Patents

Literature

2563 results about "Joint surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

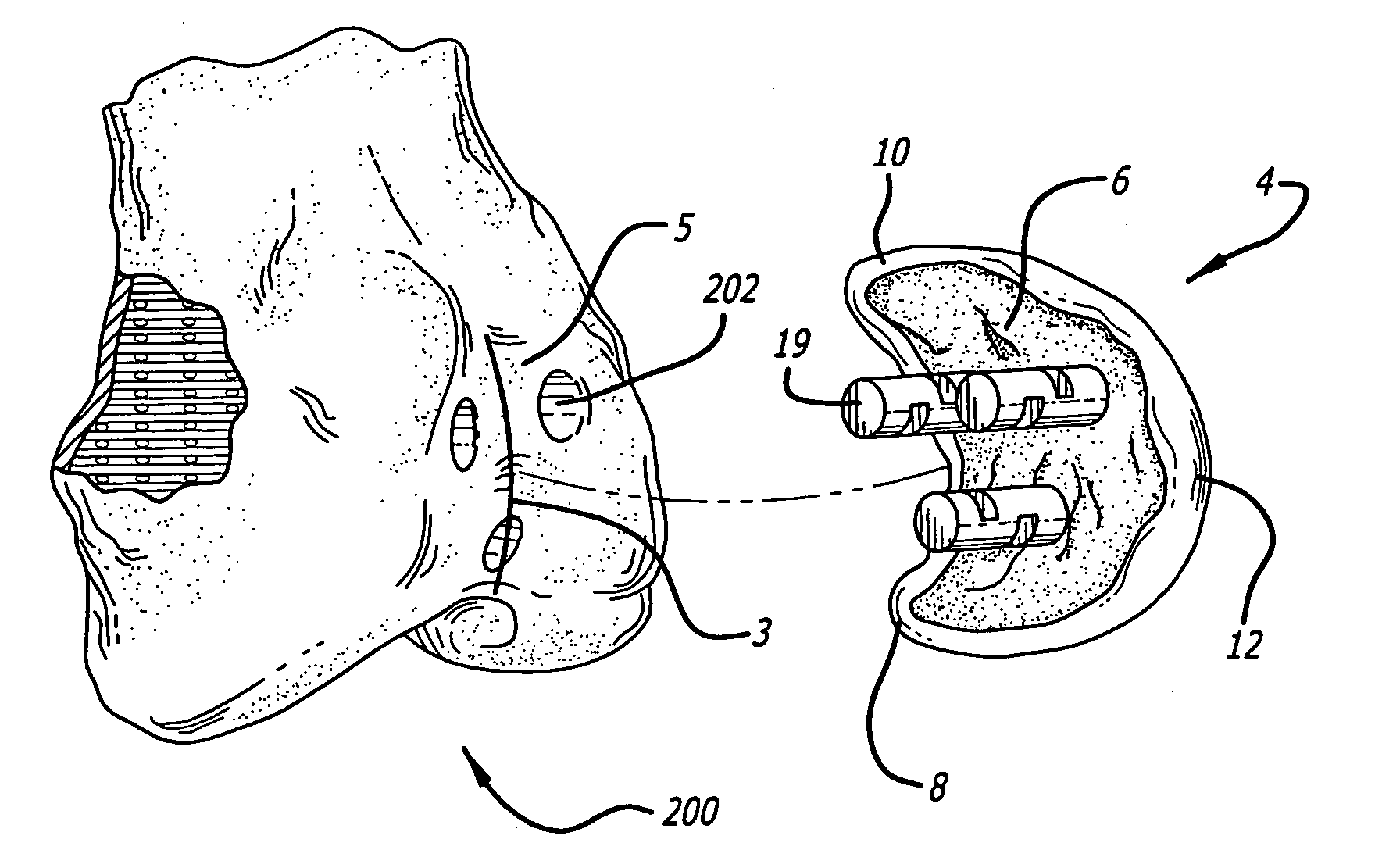

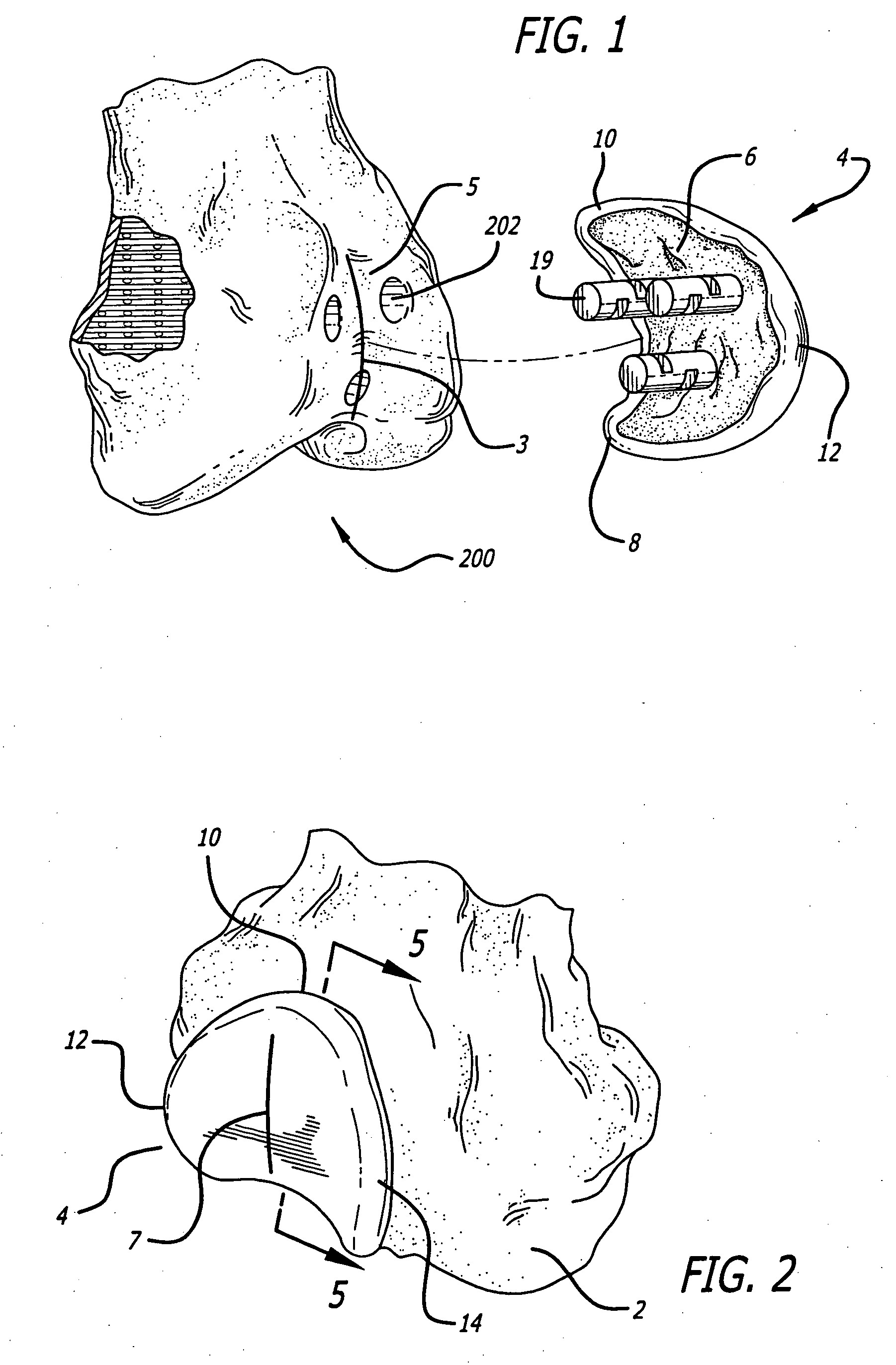

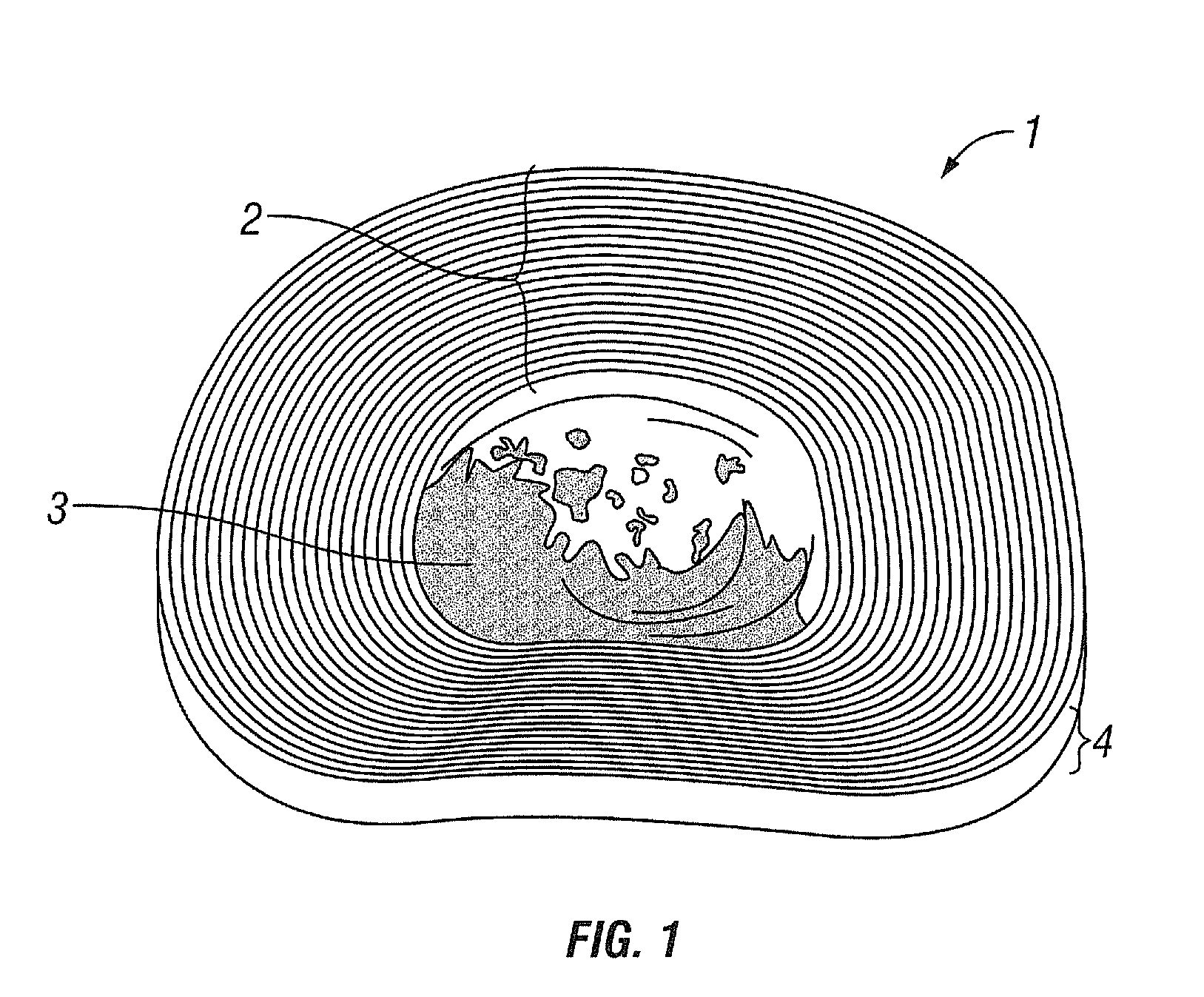

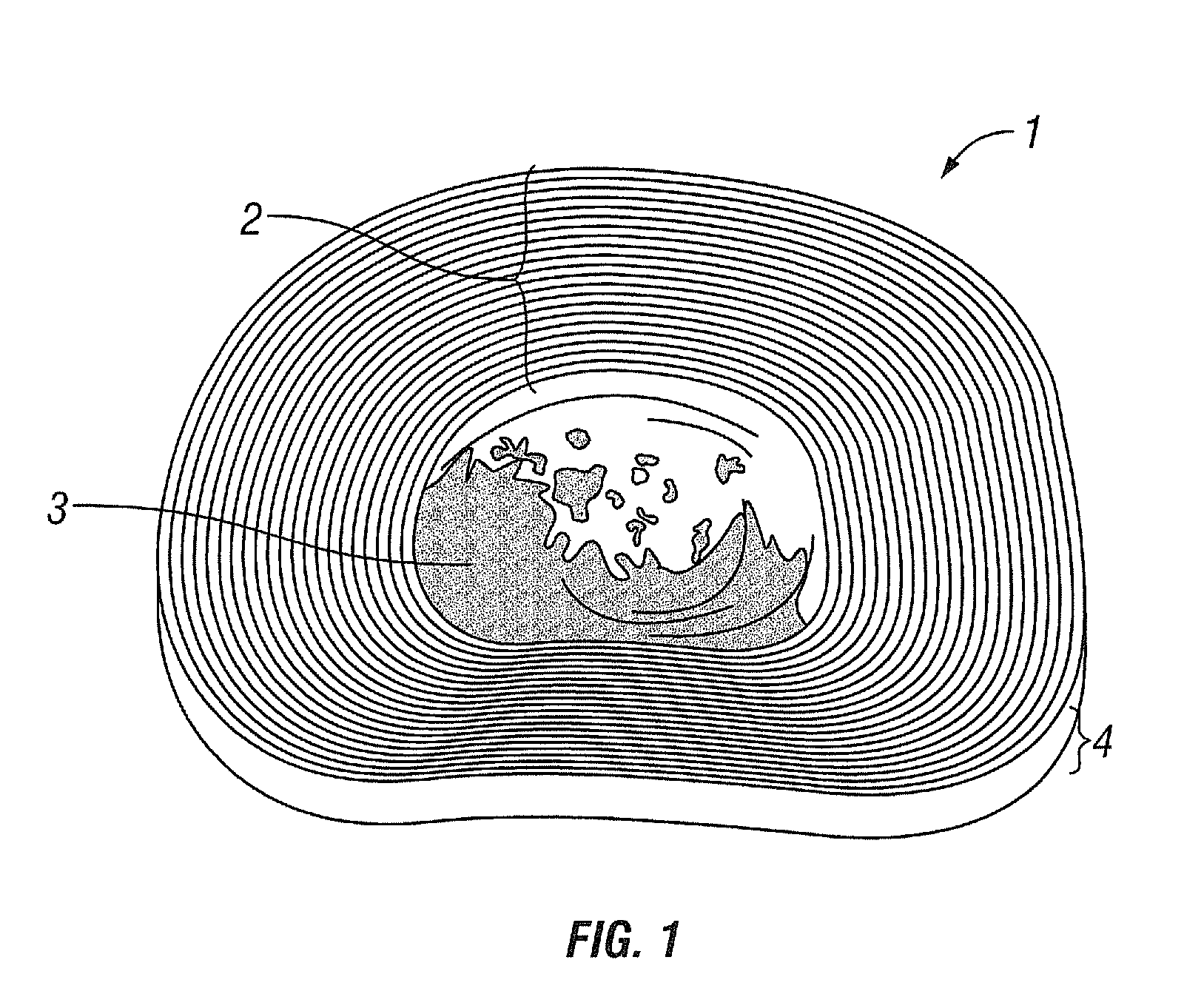

Custom replacement device for resurfacing a femur and method of making the same

InactiveUS6712856B1Joint implantsComputer-aided planning/modellingArticular surfacesRight femoral head

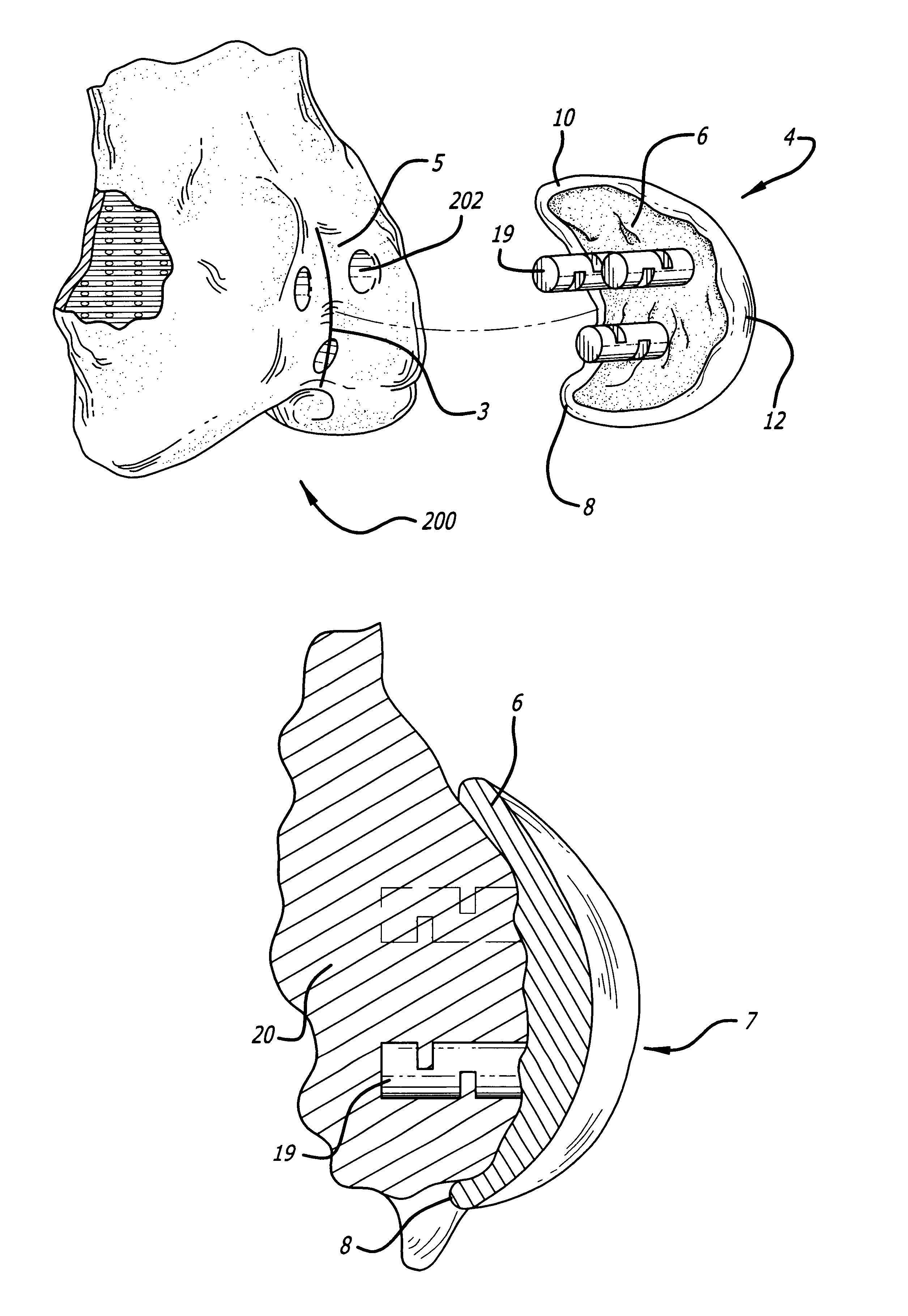

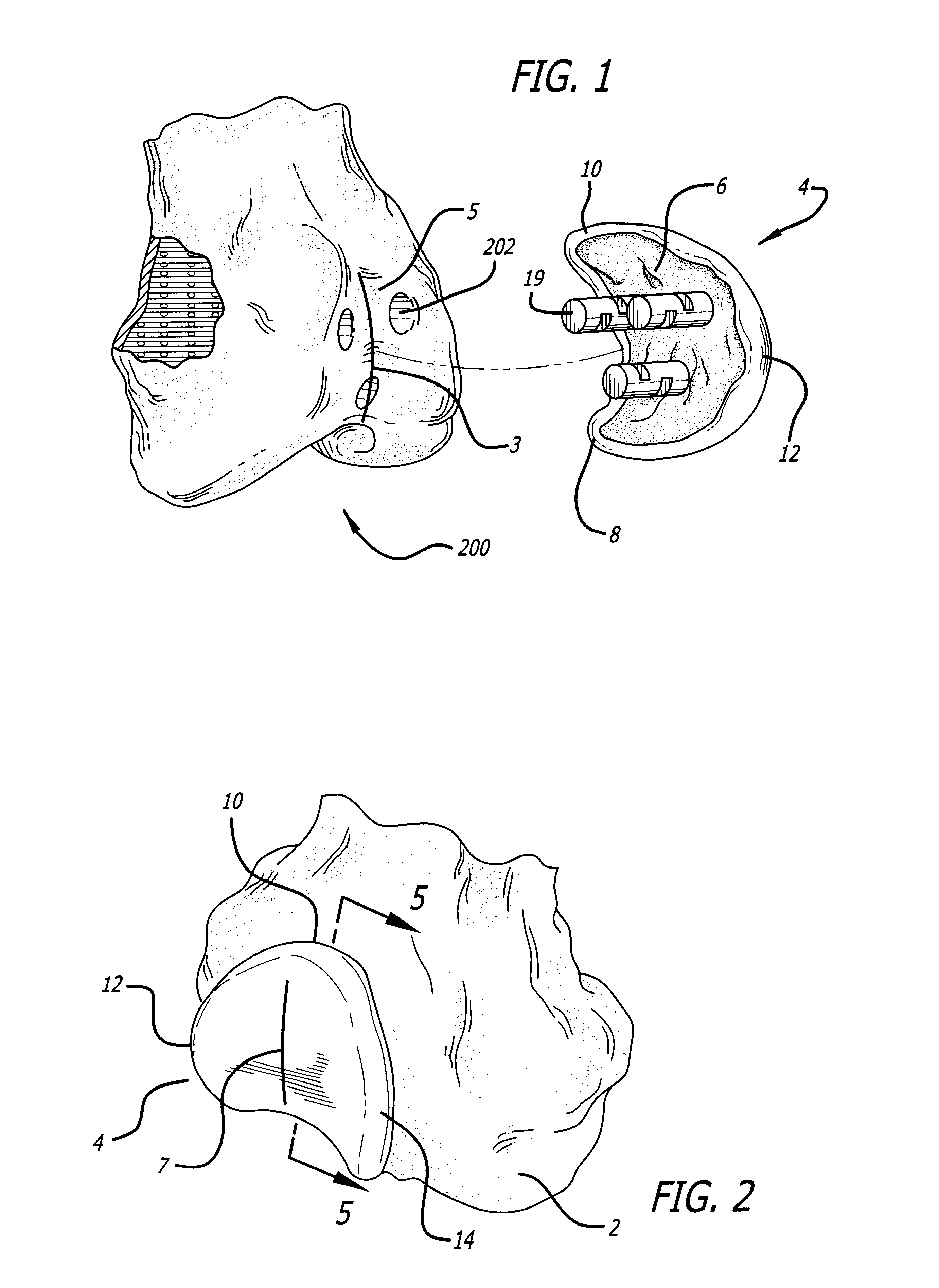

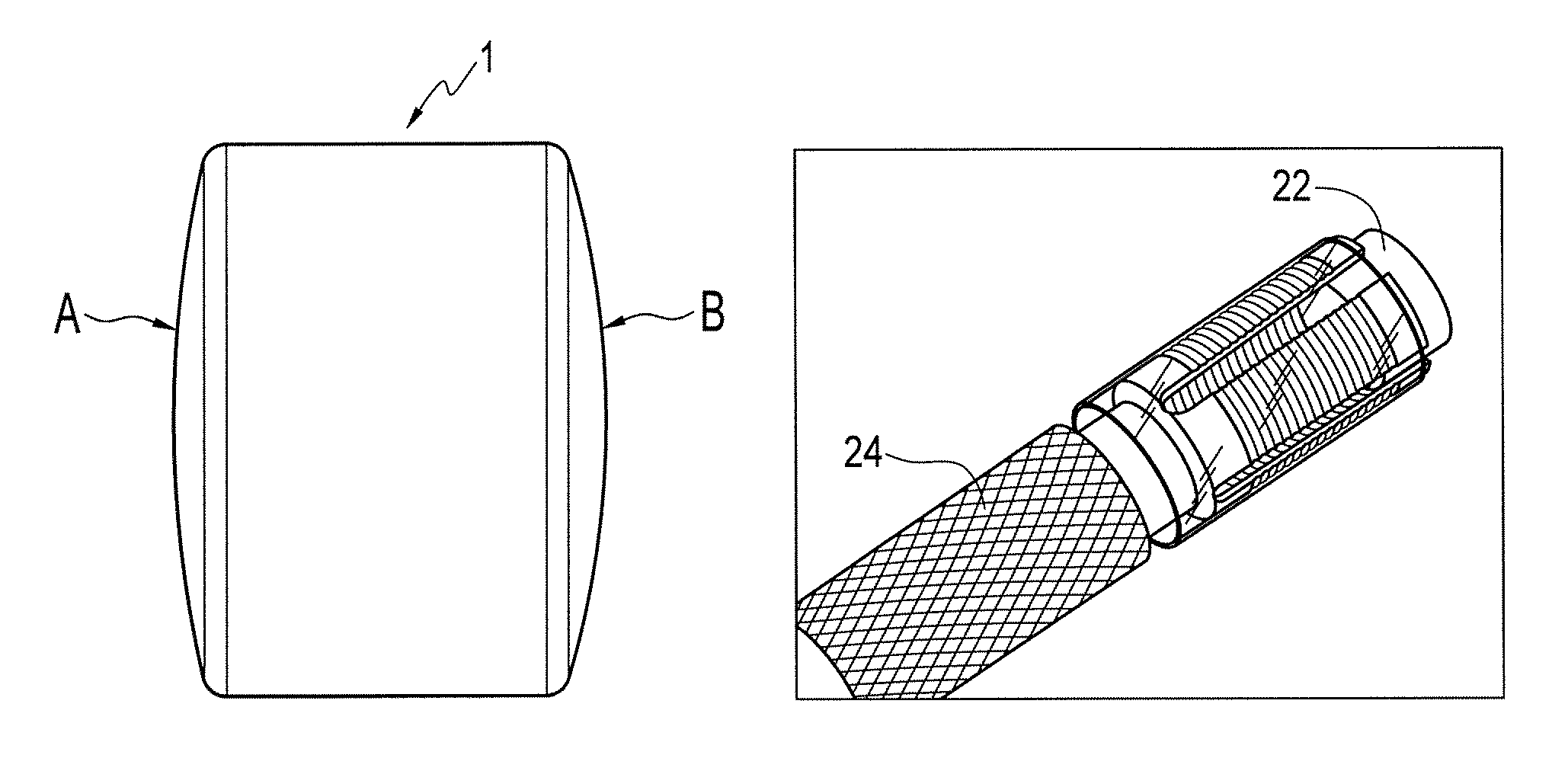

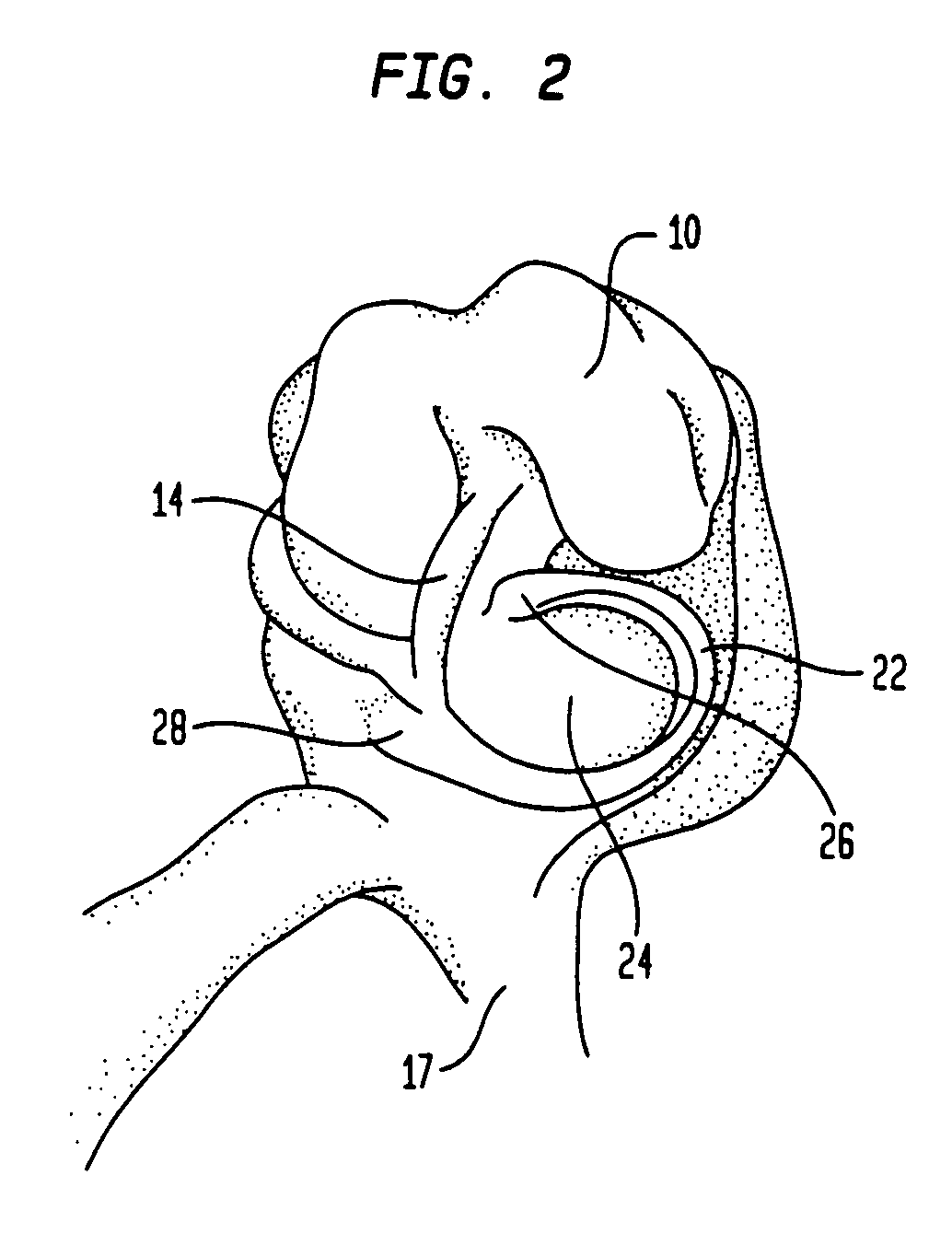

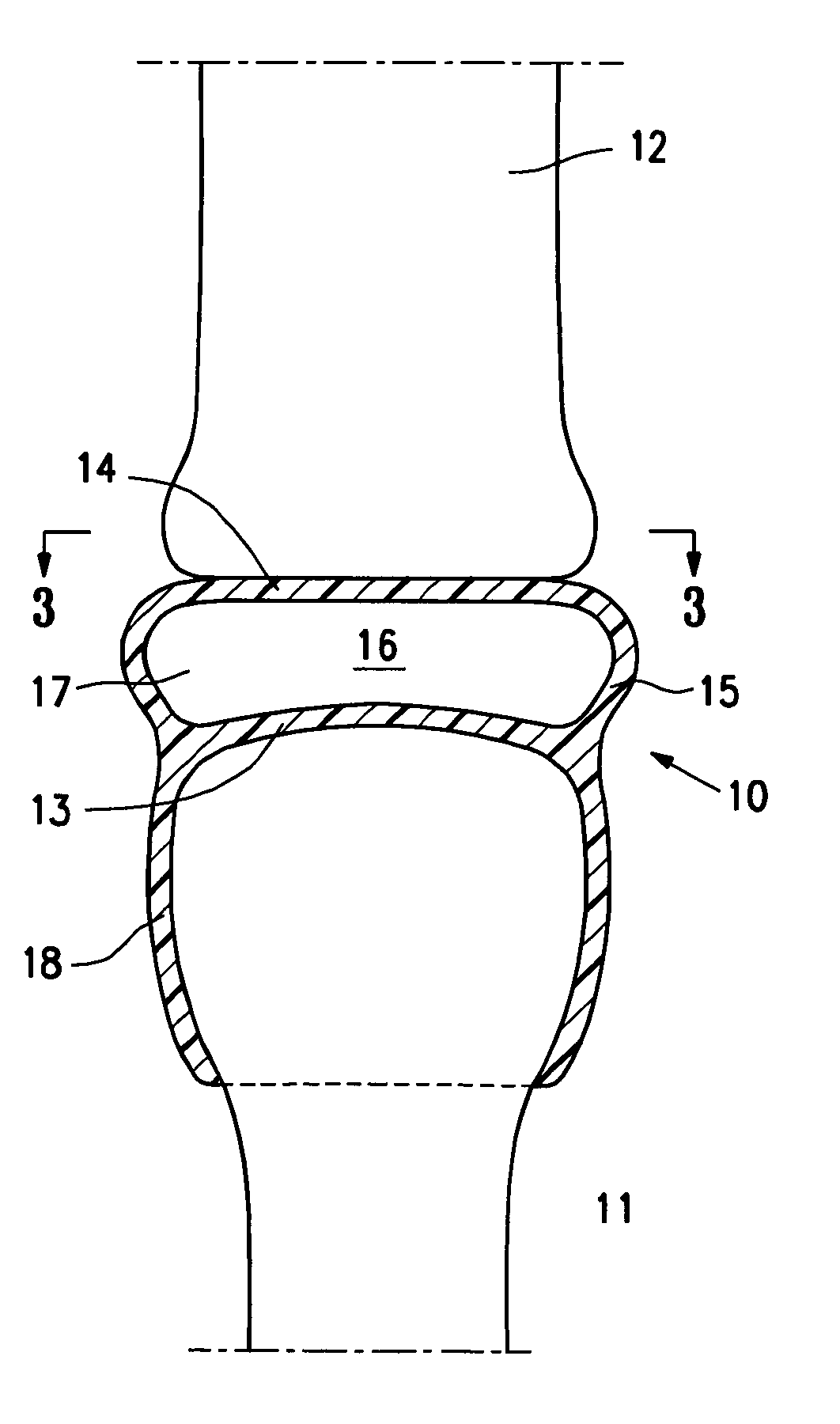

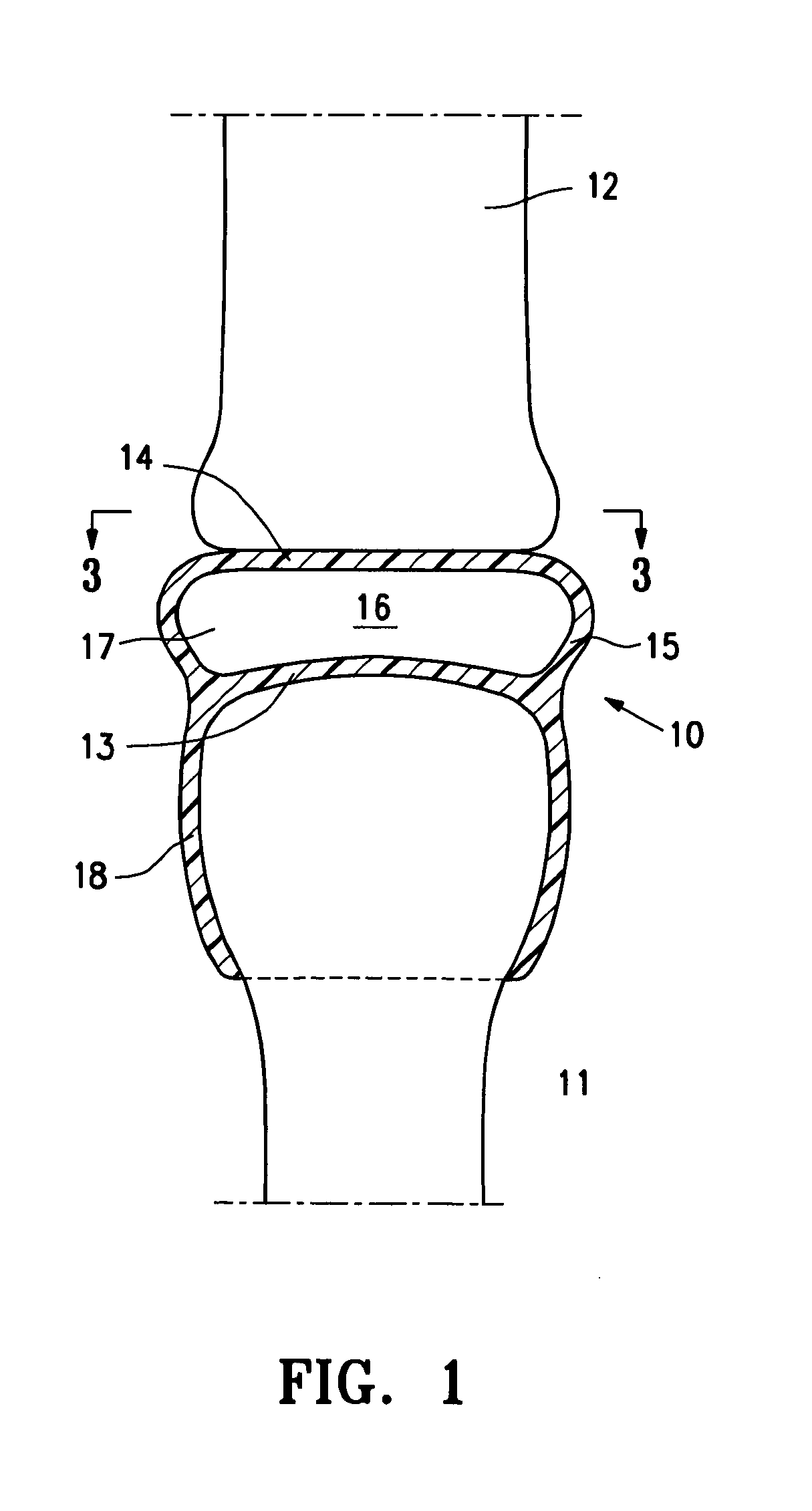

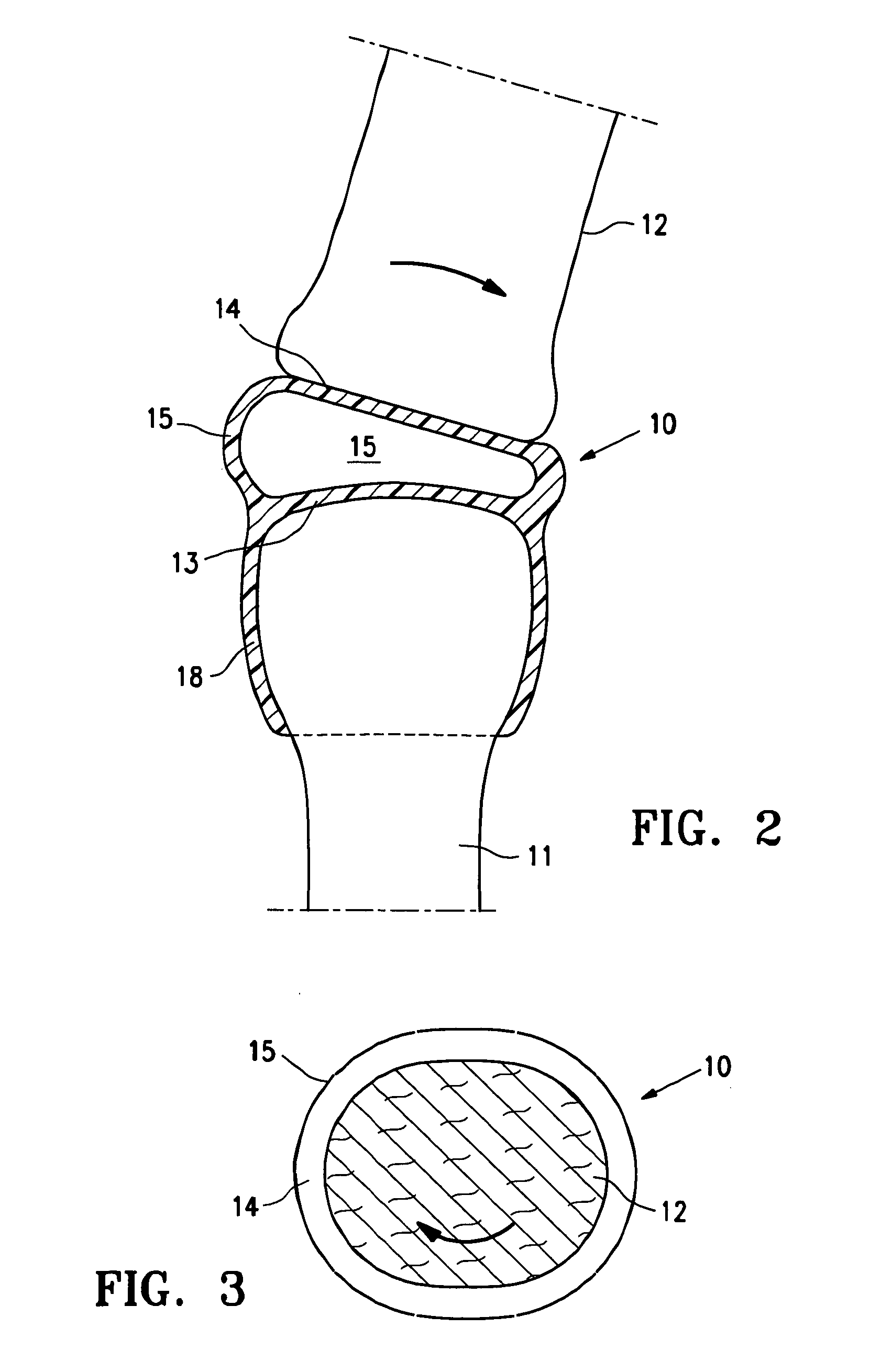

A replacement device for resurfacing a joint surface of a femur and a method of making and installing such a device is provided. The custom replacement device is designed to substantially fit the trochlear groove surface, of an individual femur. Thereby creating a "customized" replacement device for that individual femur and maintaining the original kinematics of the joint. The replacement device may be defined by four boundary points, and a first and a second surface. The first of four points is 3 to 5 mm from the point of attachment of the anterior cruciate ligament to the femur. The second point is near the bottom edge of the end of the natural articulatar cartilage. The third point is at the top ridge of the right condyle and the fourth point at the top ridge of the left condyle of the femur. The top surface is designed so as to maintain centrally directed tracking of the patella perpendicular to the plane established by the distal end of the femoral condyles and aligned with the center of the femoral head.

