Patents

Literature

646 results about "Soil cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soil cement is a construction material, a mix of pulverized natural soil with small amount of portland cement and water, usually processed in a tumble, compacted to high density. Hard, semi-rigid durable material is formed by hydration of the cement particles.

Pile forming operation method for bi-directional stirring piles

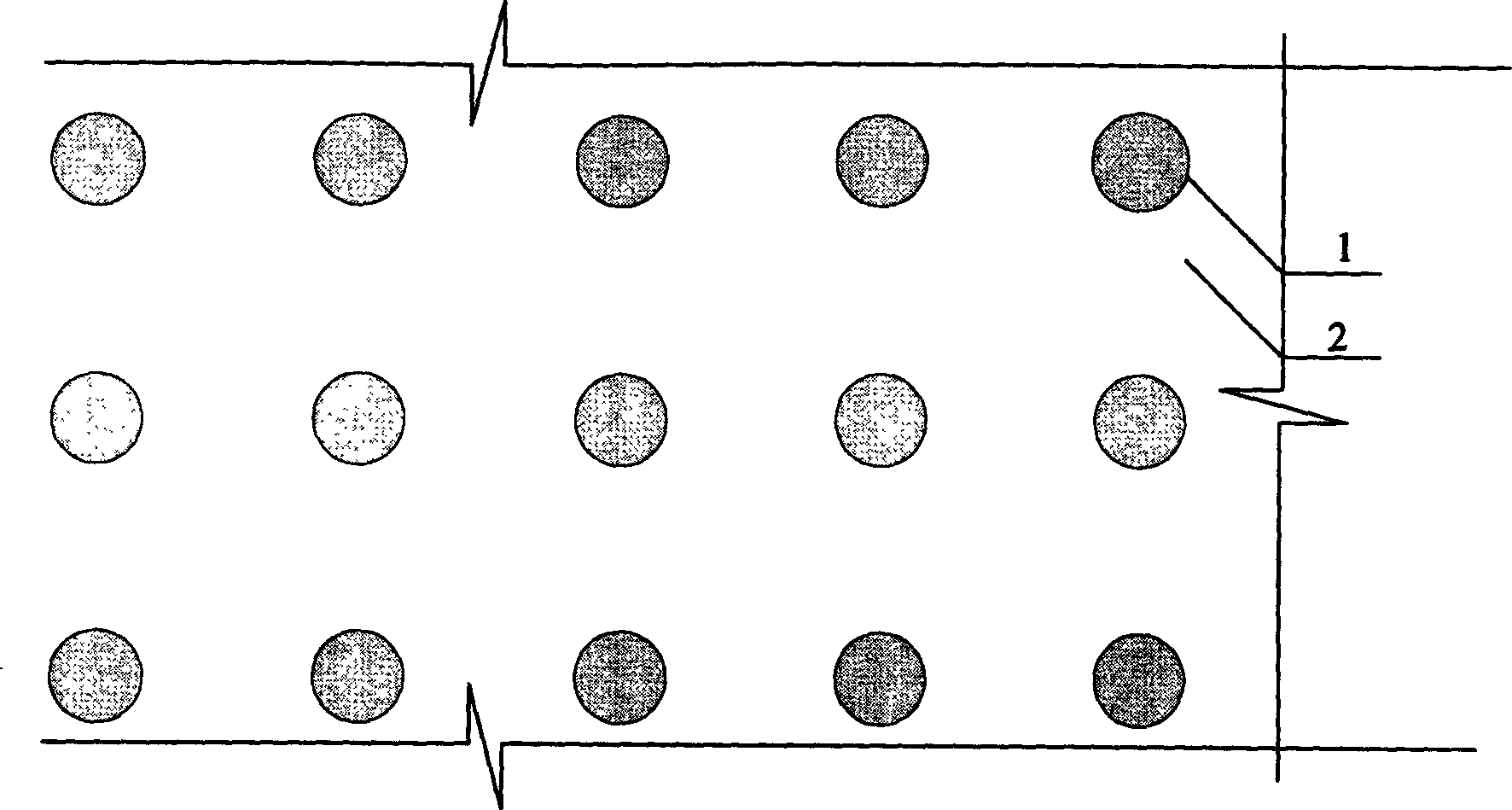

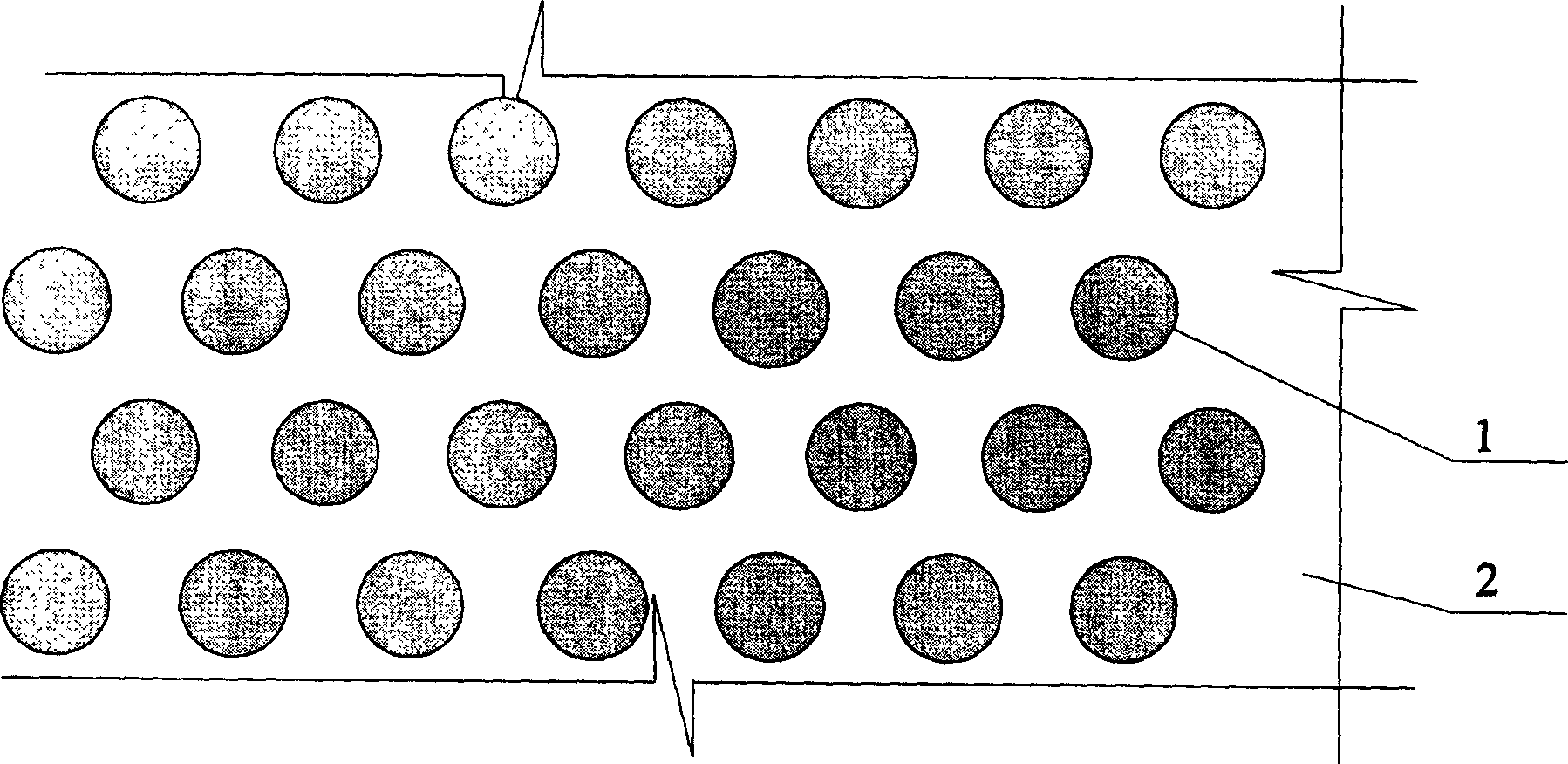

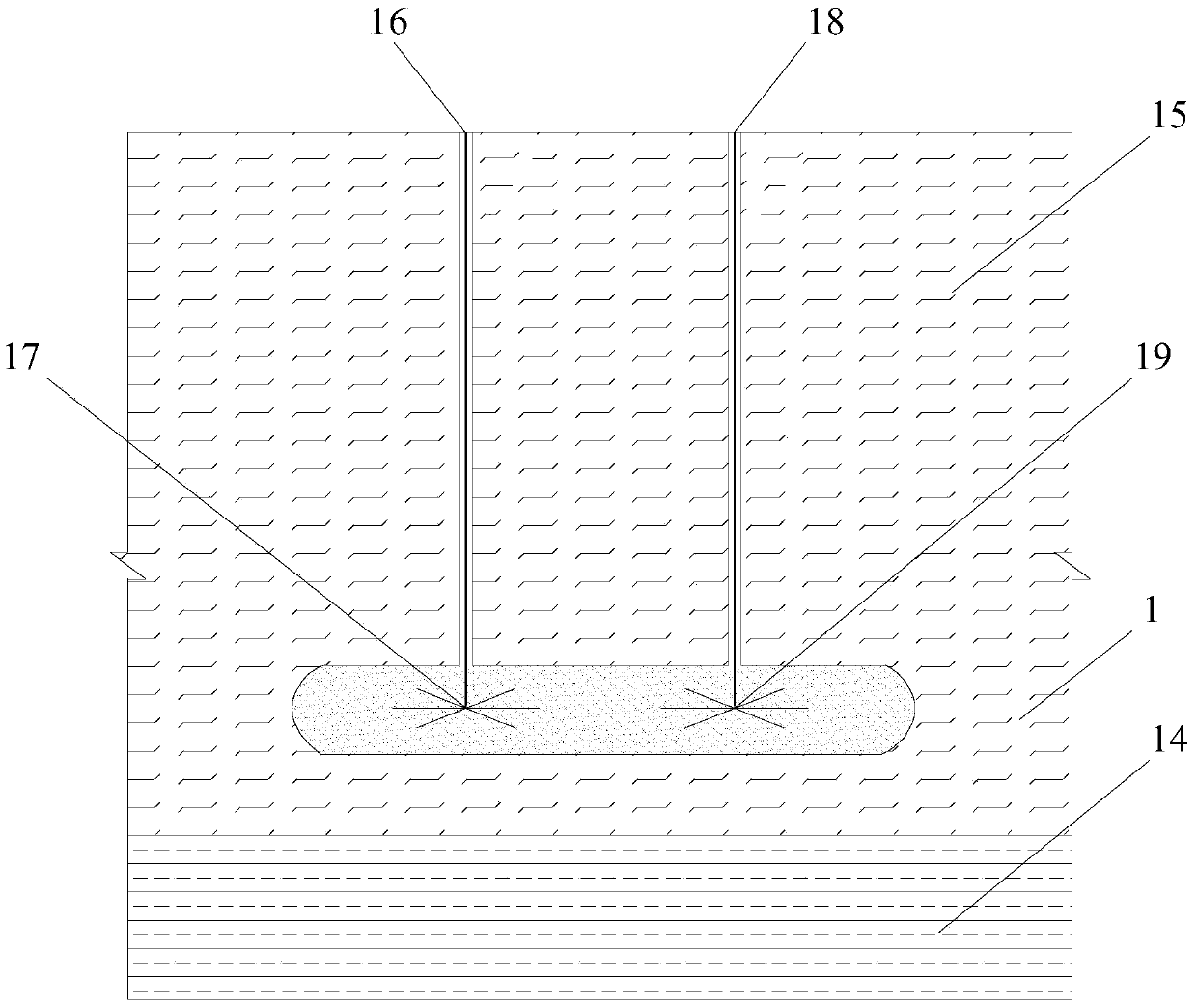

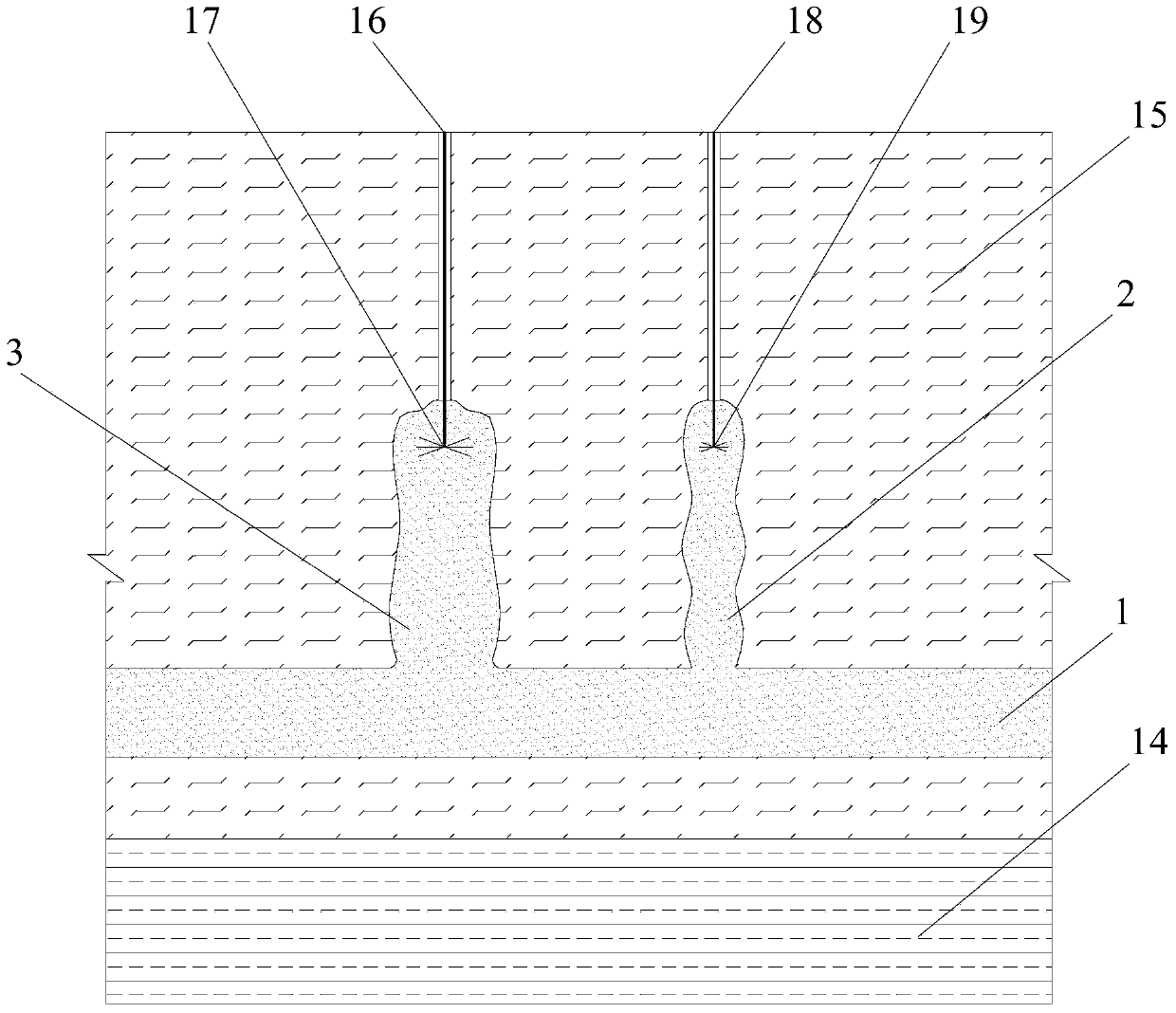

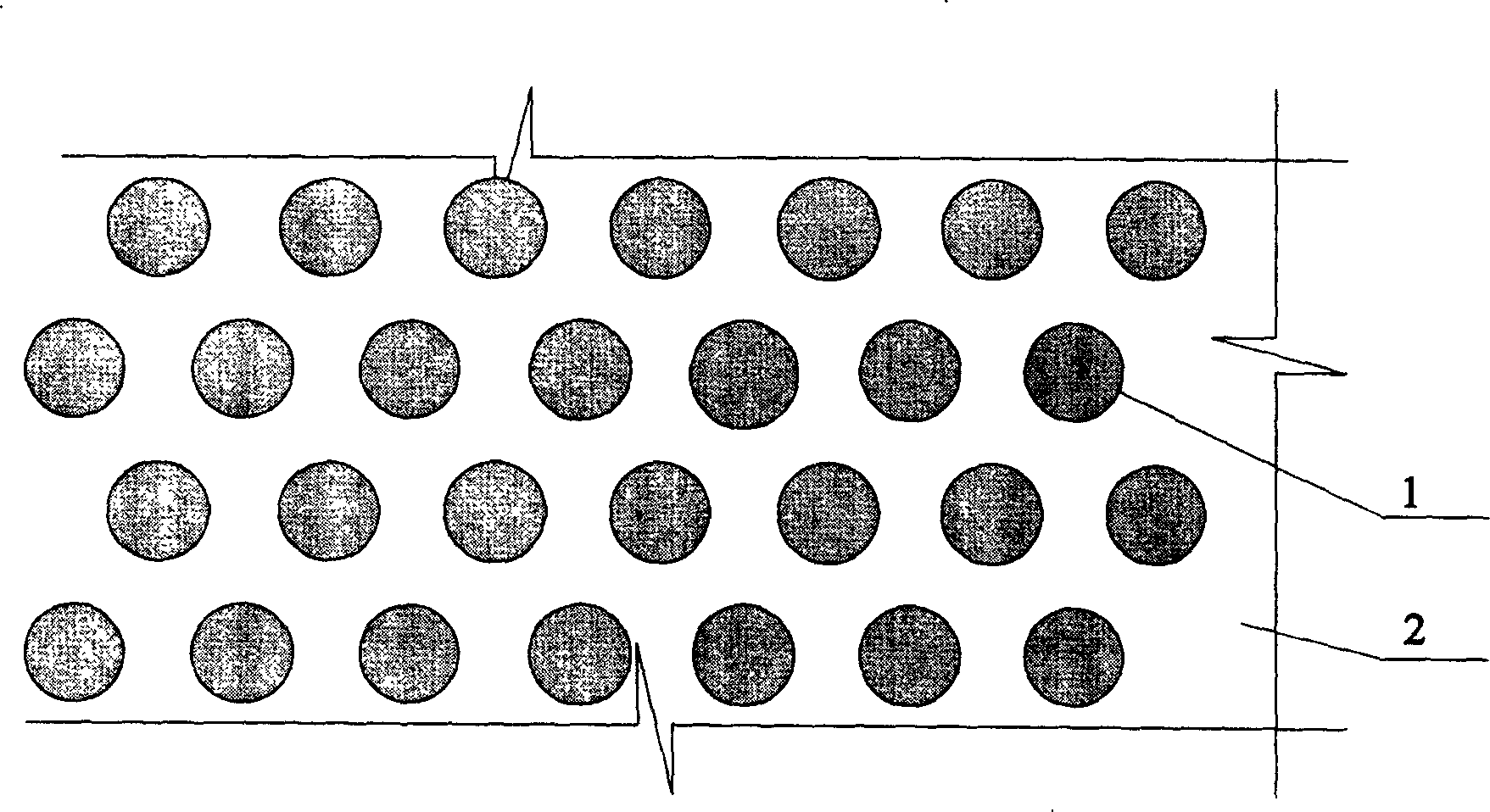

The piling operation method of two-way mixing pile is a foundation treatment method, which is suitable for soft soil foundation treatment. The operation method is: a: leveling the site; Centering; c: Stirring and sinking: start the two-way stirring pile driver, make the drill pipe of the two-way stirring pile driver cut the soil downward along the guide frame, turn on the slurry pump, spray cement slurry to the soil, and the drill pipe of the two-way stirring pile driver is respectively positive , The counter-rotating blades rotate at the same time to stir the cement and soil; d: The drill pipe of the two-way stirring pile machine continues to sink and stir the cement and soil until the design depth; e: While stirring and lifting, the drill pipe of the two-way stirring pile machine rotates forward and reverse f: lift and stir to the ground surface or 50cm above the design elevation, and complete the construction of the two-way mixing cement-soil mixing pile (1). The cement-soil mixing pile (1) is arranged in a plum blossom shape or square to ensure quality and pile quality.

Owner:南京路鼎搅拌桩特种技术有限公司

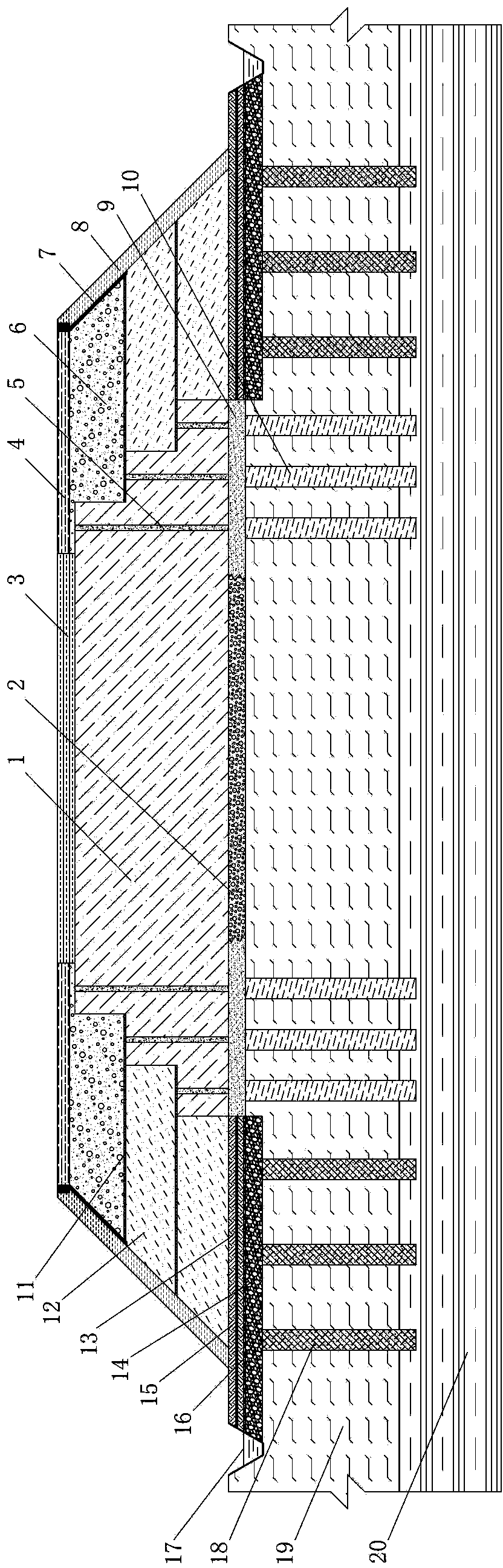

Novel highway embankment widened structure and construction method

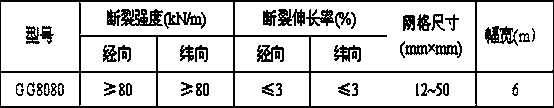

InactiveCN104278608ACoordinated settlement deformationImprove carrying capacityRoadwaysClimate change adaptationMesh reinforcementSoil cement

The invention relates to a novel highway embankment widened structure. The original roadbed slope of the structure is trimmed into a step shape, a high pressure jet grouting pile is disposed below an original roadbed slope cushion layer, pressurized continuous grouting is employed at an original roadbed cushion layer to form a slurry solid bearing plate, parts of pore cavities of the original roadbed are recharged with fine aggregate concrete or mortar; foundation treatment piles are employed to reinforce the foundation of a widened area, a drainage cushion layer is laid throughout the top of the foundation treatment piles; an earthwork cloth is laid on the drainage cushion layer, a cement soil plate is disposed on the earthwork cloth, high strength reinforcing mesh sheets are disposed in the cement soil plate; and the widened area embankment is formed by layered filling of excavation soil and light filler in a construction process. The structure provided by the invention can reinforce the bearing capacity of roadbed soil on both sides of the widened area and the original roadbed slope strength, and enhance the integrality of the embankment structure, reduce longitudinal cracks induced by differential settlement and the like at the juncture of new and old roadbeds, thus having good technical and economic benefits. The invention also discloses a construction method of the novel highway embankment widened structure.

