Patents

Literature

5516 results about "Hydraulic fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

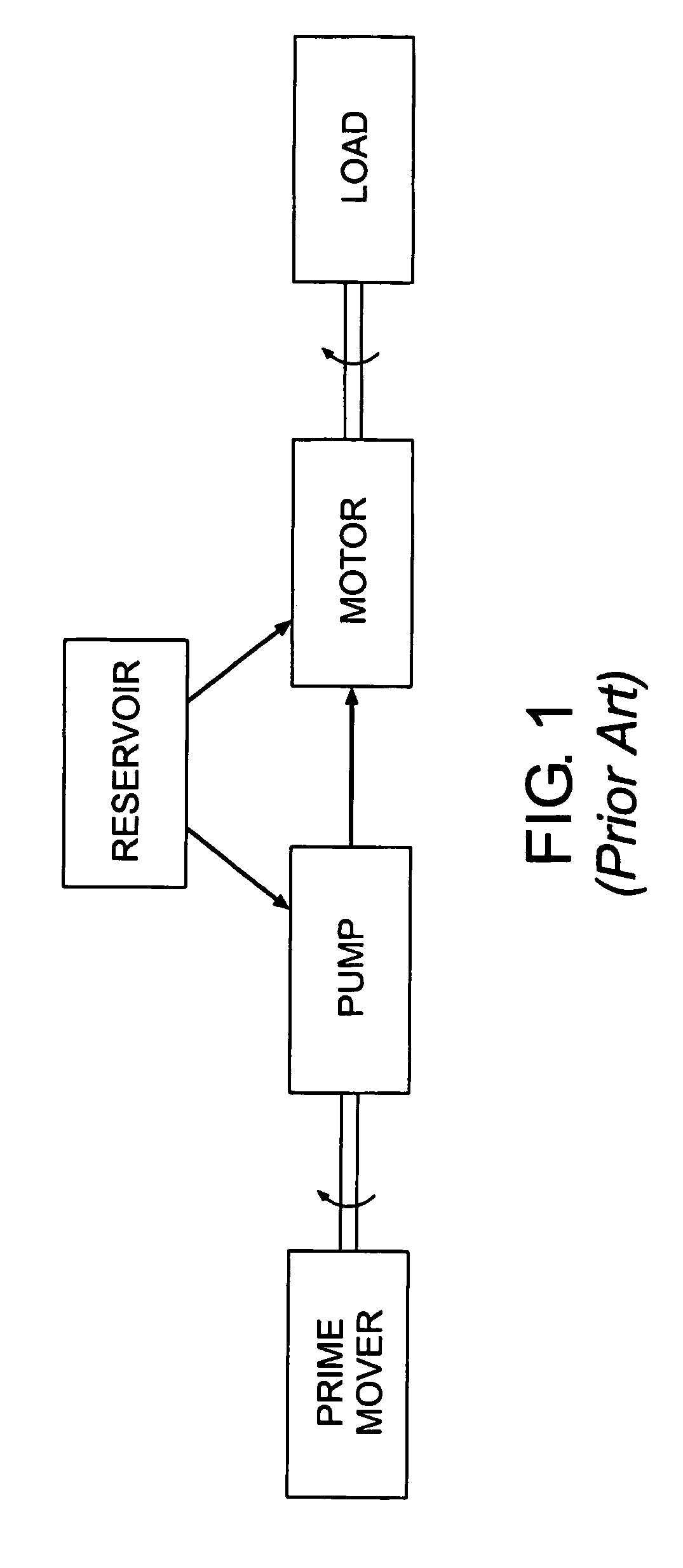

A hydraulic fluid or hydraulic liquid is the medium by which power is transferred in hydraulic machinery. Common hydraulic fluids are based on mineral oil or water. Examples of equipment that might use hydraulic fluids are excavators and backhoes, hydraulic brakes, power steering systems, transmissions, garbage trucks, aircraft flight control systems, lifts, and industrial machinery.

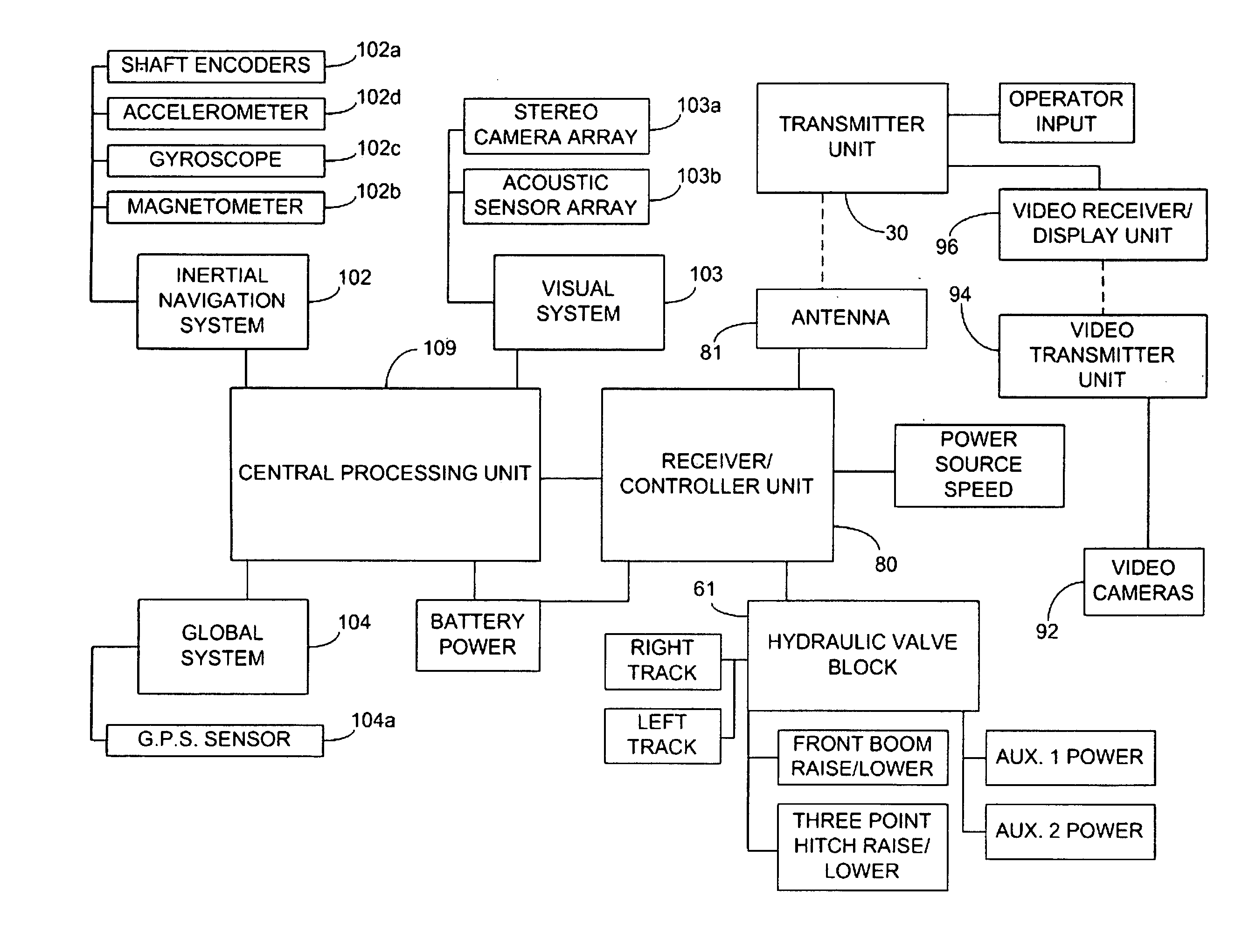

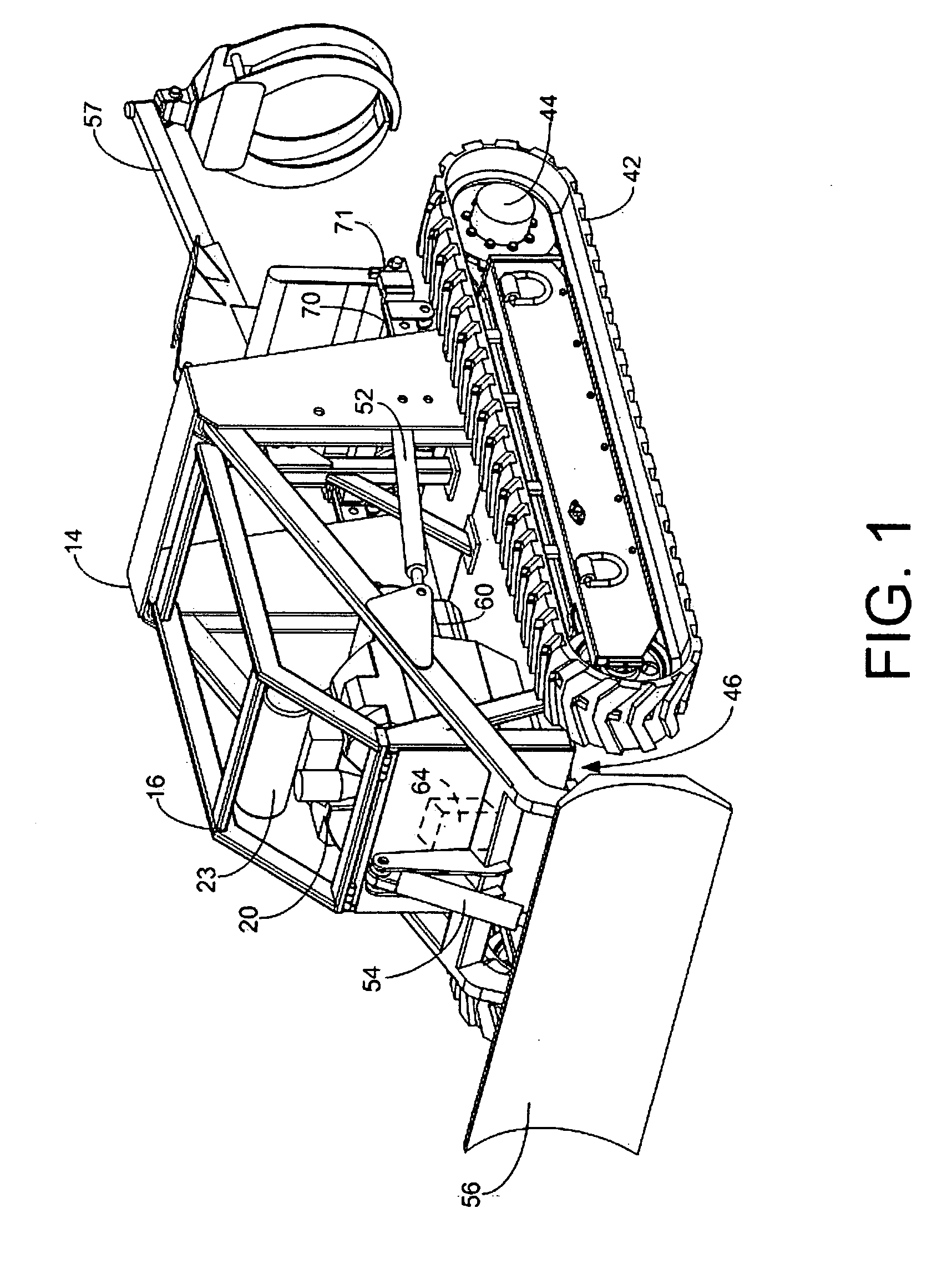

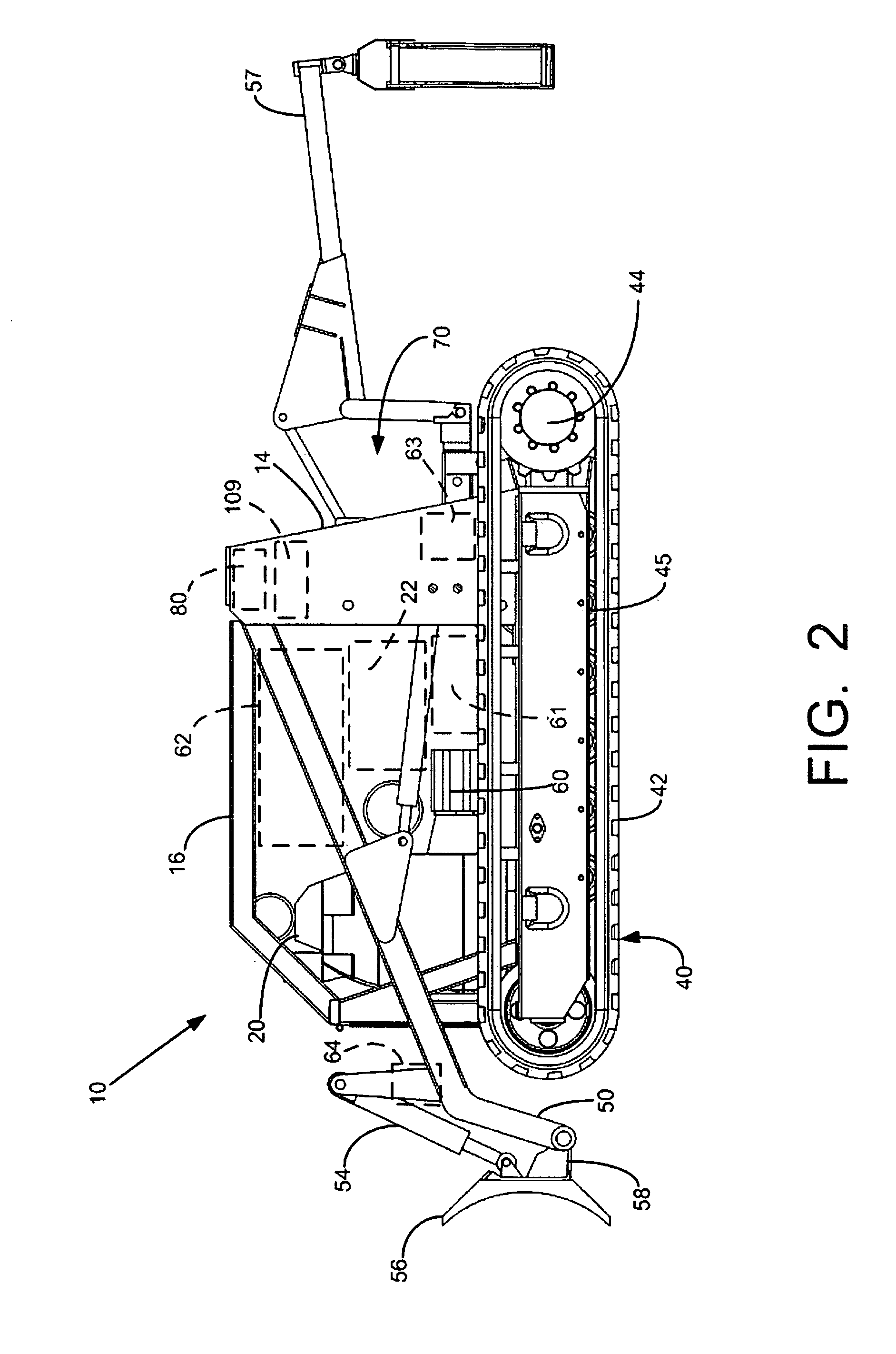

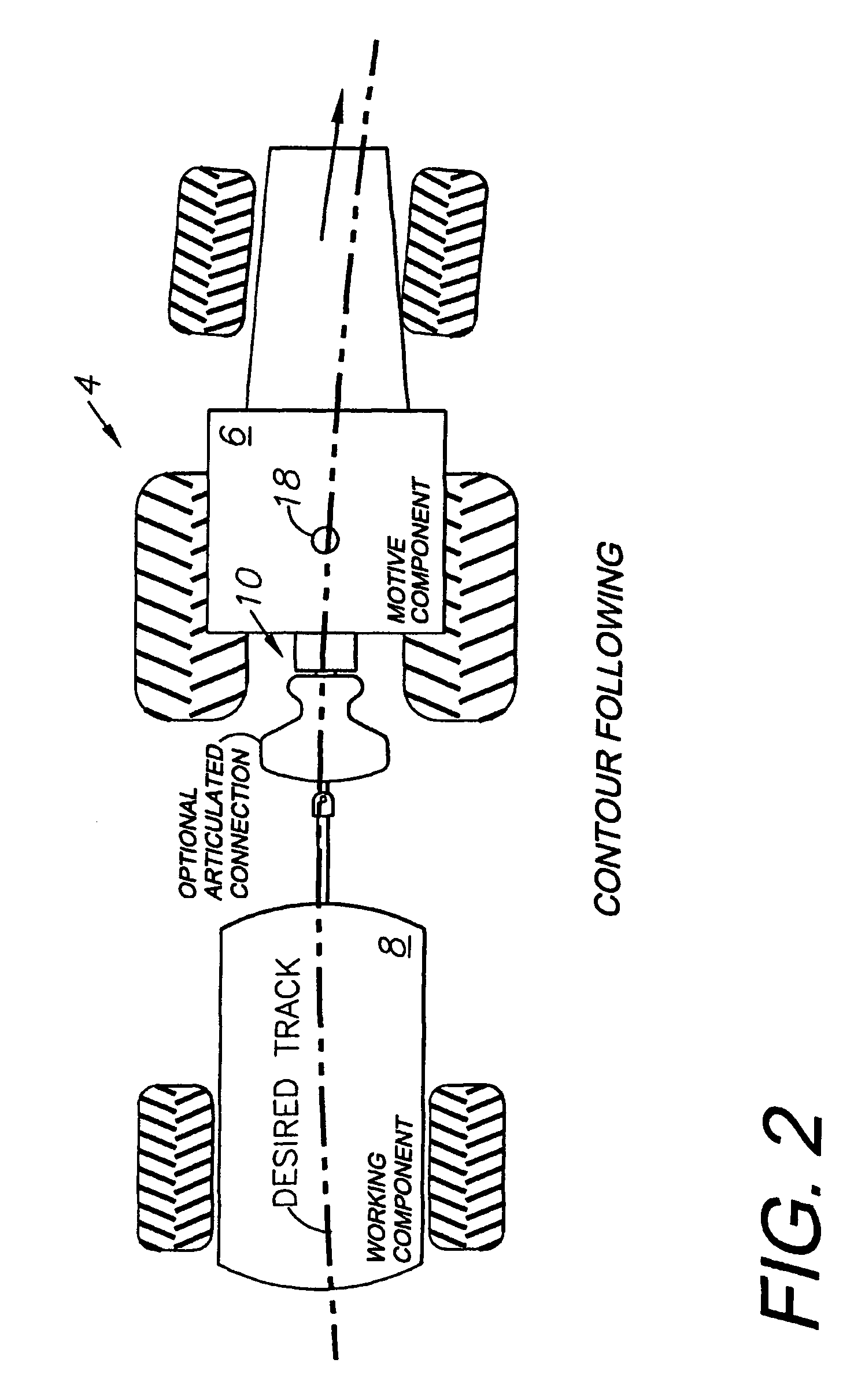

Unmanned land vehicle having universal interfaces for attachments and autonomous operation capabilities and method of operation thereof

InactiveUS20100106344A1Eliminate hazardsDigital data processing detailsSoil-shifting machines/dredgersOperational systemRemote control

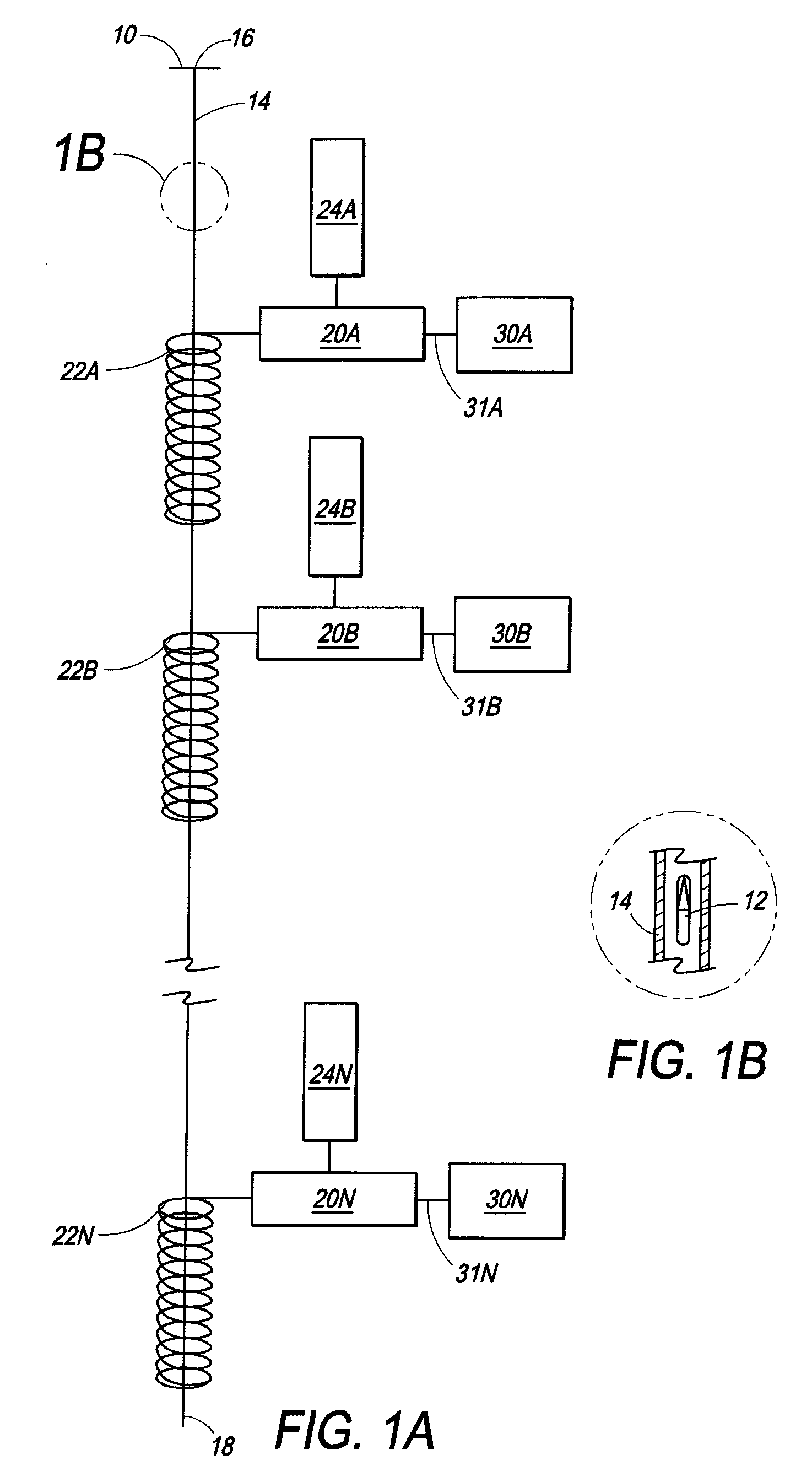

An apparatus and method is disclosed for a wireless remotely operable unmanned compact vehicle platform for use in land management comprising a frame and providing a pair of ground engageable endless drive tracks powered by a hydraulic fluid power source. The vehicle supports working attachments on the front end by utilizing a universal working attachment coupling interface carried on a pair of loader boom structures, and the vehicle supports working attachments on the rear end by utilizing a three point hitch apparatus. Working attachments coupled to the vehicle may be powered by the hydraulic fluid power source carried on the frame. A wireless remote control apparatus allows an operator to control the vehicle at a safe distance and a wireless video system allows an operator to control the vehicle accurately. A system of autonomous operation is integrated with the vehicle for travel in complex, unstructured environments. The claimed invention also utilizes a method of operation for the wirelessly operable unmanned vehicle control system which comprises a system wherein one or more mobile transmitters can be used to control one or more vehicles individually.

Owner:EDWARDS DEAN B +1

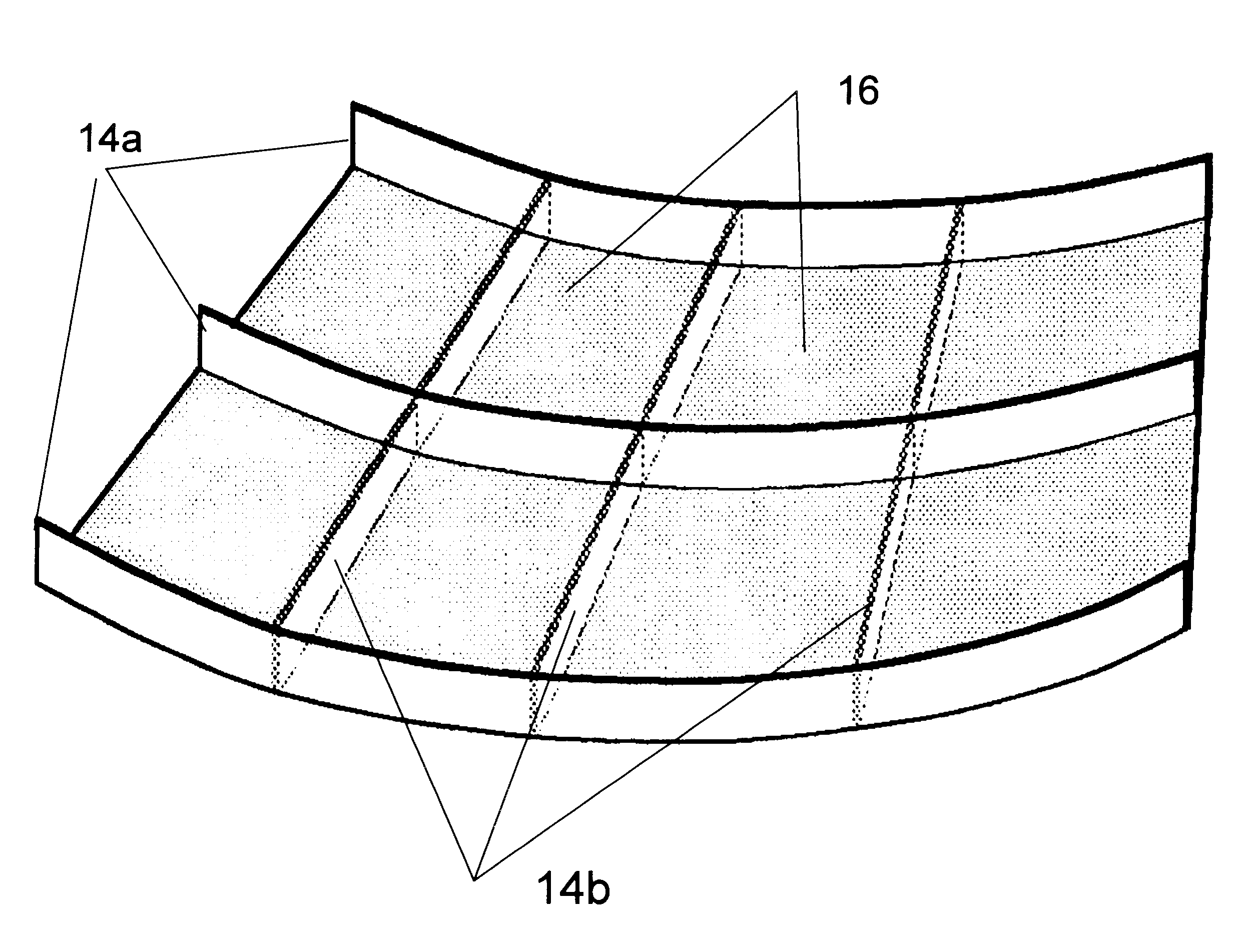

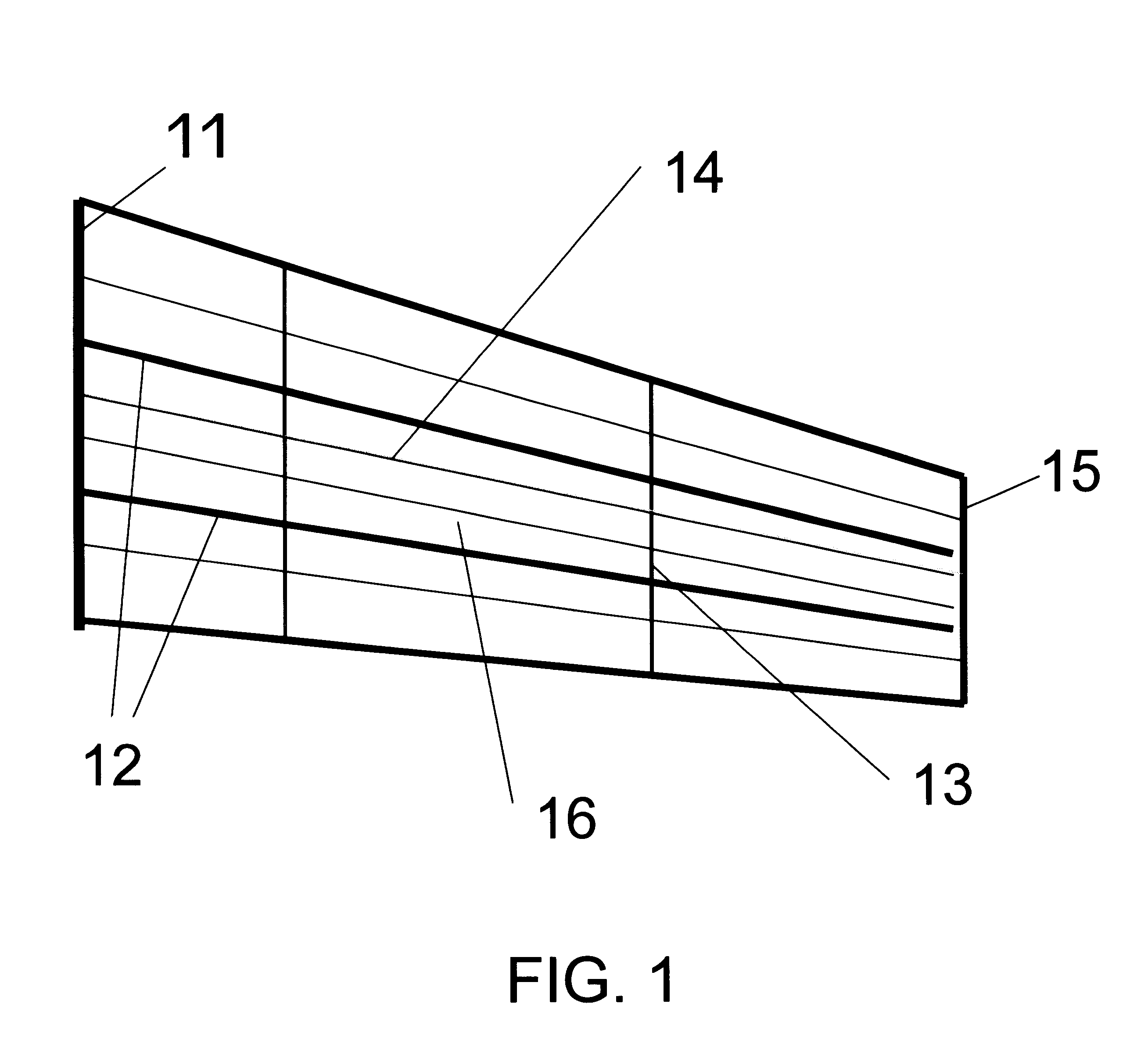

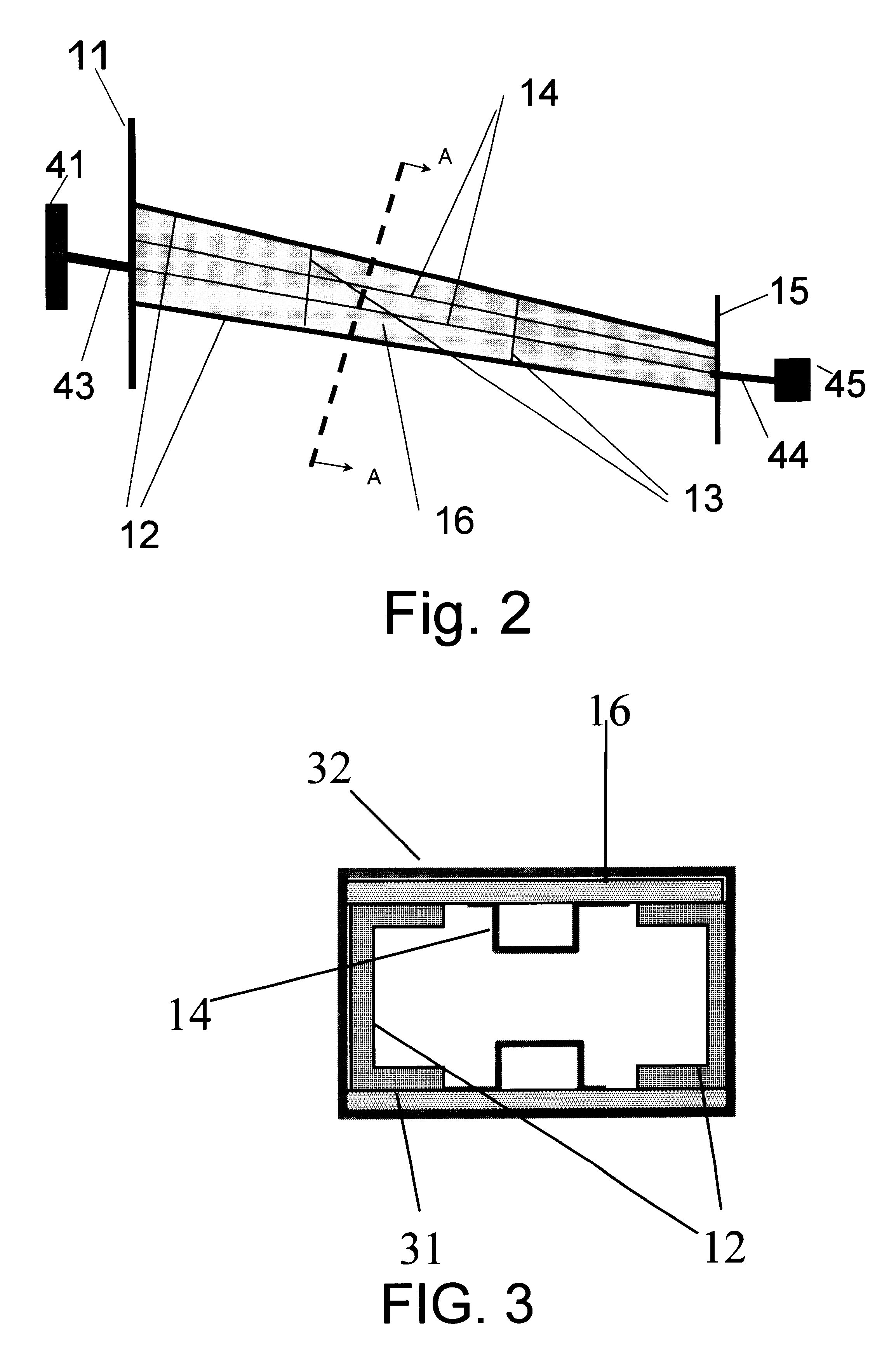

Monolithic composite wing manufacturing process

InactiveUS6190484B1Aircraft stabilisationPaper/cardboard wound articlesLeading edgeIncreased torsion

A method of manufacturing a monolithic composite wing without using mechanical fasteners is described. The process begins with the formation of a center wing box in combination with a pair of spars, riblets and a pair of skin-molds including the wrapping and binding of the box by means of resin impregnated composite tapes. Next, additional cells are adjoined contiguously on either side of the current framework and an overlap wrapping and bonding process is continued around the current framework. The overlap wrapping and binding procedure provides increased torsion stiffness and reduced structural weight. All cells up to the leading and trailing edges will be included in the assembly process. Conduits to convey fuel, hydraulic fluid and electrical wiring will also be installed in designated cells. Finally, the completed wing will be cured in an autoclave under uniform pressure and temperature.

