Patents

Literature

314 results about "Arthroplasty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arthroplasty (literally "[re-]forming of joint") is an orthopedic surgical procedure where the articular surface of a musculoskeletal joint is replaced, remodeled, or realigned by osteotomy or some other procedure. It is an elective procedure that is done to relieve pain and restore function to the joint after damage by arthritis or some other type of trauma.

Patient Selectable Joint Arthroplasty Devices and Surgical Tools

ActiveUS20070198022A1Accurate placementGeometric CADPerson identificationArticular surfacesArticular surface

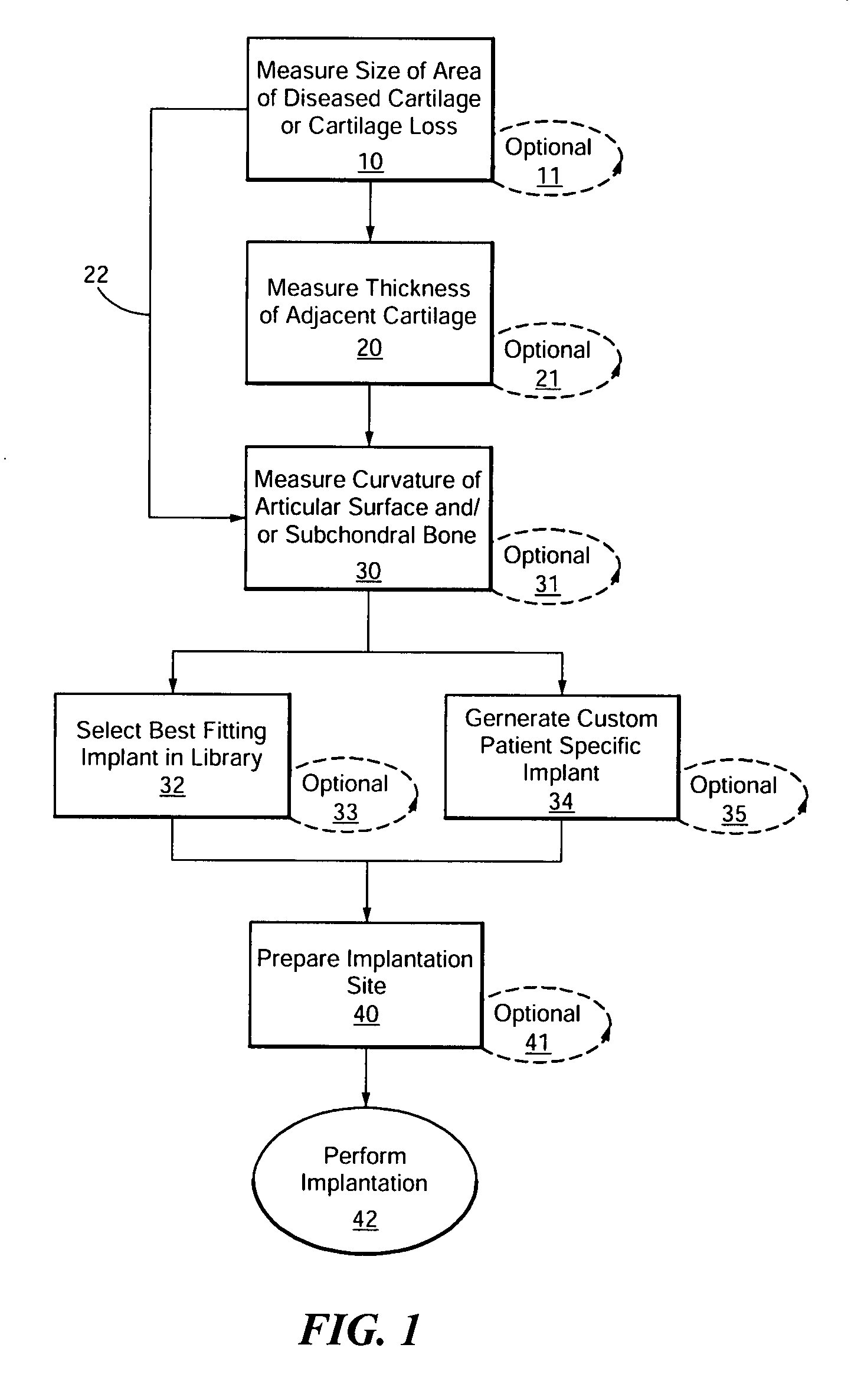

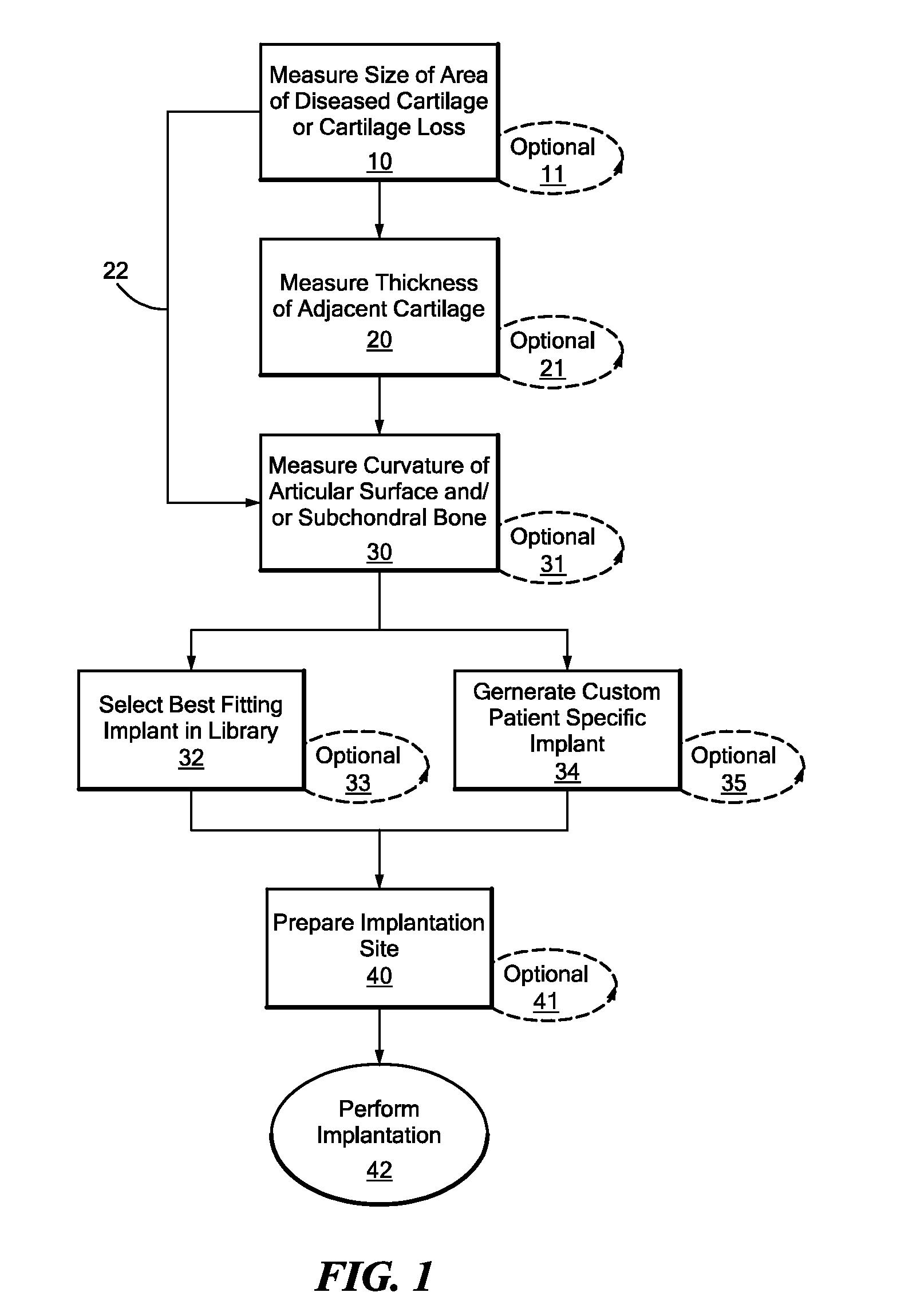

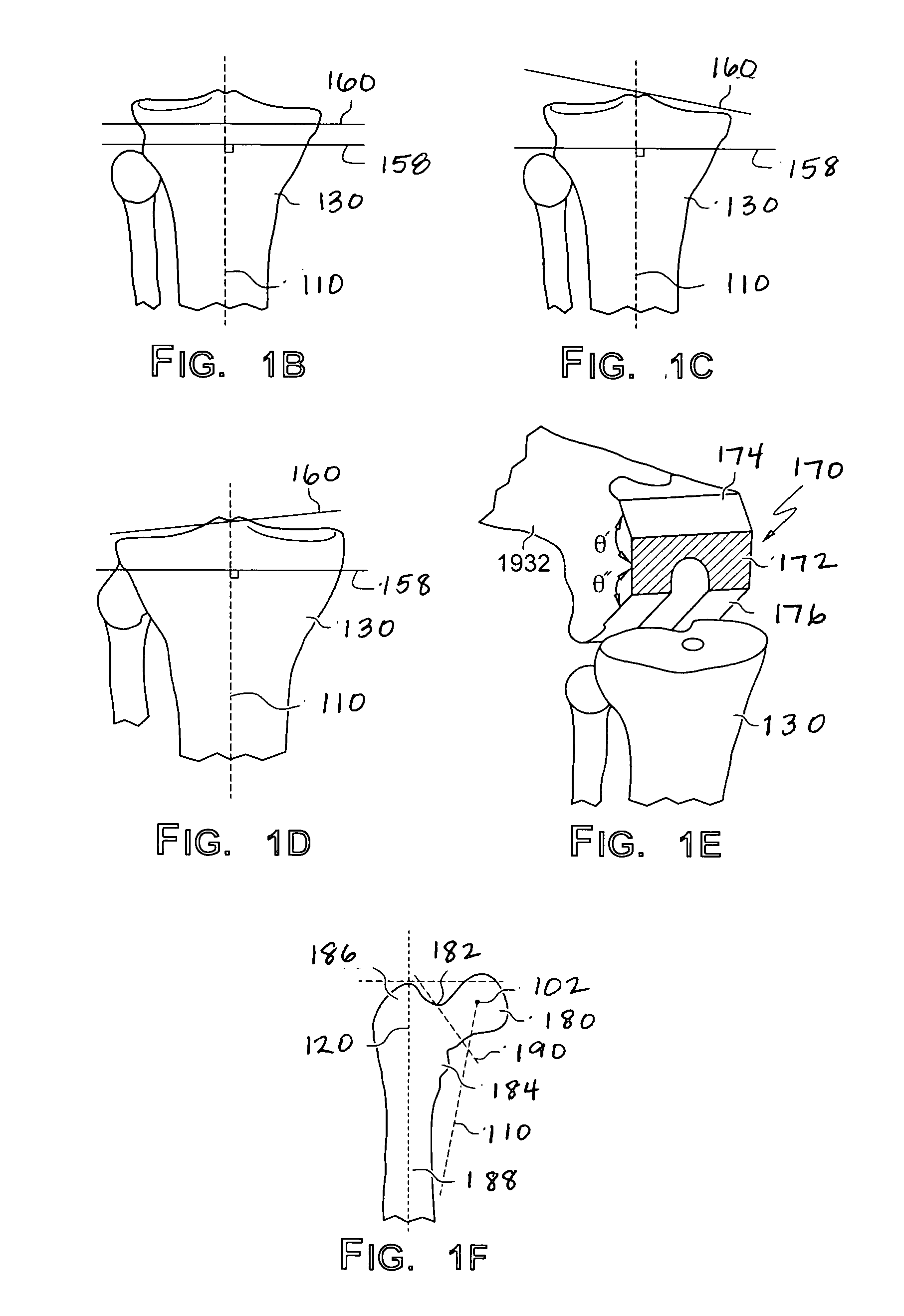

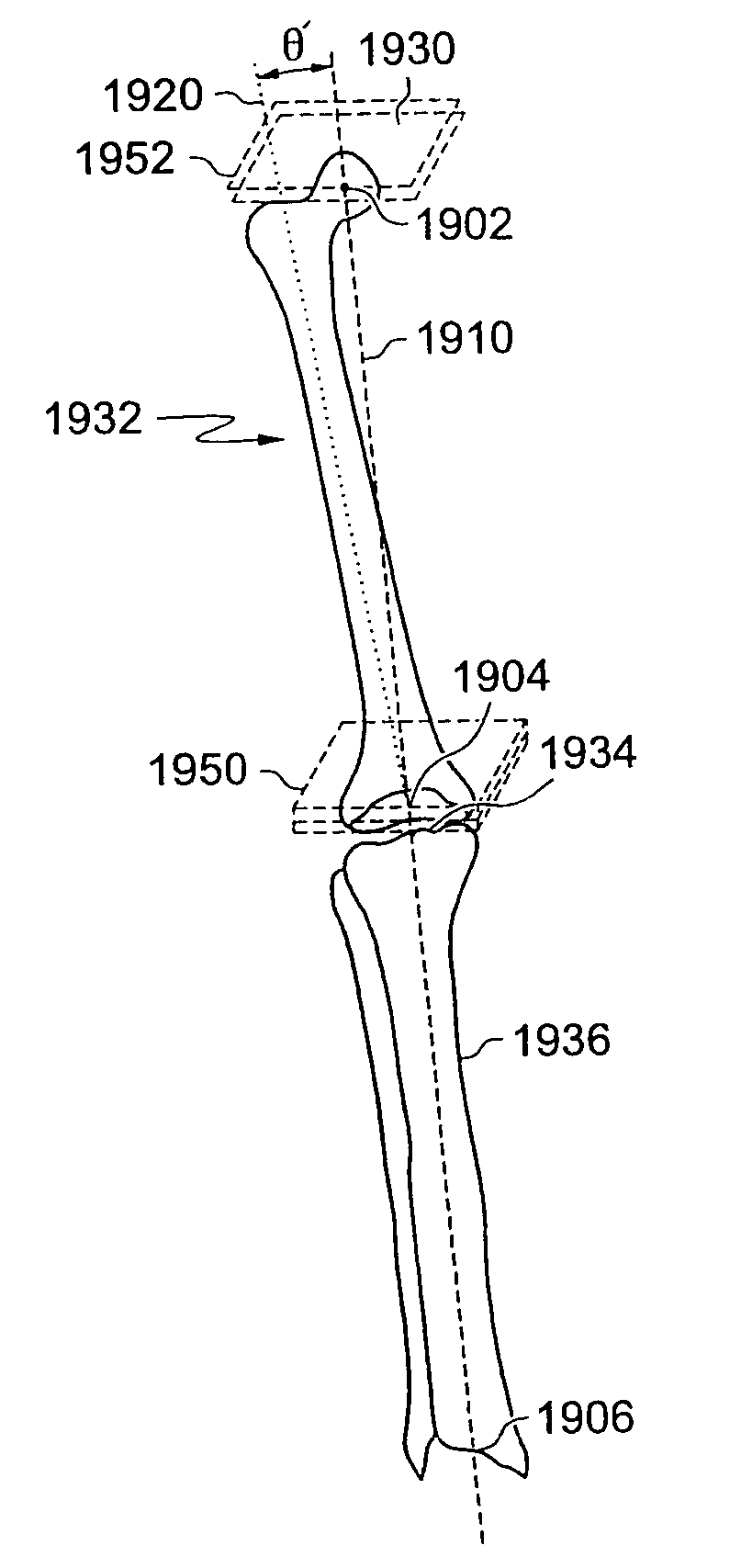

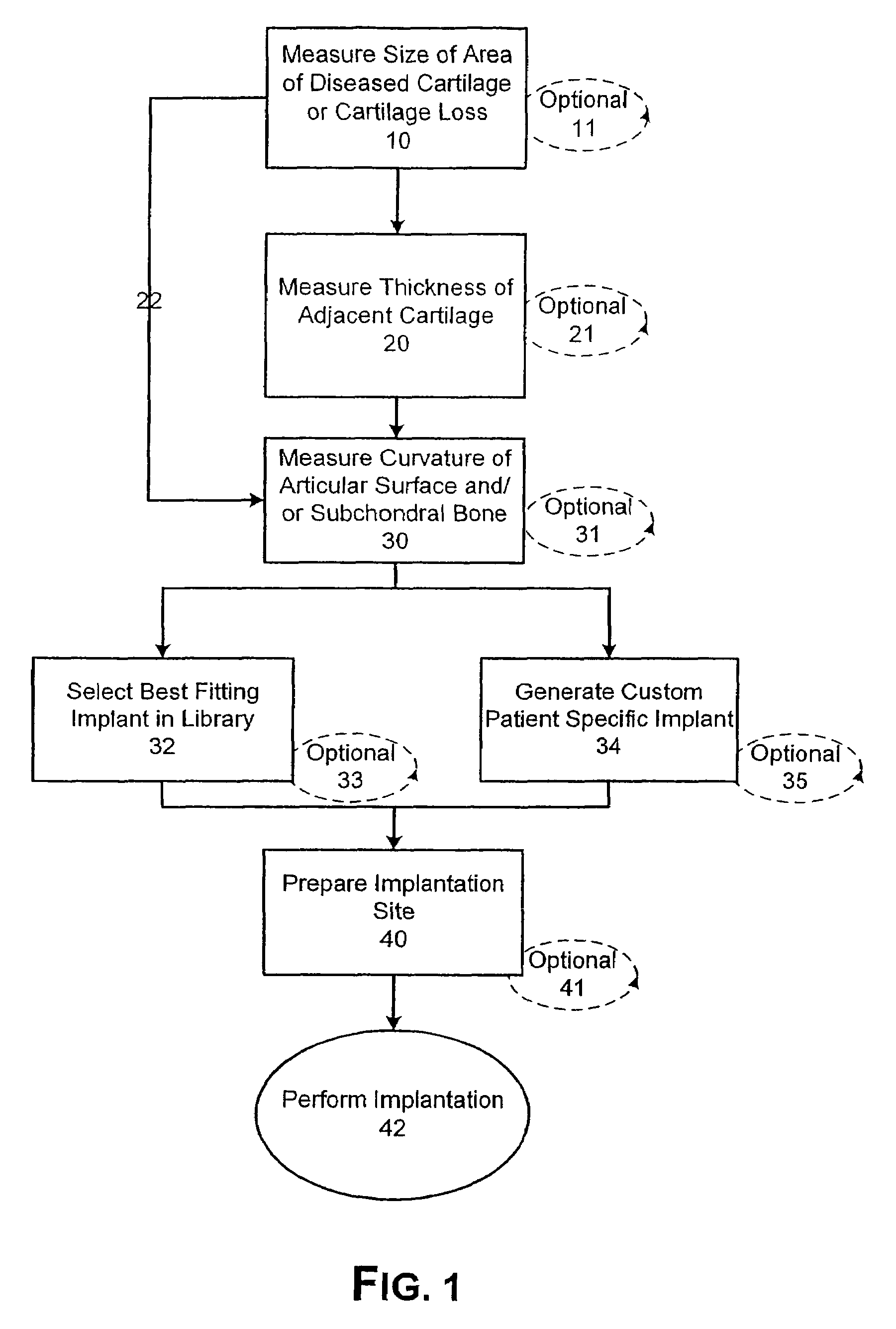

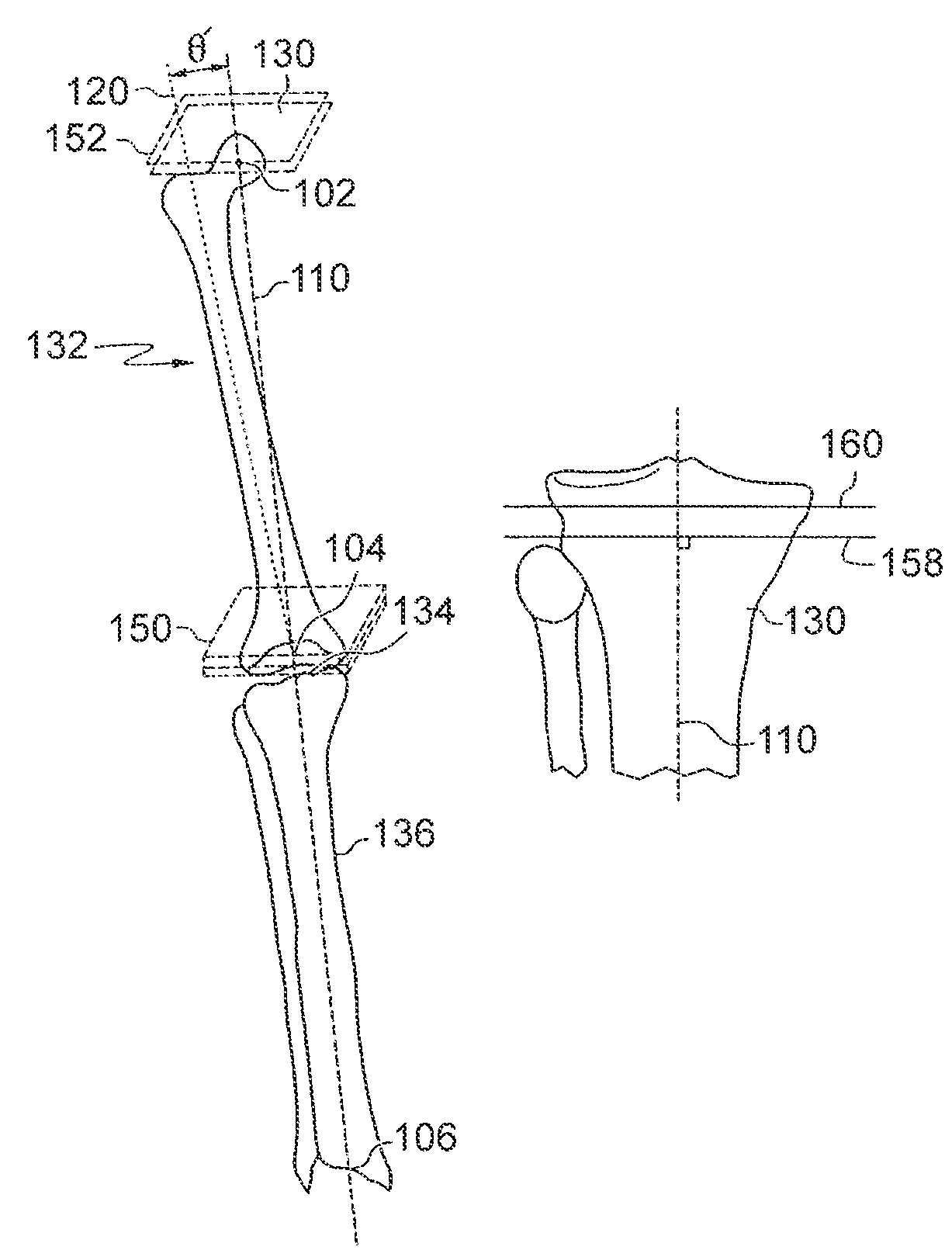

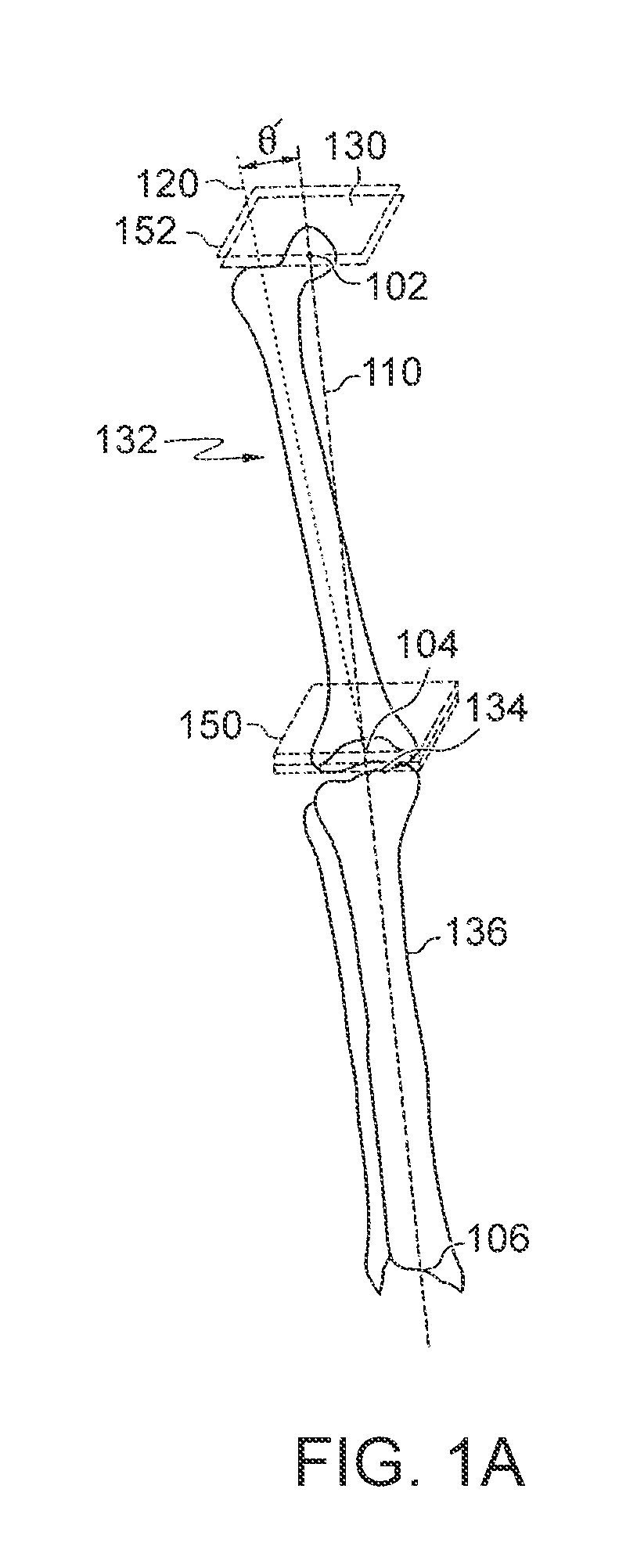

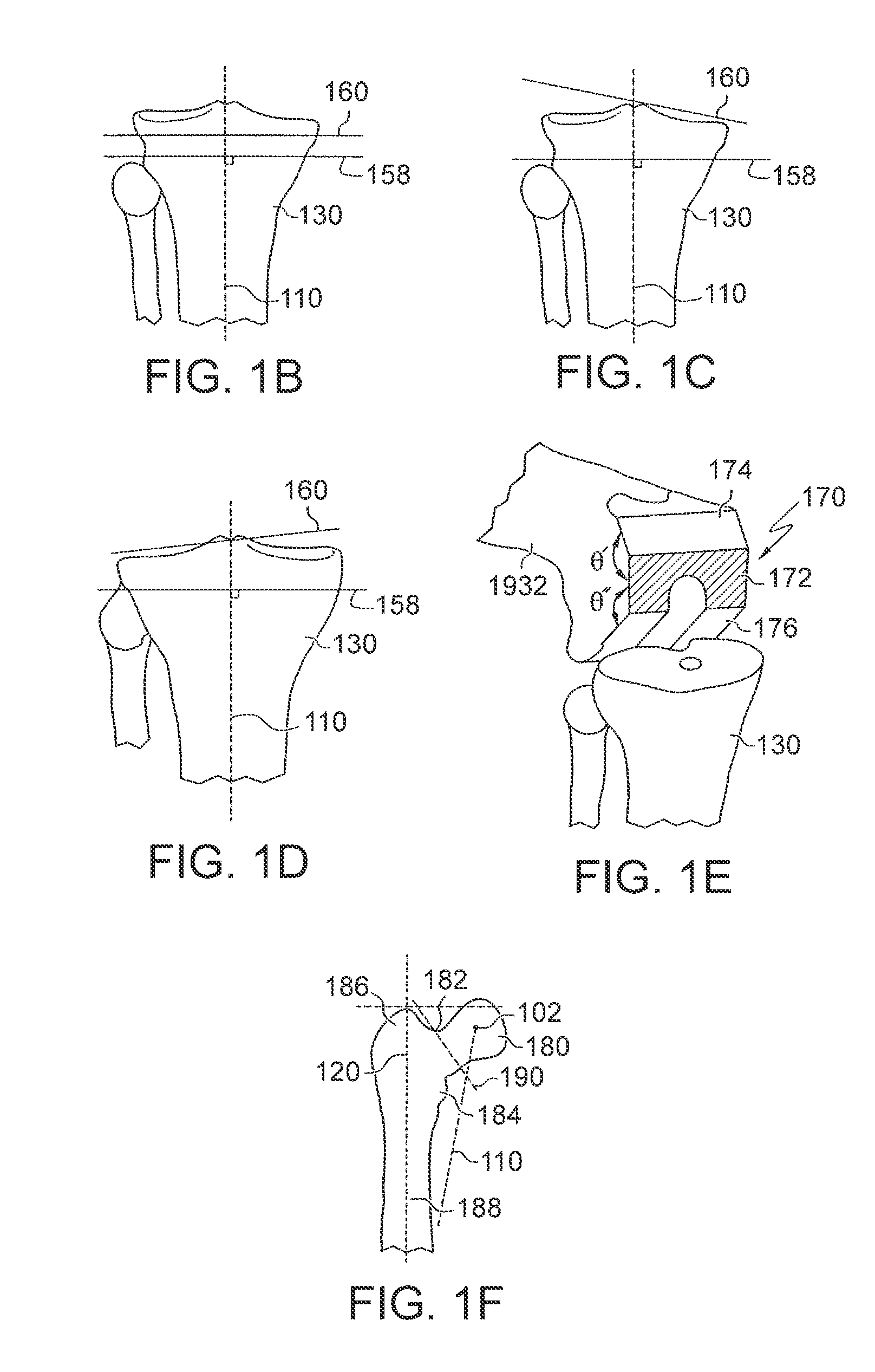

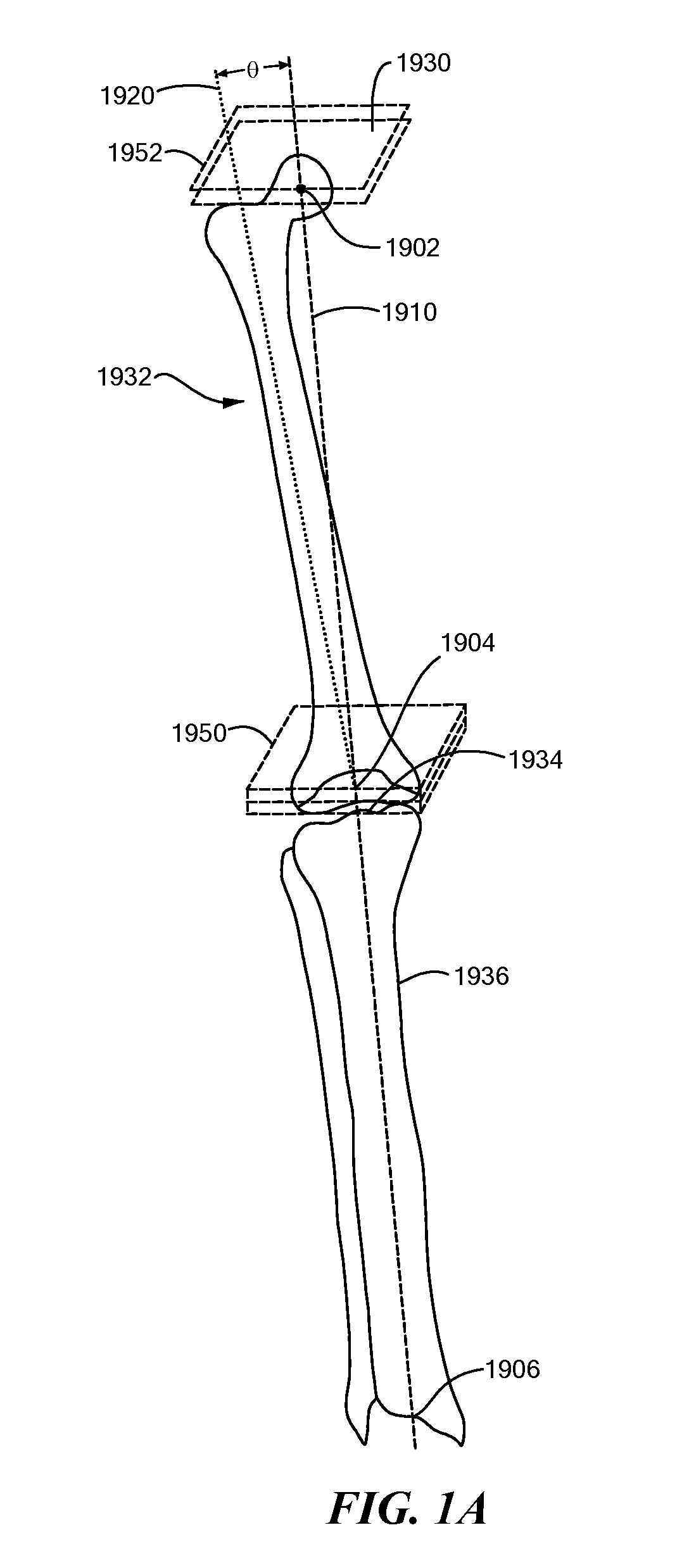

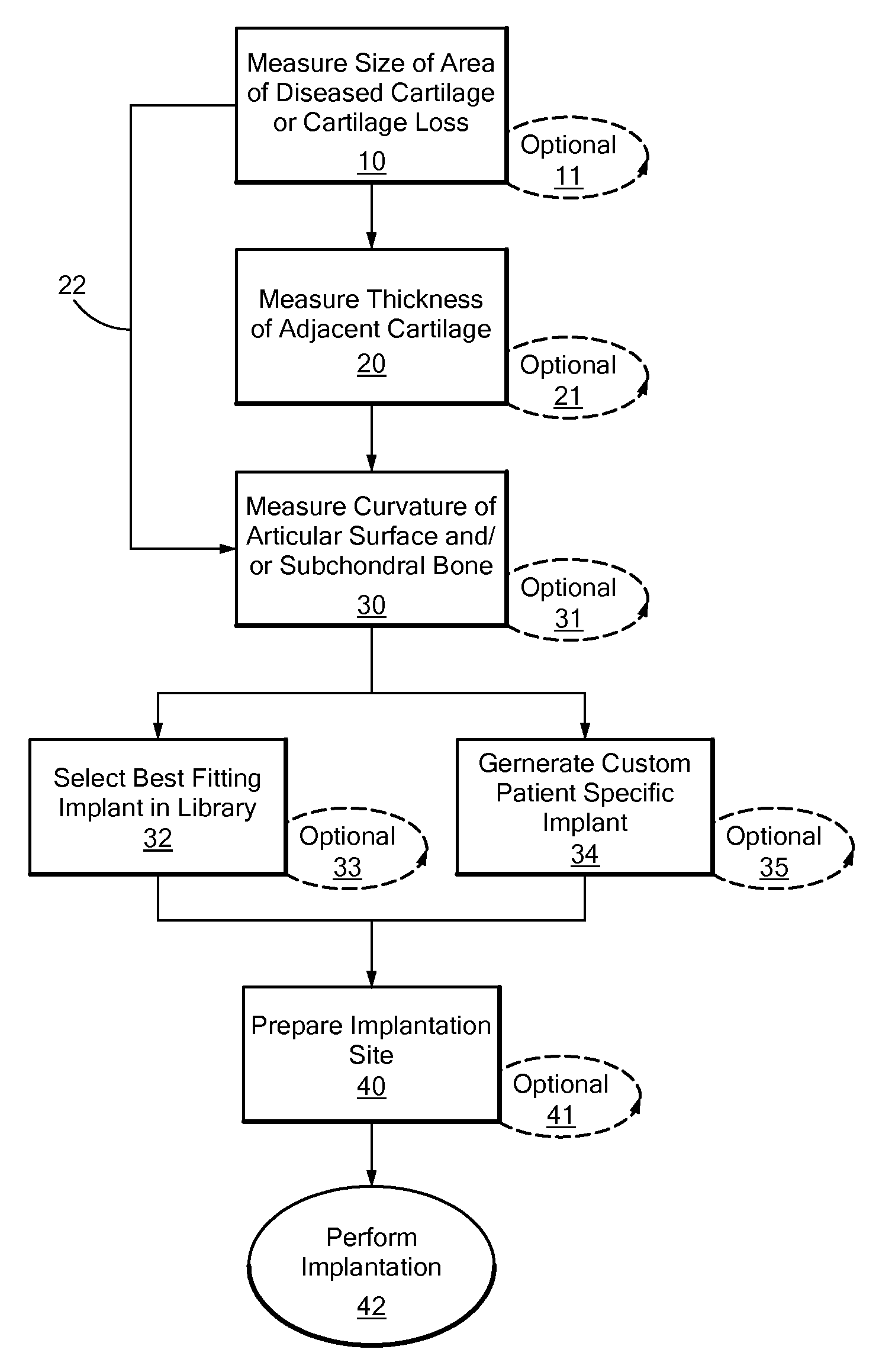

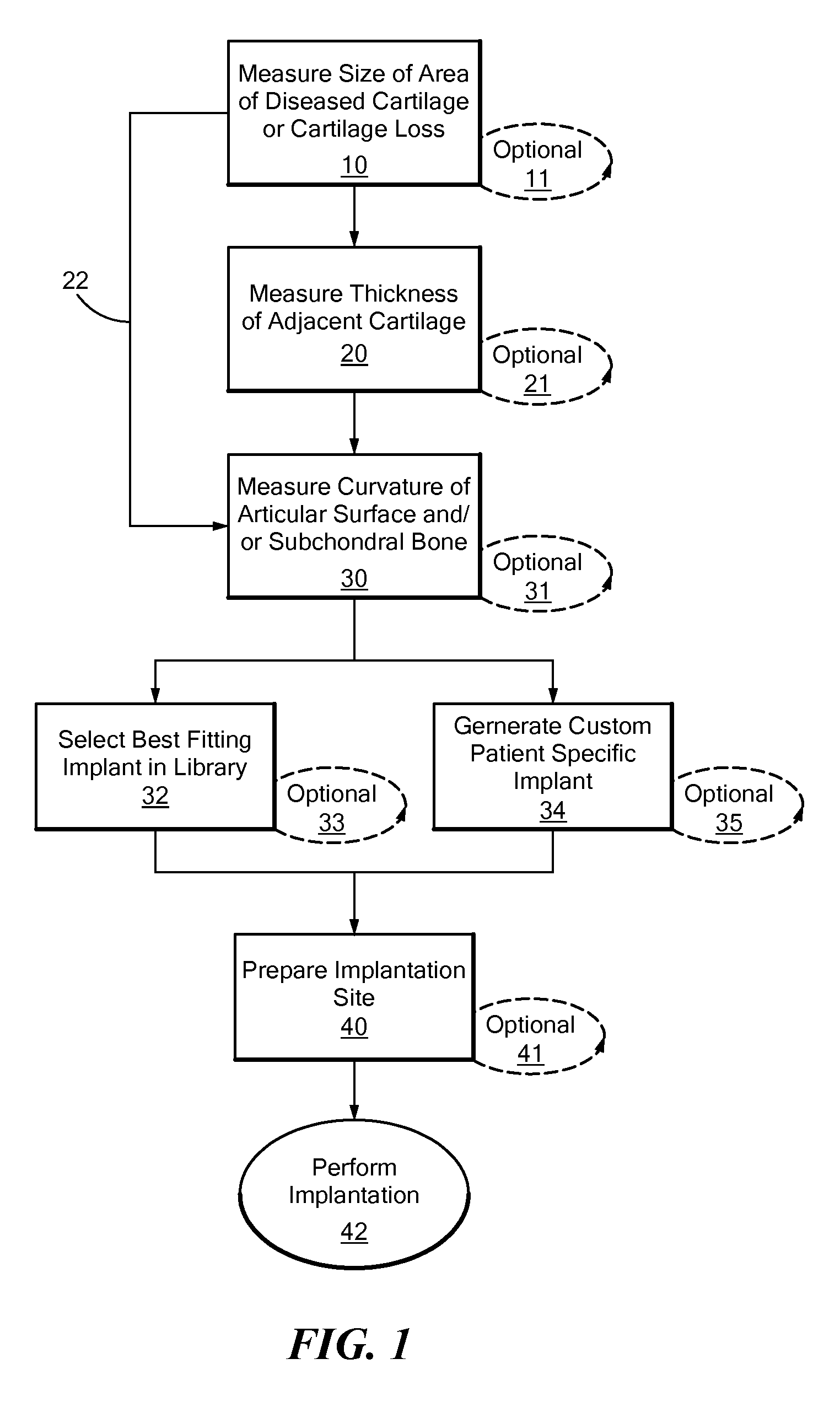

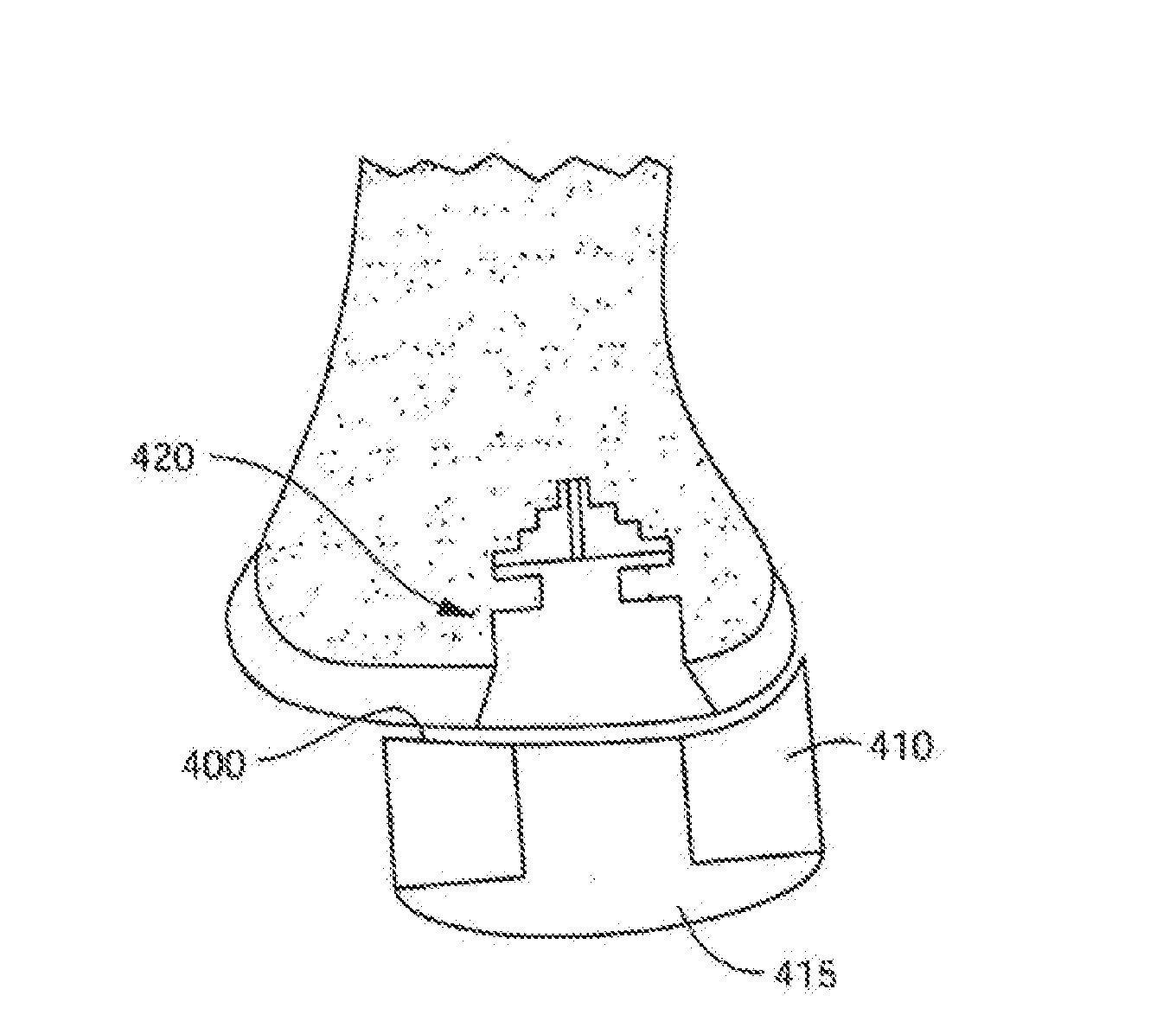

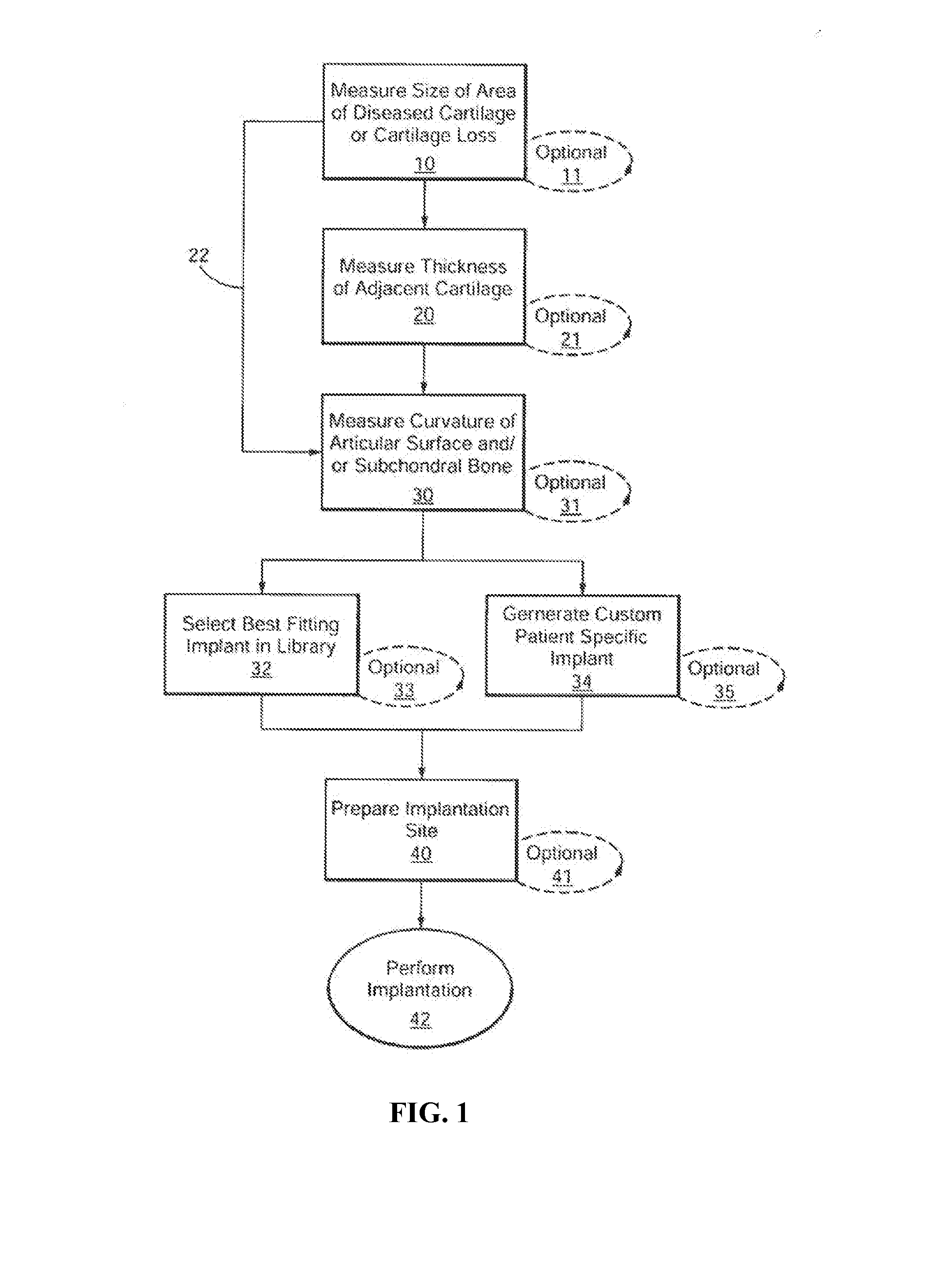

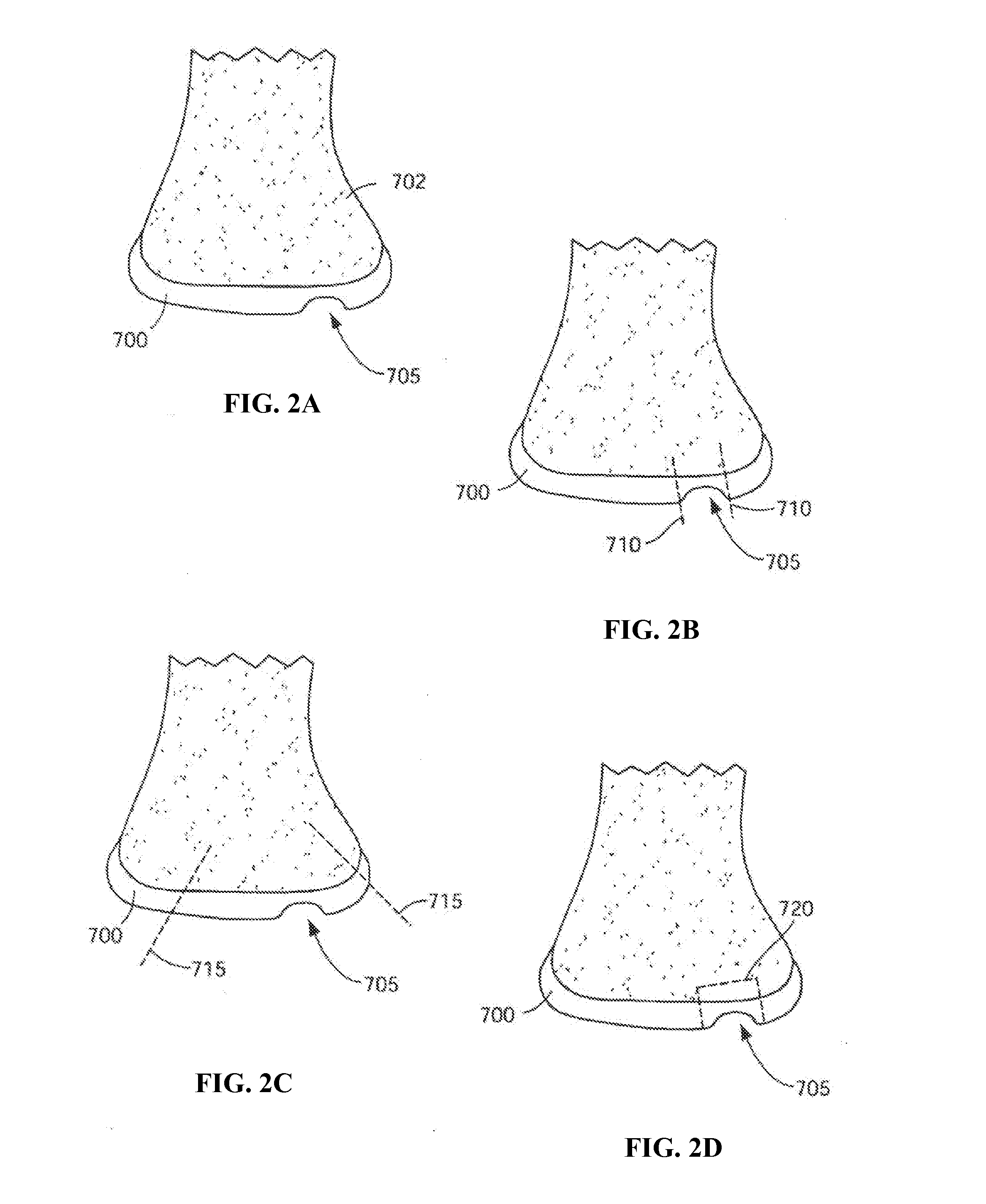

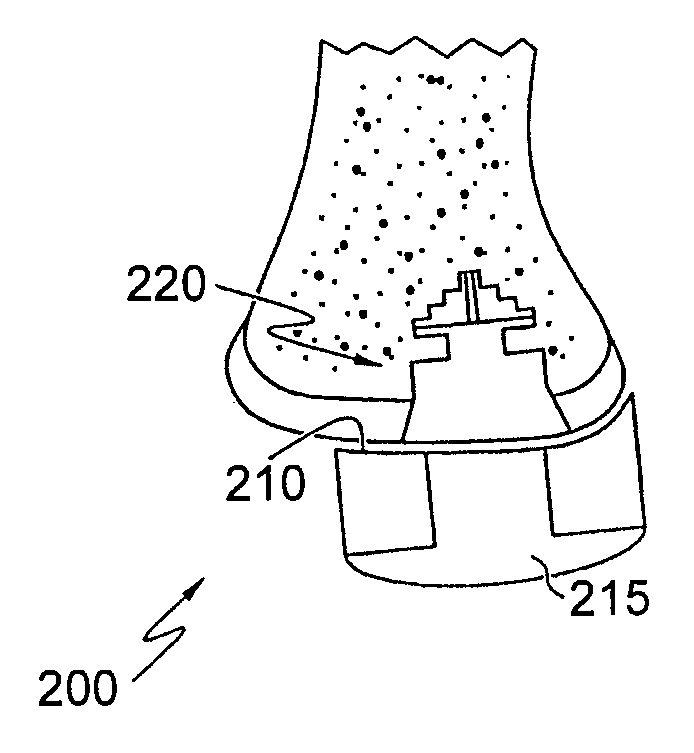

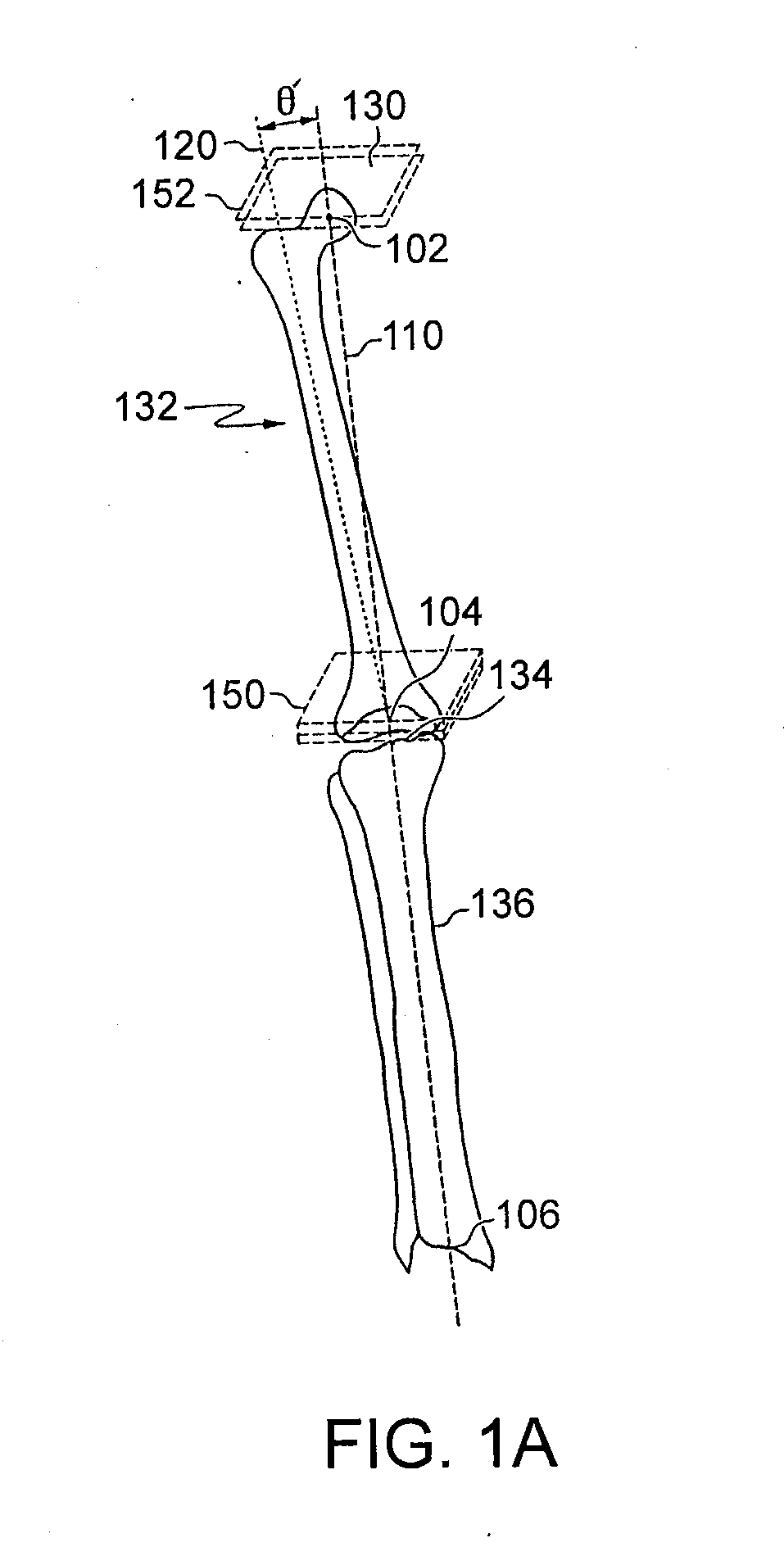

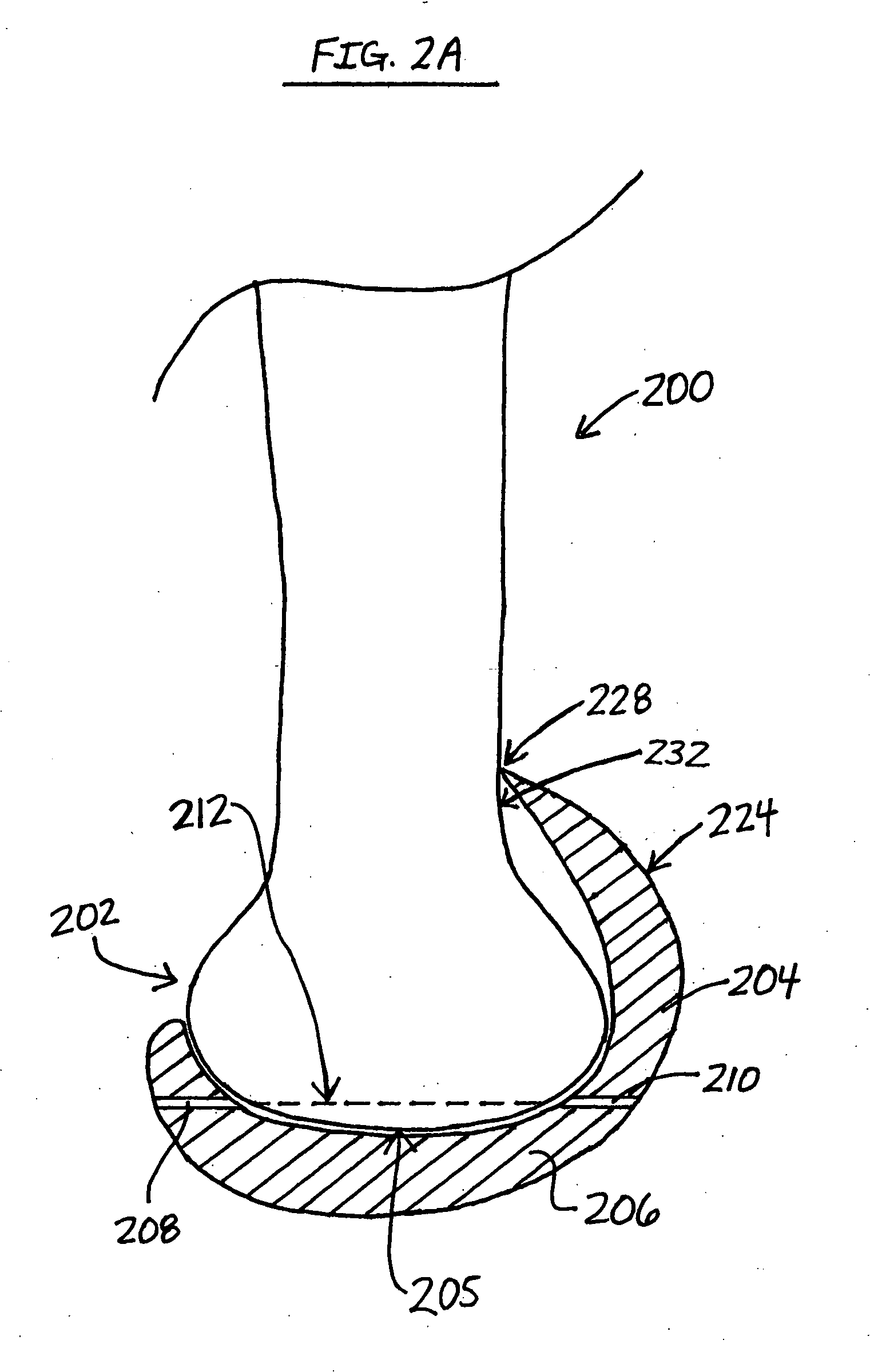

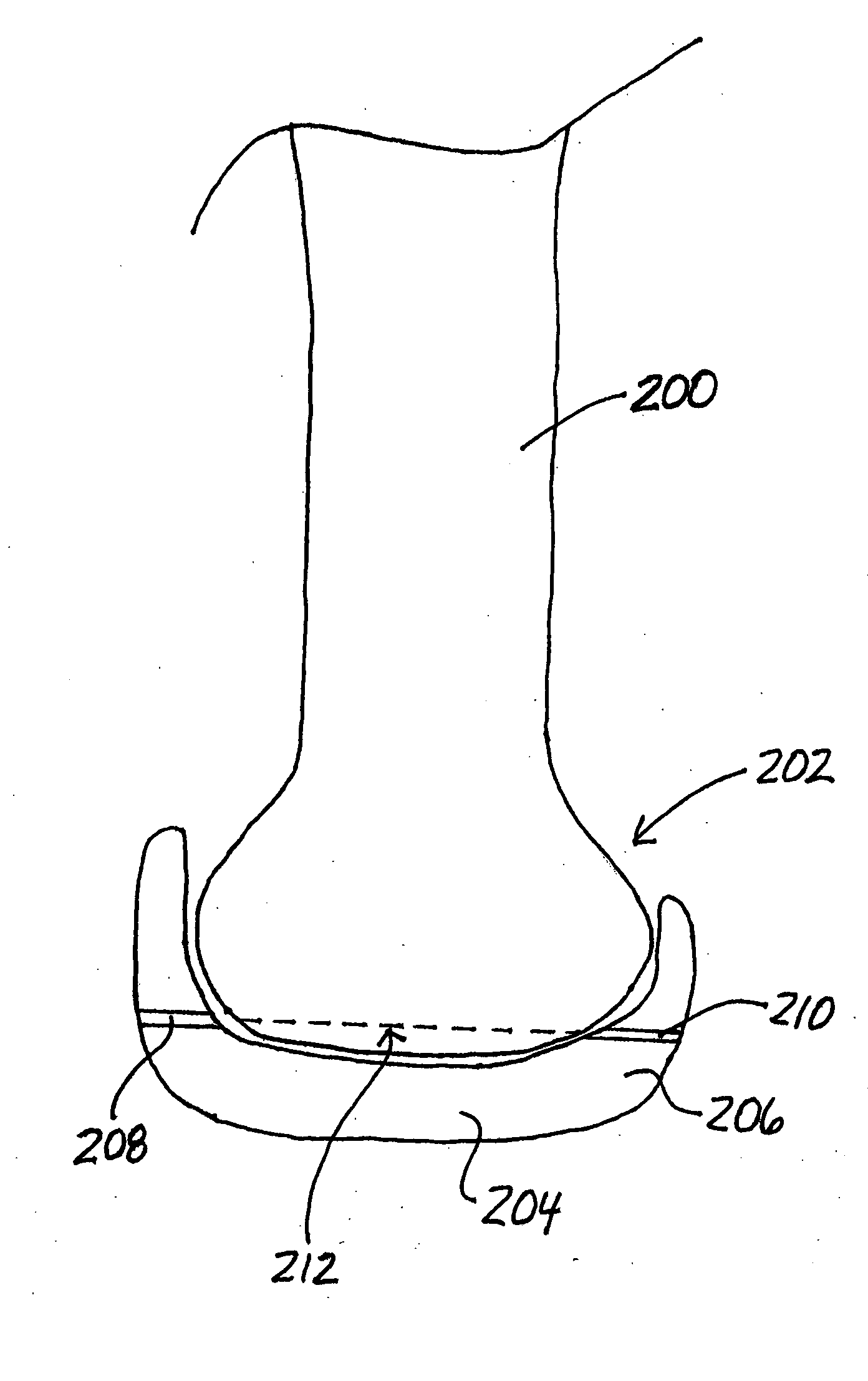

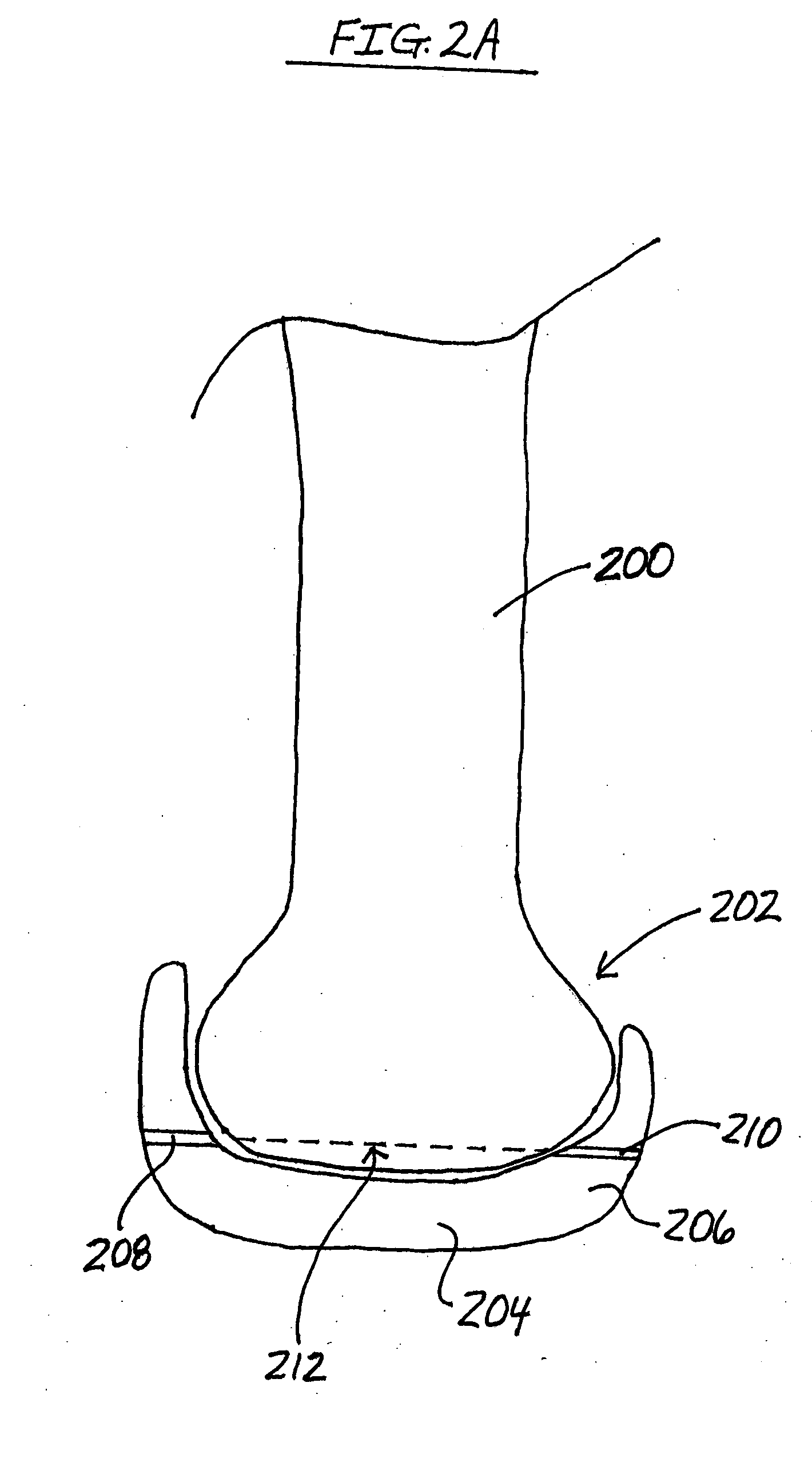

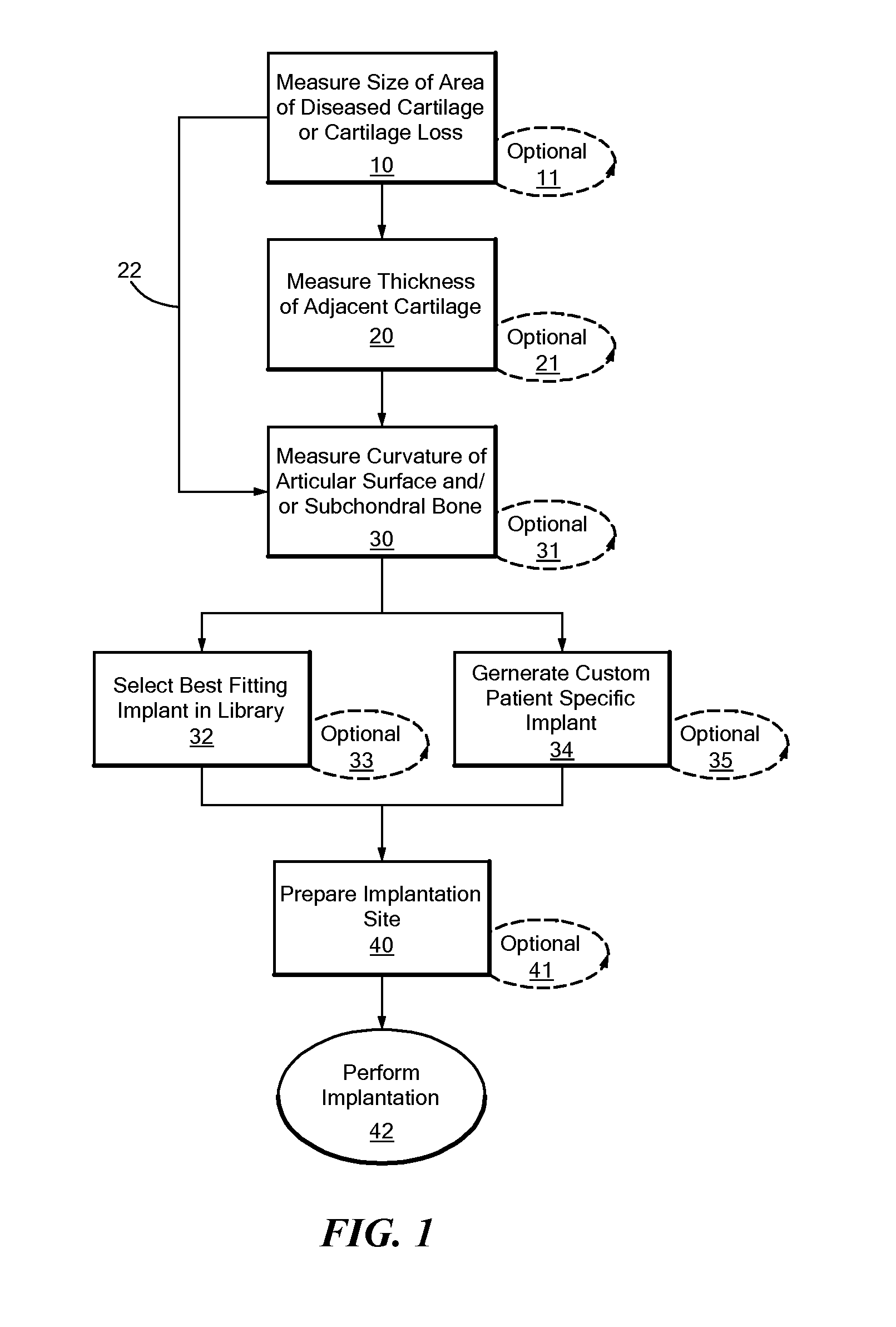

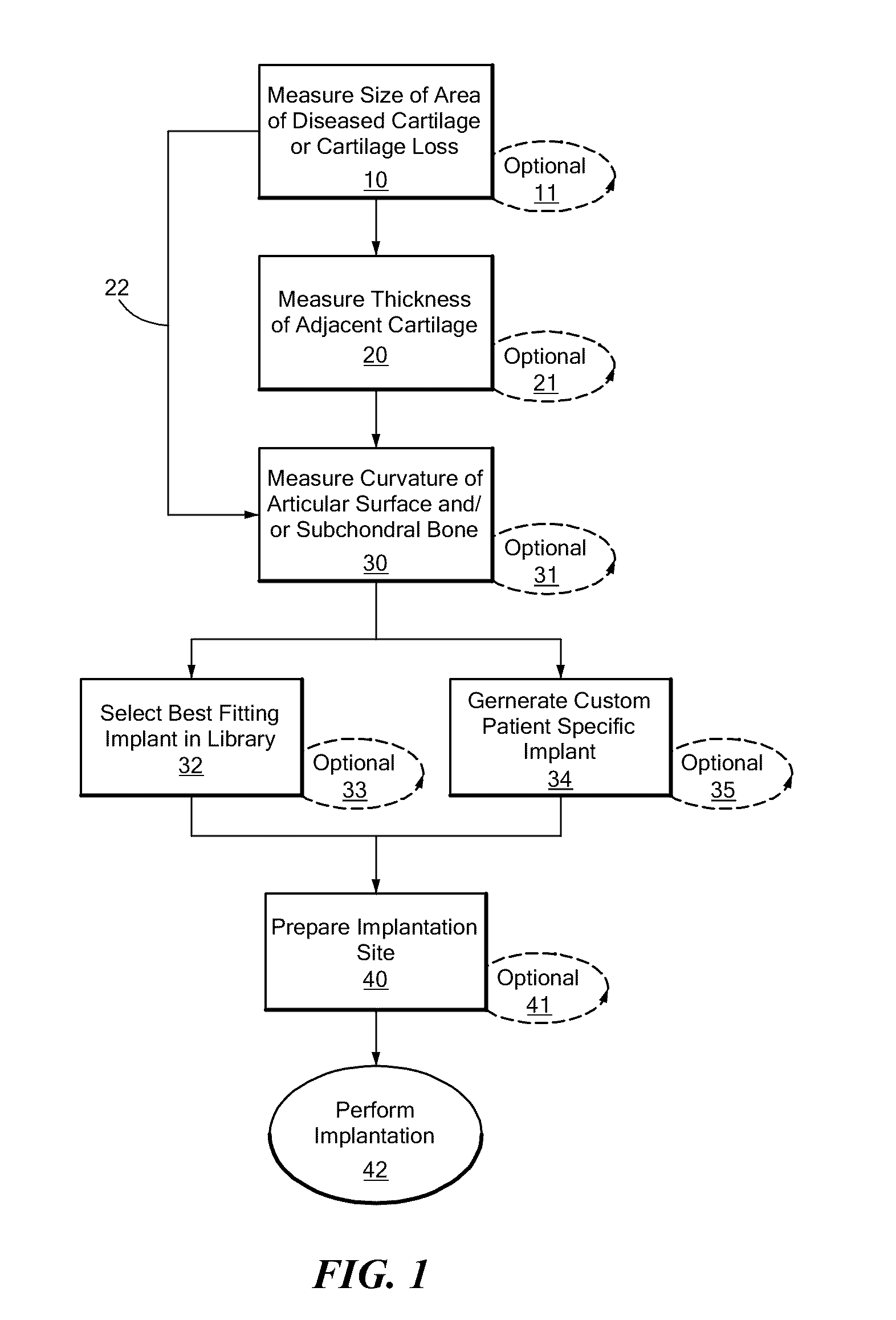

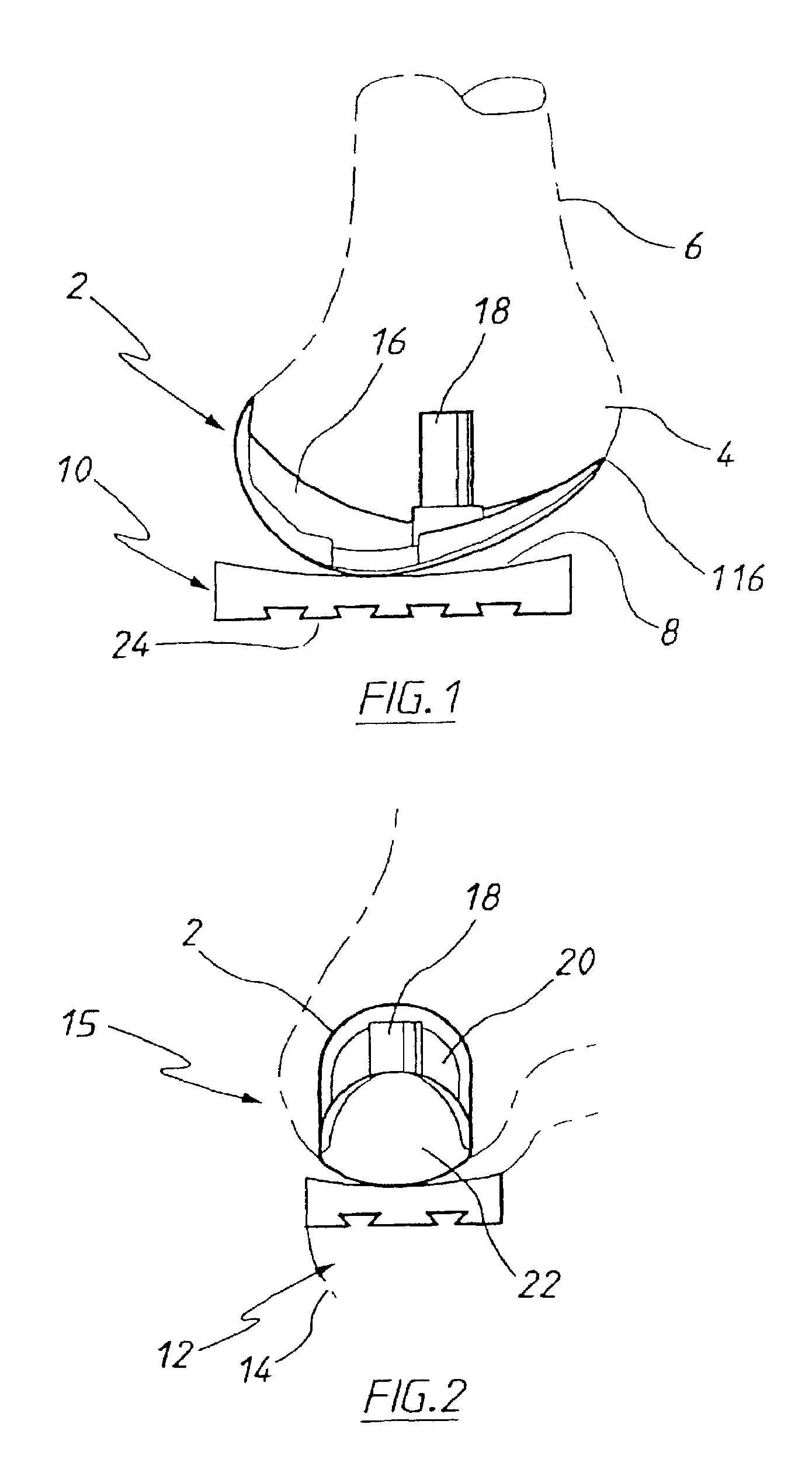

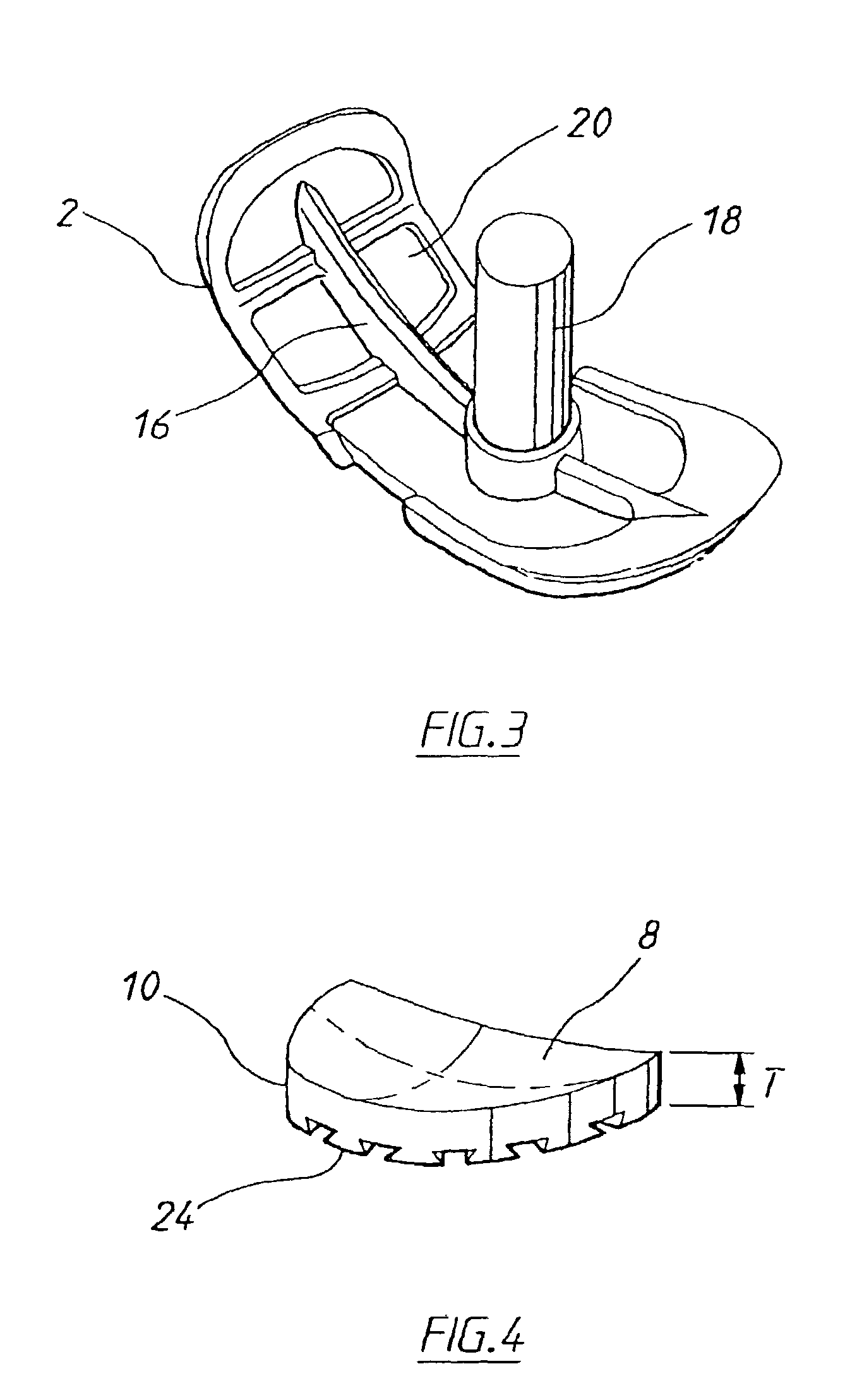

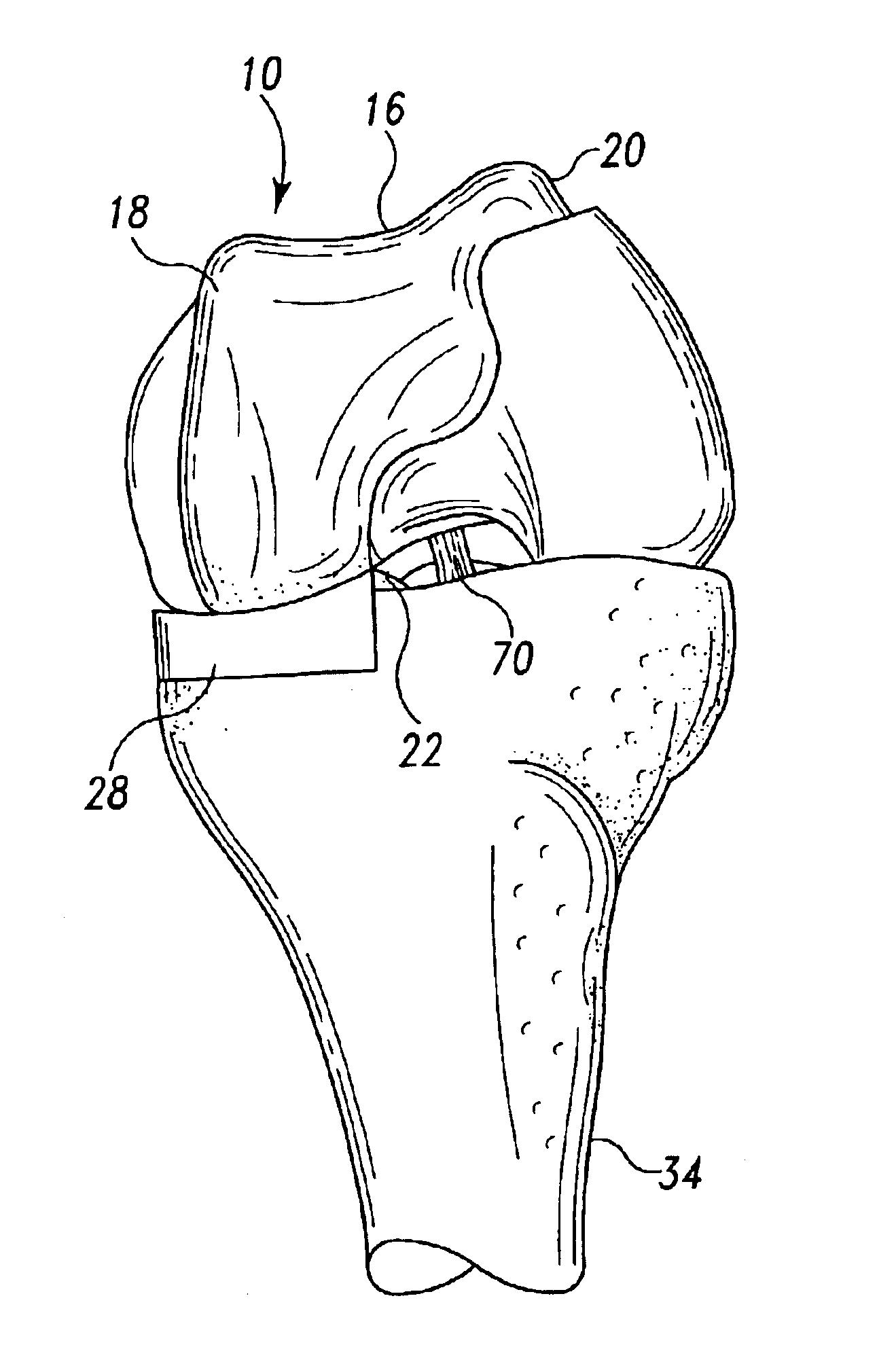

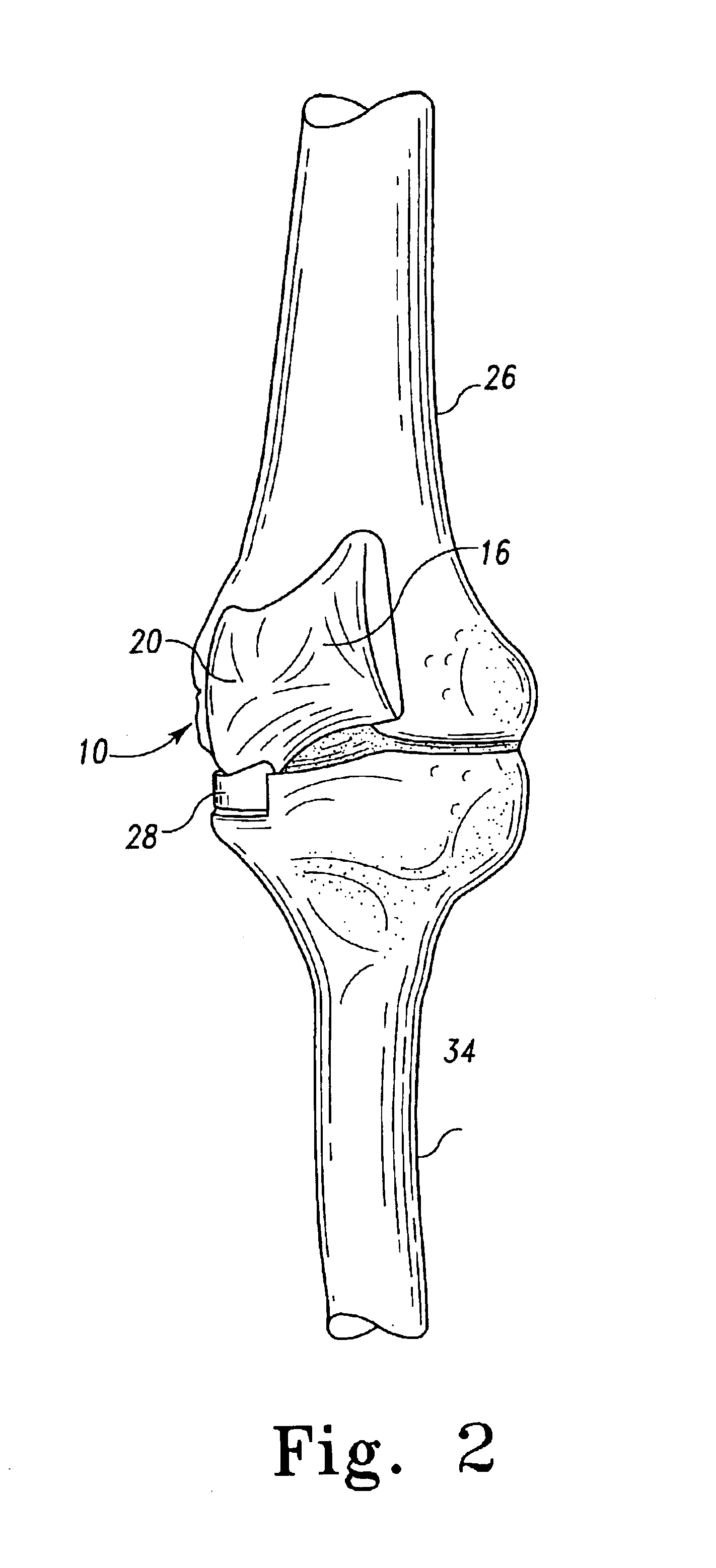

