Patents

Literature

544 results about "Parapet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A parapet is a barrier which is an extension of the wall at the edge of a roof, terrace, balcony, walkway or other structure. The word comes ultimately from the Italian parapetto (parare "to cover/defend" and petto "breast"). The German equivalent Brüstung has the same meaning. Where extending above a roof, a parapet may simply be the portion of an exterior wall that continues above the edge line of the roof surface, or may be a continuation of a vertical feature beneath the roof such as a fire wall or party wall. Parapets were originally used to defend buildings from military attack, but today they are primarily used as guard rails and to prevent the spread of fires. In the Bible the Hebrews are obligated to build a parapet on the roof of their houses to prevent people falling .

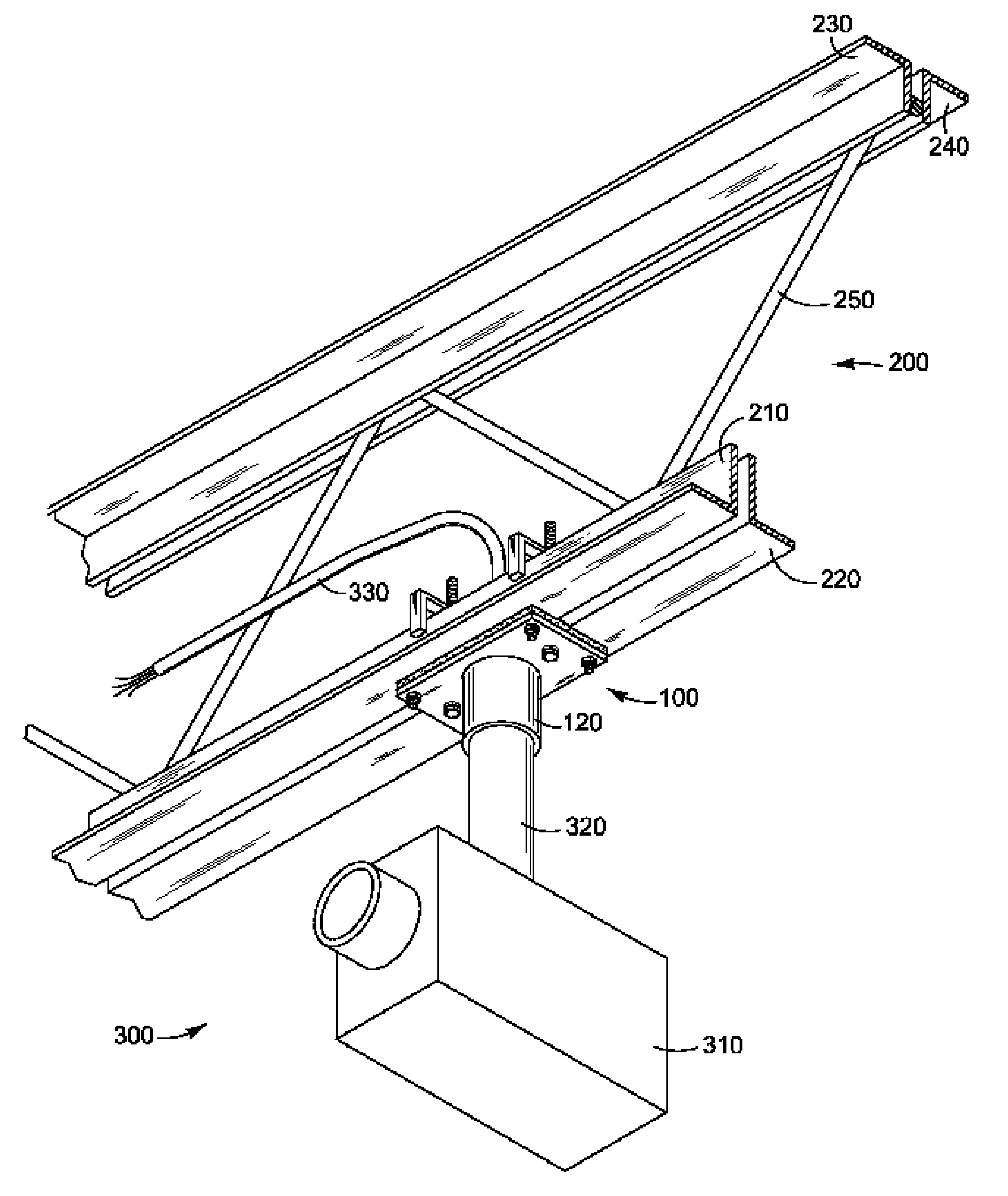

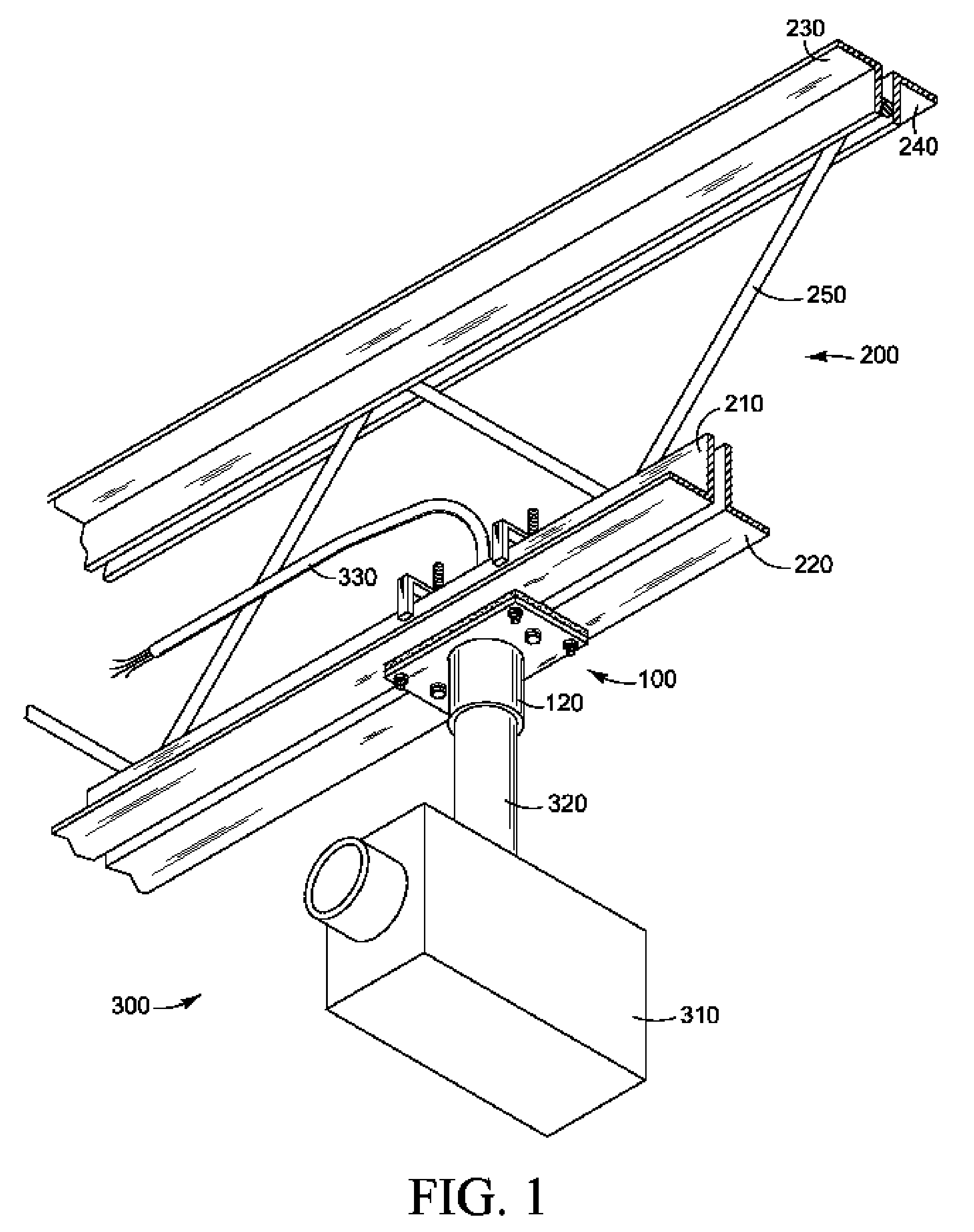

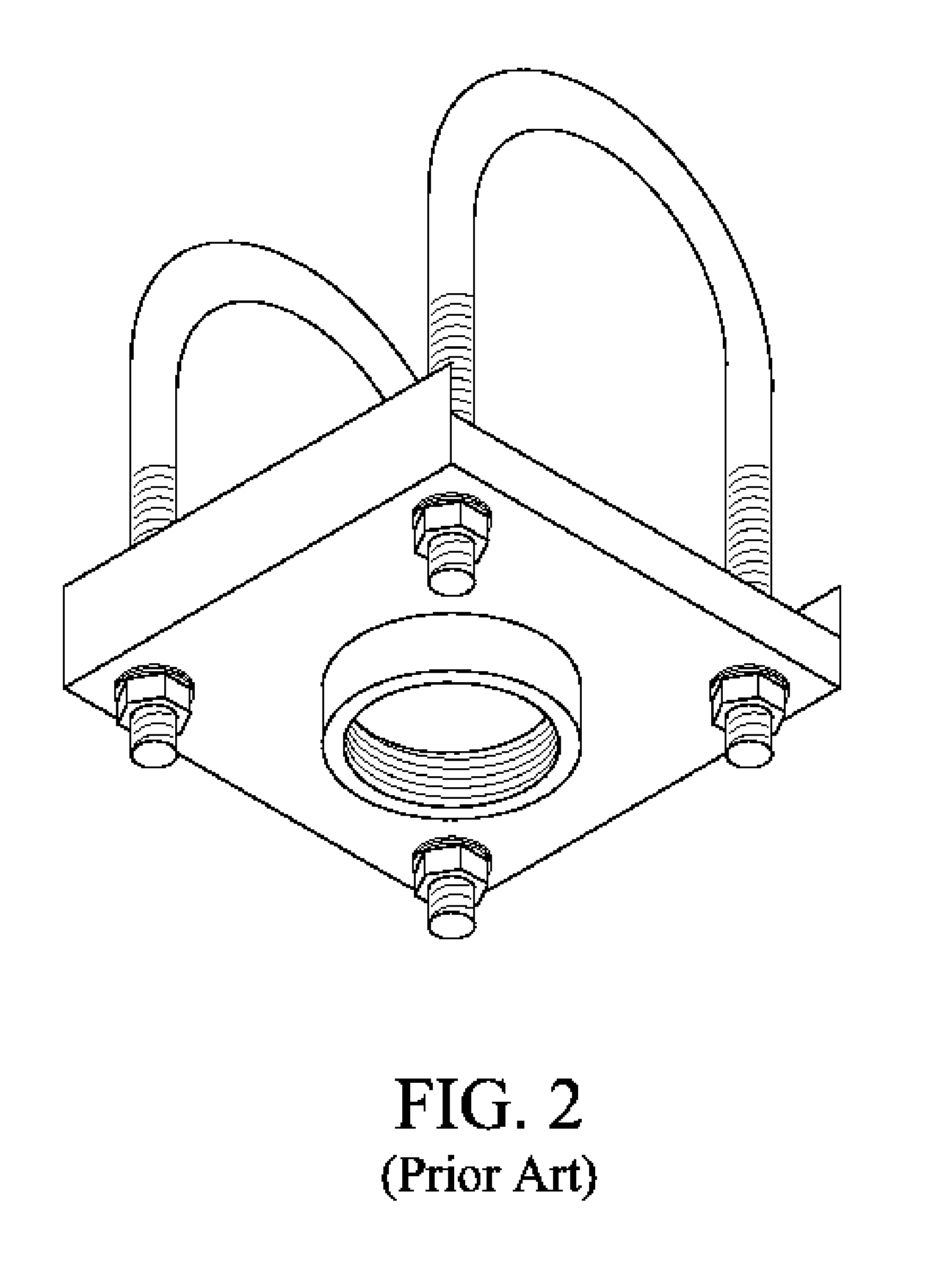

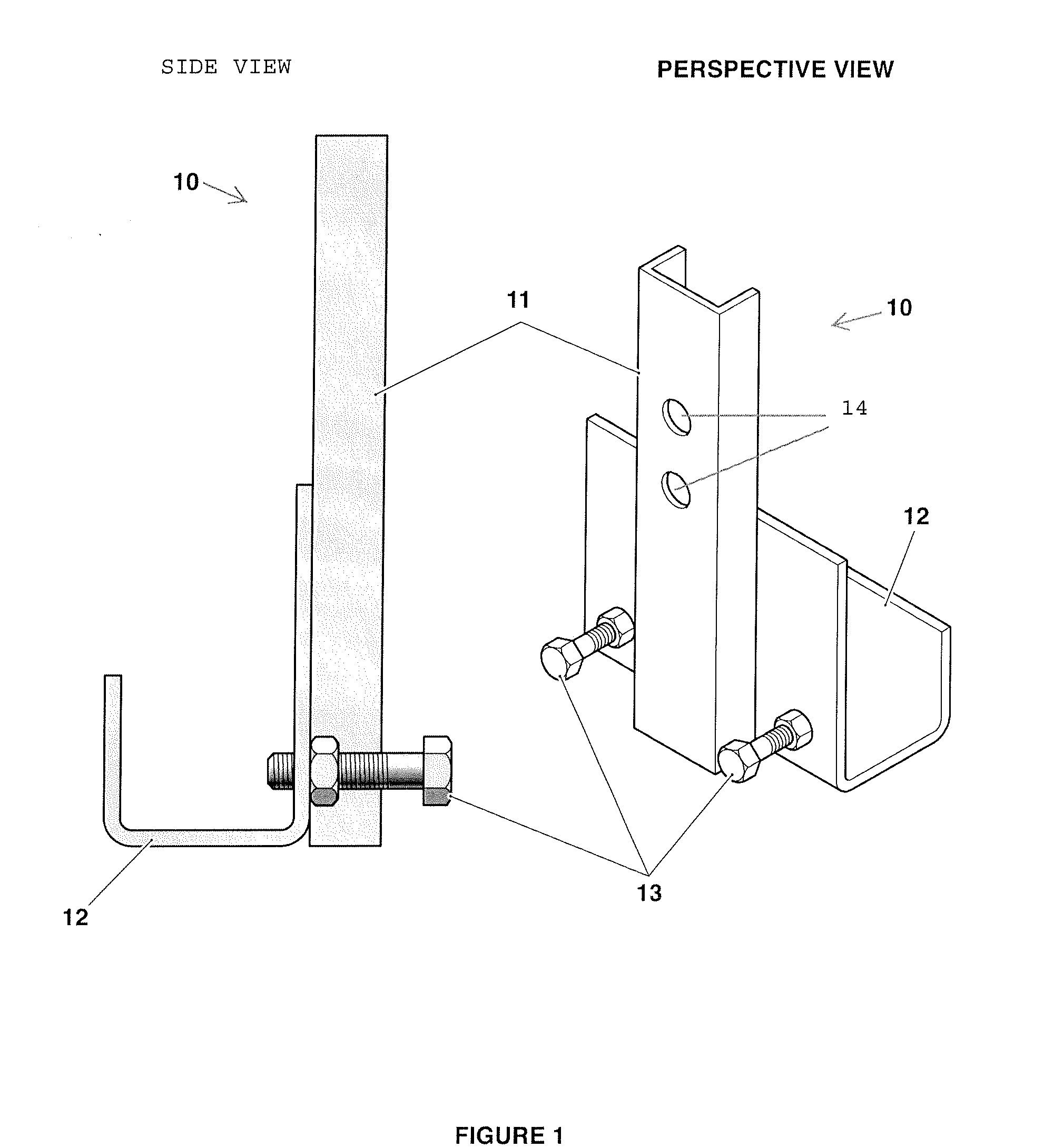

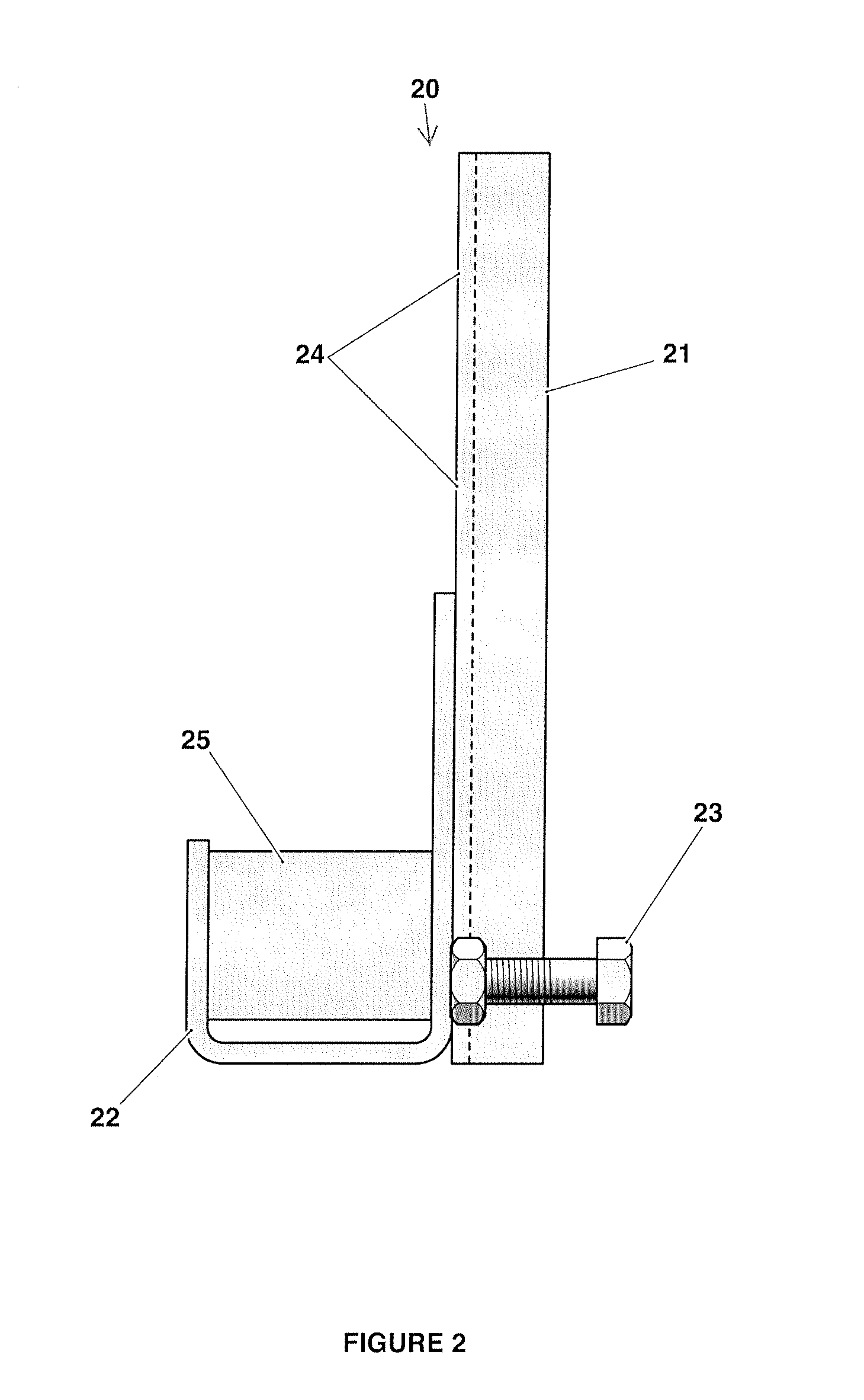

Mounting Clamp

This mounting clamp is used as a truss adapter for support of fixtures, electrical and otherwise, from a truss ceiling. The clamp comprises a plate suspended by a pair of upstanding arms, each of which is formed by a bolt connected to an inverted U-shaped rectangular hanger member. The hangers and their associated bolts are inserted upwardly between the spaced beams of a bar joist from below and then the hangers are rotated 90 degrees before they are lowered into place to rest on both of the spaced beams, spreading the load, as the hanger arms are tightened to the plate. The plate carries a connector for mating to the object to be mounted. Leveling screws provide adjustment for orienting the mounted object. A vibration damping pad is included when appropriate. Variations of the clamp may be used in wall or parapet mount configurations.

Owner:HUNT RONALD DOUGLAS

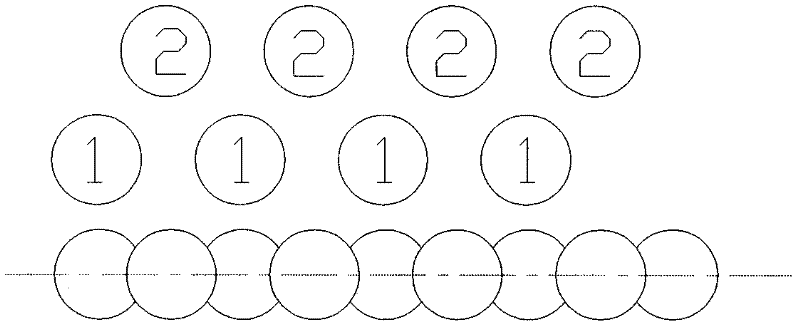

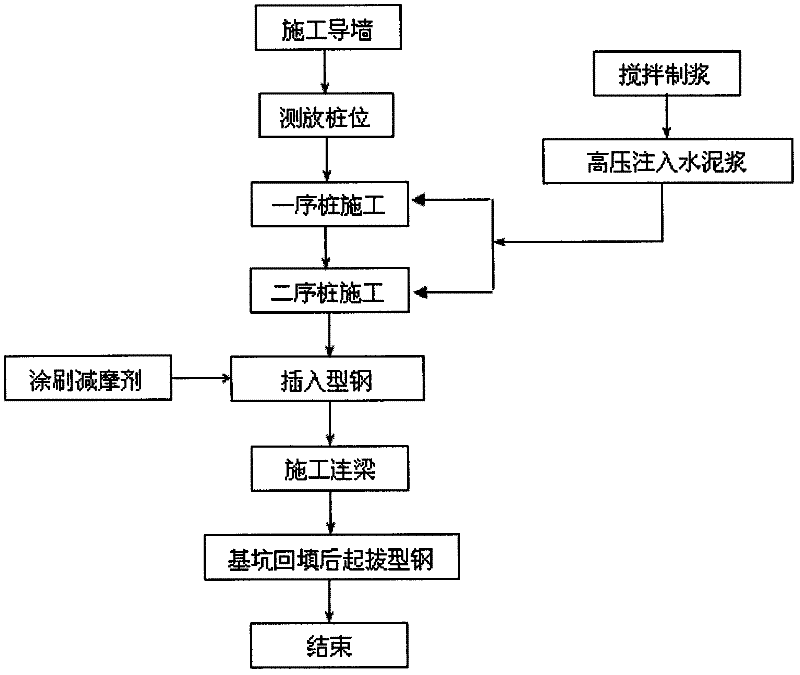

Construction method of long spiral high-pressure mixing and spraying cement-soil continuous wall

InactiveCN102296630AGood effectImprove efficacyArtificial islandsUnderwater structuresSupporting systemJet injection

The invention provides a construction method of a long spiral high-pressure spraying cement-soil continuous wall, which comprises the following steps: 1) making a guide wall or digging a guide ditch along the center line of the pile, and determining the pile position of the spraying pile; 2) injecting the long spiral high-pressure spraying The slurry stirring pile-forming device is aligned with the pile position as the drilling center, and drilled into the hole; 3) Start the grouting pump, and use the long spiral high-pressure jet grouting to stir the pile-forming device during the lifting or lowering process of high-pressure rotary spraying until it is formed. 4) insert section steel into the spigot pile; 5) repeat the steps 2), 3) and 4) until the continuous cement-soil continuous wall is formed; 6) construct the joint beam; 7) backfill the foundation pit, Pull out the section steel after finishing. Compared with the general slope protection pile support system, firstly, the section steel can be recycled, and secondly, cement soil is used instead of concrete, so it is relatively more economical and more efficient, and can achieve the two walls of the supporting wall and the curtain wall. The water stop effect is also better than the system composed of general slope protection piles + rotary grouting piles.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

