Patents

Literature

3655 results about "Shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a material along a plane that is parallel to the direction of the force. When a paper is cut with scissors, the paper fails in shear. In structural and mechanical engineering, the shear strength of a component is important for designing the dimensions and materials to be used for the manufacture or construction of the component (e.g. beams, plates, or bolts).

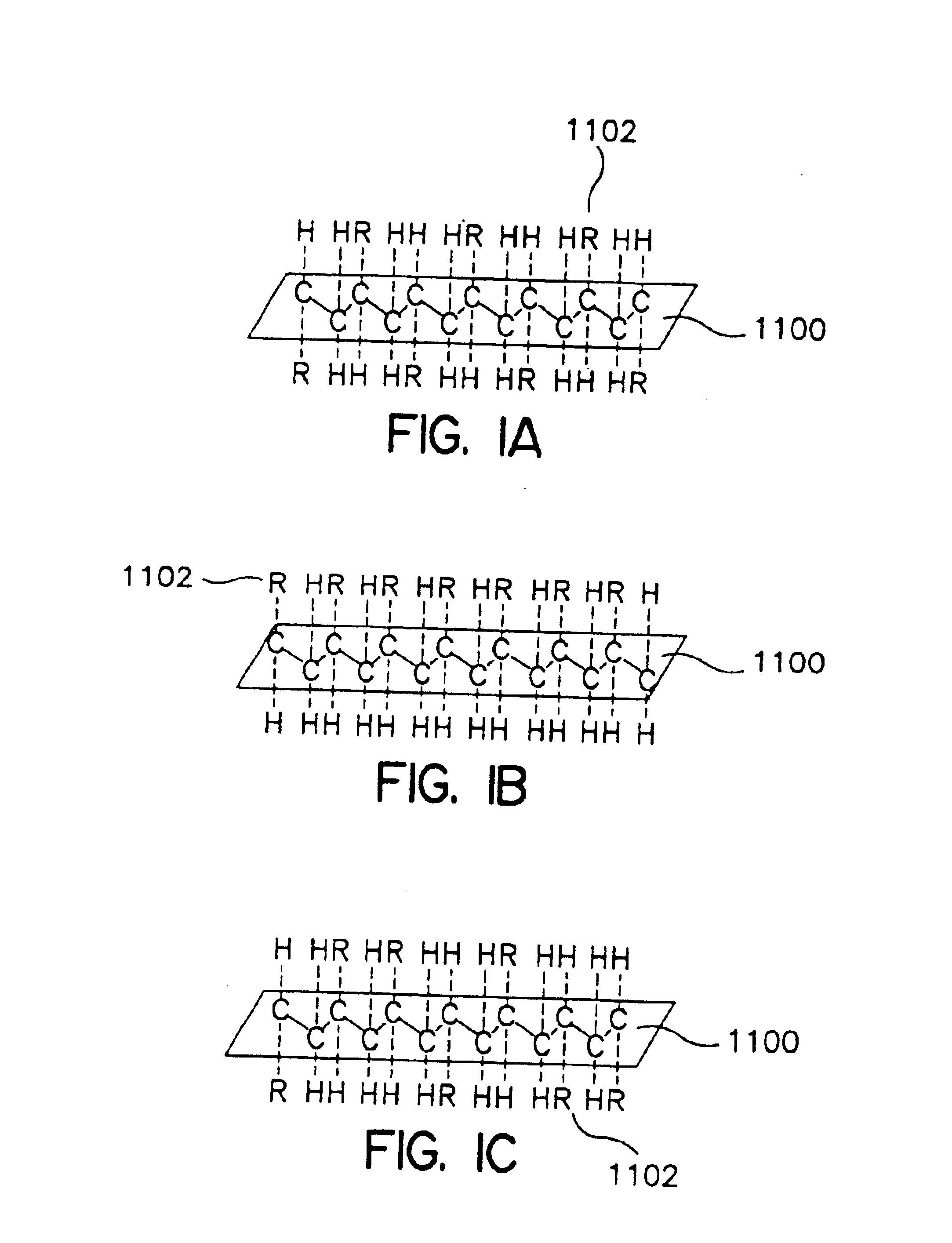

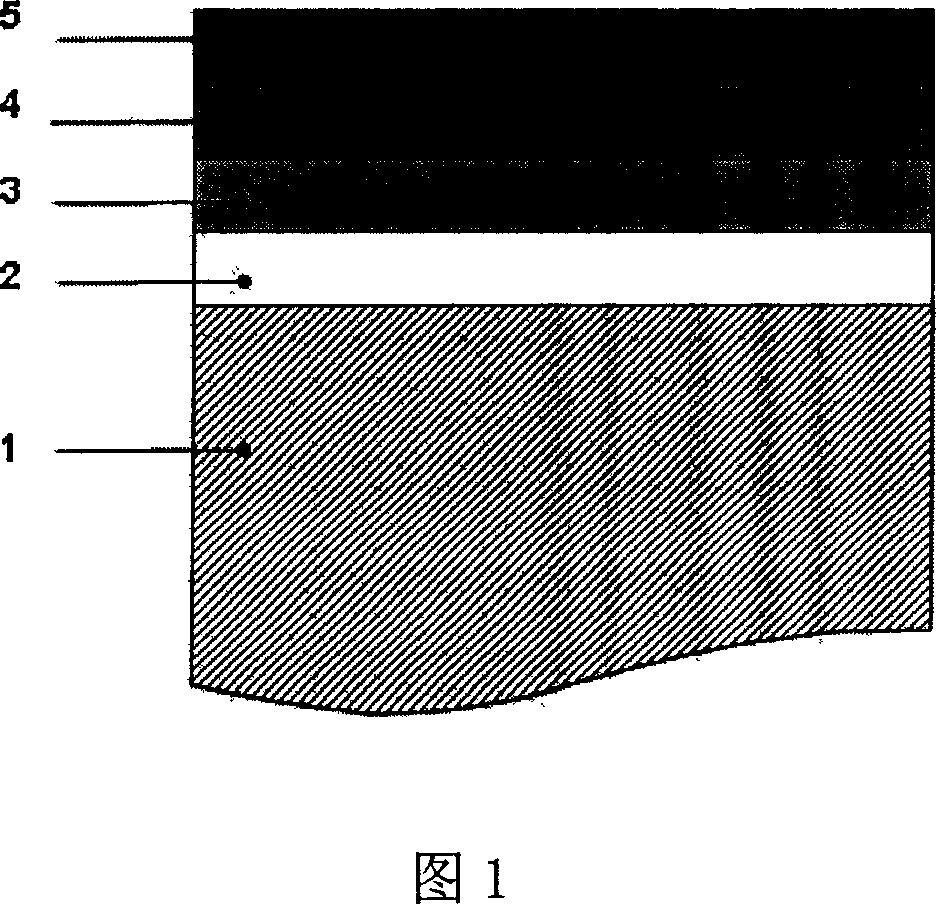

Structural and other composite materials and methods for making same

InactiveUS20050281999A1High strength-to-weight ratioEasy to manufactureSynthetic resin layered productsLaminationPolymer scienceHigh intensity

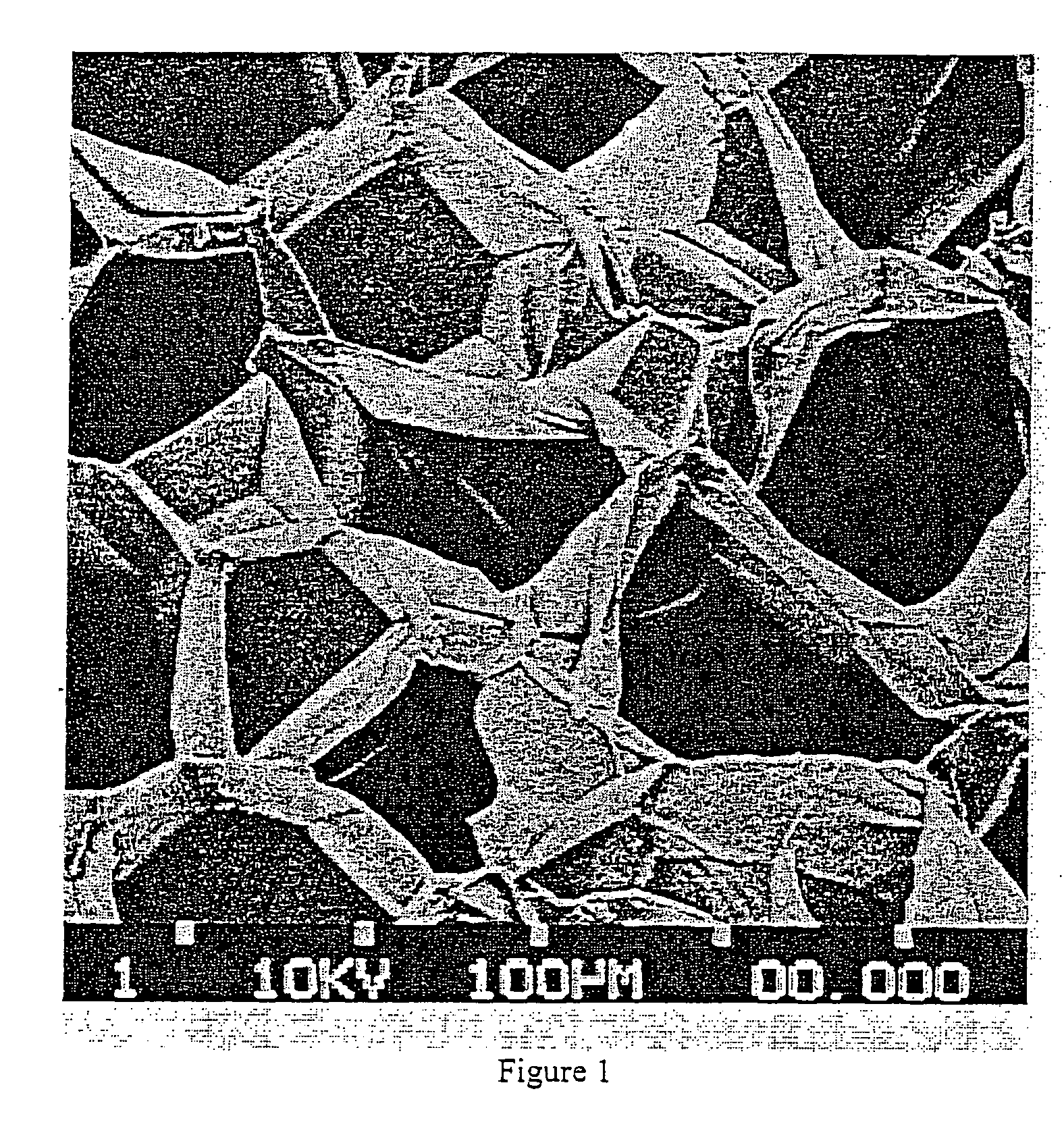

In accordance with the present invention, structural and other composite materials have been developed which have superior performance properties, including high compressive strength, high tensile strength, high shear strength, and high strength-to-weight ratio, and methods for preparing same. Invention materials have the added benefits of ease of manufacture, and are inexpensive to manufacture. The superior performance properties of invention materials render such materials suitable for a wide variety of end uses. For example, a variety of substances can be applied to invention materials without melting, dissolving or degrading the basic structure thereof. This facilitates bonding invention materials to virtually any surface or substrate. Moreover, the bond between invention materials and a variety of substrates is exceptionally strong, rendering the resulting bonded article suitable for use in a variety of demanding applications. Invention materials can be manufactured in a wide variety of sizes, shapes, densities, in multiple layers, and the like; and the performance properties thereof can be evaluated in a variety of ways.

Owner:PETRITECH

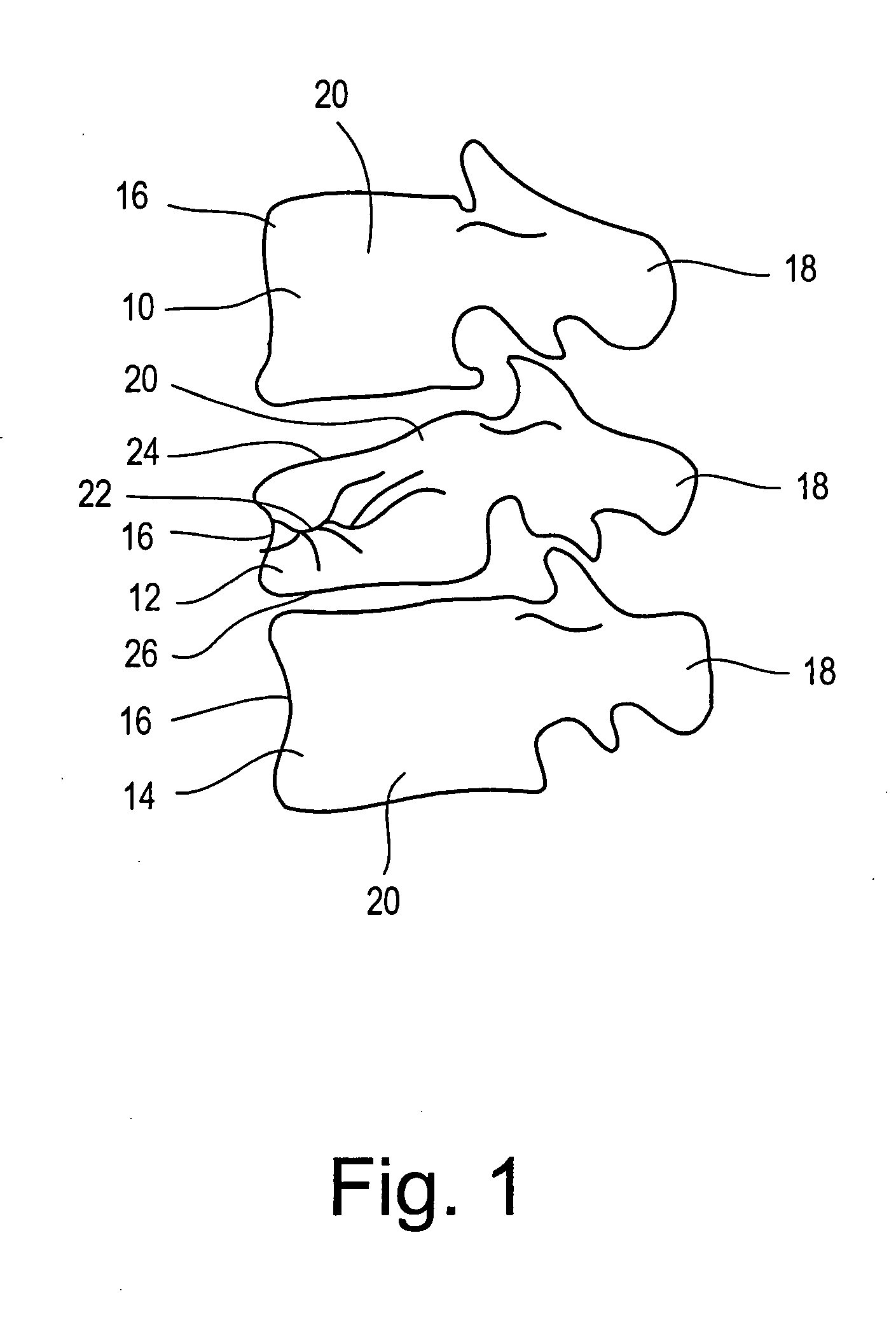

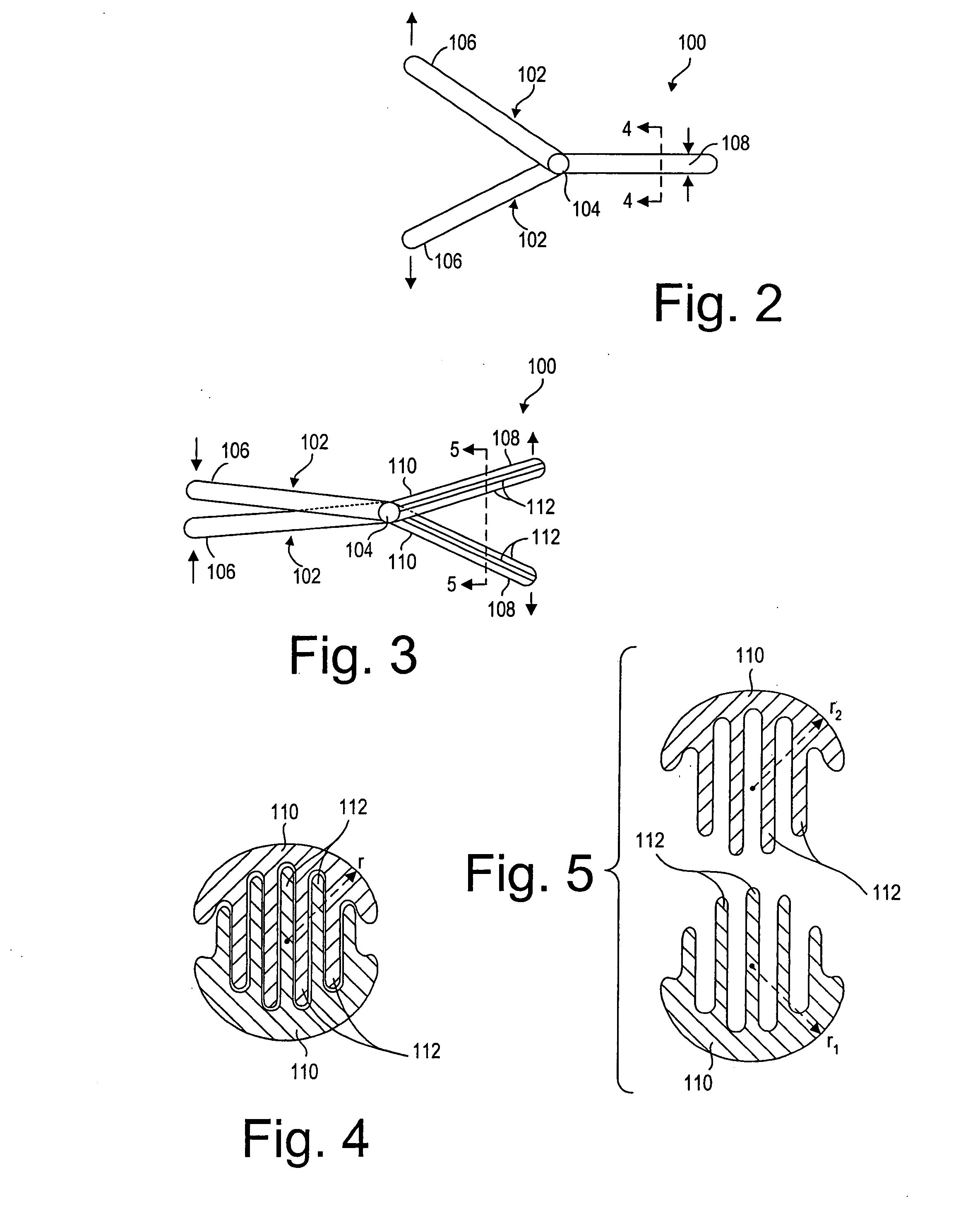

Apparatus and methods for reducing compression bone fractures using high strength ribbed members

InactiveUS20050070911A1Small combined profilePreserving shear strengthInternal osteosythesisDiagnosticsCommon baseBone structure

