Patents

Literature

193 results about "Squeeze film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

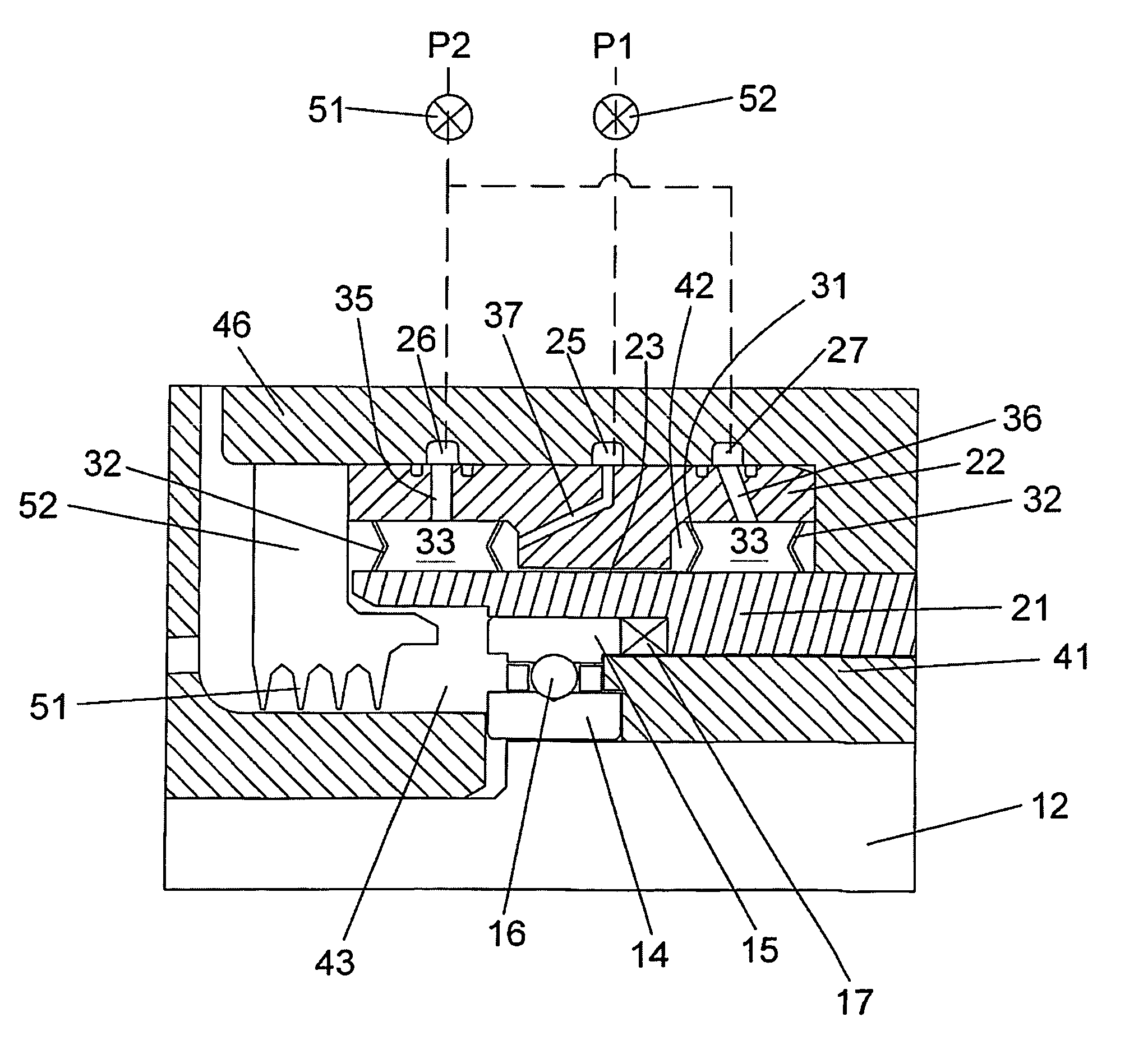

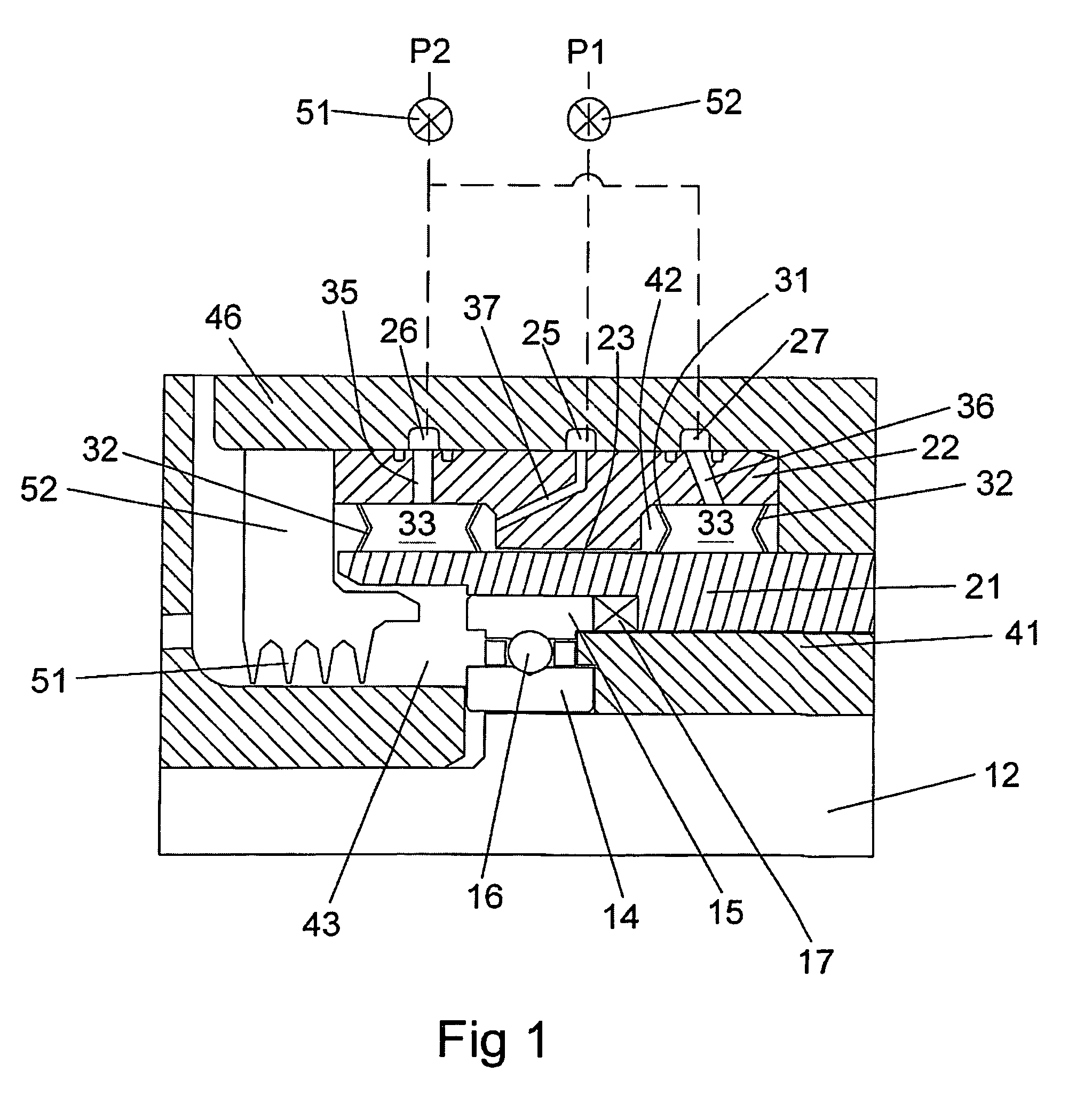

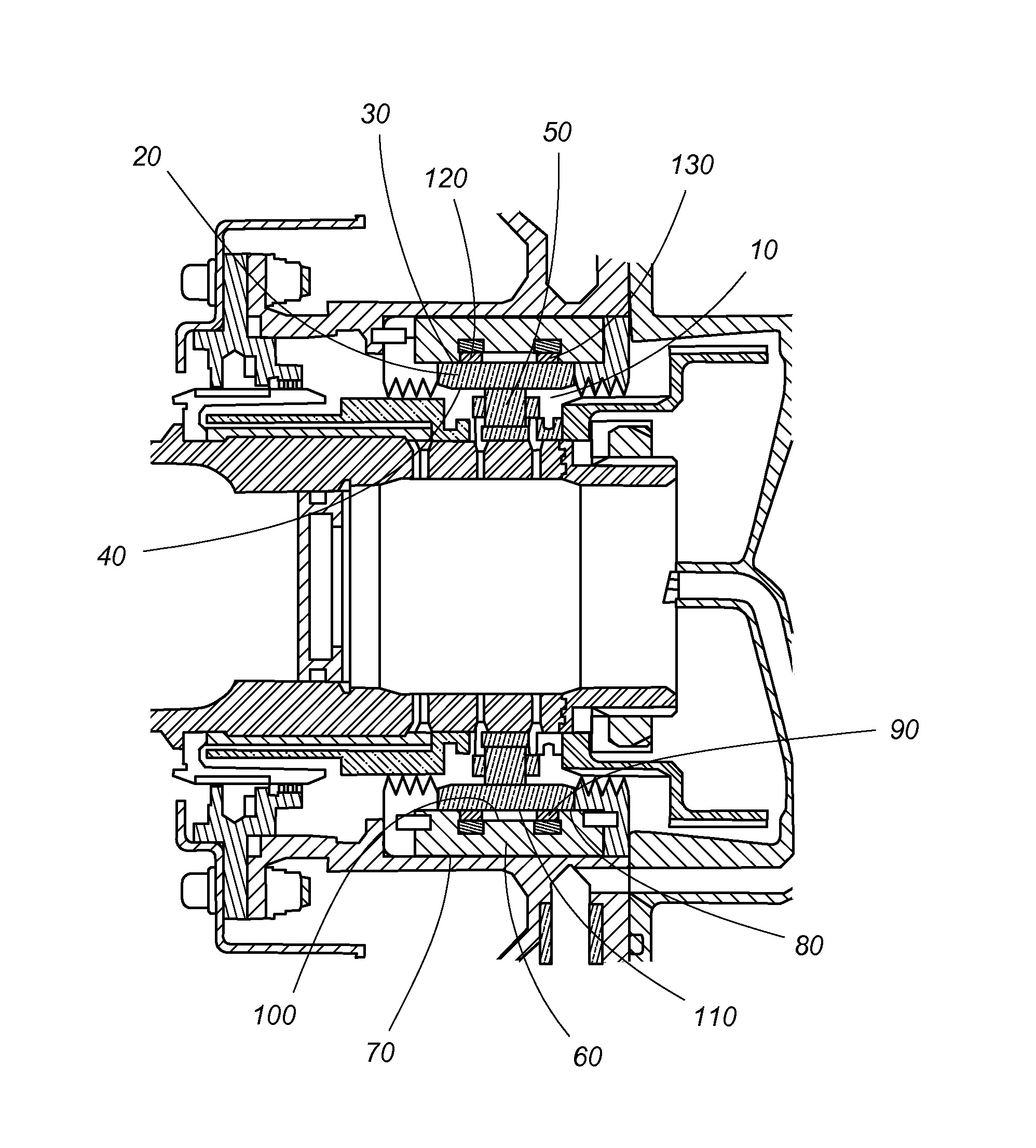

Squeeze film damper with variable support stiffness

A squeeze film damper assembly having a variable stiffness and damping control. The squeeze film damper includes a damper chamber formed by two flexible bellows chambers of the sides. A first pressure source is applied to the damper chamber to regulate the damping. A second pressure source is applied to the flexible bellows chambers to vary the stiffness of the damper. The flexible bellows chambers are secured between an outer member and an inner member of the damper assembly and form the sealed damper chamber. A pressure ratio between the bellows chambers and the damper chamber can vary to control the stiffness of the squeeze film damper.

Owner:FLORIDA TURBINE TECH

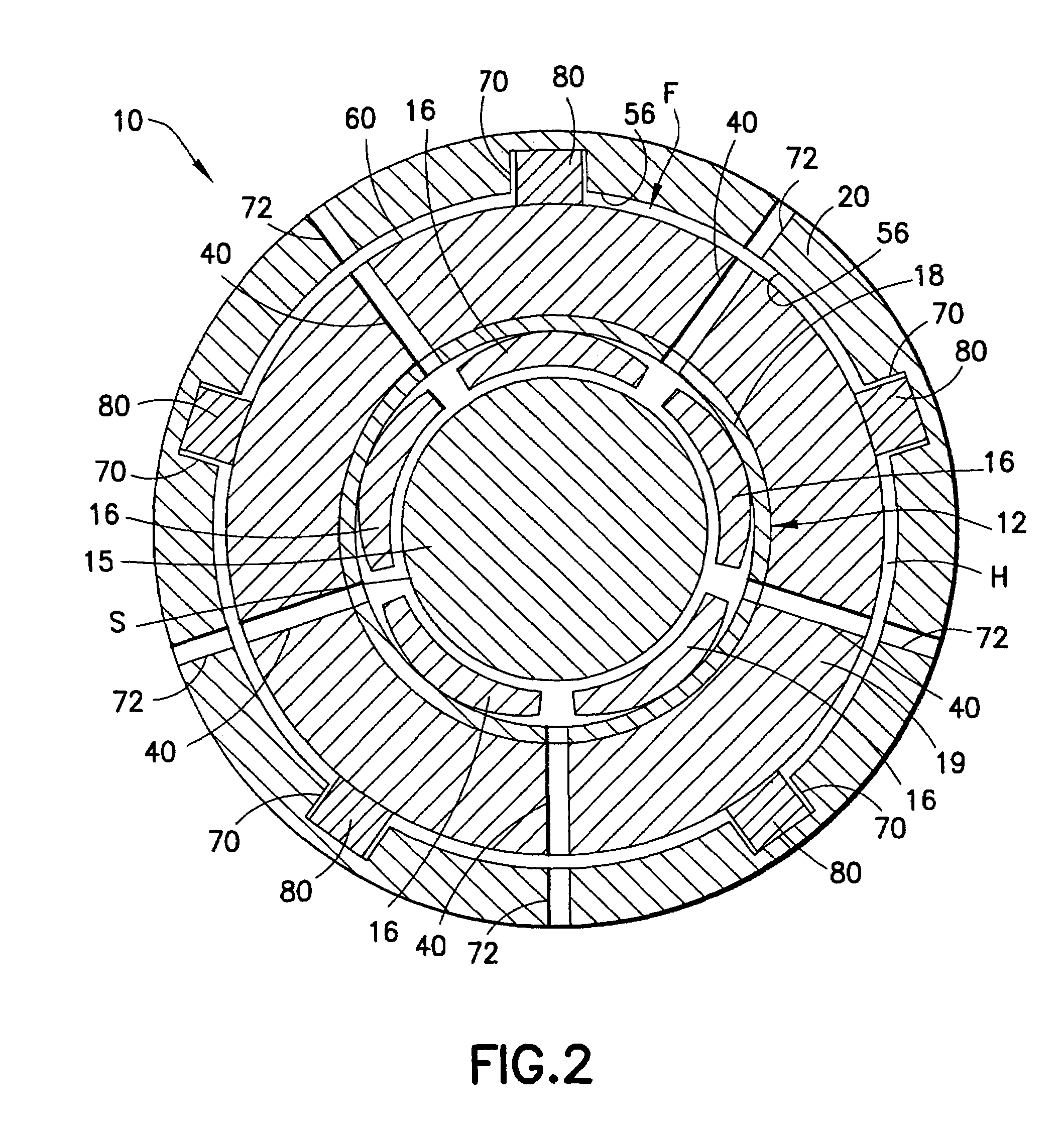

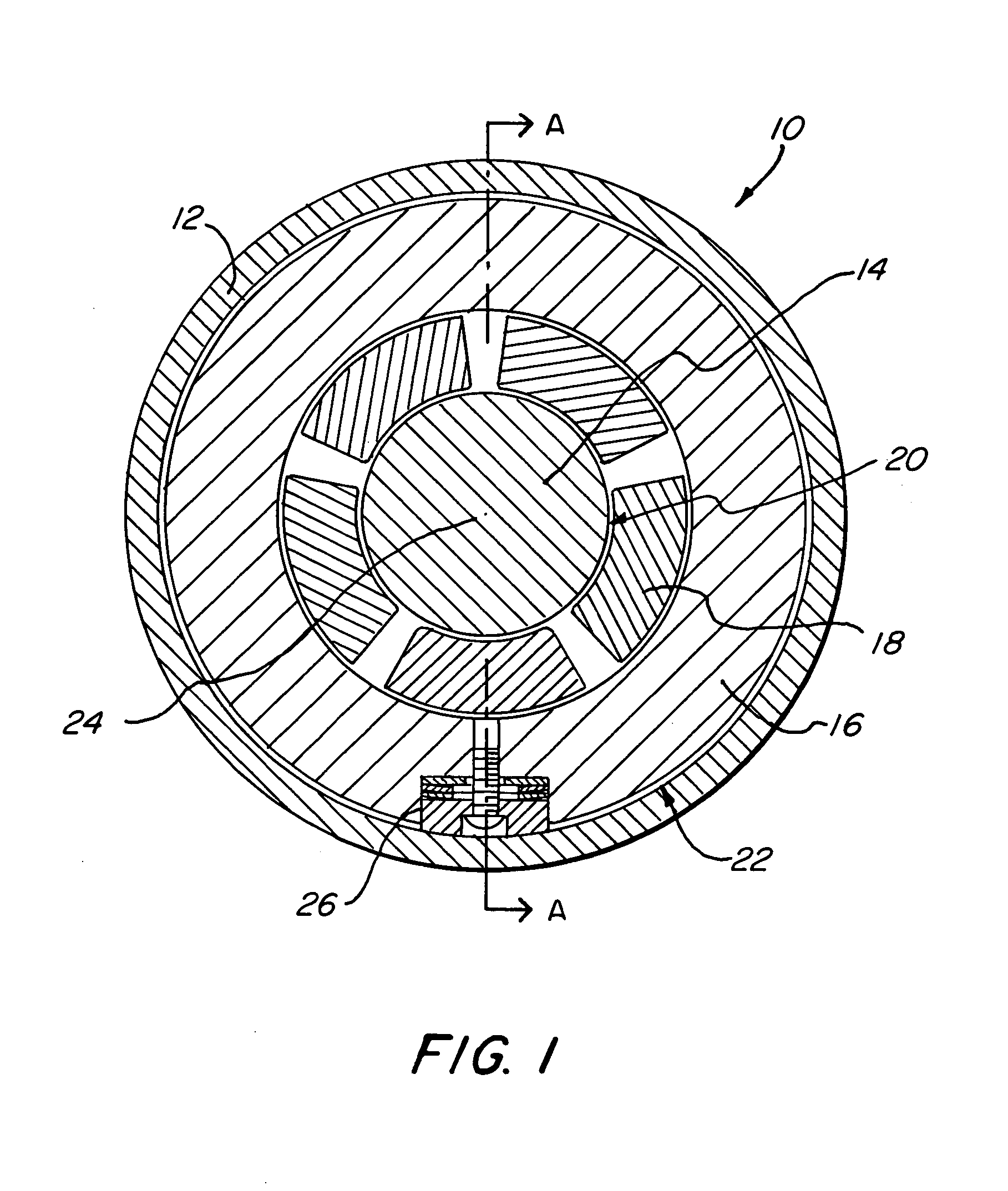

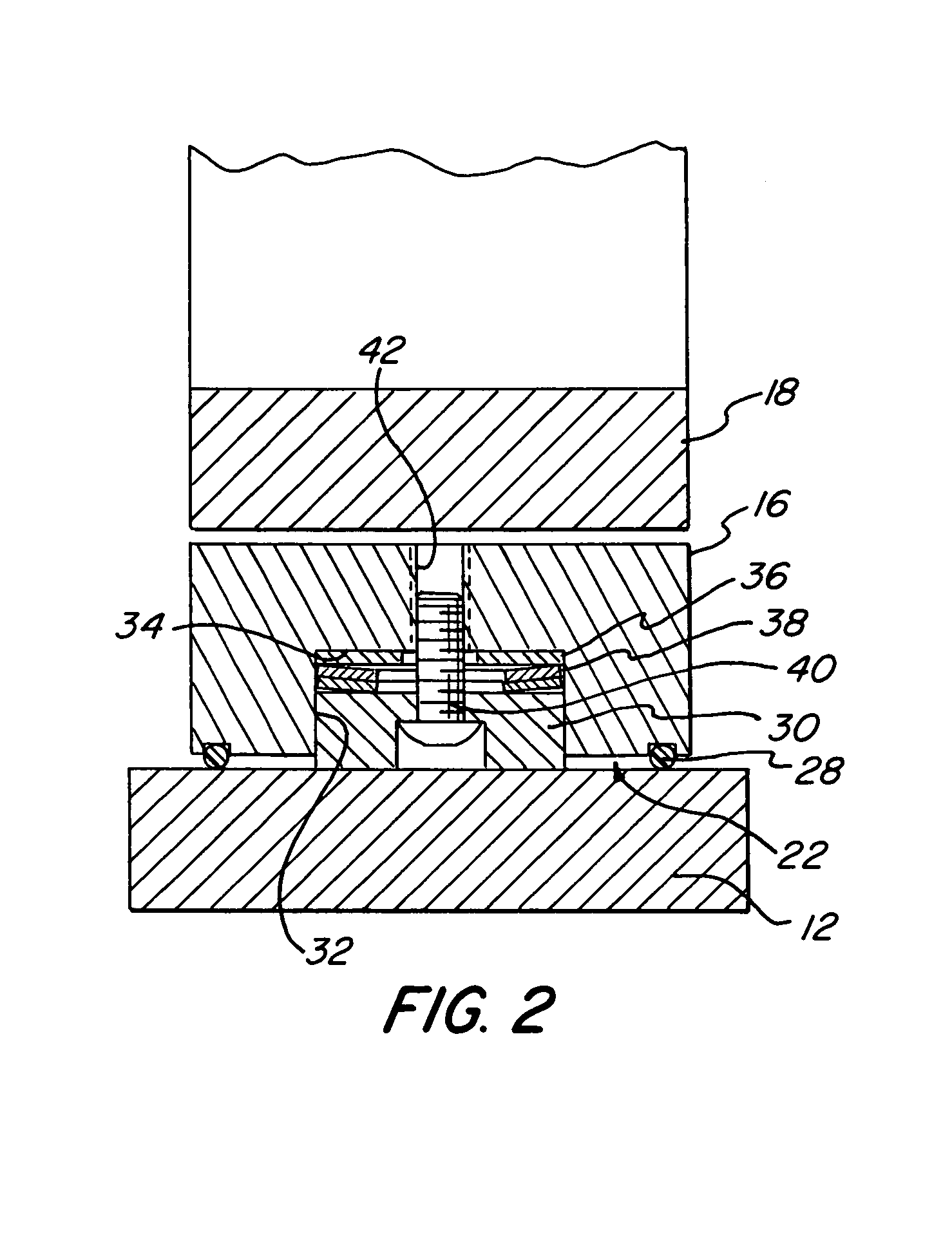

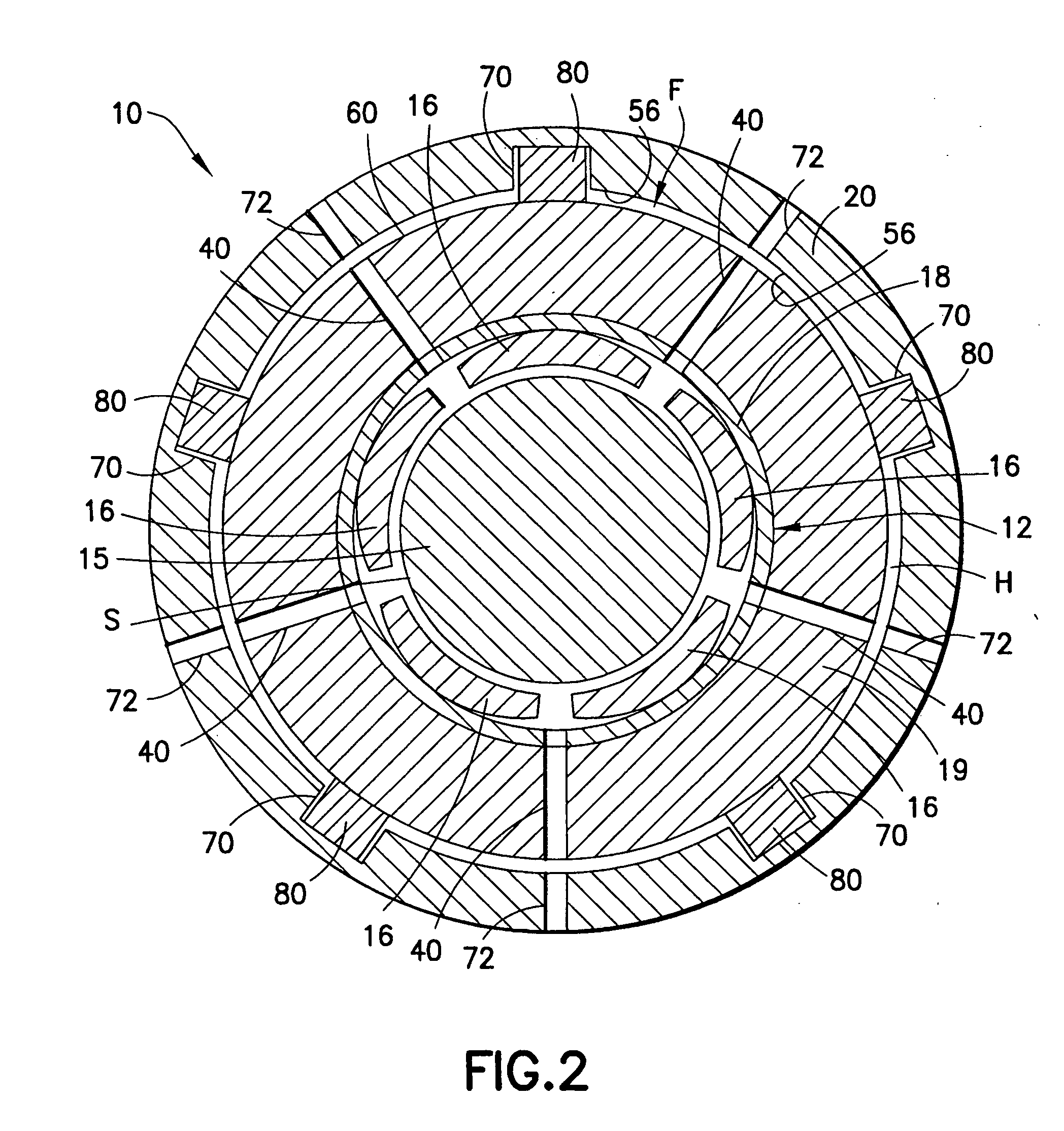

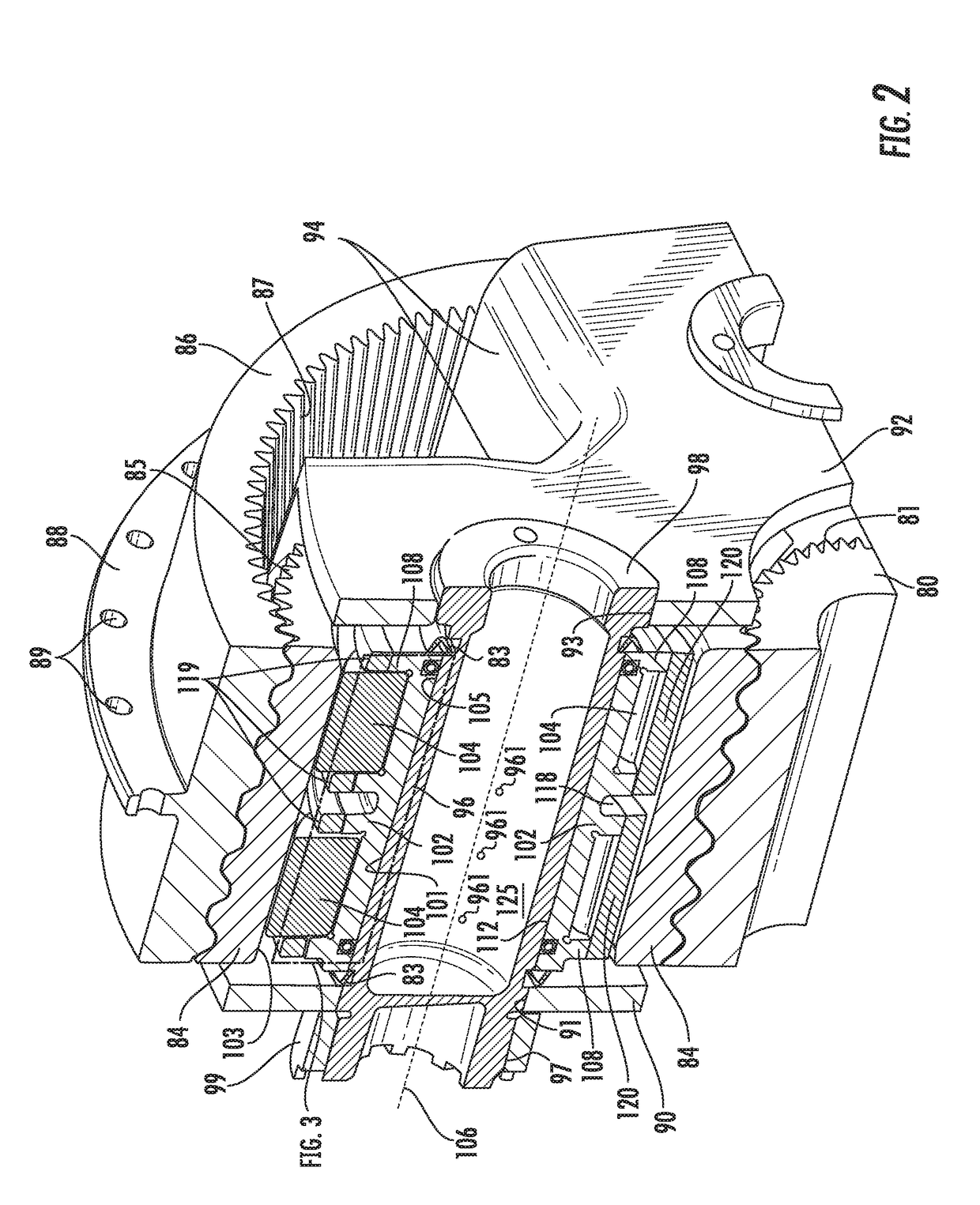

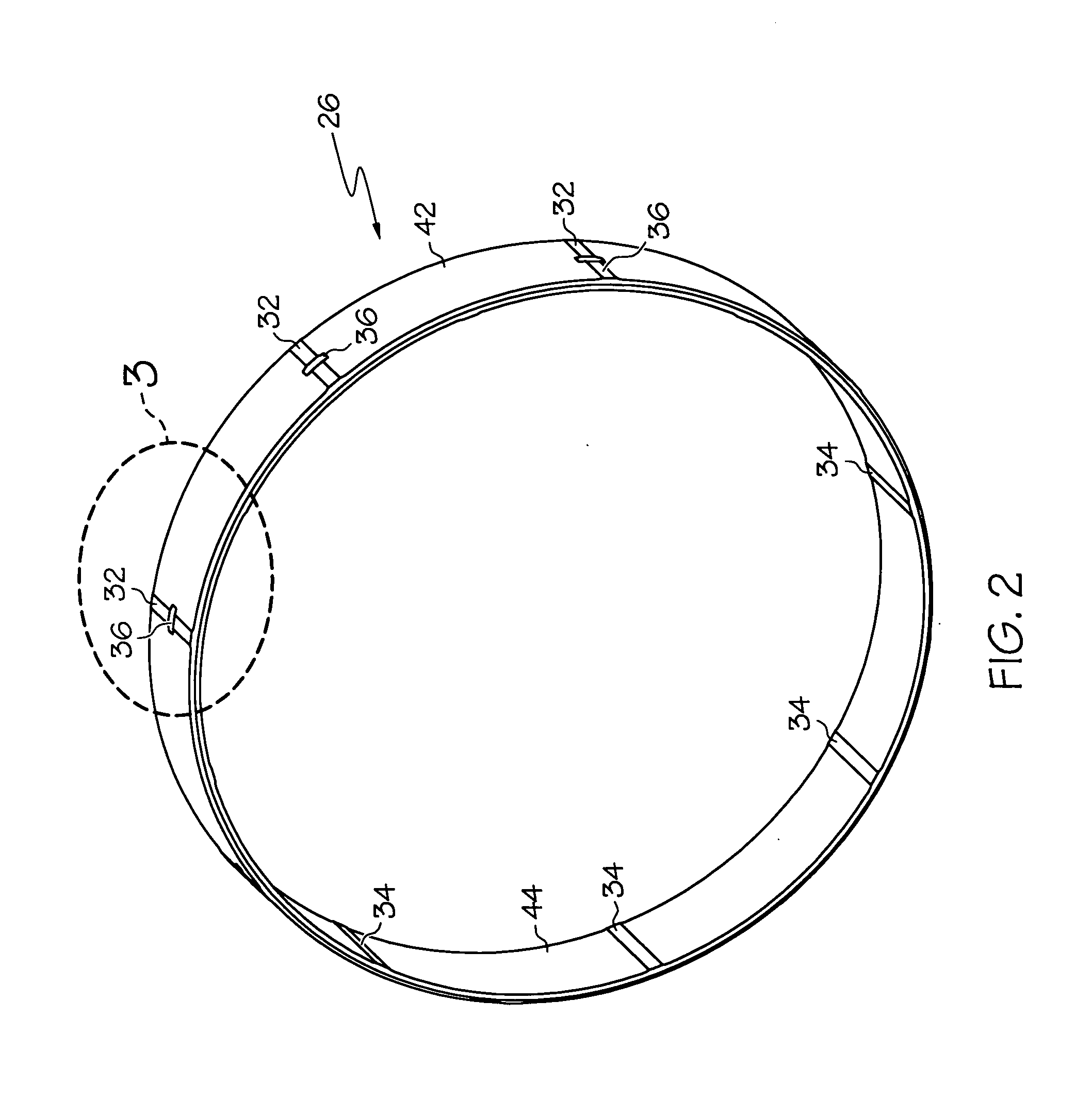

Bearing assembly and centering support structure therefor

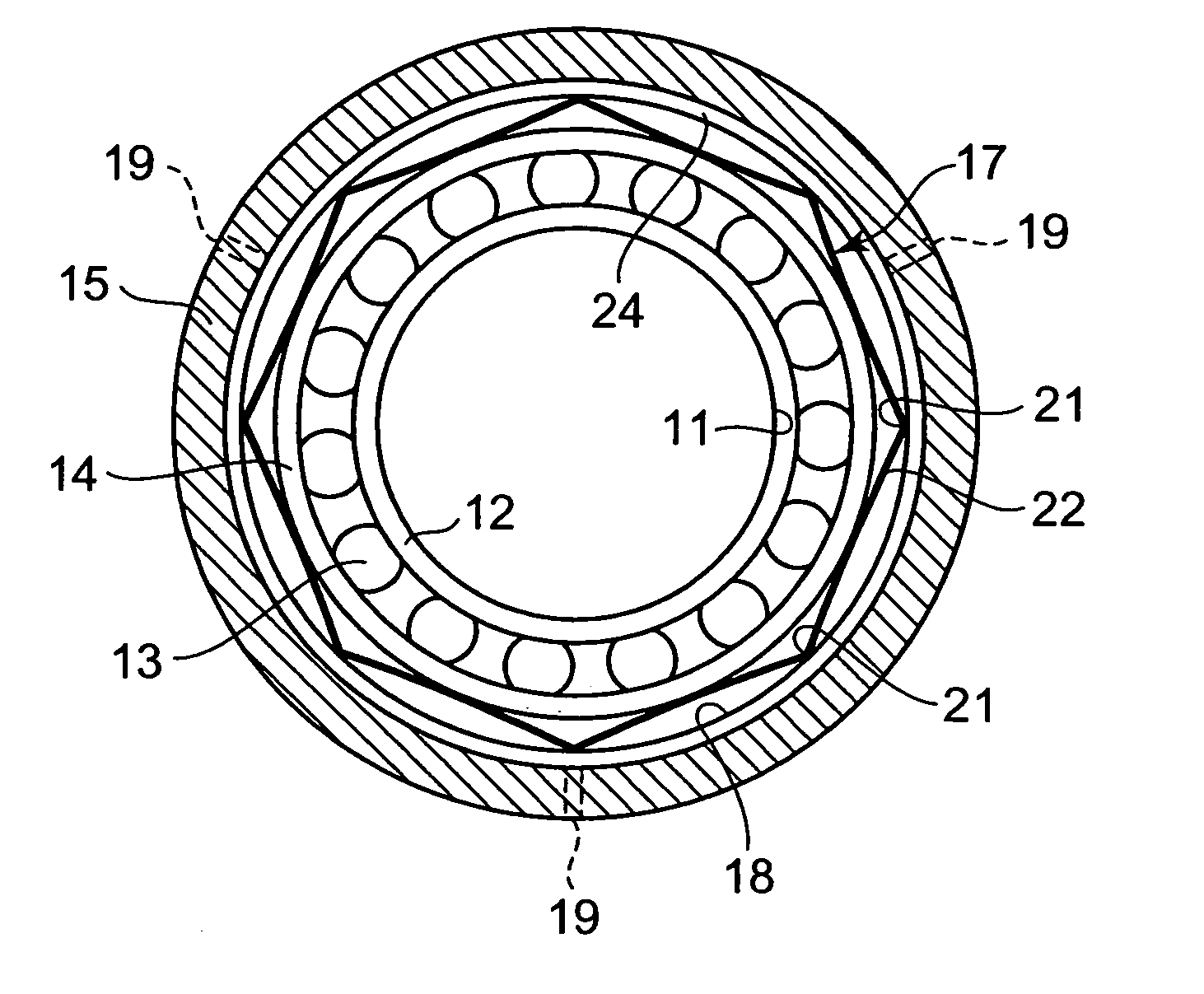

The bearing assembly includes an annular bearing in which the shaft is disposed and a support structure for supporting the bearing. The bearing support is mounted about and radially supports the bearing. The bearing support at least in part defines a squeeze film annulus of the bearing assembly. A plurality of centering elements is associated with the bearing and bearing support and act to center the bearing within the squeeze film annulus. The centering elements are provided at radially spaced locations around the bearing. The centering elements may also be cylinder springs provided at uniformly spaced locations around the bearing. The centering elements may additionally be load cell springs provided at uniformly spaced locations around the bearing. In an alternative embodiment, a singular annular wave spring may be provided in place of the plurality of centering elements.