Disclosed herein are methods, compositions and tools for repairing articular surfaces repair materials and for repairing an articular surface. The articular surface repairs are customizable or highly selectable by patient and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

Surgical Tools for Arthroplasty

ActiveUS20080243127A1Accurate placementAdditive manufacturing apparatusSurgical navigation systemsTarsal JointKnee surface

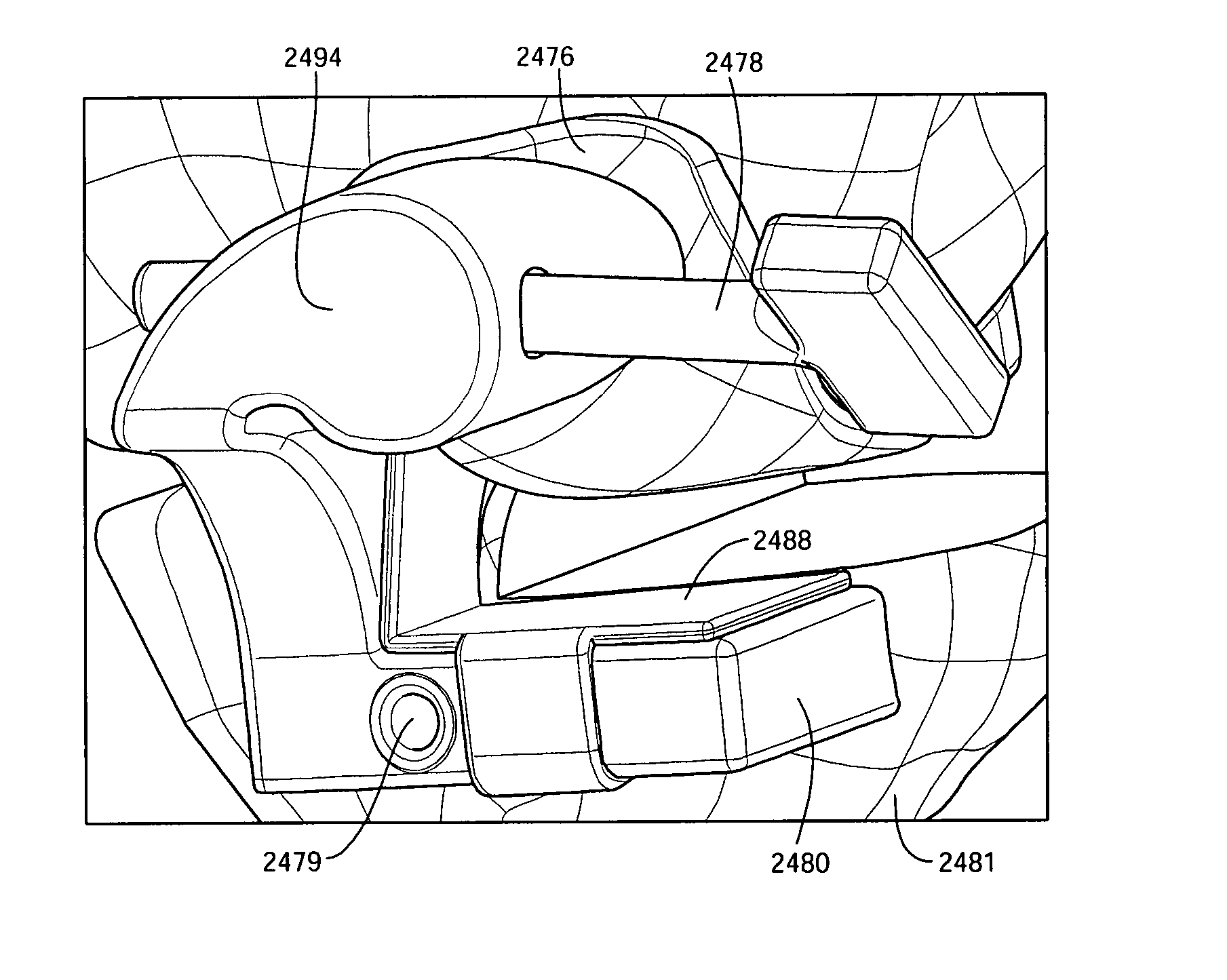

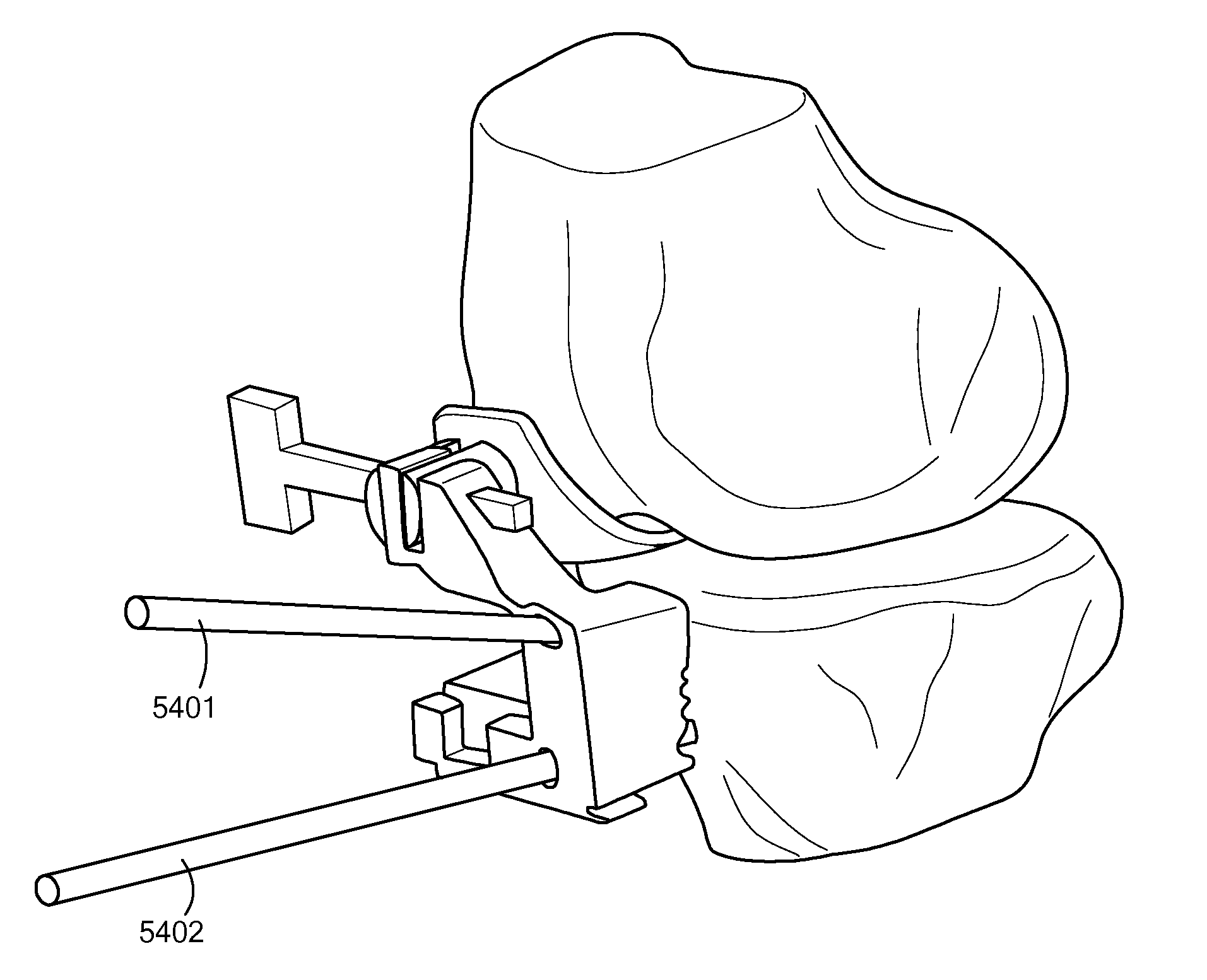

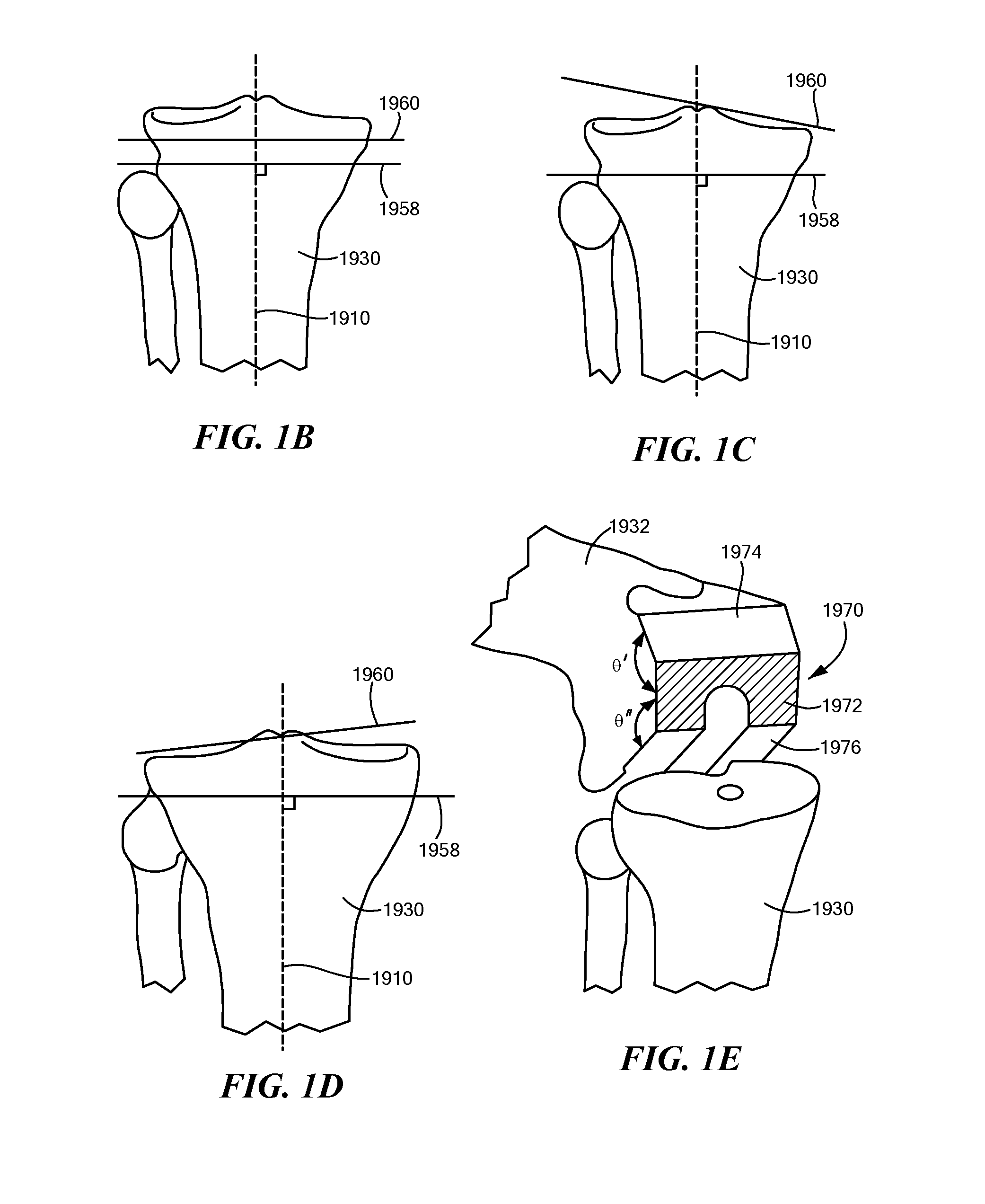

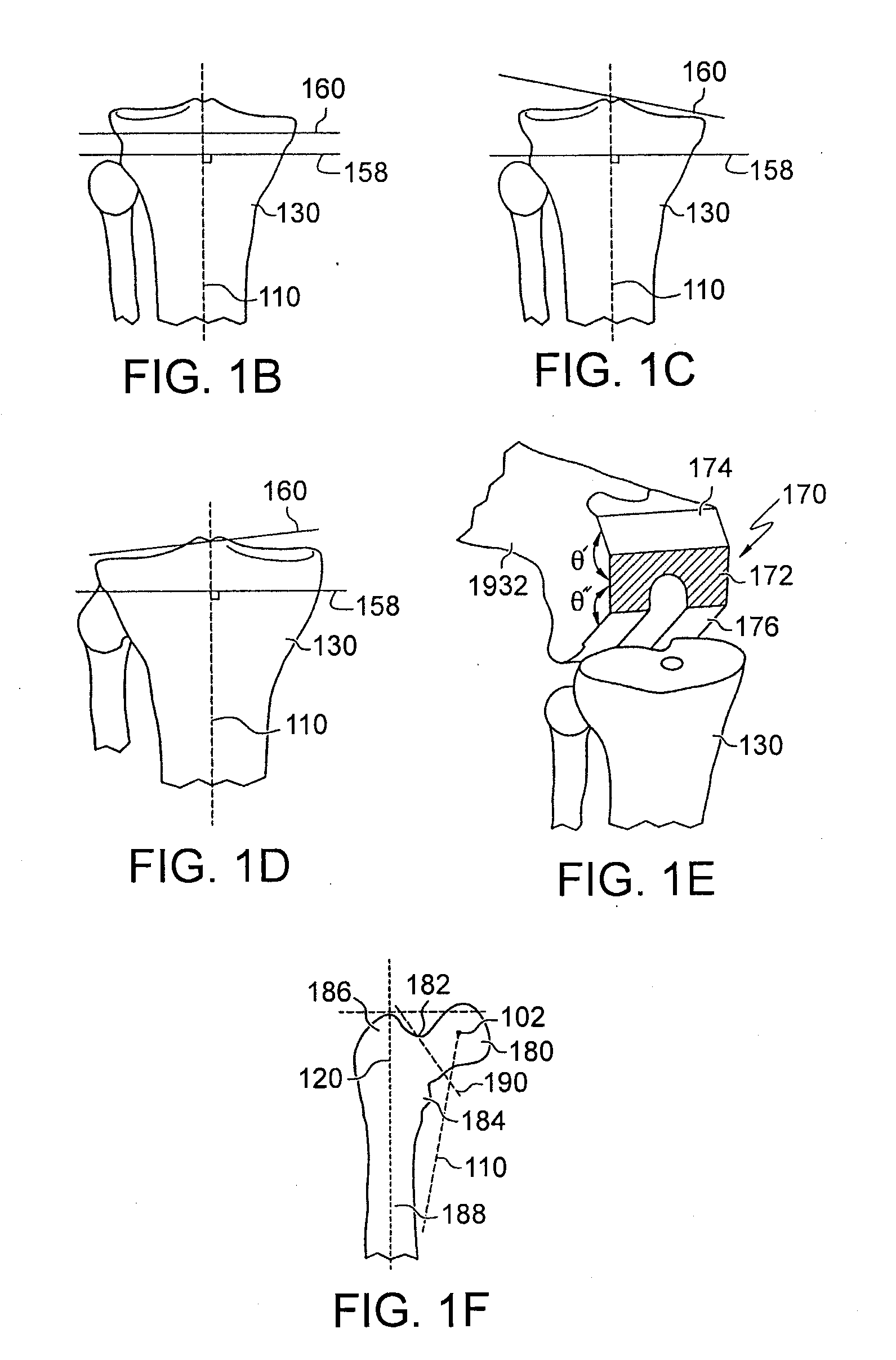

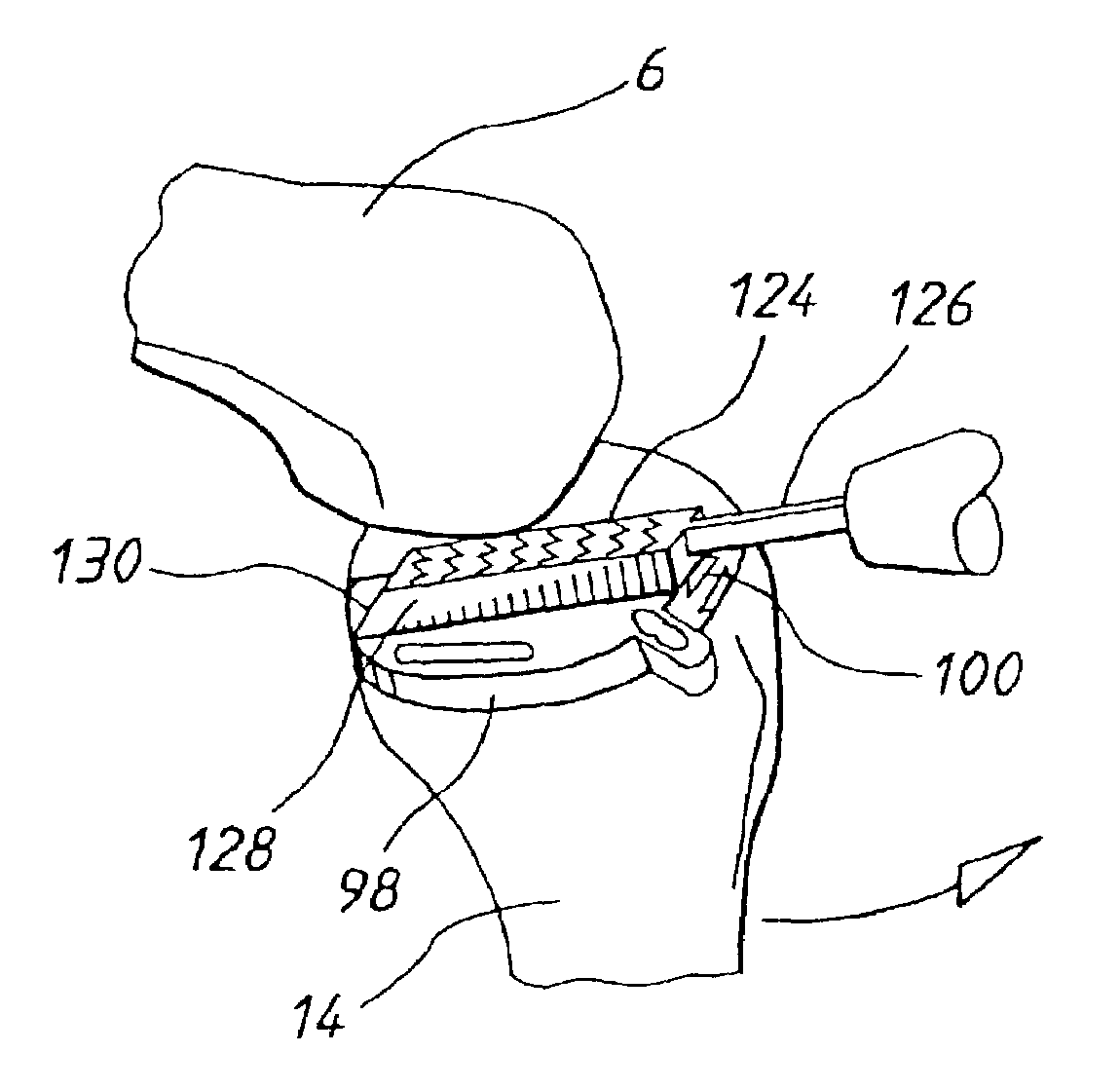

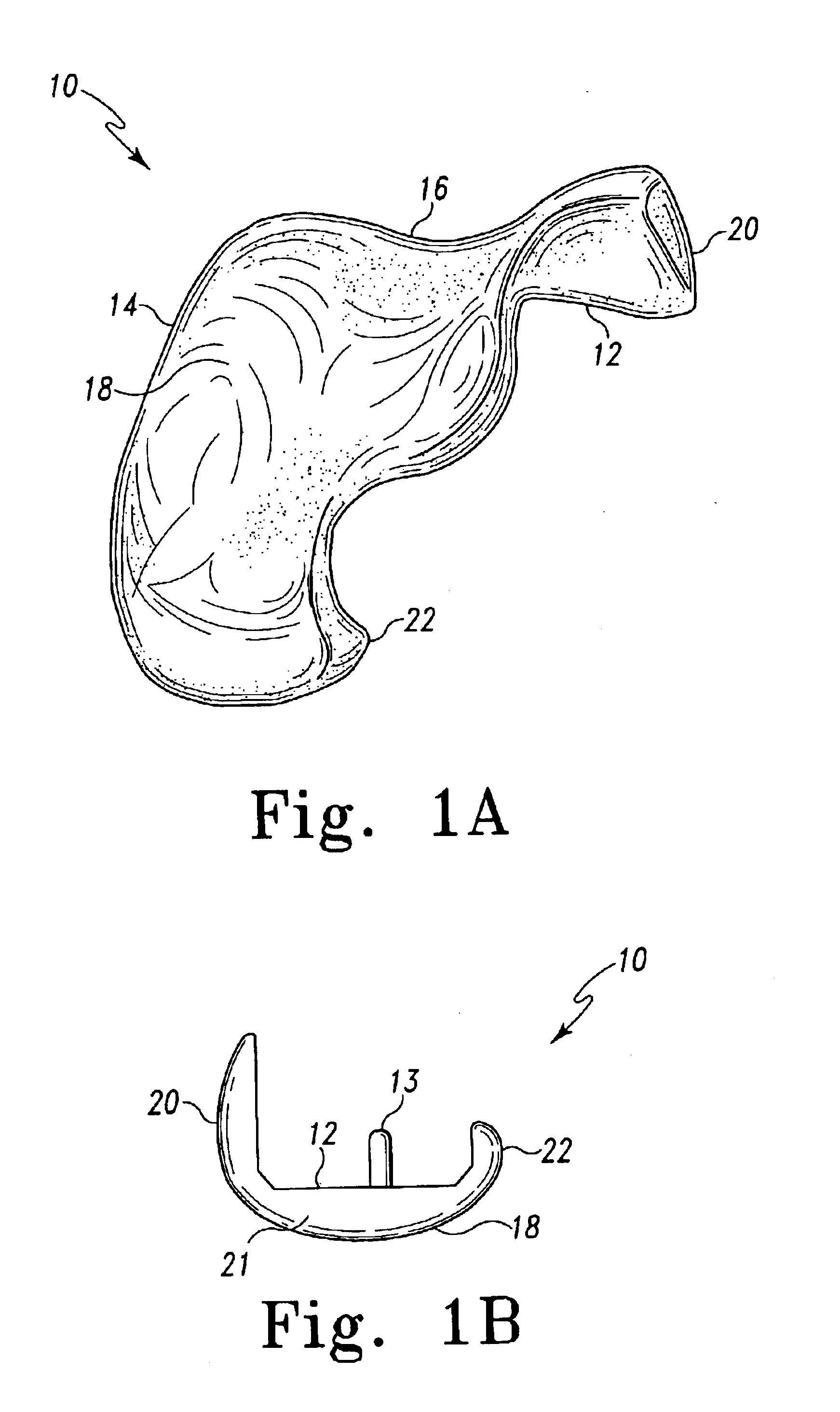

A patellar 3-D guidance tool includes a template. The template includes at least one contact surface for engaging a surface of the patella. The at least one contact surface substantially conforms with the surface associated with the patellar. At least one guide aperture directs movement of a surgical instrument, wherein the shape and / or position of the guide aperture is based, at least in part, on three or more anatomic reference points associated with the patellar.

Owner:CONFORMIS

Surgical tools facilitating increased accuracy, speed and simplicity in performing joint arthroplasty

Disclosed herein are tools for repairing articular surfaces repair materials and for repairing an articular surface. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

Patient selectable joint arthroplasty devices and surgical tools facilitating increased accuracy, speed and simplicity in performing total and partial joint arthroplasty

Disclosed herein are methods, compositions and tools for repairing articular surfaces repair materials and for repairing an articular surface. The articular surface repairs are customizable or highly selectable by patient and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

Surgical tools facilitating increased accuracy, speed and simplicity in performing joint arthroplasty