Owner:APPA KARI

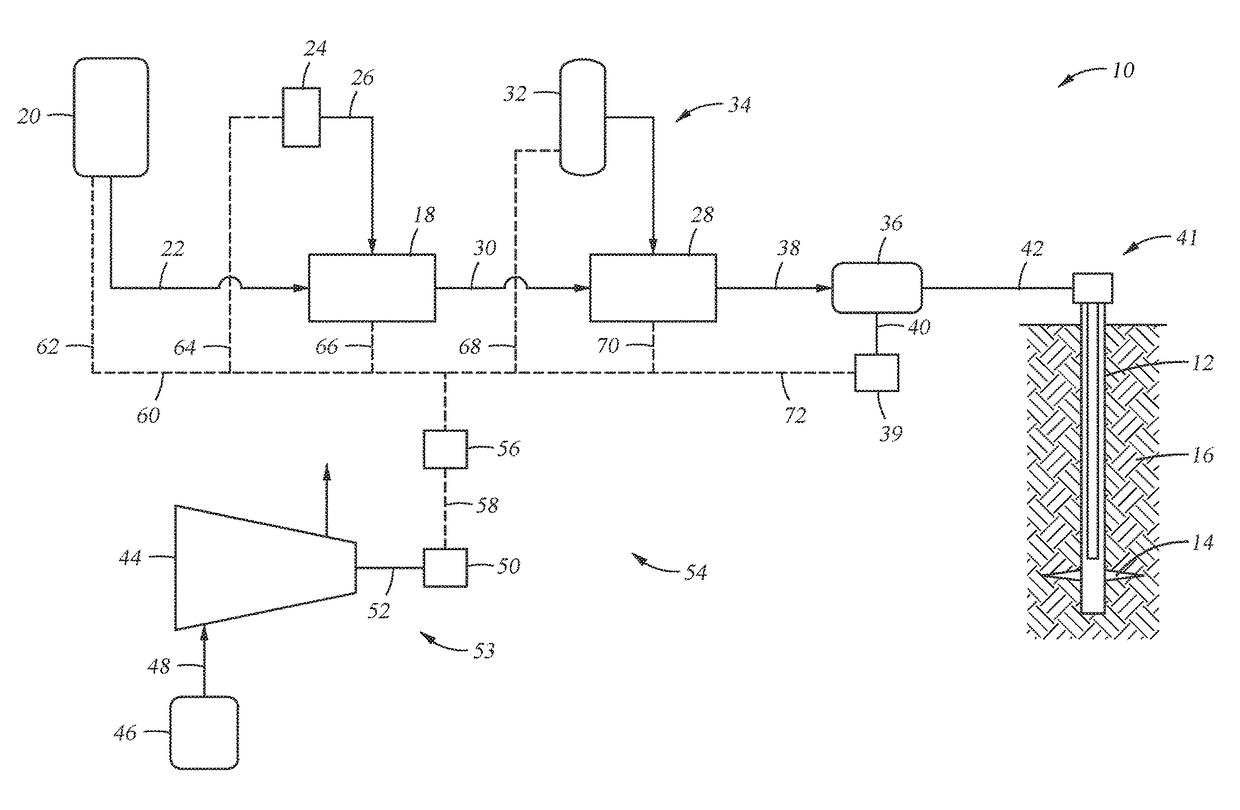

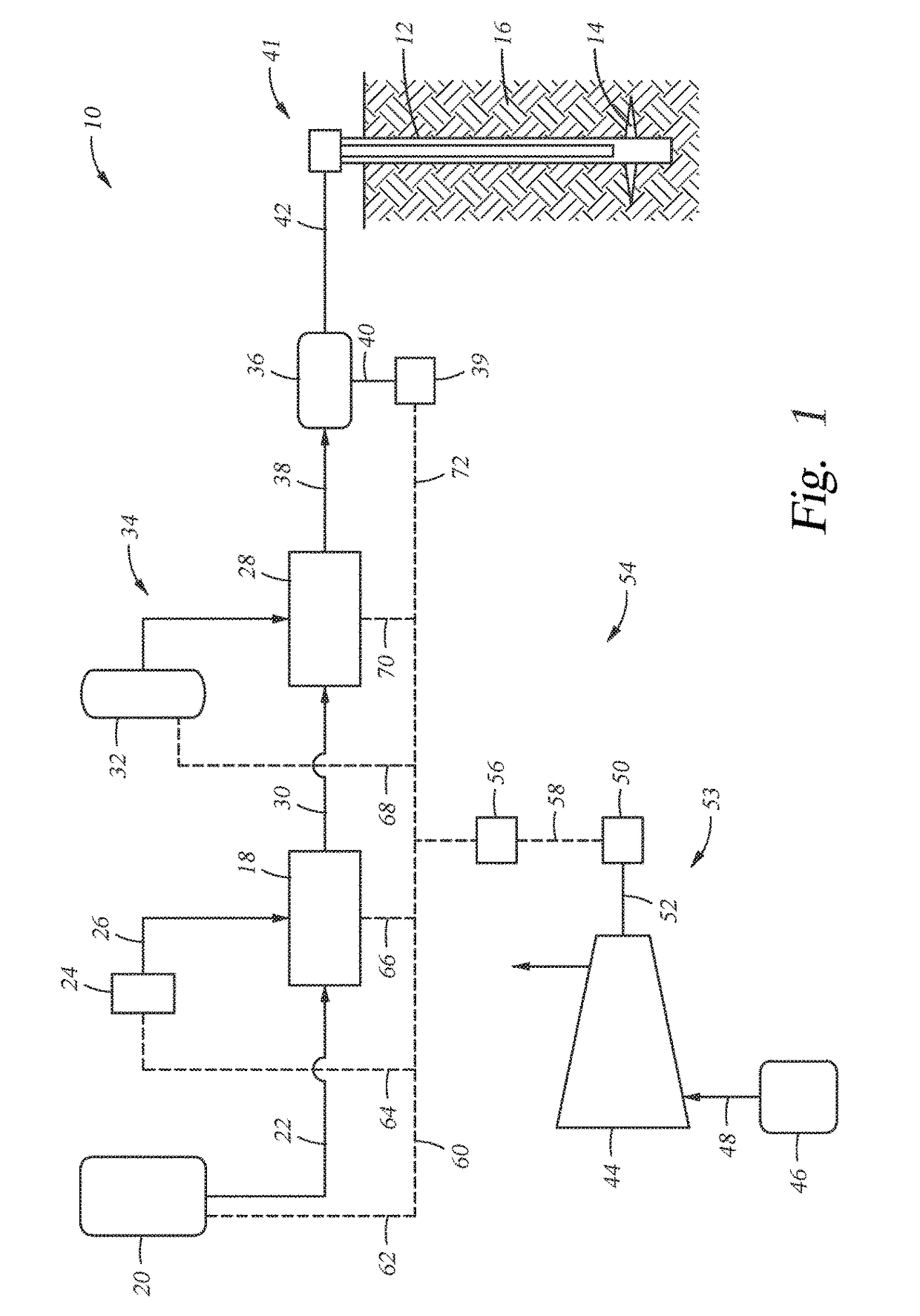

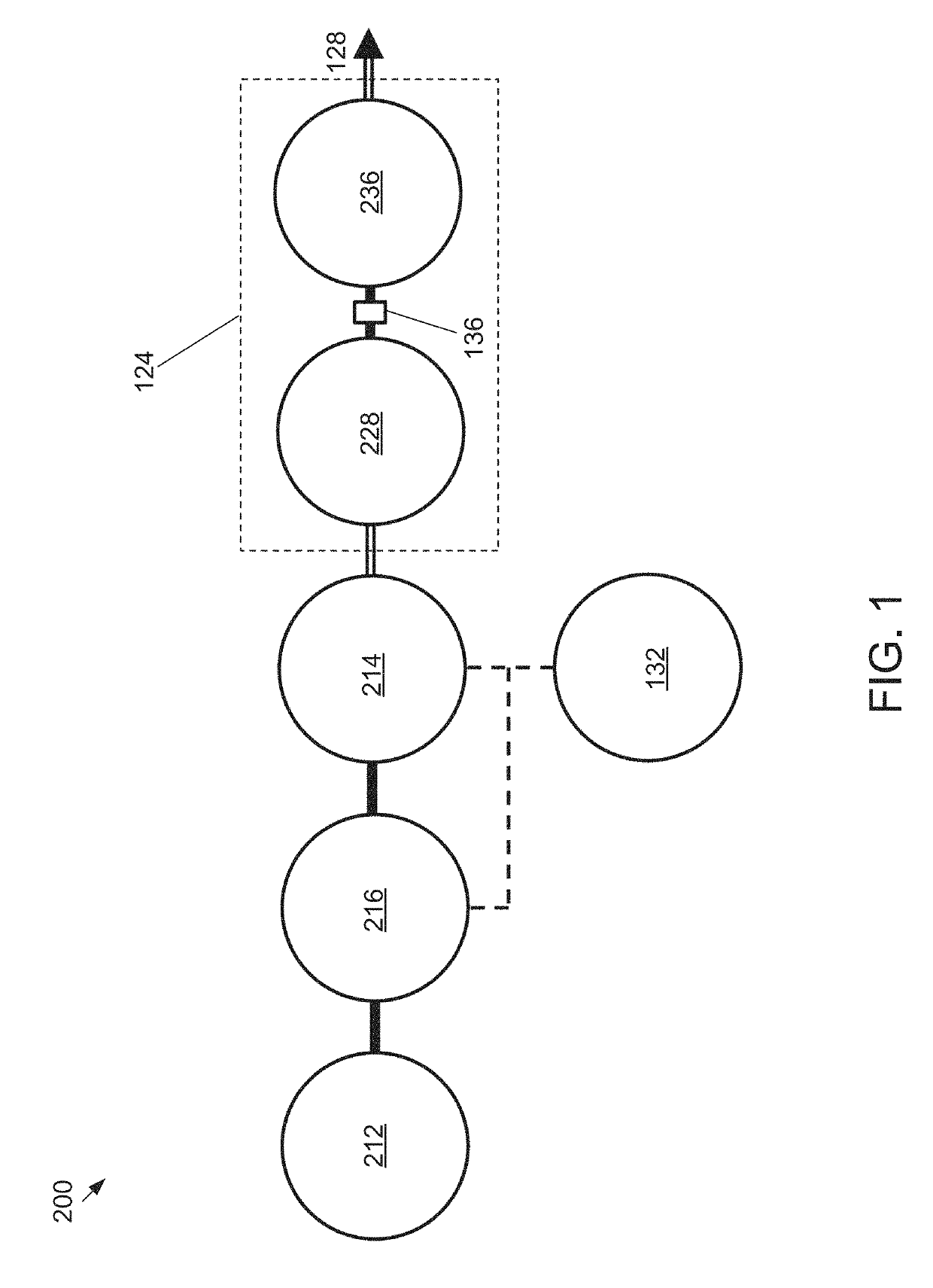

Cold weather package for oil field hydraulics

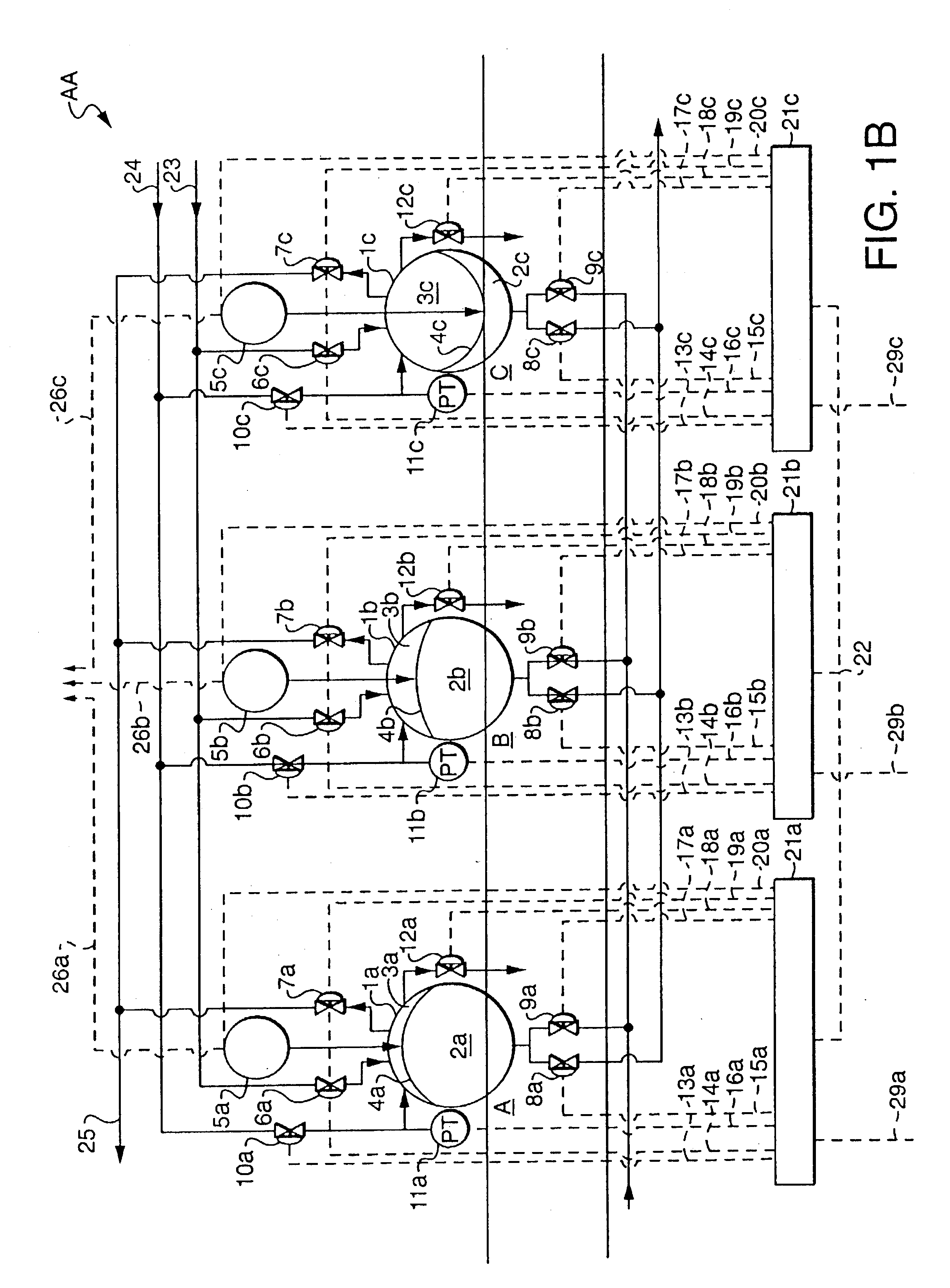

A hydraulic fracturing system includes an electrically powered pump that pressurizes fluid, which is piped into a wellbore to fracture a subterranean formation. System components include a fluid source, an additive source, a hydration unit, a blending unit, a proppant source, and a fracturing pump. The system includes heaters for warming hydraulic fluid and / or lube oil. The hydraulic fluid is used for operating devices on the blending and hydration units. The lube oil lubricates and cools various moving parts on the fracturing pump.

Owner:US WELL SERVICS LLC

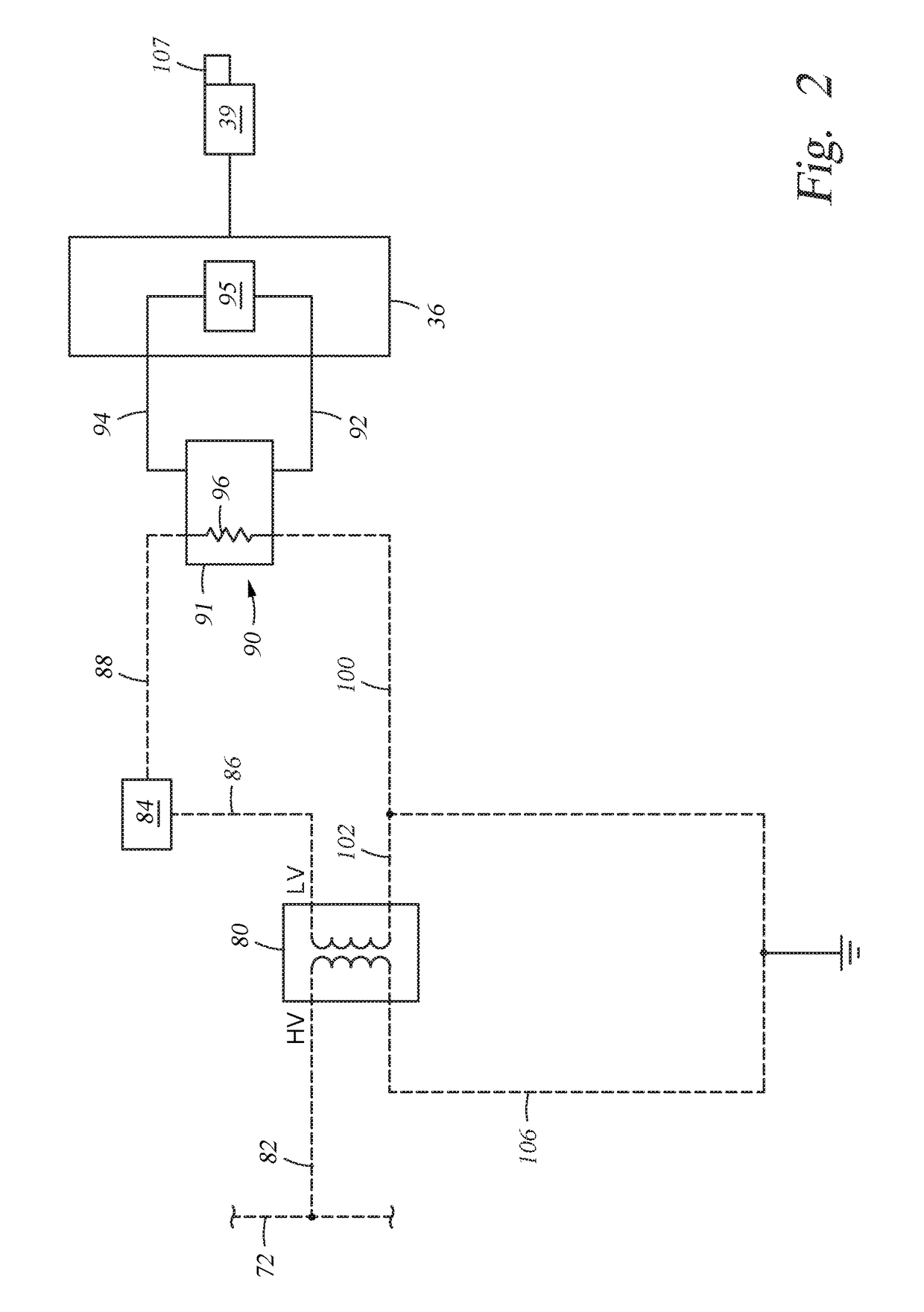

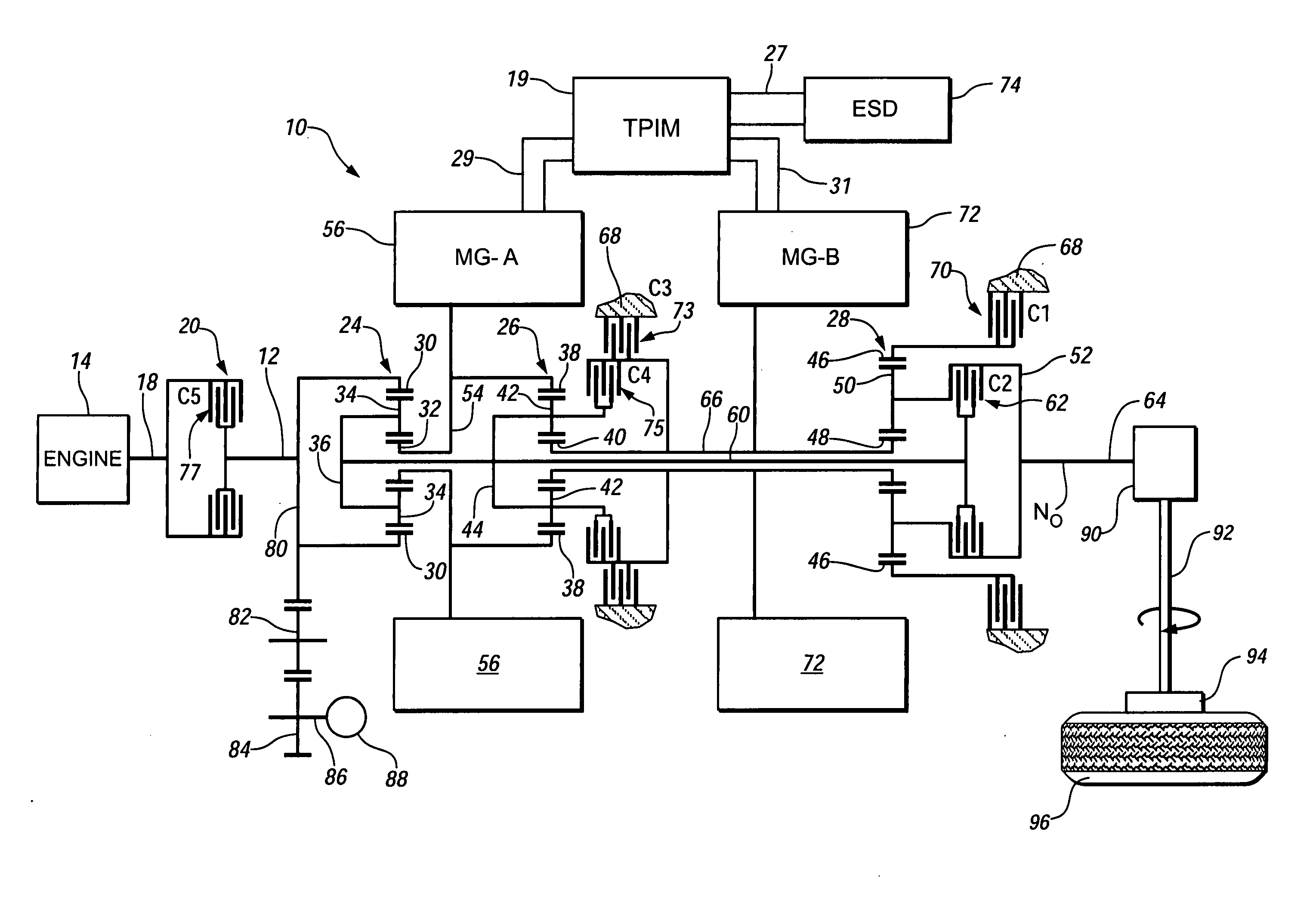

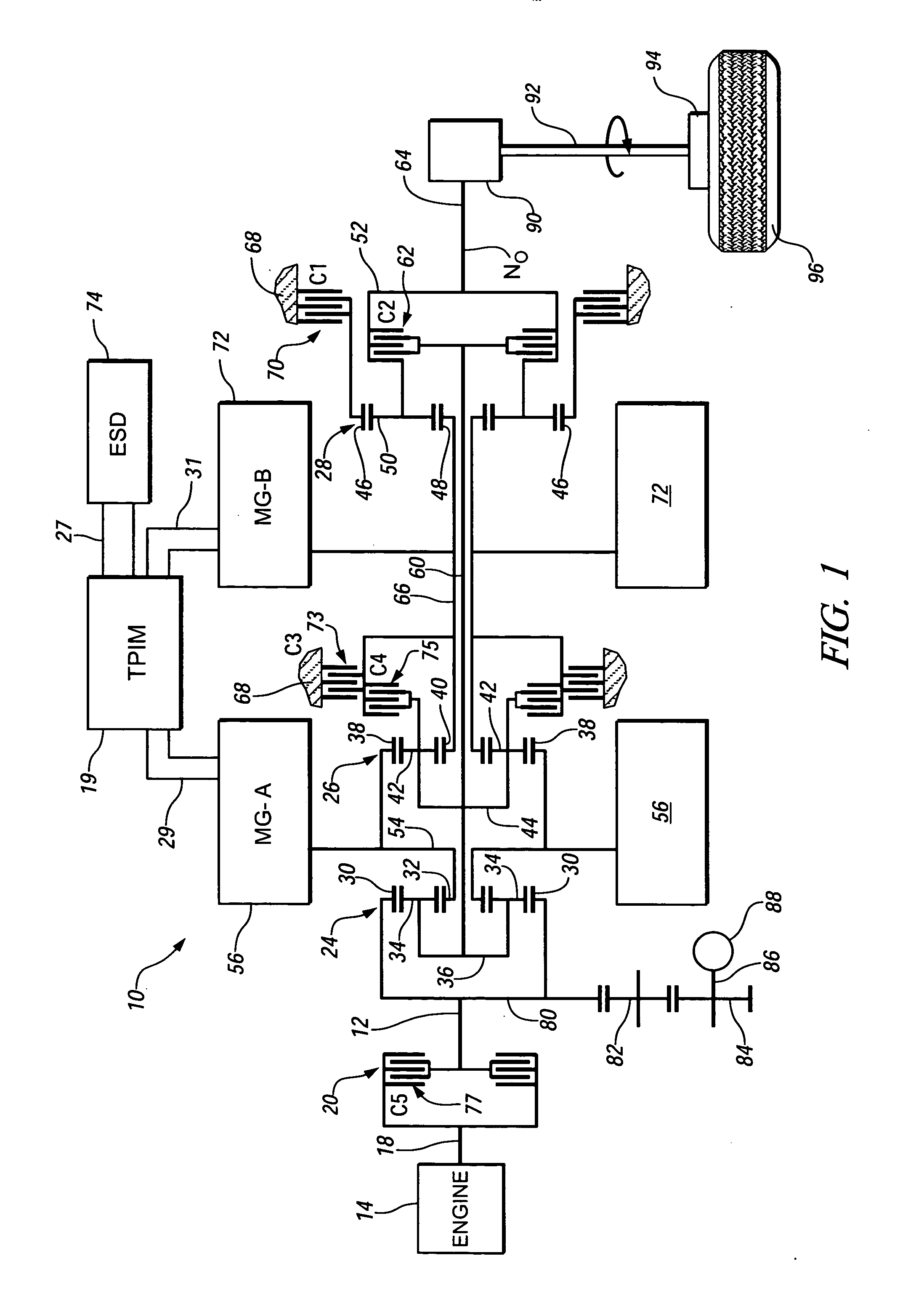

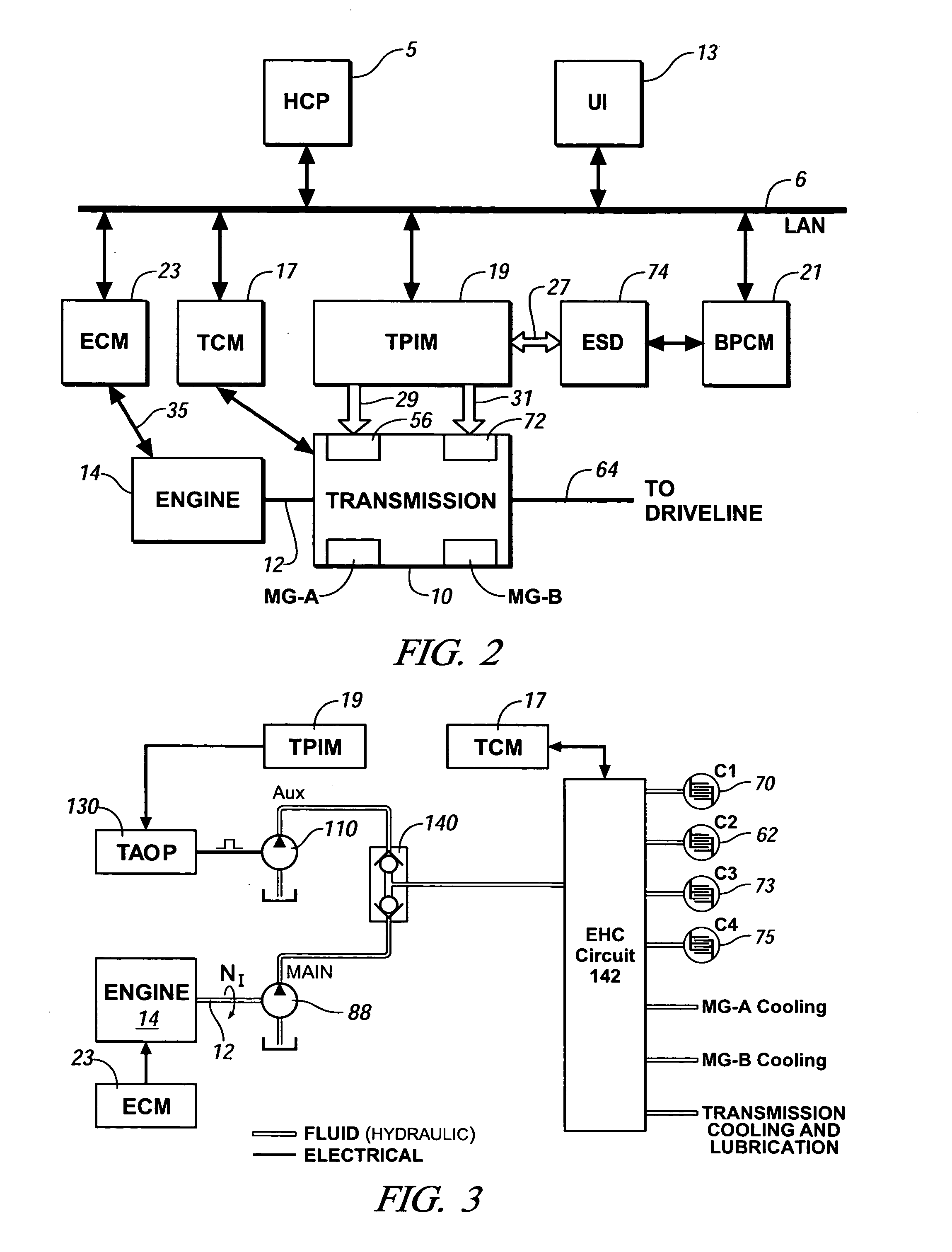

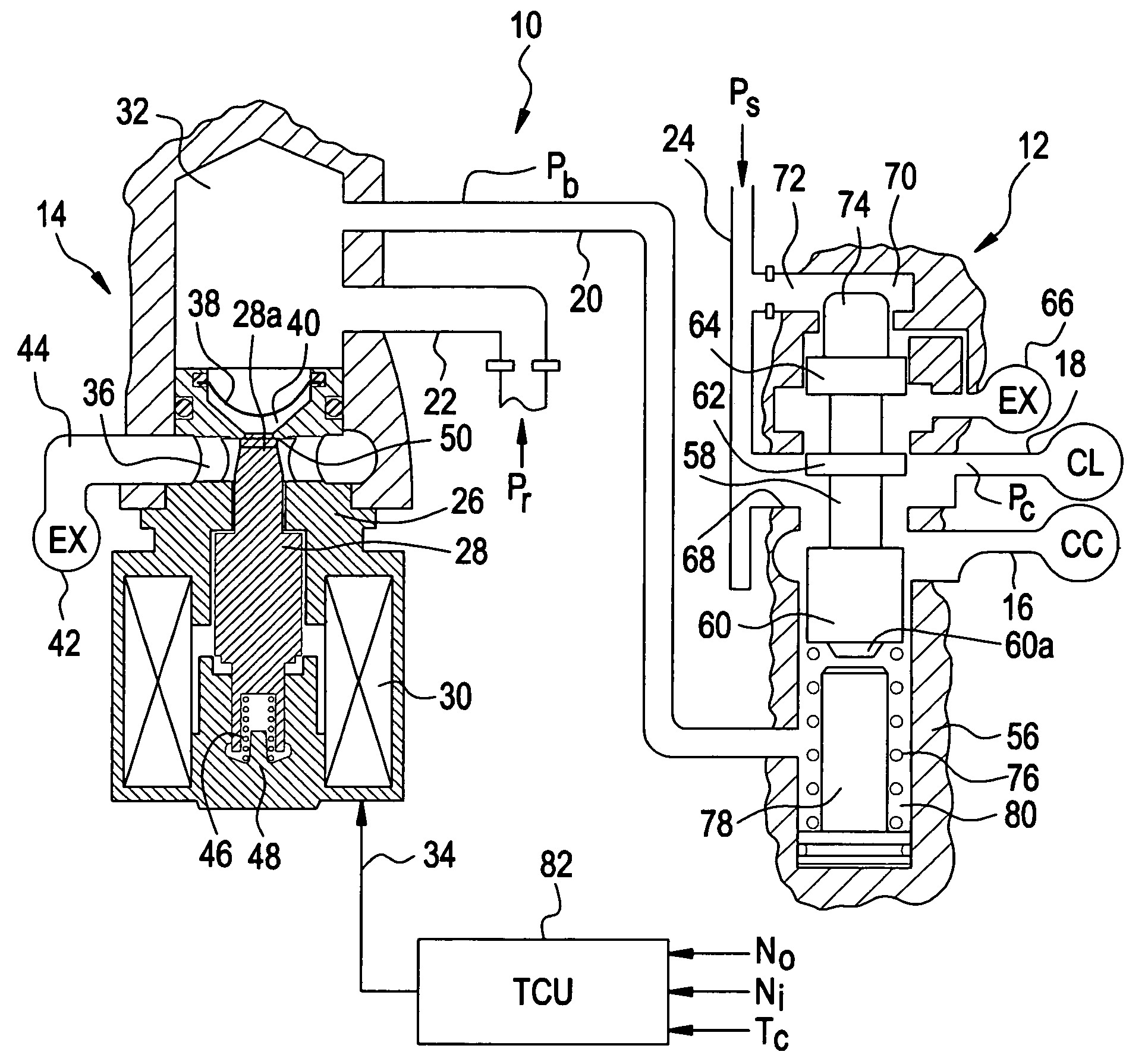

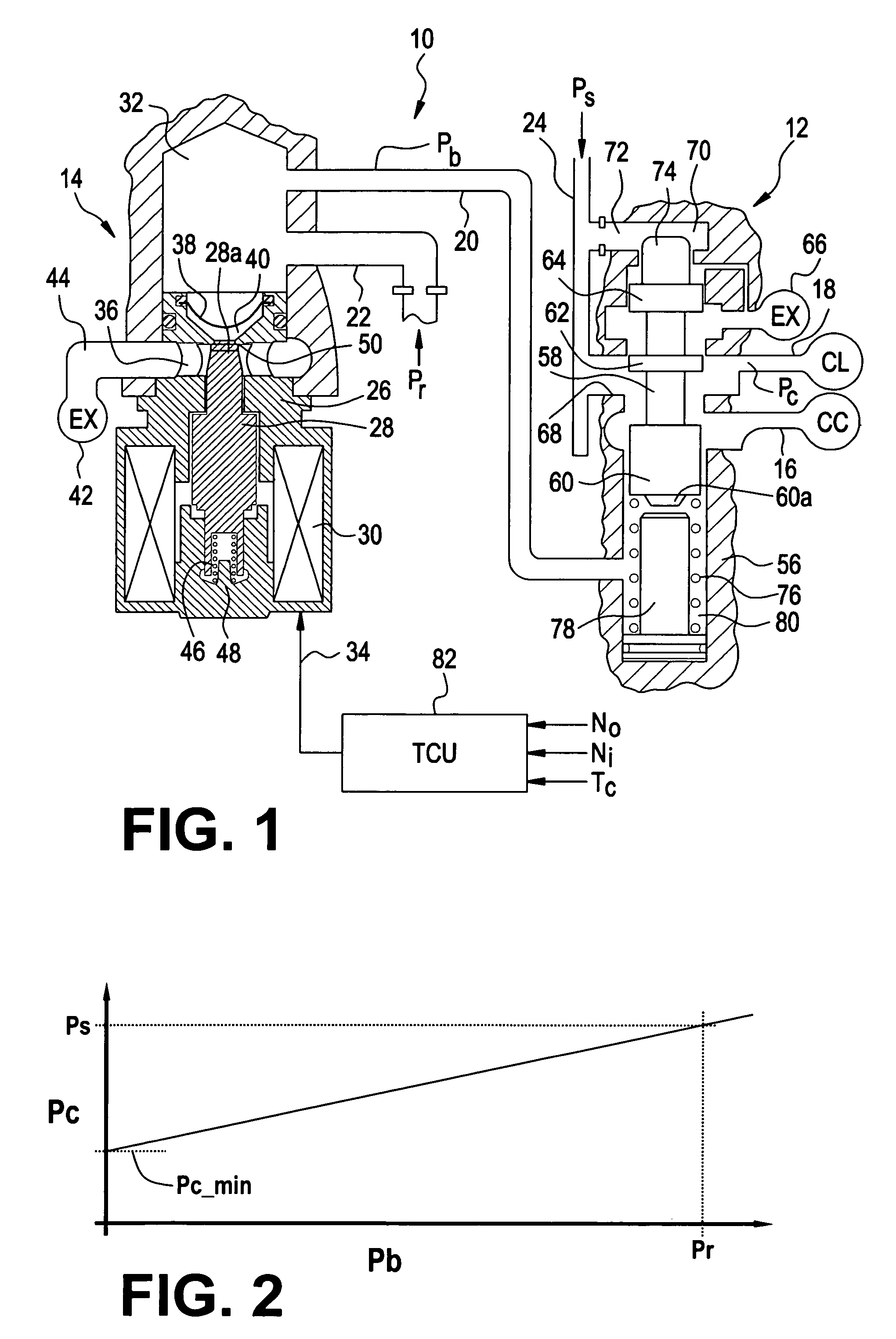

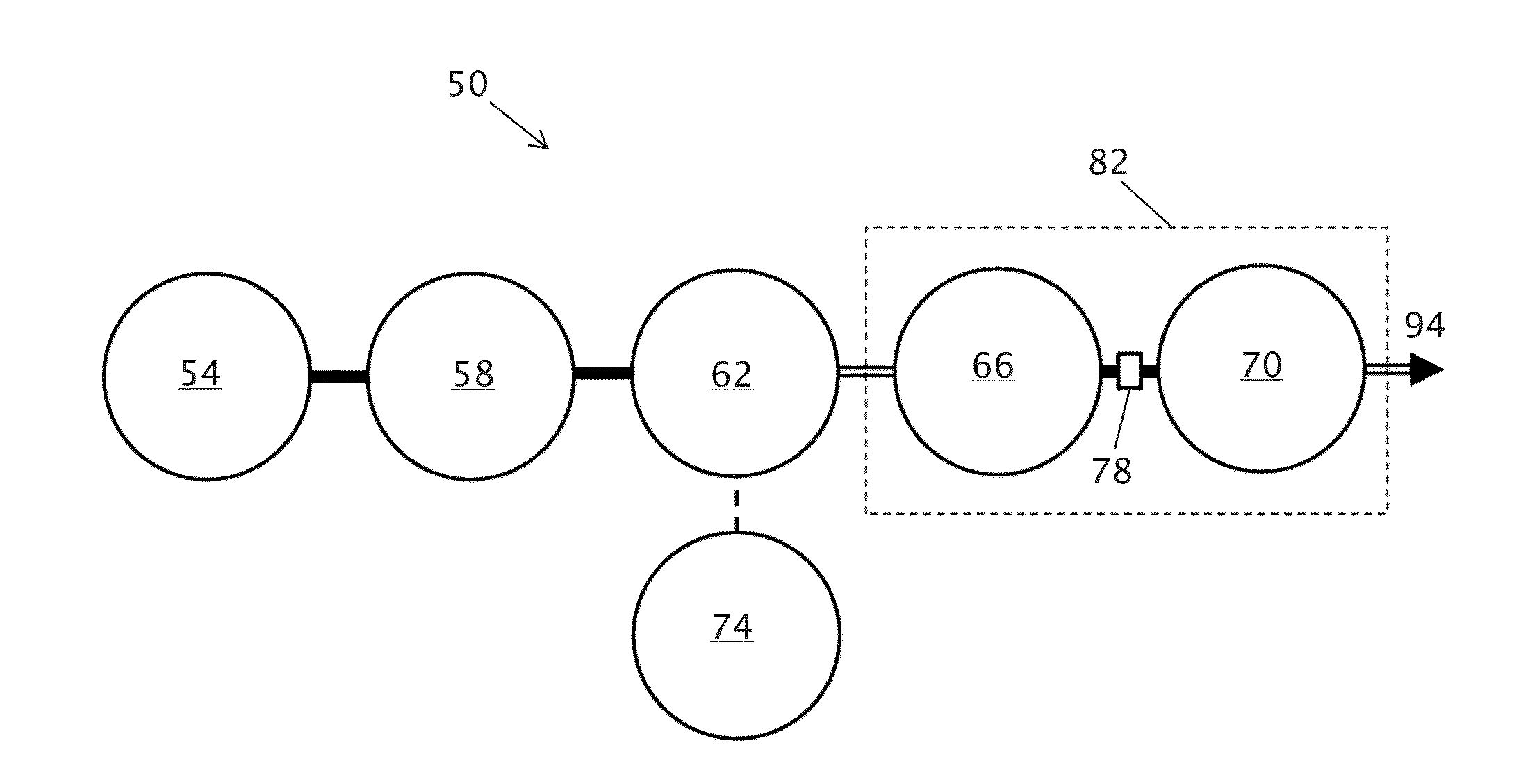

Method and apparatus to control hydraulic pressure in an electro-mechanical transmission

Owner:GM GLOBAL TECH OPERATIONS LLC

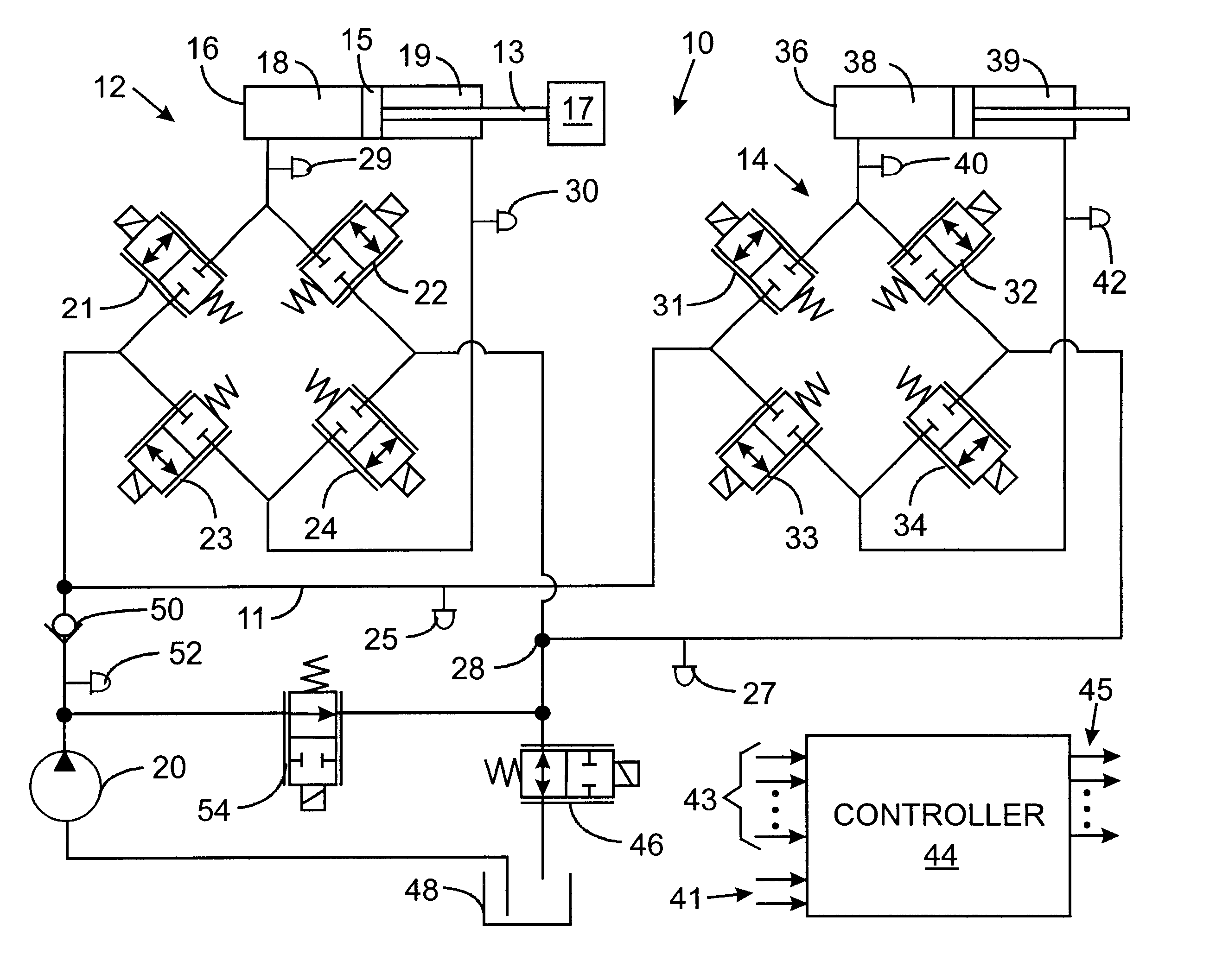

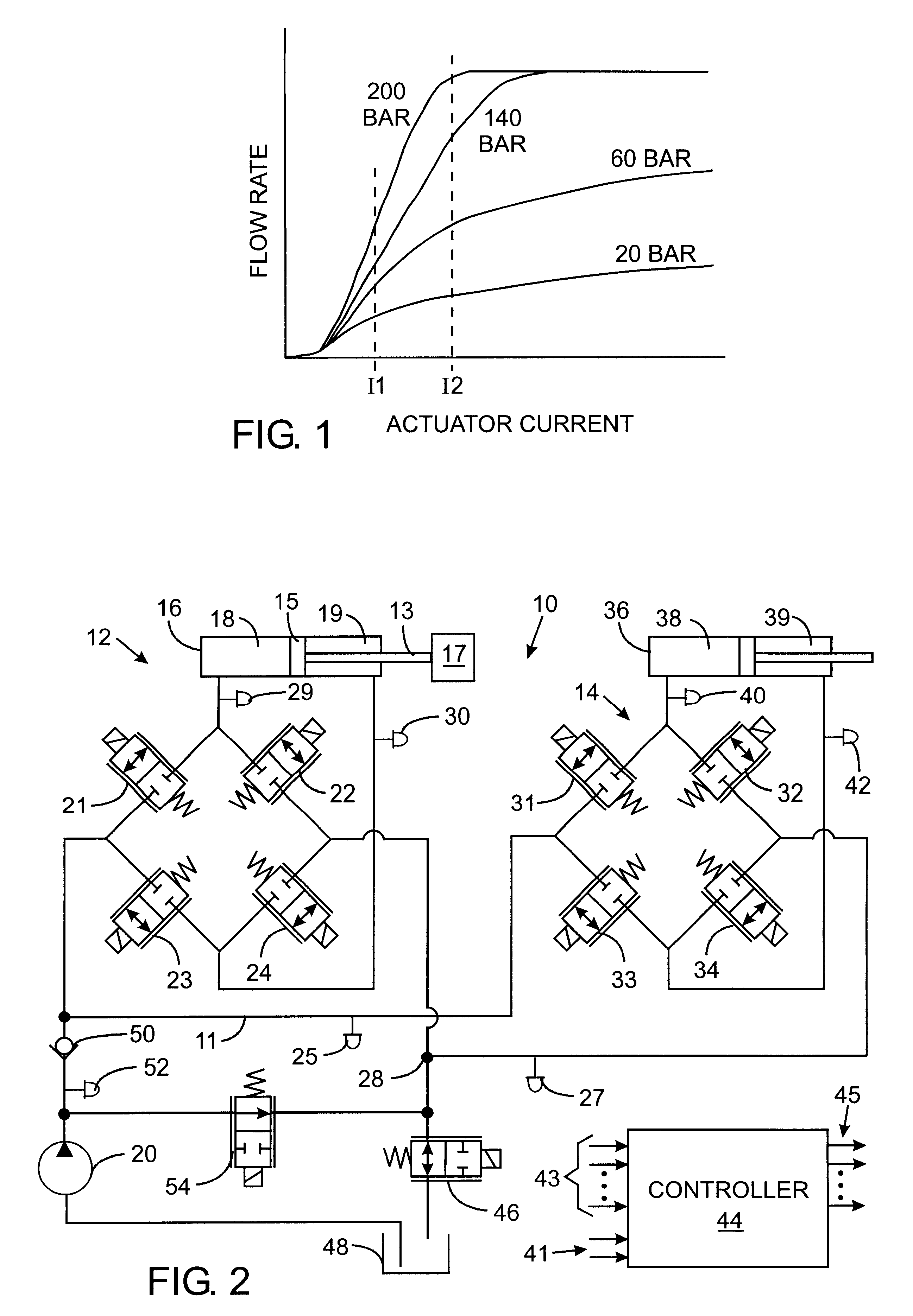

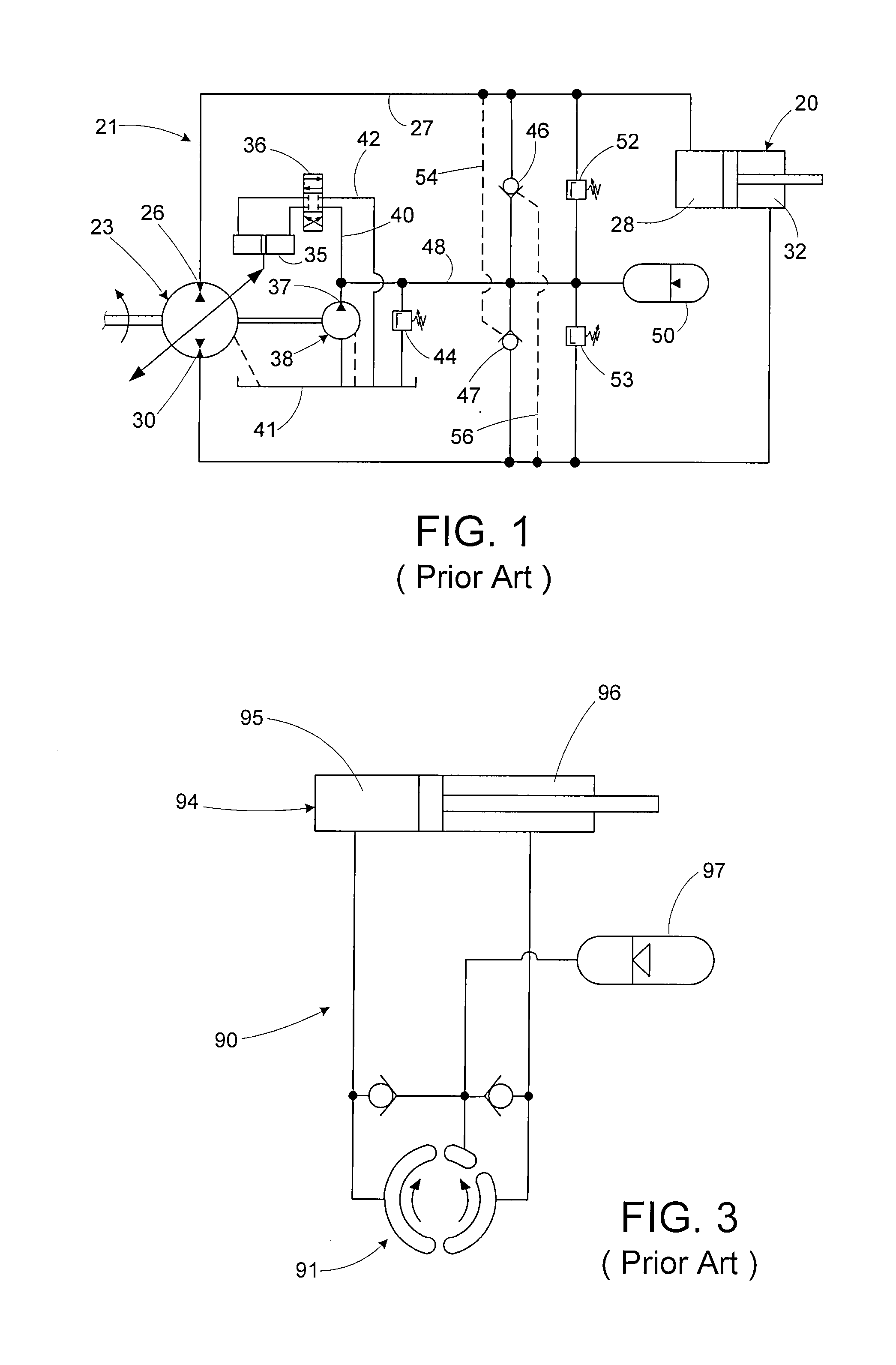

Hydraulic circuit with a return line metering valve and method of operation

A hydraulic system controls the flow of fluid to and from several functions on a machine. Each function has a valve assembly through which fluid is supplied under pressure from a source to an actuator and through which fluid returns from the actuator to a shared return line connected by a return line metering valve to the system tank. There are several regeneration modes of operation in which fluid exhausted from one port is supplied into the other port of the same actuator, which eliminates or reduces the amount of hydraulic fluid that must be supplied from the source. In some regeneration modes, input fluid for an actuator is obtained from another hydraulic function via the shared return line. In these regeneration modes an electronic controller operates the return line metering valve to restrict fluid from flowing into the tank from the shared return line, so that the fluid will be available to be supplied into an actuator port.

