Mounting Clamp

a technology of mounting clamps and clamps, which is applied in the direction of machine supports, lighting and heating apparatus, lighting support devices, etc., can solve the problems of suspended objects being loosened from their mounts, the installation time is quite long and thus expensive, and the capacity of c-shaped clamps is often insufficient, so as to reduce vibration and dampen vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

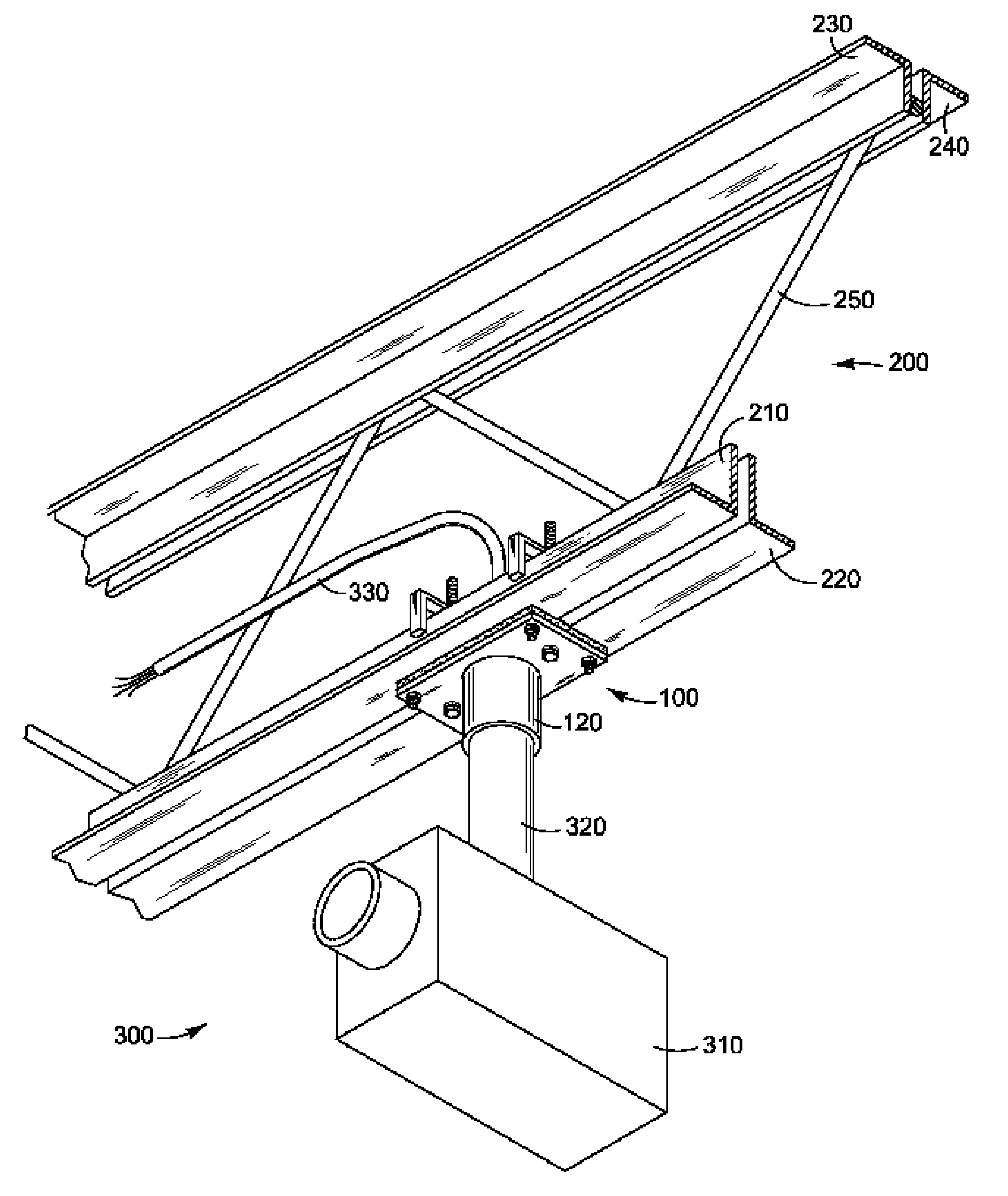

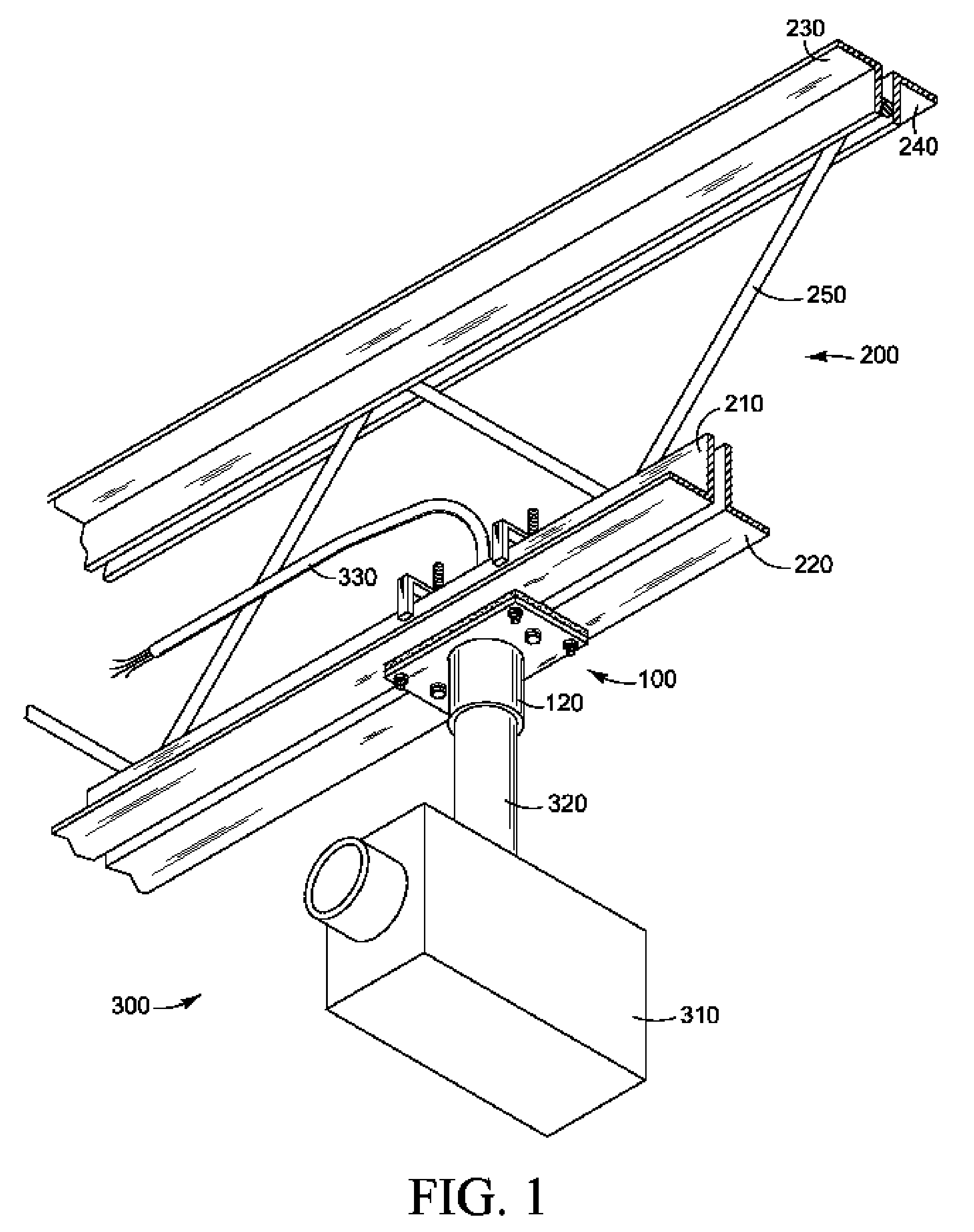

[0065] Refer to FIG. 1 where a truss is illustrated, comprising one pair of angle beams 210 and 220 acting as bar joists which form a lower chord, a second pair of bar joist angle beams 230 and 240 forming an upper chord, and braces 250. While dimensions will vary in keeping with different loads, typically the pair of angle beams forming each chord will be spaced apart by approximately one-half to one inch; that is, the vertical legs of angle beams 210 and 220 will be separated by this amount, and similarly with the vertical legs of angle beams 230 and 240. This small gap allows for connection of the braces 250 between a pair of angle beams. Whether the braces 250 are welded or bolted into place, they are inclined so as to form a truss for reinforcement of the bar joists. While rods may be used for the chords 210-240, and can be accommodated by the clamp of the present invention, angle beams are more common and will be assumed here for descriptive purposes. A clamp 100 of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com