Patents

Literature

6604 results about "Load cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A load cell is a type of transducer, specifically a force transducer. It converts a force such as tension, compression, pressure, or torque into an electrical signal that can be measured and standardized. As the force applied to the load cell increases, the electrical signal changes proportionally. The most common types of load cell used are hydraulic, pneumatic, and strain gauge.

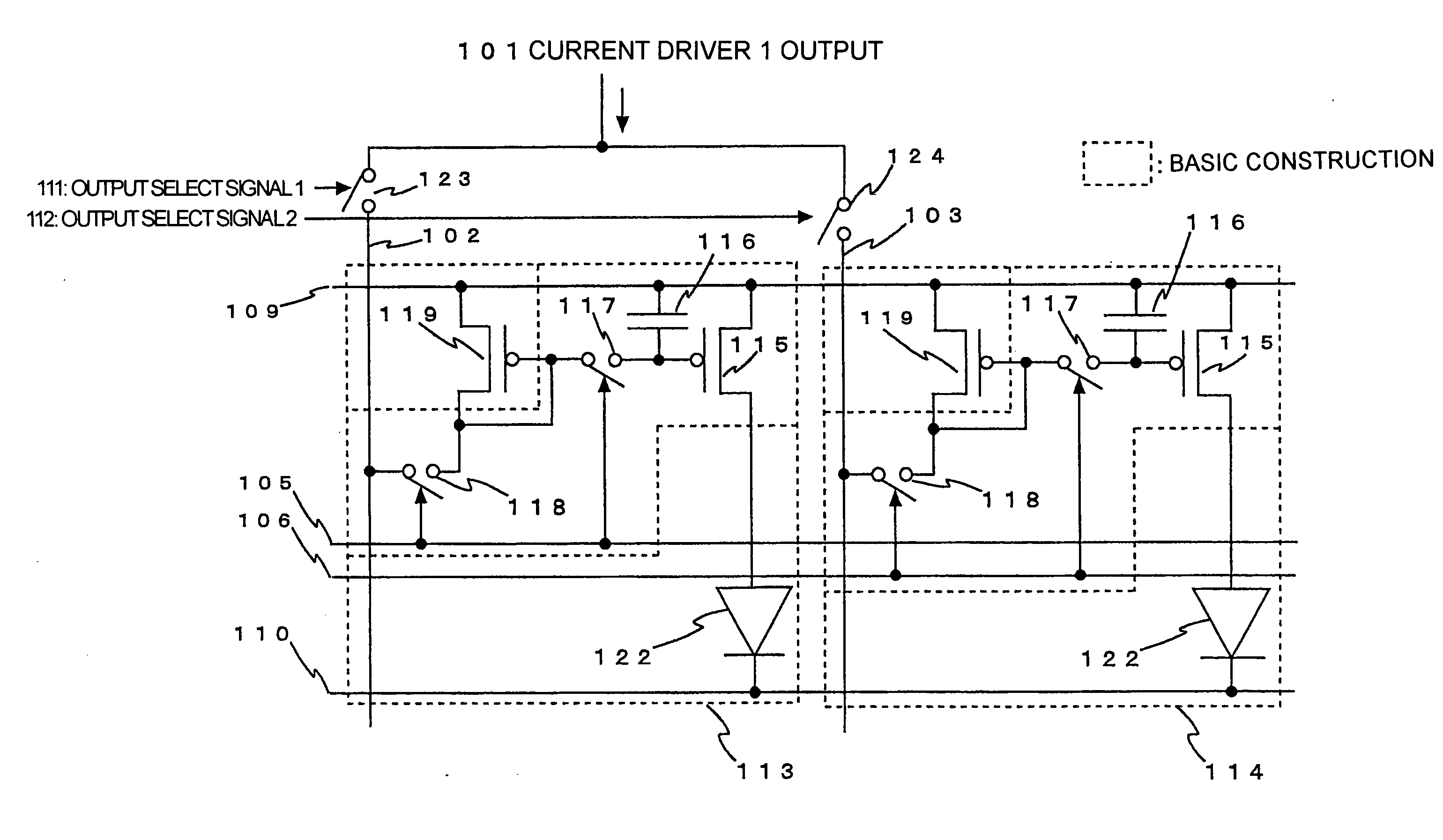

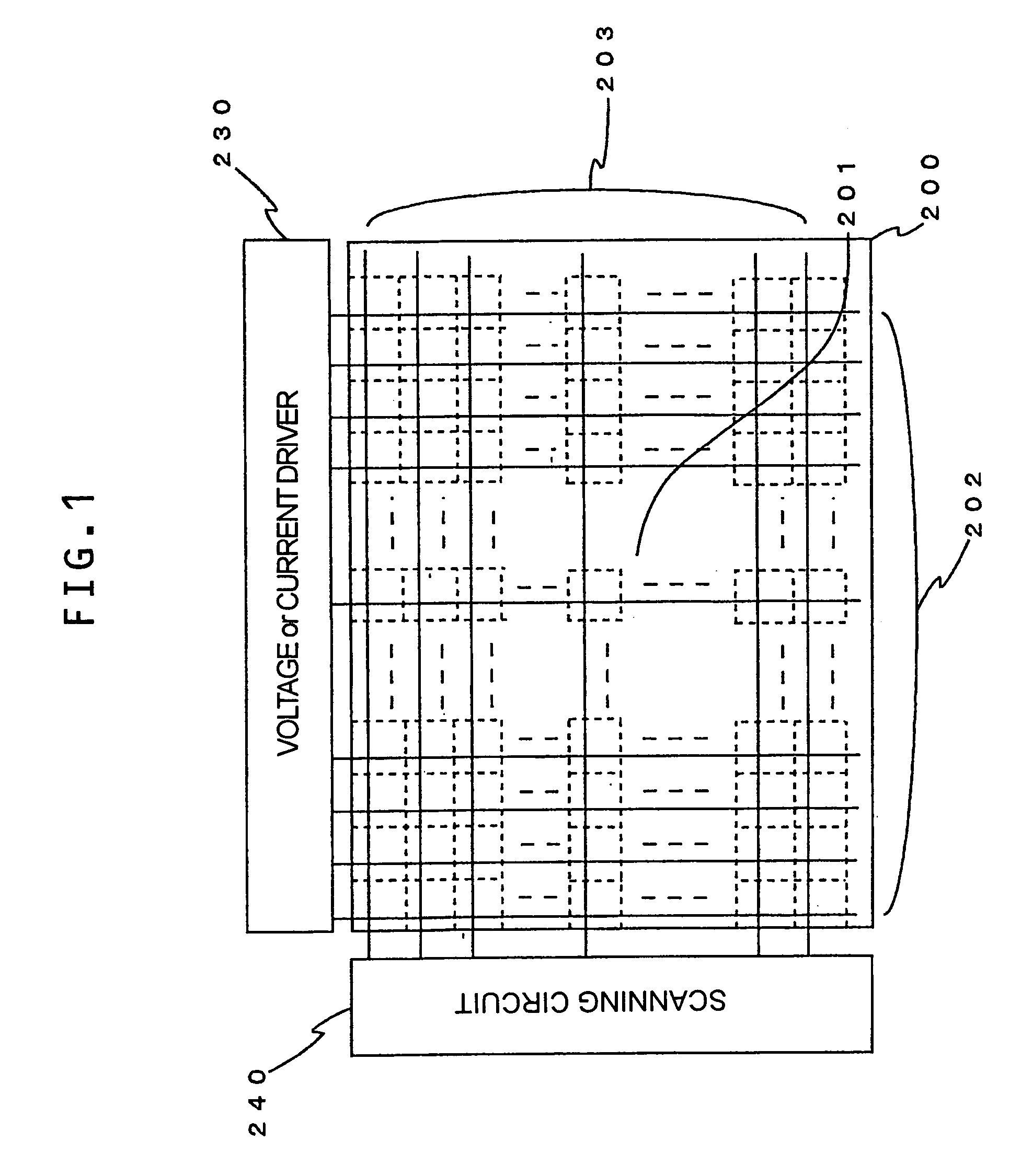

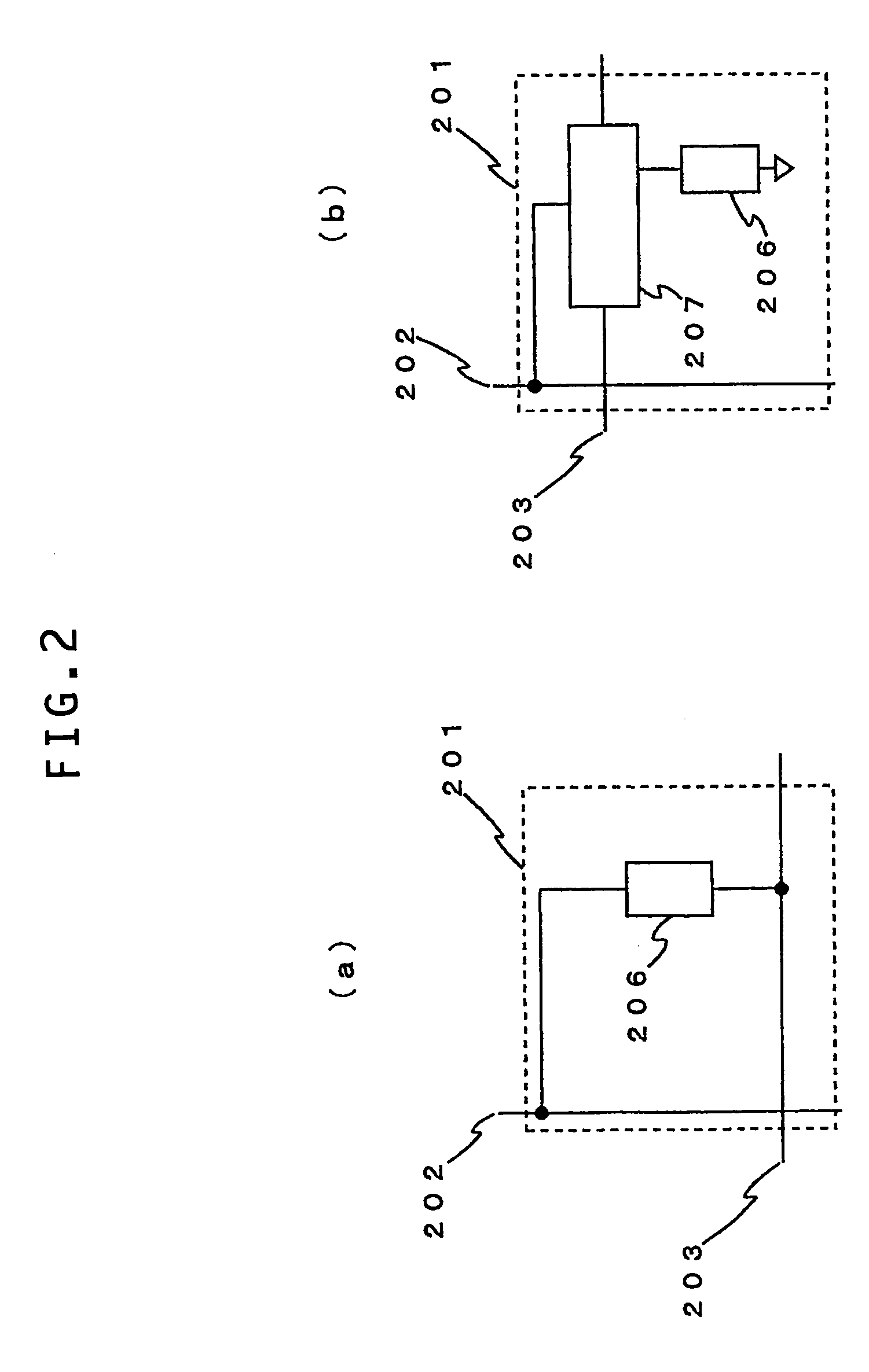

Semiconductor device provided with matrix type current load driving circuits, and driving method thereof

A semiconductor device to which active drive current programming is applied, comprising current load cells each having a current load and a current load driving circuit, which are arranged in a matrix, capable of reducing the circuit scale of a current driver with little change made in the structure of the current load driving circuit, and a driving method of the same. A current load cell (113, 114) includes a current load driving circuit which is provided with a transistor (115) connected in series with a current load (122) between first and second power supplies (109, 110); a capacitance (116) connected between the control terminal of the transistor (115) and the first power supply (109); and switches (117, 118) connected between the control terminal of the transistor (115) and a corresponding data line. The output (101) of a current driver is connected to a plurality of data lines via a selector (123, 124), and the plural data lines connected to one output of the current driver via the selector and at least one of the switches of each of the current load cells corresponding to the respective data lines are drive-controlled in a time division manner during one horizontal period.

