for diffracting incident light. In one aspect, a second mask section with cross-hatched sub-resolution aperture patterns has an area adjacent a vertical edge and a third mask section with cross-hatched sub-resolution aperture patterns adjacent the opposite vertical edge, with the first mask section being located between the second and third mask sections. The section with cross-hatched sub-resolution aperture patterns transmits approximately 40% to 70%, and preferably 50% to 60% of incident light energy density. In some aspects, the section with cross-hatched sub-resolution aperture patterns includes a plurality of different cross-hatched aperture patterns. The cross-hatched sub-resolution aperture patterns can be defined by horizontal gap and slits, as well as vertical gap and slits.

Owner:SHARP KK

Fan with reduced noise generation

InactiveUS20050147496A1Emission reductionReduce noiseRotary propellersPump componentsNoise generationAcoustic emission

Axial flow fan propellers are provided with a roughened portion along the trailing edge of the fan blades on the pressure side of the blade to minimize tonal acoustic emissions generated by laminar boundary layer vortex shedding. The roughened portion may be provided by trip surfaces formed in the blades, by strips of abrasive material adhered to the blades along the trailing edges, respectively, by parallel or cross-hatched serrations in the blades or by upturned or offset trailing edges of the blades. The height of the roughened portion should be about equal to the boundary layer thickness of air flowing over the blade surfaces during operation of the fan. The fan propellers are particularly advantageous in heat exchanger applications, such as residential air conditioning system condenser units.