Owner:HUSCO INT INC

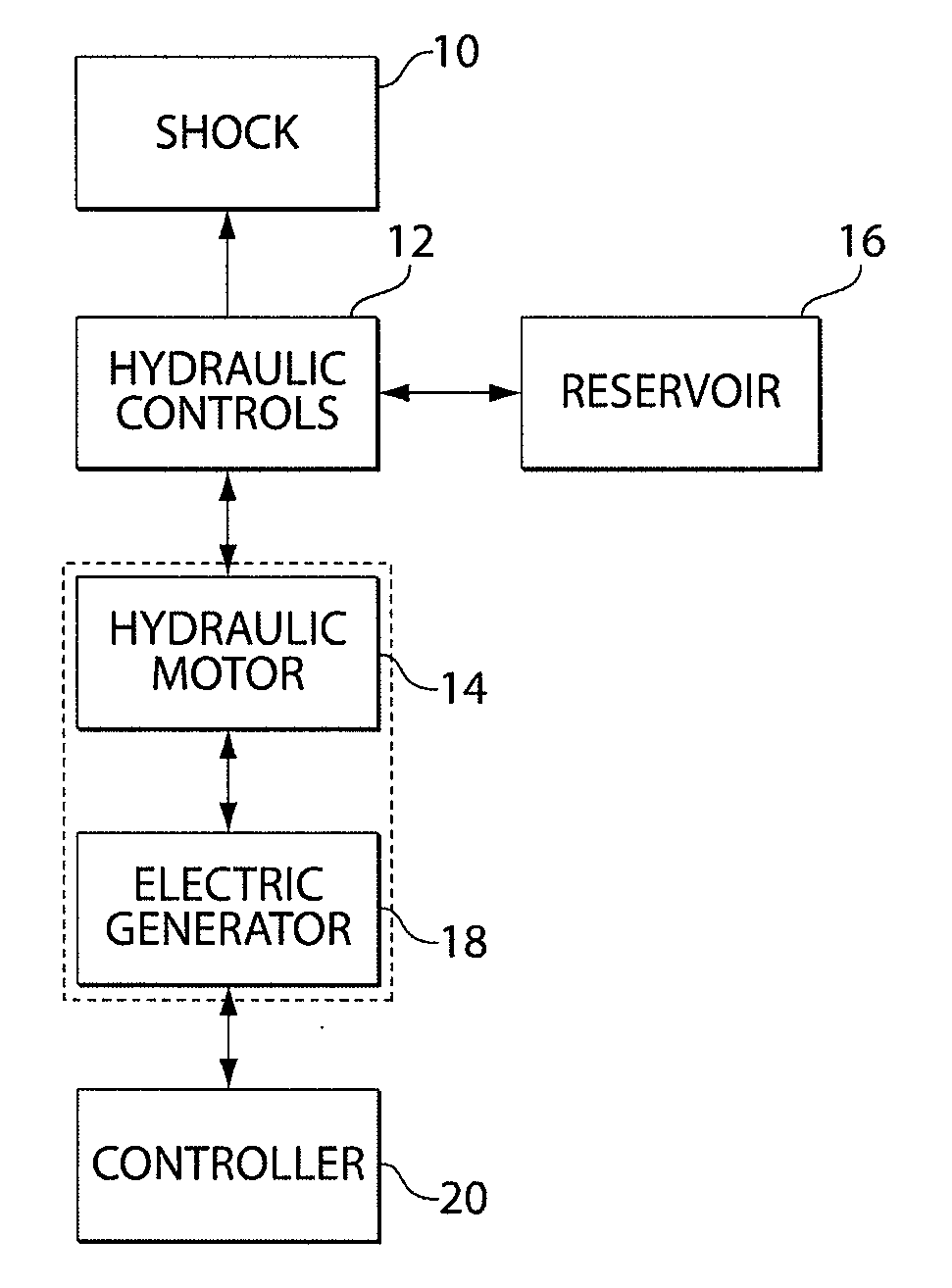

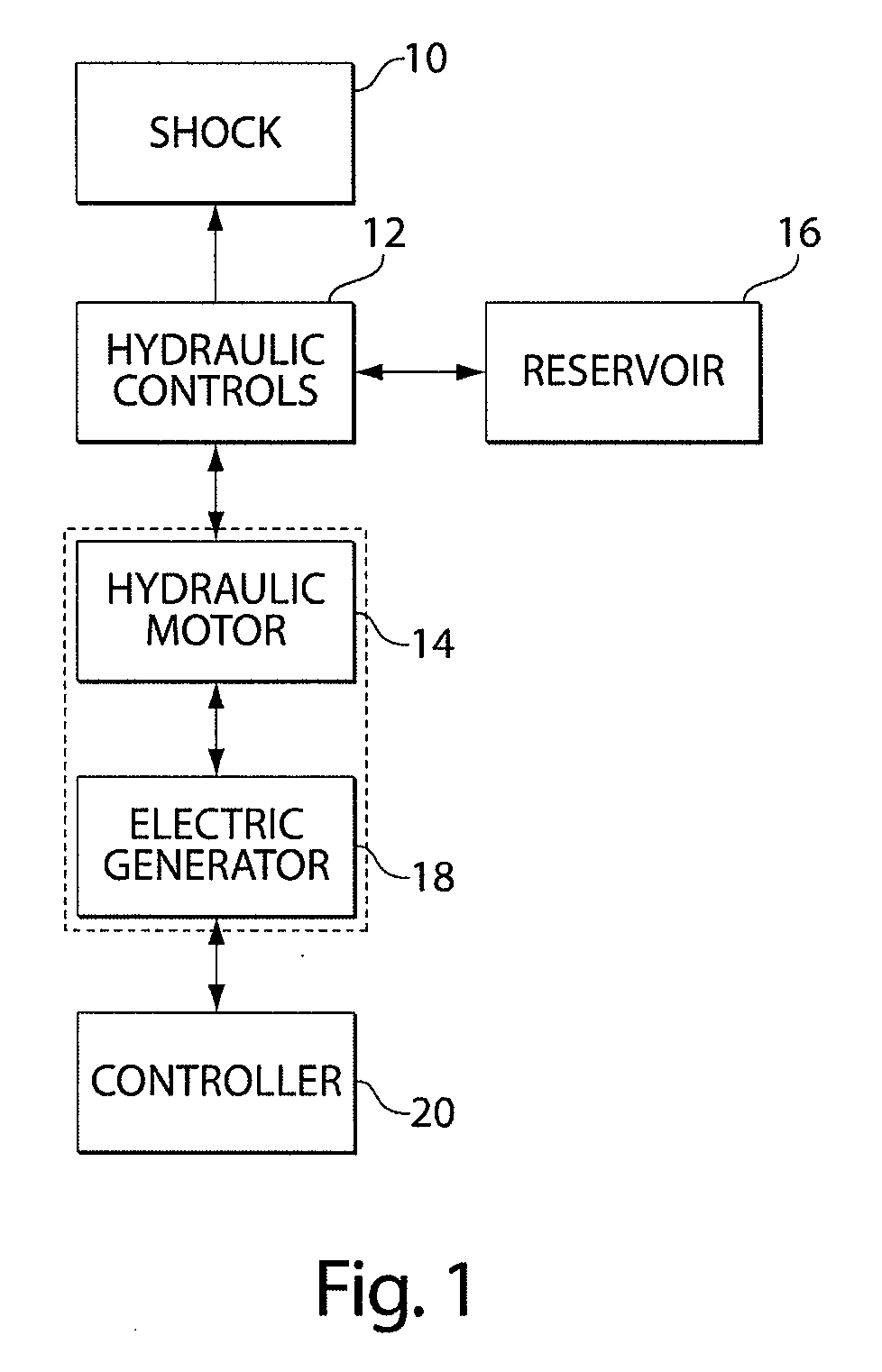

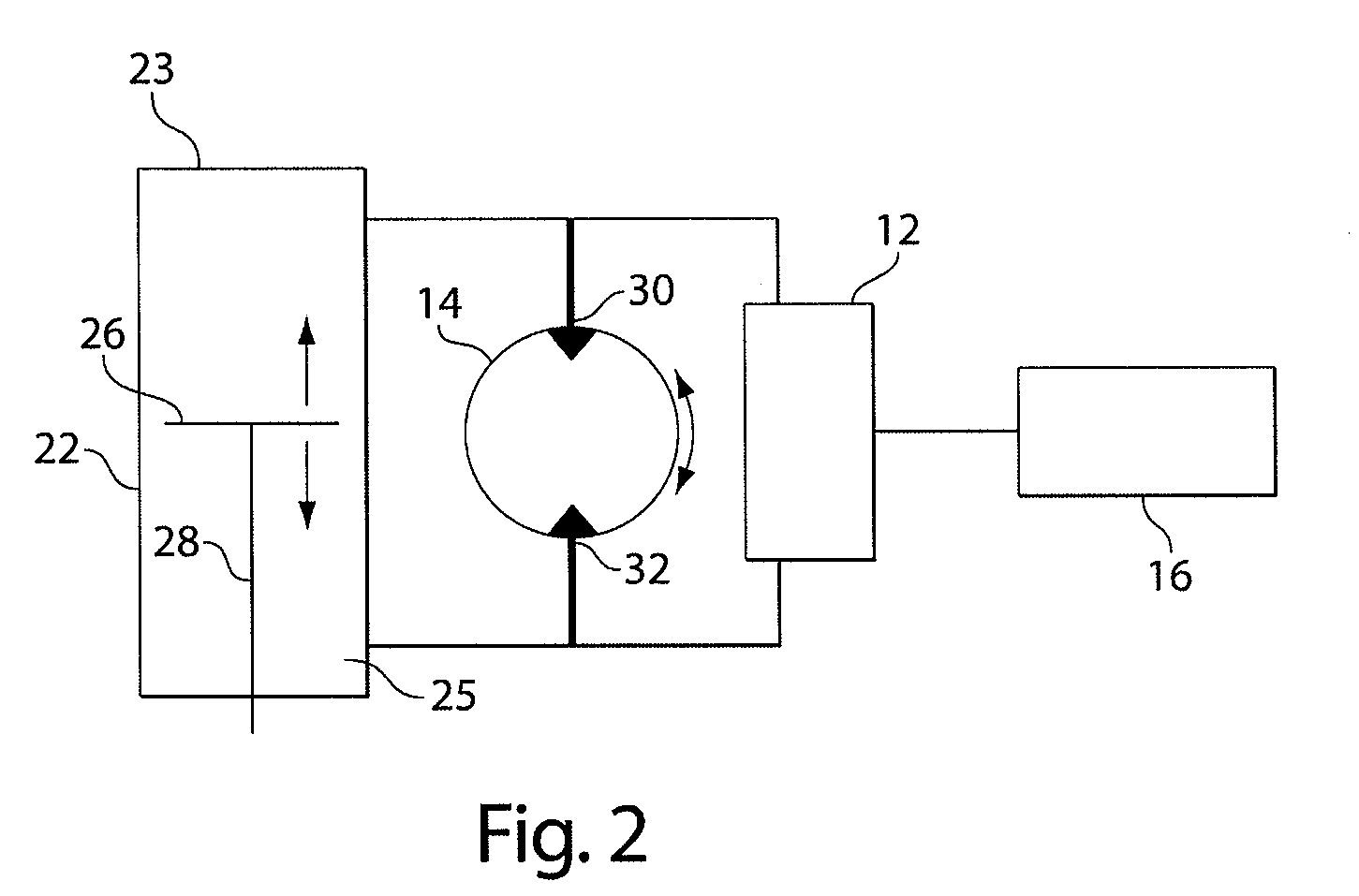

Regenerative shock absorber system

A regenerative shock absorber that include a housing and a piston that moves at least partially through the housing when the shock is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor, in turn, drives an electric generator that produced electric energy. The electric energy may be provided to a vehicle, among other things. The regenerative shock absorber may also provide ride performance that comparable to or exceeds that of conventional shock absorbers.

Owner:CLEARMOTION INC

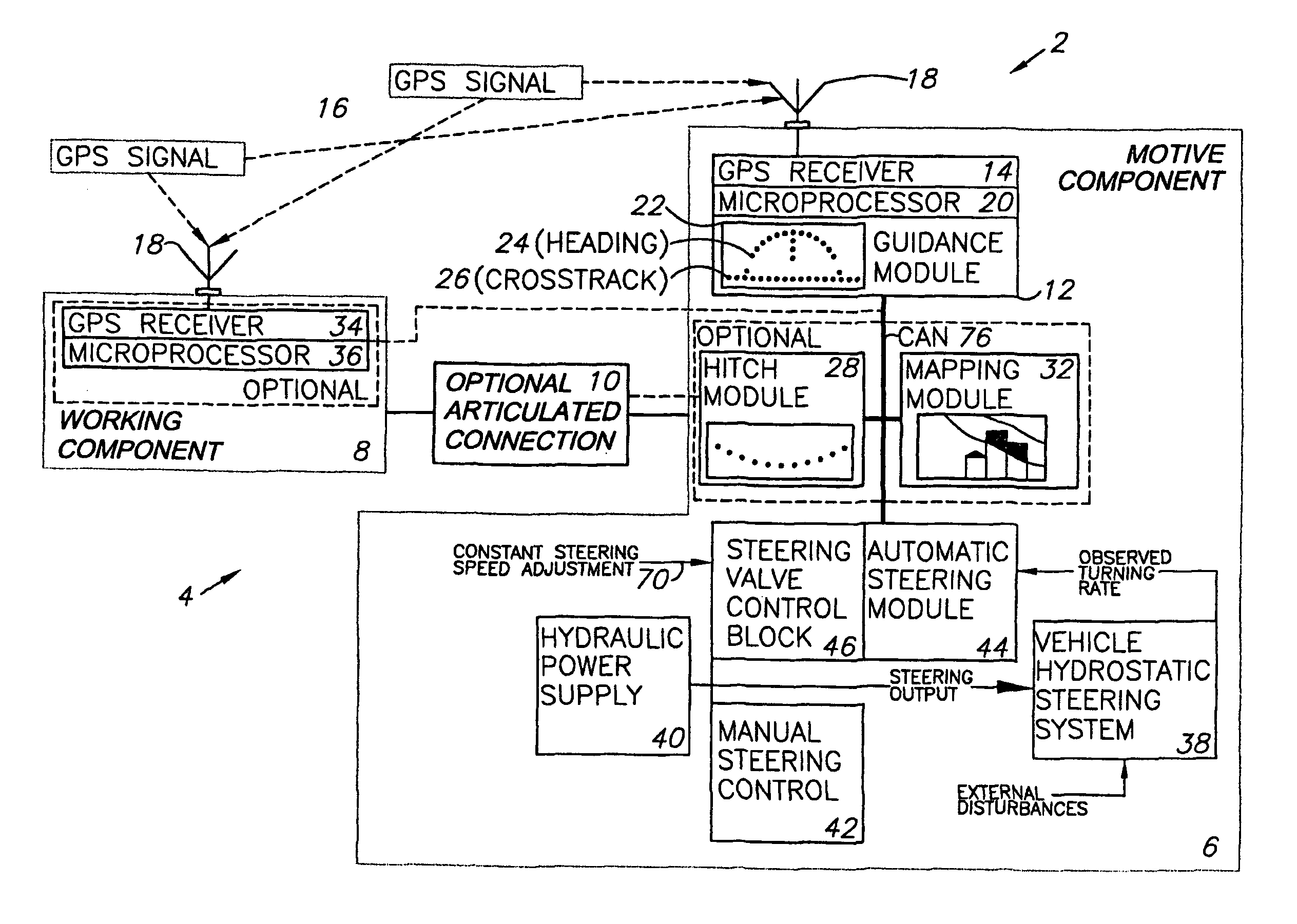

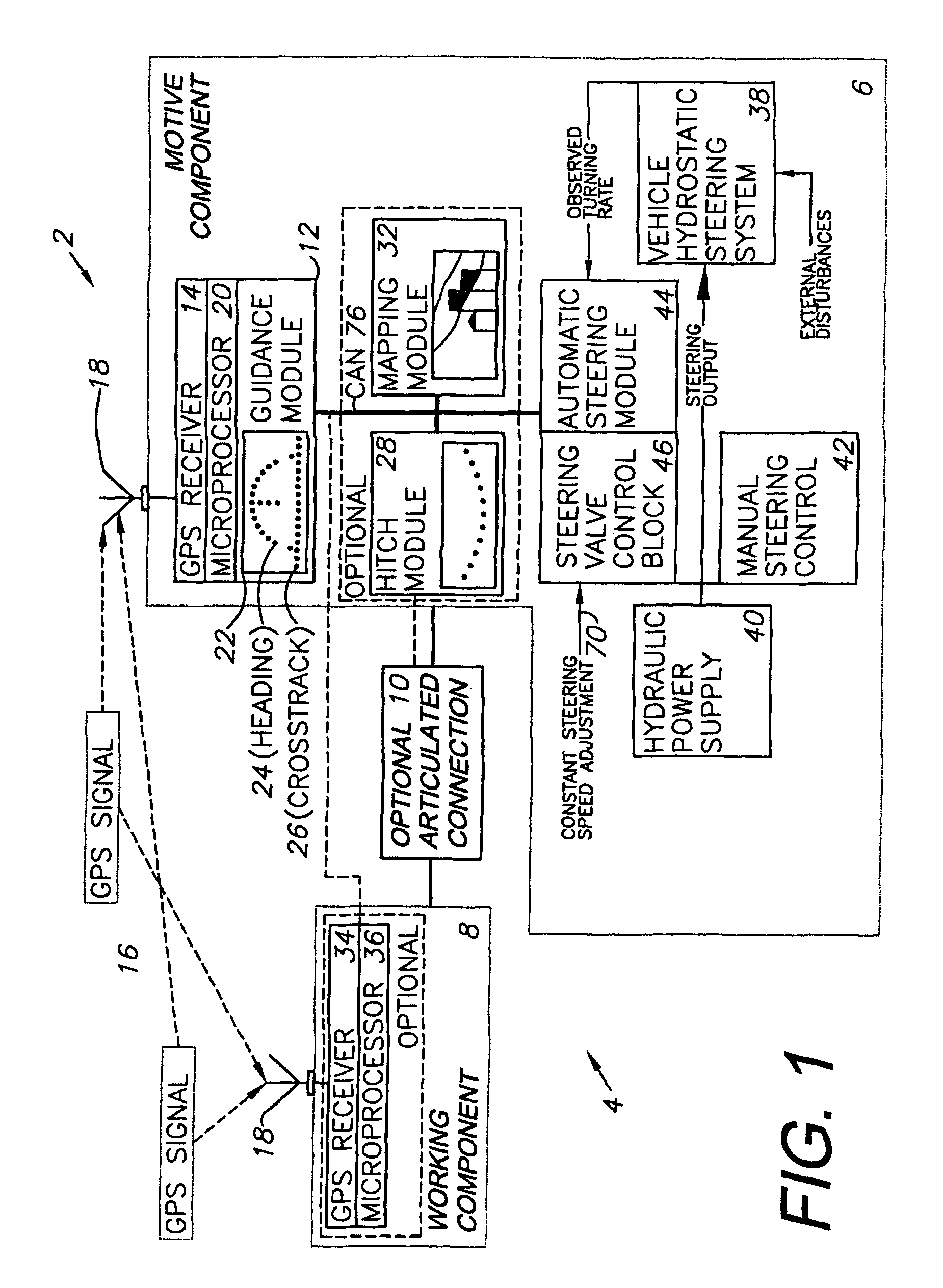

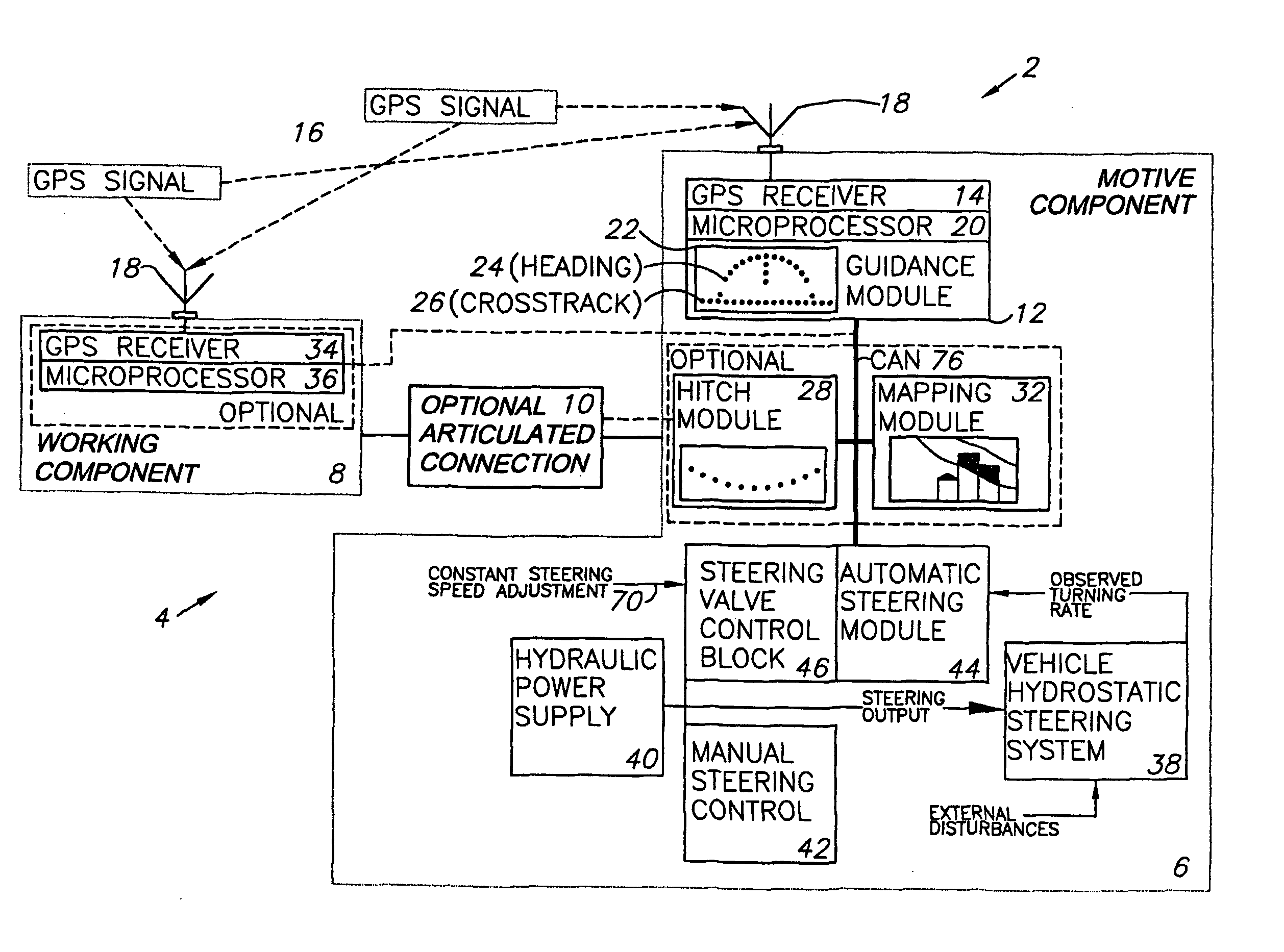

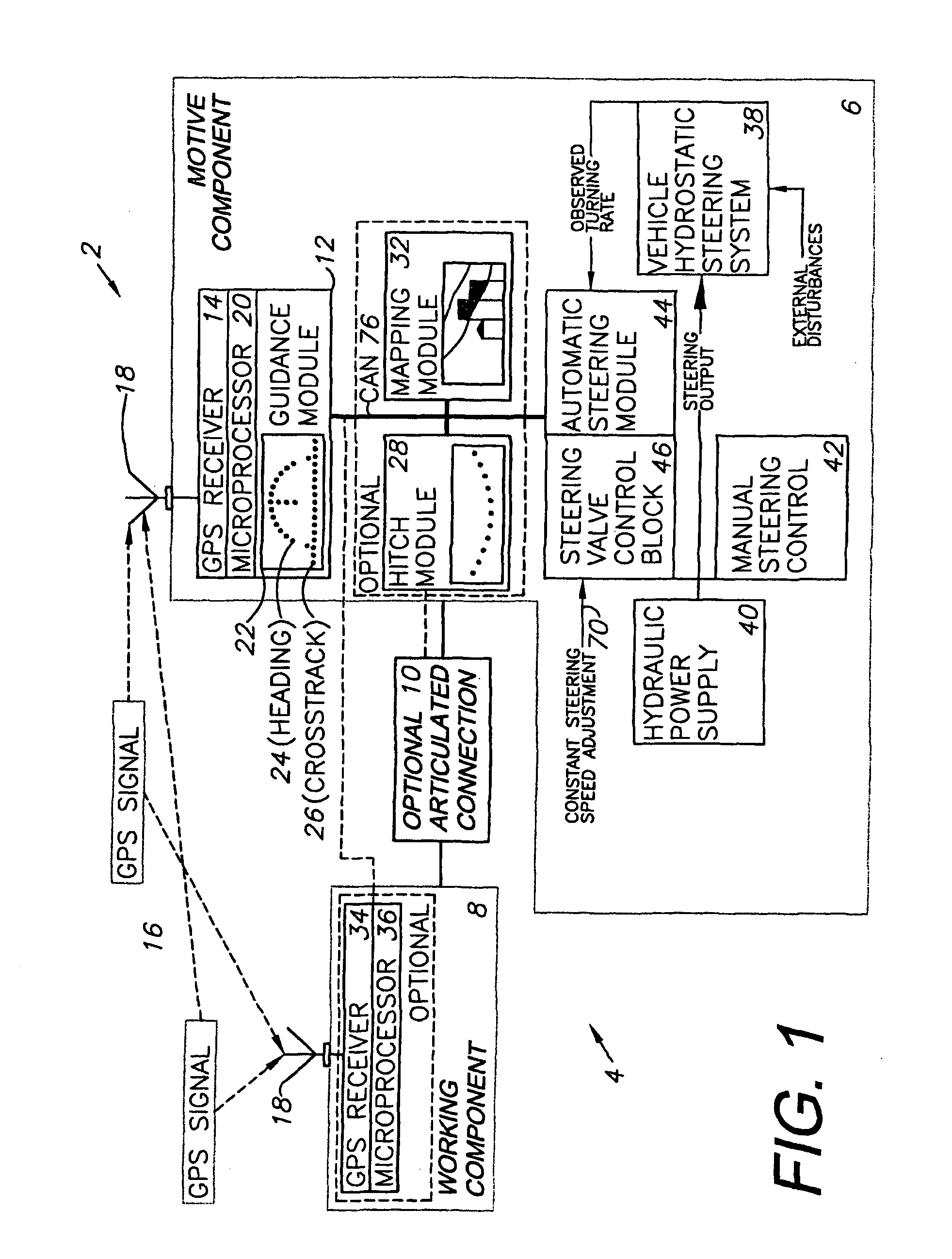

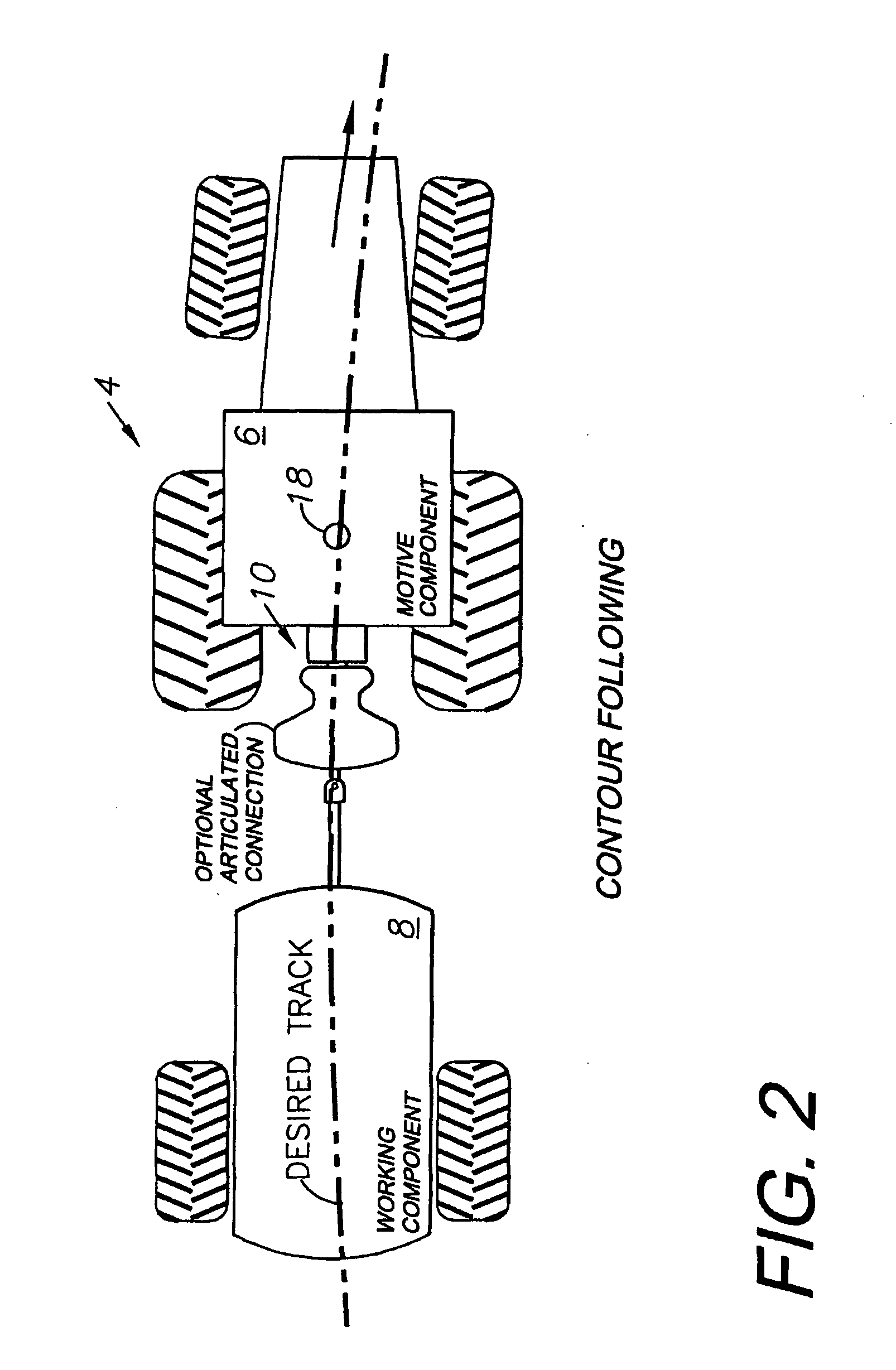

Automatic steering system and method

An automatic steering system and method are provided for a vehicle including an hydraulic primary steering system. The automatic steering system includes a guidance module with a GPS receiver and a microprocessor adapted to process and store GPS data defining travel paths, which can be associated with a cultivated field in an agricultural vehicle application. An automatic steering module is connected to the guidance module and to a steering valve control block, which provides pressurized hydraulic fluid in parallel with the vehicle's primary hydrostatic steering system. The automatic steering system utilizes a constant factor, such as steering rate, for predictability and simplicity in the operation of the automatic steering system. A feedback loop from the vehicle hydrostatic steering system uses the vehicle's actual turning rate for comparison with a desired turning rate. The system is adapted for original equipment installation and retrofitting on vehicles, such as farm tractors, with various primary hydrostatic steering system configurations. An automatic steering method includes the steps of: initializing the system; adjusting the steering with an hydraulic valve to provide a constant steering rate; providing feedback corresponding to the vehicle's actual turning rate and combining the feedback with other input signals to provide automatic steering.

Owner:AGJUNCTION

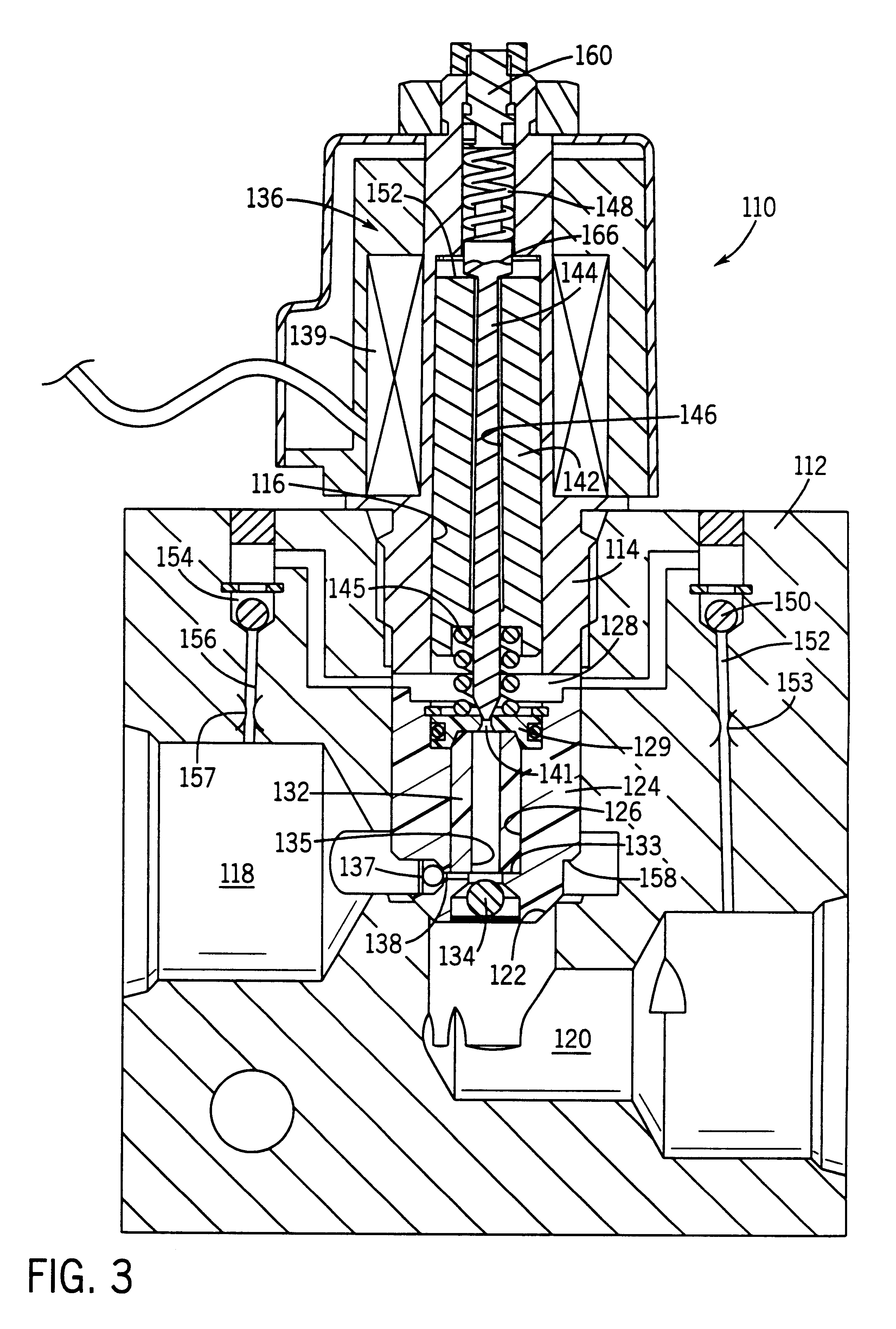

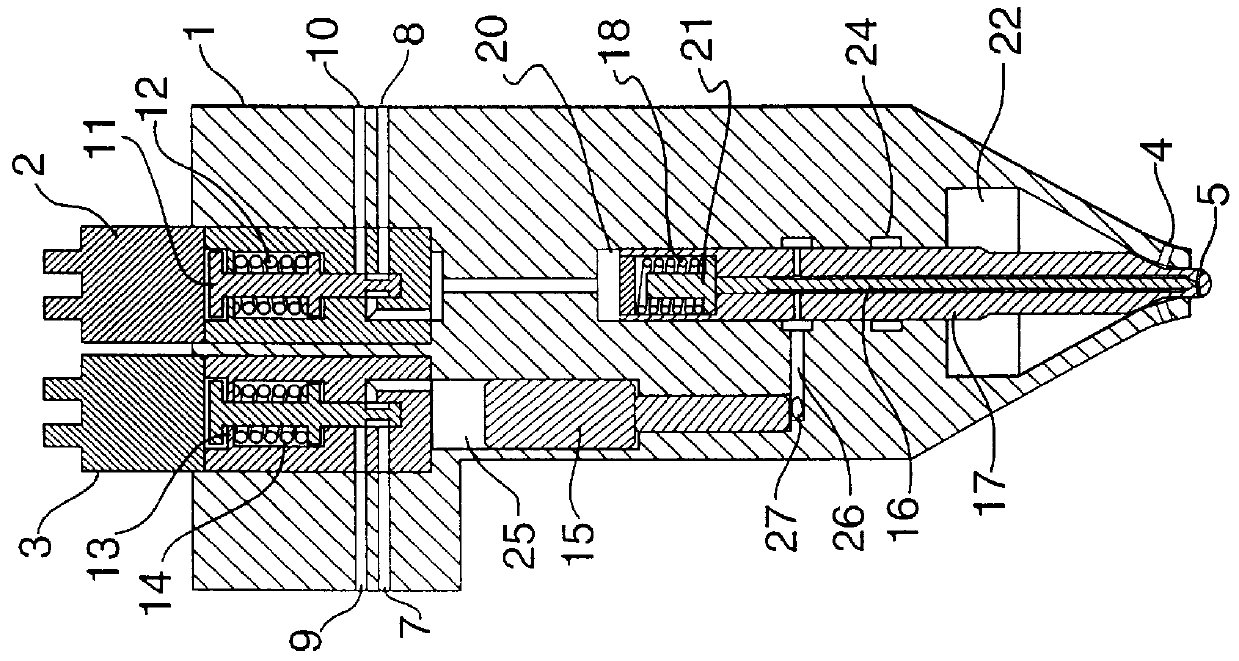

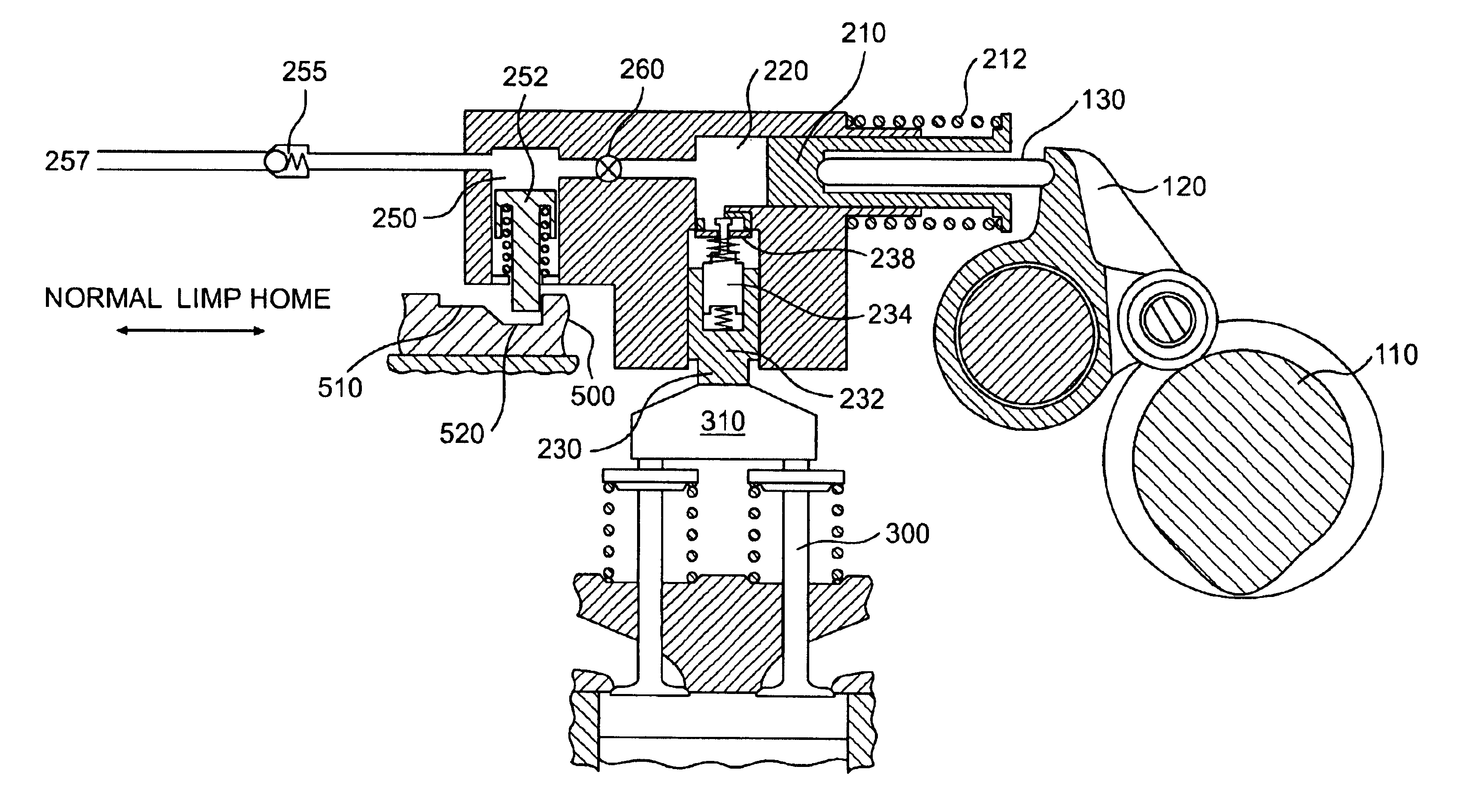

Gaseous and liquid fuel injector

A hydraulically actuated dual fuel injector for an internal combustion engine. More particularly, the application pertains to a hydraulically actuated injector for injecting controlled quantities of a first fuel and of a second fuel into an internal combustion diesel engine at different times. A dual fuel injector comprising: (a) an injector body; (b) an inlet port in the injector body for enabling pressurized hydraulic fluid from a hydraulic fluid source to be introduced into the interior of the injector body, the hydraulic fluid being of sufficient pressure to maintain injection valves in the injector body in a closed position until actuated; (c) a first inlet port in the injector body for enabling a first fuel to be introduced into the interior of the injector body; (d) a first injection valve in the injector body connected to the second inlet port for controlling injection of the first fuel from the injector through a first fuel ejection port; (e) a second inlet port in the injector body for enabling a second fuel to be introduced into the interior of the injector body; (f) a second injection valve in the injector body connected to the second inlet port for controlling injection of the second fuel from the injector through a second fuel ejection port; (g) a first control valve which causes the hydraulic fluid to actuate the first injection valve; (h) a second control valve which causes the hydraulic fluid to actuate the second injection valve; (i) a metering device in the injector body for metering the amount of first fuel injected by the first injection valve; and (j) a seal in the injector body which prevents leakage of the second fuel into the first fuel.