Disclosed herein are tools for repairing articular surfaces repair materials and for repairing an articular surface. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

Patient Selectable Joint Arthroplasty Devices and Surgical Tools

ActiveUS20090222014A1Improve and optimize positionAdditive manufacturing apparatusSurgical navigation systemsSurgical operationArticular surfaces

Disclosed herein are tools for repairing articular surfaces repair materials and for repairing an articular surface. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

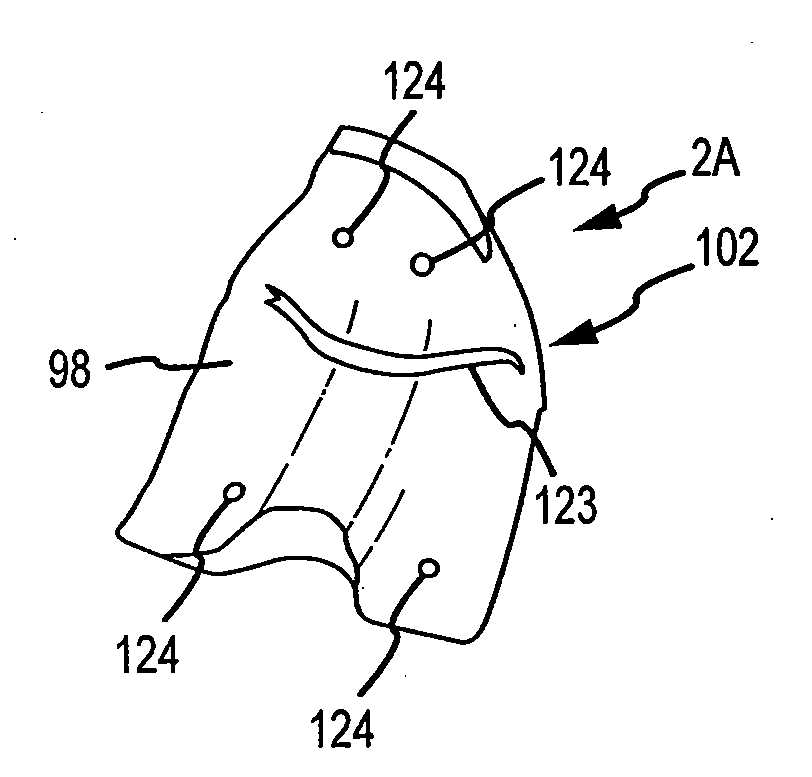

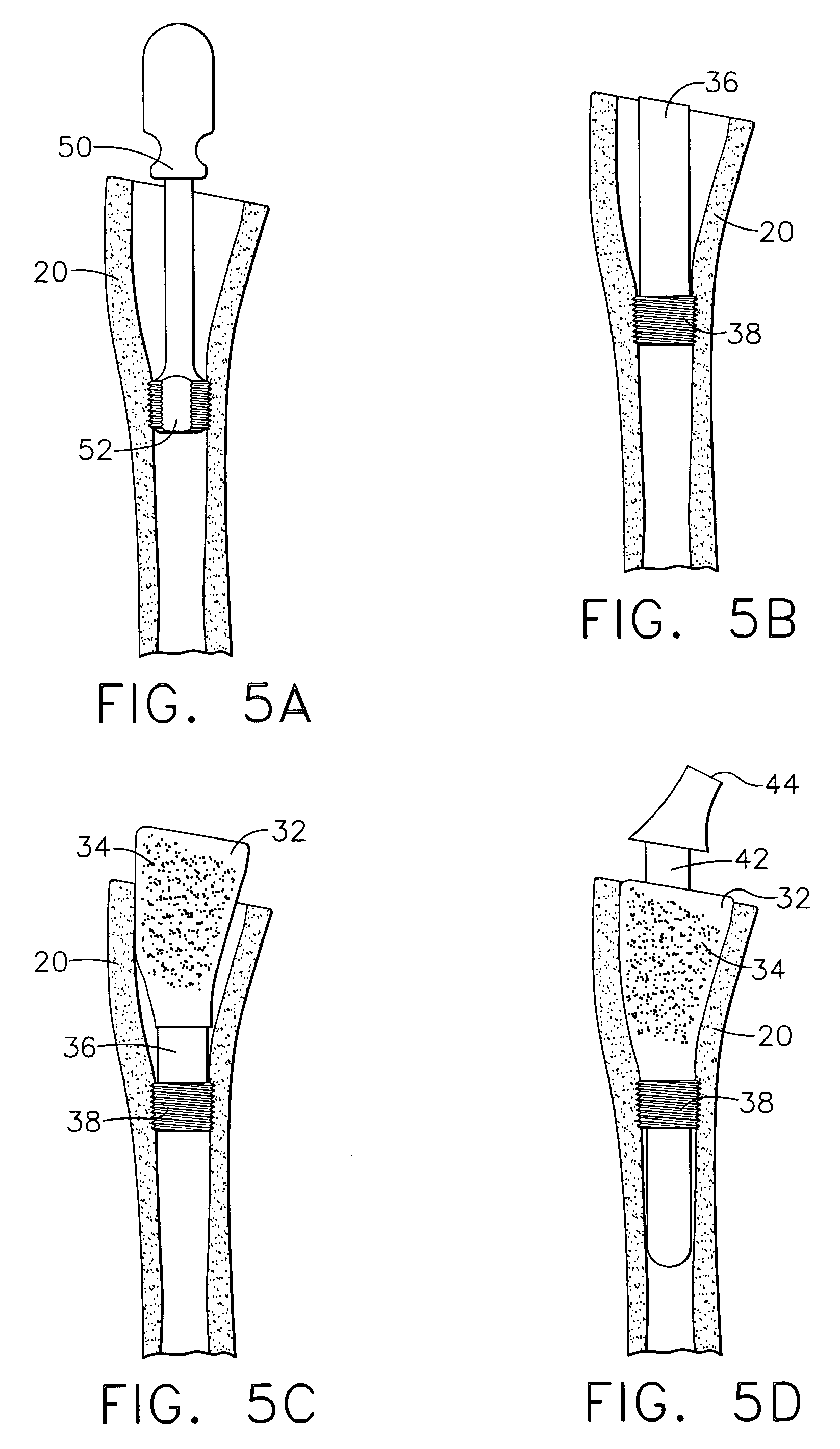

System and method for manufacturing arthroplasty jigs having improved mating accuracy

ActiveUS20100023015A1Facilitate arthroplasty implantsDiagnosticsComputer-aided planning/modellingSacroiliac jointOrthodontics

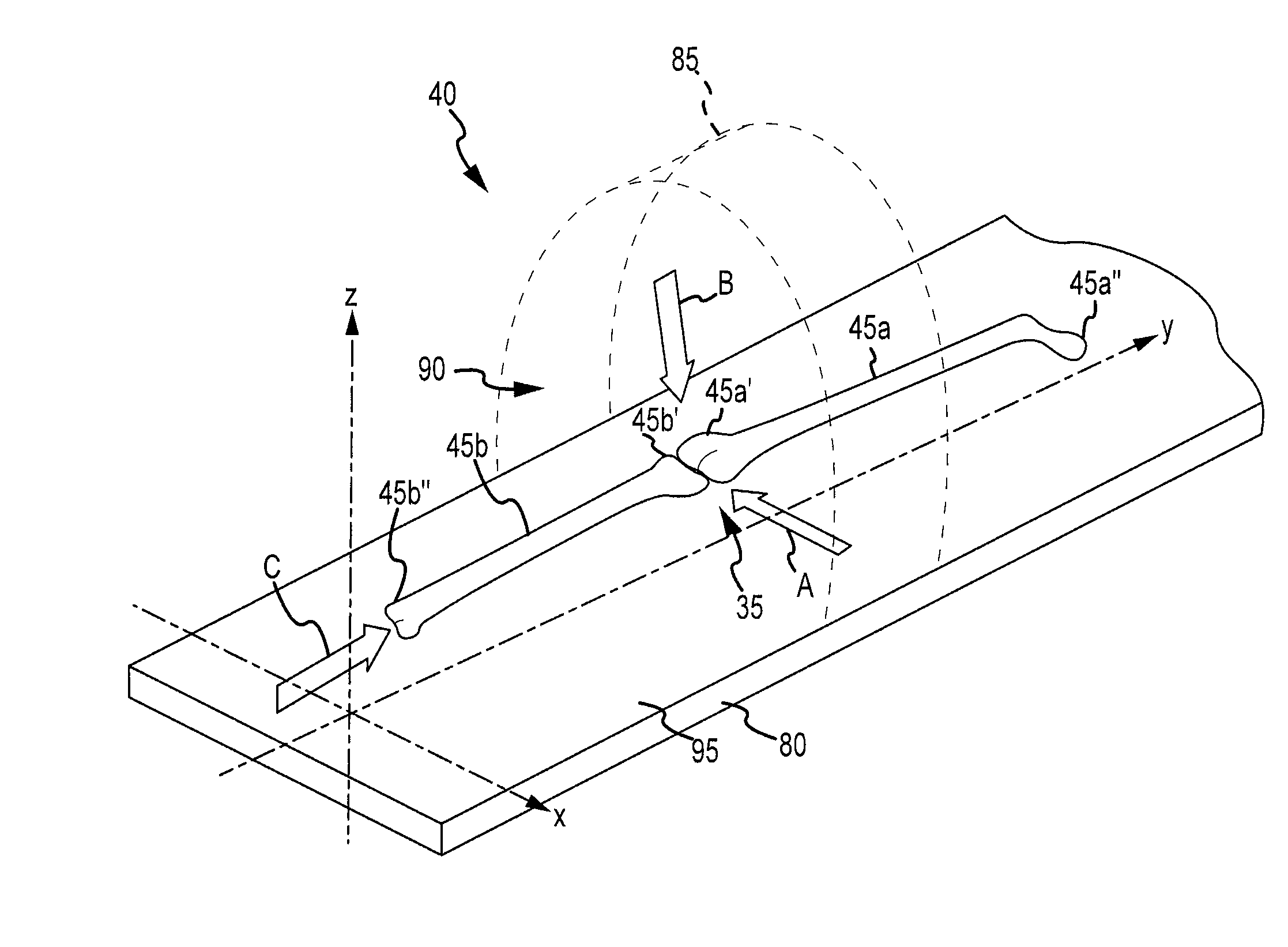

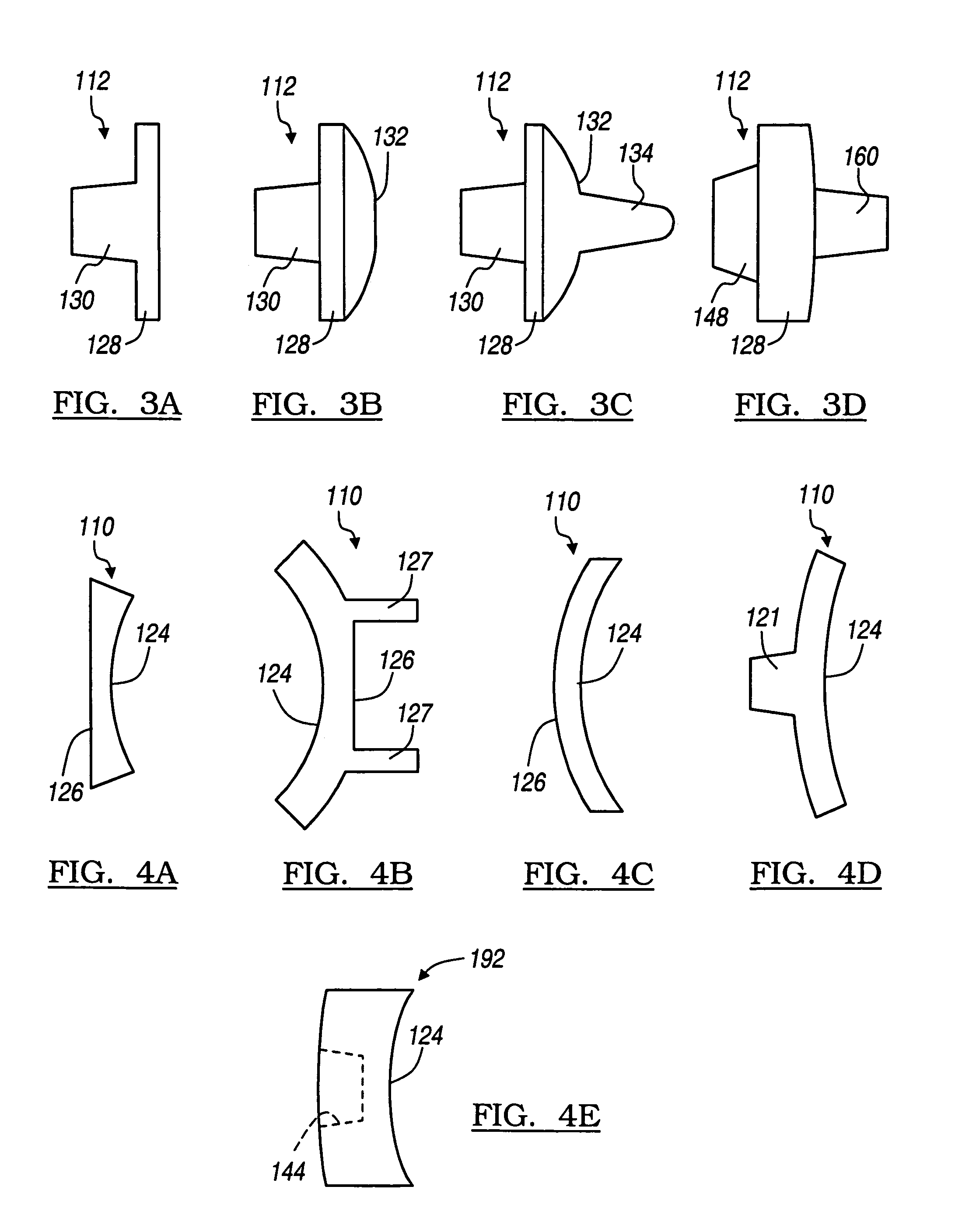

Disclosed herein is a method of defining a mating surface in a first side of an arthroplasty jig. The mating surface is configured to matingly receive and contact a corresponding patient surface including at least one of a bone surface and a cartilage surface. The first side is oriented towards the patient surface when the mating surface matingly receives and contacts the patient surface. The method may include: a) identifying a contour line associated with the patient surface as represented in a medical image; b) evaluating via an algorithm the adequacy of the contour line for defining a portion of the mating surface associated with the contour line; c) modifying the contour line if the contour line is deemed inadequate; and d) employing the modified contour line to define the portion of the mating surface associated with the contour line.