Owner:HANGZHOU HUASHUI MUNICIPAL ENG

Method for reinforcing soft soil foundation at deep mixing pile

InactiveCN102021906ASave materialReduce dosageFoundation testingBulkheads/pilesEconomic benefitsUltimate tensile strength

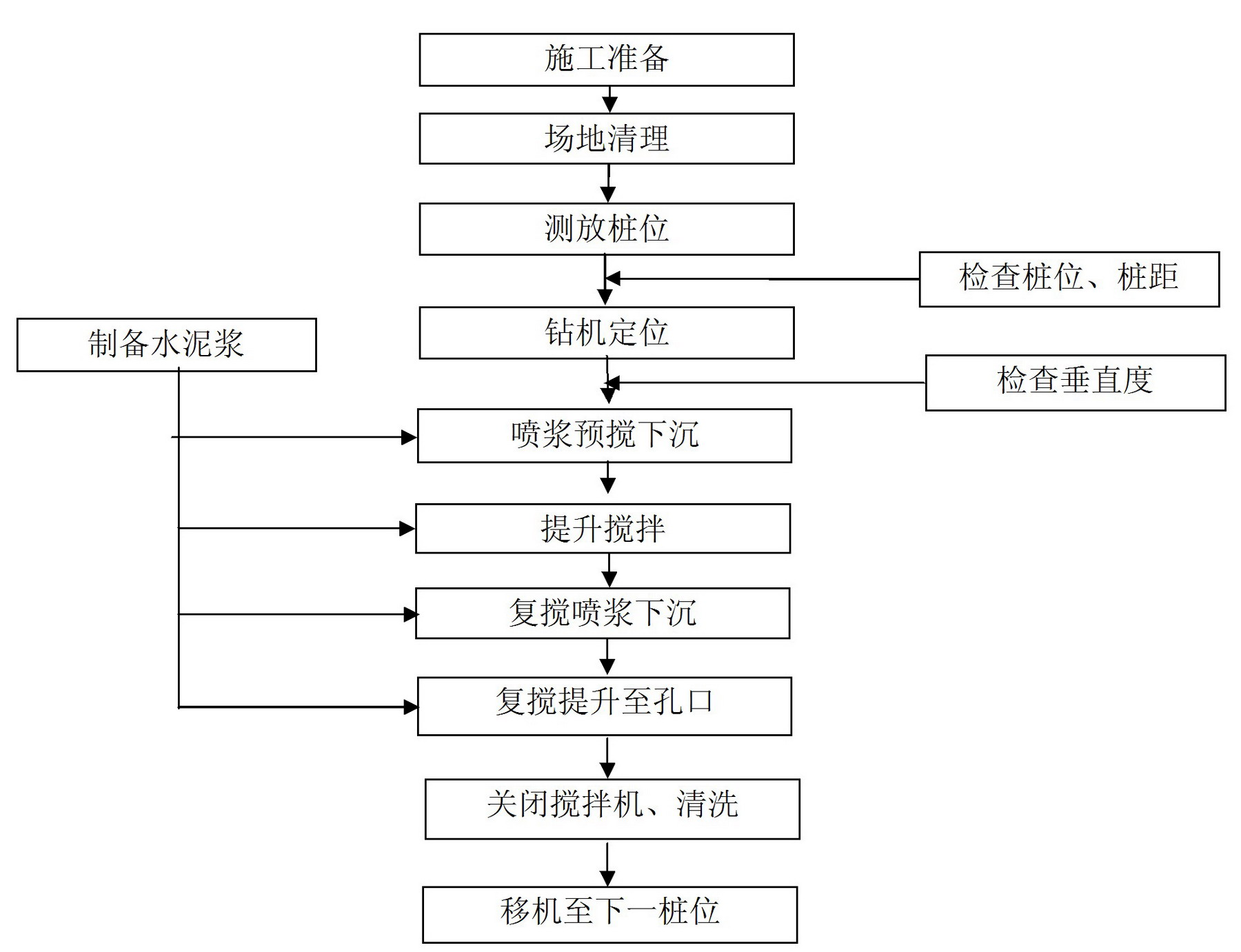

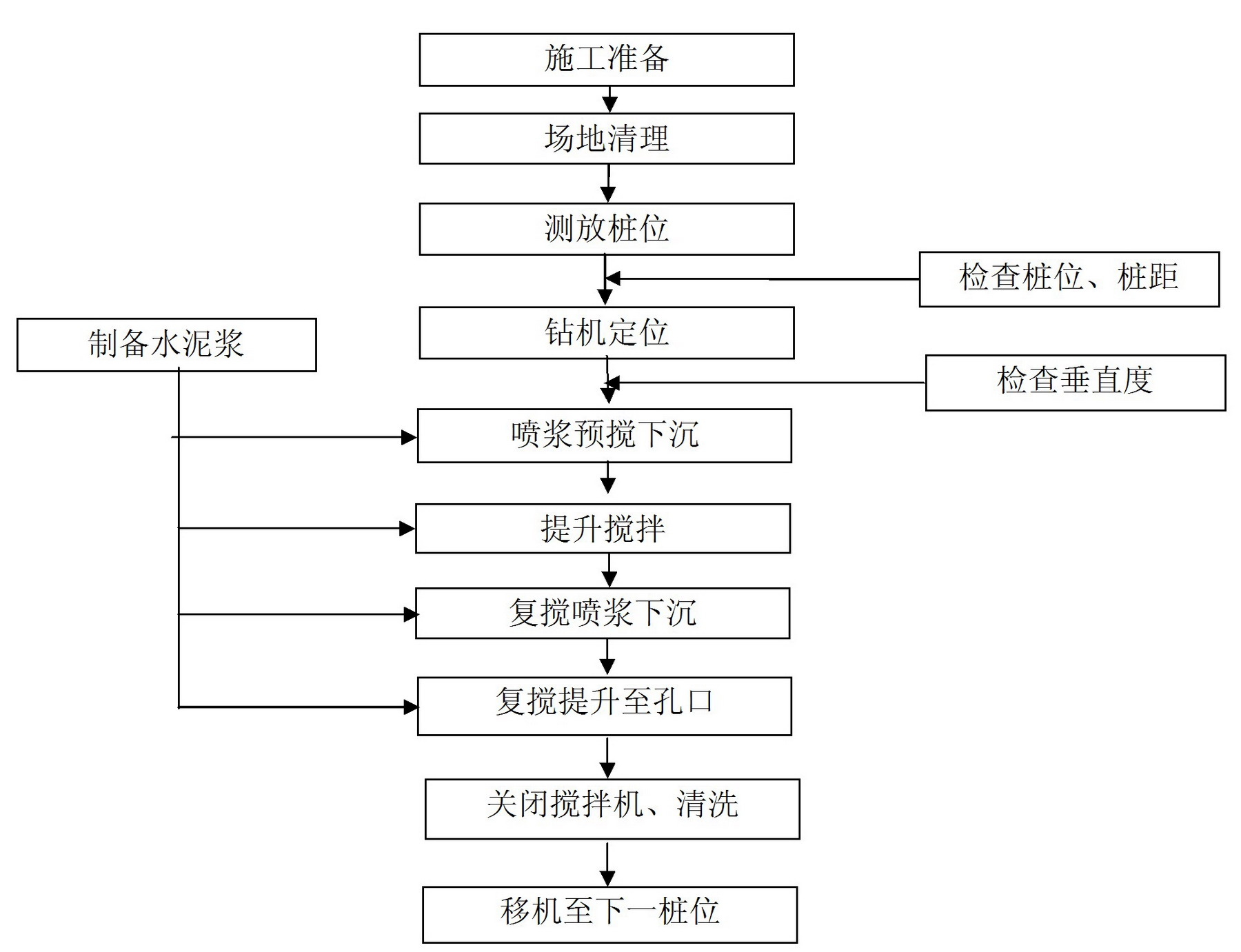

The invention relates to a method for reinforcing a soft soil foundation at a deep mixing pile, which comprises the steps of land formation, construction layout, spray mixing and sinking, curing agent grout mixing, stirring and hoisting, repeated spray mixing and sinking, and shifting, etc.; and the main technological parameters are as follows: 0.55 to 0.75 of water-cement ratio, 0.38 to 0.75 m / min of sinking and empty stirring speed, 0.3 to 0.5 m / min of hoisting speed, 18 to 30L / min of guniting quantity and 0.5 to 0.7 MPa of guniting pressure. Compared with the existing cement mixing pile foundation reinforcing process, the method provided by the invention has the advantages of appropriate water-cement ratio, high pile quality, high strength, less reinforcing agent consumption, low cost and remarkable economic benefit, and is easy to evenly stir; and meanwhile, the method also has the following advantages: (1) the cement can be hydrated fully, and during construction, the role of the cement can be exerted completely; (2) the construction quality is easy to control and guarantee; and (3) the construction on deep piles can be performed.

Owner:河南省新开元路桥工程咨询有限公司

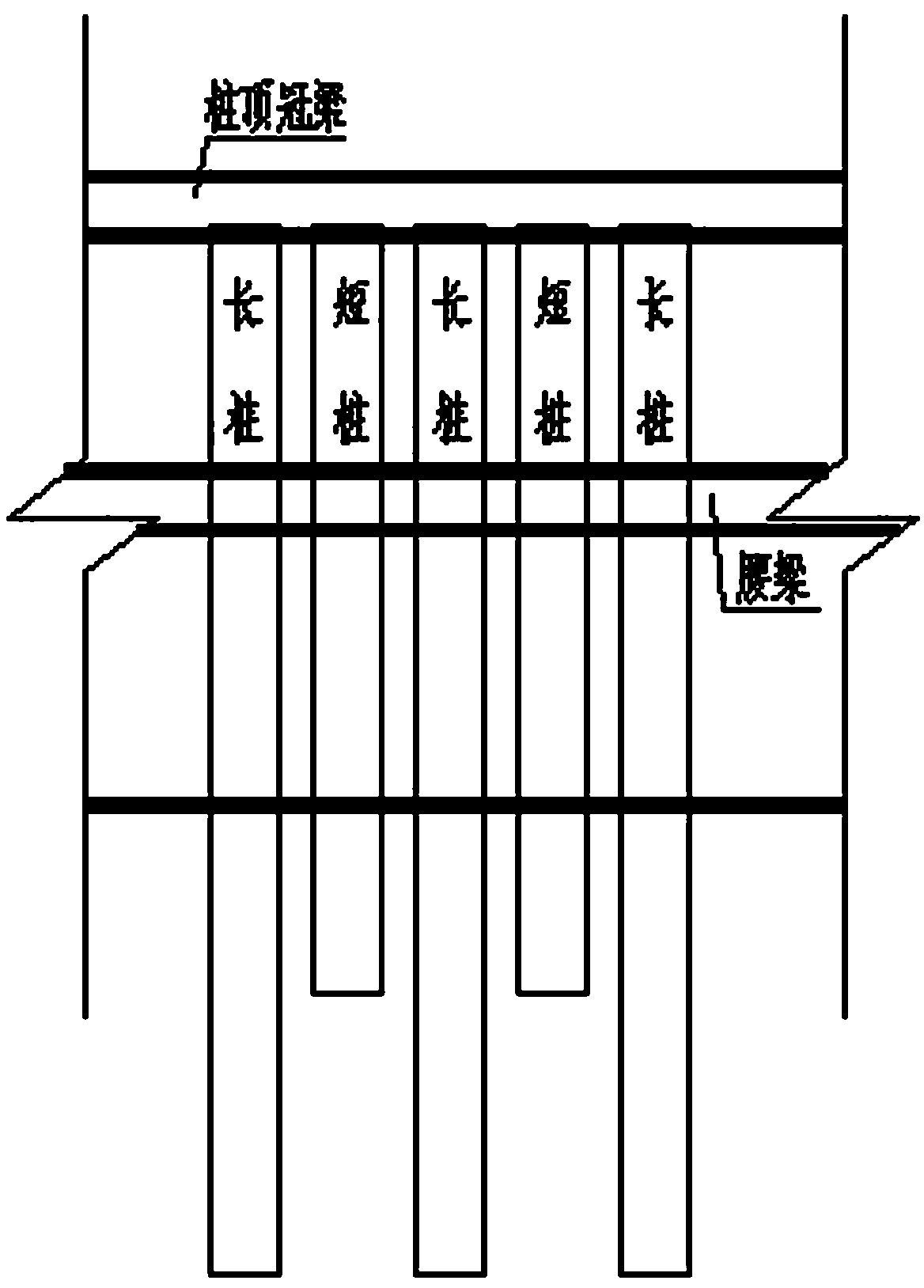

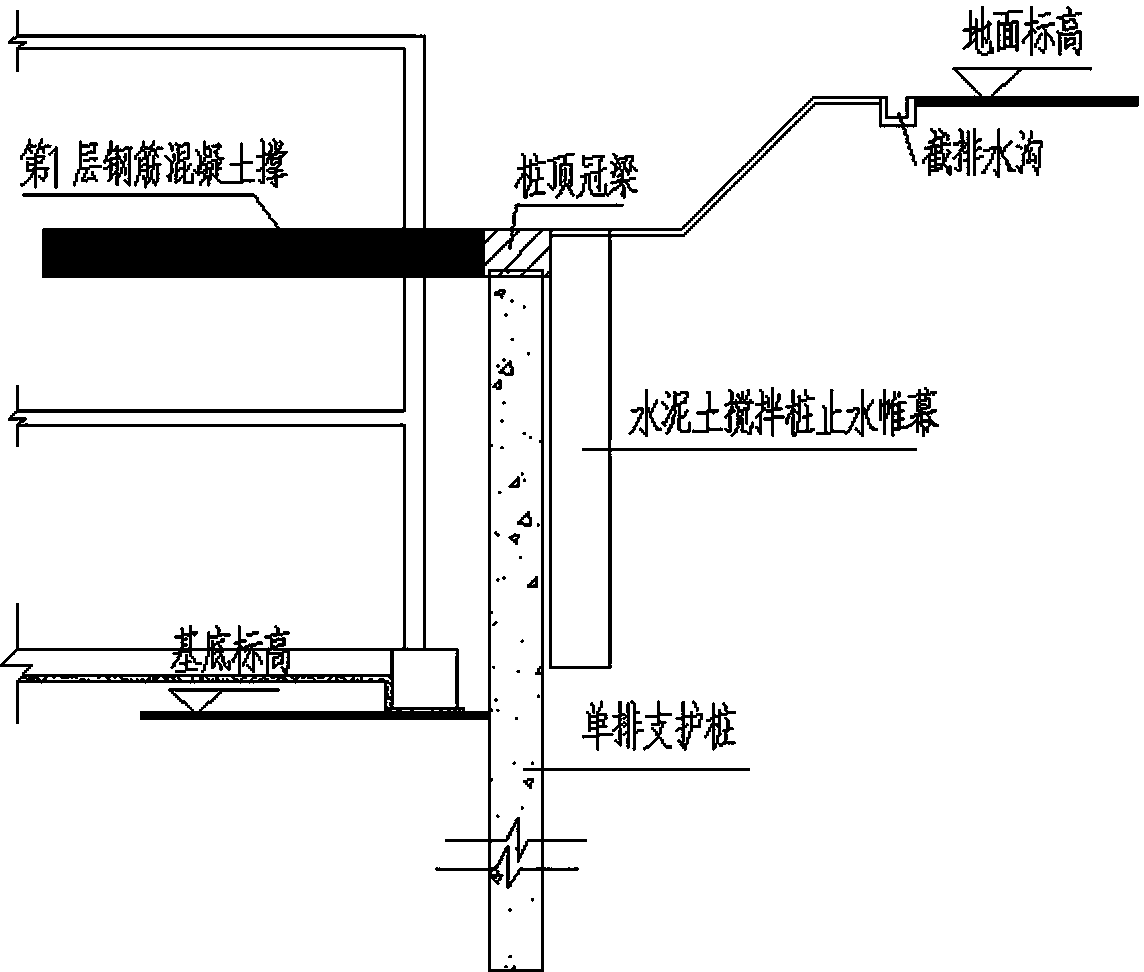

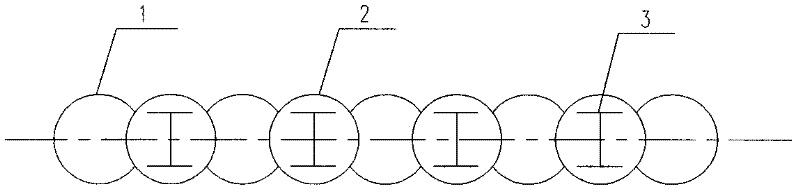

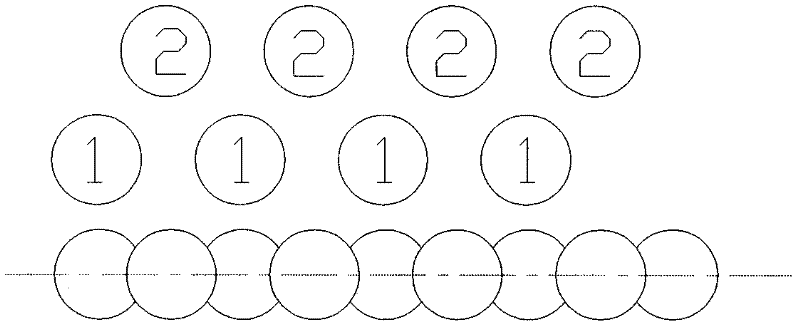

Long pile and short pile combined single-row pile and horizontal internal support pile supporting structure and construction method thereof

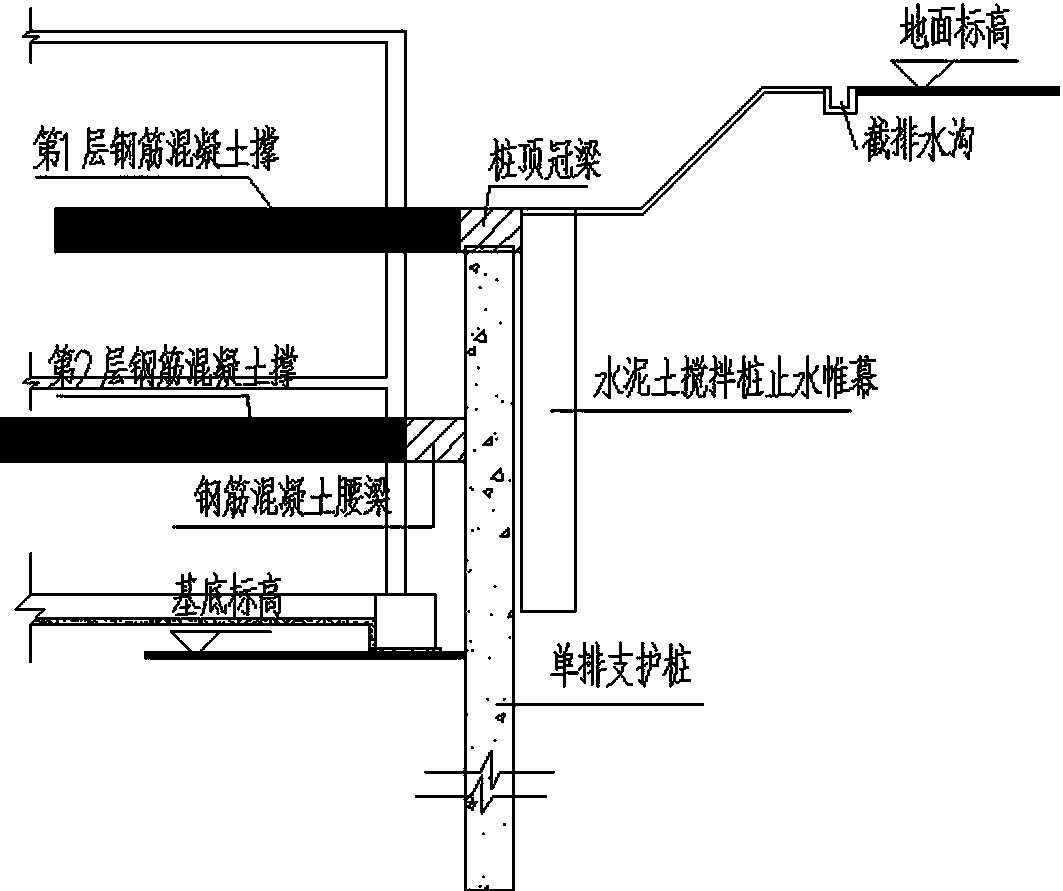

The invention discloses a long pile and short pile combined single-row pile and horizontal internal support pile supporting structure and a construction method thereof. The structure is characterized in that long piles and short piles are arranged in a staggering way at equal intervals in a single row of pile; the clear spacing between two adjacent piles is 200 to 400mm; two rows of concrete deep stirring piles are arranged behind a support pile to serve as a waterproof curtain; the layer number of internal supports is 1 to 3; the first layer of horizontal internal supports is generally arranged on the top of the support pile; the distance between the adjacent internal supports which are arranged up and down is 4 to 6m. When the supporting structure is designed, in all the rows of piles, parameters of the short piles are calculated to make sure that the requirements on the horizontal displacement, the bending capacity and the overturning resistance of the short piles are met and then parameters of the long piles are calculated to make sure that the requirement on the deep slide stability of the long piles is met. The construction method comprises the following main construction steps of constructing the long piles, constructing the short piles, constructing the concrete deep stirring pile curtain, hardening the ground before excavating a foundation pit, constructing a drainage facility, excavating the first layer of earth, constructing a pile top beam and the horizontal internal supports, excavating the second layer of earth, and performing the other steps until the earth is excavated to the bottom of the foundation pit.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Construction method of long spiral high-pressure mixing and spraying cement-soil continuous wall

InactiveCN102296630AGood effectImprove efficacyArtificial islandsUnderwater structuresSupporting systemJet injection

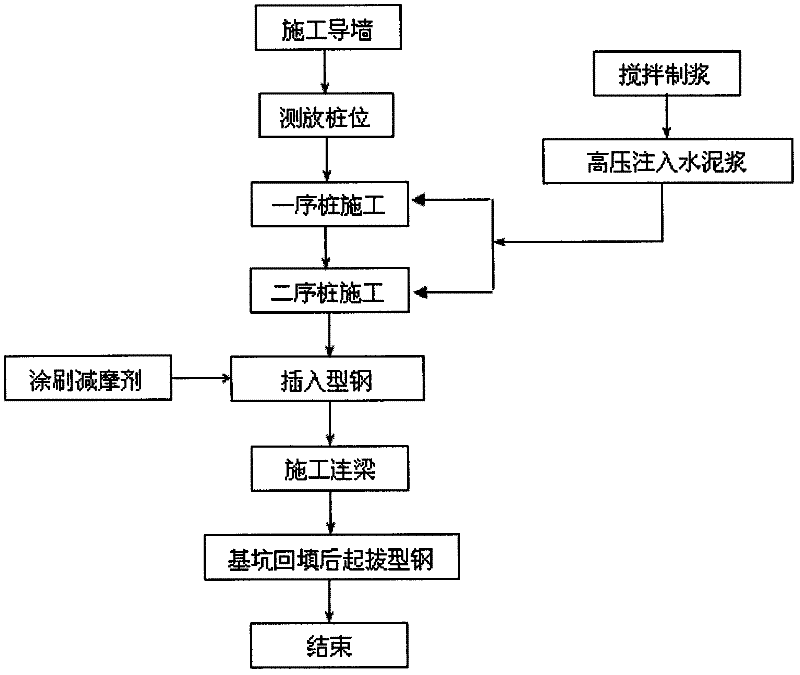

The invention provides a construction method of a long spiral high-pressure spraying cement-soil continuous wall, which comprises the following steps: 1) making a guide wall or digging a guide ditch along the center line of the pile, and determining the pile position of the spraying pile; 2) injecting the long spiral high-pressure spraying The slurry stirring pile-forming device is aligned with the pile position as the drilling center, and drilled into the hole; 3) Start the grouting pump, and use the long spiral high-pressure jet grouting to stir the pile-forming device during the lifting or lowering process of high-pressure rotary spraying until it is formed. 4) insert section steel into the spigot pile; 5) repeat the steps 2), 3) and 4) until the continuous cement-soil continuous wall is formed; 6) construct the joint beam; 7) backfill the foundation pit, Pull out the section steel after finishing. Compared with the general slope protection pile support system, firstly, the section steel can be recycled, and secondly, cement soil is used instead of concrete, so it is relatively more economical and more efficient, and can achieve the two walls of the supporting wall and the curtain wall. The water stop effect is also better than the system composed of general slope protection piles + rotary grouting piles.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