Owner:KINAMED

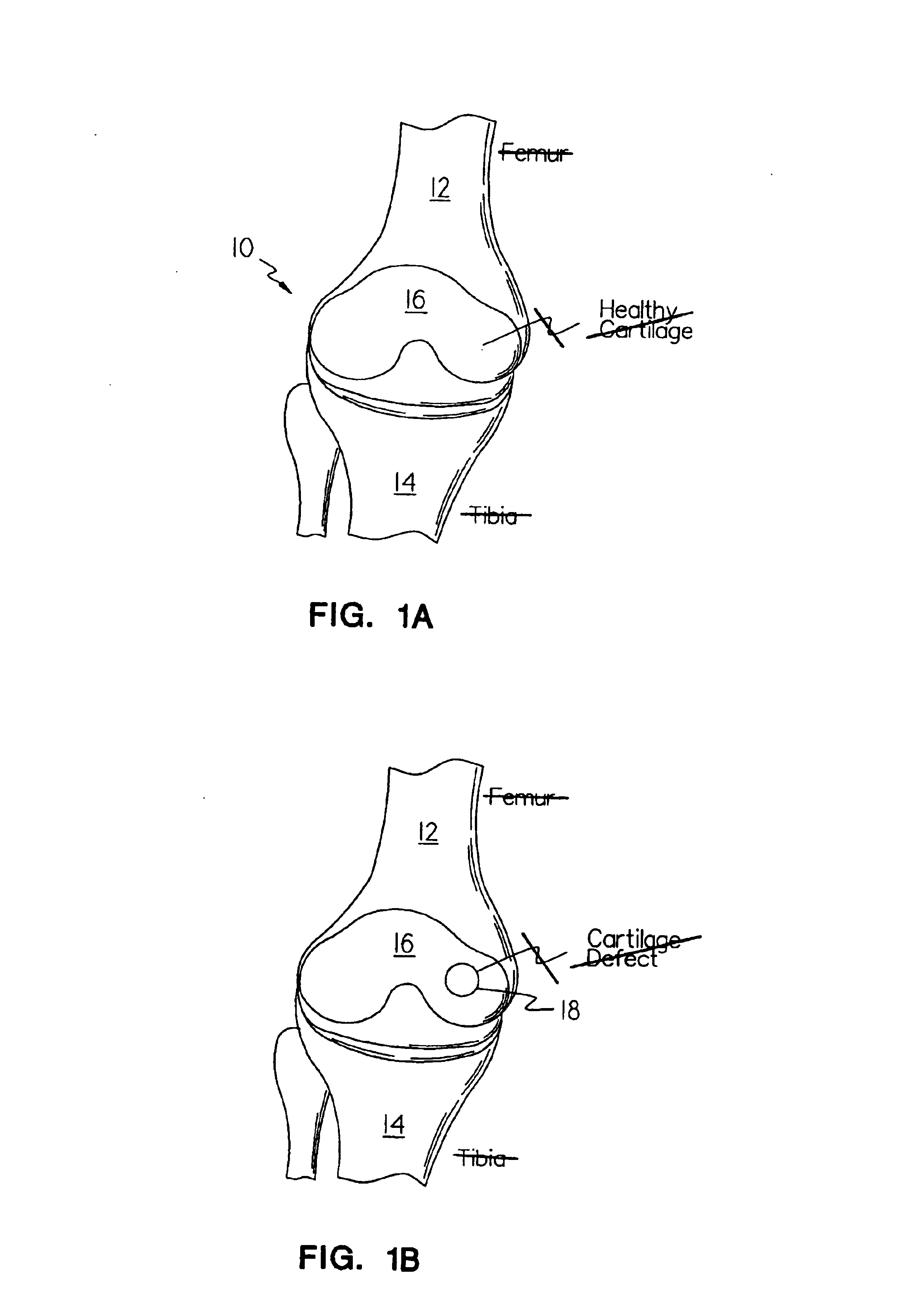

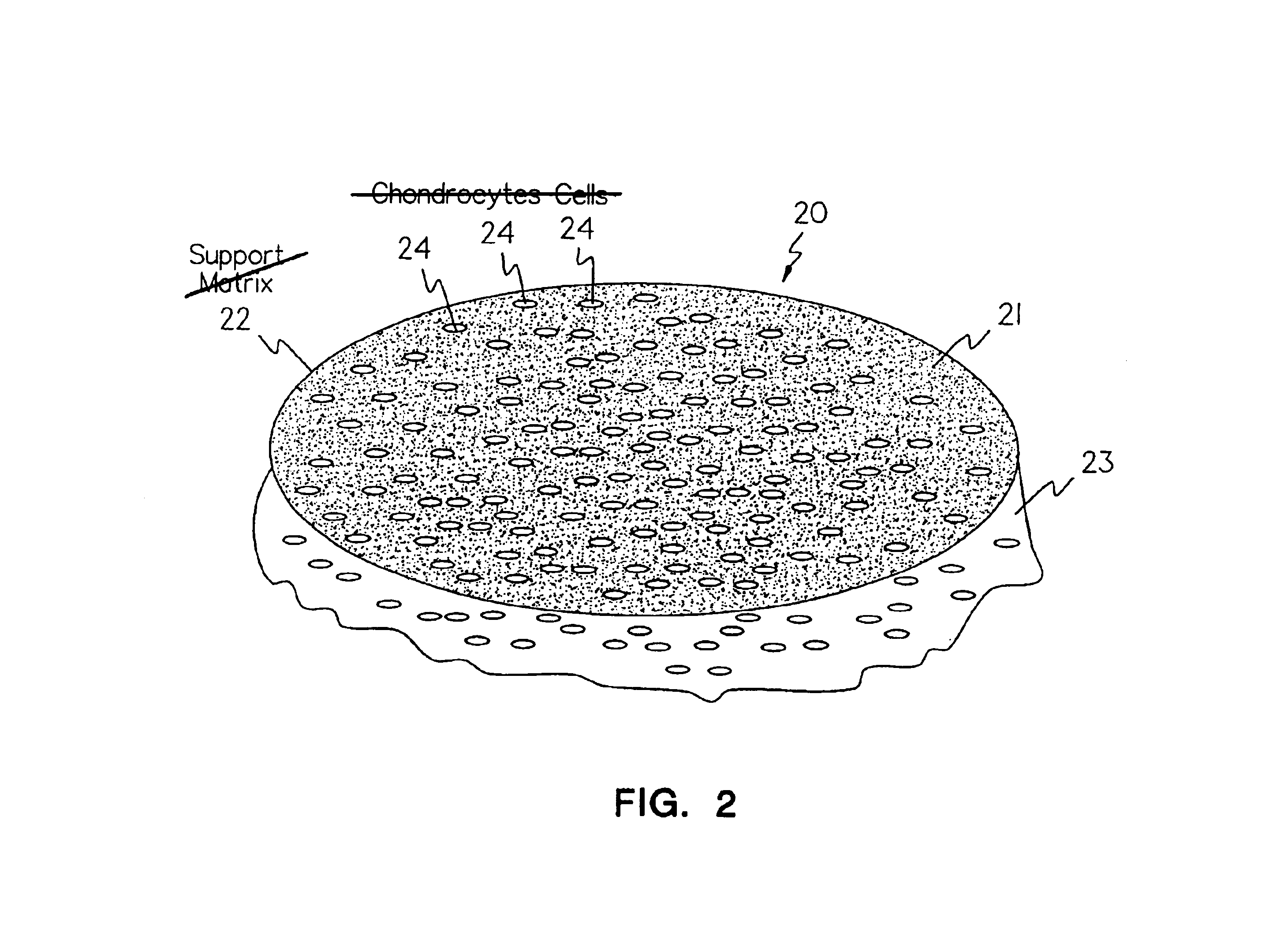

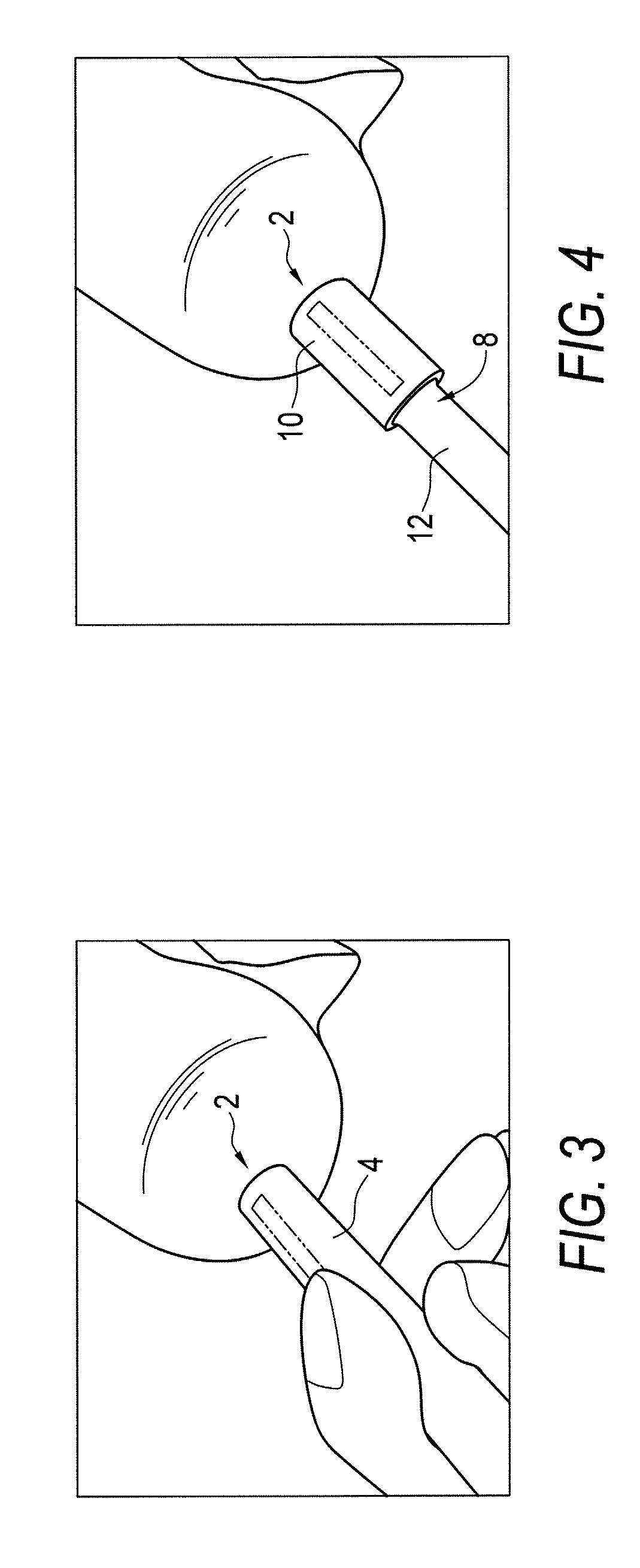

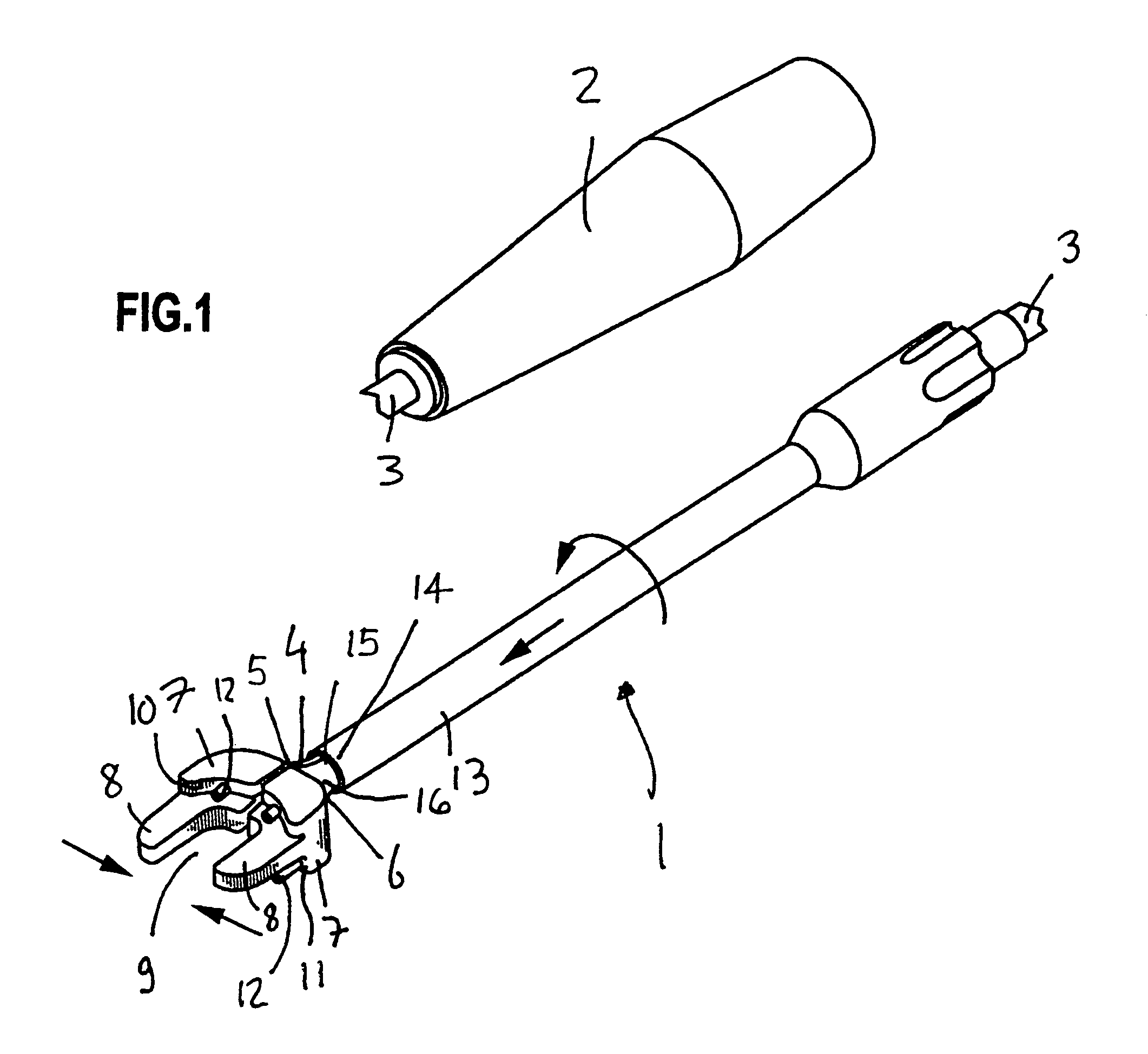

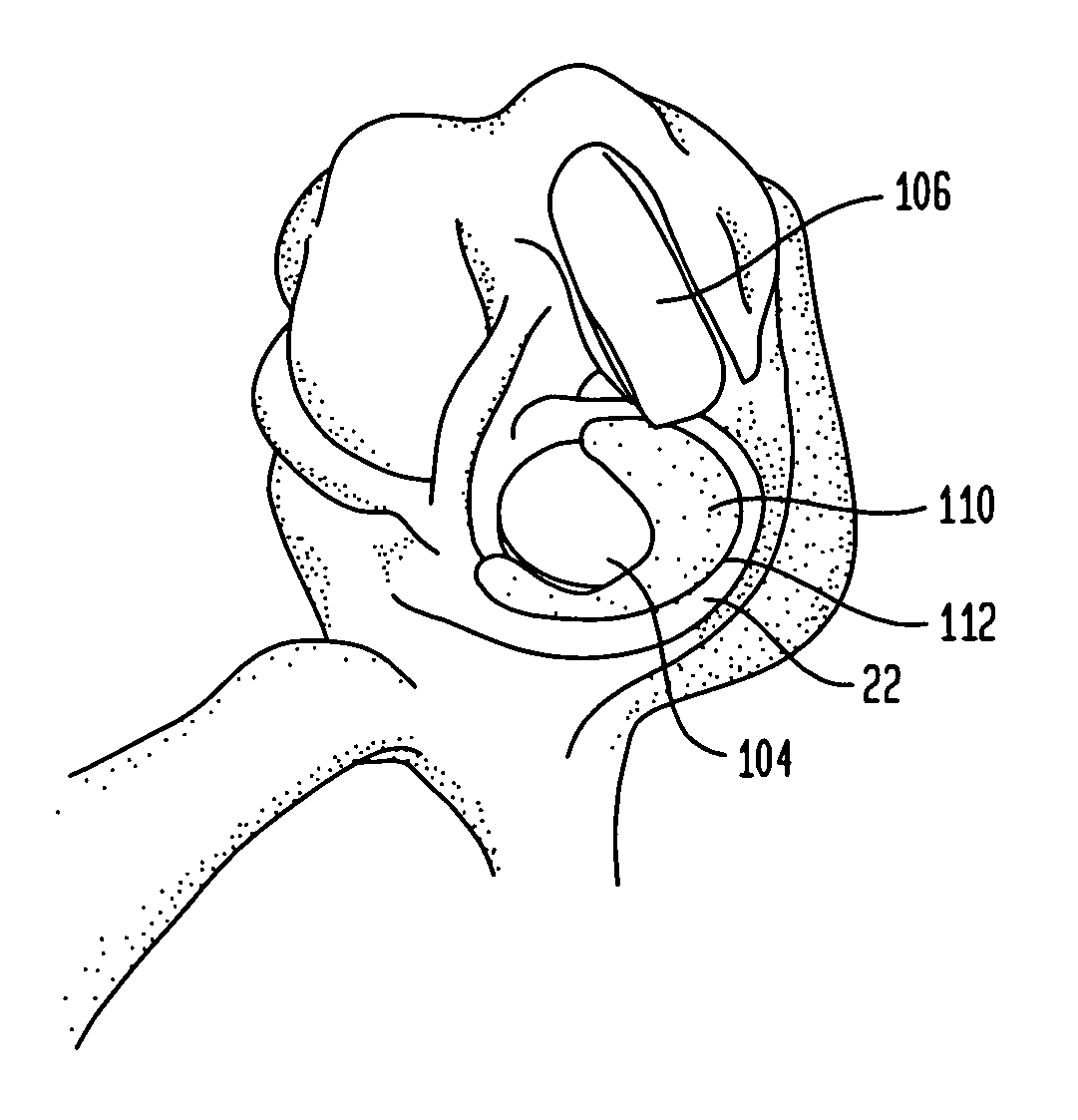

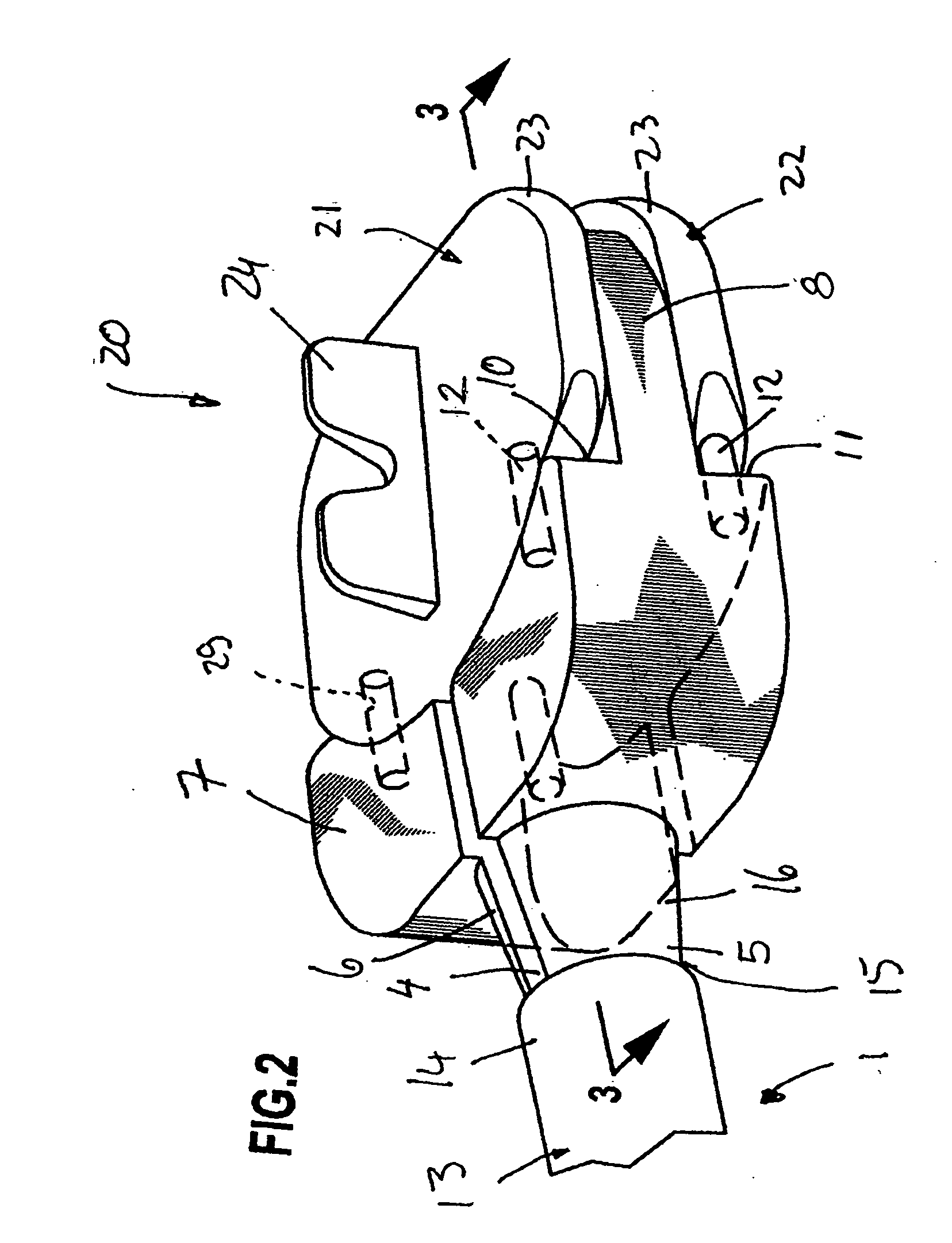

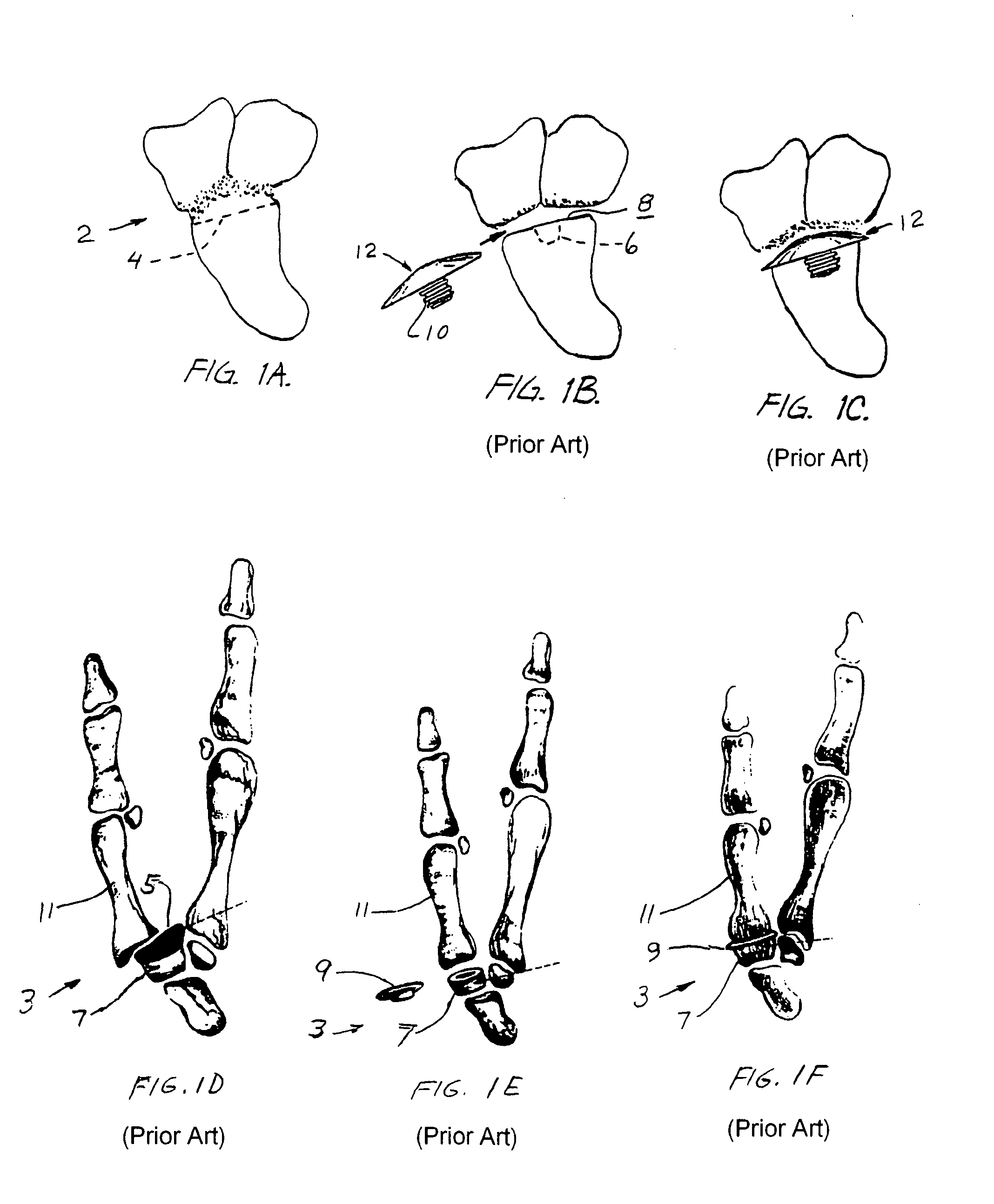

Methods, instruments and materials for chondrocyte cell transplantation

InactiveUS6866668B2Effective treatmentSuture equipmentsSurgical adhesivesSupport matrixTreated animal

A method for the effective treatment of articulating joint surface cartilage in an animal by the transplantation of an implantable article including chondrocyte cells retained to an absorbable support matrix. An instrument for placing and manipulating the implantable article at the site of implantation, and a retention device for securing the implantable article to the site of implantation. An implantable article for cartilage repair in an animal, the implantable article including chondrocyte cells retained on an absorbable support matrix, and a method of making same. An article comprising an absorbable flexible support matrix for living cells grown and adhered thereto.

