Space enclosing structure convenient for opening door opening, construction method and use method thereof

A technology of enclosure structure and construction method, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of high technical requirements and high cost in manufacturing and hoisting, and achieve high strength, low cost and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

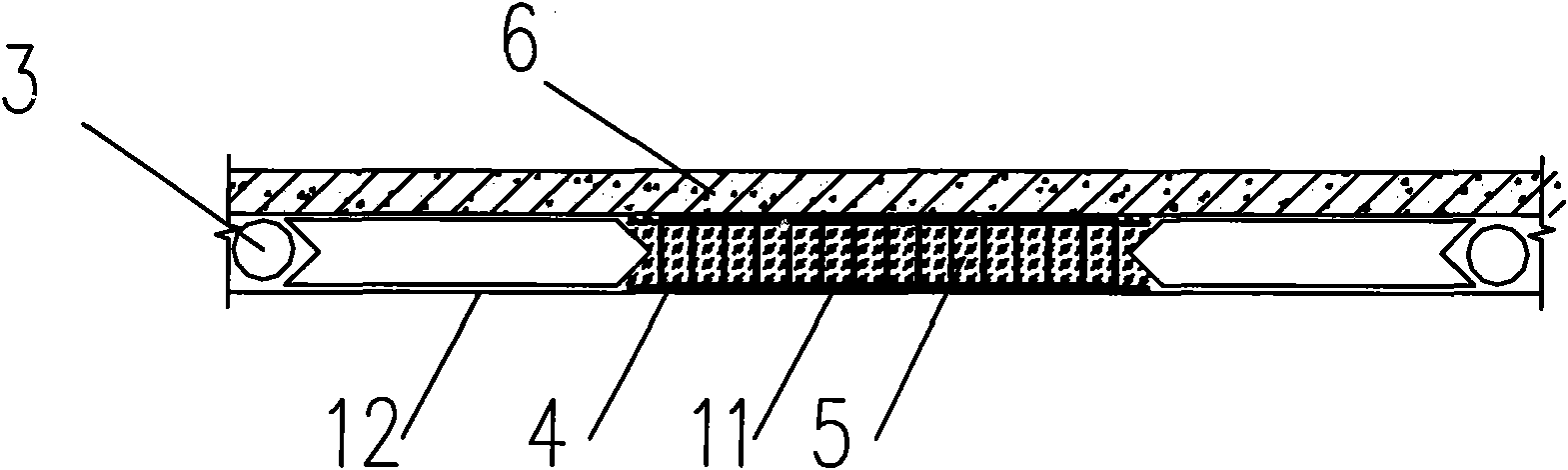

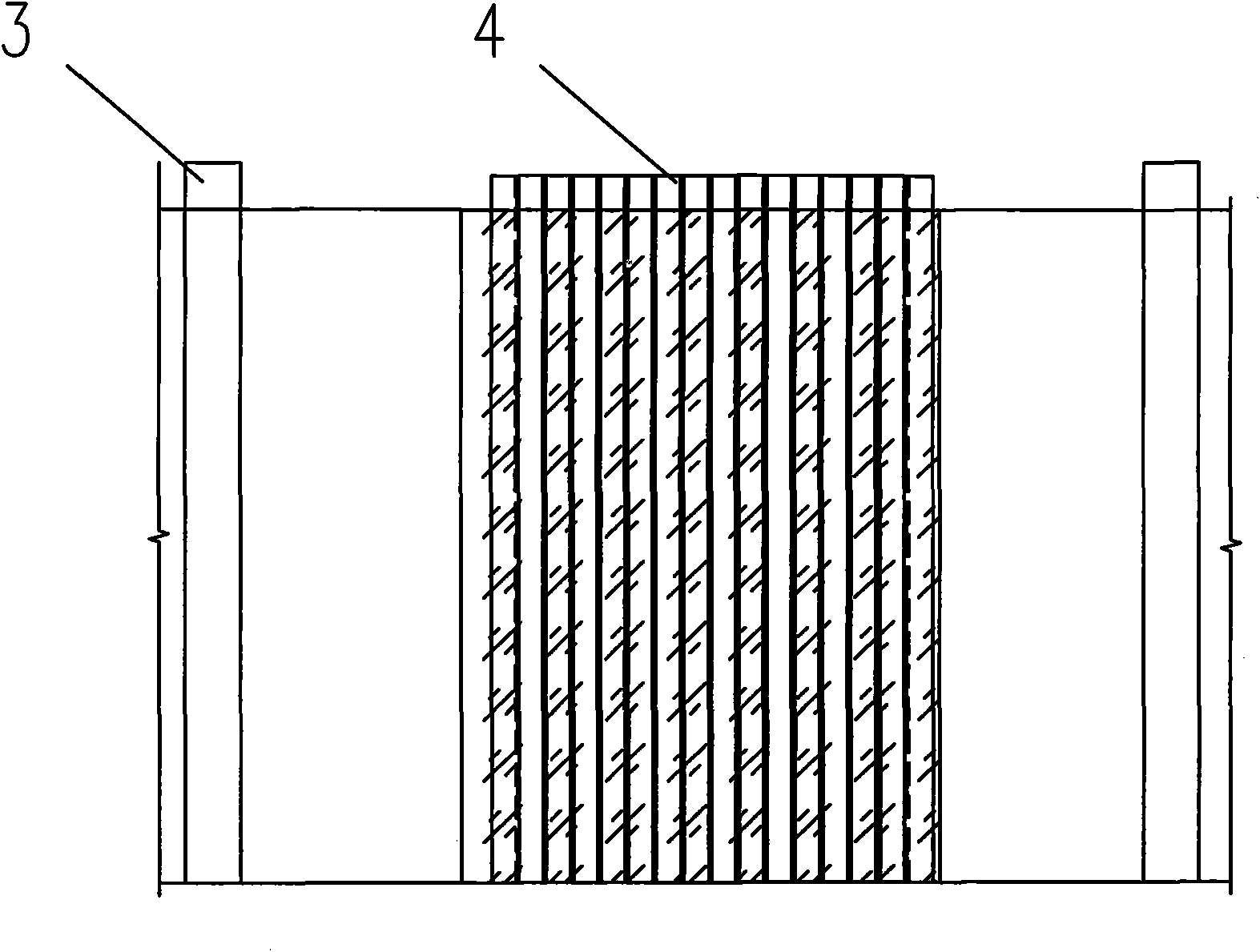

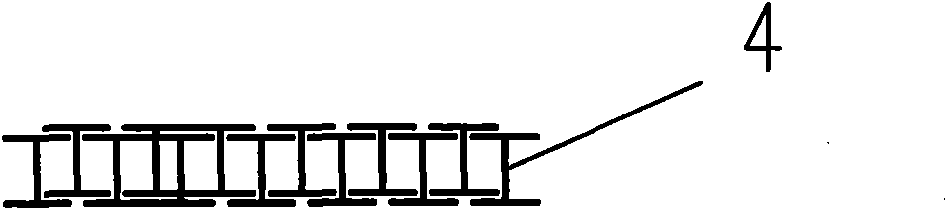

[0073] See Figure 1a , Figure 1b with Figure 1c This kind of enclosure structure 1 that facilitates opening of the doorway is composed of a doorway part 11 and a peripheral part 12 located around the doorway part 11. The enclosure structure 1 is an enclosure structure involving a doorway portion 11 in a working well enclosed by a four-sided enclosure structure. The peripheral part 12 refers to the other part of the enclosure 1 except for the doorway 11 of the side of the working well involved in the doorway part (that is, for the entry and exit of the boring machine 9 ). The working well is an originating well or a receiving well. The door portion 11 is a trough section 11 with a size corresponding to the diameter required for the entry and exit of the tunneling machine 9. The trough section 11 is filled with cement soil 5, and a number of H-shaped steels 4 are arranged vertically and staggered in sequence in the trough section 11 , Please refer to the specific setting method o...

Embodiment 2

[0094] See Figure 10a , Figure 10b with Figure 10c The difference between this embodiment and Embodiment 1 is that the arrangement of the H-shaped steel is different. The H-shaped steel in this embodiment is vertically and closely inserted into the groove section 11 in turn. The H-shaped steel 4 and cement-soil 5, which are closely connected in turn, form a steel retaining wall that can stop water and meet the rigidity required for foundation pit excavation.

[0095] The invention has the following beneficial effects because it can realize the direct cutting of the tunneling machine to replace the manual chiseling of the door hole: 1. The labor required for manually opening the door hole can be avoided. Second, it can save the construction period, without the inefficient manual excavation of the door opening time, and also save the soil improvement time required for manual excavation. 3. Reduce the risk and avoid the risk caused by manual cutting out of the vertical concrete str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com