Owner:HANNSTAR DISPLAY CORPORATION

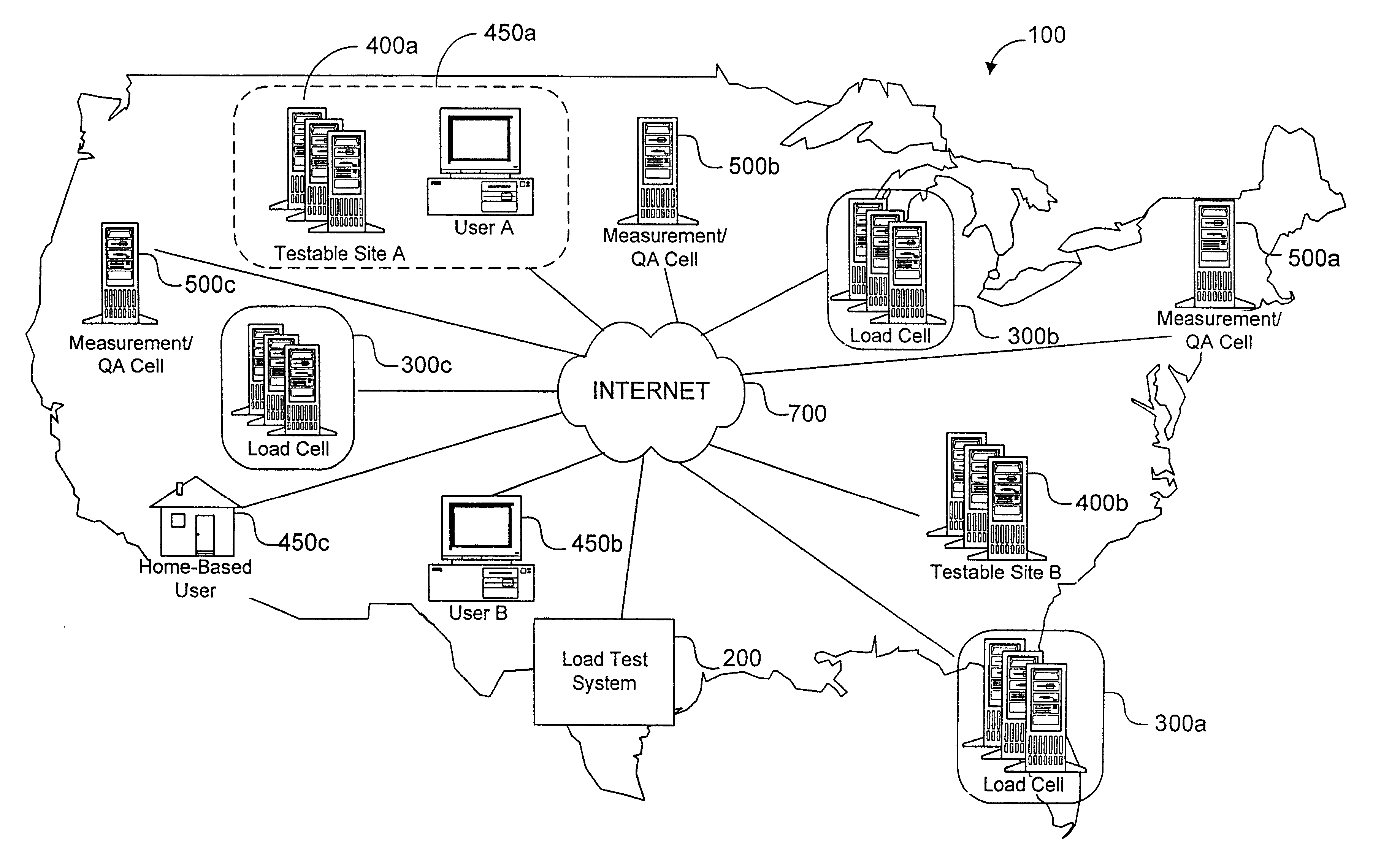

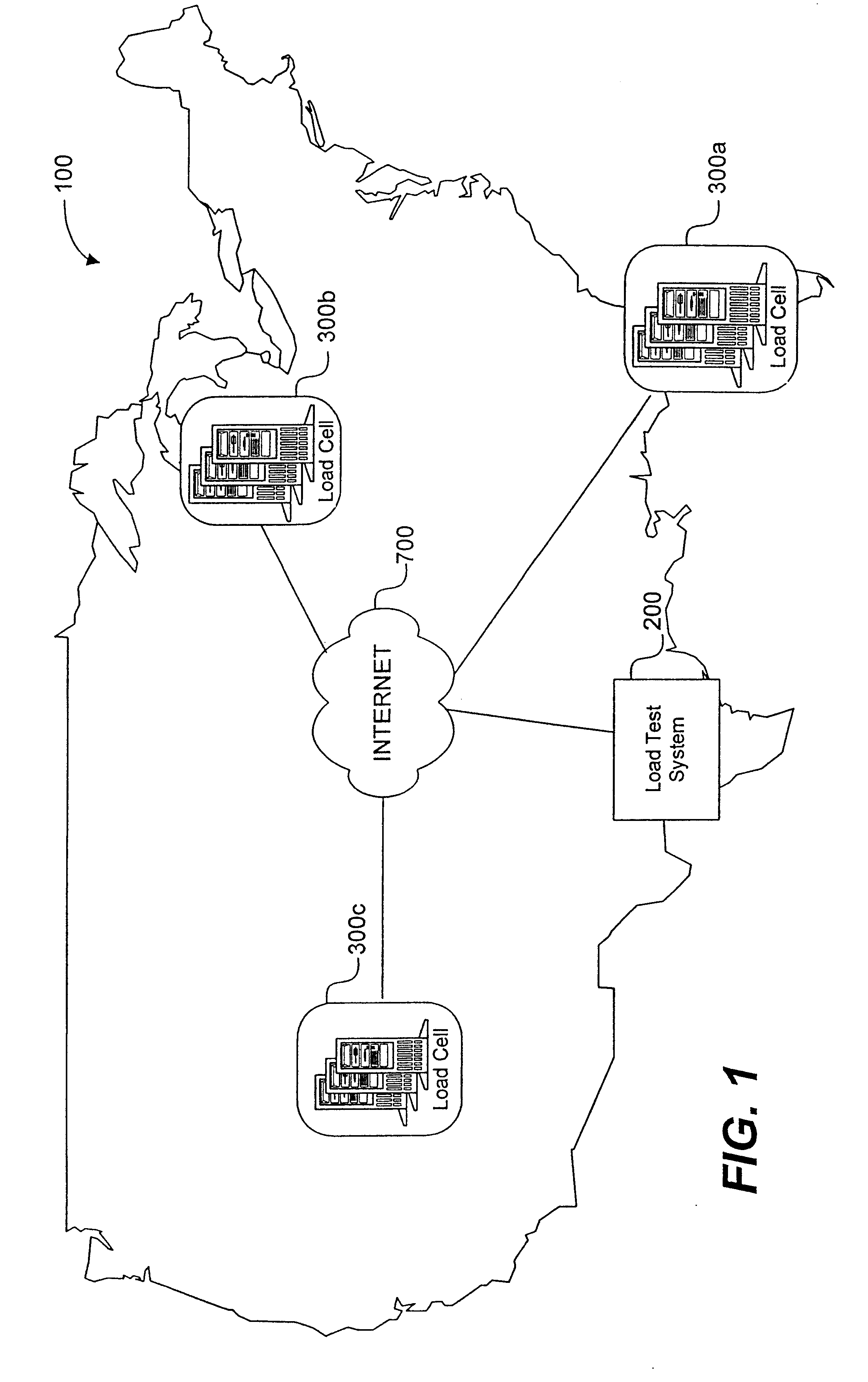

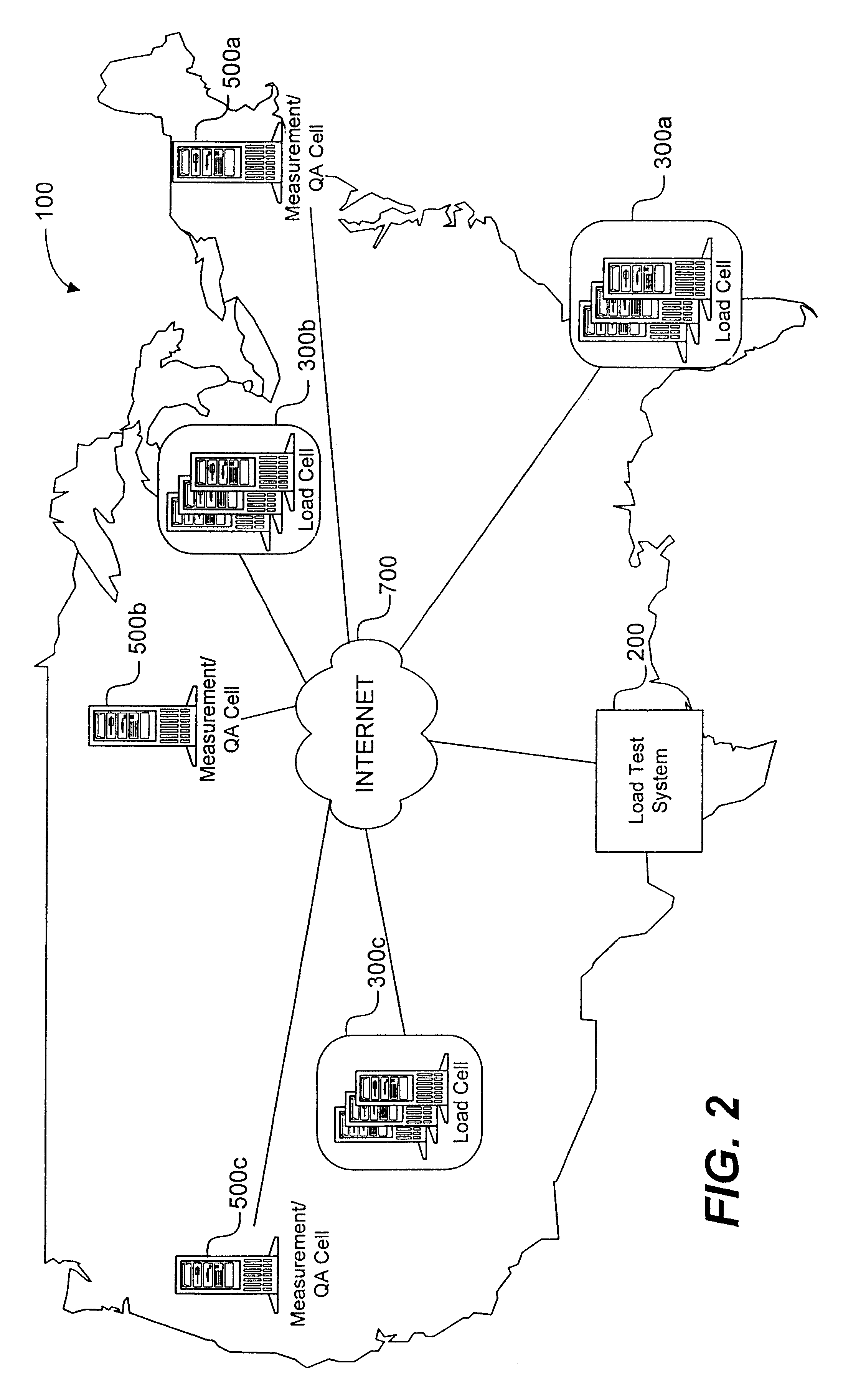

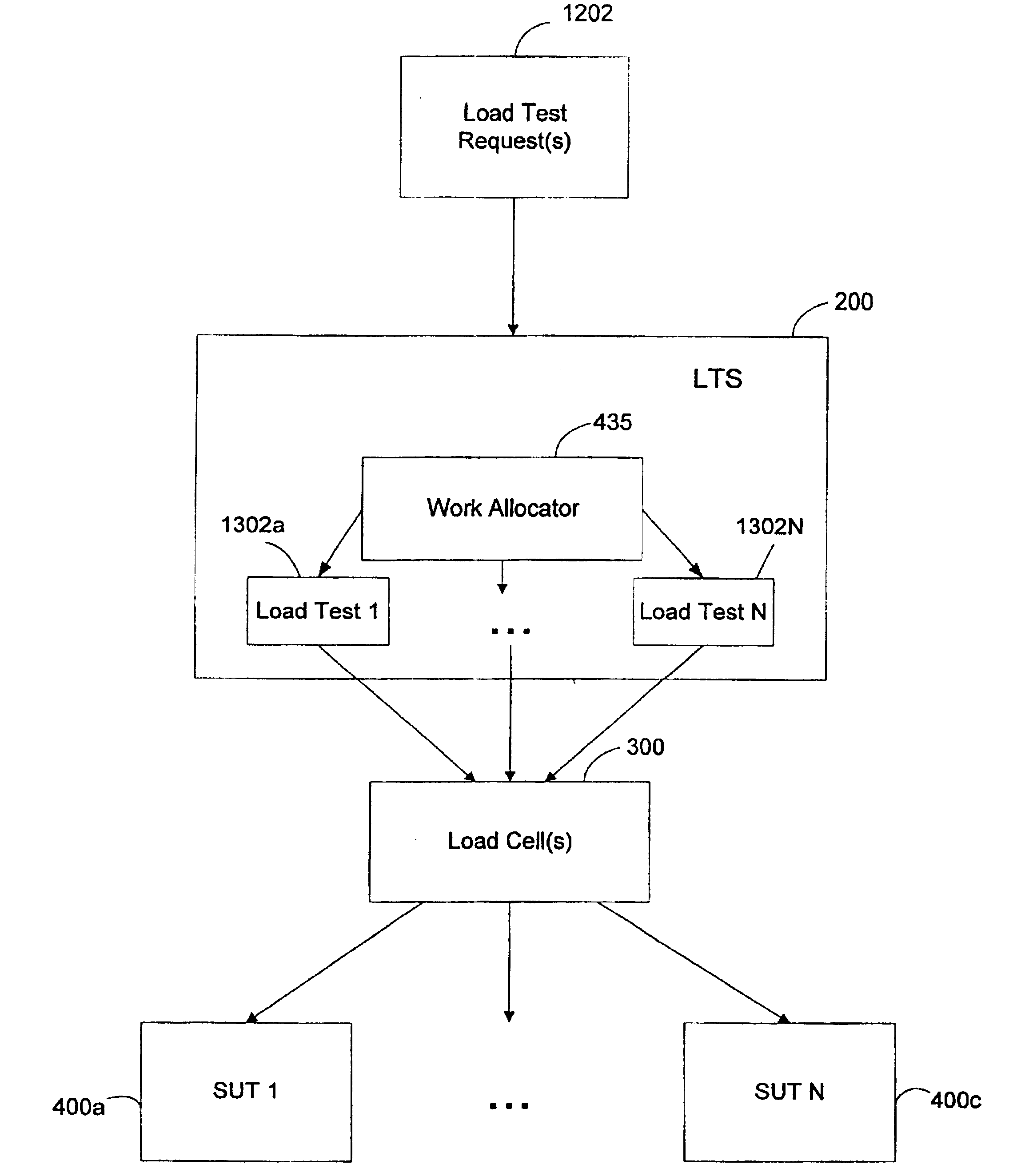

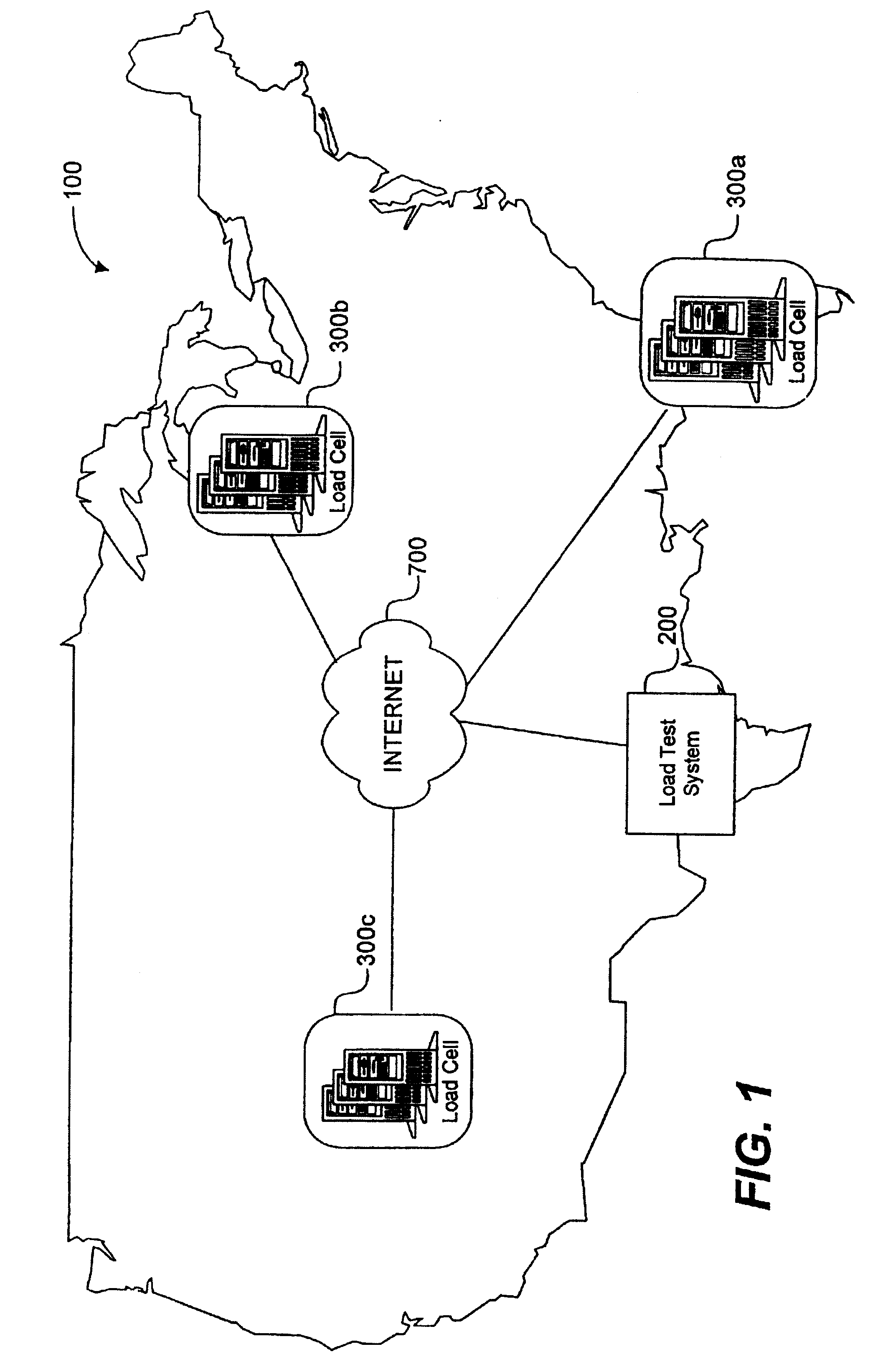

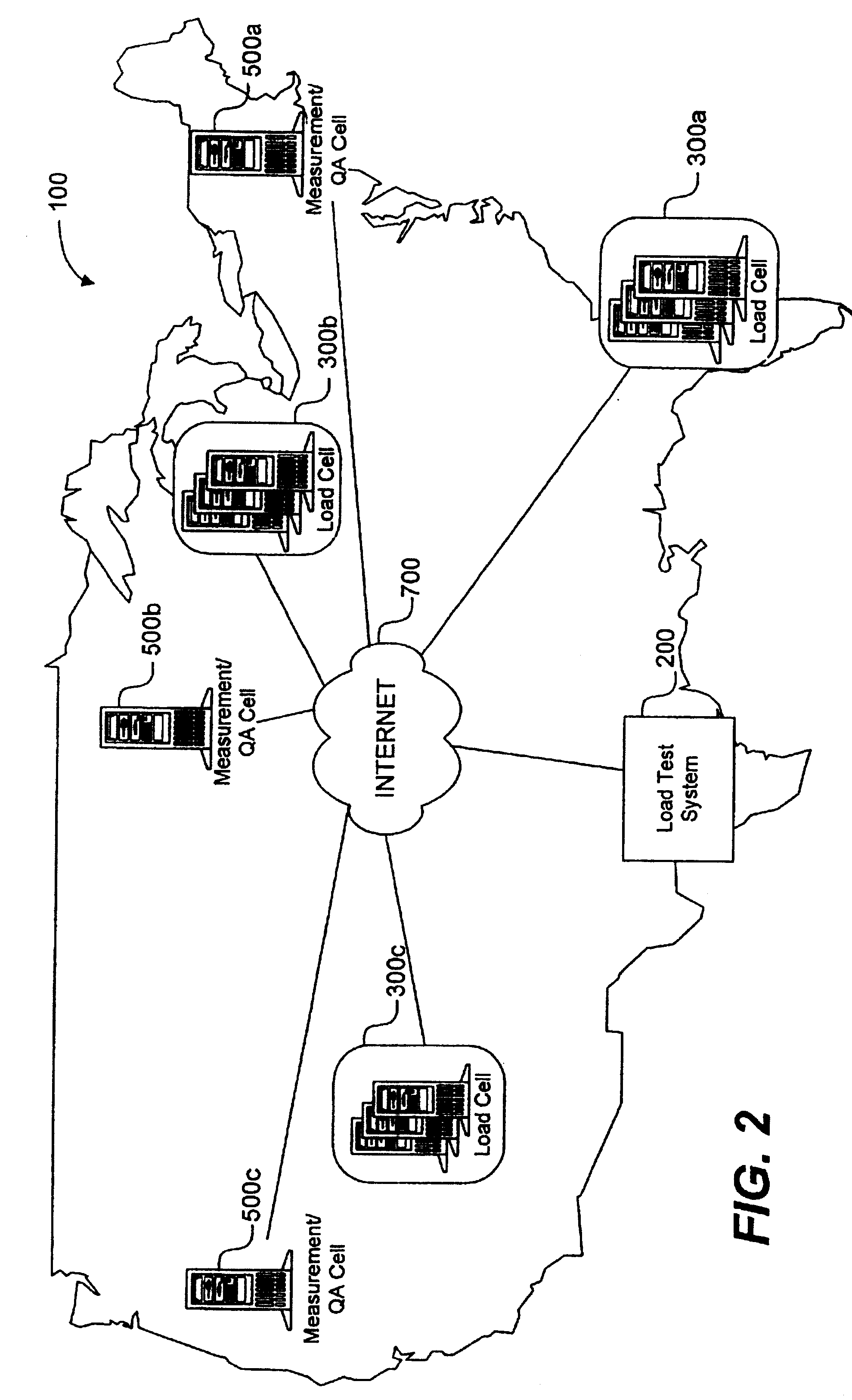

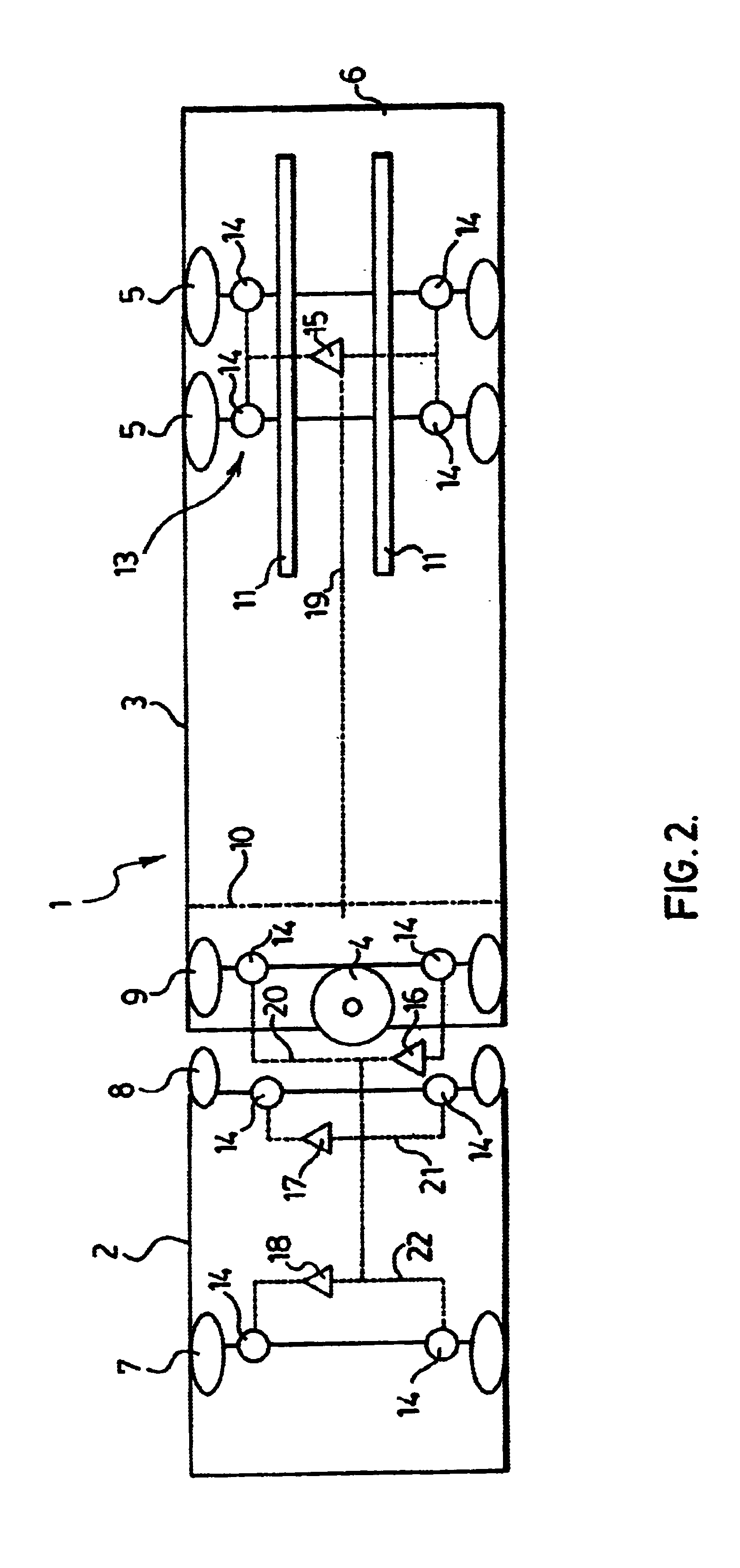

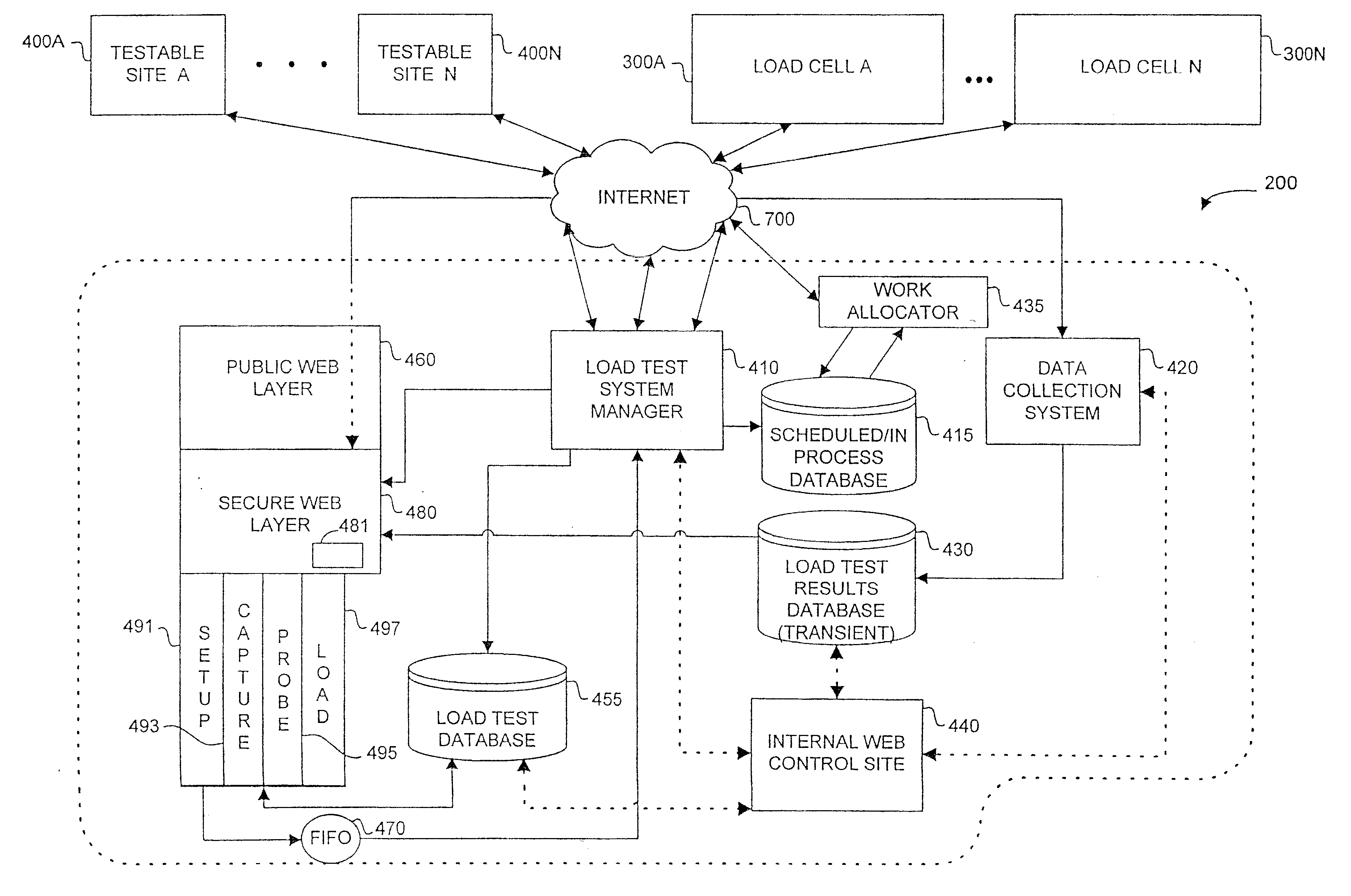

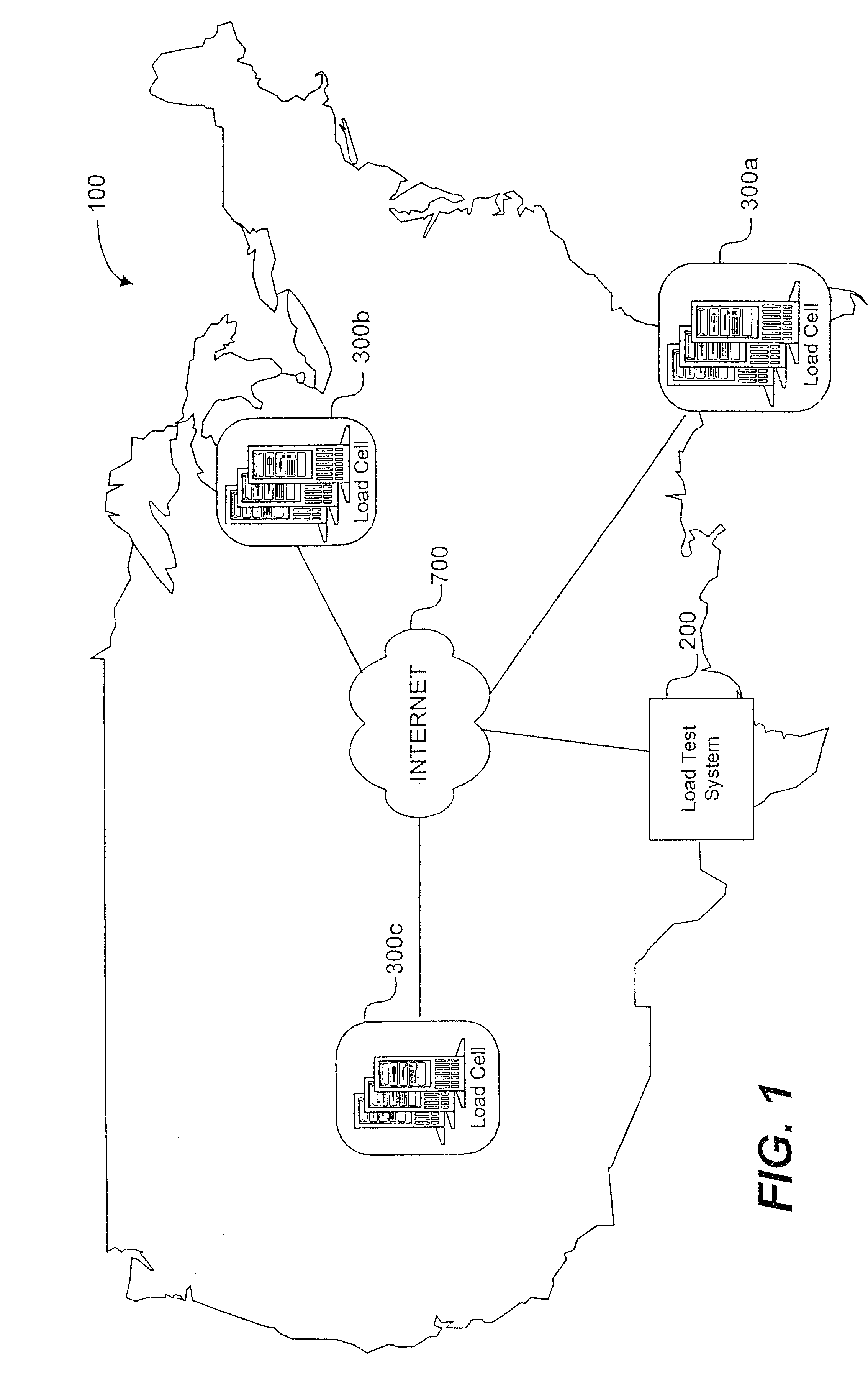

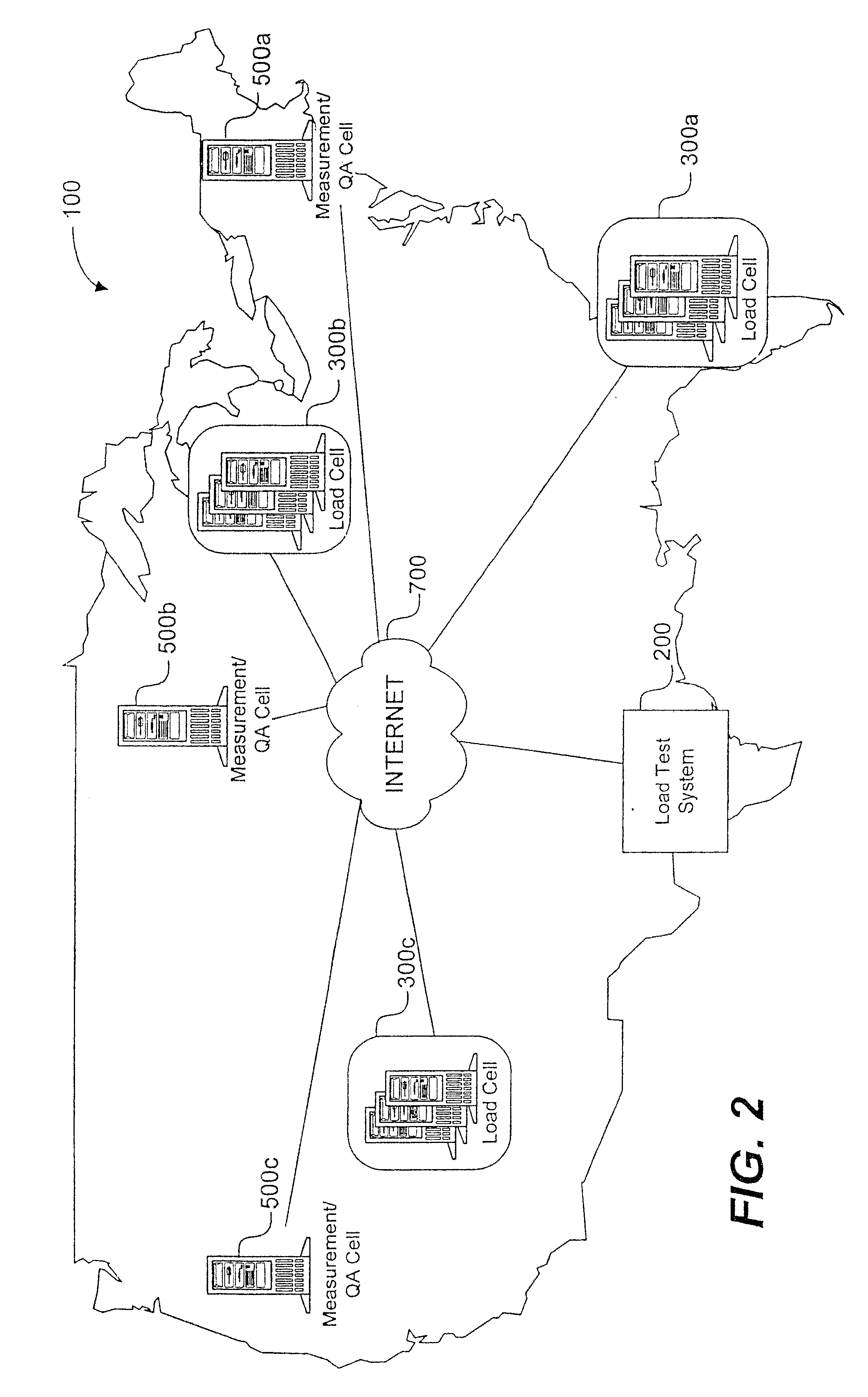

System load testing coordination over a network

A method and system using one or more load cells coordinates load testing of one or more sites under test over a network such as the Internet in accordance with one or more load test requests. In one embodiment, such method and system facilitates an economic, efficient, and accurate evaluation of the capacity of the SUTs to support concurrent users of the SUTs. A load test request is received from a User and provides information concerning a load test to be performed on a site under test (SUT). A load test is generated, and the load test is allocated to one or more load cells. The load cells perform the load test by sending load test data to the SUT and receiving responses from the SUT. Portions of a load test may be allocated to different load cells, which may be geographically remote from the SUT and / or geographically diverse. Multiple concurrent pending load tests may be processed for the same SUT. A load cell may concurrently perform all or a portion of multiple different load tests for multiple different SUT's simultaneously. A reporting function generates a report based on the responses received from the SUT. The reporting function may in addition or alternatively allow the User to view real-time results during load test execution.

Owner:EUREKA SOFTWARE SOLUTIONS

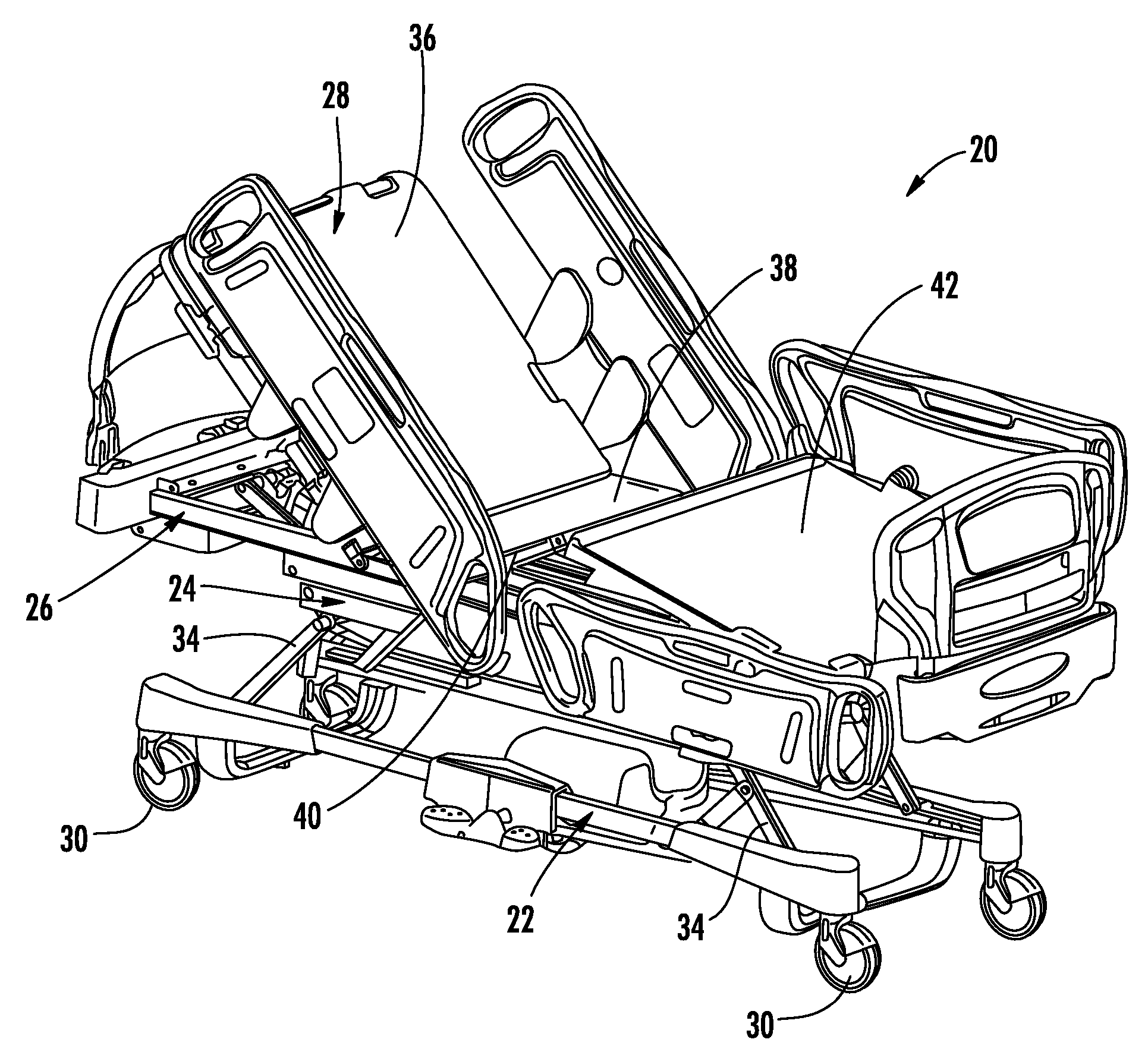

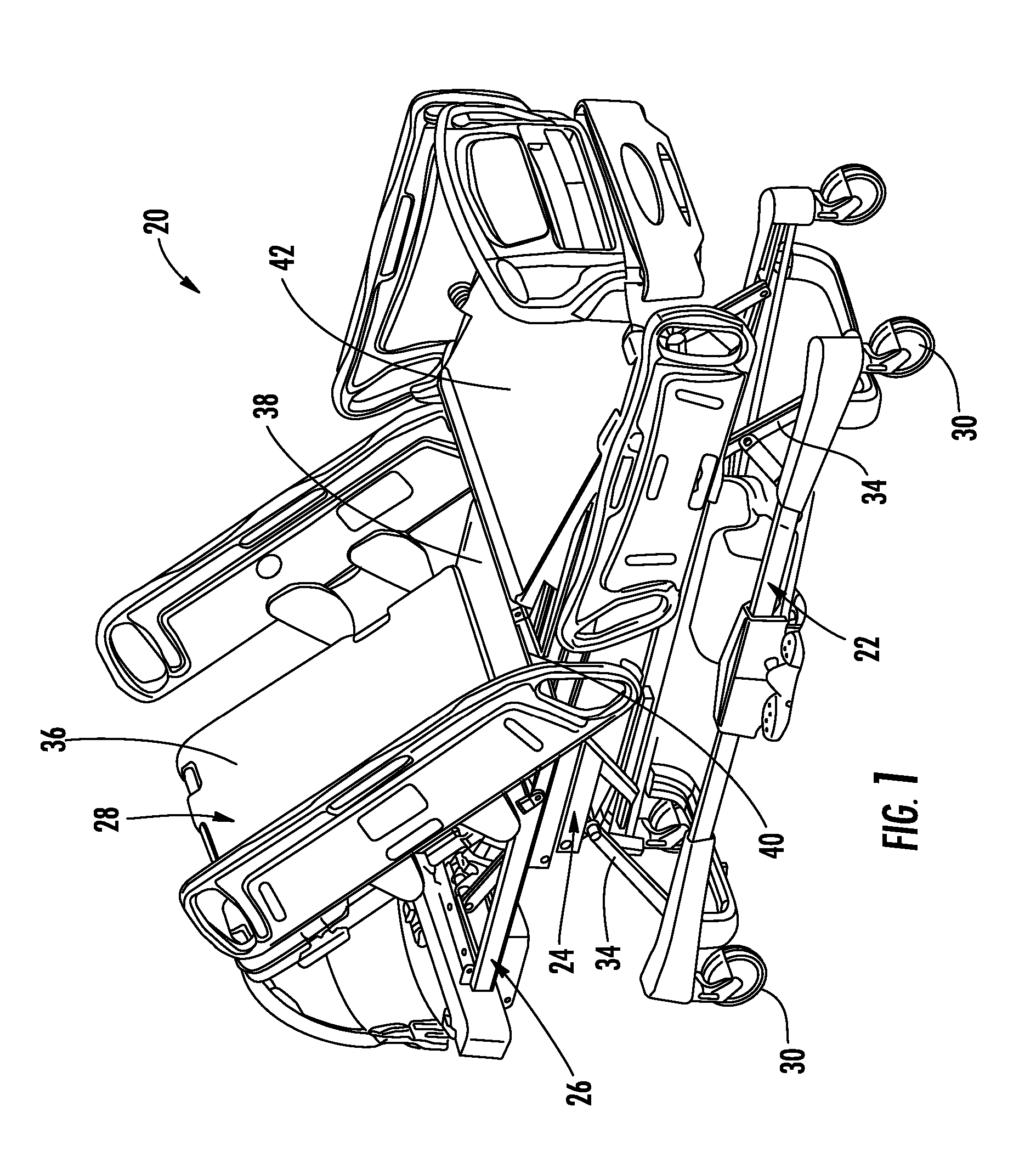

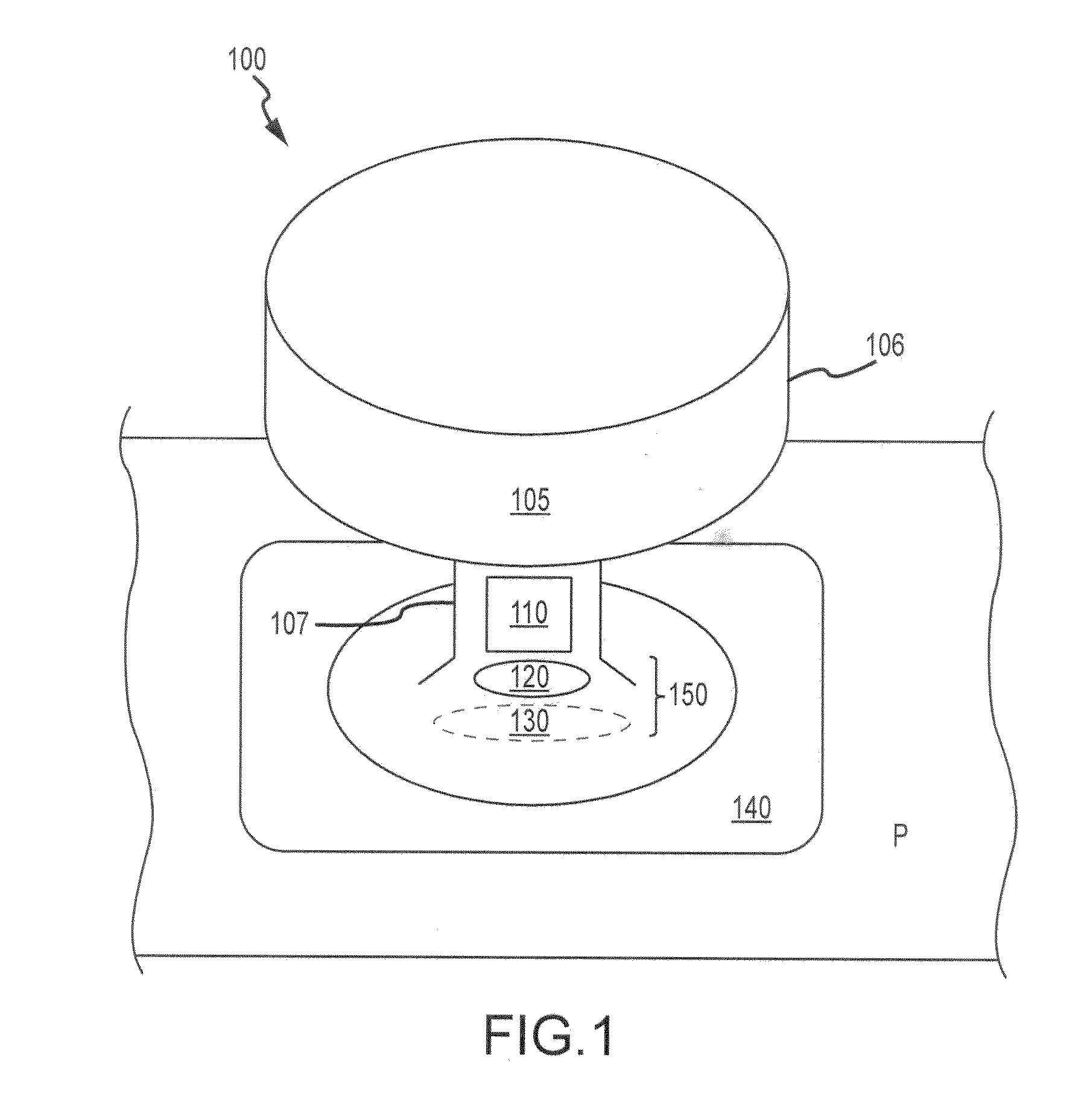

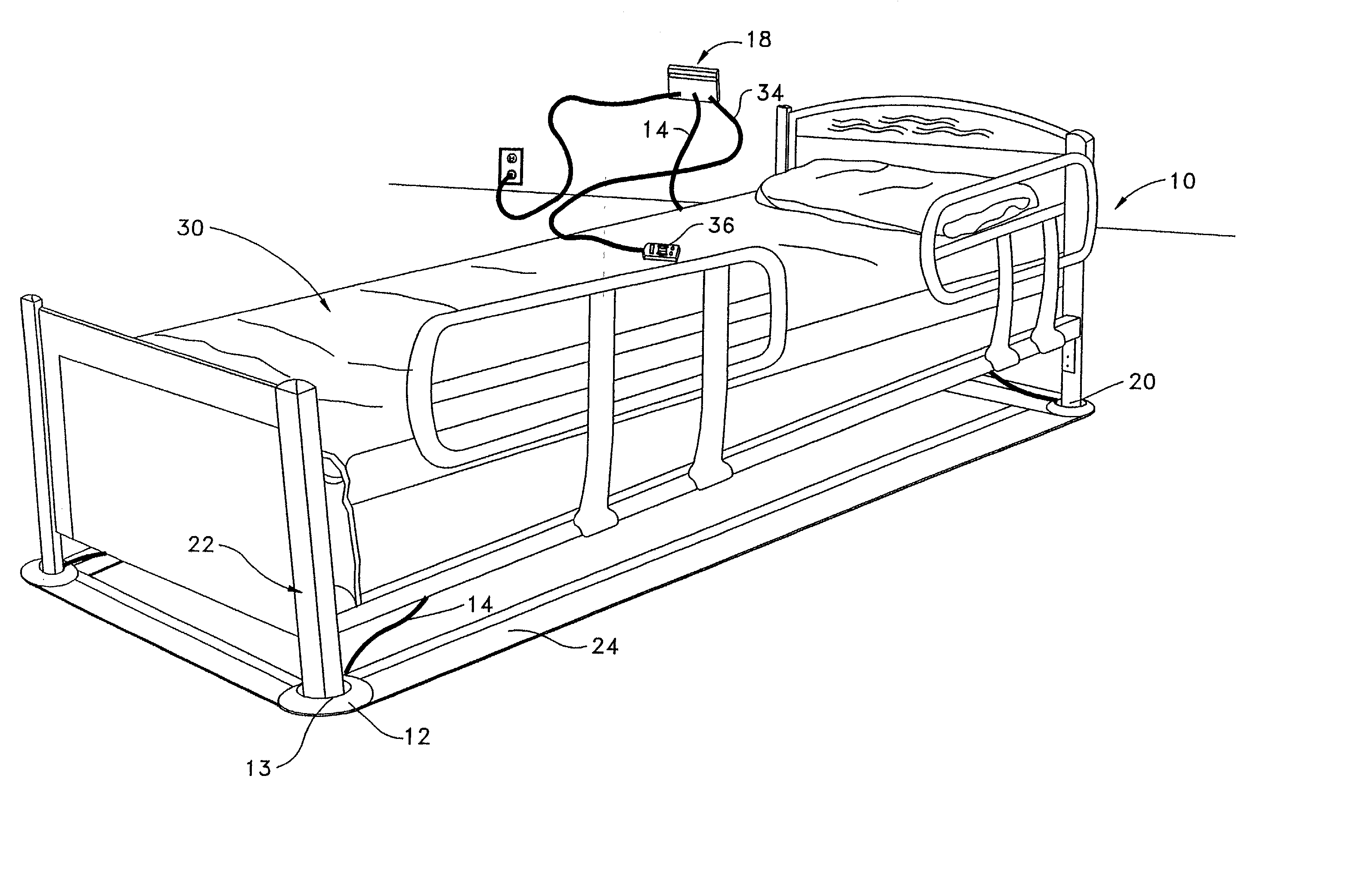

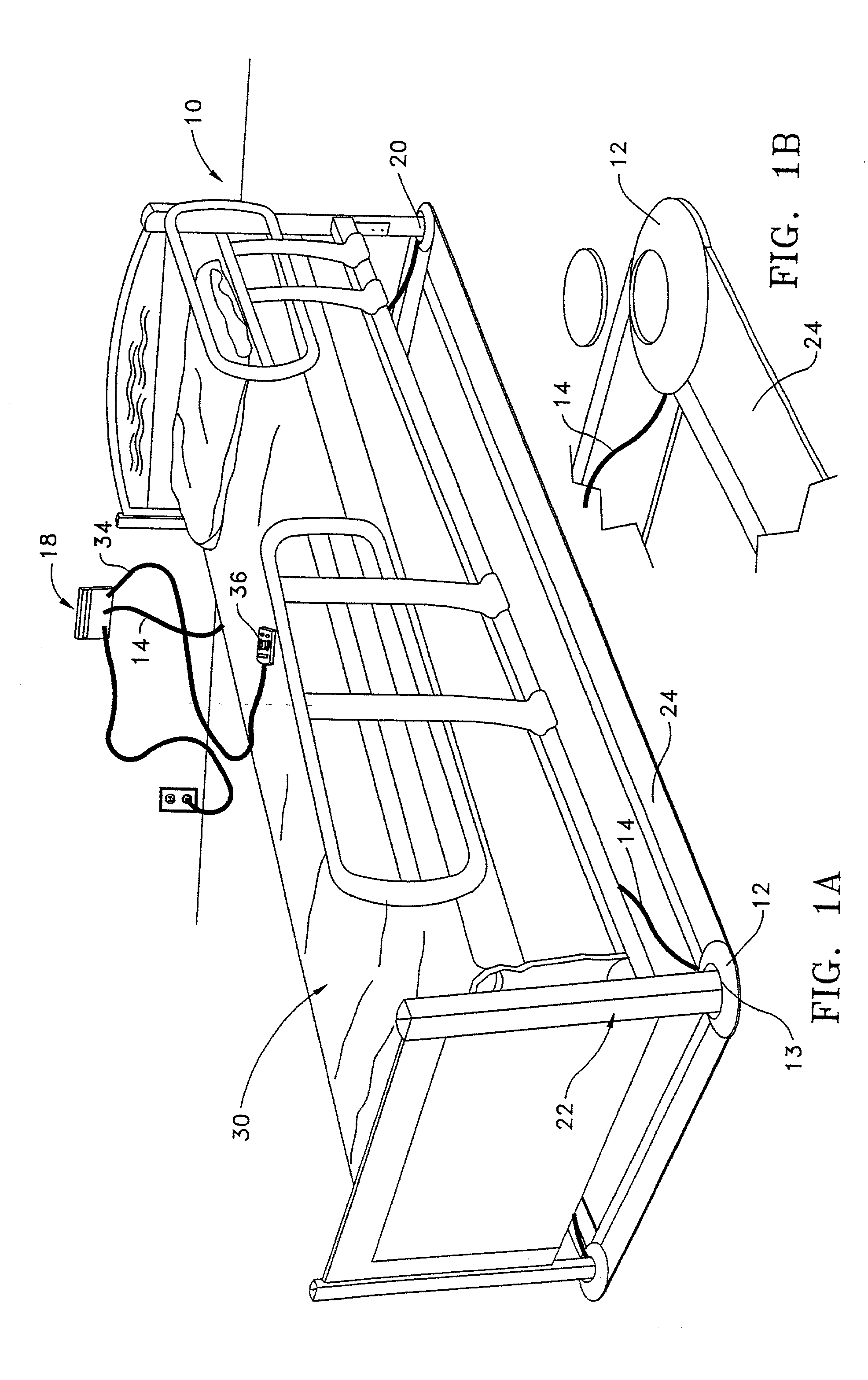

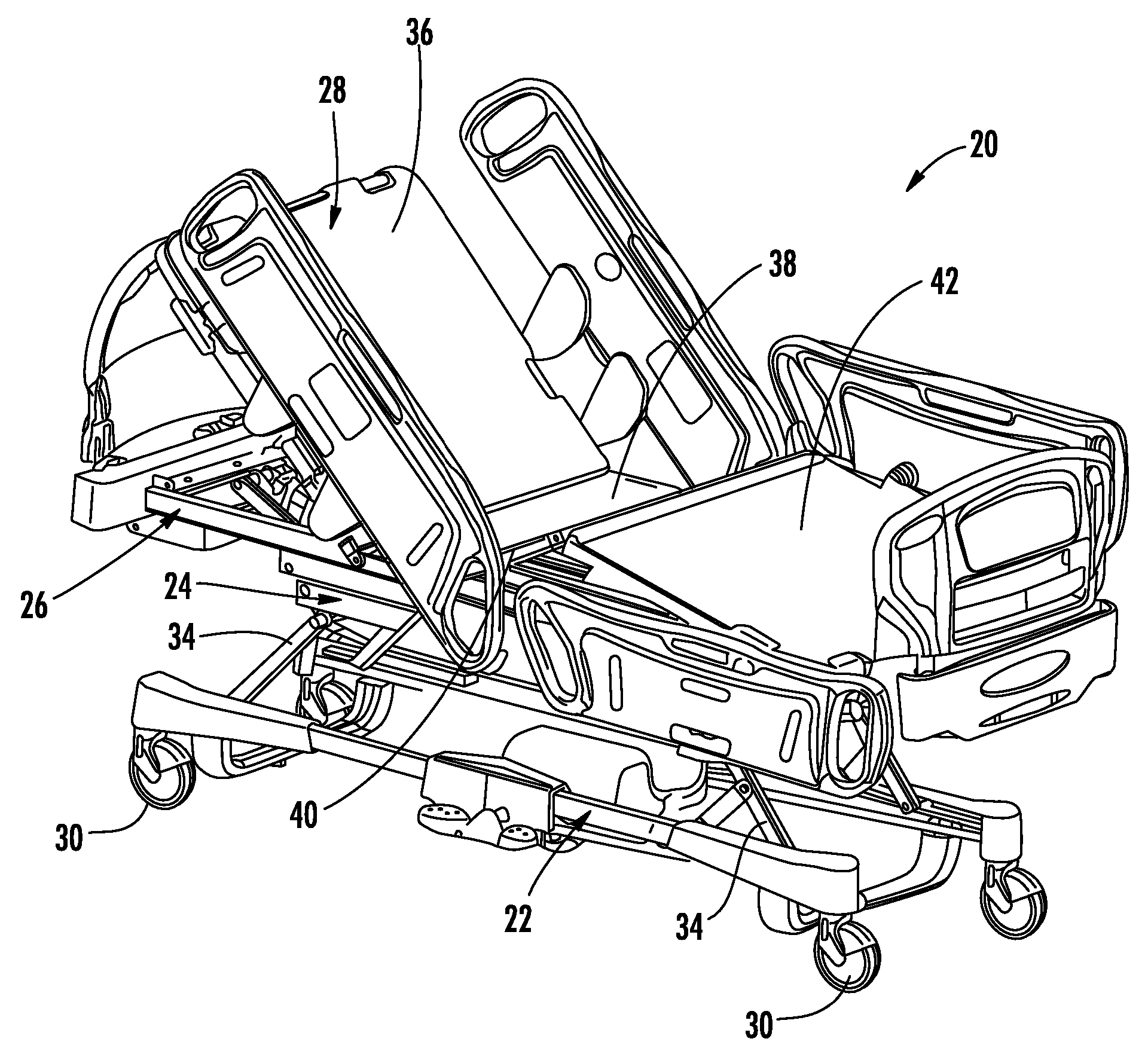

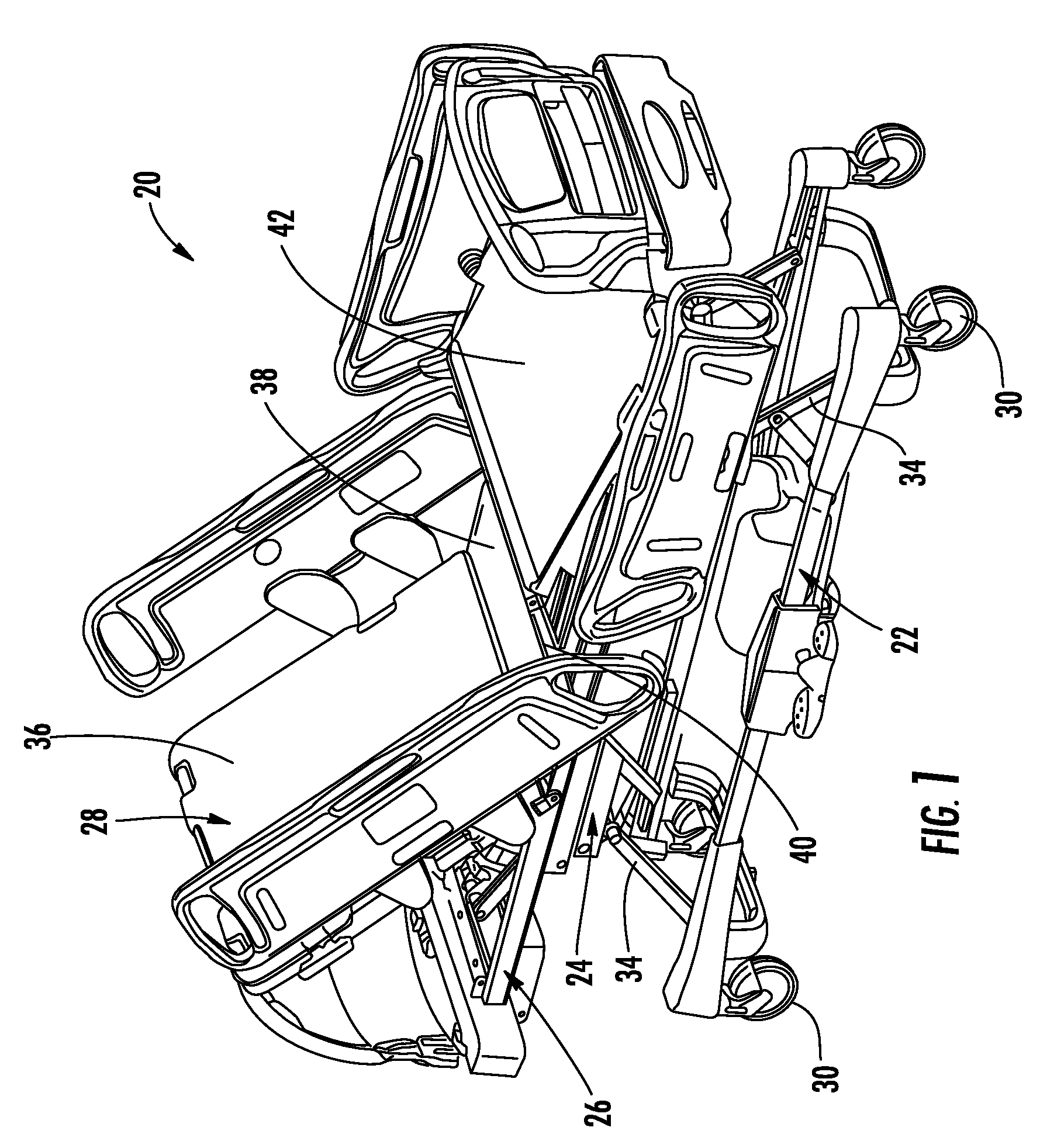

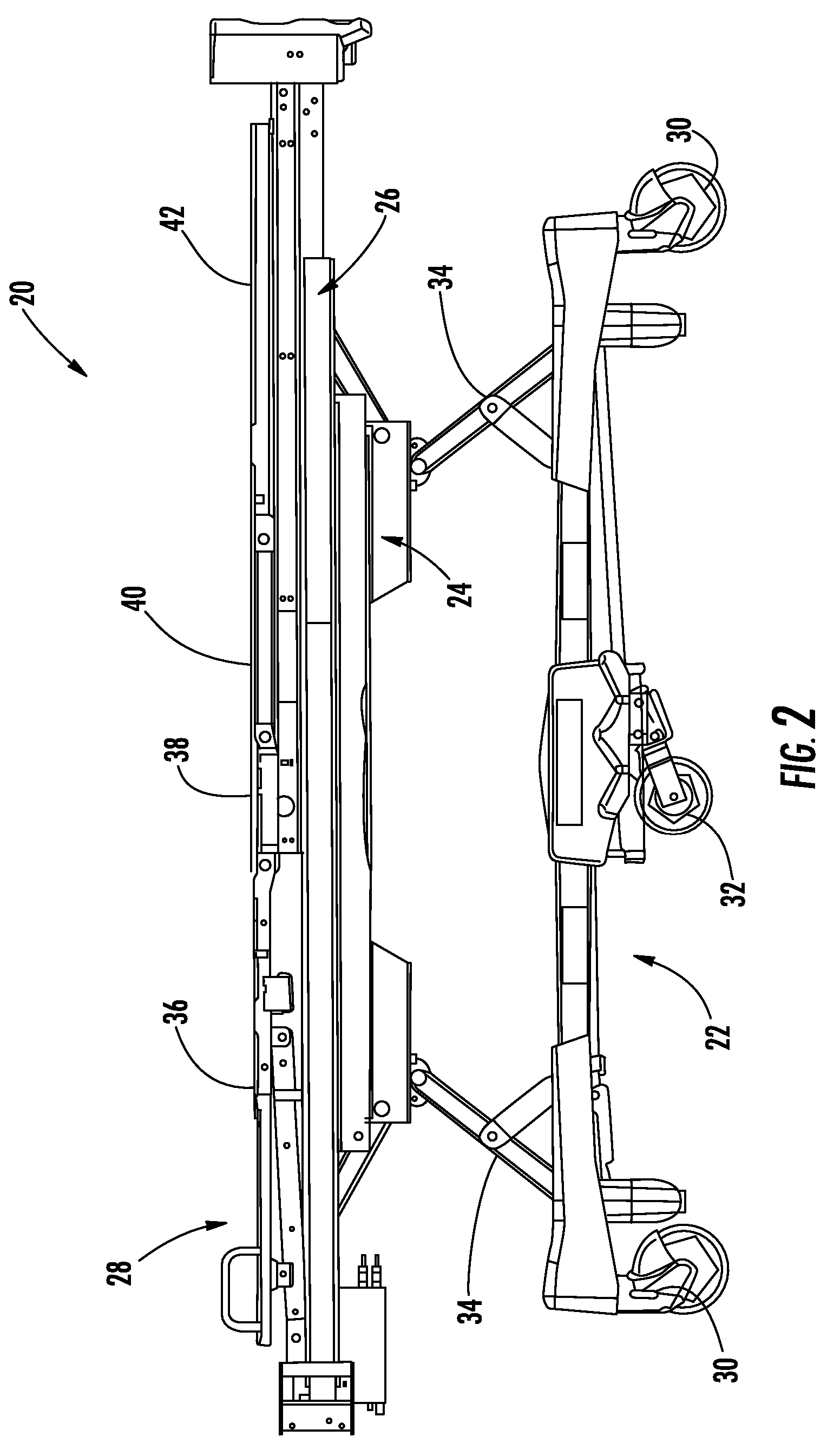

System for detecting and monitoring vital signs

ActiveUS20080005838A1Simple systemCatheterRespiratory organ evaluationFast Fourier transformPhysical therapy

A system and method for determining and monitoring various characteristics of a patient positioned on a patient support apparatus, such as a bed, stretcher, or cot, is disclosed. The system and method involve monitoring the forces exerted by the patient on one or more force sensors, which may be load cells on the support apparatus. These force sensors will detect vibrations that correspond to various conditions of the patient, including the patient's heart rate, breathing rate, and / or the seizure status of a patient. These vibrations may be analyzed, such as by Fast Fourier Transforms, in order to determine the various conditions of the patient.