Owner:VERIGEN TRANSPLANTATION SERVICE INT

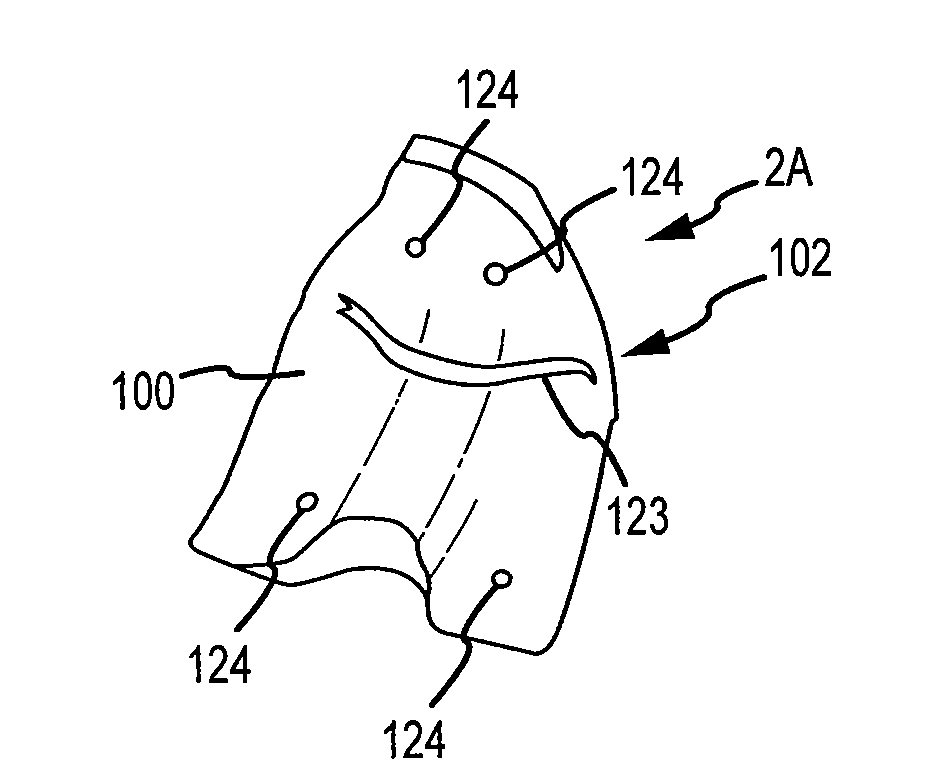

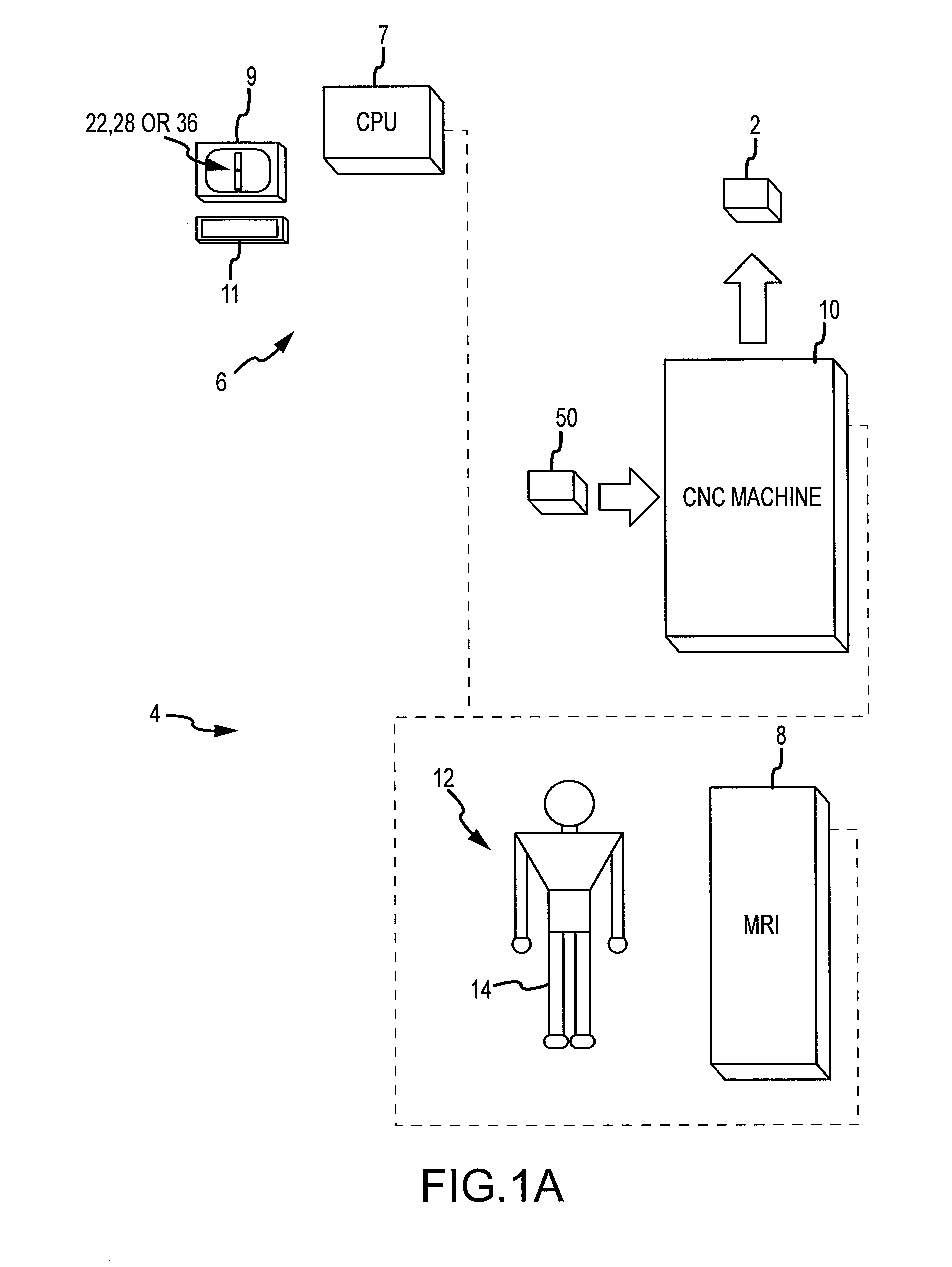

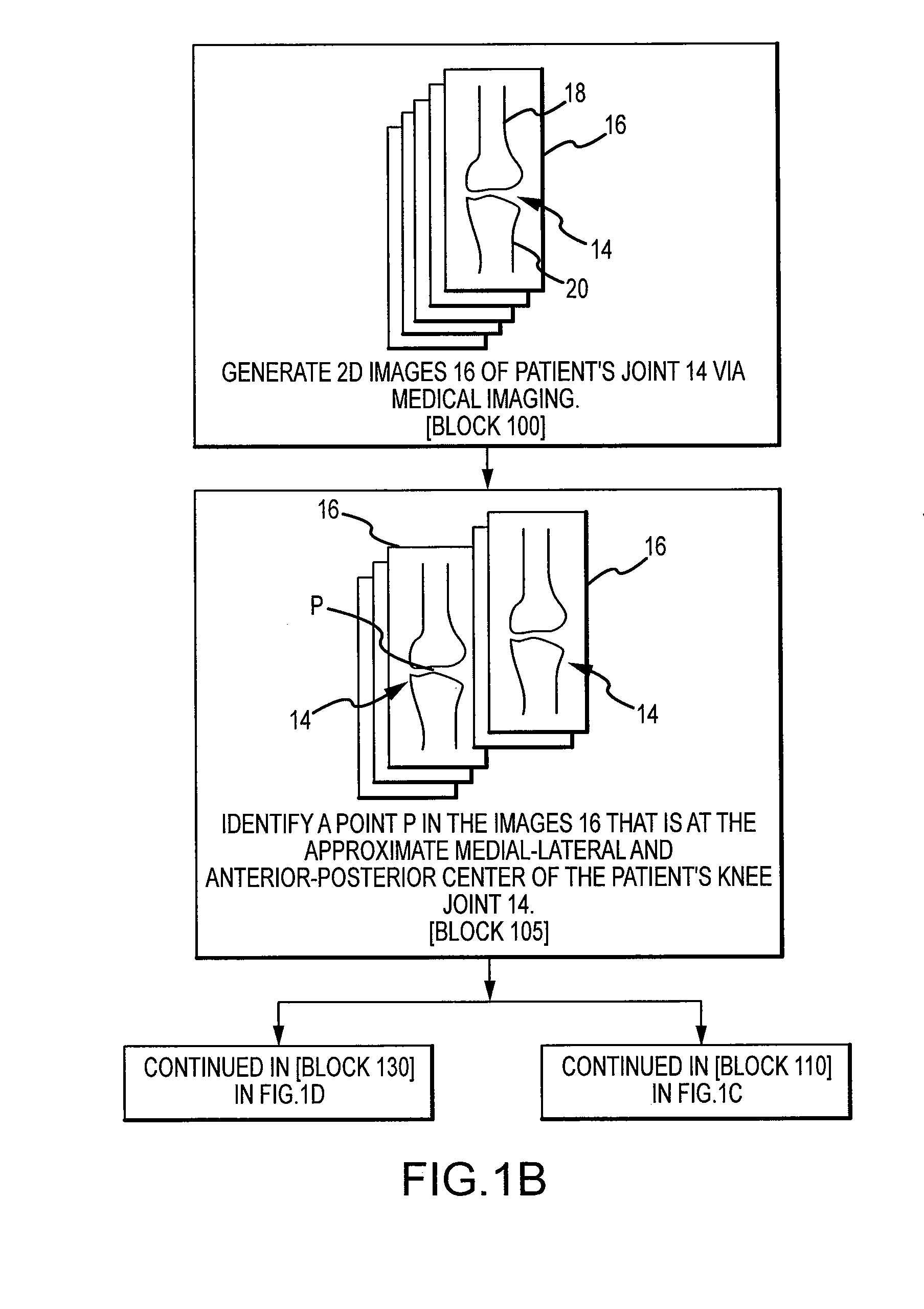

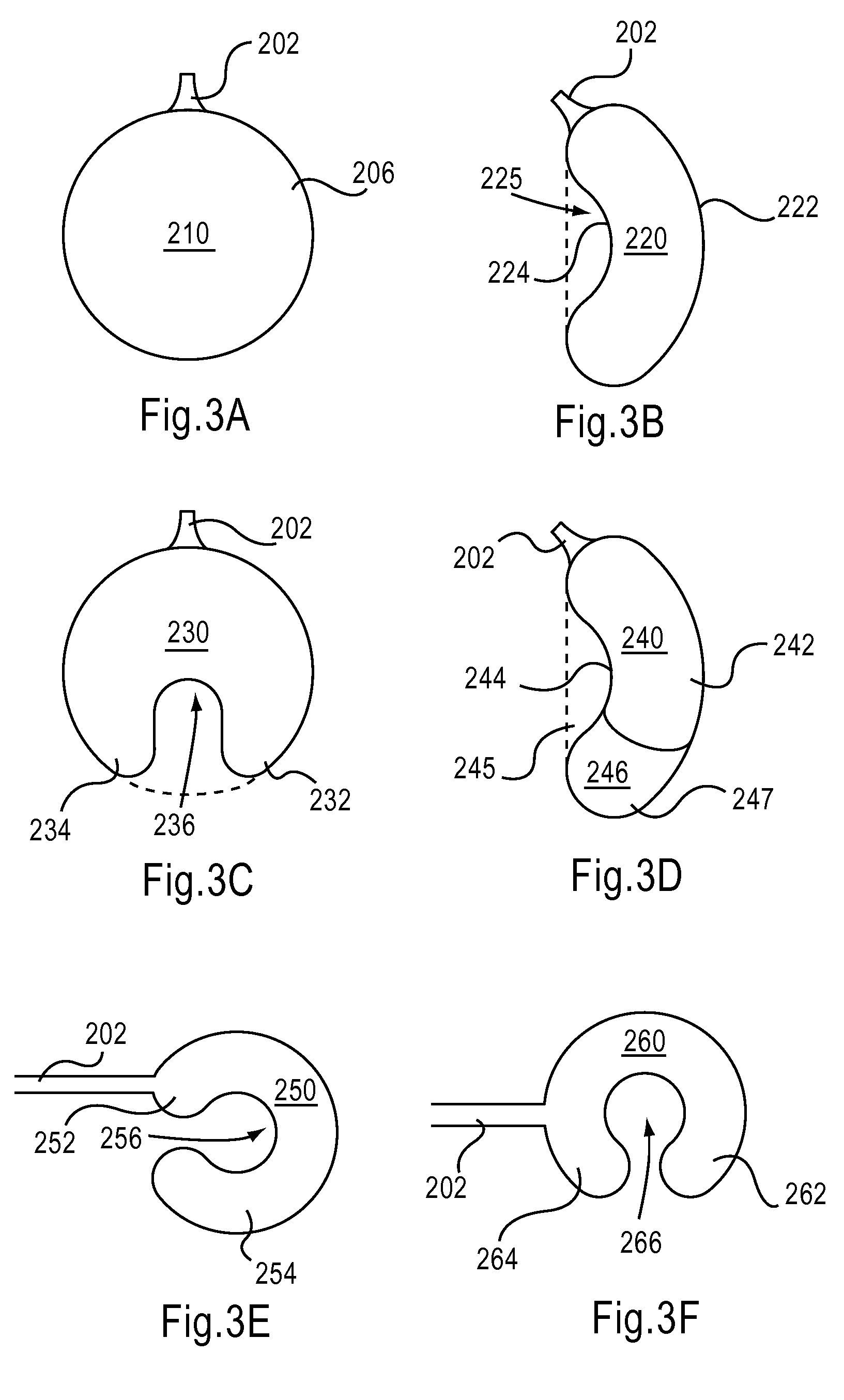

Arthroplasty system and related methods

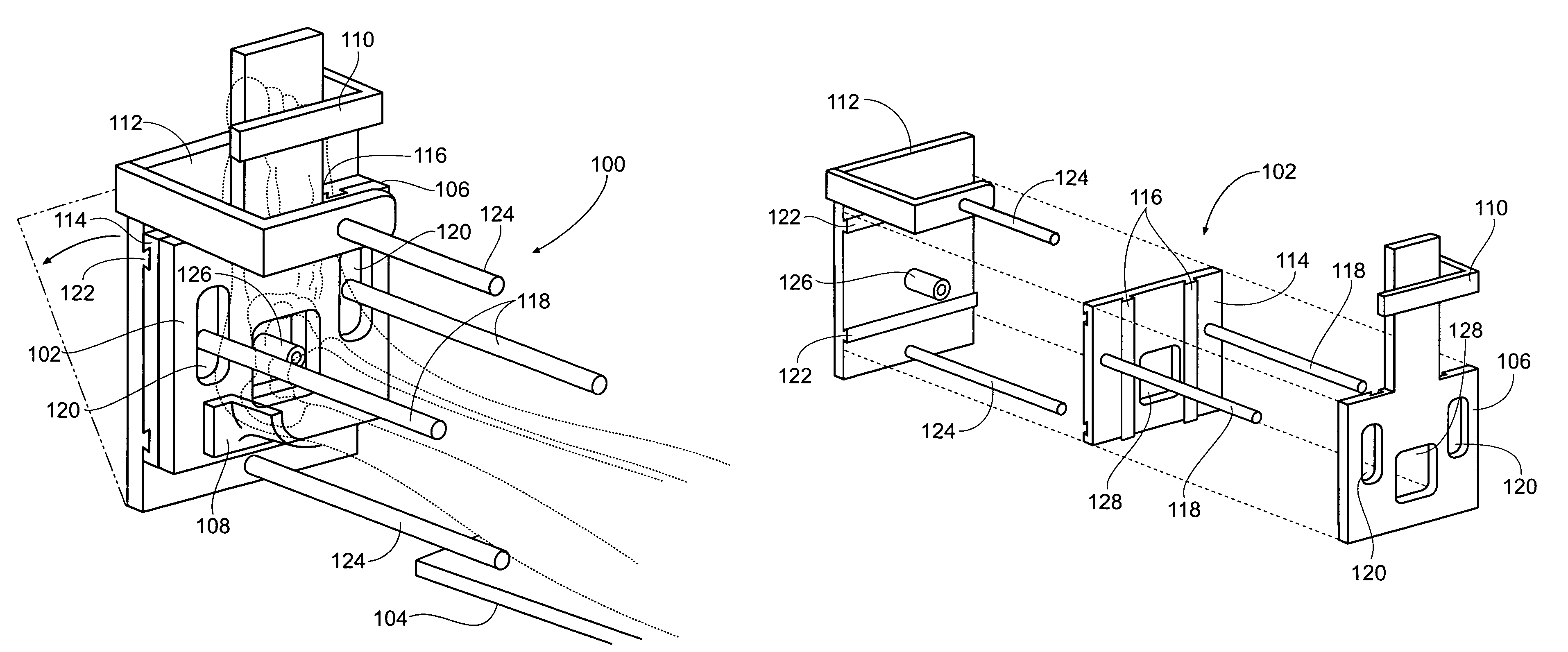

A method of manufacturing an arthroplasty jig is disclosed herein. The method may include the following: generate a bone model, wherein the bone model includes a three dimensional computer model of at least a portion of a joint surface of a bone of a patient joint to undergo an arthroplasty procedure; generate an implant model, wherein the implant model includes a three dimensional computer model of at least a portion of a joint surface of an arthroplasty implant to be used in the arthroplasty procedure; assess a characteristic associated with the patient joint; generate a modified joint surface of the implant model by modifying at least a portion of a joint surface of the implant model according to the characteristic; and shape match the modified joint surface of the implant model and a corresponding joint surface of the bone model.

Owner:HOWMEDICA OSTEONICS CORP

Custom replacement device for resurfacing a femur and method of making the same

InactiveUS20040098133A1Joint implantsComputer-aided planning/modellingArticular surfacesRight femoral head

Owner:KINAMED

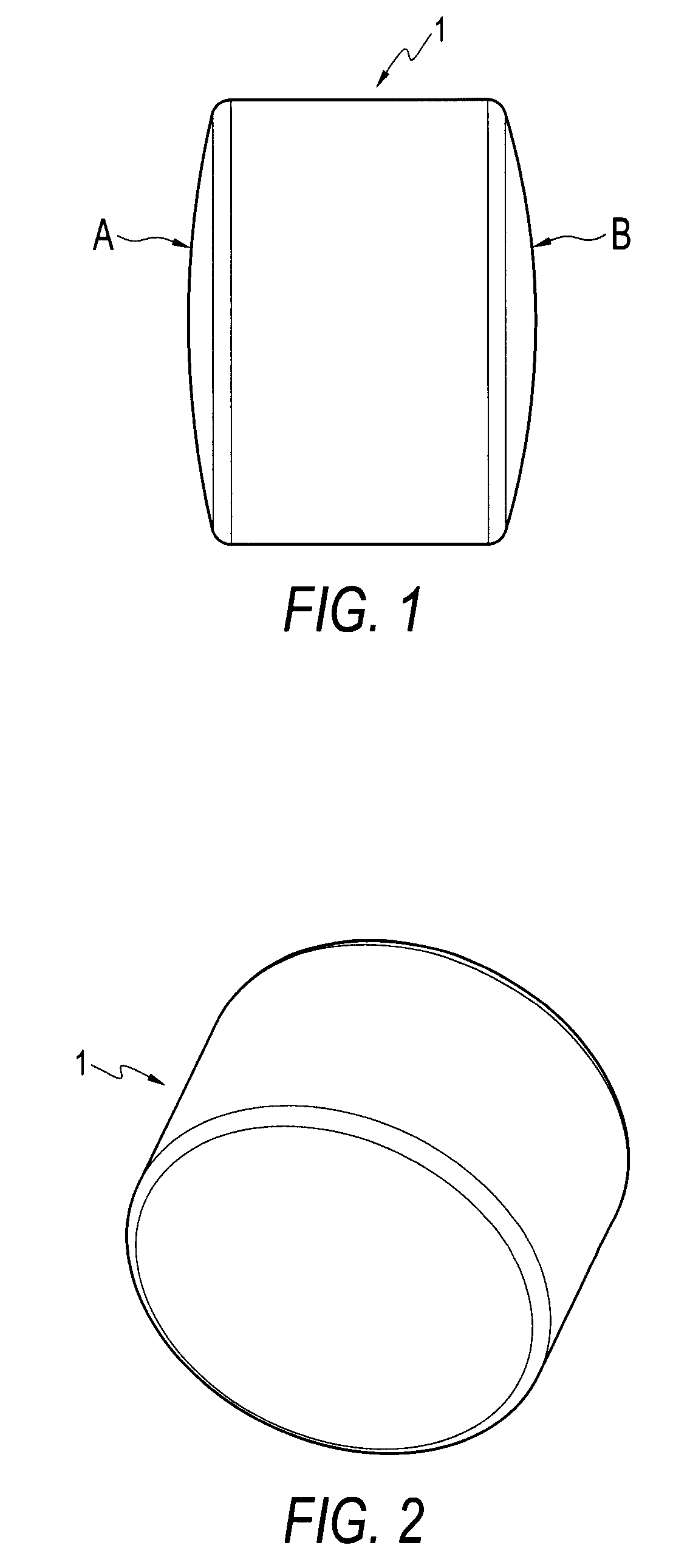

Method and instrumentation for osteochondral repair using preformed implants

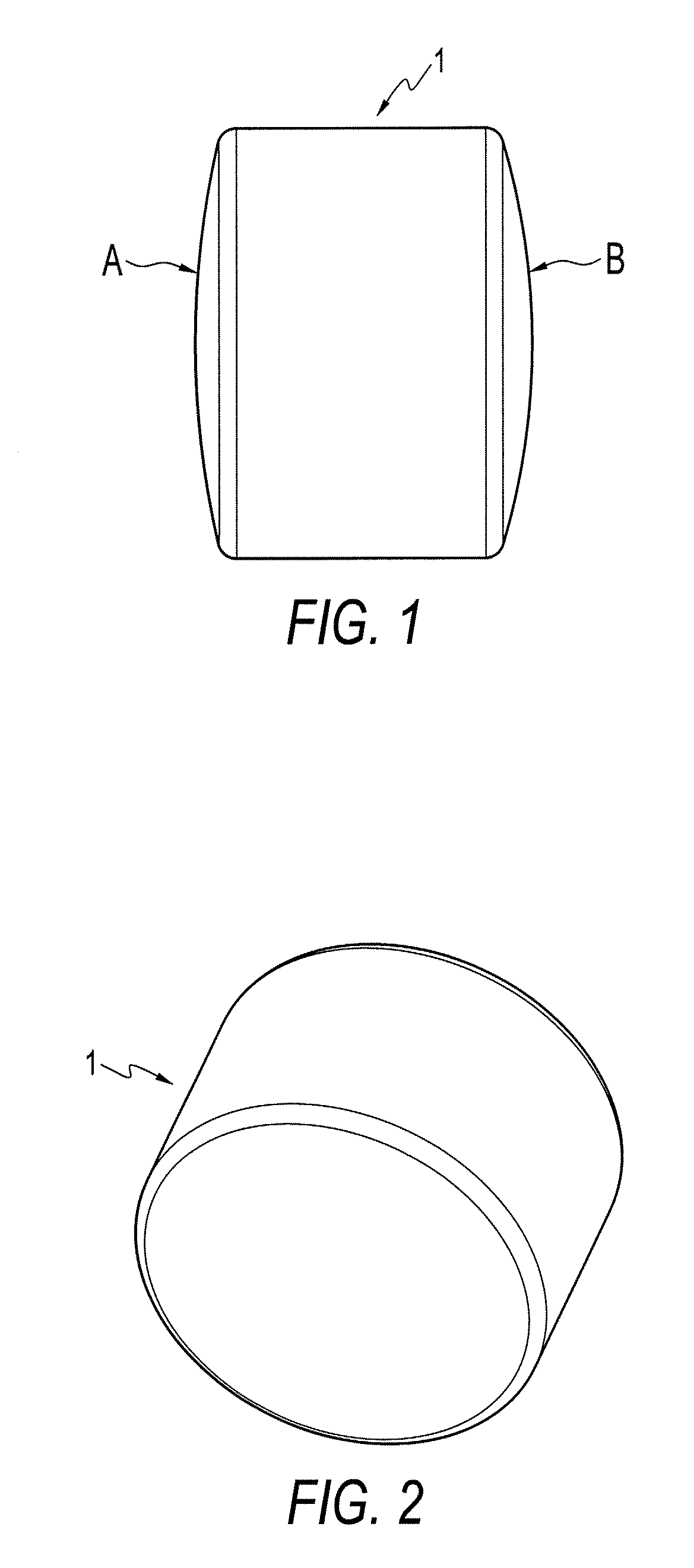

Osteochondral repair of damaged articular joint surfaces is achieved using implants in the form of cylindrical osteochondral plugs. The plugs have an articular surface formed on at least one end. If articular surfaces are provided on both ends of the implant, the articular surfaces have differently curved surfaces. The defective cartilage is removed to create a recipient socket for the implant. An implant sized to fit the recipient socket is chosen from a plurality of implants provided to the surgeon. The implants are preferably formed of a hydrogel material such as Salubria™, although metal or allograft implants can also be used.

