Patents

Literature

2975 results about "Reamer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. There are also non-precision reamers which are used for more basic enlargement of holes or for removing burrs. The process of enlarging the hole is called reaming. There are many different types of reamer and they may be designed for use as a hand tool or in a machine tool, such as a milling machine or drill press.

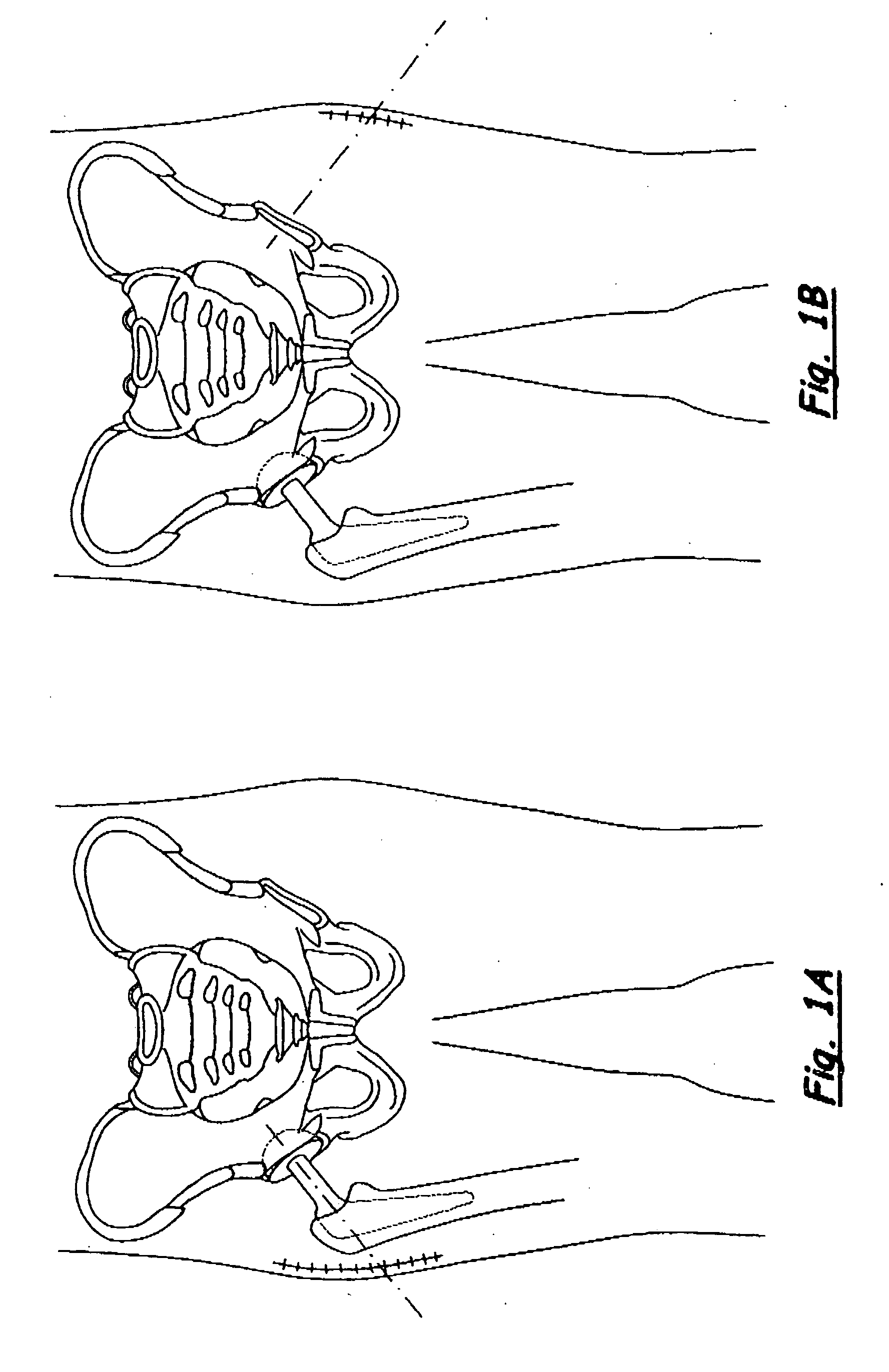

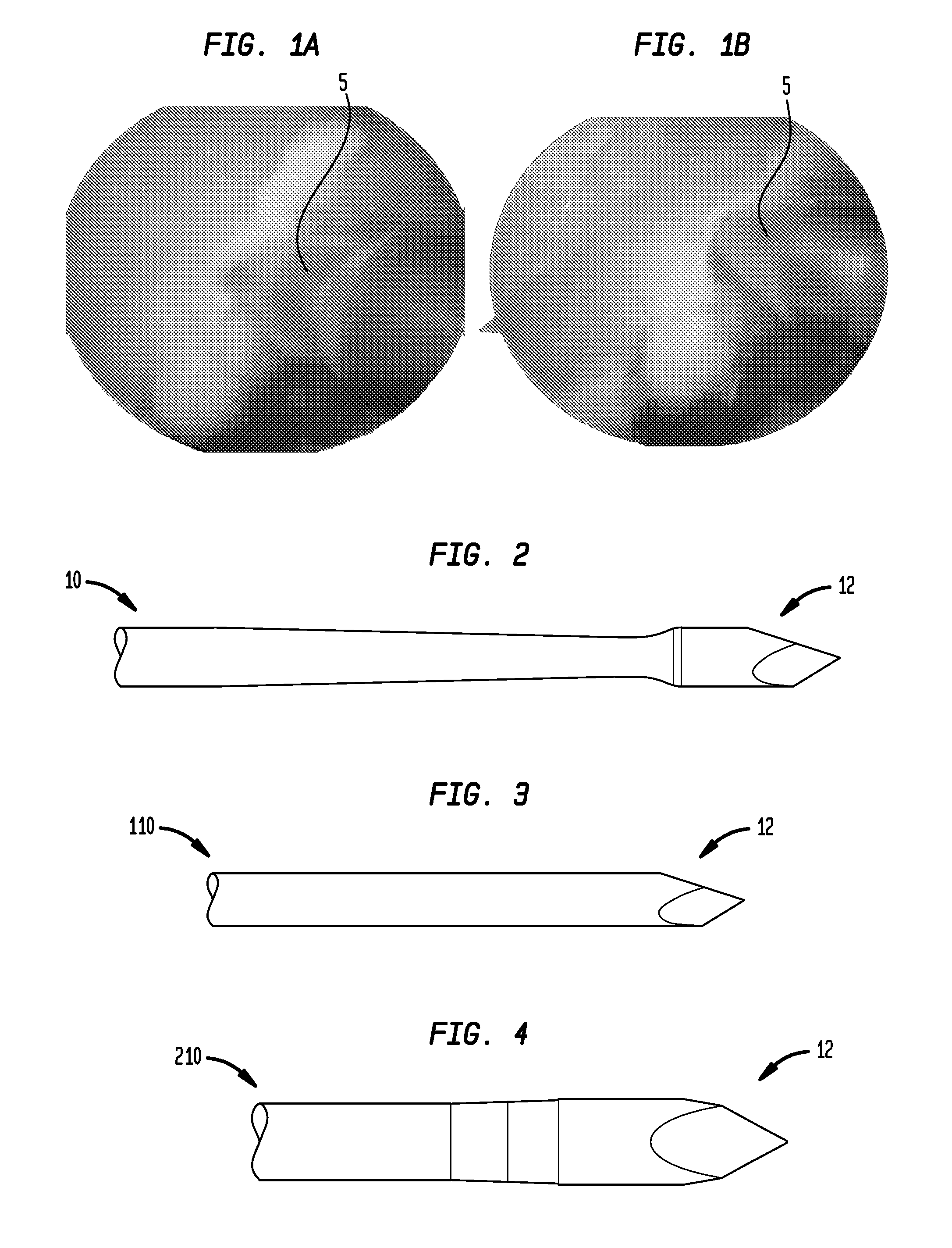

Articular cartilage repair implant delivery device and method of use

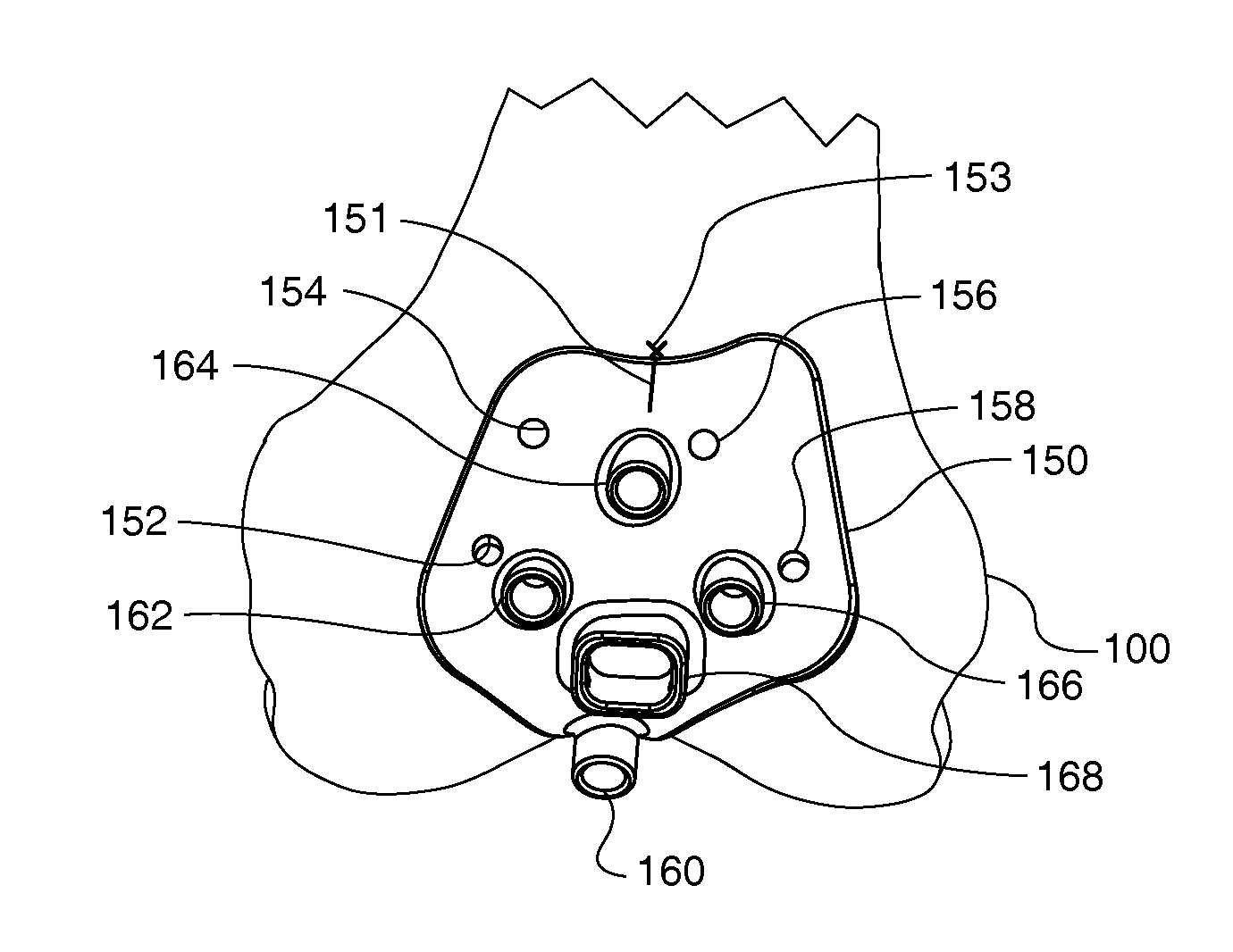

A technique for the arthroscopic delivery and fixation of an articular cartilage repair device or implant is provided. The technique includes the use of a cannula tube that functions as both a cartilage cutter and a guide to pass instruments into the body arthroscopically. One such instrument is an end-cutting reamer that both prepares the subchondral bone by re-surfacing it down to a specified depth and also simultaneously drills a pilot hole in the subchondral bone to accept the cartilage repair device. A delivery device is utilized to hold and deliver the cartilage repair device to the delivery site.

Owner:DEPUY PROD INC

Tools for performing less invasive orthopedic joint procedures

A tool set for preparing a joint, inserting an implant or removing an implant from a joint in an open or less invasive procedure generally comprises a set of nested tools, pin guides, jigs, and / or immobilization elements. The nested tool set comprises at least one pin and at least one cannulated tool. In some embodiments, the cannula can comprise tangs that project from the distal end of the cannula. The tangs can be offset such that drilling would remove different amounts of bone relative to drilling through a centered drill guide. The cannulated tool kit generally can comprise at least one tool guide / cannula, drill bits / reamer, syringe, and / or inserter. With the pin positioned into the joint, at least one cannula is positioned over and around the pin. The channel of the cannula guides the other tools into the joint. A plurality of cannulae in a nested arrangement can be used to afford selectively sized channels for tools and / or implants based on selected cannulae configuration. Jigs can be used to facilitate the procedure. Multiple implants can be placed to immobilize the joint.

Owner:ILION MEDICAL

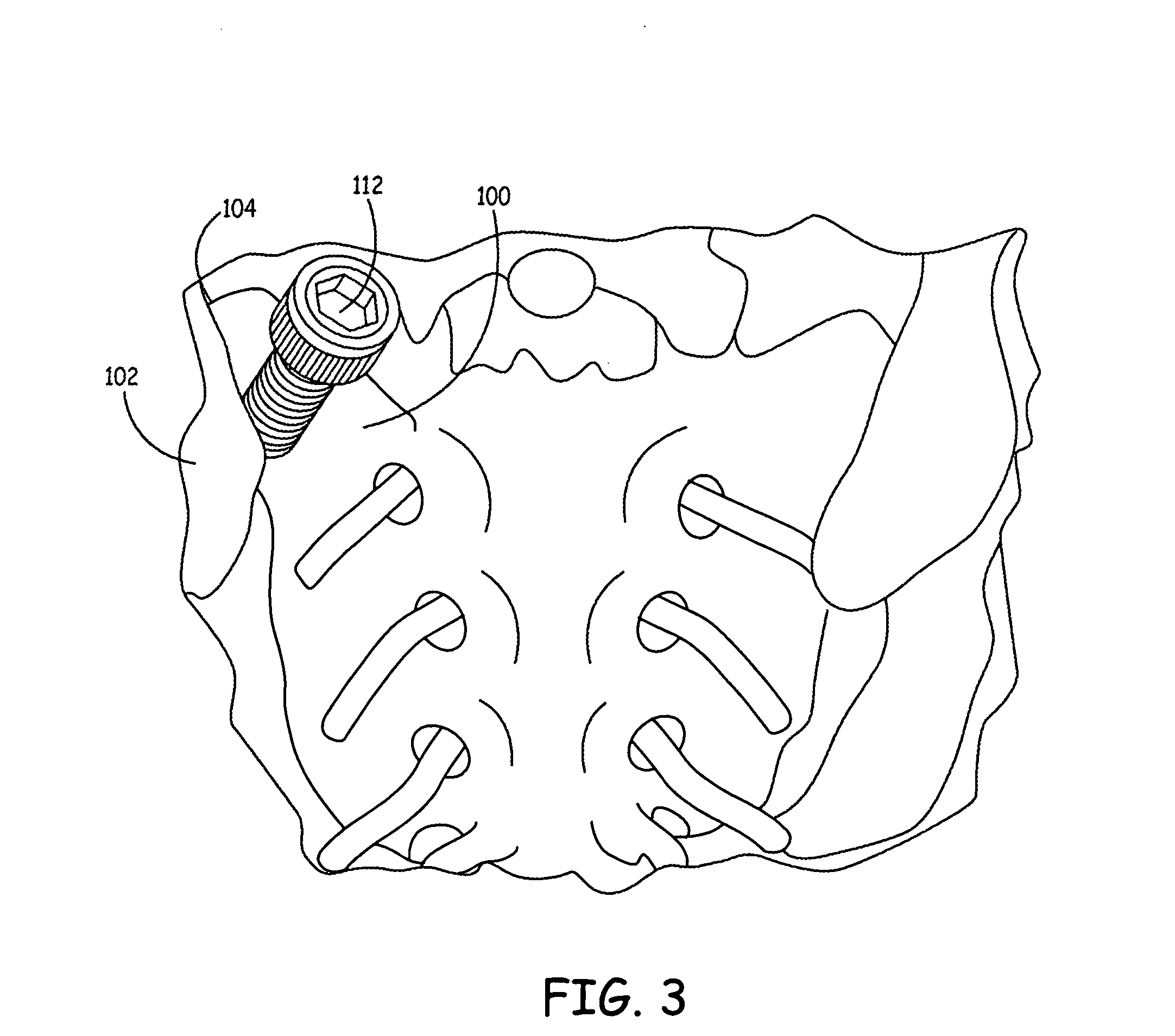

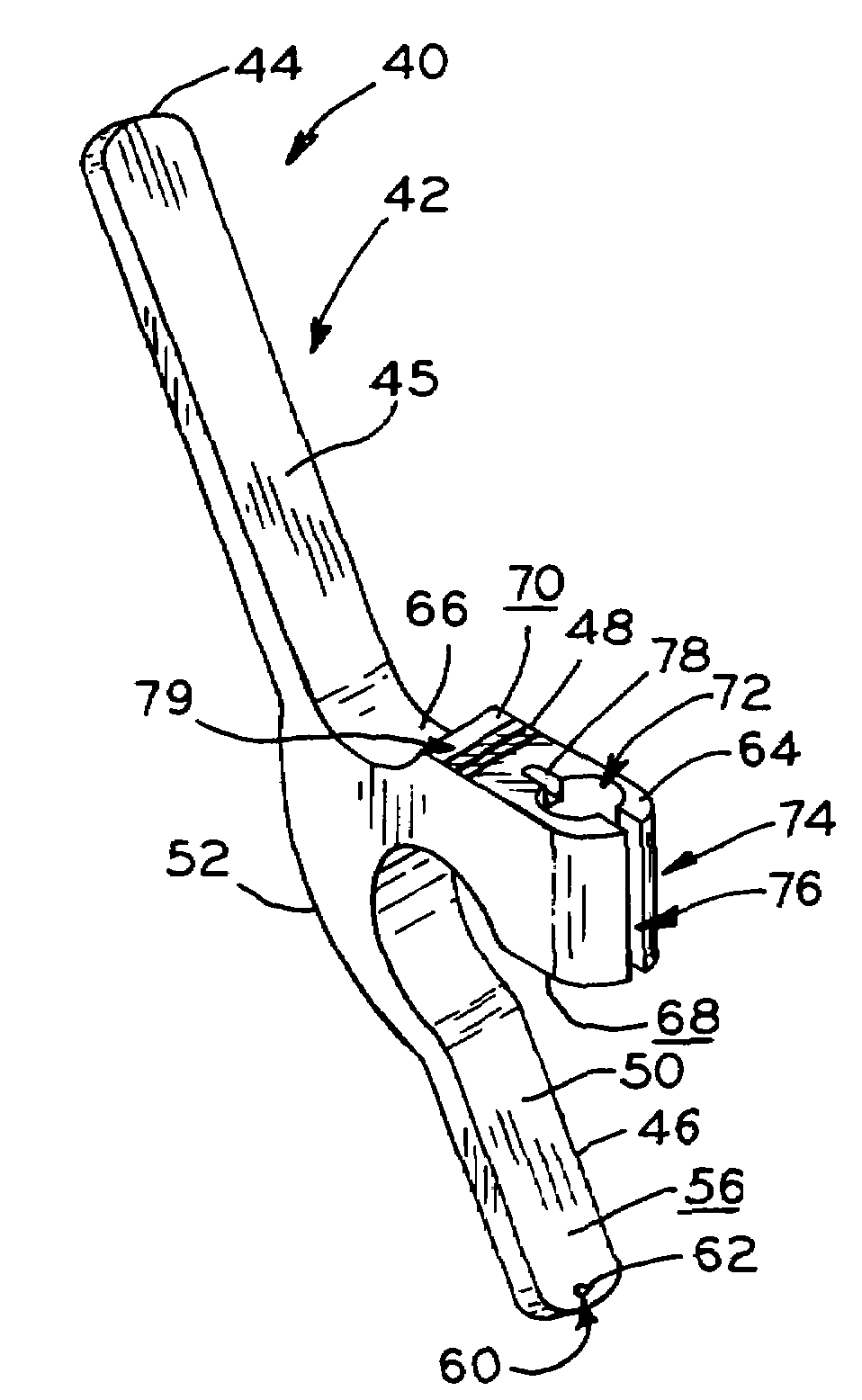

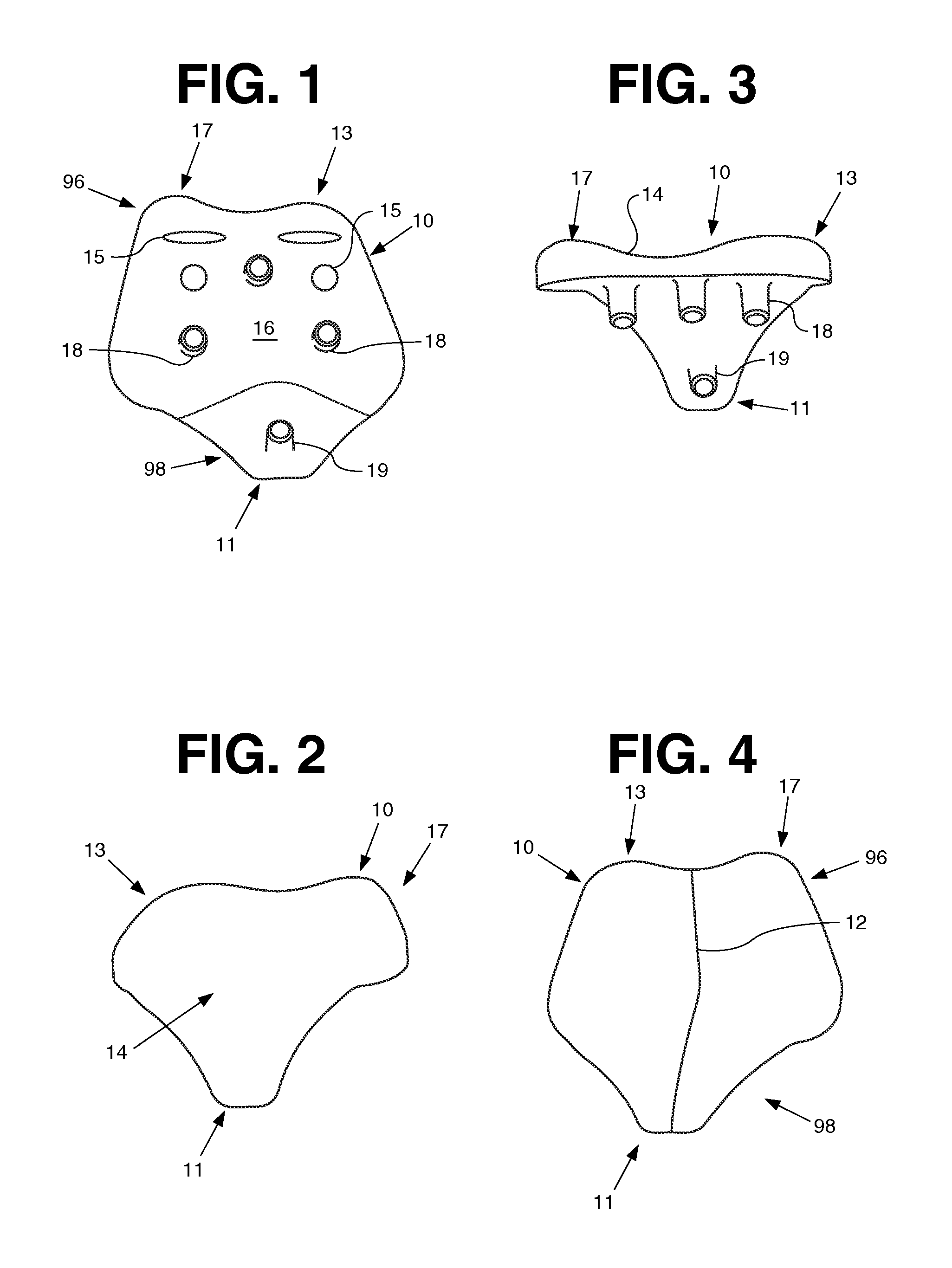

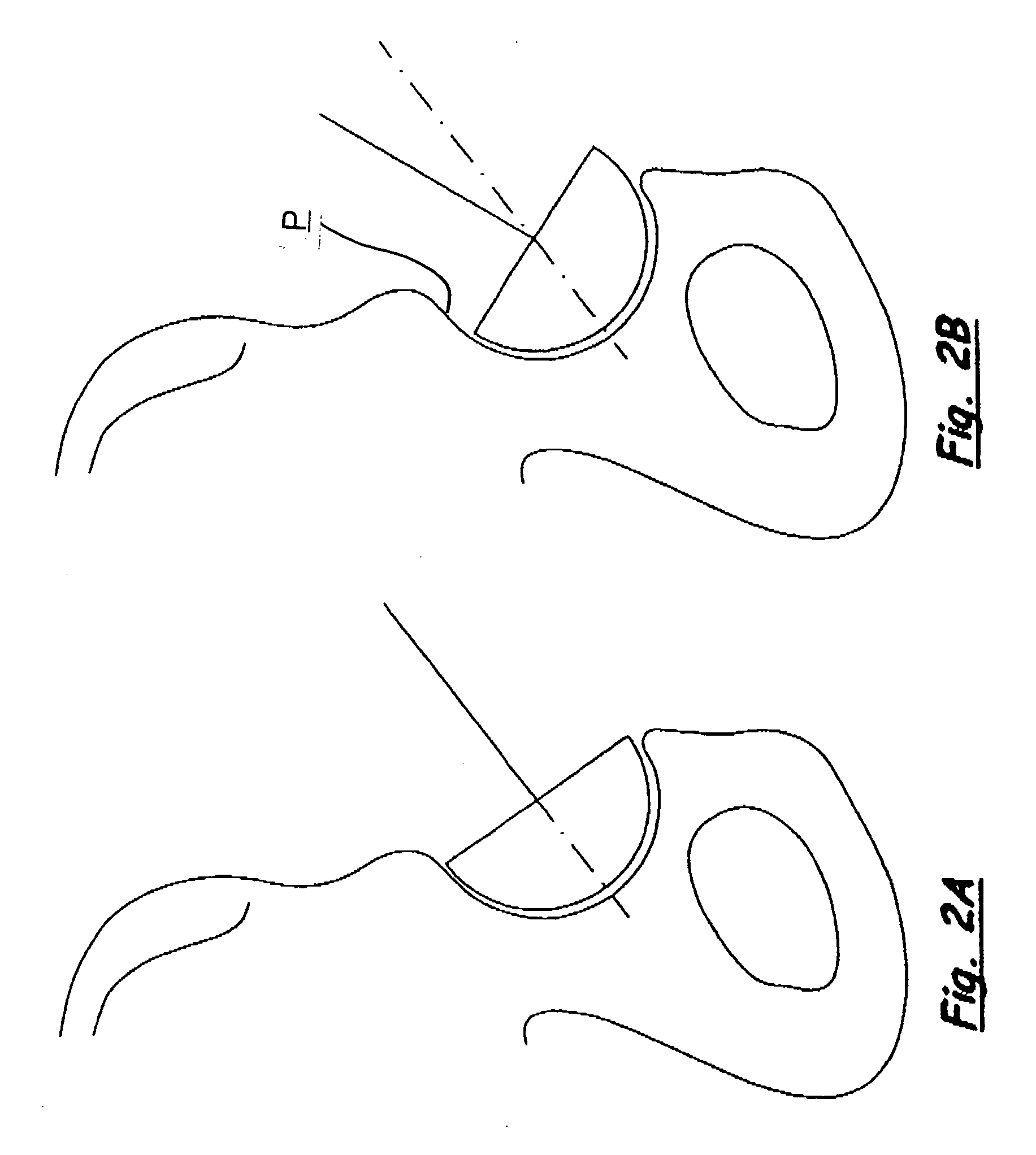

Method and apparatus for preparing a glenoid surface

ActiveUS7294133B2Easy to implantEasy to installProsthesisOsteosynthesis devicesAnterior surfaceProsthesis

A method and apparatus for facilitating shoulder arthroplasty by providing a reference to establish version of the glenoid. In one form of the invention, a guide for positioning a guide pin to facilitate implantation of a glenoid prosthesis is provided. To properly position the guide pin, the guide is first oriented with respect to the scapula. A portion of the guide is positioned over the approximate center of the glenoid surface and another portion of the guide is positioned against the anterior surface of the scapula. After the guide is properly positioned, the guide pin is inserted through an aperture in the guide and anchored in the glenoid. Thereafter, the guide pin can serve as an alignment guide for other devices used to modify the glenoid surface. For example, a reamer having a cannulated central shaft can be placed over the guide pin and utilized to resurface the glenoid.

Owner:ZIMMER INC

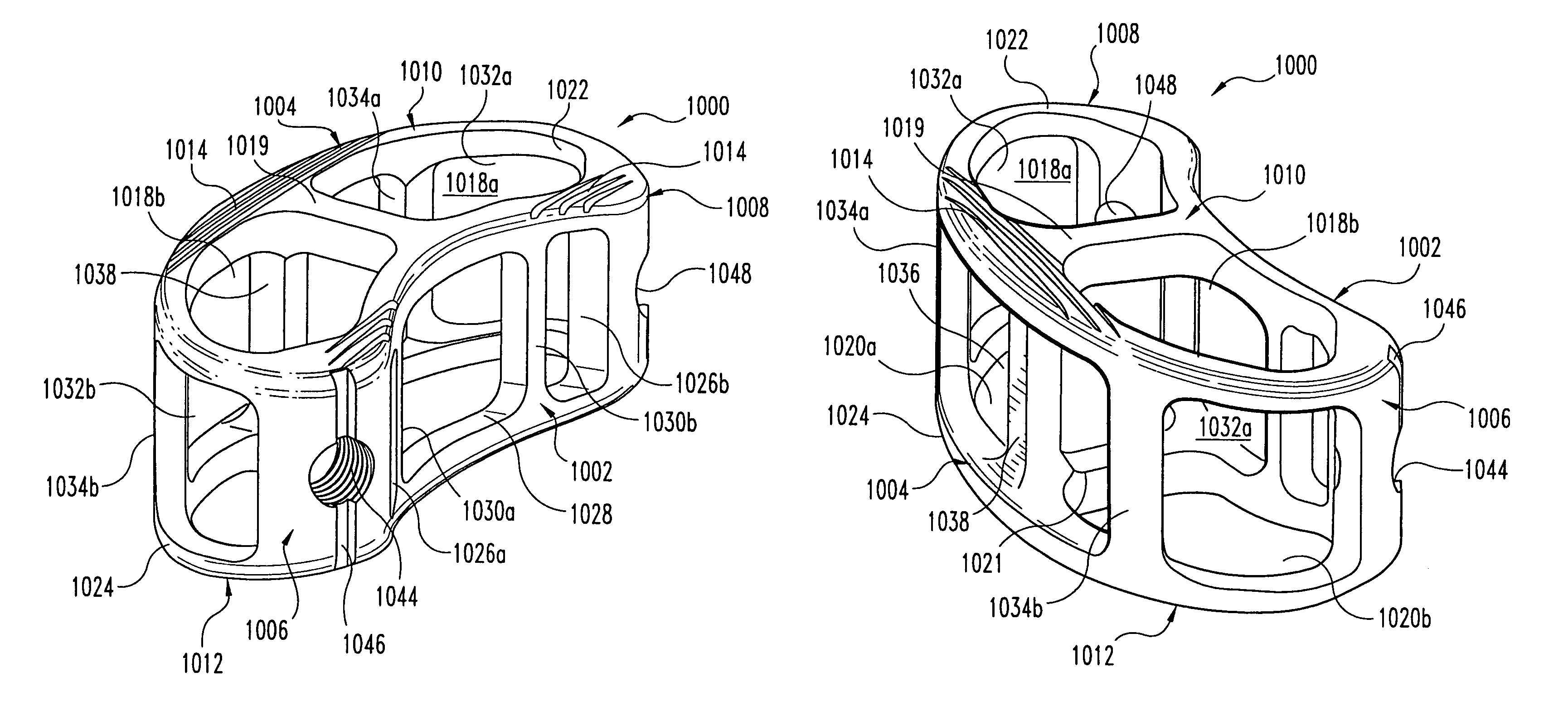

Expandable reamer

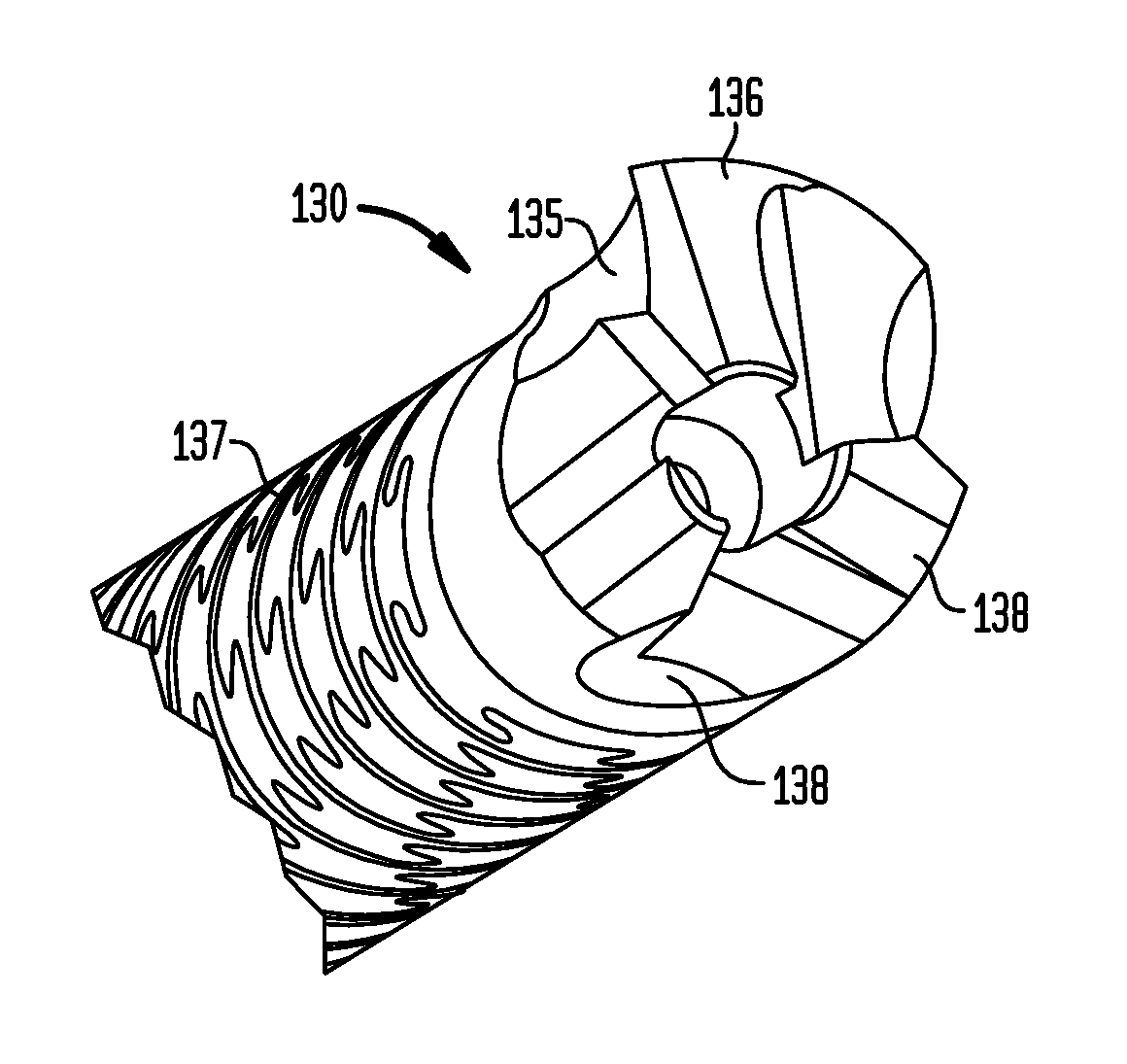

An expandable reamer includes, in one exemplary embodiment thereof, a cannulated shaft and a plurality of straight cutting blades having deformable points. The blades are hingably outwardly rotatable at the deformation points between a contracted position and an expanded position. In the contracted position, the blades are substantially parallel to the longitudinal axis of the cannulated shaft and, in the expanded position, the blades have at least a portion oriented radially outward from the longitudinal axis, thereby forming a larger diameter cutting surface in the expanded position and in the contracted position. The blades are formed from a portion of the cannulated shaft by, e.g. milling longitudinally extending slots through the wall of the cannulated shaft, the slots serving as flutes dividing the cutting edge and trailing edge of each adjacent blade. Each blade may also include more than one segment arranged along its length, the segments coupled by deformation points. The expandable reamer may be used for cutting a cavity in a bone or other structure that is larger than the diameter of the entry point into the bone and greater than the diameter of the contracted reamer.

Owner:ZIMMER TECH INC

Patello-femoral joint implant and instrumentation

A system for preparing a trochlear region of a resected femur is disclosed. The system includes a reamer guide and a reamer. The reamer guide has a first arcuate portion, a second arcuate portion, a wall, a protrusion connected to the wall, a leg connected to one of the first or second arcuate portion, and a distal tip portion connected to the leg. The reamer is adapted to rotatably connect to the distal tip portion, and the reamer has a first end portion, a second end portion, and one or more flutes.

Owner:SMITH & NEPHEW INC

Expandable reaming device

InactiveUS20060276797A1Increase the effective diameterGood flexibilitySurgerySurgical drillProsthesis

An expanding reamer for reaming or cutting a concave surface, for example, for reaming an acetabulum in preparation for implanting a prosthetic component, such as an acetabular cup or socket, during a hip arthroplasty. The reamer includes a rotating shaft cooperating with a surgical drill or other power source at one end and rotating a reamer head at the other end, and a system adapted to expand one or more blades on the reamer head. In a preferred version, the reamer head comprises a plurality of generally circular, preferably substantially flat and parallel blades, the outer blades of which are radially expandable as segments of a cutting sphere to enlarge the effective diameter of the reamer head. A transverse blade may guide expansion of the blades to move upwards as well as outward to maintain a nearly perfect cutting sphere across a range of diameters. Upon rotation of the reamer head, the blades form a portion of an effective cutting sphere that is preferably greater-than-180-degrees in order to allow greater flexibility in placement of the shaft of the reamer relative to the surface being reamed, for example, relative to the center of axis of the acetabulum.