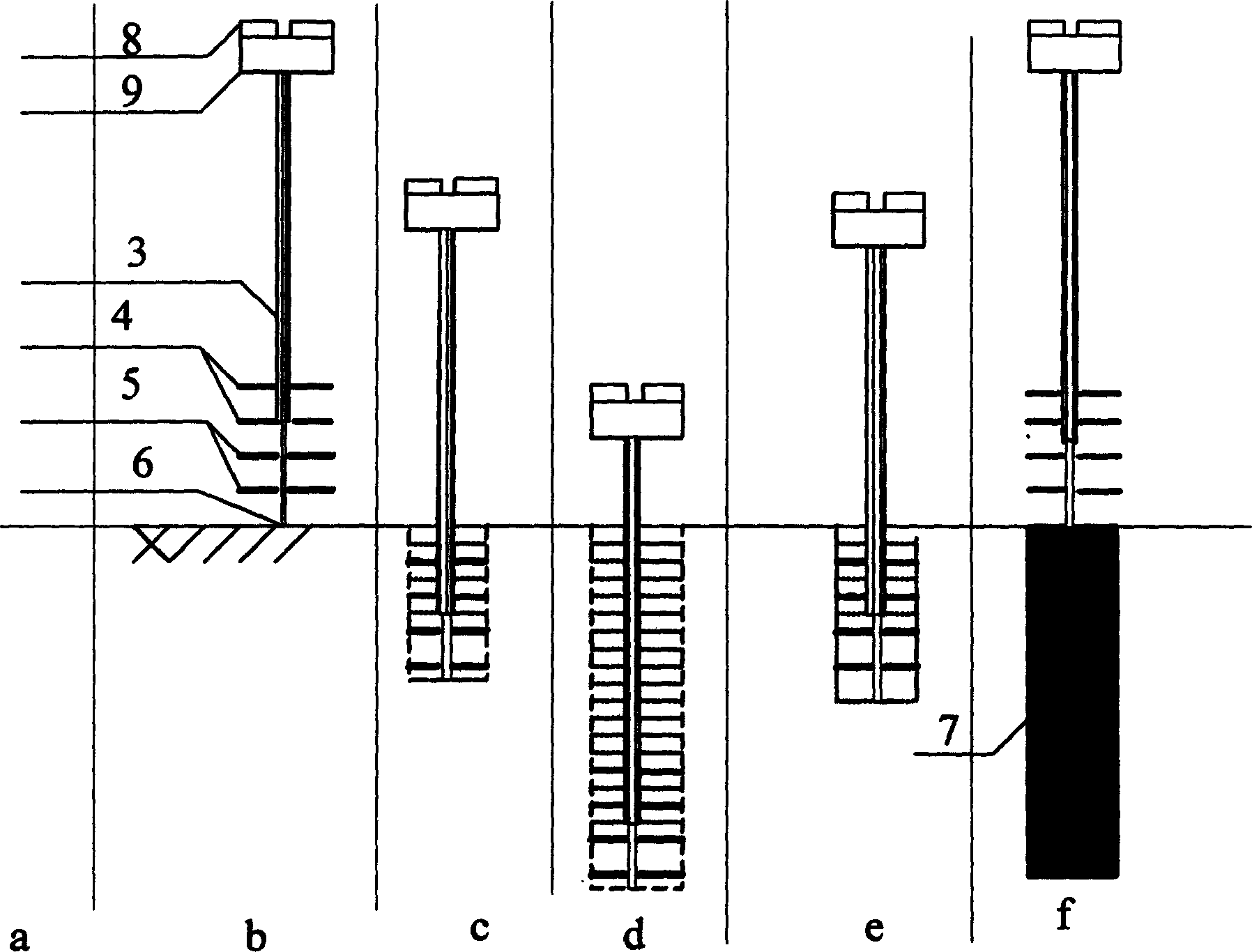

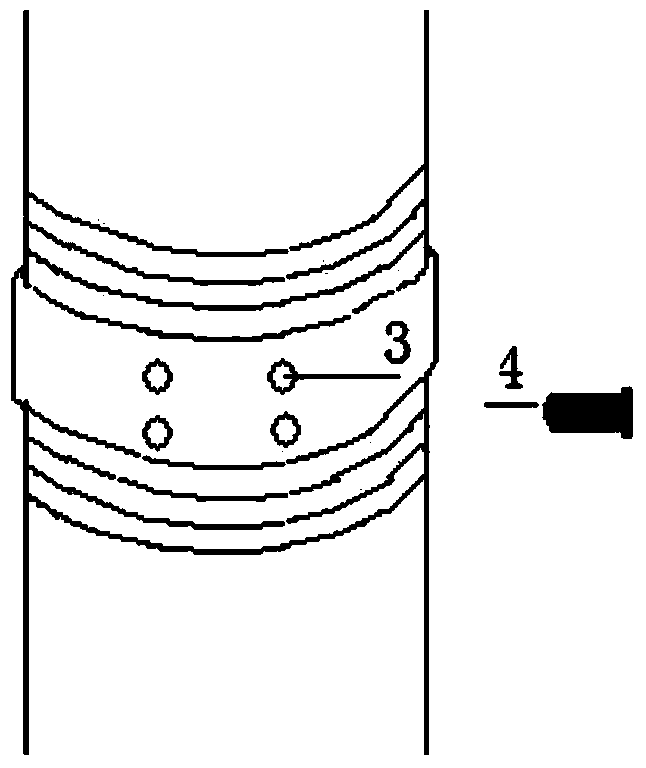

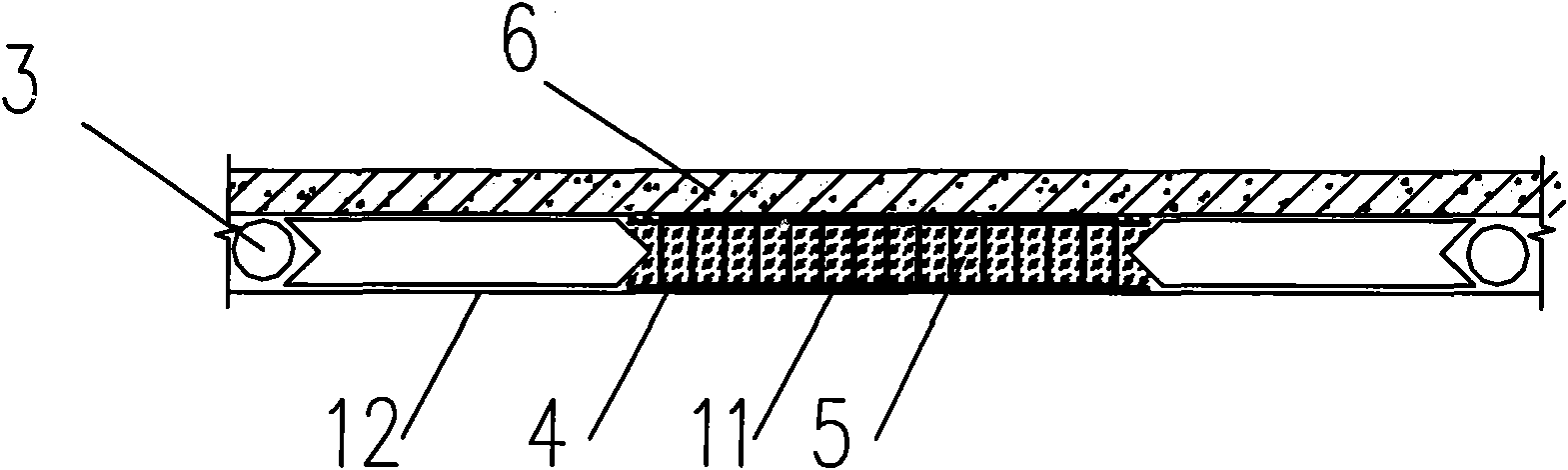

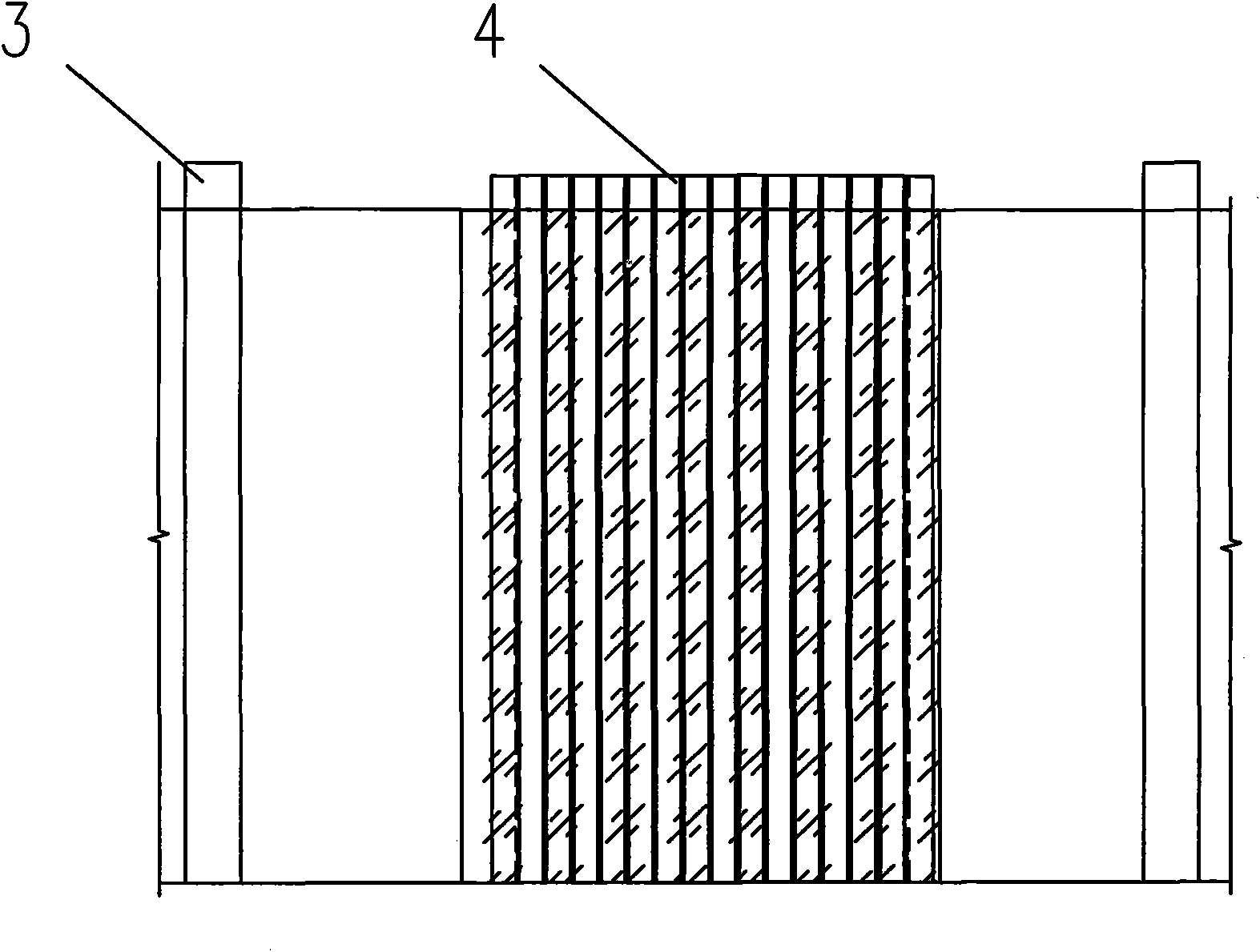

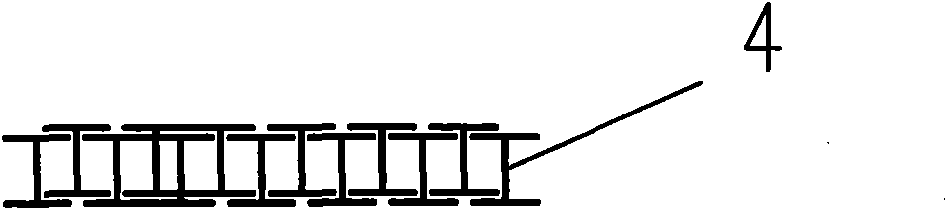

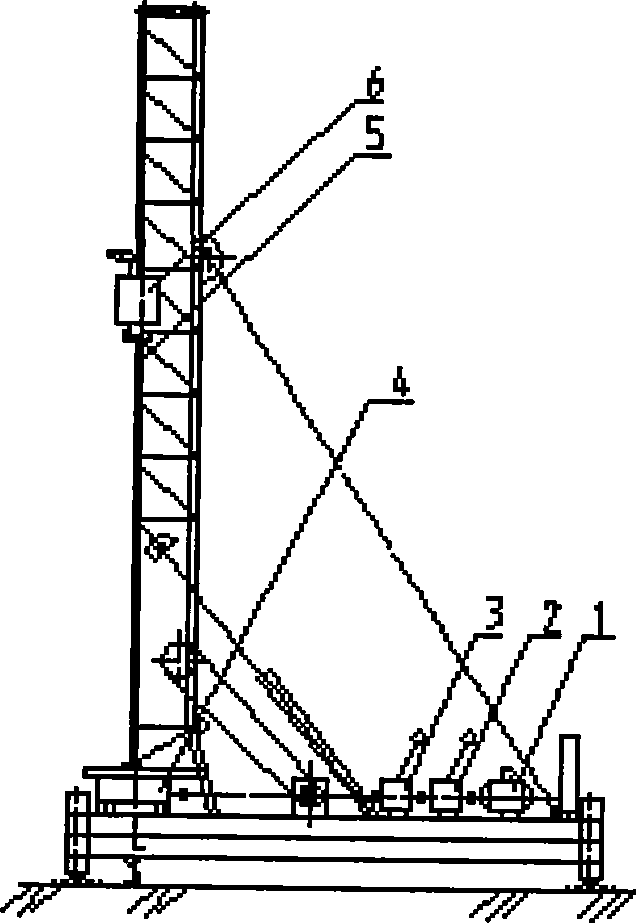

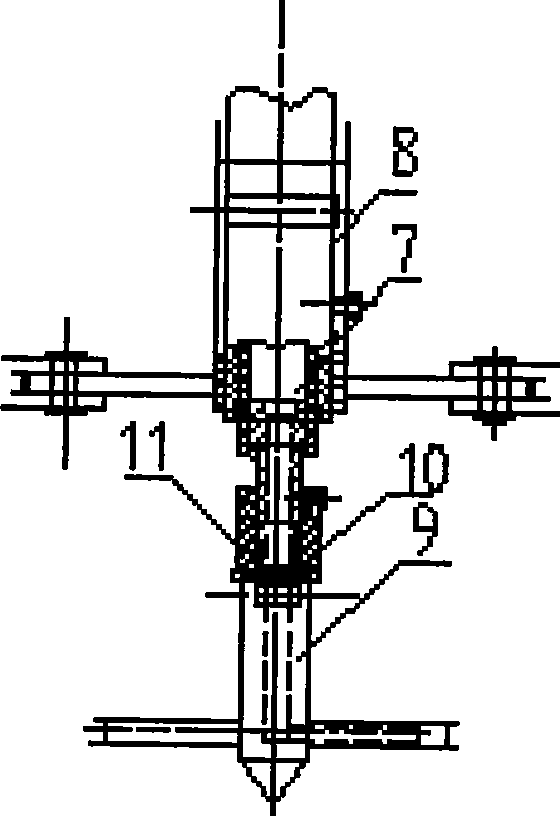

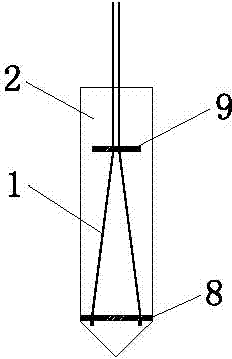

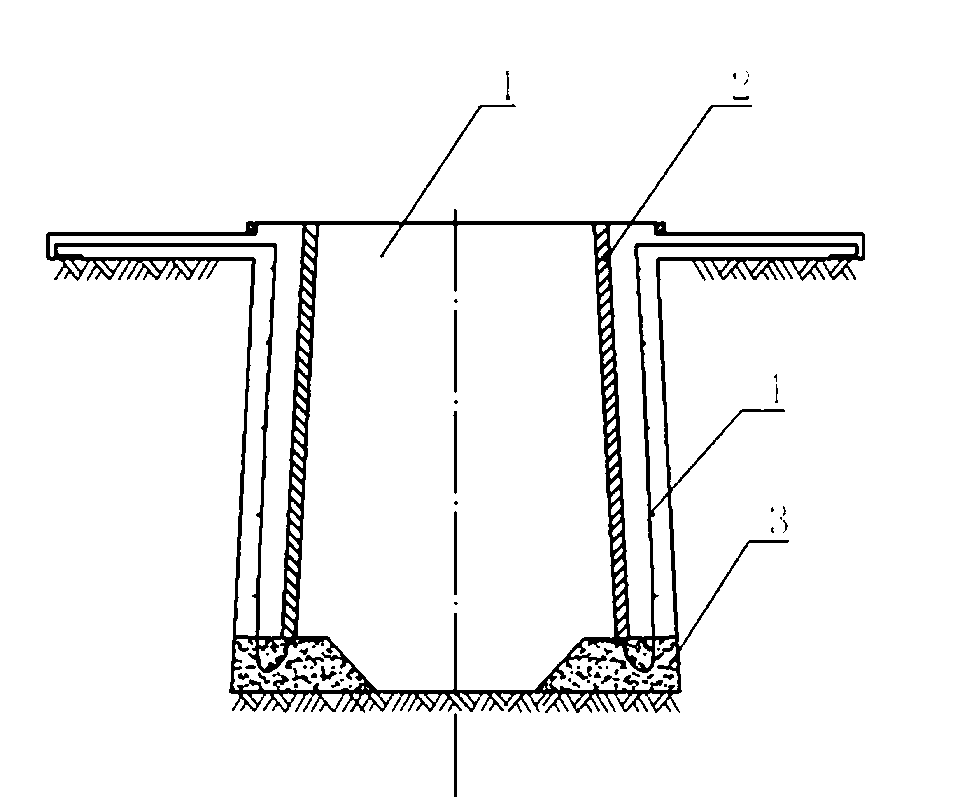

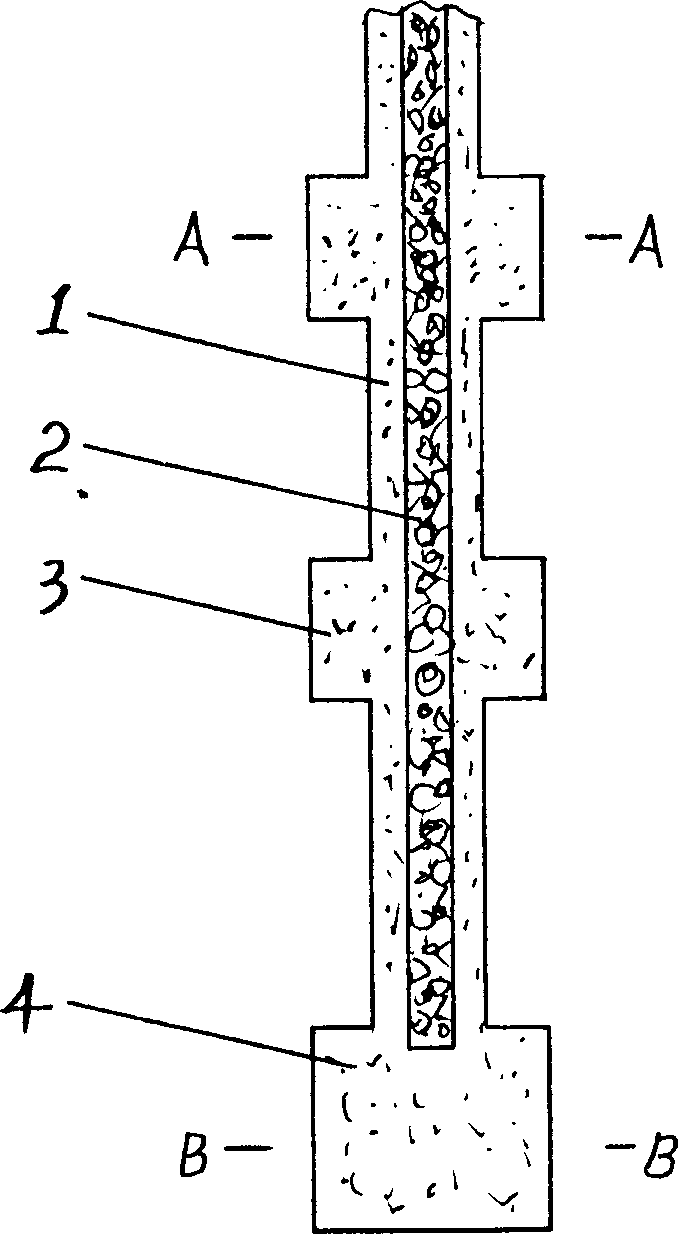

Bi-directional cement soil mixing pile machine

ActiveCN1632232AStir fully and evenlyWon't be lostBulkheads/pilesDrilling machines and methodsDrivetrainSoil mixing