Owner:ARTHREX

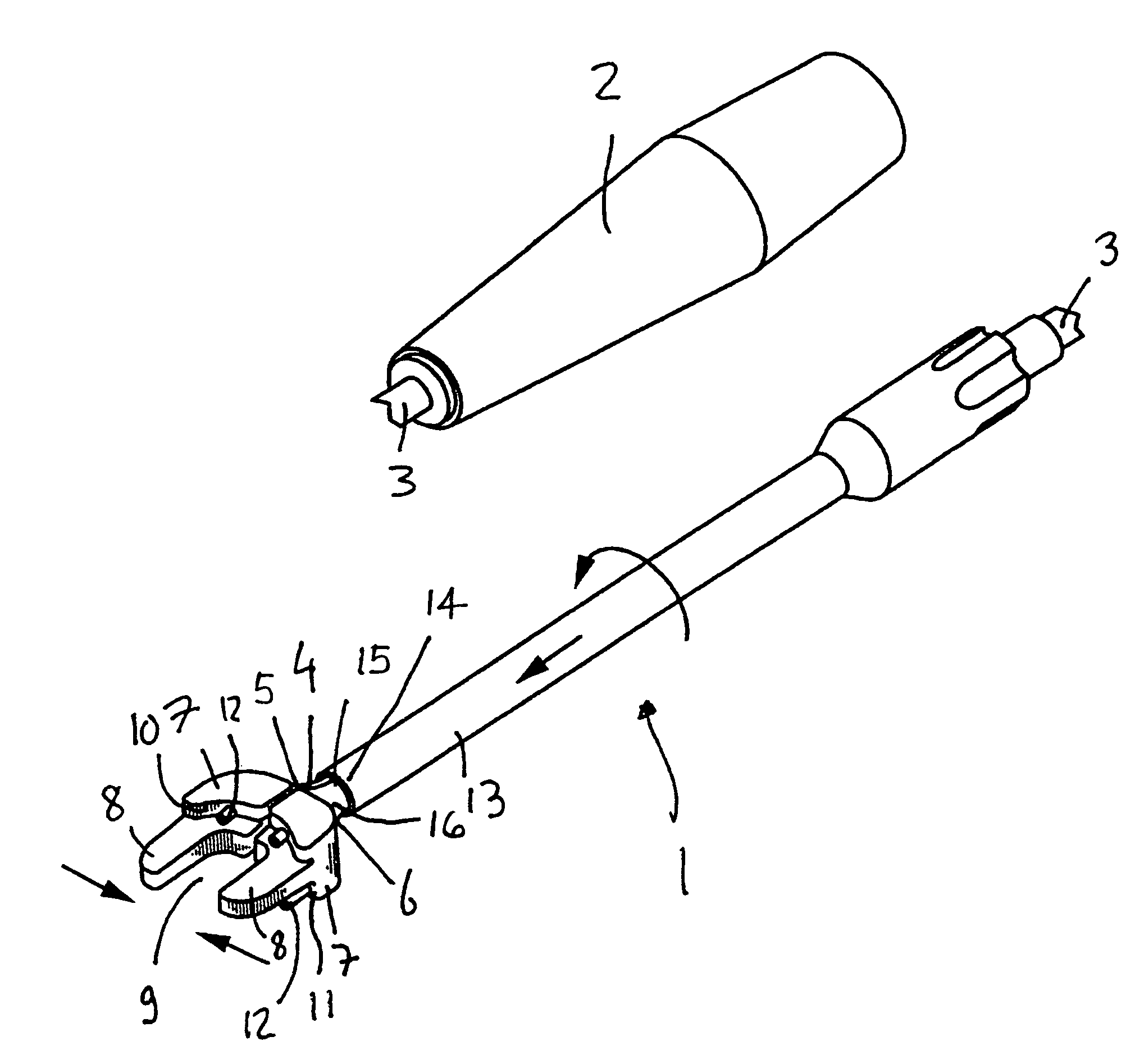

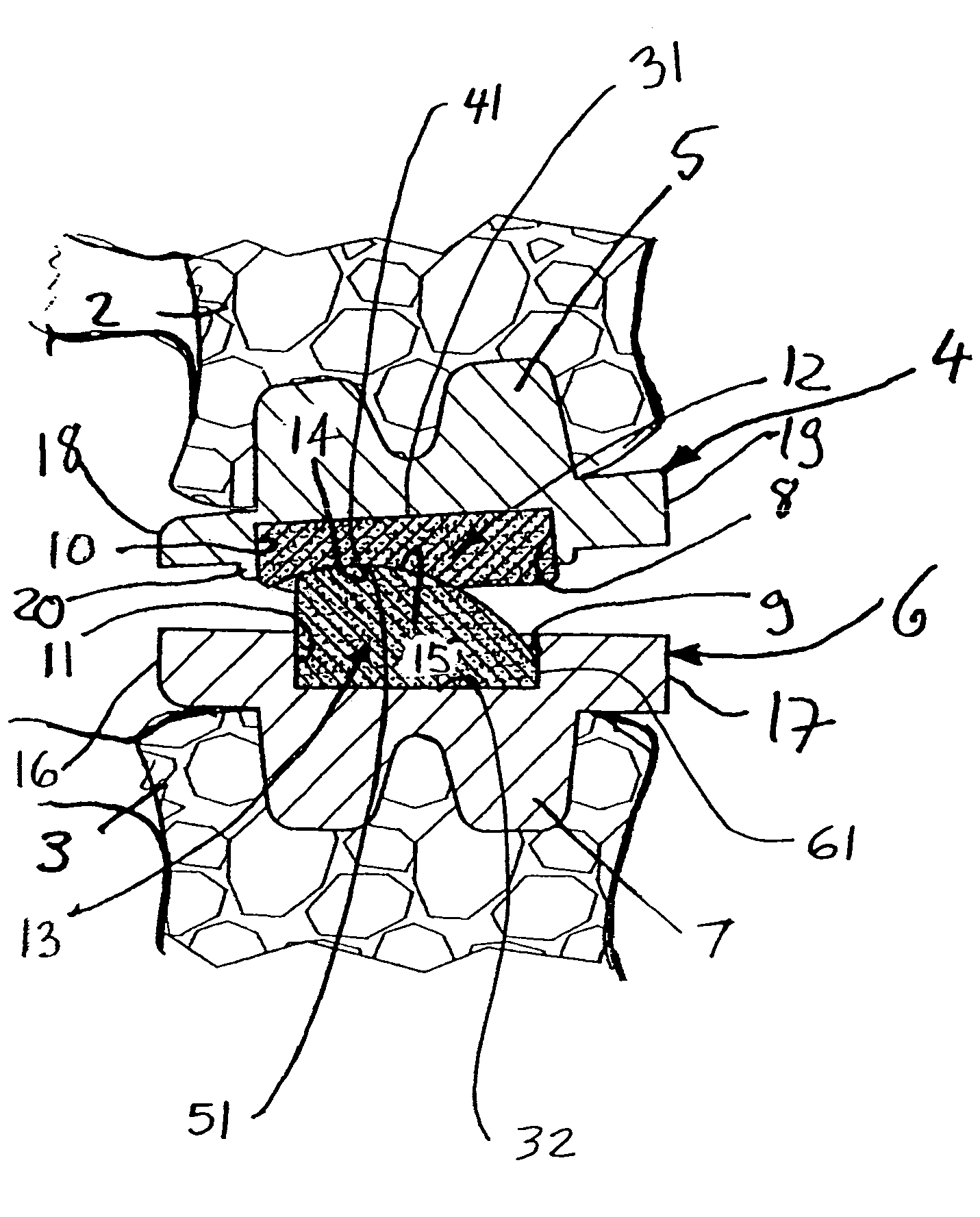

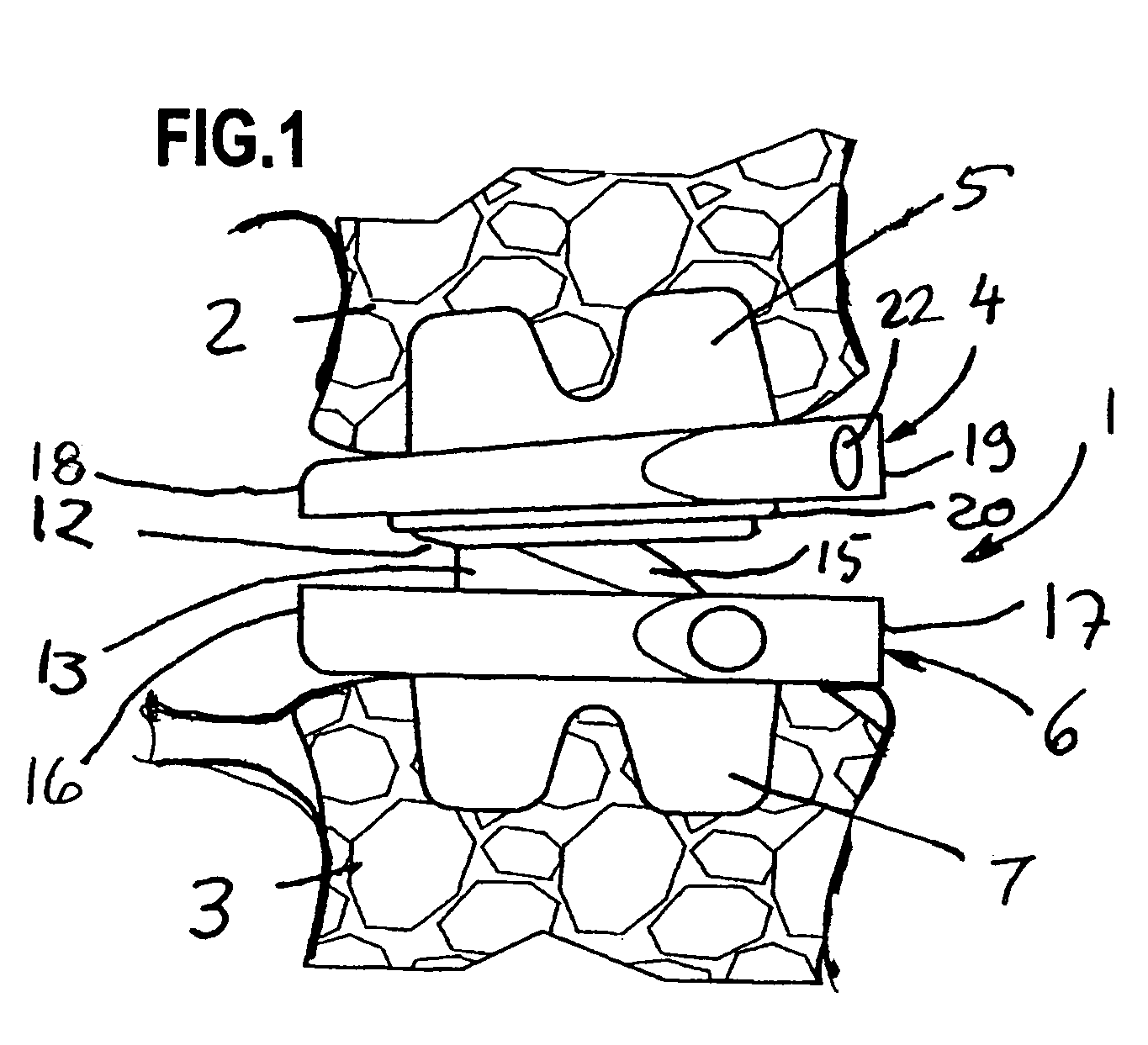

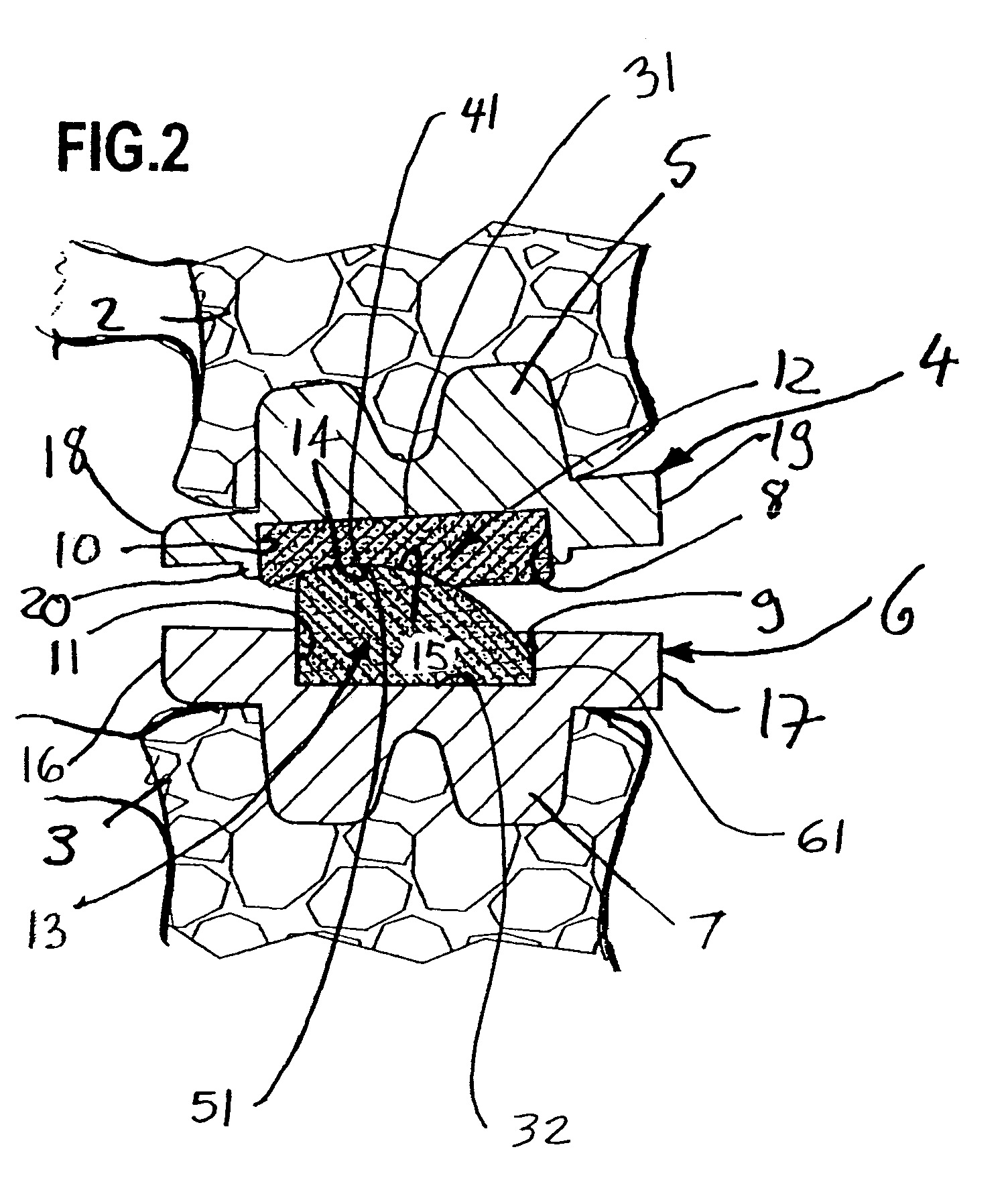

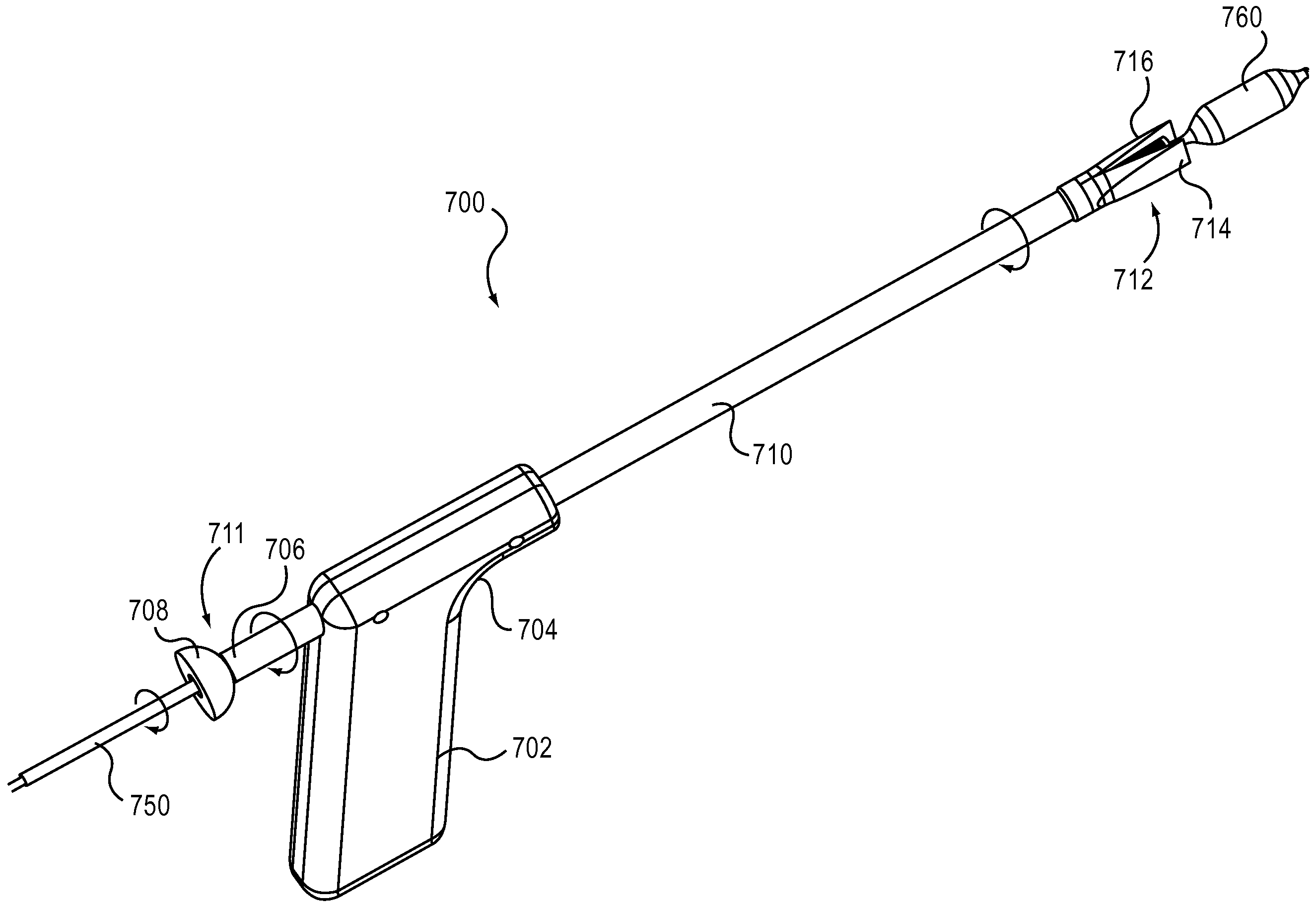

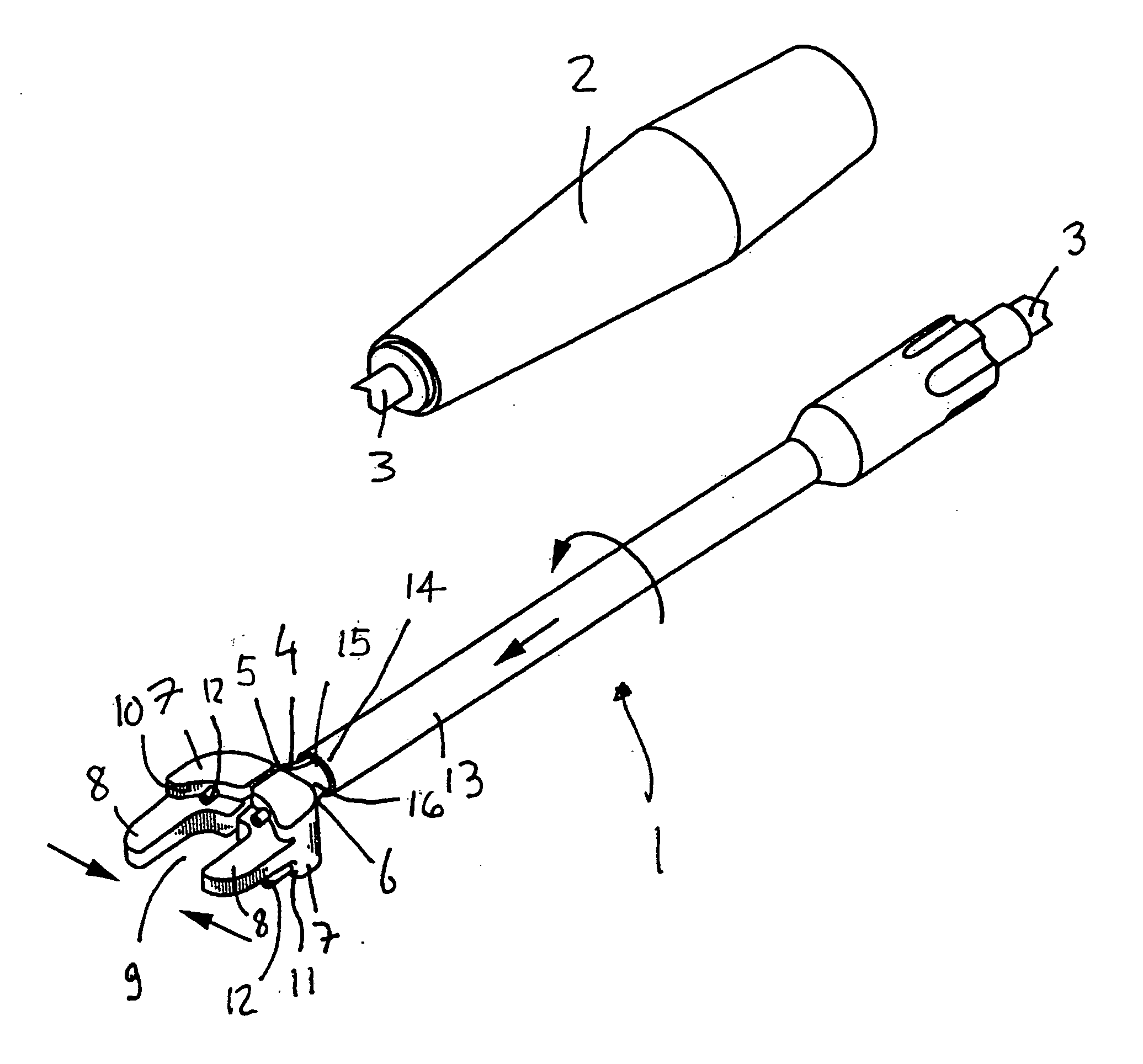

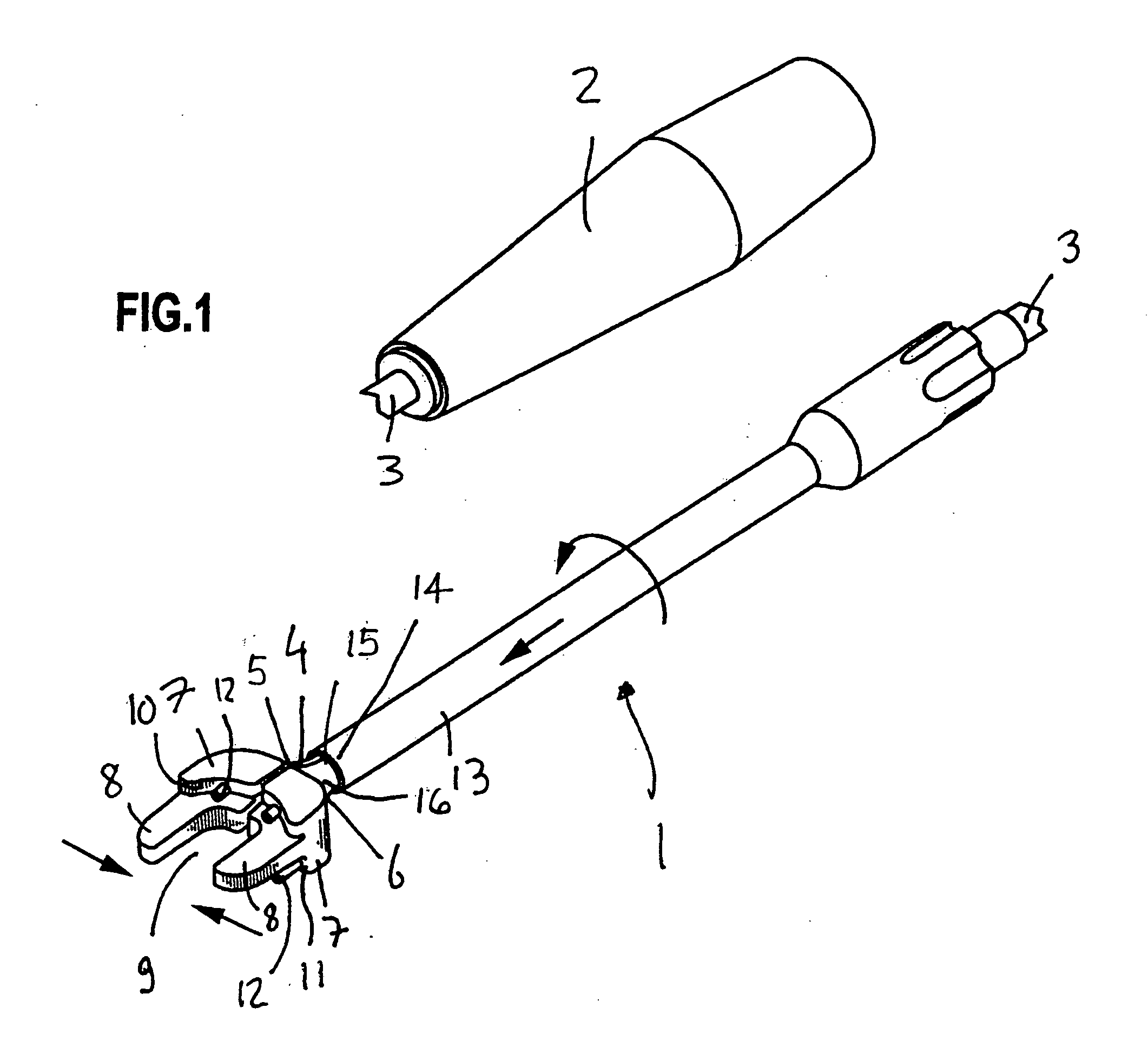

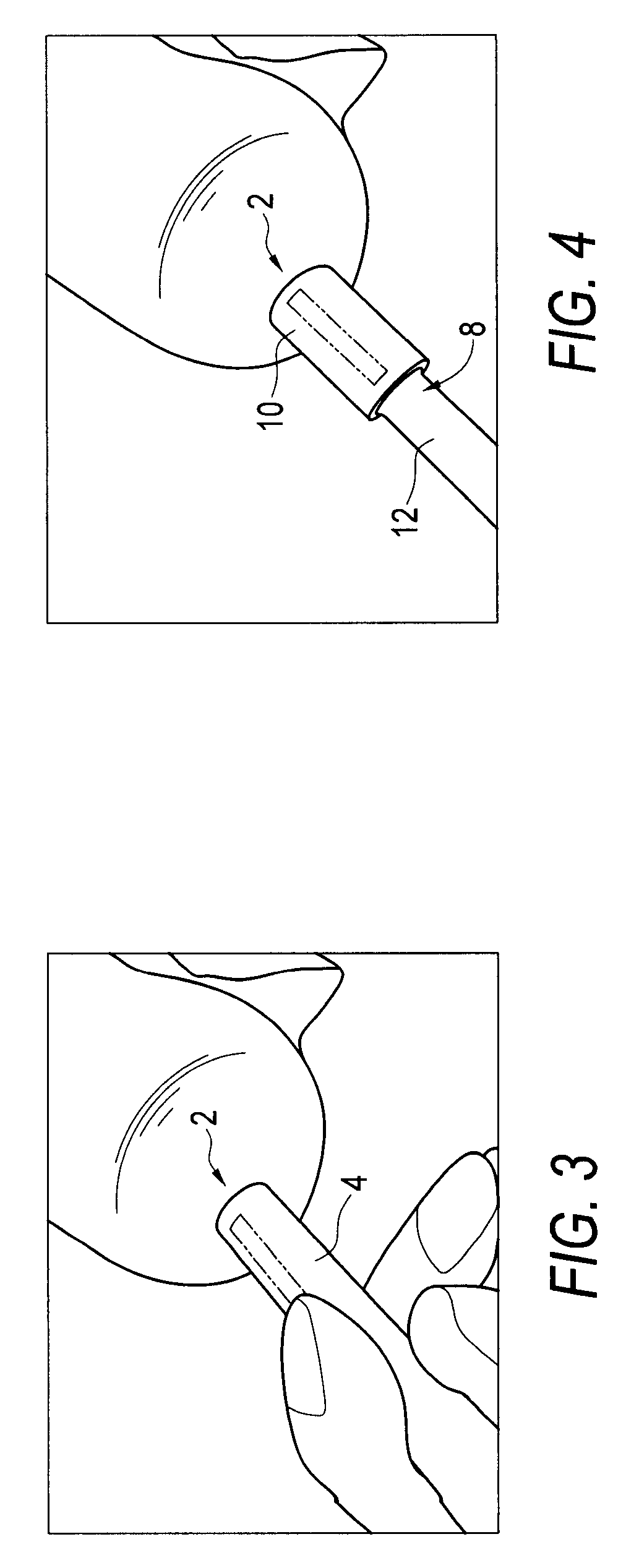

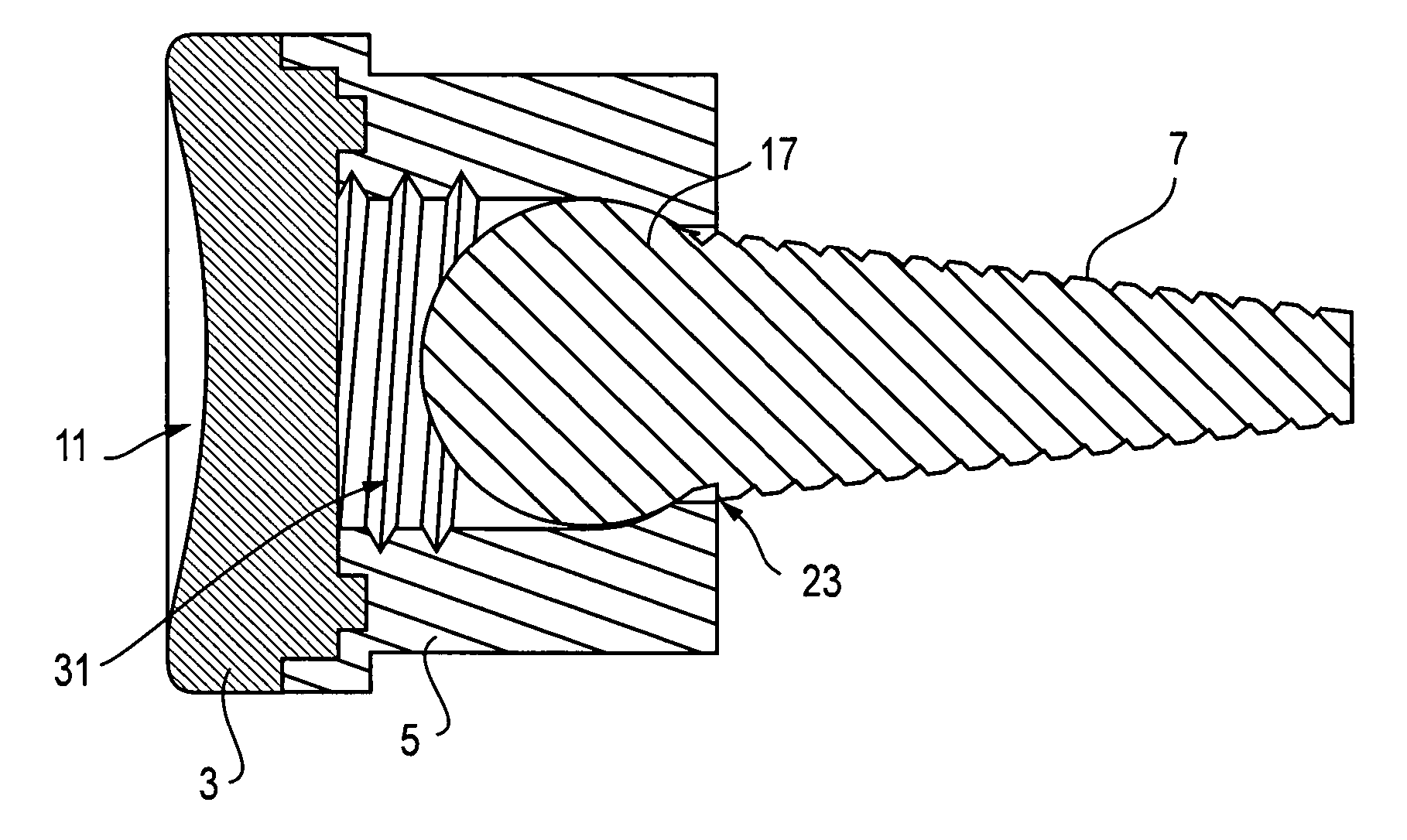

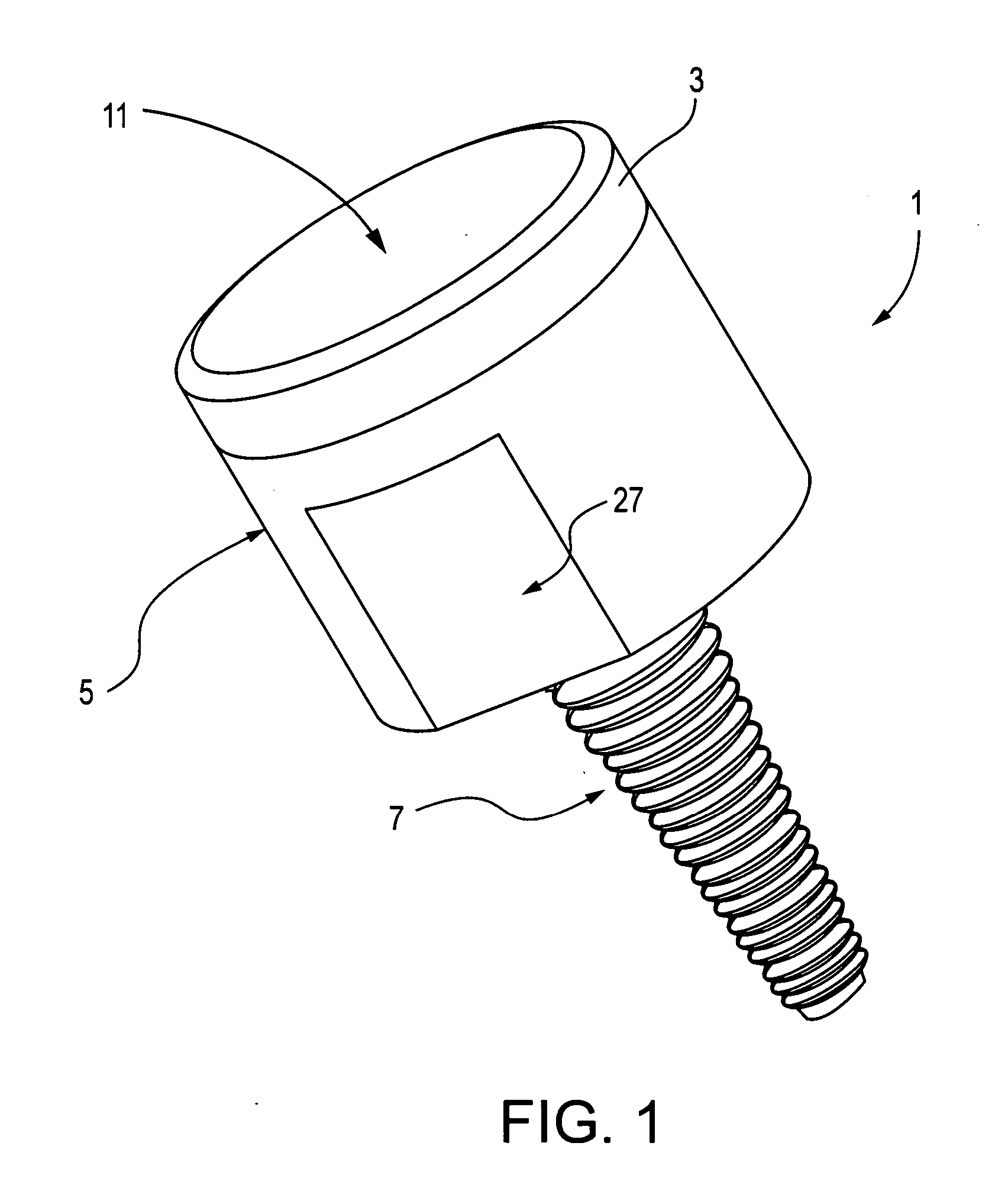

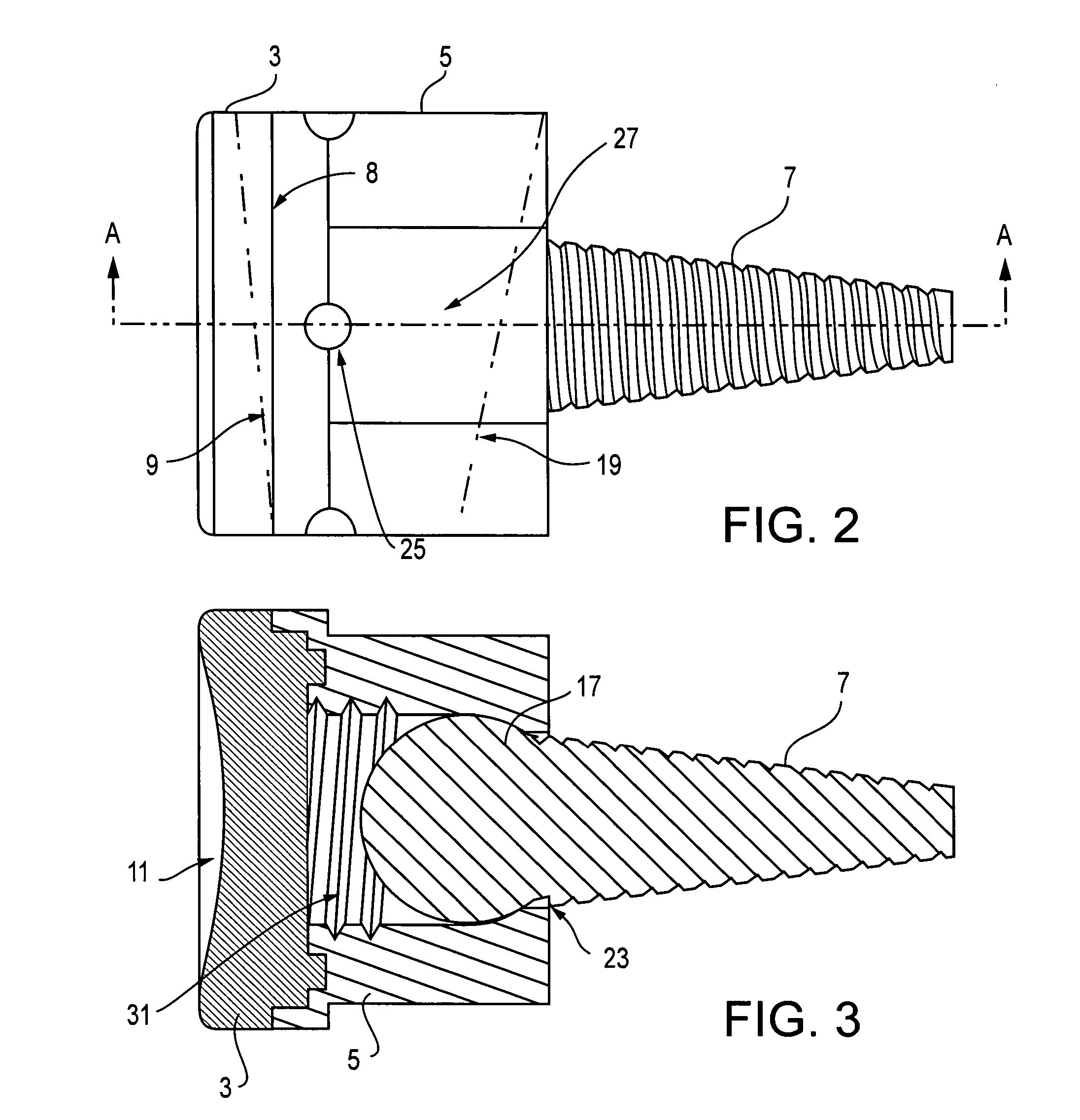

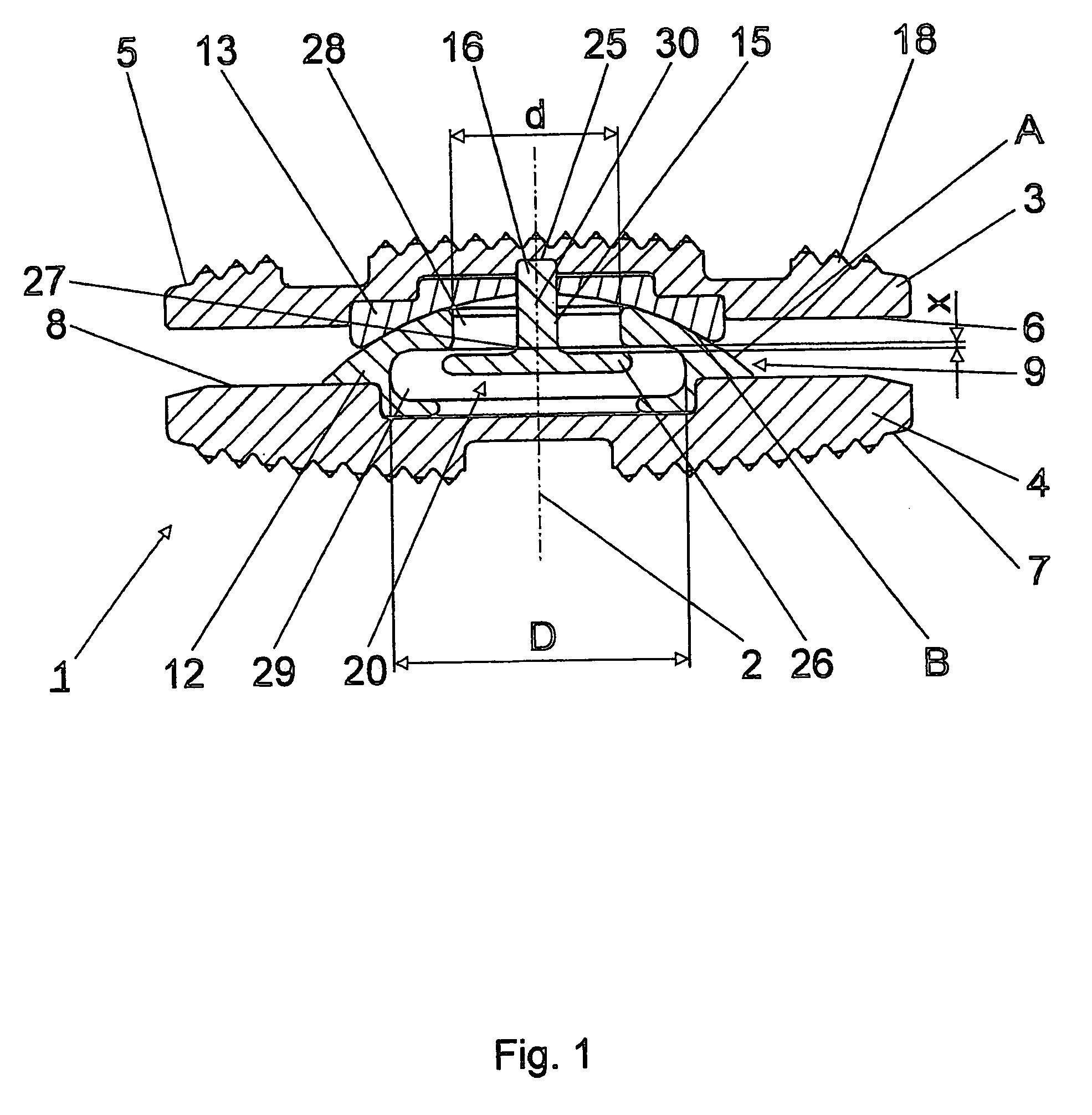

Surgical instrument for handling an implant

InactiveUS7549995B2Increase heightMinimizing developmentDiagnosticsJoint implantsJoint surfaceSurgical device

Owner:AESCULAP AG

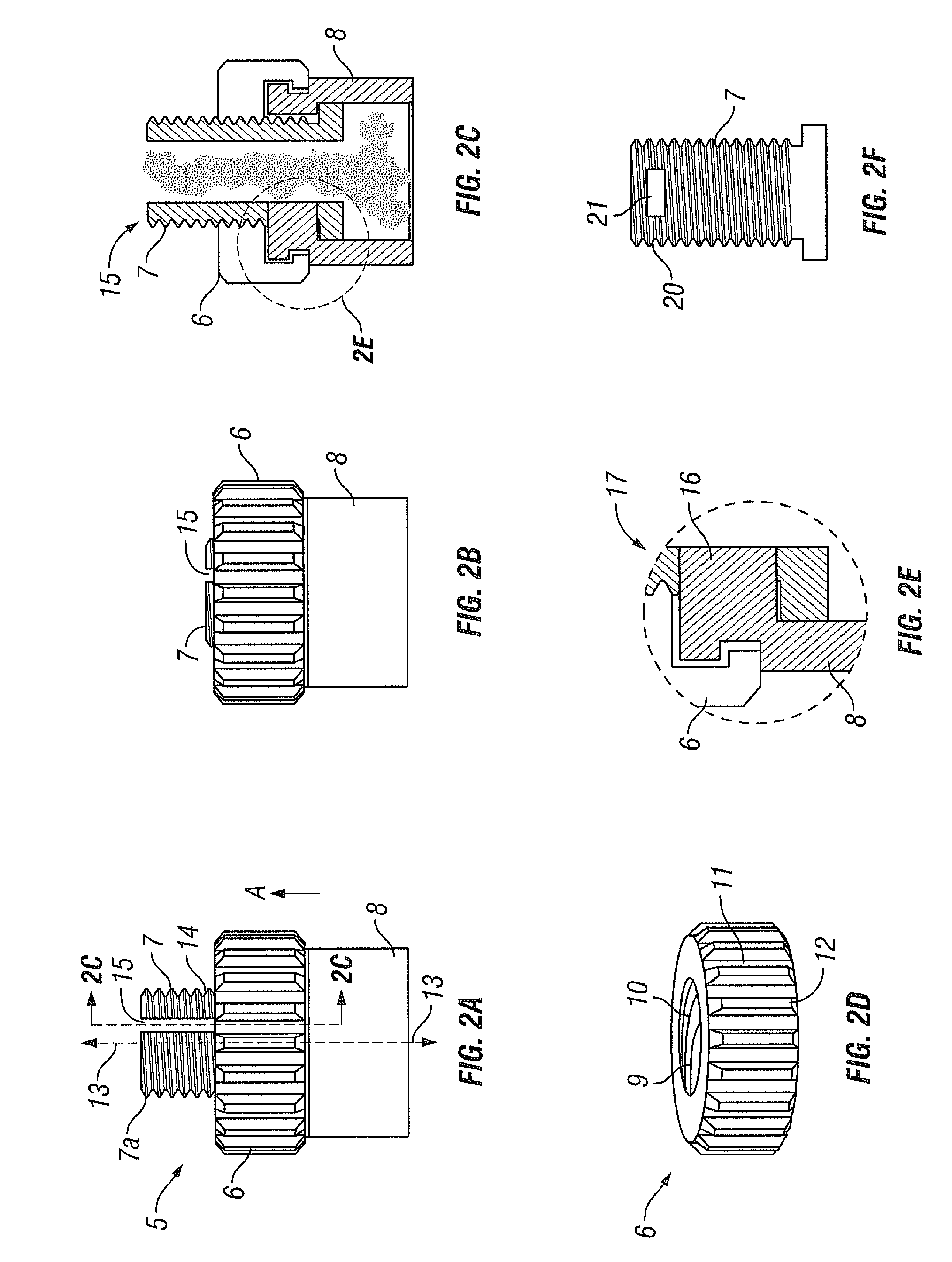

Modular joint replacement implant with hydrogel surface

An endoprosthetic joint implant includes a fixation element and a hydrogel hinge portion. The fixation element supports the hydrogel hinge portion on a resected bone-end, for example, for use in surgical joint replacement. The fixation element of one embodiment features a stem made of titanium. The stem is threaded for insertion distally into an intramedullary canal. The hydrogel hinge portion connects to the stem using a snap-fit arrangement. The hydrogel is available in various surface configurations and can articulate against a natural joint surface or a synthetic joint surface. A total joint-replacement implant is provided by attaching a second stem to an opposite side of the hinge for insertion into bone on the opposed side of the articulation.

Owner:ARTHREX

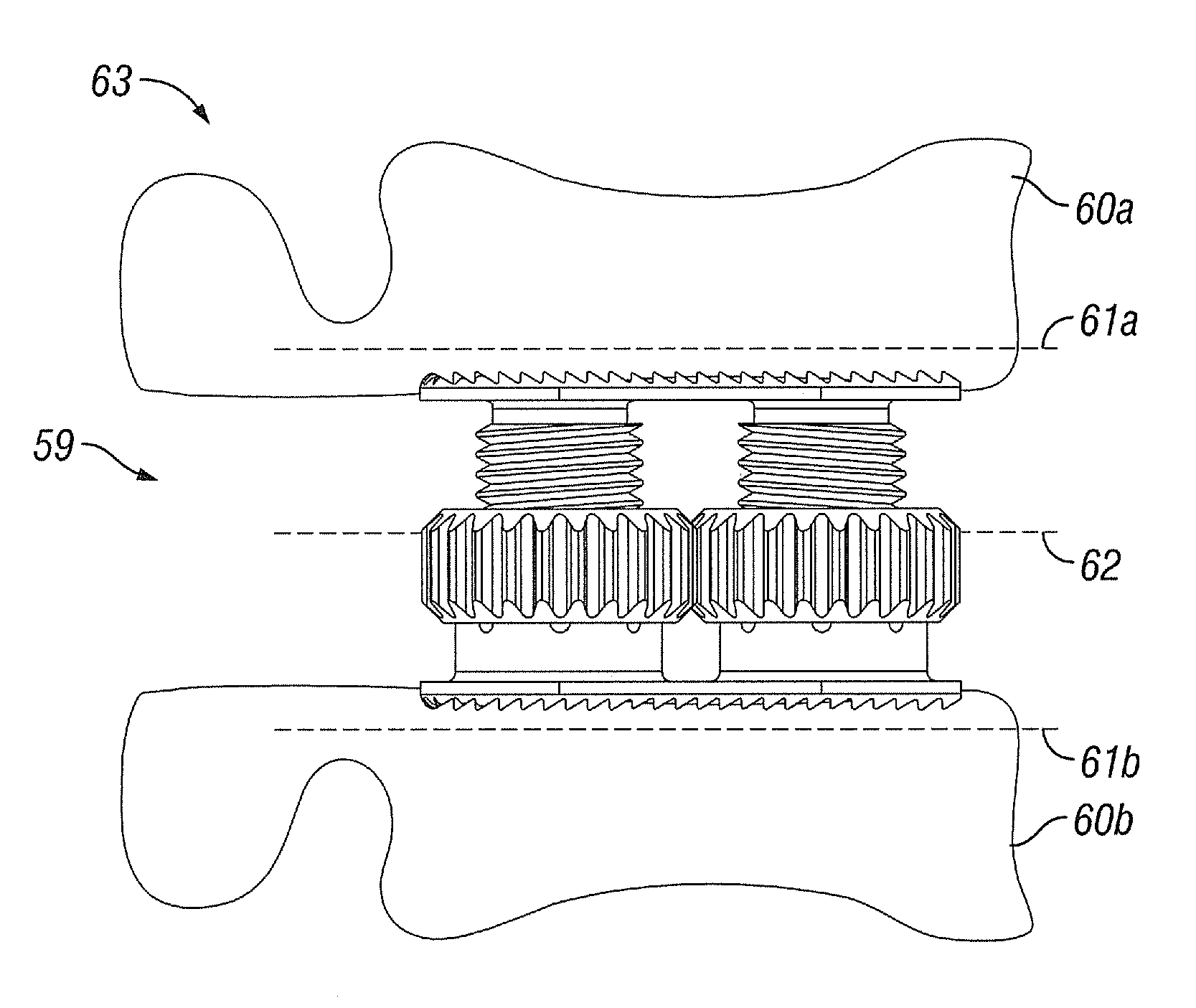

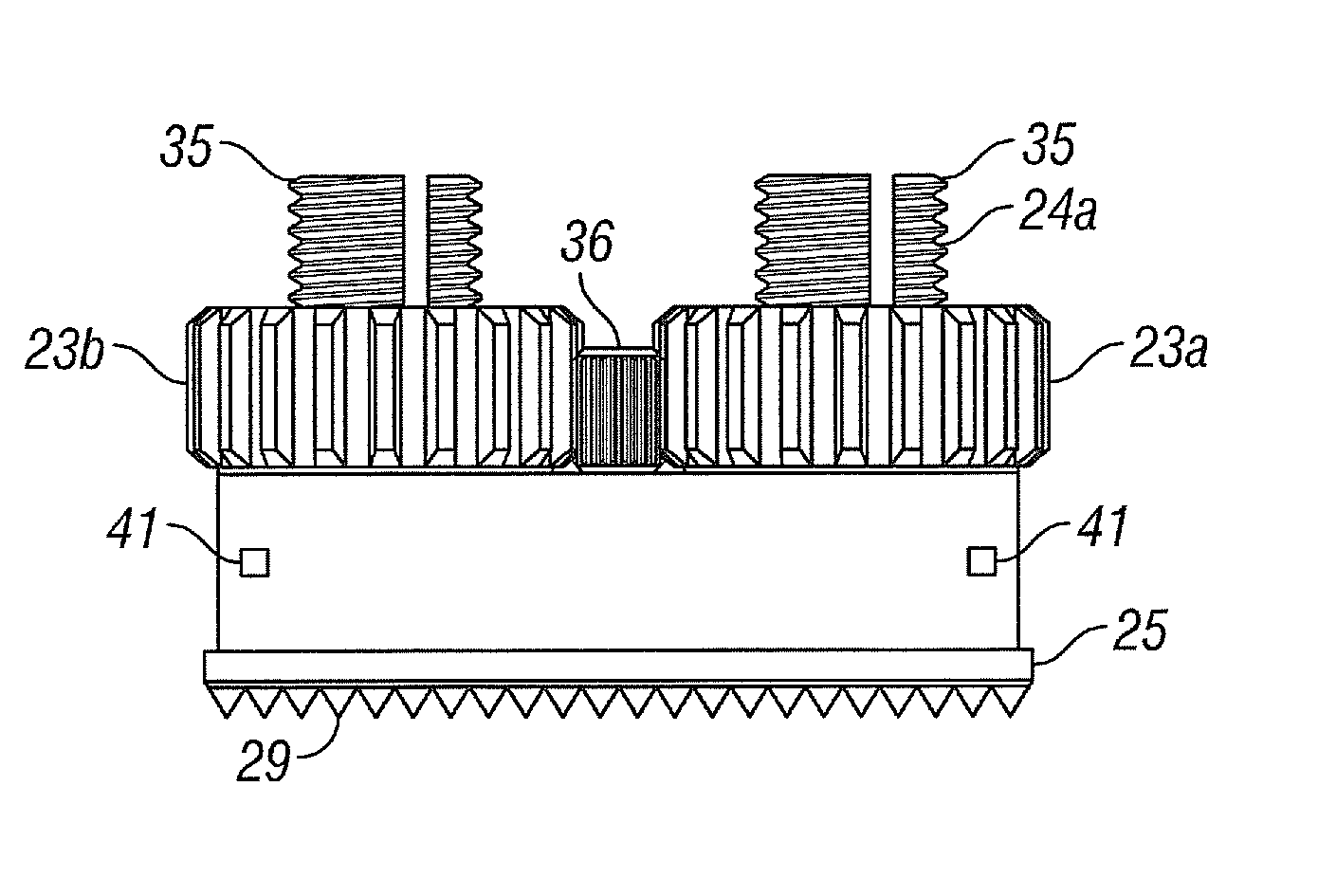

Expandable Spacer and Method For Use Thereof

ActiveUS20110172716A1Facilitates arthrodesisEasy to fuseBone implantJoint implantsArticular surfacesJoint arthrodesis

An expandable implant is disclosed having an adjustable height for insertion between two adjacent bony structures or joint surfaces, for example between two adjacent spinal vertebrae. The implant includes at least one gear associated with at least one threaded shaft. Rotation of the gear engages the threaded shaft to expand the implant. The implant can be inserted in a collapsed configuration and expanded in situ. The invention also provides methods for using the implant to facilitate arthrodesis or fusion of adjacent joint surfaces or spinal vertebrae.

Owner:GLOBUS MEDICAL INC

Expandable spacer and method for use thereof

ActiveUS8353963B2Facilitates arthrodesis and fusionEasy to adjustBone implantJoint implantsArticular surfacesJoint arthrodesis

Owner:GLOBUS MEDICAL INC

Intervertebral implant

ActiveUS7198644B2Reduce riskConvenient ArrangementJoint implantsSpinal implantsFront edgeJoint surface

An intervertebral implant for contact with adjacent vertebral bodies is provided. The implant includes a first carrier plate including a front edge, a middle, a rear edge, and a concave, crowned joint surface comprising a lowest point. The implant further includes a second carrier plate including a front edge, a middle, a rear edge, a center line extending between said front edge and said rear edge, and a convex, crowned joint surface comprising a highest point. The joint surfaces are positioned flatly in contact with one another and are configured to support the carrier plates pivotably with respect to one another. The highest and lowest points of the joint surfaces are positioned between the rear edges and the middles of the carrier plates. The convex joint surface projects farther away from the second carrier plate at its end facing the rear edge than at its end facing the front edge.

Owner:AESCULAP AG

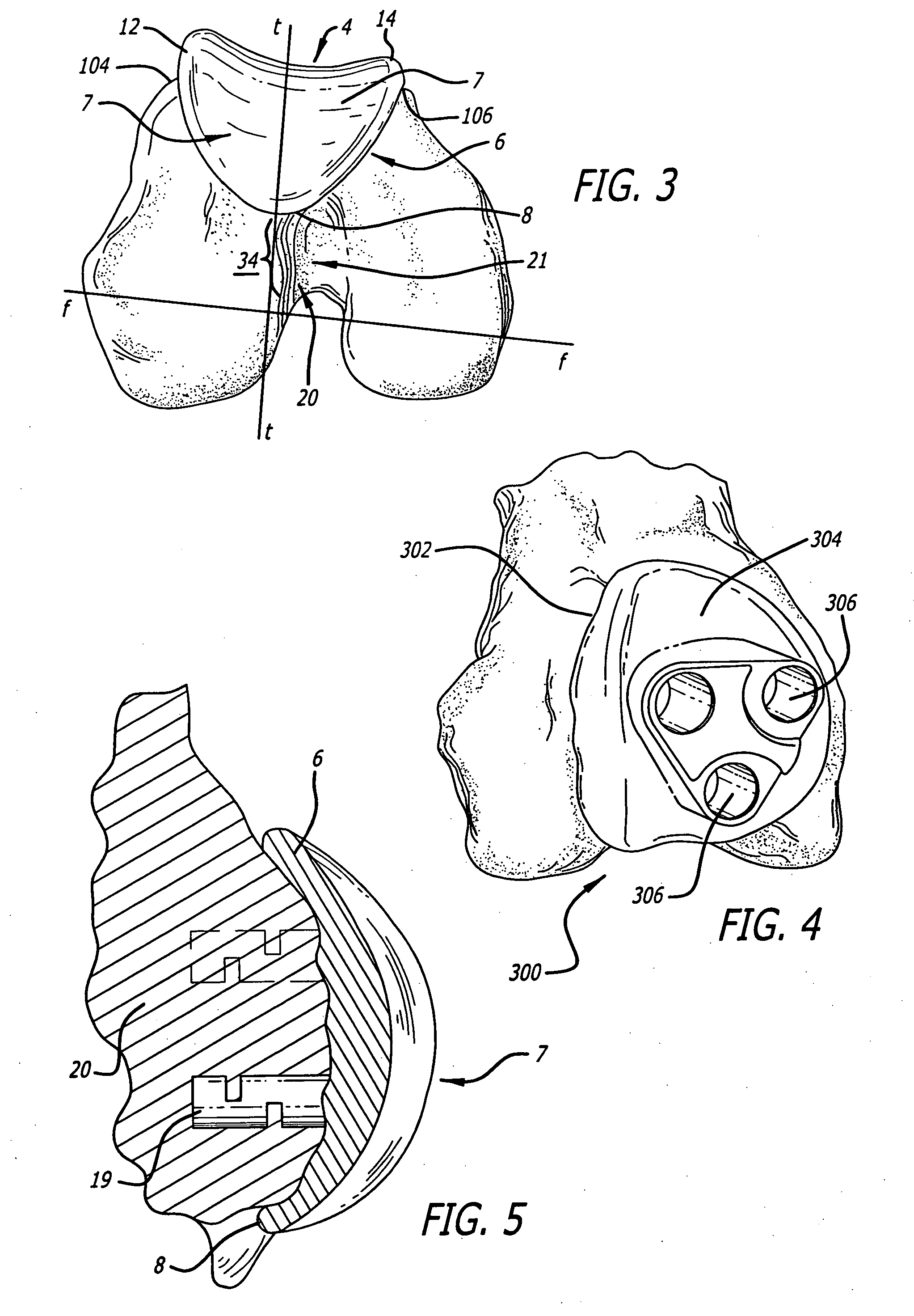

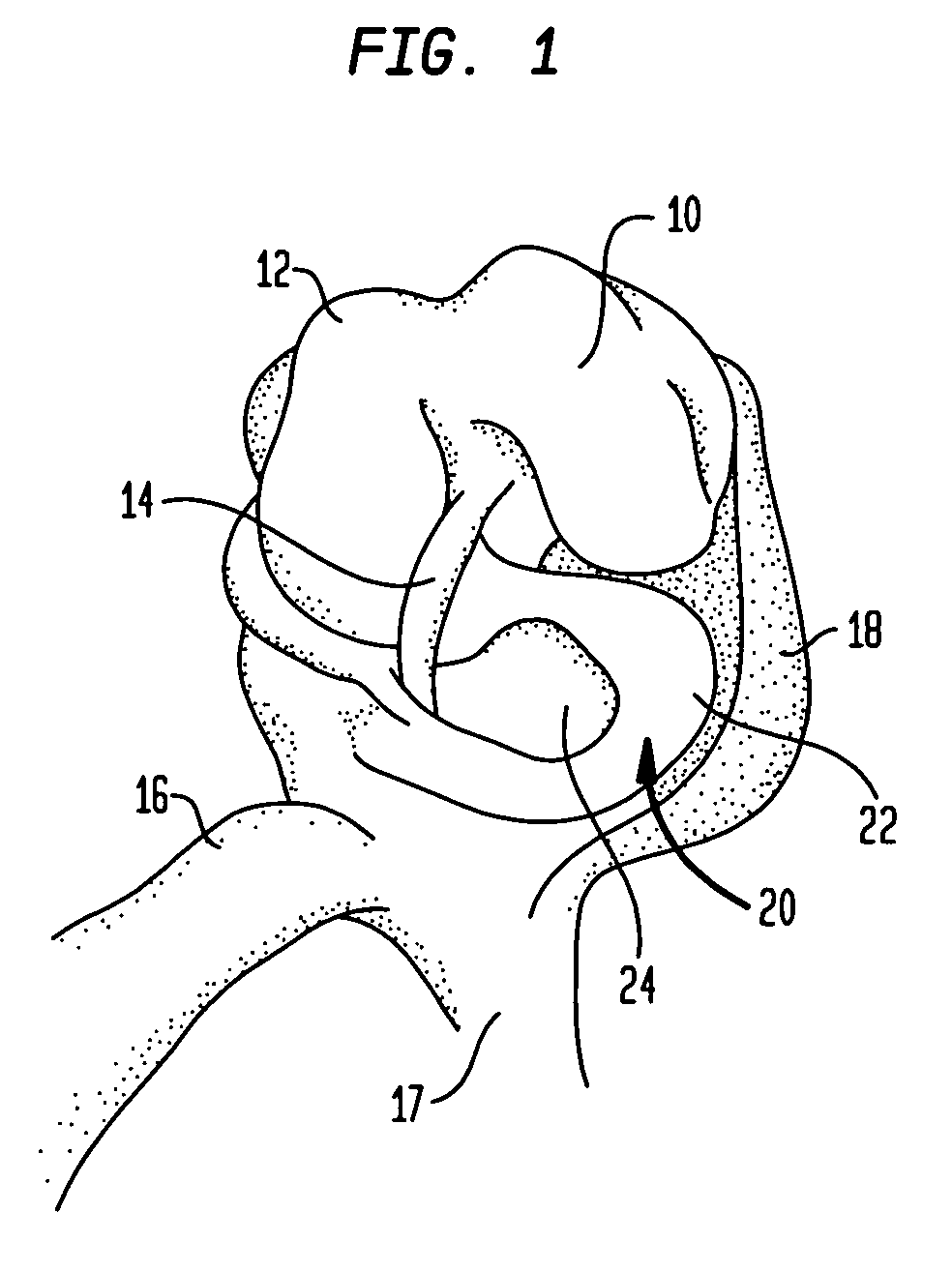

Meniscal and tibial implants

InactiveUS6994730B2Highly mobile but stable jointSuture equipmentsDiagnosticsArticular surfacesTibia

Instrumentation and a method for resurfacing a joint capsule having cartilage and meniscal surfaces such as a knee joint includes resecting a central portion of the joint cartilage on one joint member such as the tibia while leaving a meniscal rim attached to the peripheral joint capsule. A cavity is then formed in the bone underlying the central portion of the joint surface such as the lateral tibial surface. A resurfacing implant is then coupled, by cementing for example, to the cavity. A soft prosthetic meniscal implant is then coupled to the remaining meniscal ring such as by suturing.