Owner:LENNOX IND

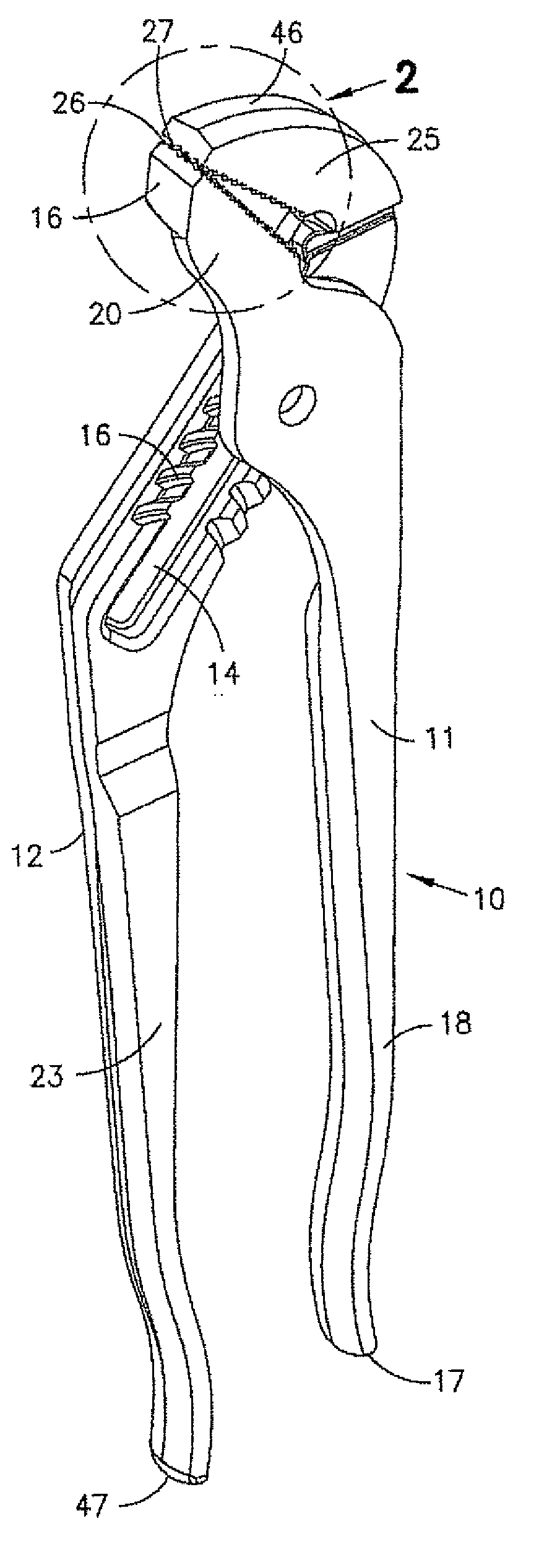

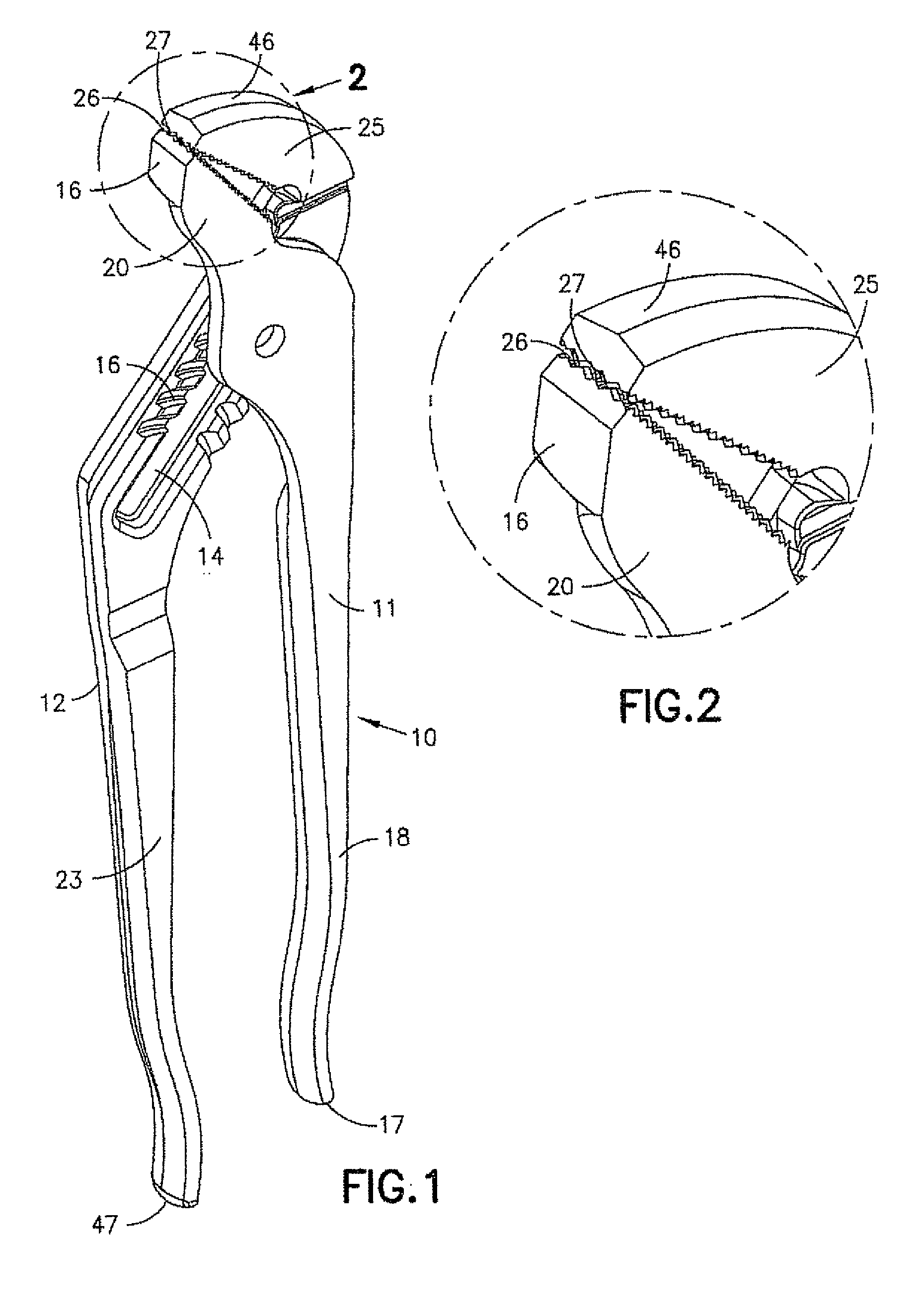

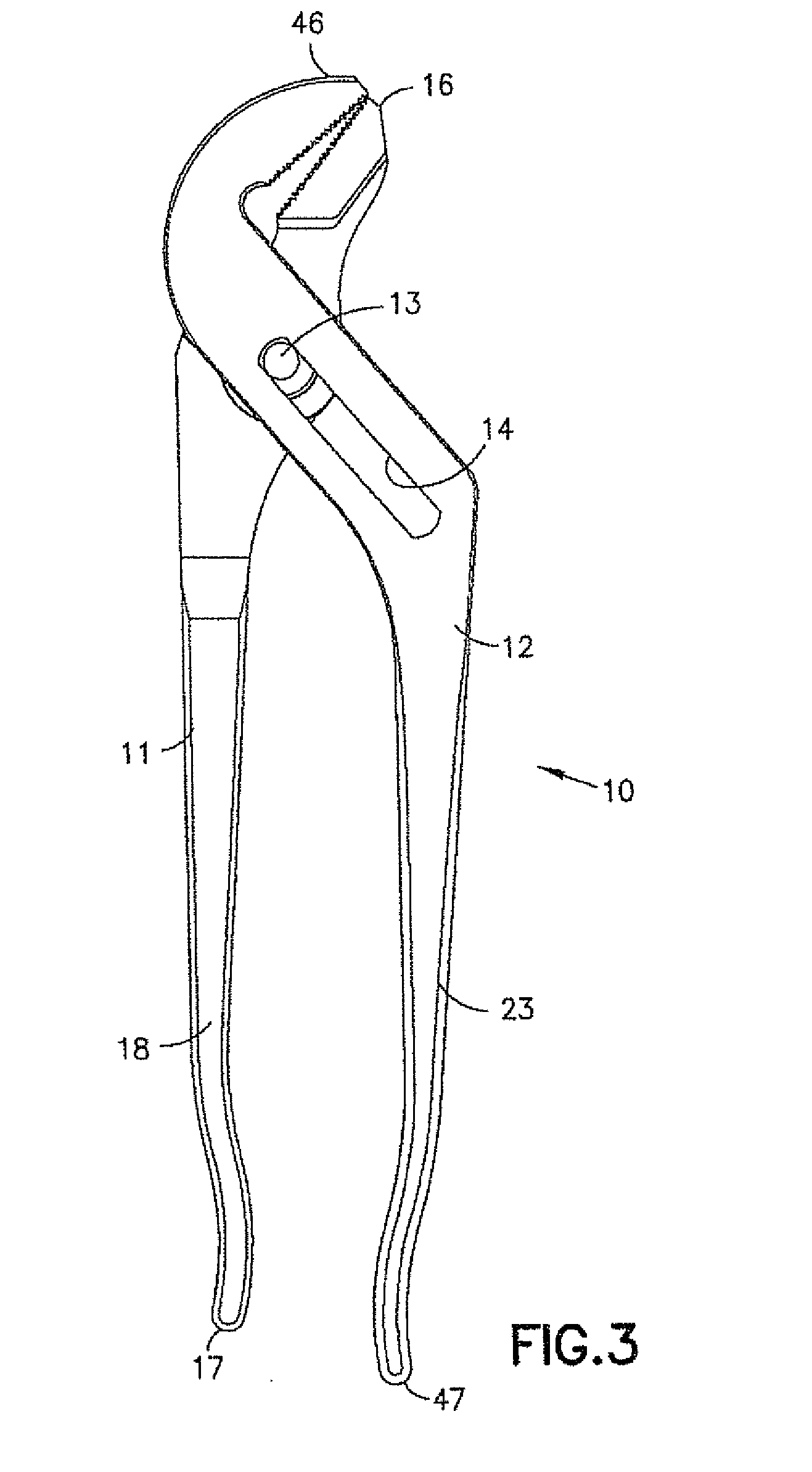

Torque grip slip force pliers

A slip-joint pliers having opposed parallel jaws with a specific cross-hatch pyramidal teeth construction develops a high torque grip slip force on a seized or overly tightened cylindrical workpiece such as a pipe or bar. The pliers includes a tongue in groove type slip-joint construction. The cross-hatch teeth are disposed at between 110° and 150°, and the rows of cross-hatch teeth are spaced at less than about 10 teeth / inch on each jaw face. The pliers are a compact yet heavy-duty use tool that develops a torque grip slip force greater than similarly sized prior art pliers.

