Patents

Literature

76 results about "Double cantilever beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

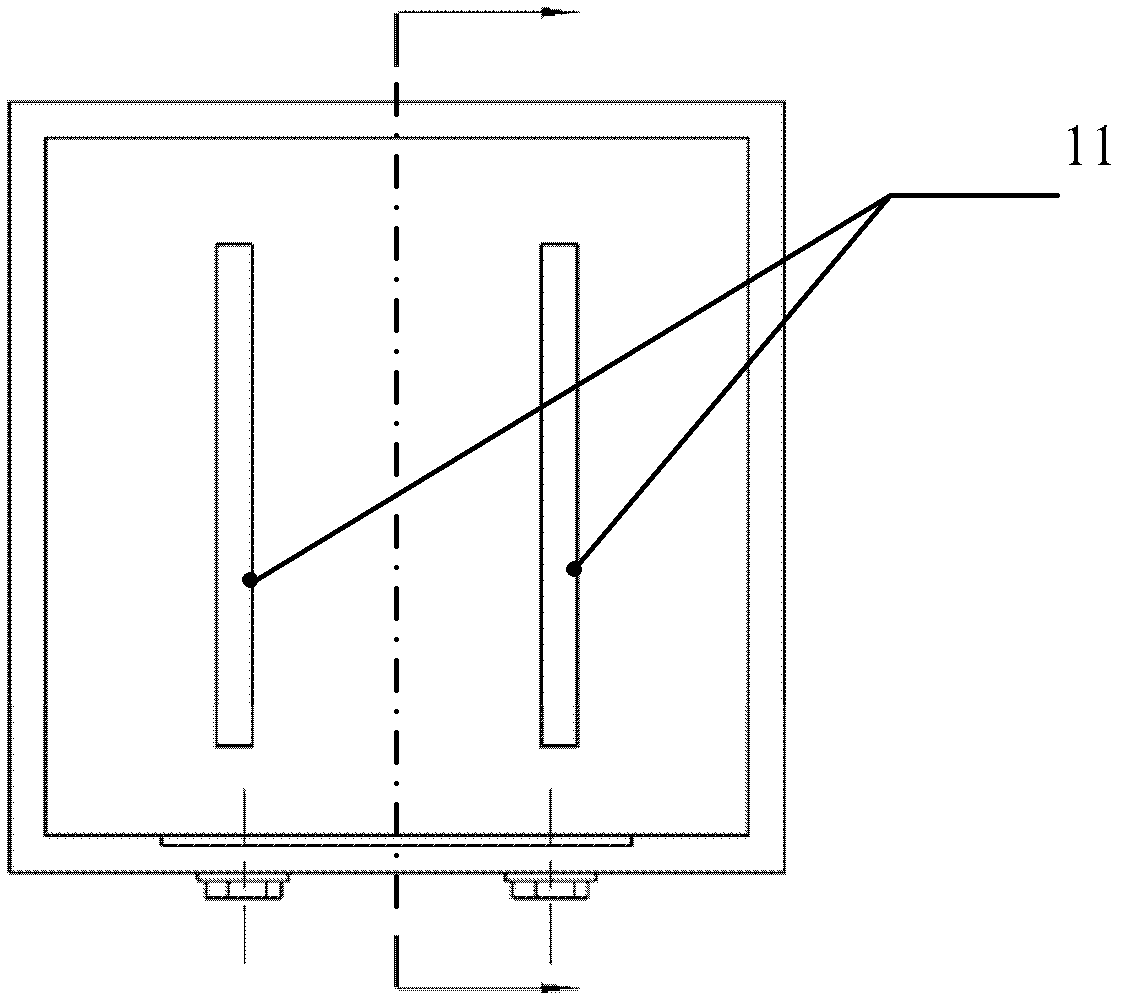

Bistable and double cantilever beam piezoelectric power generating device

InactiveCN102790547AOvercome the limitations of resonanceImprove power generation efficiencyPiezoelectric/electrostriction/magnetostriction machinesElectricityMagnetic poles

The invention discloses a bistable and double cantilever beam piezoelectric power generating device. A clamp is fixed in a casing; two bistable piezoelectric cantilever oscillator structures are respectively arranged at two ends of the clamp and the inner wall of the casing at the same side of the clamp; each bistable piezoelectric cantilever oscillator structure comprises a twin crystal bistable piezoelectric cantilever beam fixed with the clamp; a first permanent magnet is arranged at the free end of the twin crystal bistable piezoelectric cantilever beam; a second permanent magnet is fixed on the inner wall of the casing of the same side of the clamp and positioned at the same horizontal position of the first permanent magnet; two permanent magnets are oppositely arranged according to magnetic poles; the twin crystal bistable piezoelectric cantilever beam comprises an elastic beam and piezoelectric layers which are attached to an upper surface and a lower surface of the elastic beam; the elastic beam is respectively equal to the piezoelectric layers in width and length; and electrodes are respectively arranged on the upper surface and the lower surface of each piezoelectric layer. According to the coherent nonlinear characteristic of the bistable and double cantilever beam piezoelectric power generating device disclosed by the invention, the great motion under wide-narrow frequency excitation can be realized, environment vibration can be effectively utilized for generating power and the power generating efficiency is increased. Two groups of piezoelectric cantilever beams are combined so as to effectively increase the power generation amount of the device in unit time.

Owner:TIANJIN UNIV

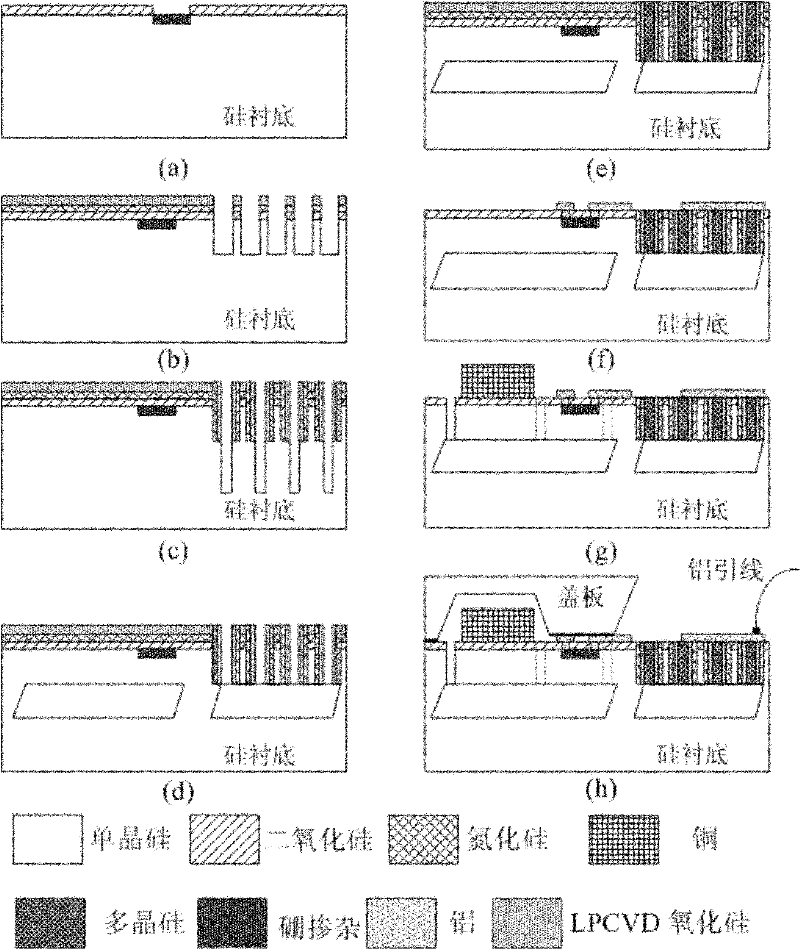

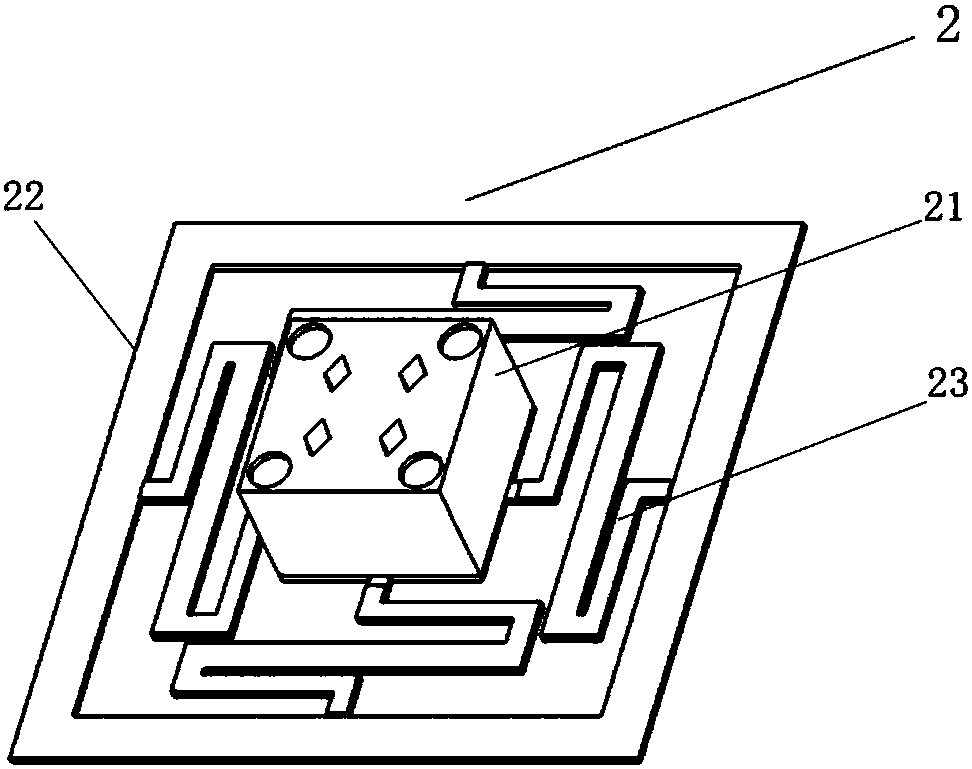

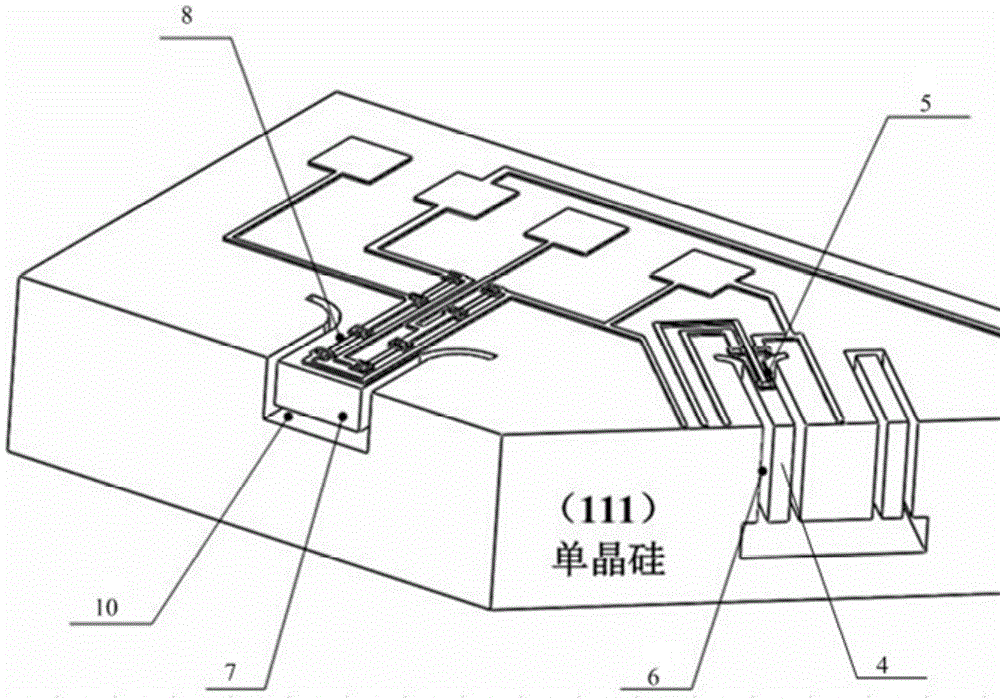

Single silicon chip integrated chip combining acceleration sensor and pressure sensor and manufacturing method of single silicon chip integrated chip

ActiveCN102476786ASmall sizeEasy to packAcceleration measurement using interia forcesFluid pressure measurement using ohmic-resistance variationHigh volume manufacturingCantilever

The invention relates to a single silicon chip integrated chip combining an acceleration sensor and a pressure sensor and a manufacturing method of the single silicon chip integrated chip. The single silicon chip integrated chip comprises a single crystal silicon substrate and an acceleration sensor and a pressure sensor both integrated on the single crystal silicon substrate. The acceleration sensor and the pressure sensor are integrated on the same surface of the single crystal silicon substrate through adopting a single silicon chip single-side micro-processing method; a single crystal silicon thin film with a uniform and controllable thickness and an embedded cavity are formed through adopting the side wall root transversal etching technology, and pressure resistance is reasonably distributed on the upper surface of the single crystal silicon thin film to manufacture the pressure sensor; and the acceleration sensor adopts double cantilever beams and a mass block, both the mass block and the cantilever beams are processed and released through the follow-up optional galvanizing and etching to the single crystal silicon thin film, and the quality of the mass block is increased through adopting an electrocoppering method, so as to improve sensitivity. The single silicon chip integrated chip disclosed by the invention has the advantages that the structure is simple; and a non-bonding single silicon chip micro-machinery technology is adopted to realize the manufacturing of a single-side structure of the integrated chip, thereby meeting the requirements on small dimension, low cost and mass production of the sensor chip in TPMS (Tire Pressure Monitor System) application.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

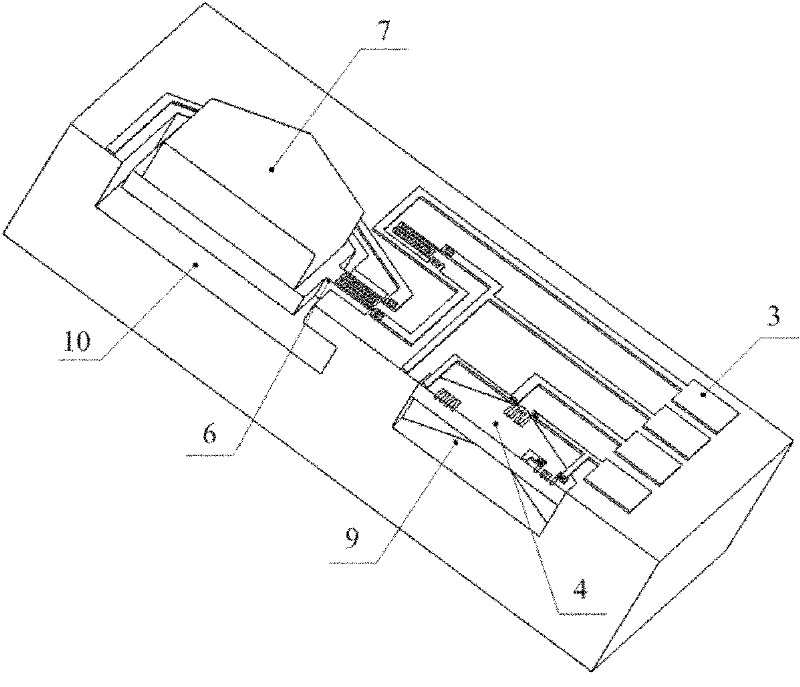

Ultra-wideband energy-efficient piezoelectric vibration energy harvesting device

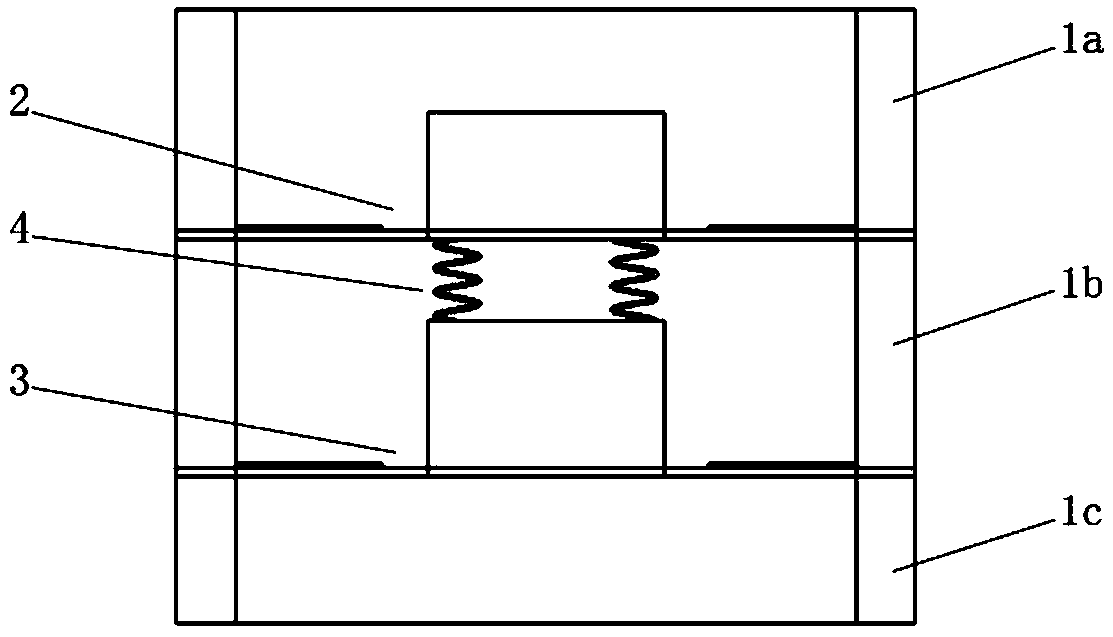

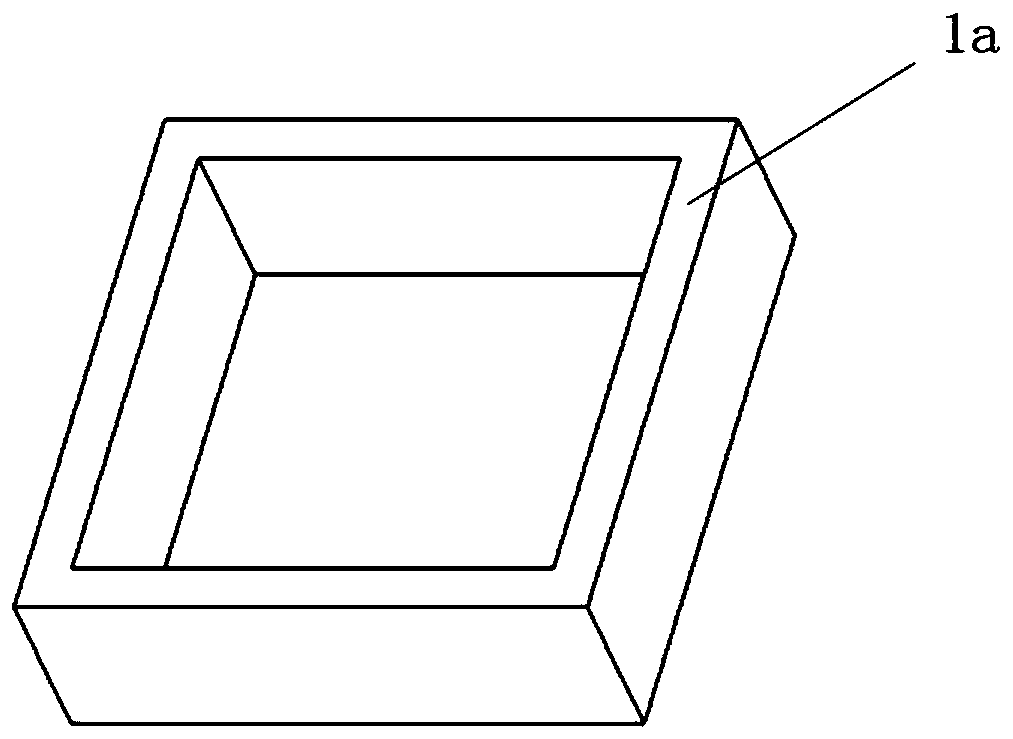

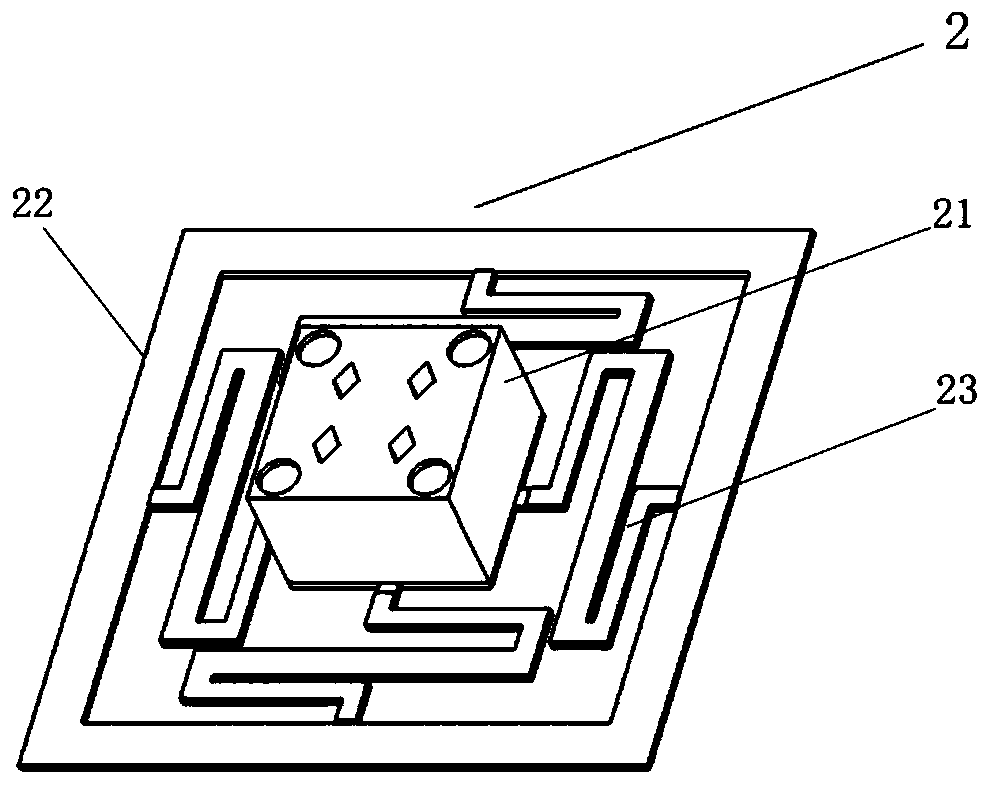

ActiveCN107707155AIncreased bandwidthAvoid the defect of collecting vibration energy with small frequency widthPiezoelectric/electrostriction/magnetostriction machinesElectricityCantilevered beam

The present invention provides an ultra-wideband energy-efficient piezoelectric vibration energy harvesting device for solving the technical problem of low energy conversion efficiency when the external vibration frequency is not stable in the prior art, including brackets and an oscillating body. The oscillating body includes a low frequency oscillating body and a high frequency oscillating body.The brackets include a top bracket, a middle bracket and a bottom bracket which are sequentially stacked from top to bottom. The three brackets adopt a three-dimensional structure with a cavity penetrating the upper and lower end faces; the low frequency oscillating body comprises a low frequency reed between the middle bracket and the bottom bracket, a low frequency mass fixed to the central bearing section of the low frequency reed, and a low frequency cantilever module attached to the cantilever of the low frequency reed; the high frequency oscillating body includes a high frequency reed between the top bracket and the middle bracket, a high frequency mass fixed to the central bearing section of the high frequency reed and a high frequency cantilever module attached to the double-cantilever beam of the high frequency reed; and the low frequency mass and the high frequency reed are connected by at least three compression springs.

Owner:XIDIAN UNIV

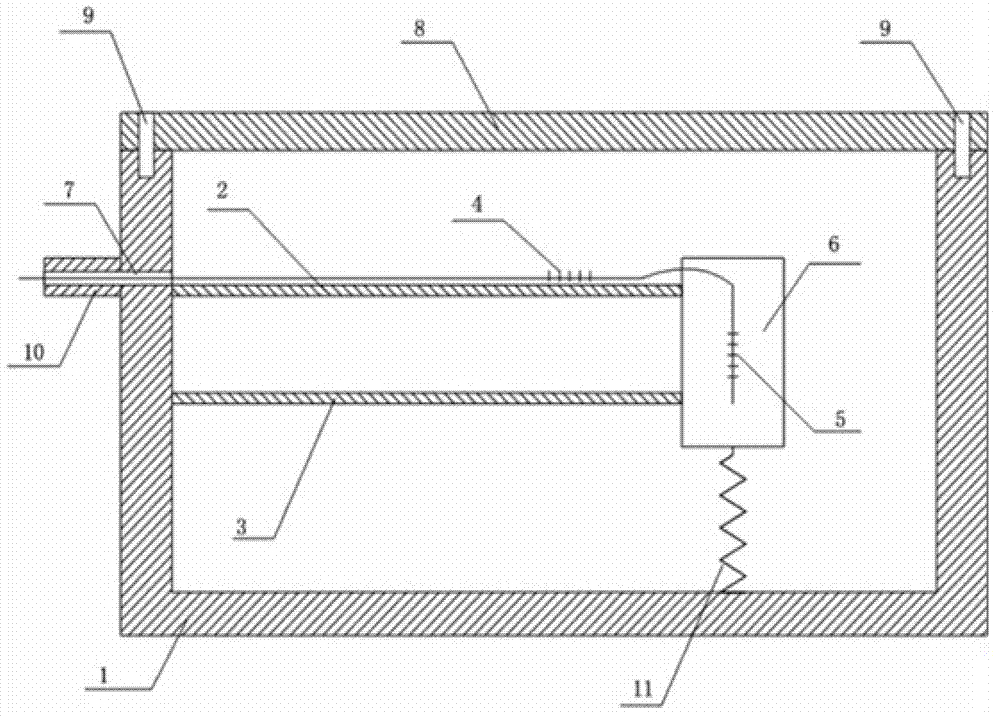

Double-cantilever beam fiber grating acceleration sensor

InactiveCN103197099AImprove accuracyImprove stabilityAcceleration measurement using interia forcesCantilevered beamFiber

The invention provides a double-cantilever beam fiber grating acceleration sensor which is good in stability and even in beam structural stress. An upper cantilever beam and a lower cantilever beam are of a shape of a combination of a rectangle and an equicrural triangle. Top points of top angles of the equicrural triangle are free ends, a bottom edge of the equicrural triangle is connected with a wide edge of the rectangle, and the length of the bottom edge of the equicrural triangle is the same with the length of the width of the rectangle. The other wide edge of the rectangle is a fixed end, and the height on the bottom edge of the equicrural triangle is larger than or equal to the length of the rectangle. When the height on the bottom edge of the equicrural triangle is larger than the length of the rectangle, the combination shape of the rectangle and the equicrural triangle can not only effectively avoid a chirp effect of the fiber grating but also greatly improve the stability of the sensor at the same time.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