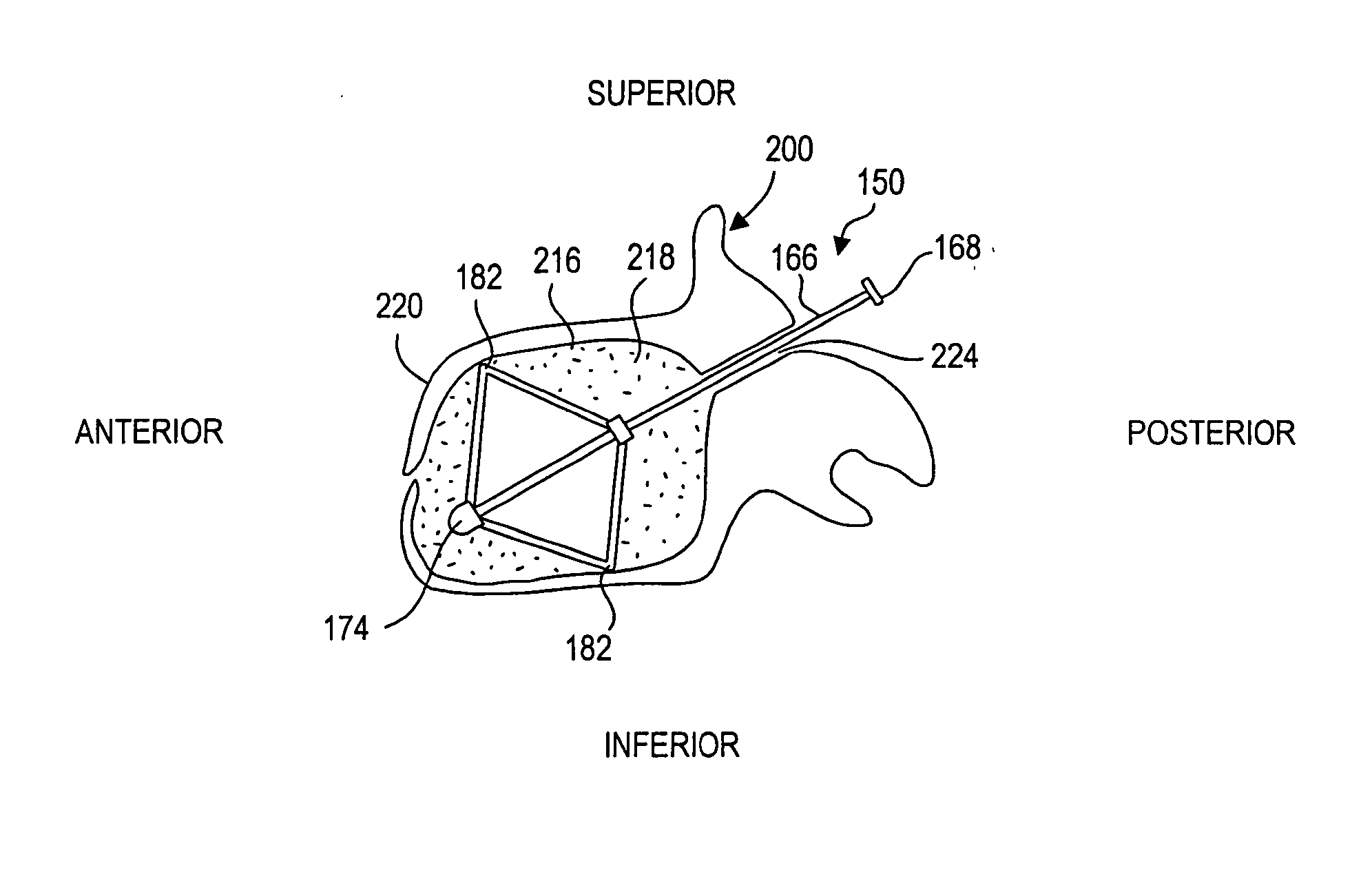

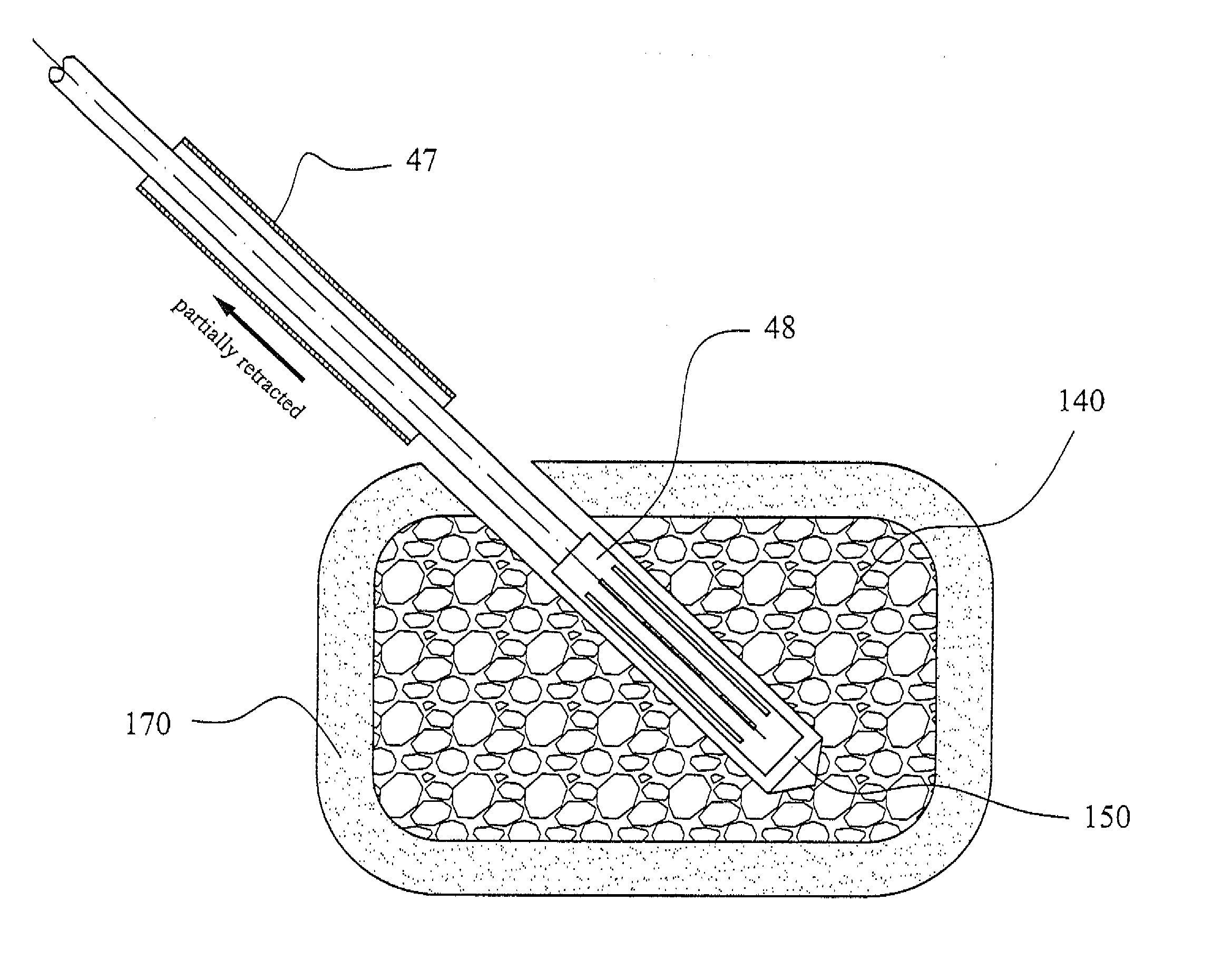

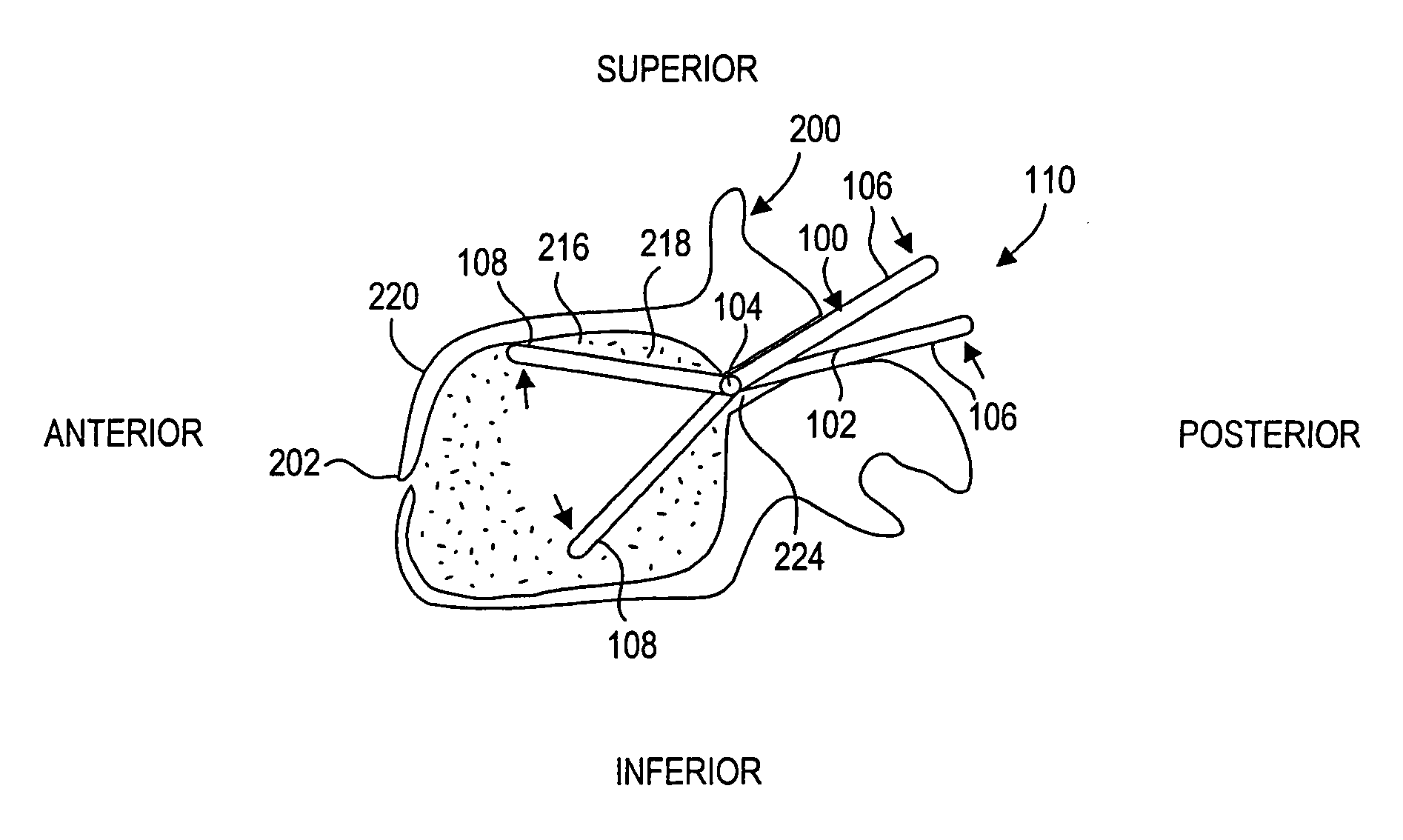

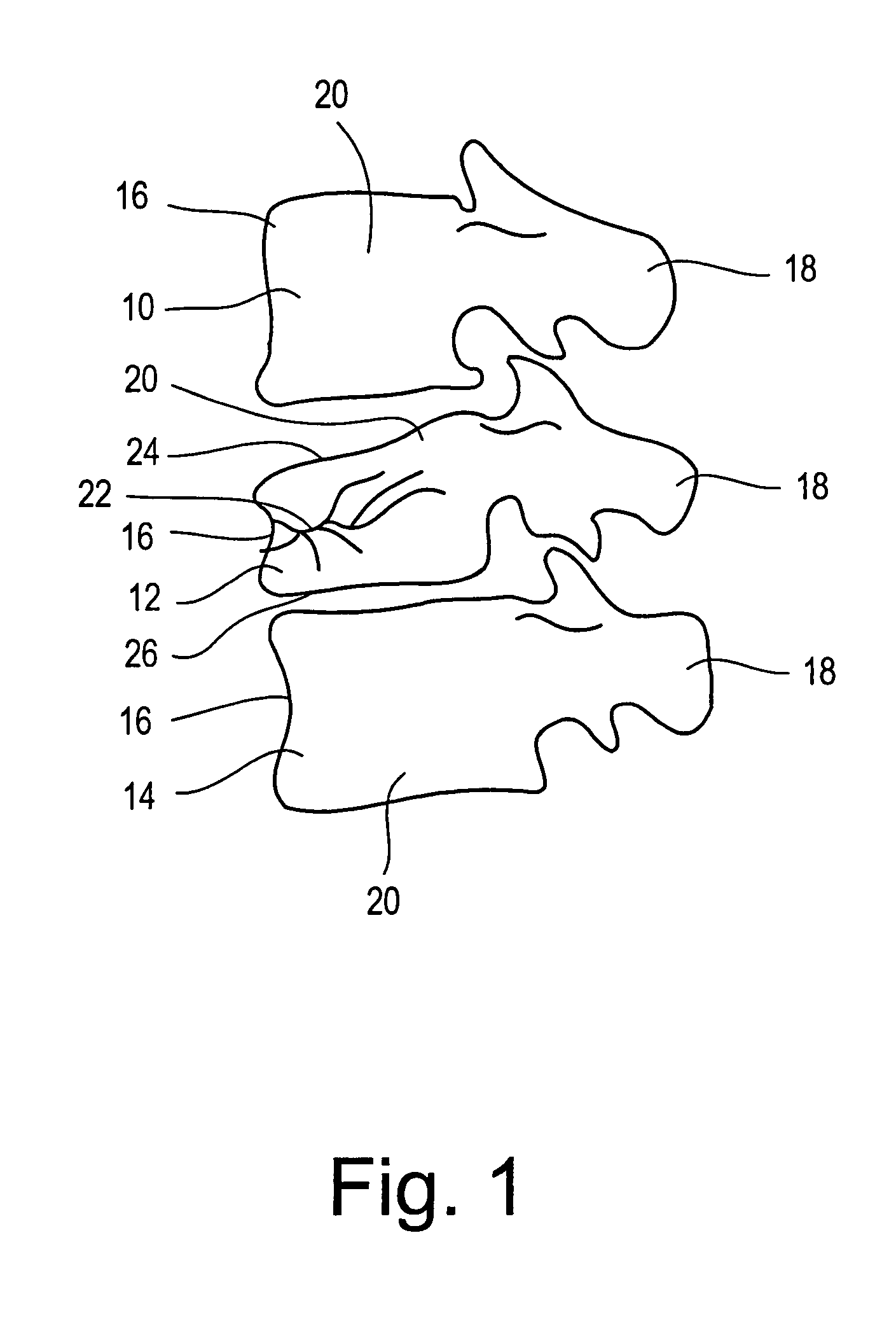

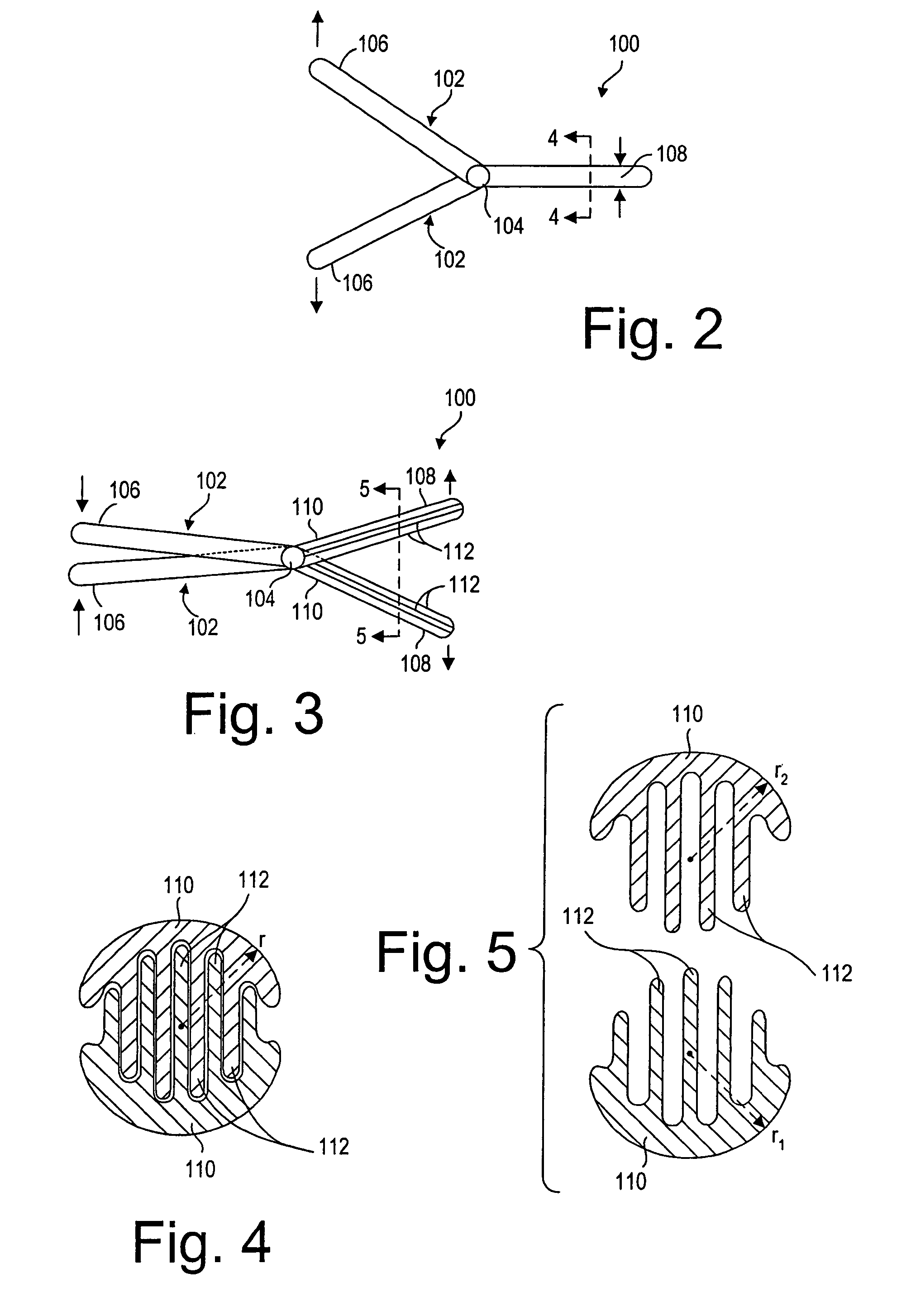

Devices and methods are provided for treating a bone structure (such as, e.g., reducing a bone fracture, e.g., a vertebral compression fracture, or stabilizing adjacent bone structure, e.g., vertebrae) is provided. The device comprises rigid or semi-rigid members, each of which comprises a common base and a plurality of ribs that extent along the a longitudinal portion of the common base. The device is configured to be placed in a collapsed state by engaging the pluralities of ribs of the members in an interposed arrangement, and configured to be placed in a deployed state by disengaging the pluralities of ribs. The ribs can be any shape, e.g., flutes, that allows opposing ribs to intermesh with one another. In this manner, the device has a relatively small profile when placed in the collapsed state, so that it can be introduced through small openings within the bone structure, while preserving the shear strength of the members during deployment of the device.

Owner:BOSTON SCI SCIMED INC

Bi-component epoxide-resin adhesive and preparation method thereof

InactiveCN101397486AImprove heat resistanceImproved tensile shear strengthEpoxynovolac adhesivesEpoxyBenzene

The invention relates to a two-component epoxy resin adhesive, including the following components: novolac epoxy resin, lipid ring type epoxy resin and terminal carboxylic acrylonitrile butadiene rubber in component A, and 1, 4-di-benzene (2, 4-diaminobenzene oxygen) in component B, wherein, the mass percentage of the lipid ring type epoxy resin is 20-35 percent of the novolac epoxy resin, the mass percentage of the terminal carboxylic acrylonitrile butadiene rubber CTBN is 12 percent of the novolac epoxy resin and the mass percentage of the 1, 4-di-benzene (2, 4-diaminobenzene oxygen) is 15-20 percent of the novolac epoxy resin; and the preparation of the two-component epoxy resin adhesive includes the step of evenly mixing the component A and the component B for use. The two-component epoxy resin adhesive used for conductive adhesive has good heat resistance, average stretching and shearing strength of 21.28MPa, simple preparation process and operation without solvent, and plays the role of protecting environment.

Owner:DONGHUA UNIV +1

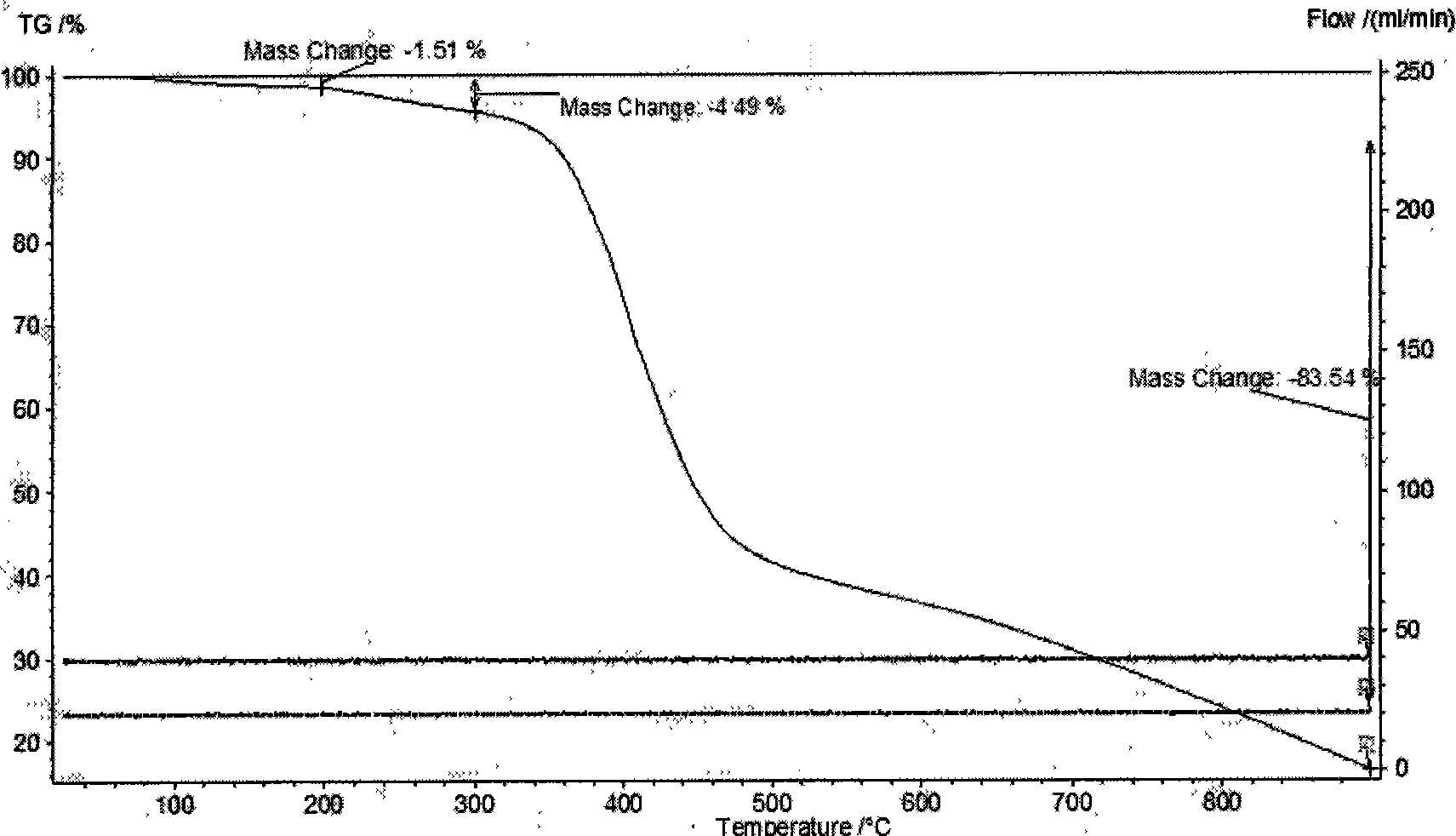

Two-dimensional fiber cloth reinforced composite material and preparation method thereof

InactiveCN101224989AImprove fracture toughnessImprove use reliabilityMetal powderStructural stability

The invention discloses a two-dimensional fiber cloth reinforced ceramics based composite material and the preparation technique, which adopts the two-dimensional fiber cloth as the reinforcing phase and the ceramic powder or the refractory metal powder as the stuffing, and the carbon and the carborundum as the base. The process steps are following: first the sizing agent with different ceramic powder and metal powder is coated on the two-dimensional fiber cloth, and then overlapping, puncturing and repeated densification are carried out. The preparation method has the advantages of lowering preparation cost and shortening preparation cycle, and the two-dimensional fiber cloth reinforced ceramics based composite material has the advantages of high shear strength between layers, structural stability and high reliability. The types of fiber cloth and the base can be adjusted and optimized in a wider range according to the applications, so as to be applicable for different fields.