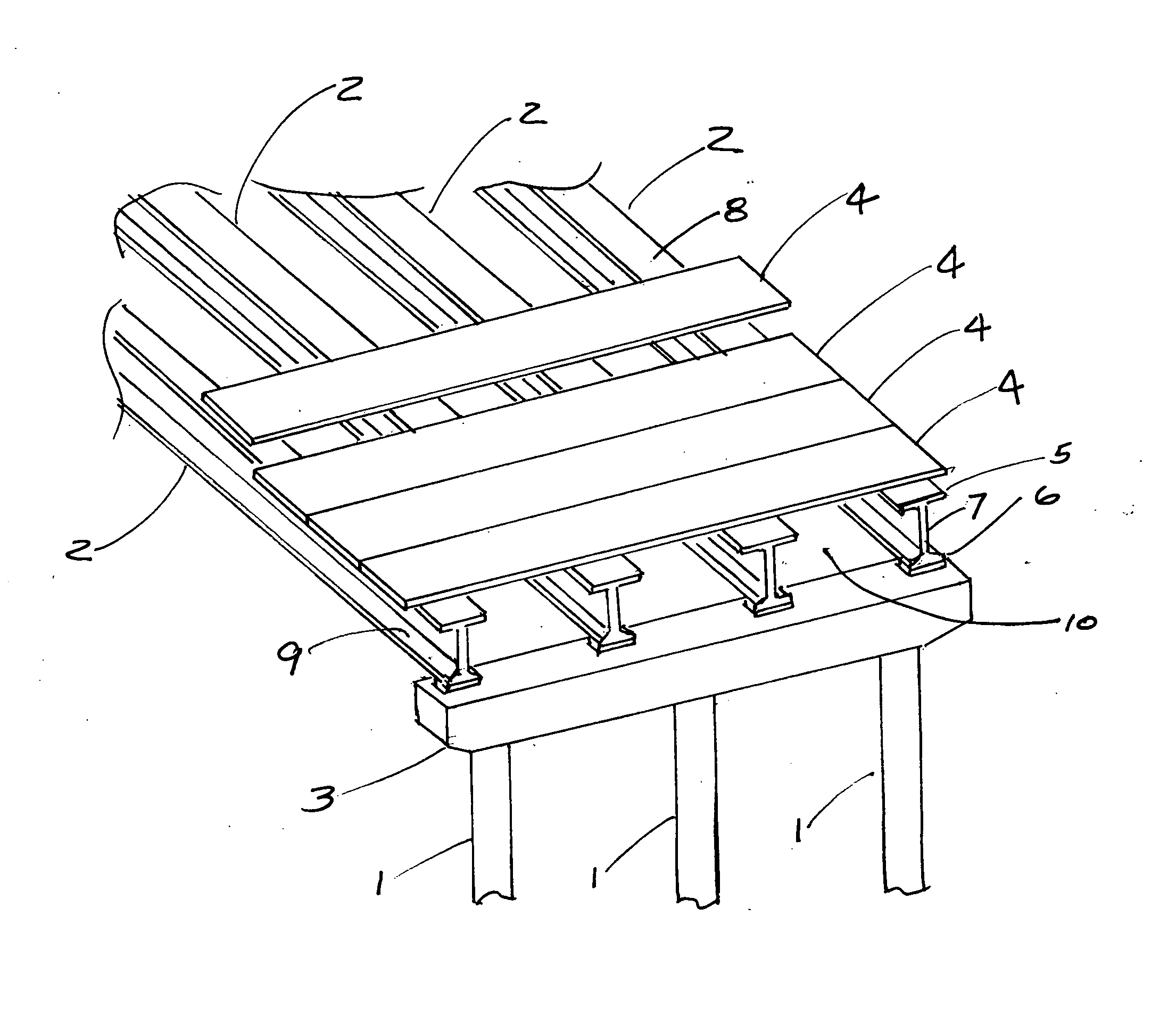

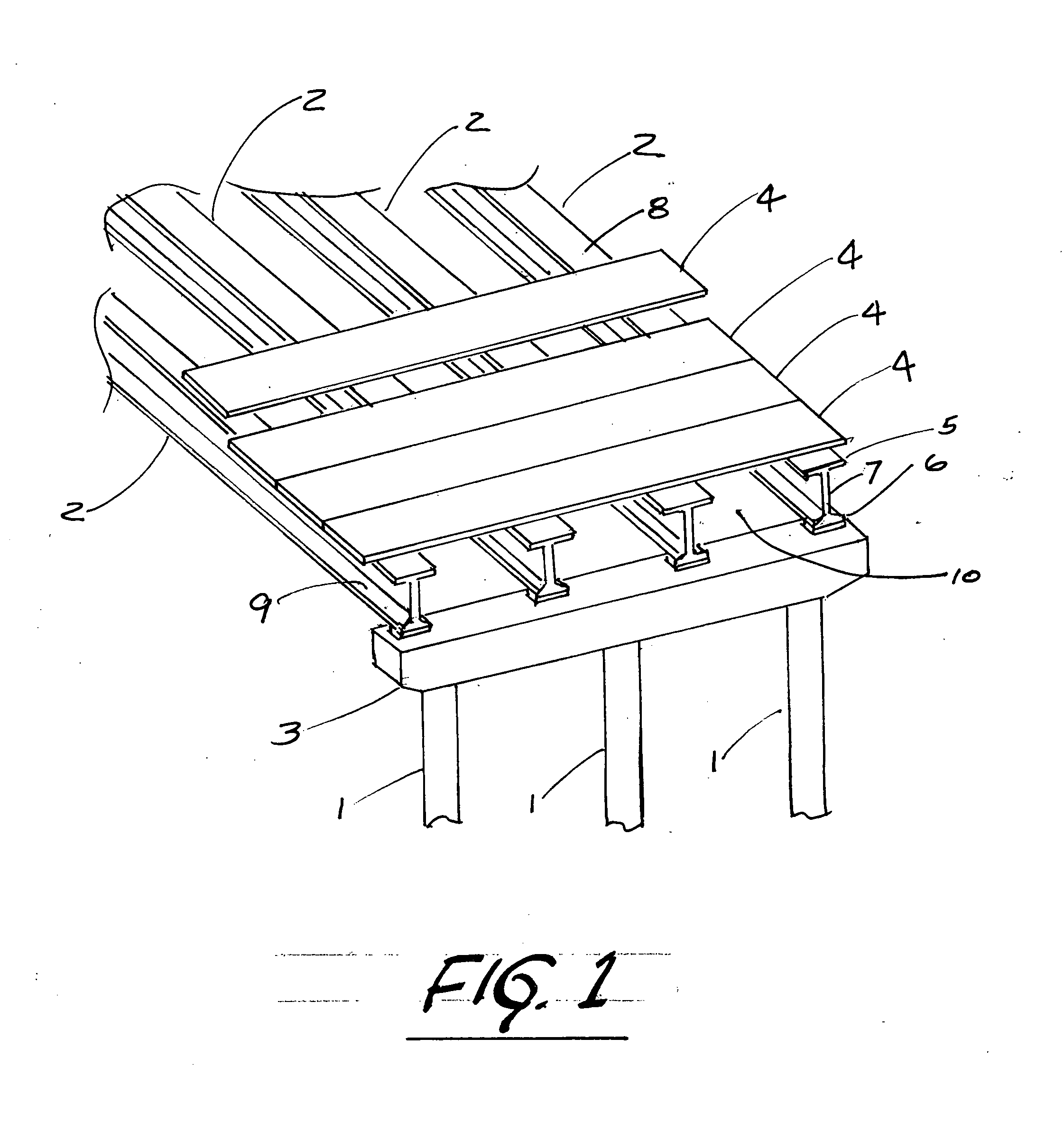

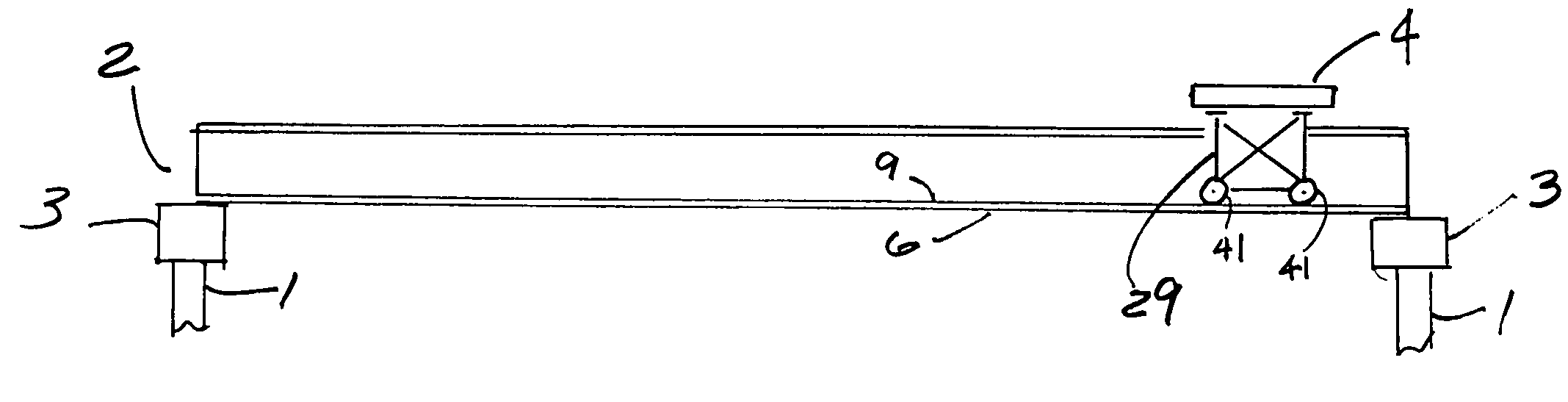

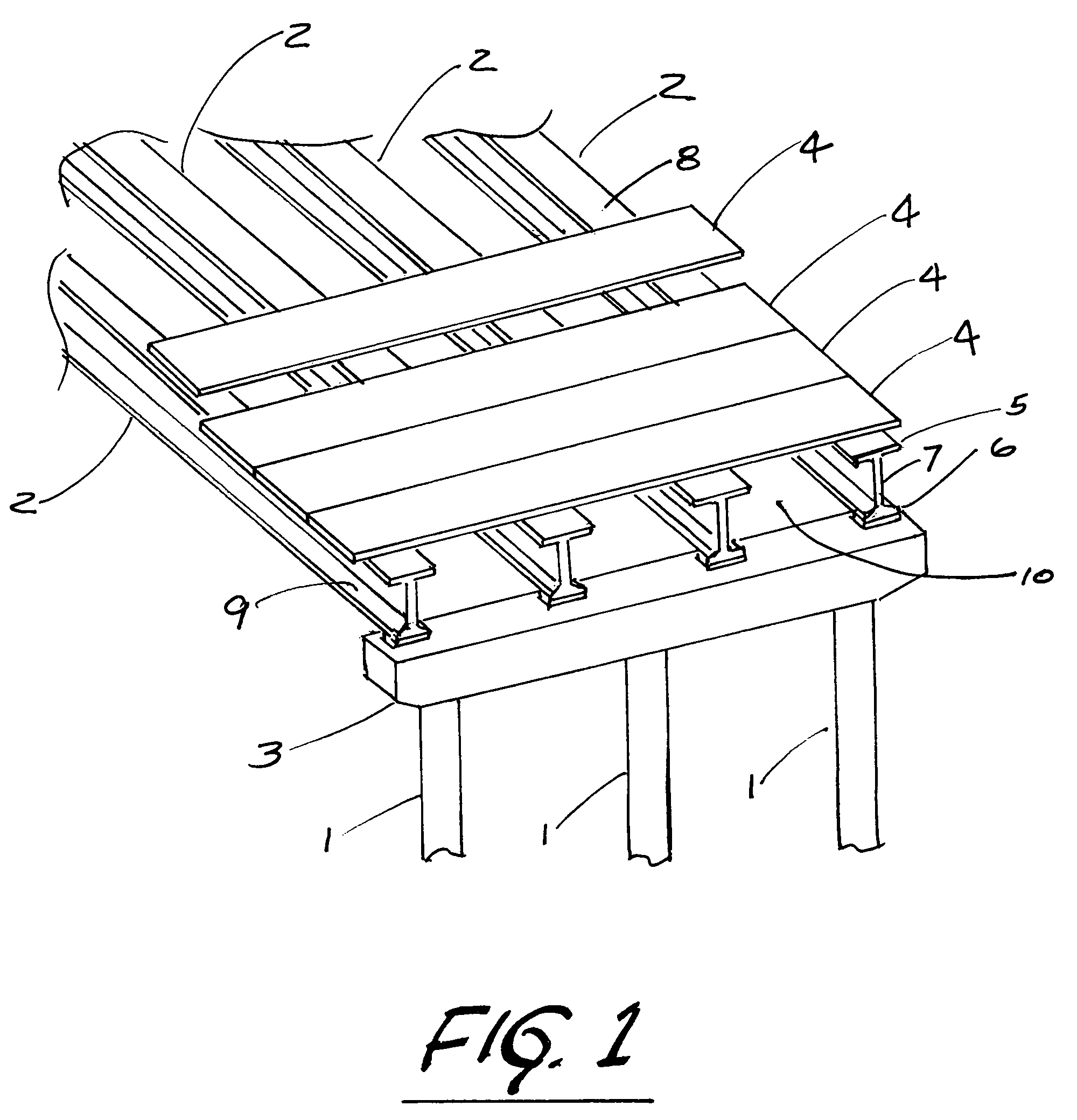

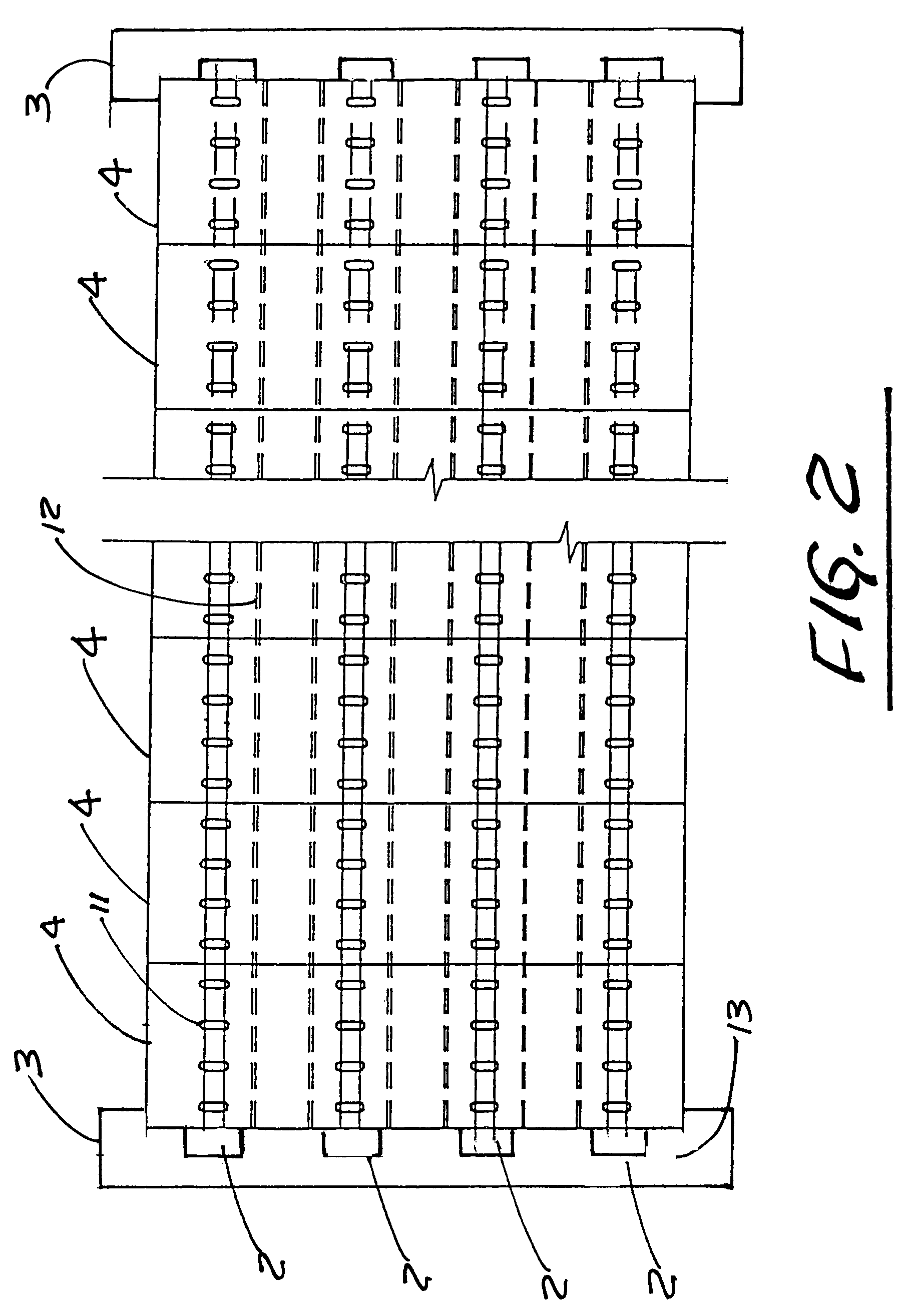

Bridge construction system and method

InactiveUS20060117504A1Expanded span capabilityOvercome problemsBridge structural detailsBridge erection/assemblyBogiePre stress

A system and method for construction of bridges and elevated roadways with pre-stressed concrete or steel bridge girders is provided including cast-in-place concrete deck slabs and partial and full depth pre-stressed pre-cast concrete deck slabs with post-tensioning conduits for post-tensioning a series of deck slabs. A plurality of bogies traveling on the lower flanges of the bridge girders are provided to place and level the deck slabs and to pre-load the bridge girders to eliminate camber before placement of the deck slabs on the bridge girders or to level, place, support and remove deck forms for a cast-in-place deck slab on the bridge girders. Also provided is a system for attachment of cast-in-place parapets.

Owner:RAPID PRECAST CONSTR SYST

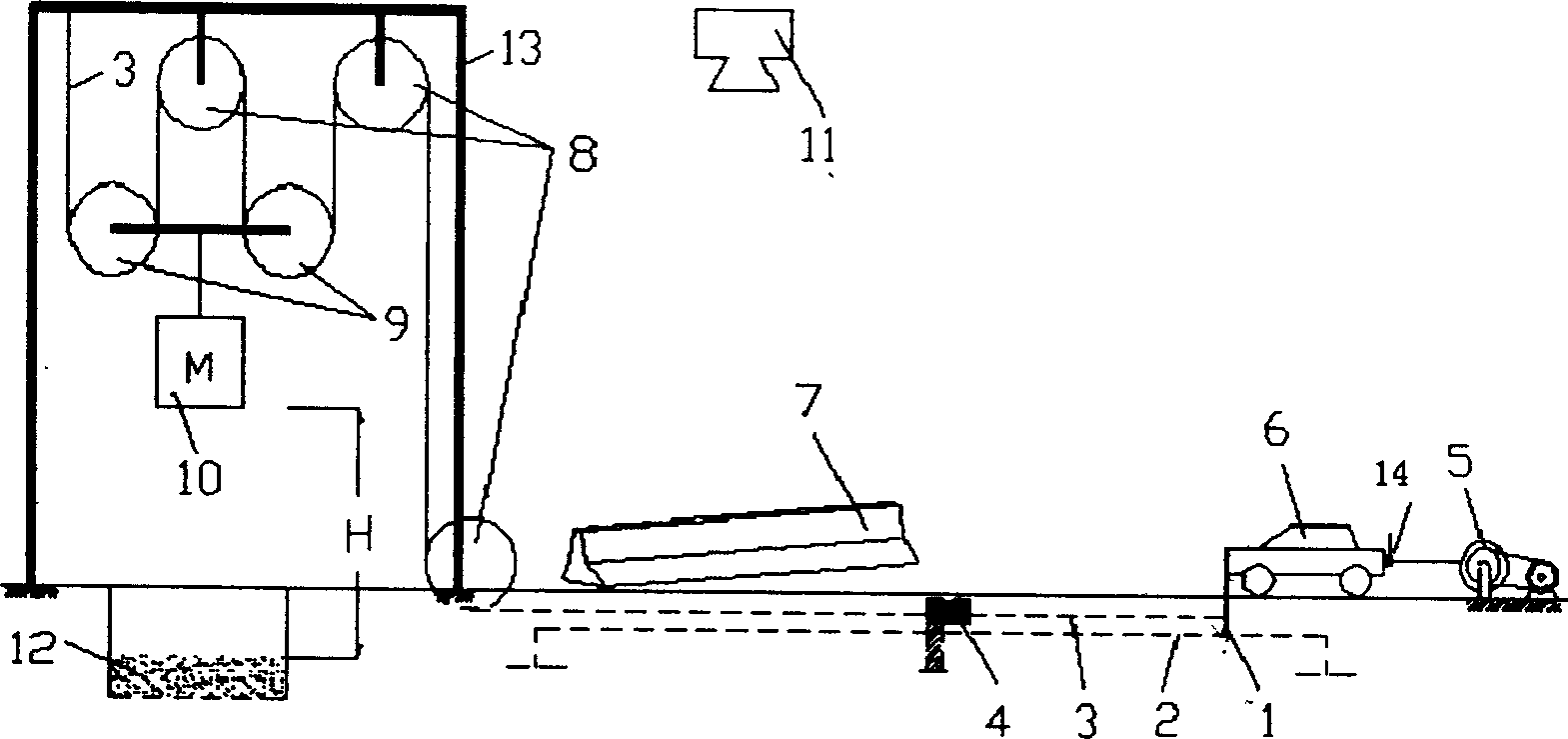

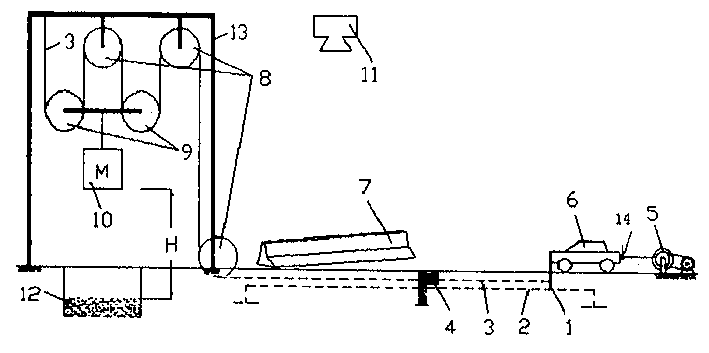

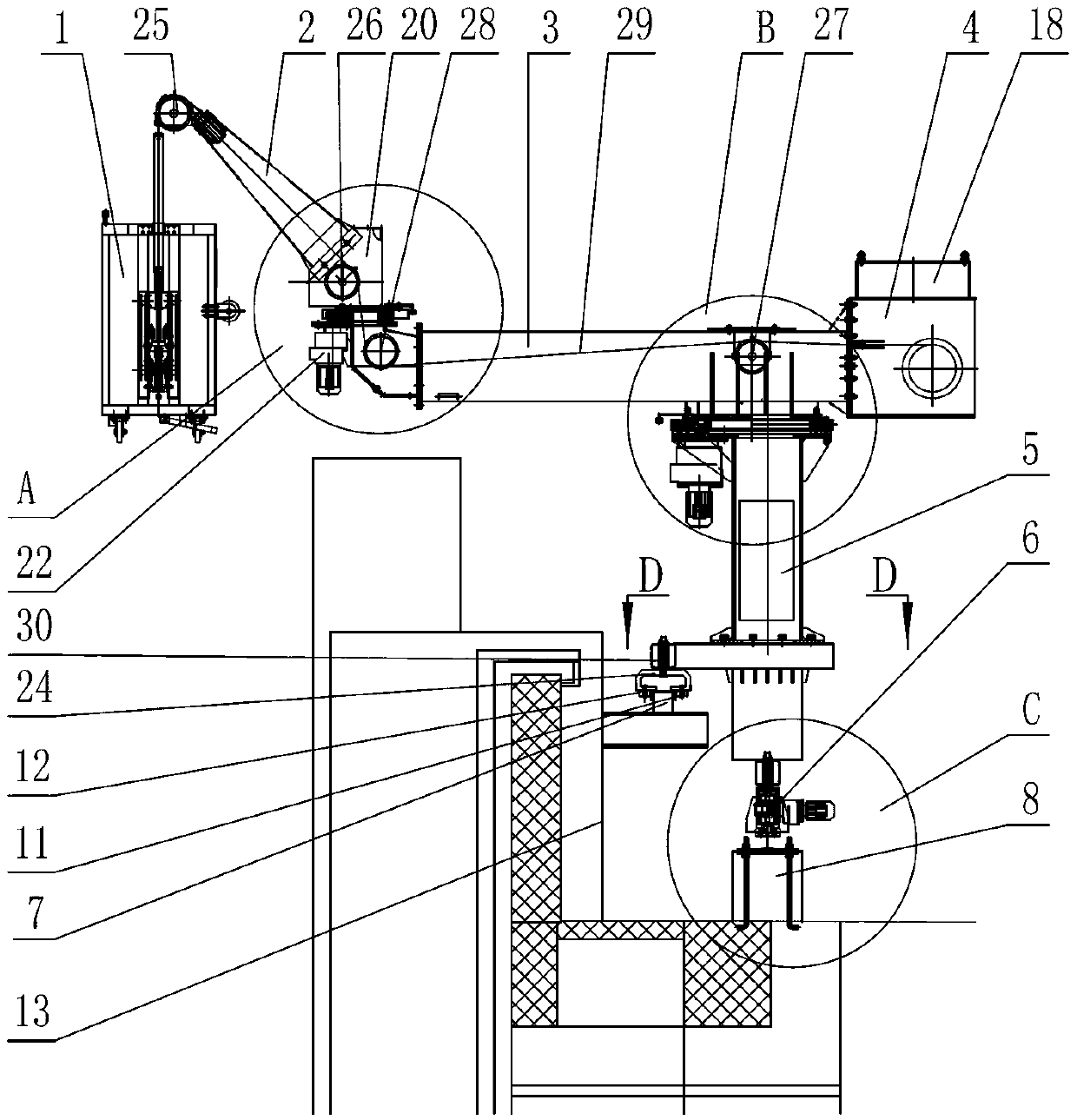

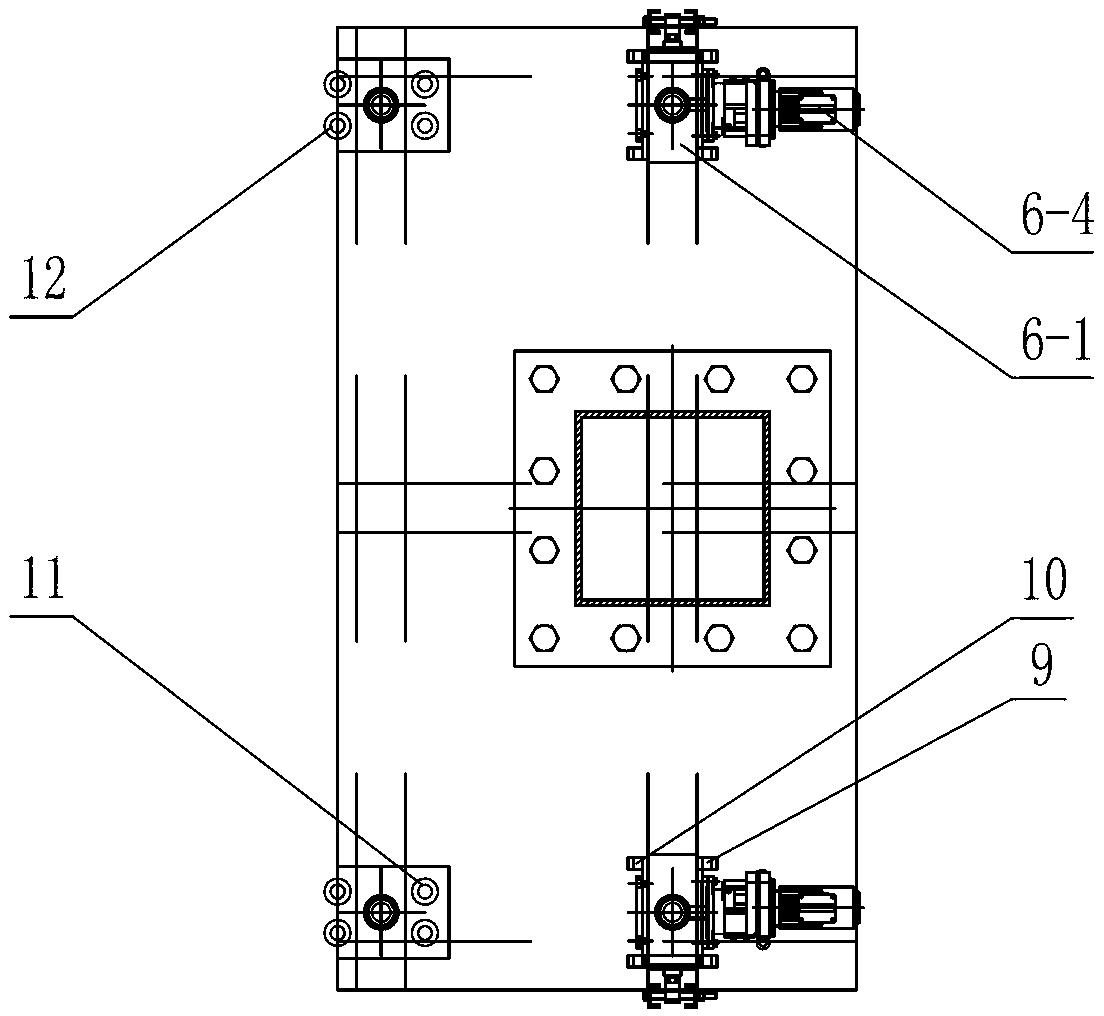

Experiment system and method for simulating collision between automobile and parapet

InactiveCN1417055ASolve the problem of getting high speedRealize free ejectionVehicle fittingsSpeed/accelaration controlTowerKinetic energy

The present invention relates to an experiment system and a method for simulating collision between automobile and parapet. The system includes hoist connected via elevating mechanism to the tail unhooking mechanism of model automobile; model automobile with head hook connected to drawing steel cable, which is parallel to the pressure guide steel cable with ends fixed in two ends of the guide slot and has the other end connected to weight drop hammer via pulley block; guide rack to guide the model automobile; guide rack stopping block in the unhooking position of the model automobile; high speed camera installed in the camera tower; and acceleration measurer in the model automobile. When the drop hammer falls to sand surface, the stopping block makes the drawing hook in the guide mechanism separate from the model automobile.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

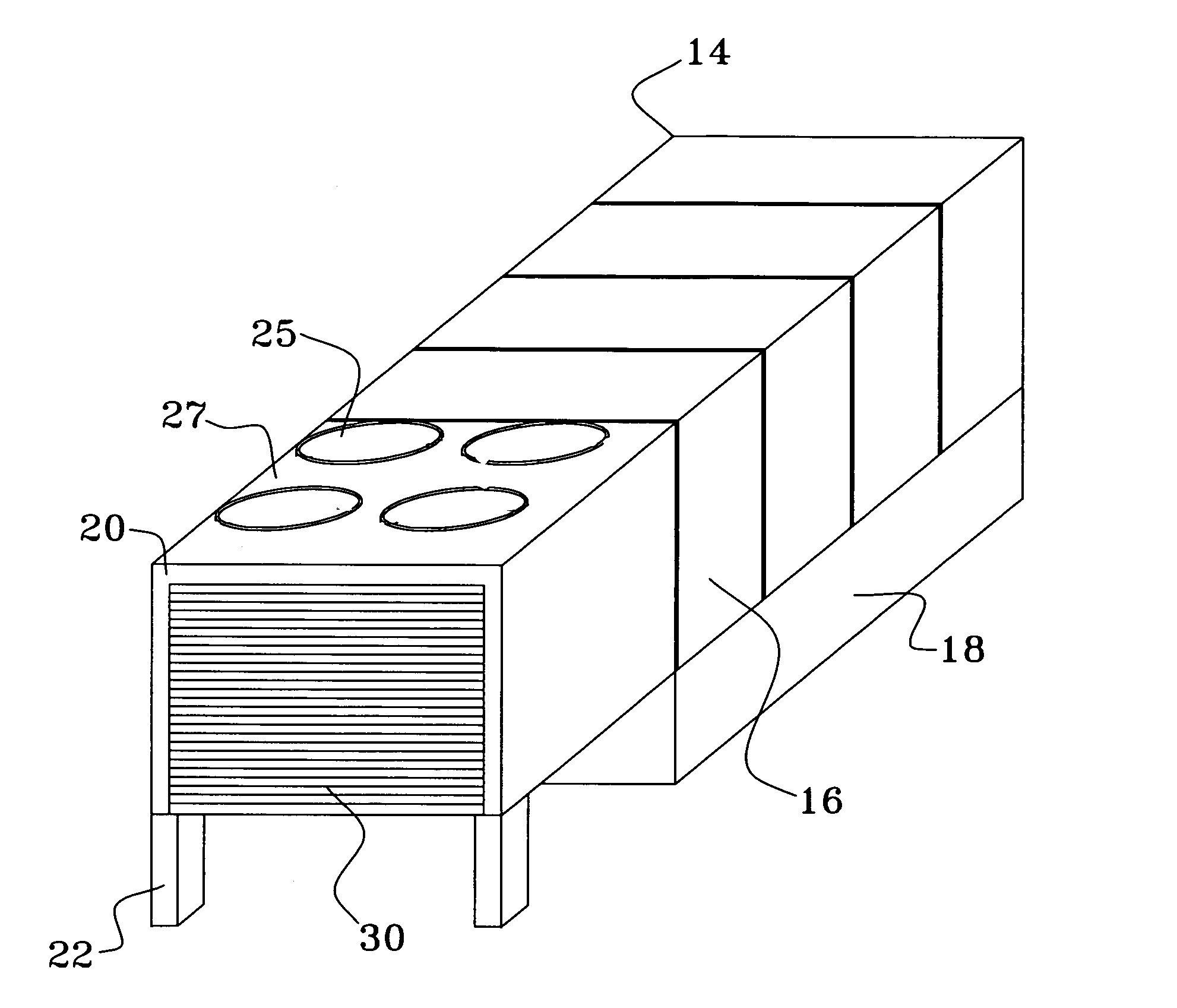

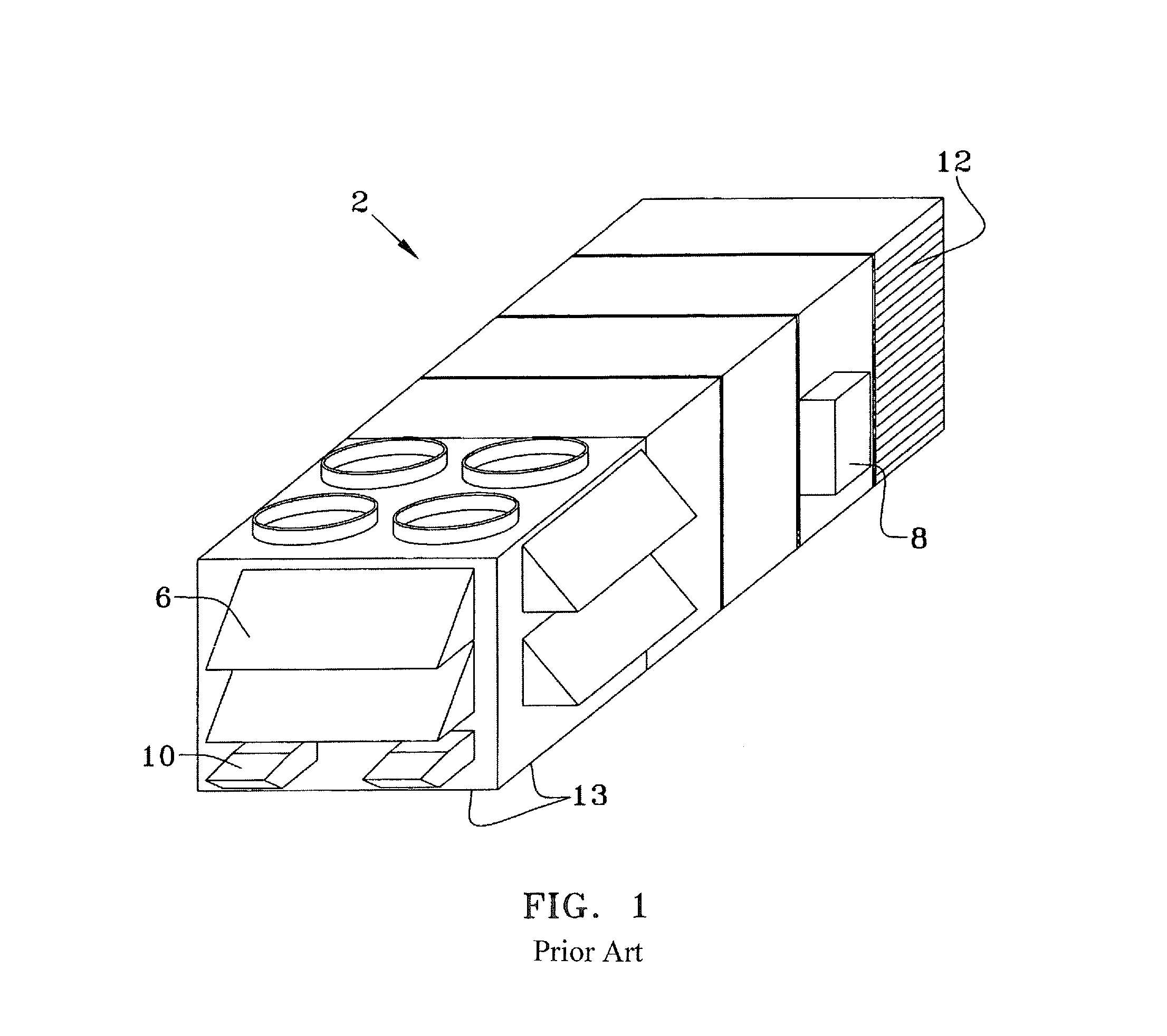

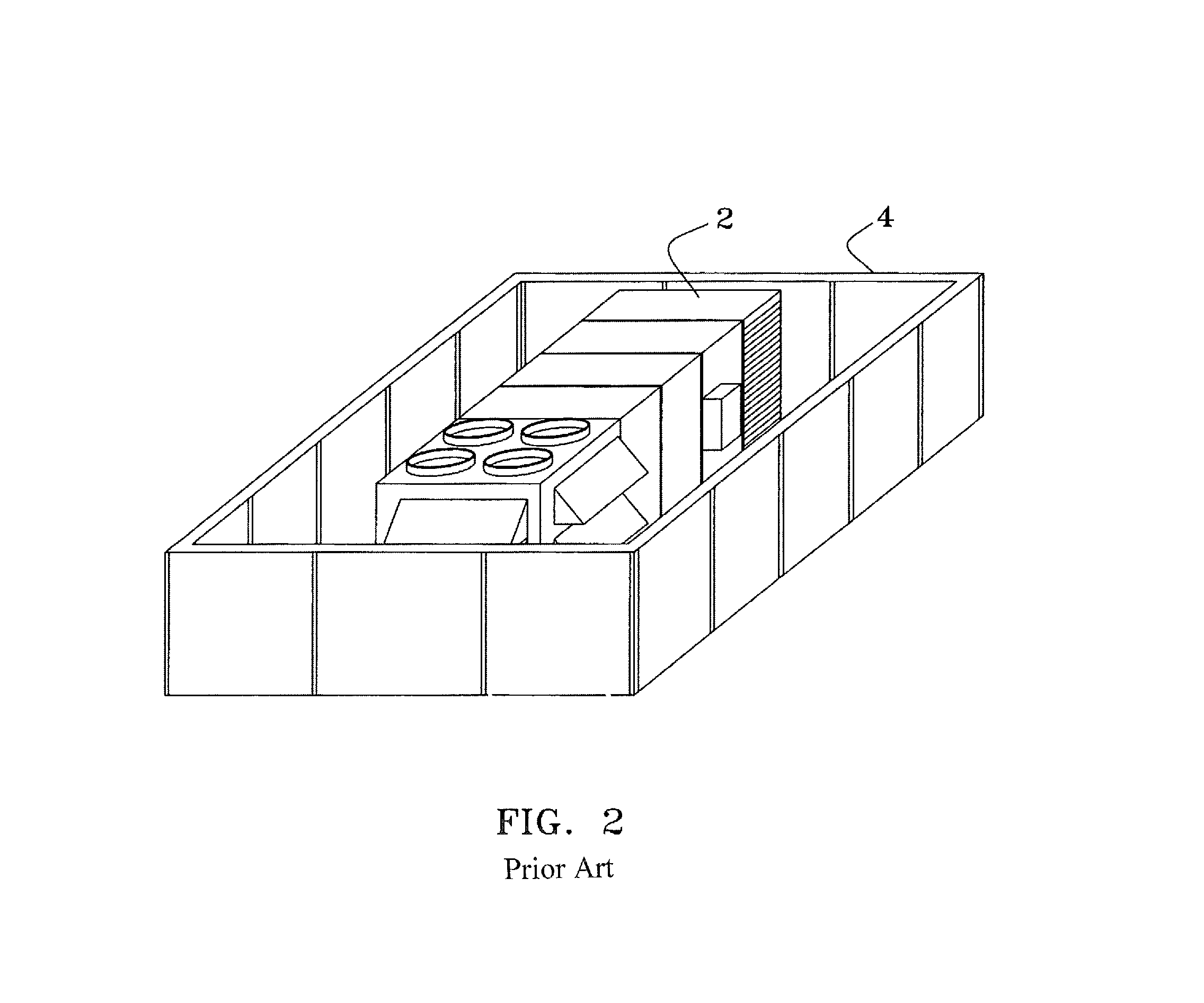

Architecturally advanced air handling unit

ActiveUS8360834B1Easily architecturally disguisedImprove efficiencyLighting and heating apparatusHeating and ventilation casings/coversAir filtrationModular unit

The present invention is an improved AHU that can be easily architecturally disguised, made in a modular unit, have increased overall efficiency and ease of servicing, reduce radial noise emissions and allow for the direct adjacent placement of additional AHU's. This AHU has a cuboid structure with smooth side walls that are insulated and adapted for the attachment of aesthetic surface treatments, roof inset fans louvered end walls with door access. Heat removal can accomplished through angled heat exchangers also housed within the enclosure. Air filtration is also accomplished with angled filters. The improved aesthetic appearance of these units also eliminates the use of surrounding architectural parapet walls or screening units. The improved space effectiveness and modularity shall provide greater flexibility in building construction.

Owner:SEMMES THOMAS MIDDLETON

Roof perimeter cable guard system

ActiveUS7806232B2Easy to insertEasy to removeWindow cleanersBuilding material handlingEngineeringMechanical engineering

A roof perimeter cable guard system has a main stanchion member supported at its lower end by an anchor bracket screwed to the roof perimeter. A main brace member extends outward and downward from the upper end portion of the main stanchion member and curves around and under the perimeter feature. The main brace has a lower sleeve receiving an adjustable wall-engaging member to provide bracing against the wall of the structure. In one configuration the wall-engaging member has an additional supporting extender member, which allows the wall-engaging member to engage the soffit of an overhang. An inward extender member and parapet engagement bracket allow for position attachment to a parapet feature. Pairs of barrier cable engagement brackets having barrier cable receiving slots are spaced along the inner side of the stanchion vertical members for easy insertion or removal of an equal number of barrier cables, normally three.

