Patents

Literature

2534 results about "Inverted u" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inverted U theory. The Inverted U theory was developed in 1908 by Yerkes and Dodson and it is a theory of arousal that considers that optimal performance occurs when the performer reaches an optimal level of arousal. The Inverted U theory seems to fit more accurately with observations of performance than the Drive theory.

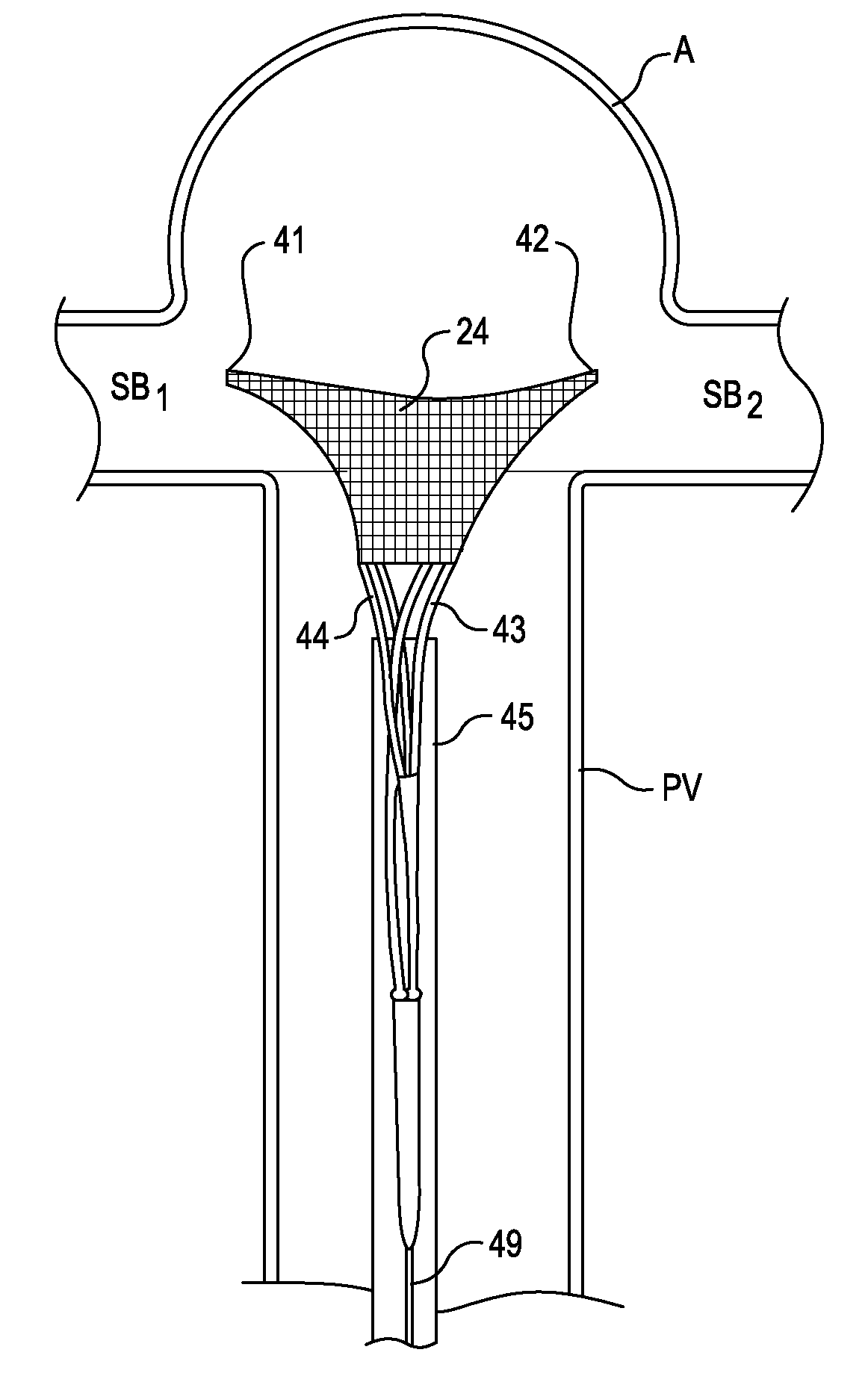

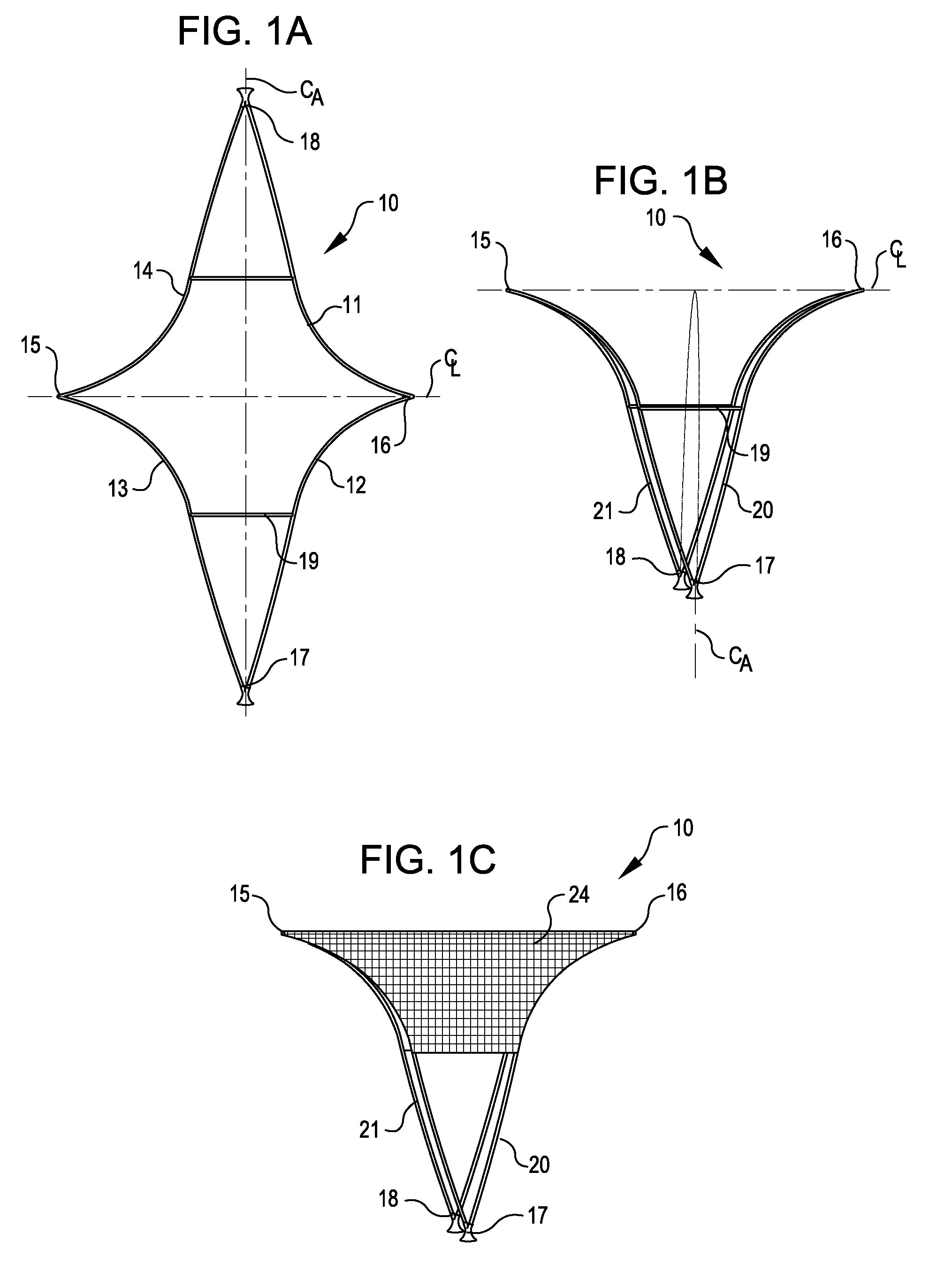

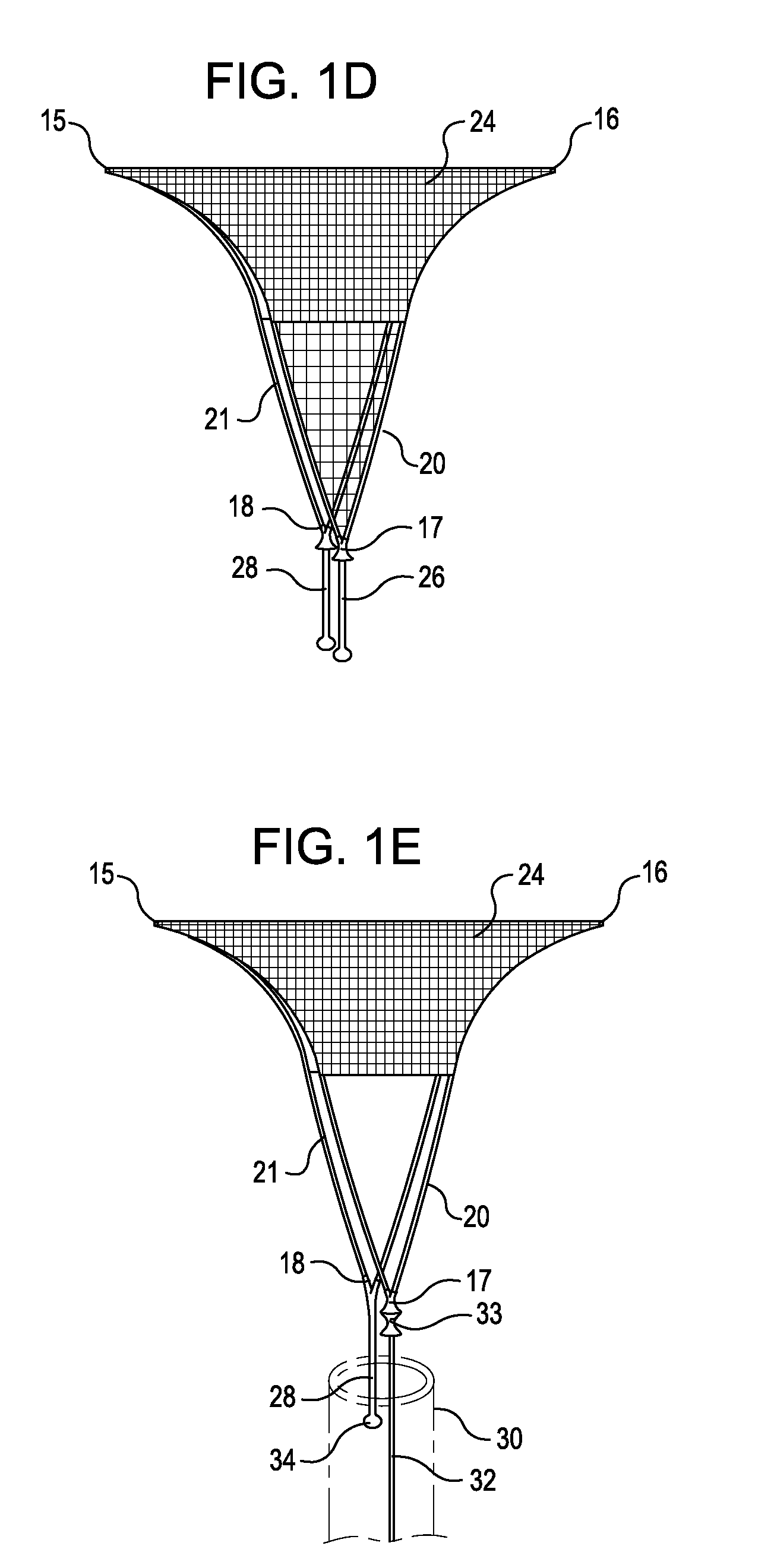

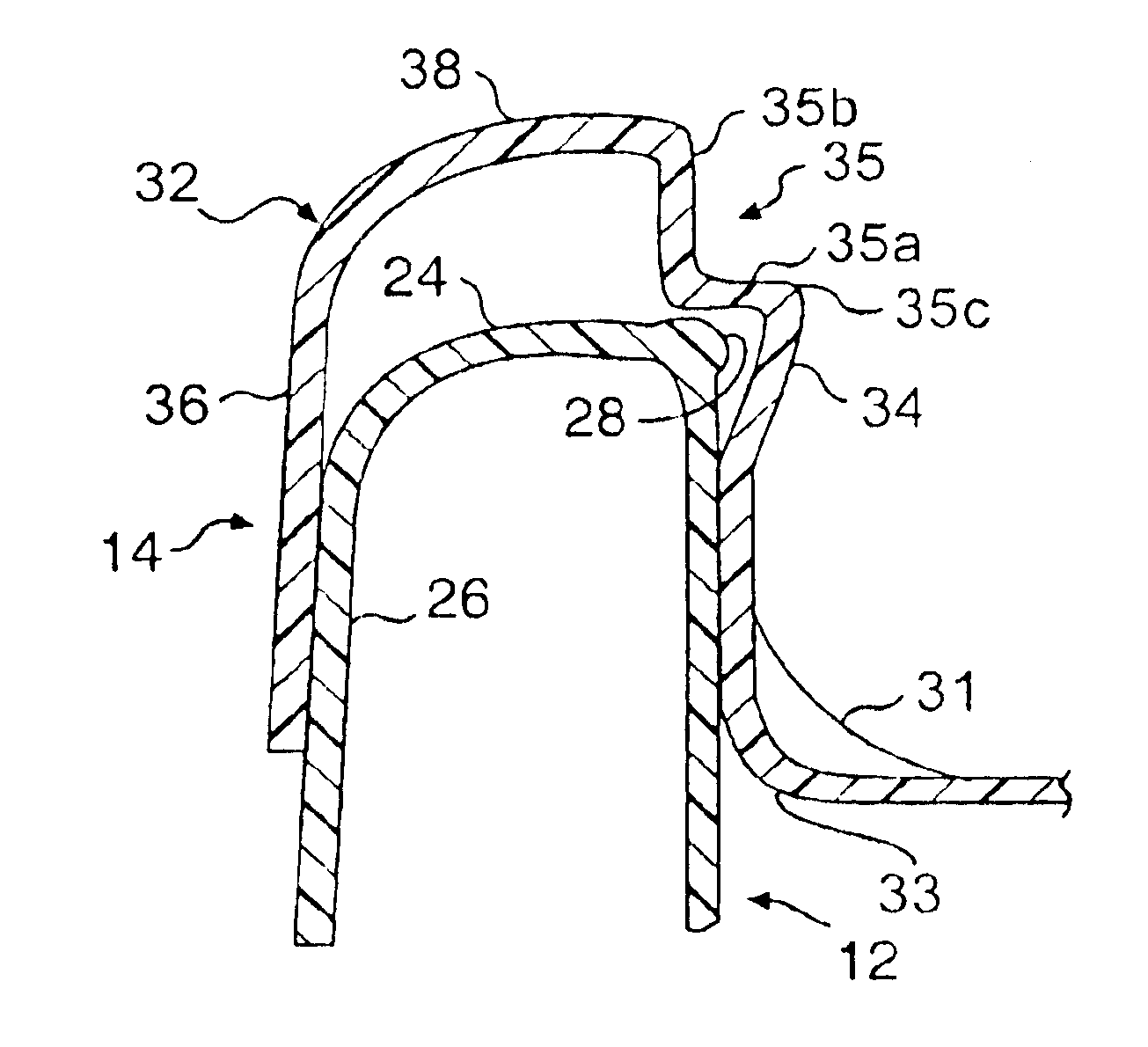

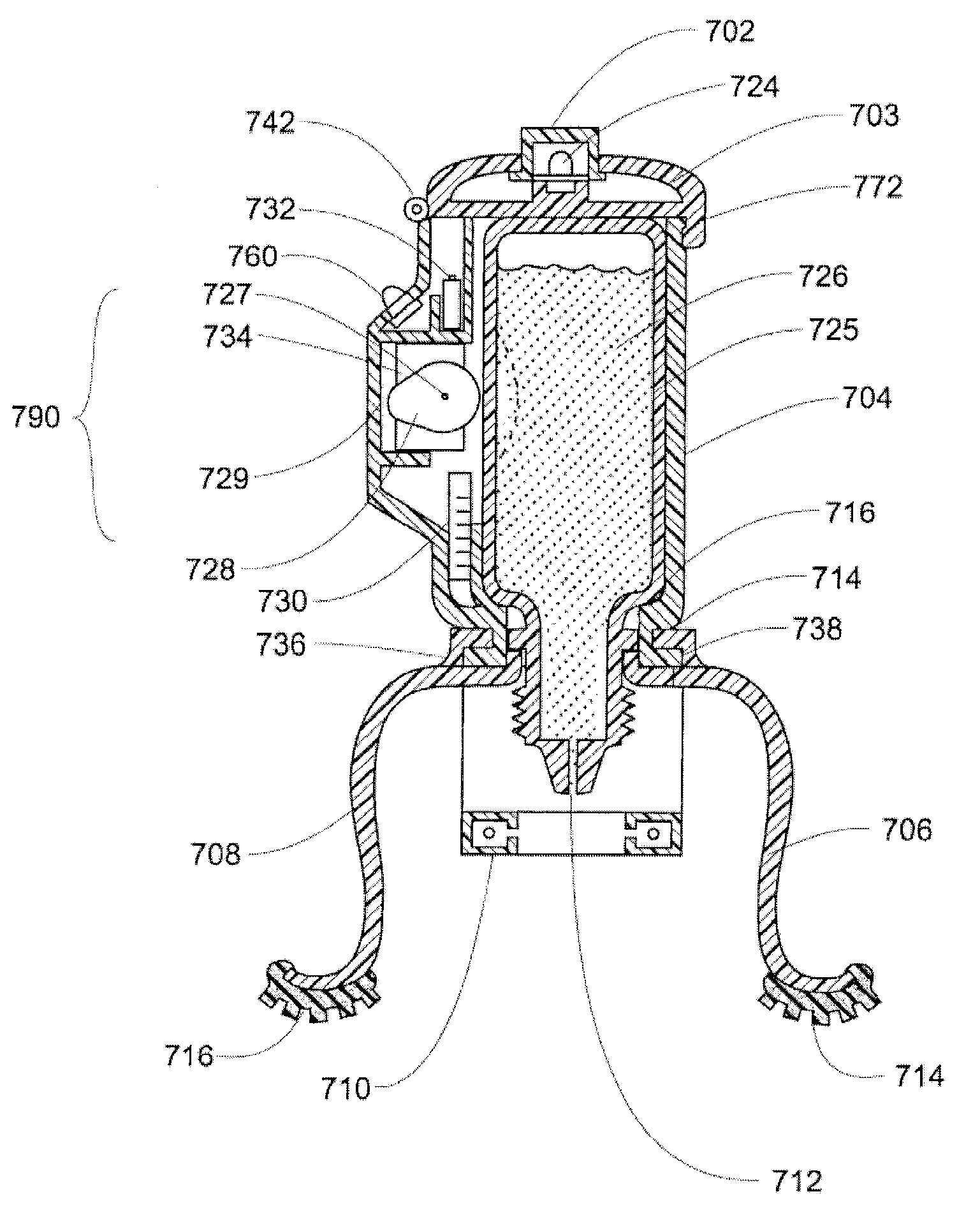

Systems and methods for supporting or occluding a physiological opening or cavity

ActiveUS20100094335A1Promote re-endothelializationPromote tissue growthStentsDilatorsImplanted deviceEngineering

Implantable devices for placement at a cavity or opening such as an aneurysm are disclosed. The implantable devices, in a deployed condition, have a generally inverted U-shaped profile with a curved or angled framework support structure sized and configured for placement in proximity to tissue surrounding the opening and anchoring legs extending proximally from the framework structure sized and configured to contact the wall of a neighboring lumen at opposed locations. Occlusive and semi-occlusive membranes may be associated with the framework support structure and deployed over the opening to provide exclusion of the opening and flow diversion. Proximal anchoring segments providing additional lumen wall surface area contact for the implantable device following deployment may be incorporated.