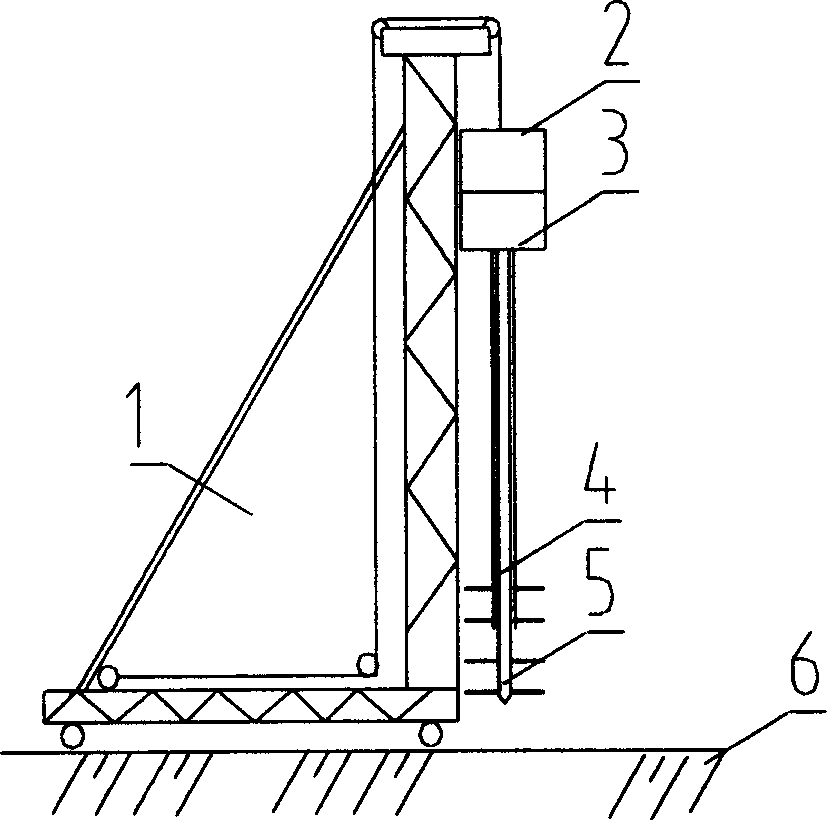

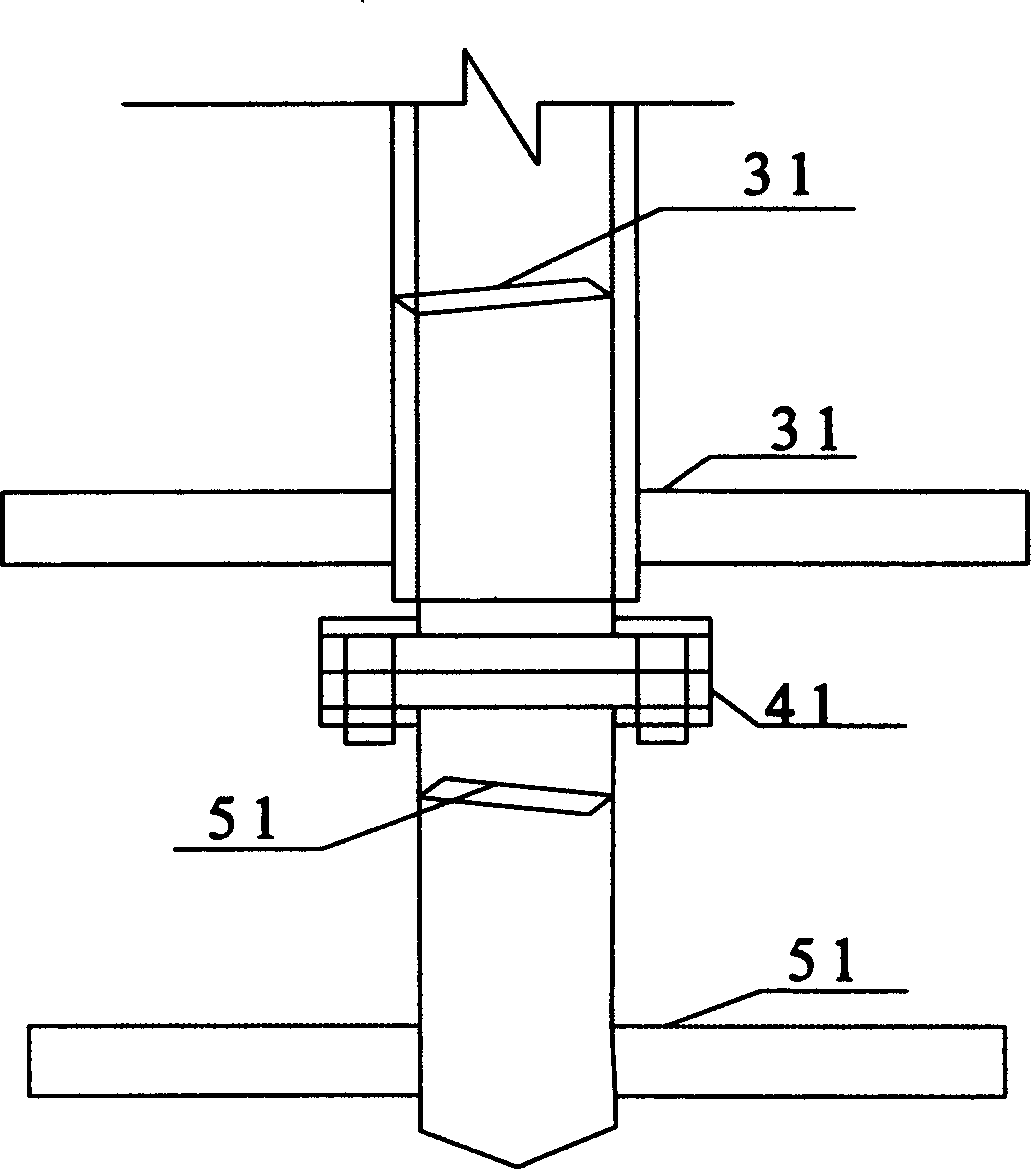

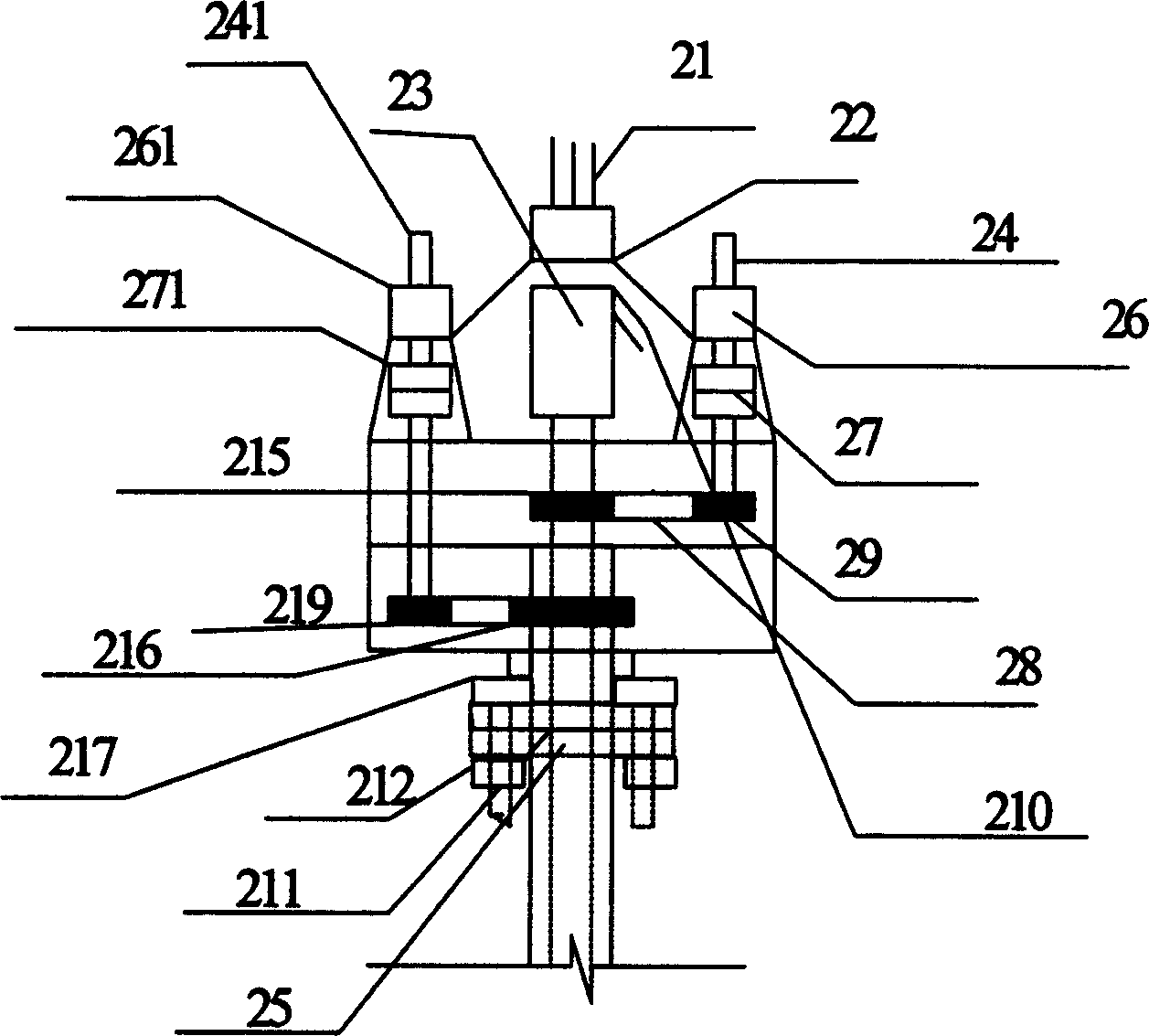

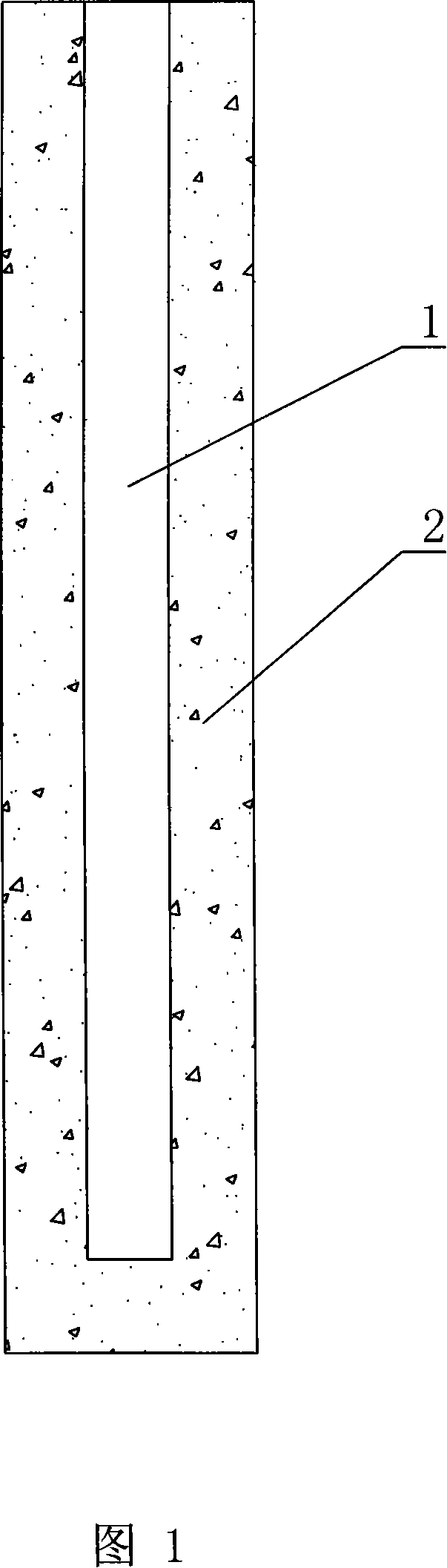

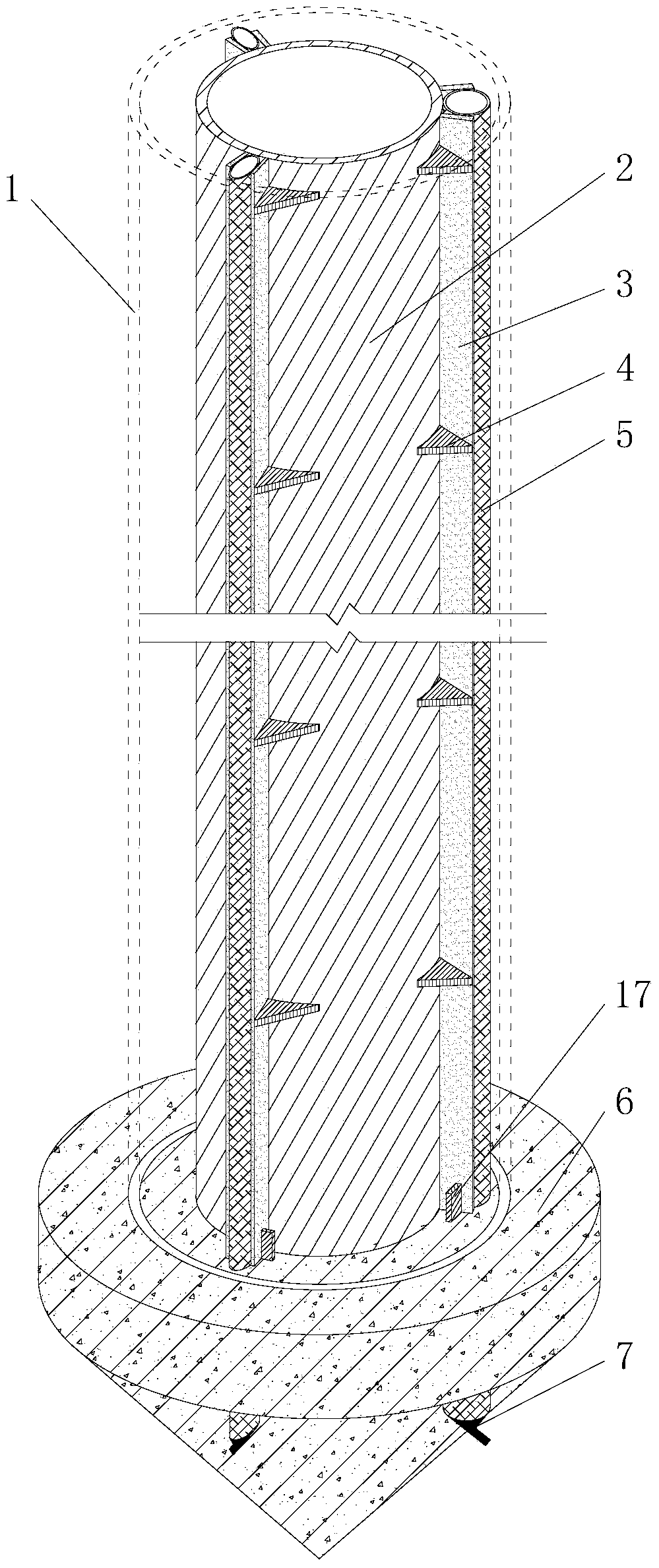

Two-way cement-soil mixer is a kind of construction machinery equipment suitable for soft soil foundation treatment. The mixer consists of body (1), power transmission system (2), outer drill rod (3), inner drill rod (4), drill bit ( 5) Composition, wherein the power transmission system is located on the upper part of the fuselage (1), the inner drill rod (4) is located in the outer drill rod (3), and the inner drill rod (4) and the inner drill rod in the power transmission system (2) The rod power transmission system connection flange (211) is connected, the outer drill rod (3) is connected with the outer drill rod power transmission system connection flange (25), and the drill bit (5) is located at the bottom of the inner drill rod (4). The machine is easy to construct, easy to operate, and easy to master. The two-axis two-way rotation drives two sets of mixing blades to rotate in two directions at the same time, which can ensure the mixing amount of cement slurry in the pile body, and there will be no slurry phenomenon; at the same time, it can ensure that the pile body cement The soil is fully stirred evenly to ensure the quality of the pile and the quality of the pile body; the efficiency is more than doubled.

Owner:南京路鼎搅拌桩特种技术有限公司

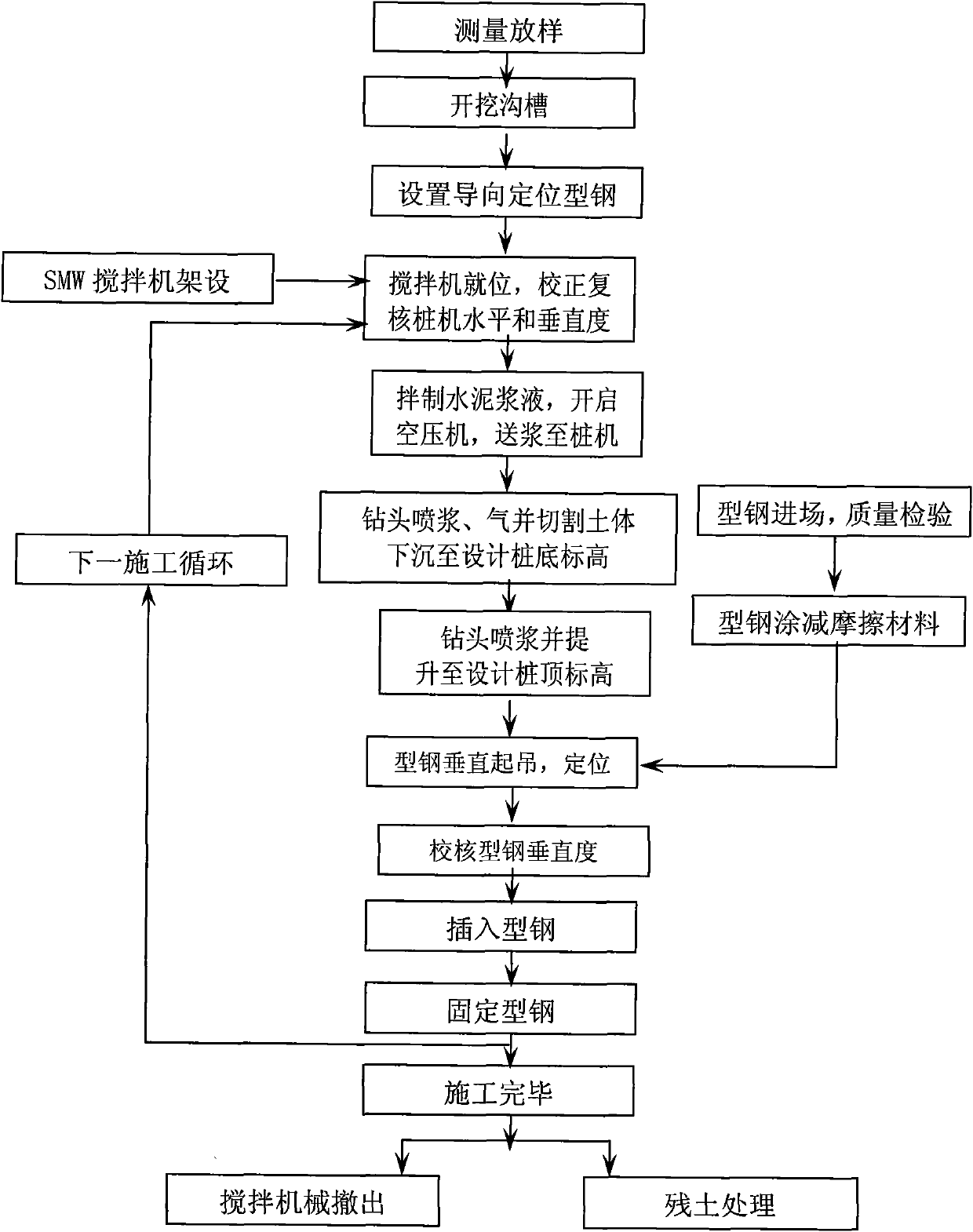

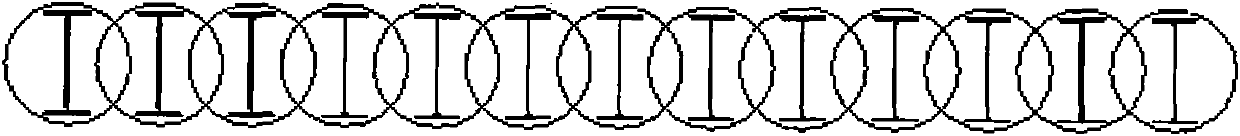

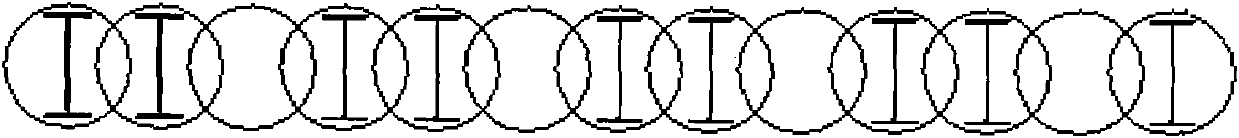

Construction method of section-steel triaxial soil-cement mixing pile

InactiveCN101768961ASolve the difficult problem of pre-stirring and sinkingSolve the problem of too long remixing process timeBulkheads/pilesSlurryEngineering

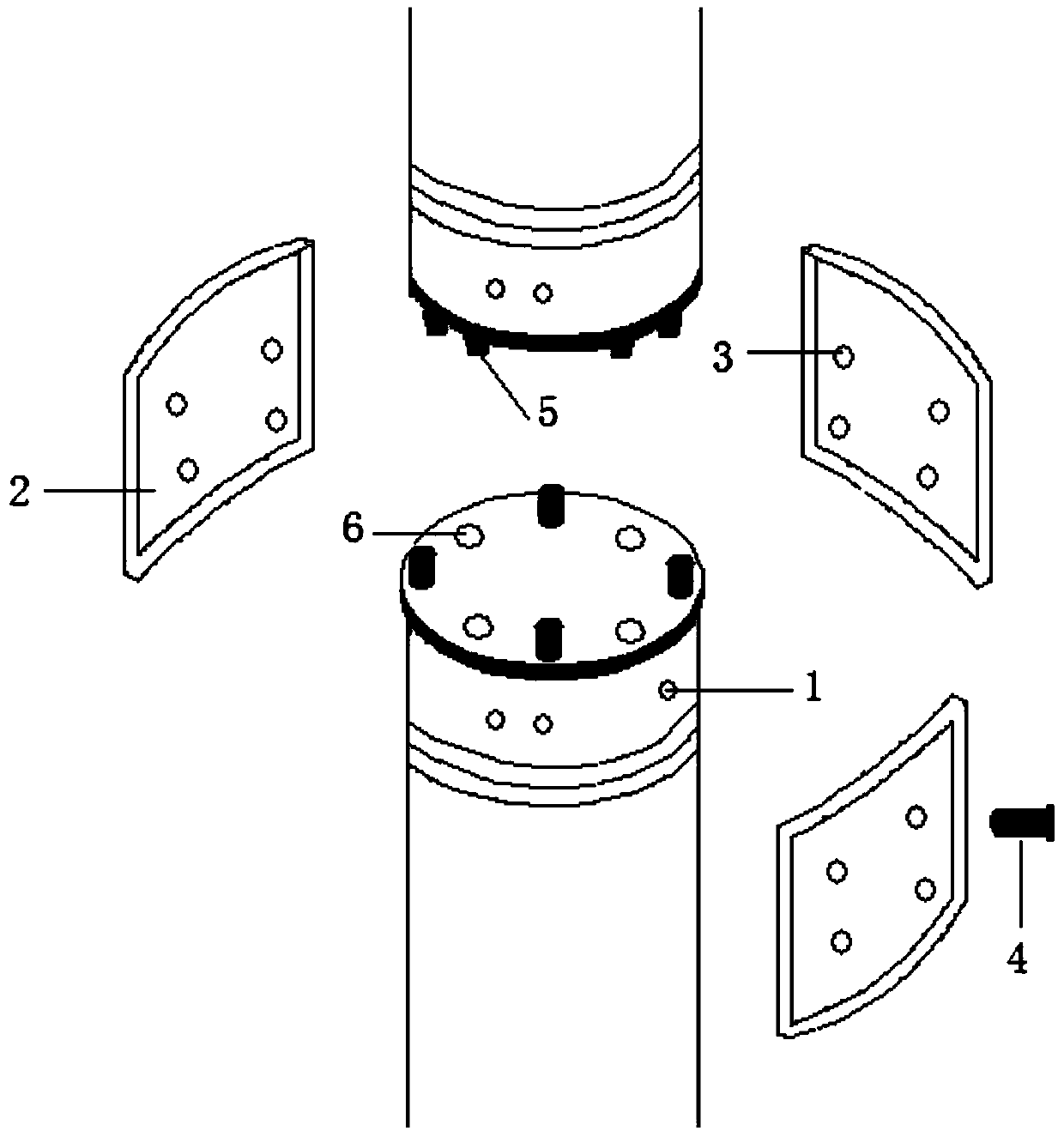

The invention discloses a construction method of a section-steel triaxial soil-cement mixing pile, comprising the following construction steps: (1) measuring paying-off positioning pile; (2) digging trench; (3) arranging guide positioning section-steel; (4) the mixer taking place, correcting and reviewing levelness and verticality of the pile driver; (5) mixing cement grout, starting an air compressor, and sending the grout to the pile driver; (6) a drill bit spraying grout, gas, cutting soil body and sinking to the elevation of designed pile bottom; (7) the drill bit spraying the grout and elevating to the elevation of designed pile top; (8) vertically lifting the section-steel and positioning the section-steel; (9) correcting and reviewing the verticality of the section-steel; (10) inserting and fixing the section-steel. The pilling process provided by the invention is suitable for cohesive soil with large compression modulus, soft ground layer which is mainly composed of cohesive soil and silty cohesive soil, mucky soil, plain fill and saturation loose sand without flowing underground water; especially for the cohesive soil with large compression modulus, the invention not only can solve the problem that the pre-mixing sinking is difficult, but also can solve the problem that the time of repeatedly-mixing process is too long.

Owner:中铁城建集团第三工程有限公司 +1

Composite type combined piles and construction method thereof

The invention provides composite type combined piles. The composite type combination piles comprise a combination of a plurality of rectangular piles, a plurality of non-prestressed piles, a plurality of bamboo joint type piles and a plurality of prestressed pipe piles. The composite type combined piles of different pile types are combined, and every two vertical piles of the composite type combined piles of each pile type are connected in a mechanical connection method. Meanwhile, the invention provides a construction method of the composite type combined piles. The composite type combined piles have the advantages that compression bearing capacity of a single pile is high, strength of pile body concrete is brought into full play, extraction resistant performance of a pile body can be greatly improved, compression bearing capacity of the pile body is greatly improved, construction has no influence on peripheral facilities, noise and air pollution are avoided, the piles are suitable for the geological condition that a pile tip bearing stratum greatly changes, particularly, the connector part of the pile body is protected by cement inside and outside the pile body, and the pile body integration is more reliable. A pile connection method is fast, safe and stable, the bearing force of a single pile is high, and the composite type combined piles have good social benefits and popularization value.

Owner:TIANJIN JIANCHENGJIYE GRP

Cement base soil-solidified-agent and preparation and application thereof

InactiveCN101597496AImprove adhesionReduce consumptionBuilding constructionsOrganic fertilisersPotassium hydroxideSodium sulfate

The invention discloses a cement base soil-solidified-agent and preparation and application thereof. The soil-solidified-agent is prepared by the following raw materials by weight percent: 10-40% of sodium sulfate, 2-6% of sodium tripolyphosphate, 2-5% of carbamide, 2-8% of polyacrylamide, 1-5% of lauryl sodium sulfate emulsifier, 2-10% of triethanolamine, 10-60% of sodium silicate, 4-12% of sodium hydroxide, 2-15% of sodium carbonate,2-6% of potassium hydroxide and 2-8% of methyl sodium silicate; and the sum of the percentage is 100%. The soil-solidified-agent can be prepared into powder or liquid, can fully activate various physical, chemical and physical chemistry reactions of cement and soil, so as to greatly improve engineering performance of cement soil, improve strength, reduce dry shrinkage and improve durability. The invention can be widely applied to projects such as road foundation, embankment reinforcement, channel seepage prevention, water and soil conservation, side slope protection, pile foundation processing and the like.

Owner:NORTHWEST A & F UNIV

Guiding horizontal jet grouting pile pre-support construction method for scattered particle rock surrounding tunnel

ActiveCN102251781AEasy constructionReasonable structureUnderground chambersTunnel liningSlurryCement paste

The invention discloses a guiding horizontal jet grouting pile pre-support construction method for a scattered particle rock surrounding tunnel. The method comprises the following steps of: drilling a guide hole with precision of more than 0.5 percent by adopting a horizontal directional drilling machine, retracting a drill rod by rotating after the guide hole is drilled to the design length, andspraying the prepared cement paste to the soil through the drill rod under the pressure of 35 to 40MPa while retracting the drill rod. Jet stream cuts the soil with huge impact force, soil particles are forcibly stirred and mixed with the cement paste, and a horizontal cylindrical cement soil solidified body, namely a horizontal jet grouting pile, is formed after cementing and hardening. After the jet grouting piles are mutually engaged, a closed horizontal jet grouting curtain body for forming an ultra pre-support is formed at the outer side of an arch of the tunnel in a concentric circle form, so that collapse caused by sand leakage is effectively prevented; and the cost is low, and the construction speed is greatly quickened when the safety is ensured.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