Owner:HOWMEDICA OSTEONICS CORP

Surgical Tools for Arthroplasty

InactiveUS20080281328A1Accurate placementAdditive manufacturing apparatusSurgical navigation systemsArticular surfacesArticular surface

Disclosed herein are methods, compositions and tools for repairing articular surfaces repair materials and for repairing an articular surface. The articular surface repairs are customizable or highly selectable by patient and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

Patient Selectable Joint Arthroplasty Devices and Surgical Tools Incorporating Anatomical Relief

ActiveUS20120041446A1Improve fitMore natural movementAdditive manufacturing apparatusSurgical navigation systemsArticular surfacesArticular surface

Disclosed herein are methods, compositions and tools for repairing articular surfaces repair materials and for repairing an articular surface. The articular surface repairs are customizable or highly selectable by patient and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

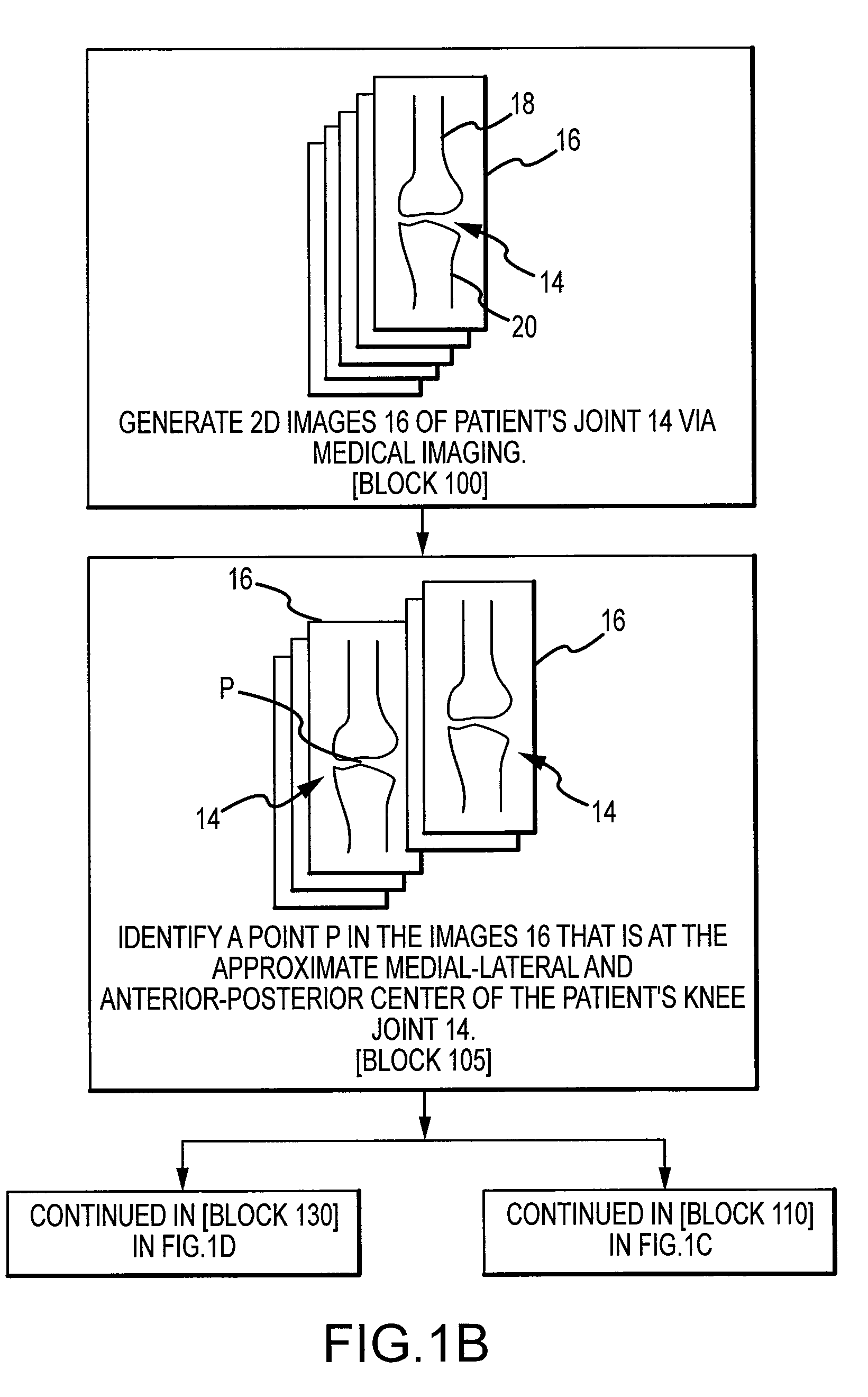

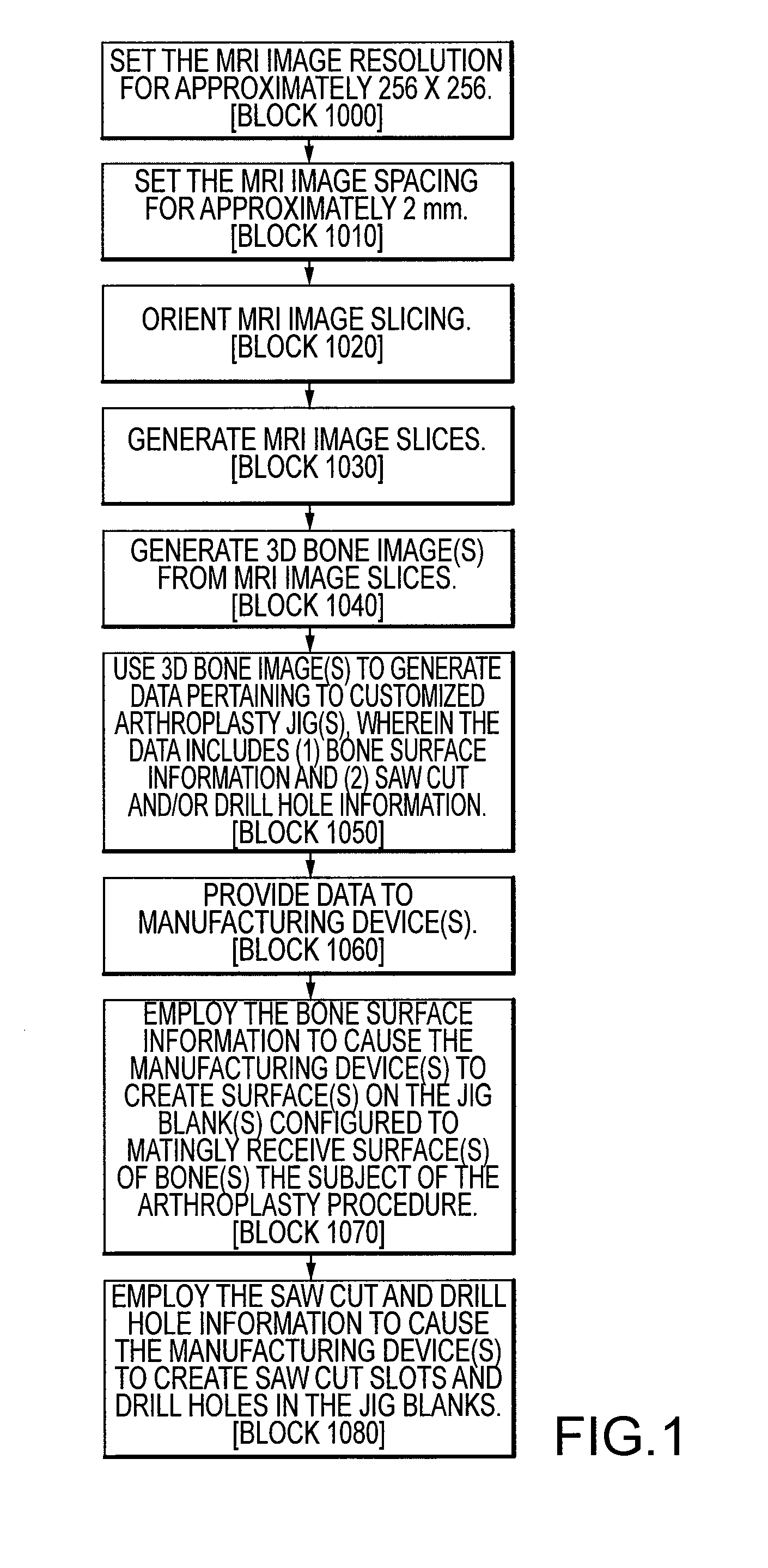

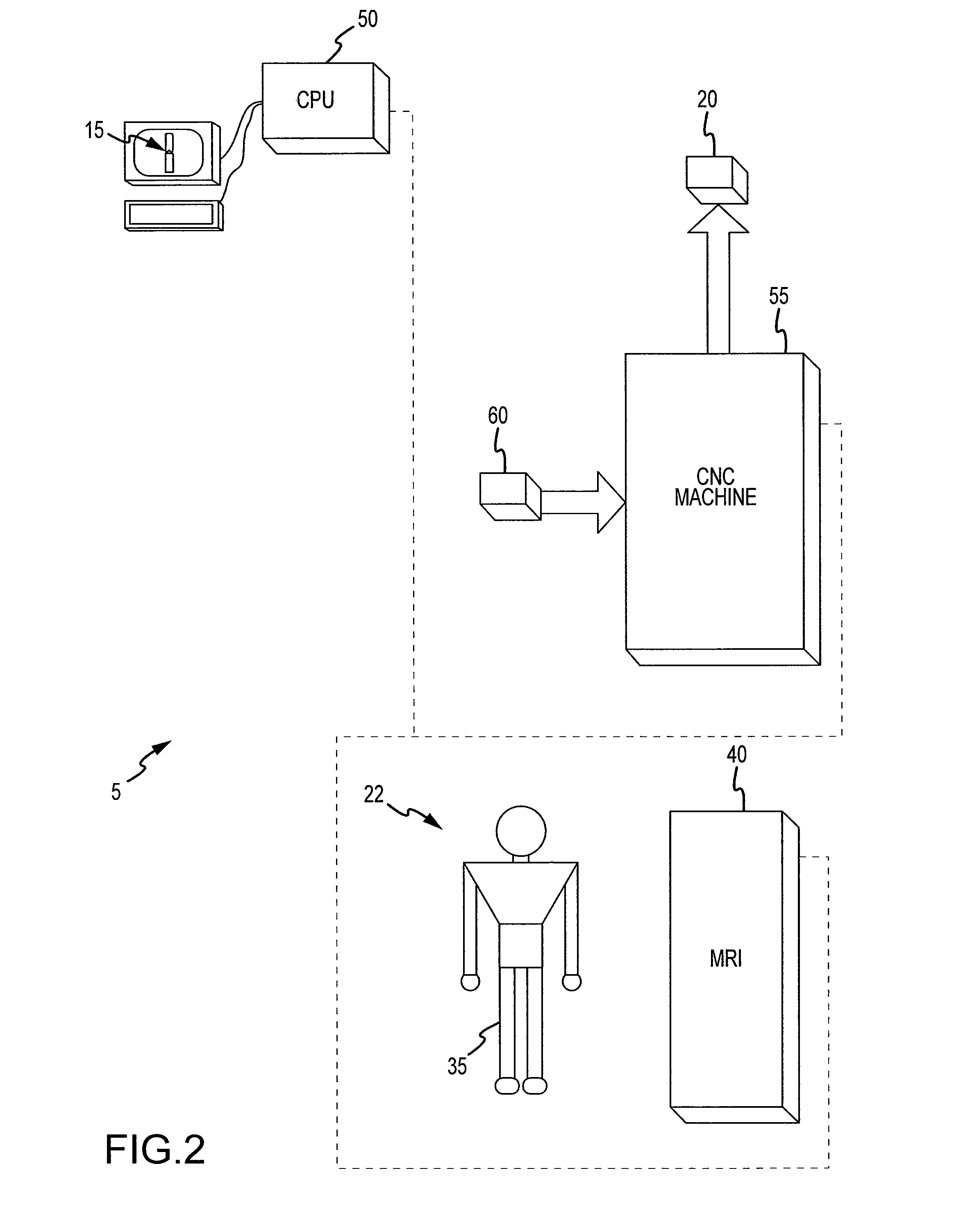

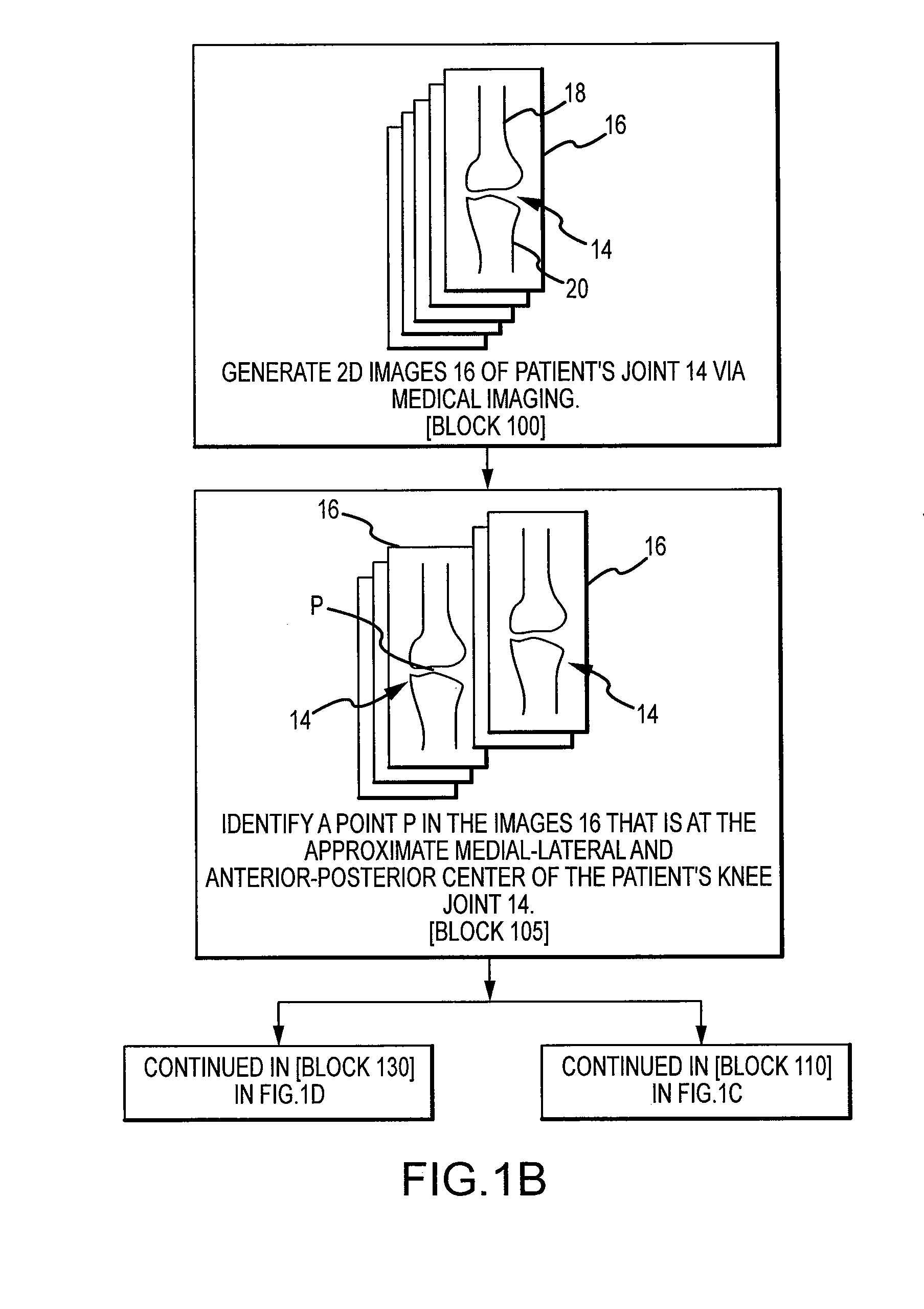

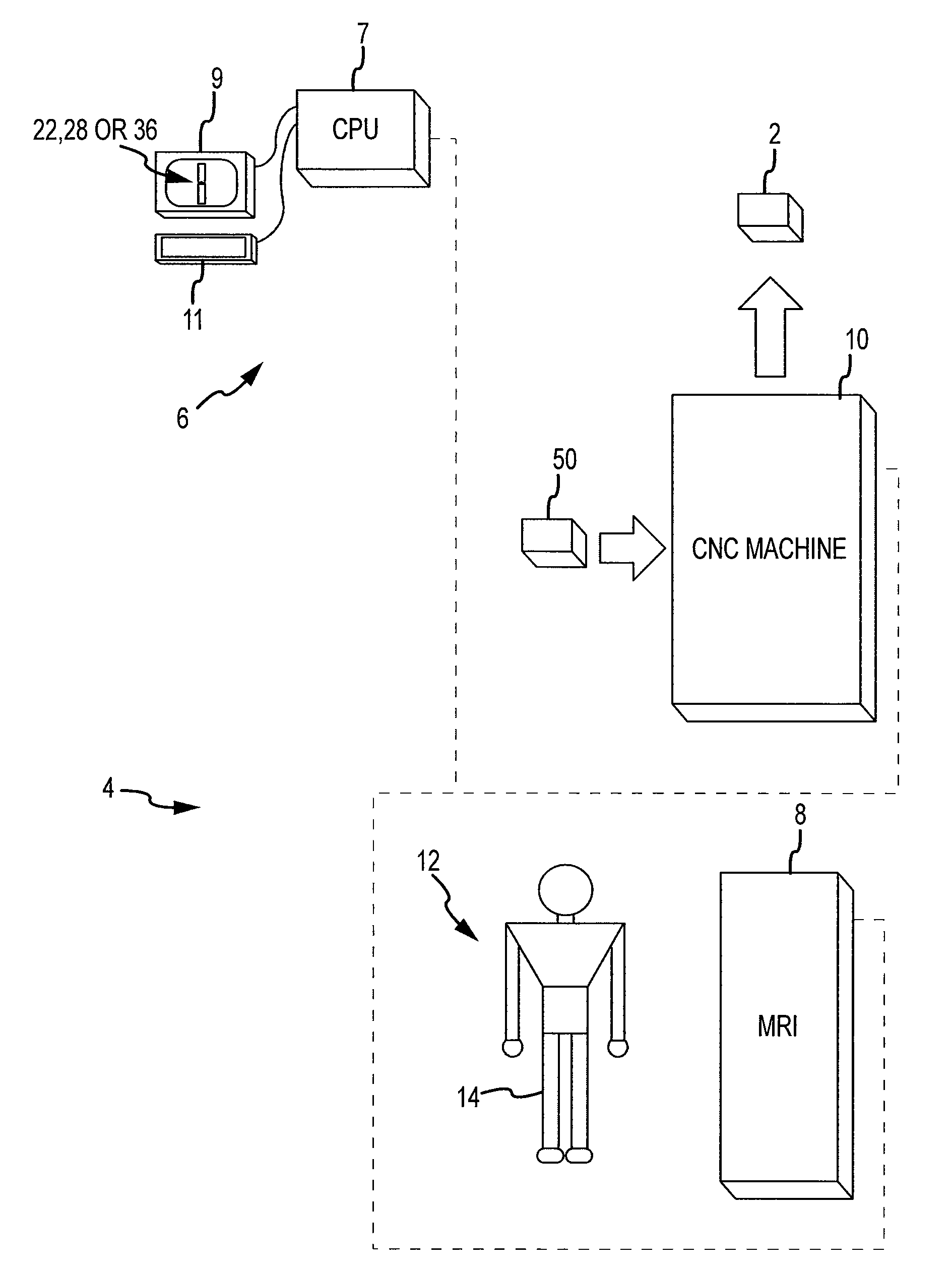

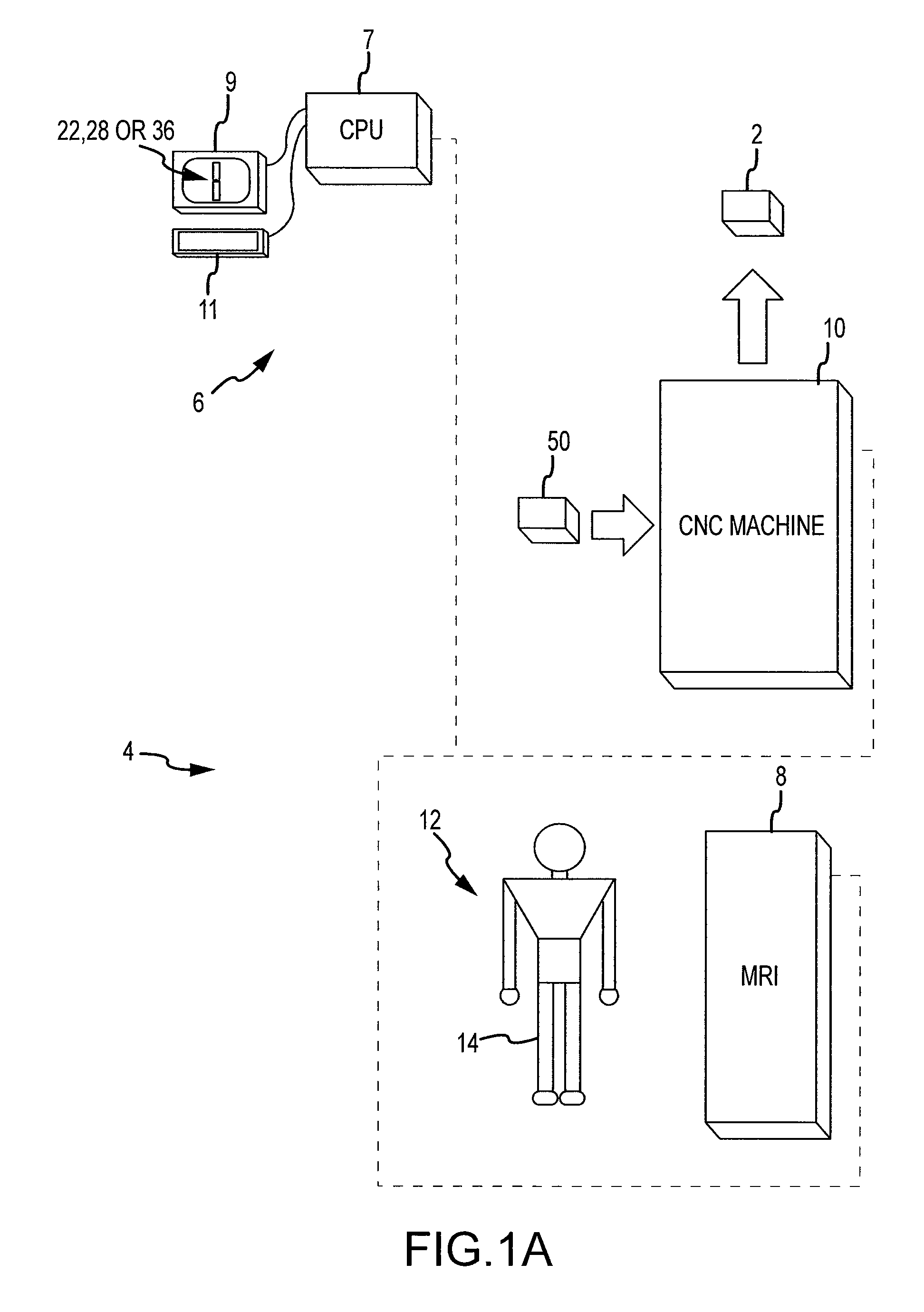

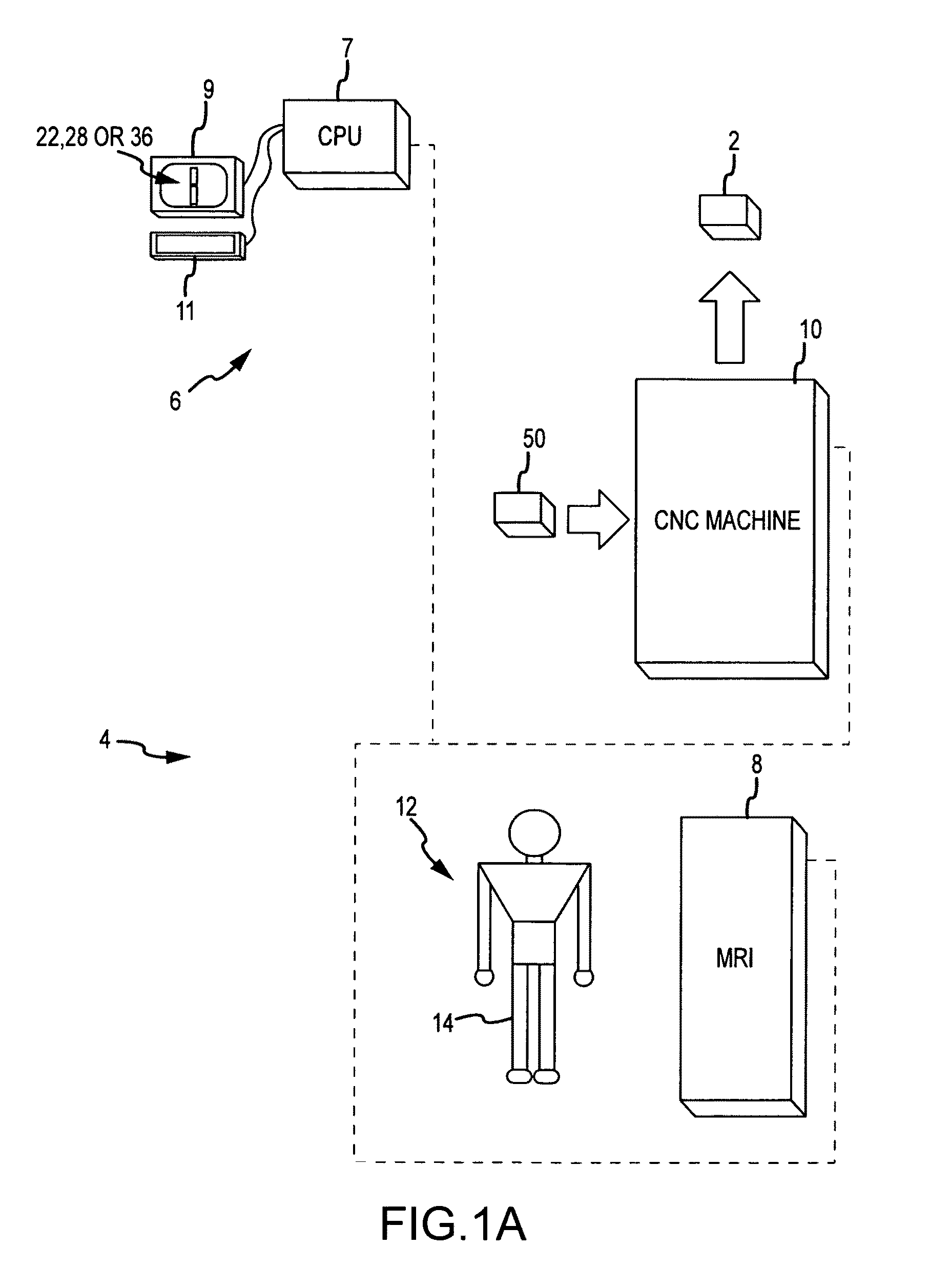

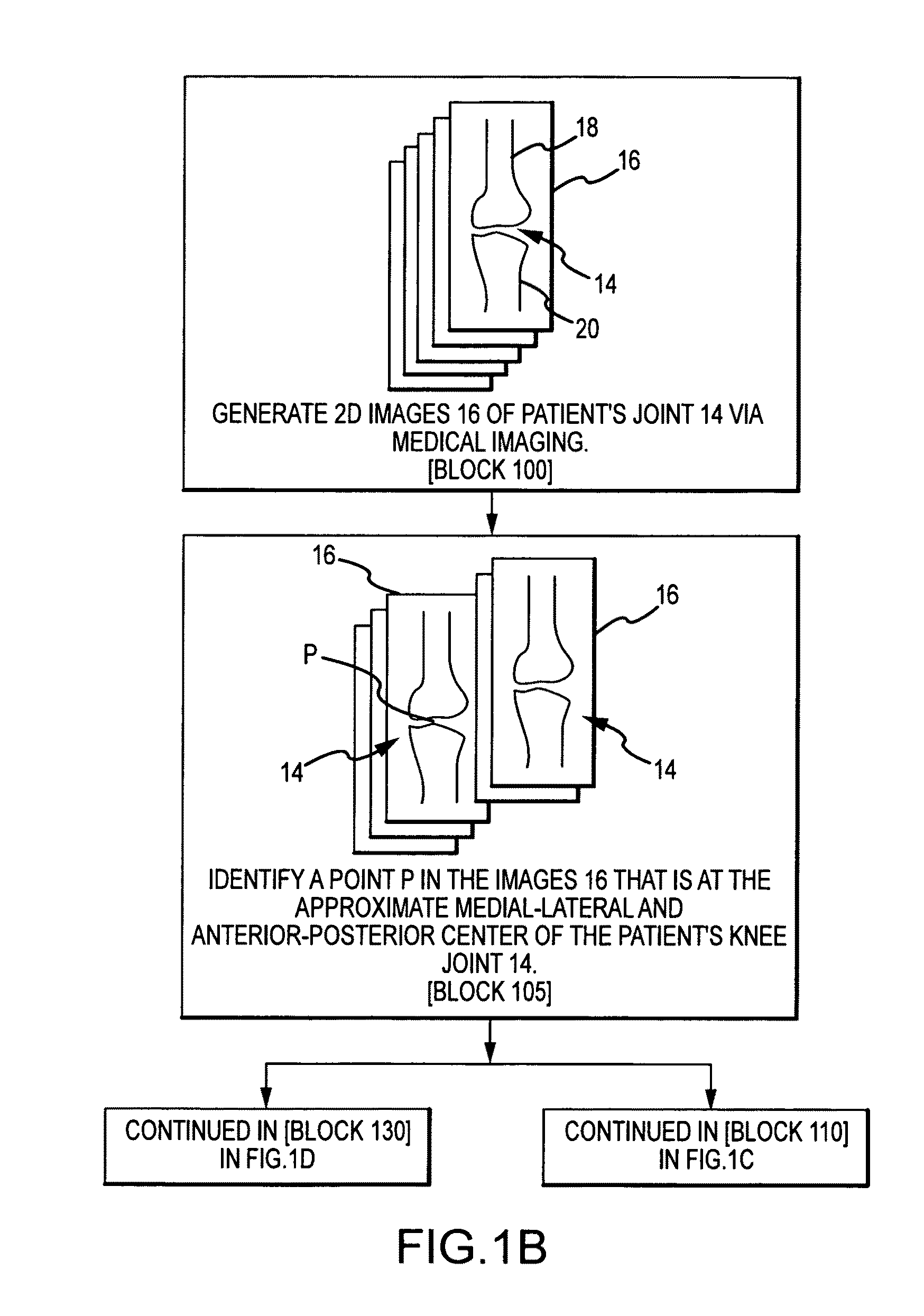

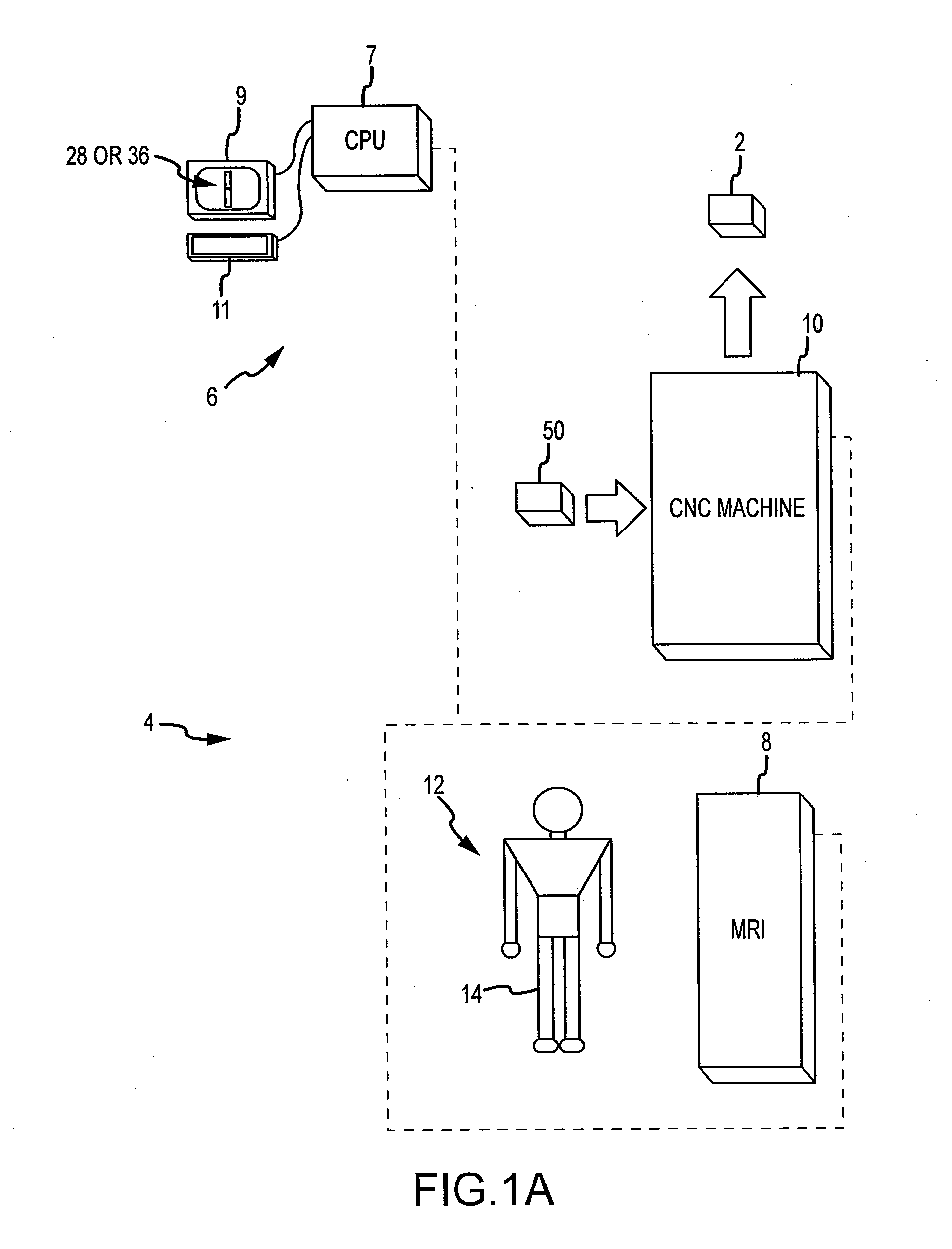

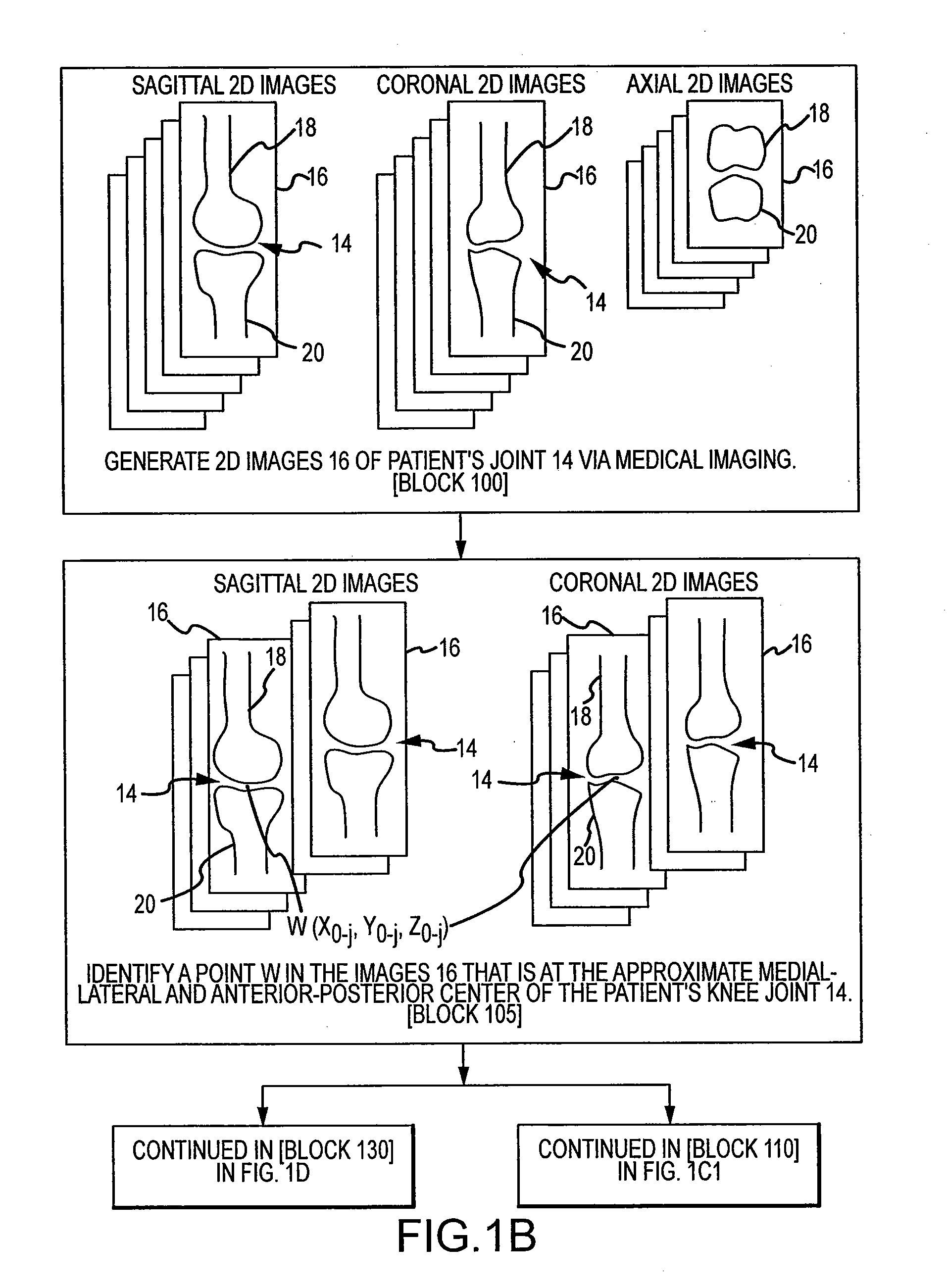

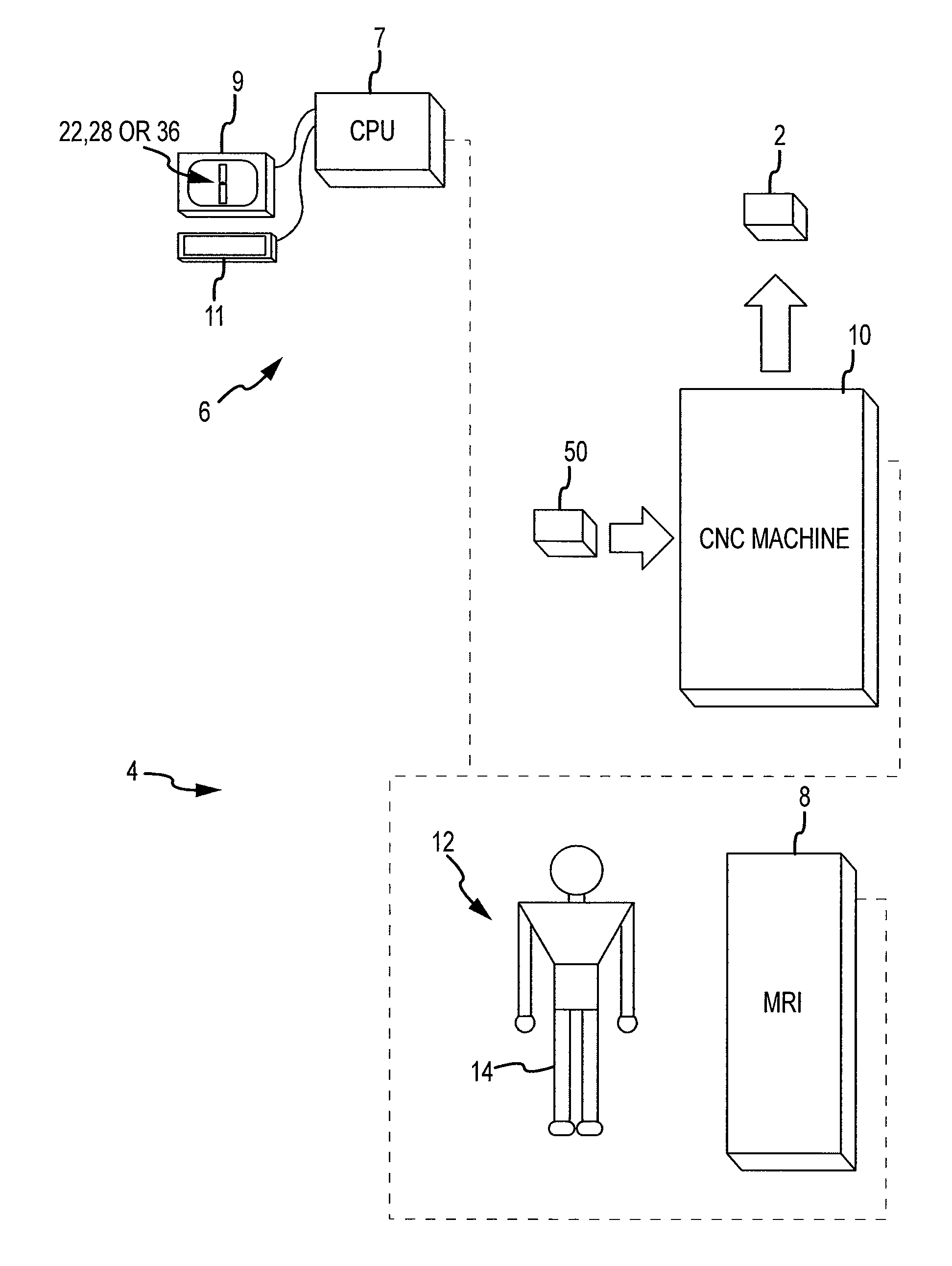

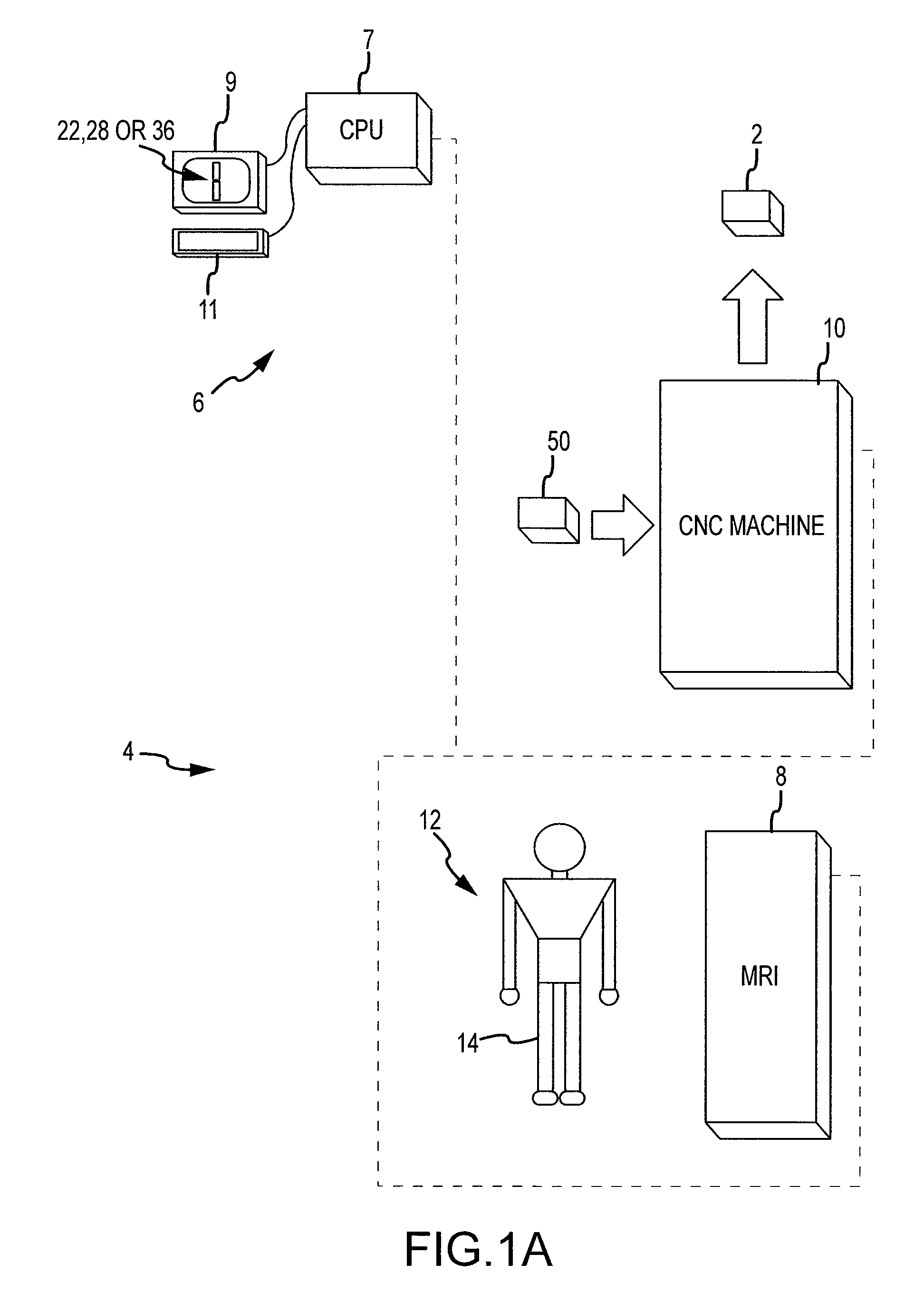

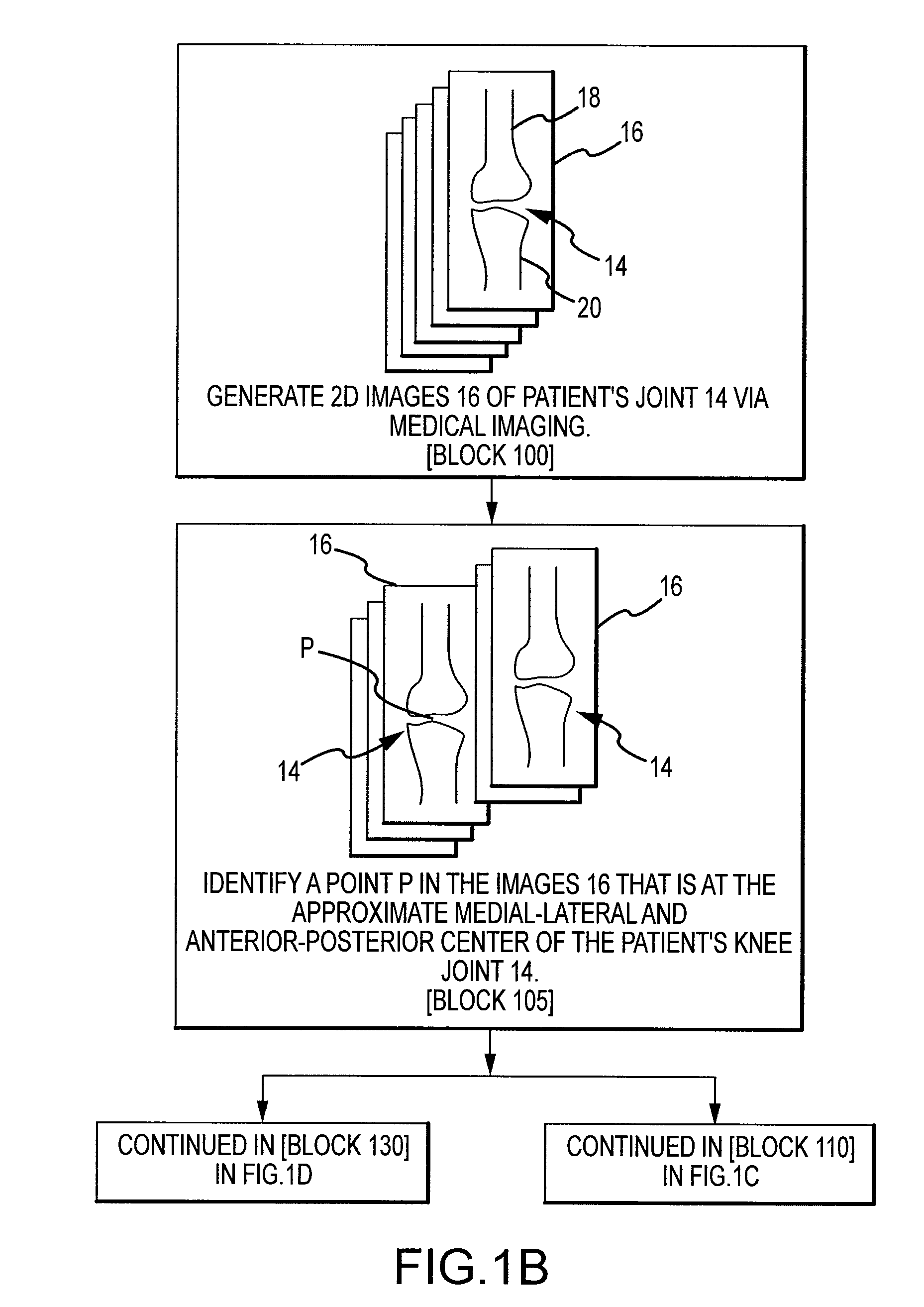

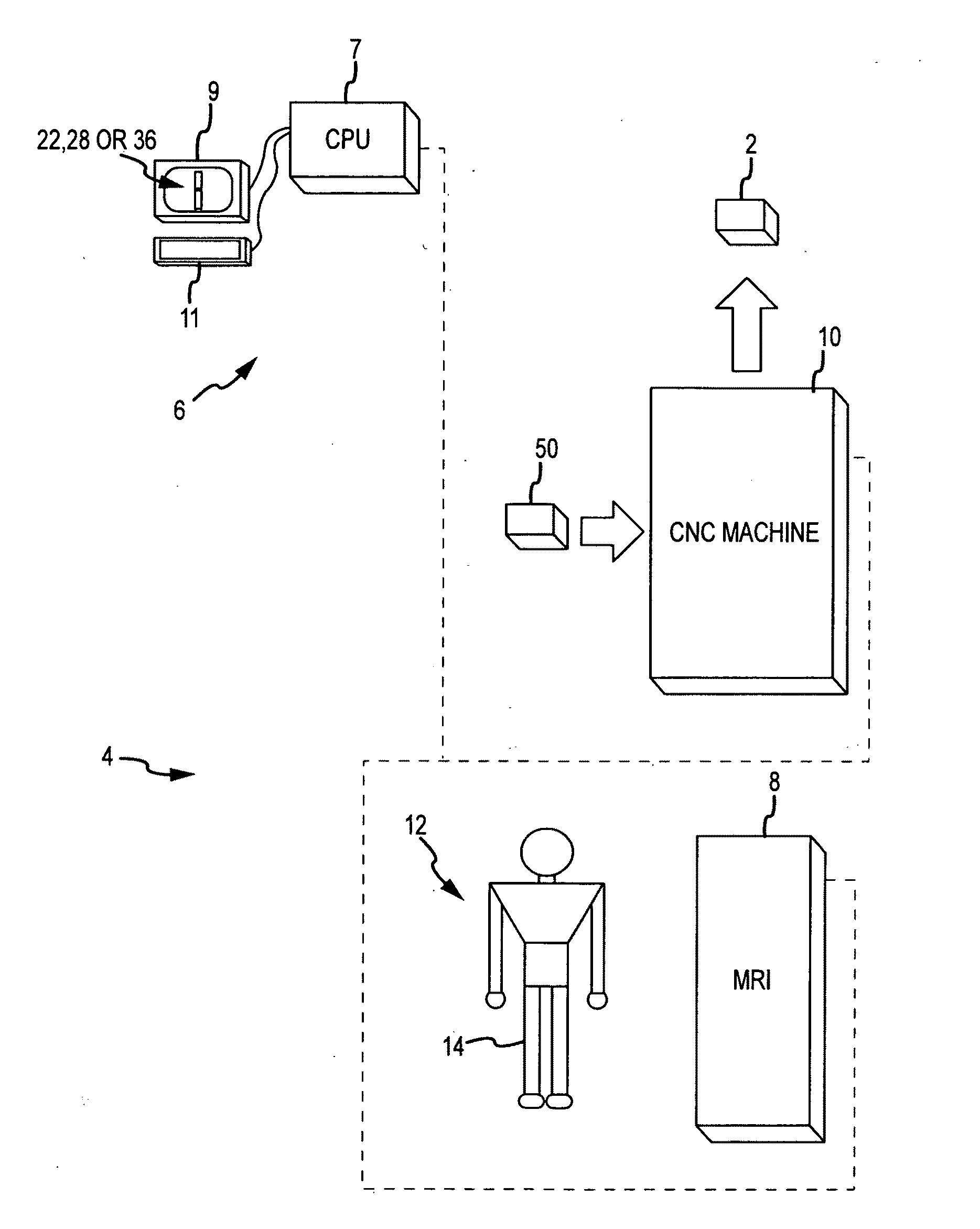

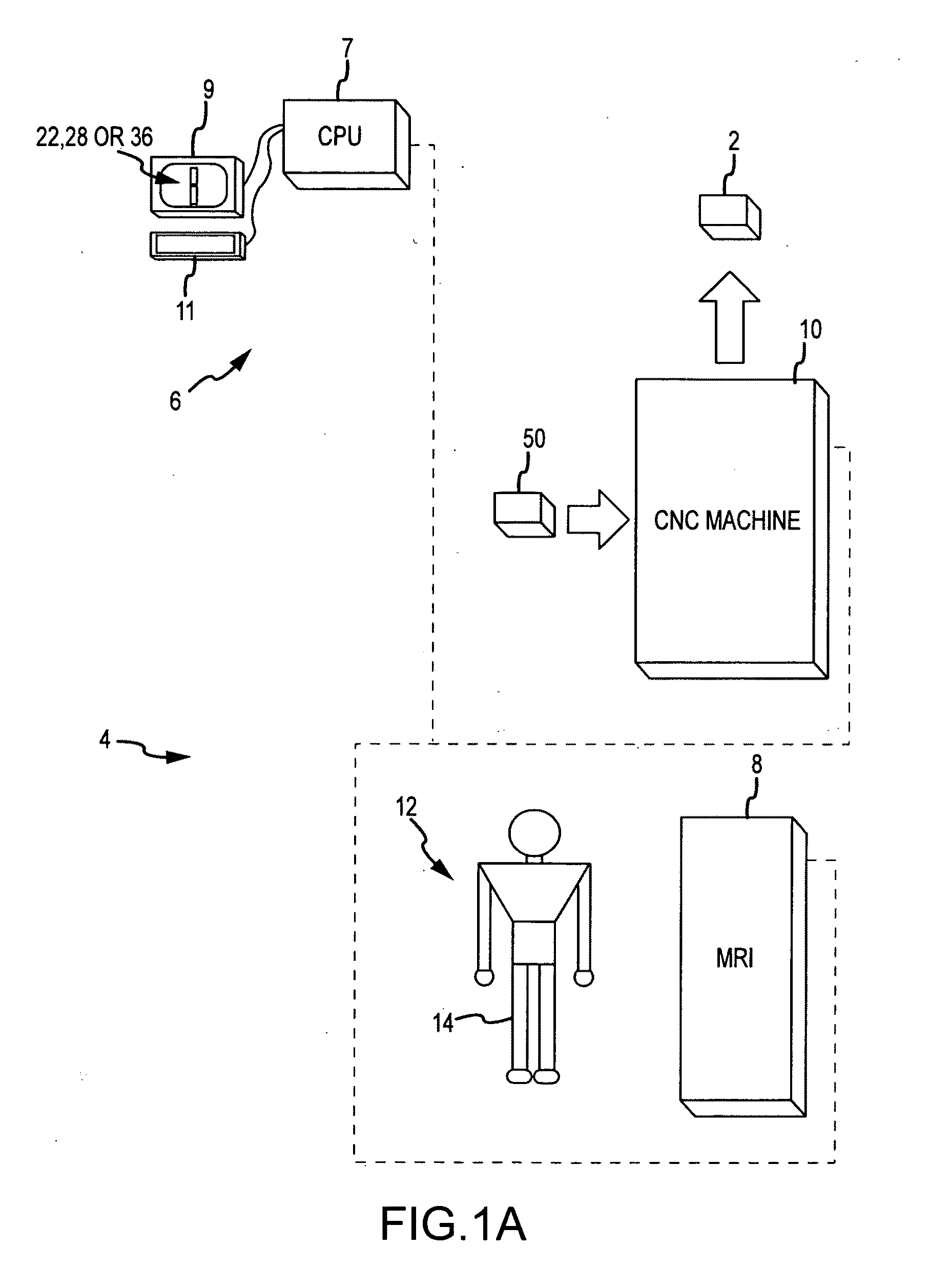

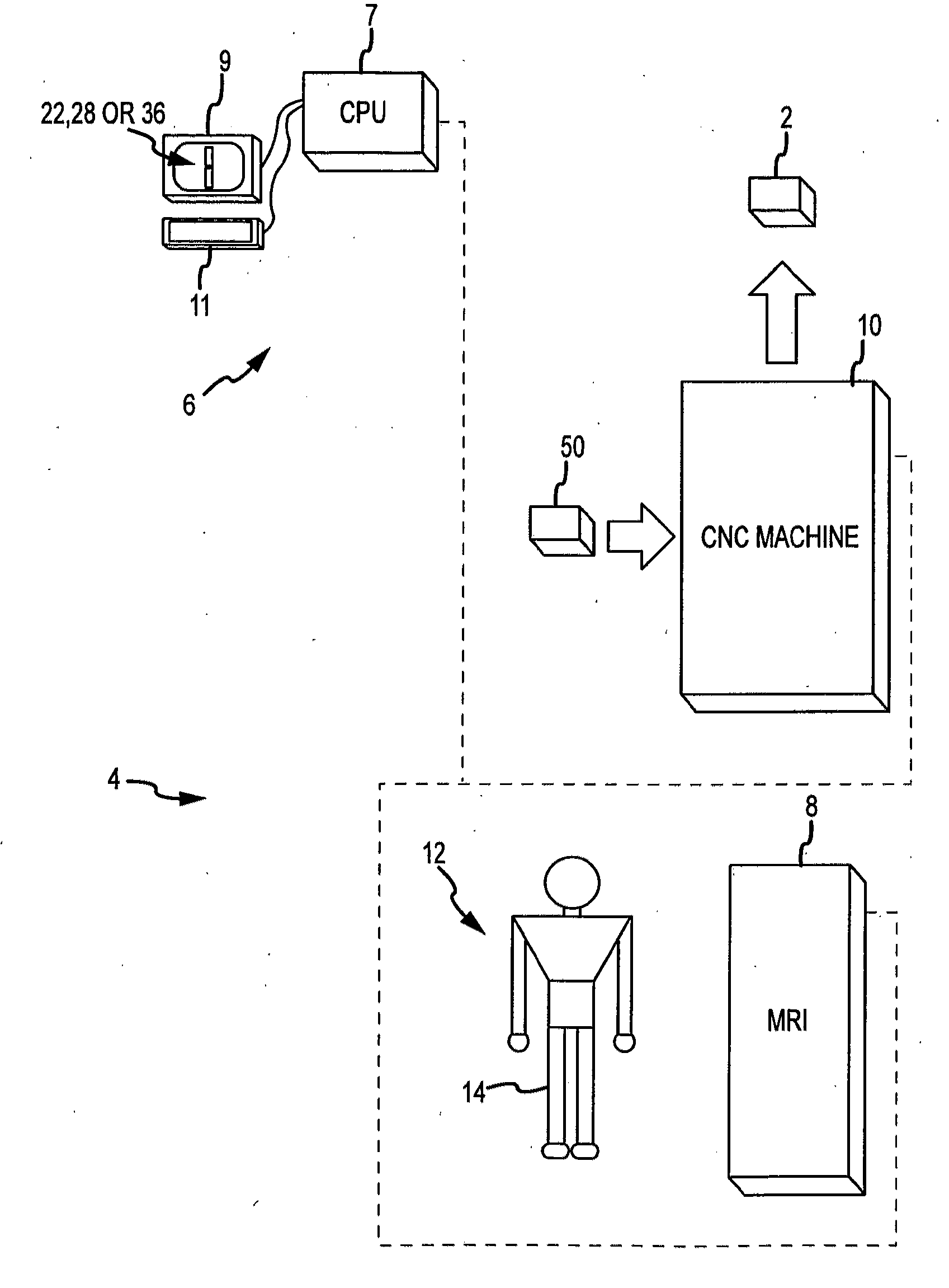

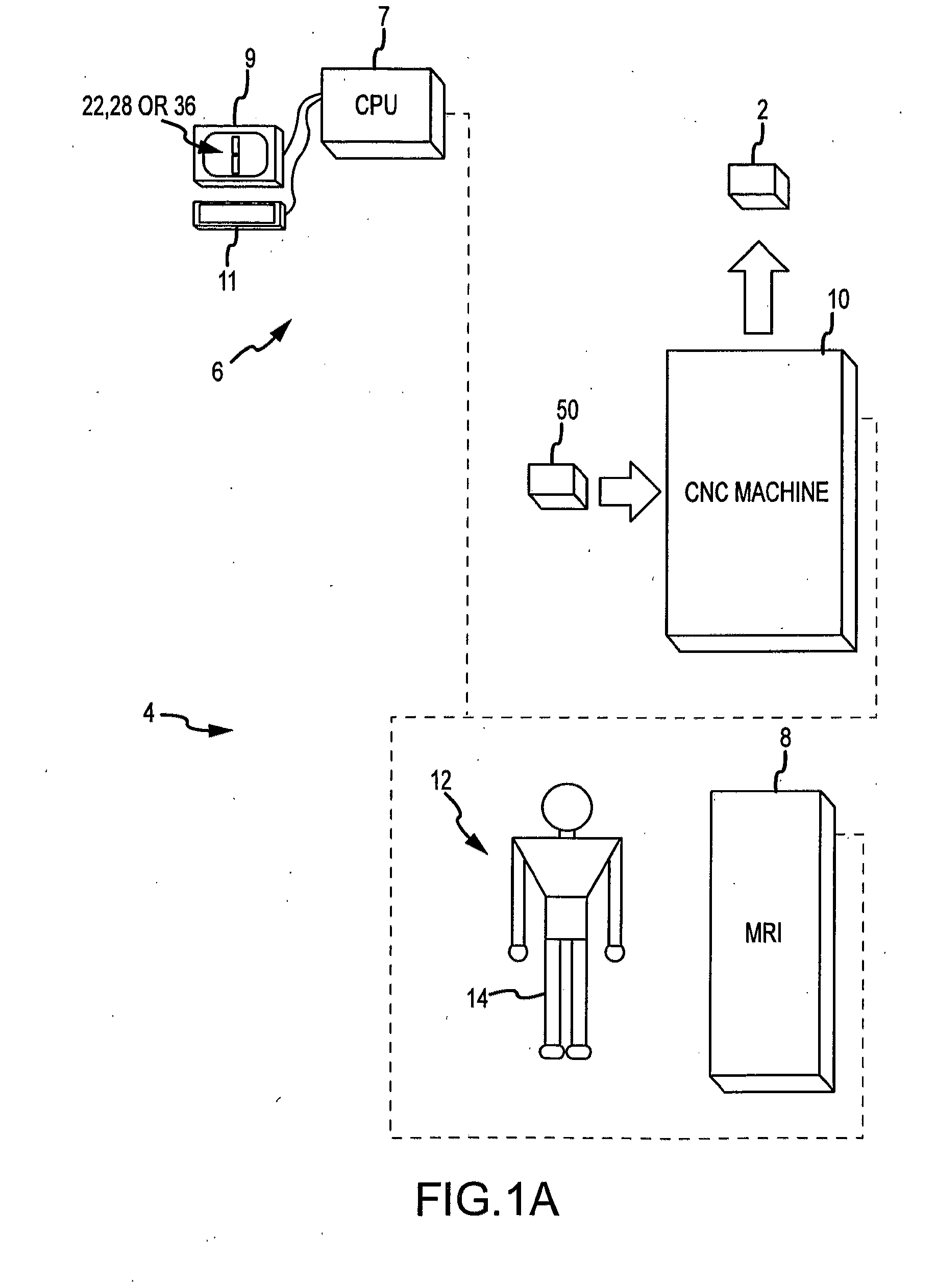

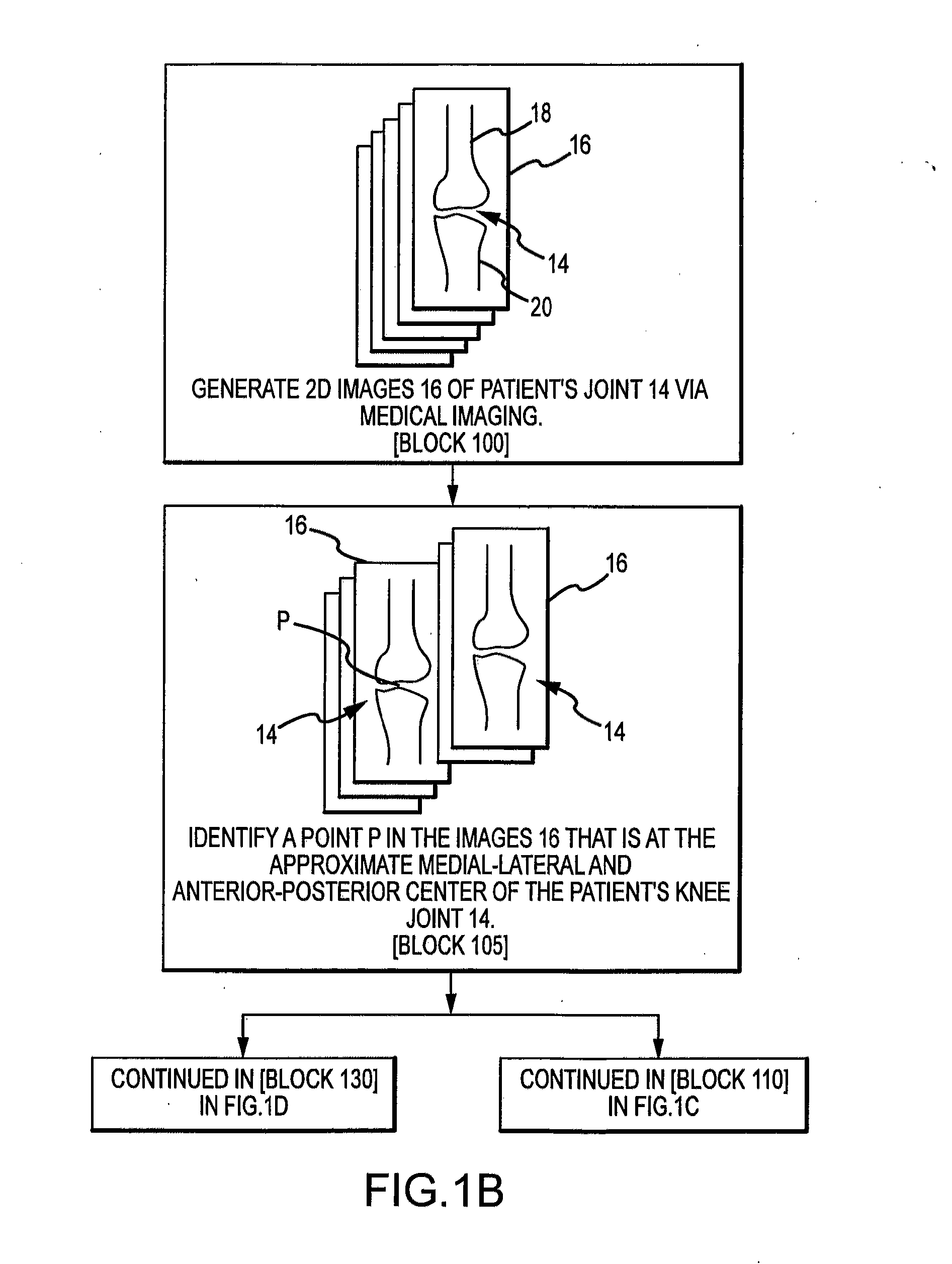

Generating MRI images usable for the creation of 3D bone models employed to make customized arthroplasty jigs

ActiveUS20090138020A1Character and pattern recognitionComputer-aided planning/modellingMri imageSacroiliac joint