Owner:PULSAR VASCULAR

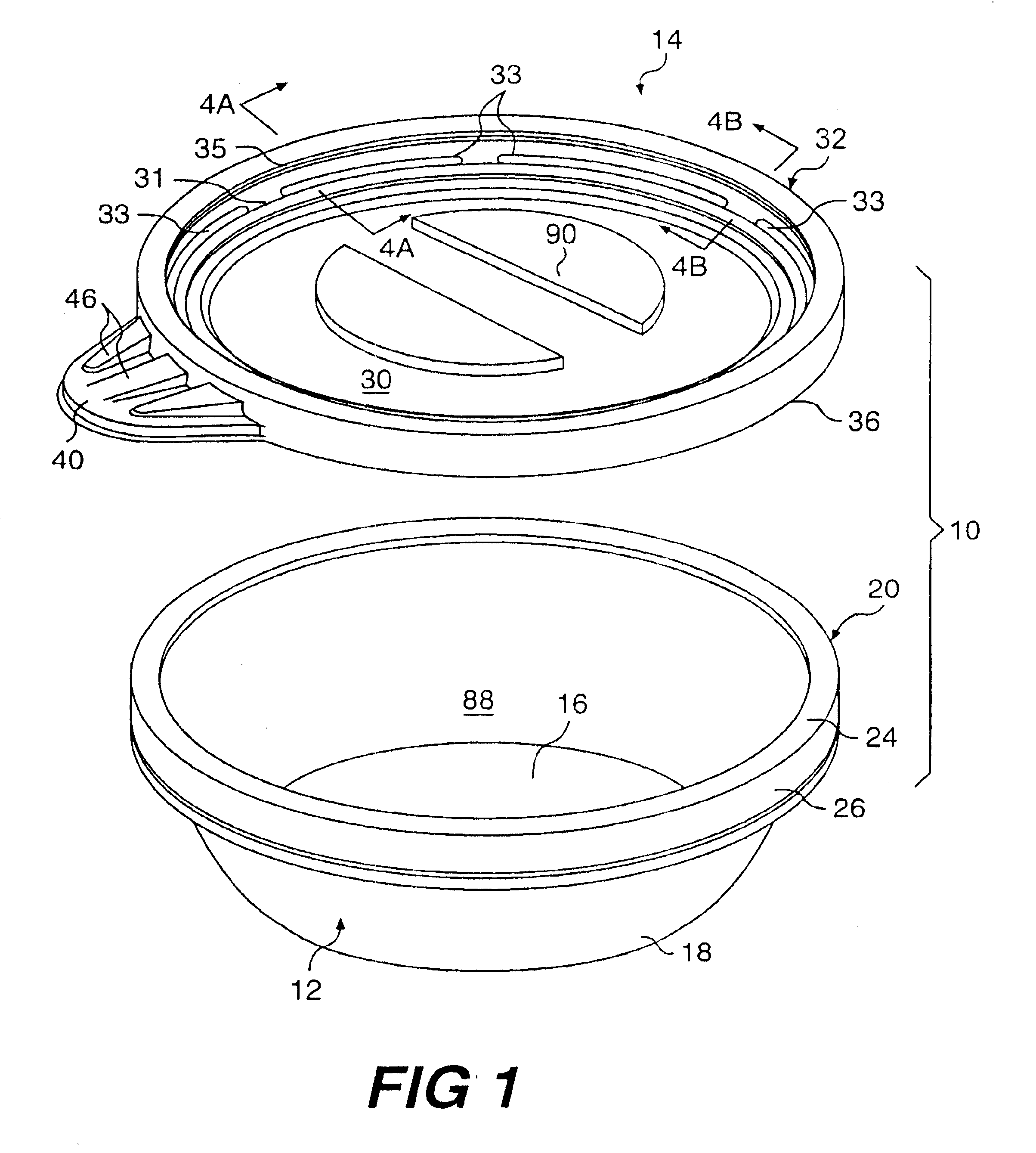

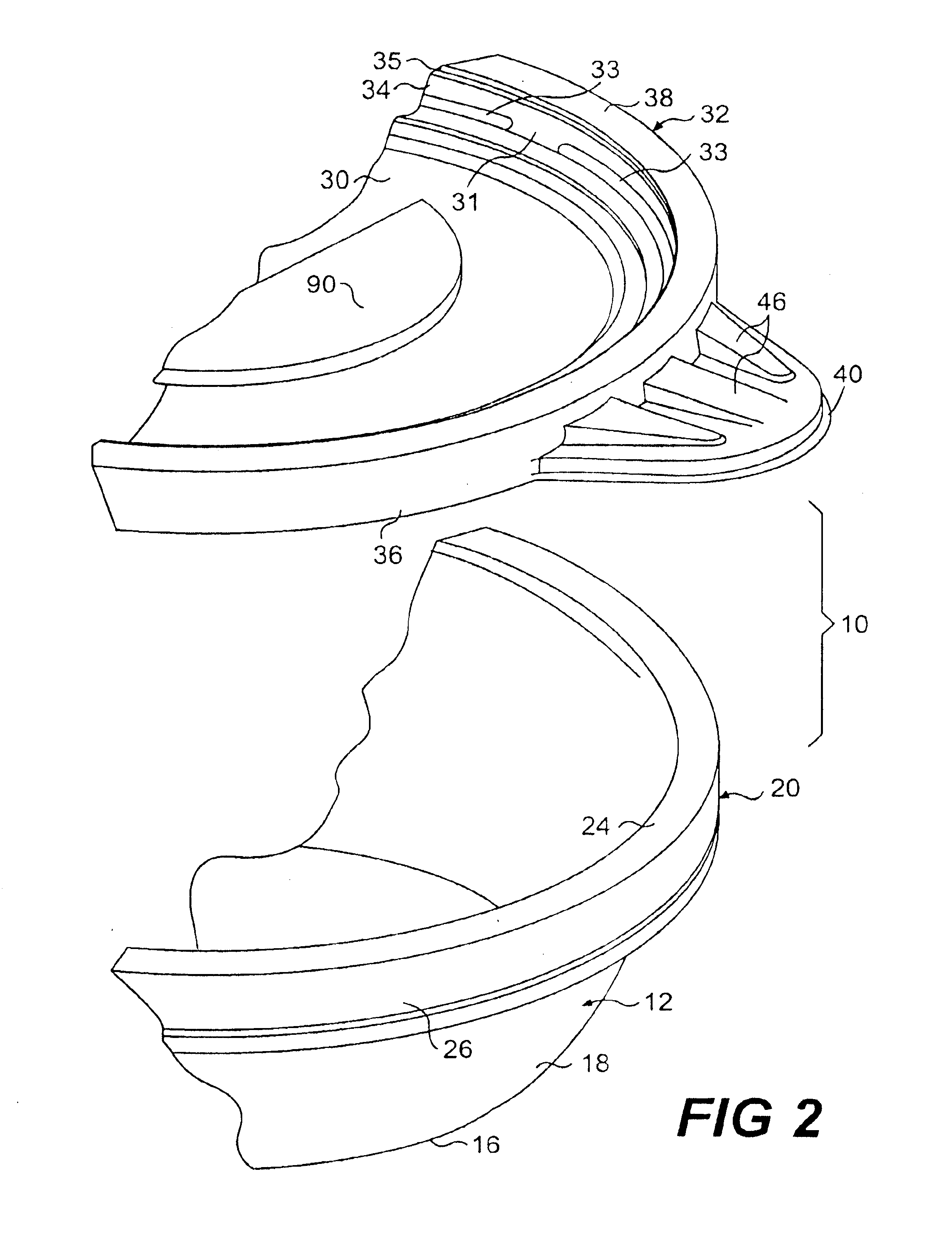

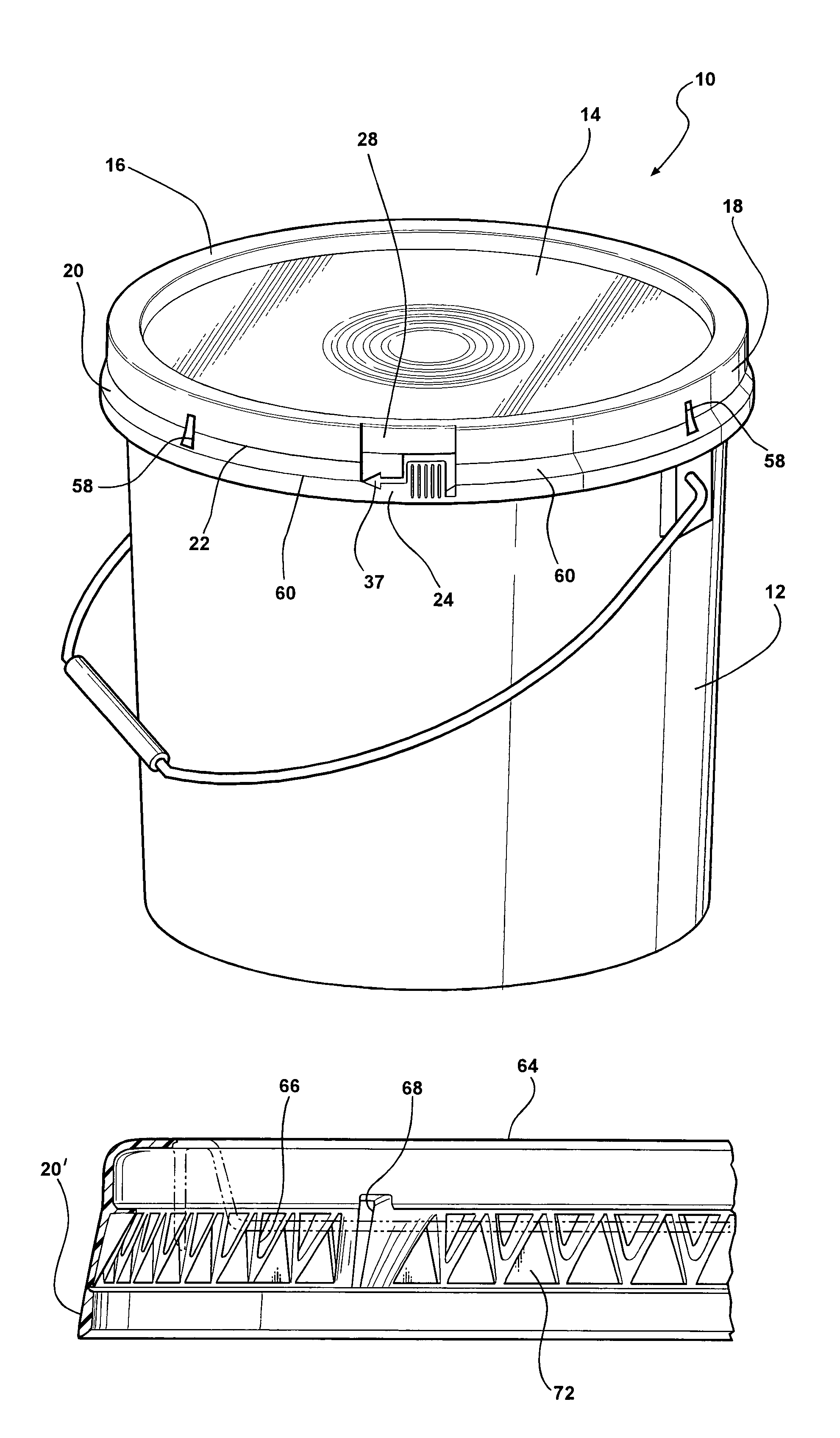

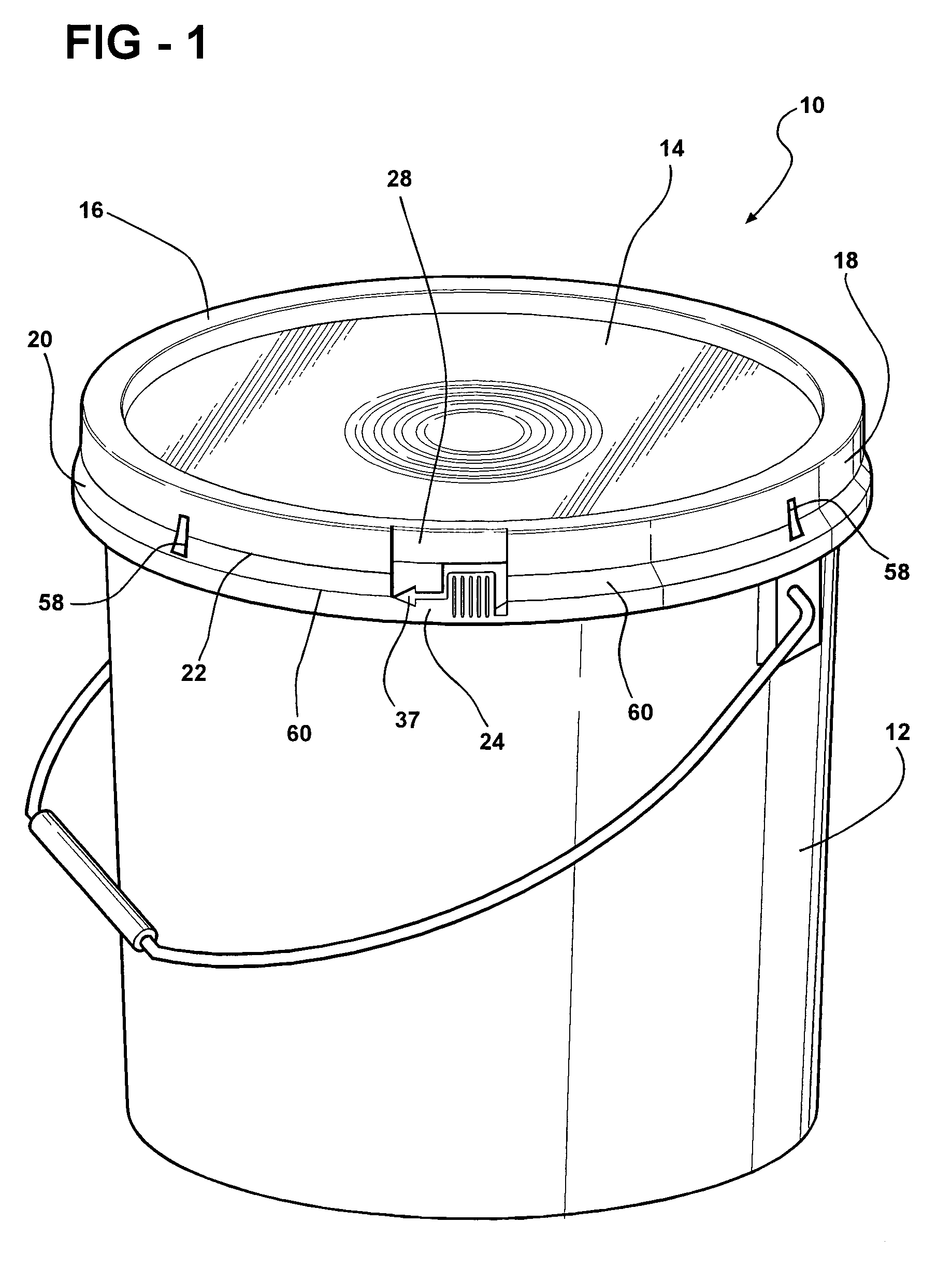

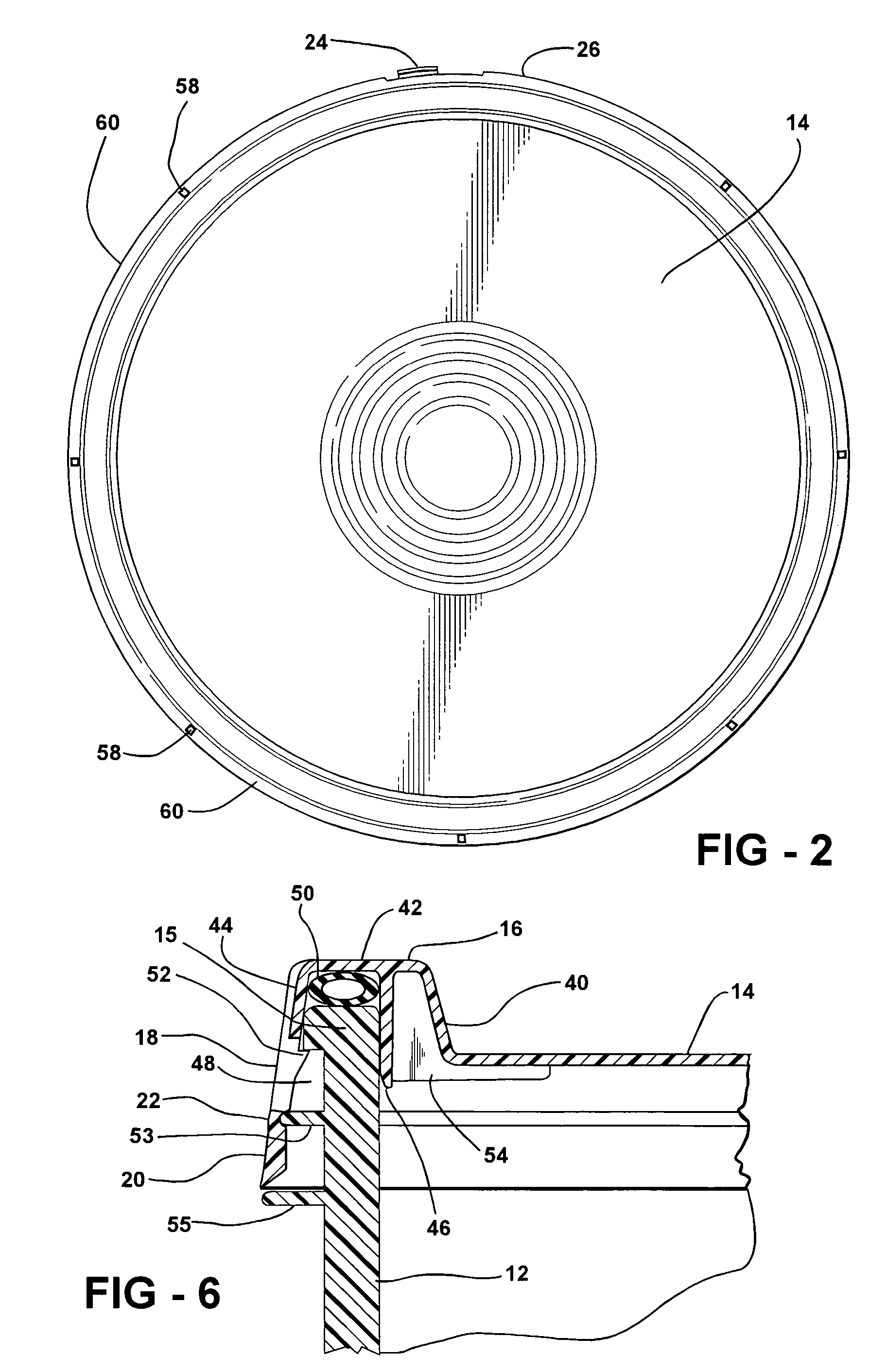

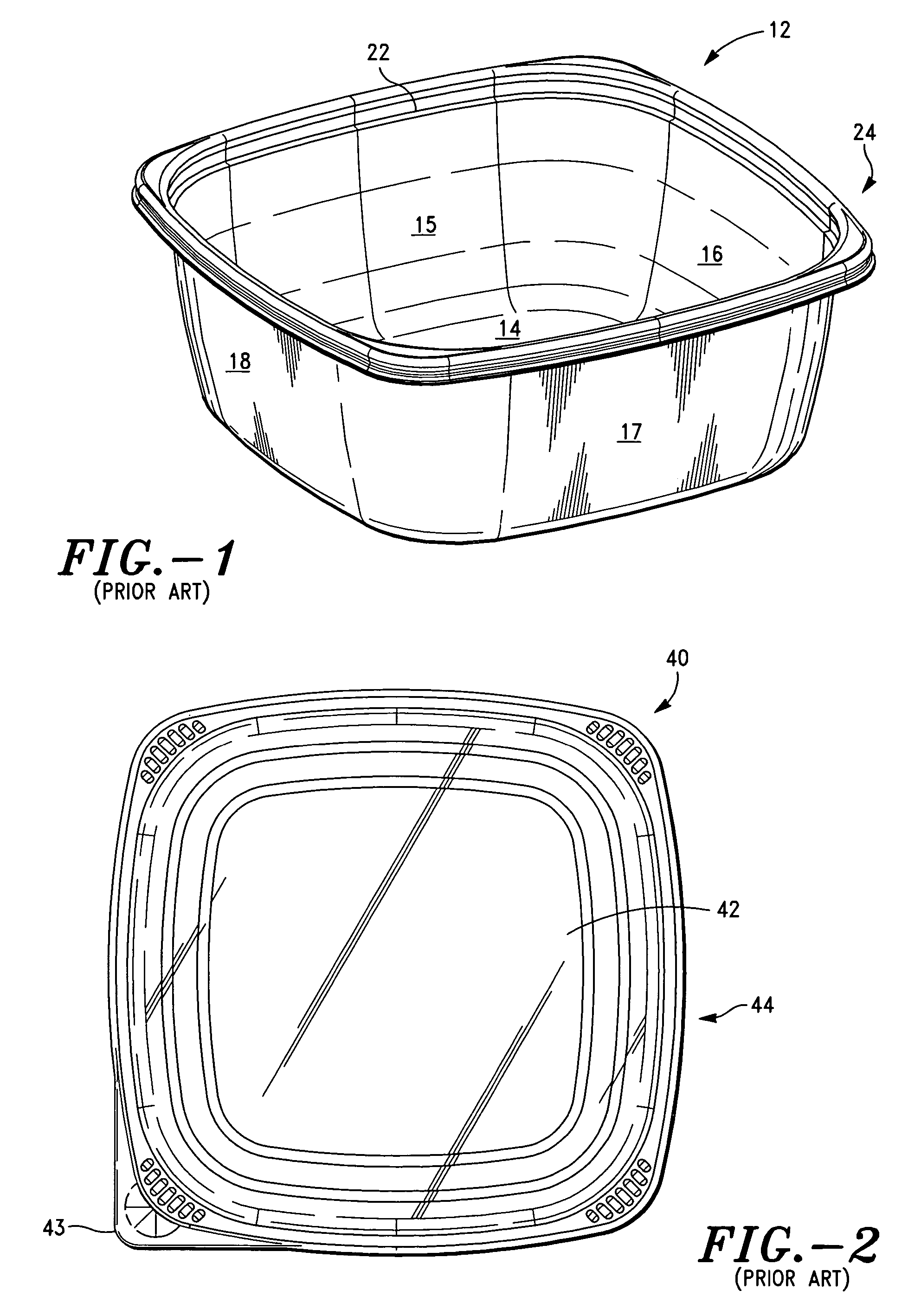

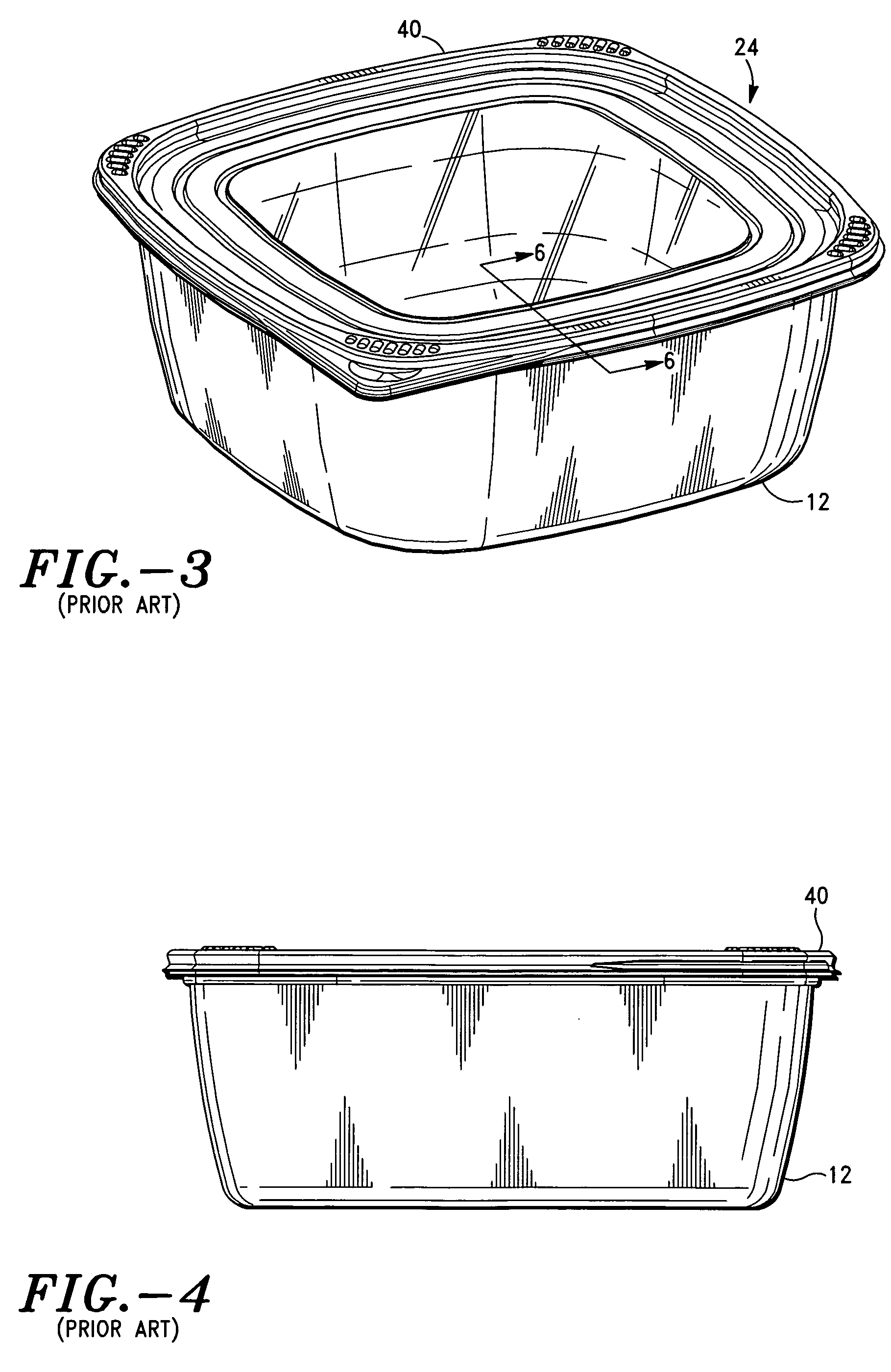

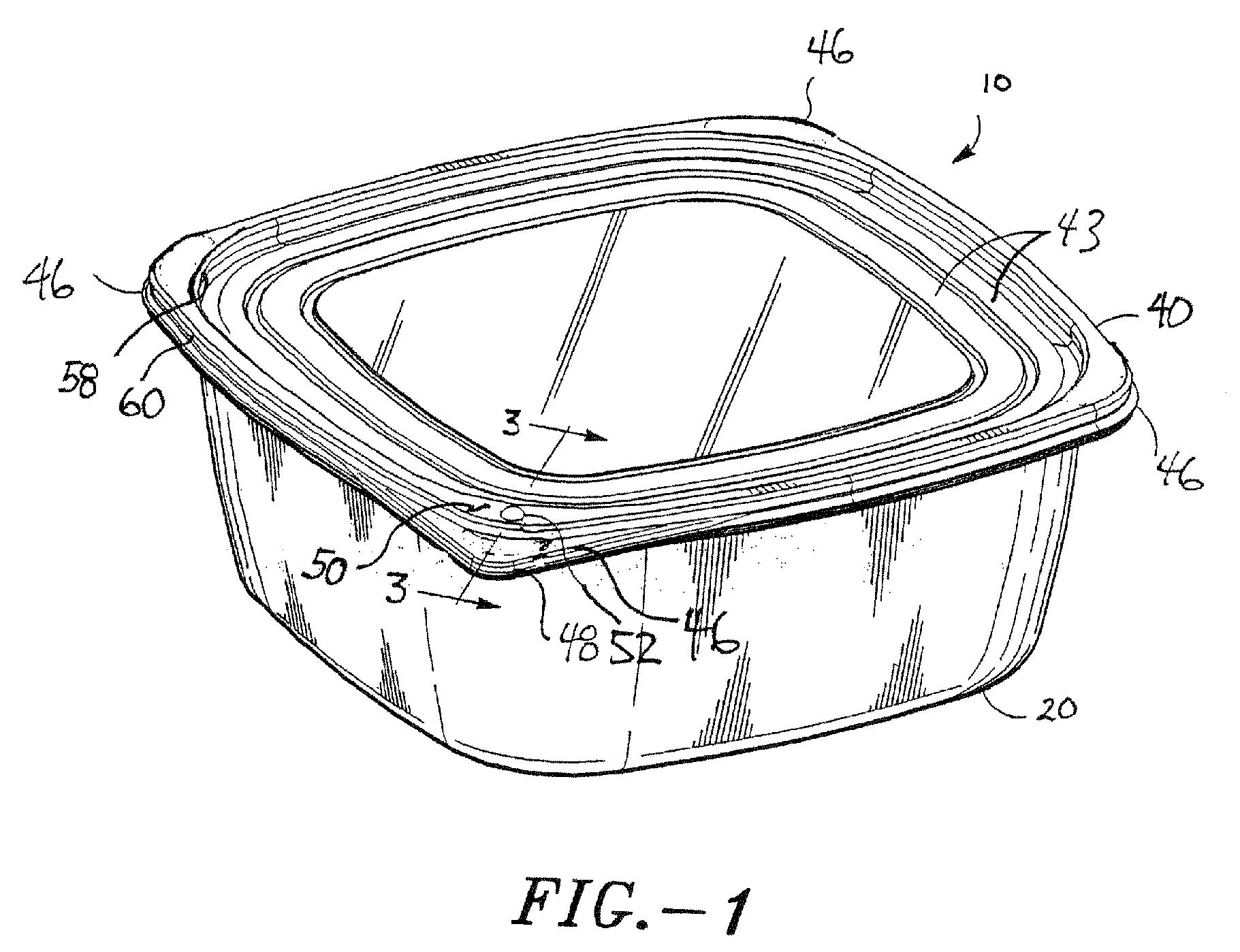

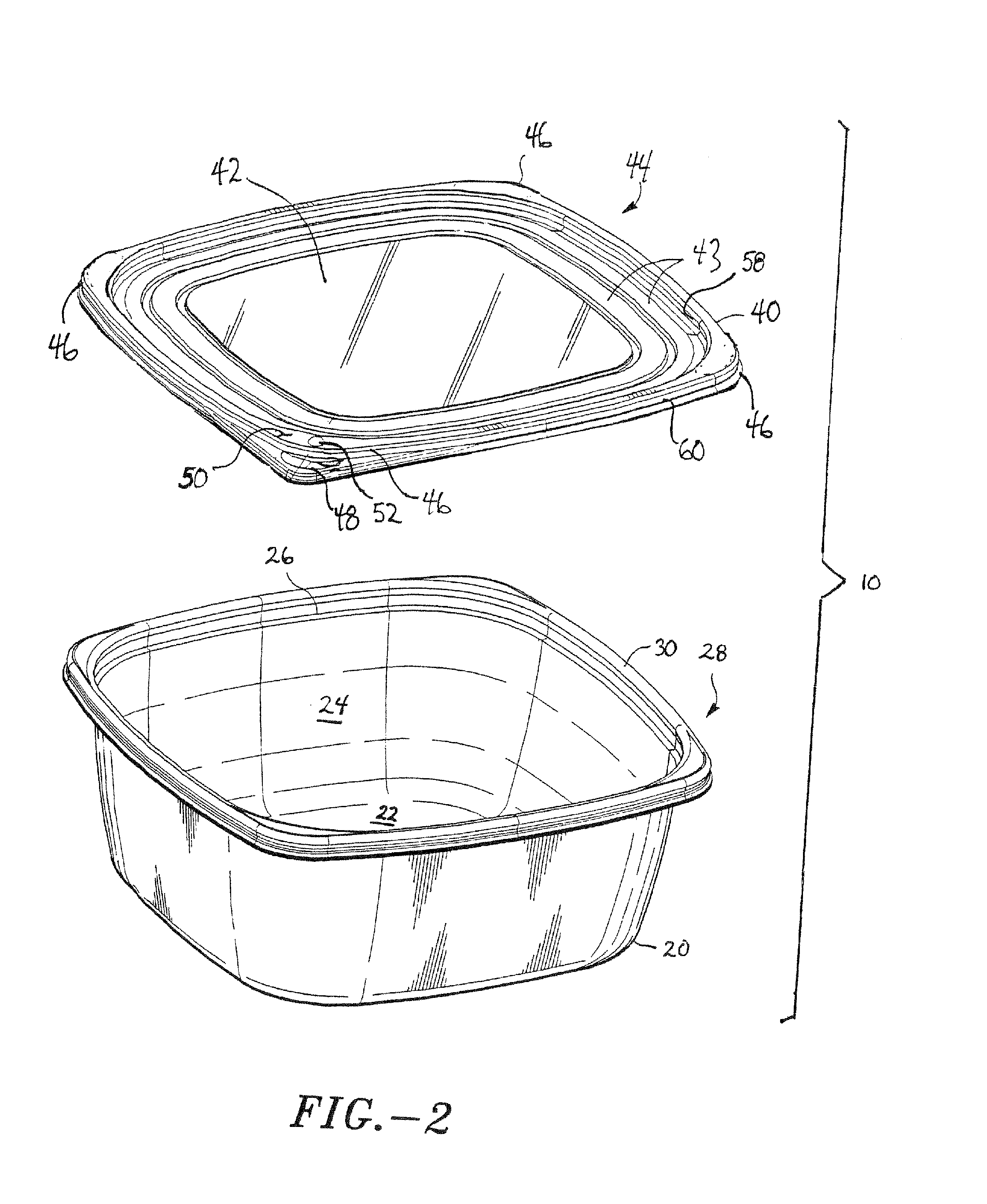

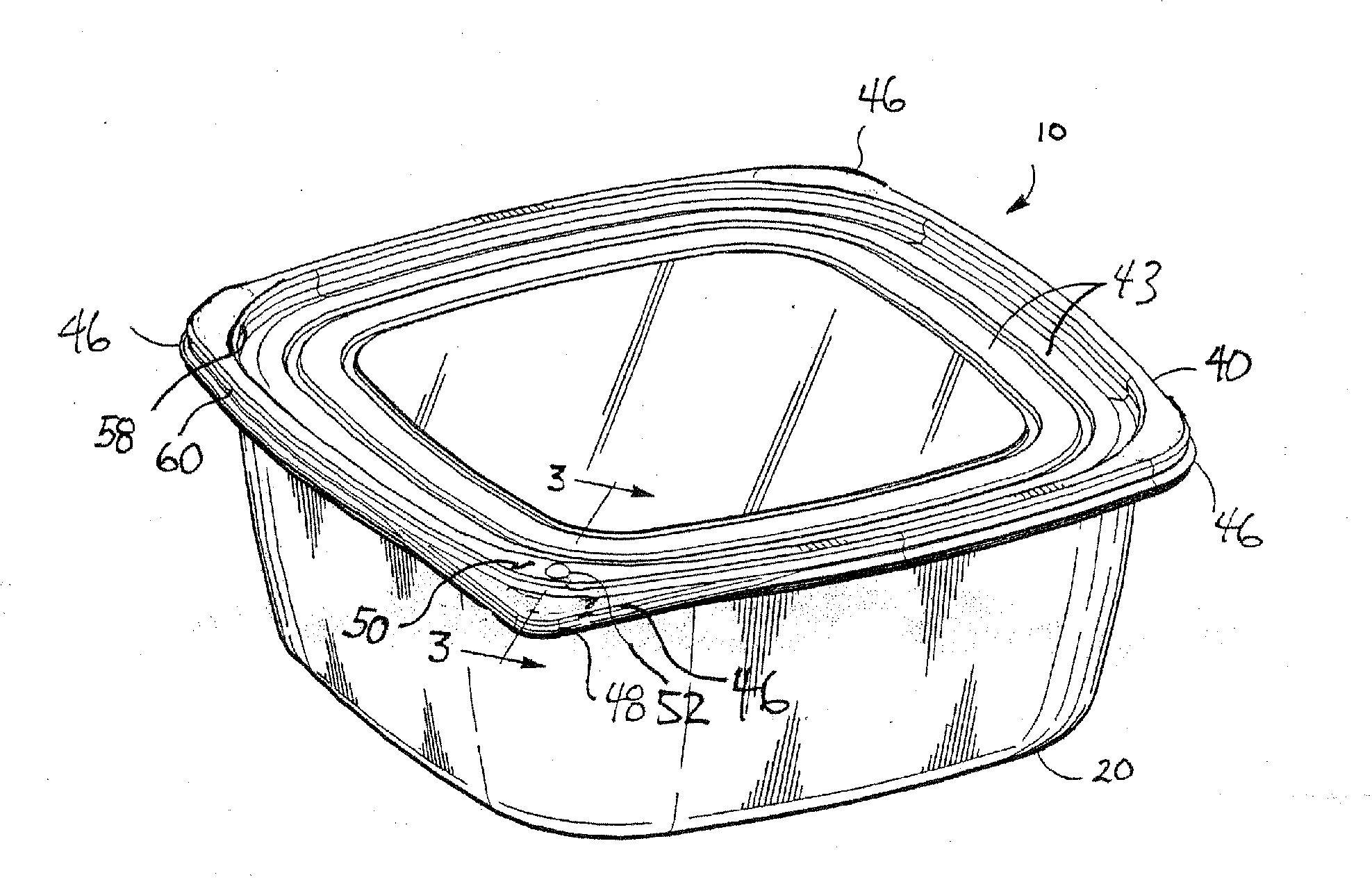

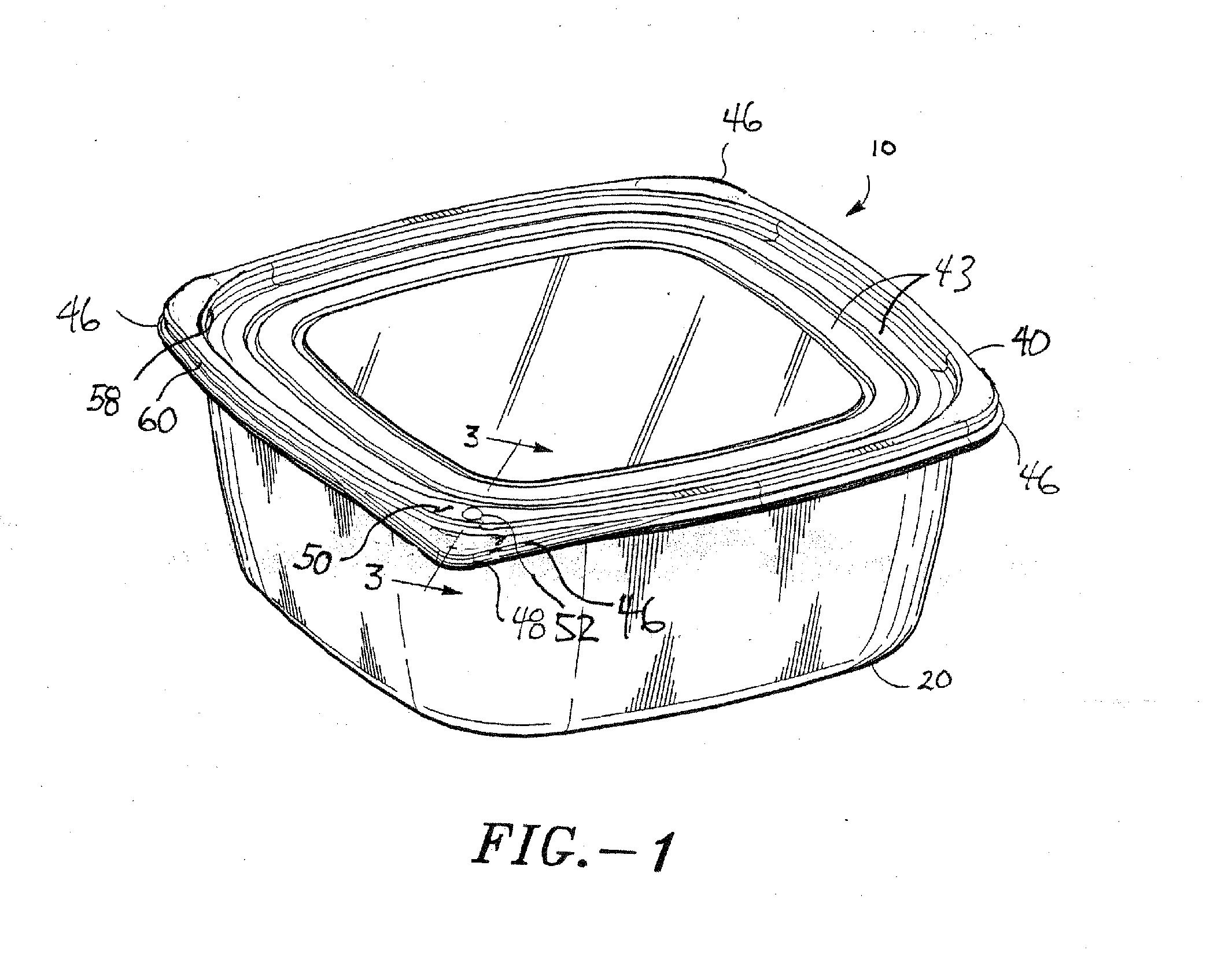

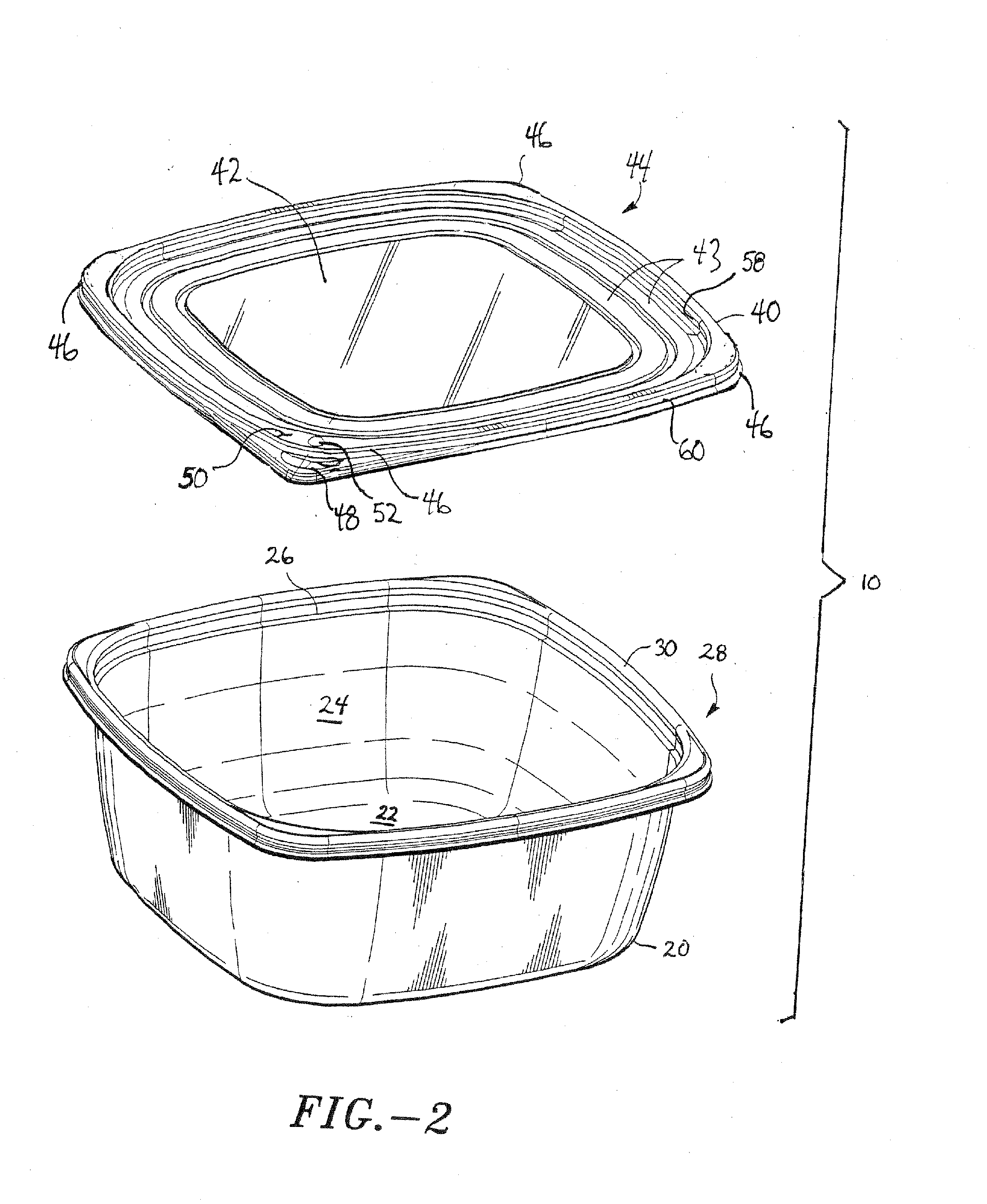

Container lid including venting and denesting features, and container having such a lid

A selectively detachable container lid includes a center panel and a peripheral sealing lip surrounding the panel. The peripheral sealing lip has a generally inverted U-shaped cross section so as to define a channel into which a bowl rim fits. The lid also includes at least one ridge formed between the panel and the peripheral sealing lip. The ridge is interrupted by at least one gap. The ridge and the peripheral sealing lip partially overlap when viewed in a direction substantially normal to the panel. The ridge also abuts the bowl when the lid is placed loosely on the bowl. Also disclosed is a container that includes such a lid.

Owner:SC JOHNSON & SON INC

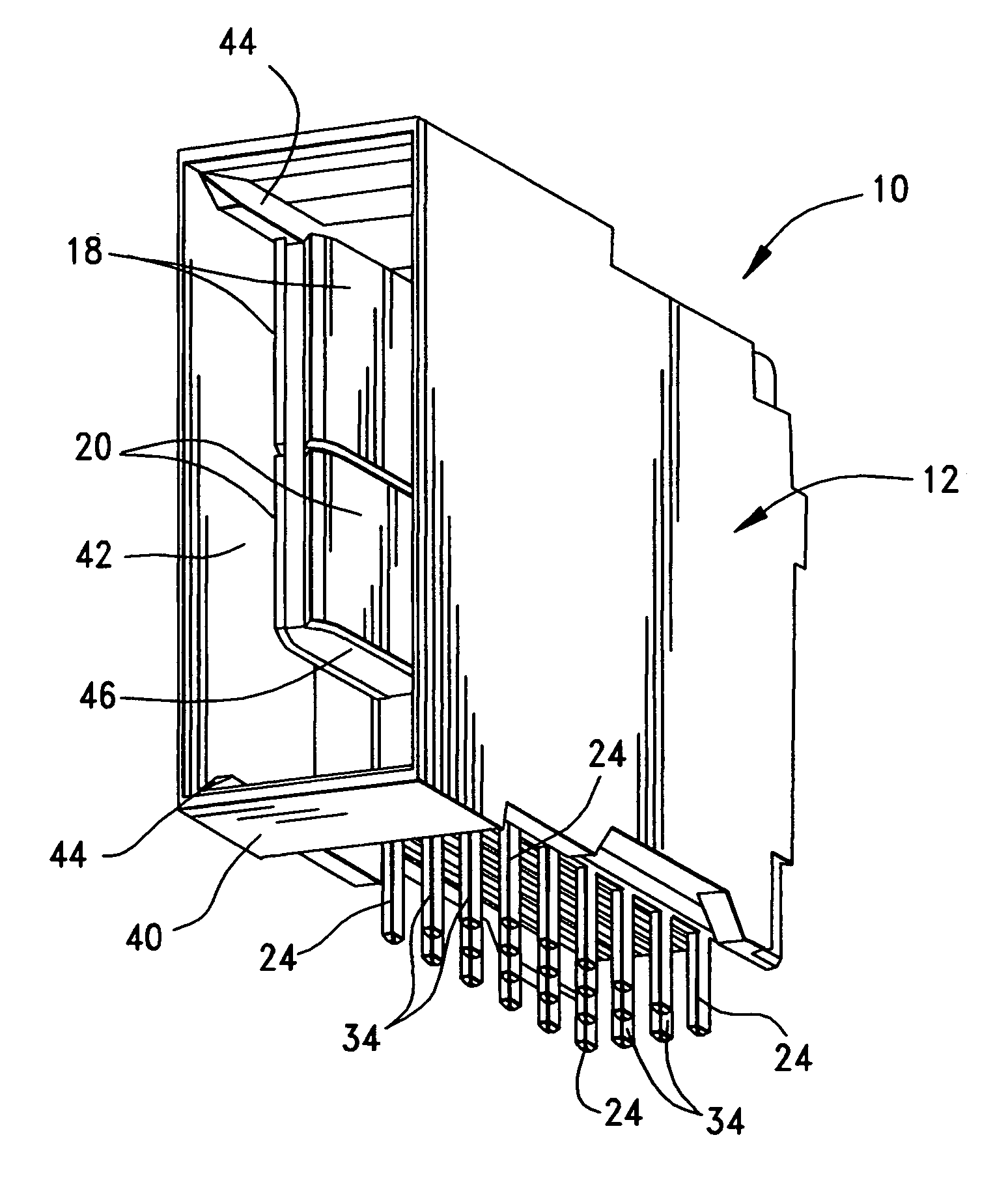

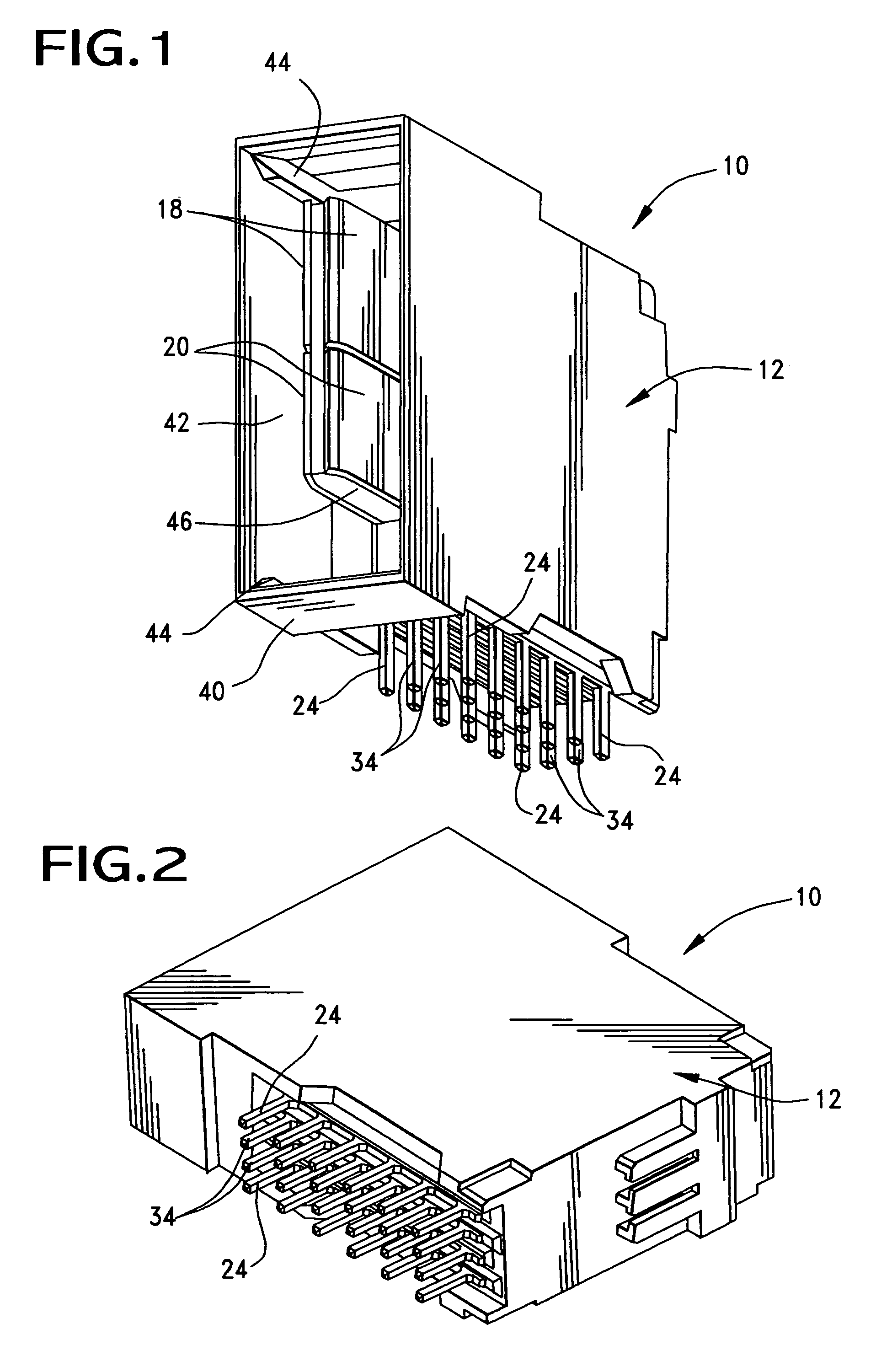

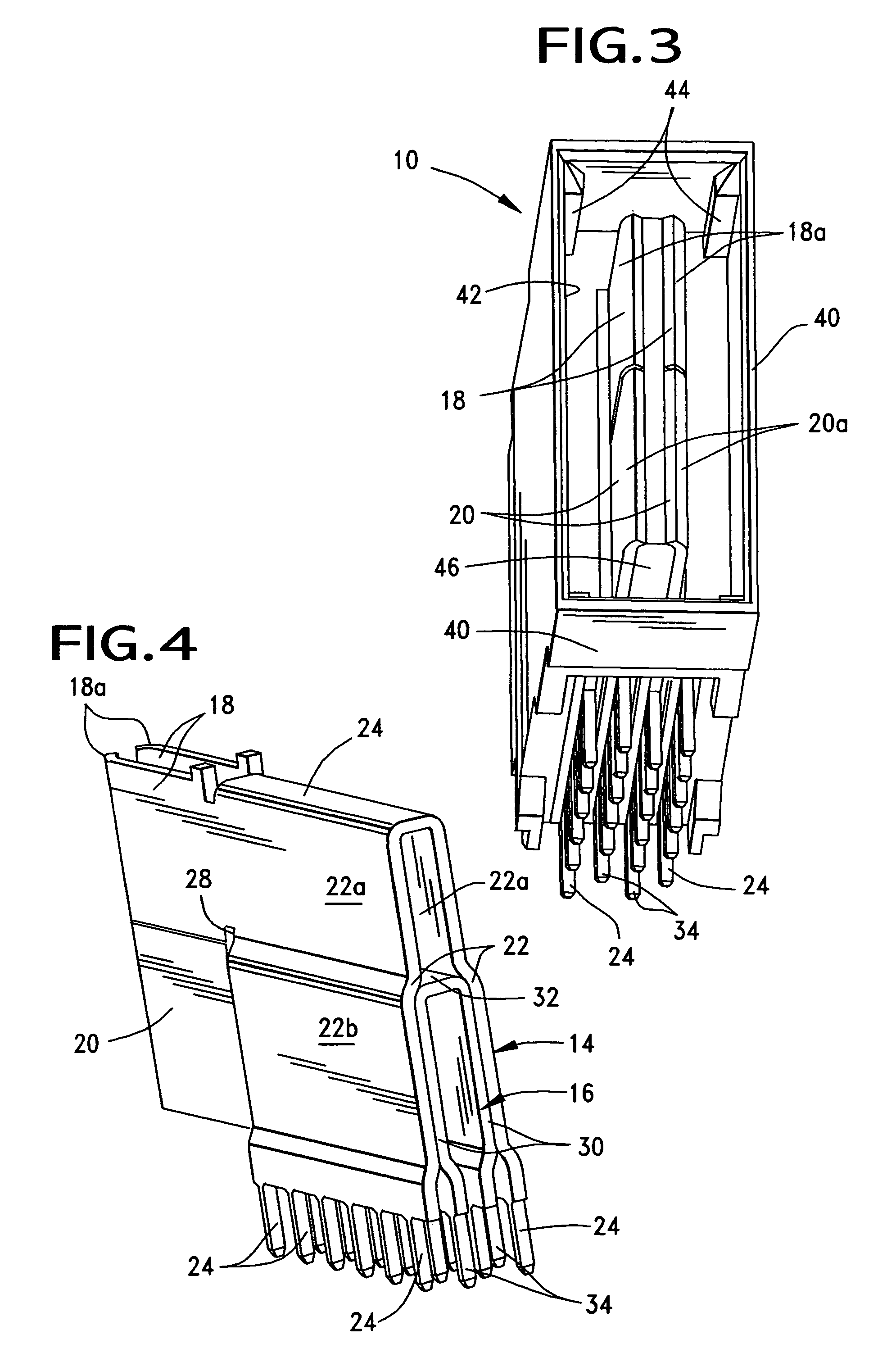

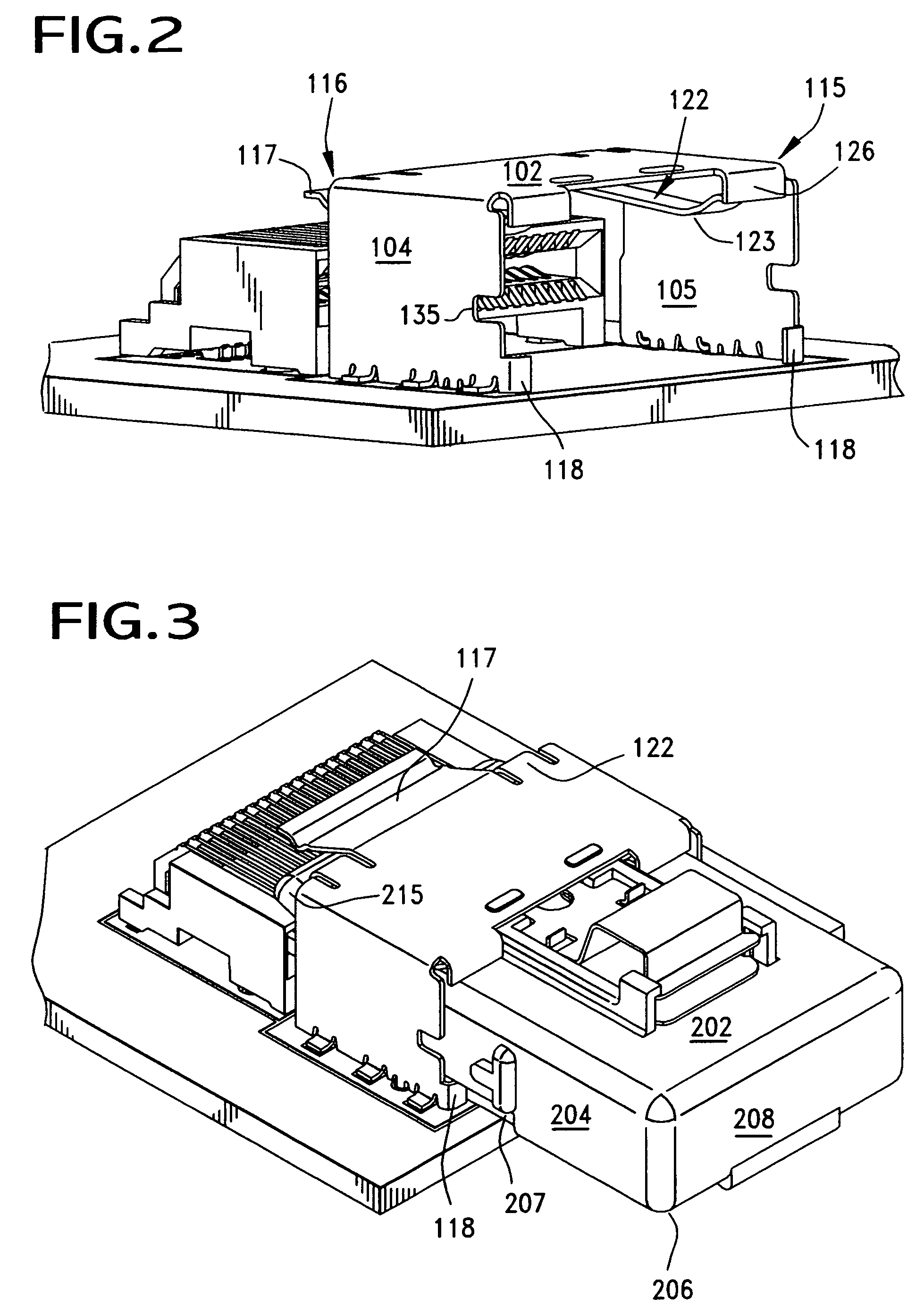

Board mounted power connector

ActiveUS7001189B1Coupling device connectionsLine/current collector detailsEngineeringPrinted circuit board

An electrical power connector is mountable on a printed circuit board. The connector includes an outer terminal and an inner terminal, both of which are of generally inverted U-shaped configurations, with the inner terminal nested in the outer terminal. Solder tails project downwardly from bottom edges of side walls of the two terminals. Both terminals have a pair of blade portions projecting forwardly from the respective side walls of the terminals, whereby the blade portions of each terminal are spaced from each other. The blade portions of one terminal are generally coplanar with the blade portions of the other terminal. A dielectric housing is overmolded about the side walls of the outer terminal, leaving the solder tails and the outside surfaces of the blade portions exposed. The housing has a projecting portion extending into the spacing between the blade portions of the two terminals against the inside surfaces of the blade portions, leaving the outside surfaces of the blade portions exposed.