Owner:WESTPORT POWER

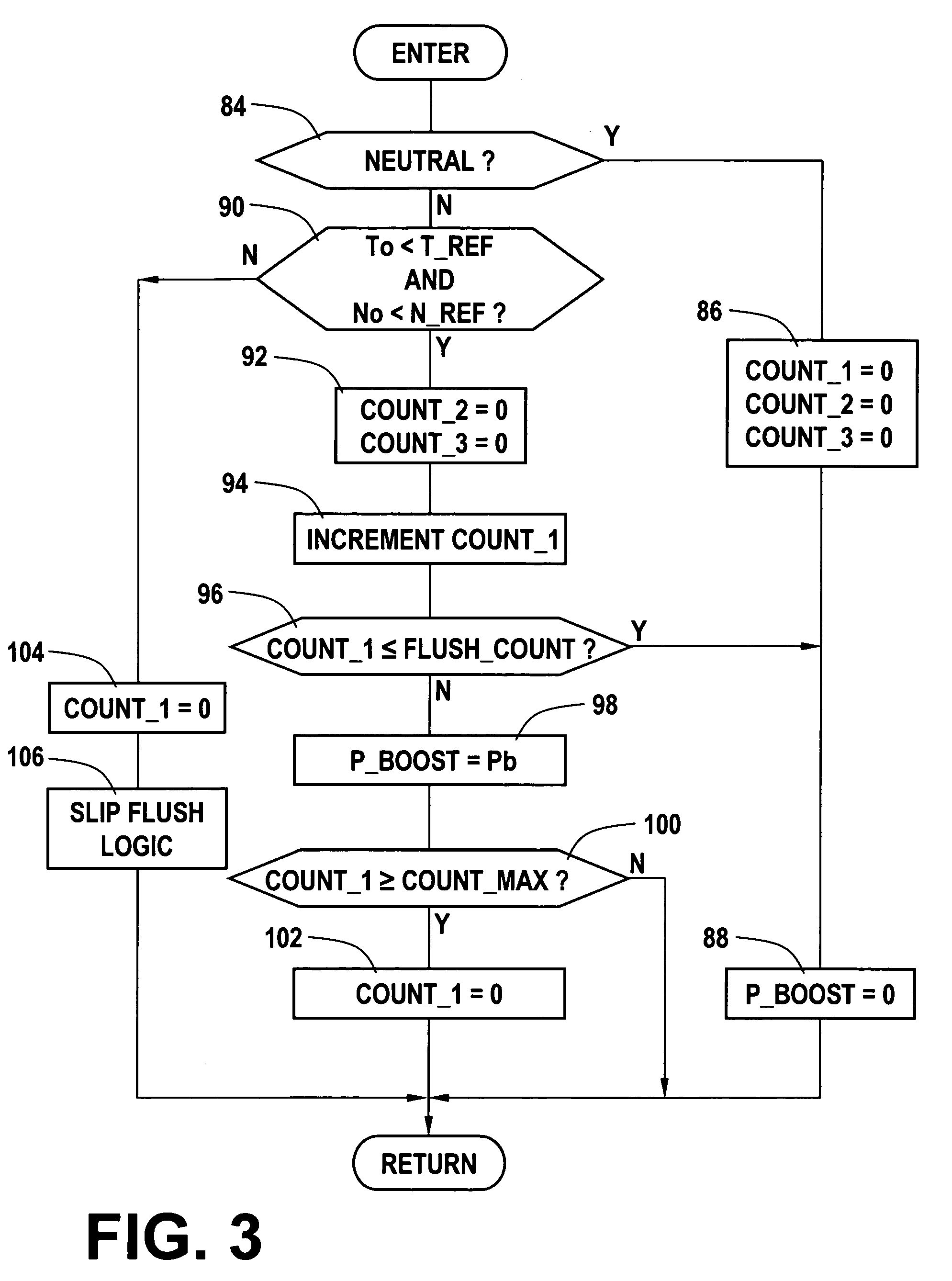

Method of automatically flushing debris from an electrically-operated hydraulic valve

InactiveUS20050255967A1Operating means/releasing devices for valvesGearing controlEngineeringHydraulic fluid

The normal control of an electrically-activated hydraulic valve armature is overridden to automatically and periodically open the armature for flushing out debris that has accumulated between the armature and a seat that the armature is designed to engage. The valve develops fluid pressure for maintaining engagement of a motor vehicle transmission clutch, and when excessive slippage of the clutch is detected, the armature is forced into engagement with the seat until the slippage is reduced or a predetermined period of time has elapsed, after which the armature is temporarily positioned away from the seat to provide full flow of hydraulic fluid across the seat to flush out debris that prevents the armature from engaging the seat. During Neutral operation of the transmission, the armature is continuously positioned away from the seat, and during low torque conditions the armature is temporarily positioned away from the seat.

Owner:GM GLOBAL TECH OPERATIONS LLC

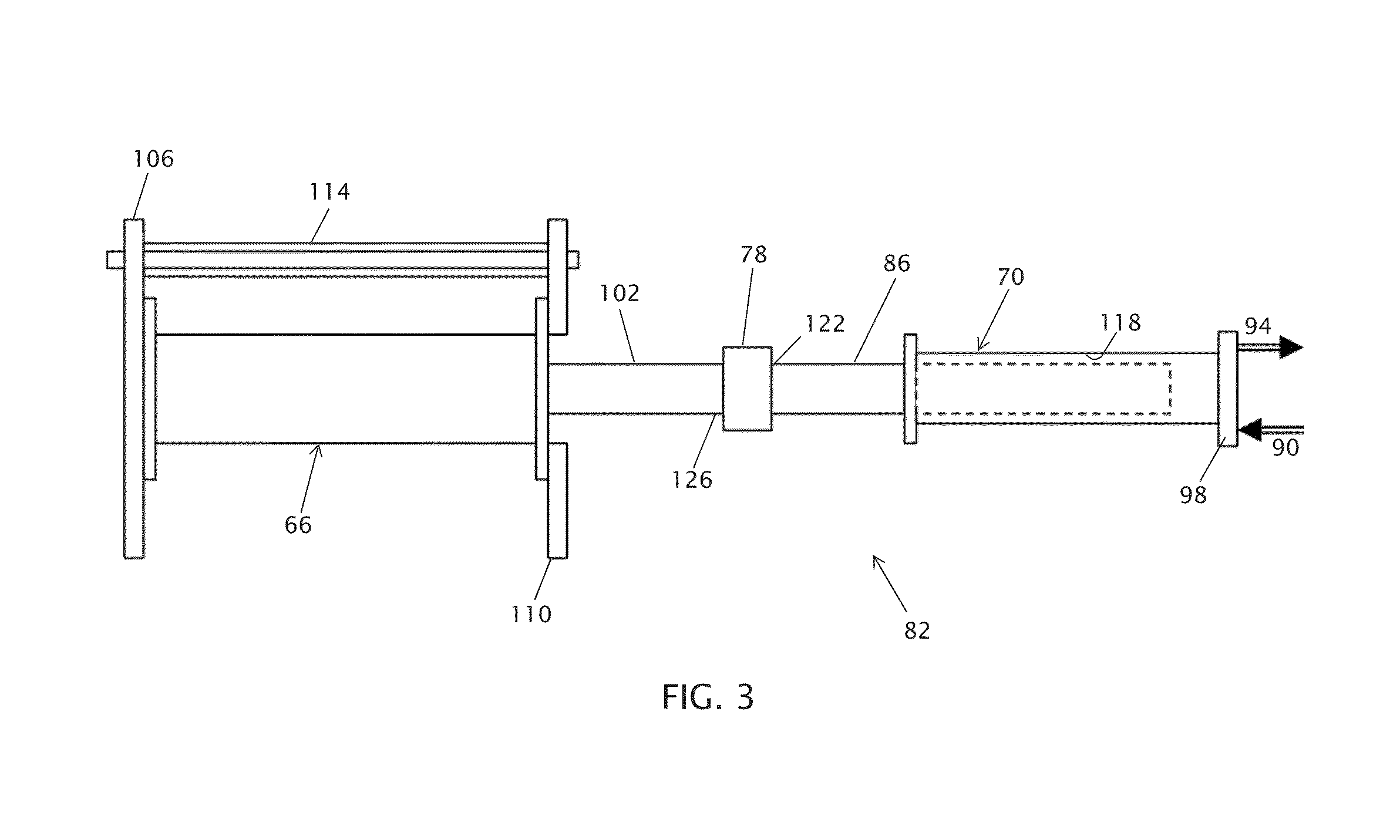

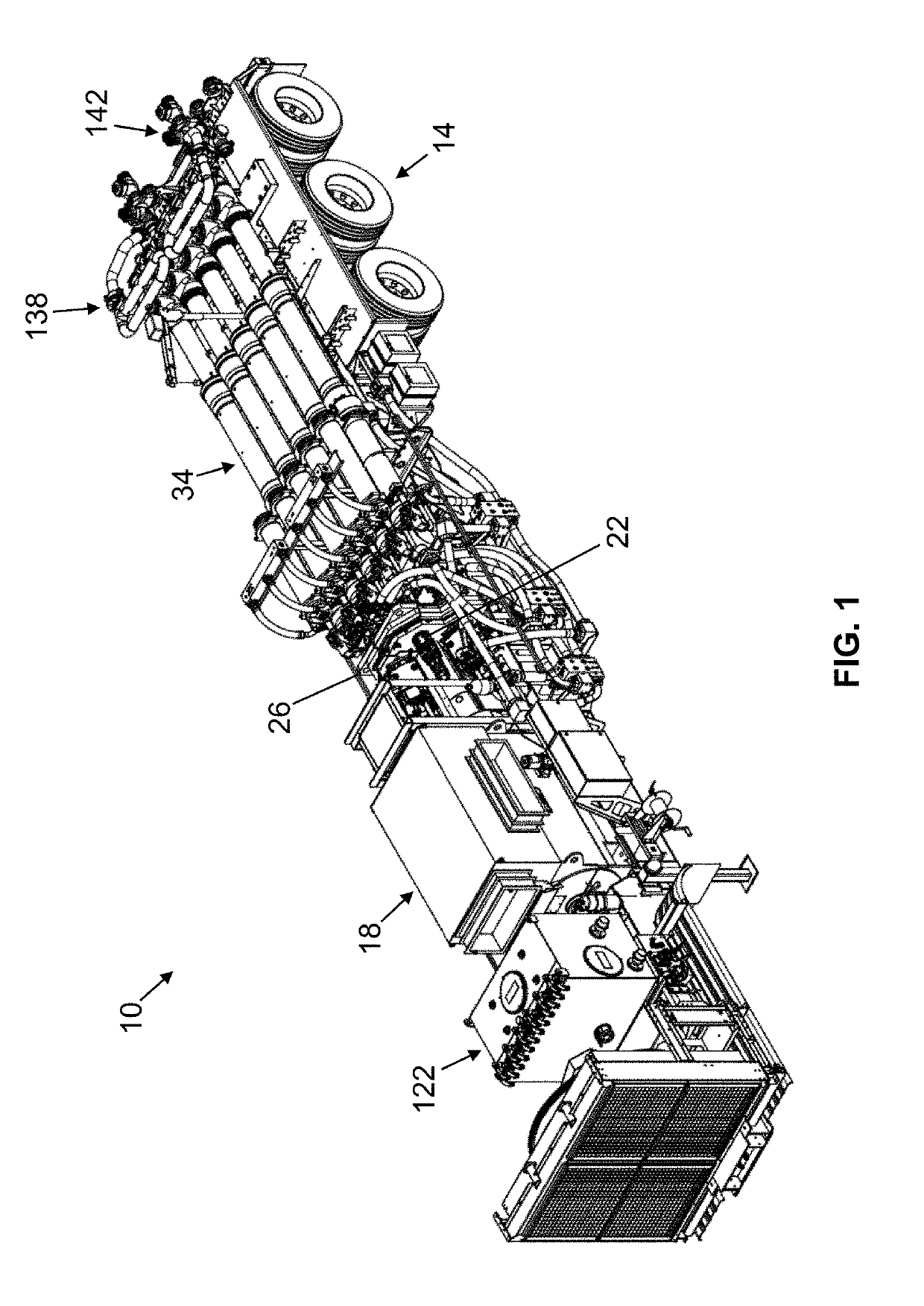

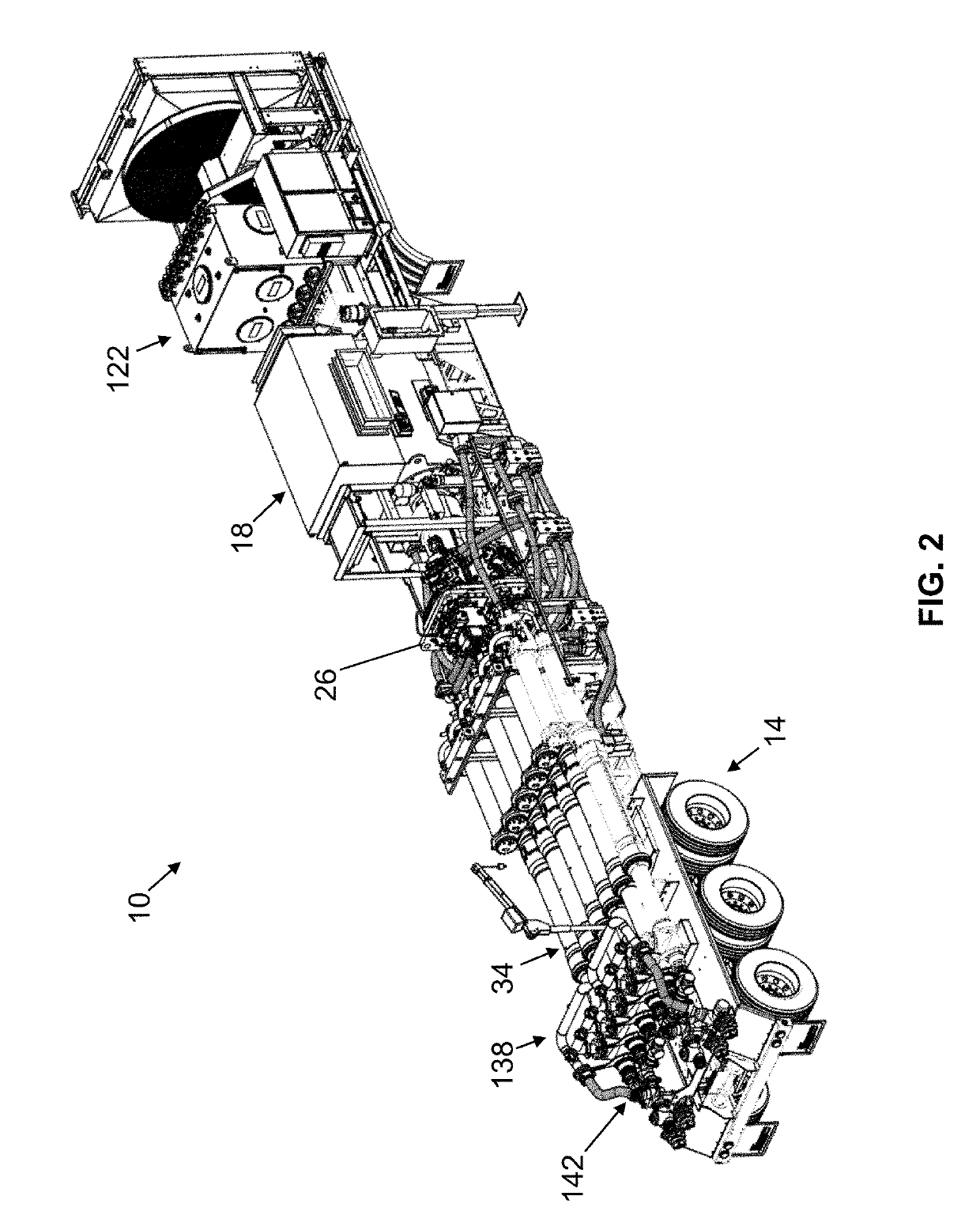

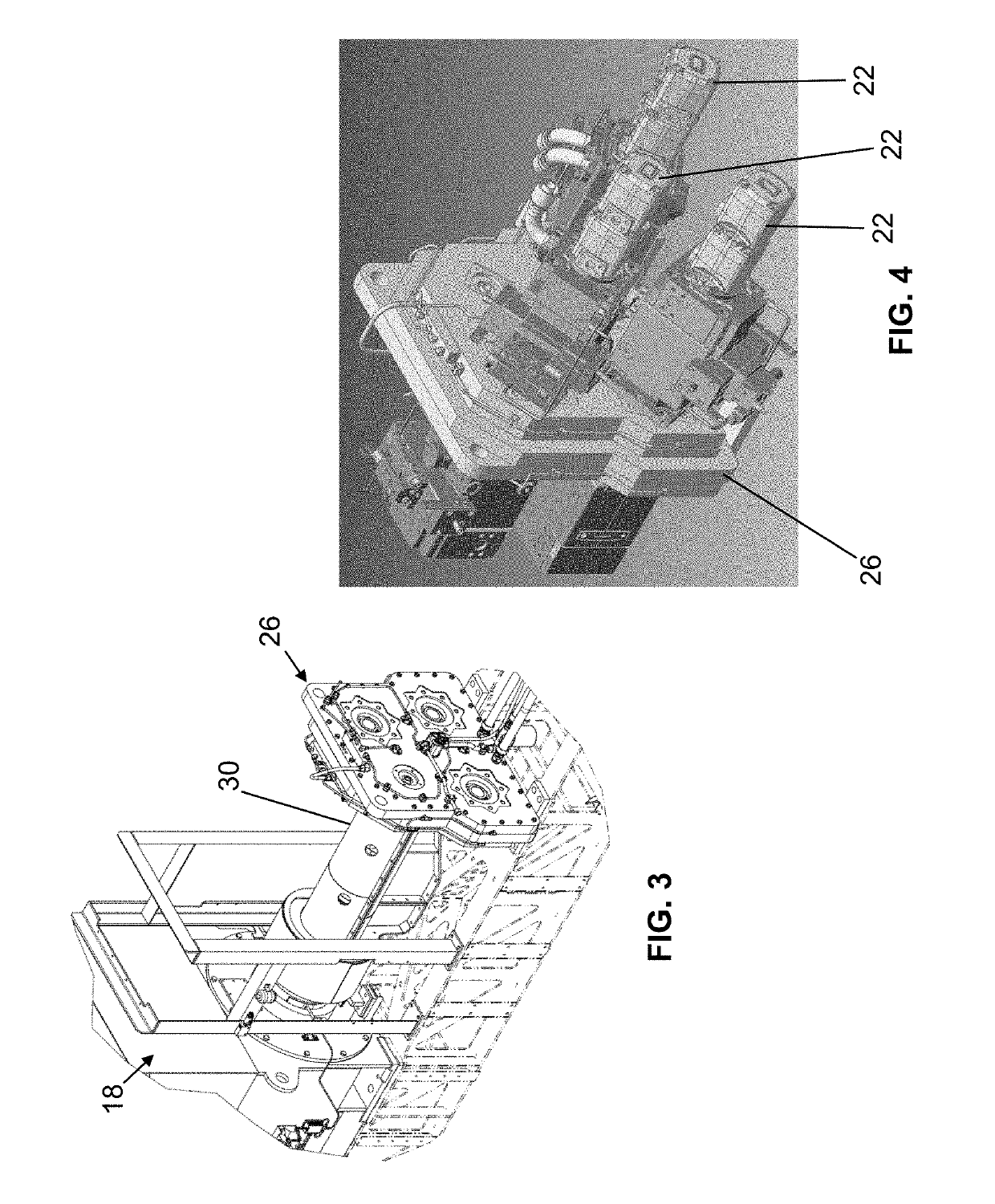

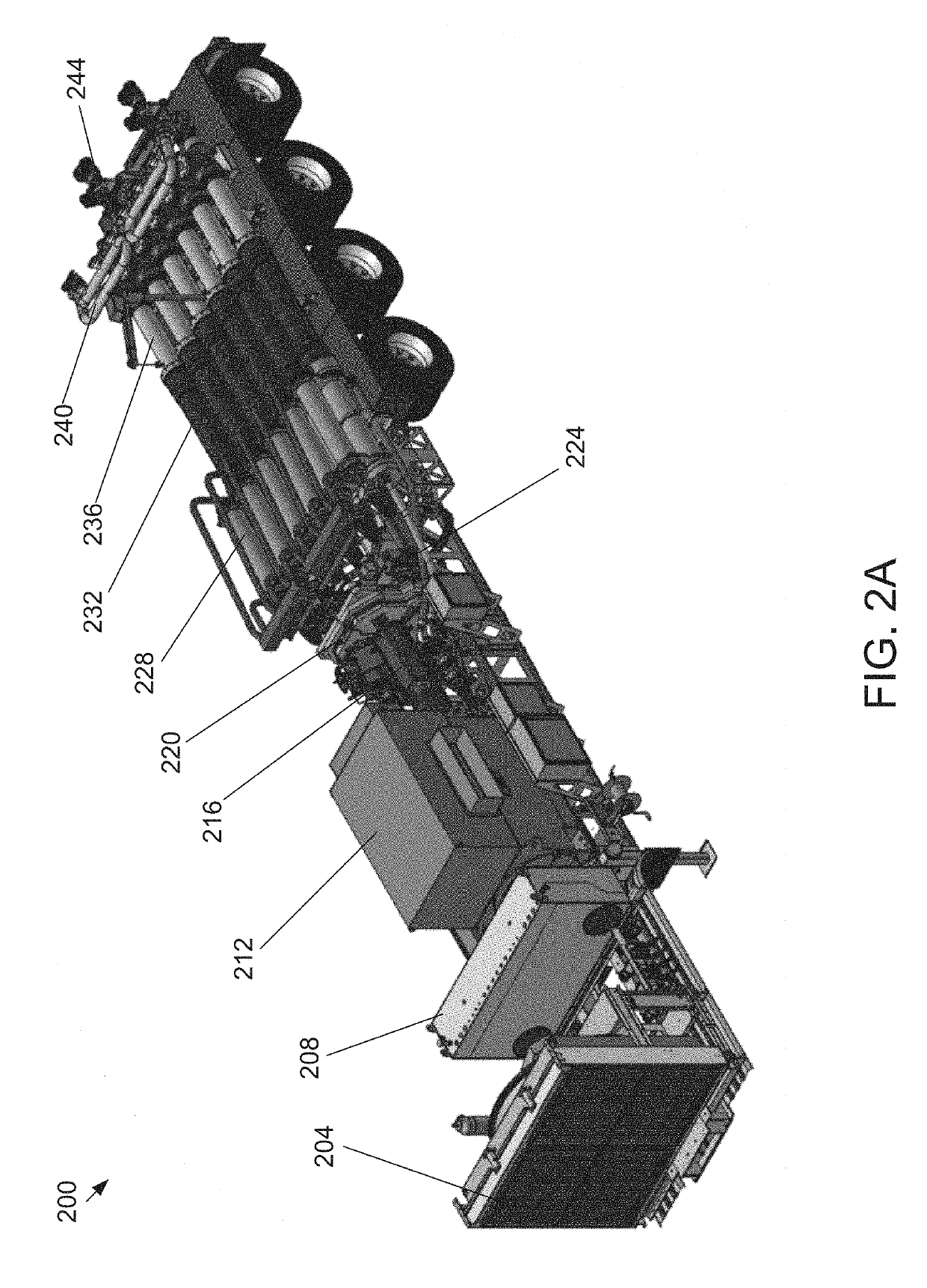

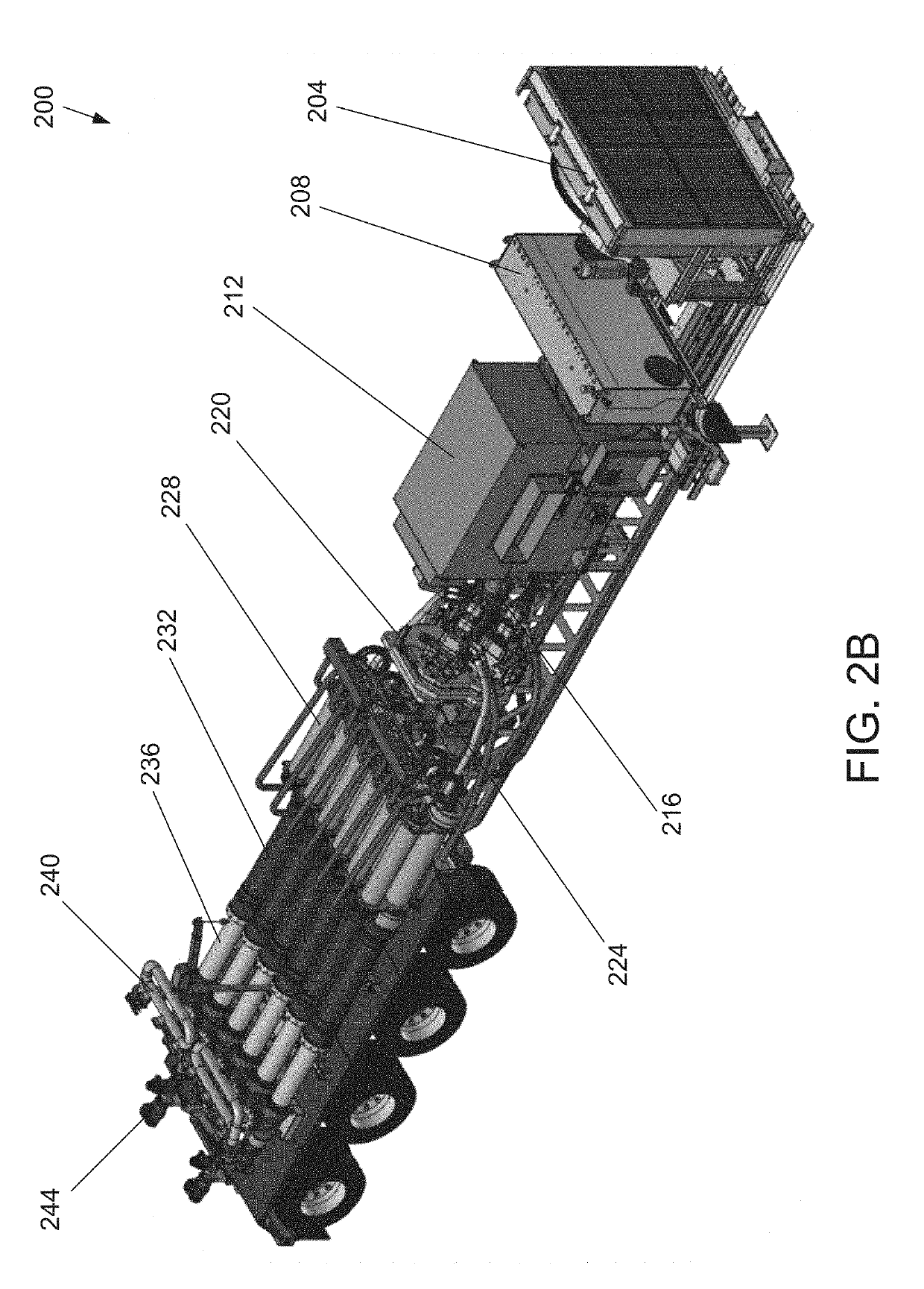

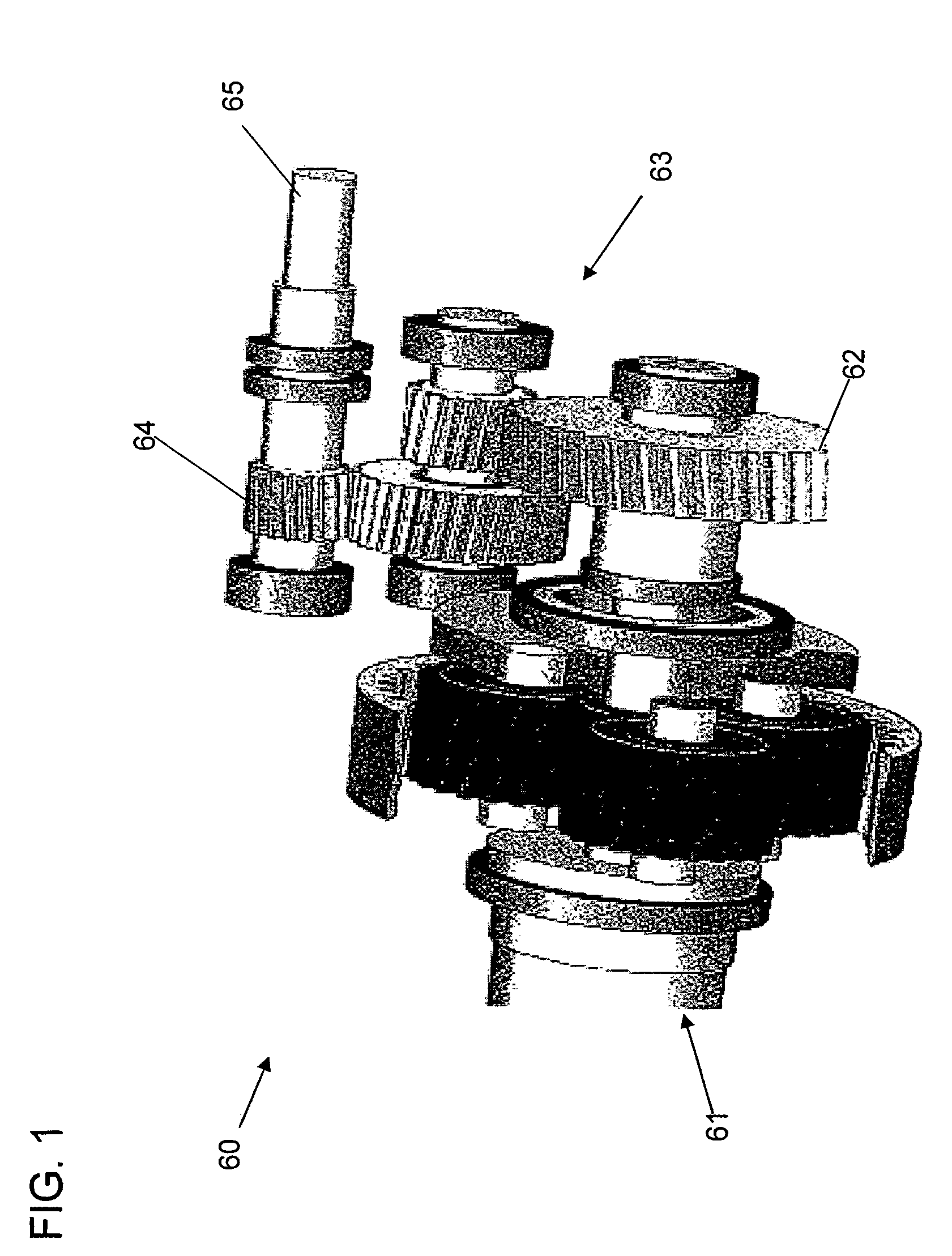

Well Service Pump System

A well service pump system supplies high pressure working fluid to a well. The pump system is a linear design which incorporates a diesel engine, a hydraulic drive gear box, open loop hydraulic Pumps, hydraulic ram cylinders, controls for the hydraulic system hydraulic cylinders, working fluid end cylinders and a coupling to connect the hydraulic cylinders and the working fluid ends. The engine powers the hydraulic system which, in turn, provides hydraulic fluid to operate the hydraulic ram cylinders. Each of the polished rods of the hydraulic ram cylinders is connected axially to a plunger rod end of a working fluid end cylinder. There is no crankshaft or automatic transmission required. The linear design allows for a longer plunger stroke length while still allowing highway transport on a truck or skid.

Owner:AMERIFORGE GRP

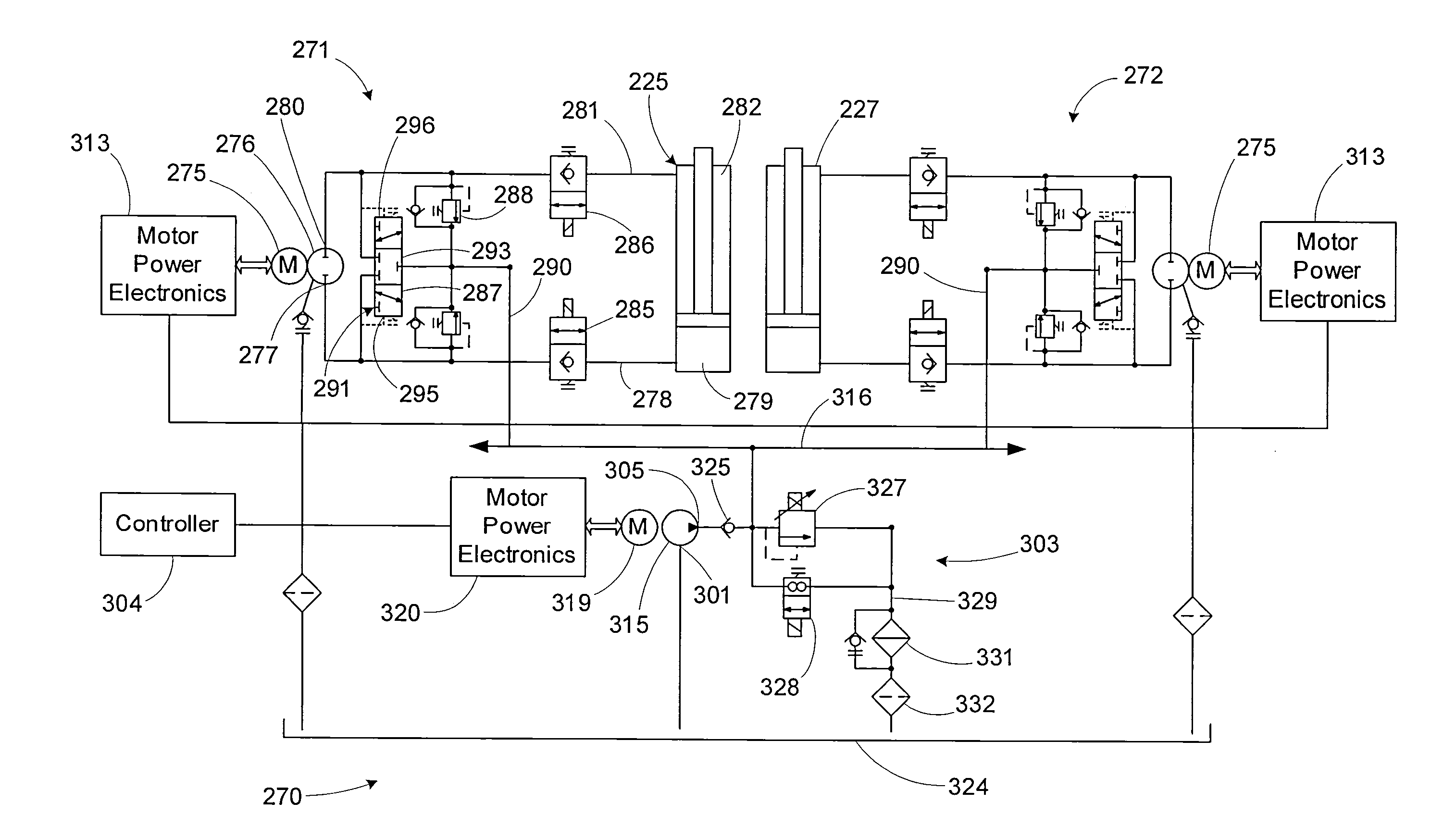

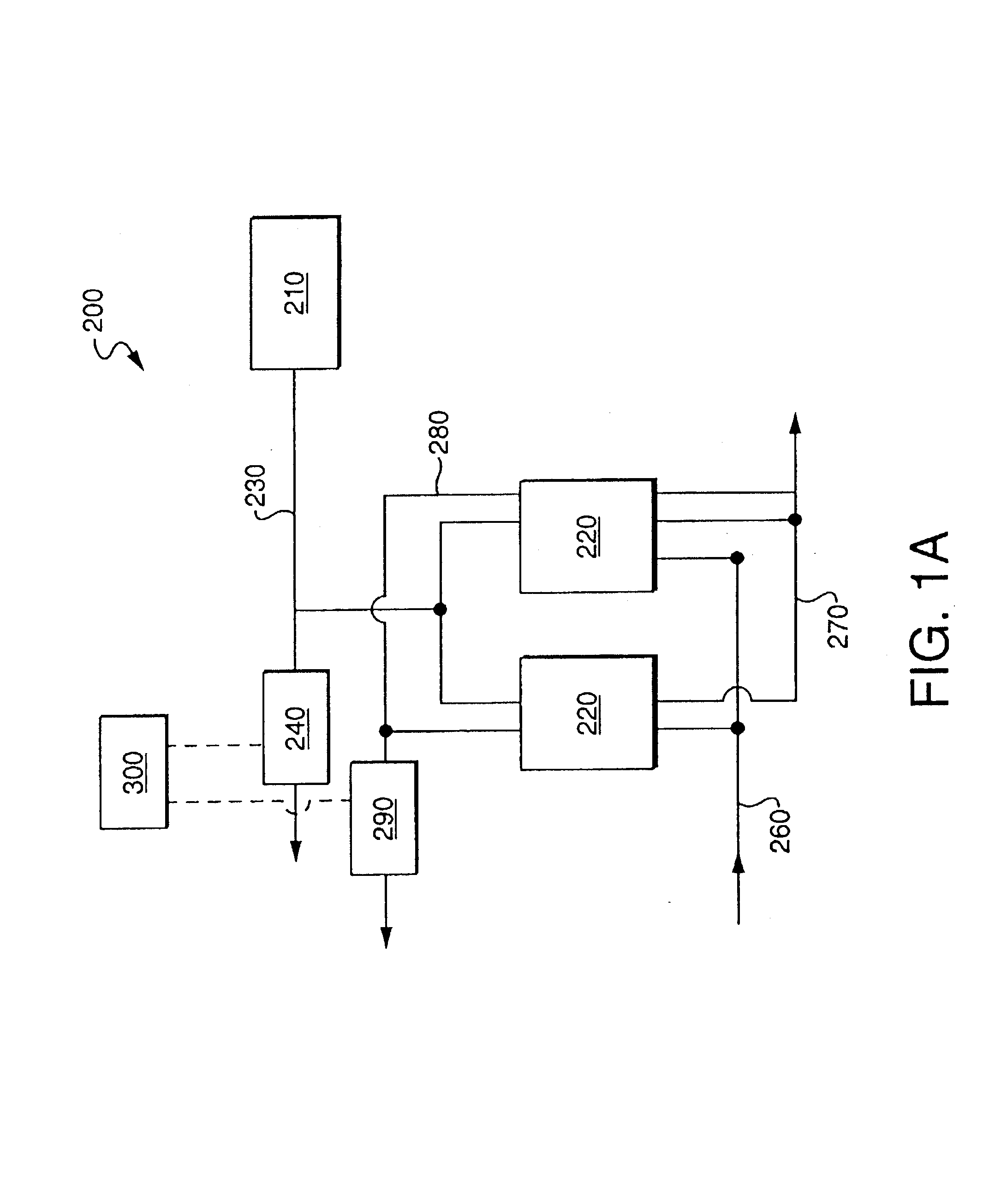

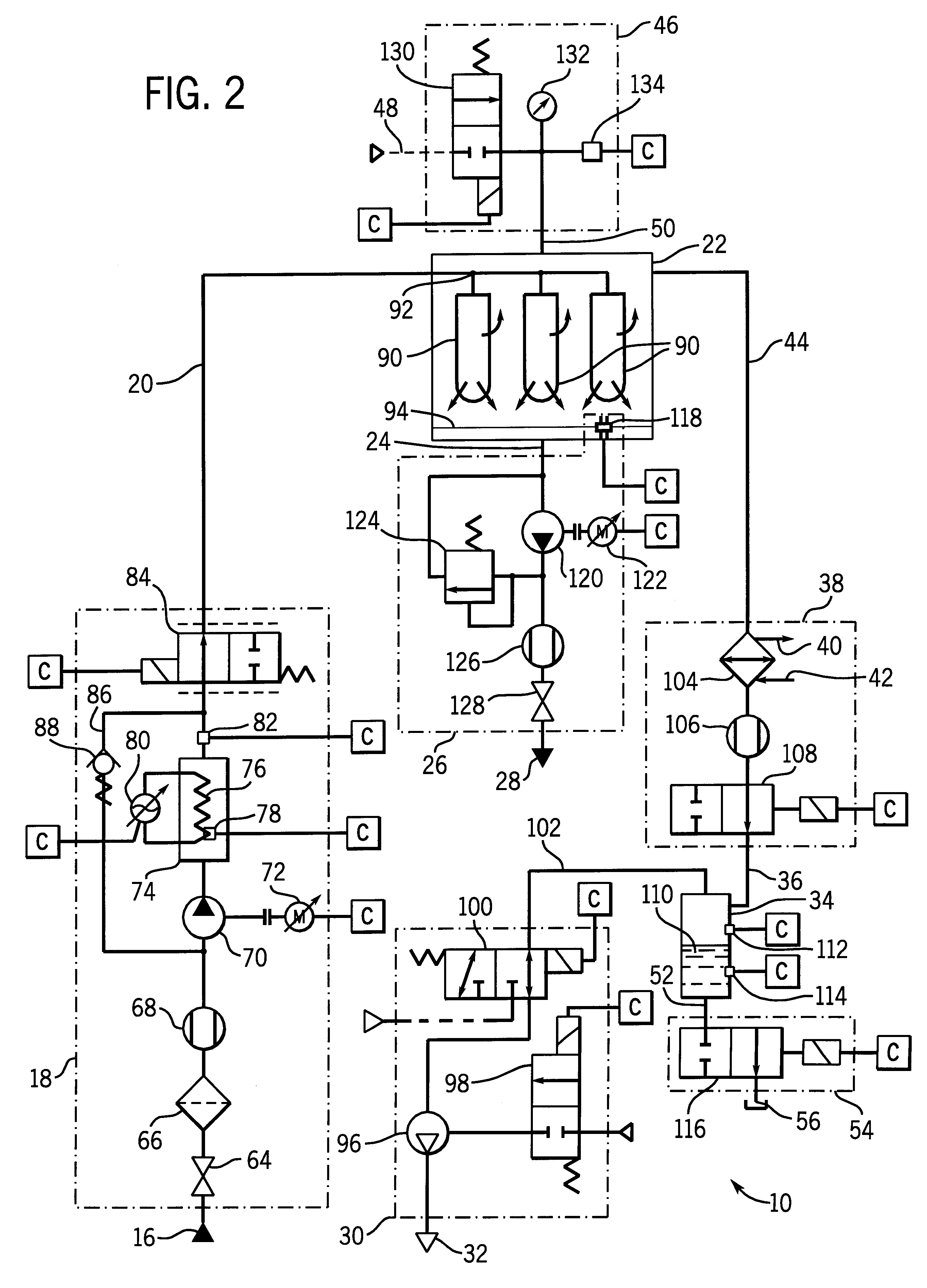

Flow management system for hydraulic work machine

A flow management system capable of providing adjustable hydraulic fluid flow or pressure at a common line to supply bidirectional pumps in electro-hydrostatic actuation systems and conditioning re-circulated hydraulic fluid. The system enables flow sharing between multiple actuation systems and minimization of energy consumption by a power-on-demand approach and / or electrical energy regeneration while eliminating the need for an accumulator. The system has particular application to electro-hydrostatic actuation systems that typically include bi-directional electric motor driven pumps and unbalanced hydraulic actuators connected within closed circuits to provide work output against external loads and reversely recover energy from externally applied loads.