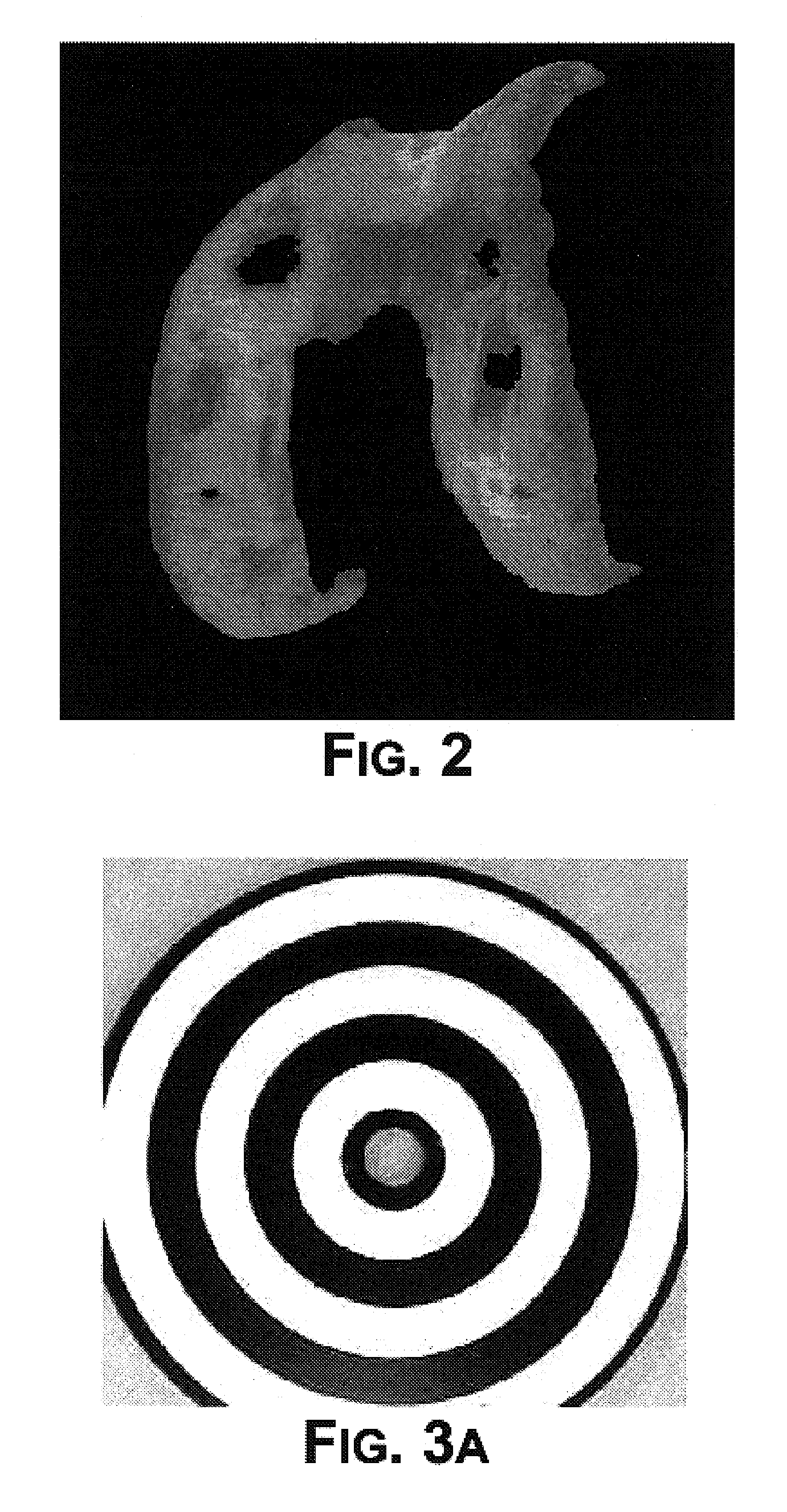

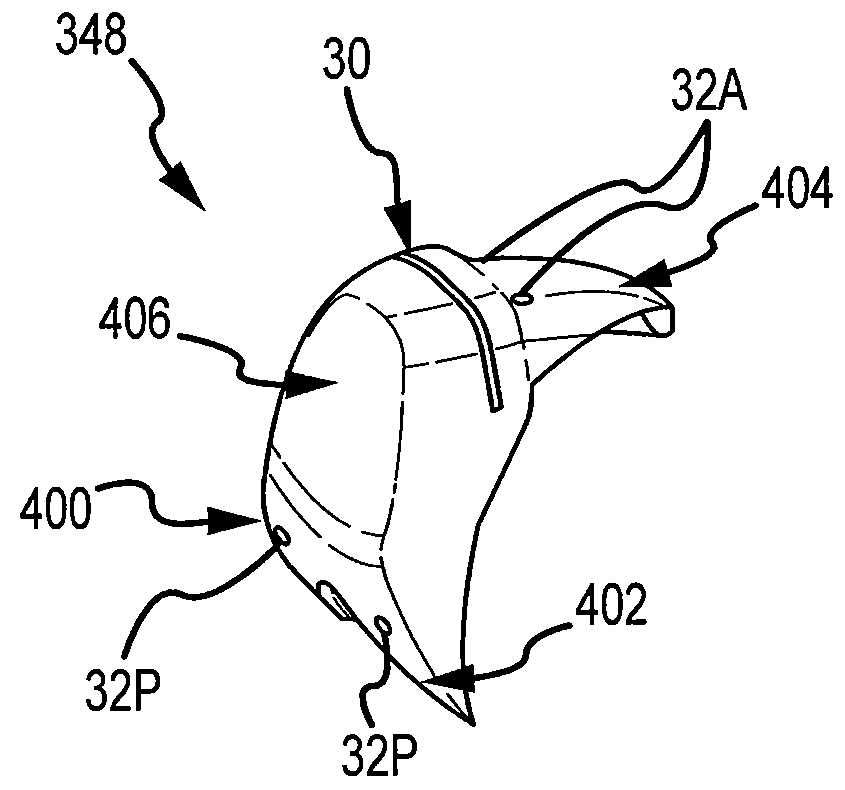

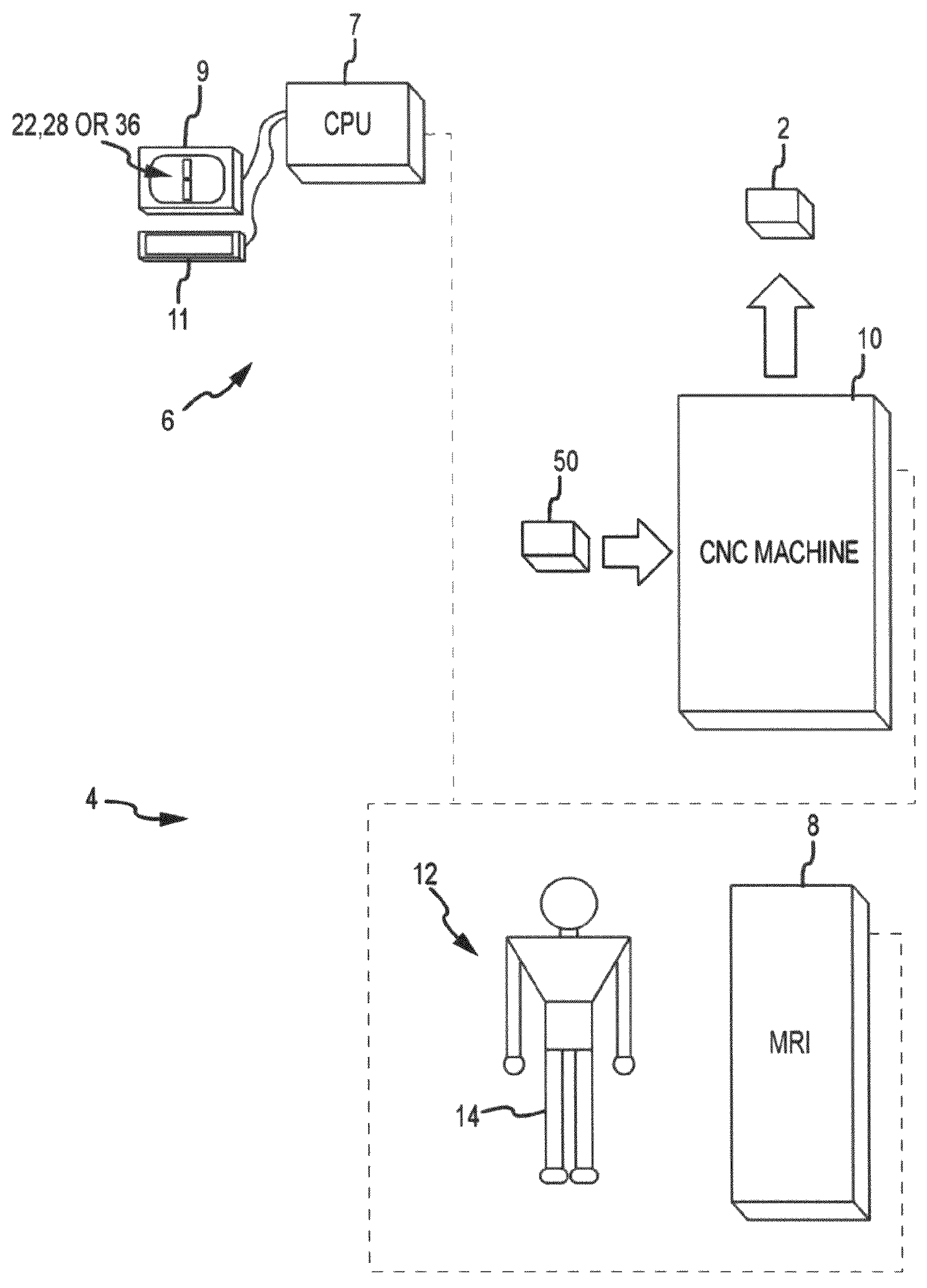

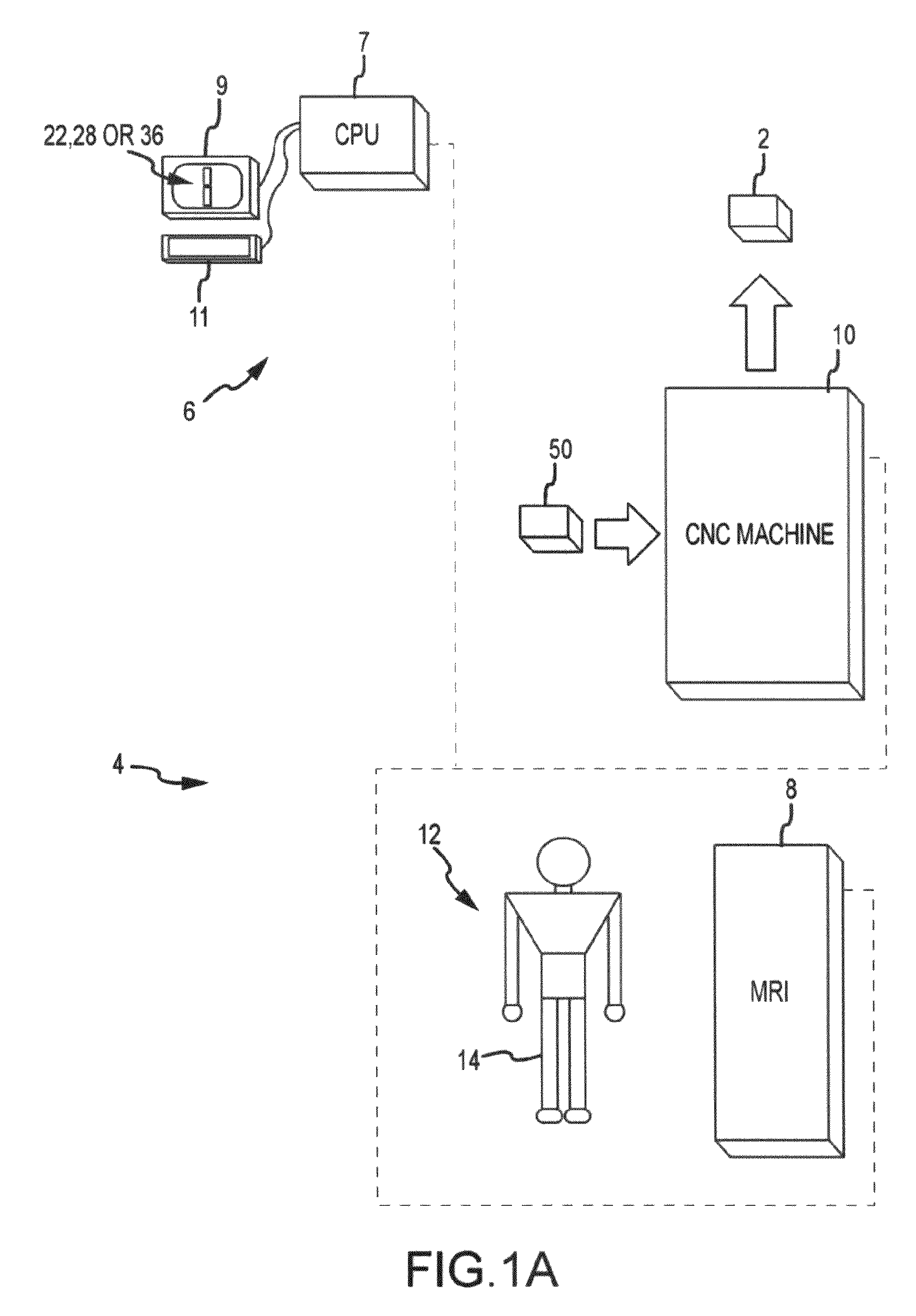

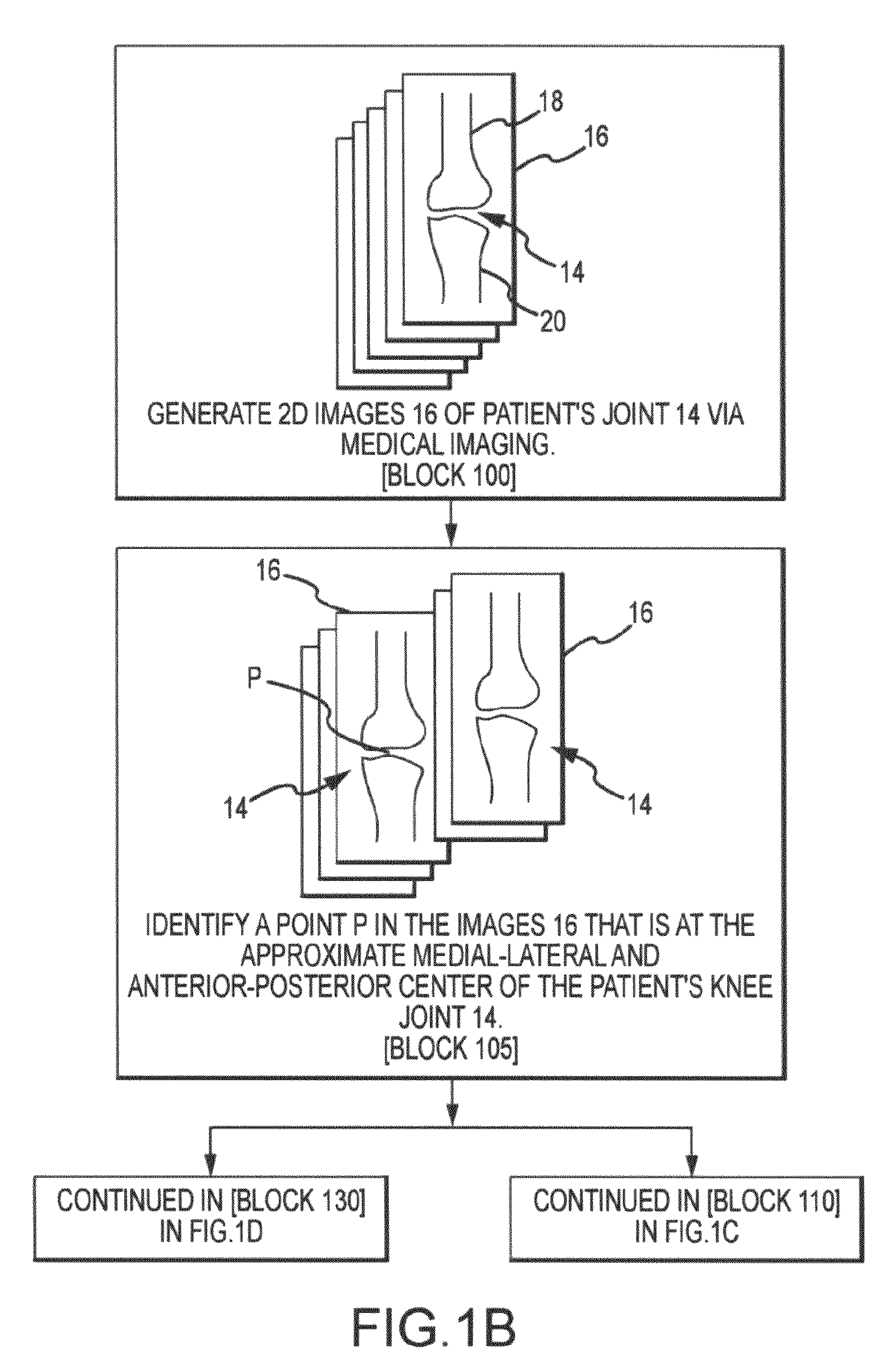

Disclosed herein is a method of creating a customized arthroplasty jig. The method may include: generating two-dimensional MRI images of a patient's joint area to undergo arthroplasty; electronically orienting the two dimensional MRI image slices to account for the patient's joint area being randomly physically oriented in a scanning area of a MRI machine; generating a three-dimensional bone image of at least a portion of a bone of the patient's joint area from the generated two-dimensional MRI images; using the three-dimensional bone image to generate data pertaining to the customized arthroplasty jig, wherein the data includes bone surface information; providing the data to at least one manufacturing device; and employing the bone surface information to cause the at least one manufacturing device to create a surface on the arthroplasty jig configured to matingly receive a surface of the bone.

Owner:HOWMEDICA OSTEONICS CORP

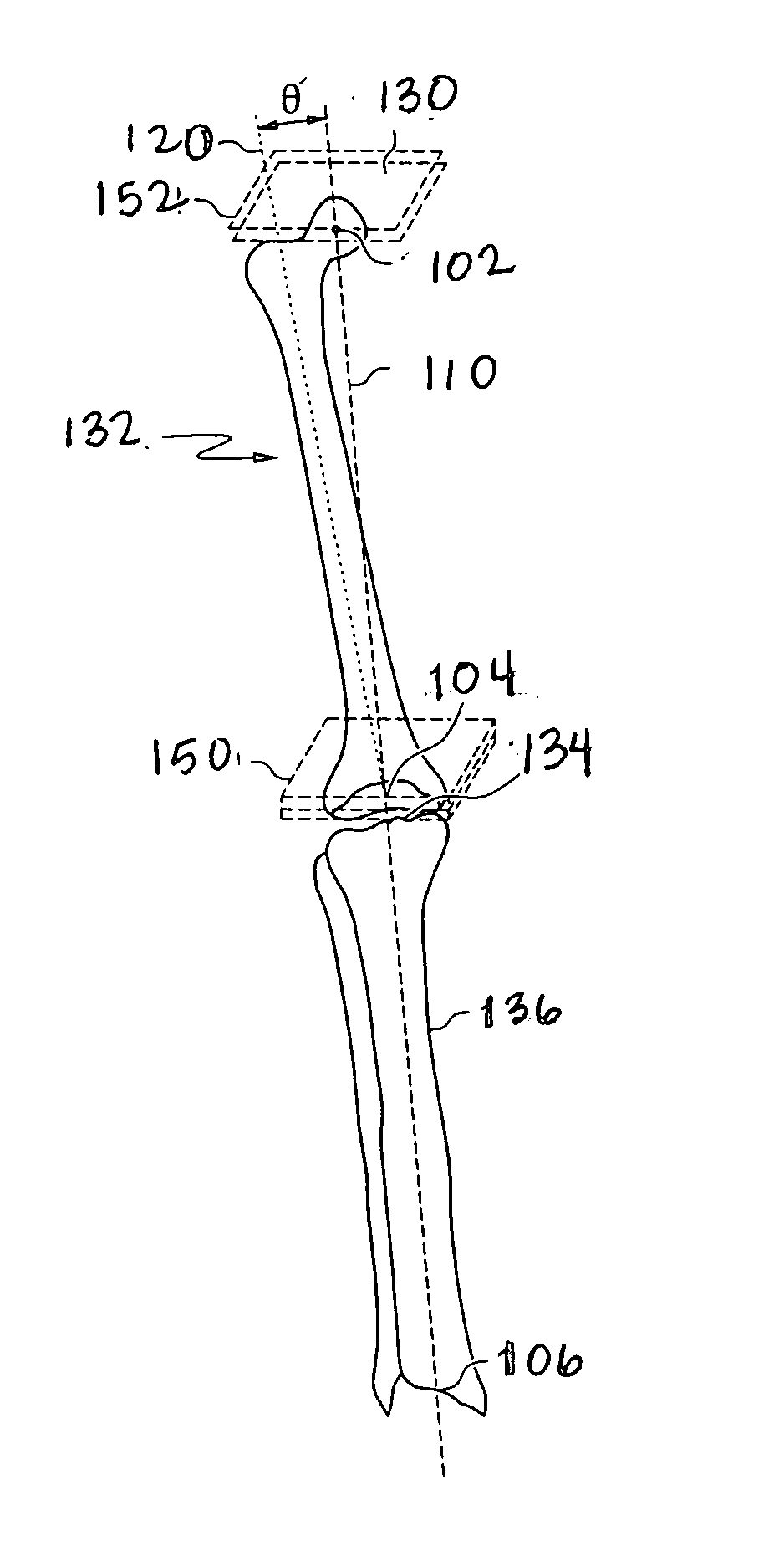

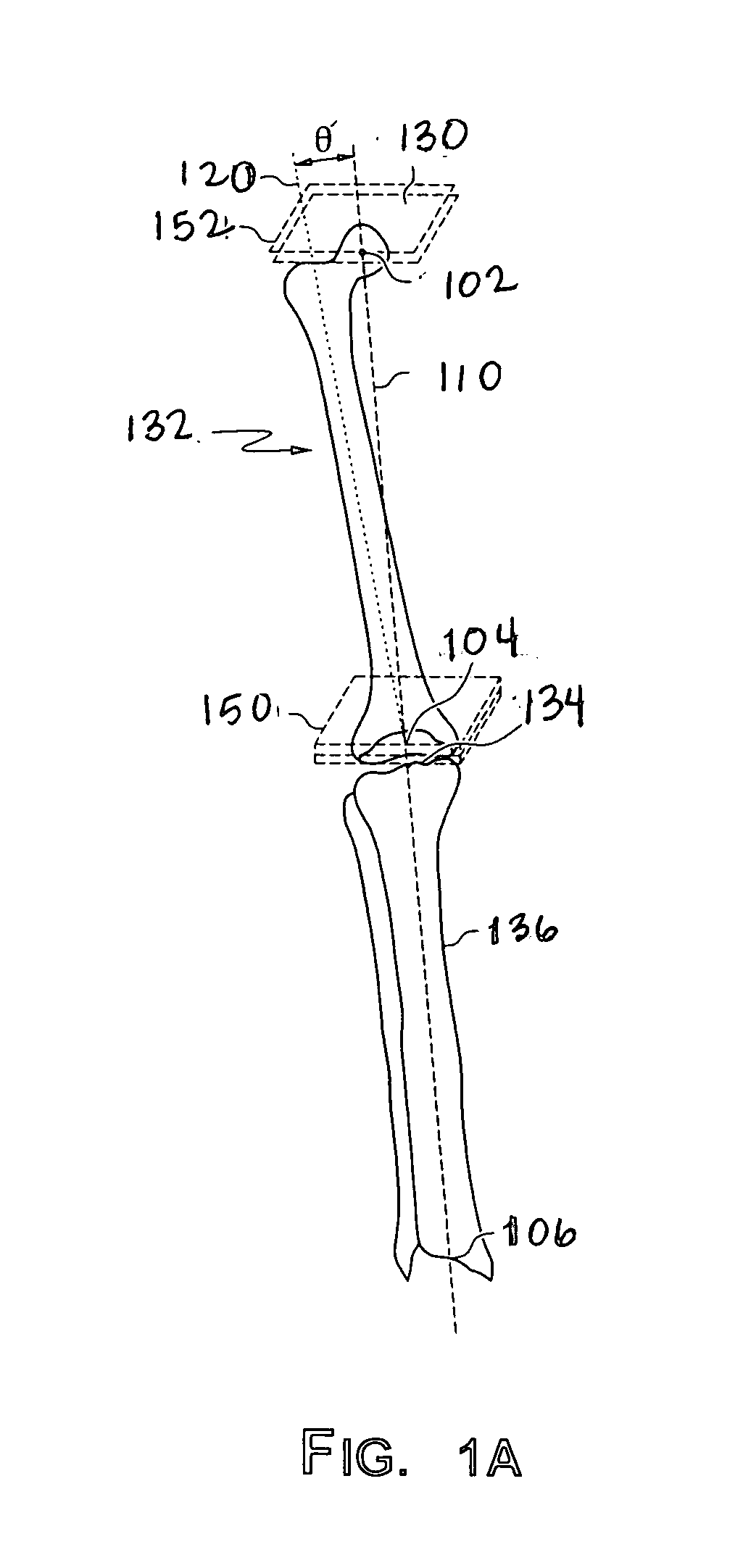

Arthroplasty system and related methods

A method of manufacturing an arthroplasty jig is disclosed herein. The method may include the following: generate a bone model, wherein the bone model includes a three dimensional computer model of at least a portion of a joint surface of a bone of a patient joint to undergo an arthroplasty procedure; generate an implant model, wherein the implant model includes a three dimensional computer model of at least a portion of a joint surface of an arthroplasty implant to be used in the arthroplasty procedure; assess a characteristic associated with the patient joint; generate a modified joint surface of the implant model by modifying at least a portion of a joint surface of the implant model according to the characteristic; and shape match the modified joint surface of the implant model and a corresponding joint surface of the bone model.

Owner:HOWMEDICA OSTEONICS CORP

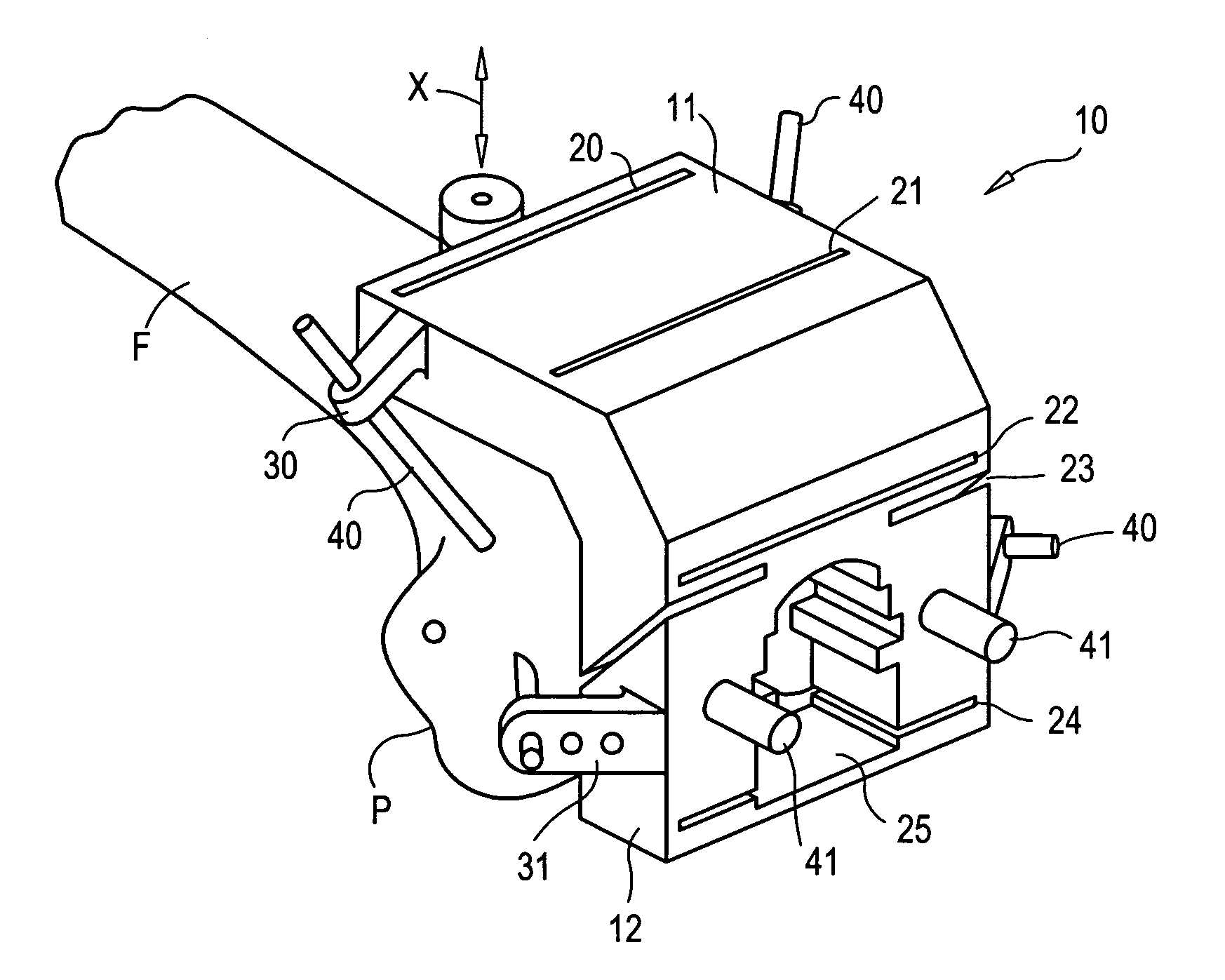

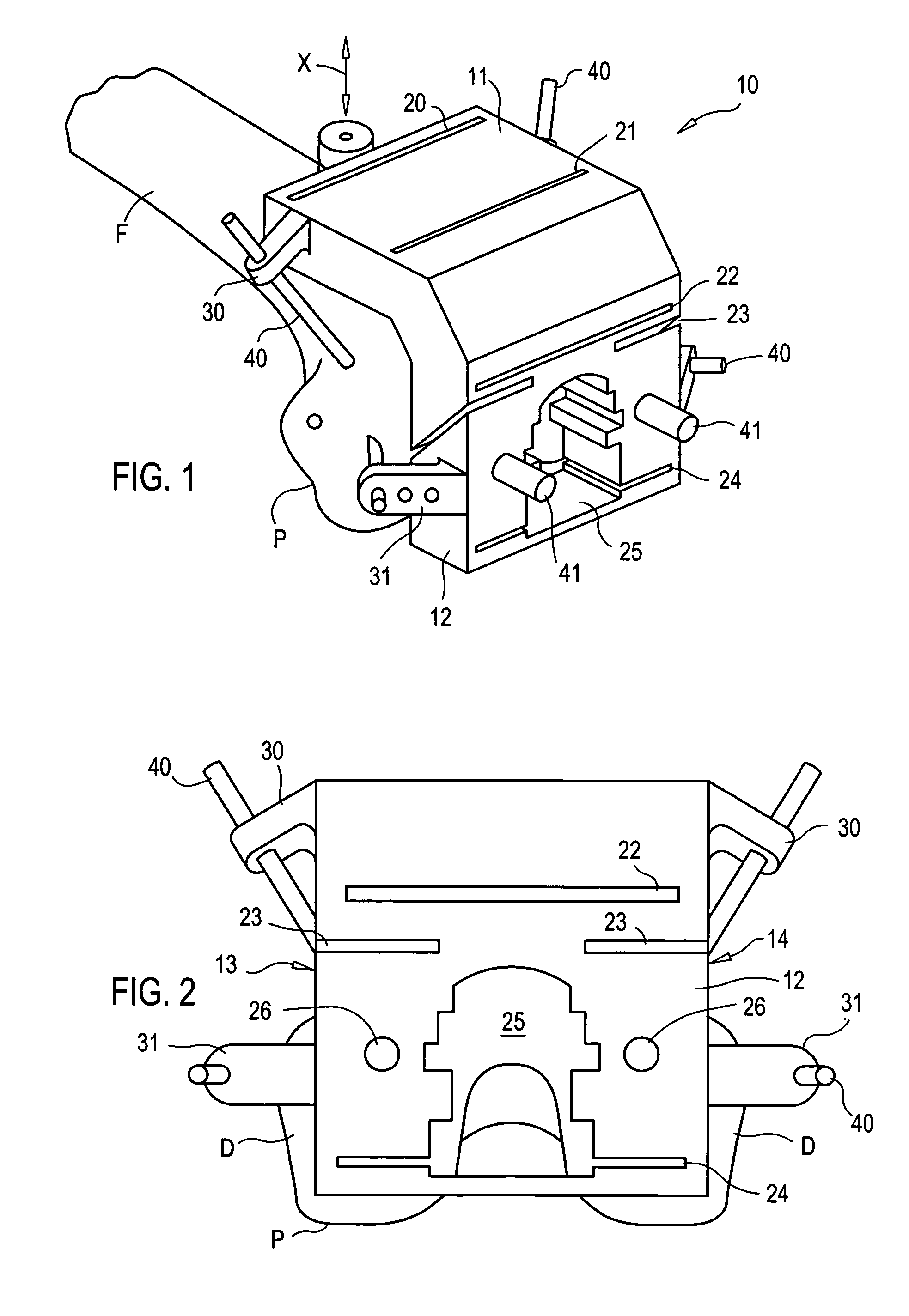

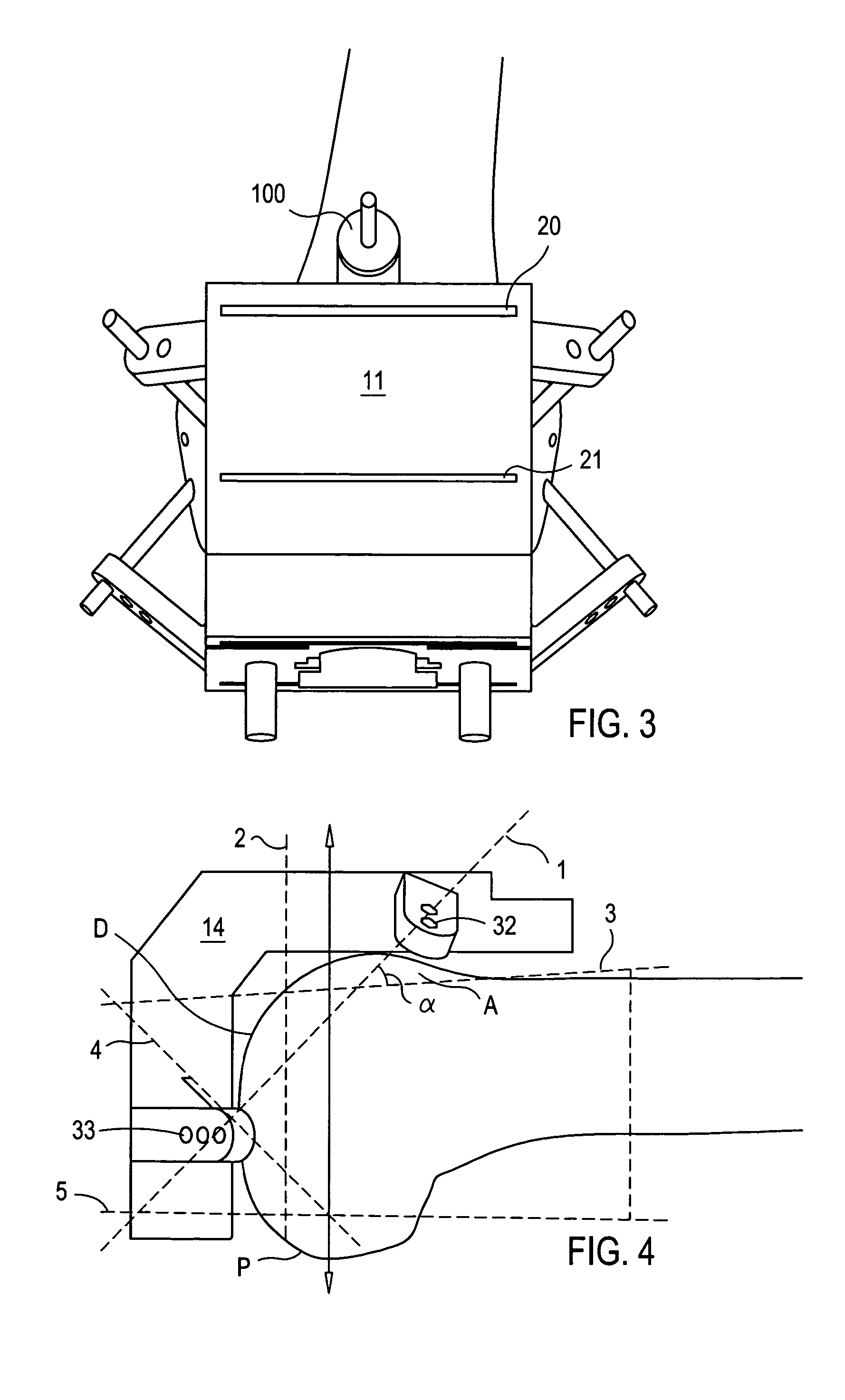

Cutting guide apparatus and surgical method for use in knee arthroplasty

InactiveUS7104997B2Avoiding minimizing errorPrecise alignmentSurgical sawsProsthesisSurgical approachSurgical incision

Novel cutting guides and surgical methods for use in knee arthroplasty are described. Embodiments of the inventive cutting guide apparatus include fixed and adjustable cutting guide blocks having a series of slots designed to accommodate a cutting saw. The cutting guides and surgical method are designed to allow for the provision of all desired surgical cuts upon the distal end of the femur, for subsequent implantation of a prosthesis thereto, without having to remove the cutting guide block.

Owner:LIONBERGER DAVID +1

Surgical Tools Facilitating Increased Accuracy, Speed and Simplicity in Performing Joint Arthroplasty

InactiveUS20090307893A1Metal rolling stand detailsDiagnostic recording/measuringArticular surfacesArticular surface

Disclosed herein are tools for repairing articular surfaces repair materials and for repairing an articular surface. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

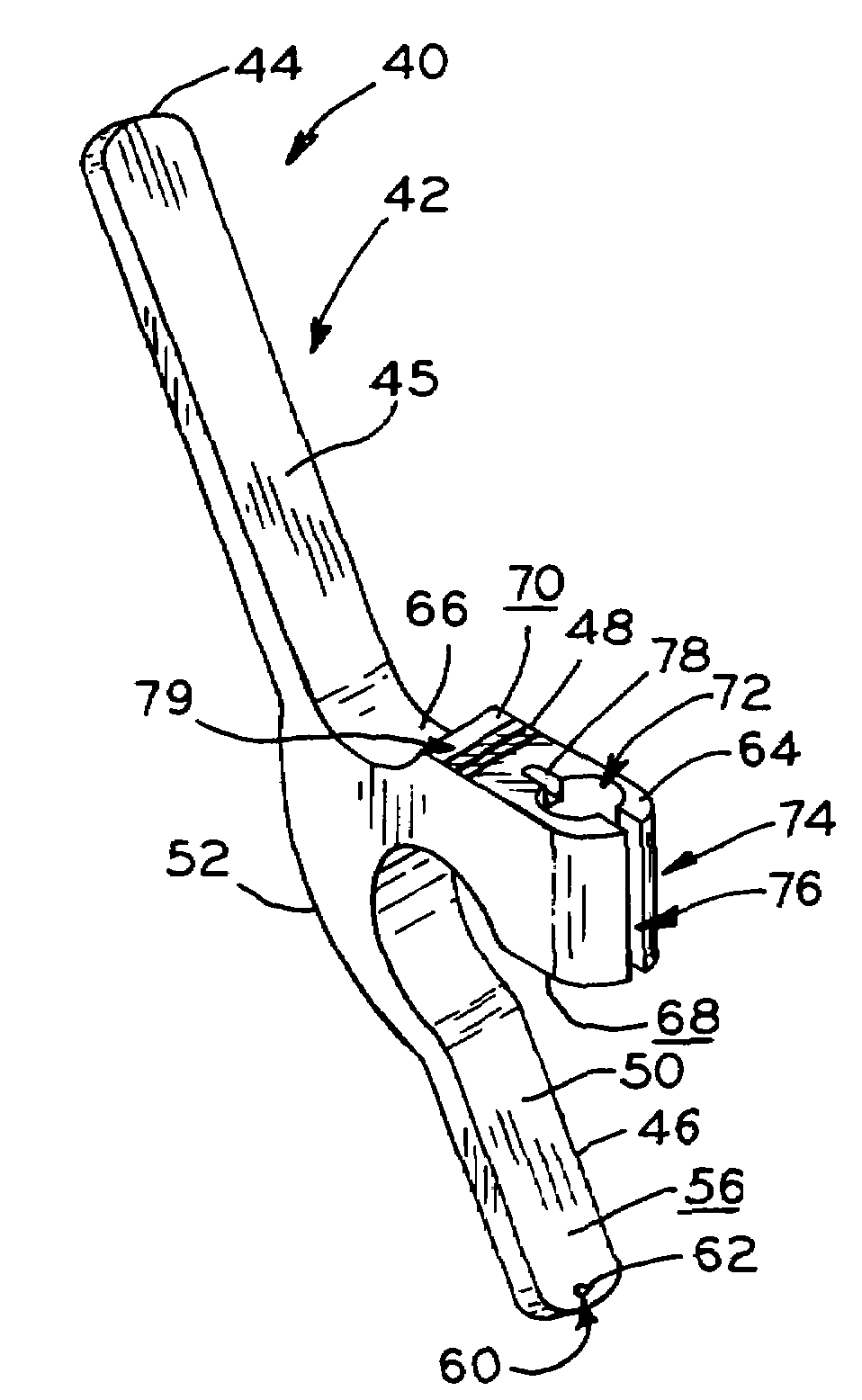

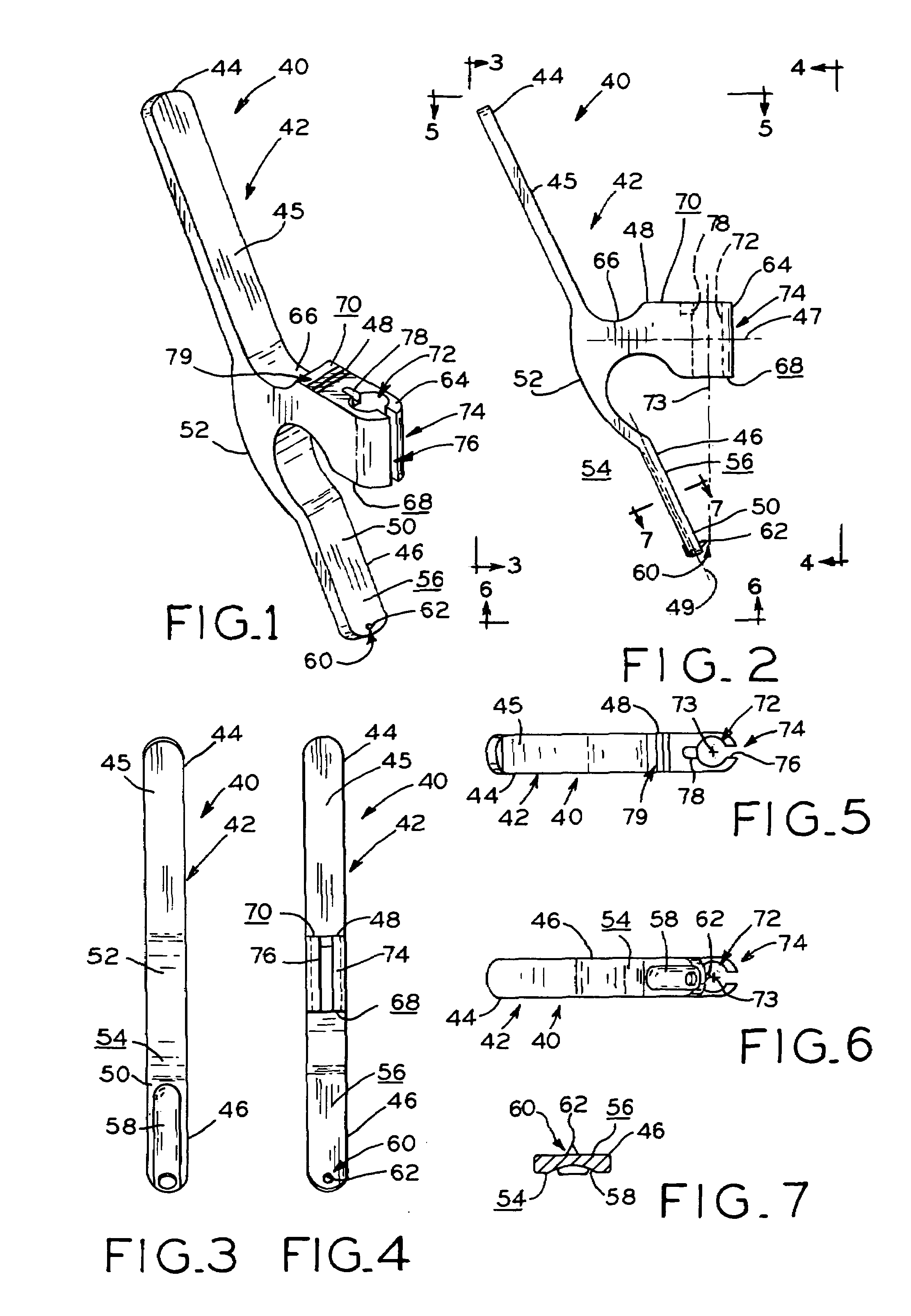

Arthroplasty devices and related methods

ActiveUS20070233141A1Easy alignmentImprove positionDiagnosticsSurgical sawsSacroiliac jointBiomedical engineering

Arthroplasty jigs and related methods are disclosed. Some of the arthroplasty jigs may comprise a jig body that is configured to align with a surface of a bone, and a positioning component. Certain of the methods may comprise providing such an arthroplasty jig, and aligning the jig body with a surface of a bone so that the positioning component provides at least one of a visible, audible, or tactile indication that such alignment has been achieved. Some of the arthroplasty jigs may comprise a jig body that is configured to align with a surface of a bone, and that is marked with identifying information. Certain of the methods may comprise providing an arthroplasty jig comprising a jig body that is configured to align with a surface of a bone, or providing an arthroplasty jig blank, and marking the arthroplasty jig or the arthroplasty jig blank with identifying information.

Owner:HOWMEDICA OSTEONICS CORP

Arthroplasty devices and related methods

ActiveUS20080147072A1Short timeIncrease volumeAdditive manufacturing apparatusNon-surgical orthopedic devicesSacroiliac jointBiomedical engineering

Methods and apparatuses for forming customized arthroplasty jigs are disclosed. Some of the apparatuses may comprise a plurality of rapid production machines and an automated mechanical system. The automated mechanical system may be configured to transport a first arthroplasty jig blank to a first rapid production machine and a second arthroplasty jig blank to a second rapid production machine. The first rapid production machine may be configured to form a first arthroplasty jig from the first arthroplasty jig blank, and the second rapid production machine may be configured to form a second arthroplasty jig from the second arthroplasty jig blank, the second arthroplasty jig having a different configuration from the first arthroplasty jig.