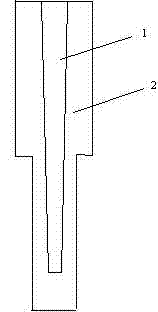

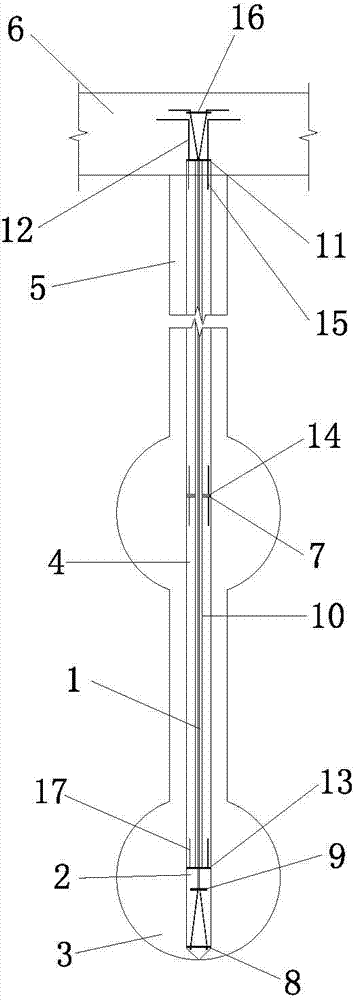

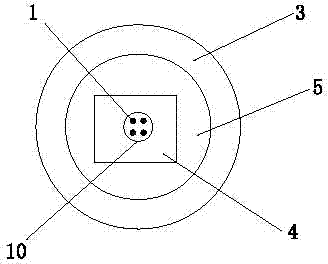

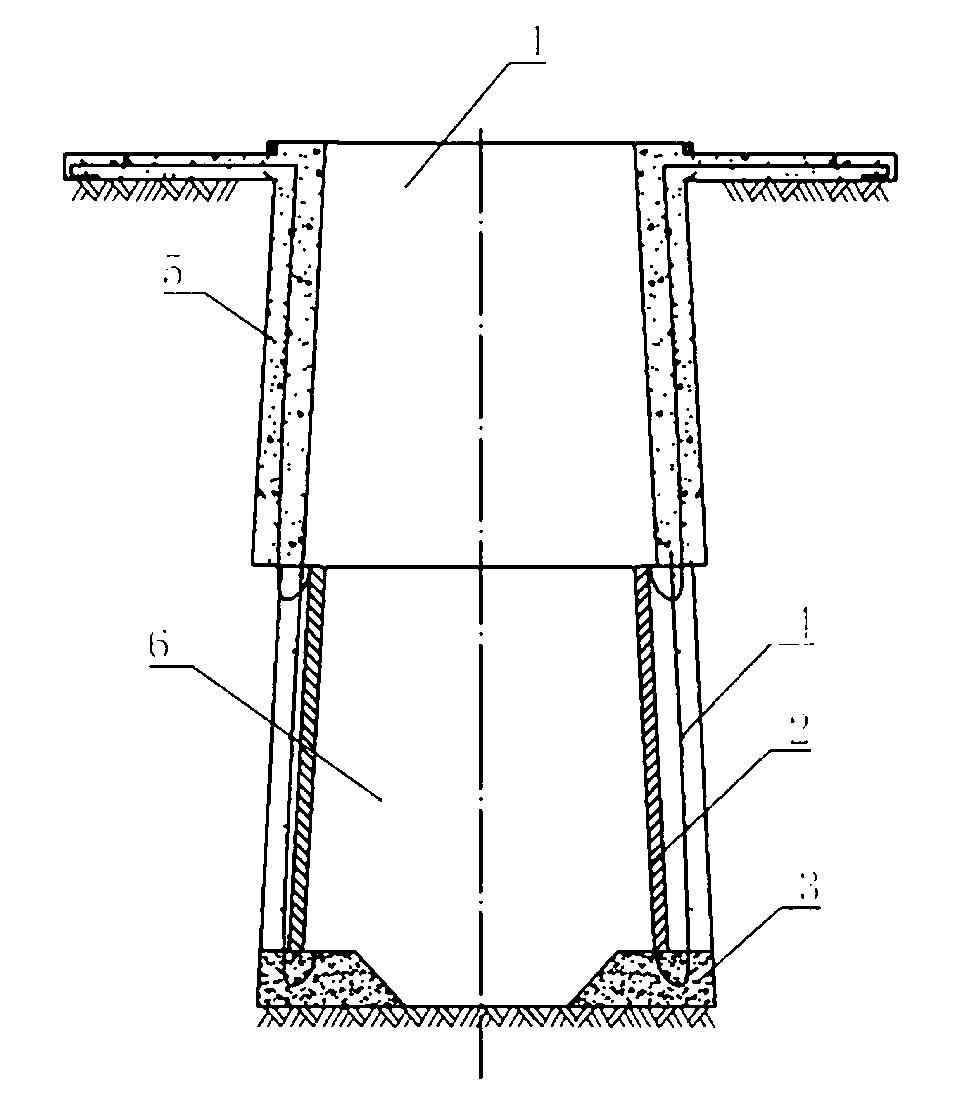

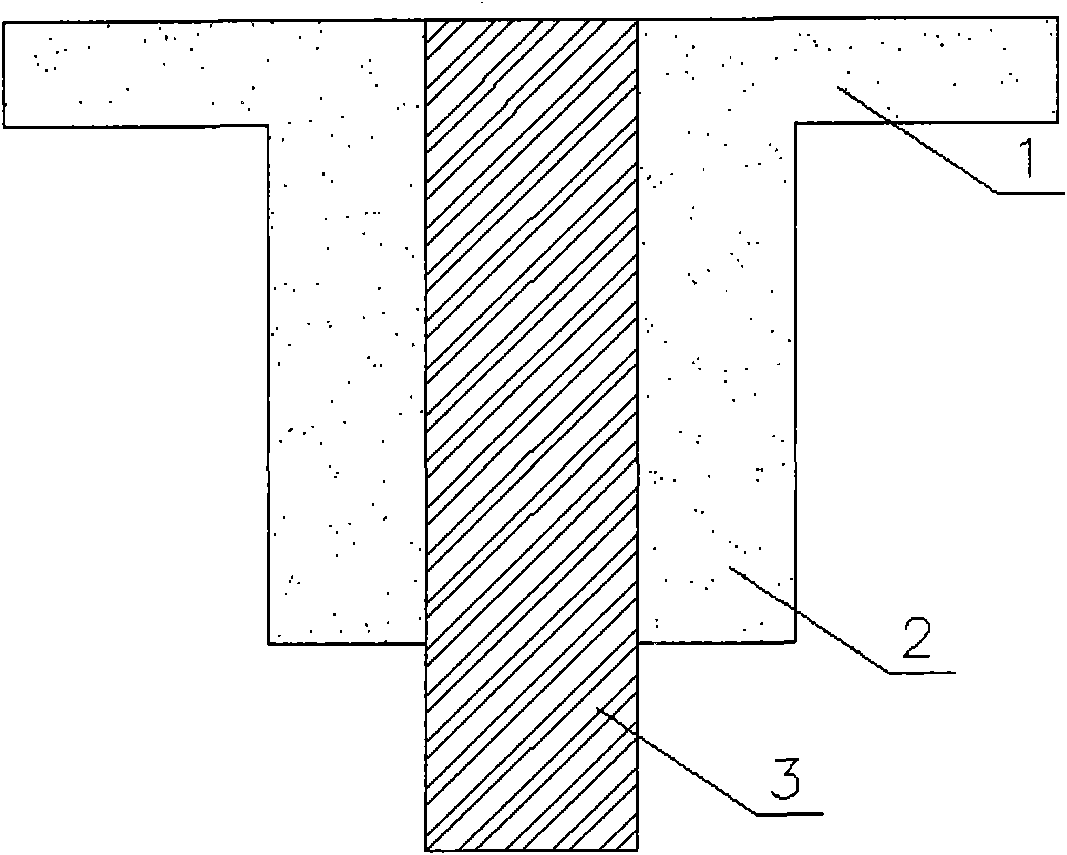

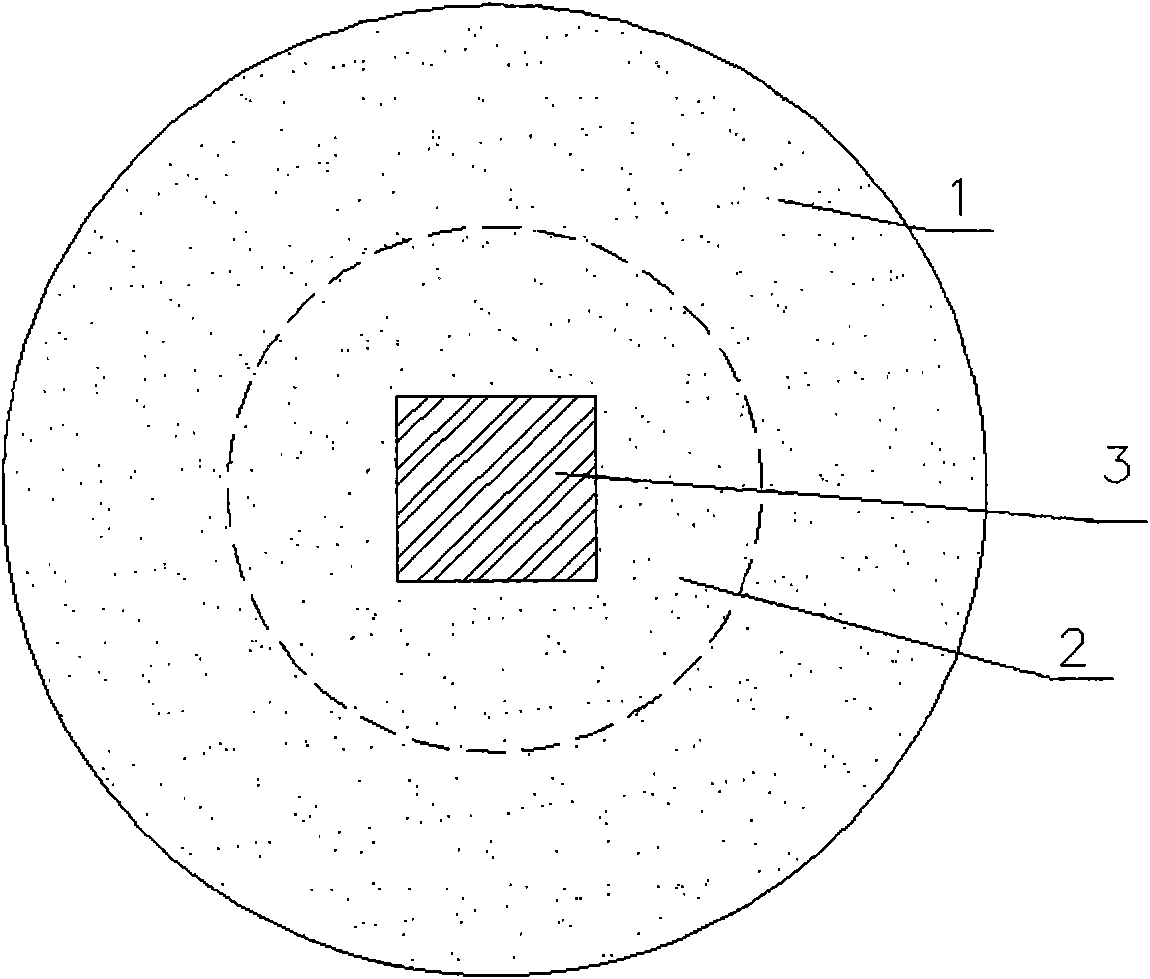

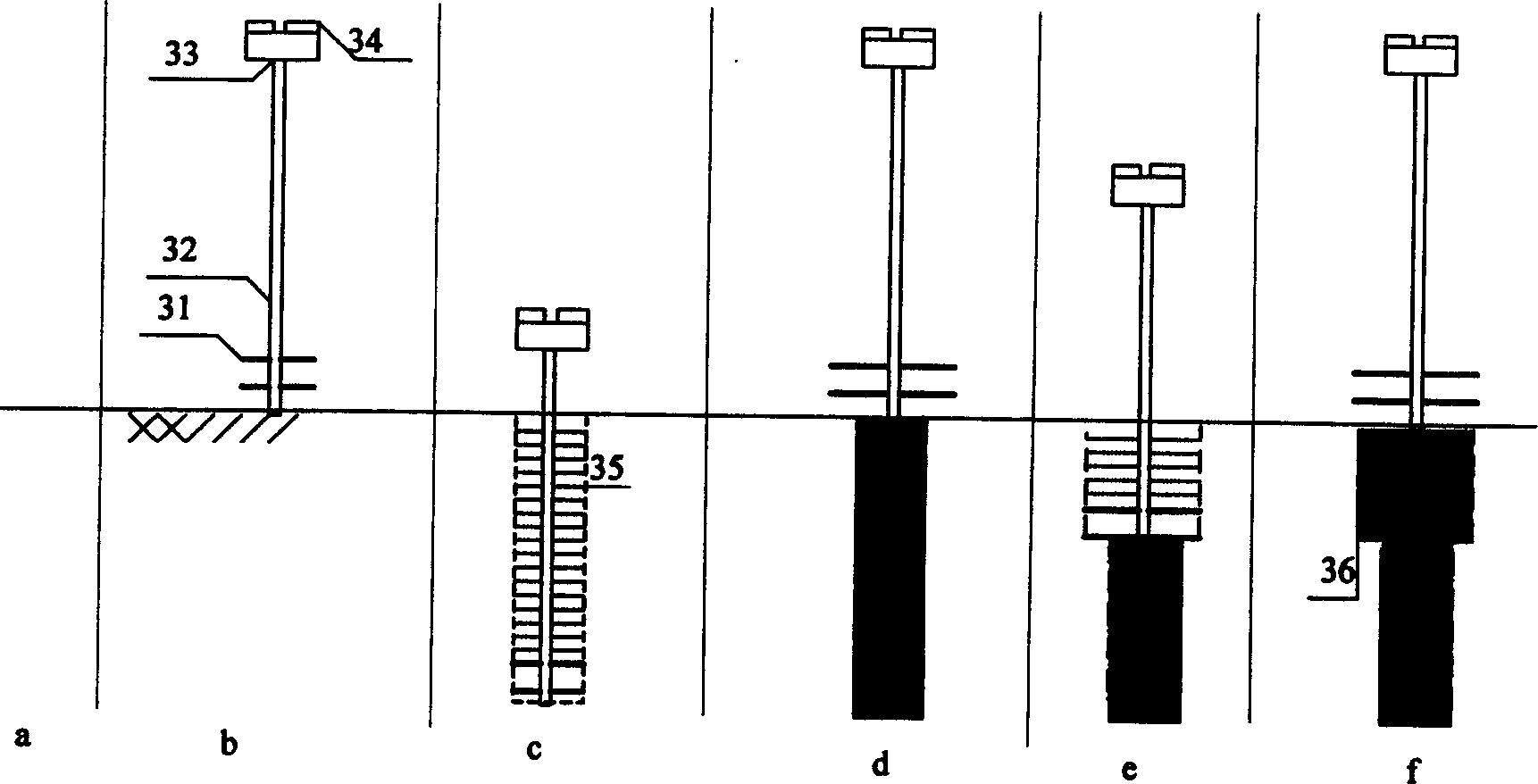

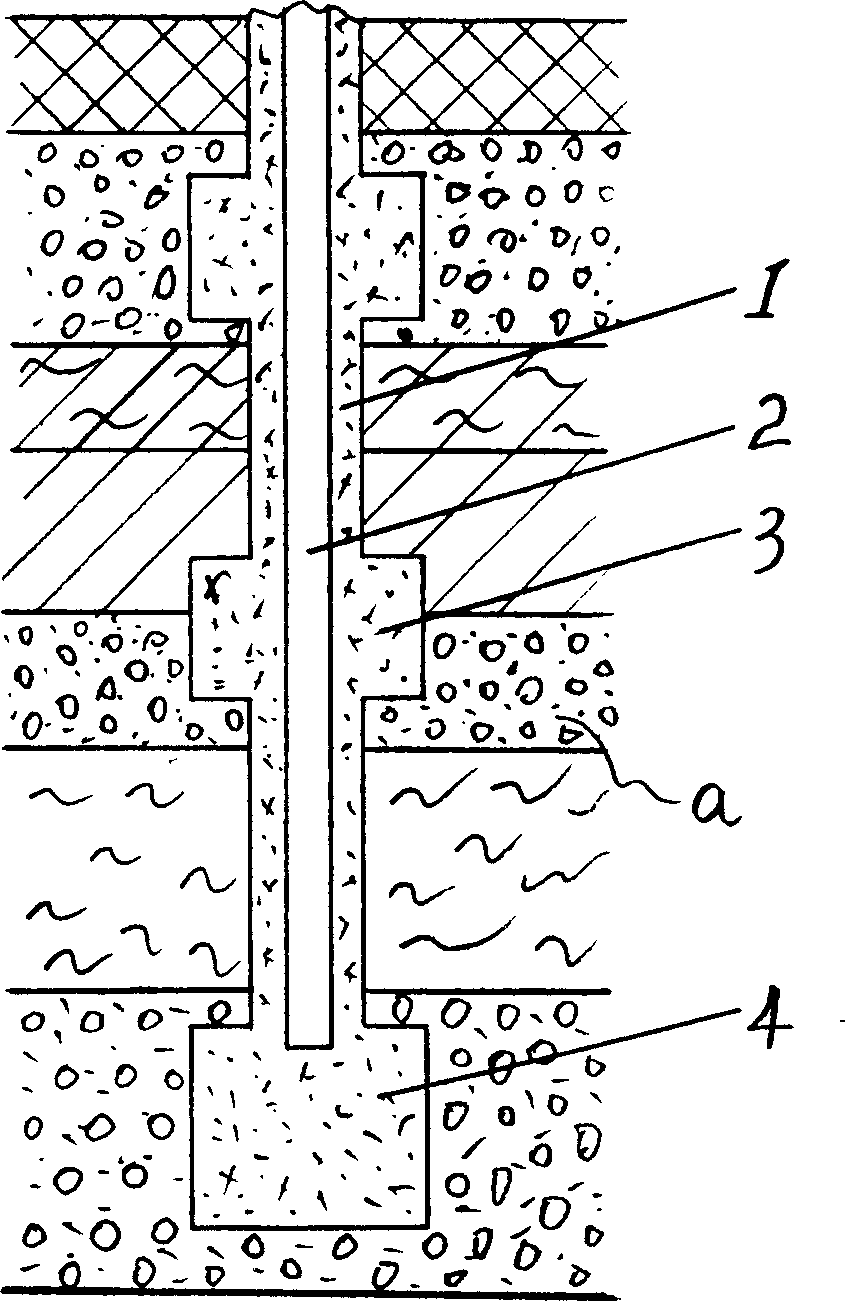

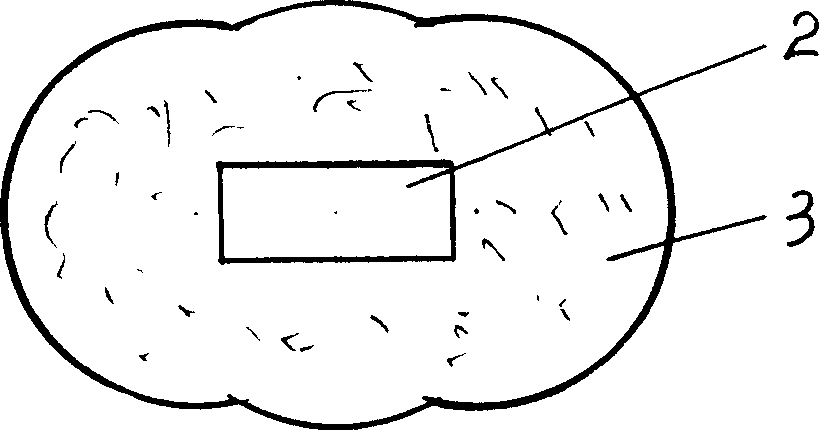

Novel cement soil composite mixing pile and pile formation method thereof

The invention belongs to the technical field of soft soil foundation treatment methods and particularly relates to a novel cement oil composite mixing pile and a pile formation method thereof. The mixing pile comprises the variable-section cement soil mixing pile and a quadrangular frustum pyramid-shaped reinforced concrete core pile, wherein the core pile is inserted into the mixing pile along the center of the section of the mixing pile and in close fit with the mixing pile. The novel cement soil composite mixing pile is manufactured by well using existing equipment and materials through changing material structure, construction process steps, the section of a pile body and the force transfer way and has the advantages of good pile formation quality, high strength of cement soil, high pile foundation bearing capacity and low cost.

Owner:岳建伟

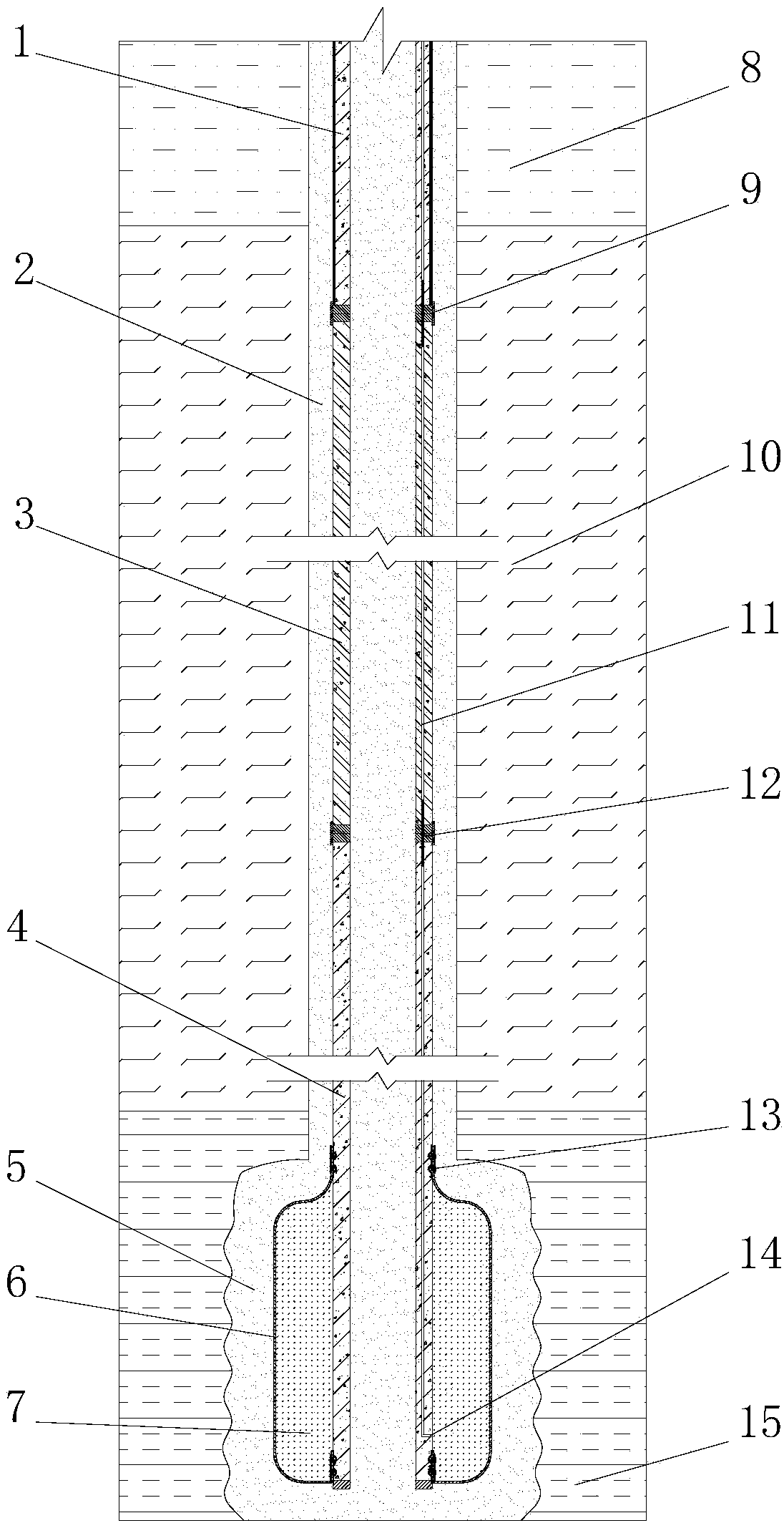

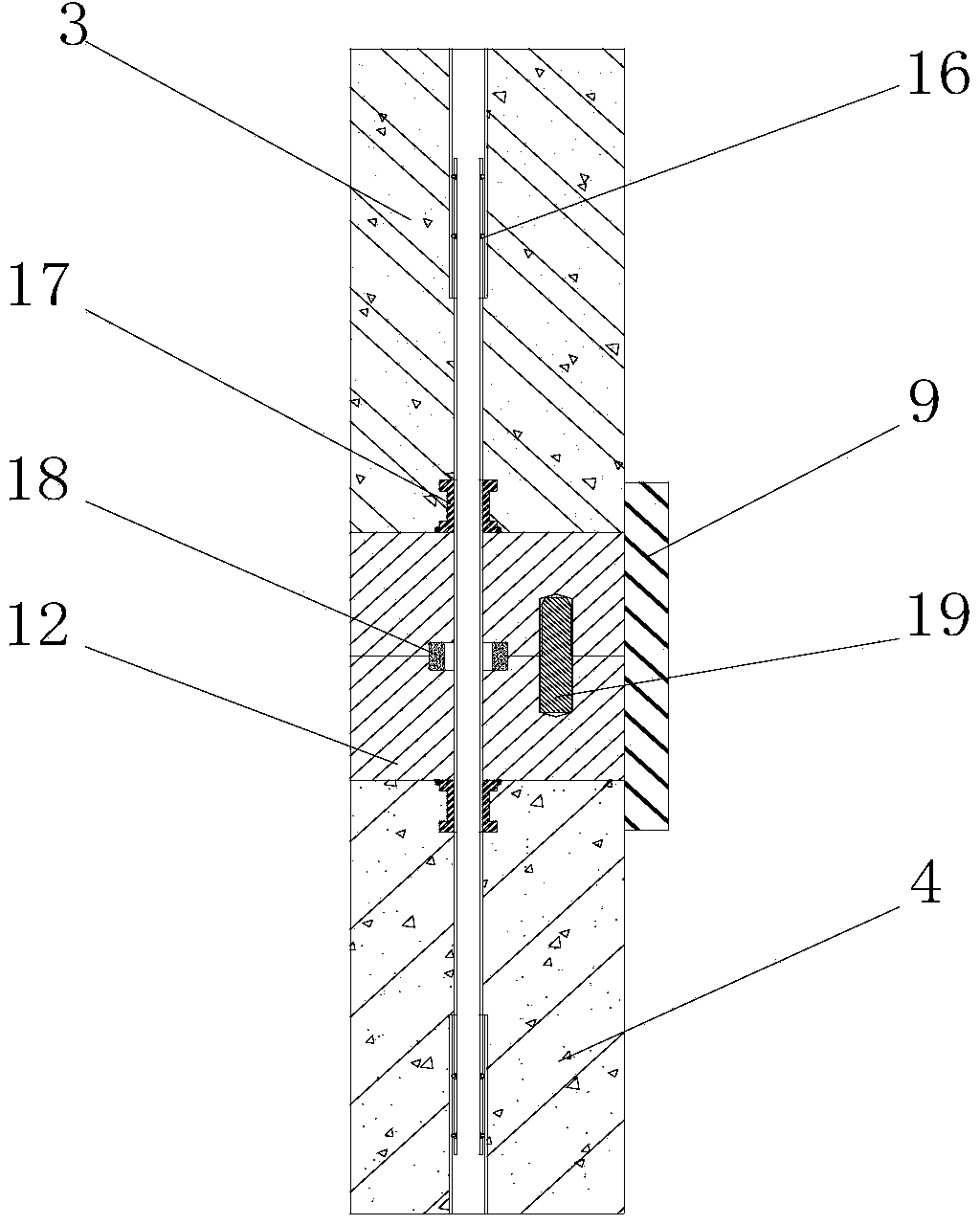

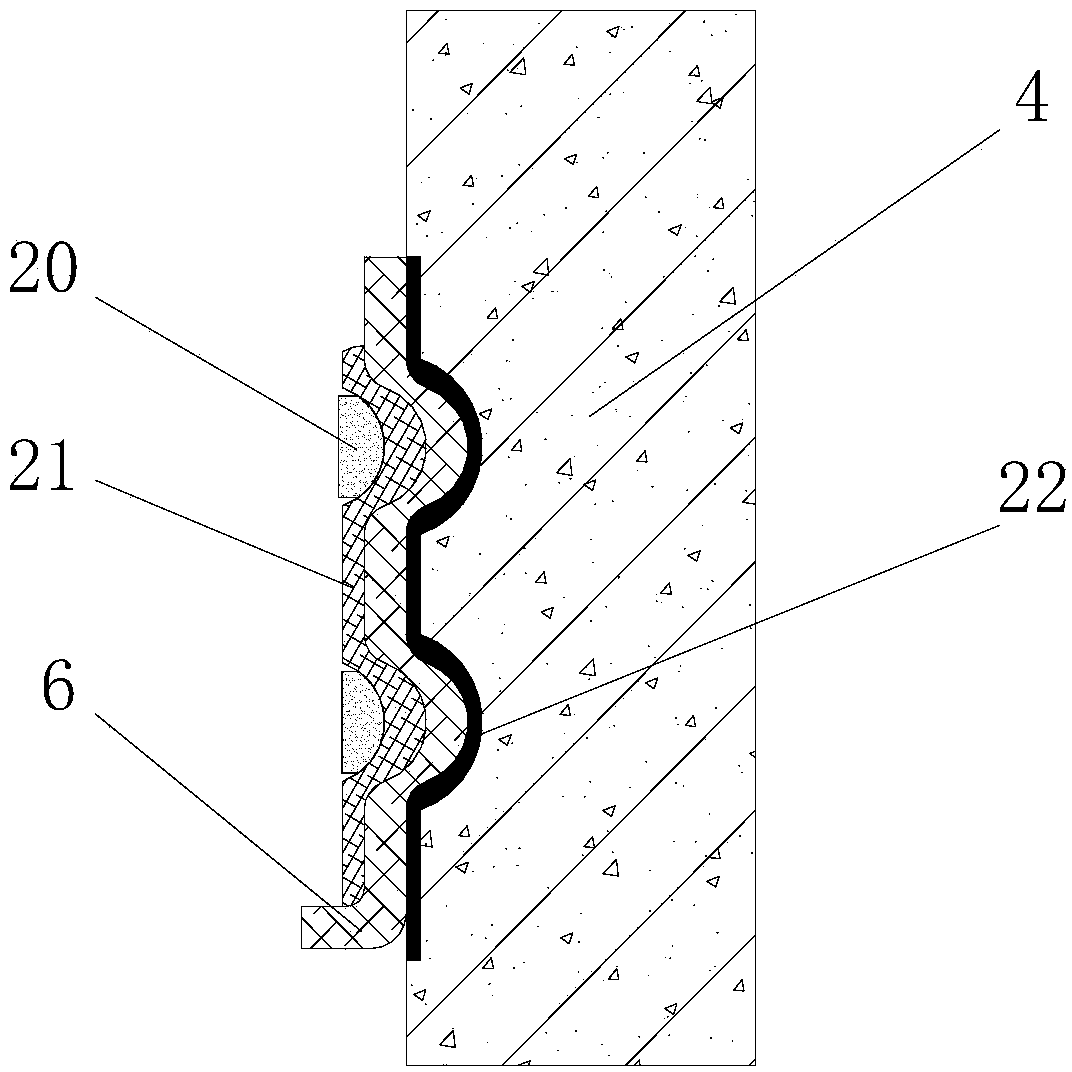

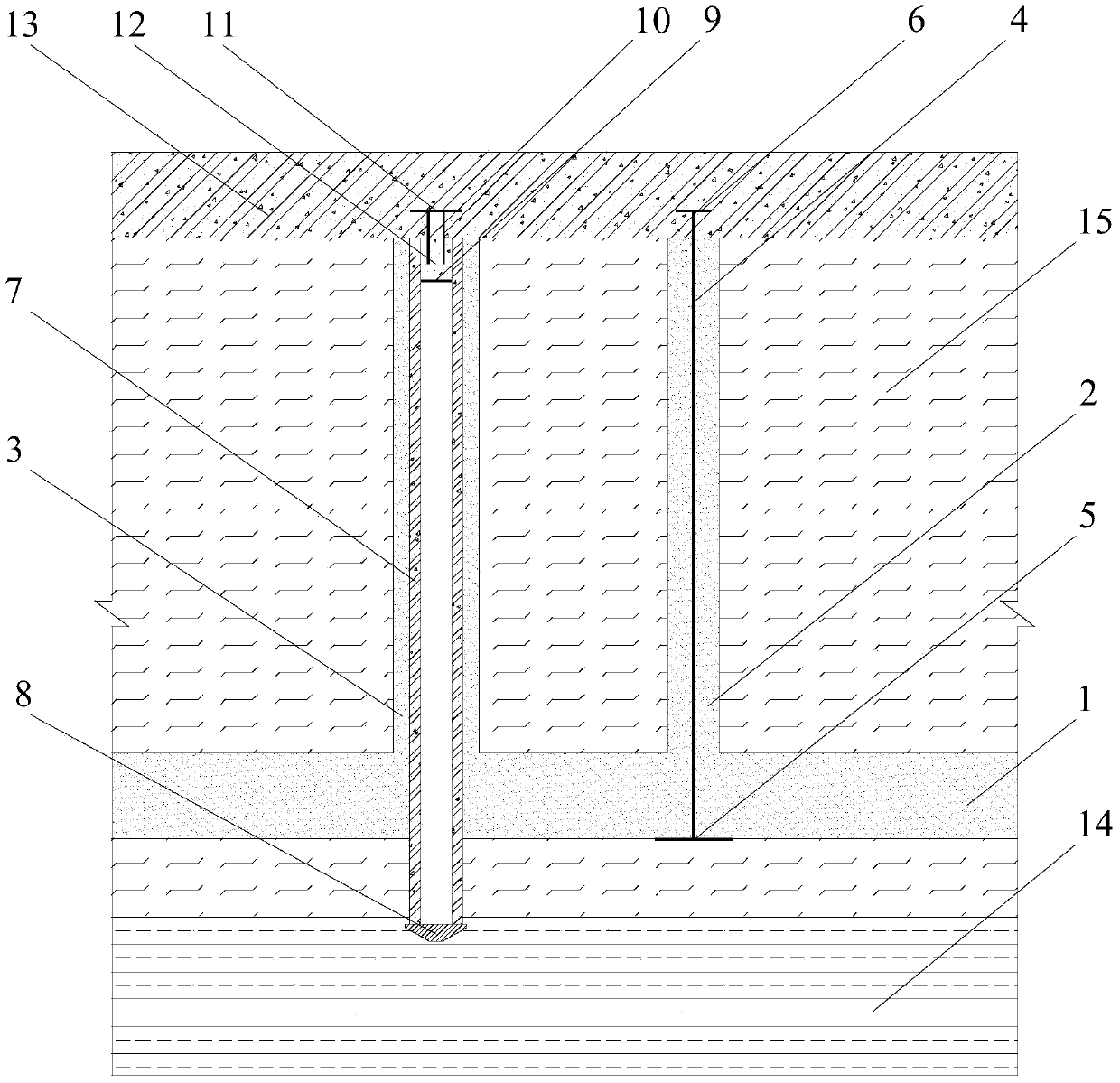

Bag bottom expanding rigid-flexible combined pile and construction method thereof

ActiveCN103741683AGive full play to the horizontal load bearing performanceNot easy to damageBulkheads/pilesEconomic benefitsSoil cement

The invention relates to a bag bottom expanding rigid-flexible combined pile. The bag bottom expanding rigid-flexible combined pile is formed by connecting the following prefabricated pipe piles including a TSC (prestress concrete thin wall concrete) pile, a PRC (prestress reinforcement concrete) pile and a PHC (prestress high-strength concrete) pile from top to bottom. The bottom end of the PHC pile is provided with a pile bottom expander packed by a bag; the inside of the prefabricated pipe piles is provided with a grouting duct; both ends of every pile is provided with perforated pipe pile joints, and the side wall of the pile at the bottom is provided with a grout outlet; the outside of the combined pile is packed by surrounding cemented soil. According to the bag bottom expanding rigid-flexible combined pile, based on the law of horizontal load bearing of the pile bodies inside soil, the prefabricated pipe piles with the anti-bending and anti-shearing performance gradually improved, which are connected in a combined mode, are sequentially planted inside the cemented soil, and the expanded is grouted after the bag with stable characteristics is set to improve the vertical bearing capacity of the piles, so that relatively higher technical and economical benefits can be obtained. The invention also discloses a construction method of the bag bottom expanding rigid-flexible combined pile.