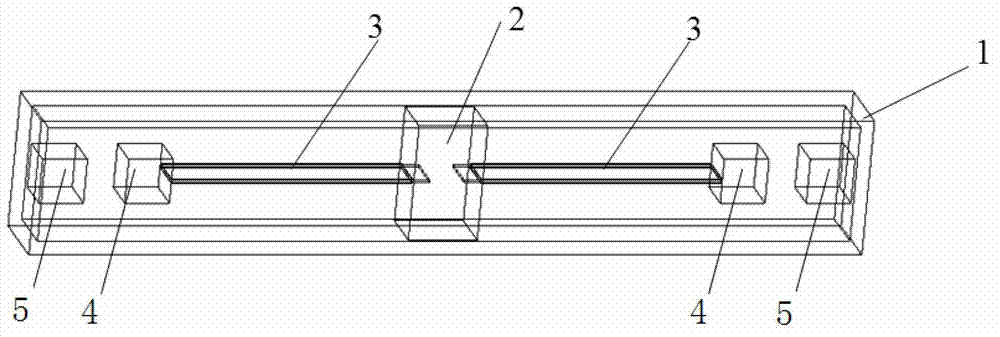

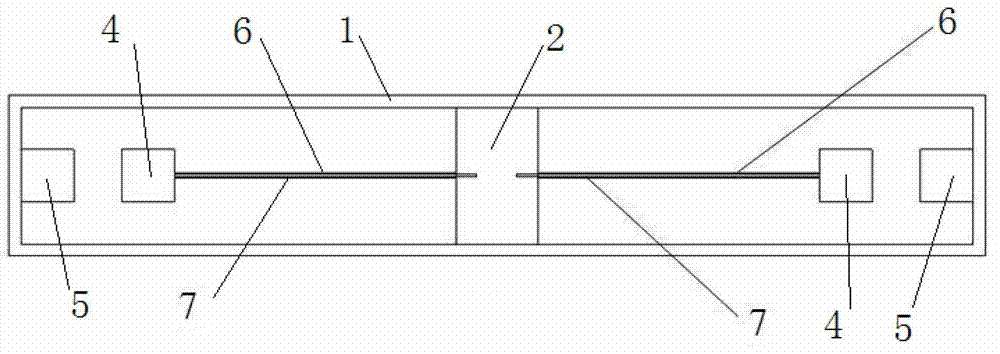

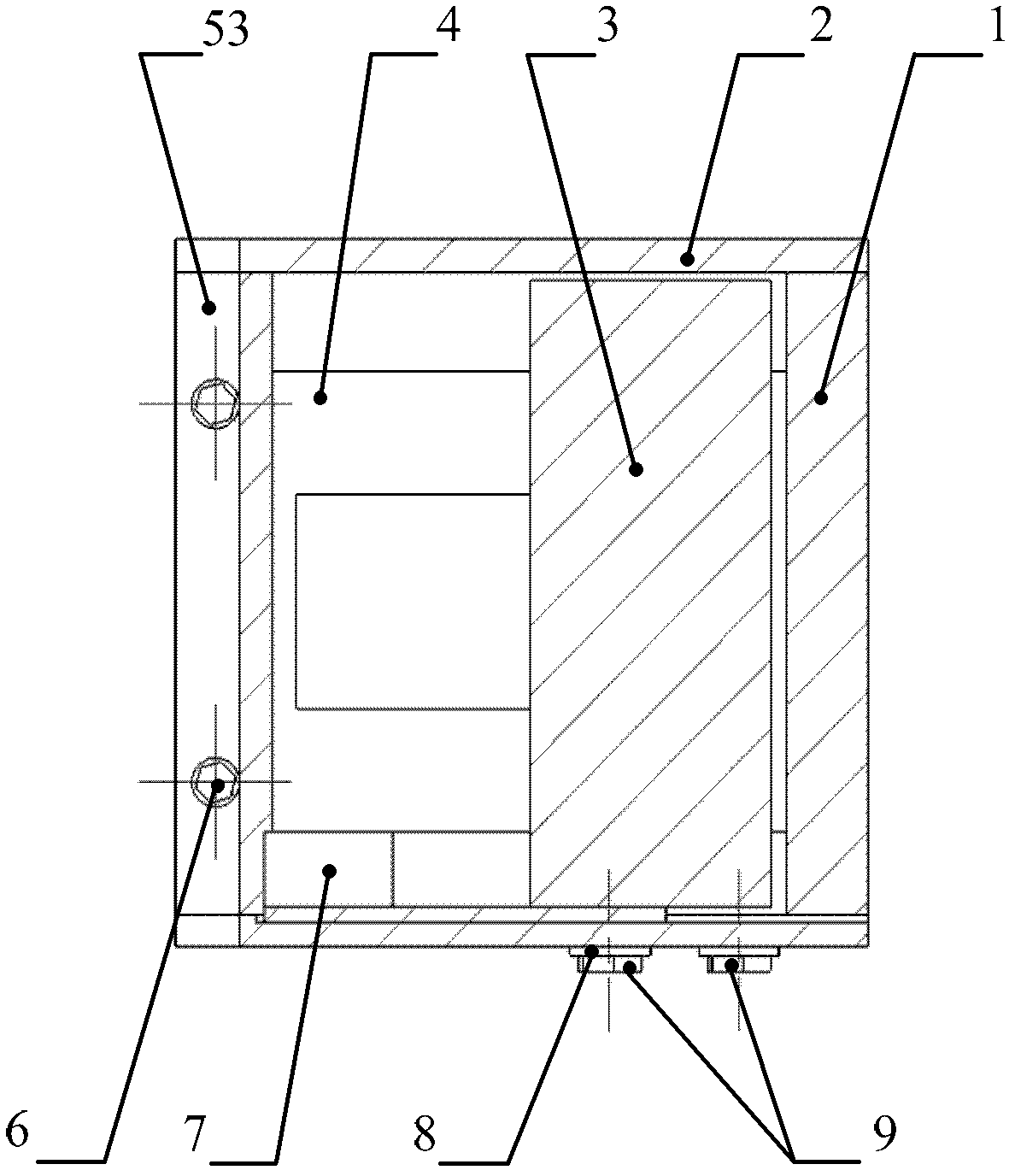

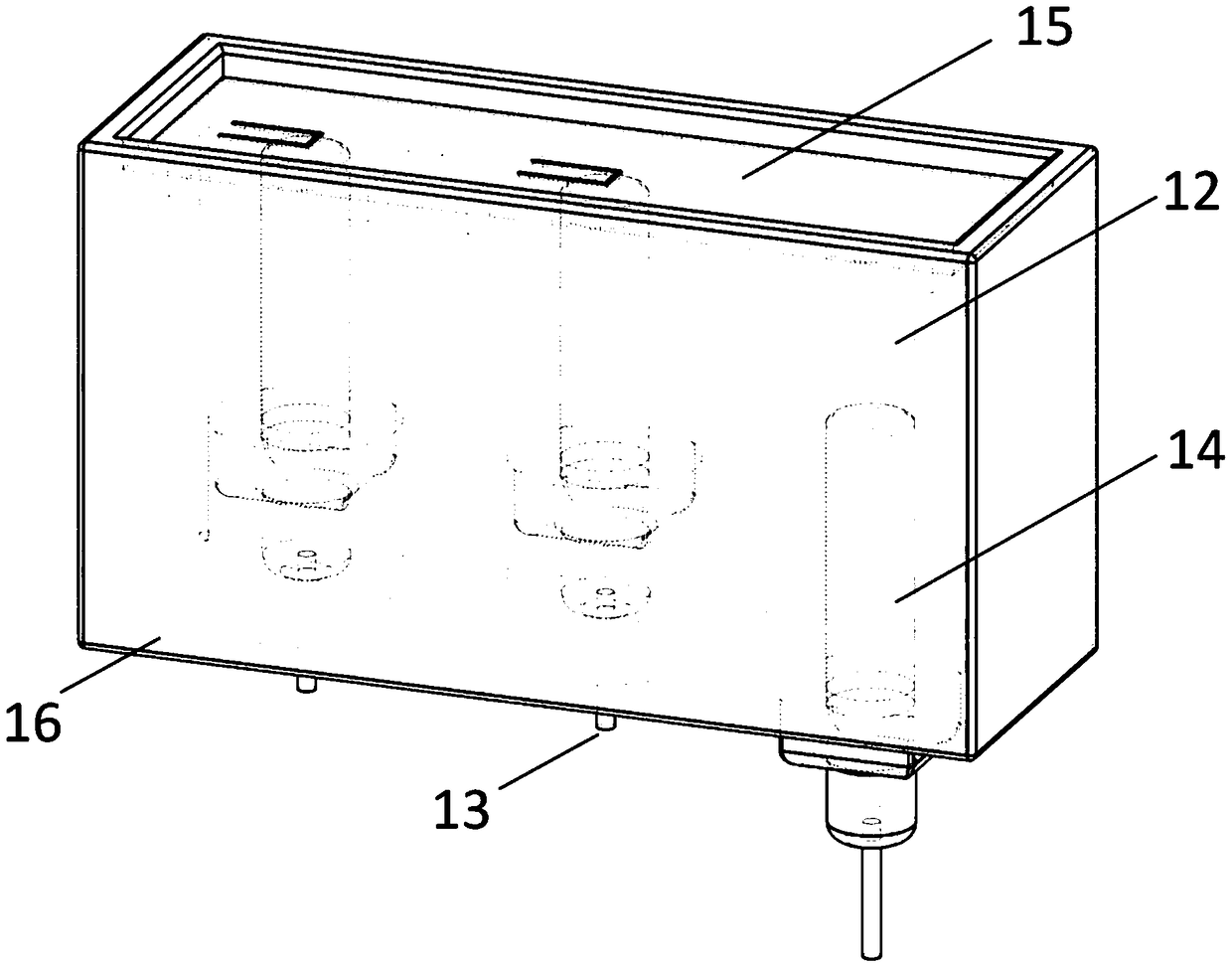

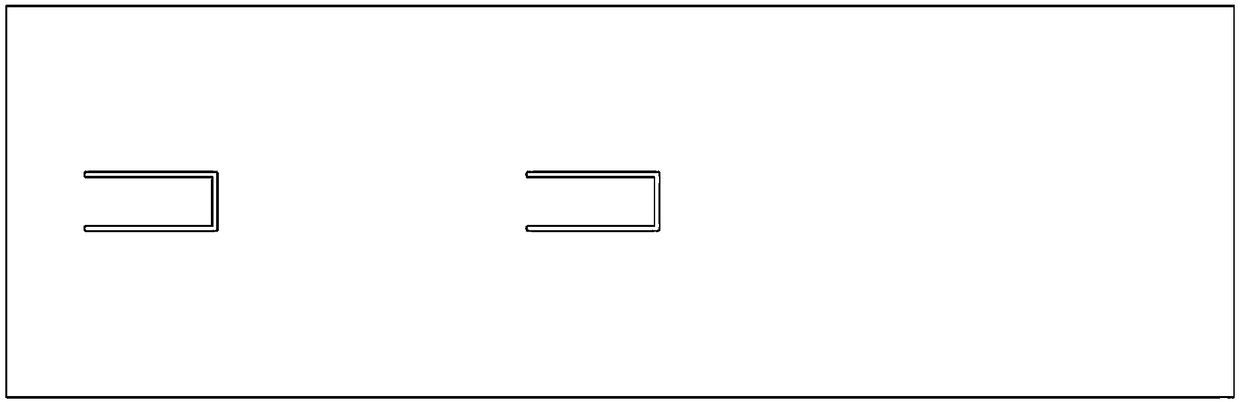

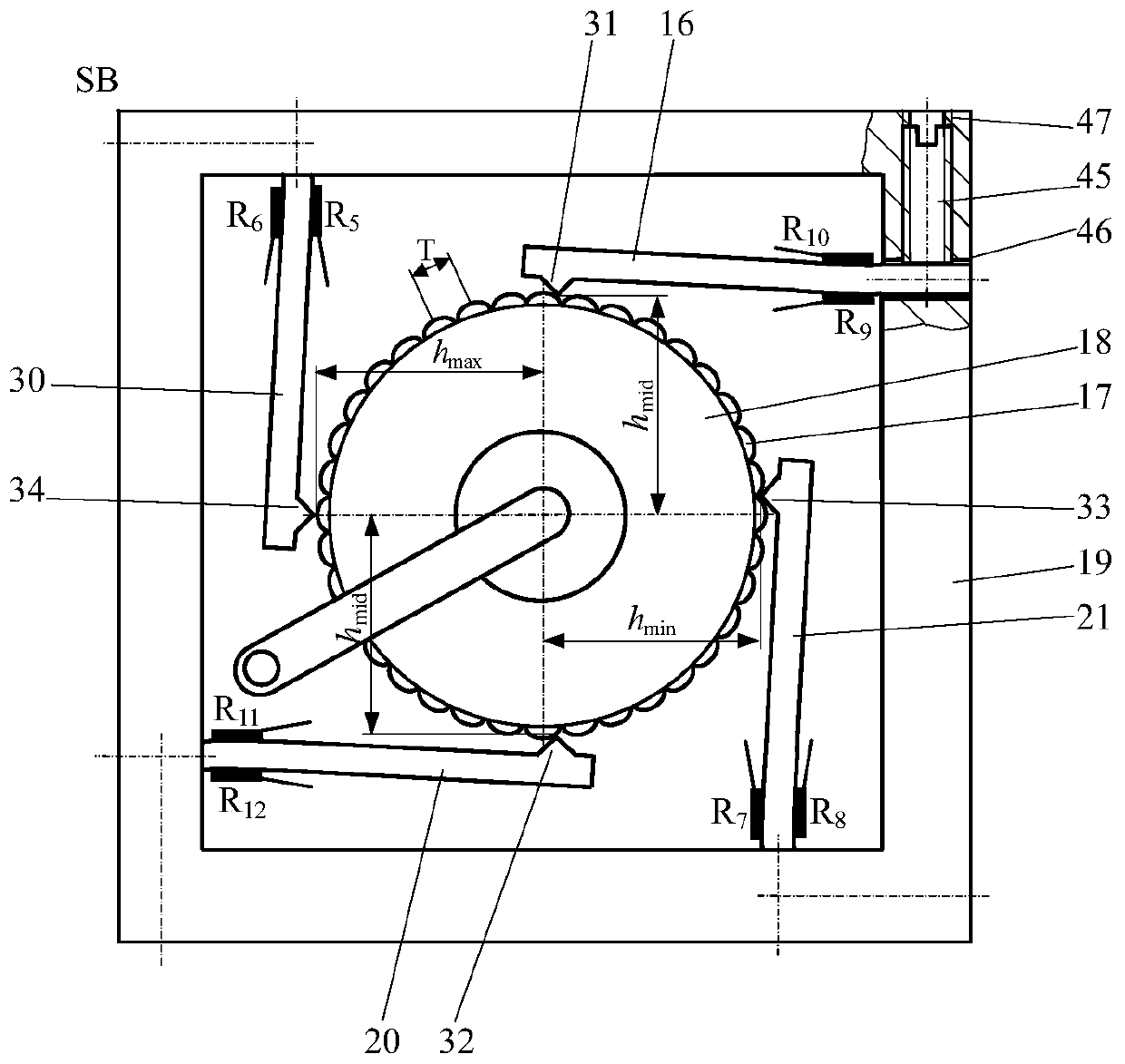

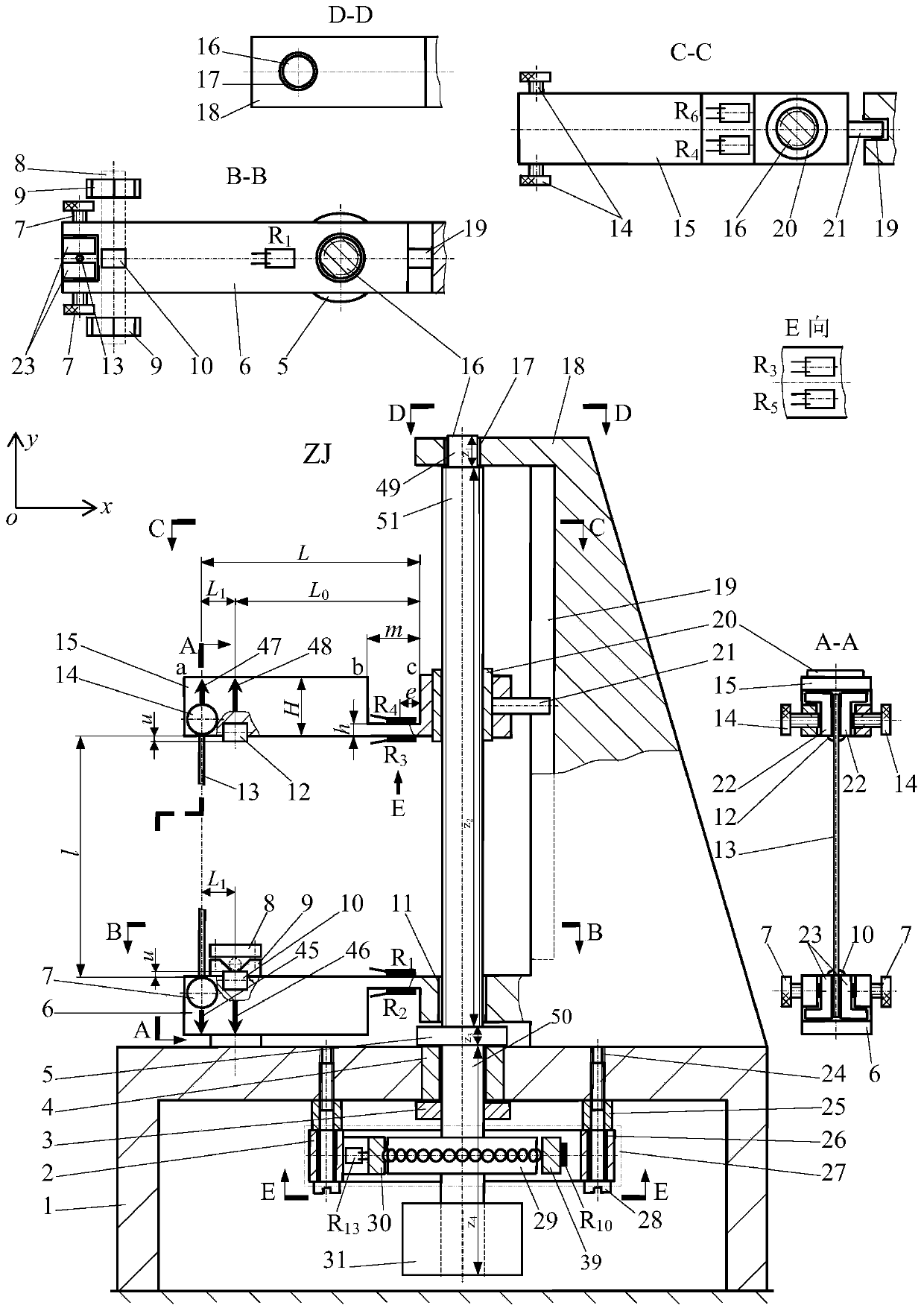

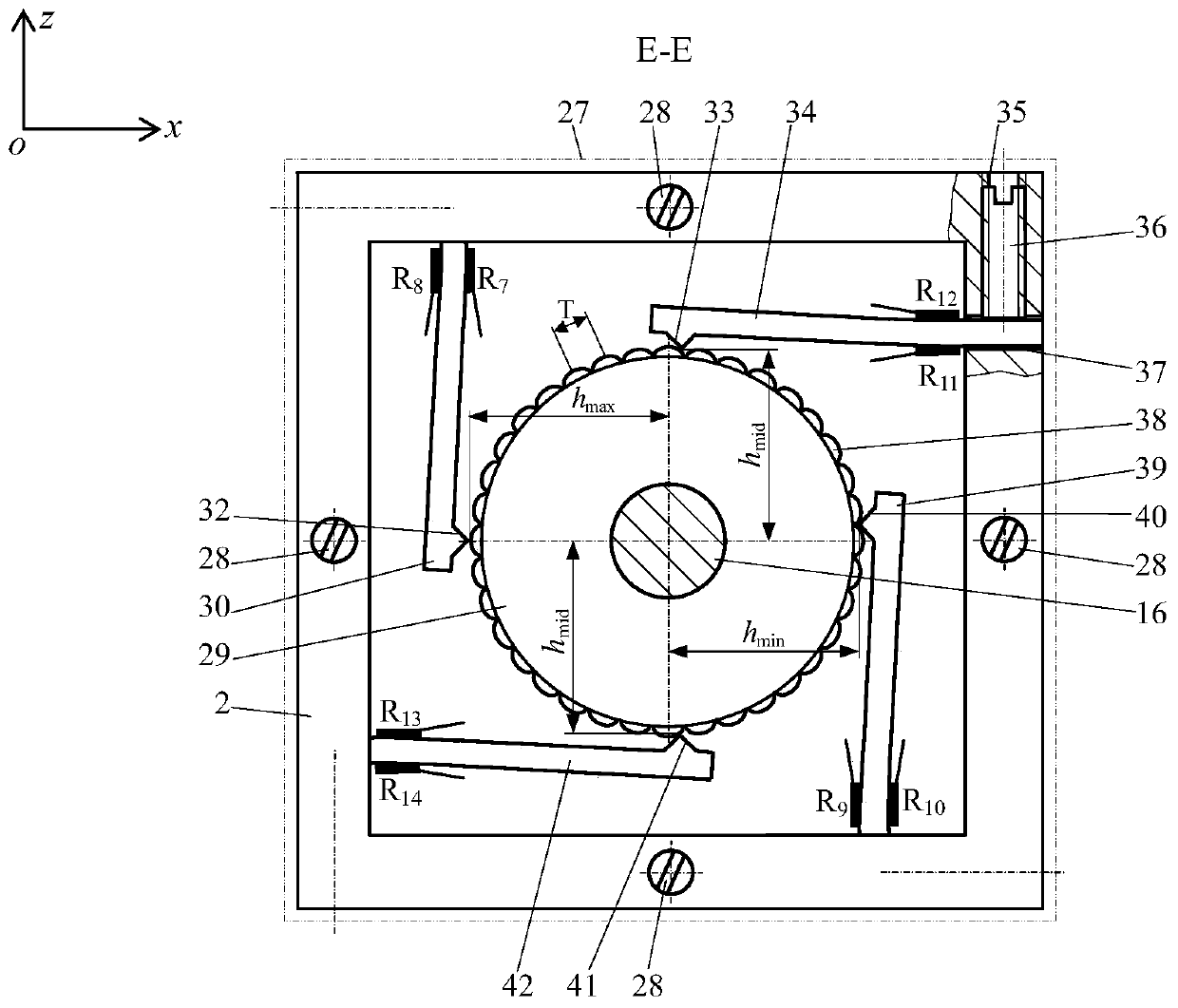

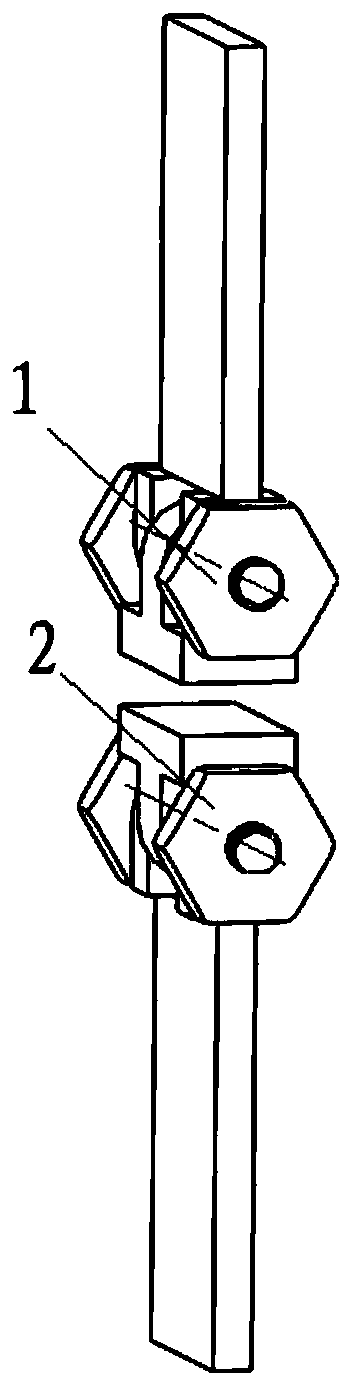

Stiffness/damping adjustable double-cantilever beam sealed passive damper

InactiveCN102418769AChange the coefficient of frictionWith stiffnessNon-rotating vibration suppressionNumerical controlCantilevered beam

The invention relates to a numerical control machine tool and workpiece passive vibration damping device which can be applied to the field of machining and has the obvious single-degree-of-freedom vibration characteristic. The device comprises a shell, a base, cantilever beams, a mass block, a screw, a nut, a gasket, a friction plate, a threaded hole and the like and is of a box-like sealed structure. The device is characterized in that main mode motion which is strictly vertical to the direction of the cantilever beams is realized, and the vibration characteristic is derived from first-orderbending vibration of the two cantilever beams. The stiffness and damping of the device are adjustable, and the adjustment can be realized by adjusting the position of the mass block in the device andthe pretightening force of the friction plate, thereby having a wider vibration suppression frequency range. The device is suitable for the characteristics that the dynamic property of a workpiece ora machine tool changes during the machining and a damper is required to be capable of adjusting parameters. The device can be mounted on a numerical control lathe, a milling machine or the workpiece for vibration damping. The device is simple in structure, convenient to implement and lower in cost, has no environmental pollution, and can be used for effectively reducing the vibration during cutting machining and realizing high-efficient and high-quality machining of parts.

Owner:BEIHANG UNIV

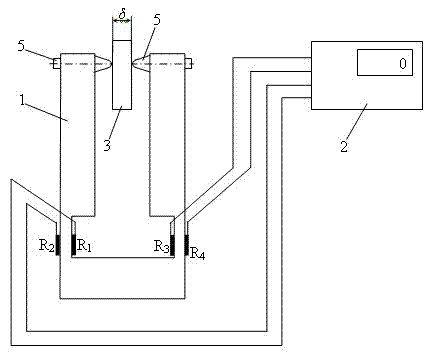

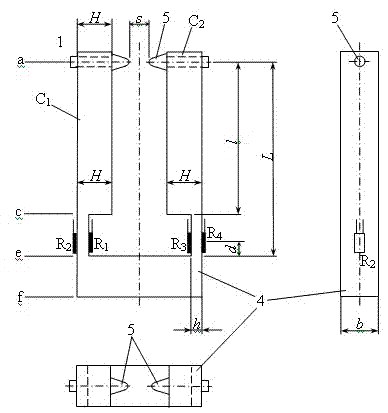

Resistance strain thickness measuring device and measurement method thereof

InactiveCN102506688AGuaranteed measurement accuracyCalibration method is simpleElectrical/magnetic thickness measurementsPhysicsDouble cantilever beam

The invention discloses a resistance strain thickness measuring device, which comprises a double cantilever beam resistance strain thickness measuring sensor and a resistance strain measuring instrument, wherein the double cantilever beam resistance strain thickness measurement sensor consists of a U-shaped elastomer, two conic apex measuring contacts with a positioning shaft pin or threaded rod and four single-shaft strainmeters R1, R2, R3 and R4. The thickness measuring device is calibrated by using a thickness regulator; and the calibrated thickness measuring device is used for measuring the static thickness and dynamic thickness of a sample. The structure of the thickness measuring device is simple, the resolution ratio of the thickness measuring device is less than 0.1 micrometer, and the thickness measuring device can measure the thickness of a geometric solid in fields of material mechanical performance tests and machining; and in the field of material mechanical performance tests, the thickness measuring device can measure the thickness of a sample in a process of deformation under load in a thickness extension manner in real time.

Owner:ZHEJIANG UNIV

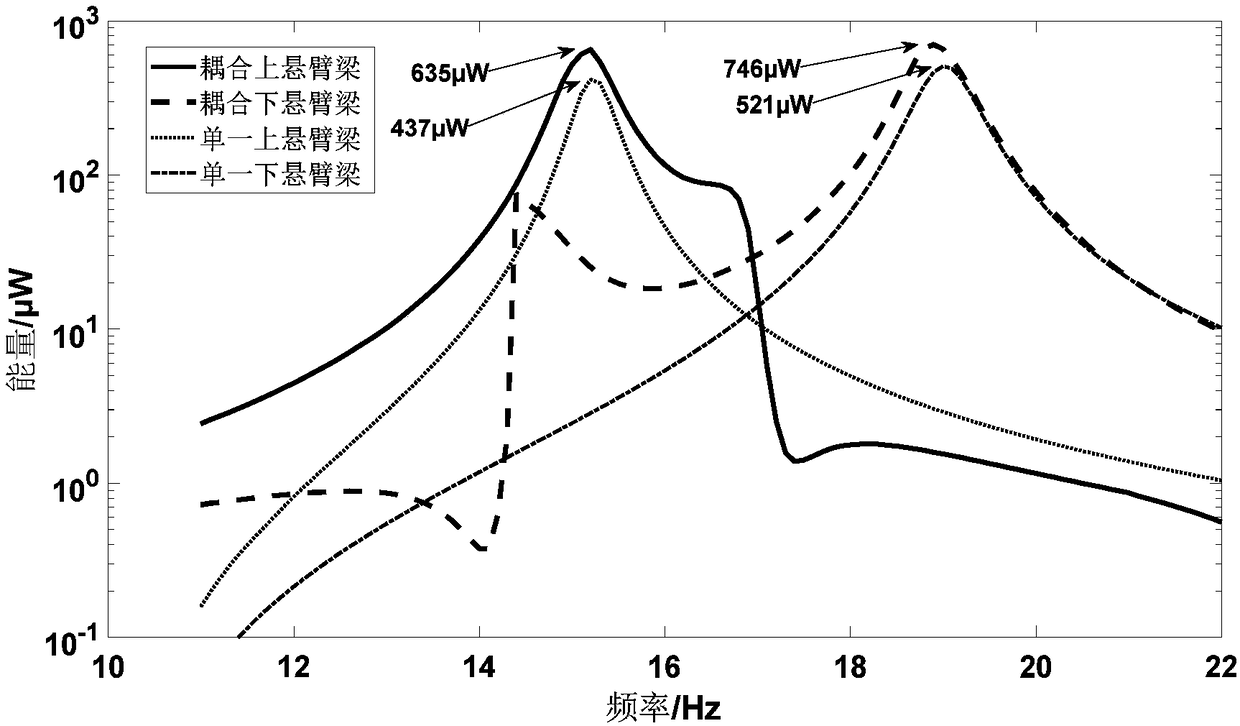

Ferromagnetic-coupling vibration energy collection device with double cantilever beams

InactiveCN108471258ASimple setupSimple designPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamDouble cantilever beam

The invention relates to a ferromagnetic-coupling vibration energy collection device with double cantilever beams. The structure of the ferromagnetic-coupling vibration energy collection device comprises a vibration structure, an external framework, a fastening piece, an upper cantilever beam, an upper piezoelectric material block, a mass block, an upper cantilever beam ferromagnetic block, a lower cantilever beam, a lower piezoelectric material block and a lower cantilever beam ferromagnetic block. The ferromagnetic-coupling vibration energy collection device has the effect that the double cantilever beams are used as a basic energy collection structure; compared with the other methods, the structure is simple to arrange and design and is easy to fabricate and maintain; the two cantileverbeams are arranged to collect energy, the resonant frequencies of the two cantilever beams can be different by attaching the mass block onto the upper cantilever beam, so that the beneficial effect of multi-resonant frequency bands is achieved; a non-linear force is introduced by ferromagnetic coupling; and compared with the same-size cantilever beam without ferromagnet, the ferromagnetic-coupling vibration energy collection device has the advantages that the energy collection efficiency is greatly improved, the bandwidth is greatly expanded, the broadening frequencies of the two cantilever beams can be coincided, so that the output is improved to be applicable to a more complicated working condition.