Owner:HOWMEDICA OSTEONICS CORP

Joint Arthroplasty Devices and Surgical Tools

InactiveUS20100160917A1Accurate placementImage analysisInternal osteosythesisArticular surfacesArticular surface

Disclosed herein are methods, compositions and tools for repairing articular surfaces repair materials and for repairing an articular surface. The articular surface repairs are customizable or highly selectable by patient and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

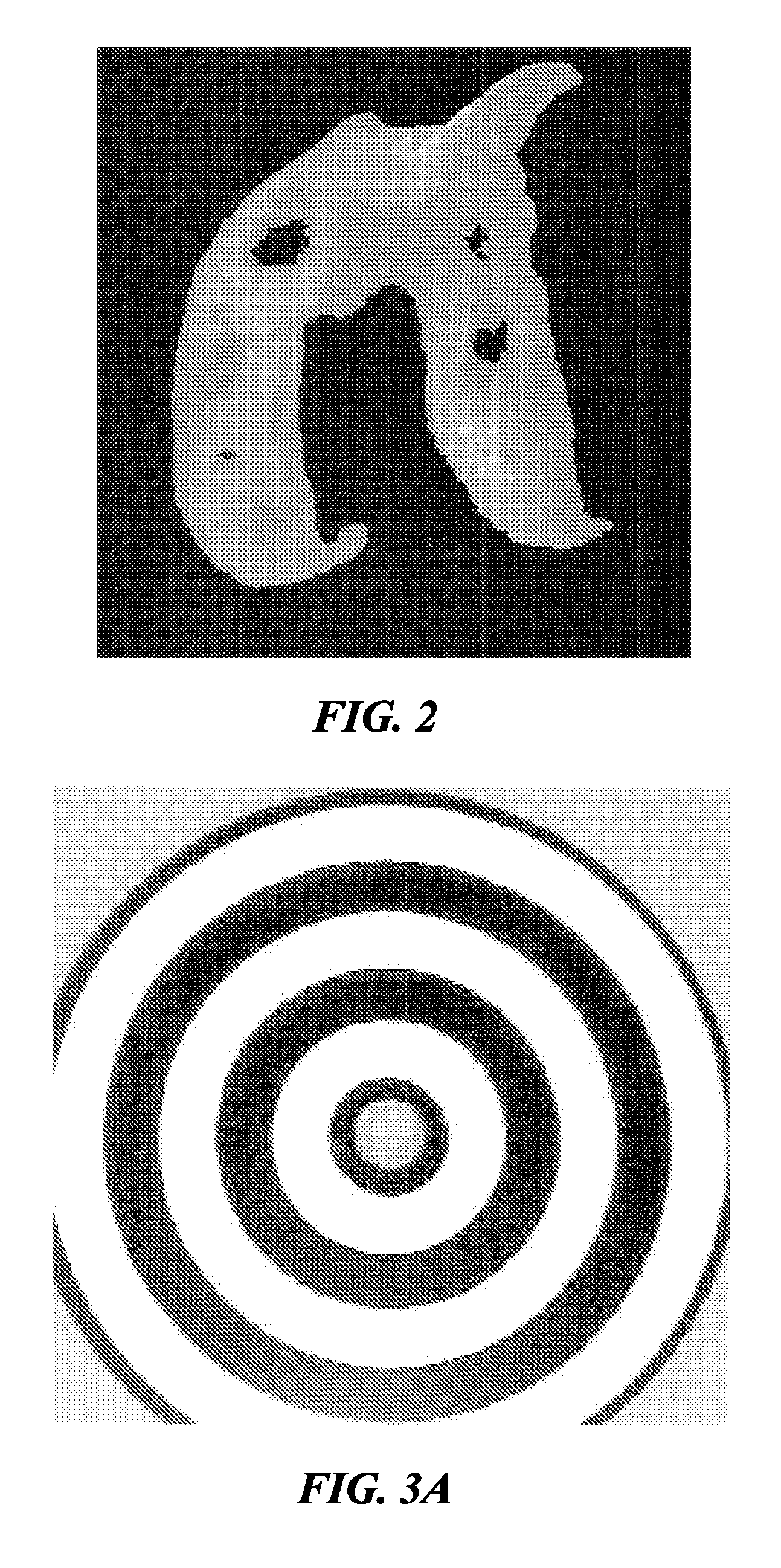

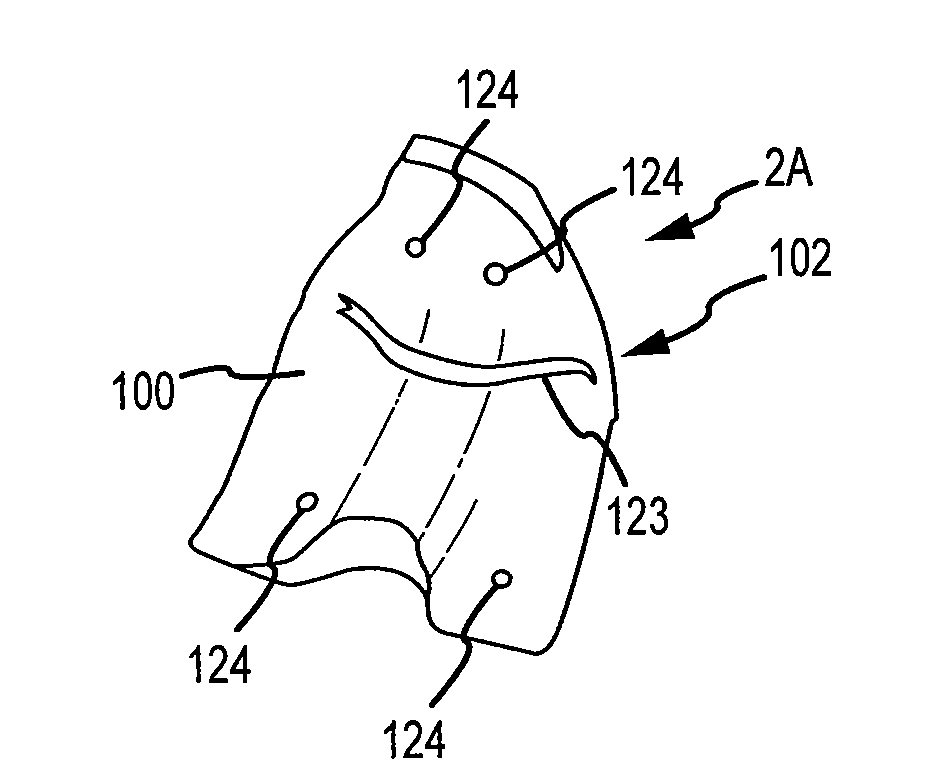

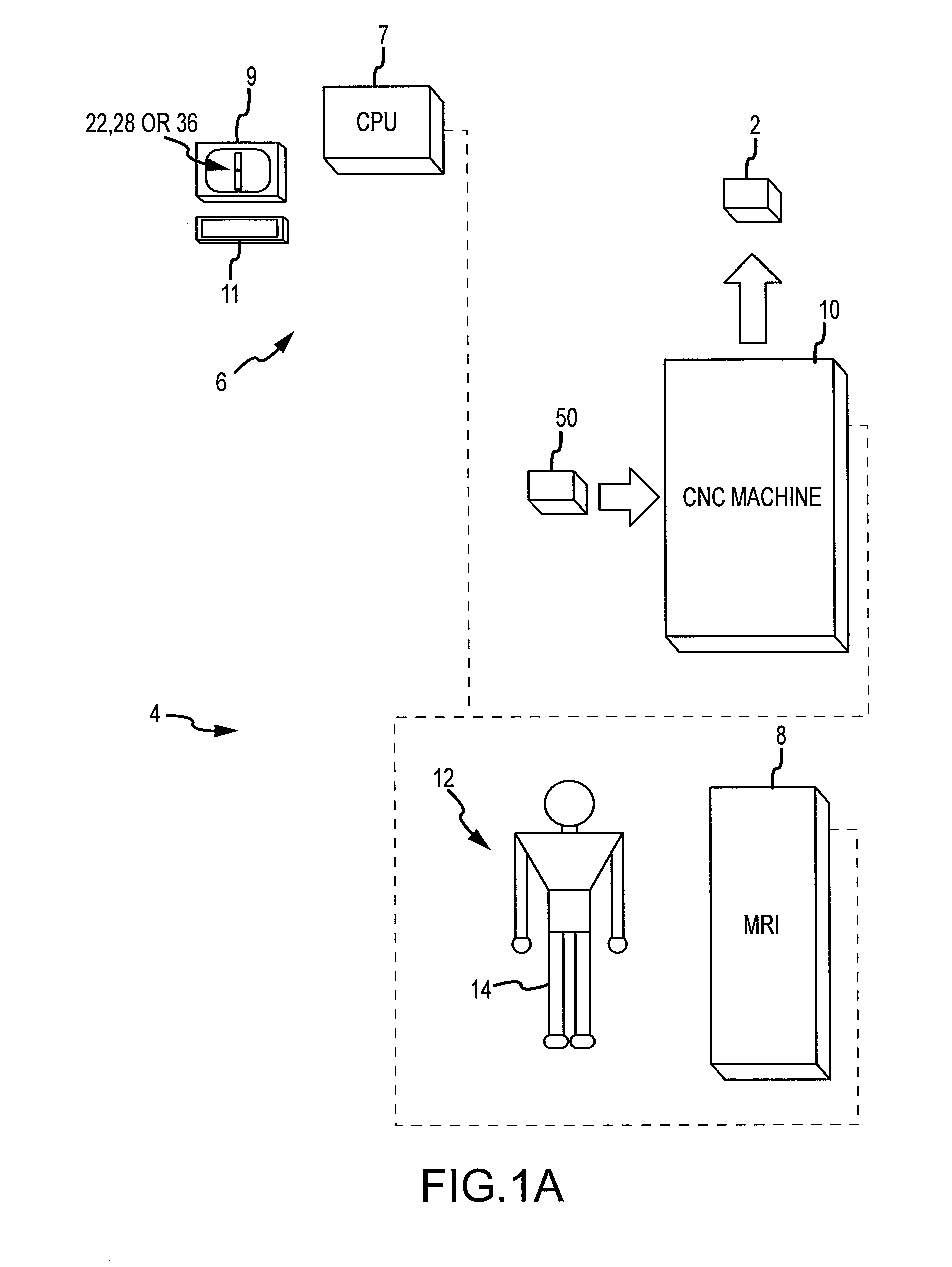

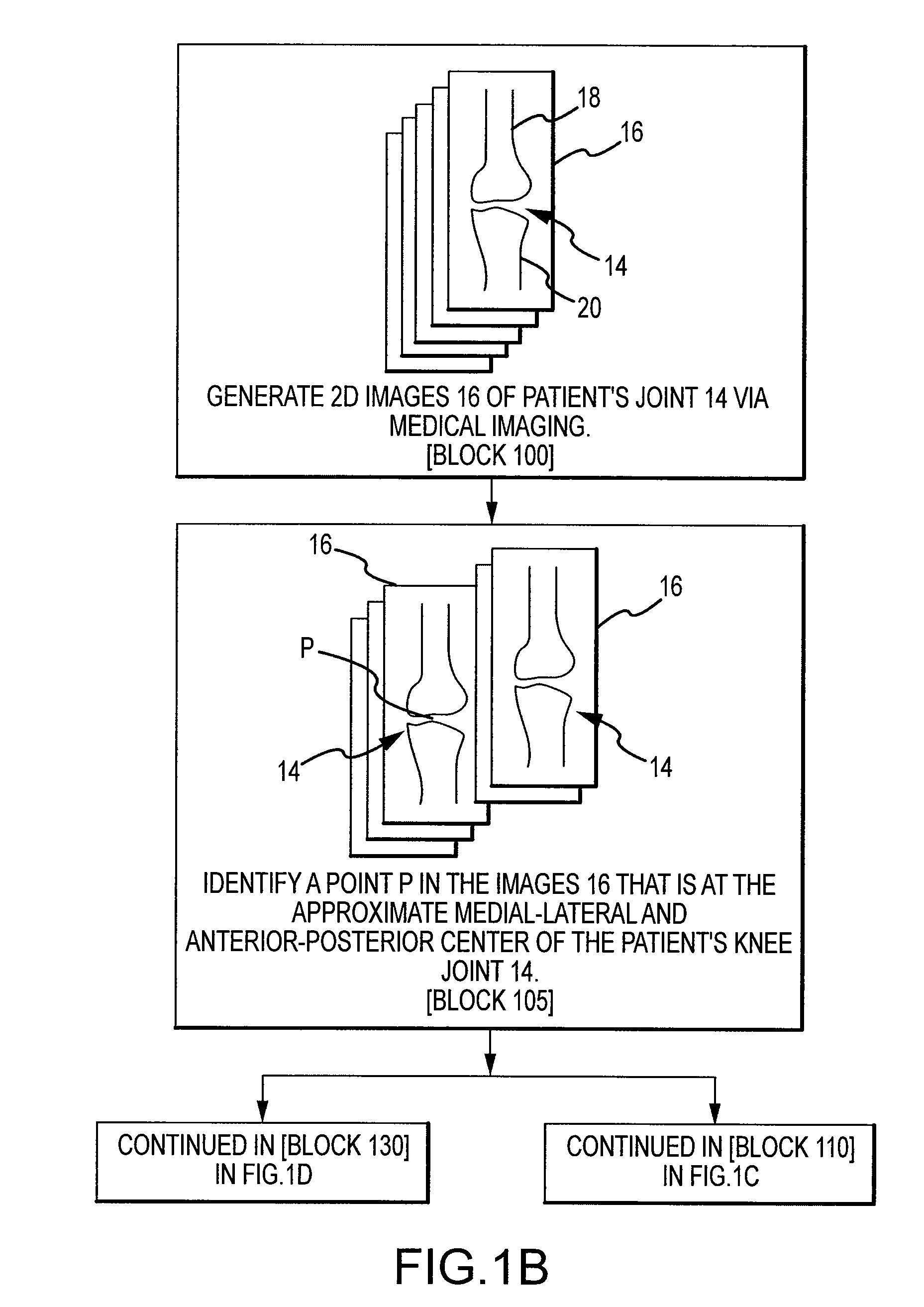

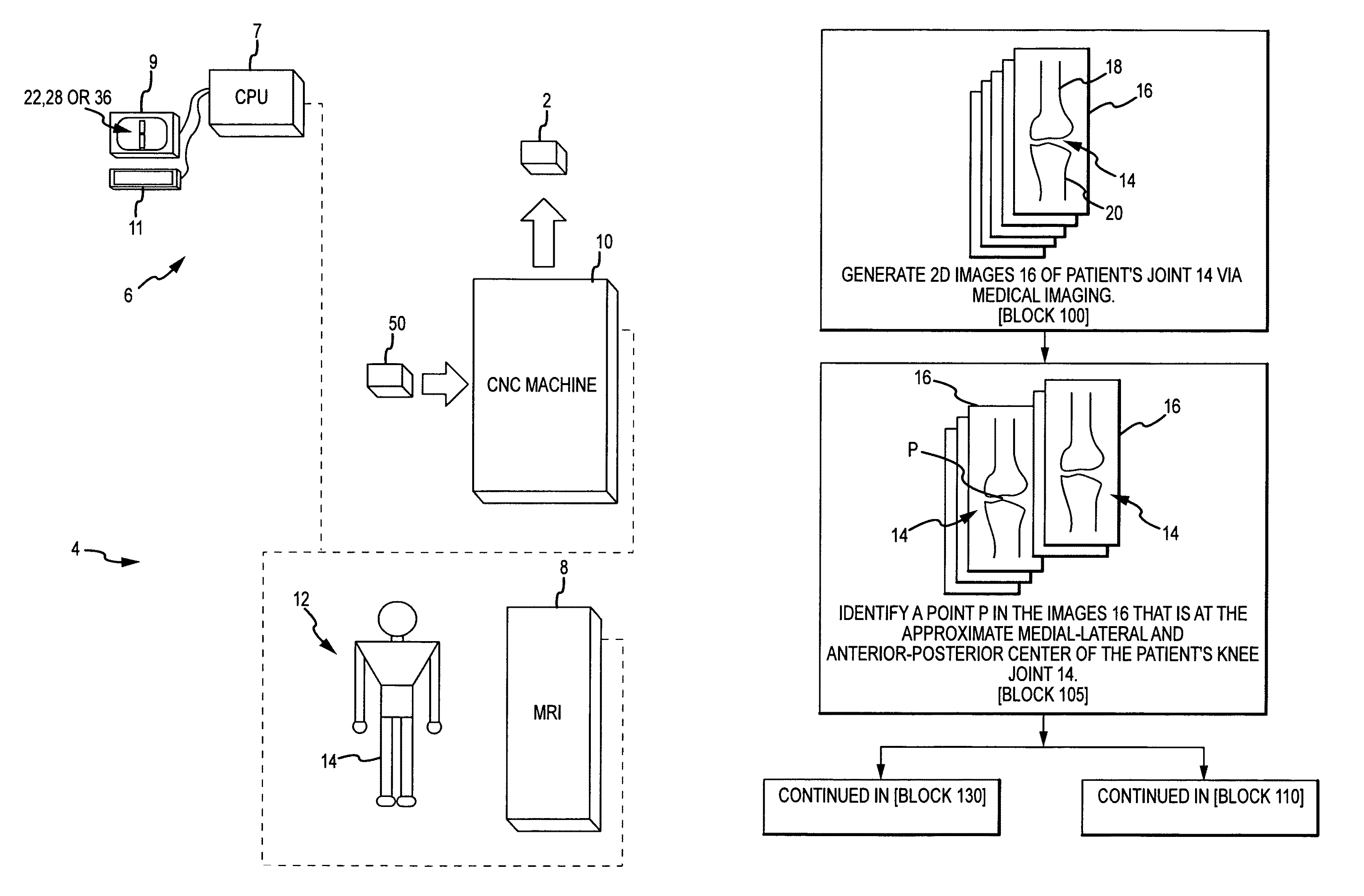

System and method for manufacturing arthroplasty jigs

ActiveUS20090157083A1Facilitate arthroplasty implantsCharacter and pattern recognitionComputerised tomographsBone formingSacroiliac joint

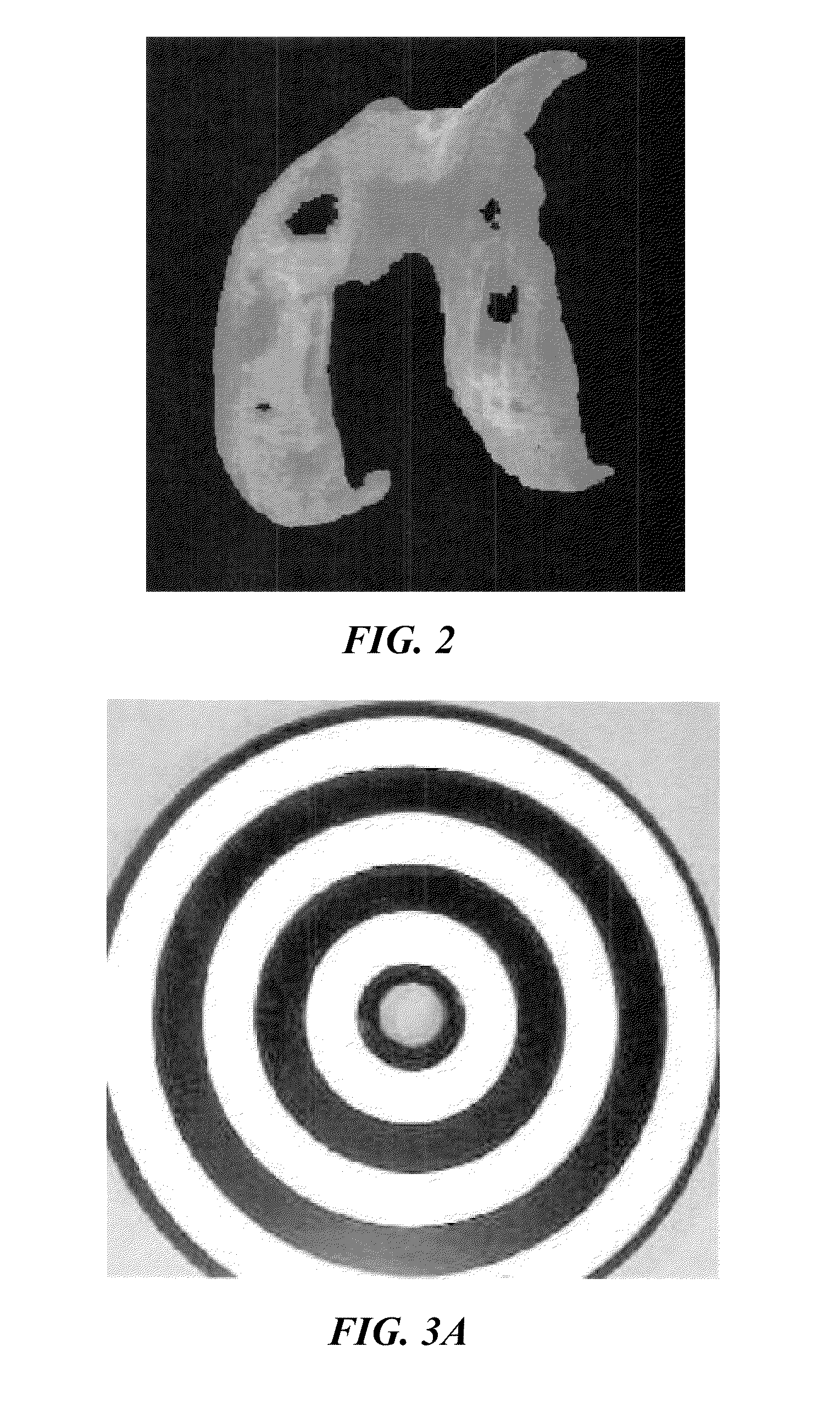

Disclosed herein is a method of computer generating a three-dimensional surface model of an arthroplasty target region of a bone forming a joint. The method may include: generating two-dimensional images of at least a portion of the bone; generating an open-loop contour line along the arthroplasty target region in at least some of the two-dimensional images; and generating the three-dimensional model of the arthroplasty target region from the open-loop contour lines.

Owner:HOWMEDICA OSTEONICS CORP

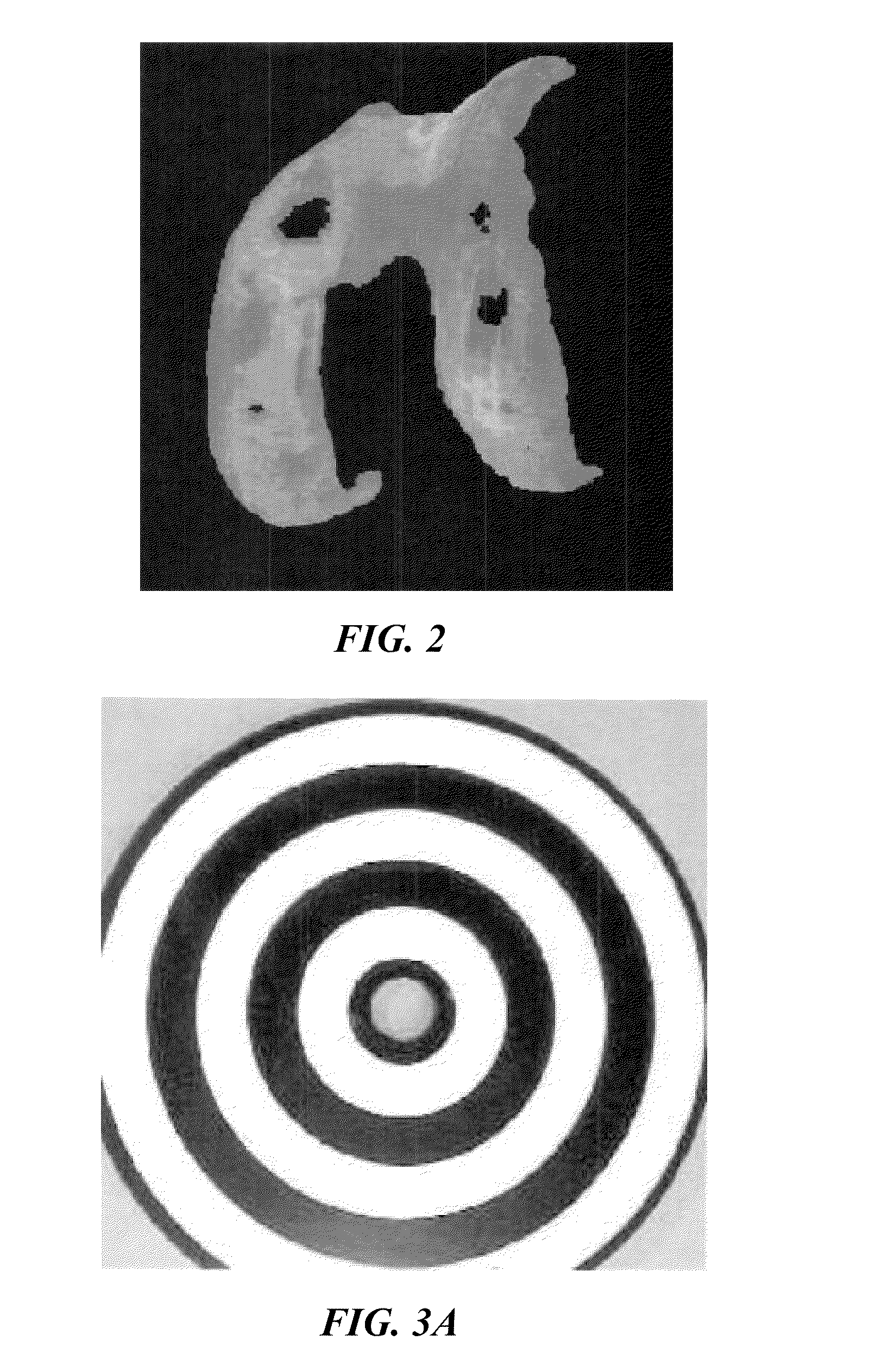

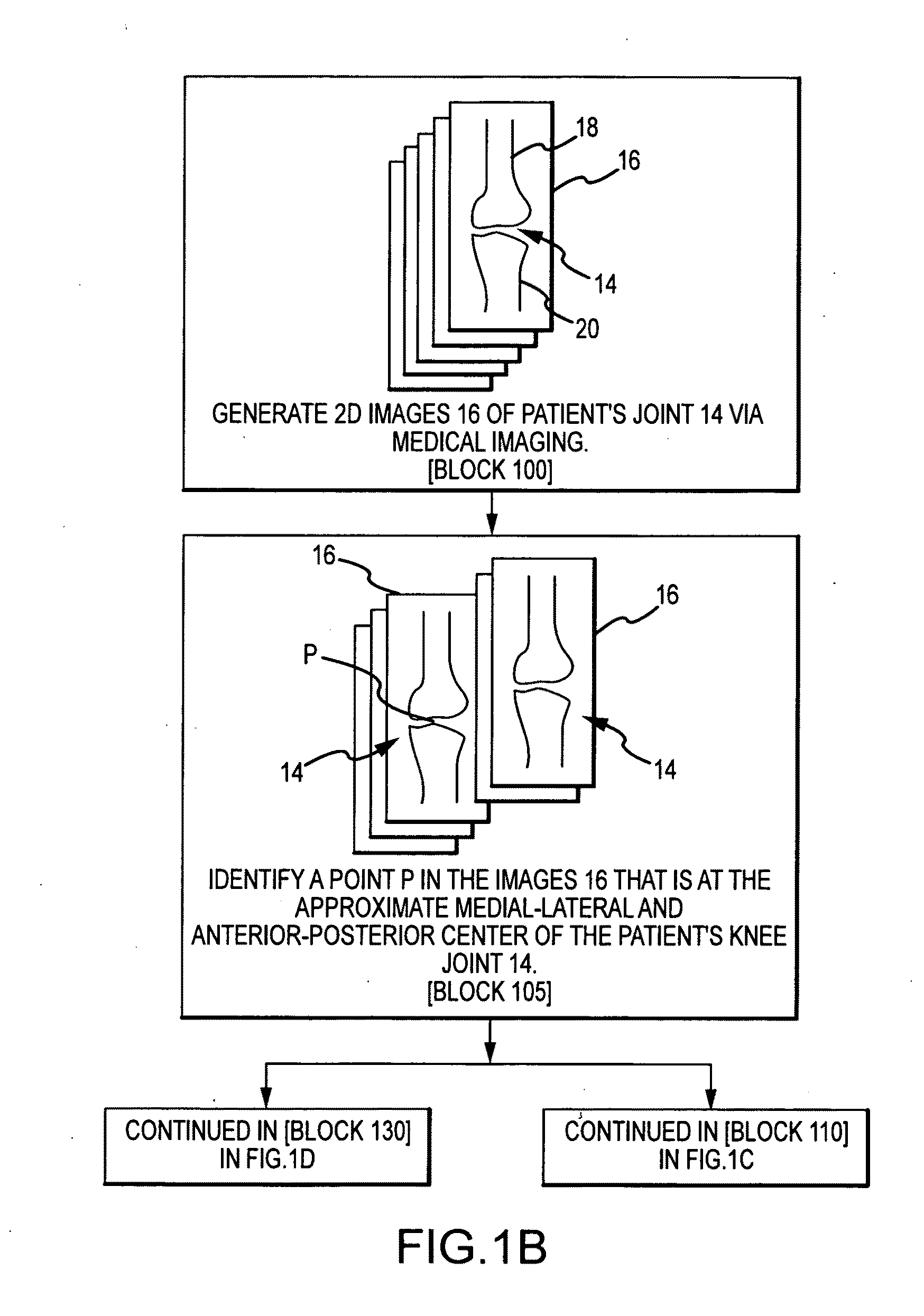

System and method for image segmentation in generating computer models of a joint to undergo arthroplasty

ActiveUS8160345B2Details involving processing stepsImage enhancementMedical imagingImage segmentation

A custom arthroplasty guide and a method of manufacturing such a guide are disclosed herein. The guide manufactured includes a mating region configured to matingly receive a portion of a patient bone associated with an arthroplasty procedure for which the custom arthroplasty guide is to be employed. The mating region includes a surface contour that is generally a negative of a surface contour of the portion of the patient bone. The surface contour of the mating region is configured to mate with the surface contour of the portion of the patient bone in a generally matching or interdigitating manner when the portion of the patient bone is matingly received by the mating region. The method of manufacturing the custom arthroplasty guide includes: a) generating medical imaging slices of the portion of the patient bone; b) identifying landmarks on bone boundaries in the medical imaging slices; c) providing model data including image data associated with a bone other than the patient bone; d) adjusting the model data to match the landmarks; e) using the adjusted model data to generate a three dimensional computer model of the portion of the patient bone; f) using the three dimensional computer model to generate design data associated with the custom arthroplasty guide; and g) using the design data in manufacturing the custom arthroplasty guide.

Owner:HOWMEDICA OSTEONICS CORP

Arthroplasty system and related methods

A method of manufacturing an arthroplasty jig is disclosed herein. The method may include the following: generate two dimensional image data of a patient joint to undergo arthroplasty, identify in the two dimensional image data a first point corresponding to an articular surface of a bone forming the joint, identify a second point corresponding to an articular surface of an implant, identify a location of a resection plane when the first point is correlated with the second point, and create the arthroplasty jig with a resection guide located according to the identified location of the resection plane.

Owner:HOWMEDICA OSTEONICS CORP

Joint Arthroplasty Devices and Surgical Tools

InactiveUS20100168754A1Accurate placementImage analysisInternal osteosythesisArticular surfacesArticular surface

Disclosed herein are methods, compositions and tools for repairing articular surfaces repair materials and for repairing an articular surface. The articular surface repairs are customizable or highly selectable by patient and geared toward providing optimal fit and function. The surgical tools are designed to be customizable or highly selectable by patient to increase the speed, accuracy and simplicity of performing total or partial arthroplasty.

Owner:CONFORMIS

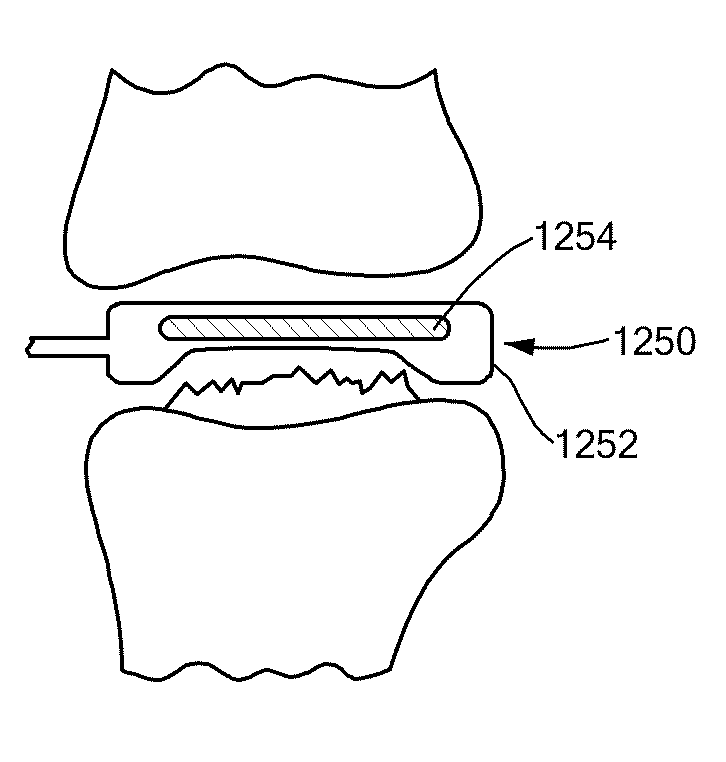

Apparatus for use in arthroplasty of the knees

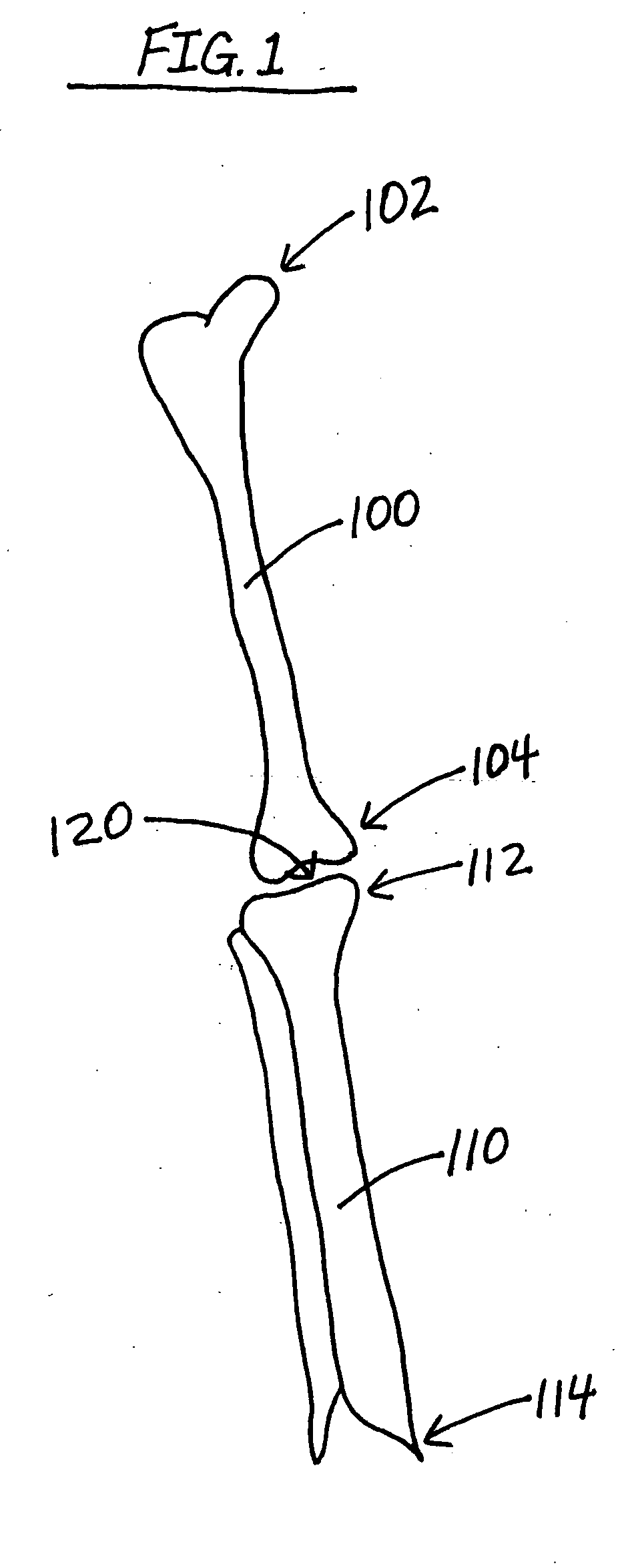

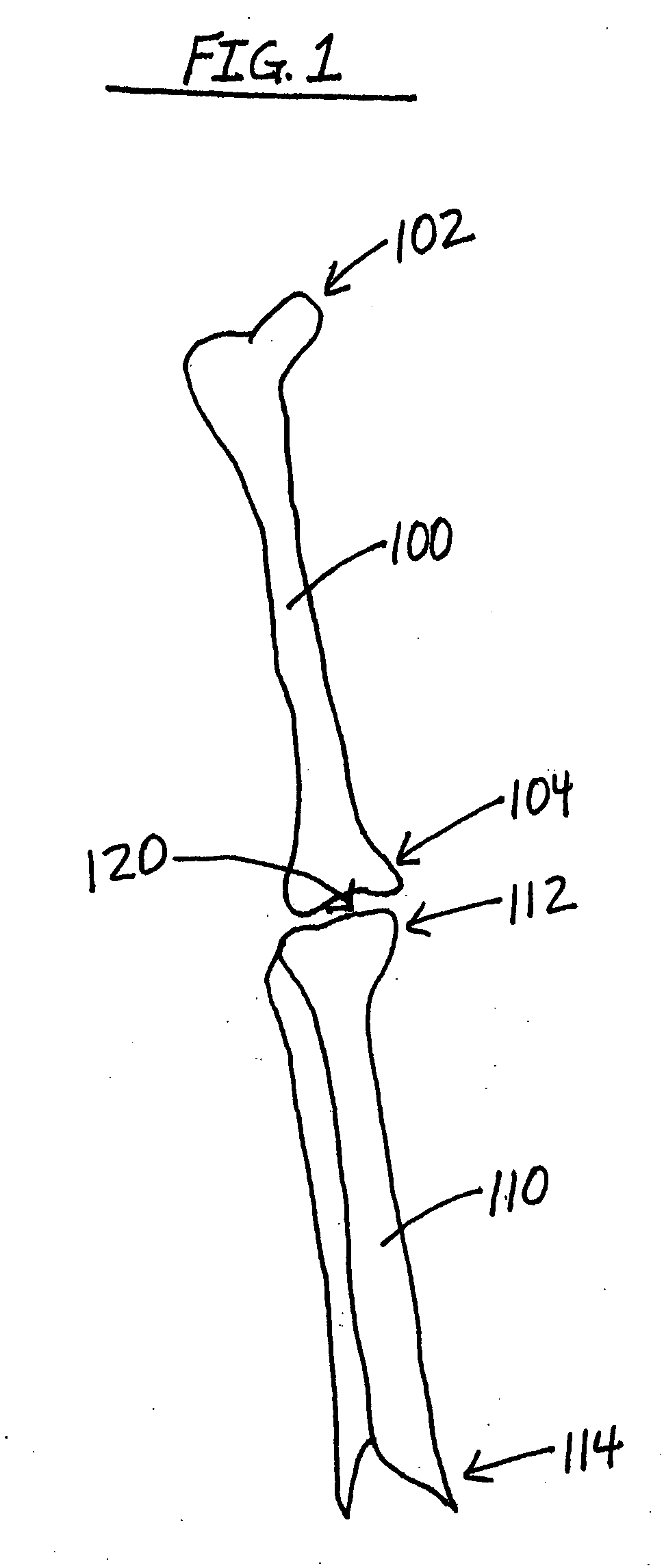

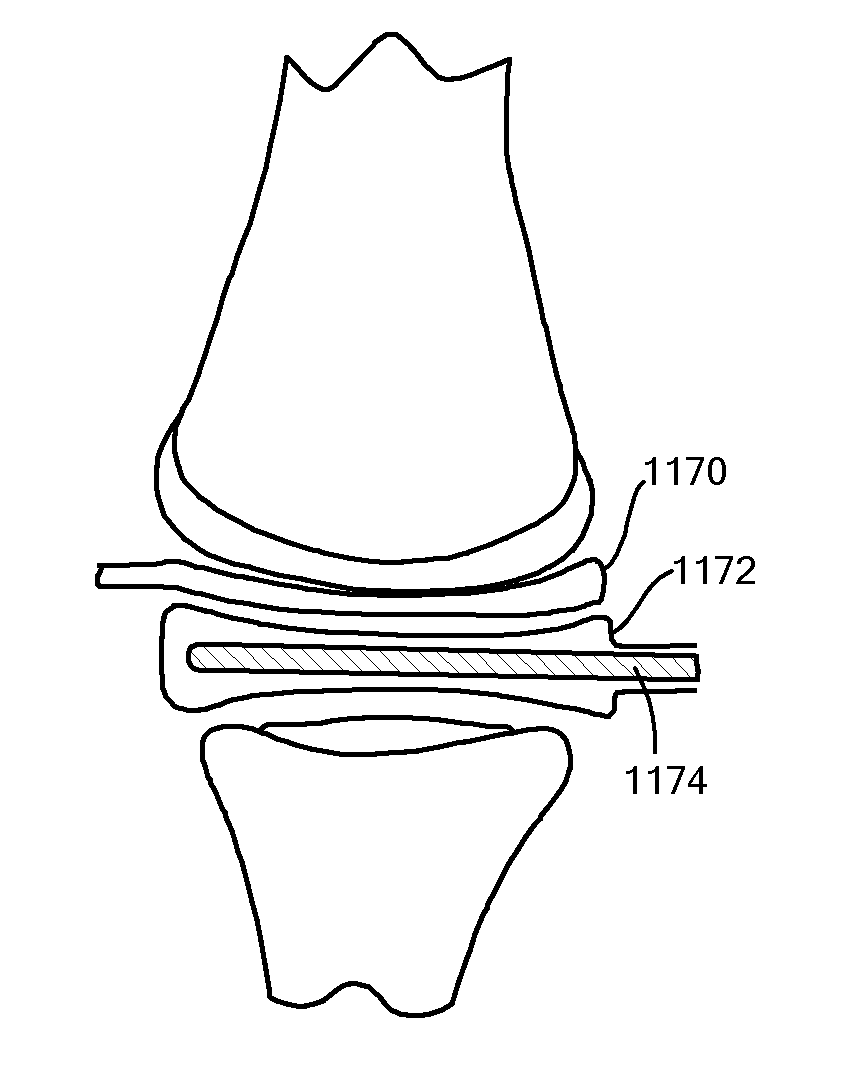

InactiveUS6969393B2Easy to guideAvoid liftingJoint implantsNon-surgical orthopedic devicesTibiaKnee Joint

A cutting device for being inserted into a knee joint between the tibia and the femur, wherein the cutting device is adapted for resecting bone from the femur to a desired depth in a path of travel of the tibia when located in the knee joint and operated as the tibia is moved through an arc of motion about the femur between backward and forward positions. A cutting device is also disclosed for being inserted into a knee joint between the tibia and the femur for resecting bone from the tibia to a desired depth to form a recess in a condyle of the tibia for reception of a tibial implant, comprising a body being located between the tibia and the femur, a cutter for resecting the bone from the tibia to form the recess and a drive mechanism for driving the cutter to resect the bone and being arranged in the body, wherein the cutter is mounted on the body and protrudes therefrom for resecting the bone from the tibia.