Owner:BOTIMER GARY

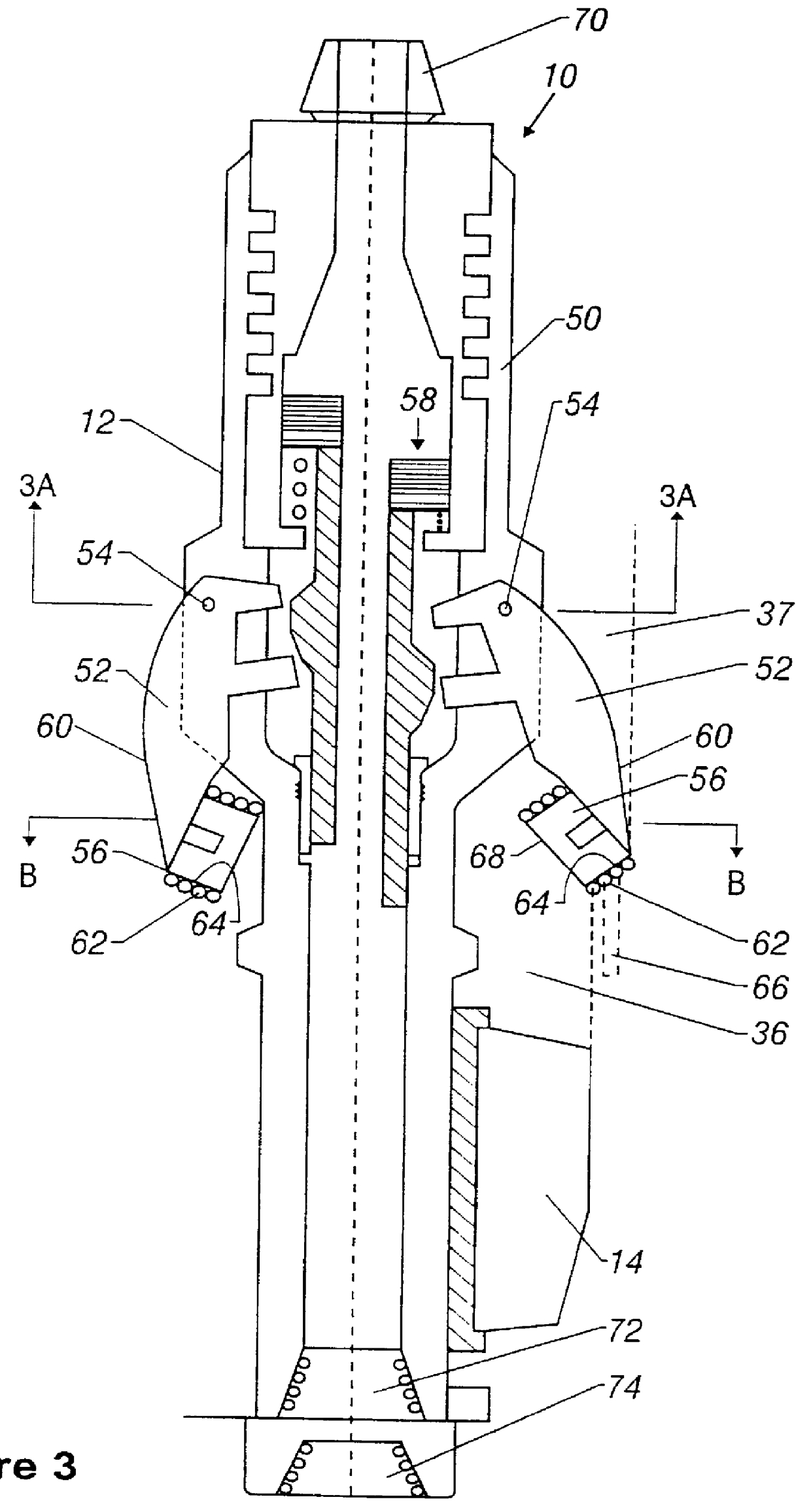

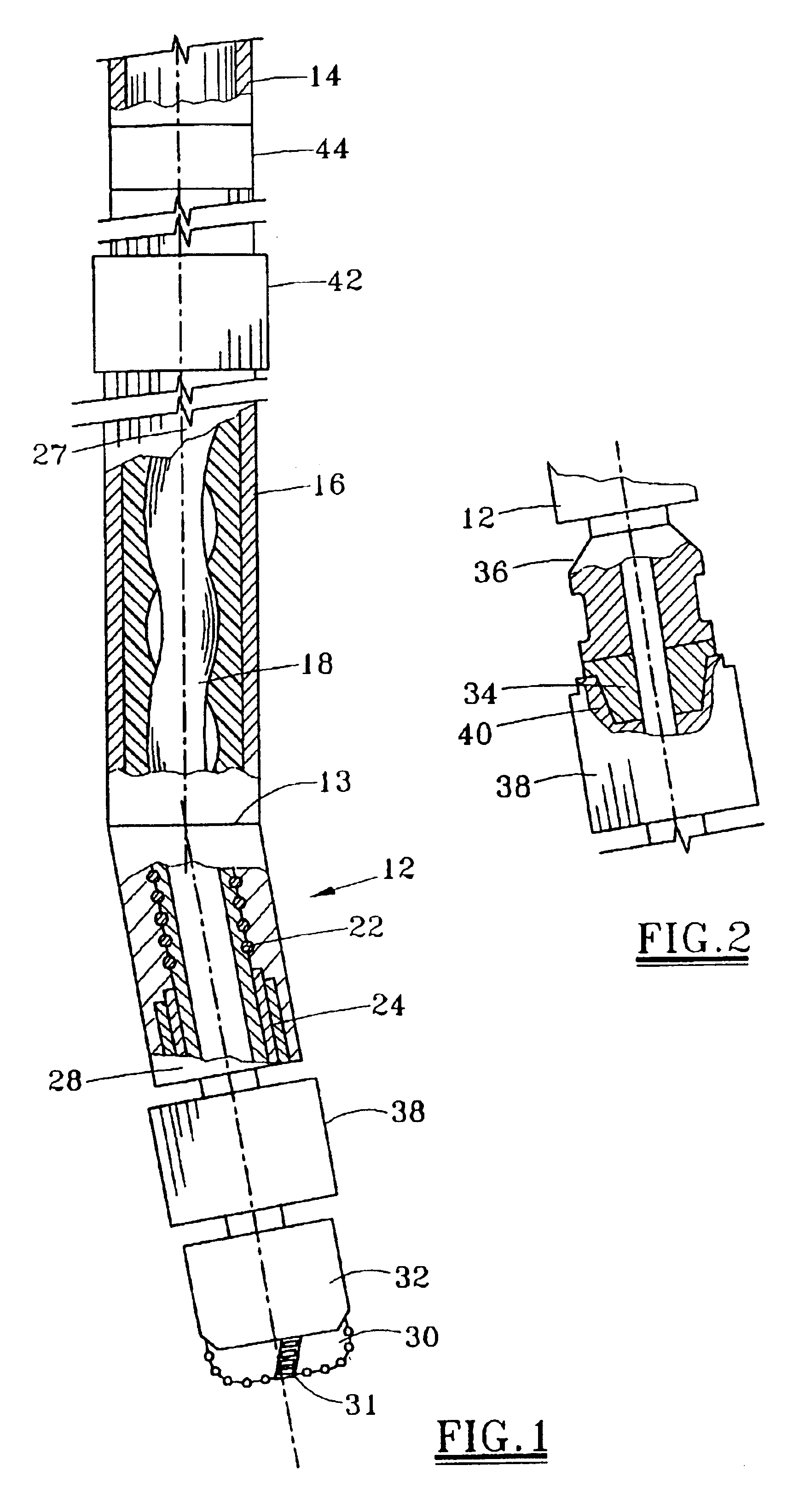

Integrated directional under-reamer and stabilizer

The present invention is an apparatus for use in drilling operations. It uses an under-reamer having a plurality of elongated arms with cutting elements at the ends of the arms for enlarging a previously drilled borehole drilled by a drill bit. One or more stabilizers in close proximity to the under-reamer provide stability to the under-reamer and the drill bit. The stabilizer could be rotating or non-rotating; and could be positioned between the under-reamer and the drill bit, or above the under reamer or above a directional device on the drillstring. The cutting arms are selectively operable to perform the enlargement. The stabilizer may be provided with members that closely fit the size of the borehole.