Owner:PARKER INTANGIBLES LLC

Multilayer plastic composition having an electrically conductive inner layer

InactiveUS6090459AAvoid disadvantagesAvoid accumulationSynthetic resin layered productsCeramic shaping apparatusMobile vehicleFiber

A multilayer plastic composition having (I) an outer layer of a thermoplastic molding composition and (II) an inner layer of an electrically conductive thermoplastic molding composition containing graphite fibrils, which are useful for the transport of (petro)chemical materials and also in the motor vehicle sector for conveying brake, cooling and hydraulic fluid and also fuel.

Owner:EVONIK DEGUSSA GMBH

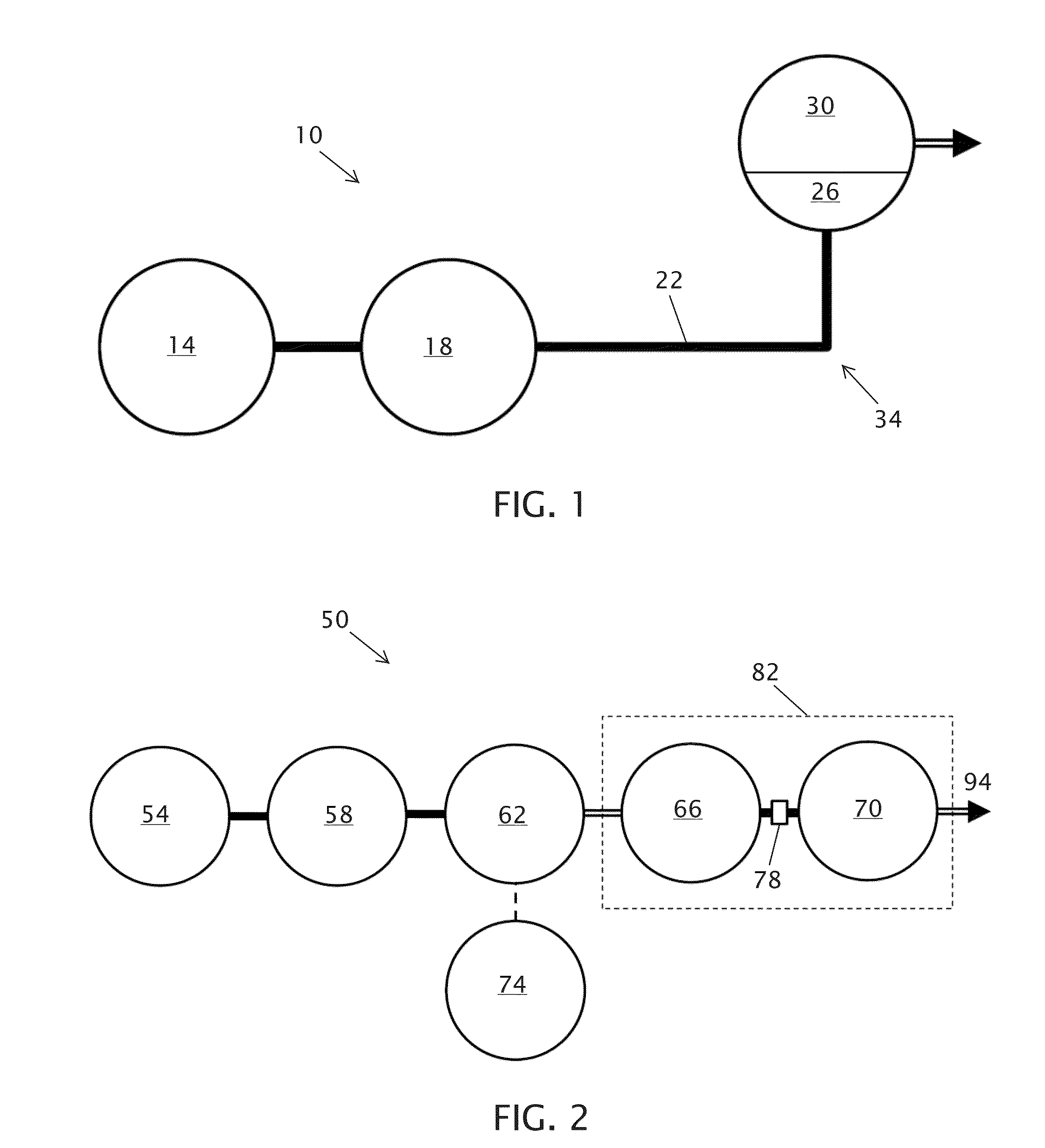

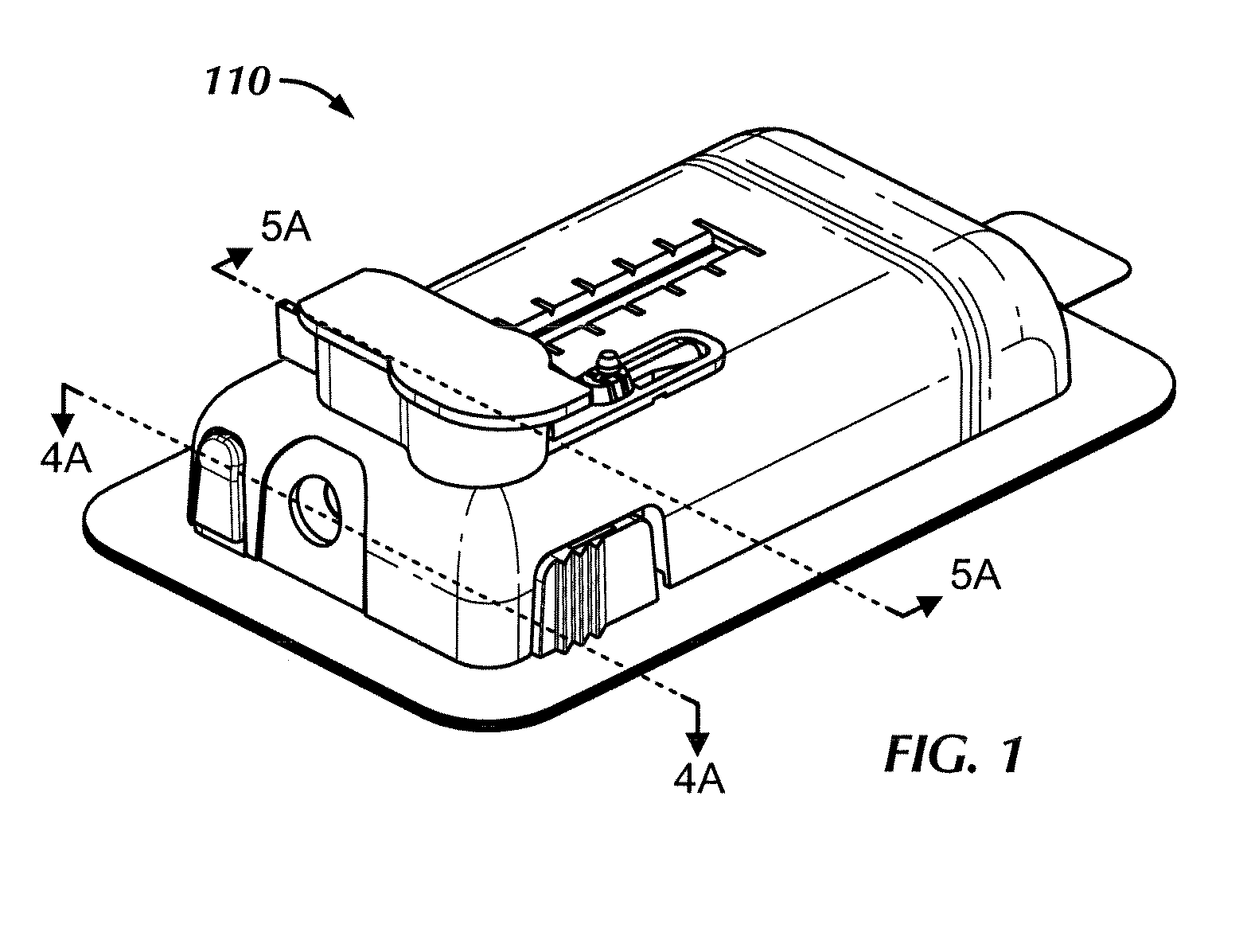

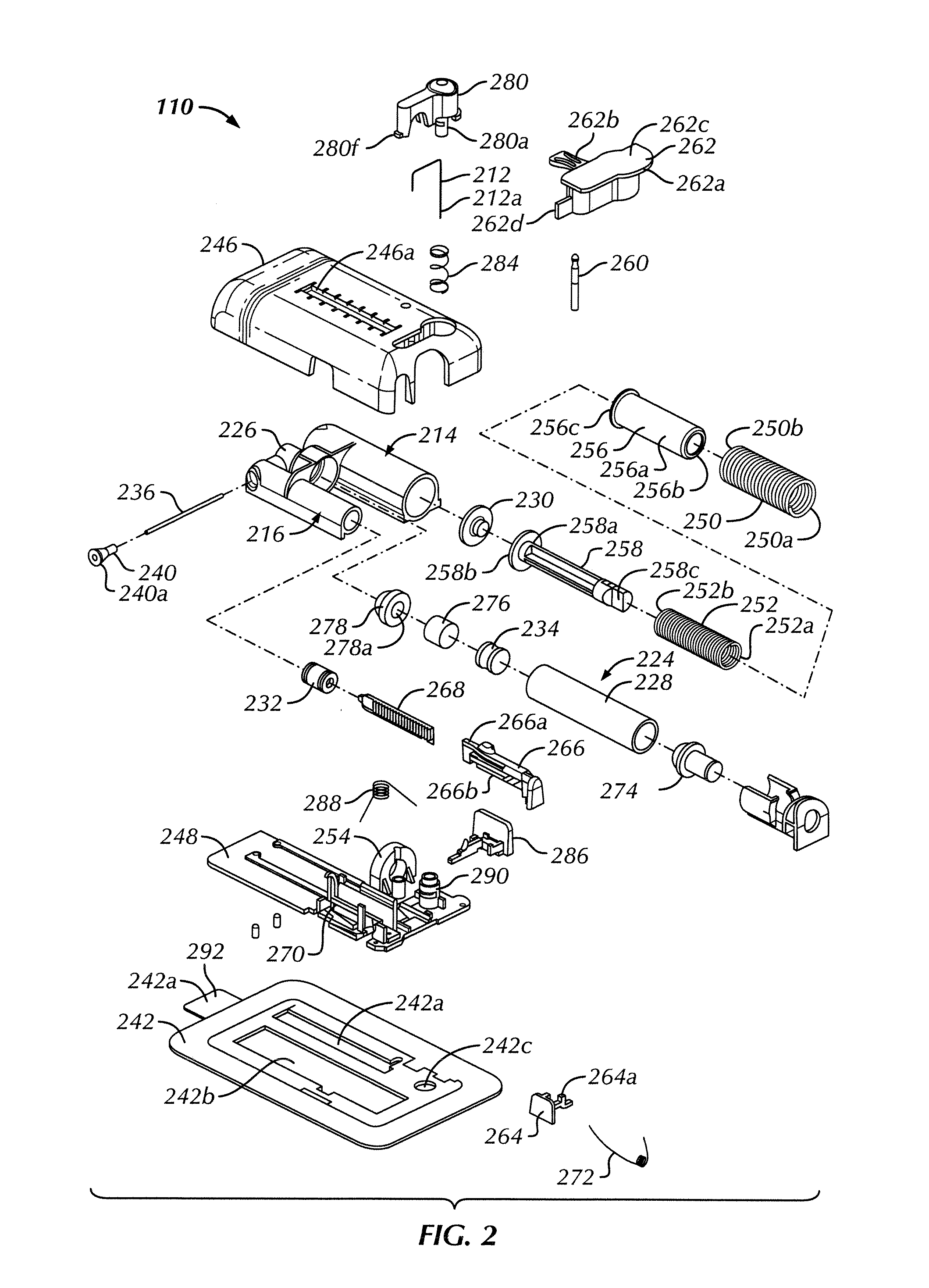

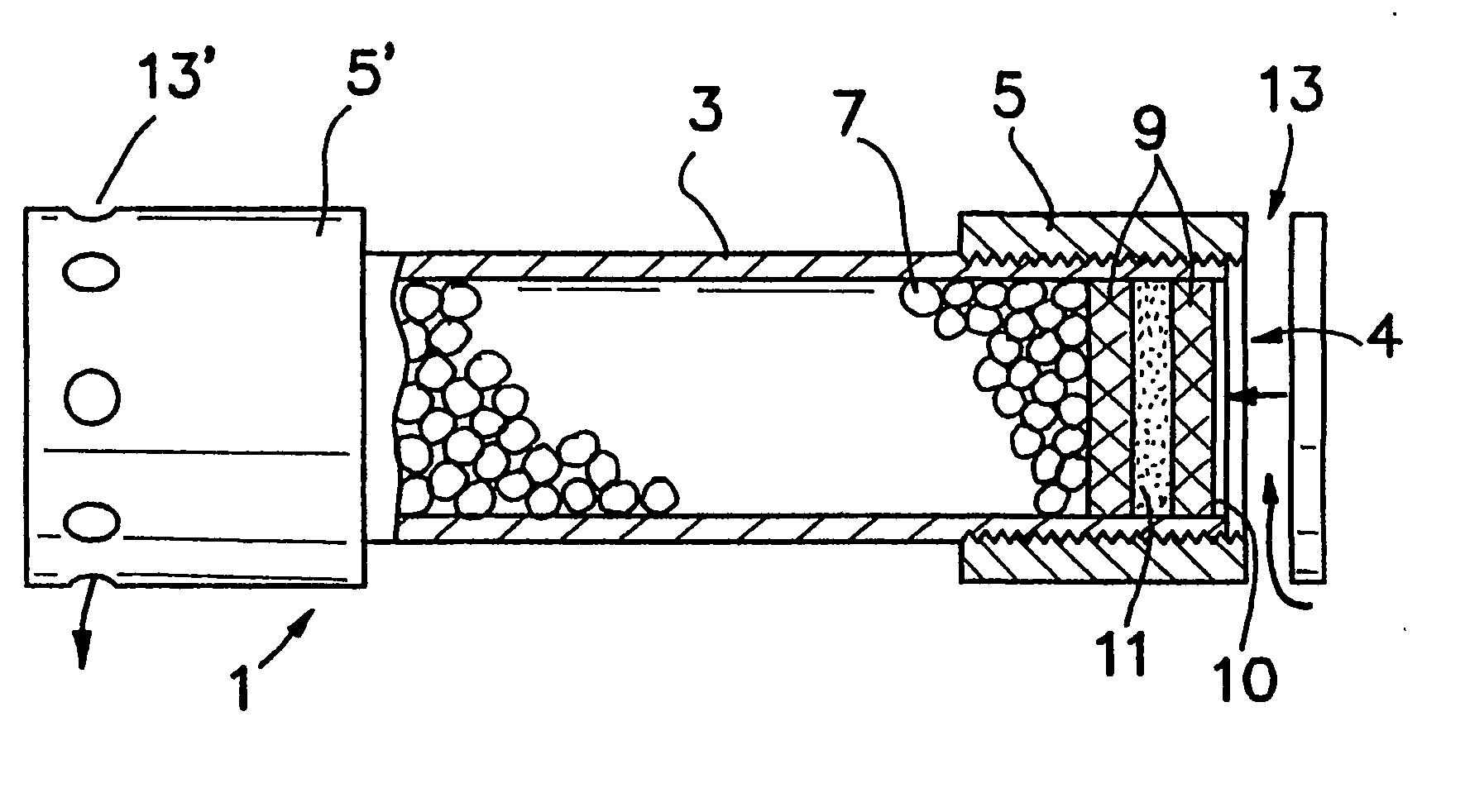

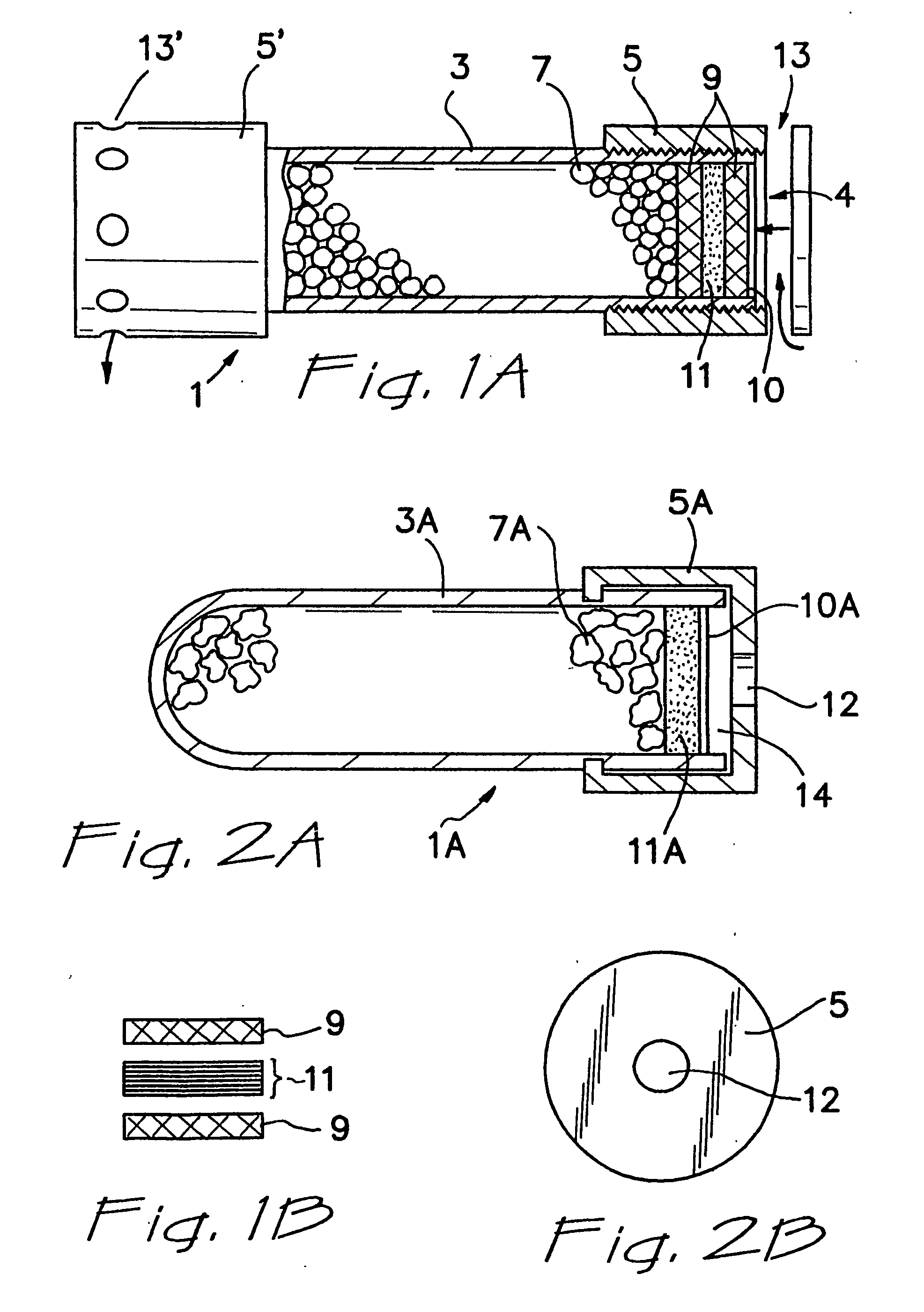

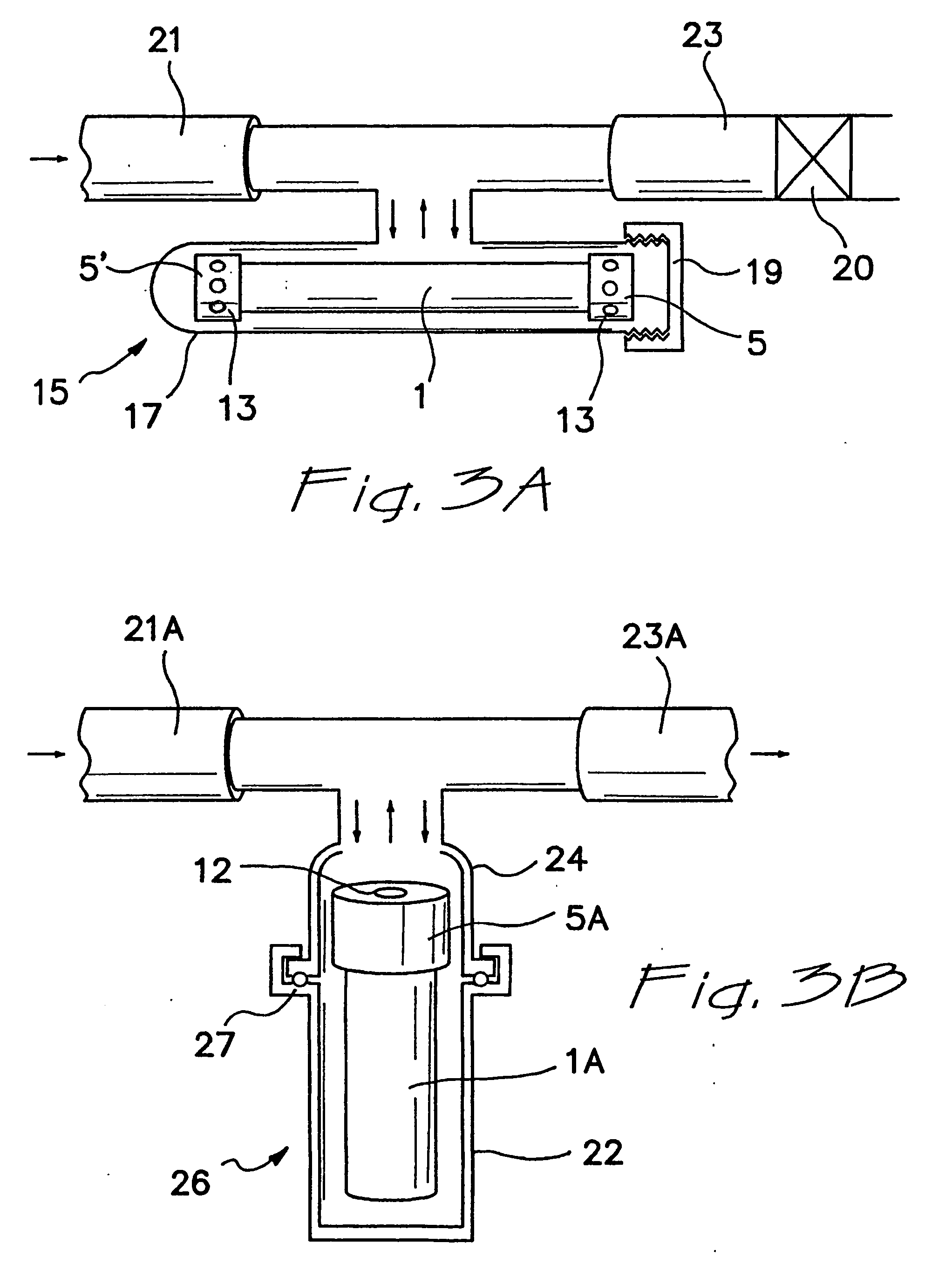

Fluid Delivery Device Needle Retraction Mechanisms, Cartridges and Expandable Hydraulic Fluid Seals

A fluid delivery device includes an automatic needle retraction mechanism configured to automatically retract a delivery end of a needle into a housing. In one embodiment, the needle assembly is configured to automatically withdraw the delivery end of the needle into the housing upon an actuator moving from the first position to the second position. In one embodiment, the needle assembly is configured to automatically withdraw the delivery end of the needle into the housing upon decoupling a bottom surface of the housing from a skin surface.

Owner:MANNKIND CORP

Regenerative shock absorber

Regenerative shock absorber. A piston is disposed for reciprocating motion within a cylinder as a vehicle's suspension system deflects. Hydraulic fluid passes through an hydraulic motor to turn its shaft. The hydraulic motor shaft is connected to an electric generator to generate electricity. Flow characteristics of hydraulic circuits are selected to provide suspension system damping for appropriate wheel control.

Owner:CLEARMOTION INC

Well service pump systems and related methods

A well service pump system supplies high pressure working fluid to a well. The pump system includes a closed-loop hydraulic circuit for actuating a plurality of working pump assemblies. The pump system is powered by a motor, which transfers mechanical energy to a plurality of pumps, which, in turn, provide hydraulic fluid to operate hydraulic ram cylinders, and thereby operate the working pump assemblies. Each of the polished rods of the hydraulic ram cylinders is connected axially to a plunger rod end of the working fluid end cylinder to operate the working pump assembly.

Owner:AMERIFORGE GRP

Well service pump power system and methods

A well service pump system supplies high pressure working fluid to a well. The pump system is a linear design which incorporates an electric motor, a variable frequency drive (VFD), a pump drive, closed loop variable flow rate hydraulic pumps, hydraulic ram cylinders, working fluid end cylinders, and a coupling to connect the hydraulic ram cylinders and the working fluid end cylinders. The electric motor powers the hydraulic system which, in turn, provides hydraulic fluid to operate the hydraulic ram cylinders. The VFD is connected to a single one of the hydraulic pumps at a time and applies power to the connected pump, via the pump drive, to drive the connected pump from a cold start to an operating speed. The VFD is connected sequentially, one pump at a time, to each of the hydraulic pumps and disconnected from each pump once the pump reaches the operating speed. Once the pump reaches operating speed, the pump is connected to receive power directly to the electric motor.

Owner:AMERIFORGE GRP

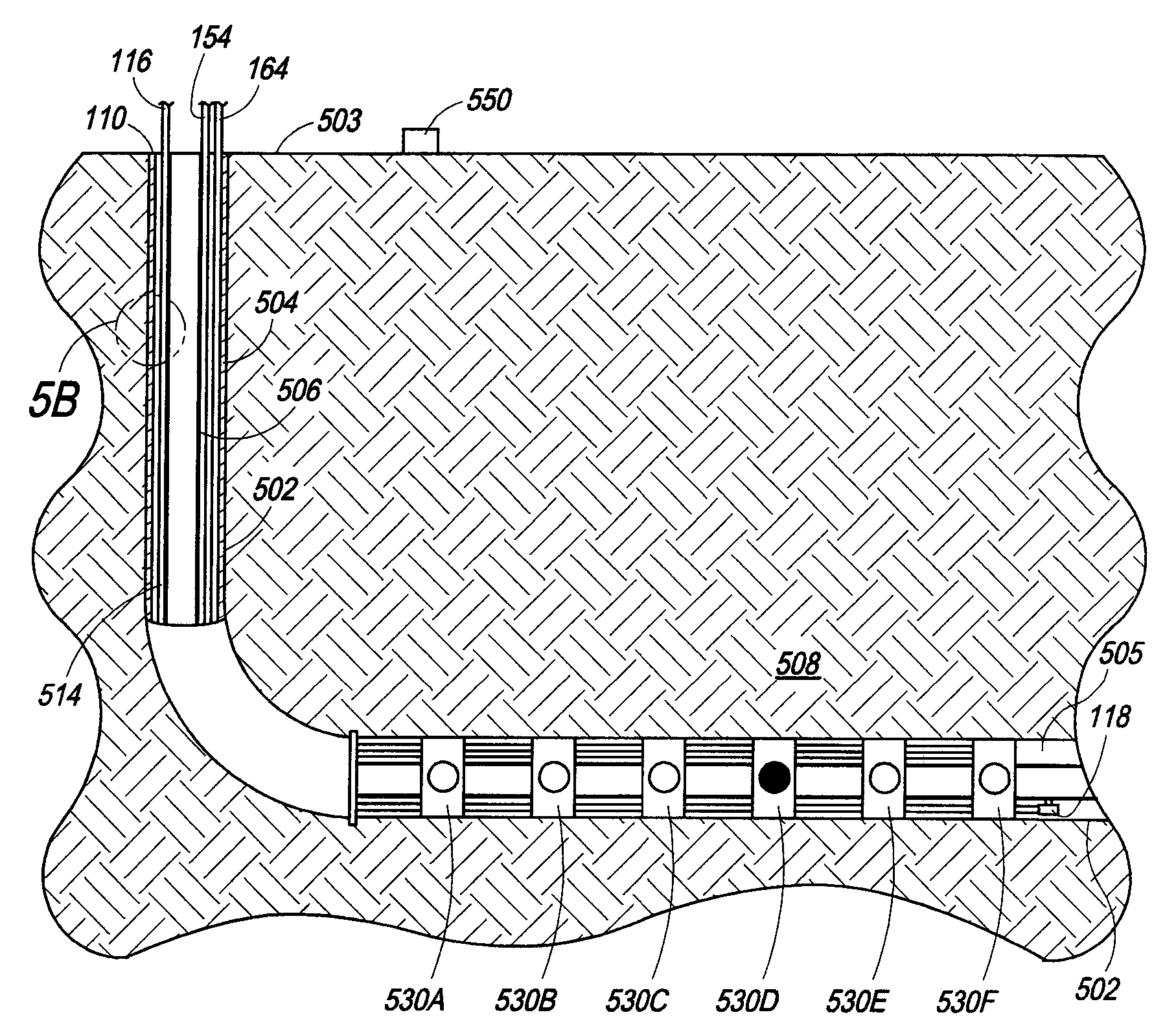

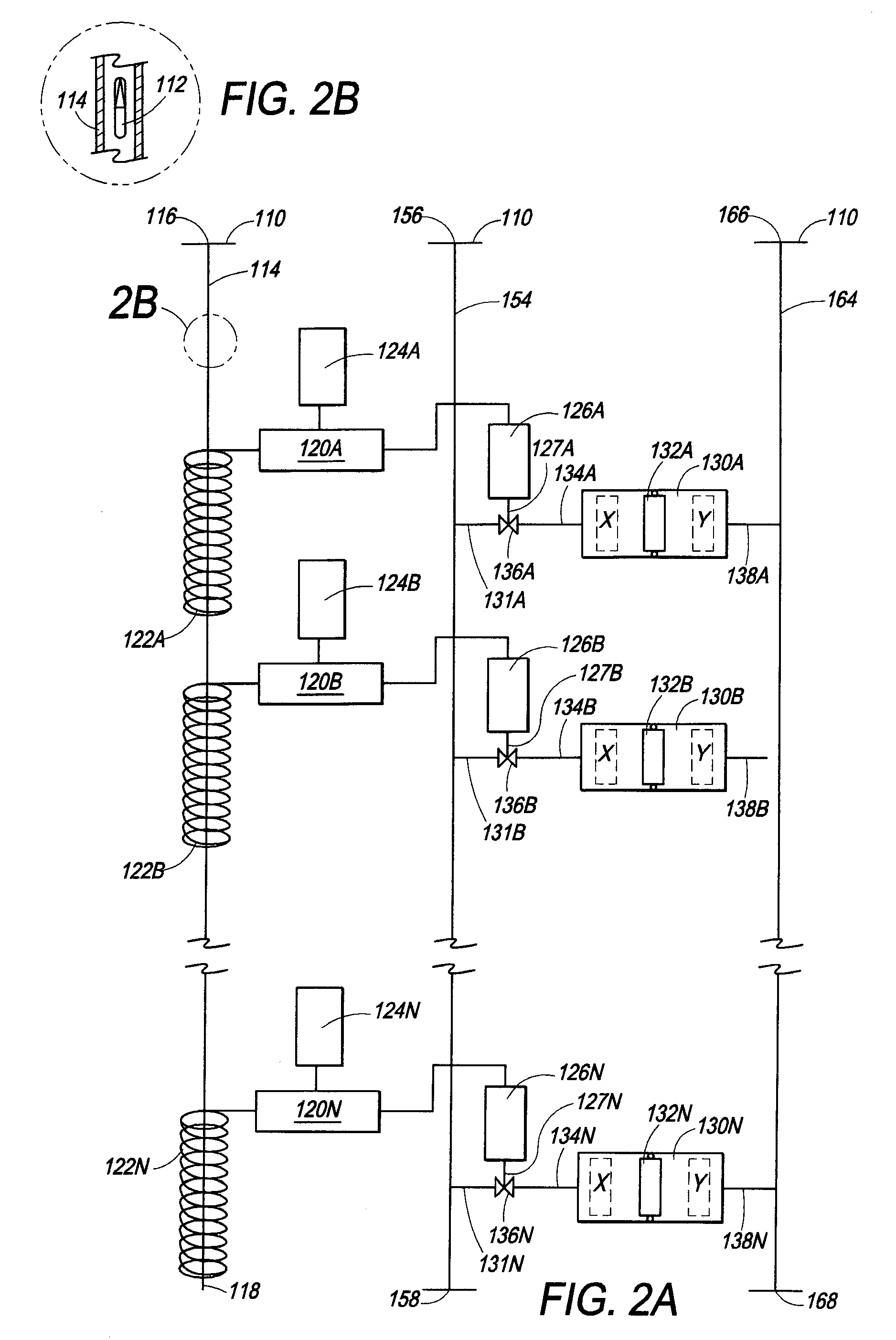

Systems, assemblies and processes for controlling tools in a well bore

A dedicated hydraulic line for transmission of a signal device capable of generating one or more unique signals to one or more tools within a subterranean well. Each tool can be equipped with a reader device for receiving signals from and transmitting signals to the signal device. Each reader device can control operation of the tool associated therewith if the reader device is programmed to respond to signals received from the control device. Hydraulic fluid used to operate the tool can be conveyed via the dedicated hydraulic line or a separate hydraulic line. A separate hydraulic line can be used to reset the tool. Where the tools include sliding sleeves, the tools can be used to hydraulically fracture subterranean environs at spaced apart locations along a well bore in any desired sequence and without removing the tools from the well during the fracturing process.

Owner:WEATHERFORD TECH HLDG LLC

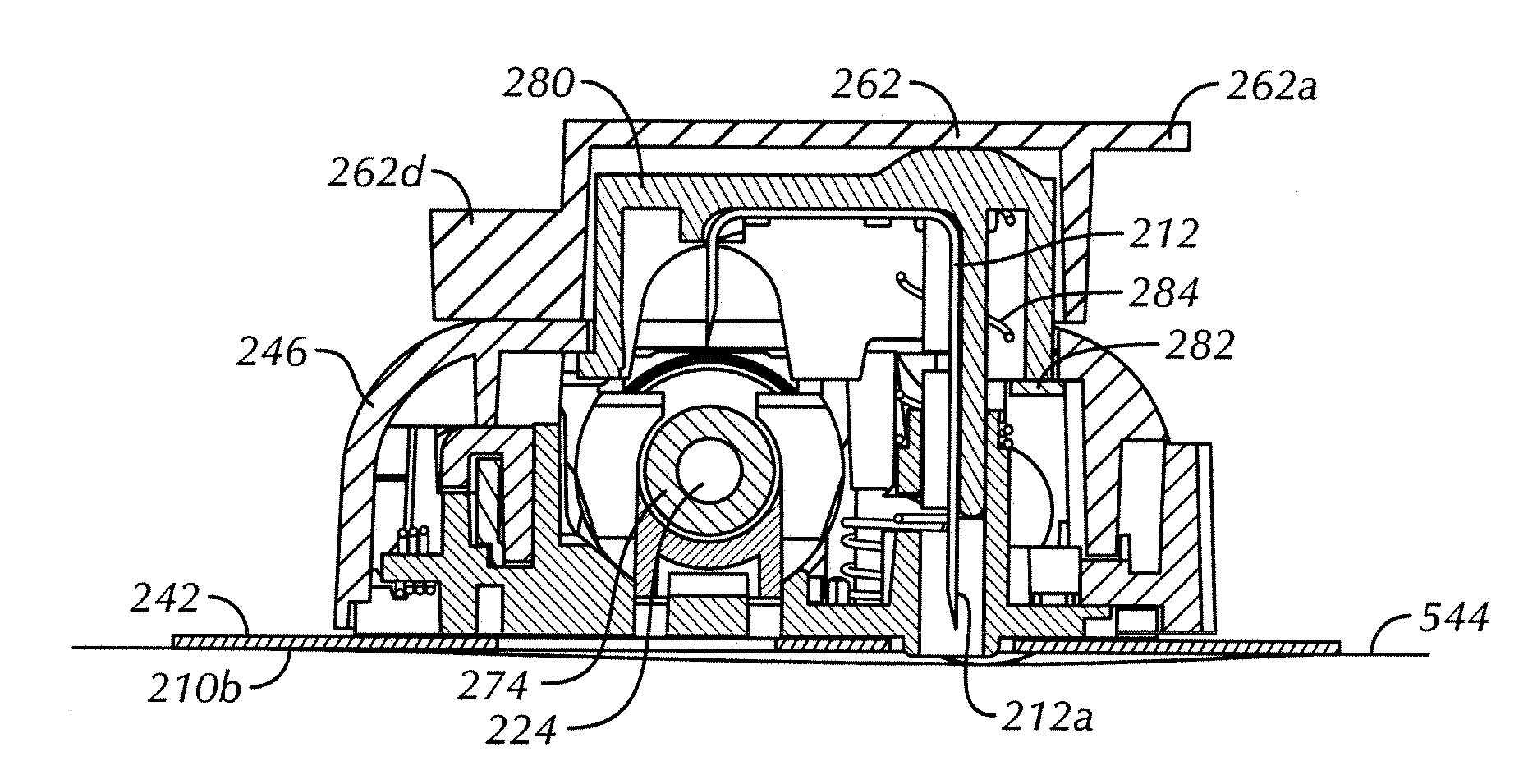

Hydraulically actuated pump for long duration medicament administration

ActiveUS20050119618A1Precise pressure regulationHigh viscosityPositive displacement pump componentsMicroneedlesHydraulic cylinderSingle-Use Device

Presently disclosed is a hydraulic pump device and its use thereof, especially in a fluid delivery system. In one embodiment, the fluid delivery system is an inexpensive, single-use device for slow dosing medicament applications. The fluid delivery system may employ a spring-compressed bellows crank or other combination of simple mechanisms operating according to the well-known peristaltic principle to force a volume of ultrapure bio-inert hydraulic fluid through an aperture, thereby expanding one chamber of a two chamber hydraulic cylinder. The second, fluid storage chamber, containing the medicament, is emptied through a conventional orifice in response to the expansion of the pump chamber. The medicament may thence flow through any suitable infusion set into a patient removeably attached thereto.