Owner:STRYKER CORP

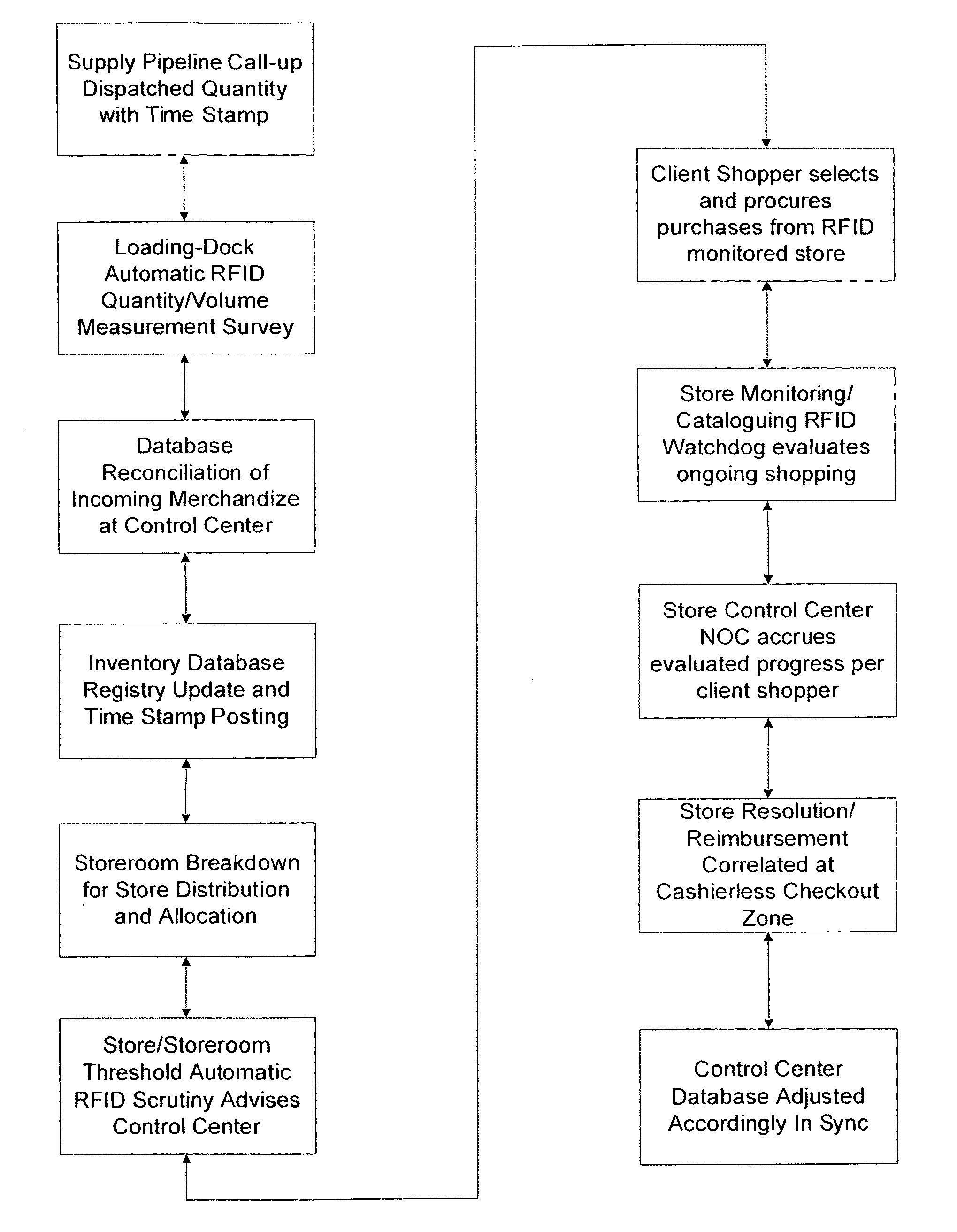

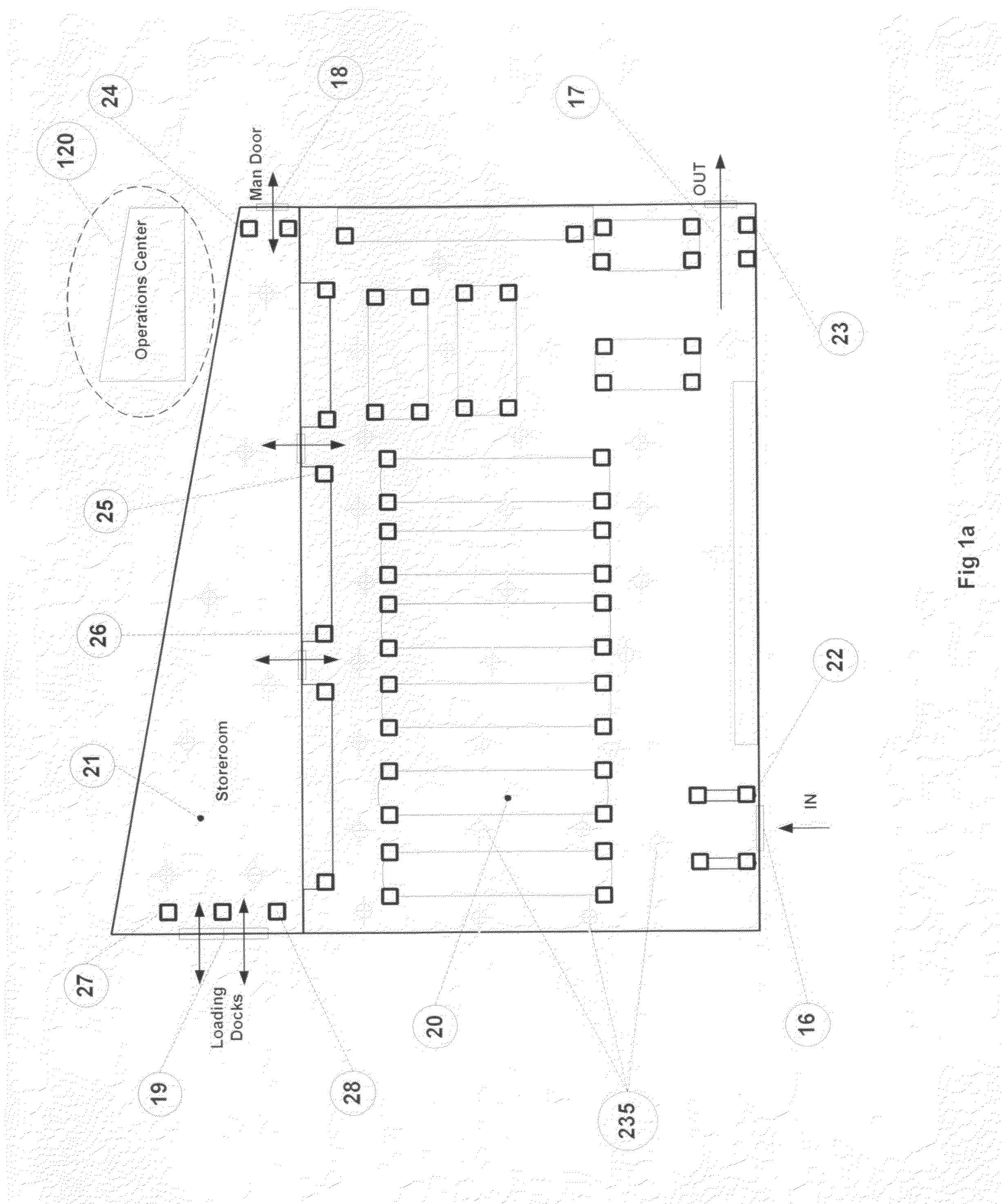

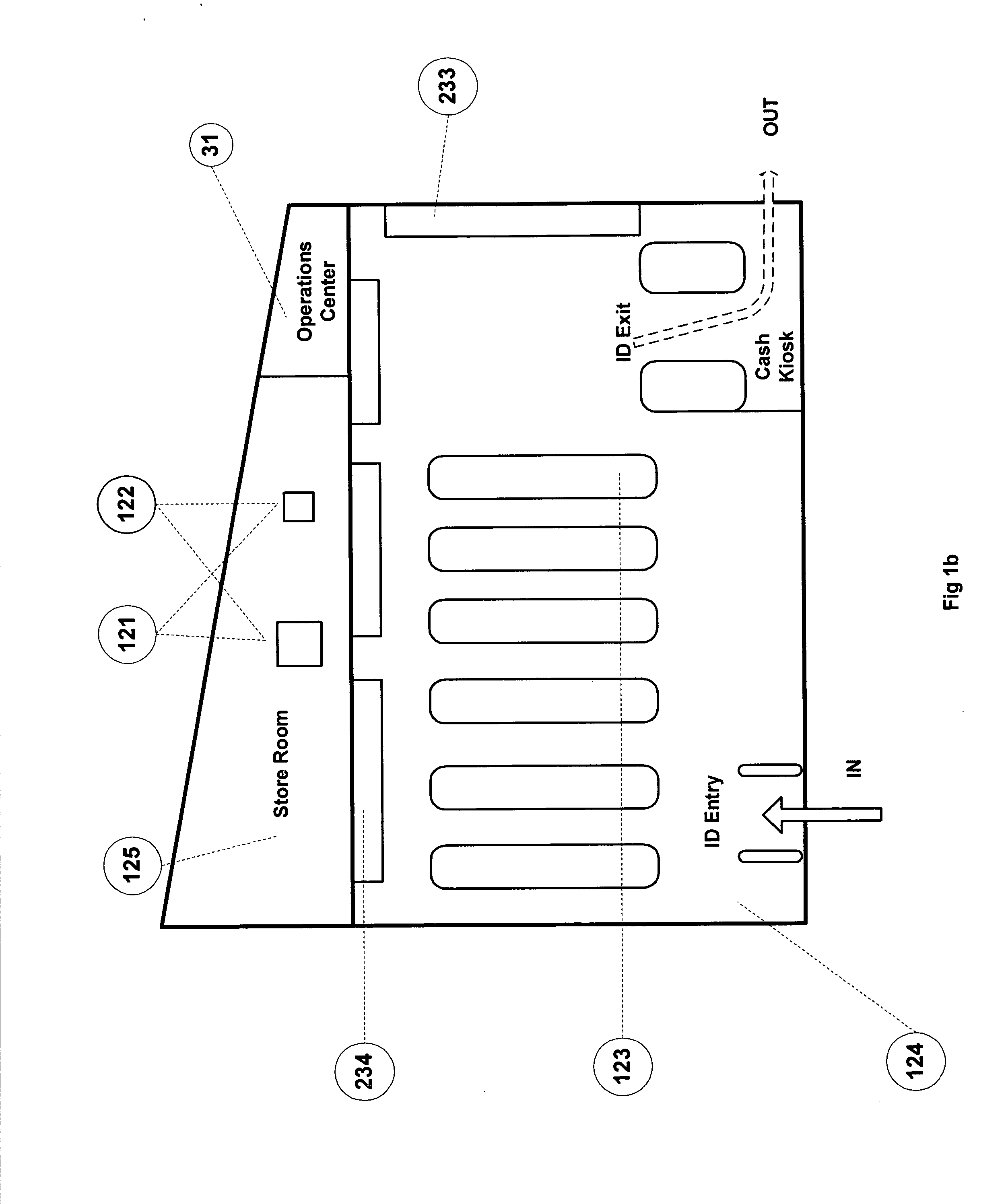

Cashierless, Hygienic, Automated, Computerized, Programmed Shopping Store, Storeroom And Supply Pipeline With Administration Cataloguing To Eliminate Retail Fraud; With Innovative Components For Use Therein

InactiveUS20100318440A1Cost expenditure increaseInstallation cost-effectivenessElectric signal transmission systemsDigital data processing detailsSensor arrayTelecommunications link

A Cashierless unattended point of sale, shopping store procurement payment means, with storeroom reordering system using a layered wireless linked monitoring and cataloguing system; includes an interfacing electronic configured self-owned reusable three-wheel fold-up shopping trolley with suspended color-coded bins; into which merchandise maybe placed and registered by a passive reading sensor array. A ‘load-cell’ integral to the trolley precisely quantifies and approves trolley bin contents for exit payment through a TCP / IP means. An evaluation wireless communication link repeatedly reviews “polled' trolley content data, this integrated communication link, is networked to the store Operations Center, wherein purchased inventory data is recorded and verified; upon shopping completion the contents are again finally substantiated for final electronic settlement. This self-contained cashierless enclosed shopping method provides retail loss prevention, real-time progressive inventory management and reorder, eliminates space to sales; being convenient for shoppers and store owners; making all egress points electronically restricted.

Owner:COVELEY MICHAEL EJ

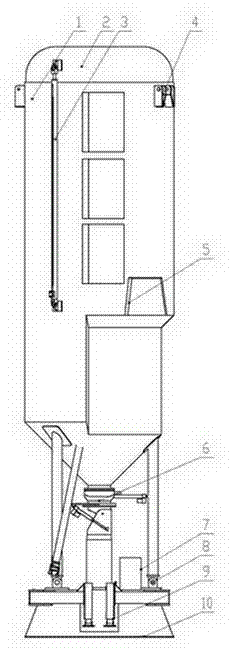

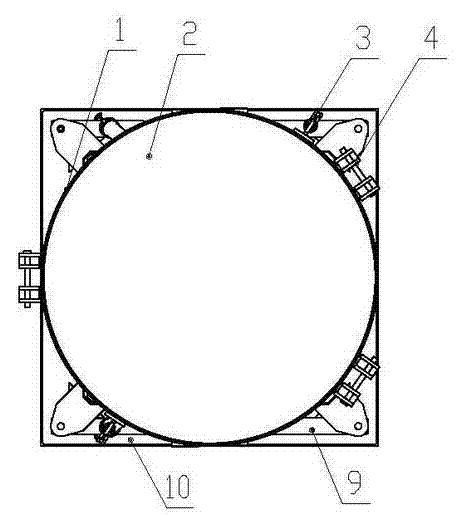

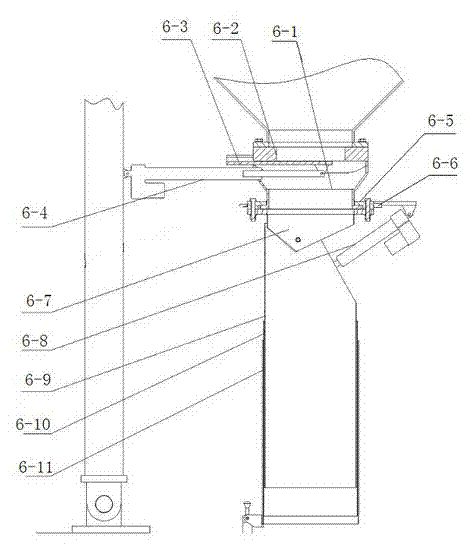

Front-tip vertical-type telescopic sand storage tank for oil field

InactiveCN102963629AStable and reliableMeet the transportation conditionsLarge containersLoad cellRoad condition

The invention discloses a front-tip vertical-type telescopic sand storage tank for an oil field, and the front-tip vertical-type telescopic sand storage tank is characterized by consisting of a cylindrical tank body (1), a telescopic inner tank body (2), a hydraulic oil cylinder (3), a lifting lug (4), a guide boot sleeve (5), a discharging device (6), an electrical device (7), a weighing device (8), an auxiliary supporting leg (9) and a fixing base (10); the telescopic inner tank body (2) slides relativelrelative y to the cylindrical tank body (1) to realize the telescopic function; and when the sand storage tank is transported, the length is greatly shortened compared with the traditional storage tank with the same volume, the transportation condition of a severe road condition can be satisfied, the discharging device (6) is convenient and flexible, a universal sand transporting function can be realized, the weighing device (8) utilizes a pin shaft weighing sensor, so that the sand transporting quantity and the sand storage quantity inside the tank can be directly read, and the tank body is stable and reliable.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

Cell and sub-cell methods for imaging and therapy

InactiveUS20070243137A1Reduce in quantityLow costPowder deliverySnake antigen ingredientsImaging agentLoad cell

Methods are disclosed to rapidly form and load cells and cell-derived vesicles. Loaded materials can include imaging agents, drugs and magnetic particles. Methods are also presented to additionally target the loaded cells or vesicles, leading to new forms of imaging, treatment, diagnosis, and detection by a large number of techniques. The preparation and use of reduced sized cells that retain subset characteristics of the parent cell are also described.

Owner:NANOPROBES

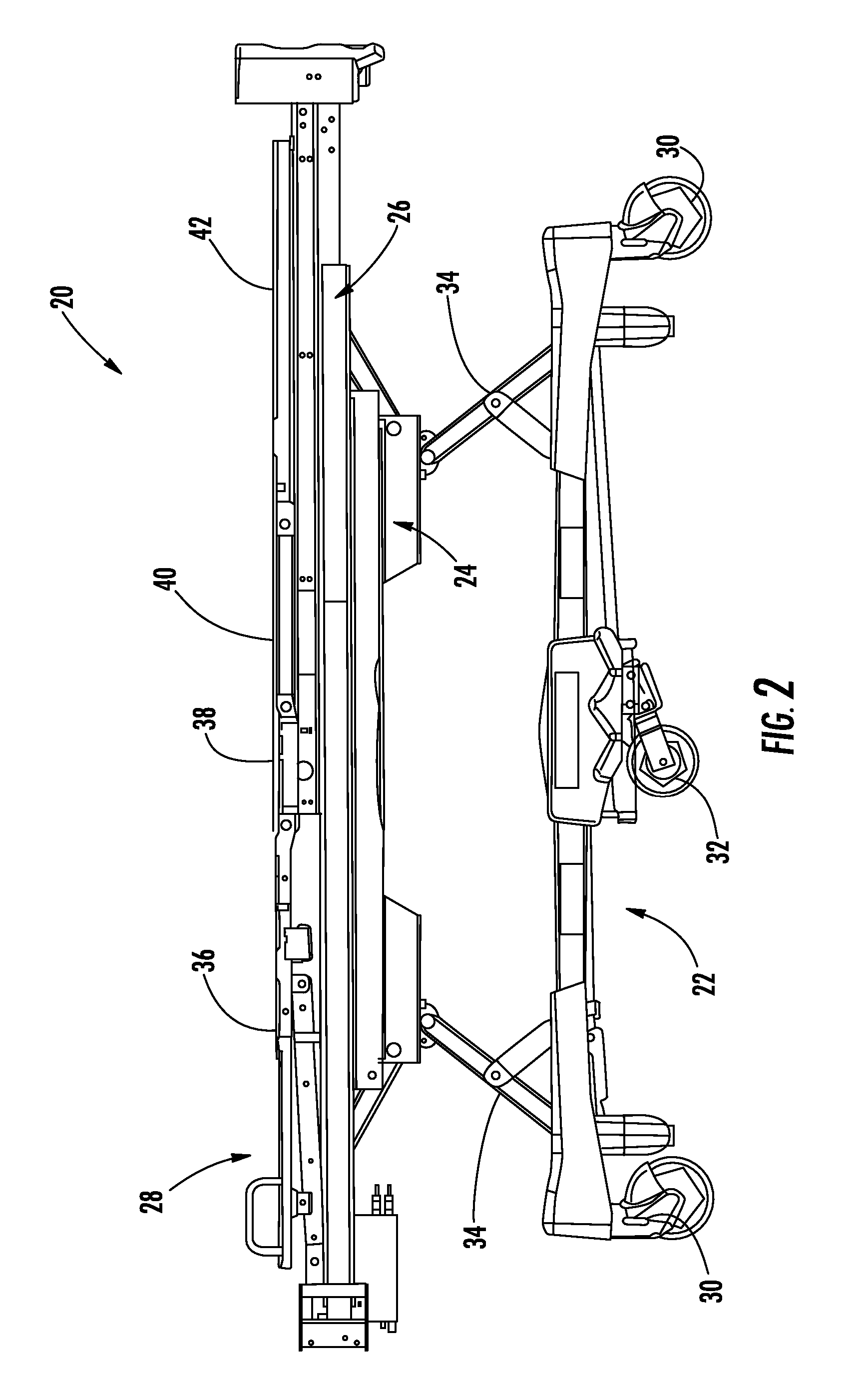

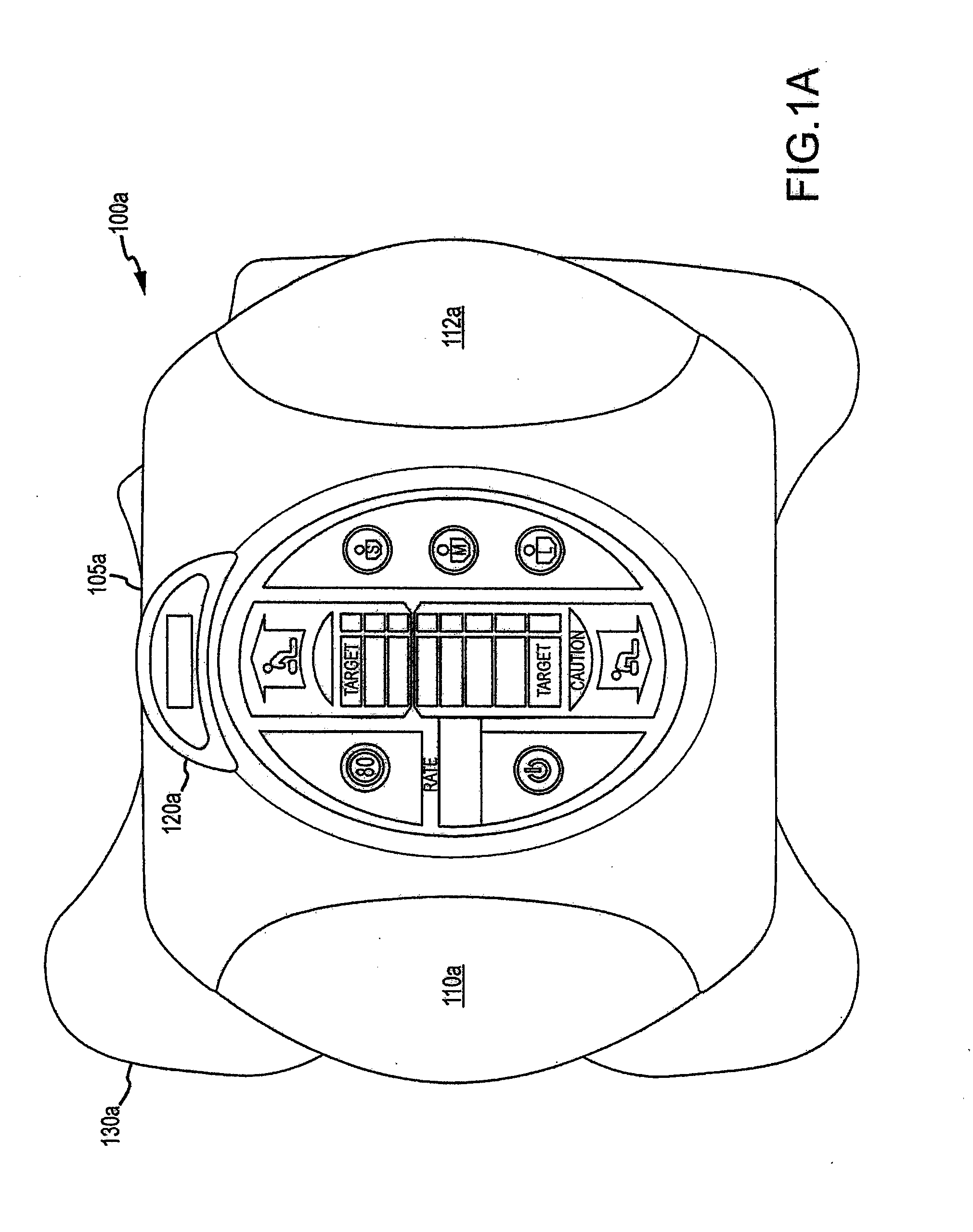

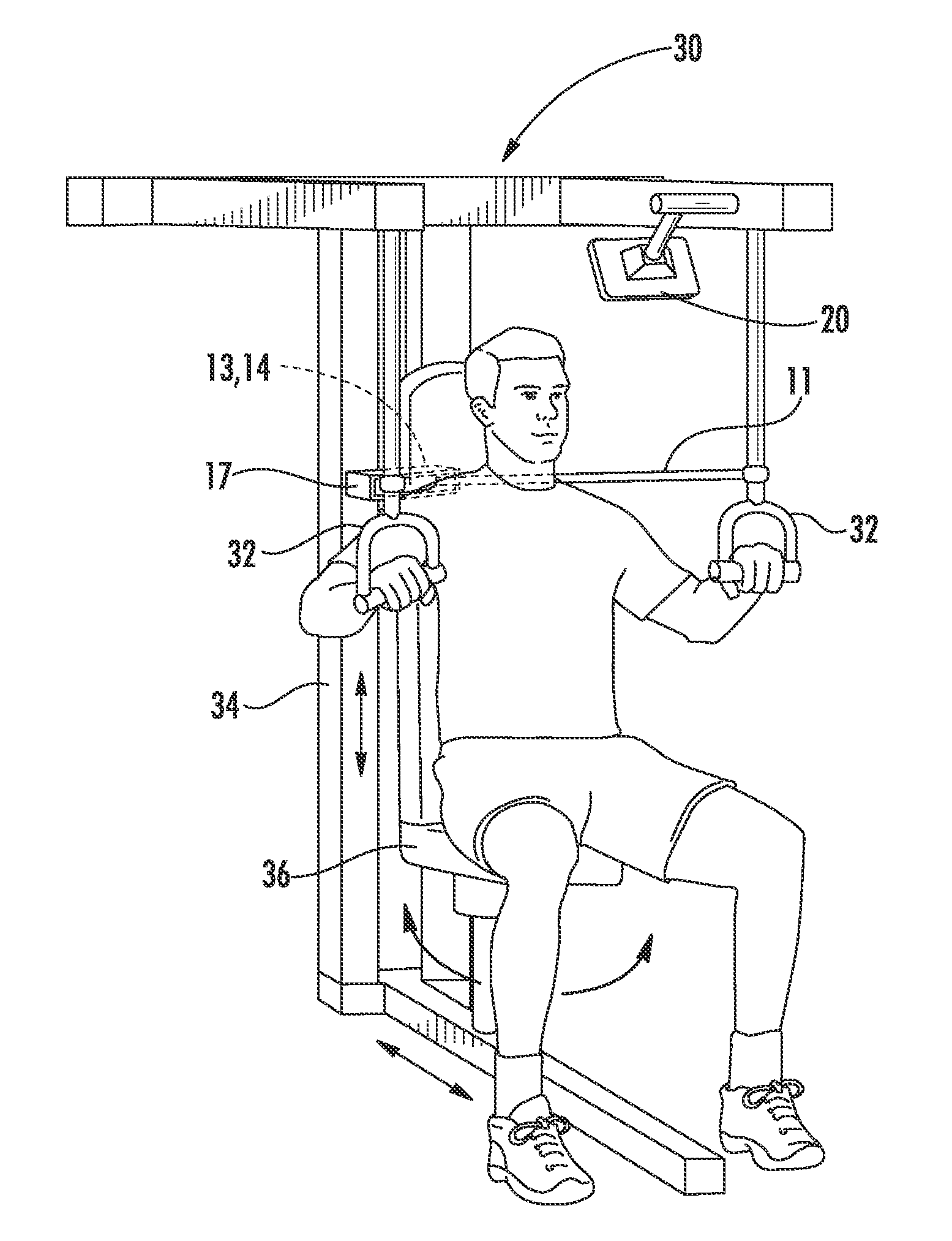

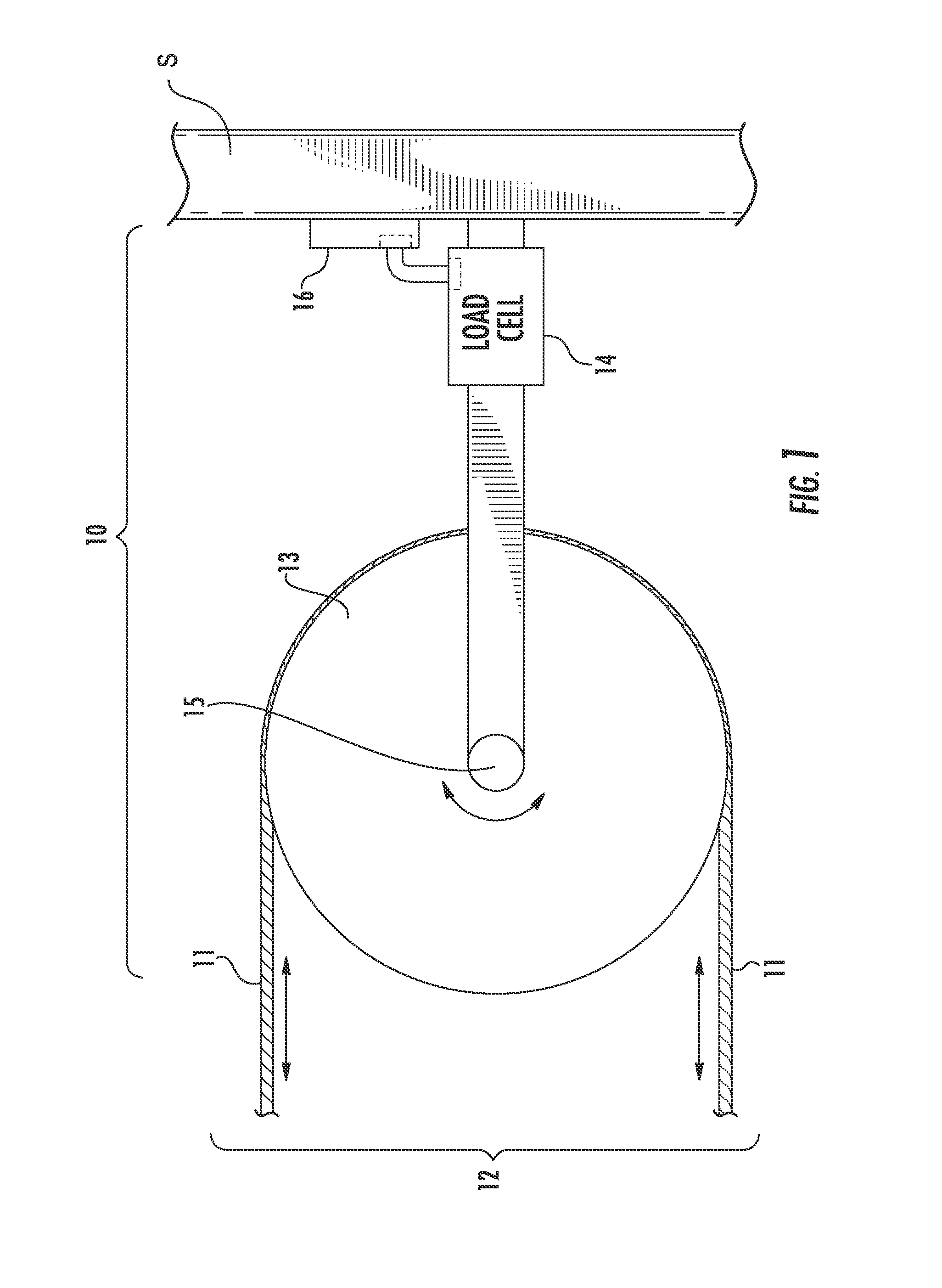

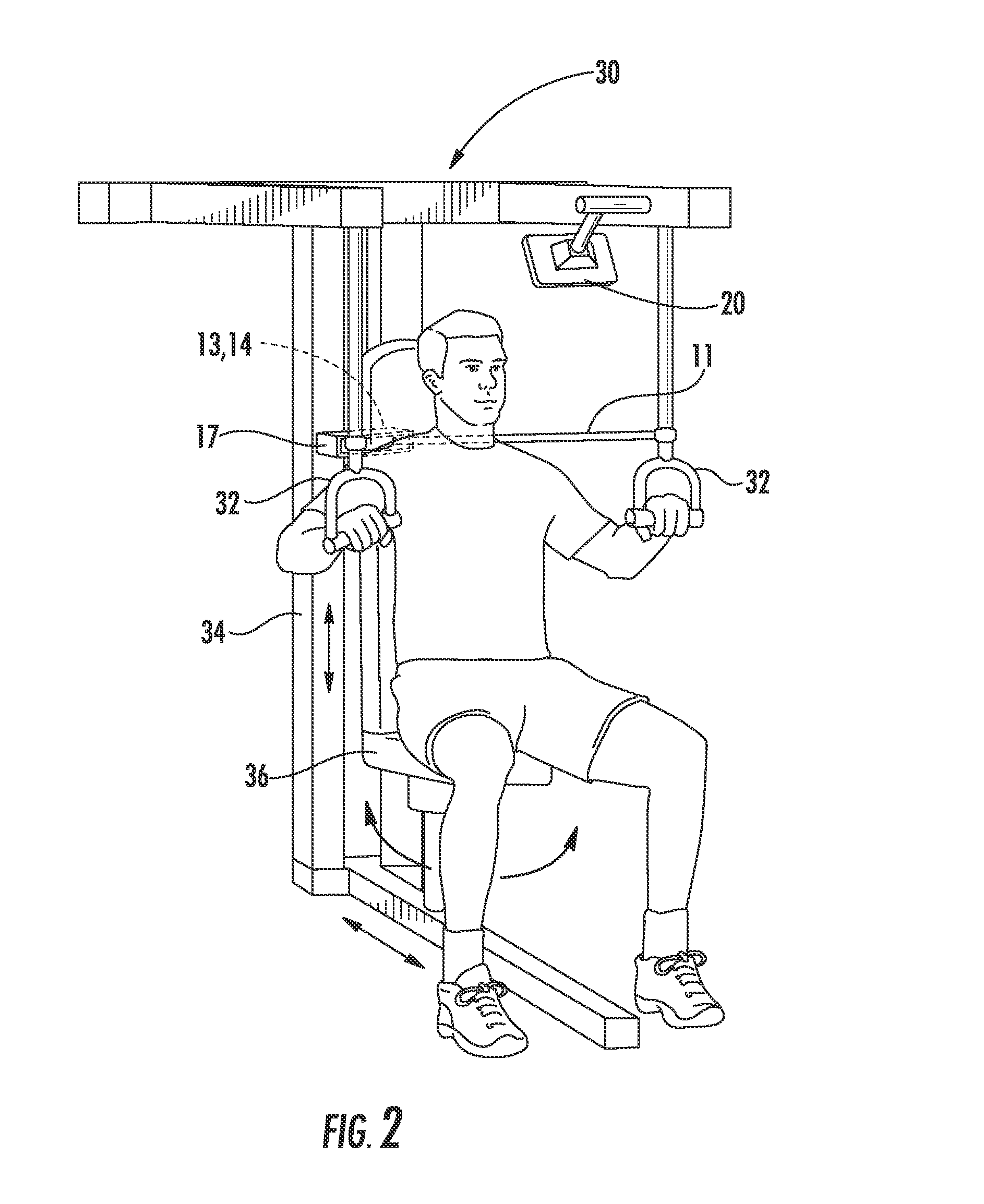

3-d, interactive exercise analysis, gaming, and physical therapy system

InactiveUS20100197462A1Build muscular strengthBuild powerPhysical therapies and activitiesDiagnostic recording/measuringEngineeringLoad cell

A system is disclosed for monitoring, recording and analysis of exercise in an exercise machine with a device, such as a handle, that enables a user to push or pull against a resistance. A sensor or “load cell” mounted on the machine produces an electronic signal representing the instantaneous force applied by the user, and an electronic computer or the like, is coupled to receive the electronic signal, for storing values representing the force as a function of time. In another embodiment, a system comprises a resistance member for providing resistance to movement by a user, a sensing device coupled to the resistance member, a force sensor, and a CPU. The sensing device generates a first signal representing the position of the resistance member, and the force sensor generates a second signal representing the force applied to the resistance member by the user. The CPU processes the first and second signals to generate useful images, displays, and audio signals.