Owner:NAT UNIV OF DEFENSE TECH

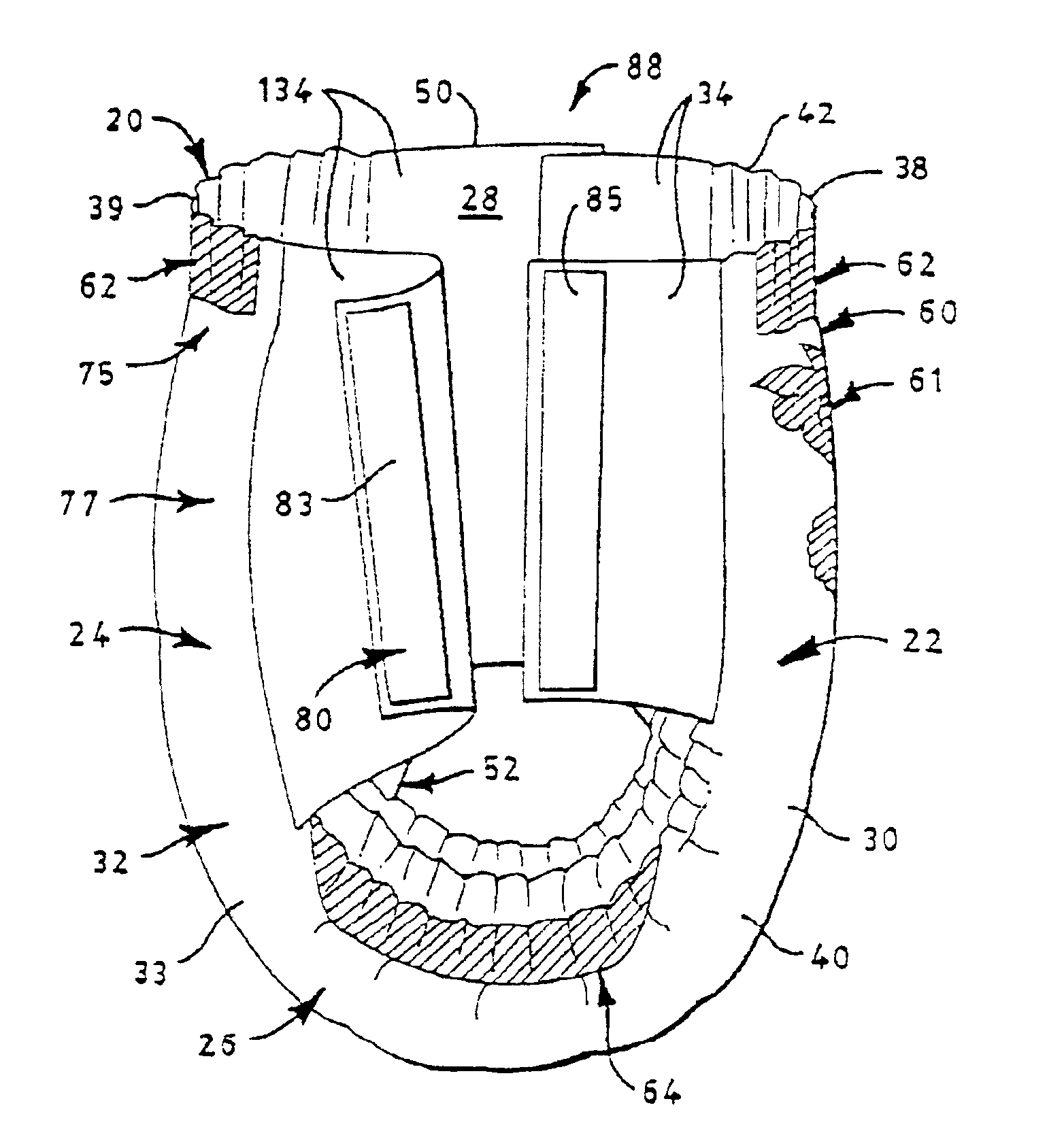

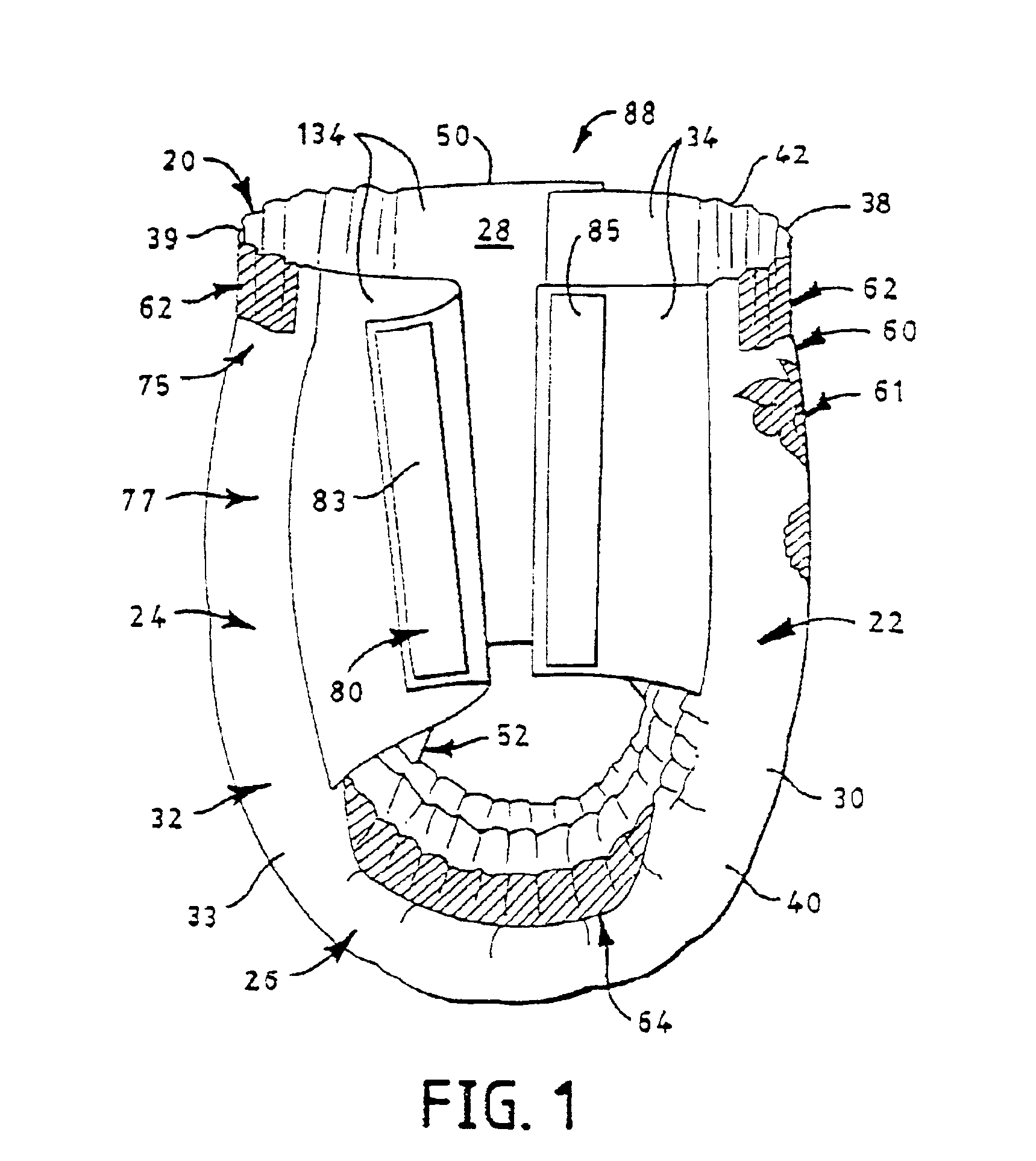

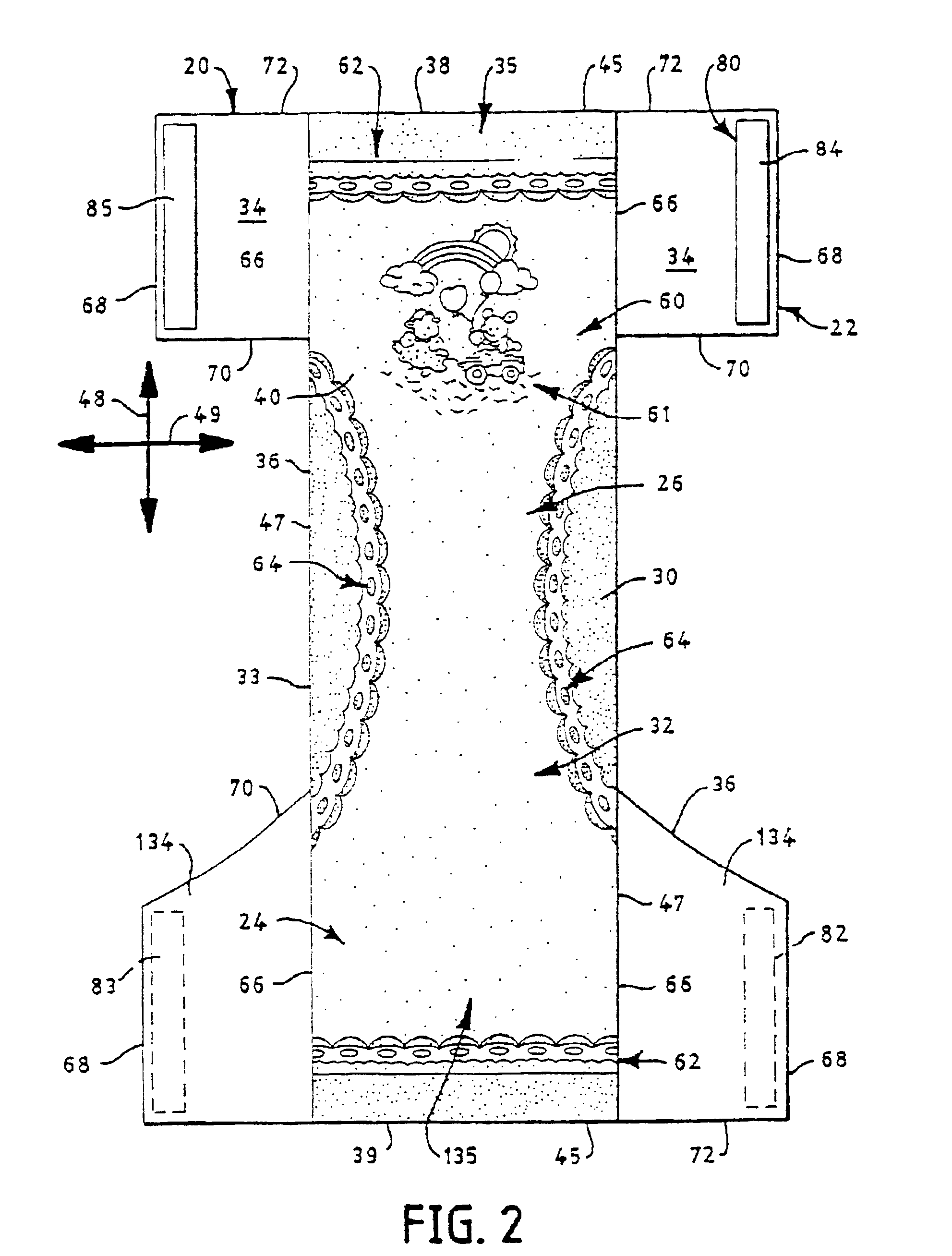

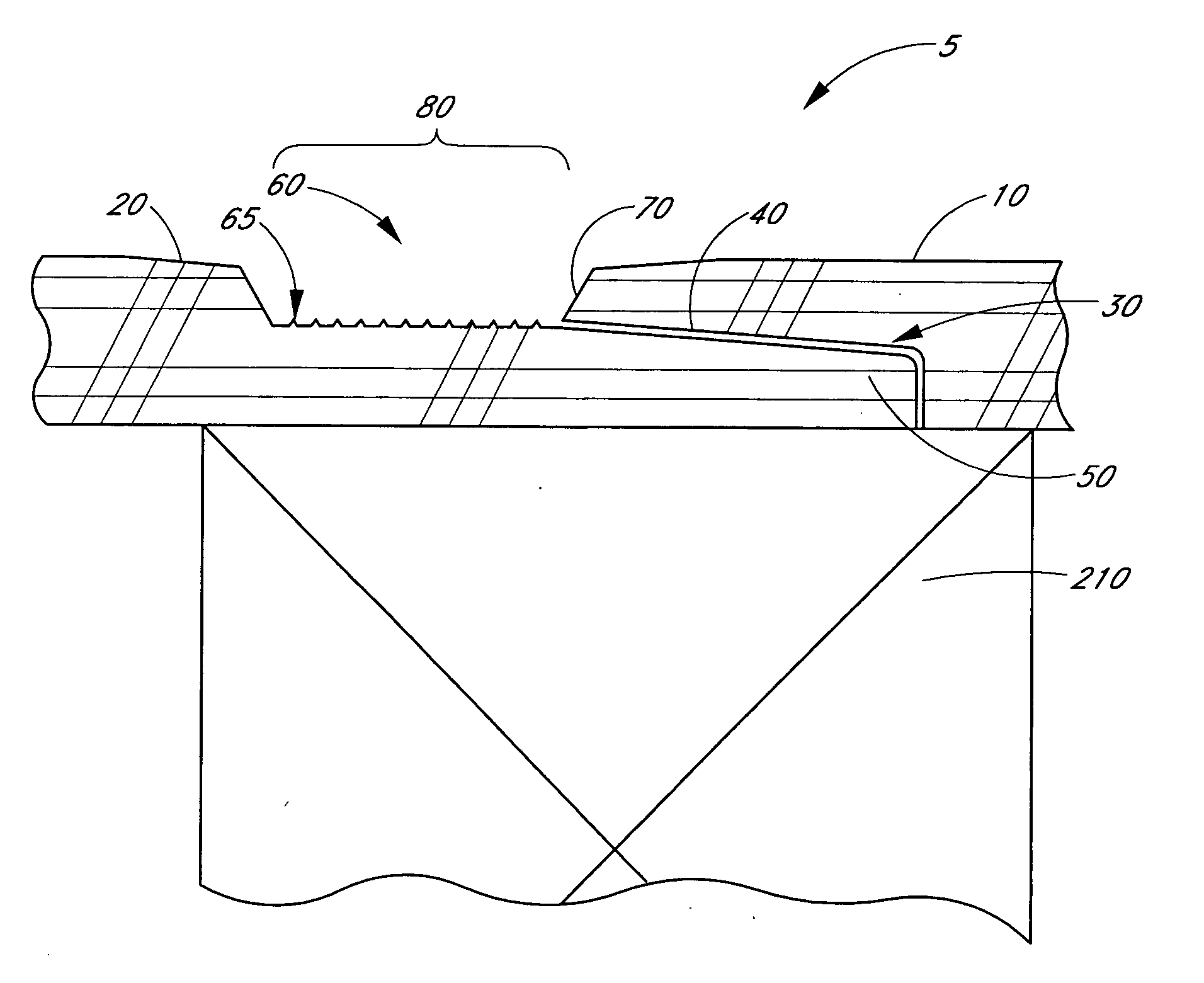

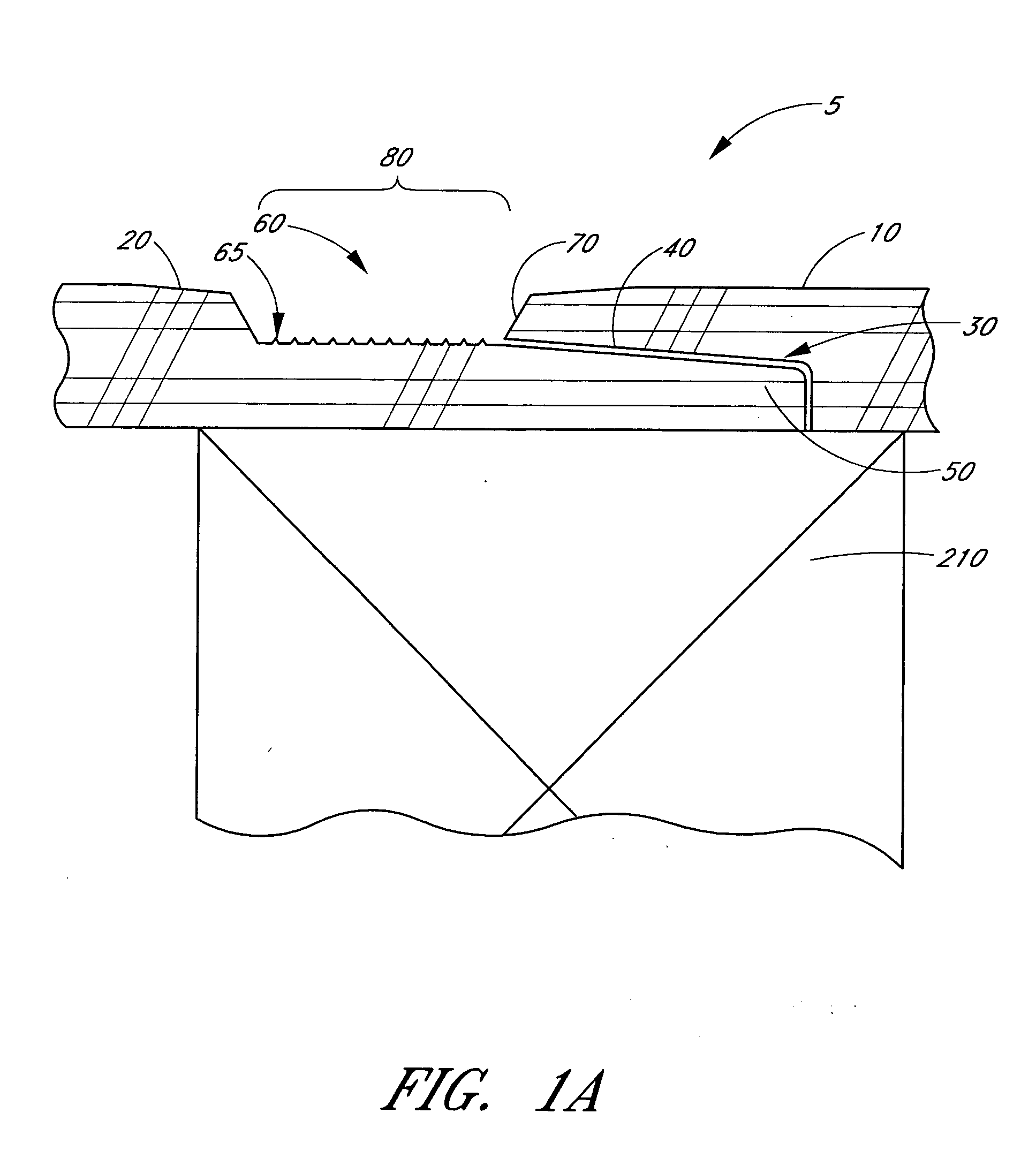

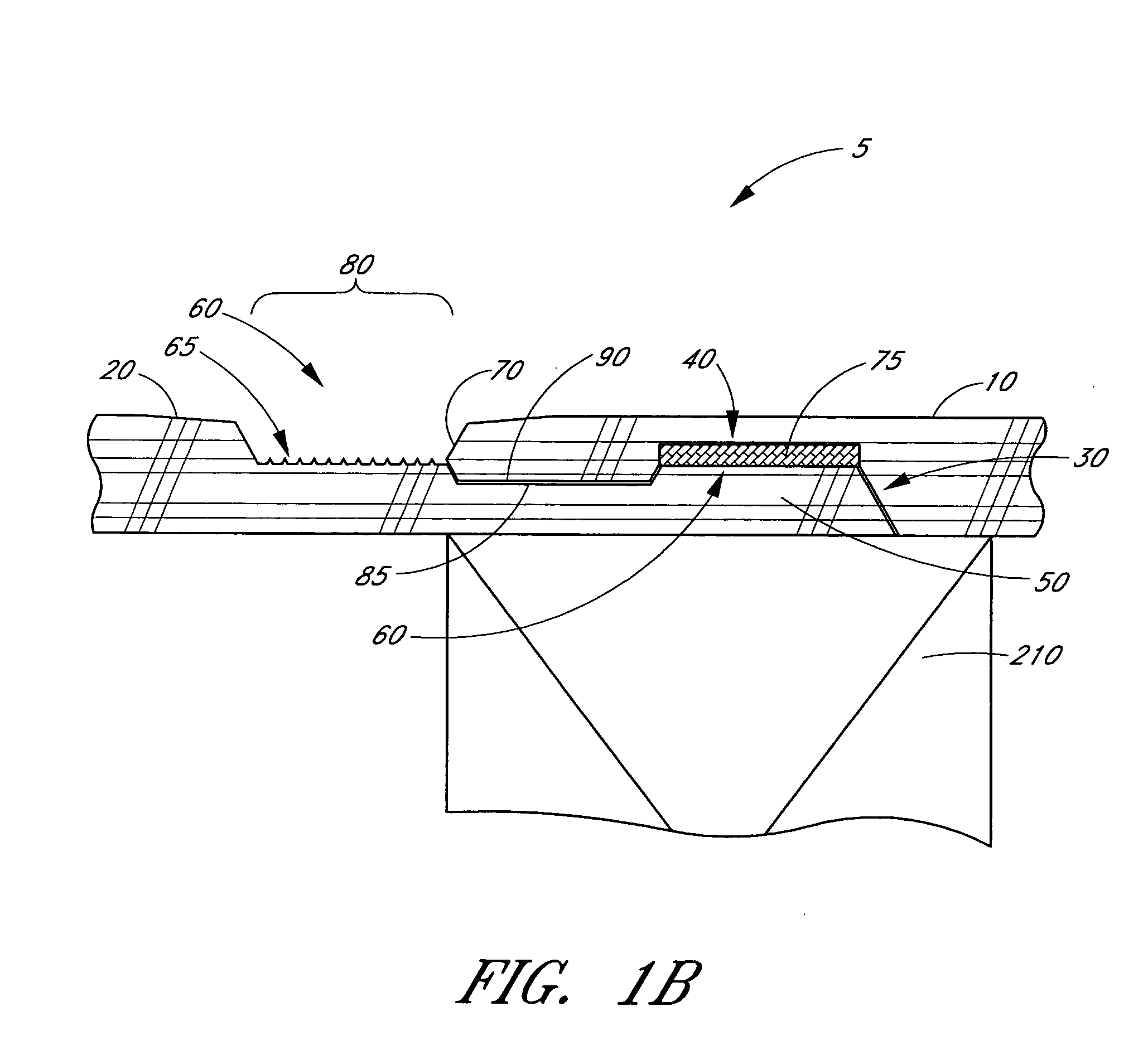

Mechanical fastening system for an absorbent article

InactiveUS6953452B2Relieve pressureLow shear strengthBaby linensTamponsUltimate tensile strengthMulti directional

An absorbent article such as infant training pants is provided with a mechanical hook-and-loop type fastening system utilizing multi-directional stretchable nonwoven materials that function well with low shear strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Laminated structures

InactiveUS6887941B2High bonding strengthImproved performance characteristicsControlling laminationSynthetic resin layered productsHot meltAlpha-olefin

Hot-melt, pressure-sensitive adhesive compositions of amorphous polyalphaolefin and crystalline polypropylene have improved bond strength over the amorphous polyalphaolefin alone. The adhesive compositions improve dynamic shear strength, dynamic peel strength, as well as static peel strength. The adhesive compositions are particularly suitable for use in absorbent articles.