Owner:ZHEJIANG TIANRUN CONSTR +4

Anti-floating piled raft structure combining deep-layer jet-grouting cement-soil board and anchor and construction method

InactiveCN103993611AResistance to buoyancyActive connectionProtective foundationBulkheads/pilesSoil sciencePre stress

The invention discloses an anti-floating piled raft structure combining a deep-layer jet-grouting cement-soil board and an anchor and a construction method. A continuous large-thickness deep-layer cement soil board which is formed in a high-pressure jet grouting mode is arranged at the design position in a foundation, a large-diameter jet grouting pile and a small-diameter jet grouting pile are further arranged on the cement soil board, a compound pile of prestressed pipe piles is inserted into the large-diameter jet grouting pile to serve as a vertical bearing pile, the top of the prestressed pipe piles is sealed and provided with an anti-floating screw and an anti-floating end plate, the anti-floating screw and the anti-floating end plate are connected with a raft foundation, the anti-floating anchor is implanted into the small-diameter jet grouting pile, and a rear expansion end plate is arranged at the bottom of the anti-floating anchor, and is arranged at the bottom of the deep-layer cement soil board. The anti-floating piled raft structure combining the deep-layer jet-grouting cement-soil board and the anchor and the construction method have the advantages that the capacity of surrounding soil is fully utilized for resisting buoyancy, a reliable anchoring point is provided for the anchor, the anchor distance can be effectively shortened, and the cost is reduced. Combination of the prestressed pipe piles, the large-diameter high-pressure jet grouting pile, the small-diameter high-pressure jet grouting pile and the short anti-floating anchor is adopted for the foundation, and the good vertical bearing capacity, the high buoyancy resistance performance and the like are achieved.

Owner:SHENZHEN GOLDEN CENTURY ENG INDAL

Composite pile and construction method thereof

InactiveCN101148875AReduce dosageImprove bearing capacityBulkheads/pilesReinforced concretePre stress

The present invention discloses one kind of composite pile comprising one pile core of high strength pre-stressed concrete pipe and one outer layer pile of soil cement coating the pile core and its construction process. The construction process includes the following steps: 1. high pressure spraying and stirring to form the outer layer pile; and 2. hoisting the pre-stressed concrete pipe pile and inserting or pressurizing into the center of the outer layer pile until reaching the designed depth. The composite pile has the advantages of both soil cement pile and reinforced concrete pile, vertical load borne by the pre-stressed concrete pipe pile and the side friction force transferred by the soil cement pile with relatively great cross section. It has clear stress mechanism, great bearing capacity and reliable quality.

Owner:山东省机械施工有限公司

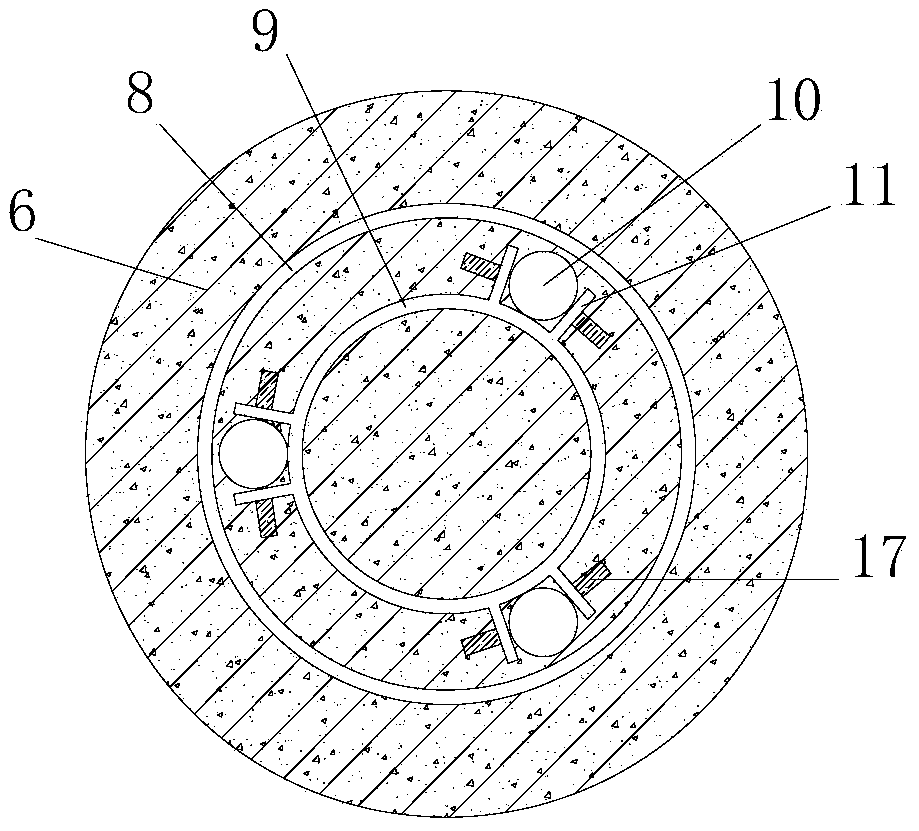

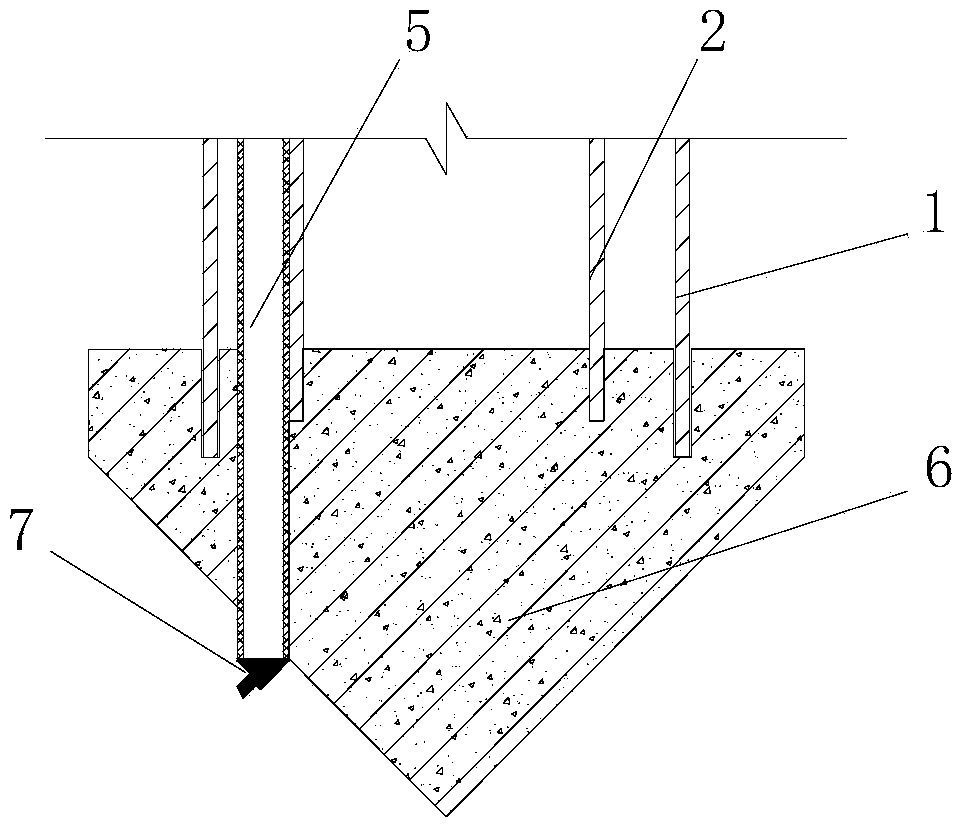

Construction device and method of pile peripheral cemented soil cast-in-place stiffness core pile

The invention relates to a construction device of a pile peripheral cemented soil cast-in-place stiffness core pile. The construction device is mainly composed of an inner immersed tube, an outer immersed tube, a precast pile toe and high-pressure guniting tubes. An outer immersed tube limiting groove, an inner immersed tube limiting groove, supporting baffle embedded grooves and torsion-resistance limiting steel plates which are used for positioning an upper portion immersed tube device are arranged on the upper surface of the precast pile toe. Hole channels which allow the high-pressure guniting tubes to pass are pre-formed inside the precast pile toe. The high-pressure guniting tubes which are provided with spraying heads at the bottom ends are evenly distributed on the outer side wall of the inner immersed tube in the circumferential direction. The two sides of each high-pressure guniting tube are respectively provided with a vertical through long supporting baffle. Stiffening ribbed plates are arranged on the outer sides of the supporting baffles in a uniformly-spaced mode. By the adoption of the construction device, the stiffness core pile can be formed inside the immersed tubes, cemented soil is formed at the periphery of the pile, the stress performance of pile body materials is brought into full play as much as possible, in the rotation sinking process of the device, high-pressure guniting is carried out on a lower portion soil body, end portion resistance and side frictional resistance can be reduced, and the sinking speed of the immersed tubes is improved. The invention further discloses a pile-forming construction method of the construction device.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

Composite high performance soil cement mortar pile construction method

InactiveCN101581093AHigh strengthImprove impermeabilitySolid waste managementBulkheads/pilesSlurrySoil cement

The invention relates to a composite high performance soil cement mortar pile construction method, comprising the following steps: 1) adopting a long spiral equipment, a sinking pipe equipment or a rotary drilling equipment to form holes, or adopting a continuous wall equipment to form grooves; 2) mixing outside the hole to form composite high performance soil cement mortar; 3) pouring or pressing the above composite high performance soil cement mortar in the holes or grooves by a grouting pump; the method is characterized in that: the soil cement mortar is composed of slurry, cement and sand, the sand mixed in every cubic meter of slurry is 150-1000 kg, and the cement mixed in every cubic meter of slurry is 150-400 kg. The invention has the advantages that: the strength and impermeability of soil cement can be increased on the condition of low cost and at the same time a novel material--composite high performance soil cement mortar is produced.

Owner:宋琼

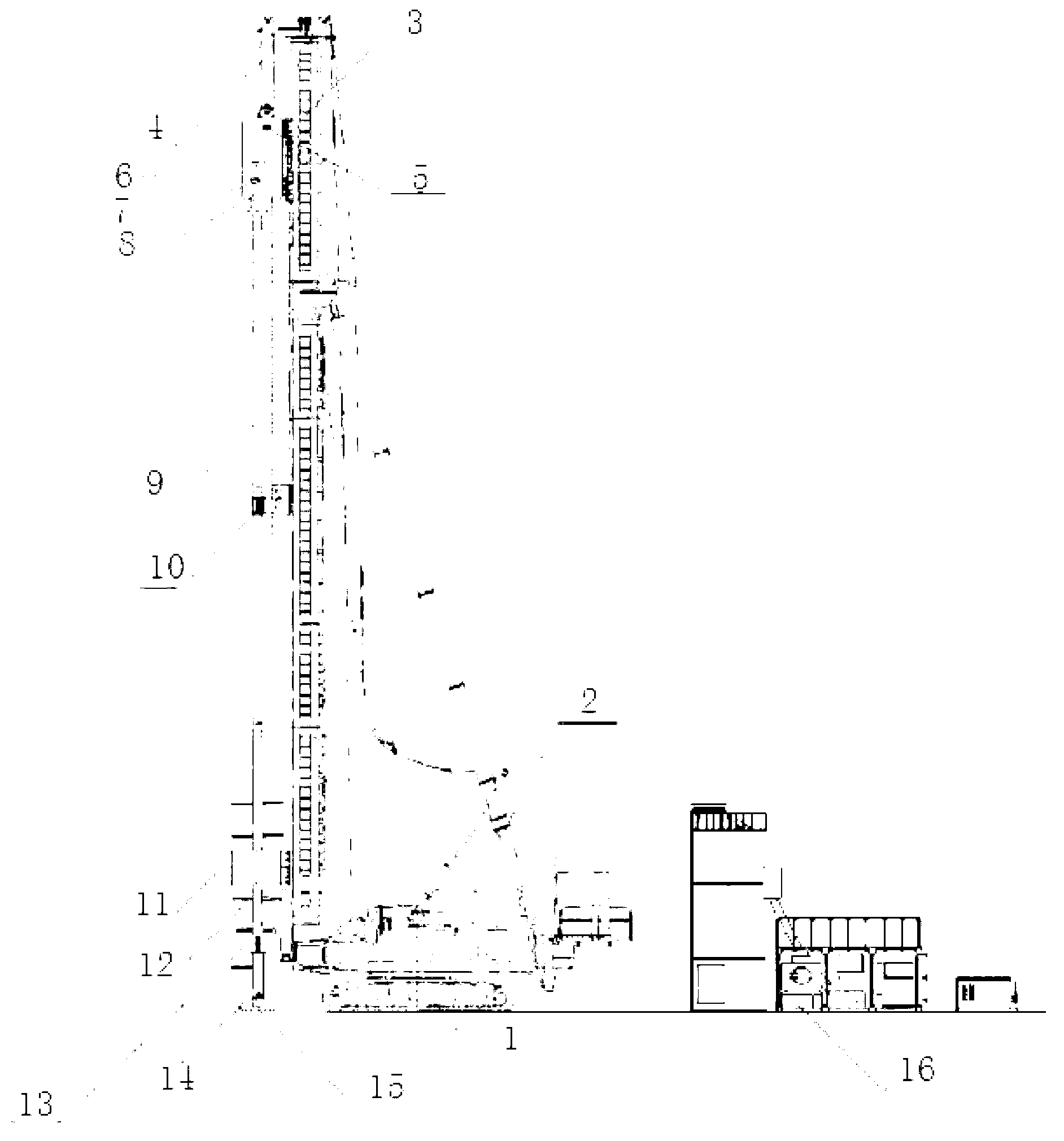

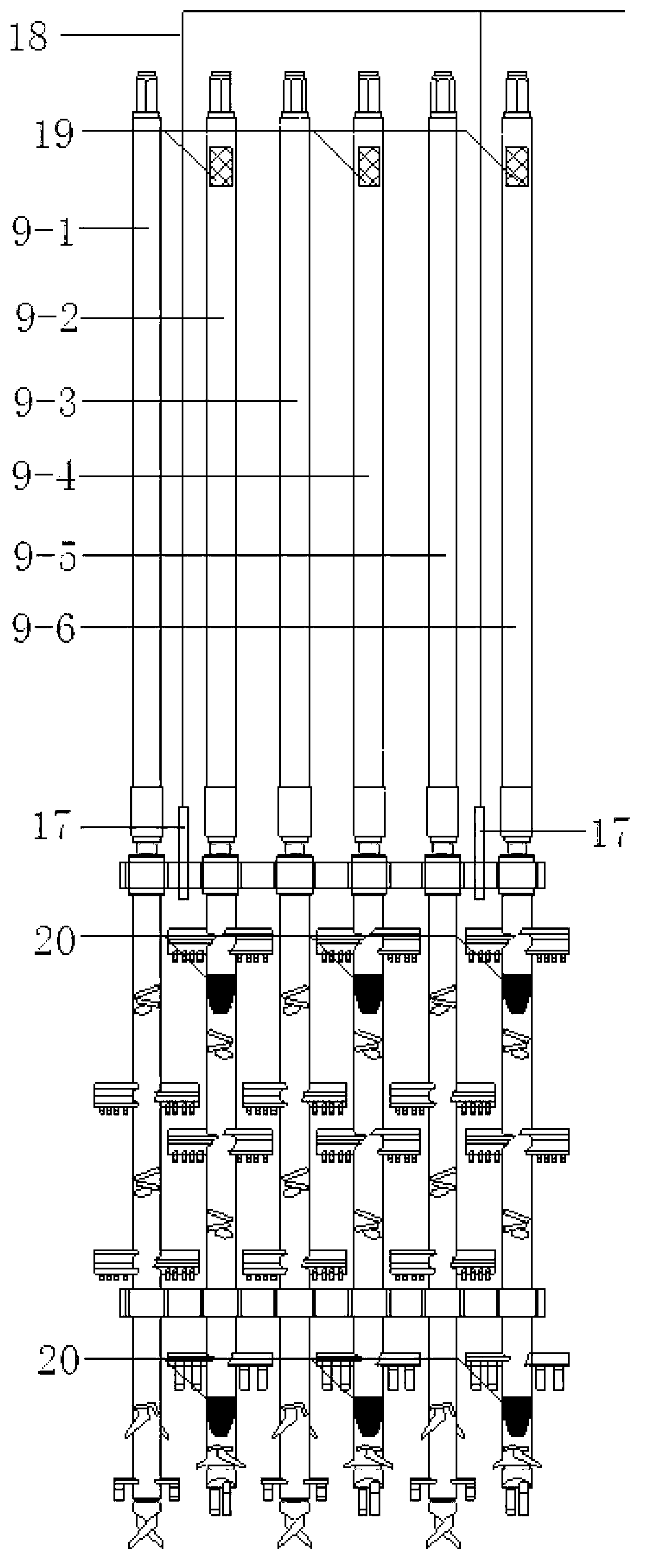

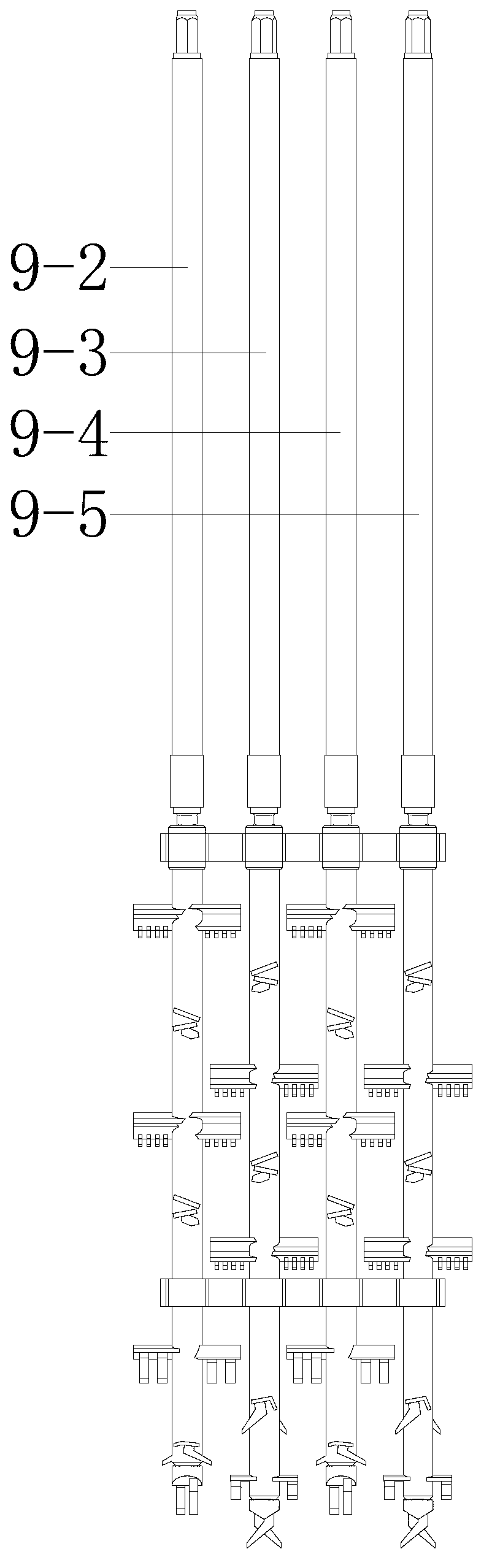

Two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and construction method thereof

ActiveCN103074892AReduce the number of lapsImprove the water-stop effectSurveyDirectional drillingCement slurrySoil cement

The invention relates to a two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and a construction method thereof. The device comprises a host, a guide rod, a power assembly, a plurality of drill pipes, drill pipes with wings, multifunction drill bits, a background cement slurry stirring system, flow meters, a soil penetrating depth sensor and verticality real-time monitors, wherein the power assembly is connected with the drill pipes, the lower end of each drill pipe with the wing is connected with each multifunction drill bit, the top part of each drill pipe is provided with a slurry inlet, the middle part of each drill pipe is provided with a middle bearing bracket, each flow meter is arranged on a slurry spraying port, the penetrating depth sensor is arranged on a slide rail of the guide rod, each verticality real-time monitor is arranged on each middle bearing bracket, the flow meters, the soil penetrating depth sensor and the verticality real-time monitors are respectively connected with the host, and detachable drill pipes are adopted as the drill pipes. Compared with the prior art, the device has the advantages that the pile forming function is versatile, the cost is saved, the verticality is controllable, the pile forming effect is good, and the like.

Owner:SHANGHAI CHENGDI CONSTR

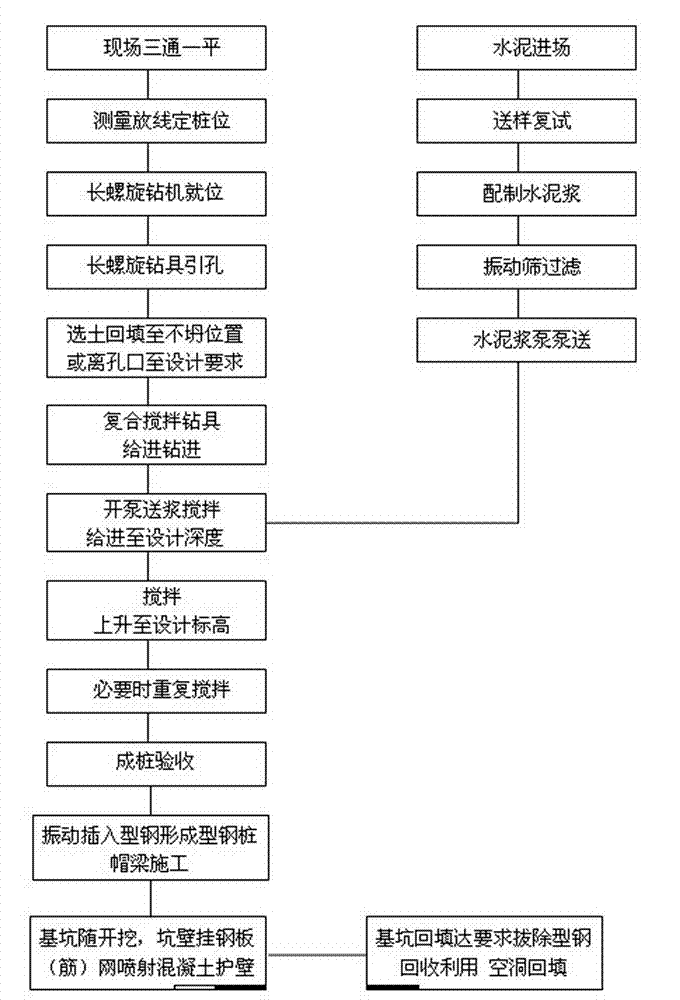

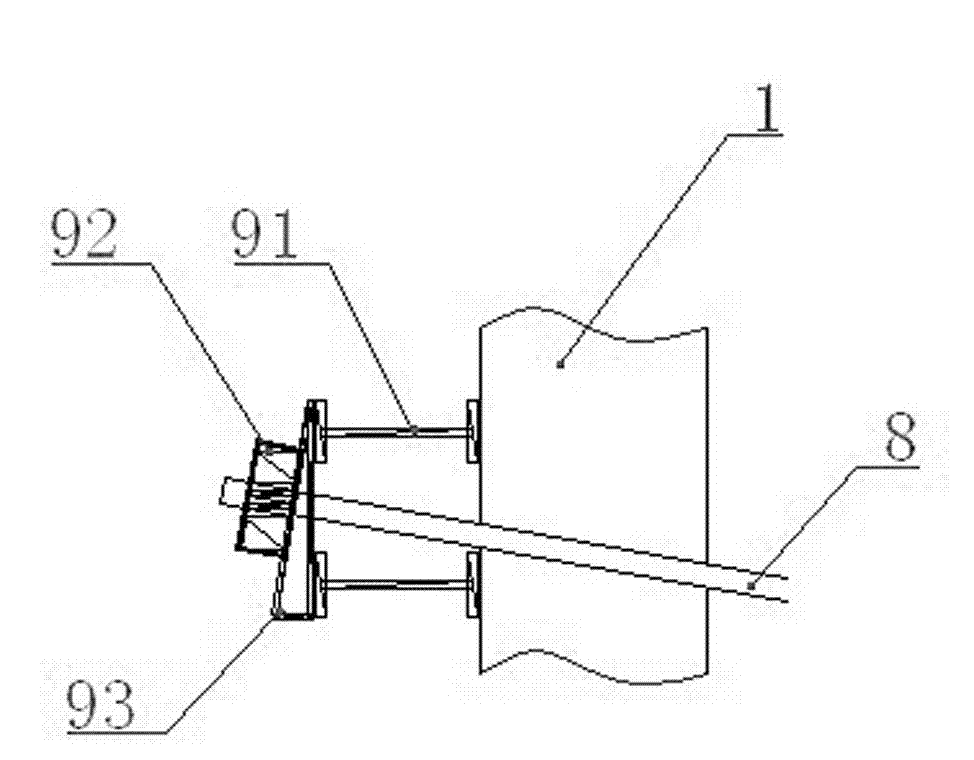

Foundation pit water-sealing supporting method by using long spiral cement soil mixing structural steel pile

InactiveCN103046557AImprove reliabilityOvercome drillingExcavationsBulkheads/pilesSoil mixingSoil cement

A foundation pit water-sealing supporting method by using a long spiral cement soil mixing structural steel pile. Construction steps include that a long spiral drill is used for constructing a cement soil mixing pile; after construction of each cement soil mixing pile, structural steel is inserted into the top end of each cement soil mixing pile; inner supports or detachable anchor rods are used for conducting composite supporting when a foundation pit is deep; pile top beam connecting construction of the cement soil structural steel pile is conducted; the foundation pit is dug, a net is hung on an inner lateral wall of the foundation pit, and concrete is sprayed; and the anchor rods or the inner supports are detached when backfilling of grooves of the foundation pit meets a requirement, and finally the structural steel is removed. The foundation pit water-sealing supporting method has the advantage that the long spiral drill can drill hard soil layers and can reach the designed depth by overcoming the hard soil layers, simultaneously designed pile diameter can be achieved, meshing reliability is guaranteed, and water sealing reliability is guaranteed. The structural steel is inserted later to achieve an effect of supporting the foundation pit, and a two-in-one effect of water sealing and supporting is achieved. Due to recycling of the structural steel and removing of the anchor rods, cost of supporting construction of the foundation pit is greatly reduced, and the method is environment-friendly.