Owner:RONKEN PERIMETER EDGE GUARDRAIL SYST INC

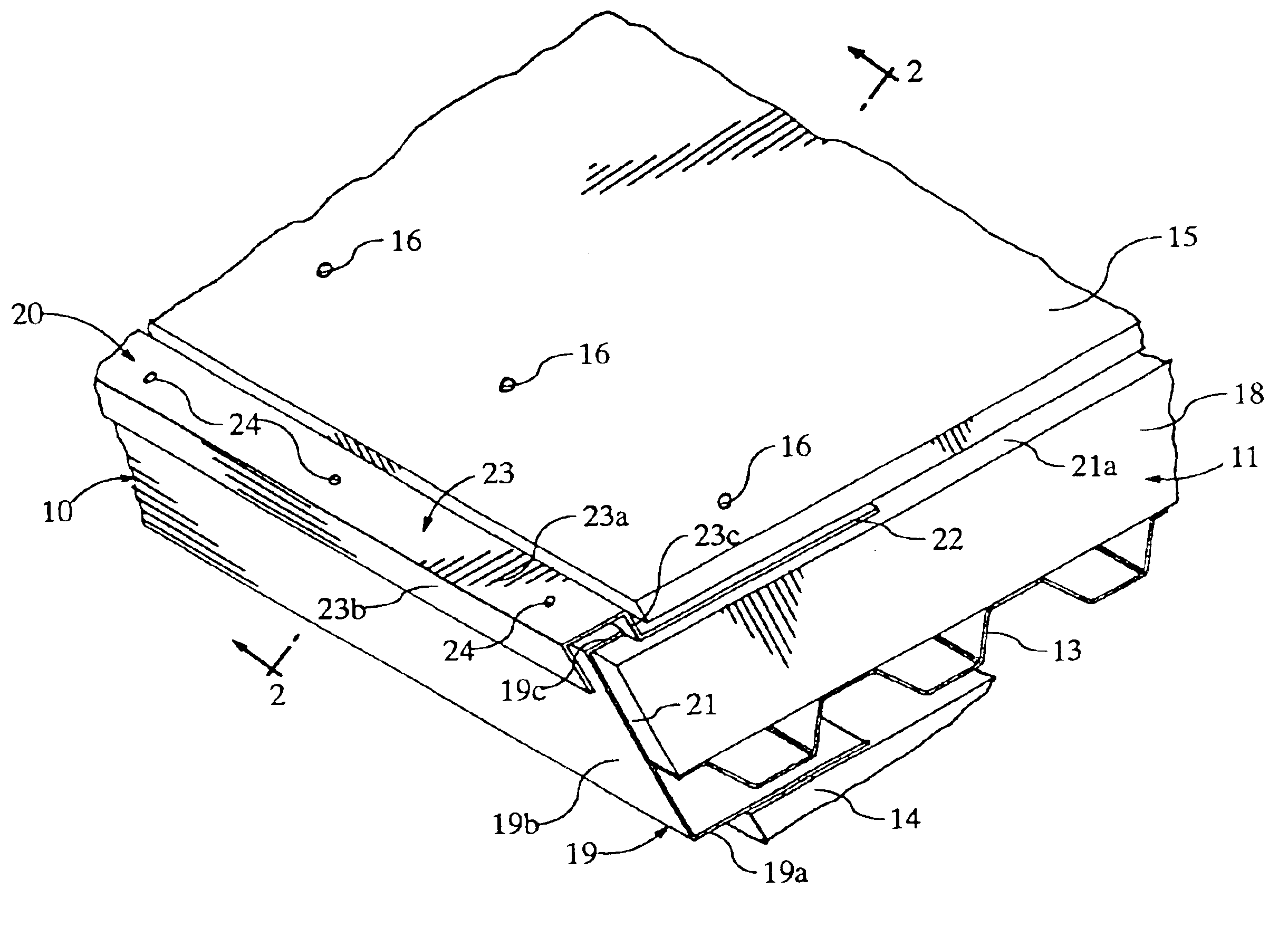

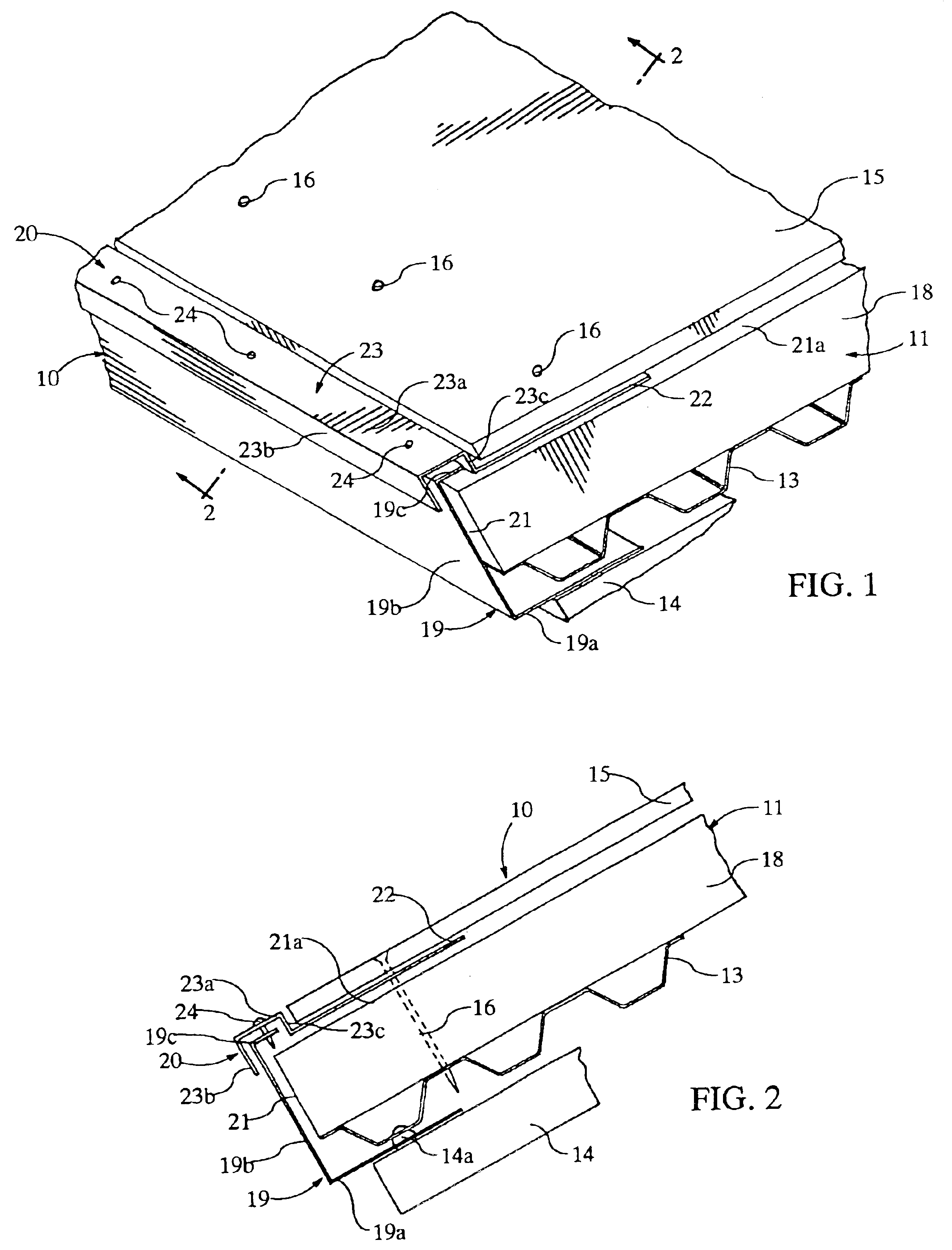

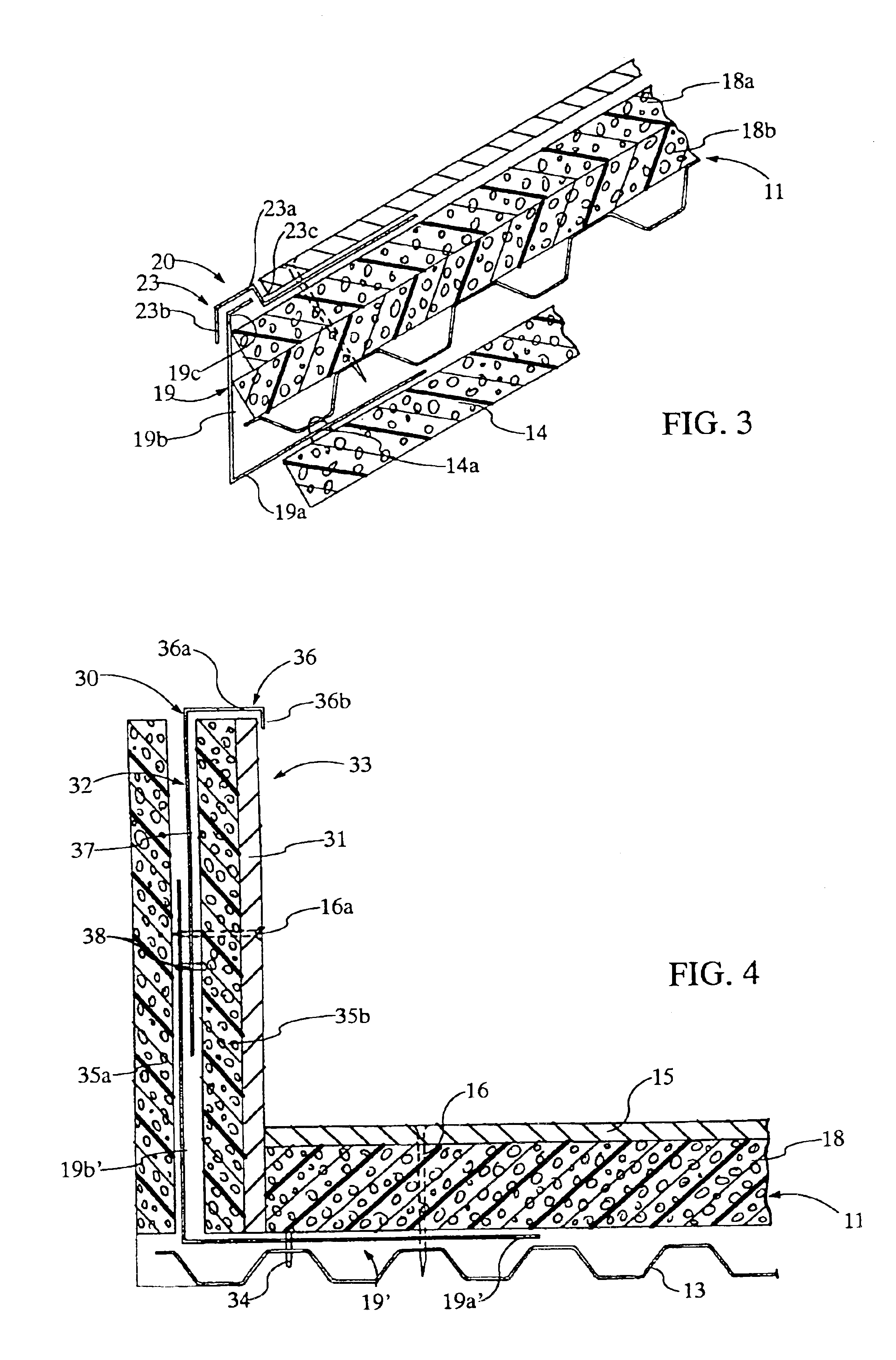

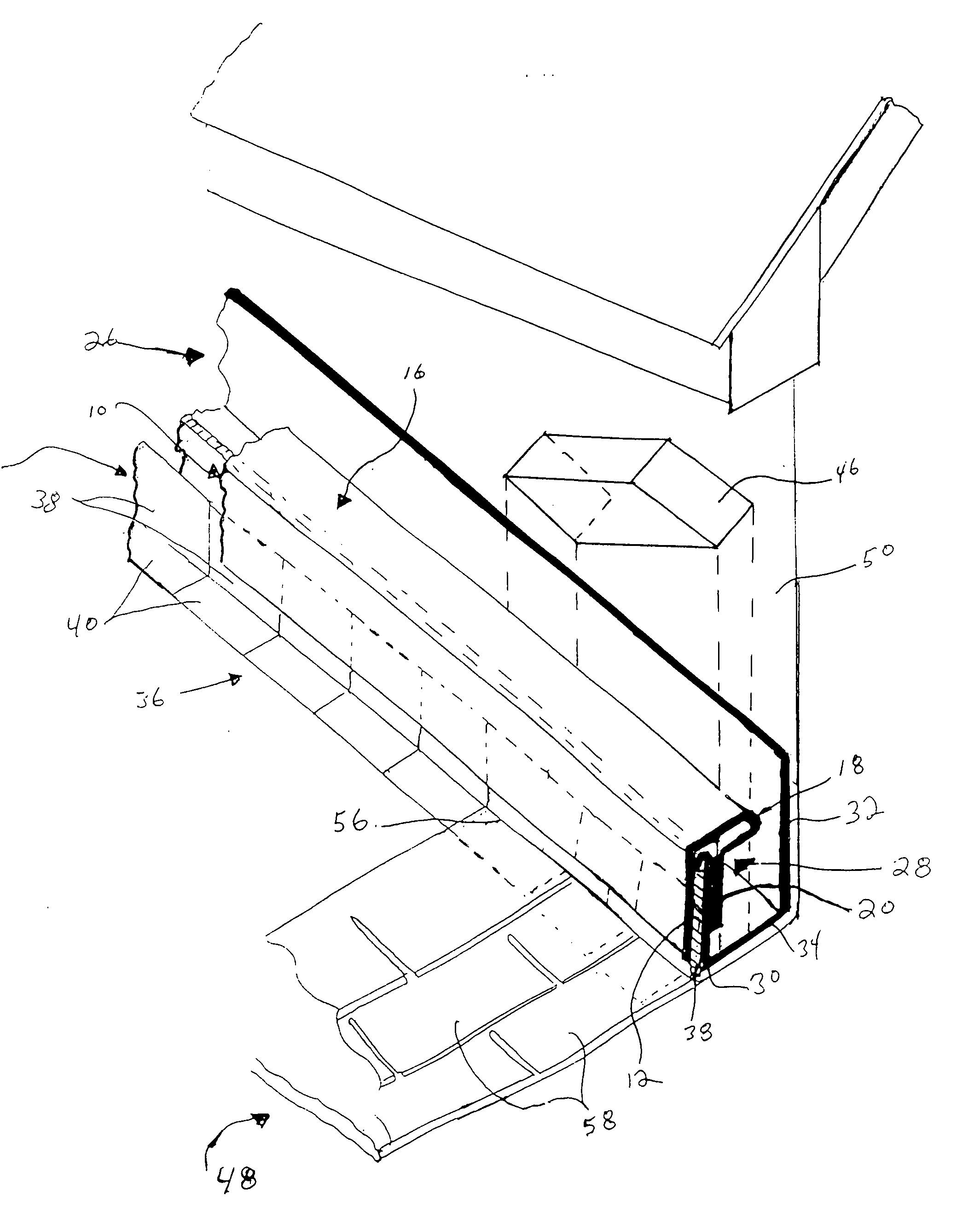

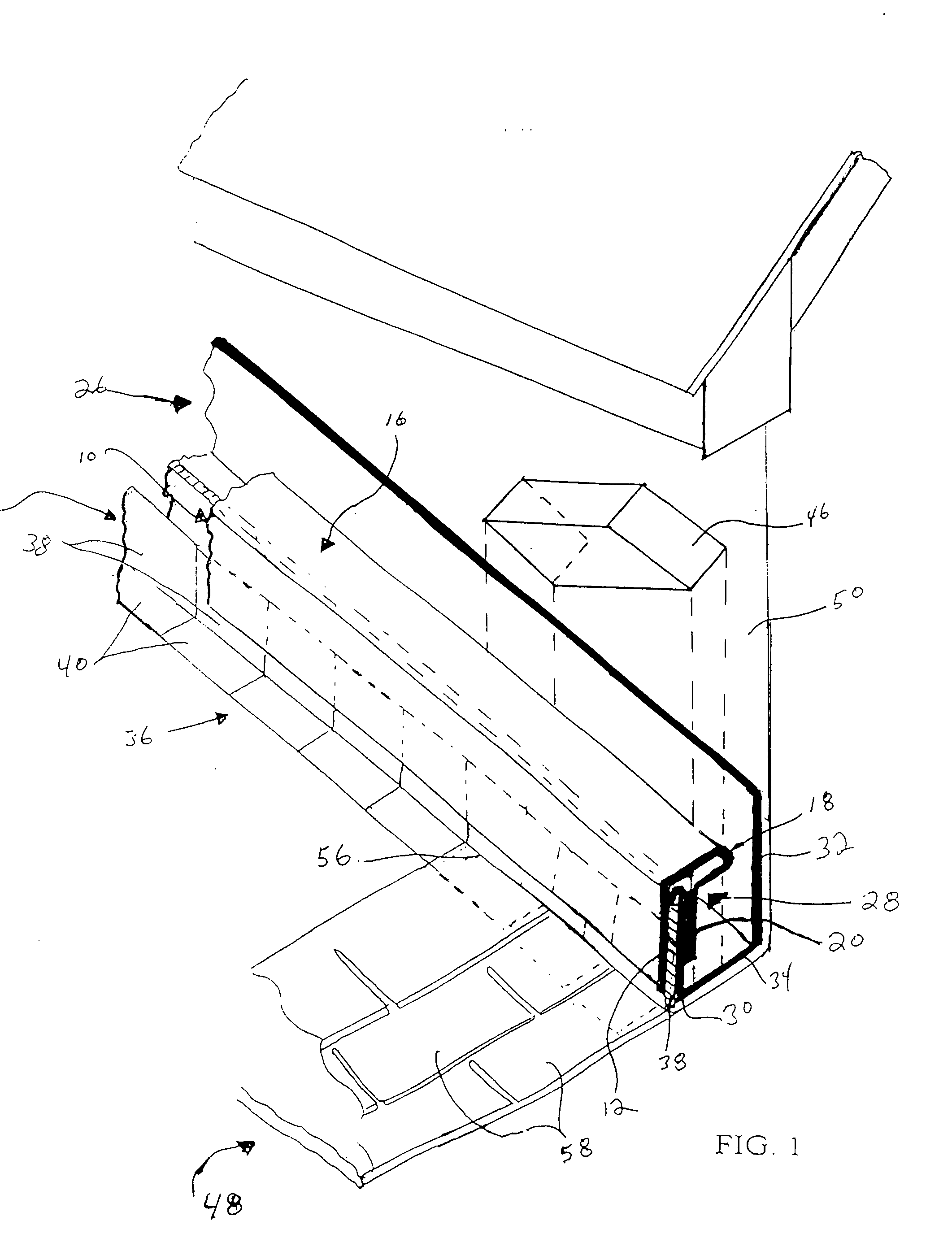

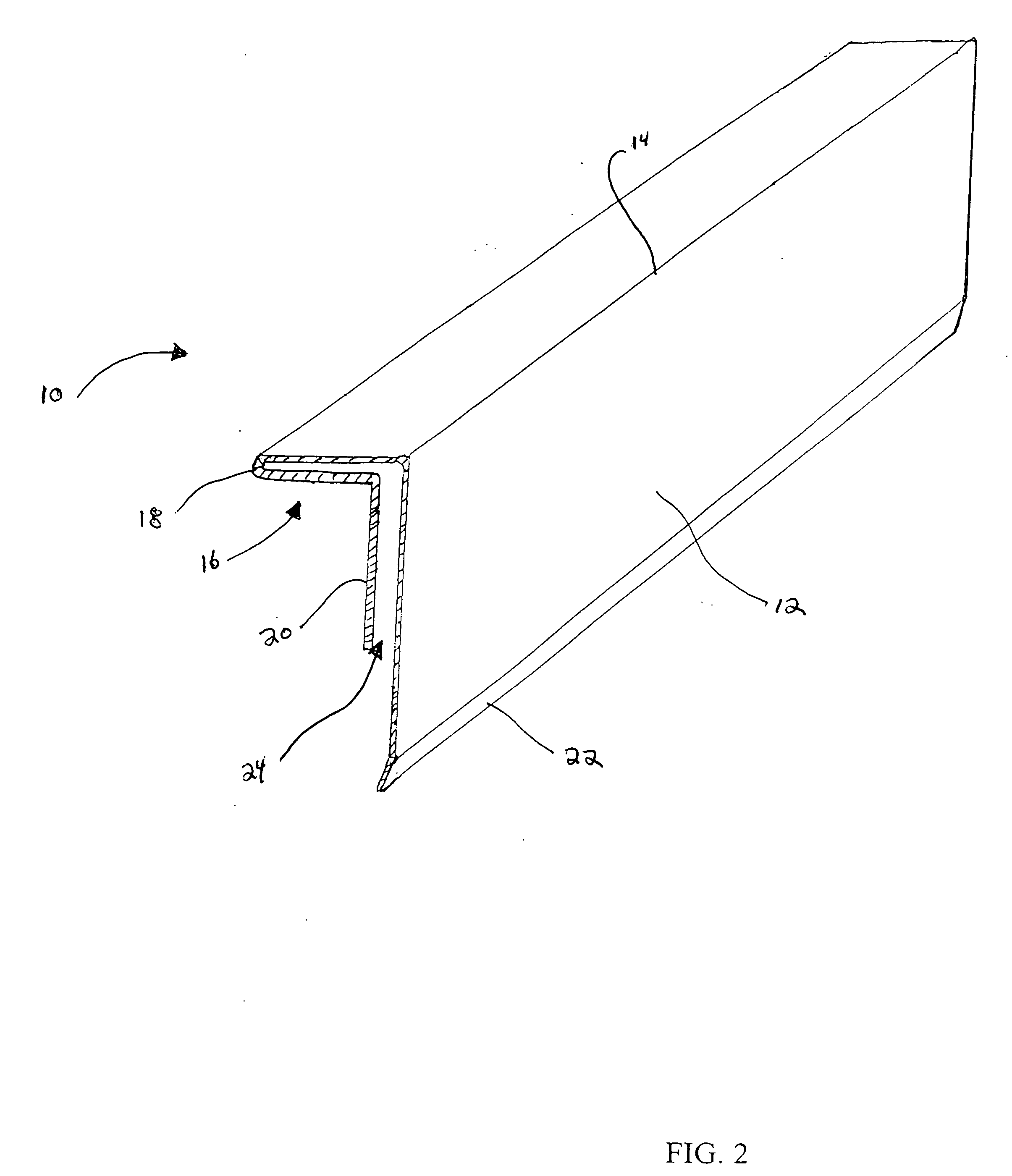

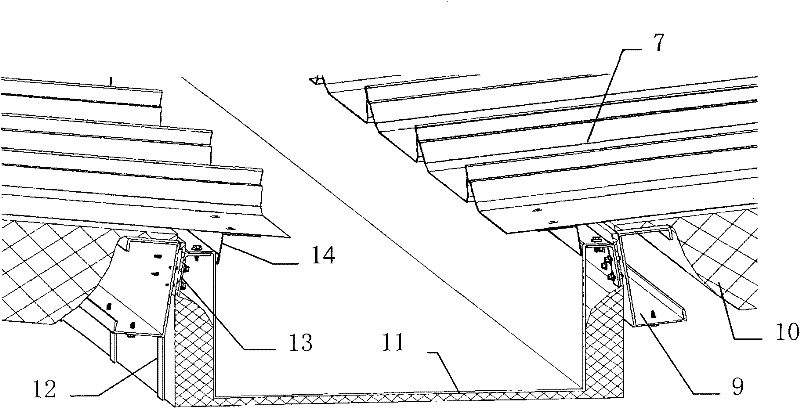

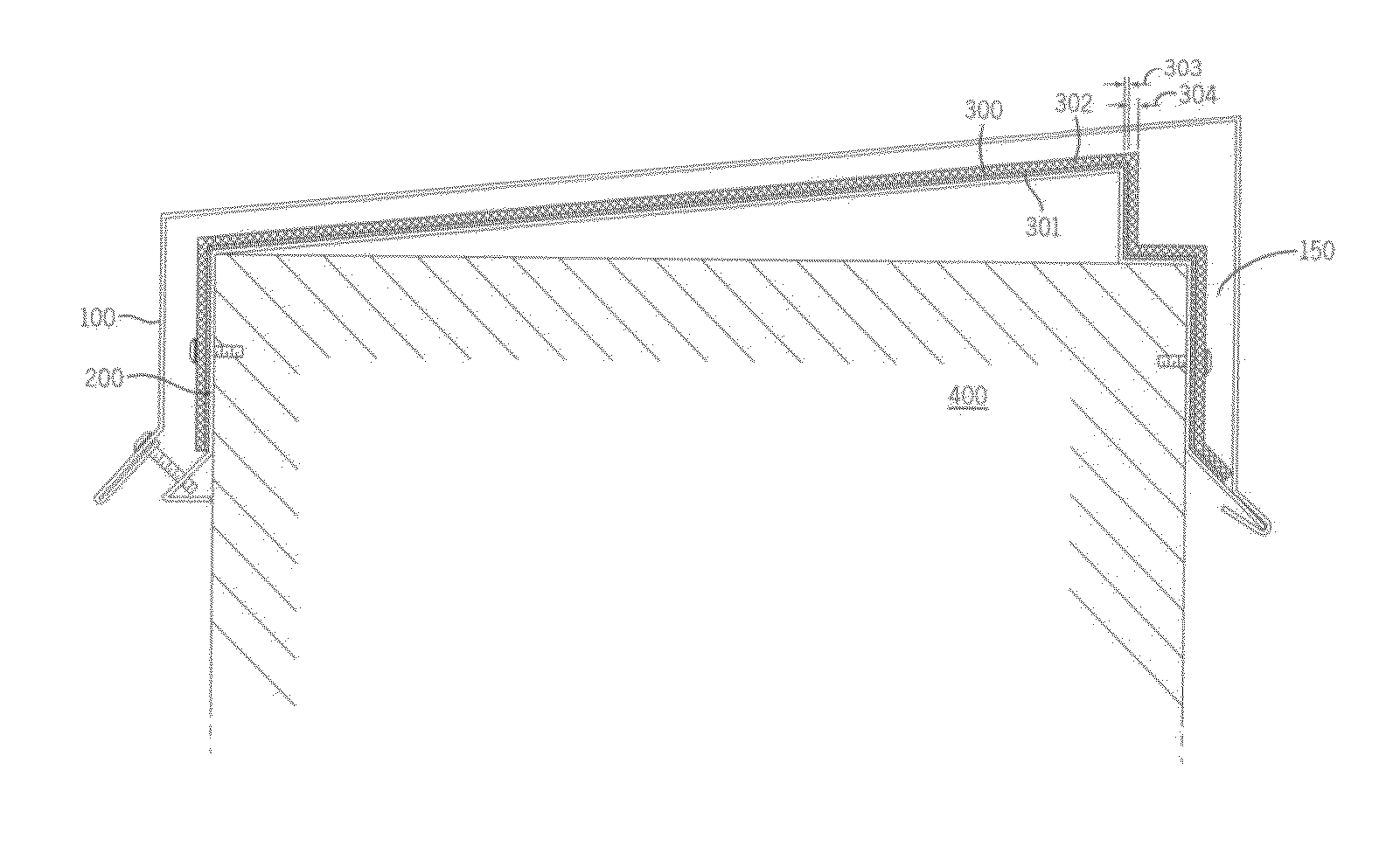

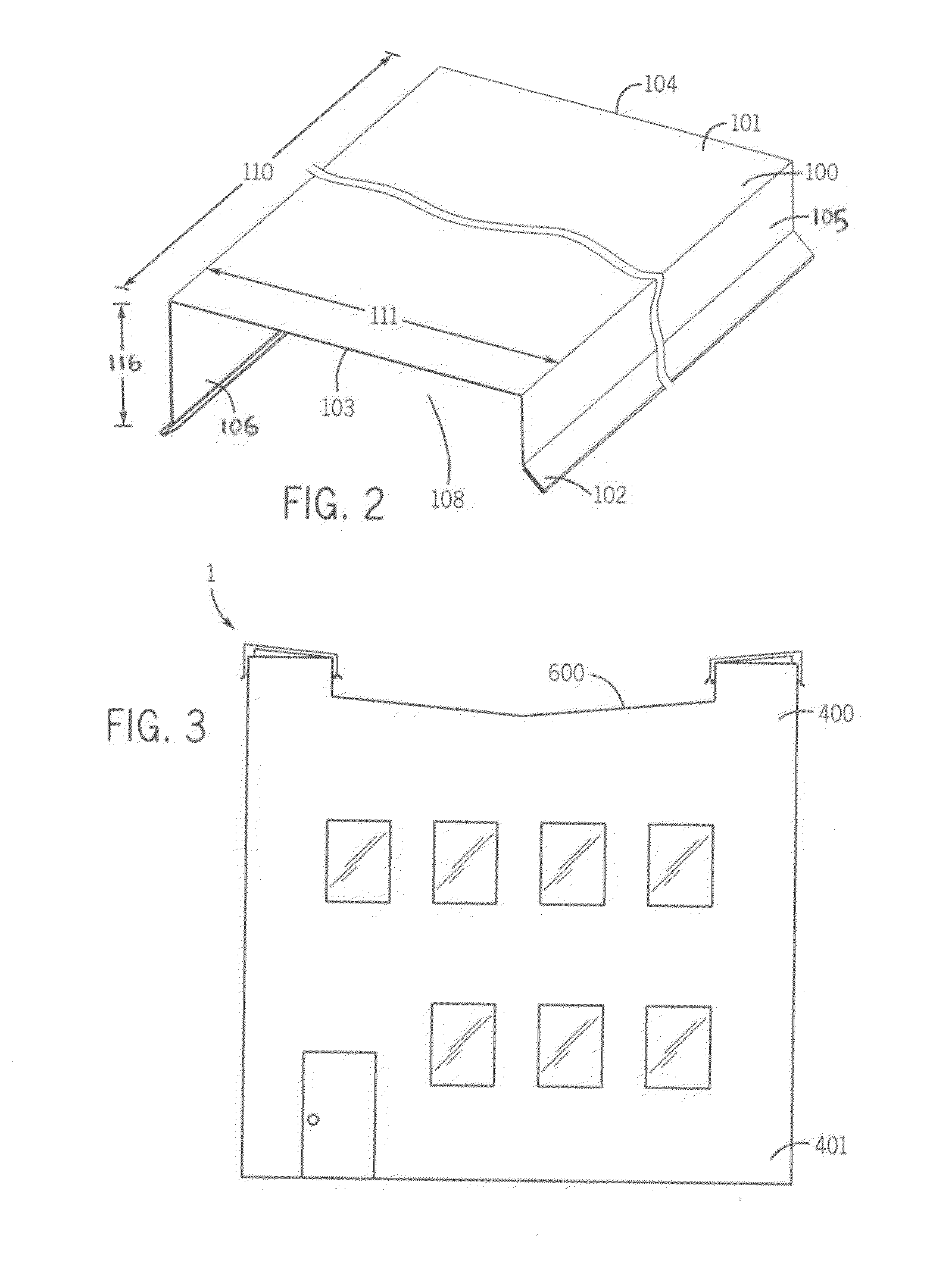

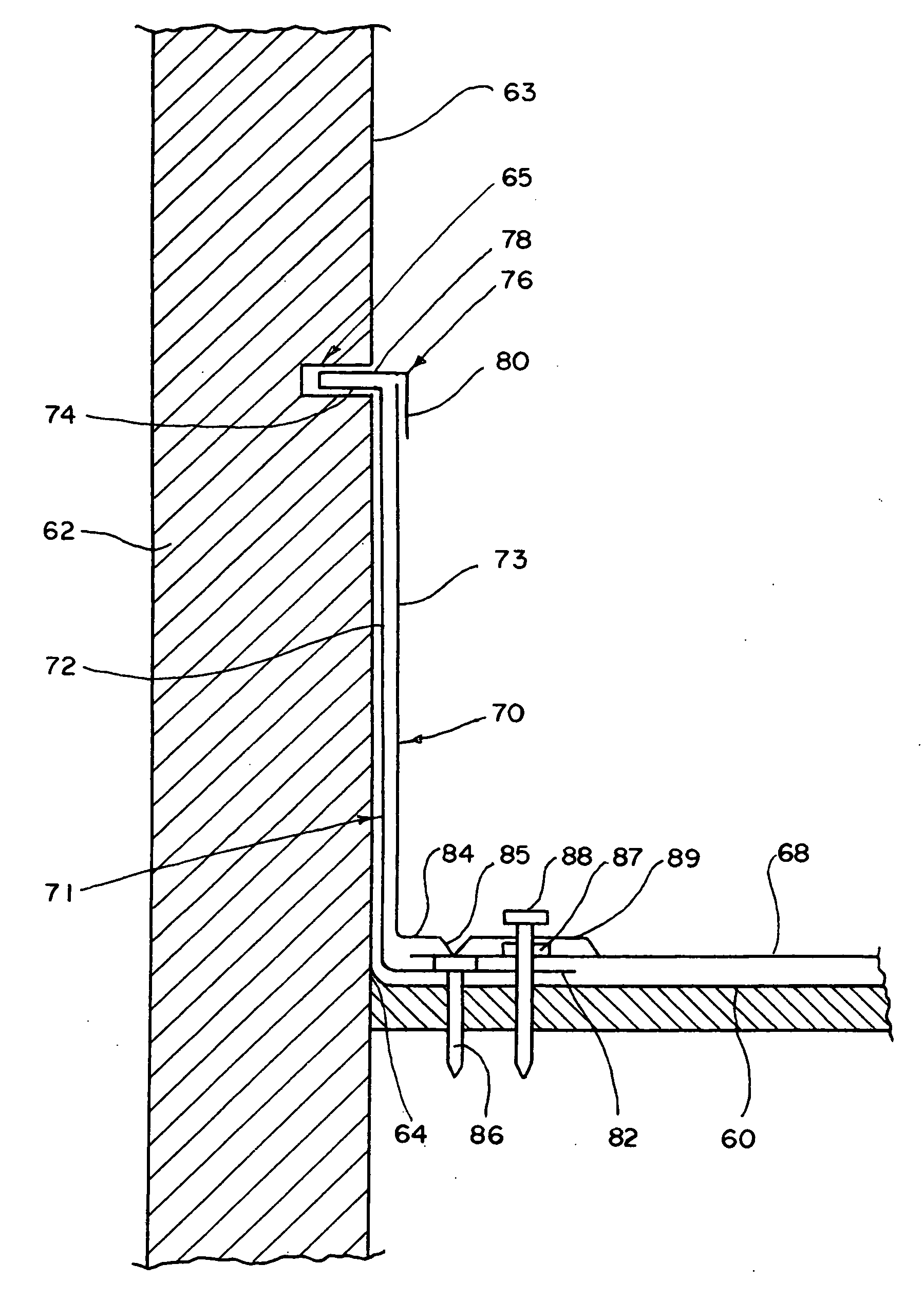

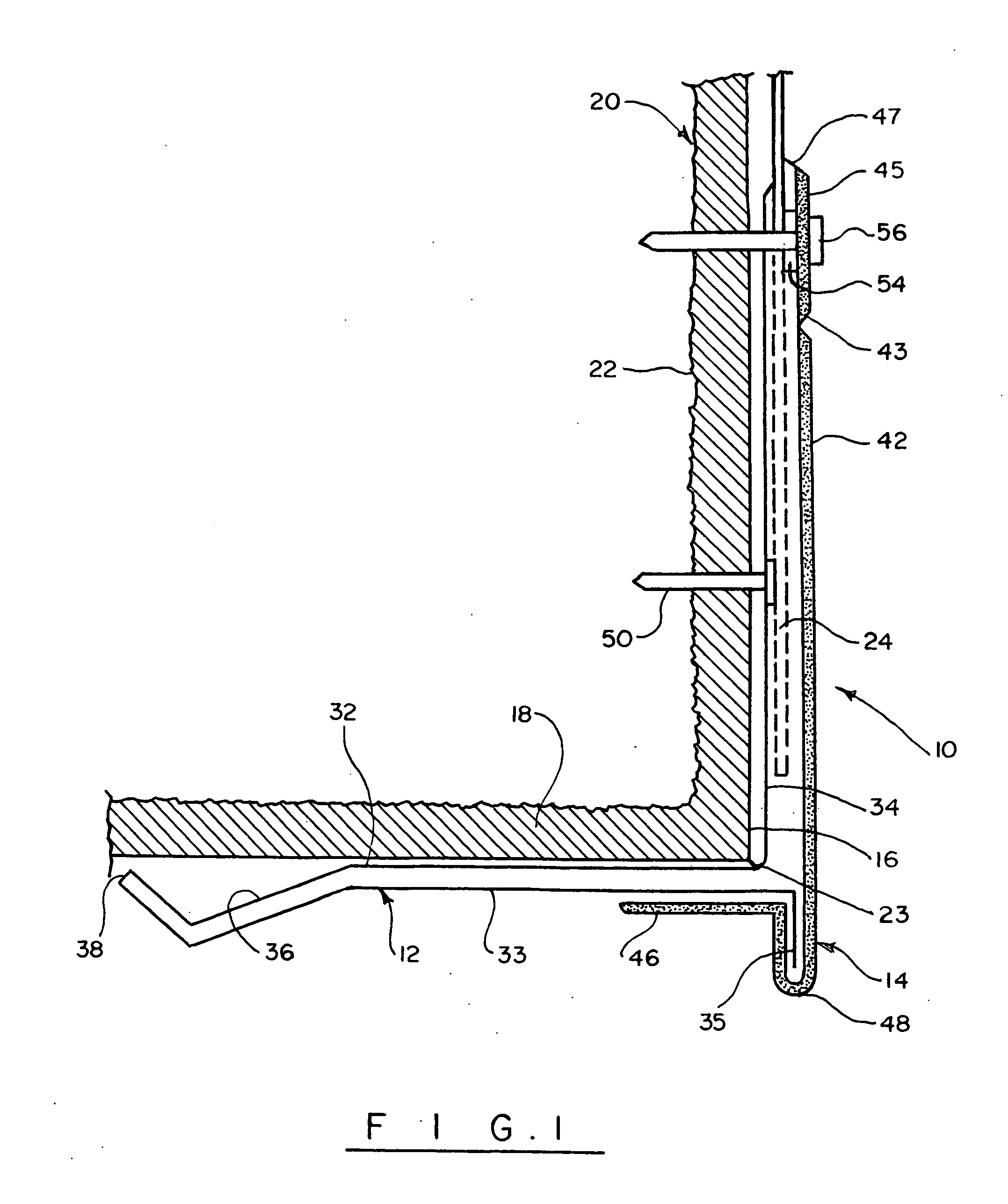

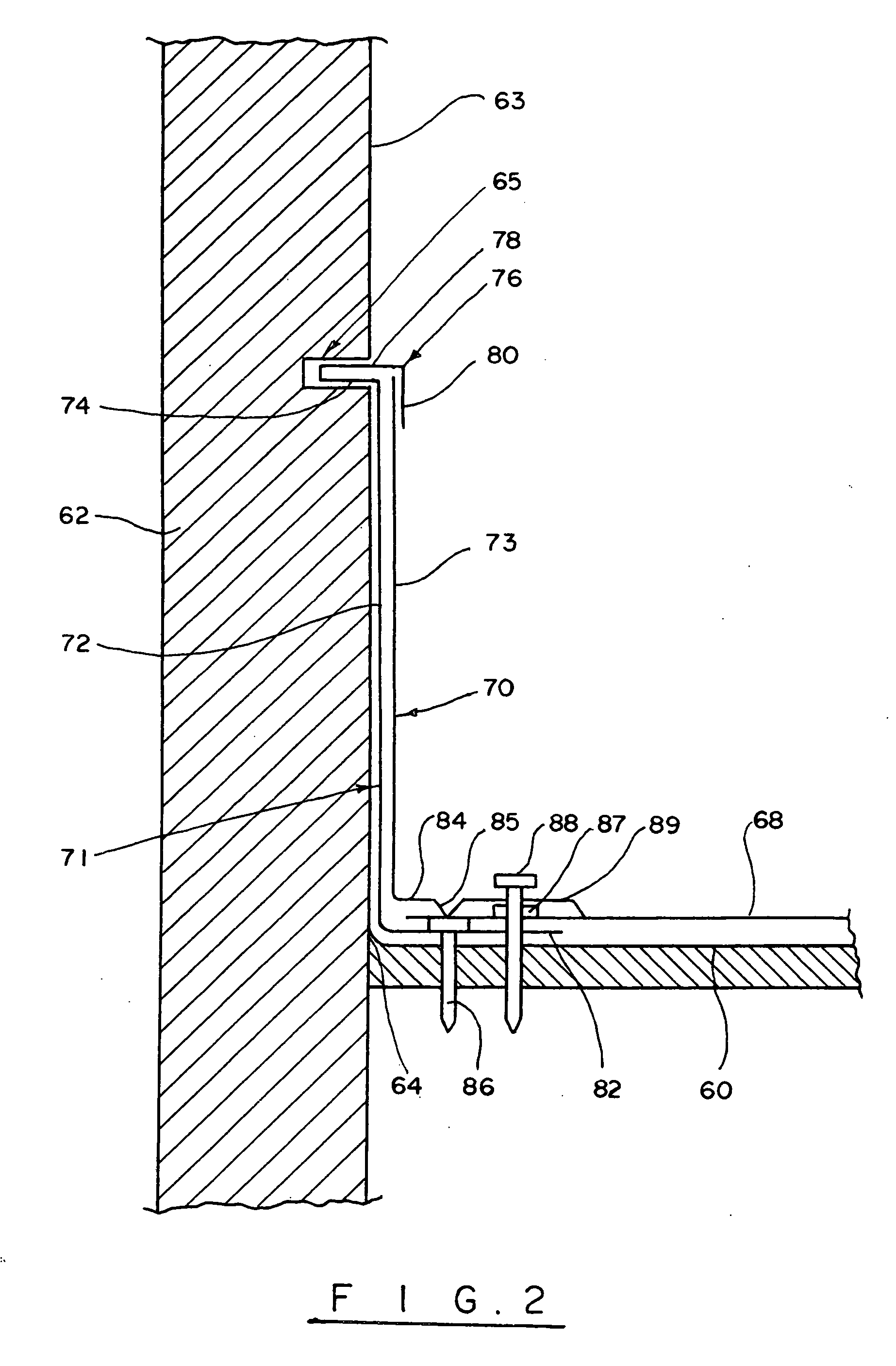

Roof deck and parapet structure

InactiveUS6945005B2Improve protectionBuilding roofsRoof covering using slabs/sheetsEngineeringFree edge

A roof transition assembly for a roof deck having a corrugated sheet and a rigid sheet wherein a base component is positioned at the perimeter of the roof deck and has two legs. The first leg secures the base component to the corrugated sheet, and the second leg extends from the first leg, generally parallel to a free edge of the roof deck. The second leg includes an anchoring surface. An upper component positioned at the perimeter of the roof deck has a connector portion and an anchor portion. The anchor portion is secured to the roof deck, and the connector portion extends from the anchor portion and overlays and is secured to the anchoring surface of the base component, thus anchoring the base component and upper component to the roof deck.