Owner:KIMBERLY-CLARK WORLDWIDE INC

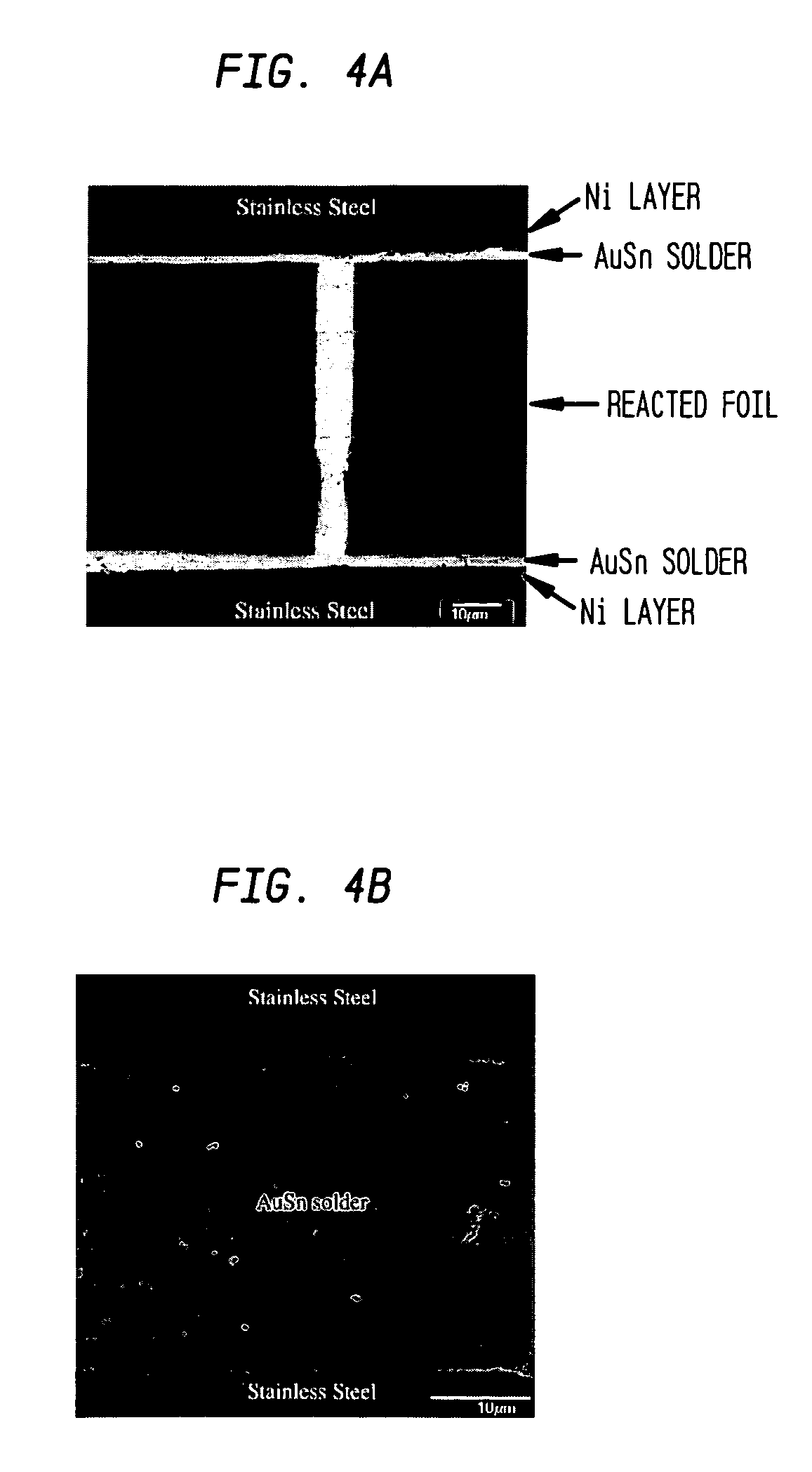

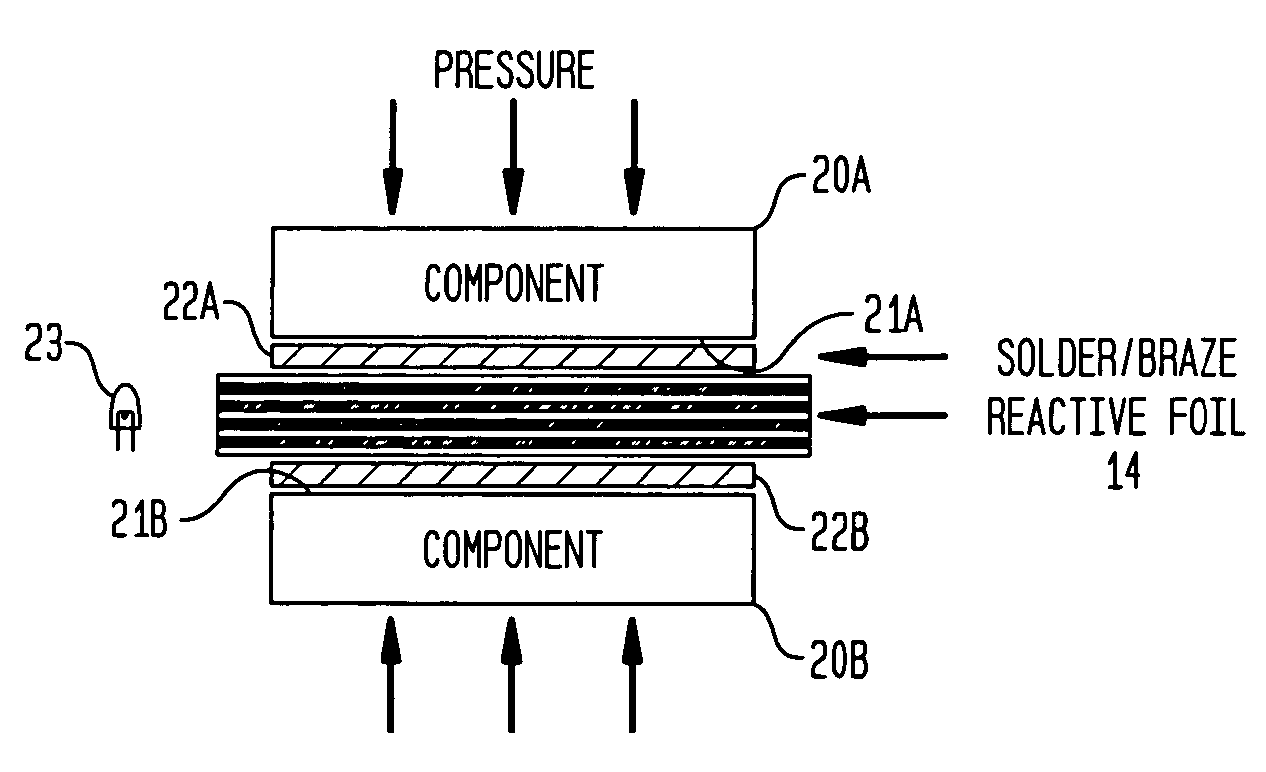

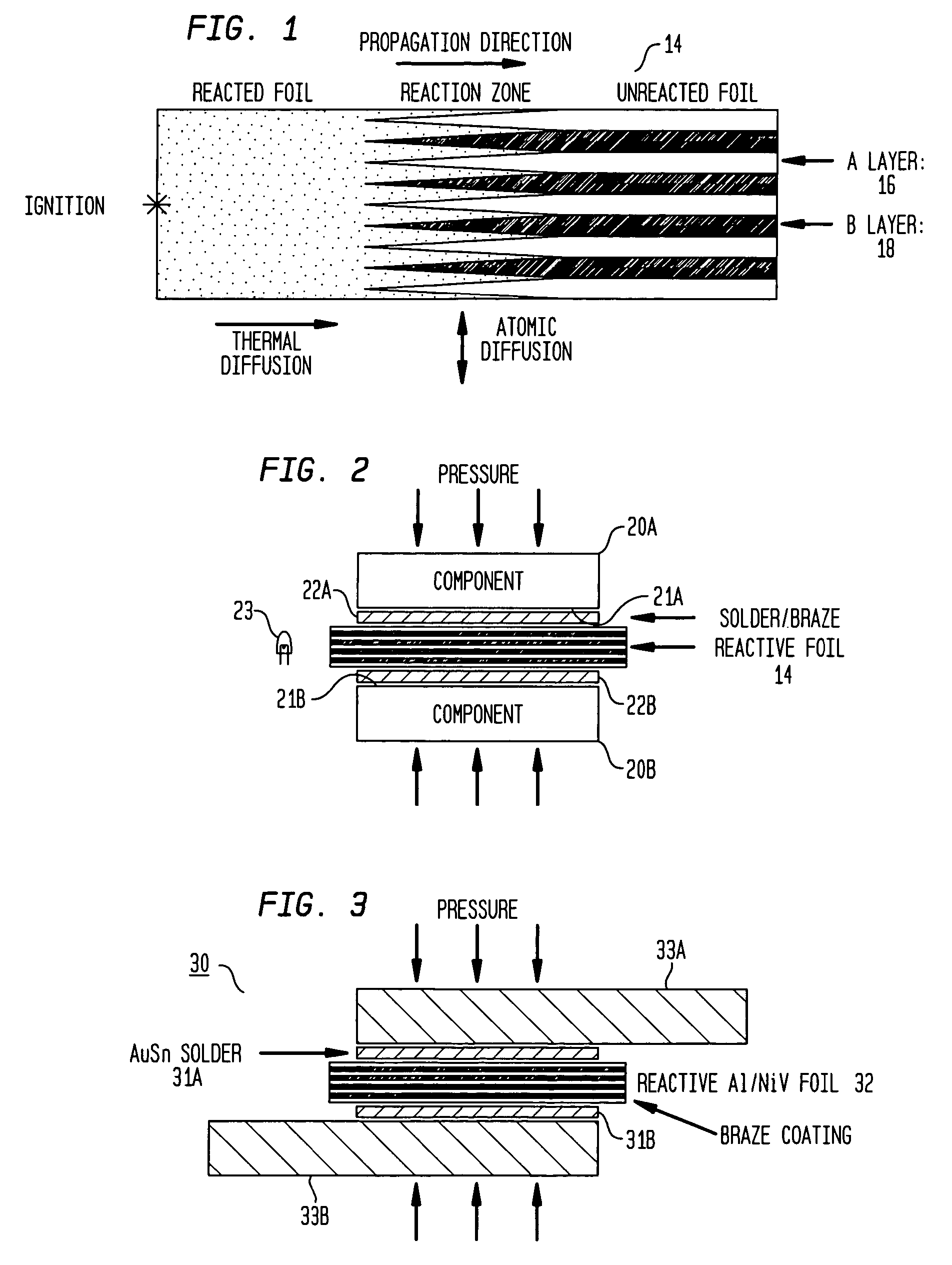

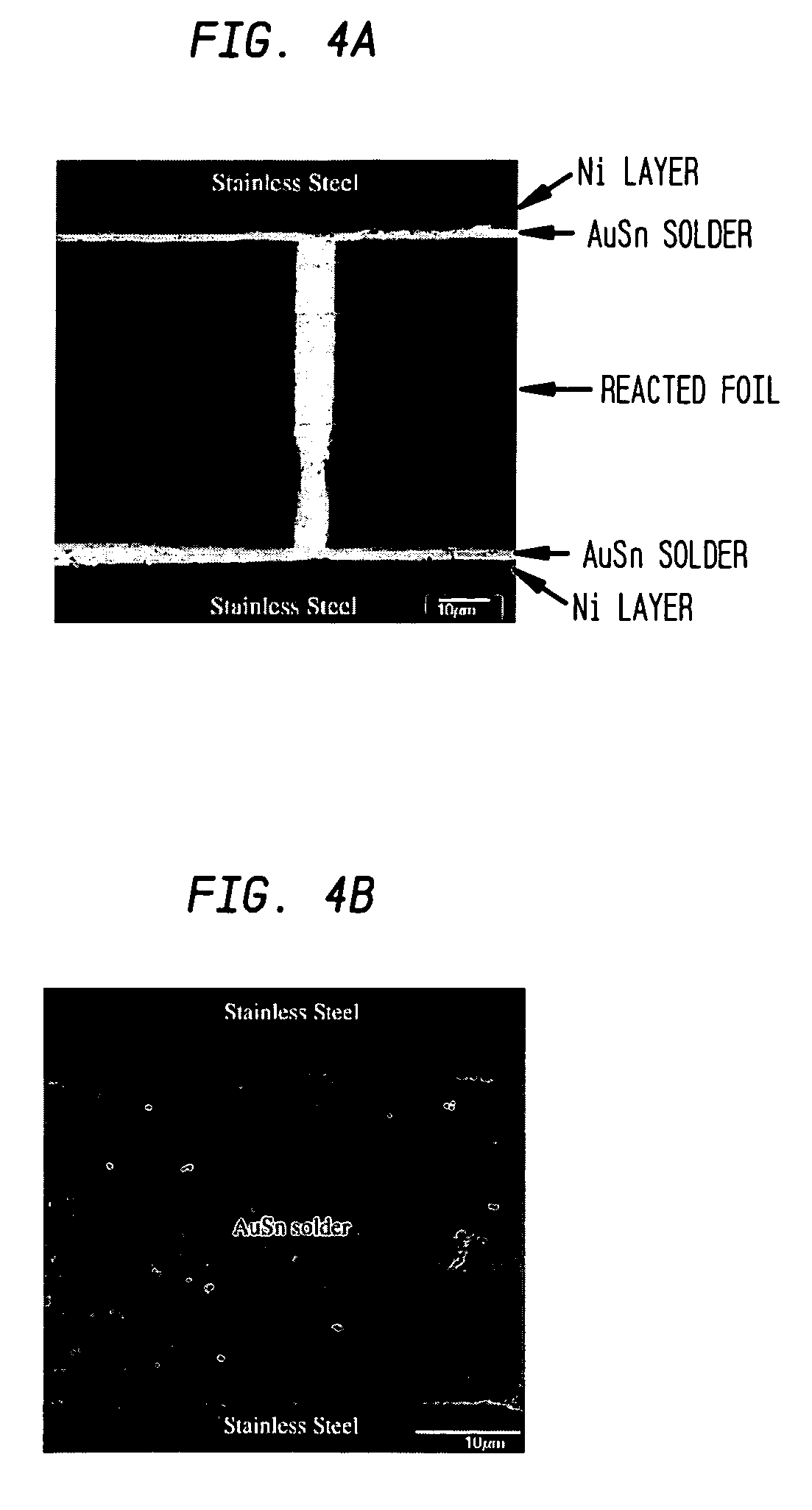

Nanostructured soldered or brazed joints made with reactive multilayer foils

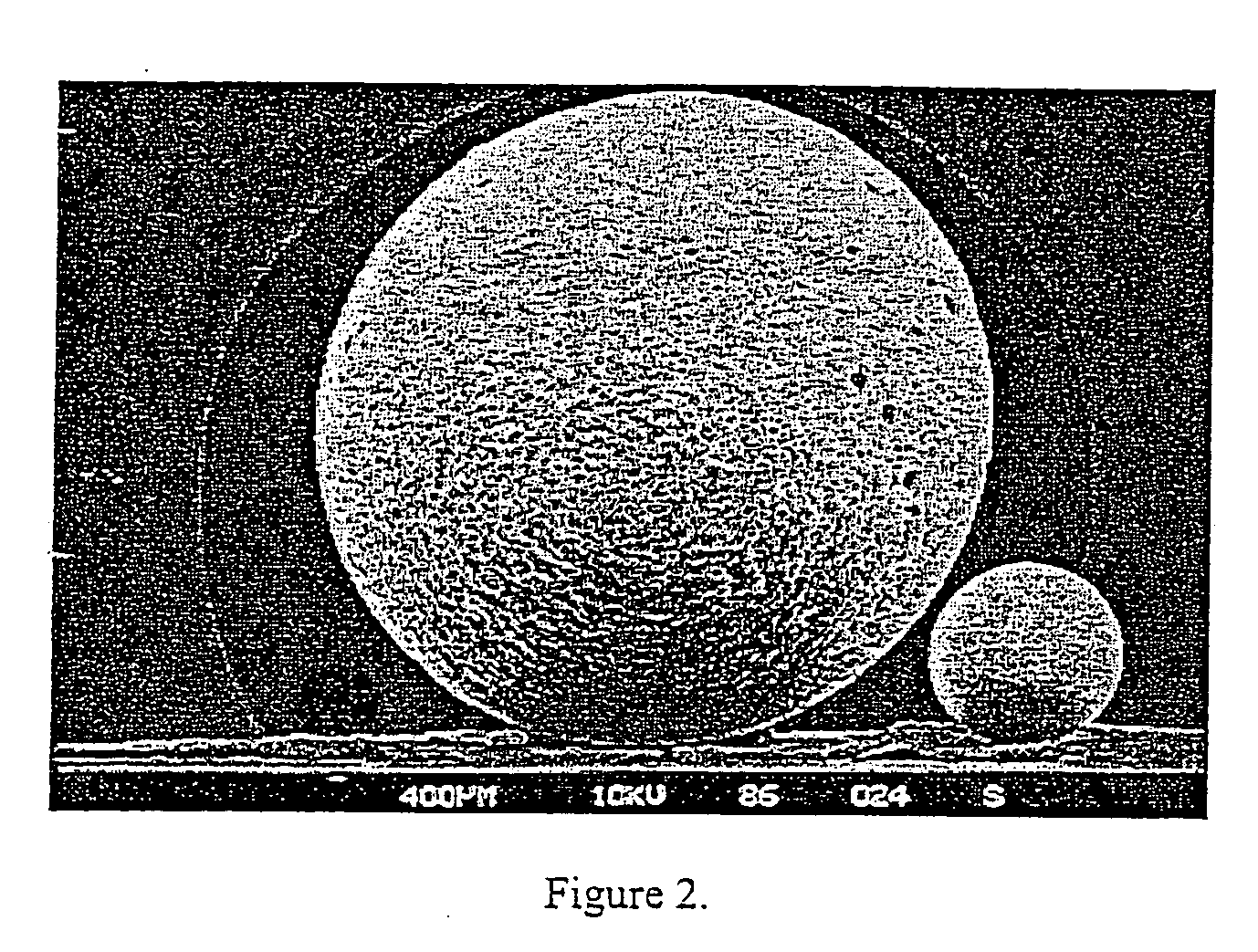

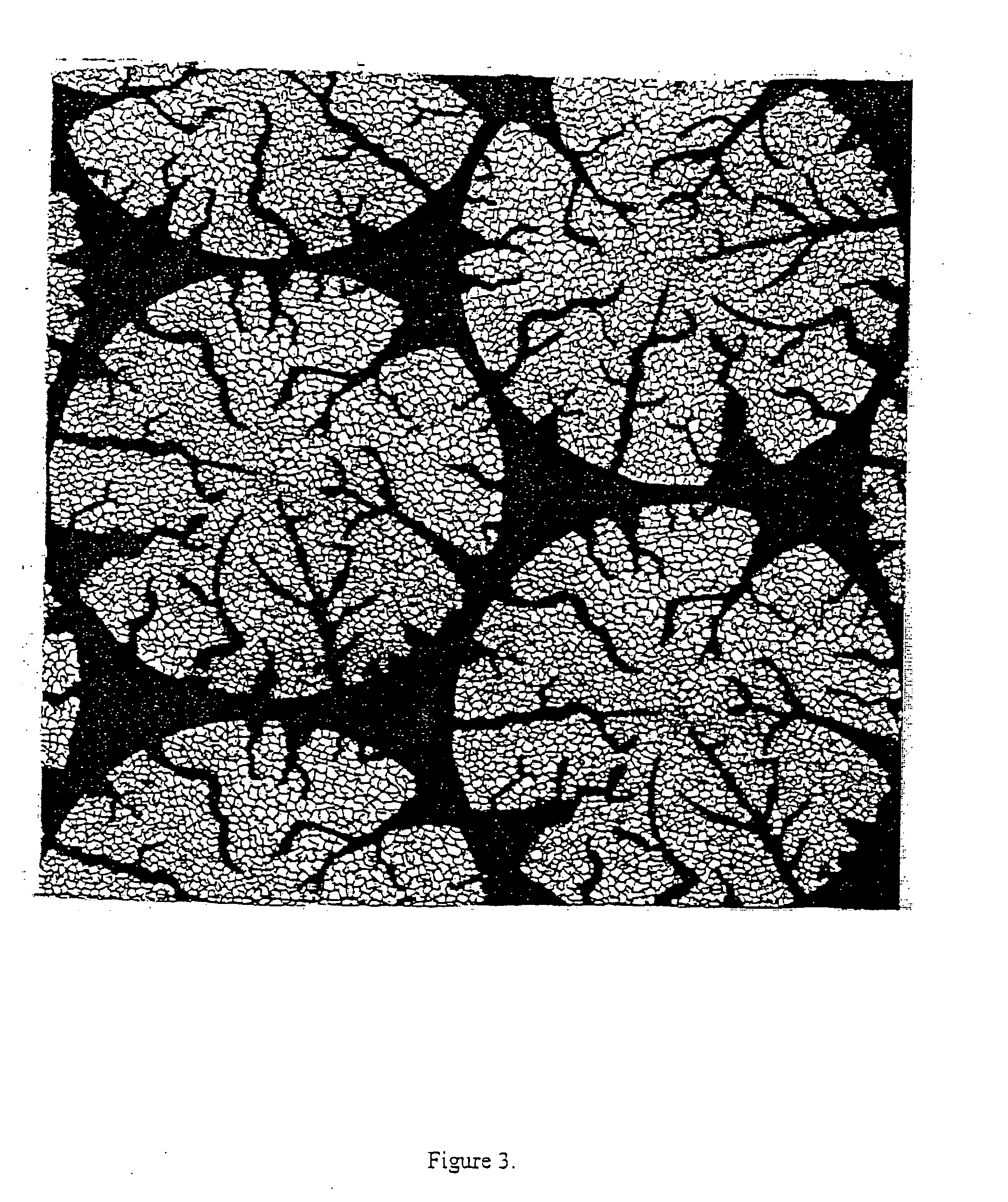

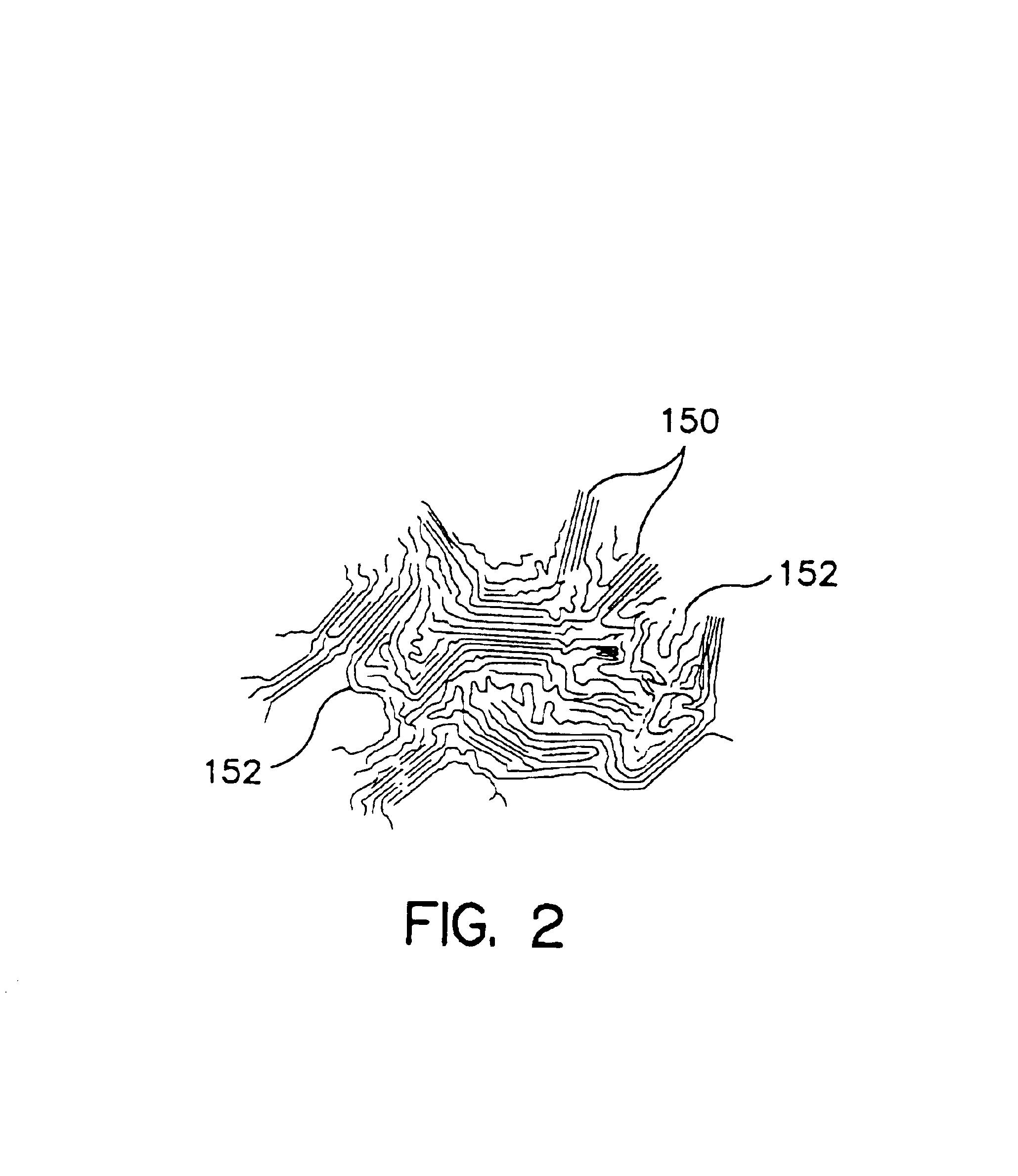

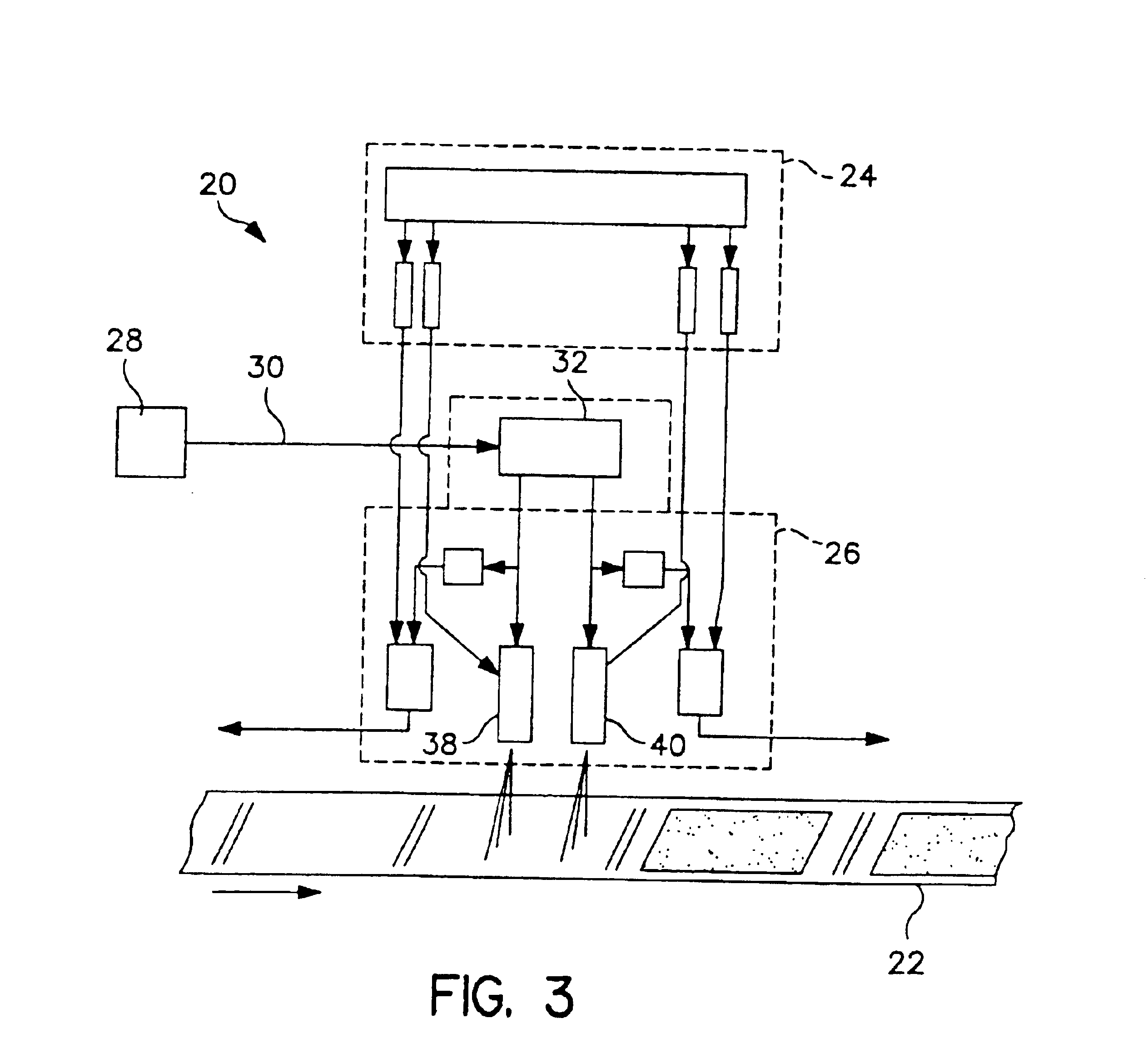

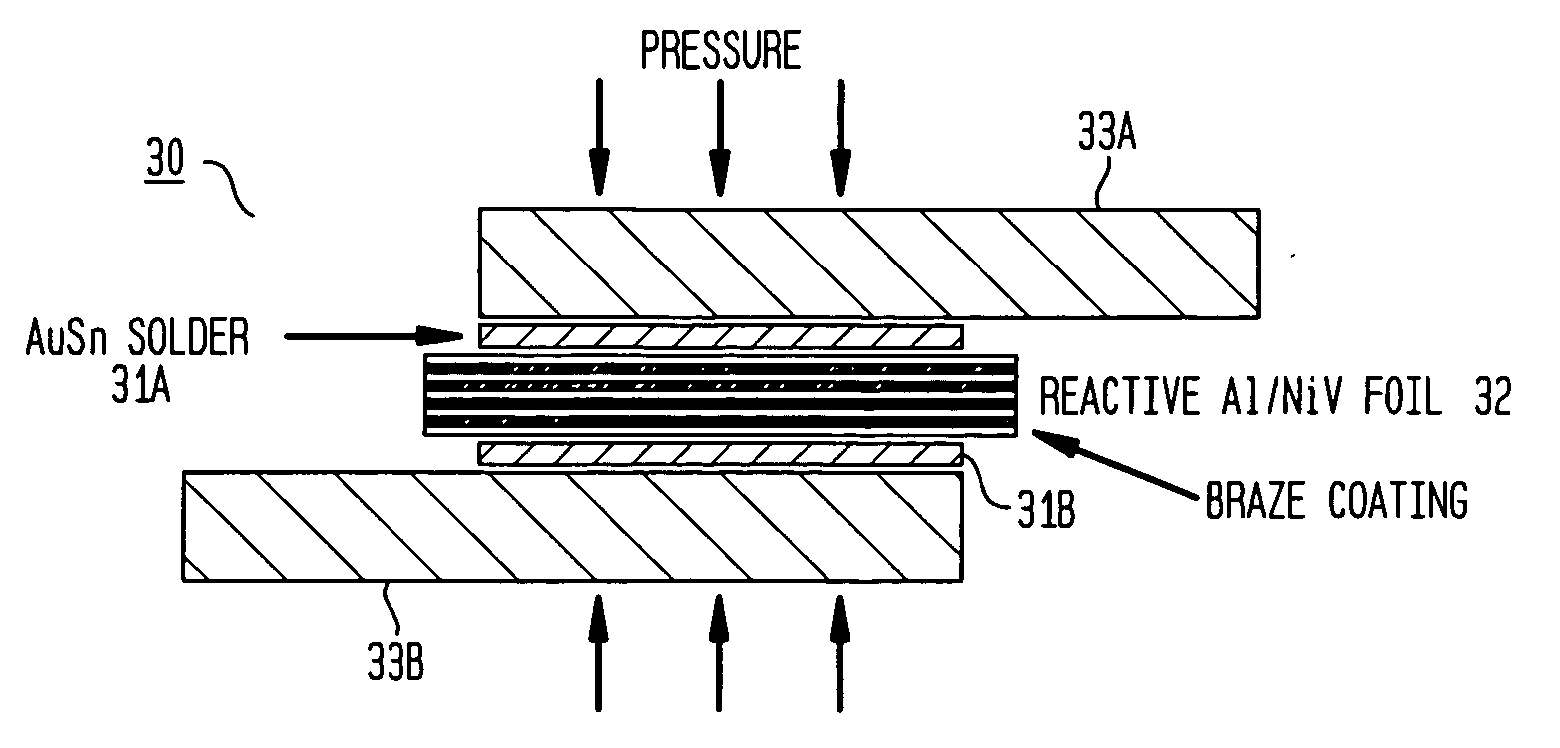

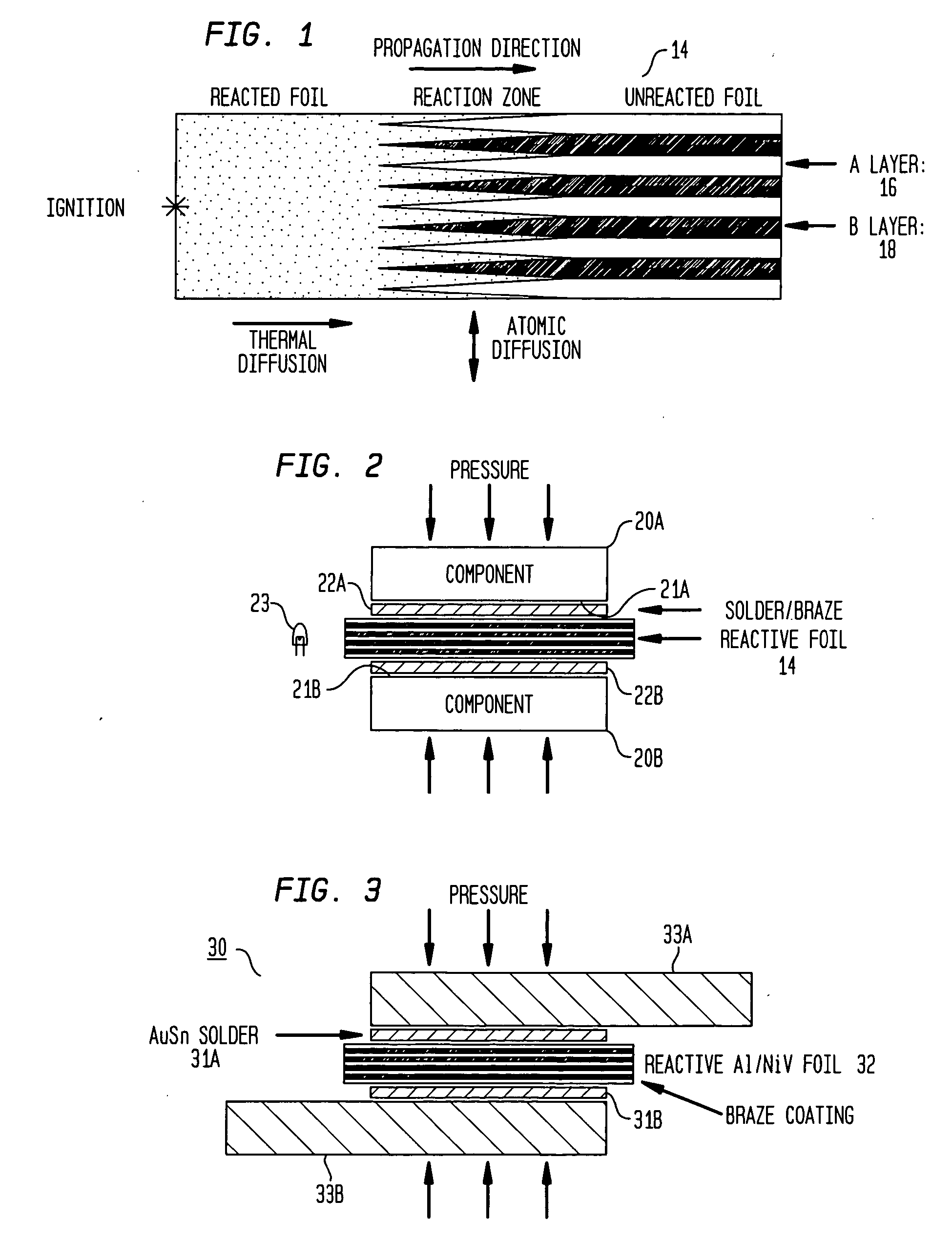

InactiveUS20050051607A1Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

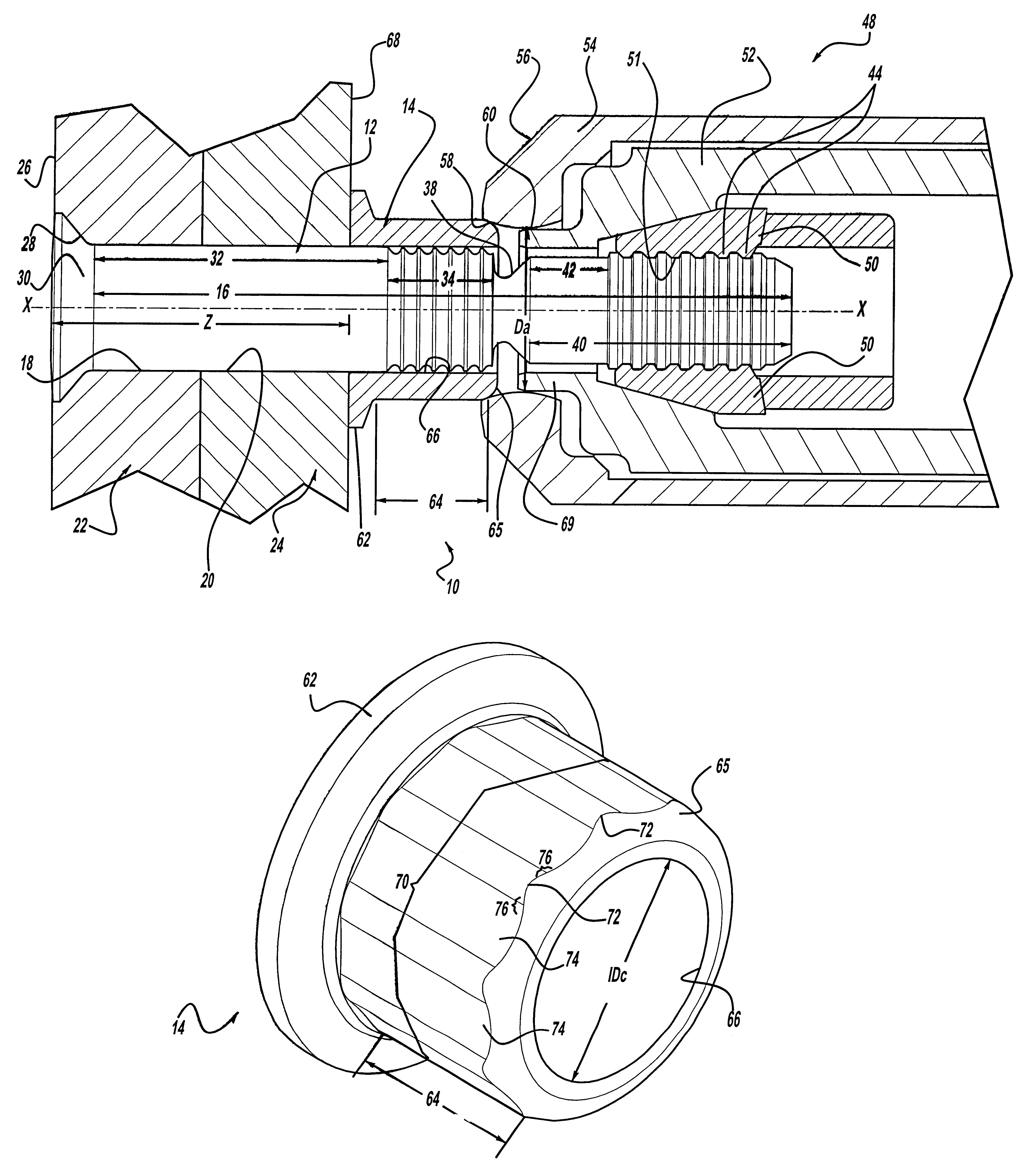

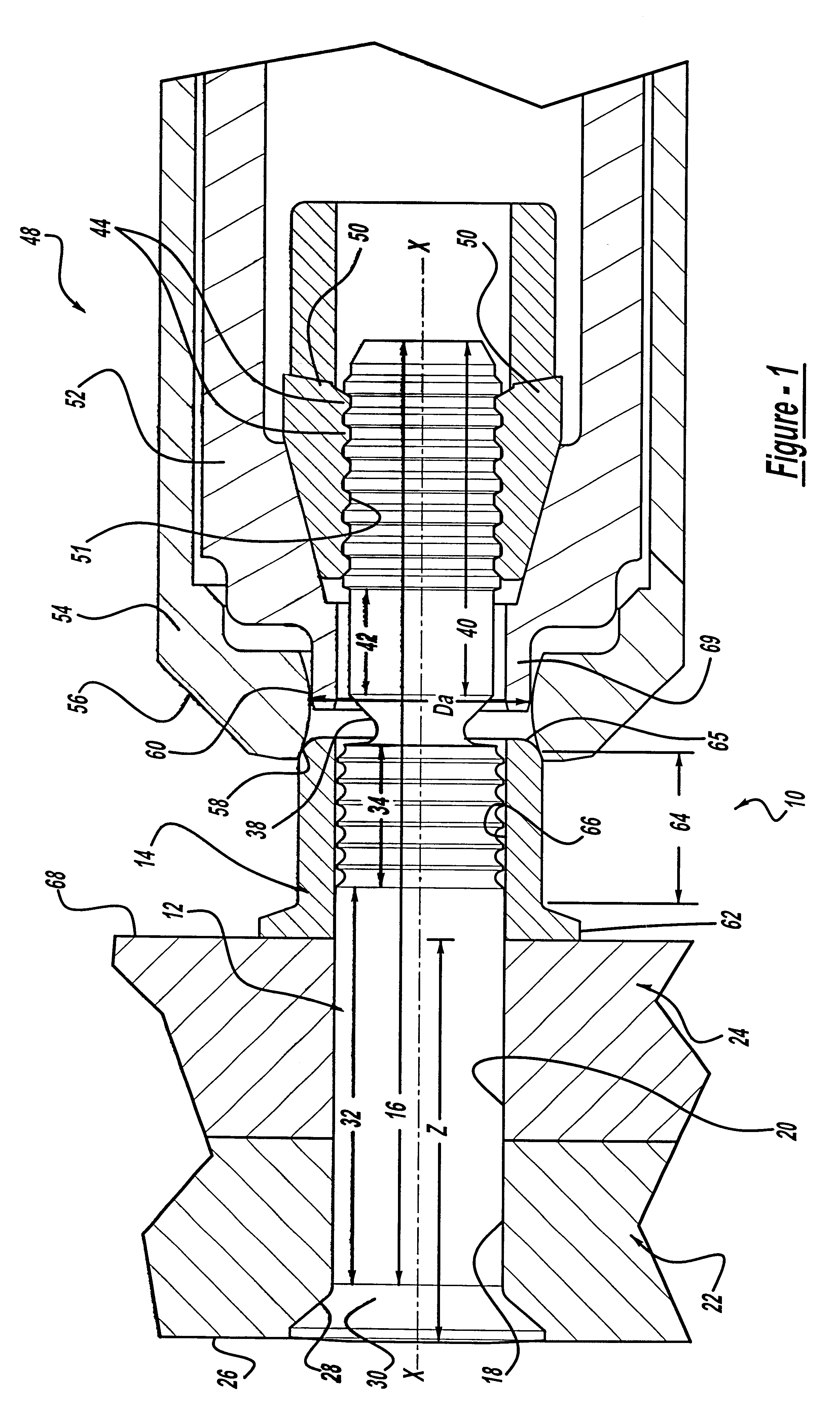

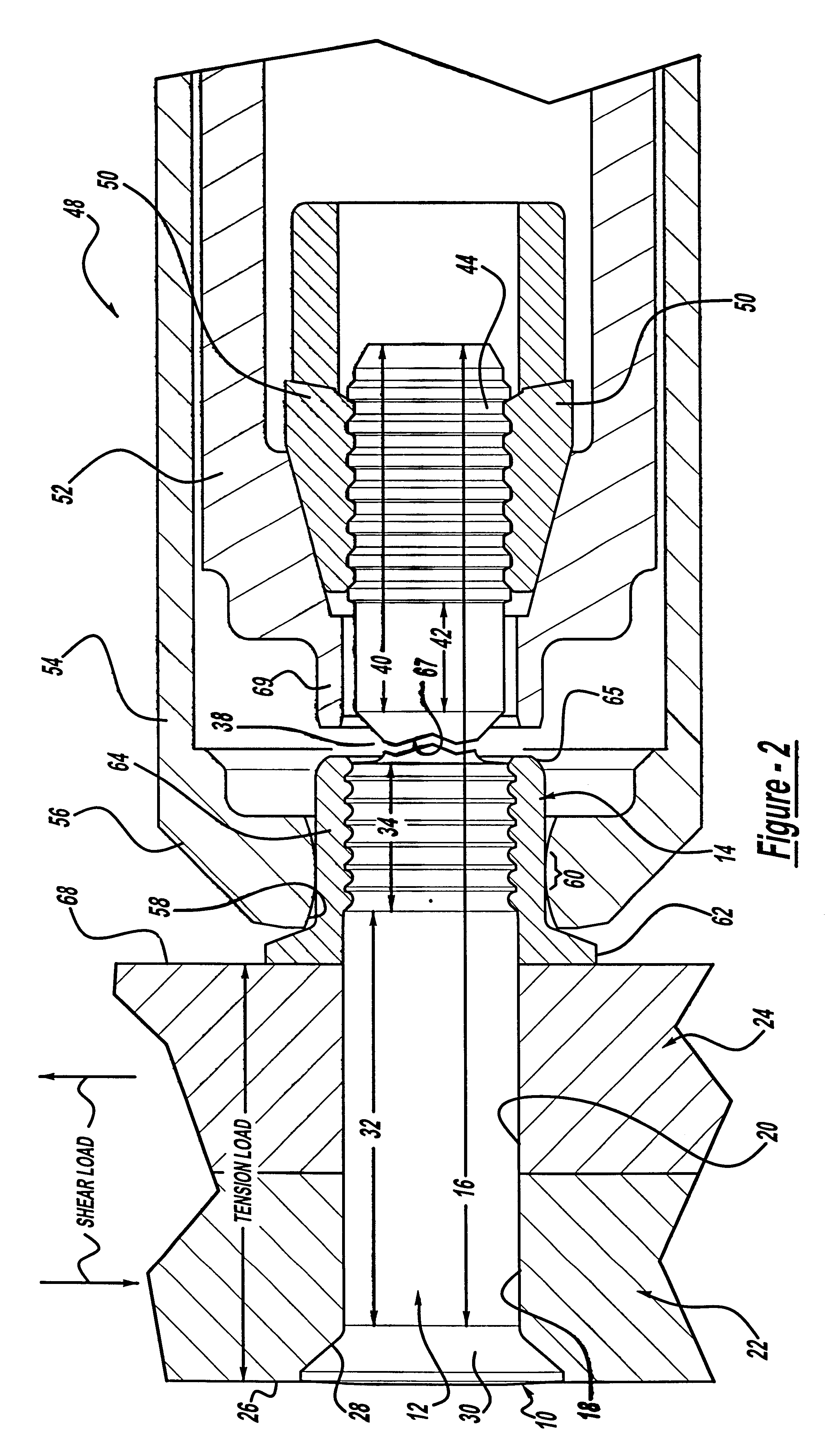

Swage type fastener with low swage load

InactiveUS6325582B1Reduce loadMinimized installation weightRivetsScrewsEngineeringUltimate tensile strength

A two piece fastener system for including a pin member and a collar having an optimized strength with the materials of the pin member and collar having a predetermined shear strength ratio; the collar has a preselected excess volume to provide a desired "overpacking' condition and is of a size whereby after swage it will define a minimum wall thickness; the collar has an outer surface with a contour which in combination with a preselected excess volume results in a reduction in load required to swage the collar and with a pull type fastener providing a breakneck groove of reduced strength whereby severance of the pintail will occur at a reduced load resulting in a reduction in shock or ghost load applied to workpieces including those of a plastic or composite material.