Owner:HOWMEDICA OSTEONICS CORP

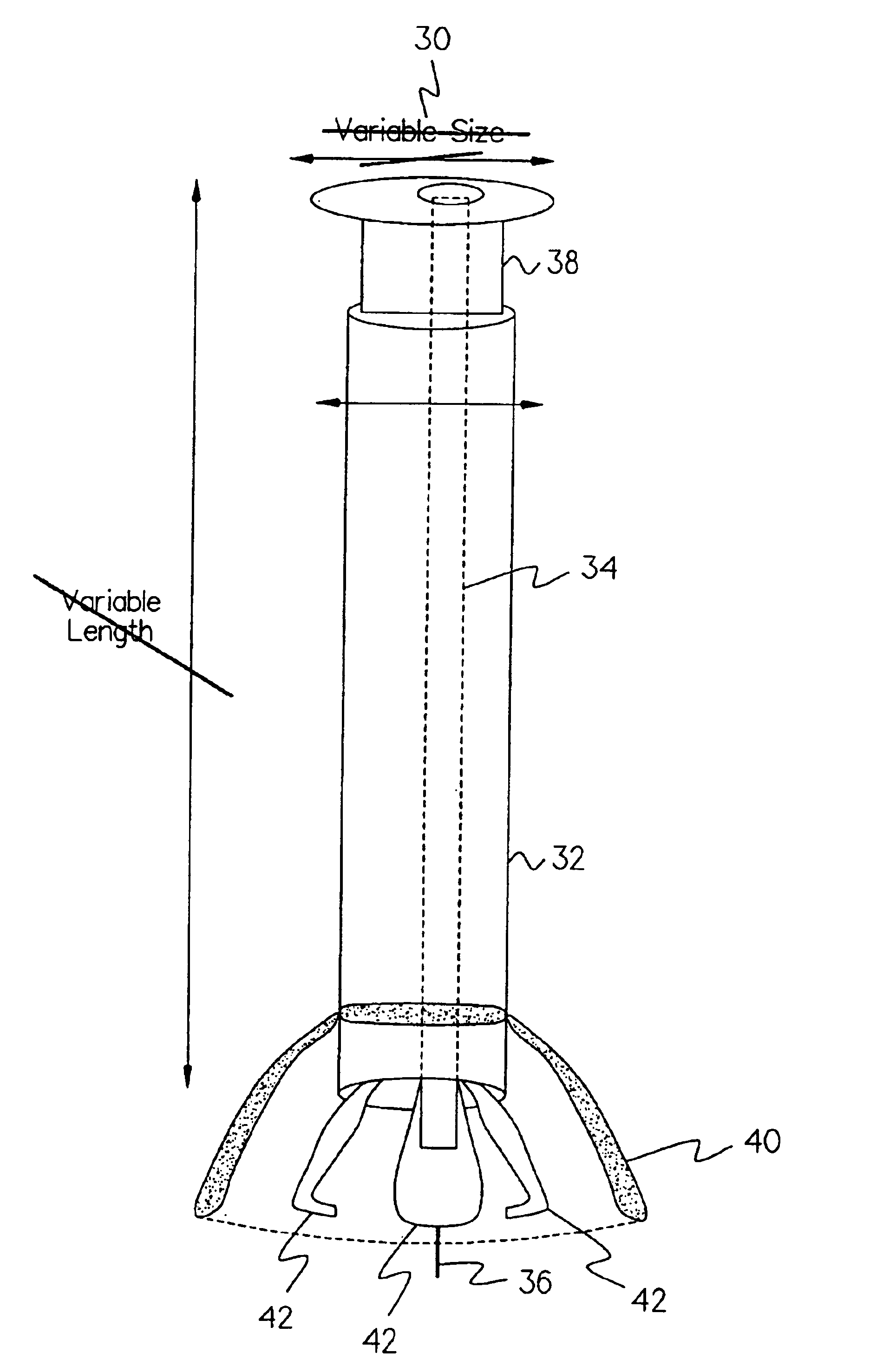

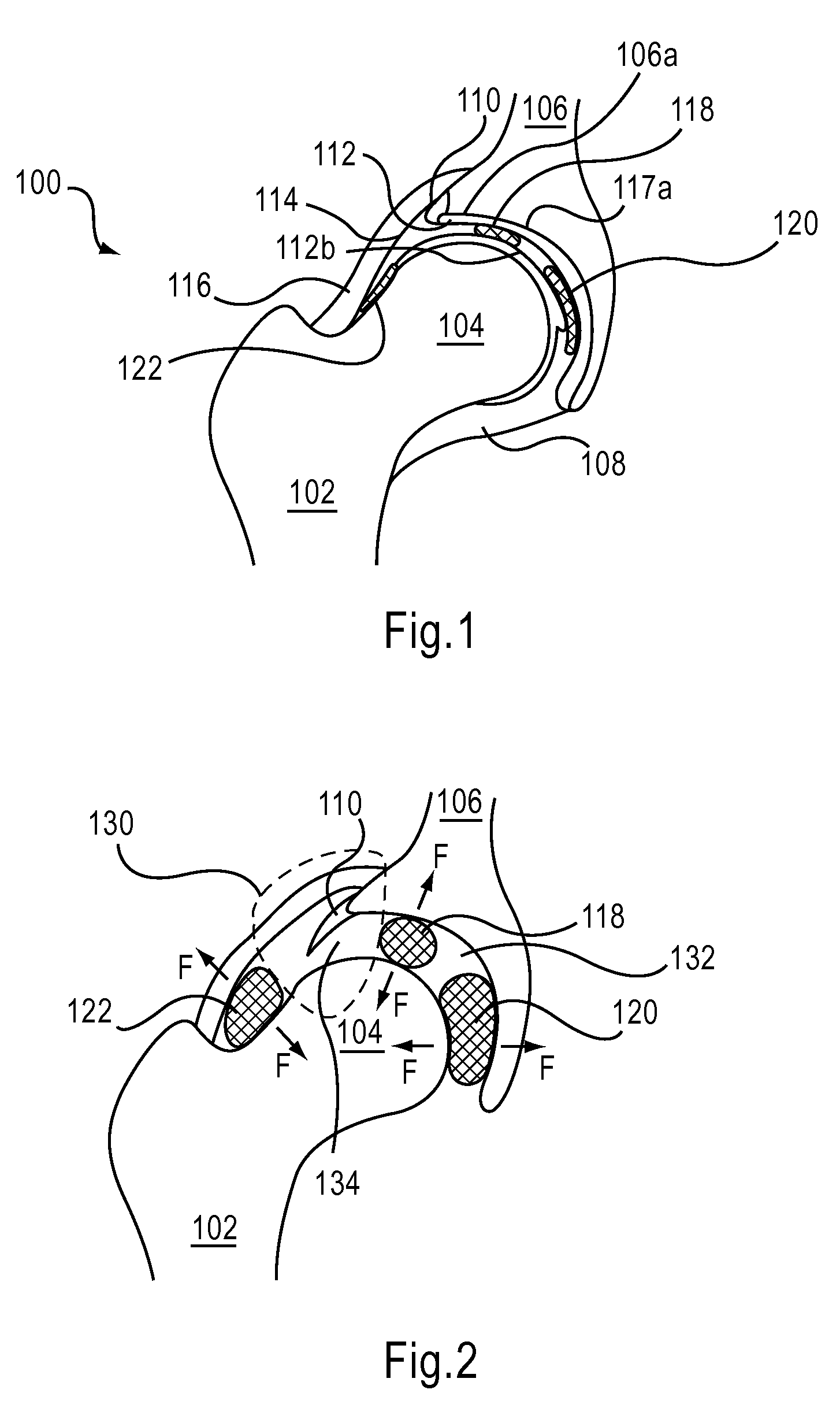

Device and Method for Hip Distention and Access

A device for accessing and distending a joint comprises a distraction structure having a generally tapered distal portion adapted to penetrate a tissue region and create an access space within a joint. The distraction structure also includes a lumen extending from a proximal surface to a distal portion. The device further includes a distention structure deployable through the lumen and adapted to exert a force between a first joint surface and a second joint surface and create a working space. The distention structure may, in some embodiments, include an elongate member having a proximal end, a distal end, and a lumen extending along at least a portion of the length of the elongate member, a first expandable region deployable from a first substantially collapsed position to a second substantially expanded position, the first expandable region adapted to exert a force between the first joint surface from the second joint surface.

Owner:HIPCO

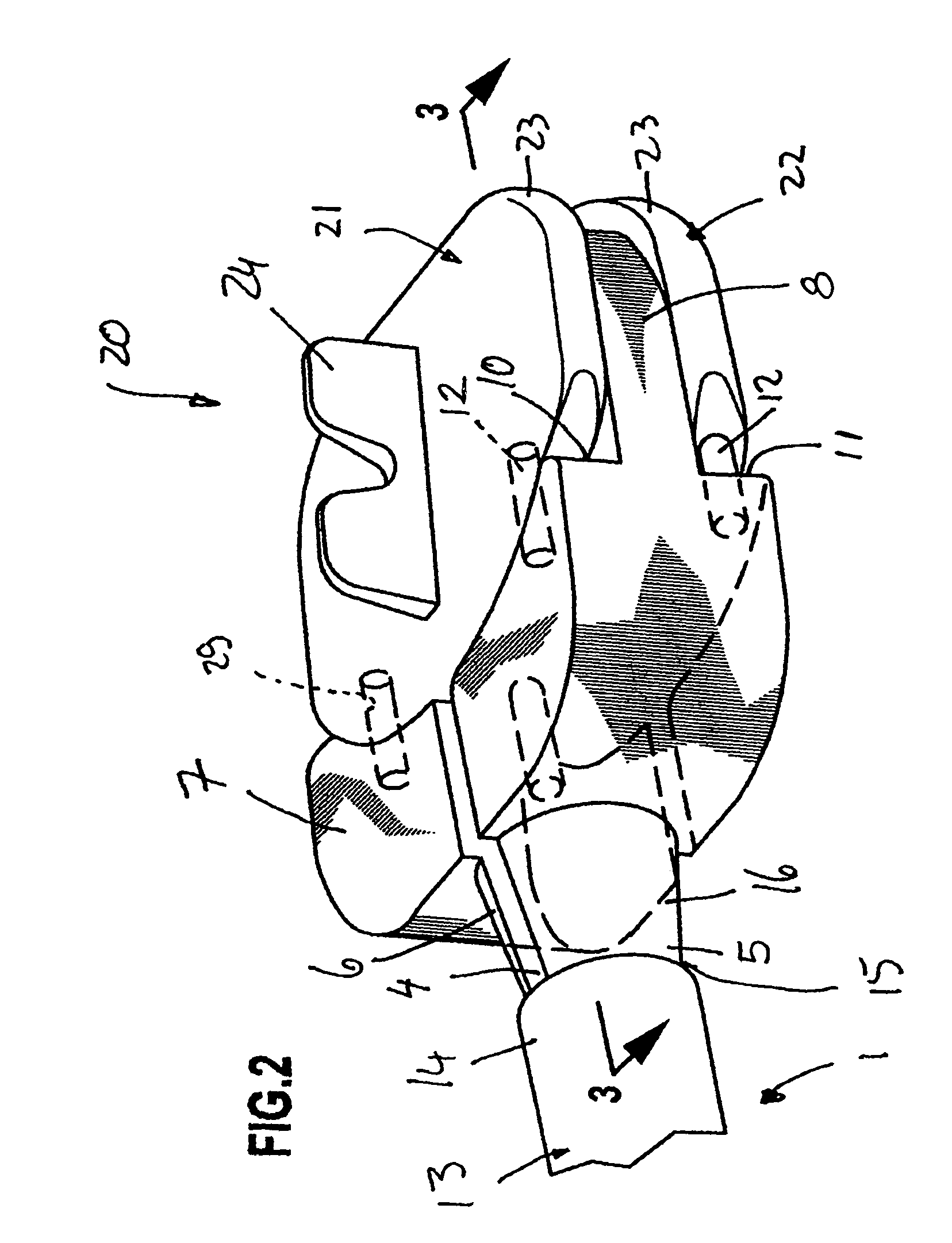

Surgical instrument for handling an implant

InactiveUS20050033305A1Increase heightMinimizing developmentDiagnosticsJoint implantsArticular surfacesSacroiliac joint

A surgical instrument for handling an implant having two parts, each of which includes a joint surface facing the other part, wherein the joint surfaces are in contact with one another in an implanted state and permit pivoting of the two parts in relation to one another, is provided. The instrument includes holding means for detachably connecting the instrument with each of the two parts of the implant. The instrument further includes a spacer element extending between the parts of the implant when the parts are connected with the instrument and maintaining a distance between the parts, thereby preventing the joint surfaces of the two parts of the implant from contacting each other.

Owner:AESCULAP AG

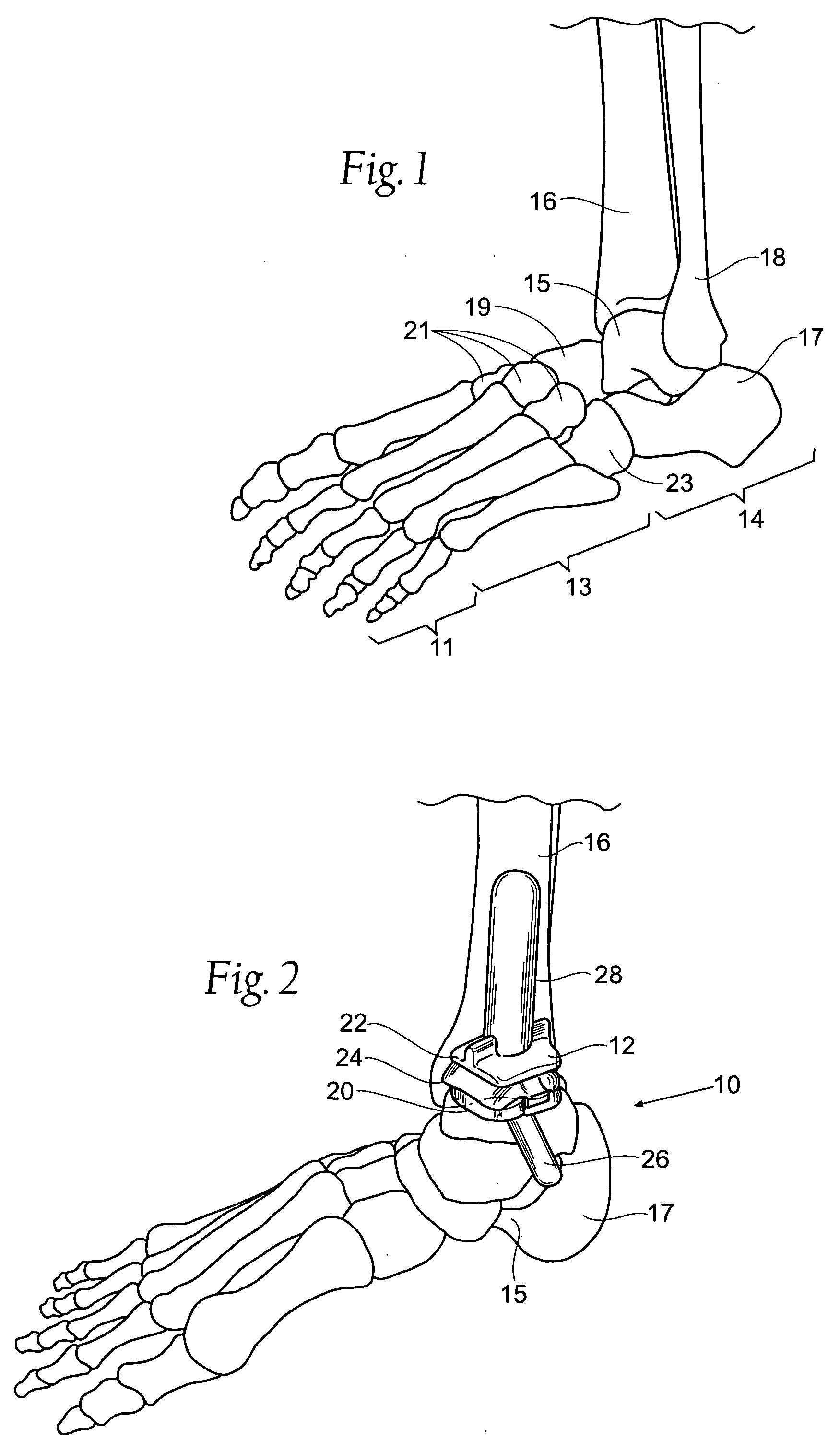

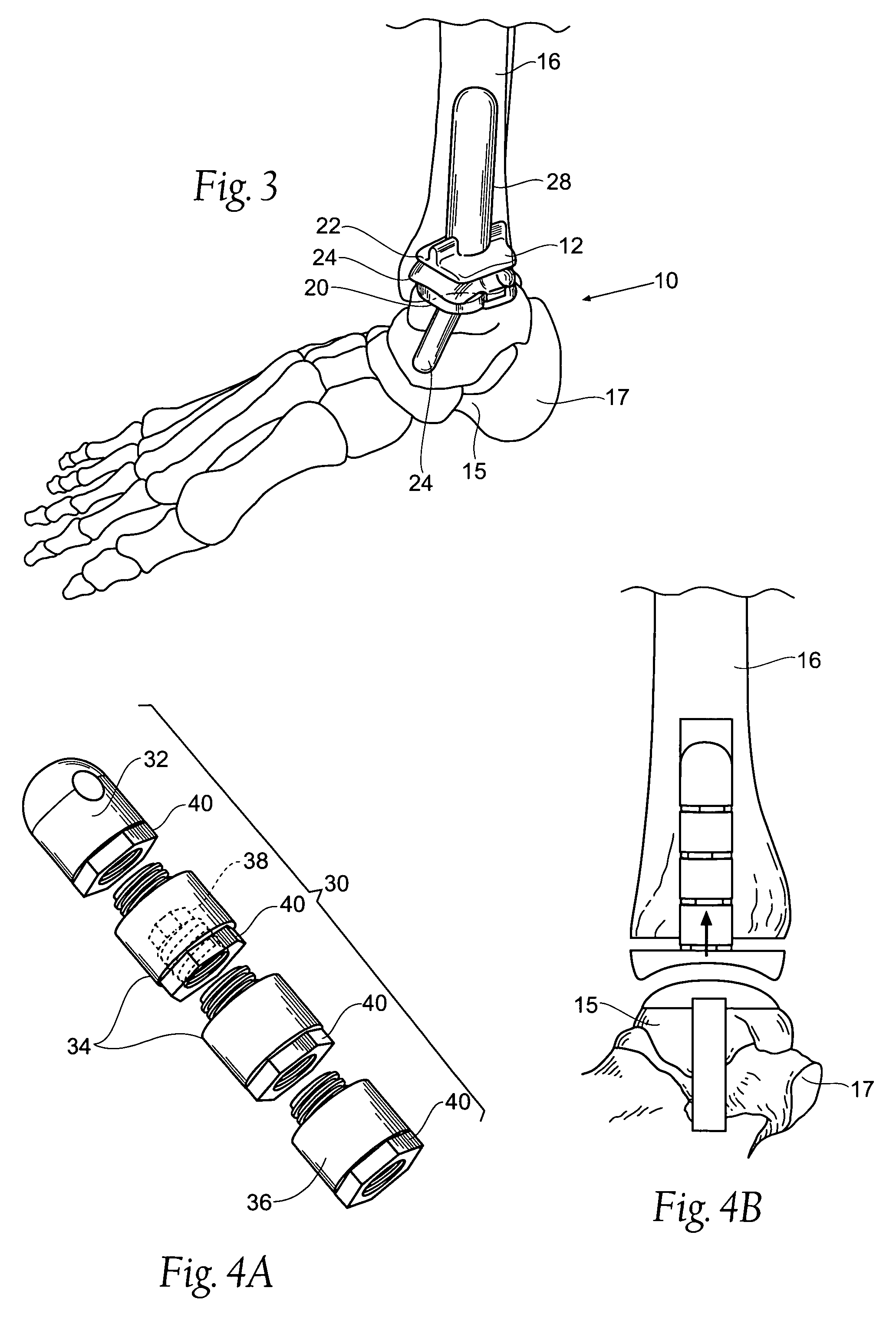

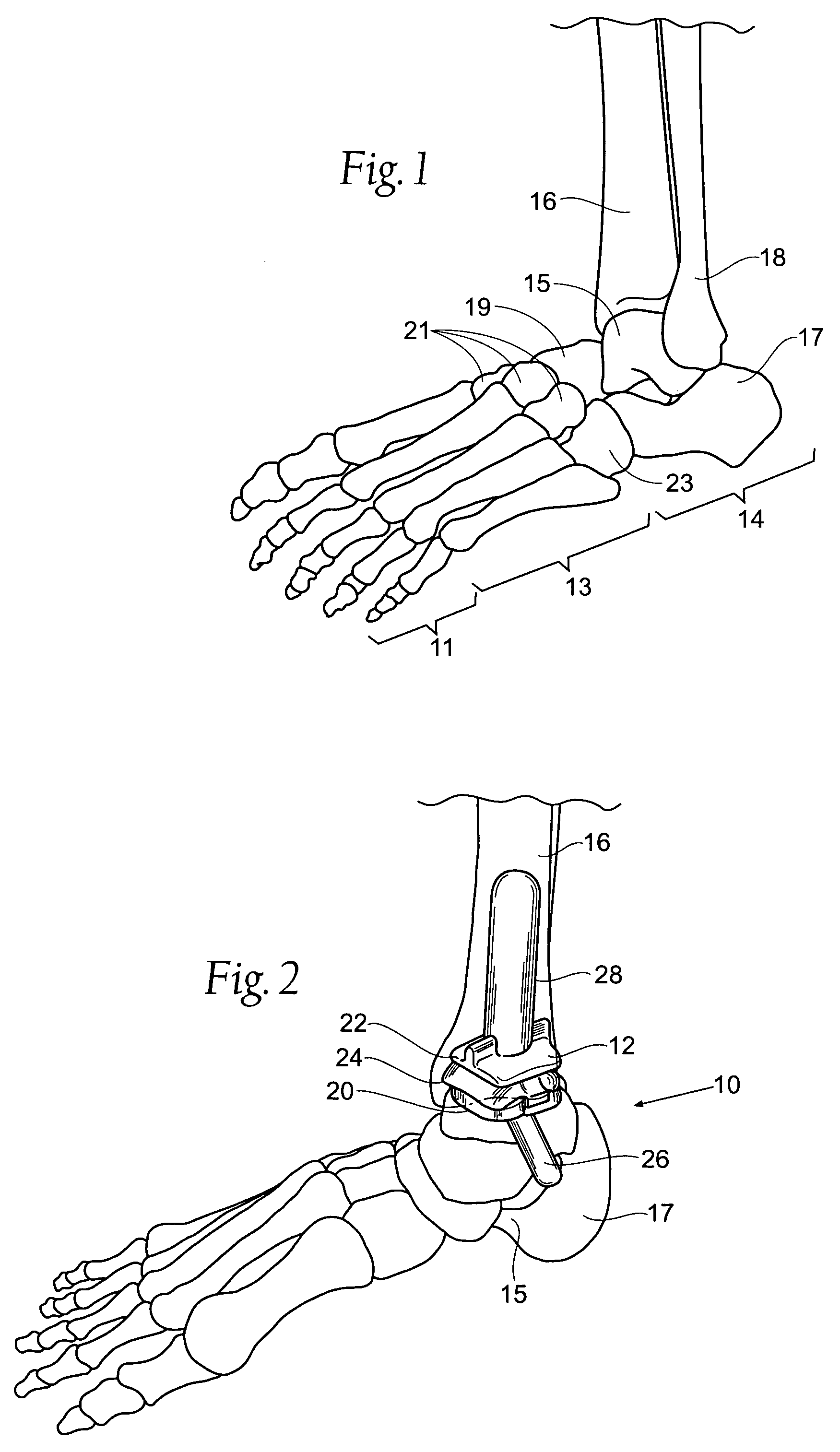

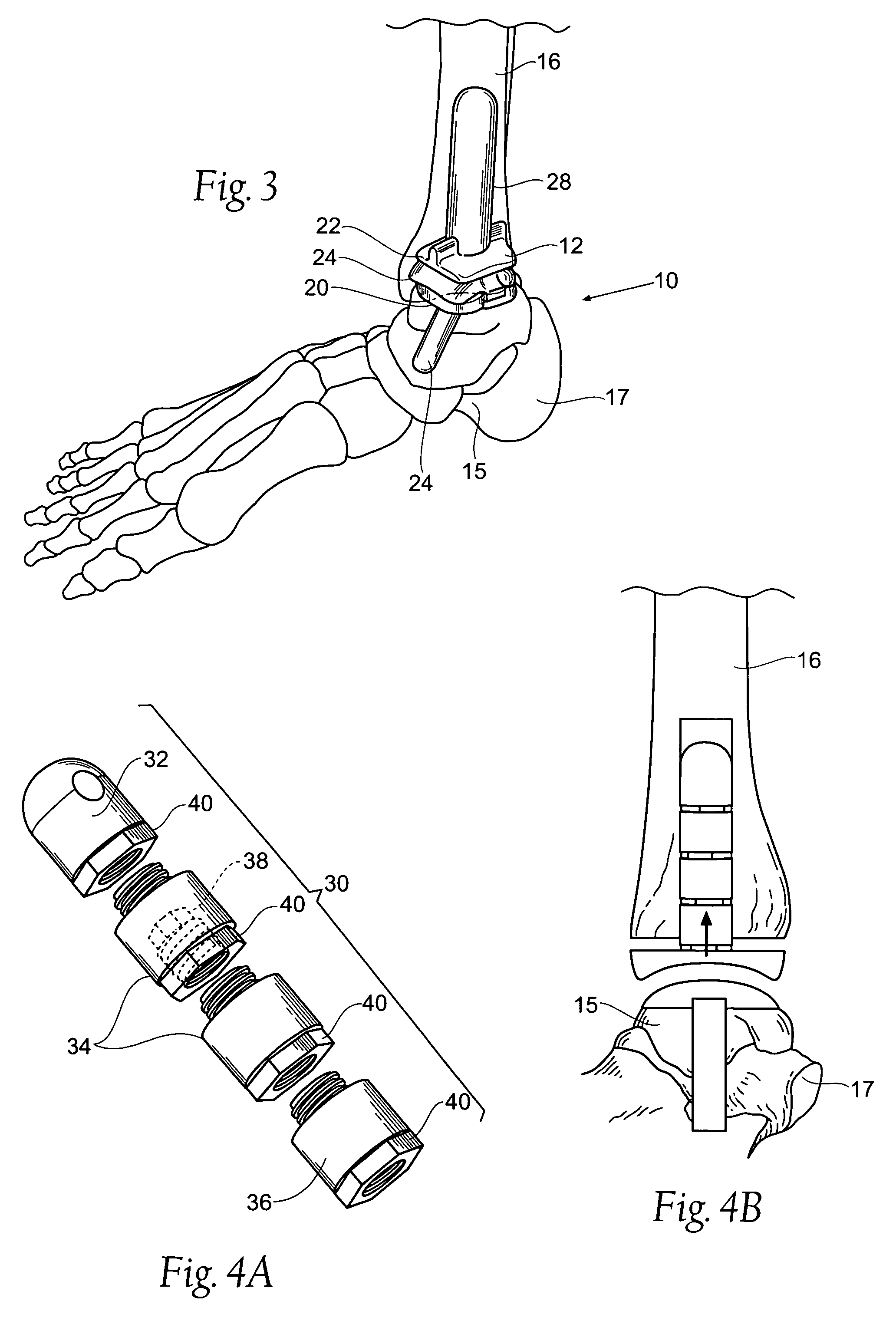

Ankle replacement system

ActiveUS20060229730A1Improved long-term resultPrecise positioningWrist jointsAnkle jointsCalcaneusAnkle joint replacement

A prosthesis suited for orthopedic implantation possesses a multi-piece stem component that supports an artificial joint surface that can articulate with another artificial joint surface in various ways. The prosthesis can be assembled in a snap fit and / or interlocking fashion that provides positive locking means without the use of screws or other fasteners. The prosthesis can accommodate fitment of a plastic joint surface made, e.g., from ultra high molecular weight polyethylene. The prosthesis is well suited for use in an ankle replacement system that can be installed using minimally invasive intramedullary guidance established with respect to the major axis of the tibia by minimally invasive access through the calcaneus, through an incision in the bottom of the foot. The prosthesis makes possible the installation of a total ankle system using minimally invasive anterior access to the ankle joint for making bony cuts and to install prosthesis components.

Owner:INBONE TECH

Ankle replacement system

ActiveUS7534246B2Function maximizationMaximize longevityWrist jointsAnkle jointsArticular surfacesAnkle joint replacement

A prosthesis suited for orthopedic implantation possesses a multi-piece stem component that supports an artificial joint surface that can articulate with another artificial joint surface in various ways. The prosthesis can be assembled in a snap fit and / or interlocking fashion that provides positive locking means without the use of screws or other fasteners. The prosthesis can accommodate fitment of a plastic joint surface made, e.g., from ultra high molecular weight polyethylene. The prosthesis is well suited for use in an ankle replacement system that can be installed using minimally invasive intramedullary guidance established with respect to the major axis of the tibia by minimally invasive access through the calcaneus, through an incision in the bottom of the foot. The prosthesis makes possible the installation of a total ankle system using minimally invasive anterior access to the ankle joint for making bony cuts and to install prosthesis components.

Owner:INBONE TECH

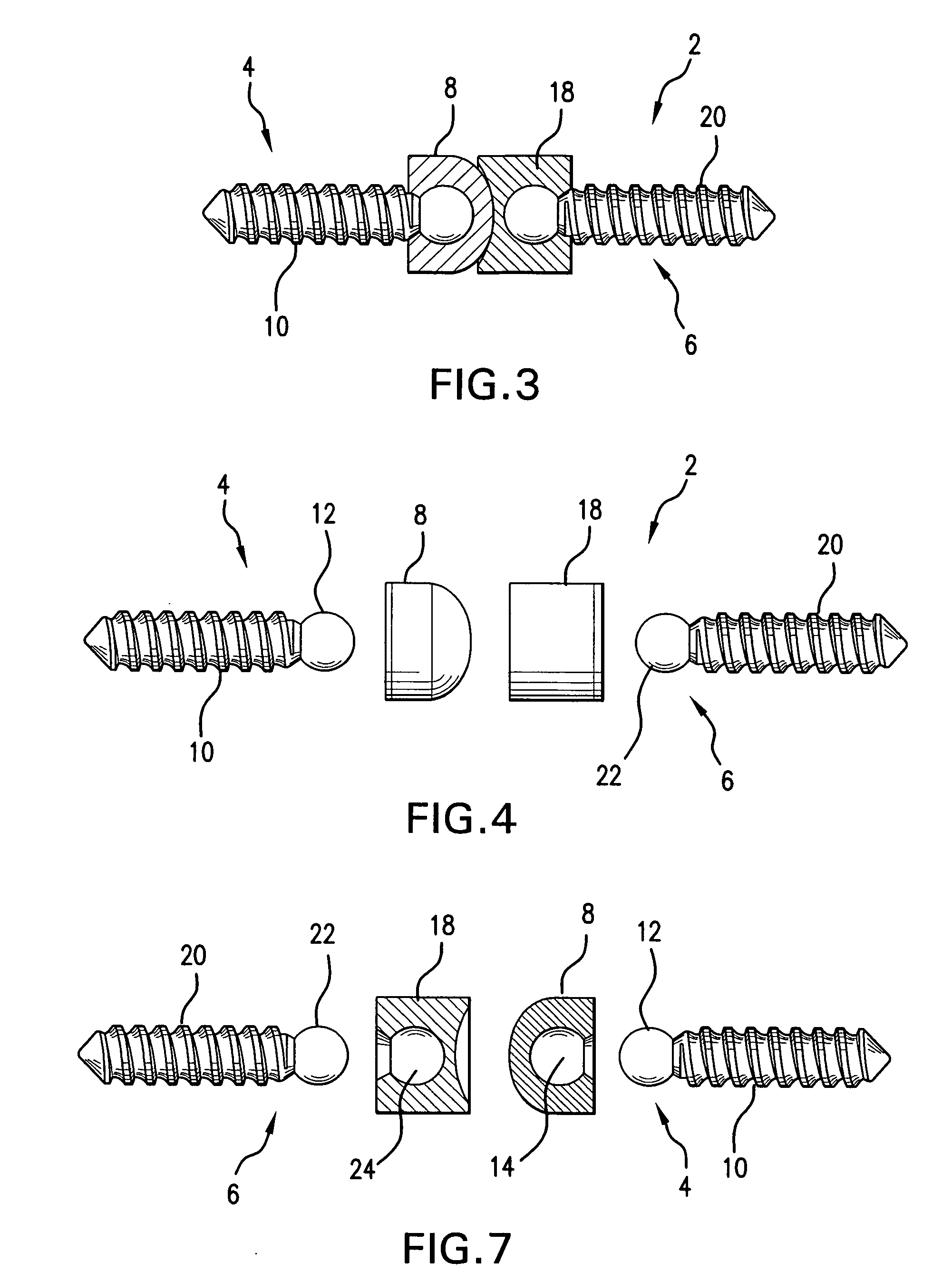

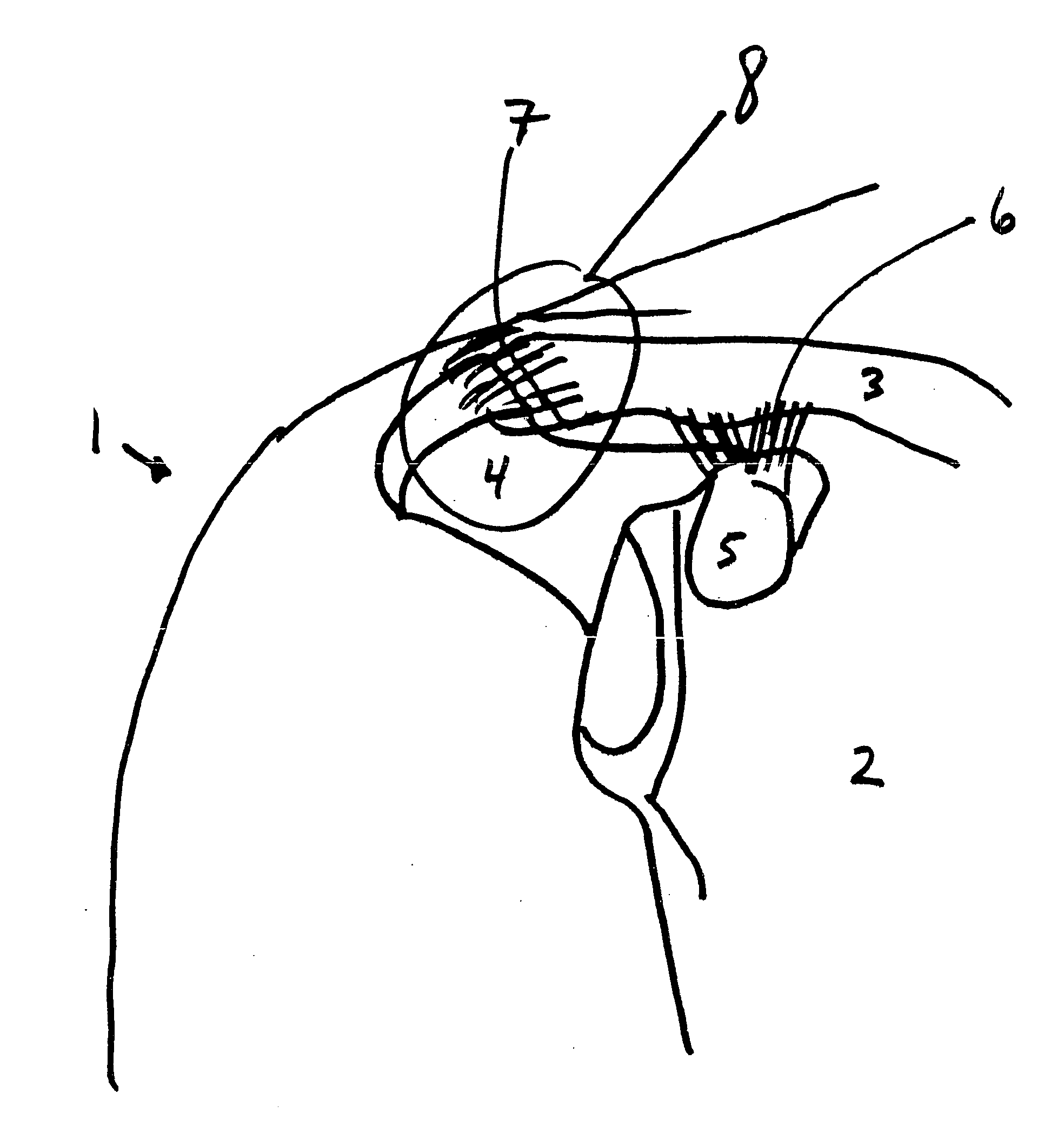

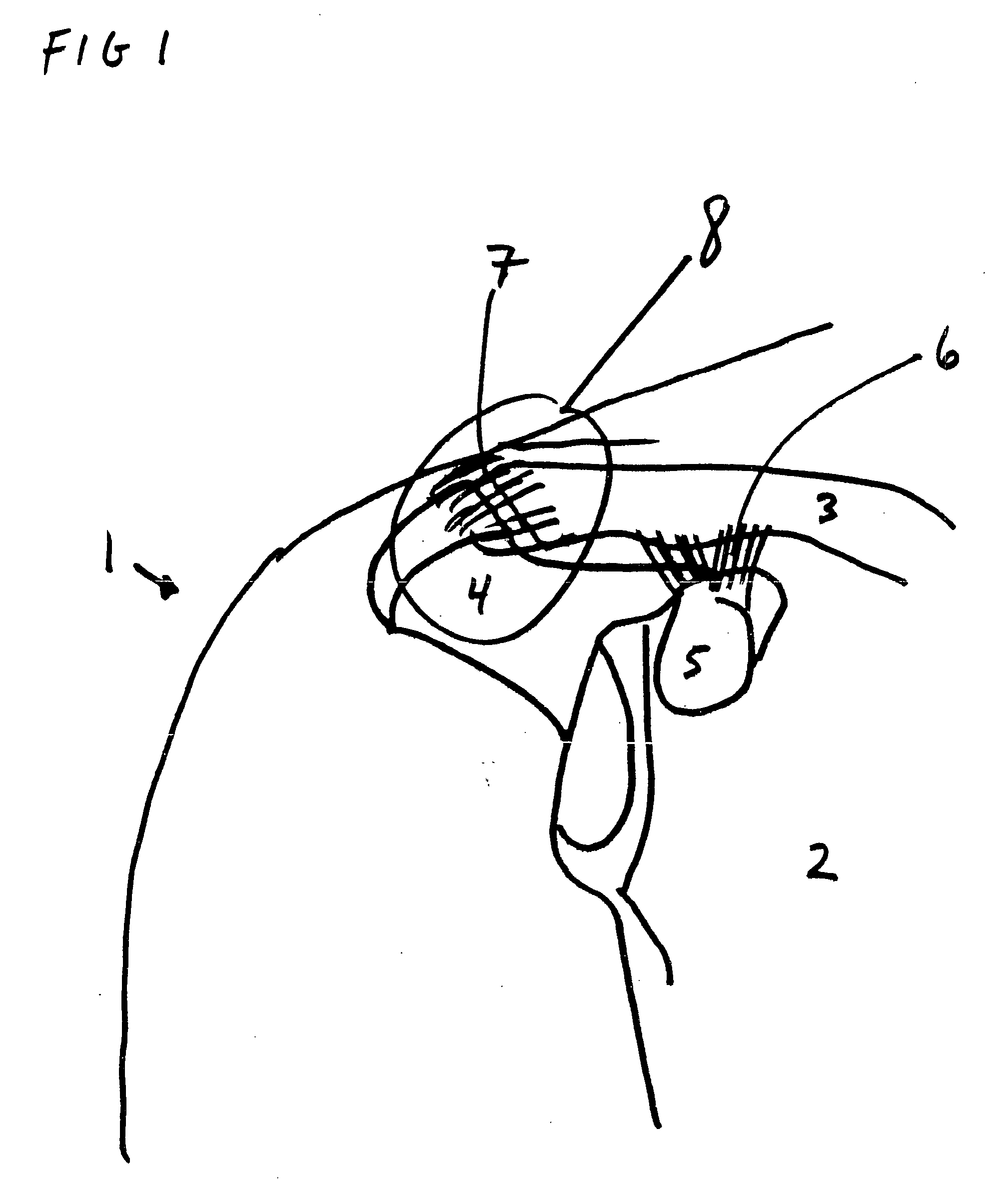

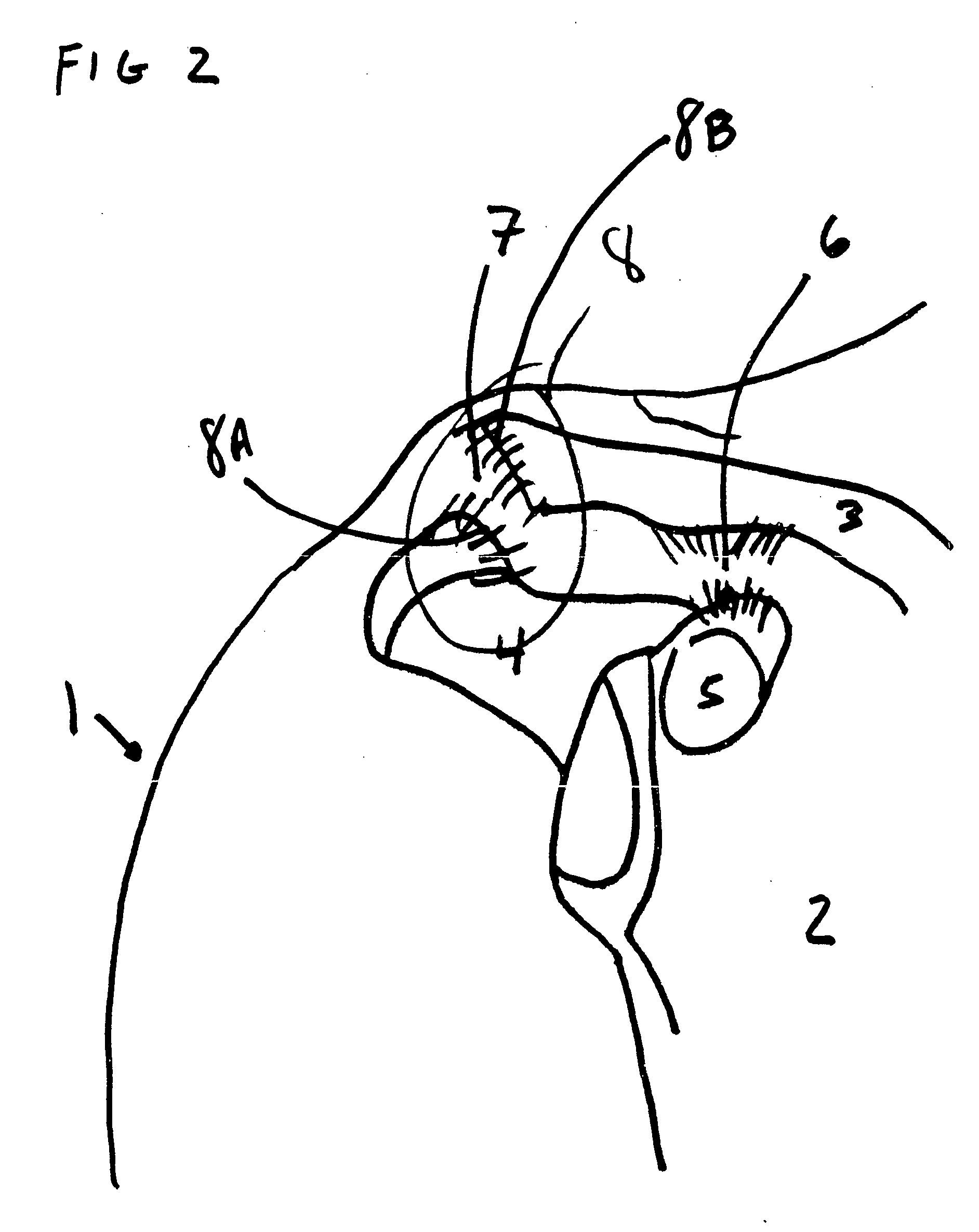

Acromioclavicular joint repair system

ActiveUS20070270804A1Promote repairMaintain alignmentSuture equipmentsInternal osteosythesisArticular surfacesEngineering

A system is disclosed for repairing and reconstructing a joint which has been injured by trauma, and especially an acromioclavicular joint. Means are disclosed to strengthen the repair or reconstruction and to maintain alignment while the ligaments in the joint heal, thus allowing more aggressive rehabilitation. A new joint repair tool is disclosed which is inserted into two separated bones adjacent to their respective articular joint surfaces to connect the two bones and approximate the adjacent bearing articular joint surfaces while still allowing motion between the two bones. Instruments to perform the methods are also disclosed.