Owner:MANNKIND CORP

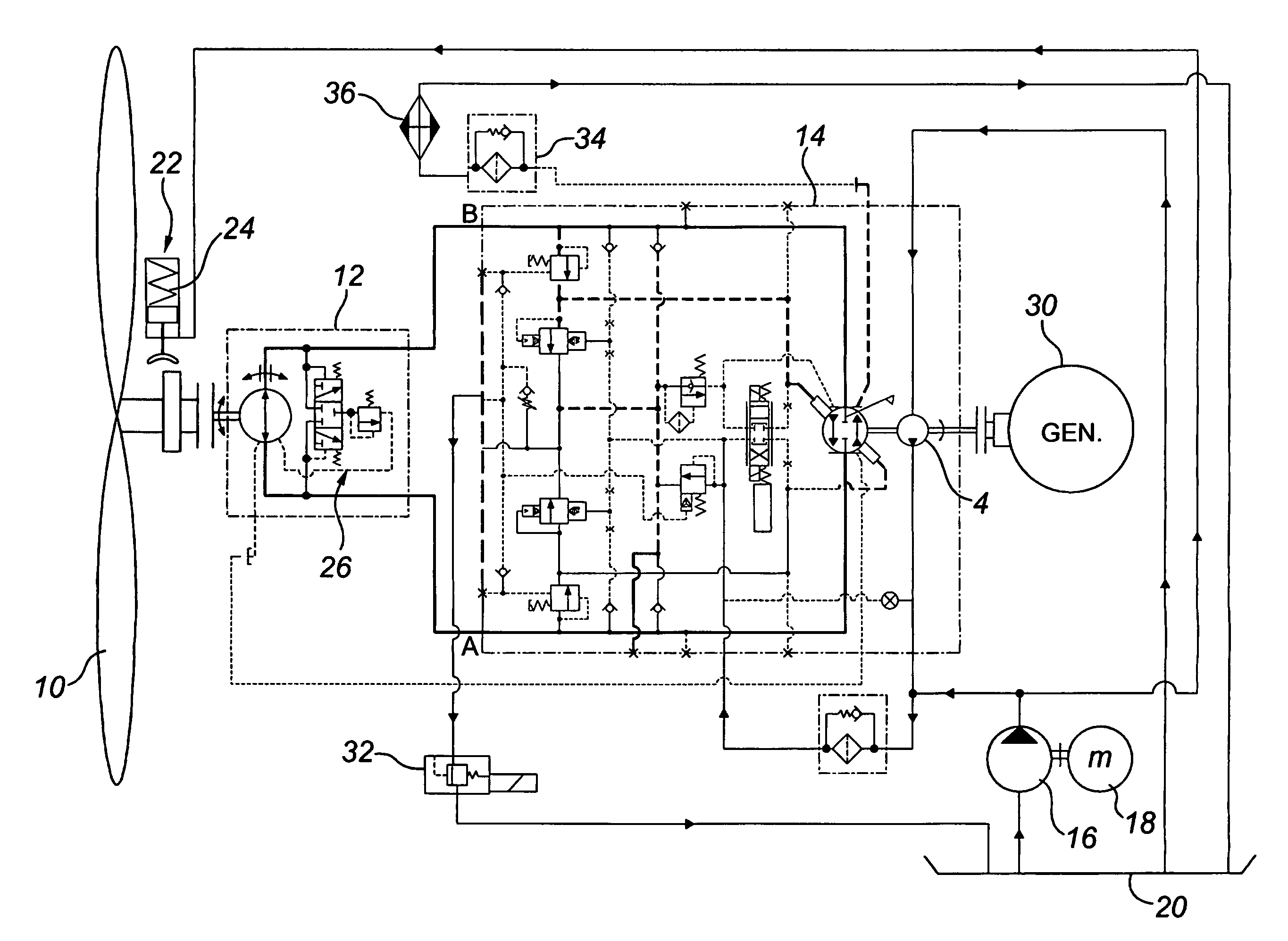

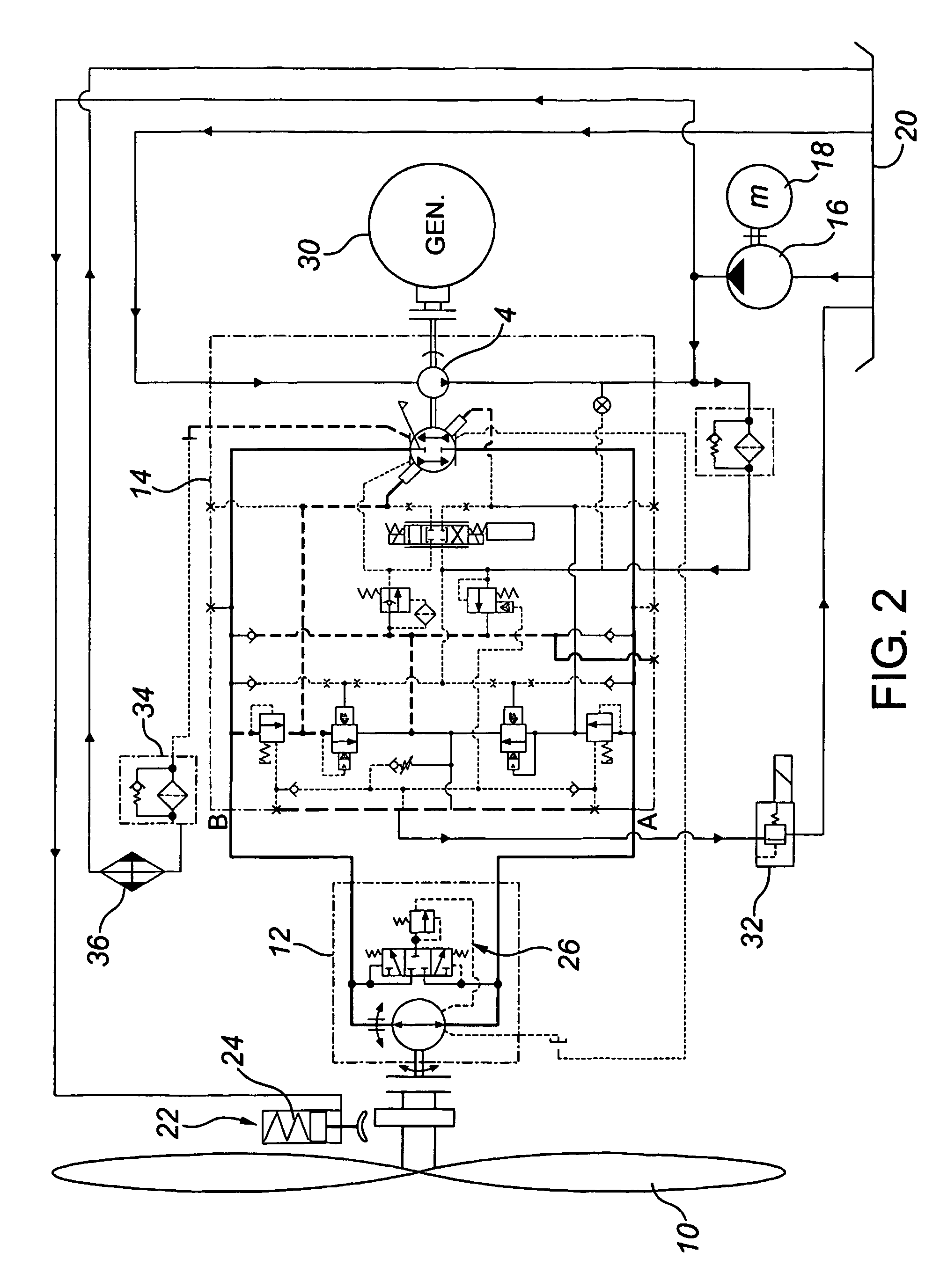

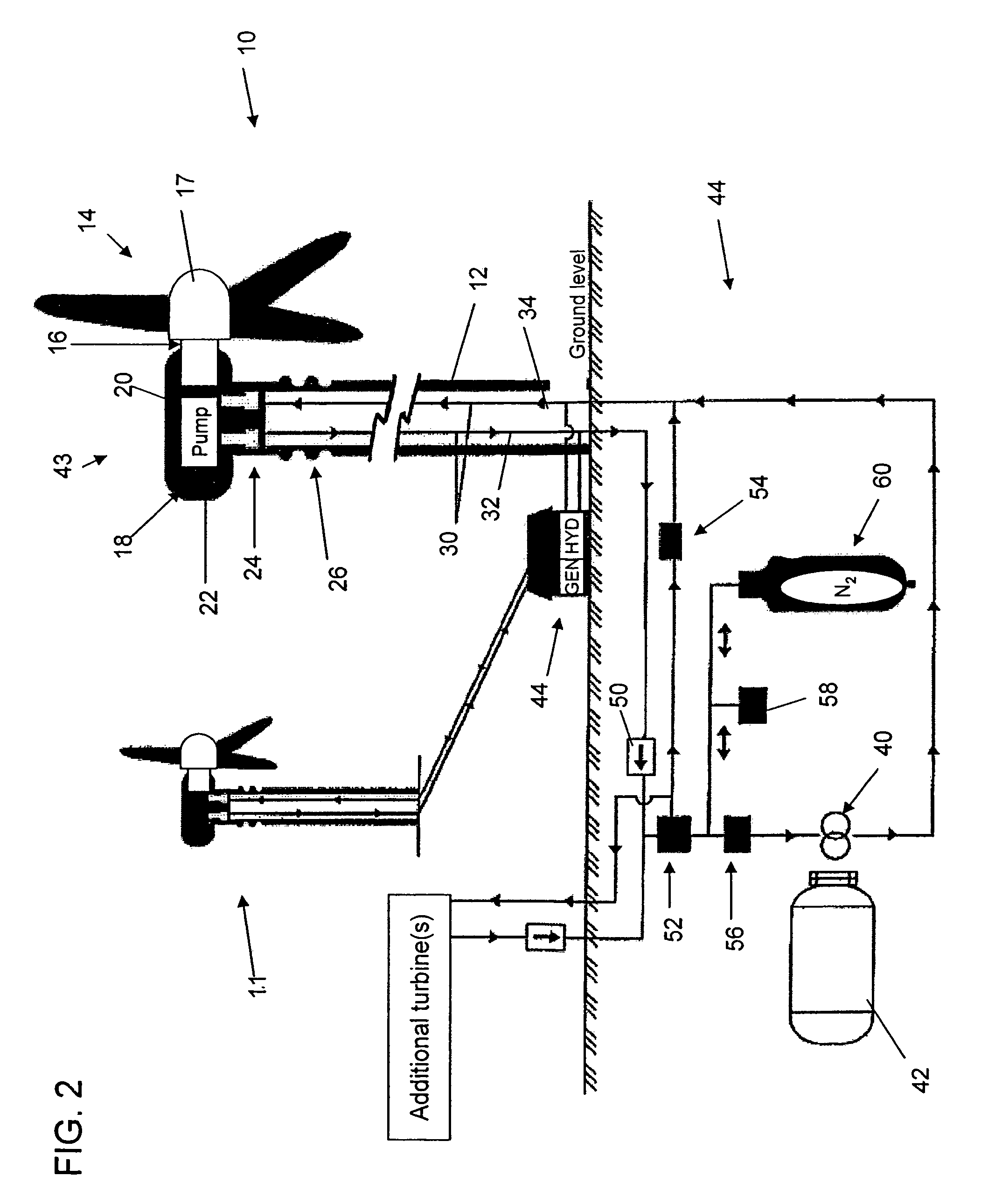

Wind turbine with hydraulic transmission

InactiveUS7418820B2Guaranteed normal transmissionAbsorb more horsepowerWind motor controlEngine fuctionsNacelleLow speed

Owner:MACKAY GARY

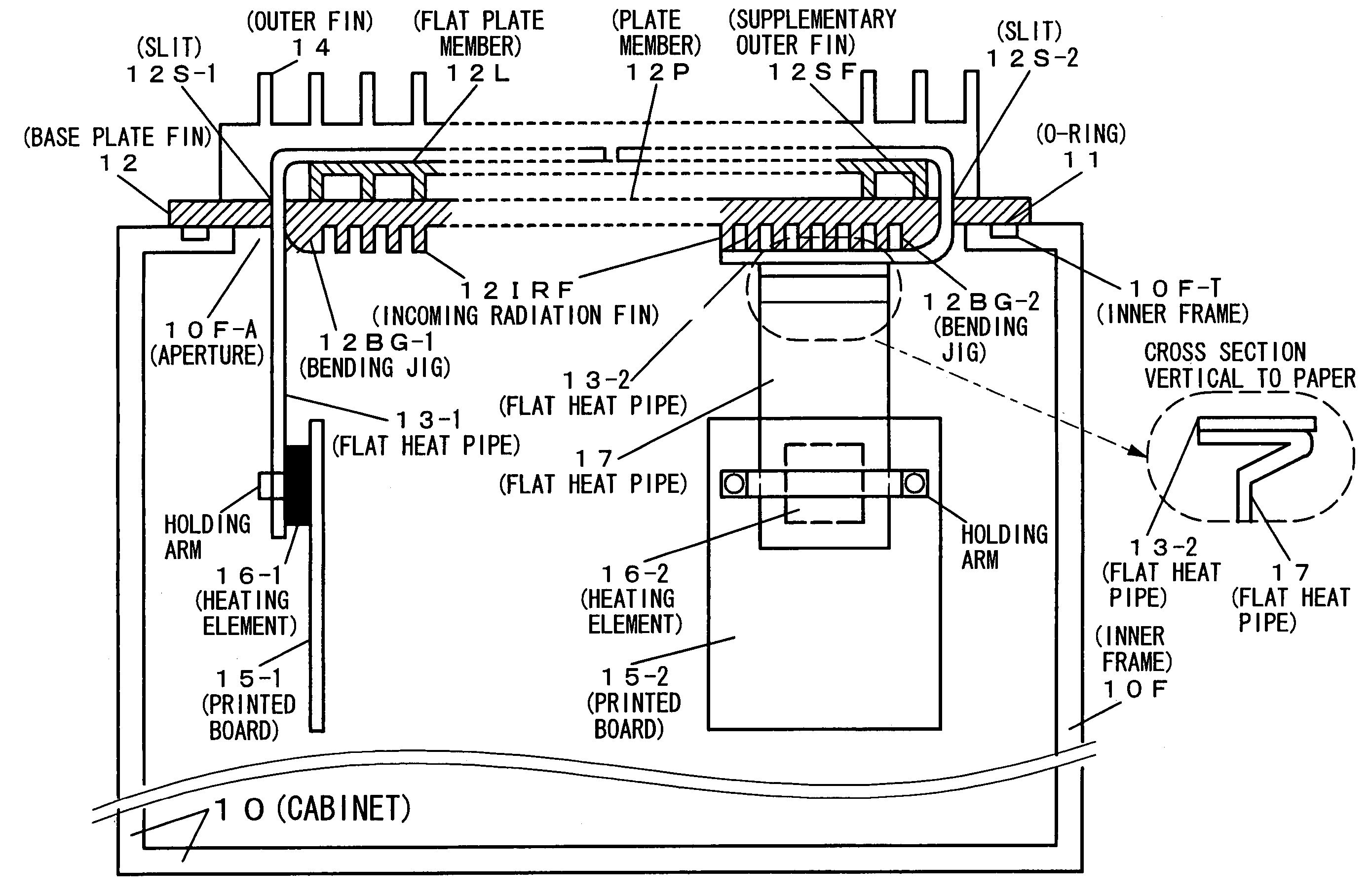

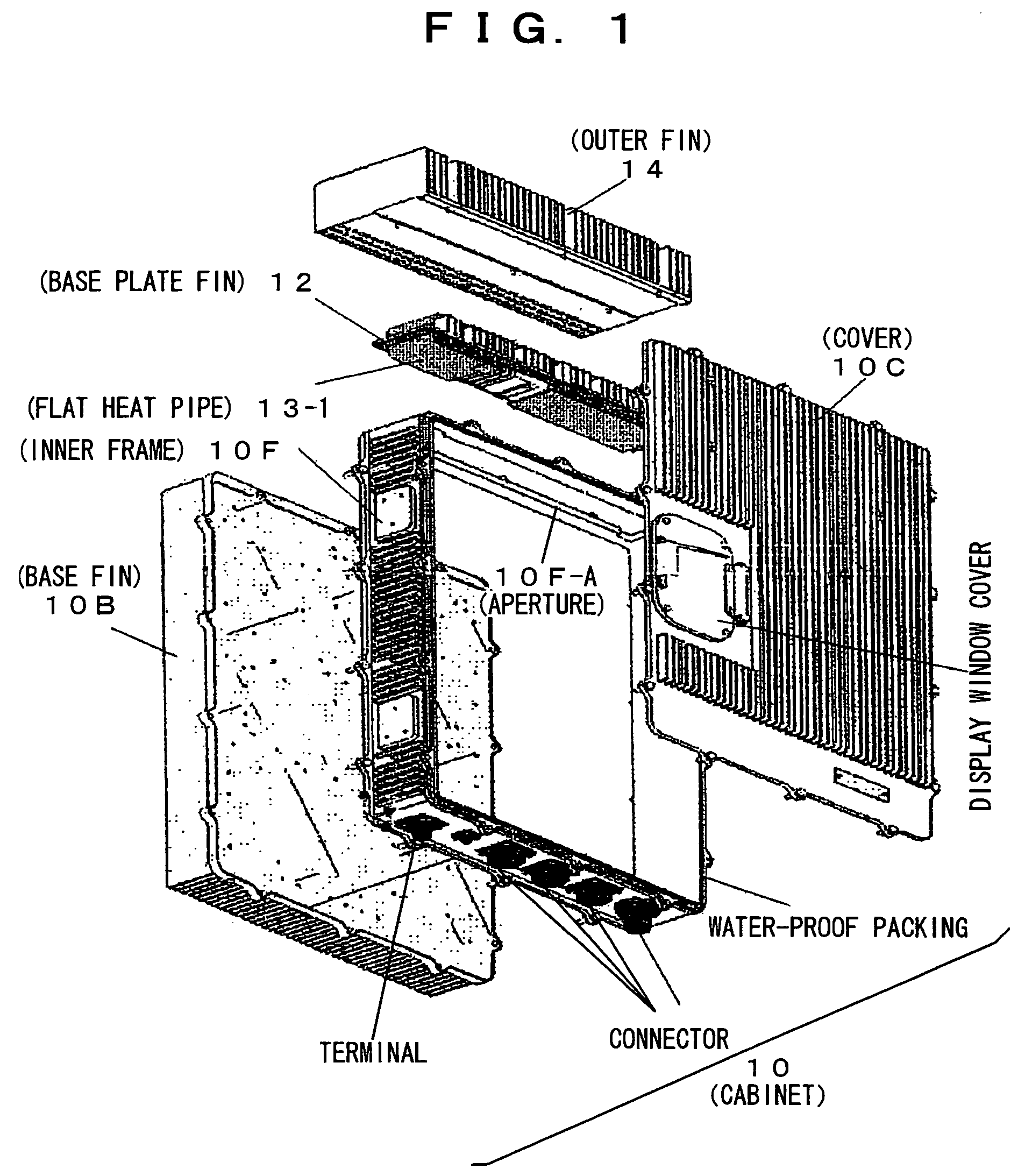

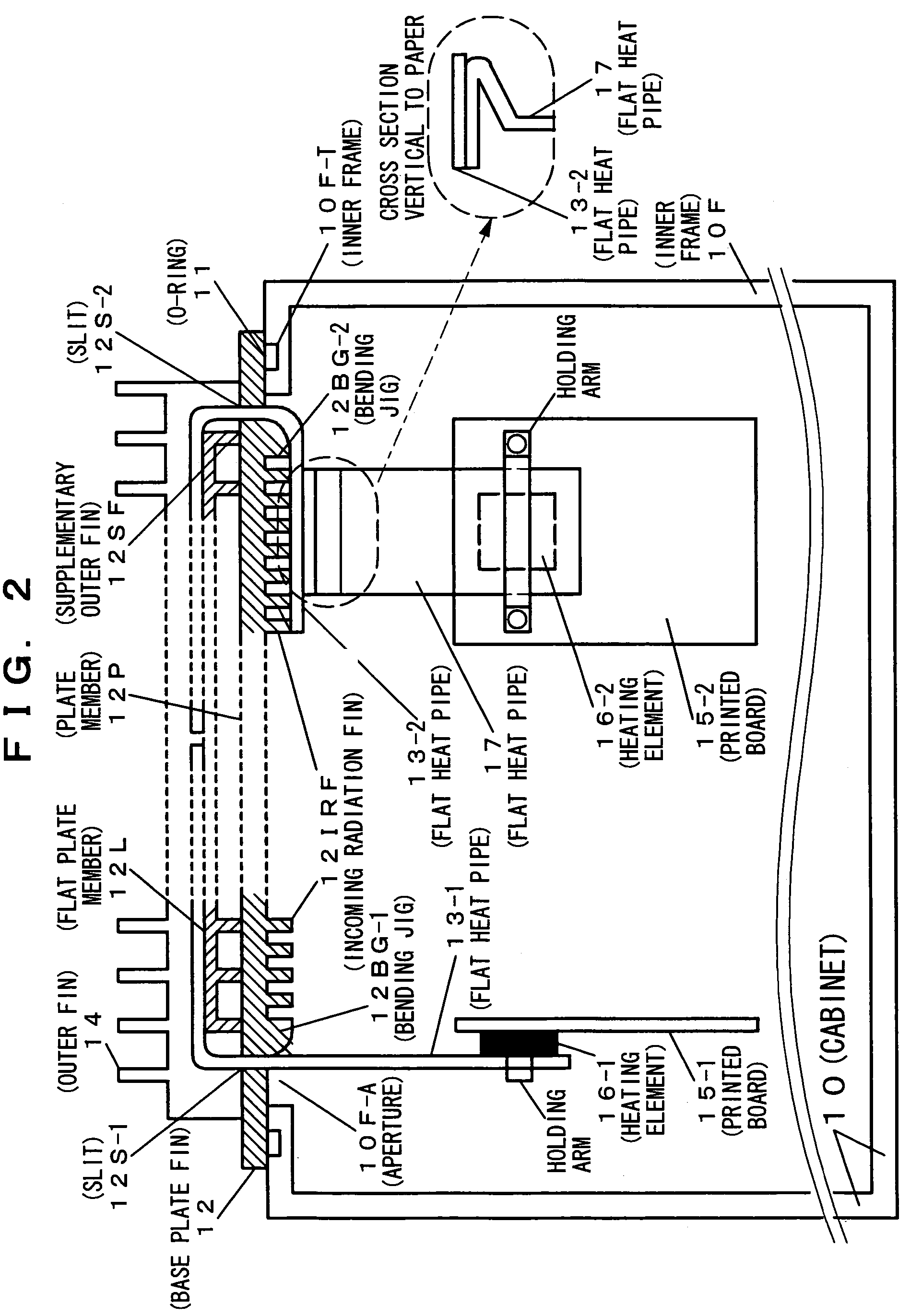

Cabinet having heat radiation function and heat radiation member

ActiveUS7130193B2Avoid it happening againImprove serviceabilityIndirect heat exchangersCooling/ventilation/heating modificationsElectrical conductorEngineering

The invention relates to a heat radiation member and a cabinet to be installed outdoors in a hermetic state, having a heat radiation function for heat radiation of devices contained therein. The object of the invention is to facilitate maintenance, downsize the cabinet, and prevent occurrence of noise. It includes: a cabinet body containing a heat source; a cover member attached to an aperture of the cabinet and having a guide portion guiding, to an exterior of the cabinet, a heat transfer member for transferring therethrough heat from the heat source by use of a hydraulic fluid; and a heat radiation part being a thermal conductor and in contact with the heat transfer member on a face and covering the heat transfer member from the exterior of the cabinet and having a heat radiation member on a face opposite to the face in contact with the heat transfer member.

Owner:FUJITSU LTD

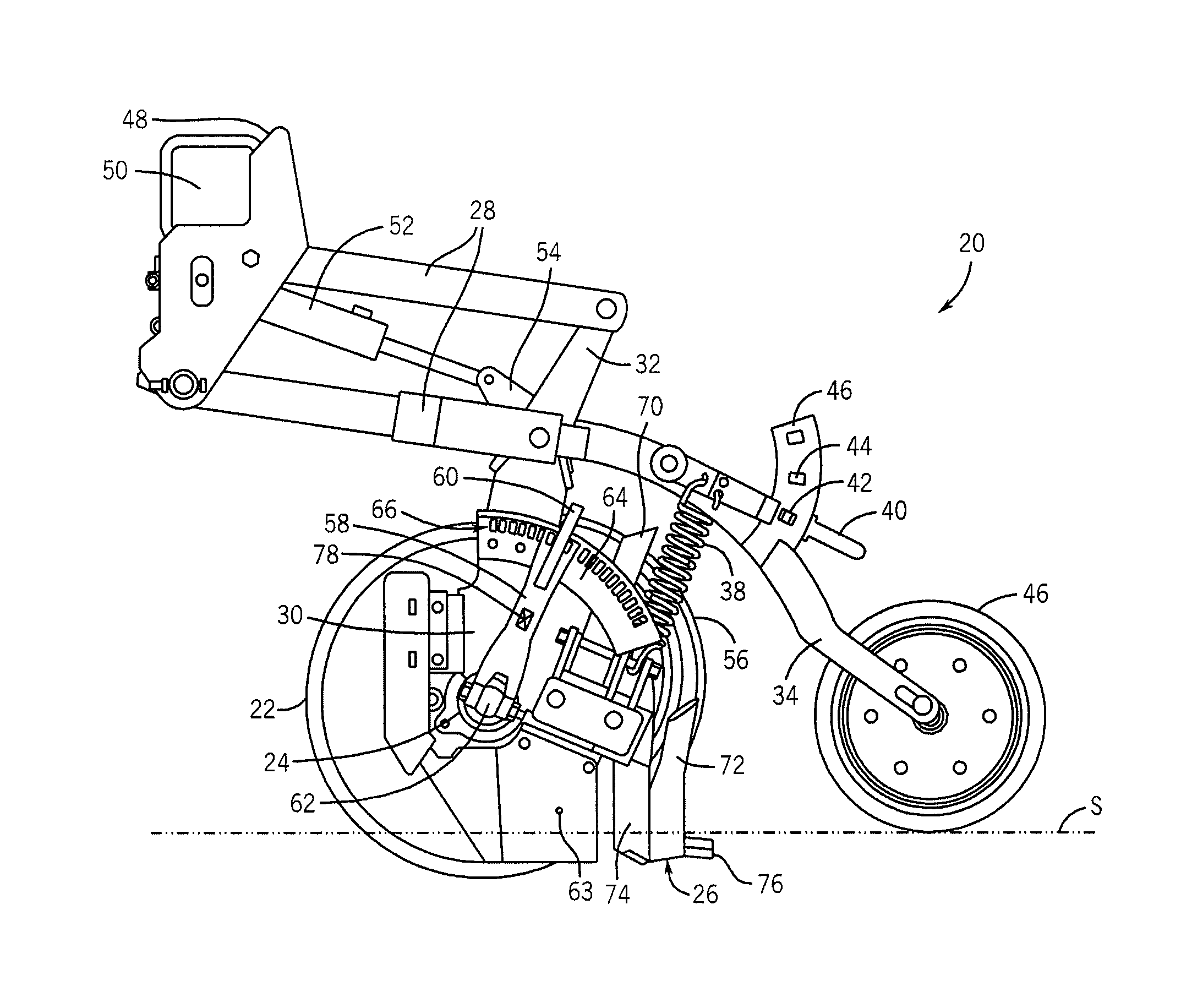

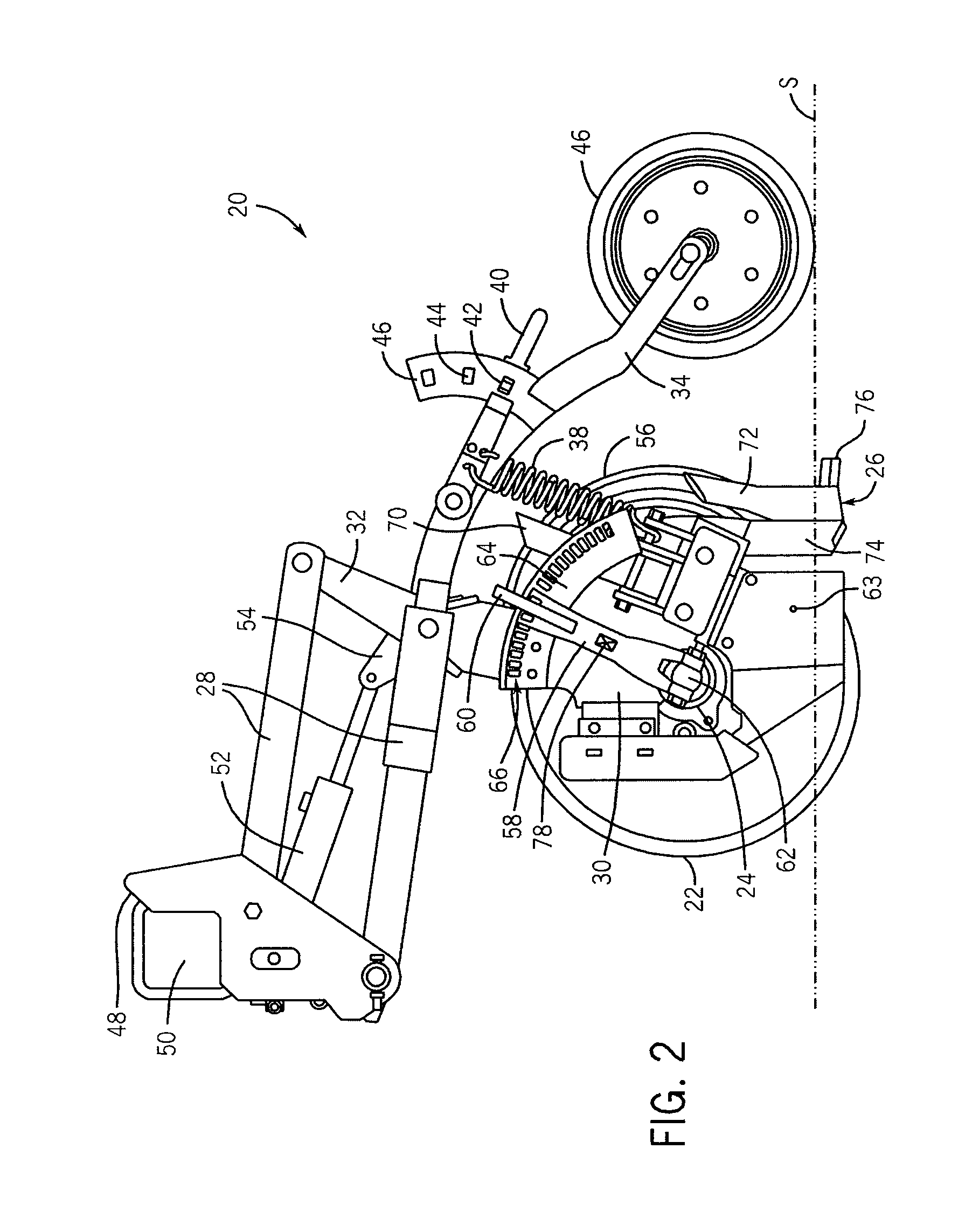

Down Pressure Adjustment Device And Method For Use With A Disc Opener Assembly Of An Agricultural Implement

A disc opener unit for an agricultural implement has a down pressure adjustment device that automatically adjusts the amount of down pressure applied on a furrowing disc based on strain measurements taken by a strain gauge or load cell. The strain gauge, which may be mounted to an arm that is used to set the position of a depth setting gauge wheel, provides feedback to a processor that in turn controls the amount of hydraulic fluid in a hydraulic cylinder to adjust the down force applied on the disc. The amount of down pressure is therefore adjusted in substantially real-time in response to changes in field conditions, which improves furrow depth consistency and reduces wear on the gauge wheel and its components.

Owner:CNH IND CANADA

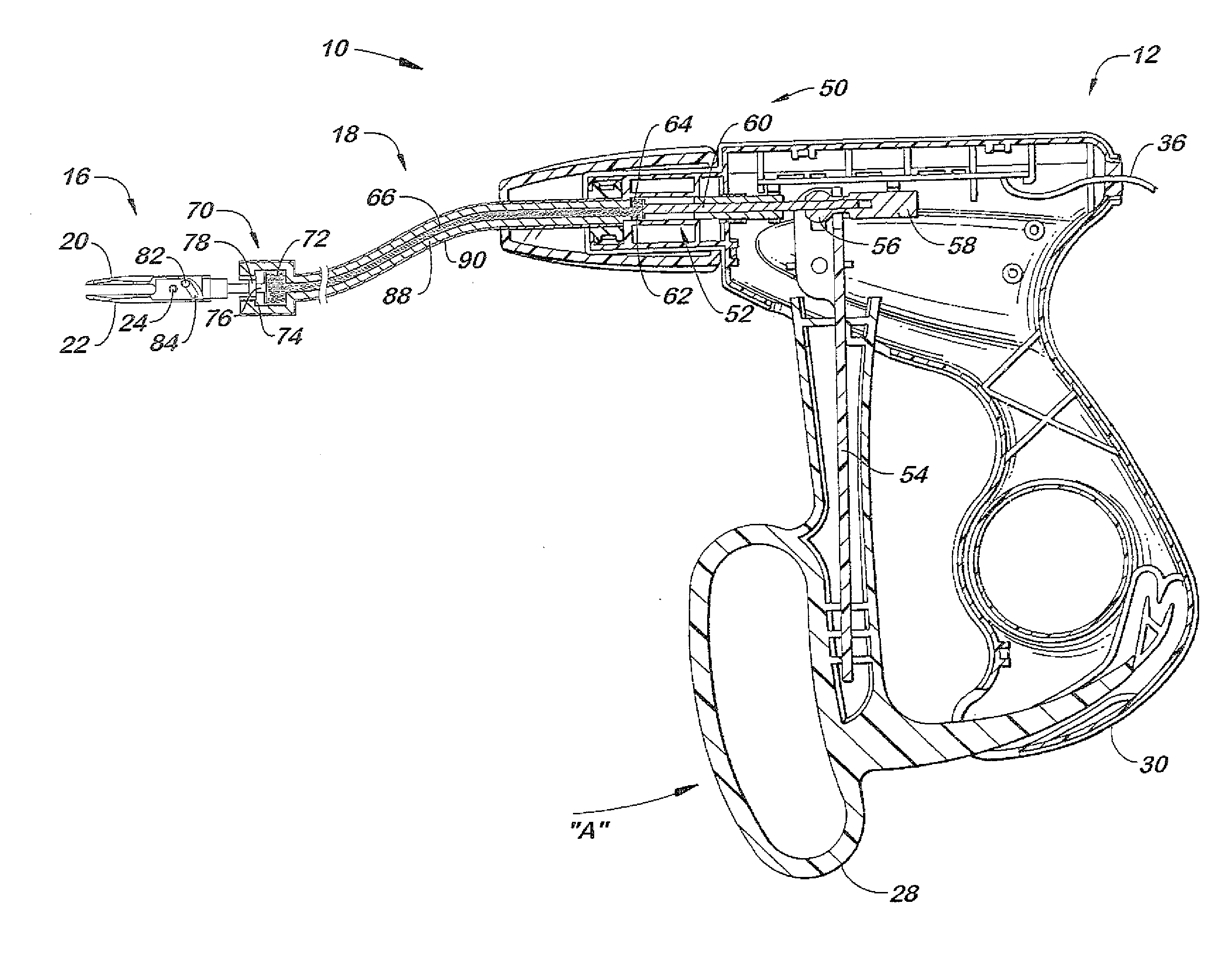

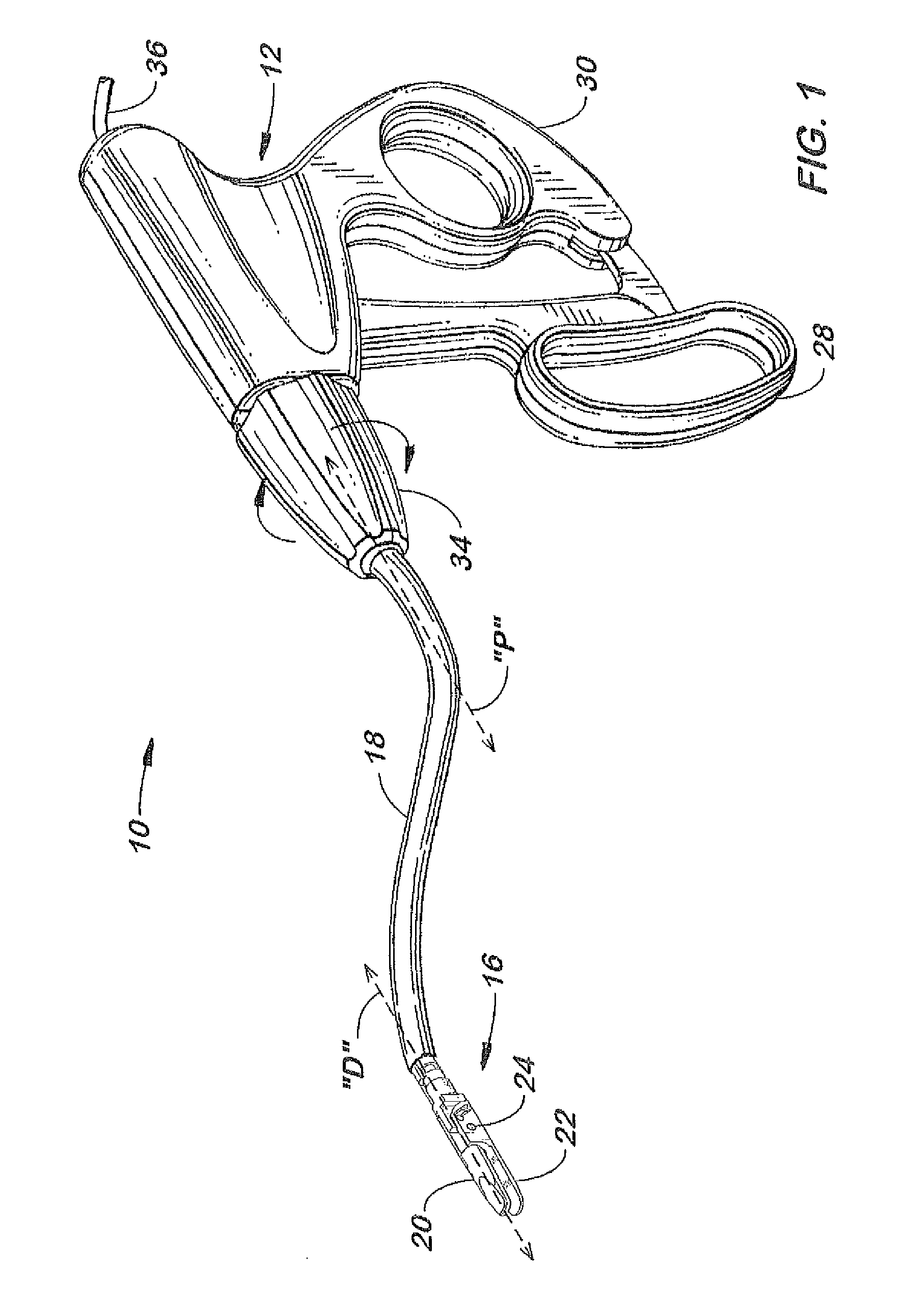

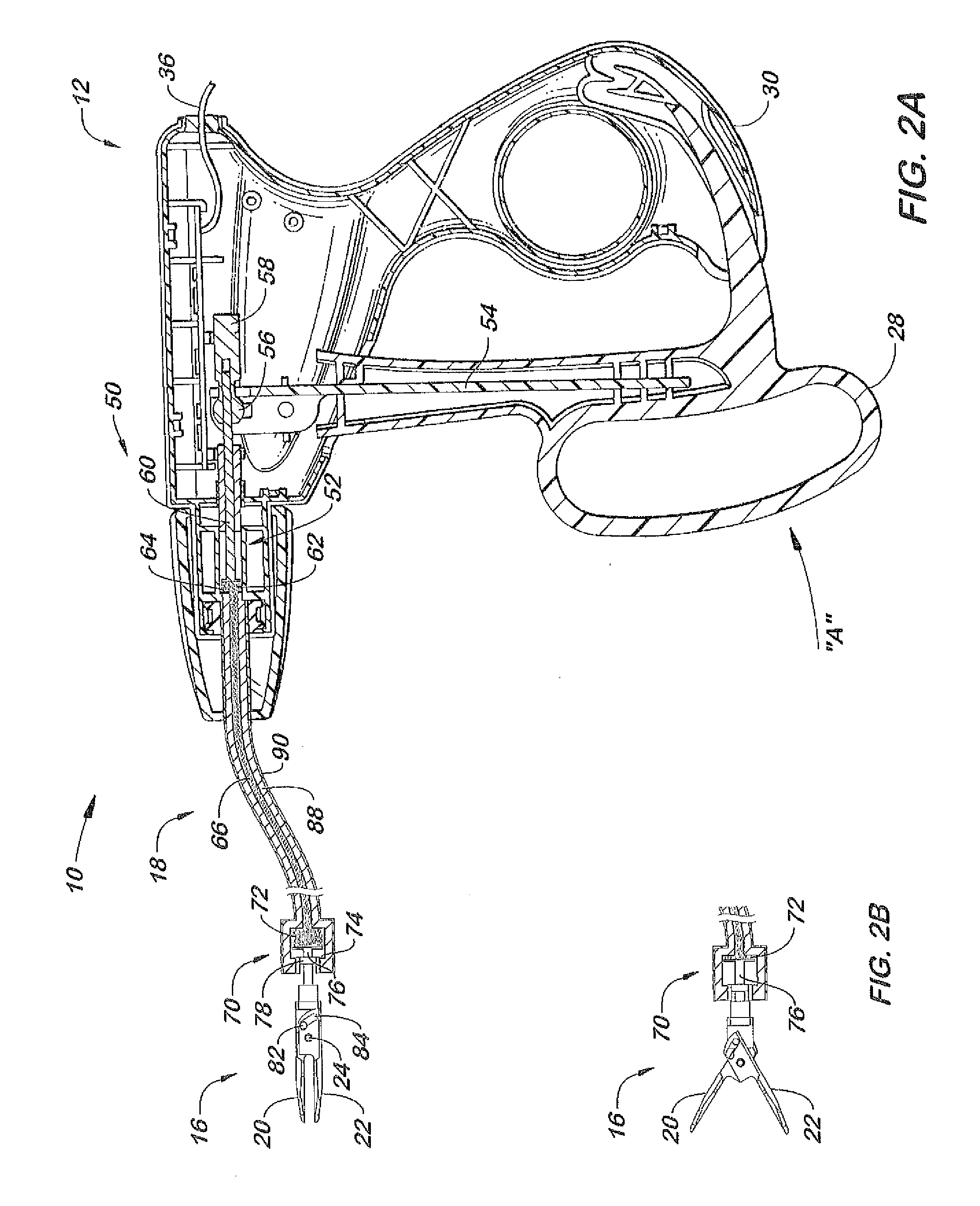

Method of Transferring Force Using Flexible Fluid-Filled Tubing in an Articulating Surgical Instrument

An endoscopic surgical instrument for sealing tissue includes an elongated shaft defining a proximal shaft axis and a distal shaft axis. The shaft axes may be misaligned to appropriately position and orient an end effector coupled to the distal end of the elongated shaft. The instrument is configured such that the shaft may resist a tendency to realign itself as the end effector moves from an open configuration for receiving tissue to a closed configuration for maintaining a closure pressure on the tissue ranging from about 3 kg / cm2 to about 16 kg / cm2. A handle coupled to the proximal end of the elongated shaft is operable to control the end effector by controlling a flow of hydraulic fluid through flow path extending s between the handle and the end effector.