Owner:北京建材地质工程有限公司 +2

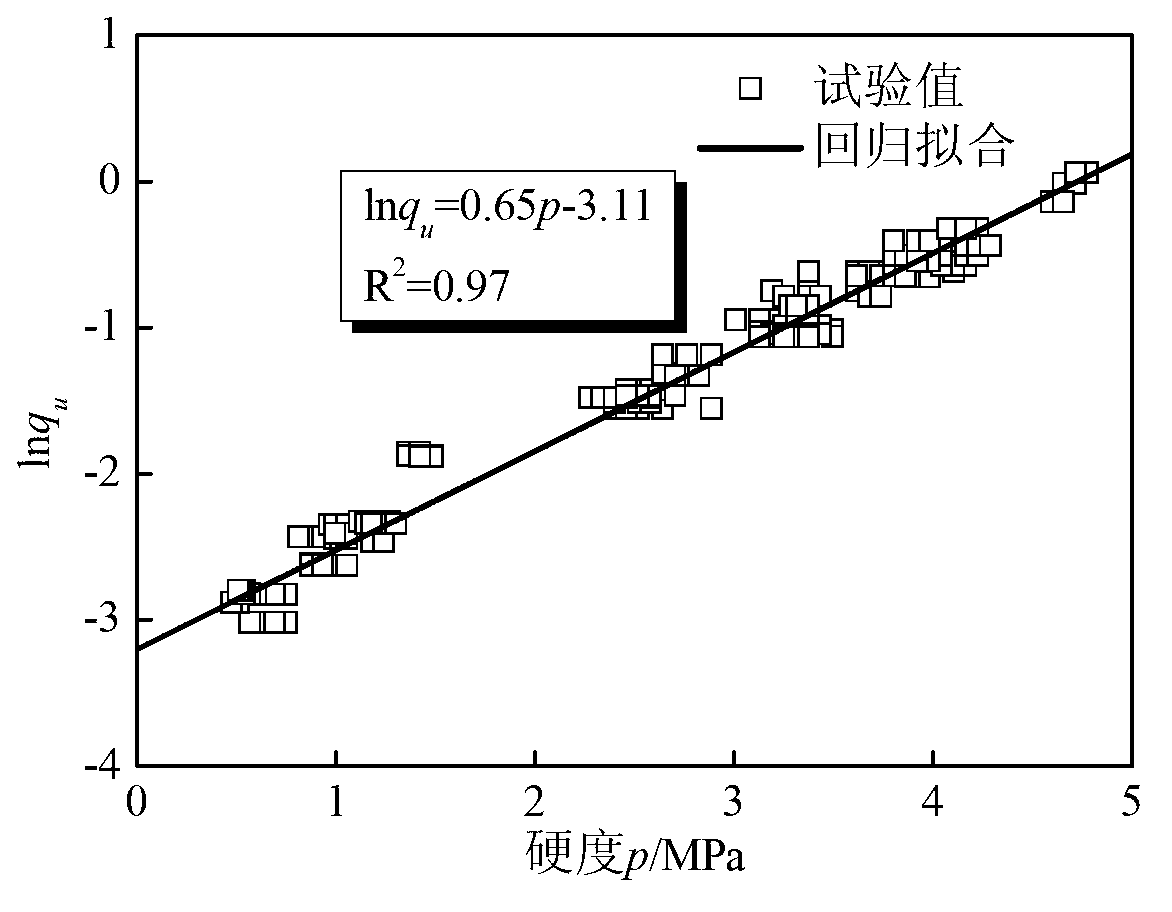

Method for detecting strength of soil-cement admixture by using hardness test

InactiveCN102980819AAvoid destructionAvoid delayPreparing sample for investigationMaterial strength using tensile/compressive forcesKnoop hardness testHardness

The invention provides a method for detecting the strength of a soil-cement admixture by using a hardness test. The method comprises the following steps: acquiring soil samples from a variety of soil layers within on-site construction depth; carrying out sample preparation on the on-site soil samples and cement and then carrying out a hardness test and a lateral confinement-free compressive strength indoor test; collating hardness values of soil cement test pieces obtained in the test and corresponding lateral confinement-free compressive strength values and drafting a graph of relation; subjecting the graph of relation to linear-regression analysis to obtain a relation between the hardness values of soil cement at the construction site and natural logarithm values of confinement-free compressive strength; during reinforcing and maintenance of on-site construction soil cement, digging out the surface of a few reinforcing sections to expose the soil cement, testing hardness of the soil cement with a Shore durometer and calculating a confinement-free compressive strength value by directly using the linear regression relation obtained through the tests. According to the invention, destroy of reinforced soil and delay of a construction period caused by boring and sampling of the reinforced soil after reinforcement construction are avoided, and the method is concise, economic, effective and fast.

Owner:SHANGHAI JIAO TONG UNIV

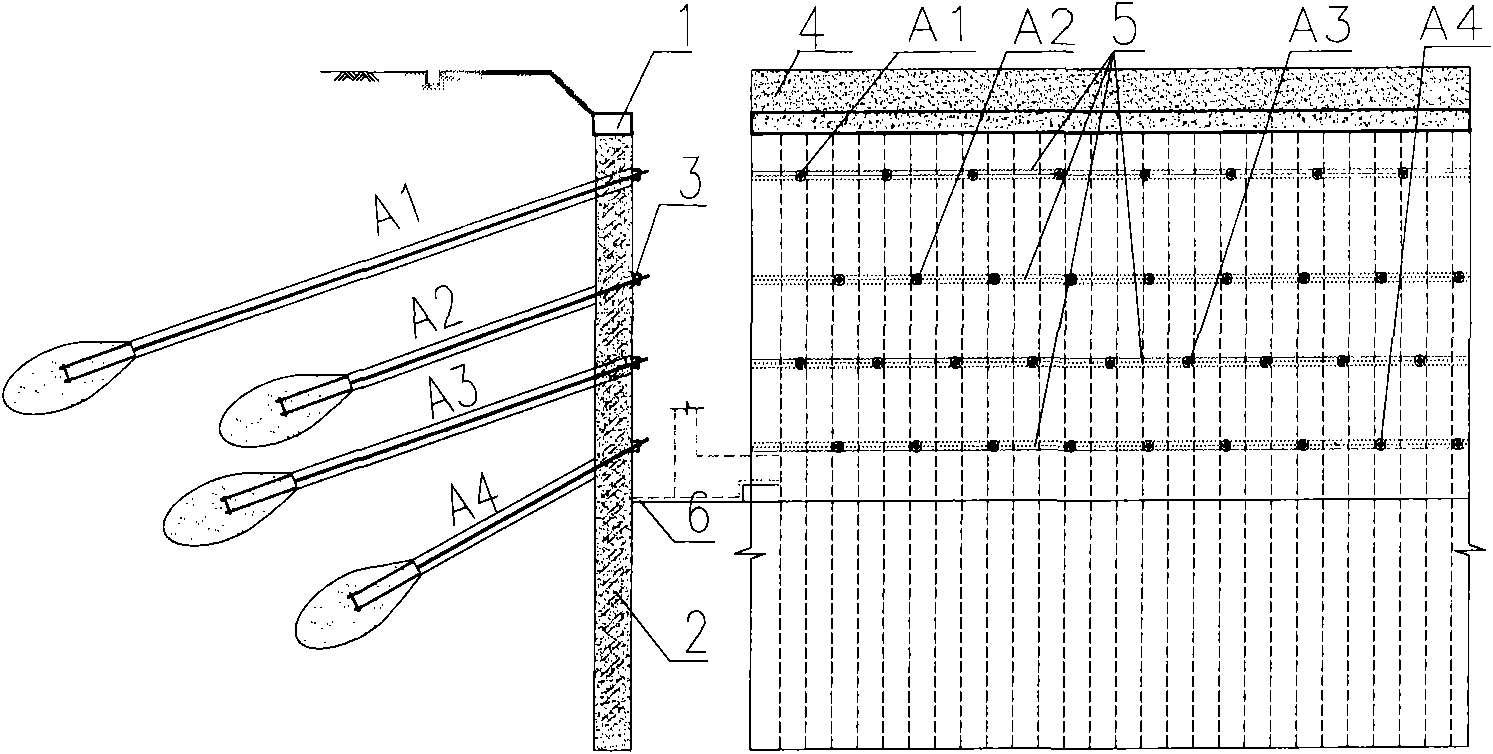

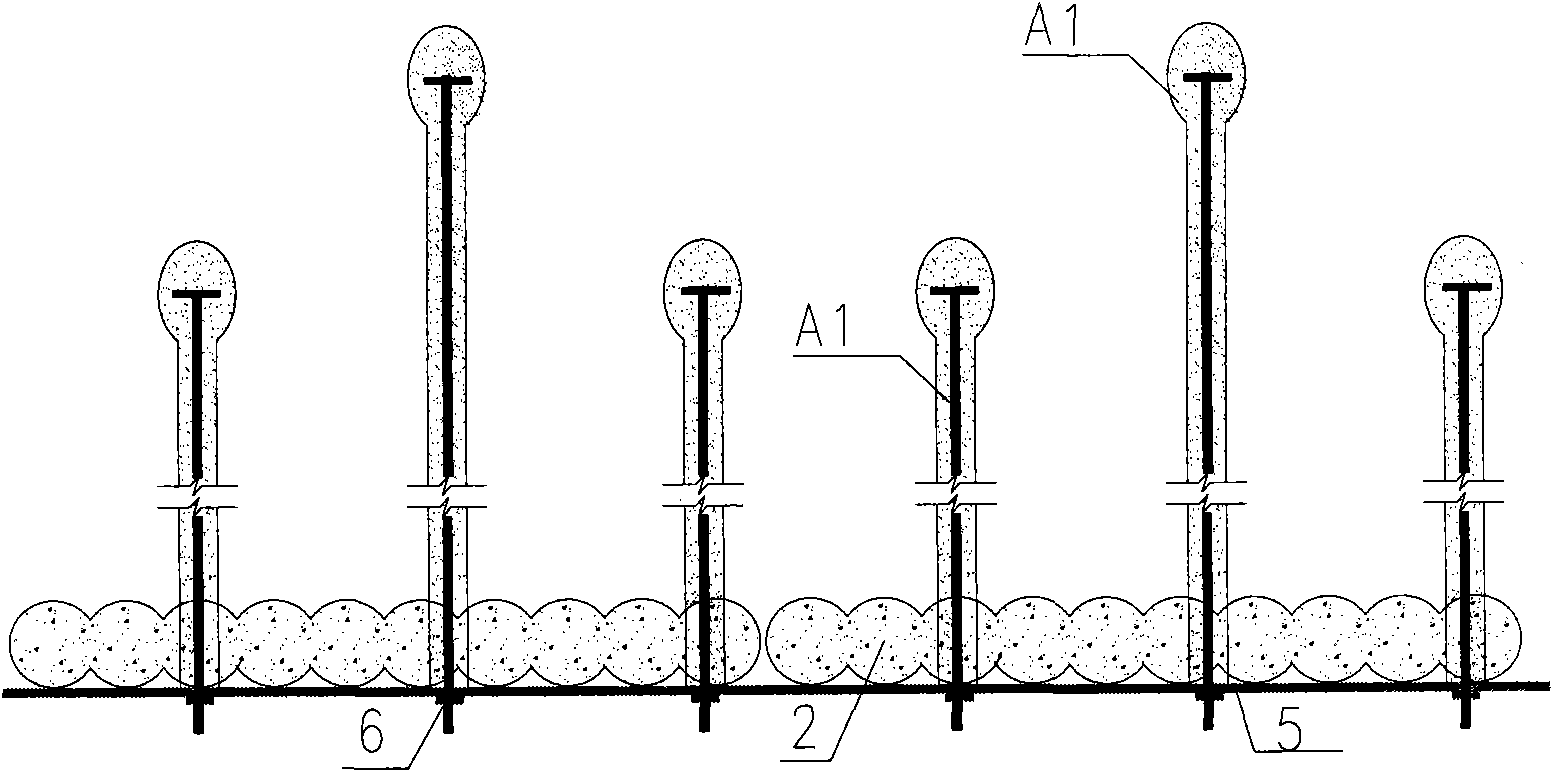

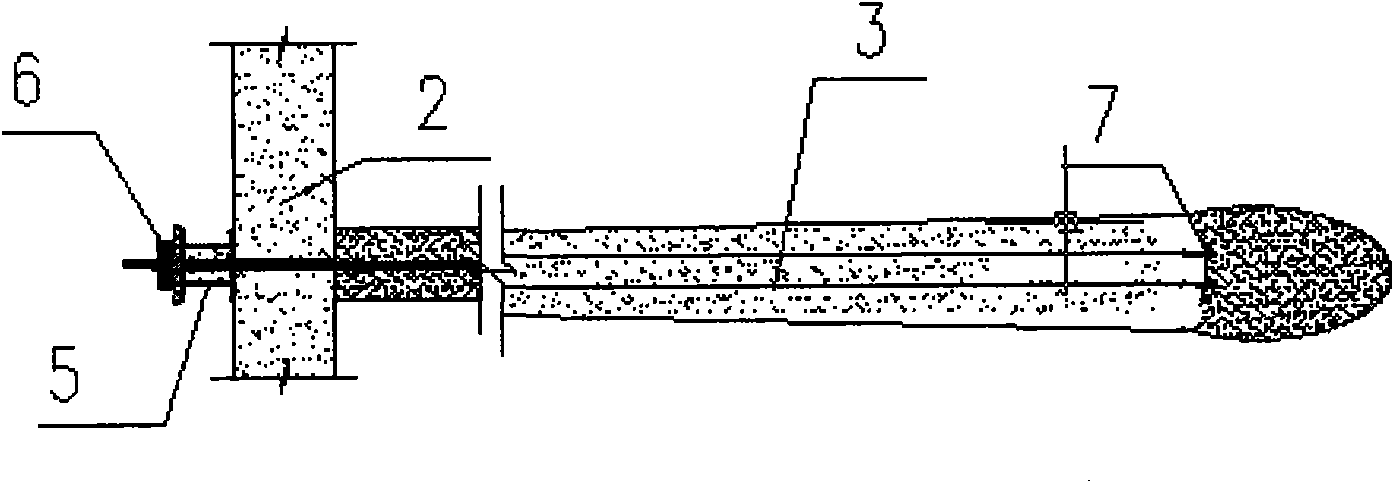

Anti-slip cement soil pile soil blocking structure and construction method thereof

ActiveCN101775814AImprove skid resistanceLow costArtificial islandsExcavationsSoil scienceRock engineering

The invention relates to the technology of reinforcing, supporting and protecting soft rock soil in the rock engineering. An anti-slip cement soil pile soil blocking structure is formed through the addition of a cement soil anti-slip pile body in the soft soil body and the combination. The anti-slip cement soil pile soil blocking structure overcomes various defects of the common soil blocking structure, and belongs to a novel structure with the advantages of safety, environment protection, economy and fast construction. The anti-slip cement soil pile soil blocking structure and a construction method thereof are characterized in that vertical cement soil piles, vertical hole drilling filled piles, steel plate piles, underground continuous walls and the like as well as cement soil anti-slip piles (with different lengths and inclination angle) tension, pull and lock the added rib bodies arranged in an anti-slip pile body through horizontal walings for being combined into the soil blocking structure, wherein tensioning bodies (such as steel stranded wires, steel pipes, cable wires, formed steel, non-metal materials and the like) are inserted inside the vertical cement soil piles, the vertical hole drilling filled piles, the steel plate piles, the underground continuous walls and the like. Through the pre-reinforcing on the soft soil body and the pre-tensioning pulling on the added rib bodies in the anti-slip pile by the soil block structure, the stability of the reinforced, supported and protected soil body is greatly improved, and the horizontal and vertical displacement amount is greatly reduced.

Owner:SHANGHAI STRONG FOUND ENG

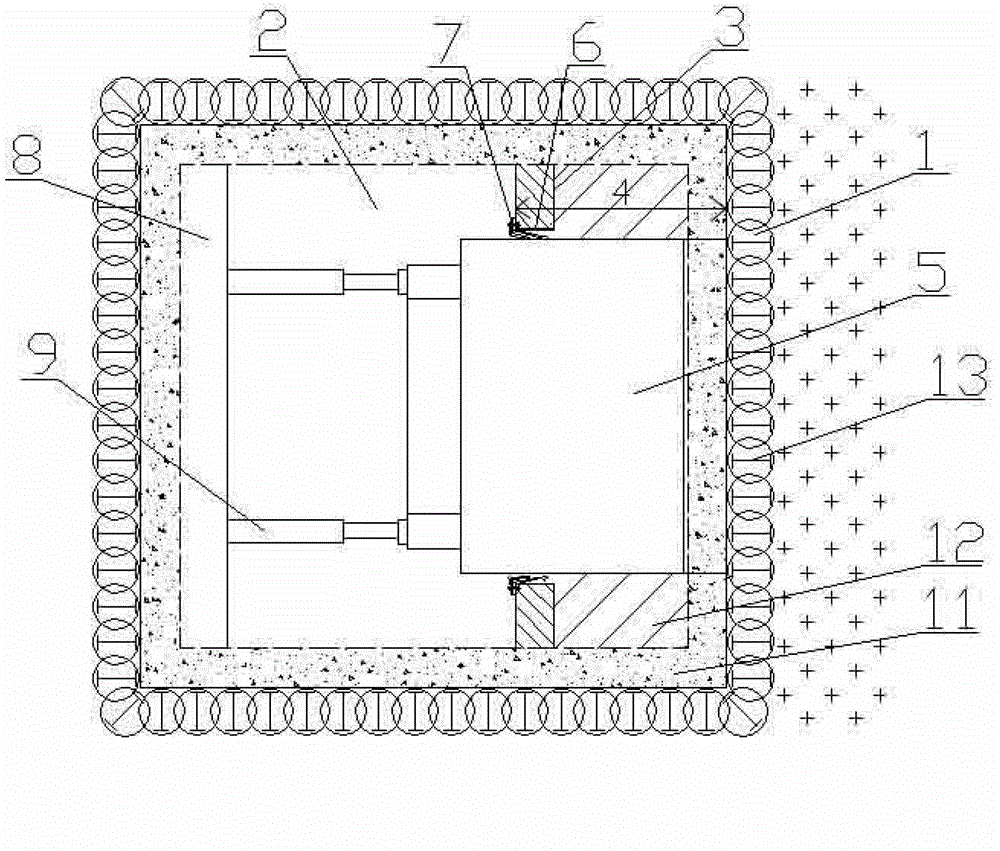

Space enclosing structure convenient for opening door opening, construction method and use method thereof

The invention discloses a space enclosing structure convenient for opening a door opening, which consists of a door opening portion and a periphery portion around the door opening portion. The door opening portion is a slotted section corresponding to a proper caliber size for the access of a tunneling machine; and the slotted section is filled with soil cement and vertically inserted with a plurality of H-shaped steels in sequence so as to form a profiled bar retaining wall that can block water and satisfy the rigidness required for digging a foundation ditch. The invention also discloses a construction method of the space enclosing structure convenient for opening the door opening, an out-start well method and an in-reception well method using the space enclosing structure convenient for opening the door opening. The invention can avoid the labour capacity required for manually opening the door opening, can save the working period and effectively reduce the construction risk. As additional large-scale devices are unnecessary to be installed and the H-shaped steel can be recycled, the invention also has the advantages of simple construction and low construction cost.

Owner:SHANGHAI CONSTRUCTION GROUP

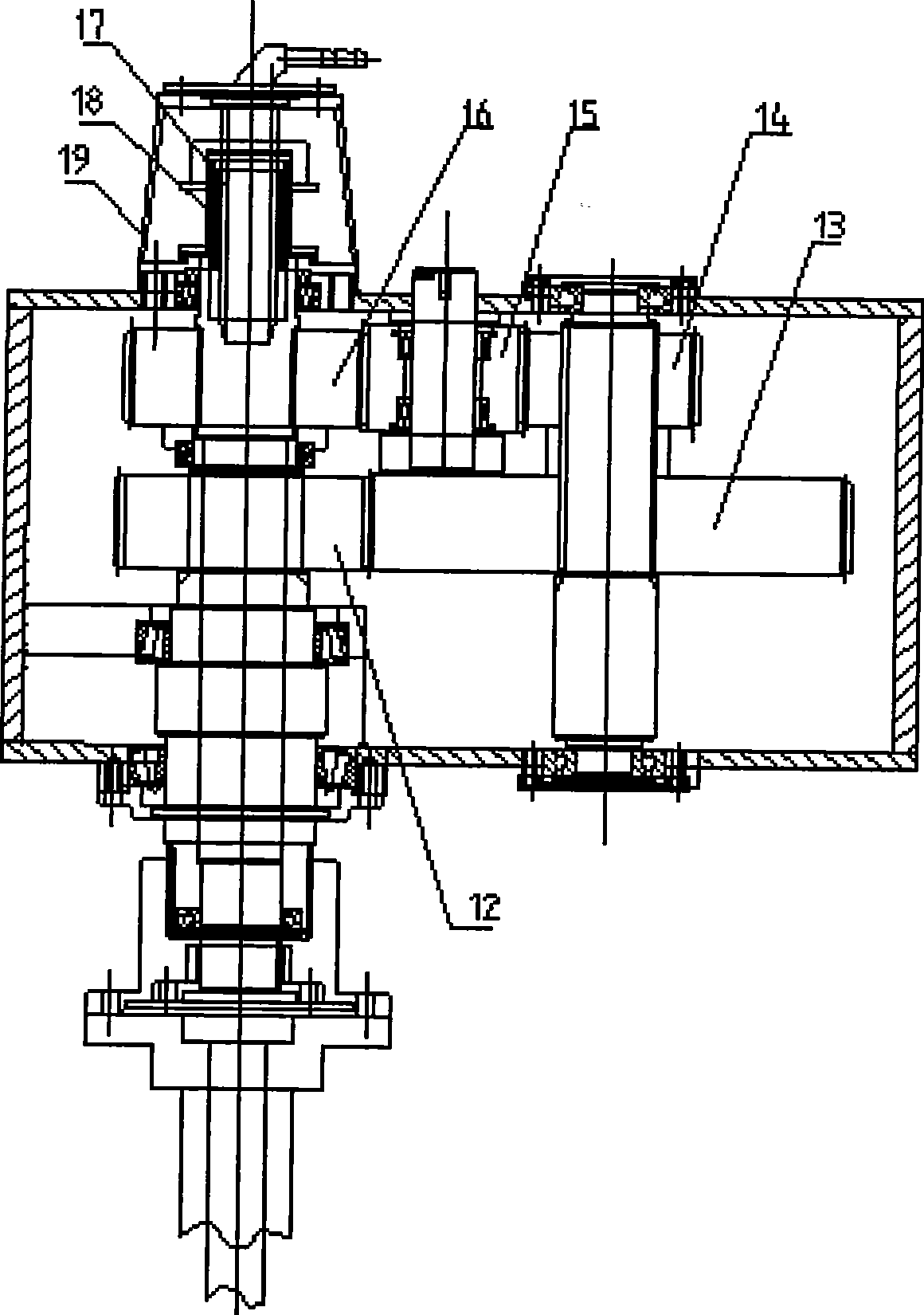

Multi-direction multi-shaft stirring concrete earth pile machine

ActiveCN101413267ARealize multi-directional stirringEasy to assemble and disassembleBulkheads/pilesDrive wheelDrive shaft

The invention provides a multi-way multi-shaft soil cement pile machine, which comprises a machine body, a motor and a gear box. The machine is characterized in that the machine also comprises a positive-negative box, a rotary disk, an outer drill rod, an inner drill rod, a transmission case, an outer stirring drill bit and an inner stirring drill bit. A main shaft of the motor is connected with a driving wheel of the gear box, a driven wheel of the gear box is connected with a driving wheel of the positive-negative box, the driven wheel of the positive-negative box is connected with the rotary disk, and the outer drill rod penetrates the rotary disk and is coaxial with the rotary disk; the inner drill rod penetrates a central hole of the outer drill rod; the driving wheel of the gear box is connected with the outer drill rod, and a reverse wheel is meshed with a gear of the inner drill rod to drive the inner drill rod to rotate; the outer stirring drill bit is fixed on the outer drill rod, and the inner stirring drill bit is fixed on the inner drill rod; the transmission case is arranged on the top part of the outer drill rod; and the motor is arranged on an under frame of the machine body. The machine has the advantages of improvement on the operating environment of the transmission case, uneasy damage, convenient maintenance, small volume, light weight and convenient assembly and disassembly of the drill bits, small drilling resistance and stable operation.

Owner:武汉谦诚桩工科技股份有限公司

Double-acting self-stressing combined uplift pile and pile forming method

InactiveCN102787595AHigh tensile strengthSave steelProtective foundationBulkheads/pilesCrack resistanceReinforced concrete

The invention relates to a double-acting self-stressing combined uplift pile and a pile forming method. The problems of influence on the durability of a pile body because a traditional prestressed concrete uplift pile is easy to generate cracks, large use quantity of reinforcing steel bars, high engineering cost and long construction period can be effectively solved. The invention has the solving technical scheme that the invention comprises a soil-cement stirring pile, prefabricated reinforcing steel bar-reinforced concrete core piles and a pile forming method thereof. The prefabricated reinforced concrete core piles are arranged in the soil-cement stirring pile, the upper part of a second reinforced concrete core pile is connected with a basic bottom plate, one end of a steel stranded wire is connected with a first anchor ingot plate in the lower part of a first reinforced concrete core pile by an anchor device, and the other end is connected with a third connecting steel plate in the basic bottom plate. According to the double-acting self-stressing combined uplift pile and the pile forming method, the problem of crack resistance of concrete is solved. The operation of prestressed tensioning is carried out before the bottom plate is poured with the concrete, the probability of water seepage of the bottom plate is lowered, the construction period is shortened, the construction difficulty is lowered, the cost is saved, the construction period is short, and the application range is extensive. The double-acting self-stressing combined uplift pile has favorable social and economic benefits.