Owner:TIANJIN UNIV

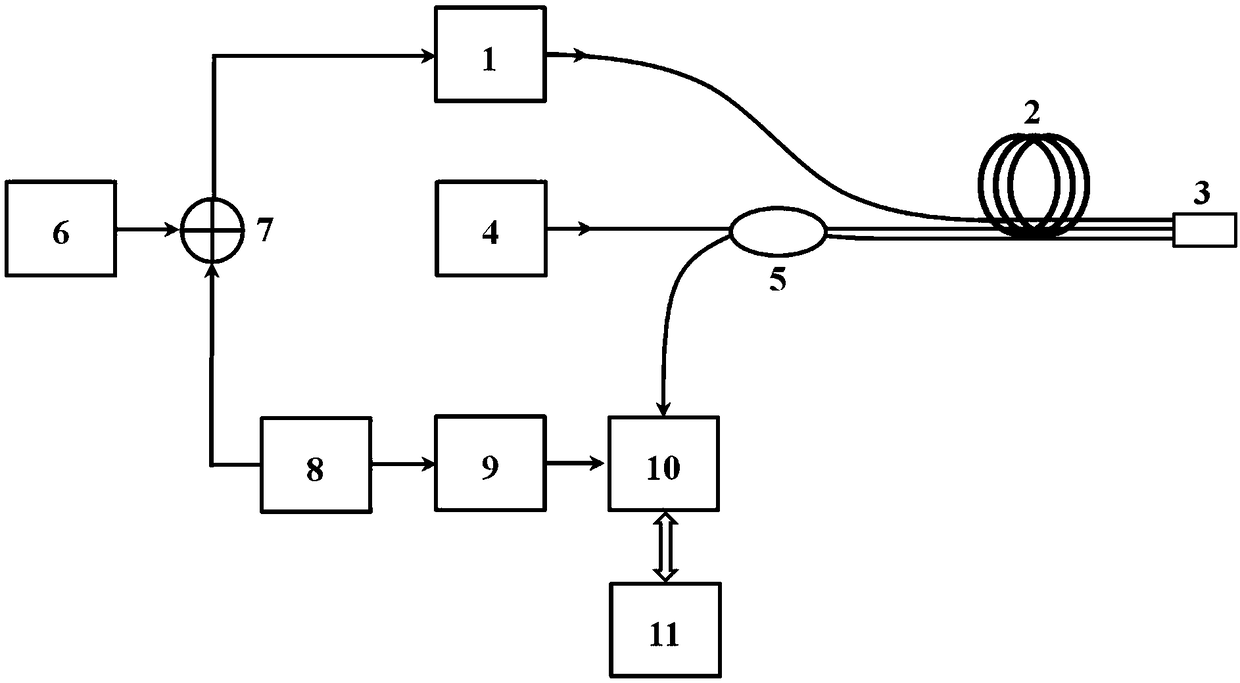

Optical fiber remote-detection type multifunctional gas leakage listening instrument and method

ActiveCN109115688AReduce measurement impactSimple structureSubsonic/sonic/ultrasonic wave measurementMaterial analysis by optical meansEnvironmental noiseNose

The invention discloses an optical fiber remote-detection type multifunctional gas leakage listening instrument and method and belongs to the technical field of optical fiber sensing and gas detection. The instrument comprises a laser light source, an optical cable, an optical fiber leakage listening probe, a broadband light source, an optical fiber coupler, a serrated signal generator, an adder,a sinusoidal signal generator, a phase-locked loop, a spectrometer and an industrial control computer. The optical fiber leakage listening probe is of a double-cantilever-beam structure, is used for directly detecting acoustic wave signals generated by leakage of gas, can reduce the influence of environmental noise and vibration on measurement of photoacoustic signals with combination of an activenoise reduction technology, and meanwhile achieves high-sensitivity and high-reliability measurement of the concentration of the gas, namely, the optical fiber leakage listening probe has an opticalear function and an optical nose function. By designing two optical fiber extrinsic Fabry-Perot interferometers with the different cavity lengths, simultaneous non-interference demodulation can be conducted on two cantilever beam acoustic sensors through one spectrometer, so that the system structure is simplified. The optical fiber remote-detection type multifunctional gas leakage listening instrument provided by the invention has the advantages of remote detection and intrinsic safety.

Owner:DALIAN UNIV OF TECH

Device for detecting resisting force of lift cabin door in opening or closing process

InactiveCN101343011ASolving Measurement ErrorsReduce the impactForce measurementElevatorsMeasurement deviceData acquisition

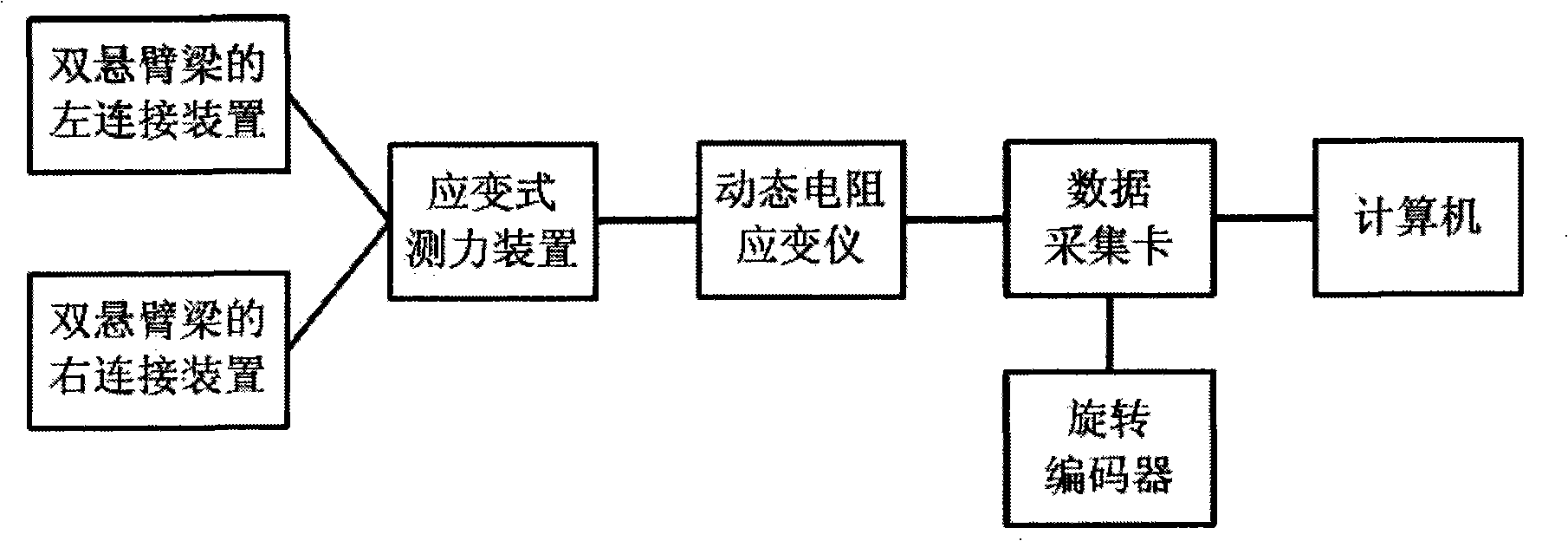

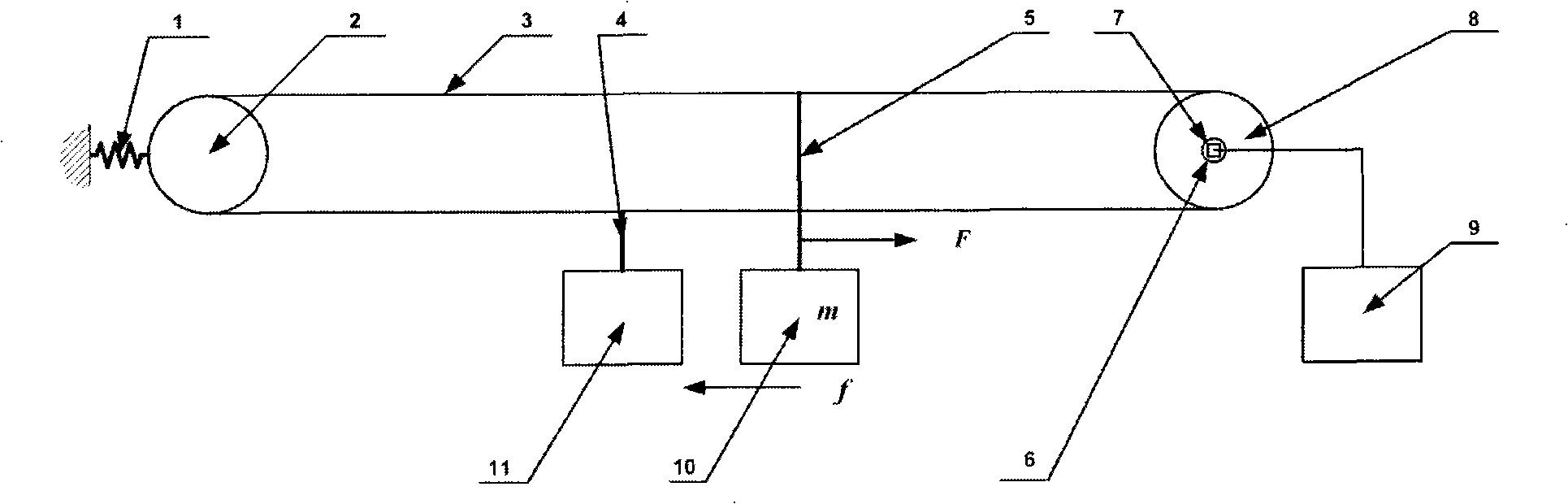

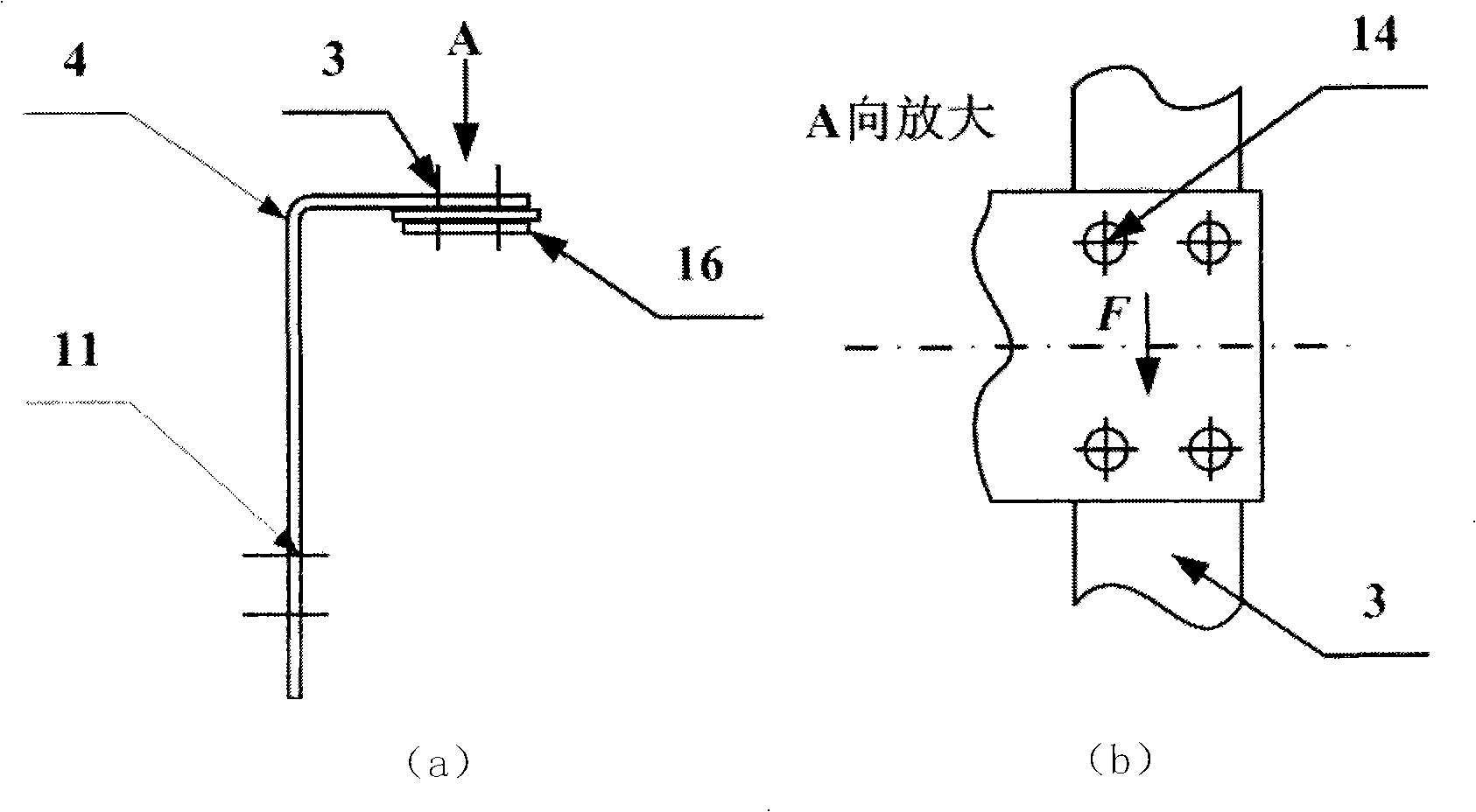

Disclosed is a resistance detection device used for the opening and closing process of the elevator door in the elevator detection technical field. In the invention, the left connecting device and the right connecting device of a double cantilever beam are arranged between a simultaneous tooth-shaped belt and a hanging plate; the left connecting device and the right connecting device of the double cantilever beam are respectively provided with strain force measurement devices; the strain force measurement devices measure the drive force applied on the connecting devices and send to a dynamic strain meter; the dynamic strain meter amplifies the signal and outputs the signal to a data acquisition card; a rotation encoder is mounted on the shaft of a permanent magnet synchronous motor in the elevator; the position information of the motor shaft is collected and transmitted to the data acquisition card; the computer processes the derivative operation towards the position information of the motor shaft in the data acquisition card to obtain the speed and acceleration values at any position during the opening and closing process; the resistance of the opening and closing of the elevator door is figured out according to the acceleration and drive force values. The resistance detection device in the implementation embodiment has the advantages of high sensitivity, easy calibration, being influenced by the environmental temperature and the humidity slightly and stable output signal.

Owner:SHANGHAI JIAO TONG UNIV

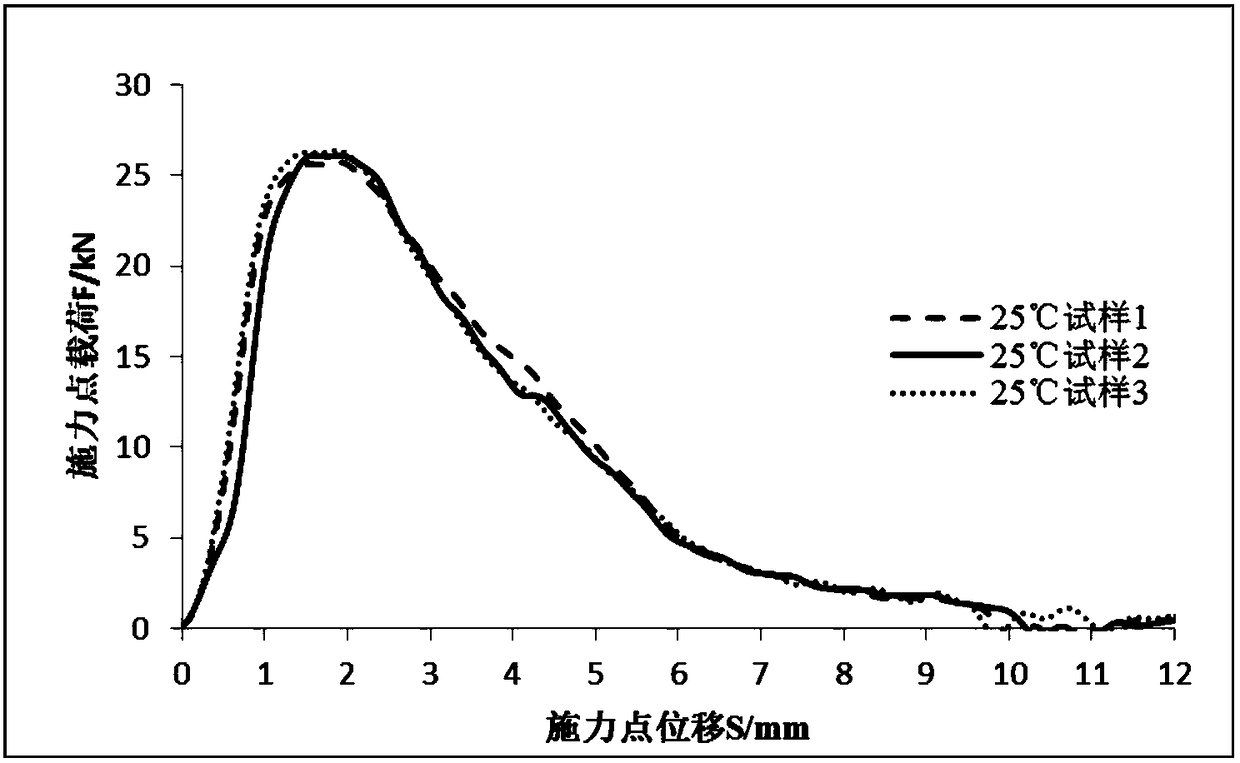

Prediction method for mixed type delamination resistance curve of composite

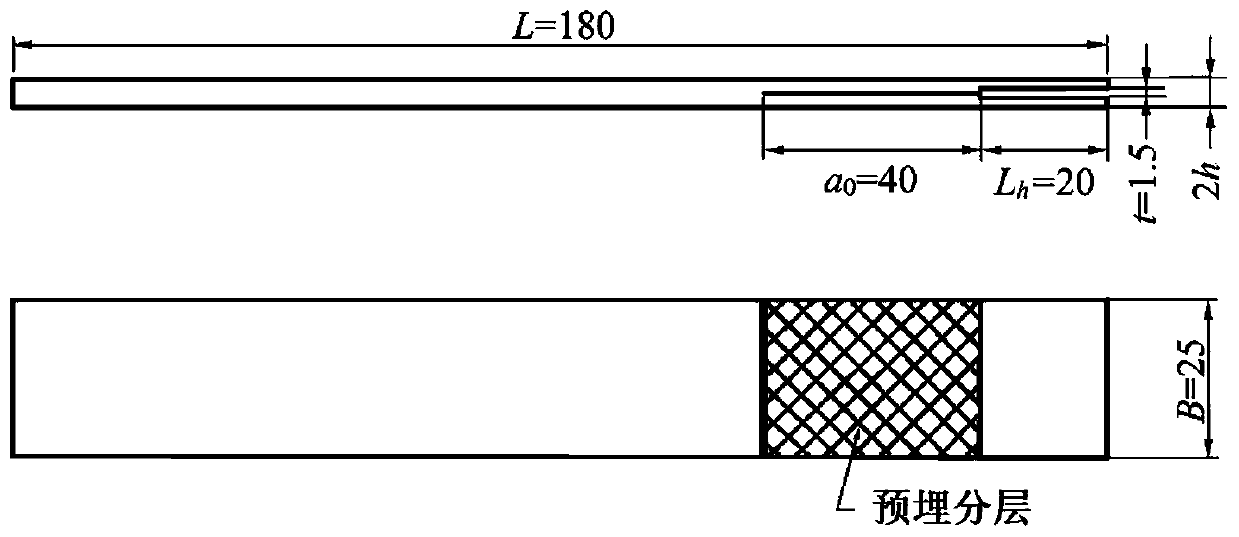

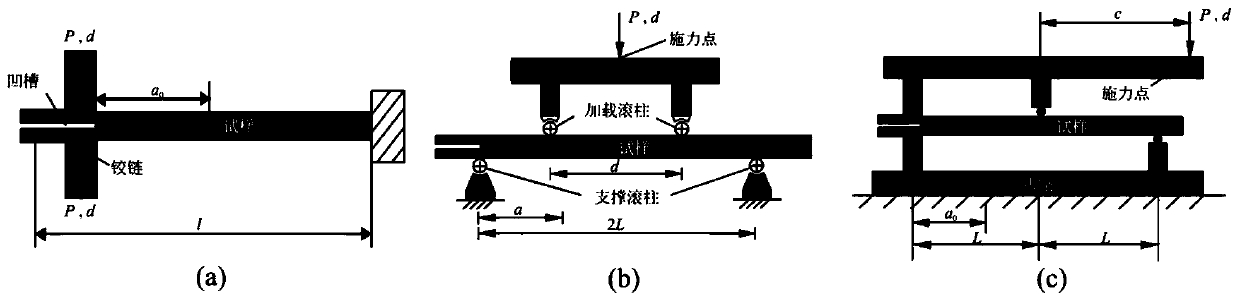

InactiveCN109991077APromote engineering applicationReduce workloadMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesHybrid typeFiber-reinforced composite

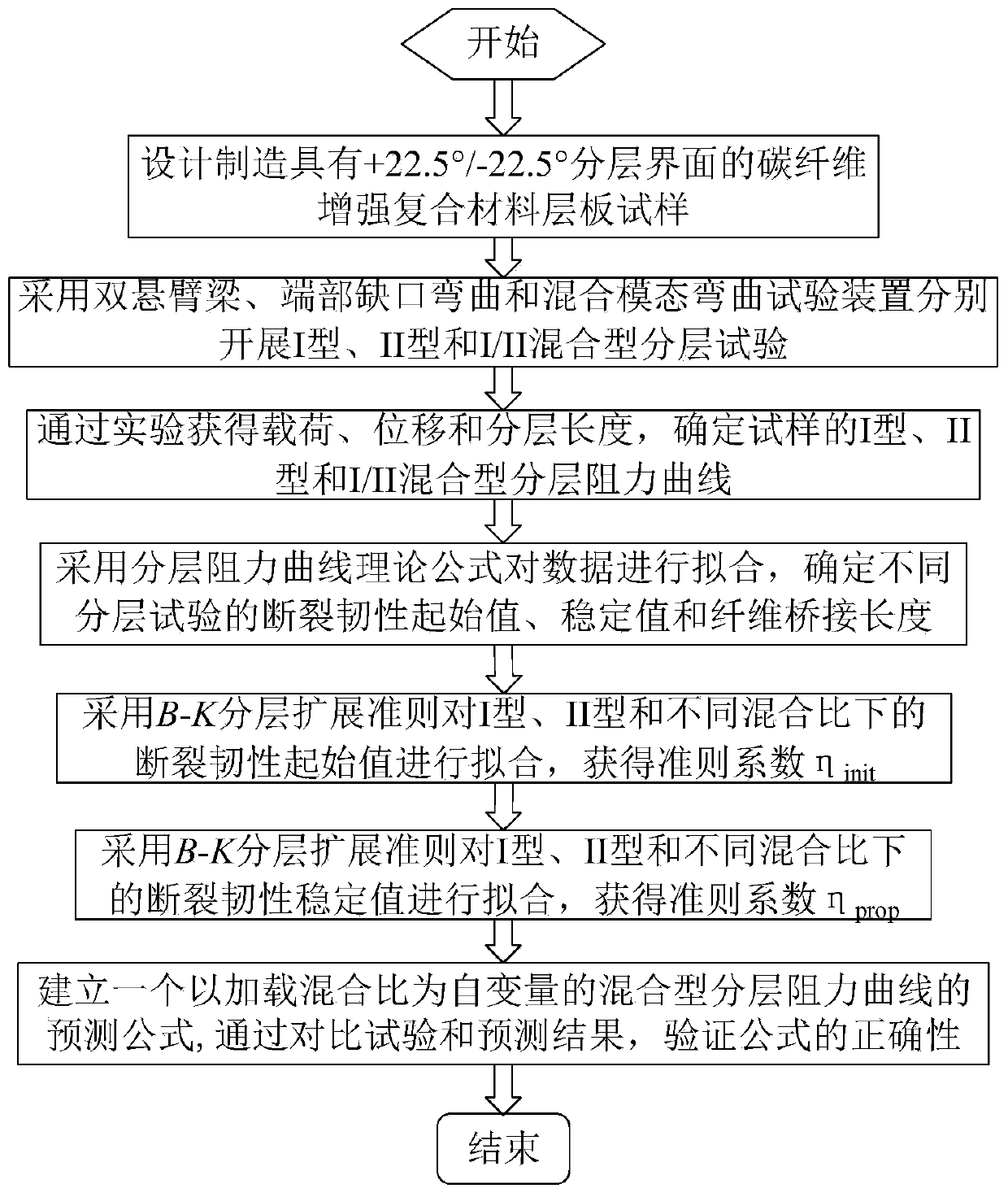

The invention relates to a prediction method for a mixed type delamination resistance curve of a composite. The prediction method comprises the following steps: (1) designing and manufacturing a carbon fiber reinforced composite laminate sample; (2) respectively carrying out an I type delamination experiment, an II type delamination experiment and an I / II mixed type delamination experiment by adopting a double cantilever beam, an end part notch bending device and a mixed mode bending device; (3) determining an I type delamination resistance curve, an II type delamination resistance curve and an I / II mixed type delamination resistance curve of the sample; (4) fitting data by adopting a delamination resistance curve theoretical formula, and determining fracture toughness initial values and stable values as well as fiber bridging lengths of different delamination experiments; (5) respectively fitting the fracture toughness initial values and stable values at different mixing ratios by adopting a B-K criterion, so that criterion coefficients etainit and etaprop are obtained; and (6) establishing a mixed type delamination resistance curve prediction formula with a loading mixing ratio as an independent variable. The prediction method provided by the invention predicts a delamination resistance curve at any other mixing ratio by virtue of delamination fracture toughness testing on acarbon fiber reinforced composite laminate at a specific mixing ratio, is convenient for engineering application and can reduce experimental cost.