Owner:BAKER HUGHES INC

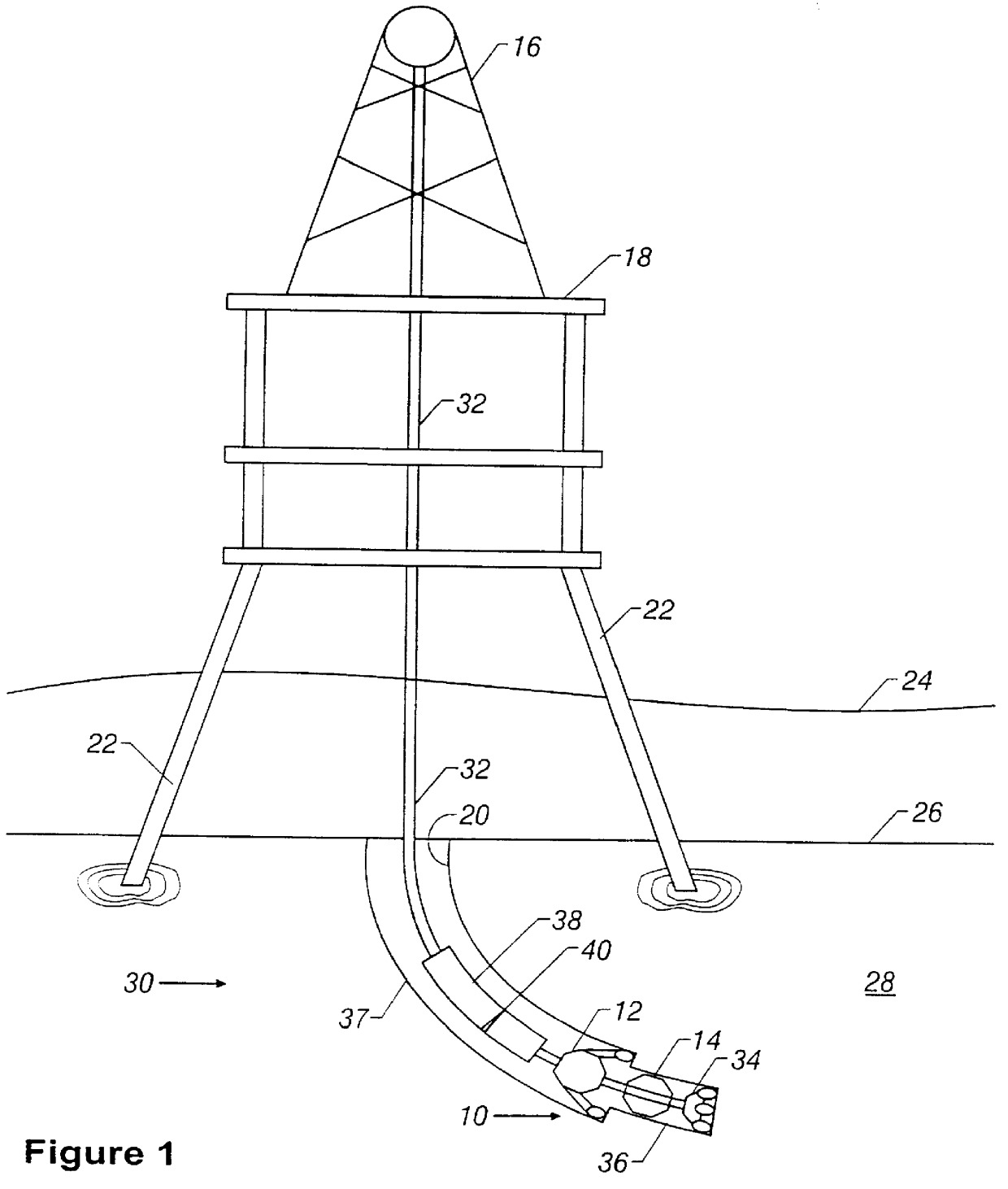

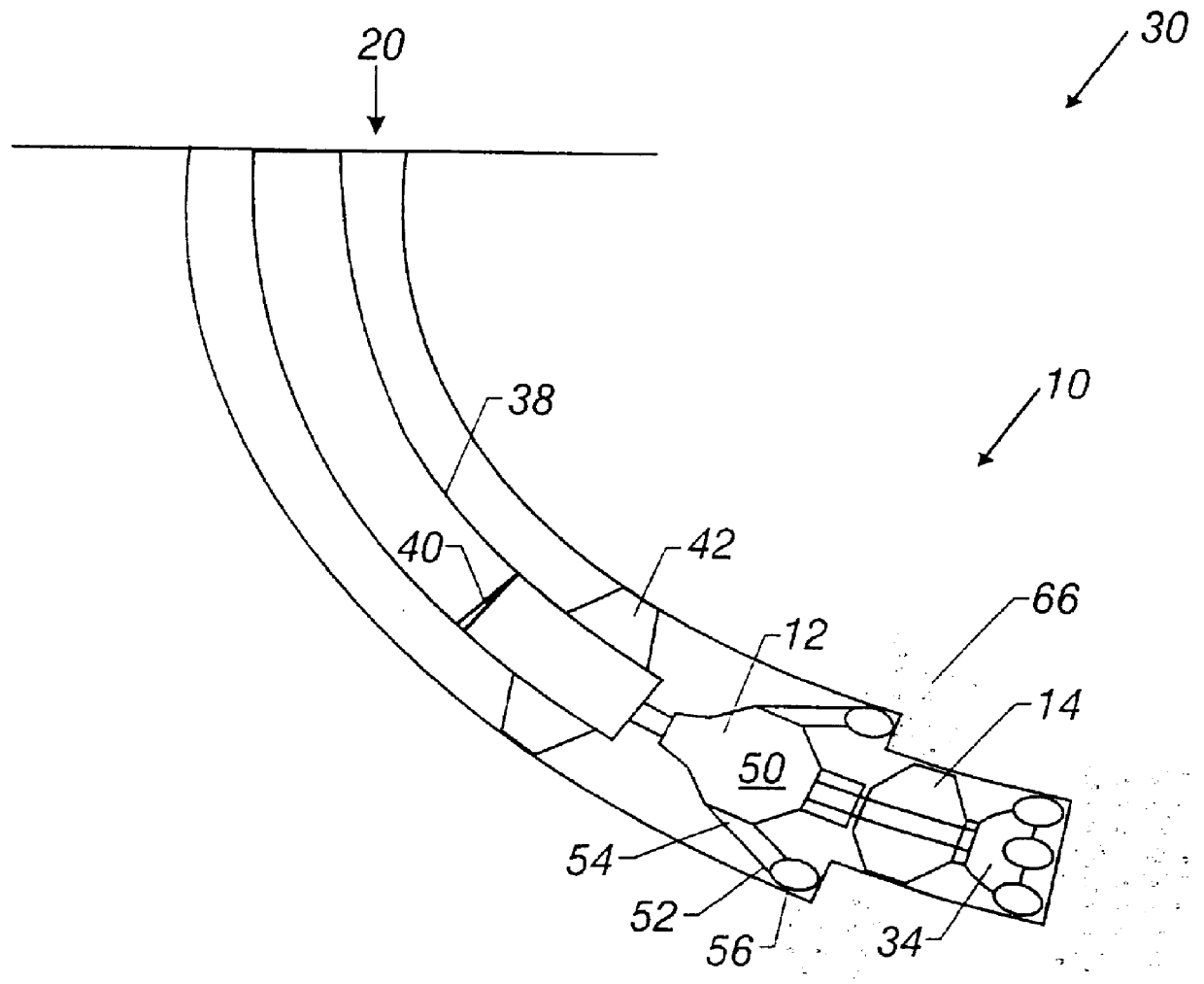

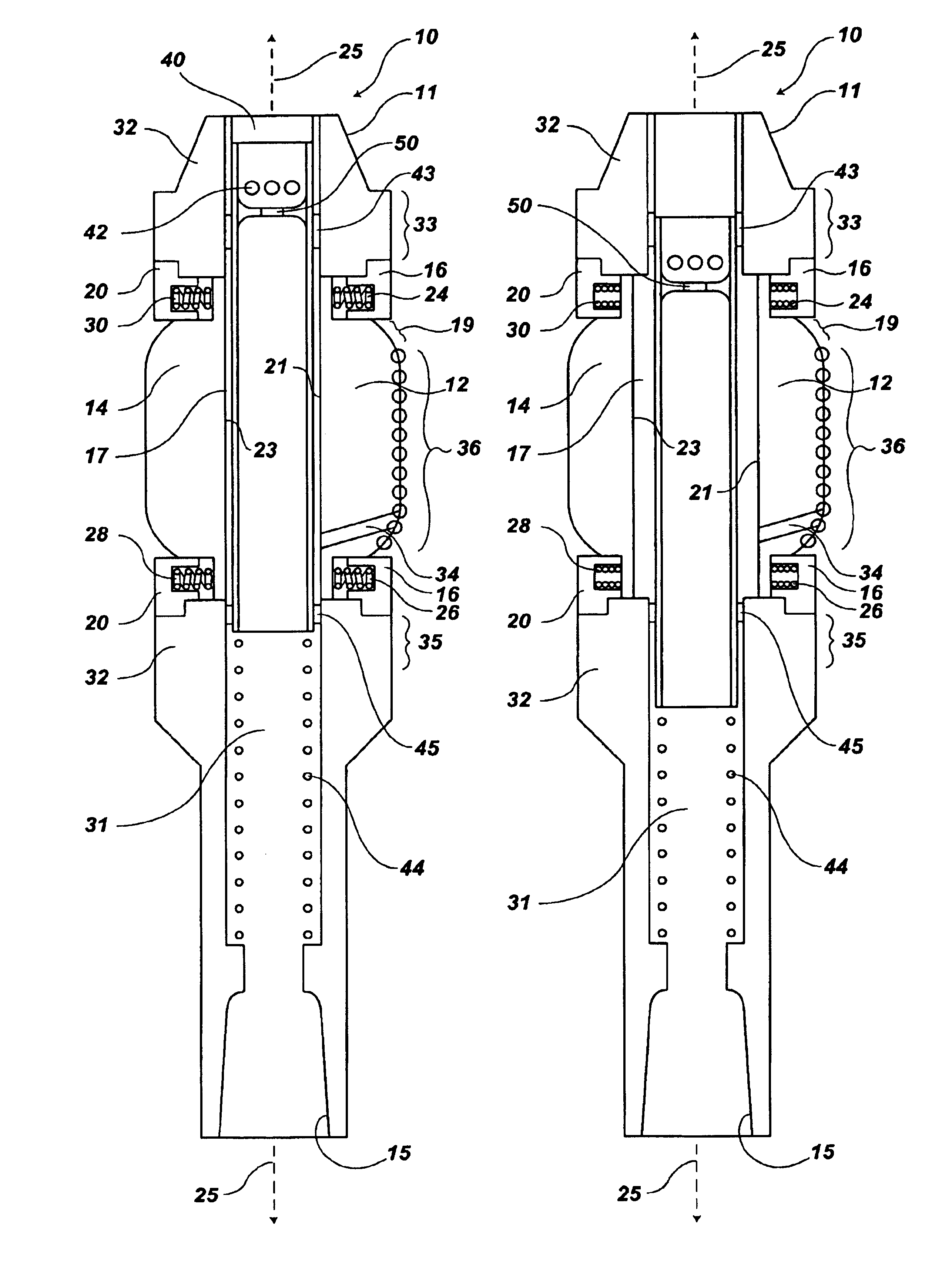

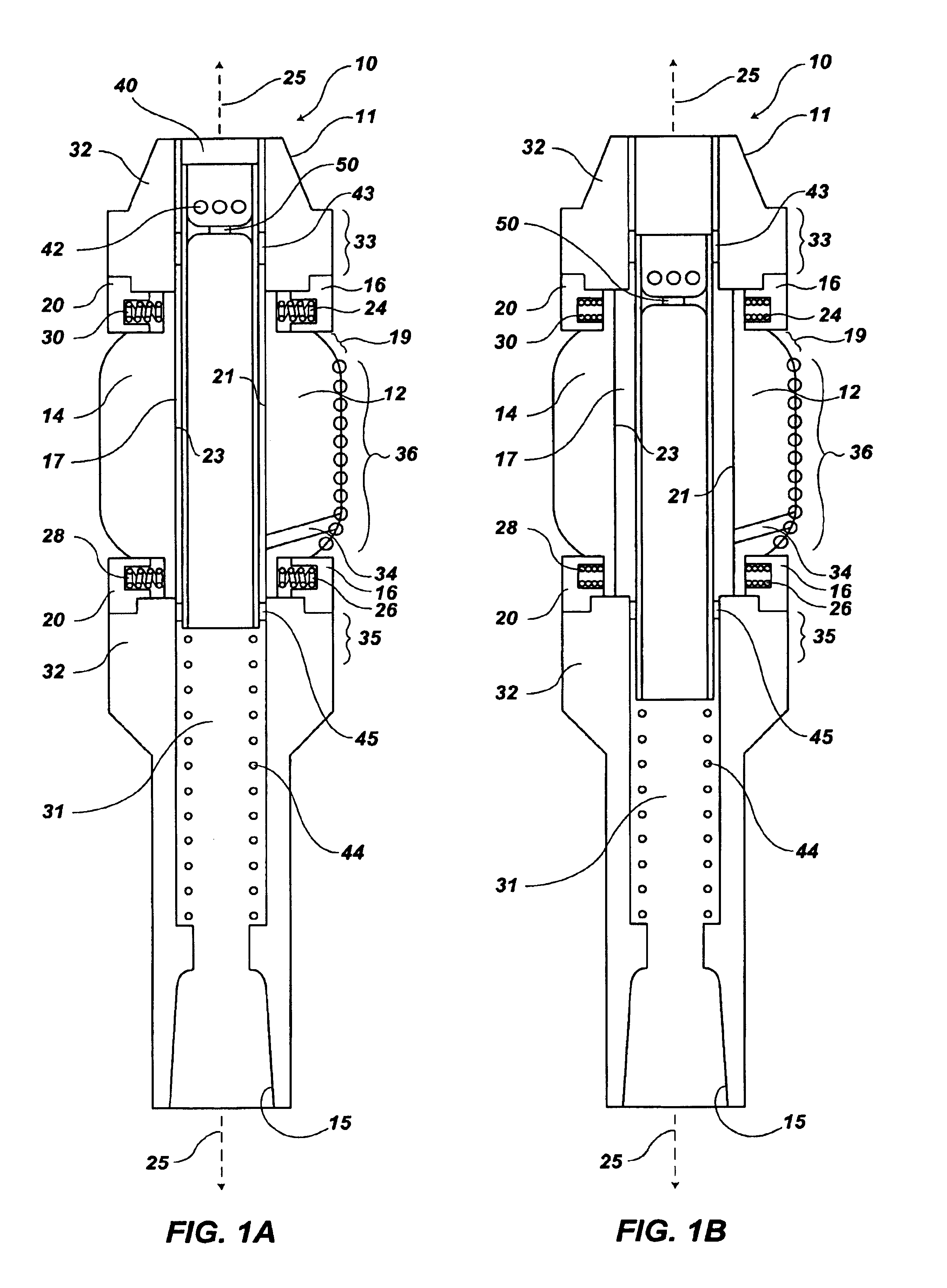

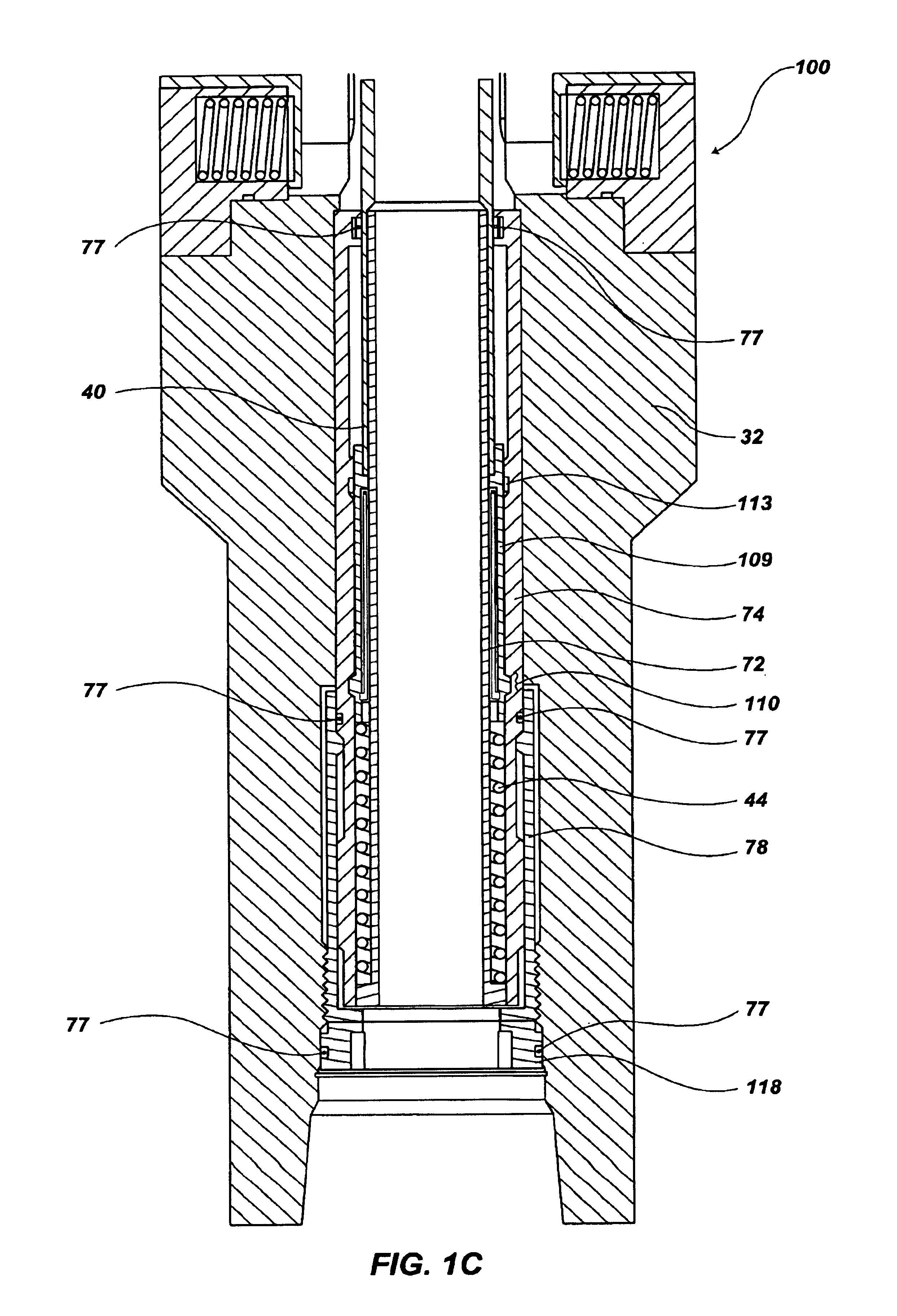

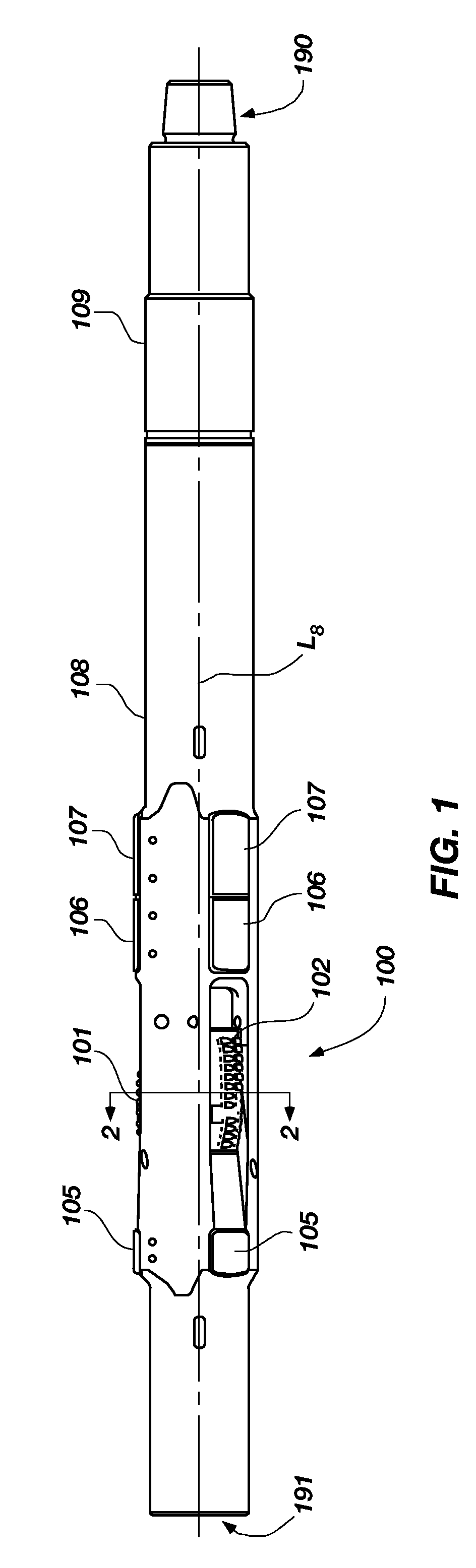

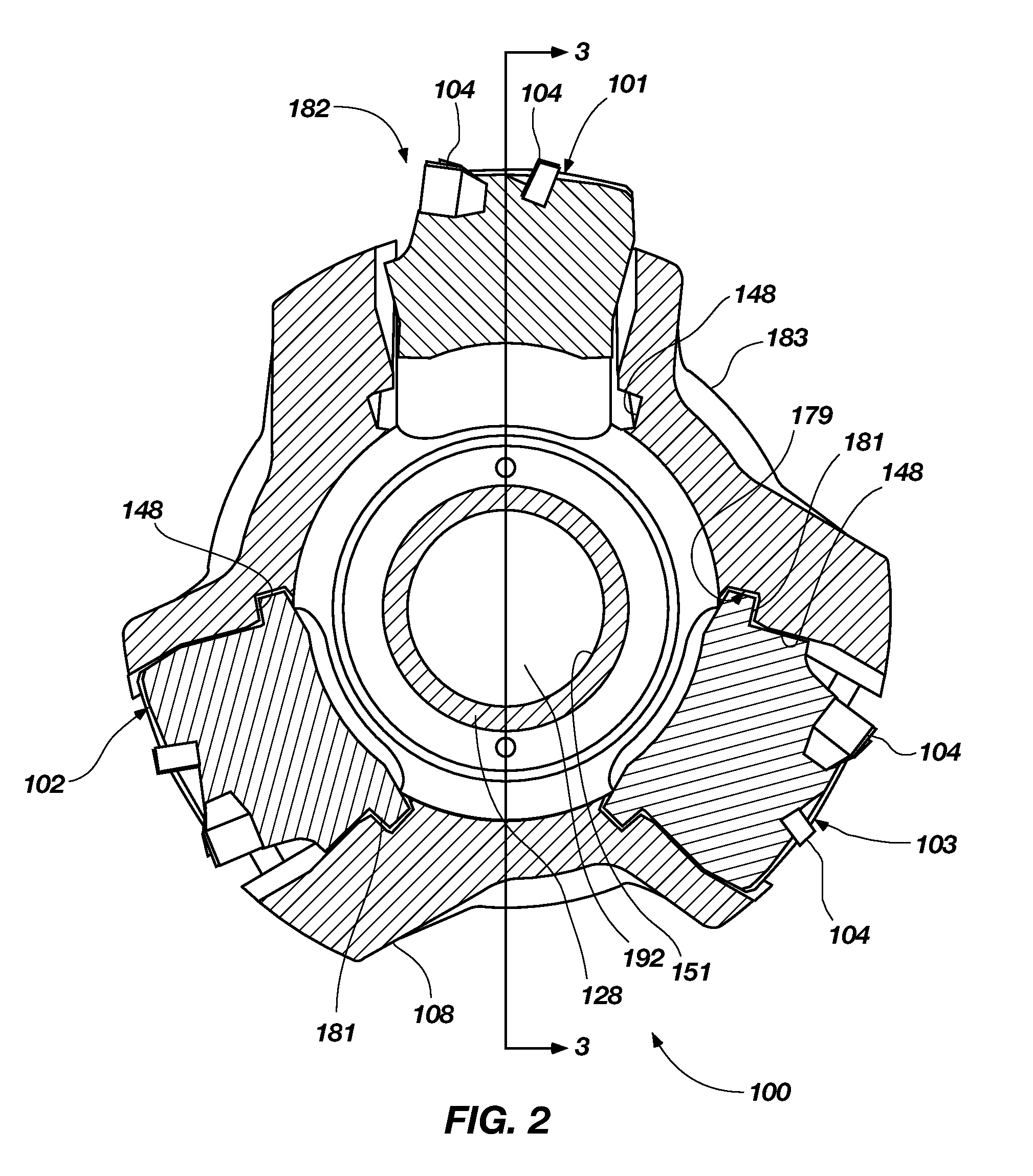

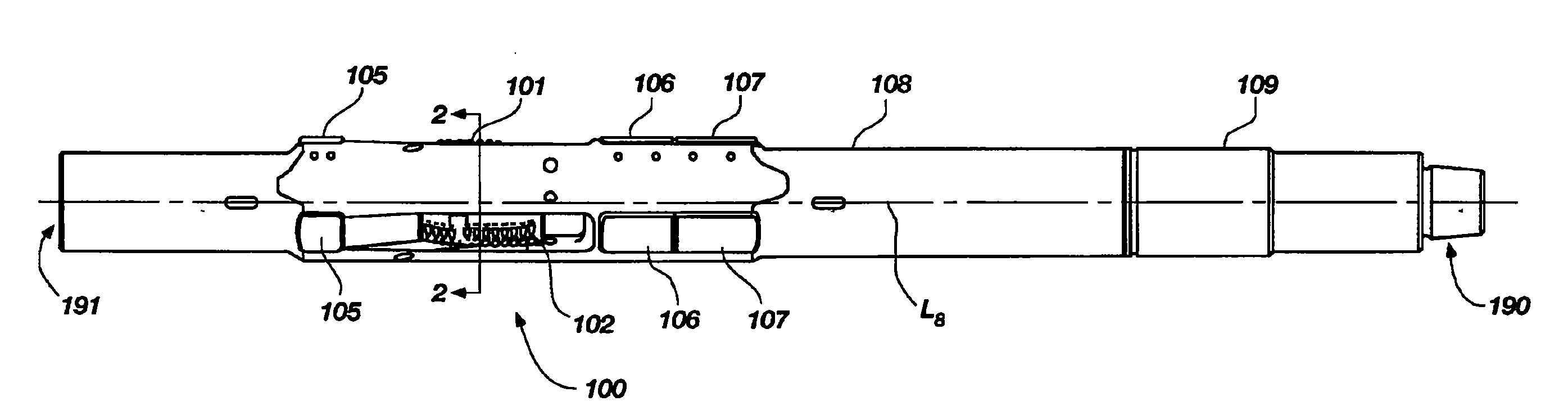

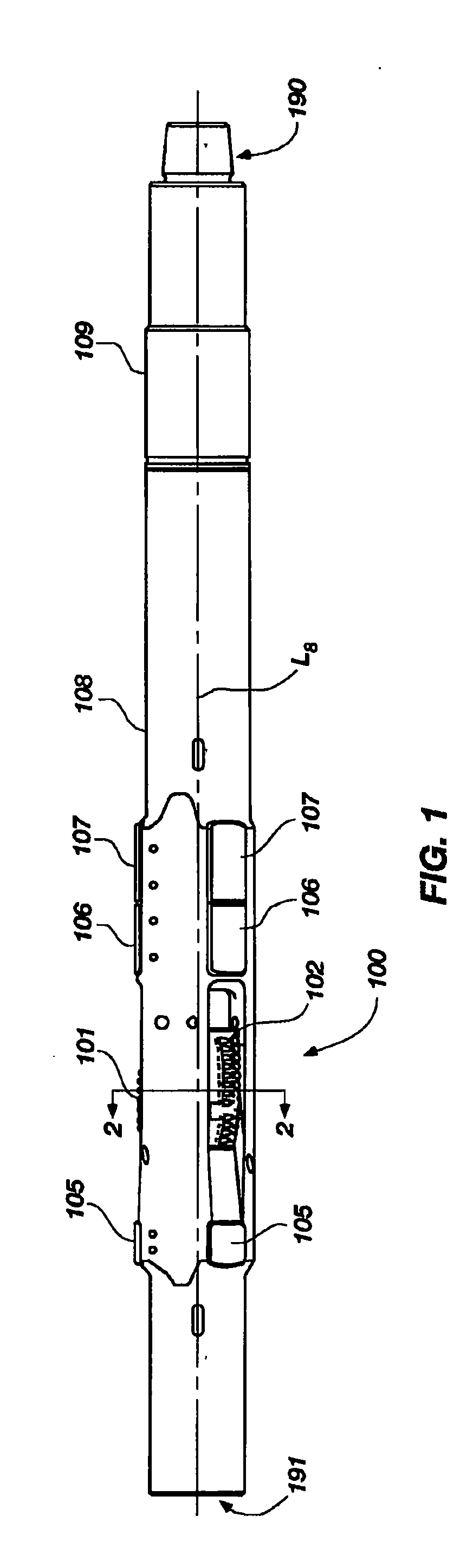

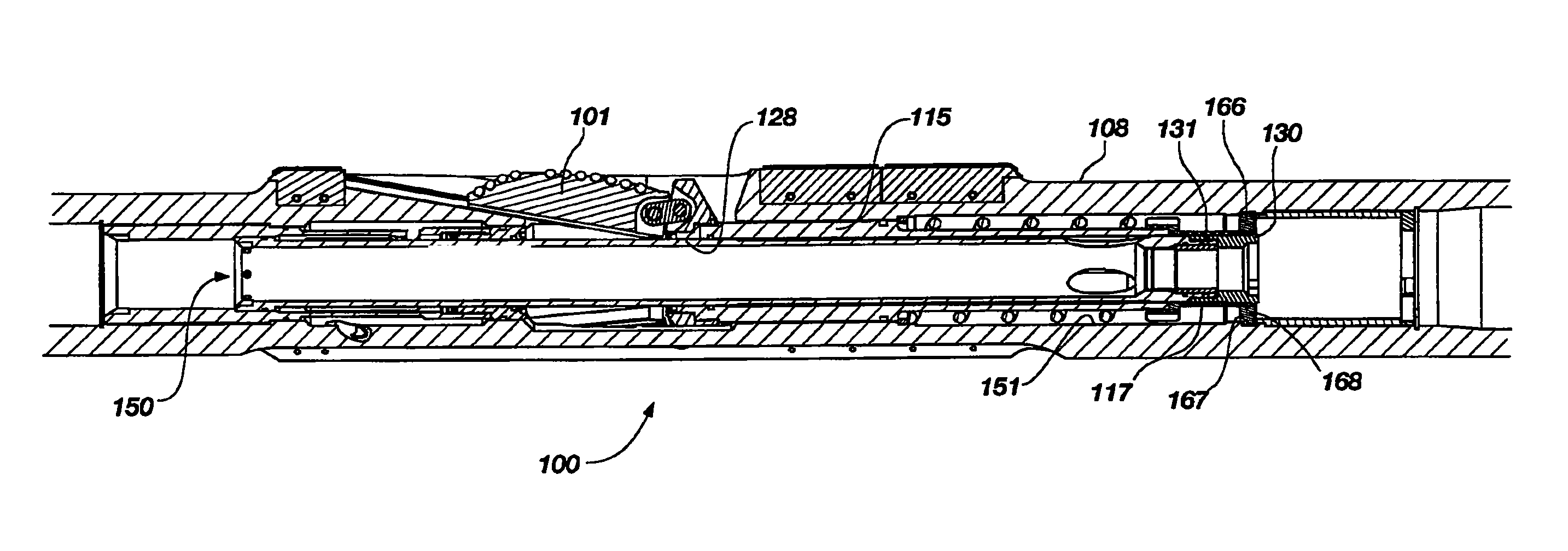

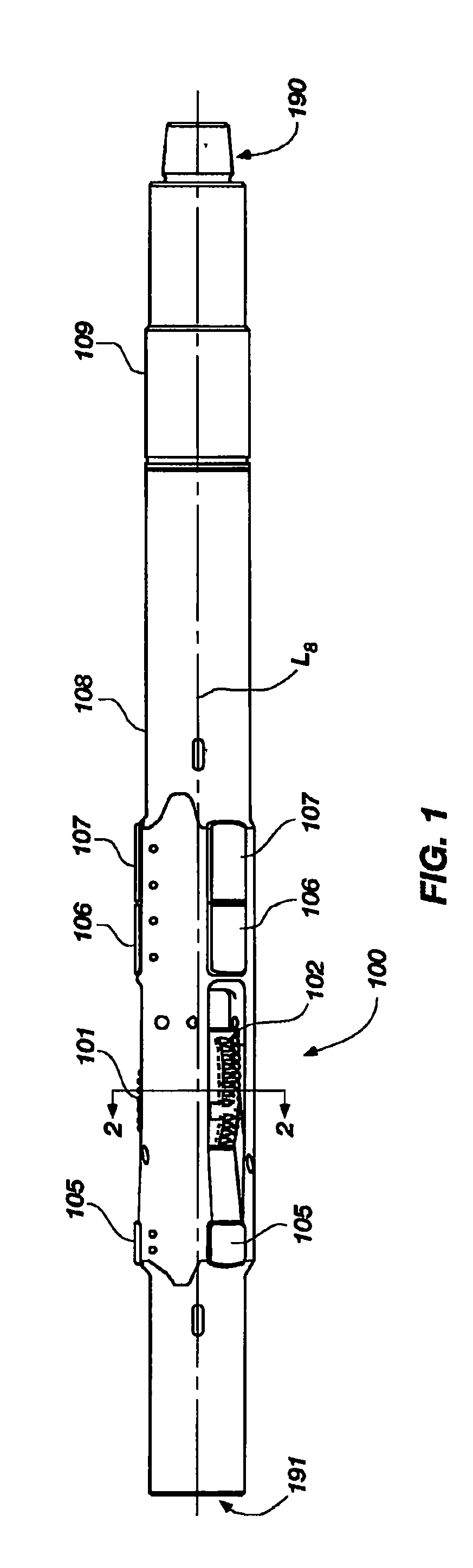

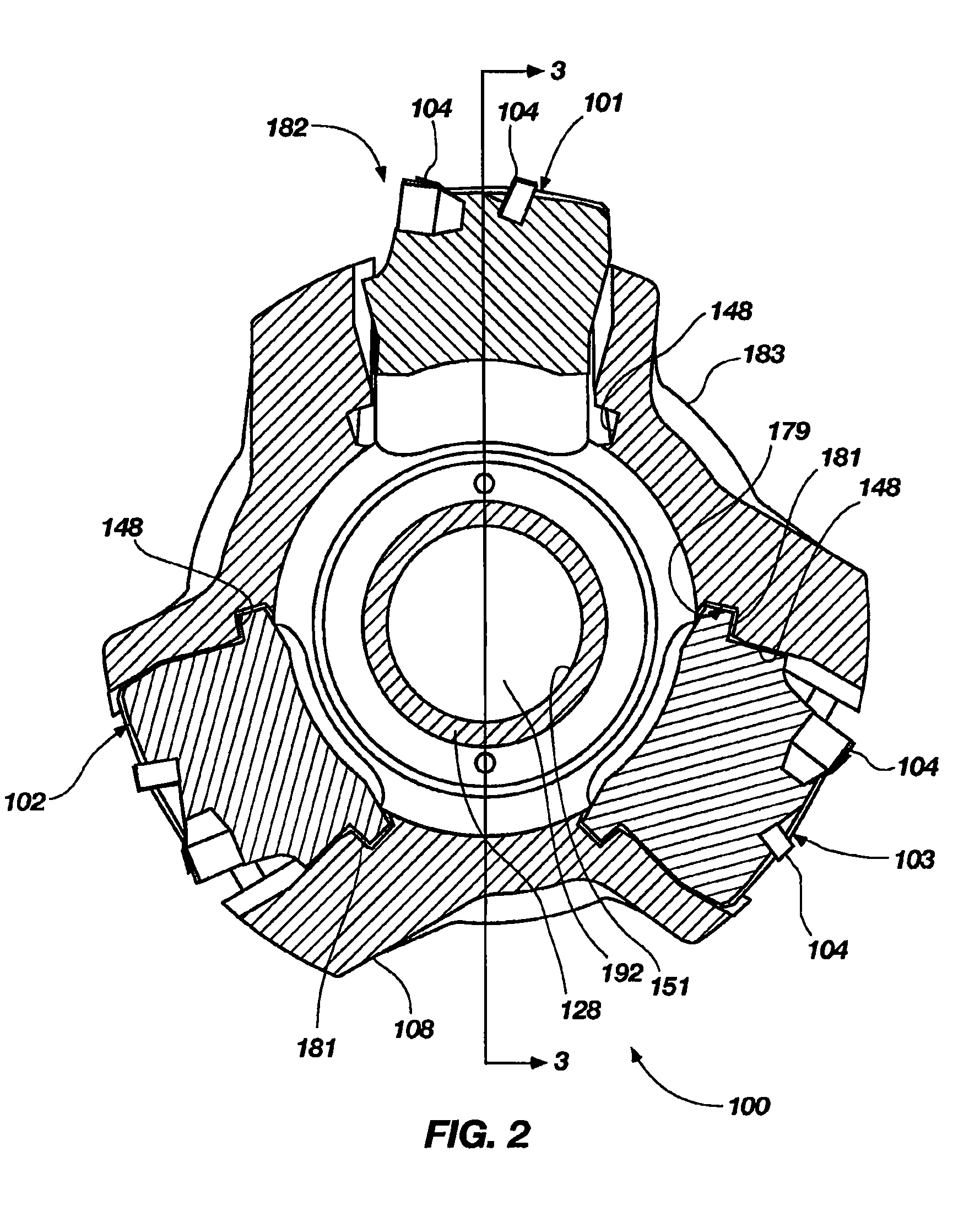

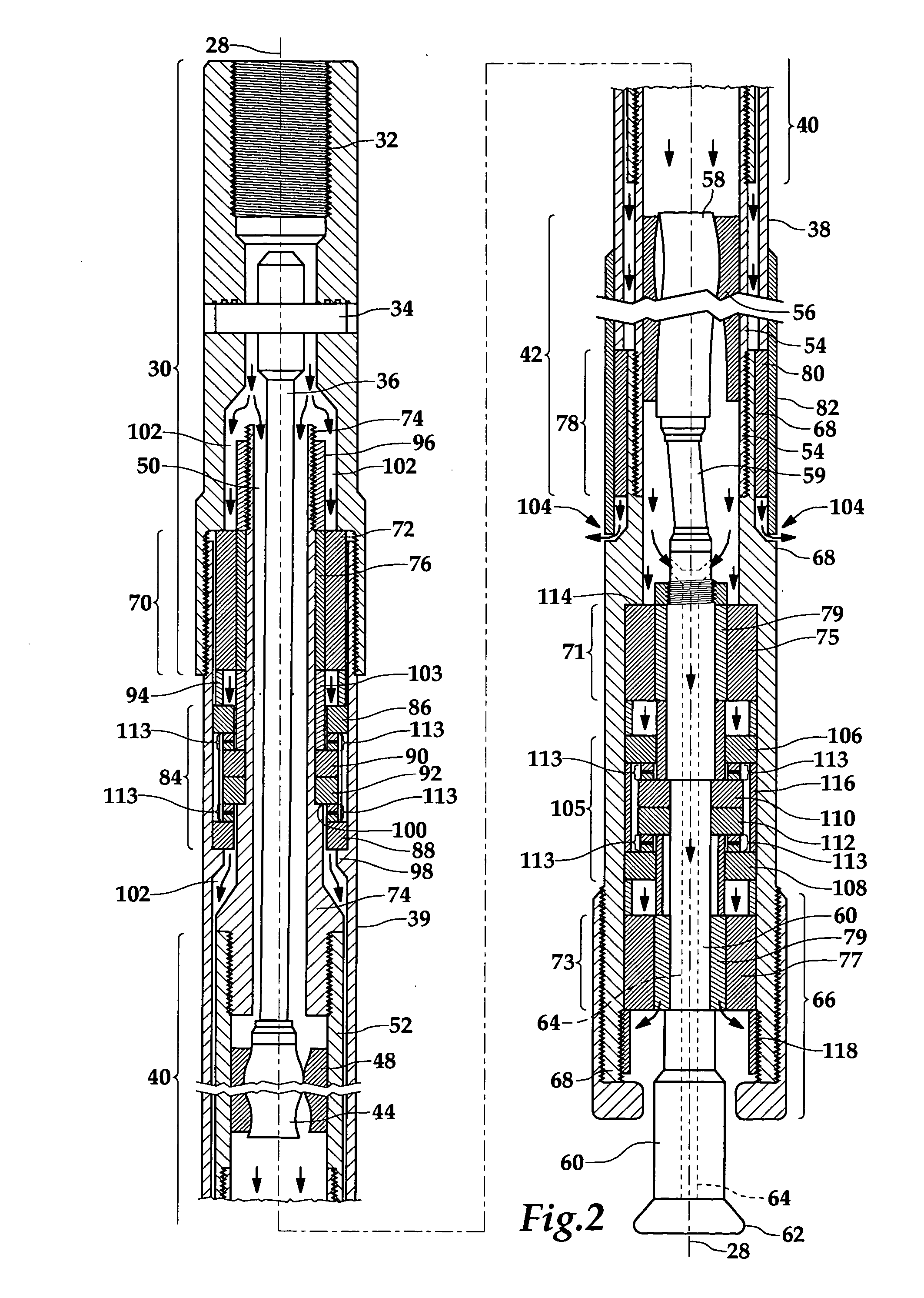

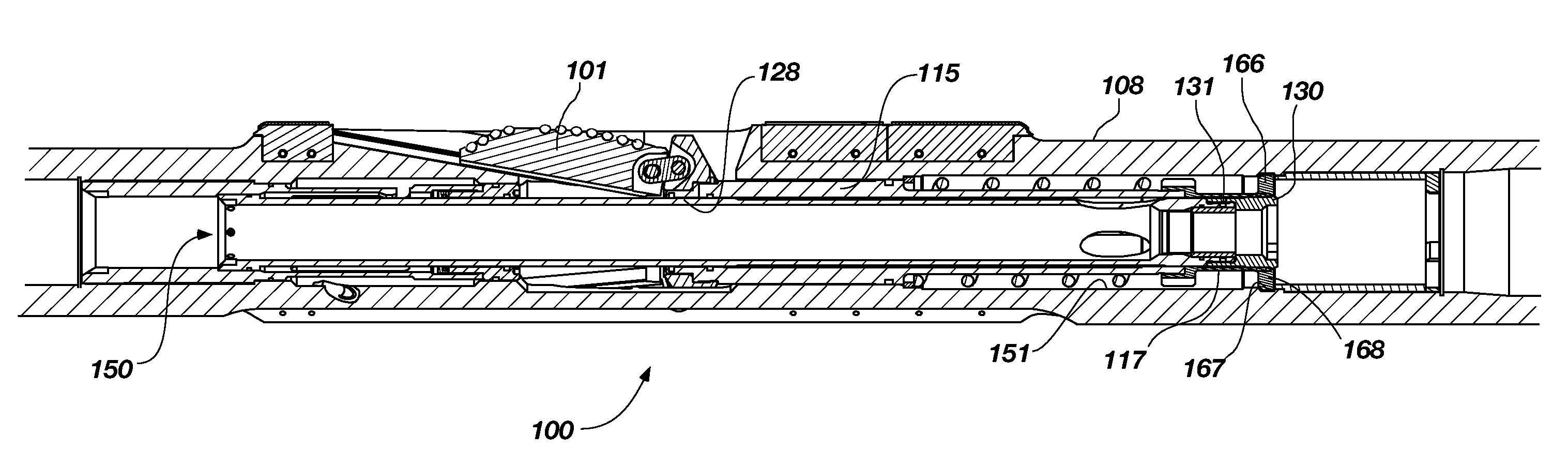

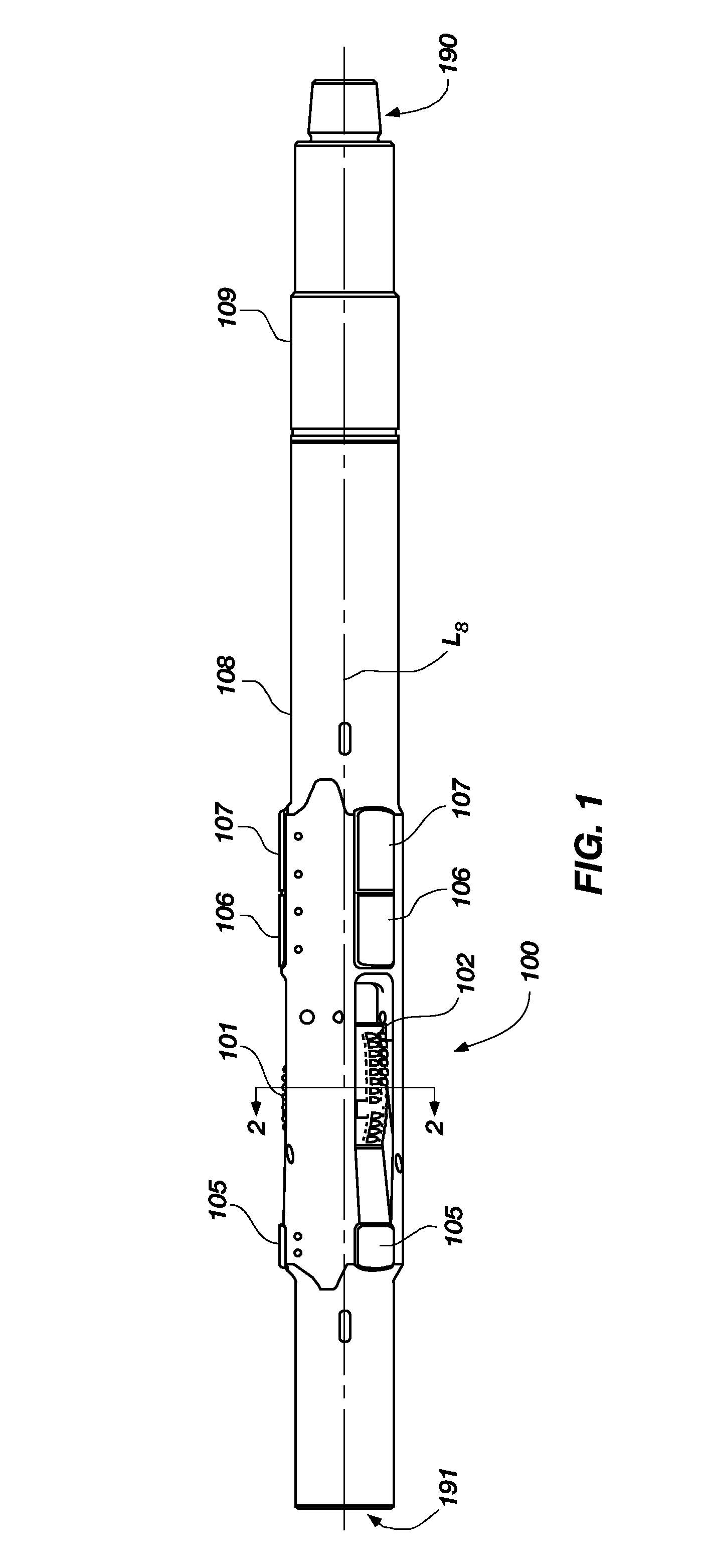

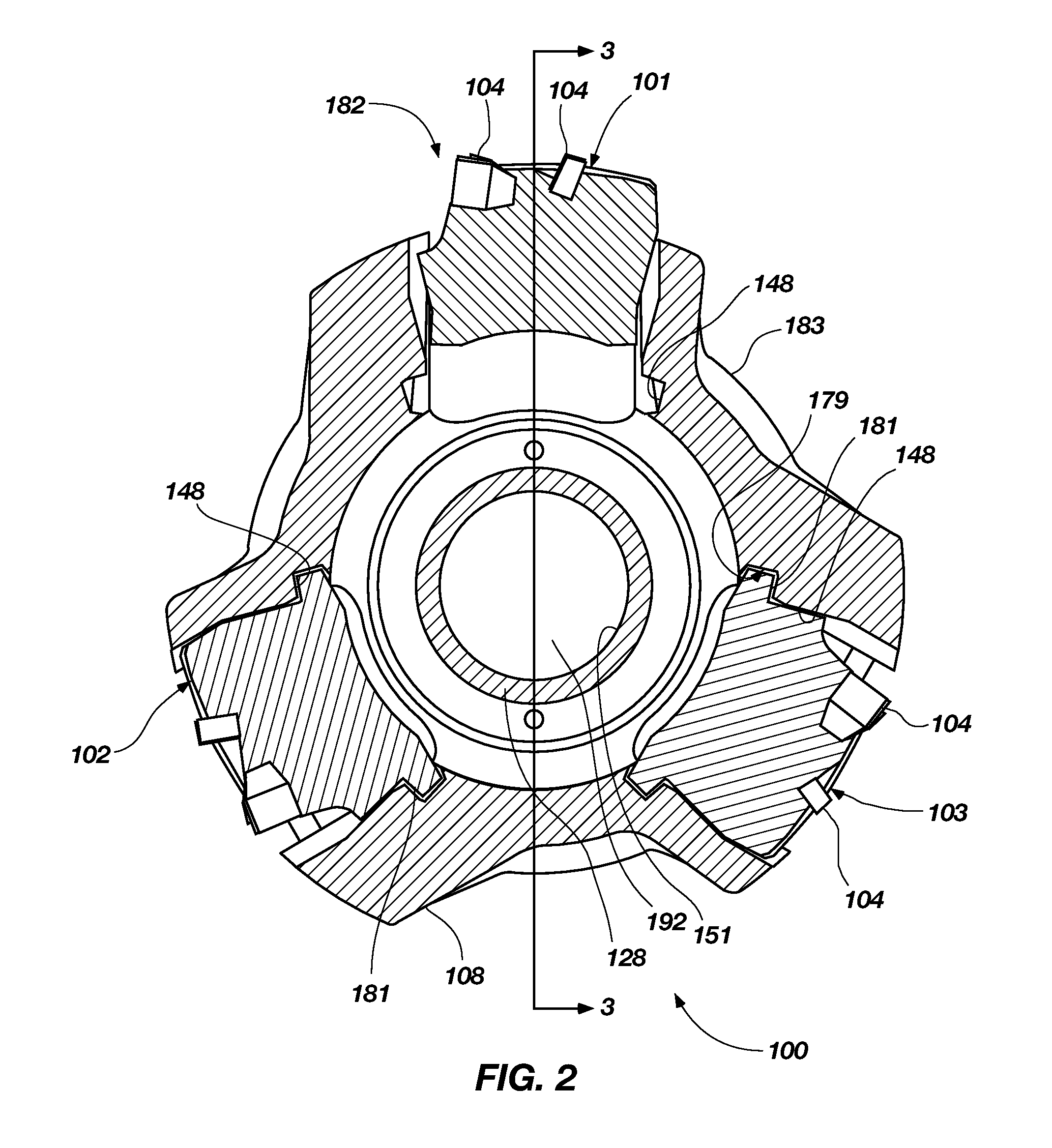

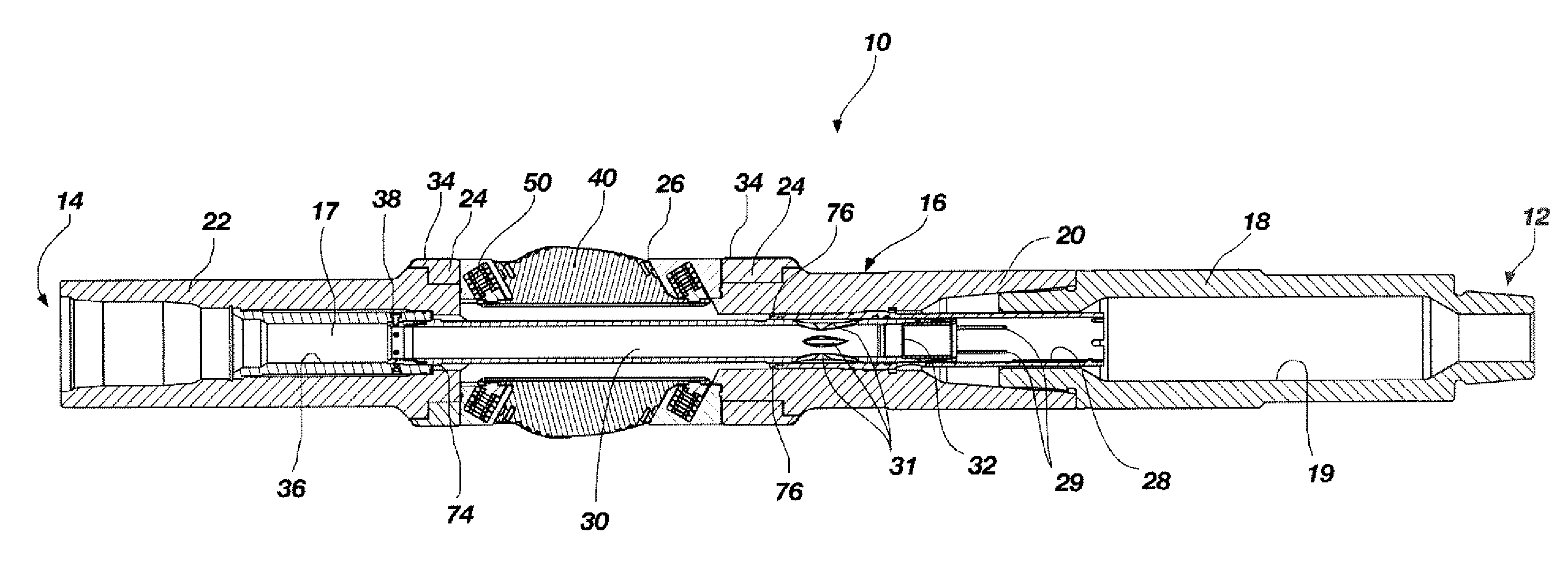

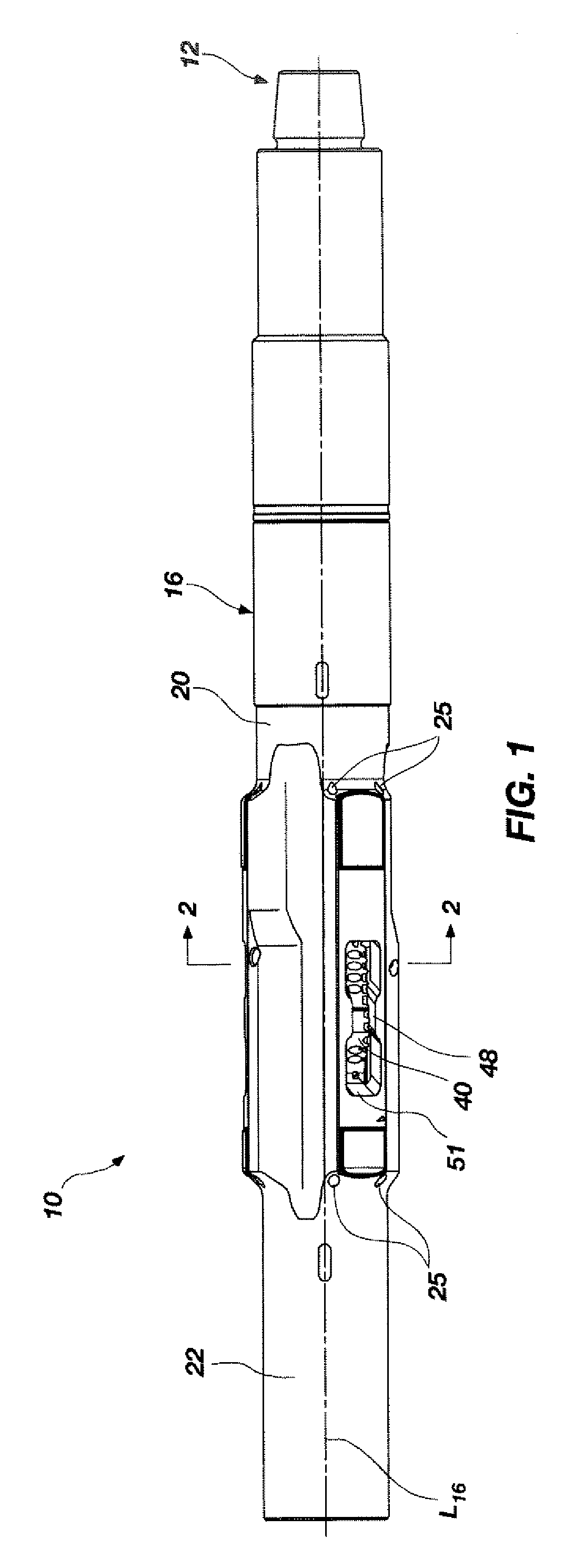

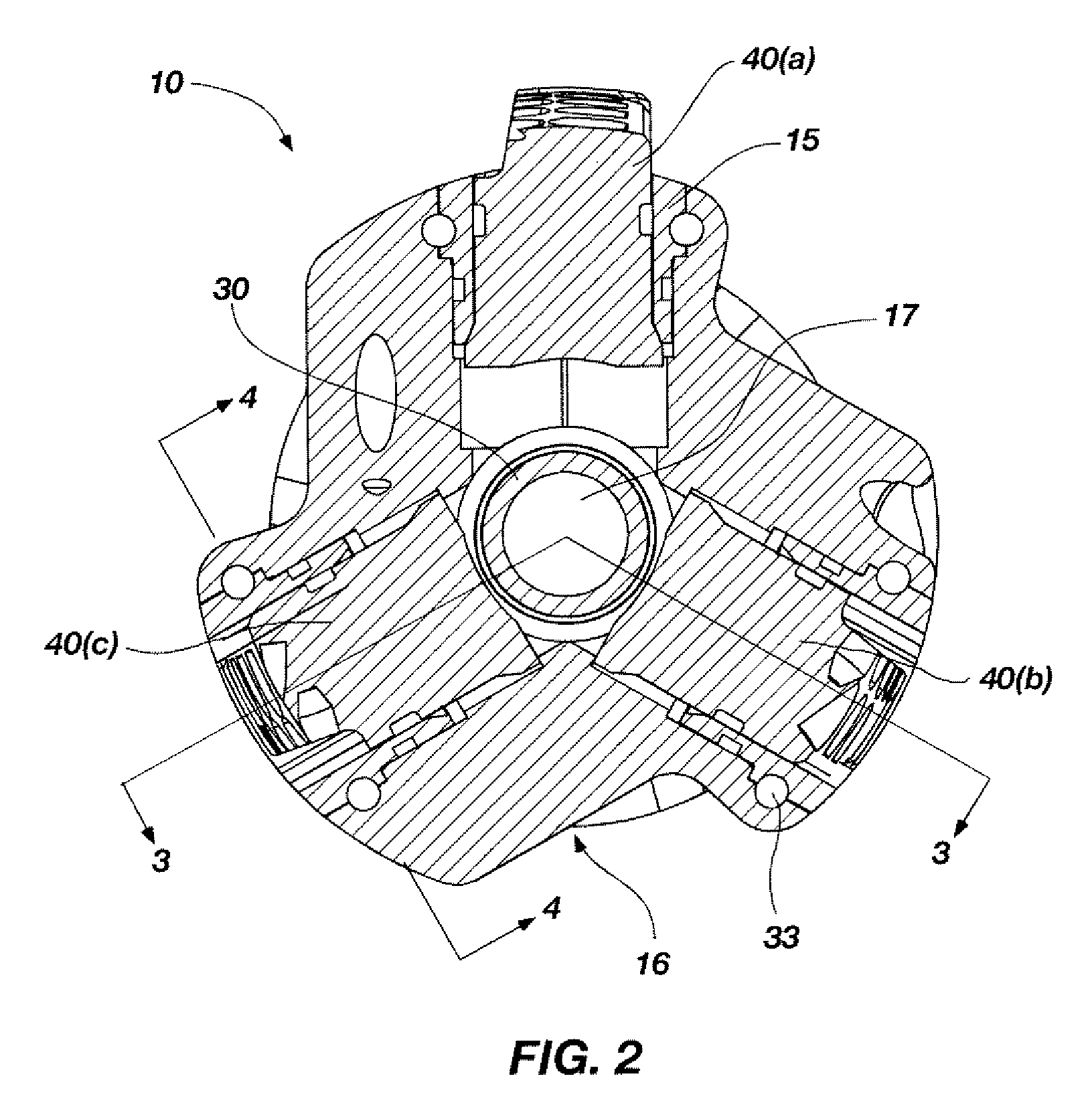

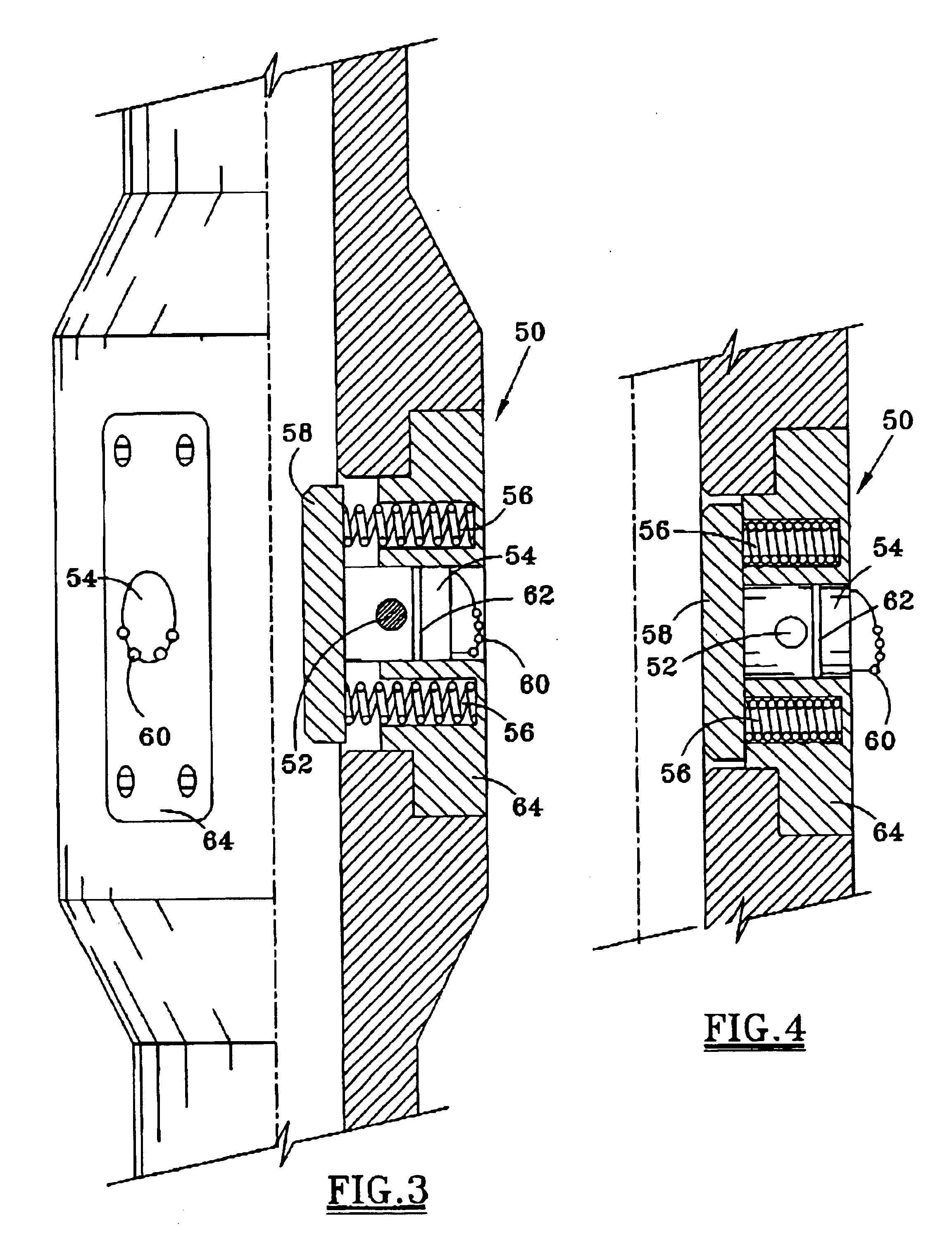

Expandable reamer apparatus for enlarging boreholes while drilling and methods of use

ActiveUS7036611B2Reduce capacityReduce the cross-sectional areaSurveyDrill bitsFixed bearingWell drilling

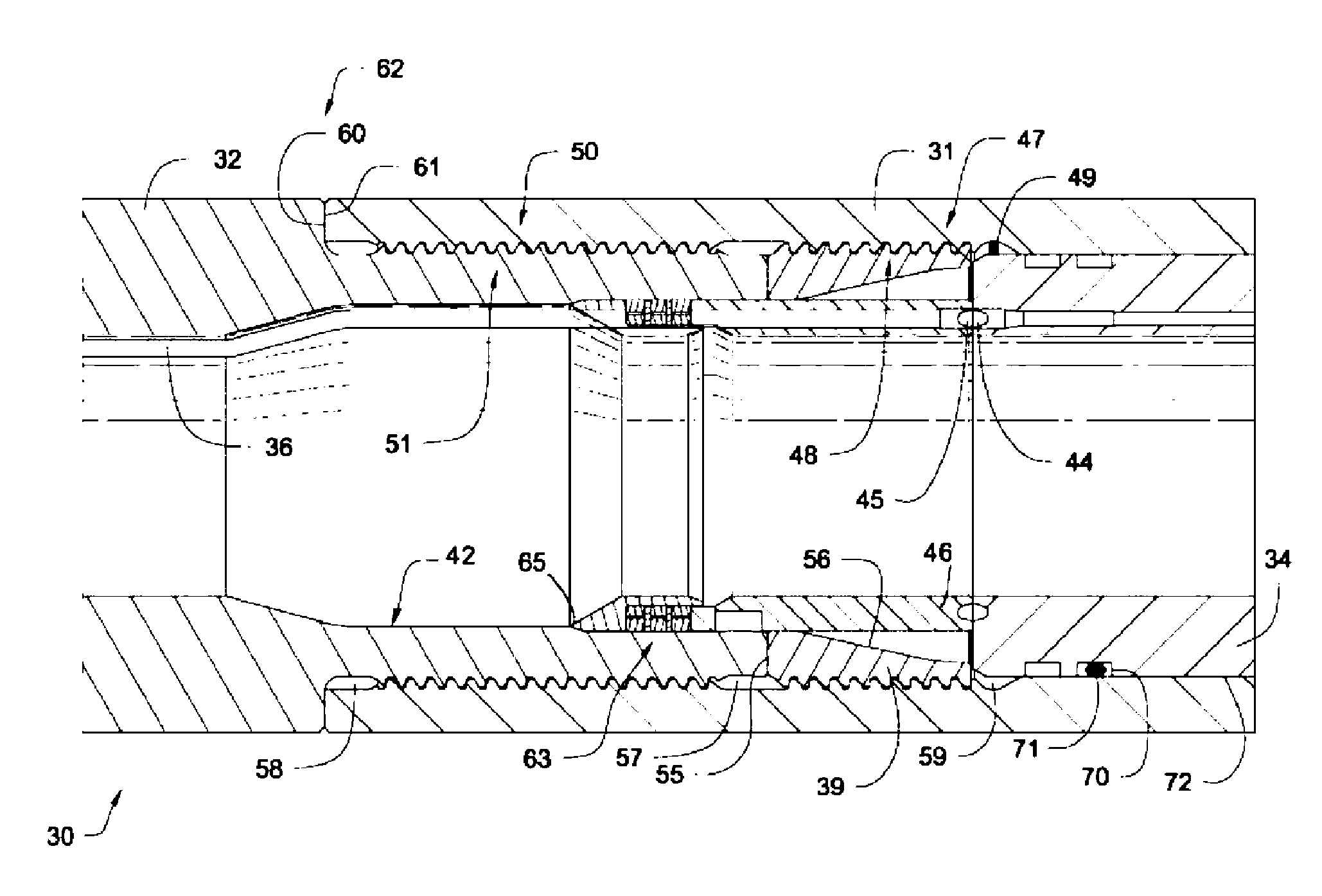

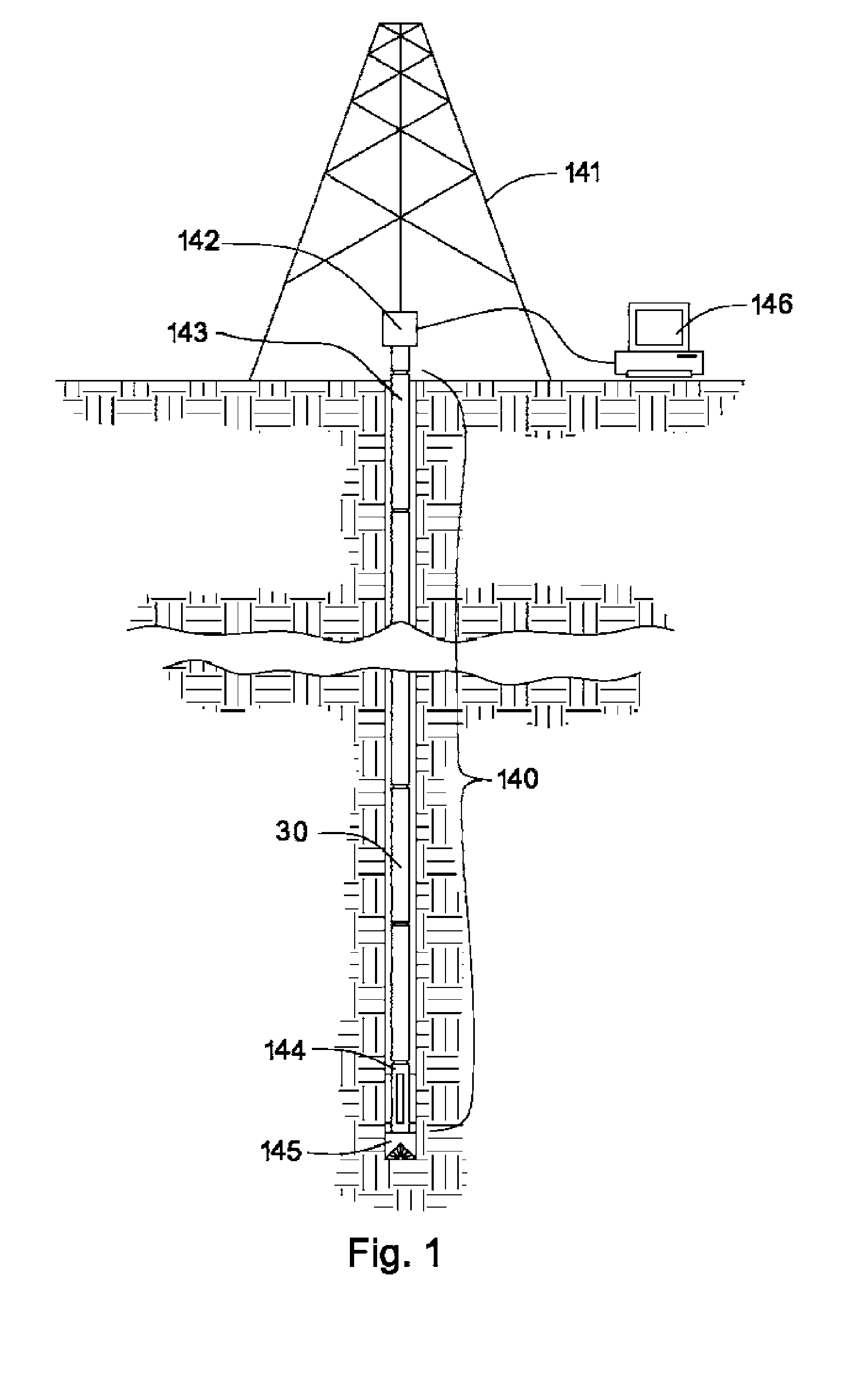

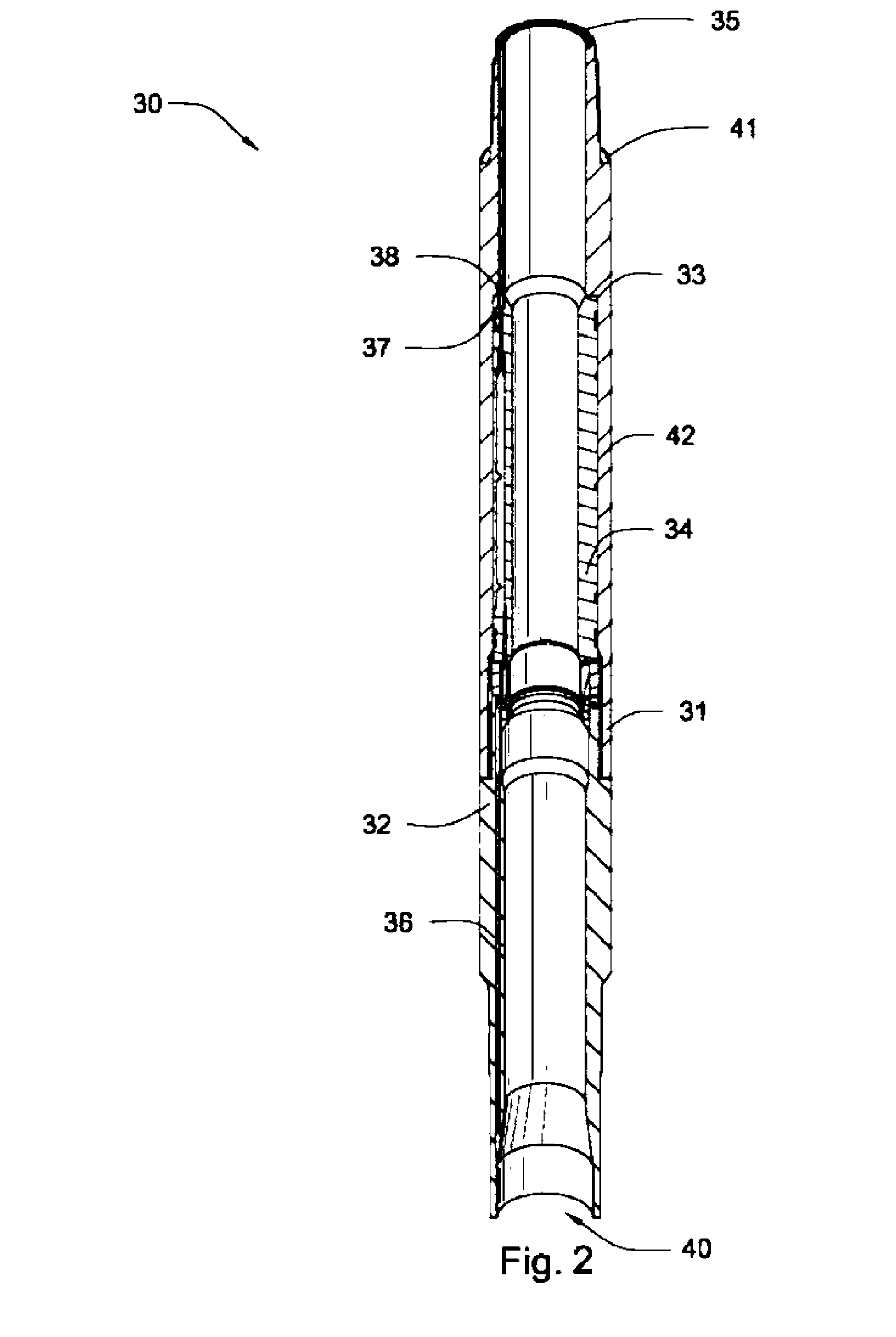

An expandable reamer apparatus and methods for reaming a borehole, wherein a laterally movable blade carried by a tubular body may be selectively positioned at an inward position and an expanded position. The laterally movable blade, held inwardly by blade-biasing elements, may be forced outwardly by drilling fluid selectively allowed to communicate therewith by way of an actuation sleeve disposed within the tubular body. Alternatively, a separation element may transmit force or pressure from the drilling fluid to the movable blade. Further, a chamber in communication with the movable blade may be pressurized by way of a downhole turbine or pump. A ridged seal wiper, compensator, movable bearing pad, fixed bearing pad preceding the movable blade, or an adjustable spacer element to alter expanded blade position may be included within the expandable reamer. In addition, a drilling fluid pressure response indicating an operational characteristic of the expandable reamer may be generated.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