Owner:ELLIOTT CO

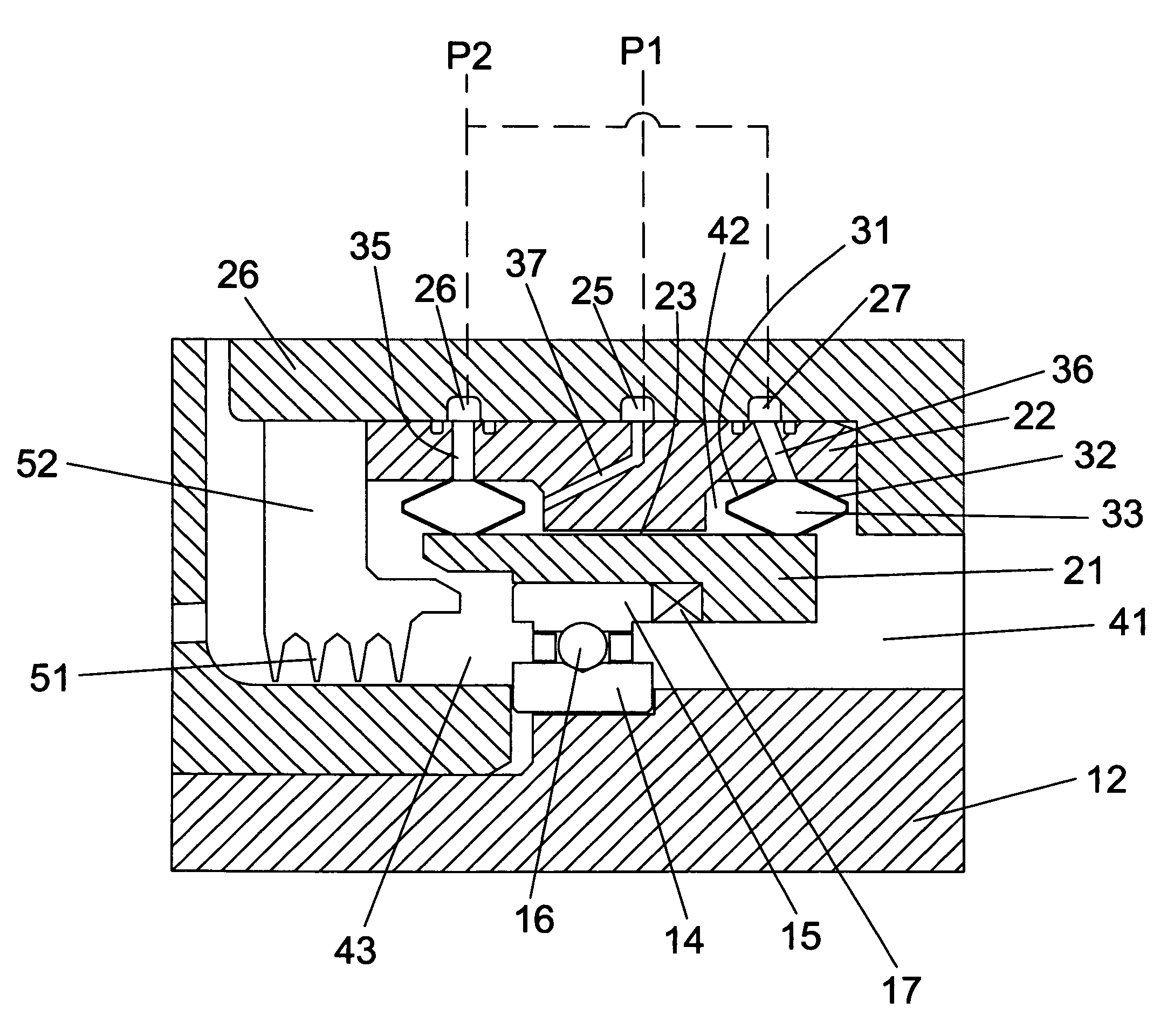

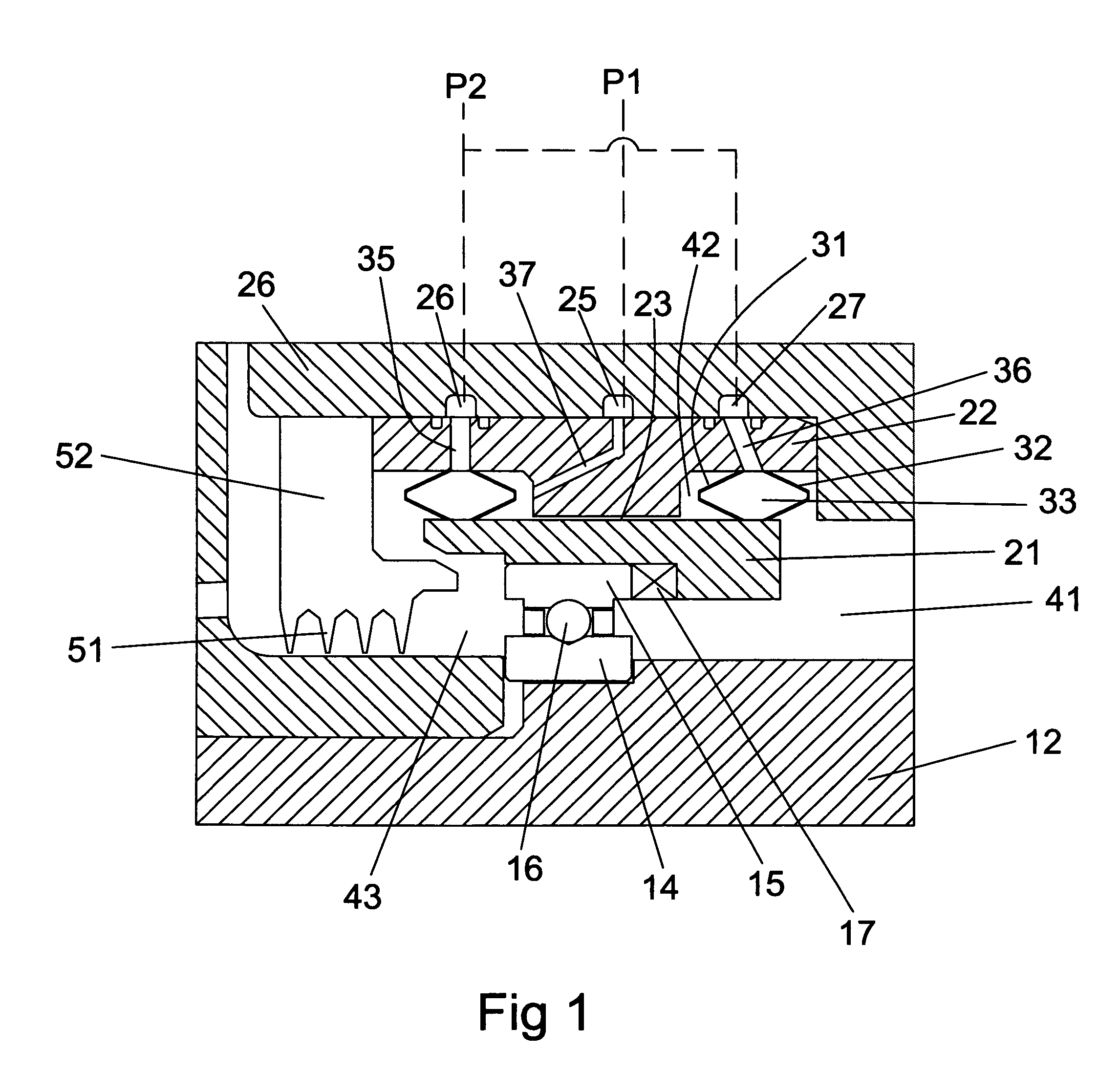

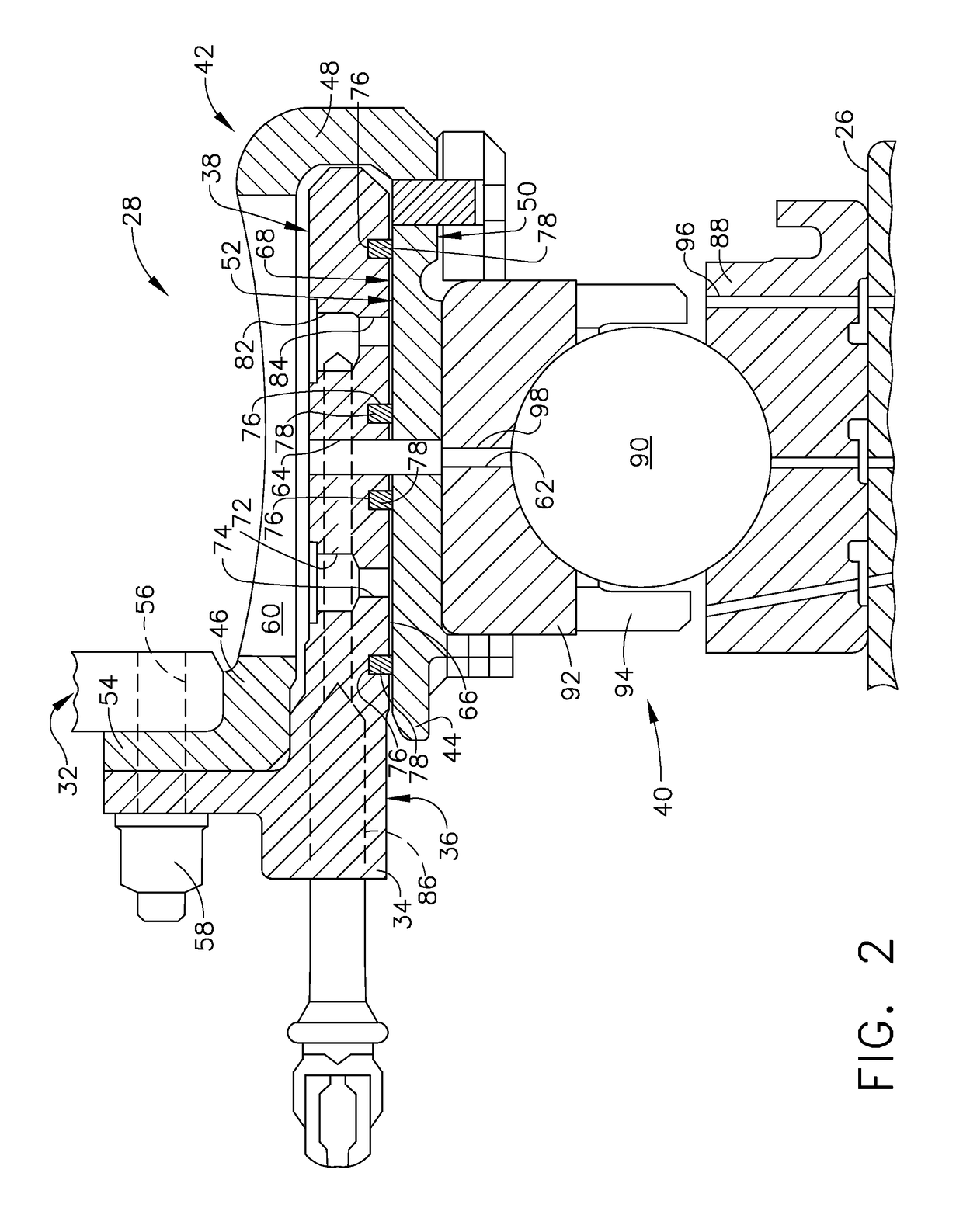

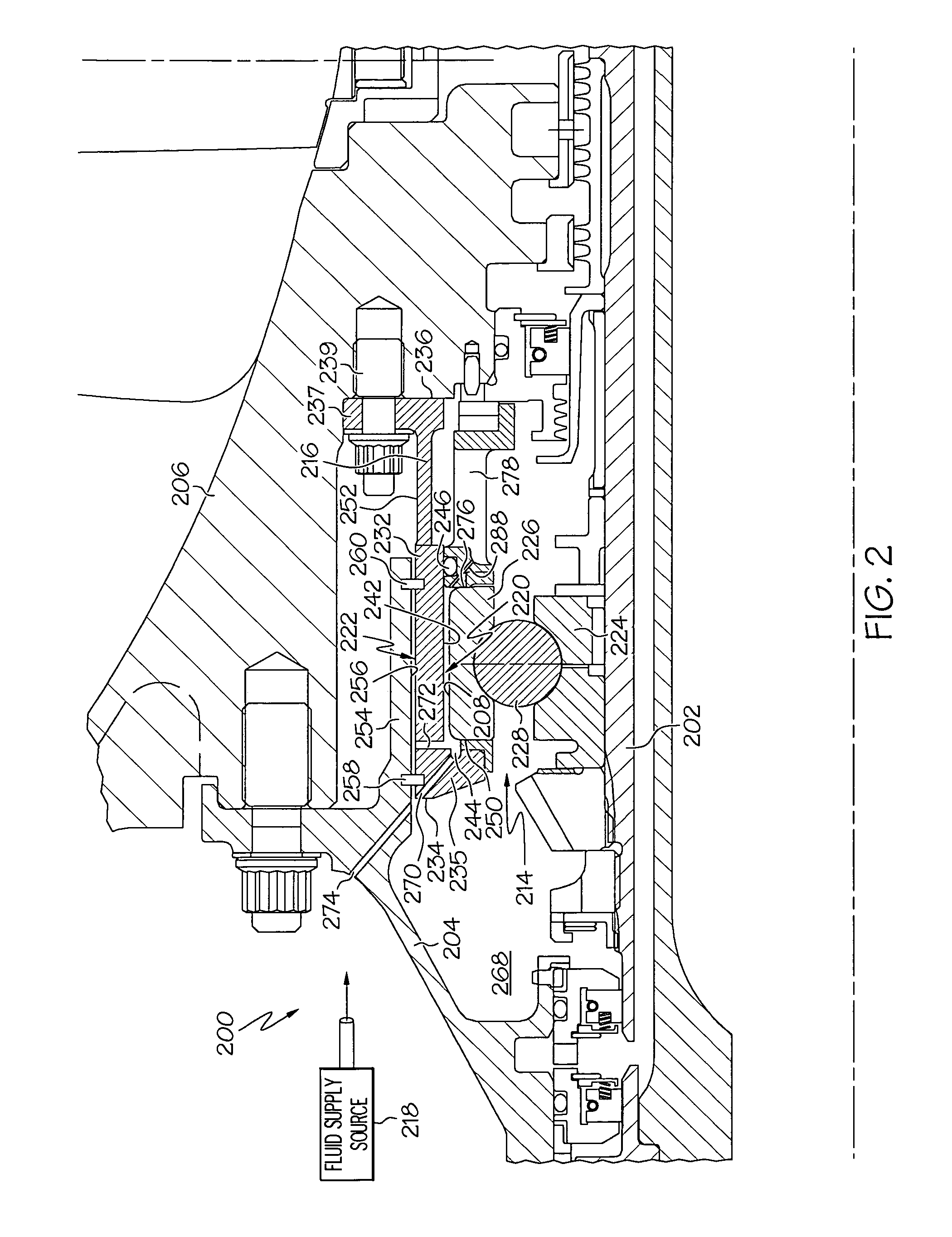

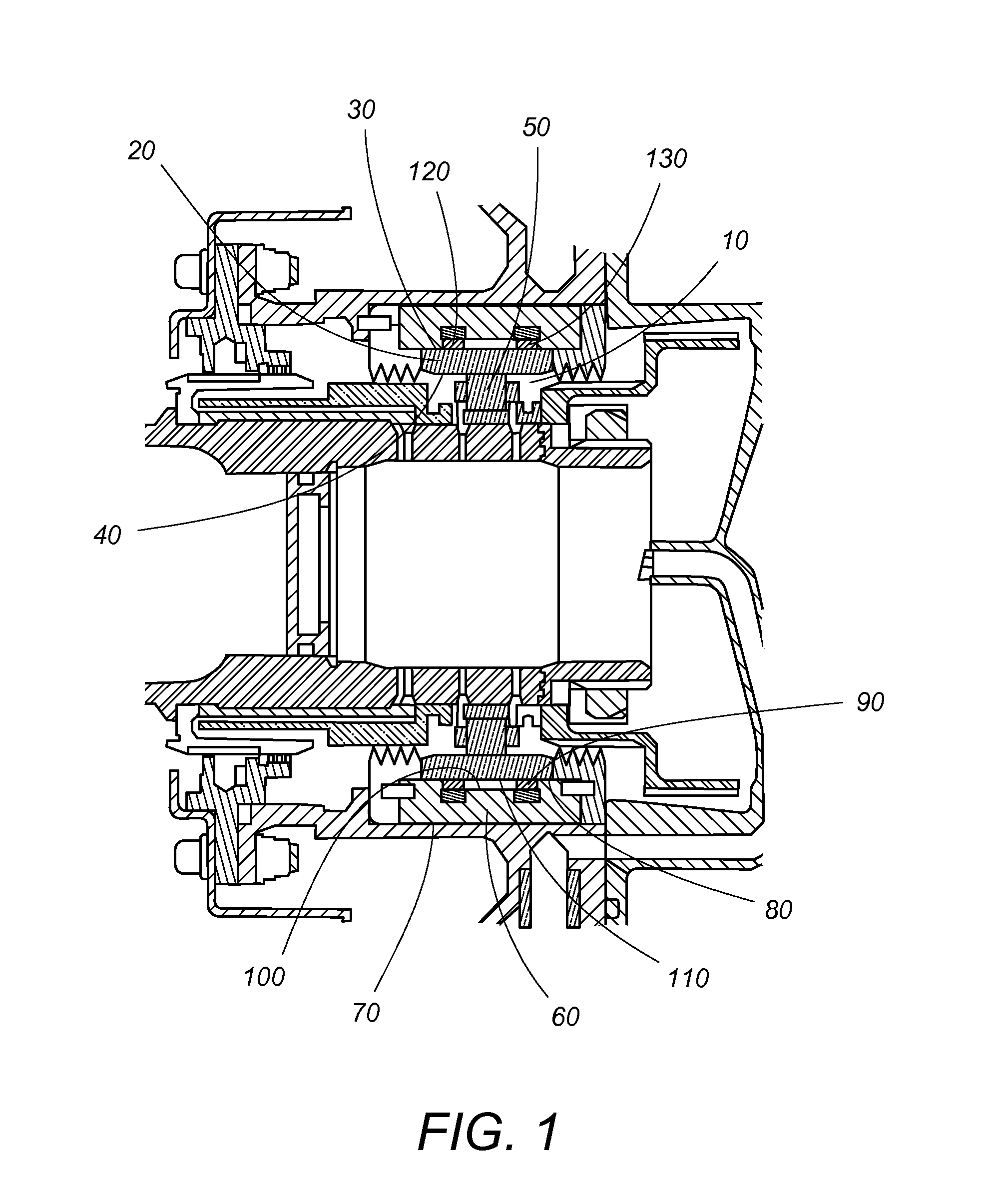

Squeeze film damper with highly variable support stiffness

InactiveUS7798720B1Reduce weight and sizeEasy to controlPump componentsShaftsVariable stiffnessEngineering

A squeeze film damper assembly having a variable stiffness and damping control. The squeeze film damper includes a damper chamber formed by two flexible bellows chambers of the sides. A first pressure source is applied to the damper chamber to regulate the damping. A second pressure source is applied to the flexible bellows chambers to vary the stiffness of the damper. The flexible bellows chambers are secured between an outer member and an inner member of the damper assembly and form the sealed damper chamber. A pressure ratio between the bellows chambers and the damper chamber can vary to control the stiffness of the squeeze film damper.