Owner:MOLEX INC

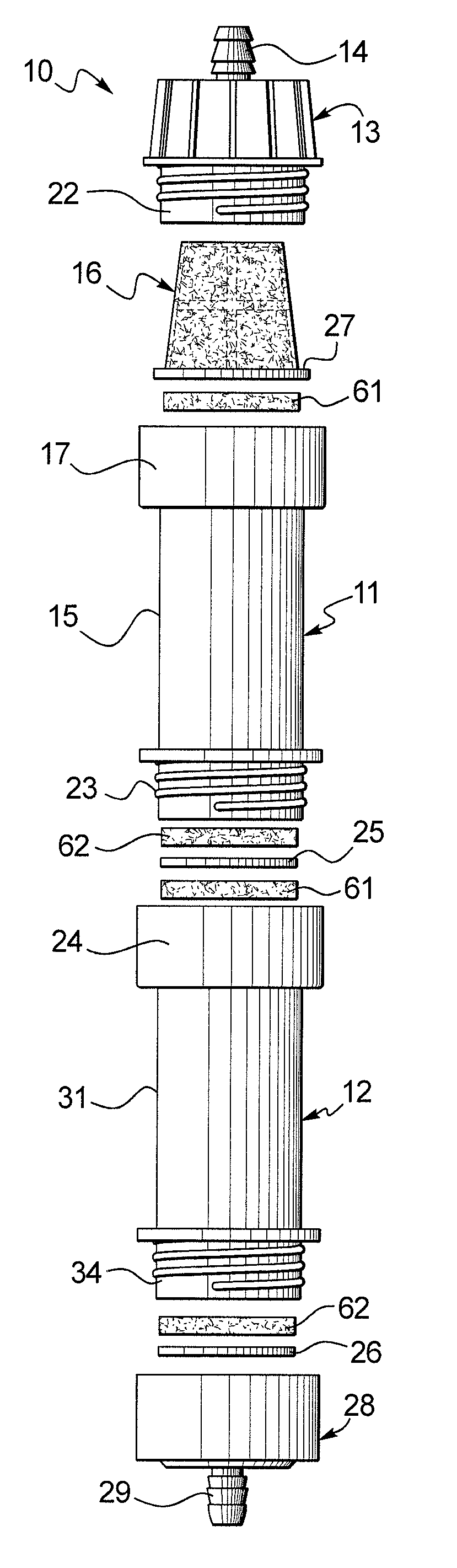

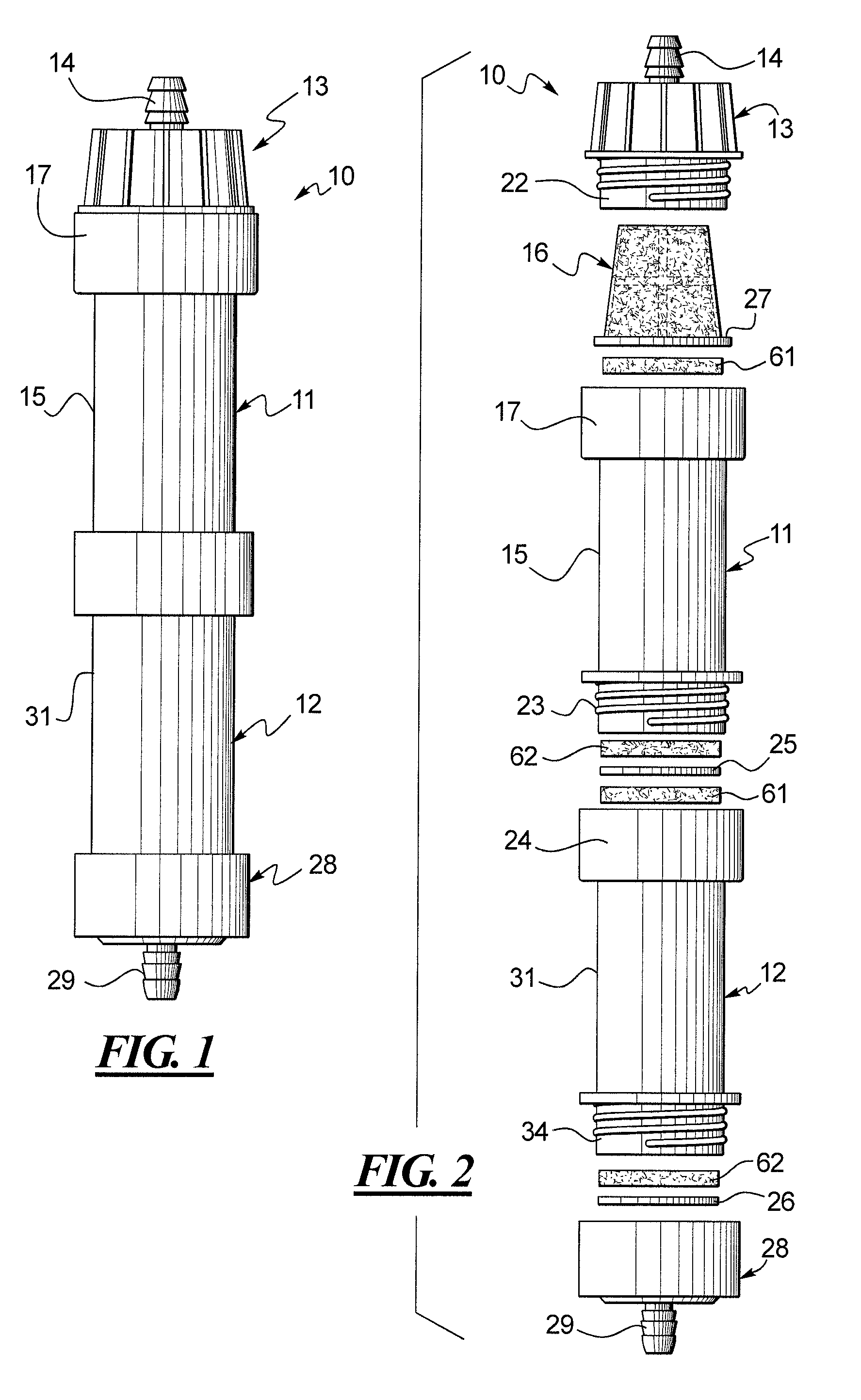

Modular Water Purification and Delivery System

InactiveUS20090008318A1Maximize capacityFlattening or eliminating the parabolic fluid flow profileUltrafiltrationWater/sewage treatment by ion-exchangeFiberHollow fibre

A modular filter system is provided with one or more modules that can be interchangeable, depending upon the specific application or specific health or environmental issue presented. Disclosed combinations can include one or more of any of the following modules in any relative position to one another: (a) a microbiological contaminant mitigation module, preferably in the form of an inverted u-shaped hollow fiber filter module wherein the fibers have ends potted on the downstream side and that consists essentially of hydrophilic fibers for water filtration with a small amount of hydrophobic fibers for venting of entrapped air; (b) a first chemical mitigation module, preferably in the form of an adsorption module comprising carbon or the combination of carbon and a deionization resin; and (c) a second chemical mitigation module, preferably in the form of a deionization resin module. Modules including a carbon bed or a resin bed may be equipped with a pair of hydrophobic foam bed restraints that apply opposing axial pressure to the bed in all operating conditions.

Owner:PRISMEDICAL CORP

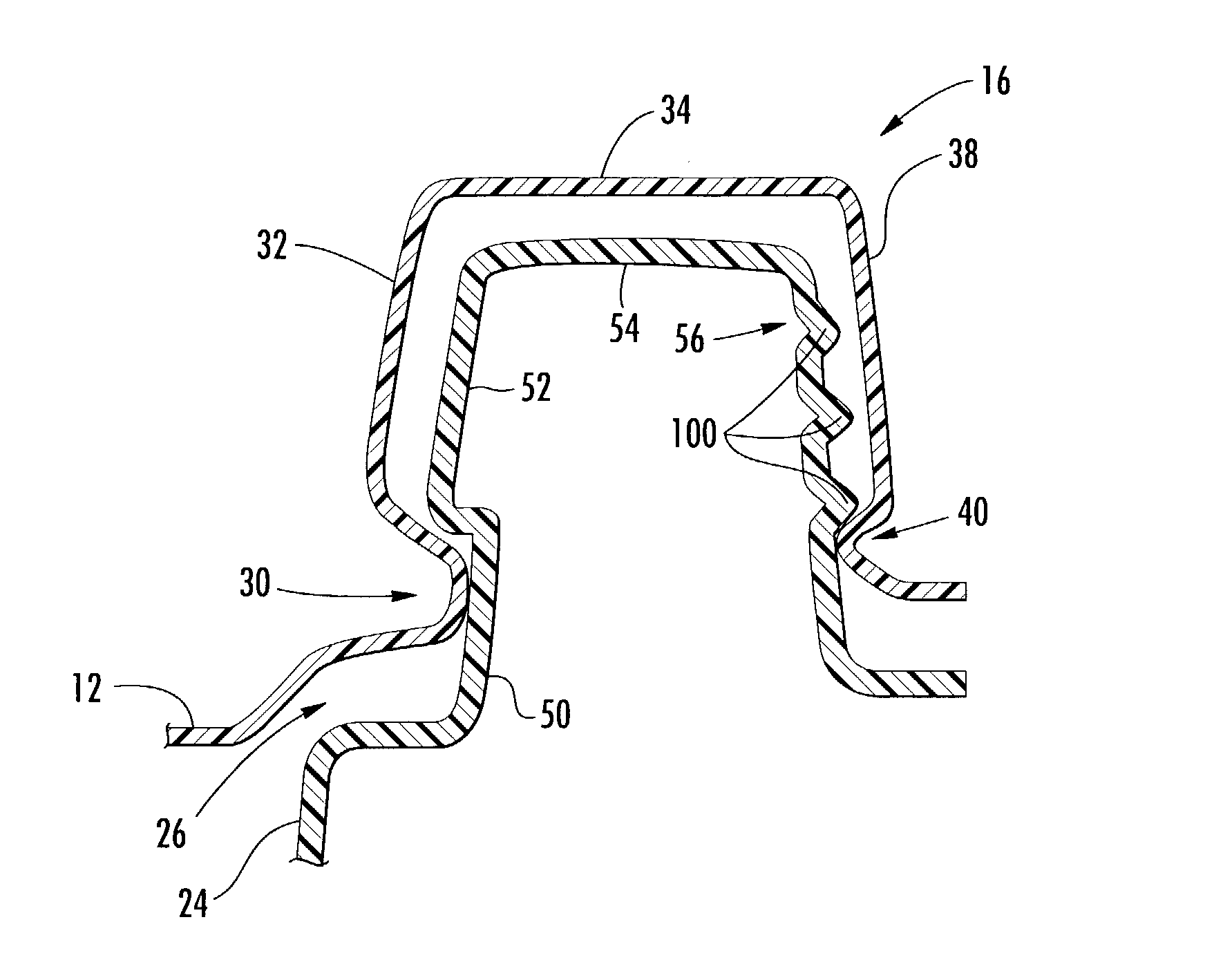

Closure with tear strip

InactiveUS7207457B2Improve effectivenessEasy to disassembleCapsClosure capsMechanical engineeringInverted u

A closure for covering an opening of a container. The closure includes an inverted U-shaped peripheral channel for receiving the rim of a container therein. A tear strip is formed with the skirt of the closure via a tear line that circumscribes the skirt. A breakaway pull tab having an inner surface with U-shaped ribs, the combination of the surface and ribs being such as to provide a concavity which assists in gripping the tab to pull the strip away. Linear vertical ribs may be provided on the outer surface to provide further assistance in the gripping function. The skirt includes a recessed area underlying the pull tab for providing access to the pull tab. An alternative embodiment uses a zig-zag structure of strengthening ribs in the skirt to reduce the amount of material necessary to provide the undercut. This reduces the probability of warpage in the closure structure.

Owner:LETICA

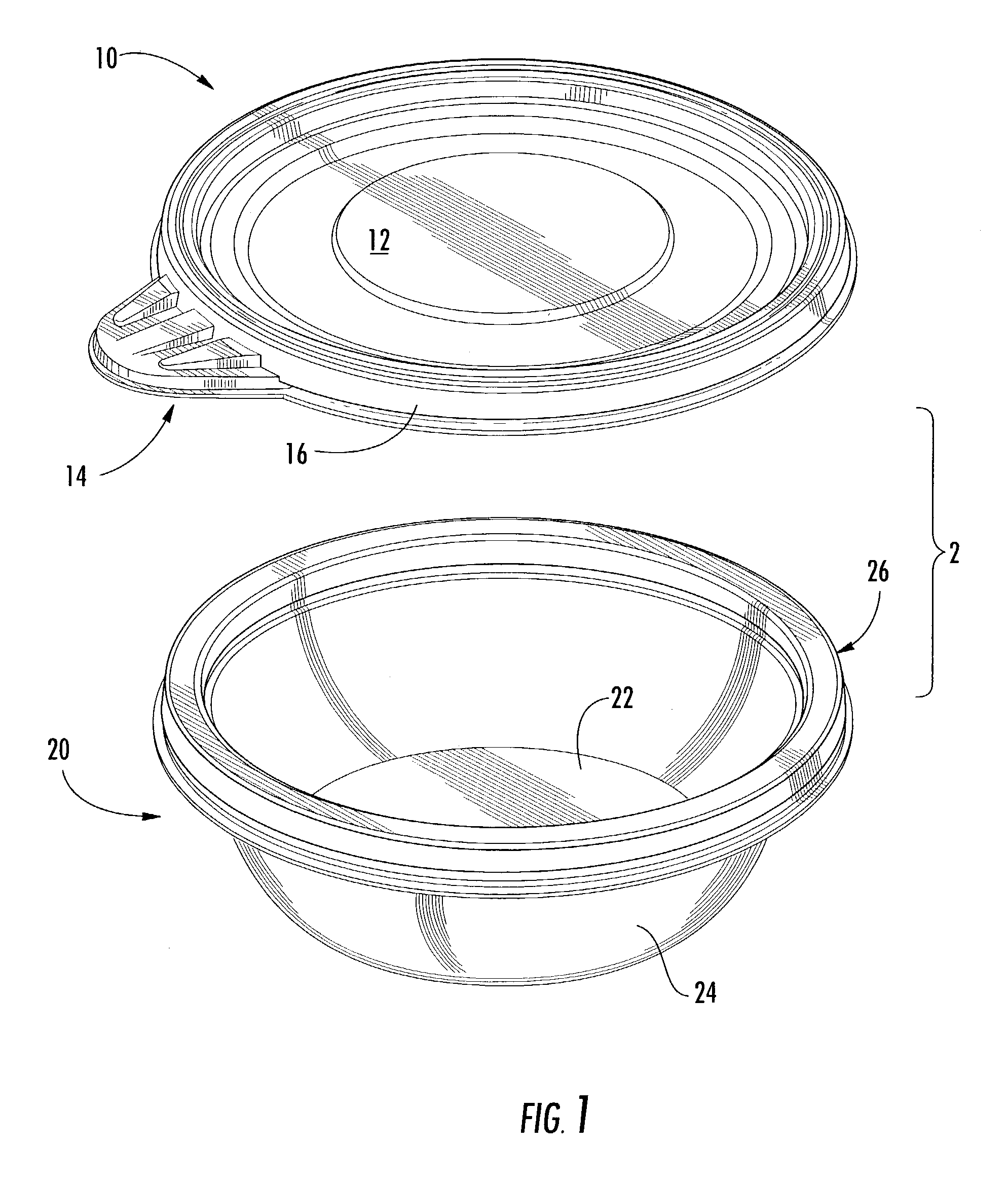

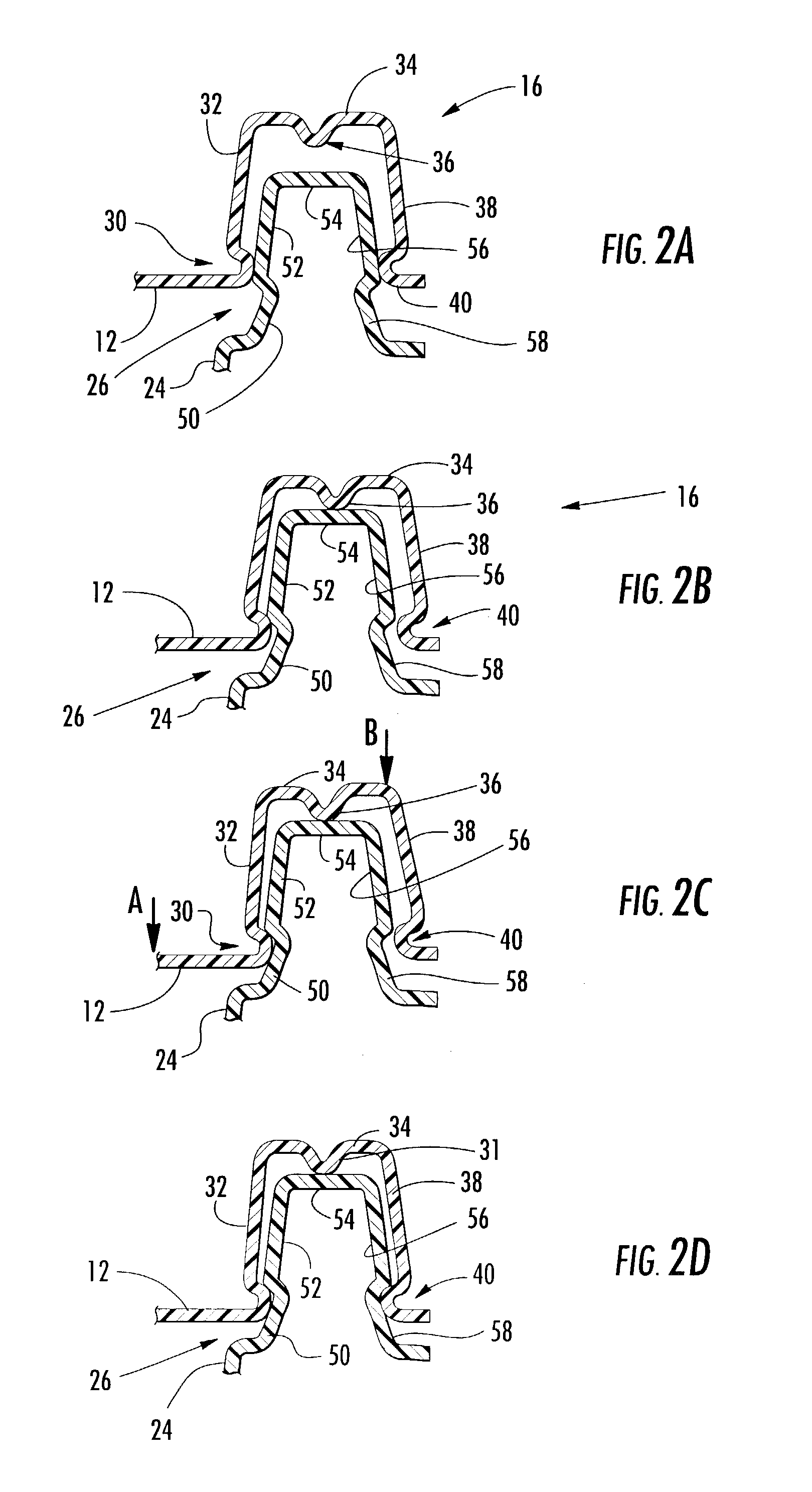

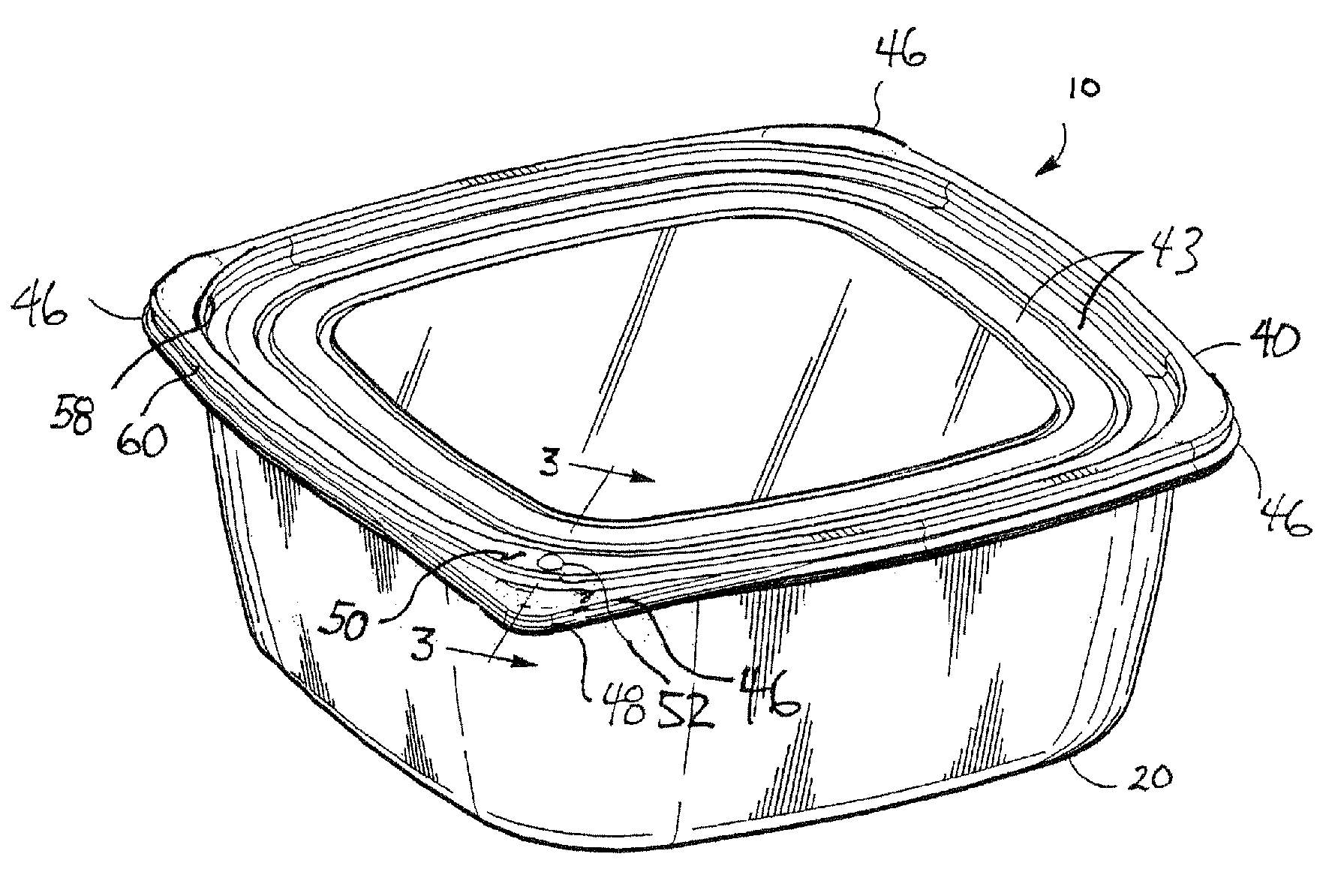

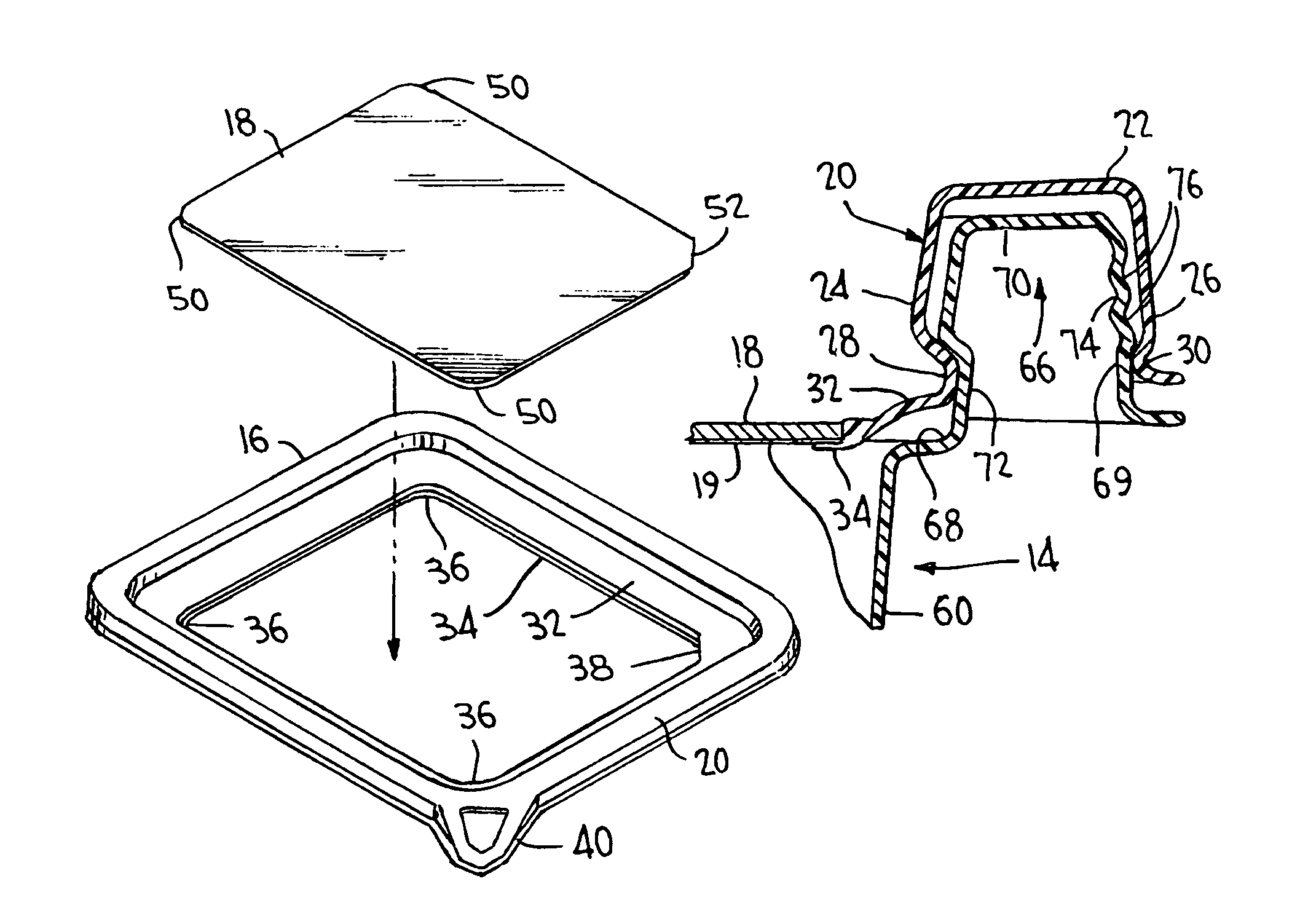

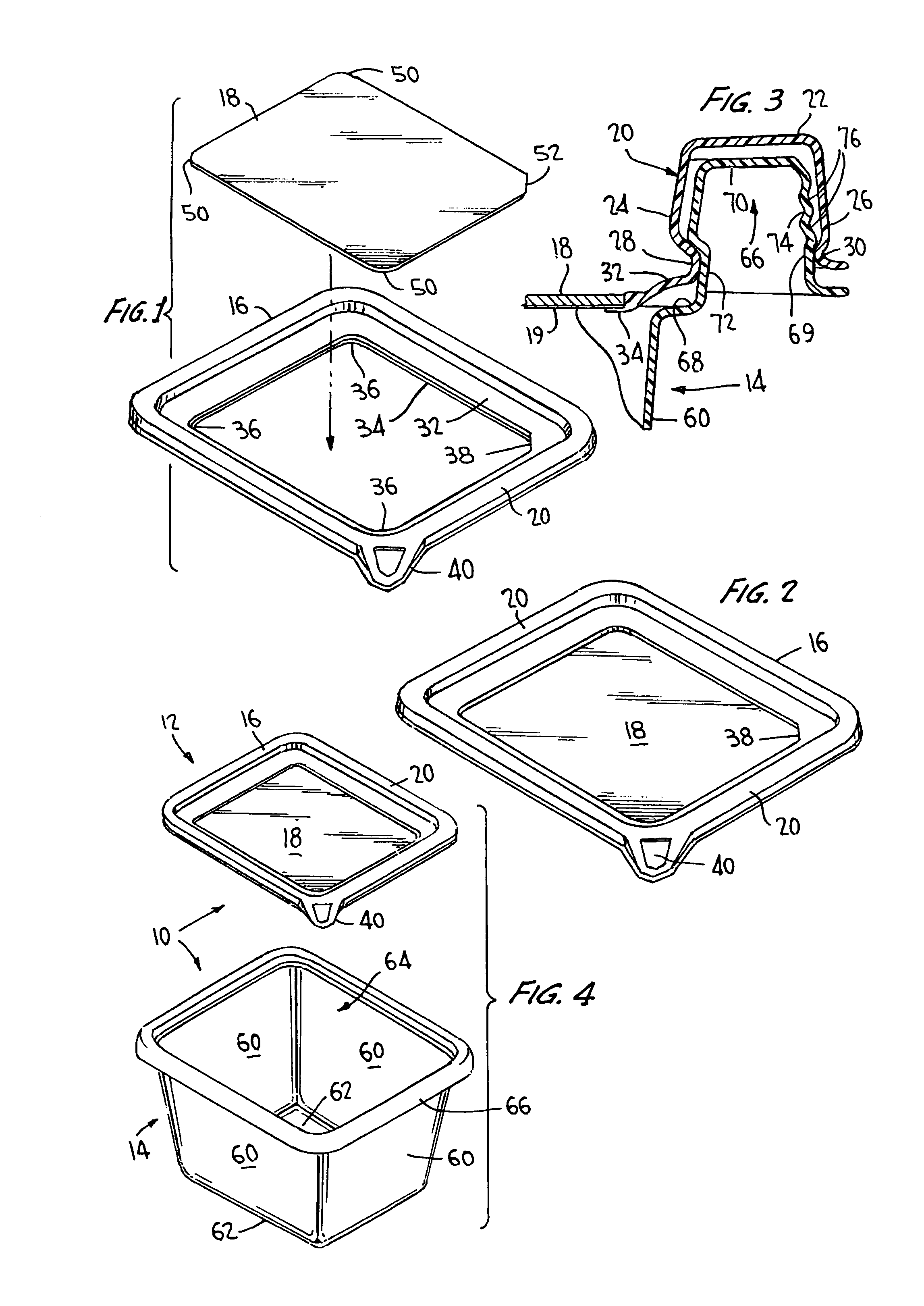

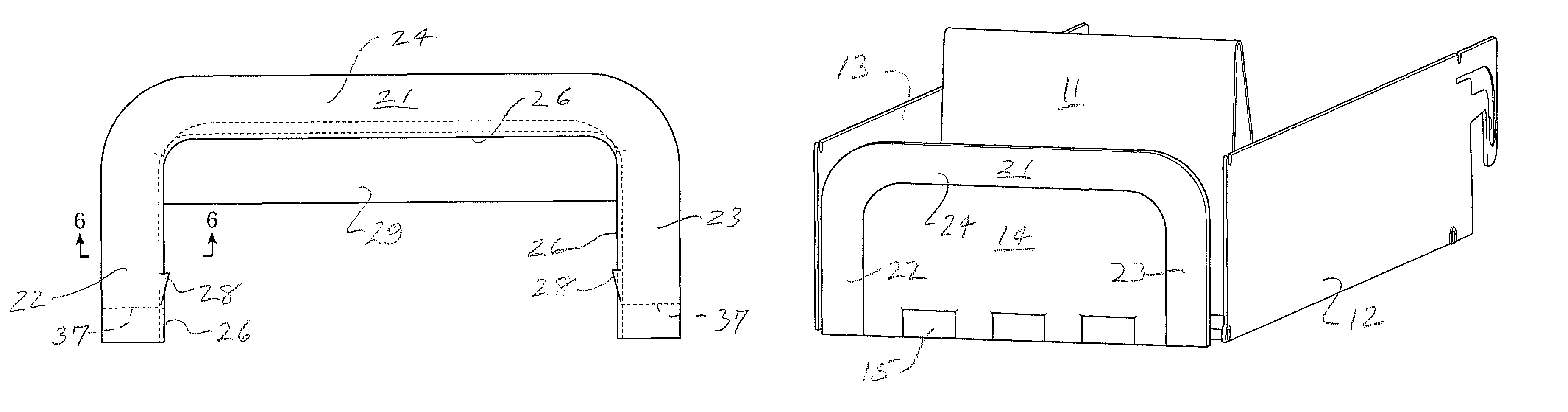

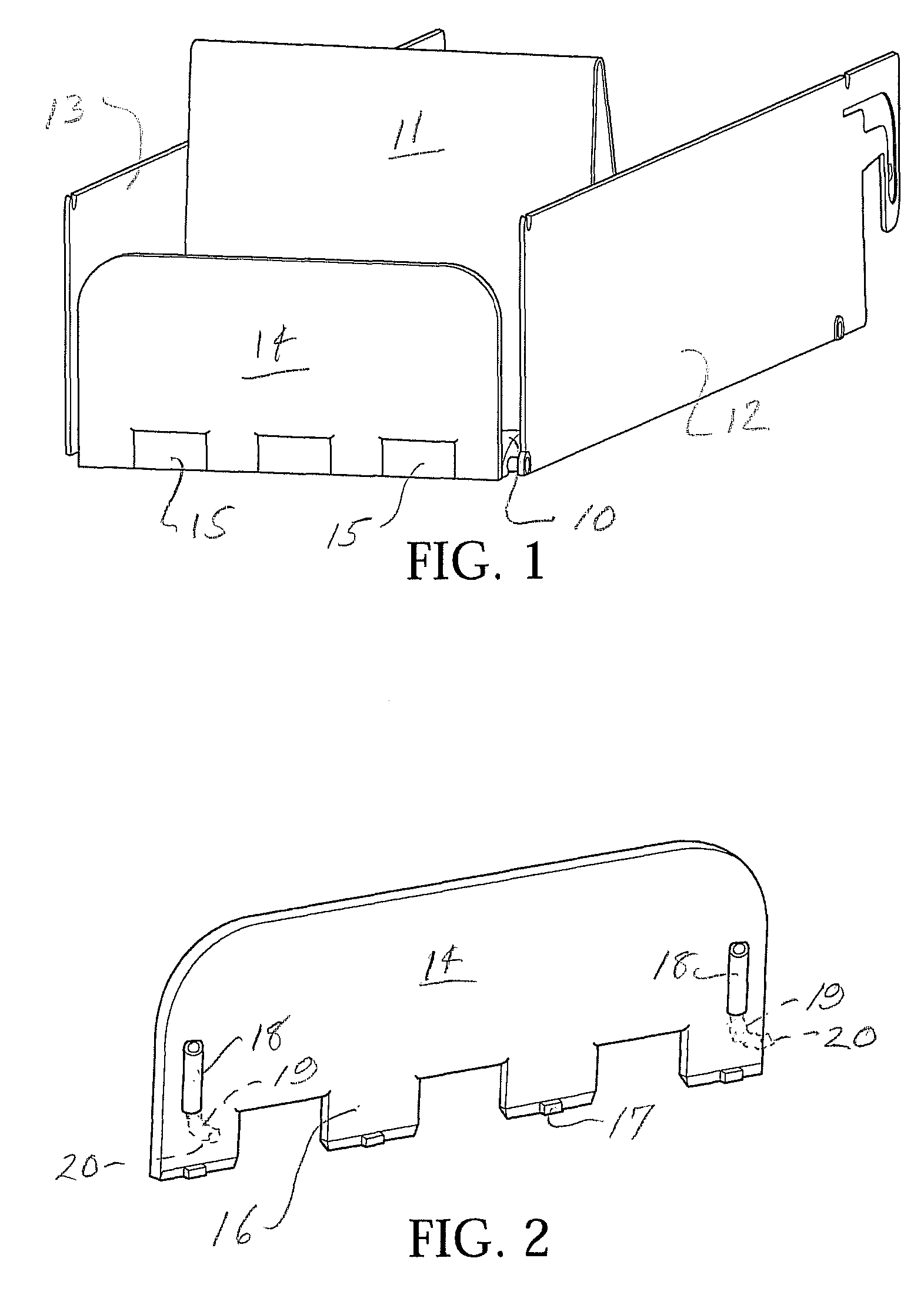

Container including a bowl and a lid each having interfitting lips

A container (2) includes a bowl (20) and a lid (10). The lid (10) includes a lid lip (16) having a generally inverted U-shape and the bowl (20) includes a bowl lip (26) having a generally inverted U-shape such that the lid lip (16) and the bowl lip (26) interfit, forming mutually opposing surfaces, with the lid lip (16) superposing the bowl lip (26). At least one of the bowl lip (26) and the lid lip (16) includes a seal in firm contact with the opposing surface, with the seal contacting the opposing surface in a small area relative to a total surface area of the bowl lip (26).