Owner:TYCO HEALTHCARE GRP LP

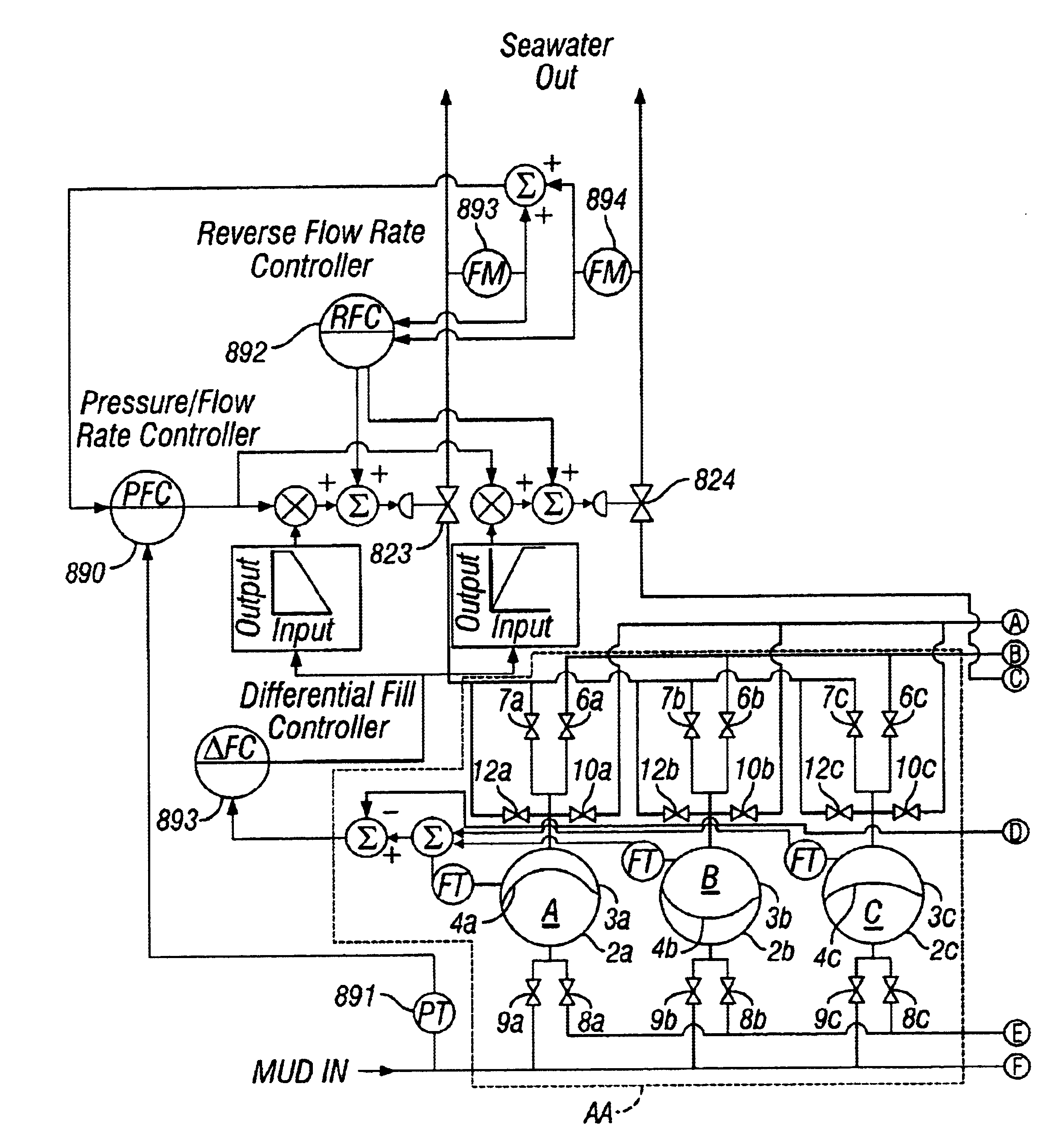

Subsea mud pump and control system

A sub-sea mud pump system includes a plurality of pump units, and each pumping unit includes a plurality of pumping elements. Each pumping element includes a pressure vessel with a first and a second chamber, a separating member between the first and second chambers, a measurement device adapted to measure the volume of at least one of the first and second chambers, a hydraulic inlet control valve and a hydraulic outlet control valve coupled to the first chamber, a mud suction valve and a mud discharge valve coupled to the second chamber. The first chamber is hydraulically coupled to receive and discharge a hydraulic fluid, and the second chamber is hydraulically coupled to receive and discharge a drilling fluid. The separating member is adapted to move within its the pressure vessel in response to a pressure differential between the first and second chambers. The pump system also includes a hydraulic control unit adapted to control the plurality of pump units.

Owner:HYDRIL USA MANUFACTURING LLC

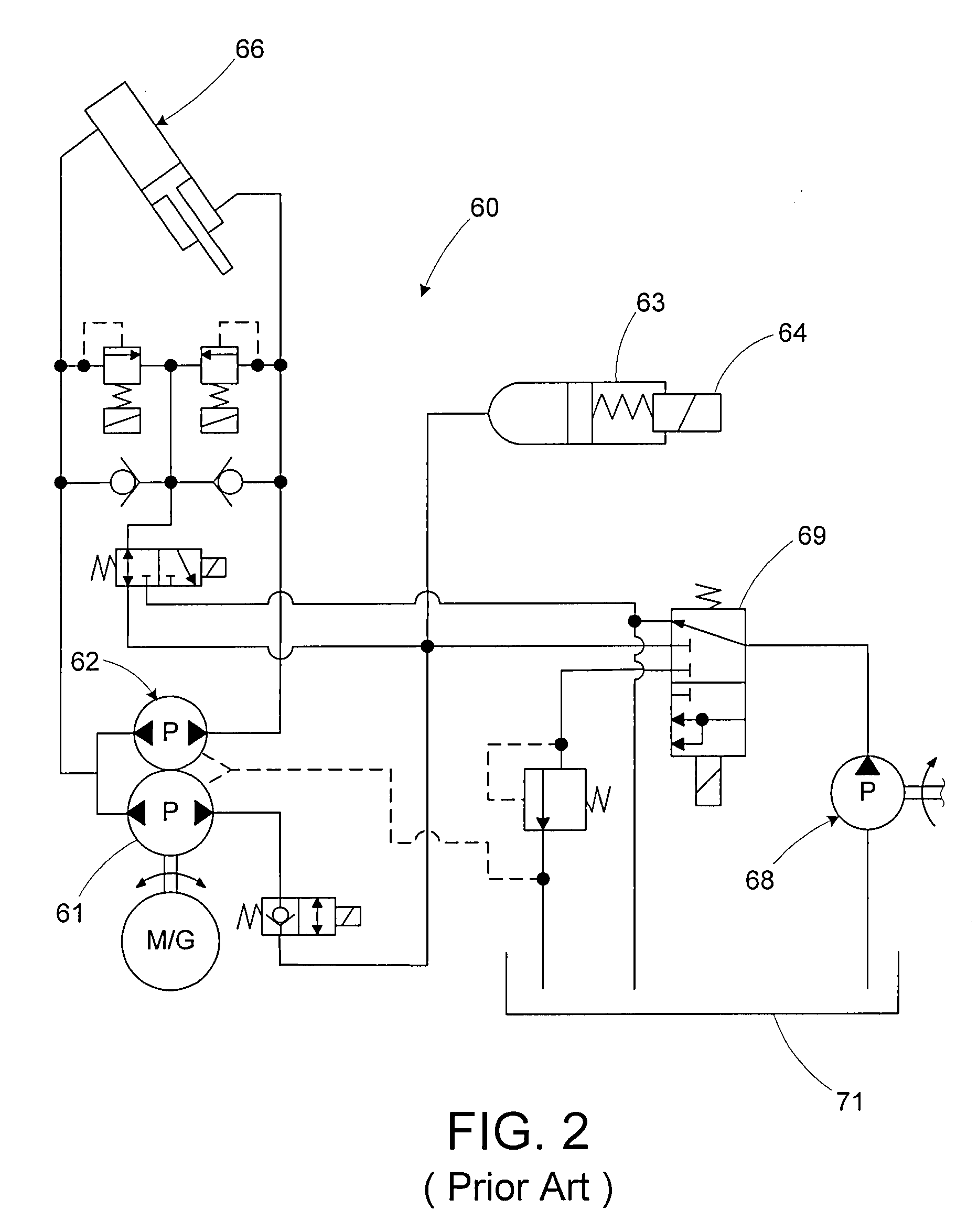

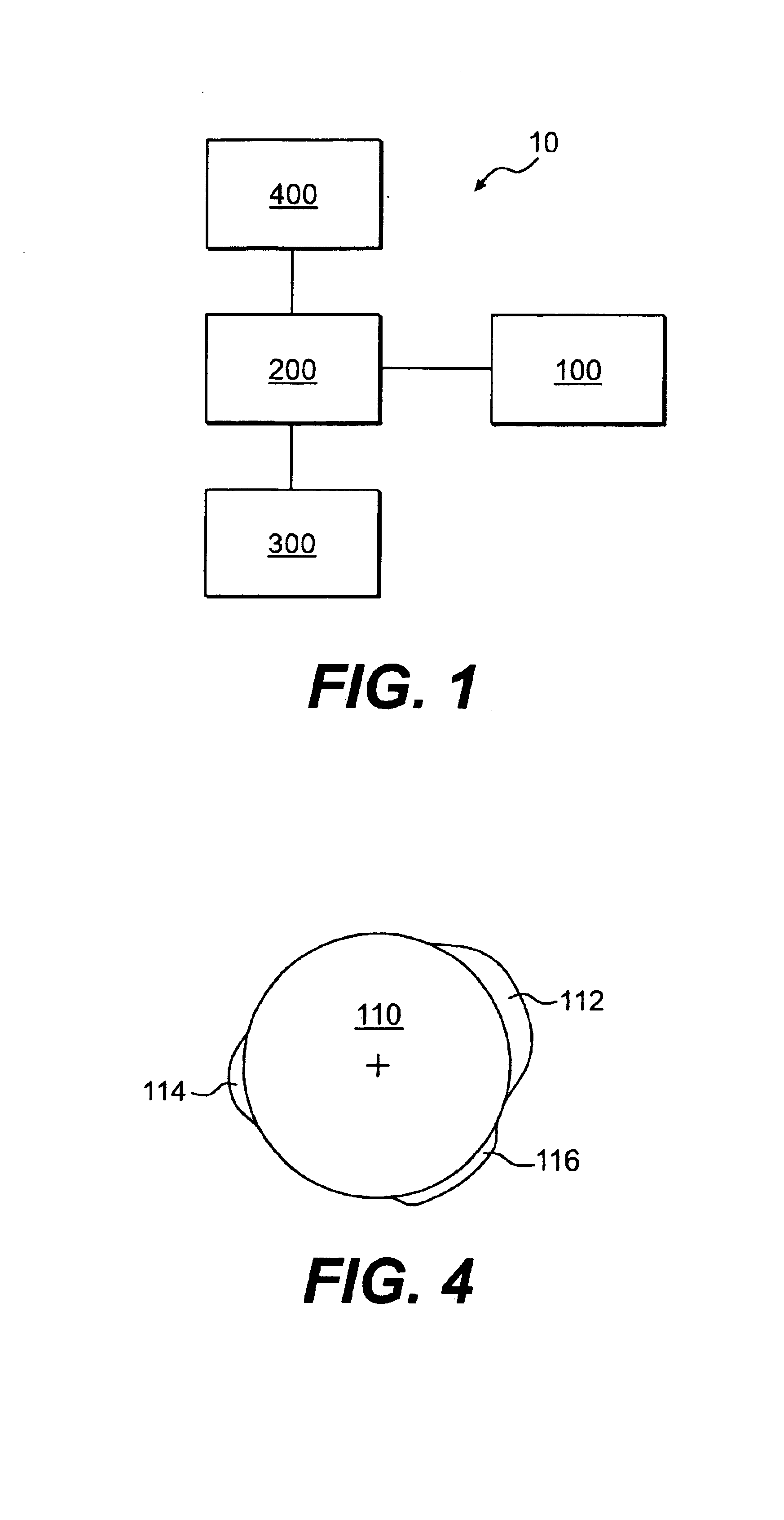

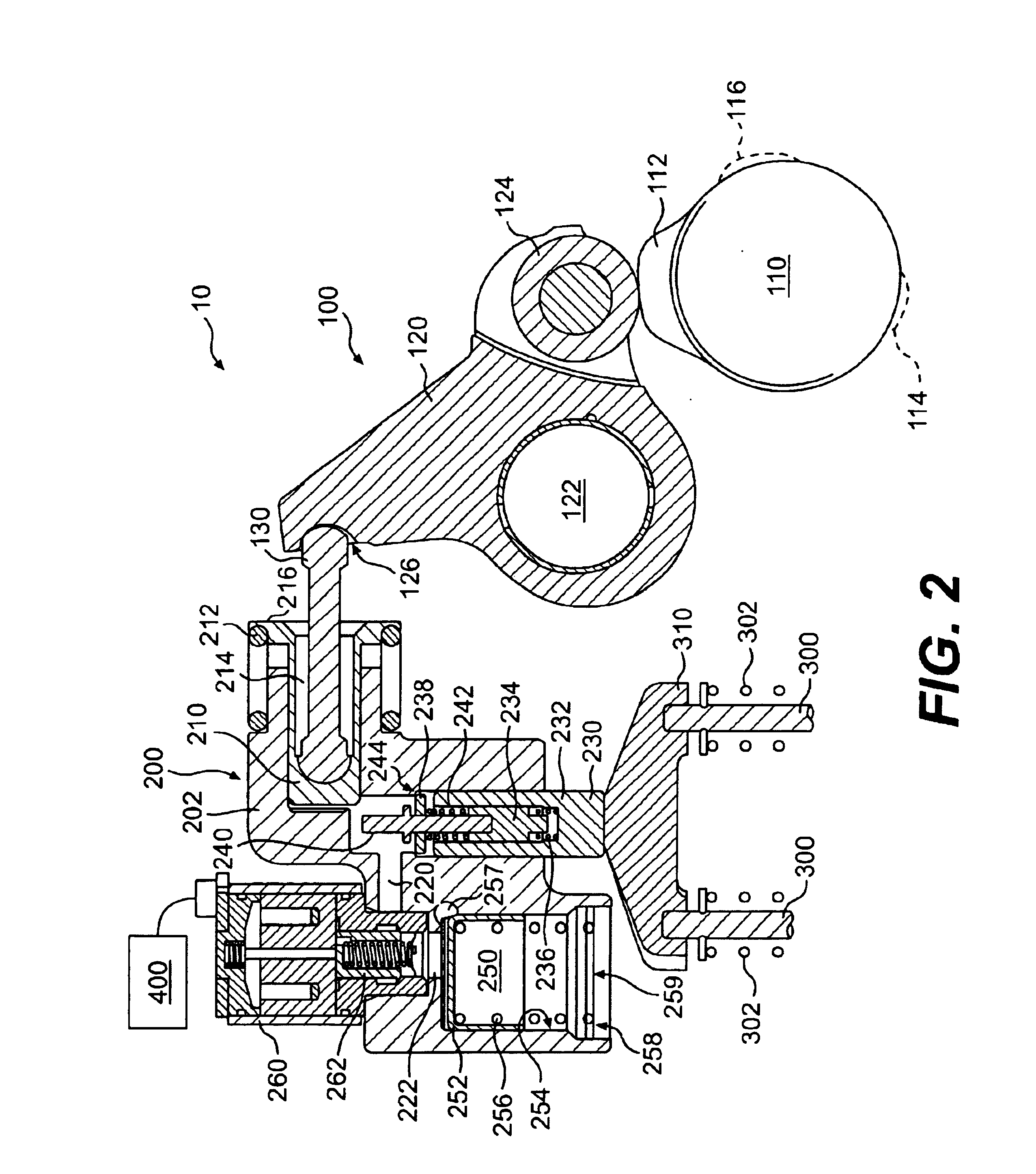

Automatic steering system and method

ActiveUS20050288834A1Analogue computers for trafficComputations using stochastic pulse trainsAutomatic steeringHydraulic fluid

An automatic steering system and method are provided for a vehicle including an hydraulic primary steering system. The automatic steering system includes a guidance module with a GPS receiver and a microprocessor adapted to process and store GPS data defining travel paths, which can be associated with a cultivated field in an agricultural vehicle application. An automatic steering module is connected to the guidance module and to a steering valve control block, which provides pressurized hydraulic fluid in parallel with the vehicle's primary hydrostatic steering system. The automatic steering system utilizes a constant factor, such as steering rate, for predictability and simplicity in the operation of the automatic steering system. A feedback loop from the vehicle hydrostatic steering system uses the vehicle's actual turning rate for comparison with a desired turning rate. The system is adapted for original equipment installation and retrofitting on vehicles, such as farm tractors, with various primary hydrostatic steering system configurations. An automatic steering method includes the steps of: initializing the system; adjusting the steering with an hydraulic valve to provide a constant steering rate; providing feedback corresponding to the vehicle's actual turning rate and combining the feedback with other input signals to provide automatic steering.

Owner:AGJUNCTION

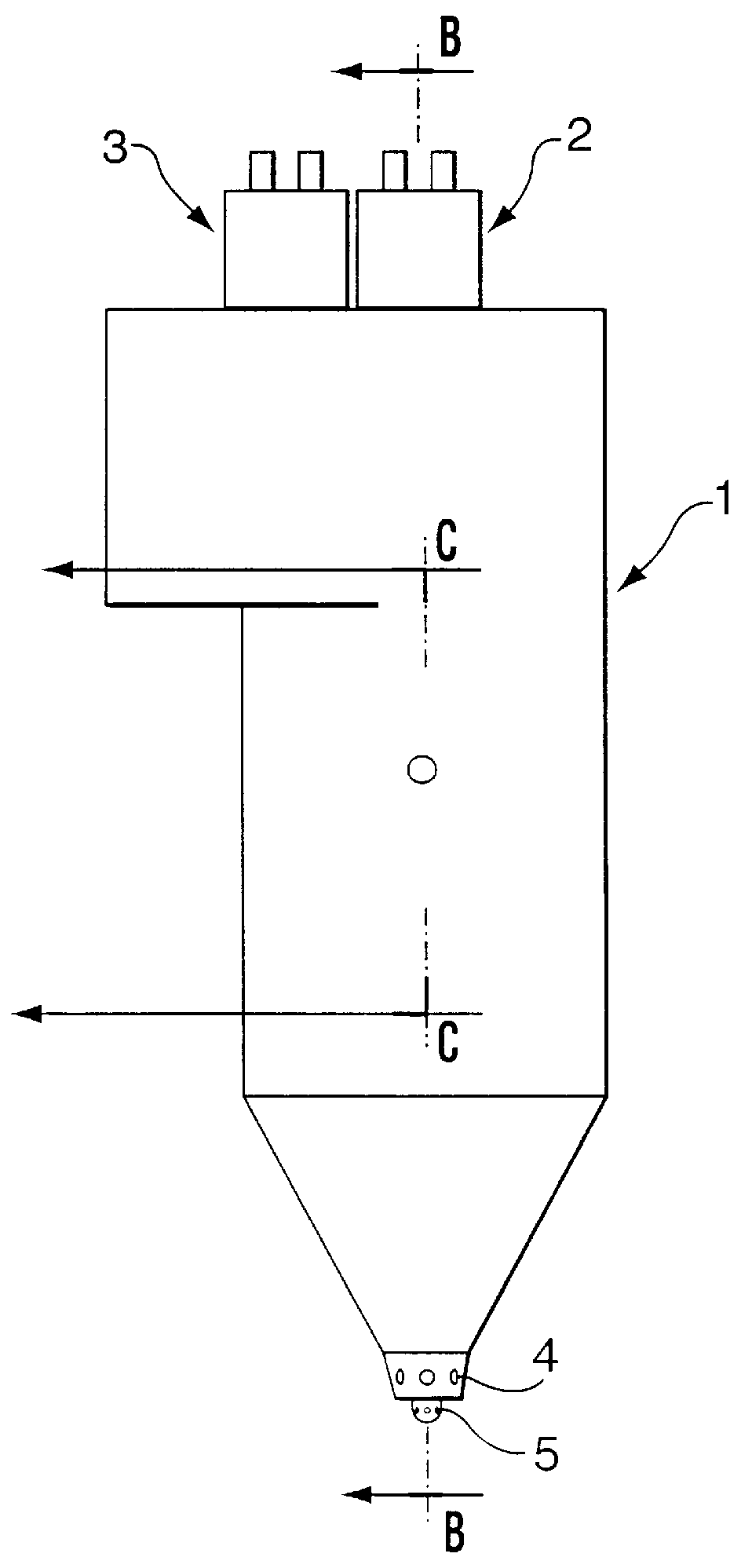

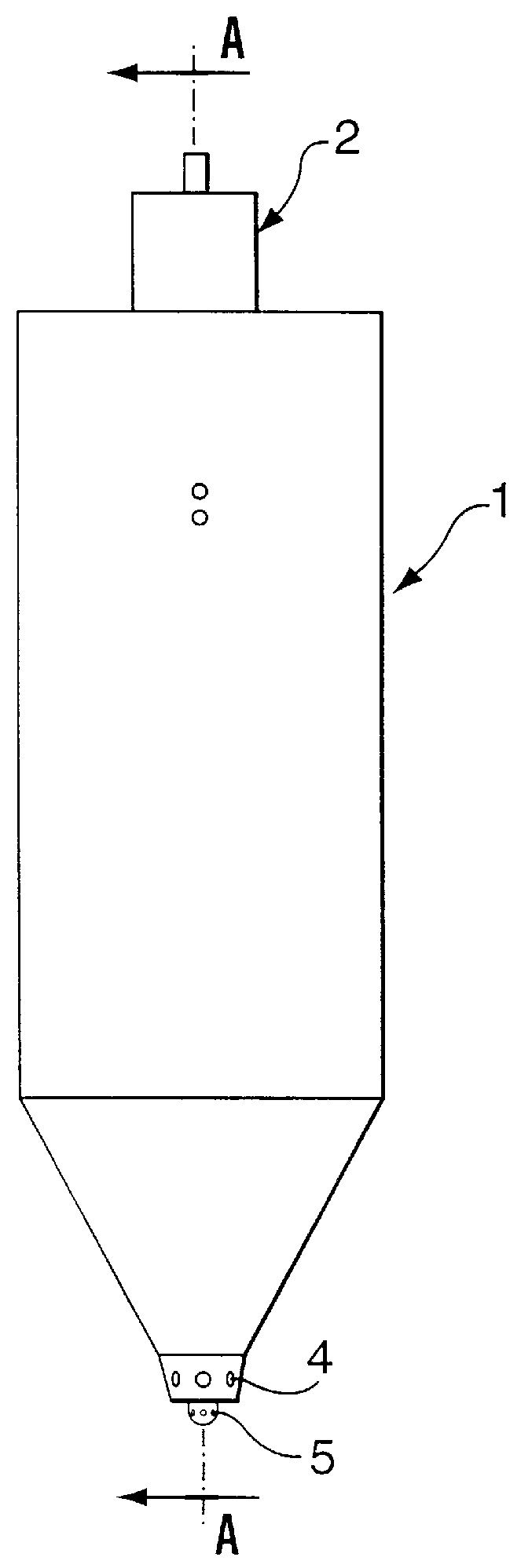

Controlled release of additives in fluid systems

ActiveUS20050019236A1Easy and straightforward to manufacture cost effectivelyCost-effective manufacturingFlow mixersSolid sorbent liquid separationControlled releaseCompound (substance)

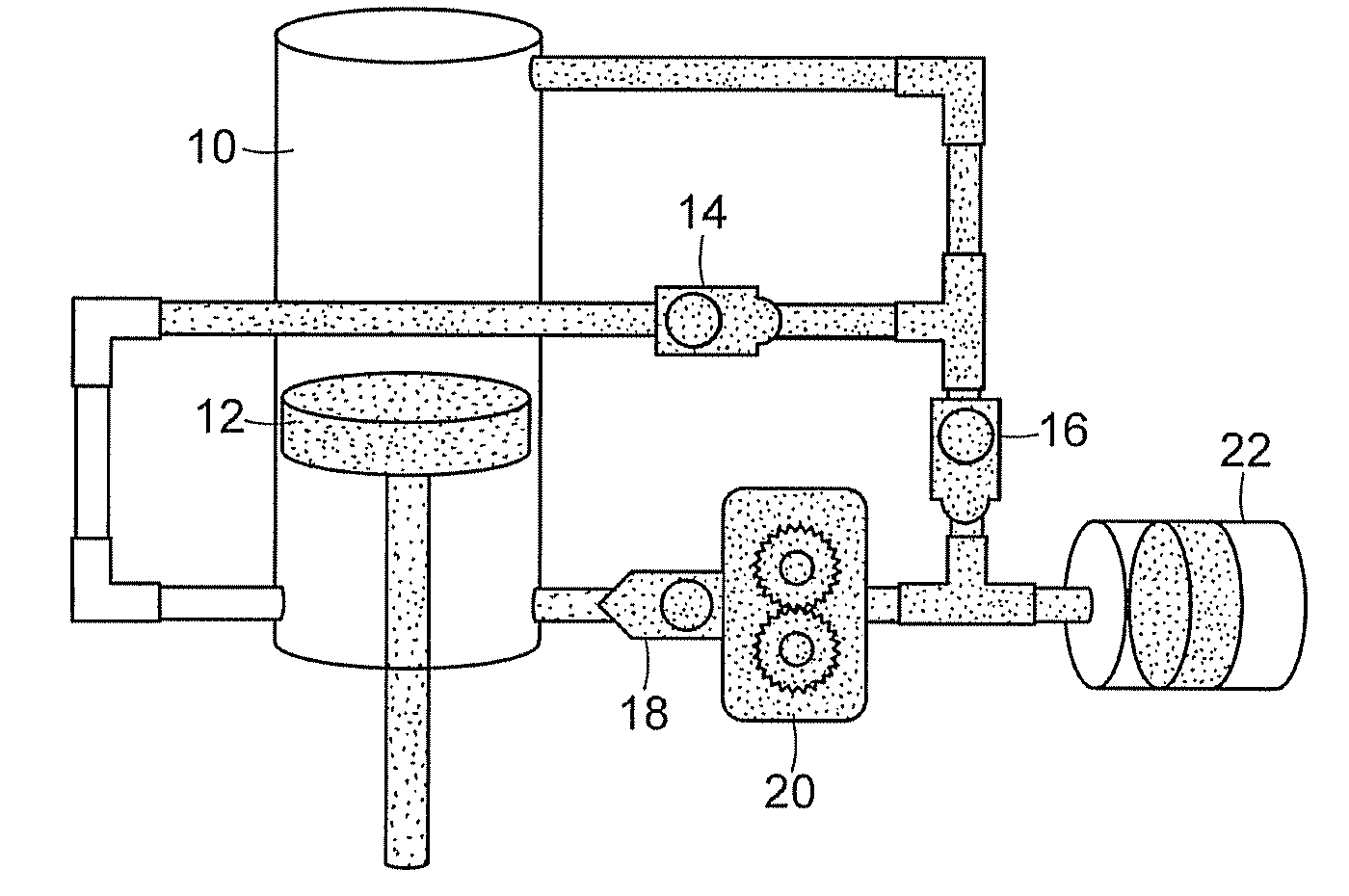

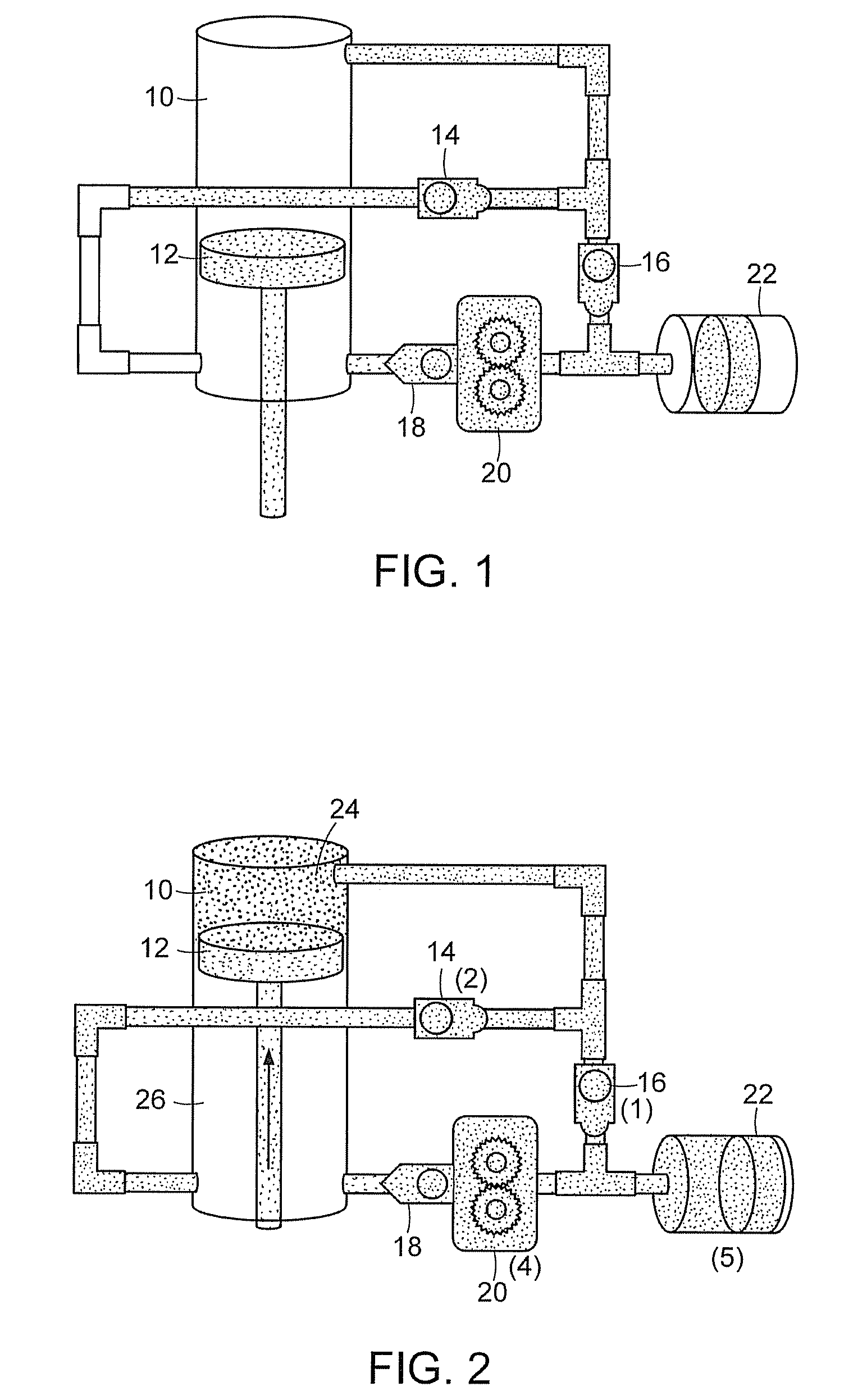

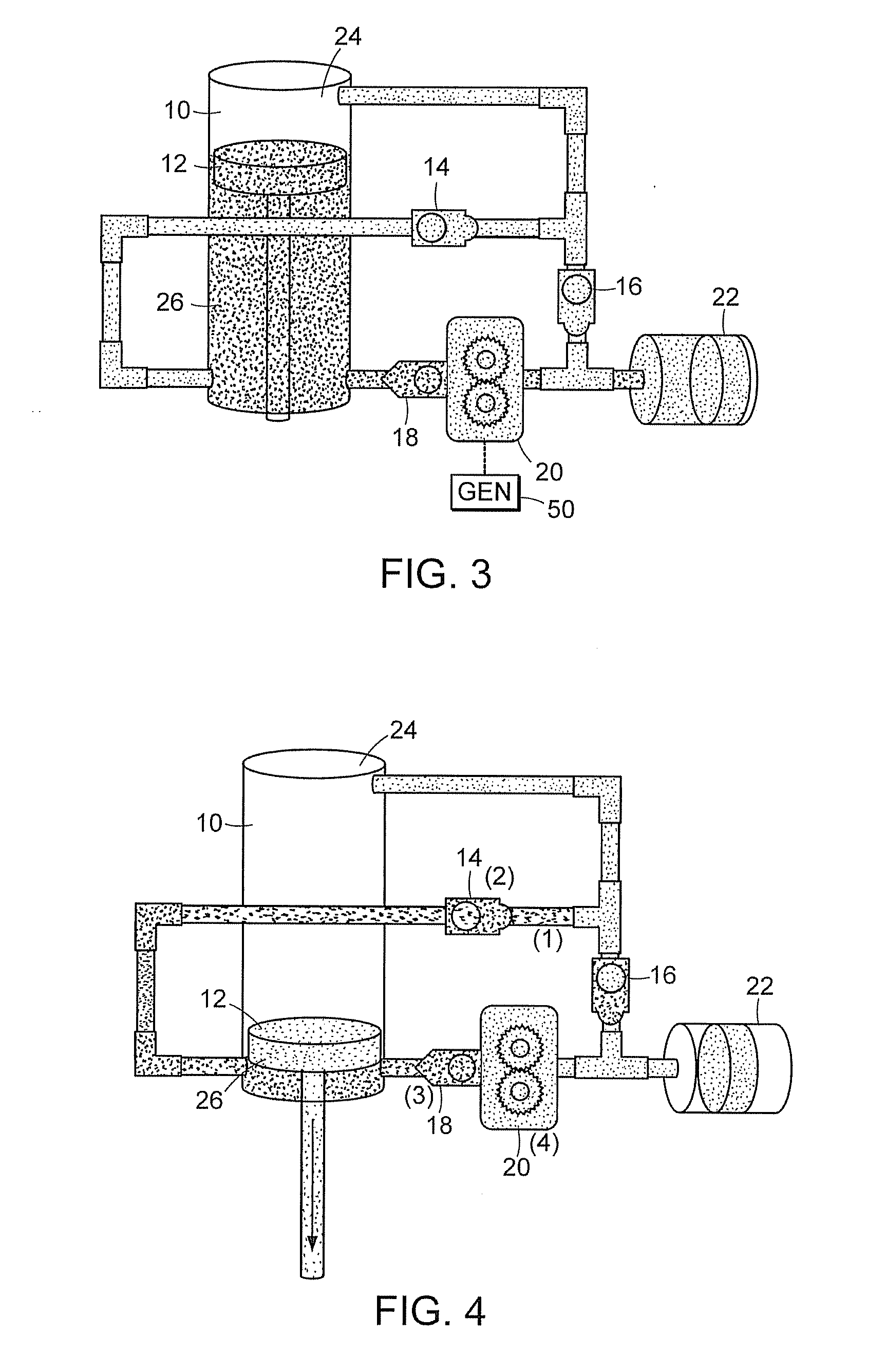

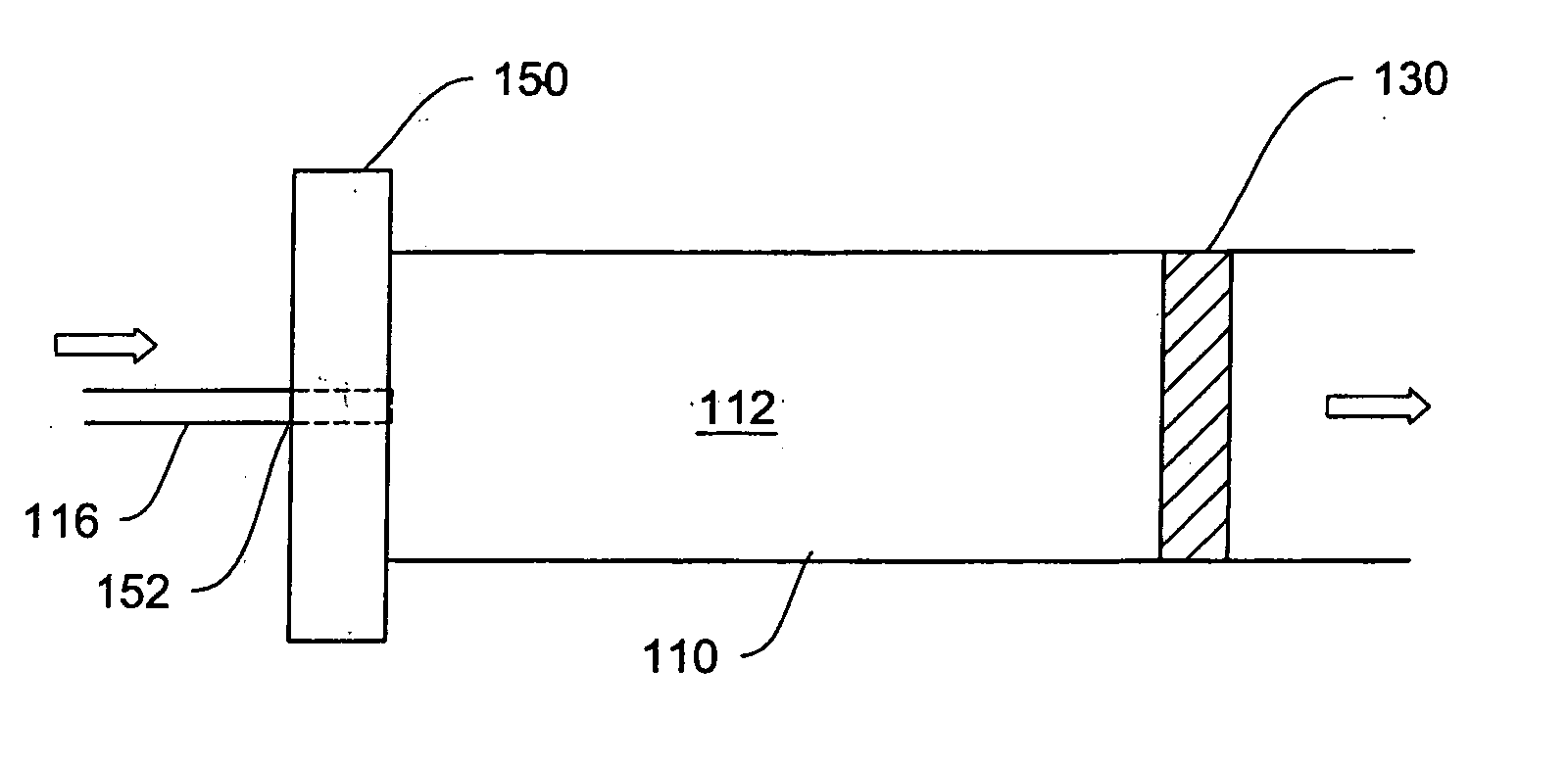

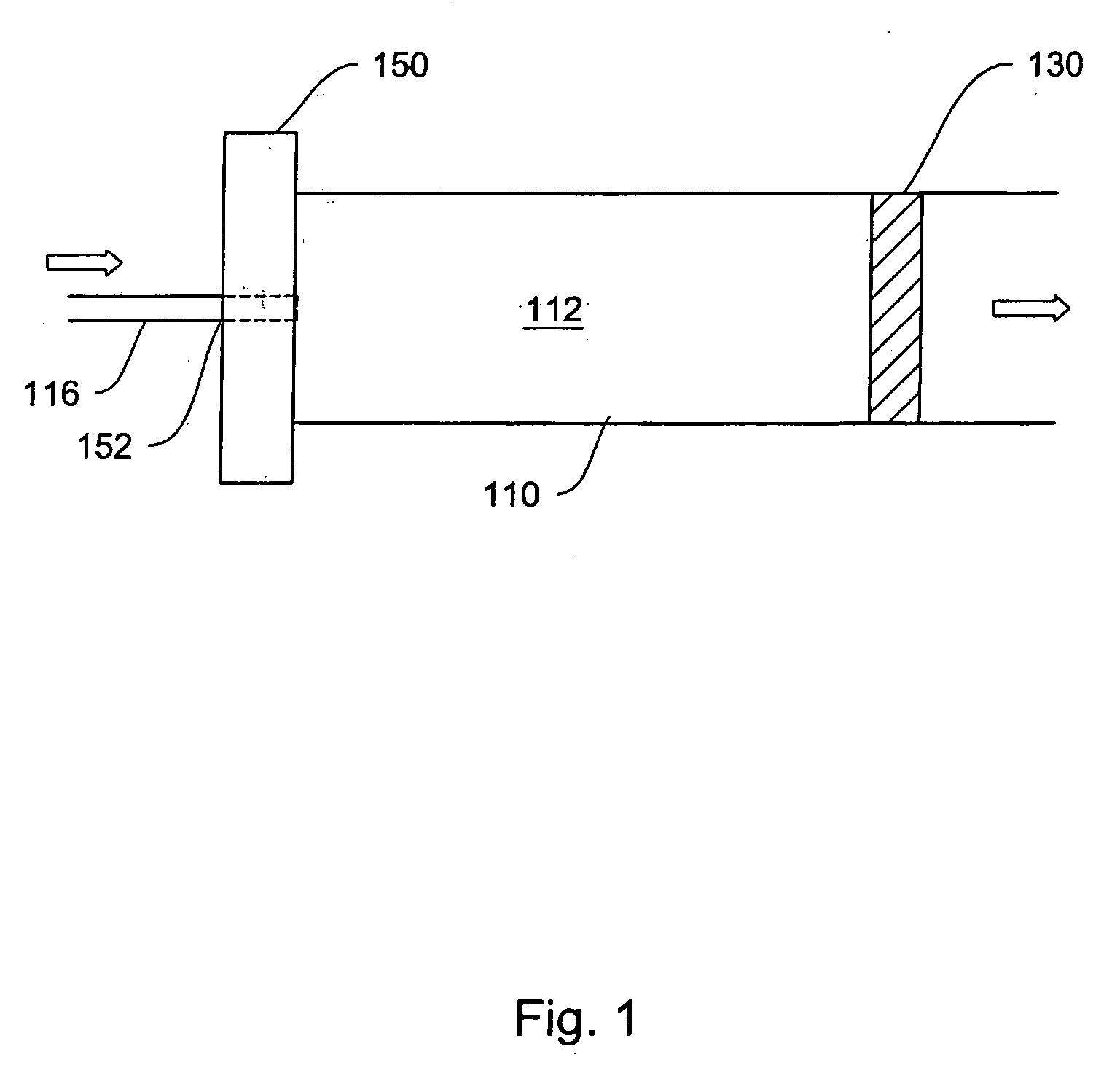

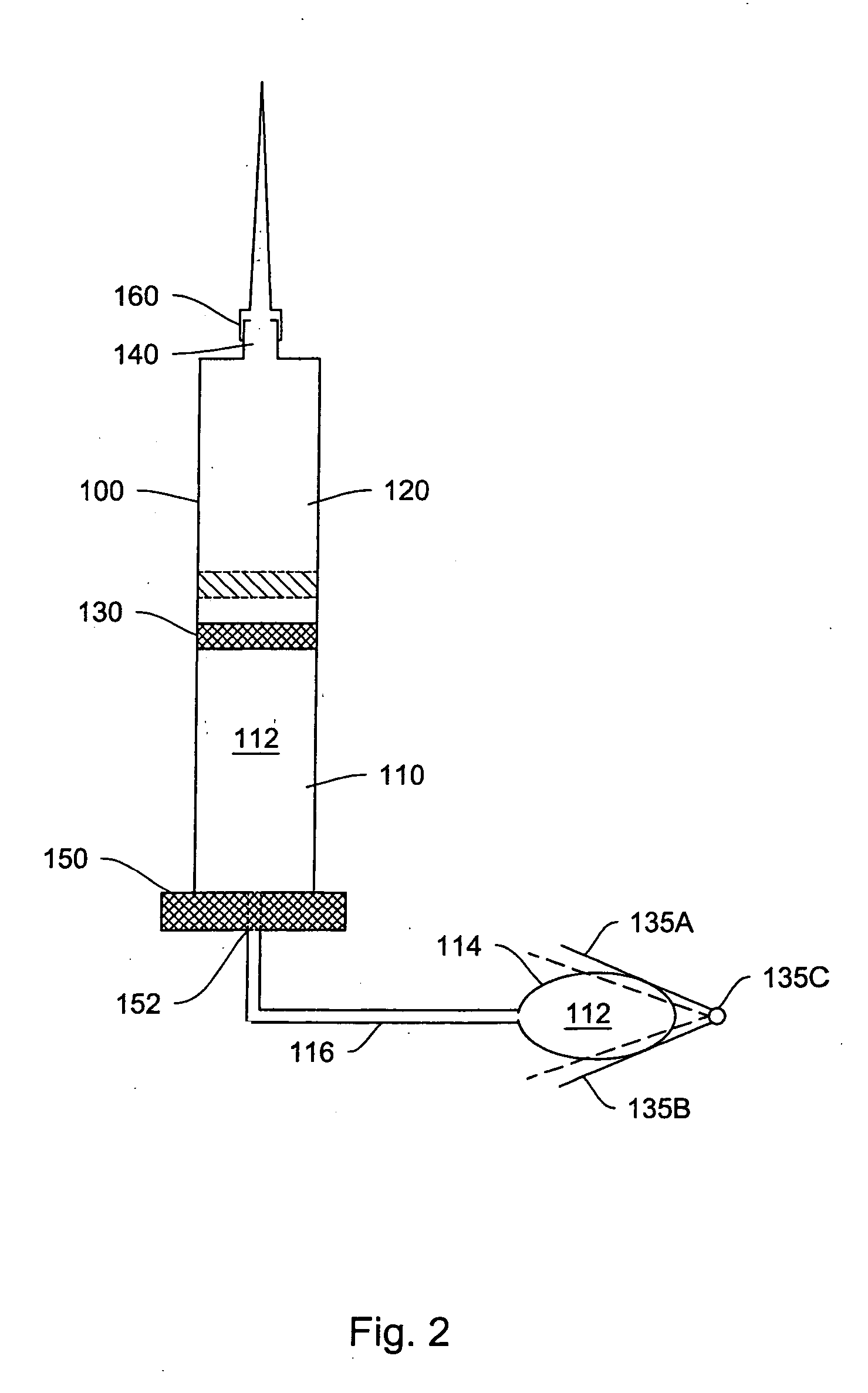

A container (1) for releasing a chemical additive (7) in a fluid material selected from a lubricant or hydraulic fluid composition comprises a fluid material-impermeable casing (3) having a hollow interior and an additive composition (7) comprising at least one fluid material-soluble additive. The additive (7) is held within the container (1) by a least one fluid material-permeable element (11) provided at or near an opening (13) in the casing (1) and is effective to provide for release of additive(s) (7) into the fluid material. Methods of releasing additives (7) into fluid material are also provided.