Owner:FLORIDA TURBINE TECH

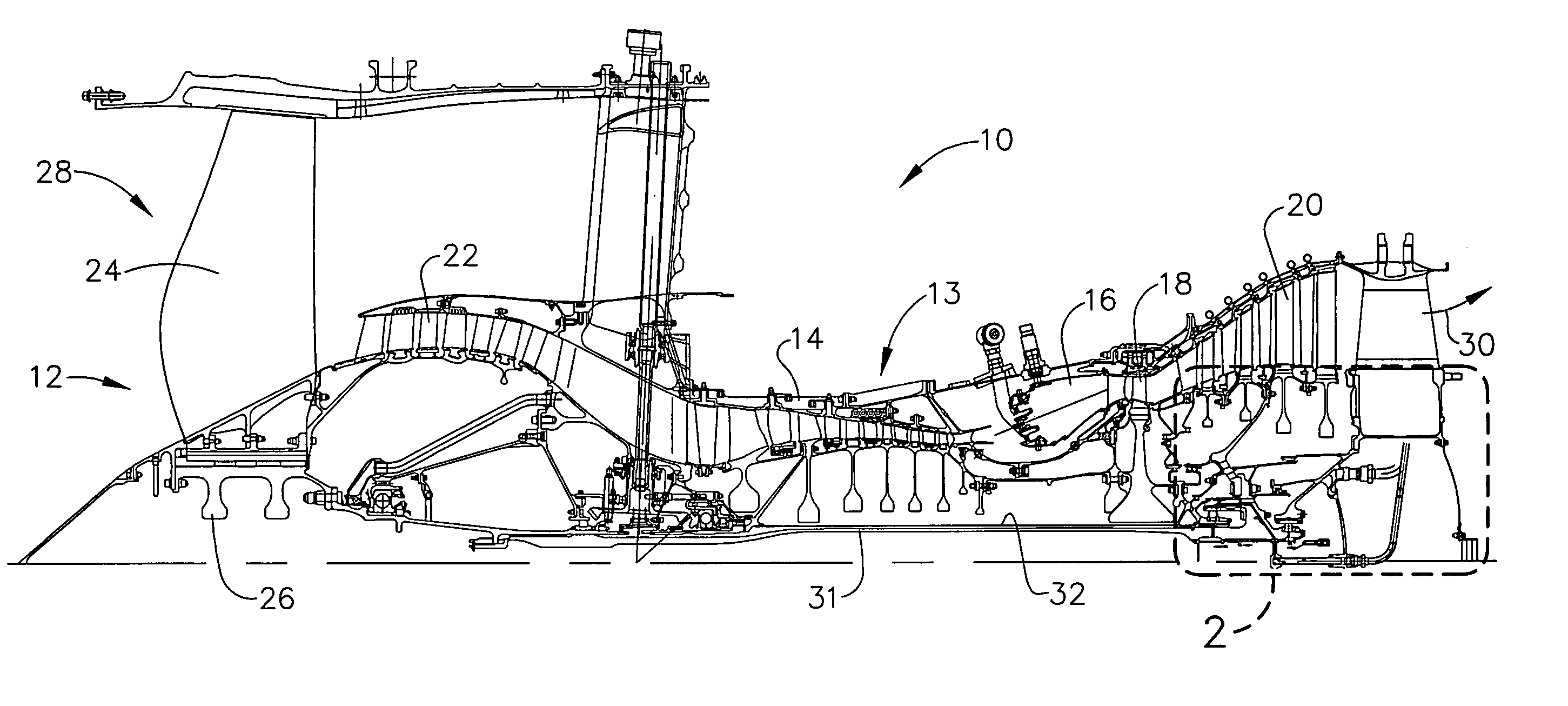

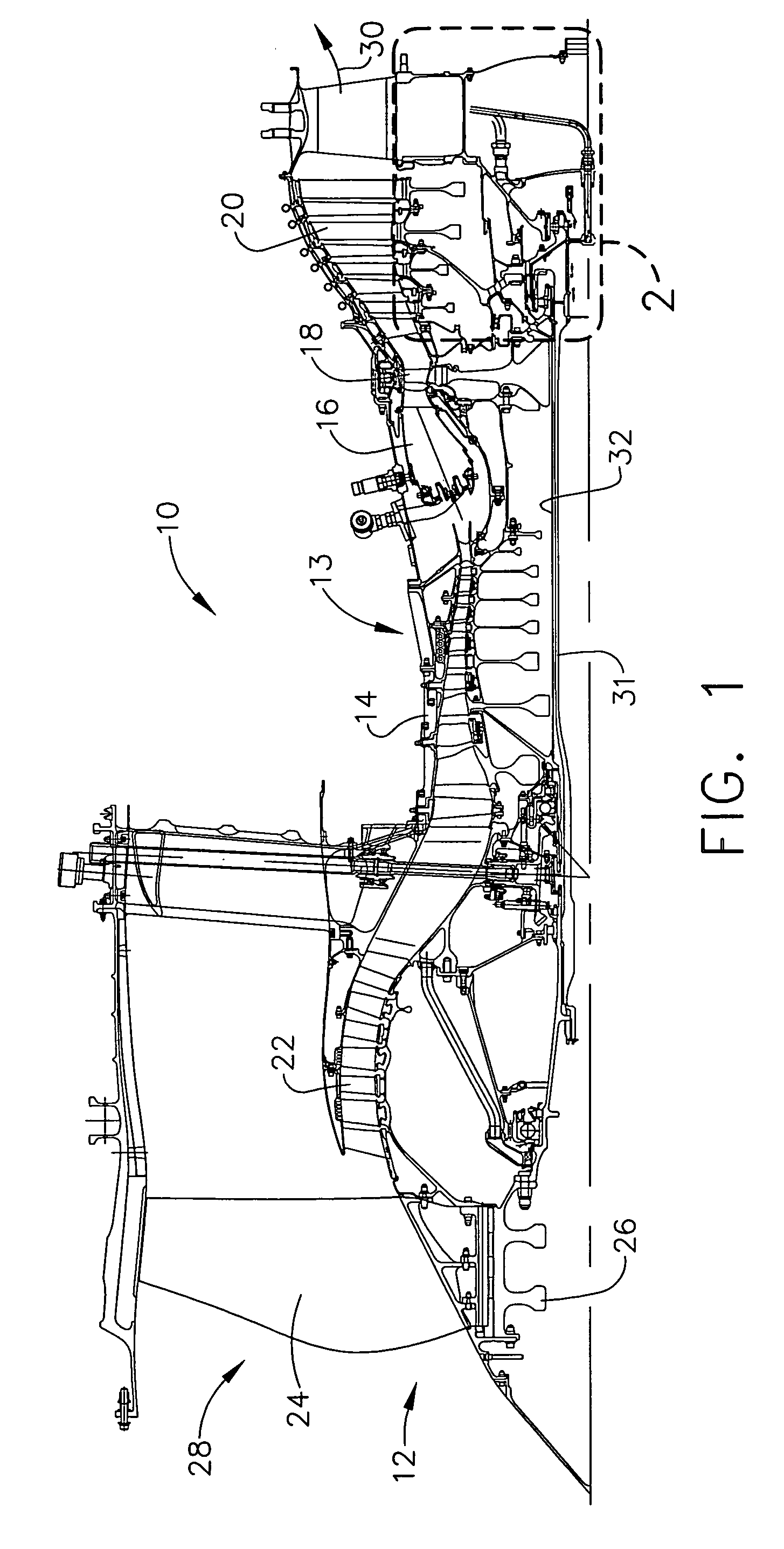

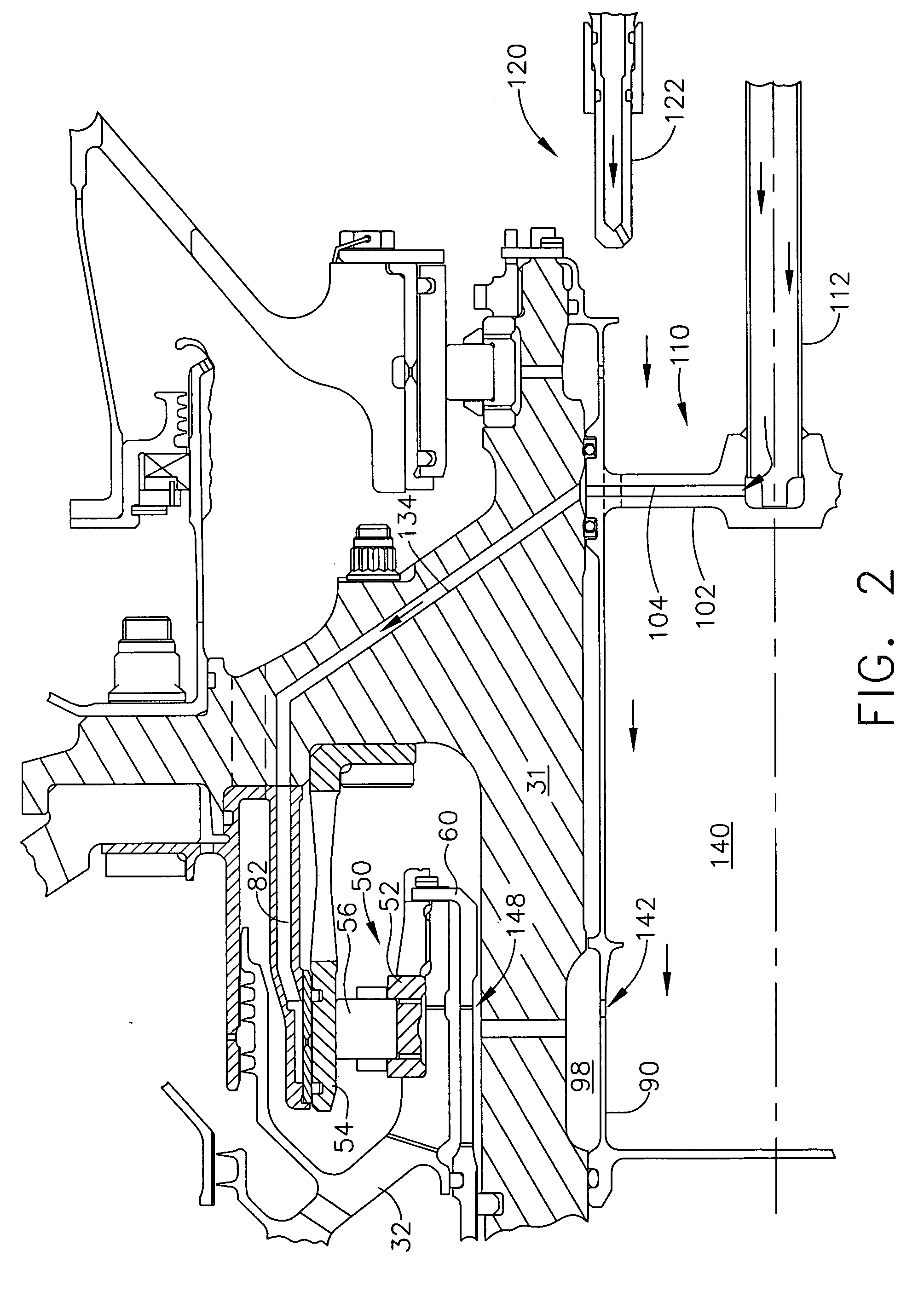

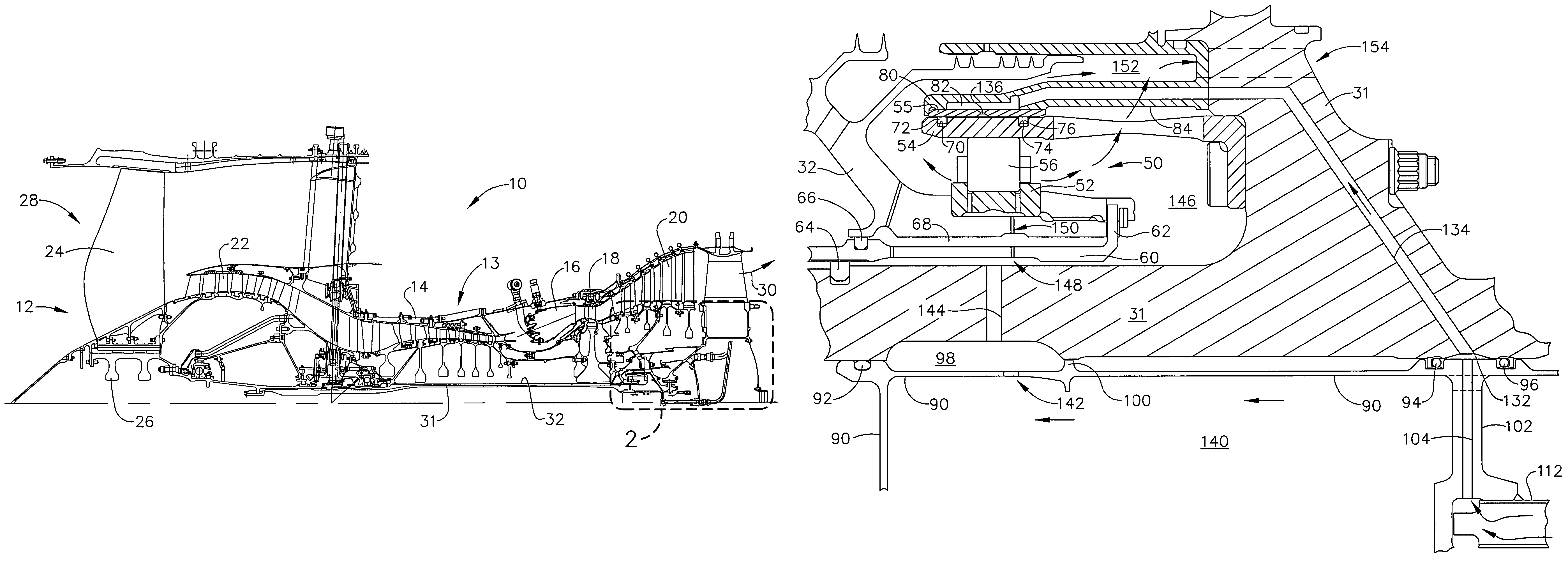

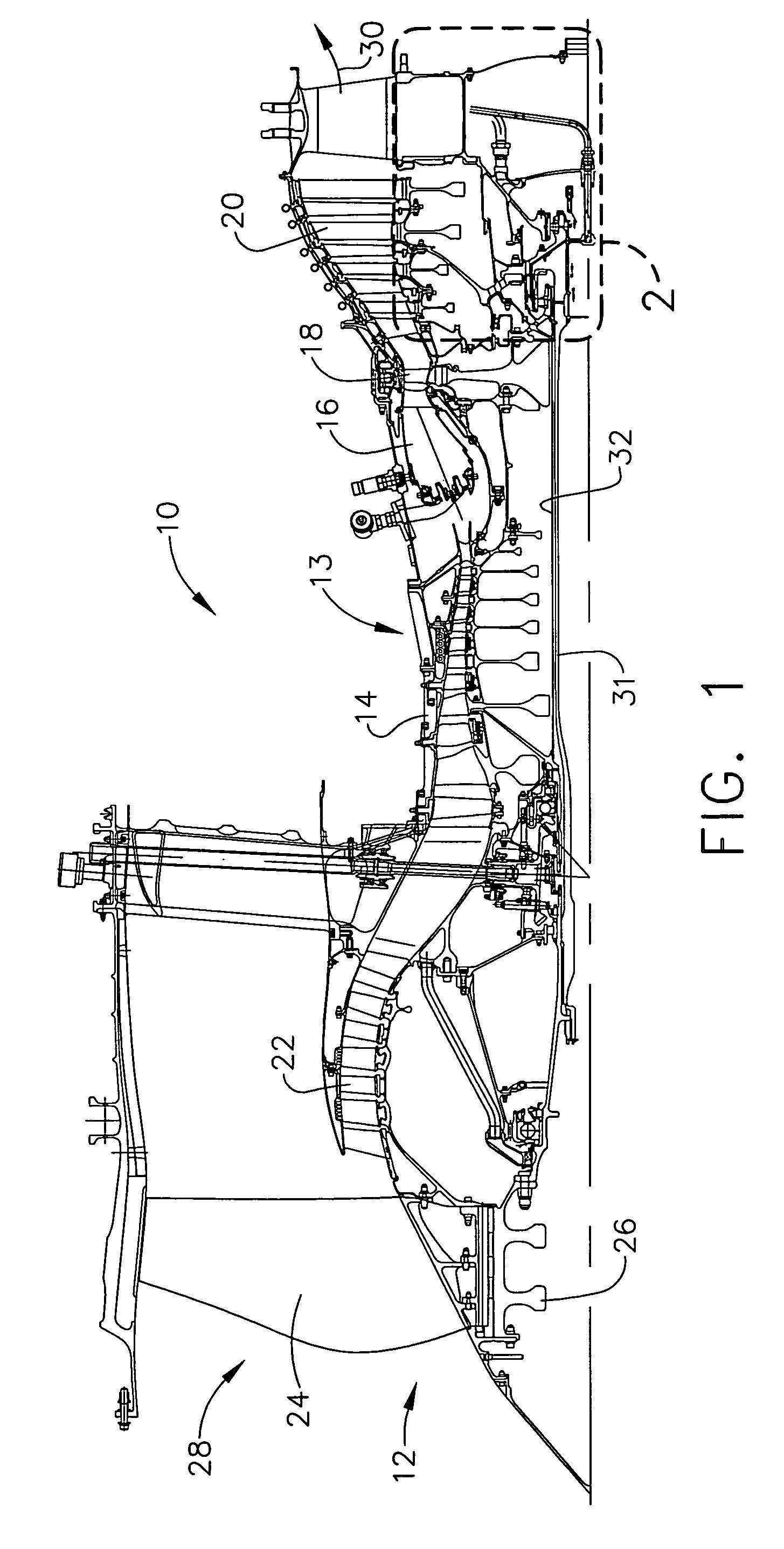

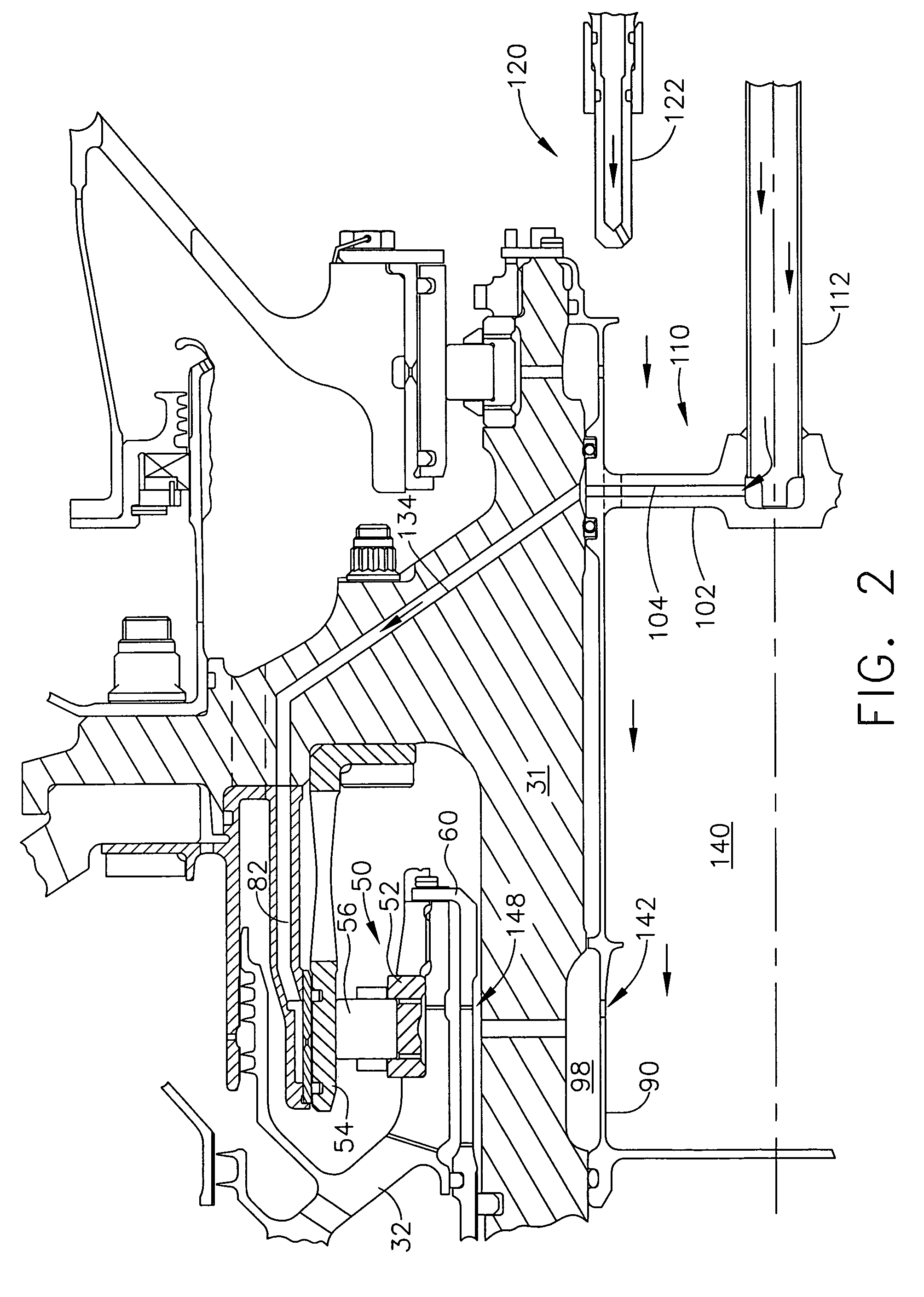

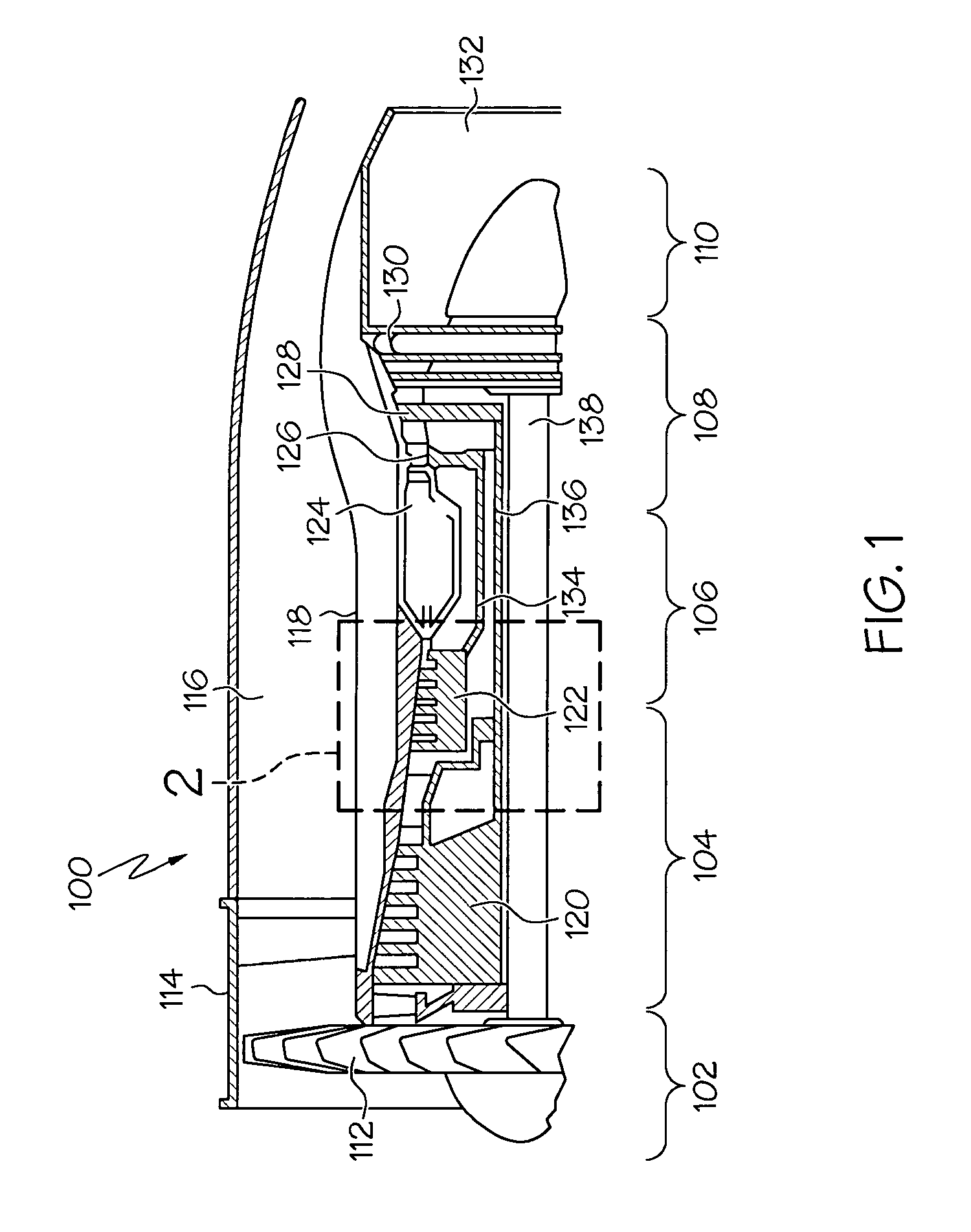

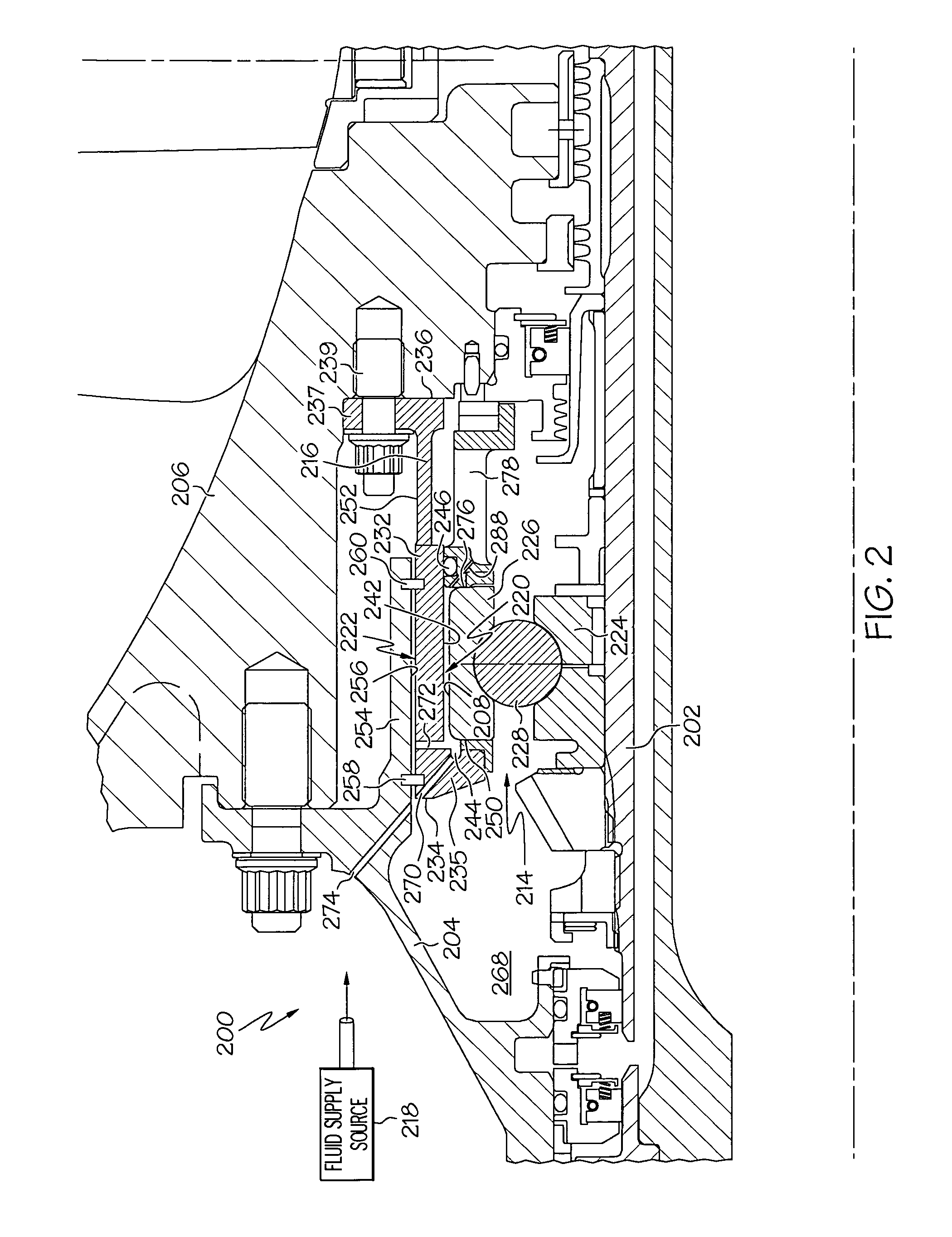

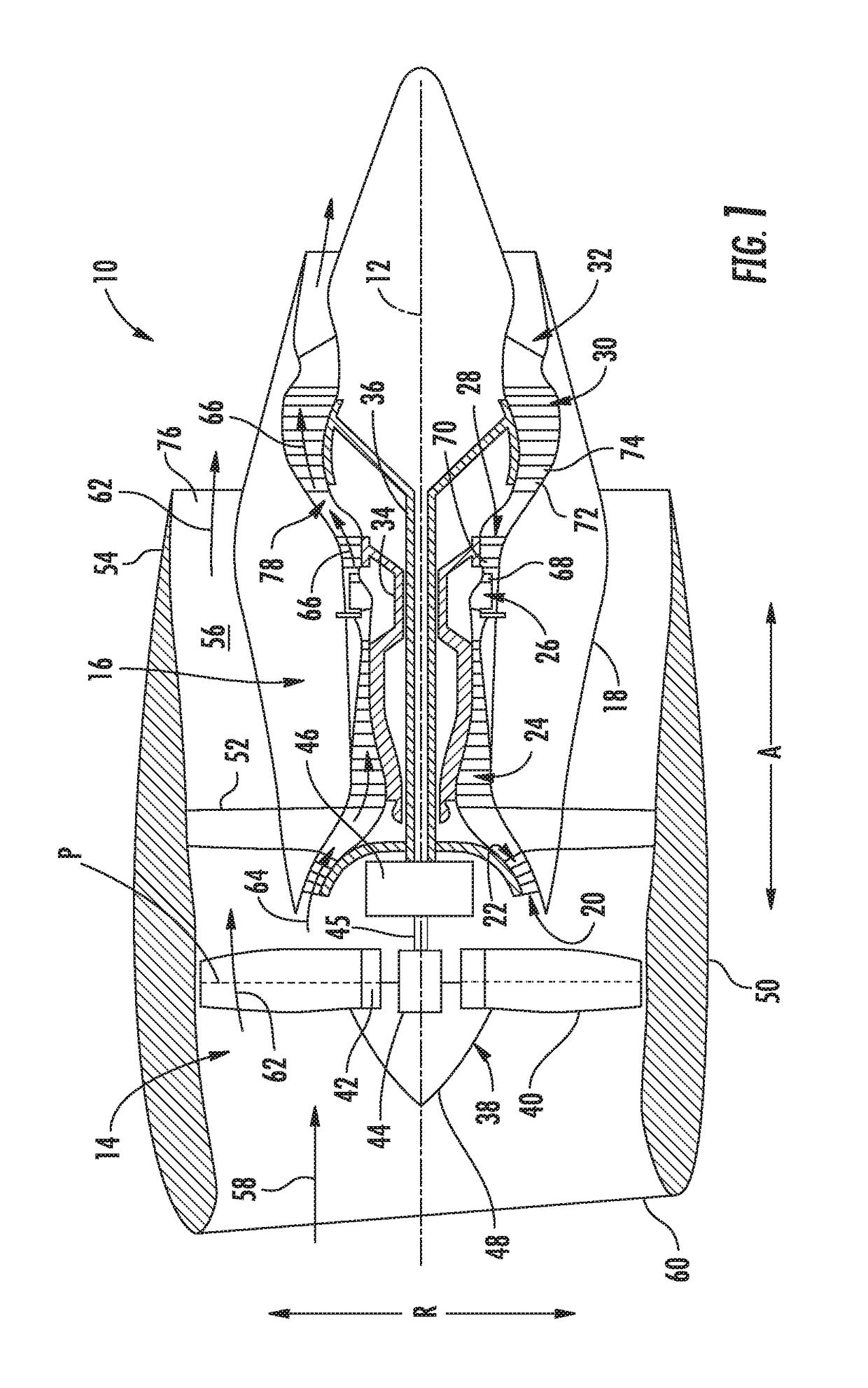

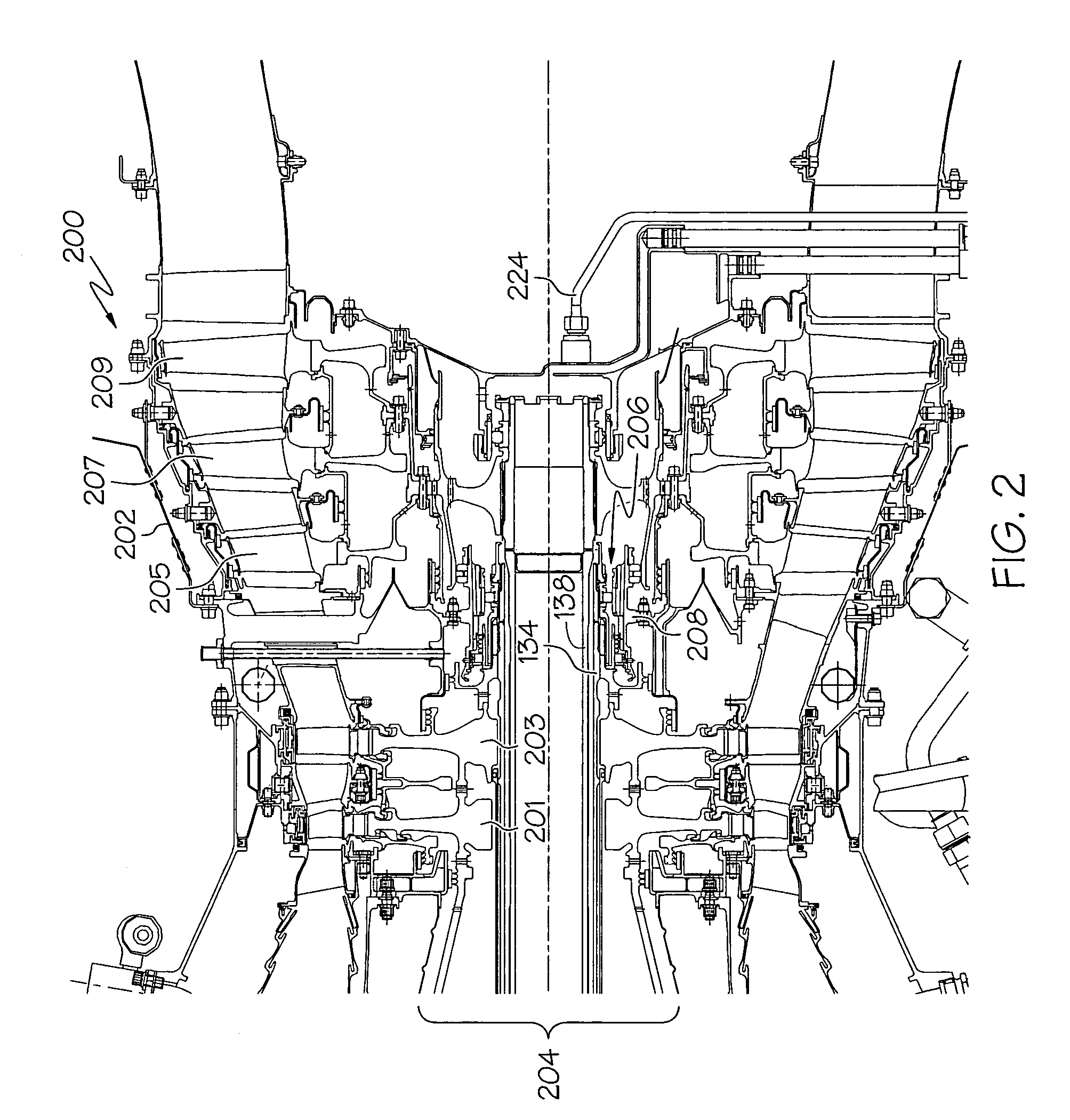

Gas turbine engine assembly and methods of assembling same

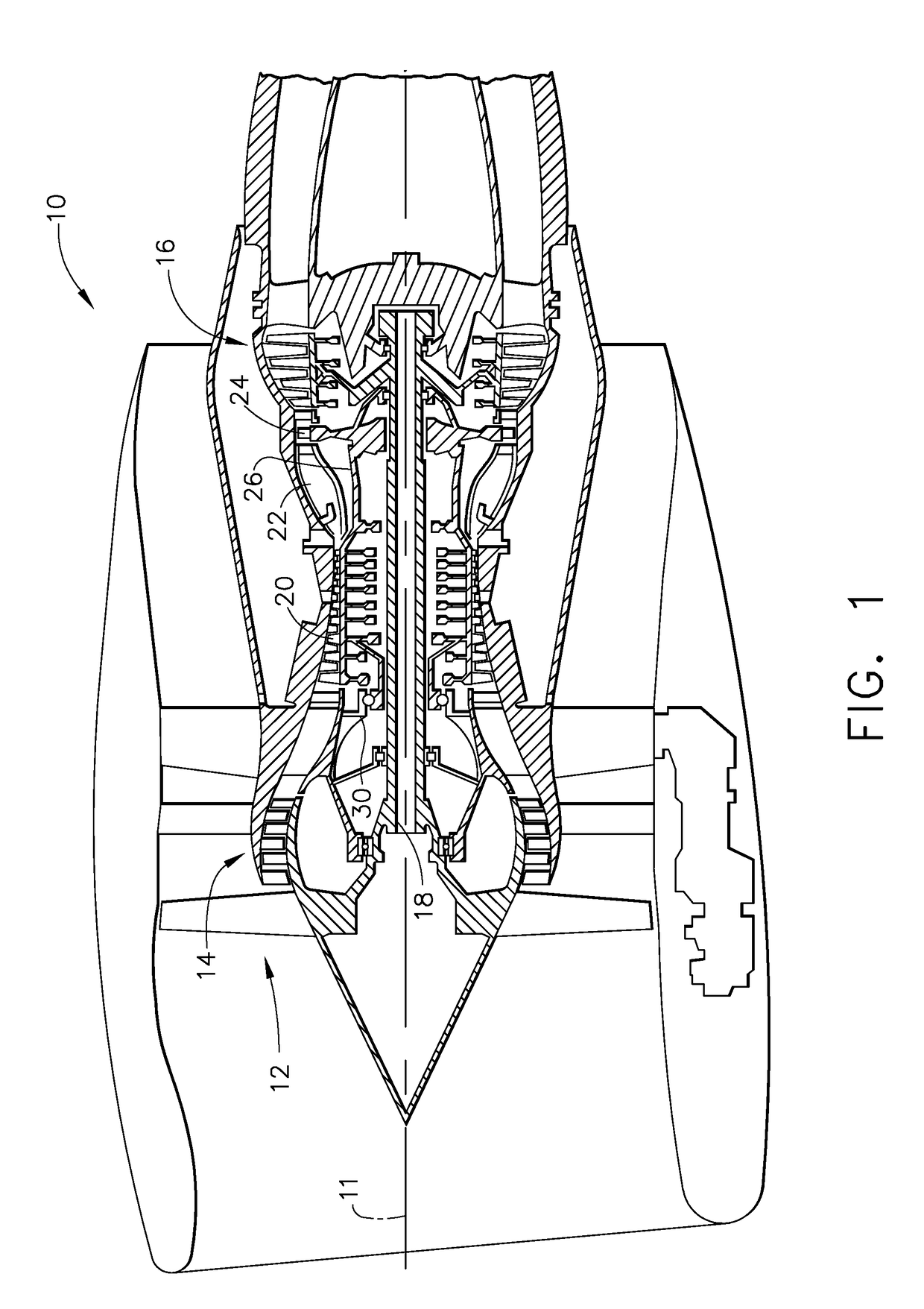

A method for assembling a gas turbine engine includes coupling a high-pressure compressor to a high-pressure turbine using a first shaft, coupling a fan assembly to a low-pressure turbine using a second shaft, and coupling a differential squeeze film damper assembly between the first and second shafts.