Owner:SC JOHNSON & SON INC

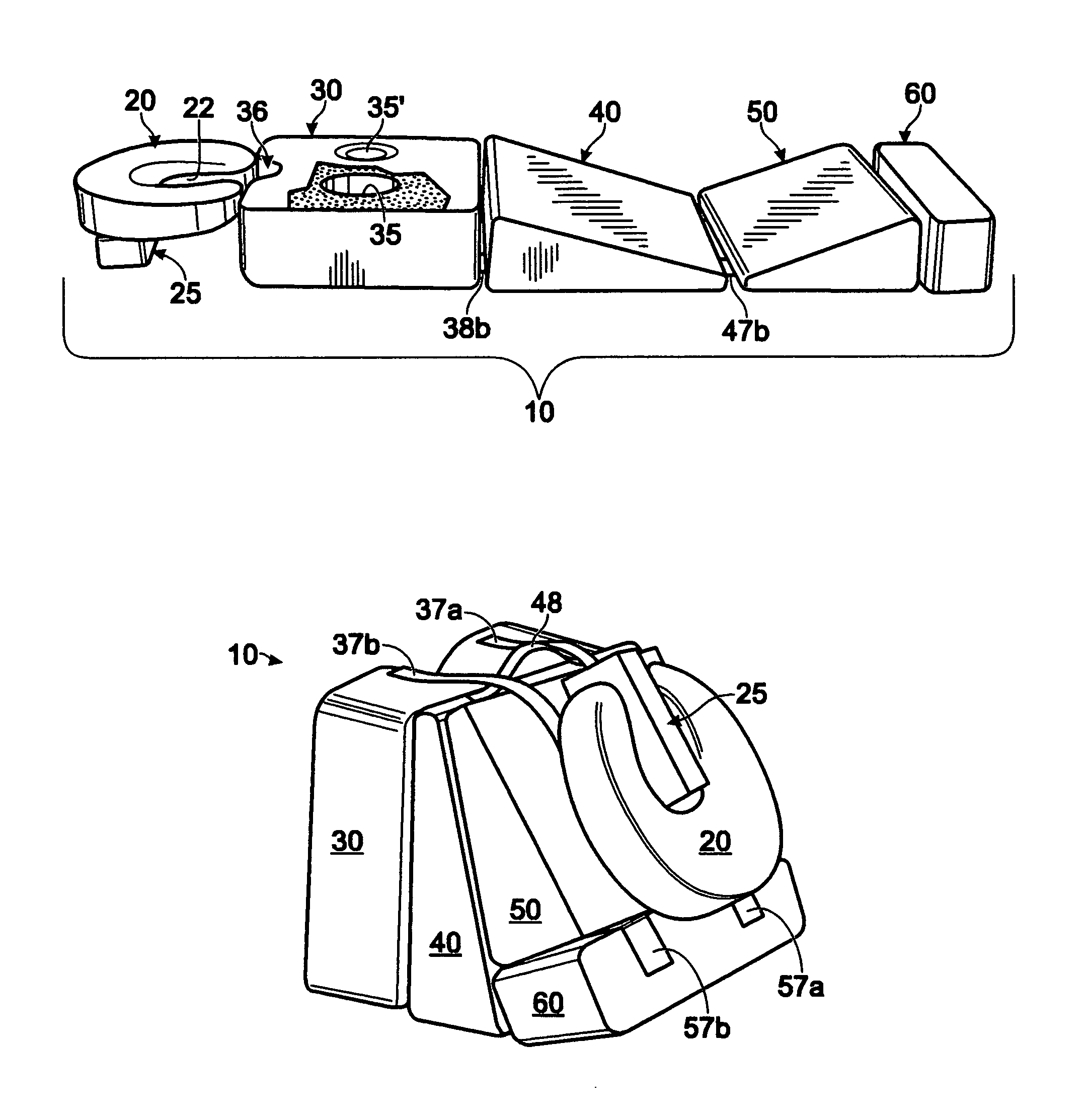

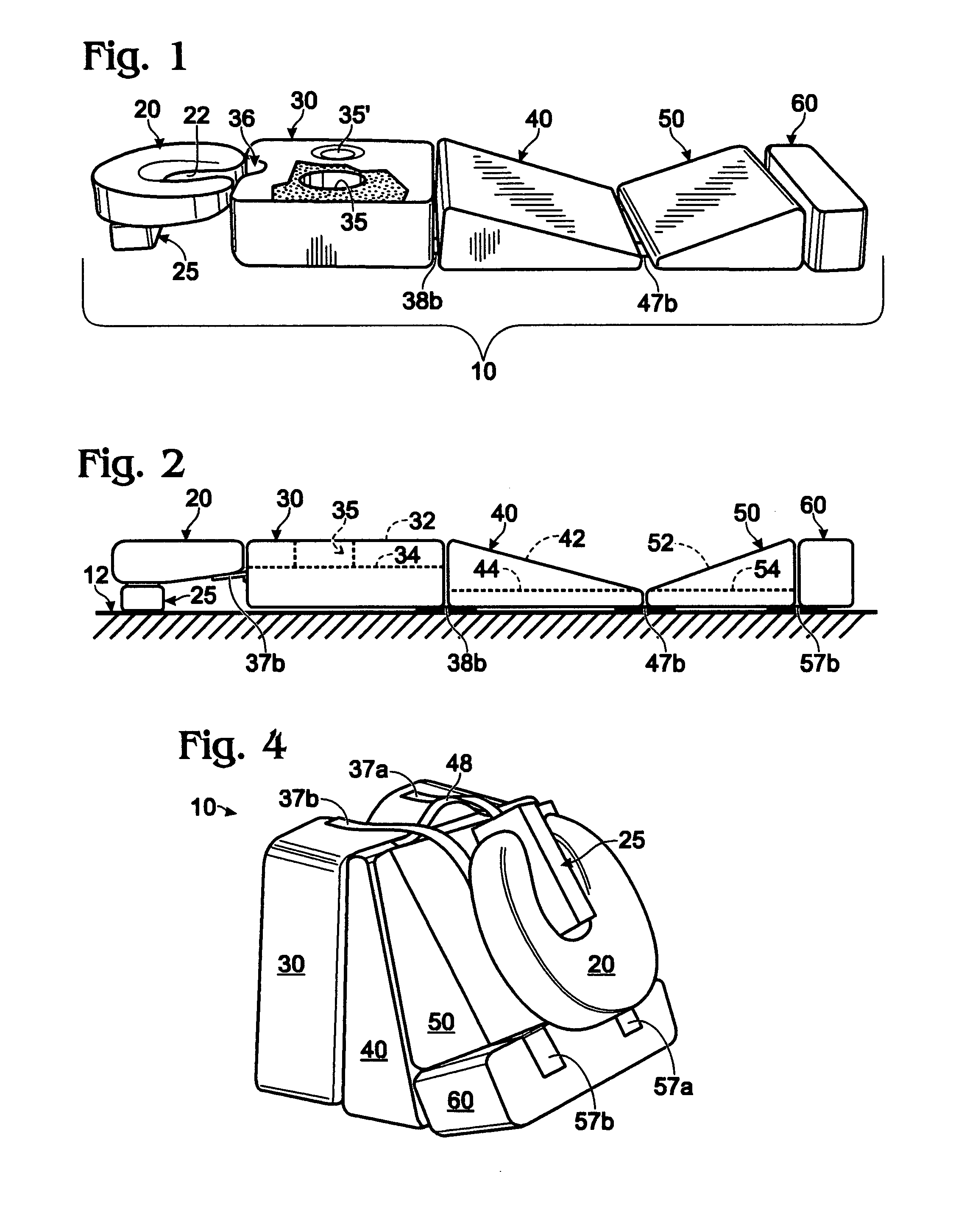

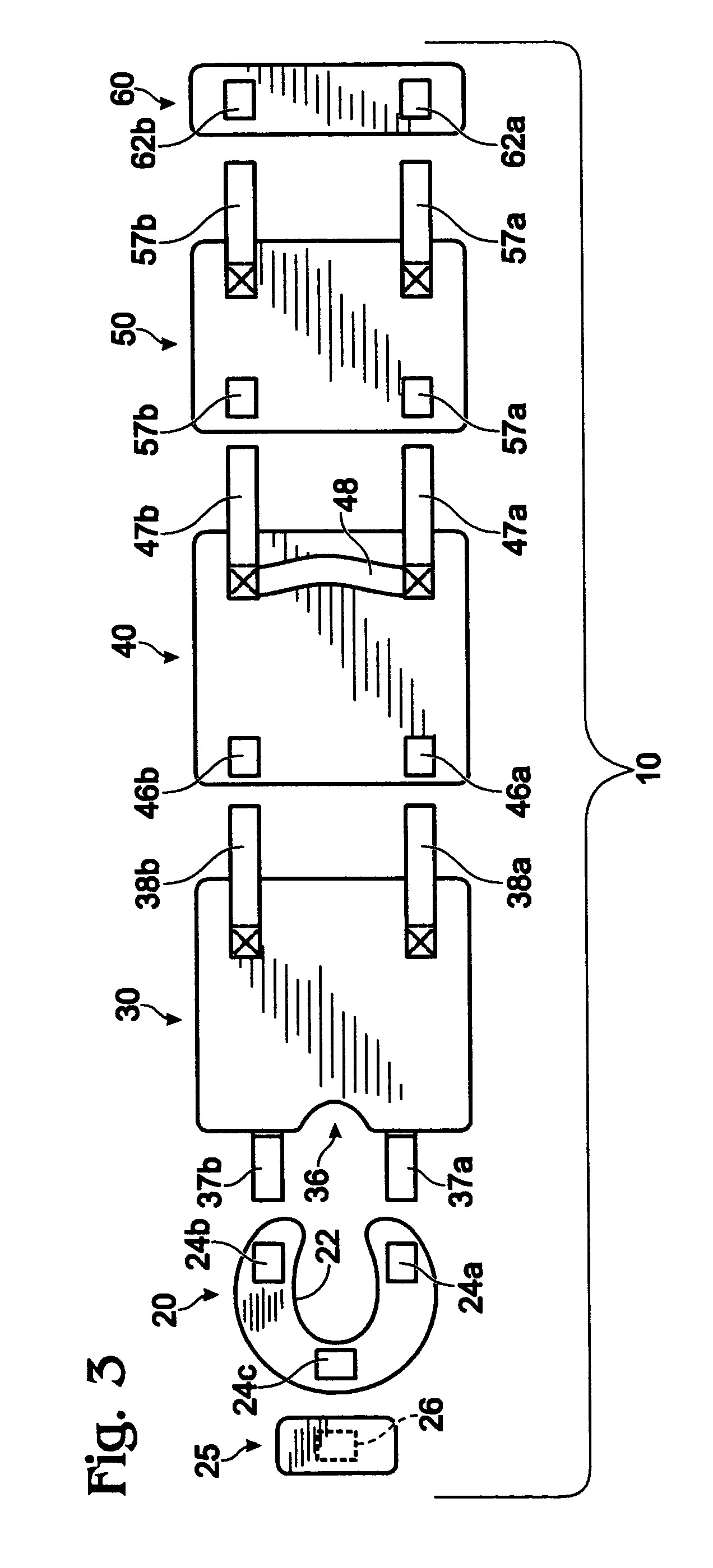

Cushion set for positioning a human body

InactiveUS7020918B1Inexpensive to fabricateStuffed mattressesOperating tablesInverted uBiomedical engineering

A cushion set for positioning a human body, including a face support cushion, a spacer block cushion, an upper torso support cushion, a lower torso support cushion, a calf support cushion and a bolster. The face support cushion is generally in the shape of an inverted “U” having a generally inverted U-shaped opening passing therethrough. The upper torso support cushion is adapted to be releasably attached to the face support cushion, the lower torso support cushion is adapted to be releasably attached to the upper torso support cushion, the calf support cushion is adapted to be releasably attached to the lower torso support cushion, and the bolster is adapted to be releasably attached to the calf support cushion. The spacer block cushion is adapted to be releasably attached to the underside of the face support cushion.

Owner:TINSLEY RONALD E

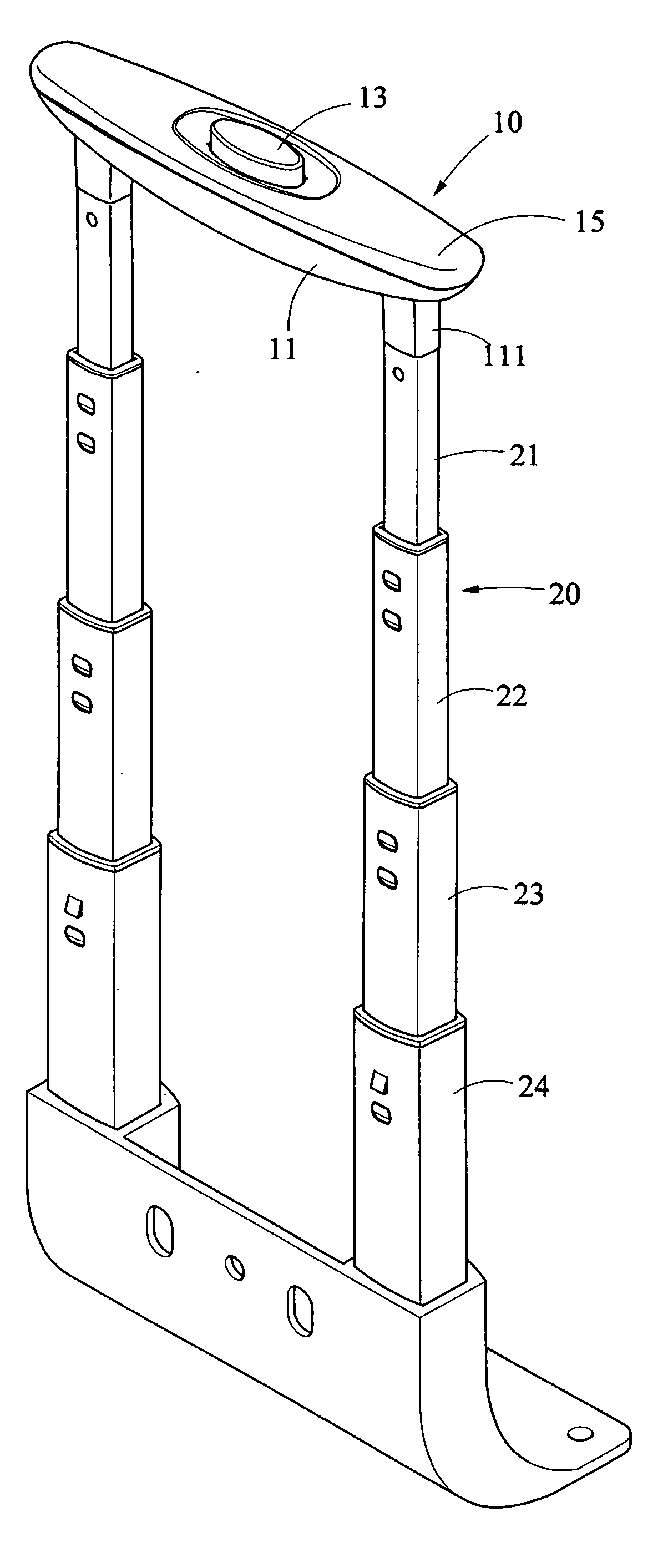

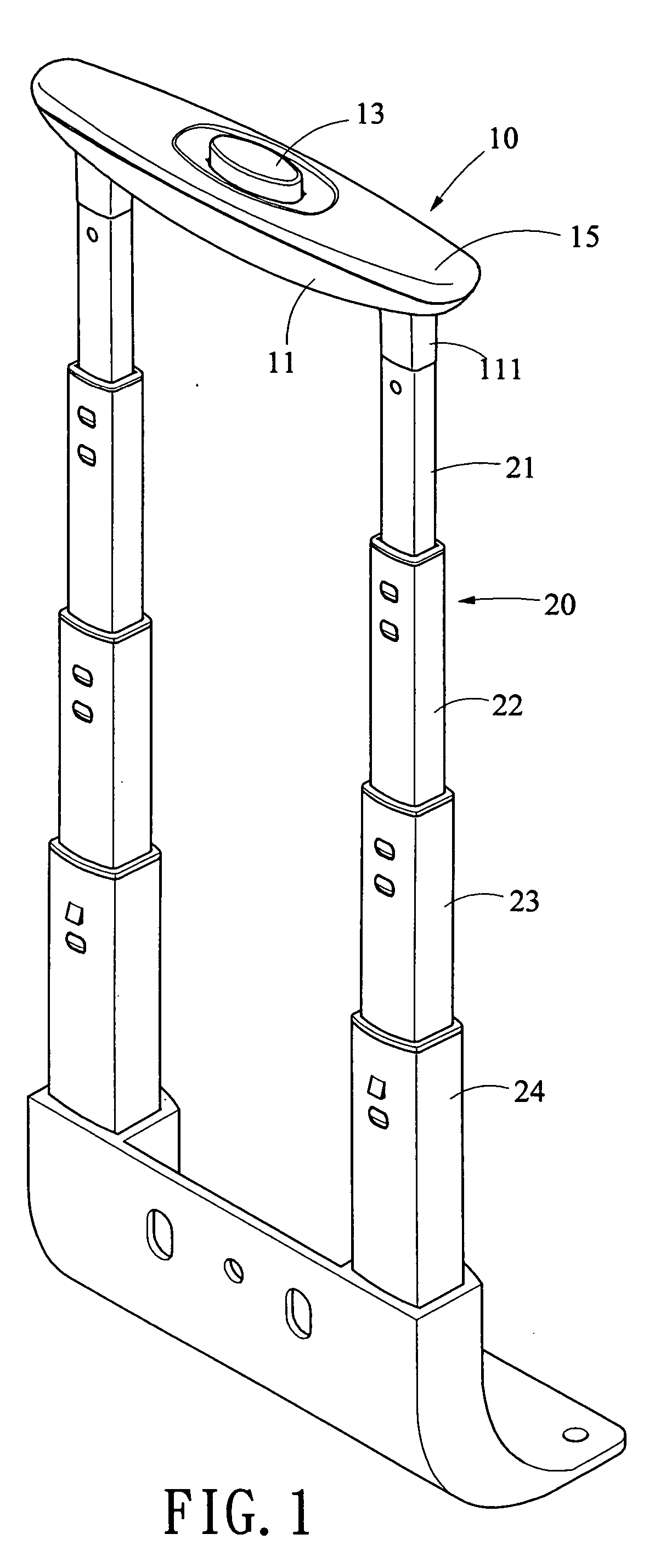

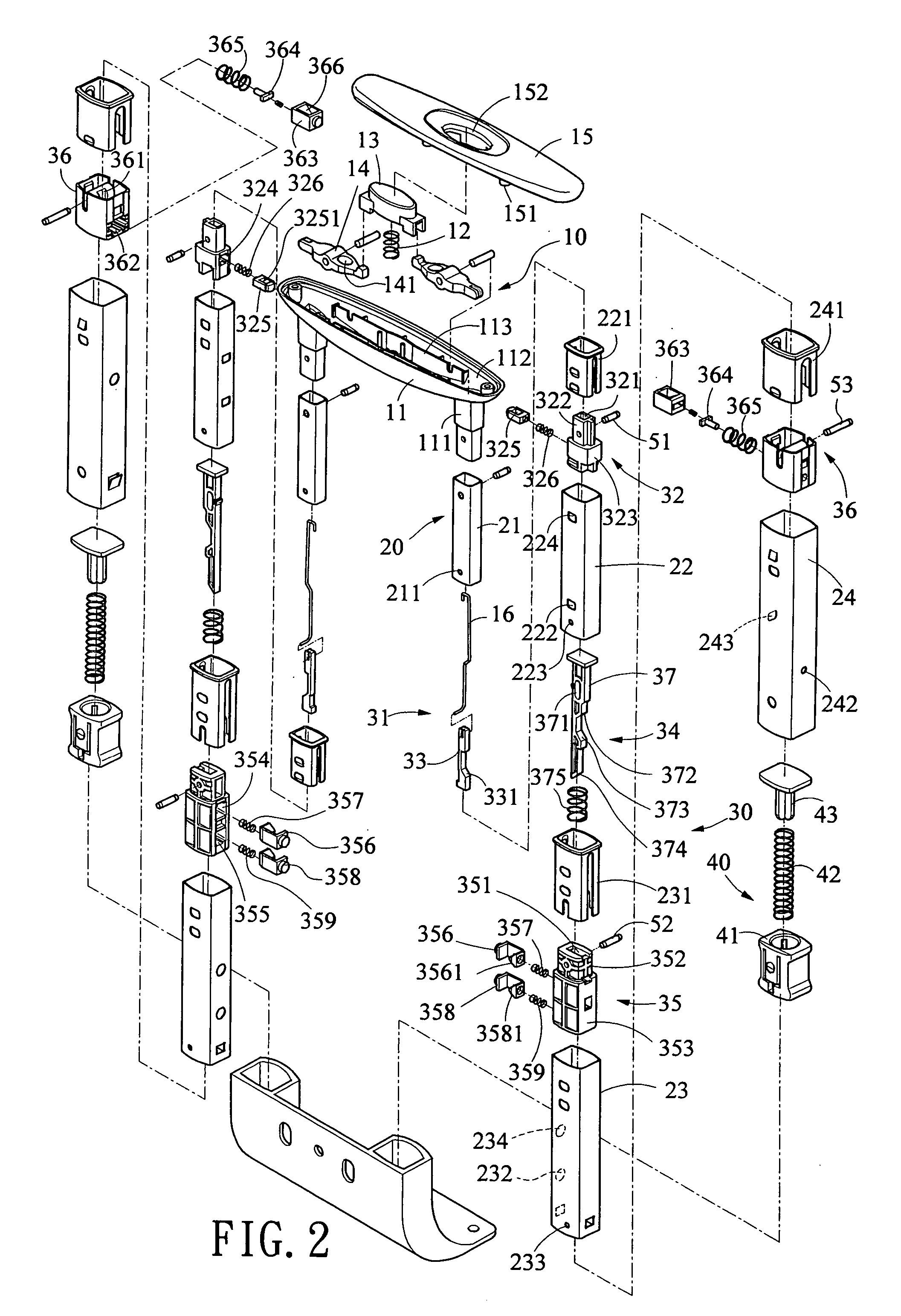

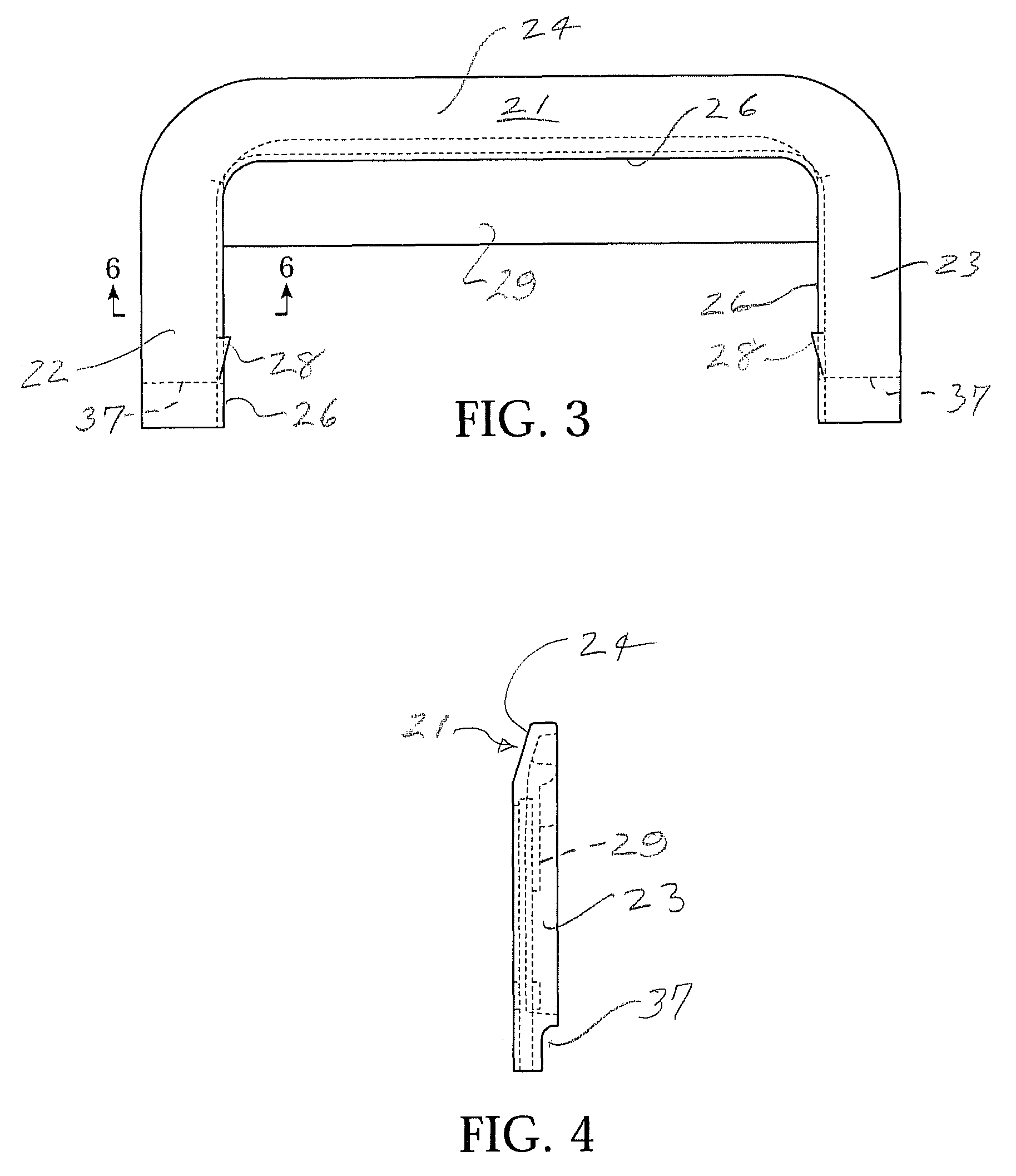

Retractable handle of carry-on luggage

Provided is a handle assembly for carry-on luggage. The inverted U-shaped handle assembly comprises two handle units each comprising a handle rod comprising a fixed bottom support tube and a plurality of sliding tubes arranged telescopically about a tube therebelow; a locking device in the tubes; and a resilient device under of the support tube. Pressing the push button will unlock the handle units and resiliently move the handle rods upward a predetermined small distance prior to being able to fully extend the handle rods.

Owner:CHAW KHONG TECH

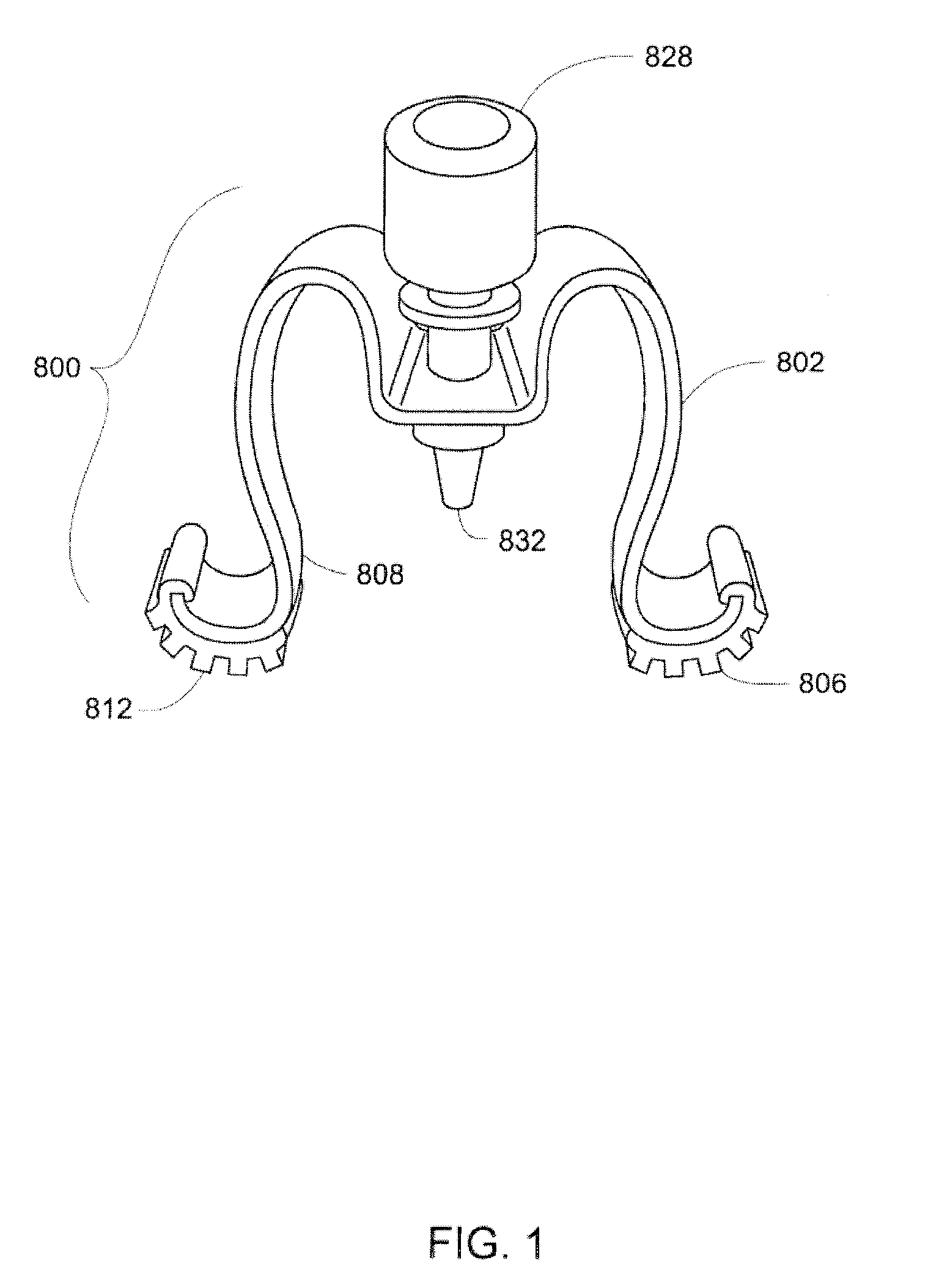

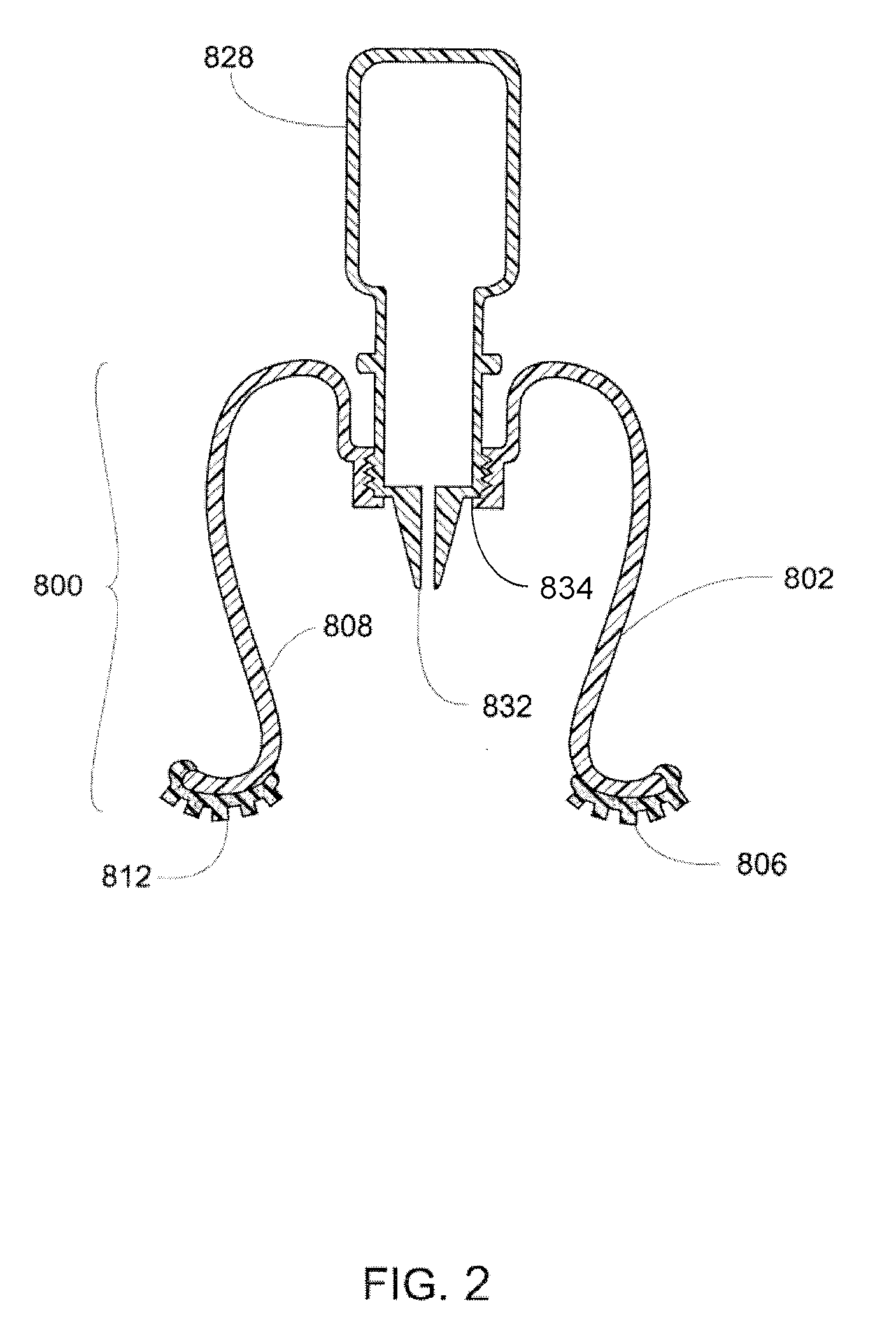

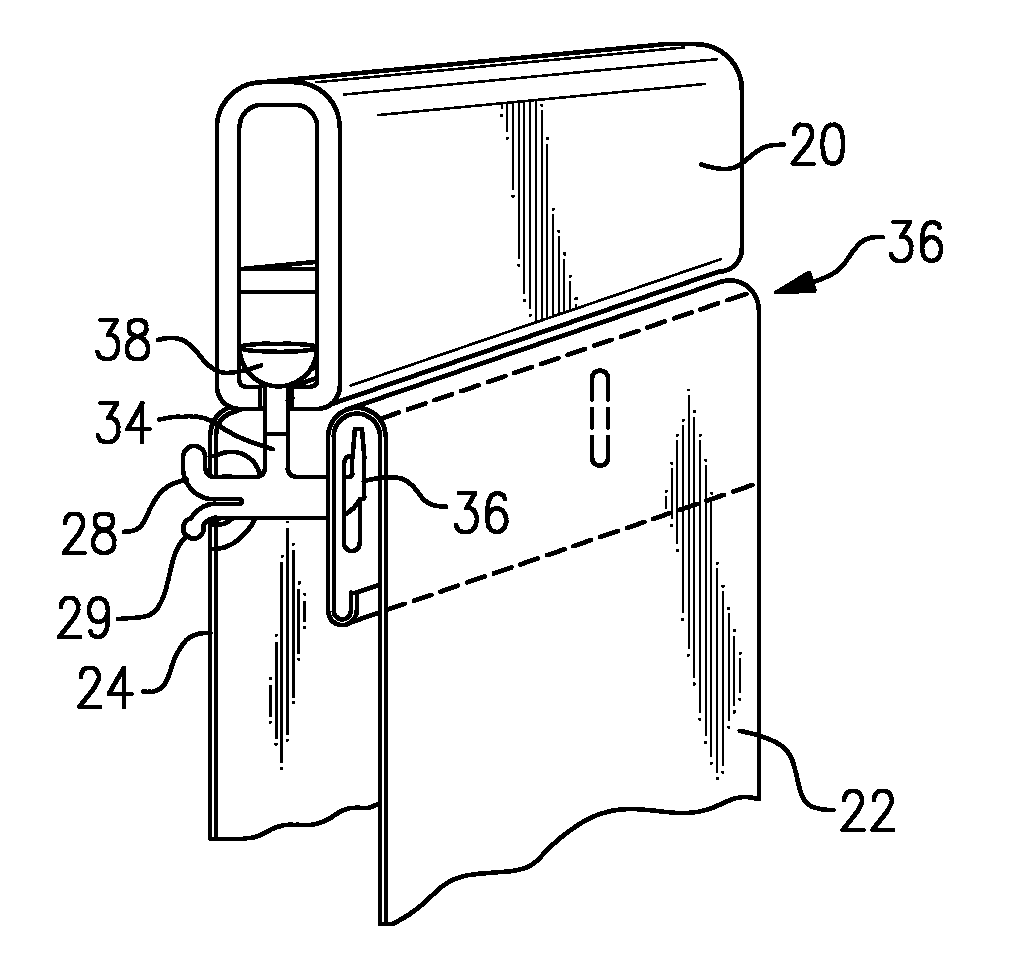

Automated Eyedrop Delivery System with Eyelid Retracting Legs

ActiveUS20100286634A1Good adhesionEasy detachmentBathing devicesMedical applicatorsLight flashesEngineering

An eye drop bottle holder with resilient legs includes an inverted U-shaped member made from resilient injection molded plastic. The top portion of the inverted U-shaped member includes an eye drop bottle holder. The right and left leg of the U-shape each terminate in an outwardly disposed J-shape covered by a soft rubber-like pad. The user can attach an eye drop bottle to the inverted U-shaped member so that the dispensing tip of the bottle is in close proximity the user's eye. The user can cause his or her eye lid to remain open by squeezing the right and left legs together, then placing the pads on the upper and lower eye orbit, then releasing the legs causing the flesh of the user's eyelids to be spread apart. In a preferred embodiment, an electro-mechanical assembly can automatically press on the side wall of the bottle to cause a predetermined amount of solution to be dispensed. An LED light flashes (is either activated or deactivated) to show the user that a dispensing event has taken place.

Owner:MARX ALVIN J

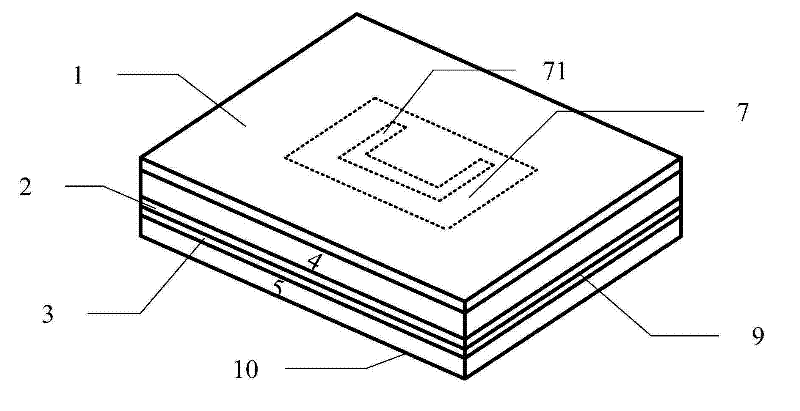

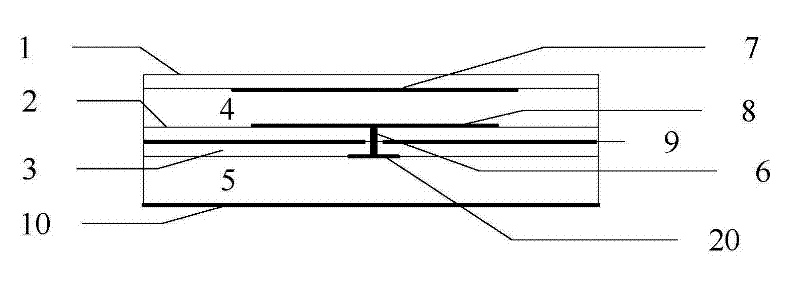

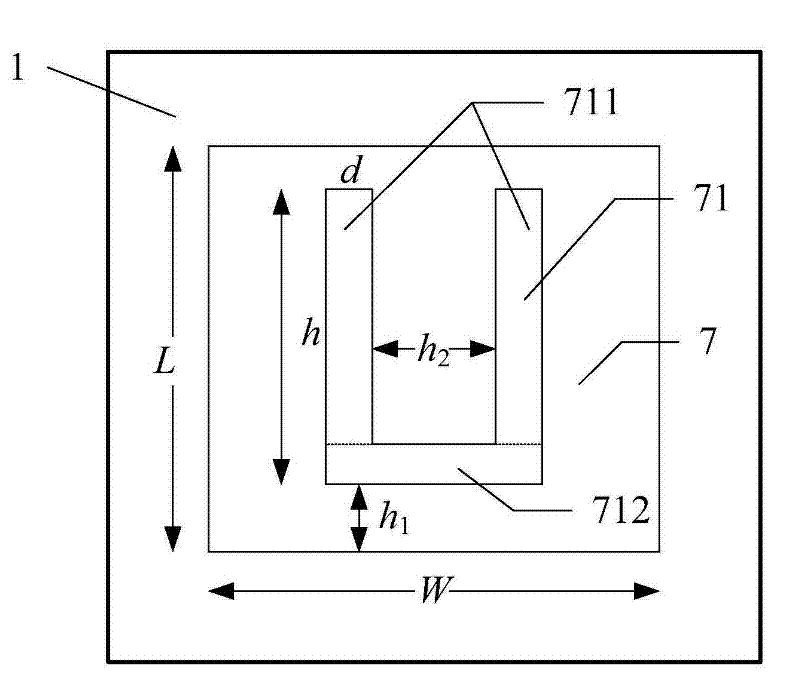

Multilayer Broadband Microstrip Antenna

InactiveCN102299418ADirectionalHigh bandwidthRadiating elements structural formsBroadband microstrip antennaAntenna gain

The invention discloses a multilayer broadband microstrip antenna, comprising an upper dielectric baseplate, a middle dielectric baseplate, a lower dielectric baseplate, an upper low dielectric constant insulating dielectric layer, a lower low dielectric constant insulating dielectric layer, a reflection plate and a feed probe, wherein rectangle radiators of metallic copper pasters are arranged on the lower surface of the upper dielectric baseplate and the upper surface of the middle dielectric baseplate and provided with U-shaped slot structures with different sizes respectively. Due to a special double-layer inverted U-shaped slot coupling feed way, the symmetry of directional diagrams on an E surface or H surface of the antenna is good, thus ensuring that the antenna has more consistent performances in more directions, and having more actual meanings as an exploration antenna and a communication antenna. The reflection plate with an EBG (electromagnetic band gap) structure can preferably restrain backward radiation in the specified frequency relative to a traditional metal reflection plate, thus improving the directivity of the antenna, thereby further improving the gain of theantenna.

Owner:JIMEI UNIV

Ventable container assembly

A ventable container comprising a container bottom having an inner cavity, the container bottom further having a side wall that terminates in a container rim; and a selectively detachable lid, the lid including a central panel and peripheral sealing lip that surrounds the panel, the peripheral sealing lip having a generally inverted U-shaped cross-section that defines a lid channel, the lid channel being adapted to receive the container rim, the lid channel being further adapted to position the lid at a first position wherein sealed engagement of the container is effectuated and at a first position relative to the container rim wherein an air passage from the inner cavity to the container surroundings is provided.