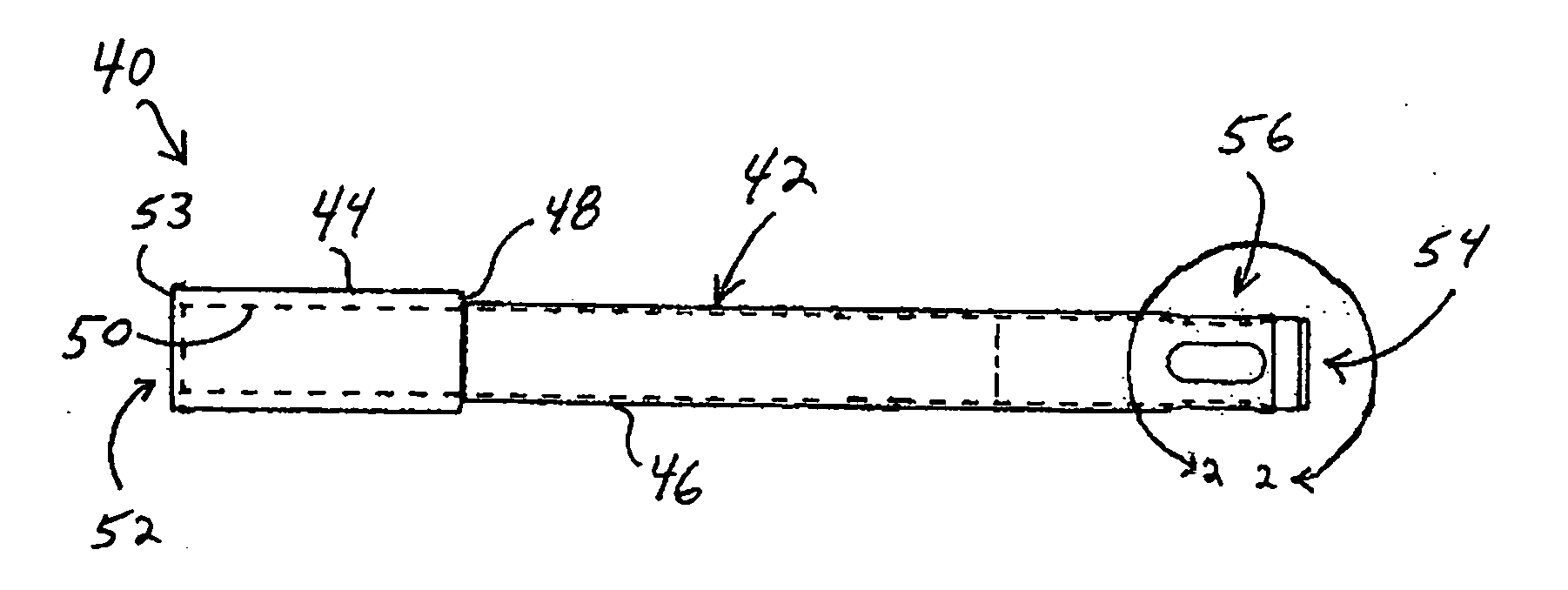

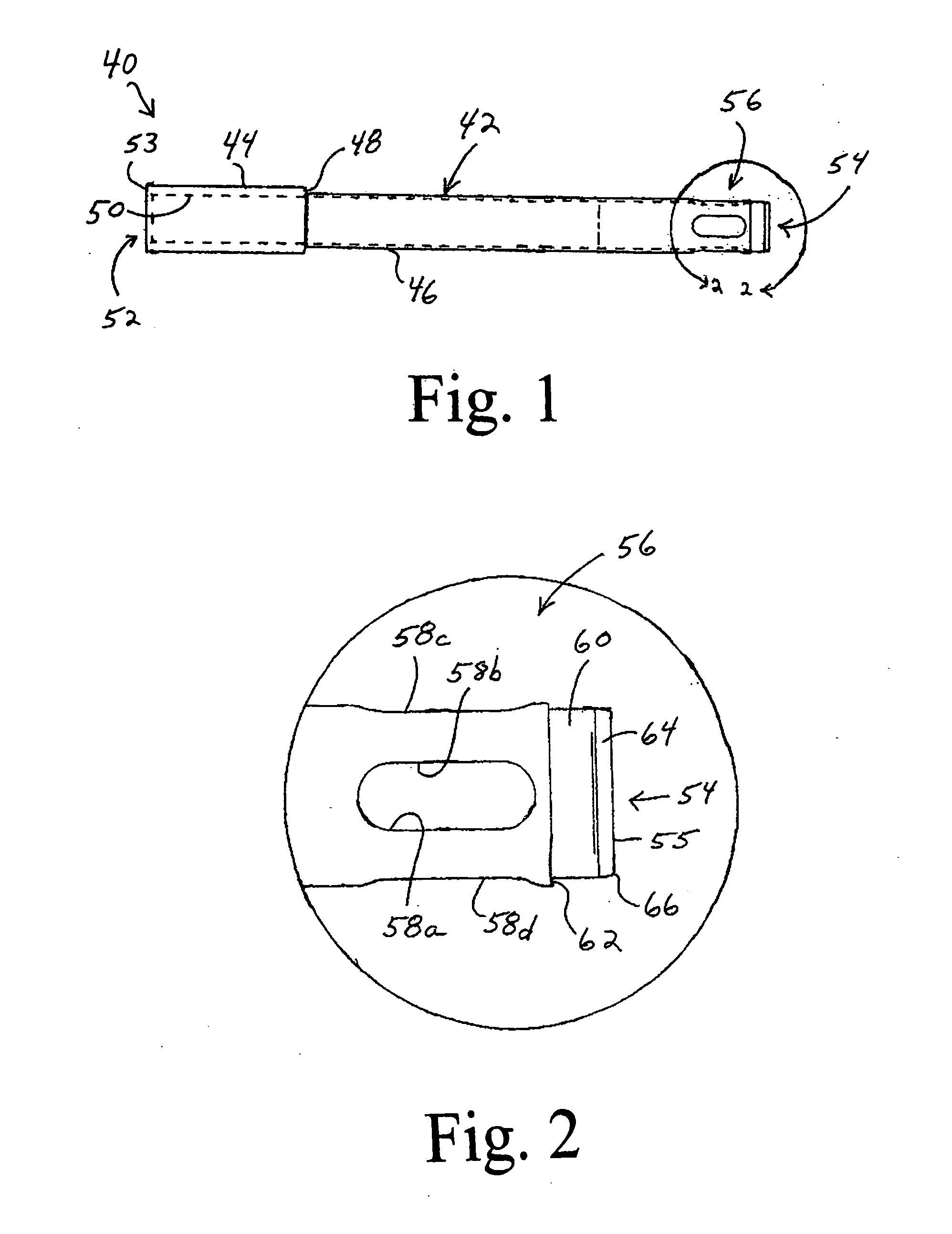

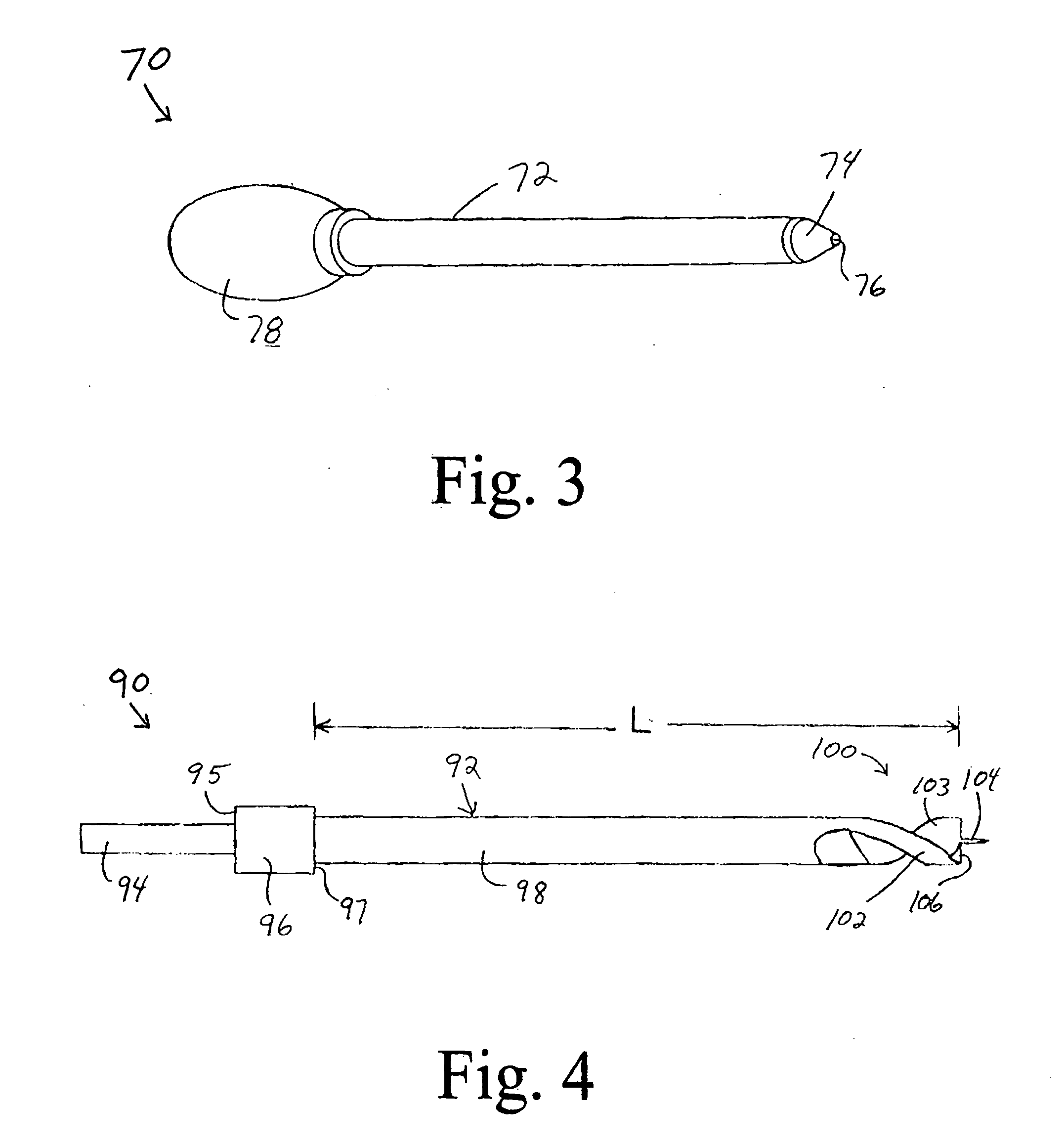

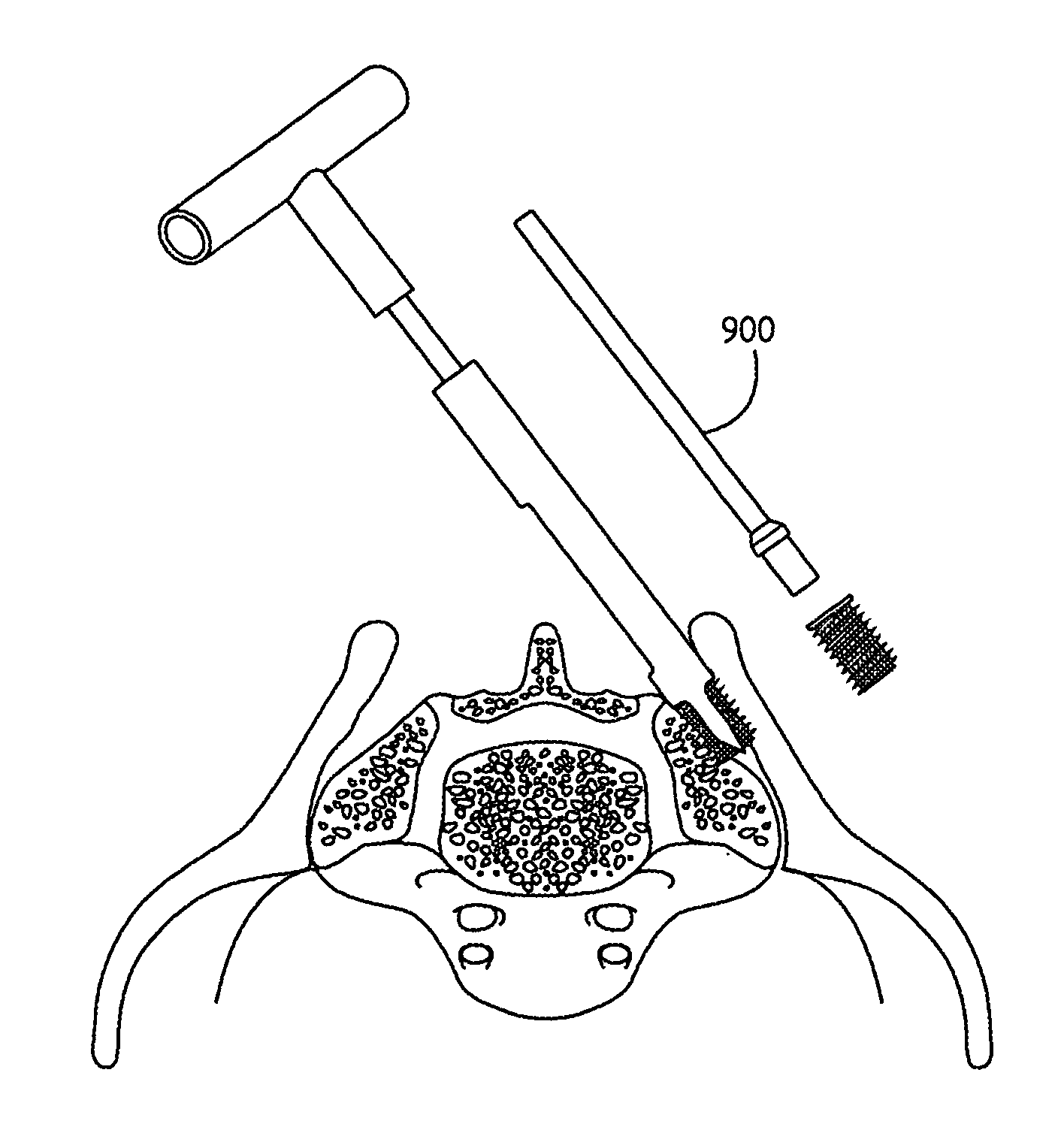

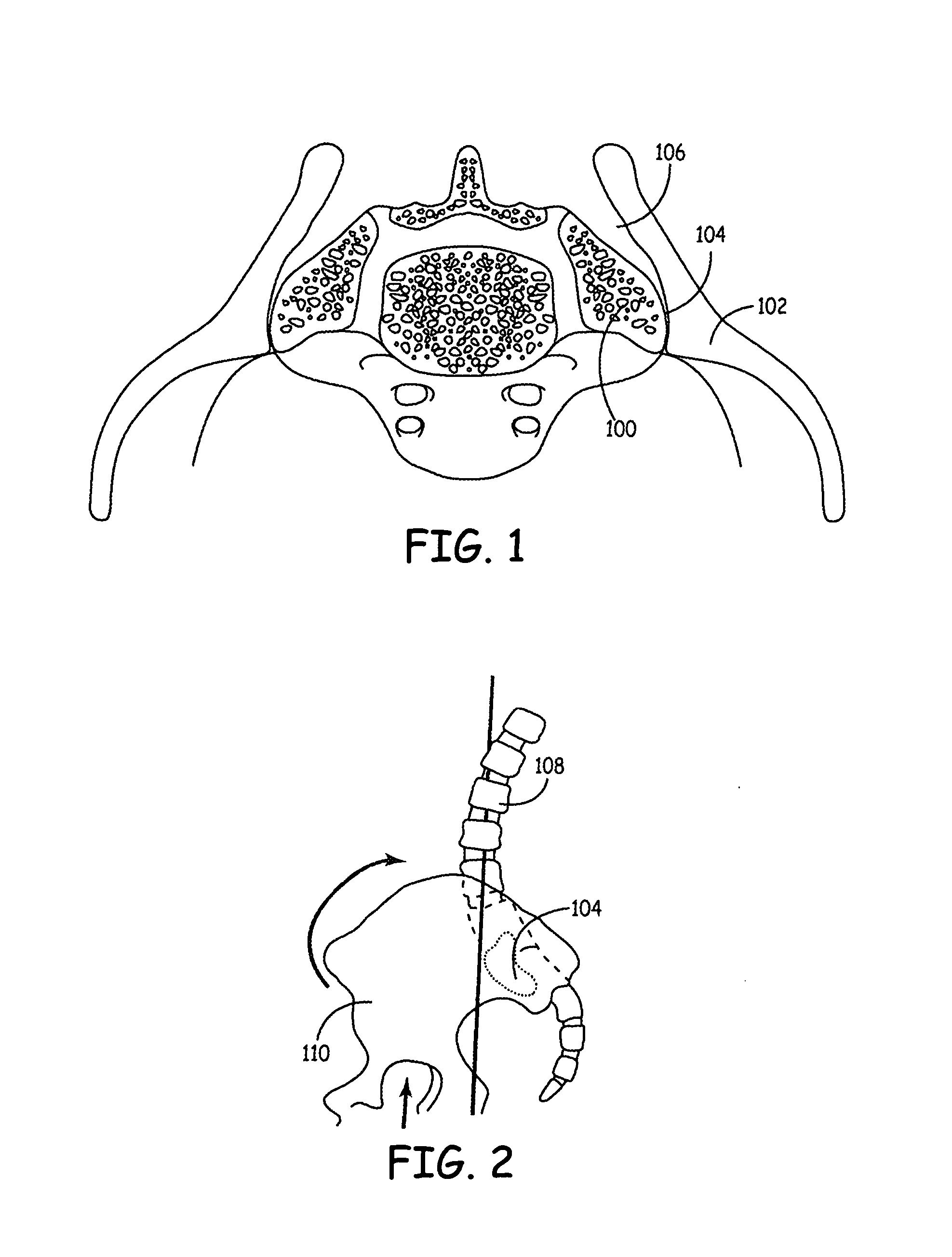

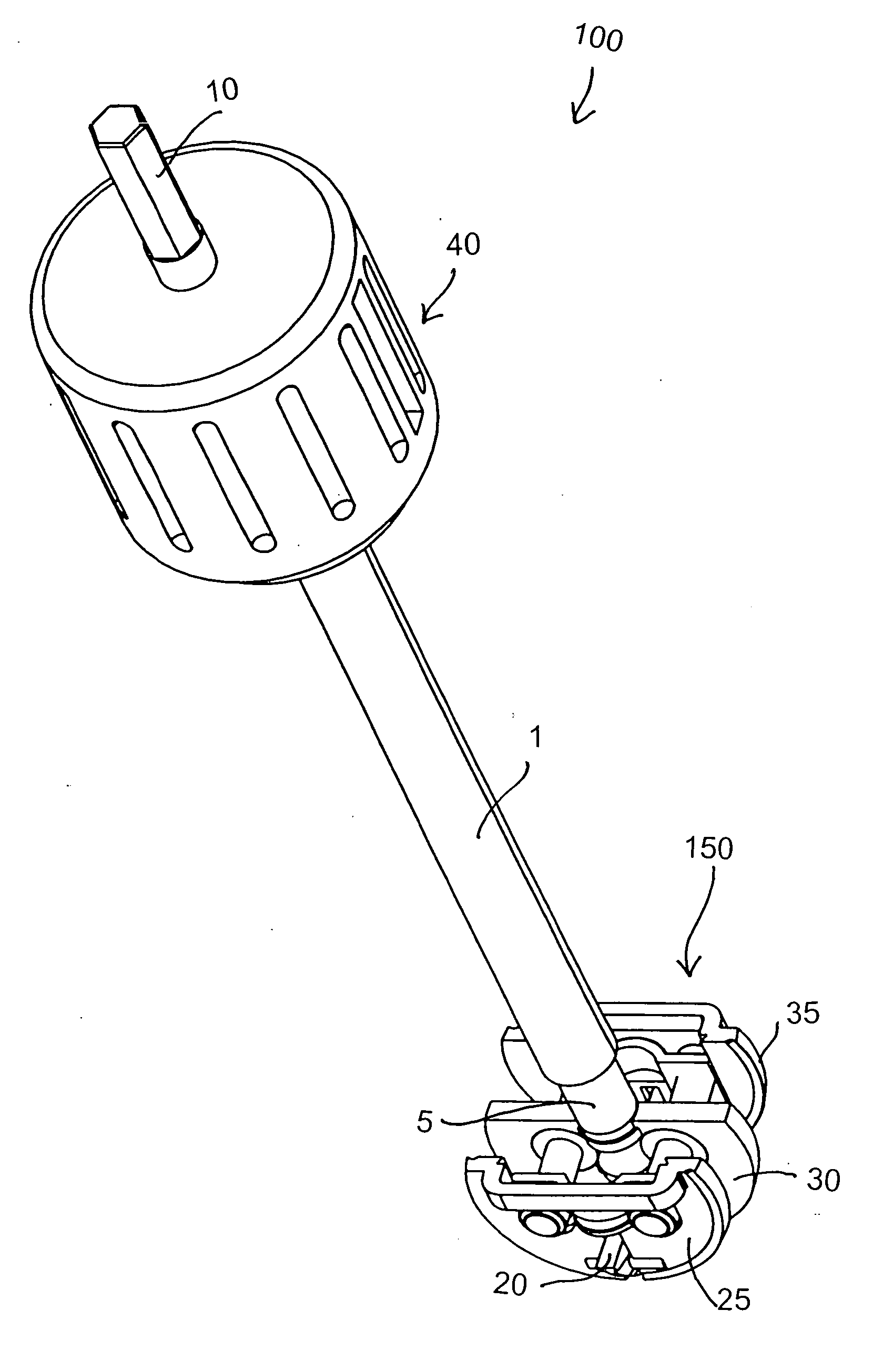

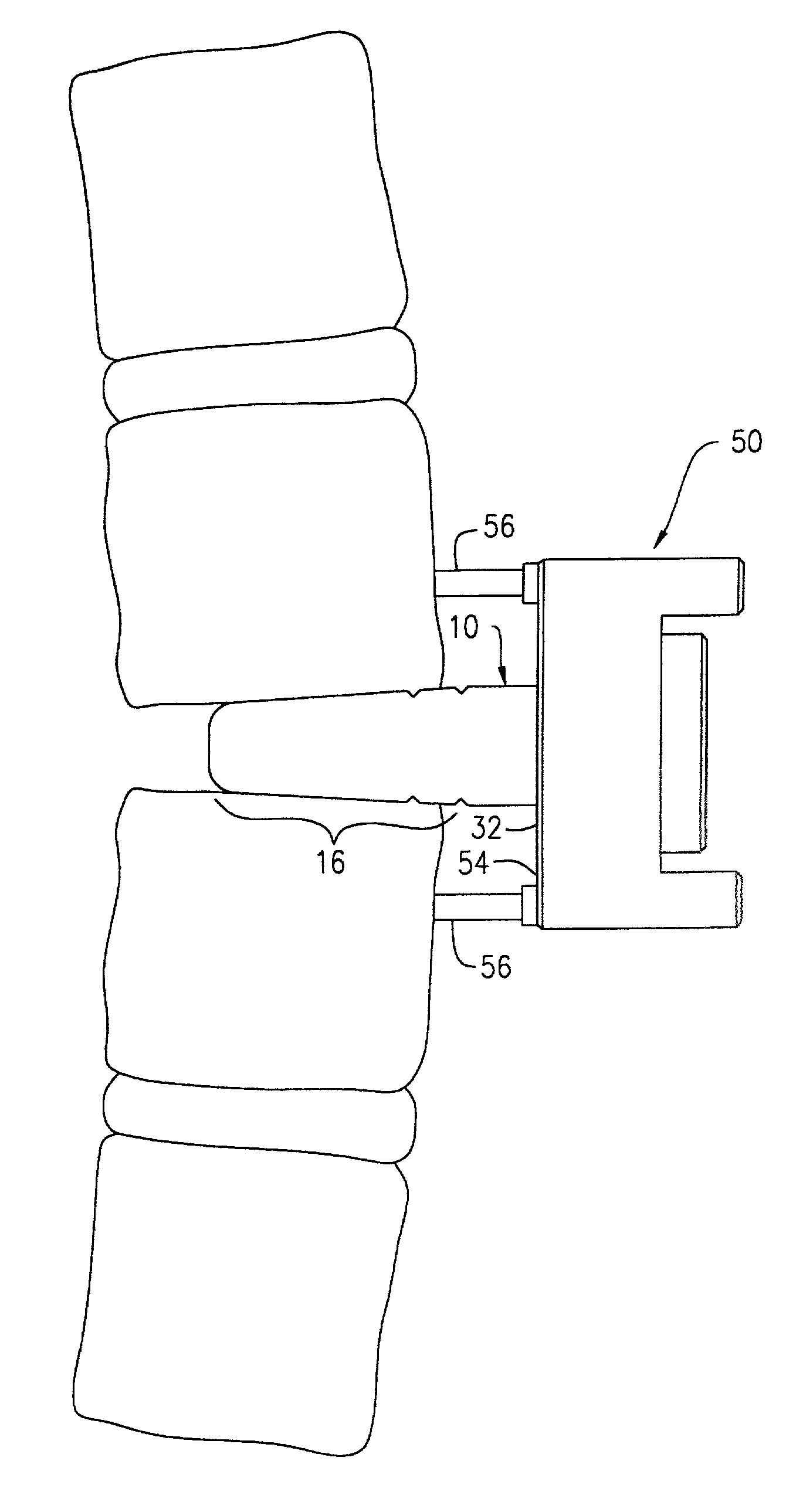

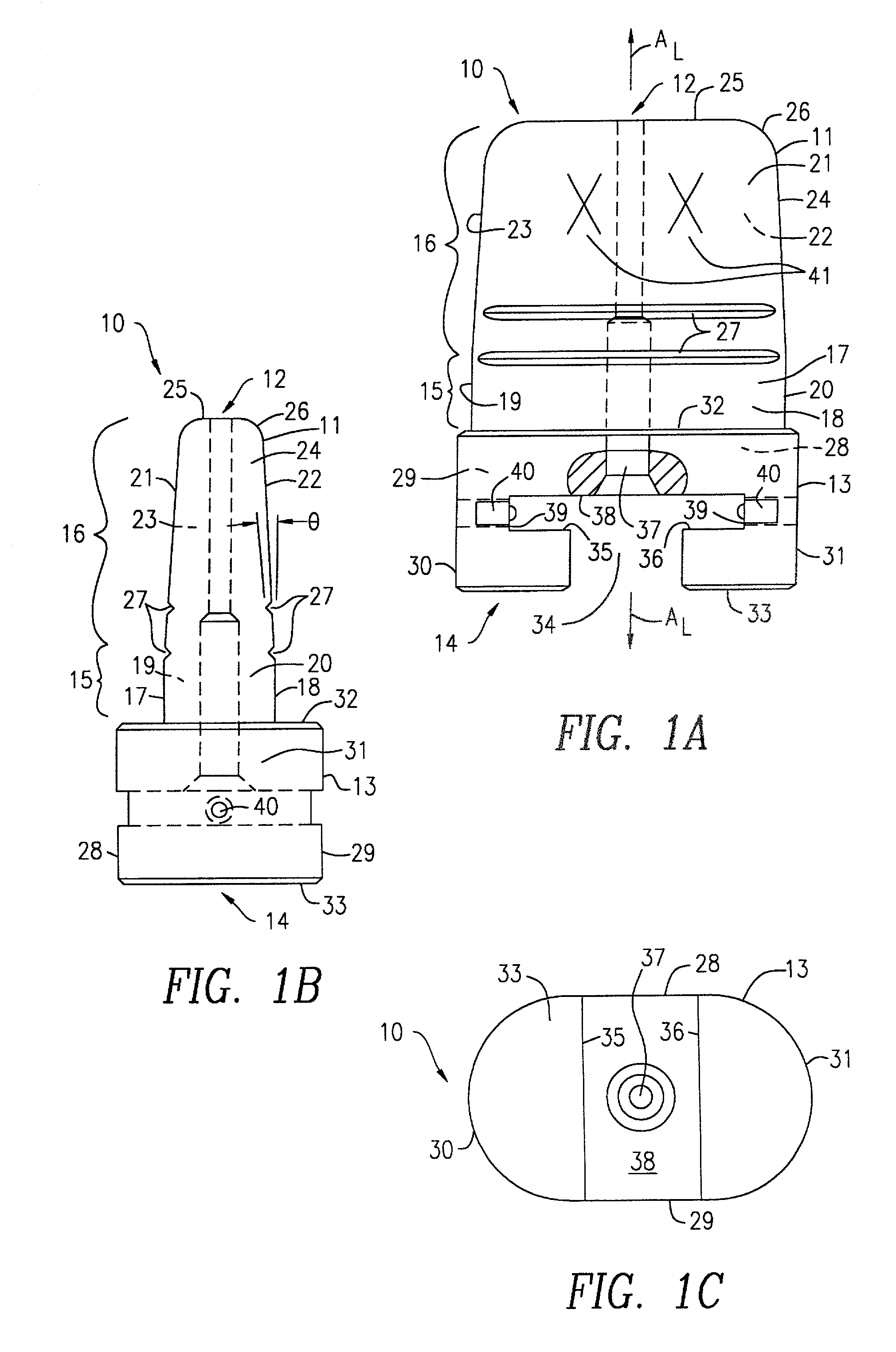

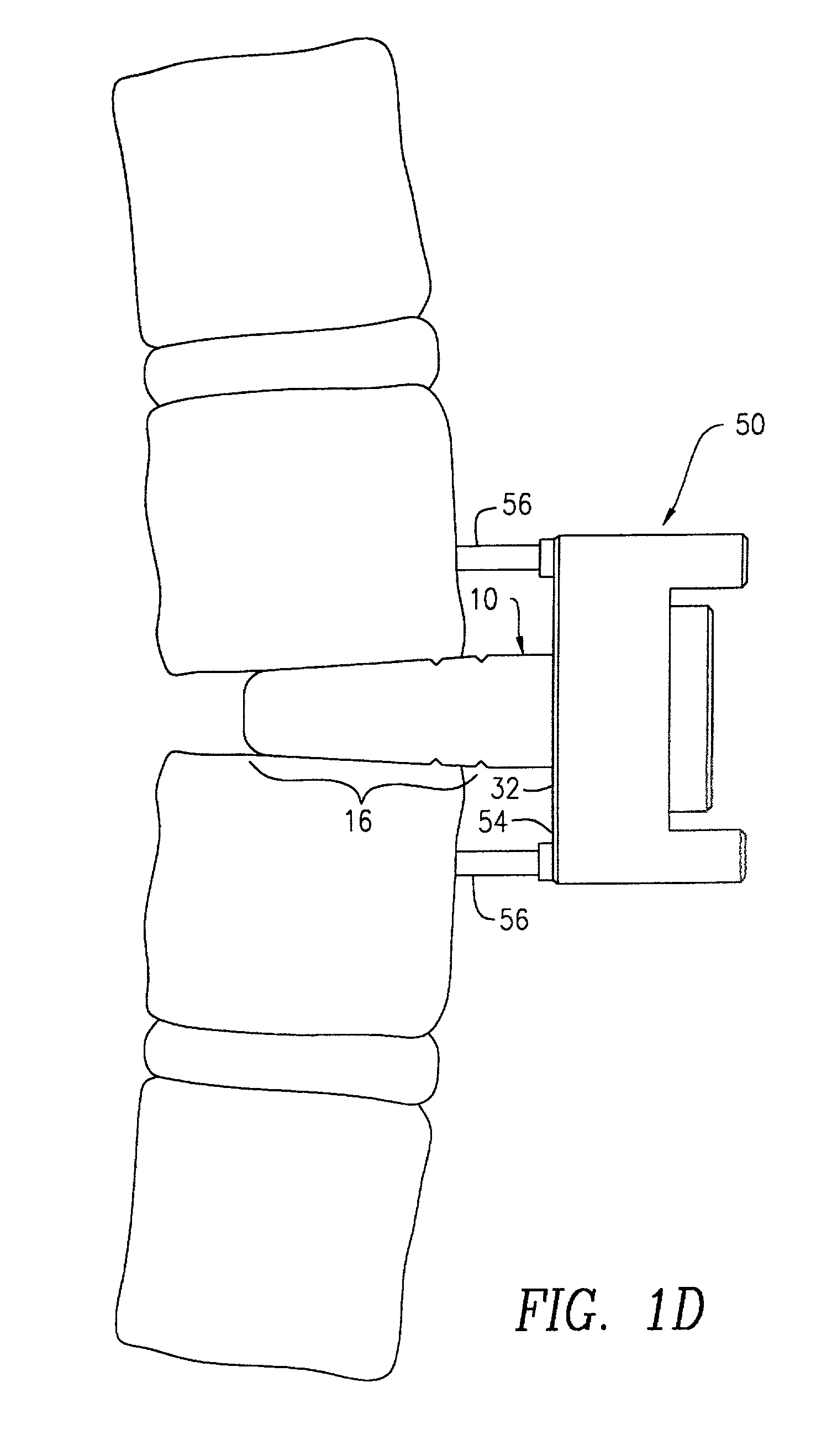

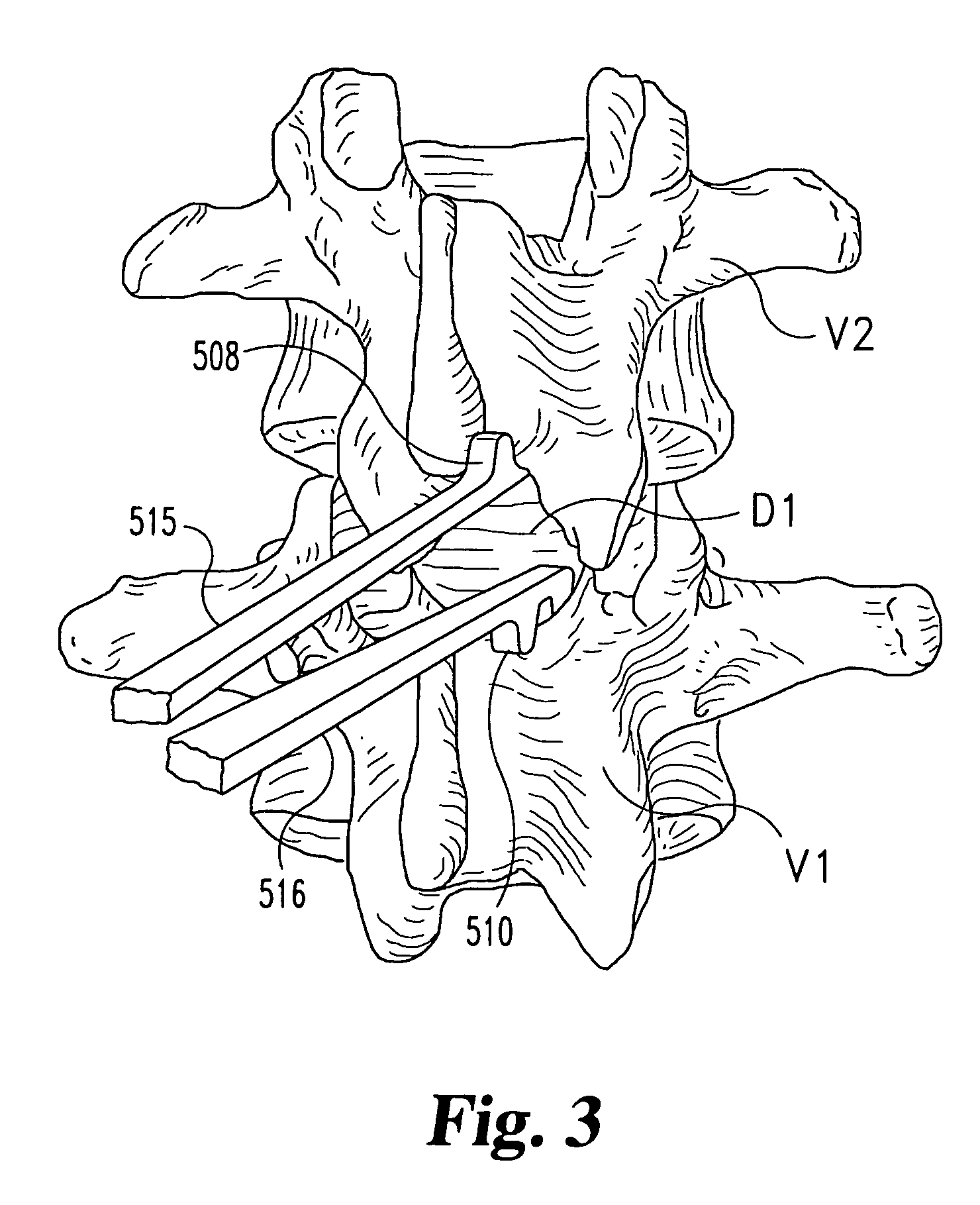

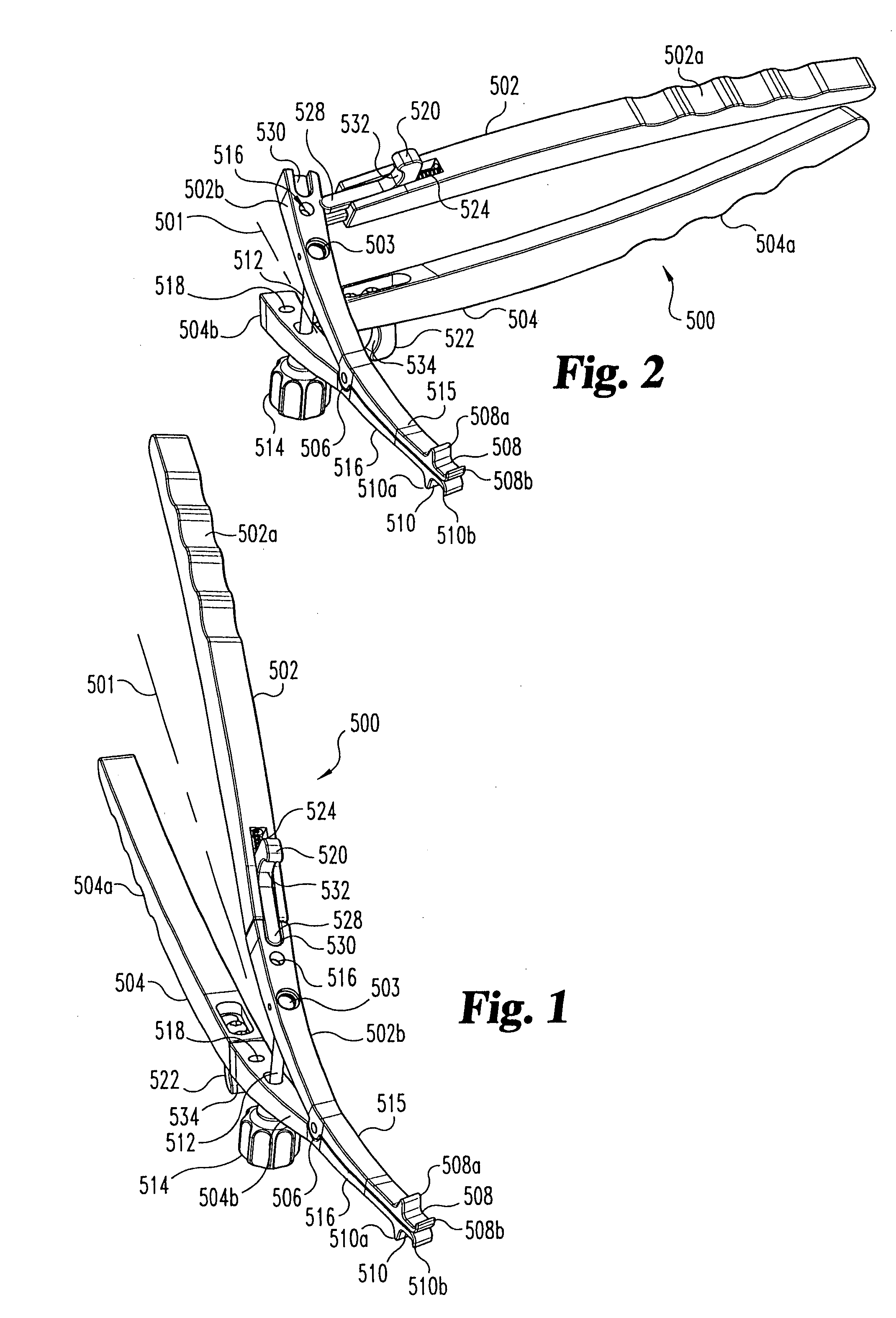

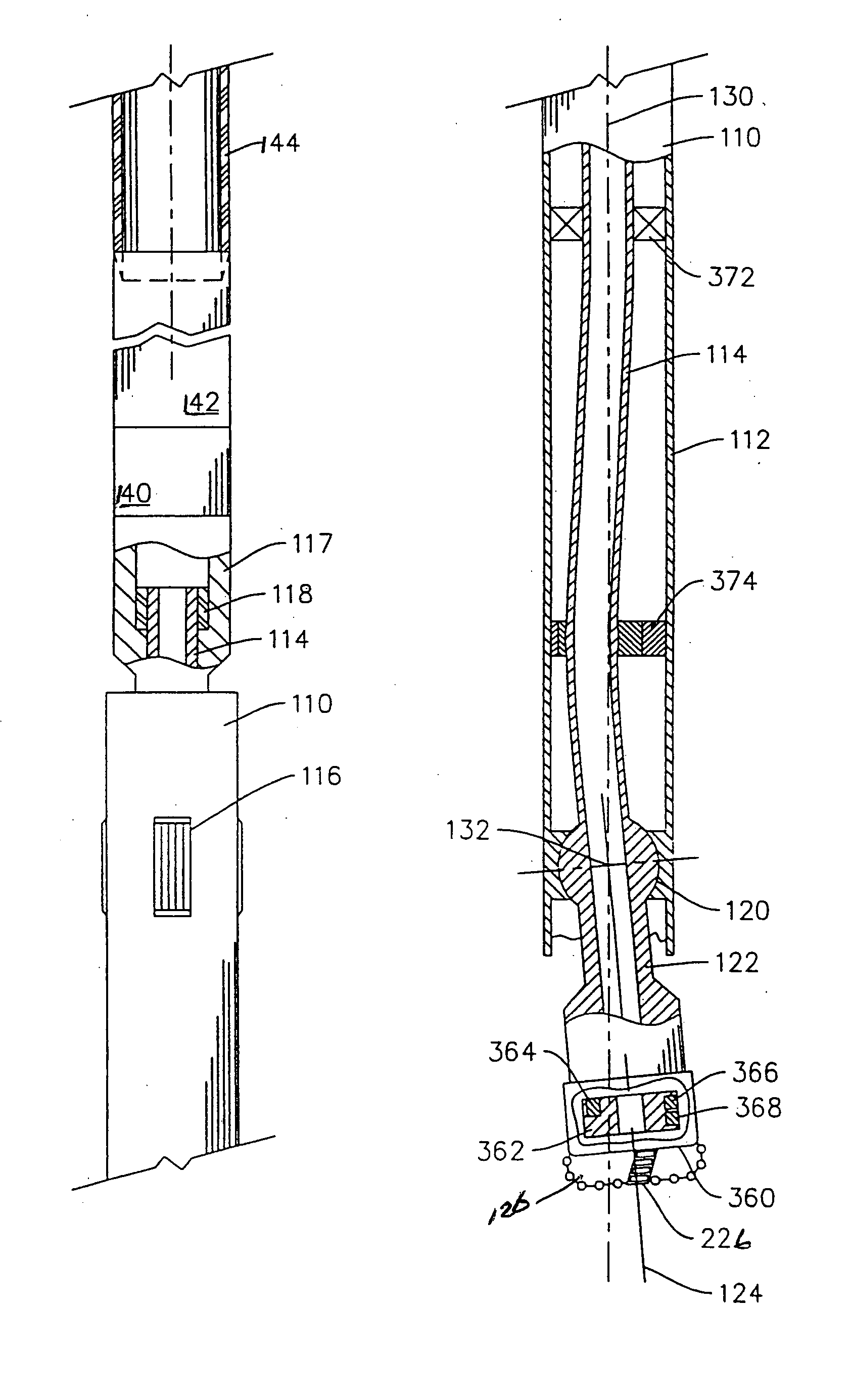

Instrument system for preparing a disc space between adjacent vertebral bodies to receive a repair device

InactiveUS7153304B2Restores natural lordosisInternal osteosythesisDiagnosticsSpinal columnLamina terminalis

An instrument system for preparing a disc space between adjacent vertebral bodies to receive a repair device includes a series of distractors for distracting the vertebral bodies in a manner that restores natural lordosis of the lumbar and cervical spine, a vertebrae immobilizing template to fix the positions of the bodies, a handle for employing the distractor and the template, and a reamer for cutting tissue from endplates of the vertebral bodies.