Owner:LOADMASTER SYST

Slopped roof flashing system and method of use

InactiveUS20050086873A1Reduce labor costsReduce material costsRoof covering using slabs/sheetsRoof covering using tiles/slatesBrickEngineering

A flanged counter flashing unit, flashing system and method is described for weather proofing the juncture of a brick wall overlying a vertical parapet wall and the edge of a sloped roof. The one-piece counter flashing unit of the flashing system has a vertical slit into which is securely fitted the low upstanding side of a J-Channel flashing positioned at the juncture and the vertical leaf member of an L-shaped roof flashing that is flush with the outer face of the upstanding low side of the J-Channel flashing, including a flange section of the counter flashing unit that extends laterally from the top edge of the counter flashing apron and partially over the J-Channel and an apron adapted for overlying the vertical leaf member of the L-shaped flashing. The J-Channel flashing, L-shaped flashing and flanged counter flashing are included in the flashing system of the present invention. According to the method of the present invention, when the flashing system is positioned at the juncture, the brick wall is constructed from within the J-channel so that the counter flashing flange is included in the brick wall. This method eliminates the need for a separate method step of attaching counter flashing to the brick wall at an angle to the horizontal plane of the brick wall after its construction by means of a gouge cut across the brick wall for that purpose.

Owner:MARES MANUEL

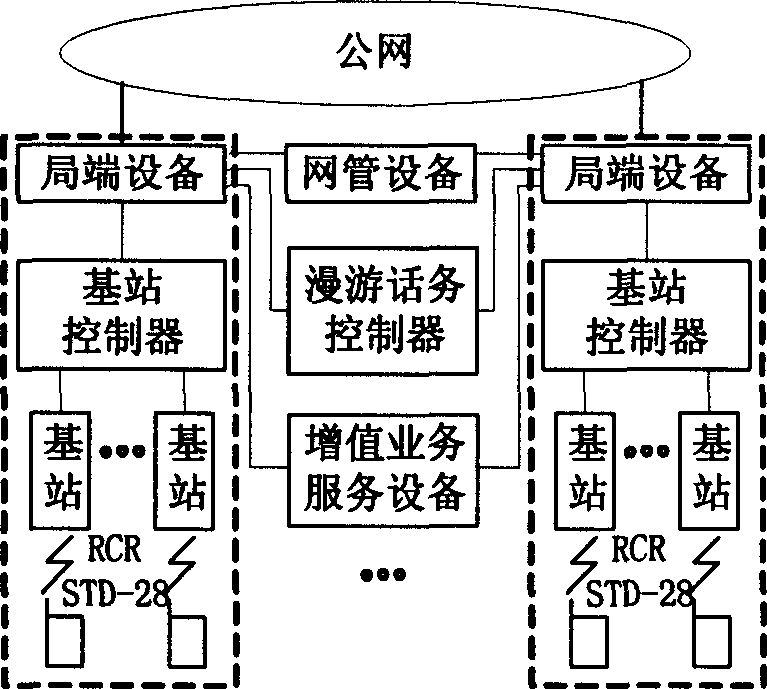

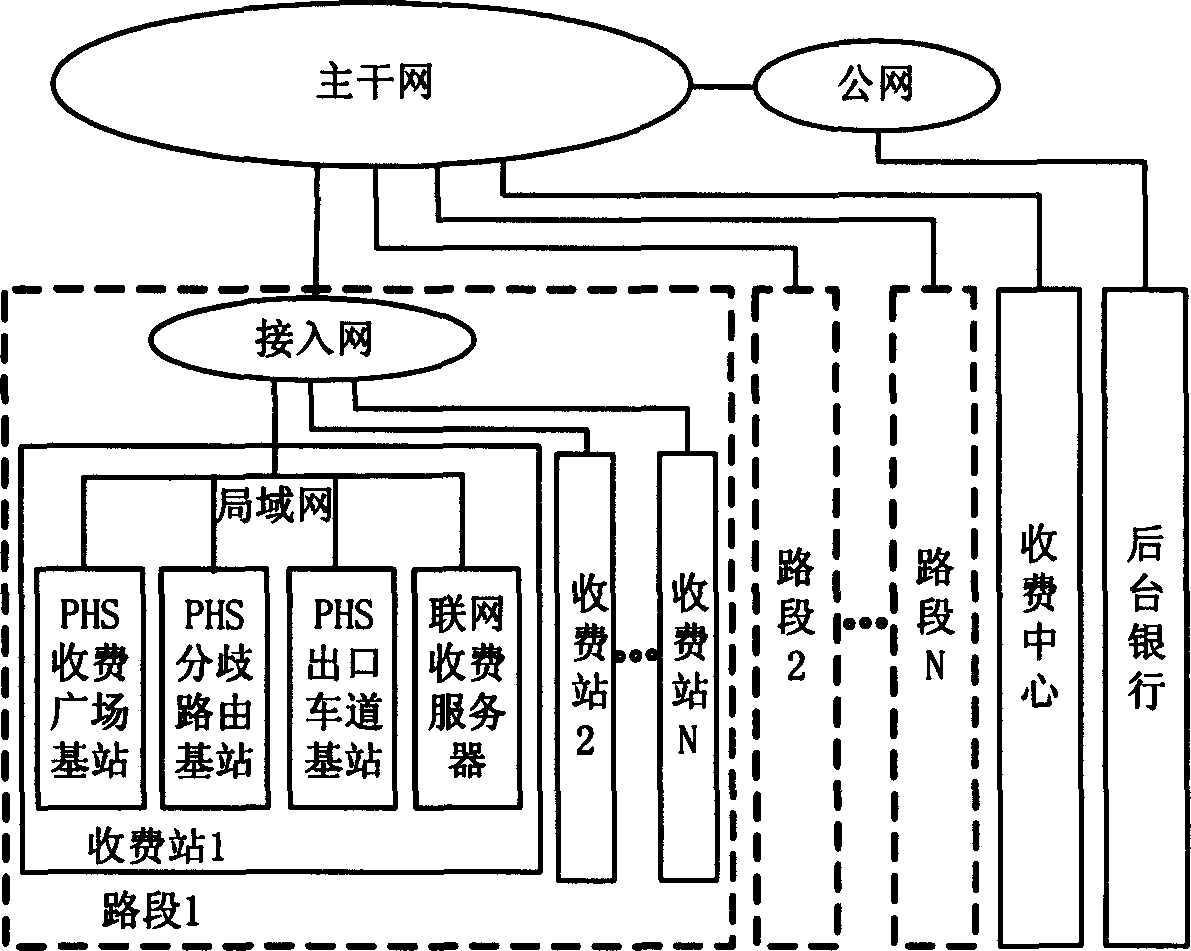

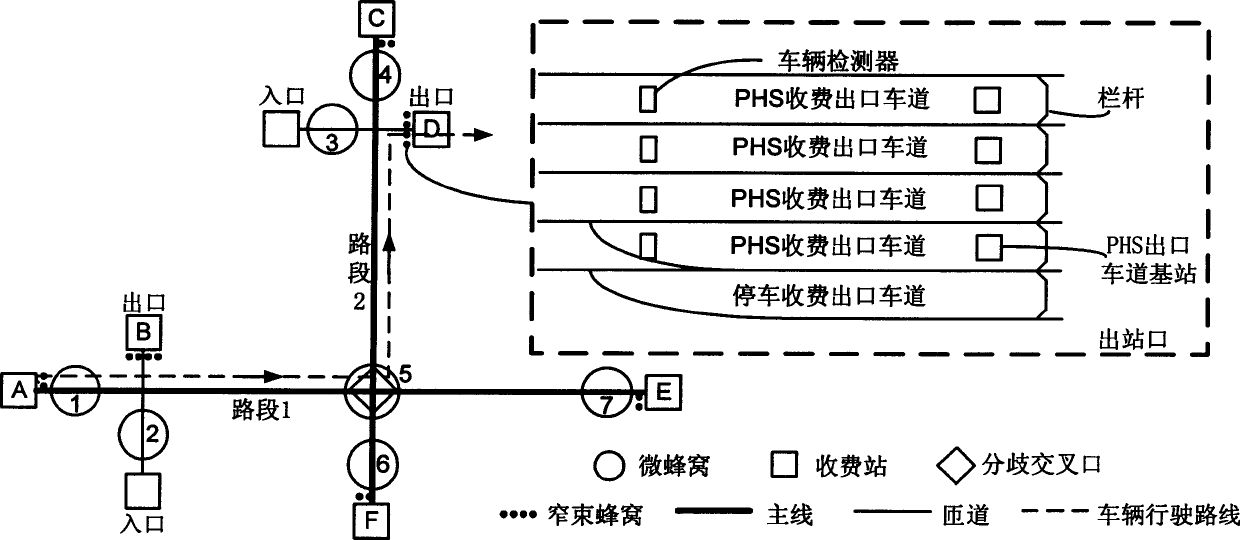

ETC networking charging method and system based on PHS

InactiveCN1598882ATicket-issuing apparatusRadio/inductive link selection arrangementsRelevant informationWireless data

The invention relates to a motor vehicles road charging method which is based on PHS. A charging special network based on PHS is set. The network includes PHS charging base station lied in square, parting of the ways and other places, lane computer lied on lane and network charging server. Adopt PHS base station to conduct wireless data exchange with charging car carrier PHS terminal; the PHS terminal corresponds with cars relative information, so cars and routes identification is made and data exchange with network charging server is made for cars enter or leave charging port. Network charging server record information like cars property, entrance and exit address, route and corresponding time data; also the information is sent to network charging server; at exit of charging station, PHS base station exchanges information with car carrier unit; the data is sent to network charging server; and parapet control, rate computing and bank process is conducted.

Owner:NANJING UNIV

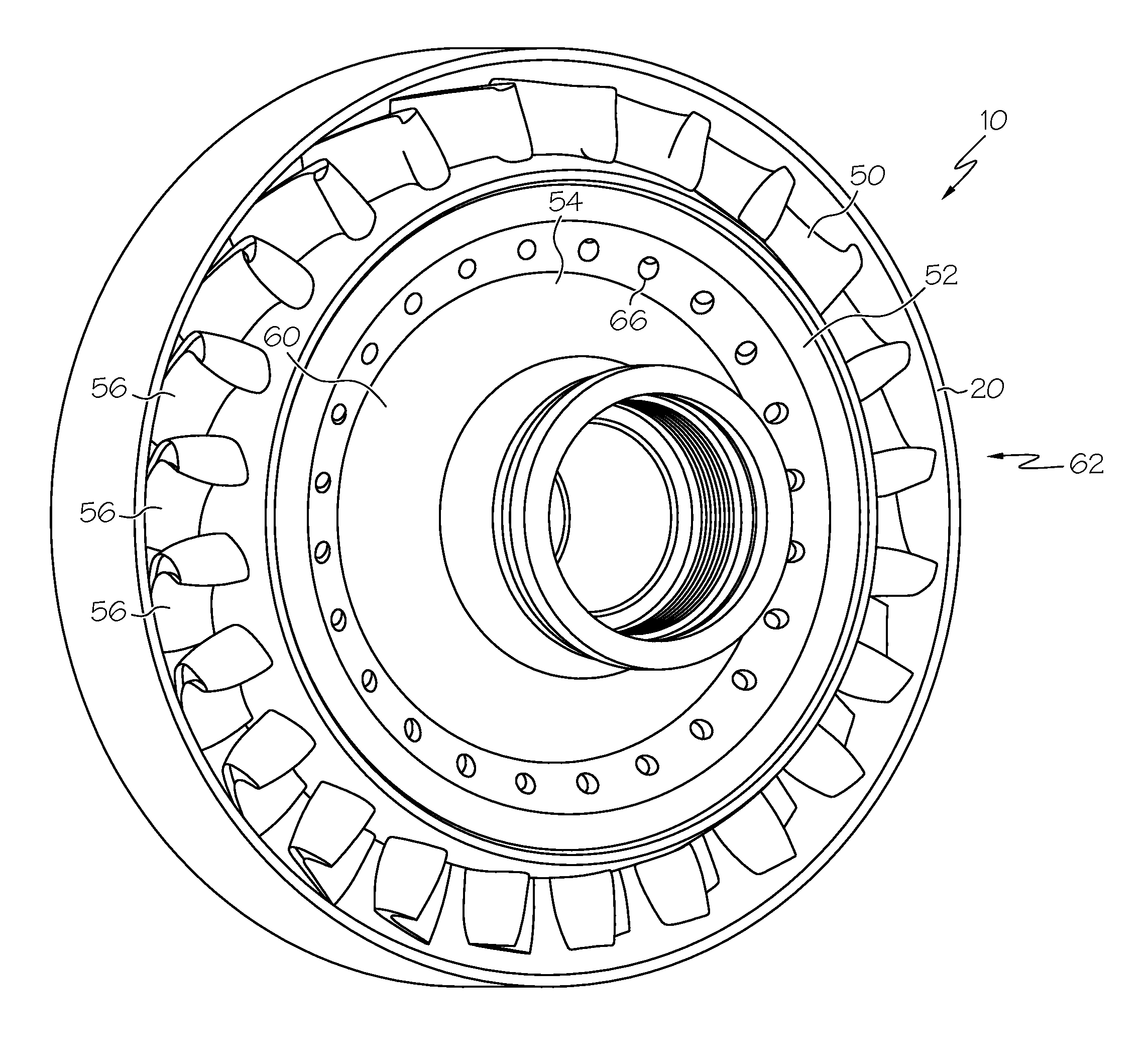

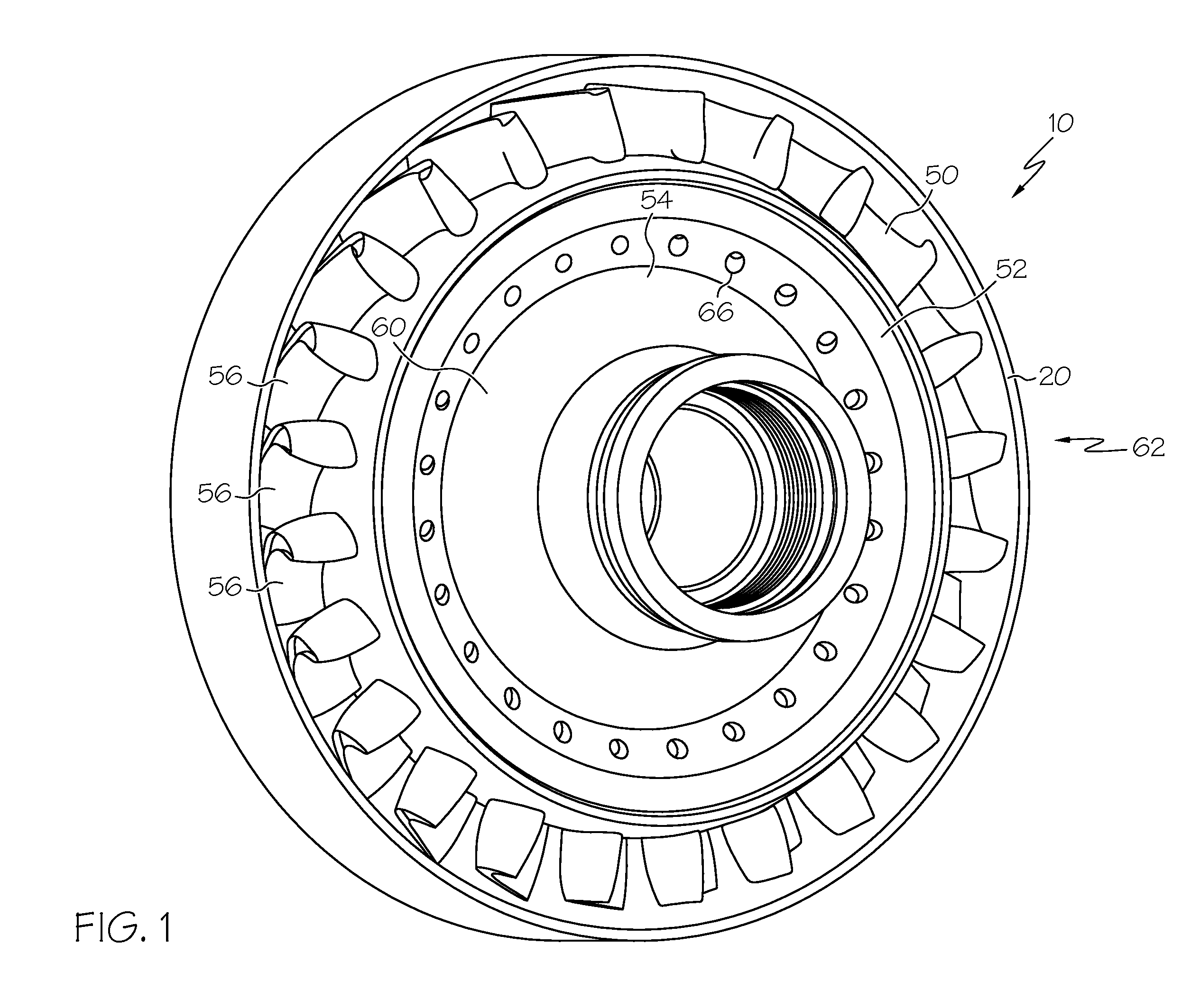

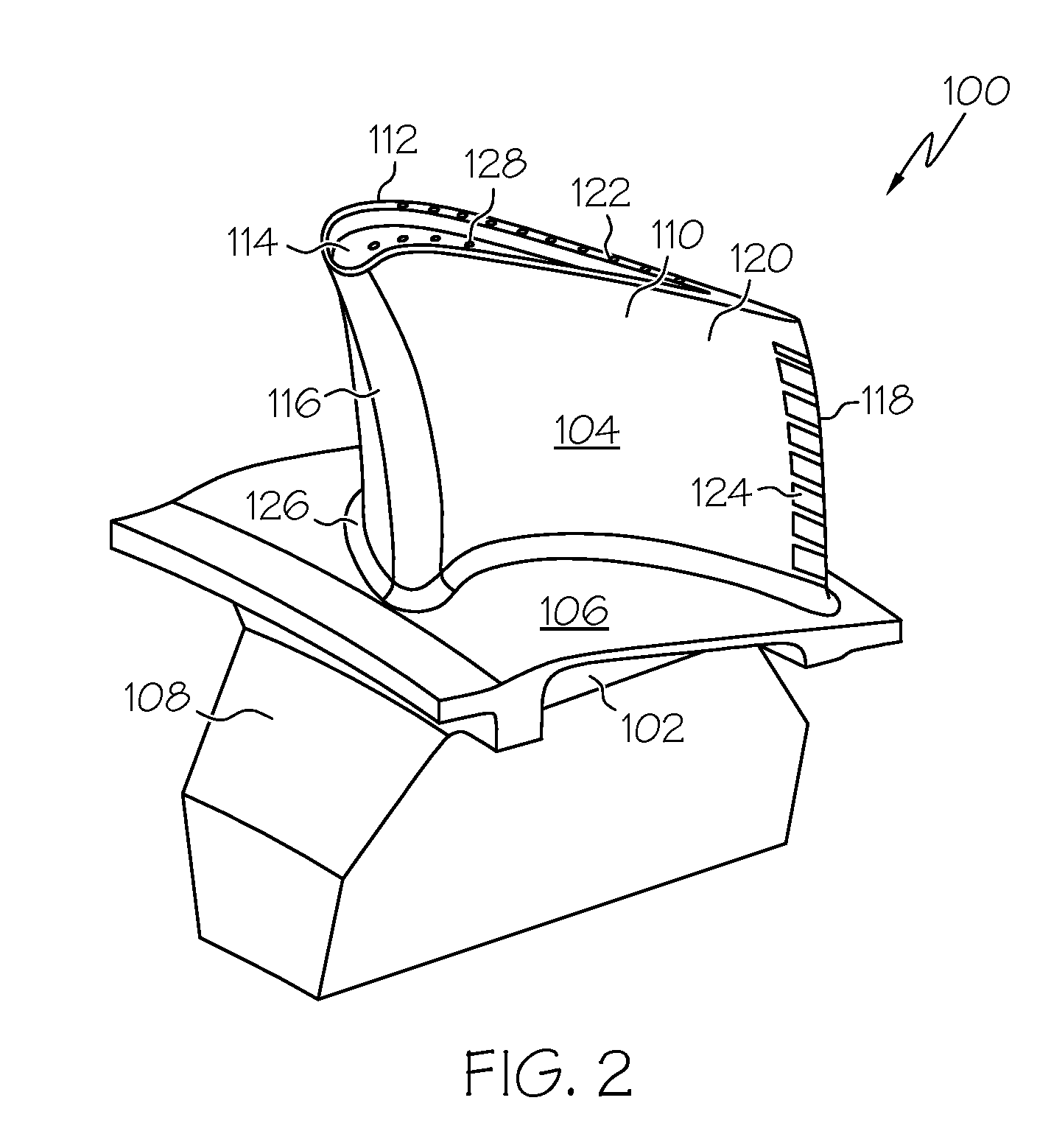

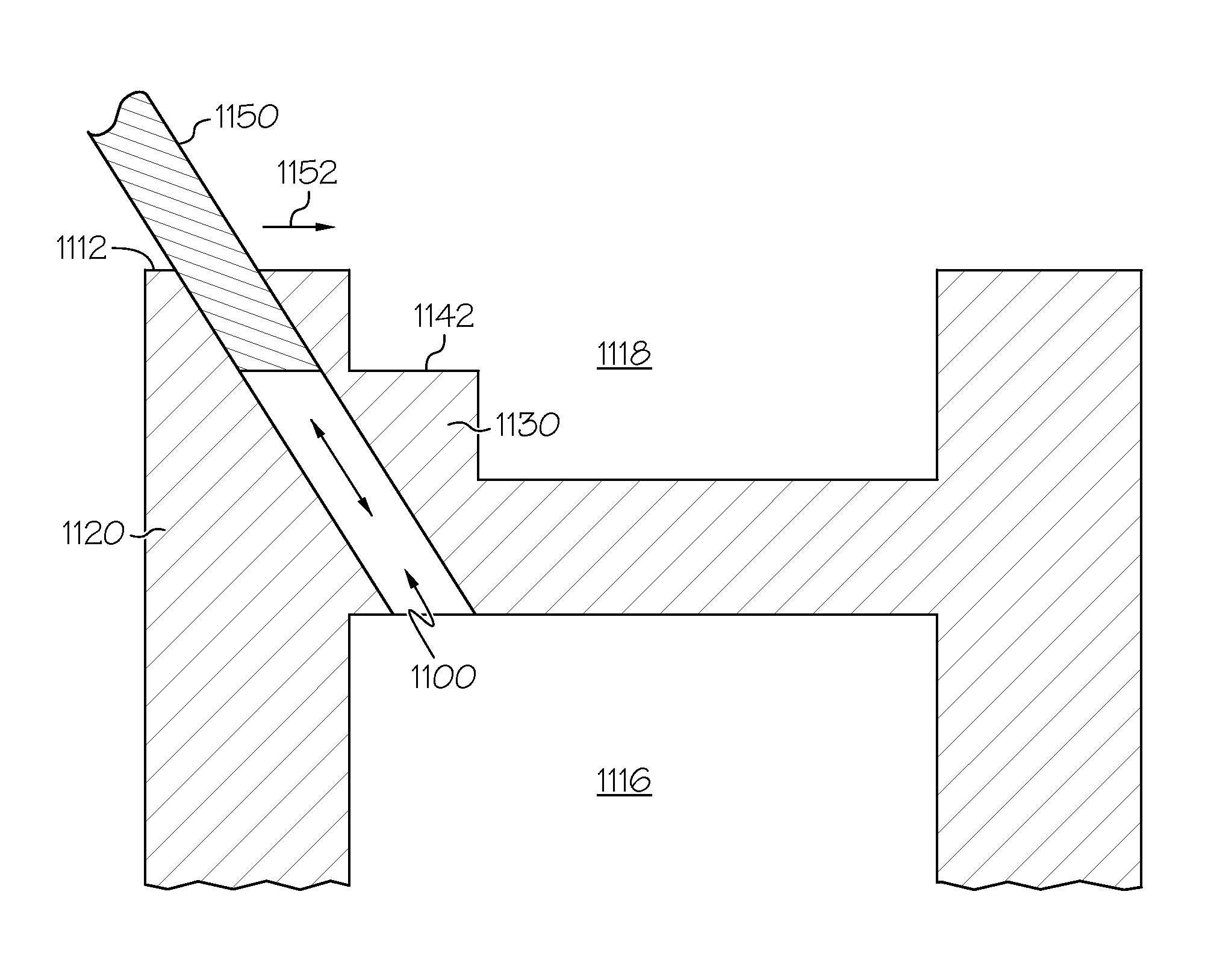

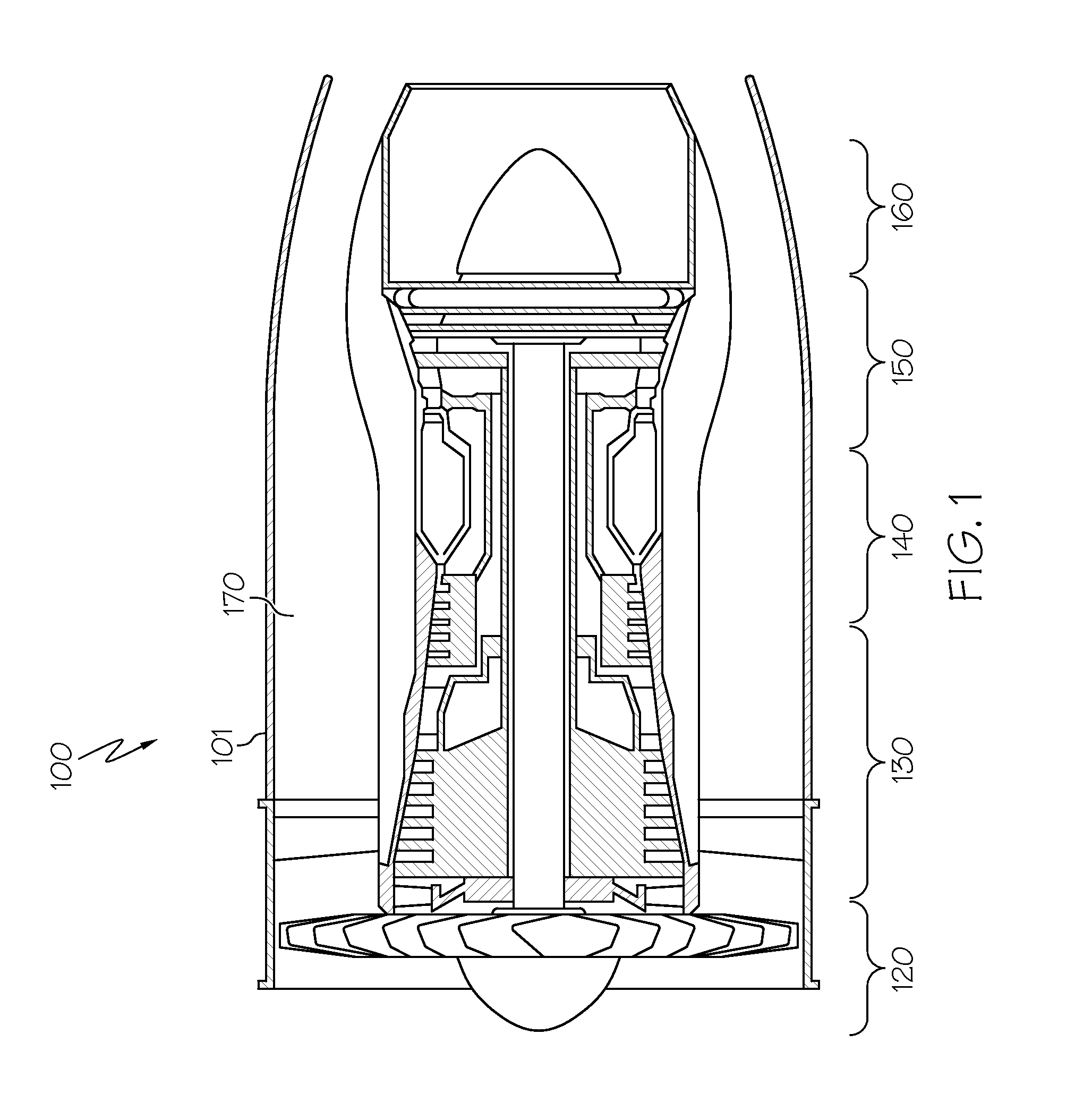

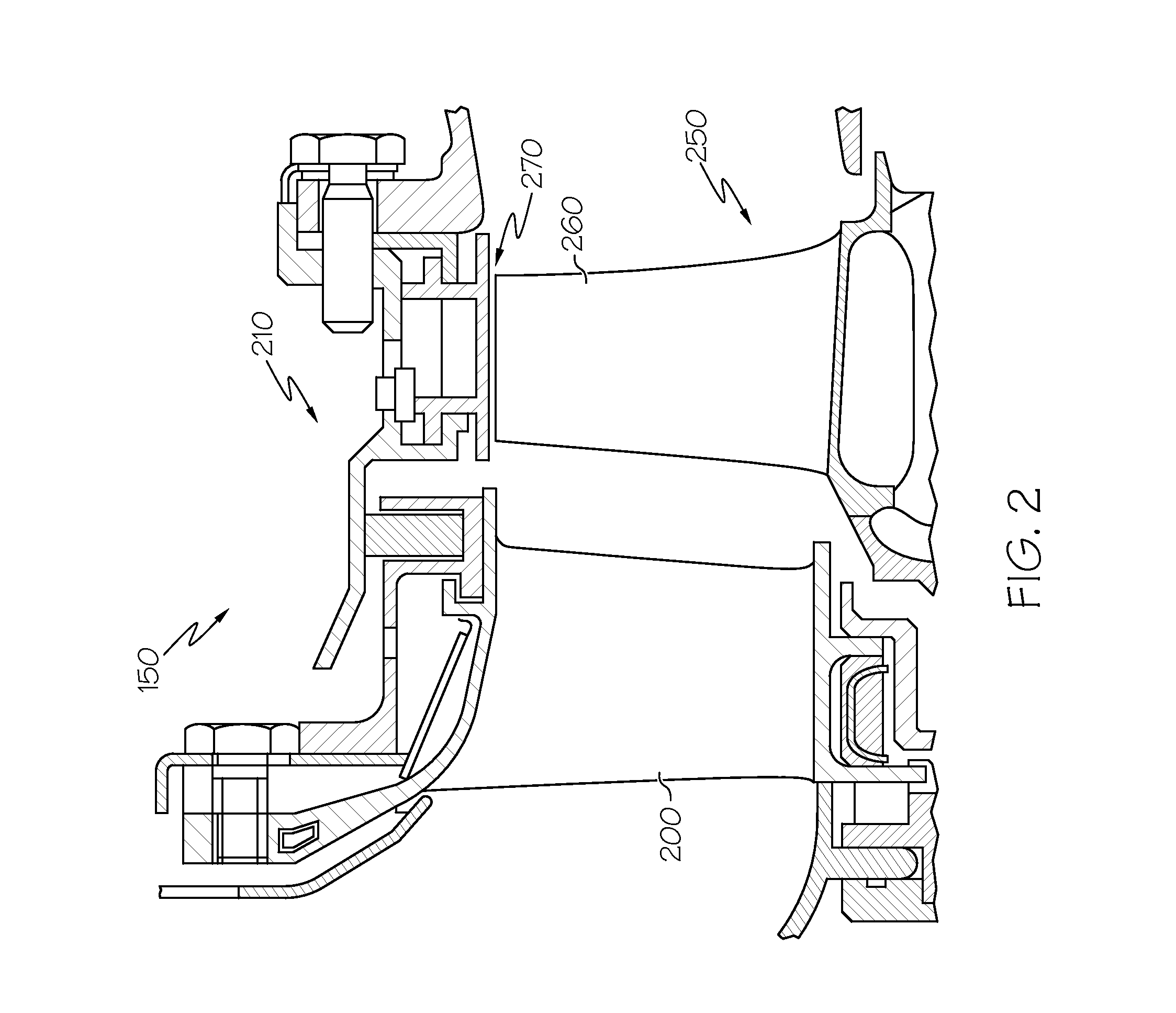

Turbine blades, turbine assemblies, and methods of manufacturing turbine blades

A turbine blade includes a first side wall including a first tip edge, a second side wall opposite the first side wall and including a second tip edge, a tip wall between the first and second side walls, the tip wall recessed from the first tip edge of the first side wall and the second tip edge of the second side wall forming a coolant cavity, a tip recess cavity, a first parapet wall on the first side wall, and a second parapet wall on the second side wall, the coolant cavity defined by the tip wall, and the tip recess cavity defined by the tip wall, and the first and second parapet walls, a step formed between the first tip edge and the tip wall, a cooling hole through the first parapet wall, the step, and the tip wall, the cooling hole including an open and a closed channel section.