Owner:HUCK INT INC

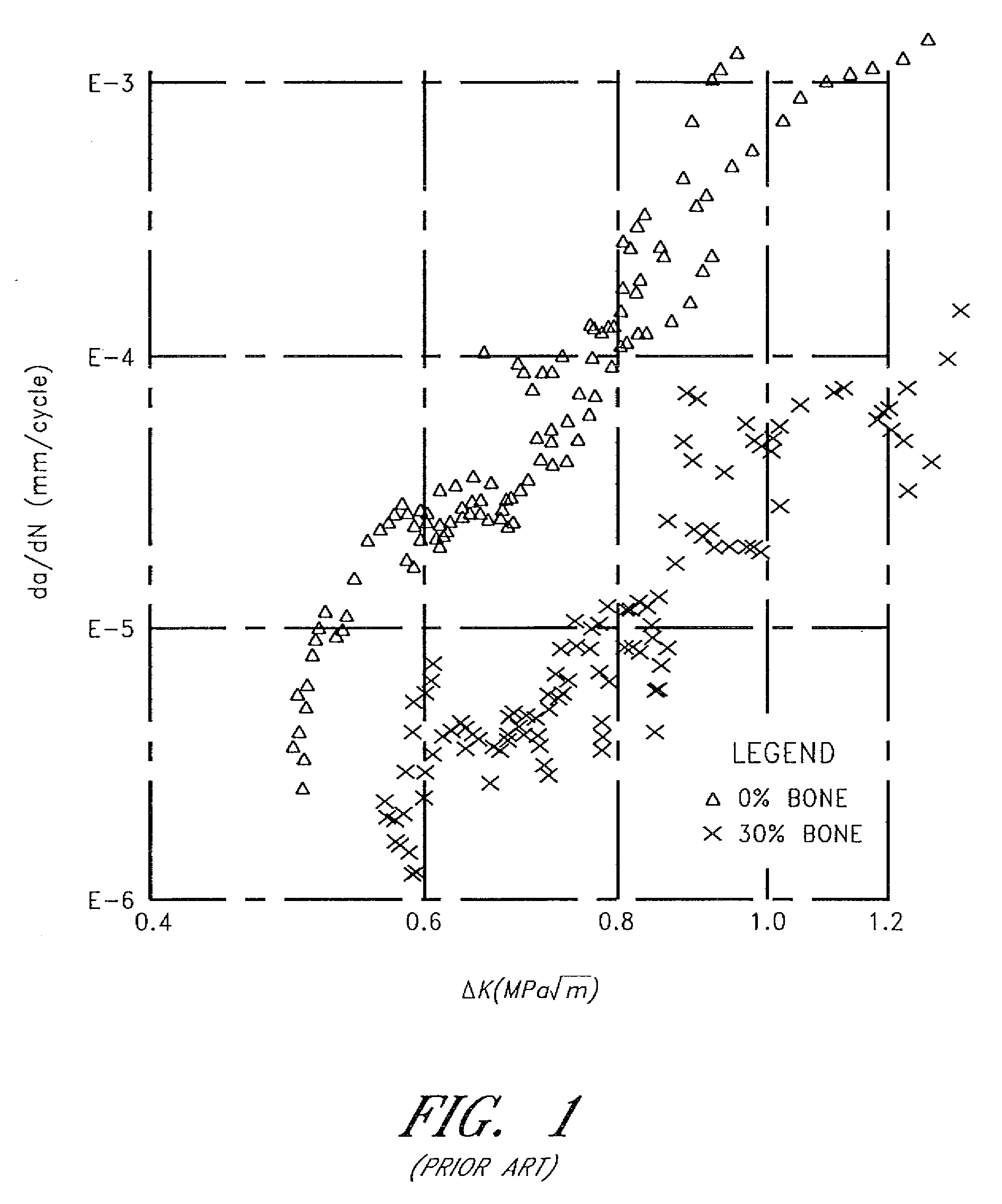

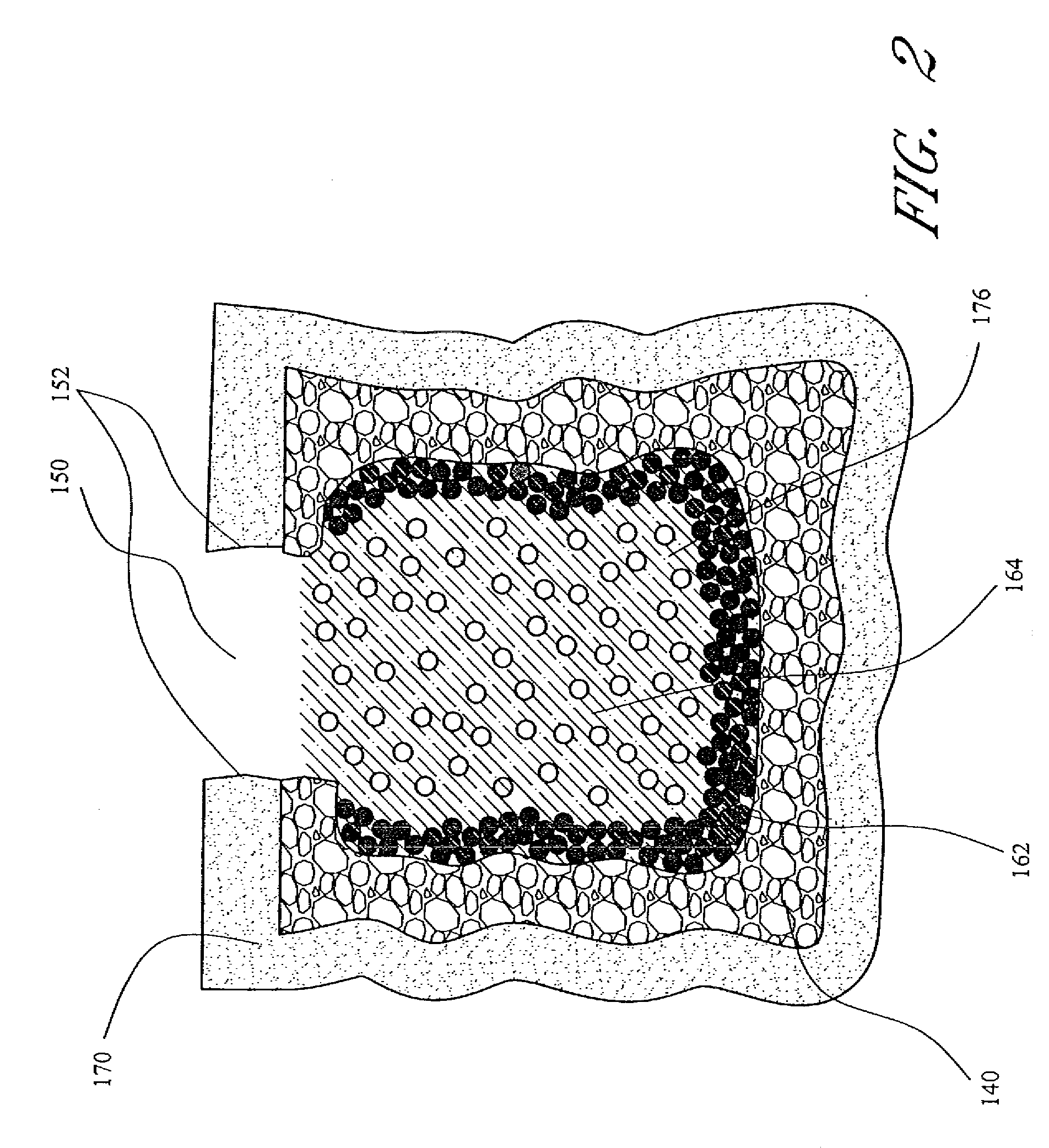

Vertebroplasty methods with optimized shear strength and crack propagation resistance

InactiveUS20080195112A1Reduce cavity volumeImpression capsSurgical adhesivesNatural boneControl manner

Owner:LIU Y KING +3

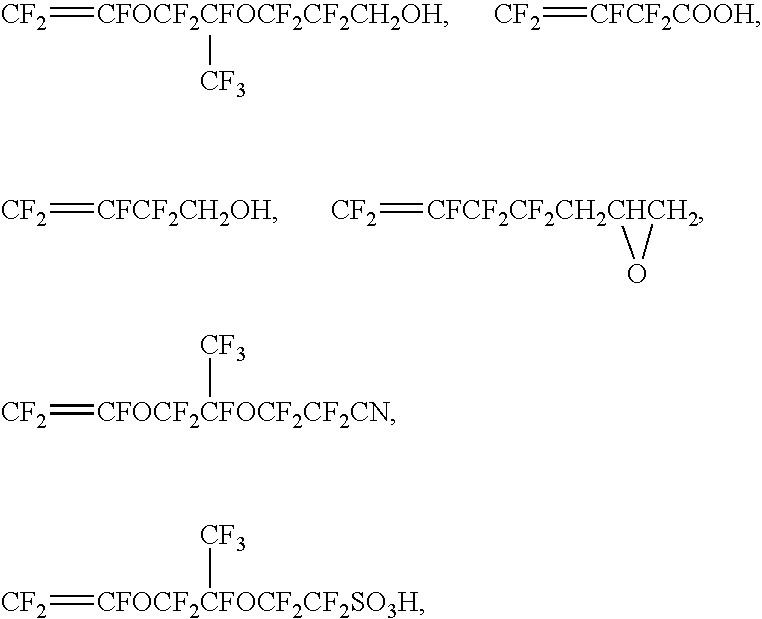

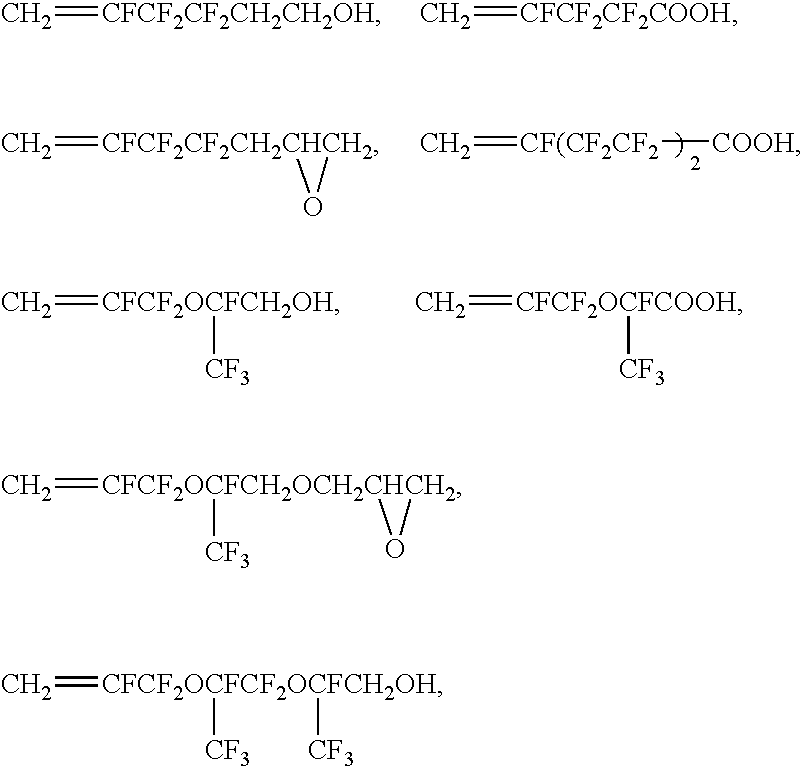

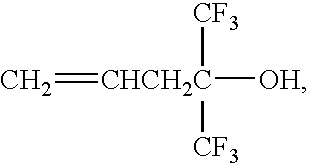

Structural member of fluorine-containing polymer having adhesive property at high temperature and sliding material produced by using same

InactiveUS6726994B1Easy to useImprove friction performanceSynthetic resin layered productsBearing componentsUltimate tensile strengthAdhesive materials

The structural member of the present invention comprises (A) a layer which comprises a fluorine-containing polymer and does not contain an adhesive material other than the fluorine-containing polymer substantially and (B) a substrate, in which the layer (A) is adhered directly to the substrate (B) without interposing a binder therebetween and a longitudinal shear strength between the layer (A) comprising a fluorine-containing polymer and the substrate (B) is not less than 0.98 N / mm<2 >at 150° C. The structural member comprising a fluorine-containing polymer and a substrate adhered to each other, particularly the structural member having improved adhesive strength at high temperature and the sliding material produced by using the structural member are provided.

Owner:DAIKIN IND LTD

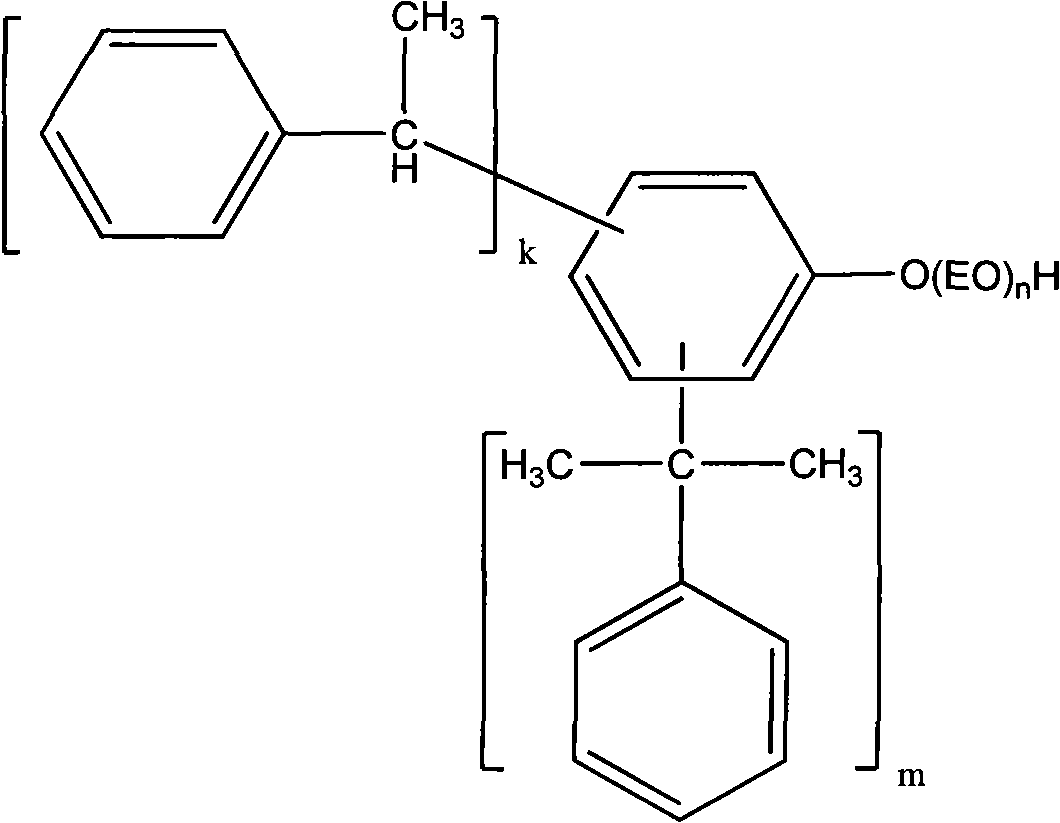

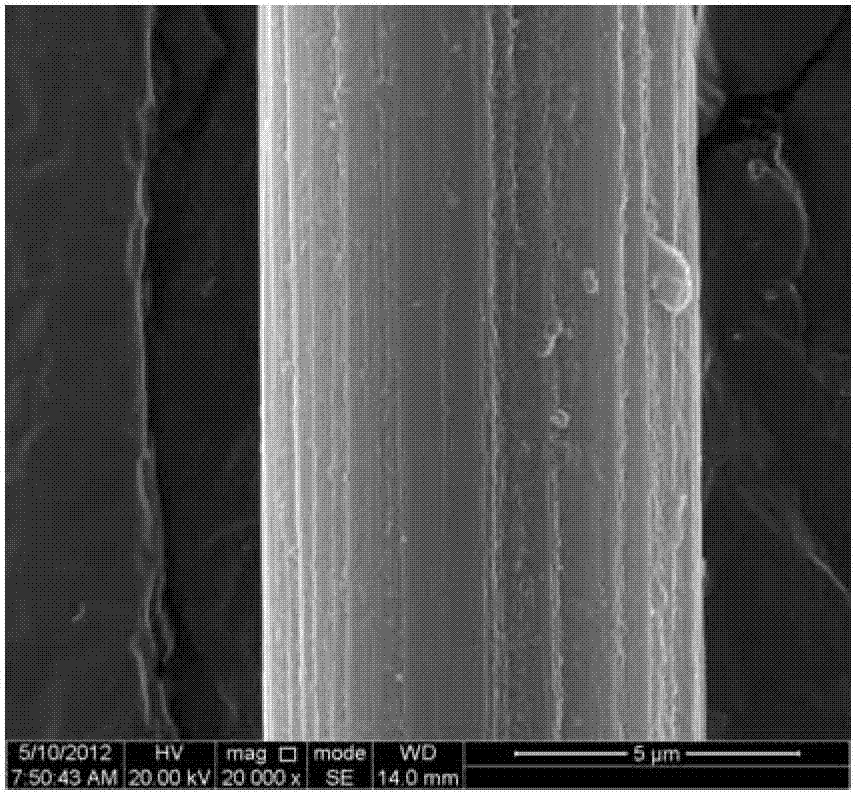

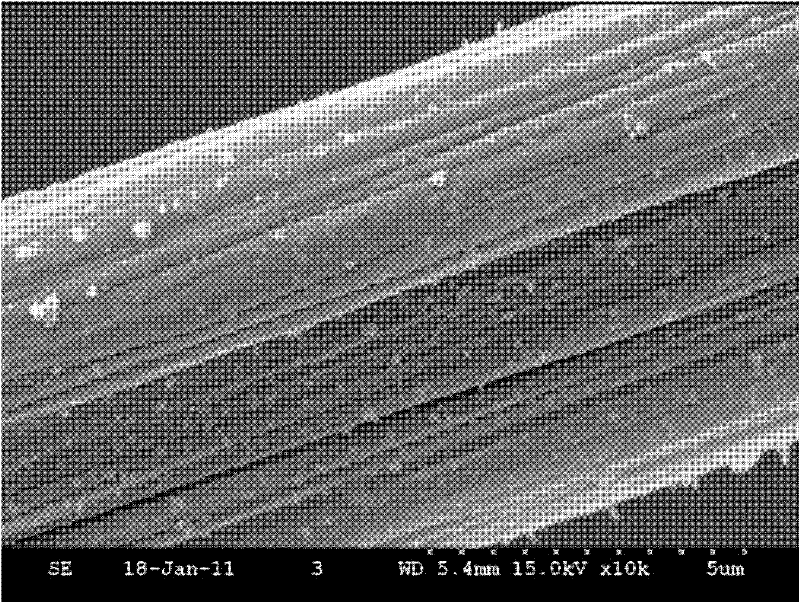

Emulsion type carbon fiber sizing agent and preparation method and application thereof

The invention discloses an emulsion type carbon fiber sizing agent, which comprises main size, an emulsifier, an aid and deionized water. The aid comprises a diluent and a penetrant, wherein the emulsifier is 5 to 15 mass percent of the main size, the diluent is 0 to 120 mass percent of the main size, the penetrant is 1 to 5 mass percent of the main size, and the mass ratio of the deionized water to the main size is 50-90:10-50. The invention also discloses a preparation method and application of the sizing agent. The sizing agent is suitable for unsaturated polyester resin and solves the problem of poor adhesion of the unsaturated polyester resin and the carbon fiber. After the sizing agent is used for sizing, the wear resistance of the carbon fiber is improved, and the broken filament amount is reduced, the post-processing performance of the fiber is improved, the interface adhesion of the carbon fiber and matrix resin is better, the shear strength between layers is improved, and the performance of composite materials is also improved.