Owner:ZIMMER BIOMET SPINE INC

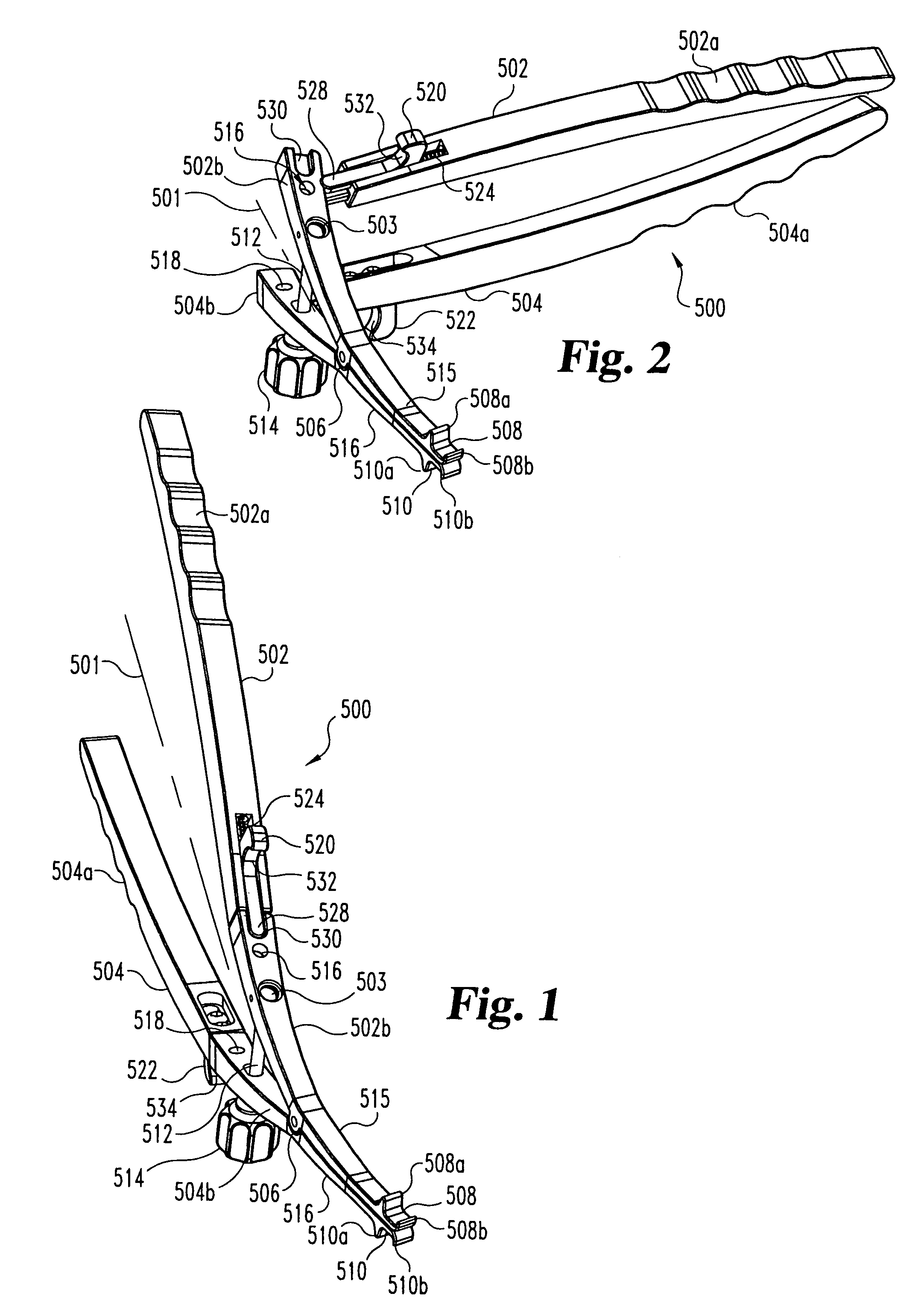

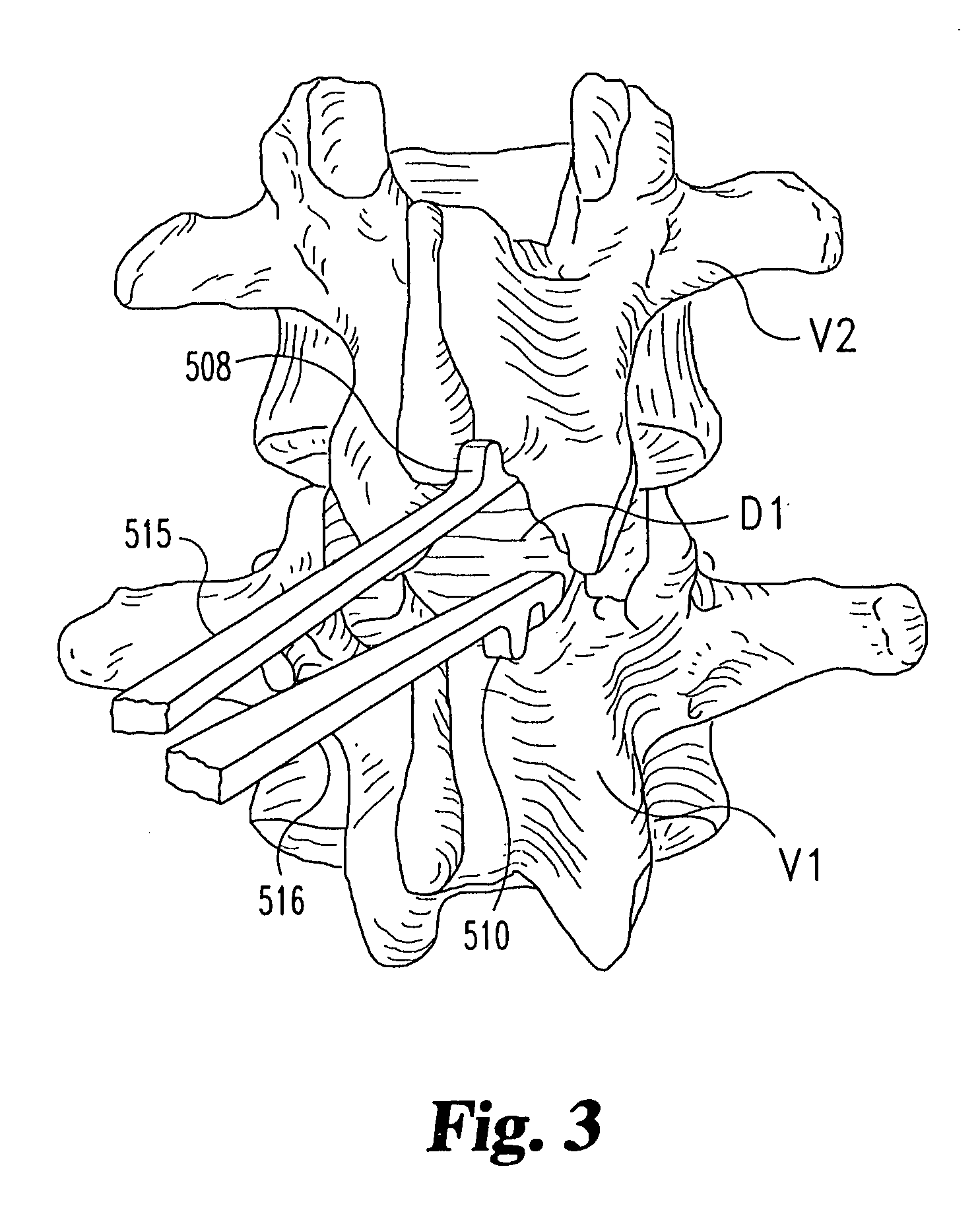

Devices and techniques for a posterior lateral disc space approach

This invention relates to methods and instruments for performing disc space preparation and implant insertion from a unilateral approach to the spine through a posterior lateral opening to the disc space. The instruments include spreaders, distractors, reamers, scrapers, cutters, chisels, pushers and implant inserters. A surgical procedure is provided that allows bilateral support of the adjacent vertebrae with at least one interbody fusion device inserted into the disc space via a unilateral approach. Implants for insertion into the disc space are also provided.

Owner:WARSAW ORTHOPEDIC INC

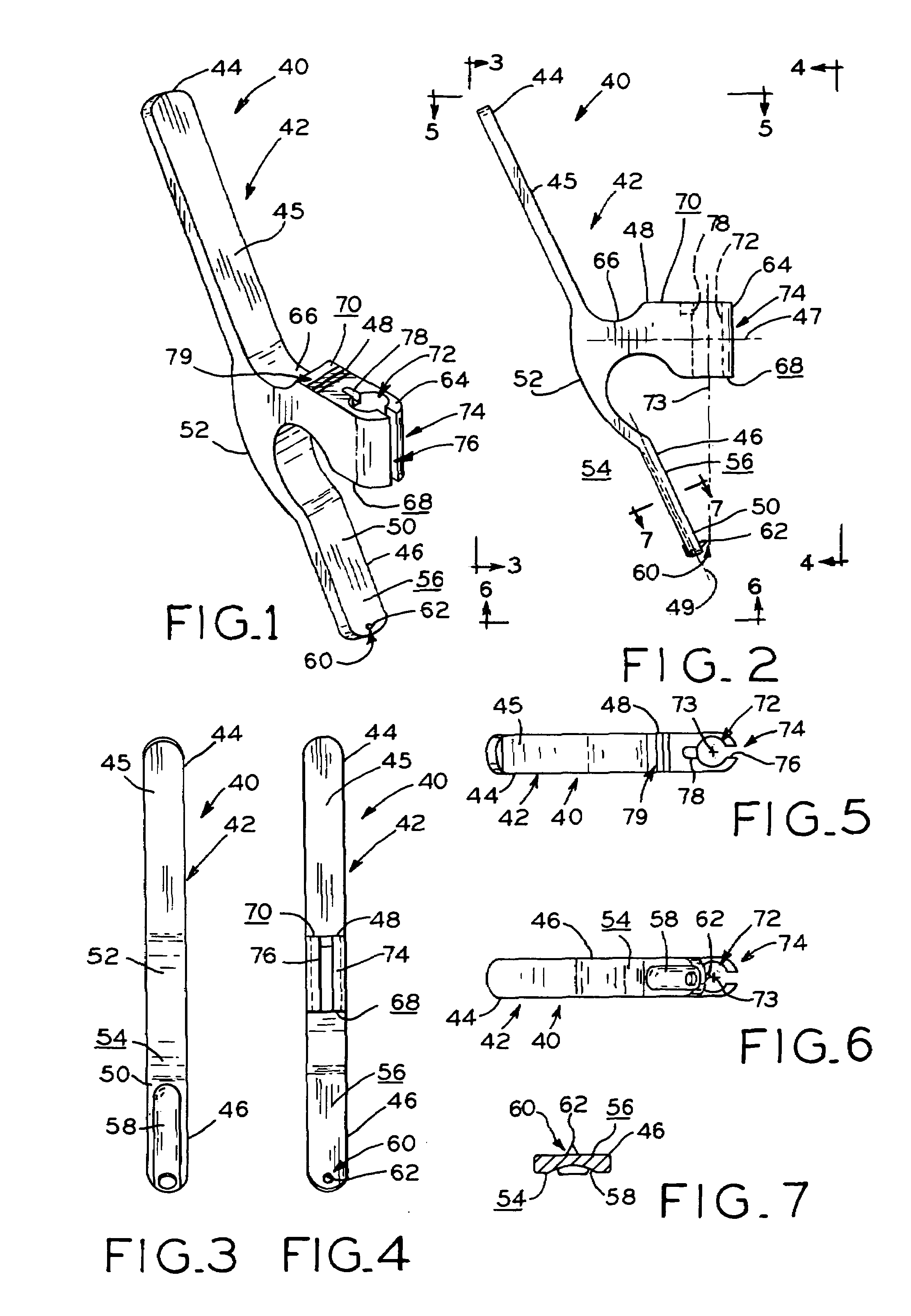

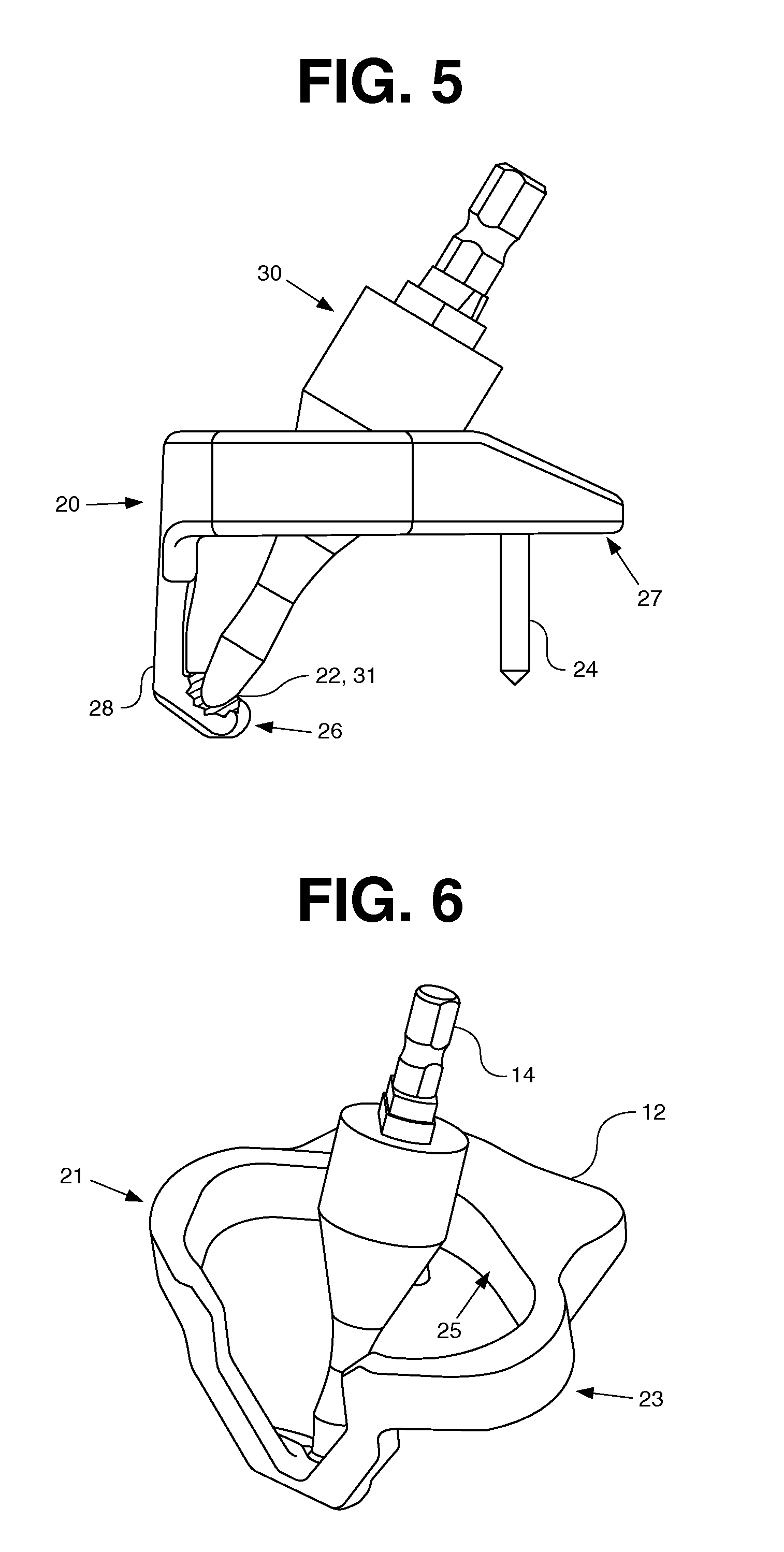

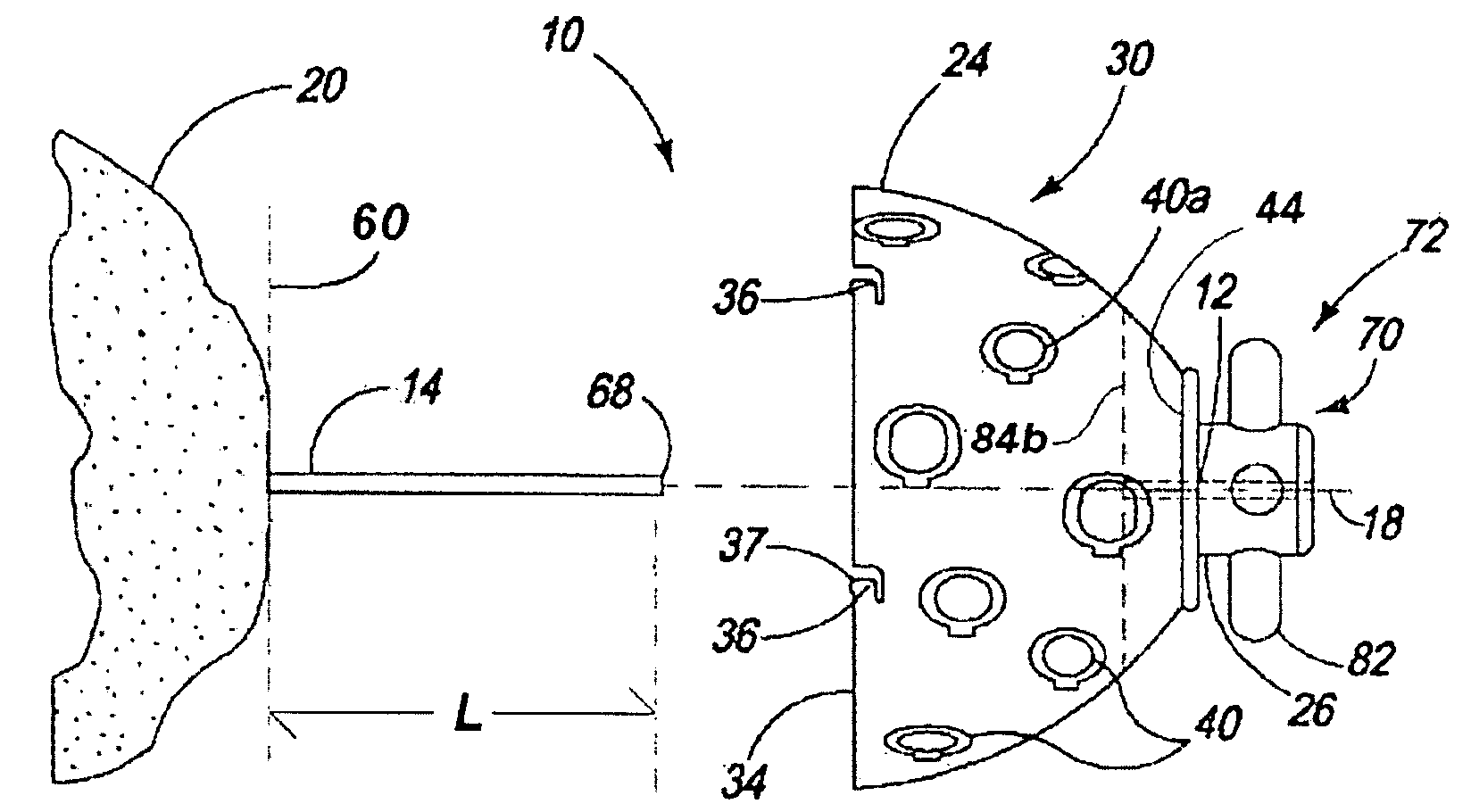

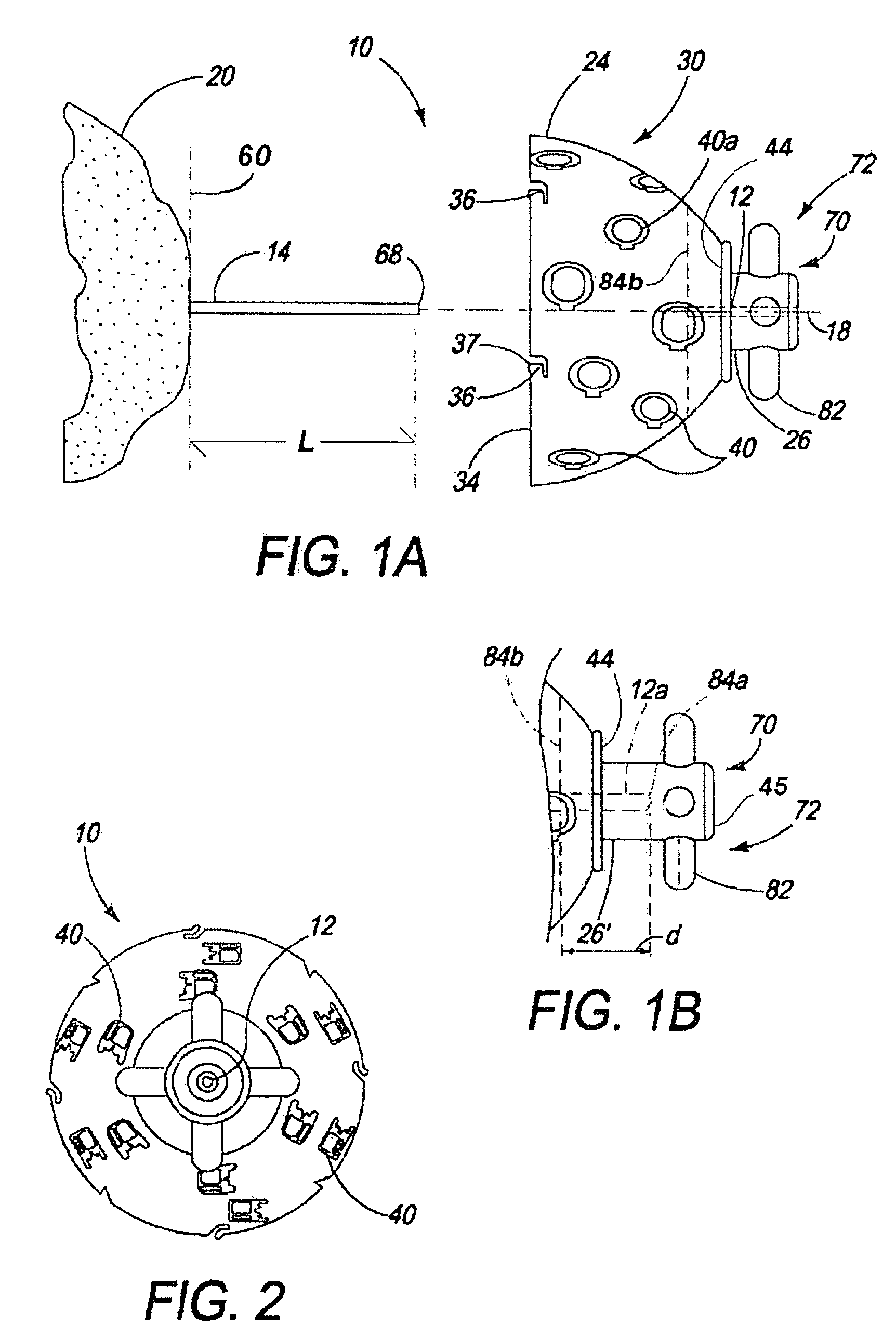

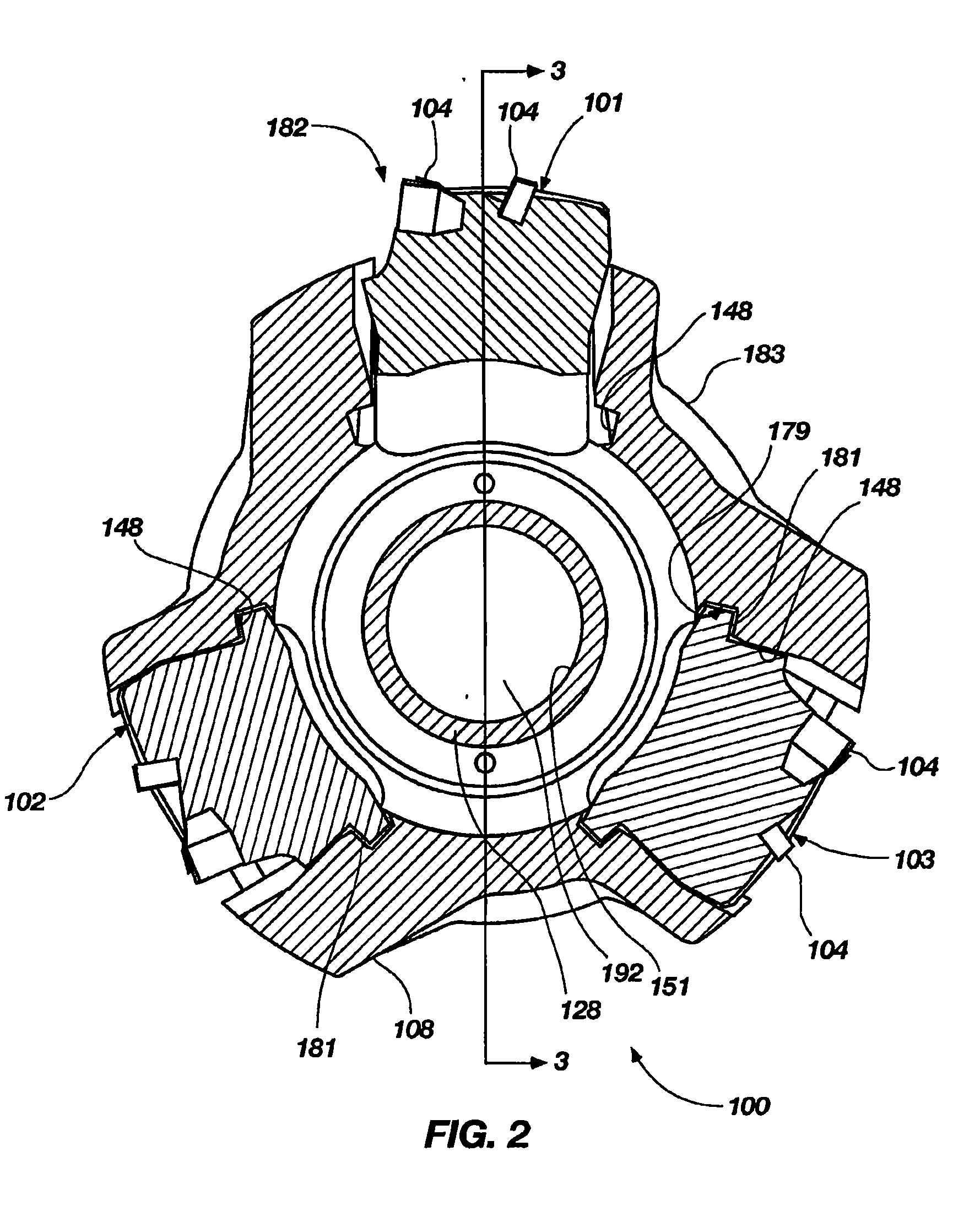

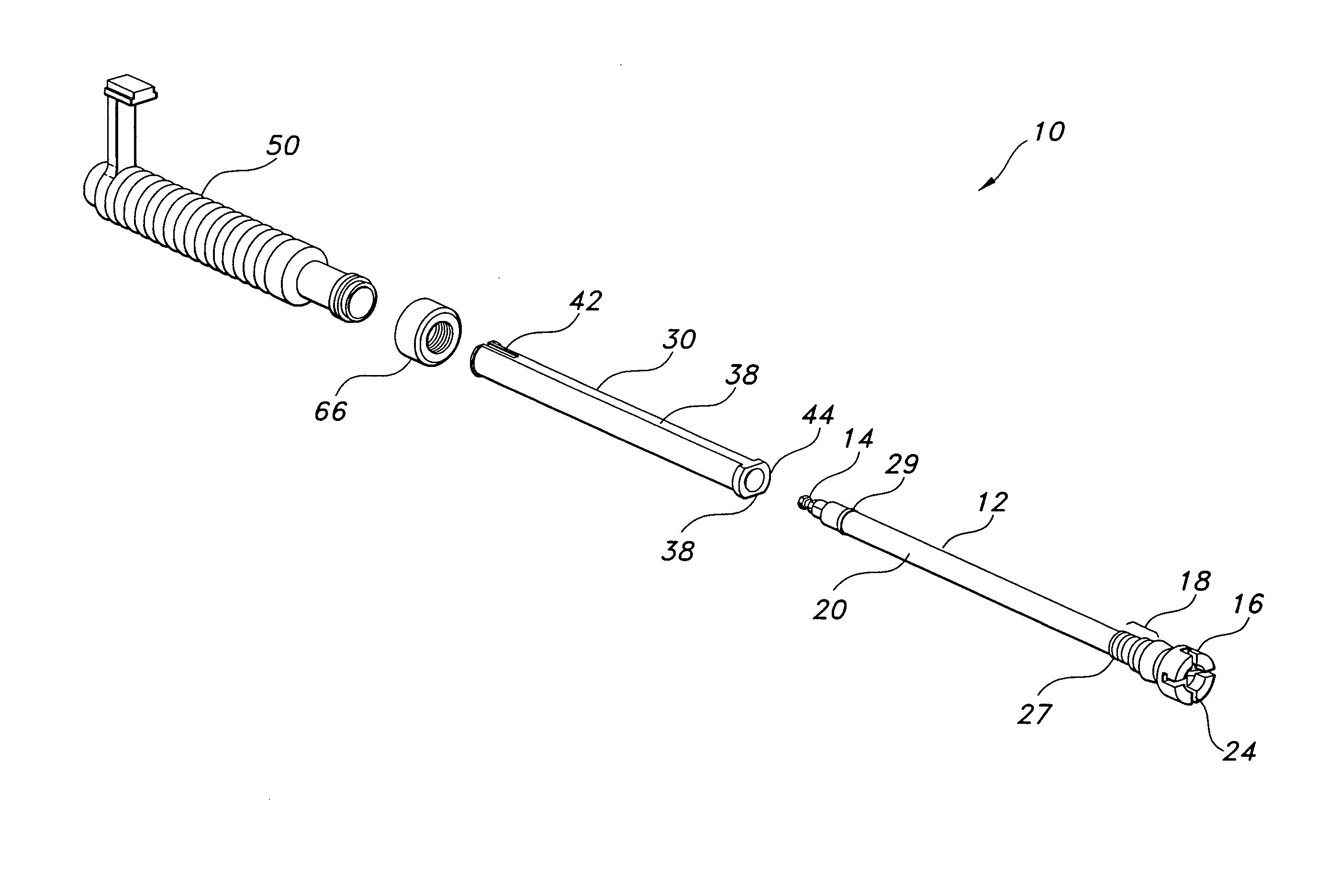

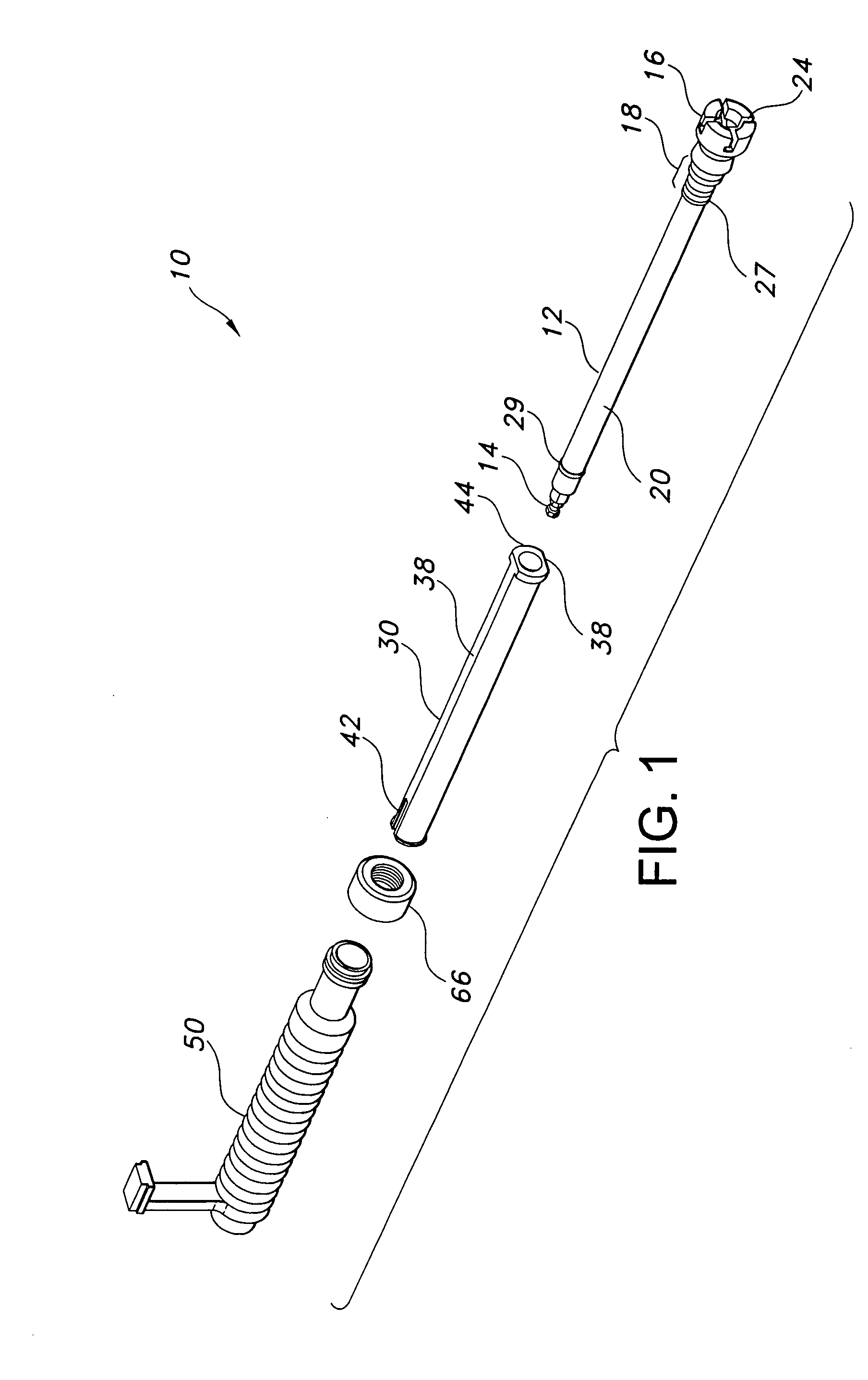

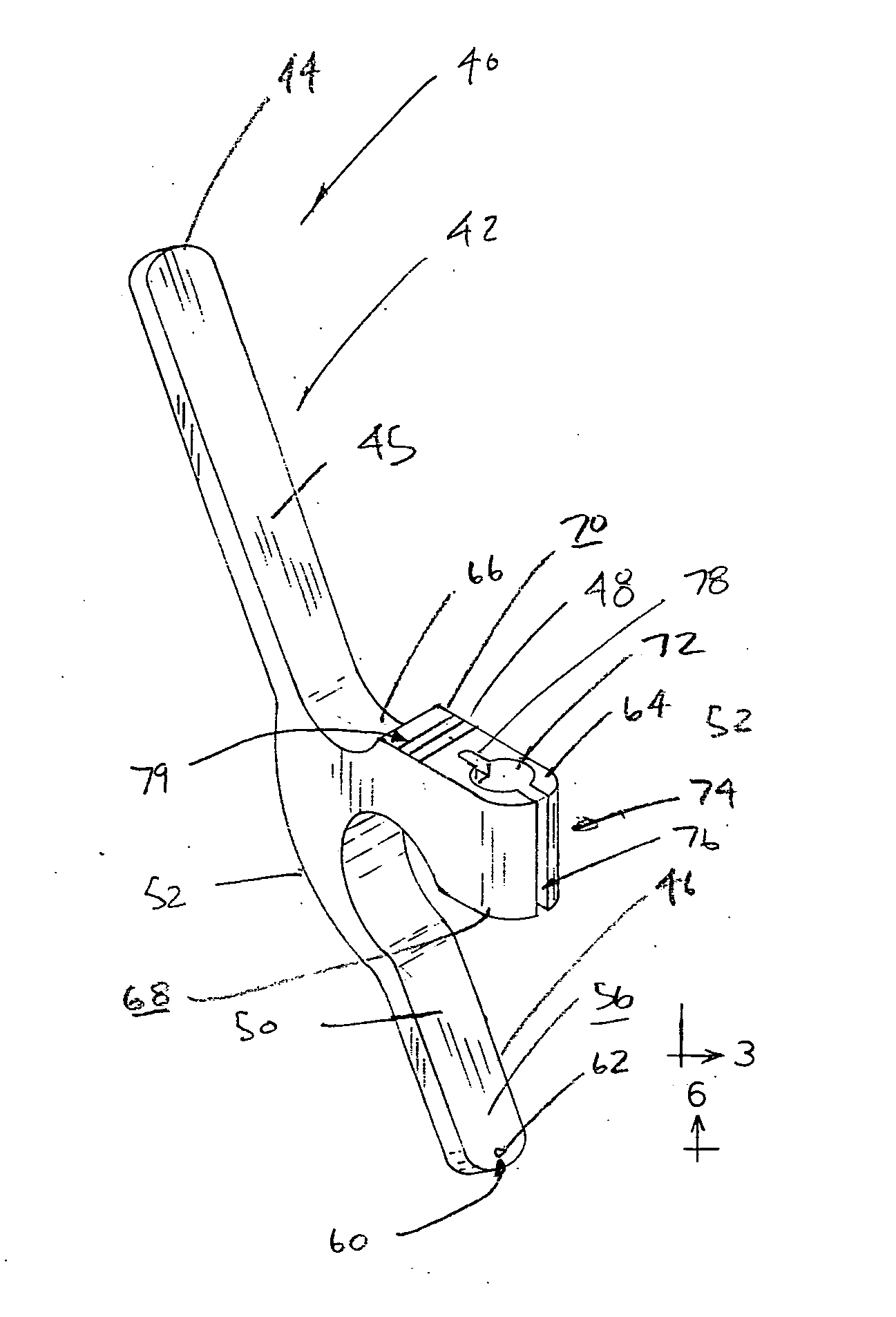

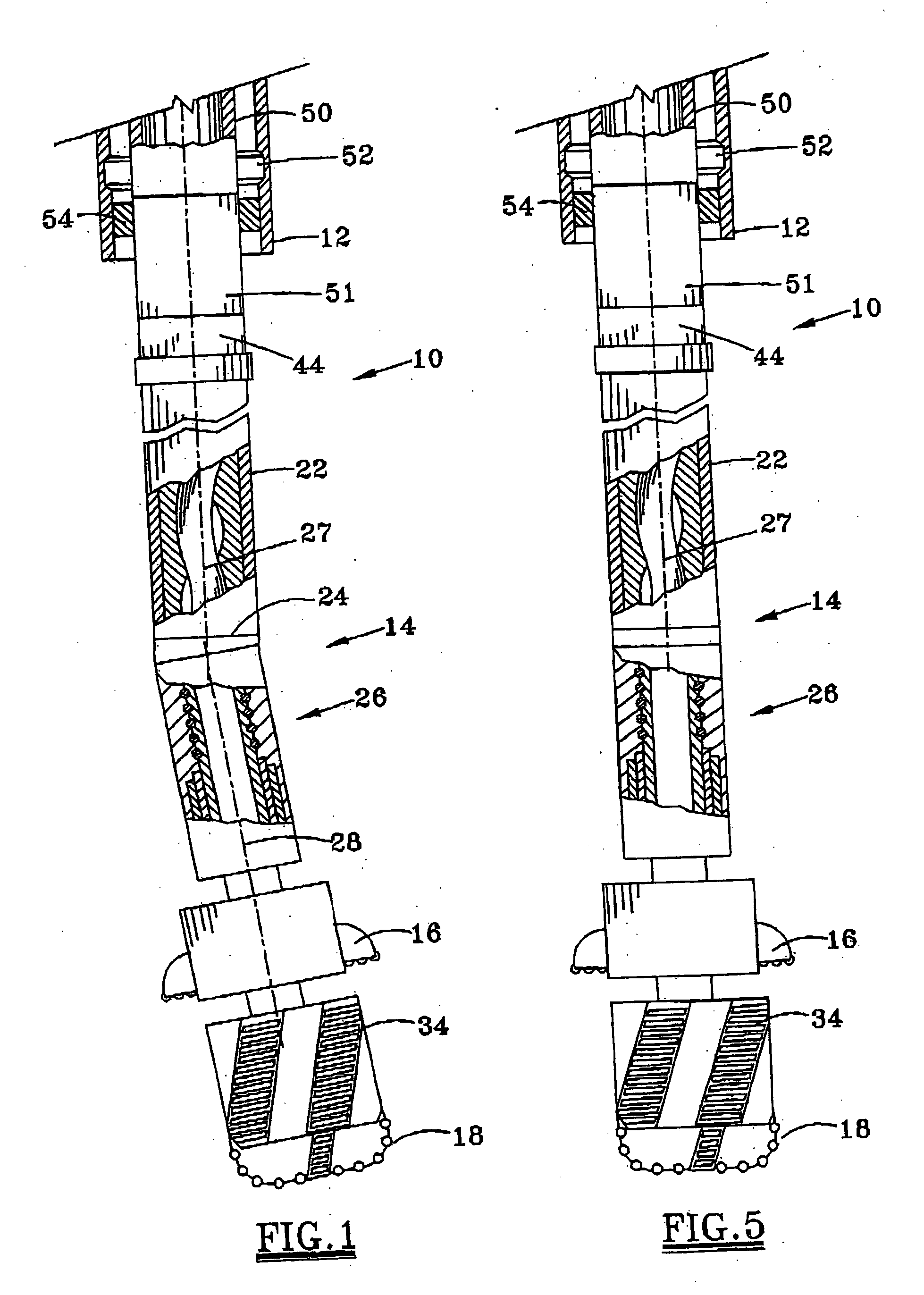

Resurfacing reamer with cutting struts

ActiveUS20080300600A1High precisionShorten the timeDiagnosticsNon-surgical orthopedic devicesReamerPlastic surgery

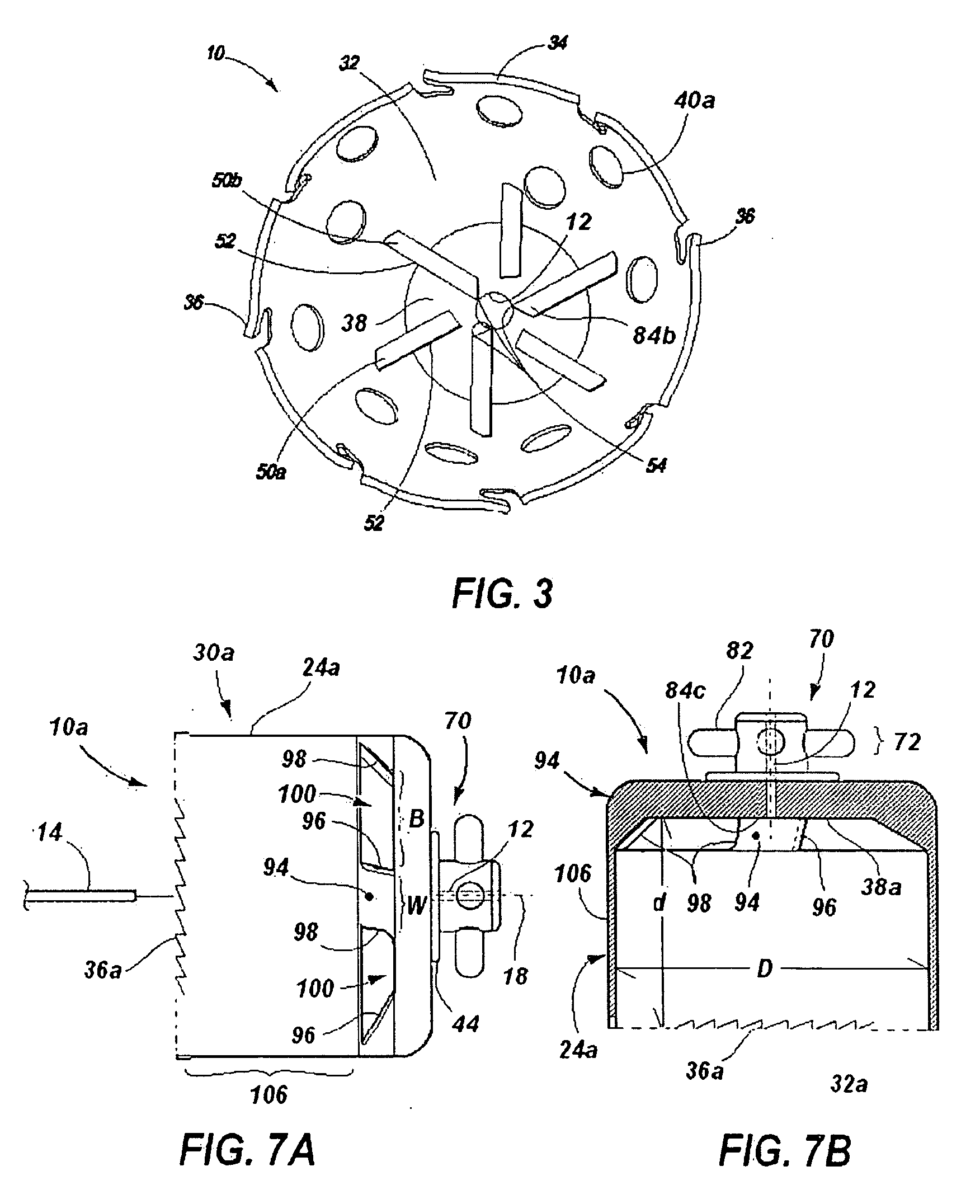

Disclosed is a guided orthopedic bone reamer (10a) for cutting a profile relief shape (21a) into a joint bone (20). The reamer (10a) has a cutting head (30a) and an axial guide assembly (70). The cutting head (30a) has a profile cutting form (24a) with a rim (34) and an apex (38a). The apex (38a) connects to the cutting form (24a) by a set of struts (94). An axial guide assembly (70) has one end (44a) fixed to the apex (38a) and at the other end has a bayonet mechanism (76) connectable to a drive handle. Rim cutting teeth (36a) are set into the rim (34) to cut a cylindrical profile (21a), and bevel cutting teeth (96) integral to the struts (94) cut a bevel (25) onto the cylindrical form (21a) cut into the bone (20). A guide pin bore (12a) passes through the apex (38a)and the guide assembly (70) concentric with the axis of rotation (18) to receive a guide pin (14) to guide the reamer (10a) in cutting alignment relative to the joint bone (20) to be cut.