Owner:GENERAL ELECTRIC CO

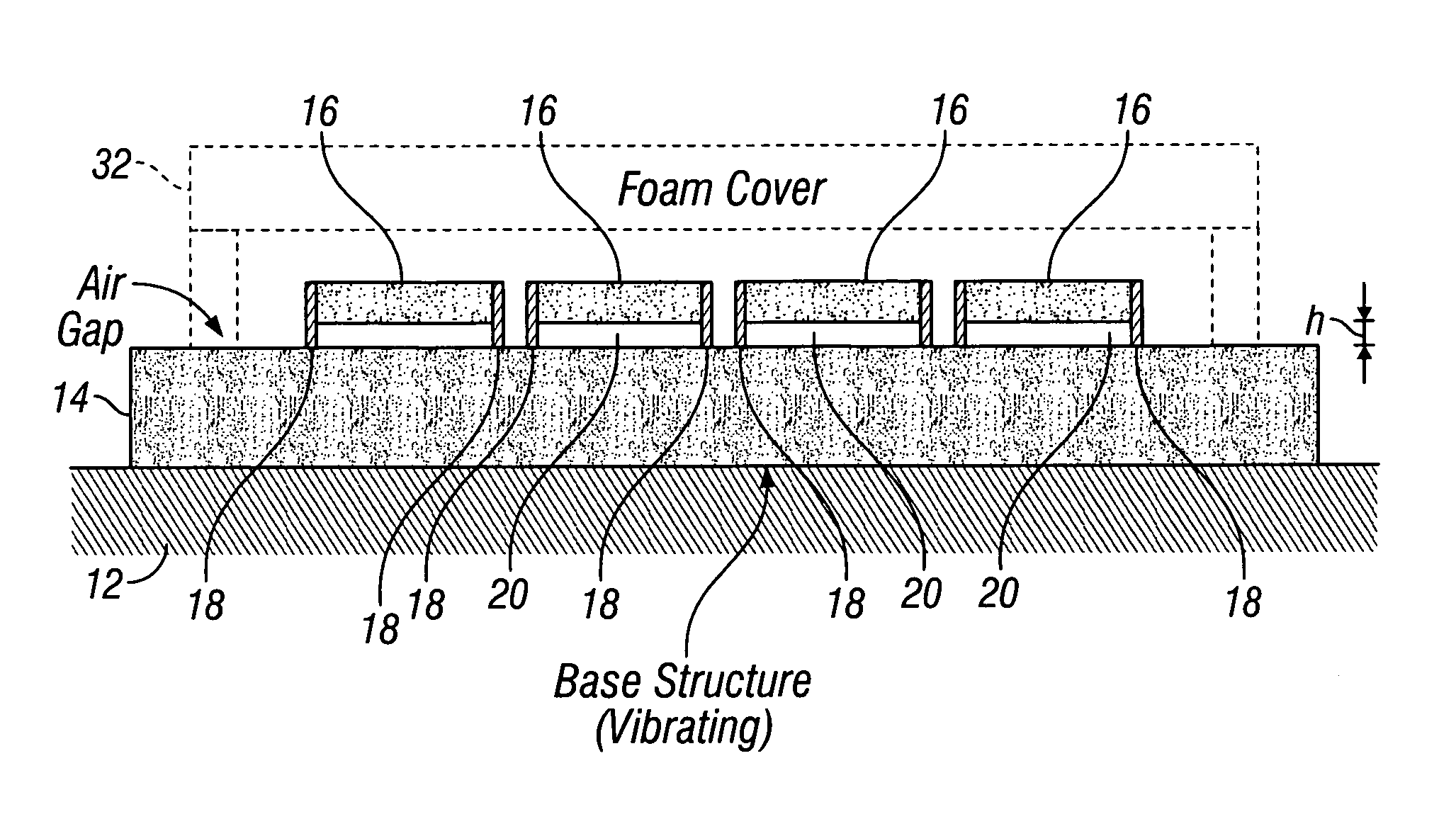

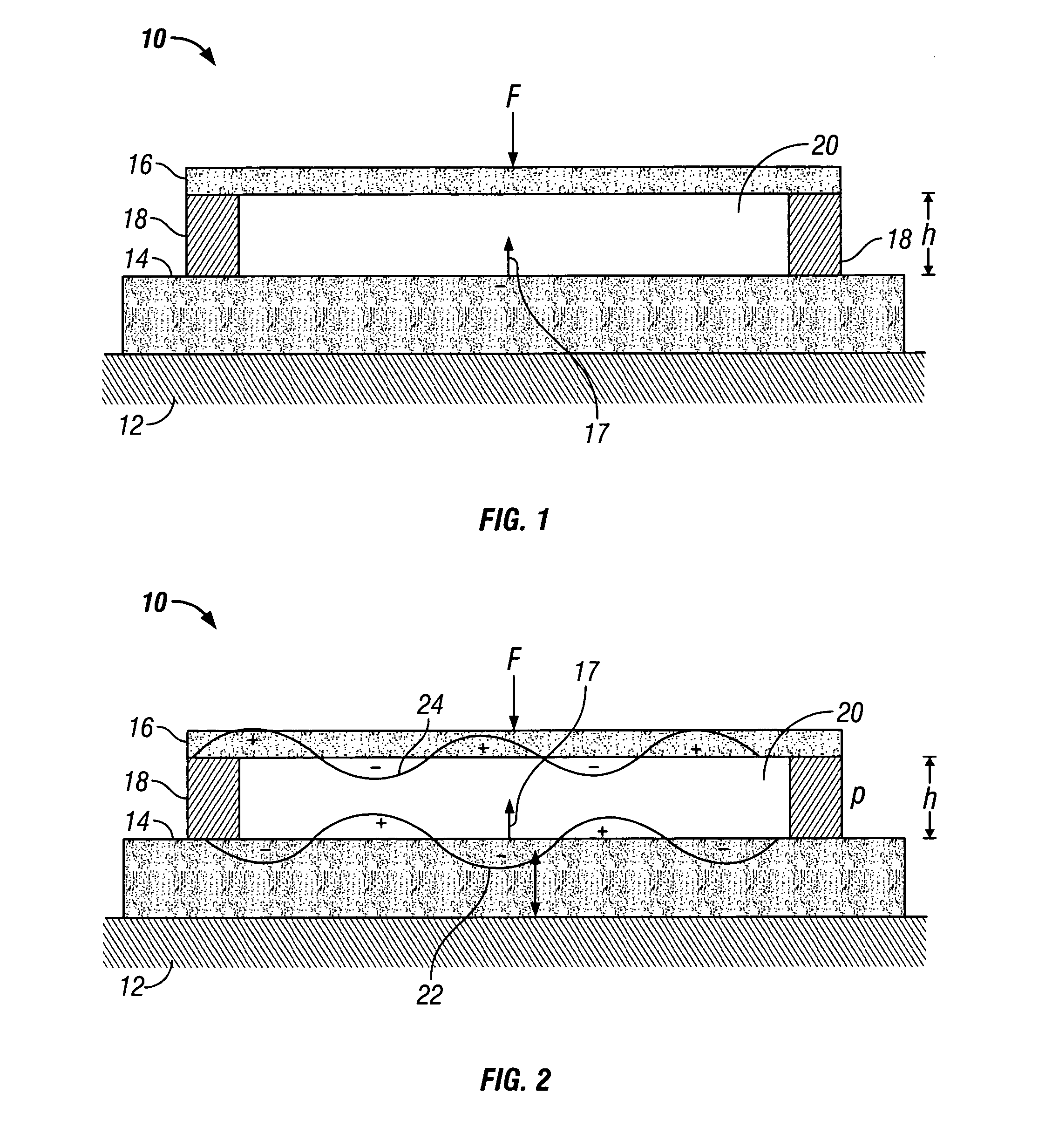

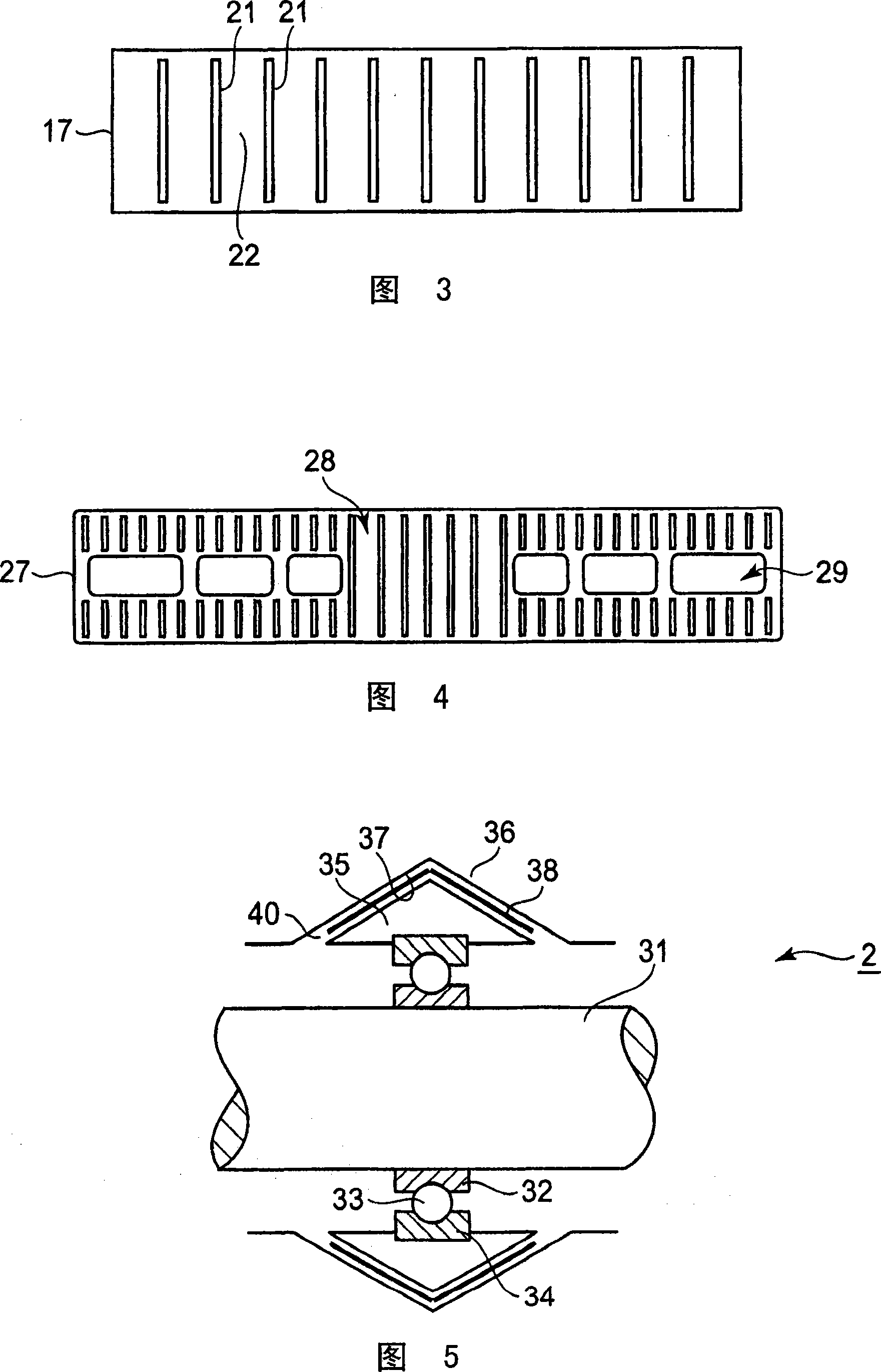

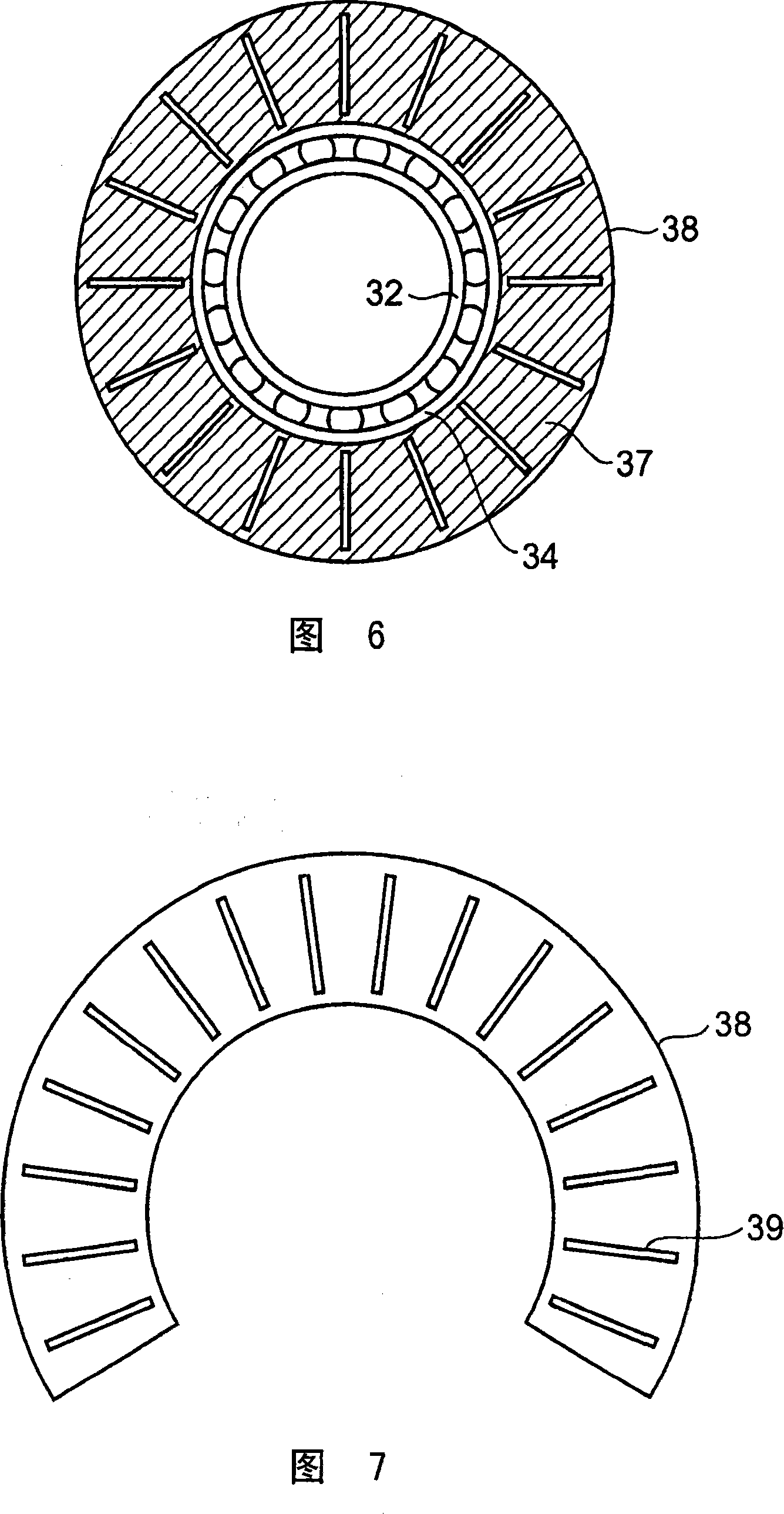

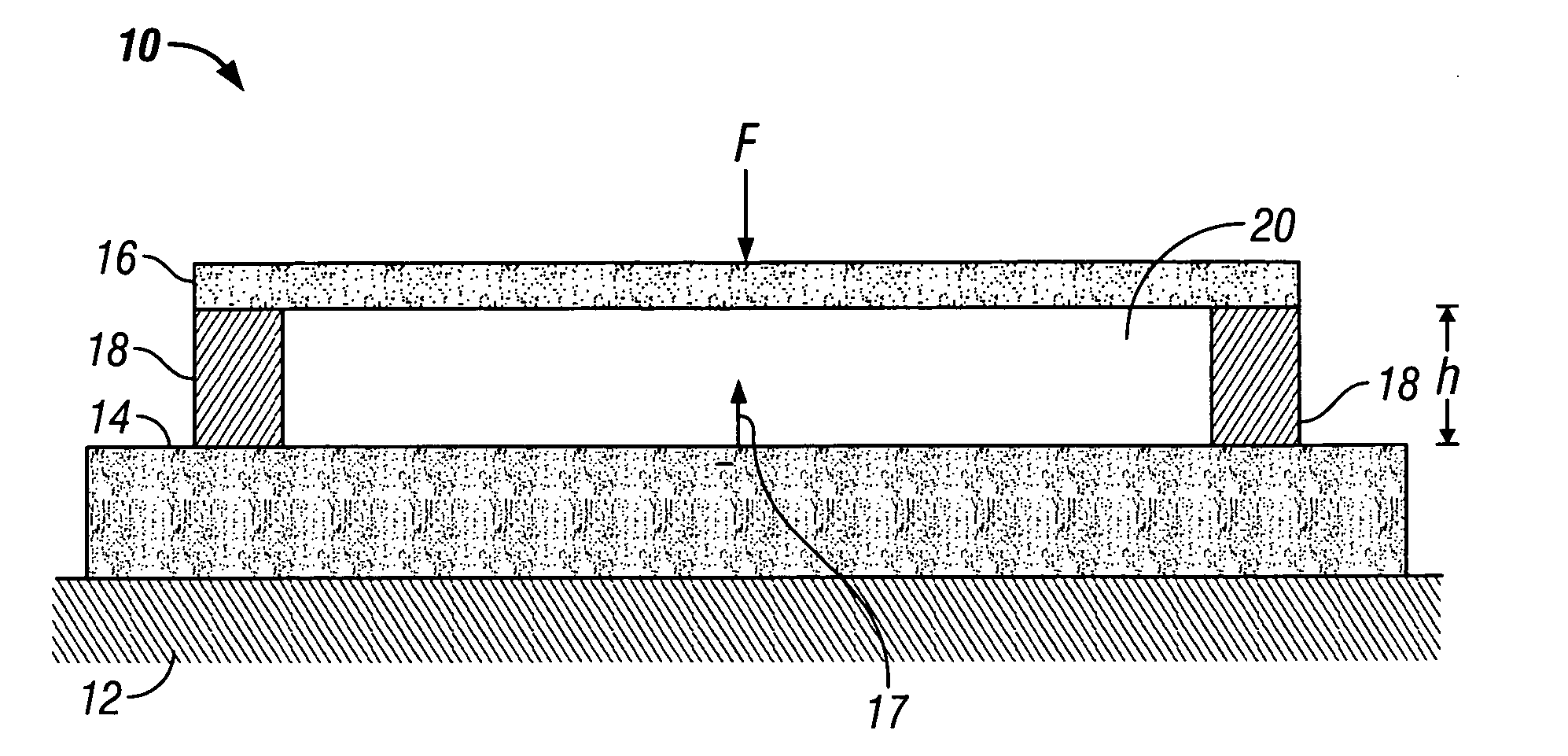

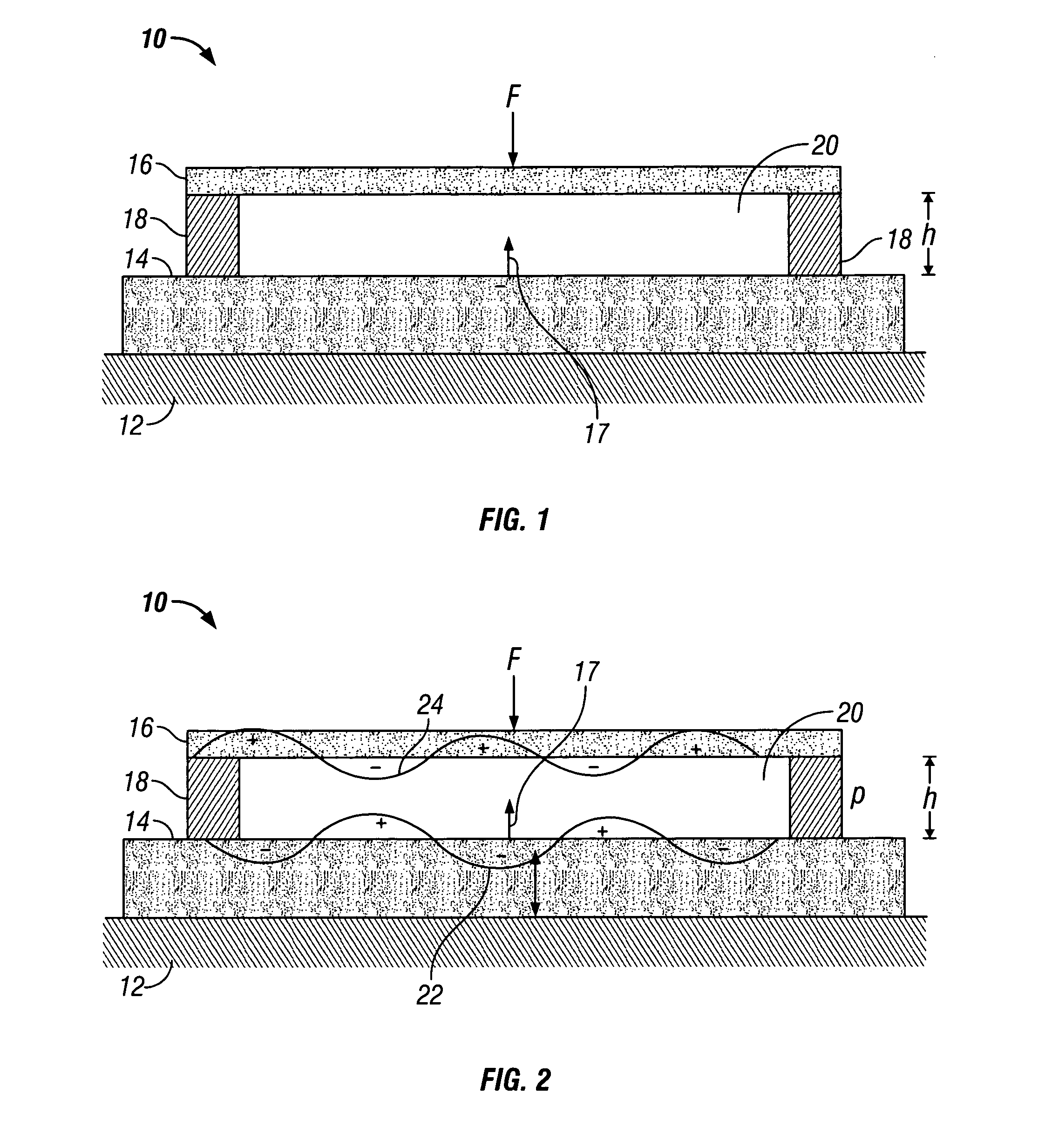

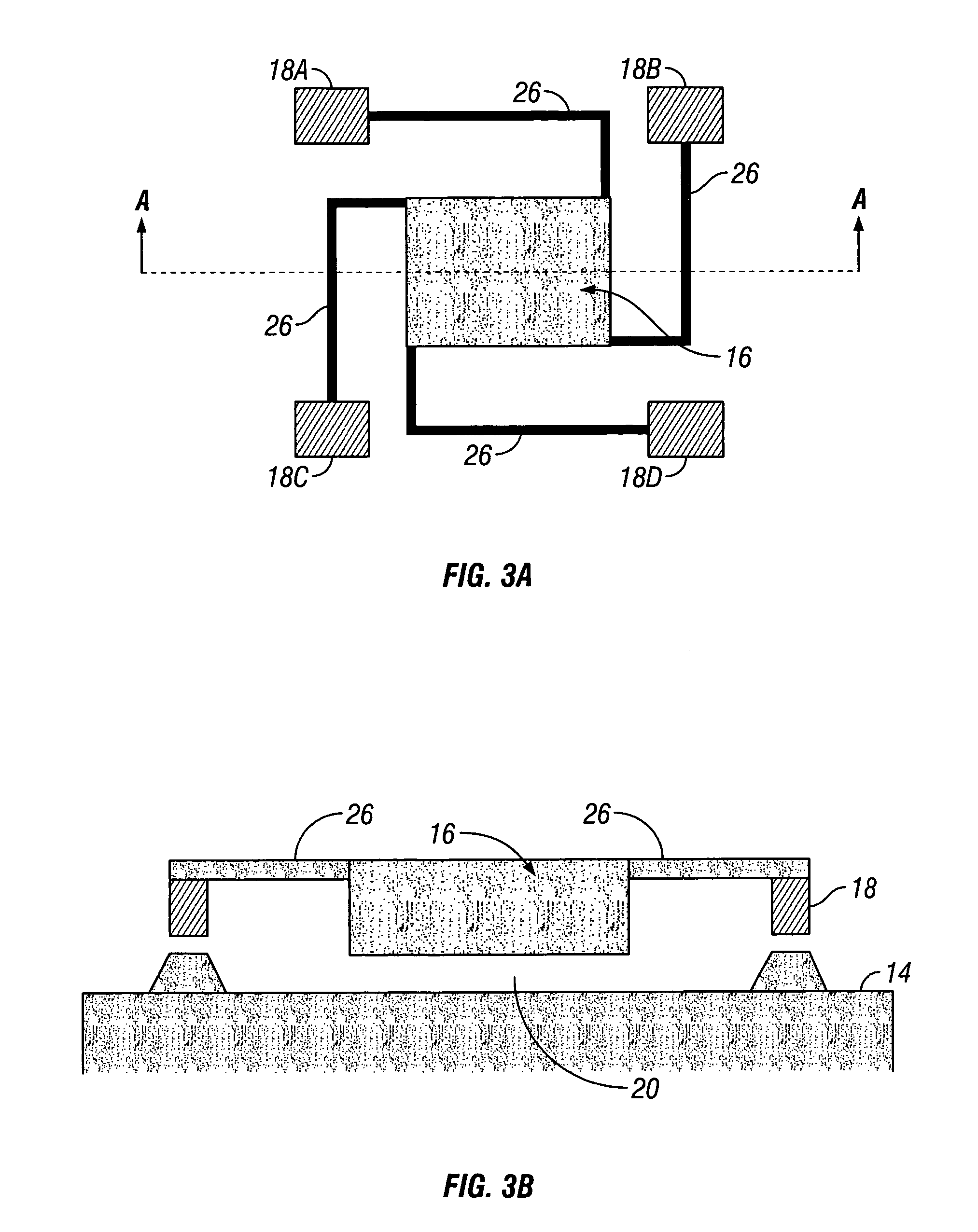

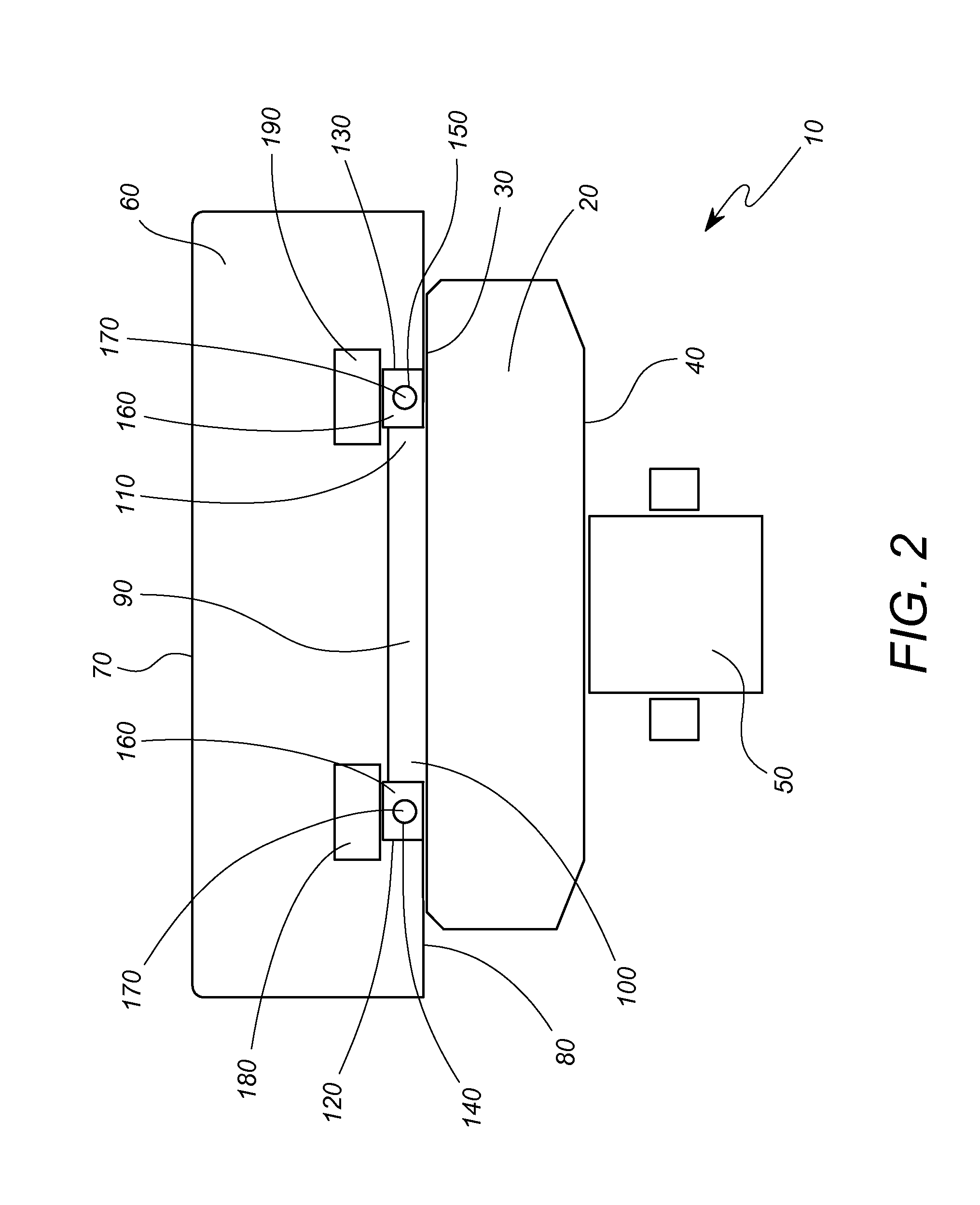

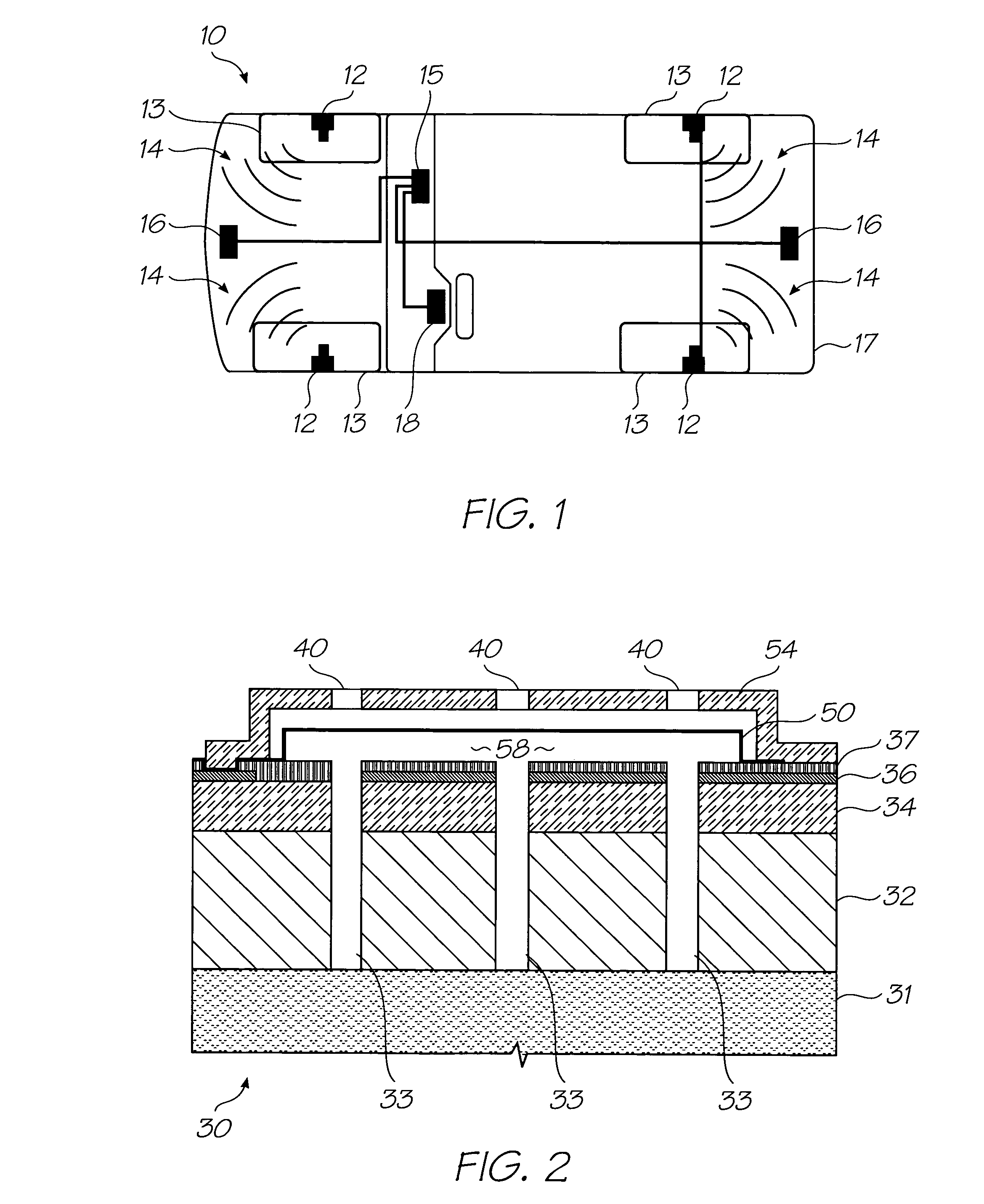

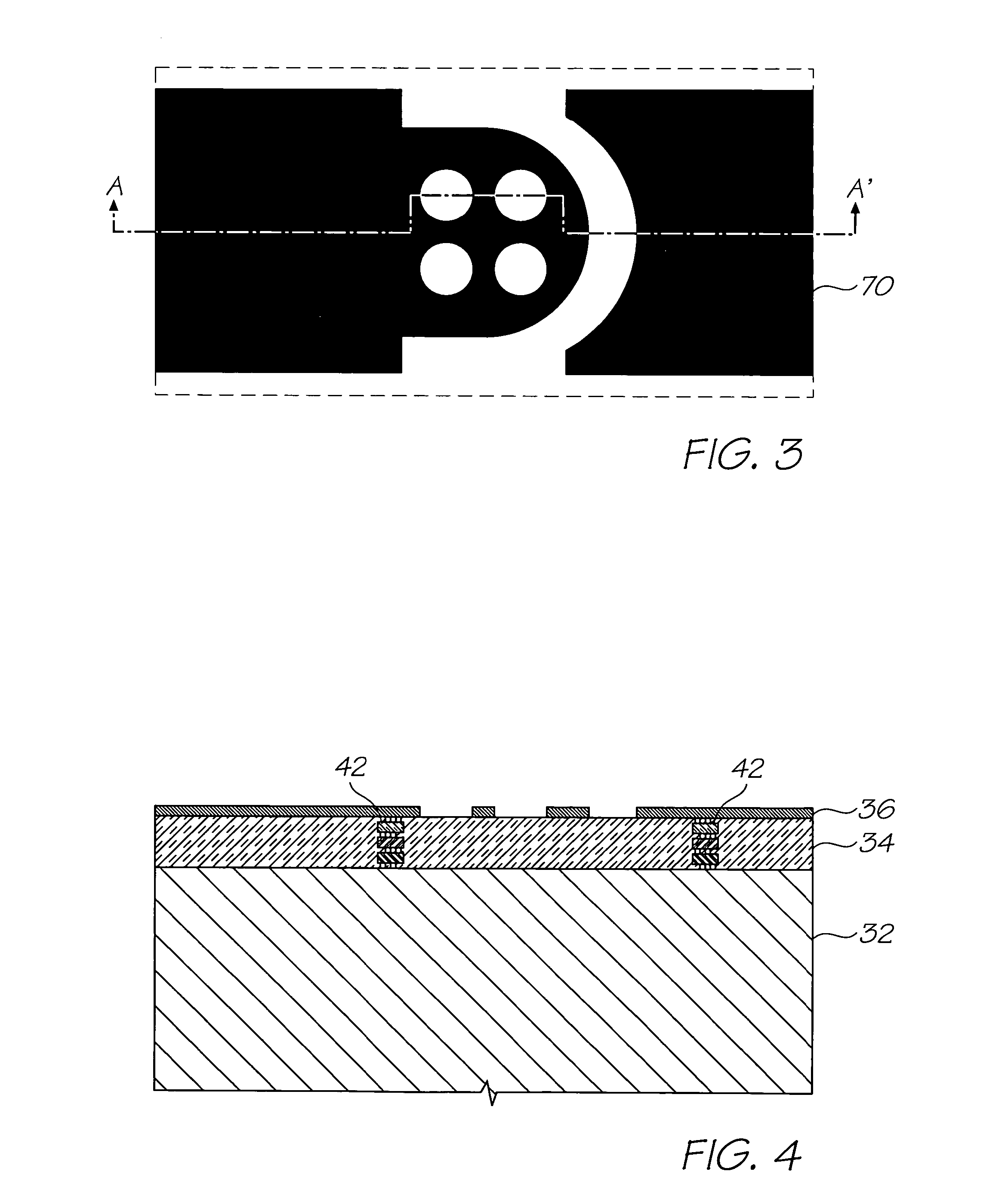

Method and apparatus for reducing acoustic noise

ActiveUS7267196B2Reduce transmissionImprove vibrationMachine framesLiquid springsMicrometerAcoustic energy

A squeeze film damper reduces acoustic wave transmission by the damping and spring forces produced by squeezing a very thin layer of air trapped between two vibrating plates. The damping effect is most pronounced when the gap between vibrating plates is very small, e.g., of the order of micrometers, thus, the squeeze film dampers have two, very closely-spaced opposing plates, the top of which vibrates out-of-phase with respect to the lower plate, when the lower plate is attached to a vibrating surface. The relative motion of plates squeezes out the thin film of air trapped within the plates and adds substantial amount of passive damping over a wideband of frequency to the base vibrating structure thereby reducing vibrations and noise radiated by the structure. The out-of-phase displacement of the top plate, with respect to the bottom plate, tends to cancel acoustic energy imparted to the lower plate by a vibrating surface. Squeeze film dampers can be applied in arrays to a vibrating surface.

Owner:THE BOEING CO

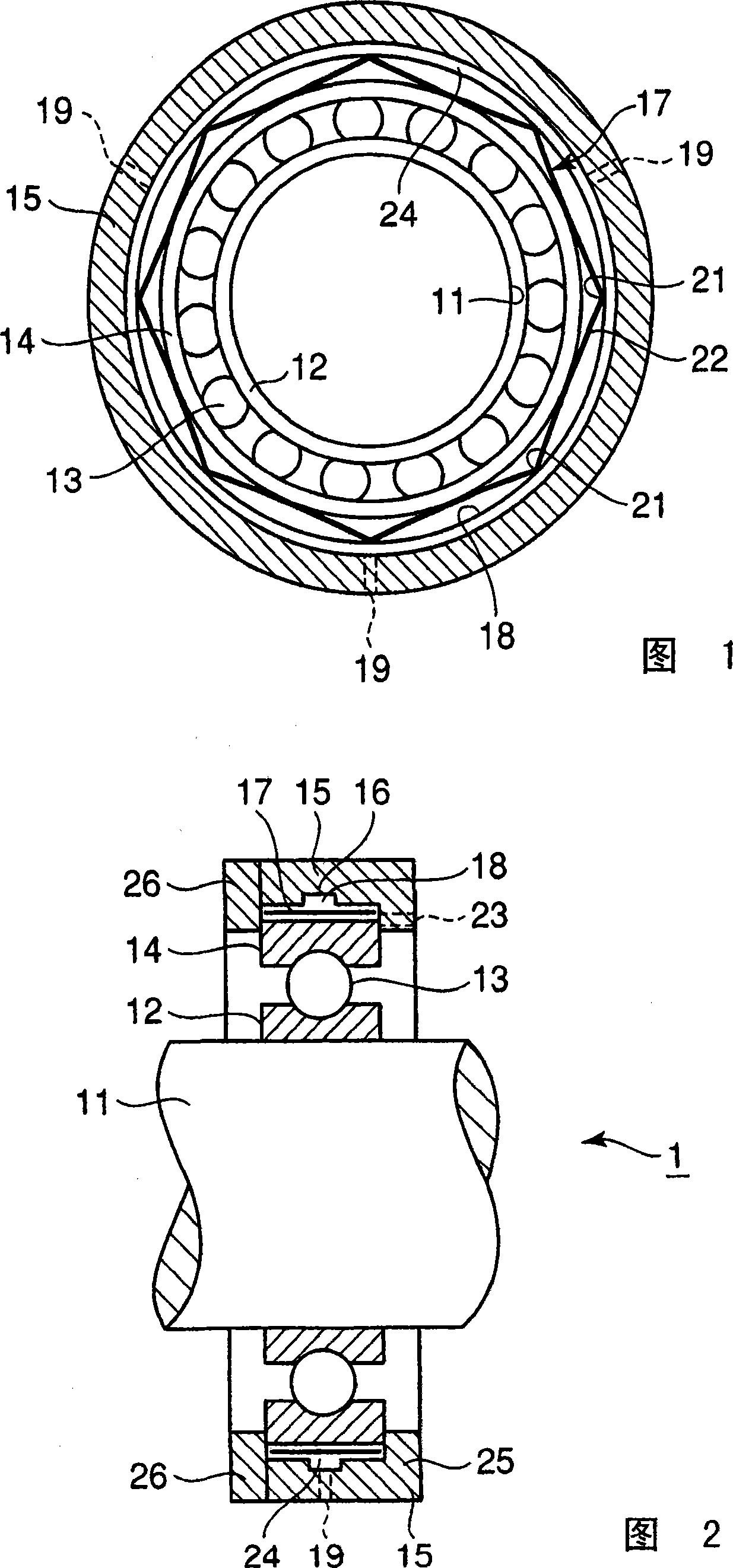

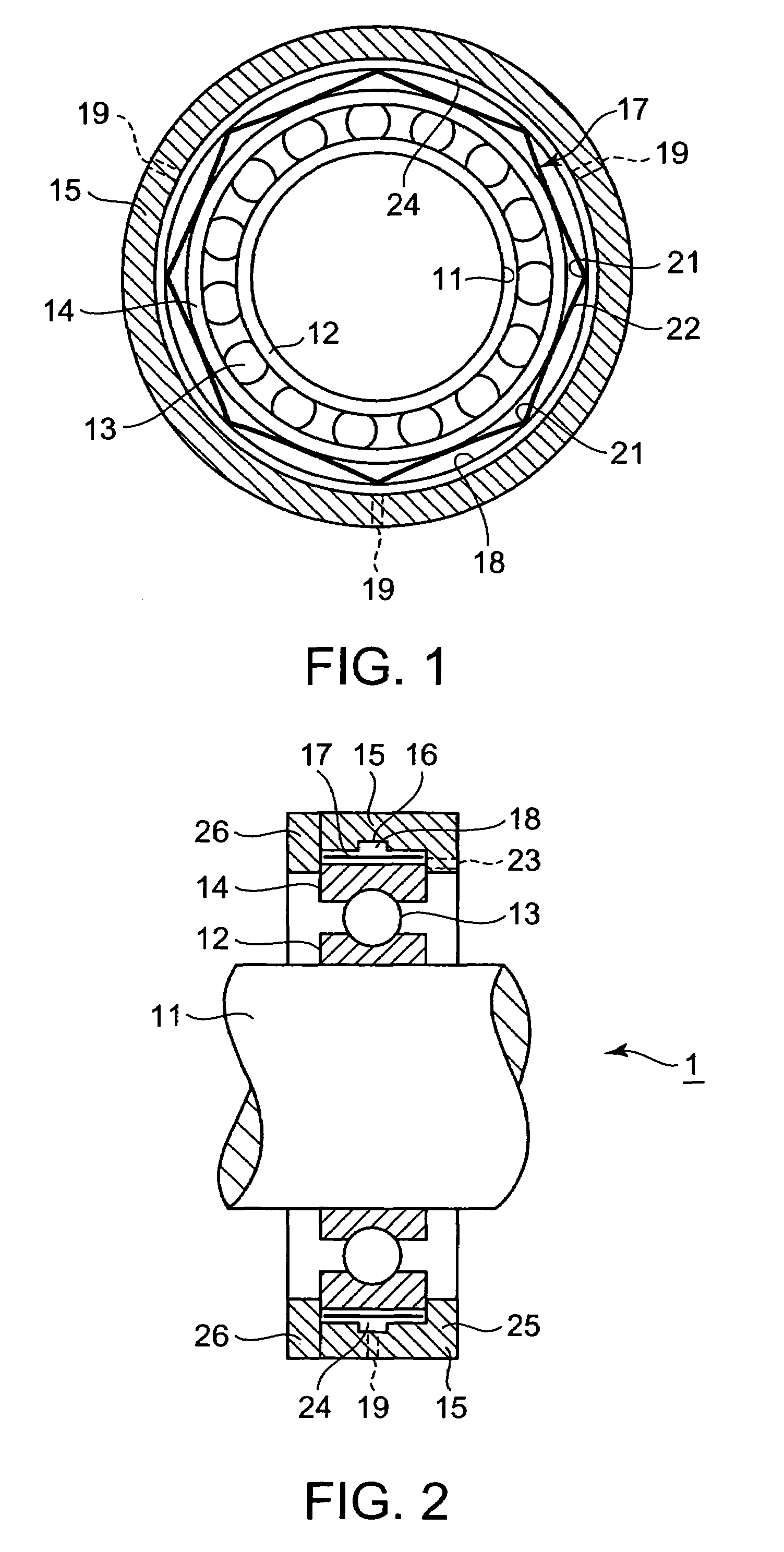

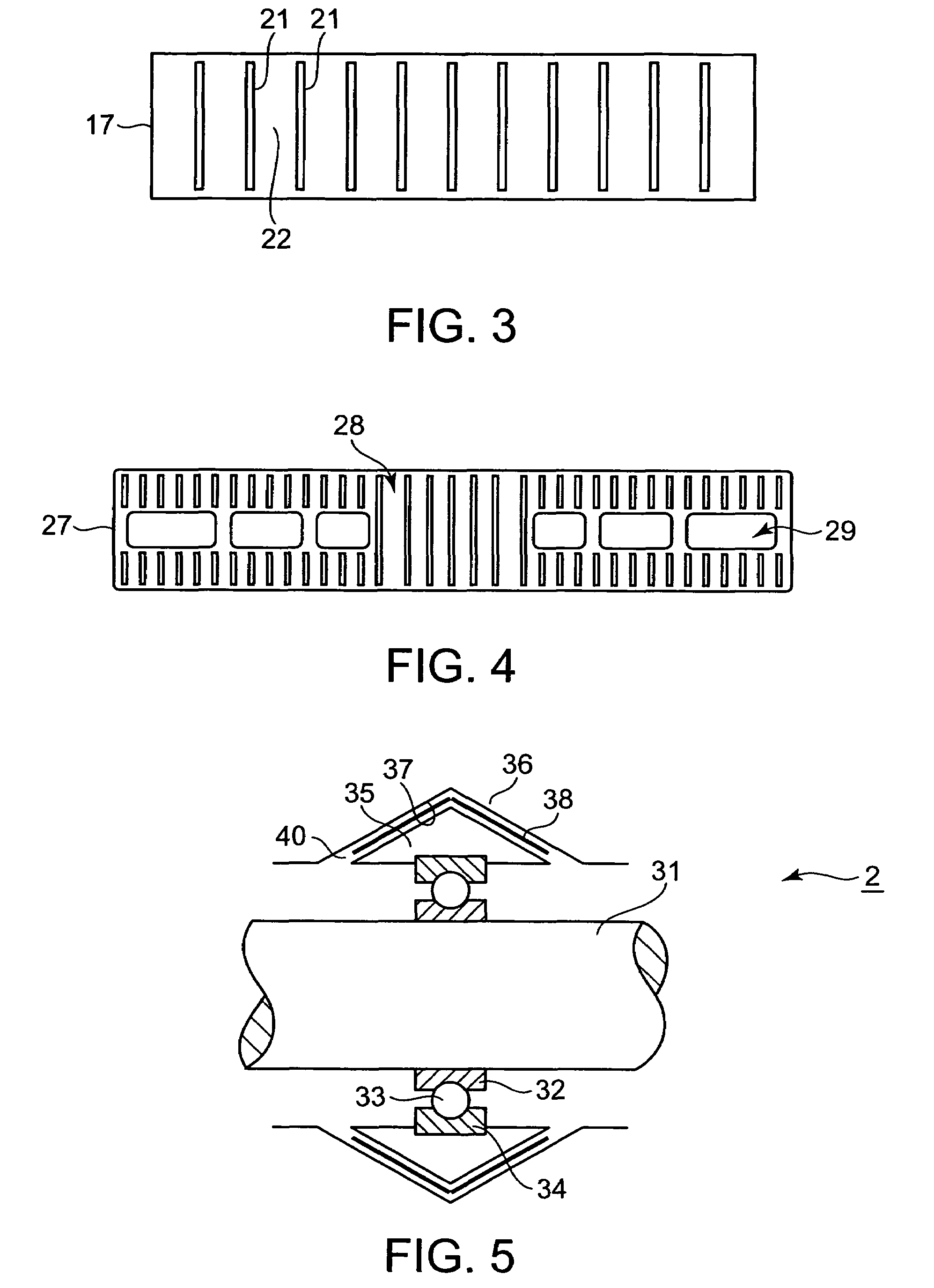

Vibration damping mechanism for bearing

ActiveCN101010521AInhibit sheddingInhibition releaseLeaf springsShaftsRolling-element bearingEngineering

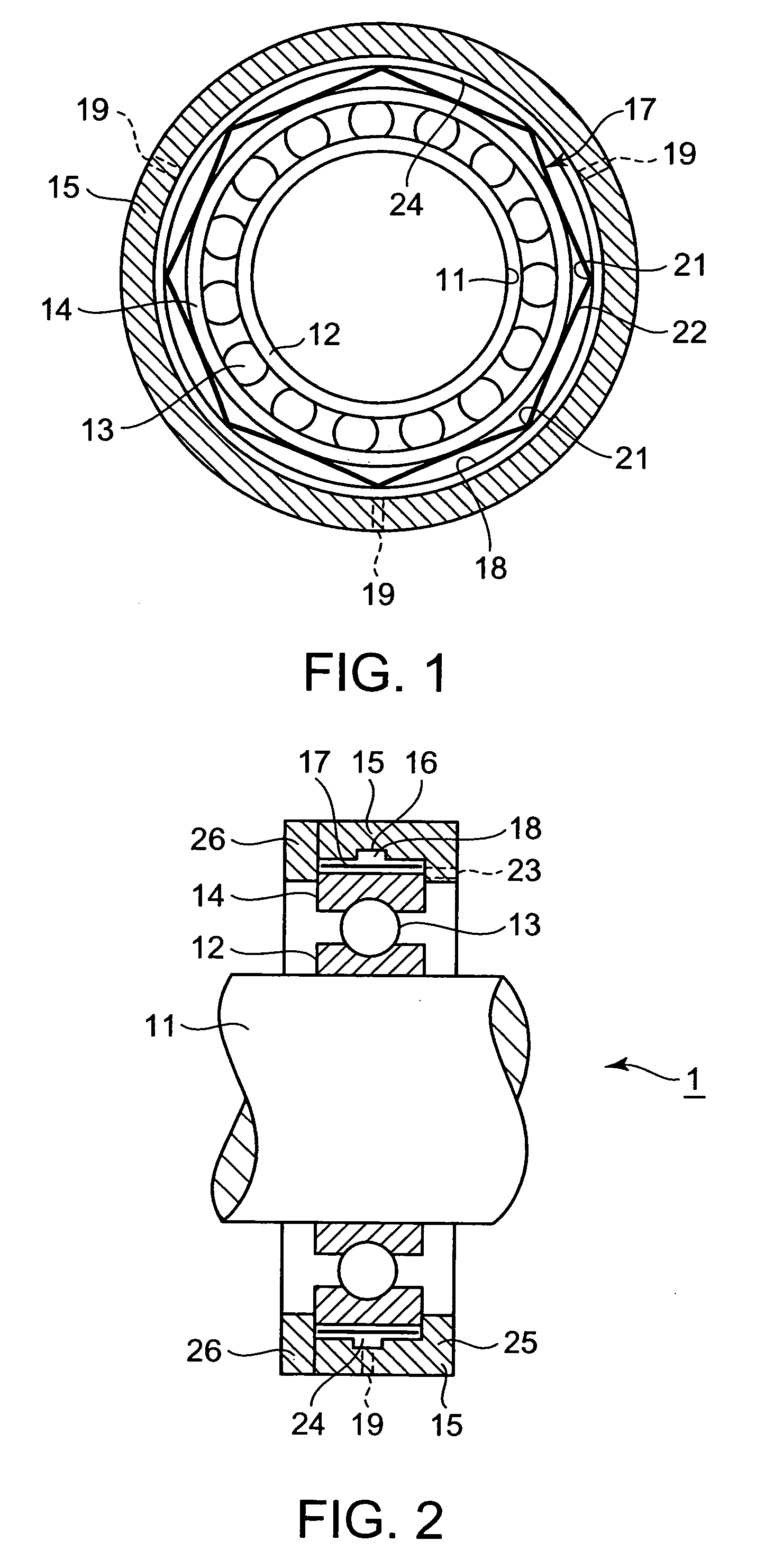

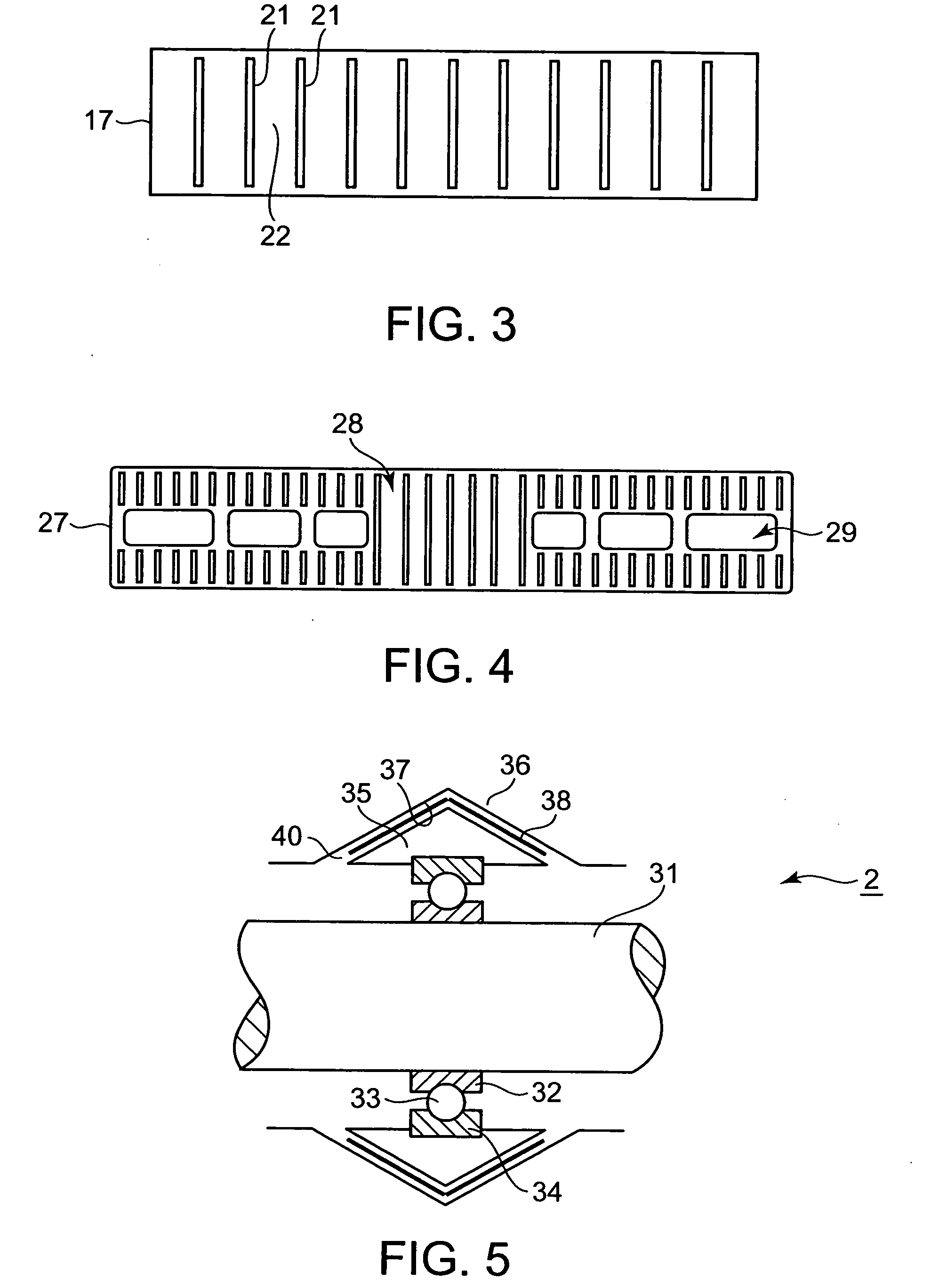

A squeeze film damper bearing easily manufacturable, having excellent productivity, and reduced in size and a vibration damping mechanism for the rolling bearing capable of having an effect on loads in two of radial and thrust directions. In the vibration damping mechanism (1) for the rolling bearing, a storage hole (16) having a diameter larger than the diameter of the outer periphery (14) of the bearing is formed on the inside of a housing (15) and an oil supply hole (19) supplying an oil into the storage hole is formed in the wall of the housing (15), the bearing is inserted into the storage hole to form an annular clearance (18) on the outer periphery of the bearing, and a thin flat plate (17) having a plurality of slits is inserted into the annular clearance along the circumferential direction. The portions of the thin flat plate held by the slits are formed in an elastic beam to elastically support the bearing at a center position, and the vibration of the bearing is damped by a squeeze film action caused by an oil film generated by supplying the oil into the annular clearance.