Owner:CHONGQING UNIV

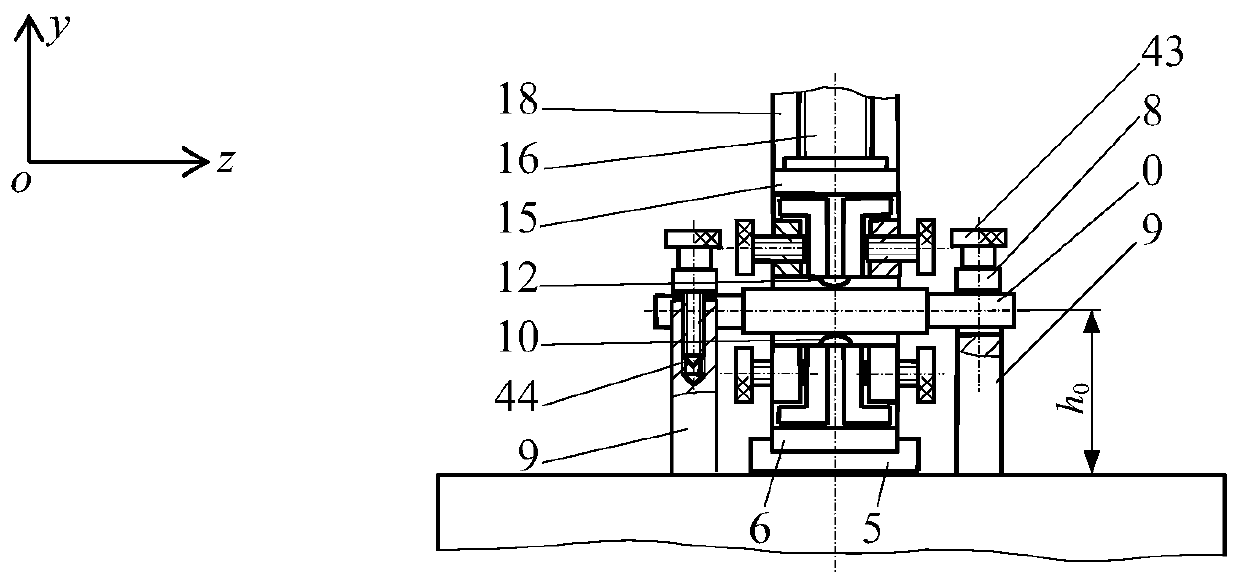

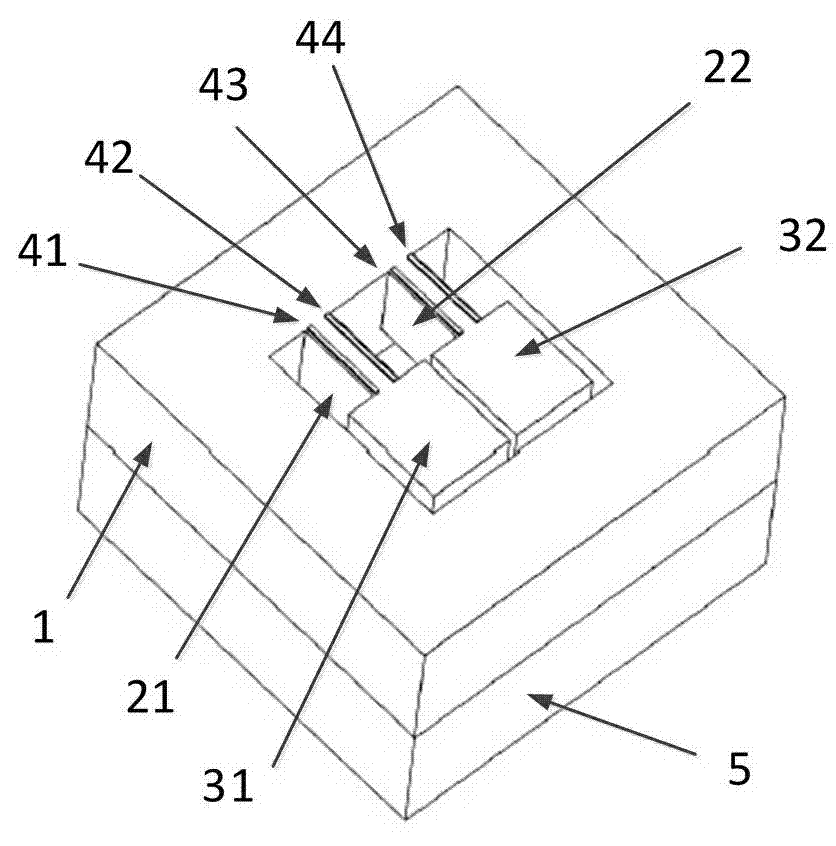

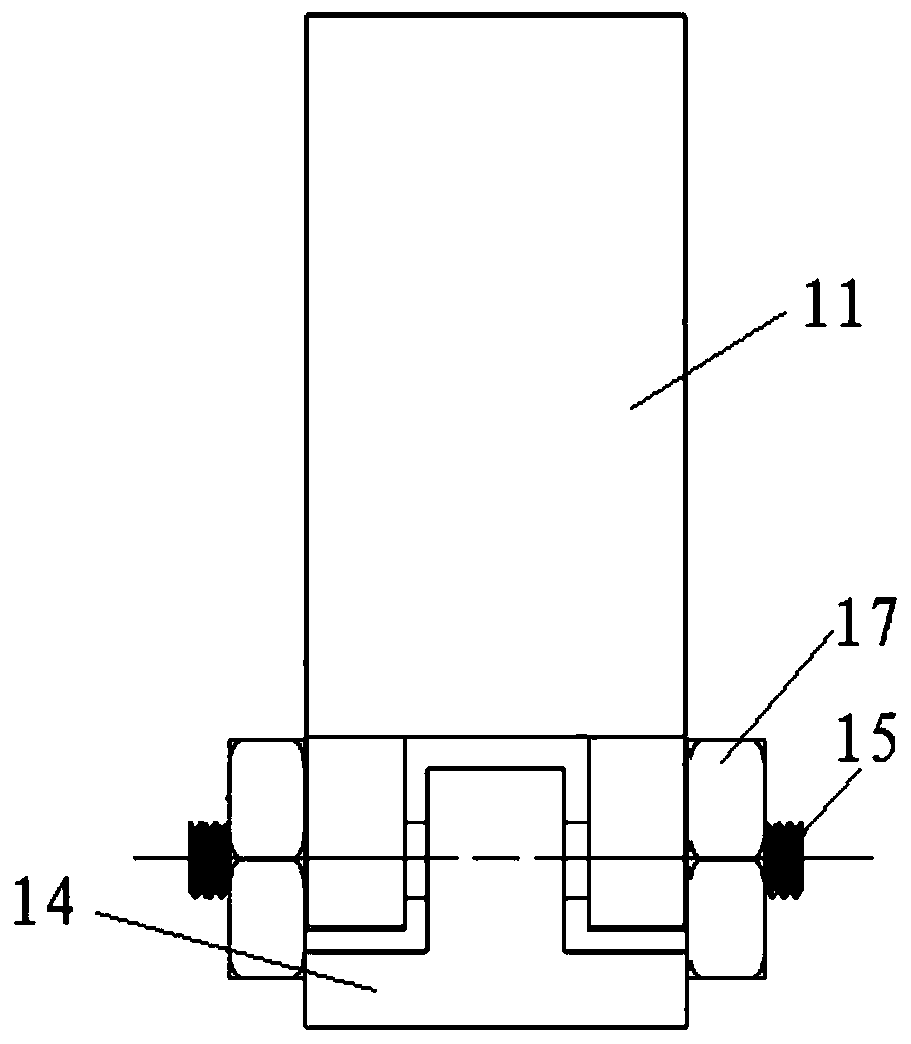

Method and device for measuring diameter through cantilever beam sensor and coding lead screw

ActiveCN110631466AIncrease rangeHas the ability to distinguishElectrical/magnetic diameter measurementsCantilevered beamData acquisition

The invention discloses a method and a device for measuring the diameter through a cantilever beam sensor and a coding lead screw. The device comprises a measurement host, an auxiliary positioning mechanism, a standard, a positioning block, a tested piece and a data acquisition-analysis-processing unit. The measurement host is composed of a base, a coding lead screw and a double-cantilever beam sensor. The coding lead screw is composed of a transmission lead screw and a three-state coder. The three-state coder is composed of a fluted disc and four pairs of cantilever beam sensors. The double-cantilever beam sensor is composed of a fixed cantilever beam sensor and a movable cantilever beam sensor. And system calibration, data analysis and error correction software is arranged in the data acquisition-analysis-processing unit. During measurement, the double-cantilever beam sensor clamps the tested piece and is matched with the coding lead screw to transmit a measurement signal to the dataacquisition-analysis-processing unit, and the data acquisition-analysis-processing unit gives a diameter value of the tested piece.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

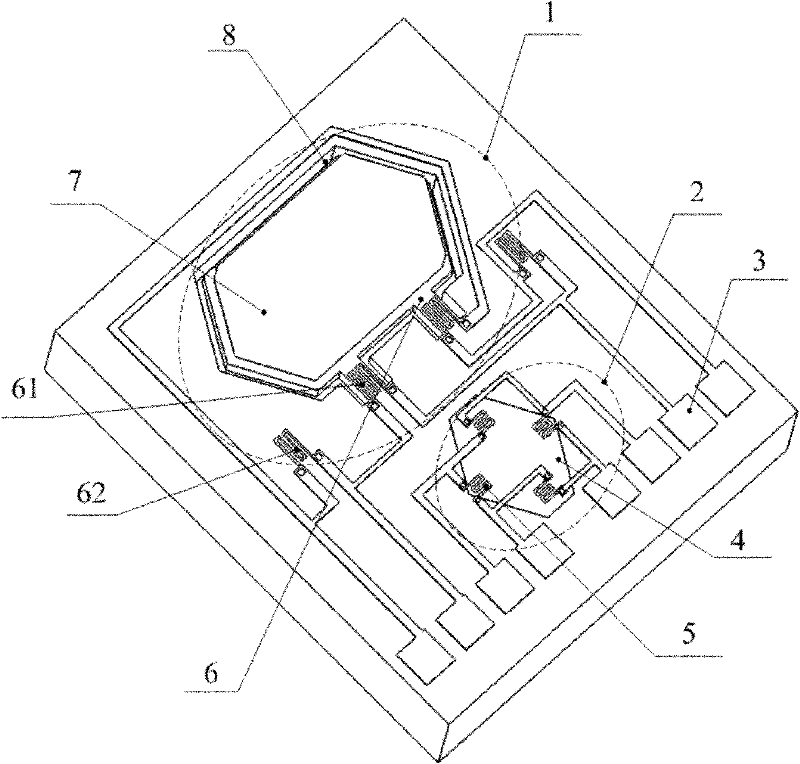

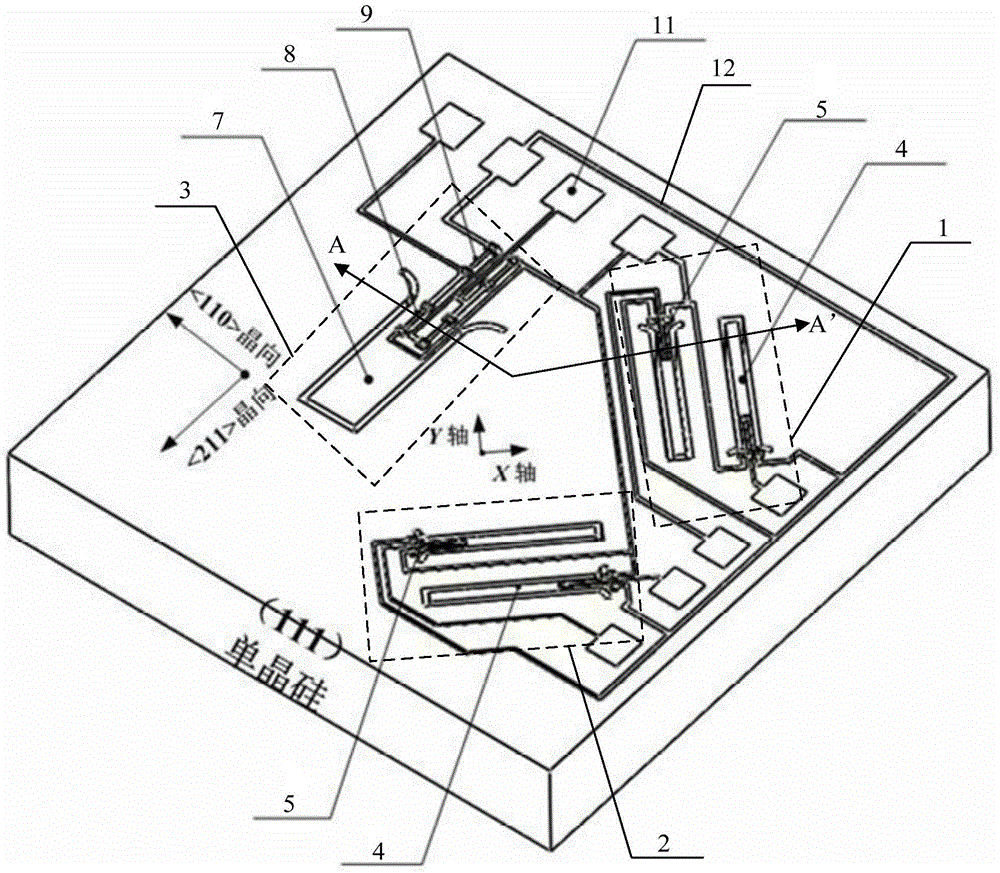

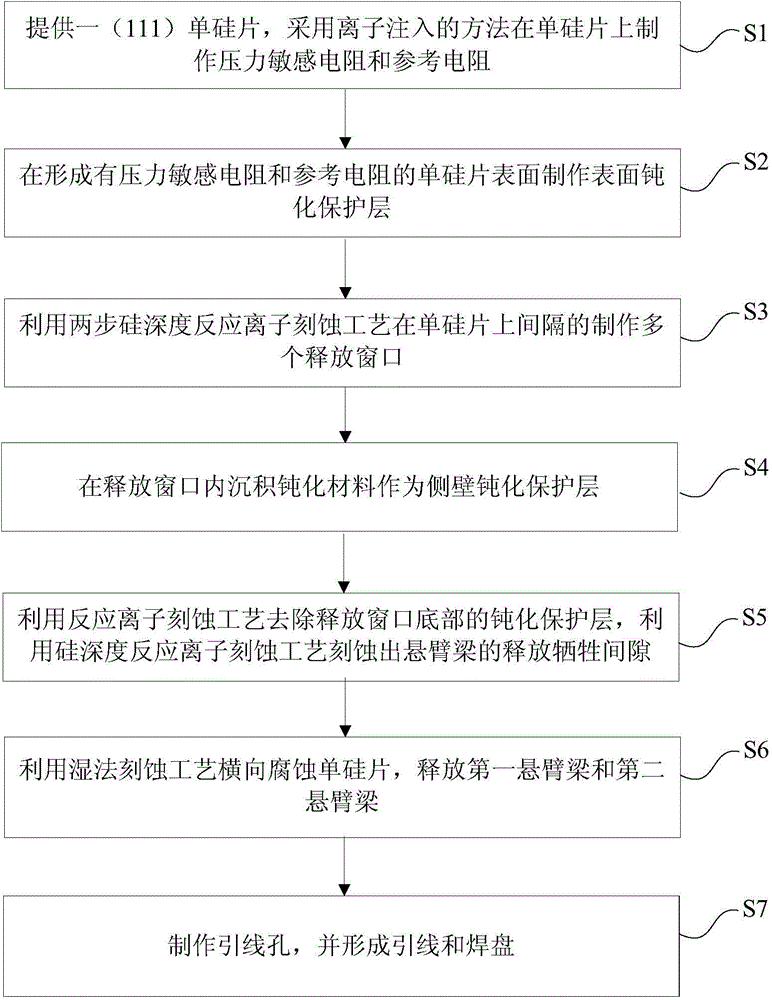

(111) single silicon wafer-integrated three-axis micromechanical acceleration sensor and manufacturing method

ActiveCN104483511AImproved dynamic output characteristicsReduce manufacturing costAcceleration measurement using interia forcesDecorative surface effectsCantilevered beamSelective leaching

The invention provides a (111) single silicon wafer-integrated three-axis micromechanical acceleration sensor and a manufacturing method. According to the three-axis acceleration sensor, a single-silicon wafer single-surface body silicon micromechanical process is adopted, and the three-axis acceleration sensor can be molded with one step on the same surface of a (111) single silicon wafer; acceleration sensor units at the directions of an X axis and a Y axis are of double-cantilever beam structures; an acceleration sensor unit at the direction of a Z axis is of a single-cantilever beam structure; and one-step release molding of the cantilever beam structures of different sizes can be realized through selectively corroding the interior of the substrate of the single silicon wafer; and squeeze-film damping and overload protection at the sensitive direction of the acceleration sensor unit at the direction of the Z axis can be adjusted through movable clearances buried at the interior of the substrate of the single silicon wafer, and therefore, problems such as residual stress, poor anti-impact strength and high production cost which are caused by multi-chip bonding of a traditional multi-axis sensor can be solved. The single silicon wafer-integrated three-axis micromechanical acceleration sensor has the advantages of small size, low cost, high processing compatibility, suitability for high-g value acceleration measurement and bright application prospect.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