Owner:CHANNELLOCK

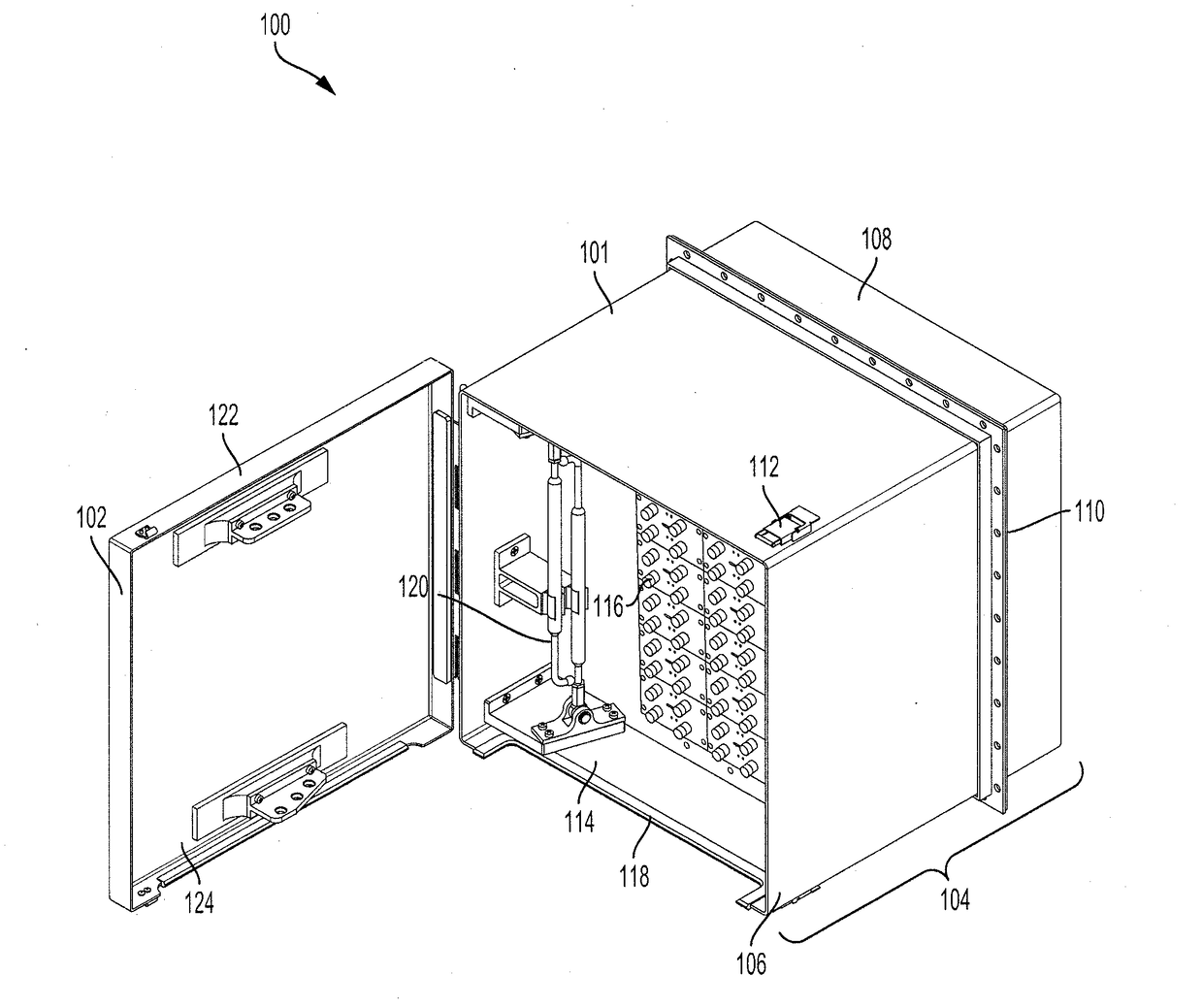

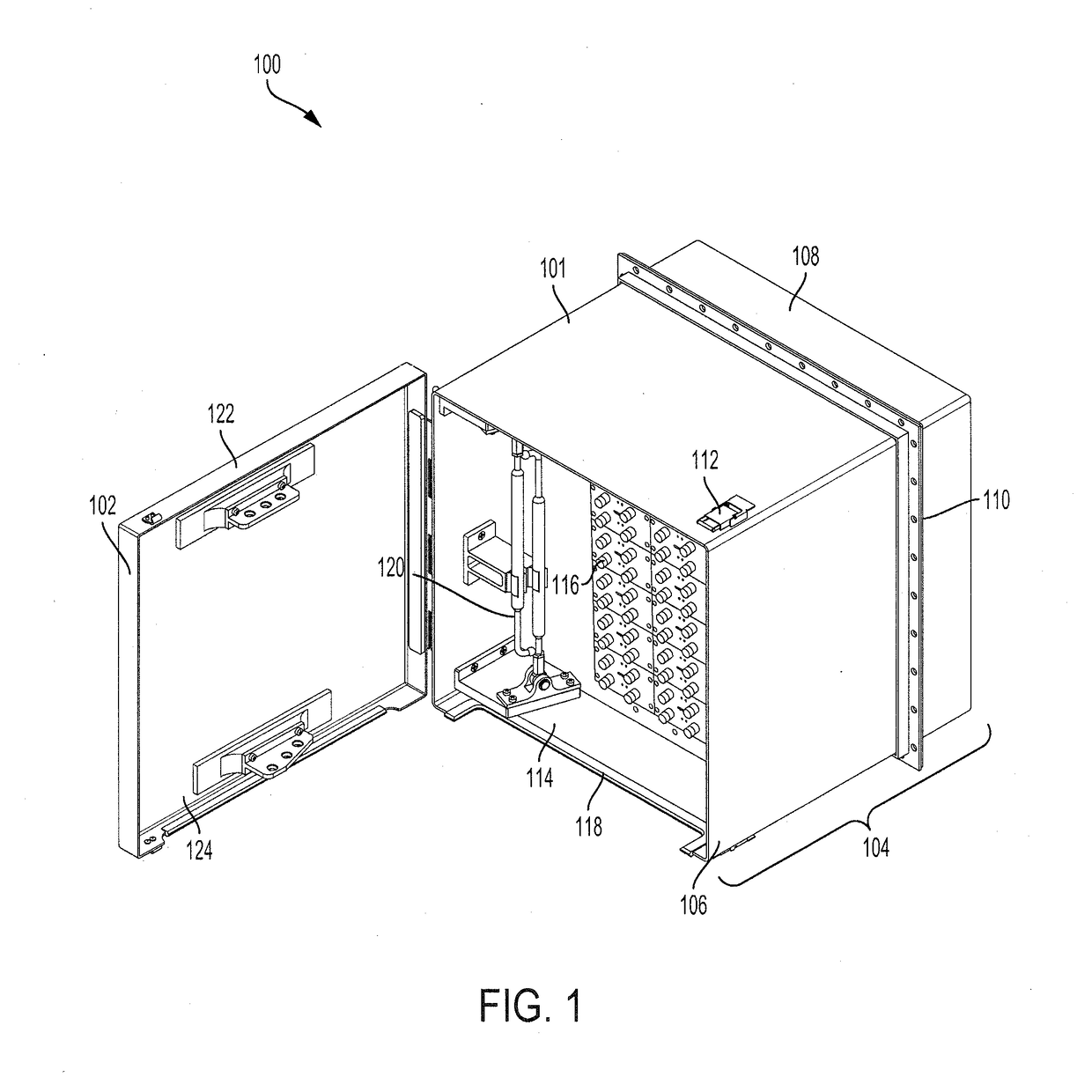

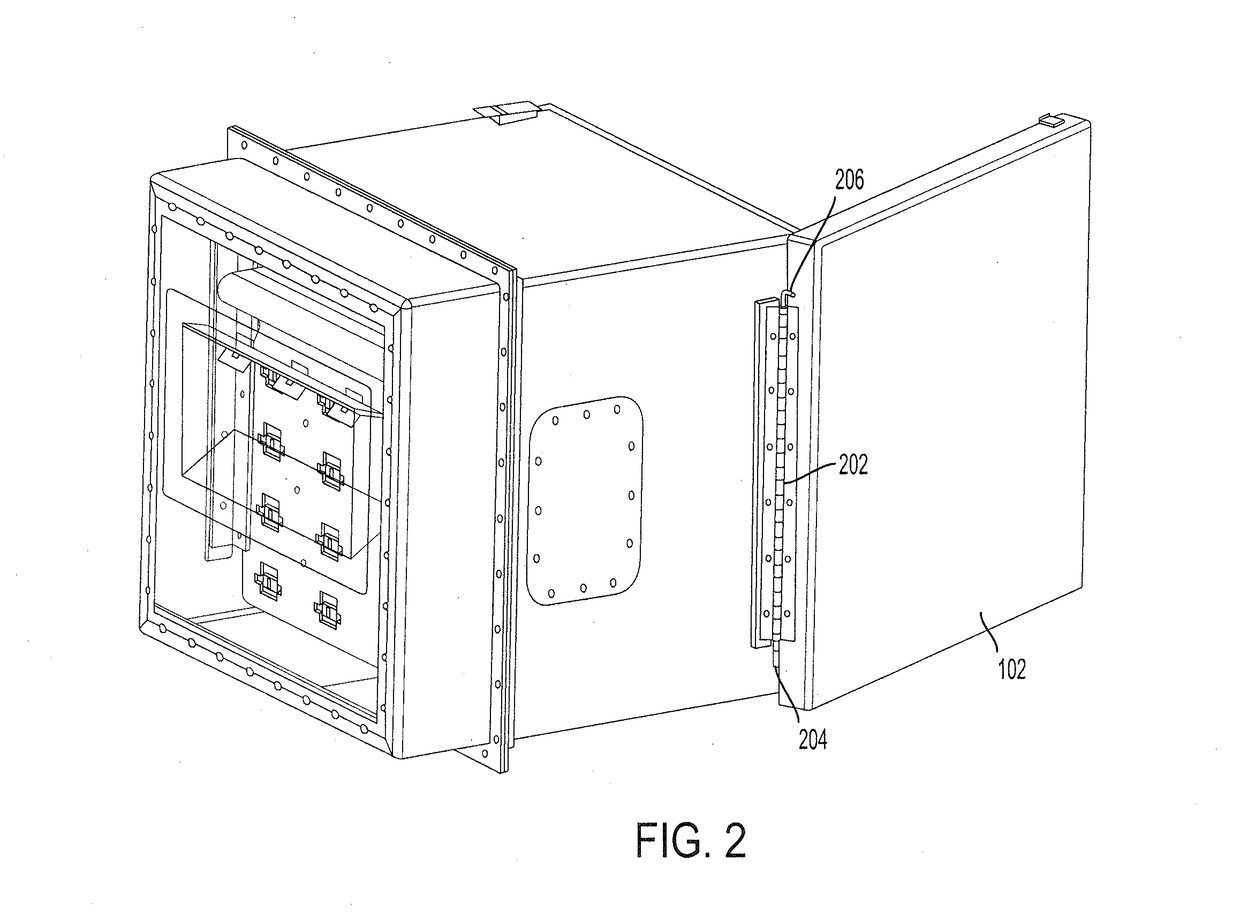

Modular protection cabinet with flexible backplane

ActiveUS20180235099A1Excellent characteristicsIncrease flexibilitySupport structure mountingElectrical apparatus casings/cabinets/drawersElectricityModularity

An enclosure for an electronic device. The enclosure has a rear base defining a cavity for holding the electronic device and having one or more input / output connectors. The enclosure has a front cover coupled to the rear base. The enclosure has a backplane within the cavity of the rear base. The backplane has a printed circuit board. The enclosure has as interconnect that electrically connects the printed circuit board with the one or more input / output connectors. The interconnect has a cross-hatched ground (or power) plane.

Owner:INFINITE ELECTRONICS INT INC

UV solidified intaglio printing decorative ink

The present invention relates to a decorative printing ink for gravure printing, its composition is formed from (wt%) 10-50% of oligomer, 10-40% of active diluent, 3-8% of photoinitiator, 0-46% of forming agent whose fineness is less than 10 micrometer, 0.01-1% of retarder and 0-5% of adjuvant. Said UV gravure printing decorative ink possesses reduced oxyinhibition and its solidifying speed is greatly raised, for example, UV light source is 80W / CMX3, at 150M / min. it can be well solidified, and can make cross-hatch with different effects, can print various patterns of imitation metal etching (corning), dioptric, buckle, ice flower and coral form, and its storage stability is good. Said ivnented product is a colorless one, the pigment or colour ink can be added, and the colour pattern can be printed.