Owner:BVP HLDG

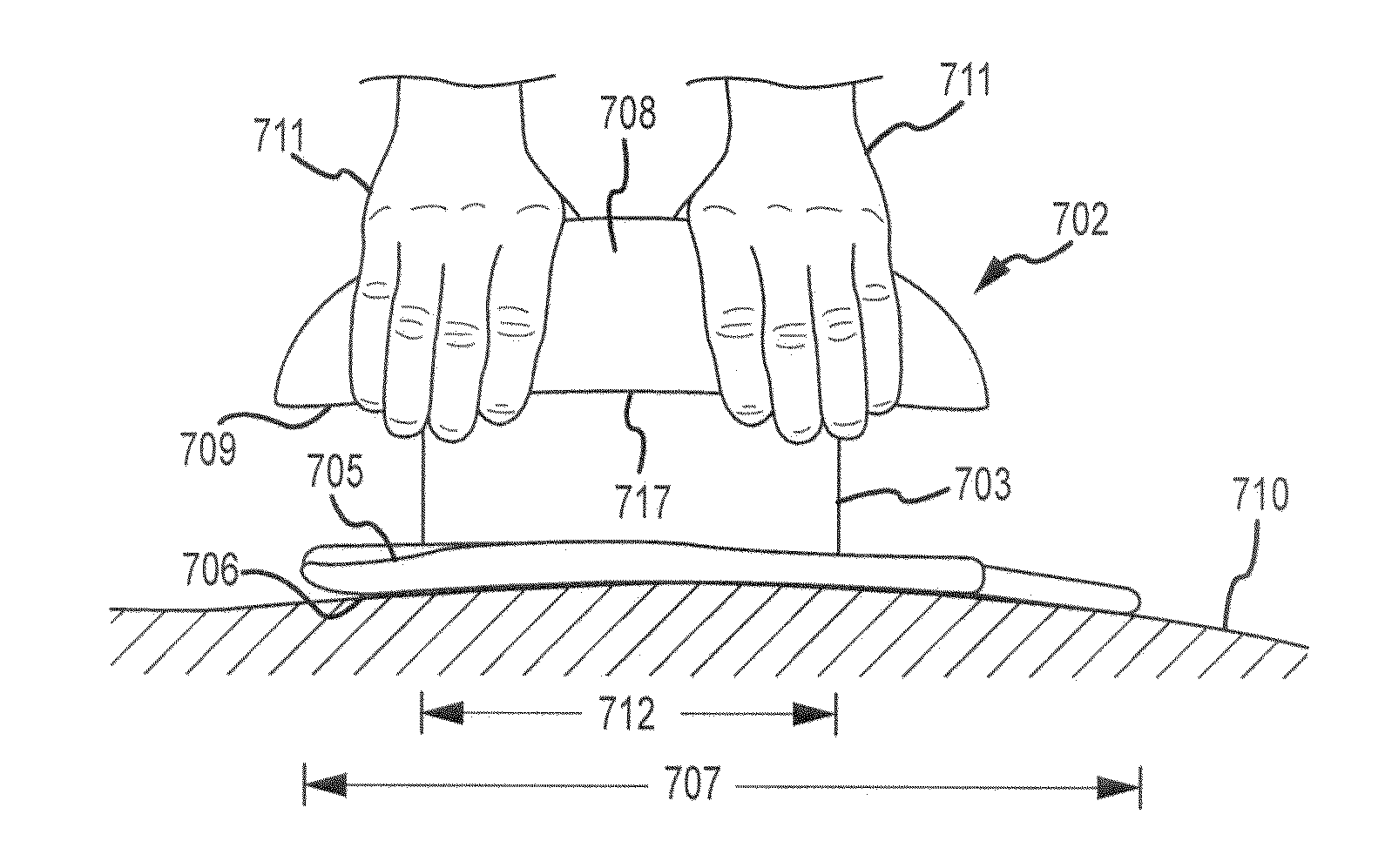

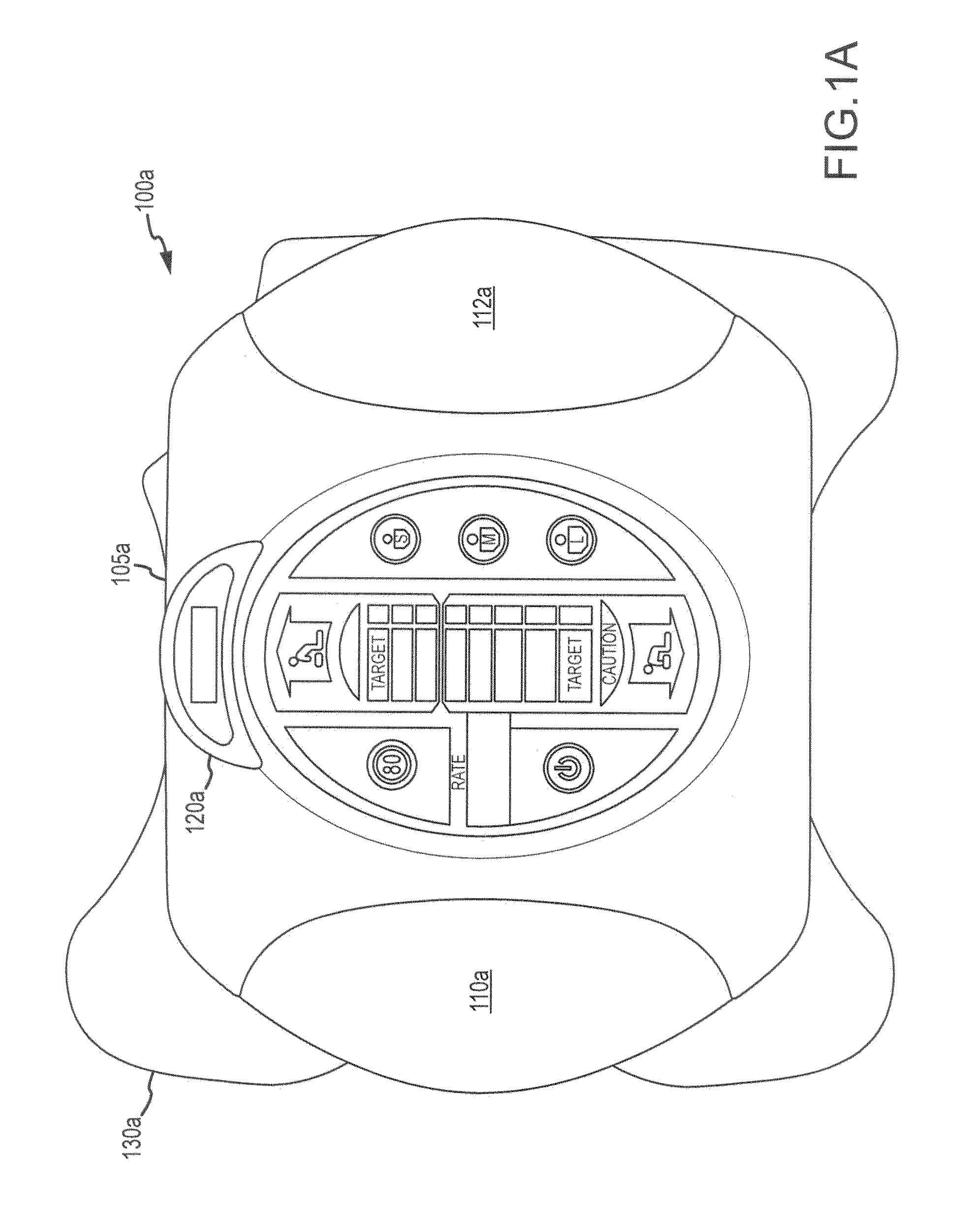

Enhanced guided active compression decompression cardiopulmonary resuscitation systems and methods

ActiveUS20120330200A1Promote blood circulationImprove ventilationElectrotherapyDiagnosticsCouplingEngineering

Owner:ZOLL MEDICAL CORPORATION

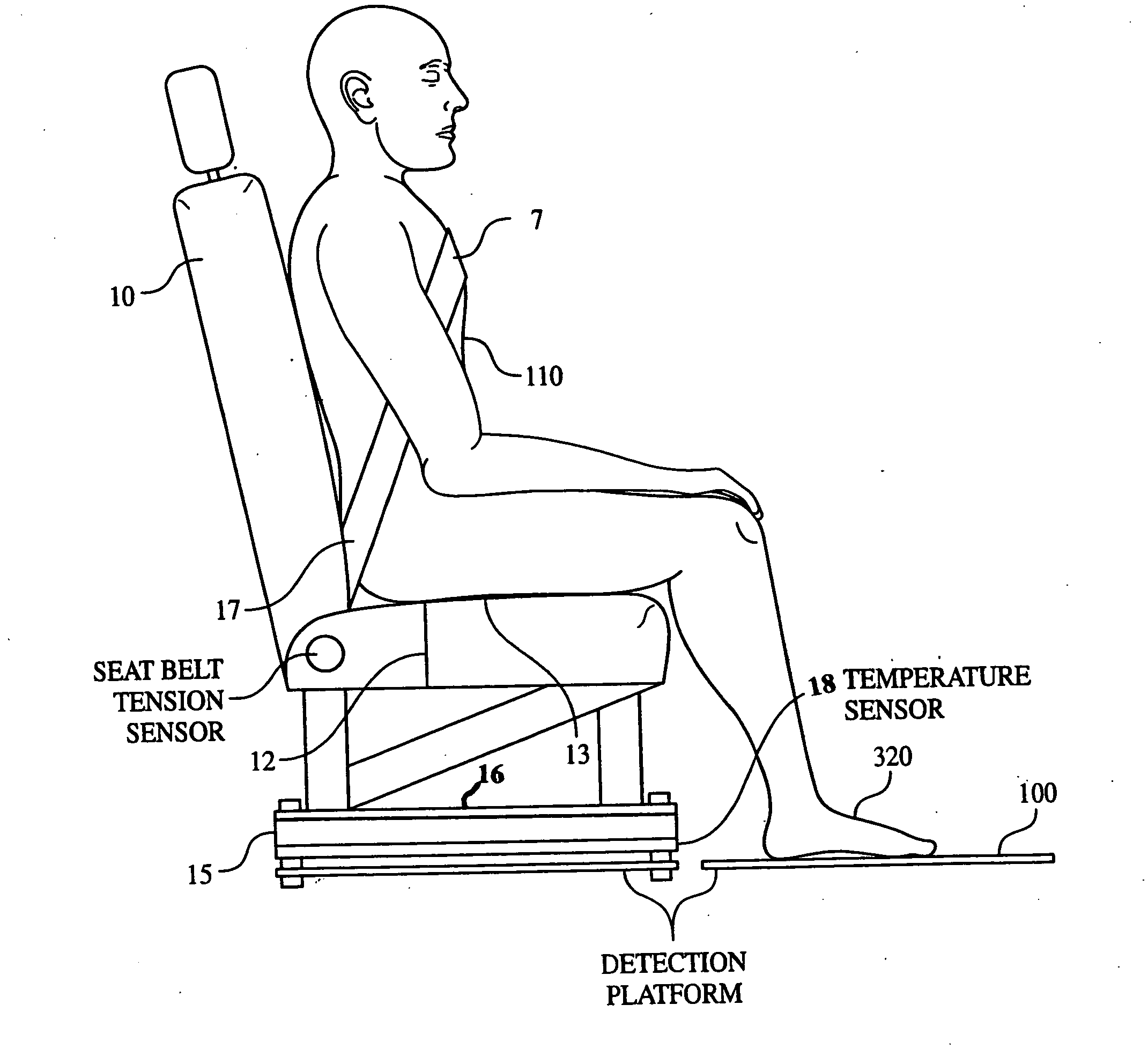

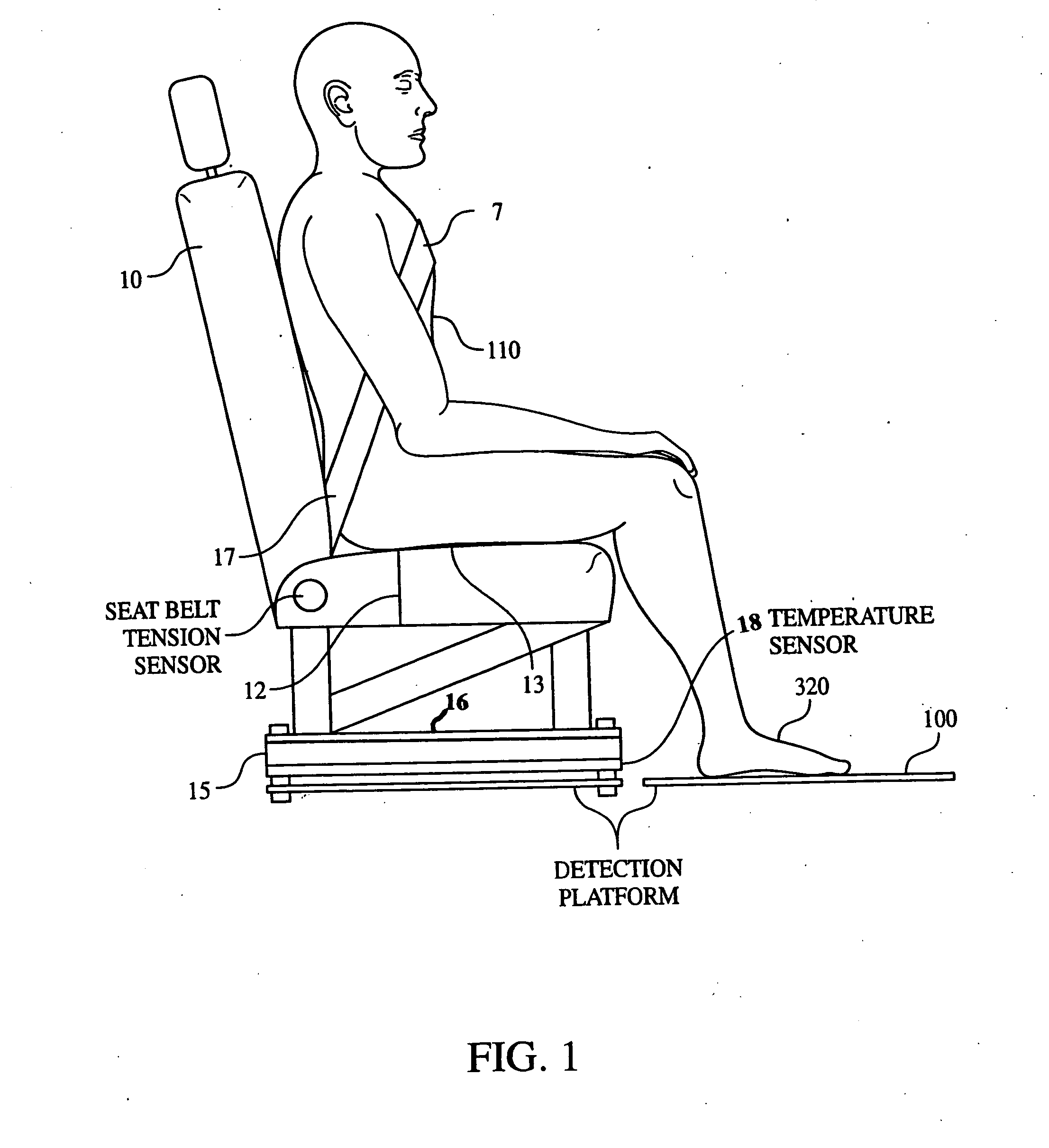

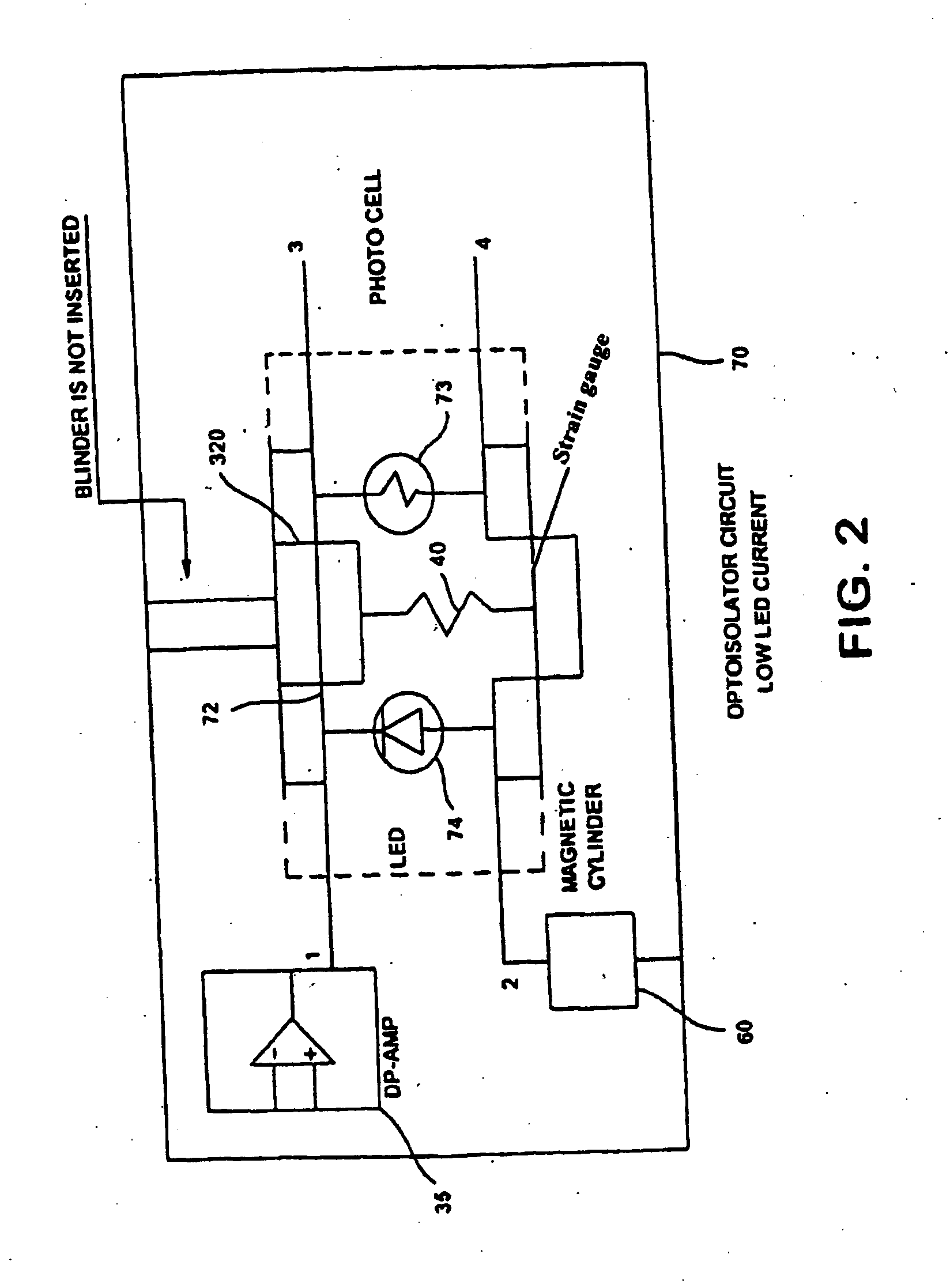

Smart seatbelt control system

InactiveUS20070096447A1Reducing potential of serious injury and deathReduce fatalityBelt retractorsElectric devicesOccupant safetyControl system

An apparatus for preventing occupant injury during accident has various features to ensure safety. A sensor 70, detecting seat belt engagement is provided. In addition, there is a means for varying the tension of a seatbelt 17, depending upon the weight of the occupant 110 and the speed of the vehicle carrying the occupant 110. When the occupant 110 seats on any of the seats 17, the load cell switch 18 will close, allowing the load cell output energy to energize the control module 25. The control module 25 will then enables the counter 50 to count the number of closed load cell switches 18. The control module 25 further enables an optoisolator switch configured with the sensor 70 to then energize a latching relay 80 operatively configured to check the seat belt latching of all occupied seats 10 with closed load cell switches 18, to assure occupants safety. The load cells are configured with strain gauges and temperature sensors to ensure human occupants. Such that, when the switch 18 for the occupied seat 10 is closed, the latching relay 80 circuit is energized so that the seat belt 17 for the occupied seat location is checked for buckling. The latching relay 80 circuit and the counter 50 circuit are operatively configured and closed only when an occupant 110 takes any of the seats 10. The latching relay switch 85 is only energized when the counter circuit 50 is closed.

Owner:TABE JOSEPH AKWO

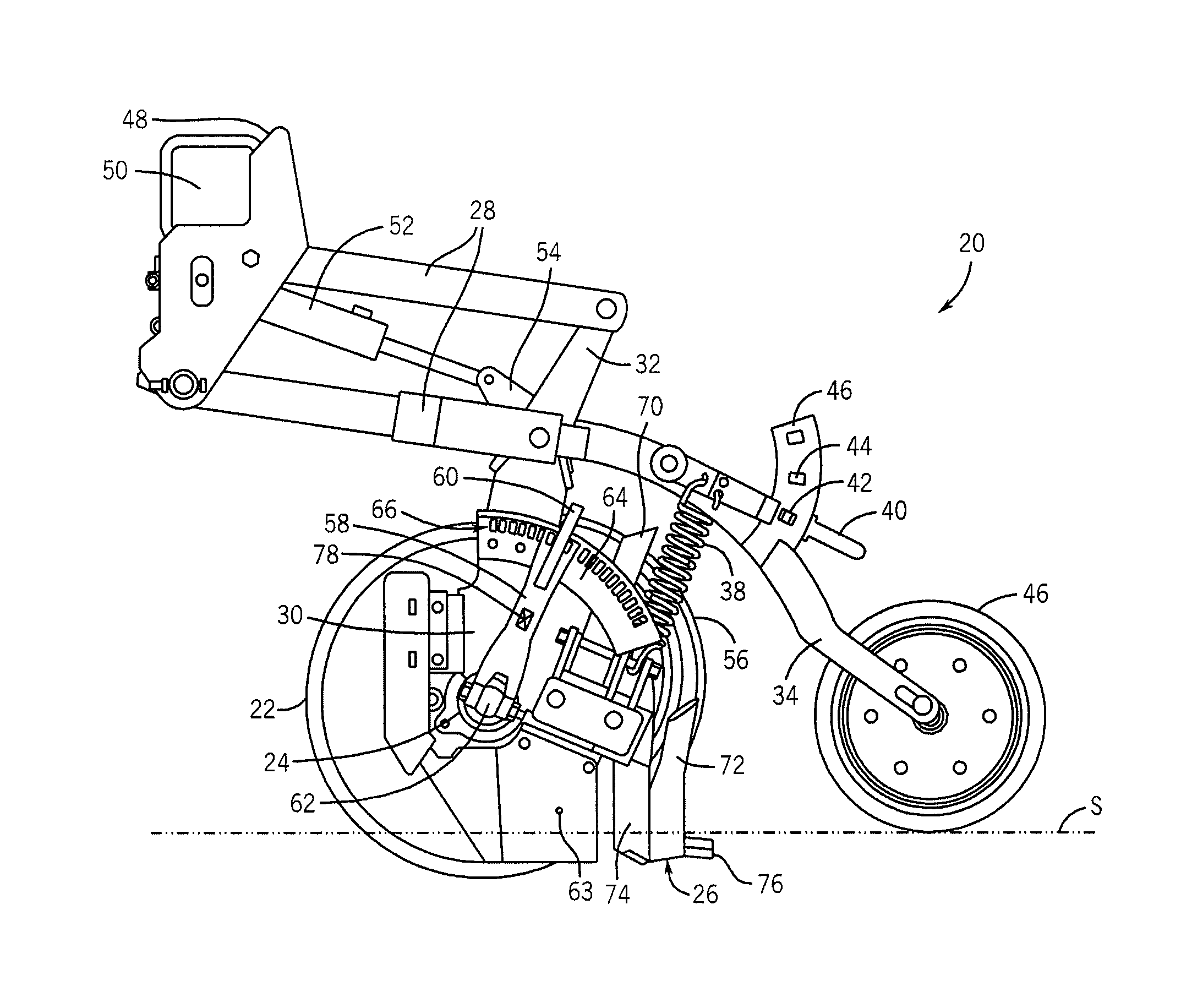

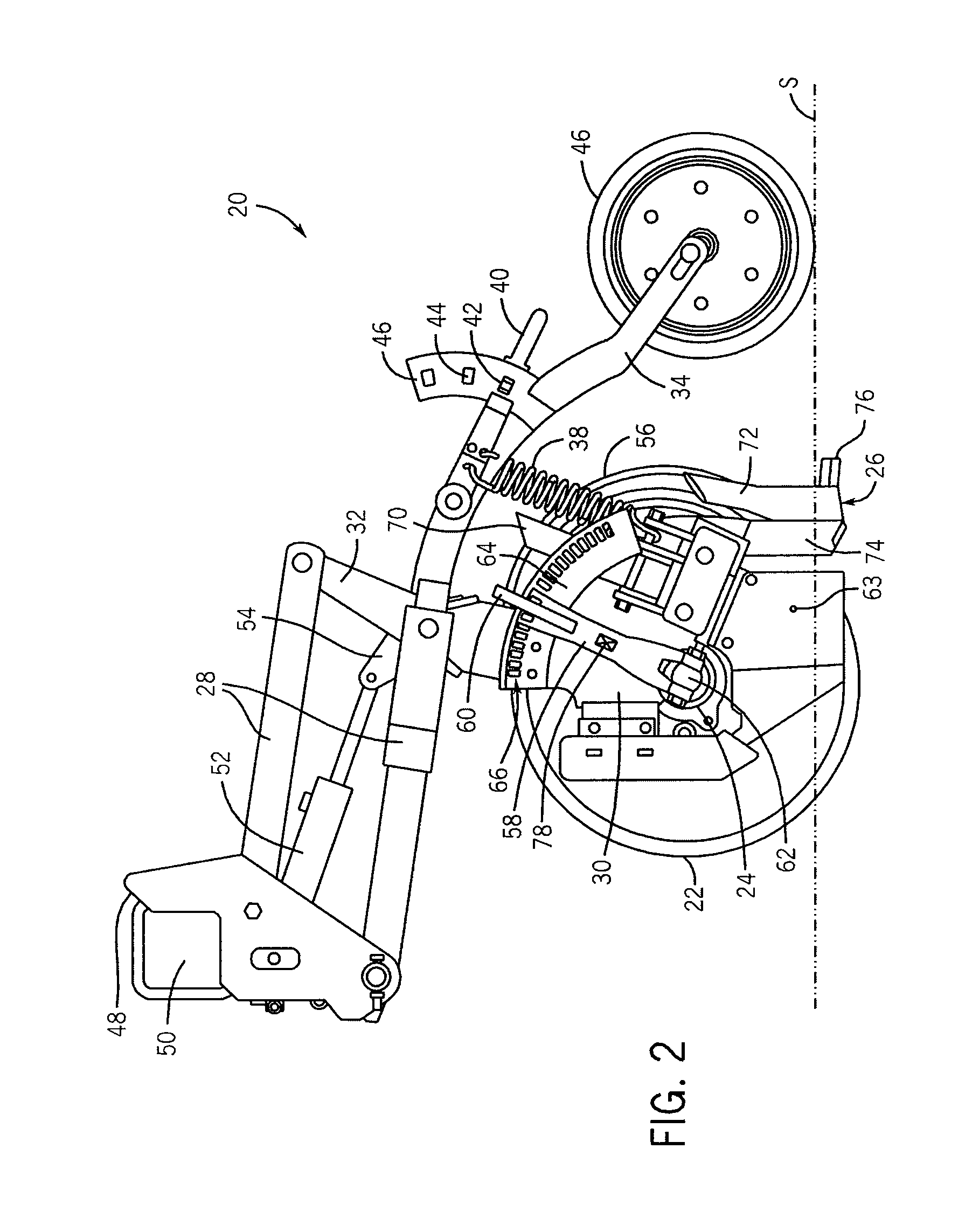

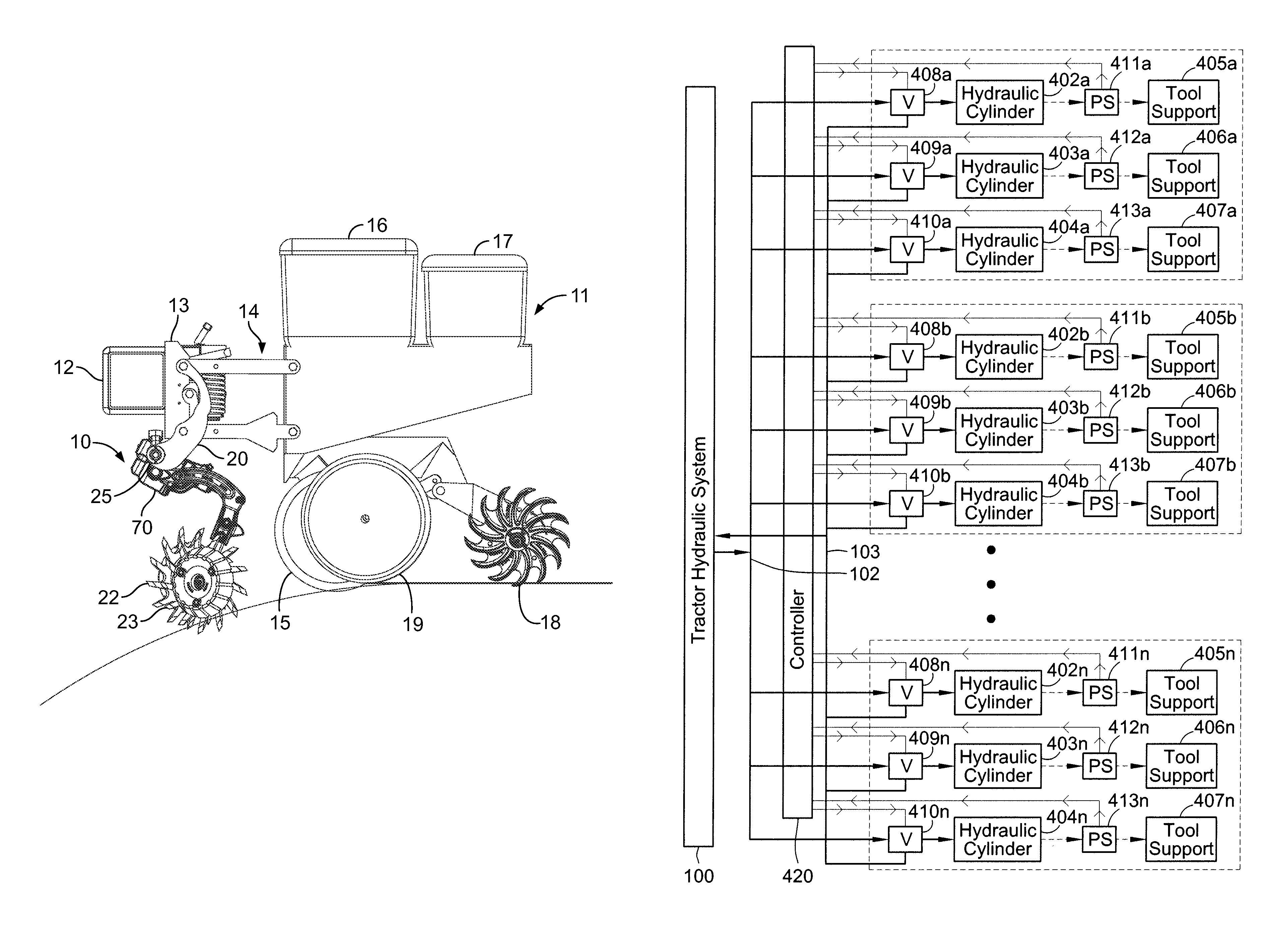

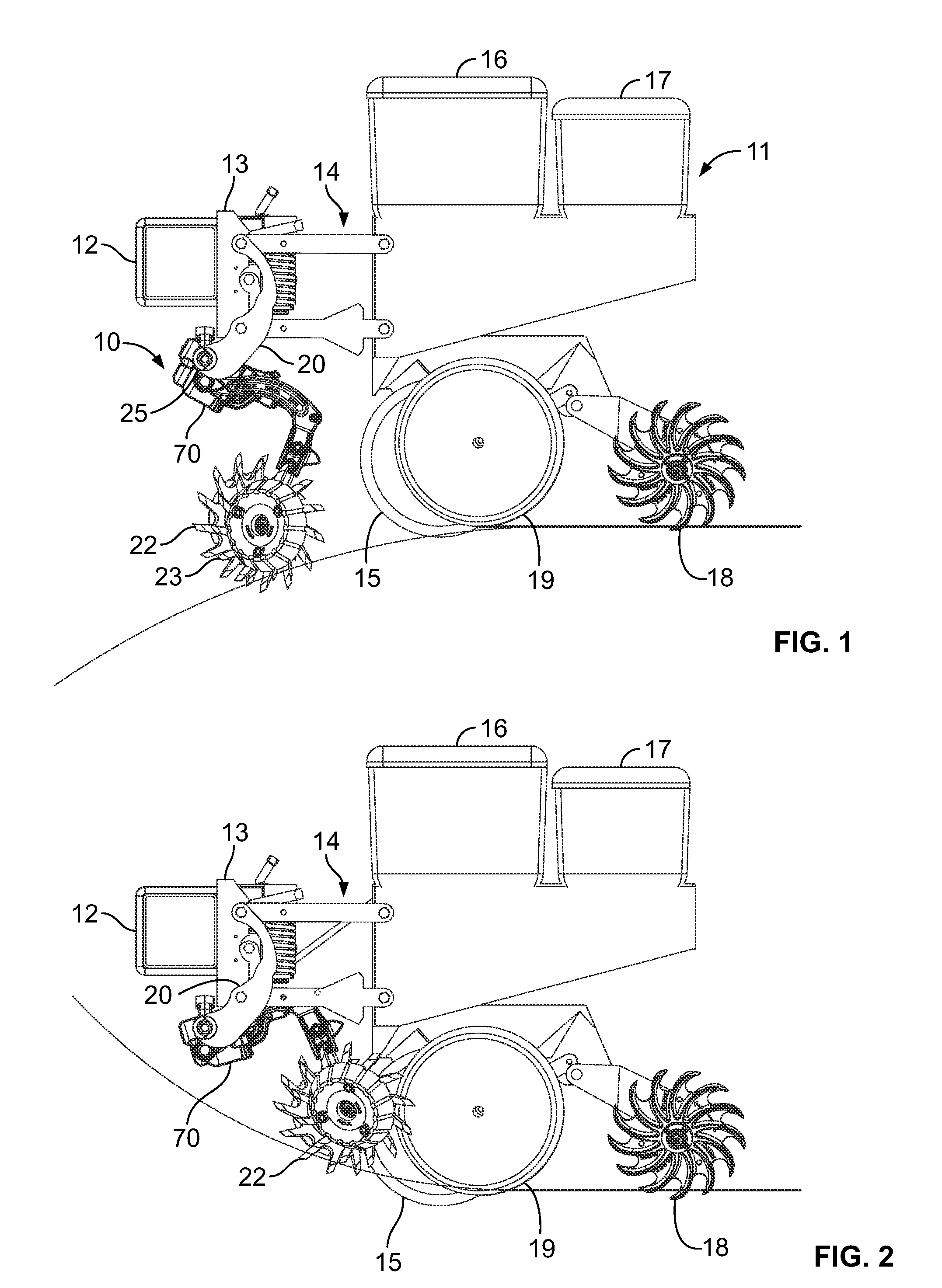

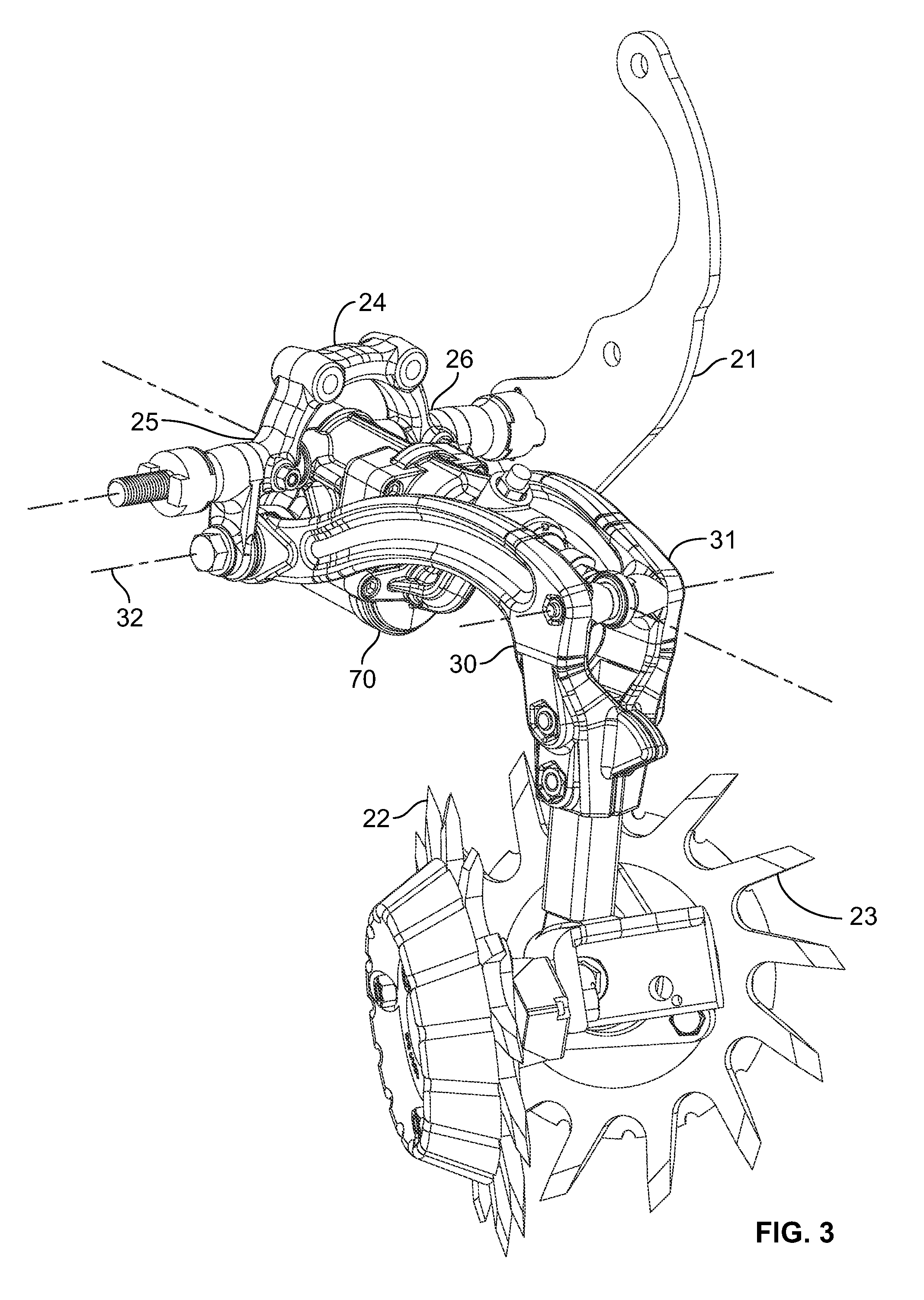

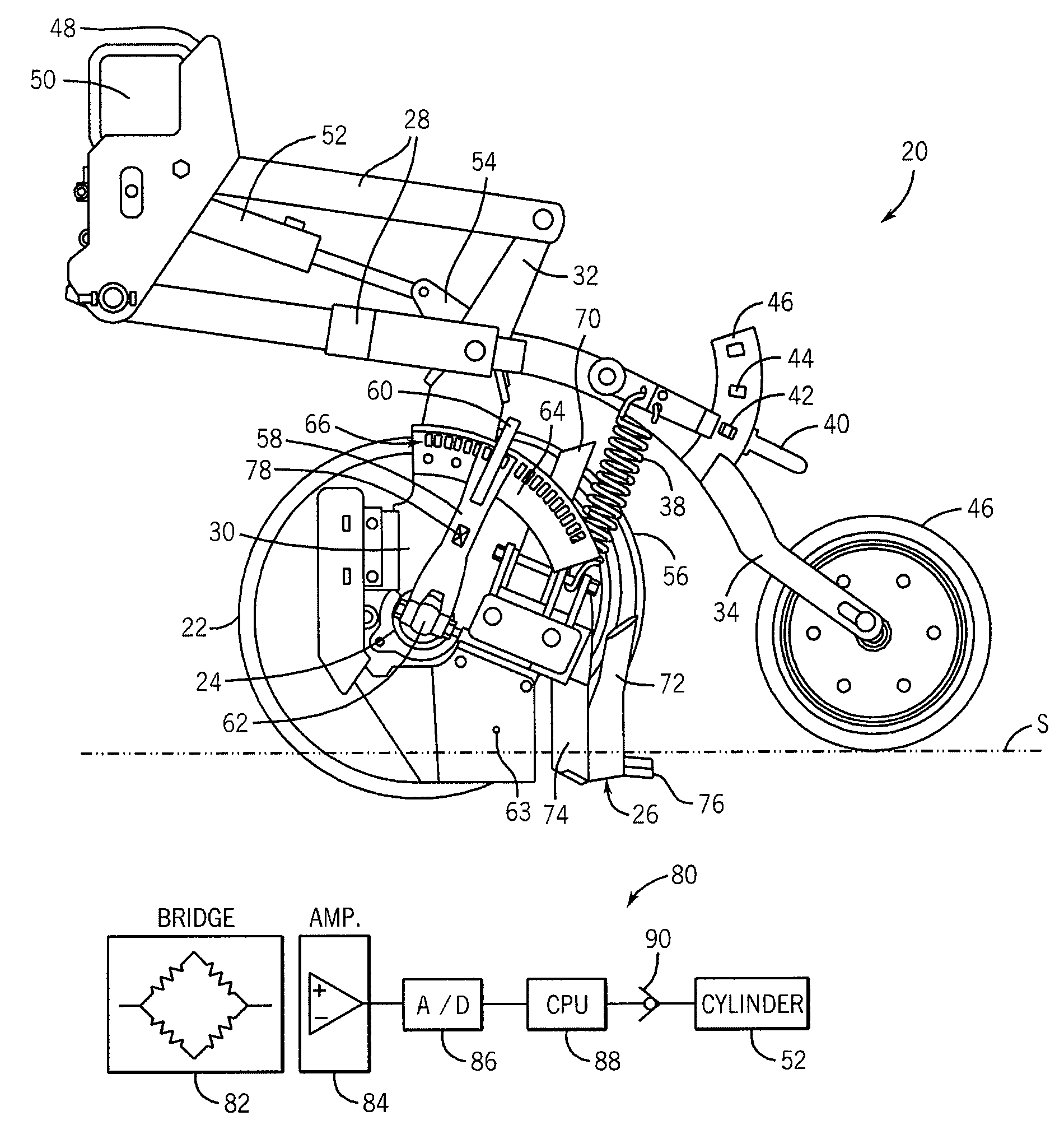

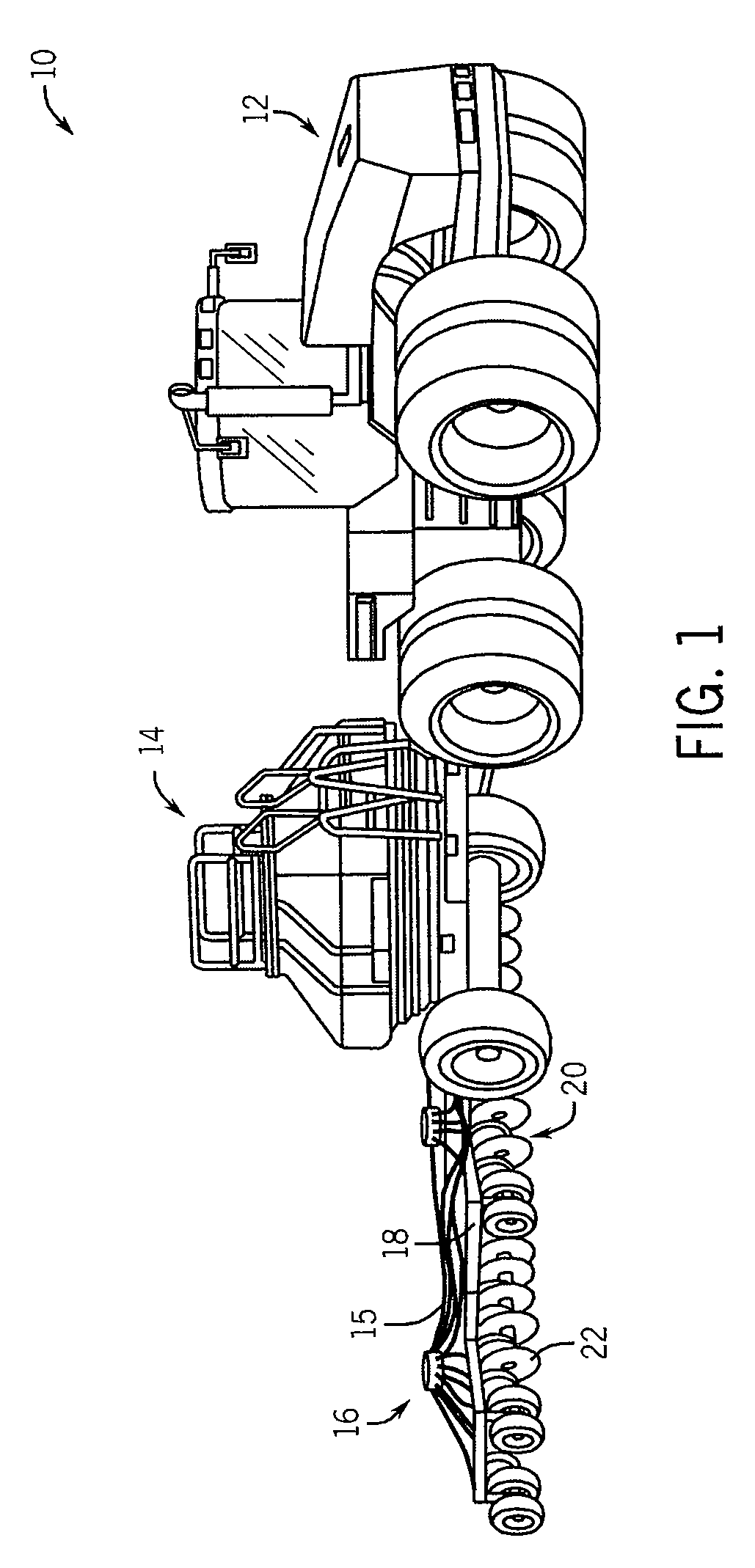

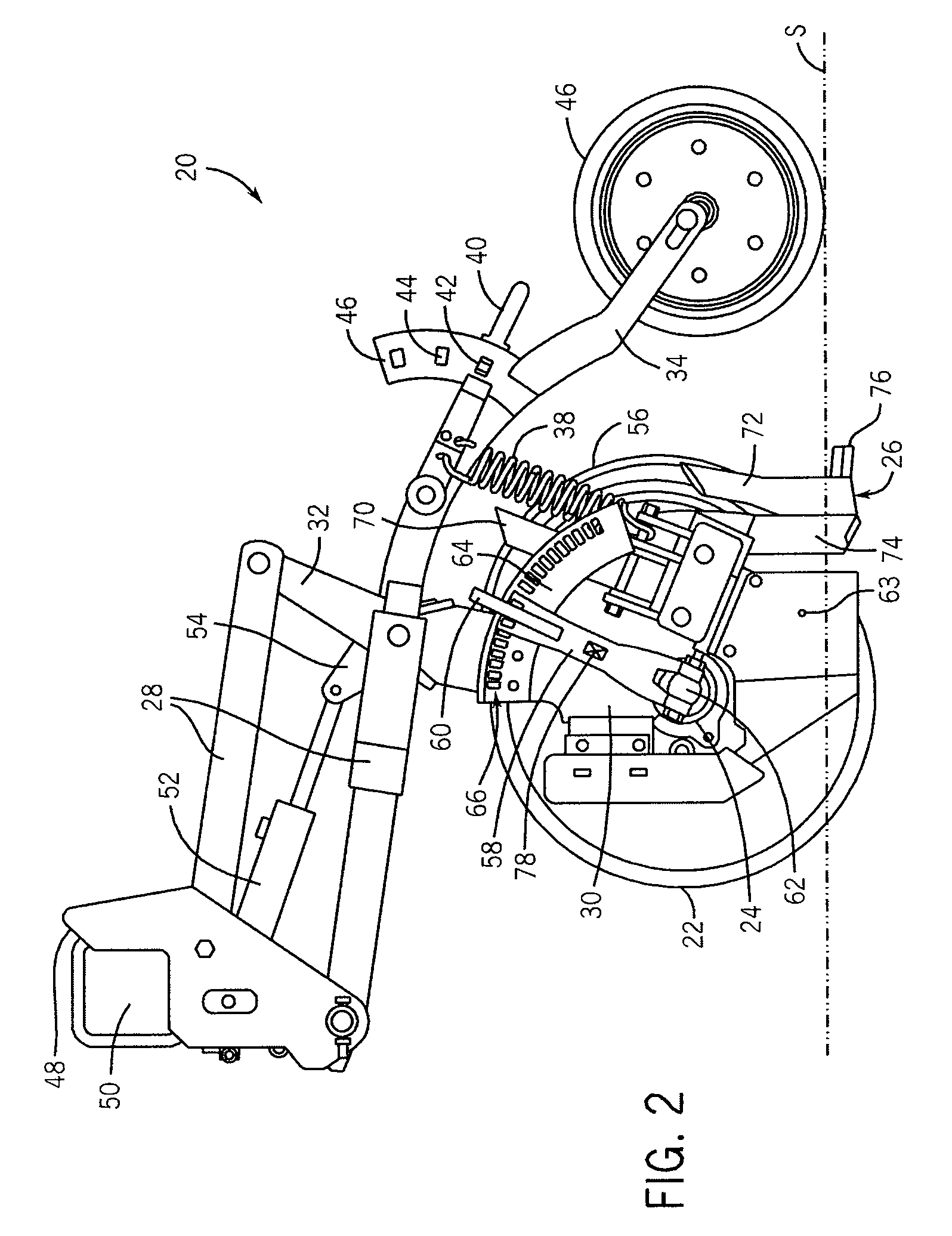

Down Pressure Adjustment Device And Method For Use With A Disc Opener Assembly Of An Agricultural Implement

A disc opener unit for an agricultural implement has a down pressure adjustment device that automatically adjusts the amount of down pressure applied on a furrowing disc based on strain measurements taken by a strain gauge or load cell. The strain gauge, which may be mounted to an arm that is used to set the position of a depth setting gauge wheel, provides feedback to a processor that in turn controls the amount of hydraulic fluid in a hydraulic cylinder to adjust the down force applied on the disc. The amount of down pressure is therefore adjusted in substantially real-time in response to changes in field conditions, which improves furrow depth consistency and reduces wear on the gauge wheel and its components.