Owner:CHUDIK STEVEN C

Resilient arthroplasty device

ActiveUS20100023126A1Preserve joint motionFree from painAnkle jointsSurgeryDiseaseArticular surfaces

The disclosure is directed to a resilient implant for implantation into human or animal joints to act as a cushion allowing for renewed joint motion. The implant endures variable joint forces and cyclic loads while reducing pain and improving function after injury or disease to repair, reconstruct, and regenerate joint integrity. The implant is deployed in a prepared debrided joint space, secured to at least one of the joint bones and expanded in the space, molding to surrounding structures with sufficient stability to avoid extrusion or dislocation. The implant has opposing walls that move in varied directions, and an inner space filled with suitable filler to accommodate motions which mimic or approximate normal joint motion. The implant pads the damaged joint surfaces, restores cushioning immediately and may be employed to restore cartilage to normal by delivering regenerative cells.

Owner:IORTHOPEDICS INC

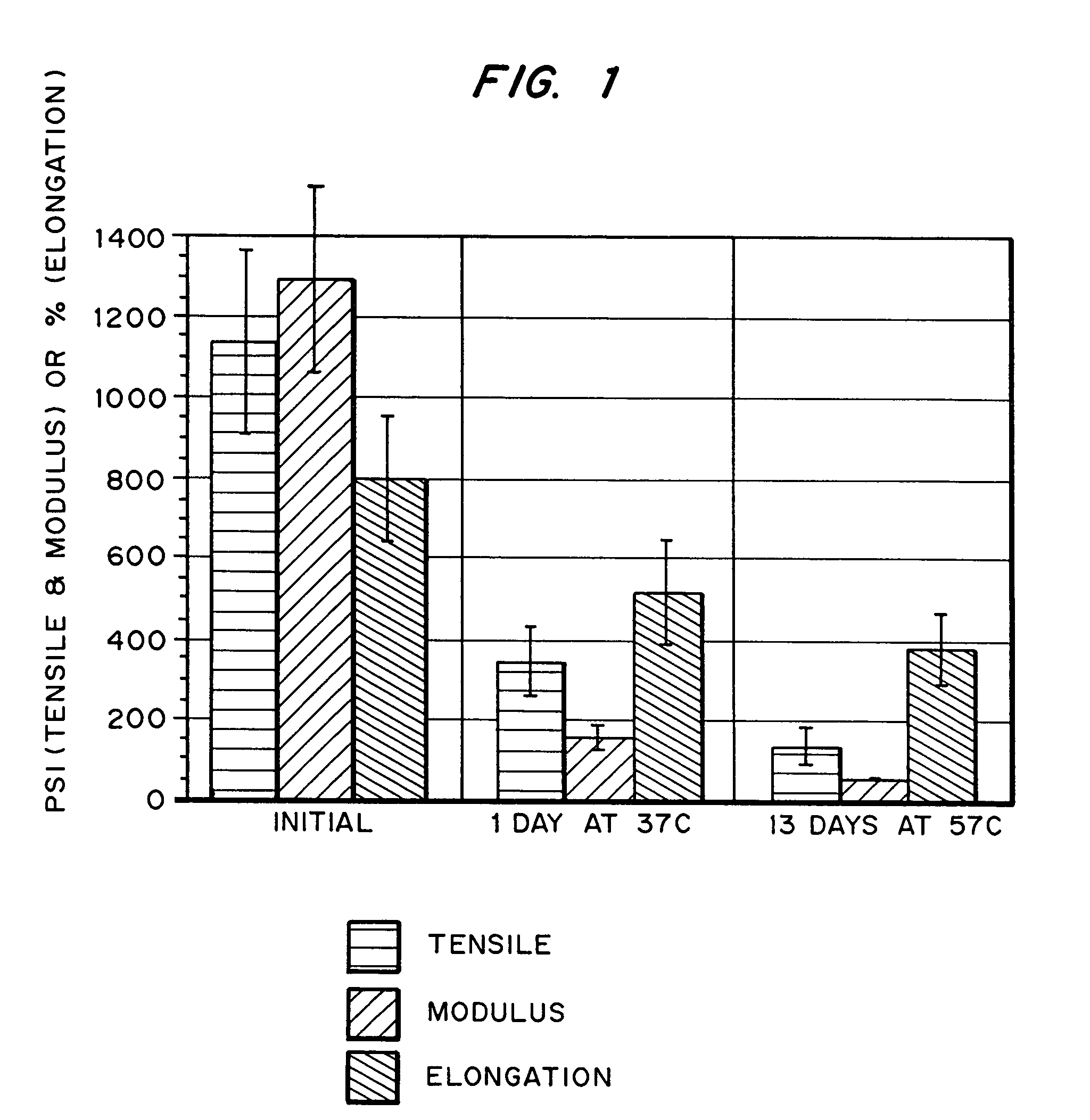

Hydrogels for orthopedic repair

InactiveUS7008635B1Effective treatmentGood biocompatibilityPowder deliveryOintment deliveryPorosityTarget tissue

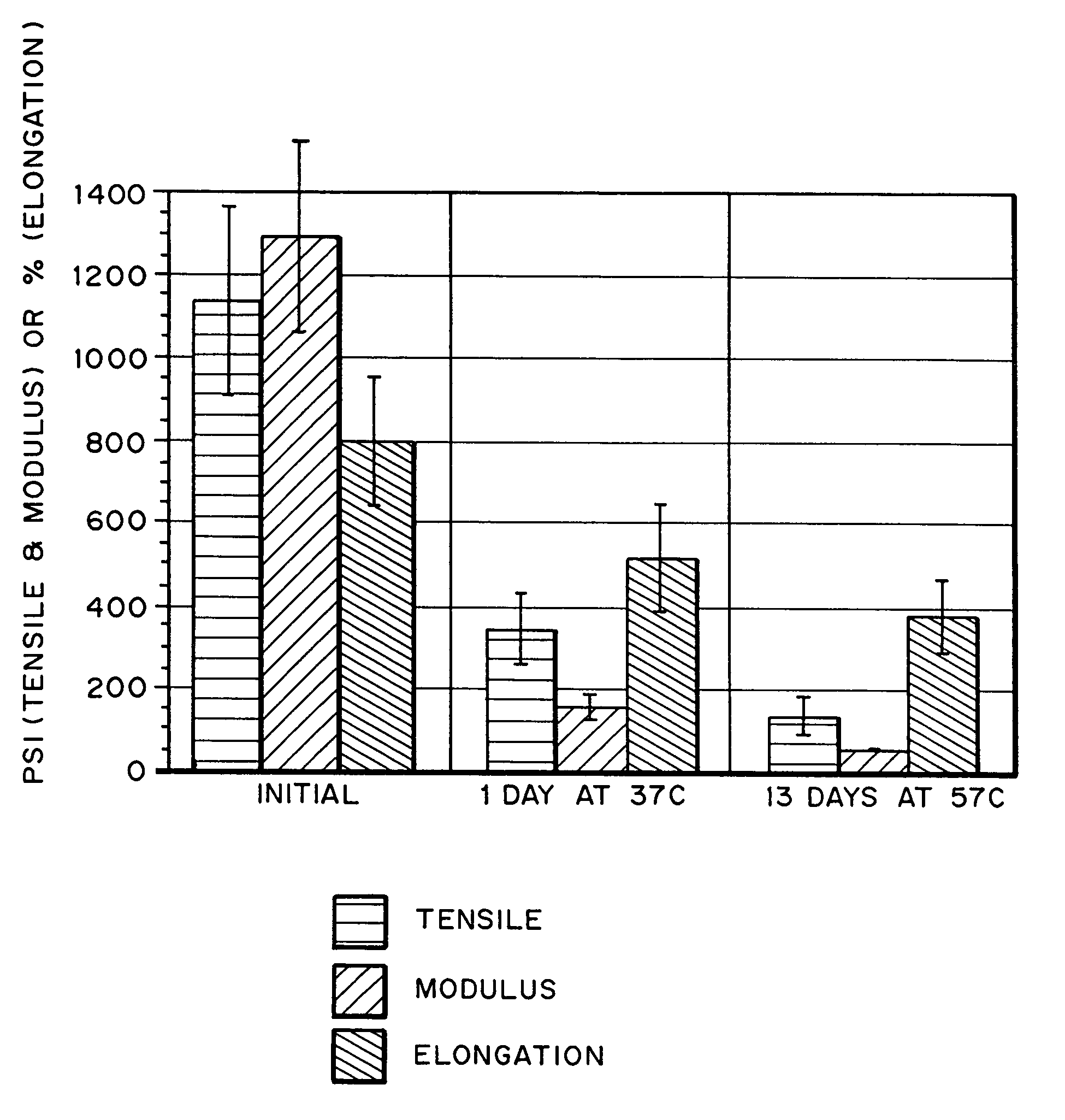

Hydrogels intended for orthopedic applications, including repair and regeneration of cartilage, bone, joint surfaces and related tissues, must possess greater strength and toughness than hydrogels used in soft tissue repair. A hydrogel formulation is provided which has high strength, toughness, a suitable mechanical modulus and low equilibrium hydration. It may also have controlled porosity or degradation time. It can be made to polymerize in situ with high (“good” to “excellent”) adherence to target tissue or surfaces. A preferred formulation for forming such gels comprises 40 to 80% by weight of a low-molecular weight polar monomer and 30 to 10% of a hydrophilic macromeric crosslinker.

Owner:GENZYME CORP

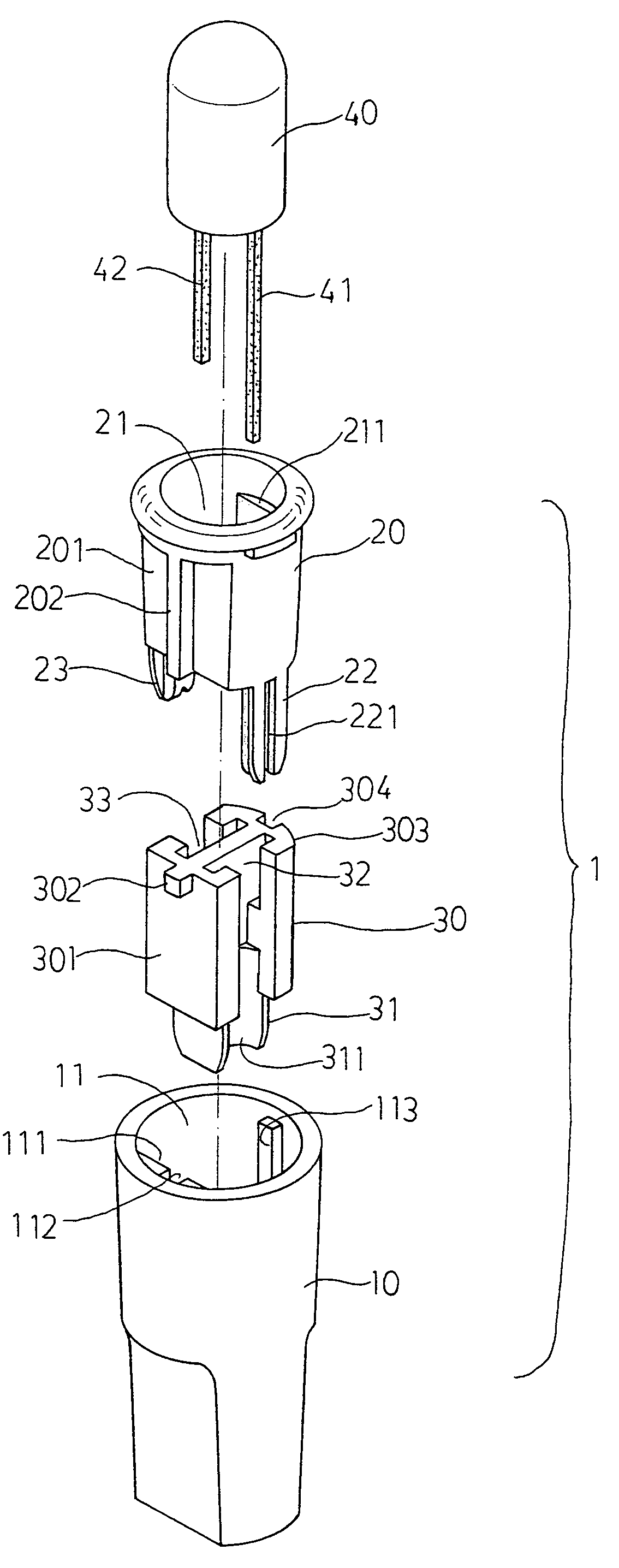

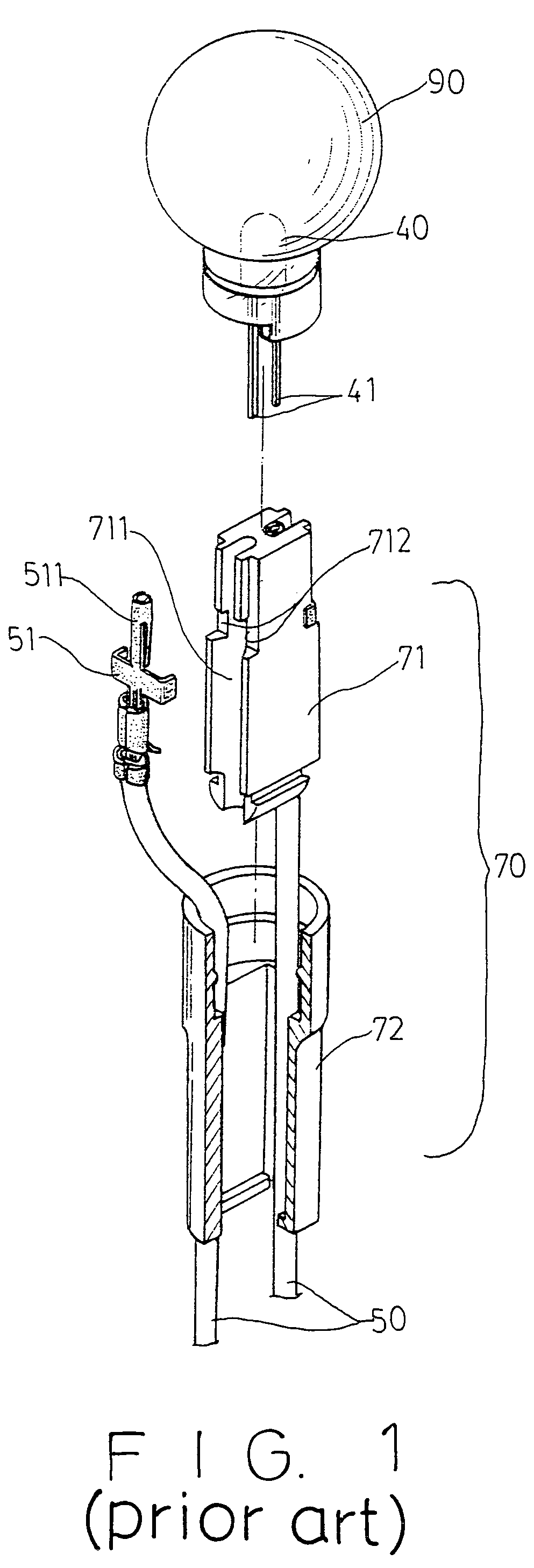

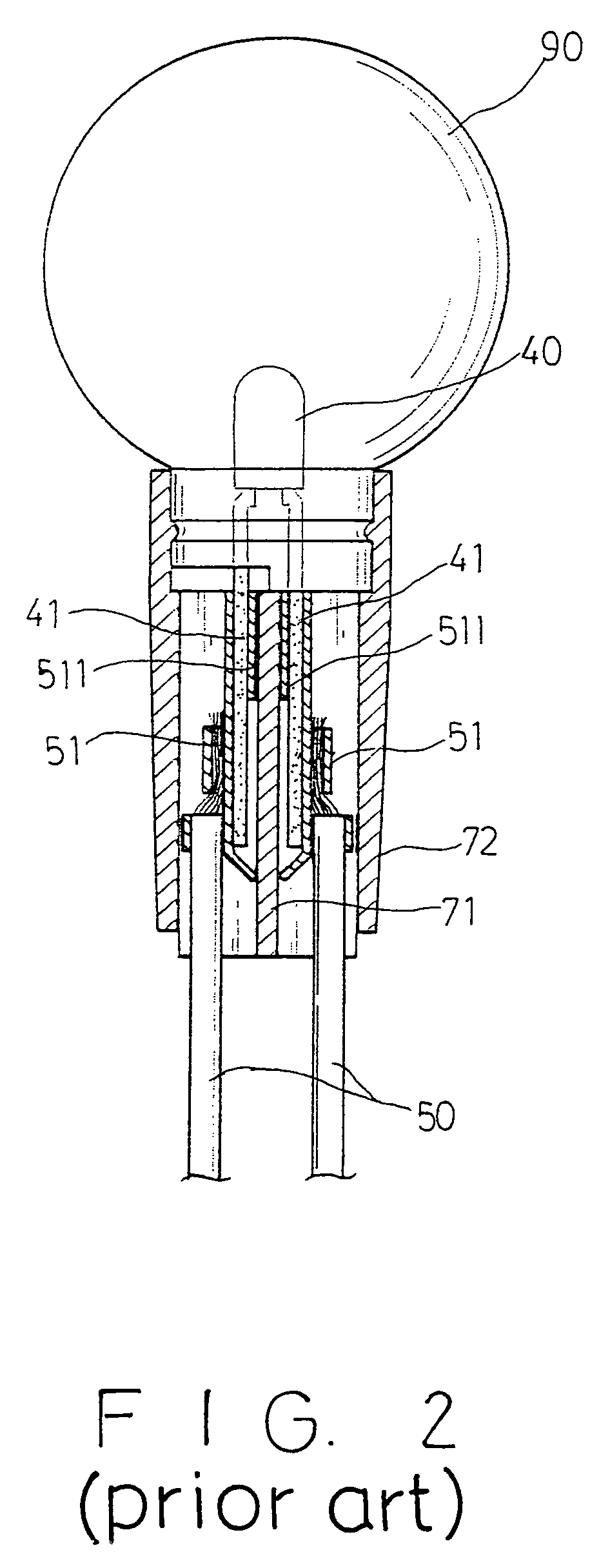

Stand structure of an LED Christmas lamp

An LED Christmas lamp has the lamp stand composed of a main stand, a supporting stand and a conductive lead stand. A positioning protruding surface with a long concave groove is formed in the front side of the containing groove space, and a protruding bar is formed in the relative rear side of the containing groove space. A smaller compartment groove stand is extended in the bottom of the conductive lead stand. An arc shaped protruding groove surface is formed on the joint surface of the compartment stand and containing groove. A lamp laying groove space with protruding stop surfaces in its front and rear sides are formed inside the supporting stand. A positioning cutting surface with a long protruding bar is formed in the front side of the supporting stand and a concave groove is set in the rear side. Then, they are laid in the main stand to let the two pins of LED to be stick with the conductive copper plates of the two power conductive leads smoothly.

Owner:HSU FU HSIEN

Joint treating method

InactiveUS7128763B1Stimulate and promote formationKeep movingJoint implantsArticular surfacesFibrocartilage

A method for treating a non-weight bearing arthritic joint involves resecting at least one of the opposed joint surfaces to expose a cancellous bone surface. A bioresorbable implant is mounted to one of the joint surfaces so that the resected joint surface rubs against the surface of the implant. This causes the fibroblast to change into fibrocartilage at the resected bone surface as the implant is resorbed thereby effectively replacing the implant with fibrocartilage during such resorption.

Owner:BLATT GERALD

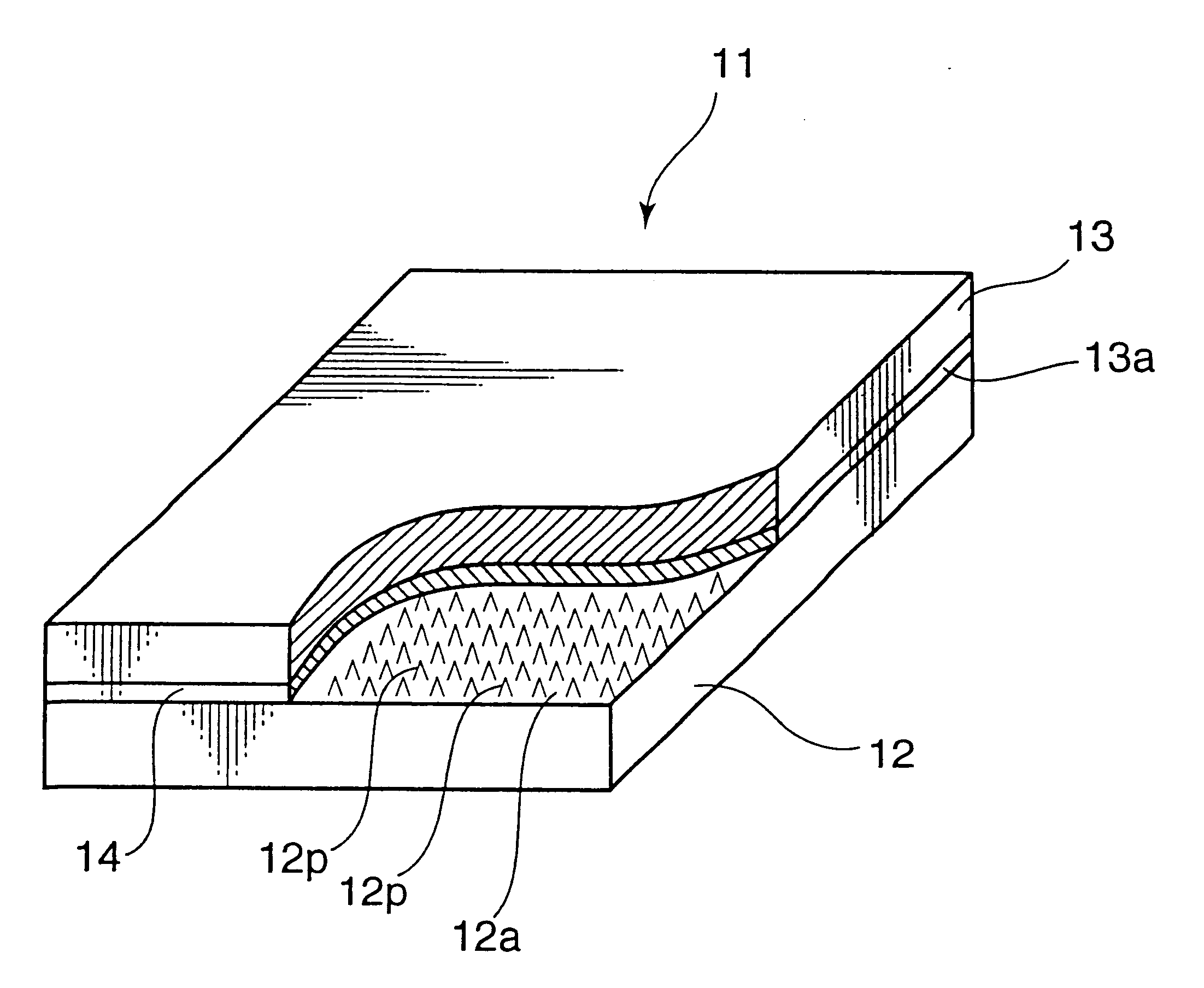

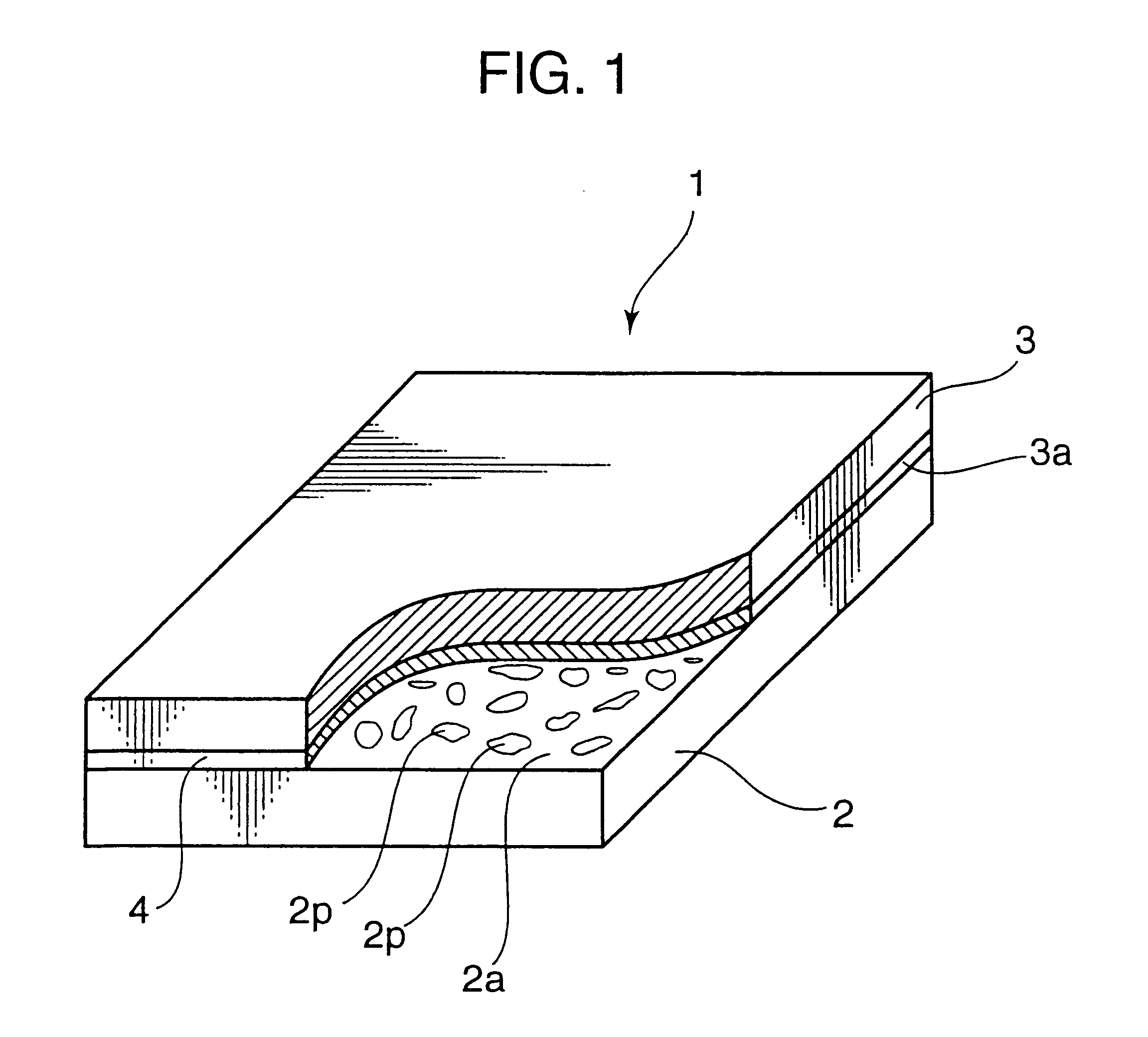

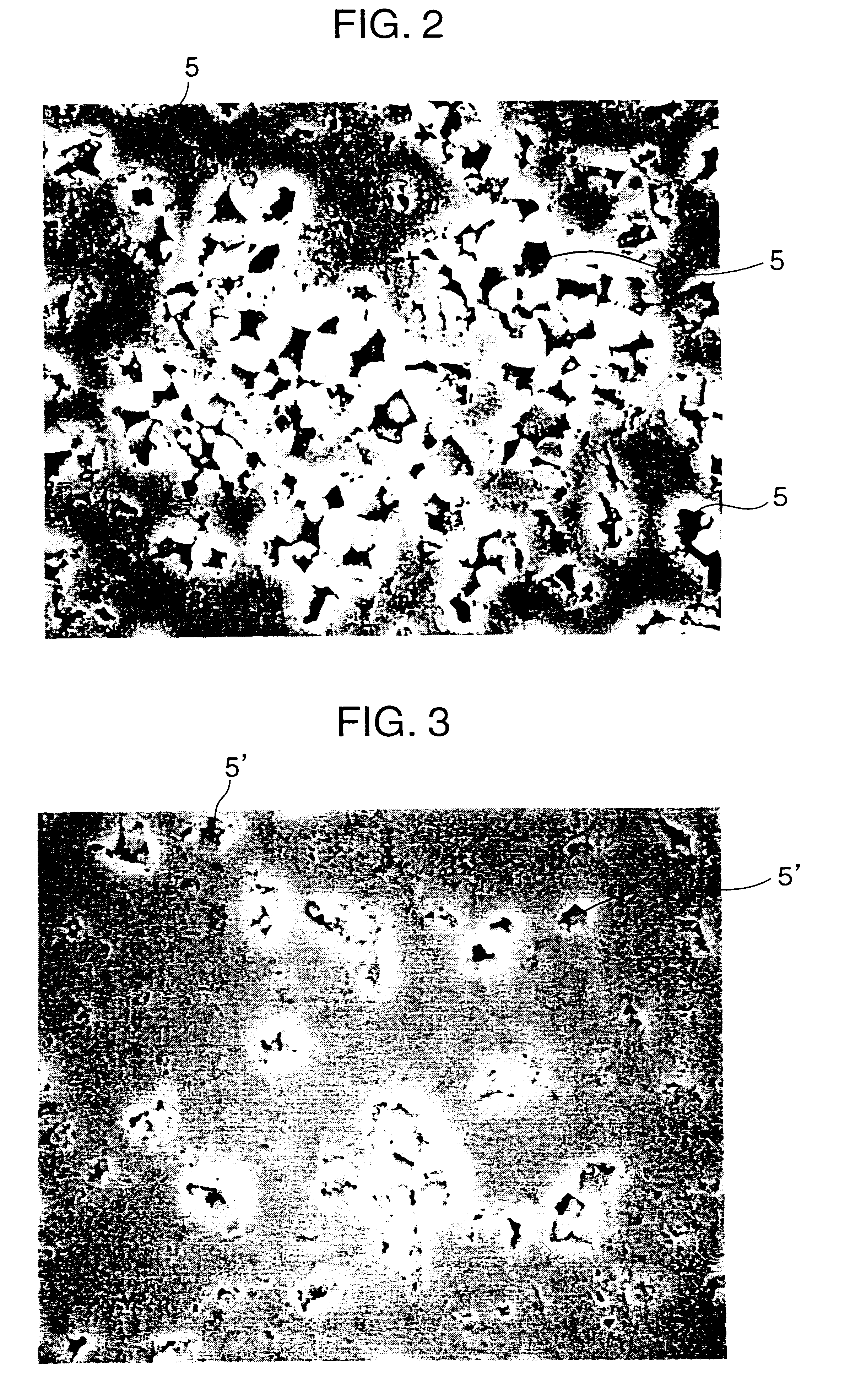

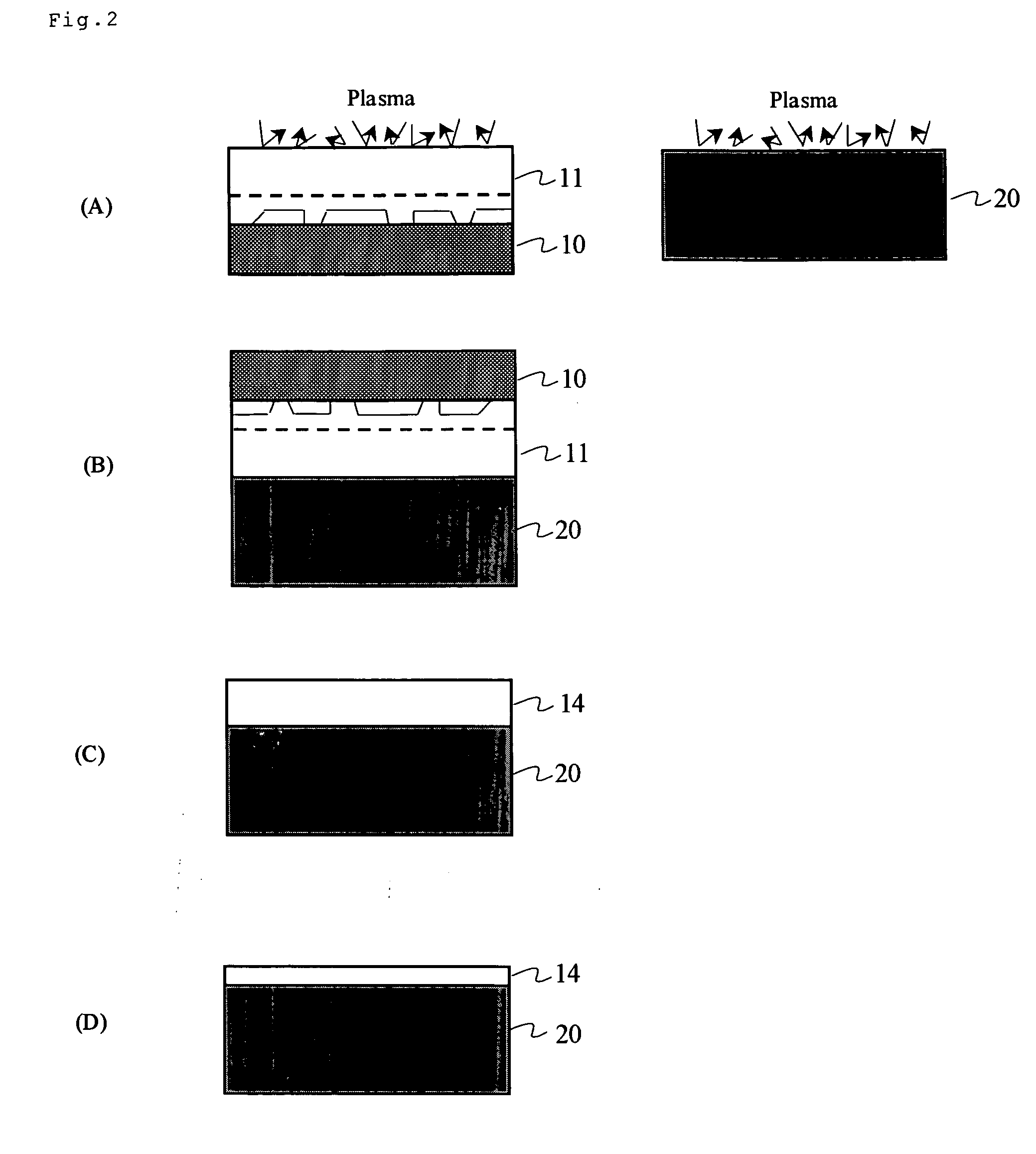

Layered unit provided with piezoelectric ceramics, method for producing the same, and ink jet printing head employing the same

InactiveUS6626526B2Piezoelectric/electrostrictive device manufacture/assemblyPrintingJoint surfaceBiomedical engineering

A layered unit provided with piezoelectric ceramics having an increased adhesive strength while lowering cell content in an adhesive layer, a method for producing the layered unit, and an ink jet printing head incorporated with such layered unit having improved ink emission precision and durability as well as suppressing occurrence of assembly failure at the time of producing the ink jet printing head. The layered unit has a first member made of piezoelectric ceramics, a second member which is placed over the first member, and an adhesive layer which is formed between the first member and the second member to adhere the first member and the second member. A joint surface of the first member to be jointed to the second member is formed with a multitude of recesses. A sum of opening areas of the recesses occupies 50% or more relative to a total surface area of the joint surface of the first member. Alternatively, a crystalline part comprising the joint surface of the first member is formed with a multitude of microprotrusions.