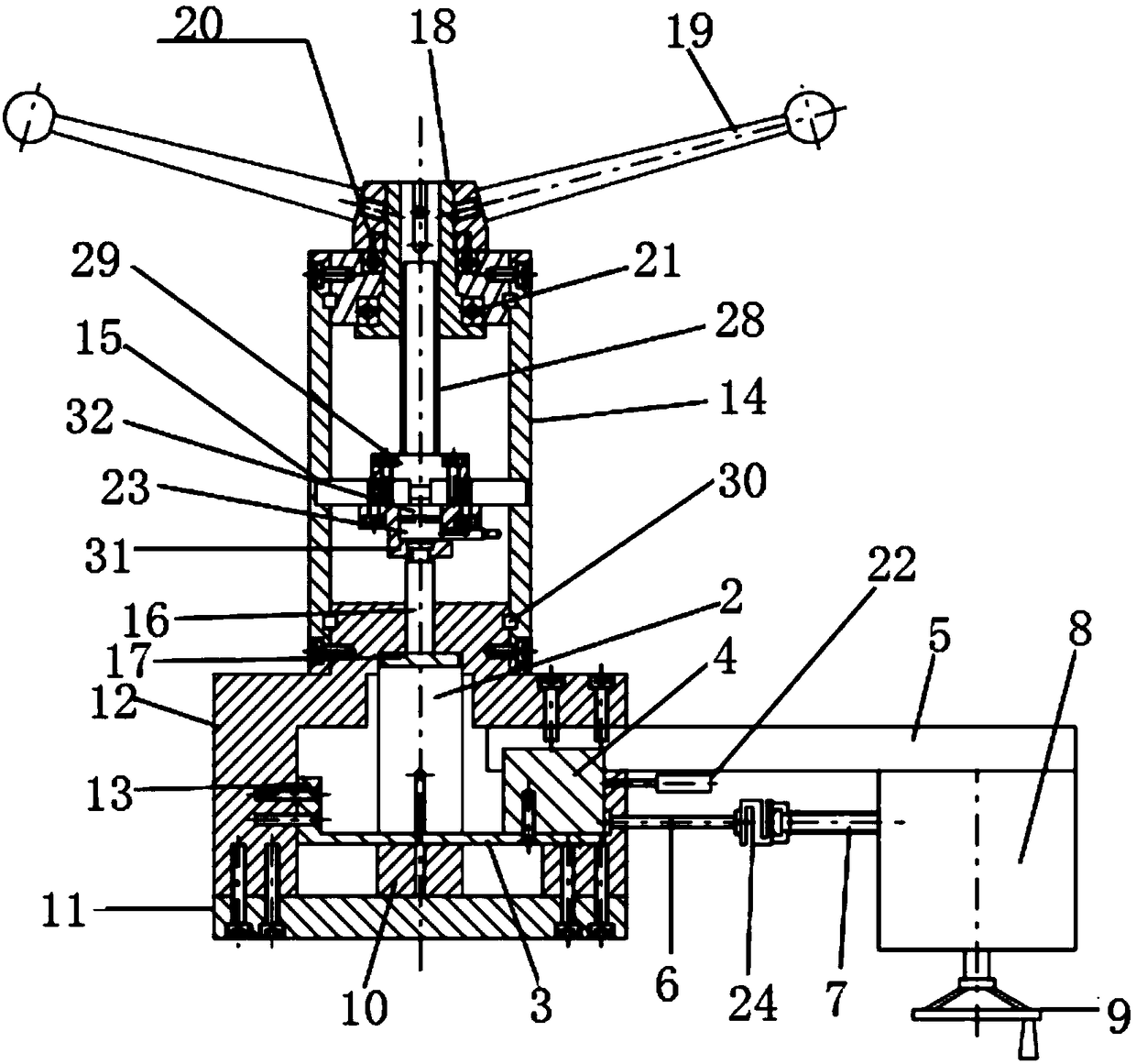

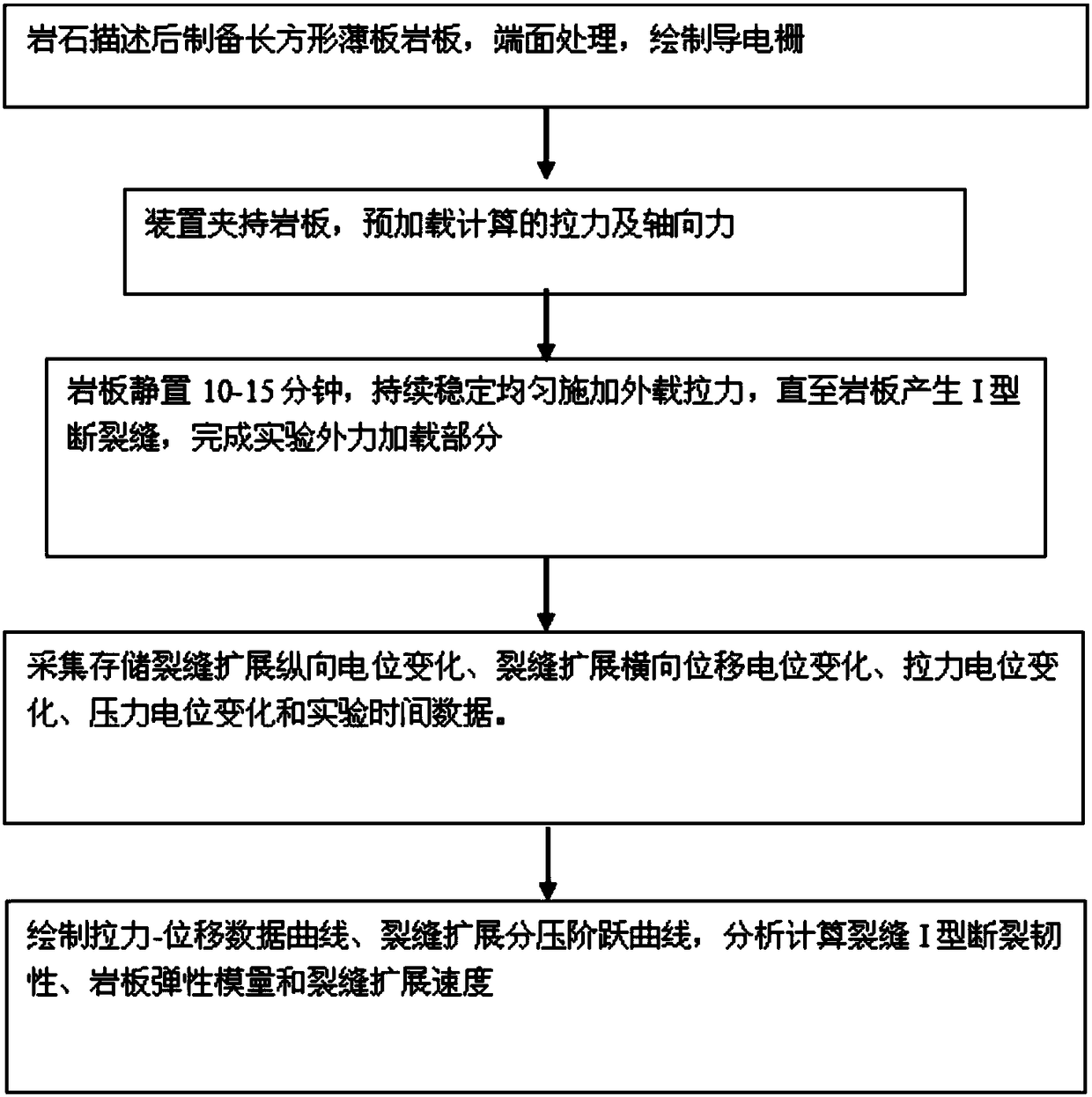

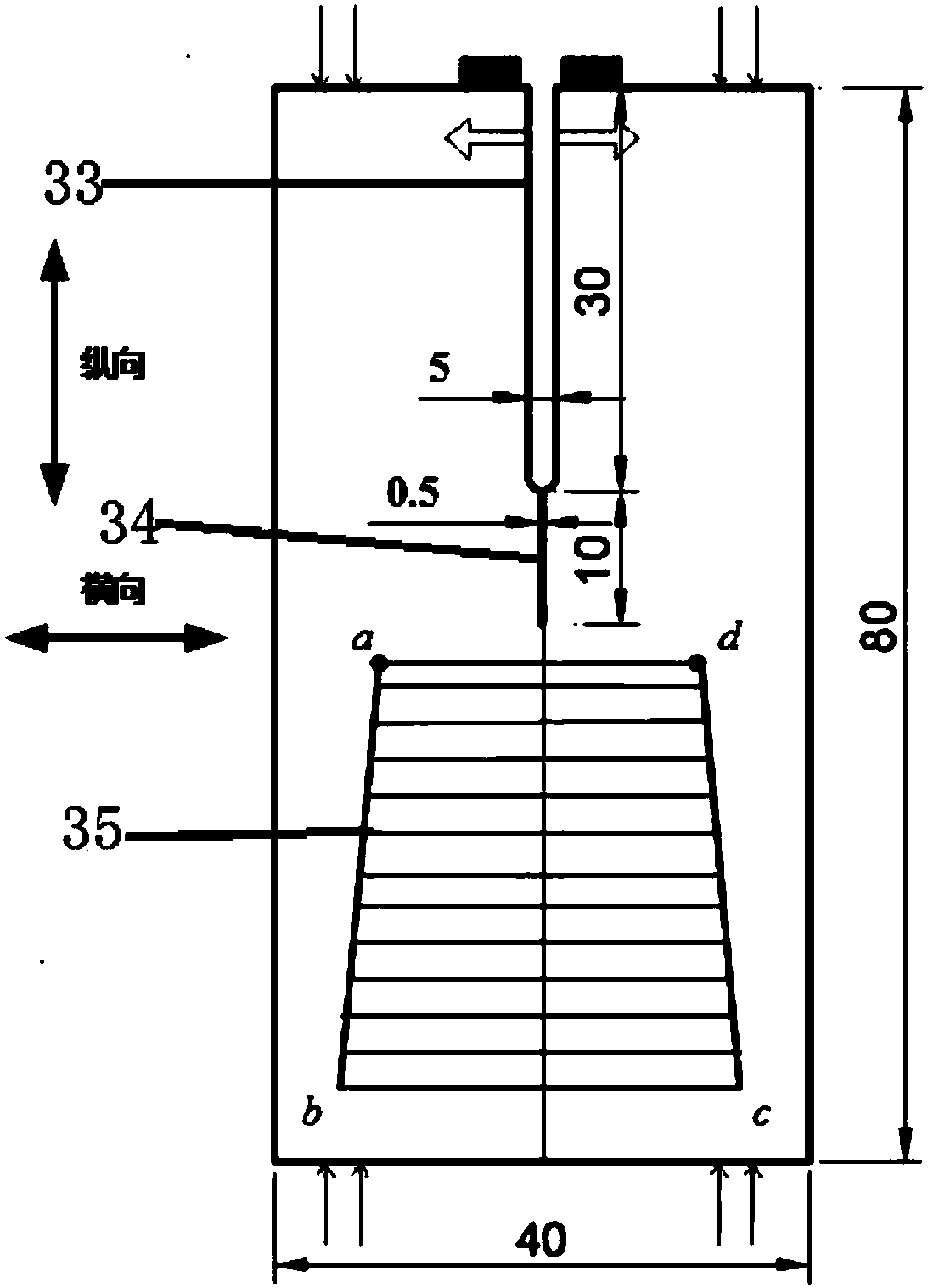

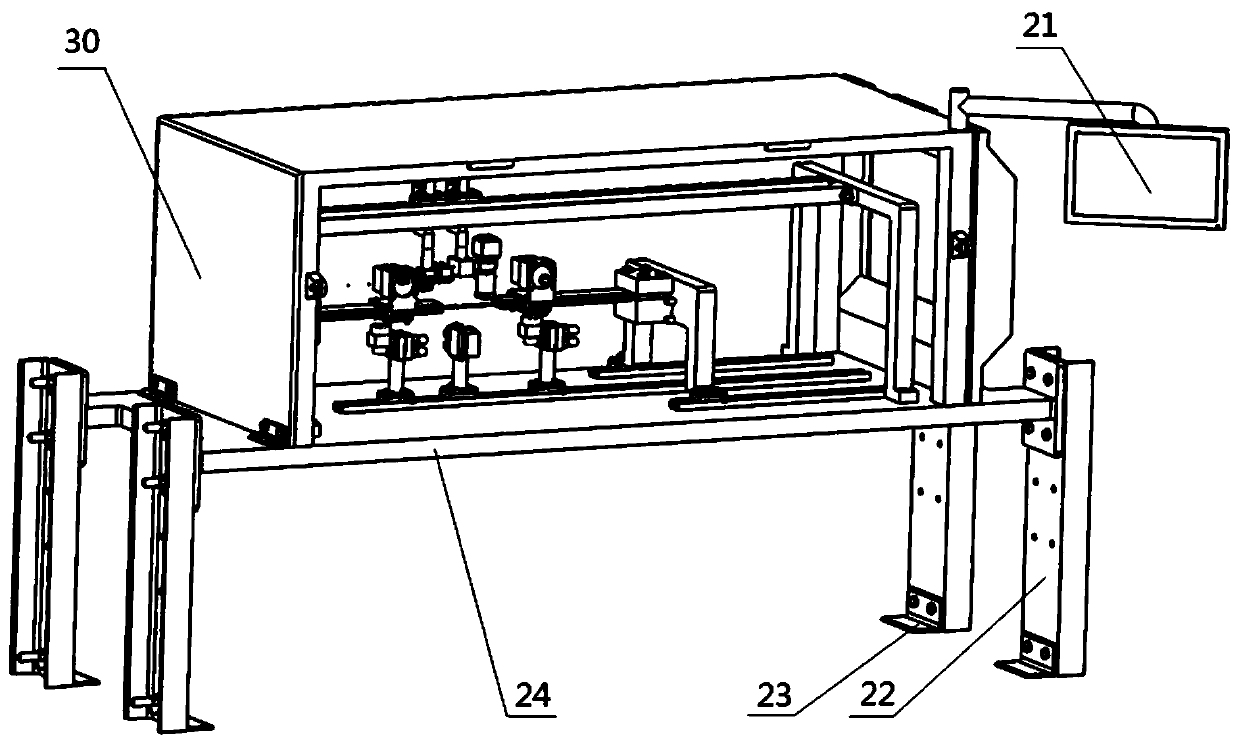

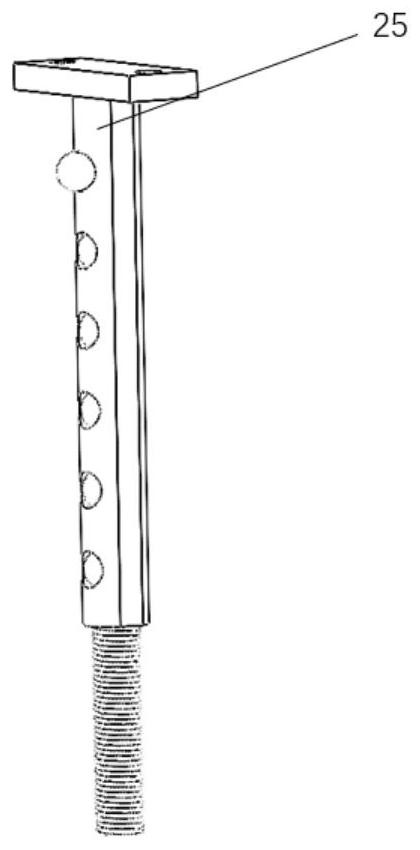

DCB (double-cantilever beam) fracture toughness testing device

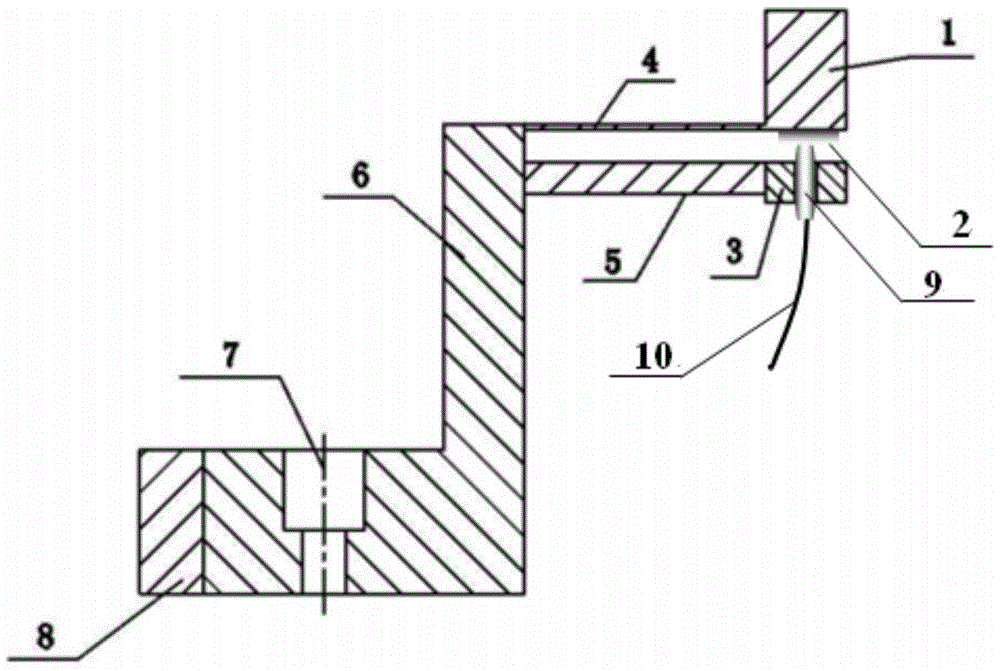

ActiveCN108303314AEasy to operateSimple structurePreparing sample for investigationMaterial strength using tensile/compressive forcesPressure transmissionCollection system

The invention discloses a DCB (double-cantilever beam) fracture toughness testing device. The device comprises a mechanical transmission system, an electronic collection system and a data terminal processing system, wherein the electronic collection system is connected with the mechanical transmission system and the data terminal processing system; the mechanical transmission system comprises a sample clamping component, a tension transmission mechanism and a pressure transmission mechanism; the electronic collection system comprises a potential data collection card, an LVDT (linear variable differential transformer) displacement sensor, a pressure sensor and a tension sensor; the data terminal processing system is used for processing, filtering and sampling the collected data. The DCB fracture toughness testing device is simple, easy to understand and convenient to operate, a test result is accurate, data such as extension speed, cracking displacement, extension length and the like ofa type I fracture can be recorded and measured effectively, and a method foundation is provided for design research of rock fracture toughness.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

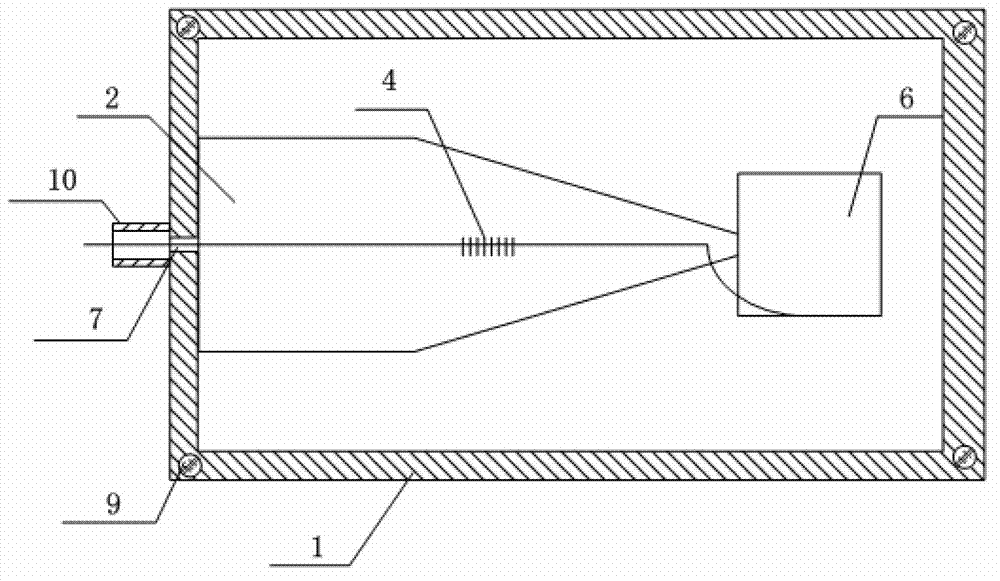

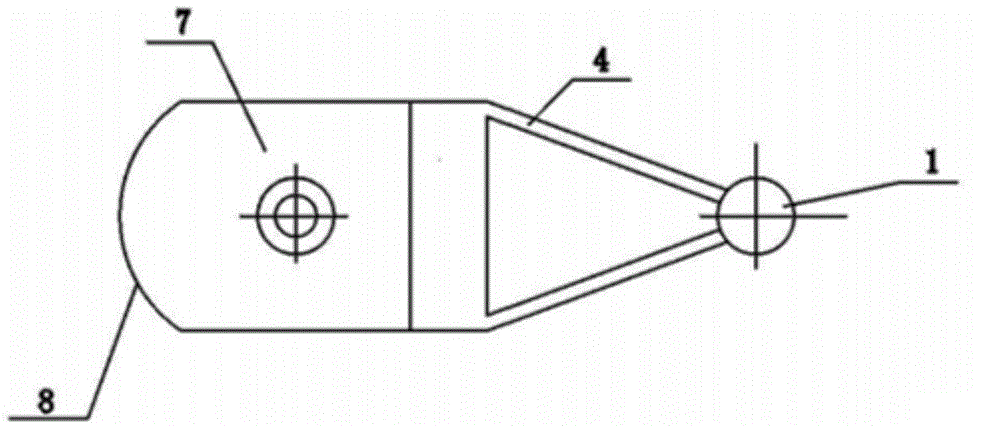

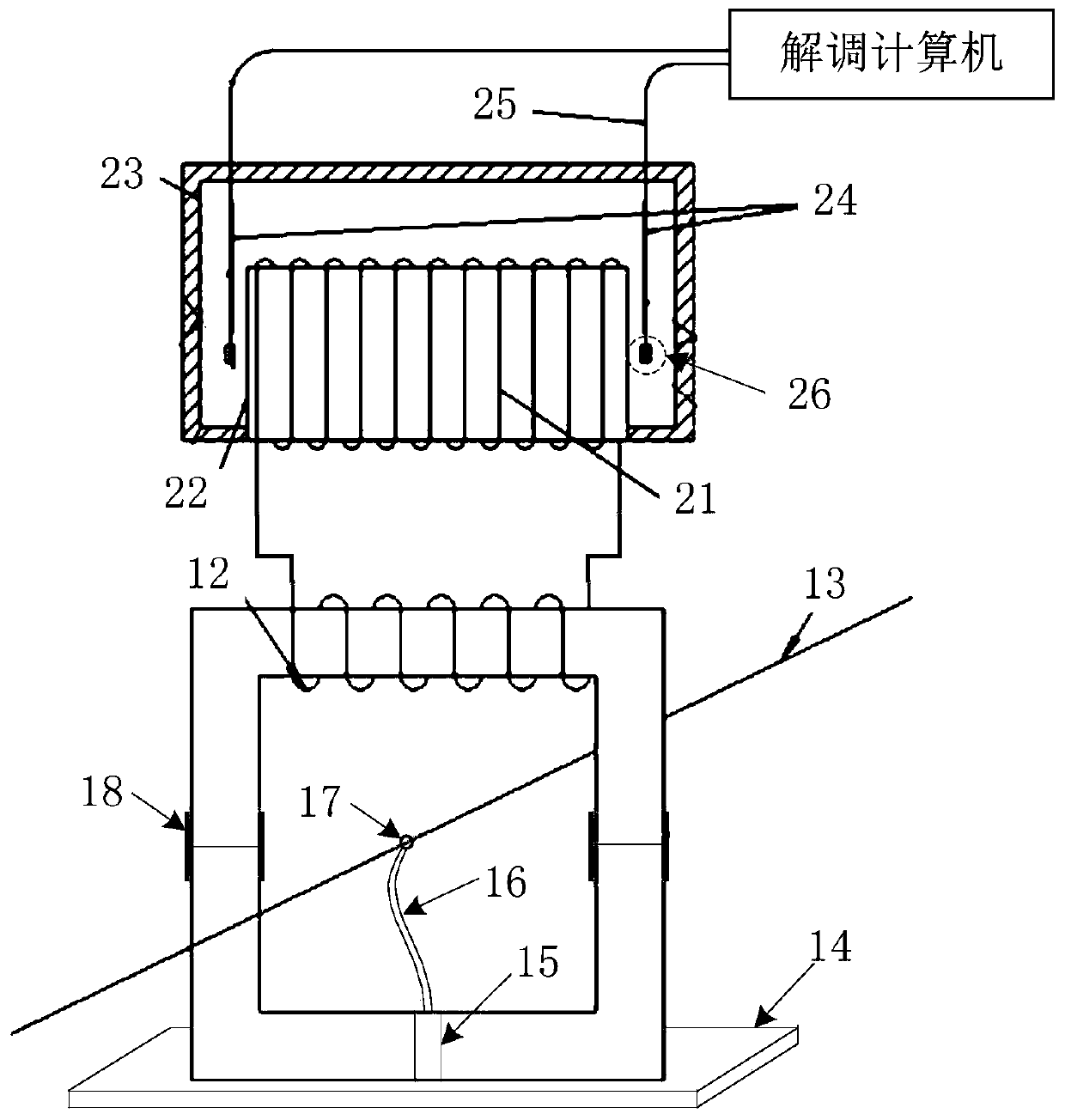

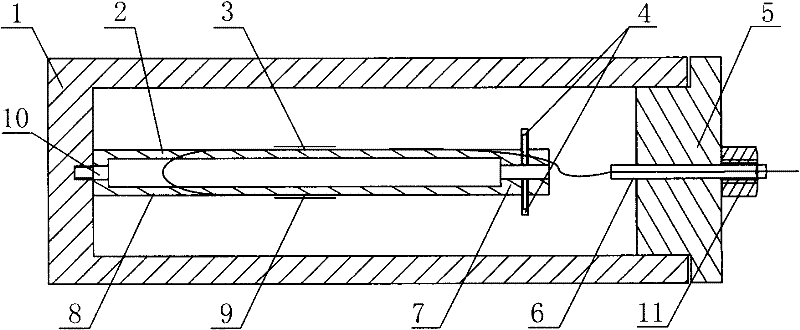

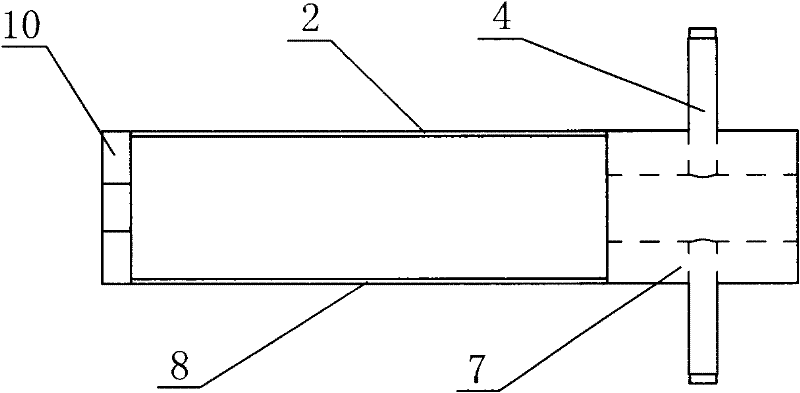

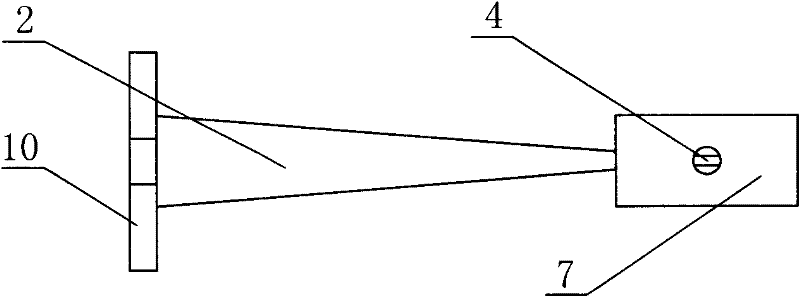

Differential type optical fiber F-P vibrating sensor with wide frequency response and high sensitivity

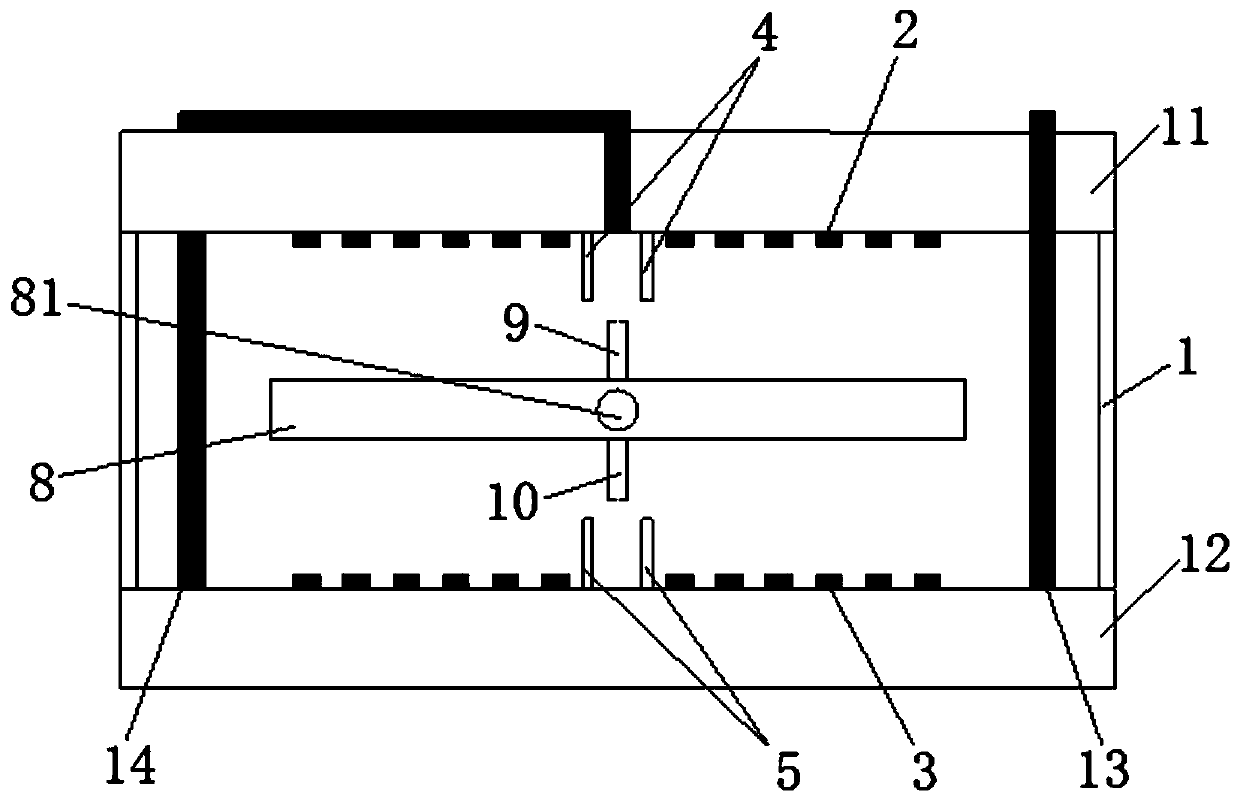

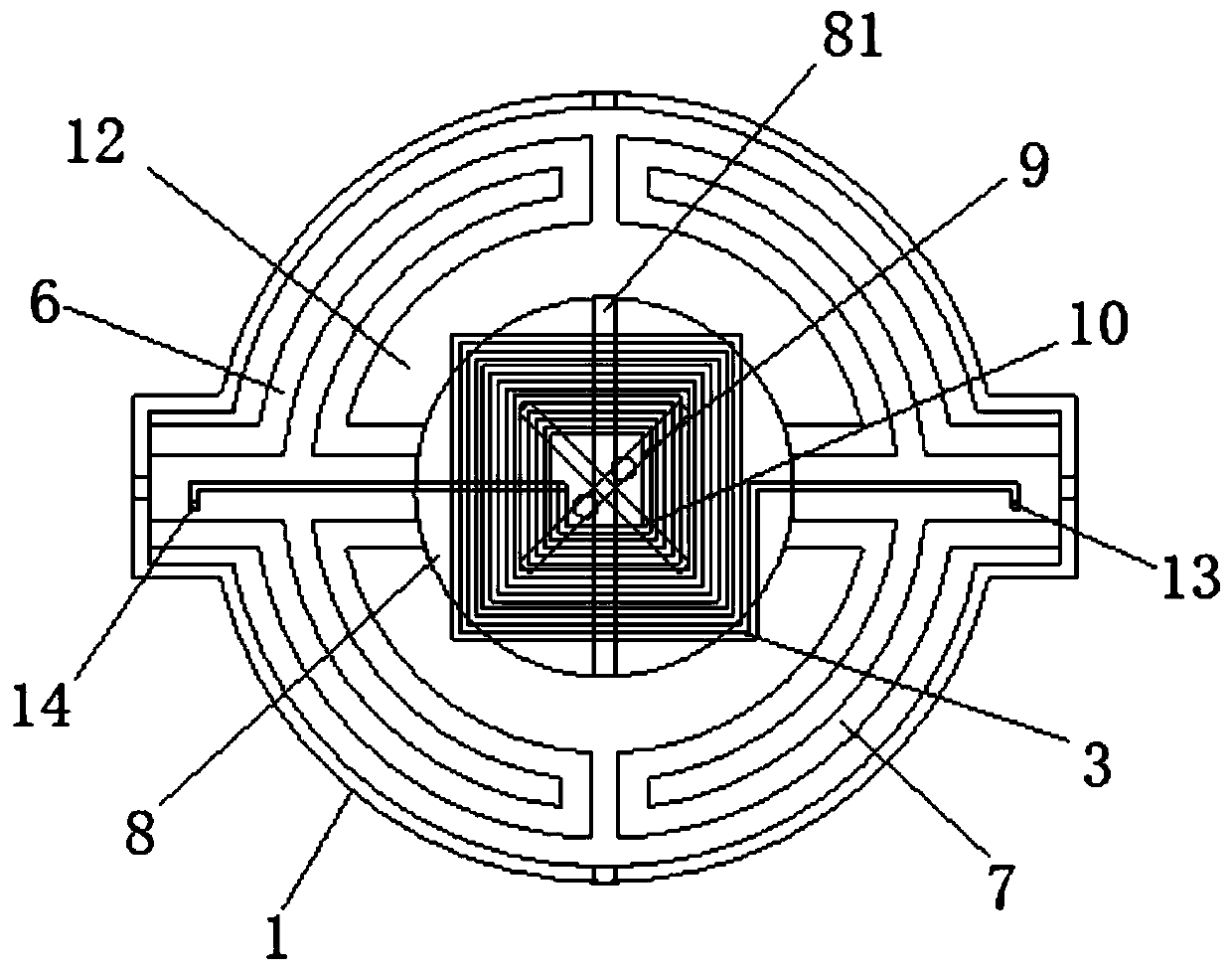

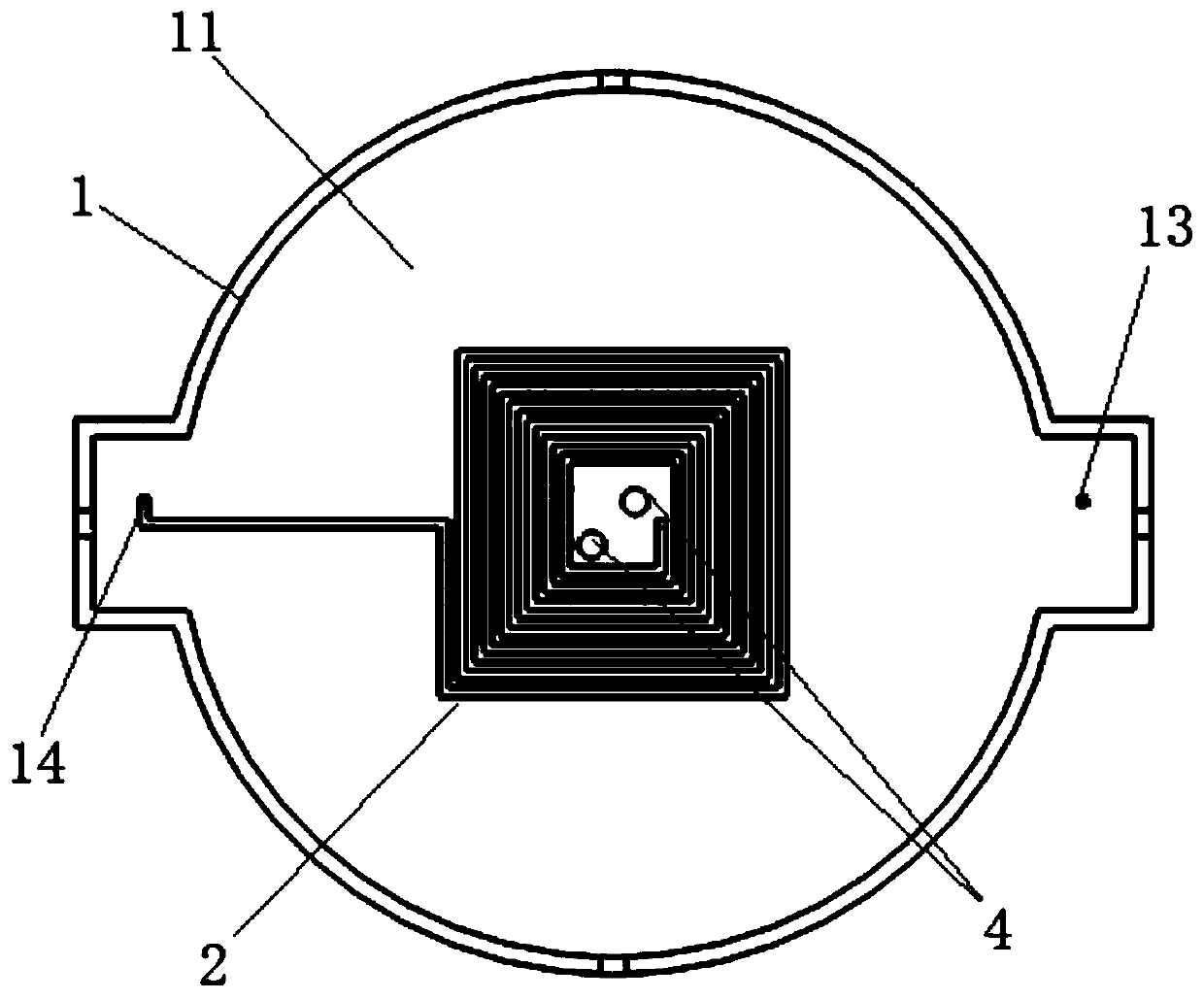

ActiveCN104568117ASimple structureEnsure vibrationSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberResponse Frequency

The invention discloses a differential type optical fiber F-P vibrating sensor with a wide frequency response and high sensitivity. The differential type optical fiber F-P vibrating sensor is mainly composed of a balance weight body (1), a reflector (2), a first V-shaped cantilever beam (4), a second V-shaped cantilever beam (5), a fixed base (6), a packaging box contact position (8), an optical fiber micro lens (9) and a tail fiber (10). Response frequency and sensitivity of the first V-shaped cantilever beam and the second V-shaped cantilever beam compensate each other, the sensor is high in sensitivity, and the frequency response range reaches 50 Hz-10,000 Hz. When external vibration acts on an F-P cavity through the action of the double cantilever beams of the sensor, a reflecting light signal changes along with the reciprocating change of the balance weight body, and therefore an optical light reflected back by the F-P cavity is changed, and external vibration parameters are obtained by measuring the change amount of the signal. The differential type optical fiber F-P vibrating sensor is simple in structure and convenient to use, the optical signal is not interfered with an electromagnetic field, and the sensor can work quite effectively and precisely, and is simple in structure and low in cost.