Owner:CNH IND CANADA

Guided active compression decompression cardiopulmonary resuscitation systems and methods

ActiveUS20110201979A1Promote circulationImprove ventilationElectrotherapyIron-lungsCouplingEngineering

Owner:ZOLL MEDICAL CORPORATION

Weight-filling method, and a corresponding device

InactiveUS6073667ASuppress mutationAccurate weighingLiquid fillingWeighing apparatus using elastically-deformable membersEngineeringLoad cell

Owner:SERAC GROUP

System load testing coordination over a network

A method and system using one or more load cells coordinates load testing of one or more sites under test over a network such as the Internet in accordance with one or more load test requests. In one embodiment, such method and system facilitates an economic, efficient, and accurate evaluation of the capacity of the SUTs to support concurrent users of the SUTs. A load test request is received from a User and provides information concerning a load test to be performed on a site under test (SUT). A load test is generated, and the load test is allocated to one or more load cells. The load cells perform the load test by sending load test data to the SUT and receiving responses from the SUT. Portions of a load test may be allocated to different load cells, which may be geographically remote from the SUT and / or geographically diverse. Multiple concurrent pending load tests may be processed for the same SUT. A load cell may concurrently perform all or a portion of multiple different load tests for multiple different SUT's simultaneously. A reporting function generates a report based on the responses received from the SUT. The reporting function may in addition or alternatively allow the User to view real-time results during load test execution.

Owner:EUREKA SOFTWARE SOLUTIONS

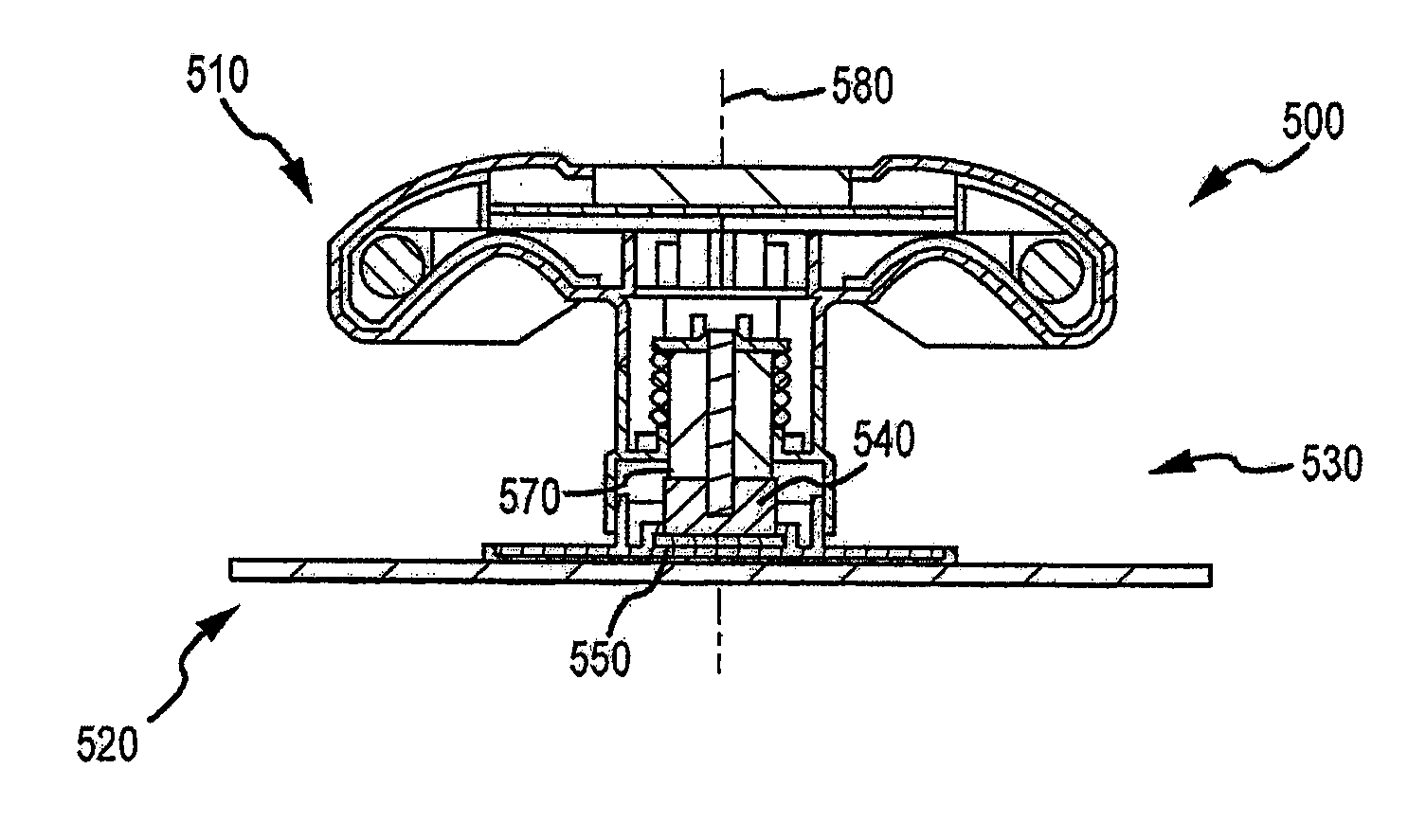

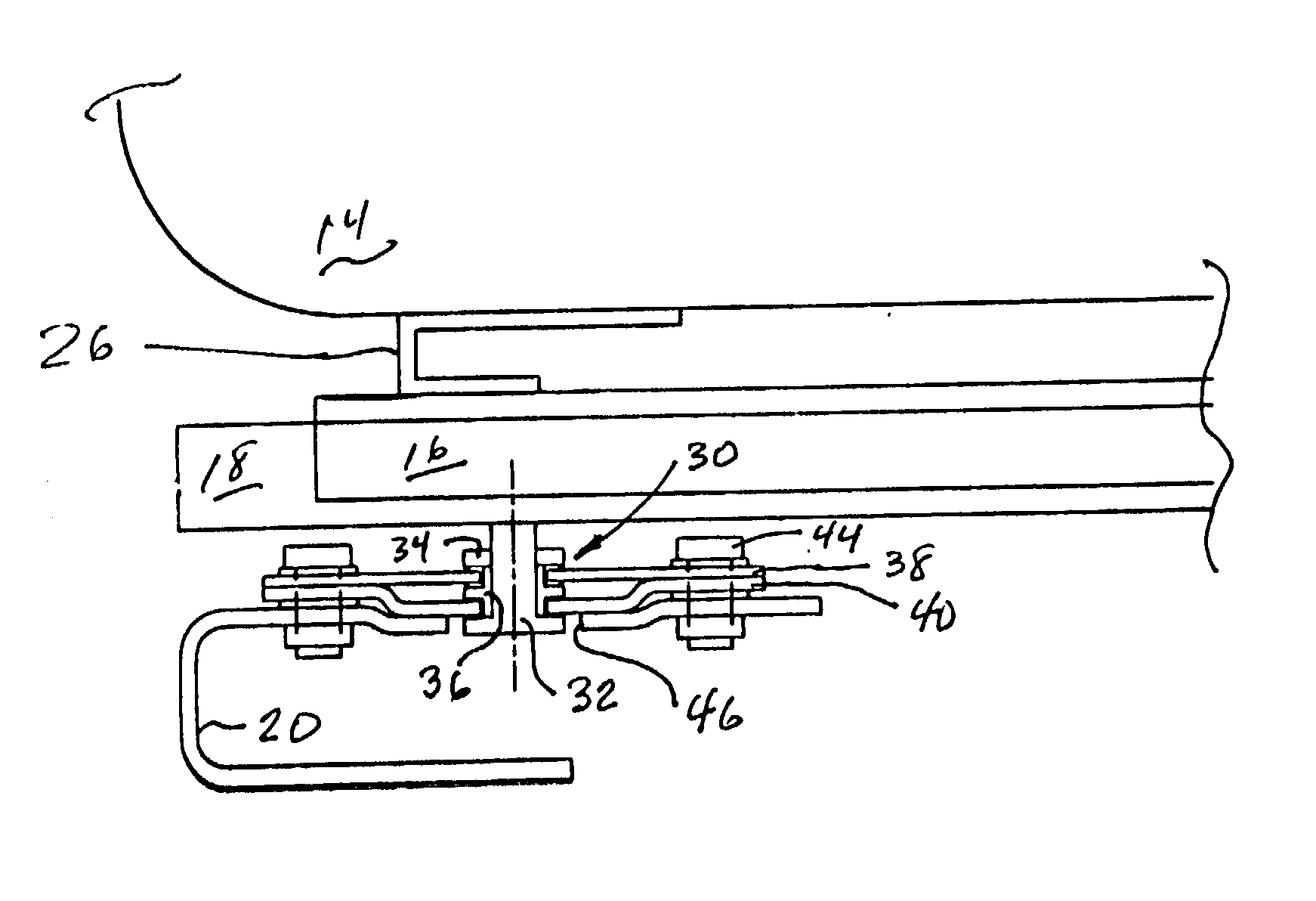

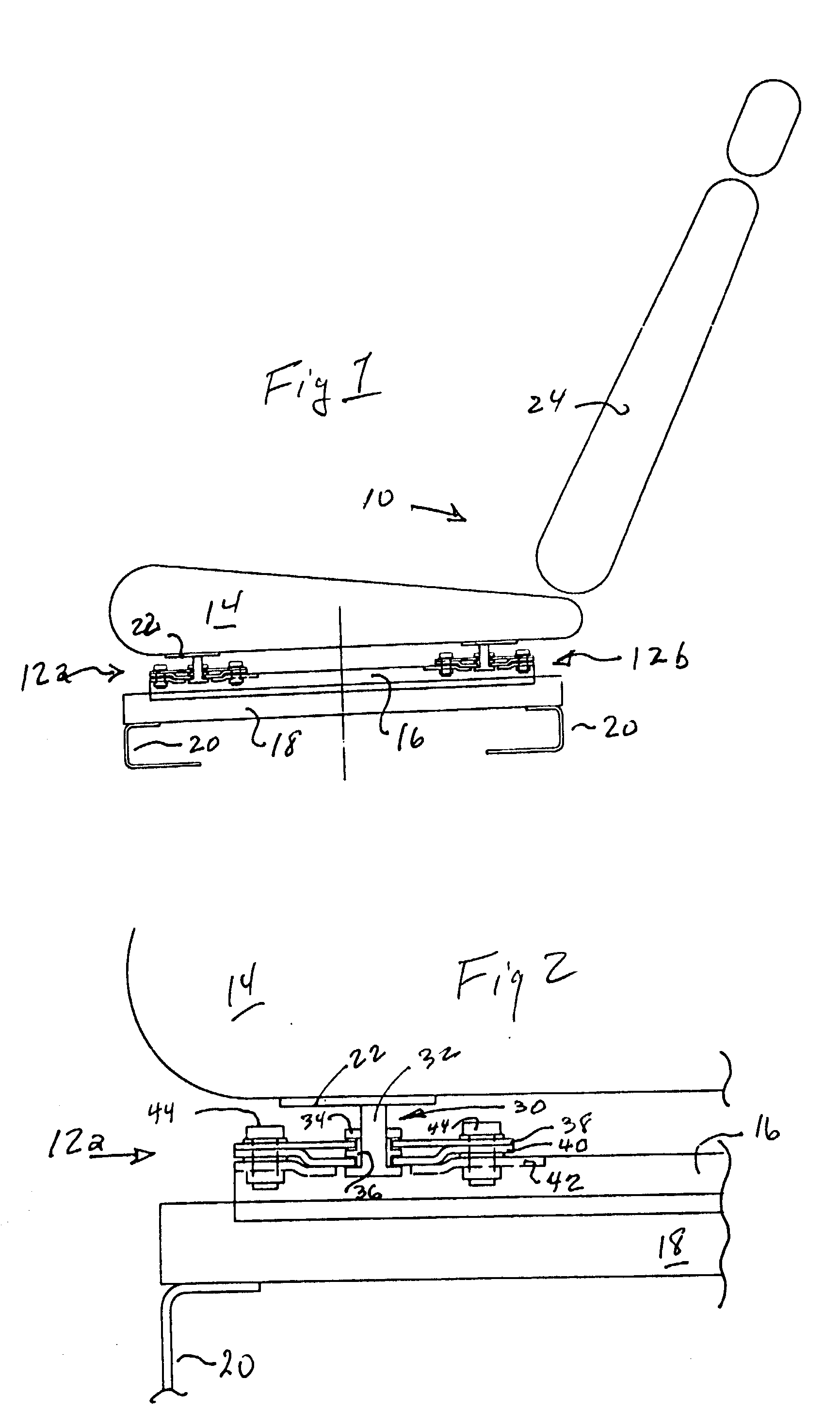

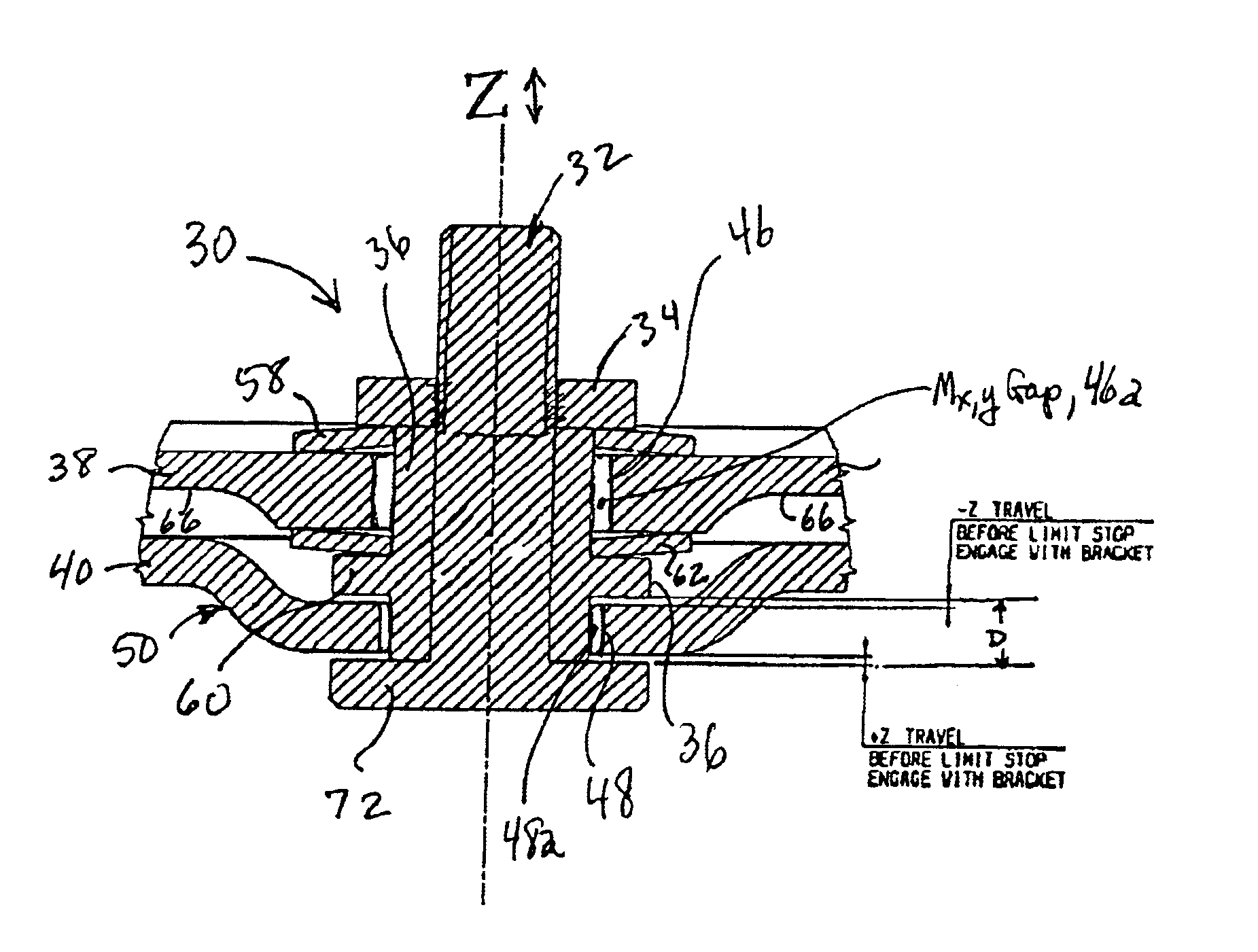

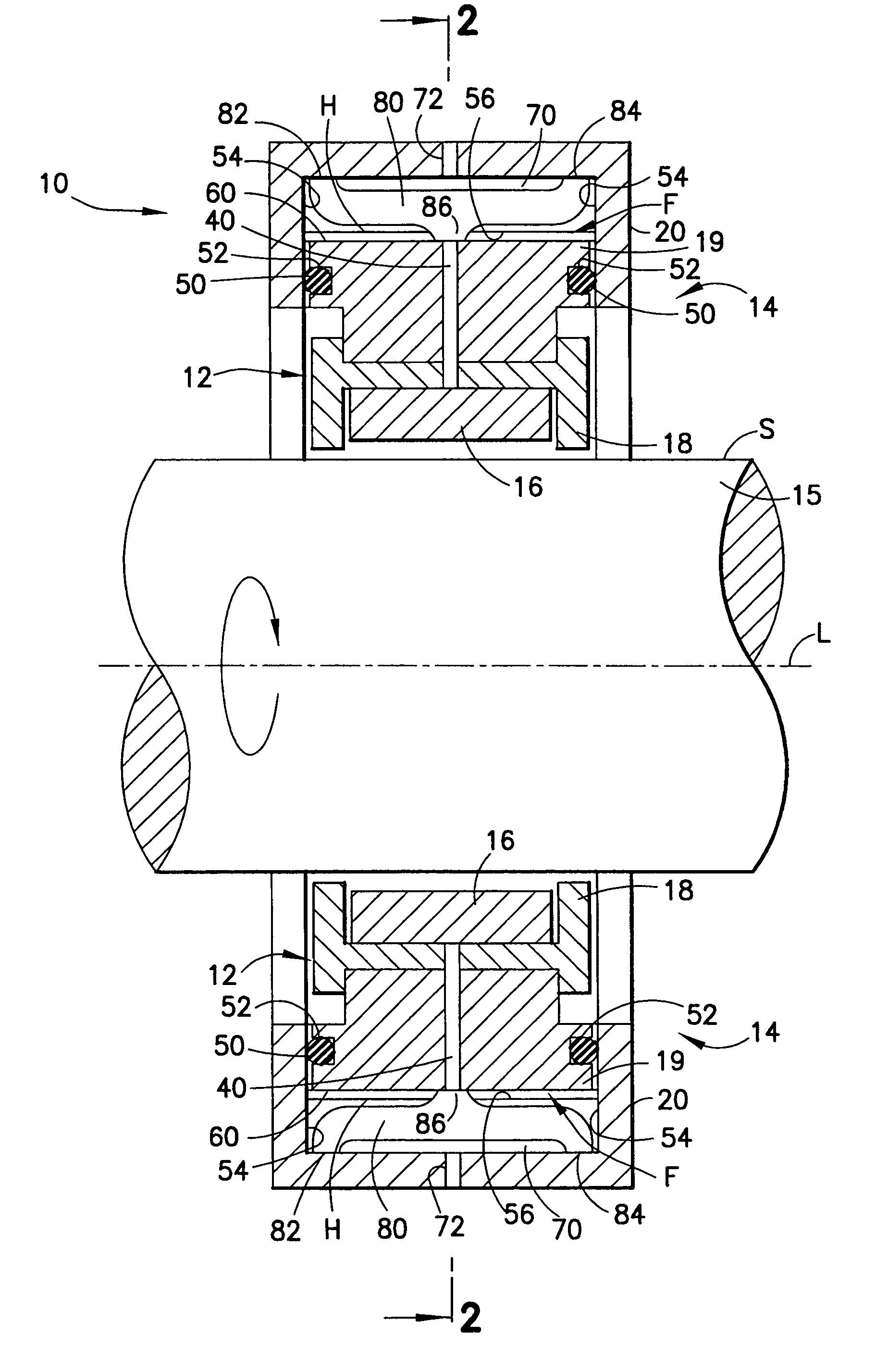

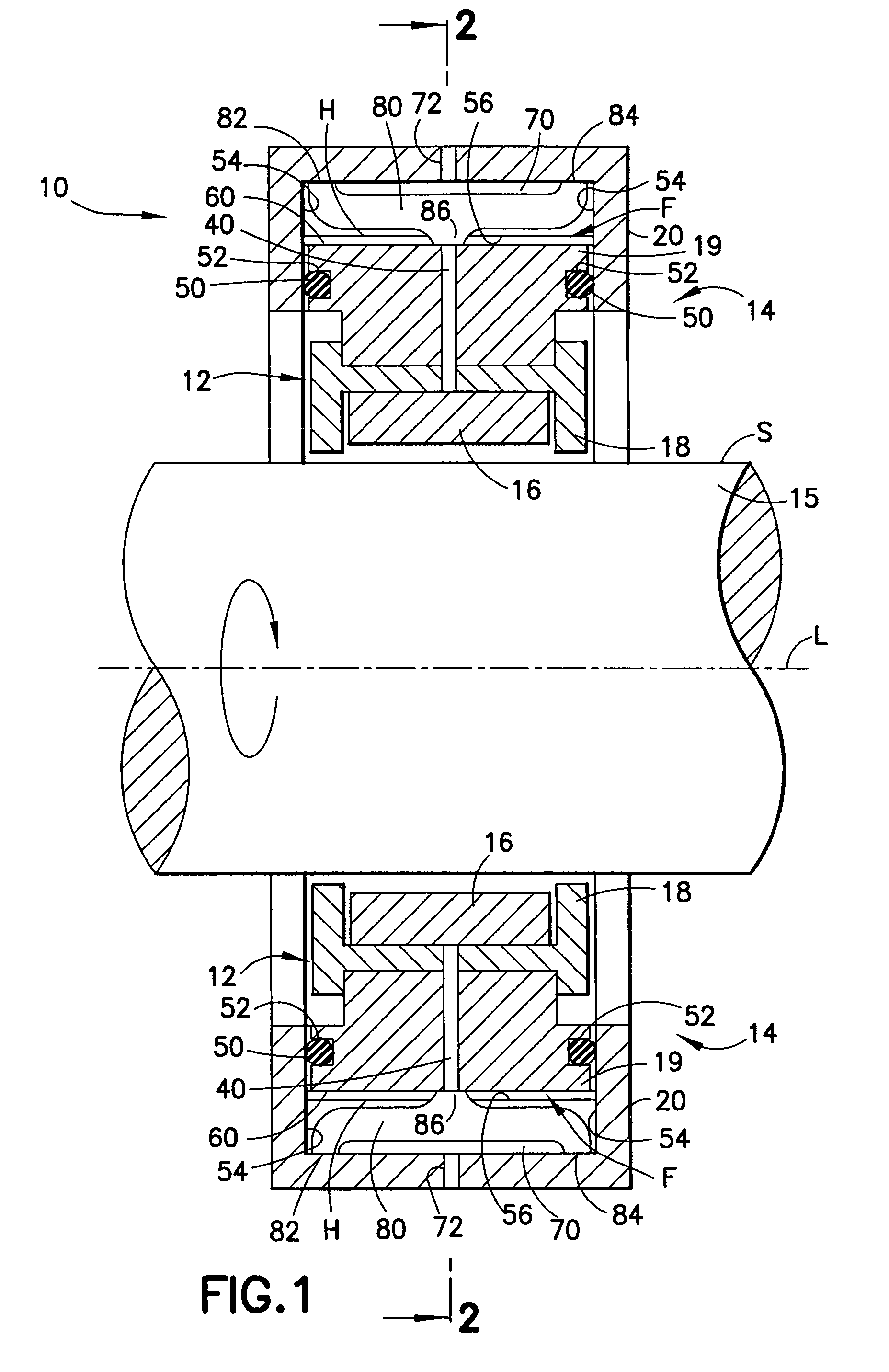

Weight sensors having centralized loose tolerance universal force and Mx/My moments overload stops

InactiveUS20030106723A1Increase angular travel permittedConvenient travelWeighing apparatus using elastically-deformable membersElectric devicesModularityAngular rotation

Automotive load cells having centralized, multi-axis, loose tolerance overload / limit stops provide improved strain gauge response. The modular, integrated stop assemblies magnify sensor substrate deflection by use of opposed concave (Belleville) springs are used in direct contact with the substrate to accommodate ±Z axis deflection and Mx / My moment angular rotation. A flanged guide member on the load stud permits a wide range of geometries. The substrate is thickened around the load stud hole and the outboard support bolt holes. Hollow rivets assist in design modularity. Strain gauges are placed at the yield zones symmetrically with respect to the X axis. The substrate hole Mx / My gap is larger than the stop bracket hole to insure a positive stop for Mx / My moments prior to yield. The inventive multi-axis stop assembly is used in any type load cell, including rectangular, thinned, notched, necked / dogbone, or cantilever substrates with any strain gauge layout configuration.