Owner:THE GLAD PROD CO

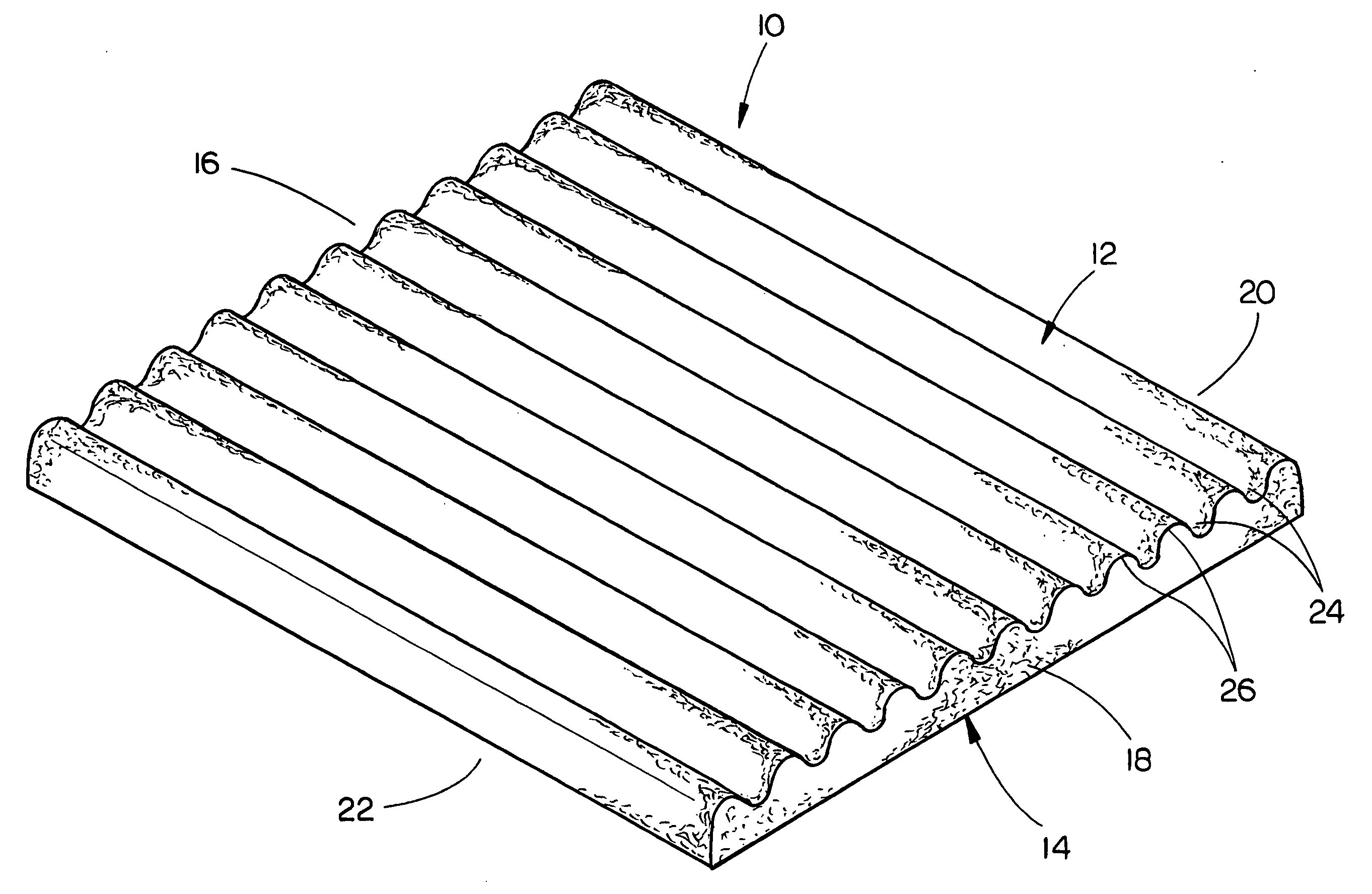

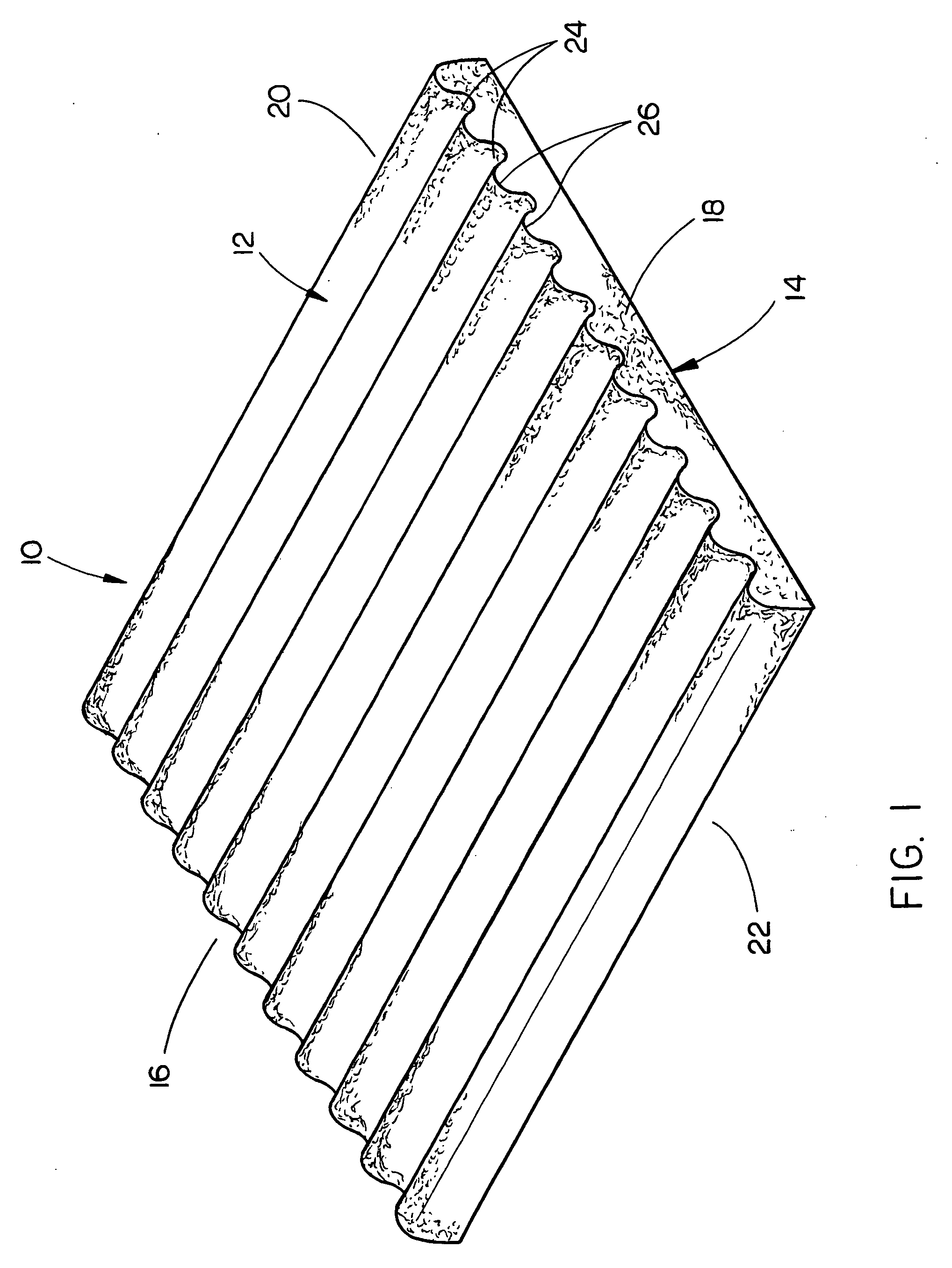

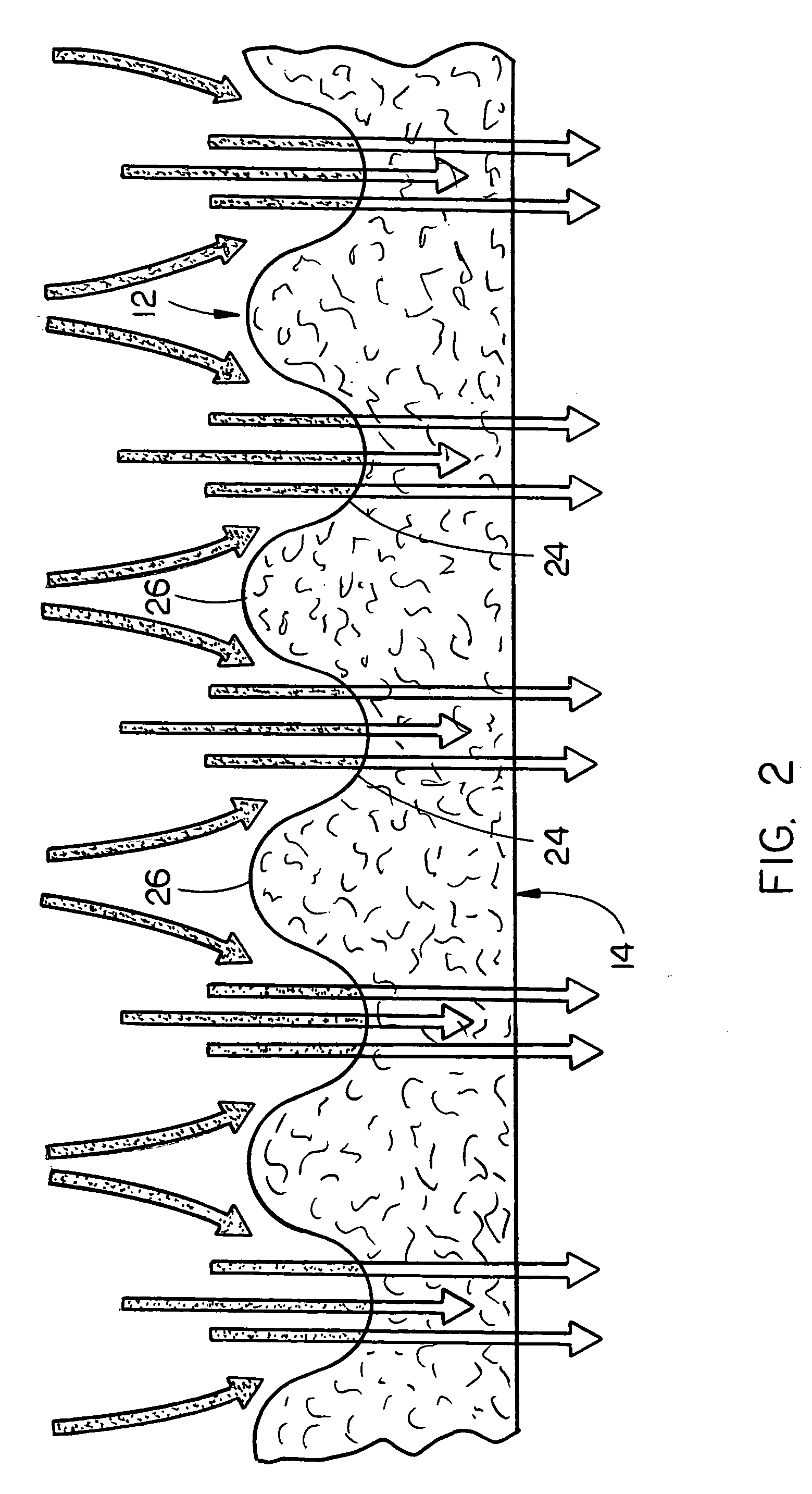

Fluid filter

InactiveUS20060000196A1Increase exposureRetain more particulate more quicklyDispersed particle filtrationMembrane filtersEngineeringVolumetric Mass Density

A fluid filter is disclosed which comprises a layer of high loft, non-woven, fibrous, fluid-permeable material having a length and a width, an upper surface, a lower surface, and a thickness measured between the upper and lower surfaces which is non-constant. The non-constant thickness is achieved by providing a series of spaced-apart grooves separated by a series of spaced-apart ridges. The lower surface is substantially planar and the grooves each have a generally U-shaped cross section with the ridges having a generally inverted U-shaped cross section. A modified form of the invention is also disclosed wherein the zones of higher flow resistance have a greater density than the zones of lower flow resistance. In this embodiment, the thickness of the filter is constant. The method of filtering particulate material from a fluid stream is also disclosed.

Owner:PROD UNLIMITED

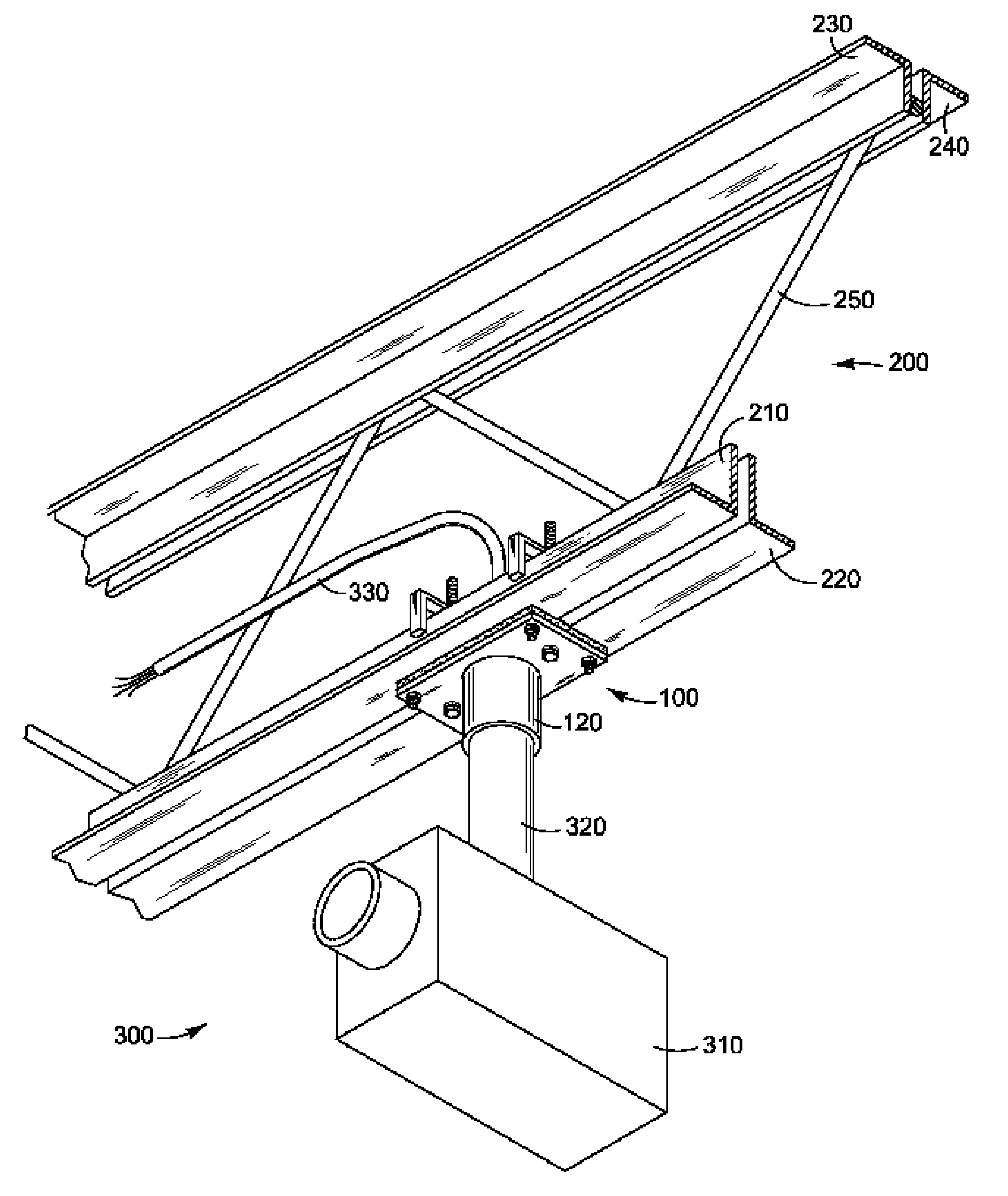

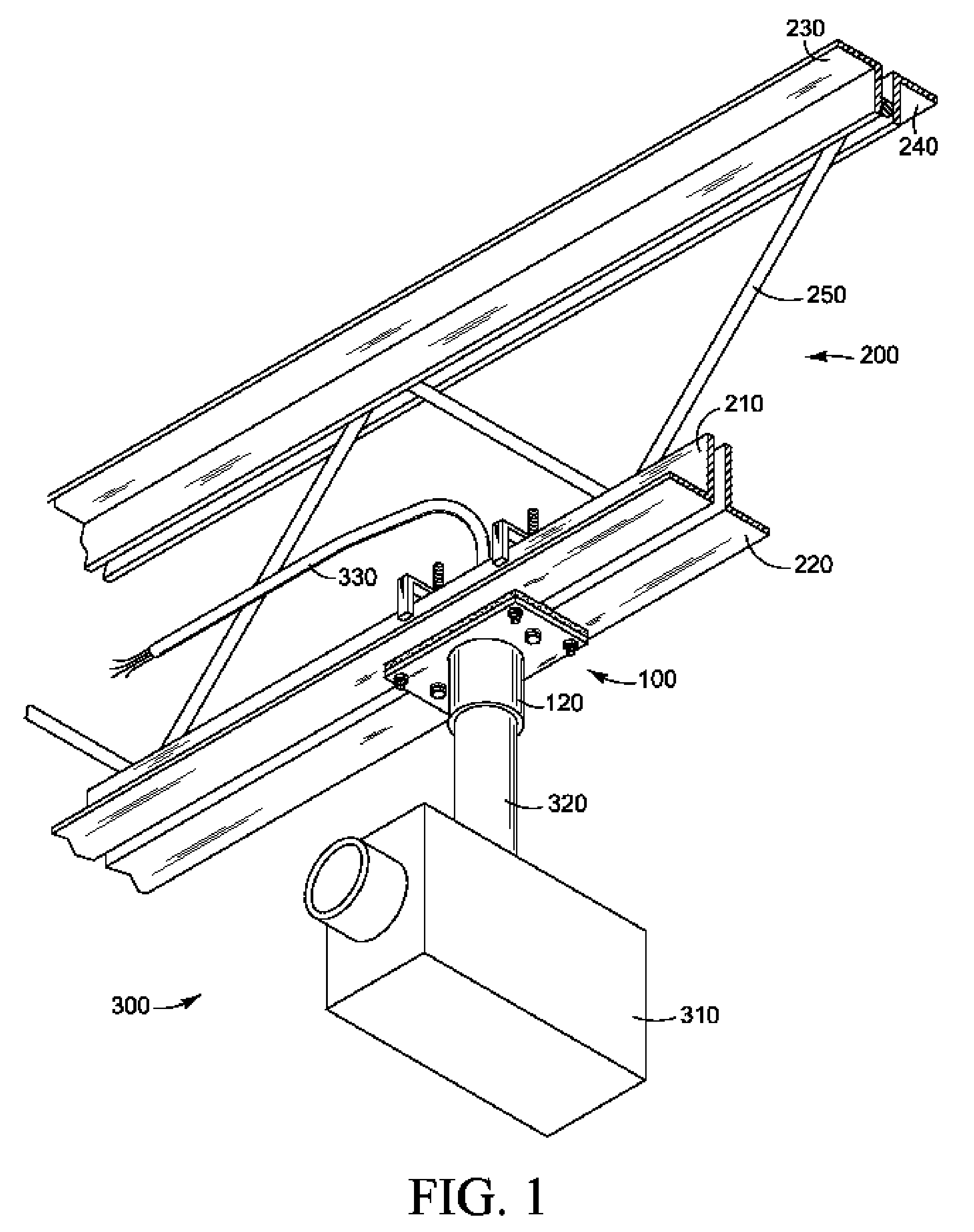

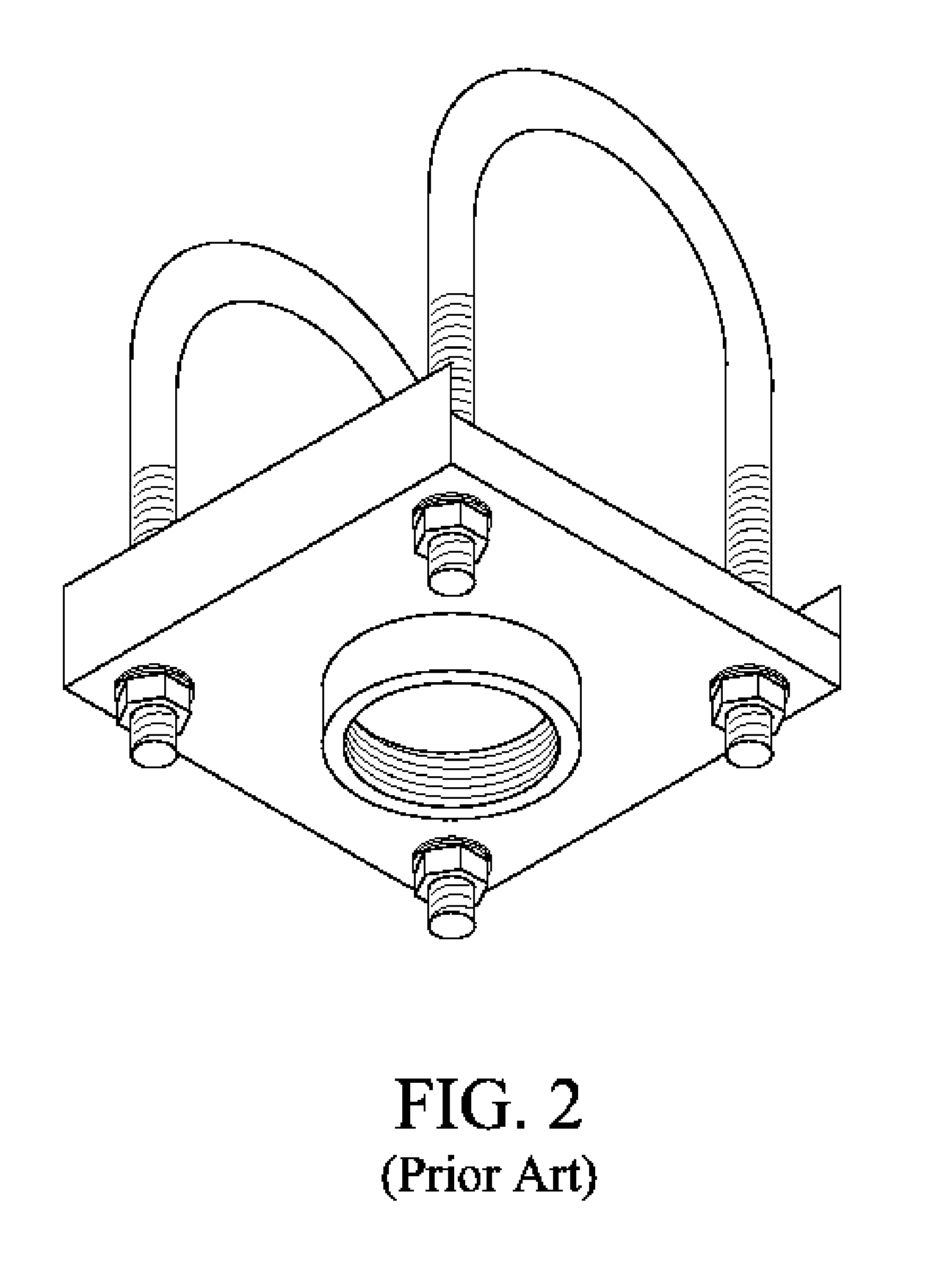

Mounting Clamp

This mounting clamp is used as a truss adapter for support of fixtures, electrical and otherwise, from a truss ceiling. The clamp comprises a plate suspended by a pair of upstanding arms, each of which is formed by a bolt connected to an inverted U-shaped rectangular hanger member. The hangers and their associated bolts are inserted upwardly between the spaced beams of a bar joist from below and then the hangers are rotated 90 degrees before they are lowered into place to rest on both of the spaced beams, spreading the load, as the hanger arms are tightened to the plate. The plate carries a connector for mating to the object to be mounted. Leveling screws provide adjustment for orienting the mounted object. A vibration damping pad is included when appropriate. Variations of the clamp may be used in wall or parapet mount configurations.

Owner:HUNT RONALD DOUGLAS

Venting container

ActiveUS7866502B2Increase volumeReduces and eliminates disadvantage and drawbackCapsClosure capsEngineeringMechanical engineering

A venting container including a lid and base having an inner cavity and a side wall that terminates in a rim, the lid including a central panel and a peripheral sealing lip that surrounds the panel, the peripheral sealing lip having a generally inverted U-shaped cross section that defines a lid channel into which the container rim fits, the sealing lip including at least one venting feature in the form of a flexible venting button that is adapted to transition from a first position to a second position upon application of an actuation force, the venting button being further adapted and positioned whereby when the container rim is positioned in the lid channel and the venting button is in the first position, sealed engagement of the lid to the container is effectuated and when the venting button is in the second position a venting air passage is provided from the container cavity to the container surroundings. In a second embodiment, the venting feature is in the form of a downwardly protruding venting boss provided to the lid closure and a boss seat formed in the base closure whereby the venting boss is received with the boss seat when the lid is oriented in a first non venting attachment position and the venting boss abuts against a surface of the base closure to provide a vent passage between the lid and base upon removal and repositioning of the lid to a second venting attachment position.

Owner:THE GLAD PROD CO

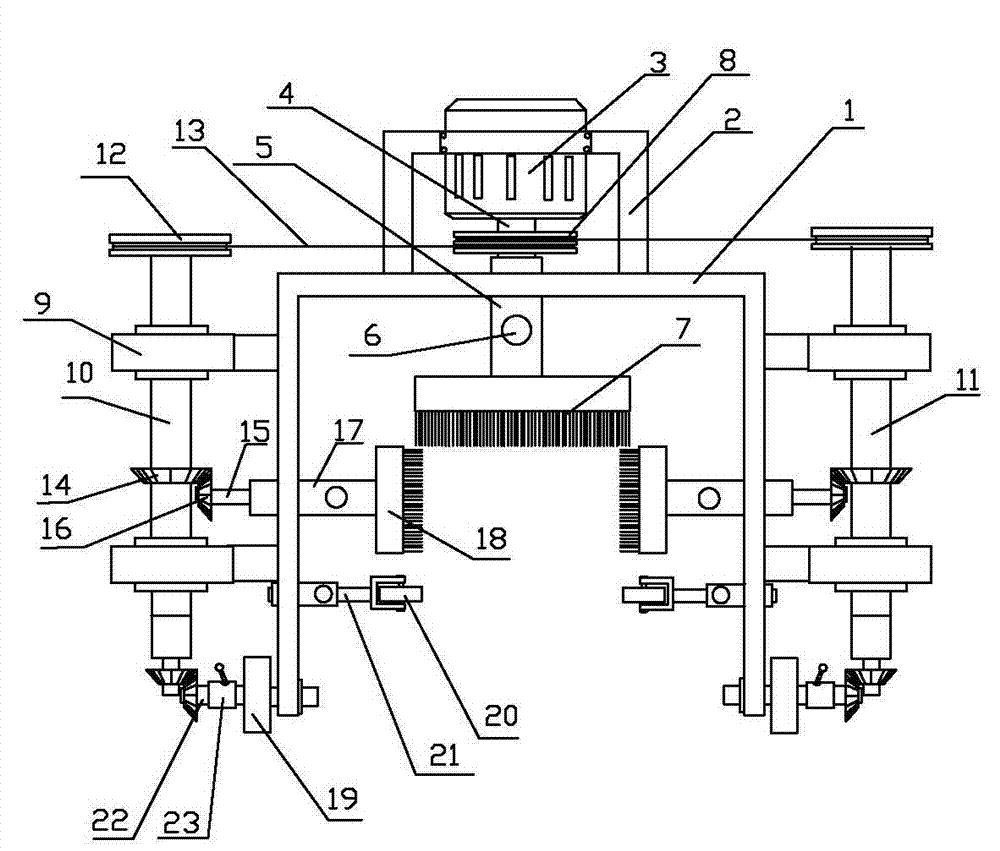

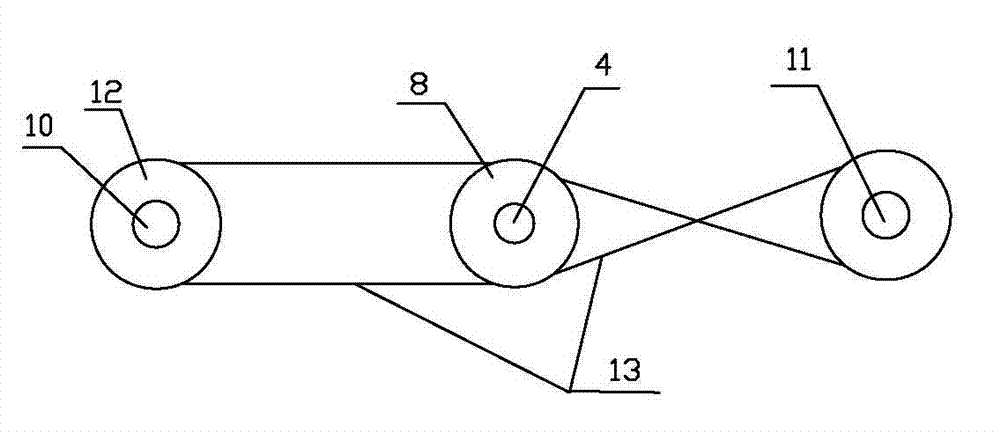

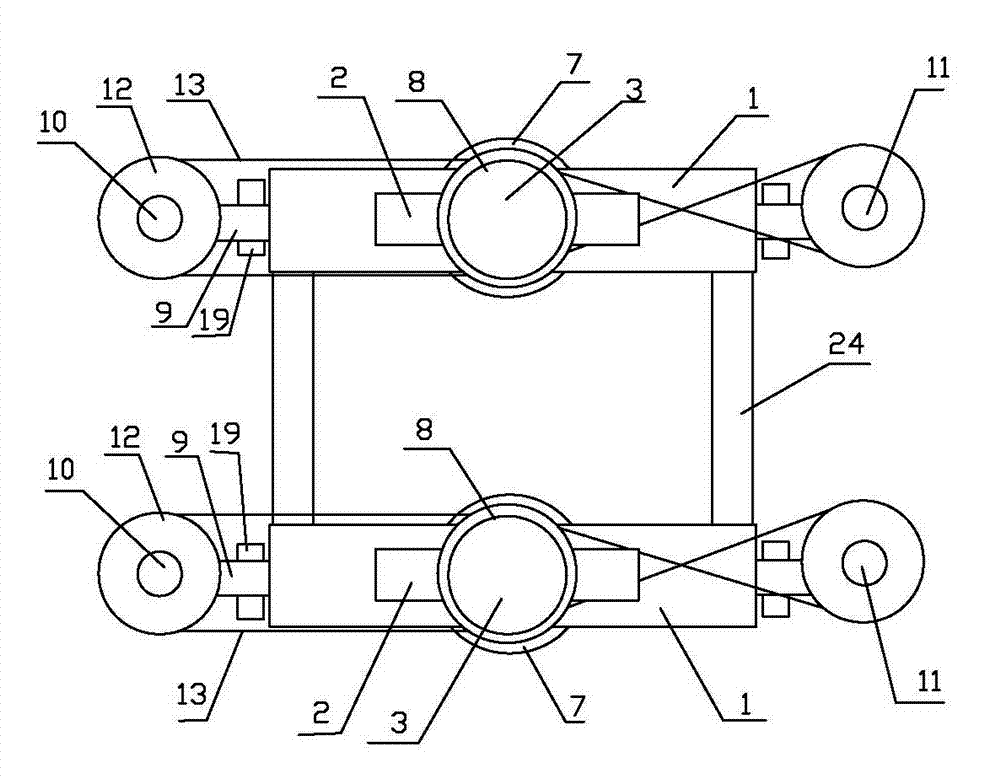

Square tube multiple face synchronous derusting machine

The invention discloses a square tube multiple face synchronous derusting machine. The derusting machine comprises an inverted-U-shaped rack and is characterized in that an upper motor is fixed to the middle of the upper wall of the inverted-U-shaped rack, and an upper horizontal rotating wire brush is fixed to the lower end of a shaft sleeve of a motor spindle, a fixed belt wheel at the upper end of the spindle is connected with driven shafts outside the left wall and the right wall of the inverted-U-shaped rack for transmission, and the middle of the driven shaft on the left and the middle of the driven shaft on the right are respectively meshed with a shaft end bevel gear of a transverse rotating shaft for transmission through a bevel gear; each transverse rotating shaft is provided with a transverse shaft sleeve connected with the transverse rotating shaft in a matched mode through a spline, and an upper perpendicular face rotating wire brush is fixed to the inner end of each transverse shaft sleeve; idler wheels are arranged at the bottom end of the inverted-U-shaped rack; synchronous rotation of the horizontal rotating wire brush and the perpendicular face rotating wire brushes is achieved through one motor, and thus the upper surface and the two side faces of a square tube can be polished and derusted synchronously. Thus, dust on the surface of the square tube can be cleared away fast with the derusting machine, energy is saved, labor efficiency can be improved, and the using effect of the square tube is improved.

Owner:南通通州东大机械有限公司

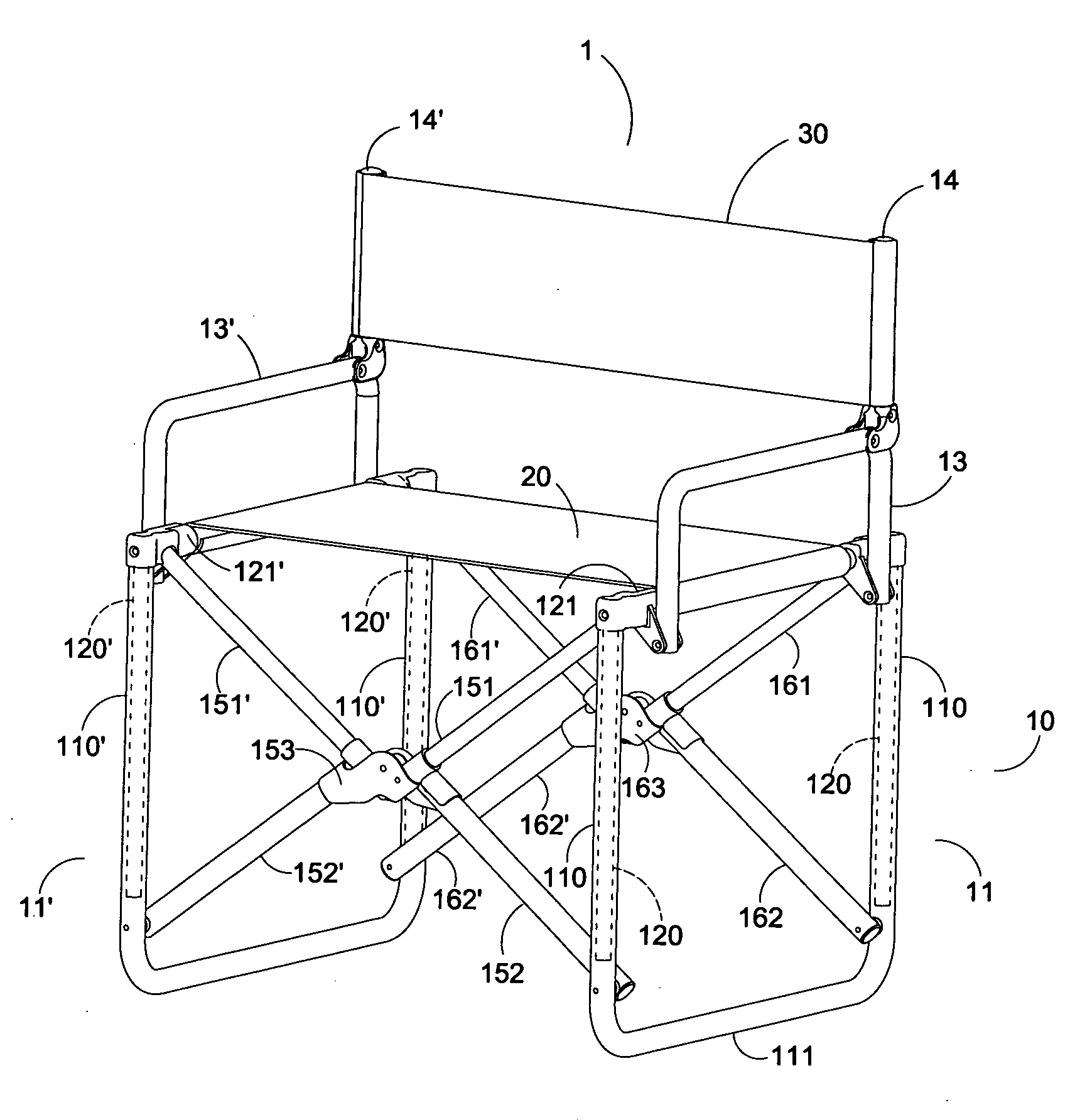

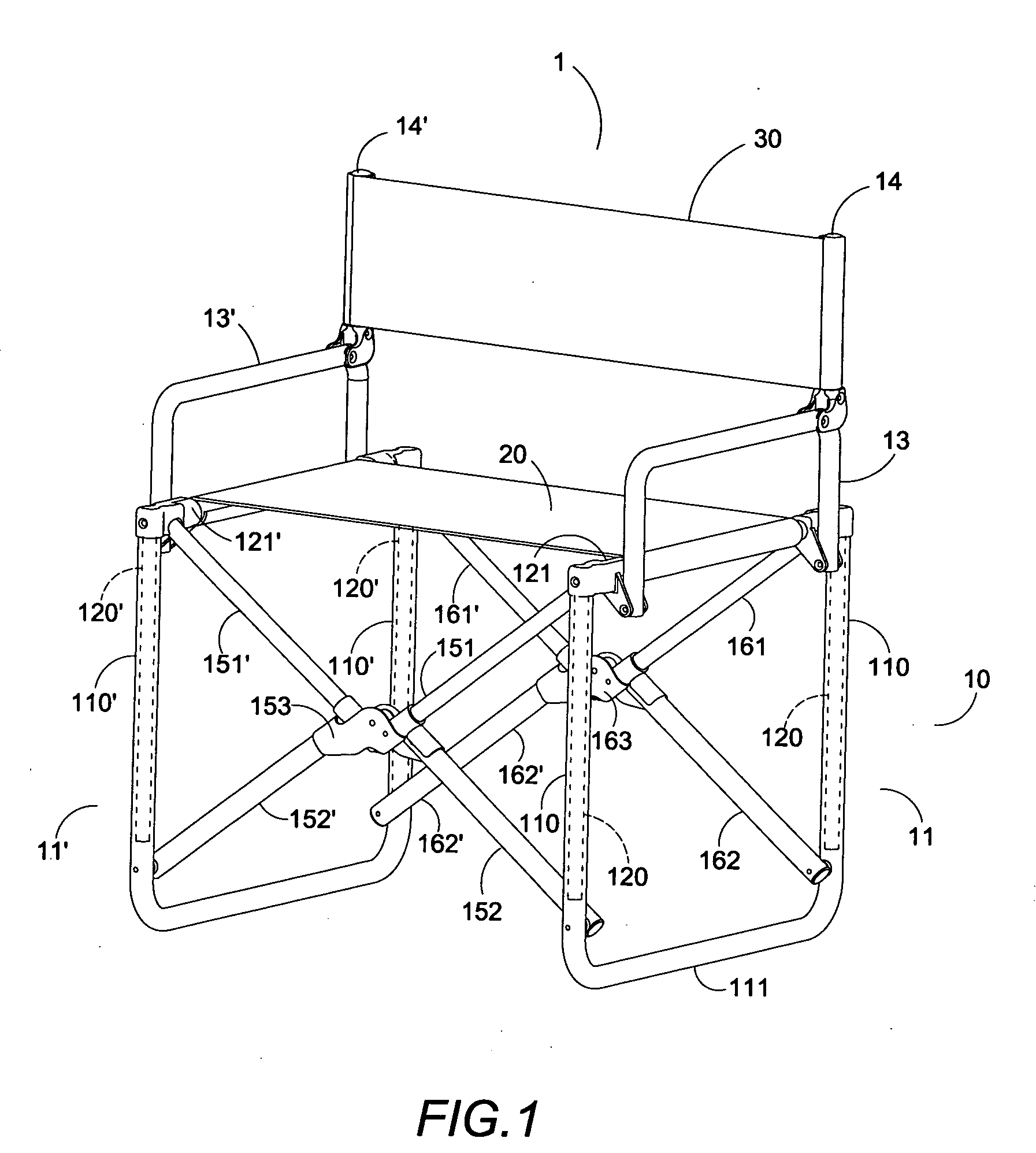

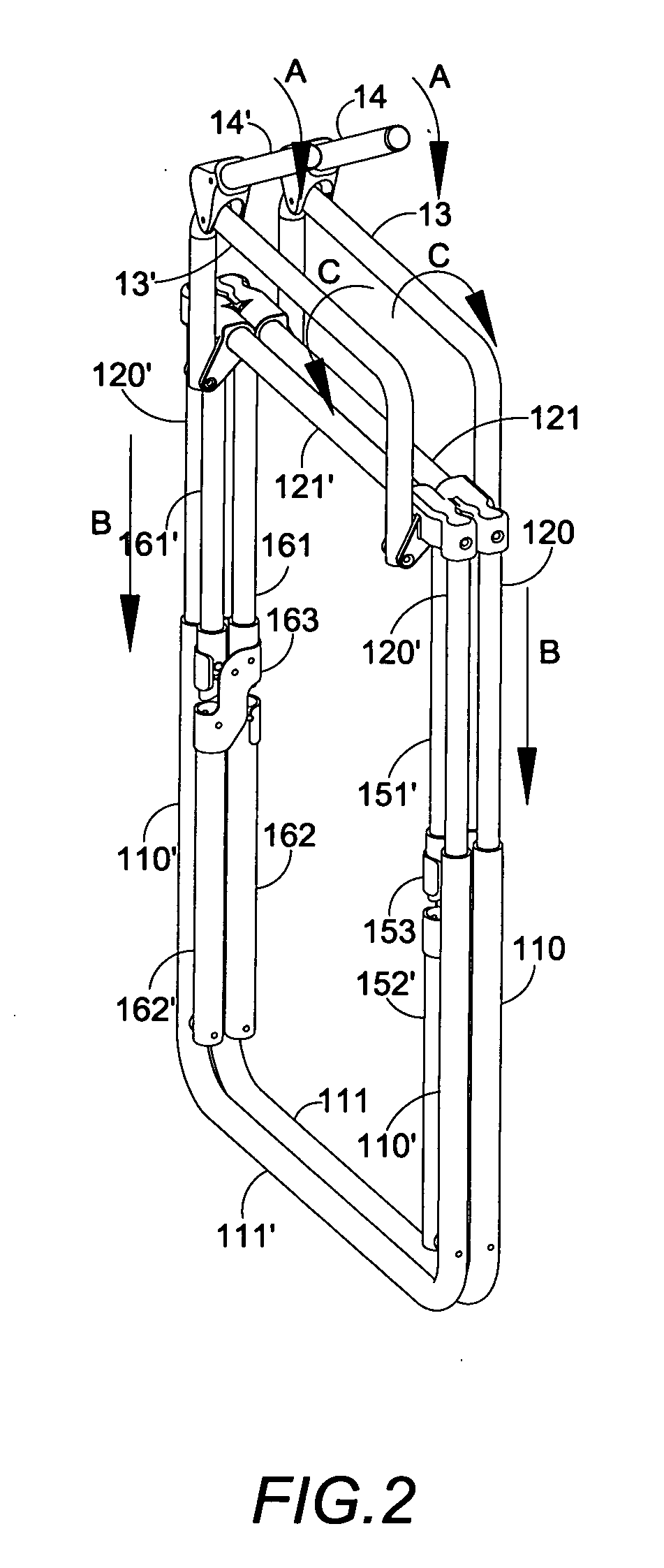

Telescoping foldable chair

InactiveUS20100171342A1Strong and stable structureSmall folded volumeDismountable chairsFoldable chairsEngineeringMechanical engineering

A telescoping foldable chair having a skeleton having a pair of lower leg frames of U shape each having a pair of outer legs connected with a ground bar, a pair of upper leg frames of inverted U shape each having a pair of inner legs connected with a top cross bar respectively slidable contained in one of the outer legs, a front and a rear sets each having a pair of inner tubes respectively pivotally linked to the top cross bars, a pair of outer tubes respectively pivotally linked to one lower end of the outer leg frames, and a central link which pivotally connects free ends of the inner and outer tubes, and, a sitting cloth attached on the skeleton. The telescoping foldable chair has a strong structure yet small folded volume.