Owner:WUHAN UNIV OF TECH

Suspended unbalanced dynamic tension sensor

InactiveCN105203239ANo fixed installation requiredAvoid ablationForce measurementCantilevered beamDynamic Tension

The invention discloses a suspended unbalanced dynamic tension sensor. Through double cantilever beam structures and by adopting strain gauges for indirect measurement and roller design, the friction can be reduced during instant large tension measurement, and the phenomenon that a measured rope belt is burnt after being heated is effectively prevented; in addition, the unbalanced suspended structural design is adopted, so that the suspended unbalanced dynamic tension sensor is not required to be fixed on a base during measurement, on one hand, the fact that the rope belt doses not fall off to avoid measurement failure during a measuring process is guaranteed, and on the other hand, bad influences of non-uniform force during dynamic measurement are eliminated effectively and the accuracy during dynamic measurement is ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

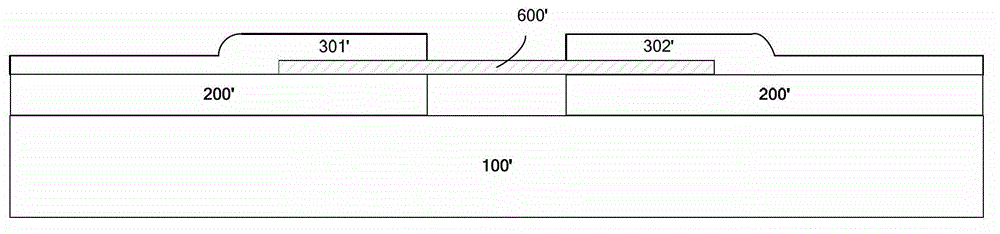

Double-cantilever-beam MEMS (Micro-electromechanical System) device based on inversion process and forming method thereof

ActiveCN102862949AGuaranteed accuracyAvoid contaminationDecorative surface effectsChemical vapor deposition coatingDouble cantilever beamMedia layer

The invention discloses a double-cantilever-beam MEMS (Micro-electromechanical System) device based on an inversion process and a forming method thereof. The method comprises the following steps of: providing a substrate; forming a transition layer, a bottom layer electrode and an interlaminar medium layer on the substrate in sequence; forming an upper electrode layer on the interlaminar medium layer; etching the upper electrode layer and the interlaminar medium layer to form an opening for exposing a part of the bottom layer electrode, and forming a first upper layer electrode and a second upper layer electrode by using the upper electrode layer; forming a two-dimensional material film on the first upper layer electrode and the second upper layer electrode, wherein the two-dimensional material film crosses the opening; and forming a first metal contact and a second metal contact above the two ends of the two-dimensional material film respectively, wherein the first metal contact is connected with at least one part of the first upper layer electrode, and the second metal contact is connected with at least one part of the second upper layer electrode. The method disclosed by the invention has the advantages of mature process, easiness in implementing, small device contact resistance, stability and reliability.

Owner:TSINGHUA UNIV

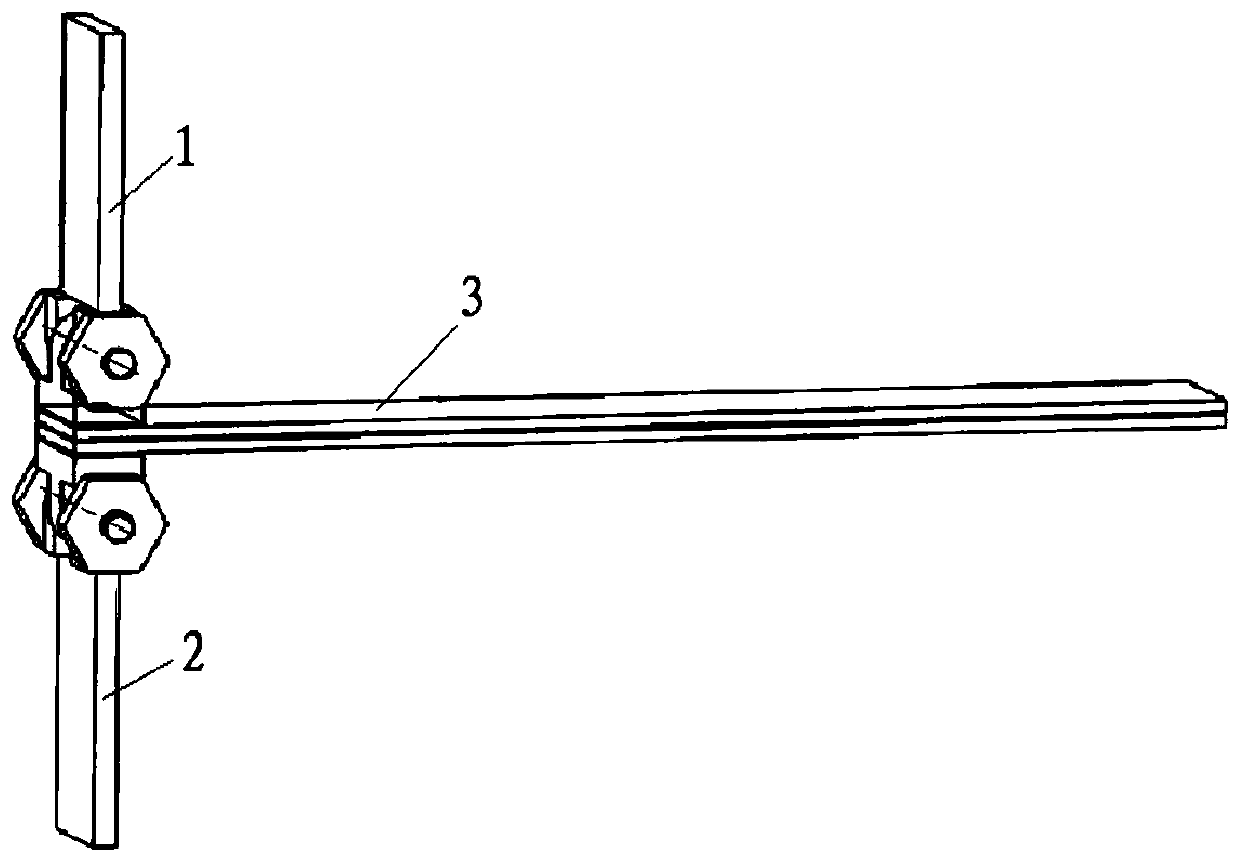

Double cantilever beam-coding screw rod composite sensing tensile test method and device

PendingCN110567807AGuaranteed accuracyFull use of precisionMaterial strength using tensile/compressive forcesNumerical controlMicrocomputer

The invention discloses a double cantilever beam-coding screw rod composite sensing tensile test method and device. The test device comprises a main machine, an etalon, a tested piece and a microcomputer numerical control unit. A force-deformation composite sensing mechanism composed of double cantilever-beam sensors, an encoding lead screw and a driving device serves as the main machine, the double cantilever-beam sensors include a fixed cantilever beam sensor and a movable cantilever beam sensor, and the encoding lead screw is composed of a transmission lead screw and a three-state encoder.The double cantilever-beam sensors cooperate with the encoding lead screw to realize functions of clamping, force sensing and deformation sensing of the test piece, and the size of the test piece canbe measured. When a system works, the force-deformation composite sensing mechanism is controlled by the microcomputer numerical control unit to load the test piece, and outputs a load-deformation signal of the test piece to the microcomputer numerical control unit in real time.

Owner:YANTAI UNIV

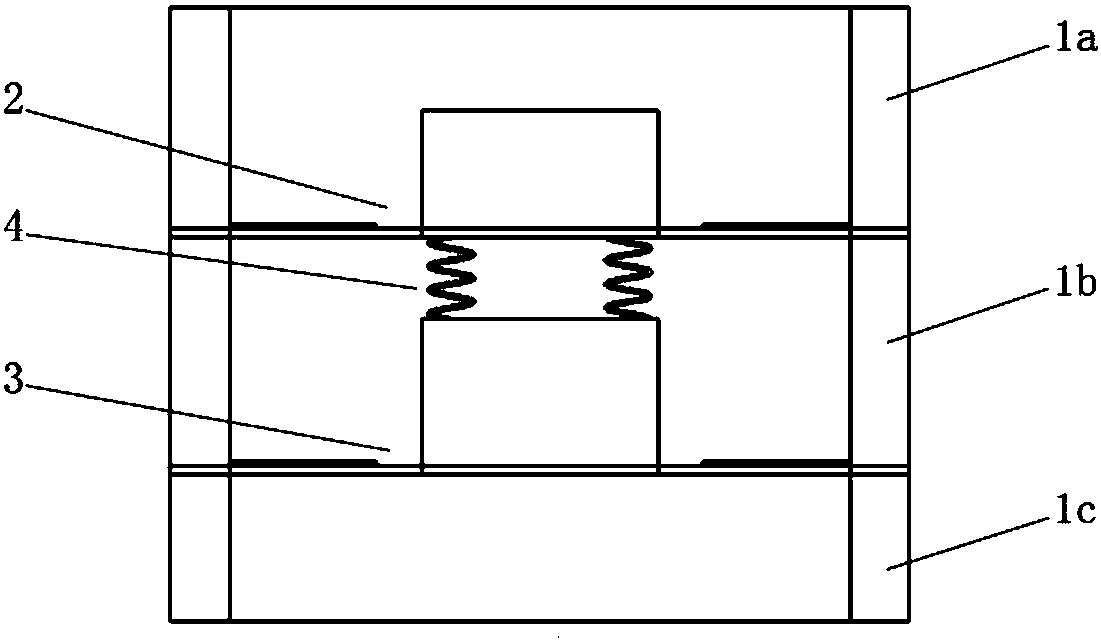

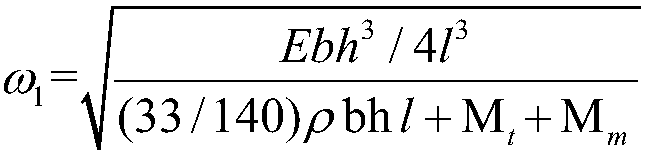

Double-cantilever beam type micro-mechanical acceleration sensor

InactiveCN103293336AHigh sensitivitySmall lateral effectAcceleration measurement using interia forcesCantilevered beamGlass sheet

The invention provides a double-cantilever beam type micro-mechanical acceleration sensor. The double-cantilever beam type micro-mechanical acceleration sensor is characterized by comprising a sensitive chip and a lower glass plate, wherein the sensitive chip comprises a framework, cantilever beams, a mass block and four piezoresistors; the connection relationships are that the framework is internally provided with two mutually independent cantilever beams, one end of each cantilever beam is connected to the framework while the other end thereof is connected to the mass block, one end of each cantilever beam is connected to the framework while the other end thereof is connected to the mass bock, and the cantilever beams and the mass block compose a movable part of the sensitive chip; the piezoresistors are arranged on the upper surfaces of the cantilever beams; the piezoresistors are arranged on the upper surfaces of the cantilever beams; and the sensitive chip is connected to the lower glass plate through bonding. For an occasion where high resonant frequency of the sensor is necessary, the double-cantilever beam type micro-mechanical acceleration sensor can increase the sensitivity of the sensor by nearly one time, and avoids uncoordinated contradiction in a conventional design.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

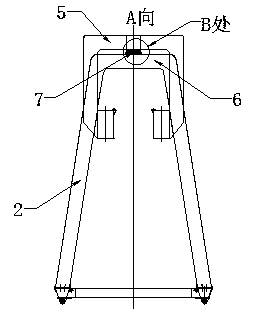

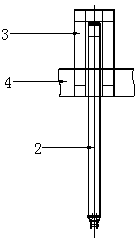

Flexible leg installing structure for double-beam portal crane

InactiveCN103407884AChange the phenomenon that only double rigid outriggers can be appliedSolve the problem that one rigid and one soft cannot be setBase supporting structuresBraking devices for hoisting equipmentsCantilevered beamEngineering

The invention discloses a flexible leg installing structure for a double-beam portal crane. The flexible leg installing structure comprises a flexible support leg body, and the flexible support leg body and a rigid support leg are arranged in a pair; the two sides of the flexible support leg body is provided with two inverse U-shaped supporting frames, and two main beams between the rigid support leg and the flexible support leg body are respectively fixed on left and right inner sides of the lower parts of the supporting frames; a vertical beam, which is perpendicular to an upper beam, is arranged below the upper beam of the two supporting frames, and a flexible hinging device is arranged between the vertical beam and a top beam of the flexible support leg body. The flexible leg installing structure provided by the invention has the advantages that the long span double-beam portal crane with double cantilevers only needs a rigid support leg and a flexible support leg, so that a problem that a long span double-beam portal crane with double cantilevers cannot be provided with a rigid support leg and a flexible support leg in the prior art is solved, the flexible leg installing structure is capable of bearing and defusing deflection, torsion and additional torque of a complete machine steel structure caused by negative factors such as large bending moment and large deviation, and the rail gnawing probability of a cart walking wheels is effectively reduced.

Owner:ELEPHANT KING HEAVY IND

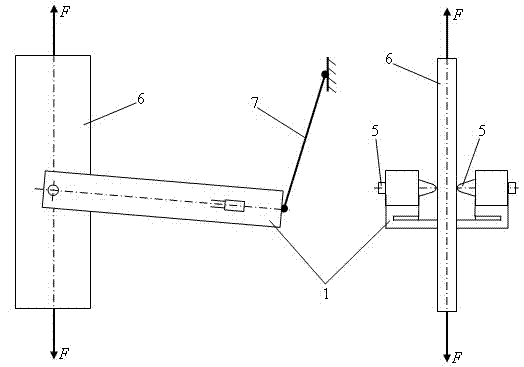

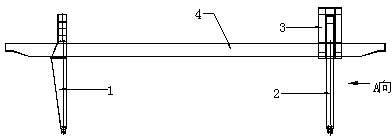

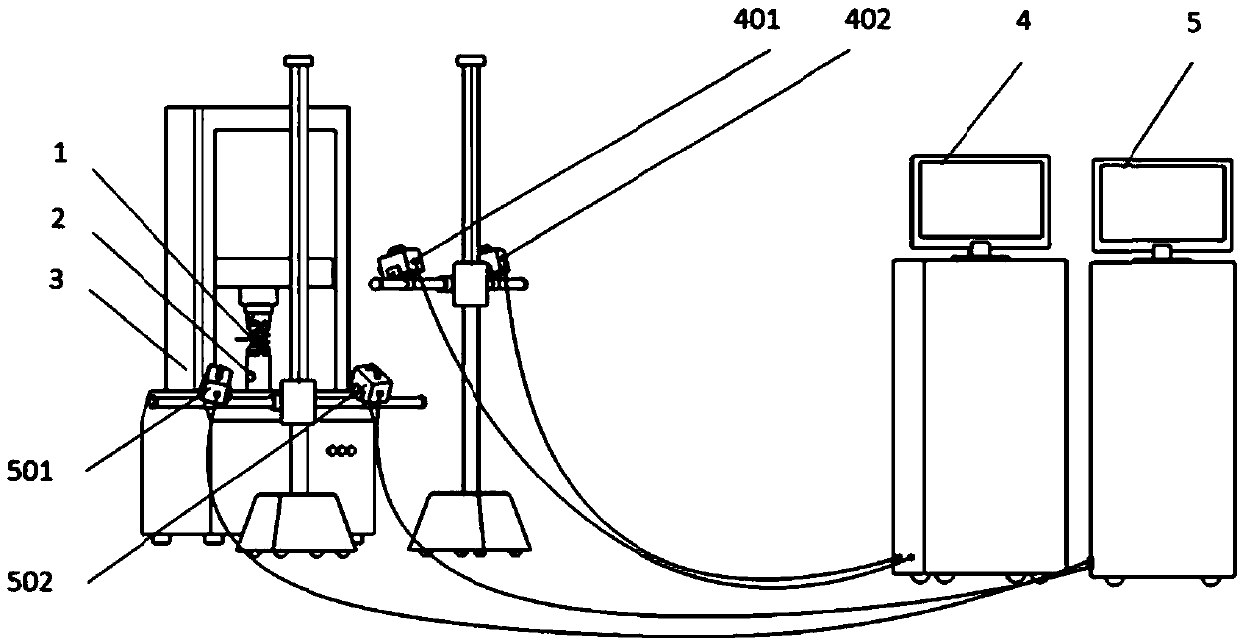

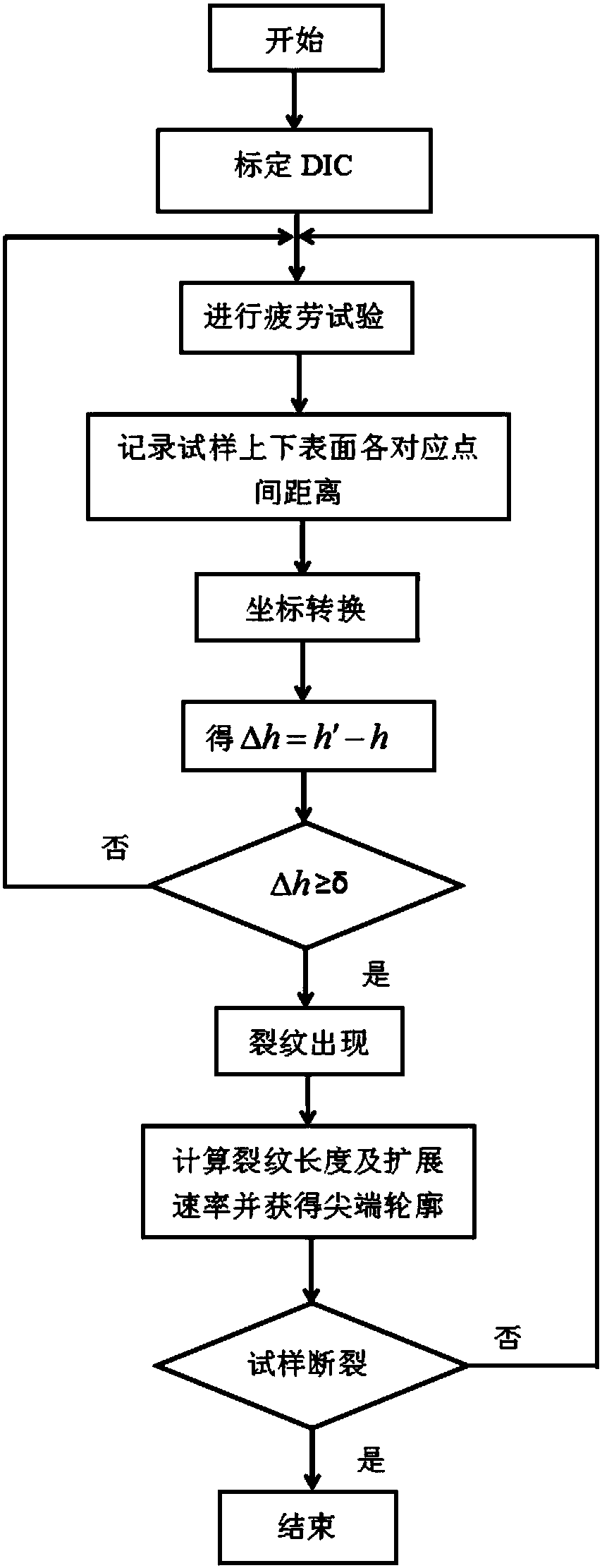

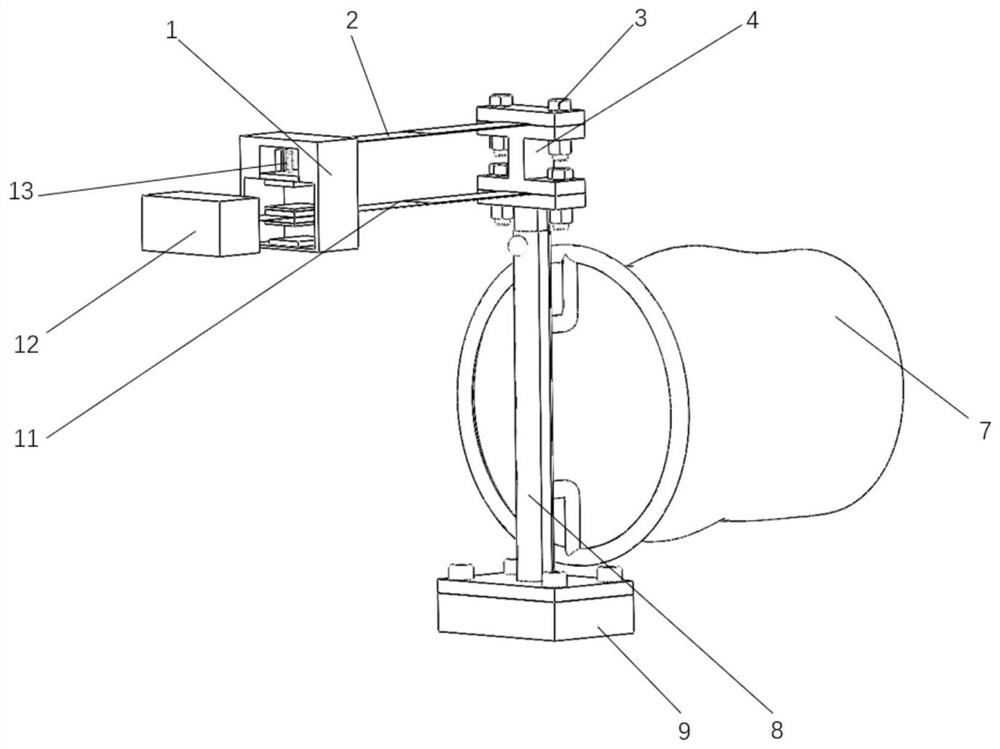

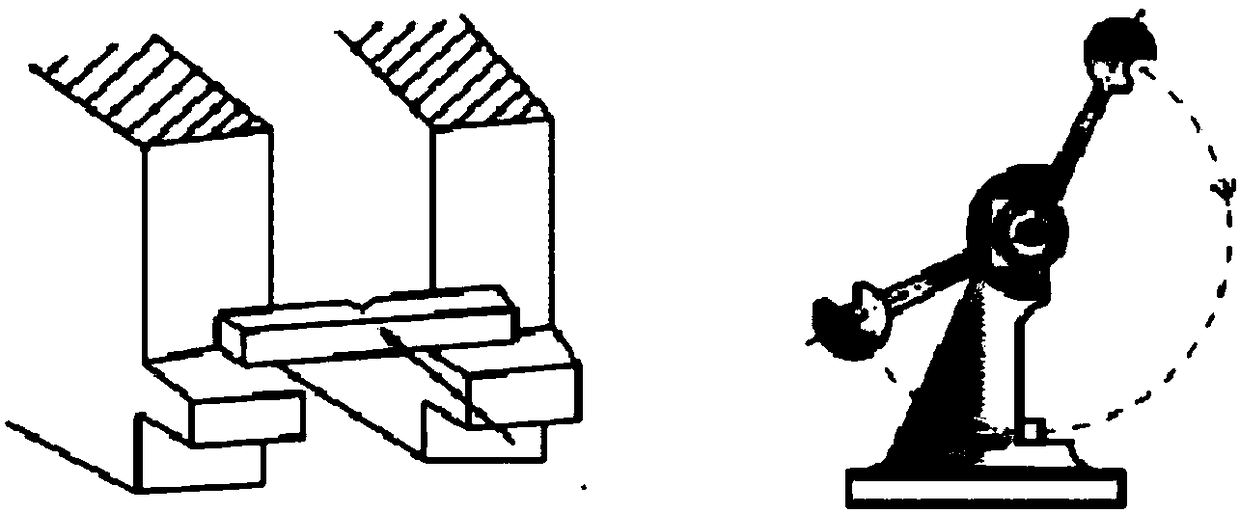

Testing system used for three-dimensional structure internal crack propagation experiment

ActiveCN107741368AImprove reliabilityEasy to operateMaterial strength using repeated/pulsating forcesCoordinate changeFatigue loading

The invention provides a testing system used for a three-dimensional structure internal crack propagation experiment. The test system comprises a fatigue testing machine (3), a clamp (2), first DIC equipment (4) and second DIC equipment (5), and is characterized in that the fatigue testing machine (3) is used for fatigue loading; a double cantilever beam sample (1) serves as a sample for detectingcracks; the clamp (2) is used for connecting and fixing the double cantilever beam sample (1) and the fatigue testing machine (3); a first lens (401) of the first DIC equipment (4), a second lens (402) of the first DIC equipment (4), a first lens (501) of the second DIC equipment (5) and a second lens (502) of the second DIC equipment (5) align to the upper surface and the lower surface of the double cantilever beam sample (1) respectively, and are used for observing the coordinate change of each point on the upper surface and the lower surface of the double cantilever beam sample (1). According to the testing system, the testing process can be closer to an actual loading process, so that detected crack propagation actions are closer to the actual situation, and the system is of preferable guiding significance.