Owner:UNIV OF JINAN

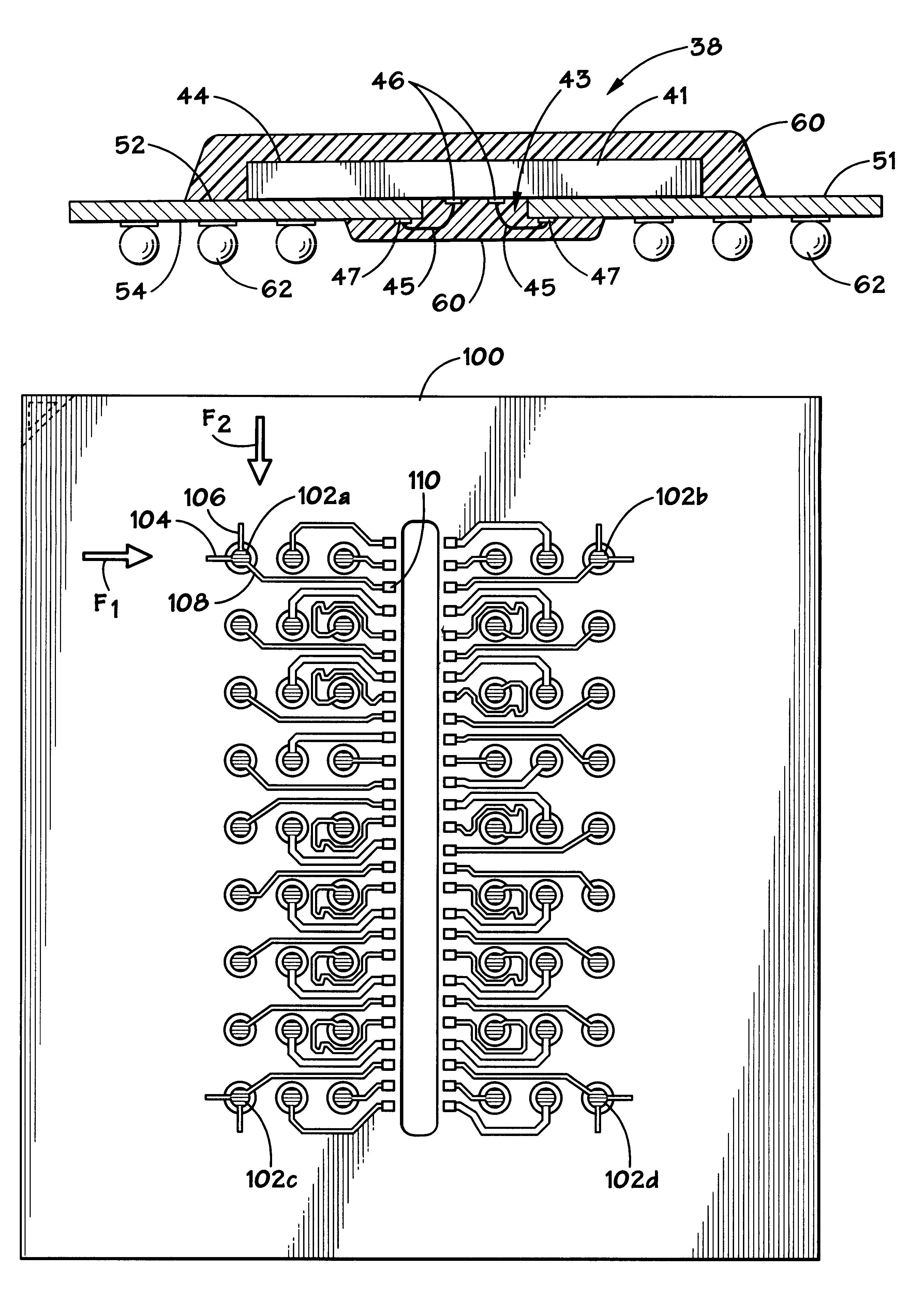

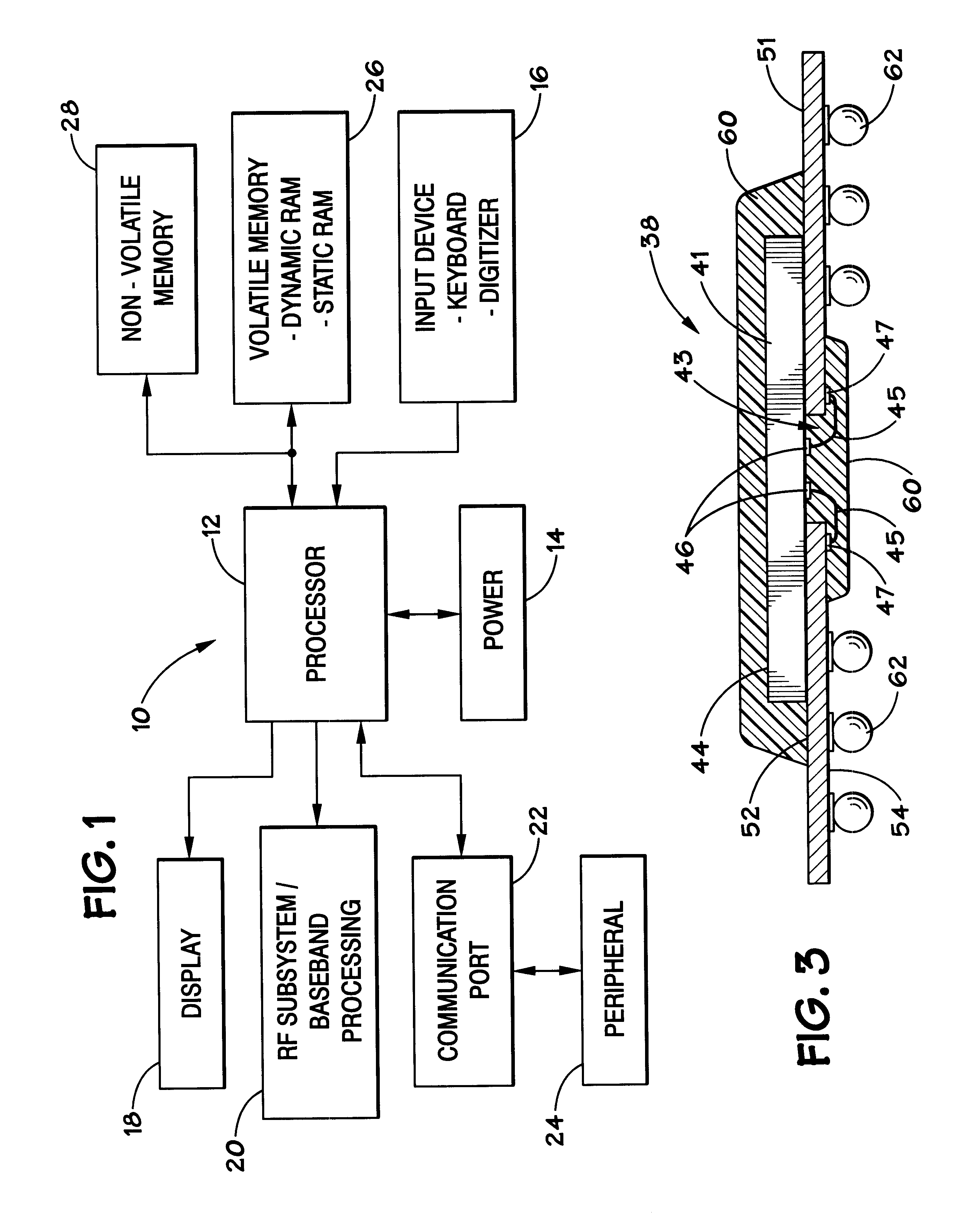

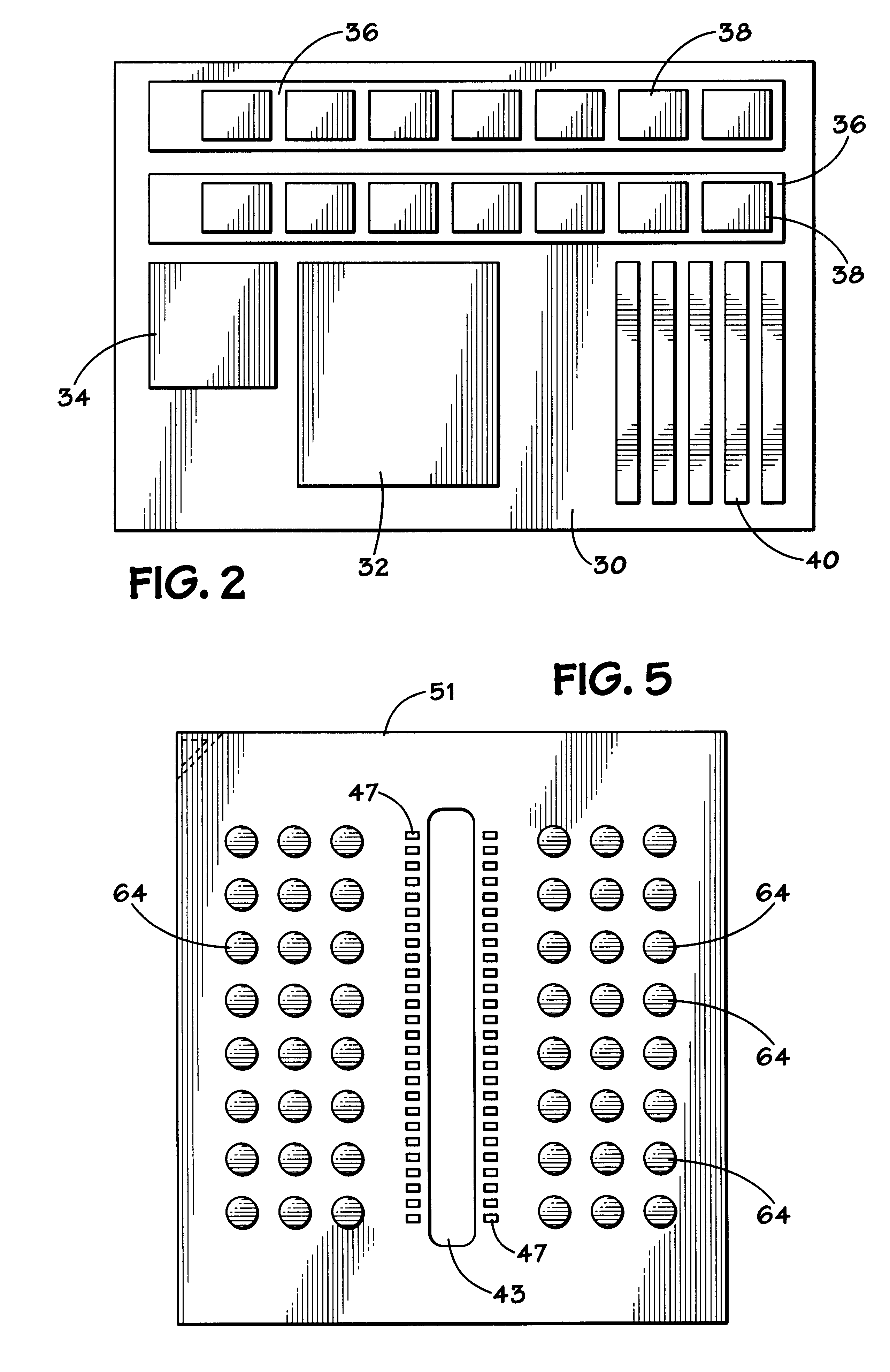

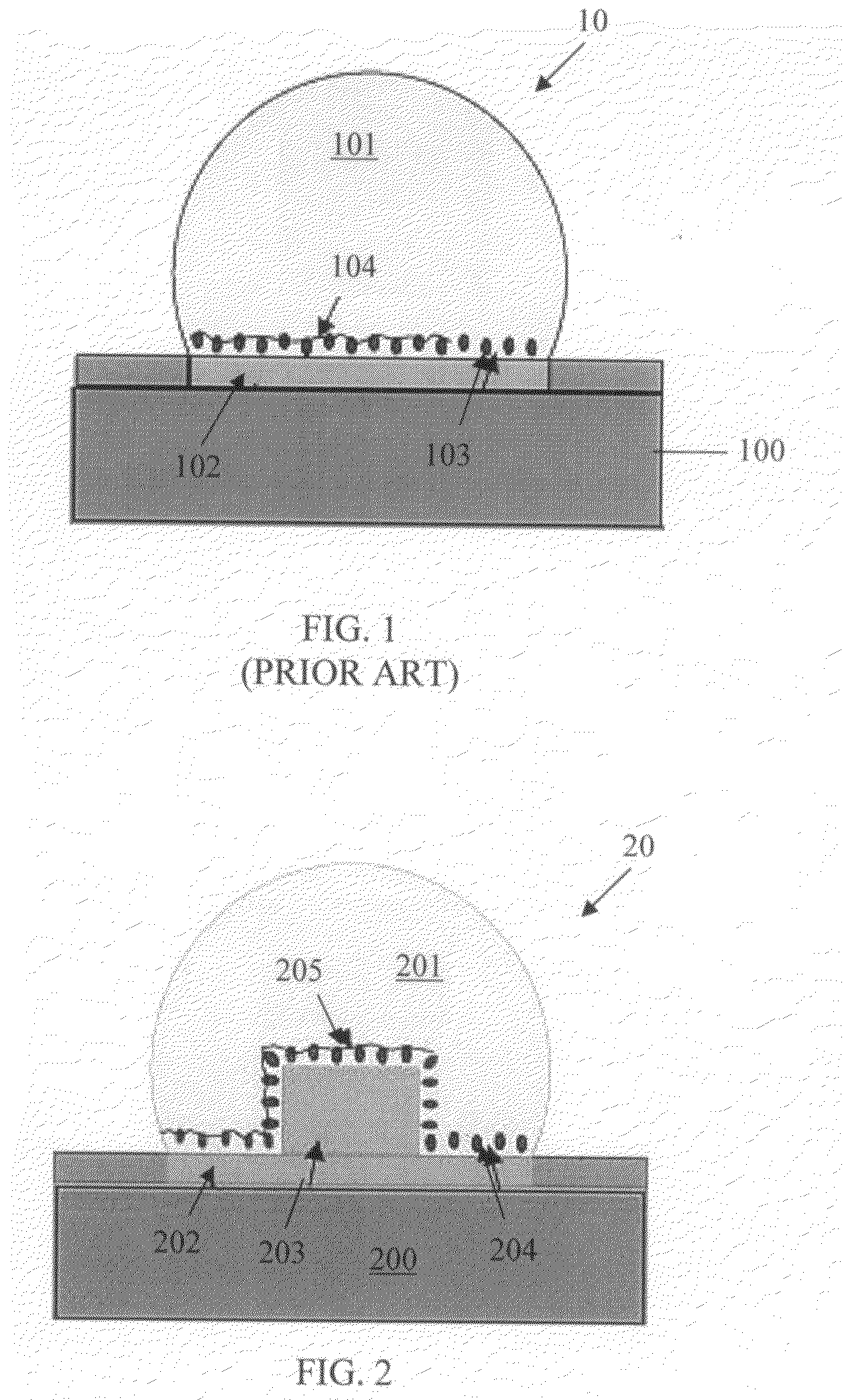

Solder ball landpad design to improve laminate performance

InactiveUS6577004B1Semiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

A method and apparatus for improving the laminate performance of the solder balls in a BGA package. Specifically, the ball pads on the substrate are configured to increase the shear force necessary to cause delamination of the solder balls. Conductive traces extending planarly from the pads and arranged in specified configurations will increase the shear strength of the pad.

Owner:ROUND ROCK RES LLC

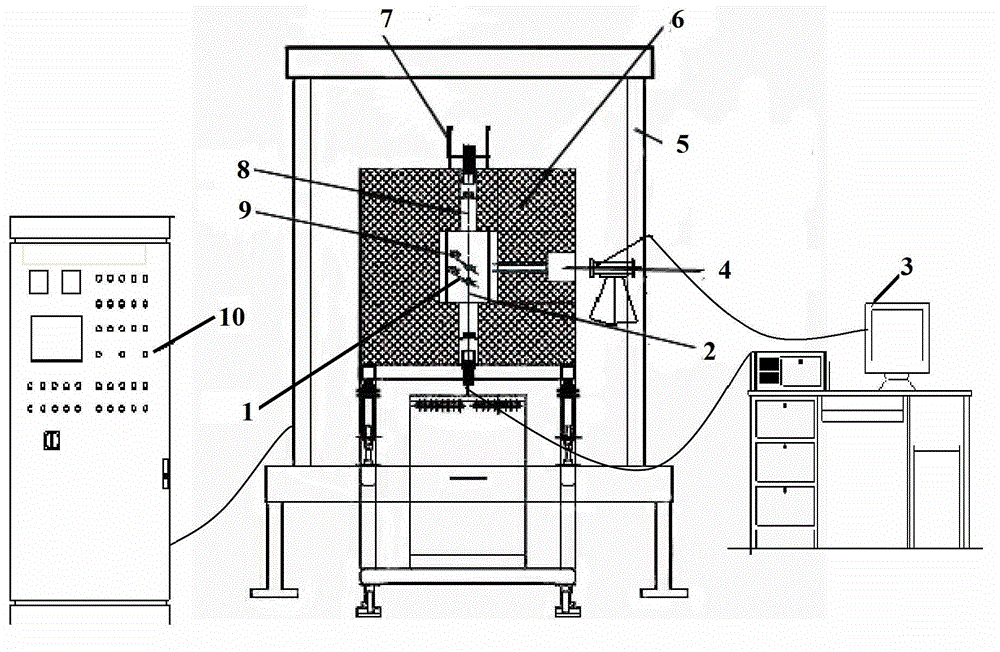

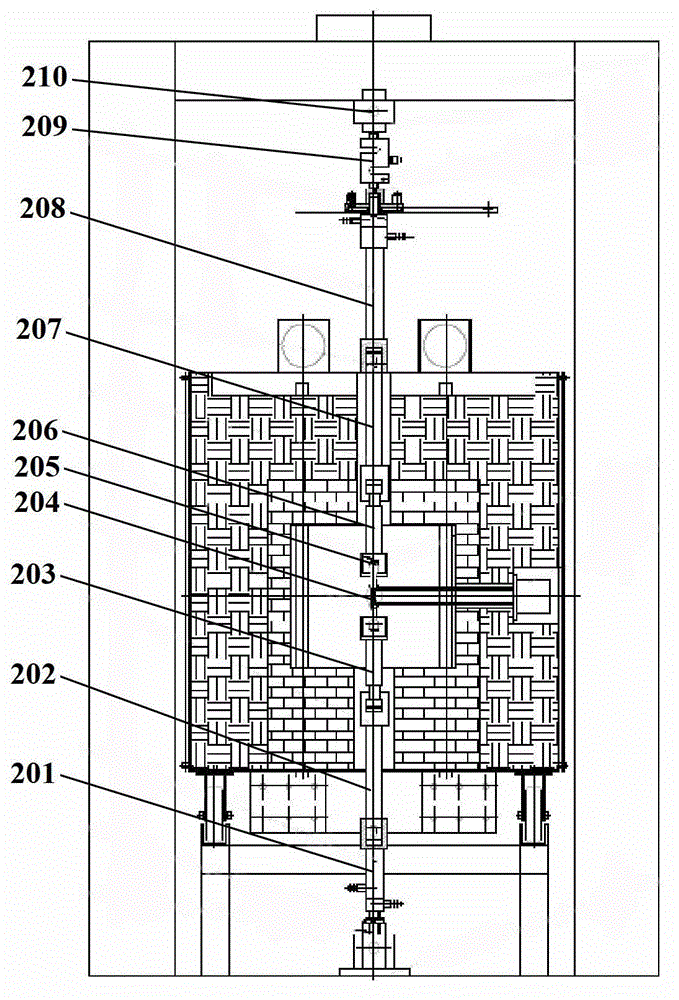

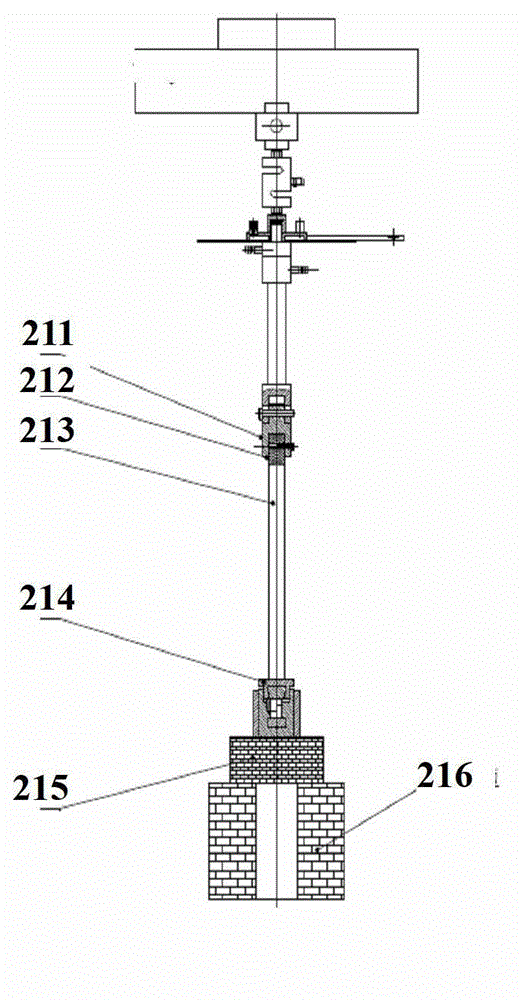

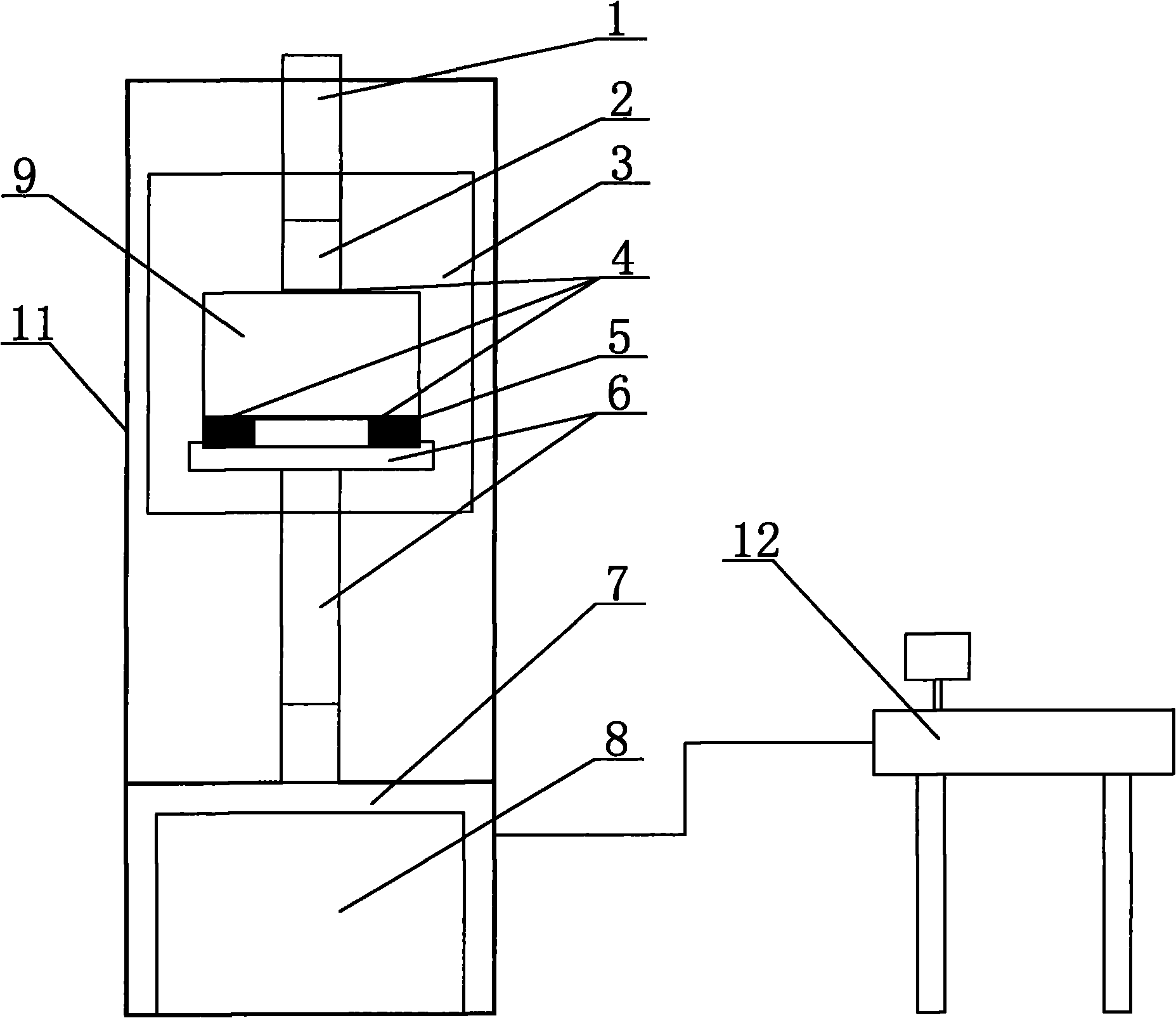

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

ActiveCN102944466AMeasuring Tensile StrengthMeasuring Compressive StrengthMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectric controlMeasurement precision

The invention provides a device and a method for testing mechanical properties such as stretching, compression, bending, fracture toughness, shear strength and deformation of a high-temperature material in an ultrahigh temperature oxidation atmosphere in a temperature range from normal temperature to 1,800 DEG C. The experimental device is formed by assembling an electric control cabinet, a loading clamp, a load control and deformation sensing measurement system, a furnace body, a non-contact deformation measurement system, a display recording system and the like. According to the method, a furnace oxidation environment is uniformly and stably heated and kept through a heating body, so that the mechanical properties can be tested at temperature range from the room temperature to 1,800 DEG C, and mechanical property parameters such as stretching, compression, bending, shear strength and strain are captured by utilizing the contact sensing system and the non-contact measurement system. The device has the greatest characteristics of multiple testing parameters, high data measurement precision and high experimental repeatability.

Owner:PEKING UNIV +2

Carbon fiber prepreg, and a production process thereof

InactiveUS6117551AImprove impact resistanceHigh tensile strengthDecorative surface effectsAdhesive processes with surface pretreatmentHigh concentrationFiber bundle

PCT No. PCT / JP97 / 04642 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Dec. 16, 1997 PCT Pub. No. WO98 / 26912 PCT Pub. Date Jun. 25, 1998The present invention relates to a carbon fiber prepreg. The carbon fiber prepreg of the present invention is characterized in that a carbon fiber bundle comprising a plurality of continuous carbon filaments and having a hook drop value of 10 cm or more as the degree of fiber entanglement is impregnated with a base resin mainly composed of a thermosetting resin, and that particles of 150 mu m or less in particle size made of a thermoplastic resin account for 20 wt % or less based on the weight of the entire prepreg and distributed at a higher concentration in the surface zone than in the inside. The carbon fiber prepreg of the present invention is good in tackiness and less changing in tackiness with the lapse of time, and can form a composite with an excellent compression interlaminar shear strength (CILS) at high temperature after moisture absorption while maintaining good impact resistance. It also allows the production of a composite very higher than the conventional composite in the compressive strength (LCS) of a cross laminated panel. The carbon fiber prepreg of the present invention can be preferably used as a structural member in such areas as aerospace area, sporting area and civil engineering and architecture area.

