Device and method for testing shear performance of asphalt mixture

A technology of asphalt mixture and test device, which is applied in the direction of using stable shear force to test the strength of materials and preparation of test samples, etc., can solve the problem that the constant height repeated shear test equipment is expensive and cannot form a shear failure surface. , Judging the shear failure of the test piece and other problems, to achieve the effect of stable test results, simple and cheap test equipment, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

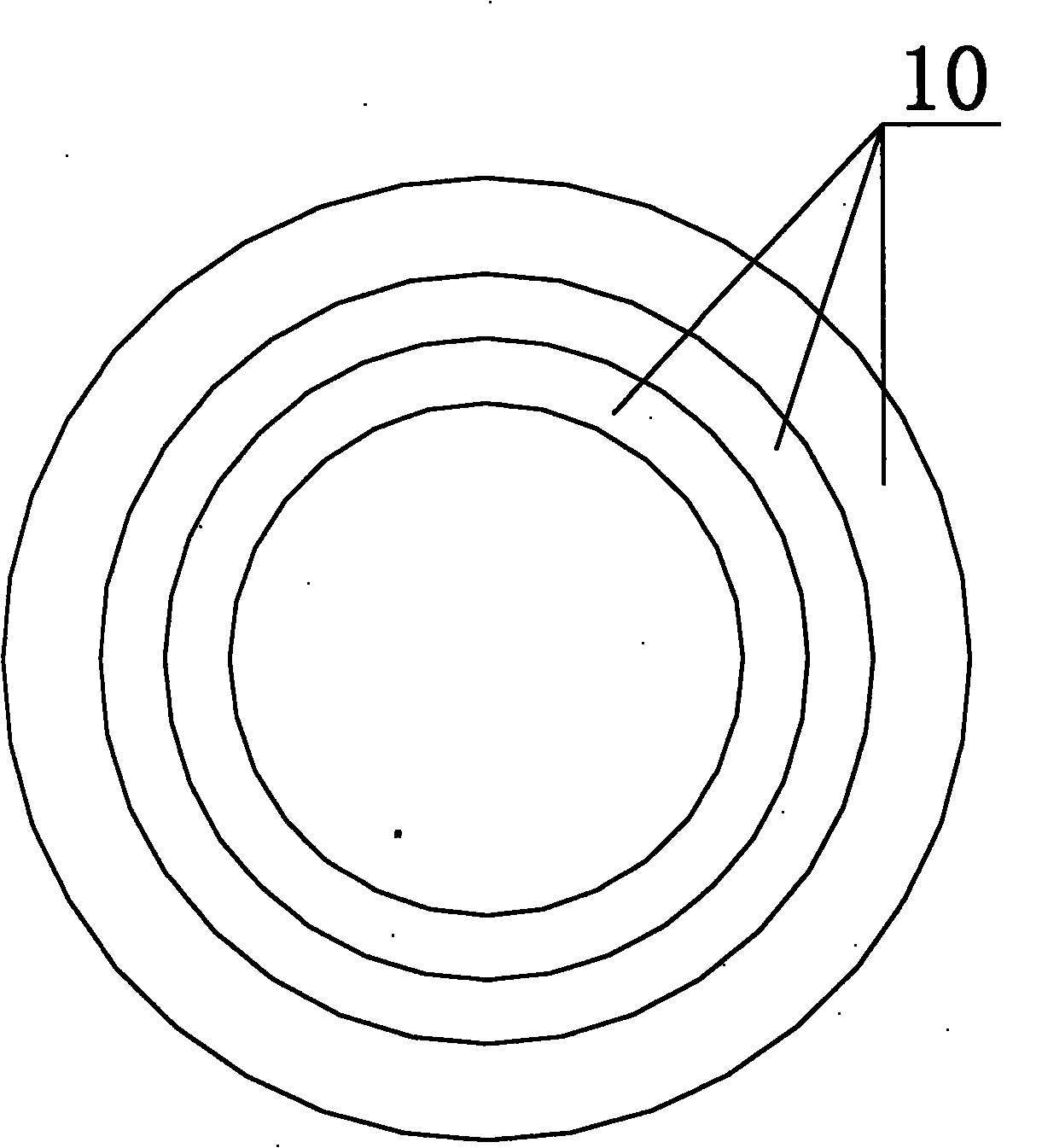

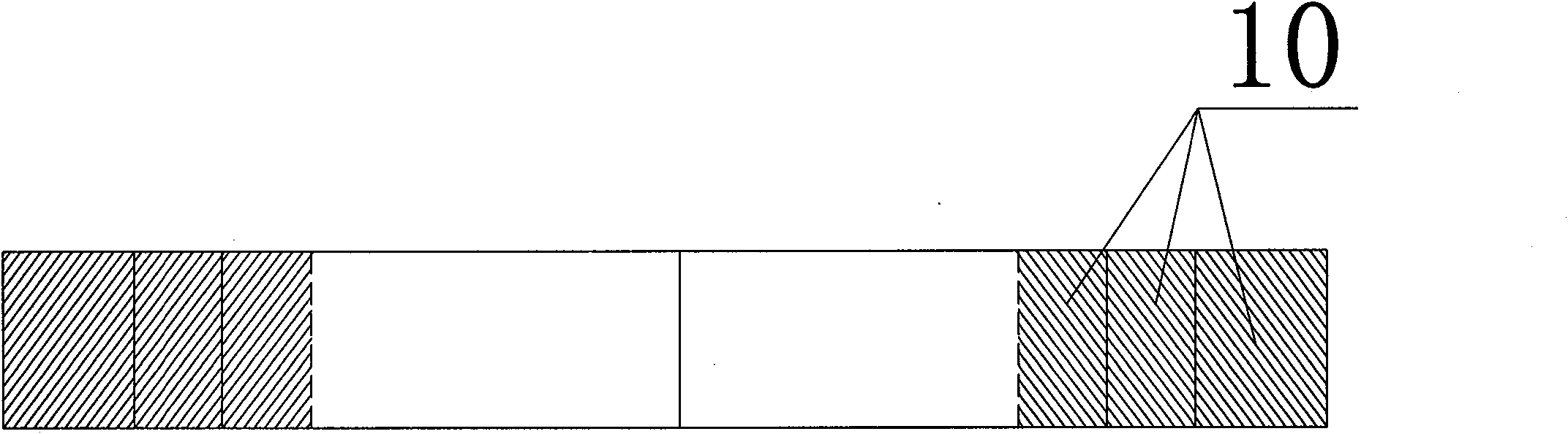

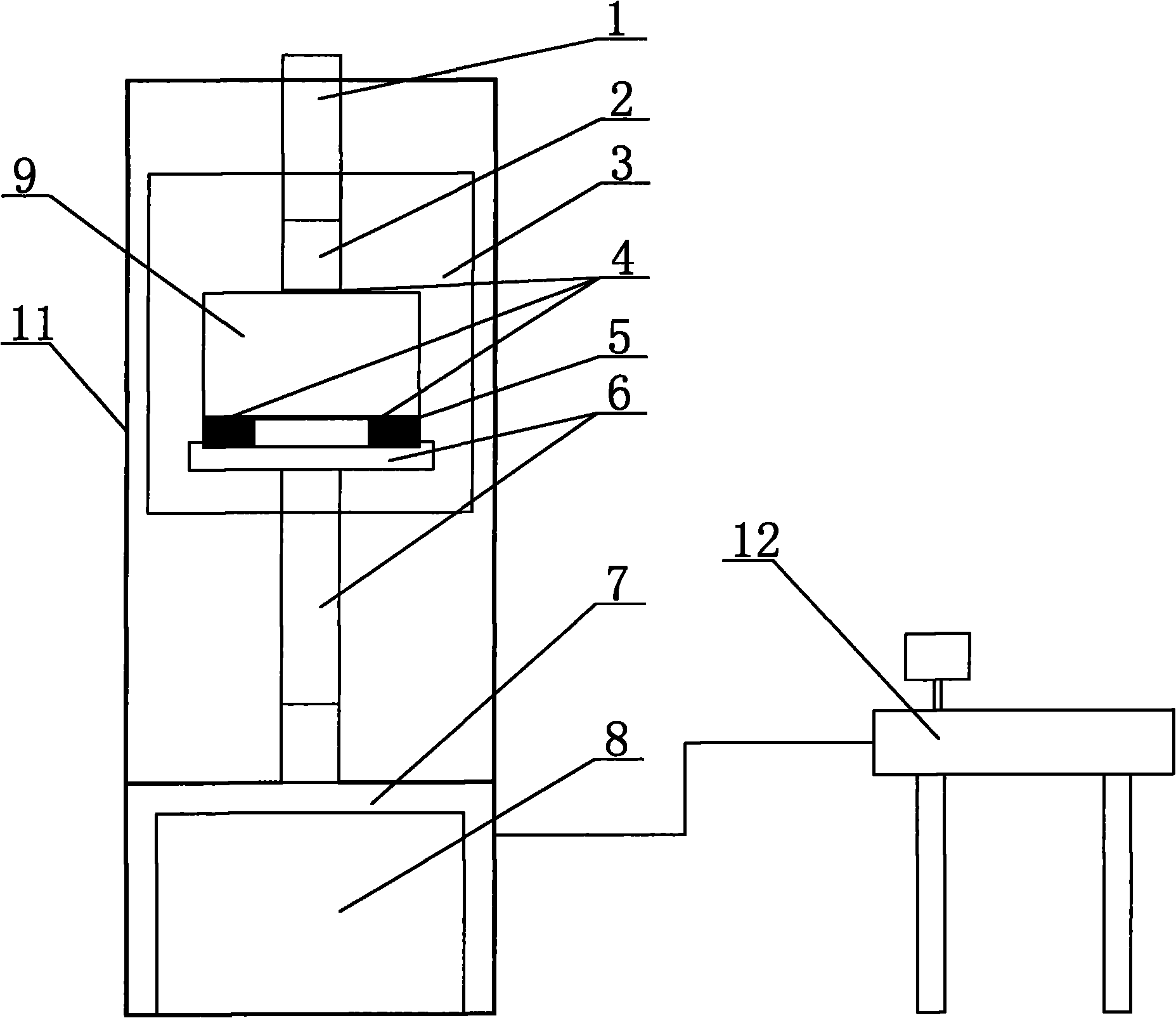

[0054] 1. The diameter of the indenter is 40mm; the size of the test piece is: the diameter of the asphalt mixture sample is 150mm, and the height is 95mm; the size of the ring is: the outer diameter is 150mm, and the inner diameter is 80mm. The mechanical model is established by computer general finite element program for calculation and analysis. The load is the load compressive stress p=1Mpa acting on the indenter; the boundary condition is that the bottom of the specimen is fixed in the vertical direction, and there are no lateral constraints around the specimen. Use the finite element program to calculate the first principal stress σ of each point in the specimen 1 and the third principal stress σ 3 , according to the third strength theory, the maximum shear stress τ max . The conversion relation between maximum shear stress and load compressive stress is: τ max = Load compressive stress × 0.52. The compression-shear conversion coefficients of the ring shear test are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com