Owner:HUNAN UNIV

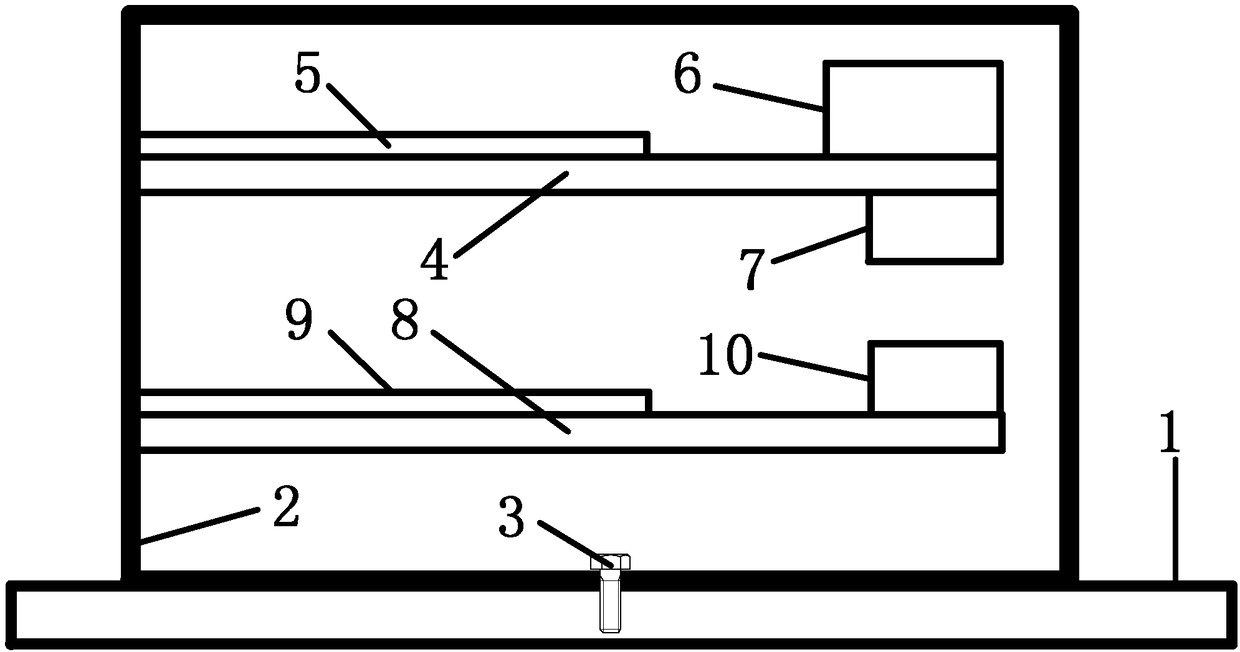

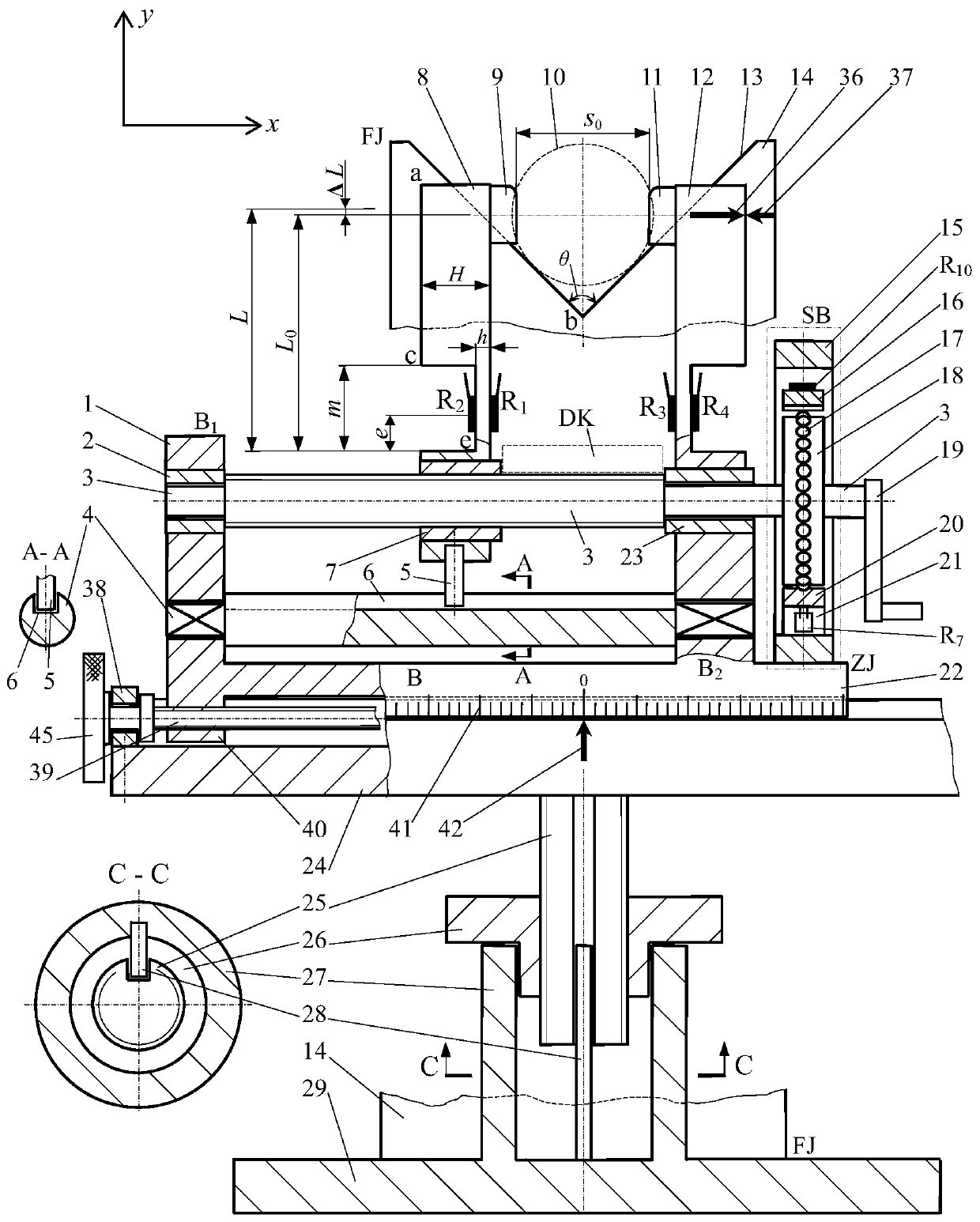

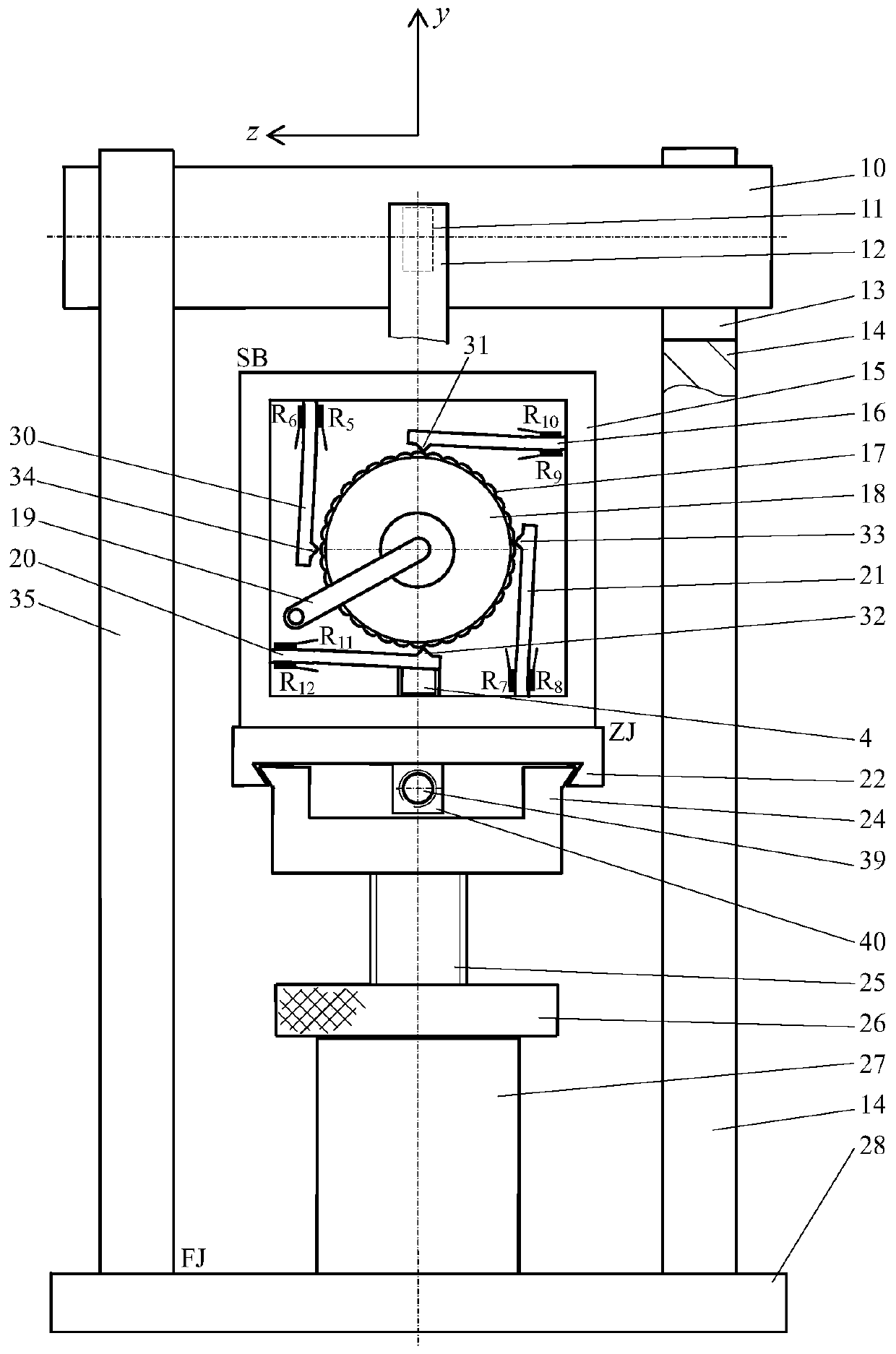

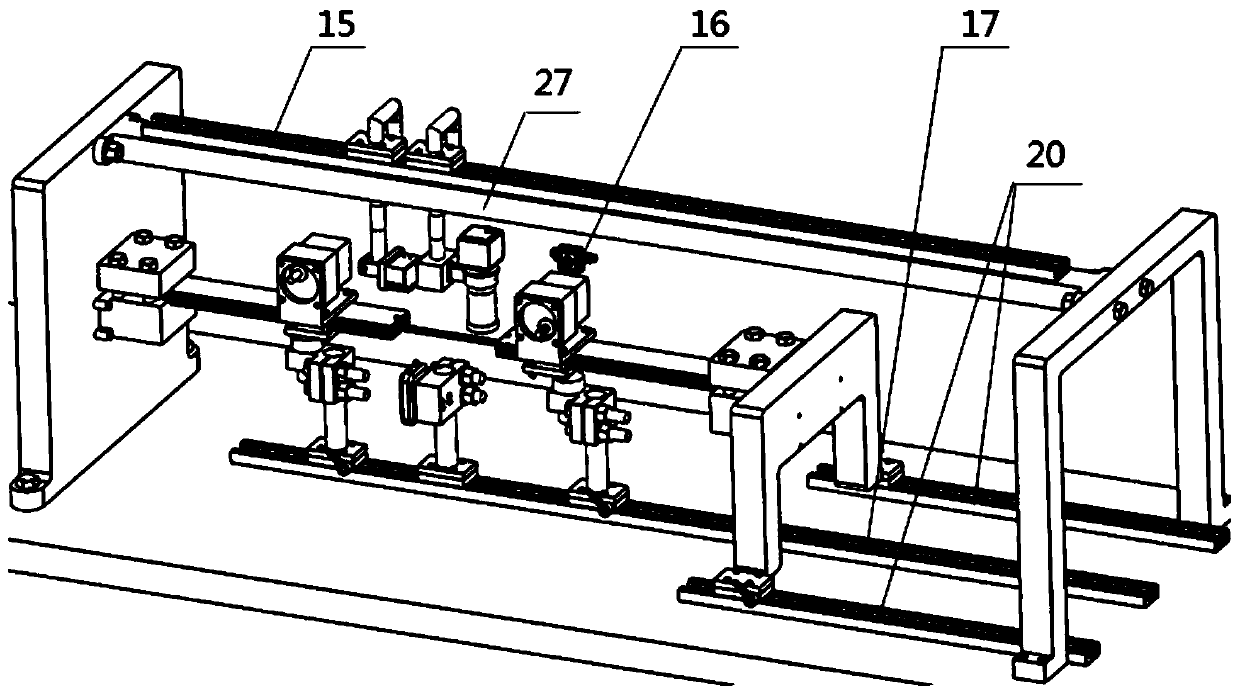

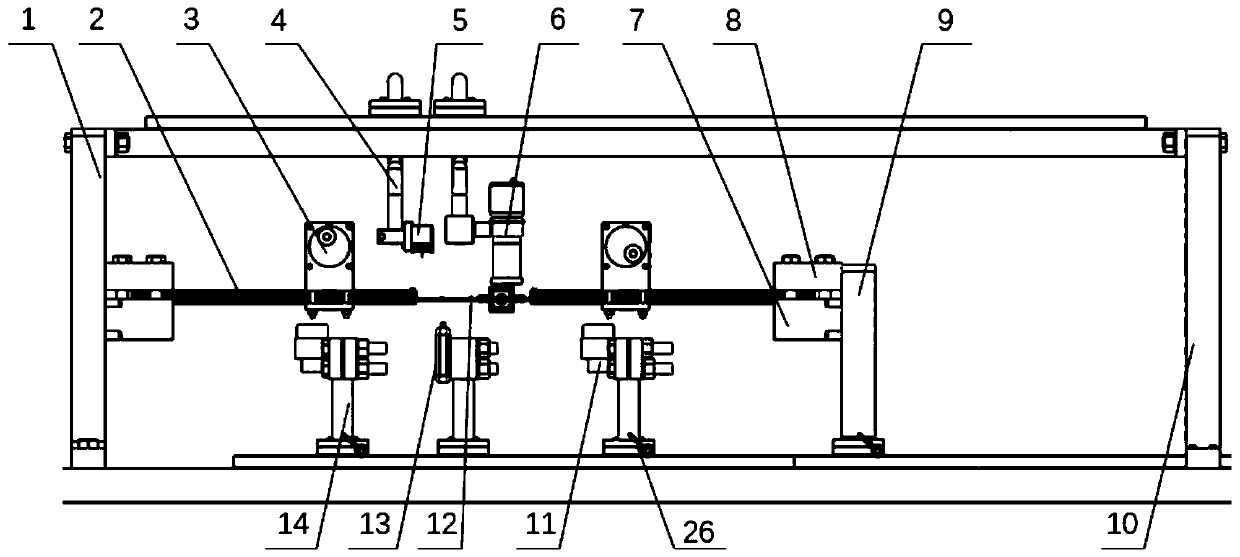

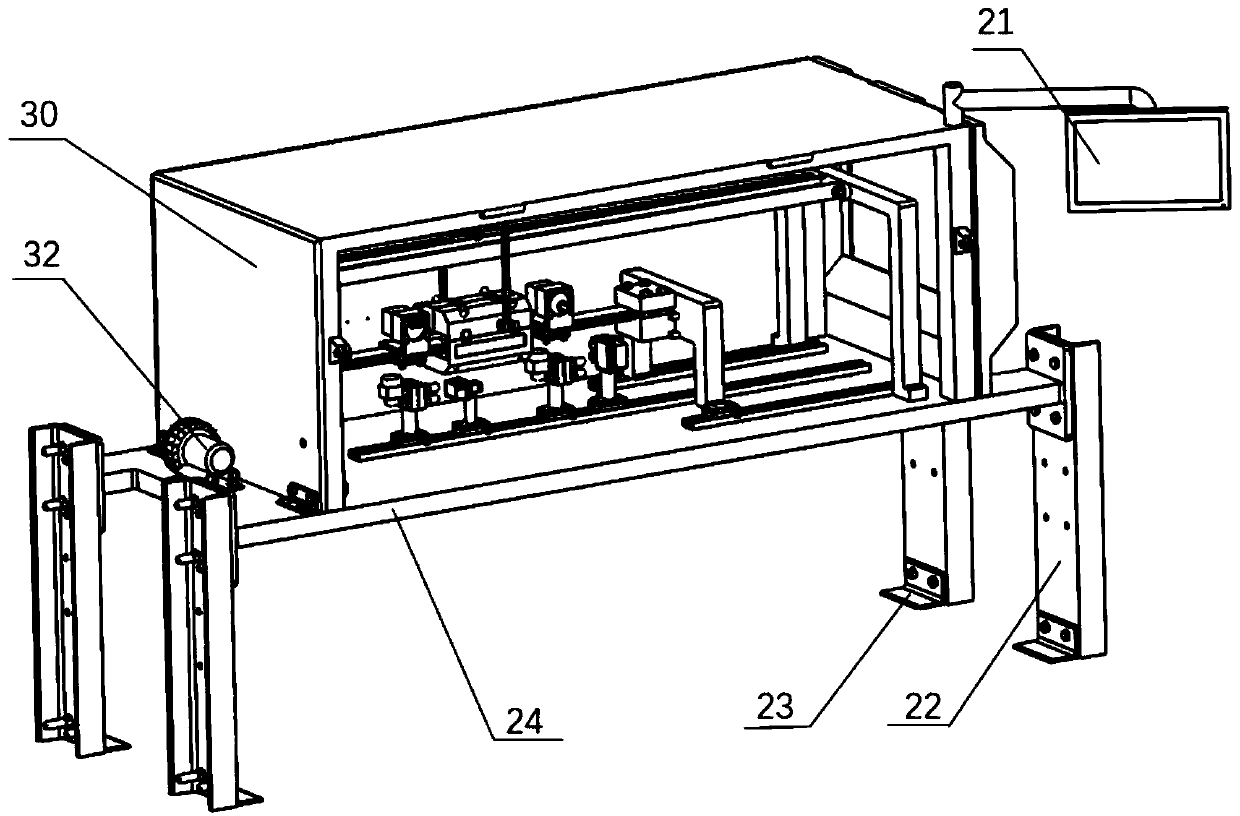

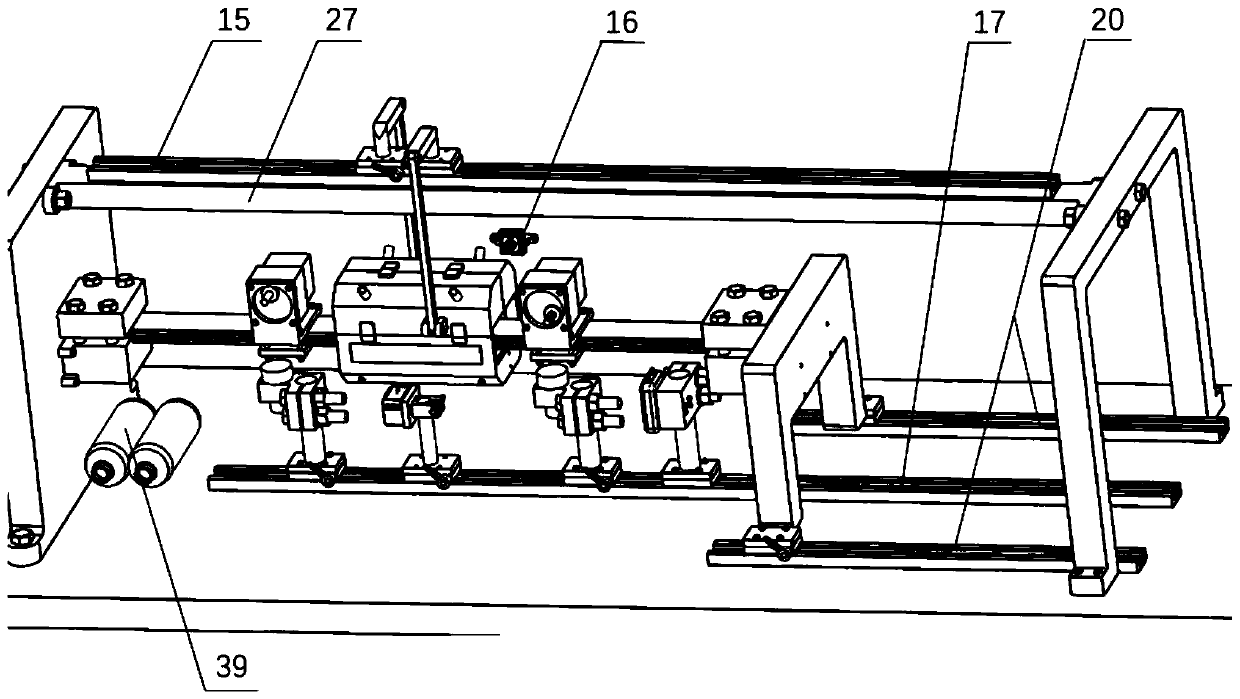

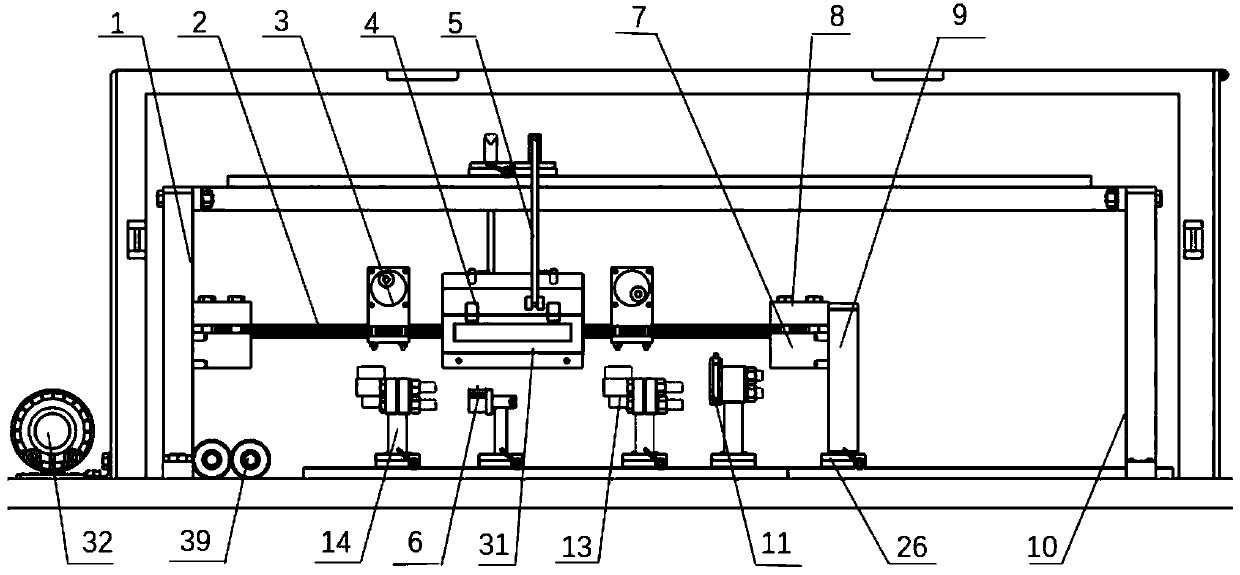

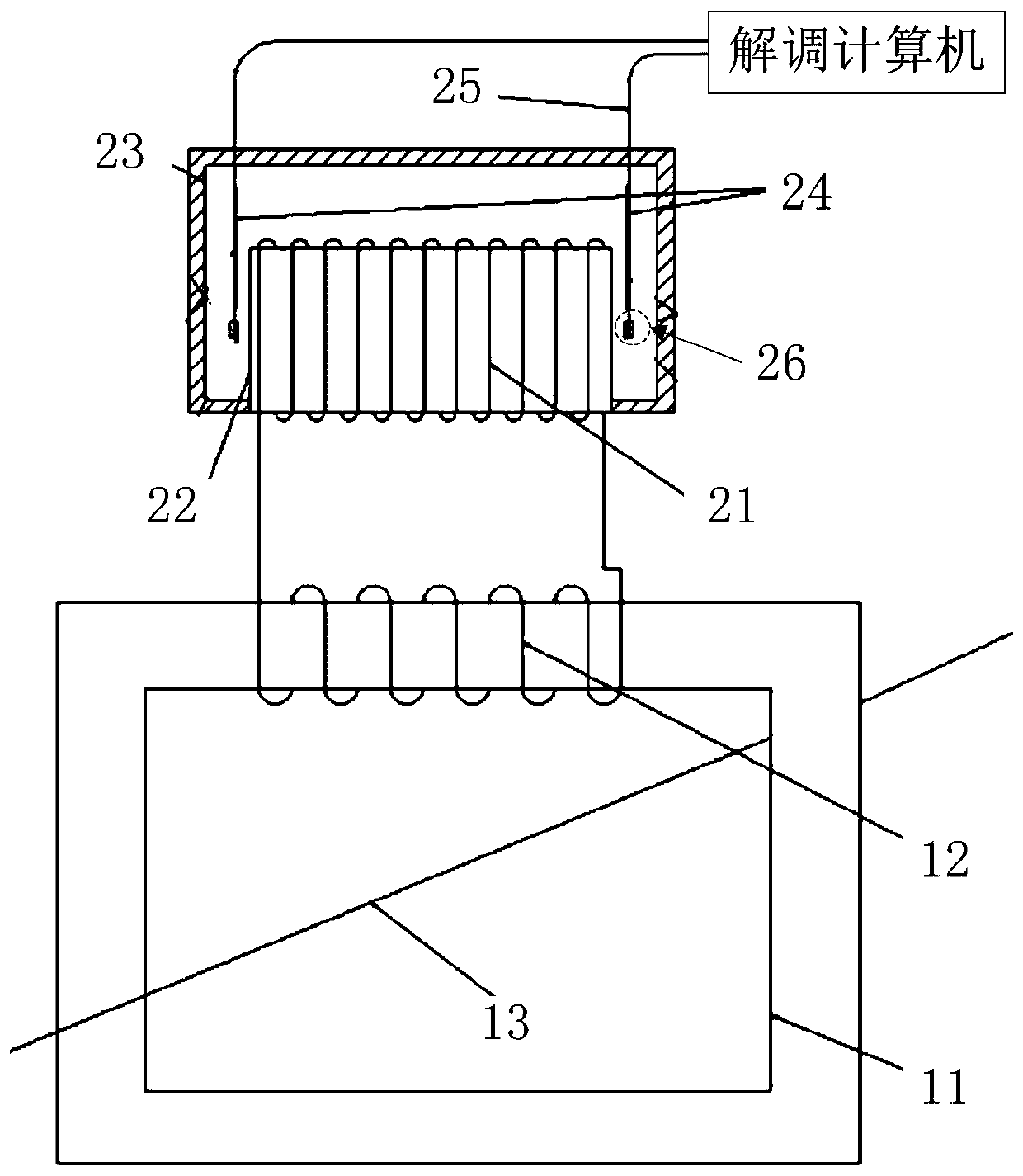

Composite material dynamic fatigue testing device and method based on reverse resonance

InactiveCN109900790AIncreased amplitude rangeImprove test accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesStrength propertiesEngineeringVibration exciter

The invention belongs to the composite material structure fatigue testing technology field and discloses a composite material dynamic fatigue testing device and method based on reverse resonance. Thetesting device comprises a double-cantilever-beam vibration testing system, an electronic acquisition system and a measurement and control system. An eccentric motor is used to drive vibration of a beam to be tested. Compared with a vibration exciter, the device has a small size and less energy consumption, and is convenient to carry. The reverse resonance of a double-cantilever vibration beam isused to drive the vibration of the beam to be tested, test efficiency is improved and energy is saved. Compared with an existing testing device, the device can be used to broaden an amplitude range ofthe beam to be tested. The eccentric motor is precisely controlled, a variety of precision instruments are used to measure and analyze a fatigue characteristic of the material to be tested from optics, acoustics, time domain waveform and other aspects, and test accuracy is extremely high. The device is simple, most of components are detachable, dismounting is convenient, portability is good and the device is easy to operate.

Owner:NORTHEASTERN UNIV

Composite material thermal vibration fatigue test device and method based on reverse resonance

InactiveCN109839254AIncreased amplitude rangeImprove test accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration testingVibration exciterDouble cantilever beam

A composite material thermal vibration fatigue test device and method based on a reverse resonance are disclosed. The test device comprises a double-cantilever-beam vibration test system, a thermal environment simulation system, an electronic acquisition system, and a measurement and control system; an eccentric motor is used to drive a beam to be tested to vibrate. Compared with a vibration exciter, the device of the invention has a small size and less energy consumption, and is convenient to carry. The reverse resonance of a double-cantilever vibration beam is used to drive the beam to be tested to vibrate, test efficiency is improved, energy is saved, and an amplitude range of the beam to be tested is widened compared with existing test equipment. A variety of precision instruments areused to measure and analyze a fatigue characteristic of a material to be tested from optical, acoustic, time domain waveforms and other aspects, and high test accuracy is achieved. A thermal environment where the composite material is located can be simulated, and the fatigue characteristic of the composite material at different temperatures can be tested. The device of the invention is simple, components adopt a detachable design, disassembling is convenient, the portability is good, and the operation is easy.

Owner:NORTHEASTERN UNIV

Wind-induced vibration piezoelectric-triboelectricity coupling energy collection device

PendingCN114865943AImprove conversion efficiencyWind disturbancePiezoelectric/electrostriction/magnetostriction machinesWind energy generationEngineeringMechanical engineering

The invention discloses a piezoelectric-triboelectric coupling energy collection device with wind-induced vibration. The problems that in the prior art, a wind-induced vibration energy collector is low in output power, narrow in working wind speed range and single in energy conversion form are solved. According to the invention, a double-cantilever beam structure is arranged, and piezoelectric ceramics are fixed on the surfaces of the long cantilever beam and the short cantilever beam; the rectangular bluff body is fixed at the free end of the cantilever beam; an elastic sliding block is arranged in a first bluff body fixed with the short cantilever beam; a friction material and a conductive metal layer are respectively fixed on the opposite surfaces of the long cantilever beam and the first bluff body; the fixed end of the double-cantilever beam and the supporting rod are fixed by a plurality of jump springs; a wind direction bag is fixed to the pipe sleeve and forms a rotating pair with the fixed base. The collecting device can be adjusted in a self-adaptive mode and is parallel to the wind direction all the time, the wind energy utilization rate is increased, the vibration frequency is improved, meanwhile, high potential difference is generated through piezoelectric ceramics and friction materials, and the energy output power of the device is improved.

Owner:HANGZHOU DIANZI UNIV

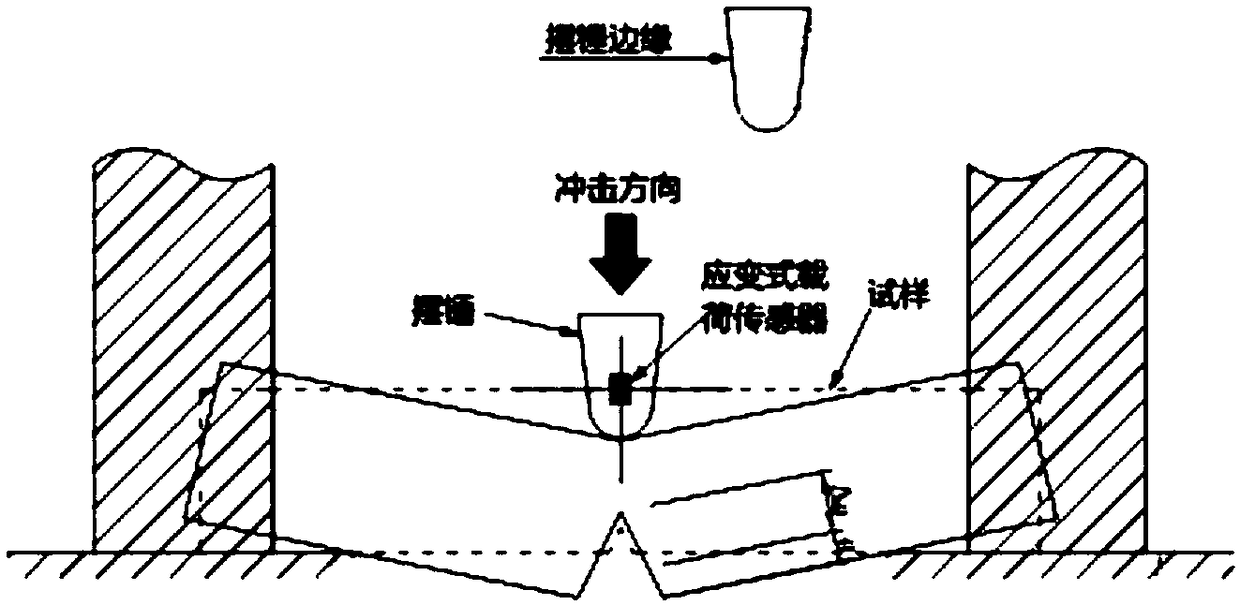

Metal pipe fracture toughness detection method and system

InactiveCN109211695AFew parametersSimple calculationMaterial strength using single impulsive forceObservational errorStress intensity factor

The present invention relates to a metal pipe fracture toughness detection method and system, and relates to the technical field of fracture toughness testing. The method has following steps: according to crack propagation characteristics of the Charpy V-type sample in the dynamic impact test, making a metal pipe to be tested into a Charpy V-shaped sample, establishing a corresponding relationshipbetween load of force point and displacement of force point during the crack propagation process of the Charpy V-shaped sample, combined with the crack propagation characteristics of three-point bending standard sample SEB in the static impact test, establishing corresponding relationship between load of force point and actual crack length during the crack propagation process of the Charpy V-shaped sample, and then determining corresponding relationship between stress intensity factor and the actual crack length during the crack propagation process, and finally determining fracture toughnessvalue of the metal pipe. The method can obtain detection results consistent with results of a DCB test with double cantilever beam sample, and adopts mathematical model processing method of loop iteration for the whole detection process, requires less parameters, and has simple calculation process and small measurement deviation.