Owner:VIANT AS&O HLDG LLC

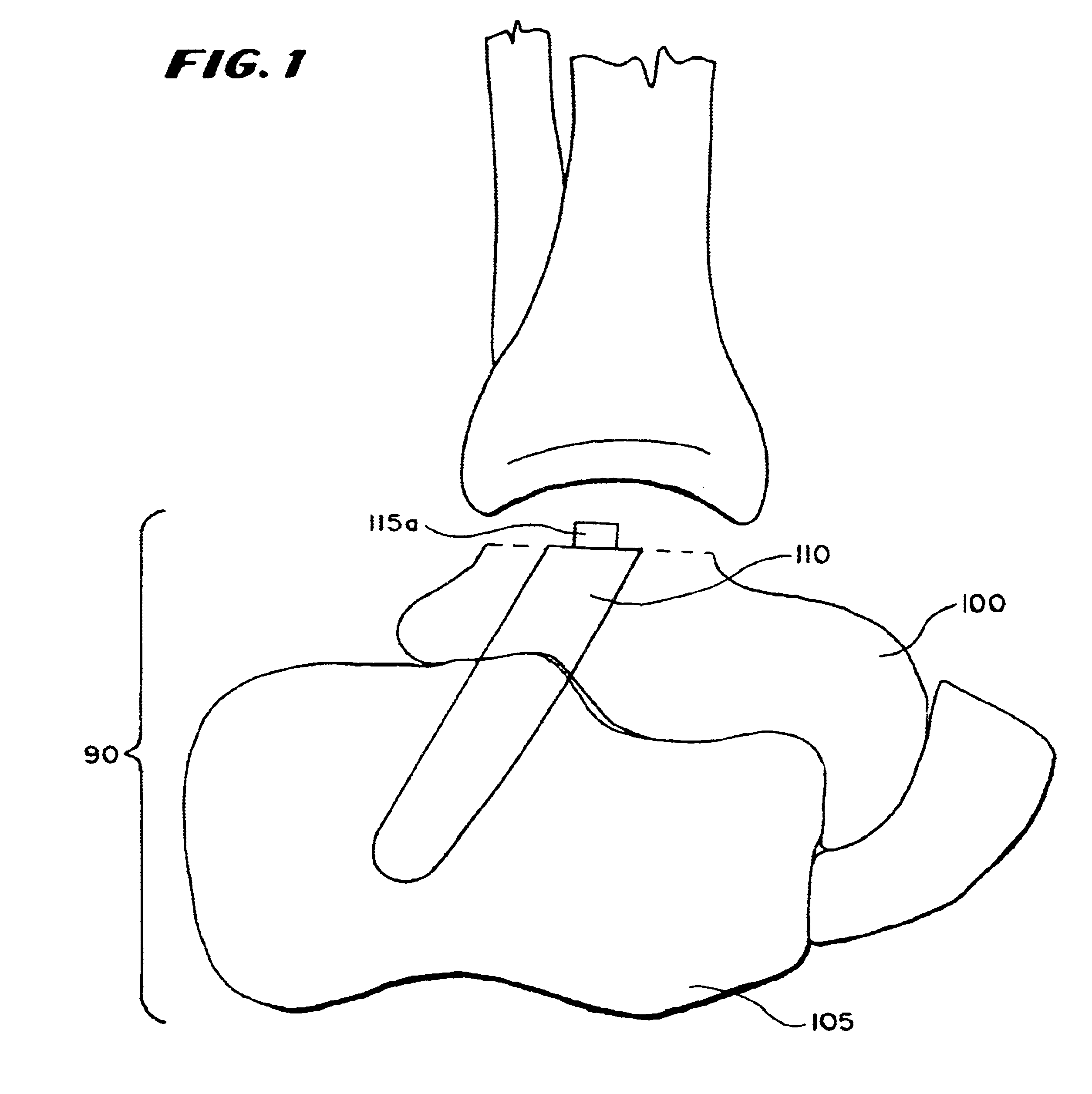

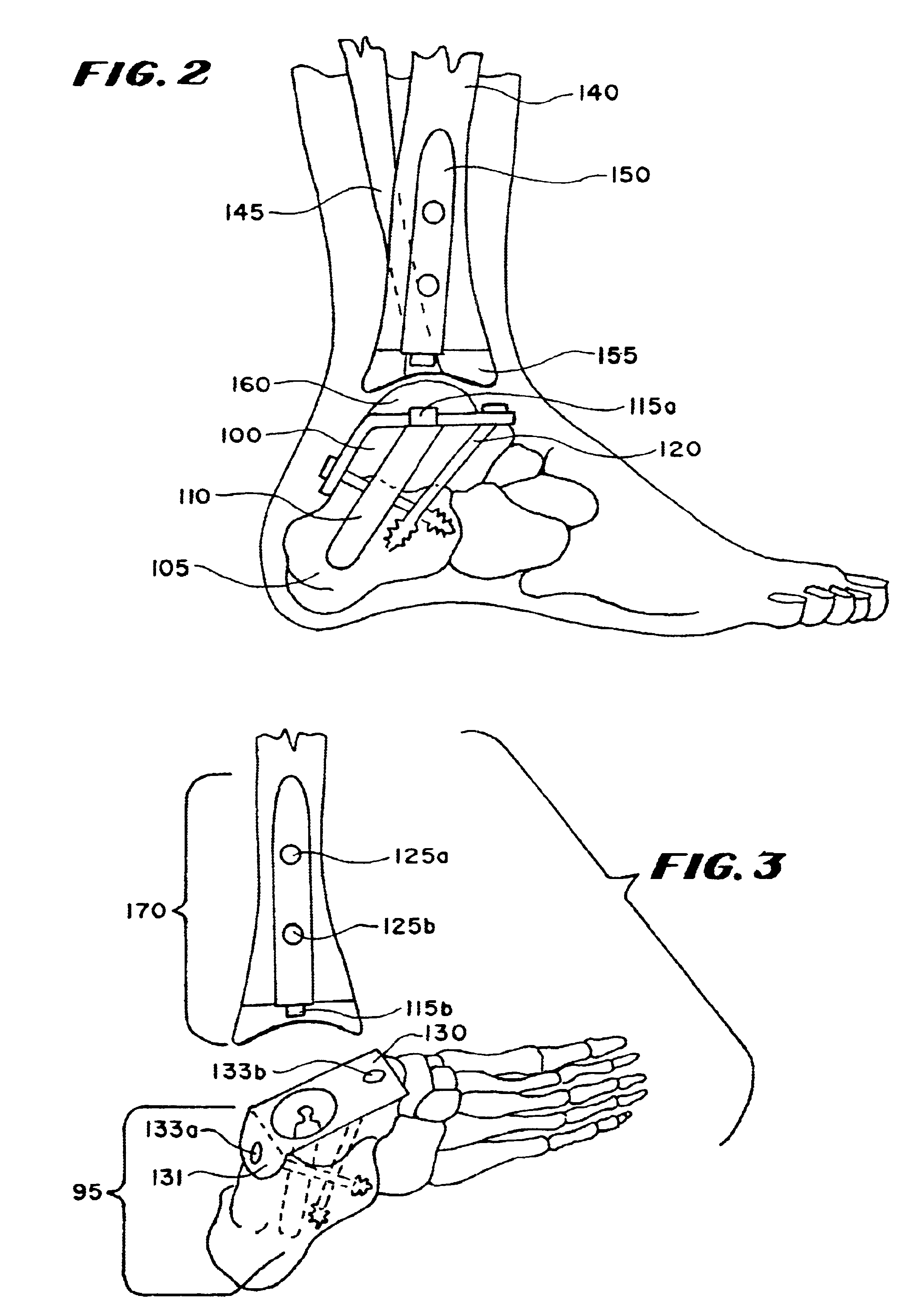

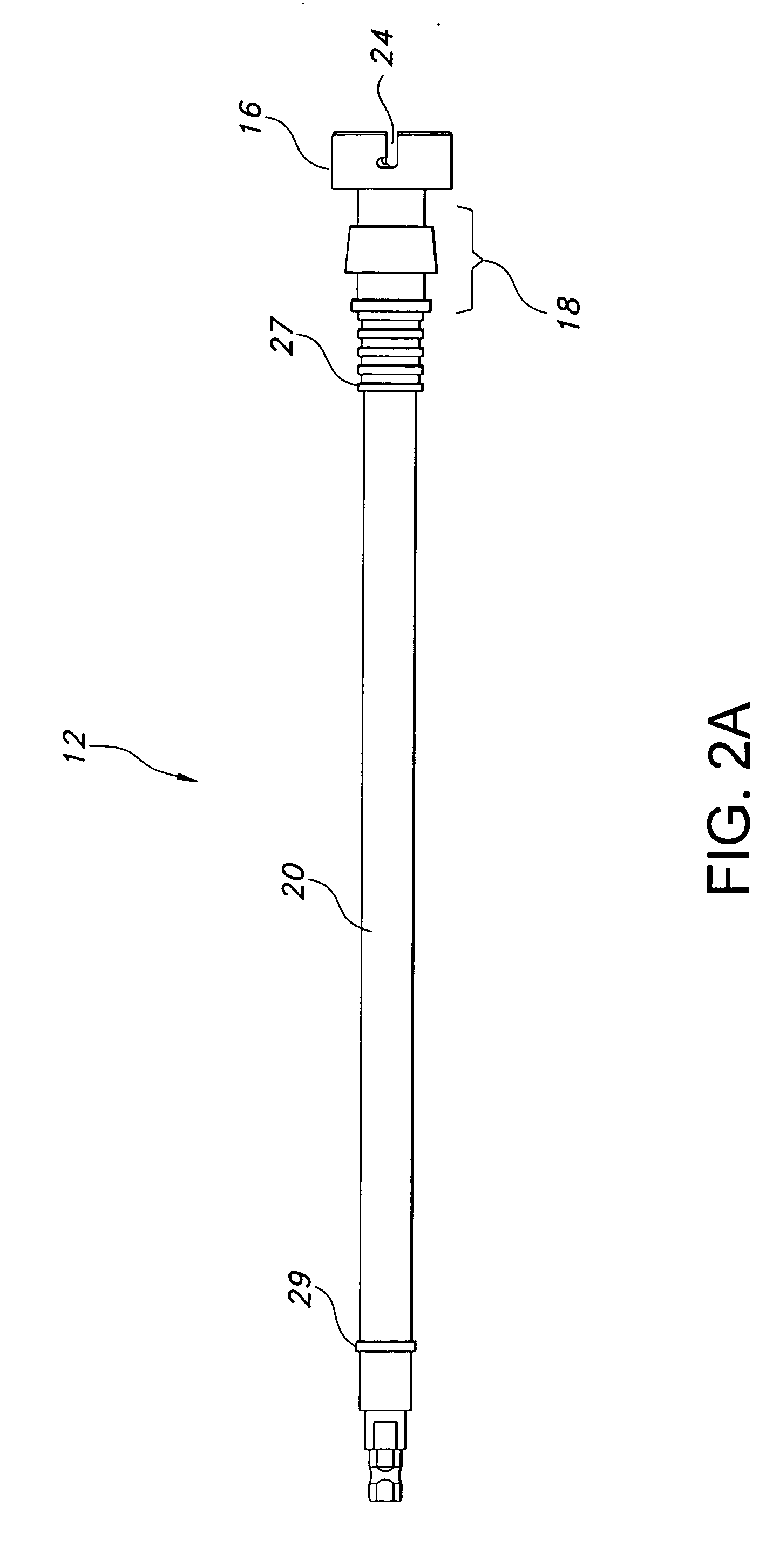

Ankle replacement system

A total ankle replacement system, novel surgical method for total ankle replacement, and novel surgical tools for performing the surgical method are described. The total ankle replacement system includes the calcaneus in fixation of a lower prosthesis body, thereby significantly increasing the amount of bone available for fixation of the lower prosthesis body and allowing the lower prosthesis body to be anchored with screws. The total ankle replacement system further includes a long tibial stem which can also be anchored into the tibia with, for example, screws, nails, anchors, or some other means of attachment. The novel surgical arthroscopic method allows introduction of ankle prostheses into the ankle joint through an exposure in the tibial tubercle. Various novel surgical instruments, such as a telescoping articulating reamer and a talo-calcaneal jig, which facilitate the novel surgical method, are also described.

Owner:INBONE TECH

Downhole Tool

A double shouldered downhole tool connection comprises box and pin connections having mating threads intermediate mating primary and secondary shoulders. The connection further comprises a secondary shoulder component retained in the box connection intermediate a floating component and the primary shoulders. The secondary shoulder component and the pin connection cooperate to transfer a portion of makeup load to the box connection. The downhole tool may be selected from the group consisting of drill pipe, drill collars, production pipe, and reamers. The floating component may be selected from the group consisting of electronics modules, generators, gyroscopes, power sources, and stators. The secondary shoulder component may comprises an interface to the box connection selected from the group consisting of radial grooves, axial grooves, tapered grooves, radial protrusions, axial protrusions, tapered protrusions, shoulders, and threads.

Owner:INTELLISERV

Expandable reamers for earth boring applications

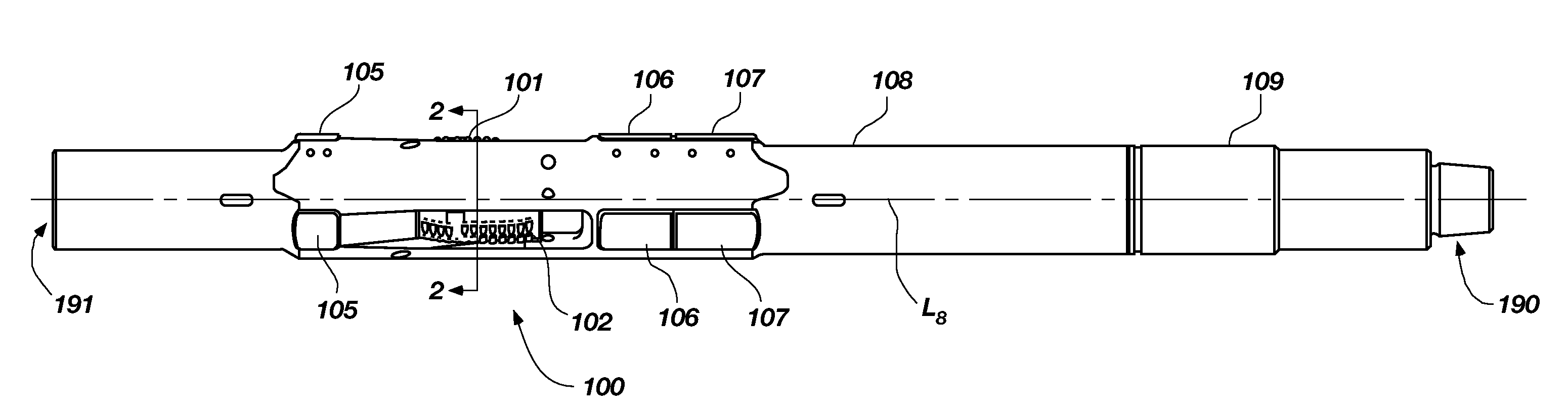

An expandable reamer apparatus for drilling a subterranean formation includes a tubular body, one or more blades, each blade positionally coupled to a sloped track of the tubular body, a push sleeve and a drilling fluid flow path extending through an inner bore of the tubular body for conducting drilling fluid therethrough. Each of the one or more blades includes at least one cutting element configured to remove material from a subterranean formation during reaming. The push sleeve is disposed in the inner bore of the tubular body and coupled to each of the one or more blades so as effect axial movement thereof along the track to an extended position responsive to exposure to a force or pressure of drilling fluid in the flow path of the inner bore. Other embodiments of the expandable reamer apparatus are provided.

Owner:BAKER HUGHES INC

Expandable stabilizer with roller reamer elements

An expandable reamer apparatus for drilling a subterranean formation may include a tubular body, one or more blades, each blade positionally coupled to a sloped track of the tubular body, a push sleeve and a drilling fluid flow path extending through an inner bore of the tubular body for conducting drilling fluid therethrough. Each of the one or more blades may be configured to ream a subterranean formation. The push sleeve may be disposed in the inner bore of the tubular body and coupled to each of the one or more blades so as effect axial movement thereof along the track to an extended position responsive to exposure to a force or pressure of drilling fluid in the flow path of the inner bore. Each blade may include one or more roller elements for reaming a wellbore.

Owner:BAKER HUGHES INC

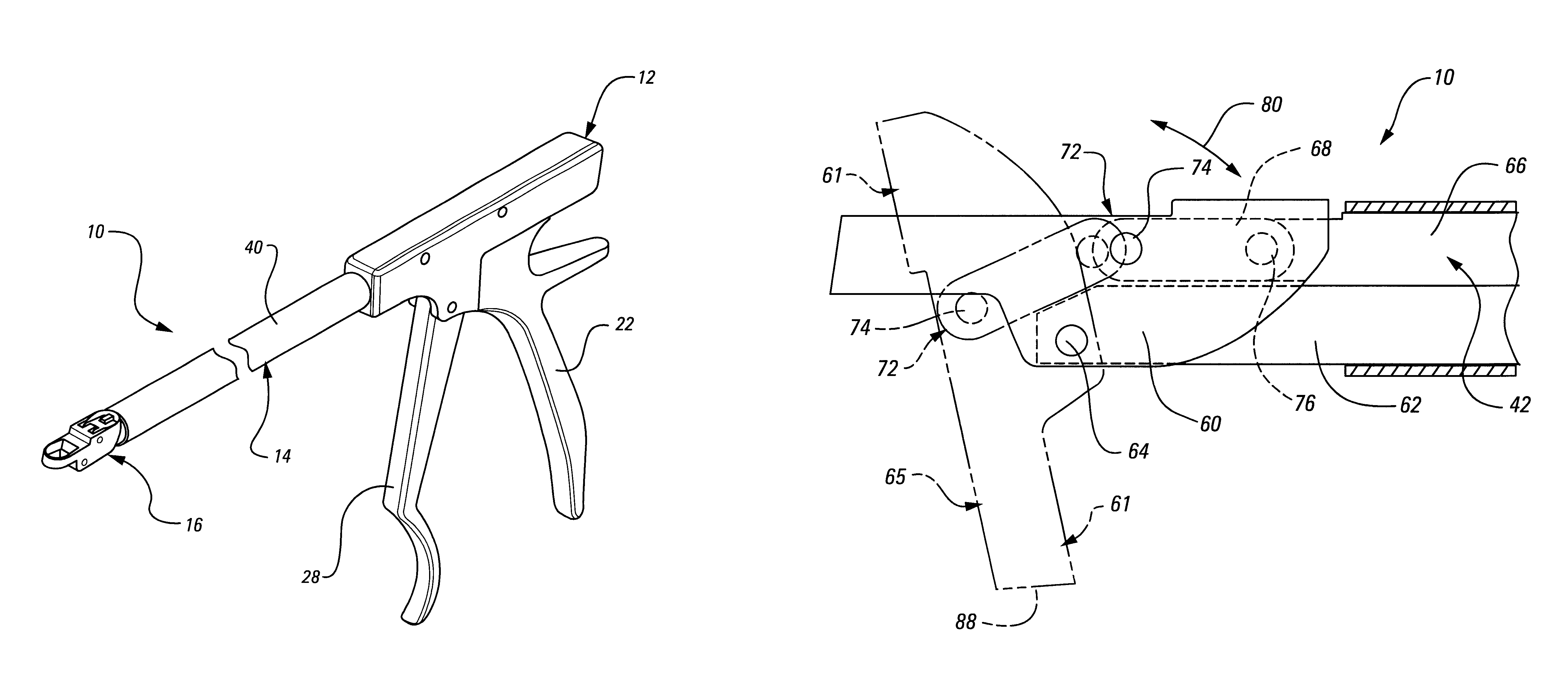

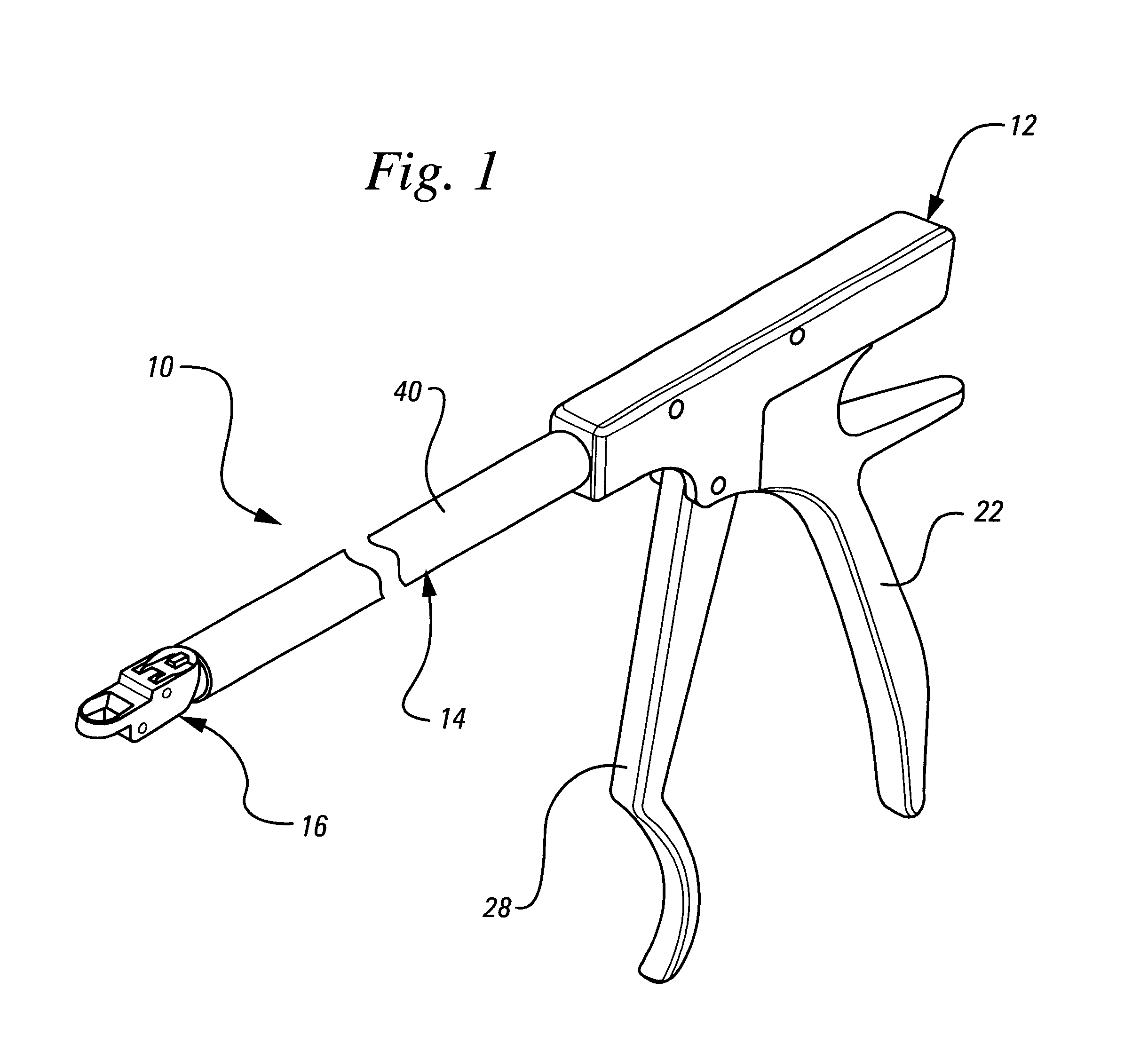

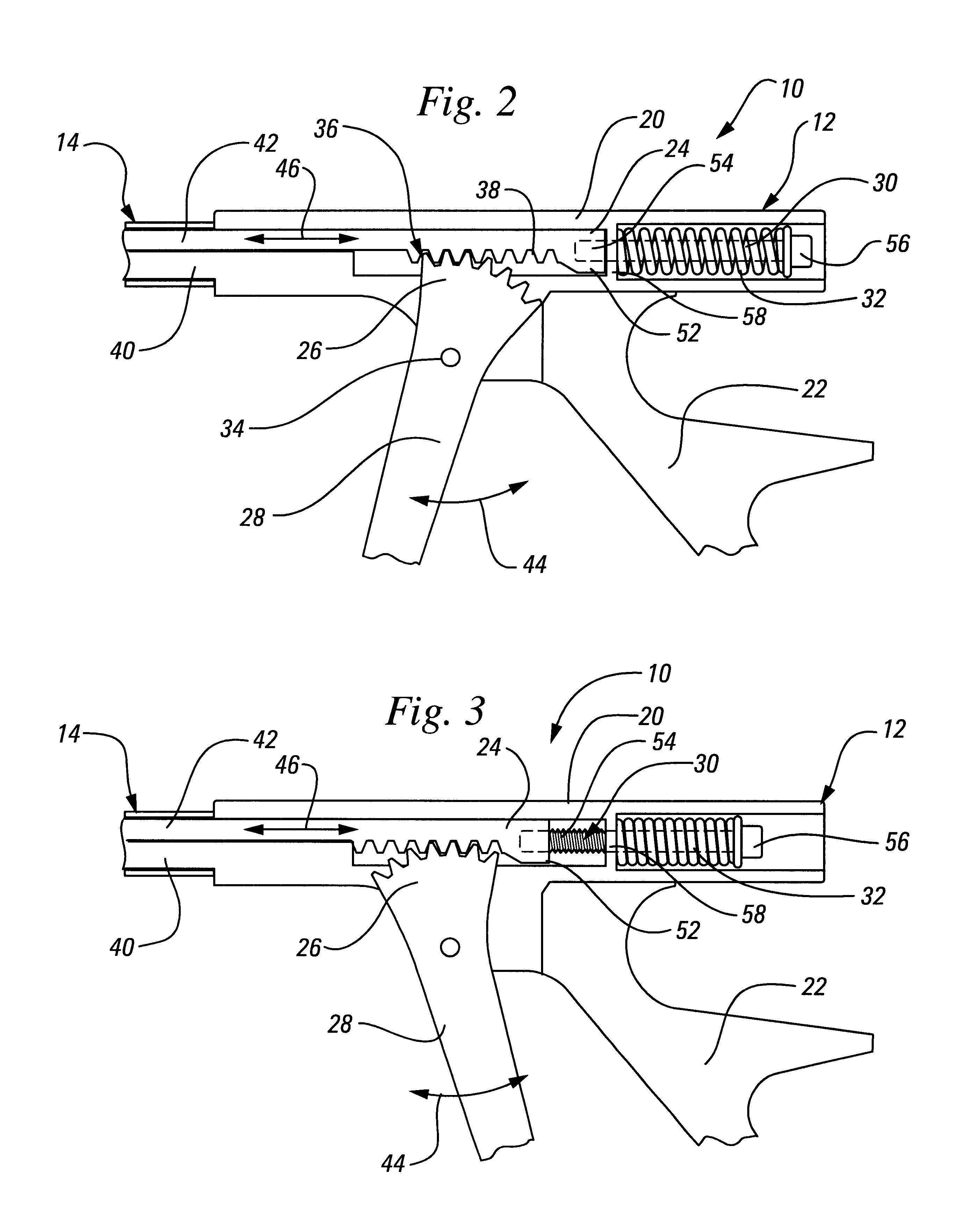

Circumferential resecting reamer tool

A tool for cutting tissue comprising a body, a handle lever, a drive rod, and a cutter beam. The drive rod constructed and arranged for longitudinal movement through the body. The handle lever being operatively engaged to the drive rod, such that when the handle lever is moved between a first position and a second position the drive rod is moved between an advanced position and a retracted position. The drive rod extending from a proximal end of the body to a distal end. The cutter beam being pivotally engaged to the distal end of the body. The cutter beam being pivotally moveable between a non-actuated position and an actuated position. A lower pivot member pivotally connects the distal end of the body and the cutter beam. The cutter beam being further pivotally engaged to a distal end of the drive rod.