Owner:CUMMINS FILTRATION IP INC +1

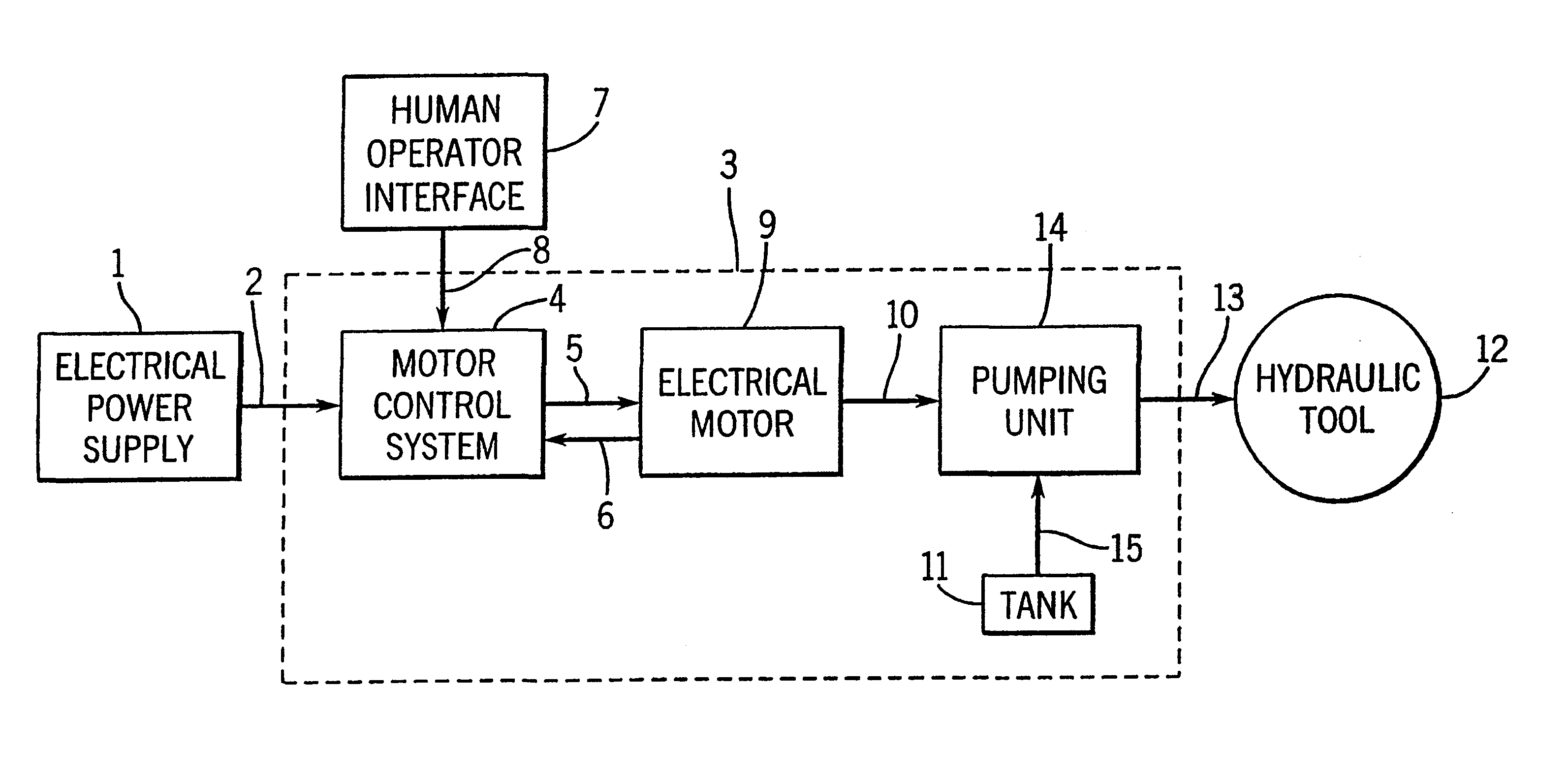

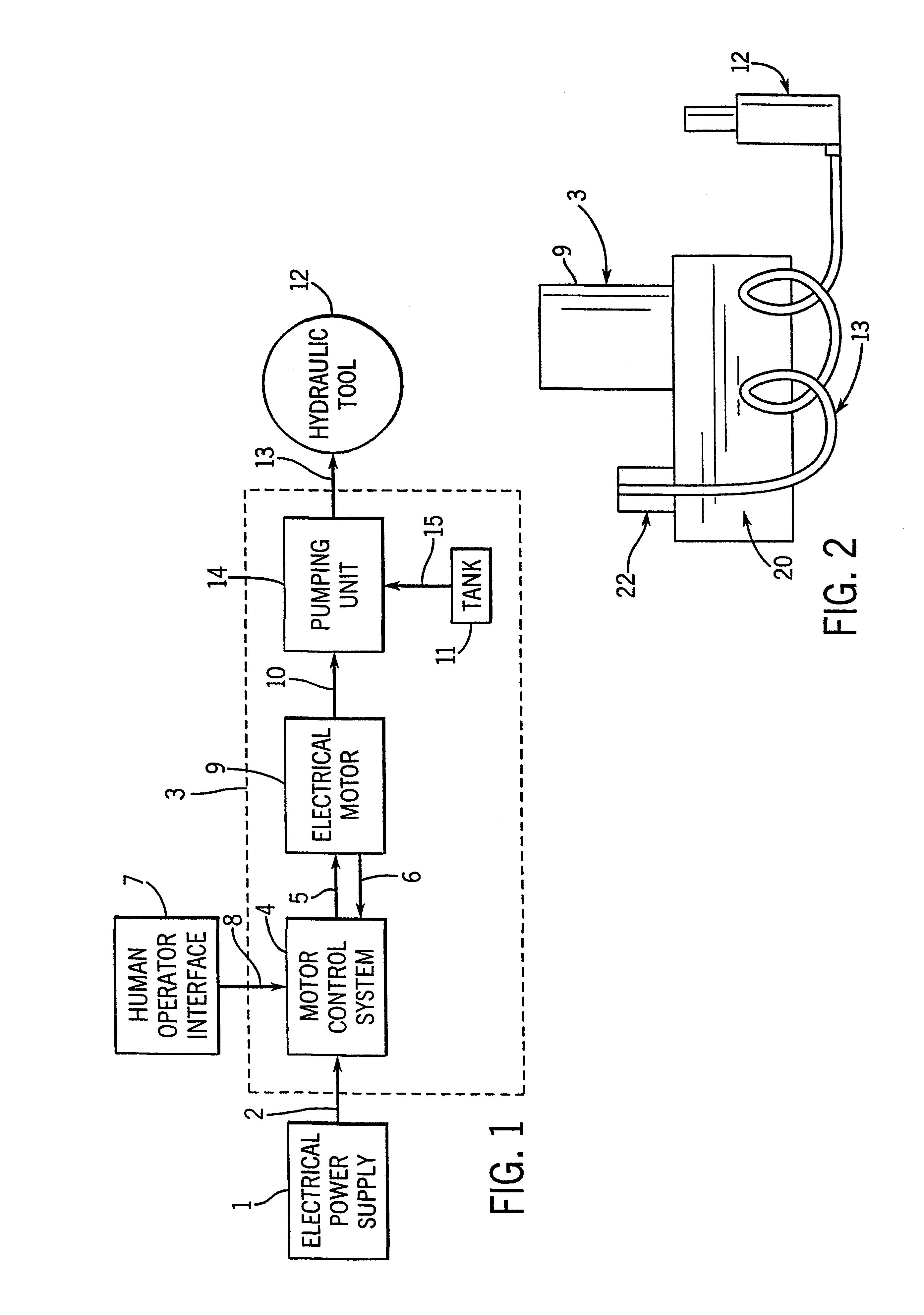

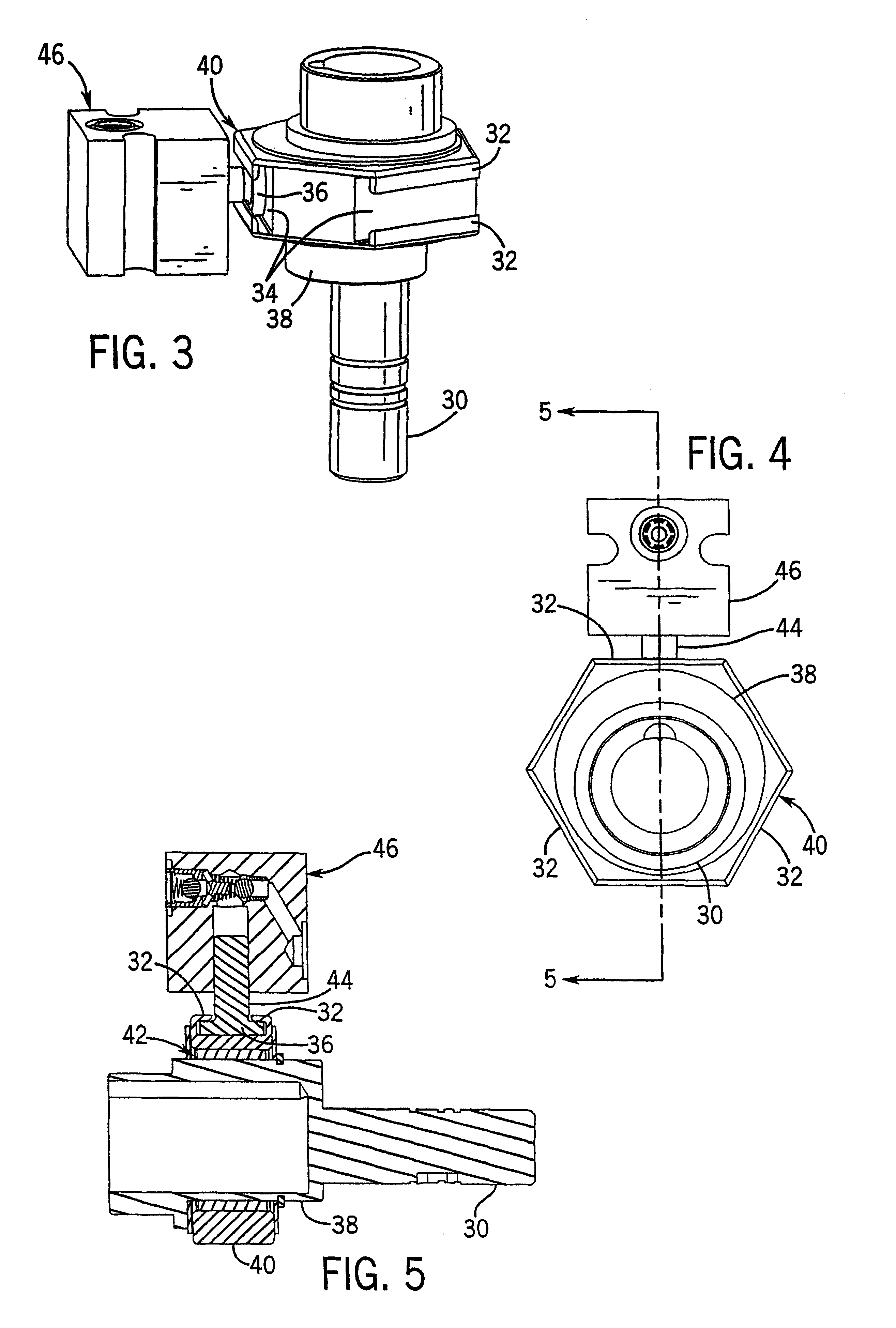

Variable speed hydraulic pump

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

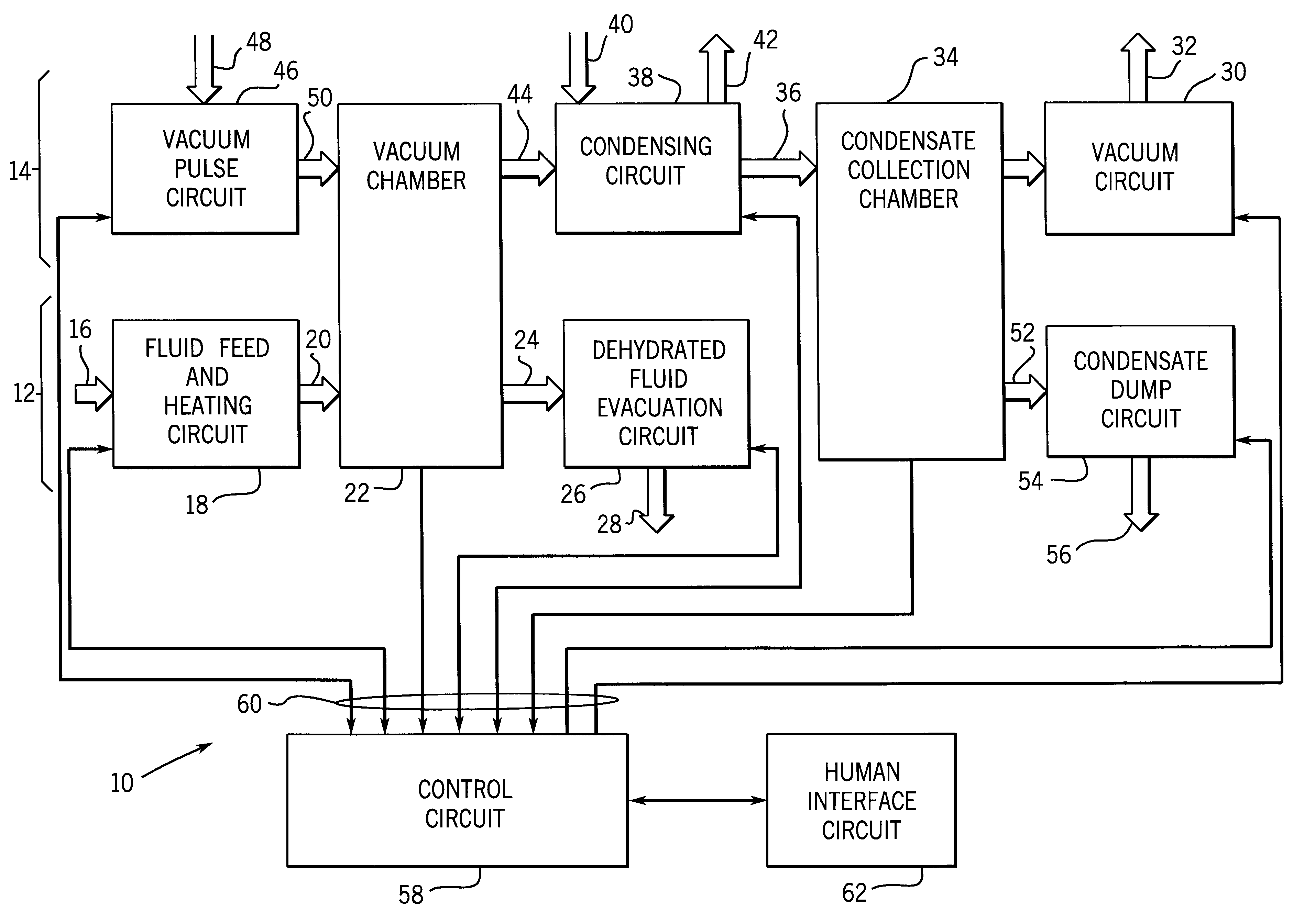

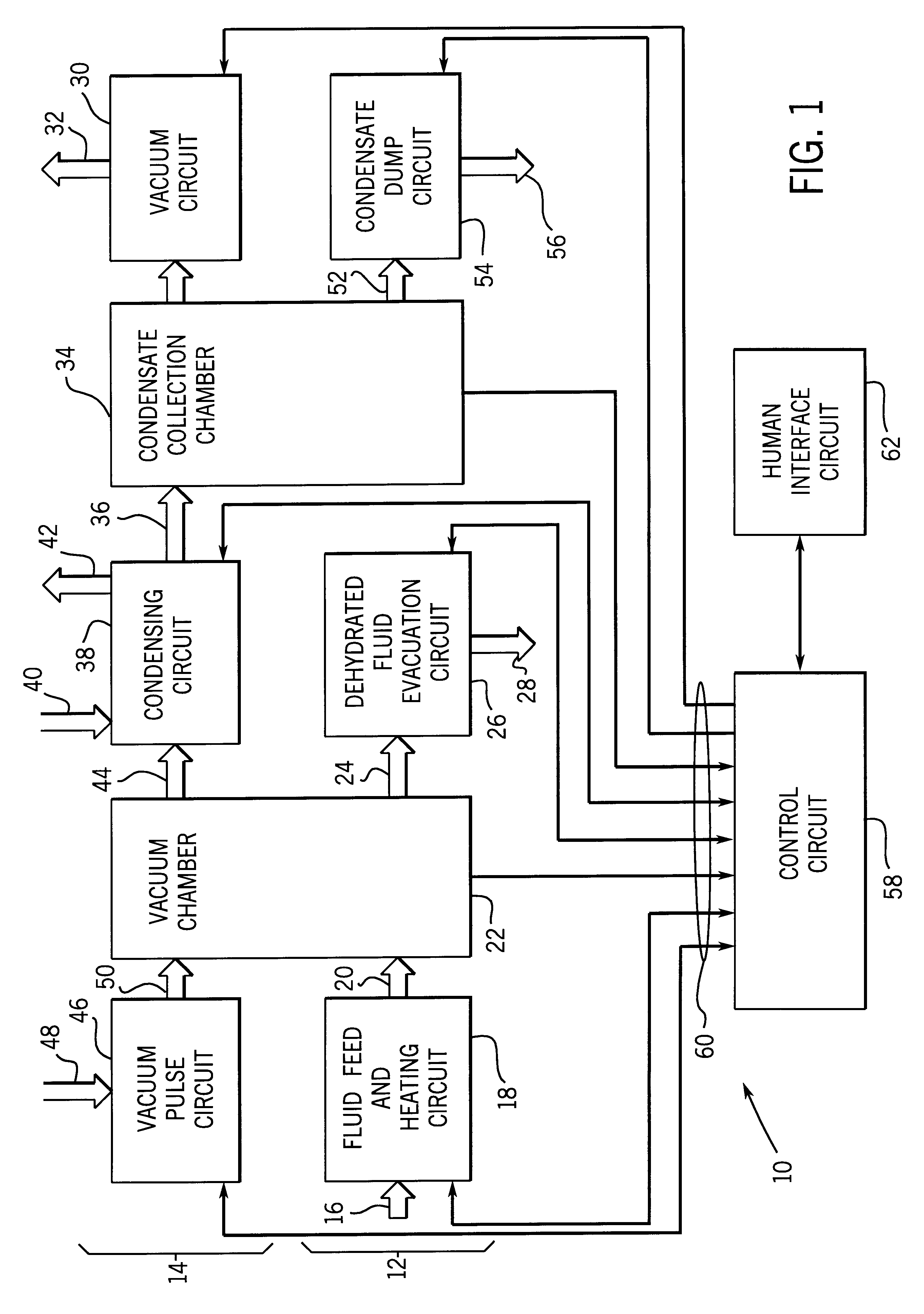

Apparatus for dehydrating oil

InactiveUS6224716B1Distillation regulation/controlEvaporation with vapour compressionVacuum pressureClosed loop

A system for dehydrating lubricating and hydraulic fluids includes a heating circuit and circuitry for creating a vacuum. The heating circuitry introduces a stream of heated fluid into a vacuum chamber in which a partial vacuum is drawn by the vacuum circuit. Aqueous components of the fluid stream are flashed in the vacuum chamber by virtue of the elevated temperature and reduced pressure. Dehydrated fluid is then collected and evacuated from the vacuum chamber. Vapor from the vacuum chamber, including the aqueous components of the fluid stream are collected, condensed and separately evacuated. The heating circuit limits surface temperature of a heating element in a closed-loop manner to avoid degradation of the fluid. The fluid stream is introduced into the vacuum chamber or is recirculated through the heating circuit to maintain a desired level of fluid temperature in a closed-loop manner. The system includes circuits for evacuating dehydrated fluid in a closed-loop manner and for automatically discharging condensate. The technique avoids undesirable foaming of dehydrated fluid within the vacuum chamber. A vacuum pulsing circuit is provided for periodically pulsing vacuum pressure within the vacuum chamber to aid in flashing aqueous components from the heated fluid stream.

Owner:OILQUIP

Compact lost motion system for variable valve actuation

InactiveUS6883492B2Wide rangeNon-fuel substance addition to fuelInternal combustion piston enginesVariable valve timingHydraulic circuit

Lost motion systems and methods for providing engine valves with variable valve actuation for engine valve events are disclosed. The system may include a master piston hydraulically linked to a slave piston, and a dedicated cam operatively connected to the master piston. The slave piston may be disposed substantially perpendicular to the master piston in a common housing. The slave piston is adapted to actuate one or more engine valves. The slave piston may incorporate an optional valve seating assembly into its upper end. A trigger valve may be operatively connected to the master-slave hydraulic circuit to selectively release and add hydraulic fluid to the circuit.

Owner:JACOBS VEHICLE SYST

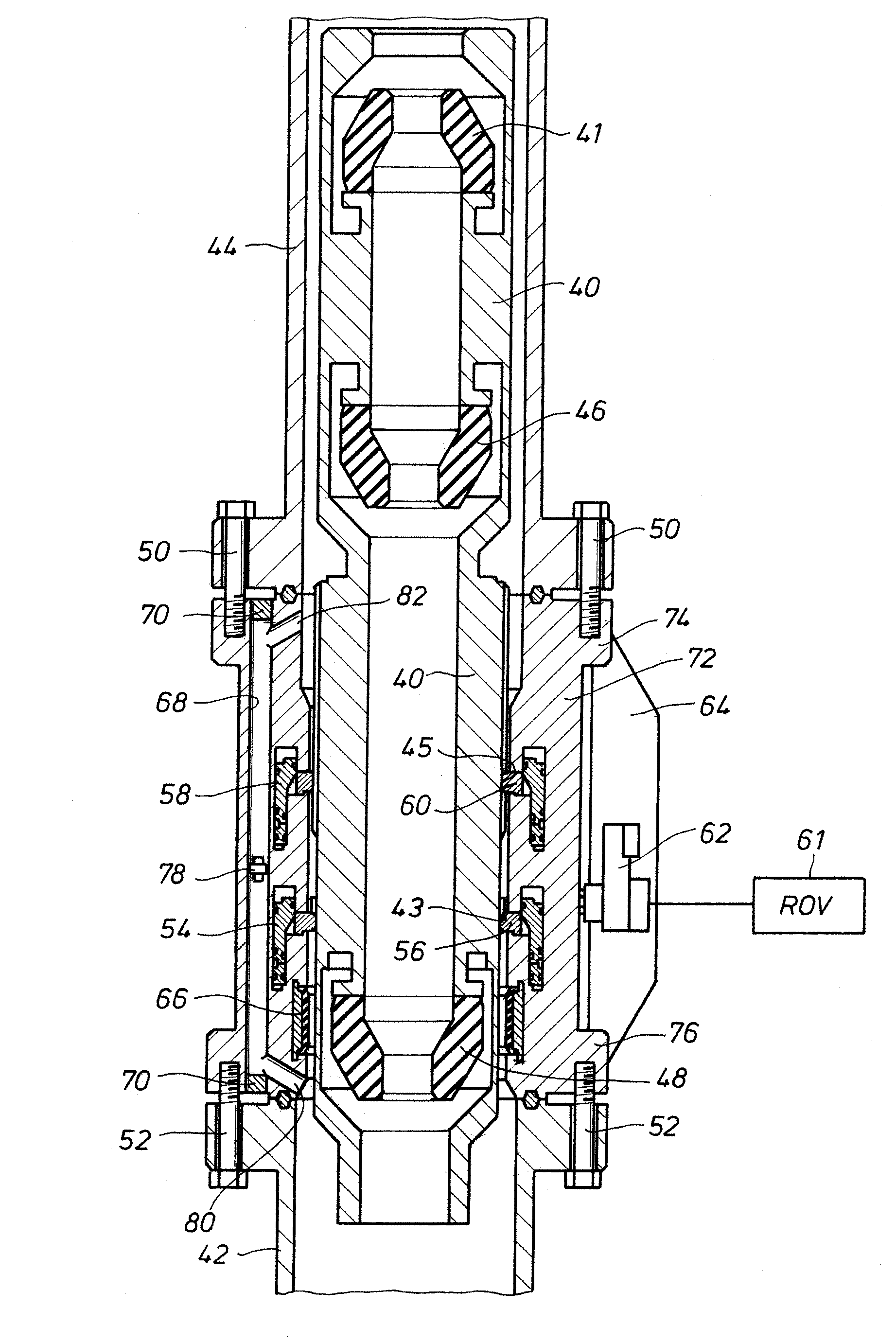

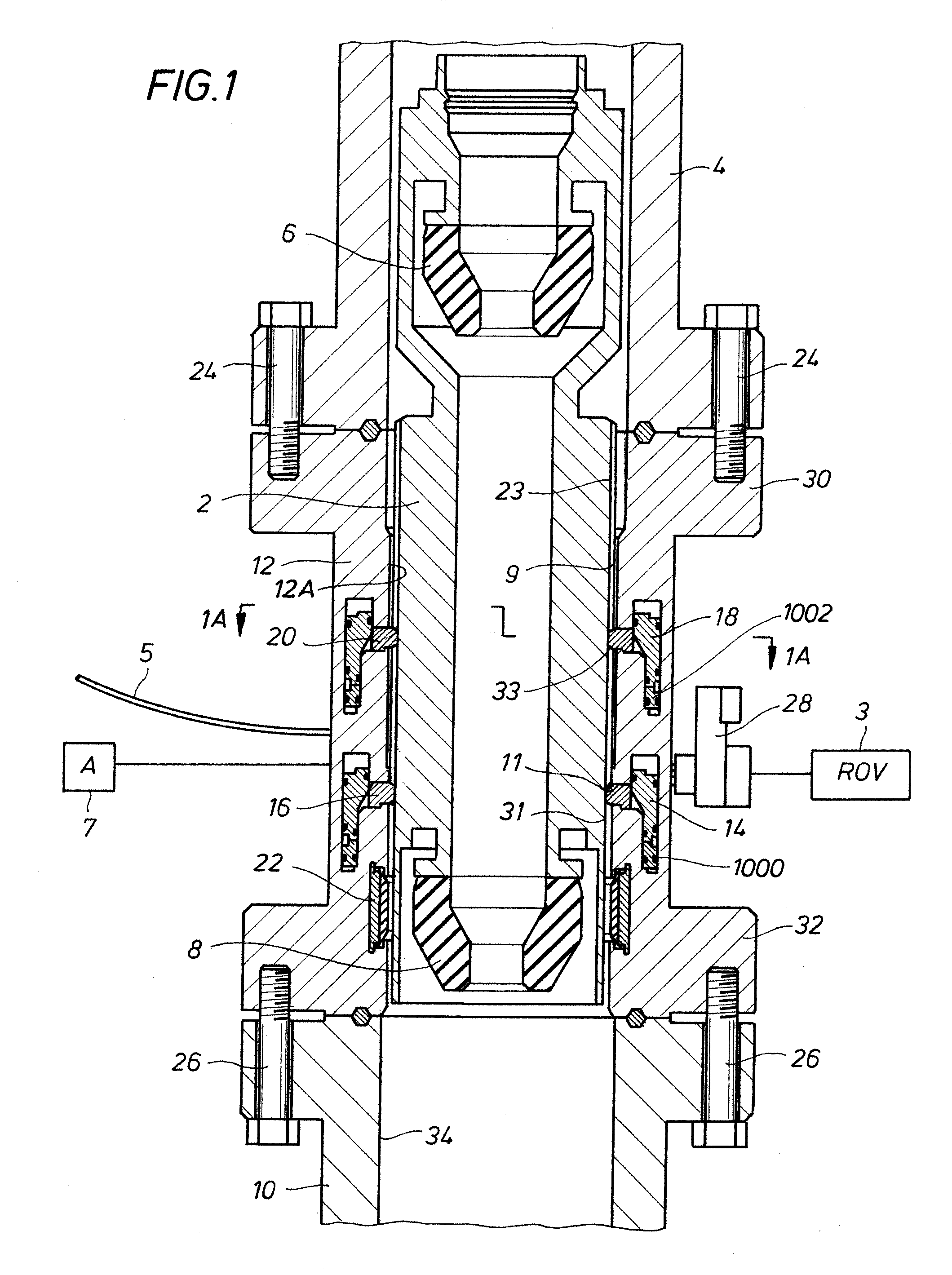

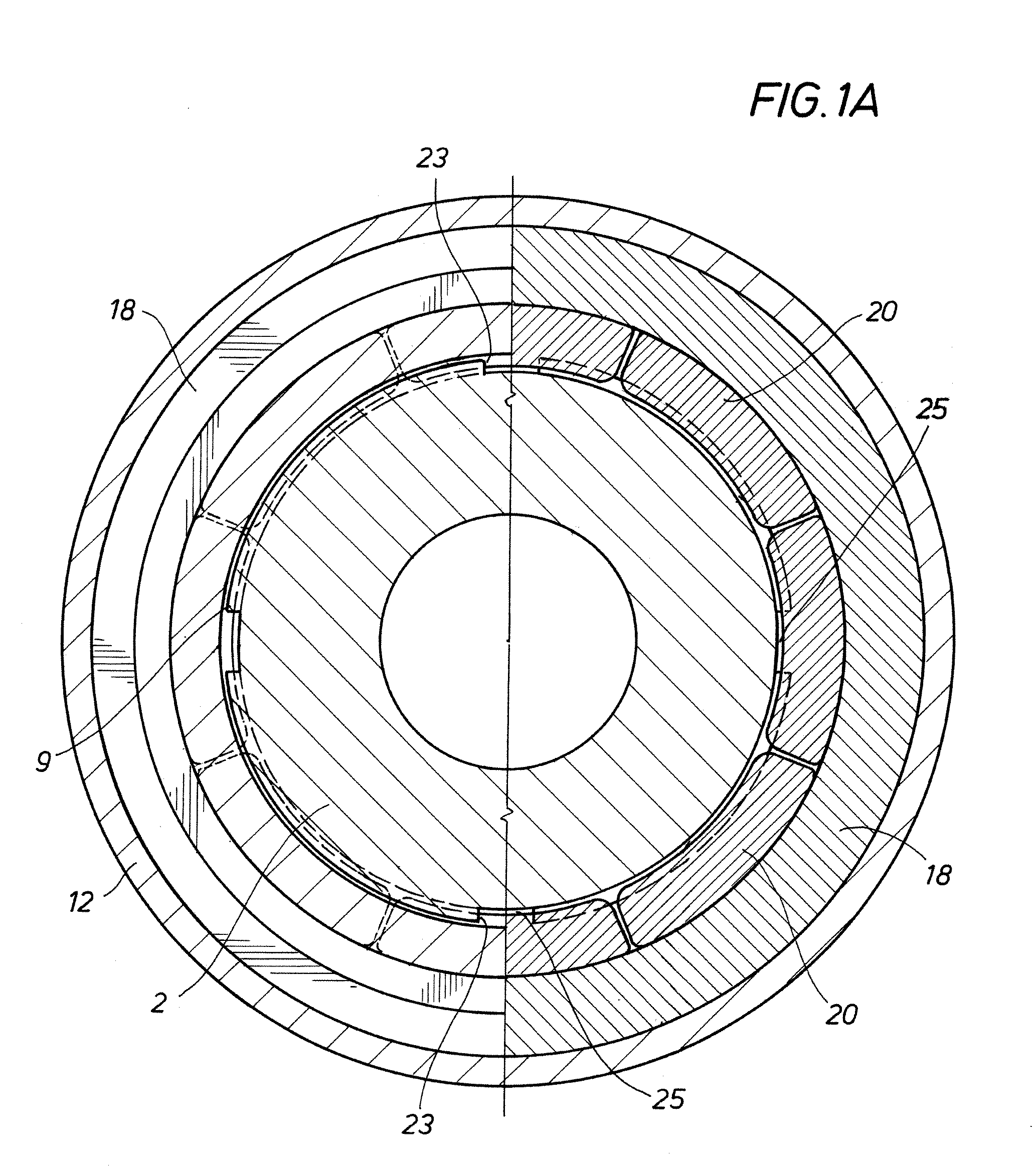

Acoustically Controlled Subsea Latching and Sealing System and Method for an Oilfield Device

An acoustic control system wirelessly operates a subsea latching assembly or other subsea device, such as an active seal. The acoustic control system may control a subsea first accumulator to release its stored hydraulic fluid to operate the latch assembly or other subsea device, such as an active seal. An RCD or other oilfield device may be unlatched or latched with the latching assembly. The acoustic control system may have a surface control unit, a subsea control unit, and two or more acoustic signal devices. A valve may allow switching from an umbilical line system to the acoustic control system accumulator.

Owner:WEATHERFORD TECH HLDG LLC

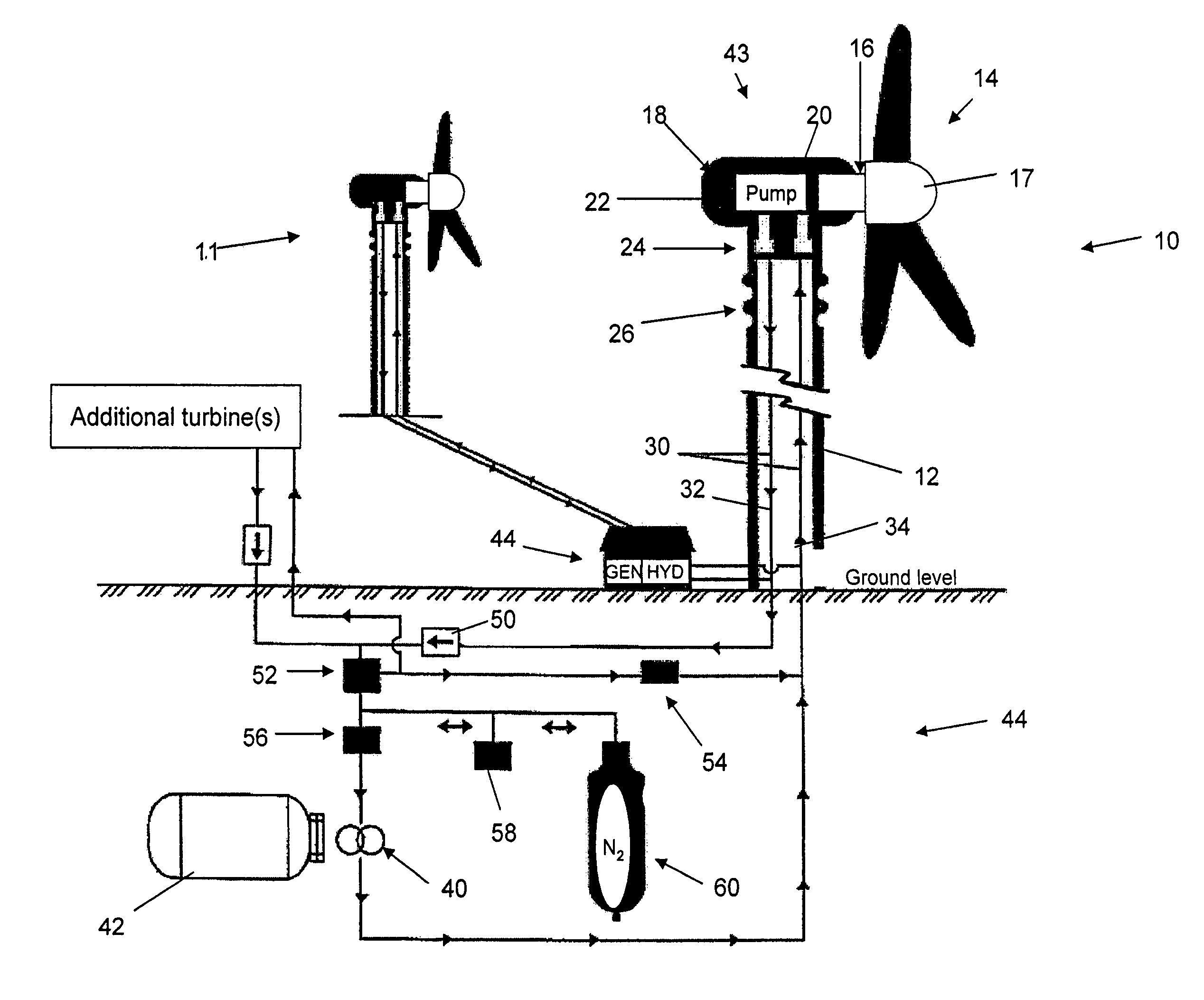

Hydro-wind power generating turbine system and retrofitting method

InactiveUS7656055B2Reduce wind speedProducing more kilowatt-hoursEngine fuctionsWind motor supports/mountsMechanical energyHydraulic pump

An electrical power producing wind turbine eliminates the possibility of being struck by lightning, reduces the complexity of gear trains and simplifies maintenance at heights. The wind turbine is electrically isolated from ground to reduce the possibility of being struck by lightning and the generator is located at ground level to simplify maintenance. The turbine blade shaft is directly attached to a hydraulic pump. The hydraulic fluid is transmitted to ground level through dielectric tubing and acts both as an electrical isolating medium and a transmitter of mechanical energy to the generator located at ground level. The wind turbine blade, shaft and hydraulic pump are electrically isolated from the support structure at the upper end.

Owner:PERRY ROBERT NELSON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com