Owner:KAWASAKI JUKOGYO KK

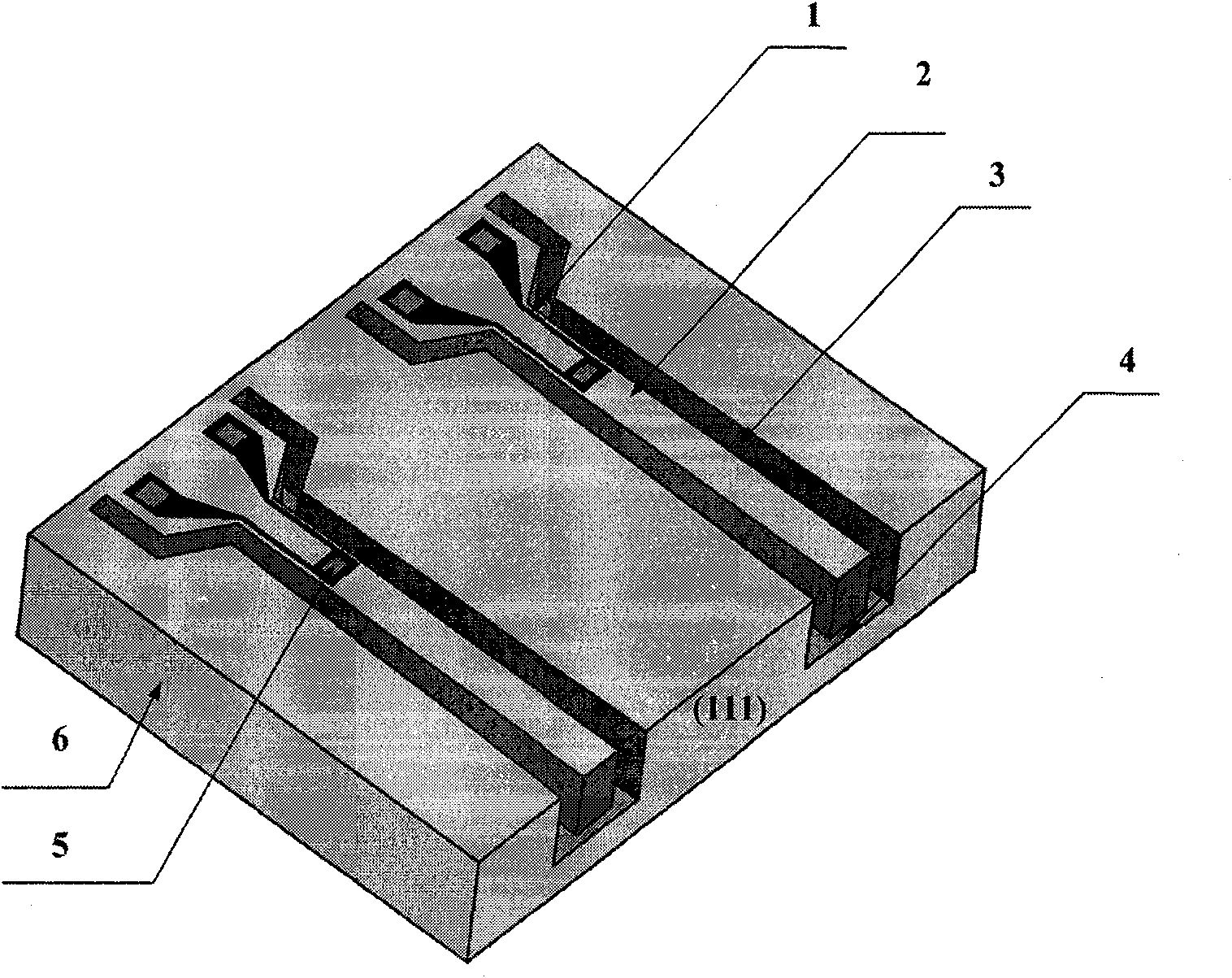

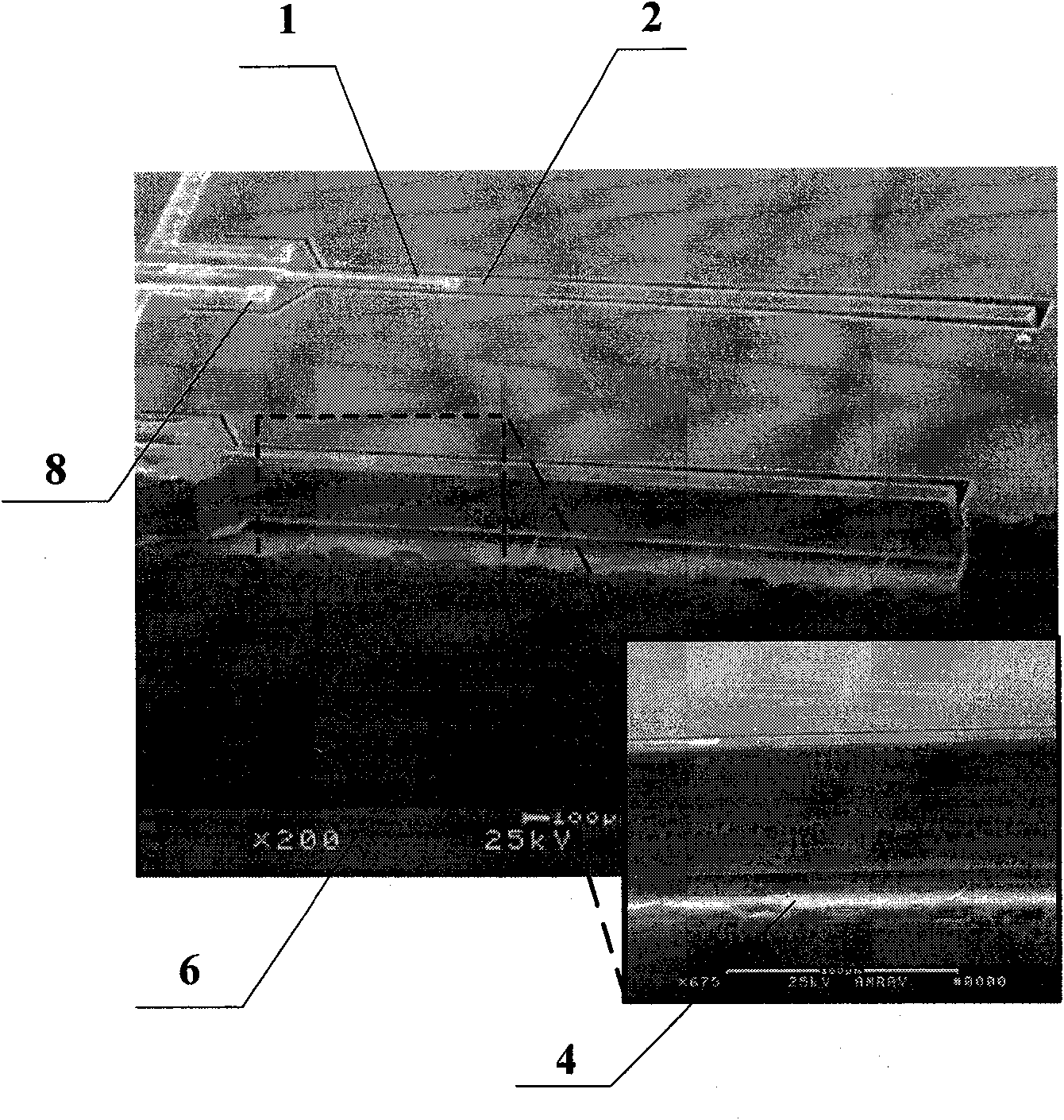

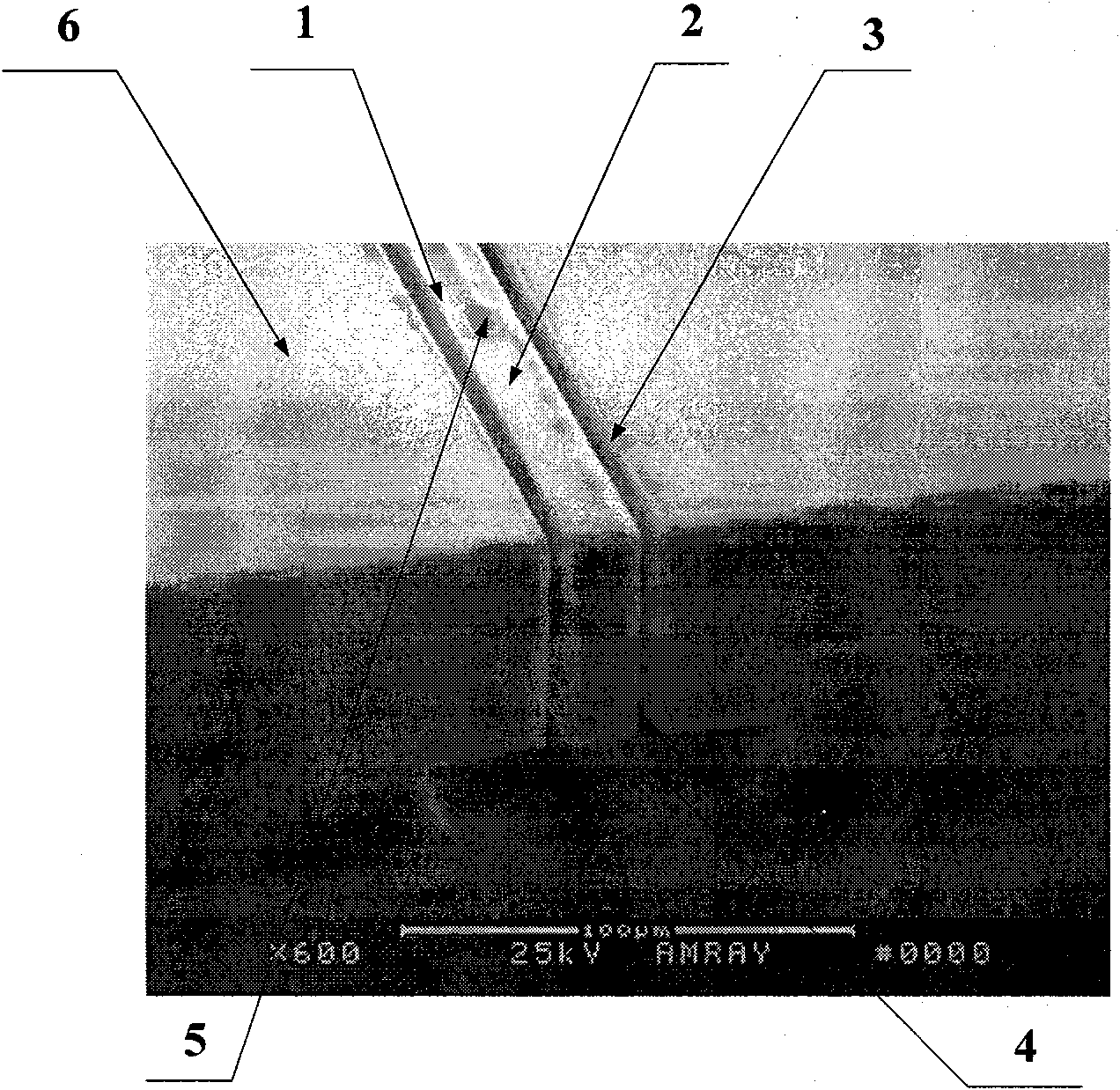

Cantilever beam acceleration transducer manufactured by micro-machining on single side of single silicon chip and method

ActiveCN101968495AHigh sensitivityImprove stabilityAcceleration measurement using interia forcesDecorative surface effectsEtchingAccelerometer

The invention relates to a cantilever beam acceleration transducer manufactured by micro-machining on a single side of a single silicon chip and a manufacturing method. The acceleration transducer is characterized in that: an accelerometer is manufactured by micro-mechanical single side machining through the single silicon chip, so that stress caused by the bonding process of a plurality of chipsand different materials is avoided. In order to realize a single side-machined cantilever beam sensitive structure, the cantilever beam structure is released by transversely etching the bottom of thecantilever beam by an anisotropic corrosion method after deep structural etching. The structure provides air squeeze-film damping and mechanical overload protection in a sensitive direction, solves the problem of the absence of air squeeze-film damping in the vertical sensitive direction of the conventional structure and prevents parasitic signal interference caused by structural resonance in thevertical direction. The acceleration transducer has the characteristics of particular suitability for measuring a high g value, simple structure, small size of the chip and the like. Simultaneously, a single side process can use low-cost single throwing silicon chips, is suitable for low-cost mass manufacturing and has higher performance and wide application prospects.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

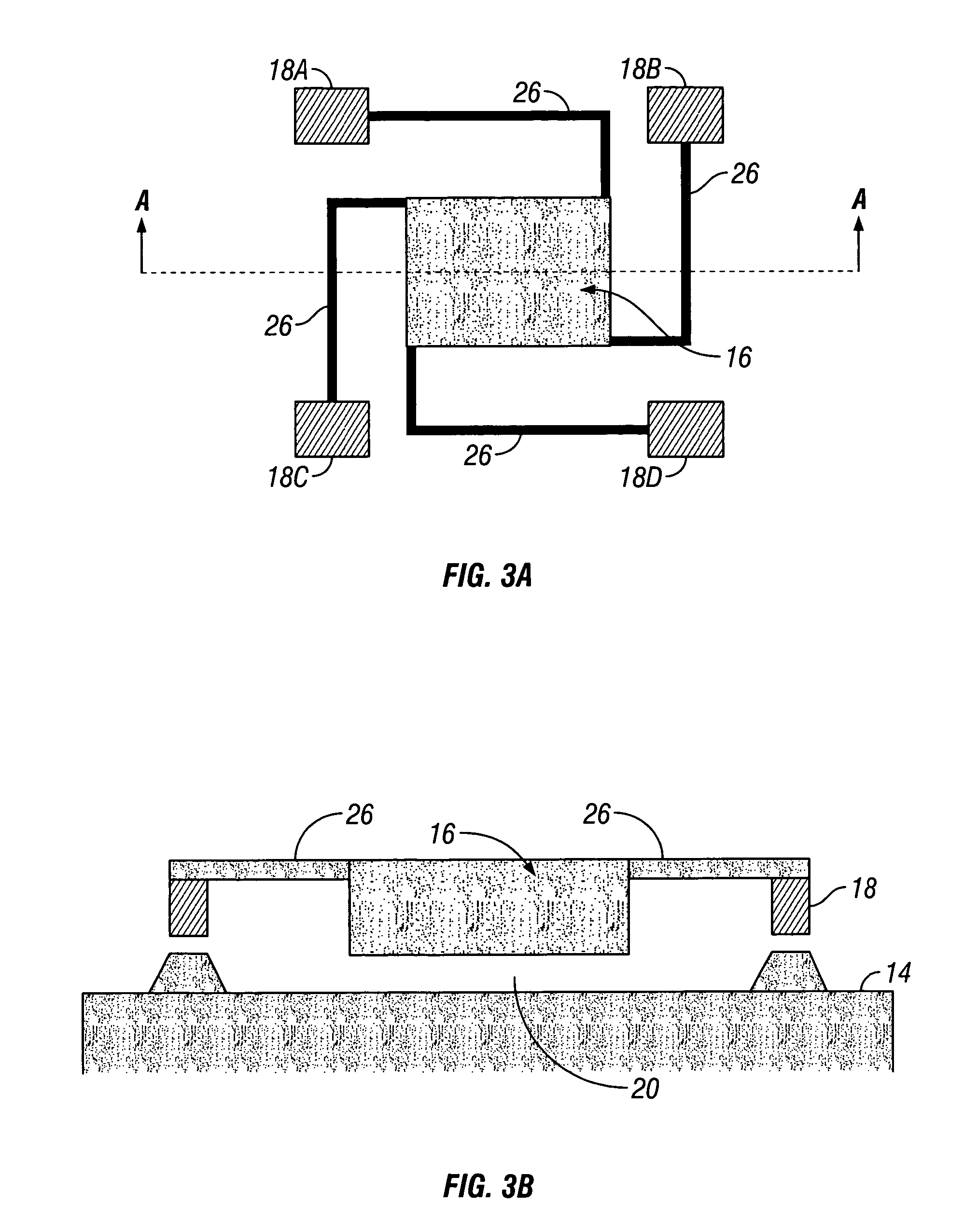

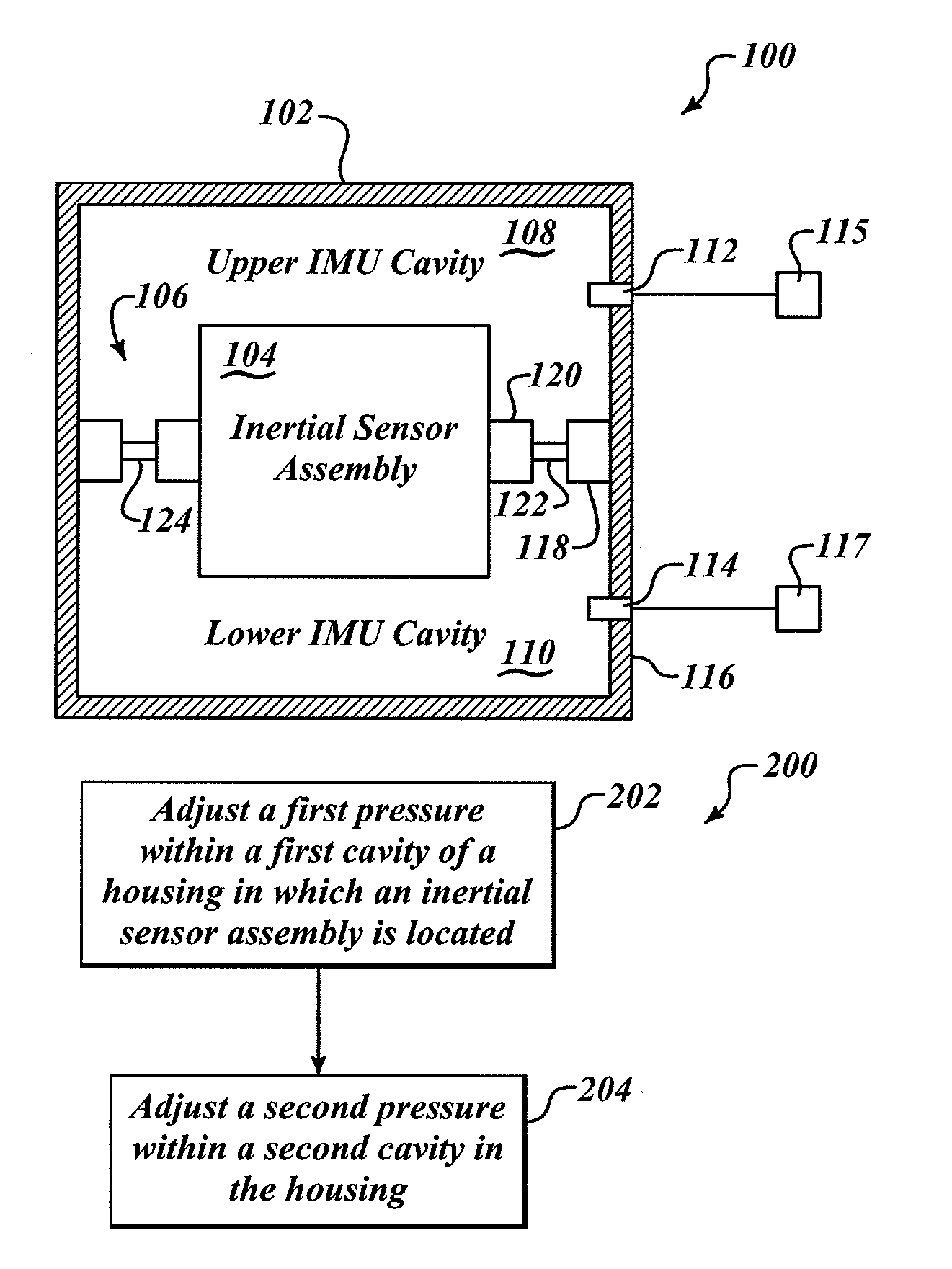

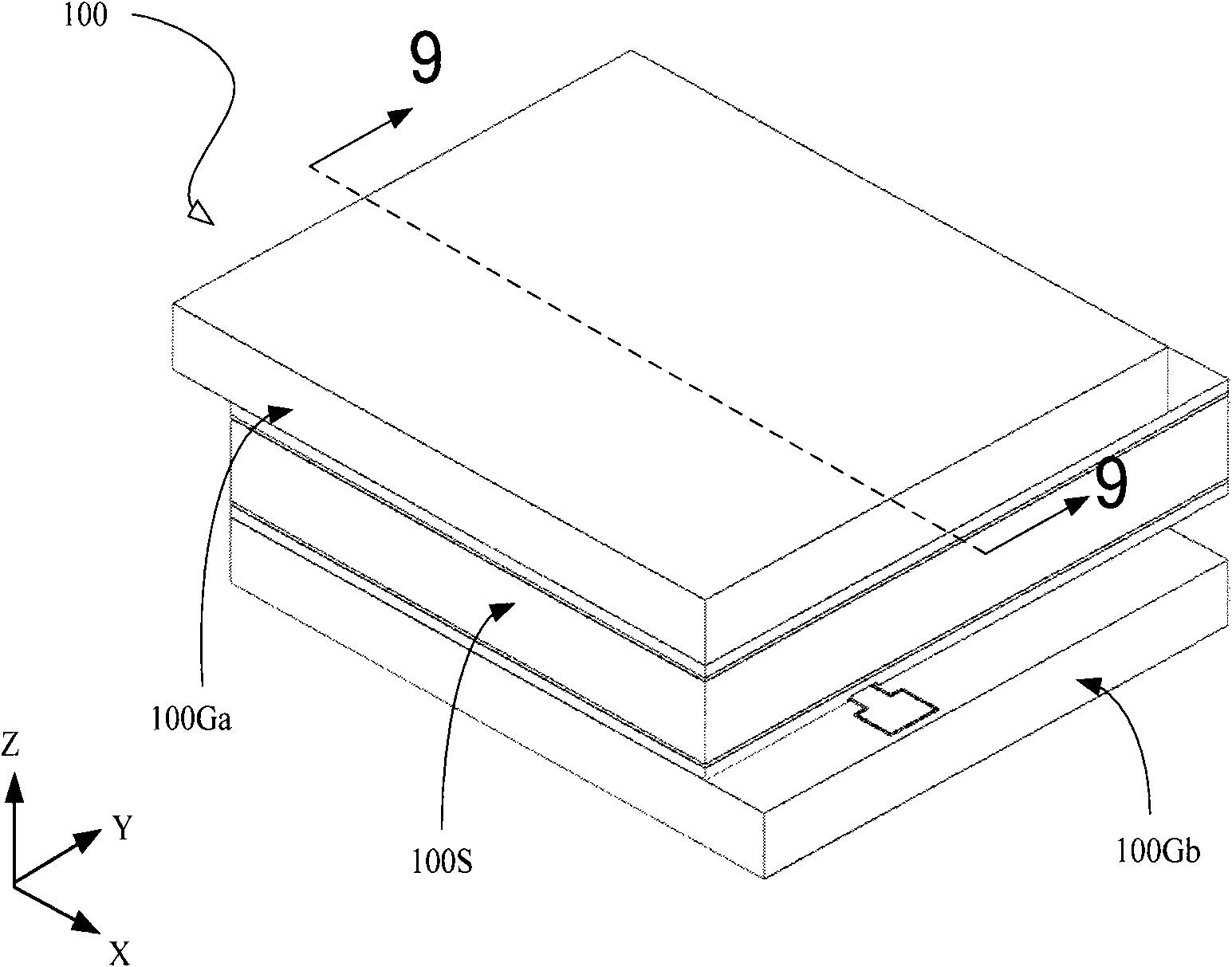

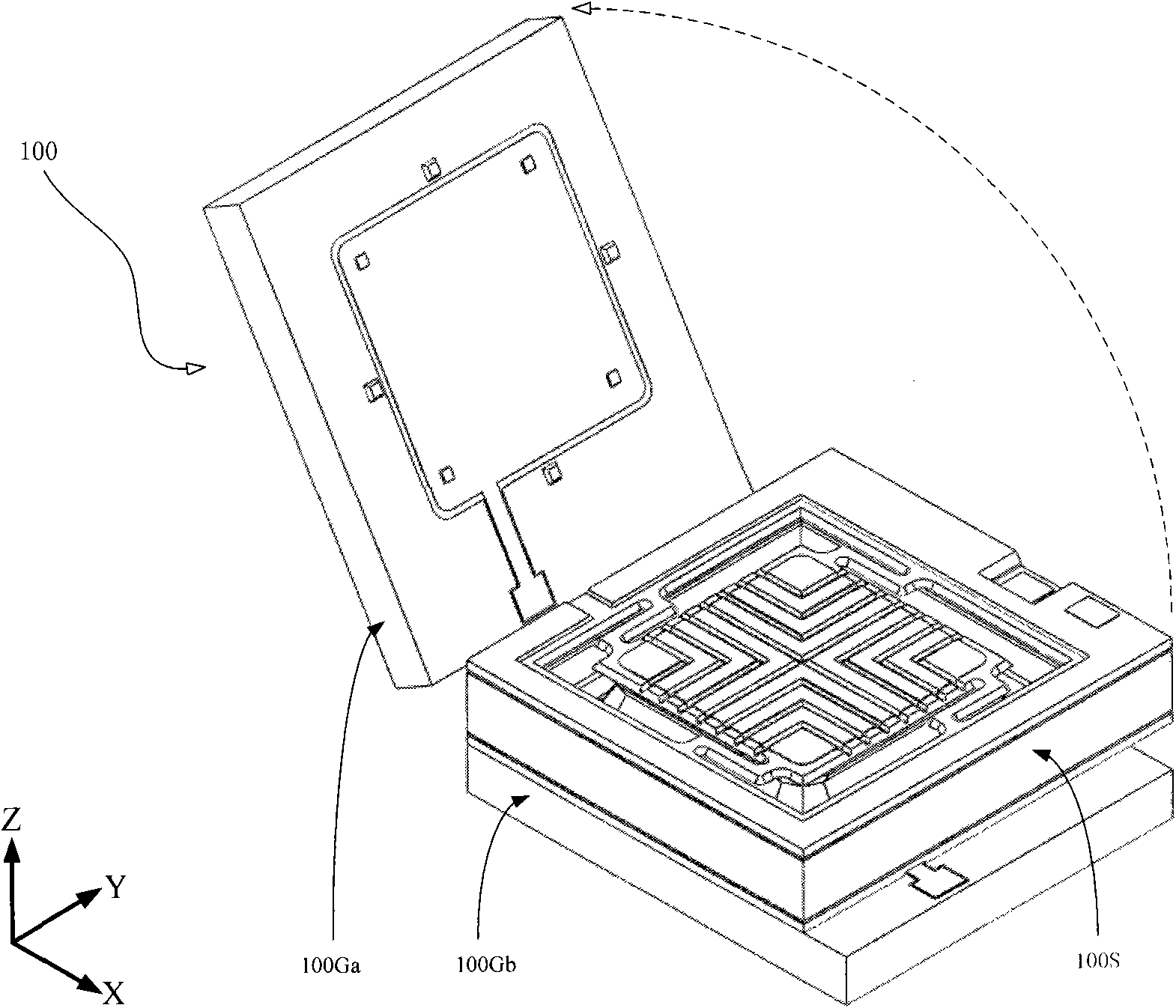

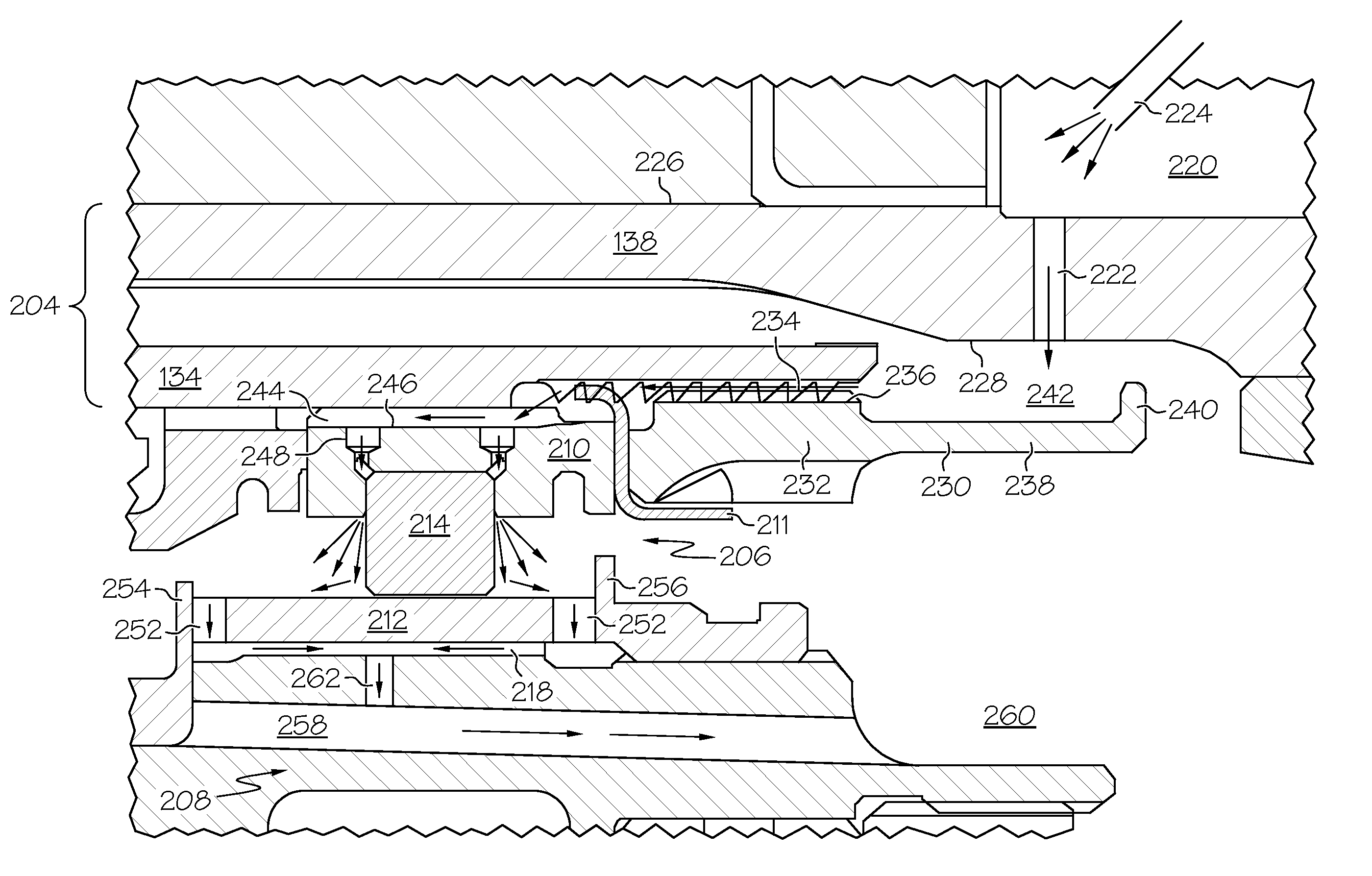

Adjustable gas damping vibration and shock isolation system

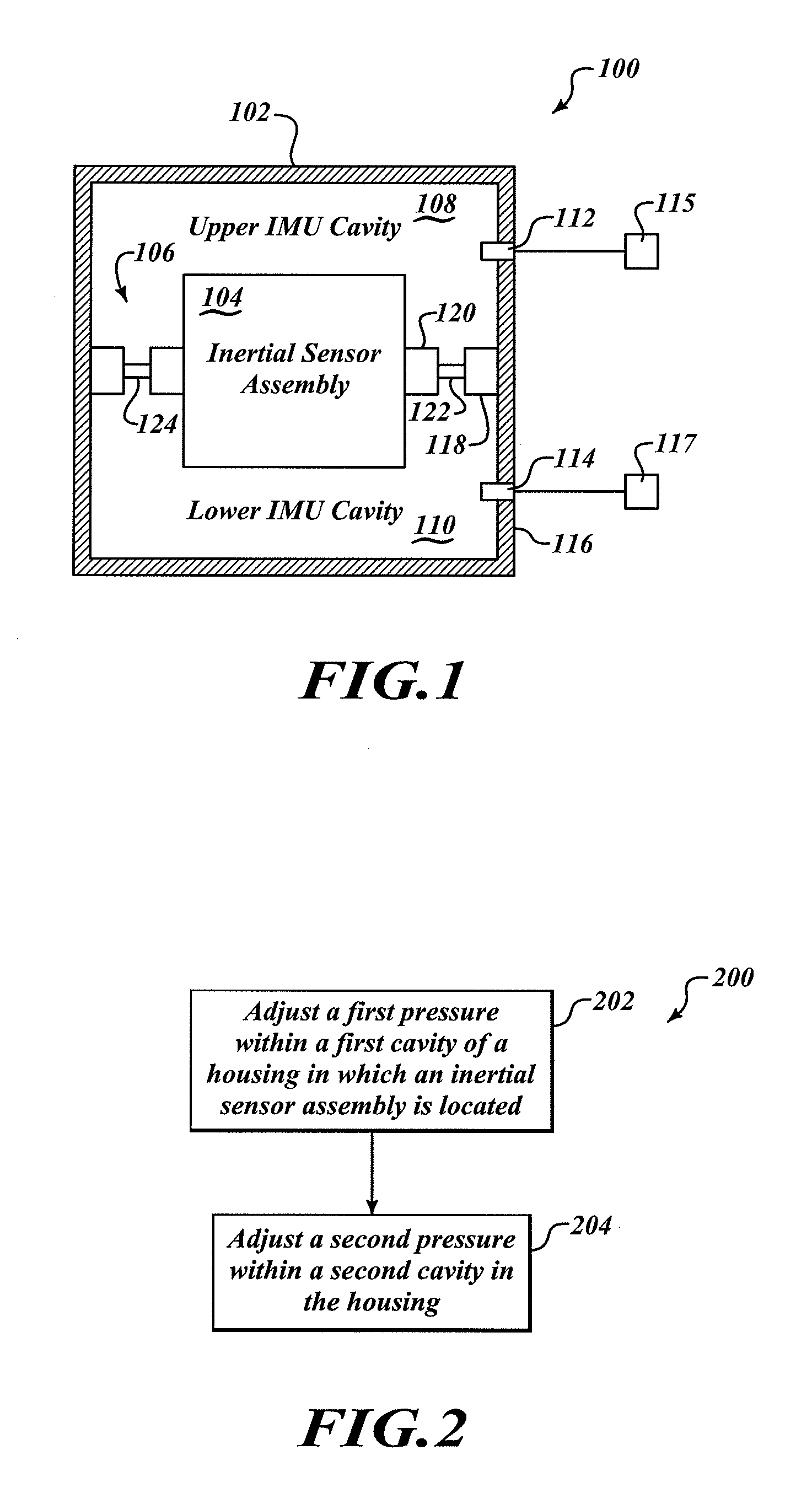

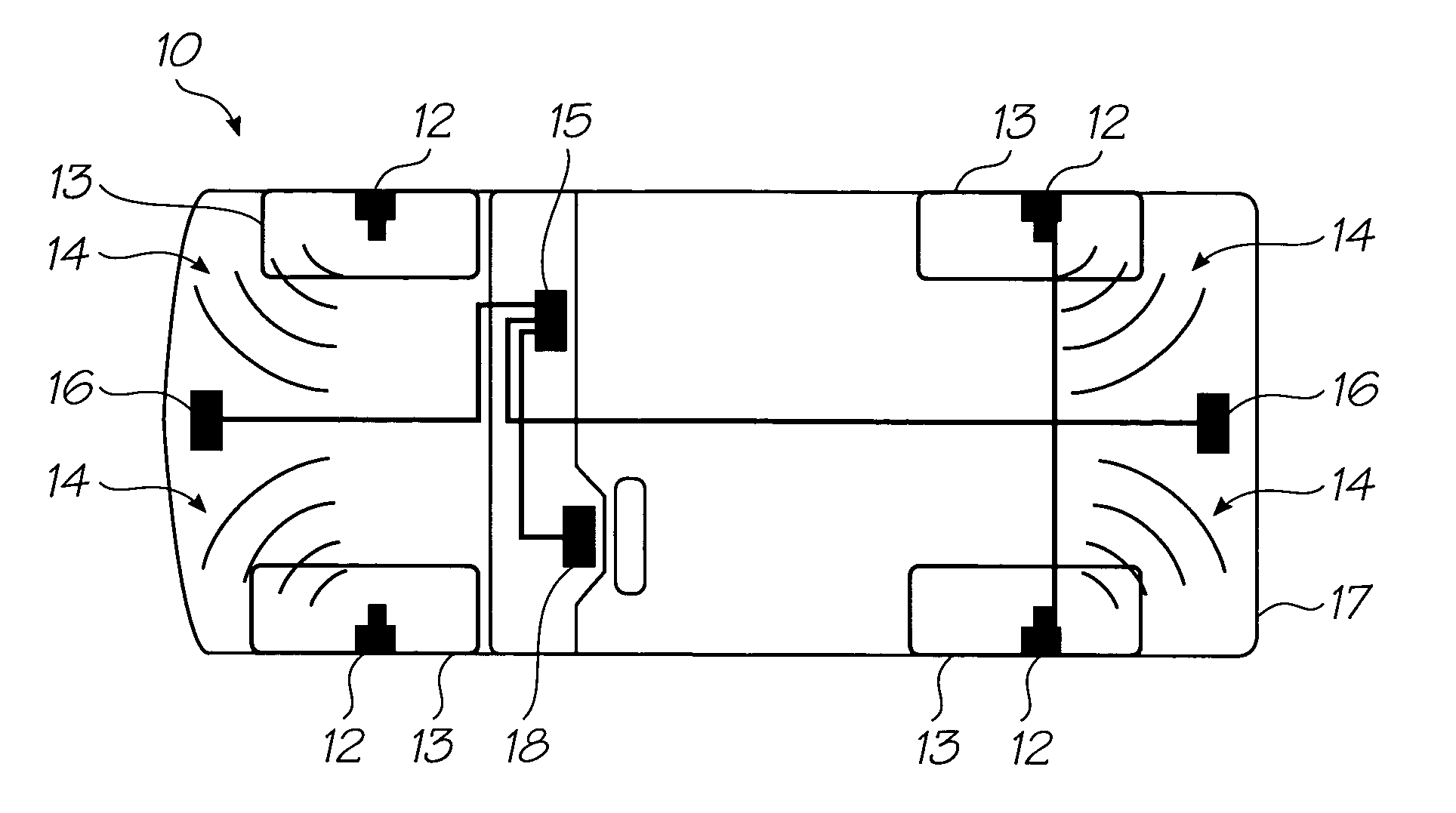

InactiveUS20100059911A1Machine framesNavigation by speed/acceleration measurementsEngineeringSqueeze film

An inertial measurement unit includes a housing with openings to permit fluid communication between at least one pressure source and two distinct cavities within the housing. The cavities are separated by an inertial sensor assembly coupled to a vibration isolator assembly. The pressure in the cavities may be adjusted or tuned to change a natural frequency of the inertial measurement unit, thus allowing the unit to be configured and even optimized for a variety of different applications. By adjusting the pressure in the respective cavities, gas squeeze film damping effects may be optimized when the inertial measurement unit undergoes a shock event and / or when the inertial measurement unit experiences vibration loads during operation. In one embodiment, the vibration isolator assembly includes perforations to permit fluid communication between the first and second cavities during specific operational events.

Owner:HONEYWELL INT INC

Method and apparatus for reducing acoustic noise

ActiveUS20050189165A1Reduce transmissionGood vibration dampingMachine framesLiquid springsMicrometerAcoustic energy

A squeeze film damper reduces acoustic wave transmission by the damping and spring forces produced by squeezing a very thin layer of air trapped between two vibrating plates. The damping effect is most pronounced when the gap between vibrating plates is very small, e.g., of the order of micrometers, thus, the squeeze film dampers have two, very closely-spaced opposing plates, the top of which vibrates out-of-phase with respect to the lower plate, when the lower plate is attached to a vibrating surface. The relative motion of plates squeezes out the thin film of air trapped within the plates and adds substantial amount of passive damping over a wideband of frequency to the base vibrating structure thereby reducing vibrations and noise radiated by the structure. The out-of-phase displacement of the top plate, with respect to the bottom plate, tends to cancel acoustic energy imparted to the lower plate by a vibrating surface. Squeeze film dampers can be applied in arrays to a vibrating surface.