Owner:ROBERT BOSCH CORP

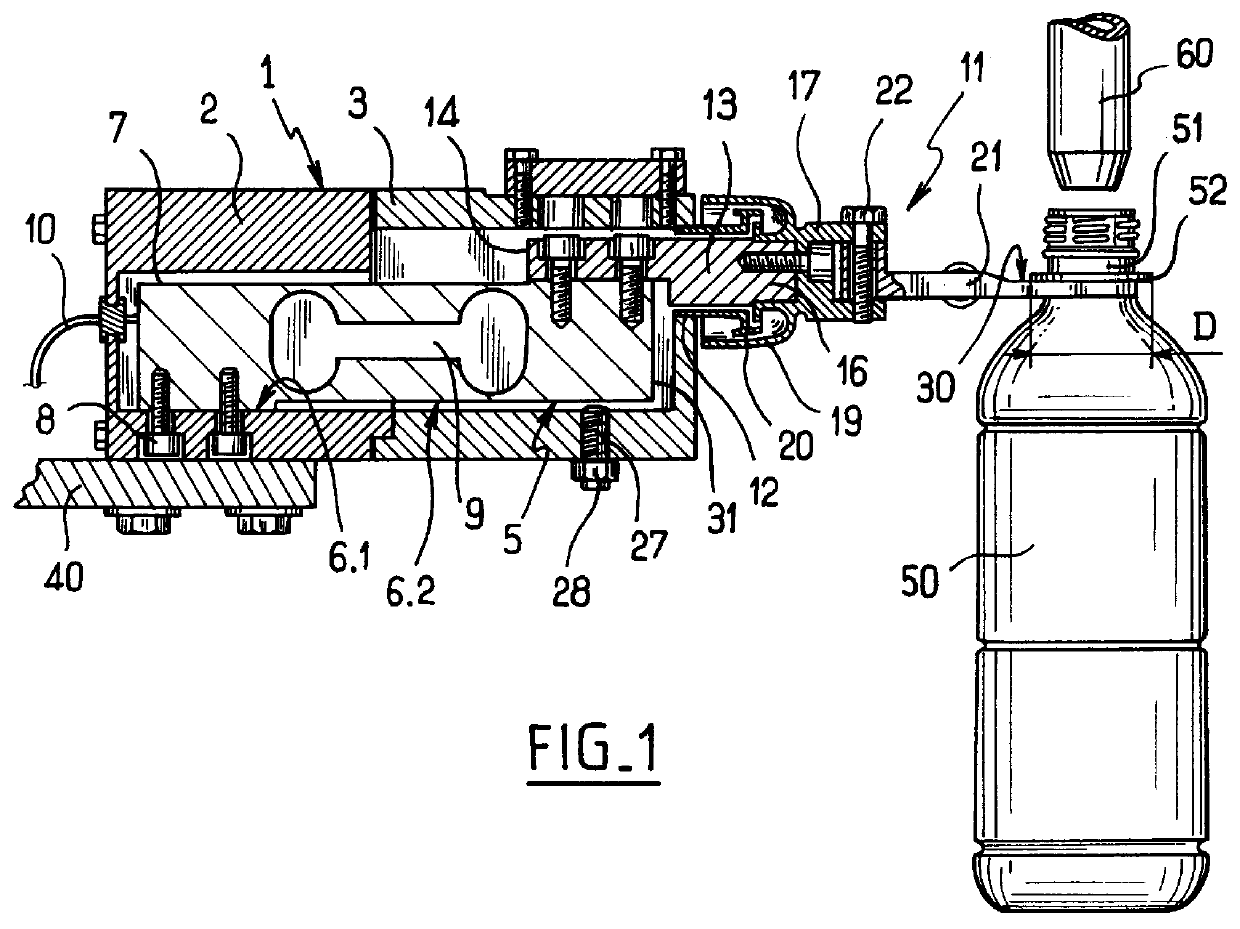

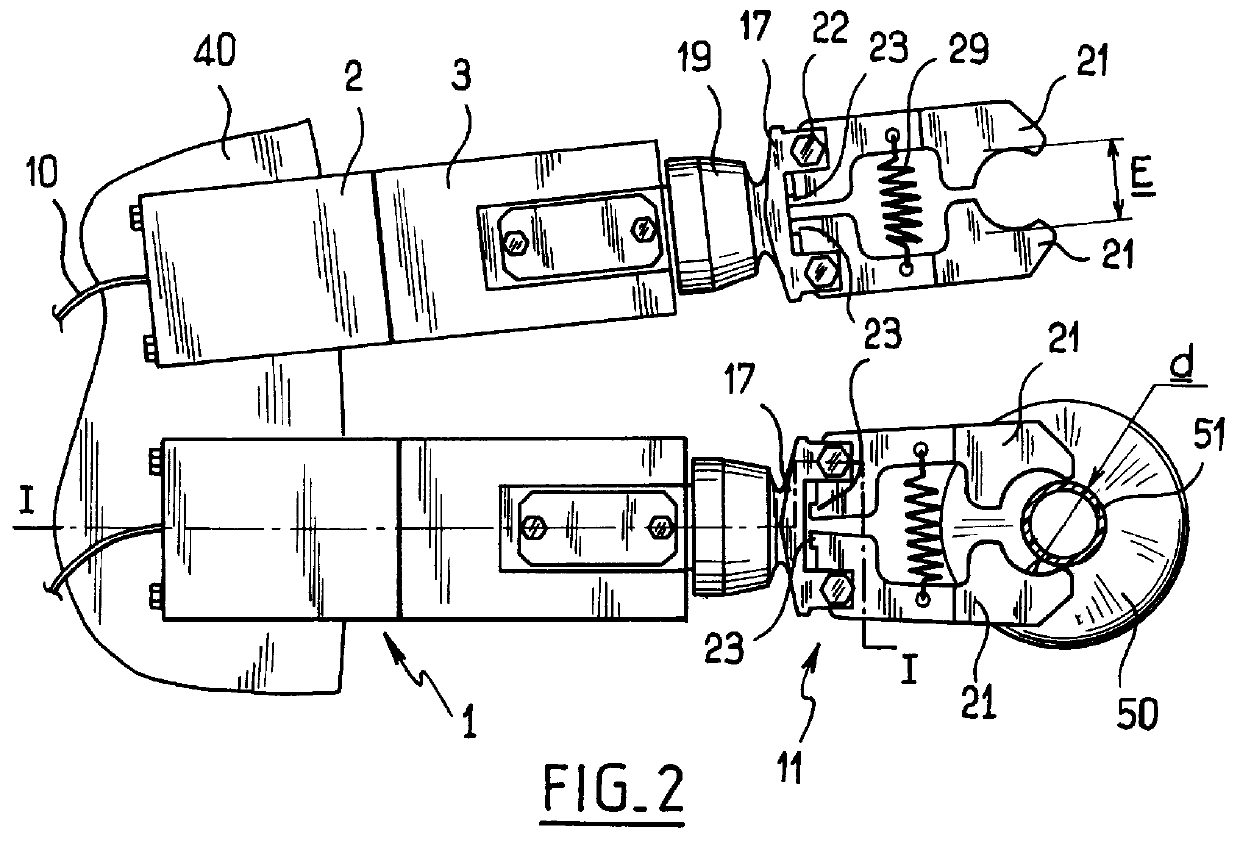

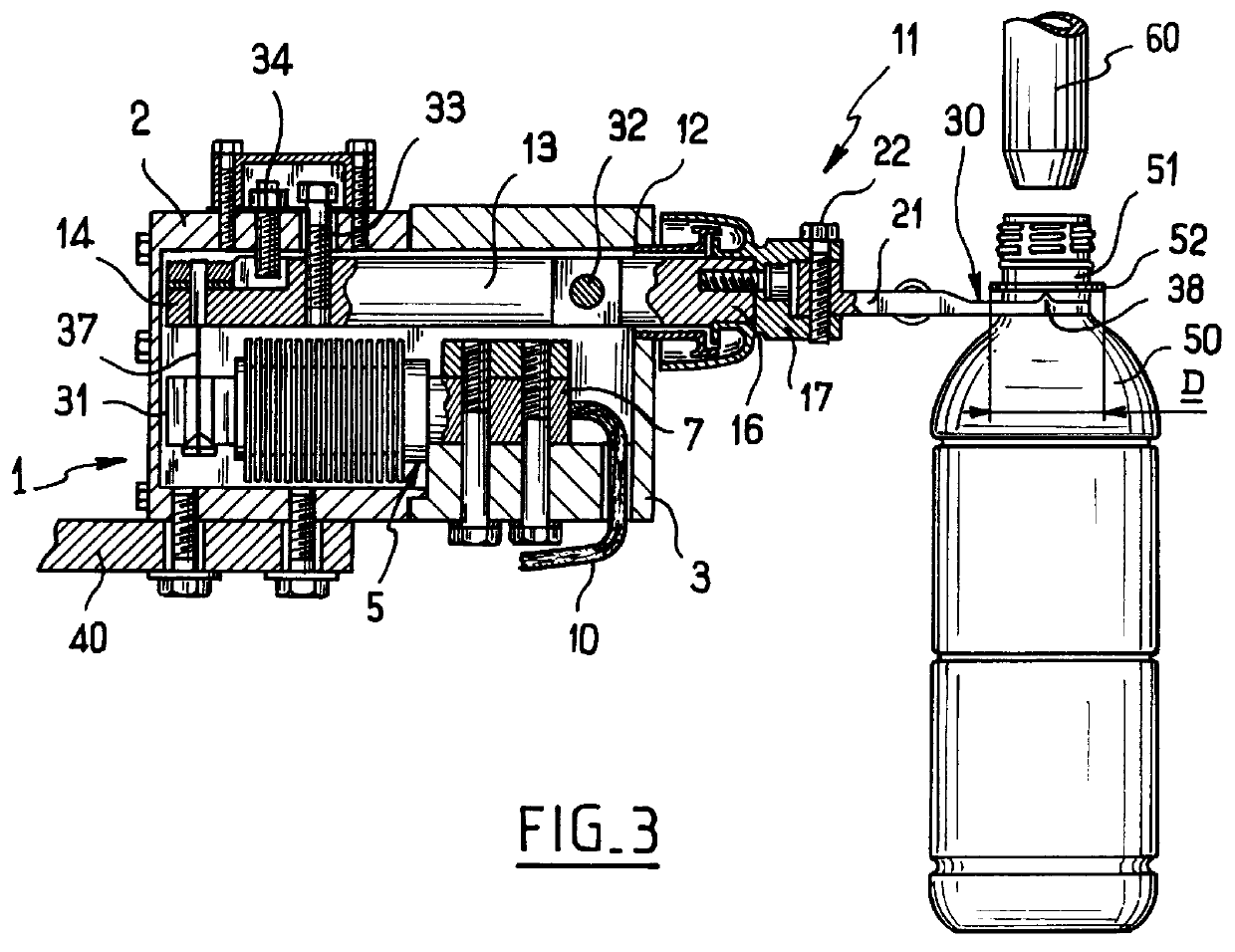

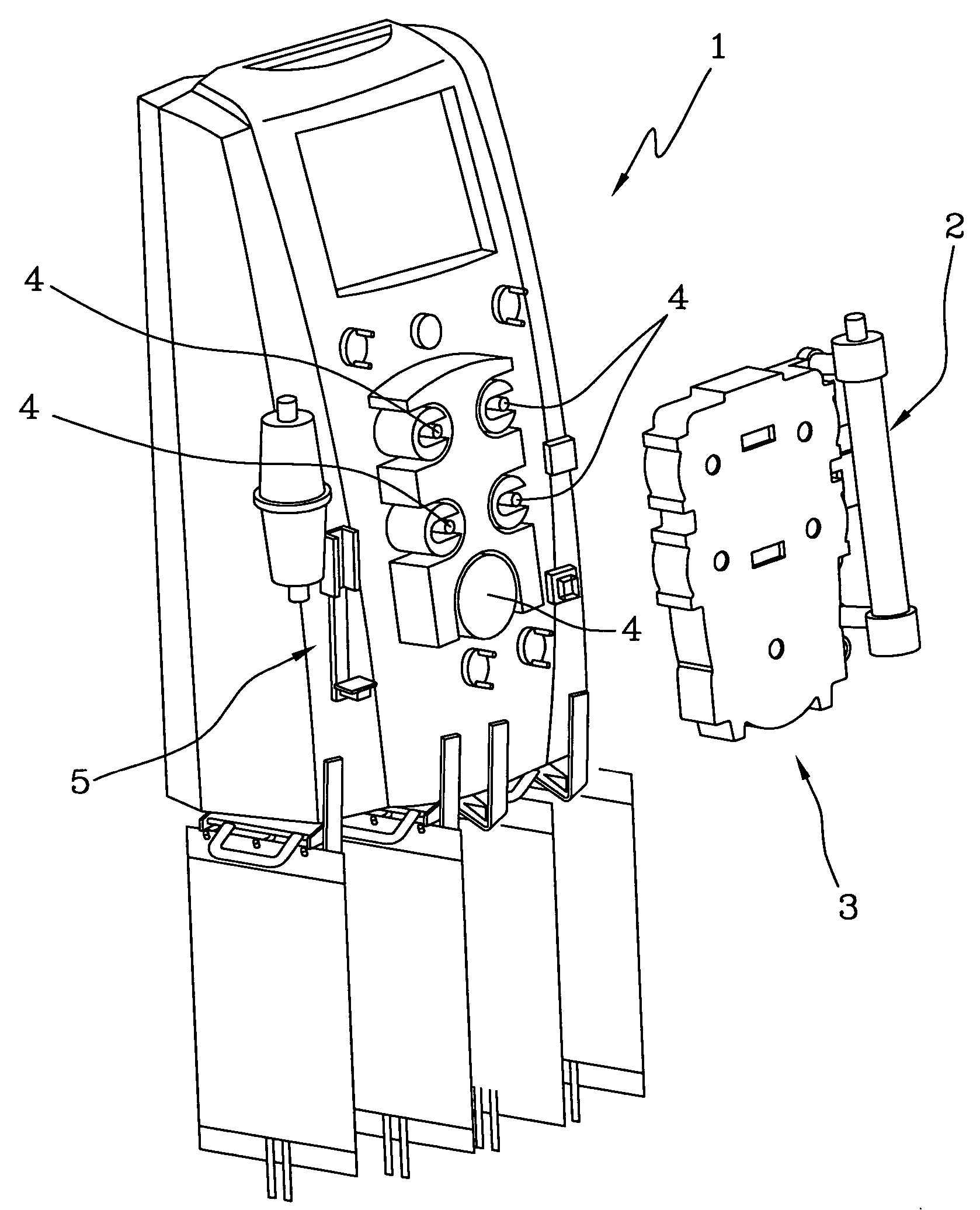

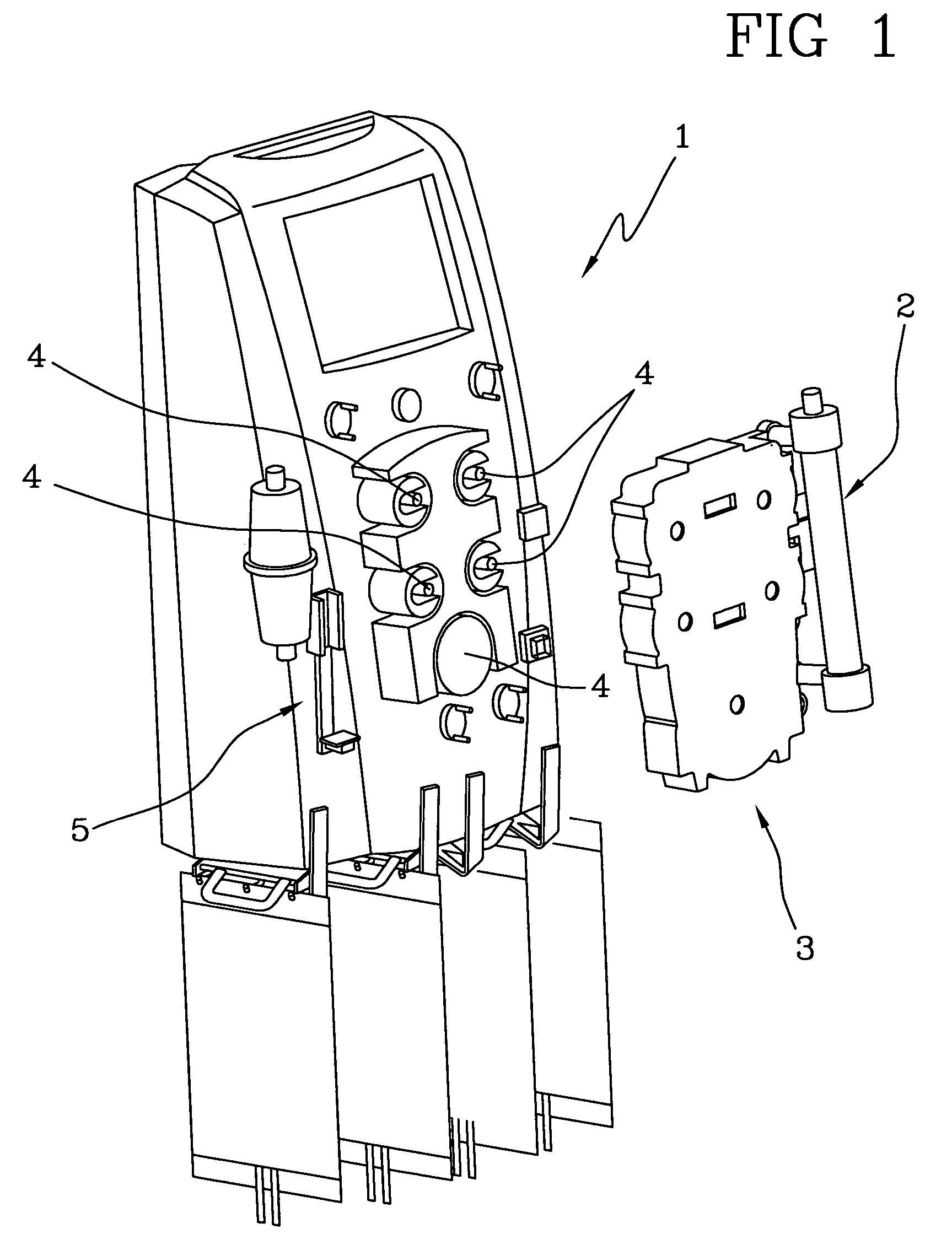

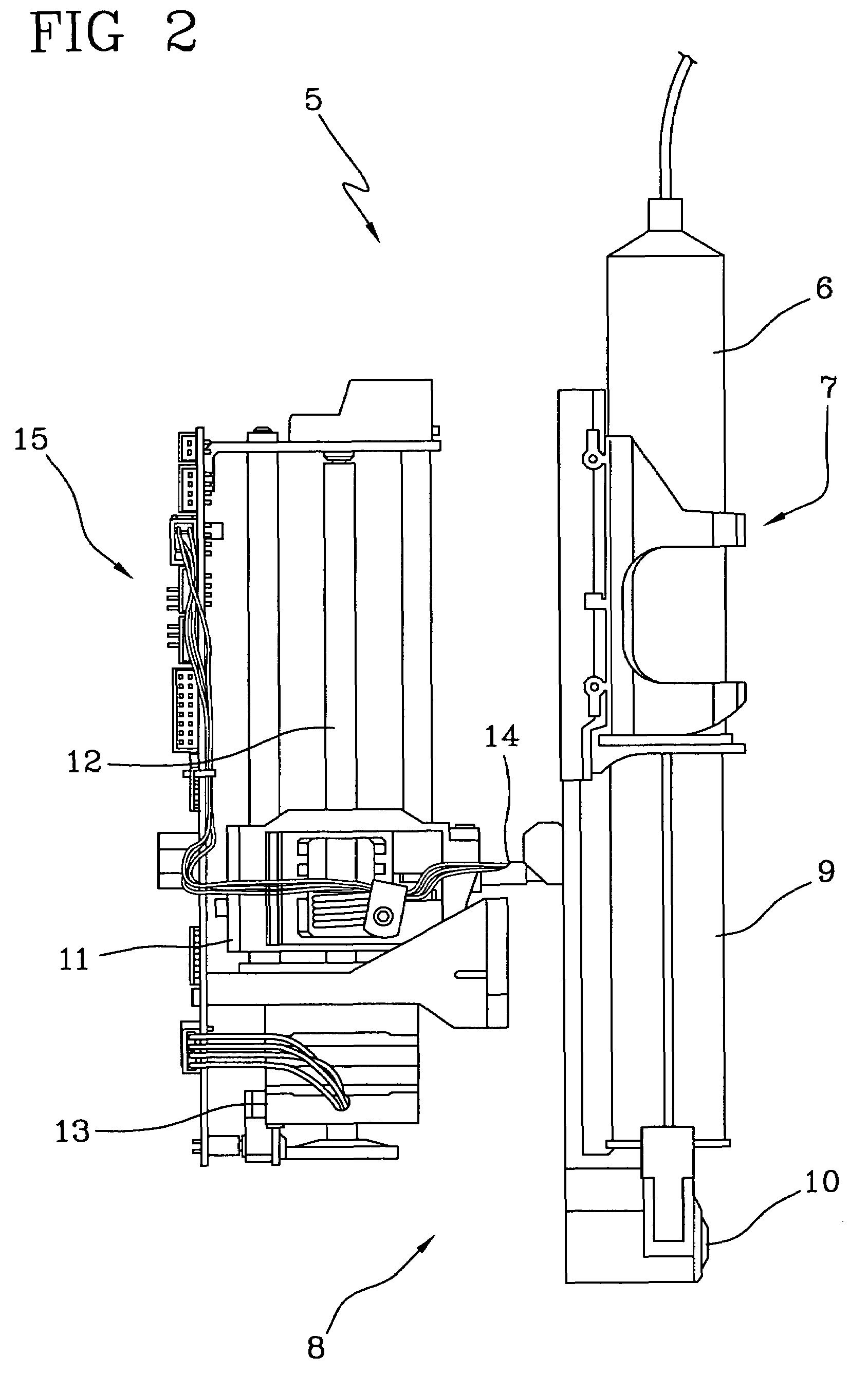

Infusion device for medical fluids

ActiveUS7517332B2Highly reliable and very precise.Other blood circulation devicesFlexible member pumpsMedicineAnticoagulant

An infusion device comprises a pusher for a plunger of a syringe containing a liquid to be infused. A load cell measures the push force. An encoder associated to a motor commanding the pusher measures the displacement of the pusher. A controller signals an alarm when the ratio between the variation of the push force and the displacement exceeds a predetermined threshold. The device, which serves for infusing an anticoagulant into an extracorporeal blood circuit in a dialysis apparatus, is able to signal an onset of an anomalous situation of lack of infusion in good time.

Owner:GAMBRO LUNDIA AB

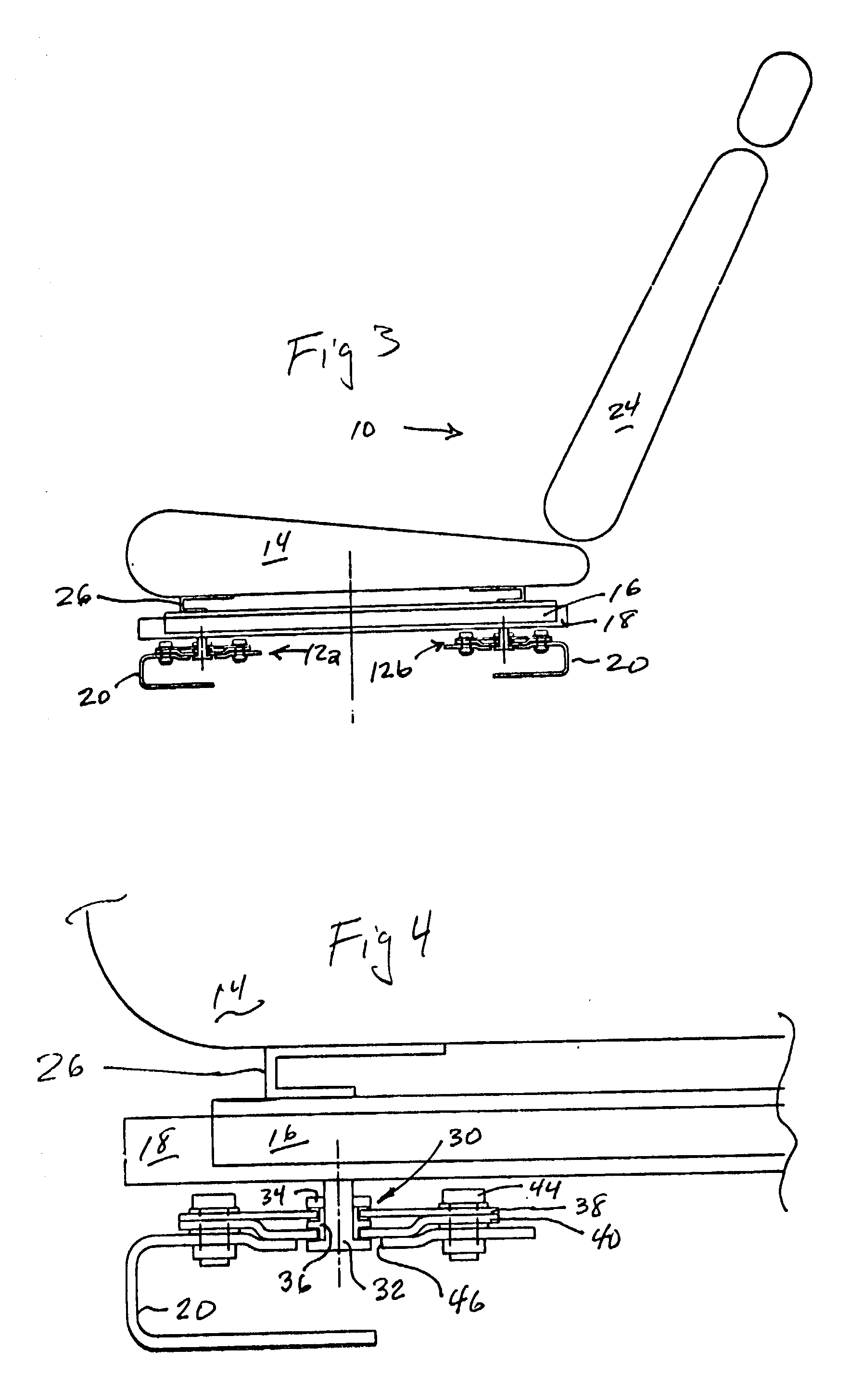

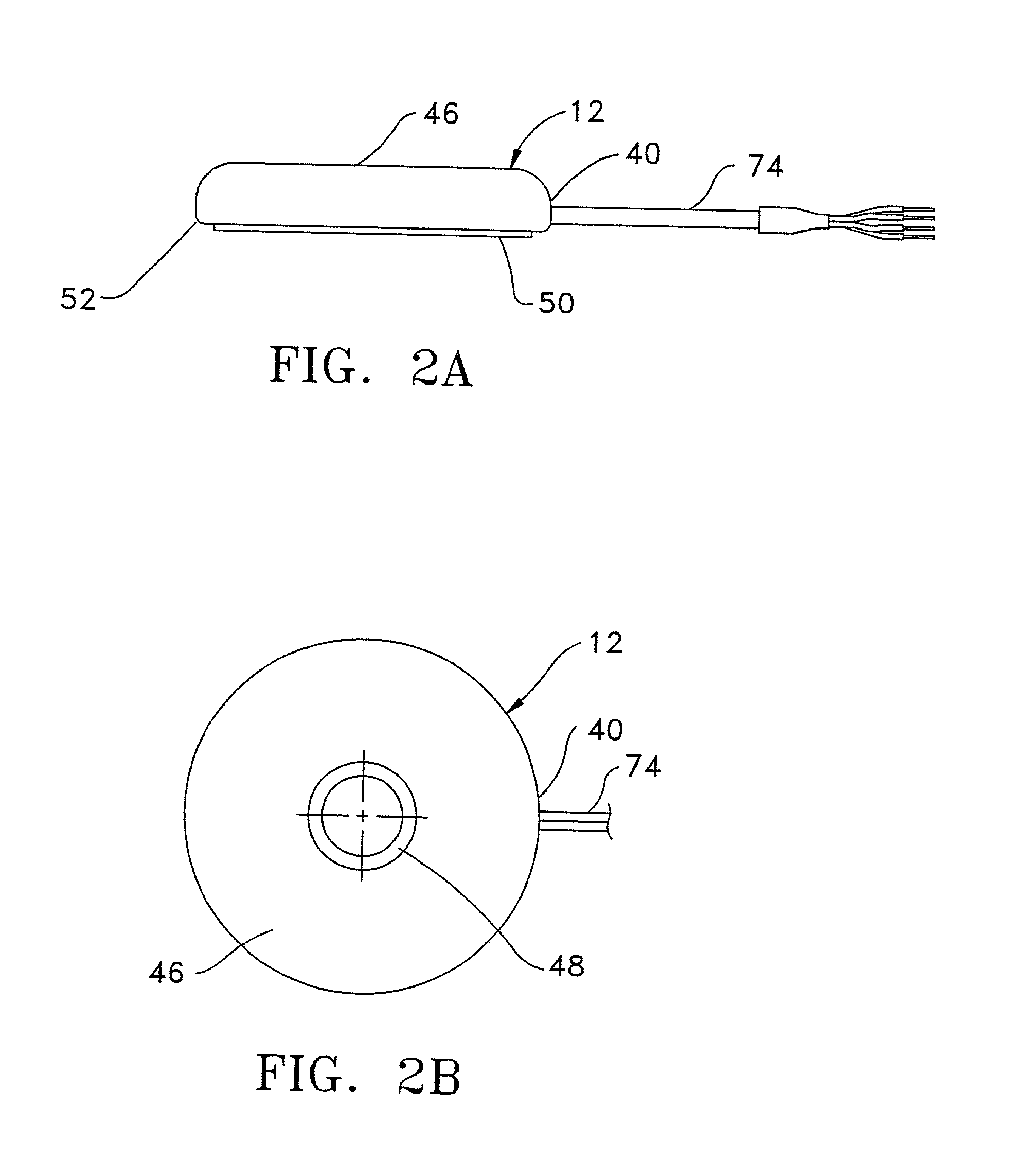

Patient movement detection apparatus

InactiveUS20020070867A1Minimize impactImprove performanceDiagnostic recording/measuringSensorsEngineeringLoad cell

A patient movement detection device is provided comprising a plurality of load cell disks, beams, or columns placed under a support member of a patient support device. The load cells are connected to a processing unit by a plurality of transmission cables. The processing unit is connected to a peripheral communication device. A method of detection of movement of a patient is provided comprising the steps of generating a signal by a load cell disk or beam when a change in a patient's center of gravity occurs on the patient support device, transmitting the signal to a processing unit, and further transmitting the signal to the peripheral communication device.

Owner:STRYKER CORP

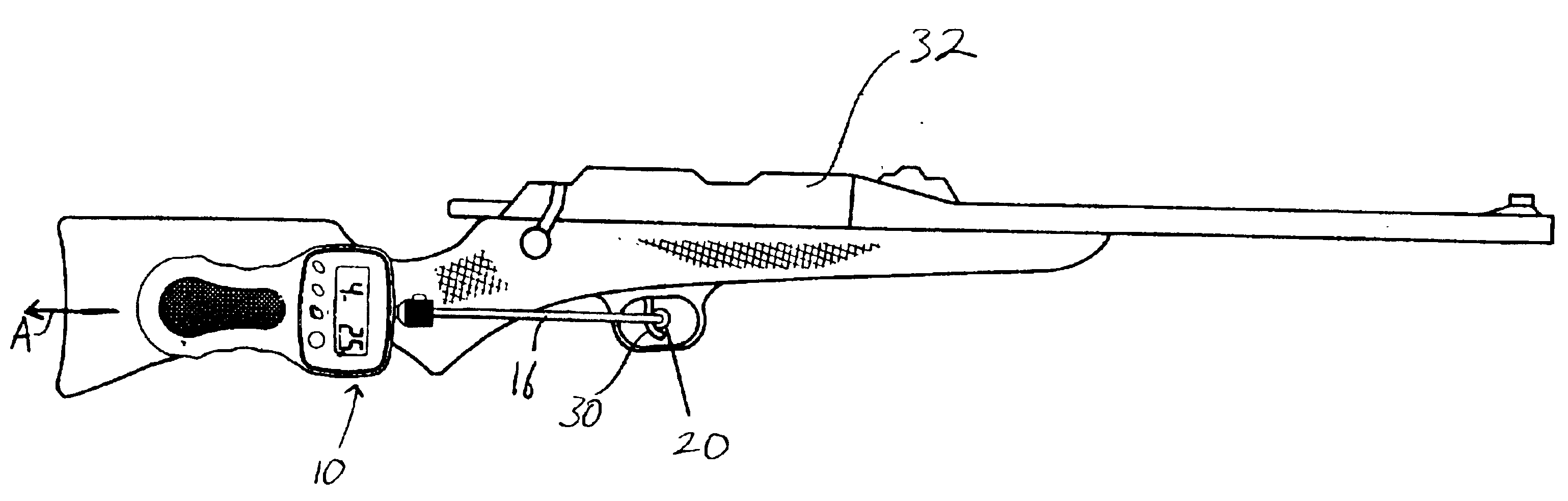

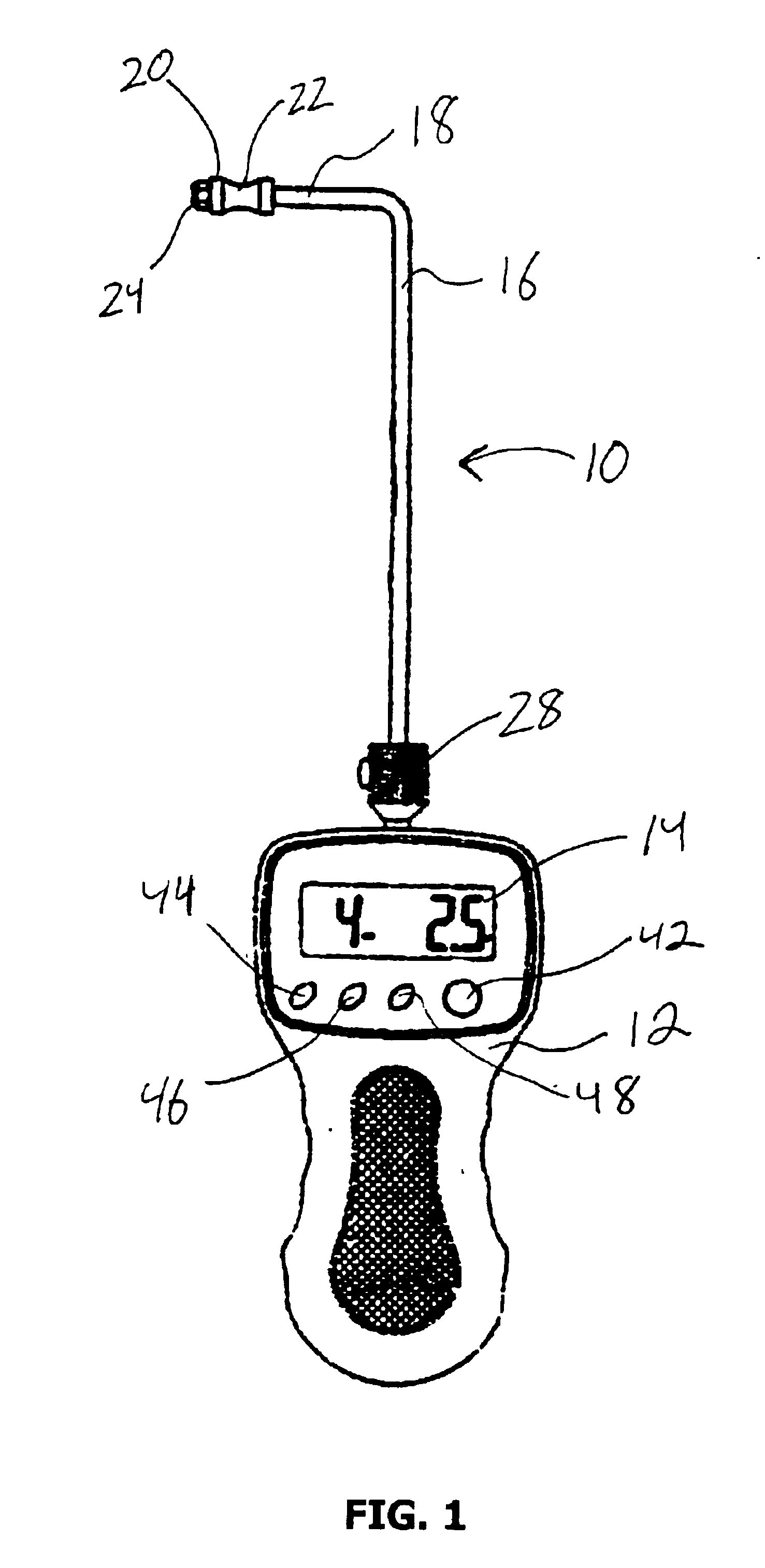

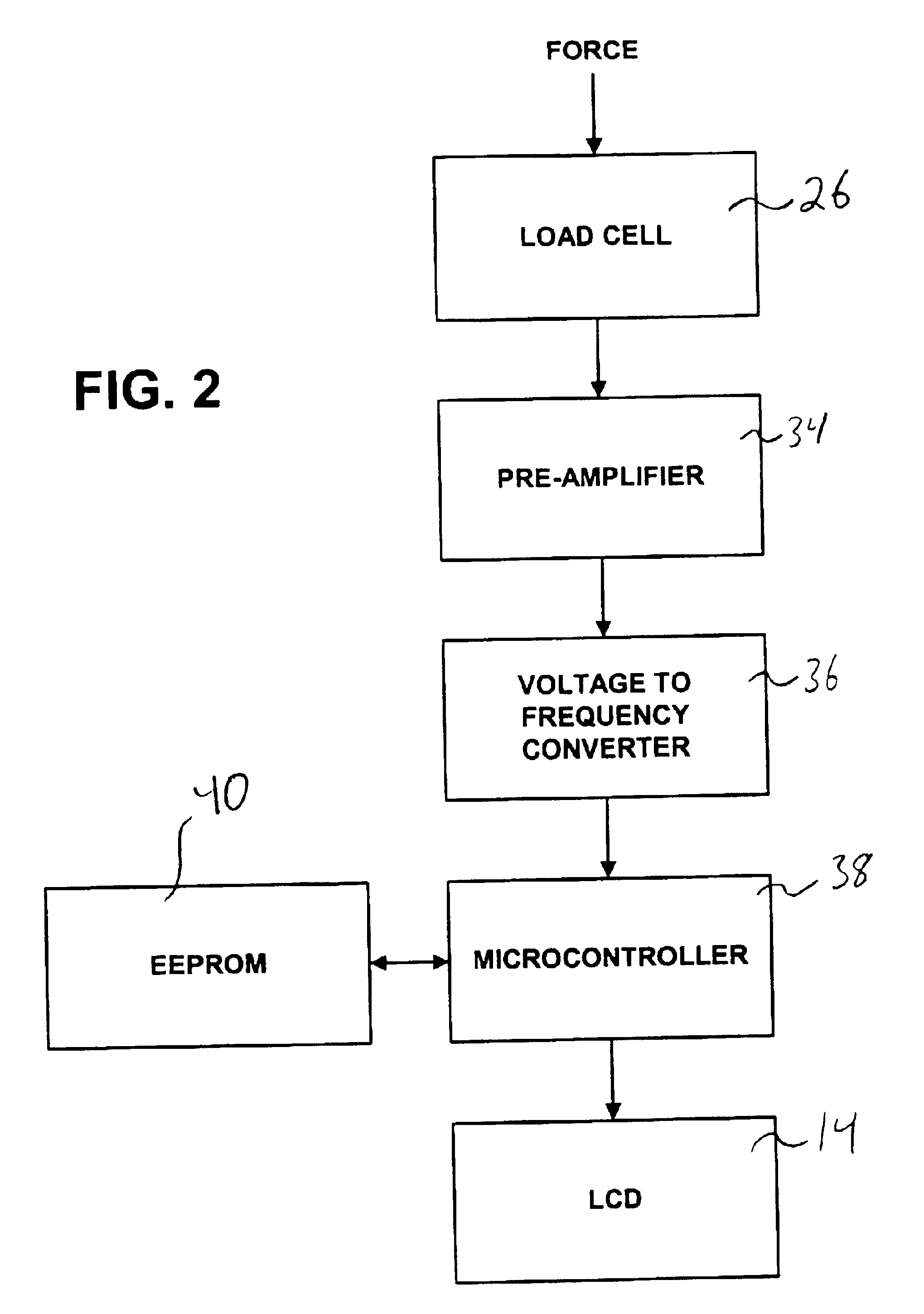

Electronic trigger pull gauge

InactiveUS6854975B2Easy to operateThe result is accurateAiming meansTraining adaptationMicrocontrollerControl theory

A gauge for measuring the force required to discharge a firearm by pulling its trigger includes a housing and a rod including a trigger hook portion at a distal end thereof for engaging the trigger. A load cell is connected to the housing and to a proximal end of the rod such that the load cell generates an electrical signal in response to forces on the rod as the housing is pulled while the trigger hook portion is engaged with the trigger. The magnitude of the electrical signal is proportional to the forces on the rod. A microcontroller receives the electrical signal and calculates a force value based thereon. The microcontroller also continuously monitors the forces on the rod and identifies a trigger pull value of the firearm as being the maximum force on the rod until pulling on the housing is ceased once the trigger of firearm has released.

Owner:LYMAN PRODS CORP

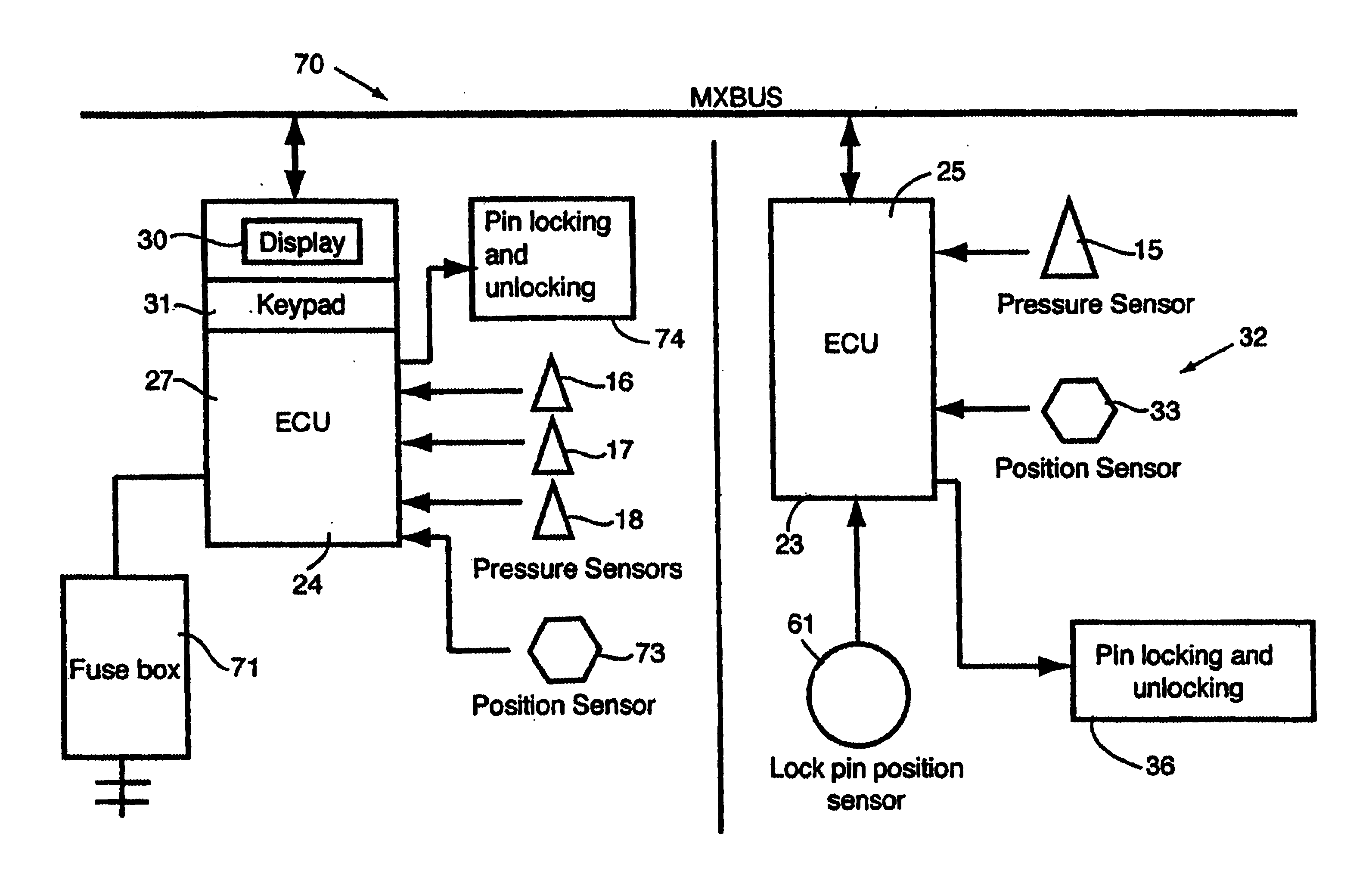

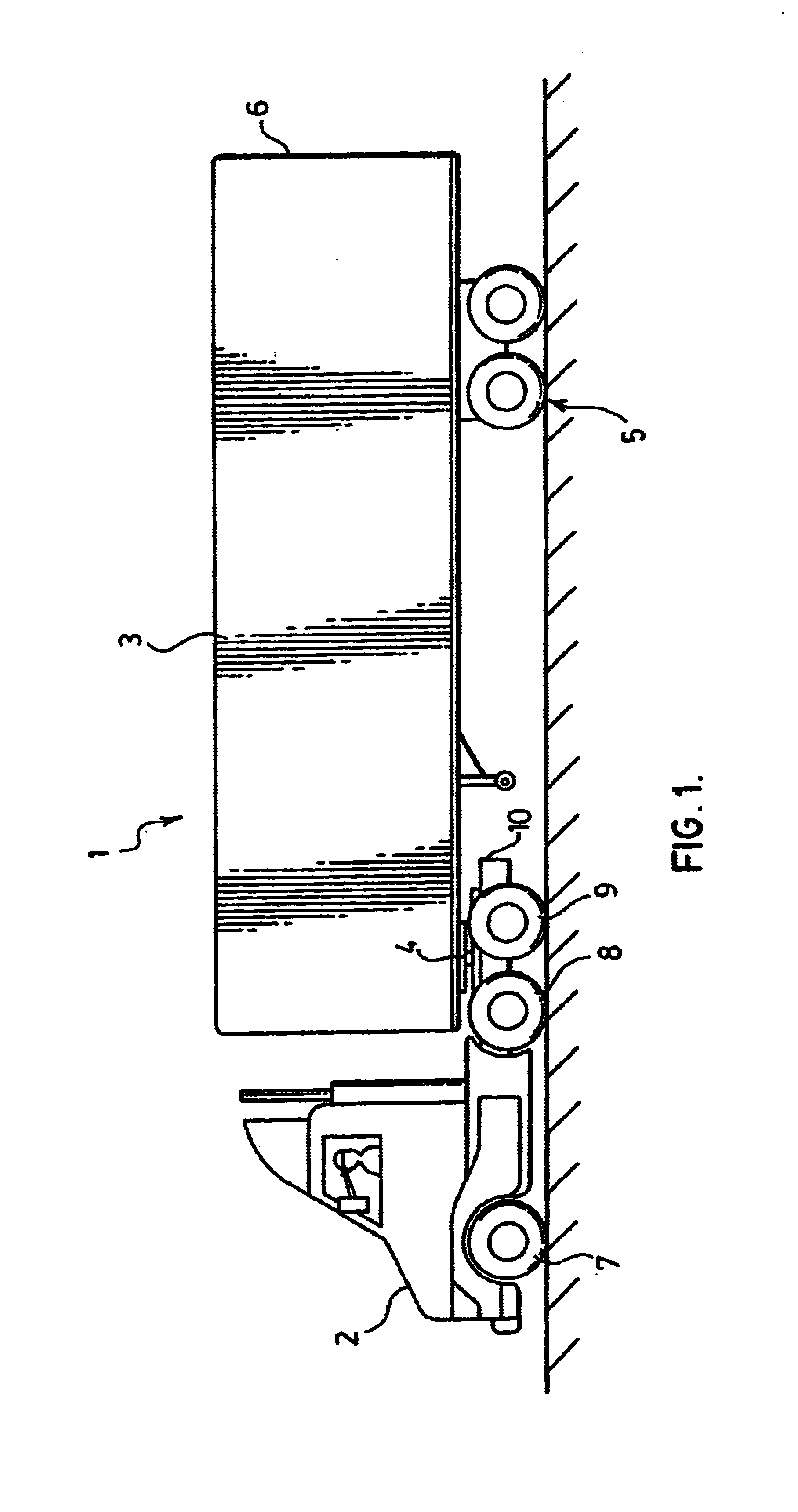

Axle weight distribution system

InactiveUS6921100B2Improve securityConvertible cyclesOptical signallingCommunication interfaceDisplay device

The present invention relates to a system for adjusting weight distribution throughout all axle groups of the truck and trailer. The trailer has at least one axle group mounted on a pair of rails attached to the frame of the trailer. These axle groups are locked in position on the rails by locking pins. The system for adjusting weight distribution according to the present invention measures the weight on every axle group on the truck and trailer. The measurement may be of weight directly by load cells etc. or indirectly, by taking measurements from the air suspension system to calculate weight. The measurements are delivered as an electrical signal to one or more microprocessors capable of receiving the electrical signals and calculating the optimum position of the axle group on the trailer. The position of the trailer axle groups relative to the rails is also determined and the position delivered to the microprocessor(s). The microprocessor(s) is programmed to calculate the weight on each axle group and determine any change in position of the trailer axle group(s) on the rails to optimize the weight distribution. The information is presented to the driver on a display located in the cab of the truck. The system further includes apparatus to lock and unlock the locking pins that lock the trailer axle group(s) in position on the rails. The system also includes a communication interface between the truck and the trailer.