Owner:SMITH & NEPHEW INC

System and method for manufacturing arthroplasty jigs

ActiveUS8221430B2Facilitate arthroplasty implantsCharacter and pattern recognitionComputerised tomographsBone formingSacroiliac joint

Disclosed herein is a method of computer generating a three-dimensional surface model of an arthroplasty target region of a bone forming a joint. The method may include: generating two-dimensional images of at least a portion of the bone; generating an open-loop contour line along the arthroplasty target region in at least some of the two-dimensional images; and generating the three-dimensional model of the arthroplasty target region from the open-loop contour lines.

Owner:HOWMEDICA OSTEONICS CORP

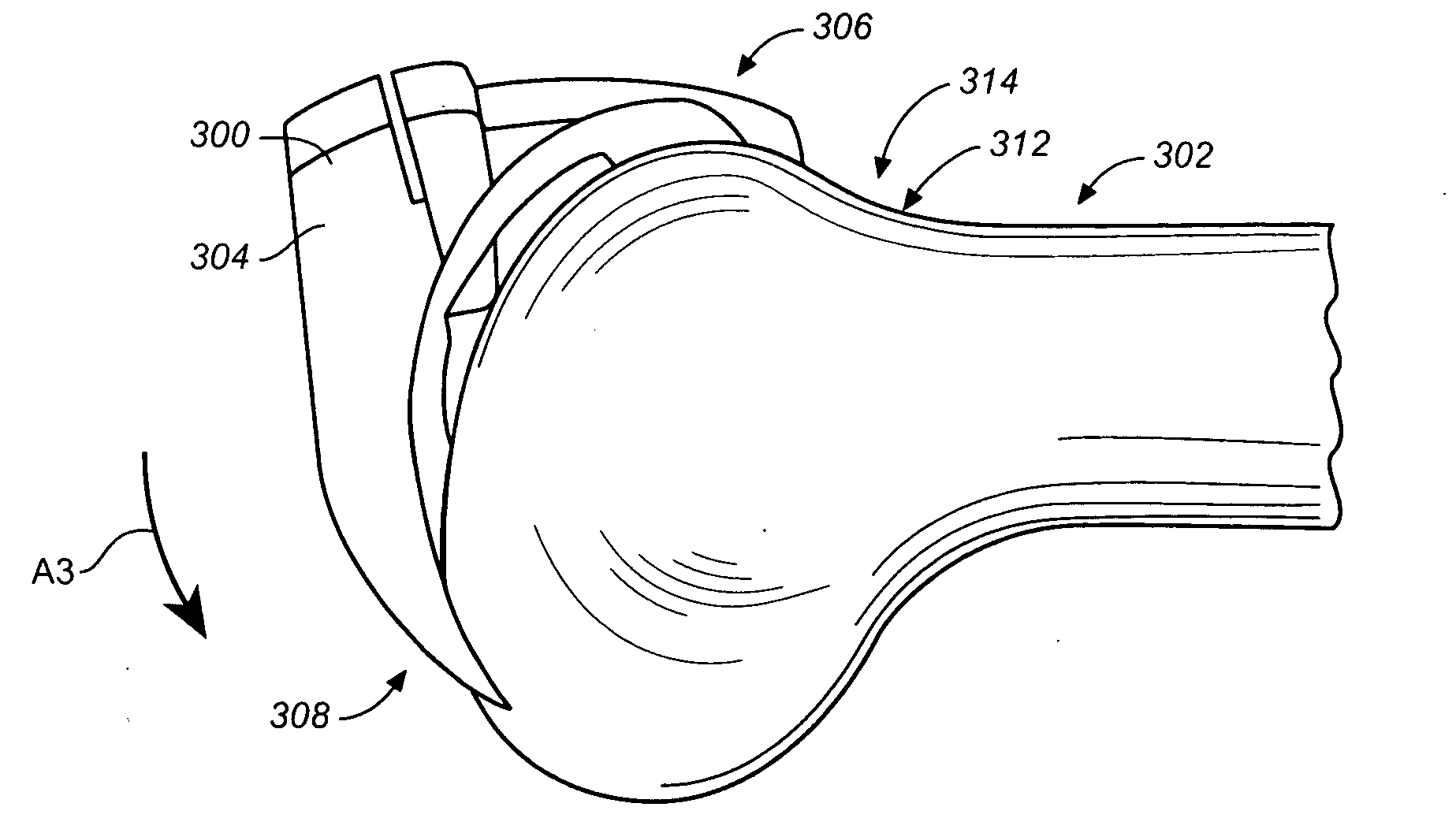

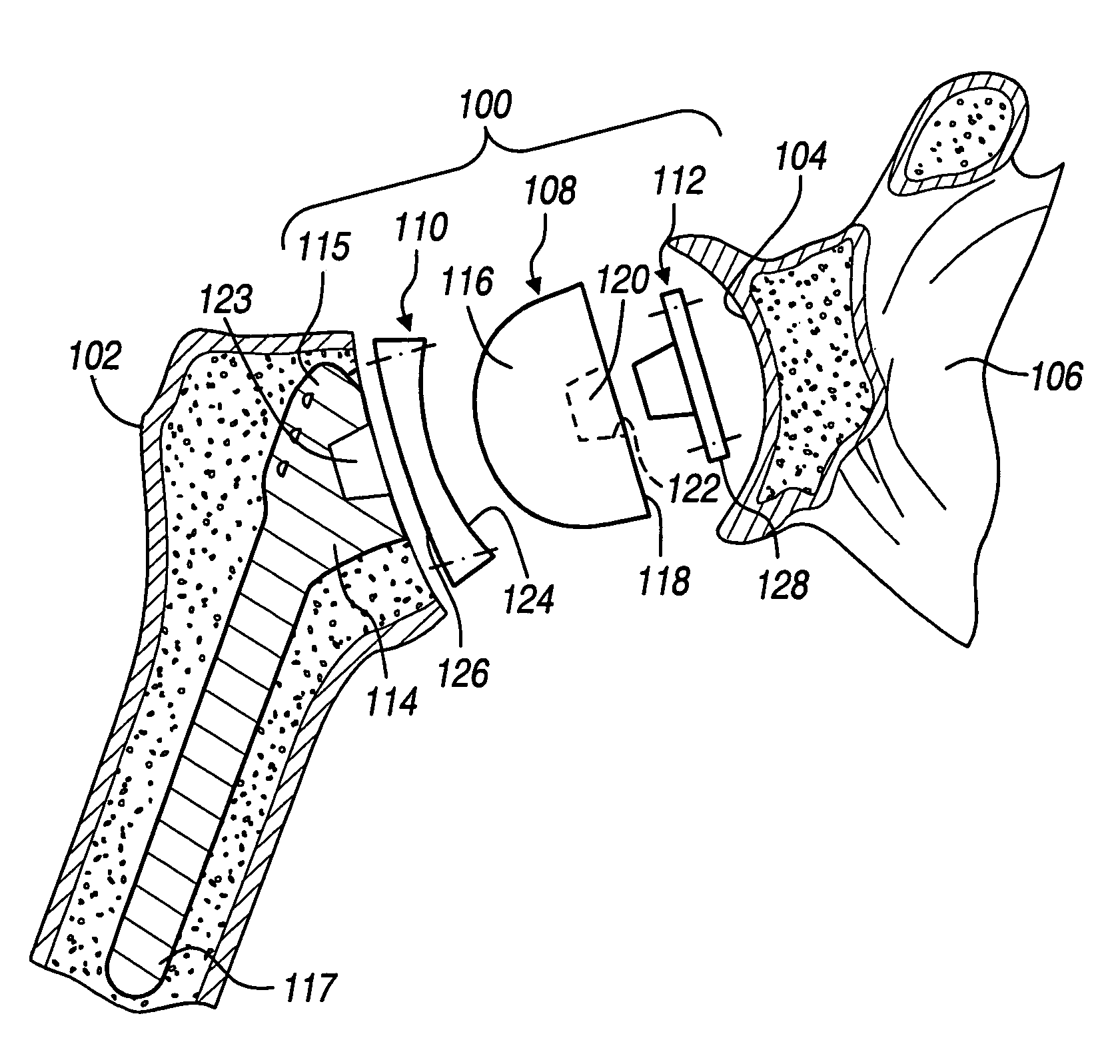

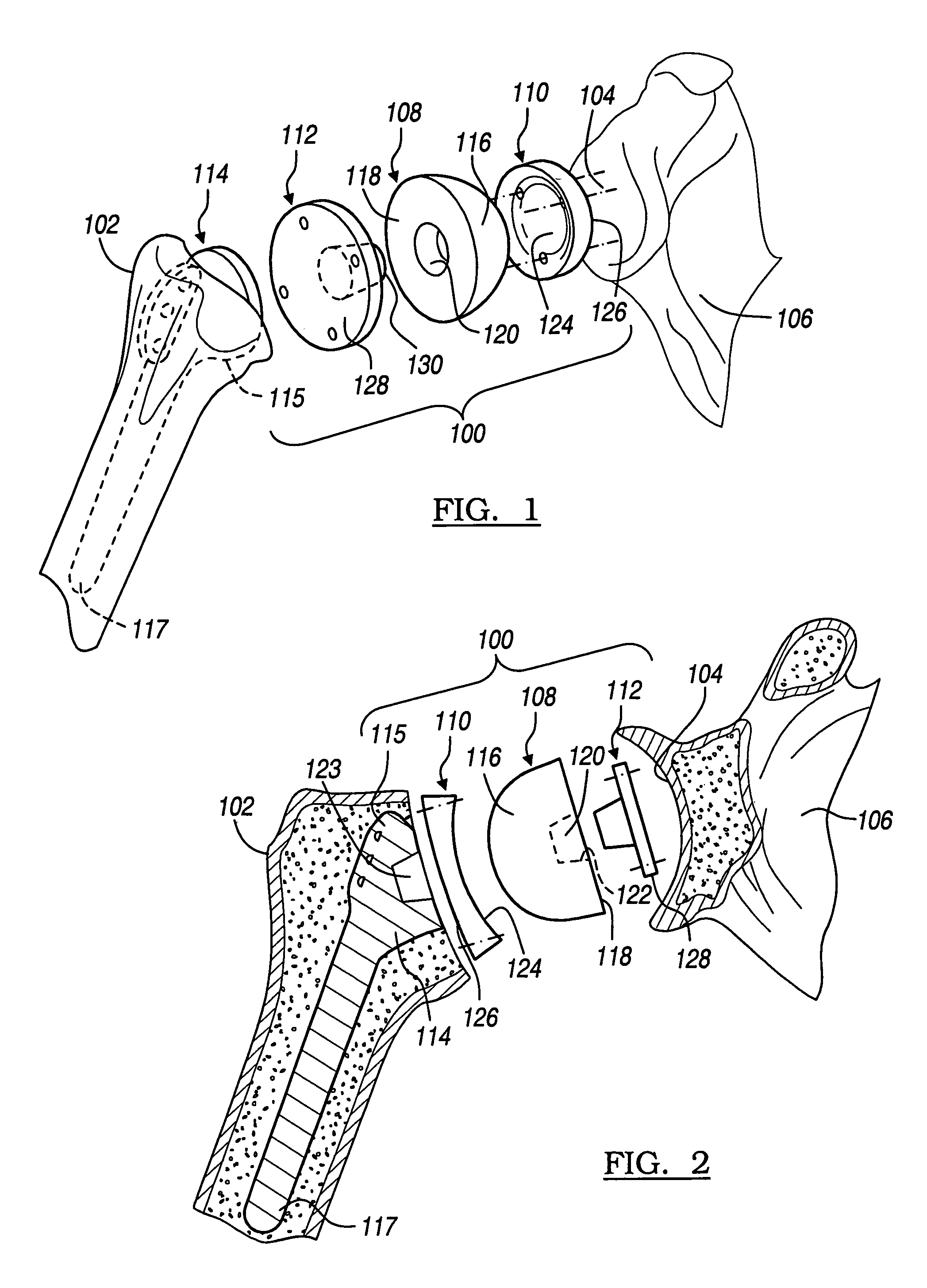

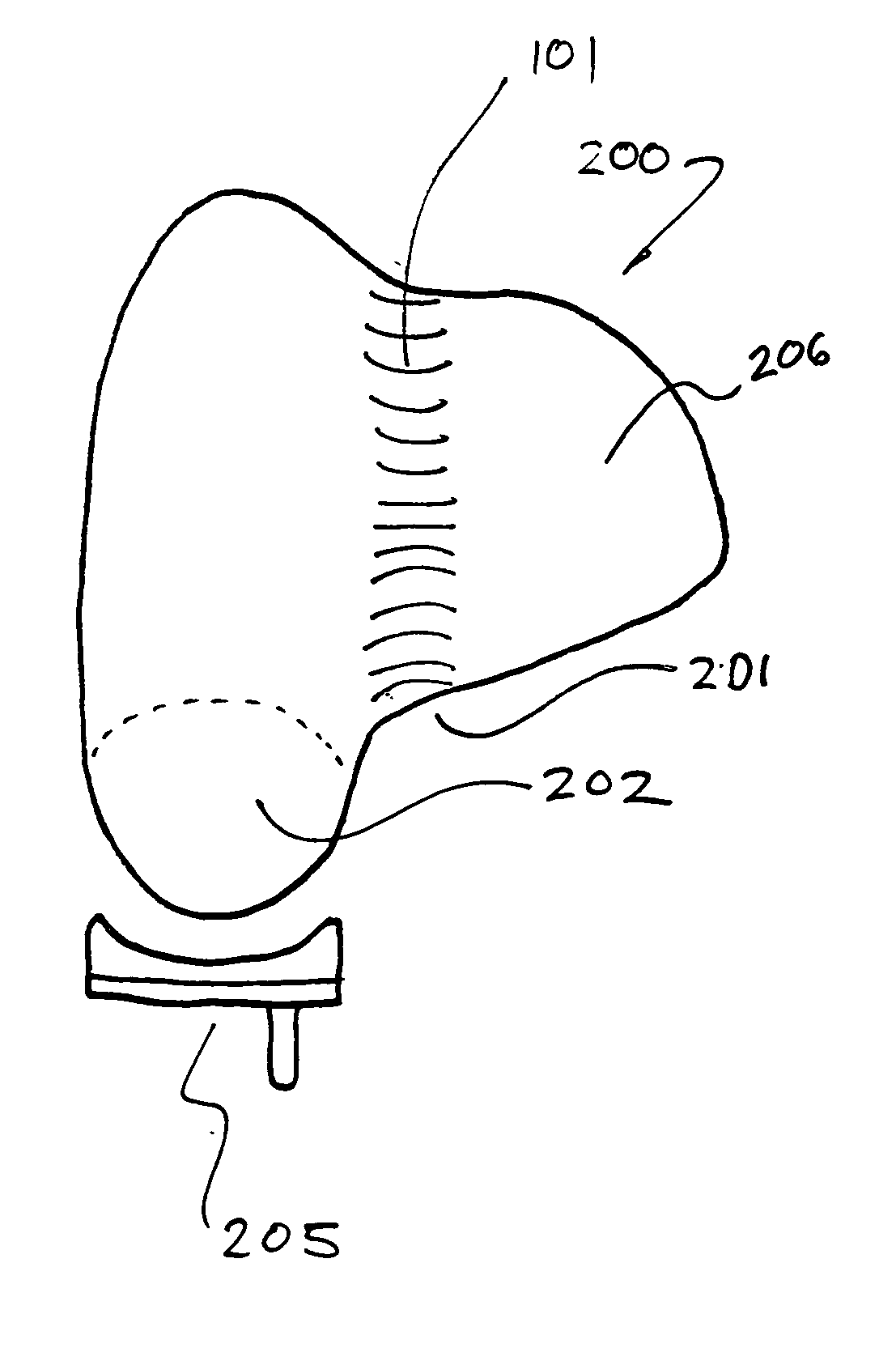

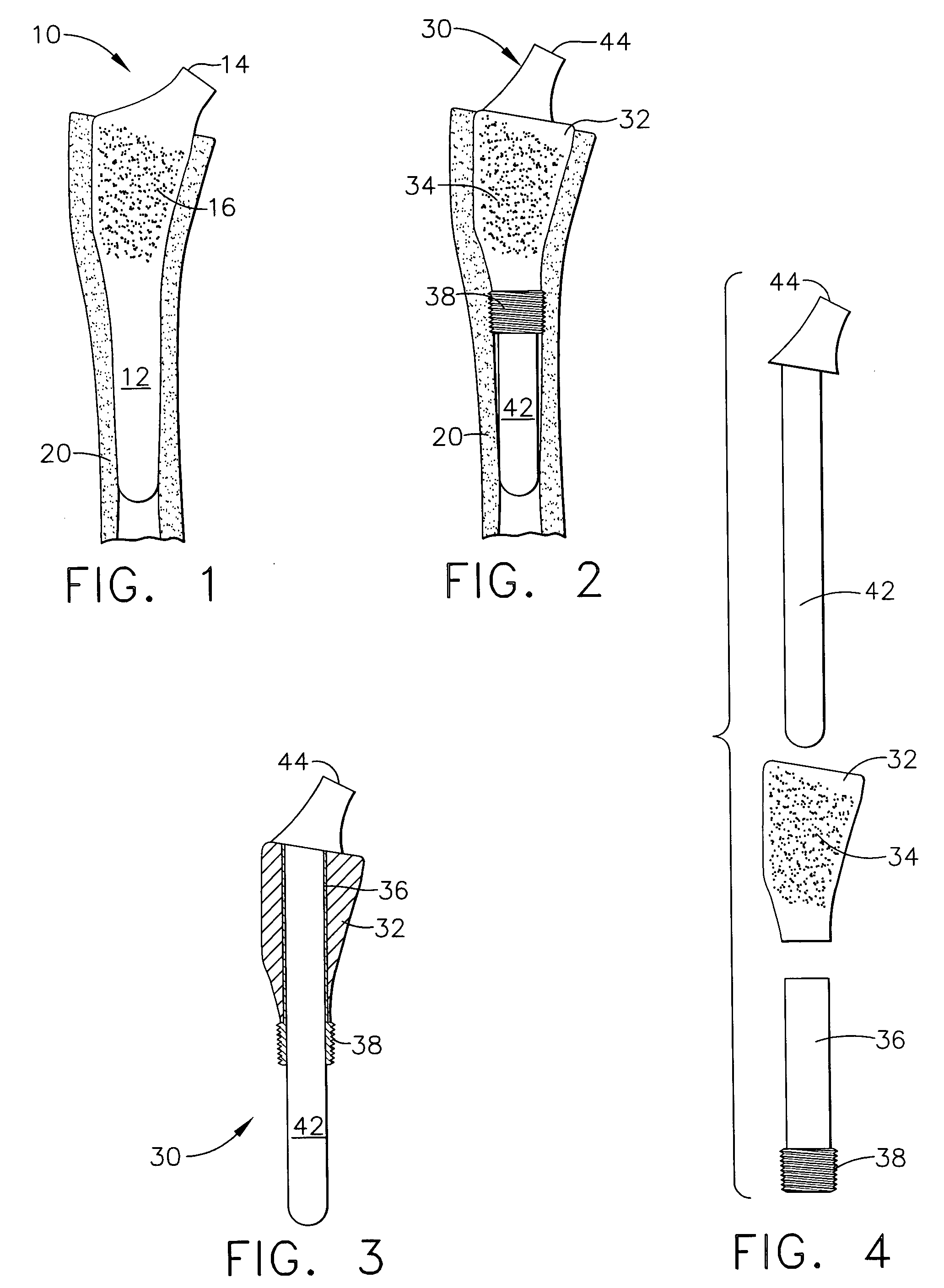

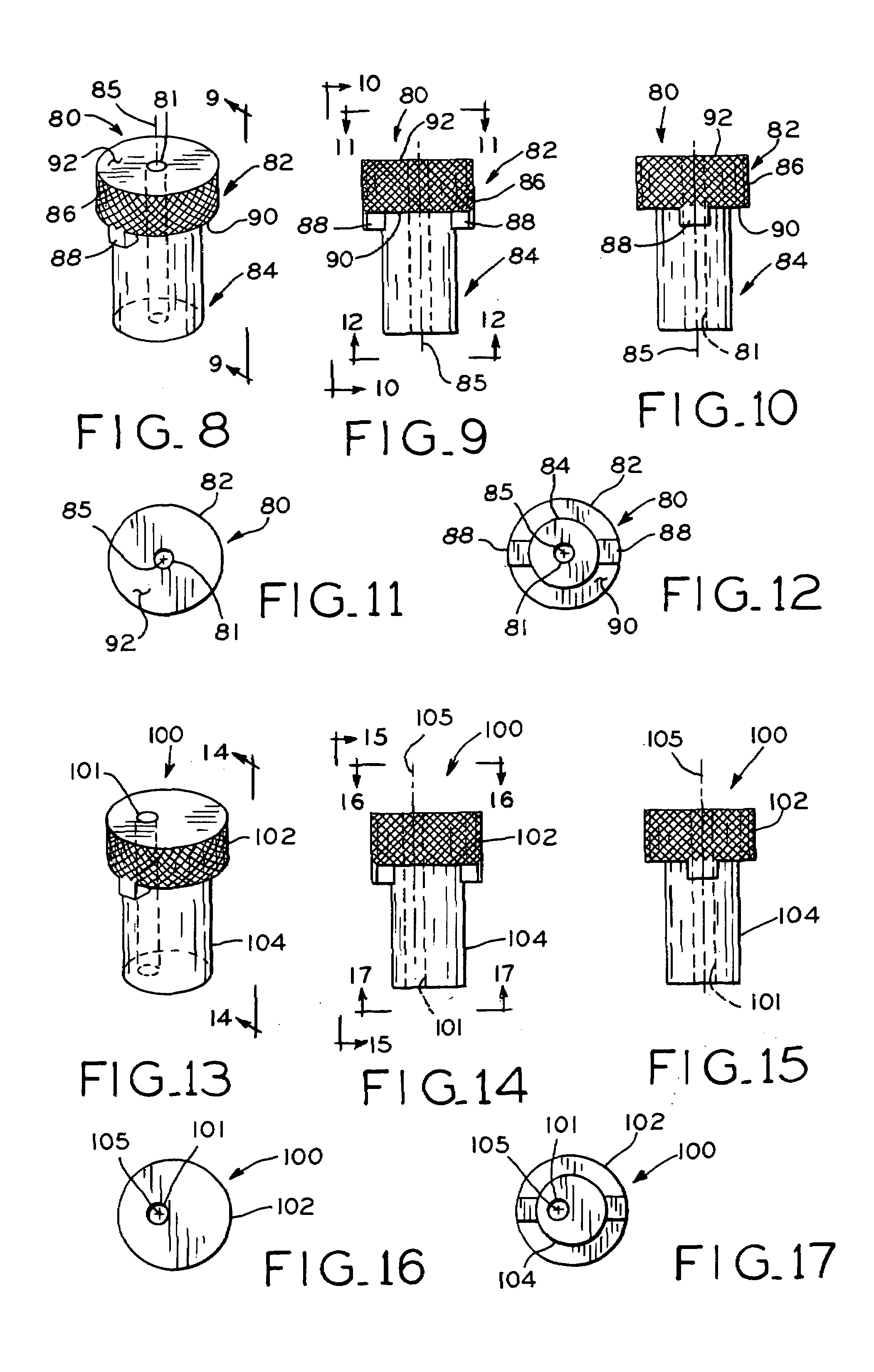

Shoulder implant assembly

An implant assembly and associated method for selectively performing reverse and traditional arthroplasty for a shoulder joint that includes a humerus and a glenoid. The implant assembly may include a head, a cup, a humeral stem and an adapter. The method includes inserting the humeral stem to the humerus and connecting a male taper of the adapter to a female taper of the head. For reverse arthroplasty, the method includes attaching the adapter to the glenoid and the cup to the stem. For traditional arthroplasty, the method includes attaching the adapter to the humeral stem and the cup to the glenoid. The method also includes articulating the head with the cup.

Owner:BIOMET MFG CORP

System and method for image segmentation in generating computer models of a joint to undergo arthroplasty

Systems and methods for image segmentation in generating computer models of a joint to undergo arthroplasty are disclosed. Some embodiments may include a method of partitioning an image of a bone into a plurality of regions, where the method may include obtaining a plurality of volumetric image slices of the bone, generating a plurality of spline curves associated with the bone, verifying that at least one of the plurality of spline curves follow a surface of the bone, and creating a 3D mesh representation based upon the at least one of the plurality of spline curve.

Owner:HOWMEDICA OSTEONICS CORP

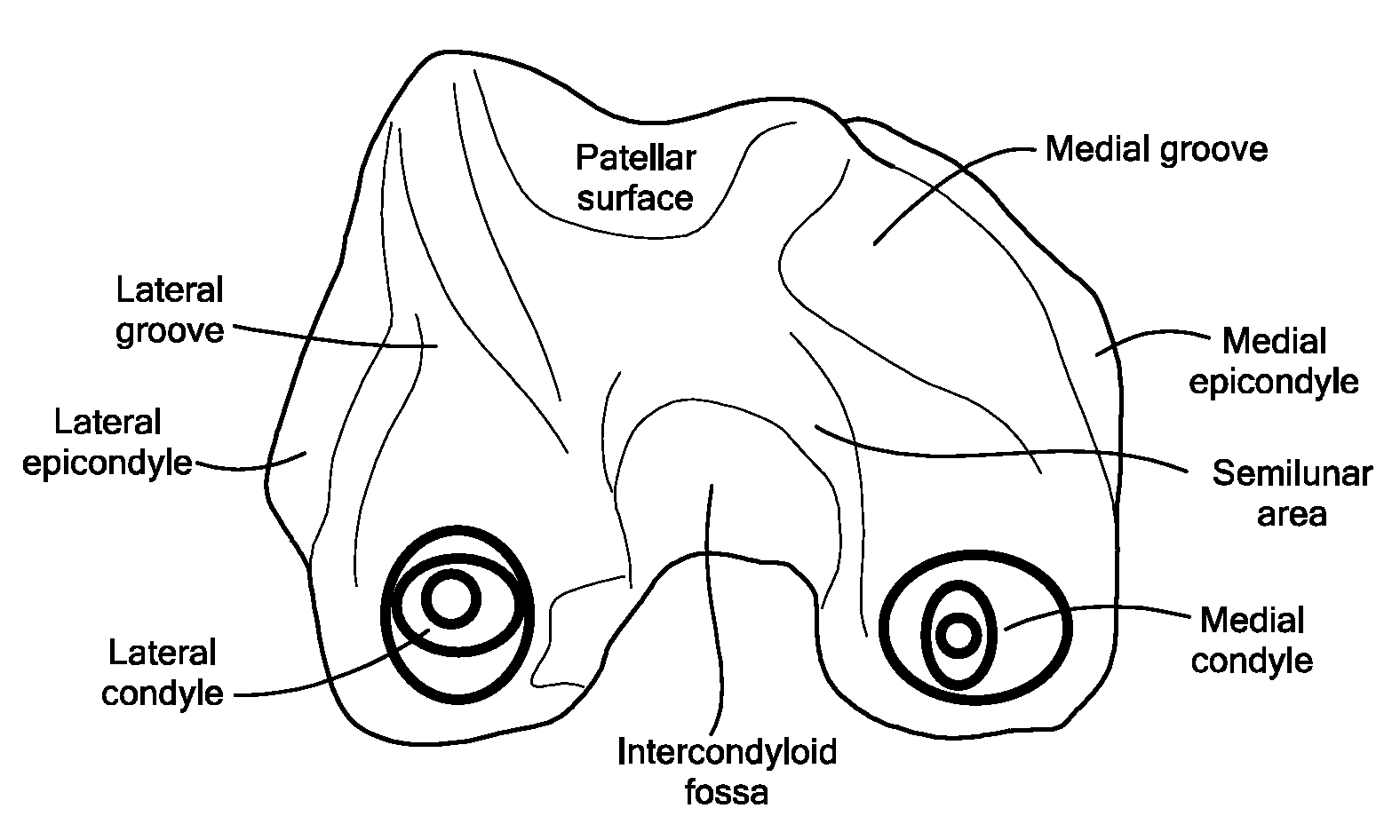

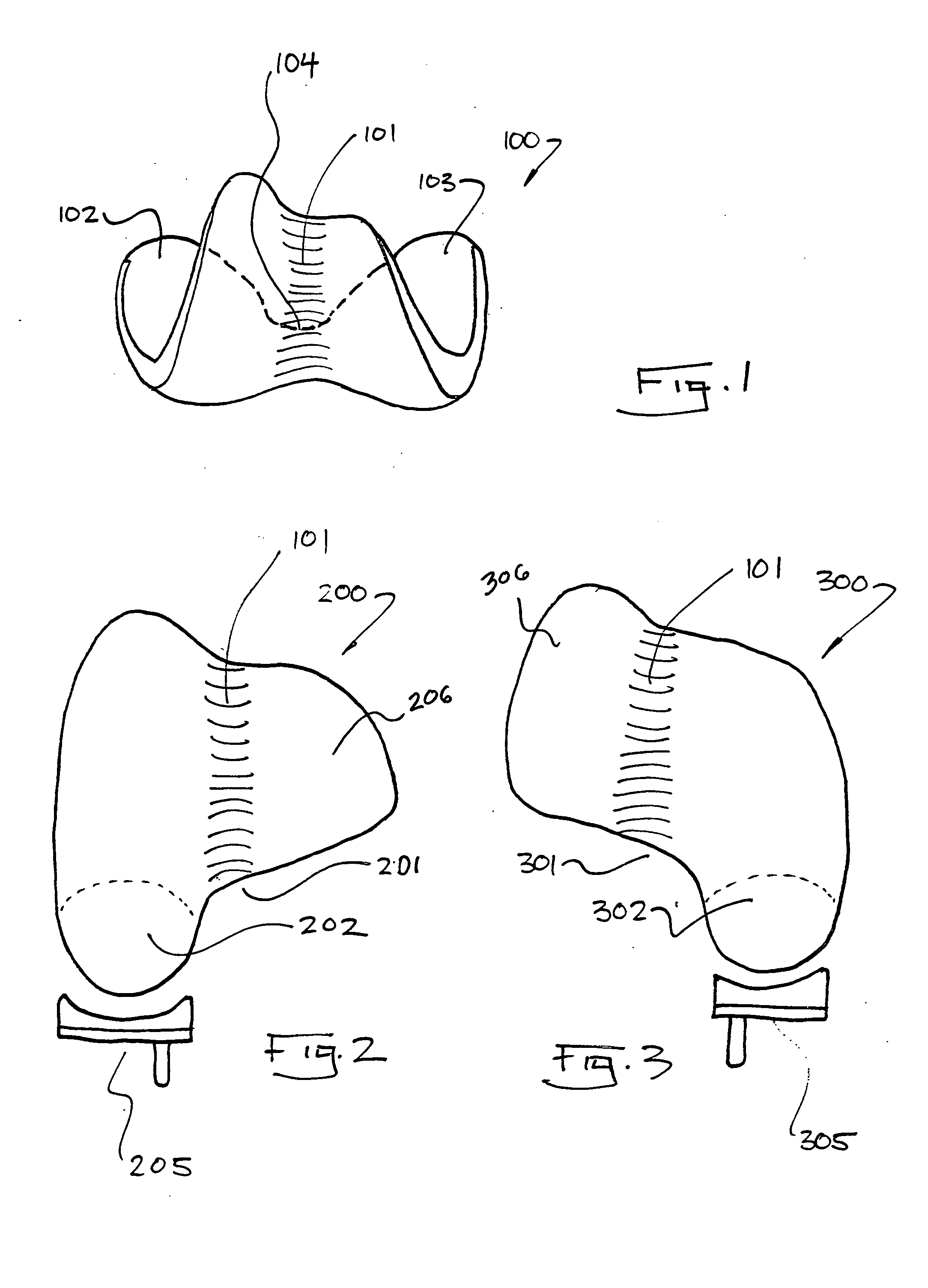

Device and method for bicompartmental arthroplasty

Disclosed is a device and method of bicompartmental arthroplasty of the knee. The device permits arthroplasty of the medial or lateral and patellofemoral compartments of the knee while leaving the opposite compartments and the anterior and posterior cruciate ligaments intact. The device provides a femoral prosthesis component that includes a trochlear surface and a tibial prosthesis component which can be secured to the tibia. The femoral component is essentially “u” shaped having an anterior leg upon which the trochlear surface is positioned and a posterior leg which engages the posterior surface of the distal end of the femur. The femoral component also has a convex articulating surface which engages a concave articulating surface of the tibial prosthesis component to approximate the articulation of a healthy knee.

Owner:ROLSTON LINDSEY R

Two-thirds prosthetic arthroplasty

A two-thirds prosthetic arthroplasty having a trochlear groove, a patello-femoral component, and either a lateral condyle or a medial condyle. The arthroplasty may be configured to be a prosthetic for either a right or left knee. The condyle and patello-femoral component are separated by a modified intercondylar notch that is blended to avoid protrusions or sharp angles. The prosthetic arthroplasty is inserted after preoperative MRI mapping of articular cartilage damage. The prosthetic arthroplasty may be cemented during surgery and the two-thirds design of the present invention obviates the problem of cement retrieval from remote parts of the prosthesis.

Owner:WOOD DAVID JOHN

System and method for image segmentation in generating computer models of a joint to undergo arthroplasty

ActiveUS20110282473A1Image enhancementDetails involving processing stepsImage segmentationMedical imaging

A custom arthroplasty guide and a method of manufacturing such a guide are disclosed herein. The guide manufactured includes a mating region configured to matingly receive a portion of a patient bone associated with an arthroplasty procedure for which the custom arthroplasty guide is to be employed. The mating region includes a surface contour that is generally a negative of a surface contour of the portion of the patient bone. The surface contour of the mating region is configured to mate with the surface contour of the portion of the patient bone in a generally matching or interdigitating manner when the portion of the patient bone is matingly received by the mating region. The method of manufacturing the custom arthroplasty guide includes: a) generating medical imaging slices of the portion of the patient bone; b) identifying landmarks on bone boundaries in the medical imaging slices; c) providing model data including image data associated with a bone other than the patient bone; d) adjusting the model data to match the landmarks; e) using the adjusted model data to generate a three dimensional computer model of the portion of the patient bone; f) using the three dimensional computer model to generate design data associated with the custom arthroplasty guide; and g) using the design data in manufacturing the custom arthroplasty guide.

Owner:HOWMEDICA OSTEONICS CORP

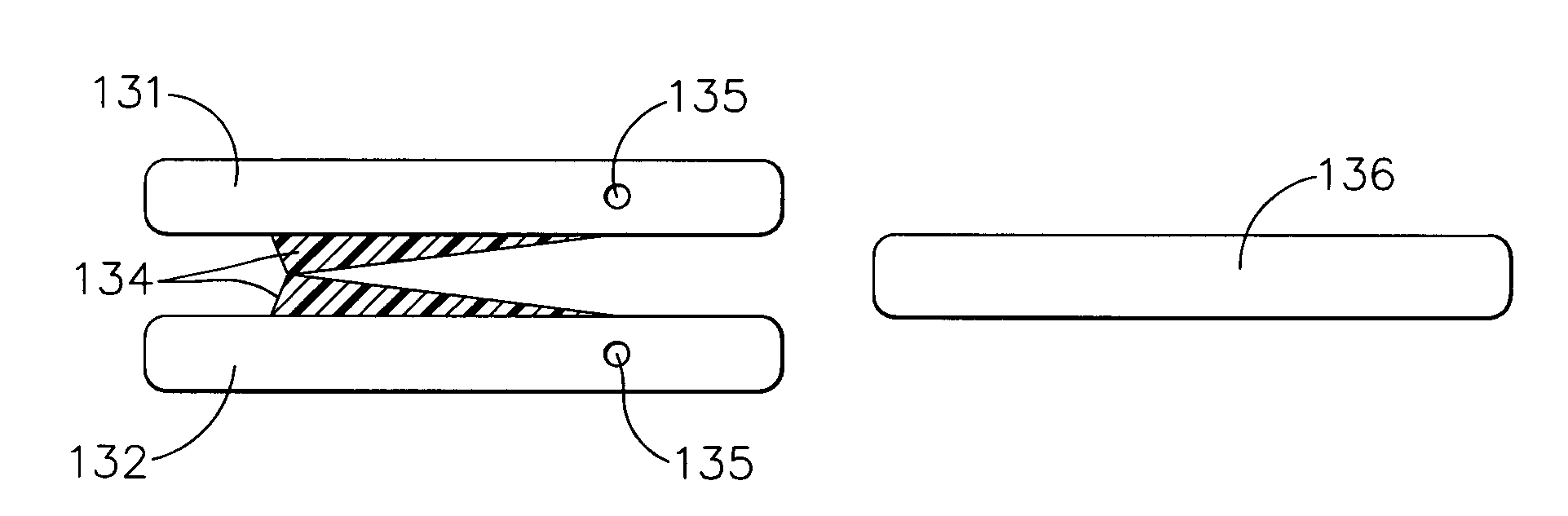

Artificial disc replacements with deployable fixation components

InactiveUS20040030389A1Reduce shear stressInternal osteosythesisDiagnosticsIntervertebral discBone growth

Arthroplasty devices having improved bone in growth to provide a more secure connection within the body. Different embodiments disclosed include devices having threaded intramedullary components, devices configured to receive bone growth promoting substances, devices with resorbable components, and devices configured to reduce shear stress.

Owner:FERREE BRET A

System and method for image segmentation in generating computer models of a joint to undergo arthroplasty

ActiveUS20120192401A1Image enhancementDetails involving processing stepsImage segmentationMedical imaging

A custom arthroplasty guide and a method of manufacturing such a guide are disclosed herein. The method of manufacturing the custom arthroplasty guide includes: a) generating medical imaging slices of the portion of the patient bone; b) identifying landmarks on bone boundaries in the medical imaging slices; c) providing model data including image data associated with a bone other than the patient bone; d) adjusting the model data to match the landmarks; e) using the adjusted model data to generate a three dimensional computer model of the portion of the patient bone; f) using the three dimensional computer model to generate design data associated with the custom arthroplasty guide; and g) using the design data in manufacturing the custom arthroplasty guide.

Owner:HOWMEDICA OSTEONICS CORP

Method and apparatus for preparing a glenoid surface

ActiveUS7294133B2Easy to implantEasy to installProsthesisOsteosynthesis devicesAnterior surfaceProsthesis

A method and apparatus for facilitating shoulder arthroplasty by providing a reference to establish version of the glenoid. In one form of the invention, a guide for positioning a guide pin to facilitate implantation of a glenoid prosthesis is provided. To properly position the guide pin, the guide is first oriented with respect to the scapula. A portion of the guide is positioned over the approximate center of the glenoid surface and another portion of the guide is positioned against the anterior surface of the scapula. After the guide is properly positioned, the guide pin is inserted through an aperture in the guide and anchored in the glenoid. Thereafter, the guide pin can serve as an alignment guide for other devices used to modify the glenoid surface. For example, a reamer having a cannulated central shaft can be placed over the guide pin and utilized to resurface the glenoid.

Owner:ZIMMER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com