Owner:CHEN LIBIN

Shower curtain rail and glide assembly

A shower curtain and support system employs an elongated rail supported at the shower or tub. The rail extrusion can be an extrusion with an inverted U profile, with an open slot or slots at its base. There are glides, e.g., nylon members with a ball, hemisphere, or other wide head portion and shaft that projects out through the slot from the open interior of the rail. The glides have one or two hook structures for attaching to a fabric curtain and a vinyl curtain liner. In one preferred version, there is a liner hook and spring retaining arm on one side that fits into the grommet at the top of the liner. On the other side is a short arm with a button that fits into a button hole on the cloth or fabric curtain. The curtain has blind button holes or grommets at its upper hem, so that the hook structure, e.g., button, does not show.

Owner:KARTRI SALES

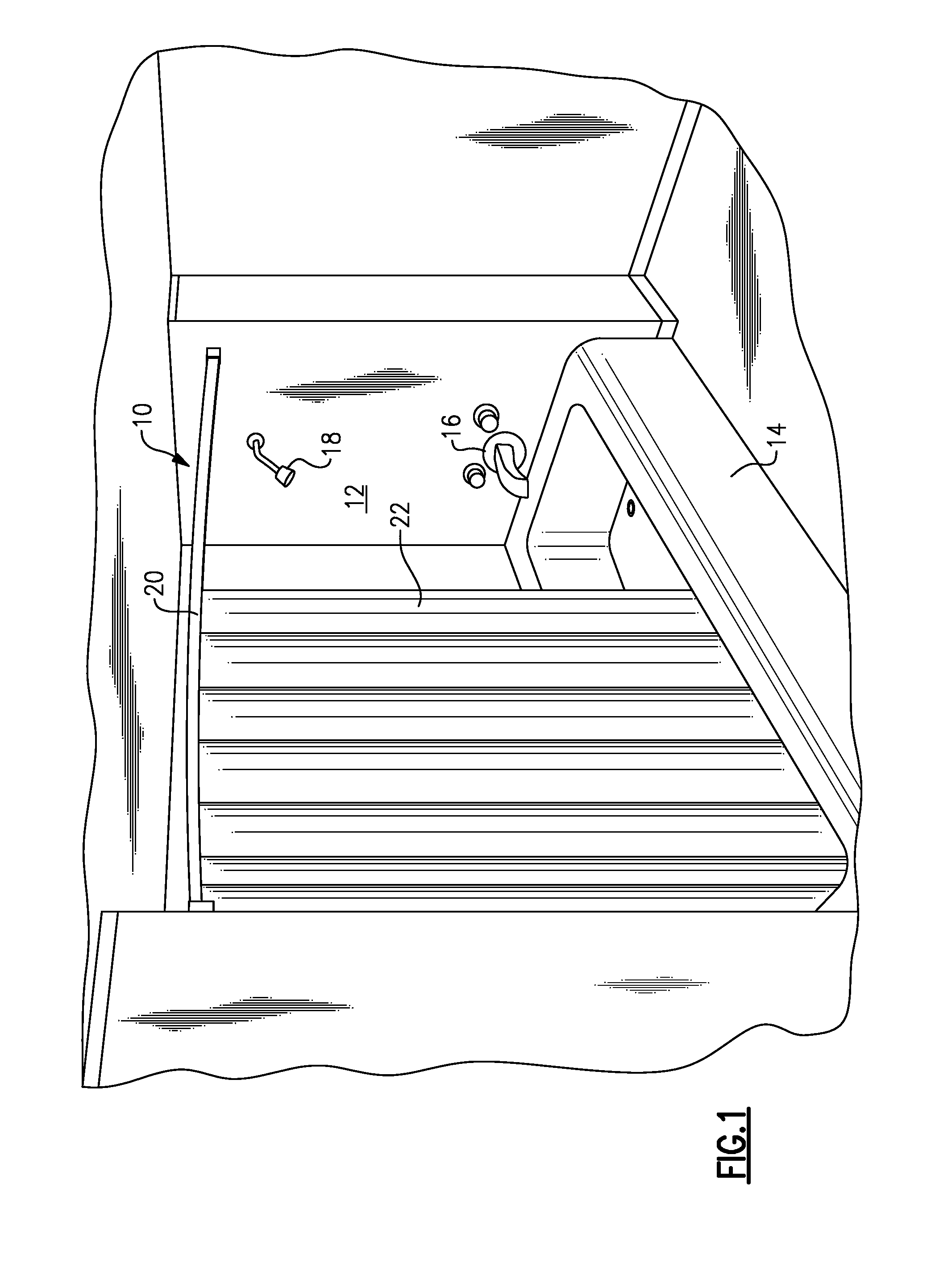

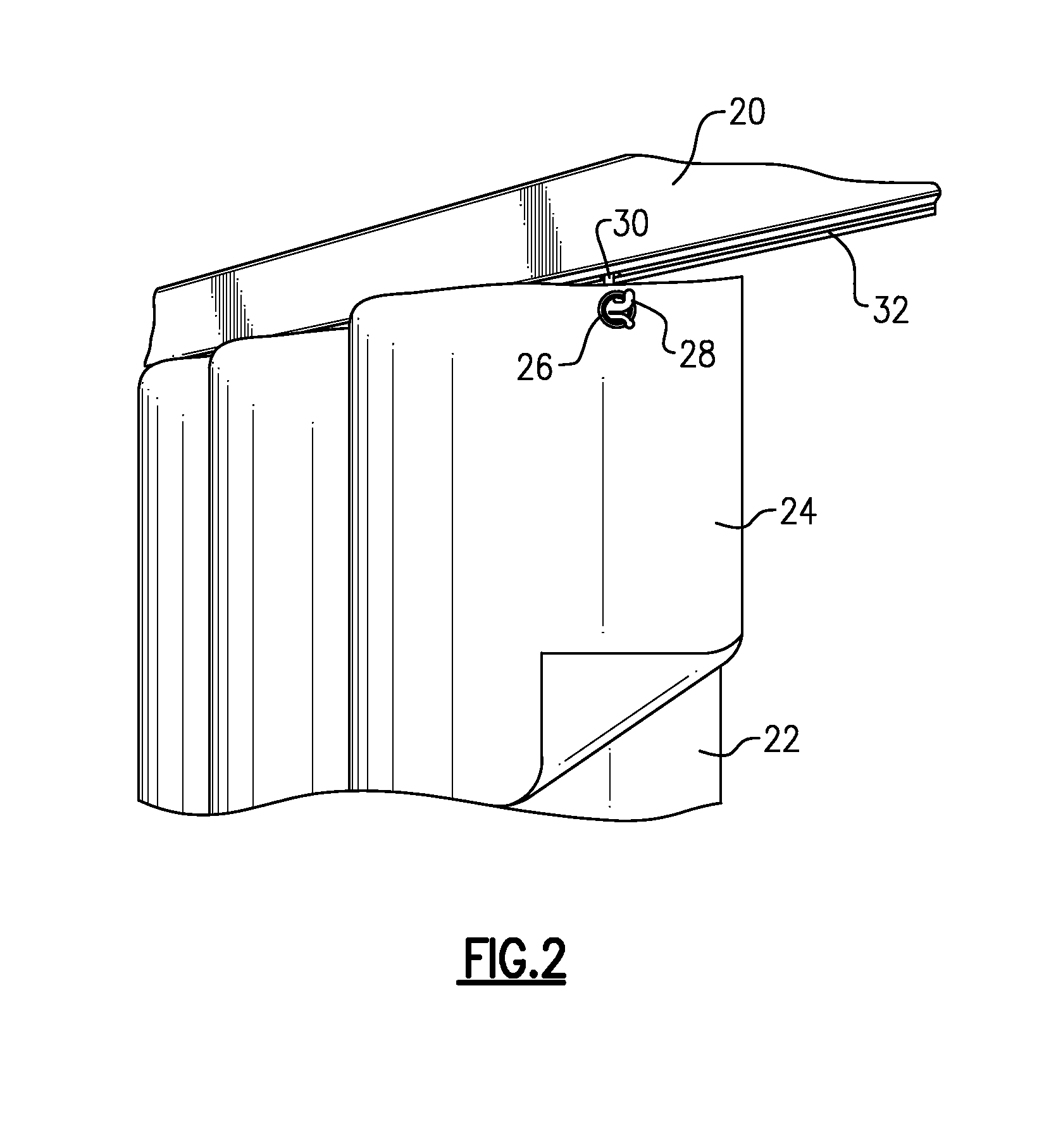

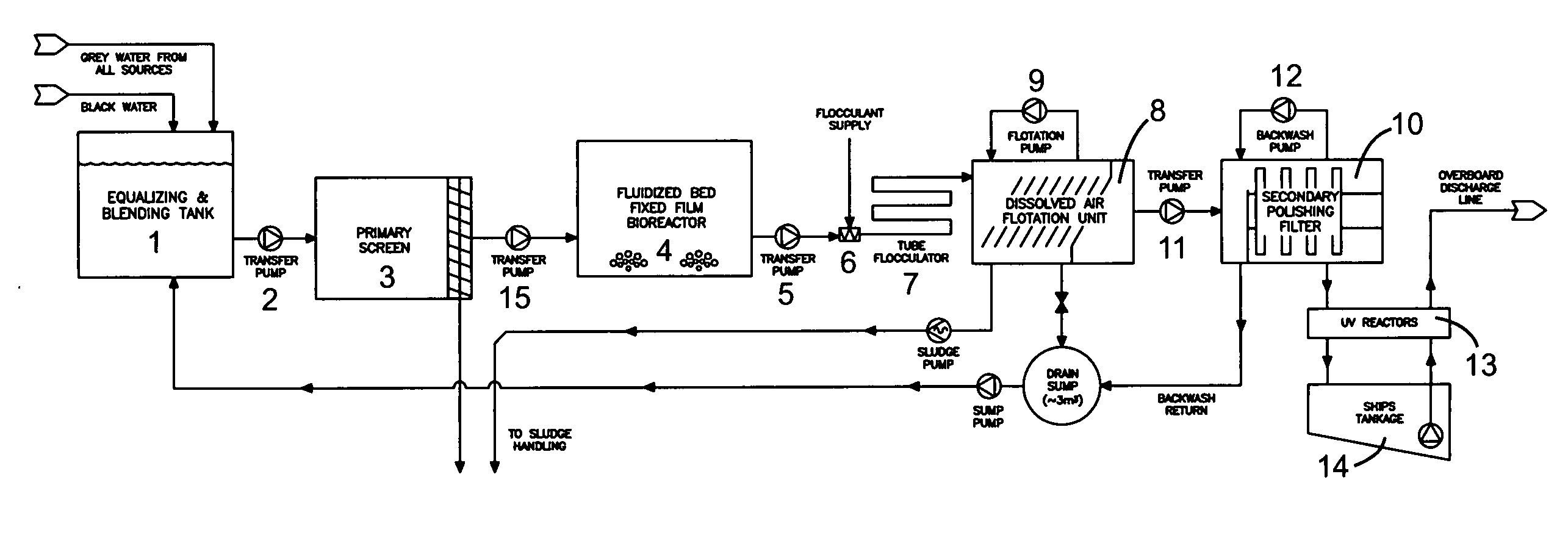

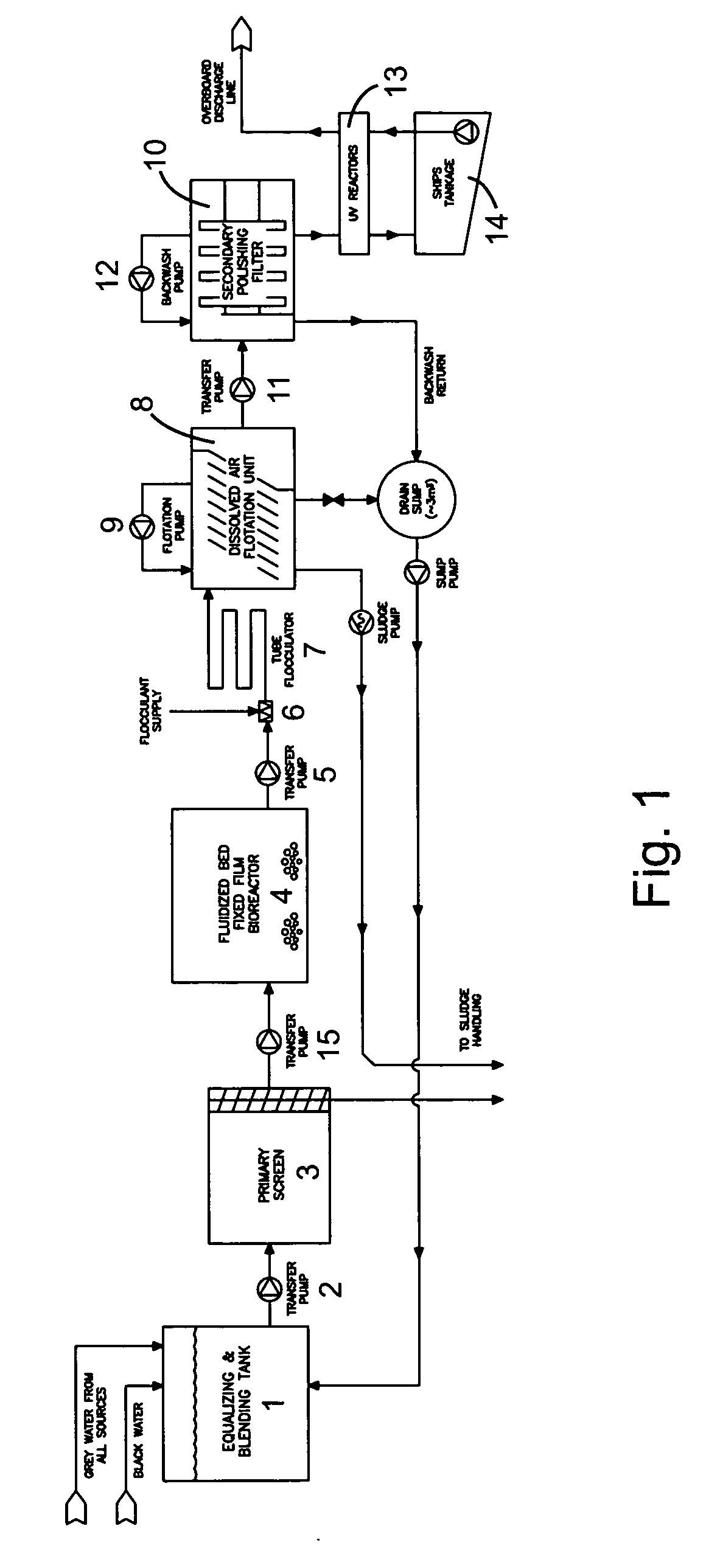

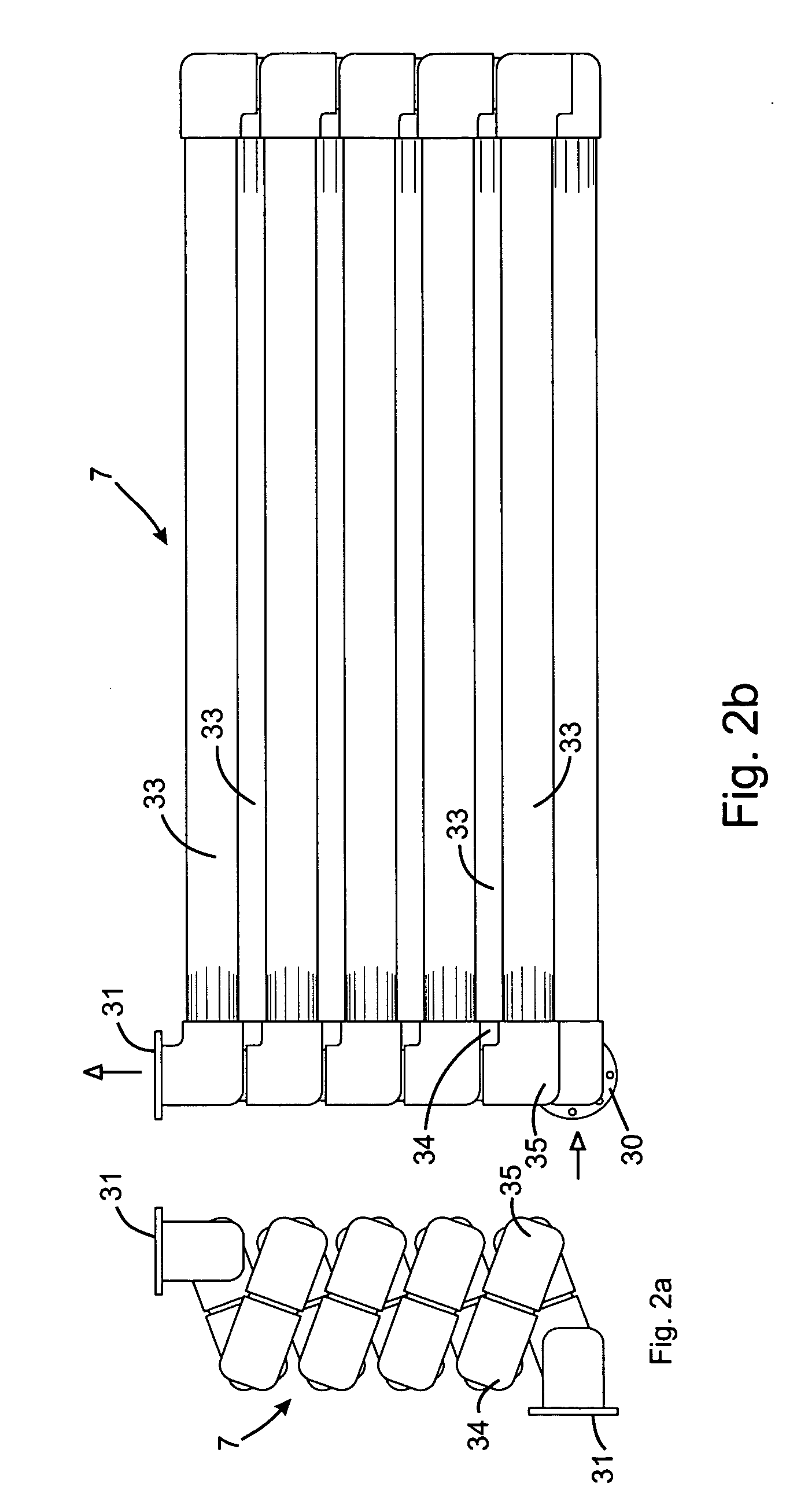

Wastewater treatment system for a marine vessel

InactiveUS20070114182A1Reduce movementAvoid erratic movementTreatment using aerobic processesTreatment involving filtrationCompound (substance)Membrane bioreactor

A wastewater treatment system for use on a marine vessel comprising an aerobic fixed film biological reactor, a tubular flocculator and a dissolved air flotation (DAF) unit. The process units desirably include means for reducing erratic movement of the wastewater due to sea-induced movement of the marine vessel. The DAF unit includes a plurality of inclined baffles arranged to create a plurality of parallel inverted U-shaped flow paths that effect combined co-current and counter-current flotation separation while reducing erratic movement of the wastewater. The selection of process units and operating conditions advantageously reduces the footprint of the wastewater treatment system and reduces cost and complexity associated with the handling of wastewater treatment chemicals.

Owner:HYDROXYL SYST

Disposable storage container

InactiveUS8308021B2Reduce weightAvoid dissatisfactionCapsClosure capsMechanical engineeringInverted u

The invention is directed to a single use disposable storage container and a lid therefor. The container includes a base and lid. The base includes a generally inverted U-shape rim for mating with the lid to secure the lid to the container base. The container lid includes a composite of paper and plastic. The plastic portion of the lid generally includes an inverted U-shape ring for mating with the base and securing the lid to the base. The plastic ring includes a peripheral ledge and seat extending from an inner side wall of the ring. The paper center panel is secured to the peripheral ledge and seat.

Owner:SC JOHNSON & SON INC

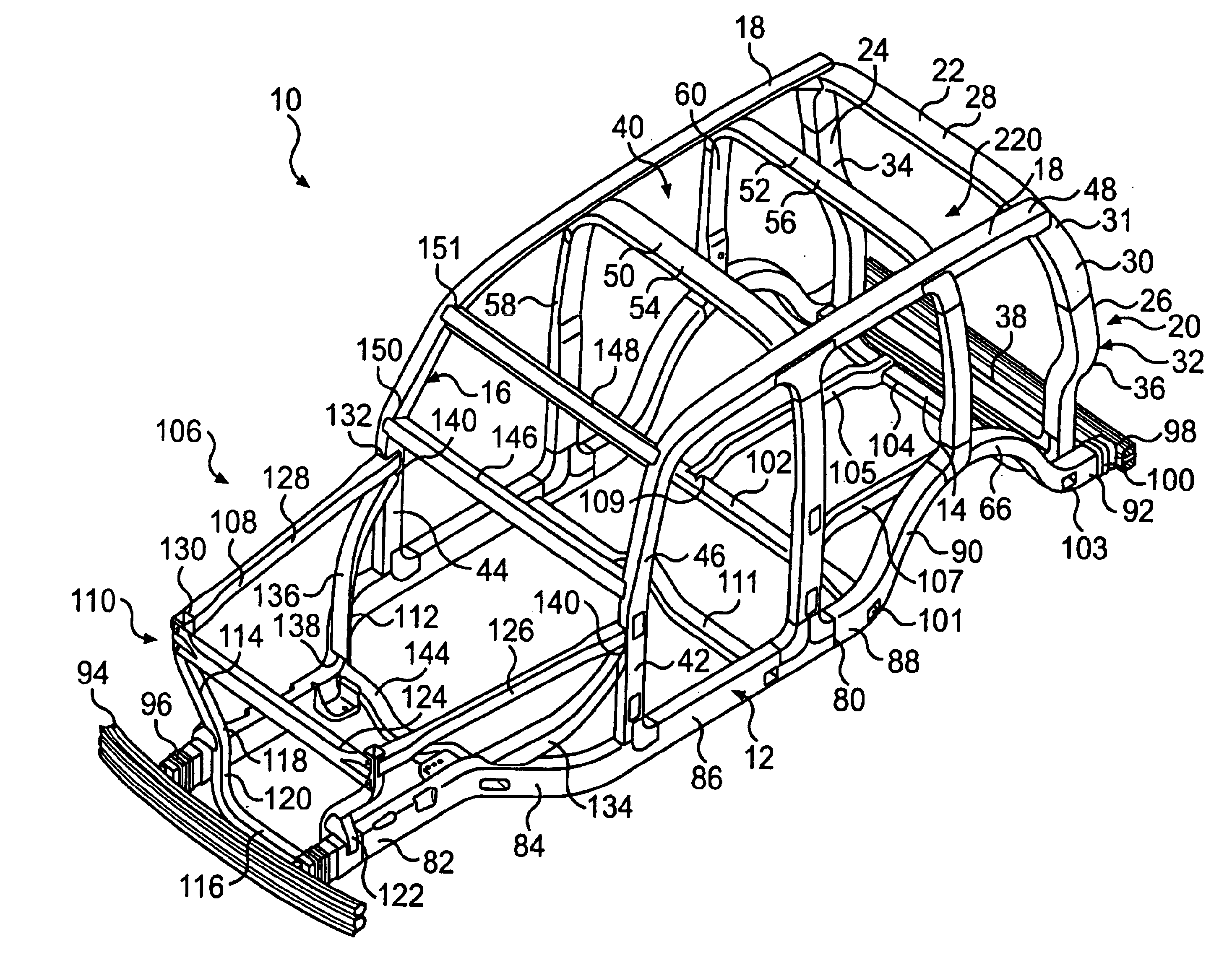

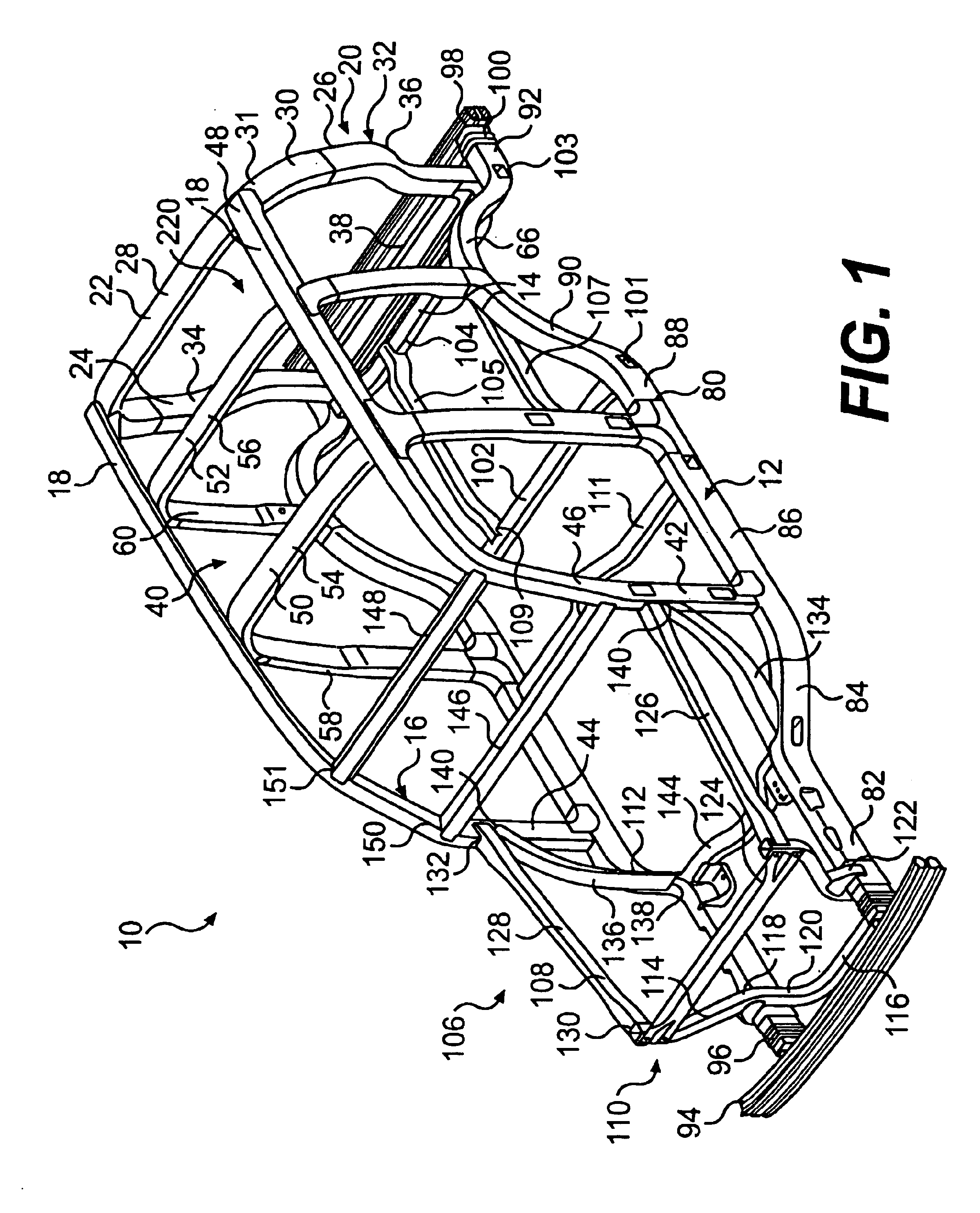

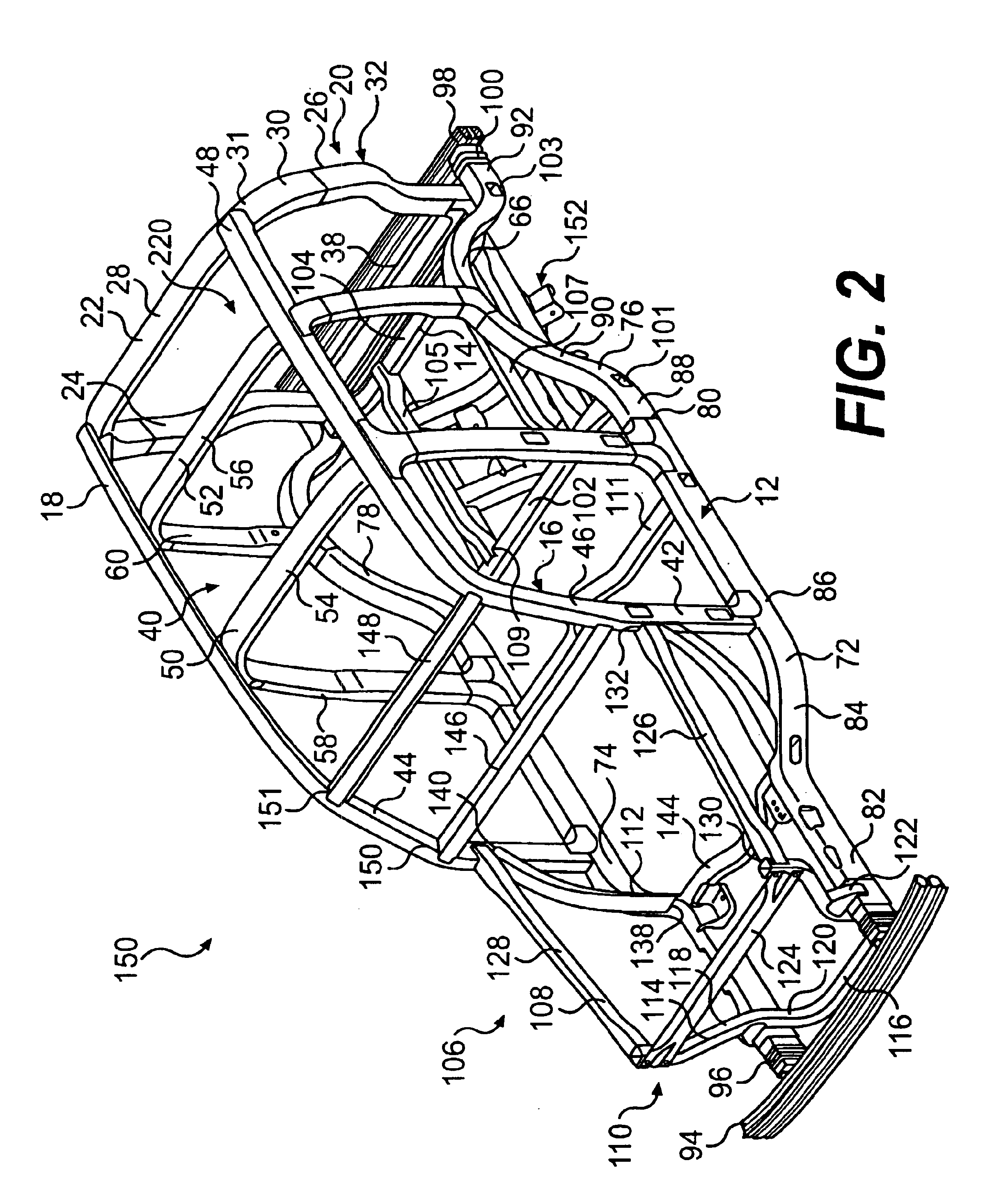

Hydroformed space frame and rearward ring assembly therefor

A space frame for a motor vehicle having a pair of laterally spaced, longitudinally extending side rail structures, a pair of forward-most upright structures each being connected to a respective side rail structure, thereby forming a pair of A pillars, a pair of roof rail structures, a forward end of each roof rail structure being connected to an upper end of an associated A pillar, and a rearward ring assembly connected at upper portions thereof with the roof rail structures and at bottom portions thereof with the side rail structures. The rearward ring assembly having (a) a tubular hydroformed inverted U-shaped upper member having a cross portion and a pair of leg portions extending downwardly from opposite ends of the cross portion, (b) a pair of tubular hydroformed side members, and (c) a cross structure rigidly connected in ring-forming relation between the second ends of the side members.

Owner:MAGNA INTERNATIONAL INC

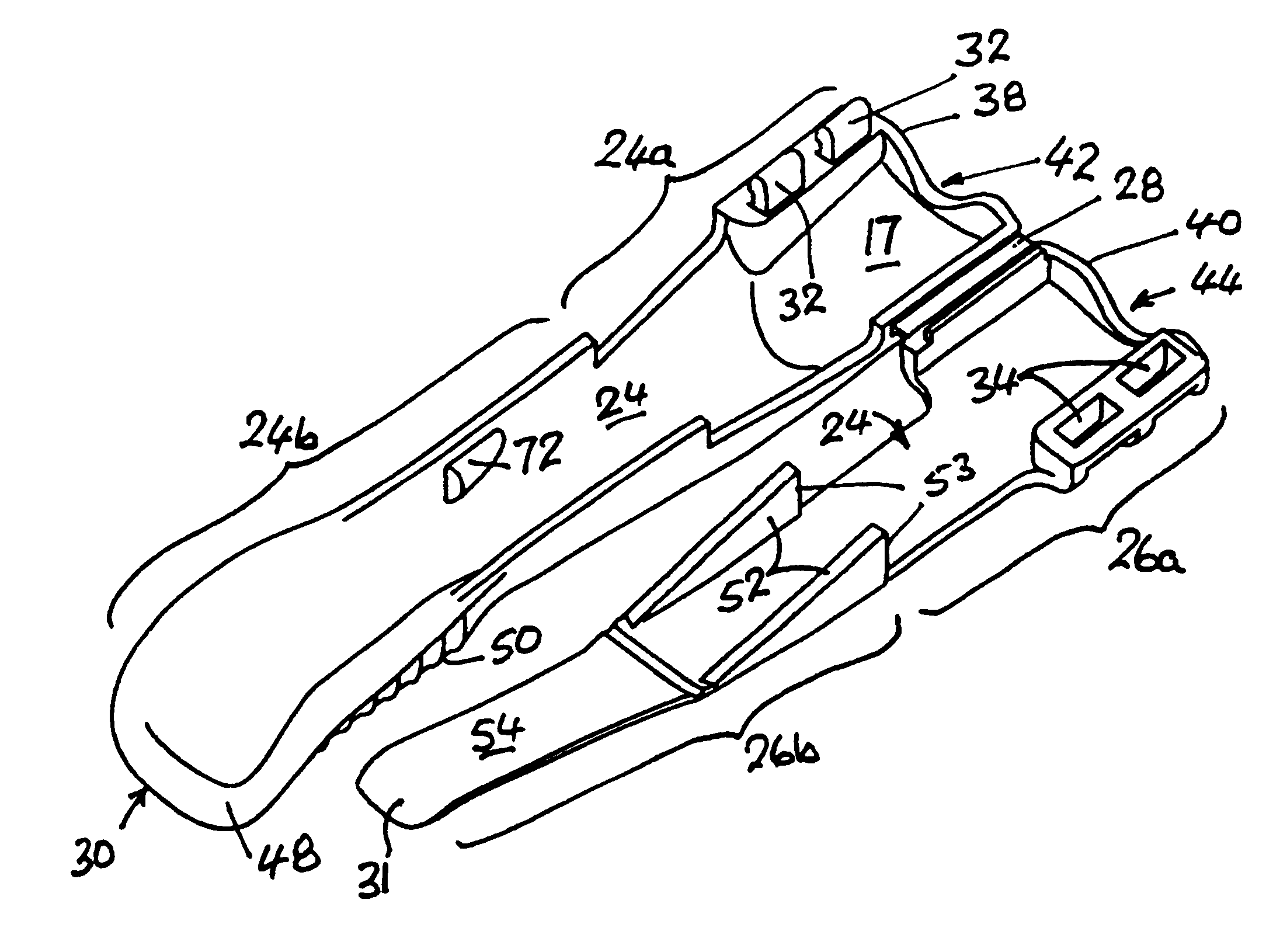

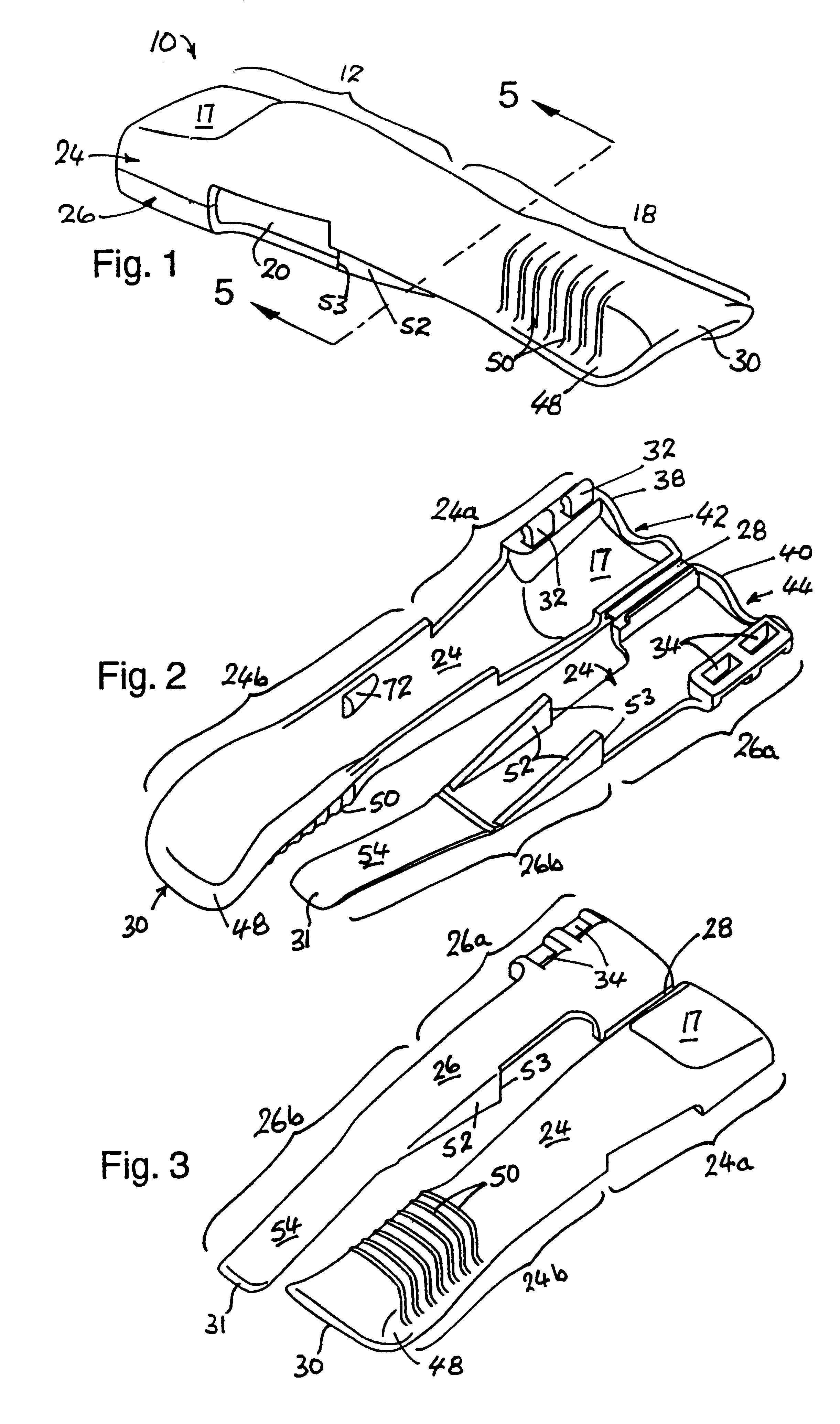

Needle guard and assembly

Needle guards are disclosed for use with needle assemblies comprising a needle hub that joins a flexible trailing tube to a medical needle, the normally open front ends of the guards being closeable after a needle and hub have been pulled therein by the trailing tube. In one example (FIG. 4c), a guard (10) has a stiff upper sidewall (24a) of an inverted U-shape and a flexible lower sidewall (26b) that fits inside the upper sidewall and is resiliently biased to bring its front end (31) into contact with the front end (30) of upper sidewall (24b) so as to close the front aperture of the guard after the needle assembly (16) has been withdrawn into the guard. The lower sidewall (26b) can be locked or clipped into the upper sidewall (24b) by pressing lower sidewall passed catches (72). In this way, the needle is completely and safely enclosed after use to reduce the danger of needle-stick injury and blood-splash contamination.