Owner:WHEEL MONITOR

System for detecting and monitoring vital signs

Owner:STRYKER CORP

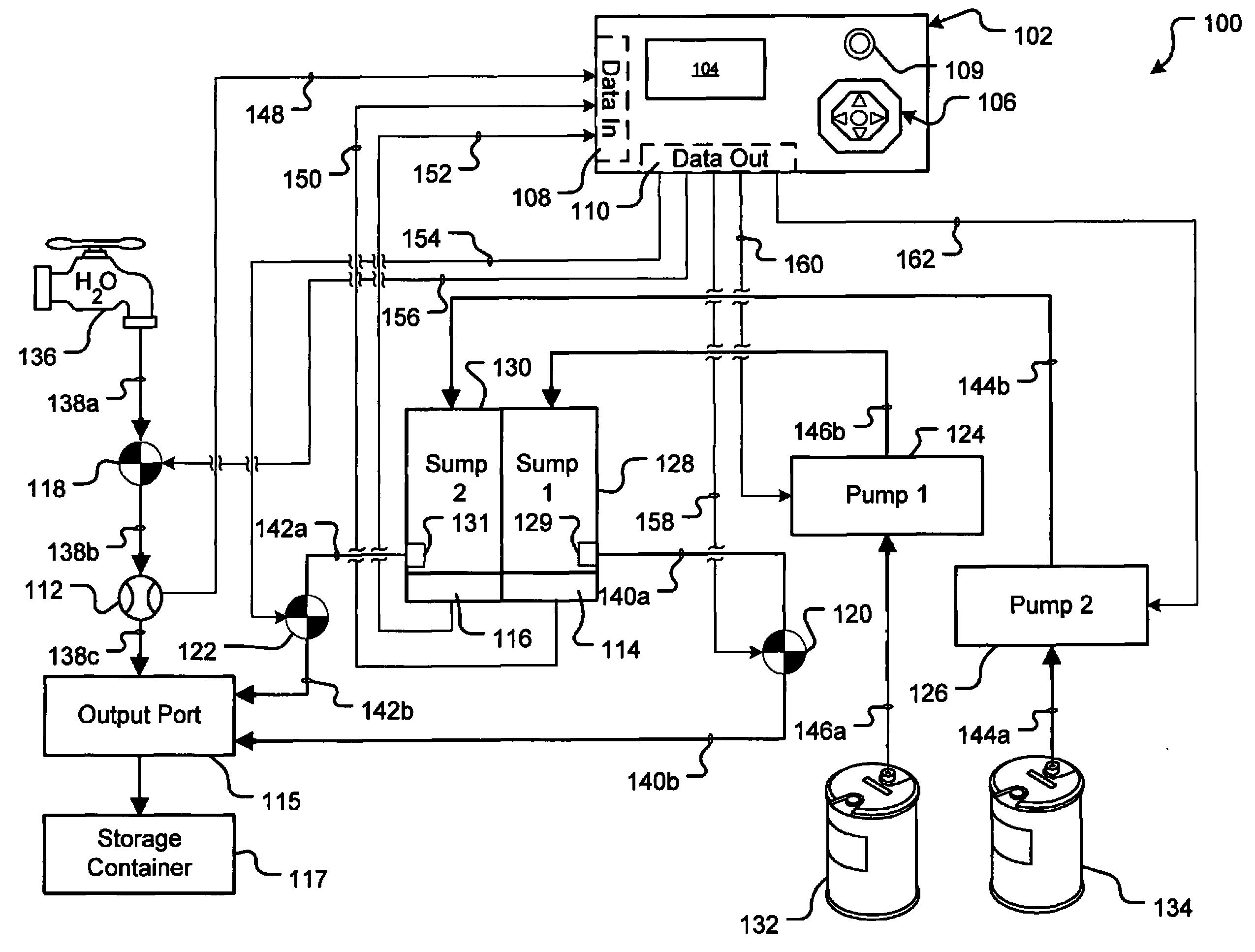

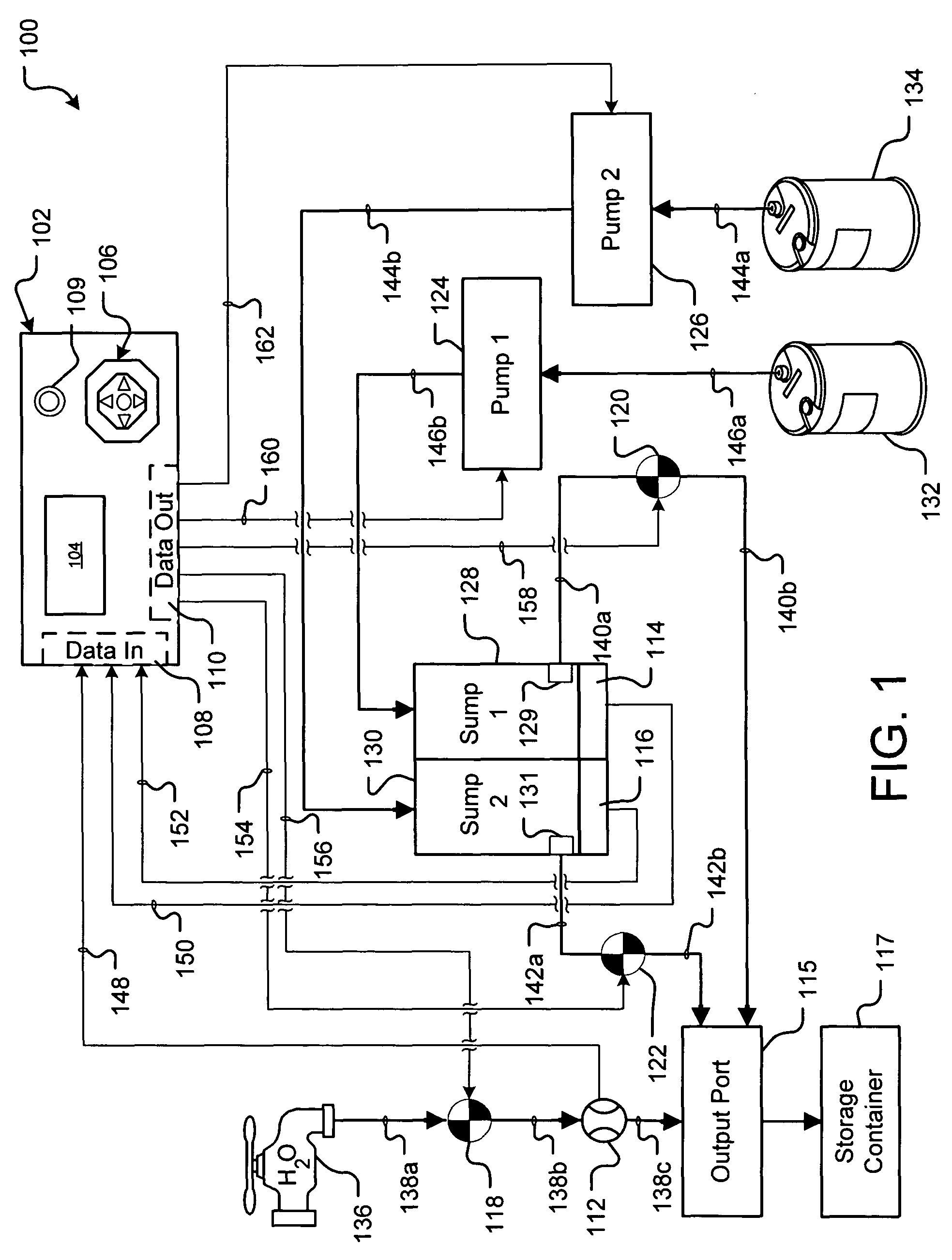

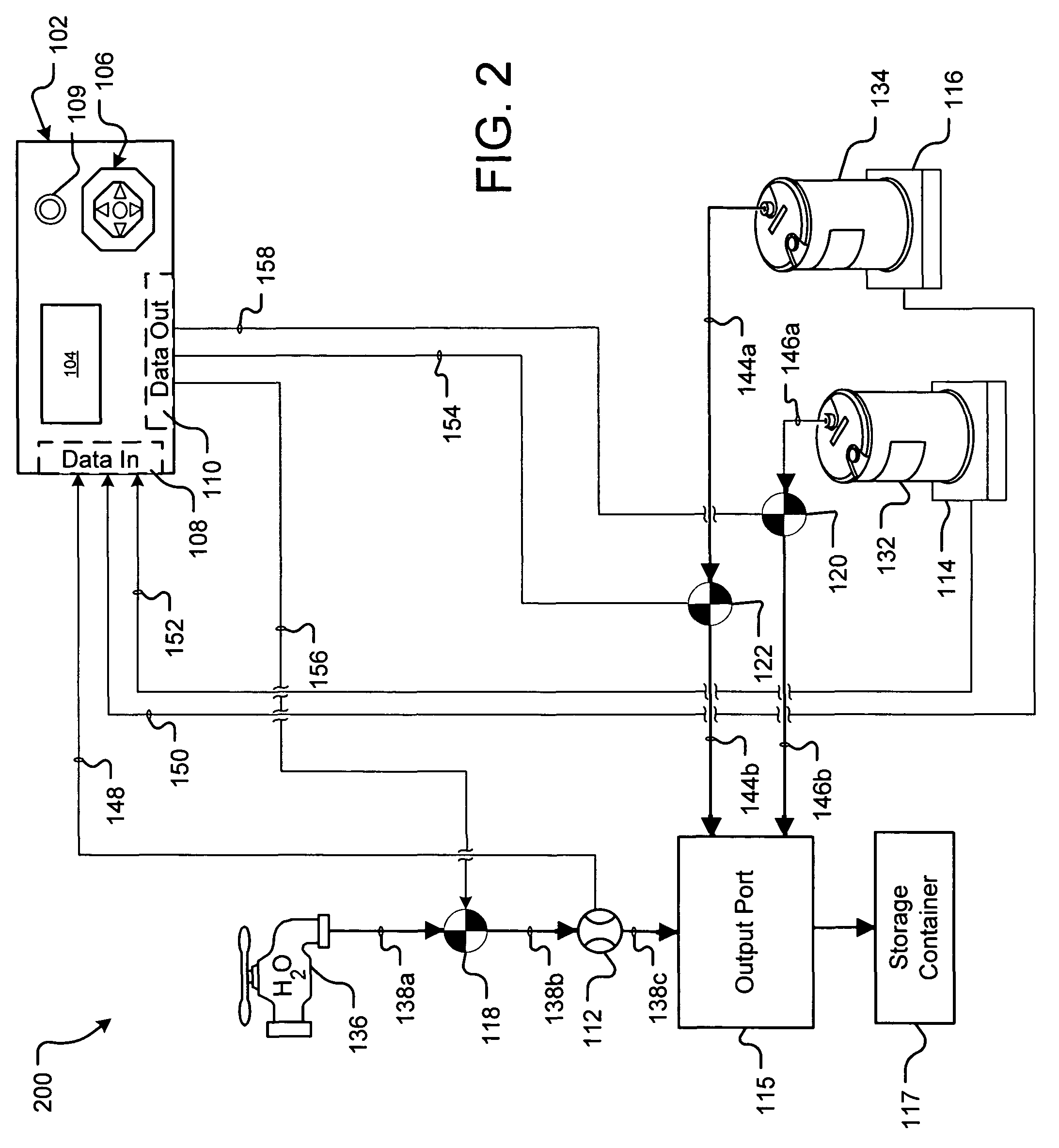

Formulating chemical solutions based on volumetric and weight based control measurements

A system and method for formulating a chemical solution using both volumetric and weight based measurements of components of the chemical solution is disclosed. The components of the chemical solution include water and at least one other component, which may take any form, such as, without limitation, liquid, solid, powder or gaseous form. Formulation of the chemical solution is administered by combining water with the one or more other components at an output port, from which this combination is dispensed to a solution storage tank. In response to a user's request to formulate a specified amount of the chemical solution, the volume of water provided to the output port is monitored by a flow meter and the weight of the other component(s) provided to the output port is monitored by one or more load cells. Based on such monitoring, appropriate amounts of water and the other component(s) are combined together to formulate the specified amount of the chemical solution in the solution storage tank.

Owner:ECOLAB USA INC

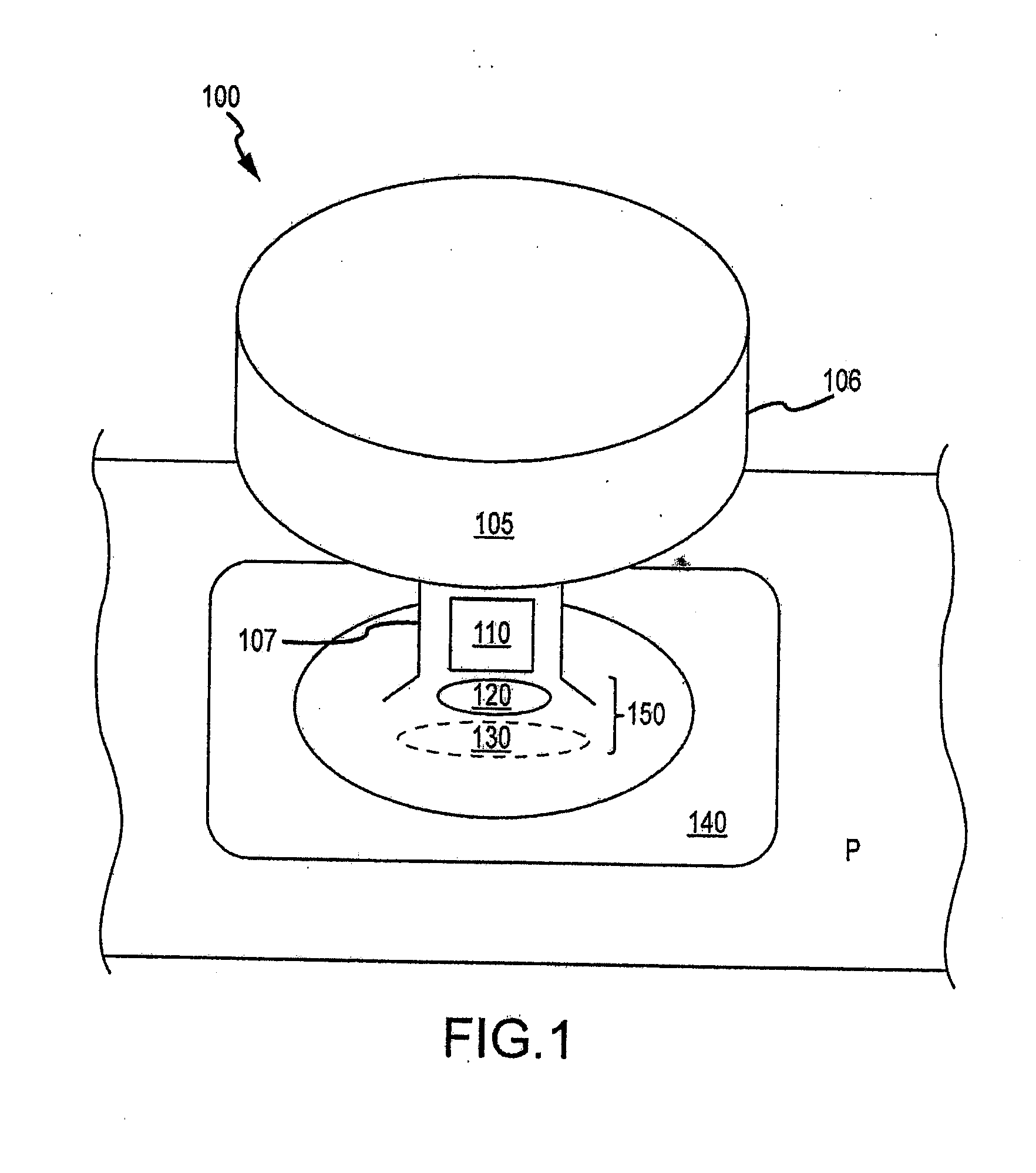

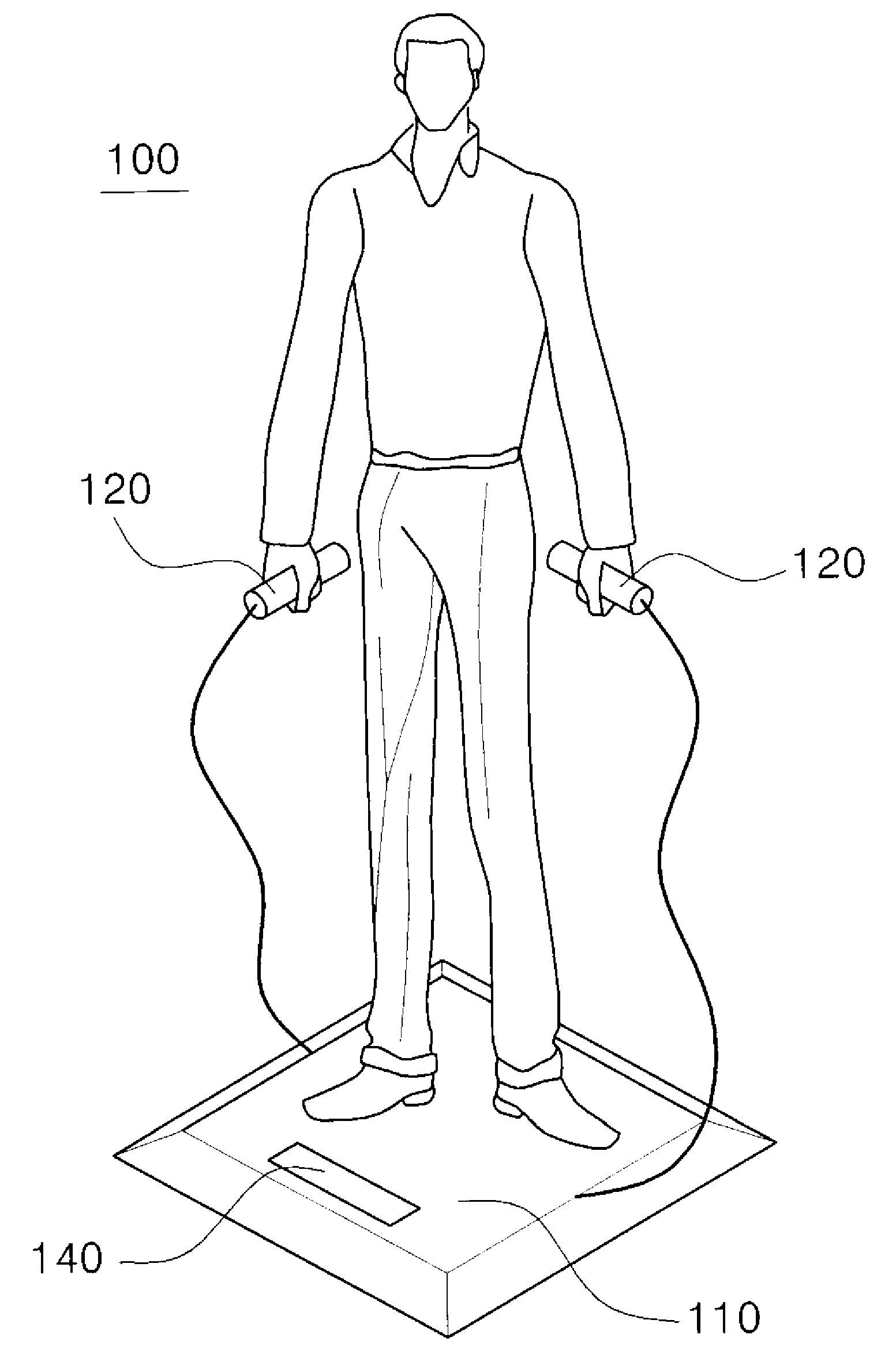

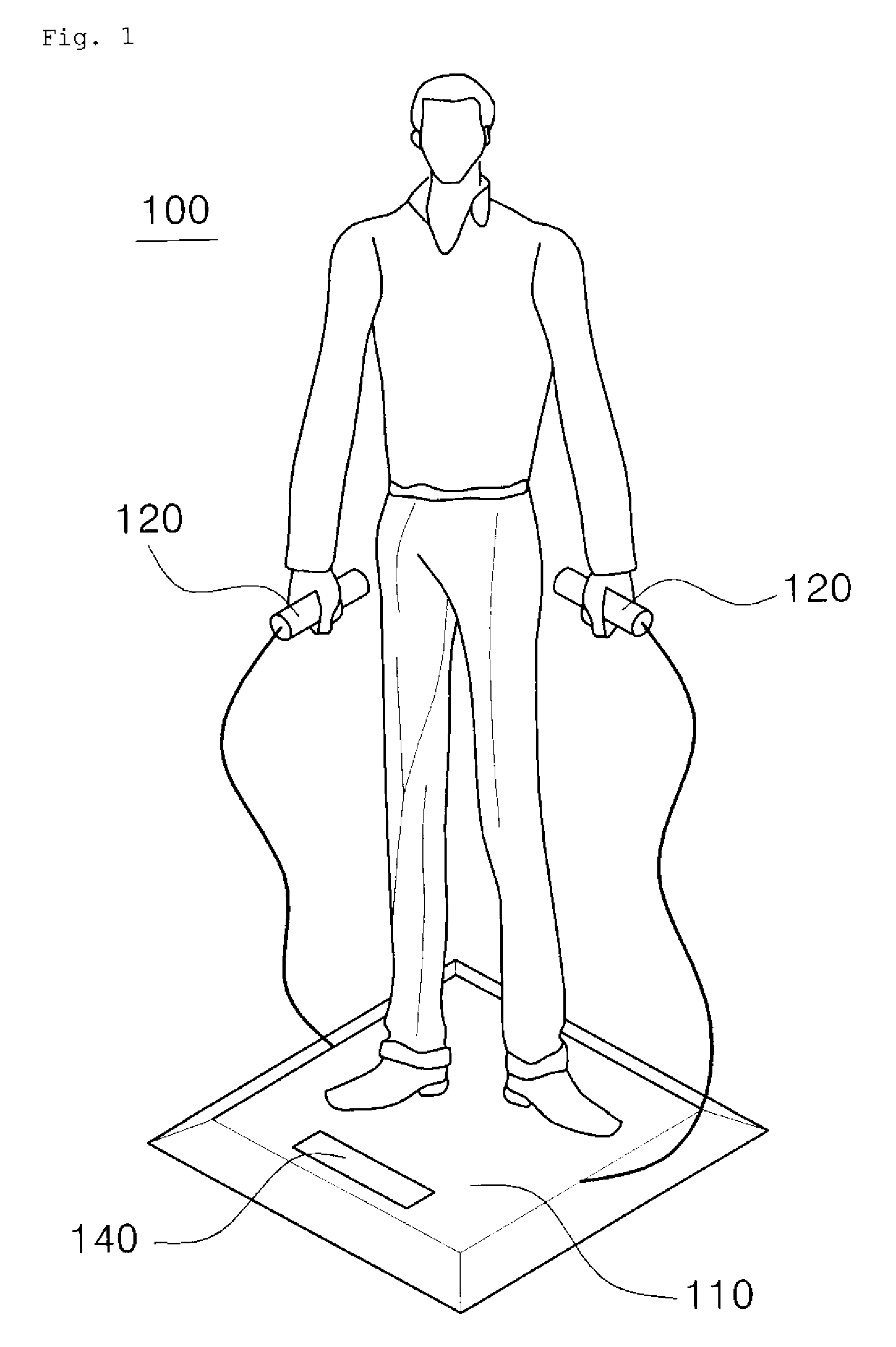

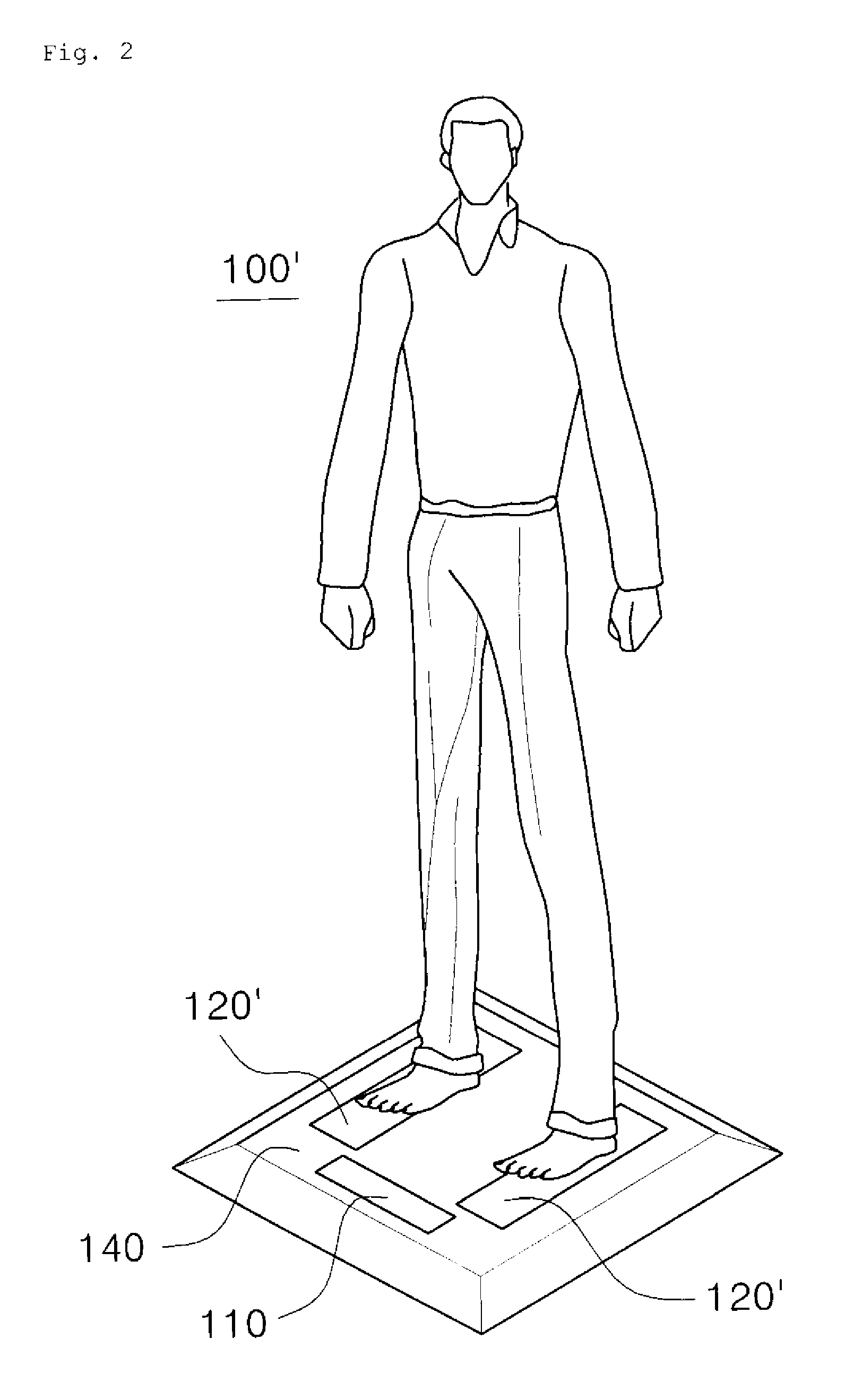

Scale-type nonconstrained health condition evaluating apparatus and method

ActiveUS20100210921A1Easily monitor cardiovascular health conditionMeasure securityElectrocardiographyCatheterHealth conditionLoad cell

A scale-type nonconstrained health condition evaluating apparatus includes a load cell sensor for sensing a ballistocardiogram signal and a weight signal from a measured person, an electrocardiogram sensor for sensing an electrocardiogram signal from the measured person, and a signal processor for calculating at least one of the heart rate, normalized stroke volume force, blood pressure and equilibrium sense abnormality of the measured person from the ballistocardiogram, weight and electrocardiogram signals sensed by the load cell sensor and the electrocardiogram sensor.