Owner:潘治平

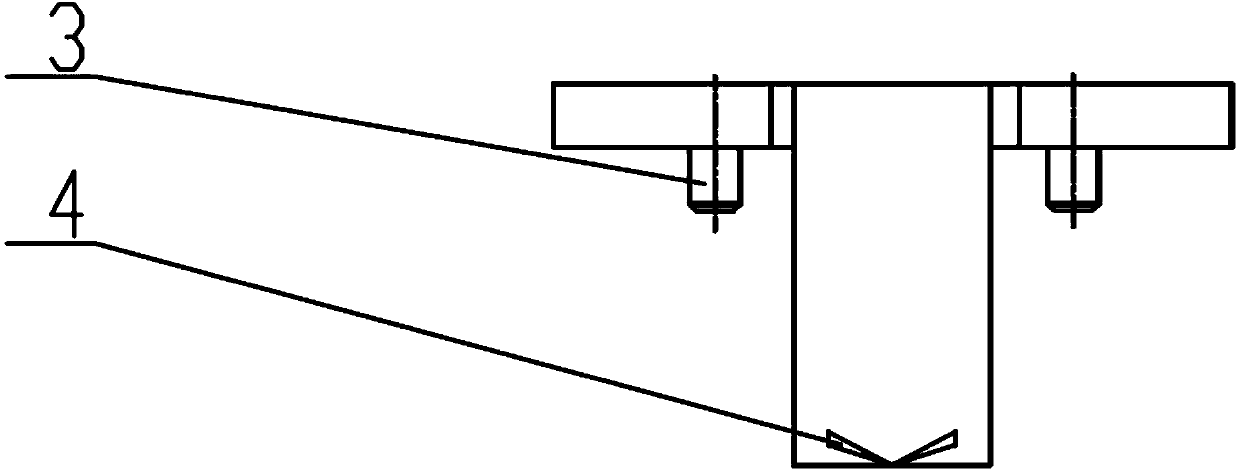

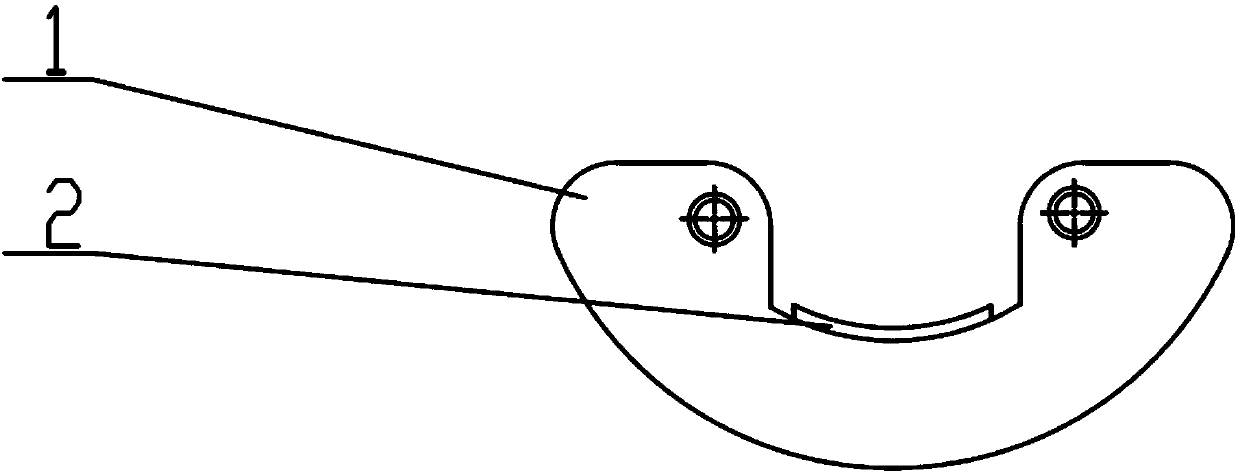

Detection device and detection method for cross-hatch angle measurement of cylinder hole of cylinder body

InactiveCN103471486AObserving overlap clearlyJudge eligibilityAngles/taper measurementsCross hatchDegrees of freedom

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Method for optimized laser annealing smoothing

InactiveUS7029961B2Diffraction reductionSemiconductor/solid-state device manufacturingLaser beam welding apparatusVertical edgeLight energy

A laser annealing mask is provided with cross-hatched sub-resolution aperture patterns. The mask comprises a first section with aperture patterns for transmitting approximately 100% of incident light, and at least one section with cross-hatched sub-resolution aperture patterns for diffracting incident light. In one aspect, a second mask section with cross-hatched sub-resolution aperture patterns has an area adjacent a vertical edge and a third mask section with cross-hatched sub-resolution aperture patterns adjacent the opposite vertical edge, with the first mask section being located between the second and third mask sections. The section with cross-hatched sub-resolution aperture patterns transmits approximately 40% to 70%, and preferably 50% to 60% of incident light energy density. In some aspects, the section with cross-hatched sub-resolution aperture patterns includes a plurality of different cross-hatched aperture patterns. The cross-hatched sub-resolution aperture patterns can be defined by horizontal gap and slits, as well as vertical gap and slits.