Owner:NOBLE HOUSE GROUP

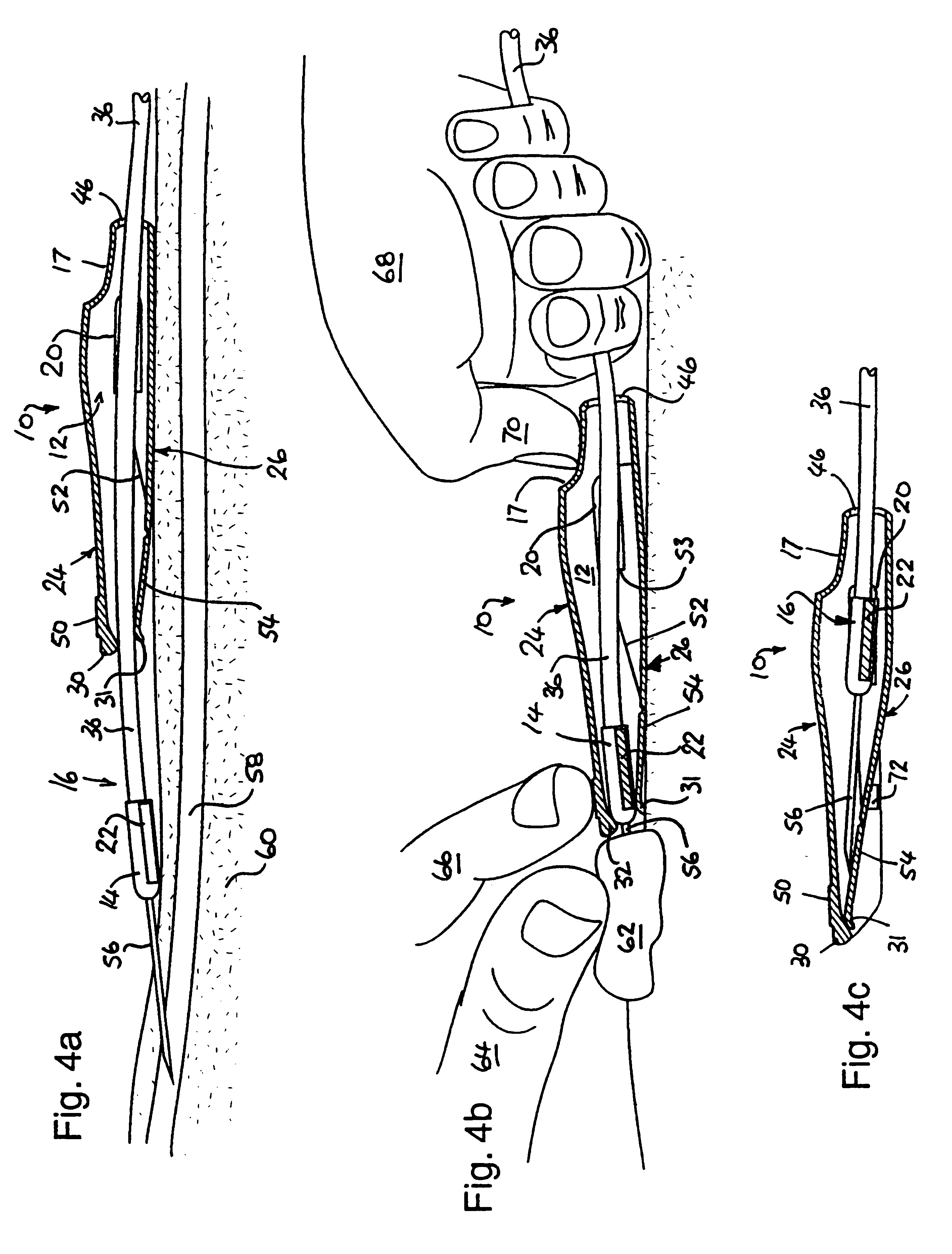

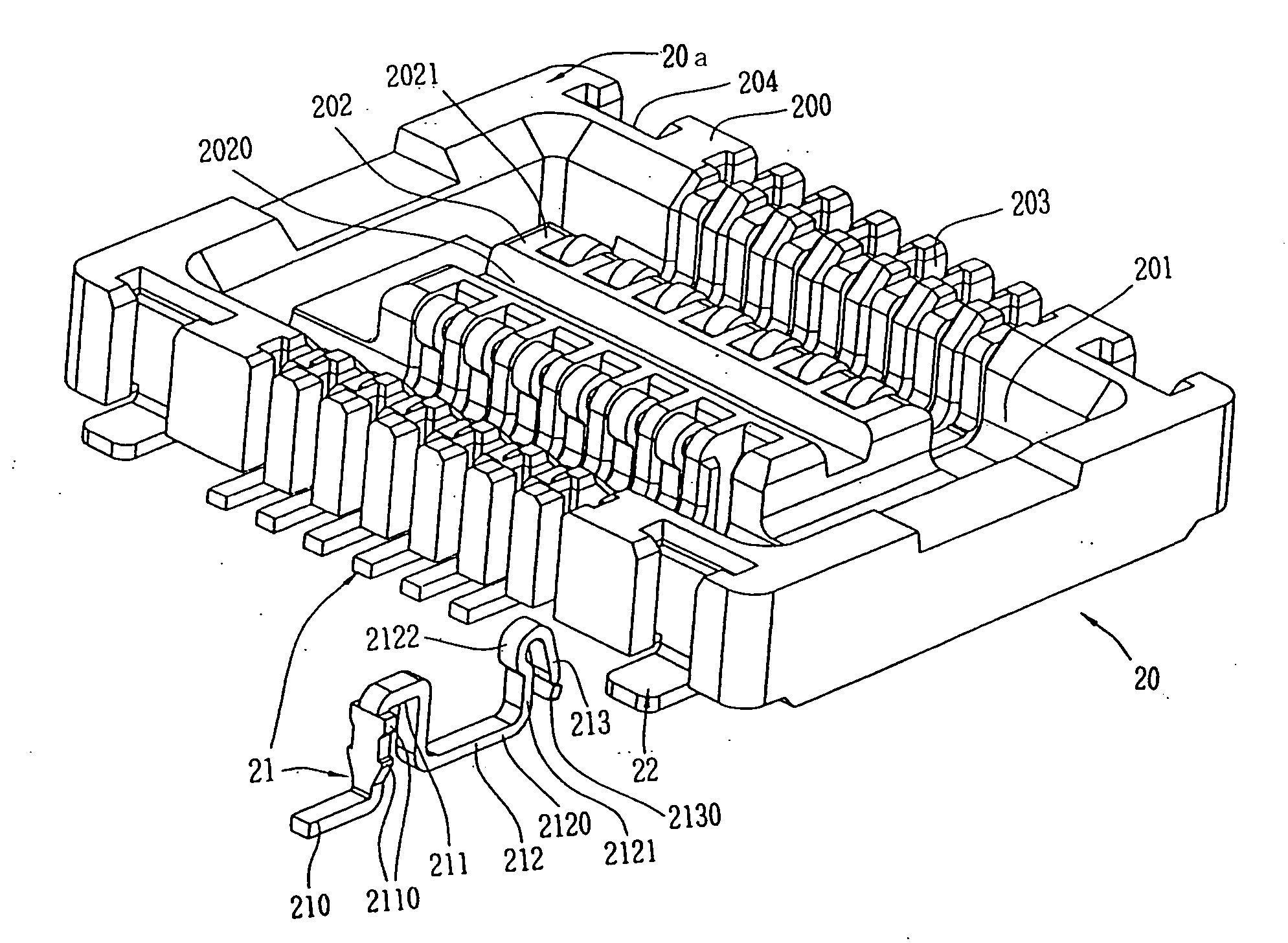

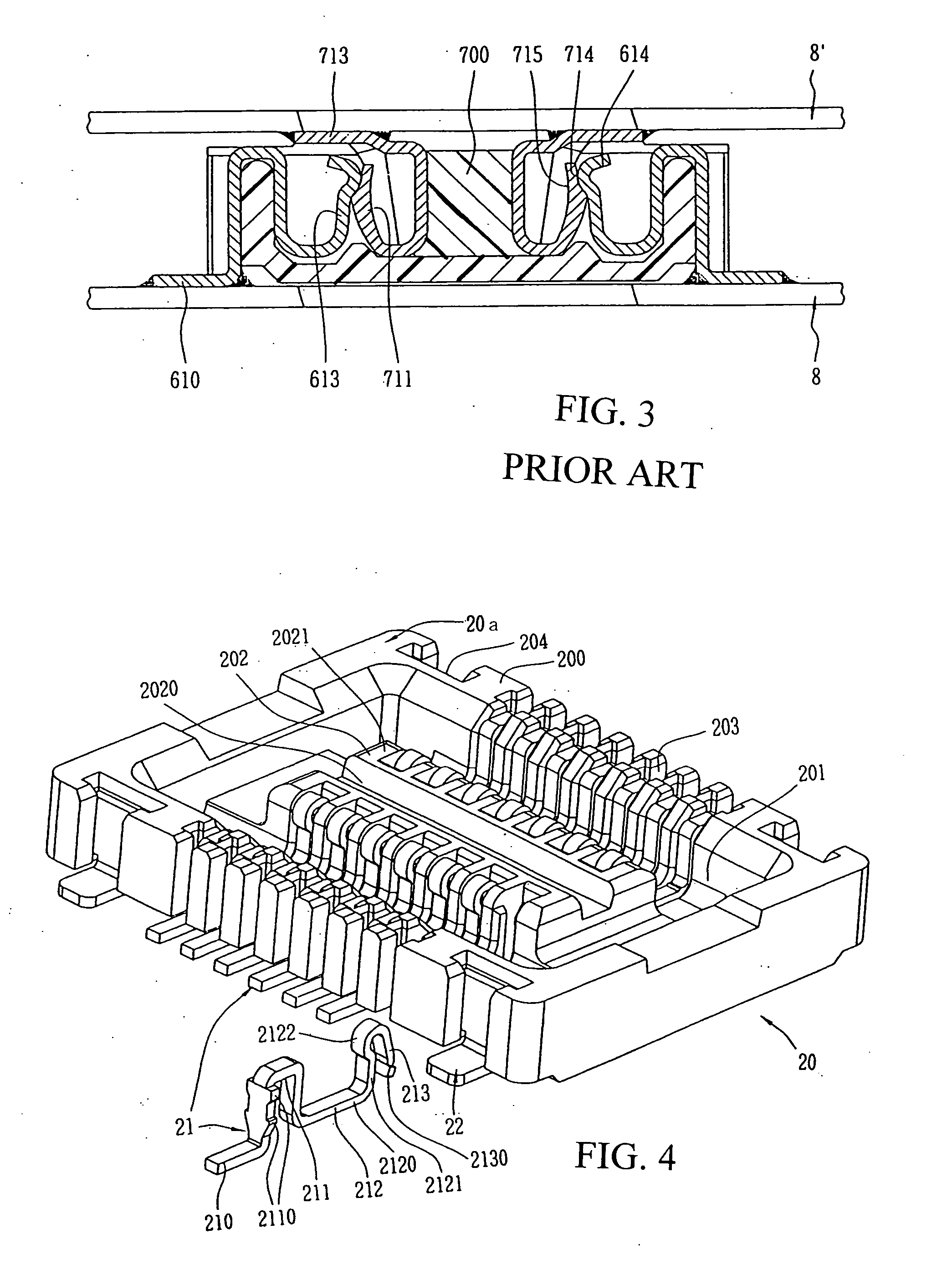

Contacts of board-to-board connector

InactiveUS20060178022A1Reliable electrical connectionAccurate contactCoupling contact membersTwo-part coupling devicesElectrical connectionBoard-to-board connector

An electrical connector assembly includes a socket connector soldered on one circuit board and a plug connector soldered on another circuit board. The socket connector includes an insulating socket base and a plurality of first terminals received in the first terminal-receiving slots of the insulating socket base. Each first terminal successively extends to form a first terminal lead, a first inverted U-shaped portion, a base U-shaped portion and an auxiliary-clamping portion. One leg of the base U-shaped portion includes a first elastic-contact portion. The plug connector includes an insulating plug base and a plurality of second terminals received in the second terminal-receiving slots of the insulating plug base. Each second terminal successively extends to form a second terminal lead and a second inverted U-shaped portion having a second elastic-contact portion. The second inverted U-shaped portion of the second terminal is inserted into the base U-shaped portion of the first terminal, and the first elastic-contact portion contacts the second elastic-contact portion when mating. The invention can provide stable mating and electrical connection and is in compliance with recent downsizing trends.

Owner:MOLEX INC

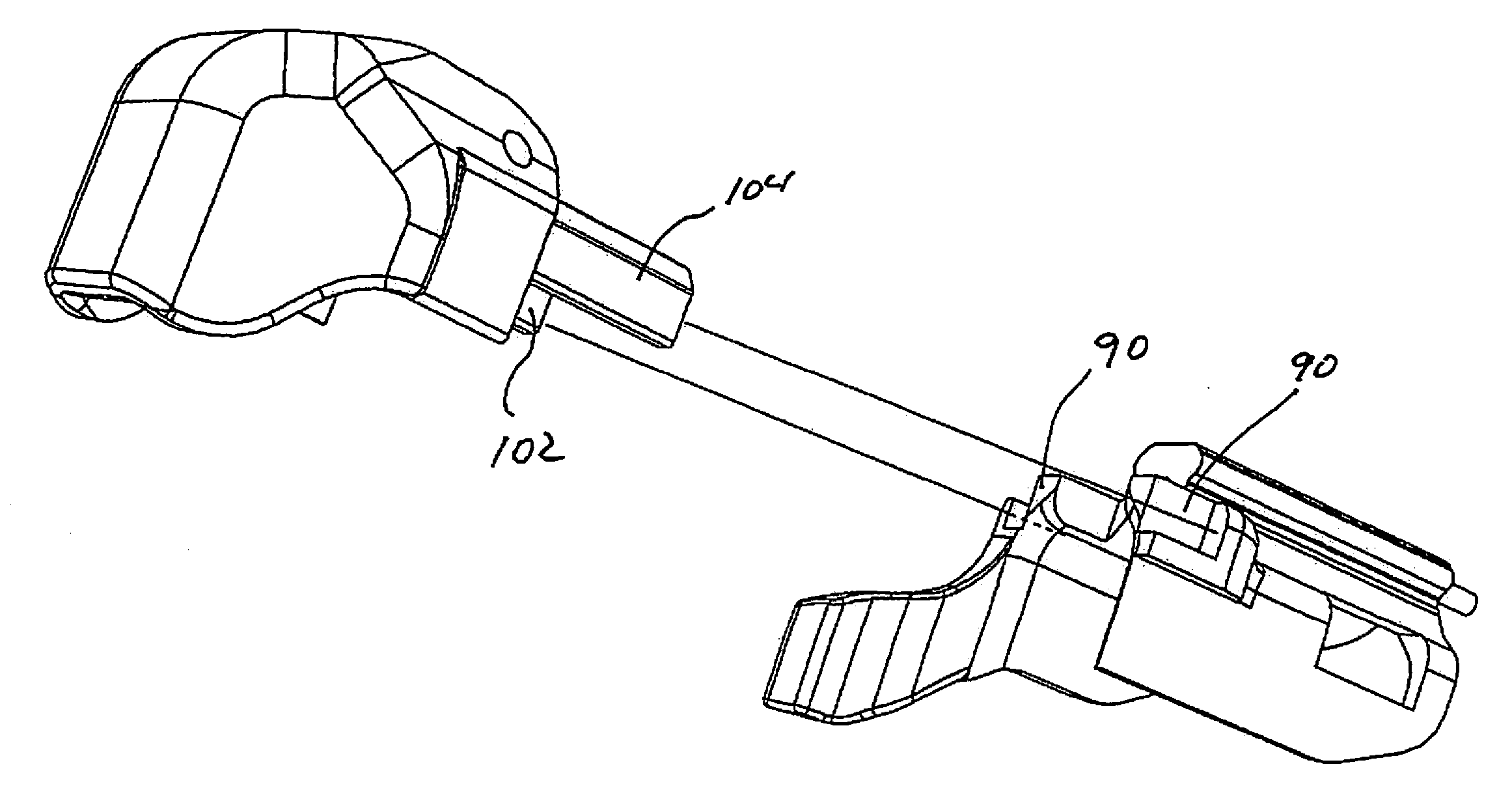

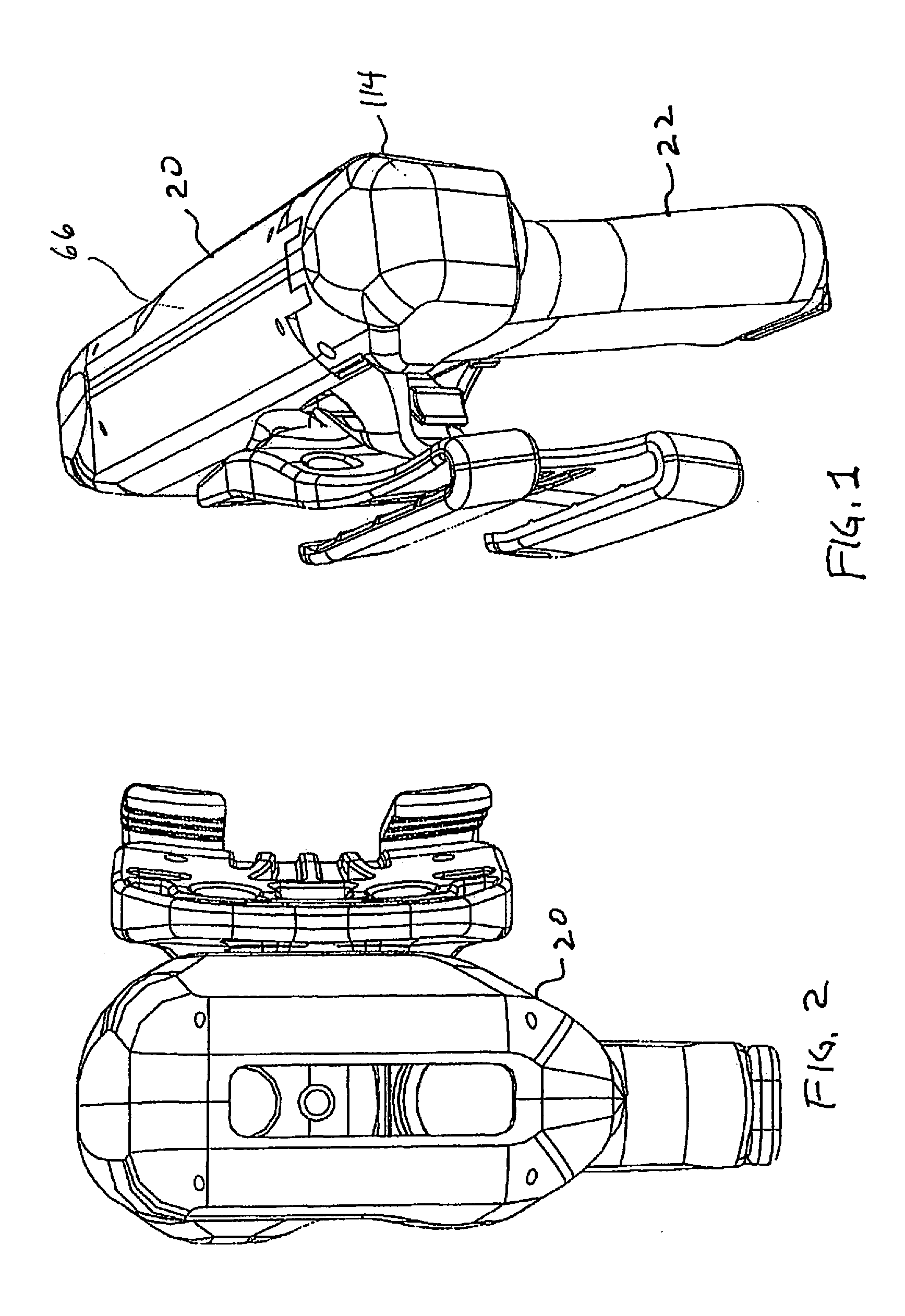

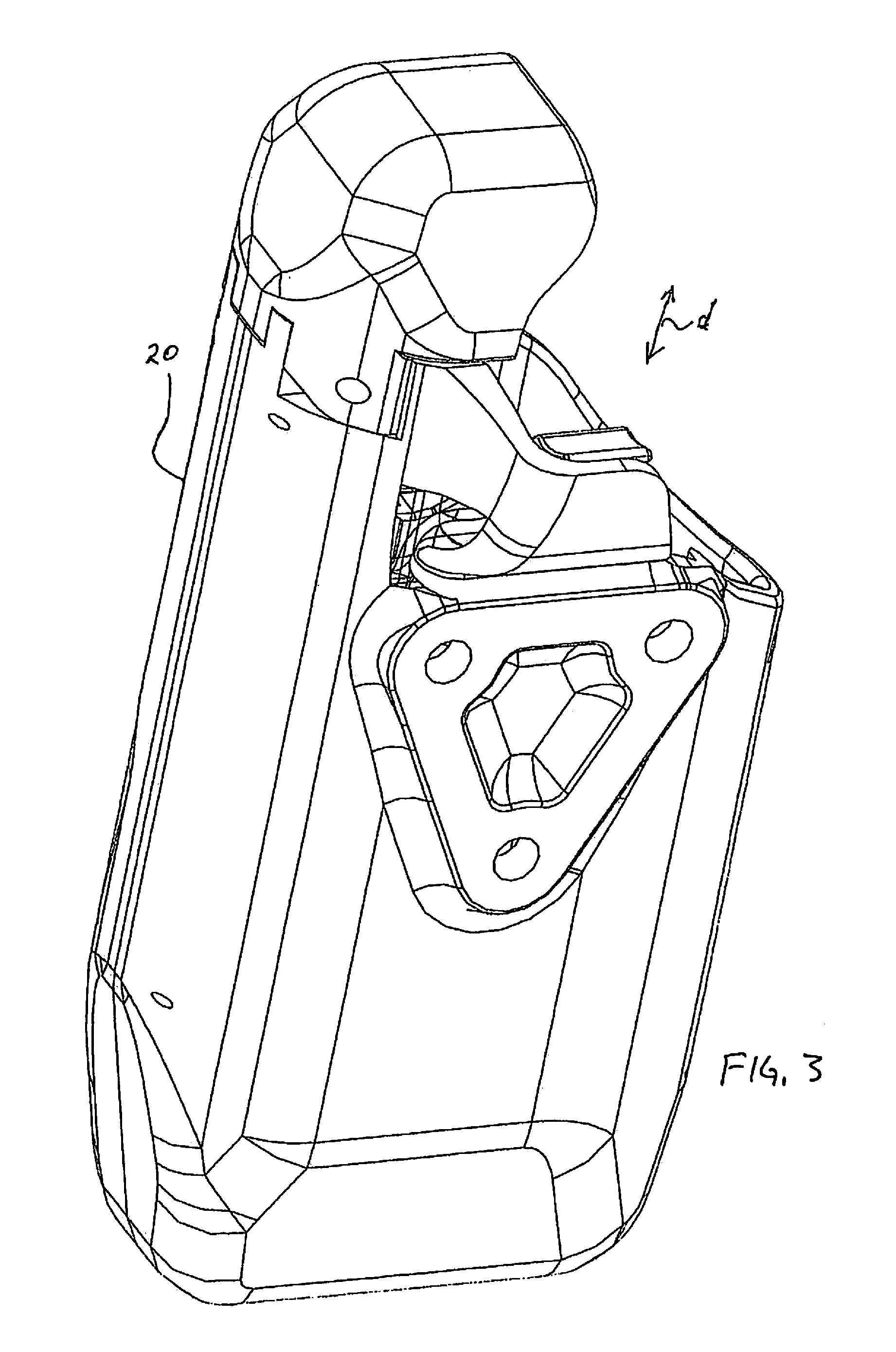

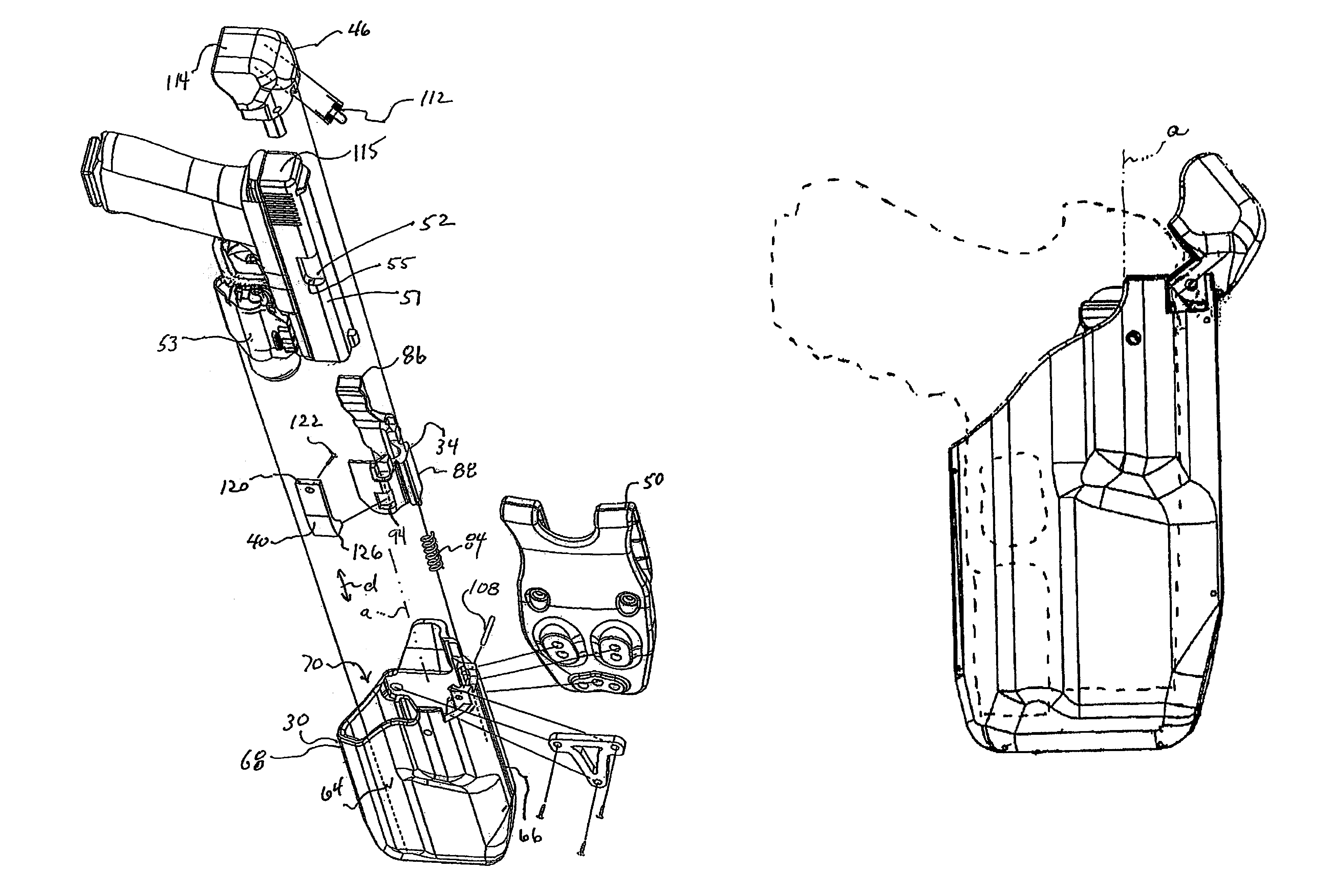

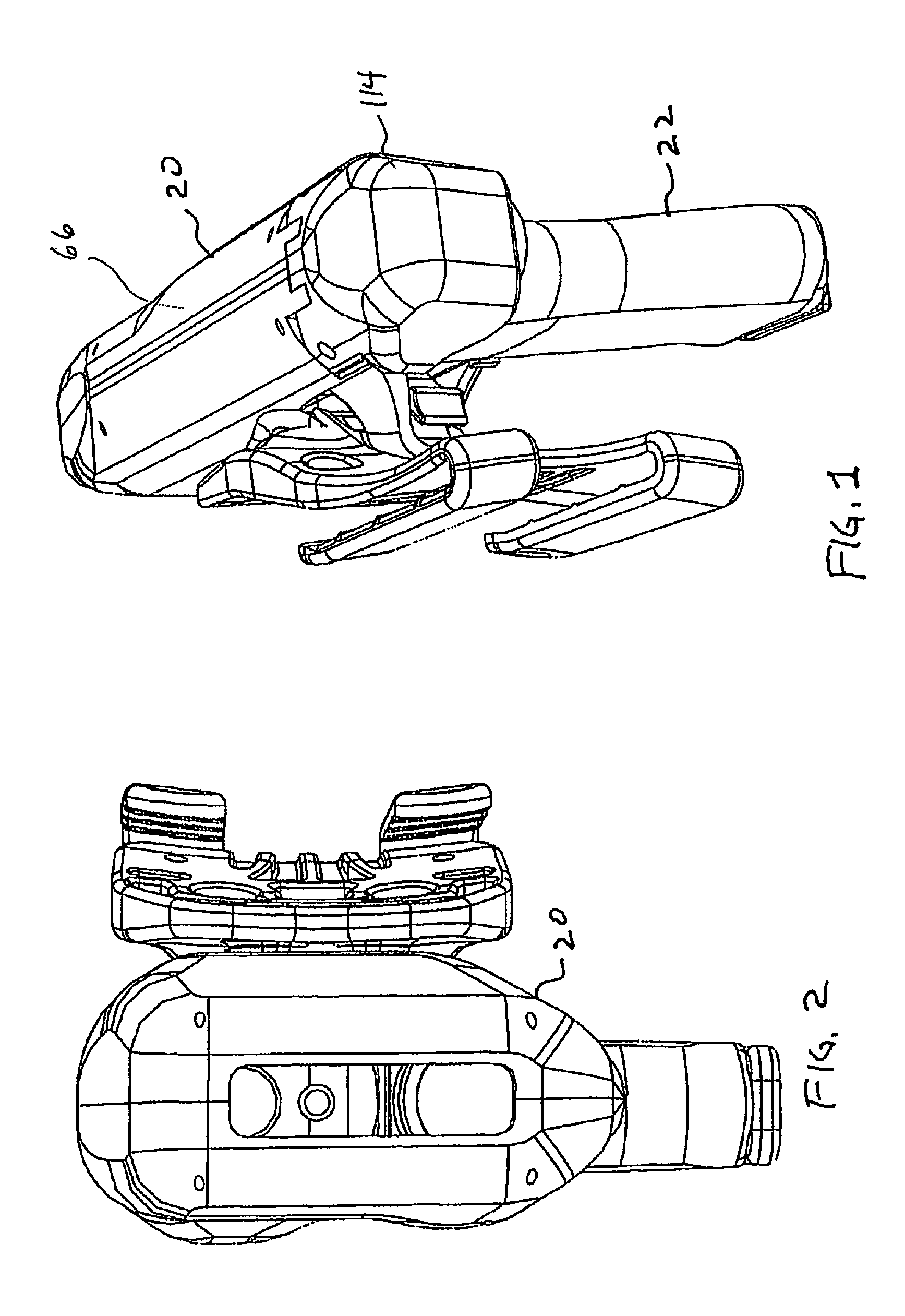

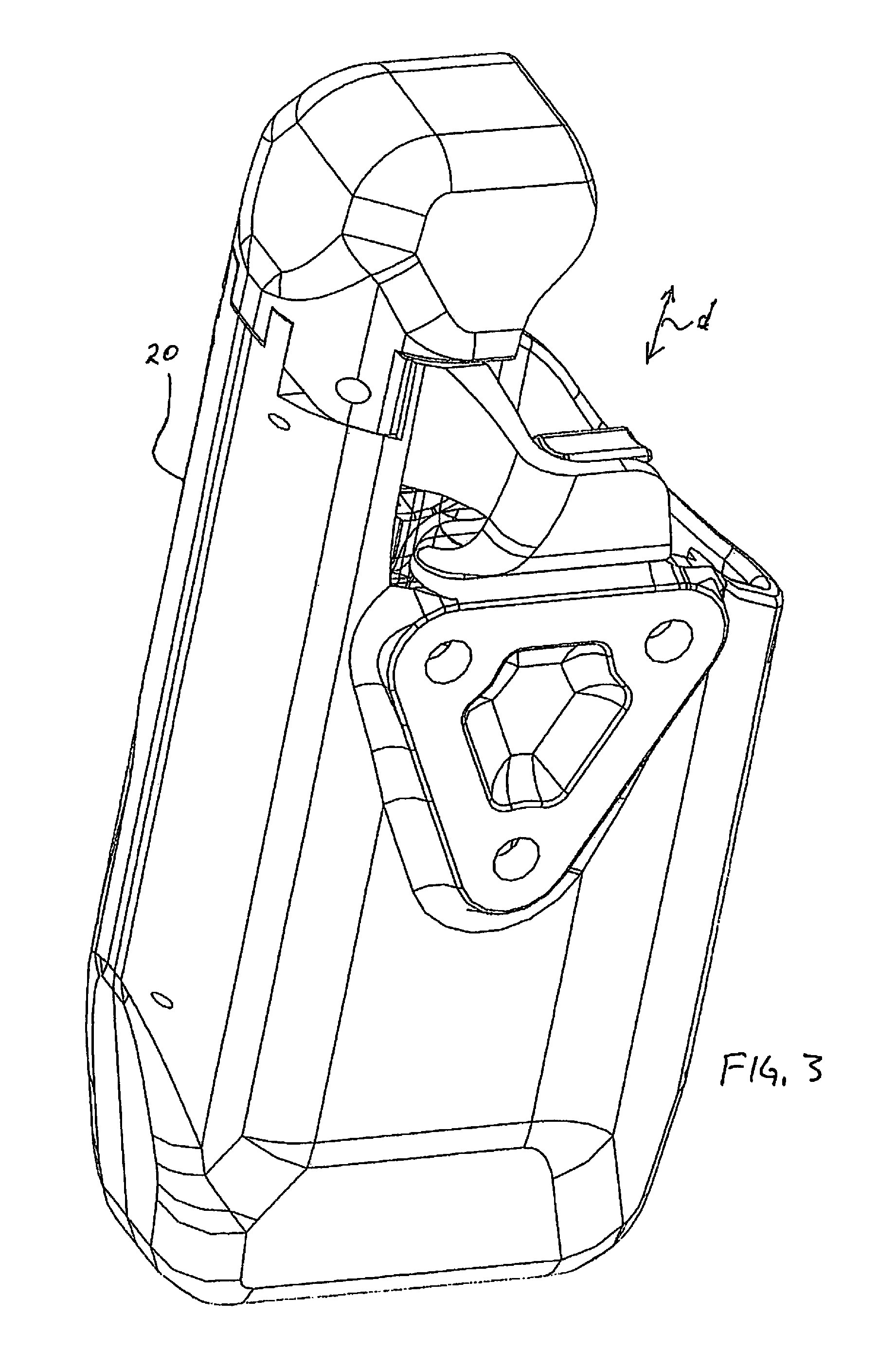

Holster

ActiveUS20140048572A1Less retention levelManufacturing costs for holsters for different handguns can be reducedTravelling carriersArms wearablesEngineeringInverted u

A holster for a handgun that comprises a holster body with a handgun cavity for receiving and retaining the handgun by way of a obstructing member at the ejection port and at the rear portion of the handgun slide. Moreover, a single obscured push button actuates both mechanisms. An internal retention sleeve having an inverted U-shape is slidingly mounted within the holster body and movable between a first securement position and a second release position. The sleeve having an integral thumb button depressible downwardly whereby the sleeve moves downwardly within the body to release a ejection port stop catch and the latch hood. The sleeve biased toward a normal retention position, the handgun withdrawal obstructing member biased toward the normal retention position, the latch hood biased toward a release position but having a normal latched obstructing position until released by the sleeve.