Owner:THE BOEING CO

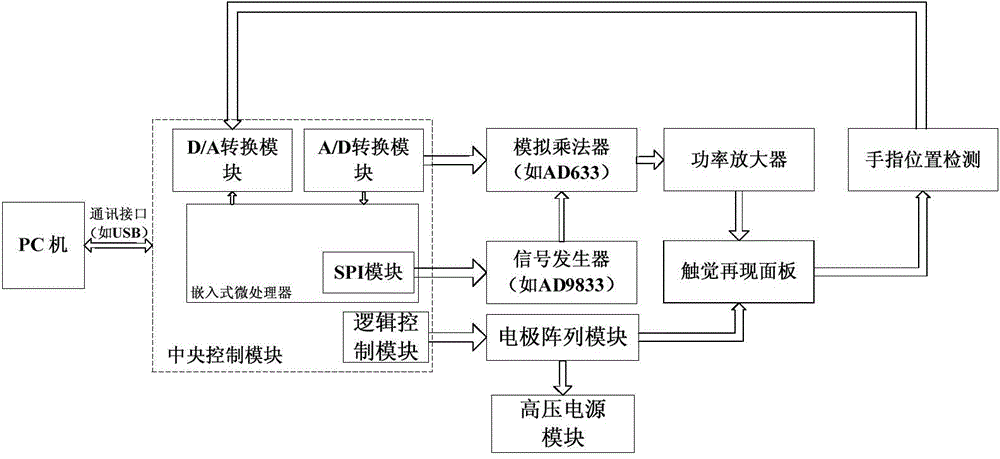

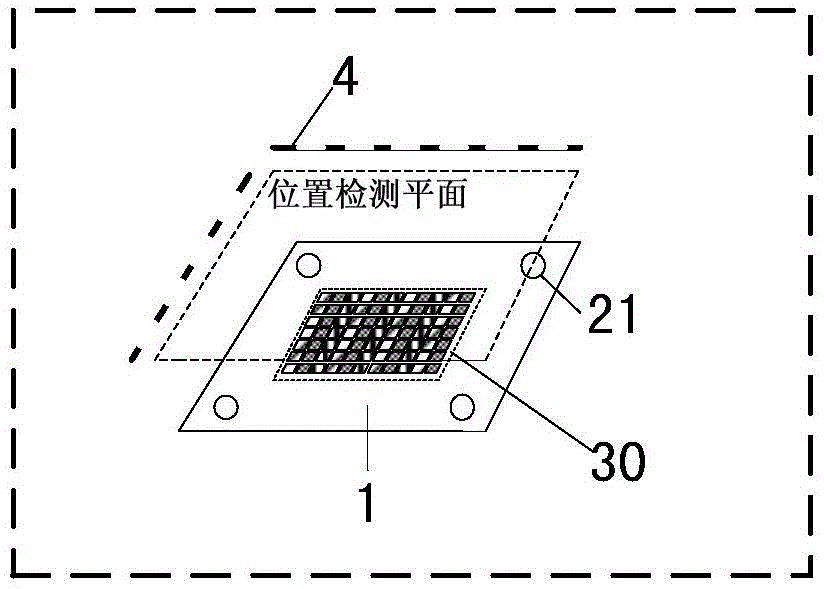

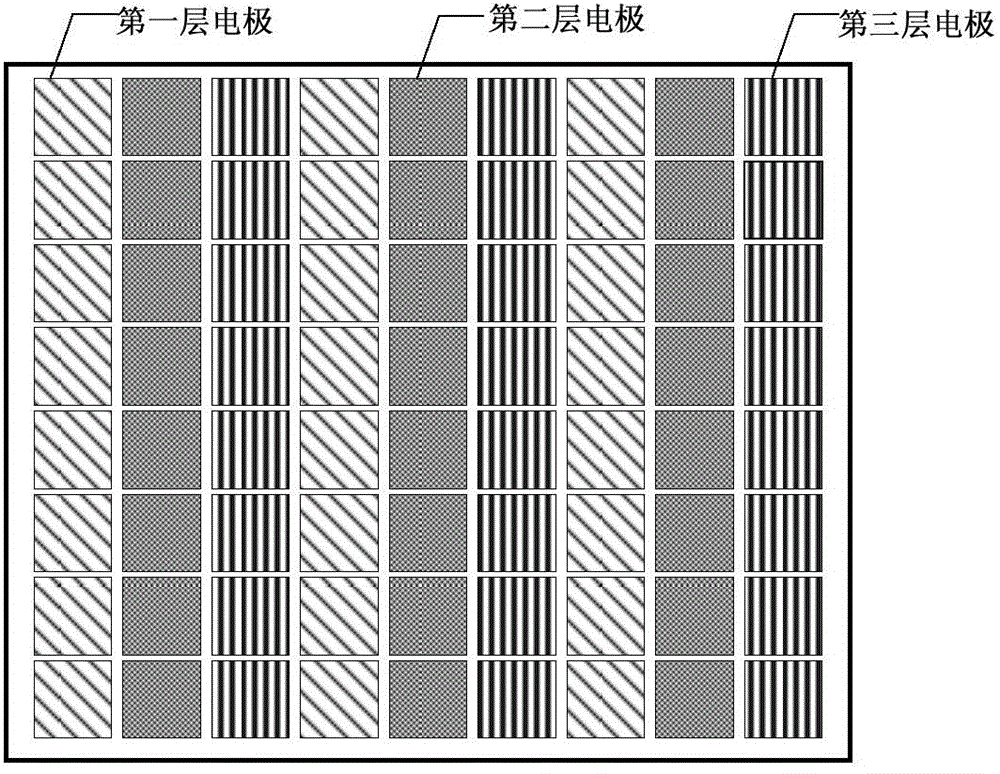

Touch reproduction device and touch reproduction method based on bi-directional frictional force control

ActiveCN104063054AWide friction coefficient control rangeRich friction levelInput/output for user-computer interactionGraph readingElectricityCommunication interface

The invention discloses a touch reproduction device based on the bi-directional frictional force control. The device comprises a touch reproduction module, a piezoelectric ceramic stimulation module, a central control module, an electrode array stimulation module, a finger position detecting module and a communication interface module, wherein the touch reproduction module comprises a rigid touch panel, a piezoelectric ceramic array module and an electrode array module; the piezoelectric ceramic array module is arranged on the lower surface of the rigid touch panel; the electrode array module is embedded into the inner part of the rigid touch panel, and a wider, finer, and more flexible touch reproduction module is realized. The invention further discloses a touch reproduction method based on the bi-directional frictional force control. According to the method, through touching the rigid touch panel by a finger, the air squeeze film effect is achieved between the finger and the rigid touch panel, and the electro-vibration effect is achieved between the finger and the electrode array module; the bi-directional friction force coefficient adjusting and friction force coefficient fine tuning are implemented, and further the touch reproduction based on the friction force control is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

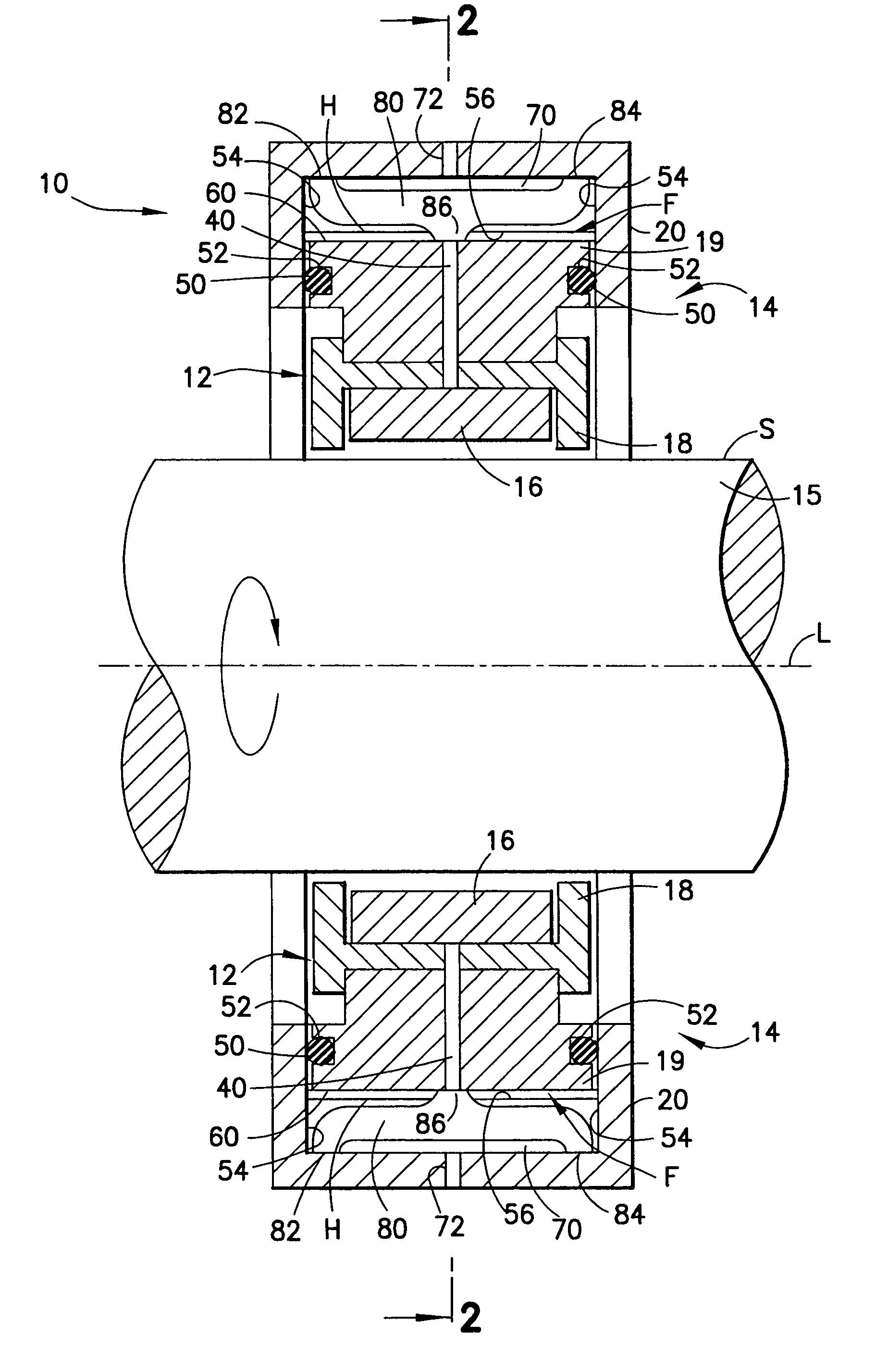

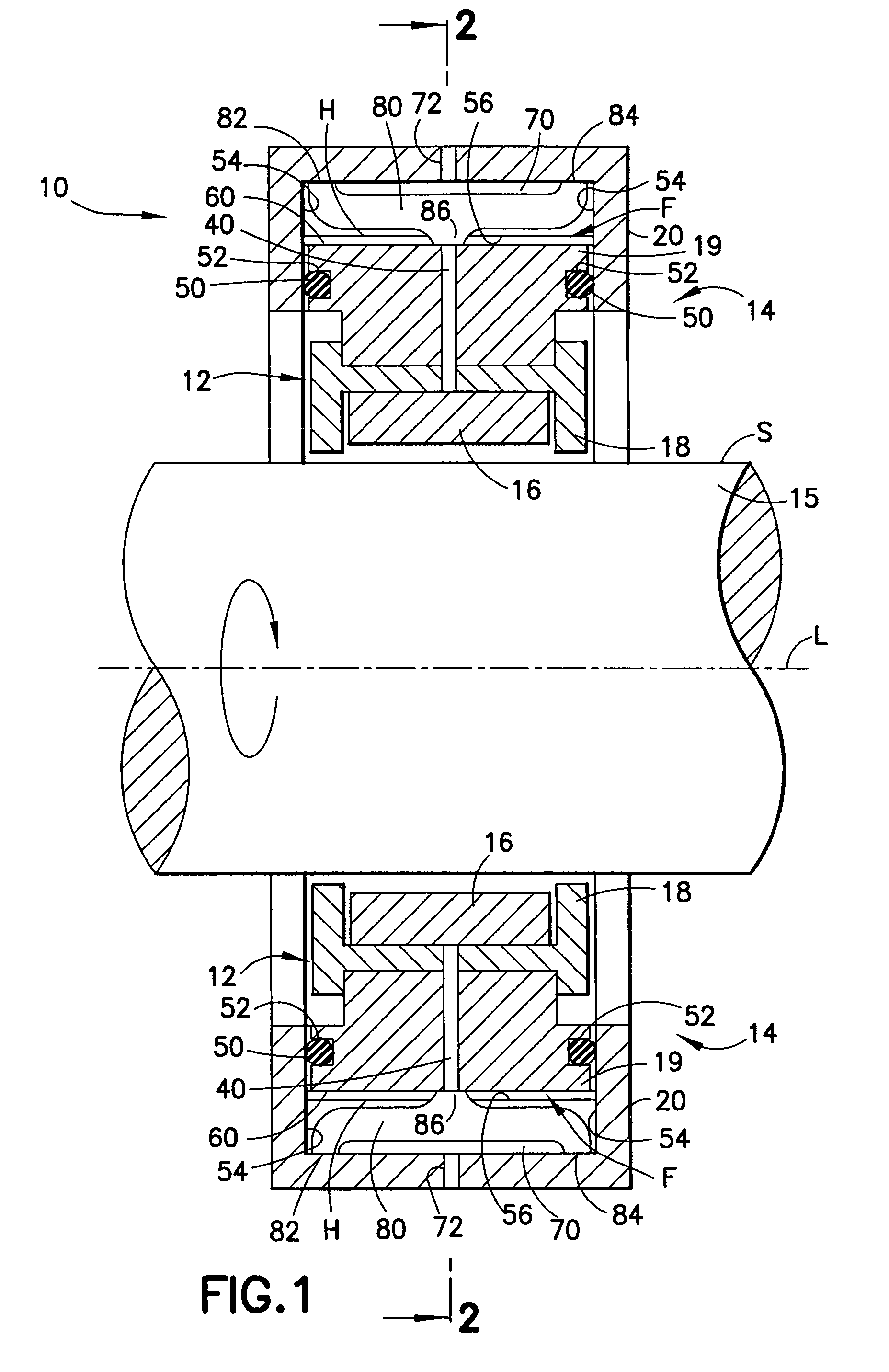

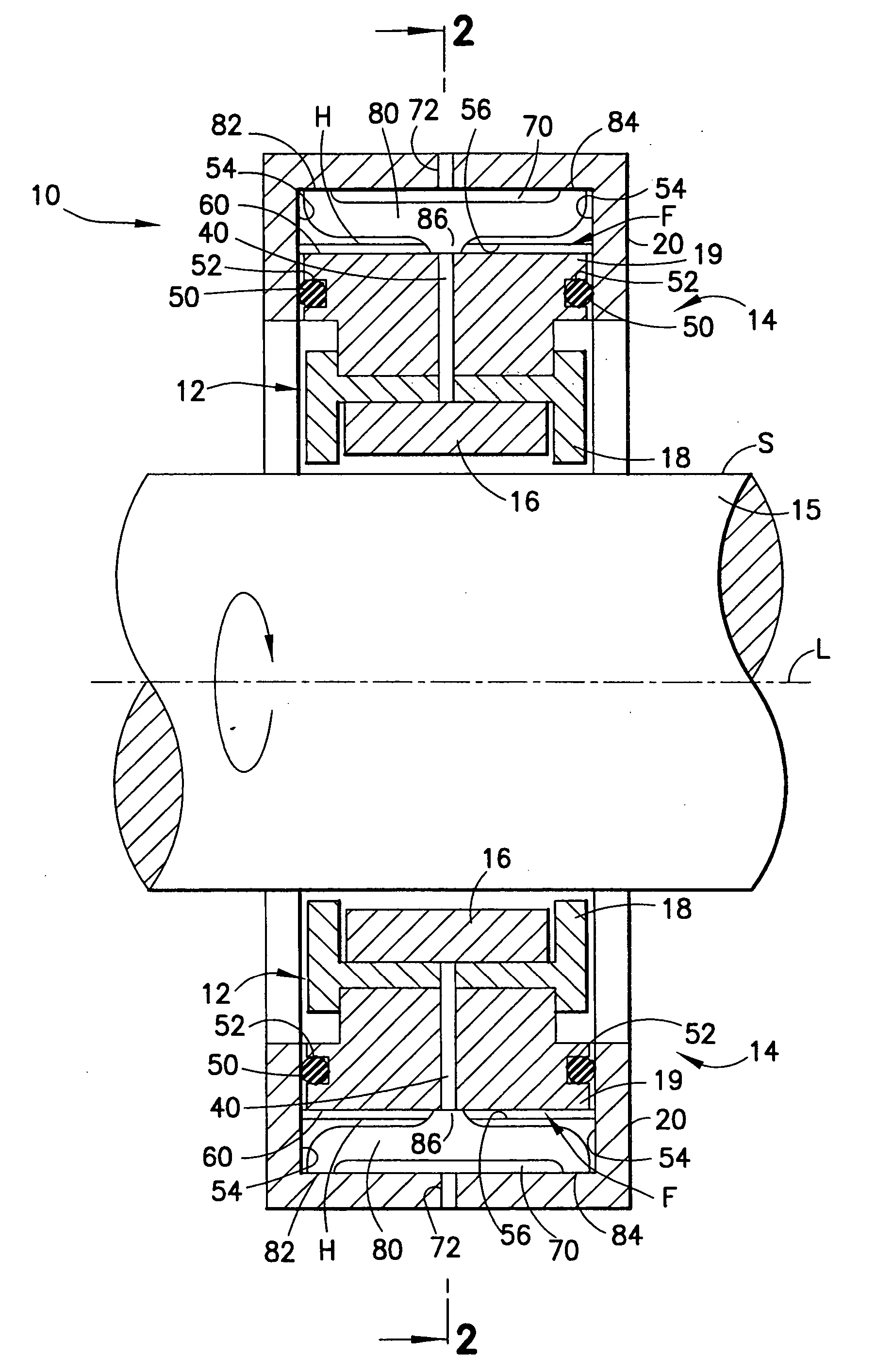

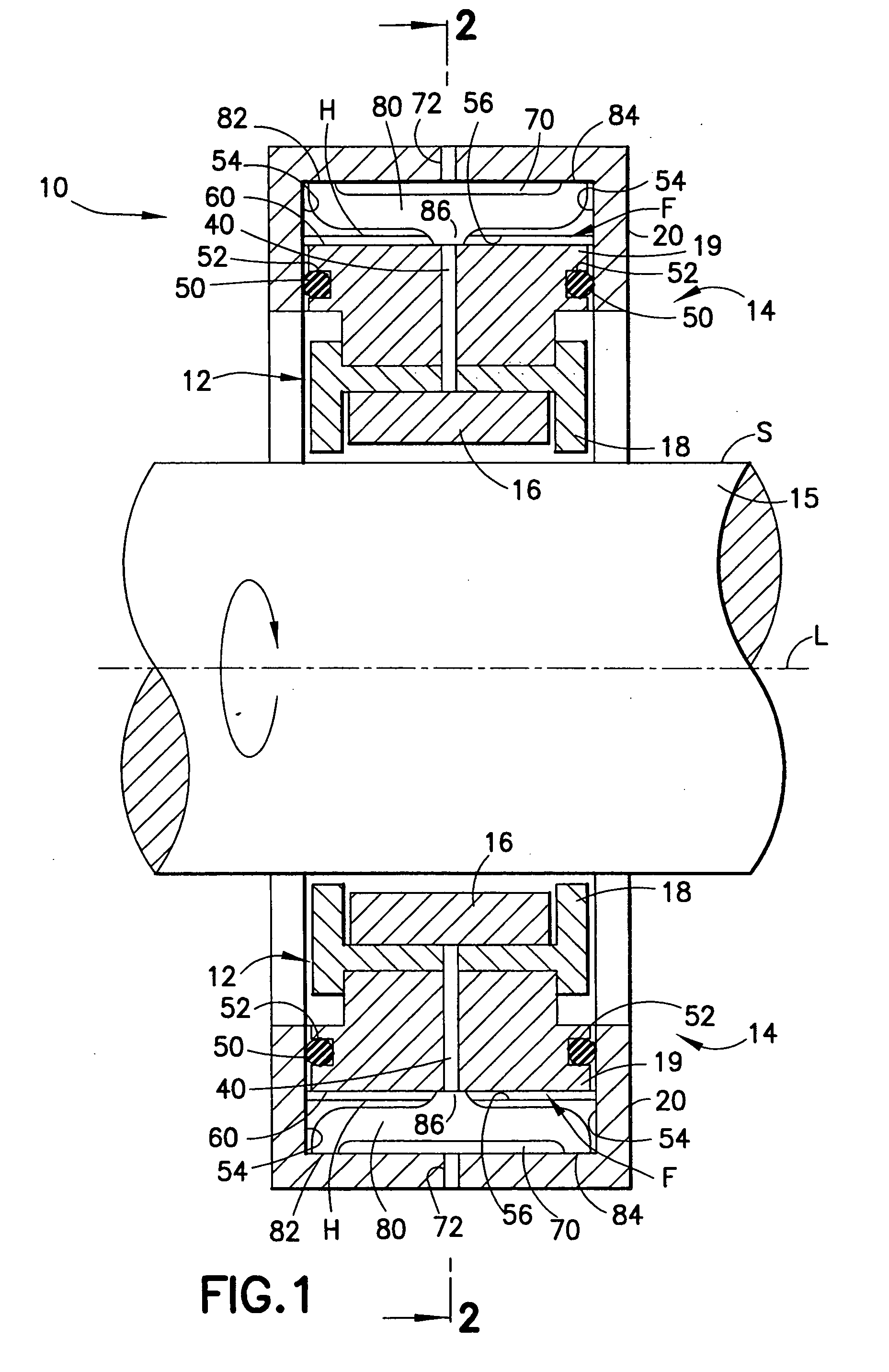

Bearing vibration damping mechanism

ActiveUS7628542B2Easy to produceReduce vibrationLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper for a bearing and a vibration damping mechanism capable of damping the vibration of a rolling bearing are provided. The squeeze film damper is small in construction and can be easily made by mass production. The vibration damping mechanism is capable of damping both radial and axial vibrations. A bearing housing 15 is provided with a bearing holding bore 16 of a diameter greater than the outside diameter of the outer ring 14 of a bearing, and an oil hole 19 through which oil is supplied into the bearing holding bore 16. A vibration damping mechanism 1 is formed by inserting a thin, flat sheet 17 provided with slits into an annular space formed between the inner wall of the bearing holding bore 16 and the outside surface of a bearing held in the bearing holding bore 16 so as to surround the bearing. Parts of the thin, flat sheet extending between the adjacent slits serve as elastic beams. The elastic beams center the bearing and support the centered bearing elastically. The vibration of the bearing is damped by the squeeze film effect of an oil film formed by supplying oil into the annular space.

Owner:KAWASAKI HEAVY IND LTD

Micro machine differential capacitance accelerometer with symmetrical structure

ActiveCN101625372AFacilitate adjustment of film damping effectReduce the impactTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCapacitanceAccelerometer

The invention relates to a micro machine differential capacitance accelerometer with a symmetrical structure, which is connected with a movable silicon structure component through an anchoring area along the upper direction and the lower direction. Elastic supporting beams of the silicon structure component are divided into an upper layer and a lower layer and distributed between a movable mass block and a fixedly supported frame as well as connected with the movable mass block and the fixedly supported frame; and the round angle transition is adopted at joints of the movable mass block and the fixedly supported frame as well as the beams; both the upper surface and the lower surface of the movable mass block are provided with gas flow guide grooves; and an electrode cover plate can be made of a silicon material. The gas flow guide grooves distributed on both the upper surface and the lower surface of the mass block are beneficial to regulating the squeeze-film damping effect of the accelerometer so as to structurally improve the dynamic characteristic of the surface separated capacitance detection accelerometer. A plurality of the elastic supporting beams of the accelerometer are made of single crystal silicon materials with a single doping concentration, thereby eliminating thermal inconsistency stress caused by adopting different materials and the thermal inconsistency stress caused by different single crystal silicon doping concentrations.

Owner:安徽云芯微系统科技有限公司

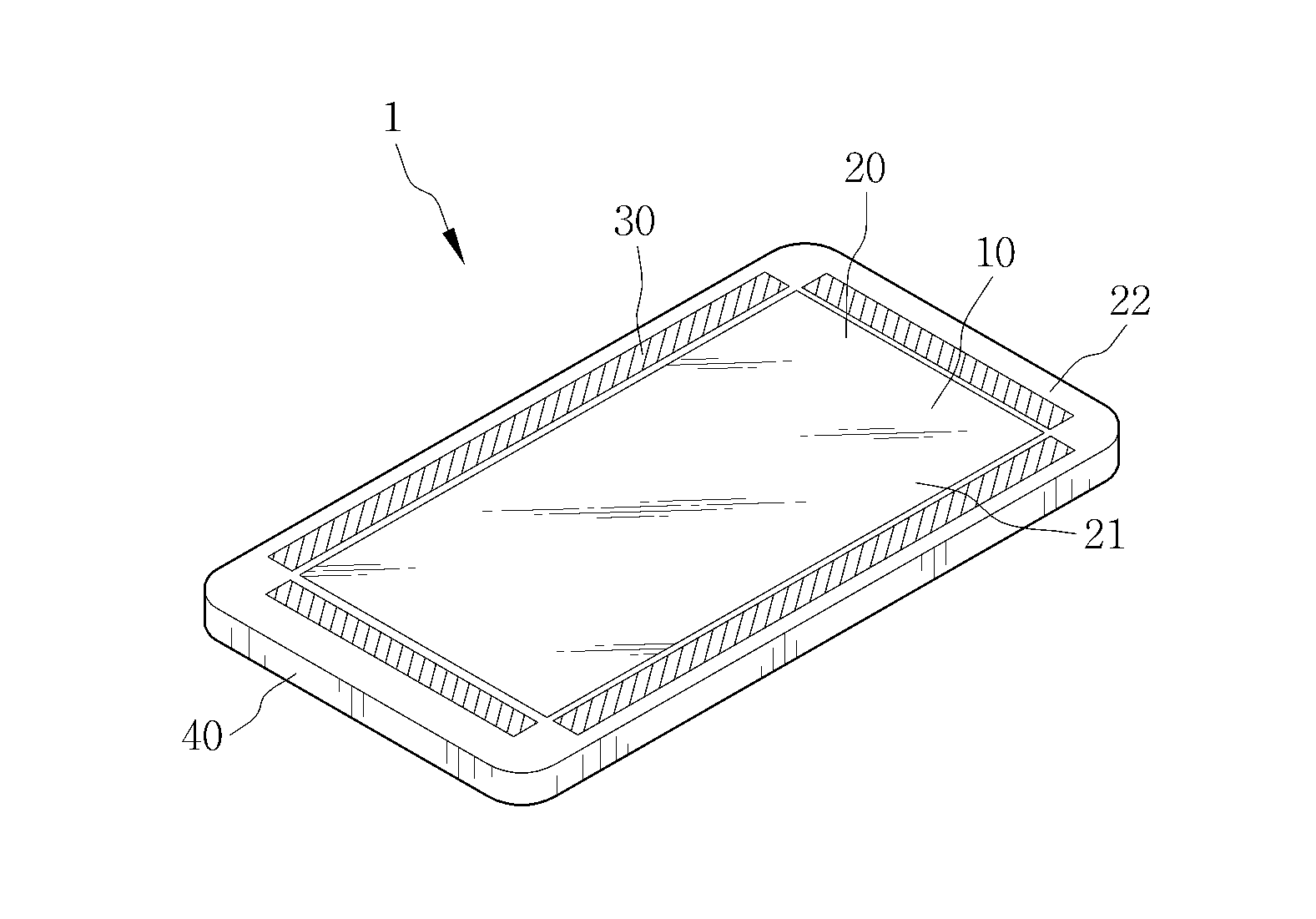

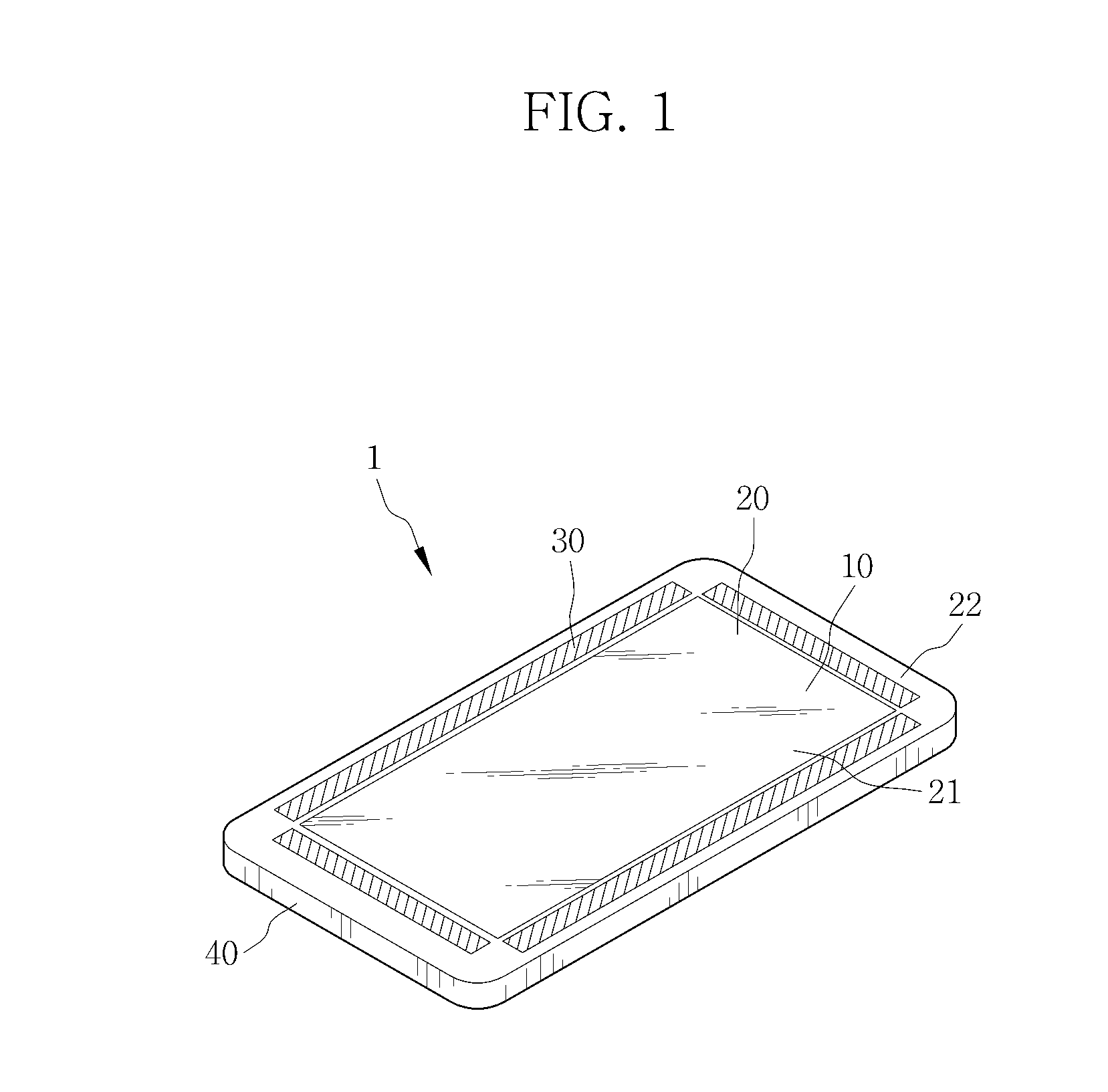

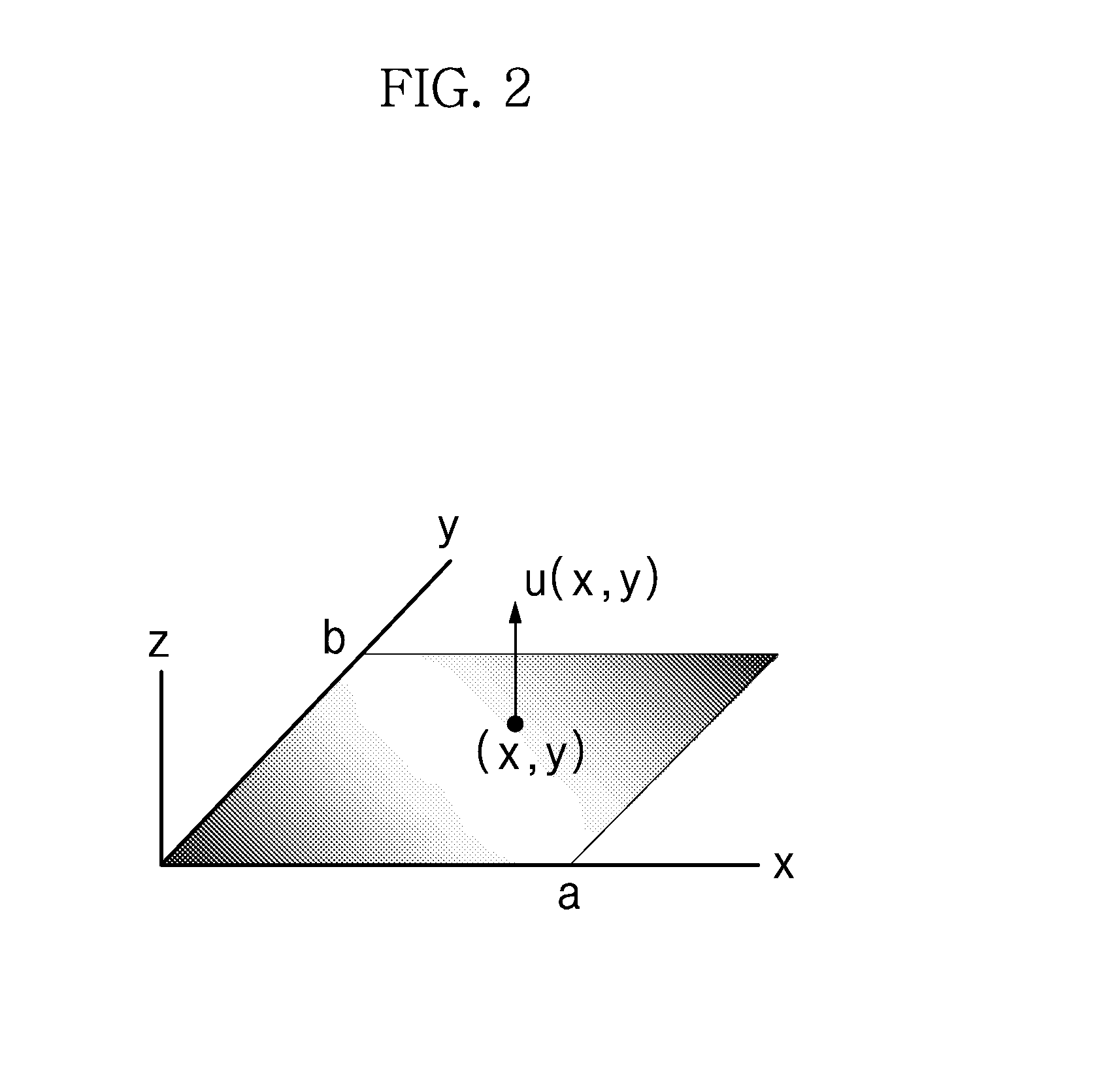

Electronic device having tactile display using squeeze film effect

InactiveUS20130321299A1Realistic and useful user interfaceReduce frictionPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationDisplay deviceEngineering

An electronic device has a touch screen, a protecting panel for protecting the touch screen by covering the touch screen, a vibration actuator coupled to the protecting panel to vibrate the protecting panel, and a control module for collecting location information of an input unit which touches the protecting panel, wherein the control module controls vibration characteristics of the vibration actuator according to a location of the input unit and forms a squeeze film between the input unit and the protecting panel to decrease a frictional force between the input unit and the protecting panel. The protecting panel has a visible area where the touch screen is exposed to be checked by the naked eyes, and an invisible area other than the visible area, and the vibration actuator is coupled to the invisible area.

Owner:KOREA INST OF SCI & TECH

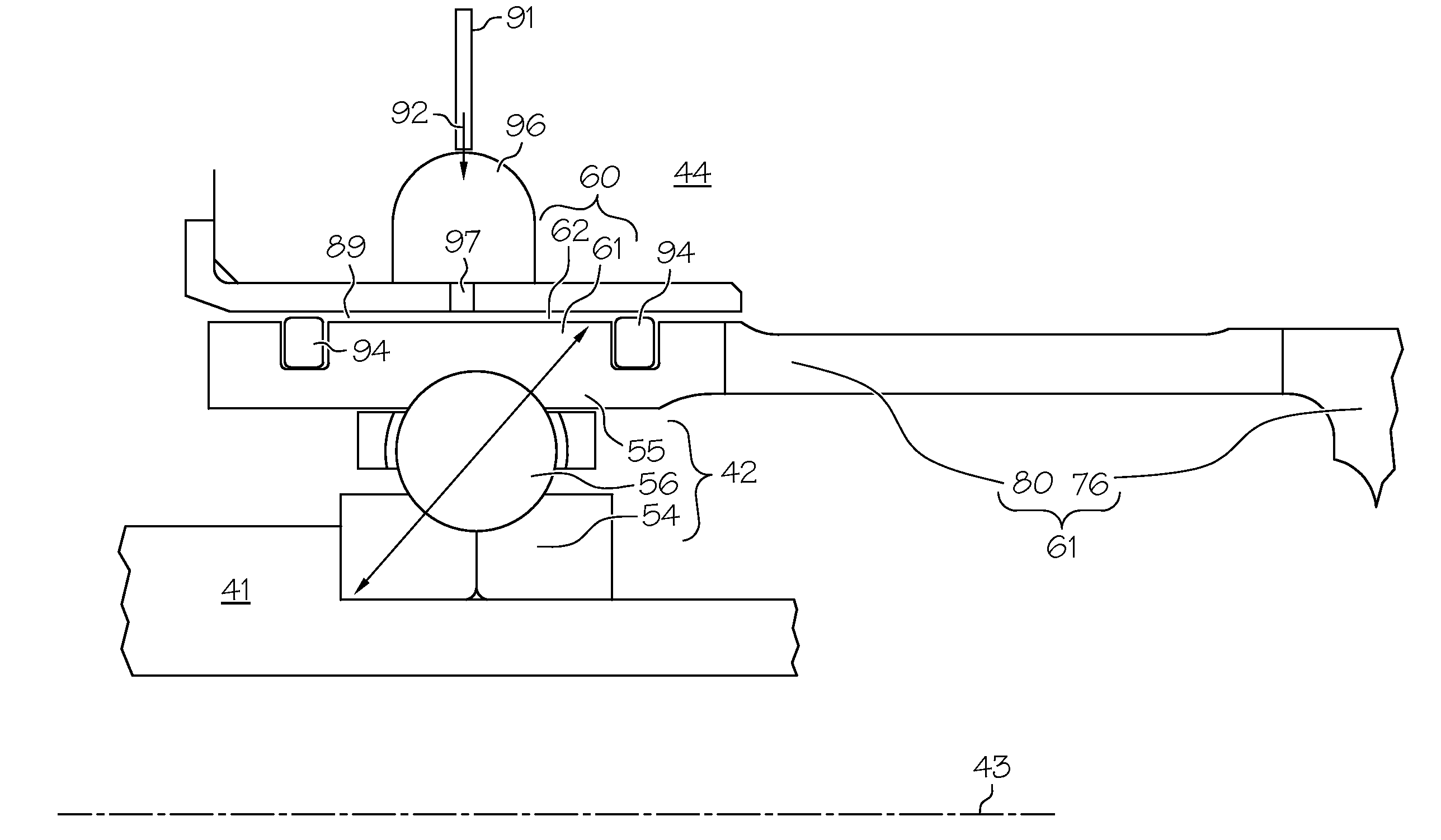

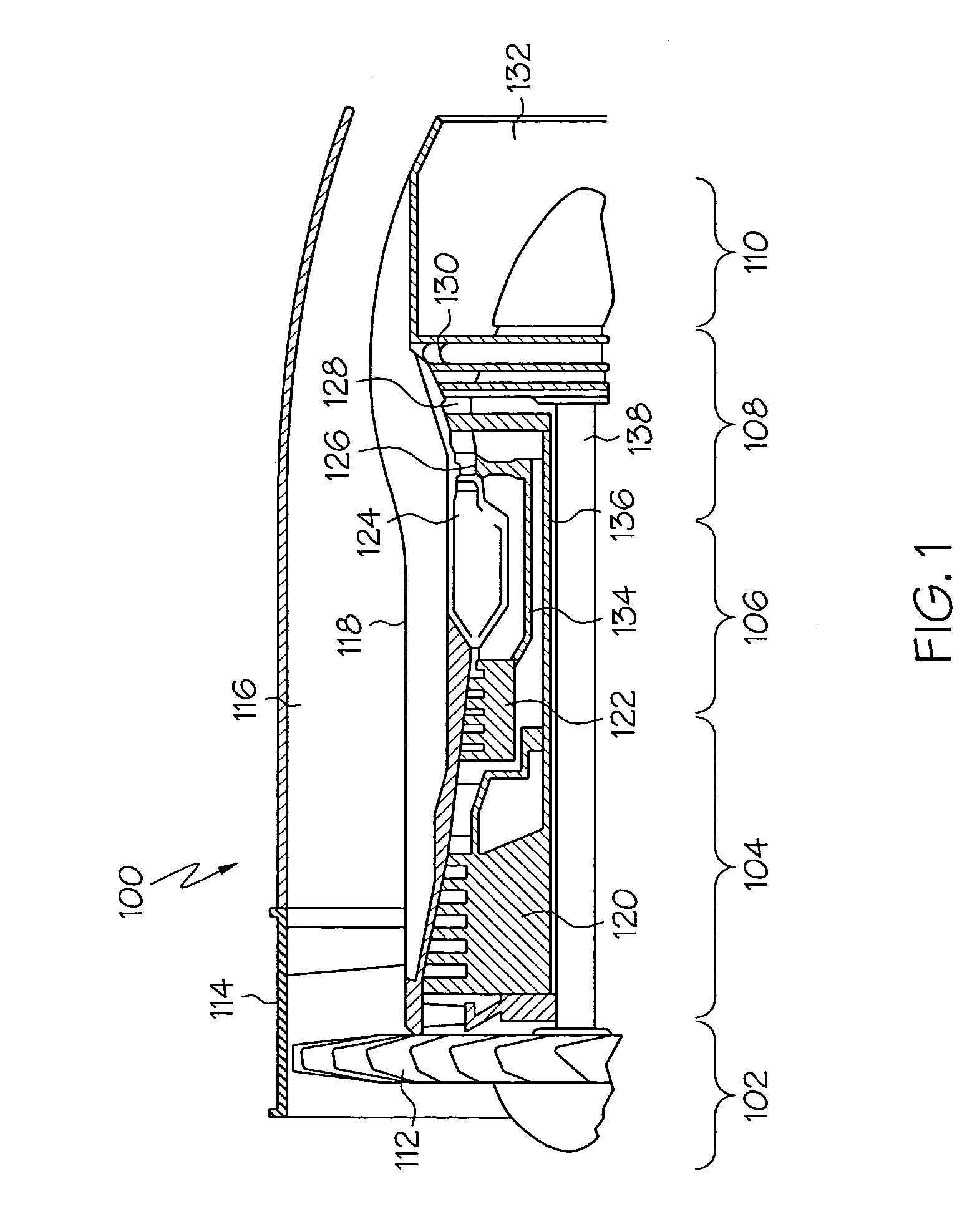

High speed aerospace generator resilient mount, combined centering spring and squeeze film damper

Owner:HONEYWELL INT INC

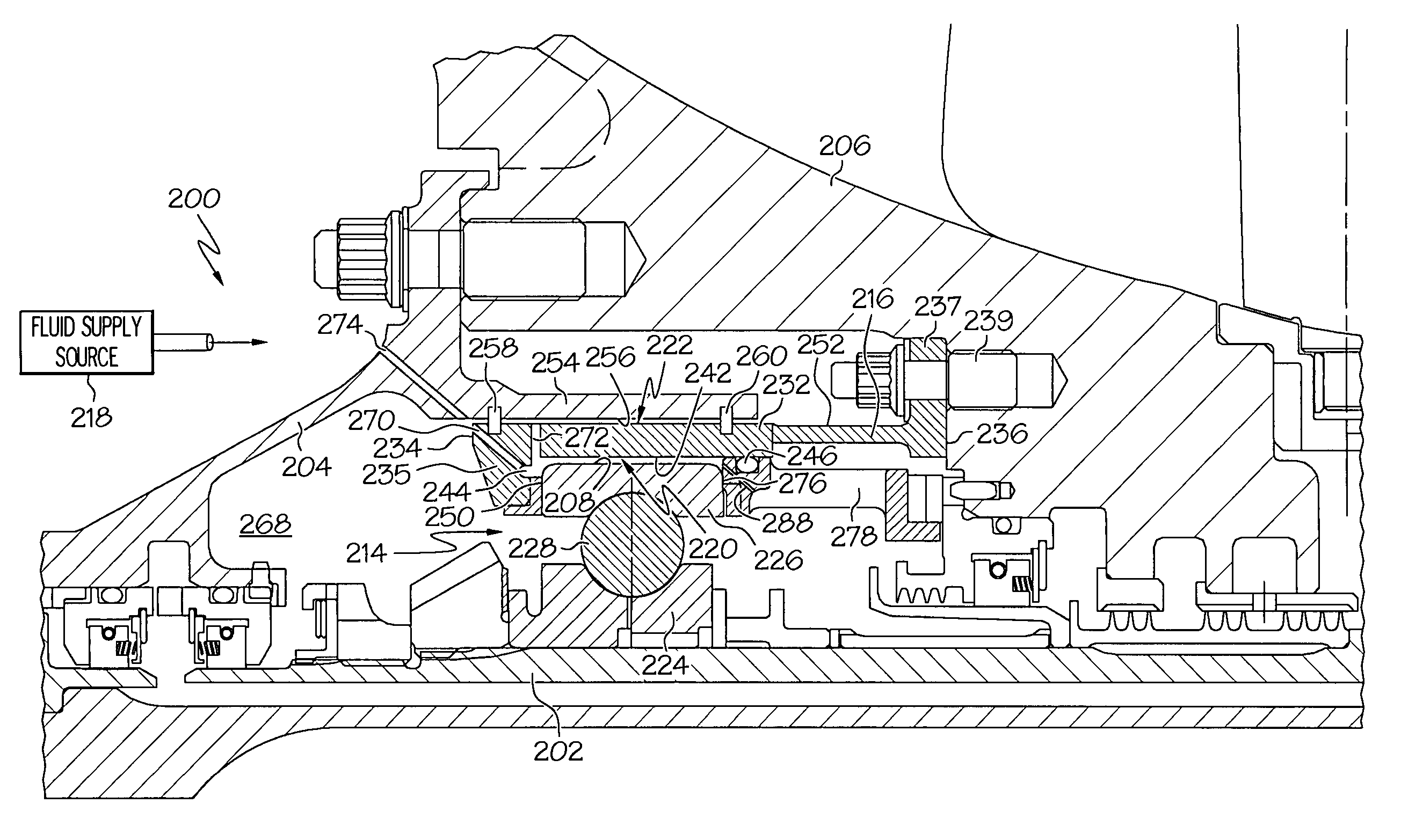

Gas turbine engine assembly and methods of assembling same

A method for assembling a gas turbine engine is provided. The method includes coupling a high-pressure compressor to a high-pressure turbine using a first shaft, coupling a fan assembly to a low-pressure turbine using a second shaft, and coupling a differential squeeze film damper assembly between the first and second shafts.

