Cantilever beam acceleration transducer manufactured by micro-machining on single side of single silicon chip and method

An acceleration sensor and cantilever beam technology, applied in the direction of acceleration measurement using inertial force, technology for producing decorative surface effects, microstructure technology, etc., can solve the problem of reduced working bandwidth and high-range impact resistance, insufficient sensors Large gaps and other issues, to avoid spurious signal interference, reduce production costs, and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

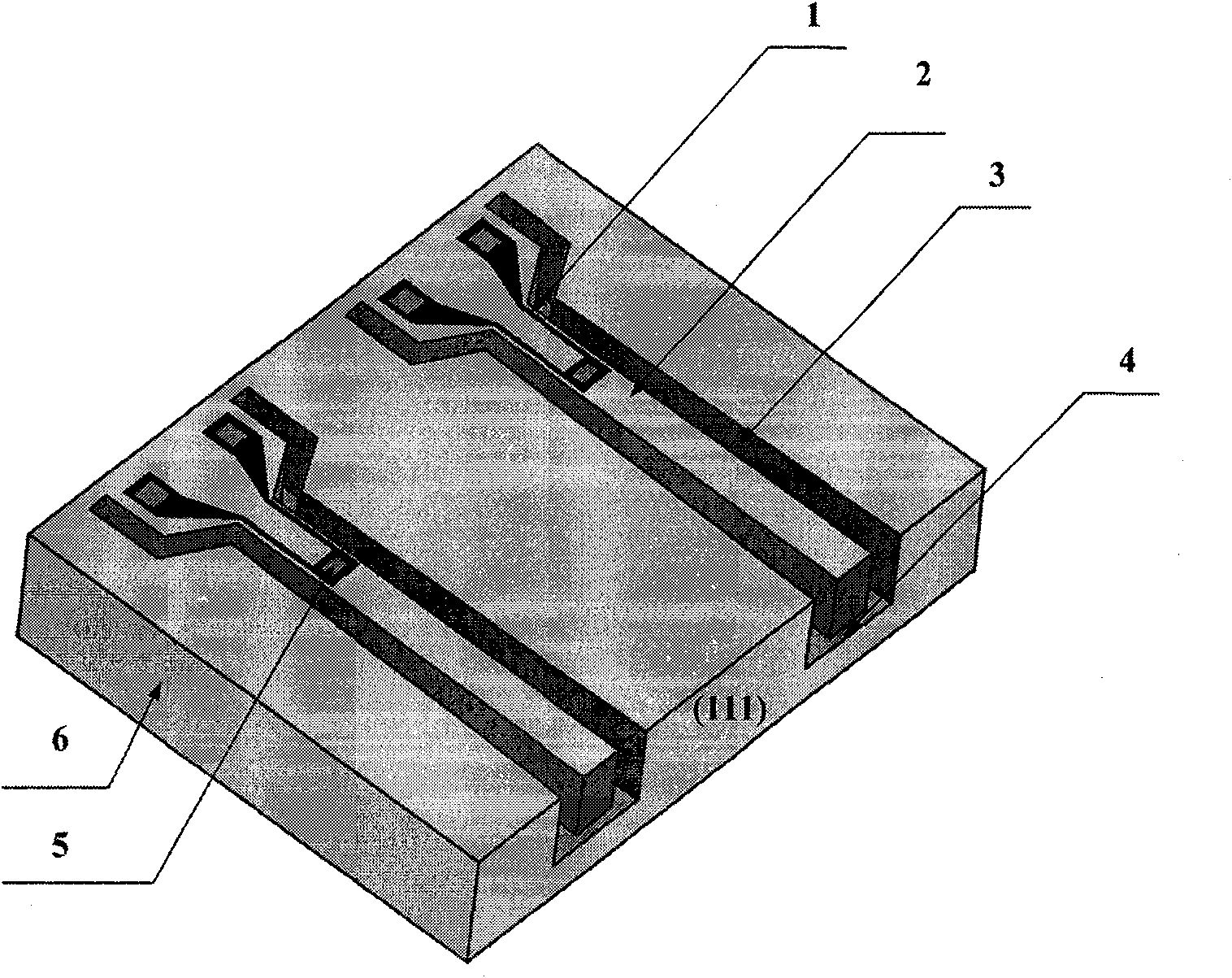

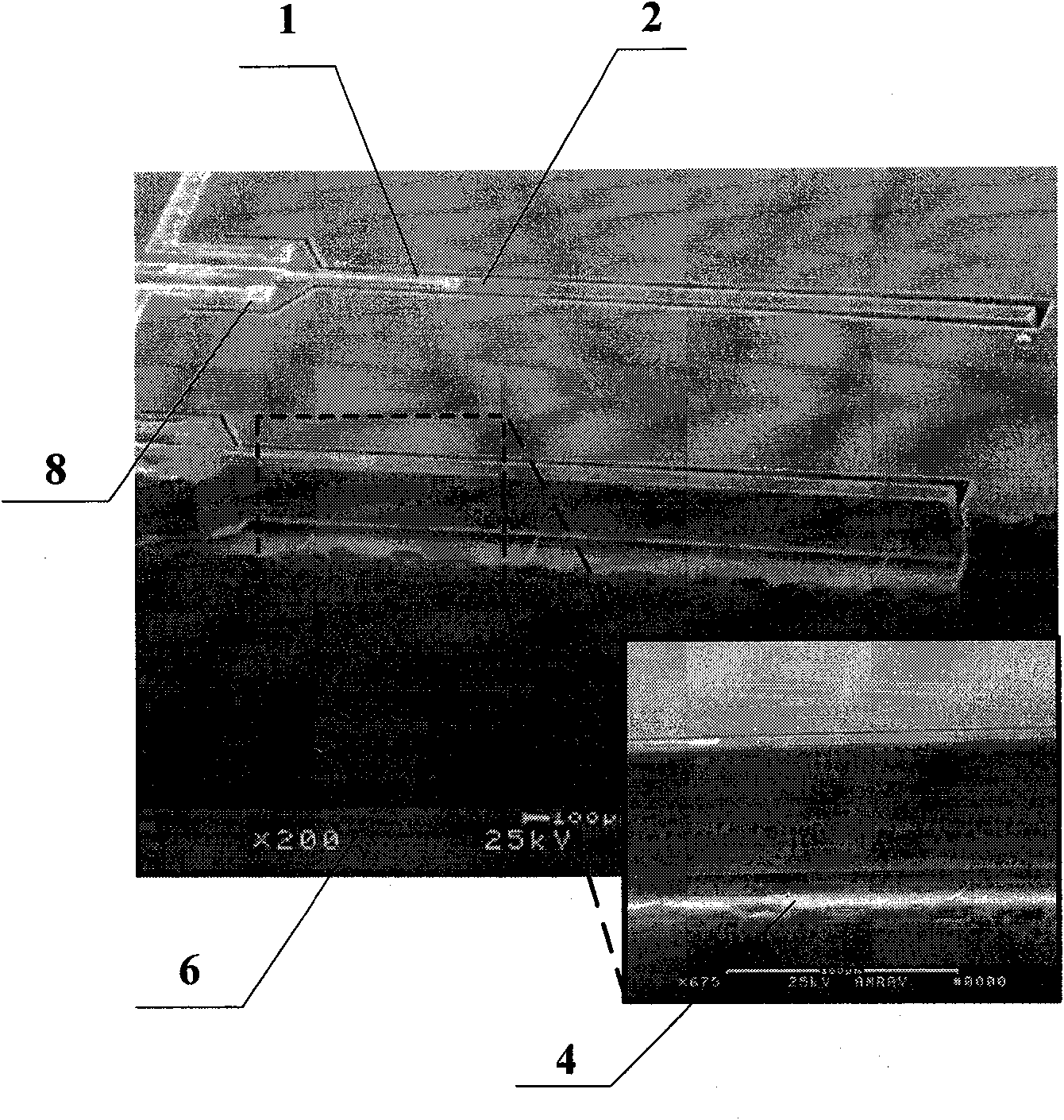

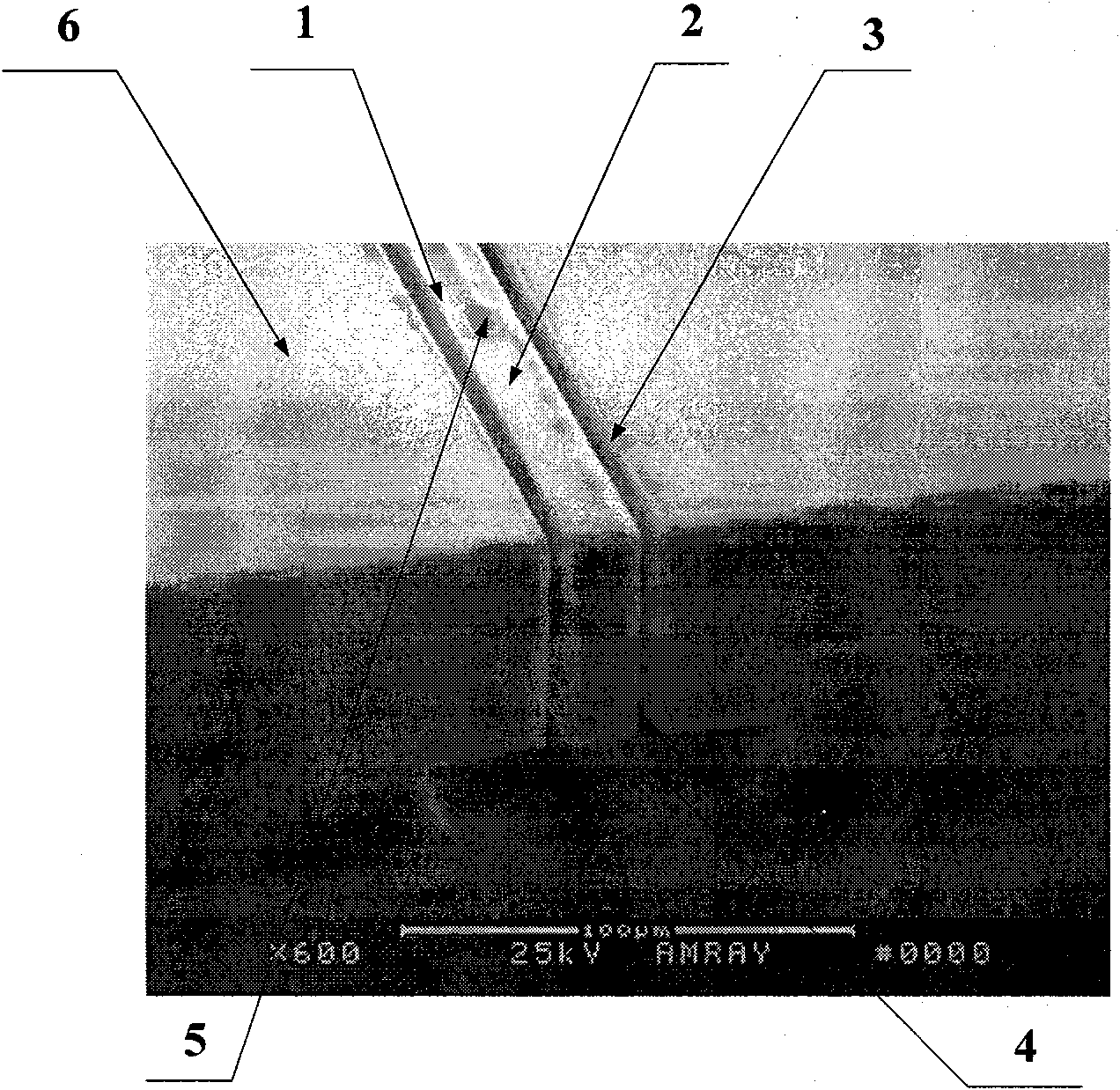

[0040] A cantilever beam accelerometer produced by single-sided microprocessing on a single silicon chip, its structure is mainly composed of a single crystal silicon substrate, a detection cantilever