Owner:HONEYWELL INT INC

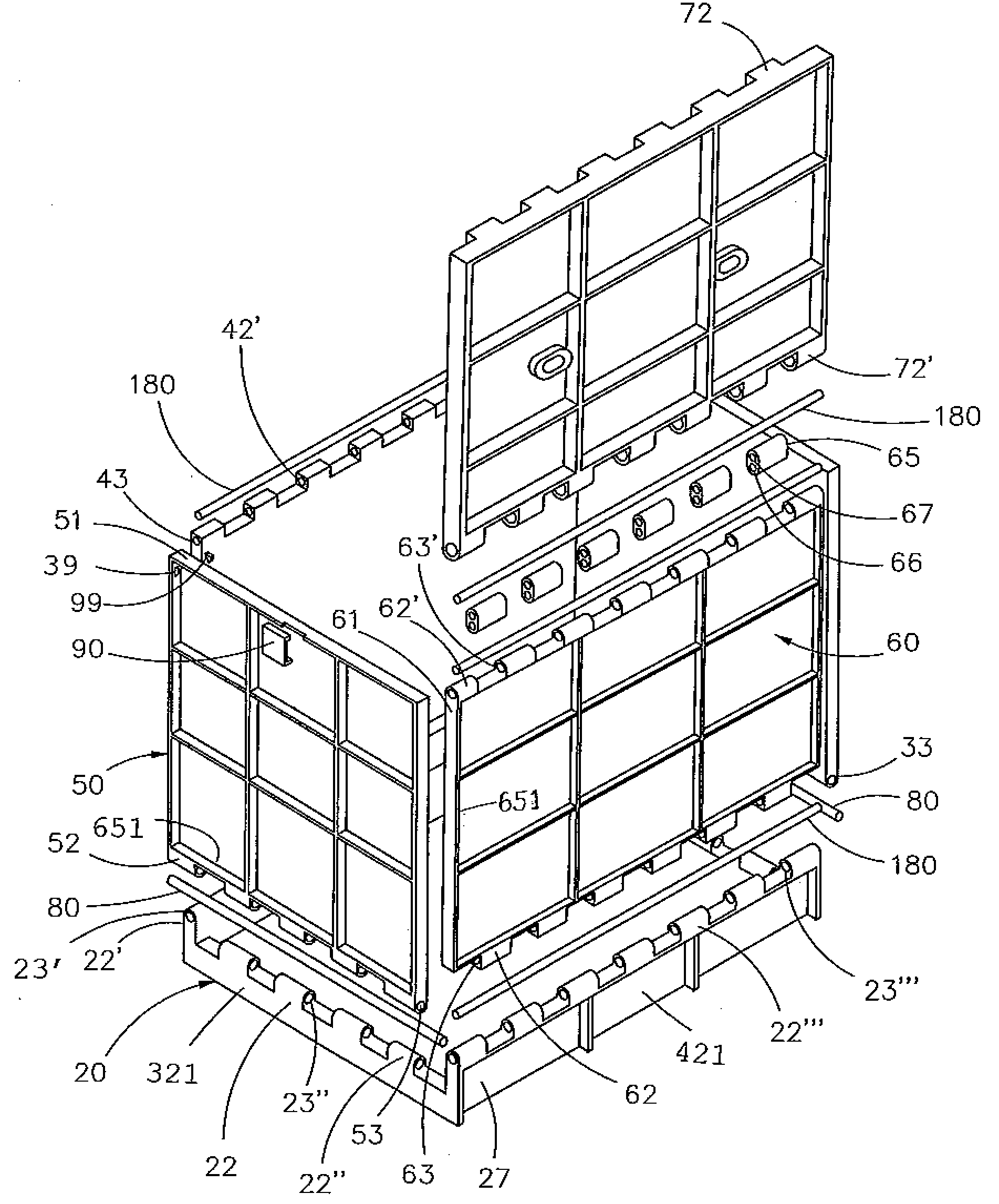

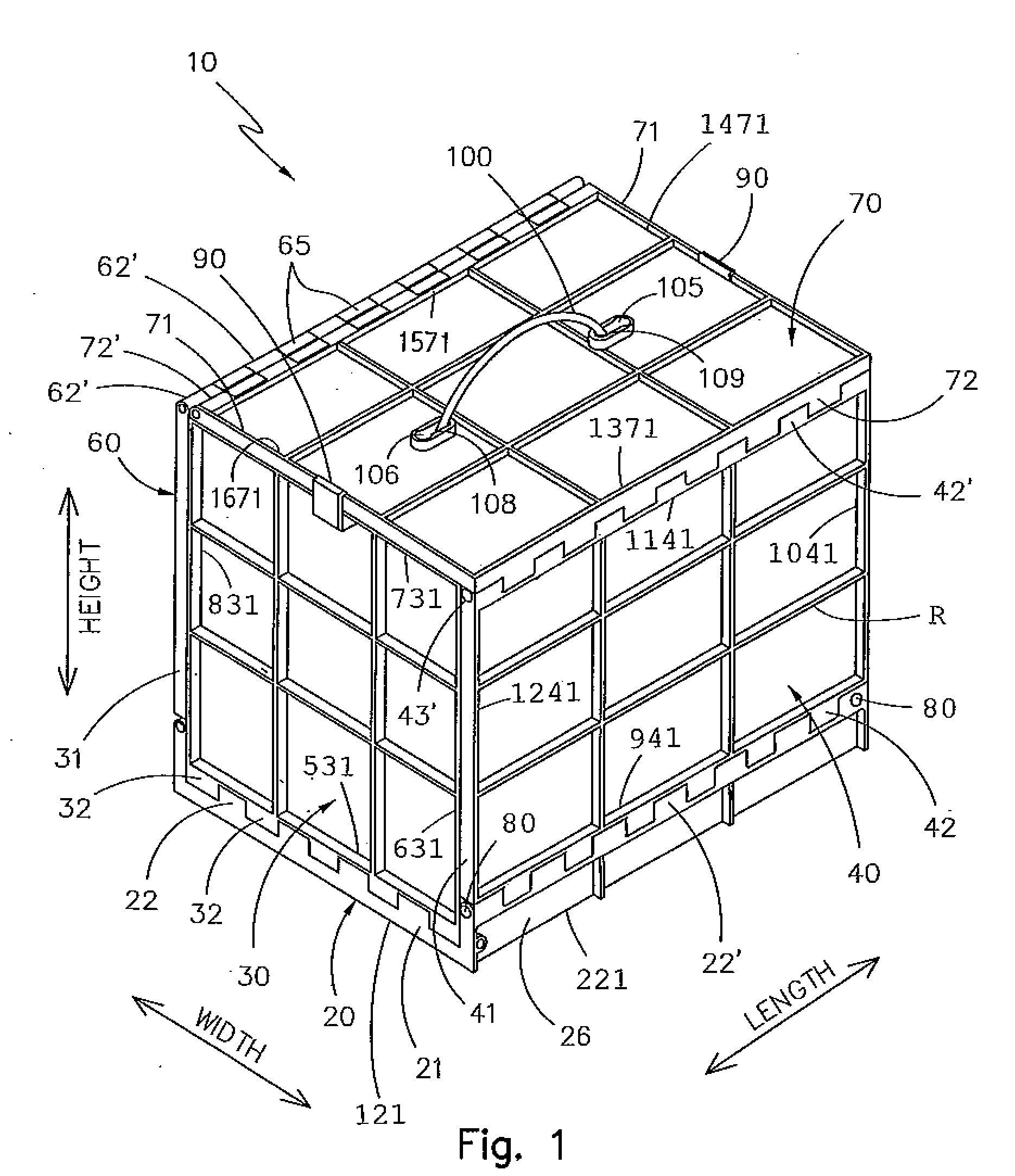

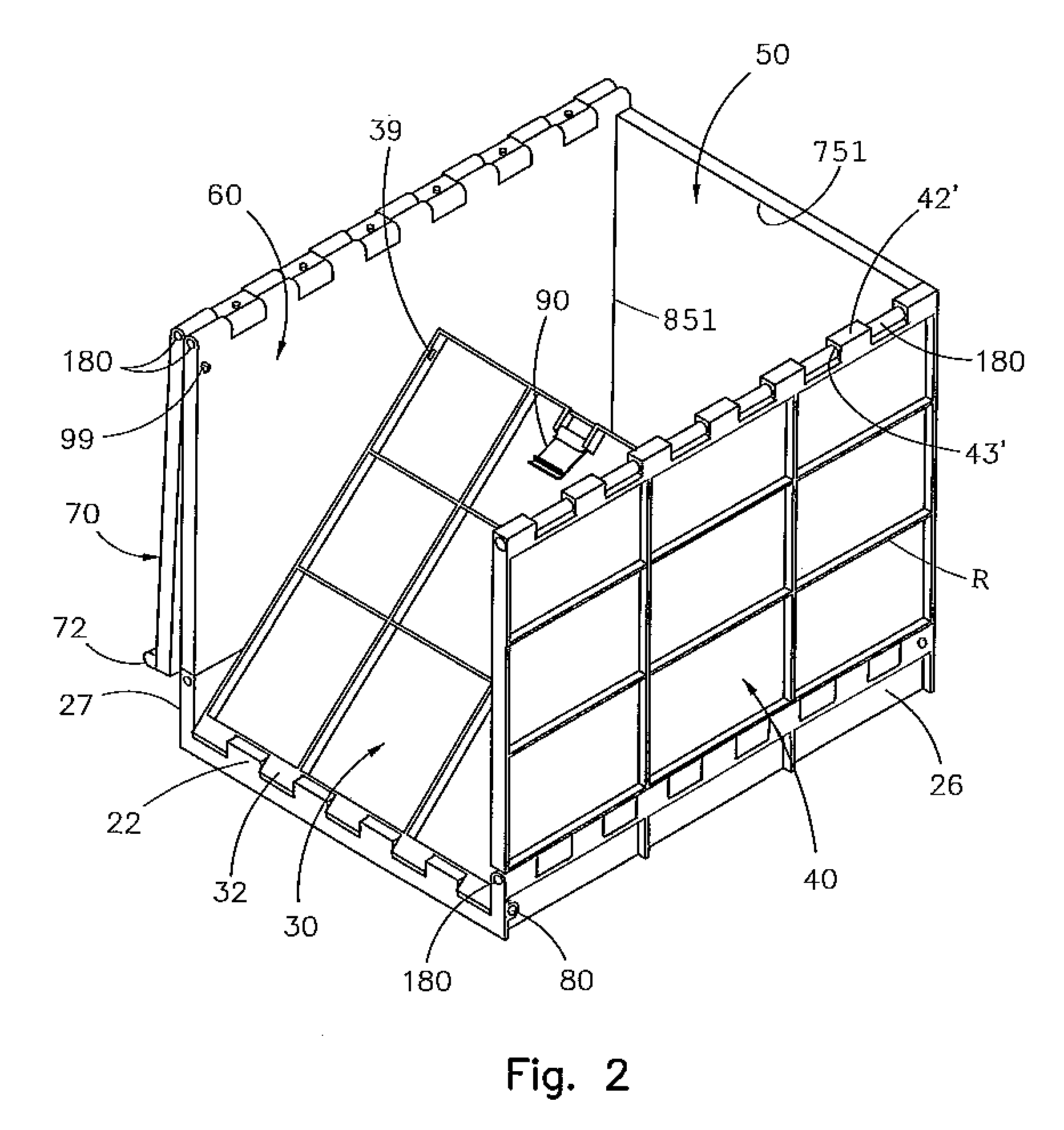

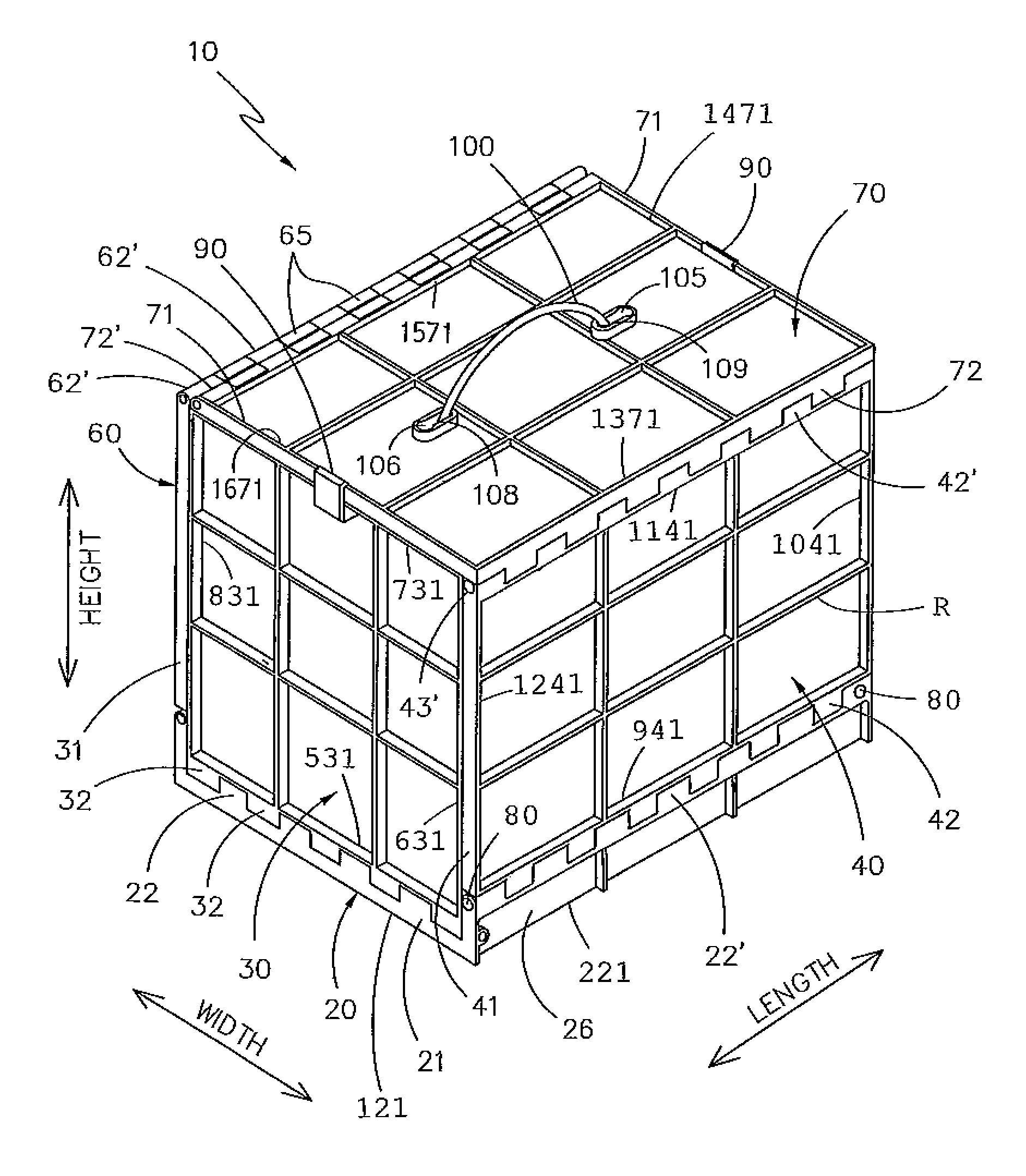

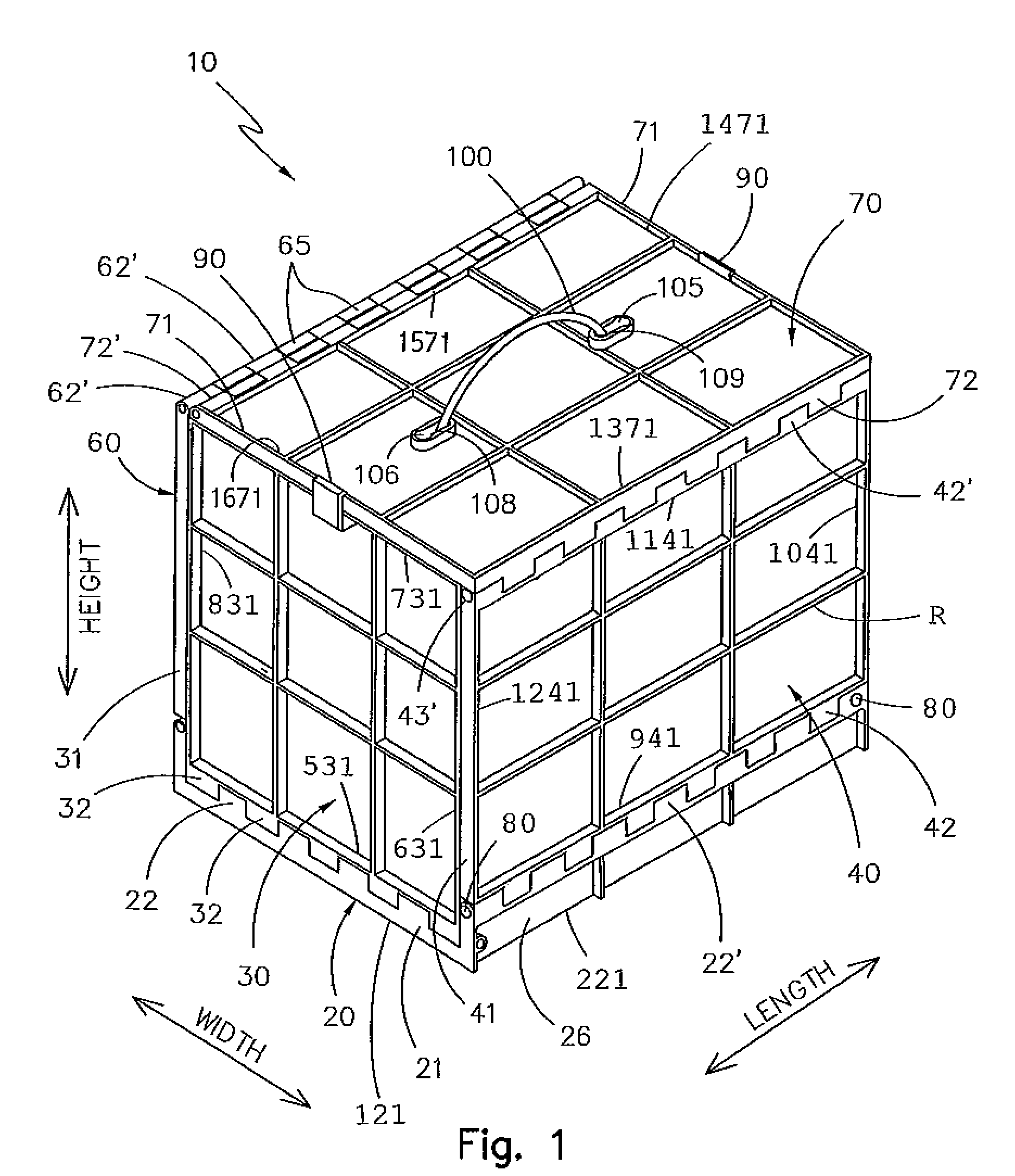

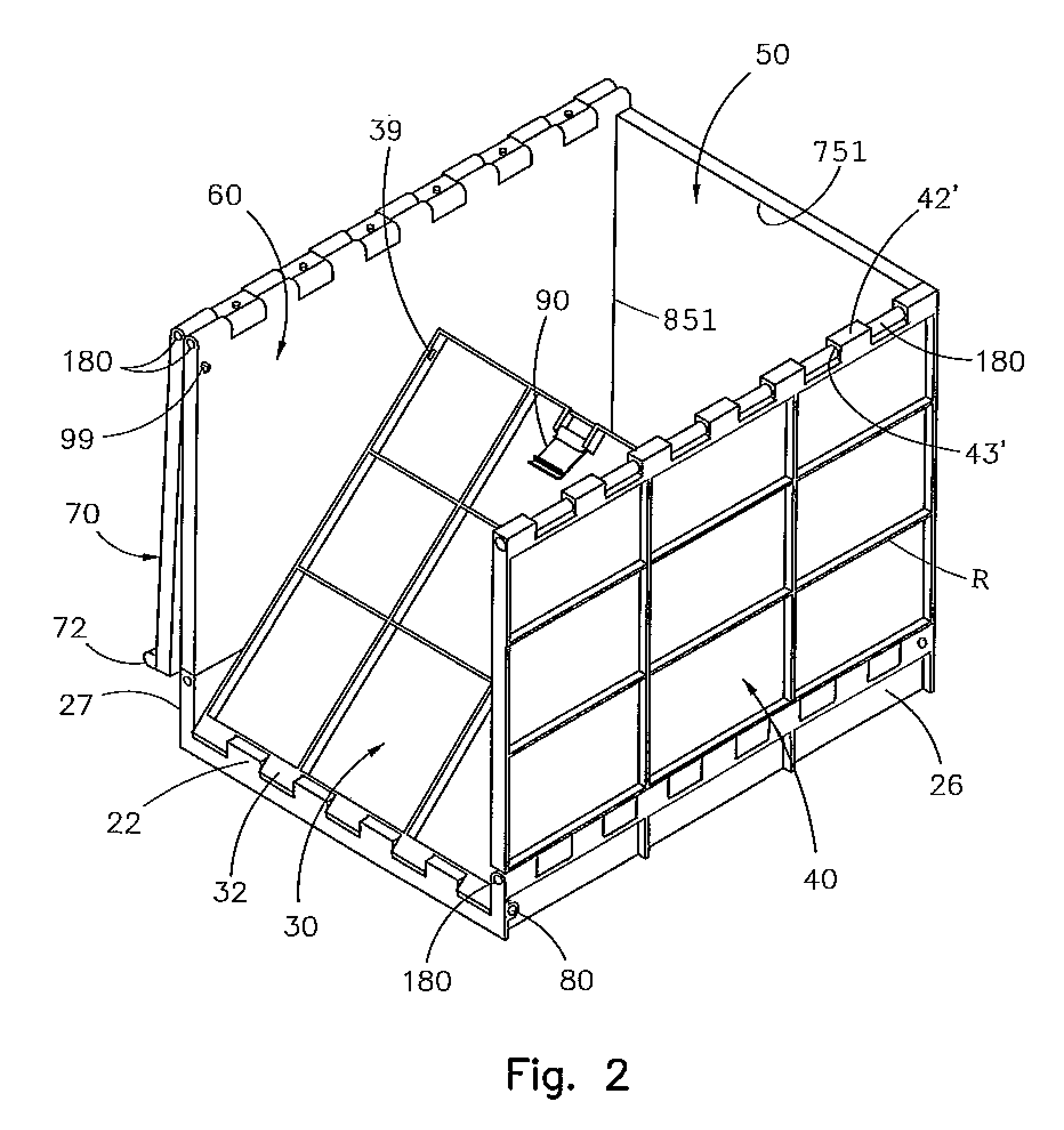

Collapsible container

InactiveUS20090134057A1Other accessoriesContainer/bottle contructionEngineeringMechanical engineering

A collapsible container that in the assembled configuration provides for a predetermined central space protected by six walls that are perpendicularly mounted with respect to each abutting wall and in the e collapsed configuration occupies minimum space. A bottom wall is provided with a predetermined umber of hinge knuckles with a central through opening through which pins are passed. Parapets of different heights are provided to raise the knuckles to predetermined heights that will clear the stacked up thickness of the folded walls. The height of the front, rear and the two side lateral walls is determined by the width of the bottom wall which in turn will also determine the width and height of the front and rear walls. A handle is removably mounted to the top wall, protruding toward the exterior.

Owner:HIDALGO VARGAS EDGAR

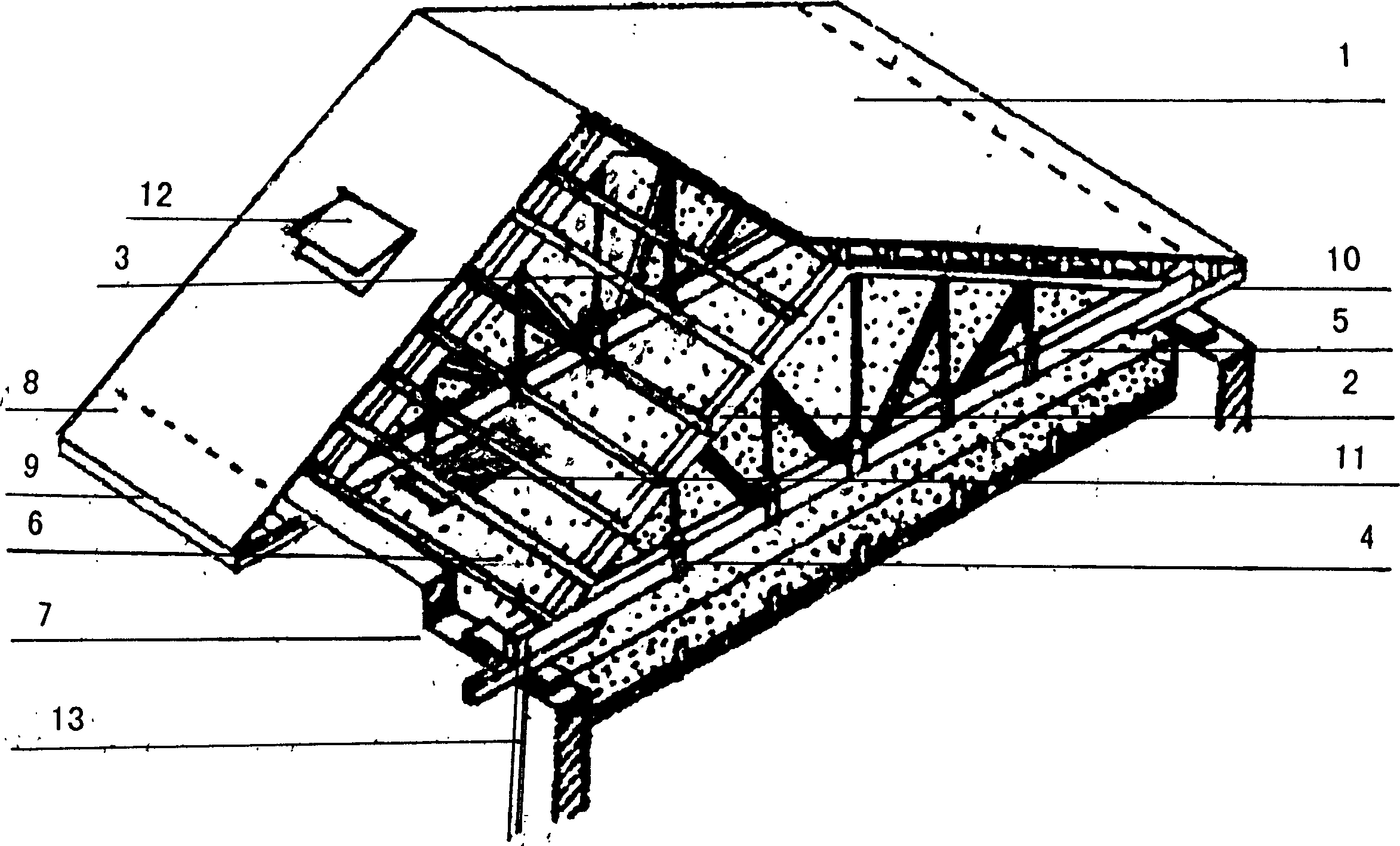

Water-proof heat insulation metal roof

InactiveCN1425836APollution impactExtended service lifeBuilding roofsRoof covering using tiles/slatesEngineeringMetal

The waterproof heat insulating metal roof consists of metal tiles, roof frame, roof surface frame, containing parts and horizontal crossbeam, and is constructed on structure and apart from the top layer ceiling. The metal tile may be corrugated tile, flat tile or composite tile; and there is one lightning arrester earthing wire. The waterproof heat insulating metal roof can play the roles of preventing water and isoalting heat, and has very long service life, over 25 years, without need of maintenance. In addition, the used roof material may be recovered and has no environmental pollution.

Owner:林渝茂

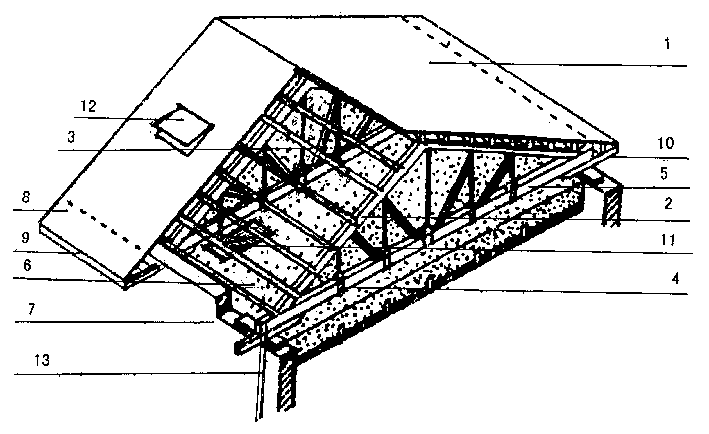

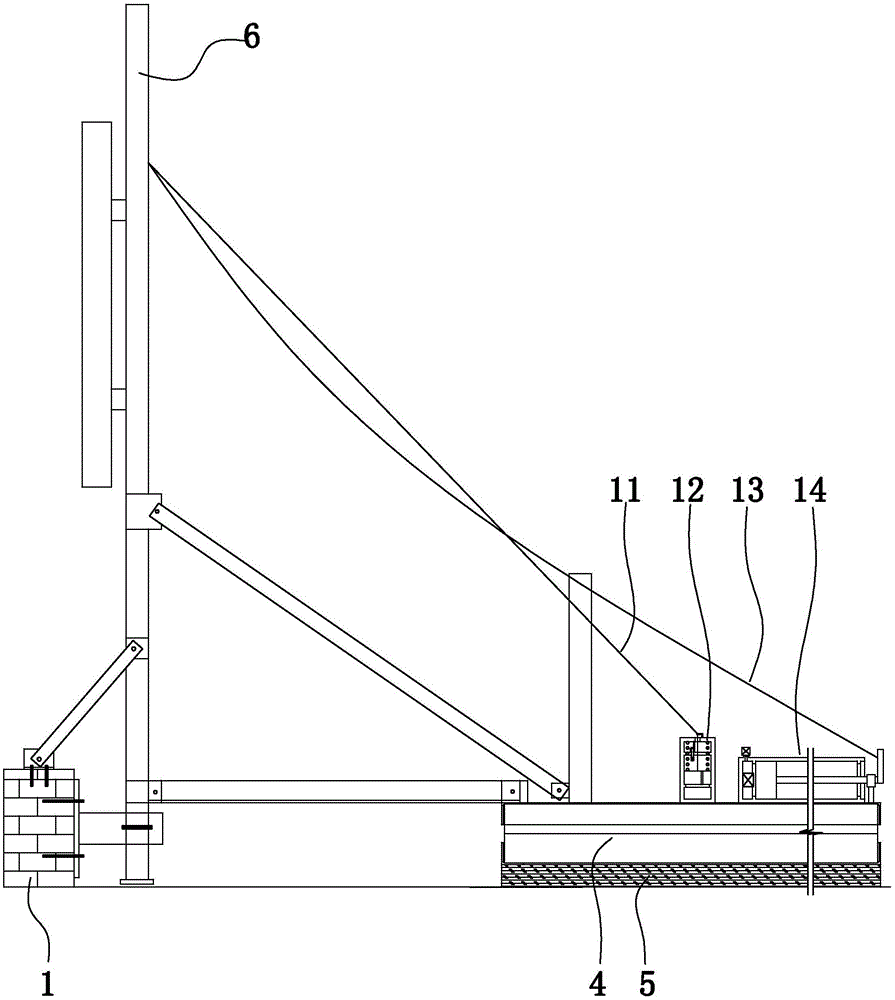

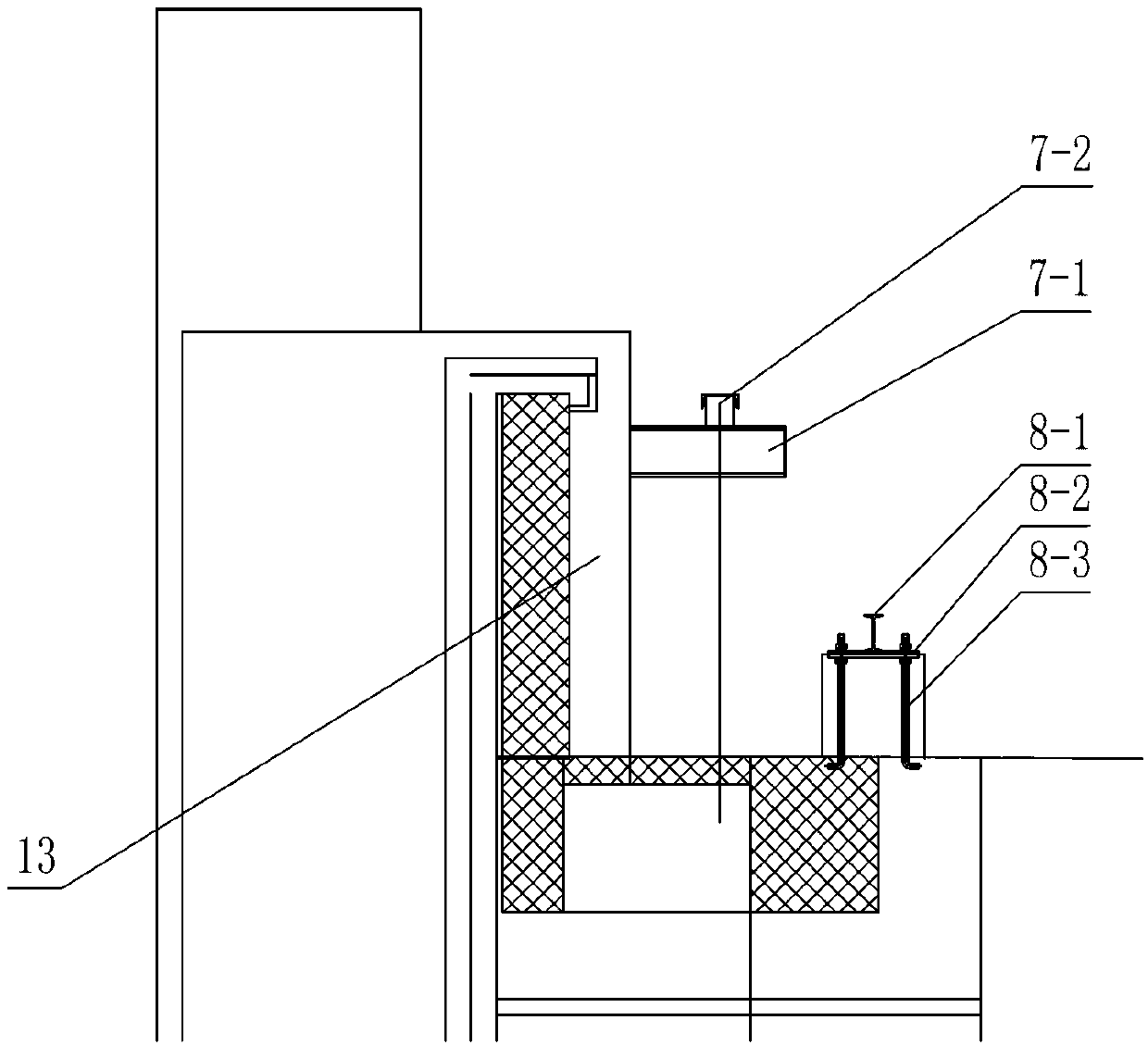

Combined type roof communication tower

ActiveCN105155901AAvoid destructionImprove installation strengthTowersSnow trapsTowerUltimate tensile strength

The invention discloses a combined type roof communication tower. While a roof waterproof layer is prevented from being damaged, mounting strength, firmness and stability of the communication tower can be improved effectively, and then the hanging amount of a communication antenna is increased effectively. The combined type roof communication tower comprises a communication pole and a balancing weight; the communication pole is fixedly arranged on a parapet wall of a roof; the balancing weight is arranged on the upper surface of the roof; a reinforcing supporting structure is arranged between the balancing weight and the communication pole, and comprises a lower supporting rod and an upper supporting rod; the lower supporting rod and the upper supporting rod are connected with the balancing weight and the communication pole; the upper supporting rod is positioned above the lower supporting rod; one end of the upper supporting rod is connected with the middle of the communication pole; the other end of the upper supporting rod slants down, extends to the direction of the balancing weight, and is connected with the balancing weight; one end of the lower supporting rod is connected with the lower portion of the communication pole; and the other end of the lower supporting rod is connected with the balancing weight.