Owner:SEOUL NAT UNIV R&DB FOUND

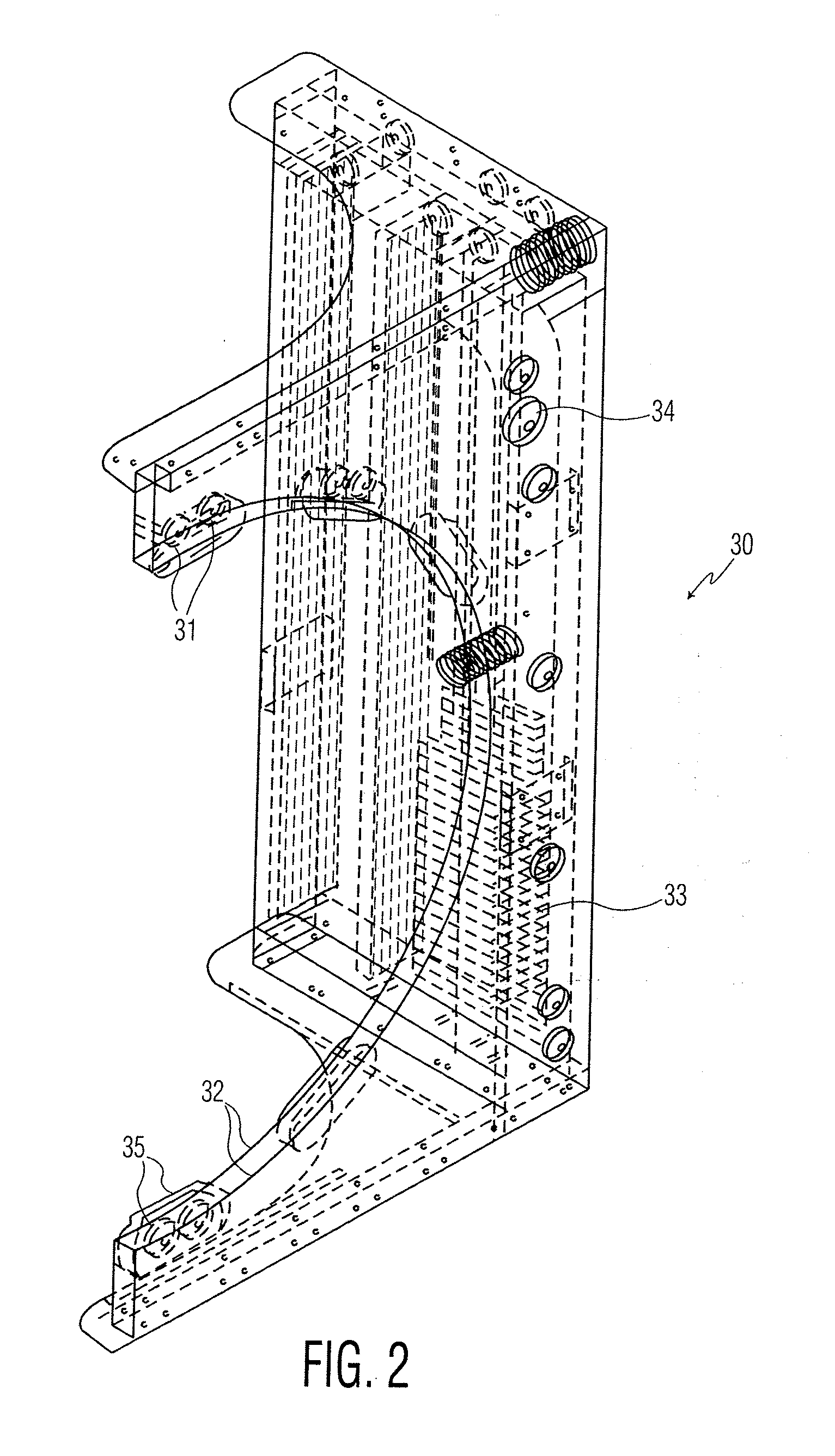

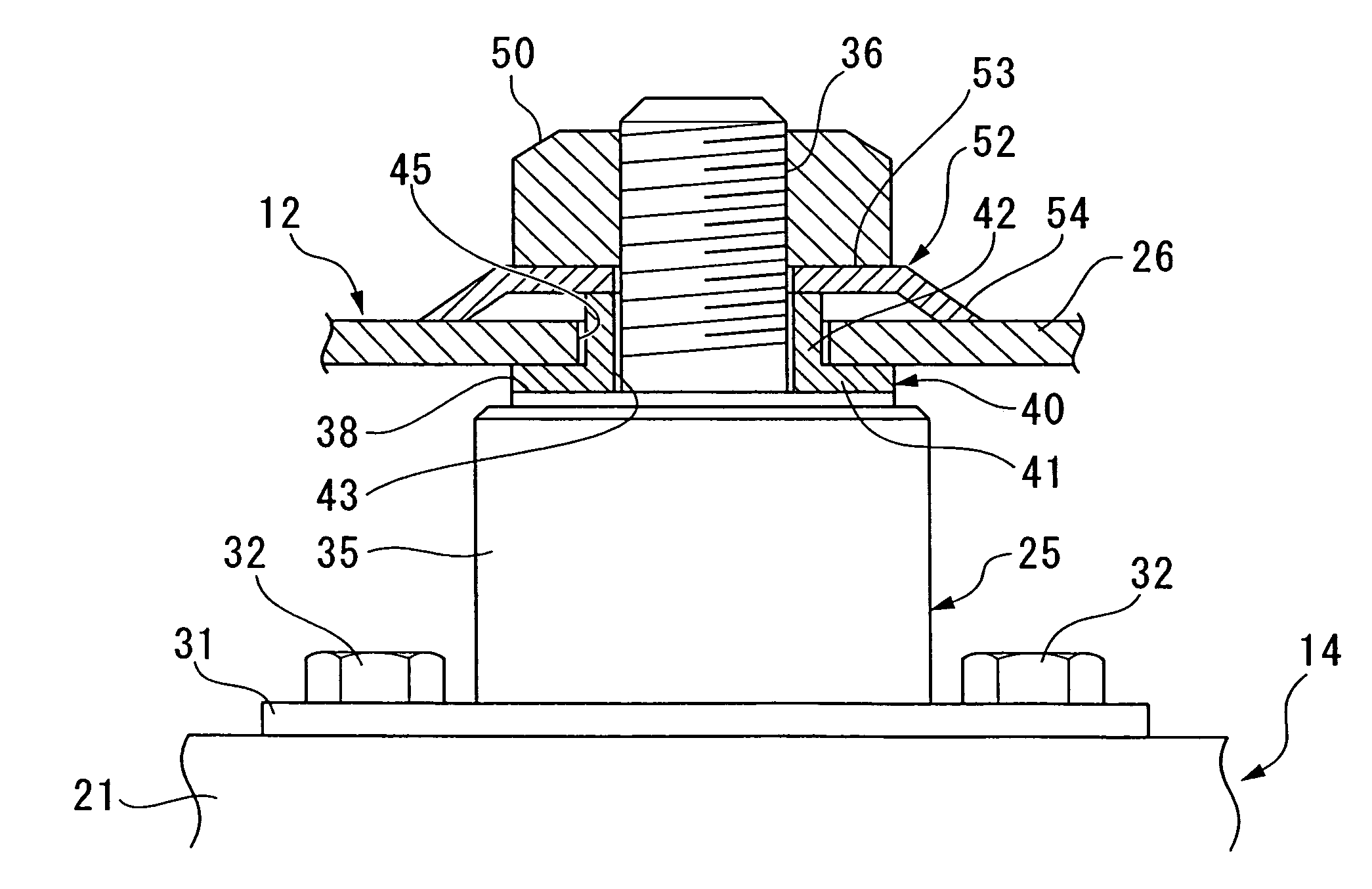

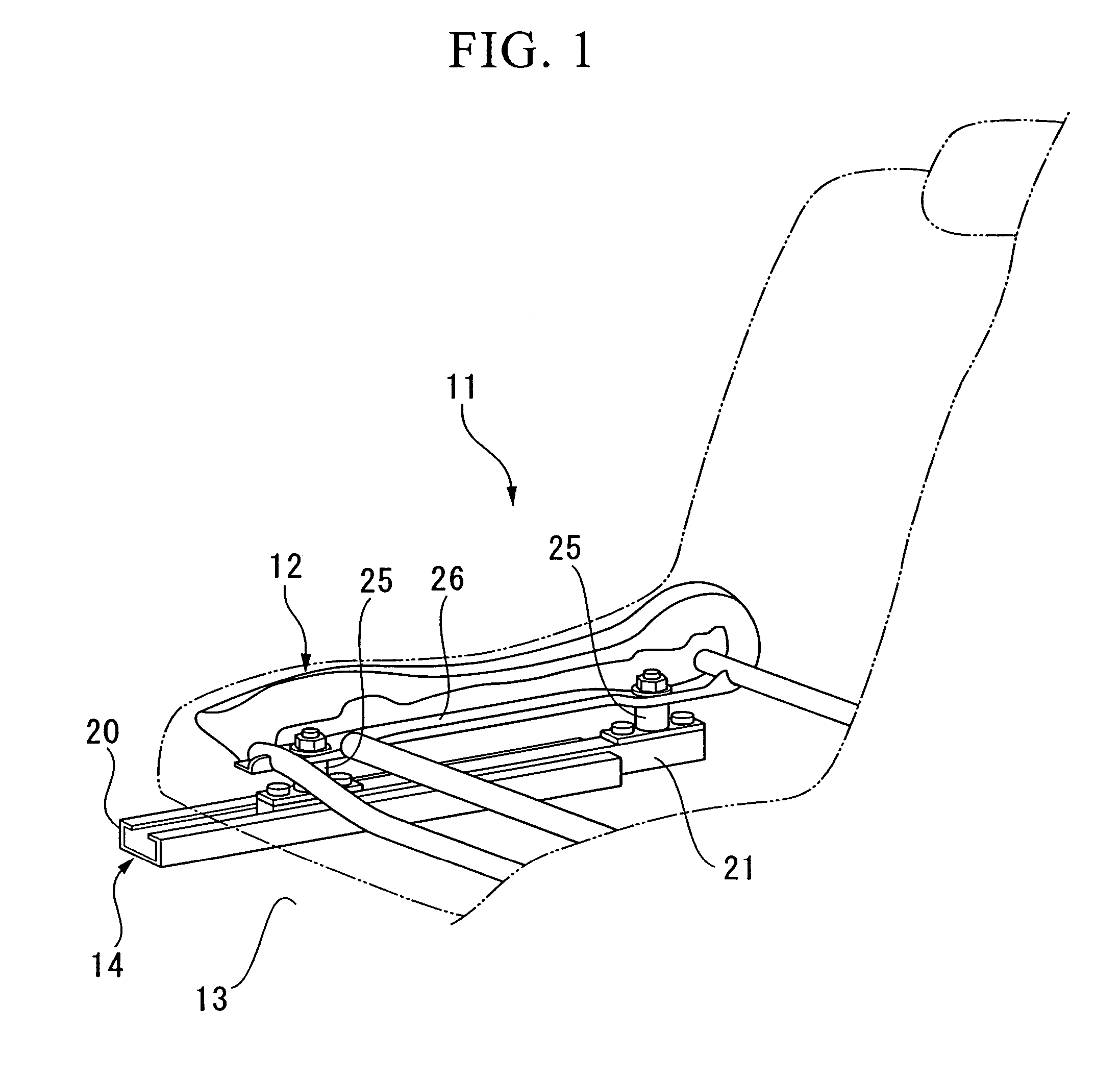

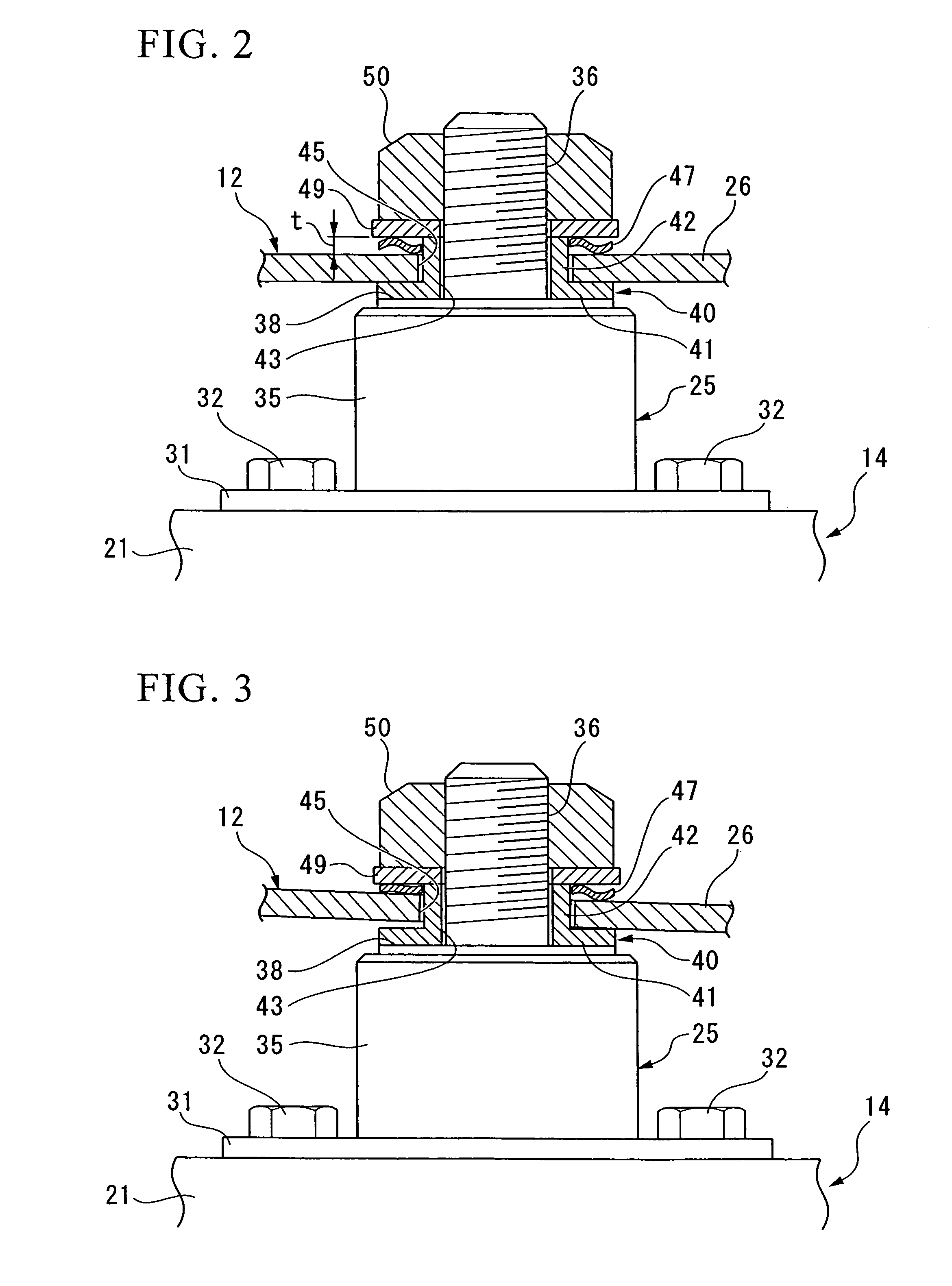

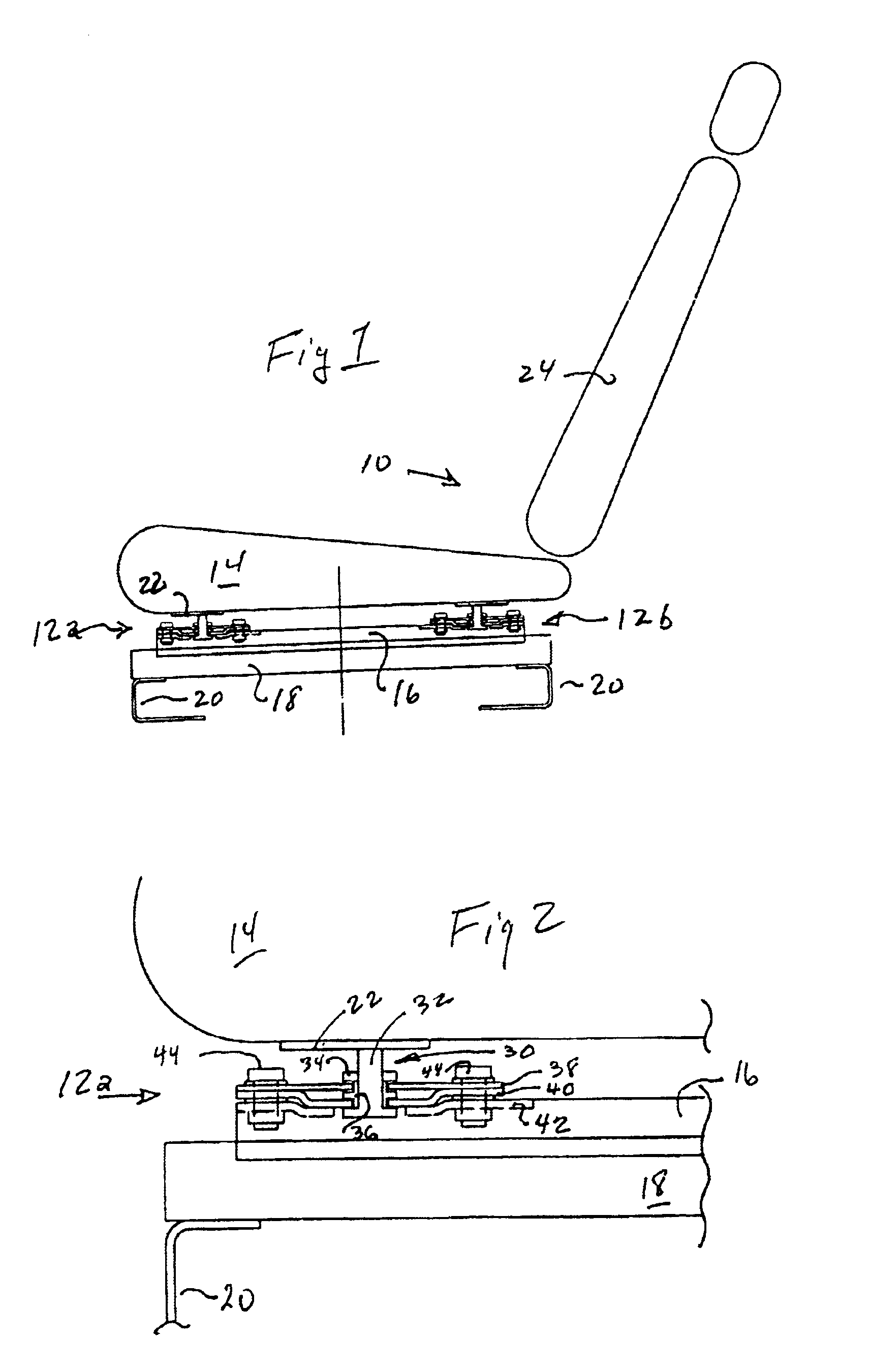

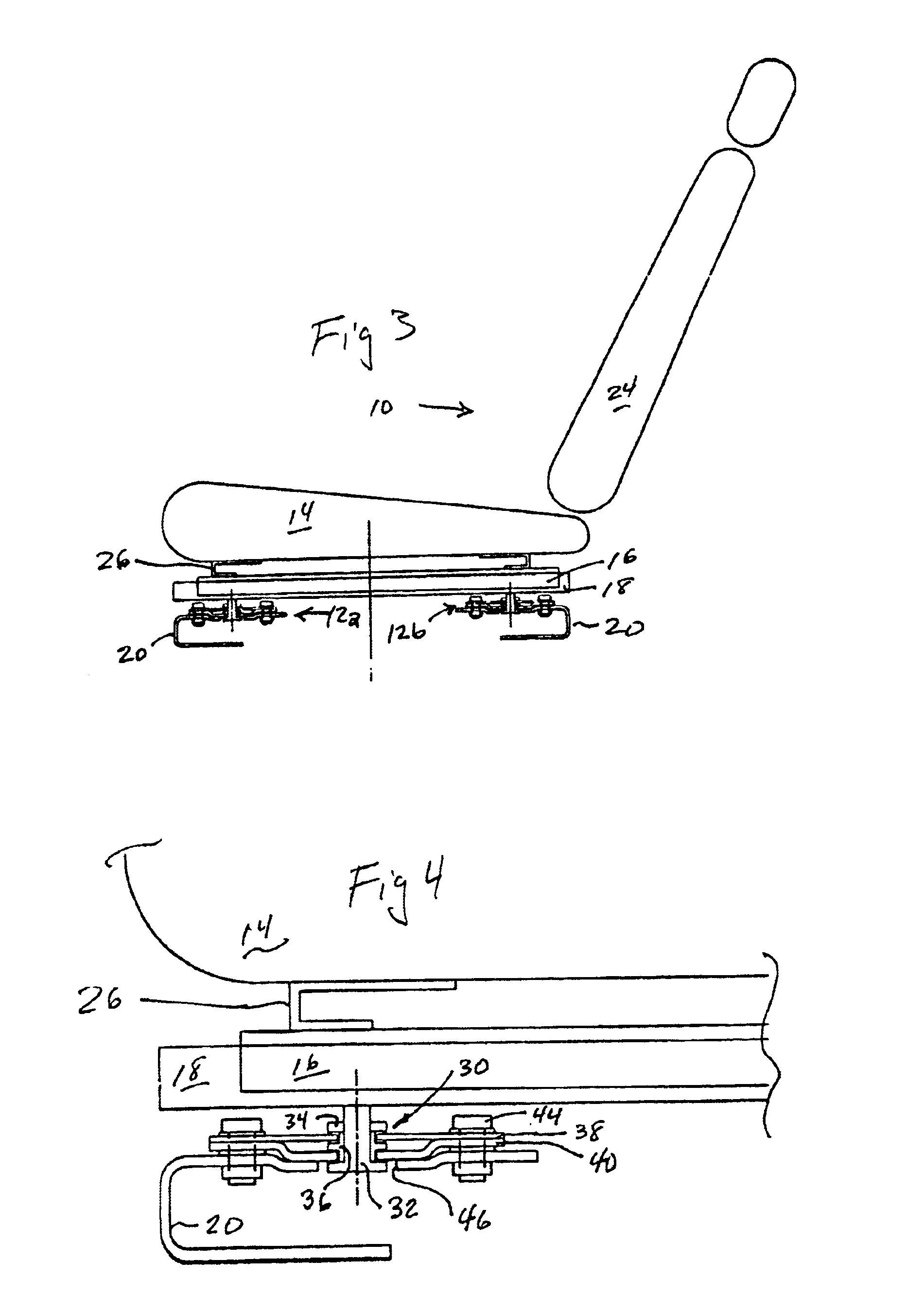

Load cell attachment structure

ActiveUS7373846B2Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

Agricultural implement with automatic down pressure control

Owner:DAWN EQUIPMENT COMPANY

Automatic down pressure adjustment system for set of ganged disc openers

A disc opener unit for an agricultural implement has a down pressure adjustment device that automatically adjusts the amount of down pressure applied on a furrowing disc based on strain measurements taken by a strain gauge or load cell. The strain gauge, which may be mounted to an arm that is used to set the position of a depth setting gauge wheel, provides feedback to a processor that in turn controls the amount of hydraulic fluid in a hydraulic cylinder to adjust the down force applied on the disc. The amount of down pressure is therefore adjusted in substantially real-time in response to changes in field conditions, which improves furrow depth consistency and reduces wear on the gauge wheel and its components.

Owner:CNH IND CANADA

Weight sensors having centralized loose tolerance universal force and Mx/My moments overload stops

InactiveUS6916997B2Convenient travelReduce loadWeighing apparatus using elastically-deformable membersElectric devicesModularityAngular rotation

Automotive load cells having centralized, multi-axis, loose tolerance overload / limit stops provide improved strain gauge response. The modular, integrated stop assemblies magnify sensor substrate deflection by use of opposed concave (Belleville) springs are used in direct contact with the substrate to accommodate ±Z axis deflection and Mx / My moment angular rotation. A flanged guide member on the load stud permits a wide range of geometries. The substrate is thickened around the load stud hole and the outboard support bolt holes. Hollow rivets assist in design modularity. Strain gauges are placed at the yield zones symmetrically with respect to the X axis. The substrate hole Mx / My gap is larger than the stop bracket hole to insure a positive stop for Mx / My moments prior to yield. The inventive multi-axis stop assembly is used in any type load cell, including rectangular, thinned, notched, necked / dogbone, or cantilever substrates with any strain gauge layout configuration.

Owner:ROBERT BOSCH CORP

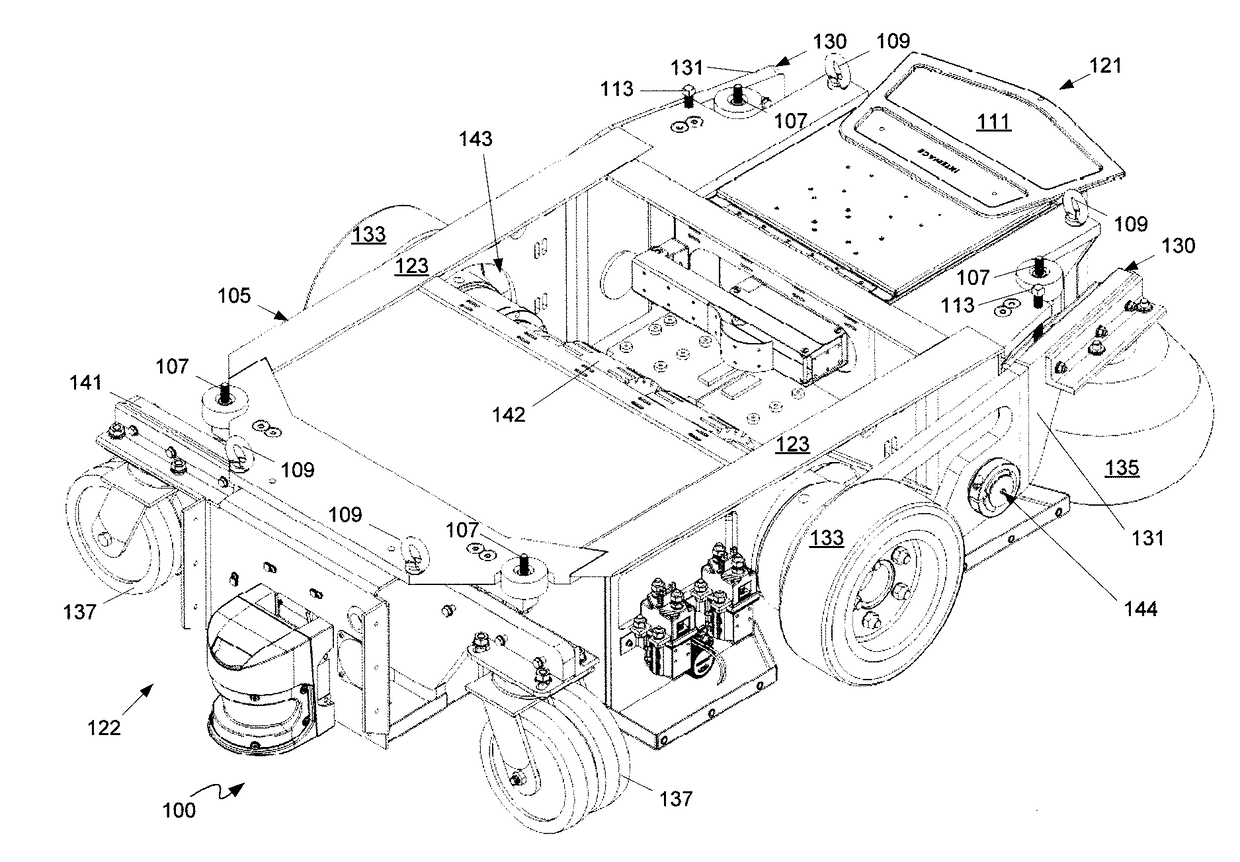

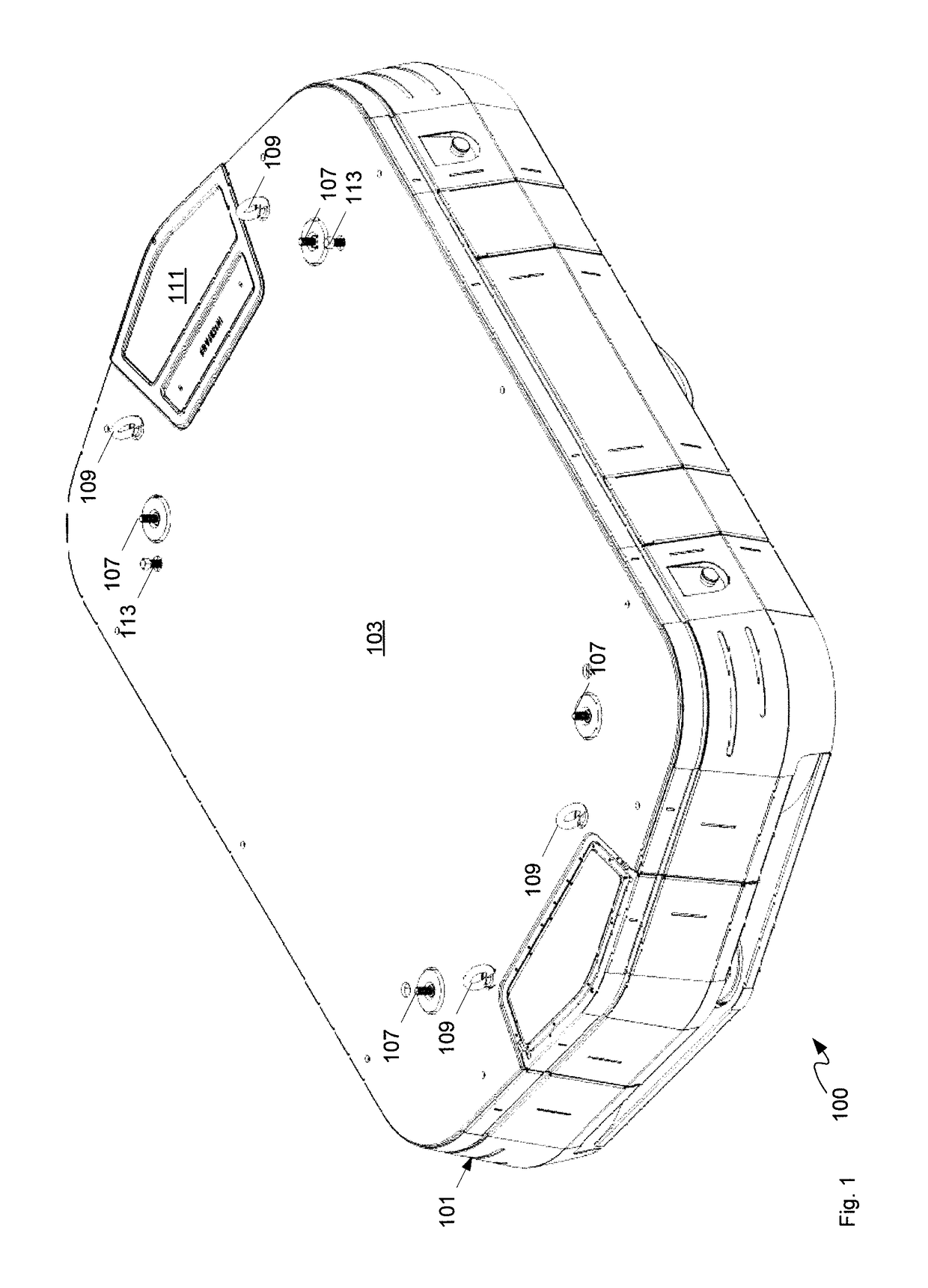

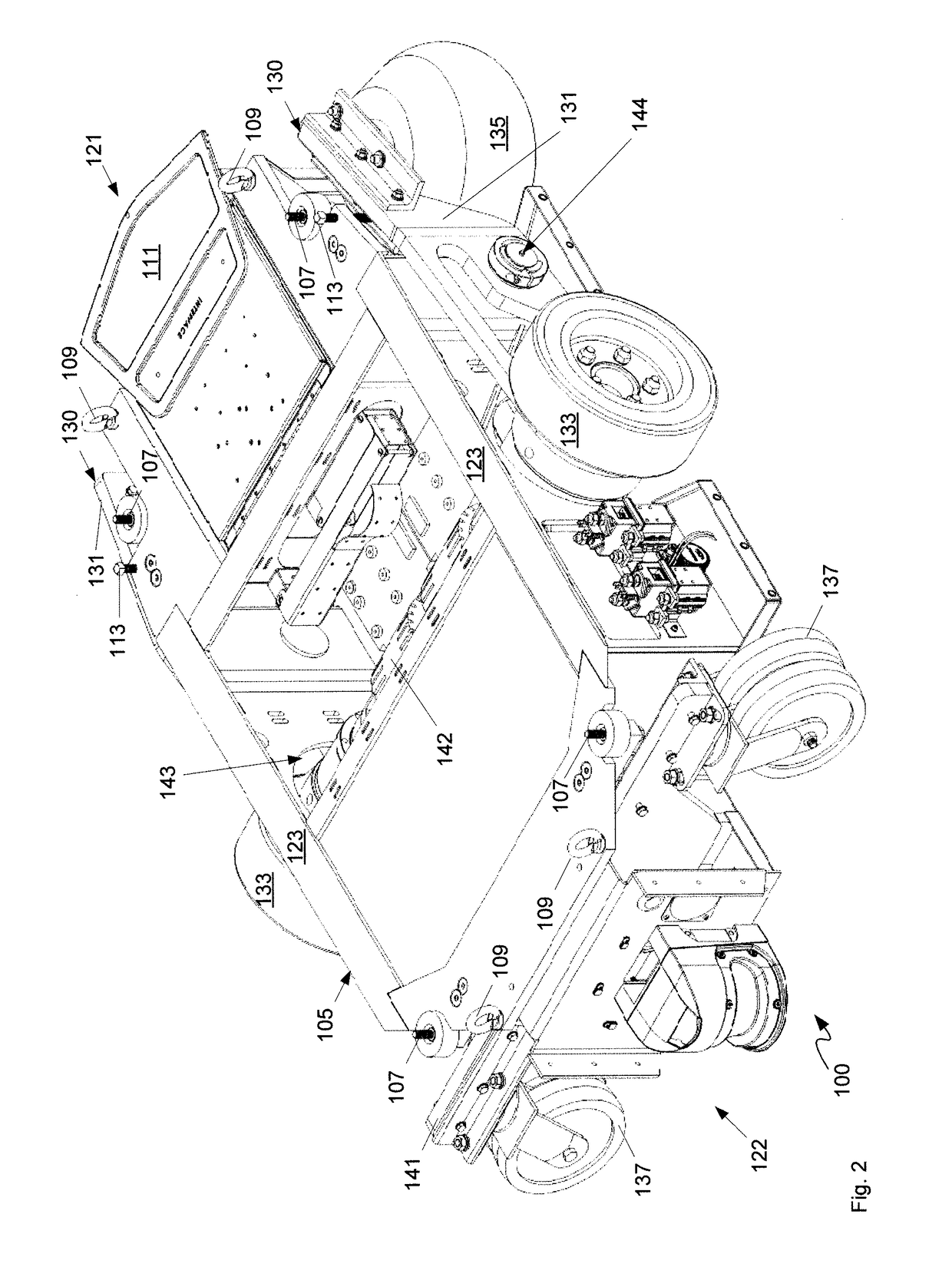

Mobile platform for materials transport

A mobile platform for materials transport is provided. The platform includes a pair of suspension devices that in turn include a pair of rocker beams which can be rotated between two positions: a first position where central wheels attached thereto can be used to drive the platform; and a second position where the central wheels are retracted and the platform can be rolled on end wheels without the friction of the central wheels, and an associated drive system, impeding movement of the platform. Furthermore, data from sensors and / or load cells can be used to control movement of the platform; specifically, shifts in load distribution and / or sensed forces at the suspension devices can indicate that a load (and / or materials) has shifted and / or is shifting and movement of the platform is adjusted accordingly, for example to prevent the platform and / or the load (and / or materials) from tipping.

Owner:CLEARPATH ROBOTICS

Apparatus and method for counter-resistance exercise

An apparatus and method for counter-resistance exercise includes a cable and pulley system and a force sensing device operatively coupled to the cable and pulley system. The cable and pulley system has at least one pulley and at least one substantially inelastic cable configured for engagement with the pulley. The force sensing device is operable to generate data relating to a mechanical force applied to the cable by a user during a counter-resistance exercise in which the mechanical force is applied by a first muscle or muscle group and is opposed by a second muscle or muscle group. In one embodiment, the mechanical force applied to the cable is transferred to a load cell and the load cell converts the mechanical force to a proportional electrical signal. In another embodiment, a wireless transmitter transmits the electrical signal to a display configured for wireless communication with the transmitter and the display provides the user with biometric feedback relating to the exercise.

Owner:HORNE EDWARD F

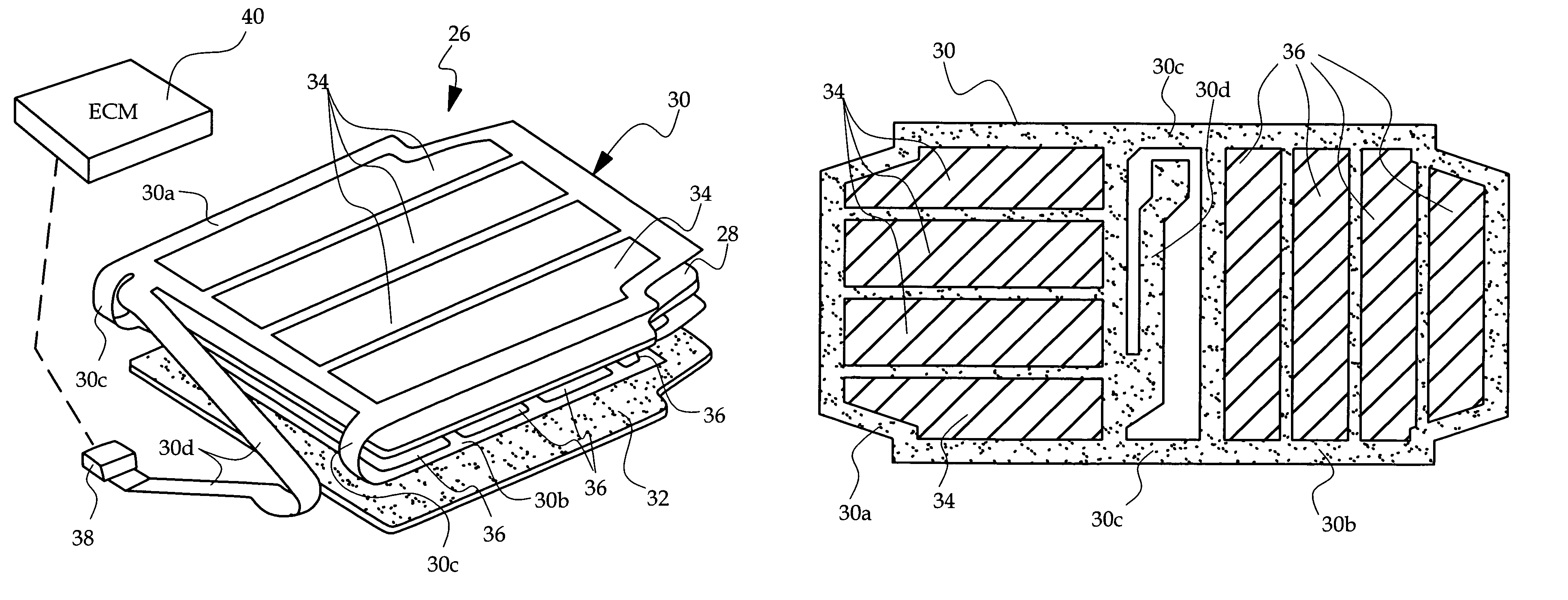

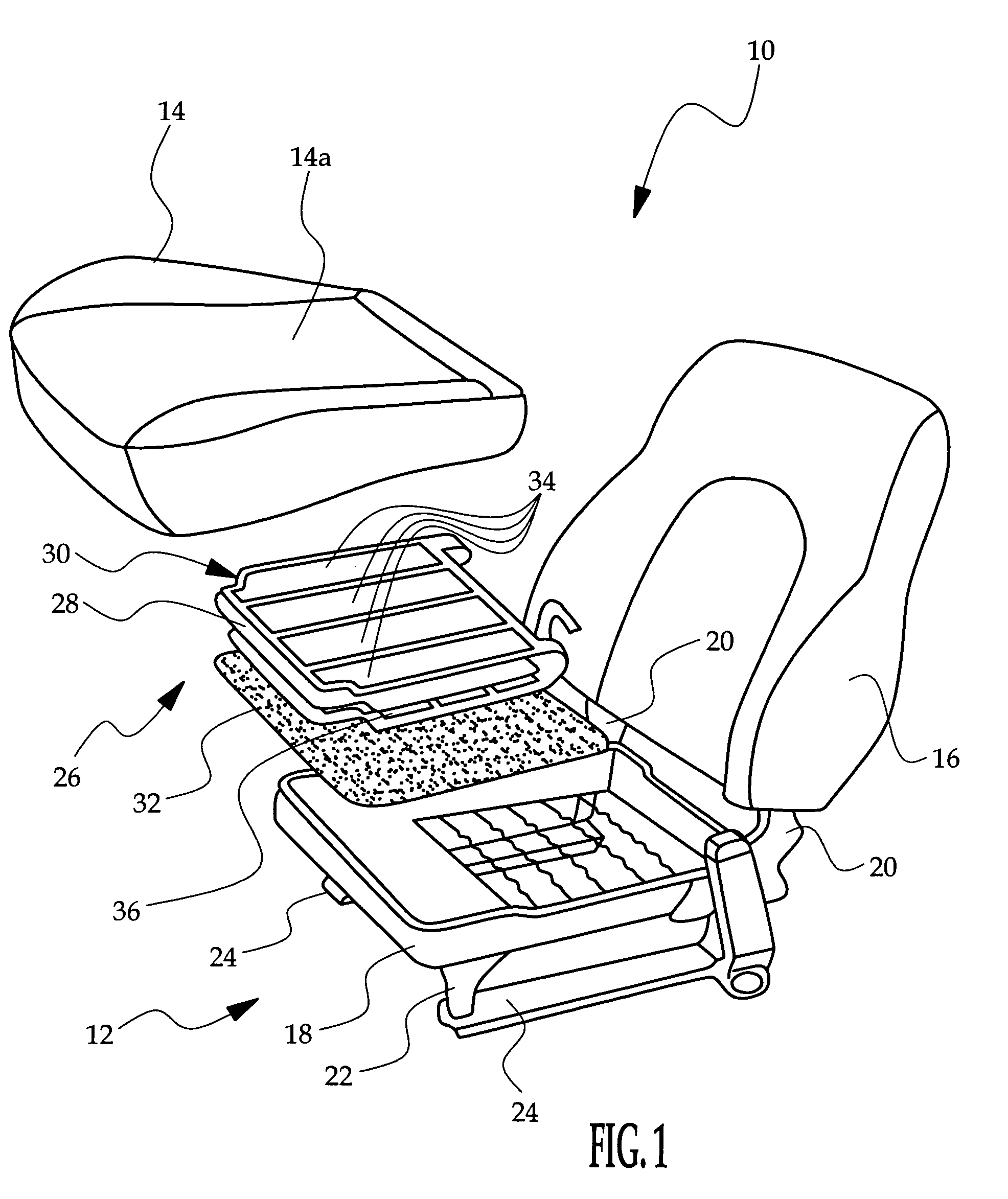

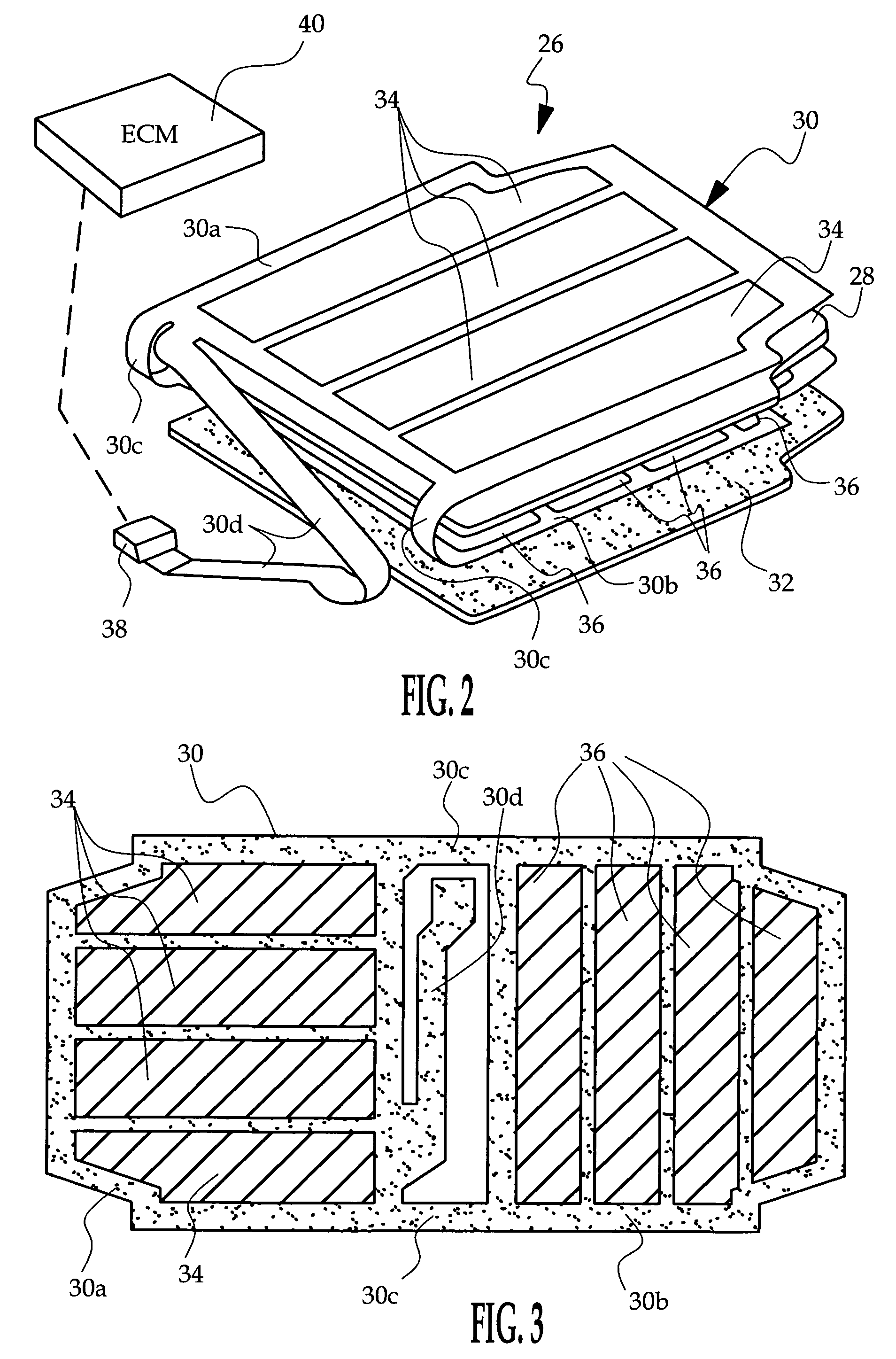

Capacitive sensing apparatus for a vehicle seat

ActiveUS7217891B2Reduces parasitic couplingImprove measurement resolutionVehicle seatsWeighing apparatus using elastically-deformable membersCapacitanceDielectric

A capacitive sensing apparatus for a vehicle seat includes a deflectable dielectric mat and a flexible printed circuit that wraps around the major surfaces of the dielectric mat to define upper and lower conductor strips that overlap in a direction perpendicular to the dielectric mat. Overlapping regions of the conductor strips define an array of capacitive load cells distributed over the seating surface. A connector stub depending from the flexible printed circuit couples the conductor strips to an external circuit that measures the capacitance of the various load cells to determine occupant weight and weight distribution.

Owner:APTIV TECH LTD

System load testing coordination over a network

A method and system using one or more load cells coordinates load testing of one or more sites under test over a network such as the Internet in accordance with one or more load test requests. In one embodiment, such method and system facilitates an economic, efficient, and accurate evaluation of the capacity of the SUTs to support concurrent users of the SUTs. A load test request is received from a User and provides information concerning a load test to be performed on a site under test (SUT). A load test is generated, and the load test is allocated to one or more load cells. The load cells perform the load test by sending load test data to the SUT and receiving responses from the SUT. Portions of a load test may be allocated to different load cells, which may be geographically remote from the SUT and / or geographically diverse. Multiple concurrent pending load tests may be processed for the same SUT. A load cell may concurrently perform all or a portion of multiple different load tests for multiple different SUT's simultaneously. A reporting function generates a report based on the responses received from the SUT. The reporting function may in addition or alternatively allow the User to view real-time results during load test execution.

Owner:EUREKA SOFTWARE SOLUTIONS

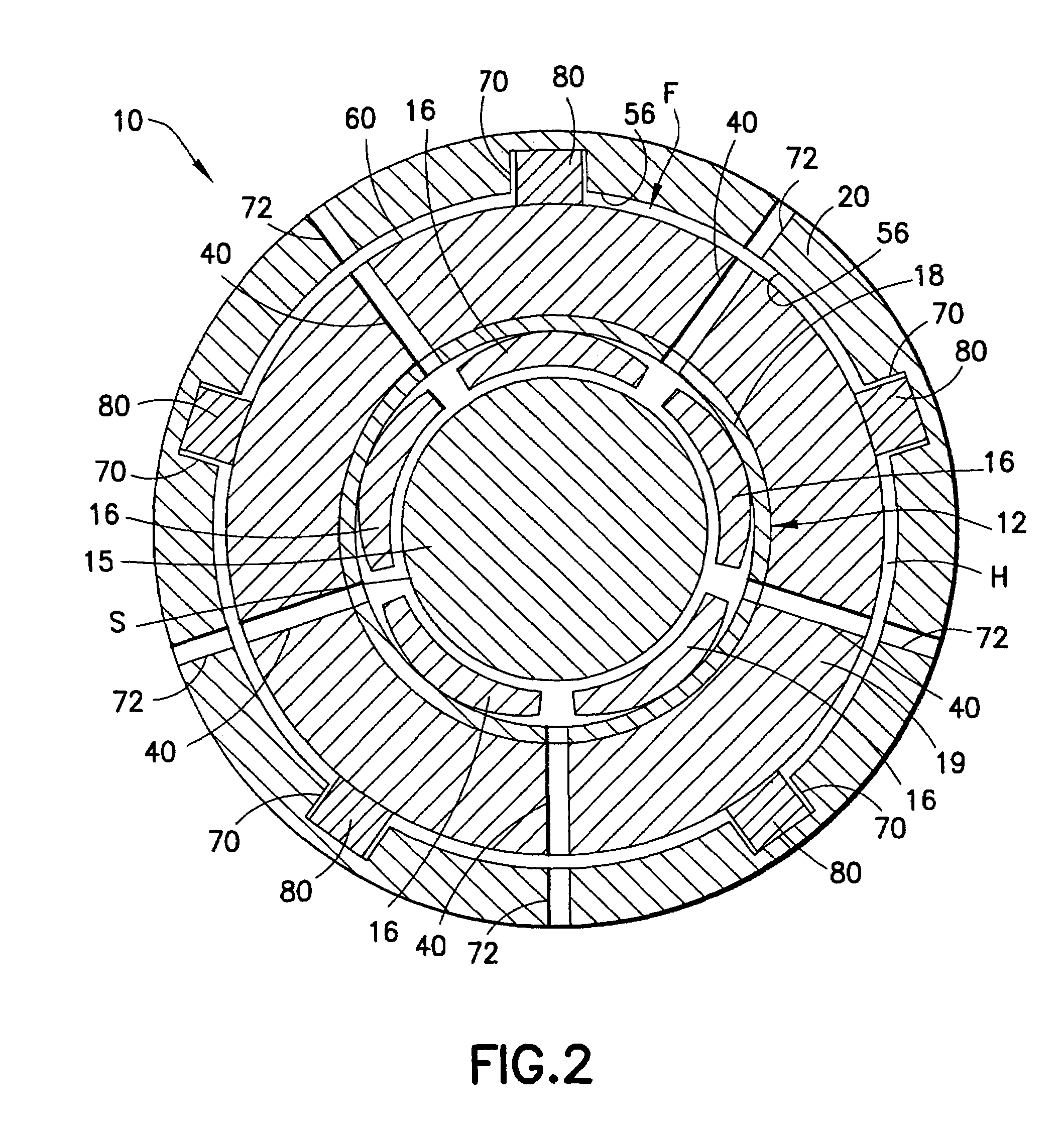

Bearing assembly and centering support structure therefor

The bearing assembly includes an annular bearing in which the shaft is disposed and a support structure for supporting the bearing. The bearing support is mounted about and radially supports the bearing. The bearing support at least in part defines a squeeze film annulus of the bearing assembly. A plurality of centering elements is associated with the bearing and bearing support and act to center the bearing within the squeeze film annulus. The centering elements are provided at radially spaced locations around the bearing. The centering elements may also be cylinder springs provided at uniformly spaced locations around the bearing. The centering elements may additionally be load cell springs provided at uniformly spaced locations around the bearing. In an alternative embodiment, a singular annular wave spring may be provided in place of the plurality of centering elements.

Owner:ELLIOTT CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com