Owner:KYOCERA CORP

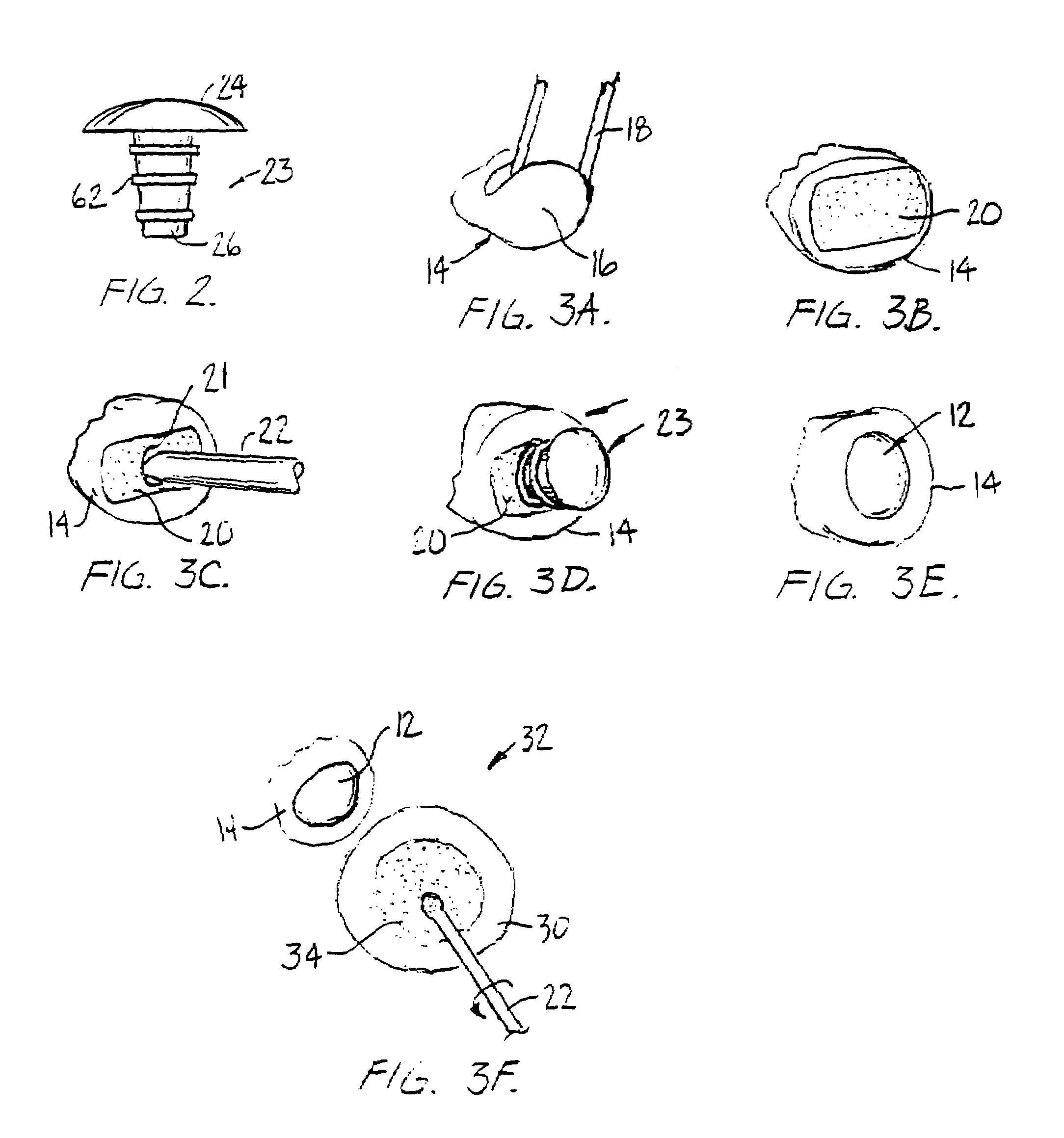

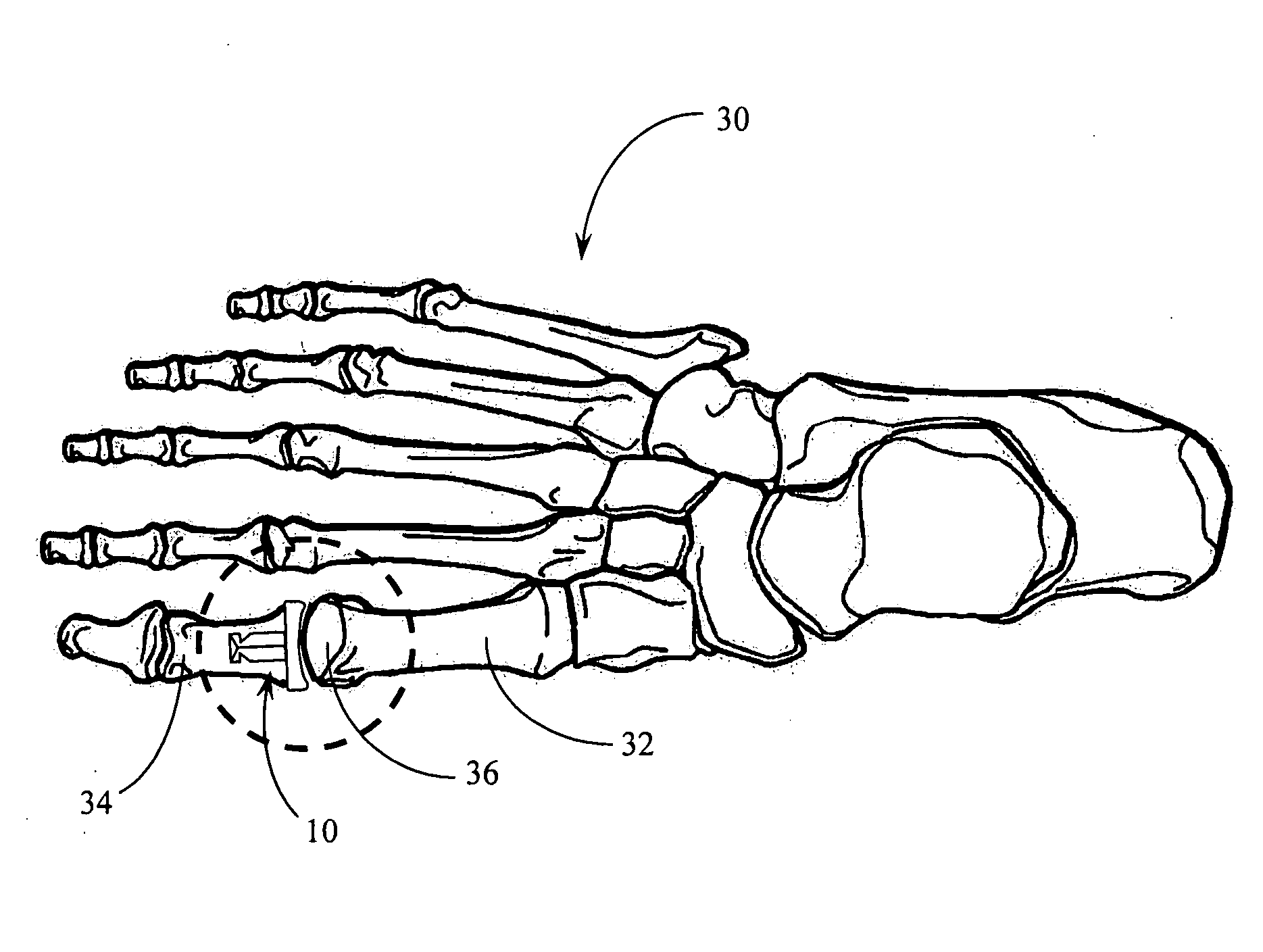

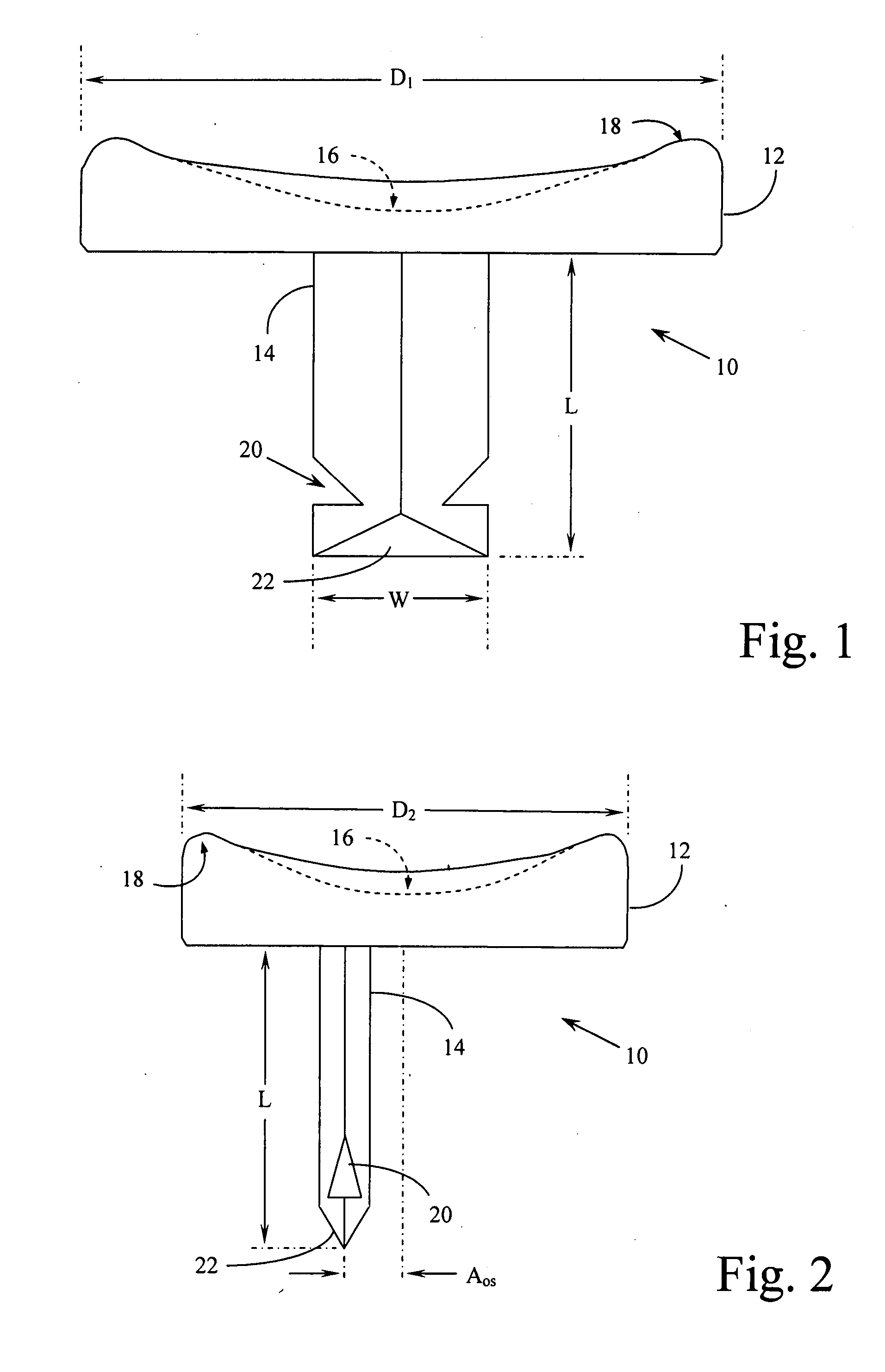

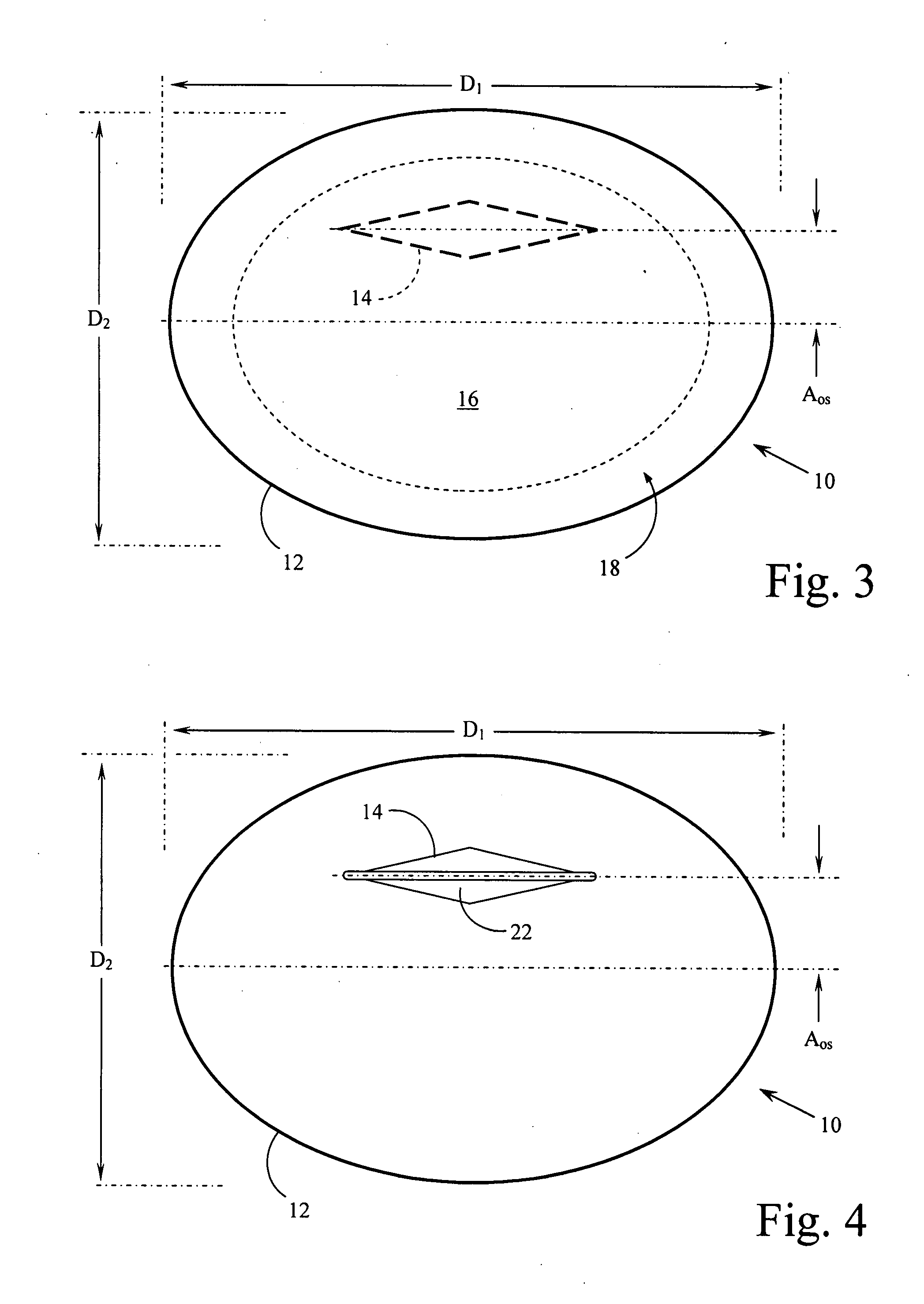

Hemi-implant for first metatarsophalangeal joint

InactiveUS20080221697A1Increase the lengthSimpler but effective retention structureAnkle jointsToe jointsJoint surfaceBiomedical engineering

An improved implant for use primarily within the first metatarsophalangeal joint. The implant includes an elliptical, concave, joint surface positioned on a stem and is designed to be placed into a prepared proximal face of the phalanx. The implant is sized according to the patient and may be provided in a number of standard incremental sizes. The improvements relate primarily to the structure, size, and position of the stem that extends into the phalanx to support the implant. The stem is off-set from a center axis of the elliptical joint surface. This off-center placement allows for a longer stem. Single deep indentations on each side of the stem facilitate retention within the bone. A size selection tool is provided to facilitate the selection and placement of an appropriately sized implant. The tool further provides a template for positioning and placing the stem in the phalanx. A method for sizing and selecting the appropriate implant, and positioning and fixing the implant as a partial joint replacement, especially for the first metatarsophalangeal joint, is also described.

Owner:LOWE JOHN PATRICK TRUSTEE CHAPTER 7 CASE NO 09 51026 C IN THE UNITED STATES BANKRUPTCY COURT FOR THE WESTERN DISTRICT OF TEXAS SAN ANTONIO DIV

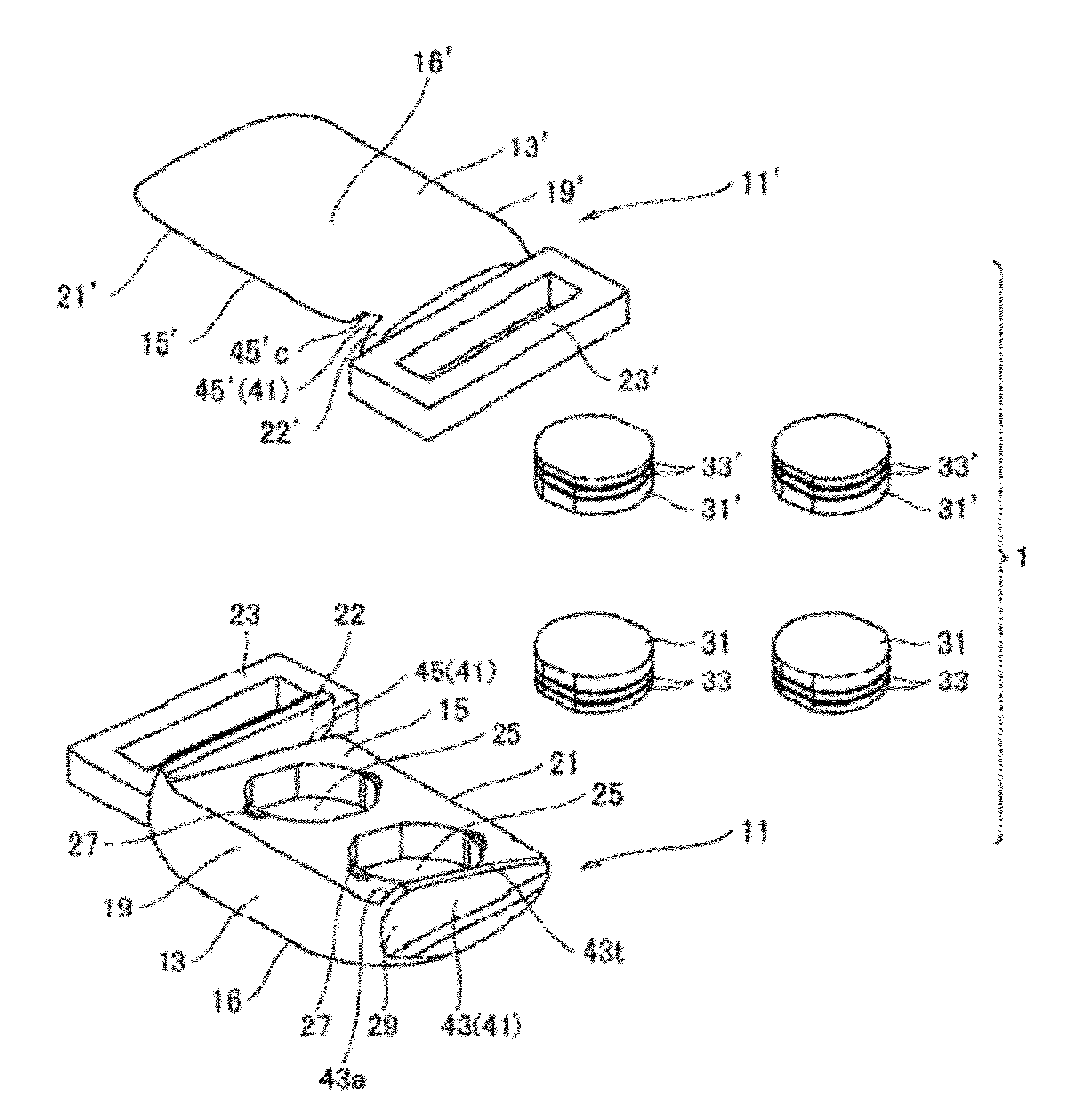

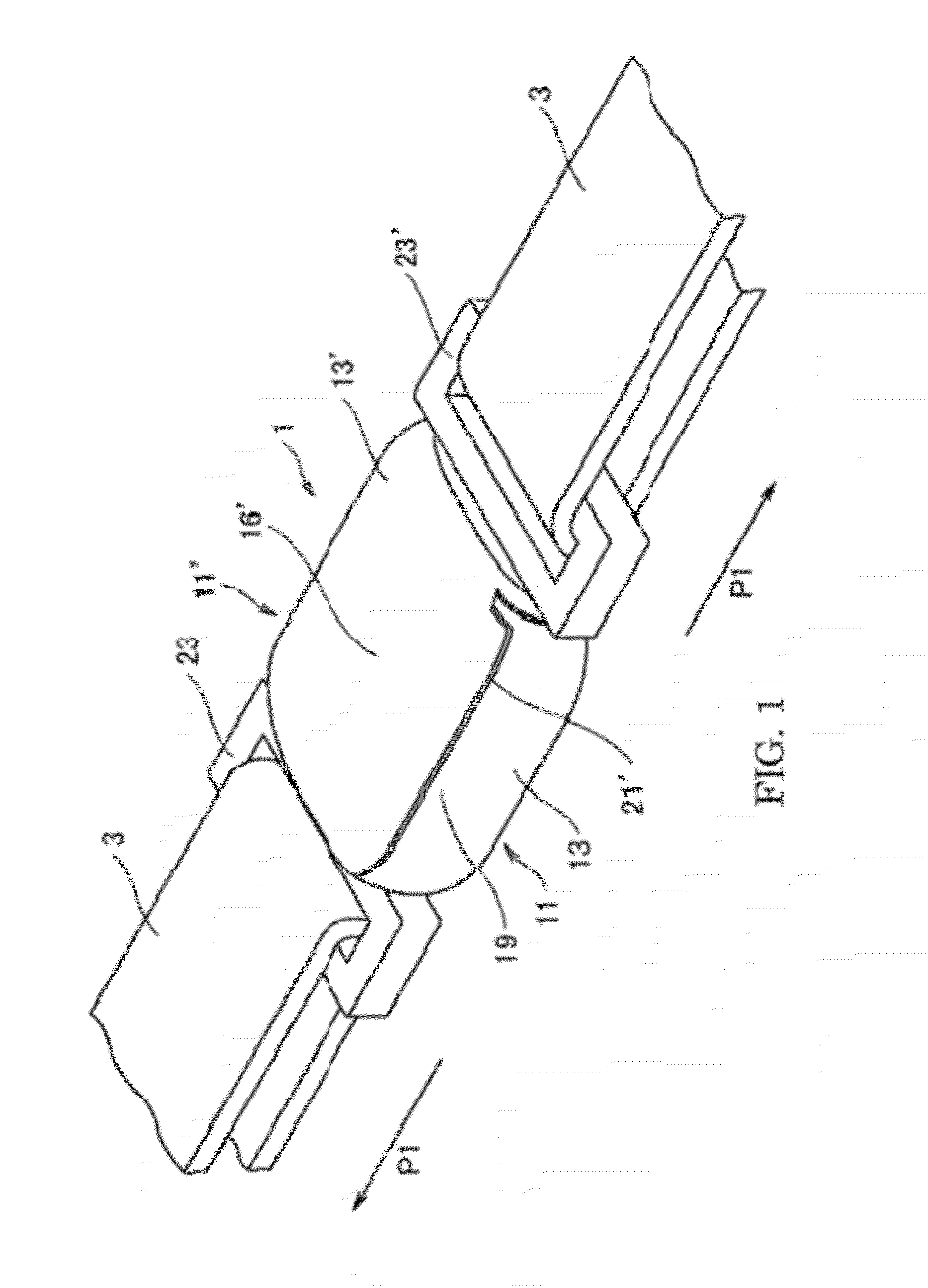

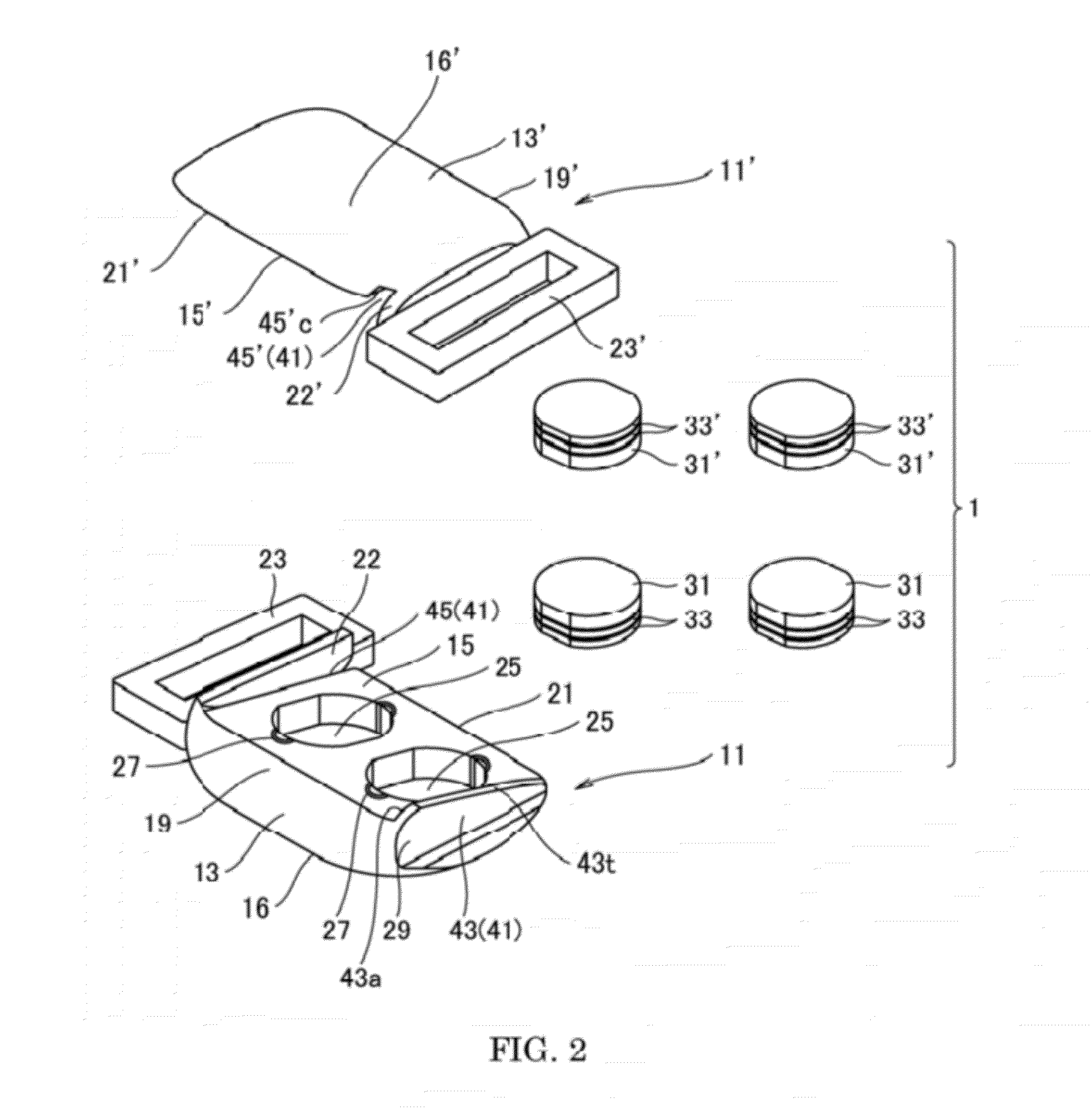

Magnetic Connector

A magnetic connecting device, which is easily separated without both hands but one that is not easily separated in a direction in which a pulling force is applied, is disclosed. Each of a pair of coupling pieces is respectively provided with each of a pair of coupling piece main bodies including joint surfaces capable of joining each other. At least one magnet piece is embedded in each of the joint surfaces such that the coupling piece main bodies attract to join each other. An attaching piece for attaching a string body is provided on each of the coupling pieces, and is provided with a slide guide structure formed on a side of the joint surface of each of the coupling piece main bodies for slidingly guiding the other in a predetermined direction with respect thereto.