Owner:SPINEOLOGY

Expandable stabilizer with roller reamer elements

Owner:BAKER HUGHES INC

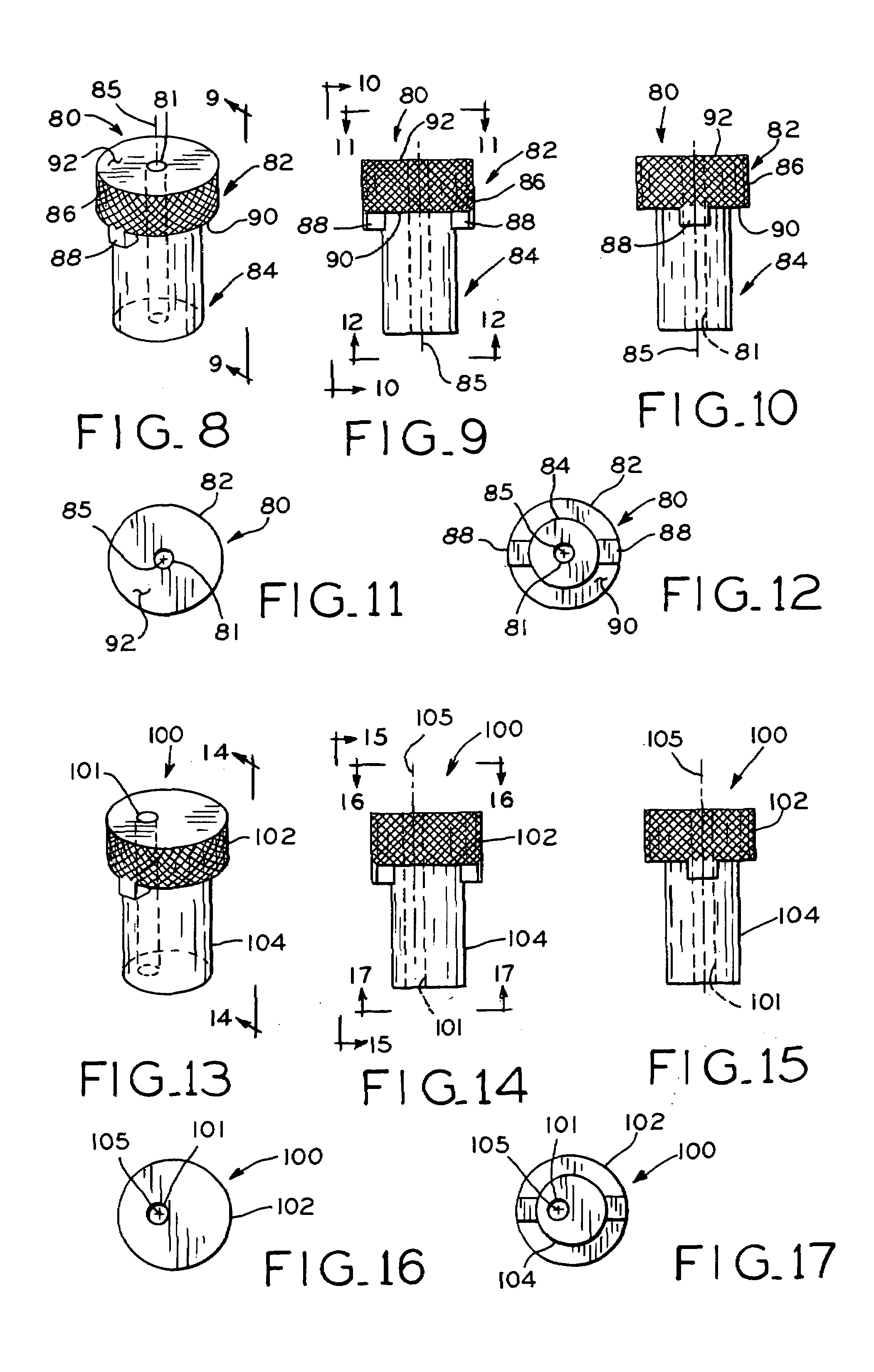

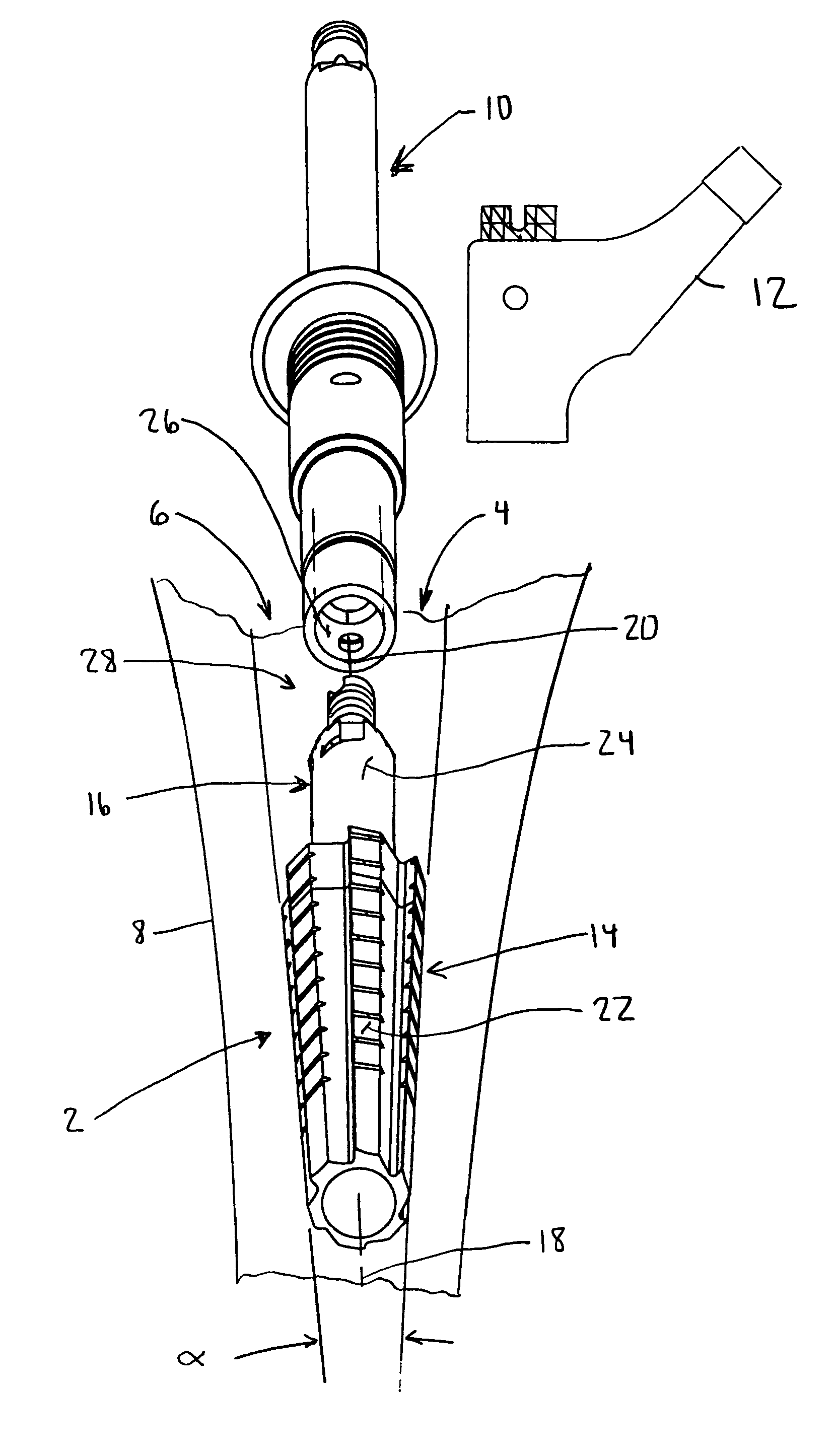

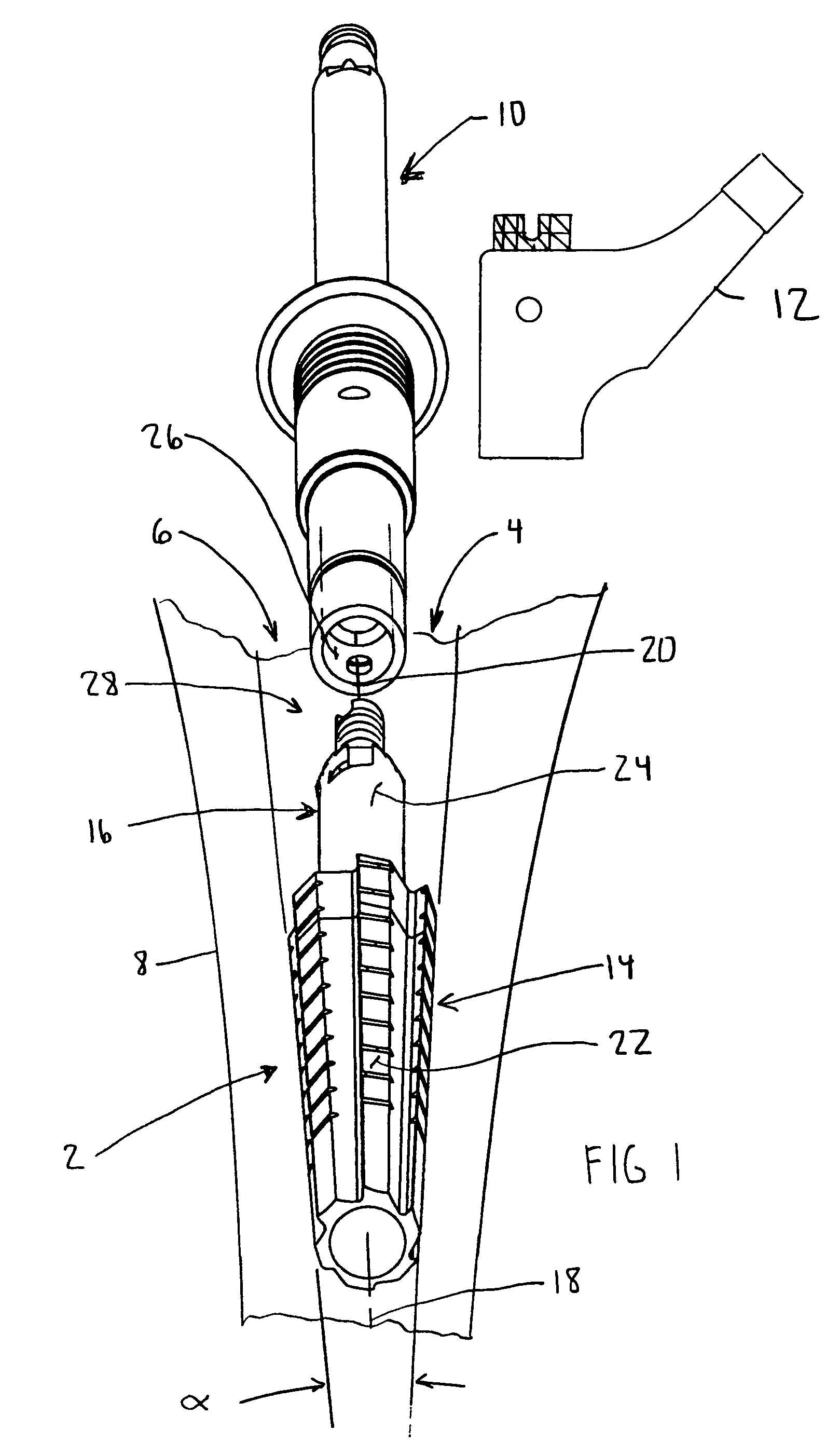

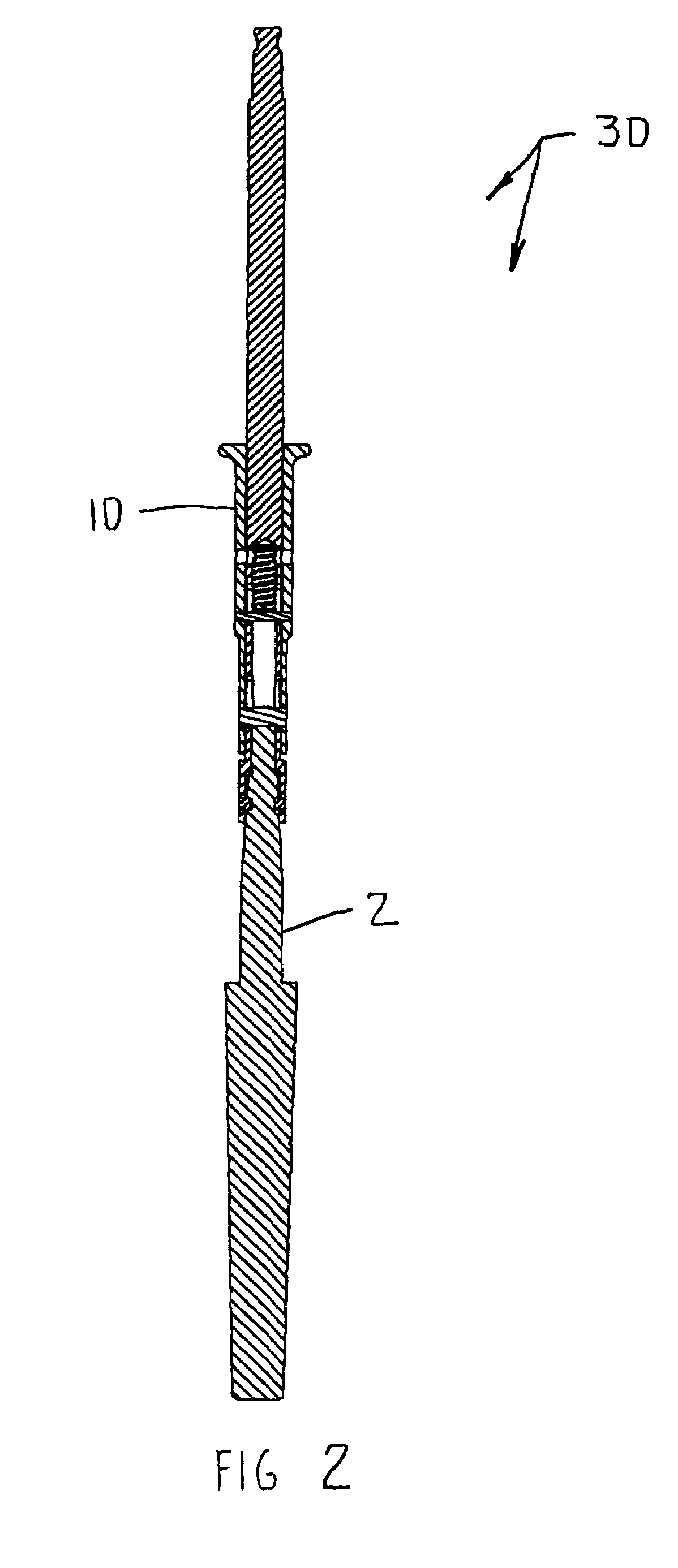

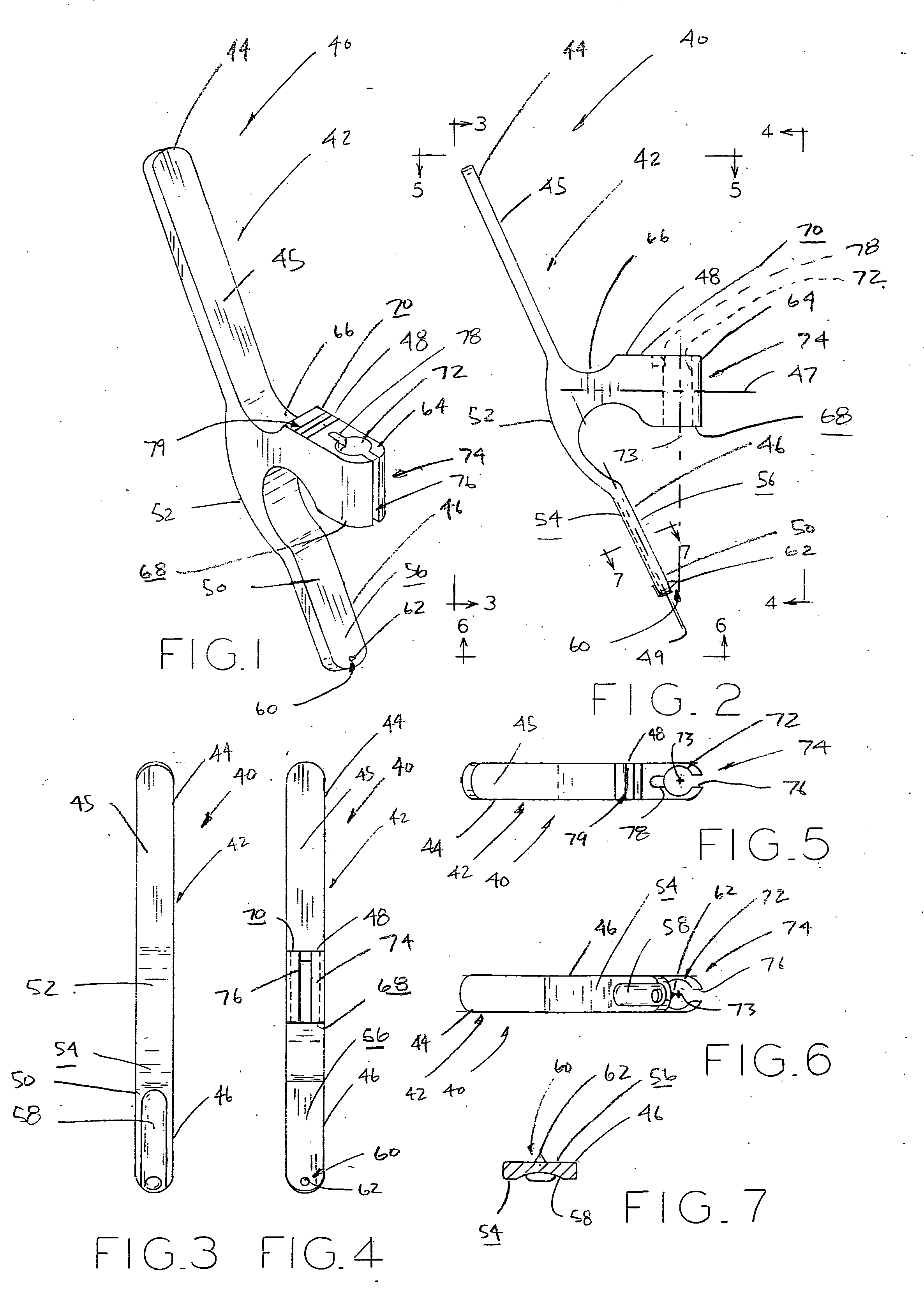

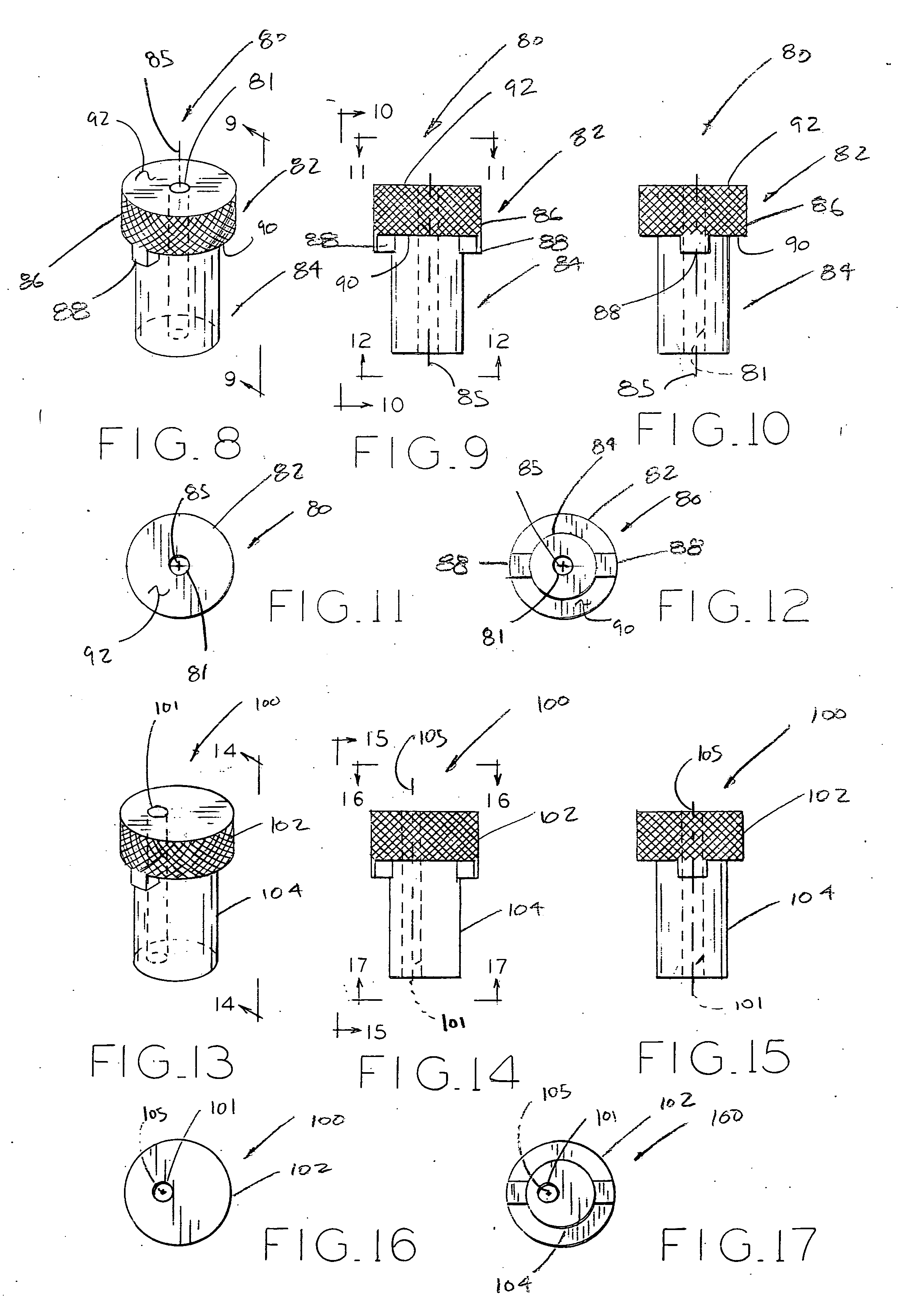

Modular tapered reamer for bone preparation and associated method

A kit (400) for use in performing joint arthroplasty is provided. The kit (400) includes a trial (12) and a reamer (2). The reamer (2) is for preparing a cavity (4) in the intramedullary canal (8) of a long bone (8) with the use of a driver (10) and to assist in performing a trial reduction. The reamer (2) includes a first portion (14) for placement at least partially in the cavity (4) of the long bone (8) and a second portion (16) operably connected to the first portion (14). The reamer (2) is removably connected to the driver (10) to rotate the reamer (2). The trial (12) is removably attachable to the reamer (2).

Owner:DEPUY PROD INC

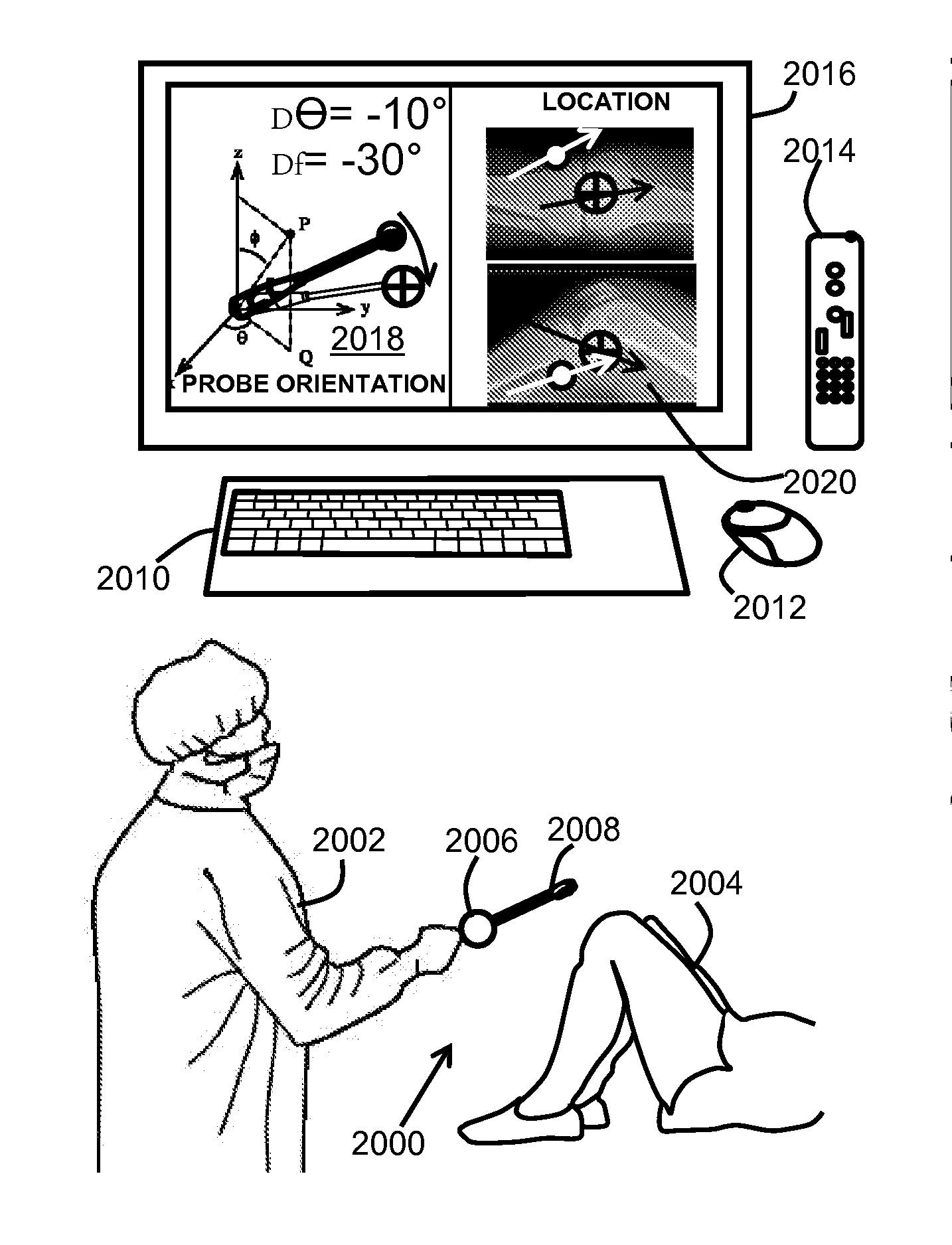

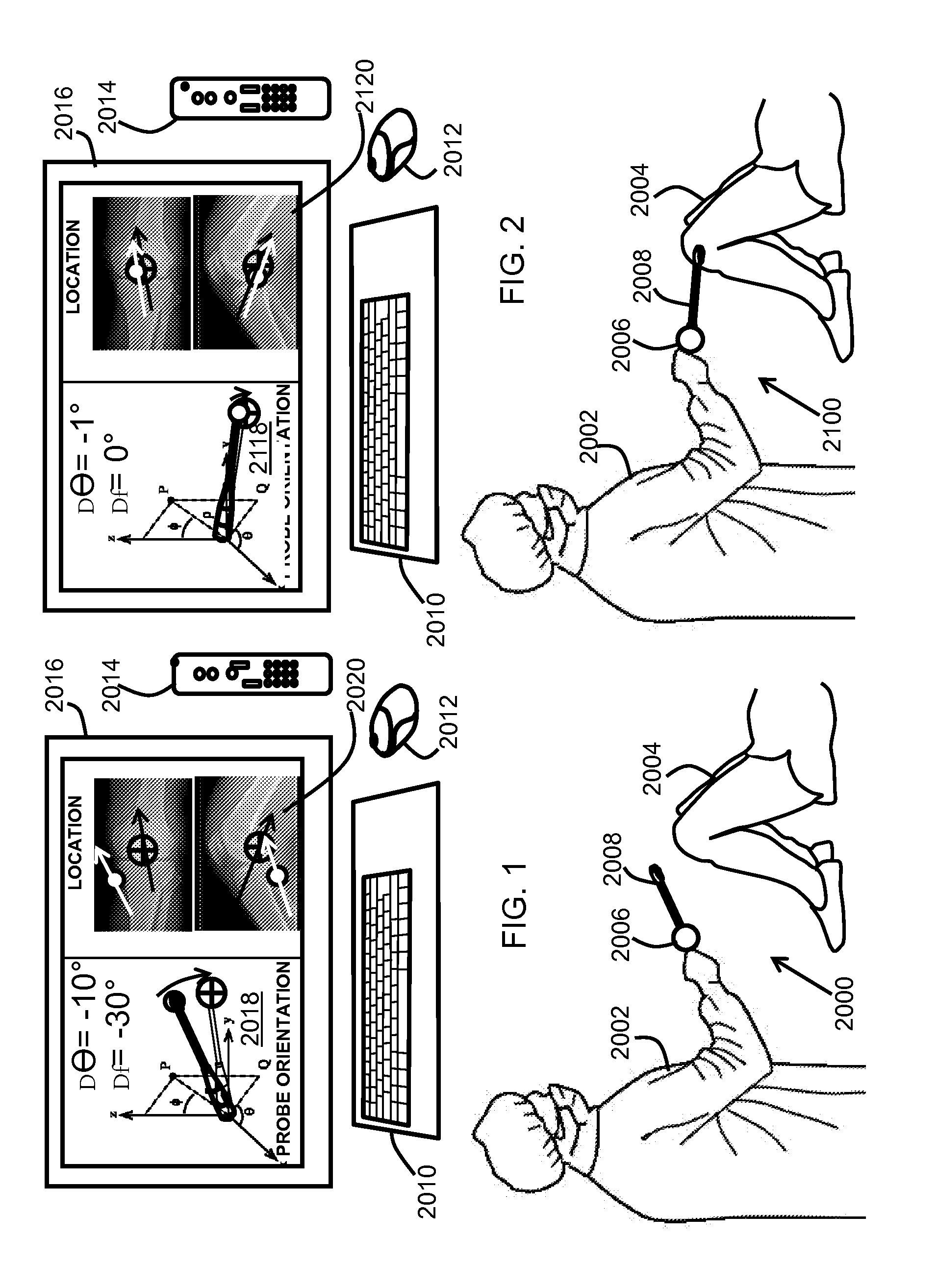

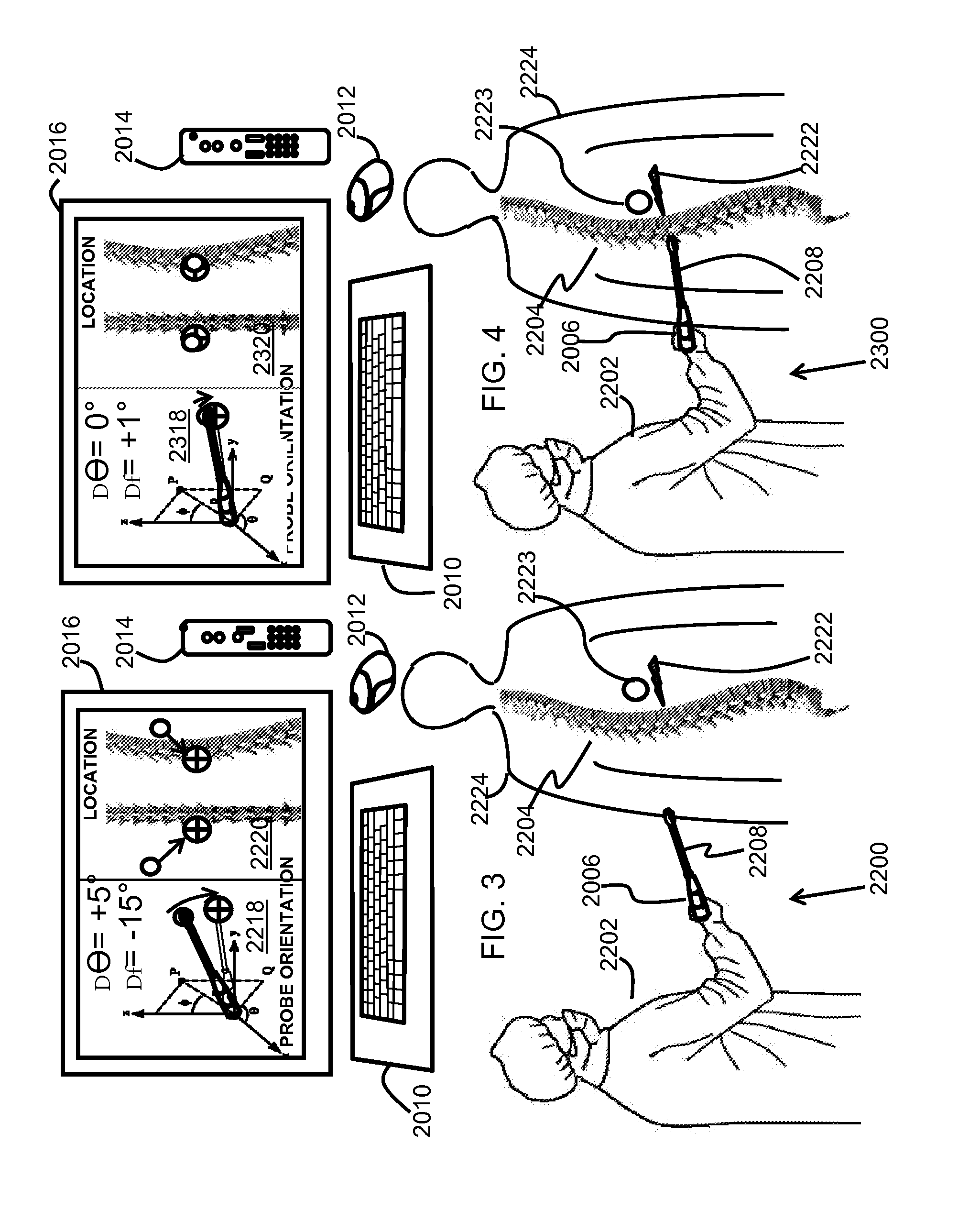

Image-guided navigated precision reamers

Methods and systems for providing an image guided navigated precision reamer are set forth. According to one embodiment, a method comprising providing a reamer device, the reamer device comprising a reamer shaft adapted to provide a locking capability for receiving a reamer component and capable of being rotated in use, an intermediate sleeve adapted to receive the reamer shaft substantially coaxially, and an outer sleeve adapted to receive the intermediate sleeve, wherein the reamer shaft is adapted to rotate relative to the outer sleeve without translation relative to the outer sleeve, and the sleeve is adapted to function as a handle during reaming; providing a sensor apparatus for sensing position and orientation of a plurality of location indicia; providing a first set of location indicia coupled to an anatomical reference; providing a second set of location indicia coupled to the reamer device; providing a prosthetic implant; referencing information obtained from the first and second set of location indicia; reaming a cavity of an osteological anatomical structure in preparation for receiving the prosthetic implant based at least in part on the referenced information; and placing the prosthetic implant into the cavity is set forth.

Owner:MCCOMBS DANIEL L +1

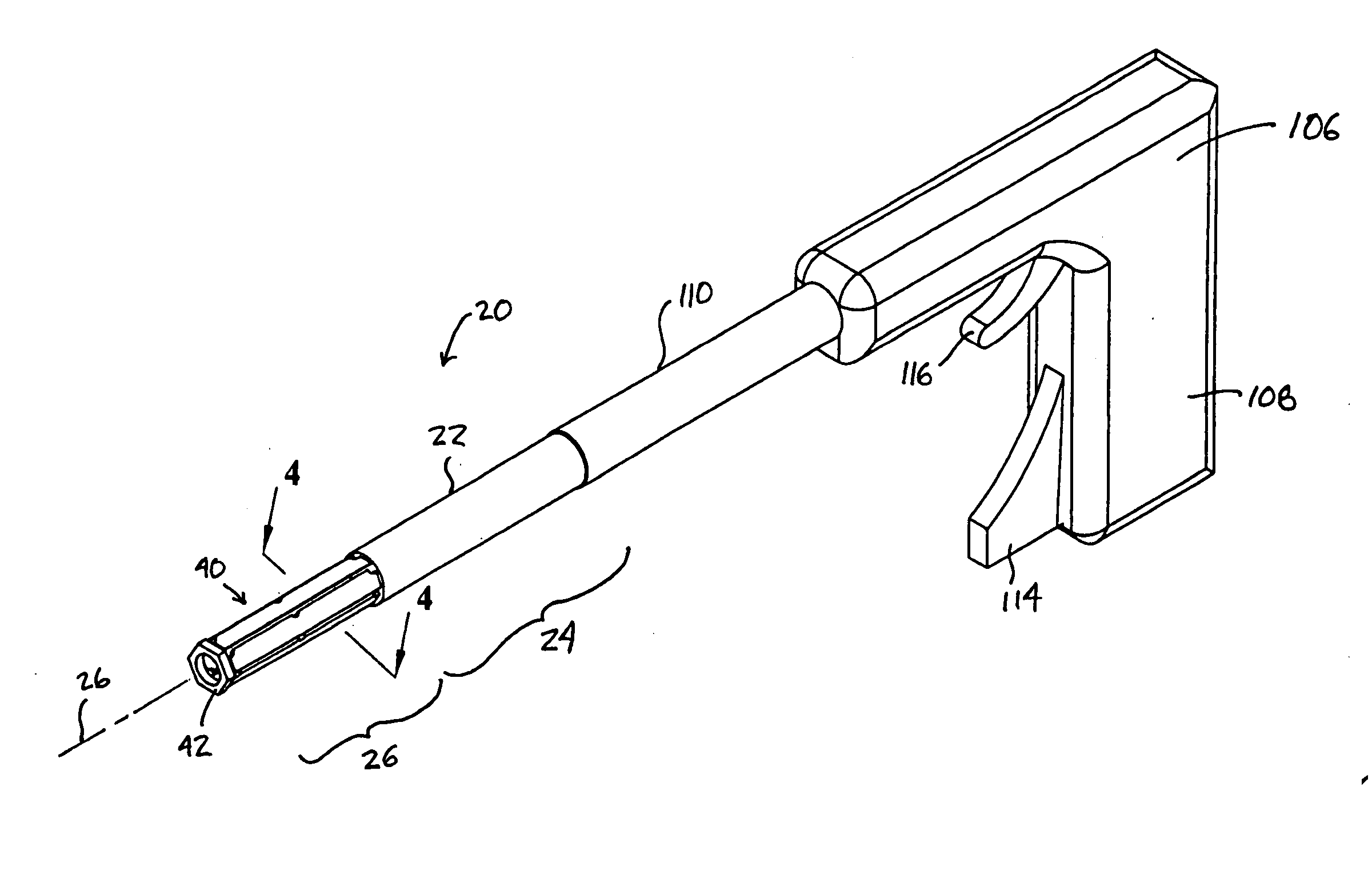

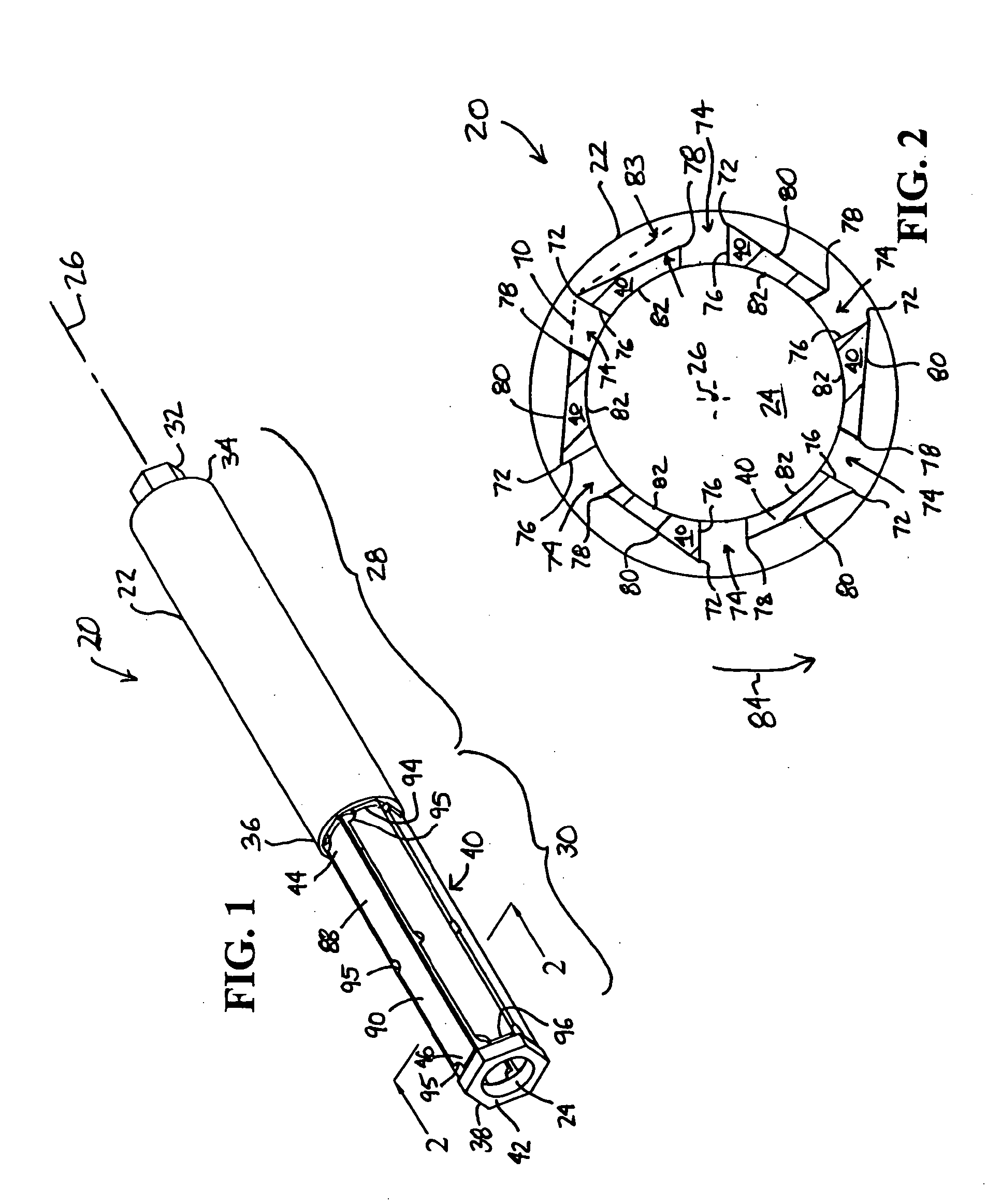

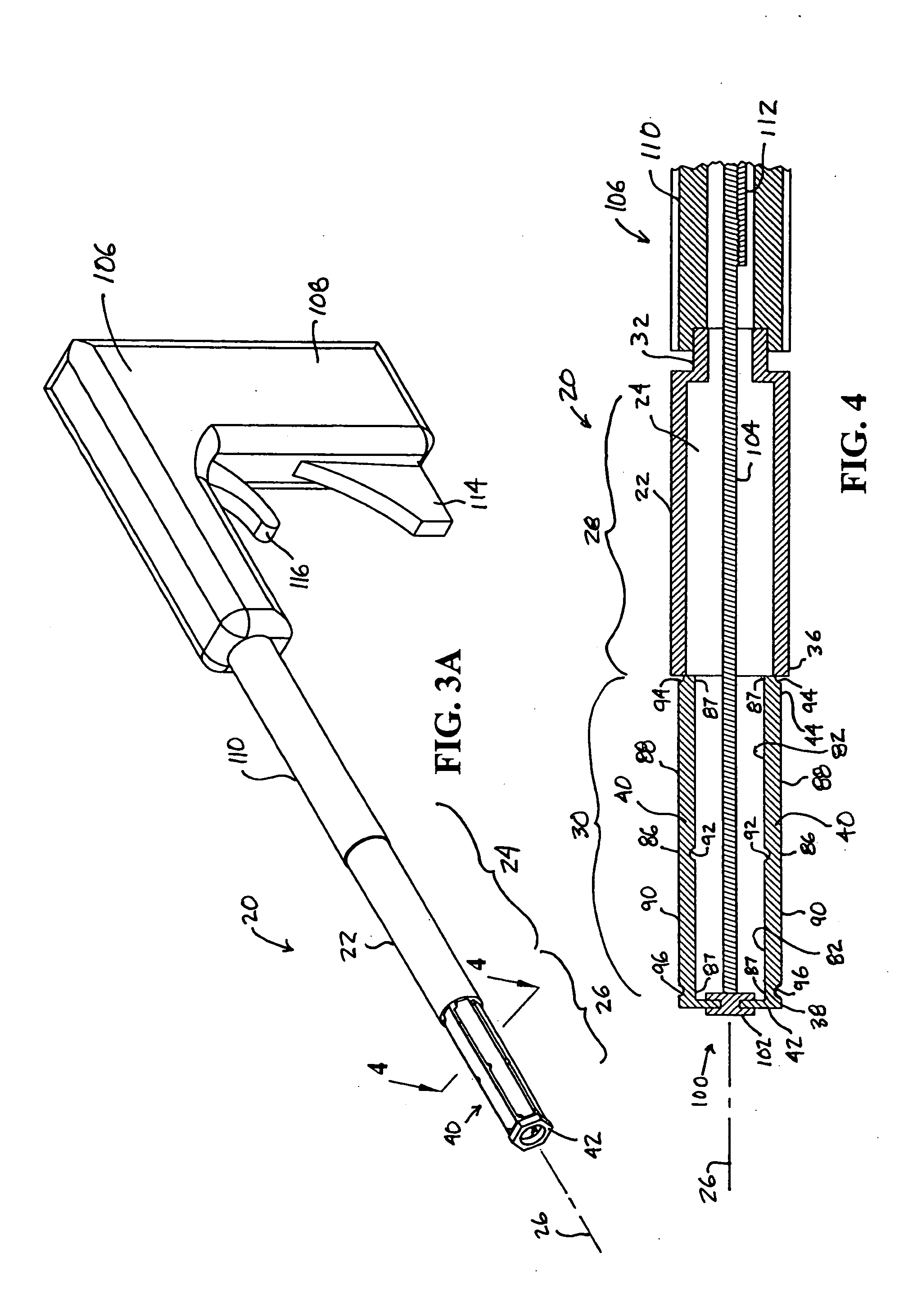

Method and apparatus for preparing a glenoid surface

ActiveUS20060058809A1Easy to implantEasy to installProsthesisOsteosynthesis devicesAnterior surfaceProsthesis

A method and apparatus for facilitating shoulder arthroplasty by providing a reference to establish version of the glenoid. In one form of the invention, a guide for positioning a guide pin to facilitate implantation of a glenoid prosthesis is provided. To properly position the guide pin, the guide is first oriented with respect to the scapula. A portion of the guide is positioned over the approximate center of the glenoid surface and another portion of the guide is positioned against the anterior surface of the scapula. After the guide is properly positioned, the guide pin is inserted through an aperture in the guide and anchored in the glenoid. Thereafter, the guide pin can serve as an alignment guide for other devices used to modify the glenoid surface. For example, a reamer having a cannulated central shaft can be placed over the guide pin and utilized to resurface the glenoid.