Owner:VISTA OUTDOOR OPERATIONS

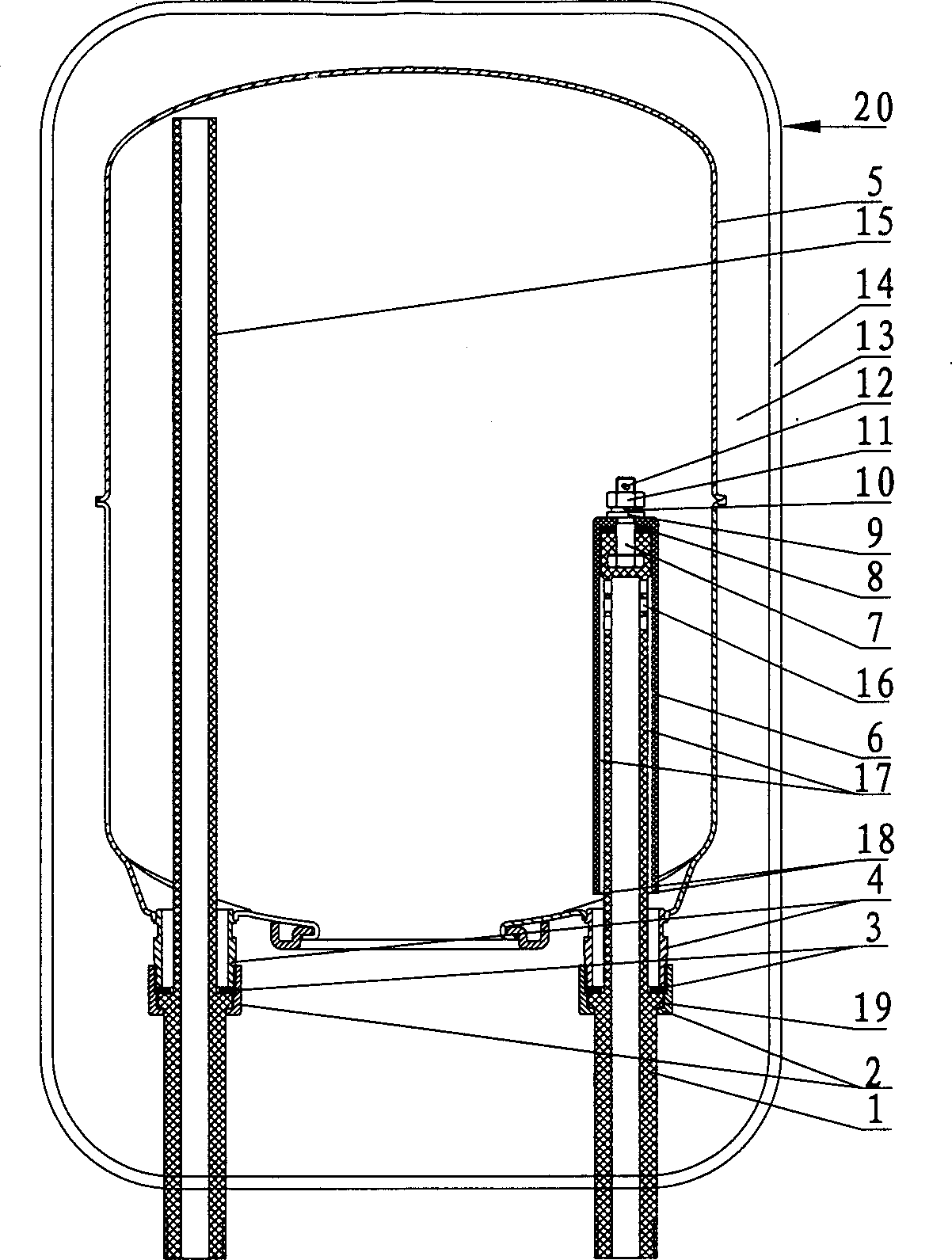

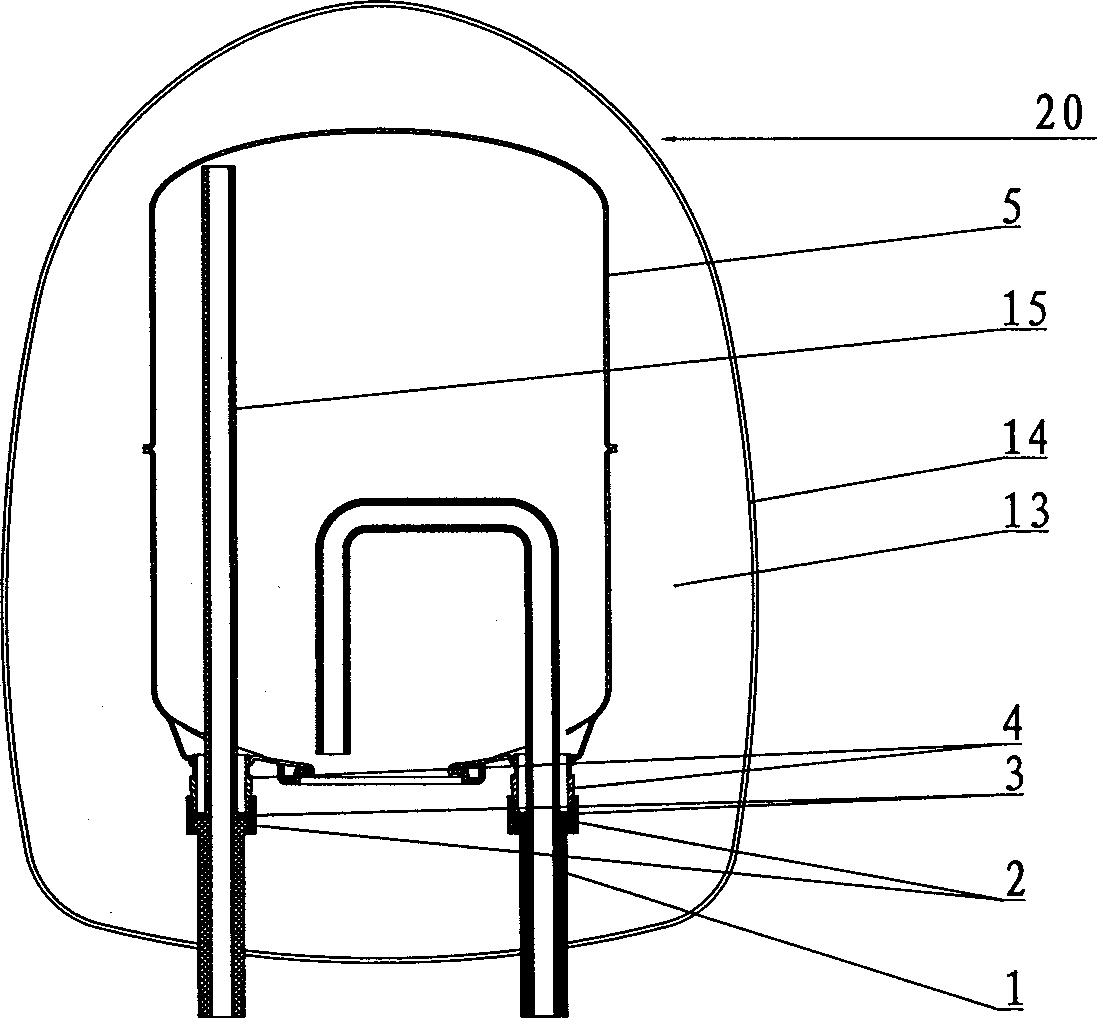

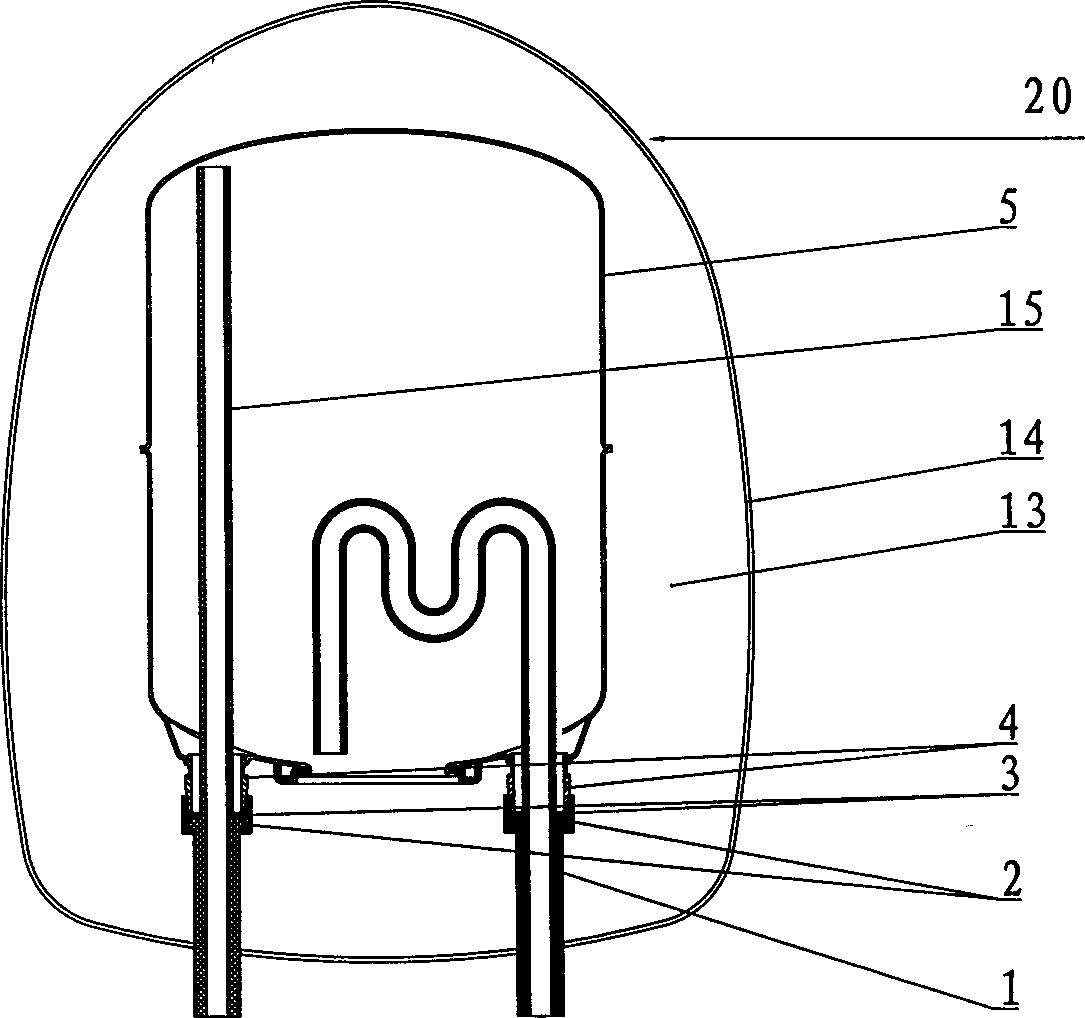

Electric shock resistant electric water heater

InactiveCN1358971ASatisfy the requirement of safe lengthSimple processFluid heatersStraight tubeWater flow

The electroshock-proofing electric water heater includes shell, internal container, water intake tube, water discharging tube, water discharging lining tube and water intake lining tube. It is characterized by that the described water intake lining tube is an insulating tube, its tube body is placed in the internal container cavity, and adopts the structural forms of inverted U shaped, M-shape or water intake straight tube and casting tube cover assembly, so that it increases zigzag length of water flow line and makes the length L from water inlet of water intake lining tube to water outlet attain the the safe length requirement of that L is greater than 53 sq.r.

Owner:HAIER GRP CORP +1

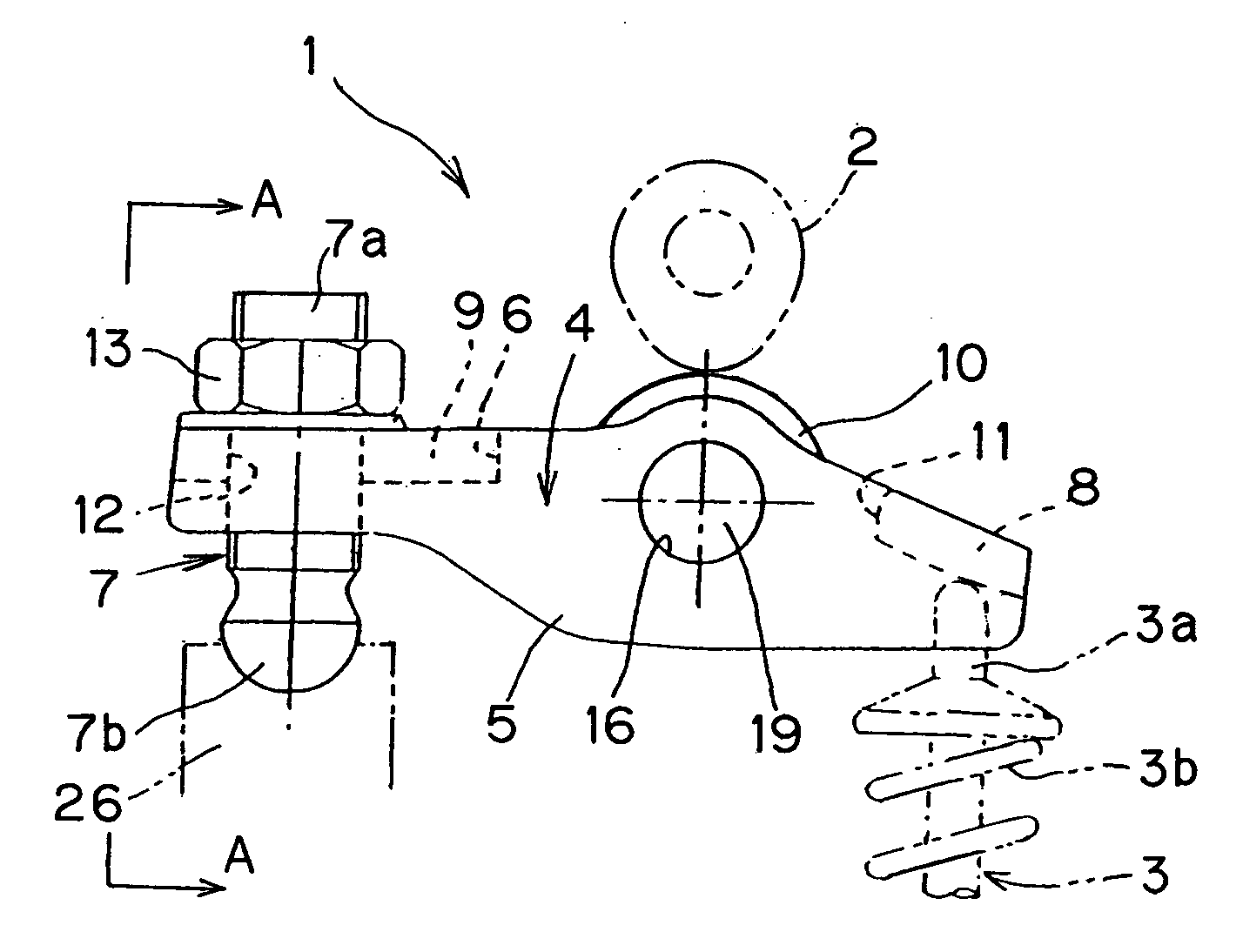

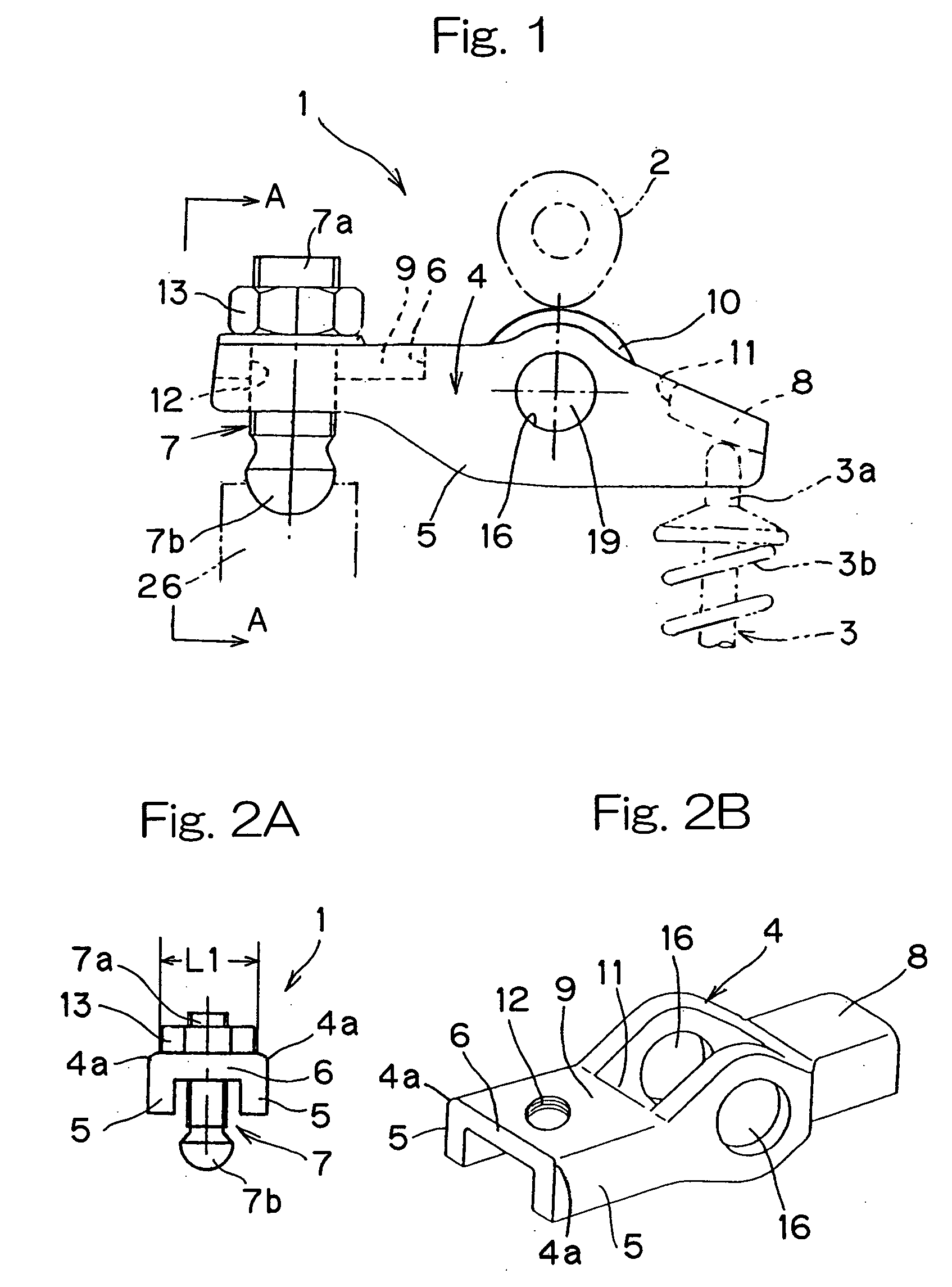

Rocker arm

There is provided a rocker arm of a kind in which even though the rocker arm is manufactured by the use of a press working technique the arm width can be minimized while the flat outer surface region of a required width is secured on an outer surface of the connecting wall, thereby contributing to reduction in size and weight of the rocker arm. This rocker arm 1 is capable of being driven by a cam 2 for selectively opening and closing a valve 3 of an internal combustion engine. This rocker arm 1 includes an arm body 4 prepared by bending a single plate material to represent a generally inverted U-shaped section including opposite side walls 5 and a connecting wall 6 bridging between the opposite side walls 5. A roller 10 engageable with the cam 2 is rotatably mounted on a portion of the arm body 4 generally intermediate of the length thereof. A valve drive element 8 is mounted on one end of the arm body 4 for driving the valve 4, while an end portion of the connecting wall 6 adjacent the other end of the arm body 4 is formed with an internally helically threaded hole 12 for threadingly receiving therein an externally helically threaded pivot member 7. An outer chamfered corner delimited between an outer surface of the connecting wall 6 and an outer surface of each of the opposite side walls and formed by bending is deformed to represent a plastically deformed portion 4a so formed by means of a plastic deformation technique that the outer chamfered corner represents a small radius of curvature R.

Owner:NTN CORP

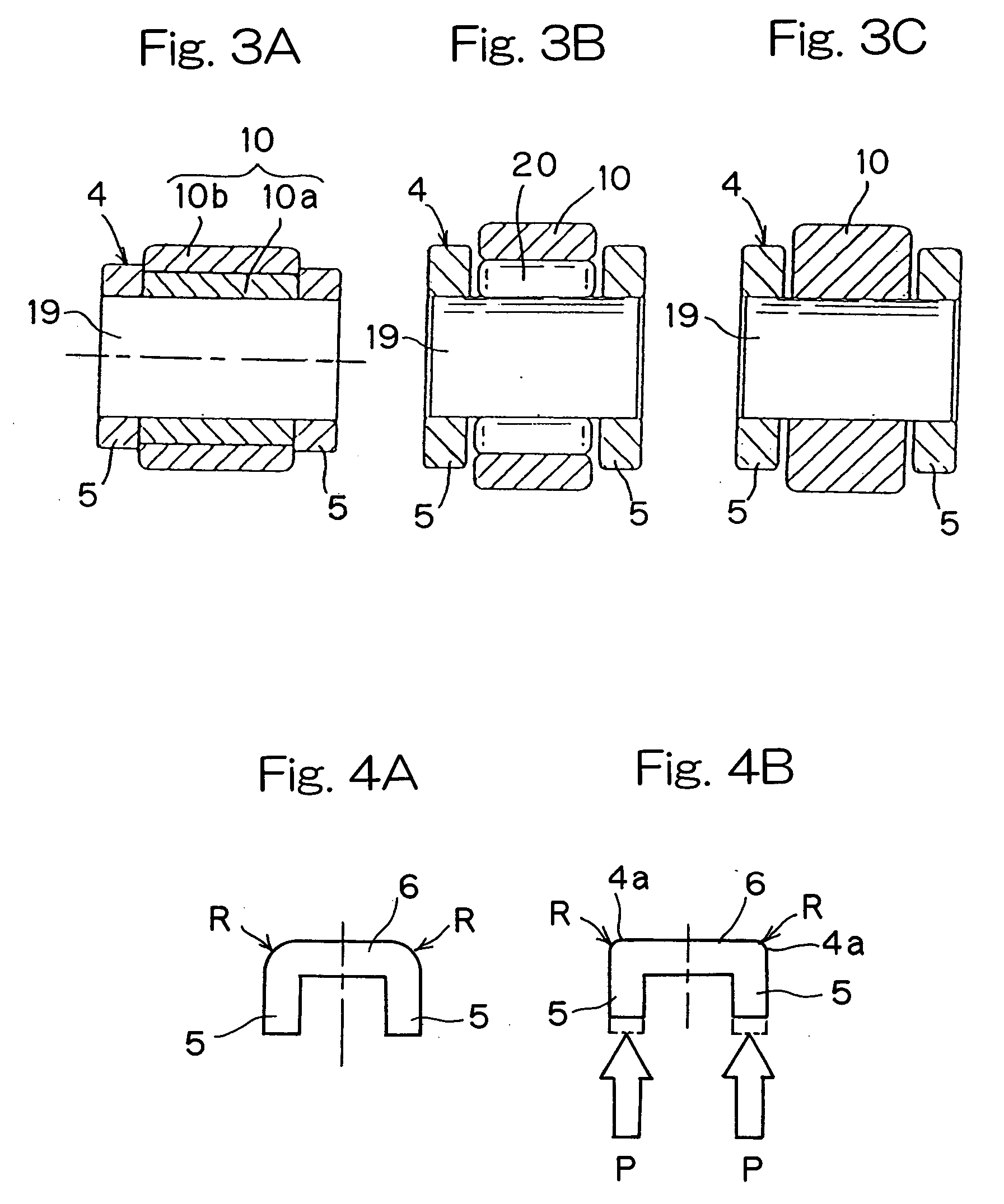

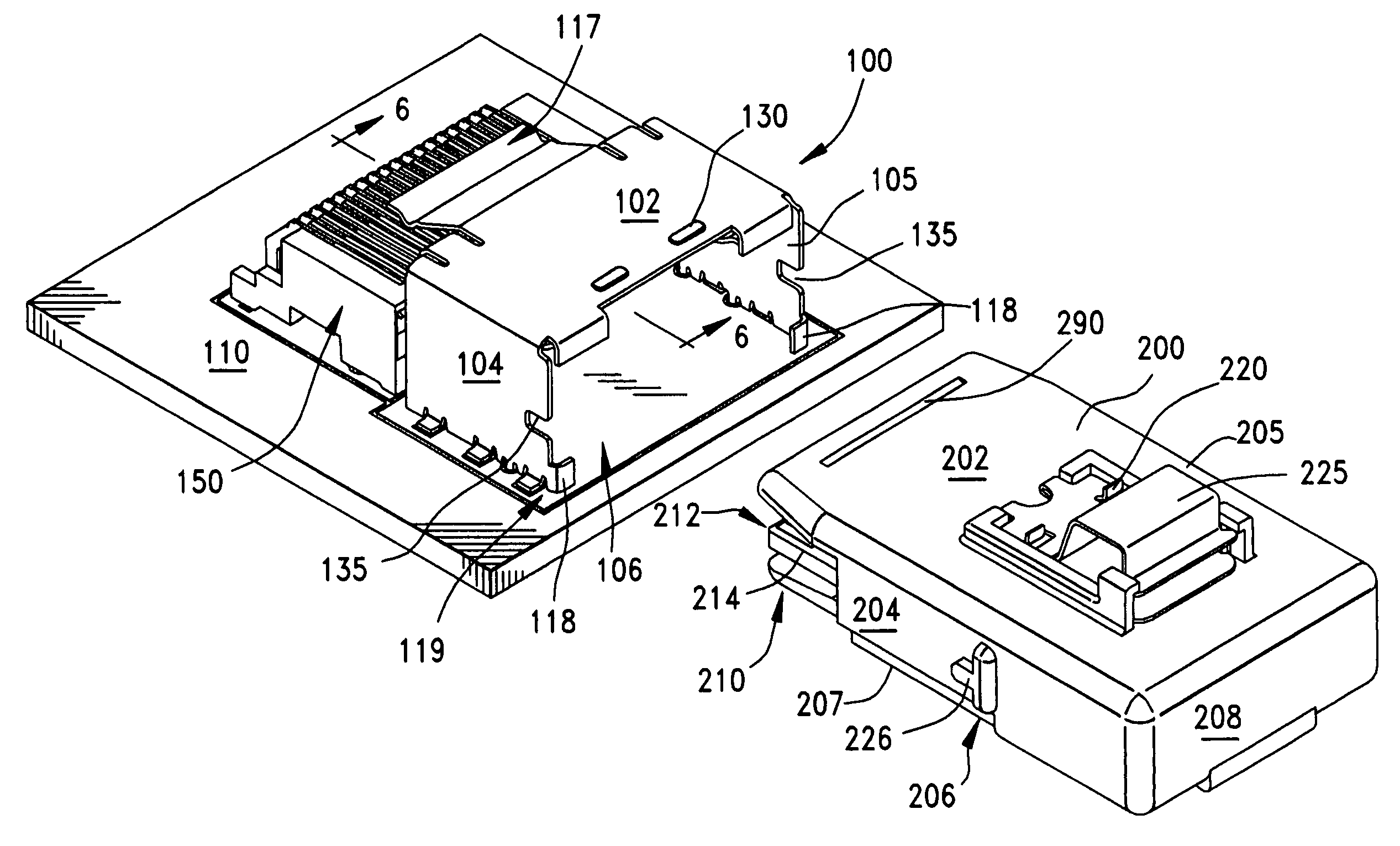

Connector and guide placement member

ActiveUS7226314B2Easy to installAccurate spacingCoupling protective earth/shielding arrangementsEngineeringMechanical engineering

A shroud that forms a guide channel for a receptacle connector is disclosed and it has the shape of an inverted U-shape, with a press tab for engaging a mating connector. The shroud has notches and tabs formed on it that serve to orient the mating connector for entry into the shroud. A placement member is described that holds the connector and the shroud together as a single unit for robotic placement of the shroud and connector in preselected positions on the circuit board.

Owner:MOLEX INC

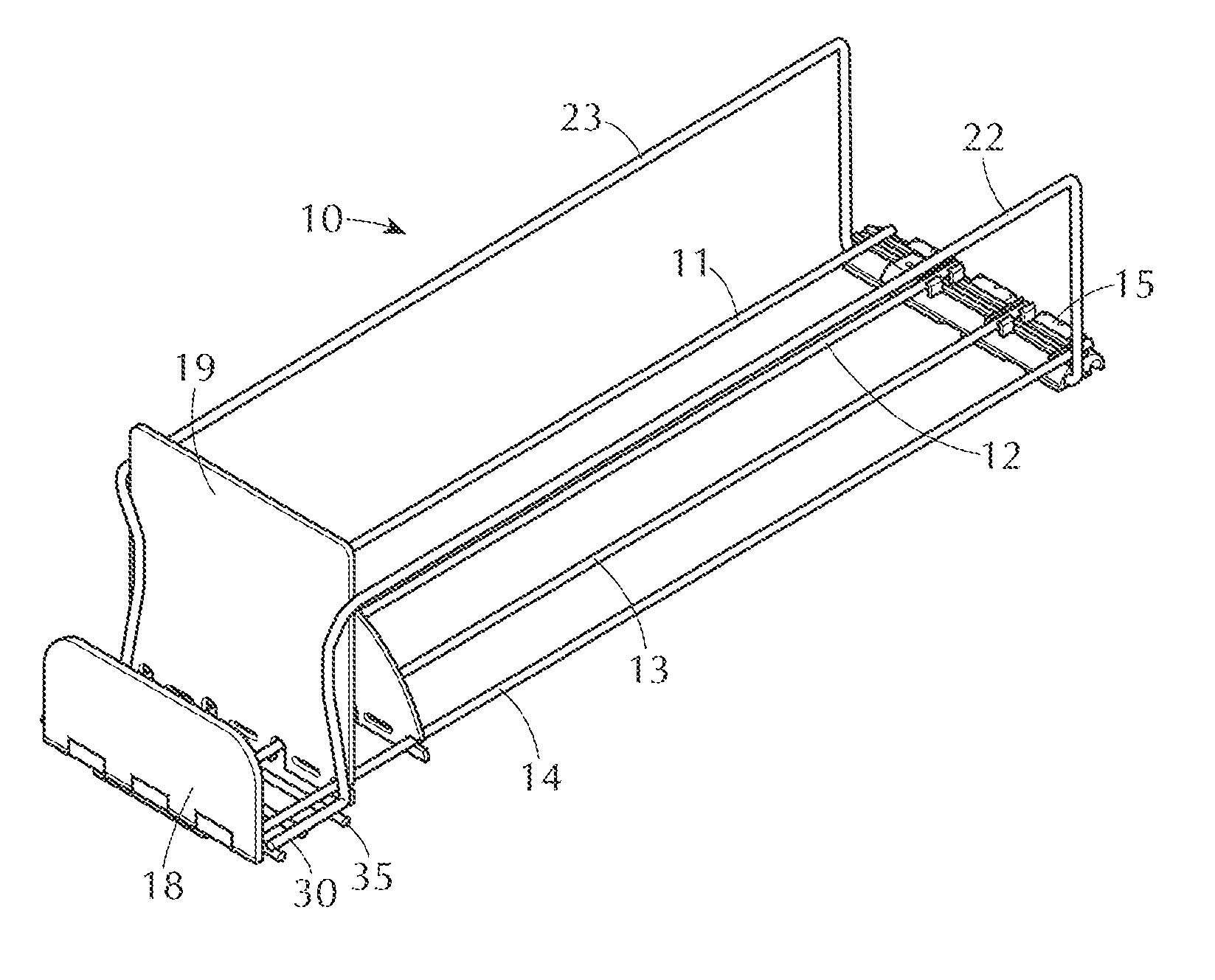

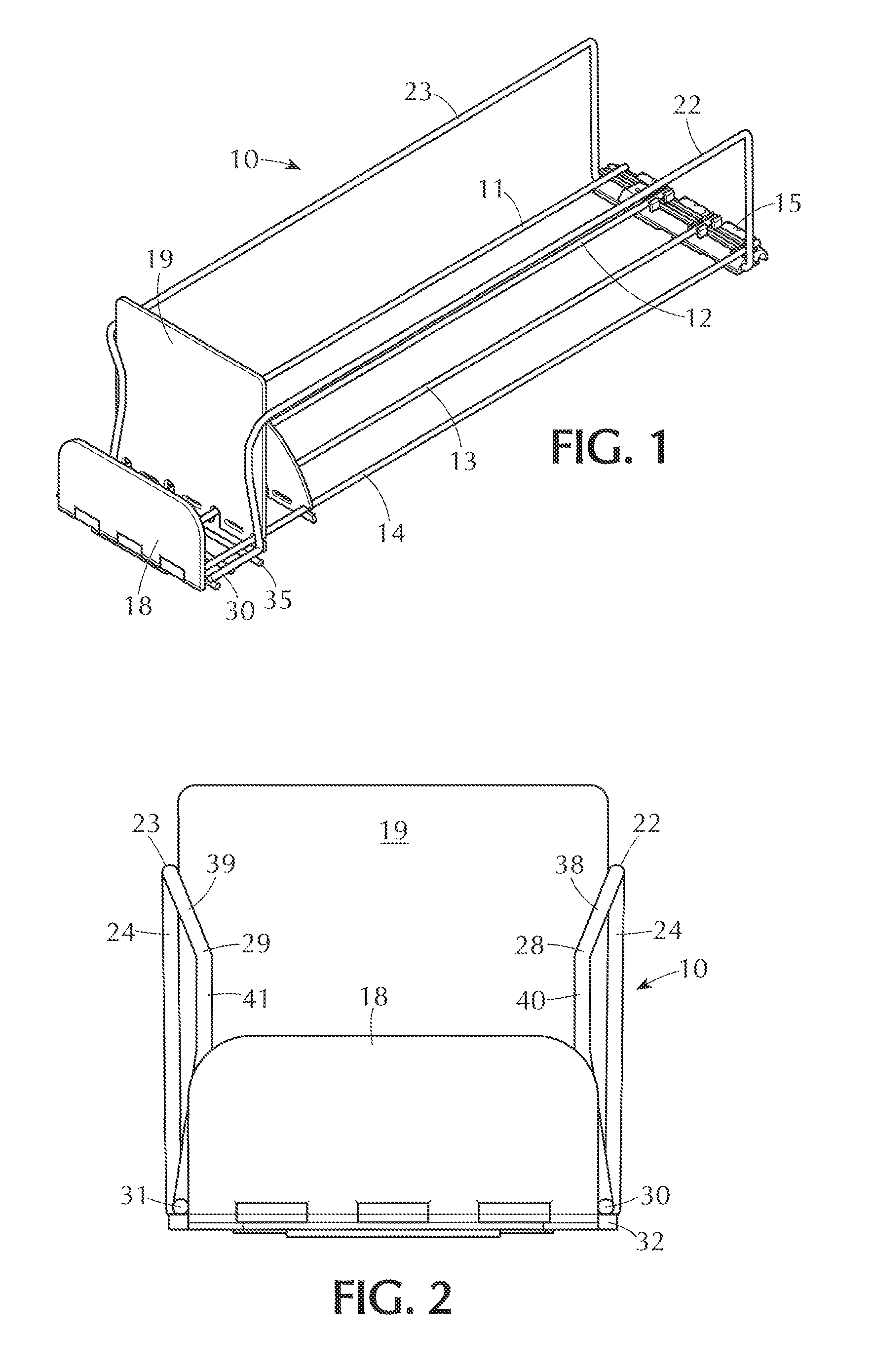

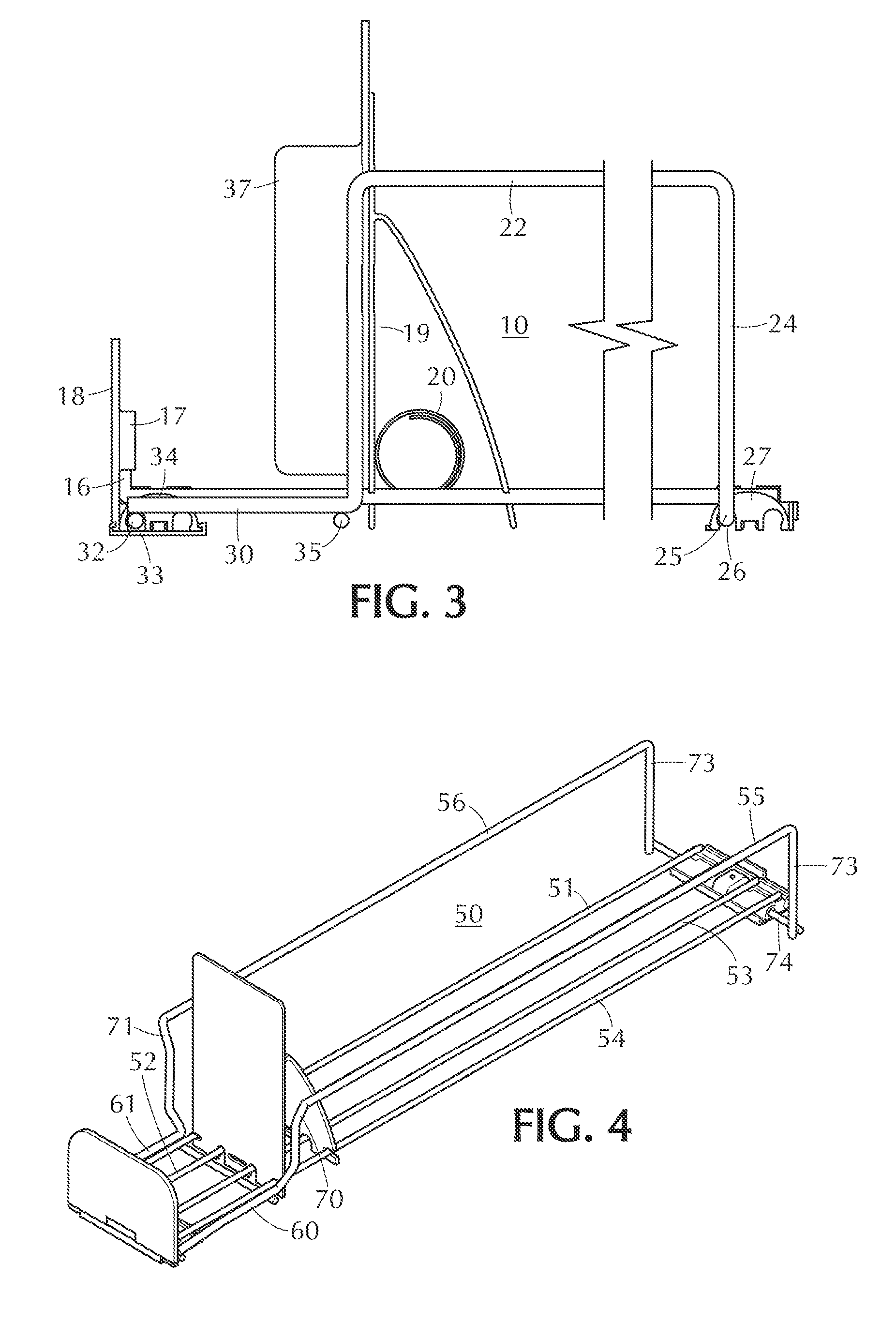

Product display tray with pull through feature

ActiveUS20110017684A1Increase deflectionEasy to disassembleRacksCoin-freed apparatus detailsEngineeringInverted u

A tray for the display and dispensing of products in blister packages. Side guide elements, of wire or sheet material, are provided in forward portions thereof with retaining elements formed integrally and in one piece therewith. The retaining elements engage side margins of a forwardmost package well below the tops of the packages and preferably below the tops of the blisters thereof. A forwardmost package is gripped by its exposed and unobstructed upper portions and pulled forwardly to remove a package. Integral, one-piece construction of the side guide elements and the retaining elements provides for economical manufacture with superior performance. Optionally, space may be provided in front of the retaining portions to accommodate return of packages by a customer who has changed his or her mind. In one embodiment, a wire retaining portion of inverted U-shaped configuration is positioned with wire ends concealed and protected by the tray side.

Owner:TRION IND

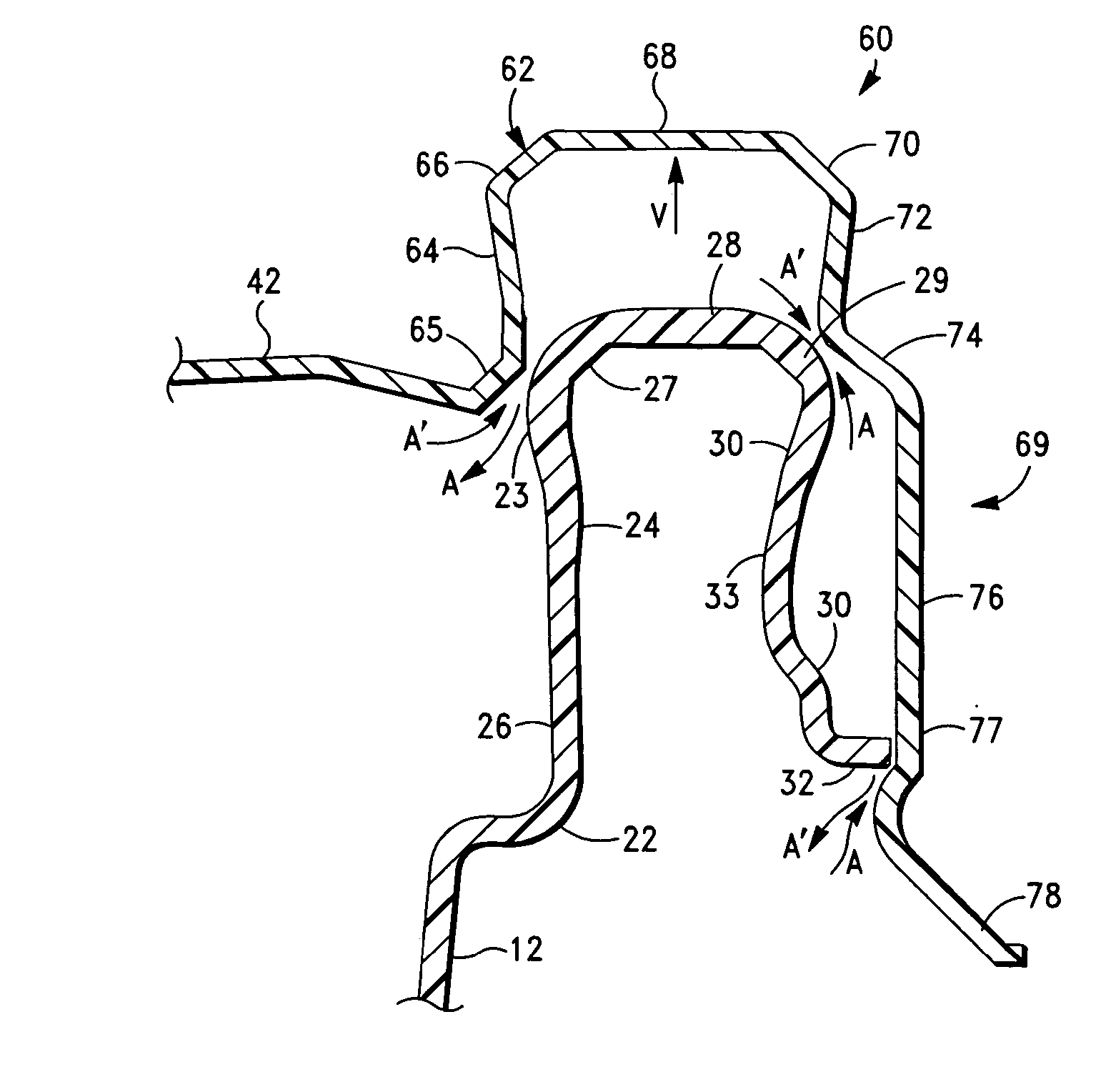

Venting Container

ActiveUS20080197134A1Increase volumeReduces and eliminates disadvantage and drawbackCapsClosure capsEngineeringMechanical engineering

A venting container including a lid and base having an inner cavity and a side wall that terminates in a rim, the lid including a central panel and a peripheral sealing lip that surrounds the panel, the peripheral sealing lip having a generally inverted U-shaped cross section that defines a lid channel into which the container rim fits, the sealing lip including at least one venting feature in the form of a flexible venting button that is adapted to transition from a first position to a second position upon application of an actuation force, the venting button being further adapted and positioned whereby when the container rim is positioned in the lid channel and the venting button is in the first position, sealed engagement of the lid to the container is effectuated and when the venting button is in the second position a venting air passage is provided from the container cavity to the container surroundings. In a second embodiment, the venting feature is in the form of a downwardly protruding venting boss provided to the lid closure and a boss seat formed in the base closure whereby the venting boss is received with the boss seat when the lid is oriented in a first non venting attachment position and the venting boss abuts against a surface of the base closure to provide a vent passage between the lid and base upon removal and repositioning of the lid to a second venting attachment position.

Owner:THE GLAD PROD CO

Holster

ActiveUS9134093B2Manufacturing costs for holsters for different handguns can be reducedReduce manufacturing costTravelling carriersArms wearablesEngineeringInverted u

A holster for a handgun that comprises a holster body with a handgun cavity for receiving and retaining the handgun by way of a obstructing member at the ejection port and at the rear portion of the handgun slide. Moreover, a single obscured push button actuates both mechanisms. An internal retention sleeve having an inverted U-shape is slidingly mounted within the holster body and movable between a first securement position and a second release position. The sleeve having an integral thumb button depressible downwardly whereby the sleeve moves downwardly within the body to release a ejection port stop catch and the latch hood. The sleeve biased toward a normal retention position, the handgun withdrawal obstructing member biased toward the normal retention position, the latch hood biased toward a release position but having a normal latched obstructing position until released by the sleeve.

Owner:VISTA OUTDOOR OPERATIONS

Product display with front barrier

A standardized or basic product display device is provided with a standard front barrier for identifying and restraining a spring-urged column of displayed products in conjunction with a plurality of secondary barrier elements which can be easily and securely mounted onto the primary barrier to accommodate reconfiguration and enlargement of the display device. The secondary elements have lower portions of inverted U-shaped configuration which can be selectively applied over external edge margins of the primary barrier and secured thereto by locking detents. The secondary barrier element enables the front barrier of the display device to be enlarged, both in width and height to accommodate larger product packages than contemplated for the standard display device in its minimum configuration. In one form, the secondary barrier element has a vertical extension of narrow width, providing effective restraint of tall packages while maximizing visibility of the front of the package.

Owner:TRION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com