Owner:HUAXIN CONSULTATING CO LTD

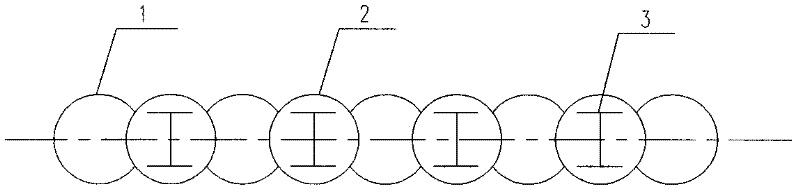

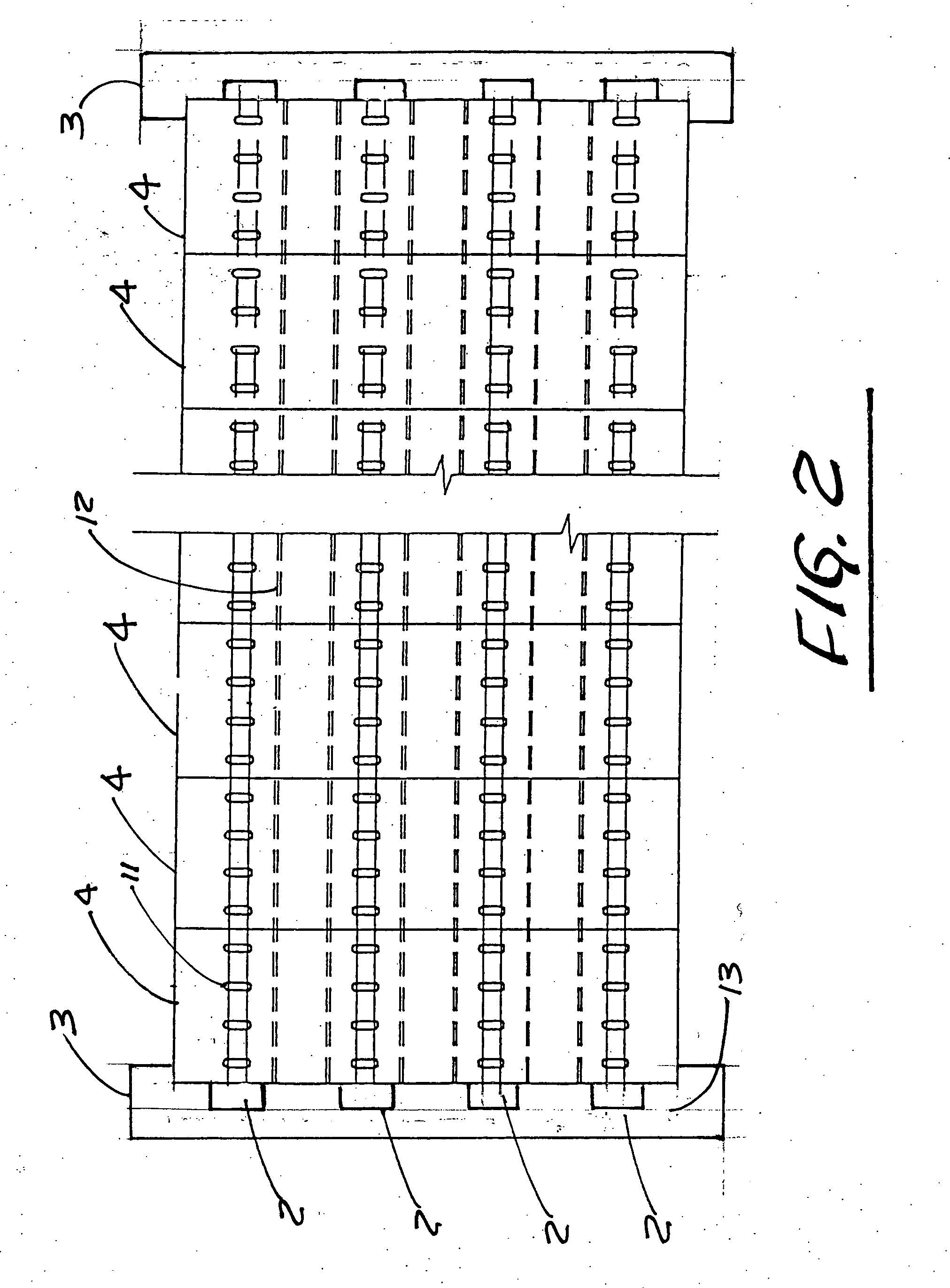

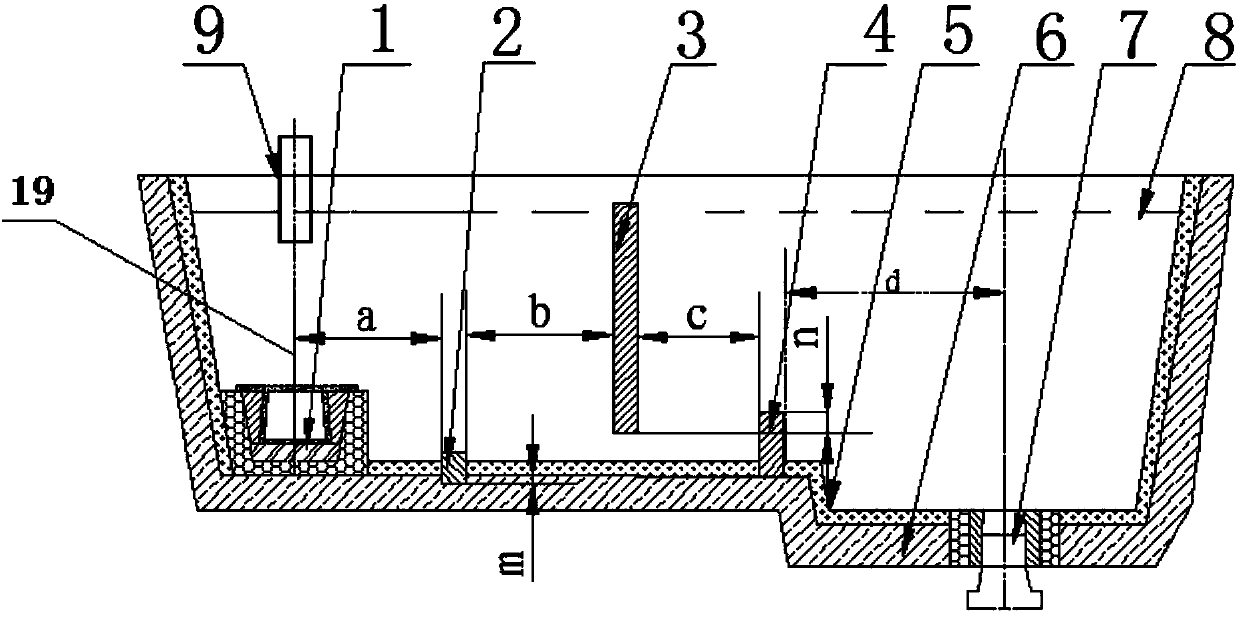

Device and method for removing molten steel slag inclusion in continuous casting tundish

The invention relates to a device and method for removing molten steel slag inclusion in a continuous casting tundish. The device comprises a turbulence controller, air curtain ventilation bricks, parapets and blocking dams, wherein the air curtain ventilation bricks (2) are located between the turbulence controller (1) and the parapet (3) and fixed to a tundish bottom permanent liner, the horizontal distance a between the longitudinal center line of the turbulence controller (1) and the longitudinal center line of the air curtain ventilation bricks (2) ranges from 400 mm to 600 mm, the horizontal distance b between the air curtain ventilation bricks (2) and the parapets (3) ranges from 200 mm to 700 mm, and the horizontal distance c between the parapets (3) and the blocking dams (4) ranges from 200 mm to 700 mm. By means of the method and device, the slag inclusion with the equivalent diameter larger than 50 microns in a continuous casting slab is basically removed, and the amount of micro slag inclusion with the equivalent diameter smaller than 50 microns in the continuous casting slab is reduced by more than 60 percent compared with the amount of the micro slag inclusion removed under the using condition that one tundish is internally provided with the turbulence controller, the parapets and the blocking dams and is reduced by more than 30 percent compared with the amount of the micro slag inclusion removed under the using condition that one tundish is internally provided with the turbulence controller and the air curtain ventilation bricks.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

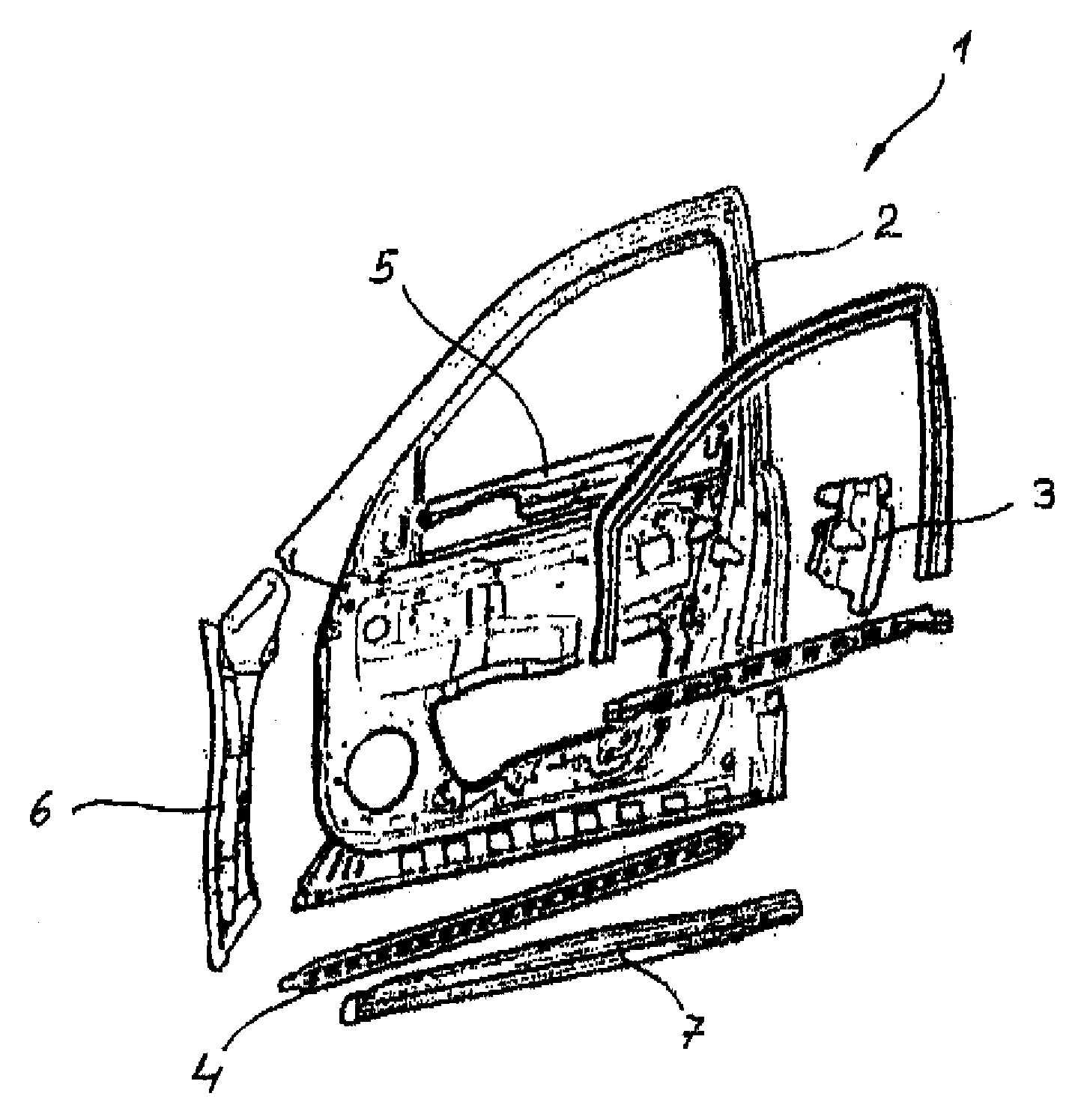

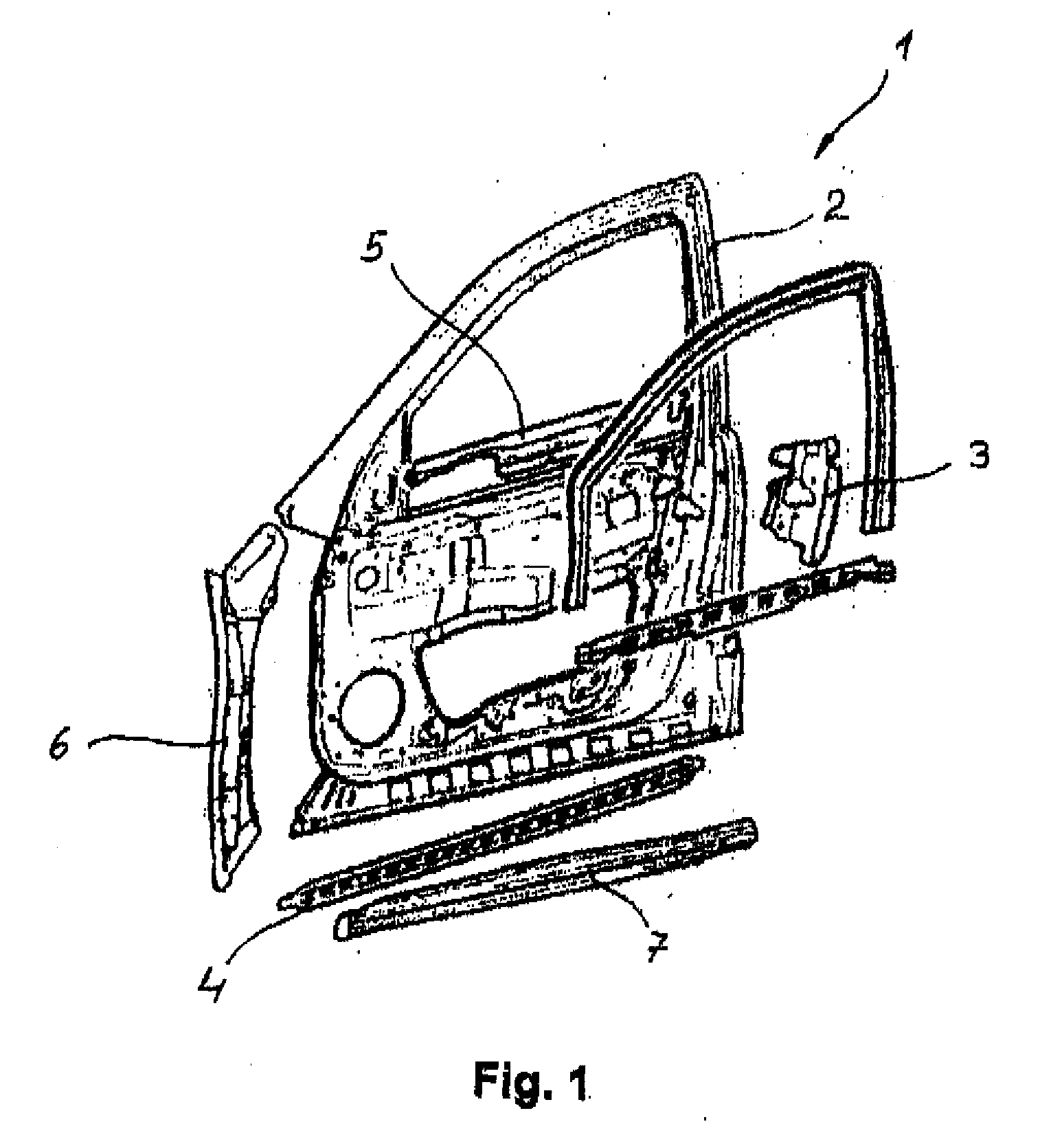

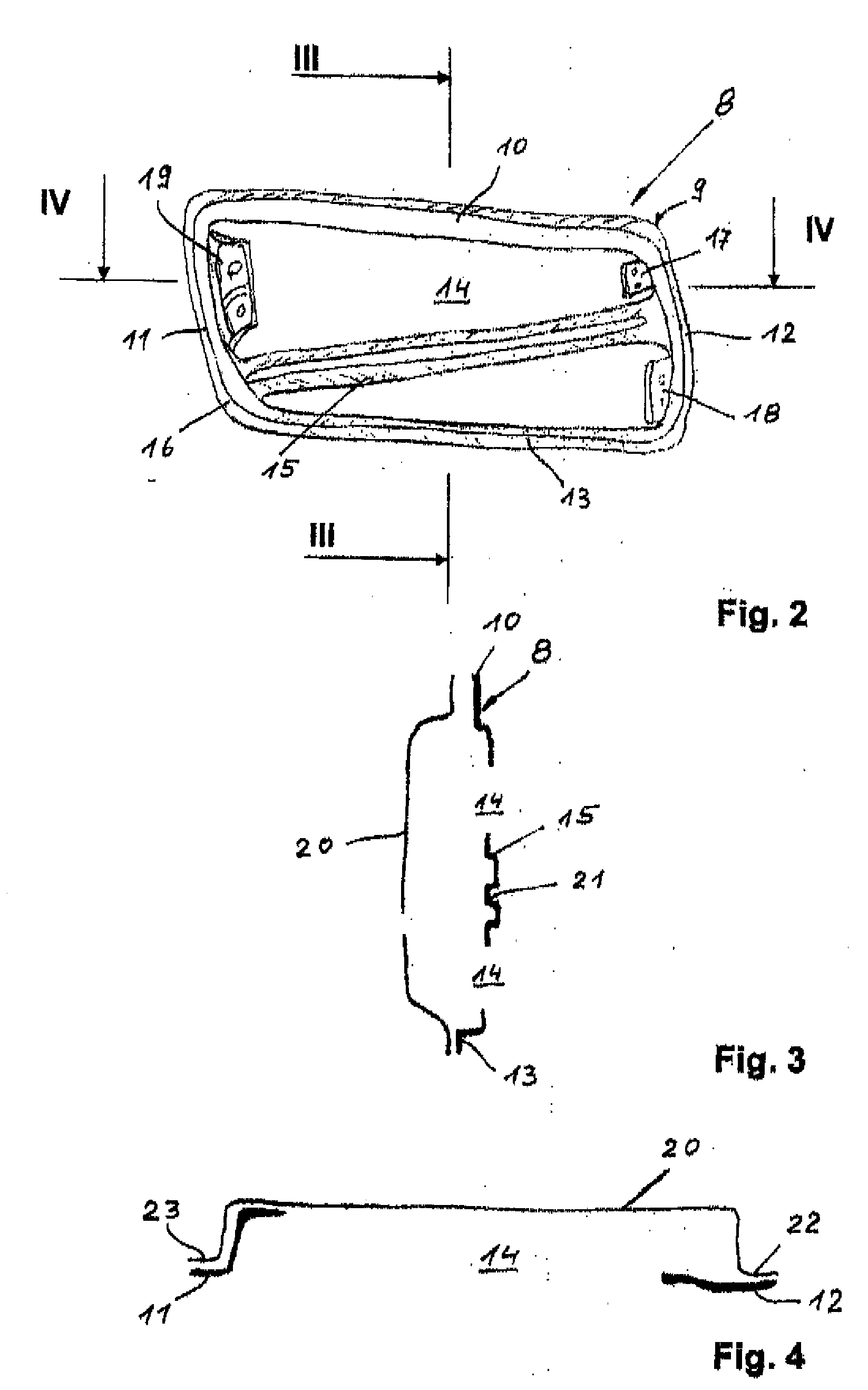

Door structure for a motor vehicle

InactiveUS20060290166A1Conserve costReduce component countMonocoque constructionsVehicle bodiesEngineeringHigh intensity

A door structure of a motor vehicle includes an inside door panel, and a single-piece reinforcement element which is disposed below a window parapet of the door structure and non-detachably secured to the inside door panel at a side distal to an outside door panel. The reinforcement element includes a wraparound frame having a top frame side extending along the window parapet, a bottom frame side extending along a lower edge of the door structure, a front frame side disposed in a hinge area between the top frame side and the bottom frame side, and a rear frame side disposed in a lock area between the top frame side and the bottom frame side, thereby defining an opening. Disposed in the opening and formed in one piece with the frame is an embossed door impact beam which extends from the front frame side to the rear frame side. The reinforcement element is made of high-strength hot formable steel defined by a tensile strength ranging from 1400 N / mm2 to 1600 N / mm2.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

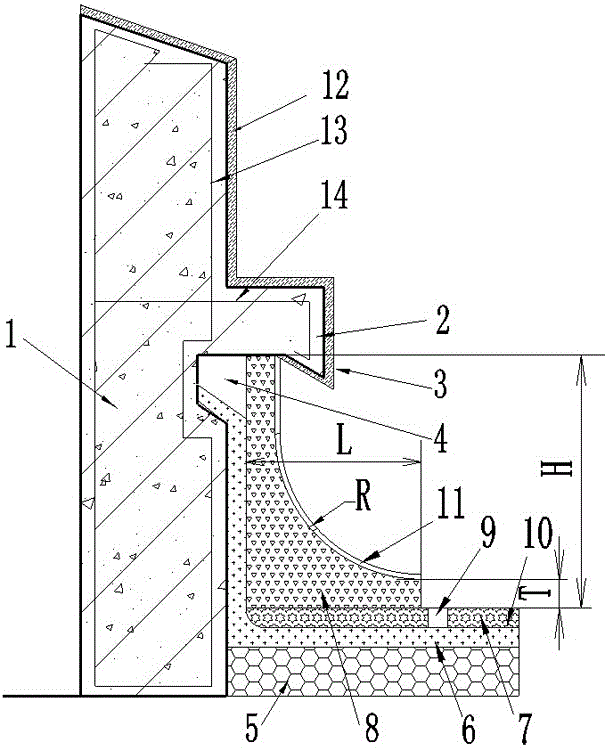

Roofing parapet water-floating structure and construction method thereof

Owner:HEBEI HENGSHAN CONSTR GRP CO LTD

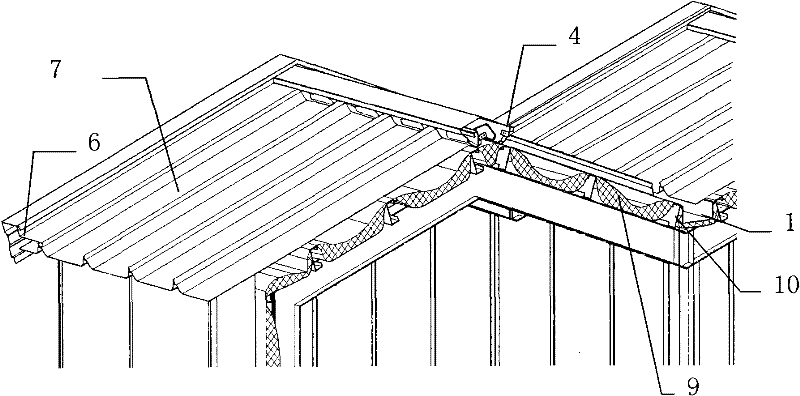

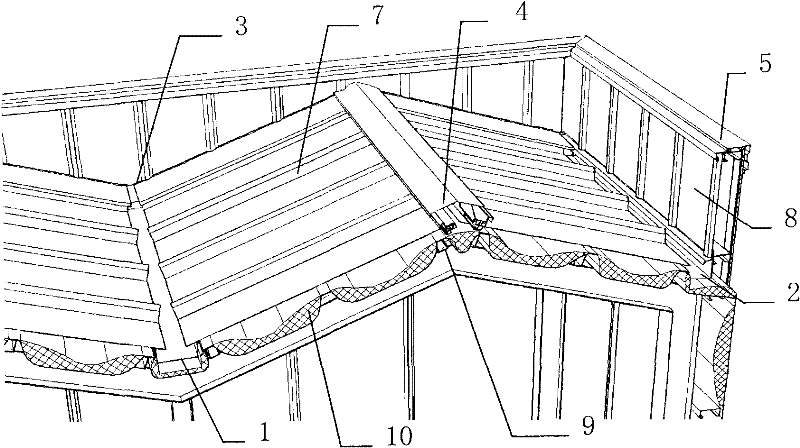

Overall rigid waterproof system of building

ActiveCN102251629ARigid waterproofOvercome the defects of aging water leakageRoof covering using slabs/sheetsRoof drainageWater leakageInsulation layer

The invention discloses an overall waterproof system of a rigid building. The overall waterproof system comprises a gutter waterproof unit, a parapet wall waterproof unit, a ridge waterproof unit, a gable edge waterproof unit, a roof panel, a wall panel, a roof purline, a heat insulation layer and the like. A gutter in the waterproof system is not directly connected with the roof purline, and the gutter has a slope, so that the problems of poor heat insulation performance, many cold bridges, water accumulation in the gutter and the like due to direct connection of the gutter and the gutter supporting beam in the prior art are thoroughly solved; through inner and outer flashing pieces, a flashing conversion piece, a ridge water blocking plate and the like in the waterproof system, the mode of spreading sealant and then performing direct connection through tensioned rivets is changed into indirect connection, so the problem of water leakage on the roof due to ageing of daub is thoroughly solved, and the waterproof performance of a light steel colored plate building is greatly improved; and because of a sliding bracket, a building main body and accessories are connected tightly and firmly and can slide relatively, and the service life of the gutter is greatly prolonged.

Owner:中安祥和(天津)建筑工程有限公司

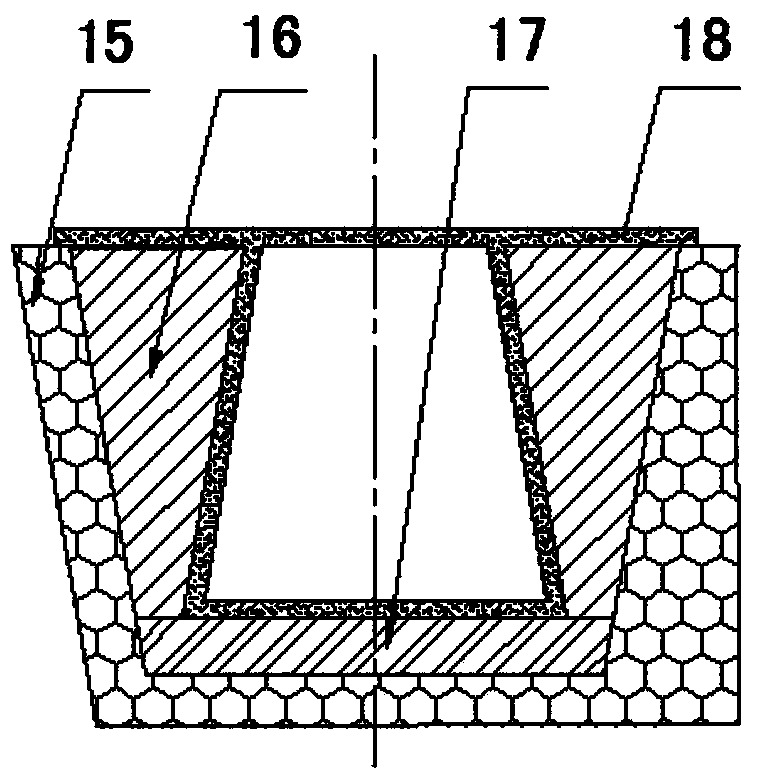

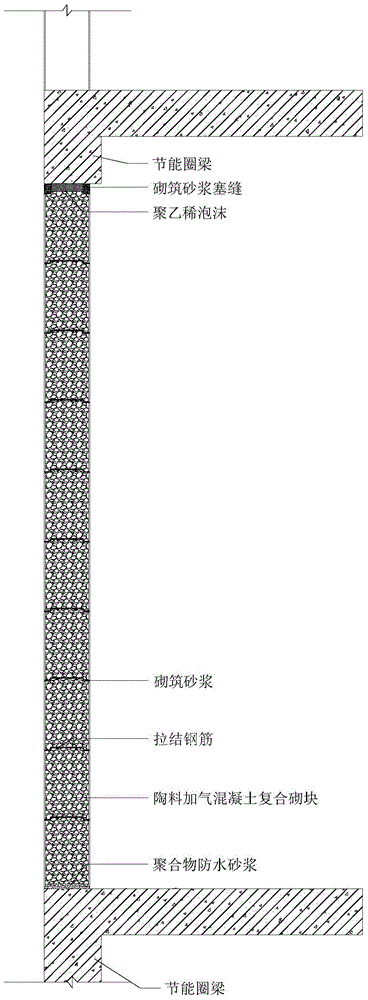

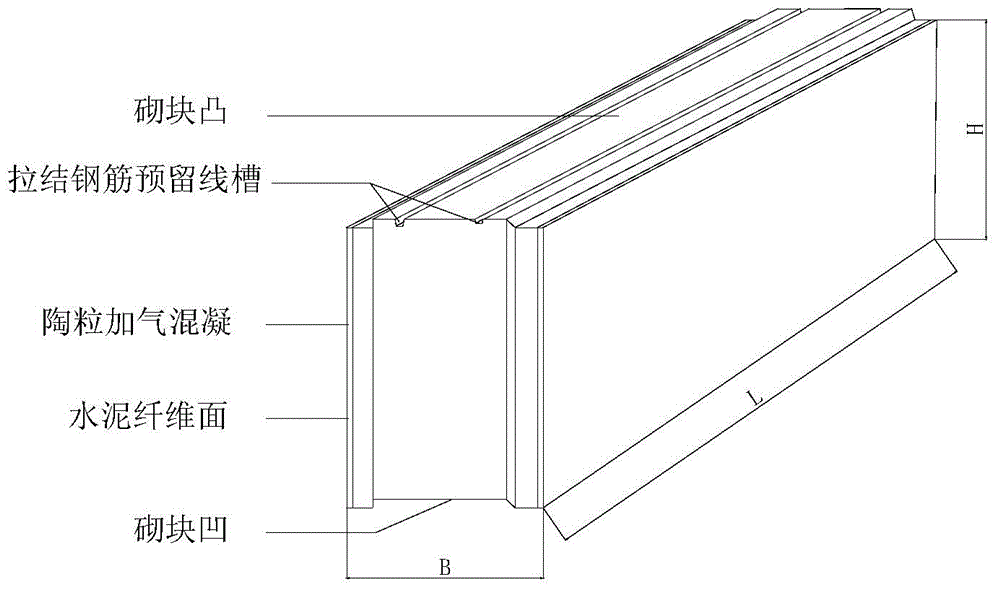

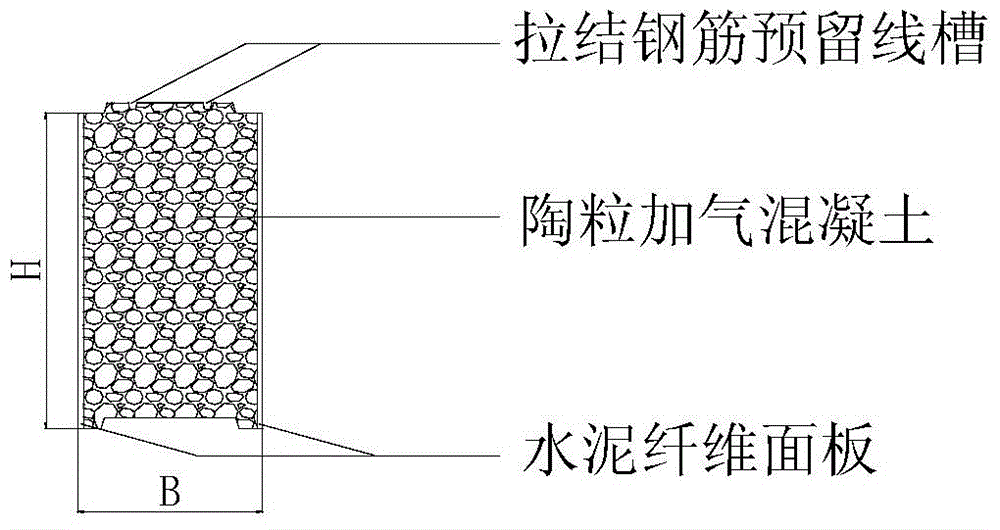

Building brickwork and masonry construction method of building brickwork

InactiveCN104358341AMeet the requirements of self-insulation systemSolve common quality problemsConstruction materialWallsMaterials scienceConcrete composites

The invention discloses a building brickwork and a masonry construction method of the building brickwork, and relates to a building brickwork of a building. The building brickwork is a brickwork which is built by light-weight aggregate concrete composite blocks; grooves and tongues are formed in the periphery of each light-weight aggregate concrete composite block; the light-weight aggregate concrete composite blocks are respectively 600-1200mm in length, 300-600mm in height and 80-200mm in thickness; the grooves are downward and the tongues are upward in field masonry; and the masonry construction method comprises the following steps: (1) building the brickwork by the blocks, namely building the first block on a foundation or floor ground, building the second composite block in a manner of being staggered with the first block, wherein the staggered-joint is 1 / 2 of the length of the block and is not smaller than 200mm at least; the composite block brickwork is connected with a building structure column and a concrete shear wall; the composite block brickwork is connected with building structure beams and plates; the building brickwork is subjected to deformation joint construction; a parapet wall is subjected to masonry construction; a switch socket is pre-buried and installed; and cable pipelines are laid; (2) fixing door frames and window frames; and (3) building a wall body corner structure by the light-weight aggregate concrete composite blocks.

