Flexible leg installing structure for double-beam portal crane

A technology of gantry crane and installation structure, which is applied to the bottom support structure, hoisting device, transportation and packaging, etc., to reduce the probability of rail gnawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The installation structure for the flexible legs of the double-girder gantry crane of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

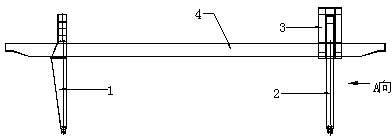

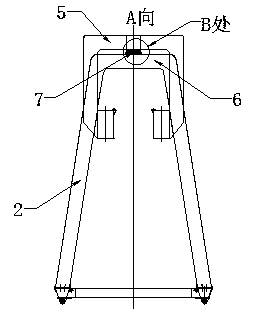

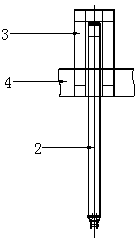

[0018] As shown in the figure, the installation structure of flexible legs for a double-girder gantry crane of the present invention includes a flexible leg body 2 arranged in pairs with a rigid leg 1, and two sides of the flexible leg body 2 are arranged in an inverted U shape. The support frame 3, the two main beams 4 between the rigid leg 1 and the flexible leg body 2 are respectively fixedly installed on the left and right inner sides of the lower part of the support frame 3, and the upper beams 5 of the two support frames are arranged below There is a longitudinal beam 13 perpendicular to the upper beam 5, and a flexible hinge device 7 is arranged between the longitudinal beam 13 and the top beam 6 of the leg body, wherein the flexible hinge devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com