Owner:ZIMMER INC

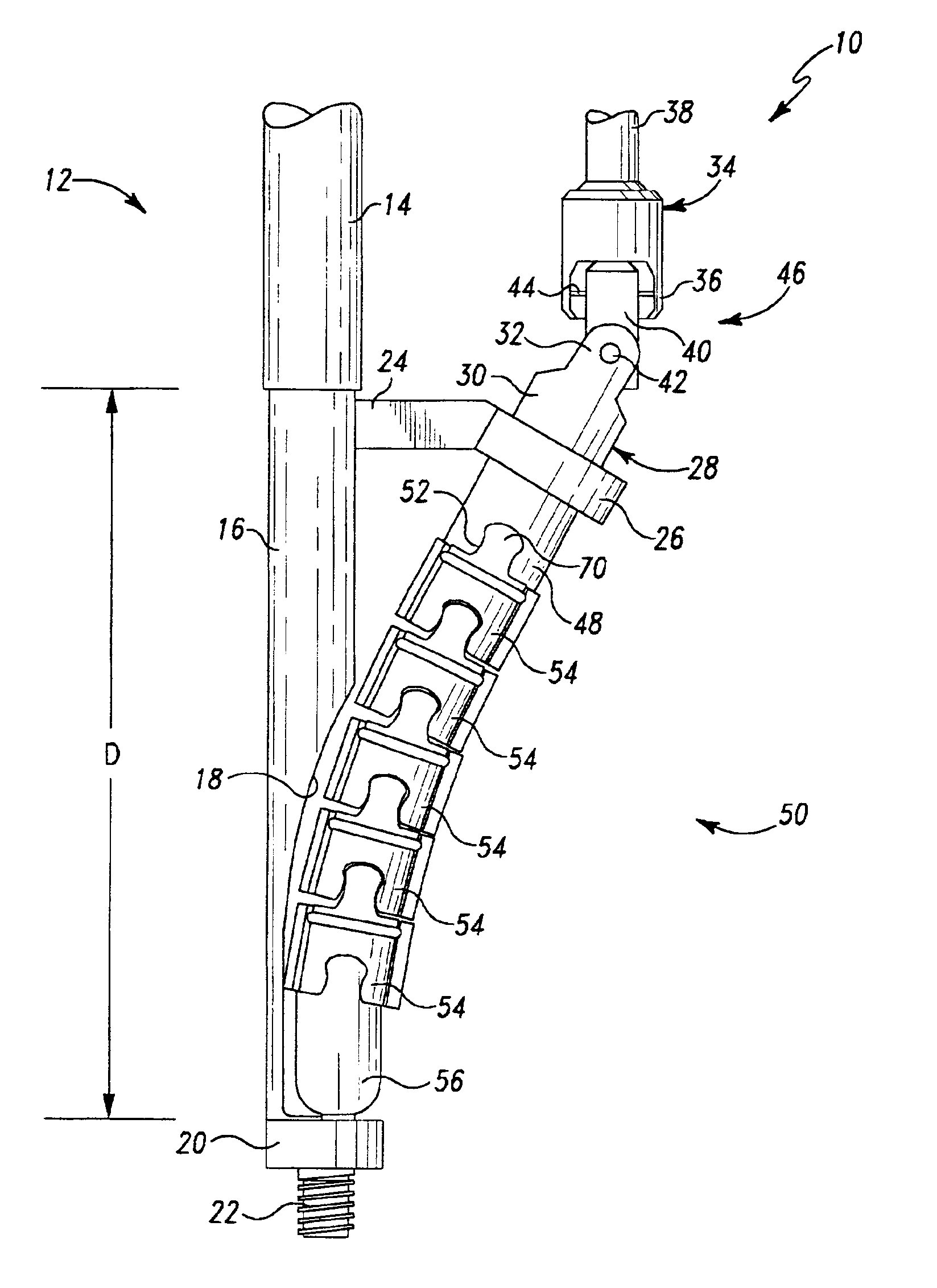

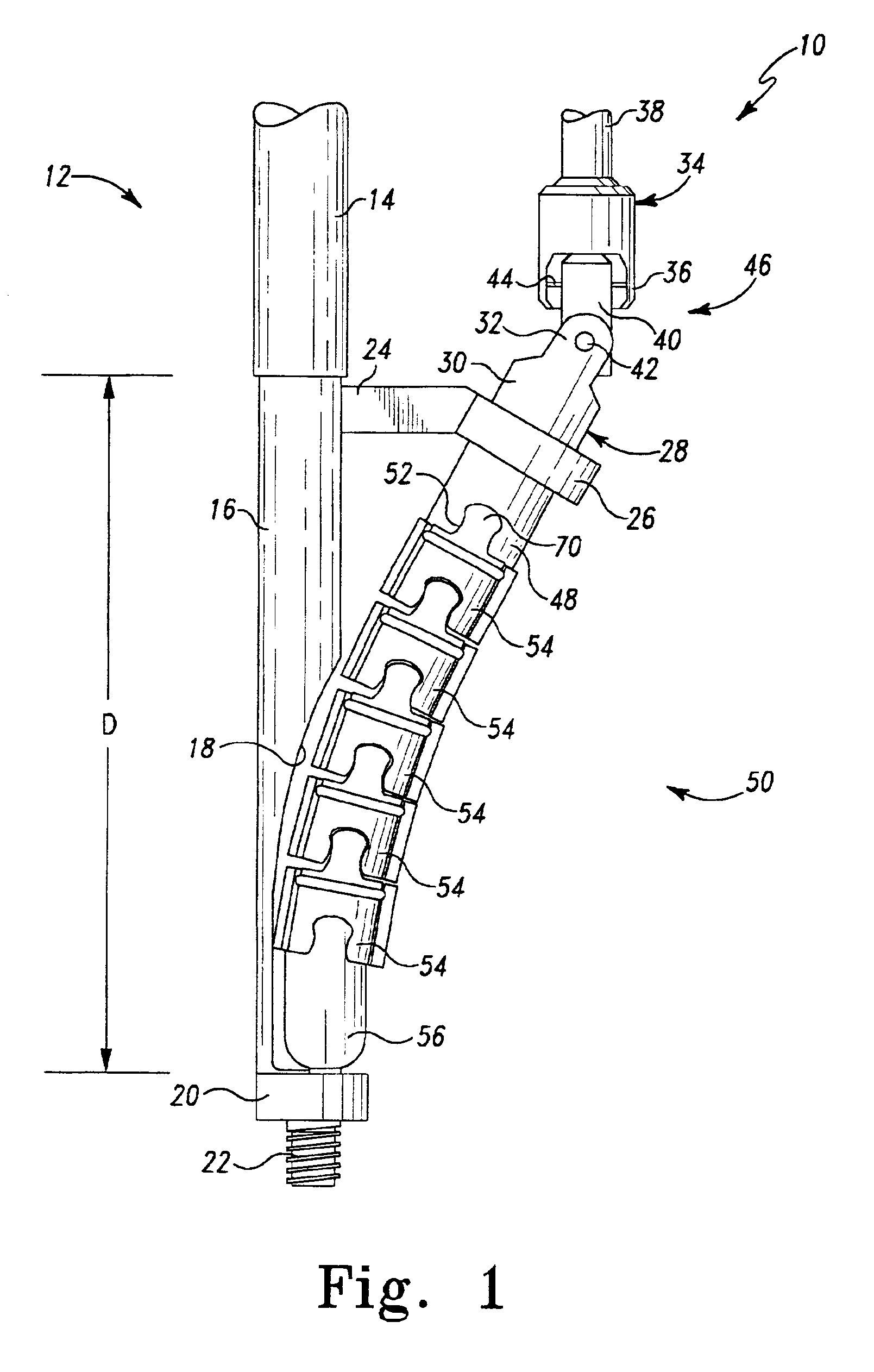

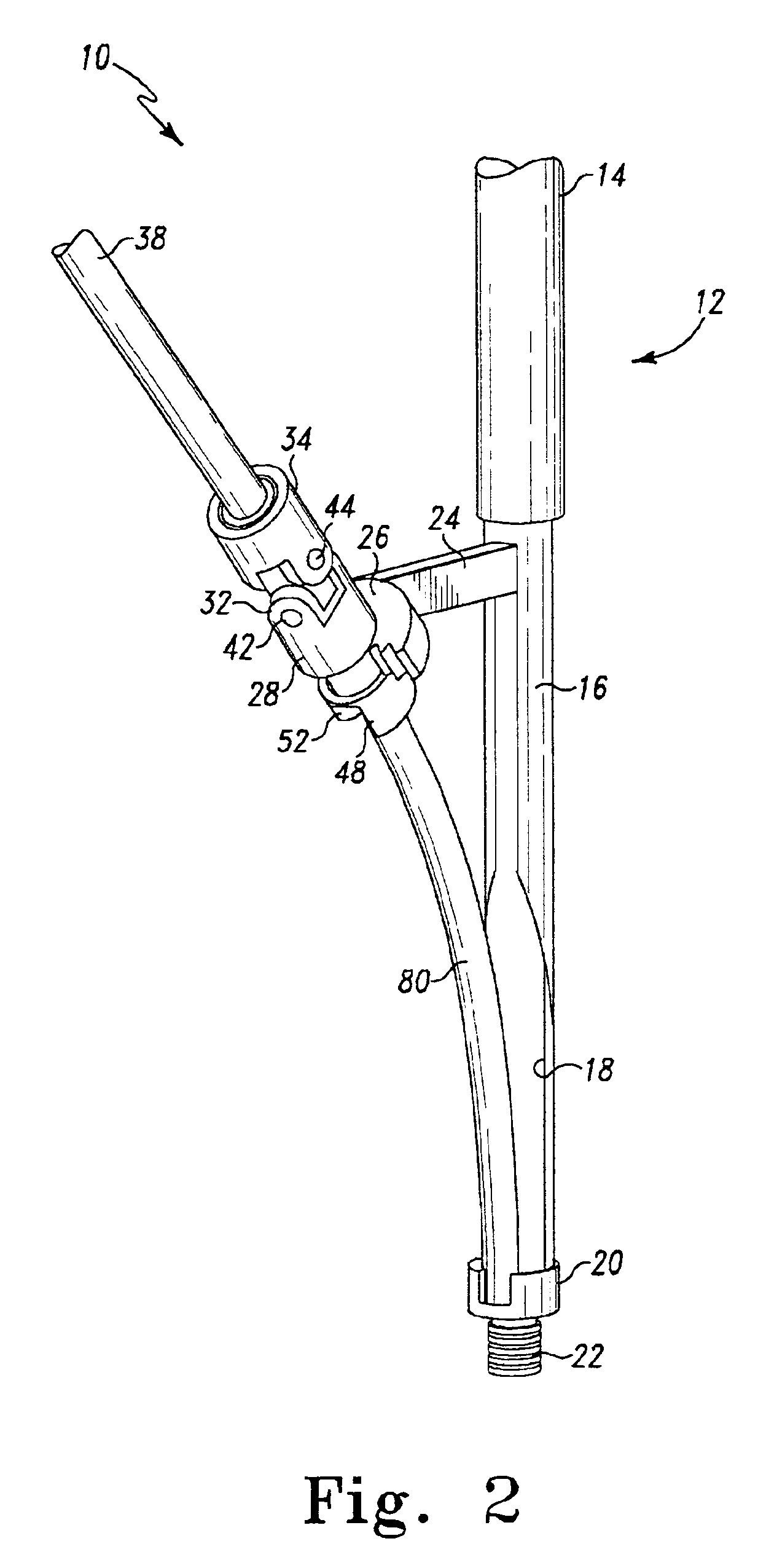

Medical instrument for milling a curved path in bone and procedure

A medical instrument and procedure is adapted to mill bone along a curve and with respect to at least two angles of orientation with respect to an input source of rotary motion. Particularly, the medical instrument is a bone milling apparatus that is configured to mill bone along a predetermined curved path or curve. The bone milling apparatus includes a reamer that is rotatable about a curved shaft which is retained by a frame. The shaft has a predetermined curve that corresponds to a desired milling curve. The reamer is comprised of a plurality of interconnected segments, with each segment having cutting surfaces such that each segment is a cutter. The reamer is thus flexible with respect to the interconnection between the individual segments.

Owner:DEPUY ORTHOPAEDICS INC

Prosthetic hip installation system

A prosthetic hip installation system comprising a reamer, an impactor, a tracking element, and a remote system. The tracking element can be integrated into the reamer or impactor for providing tracking data on the position or orientation. Alternatively, the tracking element can be housed in a separate module that can be coupled to either the reamer or impactor. The tracking element will couple to a predetermined location. Points in 3D space can be registered to provide a frame of reference for the tracking element or when the tracking element is moved from tool to tool. The tracking element sends data from the reamer or impactor wirelessly. The remote system receives the tracking data and can further process the data. A display on the remote system can support placement and orientation of the tool to aid in the installation of the prosthetic component.

Owner:ORTHOSENSOR

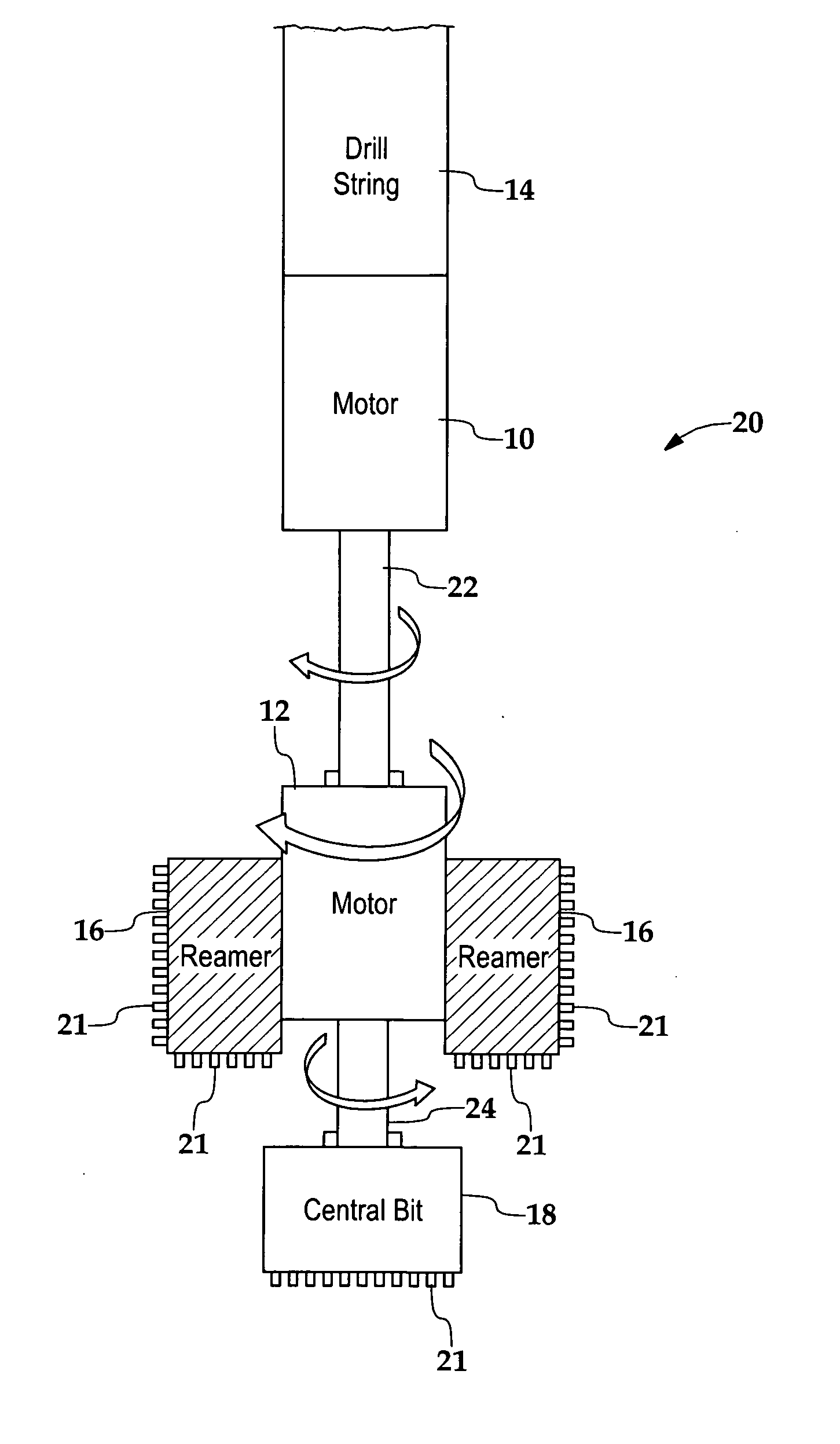

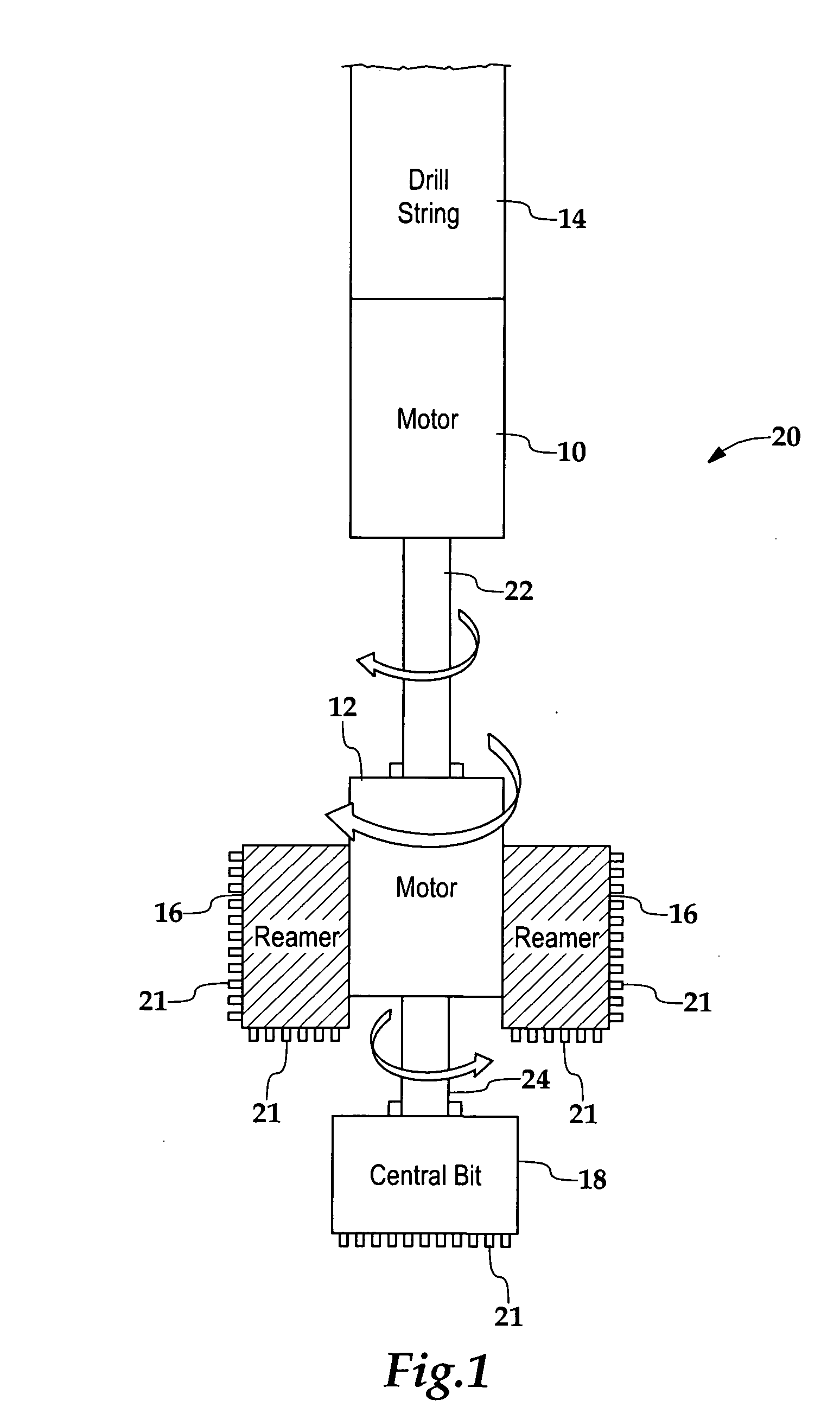

Earth boring tool

InactiveUS20060237234A1Without adversely affecting cutter performance and drilling rateAvoid excessive wearDrill bitsBorehole drivesReamerDrill bit

An earth boring tool includes two coaxially-aligned, positive displacement motors. One motor turns a pilot bit and the other turns a reamer concentric with the pilot bit. The central bit bores the center of the hole and the reamer enlarges it. The central bit is rotated relatively faster, while rotation of the larger diameter reamer is relatively slow. The tool can thus be used to bore larger diameter holes without slowing drilling rates or adversely affecting performance of the cutter elements due to higher tangential velocities.

Owner:DENNIS TOOL

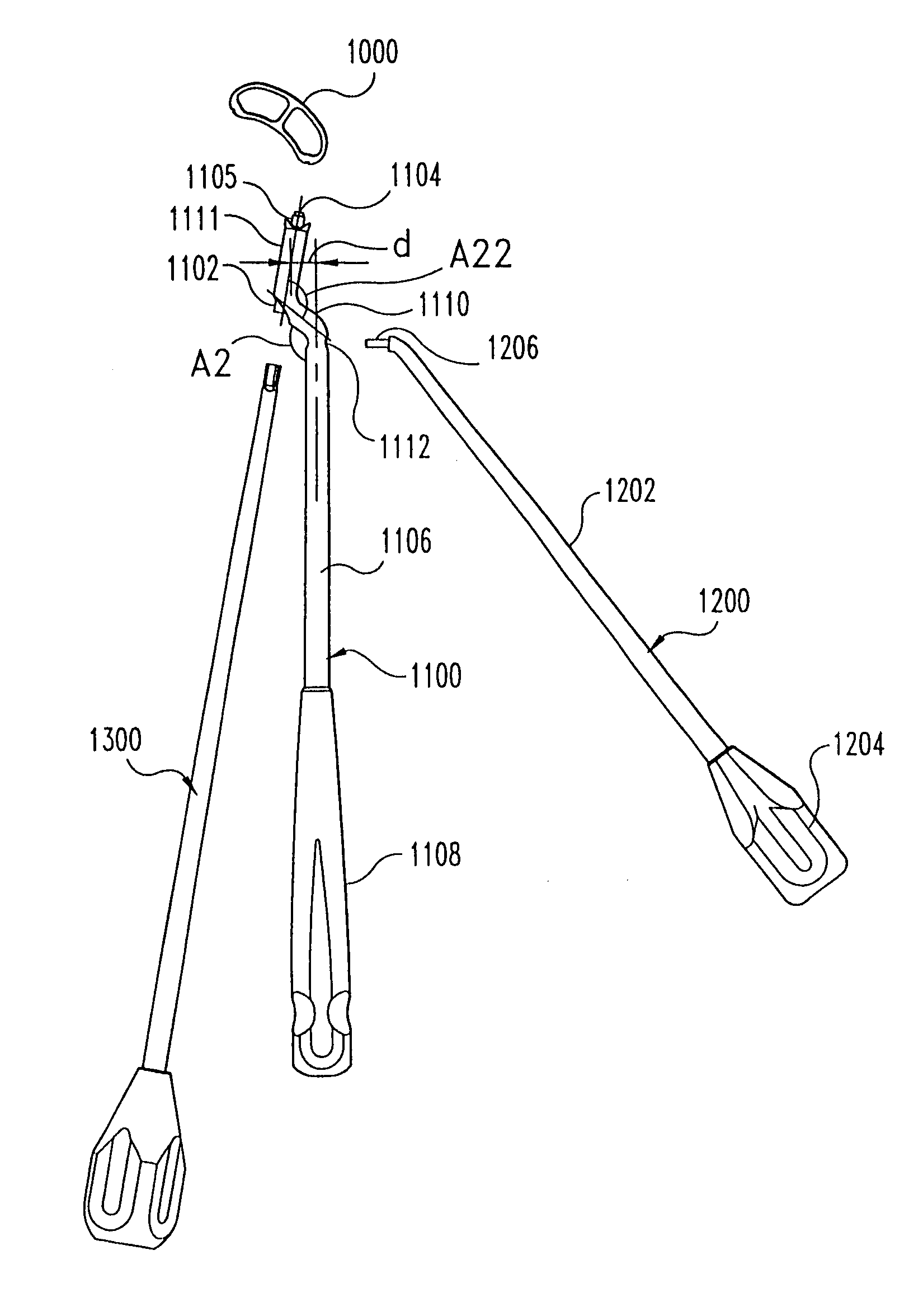

Flexible acl instrumentation, kit and method

In a first embodiment, the present invention includes an instrumentation system for preparing a bone for soft tissue repair, the instrumentation system including a flexible drill pin capable of bending along a curved path; an aimer capable of engaging the flexible pin to bend the flexible pin; and a flexible reamer having a flexible portion along at least a portion of its length, the flexible portion comprising a plurality of laser cuts. In an alternate embodiment, the present invention may also include a method for preparing a bone tunnel in a femur adjacent a knee joint, the method including introducing a flexible drill pin into the knee joint; guiding the flexible drill pin towards a surface of the femur with an instrument introduced into the knee joint; drilling the flexible drill pin into the femur; removing the instrument from the knee joint; introducing a cannulated flexible reamer into the knee joint by placing the flexible pin within the cannulation of the flexible reamer; and reaming the bone tunnel in the femur along the path of the flexible pin.

Owner:HOWMEDICA OSTEONICS CORP

Expandable reamers for earth boring applications

An expandable reamer apparatus for drilling a subterranean formation includes a tubular body, one or more blades, each blade positionally coupled to a sloped track of the tubular body, a push sleeve and a drilling fluid flow path extending through an inner bore of the tubular body for conducting drilling fluid therethrough. Each of the one or more blades includes at least one cutting element configured to remove material from a subterranean formation during reaming. The push sleeve is disposed in the inner bore of the tubular body and coupled to each of the one or more blades so as effect axial movement thereof along the track to an extended position responsive to exposure to a force or pressure of drilling fluid in the flow path of the inner bore.

Owner:BAKER HUGHES HLDG LLC

Devices and techniques for a posterior lateral disc space approach

This invention relates to methods and instruments for performing disc space preparation and implant insertion from a unilateral approach to the spine through a posterior lateral opening to the disc space. The instruments include spreaders, distractors, reamers, scrapers, cutters, chisels, rasps, pushers and implant inserters. A surgical procedure is provided that allows bilateral support of the adjacent vertebrae with at least one interbody fusion device inserted into the disc space via a unilateral approach. Implants for insertion into the disc space are also provided.

Owner:WARSAW ORTHOPEDIC INC

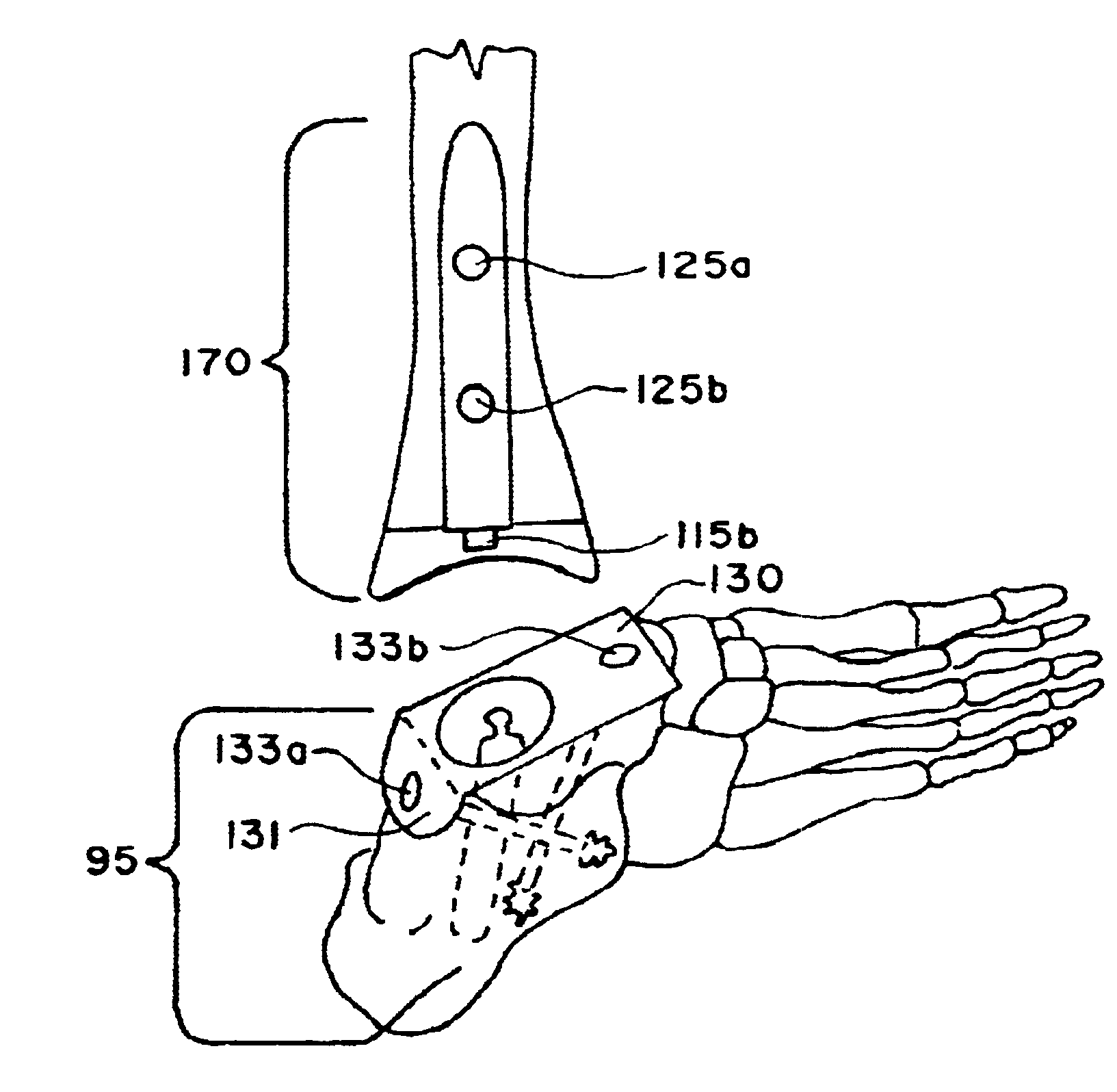

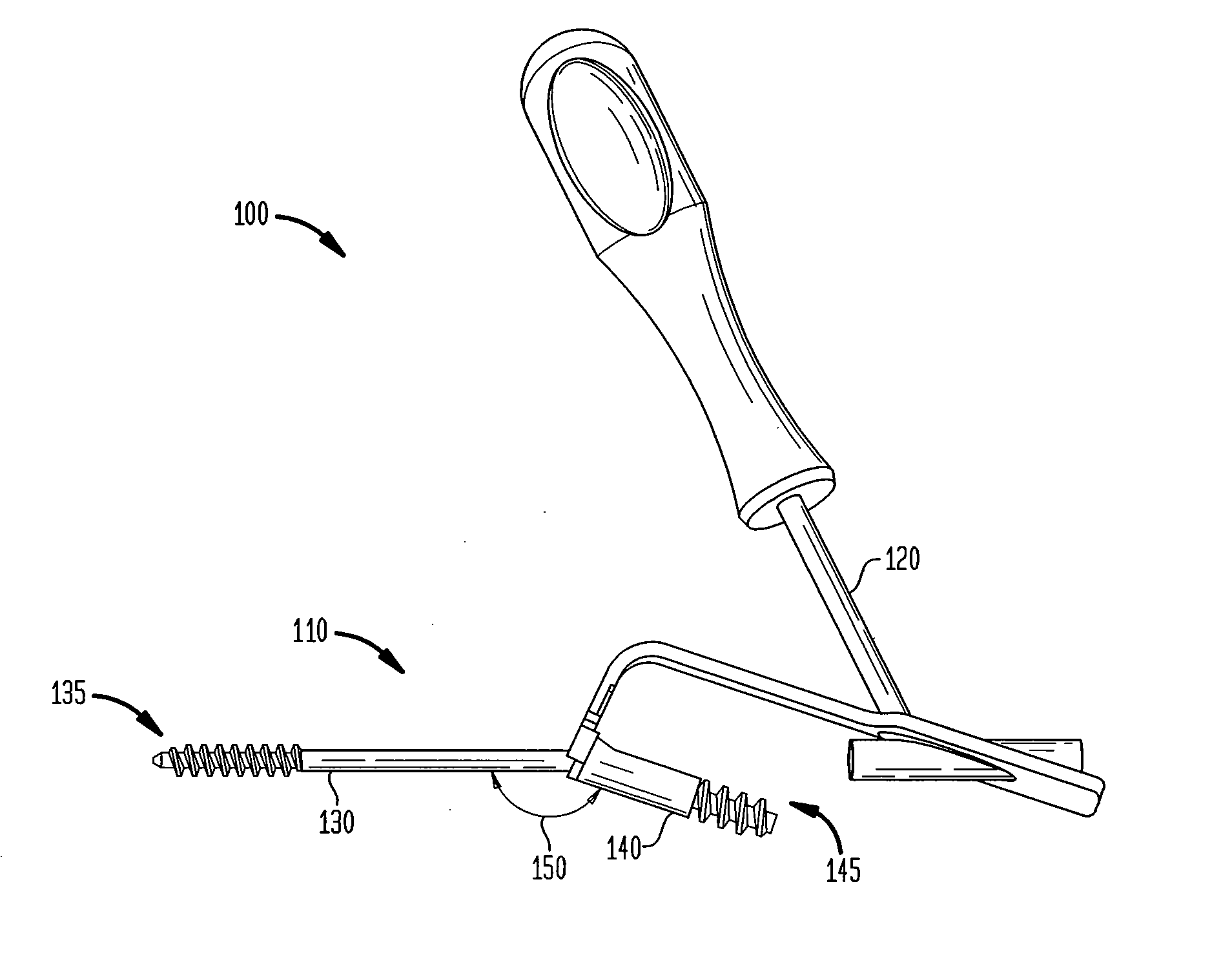

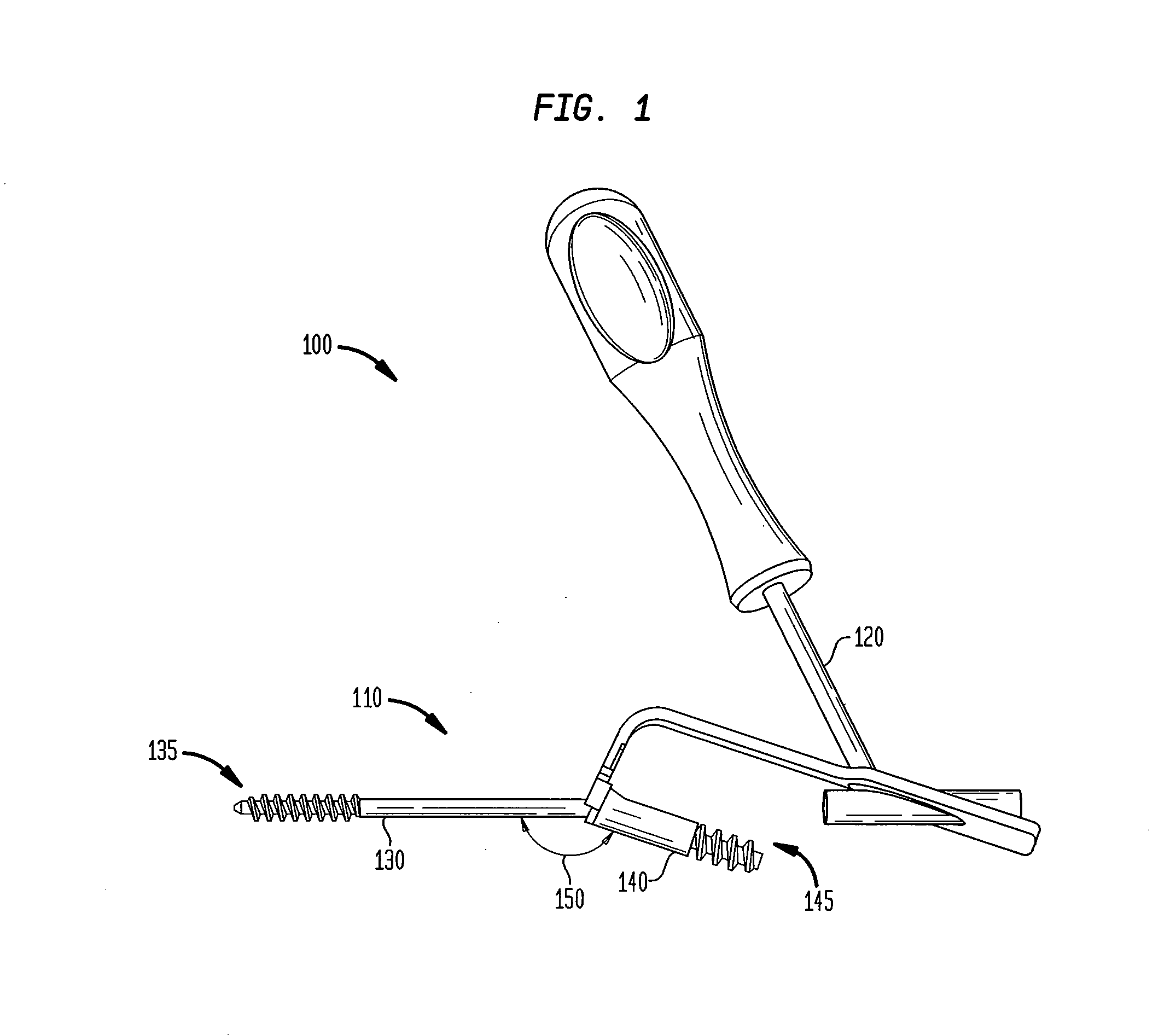

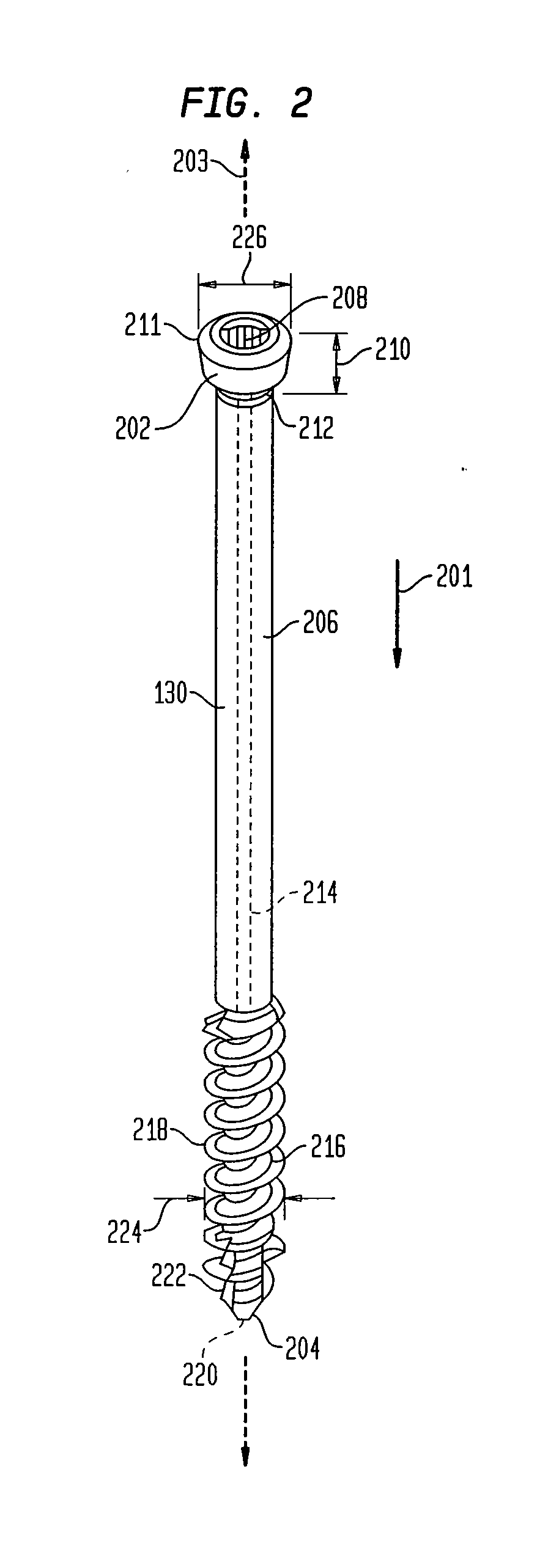

Intramedullary fixation screw, a fixation system, and method of fixation of the subtalar joint

An intramedullary screw and fixation system for intraosseous bone fusion of the subtalar joint includes a lag screw member, a reamer for reaming an internal surface of each of the calcaneus and talus medullary canals, and targeting guide assembly for alignment with the subtalar joint. The lag screw member includes an elongated body, a first threaded portion at a first end and a bulbous portion at a second end. The targeting guide assembly receives a cutting blade in an elongated rod for reaming the articulating surfaces of the calcaneus and talus intramedullary canals, where the cutting blade is inserted through a percutaneous incision into the elongated rod.

Owner:EXTREMITY MEDICAL

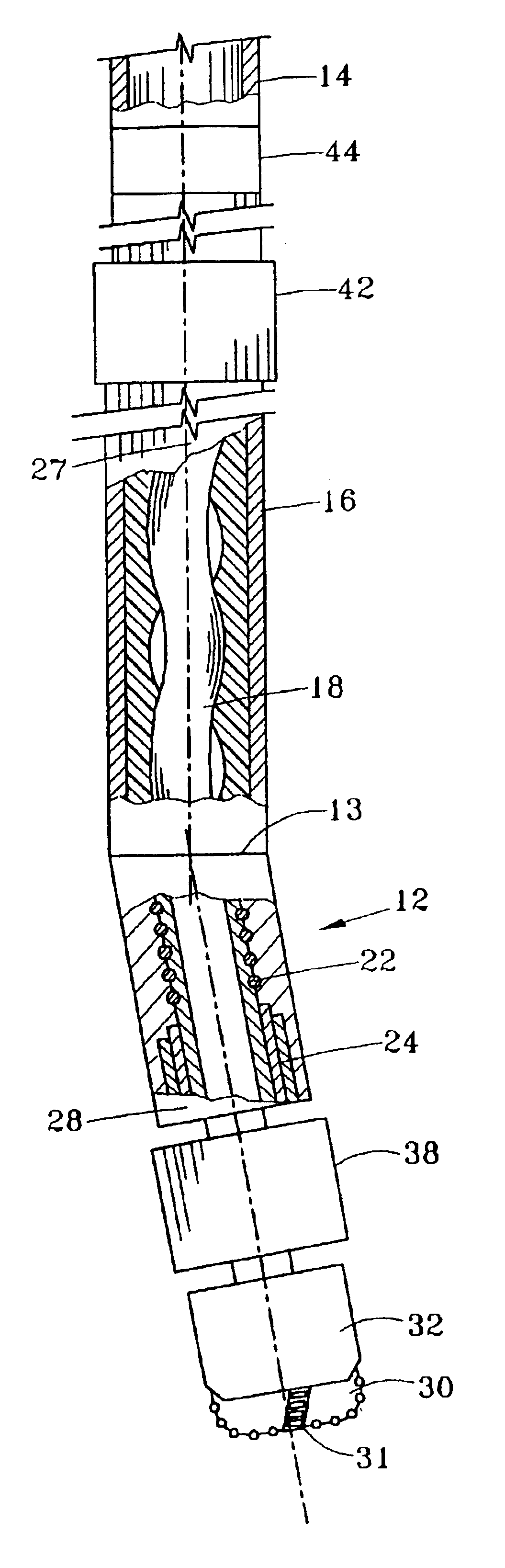

Drilling with casing

A borehole may be drilled utilizing the bottom hole assembly 10, 50 with a downhole motor 14, 110, which may offset at a selected bend angle. A bend for directional drilling may be provided by a PDM, or by a RSD. A gauge section 36 secured to the pilot bit 18 has a uniform diameter bearing surface along an axial length of at least 60% of the pilot bit diameter. The bit or reamer 16 has a bit face defining the cutting diameter of the drilled hole. The axial spacing between the bend and the bit face is controlled to less than fifteen times the bit diameter. The downhole motor, pilot bit and bit may be retrieved from the well while leaving the casing string in the well.

Owner:HALLIBURTON ENERGY SERVICES INC

Expandable reamers for earth-boring applications and methods of using the same

ActiveUS20080128174A1Preventing hydraulic pressurePrevent pressureDrill bitsFluid removalAcute angleReamer

Expandable reamer tools include an outer body, a fluid passageway extending through the outer body, and at least one blade configured to slide relative to the outer body between a retracted position and an expanded position in a direction oriented at an acute angle of less than ninety degrees (90°) to a longitudinal axis of the outer body. In some embodiments, the tools may include a moveable inner sleeve member configured to selectively allow hydraulic fluid pressure within the fluid passageway to act directly on the at least one blade. Methods for enlarging a borehole using such expandable reamer tools and methods for removing such expandable reamer tools from a borehole are also disclosed.

Owner:BAKER HUGHES INC

Steerable underreaming bottom hole assembly and method

A steerable bottom hole assembly may be used for drilling both a curved section and straight section of the borehole, with the bottom hole assembly including a reamer beneath the downhole motor 12. The bottom hole assembly includes a bit 30 having a bit face defining a bit diameter, and a gauge section 32 having a substantially uniform diameter cylindrical surface approximating the bit diameter and having an axially length of at least 75% of the bit diameter. The motor is preferably run slick without stabilizers for engaging the wall of the borehole.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com