Owner:CHINA PETROLEUM & CHEM CORP +1

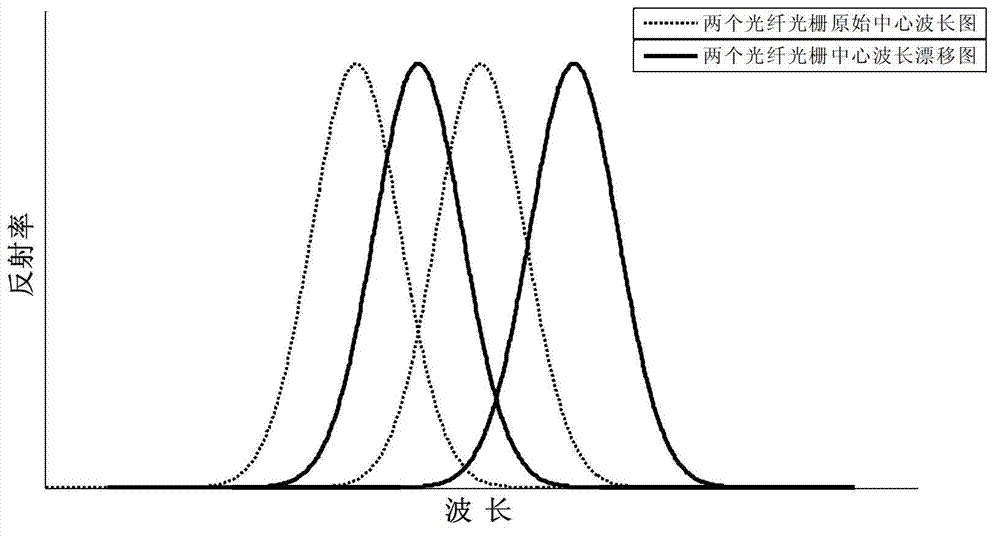

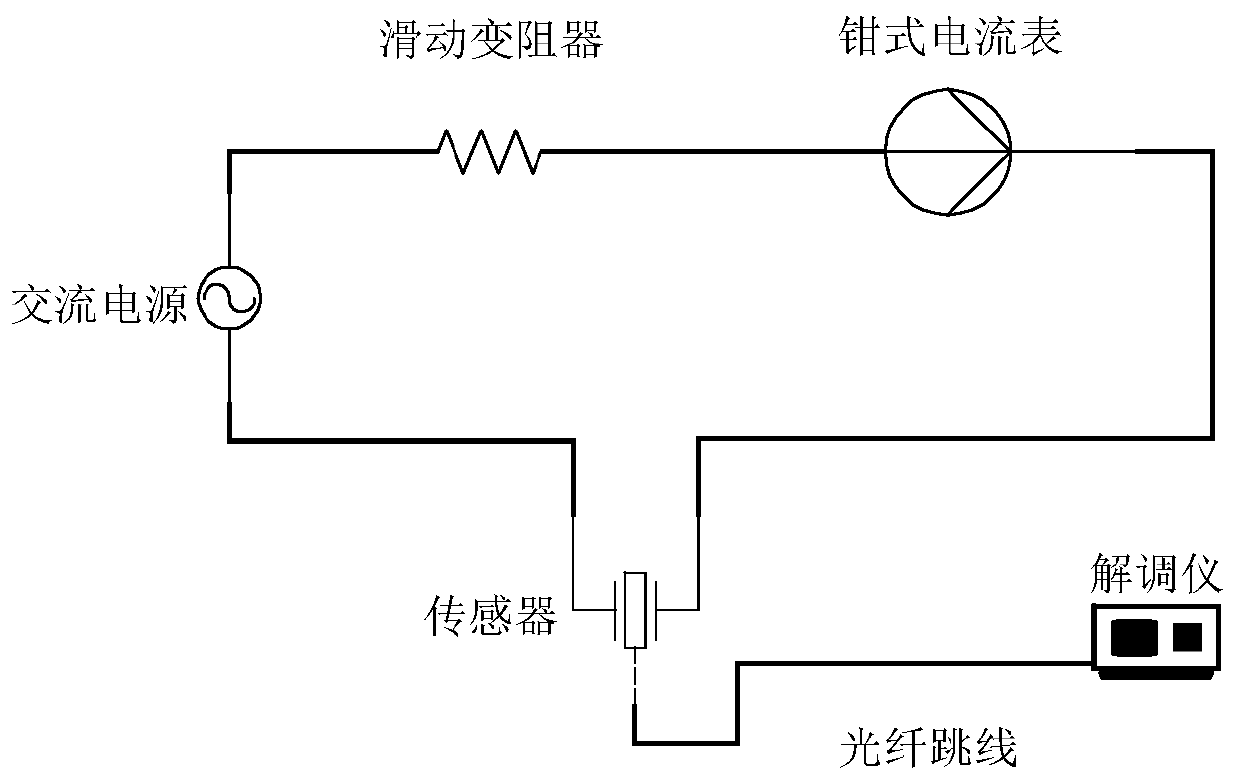

Double-cantilever differential fiber grating current transformer

InactiveCN110940844AImprove detection reliabilityReduce the impact of detection accuracyCurrent measurements onlyVoltage/current isolationFiberPigtail

The invention discloses a double-cantilever differential fiber grating current transformer, which is suitable for cable sheath grounding current detection, and comprises a first induction unit including a magnetizer and a first induction coil, the magnetizer is in hollow rectangular shape, and the first induction coil is wound on one transverse edge of the magnetizer;, a second induction unit comprises a second induction coil, an iron core, an outer supporting structure and two magnetic deformation units. The second induction coil is wound around the iron core, and the magnetic deformation units are arranged at the left and right ends of the outer supporting structure, and are fixed in the vertical direction, a magnet is arranged at the top end of each magnetic deformation unit and locatedin the center of the second induction coil, and the magnetic induction lines of the magnets at the top ends of the two magnetic deformation units are opposite in pointing direction; and a demodulation computer is connected to the two magnetic deformation units through optical fiber pigtails. According to the technical scheme, the detection reliability of the fiber bragg grating current transformer is improved, and the influence of environment temperature change on the detection precision of the fiber bragg grating current transformer is reduced.

Owner:DATONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER

An ultra-broadband high-efficiency piezoelectric vibration energy harvesting device

ActiveCN107707155BIncreased bandwidthAvoid the defect of collecting vibration energy with small frequency widthPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamElectricity

The present invention provides an ultra-wideband energy-efficient piezoelectric vibration energy harvesting device for solving the technical problem of low energy conversion efficiency when the external vibration frequency is not stable in the prior art, including brackets and an oscillating body. The oscillating body includes a low frequency oscillating body and a high frequency oscillating body.The brackets include a top bracket, a middle bracket and a bottom bracket which are sequentially stacked from top to bottom. The three brackets adopt a three-dimensional structure with a cavity penetrating the upper and lower end faces; the low frequency oscillating body comprises a low frequency reed between the middle bracket and the bottom bracket, a low frequency mass fixed to the central bearing section of the low frequency reed, and a low frequency cantilever module attached to the cantilever of the low frequency reed; the high frequency oscillating body includes a high frequency reed between the top bracket and the middle bracket, a high frequency mass fixed to the central bearing section of the high frequency reed and a high frequency cantilever module attached to the double-cantilever beam of the high frequency reed; and the low frequency mass and the high frequency reed are connected by at least three compression springs.

Owner:XIDIAN UNIV

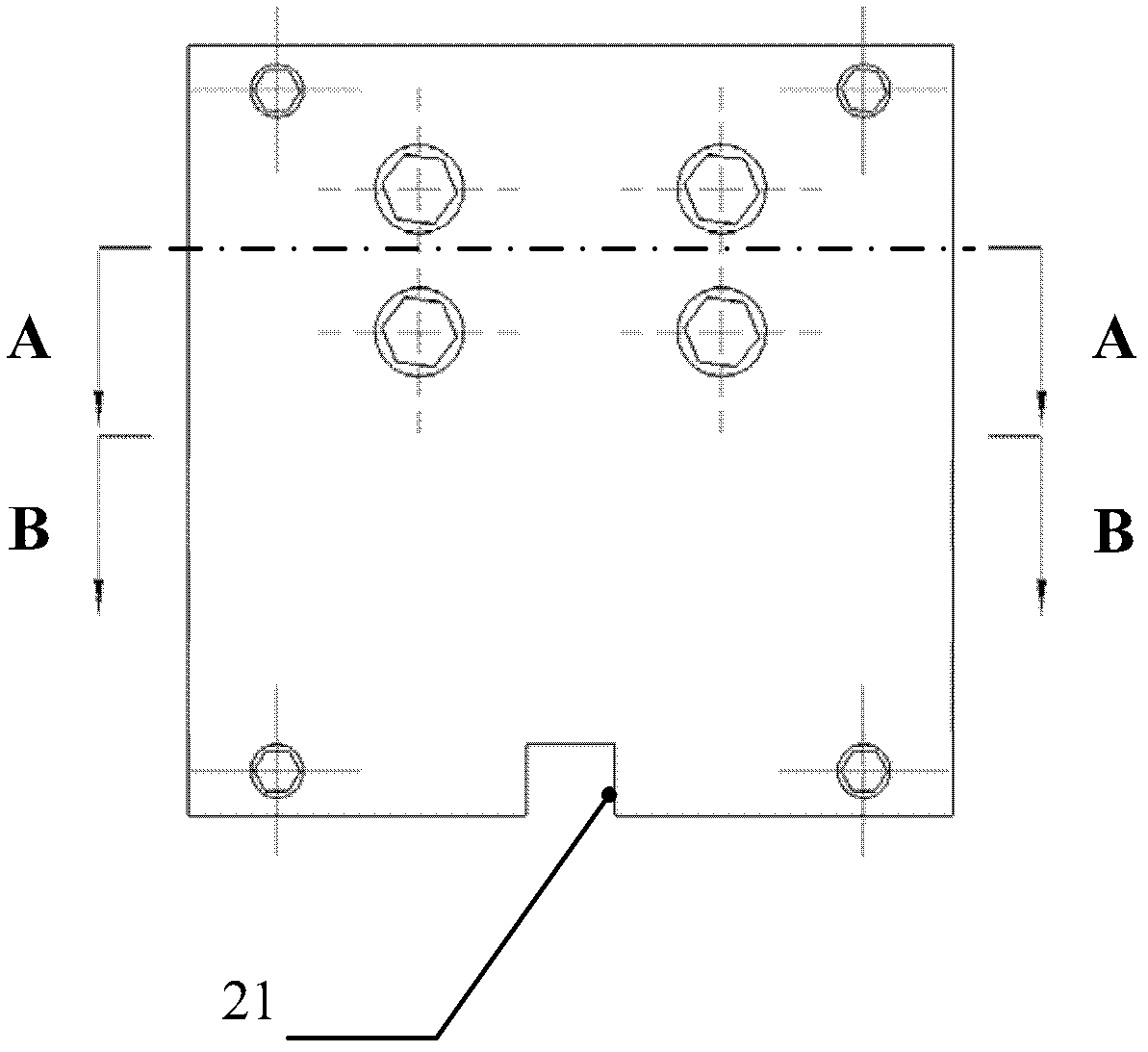

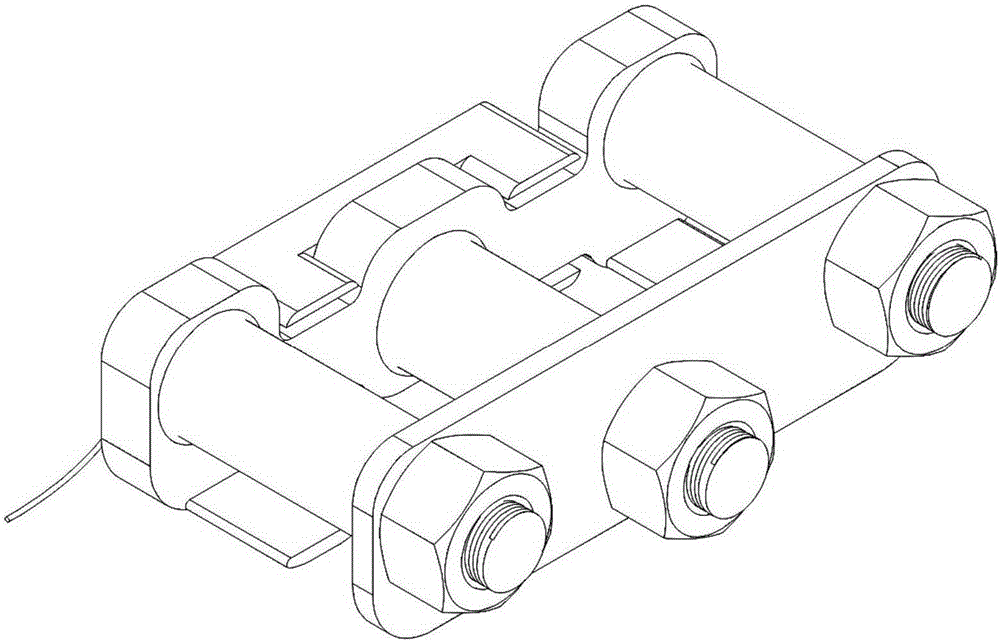

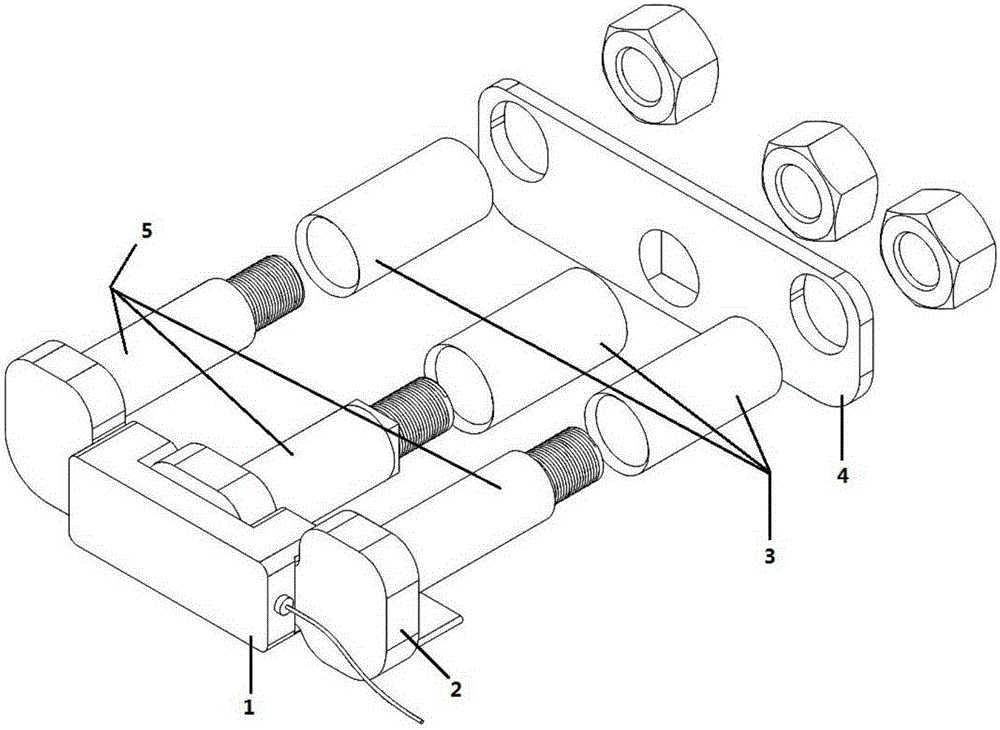

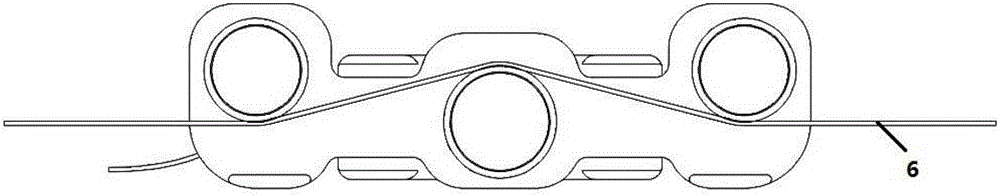

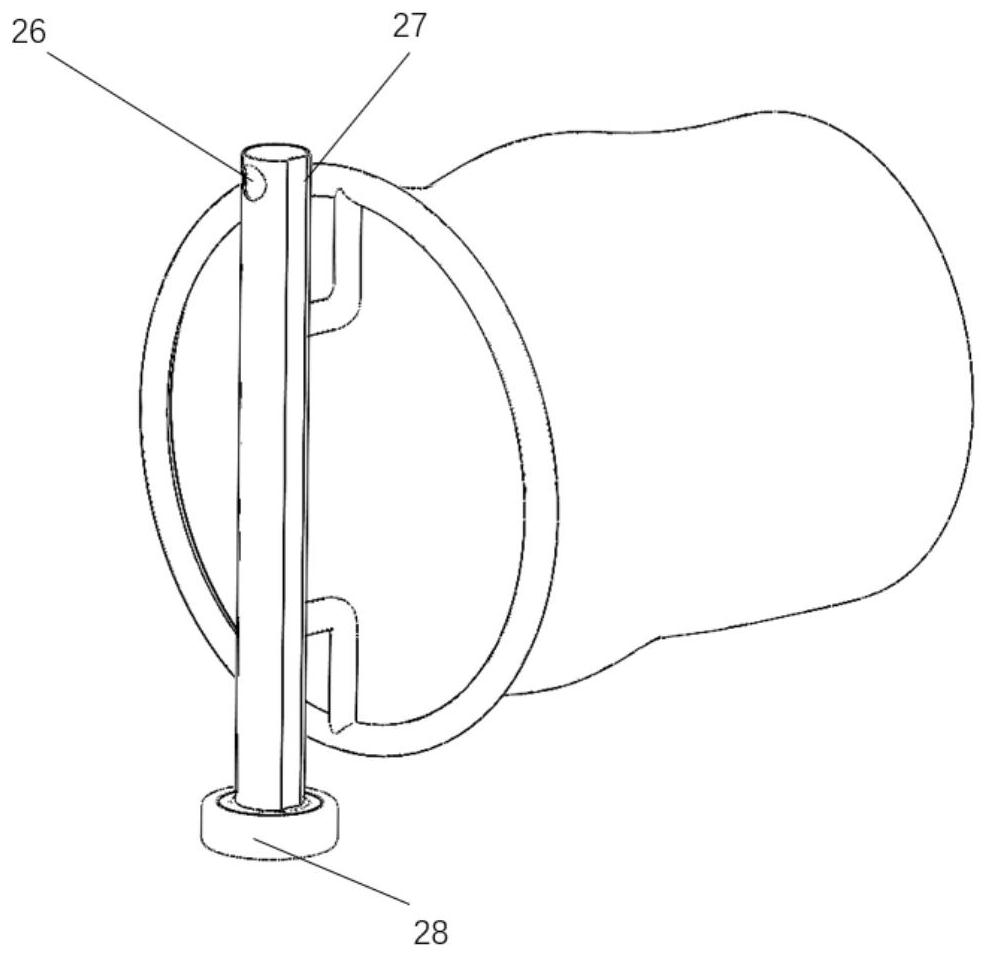

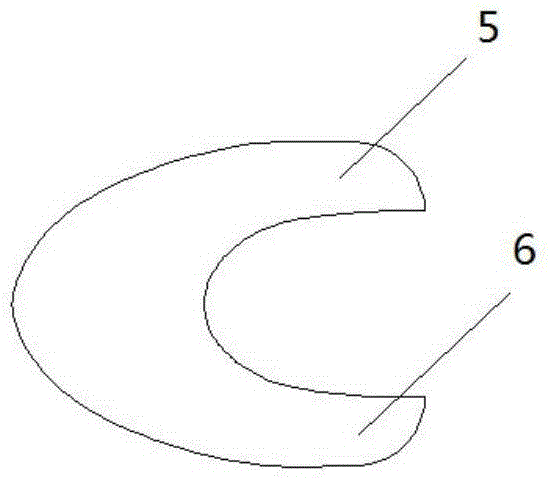

Clamp for testing mode I interlaminar fracture toughness in double-cantilever beam stretching test

InactiveCN110361255AEasy to holdEasy to useMaterial strength using tensile/compressive forcesAdhesiveEngineering

The present invention discloses a clamp for testing the mode I interlaminar fracture toughness in a double-cantilever beam stretching test. The clamp includes an upper clamping mechanism and a lower clamping mechanism which are of the same structure and are in mirror-image distribution; the upper clamping mechanism comprises a clamped portion, a clamping portion and a pin; one end of the clamped portion is held on a test machine, and the other end of the clamped portion is symmetrically provided with two first lugs; a first through hole is formed in each first lug; one end of the clamping portion is provided with a second lug; a second through hole is formed in the second lug; the other end of the clamping portion is connected with the end portion of one side of a test piece through an adhesive; the pin penetrates the first through holes and the second through hole; the second through hole is located between the two first through holes; two ends of the pin are in threaded connection with nuts; and the nuts abut against two sides of the clamping portion. With the clamp of the present invention adopted, the clamping and use of the testing machine can be facilitated, and it can be ensured that load applied in a stretching process does not deviate and is uniformly distributed.

Owner:SHANGHAI JIAO TONG UNIV

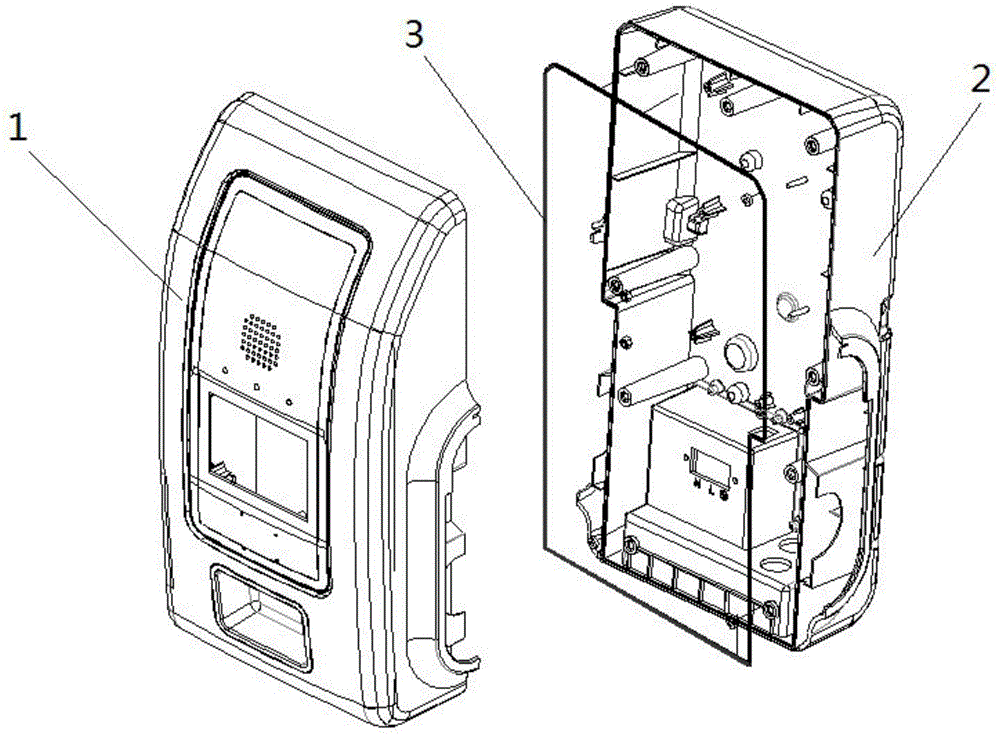

Charging pile sealing structure for new energy automobile

PendingCN105529786ASimple structureIngenious designBatteries circuit arrangementsElectric powerCantilevered beamNew energy

The invention discloses a charging pile sealing structure for a new energy automobile. The charging pile sealing structure comprises an upper cover, a lower cover and a sealing ring, wherein the sealing ring is arranged between the upper cover and the lower cover and is provided with a first cantilever beam and a second cantilever beam; an annular mounting groove is formed in the side face of the upper cover, the sealing ring is located in the mounting groove, the first cantilever beam and the second cantilever beam are located outside the mounting groove, the lower cover is arranged on the outer side of the first cantilever beam and the outer side of the second cantilever beam and is closely clung to the first cantilever beam and the second cantilever beam to generate the cantilever beam shearing force, and sealing is achieved through double cantilever beam shearing force. The charging pile sealing structure for the new energy automobile is mainly applied to easy-deformation structure pieces of a charging pile; under ultimate deformation of a combined upper structure piece and lower structure piece, the charging pile sealing structure can achieve the waterproof level higher than IP66.

Owner:SHANGHAI ZHIDA TECHNOLOGY DEVELOPMENT CO LTD

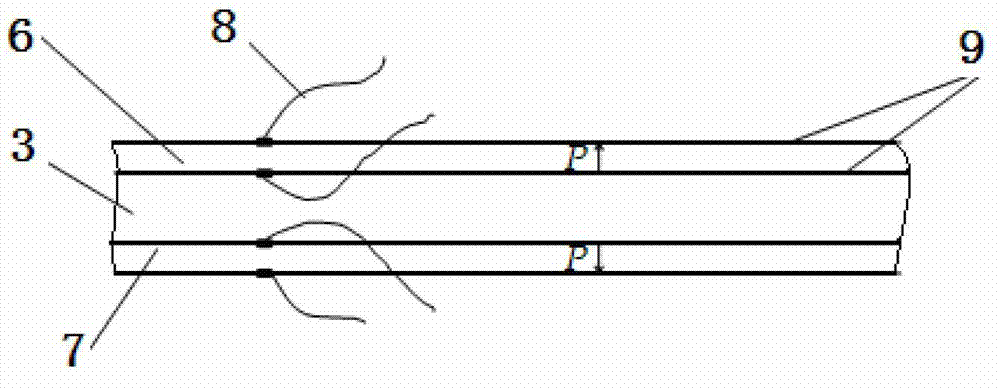

Optical fiber grating vibration sensor comprising double cantilever beams with equal strength

InactiveCN101982740BHigh sensitivityImprove reliabilitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansCantilevered beamGrating

The invention relates to an optical fiber grating vibration sensor comprising double cantilever beams with equal strength, a cantilever beam base is arranged on the left side in a housing, the fixing ends of the upper sheet-like cantilever beam and the lower sheet-like cantilever beam, which are parallel to each other are connected with the cantilever beam base into a whole, the free ends are arranged on the upper side surface and the lower side surface of a mass block, cantilever beam position-limiting columns which are vertical to the surfaces are arranged on the surfaces which are respectively parallel to the plane of the upper cantilever beam and the plane of the lower cantilever beam of the mass block, a sealing cover which is equipped with a sensor joint on the outer side is arranged at the open end of the housing, an optical fiber protective casing penetrating the center of the sealing cover and the center of the sensor joint is arranged on the sealing cover, the ratio of the width of the fixing ends of the upper cantilever beam and the lower cantilever beam to the width of the free ends is 5 at least, an upper sensing optical fiber grating is arranged on the upper surface of the upper cantilever beam, a lower sensing optical fiber grating is arranged on the lower surface of the lower cantilever beam, and the series connection output end of the upper sensing optical fiber grating and the lower sensing optical fiber grating penetrates out of the optical fiber protective casing. The optical fiber grating vibration sensor has good sensitivity, reliability and stability.

Owner:NORTHWEST UNIV

Electromagnetic type double-reflector MEMS optical switch

ActiveCN111474633AResponse is fast and stableEasy to integrateCoupling light guidesCantilevered beamPermalloy

The invention discloses an electromagnetic type double-reflector MEMS optical switch comprising a support frame, a top plane driving coil and a bottom plane driving coil are respectively arranged at the top and the bottom of the support frame; a top permalloy iron core and a bottom permalloy iron core are respectively arranged at the central parts of the top plane driving coil and the bottom planedriving coil; a left double-cantilever beam and a right double-cantilever beam are connected to the inner wall of the middle of the supporting frame, a magnetic elastic platform is connected betweenthe left double-cantilever beam and the right double-cantilever beam, an upper light reflection micro-mirror and a lower light reflection micro-mirror are arranged in the center of the top and the center of the bottom of the elastic platform respectively, and a central through hole is horizontally formed in the elastic platform in a penetrating mode. According to the electromagnetic type double-reflector MEMS optical switch, the elastic platform is attracted to move up and down through electromagnetic force generated by the bottom plane driving coil and the top plane driving coil so that switching of three optical paths is completed, and the electromagnetic type double-reflector MEMS optical switch has the characteristics of being rapid and stable in response and good in integration capacity.

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com