Owner:HENAN UNIVERSITY

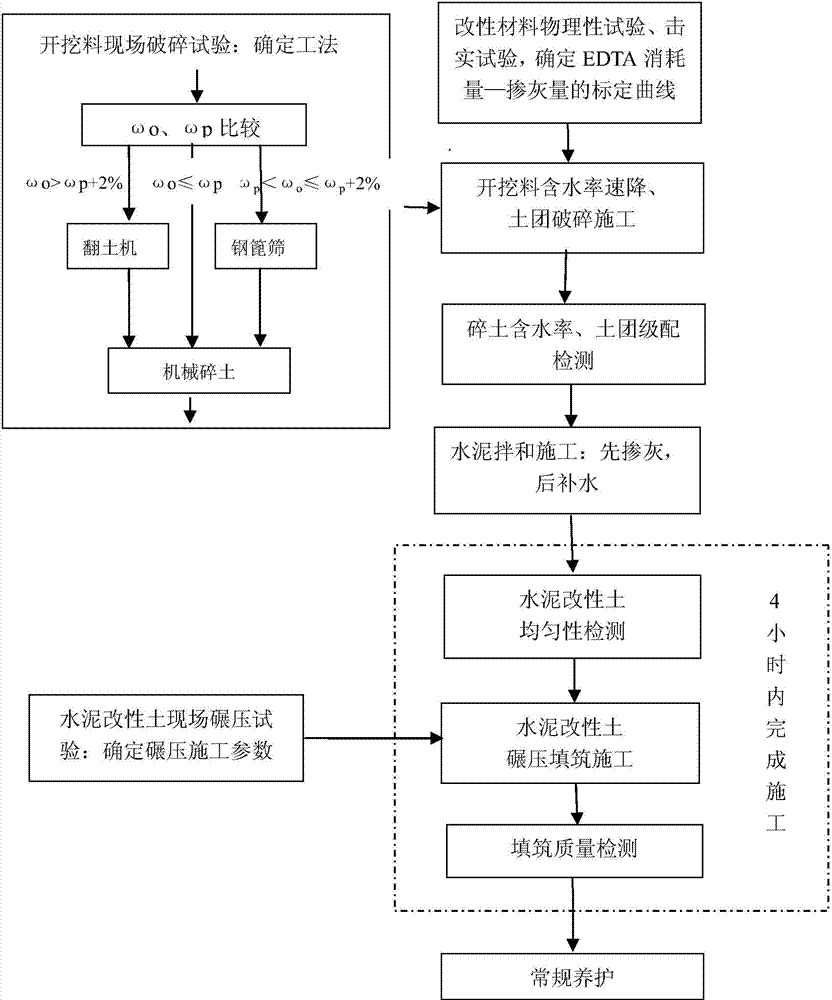

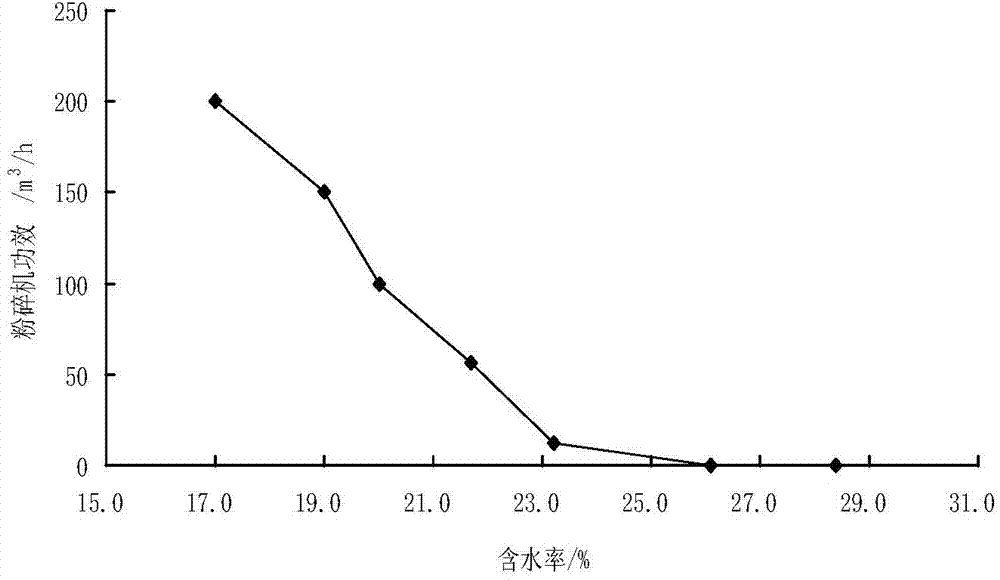

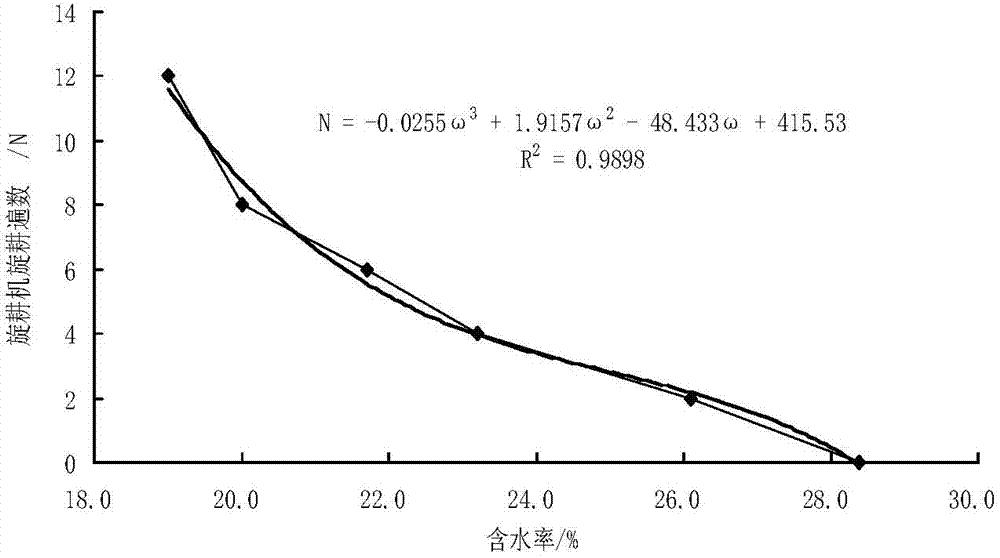

Expansive soil cement modifying and filling construction method

An expansive soil cement modifying and filling construction method includes the following steps of (1) carrying out a modified material general characteristic test; (2) carrying out excavated material moisture content prompt drop and soil mass breaking construction; (3) carrying out broken soil moisture content and soil mass graded construction quality inspection; (4) carrying out cement mixing construction; (5) carrying out modified cement soil uniformity construction quality inspection; (6) carrying out modified cement soil grinding and filling construction; (7) carrying out modified cement soil filling construction quality inspection; (8) carrying out conventional maintenance. Different breaking construction methods are selected according to the measured natural moisture content omega o for soil mass breaking construction, the requirements for soil mass grades and moisture content of cement mixing uniformity can be met, cement is uniformly mixed at first and then 3-5 percent of water is supplemented in cement mixing and construction, it is guaranteed that the moisture content is approximate to the optimum moisture content during modified cement soil grinding and filling, meanwhile the requirement for time of modified cement soil grinding and filling construction is put forward, and modified cement soil filling quality is guaranteed.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Foundation pit supporting method for manual dig-hole cement-soil steel pile

A foundation pit supporting construction method for a manual dig-hole cement-soil steel pile comprises the technological processes: manually digging cylindrical pile holes in a side-by-side or interval way; hoisting processed profile steels by a crane and then fixing the profile steels in the holes; pouring cement soil slurry well stirred in a stirrer in the pile holes, performing partial vibrating if necessary, so as to form cement-soil steel piles; manufacturing pile top coupling beams at the tops of the cement-soil steel piles; when foundation pits are deeper, adopting inner supports or detachable anchor rods to compositely support the cement-soil steel piles; hanging nets on the side surfaces of the cement-soil steel piles and then carrying out concrete spray when the foundation pits are dug; dismantling the anchor rods or the inner supports when the backfilling of foundation pit and the trough meets requirements; and finally removing the profile steels for recycle. The method has the advantages of being mainly suitable for hard soil in northern China, such as water-free dense sand gravel stratums where machinery construction is not available or the stratum suitable for manually digging, and being reduced in cost; the manual digging is economical and easy to implement; and the quality and construction period are ensured and the environment is protected.

Owner:深圳市南华岩土工程有限公司

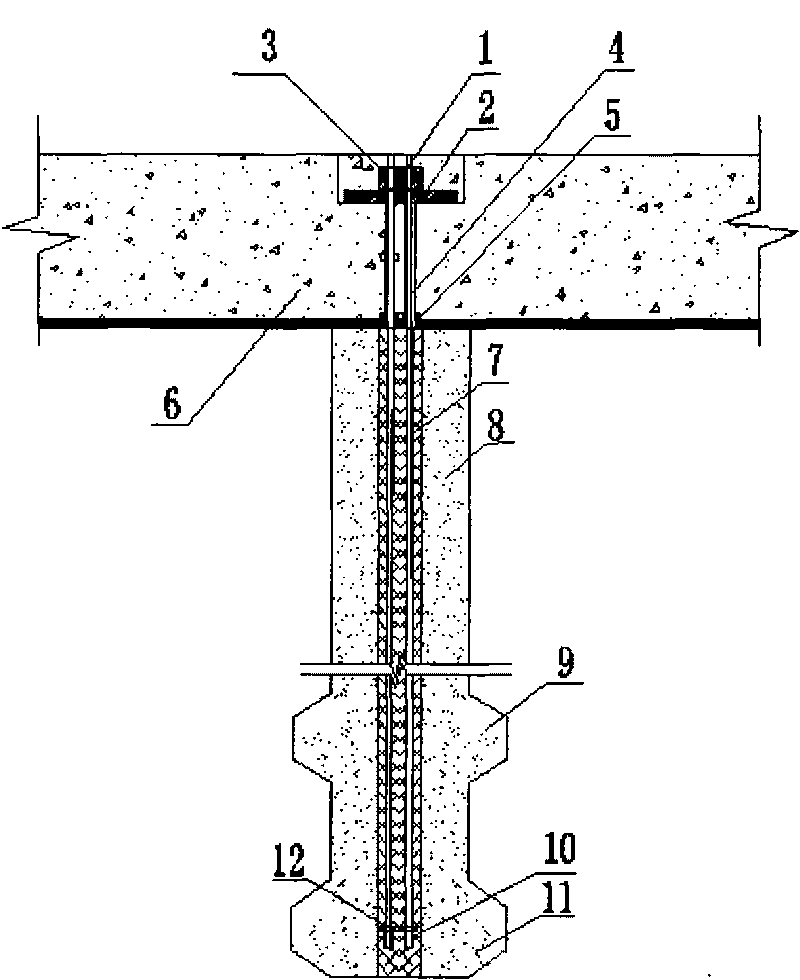

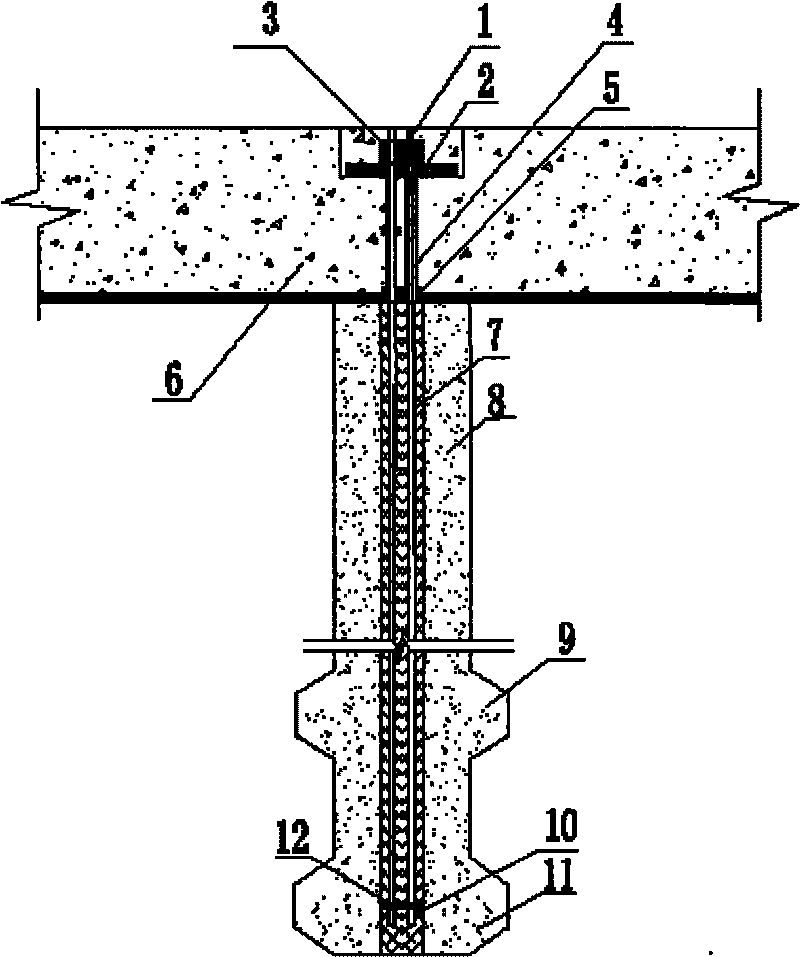

Soil cement expanding uplift pile

The invention relates to a soil cement expanding uplift pile taking anti-floating restraint for underground buildings and structures or a pile foundation for resisting the inclination of the underground buildings. The underground buildings and structures of an area with a higher underground water level all have structural anti-floating problems, so the uplift pile is necessary to be adopted to restrain the buoyancy of underground water for the underground buildings; in order to prevent the inclination of the underground buildings, inclined pulling force generated by the uplift pile foundation needs to be adopted to restrain the inclination, so the uplift pile includes a vertical uplift pile generating vertical pulling force and an inclined uplift pile generating inclined pulling force; and in order to increase the uplift force of the uplift pile inside a soft soil layer, the diameter, the pile body roughness and the expanding diameter of the uplift pile are increased. The soil cement expanding uplift pile comprises a soil cement material with changeable diameter, a set cement material, an anchorage body, an anchorage plate, an end-part locking pipe, a PVC sleeve, an anchorage device, and the like and adopts an intermediate and high pressure jet grouting and anchorage drag-in one-step molding method and a stirring jet grouting and anchorage drag-in one-step molding method.

Owner:SHANGHAI STRONG FOUND ENG

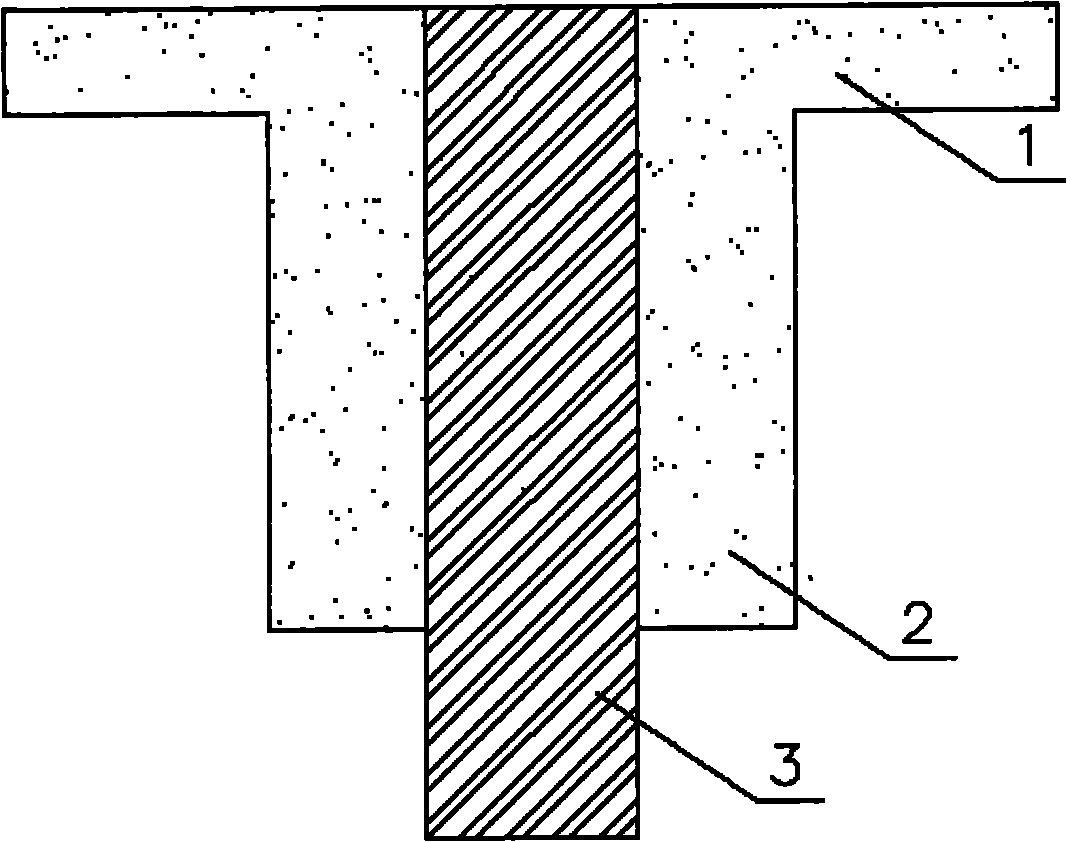

Mushroom-shaped mixed composite pile capable of effectively controlling settlement and construction method

InactiveCN101775803AImprove settlement performanceTo overcome the problem that deep stirring can only stop water but not supportBulkheads/pilesUltimate tensile strengthMushroom

The invention relates to a mushroom-shaped mixed composite pile capable of effectively controlling settlement and a construction method. The invention relates to a technique for treating soft geologies in geotechnical engineering, the pile not only solves the defects of the commonly used prior foundation treatment technique, including the low strength of the mixed pile body and the severe compression deformation of the pile body, but also can effectively control post-construction settlement and increase the pressure diffusion angle, and the invention is an economic novel foundation treatment technique. A special-purposed reducing single-shaft mixing pile driver is adopted to shape a mushroom-shaped single-shaft deep-mixed cement-soil pile body, and a precast concrete pile, or a steel pipe or a bamboo-wood material as a core material is inserted in the center of the pile body to form the novel composite pile which consists of a mushroom-shaped cement-soil mixed pile and a high-strength core pile.

Owner:SHANGHAI STRONG FOUND ENG

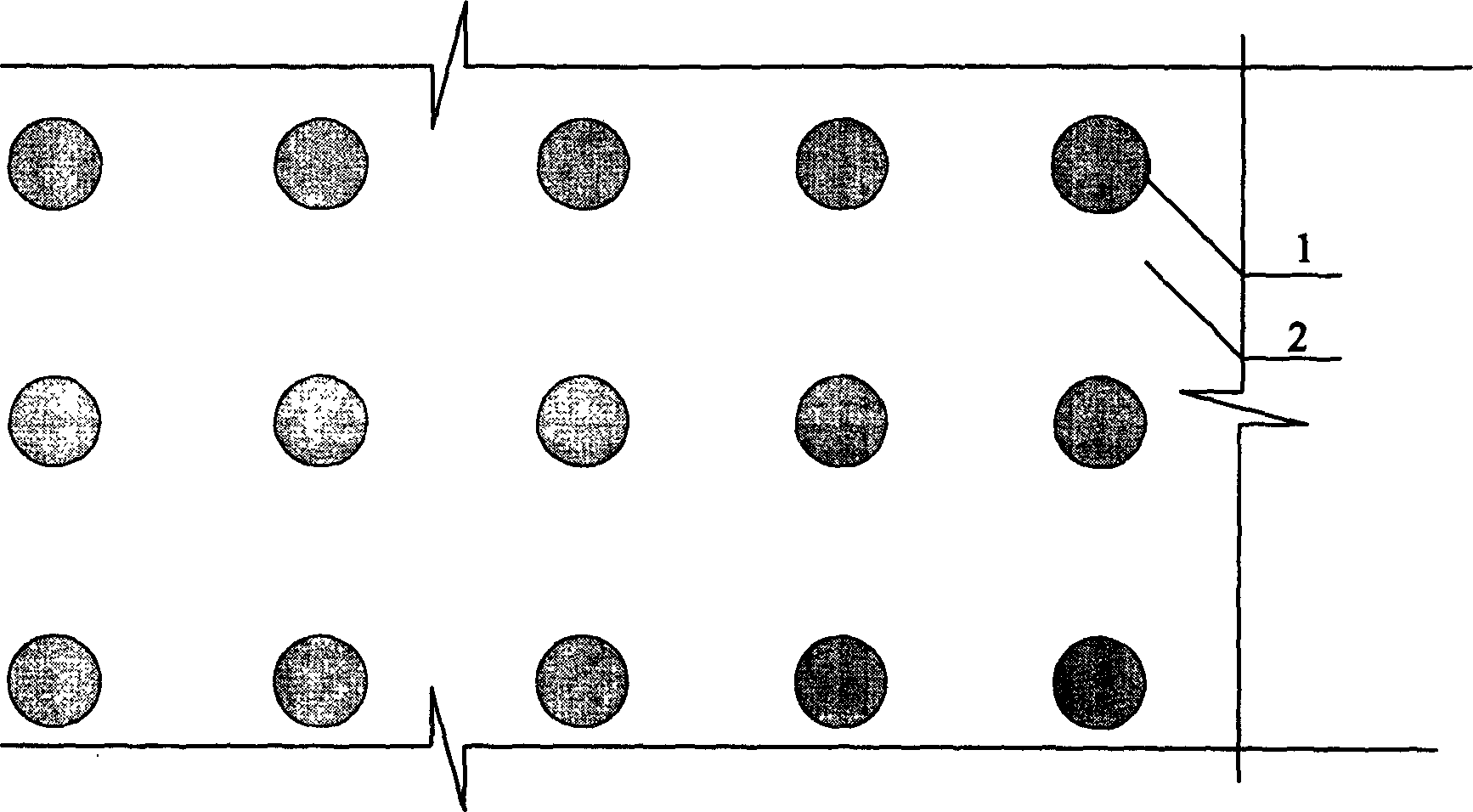

Nail type cement soil stirring pile operation method

The operation method of the nail-shaped cement-soil mixing pile is a foundation treatment method, which is suitable for the treatment of soft soil foundation. The construction operation steps are as follows: a. Level the site, and the pile position of the nail-shaped cement-soil mixing pile shall be arranged in plum or square shape; b. Positioning of the mixer: The crane suspends the mixer to the designated pile position and aligns it; c. Mixing and sinking: Start the mixer, make the mixer cut down the soil along the guide frame, and at the same time start the slurry pump to spray cement slurry to the soil, and the mixing blade rotates Stir the cement and soil, and the mixer continues to sink until the design depth; d. Lifting and stirring: the mixer is lifted while continuing to stir the cement and soil to 50cm above the surface or the design elevation; repeat the above steps c and d to complete the construction of the lower pile body; e, Construction of the expansion head: When the mixer is lifted to the surface, first turn off the slurry pump, turn on the expansion switch of the stirring blade, so that the stirring blade is extended to the design length, and then repeat the above steps c and d to complete the upper expansion head part of the construction.

Owner:南京路鼎搅拌桩特种技术有限公司

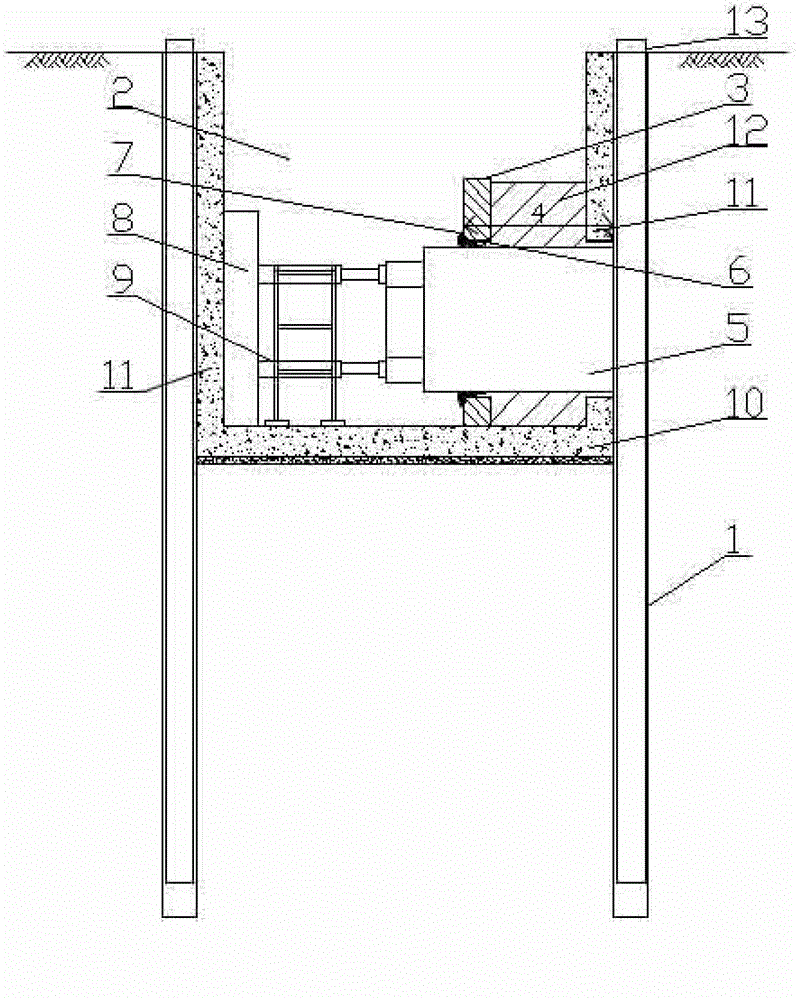

System for tube push bench to go out of starting well and unkenneling construction method of tube push bench

ActiveCN102943489AStable positionSmall manpowerArtificial islandsProtective foundationEngineeringSoil cement

The invention provides a system for a tube push bench to go out of a starting well. The system comprises a space enclosing structure for forming the starting shaft, lining walls arranged on the inner wall of the space enclosing structure, a bottom plate arranged at the bottom of the starting shaft, a lifting jack and a retaining wall, wherein the space enclosing structure adopts an SMW (Soil-cement Mixed Wall) construction method pile, the retaining wall is vertically arranged in the starting shaft, door openings through which the tube push bench passes are correspondingly formed in the retaining wall and the lining wall at one side of the space enclosing structure; the horizontal distance between the two adjacent door openings is less than the length of the tube push bench; and the lining wall at the other side of the space enclosing structure is provided with the lifting jack which is used for jacking the tube push bench; and a region formed by the retaining wall, the lining walls, the bottom plate and the tube push bench is filled with reinforcing soil mass. The invention provides a device and a method which can relatively economically and conveniently provide a soil mass condition for the smooth unkennelling of the tube push bench.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Soil-cement pile with core and diameter enlarged extension section

The cement soil pile expanding pile includes cement soil pile body and axial core rod and features diameter expanding sections with increased cross section area in pile end and / or pile body. The expanded sections may be supported or suspended inside the soil layer with best soil quality to increase pile end resistance and side friction resistance, raise the pile bearing capacity, avoid pile deposition, control deformation of foundation and ensure the safety of building. The present invention has wide application range.

Owner:曾毅学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com