Owner:SHARP KK

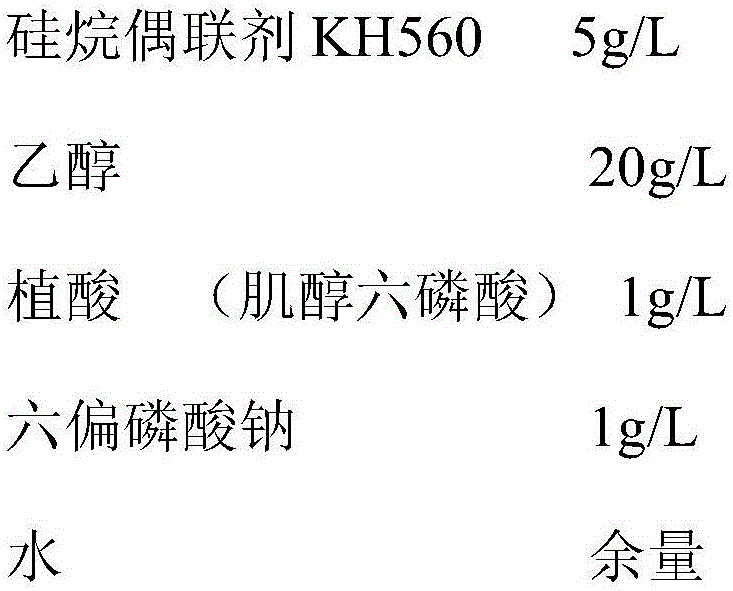

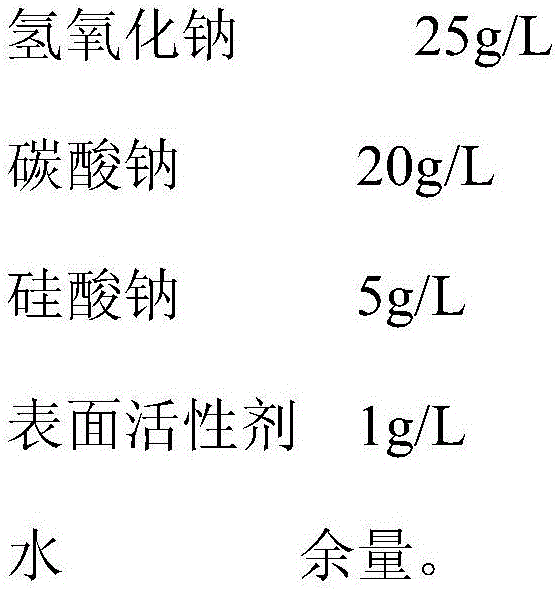

Preparation method of aluminum alloy surface silanization conversion film

A preparation method of an aluminum alloy surface silanization conversion film comprises the following steps: 1, pretreatment: grinding, carrying out alkali washing, and carrying out acid washing; and 2, coating: preparing a plating solution which comprises the following components: a silane coupling agent KH560 5 g / L, ethanol 20 g / L, phytic acid 1 g / L, sodium hexametaphosphate 1g / L and the balance of water, placing a workpiece in the plating solution after acid washing, standing for 1-3 minutes, forming a film at the room temperature, and drying for 40 minutes at the temperature of 150 DEG C to obtain the aluminum alloy surface silanization conversion film. According to the scheme, the surface of a sample does not have obvious corrosion substances after 168h neutral salt spray test; and a silanization conversion film test piece is taken, after an adhesive tape is adhered to the silanization conversion film test piece and torn from the silanization conversion film test piece by a cross-hatch method, the silanization conversion film test piece does not face, a coating does not drop, and therefore, the silanization conversion film test piece has good adhesion.

Owner:SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com