Owner:TORAY IND INC

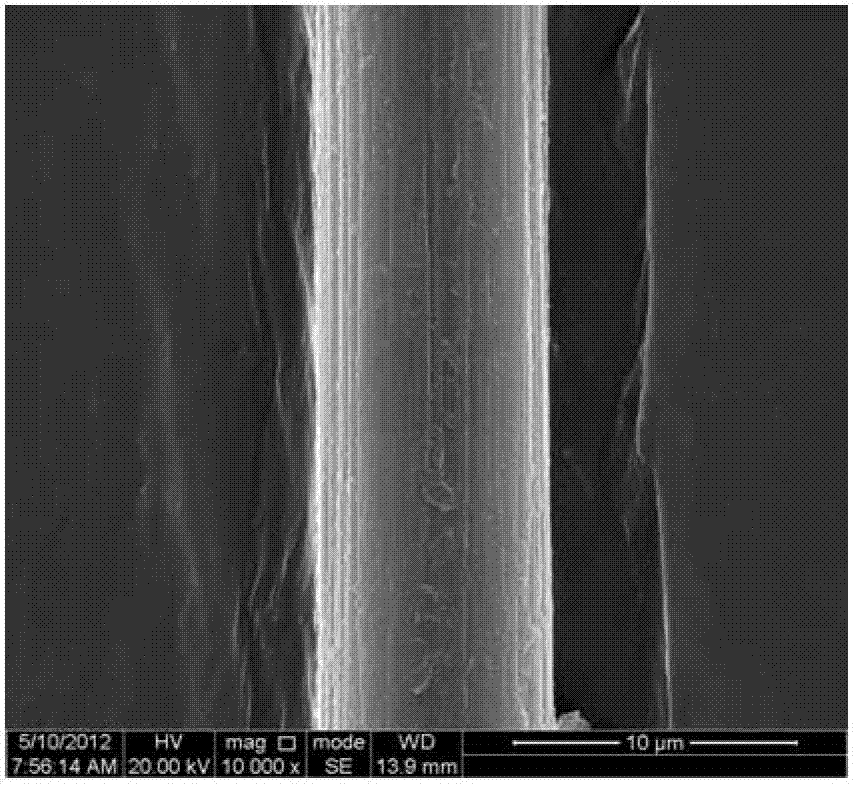

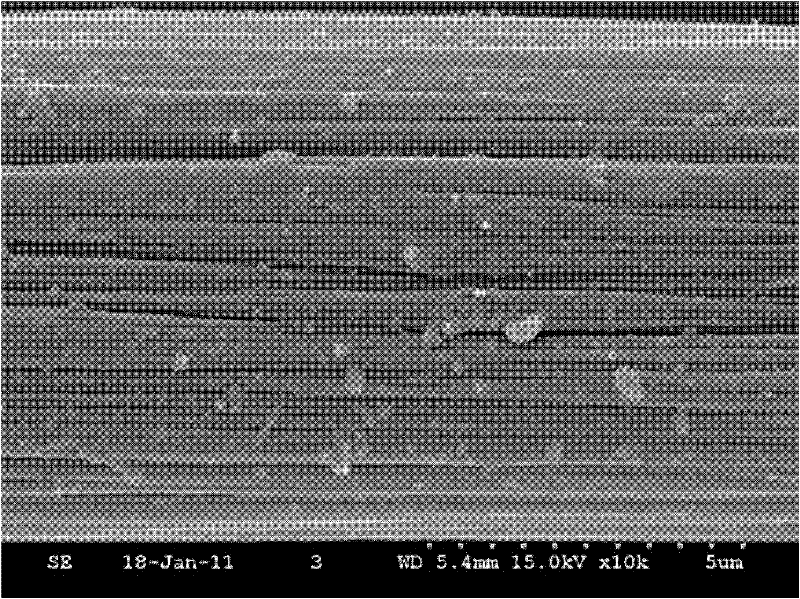

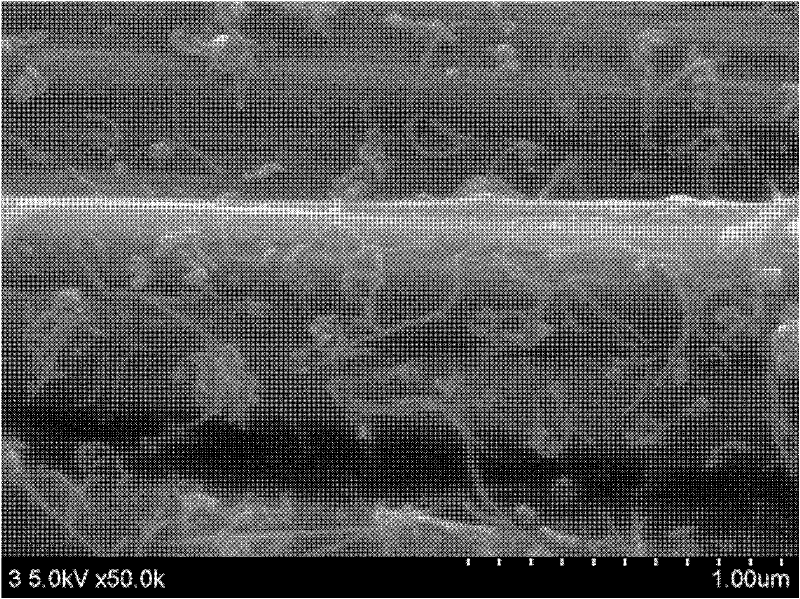

Method for preparing graphene oxide grafting surface modification carbon fiber

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

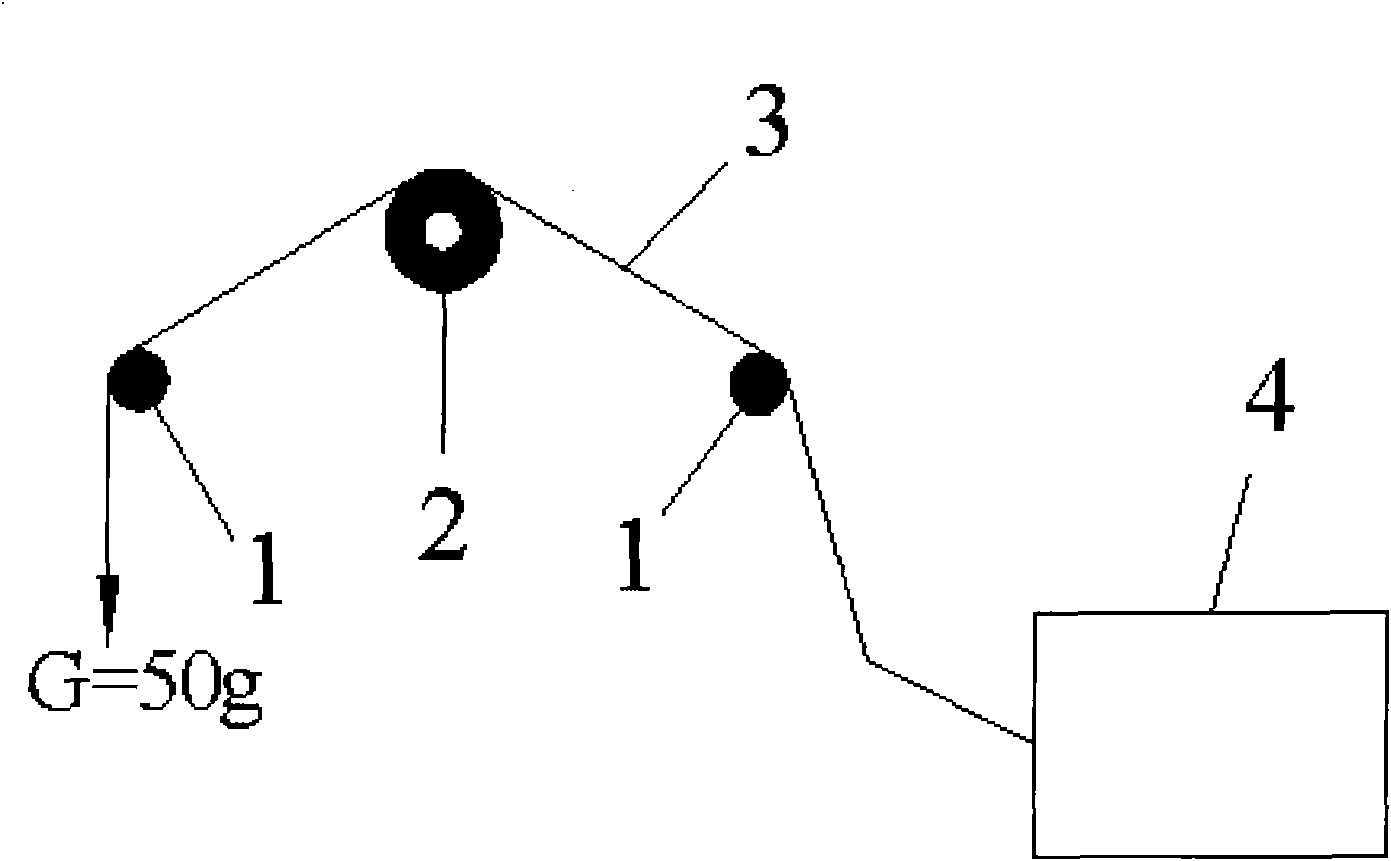

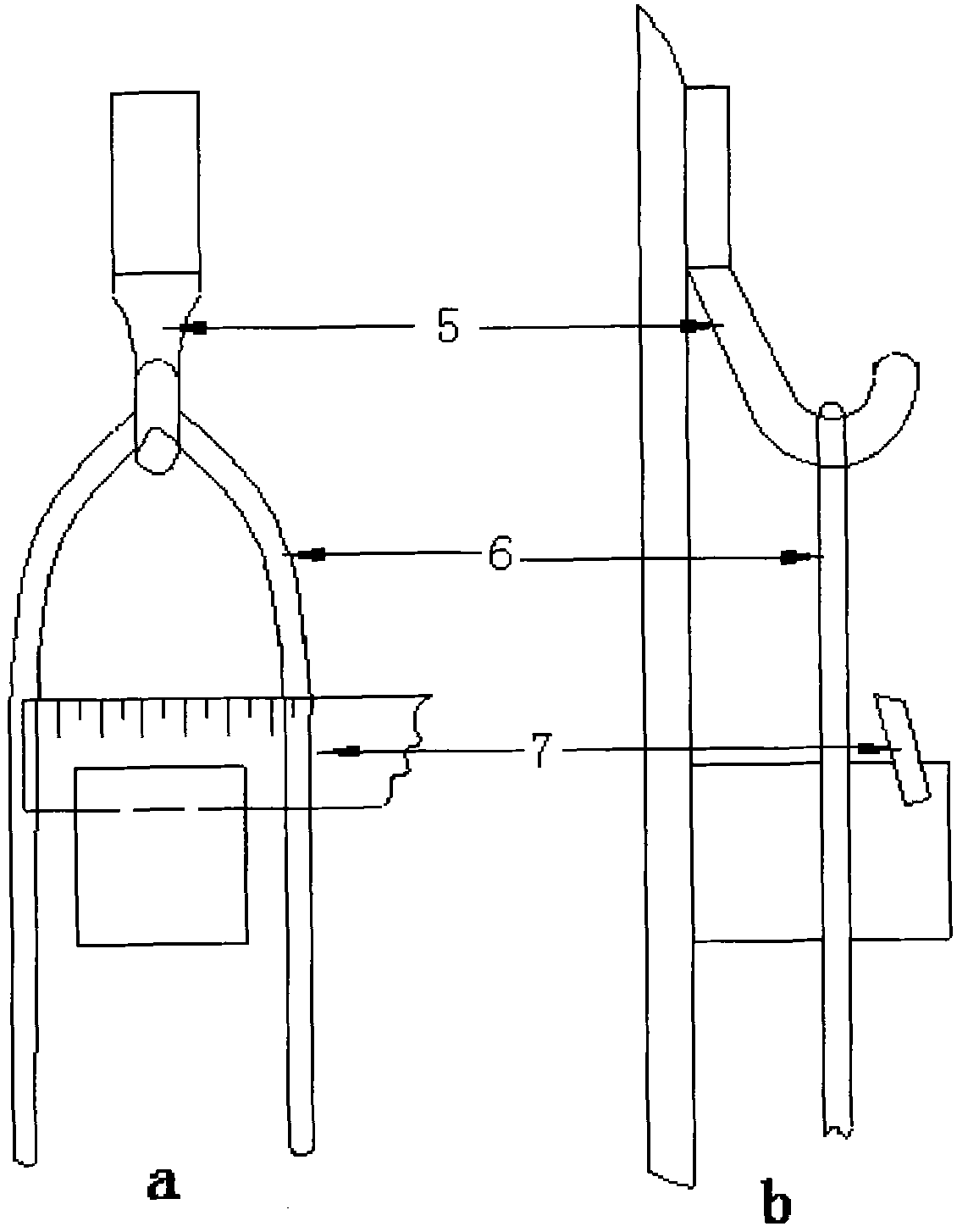

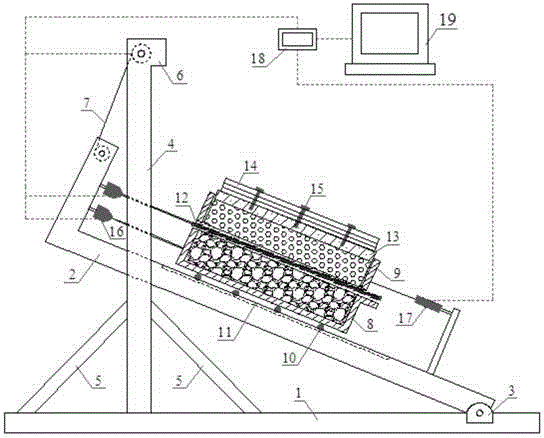

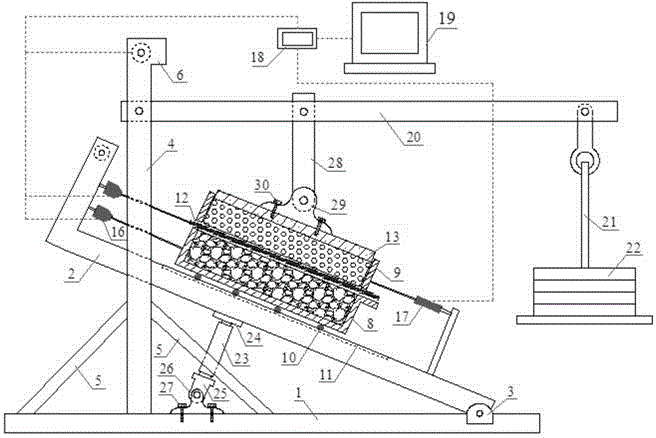

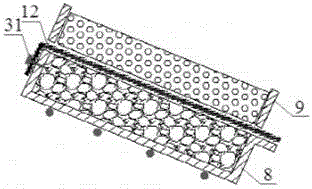

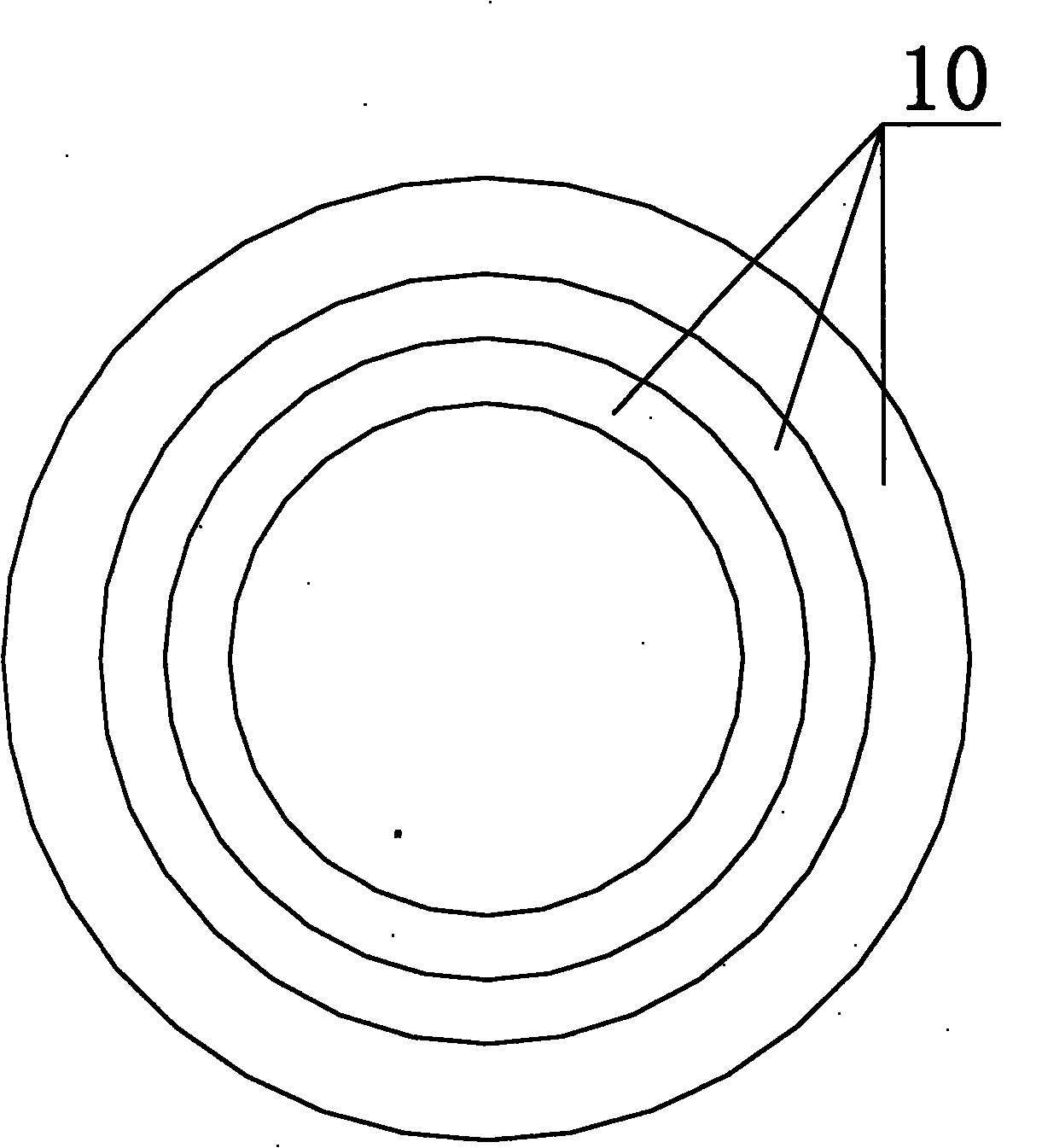

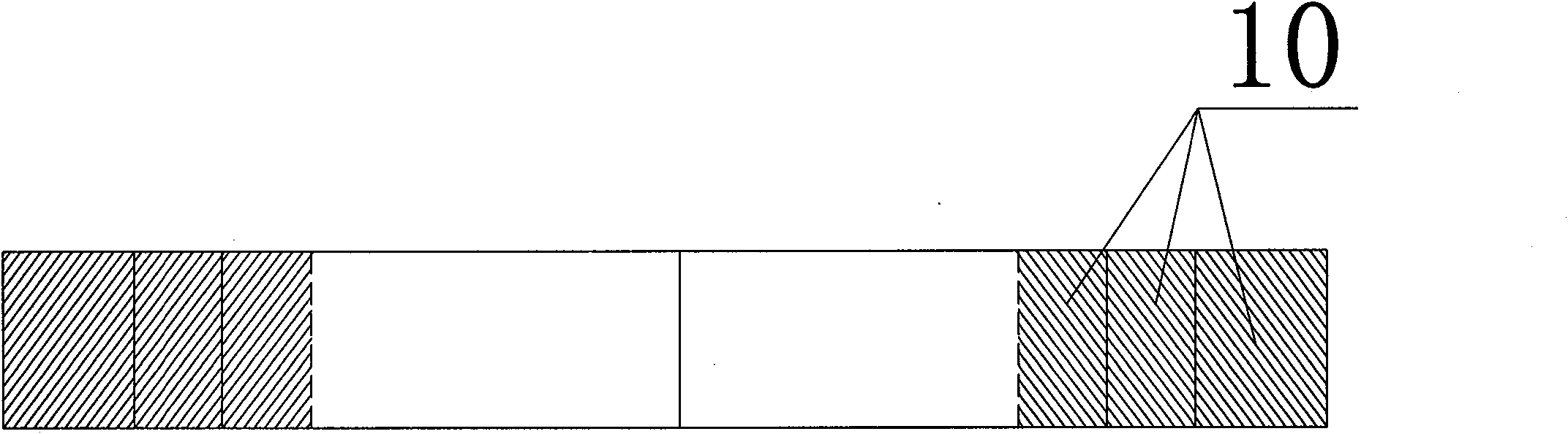

Multifunctional tilt table device used for testing interfacial shear strength characteristics of geotechnical synthetic material

InactiveCN104007025AEliminate the effects ofHigh degree of automatic test controlMaterial strength using steady shearing forcesSynthetic materialsControl system

The invention discloses a multifunctional tilt table device used for testing the interfacial shear strength characteristics of a geotechnical synthetic material. The multifunctional tilt table device comprises a testing stand, an inclined plane control mechanism, a shearing box unit, a vertical loading mechanism and a measurement and control system, wherein the inclined plane control mechanism drives a tilted plate of the testing stand through a motor so as to allow the tilted plate to rotate to any inclination angle and can fix the tilted plate at a certain inclination angle through hydraulic jacks, shearing boxes are placed on concave guide rails on the surface of the tilted plate, a geotechnical synthetic material sample is installed between upper and lower shearing boxes, multiple layers of inclined shearing interfaces are formed through rotation of the tilted plate, the vertical loading mechanism comprises two loading devices used for short-term and long-term characteristic testing of the interfaces, the measurement and control system composed of a sensor, a control and acquisition system and a computer carries out real-time monitoring on stress and displacement of the upper and lower shearing boxes and the sample, determines a critical interface instability inclination angle according to displacement and pull-up curve abrupt change points and calculates shear strength of each interface according to stress analysis. The multifunctional tilt table device can be used for short-term and long-term characteristic testing of a single layer or multiple layers of interfaces.

Owner:HOHAI UNIV

Device and method for testing shear performance of asphalt mixture

InactiveCN101788431AFree disassemblyThe testing process is simplePreparing sample for investigationMaterial strength using steady shearing forcesTemperature controlStress ratio

The invention discloses a device and a method for testing shear performance of an asphalt mixture. The shear strength and shear fatigue life of the asphalt mixture under different temperature conditions are tested by adopting a circular ring shearing test. The method comprises that: before the test, an asphalt mixture test-piece is subjected to heat preservation in a temperature control box at a preset test temperature for over 6 hours; in the test, the asphalt mixture test-piece is arranged on a circular ring, and is loaded through a pressure head to cause shear failure so as to form a conical shear failure surface, and the shear strength of the asphalt mixture is calculated; and according to requirements, a specific load in a range of 0.1 to 0.9 time of failure load is selected to perform a repeated loading fatigue test on parallel test-pieces, the loading waveform is sine waves, the frequency is 10Hz, and the shear fatigue life of the asphalt mixture at different stress ratios is read out. The test method has important significance for studying the shear performance of the asphalt mixture and designing and evaluating the material of the asphalt mixture.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

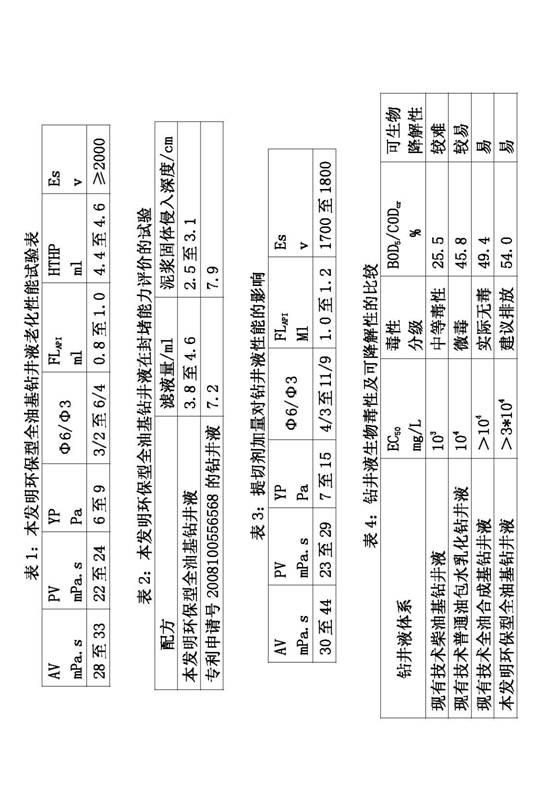

Environmental-friendly type oil-based drilling fluid and preparation method thereof

ActiveCN102304353AAvoid damageImprove the blocking effectDrilling compositionHorizontal wellsPetroleum

The invention relates to the technical field of an oil-based drilling fluid for petroleum drilling, in particular to an environmental-friendly type oil-based drilling fluid and a preparation method therefore. The environmental-friendly type oil-based drilling fluid is prepared from the following raw materials: base liquid white oil, calcium chloride water solution, an emulsifying agent, a wetting agent, organic oil for drilling fluid, a composite plugging agent, a shear strength improving agent, a basicity regulating agent and a fluid loss additive; and a weighting agent is added into a mixture of the raw materials. The oil-based drilling fluid has the following advantages of: good plugging property, high shear viscosity and strong rock carrying capability; the EC 50 (median effect concentration) of the drilling fluid is larger than 3*104mg / L; the drilling fluid has good environmental safety; the return permeability of the drilling fluid can reach 90%-98%; the drilling fluid has little damage to reservoirs; the preparation process of the drilling fluid is simple; the drilling fluid is mainly applied to a special construction technology such as underbalance, horizontal wells and the like, water sensitivity reservoirs and low-pressure low permeability gas wells.

Owner:克拉玛依市金鑫科技有限公司

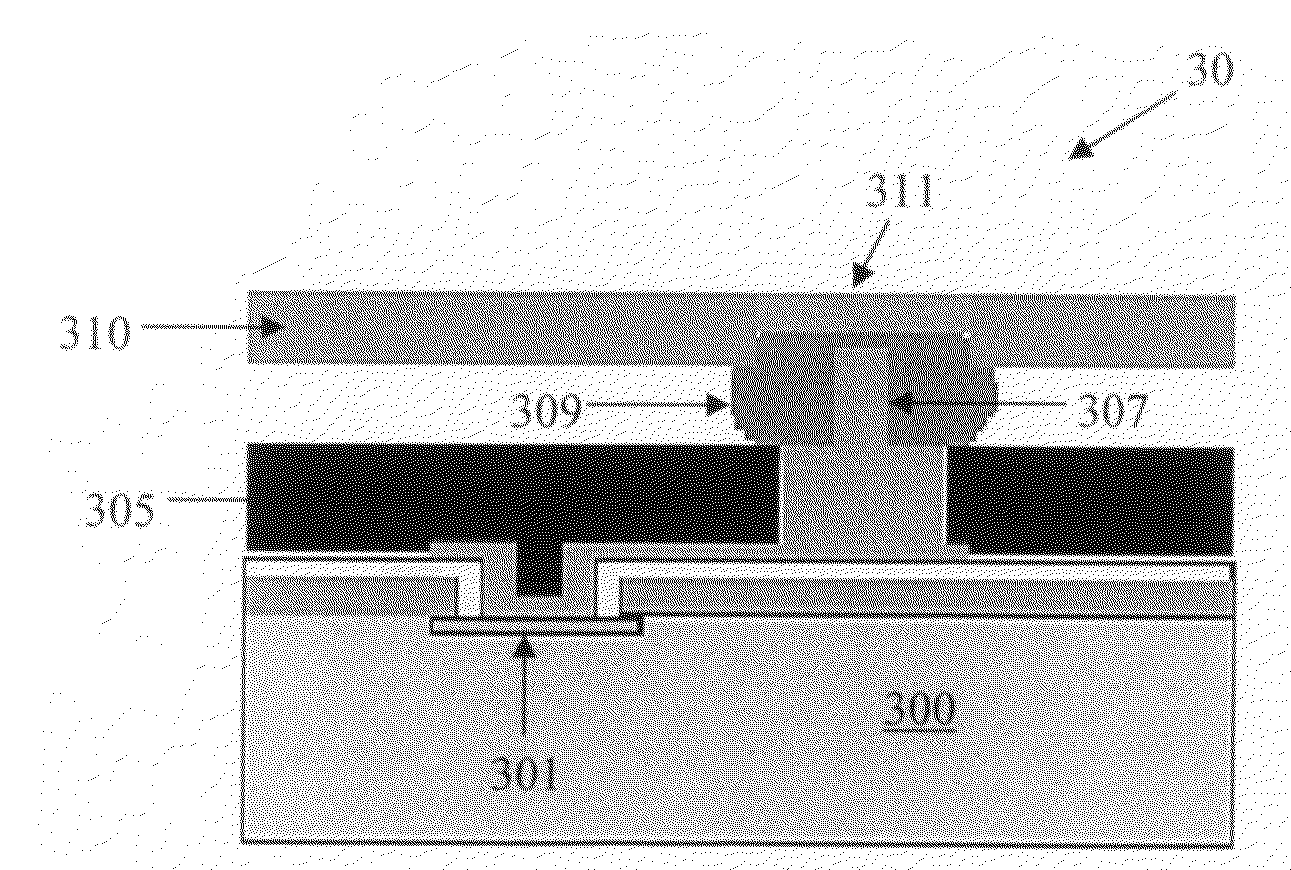

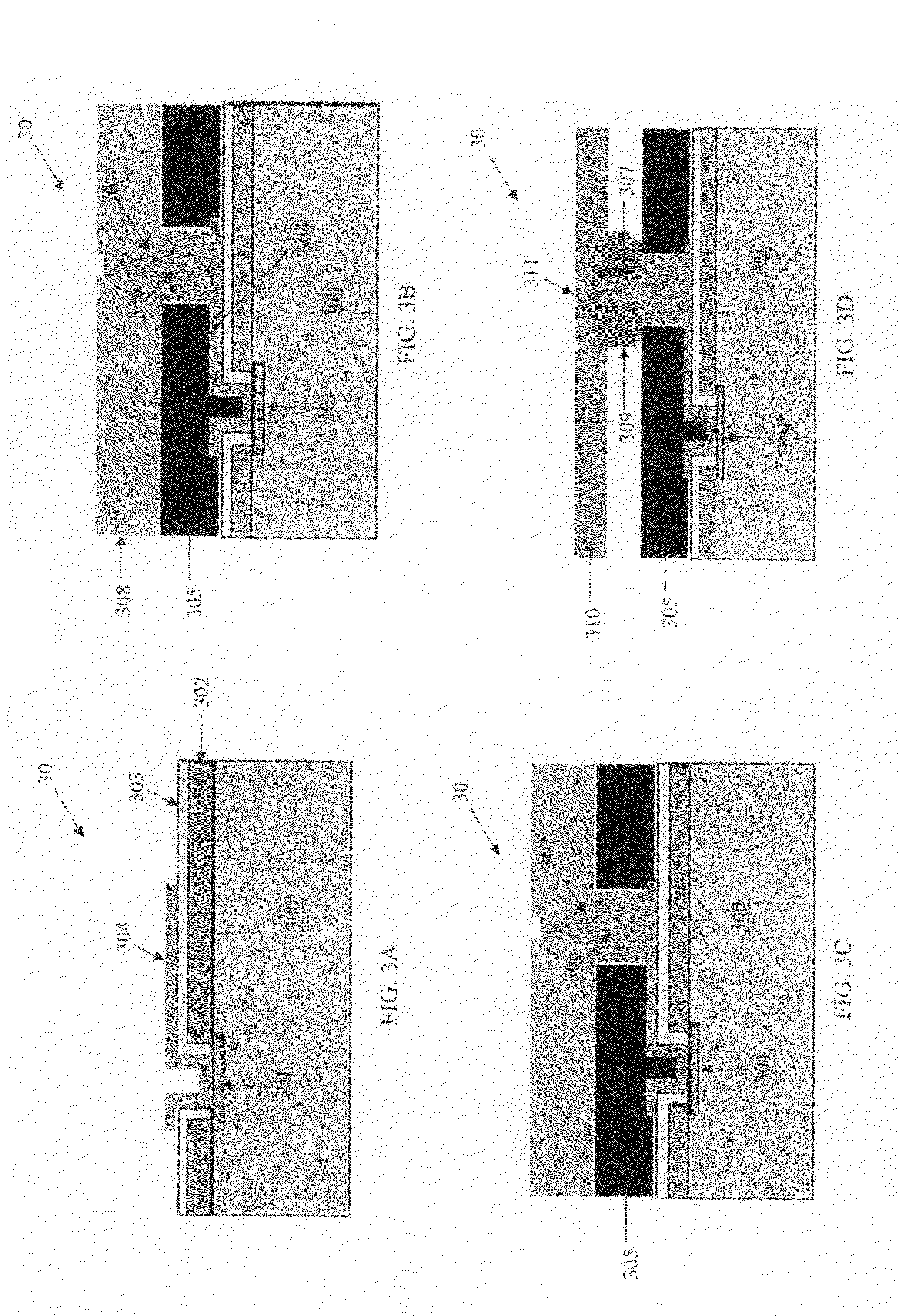

Enhanced copper posts for wafer level chip scale packaging

ActiveUS20080296764A1Increased shear strengthImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesElectrical connectionCopper electrode

An enhanced wafer level chip scale packaging (WLCSP) copper electrode post is described having one or more pins that protrude from the top of the electrode post. When the solder ball is soldered onto the post, the pins are encapsulated within the solder material. The pins not only add shear strength to the soldered joint between the solder ball and the electrode post but also create a more reliable electrical connection due to the increased surface area between the electrode post / pin combination and the solder ball. Moreover, creating an irregularly shaped solder joint retards the propagation of cracks that may form in the intermetal compounds (IMC) layer formed at the solder joint.

Owner:ADVANCED MFG INNOVATIONS INC

Self-lubricating composite soft coating cutter and manufacture method thereof

ActiveCN1927579ARealize self-lubricating functionSelf-lubricating function preventsLayered productsVacuum evaporation coatingManufacturing technologyMiddle frequency

The invention relates to a self-lubricant composite soft coat blade, and relative production. Wherein, said blade uses the MoS2 / Zr / Ti composite coat blade made from middle-frequency magnetic-control multi-arc plating method; the surface of blade is MoS2 layer, between which can base there are Ti, MoS2 / Zr / Ti, and MoS2 / Zr transition layer; when using said blade to cut, the surface of blade can form continuous lubricant layer, to realize self-lubricant function; since the solid lubricant has low shearing strength, the solid lubricant layer will be transferred to the surface of work piece, to form transfer film and the friction in the cutting process will generate inside the solid lubricant layer, to reduce friction, reduce shearing force and reduce shearing temperature.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

Protein composition and its use in restructured meat and food products

This invention relates to a protein containing composition, comprising;a protein composition, wherein at least about 75 weight % of the protein composition contains at least about 15 weight % of large pieces comprised of protein fibers at least about 4 centimeters long, protein strands at least about 3 centimeters long, and protein chunks at least about 2 centimeters long andwherein at least about 75 weight % of the protein composition has a shear strength of at least about 1400 grams.The invention also relates to a process for preparing the protein composition.The invention further relates to a restructured meat product, or a vegetable product, or a fruit product comprising;a vegetable protein composition;a comminuted meat, or a comminuted vegetable, or a comminuted fruit, respectively; andwater;wherein at least about 75 weight % of the protein composition contains at least about 15 weight % of large pieces comprised of protein fibers at least about 4 centimeters long, protein strands at least about 3 centimeters long, and protein chunks at least about 2 centimeters long andwherein at least about 75 weight % of the protein composition has a shear strength of at least about 1400 grams.In another embodiment, the invention discloses a process for preparing the restructured meat product, or the vegetable product, or the fruit product, respectively.