Owner:GENERAL ELECTRIC CO

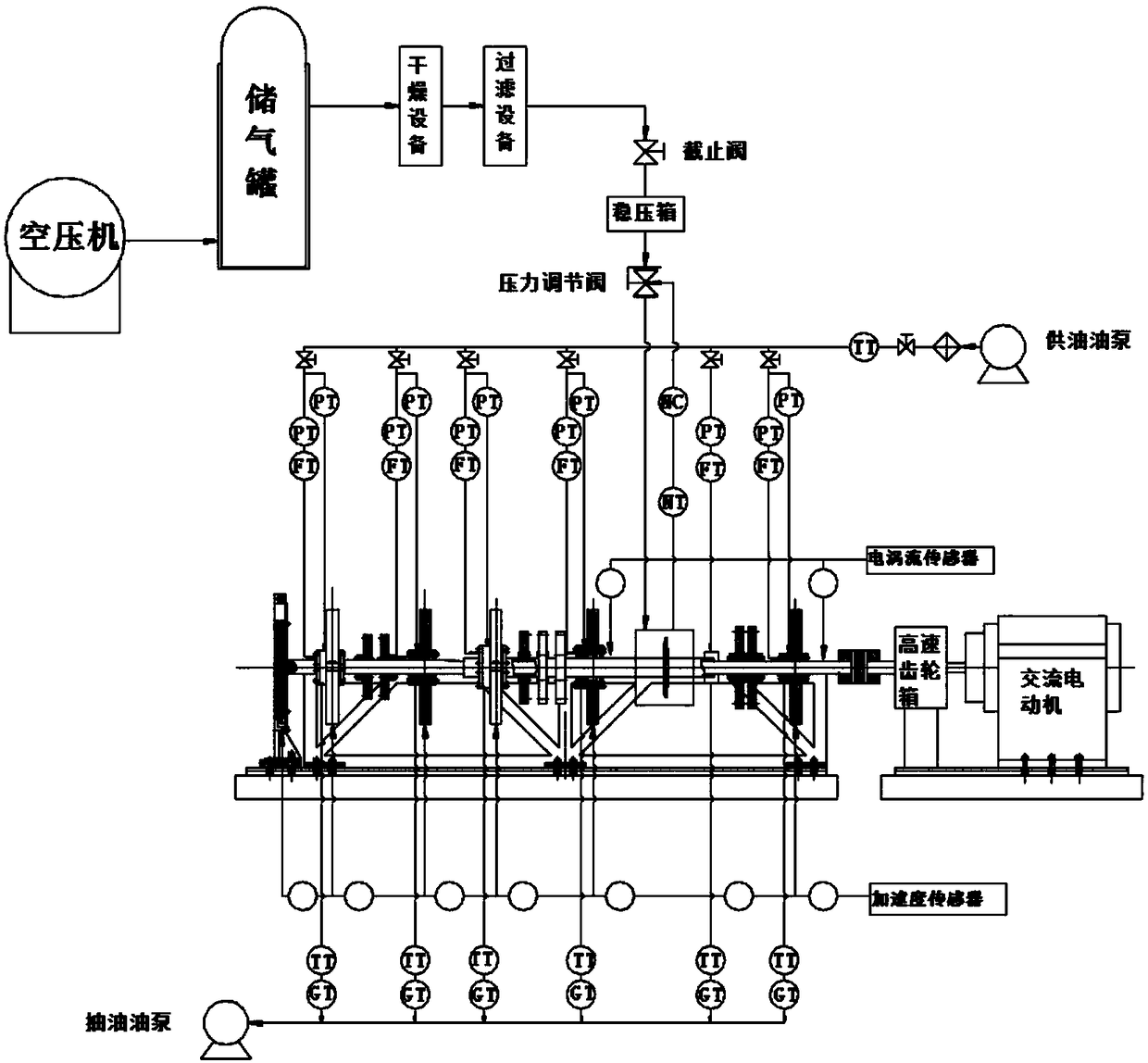

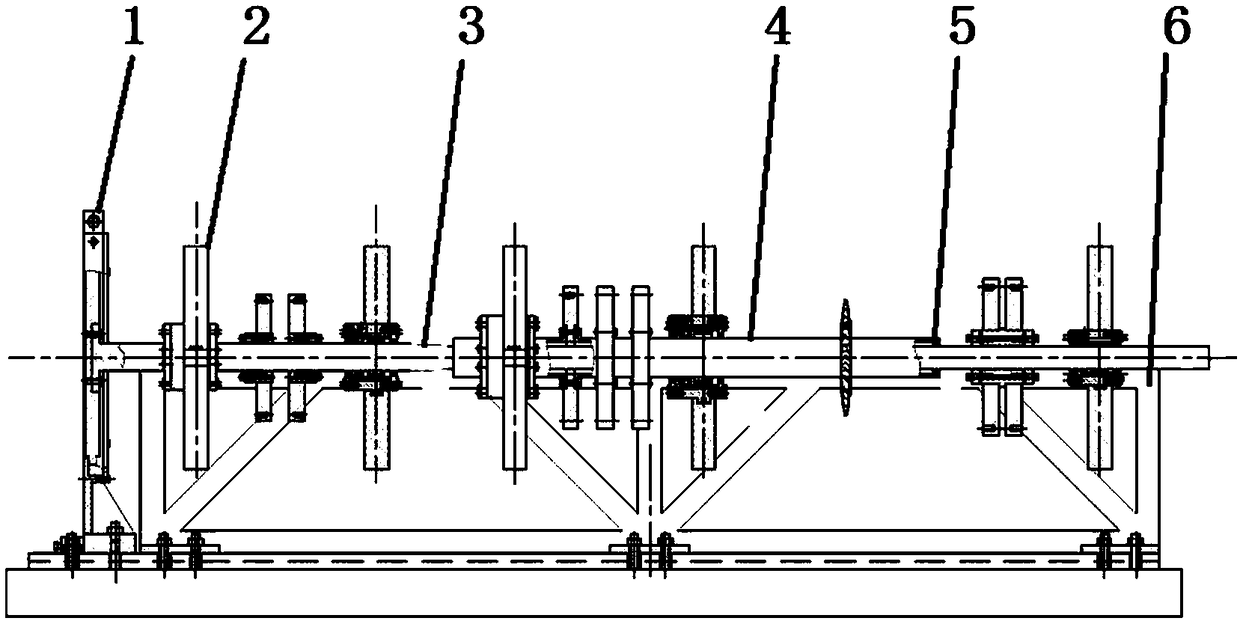

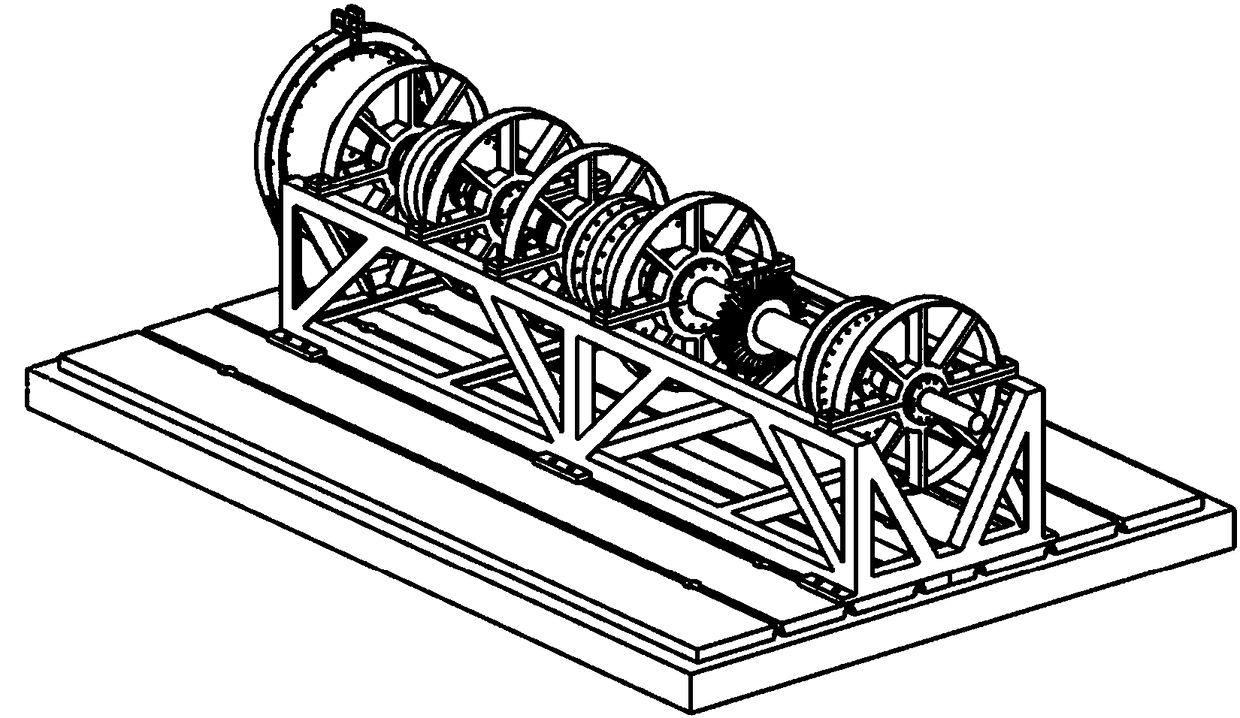

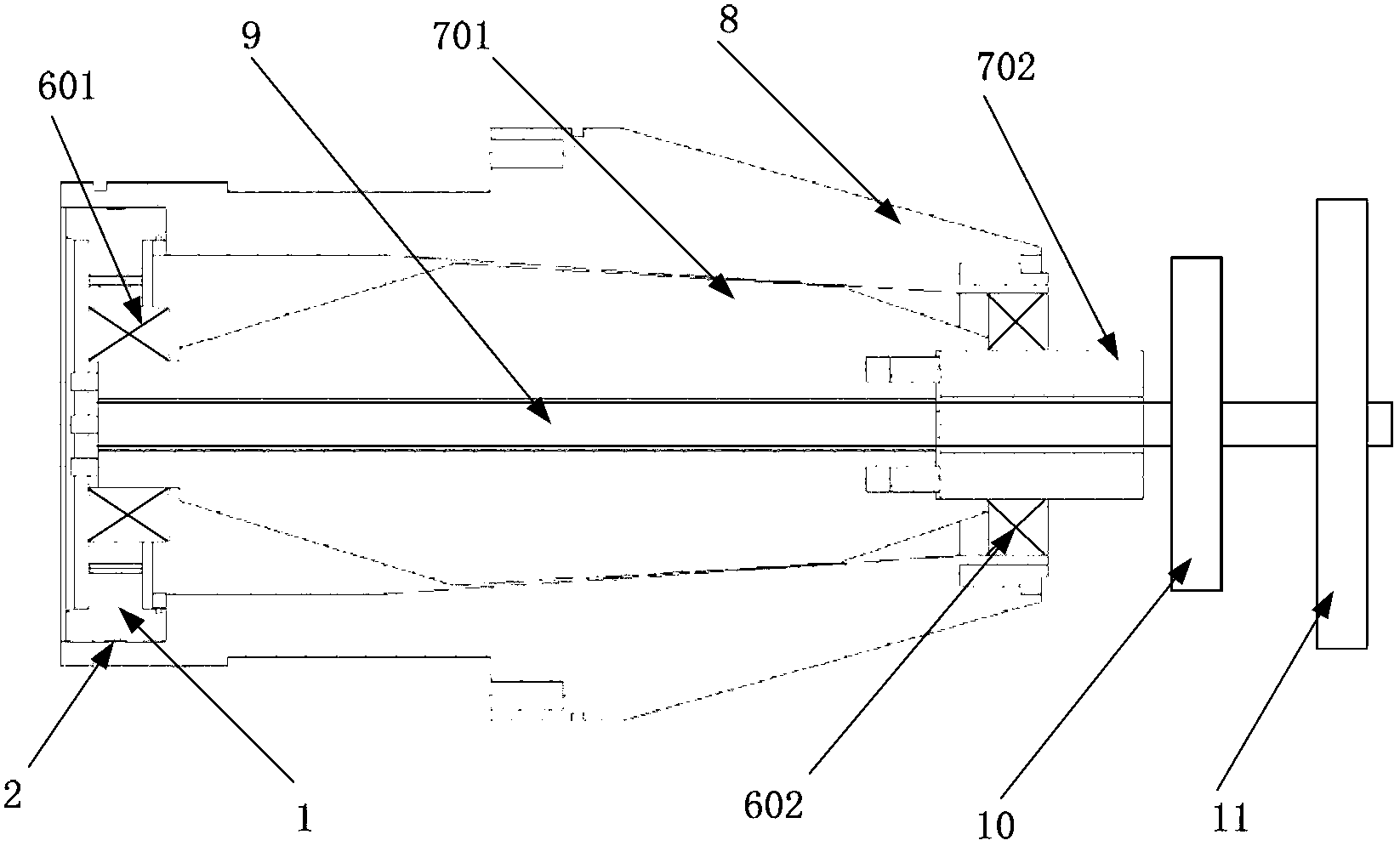

Pneumatic turbine driven double rotor test bench

ActiveCN108519235AChange dynamicsWeight increaseMachine part testingEngine testingEngineeringAir compressor

The invention discloses a pneumatic turbine driven test bench. The pneumatic turbine driven test bench comprises a rotor system, a power system, a lubrication system, a test system and a safety system. An intermediate bearing is arranged between an inner rotor and an outer rotor; the outer rotor is driven by a pneumatic turbine; a control system is a feedback control system; compressed air drivesthe pneumatic turbine mounted on the outer rotor to rotate. After the compressed air provided by an air compressor enters a pressure stabilizing box, the compressed air flows through a pressure regulating valve and then flows out of a nozzle to impact the pneumatic turbine to drive the pneumatic turbine to rotate; the rotation speed of the outer rotor is detected by a rotation speed transmitter, and then the rotation speed is fed back to a rotation speed controller; the compressed gas flow is adjusted by controlling the opening of the pressure regulating valve to control the rotation speed ofthe outer rotor. In a supporting structure, squirrel cage elastic supports and elastic ring squeeze film dampers are combined, so that the stability of the rotors can be improved. The pneumatic turbine driven test bench can be used for the experimental study of the dynamic characteristics of the double rotor-support system with the coupling of the inner and outer rotors and the simulation and research of the rotor system vibration faults.

Owner:BEIJING UNIV OF CHEM TECH

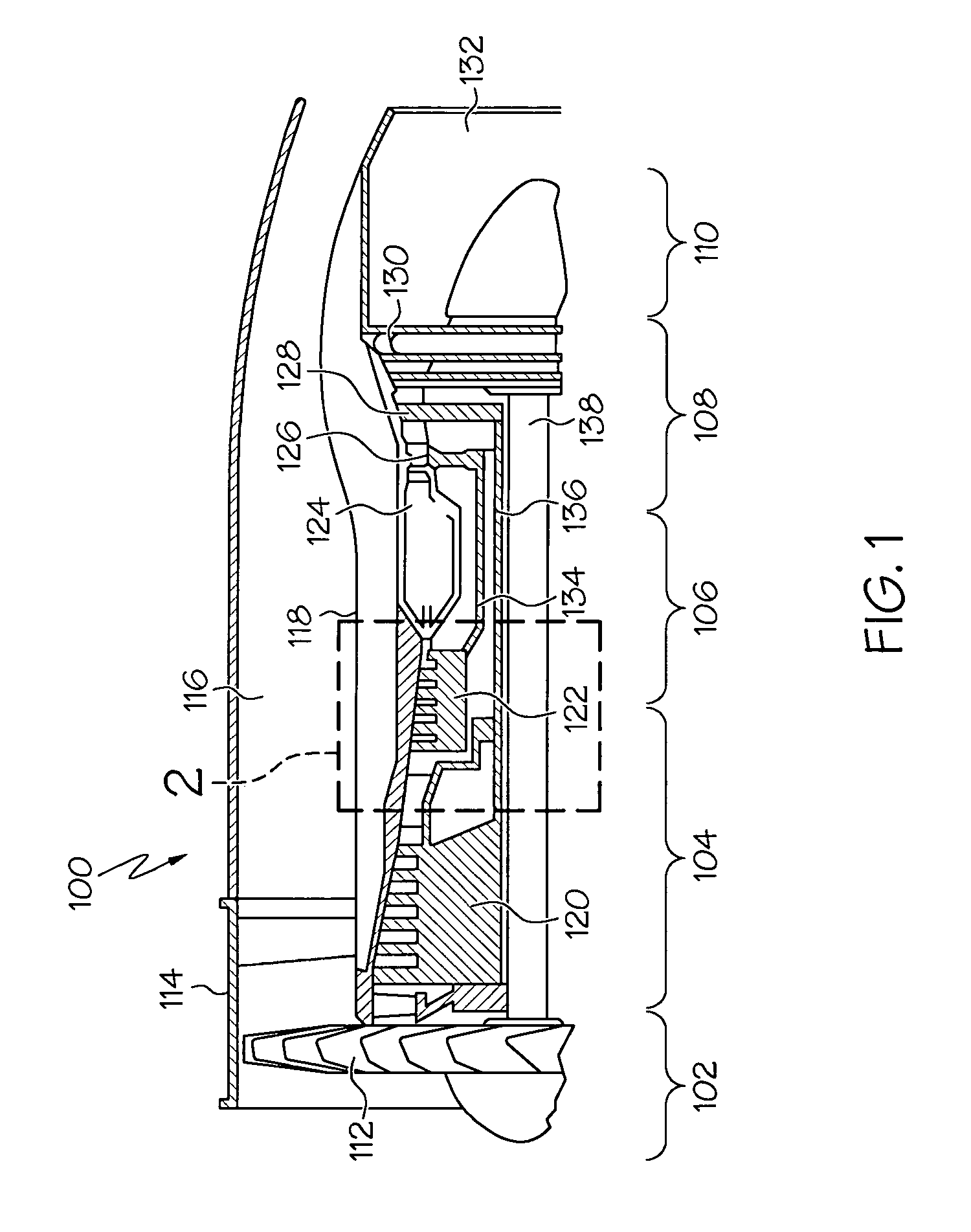

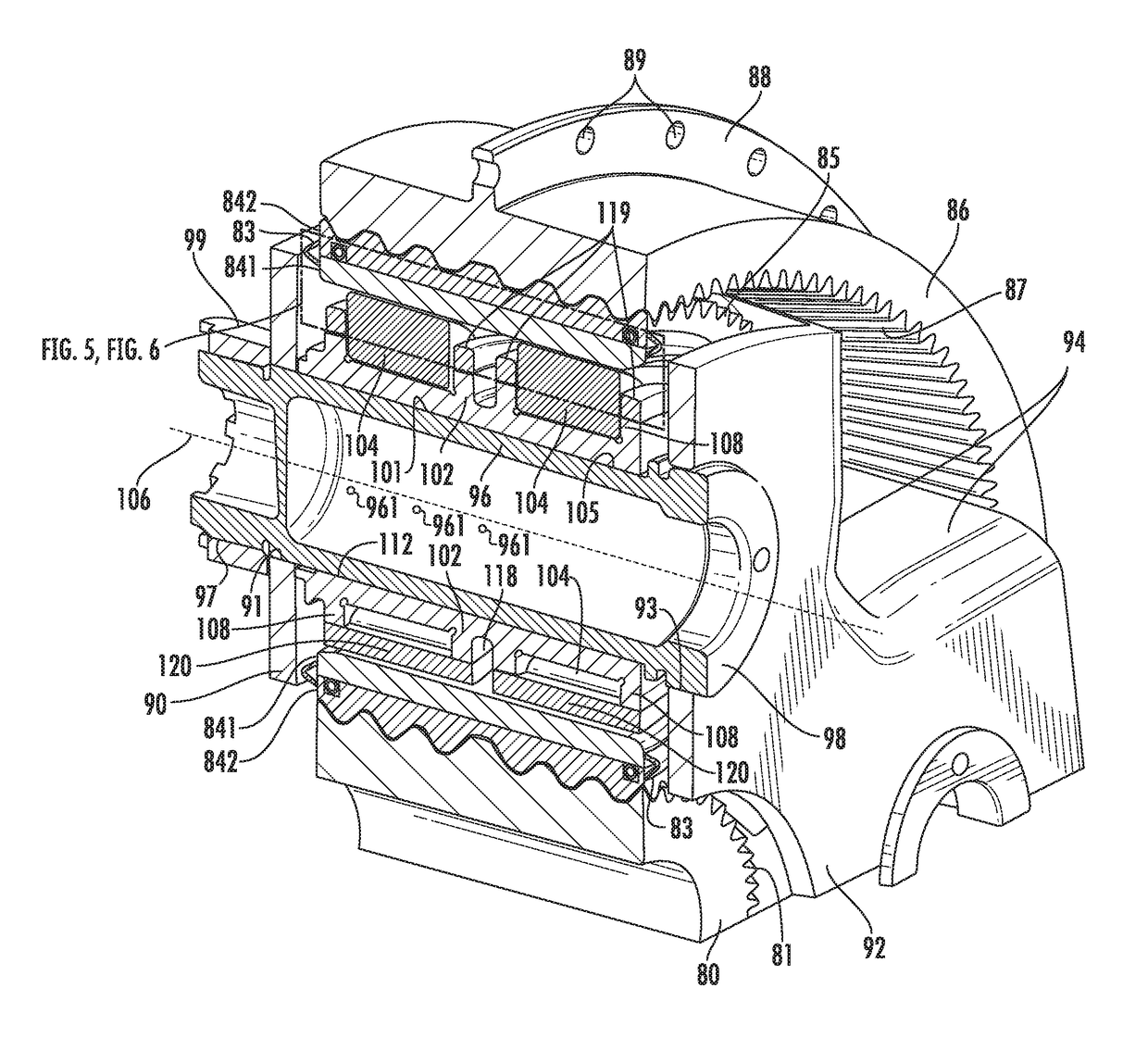

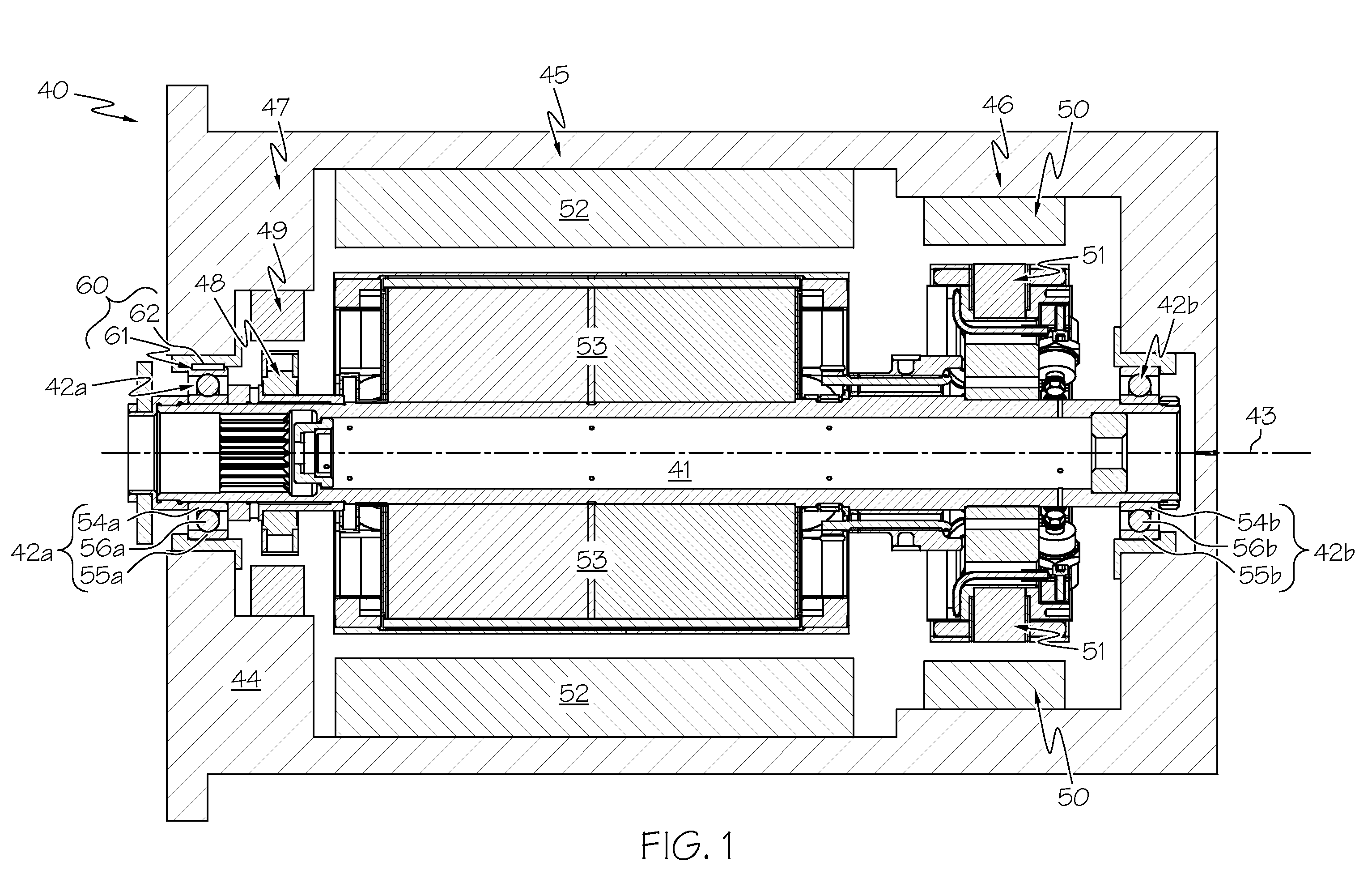

Damping systems for use in engines

Damping systems and engines including the damping systems are provided. In one embodiment, and by way of example only, the damping system includes a rotor, a bearing assembly mounted to the rotor, a spring cage disposed around the bearing assembly, an axially-extending housing surrounding the spring cage, a first squeeze film damper formed between the bearing assembly and the spring cage, and a second squeeze film damper formed between the spring cage and the axially-extending housing.

Owner:HONEYWELL INT INC

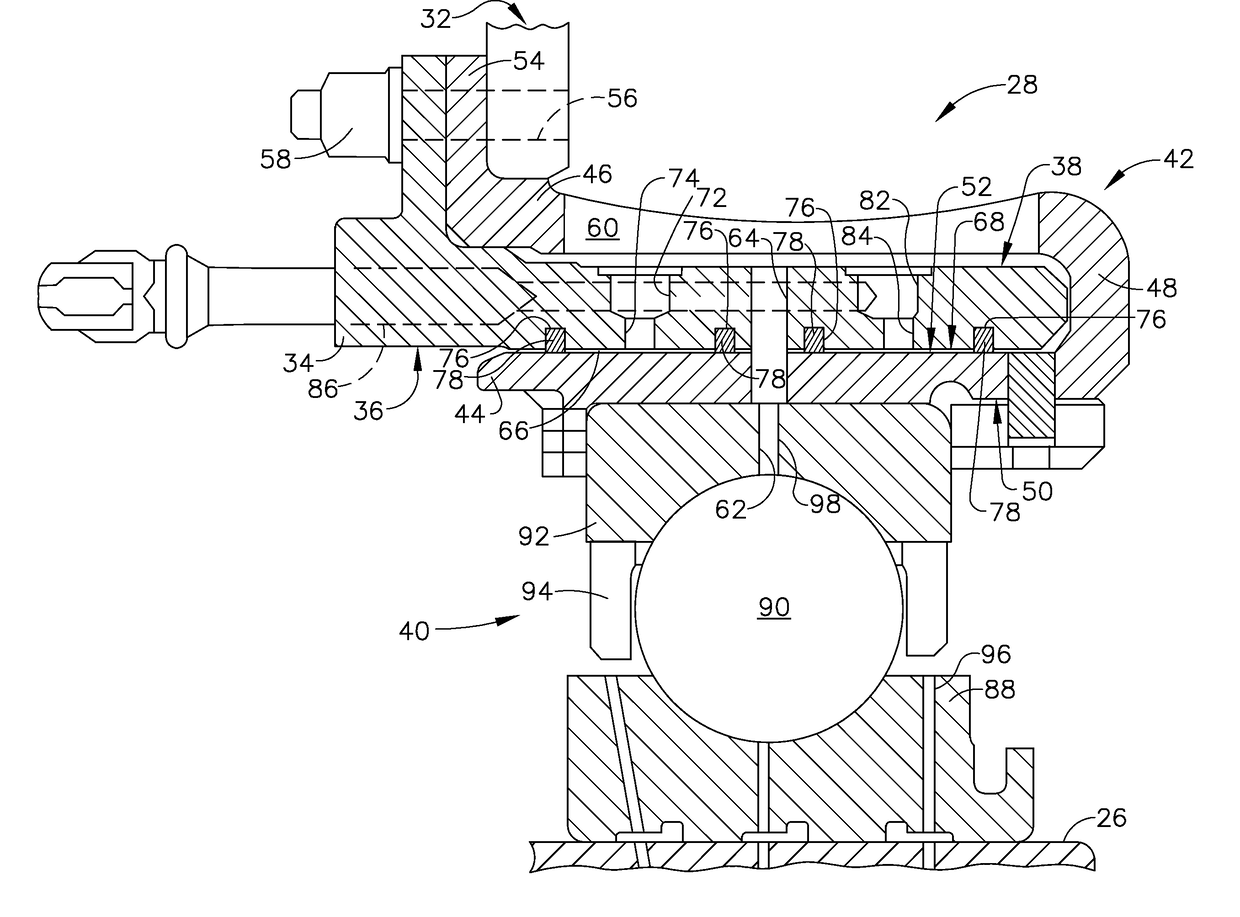

Disc spring centering device for squeeze film dampers

ActiveUS7066651B2Labor intensiveNot prone to losing its effectiveness over timeShaftsRotary machine partsSqueeze filmMechanical engineering

A damper film bearing assembly for supporting a rotatable shaft includes a bearing housing having a longitudinal opening passing therethrough for receiving the rotatable shaft. The bearing housing also has at least one radial recess formed in an outer surface thereof, the recess having a floor. The assembly further includes at least one support piston slideably disposed within the recess in the bearing housing, the support piston slideable within the recess radially toward and away from a central longitudinal axis of the rotatable shaft. At least one resilient element is disposed within the recess in the bearing housing between the floor of the recess and the support piston, the resilient element biasing the support piston away from the axis of the rotatable shaft.

Owner:LUFKIN GEARS LLC

Bearing with drained race and squeeze film damper

A bearing apparatus includes: a bearing including a first race rotatable relative to a second race, wherein the first race includes one or more drain passages extending therethrough; and a squeeze film damper connected to the first race, the squeeze film damper including first and second squeeze film spaces separated by an oil drain path which communicates with the one or more drain passages of the first race.

Owner:GENERAL ELECTRIC CO

Damping systems for use in engines

Damping systems and engines including the damping systems are provided. In one embodiment, and by way of example only, the damping system includes a rotor, a bearing assembly mounted to the rotor, a spring cage disposed around the bearing assembly, an axially-extending housing surrounding the spring cage, a first squeeze film damper formed between the bearing assembly and the spring cage, and a second squeeze film damper formed between the spring cage and the axially-extending housing.

Owner:HONEYWELL INT INC

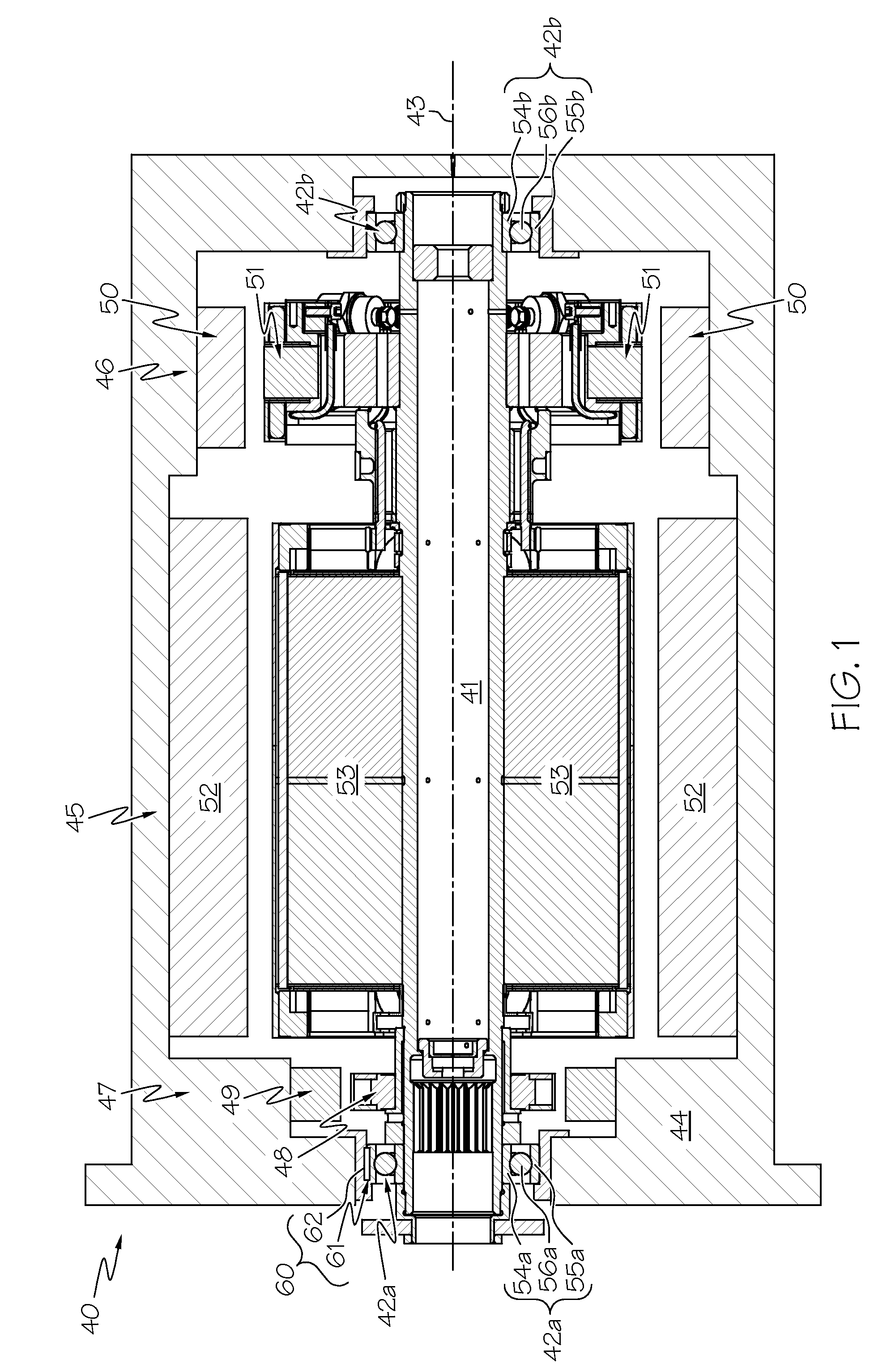

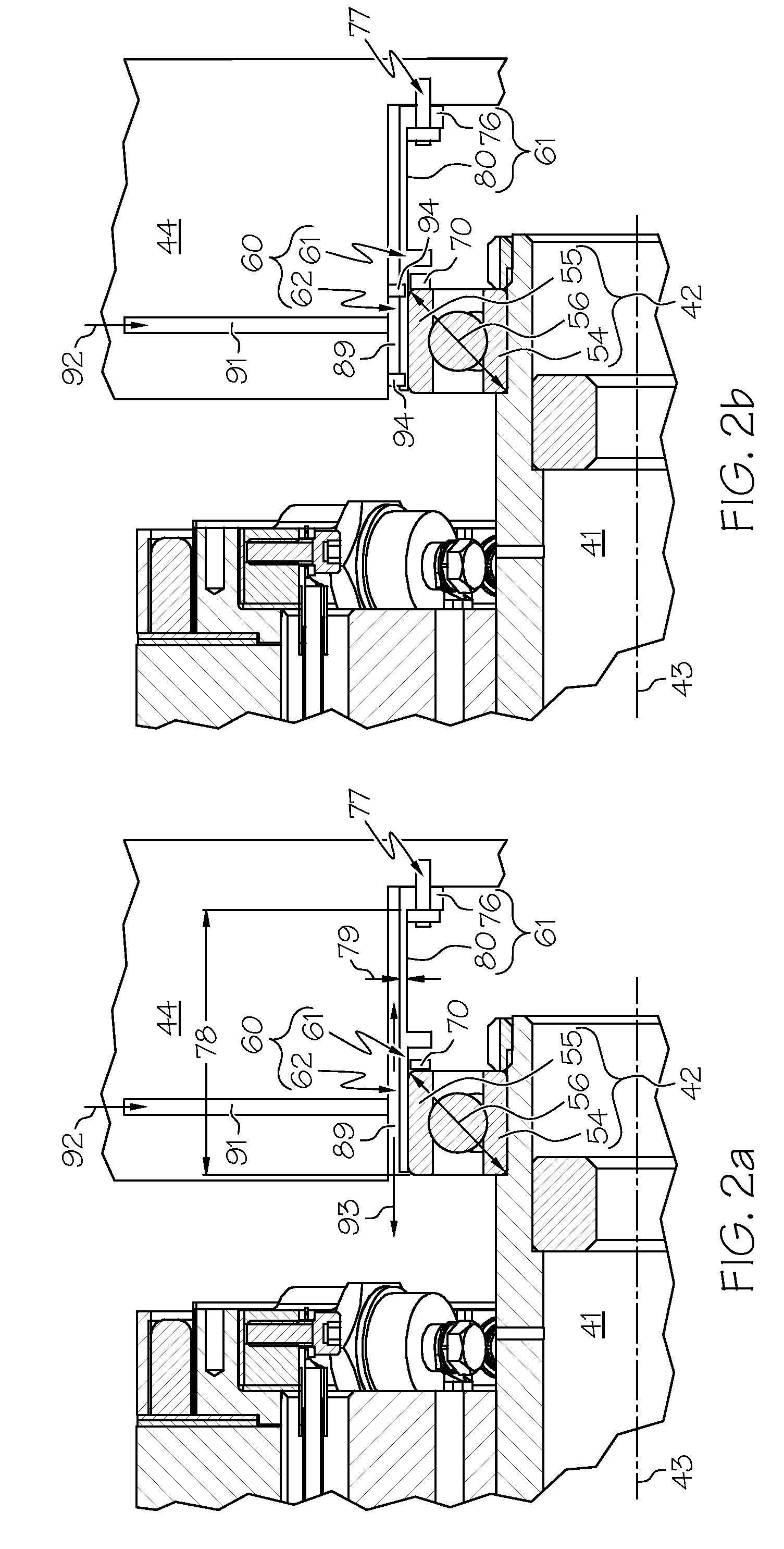

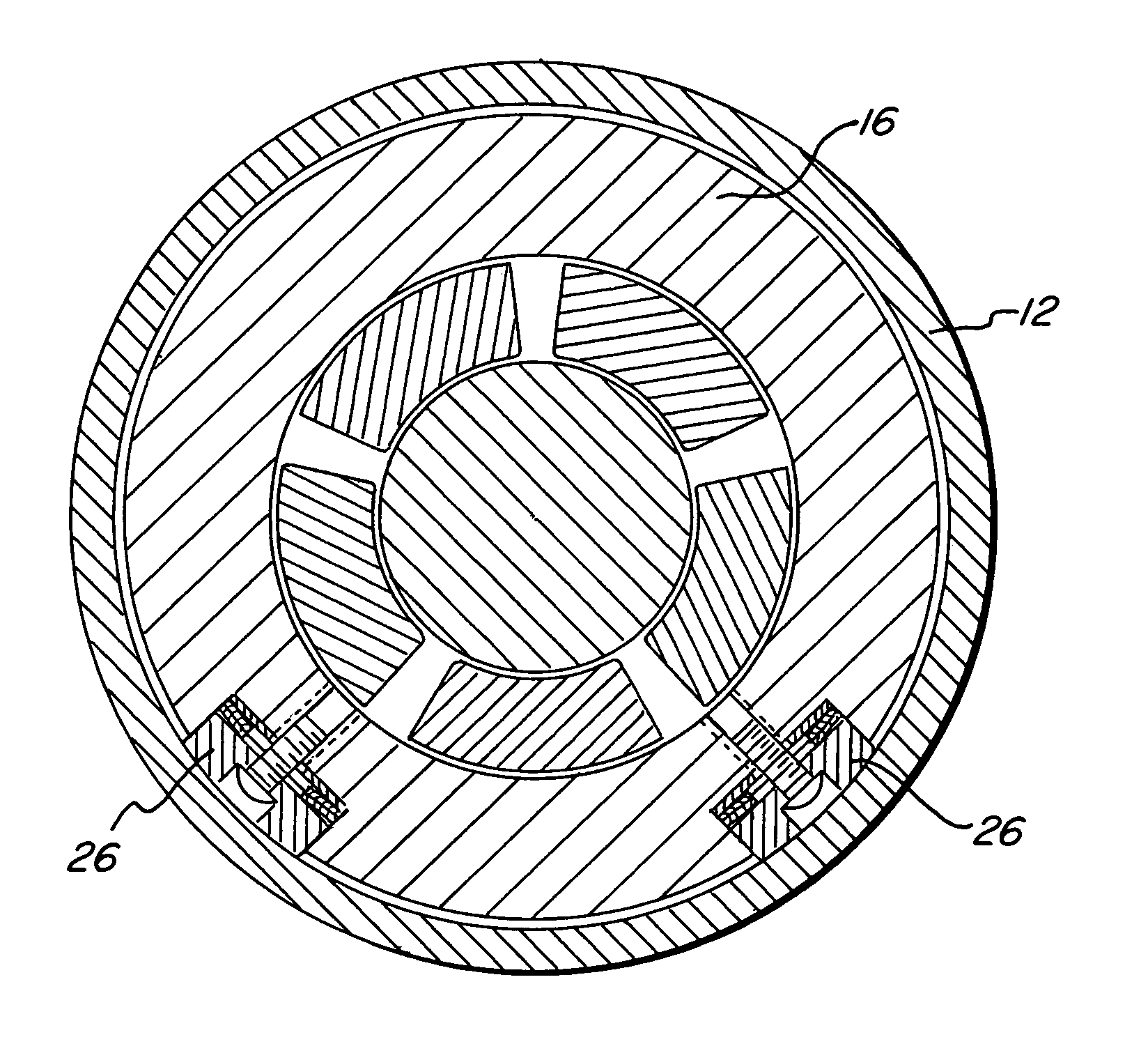

Bearing assembly and centering support structure therefor

The bearing assembly is intended for application with rotor shafts in turbomachinery. The bearing assembly includes an annular bearing in which the shaft is disposed and a support structure for supporting the bearing. The bearing support is mounted about and radially supports the bearing. The bearing support at least in part defines a squeeze film annulus of the bearing assembly. A plurality of centering elements is associated with the bearing and bearing support and act to center the bearing within the squeeze film annulus. The centering elements are provided at radially spaced locations around the bearing. The centering elements may also be cylinder springs provided at uniformly spaced locations around the bearing. The centering elements may additionally be load cell springs provided at uniformly spaced locations around the bearing. In an alternative embodiment, a singular annular wave spring may be provided in place of the plurality of centering elements.