Owner:FUJIAN MEIJINLAI GREEN BUILDING TECH +1

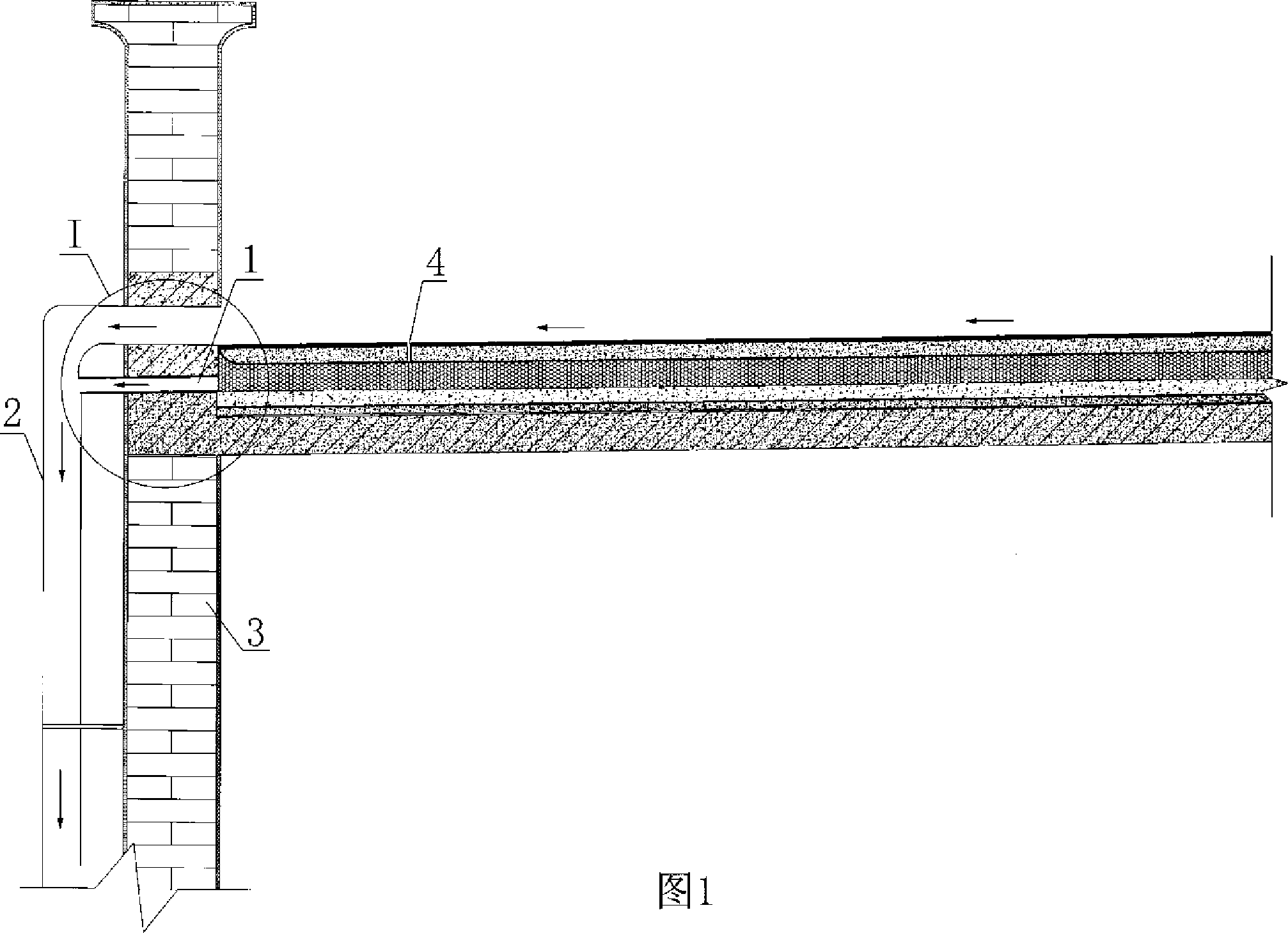

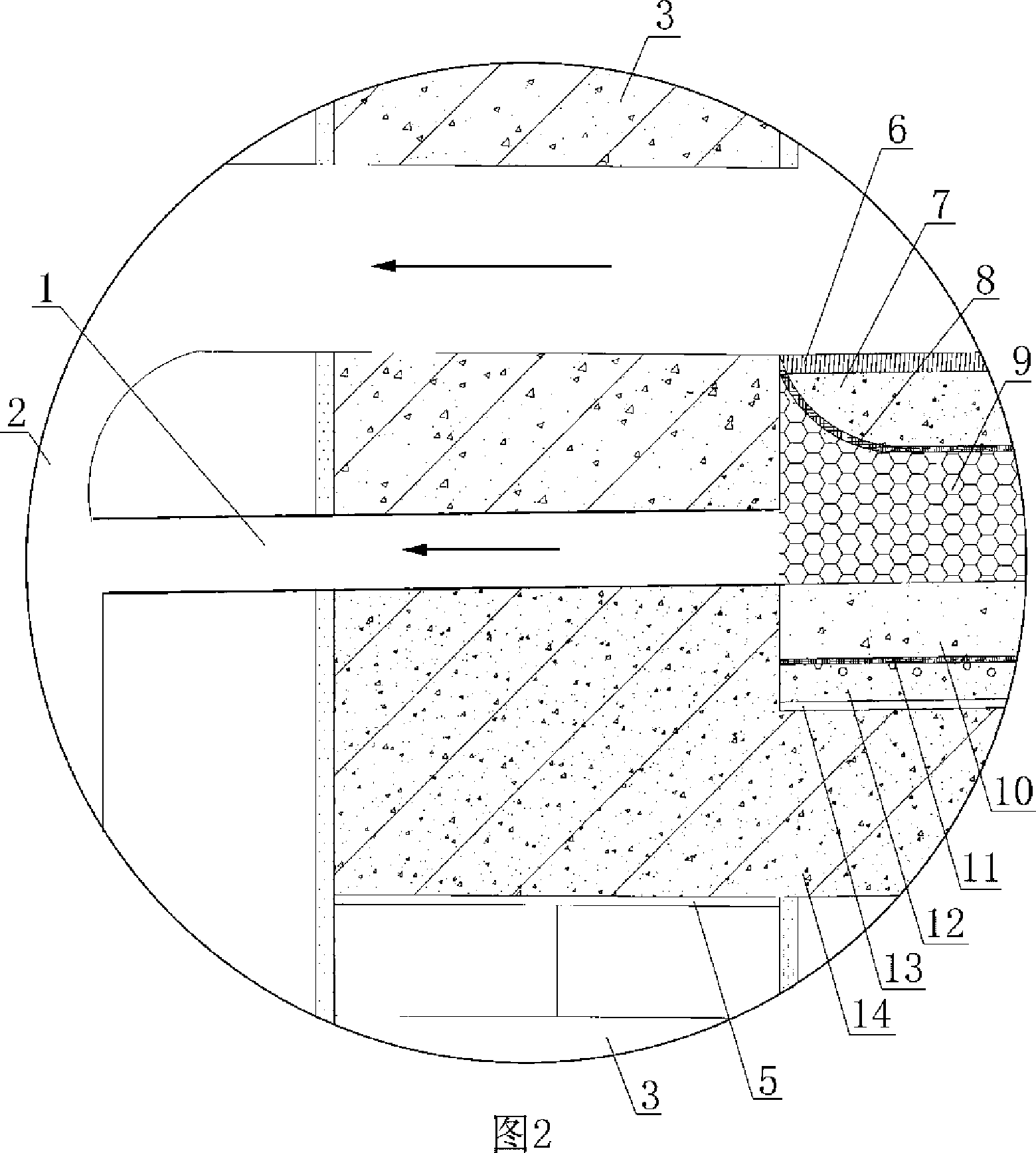

Thermal insulation waterproof roof covering gas-guiding drainage system and construction method thereof

InactiveCN101148932ASimple and fast constructionEasy to useBuild-up roofsRoof drainageReinforced concreteThermal insulation

The present invention is air leading and water draining system for heat insulating waterproof roof and its construction process. The air leading and water draining system includes a reinforced concrete roof slab layer, a plain cement slurry layer, a first leveling cement mortar layer, an elastic waterproof layer, a second leveling cement mortar layer, a heat insulating layer, a rigid waterproof layer, a fine stone concrete layer, a veneer layer, and transverse parapet connected to the lower rain water pipe successively arranged from bottom to top. It features the inclined air leading and water draining pipe passing through the parapet and communicated to the rain water pipe, and no vertical ventilating pipe. The present invention makes it possible for water permeating to the heat insulating layer to flow easily into the rain water pipe so as to avoid leakage.

Owner:CHINA CONSTR FOURTH ENG DIV +1

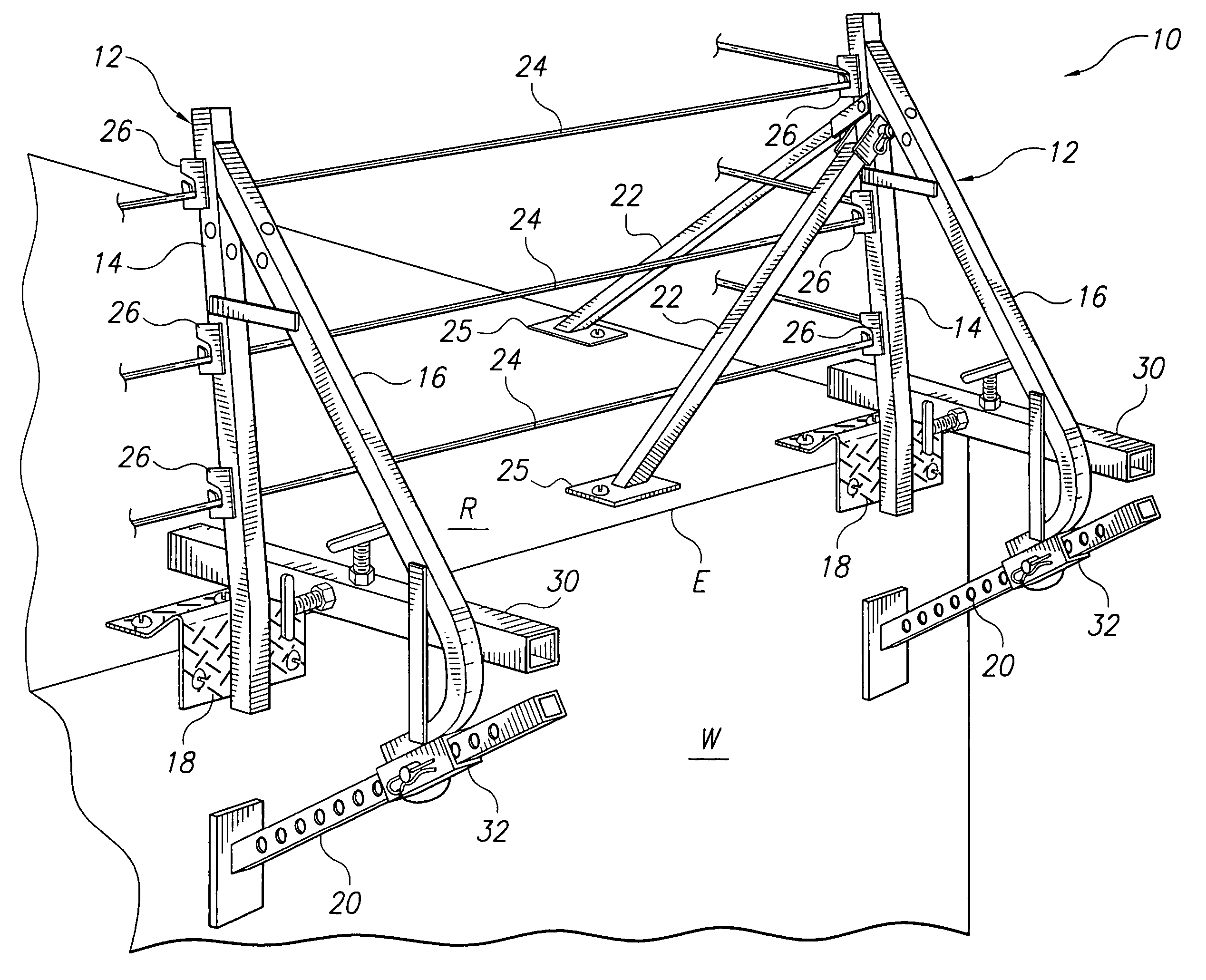

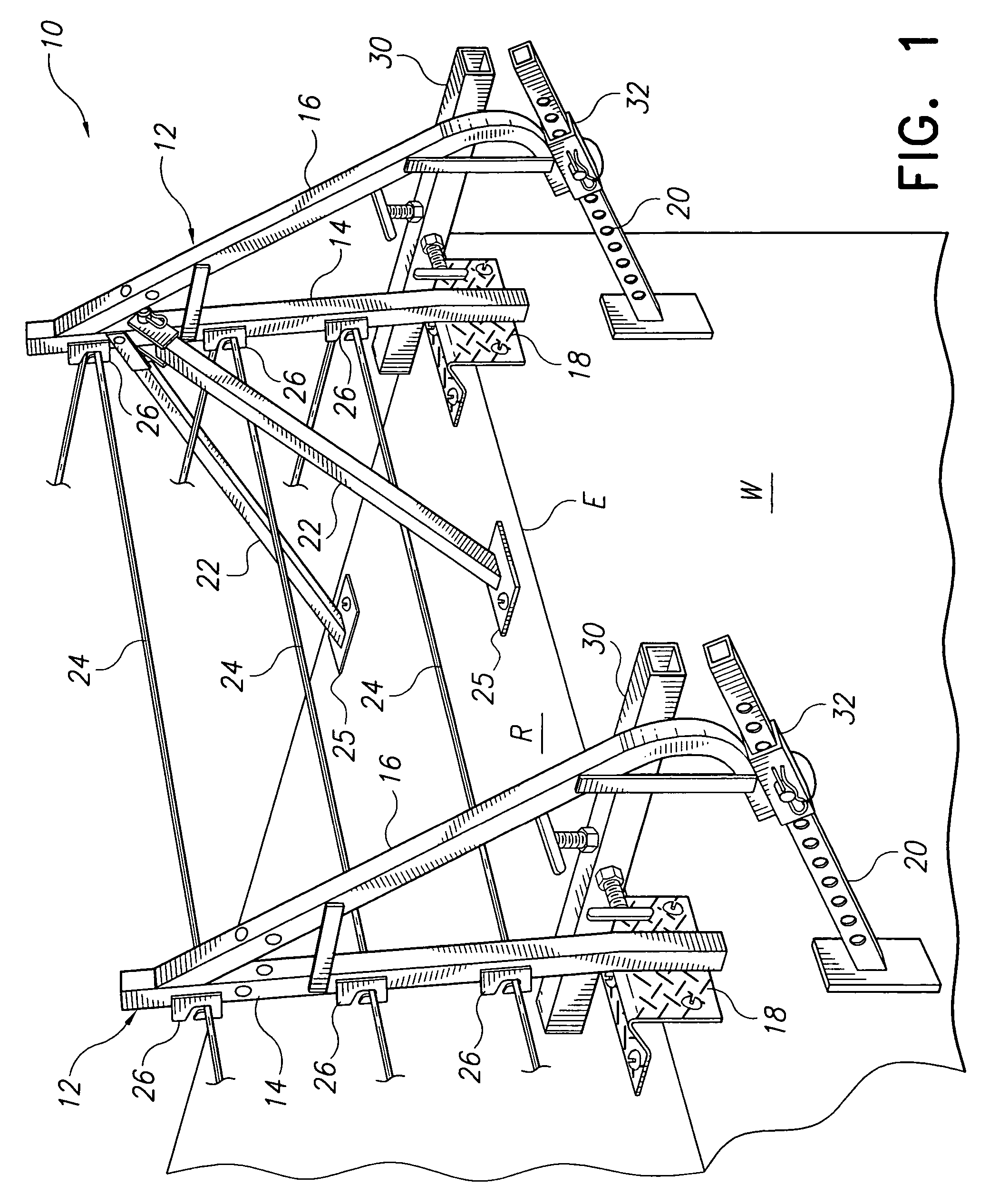

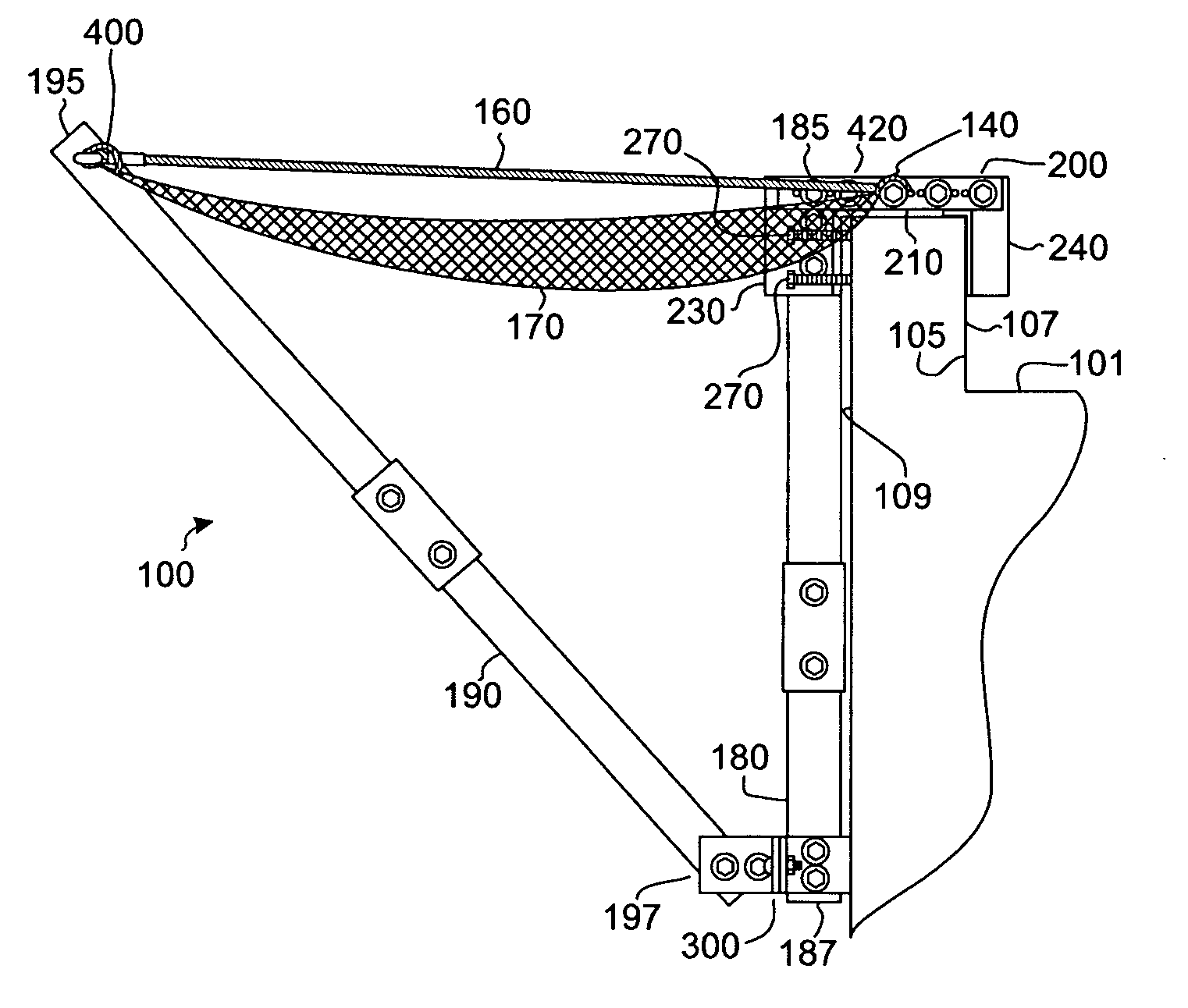

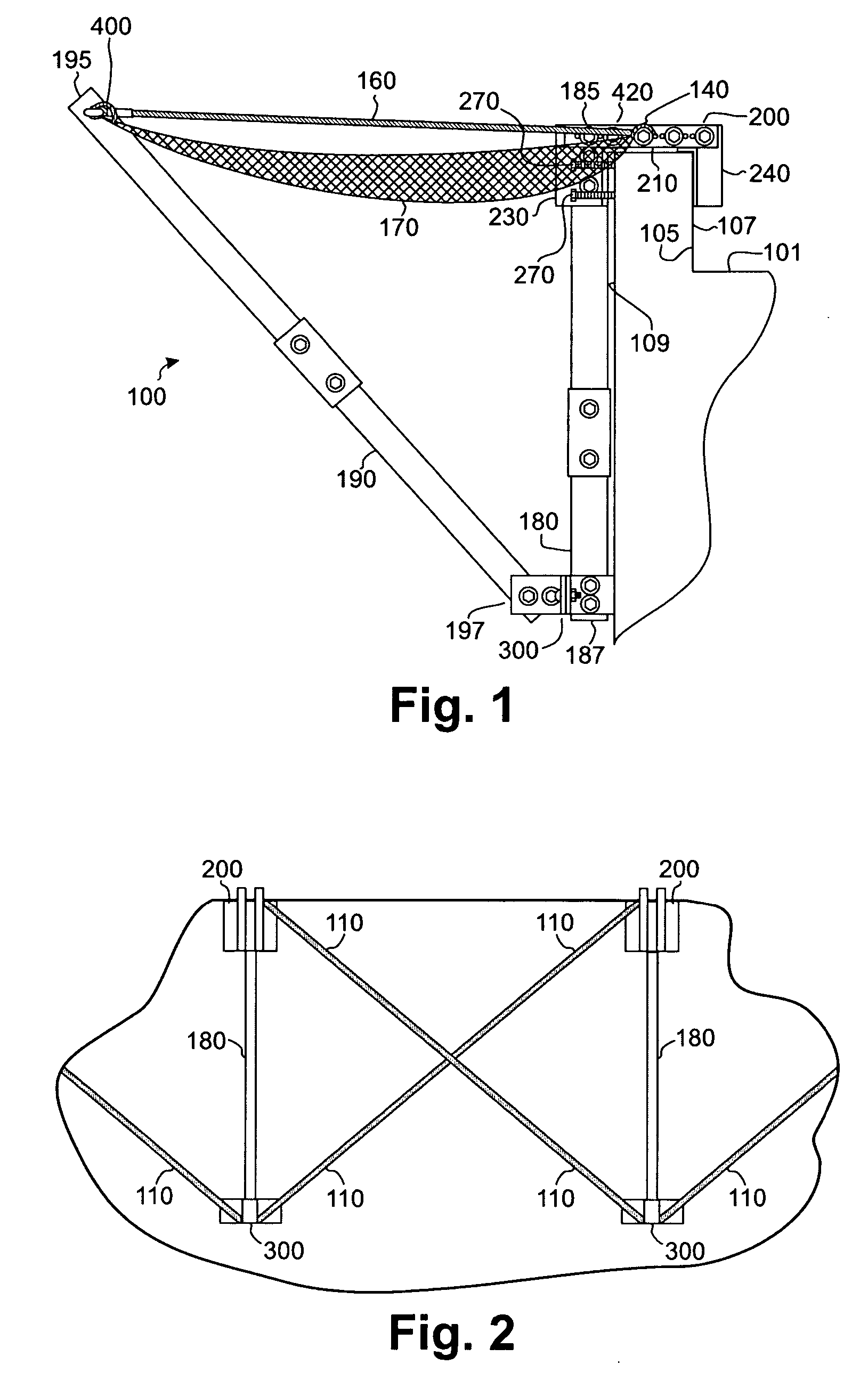

Roof edge fall protection apparatus

InactiveUS20060180390A1Easy to disassembleFencingBuilding material handlingFall protectionEngineering

The present invention relates to roof edge fall protection devices typically installed at or near such parapet walls. The apparatus of the present invention comprises several components that can be easily assembled and disassembled on site and which are adaptable to various building geometries. The apparatus comprises at least two support members, each comprised of a roof mounting portion including a first base plate member that is securely mountable on the roof of the building structure and a second base plate member that is securely and removably mountable on the wall of the building structure. A side edge portion of the first base plate member is positioned substantially adjacent to the wall. A top edge portion of the second base plate member securely and removably engages the side edge portion of the roof base plate member. A barrier mounting portion including a substantially upright post member securely engages the roof mounting portion, and a barrier holding member securely engages the post member. An elongate safety barrier member securely and removably engages each barrier holding member, with the safety barrier member securely extending between at least two support members.