Owner:SEBERU PICO

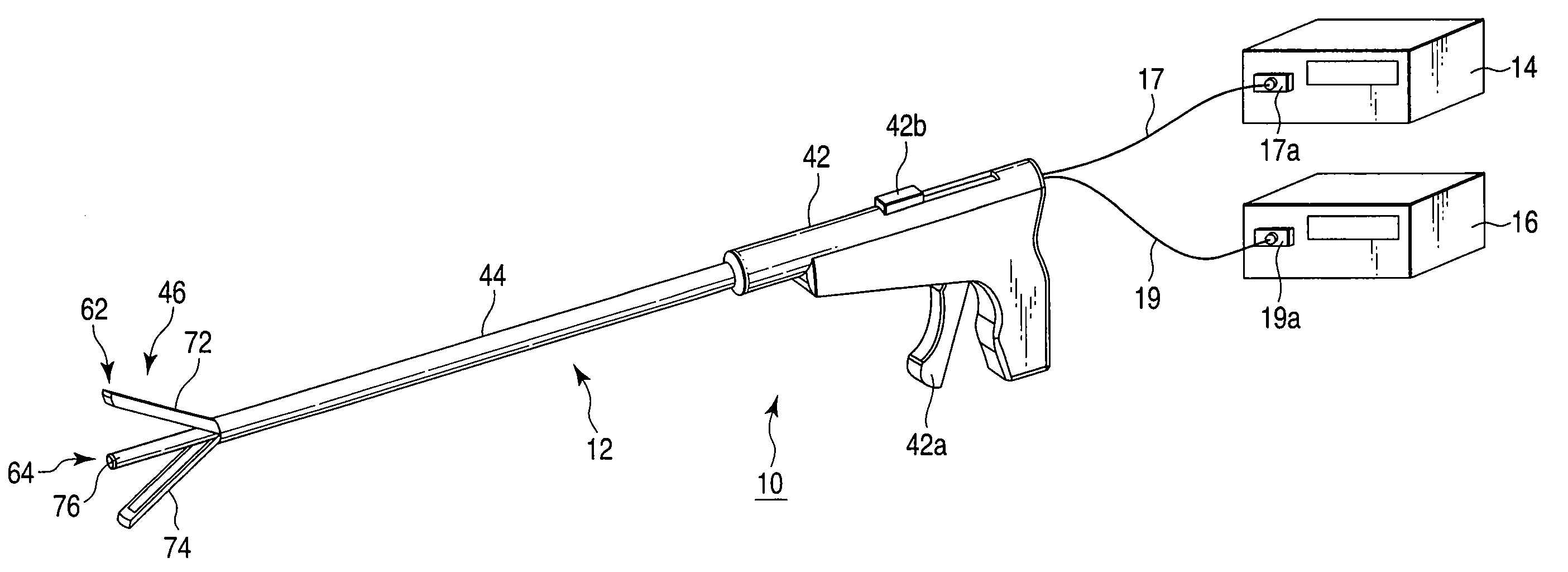

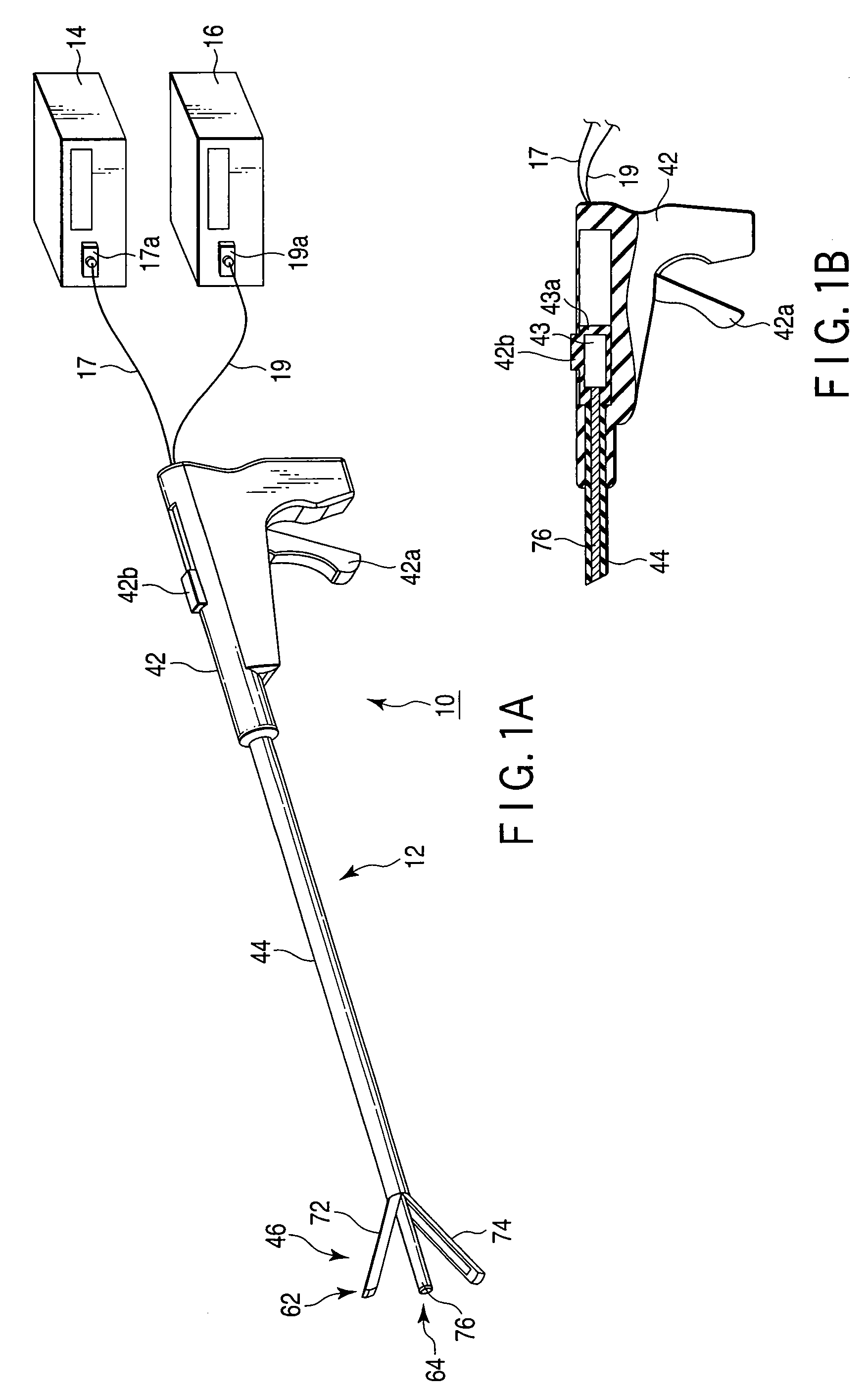

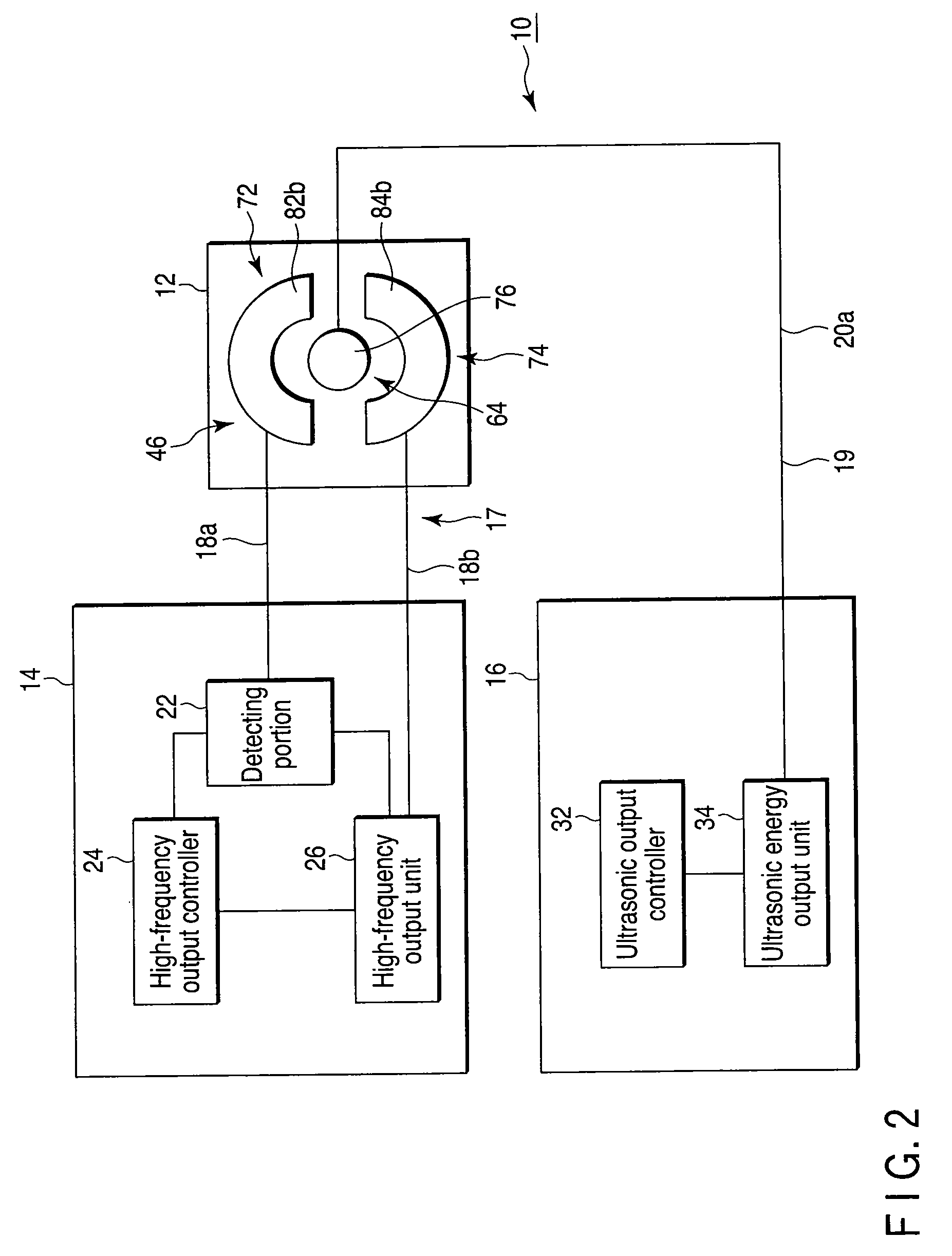

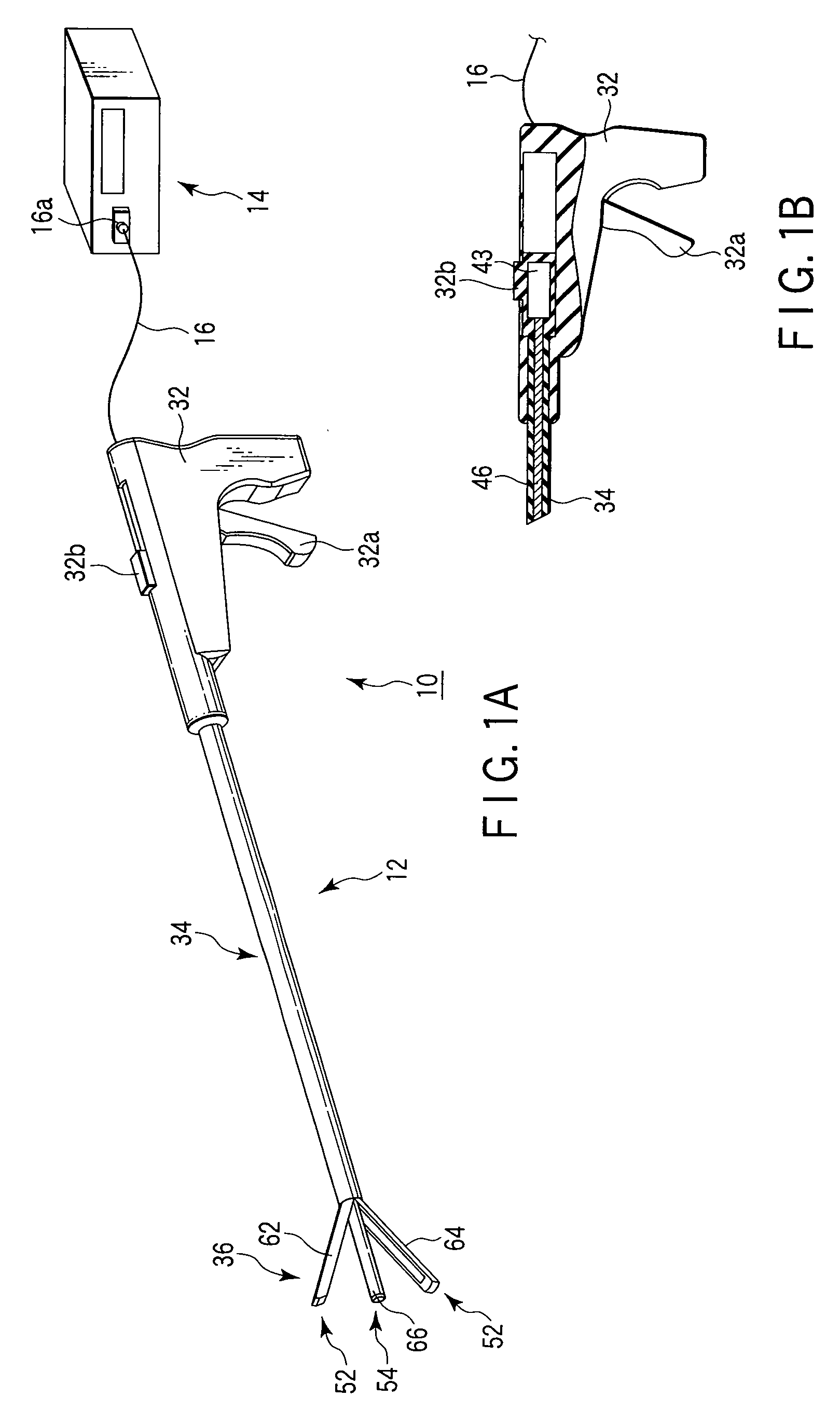

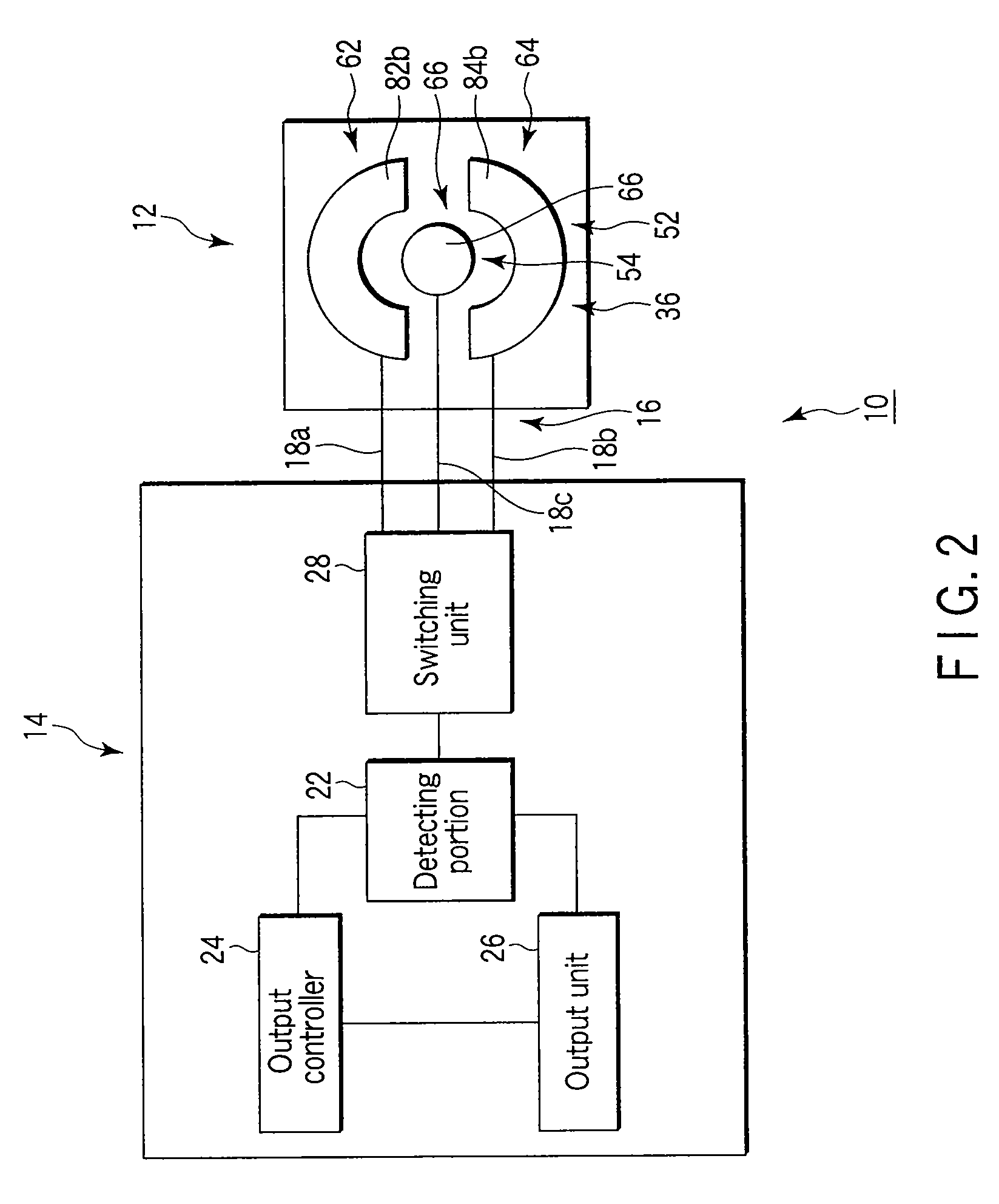

Medical treatment apparatus, treatment instrument and treatment method for living tissue using energy

InactiveUS20100185197A1Ultrasound therapySurgical instruments for heatingJoint surfaceBiomedical engineering

A medical treatment apparatus includes an energy source which applies energy to living tissues, a first treating portion which joins the living tissues together, a second treating portion which is interposed between the living tissues and which removes surface portions of tissues in the joint surfaces of the living tissues, a detecting portion, and a controller. The first treating portion includes at least a pair of holding members having holding surfaces to hold the living tissues, and an energy output unit which is provided on the holding surfaces of the holding members and which join the living tissues together when energy is applied thereto from an energy source. The detecting portion detects biological information regarding the living tissues held by the pair of holding members. The controller controls outputs from the energy output unit in accordance with the biological information regarding the living tissues obtained by the detecting portion.

Owner:OLYMPUS MEDICAL SYST CORP

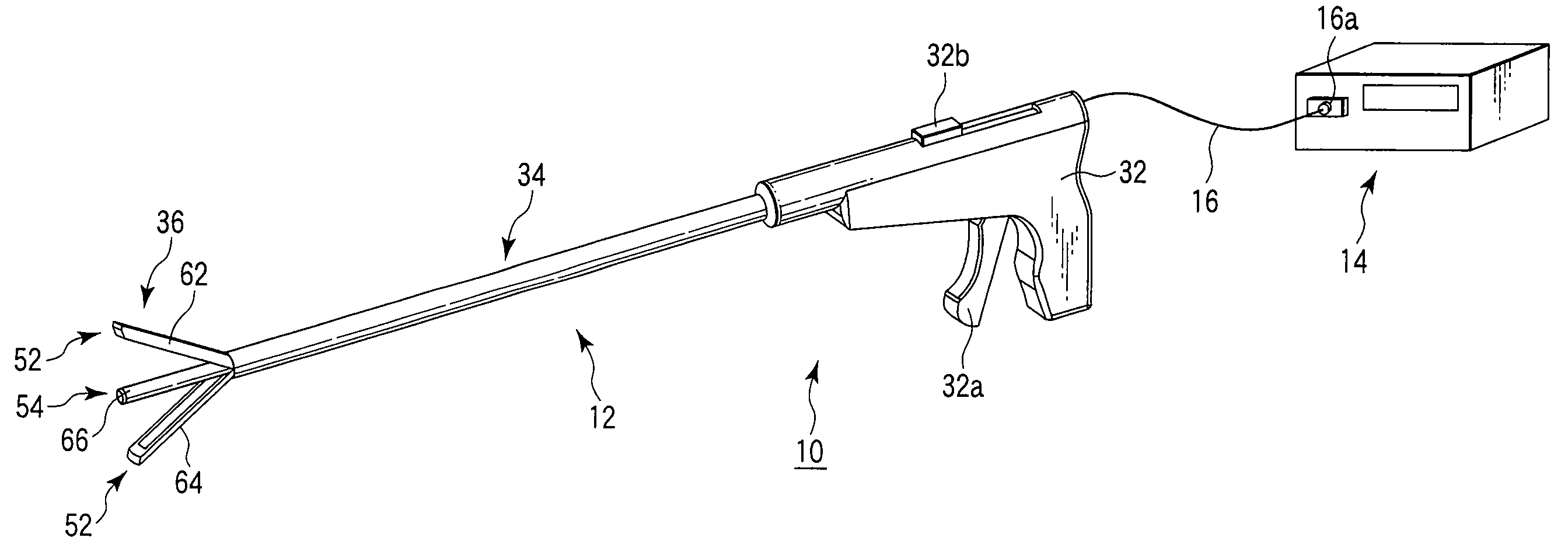

Medical treatment apparatus, treatment instrument and treatment method for living tissue using energy

InactiveUS20100185196A1Adequate denaturation and dehydrationUltrasound therapySurgical instruments for heatingArticular surfacesSacroiliac joint

A medical treatment apparatus includes an energy source, a first treating portion joining the living tissues together, a second treating portion which is interposed between the living tissues and which denatures a joint surface of the living tissues in contact with the second treating portion, a detecting portion, and a controller. The first treating portion includes holding members having holding surfaces to hold the living tissues, and an energy output unit which is provided on the holding surfaces and which join the living tissues together when energy is applied thereto from the energy source. The detecting portion detects at least one of biological information regarding the living tissues held by the pair of holding members and regarding the living tissues between the holding members and the second treating portion. The controller controls an output of the energy output unit and the second treating portion on the basis of the biological information.

Owner:OLYMPUS MEDICAL SYST CORP

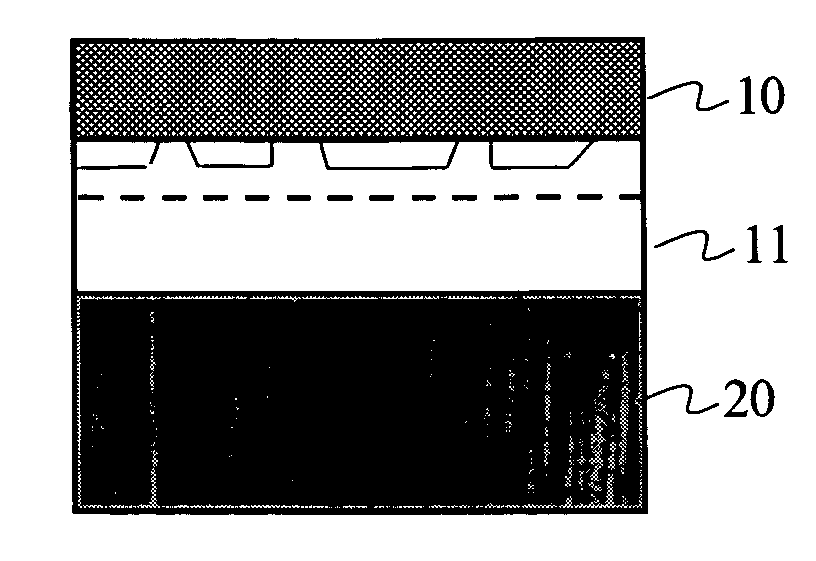

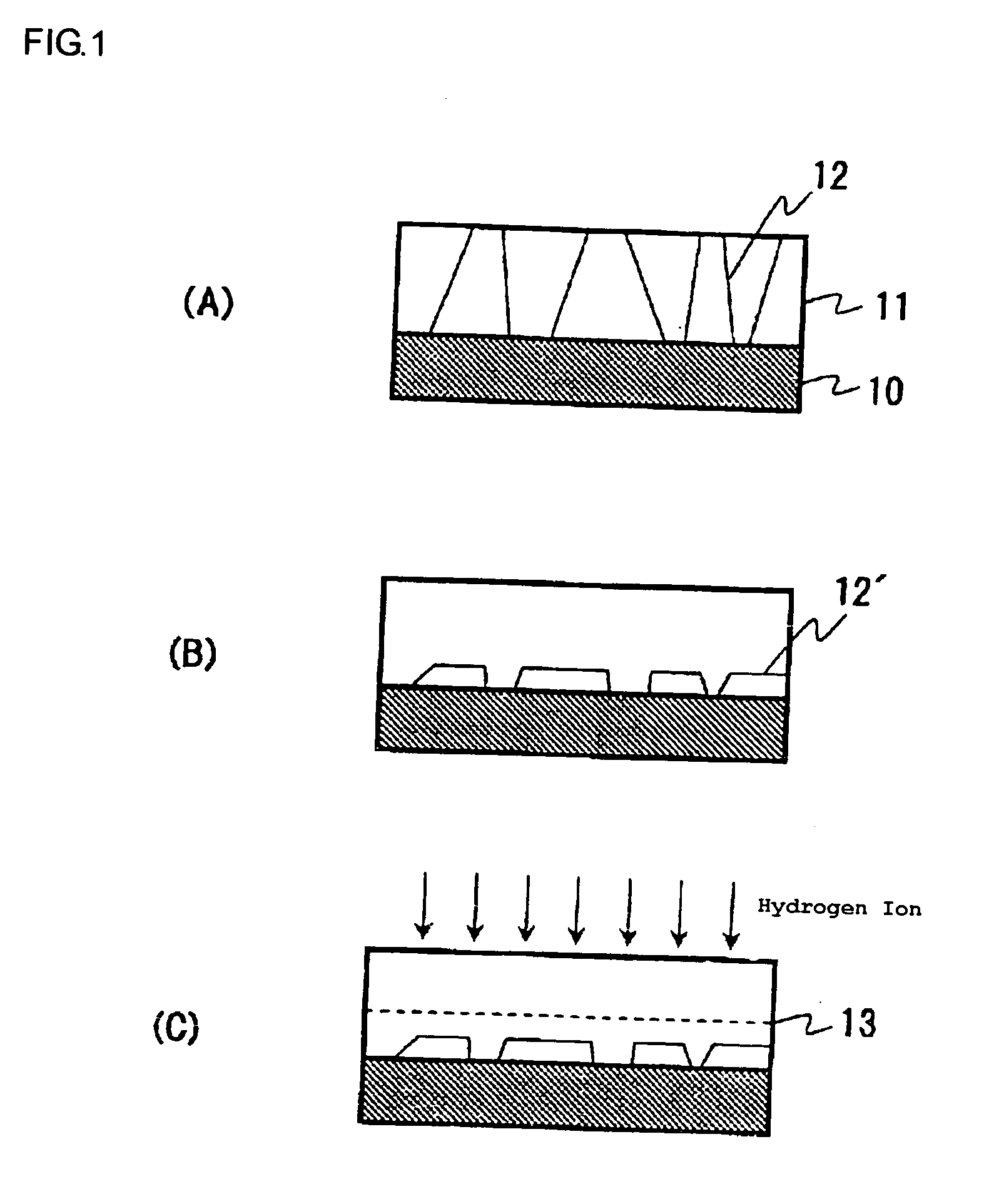

Method for manufacturing semiconductor substrate

ActiveUS20080194078A1Simple technologyQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesThreading dislocationsHigh density

To obtain a semiconductor substrate having a high-quality Ge-based epitaxial film in a large area, a SiGe mixed crystal buffer layer and a Ge epitaxial film is grown on a main surface of a Si substrate 10. Although high-density defects are introduced in the Ge epitaxial film 11 from an interface between the Ge epitaxial film 11 and the Si substrate 10, the Ge epitaxial film is subjected to a heat treatment at a temperature of not less than 700° C. and not more than 900° C. to cause threading dislocations 12 to change into dislocation-loop defects 12′ near the interface between the Ge epitaxial film 11 and the Si substrate. A main surface of at least one of the Ge epitaxial film 11 with an ion implanted layer and a support substrate 20 is then subjected to a plasma treatment or ozone treatment for the purpose of surface cleaning, surface activation, and the like, after which the main surfaces of the Ge epitaxial film 11 and the support substrate 20 are appressed against and bonded to each other with their surfaces being determined as the joint surfaces. An external impact is then applied to the bonding interface, causing the Ge epitaxial film to be delaminated along a hydrogen ion implanted interface 13, thus obtaining a Ge thin film 14. A surface of the Ge thin film 14 is subsequently subjected to a final surface treatment (for example, CMP) to remove the damage caused by the hydrogen ion implantation, thus resulting in a GeOI substrate having the Ge thin film 14 on the surface thereof.

Owner:SHIN ETSU CHEM IND CO LTD

Preformed implants for osteochondral repair

Osteochondral repair of damaged articular joint surfaces is achieved using implants in the form of cylindrical osteochondral plugs. The plugs have an articular surface formed on at least one end. If articular surfaces are provided on both ends of the implant, the articular surfaces have differently curved surfaces. The defective cartilage is removed to create a recipient socket for the implant. An implant sized to fit the recipient socket is chosen from a plurality of implants provided to the surgeon. The implants are preferably formed of a hydrogel material such as Salubria™, although metal or allograft implants can also be used.

Owner:ARTHREX

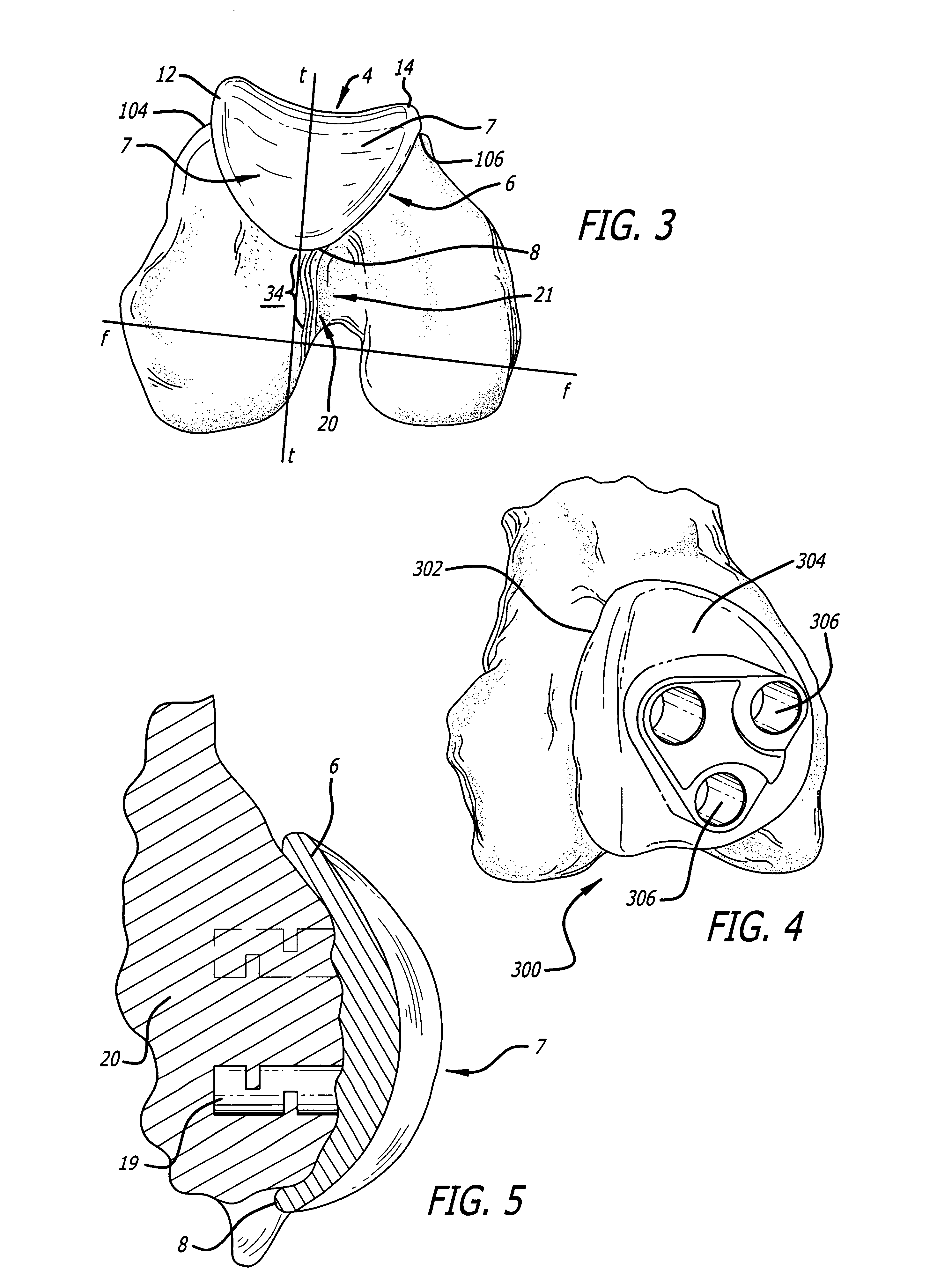

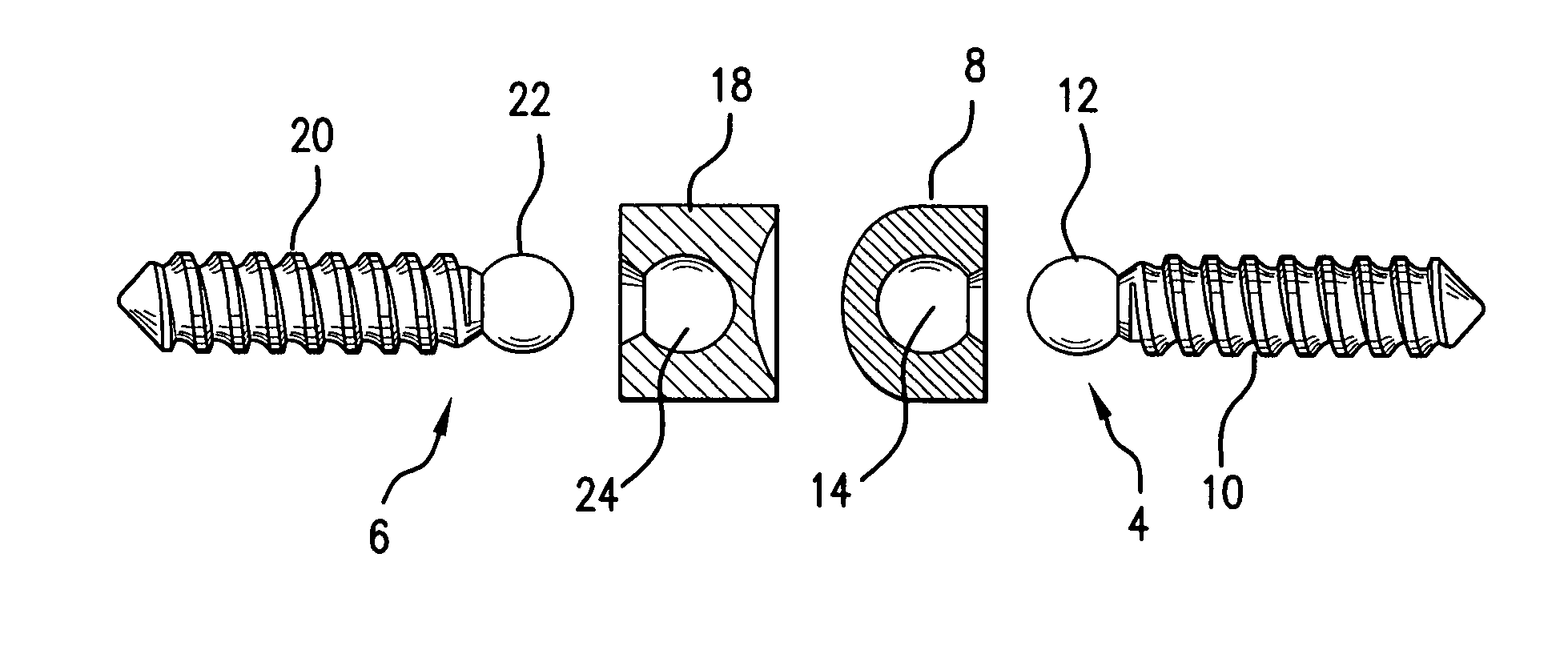

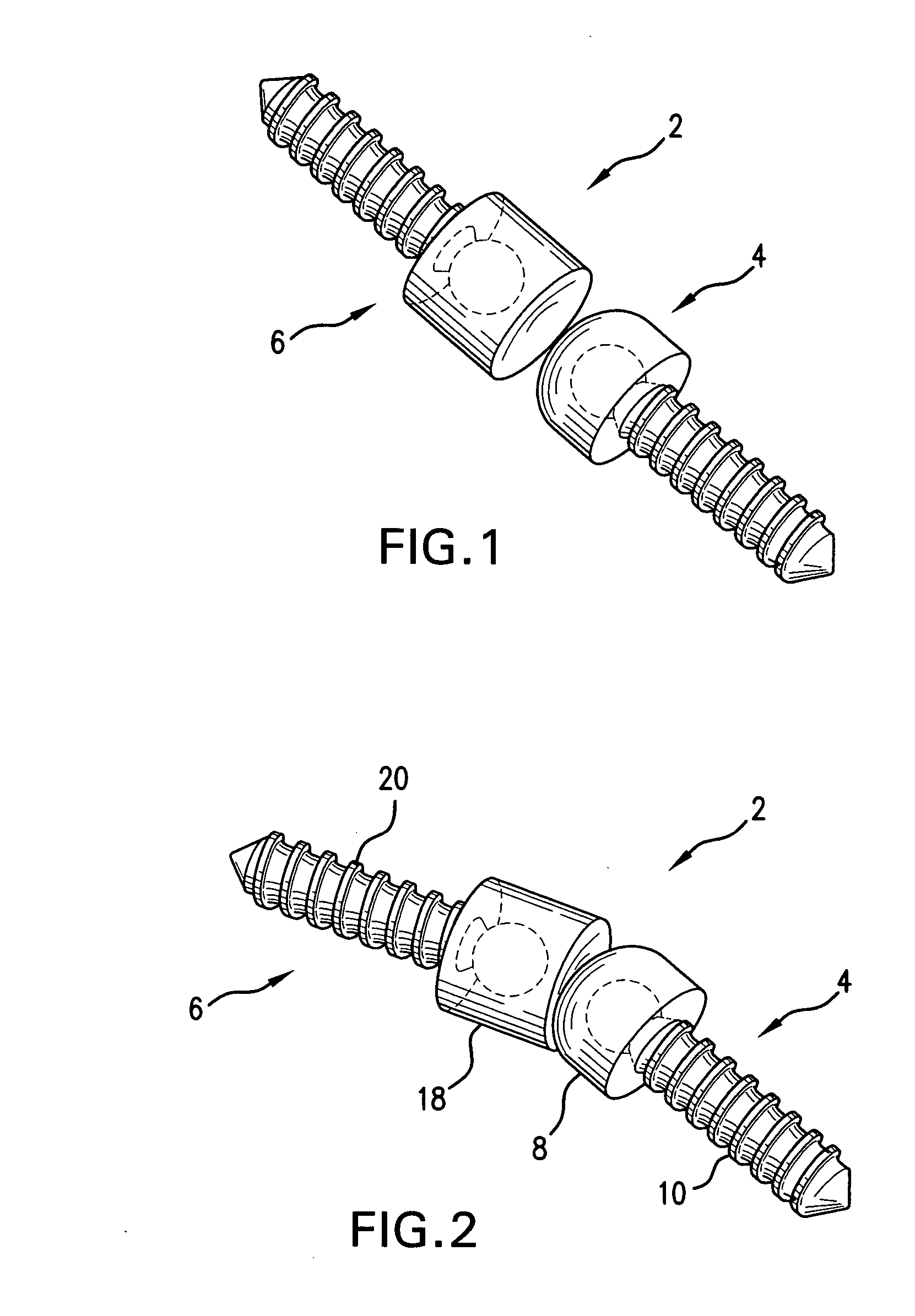

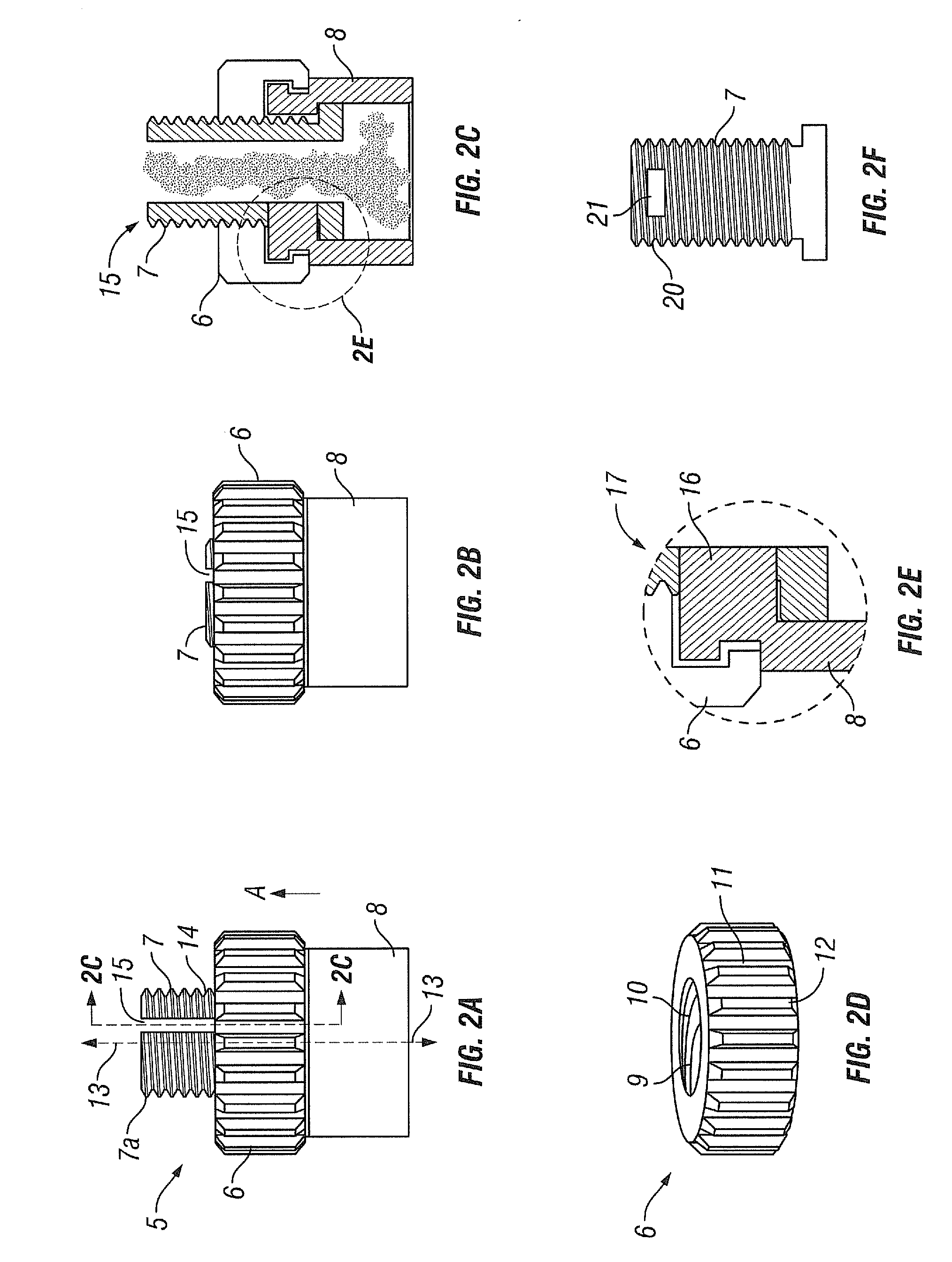

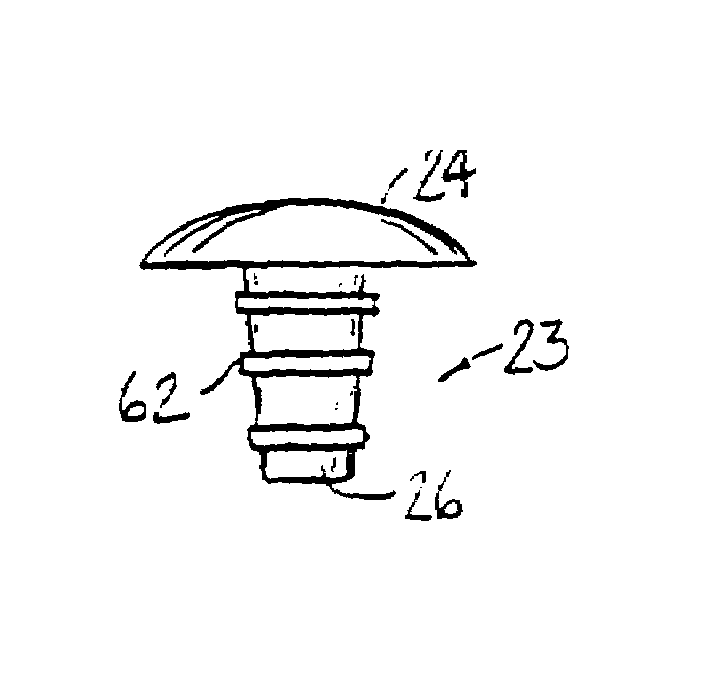

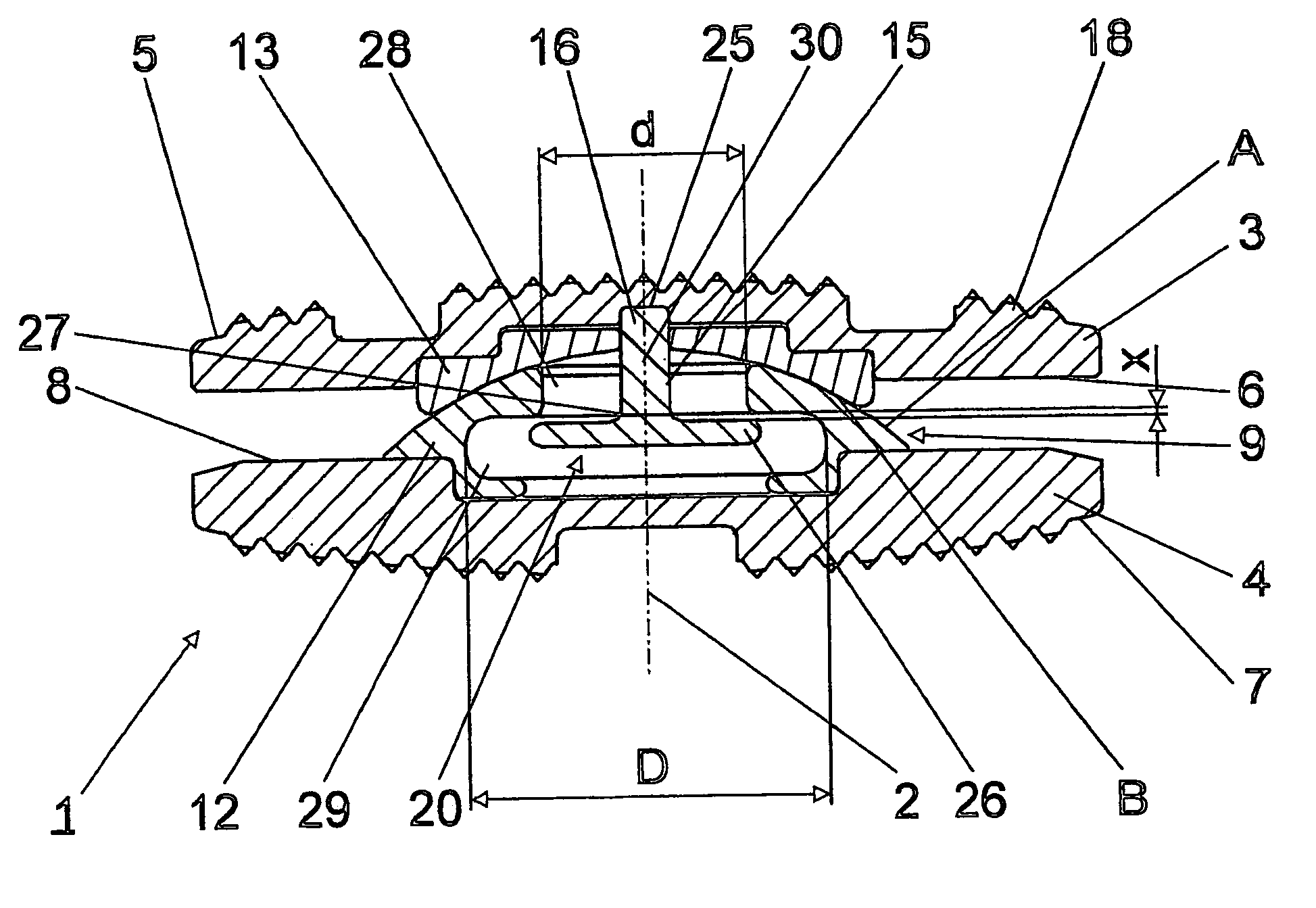

Modular system for replacement of radial head

A modular endoprosthetic radial head implant includes an end cap secured to a cannulated body held to bone by a fixation element. The fixation element supports the cannulated body on a resected radial bone end, for example. The fixation element of one embodiment features a threaded stem with a spherical head. The stem fits distally into the cannulated body and extends through a hole formed by the distal end of the cannulated body. The spherical head nests inside the cannulated body. Polyaxial alignment between the cannulated body and the fixation element is locked using a jam nut tightened inside the cannulated body. An end cap fits into place proximally on the cannulated body. The end cap is formed of a joint surface material to provide a bearing surface.

Owner:ARTHREX

Quick-disconnect storage box modular structure

InactiveUS20130048632A1Quick assemblyAssembled easily and conveniently and quicklyRigid containersDismountable cabinetsModularityEngineering

A storage box modular structure fastened by a biaxial positioning method is provided to facilitate assembling and disassembling a storage box manually and quickly. The storage box is formed by combining panels, and the modular structure is installed between two adjacent panels. A first joint surface and a second joint surface are disposed on the two panels respectively. The modular structure includes a containing hole formed on the first joint surface, a through hole formed between the second joint surface of the panel and an external wall. A fastener and a spring are installed in the containing hole, and the spring drives the fastener to be implemented into the through hole to fasten two panels. An external object is inserted from the external wall into the through hole to push the fastener to resume its original position, so as to separate the two panels and improve the convenience of use.

Owner:CHEN YI HSIANG

Intervertebral implant comprising dome-shaped joint surfaces

ActiveUS20060229725A1NotReduce manufacturing costJoint implantsSpinal implantsArticular surfacesSacroiliac joint

An intervertebral implant with a central axis, a top part, a bottom part, a joint comprising a joint part and a joint shell, and a joining means. The top part has a top apposed surface that is suitable for placing it on a vertebra situated above it; The bottom part has a bottom apposed surface, that is suitable for placing it on a vertebra situated below it. One of the two parts is operatively associated with a convex joint part and the other part to a matching joint shell. The joint part and the joint shell are mounted against one another in a sliding manner such that the top part and the bottom part can rotate relative to one another at least about one axis of rotation. The joining means holds the top part and the bottom part together without impairing the capability of the joint to pivot while allowing a clearance between the joint part and the joint shell.

Owner:SYNTHES USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com