beam, a sensitive resistor, a high overload shock resistant curved surface, and a gap in the vertical sensitive direction. It is characterized in that the whole acceleration sensor adopts (111) single silicon chip to make (see image 3 ), different from the cantilever beam sensitive structure formed by micromachining on both sides of (100) silicon wafers in the past, the sensor of the present invention adopts a single silicon wafer integrated structure, and single-sided micromachining is performed on the front side of the silicon wafer. The sensor adopts double cantilever beam piezoresistive detection method. The cantilever beams have the same structural size and are arranged in parallel in the same direction. The anti-high overload impact surface is located on both sides of the c...

Embodiment 2

[0042] A cantilever beam accelerometer with a measuring range of 100,000 g produced by single-sided microprocessing on a single silicon chip and its manufacturing method: the designed cantilever beam structure has a length of 400 μm, a thickness of 50 μm, and a width of 18.5 μm. The overall size of the chip after processing is 1.5 μm. ×1.5×0.8mm 3 (The overall size of the traditional piezoresistive acceleration sensor after processing is 6.0×6.0×1.30mm 3 , see reference [2] for details). The entire sensor is implemented on an n-type (111) single crystal silicon chip (because when n-type piezoresistors are processed on p-type (111) single crystal silicon, the piezoresistive coefficient is relatively small, which is not conducive to improving the sensitivity of the sensor, and the n-type ( 111) Silicon chip production), the sensor is an integrated structure of a single silicon chip, and the sensitivity of the sensor is 0.35μV / g (see Figure 9 ), when the temperature ranges fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com