Owner:THALER KEN

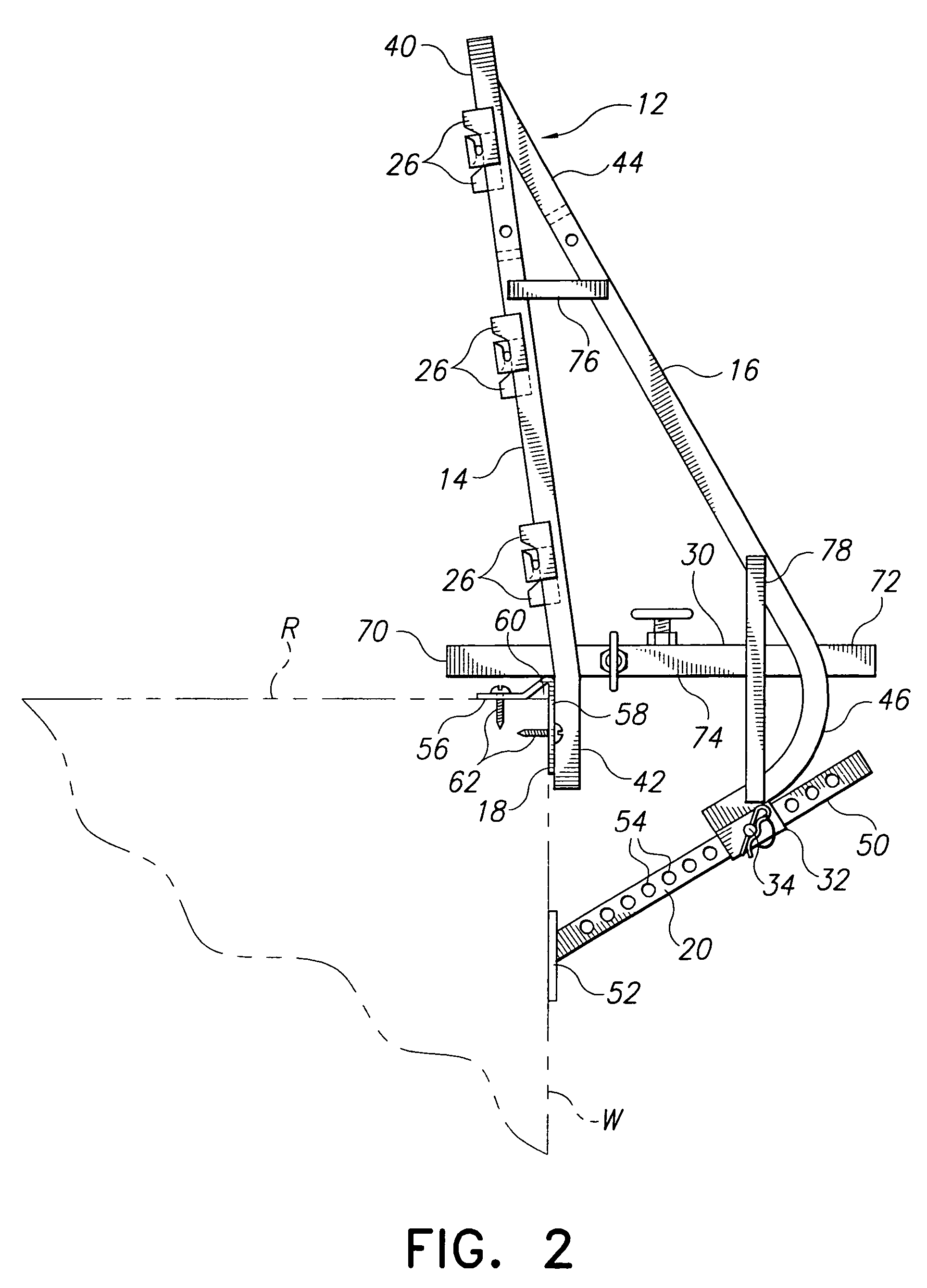

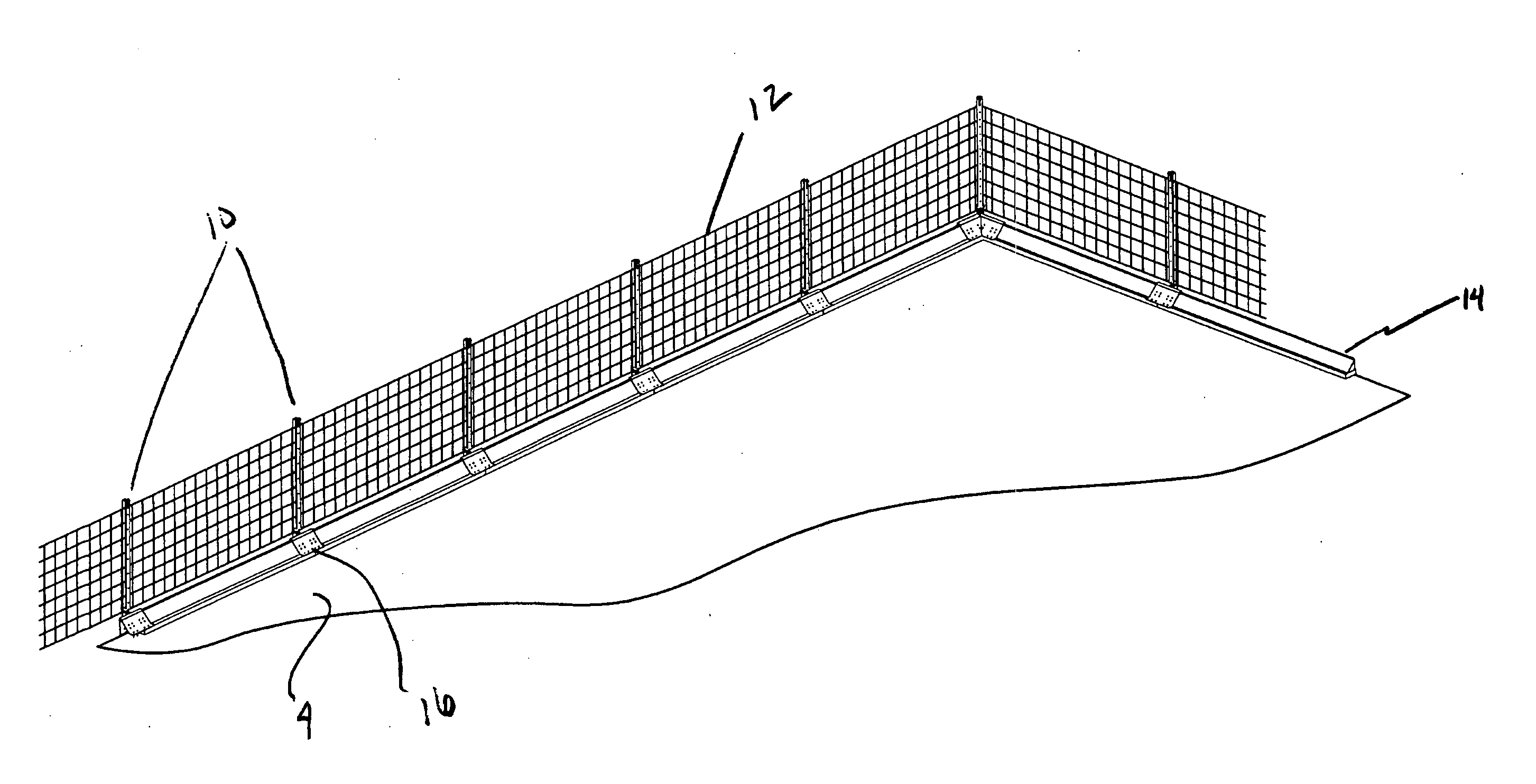

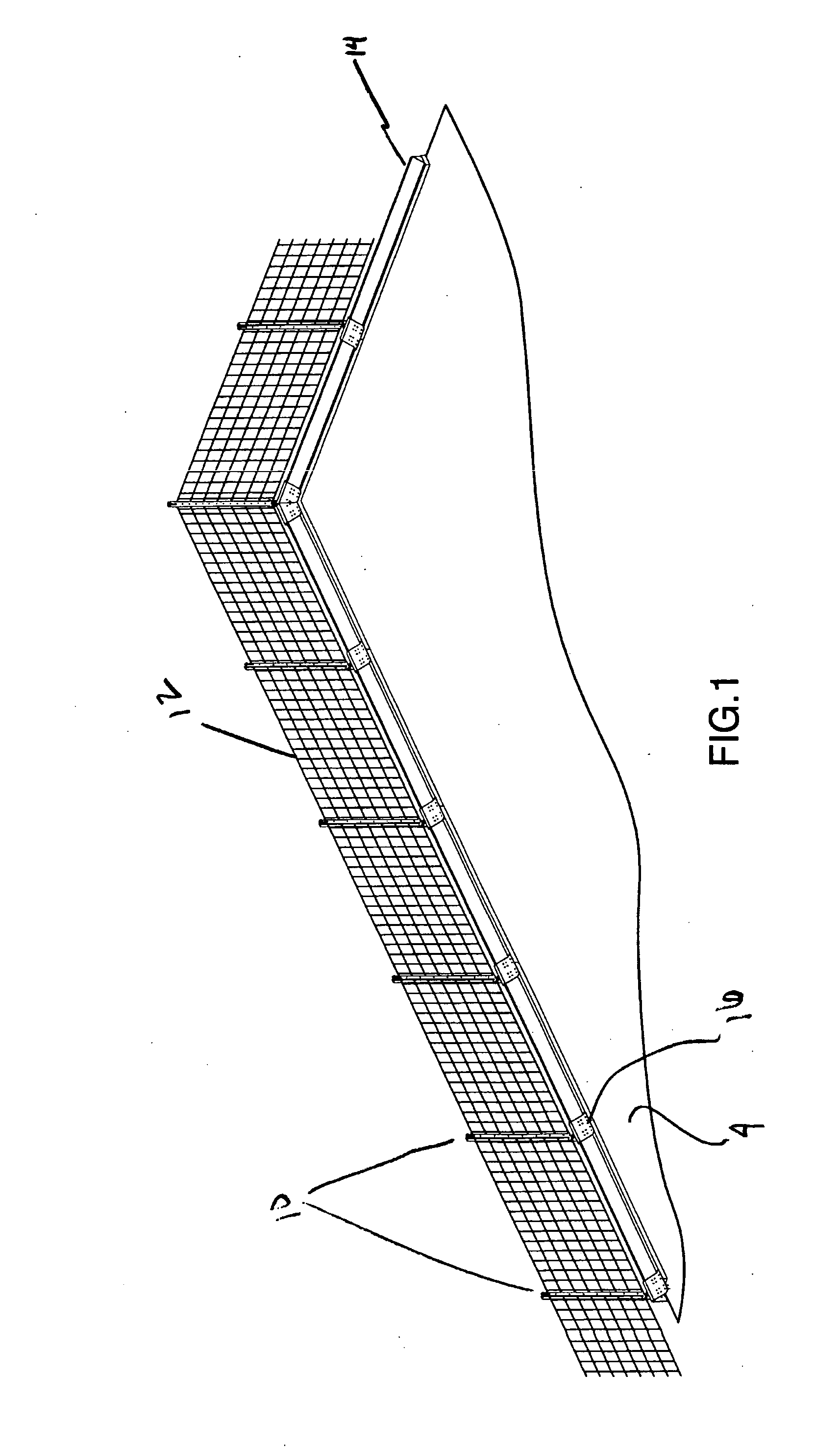

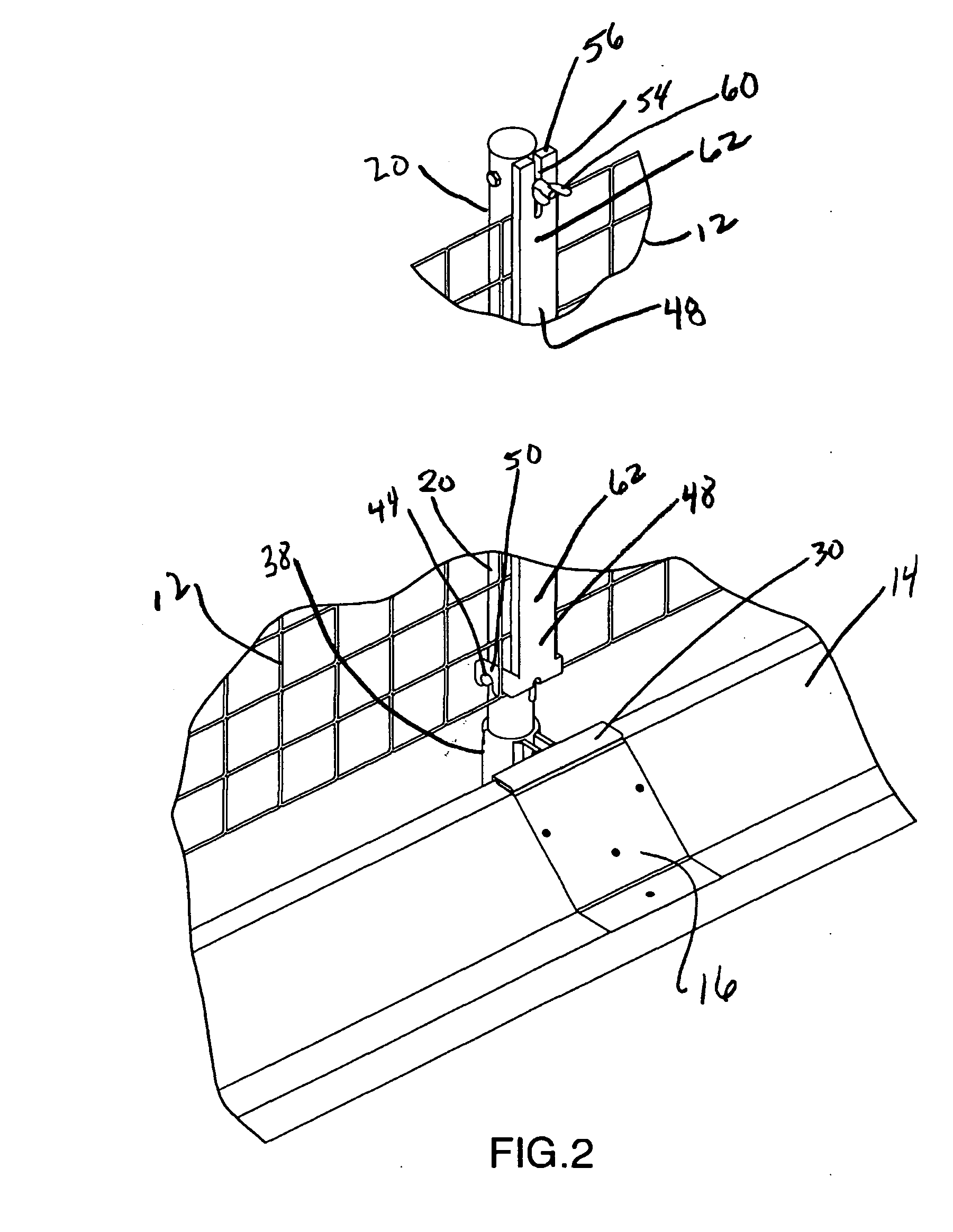

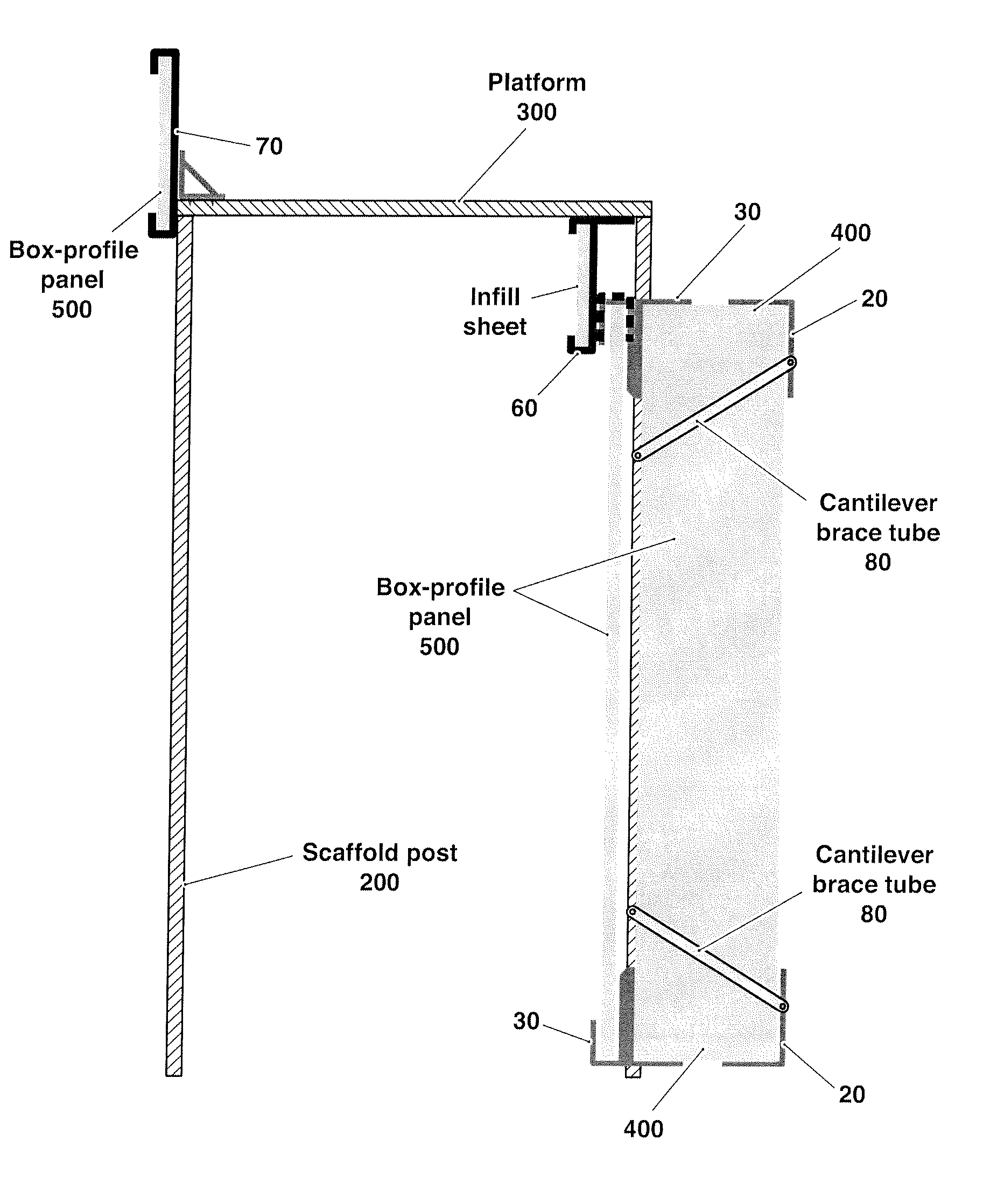

Parapet mounted net system

InactiveUS20060151243A1Quickly and easily securesEasy to installBuilding rescueEngineeringCantilever

Described is a net system that protects crew members working on high-rise buildings. The net system easily and quickly attaches to the outside of a building perimeter. The net system includes a parapet clamp, a vertical support arm, a mounting bracket, a cantilever arm, and a debris net. The parapet clamp is adjustable and also supports the debris net and vertical support arm. The vertical support arm extends down from the parapet clamp and attaches to the mounting bracket at its lower end. The lower end of the cantilever arm also attaches to the mounting bracket via a pivot pin which allows the cantilever arm to rotate. The debris net is suspended between the upper end of the cantilever arm and the parapet clamp. Among other things, the net system allows crew members to work on high-rise buildings without the risk of being injured by a fall or dropped objects.

Owner:REXROAD JOHN

Turbine rotor blades with improved tip portion cooling holes

A turbine rotor blade is provided for a turbine section of an engine. The turbine rotor blade includes a platform and an airfoil extending from the platform into a mainstream gas path of the turbine section. The airfoil includes a first side wall; a second side wall joined to the first side wall at a leading edge and a trailing edge; a tip cap extending between the first side wall and the second side wall; a first parapet wall extending from the first side wall; and a first cooling hole through the tip cap and the first parapet wall configured to deliver cooling air. The first cooling hole has a closed channel section and an open channel section. The open channel section forms a slot.

Owner:HONEYWELL INT INC

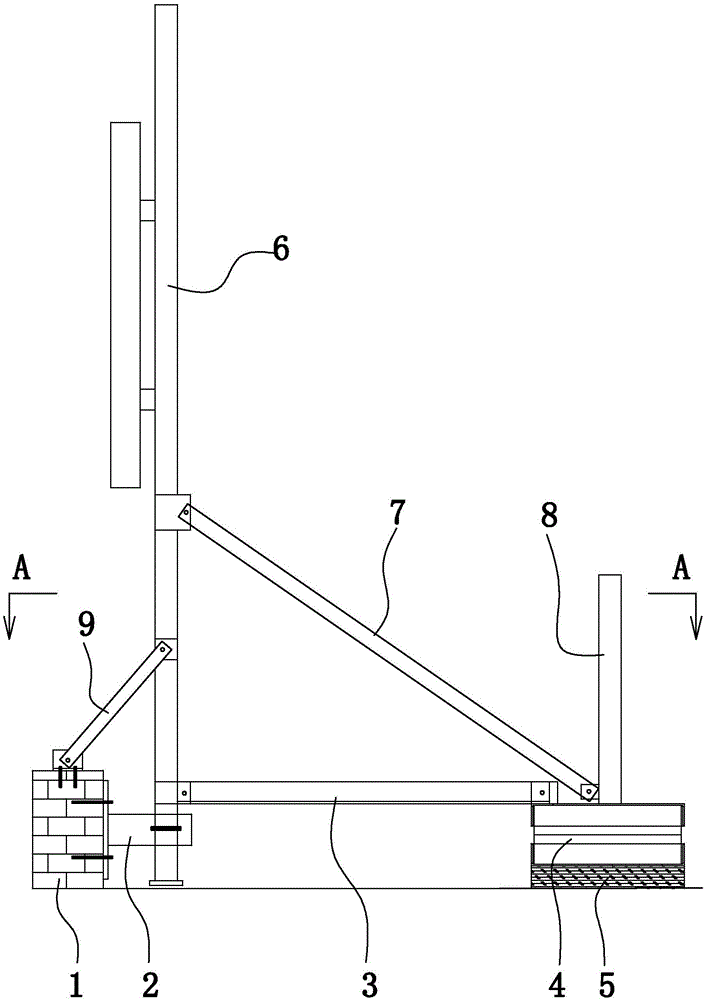

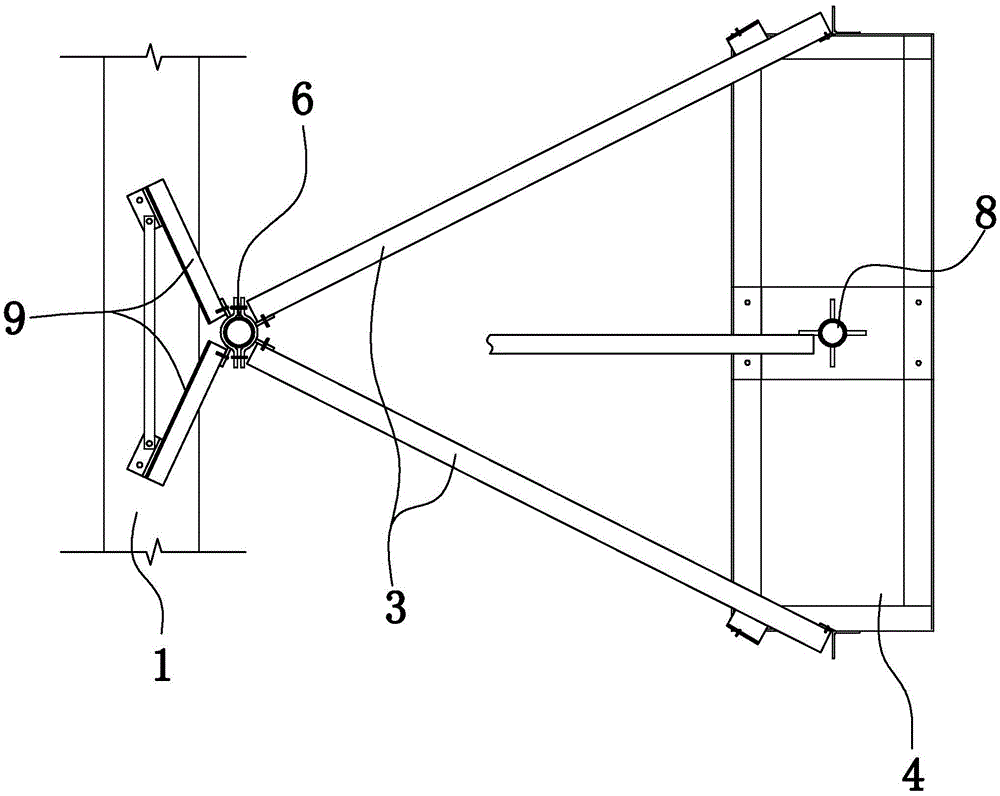

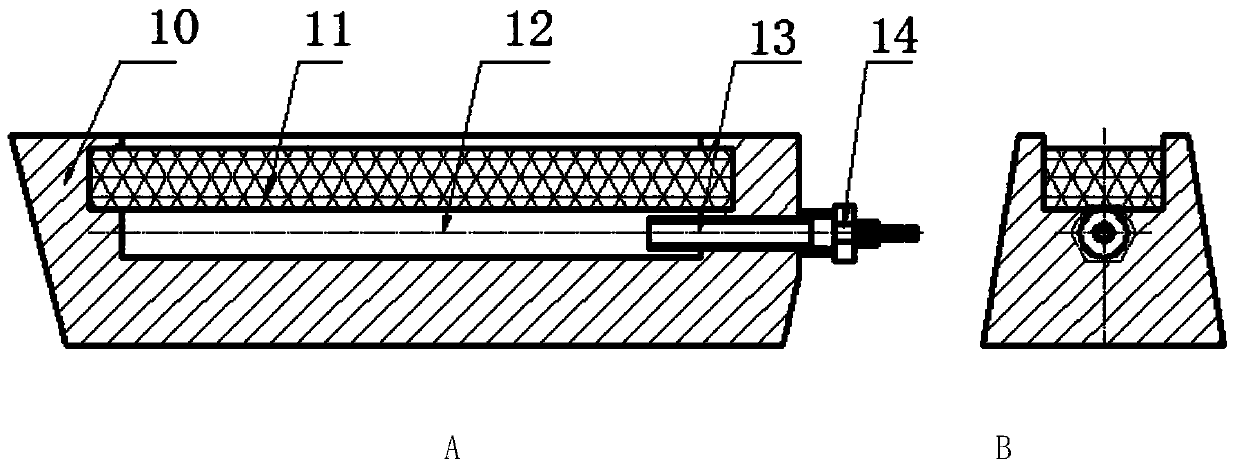

Single-rail window wiping machine

InactiveCN102987991ACompact structureFlexible steeringCarpet cleanersFloor cleanersWinchIndustrial engineering

The invention relates to a single-rail window wiping machine, which comprises an upright post and is characterized in that the upper part of the upright post is rotationally connected with a cross arm, a winch is arranged at one end of the cross arm, and the other end of the cross arm is rotationally connected with a rotary seat; the rotary seat is fixed with one end of a dovetail arm, a first pulley is arranged at the other end of the dovetail arm, a steel wire rope is arranged on the winch, the steel wire rope sequentially goes round the first pulley, and the end of the steel wire rope is connected with a gondola; a travelling mechanism is fixed at the bottom of the upright post, an anti-toppling mechanism is arranged on the side of the upright post, the travelling mechanism is arranged on a travelling track mechanism, and the anti-toppling mechanism is arranged on an anti-toppling track mechanism; and the travelling track mechanism is fixed on the ground inside a parapet wall, and the anti-toppling track mechanism is fixed on the wall inside the parapet wall. The window wiping machine can realize single-rail travelling and smoothly reach the required position under the condition that a roof passage is narrow.

Owner:博宇(无锡)科技有限公司

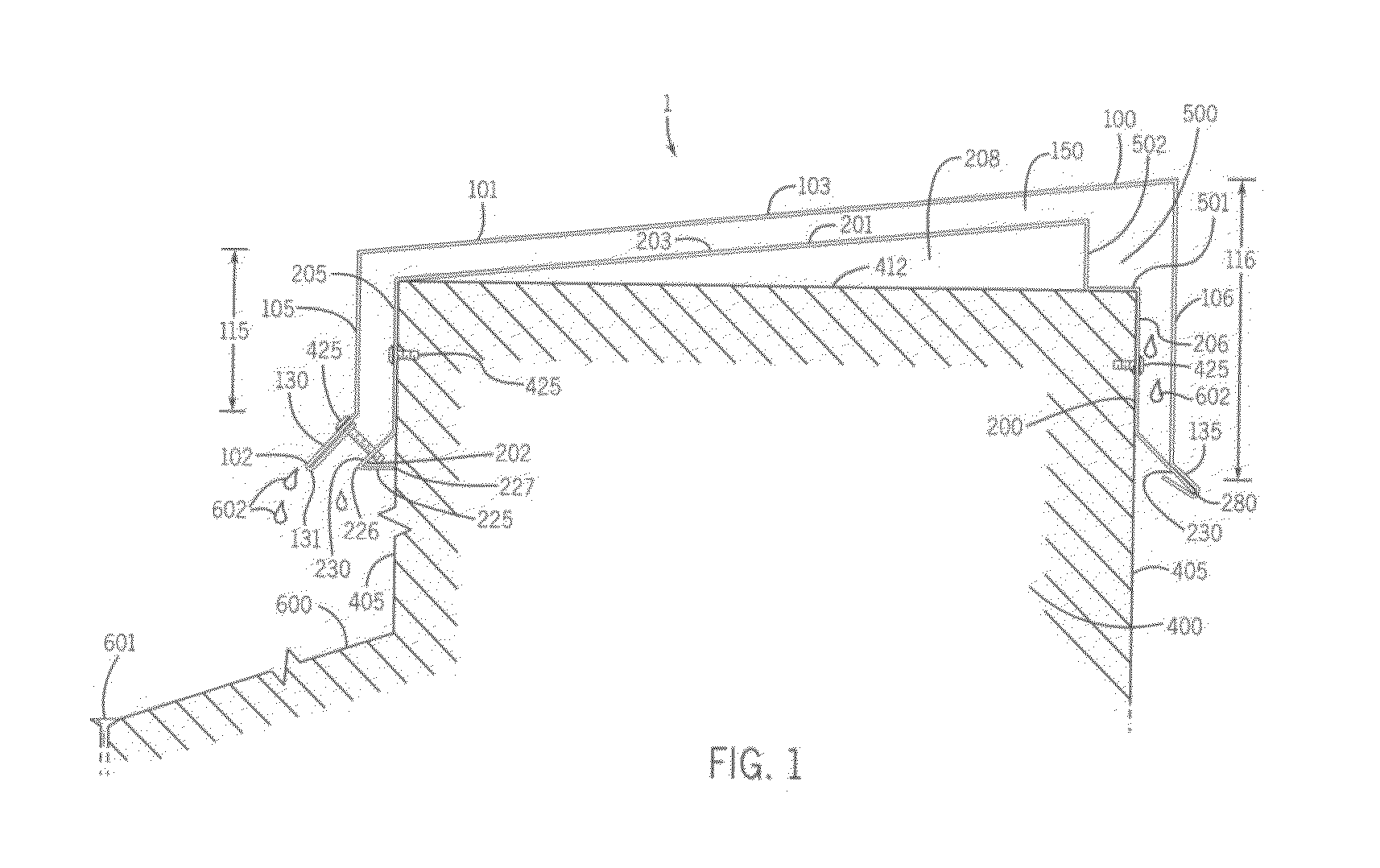

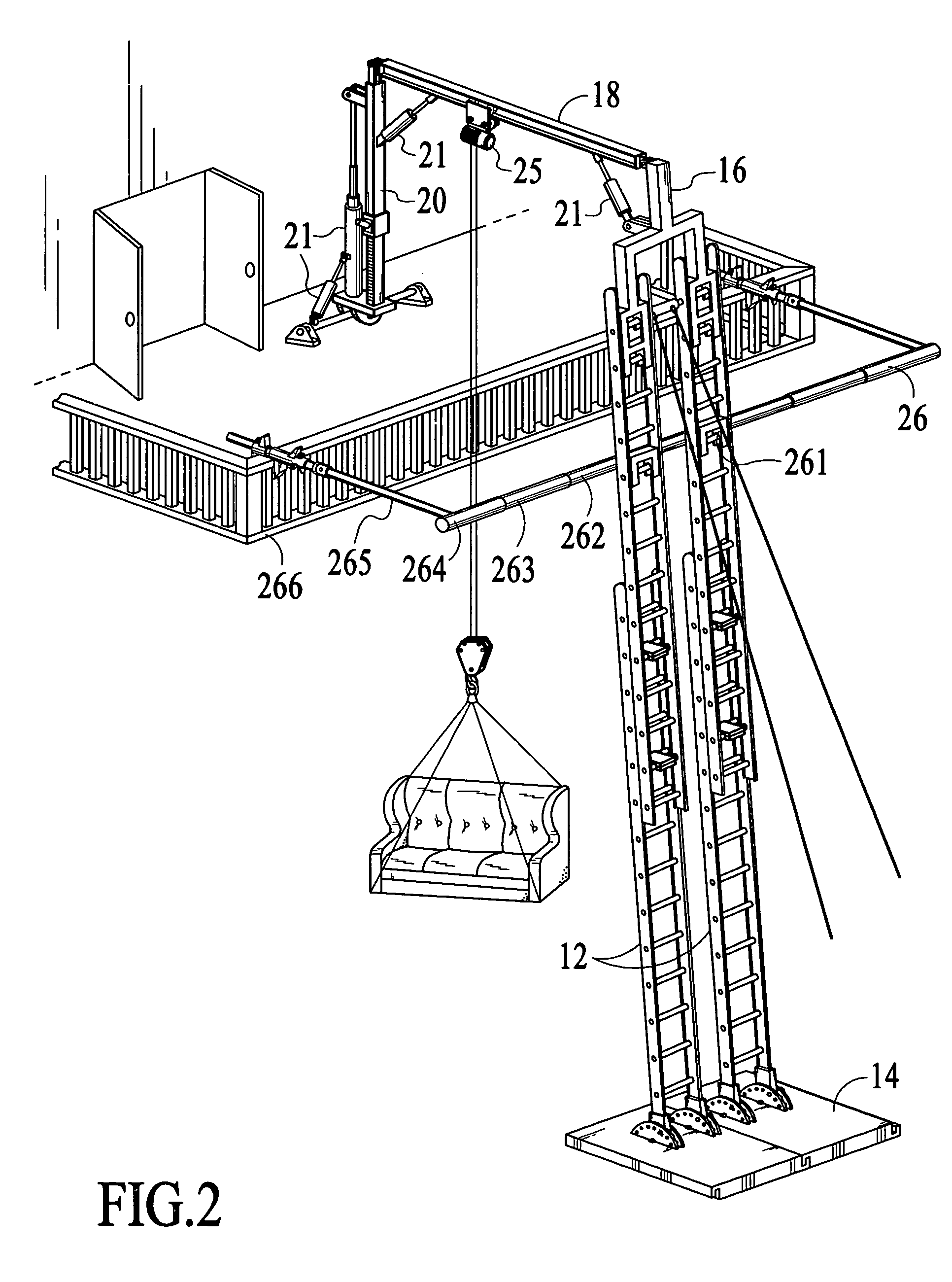

Parapet vent

InactiveUS8561367B2Remove moistureAccurate removalRoof covering using slabs/sheetsBuilding roofsBrickWater vapor

A water vapor release and moisture seal device for use in association with brick, wood, stone, and cement or concrete masonry unit (CMU) buildings is provided. The device has a first layer metal housing and second layer metal housing which are inserted over the top of the parapet walls of a flat or slightly slanted-roofed building. A water resistant cloth and mesh material layer is inserted between the metal housings. A fastener secures the second layer metal housing to parapet wall of the building in two places, once each on the exterior and interior of the parapet wall. The housings interlock with each other on the exterior side of the wall and with a fastener on the interior side of the wall. The device is secured to the top of a wall of a building and allows the wall to breathe properly and eliminate moisture.

Owner:WICKRIGHT

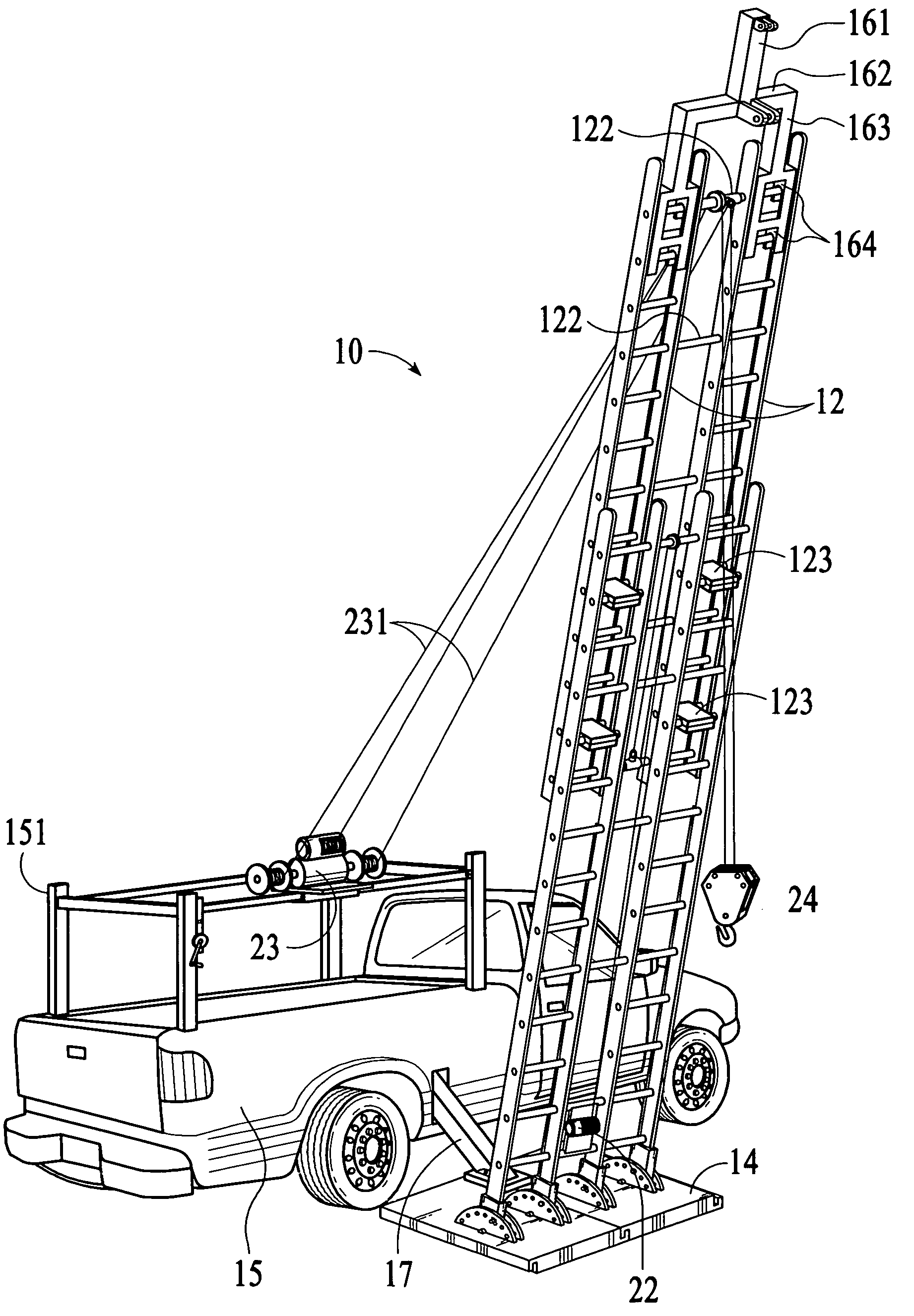

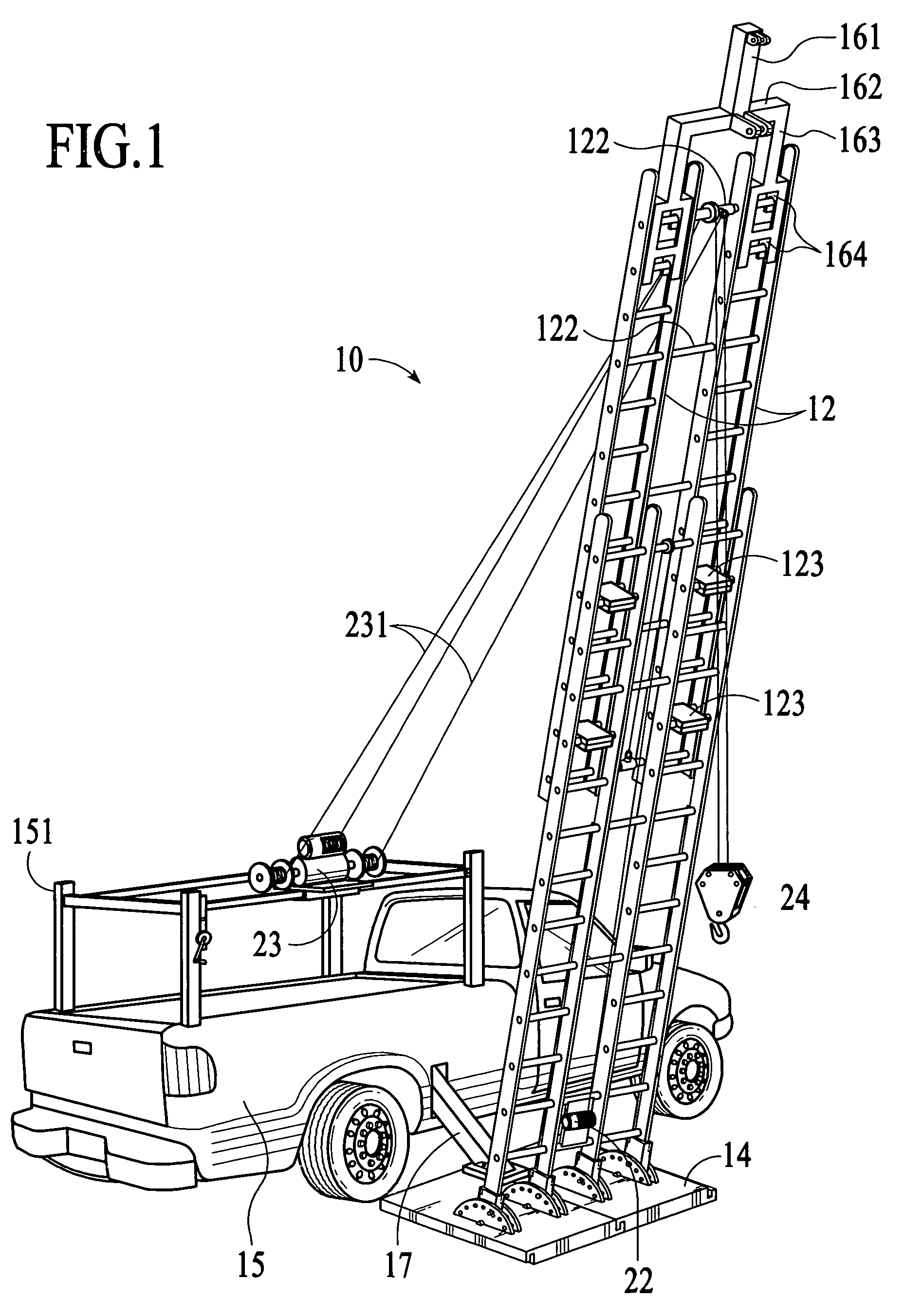

Ladder elevator device

An elevator device that is installed on one or more ladders to lift loads from the ground to a desired position on a roof. A base securing device can be added to each of the ladders to insure stability. An outrigger mounted on a user's truck can be employed to further stabilize the ladders. The elevator device includes a ladder attachment assembly to affix the device to a ladder or ladders, a lateral travel section, and a roof top mounting device. A ladder stabilization bracket that affixes the ladder to a parapet or balcony can be employed for additional stability of the device. Several winch mechanisms are utilized to position the device and raise loads. The device can be easily adapted for use on flat roofs with a parapet through the addition of a ladder stabilization bracket. The elevator device can also readily be used on flat roofs without parapets, pitched roofs, and even to load trucks.

Owner:HATCH BARLOW

Bridge construction system and method

InactiveUS7461427B2Expanded span capabilityOvercome problemsBridge structural detailsBridge erection/assemblyBogiePre stress

A system and method for construction of bridges and elevated roadways with pre-stressed concrete or steel bridge girders is provided including cast-in-place concrete deck slabs and partial and full depth pre-stressed pre-cast concrete deck slabs with post-tensioning conduits for post-tensioning a series of deck slabs. A plurality of bogies traveling on the lower flanges of the bridge girders are provided to place and level the deck slabs and to pre-load the bridge girders to eliminate camber before placement of the deck slabs on the bridge girders or to level, place, support and remove deck forms for a cast-in-place deck slab on the bridge girders. Also provided is a system for attachment of cast-in-place parapets.

Owner:RAPID PRECAST CONSTR SYST

Construction method for heat-insulation waterproofing system of roof comprising foam glass plates

InactiveCN103206085AEasy constructionGood effectRoof covering insulationsBuilding material handlingWork in processCement mortar

The invention discloses a construction method for a heat-insulation waterproofing system of a roof comprising foam glass plates. The construction method includes treating a base course of a roof plate; laying the foam glass plates; constructing a cement perlite slope making course; constructing a cement mortar leveling course; constructing waterproofing courses; constructing a fine aggregate concrete protection course; and performing skirting treatment for a parapet wall of the roof. The construction method has the advantages that the heat-insulation waterproofing system is convenient to construct and good in effect; characteristics of high strength, light weight, low heat conductivity coefficient, non-absorbency and constant performance of foam glass plate materials are sufficiently utilized, and the foam glass plates cling to a structural layer of the roof, so that a heat-insulation function is realized for the roof; and the blocky semi-finished foam glass plates can be constructed and operated easily and conveniently and are high in labor efficiency, and extra construction investment is omitted during construction for the foam glass plates.

Owner:成军

Sidewalk sheds

The present invention provides a sidewalk shed system for use with a scaffold which includes a plurality of vertical posts and a horizontal platform, the temporary fencing system comprising at least two channels, at least one channel-post coupler for coupling a first channel to a lower part of the plurality of vertical posts forming a first lower channel, at least one channel-platform coupler for coupling a second channel to the horizontal platform forming a second lower channel, at least two quadrangular panels, wherein a lower edge of a first panel is to be inserted into the first lower channel, thereby forming a fence adjacent to the plurality of vertical posts, and a lower edge of a second panel is to be inserted into the second lower channel, thereby forming a parapet perpendicular to the horizontal platform.

Owner:BOWMAN MARK

Collapsible container

A collapsible container that in the assembled configuration provides for a predetermined central space protected by six walls that are perpendicularly mounted with respect to each abutting wall and in the e collapsed configuration occupies minimum space. A bottom wall is provided with a predetermined umber of hinge knuckles with a central through opening through which pins are passed. Parapets of different heights are provided to raise the knuckles to predetermined heights that will clear the stacked up thickness of the folded walls. The height of the front, rear and the two side lateral walls is determined by the width of the bottom wall which in turn will also determine the width and height of the front and rear walls. A handle is removably mounted to the top wall, protruding toward the exterior.

Owner:HIDALGO VARGAS EDGAR

Roof flashing

InactiveUS20100180517A1Prevent moisturePrevent moisture from destroying the interfaceRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringFlange

A flashing assembly for reinforcing an interface defined between a roof and a portion of a building wall, either a flat roof or a flat roof with parapet wall. The flashing assembly has a first member configured for securing along the interface between the roof and the building wall and a second member for covering an upper part of the first member. The first member has an inner vertical part adapted for extending along the building wall, a locking flange extending at a right angle to the inner vertical part, and an outer vertical part extending in a substantially parallel orientation to the inner vertical part. In one aspect, the first member has an inclined bottom flange for diverting water away from the building while the top locking flange is secured to the roof. In another aspect, the flashing assembly has a top locking flange that is sealed in a groove formed in a parapet wall above the roof and a securing bottom flange, which is attached to the roof.

Owner:PERROT JR JOHN J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com