Owner:ELLIOTT CO

Magnetic squeeze film damper system for a gas turbine engine

A magnetic squeeze film damper system comprises a bearing assembly having an outer race with a first outer surface and a first inner surface and a bearing located along the first inner surface. The system further comprises a squeeze film damper housing having a second outer surface and a second inner surface that is contiguous with the first outer surface. A channel having a forward end and an aft end is defined within the housing along the second inner surface, the channel bordered by the first outer surface. The system further includes a first seal gland located along the forward end of the channel and a second seal gland located along the aft end of the channel. Both seal glands comprise a reservoir for holding a magneto-rheological fluid, the reservoir encased in an elastomer. At least one electromagnet is arranged in close proximity to each of the seal glands.

Owner:ROLLS ROYCE NORTH AMERICAN TECH

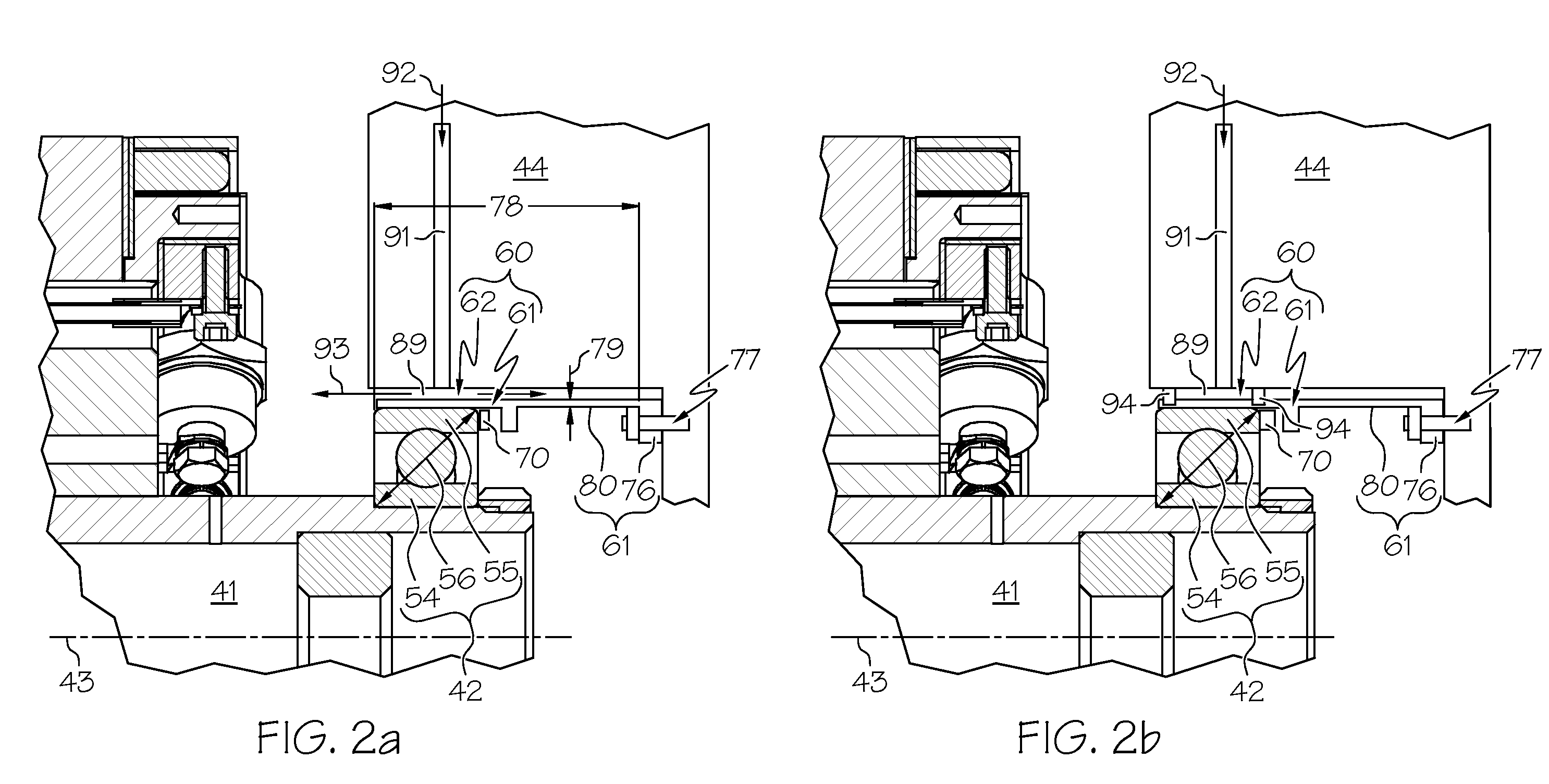

Gearbox Planet Squeeze Film Damper

ActiveUS20170219080A1Maximizing capabilityImproves engine 's time in active serviceRoller bearingsEngine fuctionsEngineeringSqueeze film

An epicyclic gearing arrangement includes a planet gear rotatable on a planet bearing that is mounted via a support pin to a carrier of the epicyclic gearing arrangement. A spring film damper is disposed between the outer surface of the bearing's outer ring and the opposing inner surface of the planet gear and includes an annular gap. The support pin and / or outer ring include oil feed holes that open into the respective annular gap(s).

Owner:GENERAL ELECTRIC CO

Method for making photo with three-dimensional stereoscopic visual effect

InactiveCN1655014AGood three-dimensionalEasy to operatePattern printingImage data processing detailsGratingComputer graphics (images)

This invention relates to a process method for 3-D stereo visual effect pictures aiming at providing a method for processing 3-D effect pictures by picture scanning, picture process, printing and process including: 1, selecting pictures, 2, carrying out picture process with plane design software, 3, printing pictures, 4, processing grating plates, 5, squeezing film to composite the picture.

Owner:崔明伦

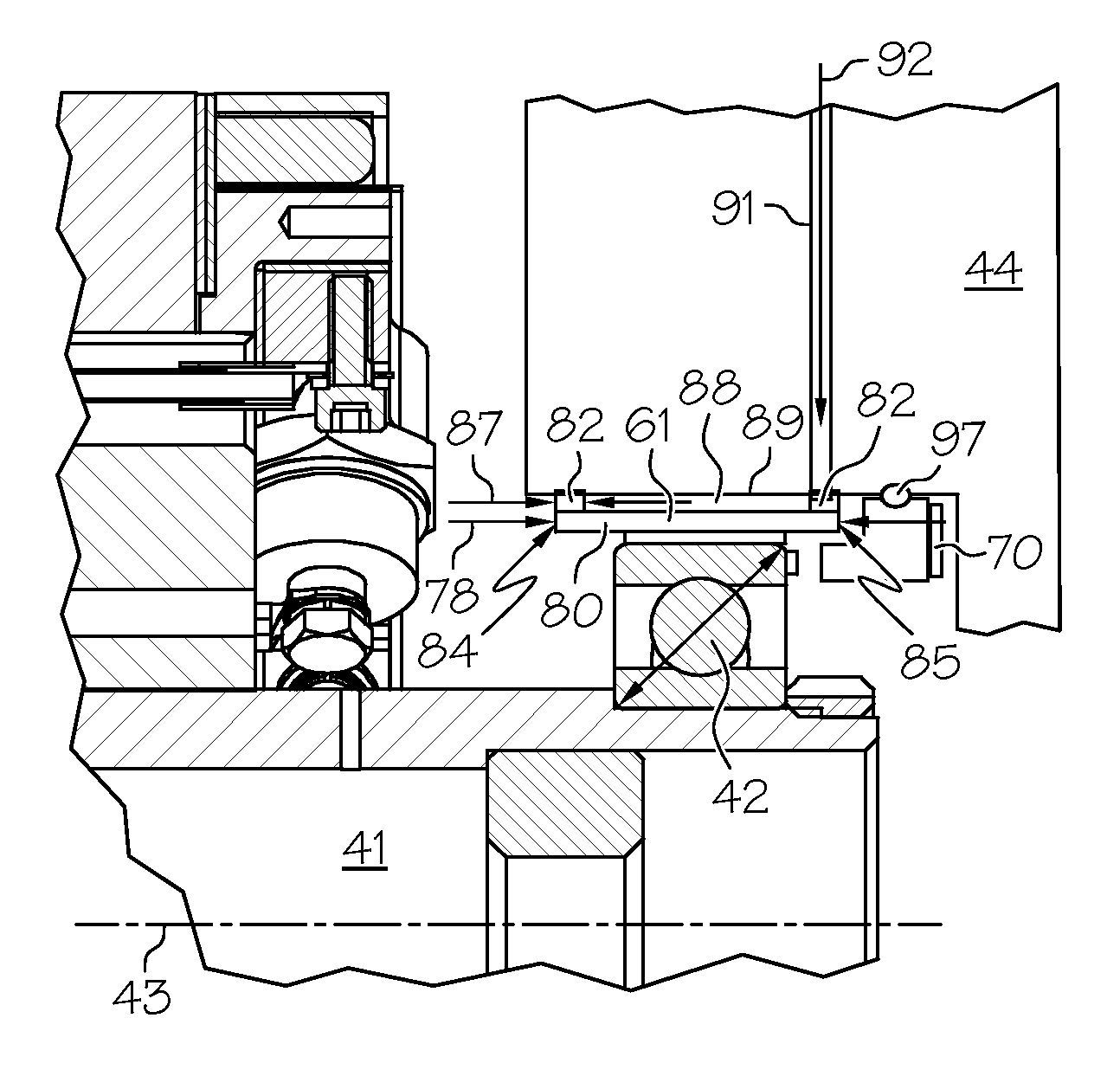

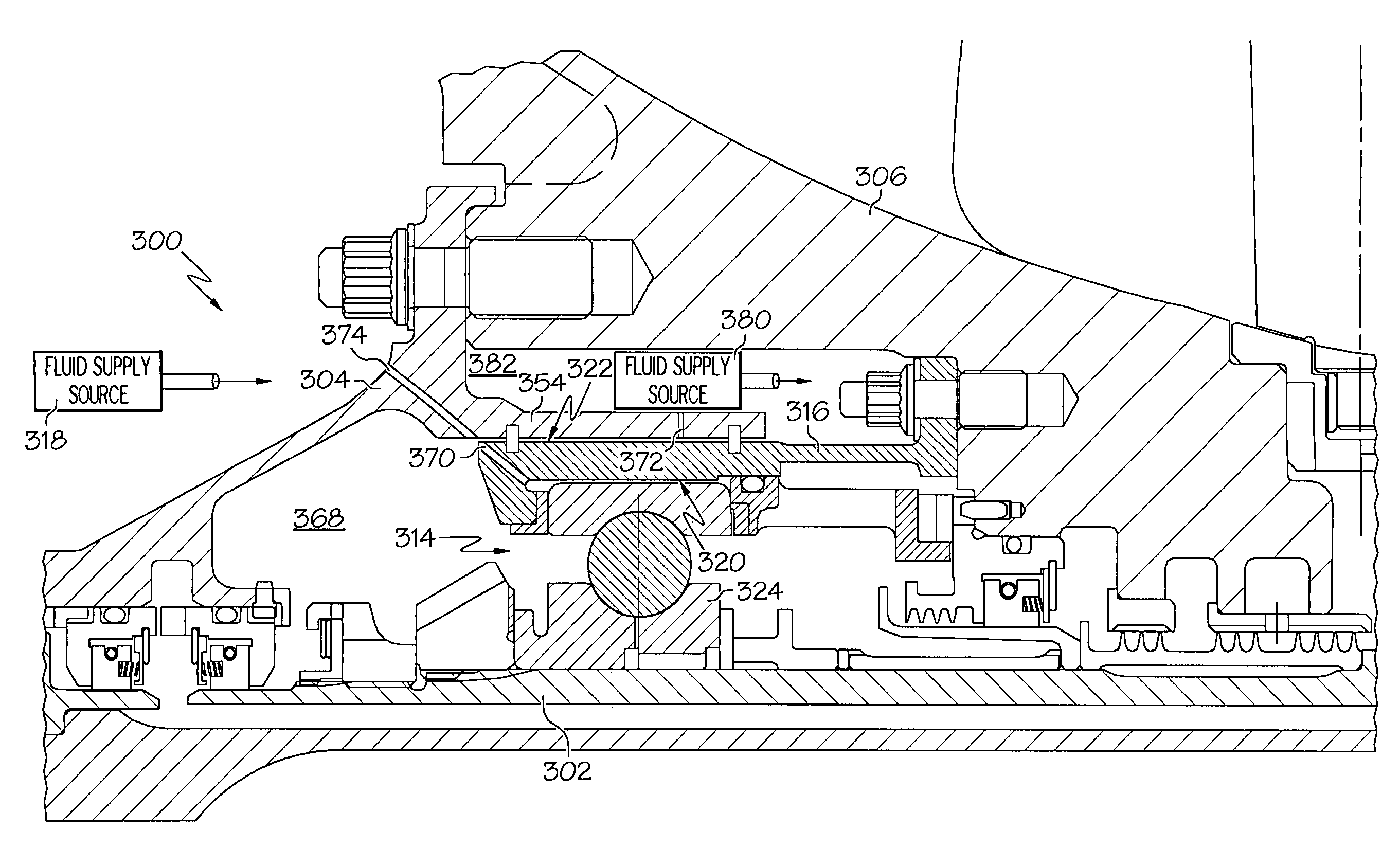

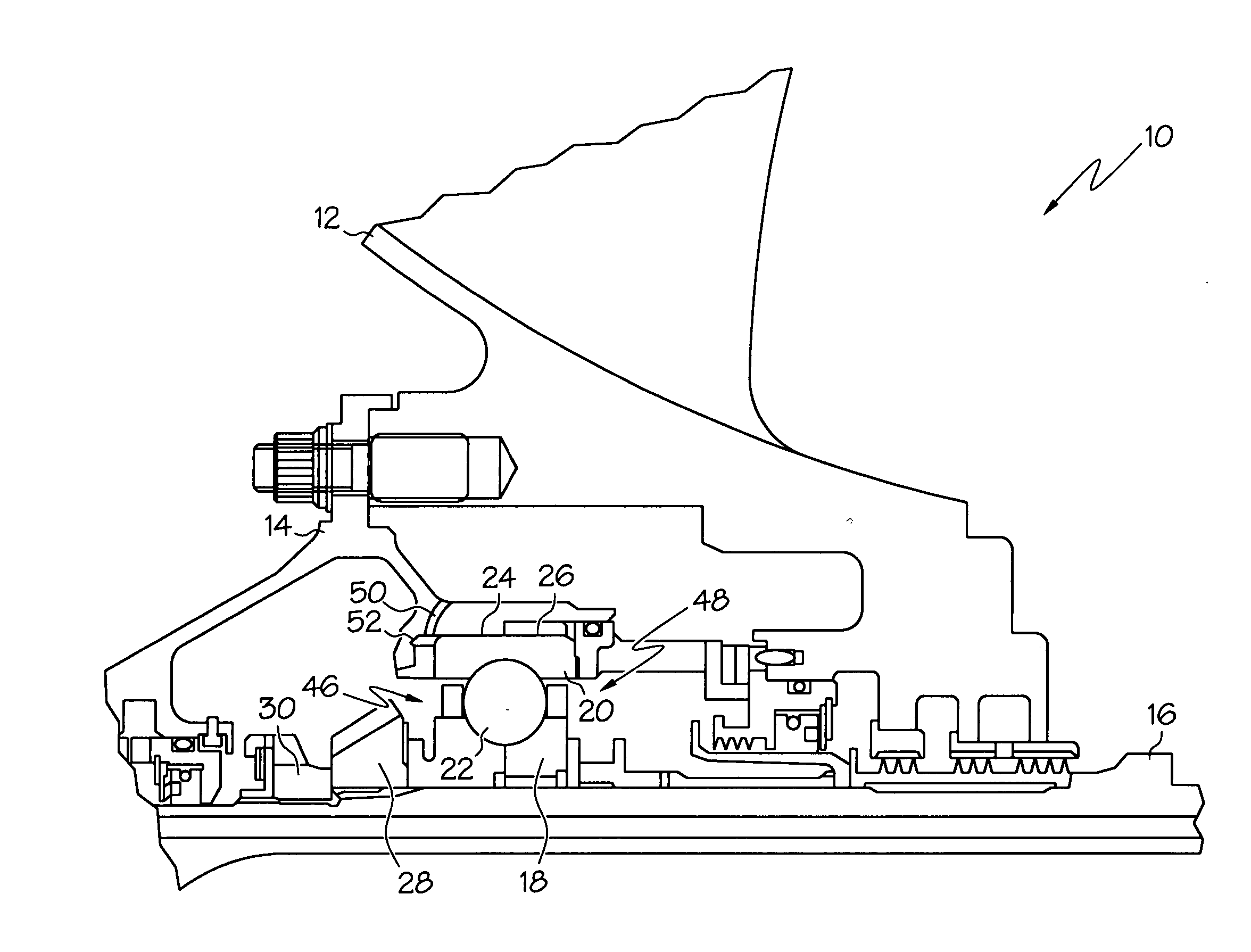

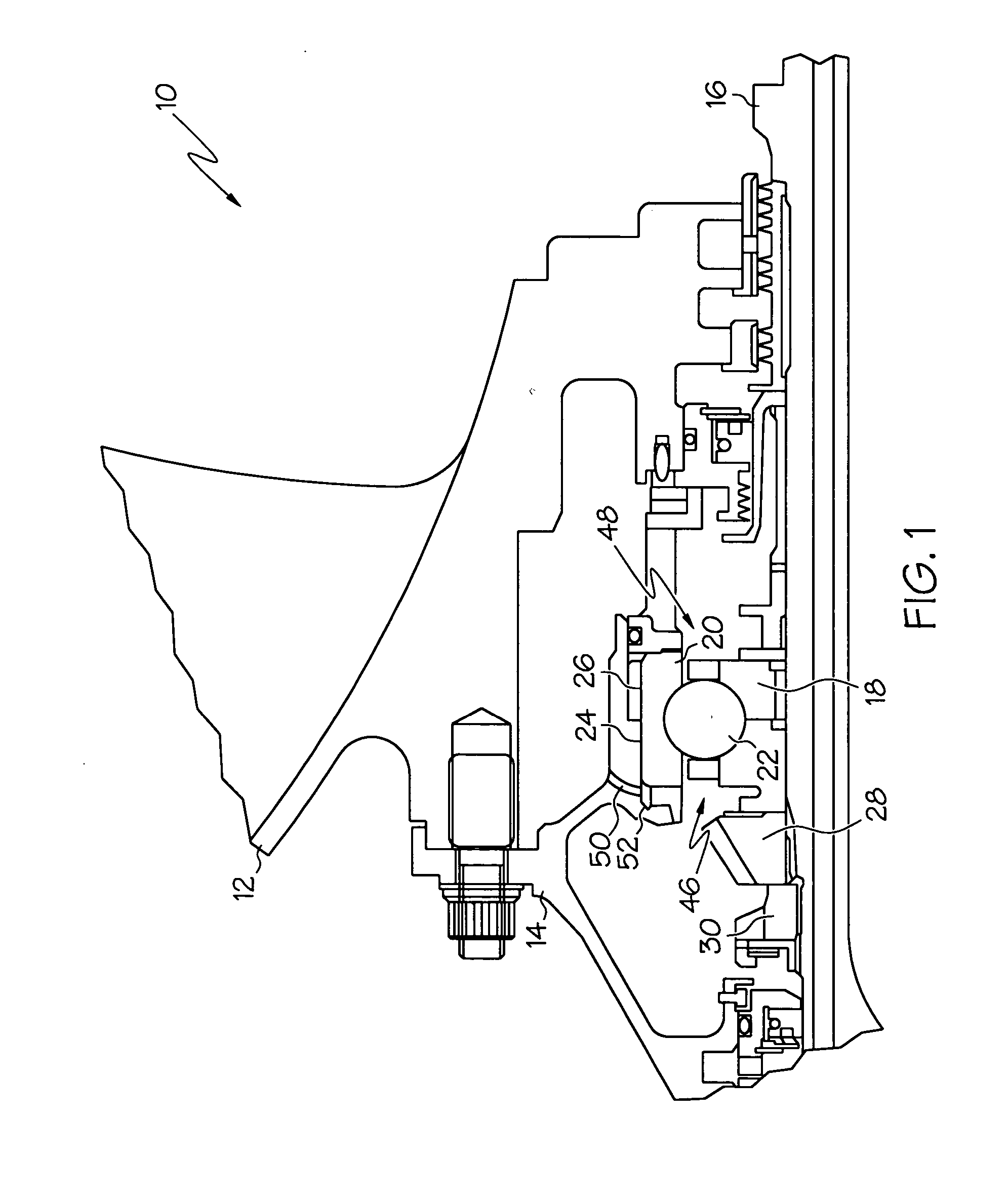

High speed aerospace generator resilient mount, combined centering spring and squeeze film damper

A rotor mount assembly for an electrical machine, such as a high speed aerospace generator, comprises a spring having a simple annular structure together with an oil squeeze film damper (SFD). The spring is engineered to move the rotor critical speeds outside of the extremes of the operating speed range and the SFD damps out the rotor responses as the speed passes through these points.

Owner:HONEYWELL INT INC

Compact compliant centering support for squeeze film damper

The present invention provides a centering feature to the bearing assembly of a turbomachine to provide optimum operating characteristics of the squeeze film damper. Unlike conventional bearing centering methods and apparatus, a compact compliant centering support for the squeeze film damper interfaces between a bearing outer race, and an outer support structure. The compact design is lightweight and inexpensive, can be retrofitted easily to an existing turbomachine, such as a turbine and compressor, for improved rotor dynamic performance. The compact compliant centering support damper may be comprised of a ring with bumpers spaced around the circumference at the inside and outside diameters to form spring elements between the bumpers. The centering support may lift the rotor inside the squeeze film cavity and may eliminate rotor weight effect on the damper performance. The centering support may be offset in the vertical direction to center the rotor under 1 g deflection to eliminate rub at the 6 o'clock location of a compressor or turbine shroud. Tangential grooves may be provided on the centering support outer bumpers to allow oil to squeeze out when the centering support is deflected to provide additional viscous damping. The outer bumper height may be controlled to limit maneuver deflection of the rotor.

Owner:HONEYWELL INT INC

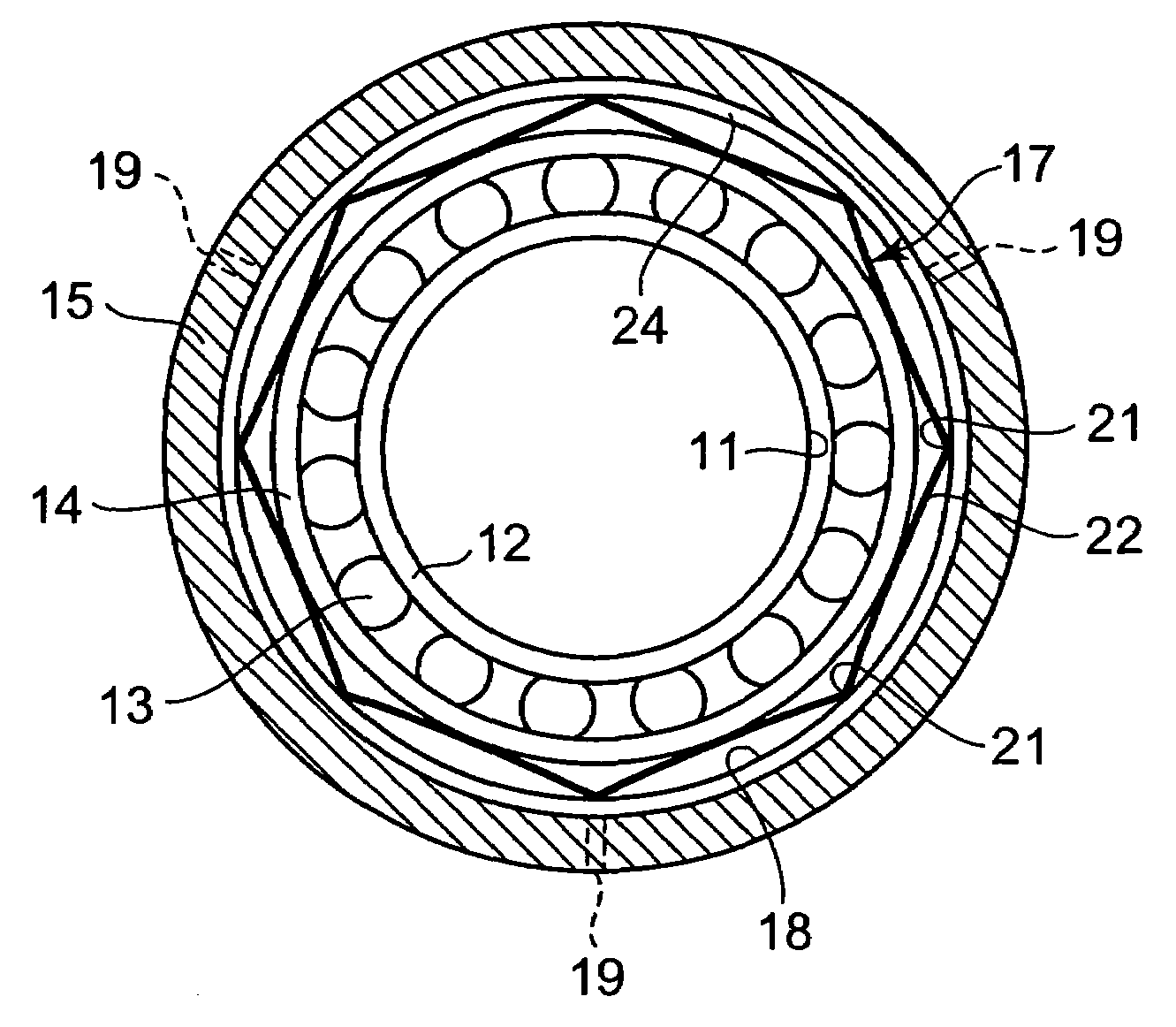

Bearing Vibration Damping Mechanism

ActiveUS20080292234A1Necessary rigidityReduce stiffnessLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper for a bearing and a vibration damping mechanism capable of damping the vibration of a rolling bearing are provided. The squeeze film damper is small in construction and can be easily made by mass production. The vibration damping mechanism is capable of damping both radial and axial vibrations. A bearing housing 15 is provided with a bearing holding bore 16 of a diameter greater than the outside diameter of the outer ring 14 of a bearing, and an oil hole 19 through which oil is supplied into the bearing holding bore 16. A vibration damping mechanism 1 is formed by inserting a thin, flat sheet 17 provided with slits into an annular space formed between the inner wall of the bearing holding bore 16 and the outside surface of a bearing held in the bearing holding bore 16 so as to surround the bearing. Parts of the thin, flat sheet extending between the adjacent slits serve as elastic beams. The elastic beams center the bearing and support the centered bearing elastically. The vibration of the bearing is damped by the squeeze film effect of an oil film formed by supplying oil into the annular space.

Owner:KAWASAKI HEAVY IND LTD

Capacitative pressure sensor

InactiveUS7121145B2High surfaceThe material is lowFluid pressure measurement using elastically-deformable gaugesPressure difference measurement between multiple valvesCapacitive pressure sensorEngineering

Owner:PRECISION MECHATRONICS

Squeeze film damper using low pressure oil

Owner:HONEYWELL INT INC

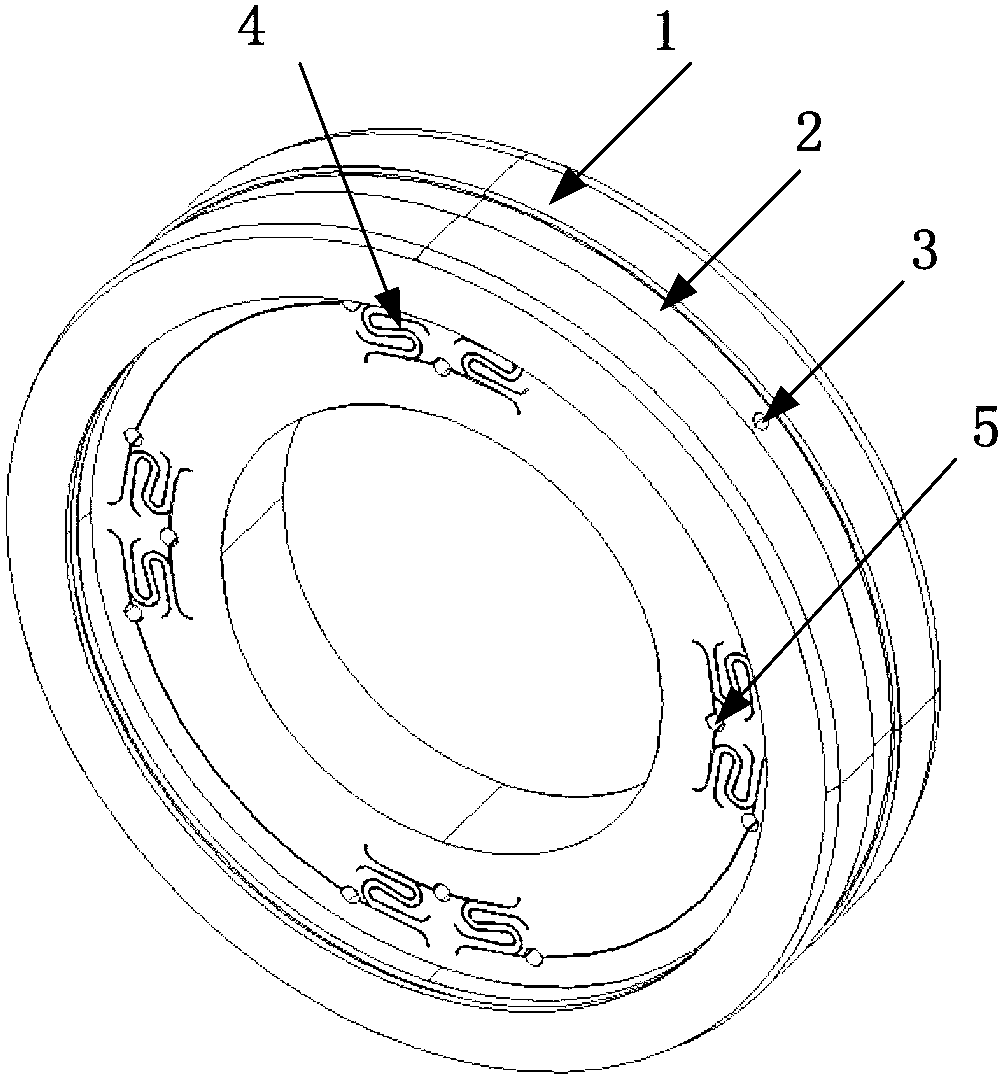

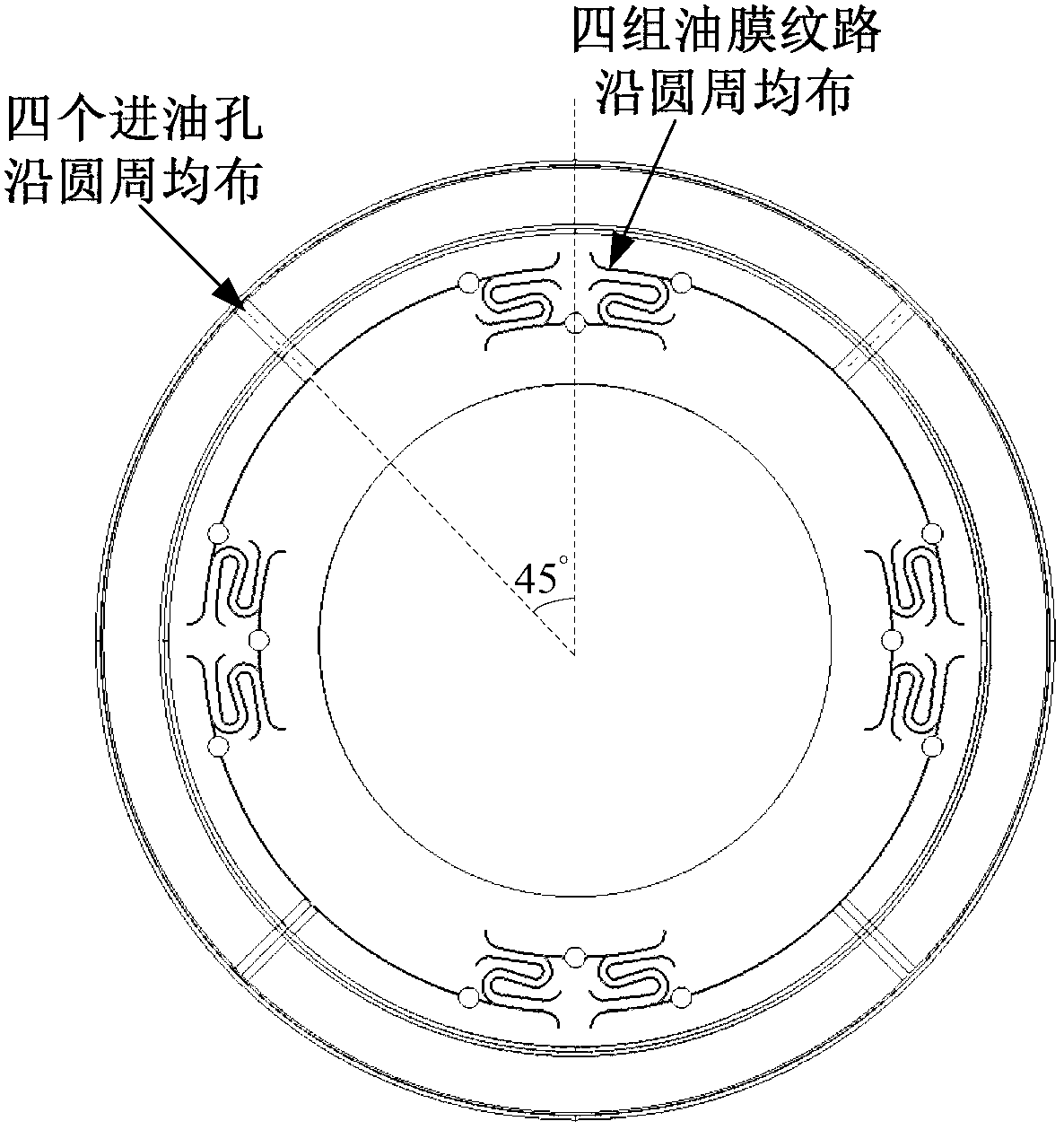

Squeeze film damper

The invention discloses a squeeze film damper, which comprises an oil inlet groove, air feed holes, oil film lines and oil storage holes. The oil inlet groove is machined on an outer circle of the squeeze film damper. The oil feed holes are machined in the oil inlet groove and communicated with the oil film lines, and supply oil to the oil film lines. The oil film lines are machined on the supporting circumference of the squeeze film damper, are slit machined on the supporting circumference of the squeeze film damper, and comprise outer lines I, inner lines III and middle line groups between the outer lines I and the inner lines III, wherein each middle line group comprises a plurality of middle lines II, which are nested and not communicated; and every two adjacent middle line groups are communicated through an inner line III. The oil storage holes are axial through holes, and are distributed in the oil film lines. The squeeze film damper is simple in structure, convenient to machine, low in cost, easy to mount and applicable to the vibration reduction of a 2-0-0 type rotor support structure, and has broad application prospect for miniature rotary type power machinery.

Owner:成都中科航空发动机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com