Owner:SOLAE LLC

Nanostructured soldered or brazed joints made with reactive multilayer foils

InactiveUS7361412B2Reduce coolingImprove microstructureExothermal chemical reaction heat productionVacuum evaporation coatingRoom temperatureSlow cooling

Self-propagating formation reactions in nanostructured multilayer foils provide rapid bursts of heat at room temperature and therefore can act as local heat sources to melt solder or braze layers and join materials. This reactive joining method provides very localized heating to the components and rapid cooling across the joint. The rapid cooling results in a very fine microstructure of the solder or braze material. The scale of the fine microstructure of the solder or braze material is dependant on cooling rate of the reactive joints which varies with geometries and properties of the foils and components. The microstructure of the solder or braze layer of the joints formed by melting solder in a furnace is much coarser due to the slow cooling rate. Reactive joints with finer solder or braze microstructure show higher shear strength compared with those made by conventional furnace joining with much coarser solder or braze microstructure. It is expected that the reactive joints may also have better fatigue properties compared with conventional furnace joints.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Lost circulation composition for fracture sealing

ActiveUS8739872B1Avoid loopsQuickly de-fluidizeSolid waste managementFluid removalSuspended particlesPortland cement

A lost circulation material and method for well treatment employing the material that is effective at sealing or plugging fractured zones and has utility over a wide range of temperatures, including high temperatures. The lost circulation material includes particulate material to quickly de-fluidize the fluid formulation, fibrous material to suspend particles in the slurrified form of the composition and increase the shear strength of the resultant seal, and non-Portland cement material for increasing the compressive strength.

Owner:HALLIBURTON ENERGY SERVICES INC

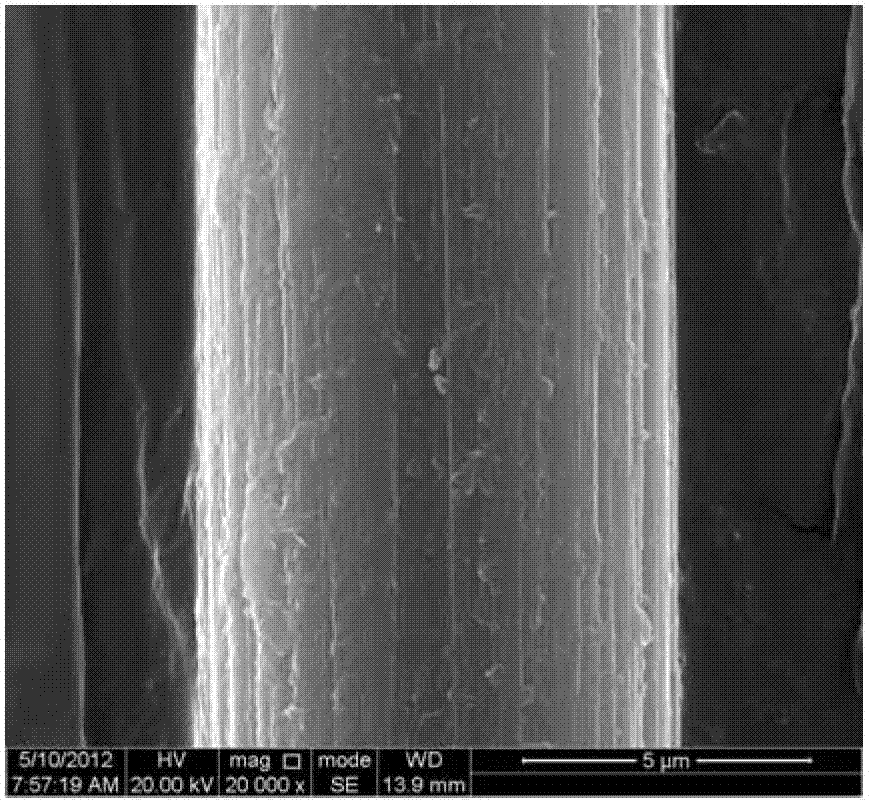

Carbon fiber emulsion sizing agent improved by carbon nano tube and preparation method of carbon fiber emulsion sizing agent

InactiveCN102212967APlay the role of stress transmissionIncreased interlaminar shear strengthCarbon fibresEmulsionCarbon fibers

The invention relates to a carbon fiber emulsion sizing agent improved by a carbon nano tube and a preparation method of the carbon fiber emulsion sizing agent. The carbon fiber emulsion sizing agent comprises a carbon fiber sizing agent, the carbon nano tube, a dispersing agent and a solvent. The preparation method comprises the following steps of: 1, preparing the carbon fiber sizing agent; and 2, adding the carbon fiber sizing agent into the solvent to prepare a sizing working solution, mixing the carbon nano tube and the sizing working solution, performing ultrasonic treatment for 1 to 4 hours at the power of 300 to 600w, adding the dispersing agent, and performing ultrasonic dispersion for 2 to 4 hours to obtain the carbon fiber emulsion sizing agent improved by the carbon nano tube. The carbon fiber emulsion sizing agent has favorable stability, the post processability of carbon fiber can be improved after being processed by the emulsion sizing agent, the interfacial bond strength between the carbon fiber and substrate resin can be enhanced, the shear strength among layers is enhanced, and the performance of a composite material is improved to a certain extent. Moreover, the preparation method is simple, low in cost and environment-friendly.

Owner:DONGHUA UNIV

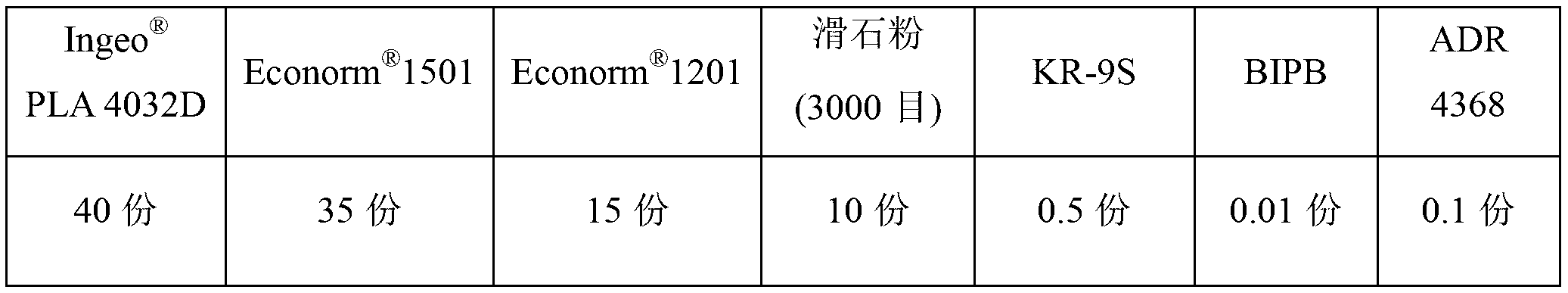

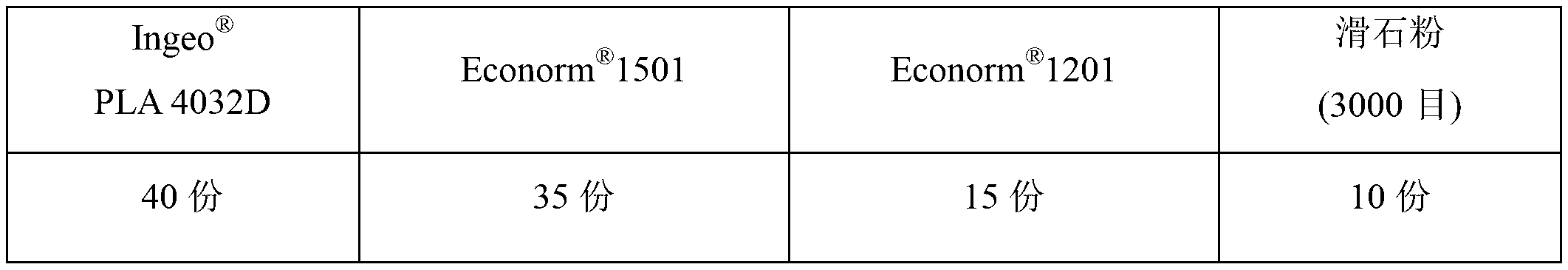

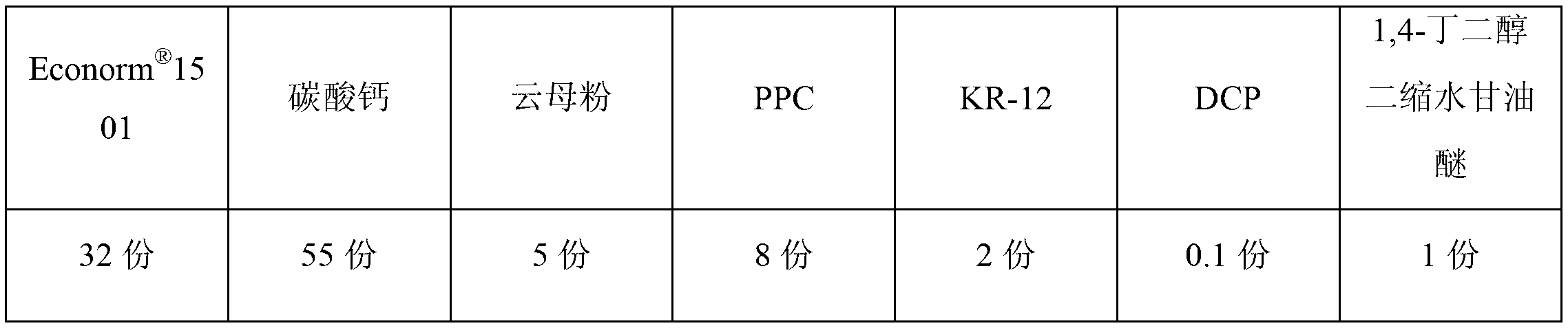

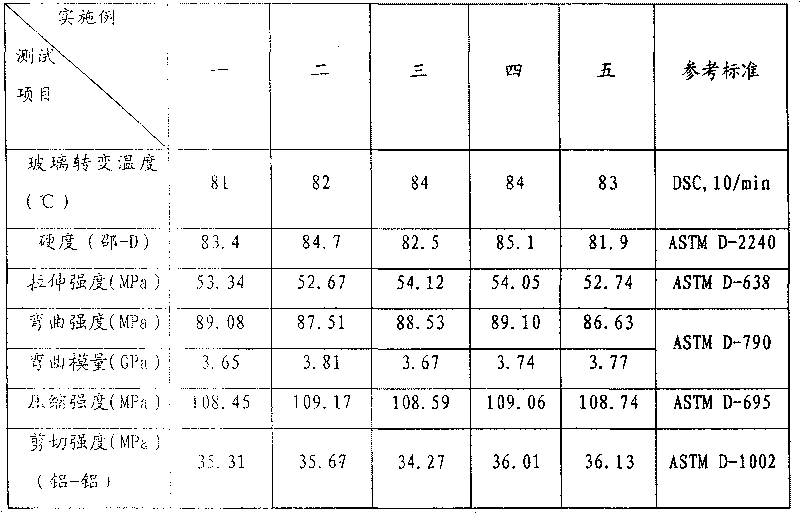

Method for increasing capacity of biodegradable polyester blend film

The invention relates to a biodegradable polyester blend film, and in particular relates to a method for increasing the capacity of a biodegradable polyester blend film. The method for increasing the capacity of the biodegradable polyester blend film comprises the steps of: adding a high-activity titanate coupling agent, a free radical cross-linking agent and a multi-epoxy group compound into a blending compound system of two or more than two biodegradable polyesters and an inorganic or organic filler; initiating and promoting transesterification, proper intermolecular cross-linking reaction and end-group chain extension in a double-screw extruder with the length-diameter ratio of more than or equal to 48 and the total kneading blocks of more than or equal to 16 under the action of high temperature and high shear strength, thus increasing the capacity of blending polyester. Through utilizing the double-screw extruder with the high length-diameter ratio and high shear strength and introducing the titanate coupling agent, the free radical cross-linking agent and the multi-epoxy group compound are introduced, on-line capacity increasing of a biodegradable polyester / filler blend compound system is carried out, so that the anisotropy of the mechanical property of the film is greatly improved.

Owner:山东悦泰生物新材料有限公司

Epoxy resin binder used for repairing blade and preparation method thereof

ActiveCN101698787AFast curingLower the activation energy of the reactionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyWind driven

The invention relates to a preparation method of repairing adhesive, in particular to a binder for repairing blade of a wind driven generator, belonging to the high polymer material field. The preparation method of double-component epoxy resin binder used for repairing blade is simple in operation and low in cost. The double-component epoxy resin binder for repairing blade which is made by the method of the invention has high tenacity, high shear strength, low heat and low shrink, thus being suitable for repairing and binding of large structural part; solidification is rapid, the binder can be rapidly solidified in 10-30 minutes at 5-25 DEG C and reach certain strength; and the binder is used for repairing defect of blade of wind driven generator.

Owner:镇江市电子化工材料工程研究中心有限公司

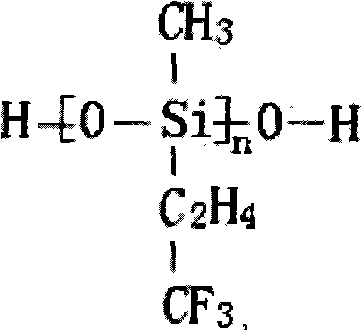

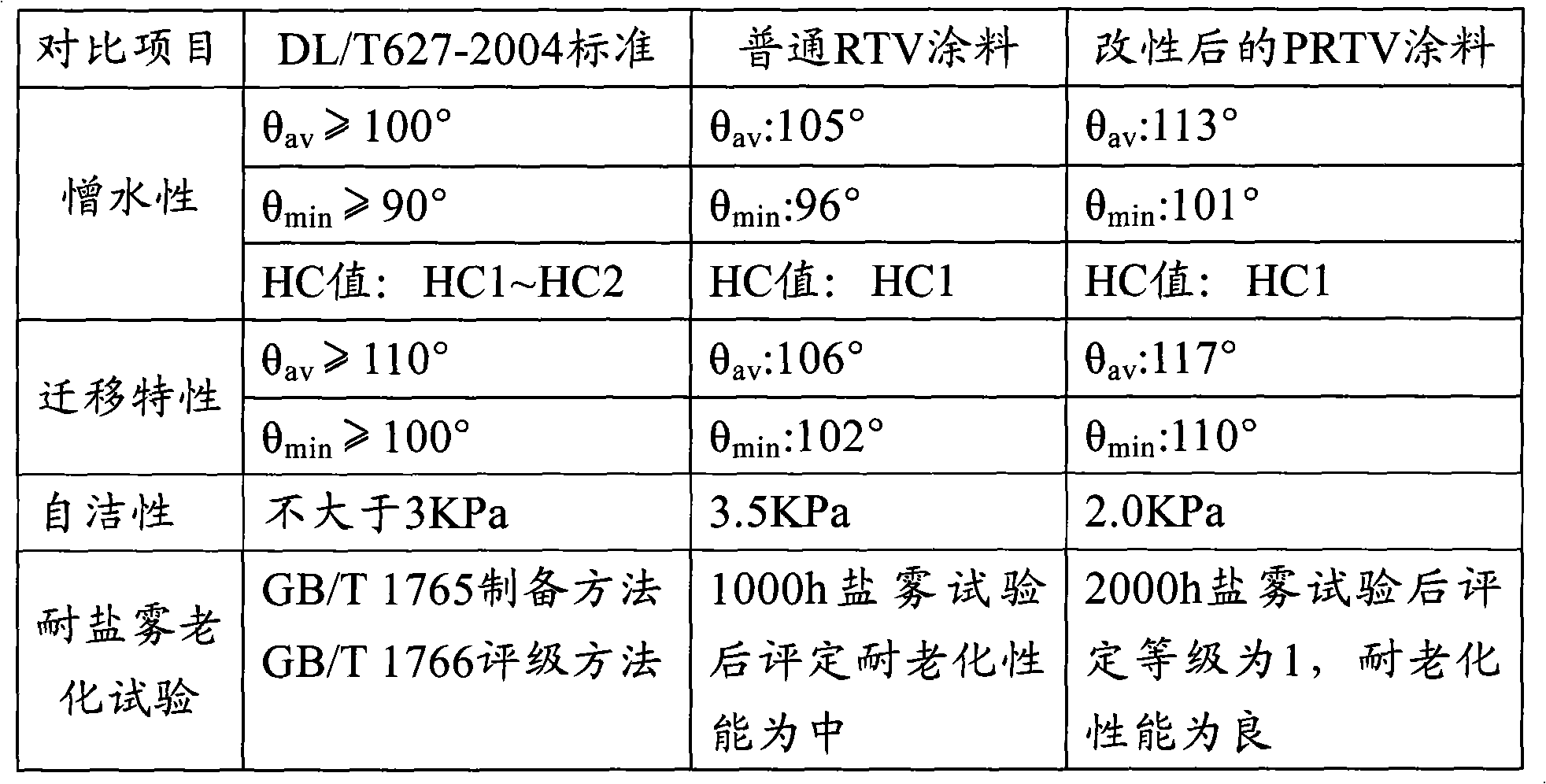

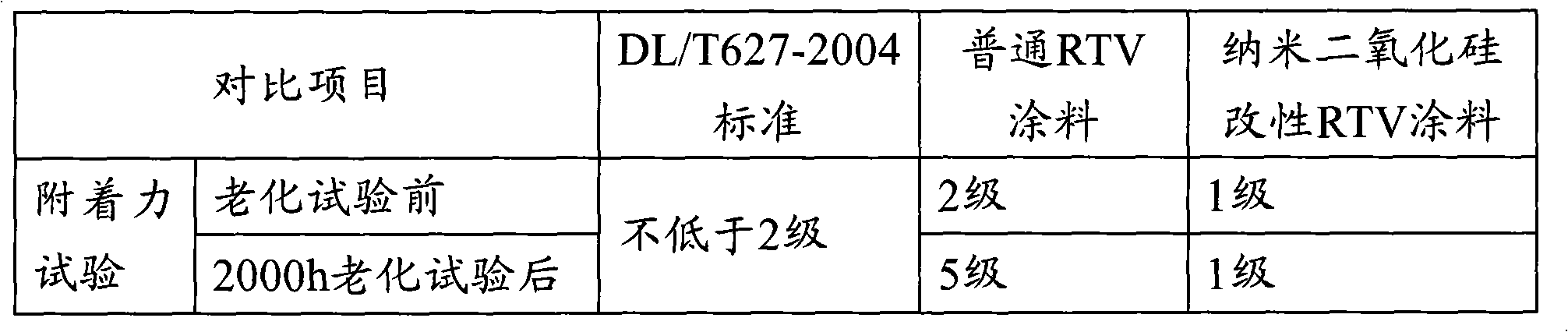

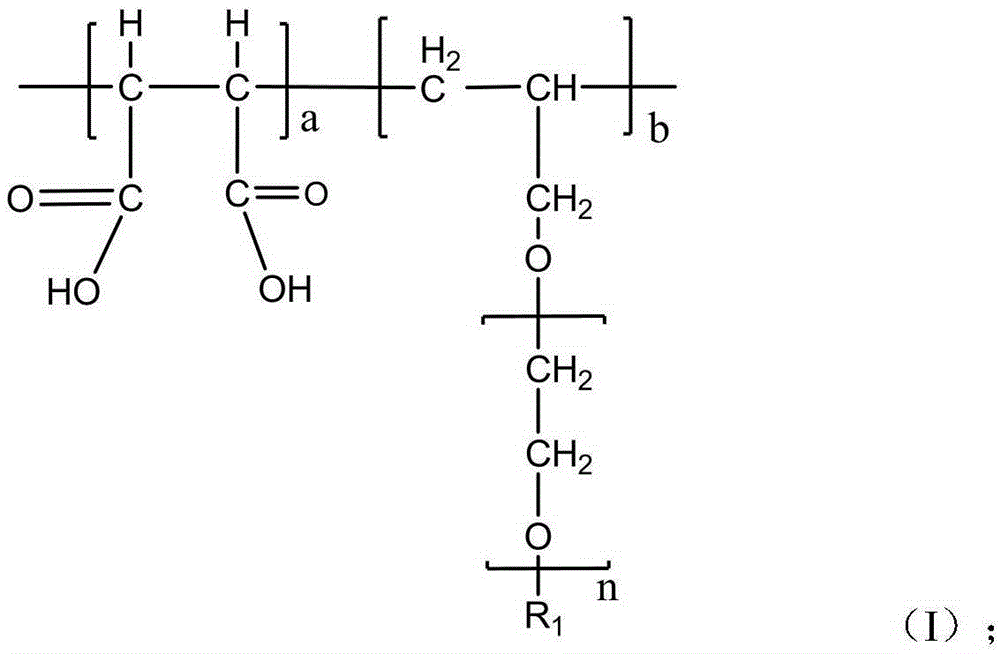

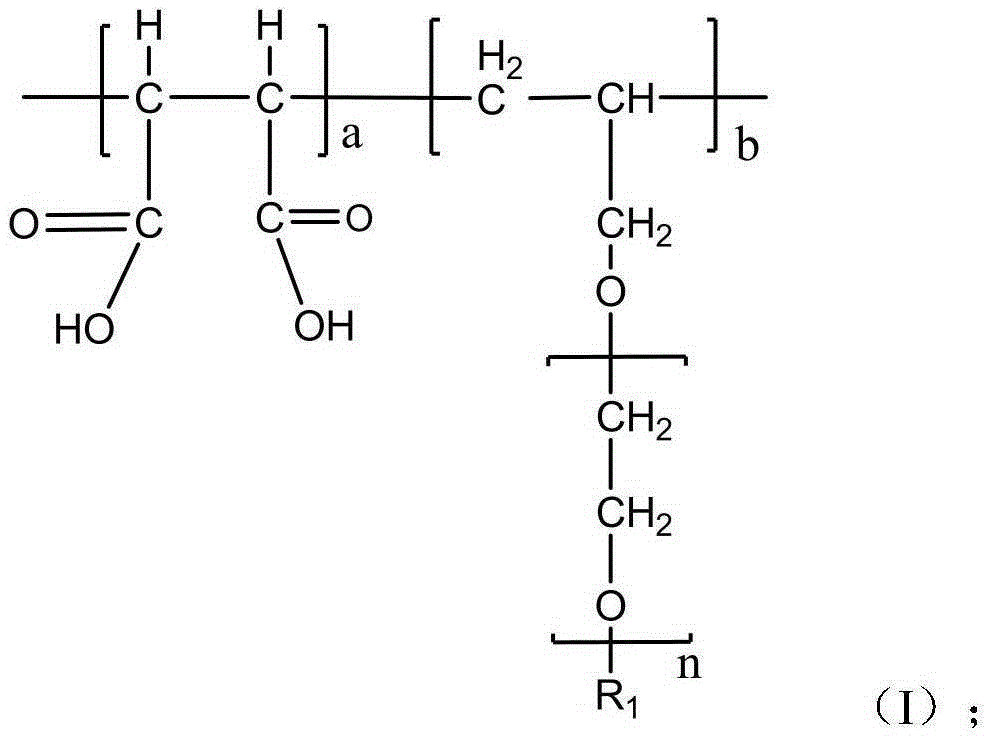

Composition for anti-pollution flashover coating and anti-pollution flashover coating

InactiveCN101942200AStrong mechanical propertiesExtended service lifeCoatingsPerformance indexSilicon dioxide

The invention provides a composition for an anti-pollution flashover coating and the anti-pollution flashover coating. The composition comprises the following components in part by weight: 25 to 40 parts of hydroxyl-terminated polyorganosiloxane, 5 to 15 parts of hydroxyl-terminated fluorine-containing polyorganosiloxane, 6.0 to 8.0 parts of nanometre silicon dioxide, 2.5 to 3.5 parts of nanometre calcium carbonate, 4.8 to 5.5 parts of cross-linking agent, 3.5 to 4.5 parts of wetting agent, 0.8 to 1.3 parts of silane coupling agent and 0.2 to 0.4 part of catalyst. The coating has the characteristic of long-term anti-pollution flashover effect and greatly improves the hydrophobicity, the hydrophobicity migration property, the tear strength, the shear strength, the acid and alkali resistance, the self-cleaning property and the aging property of a coating. The performance indexes of the coating are designed according to the actual needs of operation of electric equipment and by combining the development level of an organic silicon fluorine material. Requirements and limitations on the operation and maintenance of the equipment operating can be reduced to the maximum degree on the premise of guaranteeing the long-term anti-pollution flashover performance of the equipment.

Owner:广东鑫皇冠新材料有限公司

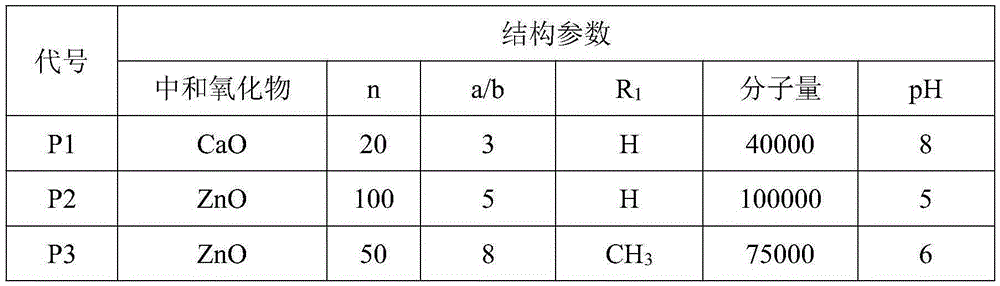

Nano suspension liquid concrete early strength agent and preparation method thereof

The invention provides a nano suspension liquid concrete early strength agent and a preparation method thereof. The nano suspension liquid concrete early strength agent is prepared from transition metal element doped nano calcium metasilicate suspension liquid, the suspension liquid is mainly composed of nanometer silicon particles, the chemical structure of the nanometer silicon particles is aCaO.bAl2O3.cZnO.SiO2.6H2O, 1<=a<=2, 0.50<=b<=1, and 0.25<=c<=0.50. The nanometer silicon particles are prepared from soluble calcium salt, soluble silicate, soluble aluminum salt, soluble zinc salt and a high polymer dispersing agent. On the one hand, the early strength agent contains no chlorine salt and has no corroding function on steel bars in concrete; on the other hand, an extremely stable suspension liquid system is achieved, adding is facilitated, and the early strength agent can be evenly dispersed easily in the concrete preparation process. The early strength of concrete can be remarkably improved, the early strength effect on concrete adopting highly-doped mineral admixtures is especially obvious, the early strength agent is especially suitable for production of precast concrete components, and a steam maintenance process can be effectively reduced and even omitted.

Owner:JIANGSU SOBUTE NEW MATERIALS

Apparatus and methods for reducing compression bone fractures using high strength ribbed members

InactiveUS7513900B2Low shear strengthSmall profileInternal osteosythesisDiagnosticsCommon baseFracture reduction

Devices and methods are provided for treating a bone structure (such as, e.g., reducing a bone fracture, e.g., a vertebral compression fracture, or stabilizing adjacent bone structure, e.g., vertebrae) is provided. The device comprises rigid or semi-rigid members, each of which comprises a common base and a plurality of ribs that extent along the a longitudinal portion of the common base. The device is configured to be placed in a collapsed state by engaging the pluralities of ribs of the members in an interposed arrangement, and configured to be placed in a deployed state by disengaging the pluralities of ribs. The ribs can be any shape, e.g., flutes, that allows opposing ribs to intermesh with one another. In this manner, the device has a relatively small profile when placed in the collapsed state, so that it can be introduced through small openings within the bone structure, while preserving the shear strength of the members during deployment of the device.

Owner:BOSTON SCI SCIMED INC

Building material and method of making and installing the same

ActiveUS20040231252A1Easy alignmentEqual and great shear strengthCovering/liningsFloorsAdhesiveUltimate tensile strength

The building material, in one embodiment, has a jointing system that is uniquely configured to cover the frame of a structure. This building material, in one embodiment, is a building board with a conforming flange that is embossed onto the board and adapted to engage or mate with an end of an adjacent board. In another embodiment, the building material is an engineered panel joint comprised of a building board and a flexible or hinged article attached to the back surface of the building board. The article is preferably attached to the building board by an adhesive and extends beyond the edge and away from the building board for receiving a fastener to fix the building board to the structure. The fastener is preferably a nail. Components of the building material are preferably attached to the frame of the structure through the use of a single row of nails while maintaining or enhancing the shear strength performance of the building board system.

Owner:JAMES HARDIE TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com